Method for preparing graphene-reinforced polyacrylonitrile carbon fibers

A technology of polyacrylonitrile carbon fiber and polyacrylonitrile, which is applied in the field of preparation of polyacrylonitrile carbon fiber, can solve the problems such as the preparation method and process of graphene-reinforced polyacrylonitrile-based carbon fiber, which have not been reported, and can improve the dispersion and interfacial bonding force. , The preparation process is simple and the effect is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

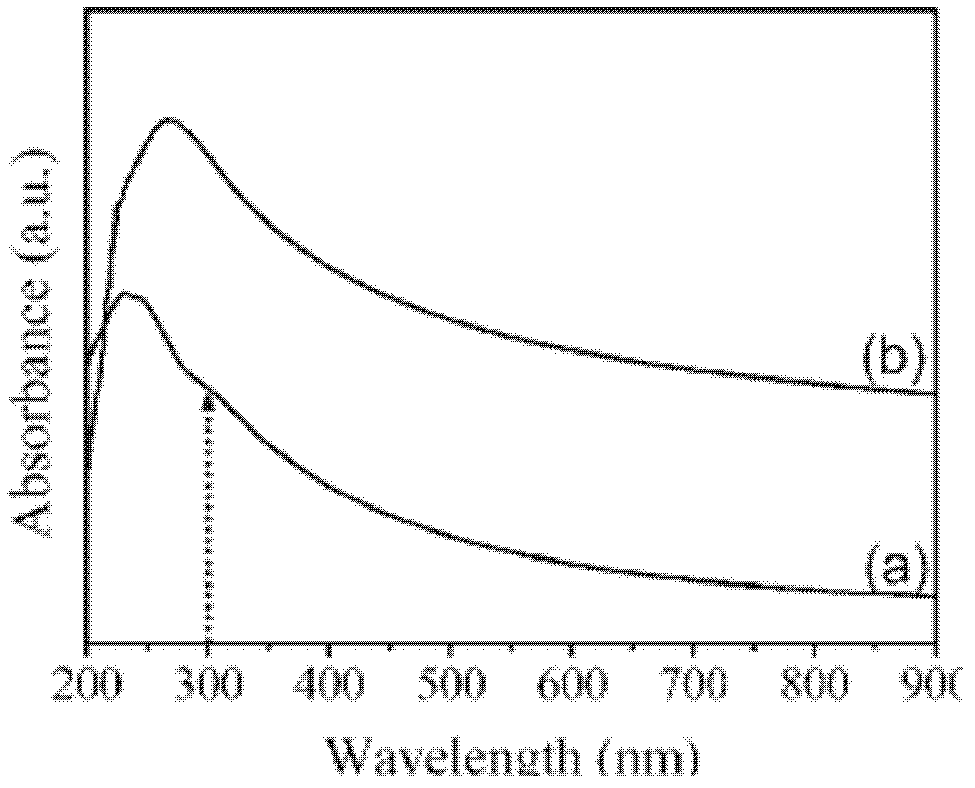

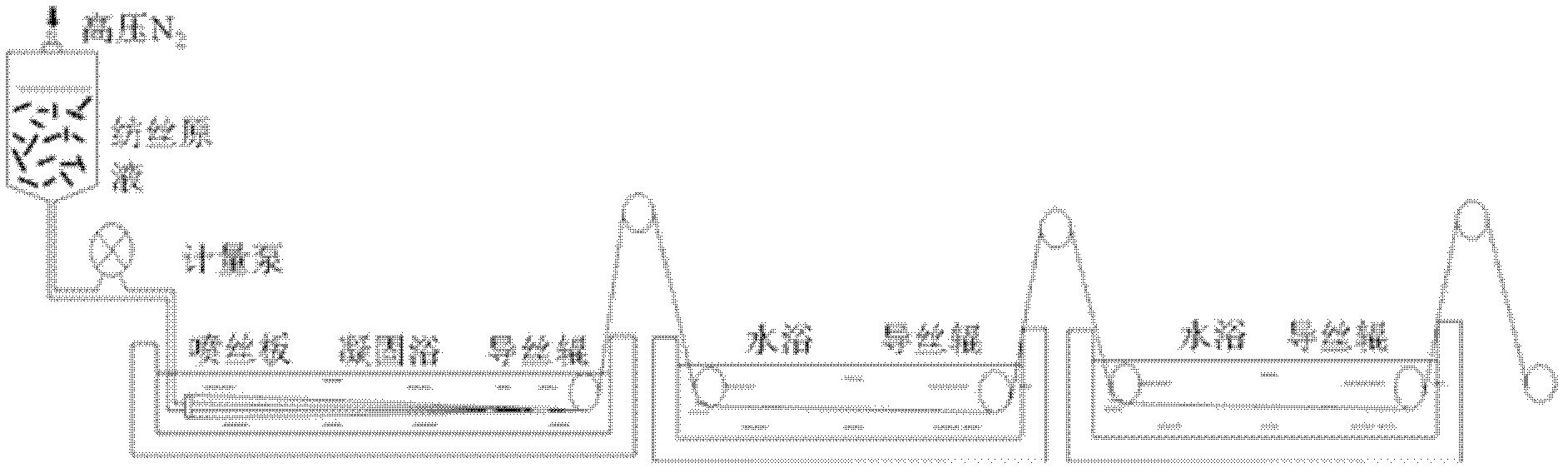

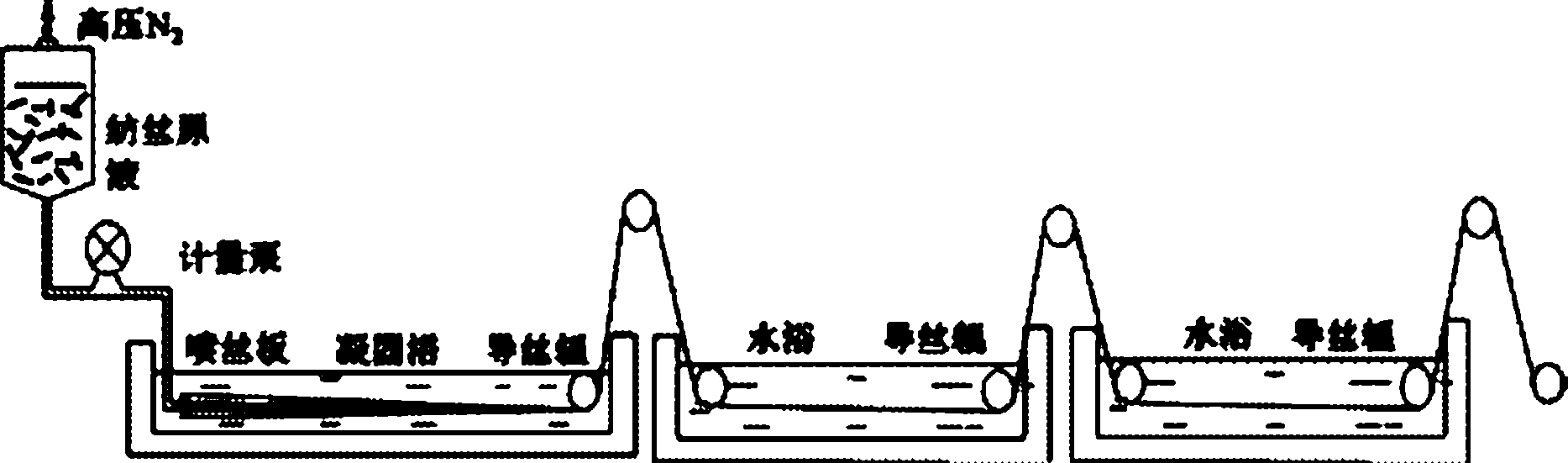

[0027] (1) Using natural graphite as raw material, graphite oxide was prepared by Hummer method. Add 92ml of concentrated sulfuric acid to a three-necked flask, stir in an ice-water bath until the temperature drops to 0°C to 3°C, then add 4g of natural graphite powder and 2g of sodium nitrate (NaNO 3 ), then stir evenly, while stirring, slowly add 60g potassium permanganate (KMnO 4 ), and ensure that the temperature is less than 20°C. After the addition is complete, heat the solution to 35±3°C and keep it for 30 minutes, then slowly add distilled water, and control the temperature within 100°C; after 15 minutes, add a large amount of distilled water and 10ml of 30% hydrogen peroxide (H 2 o 2 ) to terminate the reaction. The mixture was treated by centrifugation, filtered, washed several times with an aqueous solution containing 5% HCl, and dried in vacuum at 50-60°C to obtain a graphite oxide sample; then 2.5 g of graphite oxide was dispersed in 100 ml of N, N'-dimethyletha...

Embodiment 2

[0032] (1) Using natural graphite as raw material, graphite oxide was prepared by the Staudenmaier method. Disperse graphite oxide in water, ultrasonic power is 500W, after ultrasonic for 60 minutes, centrifuge at 5000rpm for 4 minutes, collect the upper layer solution, then centrifuge at 15000rpm for 2 minutes, collect the precipitate, and vacuum dry at 60°C to obtain graphene oxide powder. Get 2.5g graphene oxide and disperse it in 100ml N, N'-dimethylacetamide (DMAc), obtain yellow-brown dispersion liquid, after ultrasonic 40min, obtain exfoliated graphene oxide suspension uniformly dispersed in DMAc .

[0033] (2) Add 16.2g of polyacrylonitrile powder into 100ml of N,N-dimethylacetamide (DMAc) solvent, swell at 15°C for 4 hours, slowly heat the water bath to 70°C, and continue to stir for 1.5h to obtain a uniform Polyacrylonitrile (PAN) solution.

[0034] (3) Get the graphene oxide suspension that 20ml prepares, join in the polyacrylonitrile solution of 100ml, stir 4.5h...

Embodiment 3

[0037] (1) Using natural graphite as raw material, graphite oxide was prepared by Brodie method. Disperse graphite oxide in water, ultrasonic power is 500W, after ultrasonic for 60 minutes, centrifuge at 5000rpm for 4 minutes, collect the upper layer solution, then centrifuge at 15000rpm for 2 minutes, collect the precipitate, and vacuum dry at 60°C to obtain graphene oxide powder. Get 2g graphene oxide and be dispersed in 100mlN, in the N'-dimethylacetamide (DMAc), obtain yellow-brown dispersion liquid, after ultrasonic 40min, obtain the graphene oxide suspension that exfoliates uniformly dispersed in DMAc.

[0038] (2) Add 19.5g of polyacrylonitrile powder to 100ml of N,N-dimethylacetamide (DMAc) solvent, swell at 8°C for 4 hours, slowly heat the water bath to 70°C, and continue stirring for 1.5h to obtain a uniform Polyacrylonitrile (PAN) solution.

[0039] (3) Get the graphene oxide suspension prepared by 25ml, join in the polyacrylonitrile solution of 100ml, stir 4.5h a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com