Patents

Literature

19291 results about "Mechanical properties of carbon nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mechanical properties of carbon nanotubes reveal them as one of the strongest materials in nature. Carbon nanotubes (CNTs) are long hollow cylinders of graphene. Although graphene sheets have 2D symmetry, carbon nanotubes by geometry have different properties in axial and radial directions. It has been shown that CNTs are very strong in the axial direction. Young's modulus on the order of 270 - 950 GPa and tensile strength of 11 - 63 GPa were obtained.

Symmetric touch screen system with carbon nanotube-based transparent conductive electrode pairs

InactiveUS20080238882A1Input/output processes for data processingElectricityElectrical resistance and conductance

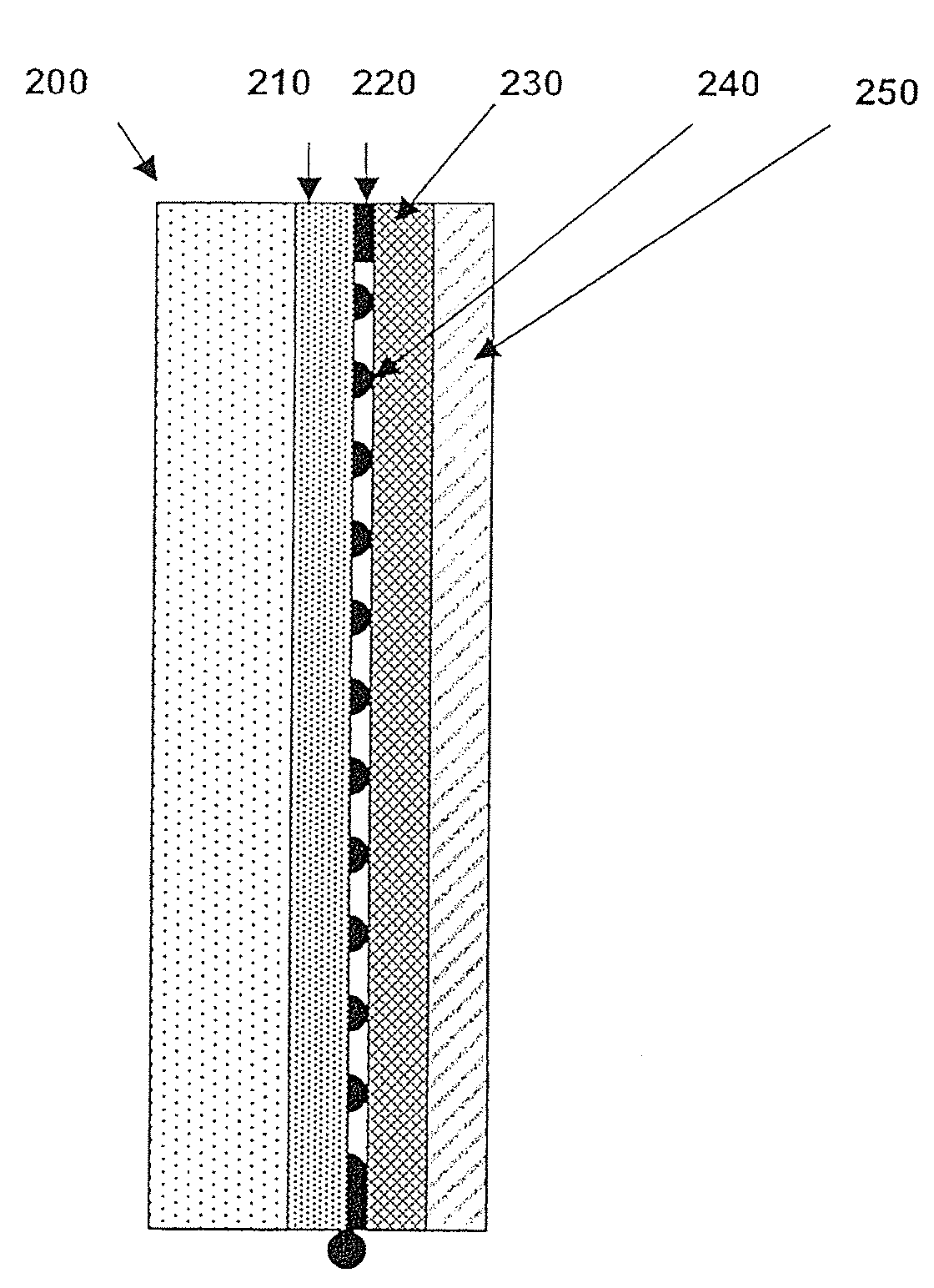

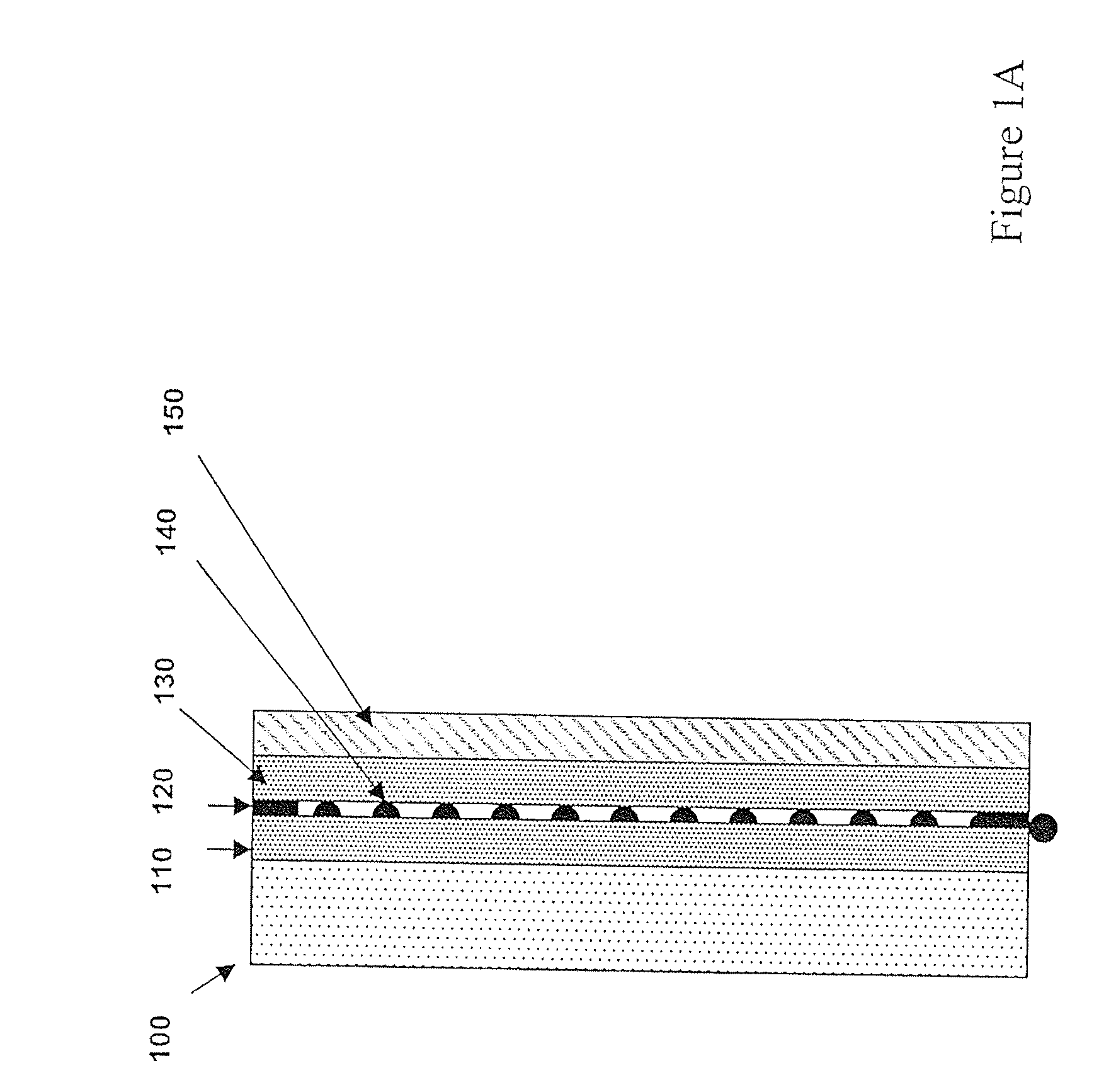

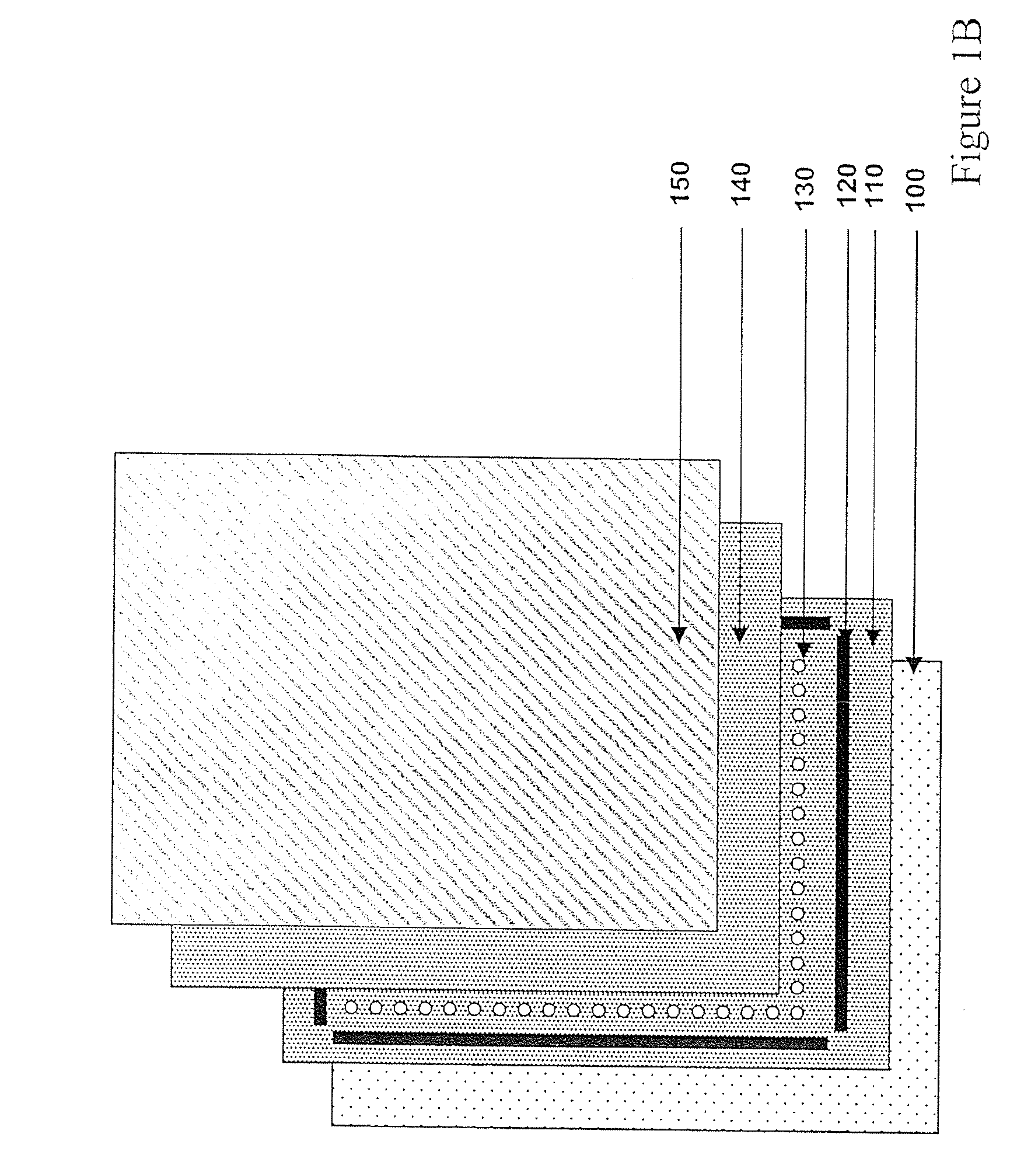

A symmetric touch screen switch system in which both the touch side and panelside transparent electrodes are comprised of carbon nanotube thin films is provided. The fabrication of various carbon nanotube enabled components and the assembly of a working prototype touch switch using those components is described. Various embodiments provide for a larger range of resistance and optical transparency for the both the electrodes, higher flexibility due to the excellent mechanical properties of carbon nanotubes. Certain embodiments of the symmetric, CNT-CNT touch switch achieve excellent optical transparency (<3% absorption loss due to CNT films) and a robust touch switching characteristics in an electrical test.

Owner:NANTERO

Perovskite/polymer composite luminescent material and preparation method thereof

ActiveCN104861958ASimple and fast operationLow costNanoopticsLuminescent compositionsPhotoluminescenceStructural formula

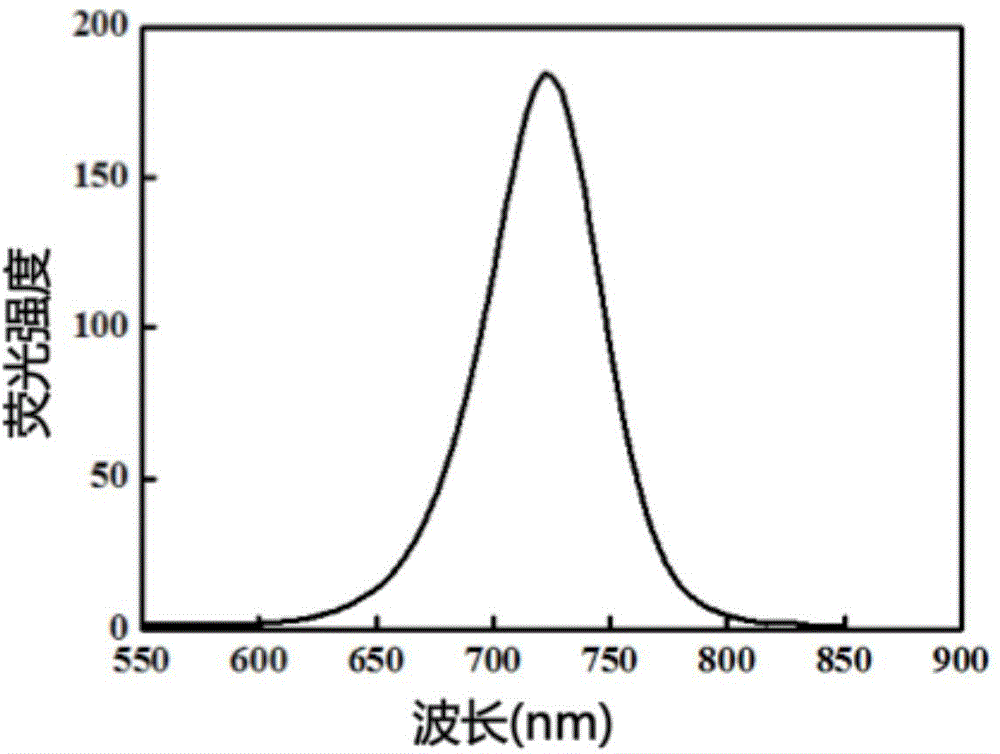

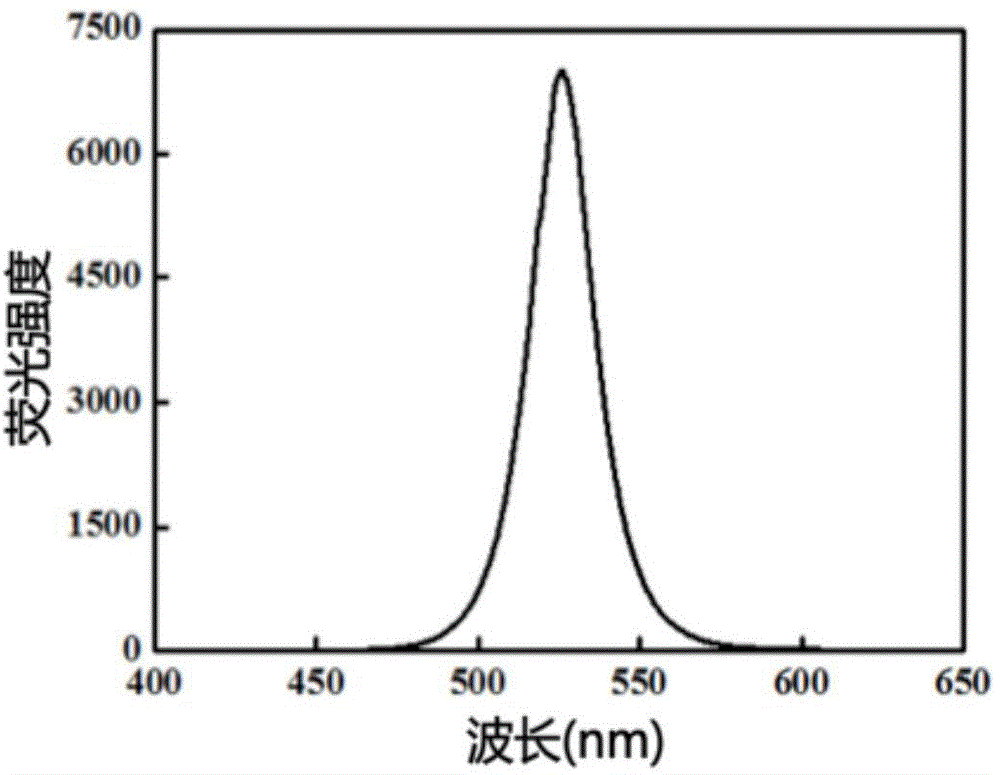

The invention relates to a perovskite / polymer composite luminescent material and a preparation method thereof, which belong to the technical field of composite materials and luminescent materials, wherein the structural formula of the perovskite is R1NH3AB3 or (R2NH3)2AB4, A and B form a ligand octahedral structure, R1NH3 or R2NH3 are filled into gaps of the ligand octahedral structure which is formed through the A and the B, R1 is methyl, R2 is a long-chain organic molecular group, the A is any one of metal Ge, Sn, Pb, Cu, Mn, Sb and Bi, the B is any one of Cl, Br and I. The perovskite / polymer composite luminescent material which is made through the preparation method is high in luminescent intensity, high in luminescent color purity, excellent in light and thermal stability and excellent chemical resistant property and mechanical property, and lays the foundation for theory research and application of the perovskite / polymer composite luminescent material in high-performance photoluminescence devices, flexible display, lasers, nonlinear optical devices. The preparation method can obtain composite materials which can cover a whole visible region through luminescent wavelengths, and has wide application prospect in the fields of wide gamut light emitting diode (LED) and high performance displays and the like.

Owner:ZHIJING NANOTECH CO LTD

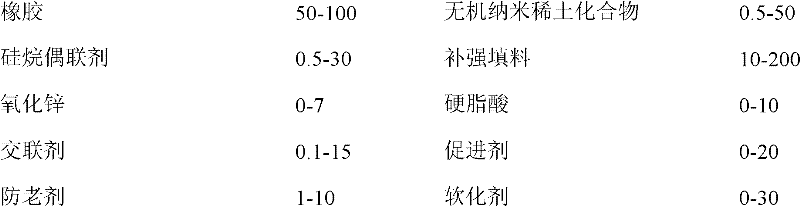

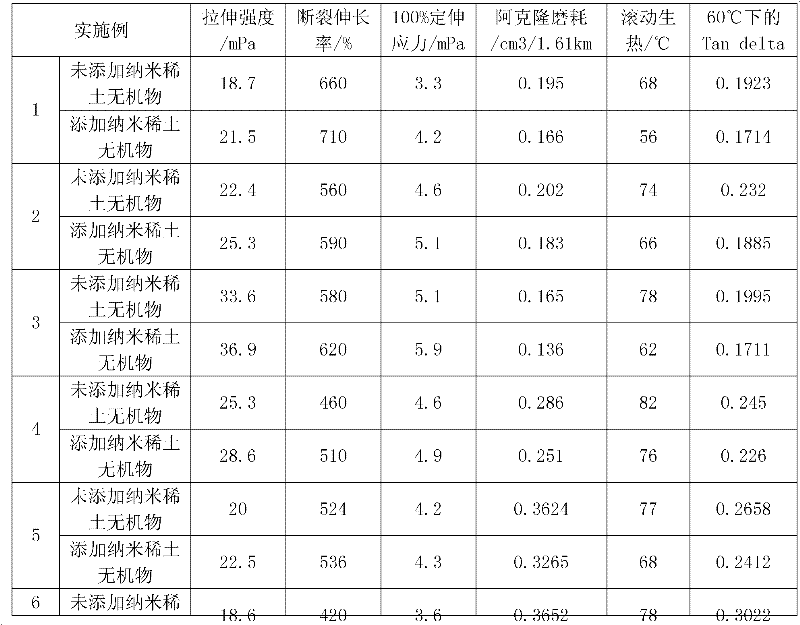

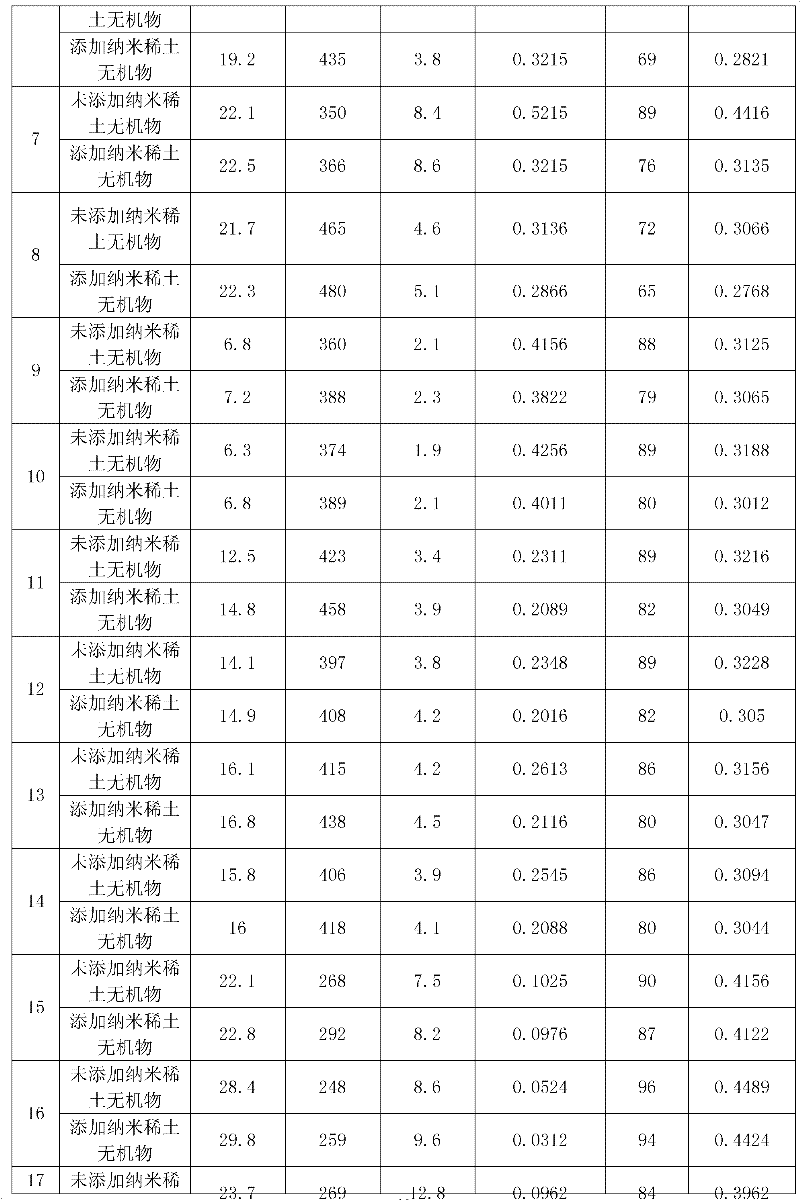

Nanometer rare earth inorganic substance/ rubber composite with high wear resistant and excellent dynamic property

The invention prepares a nanometer rare earth inorganic substance / rubber composite with high wear resistant and excellent dynamic property. The invention adopts a mechanical blending method to prepare the nanometer rare earth inorganic substance and rubber composite. After the nanometer rare earth inorganic substance and the rubber are composited, higher modulus can be provided, the mechanical property of the rubber composite is improved, the abrasion stripes are blocked up to achieve the aim of dispersing stress through the high strength of the nanometer rare earth inorganic substance so as to improve wear-resisting property, and the internal friction of the composite is improved by utilizing the specific characteristic of smooth surface of the rare earth material so as to achieve the aim of reducing internal friction and resistance to rolling. According to the material prepared by the invention, the modulus can be improved, the mechanical property is improved, the abrasion is greatly reduced simultaneously, the internal friction and the resistance to rolling are reduced, and the composite can be widely applied to materials such as tyres, conveyer belts, sealing elements, piston rings, soles and the like.

Owner:江苏绿源橡胶资源循环利用创新中心有限公司

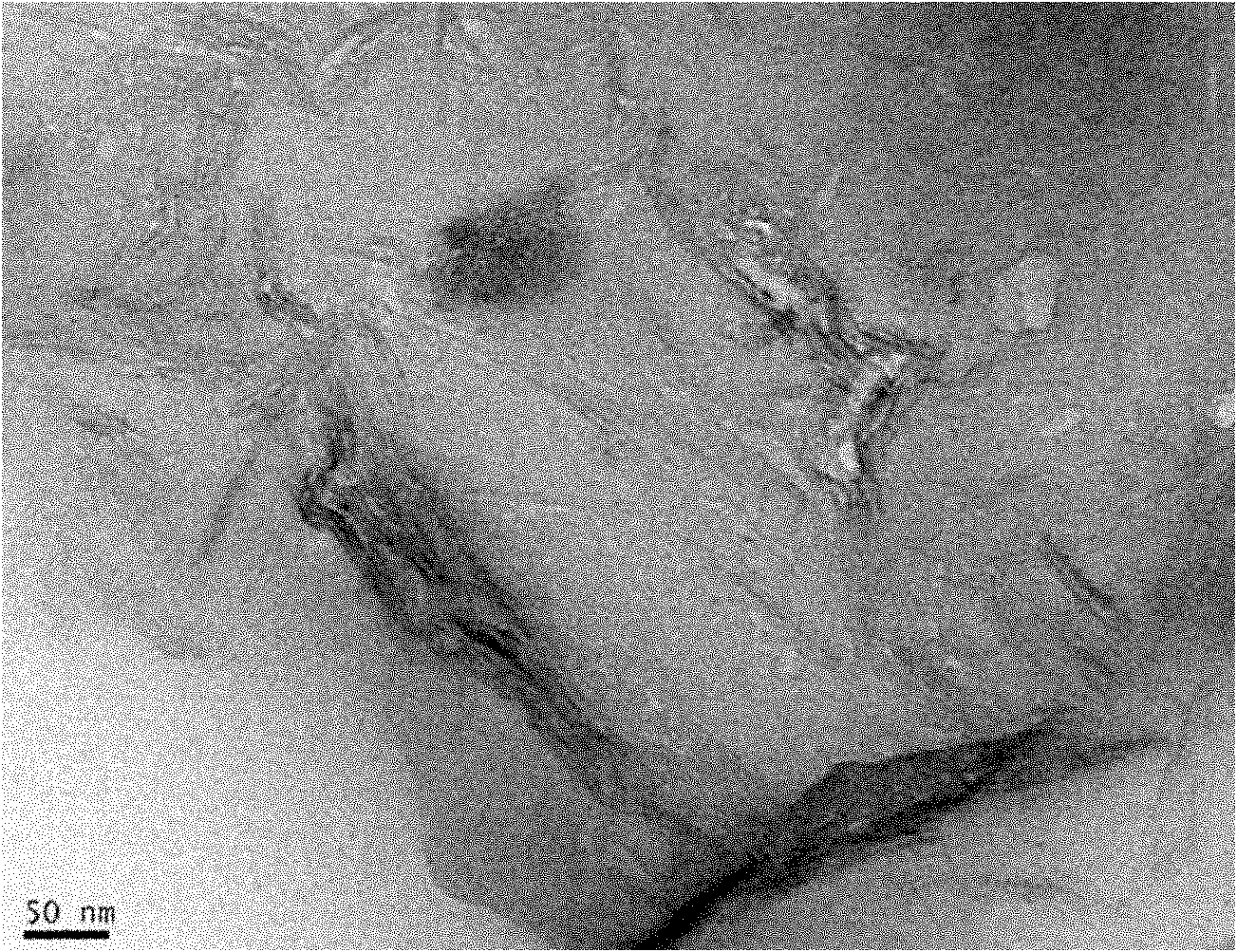

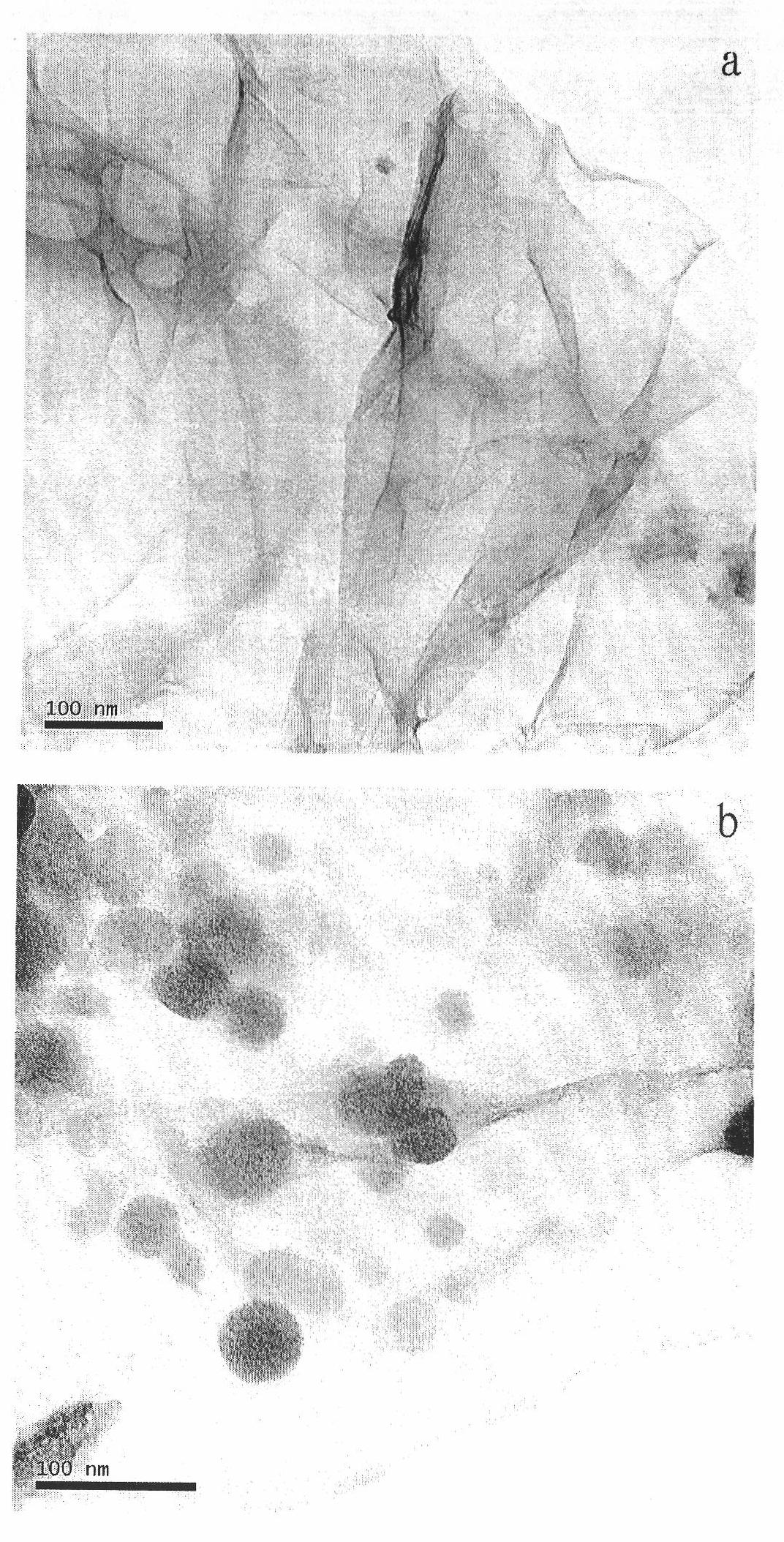

Graphene and carbon fiber composite material, and preparation thereof

The invention relates to a Graphene and carbon fiber-based composite material and a preparation method thereof. The composite material is prepared by taking the Graphene and the carbon fiber as raw materials, and coating a Graphene coating layer on the surface of the carbon fiber by a coating method, and the thickness of the coating layer is 1nm-5mum. The Graphene is taken as a surface coating material of the carbon fiber, and the Graphene and the carbon fiber are carbon materials and have high compatibility, thus Graphene solution coated on the surface of the carbon fiber can form the high-performance composite material and further improve the mechanical property, conductivity and heat resistance of the carbon fiber. The composite material has low cost, simple operation and strong applicability.

Owner:NANKAI UNIV

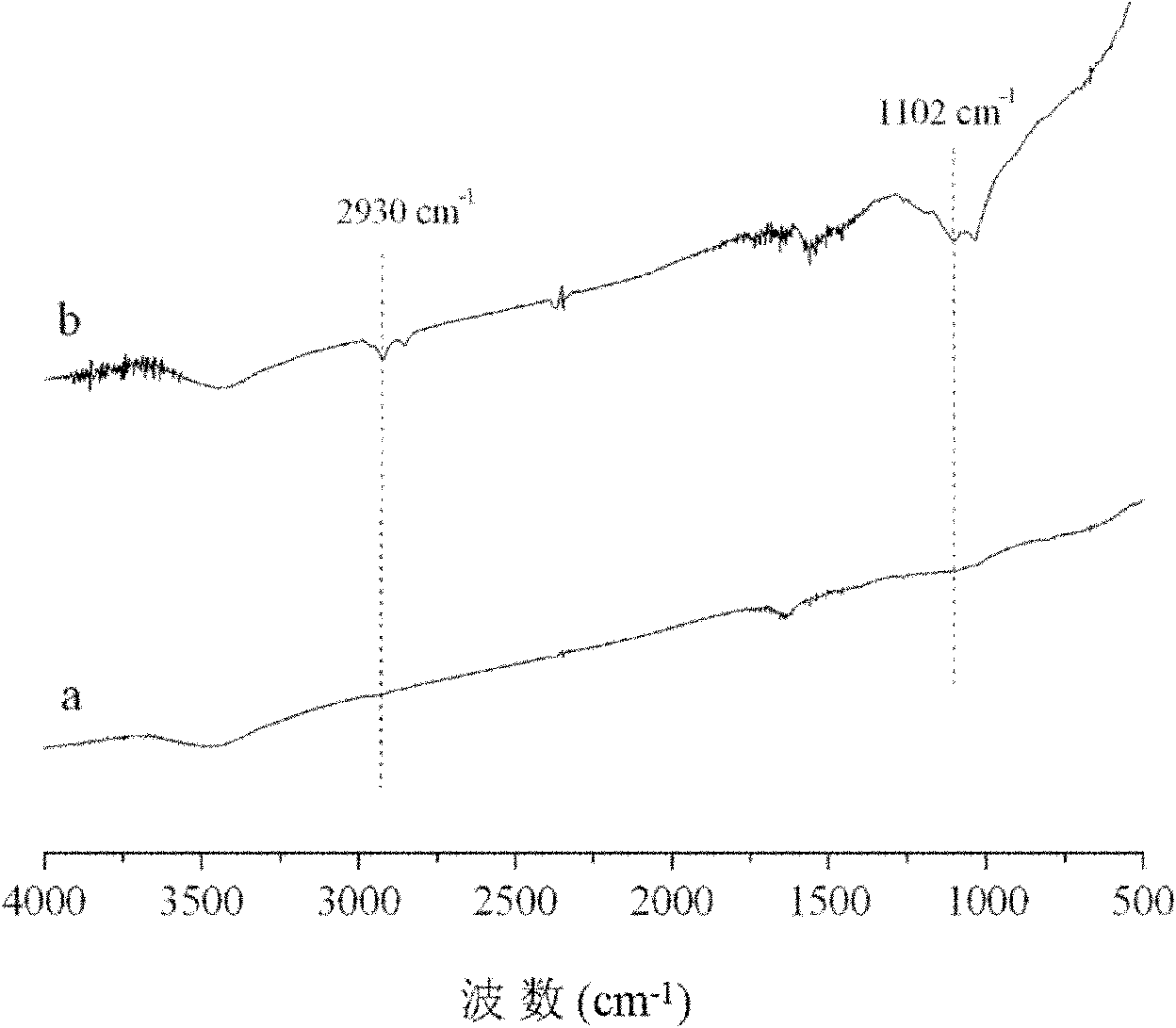

Graphene composite material and preparation method thereof

The embodiment of the invention discloses a graphene composite material and a preparation method thereof. In the method, graphene and organosilane are taken as reactants; the organosilane undergoes a hydrolysis reaction, and then undergoes a dehydration condensation reaction with hydroxyl on the graphene so as to obtain organosilane-modified graphene. Compared with the prior art, the organosilane-modified graphene expands the interlayer spacing of graphene, so that the organosilane-modified graphene is difficultly agglomerated when the organosilane-modified graphene is mixed with a polymer, the organosilane-modified graphene is uniformly dispersed in a polymer substrate, and a prepared graphene composite material has an enhanced effect. Moreover, the organosilane-modified graphene undergoes chemical bonding or intermolecular force with the polymer, so that the prepared graphene composite material has excellent interface compatibility. Proved by experiment results, the graphene composite material prepared in the invention has high mechanical property.

Owner:UNIV OF SCI & TECH OF CHINA

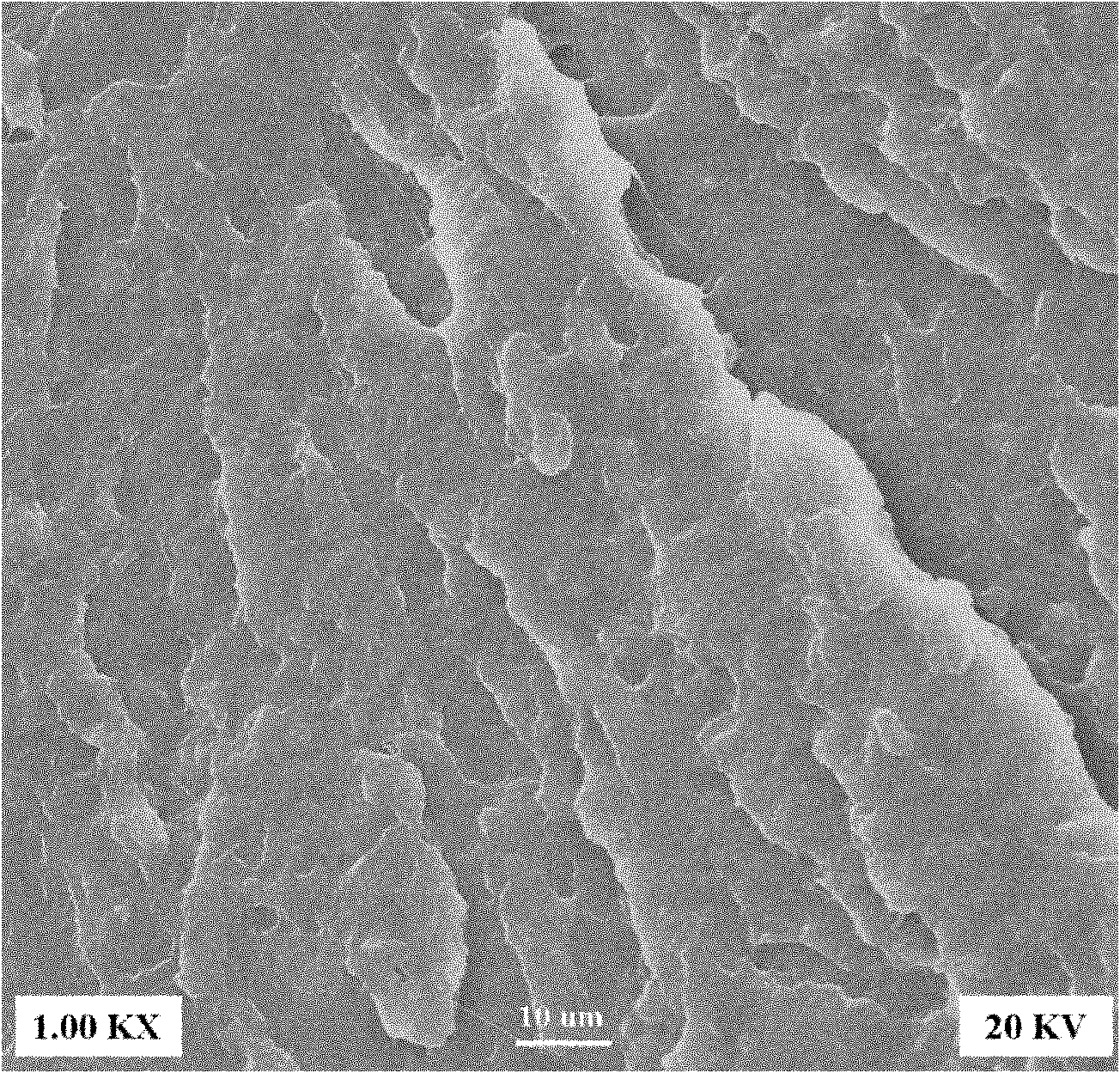

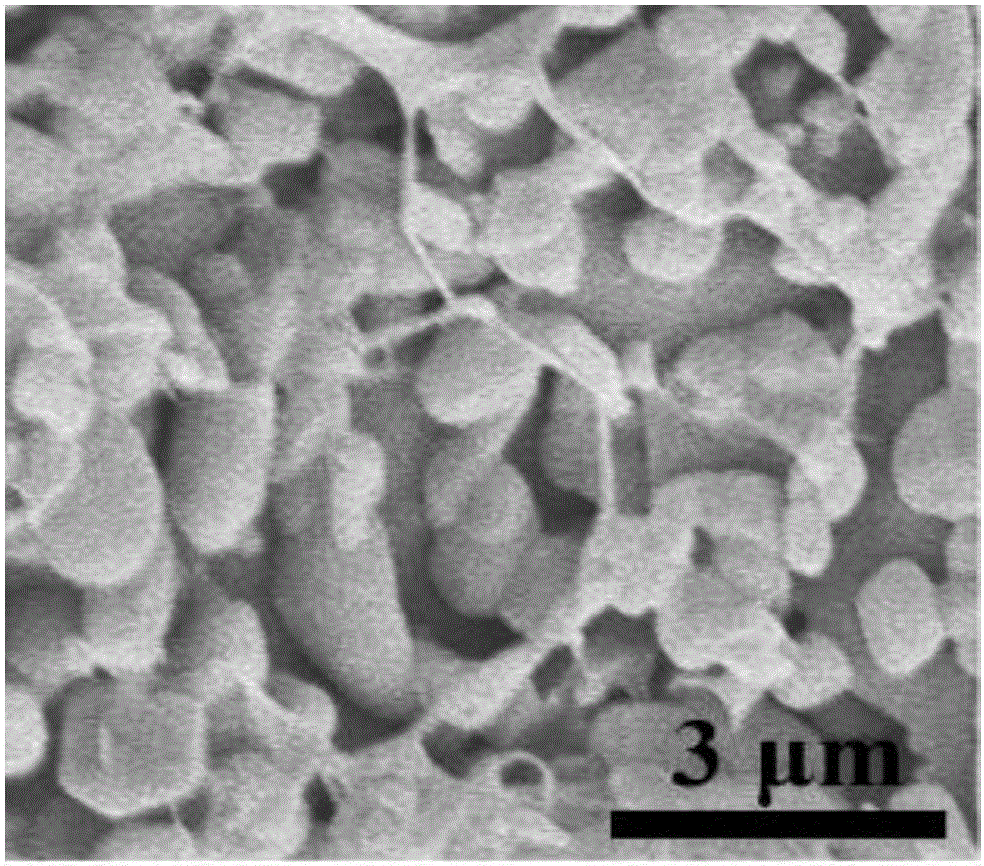

Graphene-based barrier composite material and preparation method thereof

The invention discloses a graphene-based barrier composite material, which has high barrier and mechanical performance and is prepared by using grapheme sheets which are two-dimension nano materials as an intensifier and uniformly dispersing the grapheme sheets in a polyolefin polymer by chemical crosslinking. The preparation method of the barrier composite material comprises: 1, functionally modifying the surface of the graphene oxide by using coupling agent to graft active functional groups on the surface of the graphene oxide, and reducing the modified graphene oxide into grapheme; and 2, uniformly dispersing the modified graphene into solution of the polyolefin to perform crosslinking under the action of an initiator to obtain the nano composite material. In the invention, the raw material is low in cost and readily available; the operation is easy, the process is simple, the repeatability is high, the graphene can well disperse in the polyolefin, and the prepared graphene-based barrier composite material has high polar and nonpolar solvent barrier performance and is obviously improved in tensile strength and fracture toughness.

Owner:HUBEI UNIV

Nanometer multiple-layer composite thermal insulation material and preparation method thereof

ActiveCN101799099AEasy to useInhibition of high temperature radiative heat transferThermal insulationPipe protection by thermal insulationAdhesiveMetal foil

The invention discloses a nanometer multiple-layer composite thermal insulation material and a preparation method thereof. The nanometer multiple-layer thermal insulation composite material is formed by alternatively overlapping an infrared reflecting screen and a spacer; the ratio of total layer amounts n of the infrared reflecting screens and the spacers to the total thickness of the nanometer multiple-layer composite thermal insulation material is 0.5-4; the infrared reflecting screen is a metal foil or a metal plated foil; the spacer is a thermostability nanometer porous aerogel composite thermal insulation material; the infrared reflecting screen and the spacer are combined by being adhered with thermostability adhesives or in puncturing connection by thermostability sewing threads. The invention also comprises the preparation method of the nanometer multiple-layer composite thermal insulation material. The nanometer multiple-layer composite thermal insulation material of the invention has low density, favorable mechanical property and favorable high-temperature thermal insulation property, lowers requirements on the vacuum degree by a VIP plate when being used as vacuum thermal insulation plate core materials, does not need getter and can satisfy harsh high-efficiency thermal insulation using requirements on materials by aviation, aerospace and civil fields. The method of the invention can prepare thermal insulation material members with large size and complex shape.

Owner:NAT UNIV OF DEFENSE TECH

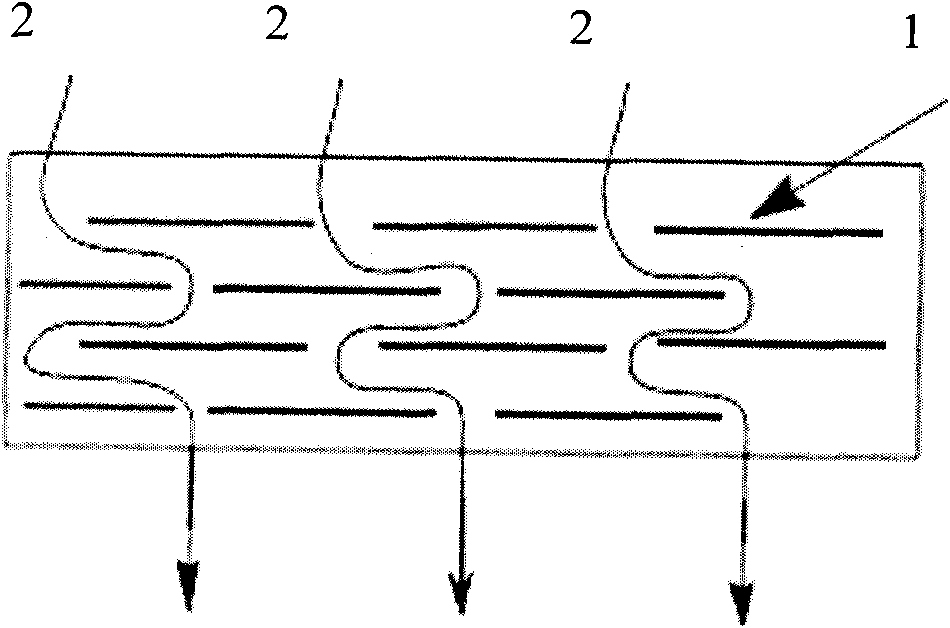

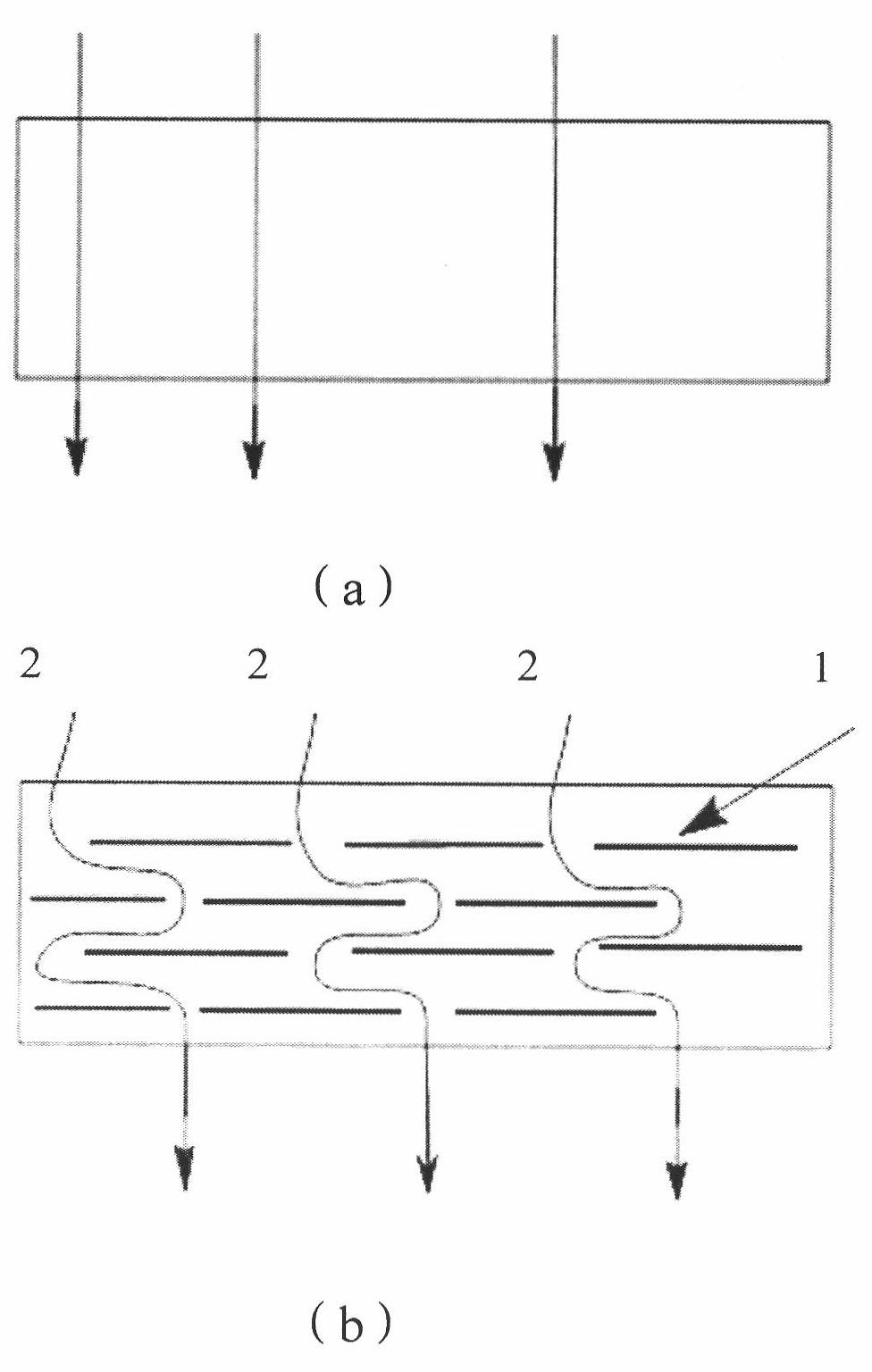

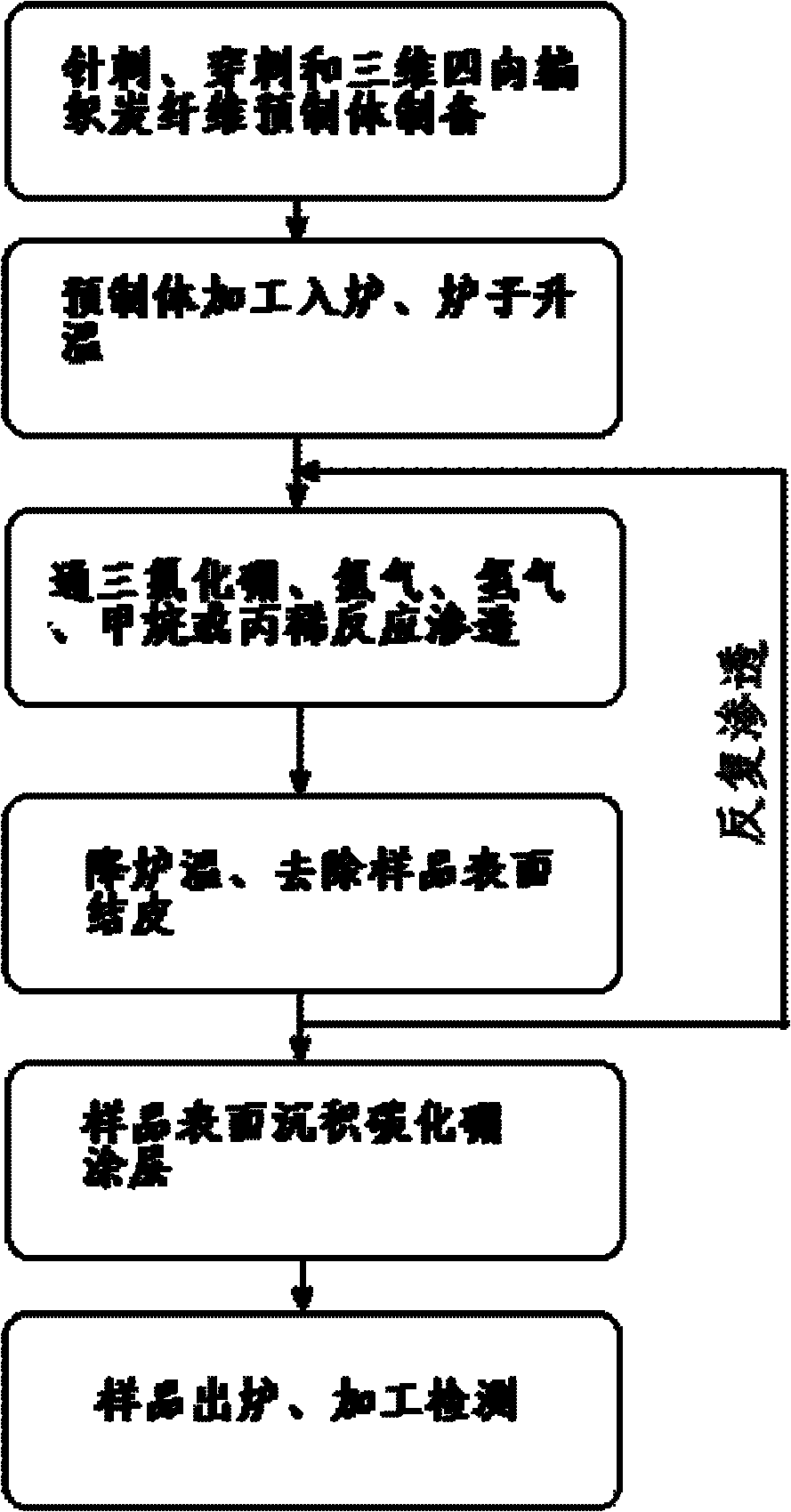

Carbon fiber reinforced boron carbide composite material and preparation method thereof

The invention relates to a carbon fiber reinforced boron carbide composite material and a preparation method thereof. The preparation method comprises the following steps of: preparing a carbon fiber preform by adopting a needling, puncturing or three-dimensional weaving process; and depositing boron carbide matrix in the porous carbon fiber preform by osmosis to form the compact carbon fiber reinforced boron carbide composite material. Aiming at a certain specific application environment, a boron carbide coat can be deposited on the surface of a sample by adopting the same chemical vapor osmosis process. The carbon fiber reinforced boron carbide-based composite material manufactured by the method has the characteristics of good mechanical property, toughness superior to that of the traditional sintered boron carbide, compact structure, light weight, abrasion resistance and high hardness, and is suitable to be applied to a high-temperature light structural component.

Owner:CENT SOUTH UNIV

Oxidized graphene and graphene reinforced cement based composite material and preparation method thereof

The invention relates to an oxidized graphene and graphene reinforced cement based composite material and a preparation method thereof. The oxidized graphene and graphene reinforced cement based composite material comprises the oxidized graphene, the graphene, a dispersing agent, a thickening stabilizer, a water reducer, a defoaming agent and a cement matrix, the mass ratio of the total mass of the oxidized graphene and the graphene to the cement matrix is (0.0005-0.5):1, and the mass ratio of the total mass of oxidized graphene and the graphene to the dispersing agent to the water reducer to the thickening stabilizer to the defoaming agent is 1:(0.05-10):(0.1-20):(0.1-20):(0.05-5). In the composite material, the oxidized graphene and the graphene are dispersed in the cement matrix uniformly; compared with the traditional cement material, the tensile strength, rupture strength and conductivity of the composite material are all improved remarkably; and the composite material has more excellent mechanical property and electrical property, and is applicable to the field of multifunctional construction materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

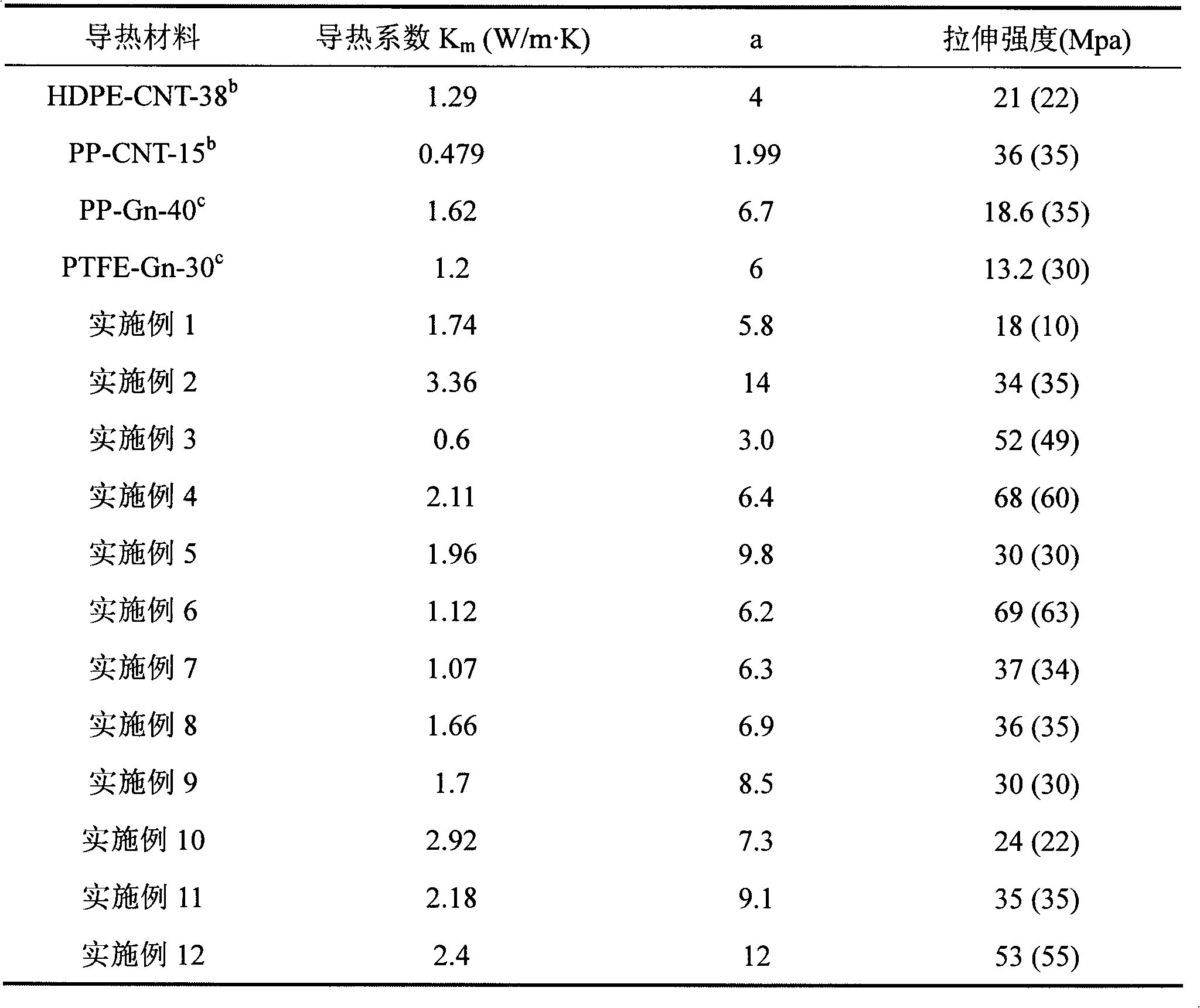

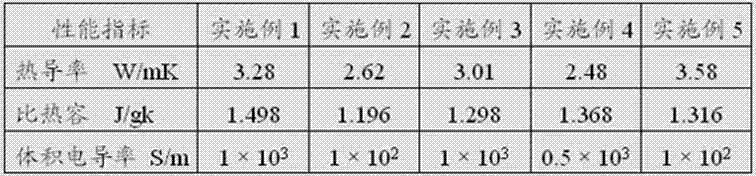

High-heat-conductivity composite material and preparation method thereof

InactiveCN102040761AImprove thermal conductivitySmall amount of thermally conductive fillerFiberCarbon fibers

The invention discloses a high-heat-conductivity composite material and a preparation method thereof. The preparation method comprises the following steps: evenly mixing fibrous heat-conduction filler and high-heat-conductivity filler graphene in a mass ratio of 1:1-1:200 with thermoplastic polymer, dispersing for 0.5-24 hours, granulating to obtain high-heat-conductivity composite grains, and putting the grains in a die to carry out hot molding at 170-280 DEG C under the pressure of 10-18 MPa. The thermoplastic polymer is any one of polyethylene, polypropylene, polyvinylidene fluoride, polytetrafluoroethylene, polyperfluoroalkoxy ester, nylon, polymethyl methacrylate, polycarbonate and polyvinyl chloride. The fibrous heat-conduction filler is carbon fiber or carbon nanotube, and the high-heat-conductivity filler accounts for 5-35 wt% of the high-heat-conductivity composite material. The high-heat-conductivity composite material has the advantages of excellent heat-conduction property, low consumption of heat-conduction filler, favorable mechanical properties, simple preparation technique and low cost.

Owner:SOUTH CHINA UNIV OF TECH

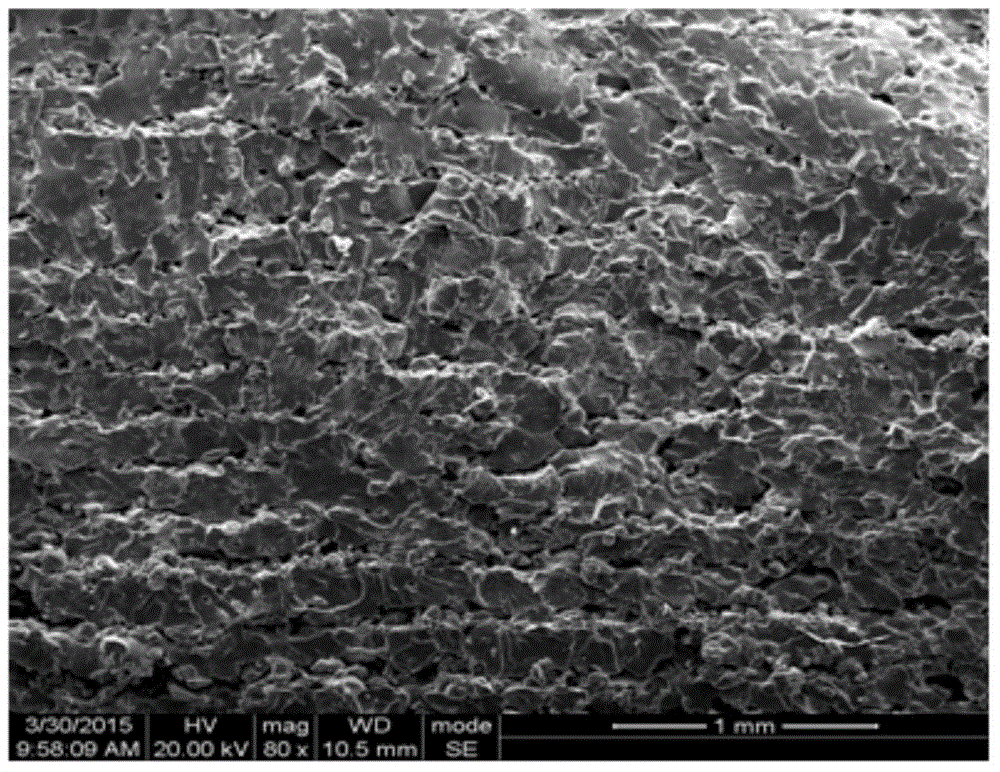

Surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and preparing method

ActiveCN105818476AMitigating Galvanic CorrosionImprove resilienceLamination ancillary operationsLaminationCarbon nanotubeFiber-reinforced composite

The invention discloses a surface-modification three-dimensional-network-carbon-fiber-reinforced composite material and a preparing method.Three-dimensional carbon fiber frameworks with different bore diameters are prepared as required, and after surface pretreatment, diamond, carbon nanometer tubes and graphene are subjected to chemical vapor deposition; then the mixture and matrix materials are compounded, wherein the matrix materials are metal or polymers; the carbon-fiber-reinforced metal-based or polymer-based composite material with the three-dimensional net-shaped framework structure is obtained.A three-dimensional continuous heat conduction channel is formed in the composite material through the surface-modification three-dimensional net-shaped carbon fibers, and therefore the heat conduction performance of the composite material is greatly improved; meanwhile, according to space distribution of carbon fibers in the matrix material, the mechanical performance of the composite material can also be improved, and the density and the thermal expansion coefficient can be decreased; the thermal expansion coefficient, the mechanical performance and the thermal performance can be further regulated and controlled by adding zero-dimensional particle reinforcement.

Owner:CENT SOUTH UNIV

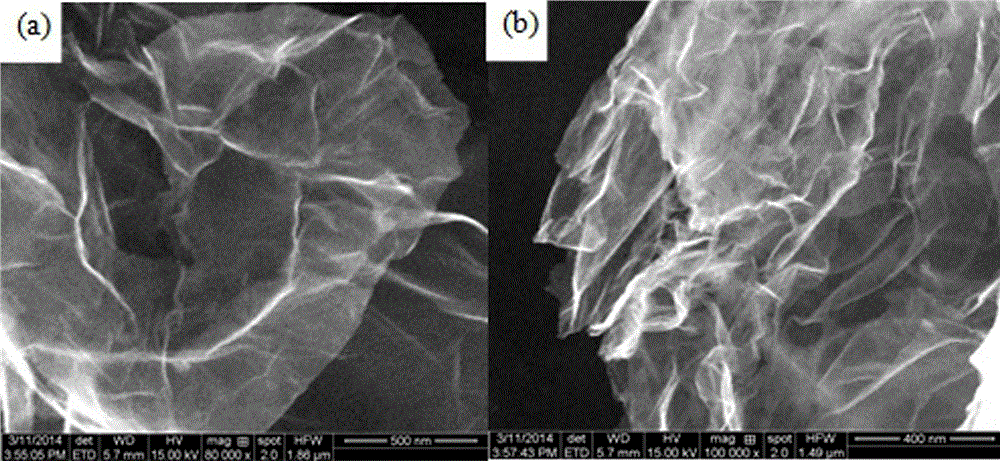

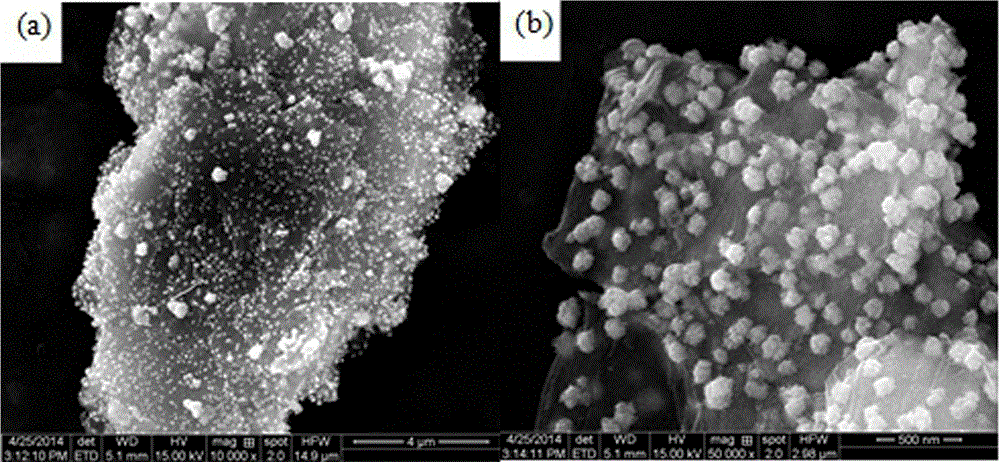

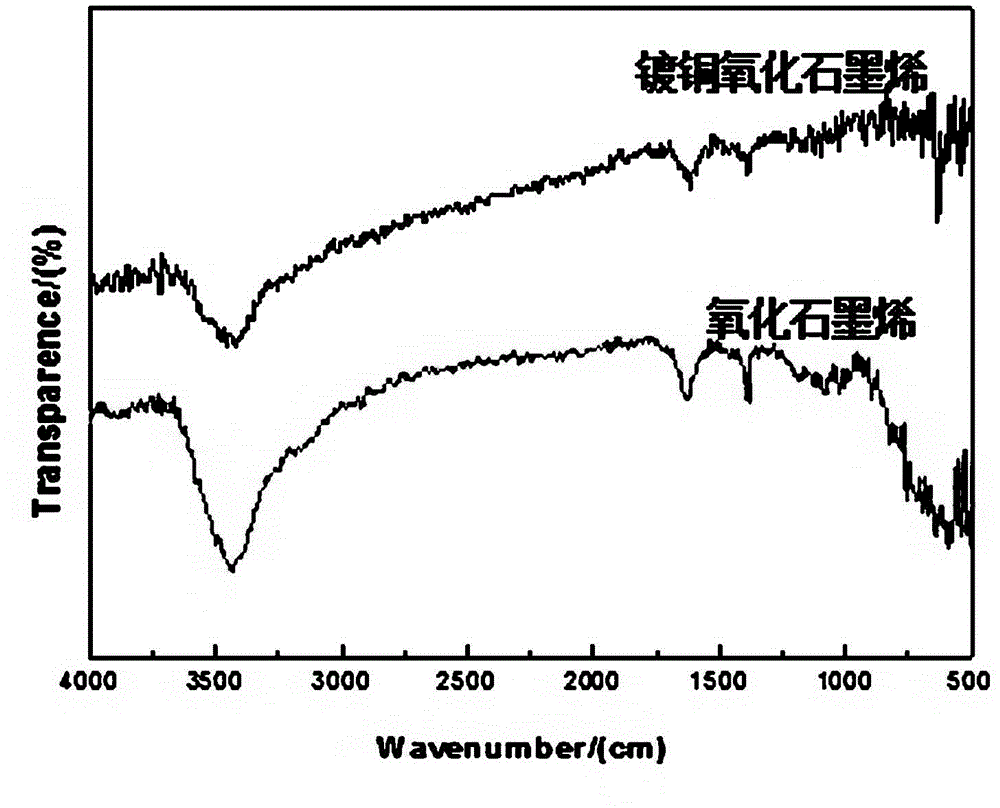

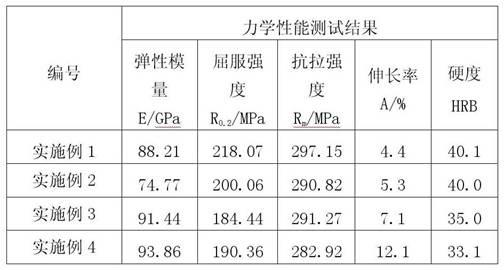

Preparation method of copper-plated graphene reinforced metal-based composite

InactiveCN104451227AInterface is well integratedHigh densityLiquid/solution decomposition chemical coatingMetallurgyMetal matrix composite

The invention discloses a preparation method of a copper-plated graphene reinforced metal-based composite. The preparation method comprises the following steps: firstly, chemically plating the surfaces of oxidized graphene powder with copper to obtain copper-plated graphene powder; ball-grinding and mixing the copper-plated graphene powder and metal powder to obtain copper-plated graphene / metal mixed powder; and performing warm-pressing forming to the copper-plated graphene / metal mixed powder by adopting powder metallurgy warm-pressing technology, sintering, and performing composite processing and forming by adopting extrusion, forging, rolling and other technologies. The copper-plated graphene powder is adopted as a reinforcing body, the preparation method is simple, the cost is low, the designability is strong, and the copper-plated graphene reinforced metal-based composite which is good in interface binding, high in compactness and good in mechanical performance and thermophysical performance can be obtained.

Owner:UNIV OF JINAN

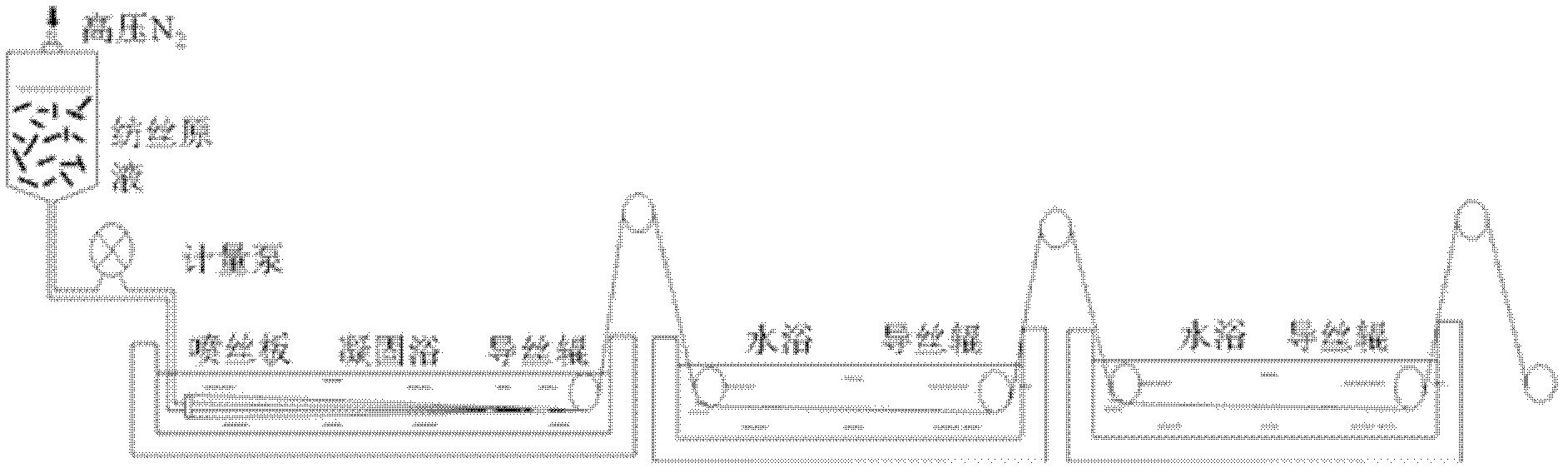

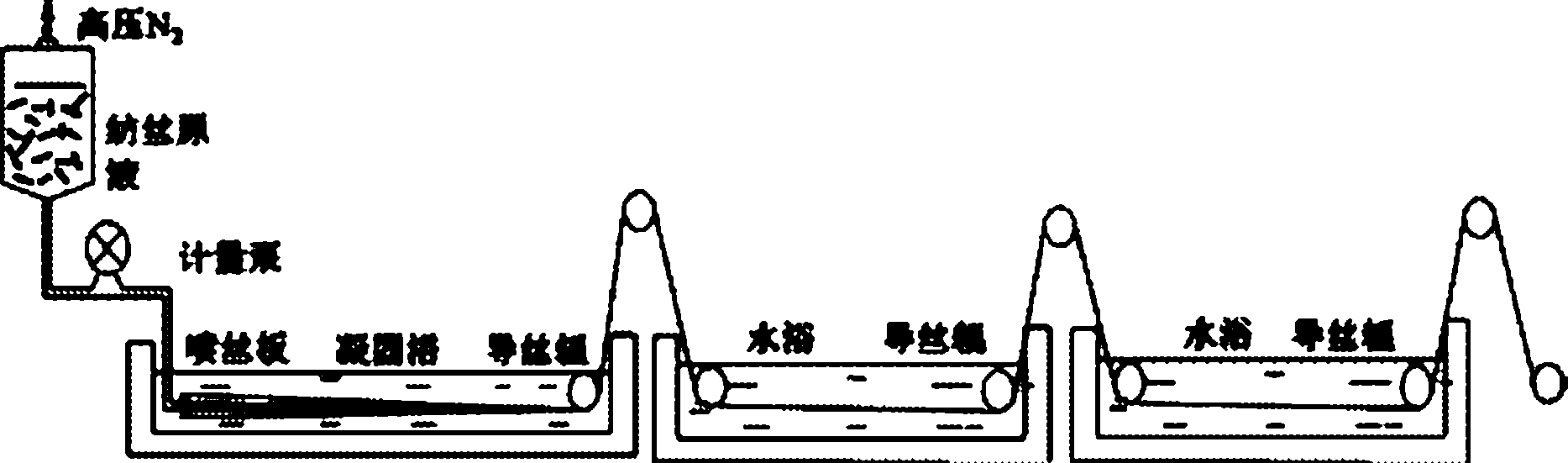

Method for manufacturing polyacrylonitrile-based carbon fiber with enganced carbon nano-tube

InactiveCN101250770ASimple preparation processEasy to controlArtifical filament manufactureCarbon fibersHeat conducting

The invention relates to a method for preparing polyacrylonitrile-based carbon fiber with reinforced carbon nanometer tubes, which comprises the following steps: respectively dispersing and dissolving carbon nanometer tubes (CNT) and polyacrylonitrile (PAN) in dissolvent, obtaining PAN / CNT spinning solution through mixing the solution, obtaining PAN / CNT fiber through carrying out the wet-spinning method to the solution, then carrying out pre-oxidation and carbonization to the wet-spinning fiber to prepare the carbon fiber with reinforced carbon nanometer tubes. The mechanical property of the carbon fiber which is prepared by the method of the invention is obviously improved, and the prepared carbon fiber can be applied to the fields of reinforcing materials, conducting, electrostatic resistance, heat conducting and the like.

Owner:DONGHUA UNIV

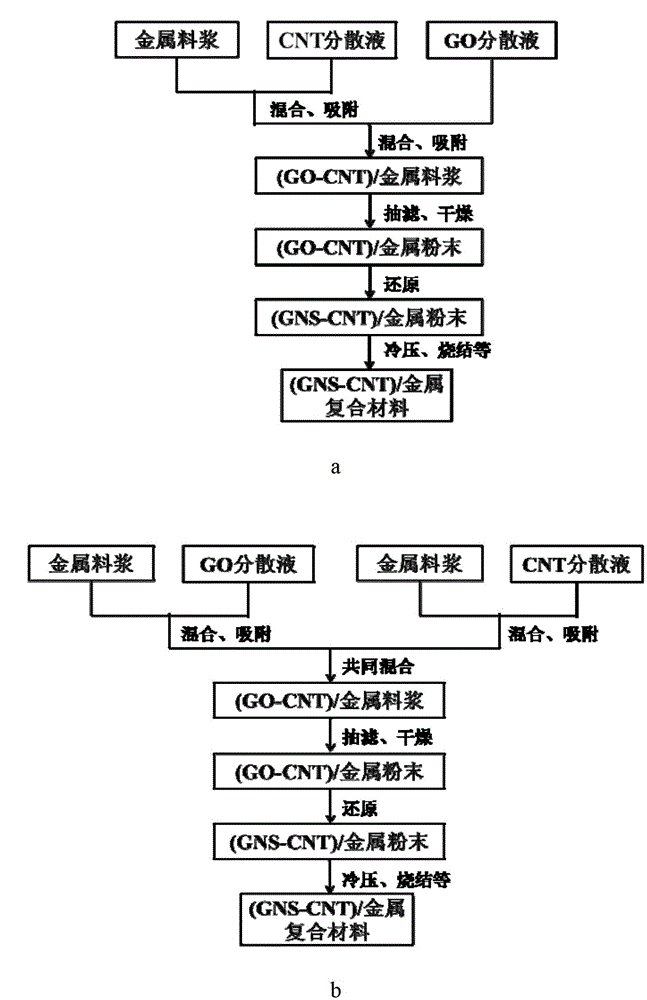

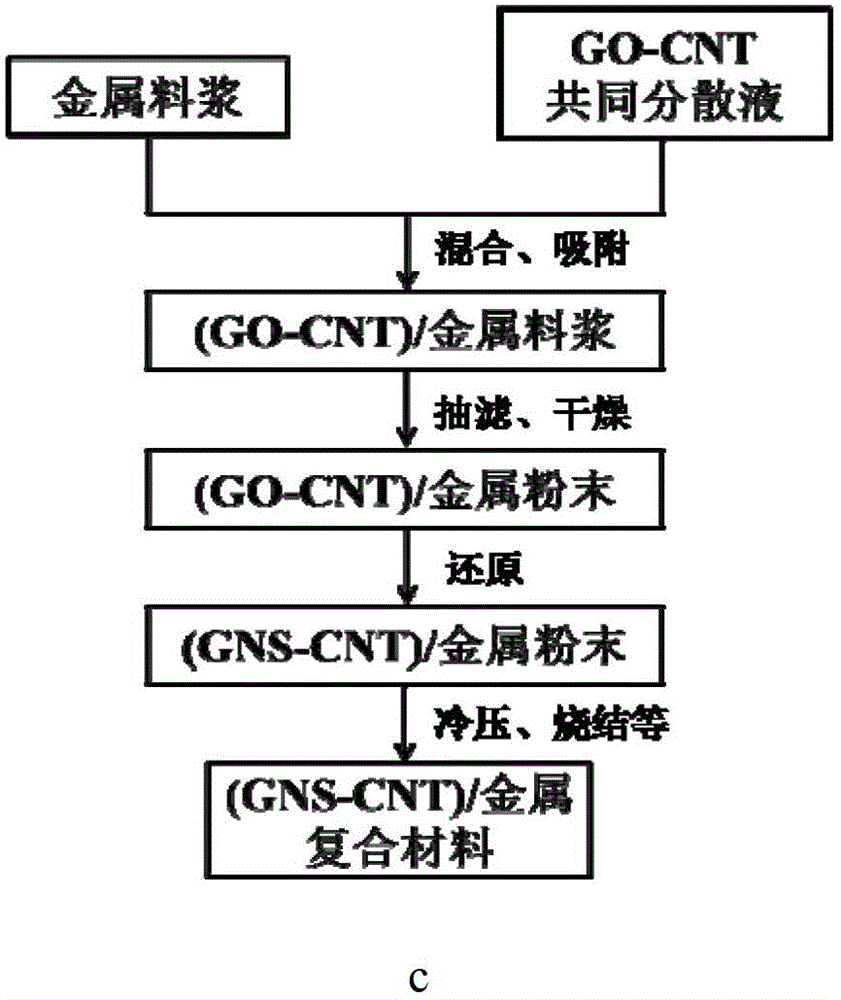

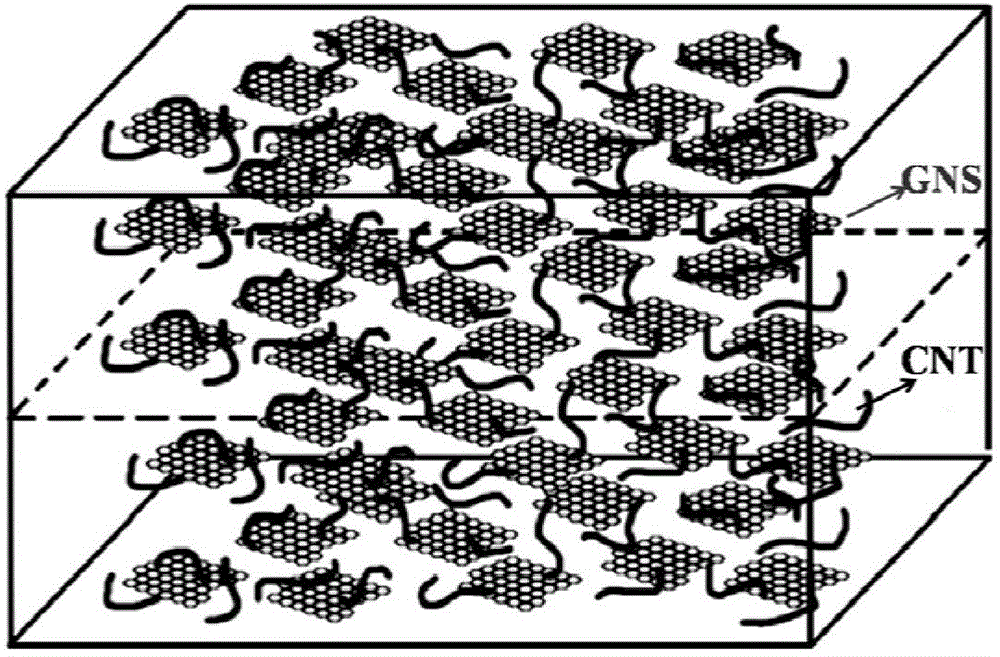

Graphene and carbon nanotube mixed enhanced metal-matrix composite material and preparation method thereof

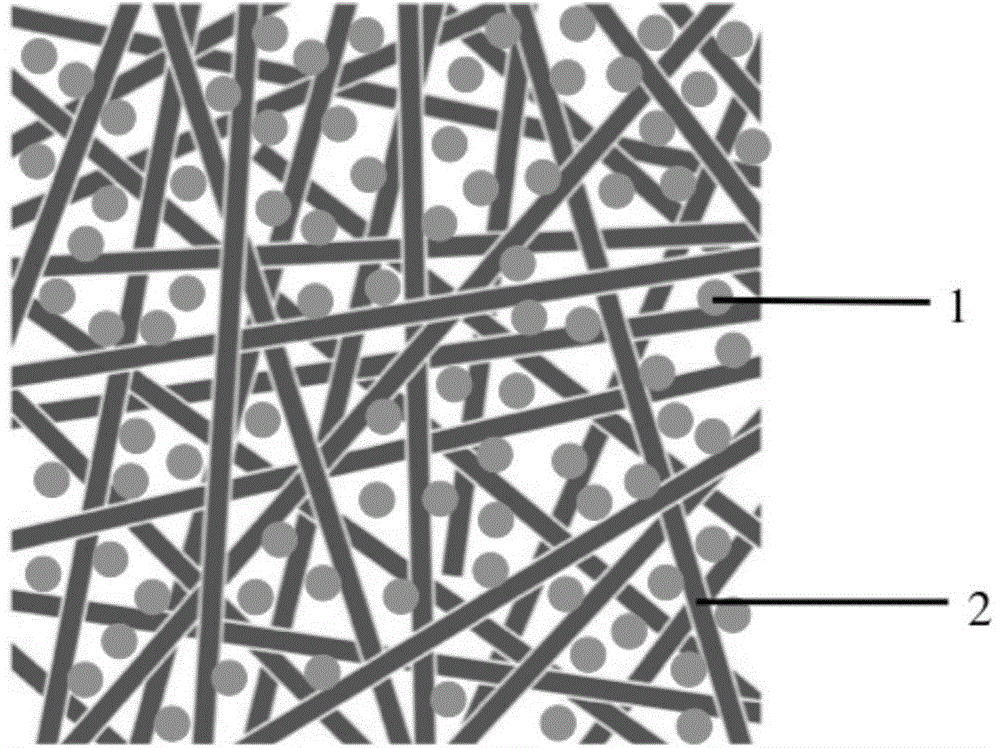

The invention discloses a graphene and carbon nanotube mixed enhanced metal-matrix composite material and a preparation method thereof. The graphene and carbon nanotube mixed enhanced metal-matrix composite material is characterized in that graphene and a carbon nanotube are mutually connected to constitute an enhanced network in a metal matrix, wherein the graphene is few-layer graphene with 10 layers or less, the radius-thickness ratio of the graphene is larger than 200, and the volume fraction of the graphene is 0.1-1%; and the carbon nanotube is a single-wall, double-wall or multi-wall carbon nanotube, the length-diameter ratio of the carbon nanotube is larger than 20, and the volume fraction of the carbon nanotube is 0.5-5%. Compared with the composite material enhanced only by the carbon nanotube, the graphene and carbon nanotube mixed enhanced metal-matrix composite material disclosed by the invention not only has greatly improved mechanical properties, but also has more excellent electric conduction and heat conduction properties, and is a multi-purpose structure and function integrated material. In addition, the preparation method provided by the invention based on slurry blending and graphene oxide reduction is simple and efficient and is easy for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing grapheme reinforced aluminum matrix composite material

The invention relates to a method for preparing a grapheme reinforced aluminum matrix composite material. The method aims at solving the technical problems that in an existing method for preparing the grapheme reinforced aluminum matrix composite material, the grapheme dispersibility is poor, and agglomeration is prone to happening. The method includes the steps that (1) oxidized grapheme is prepared; (2) surface modification on aluminum powder is carried out; (3) oxidized grapheme-aluminum composite powder is prepared; and (4) the grapheme reinforced aluminum matrix composite material is prepared. An electrostatic self-assembly method is adopted in the method, so that graphene is evenly dispersed in an aluminum matrix to enable the graphene to be more evenly dispersed, phenomena of damage to graphene size and work hardening generated on the aluminum matrix during ball-milling treatment are avoided, and graphene agglomeration is prevented; in addition, the mechanical property of the composite material is obviously improved; and compared with a pure aluminum material, the strength of extension is improved by 10%-20%, and the hardness is improved by 10%-30%.

Owner:HARBIN UNIV OF SCI & TECH

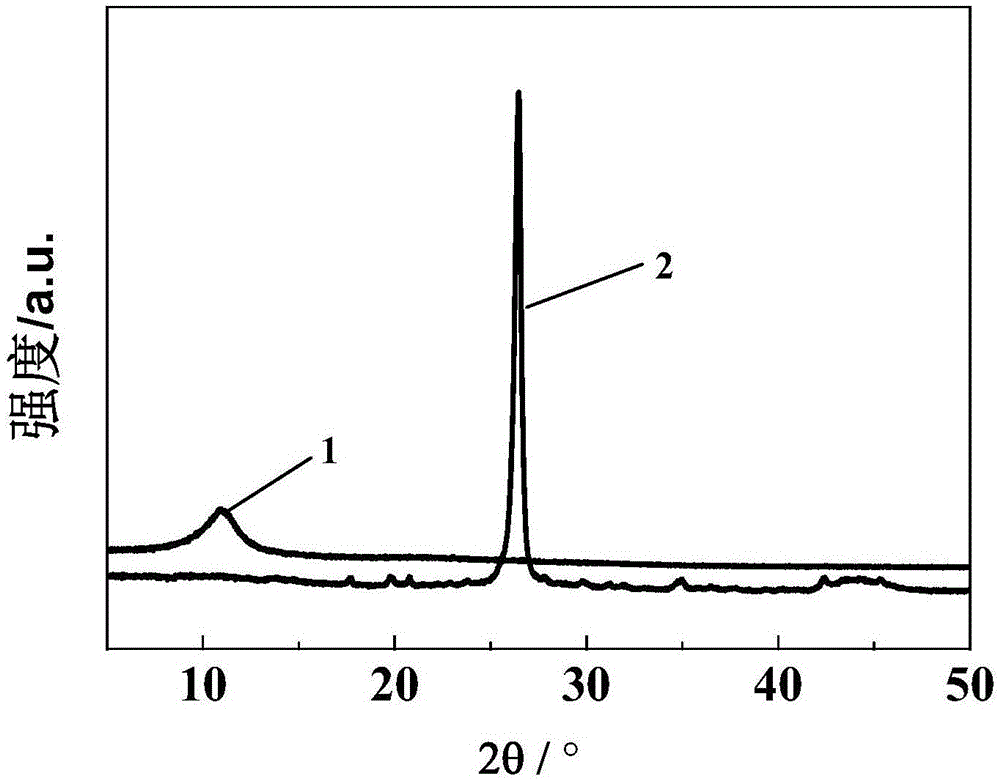

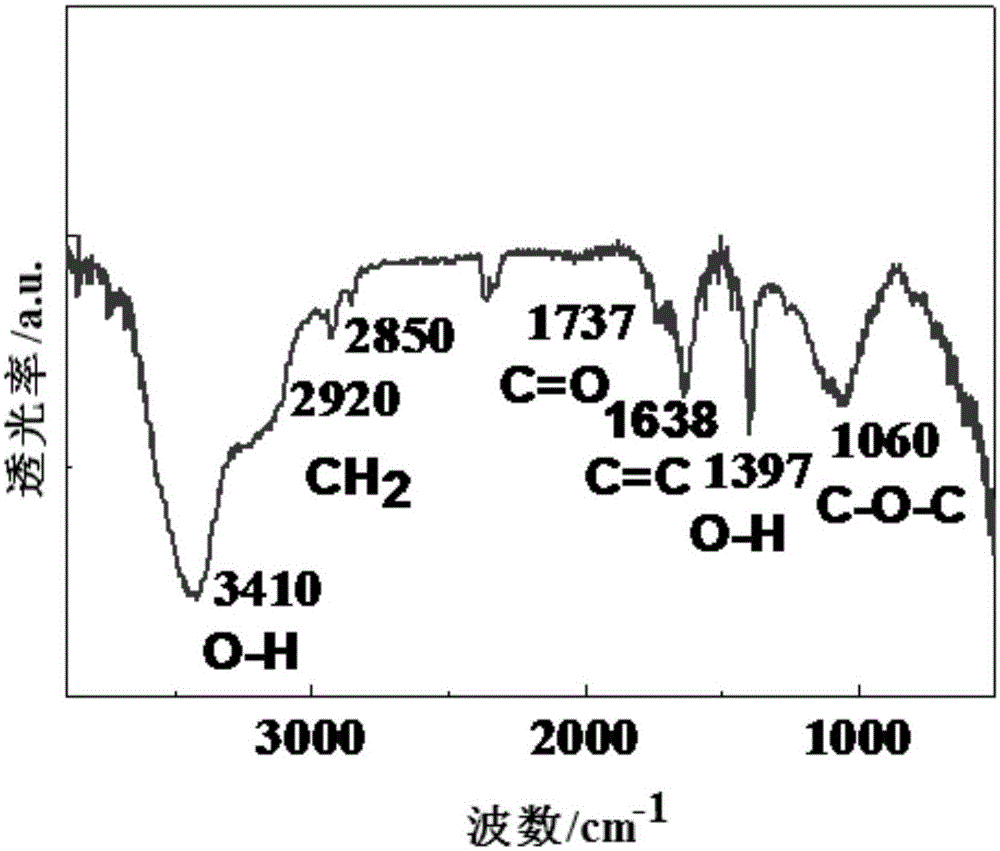

Method for preparing graphene-reinforced polyacrylonitrile carbon fibers

InactiveCN102586952AGood dispersionImprove bindingArtifical filament manufactureCarbon fibersCvd graphene

The invention relates to a method for preparing graphene-reinforced polyacrylonitrile carbon fibers. The method comprises the following steps of: (1) preparing graphene or graphene oxide; (2) preparing a graphene / polyacrylonitrile spinning solution; (3) preparing graphene / polyacrylonitrile-based composite fibers; and (4) preparing graphene / polyacrylonitrile-based carbon. By the method, the dispersibility and interface bonding strength of the graphene oxide in a polymer matrix are effectively improved, and the comprehensive performance of the carbon fibers is further improved; the mechanical properties of the prepared carbon fibers are obviously improved, and the prepared carbon fibers can be used in the fields such as material reinforcement, electric conduction, anti-static electricity and heat conduction; and moreover, the preparation process is simple, easy to control and low in cost.

Owner:DONGHUA UNIV

Preparation method of self-adhesion electroconductive hydrogel

The invention discloses a preparation method of self-adhesion electroconductive hydrogel and belongs to the technical field of biomaterial preparation. The preparation method includes following steps: introducing double bonds on biomacromolecules through methyl acrylic anhydridization to obtain double-bond biomacromolecules; preparing a polydopamine-functionalized electroconductive nano material, and polymerizing the double-bond biomacromolecules and the polydopamine-functionalized electroconductive nano material through photo-initiated free radicals to obtain the self-adhesive electroconductive hydrogel. With reference to adhesiveness of mussel-imitated materials, phenolic hydroxyl functional group with adhesiveness is introduced, and regulation of self-adhesion performance of the hydrogel is realized by changing content of the phenolic hydroxyl functional group. In addition, the self-adhesion electroconductive hydrogel prepared by the method has high electroconductivity, mechanical performance and biocompatibility, and application range of the hydrogel is widened. The preparation method has the advantages of being simple and easy to implement, controllable in polymerization process, high in polymerization speed and low in energy consumption.

Owner:SOUTHWEST JIAOTONG UNIV

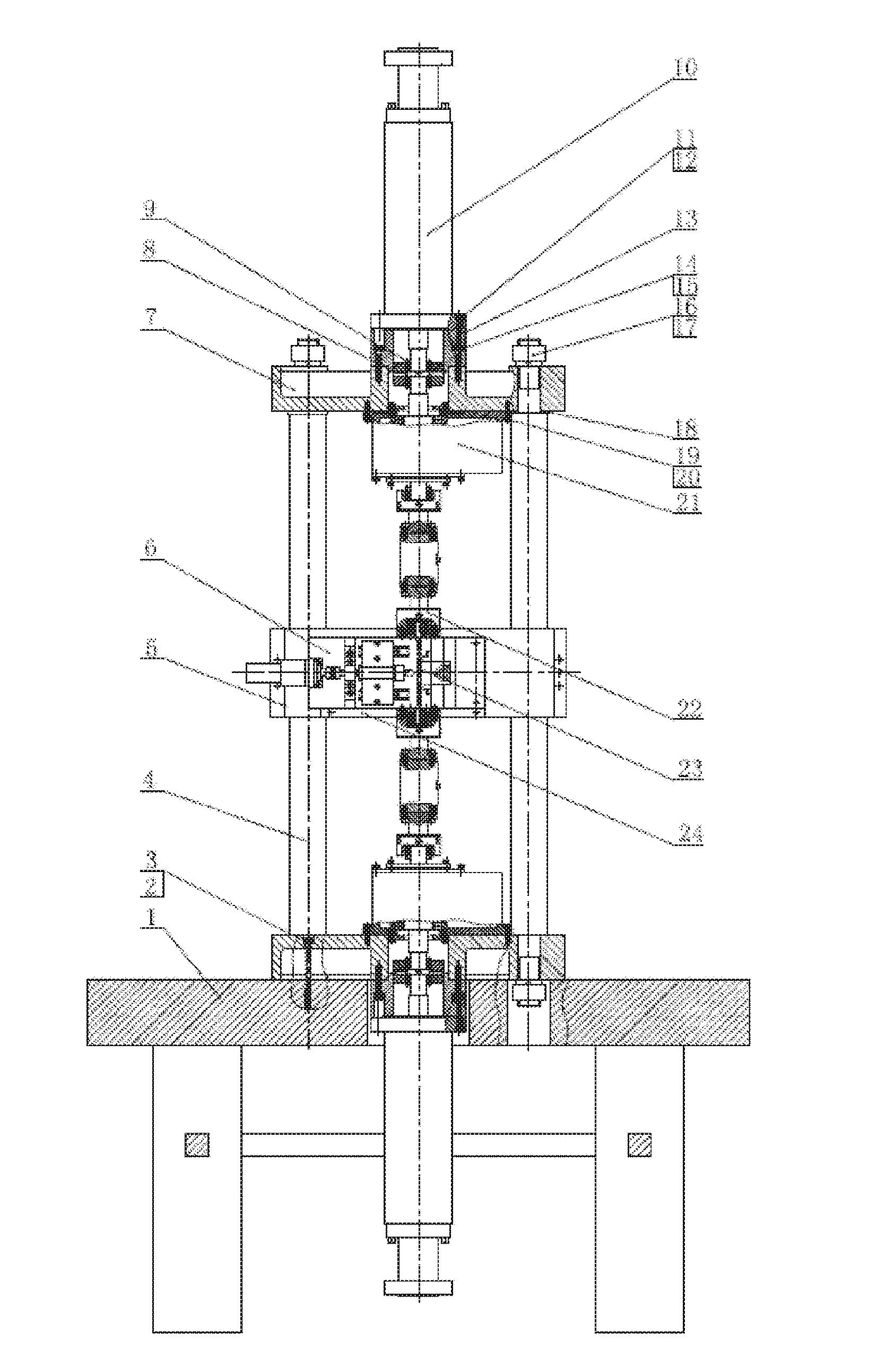

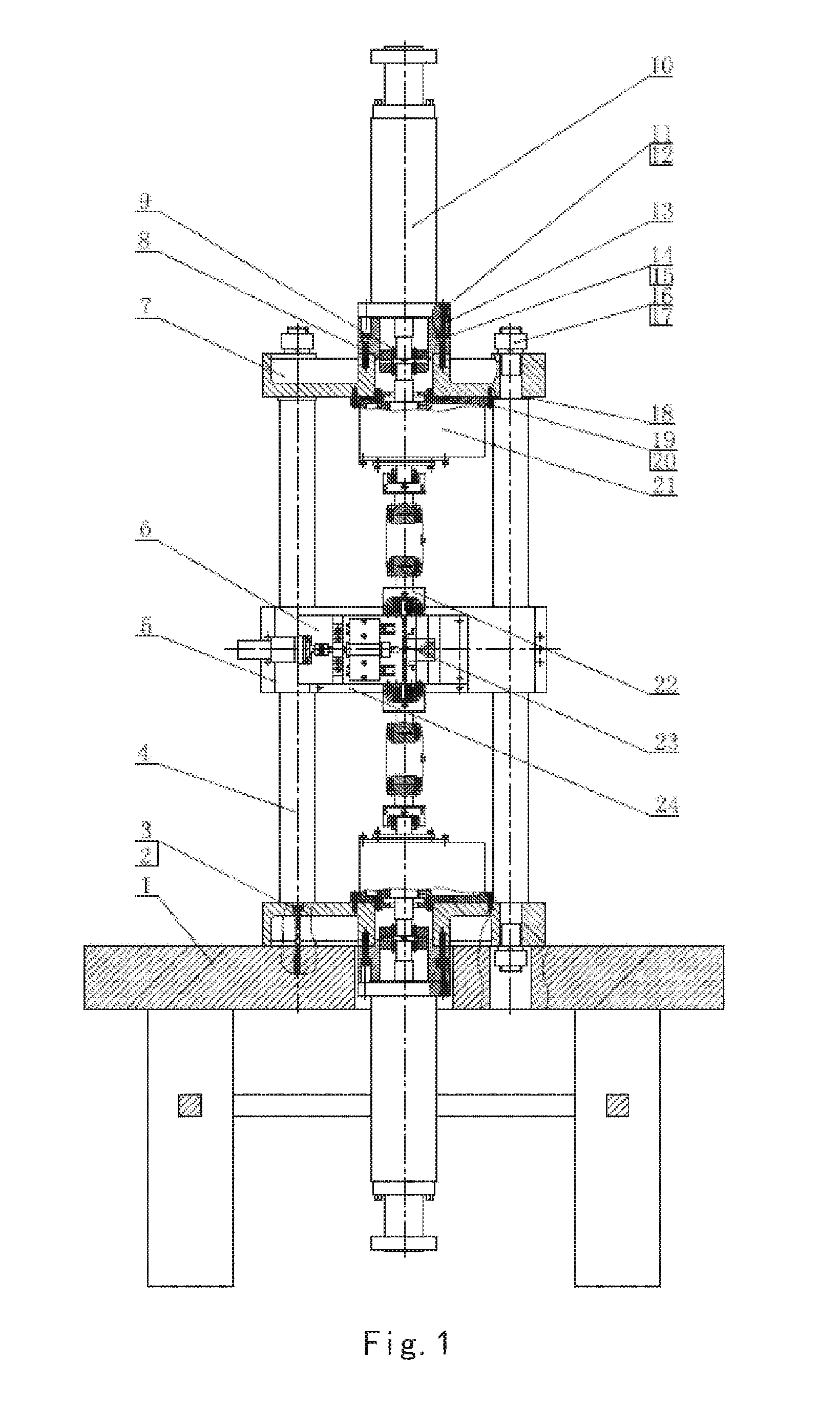

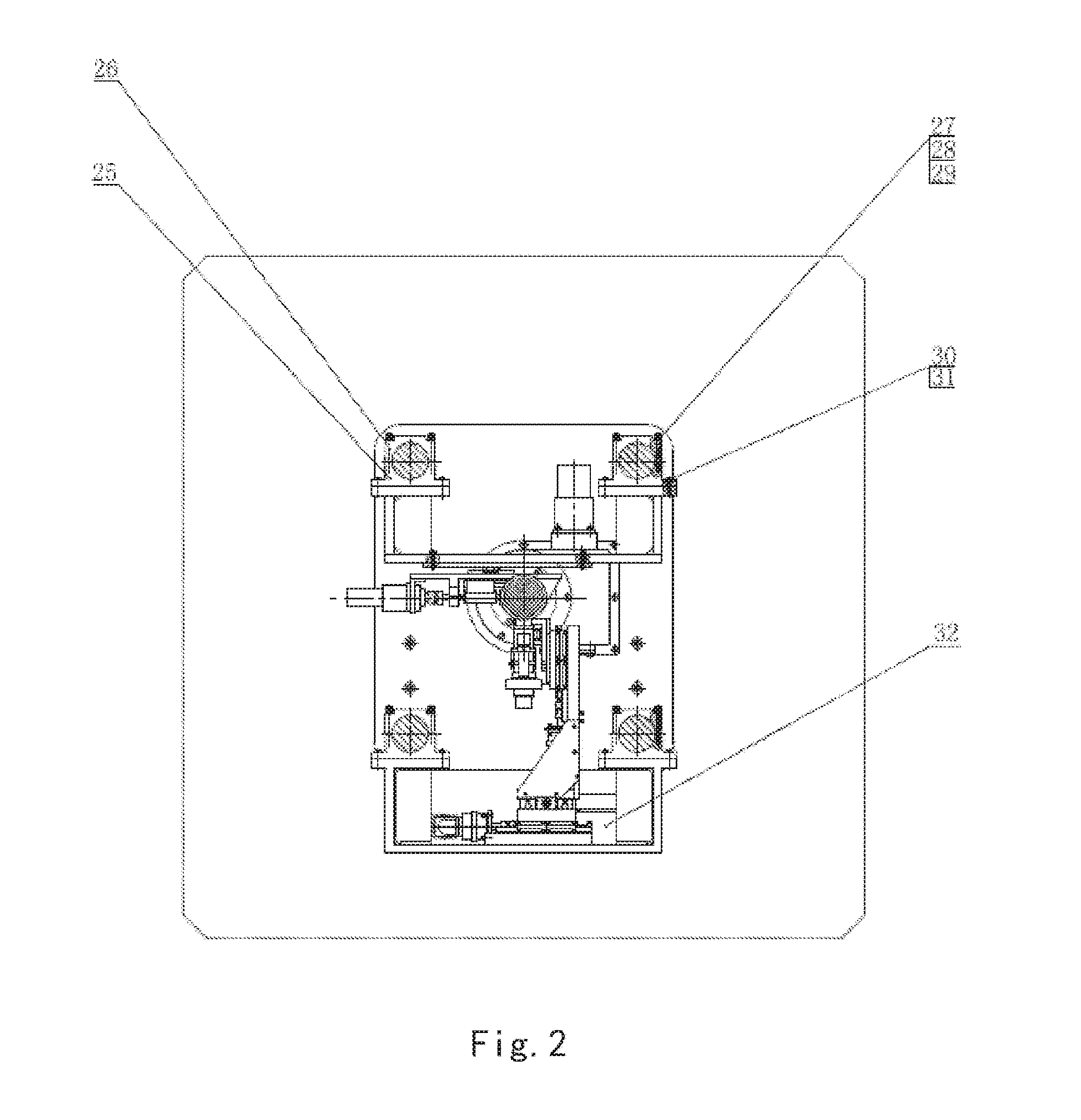

In-situ testing equipment for testing micromechanical properties of material in multi-load and multi-physical field coupled condition

ActiveUS20160216182A1Innovative structureEffective testingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTesting equipmentTest material

An in-situ testing equipment for testing micromechanical properties of a material in a multi-load and multi-physical field coupled condition is disclosed. The equipment comprises a frame supporting module, a tension / compression-low cycle fatigue module, a torsioning module (21), a three-point bending module (6), an impressing module (33), a thermal field and magnetic field application module (34), an in-situ observation module (32) and a clamp body module (22). The frame supporting module provides a structural support for the whole testing equipment, the tension / compression-low cycle fatigue module is arranged at upper and lower ends of the testing equipment, the torsioning module (21) is directly arranged at a front end of the tension / compression-low cycle fatigue module, the three-point bending module (6), the impressing module (33) and the thermal field and magnetic field application module (34) are disposed on a support post at one side of the whole testing equipment through a common replacing component, and the in-situ observation module is disposed on another support post at the other side of the testing equipment. The clamp body module is connected to a front segment of the torsioning module, so as to clamp a test piece. An overall structure of the testing equipment is configured in a vertically symmetrical arrangement achieved by using four support posts. Two identical servo hydraulic cylinders (10) and two torsioning modules (21) are located at the upper and the lower ends of the testing equipment respectively and are used to perform a symmetrical tension / compression test and a symmetrical torsion test on the test piece (23) positioned centrally. The testing equipment is capable of realizing applications of five different types of loads including tension / compression, low cycle fatigue, torsion, bending and impressing, performing an intensive study on micromechanical properties of the material in the multi-load and multi-physical field coupled condition by using built-in electric, thermal and magnetic application modules and the in-situ observation module, and acquiring relations between deformation behavior, mechanism of damage, performance weakening of the material, applied loads and material properties.

Owner:JILIN UNIV

Graphene filled polymer matrix composite material and its preparation method

ActiveCN103087404AImprove conductivityImprove thermal conductivityIn situ polymerizationMechanical property

The invention discloses a graphene filled polymer matrix composite material. The composite material is prepared through using 90-99 parts by weight of a thermoplastic resin, 0.1-10 parts by weight of a graphene microchip, 0.01-1 part of a coupling agent, and 1-10 parts of a lubricant. The invention also discloses a preparation method of the graphene filled polymer matrix composite material. Compared with other carbon system filled composite materials, the graphene filled polymer matrix composite material has the advantages of easy processing, easy forming, less filler filling amount, wide raw material source, environmental protection and the like. The composite material has the characteristics of excellent electric conductivity, excellent thermal conductivity, good mechanical properties, good dimensional stability, good weather resistance and the like; and compared with present technologies for preparing a graphene / polymer composite material through in-situ polymerization or solution polymerization, the melt blending method for preparing the graphene filled polymer matrix composite material in the invention has the advantages of continuous production, suitableness for the large-scale production, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for preparing B4C-Al composite material

ActiveCN102094132ALower requirementEasy to processAluminium alloyMechanical properties of carbon nanotubes

The invention relates to a method for preparing a B4C-Al composite material, which is characterized by comprising the following steps of: 1, uniformly mixing a certain proportion of raw material boron carbide powder with aluminum alloy powder in a high-energy ball milling way; 2, compressing the uniformly-mixed power for molding; 3, sintering compression-molded compact in the step 2 at certain temperatures; 4, extruding sintered compact sintered in the step 3 at certain temperatures; and 5, conducting multiple-time hot rolling for the extruding-molded material in the step 4 at certain temperatures to obtain B4C-Al composite boards. By adopting the preparation method in the invention, the ball milling efficiency is high, the preparation process almost has no material loss, and the prepared B4C-Al composite boards have the characteristics of uniform distribution of boron carbide and good mechanical property and can be applied to neutron absorption / shielding.

Owner:ANHUI YINGLIU JIUYUAN NUCLEAR ENERGY NEW MATERIAL TECH CO LTD

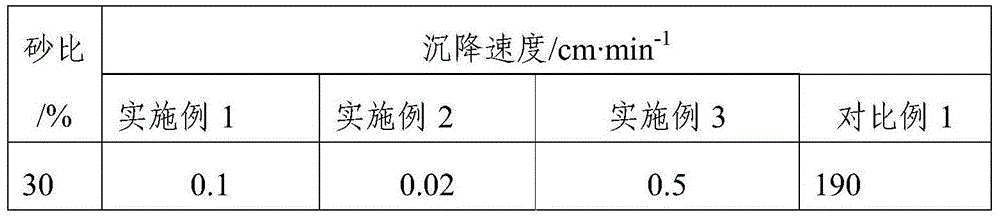

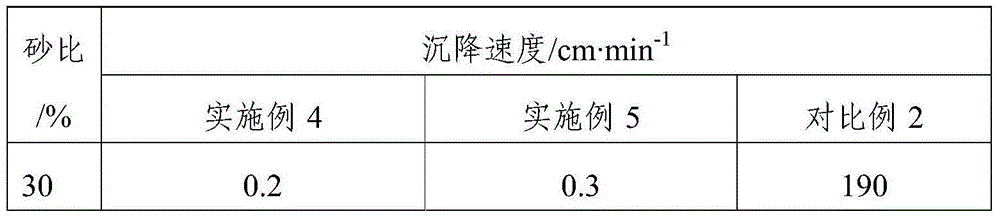

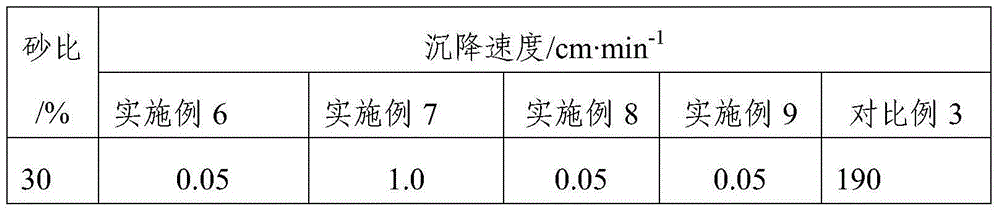

Preparation method of self-suspension proppant for natural hydrofracturing construction

The invention provides a preparation method of a self-suspension proppant for natural hydrofracturing construction, which comprises the following steps: by using 6-200-mesh granules as aggregate, adding an adhesive solution accounting for 10-30 wt% of the aggregate into the aggregate, and adding a water-soluble high polymer material accounting for 0.1-5 wt% of the aggregate; and stirring uniformly, drying and screening. The optimal selection of the raw materials and technological conditions greatly enhances the mechanical properties of the proppant. The obtained proppant has the advantages of small friction resistance and high strength, can be suitable for high-temperature conditions, and can be easily recovered; and the used coating material can not cause environmental pollution.

Owner:BEIJING RECHSAND SCI & TECH GRP

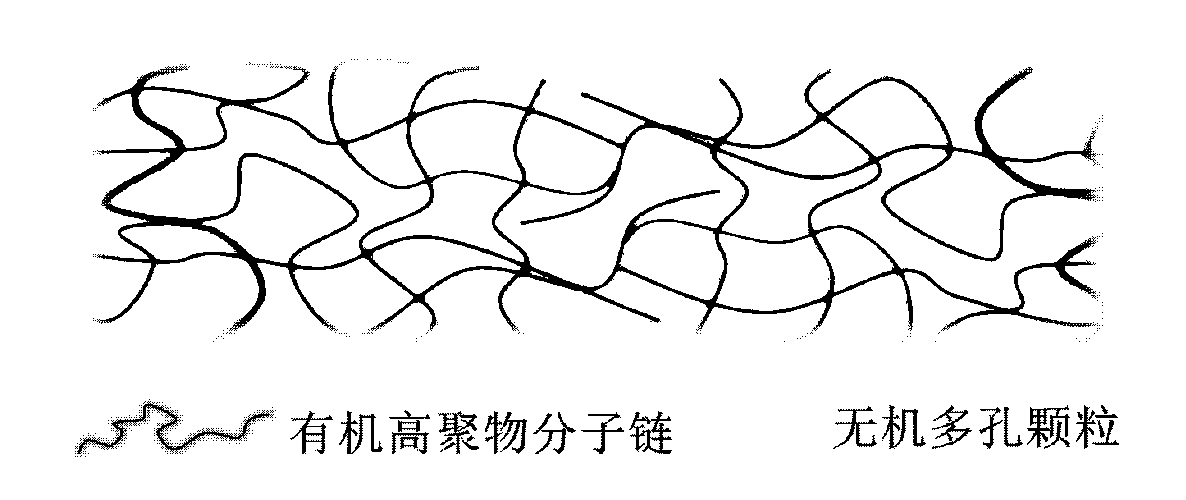

Organic-inorganic composite membrane as well as preparation and application thereof

ActiveCN103311486AChange structureImprove thermal stabilityCell component detailsLithium-ion batteryMechanical property

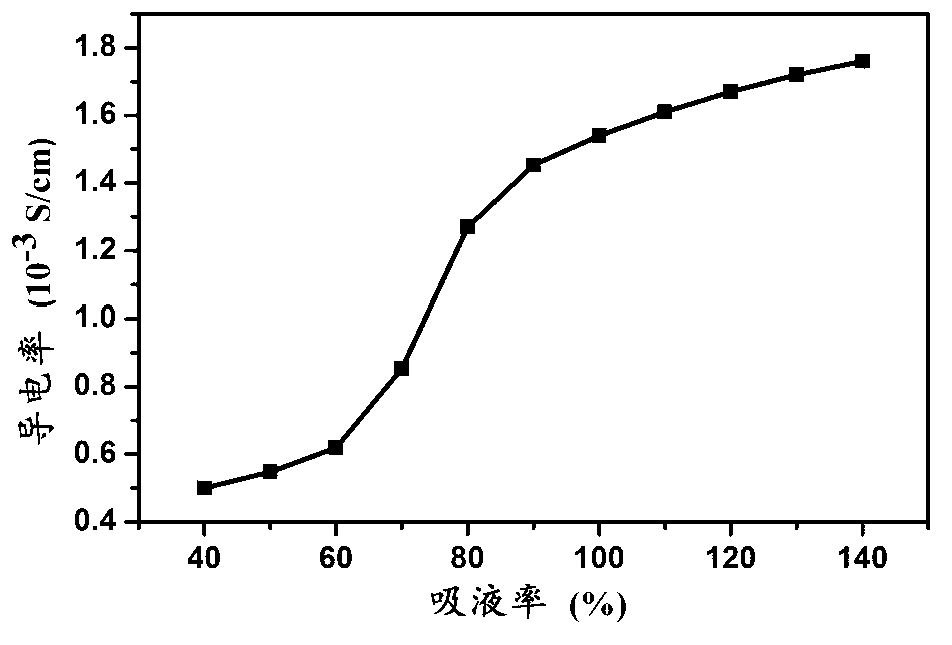

The invention discloses an organic-inorganic composite membrane as well as preparation and application thereof, and belongs to the technical field of preparation of a lithium ion battery material. The organic-inorganic composite membrane is prepared from inorganic particles and a high-molecular polymer, wherein the inorganic particles are evenly embedded and distributed inside the high-molecular polymer, and are selected from layered inorganic materials and / or porous inorganic materials; the mass ratio of the inorganic particles to the high-molecular polymer is (5-20):1; the particle sizes of the inorganic particles are 2-100nm. The organic-inorganic composite membrane disclosed by the invention has good mechanical property and lithium ionic conduction ability after absorbing electrolyte; the composite membrane has excellent safety performance after being prepared into an electric element, and is suitable for being applied to the field of a large battery, especially a large fixation energy storage battery. The organic-inorganic composite membrane is simple and feasible in preparation technology, and conveniently achieves industrial production.

Owner:王海斌

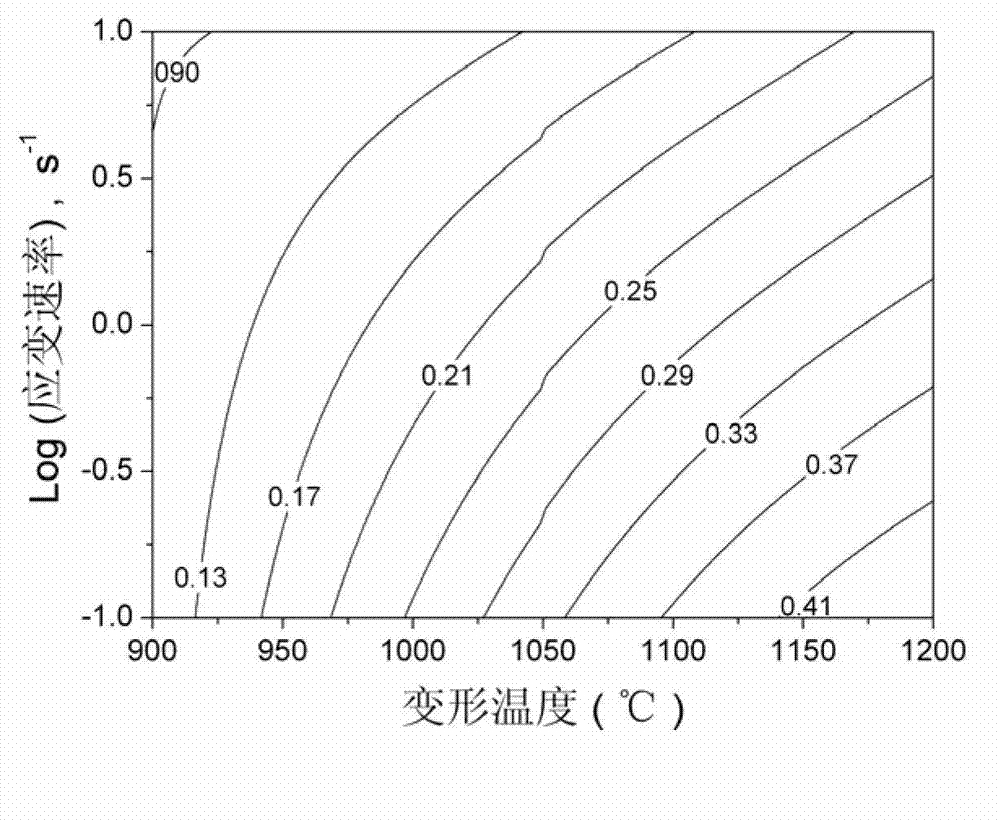

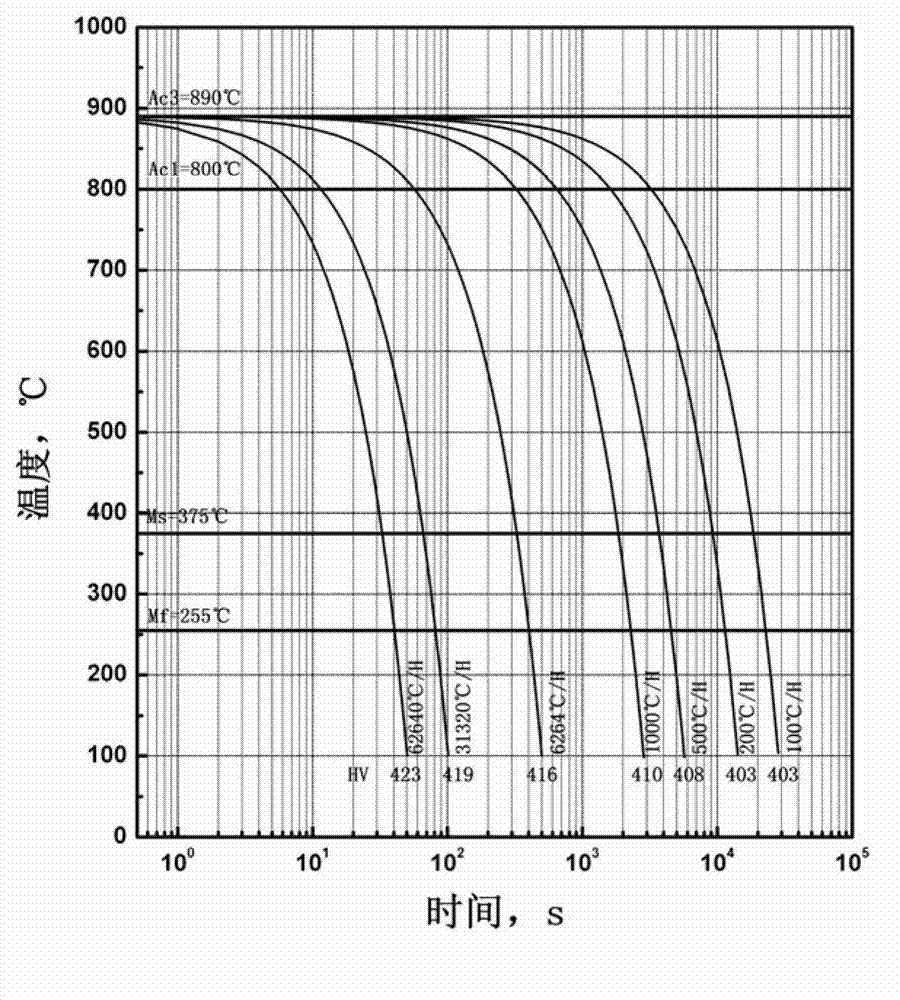

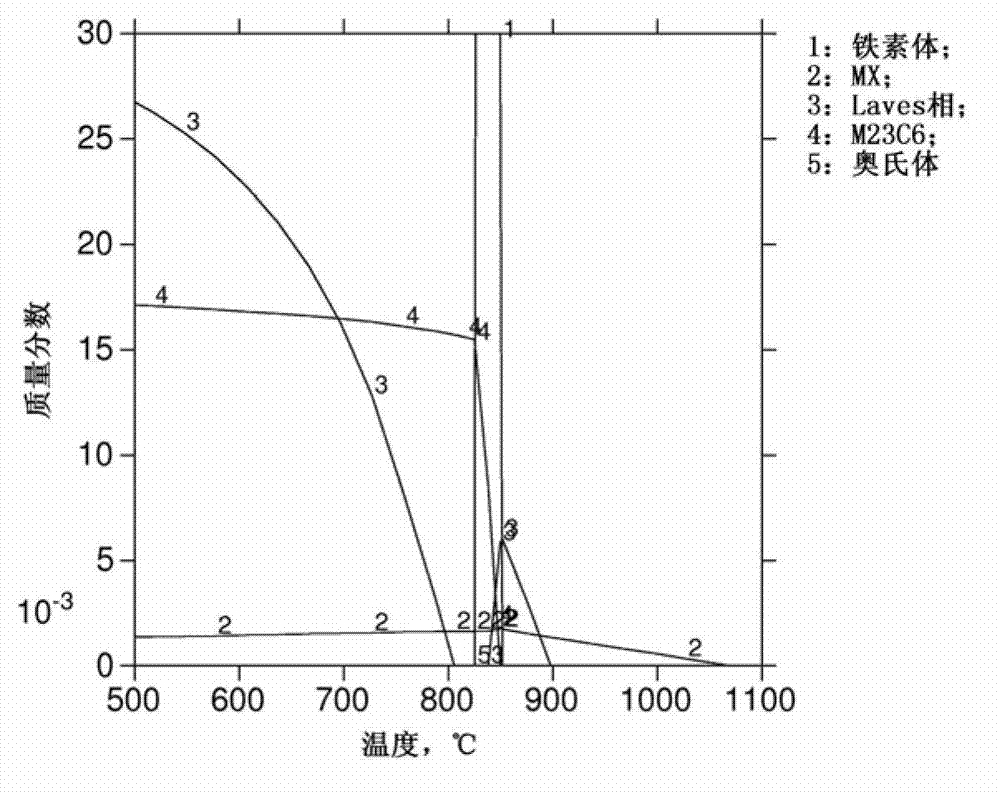

Steel for steam-temperature ultra-supercritical thermal power unit and preparation method thereof

The invention relates to steel for a steam-temperature ultra-supercritical thermal power unit and a preparation method thereof, belonging to the technical field of heat resistant steel. The steel comprises the following chemical compositions by weight percentage: 0.06-0.10 percent of carbon, 0.1-0.5 percent of silicon, 0.2-0.8 percent of manganese, not more than 0.004 percent of phosphorous, not more than 0.002 percent of sulfur, 8.0-9.5 percent of chromium, 2.5-3.5 percent of tungsten, 2.5-3.5 percent of cobalt, 0.03-0.07 percent of niobium, 0.10-0.30 percent of vanadium, 0.80-1.20 percent of copper, 0.006-0.010 percent of nitrogen, 0.010-0.016 percent of boron, 0.01-0.04 percent of rare-earth cerium, not more than 0.01 percent of nickel, not more than 0.005 percent of aluminum, not more than 0.01 percent of titanium, not more than 0.01 percent of zirconium and the balance of ferrum and inevitable impurity elements. The steel has the advantages that the steel can be used for preparing G115 steel of 650 DEG C of steam-parameter ultra-supercritical thermal power unit and a large-diameter boiler tube thereof, and the room-temperature mechanical property, the impact property, the high-temperature mechanical property and the permanence property of the steel are much higher than those of P92 steel in the Gb5310 and ASME standard.

Owner:CENT IRON & STEEL RES INST

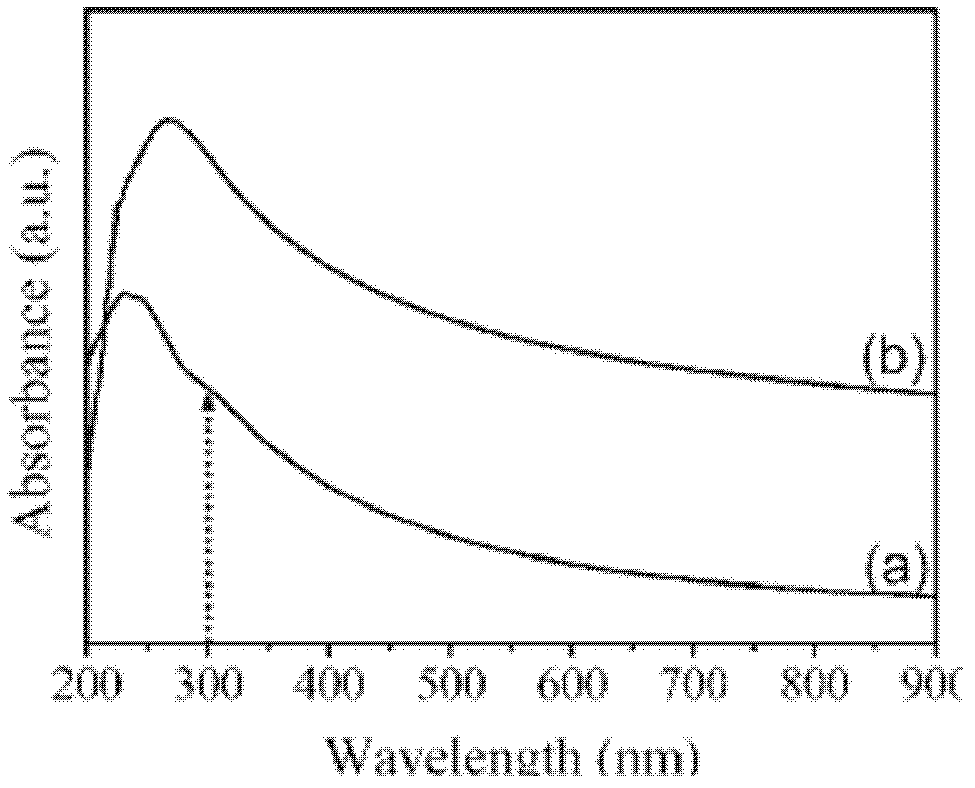

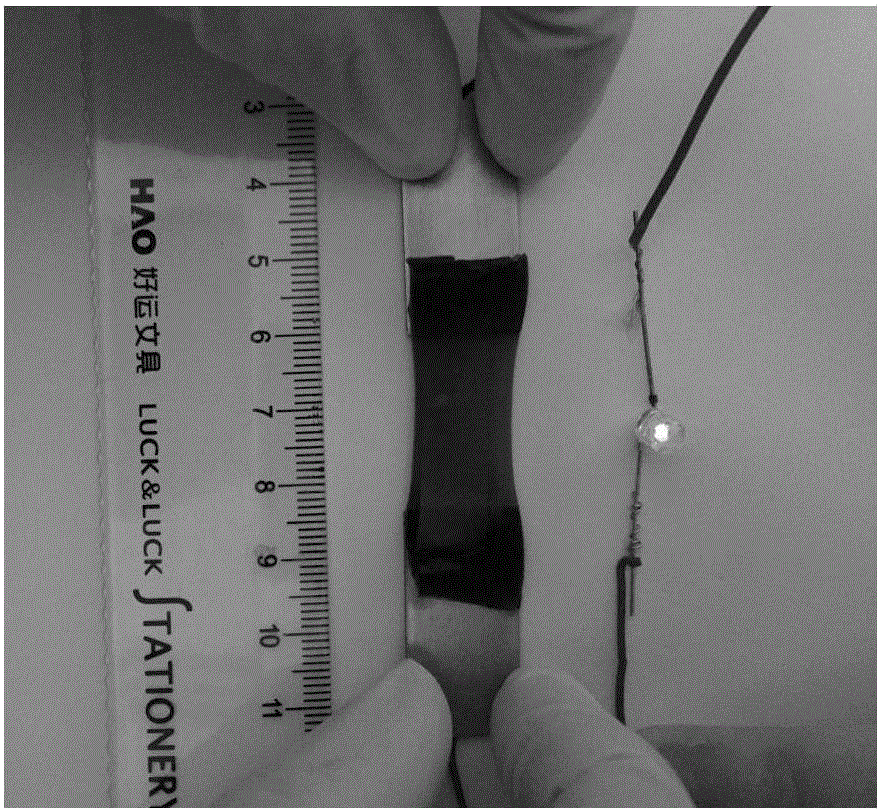

Method for preparing high-strength conductive graphene fiber by large-size graphene oxide sheet

ActiveCN102534869AWide variety of sourcesConvenient sourceGrapheneArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a method for preparing high-strength conductive graphene fiber by a large-size graphene oxide sheet. The method comprises the steps of: oxidizing expanded graphite and obtaining graphene oxide; dispersing the graphene oxide into water, carrying out centrifugal classification treatment on the dispersed graphene oxide, and obtaining the large-size even graphene oxide sheet; and finally, dispersing the graphene oxide into water or polar organic solvent, preparing spinning solution liquid crystal sol with the mass concentration of 1-20%, transferring the spinning solution liquid crystal sol into a spinning device, continuously squeezing spinning solution out from a spinning head capillary tube at the uniform velocity, leading the squeezed spinning solution into solidification liquid, drying the solidified primary fiber, obtaining graphene oxide fiber, and then obtaining the graphene fiber by chemical reduction. A spinning technology is simple; and the obtained graphene fiber is good in electrical conductivity, excellent in mechanical property and better in toughness, can be woven into pure-graphene fiber cloth, and also can be woven with other fibers in a blending way so as to make various functional fabrics, so that the high-strength conductive graphene fiber can be used for replacing carbon fiber in a plurality of fields.

Owner:杭州德烯科技集团有限公司

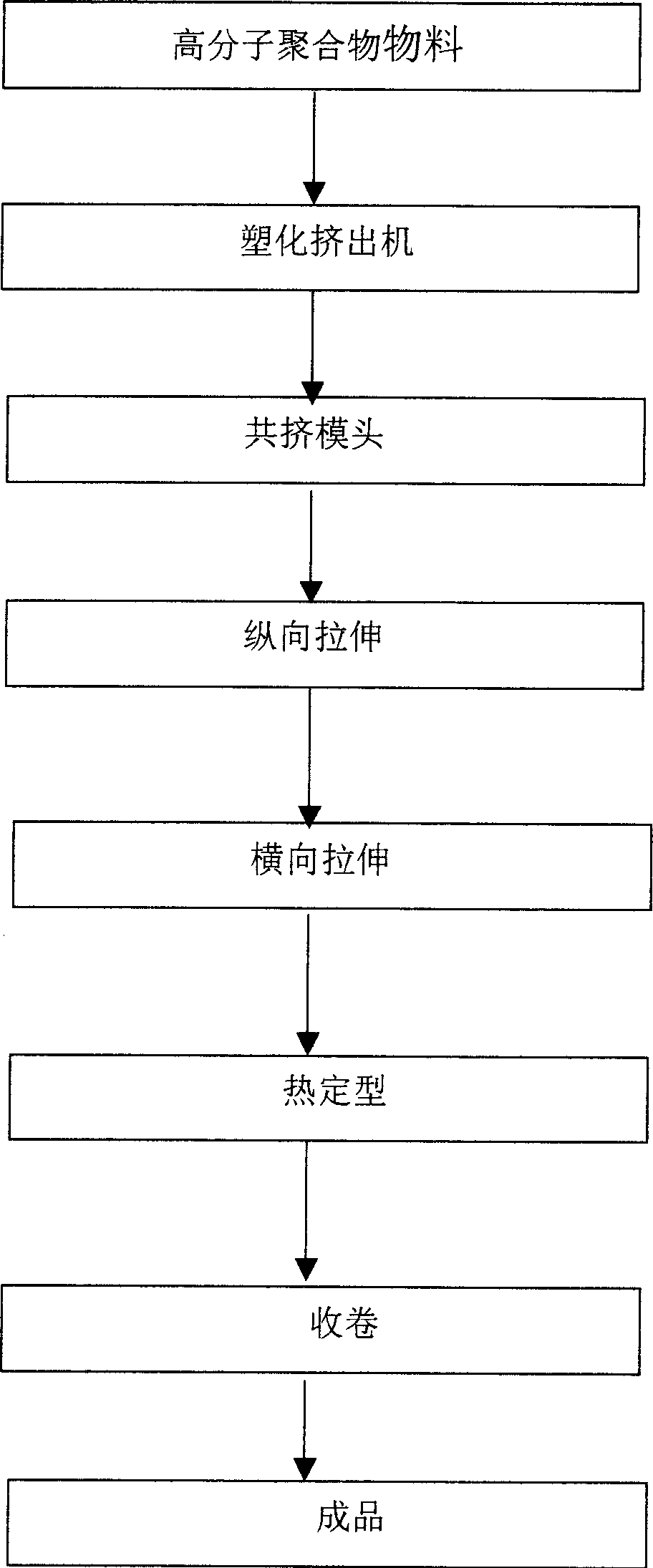

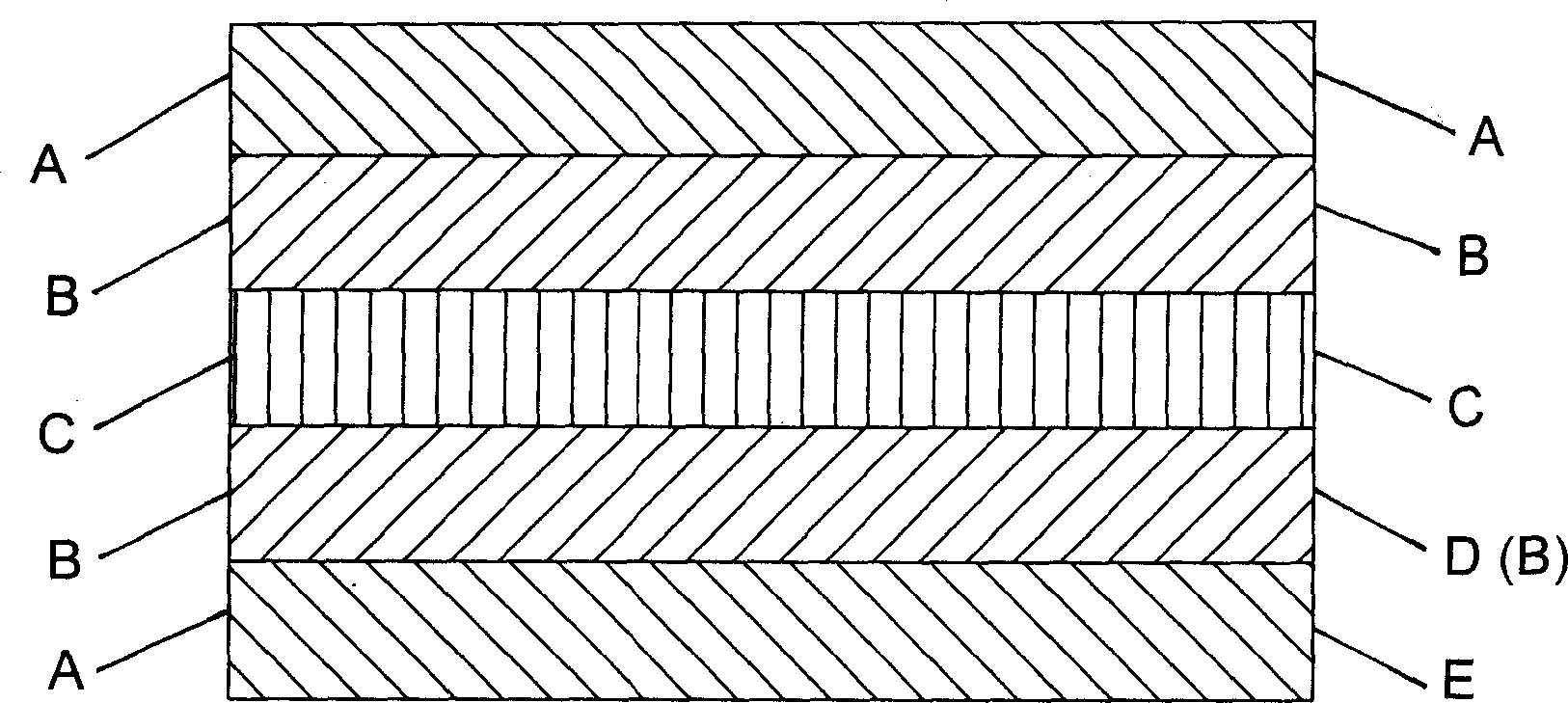

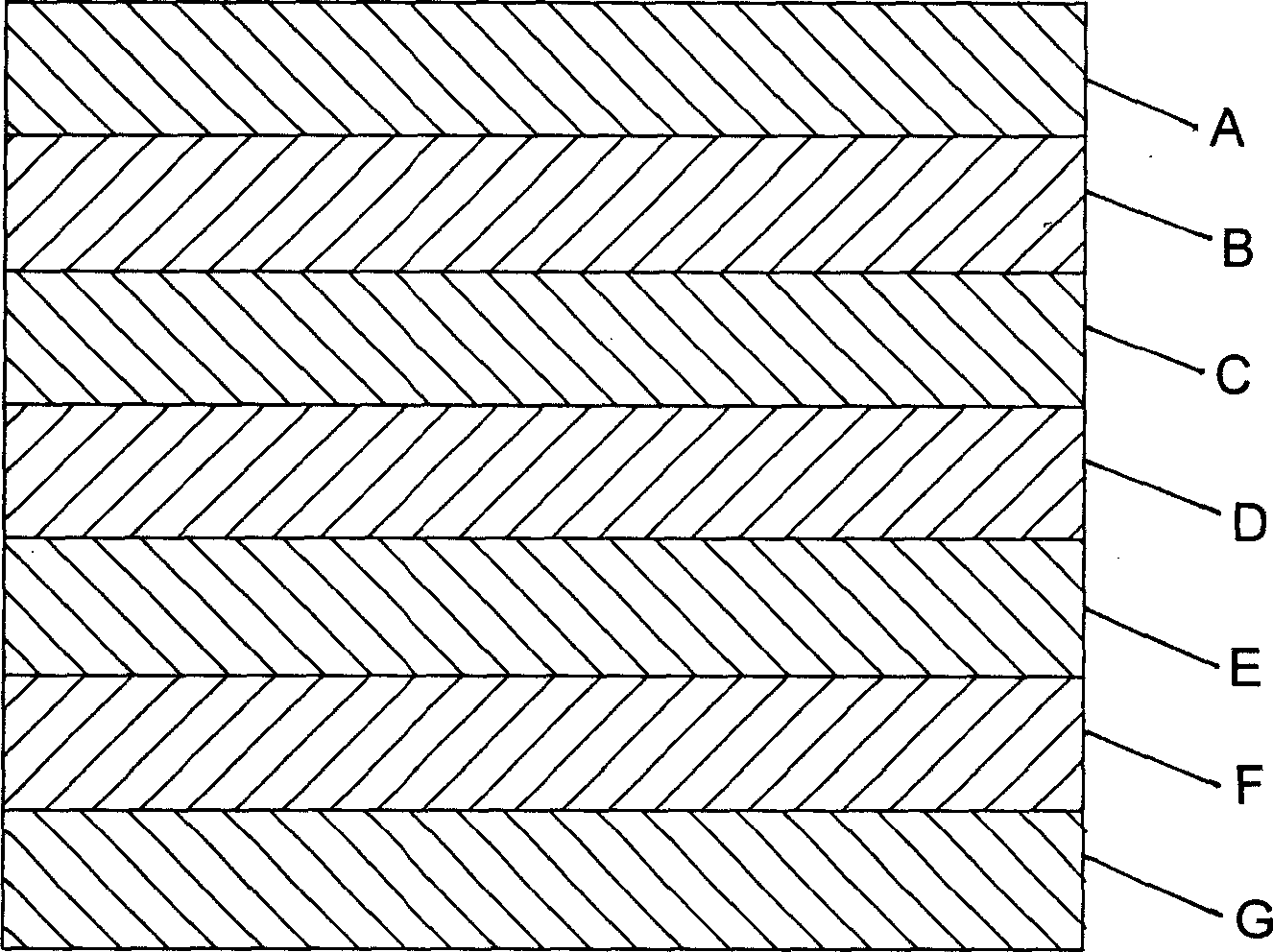

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

Polyimide froth in situ filling honeycomb composite material

InactiveCN101130632AImprove radar stealth performanceImprove stealth performanceCoatingsMicrosphereHoneycomb

The invention discloses a medlin foam original position filling honeycomb composite material, which is characterized by the following: comprising (1) foaming medlin forerunner body powder or micro sphere, (2) functional filling, (3) coupling agent or surface active agent and (4) honeycomb; making up 5% wt-89% wt of the total weight of the composite material with the (1); counting 0. 01% wt-70% wt of the total weight of the composite material with the (2); making up 1% wt-3% wt of the total weight of the composite material with the (3); counting 10% wt-94% wt of the total weight of the composite material with the (4). The material possesses good fire resistant, low temperature resistance and mechanics property.

Owner:BEIHANG UNIV

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

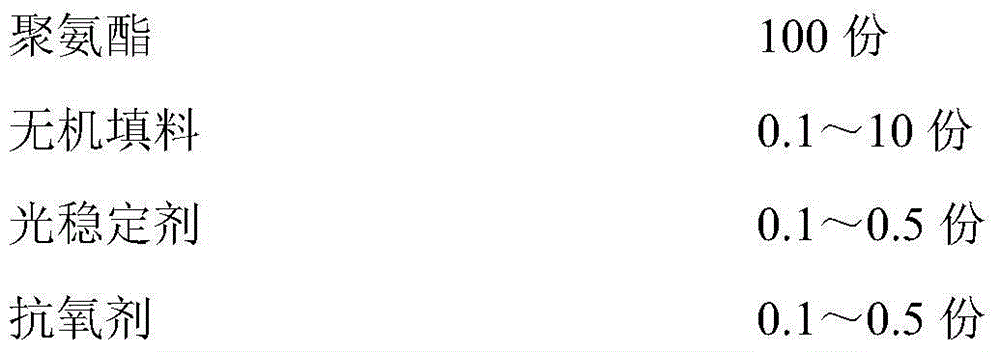

Polyurethane composite material for 3D printing, and preparation method and application thereof

InactiveCN104910609AImproved laser sintering performanceImprove mechanical propertiesAdditive manufacturing apparatusSelective laser sinteringPolymer science

The invention discloses a polyurethane composite material for 3D printing, and a preparation method and application thereof. The invention is characterized in that the polyurethane composite material is prepared from the following initial raw materials in parts by weight: 100 parts of polyurethane, 0.1-10 parts of inorganic filler, 0.1-0.5 part of light stabilizer and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps: evenly mixing 100 parts of polyurethane, 0.1-10 parts of inorganic filler, 0.1-0.5 part of light stabilizer and 0.1-0.5 part of antioxidant, and preparing power to obtain the composite material, wherein the average particle size of the composite material powder is 10-100 mu m. The product can be prepared by a 3D printing technique, such as selective laser sintering. The polyurethane has favorable flexibility; and the introduced inorganic filler improves the 3D printing performance of the polyurethane, so that the product has excellent mechanical properties. The tensile strength of the product prepared from the material by laser sintering can reach 20.12 MPa, and the elongation at break can reach 511.12%.

Owner:SICHUAN UNIV

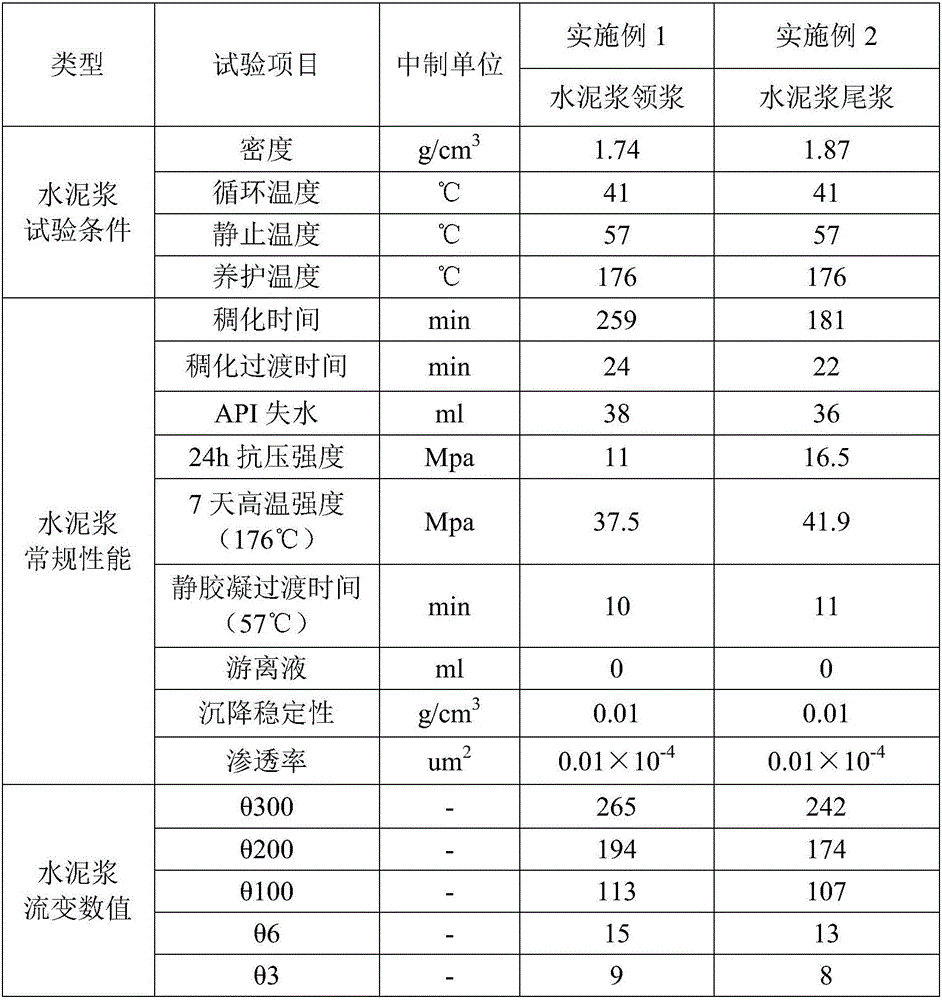

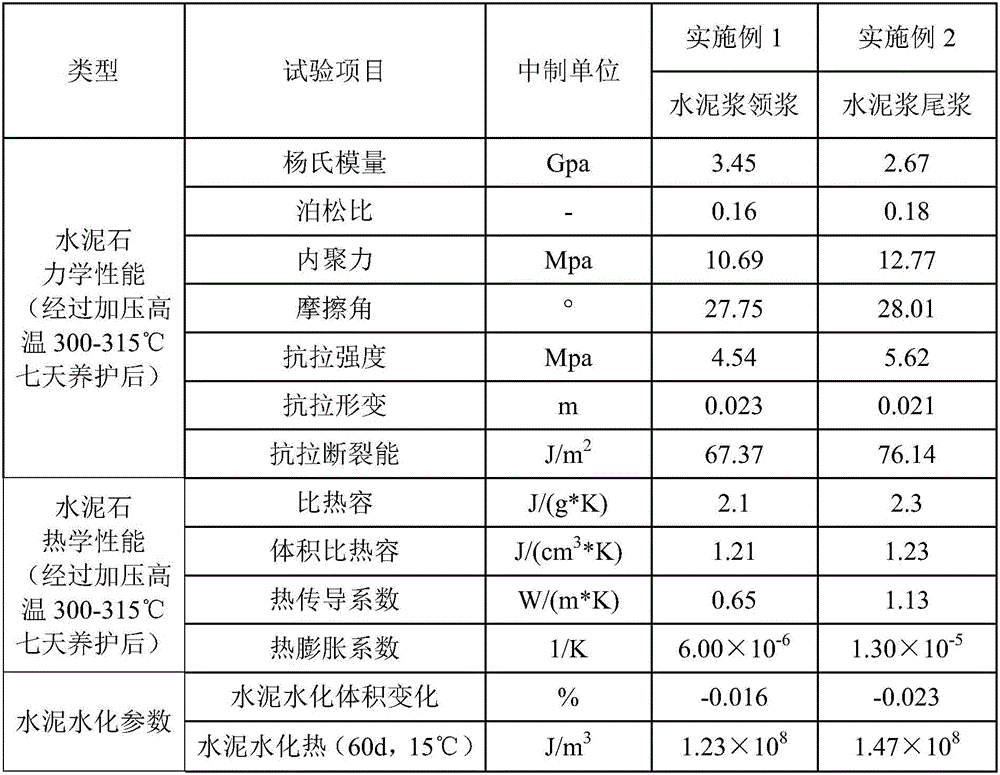

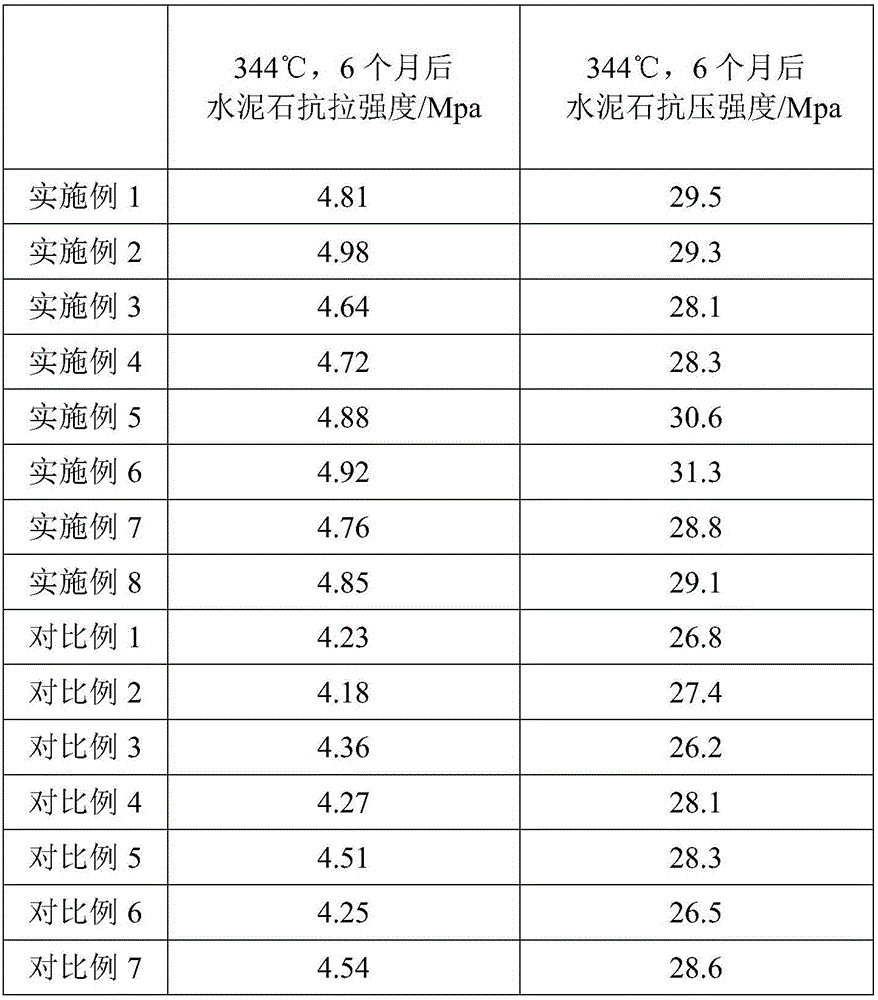

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com