Patents

Literature

15588results about "Artifical filament manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process if making fine fiber material

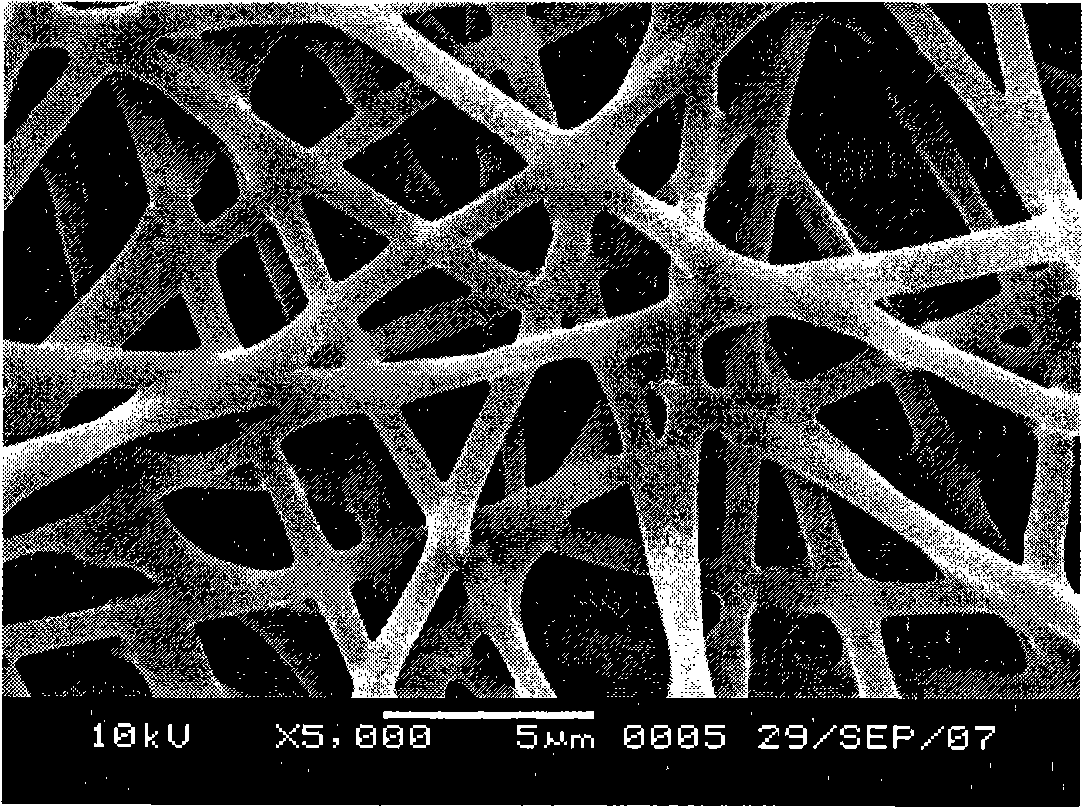

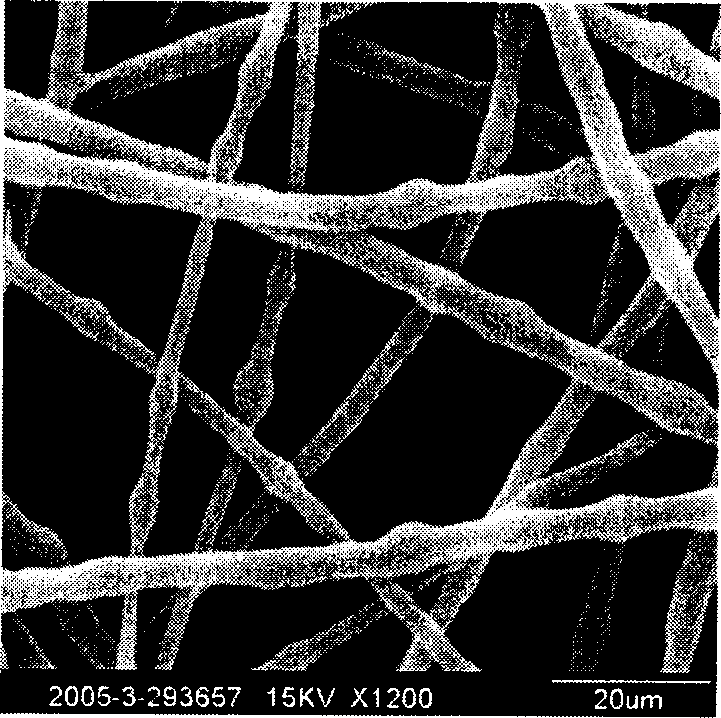

Improved polymer materials and fine fiber materials can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

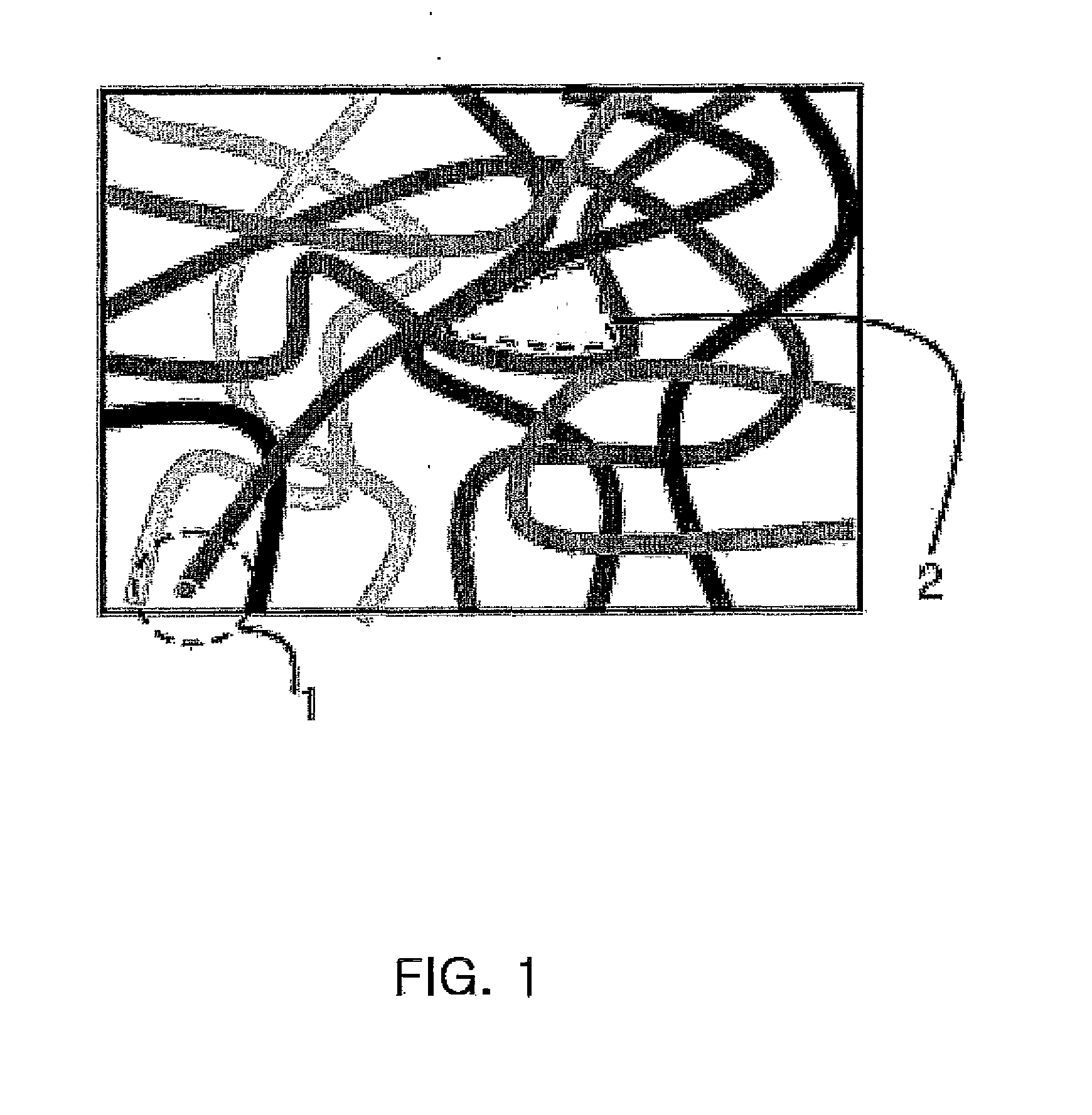

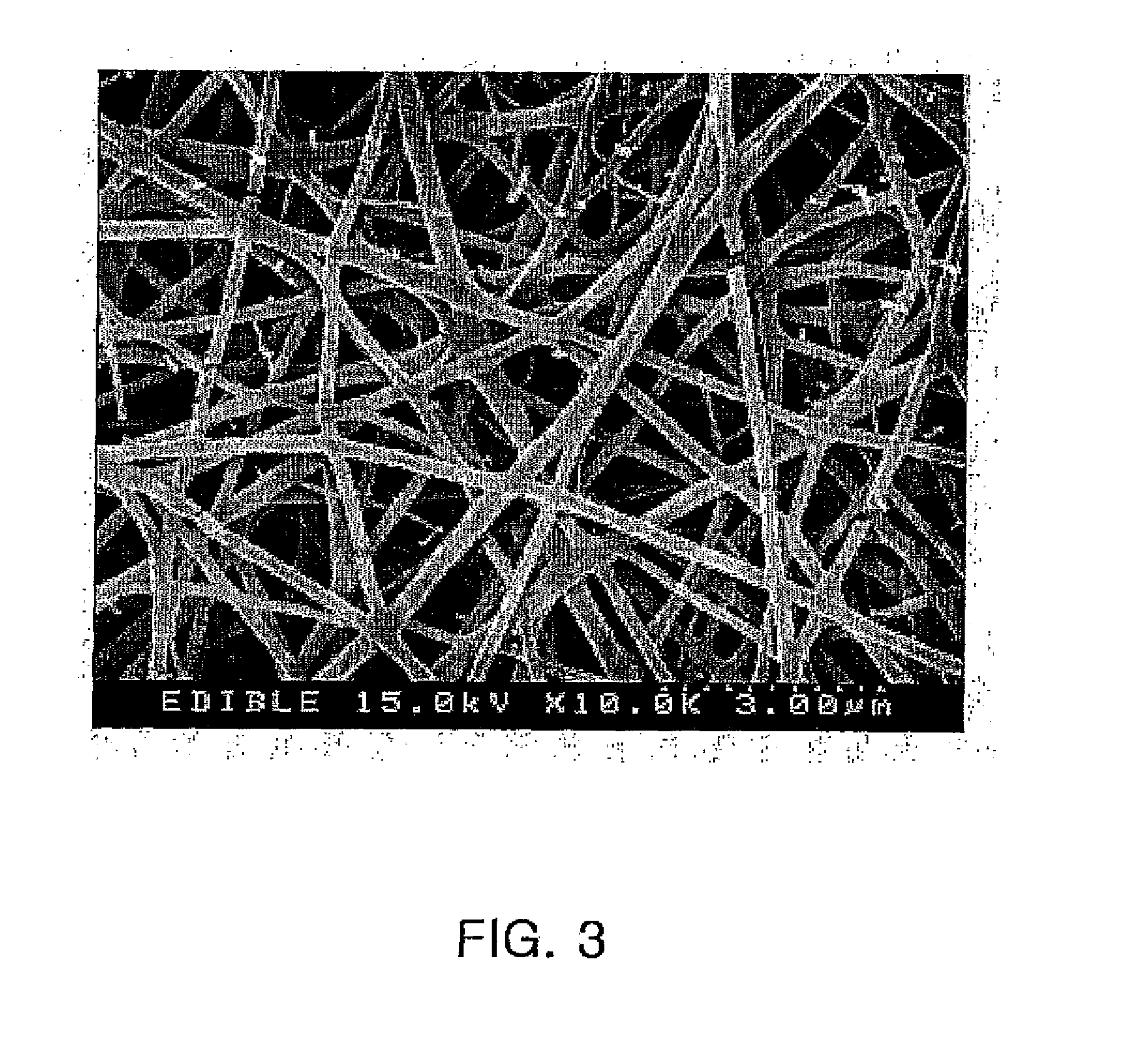

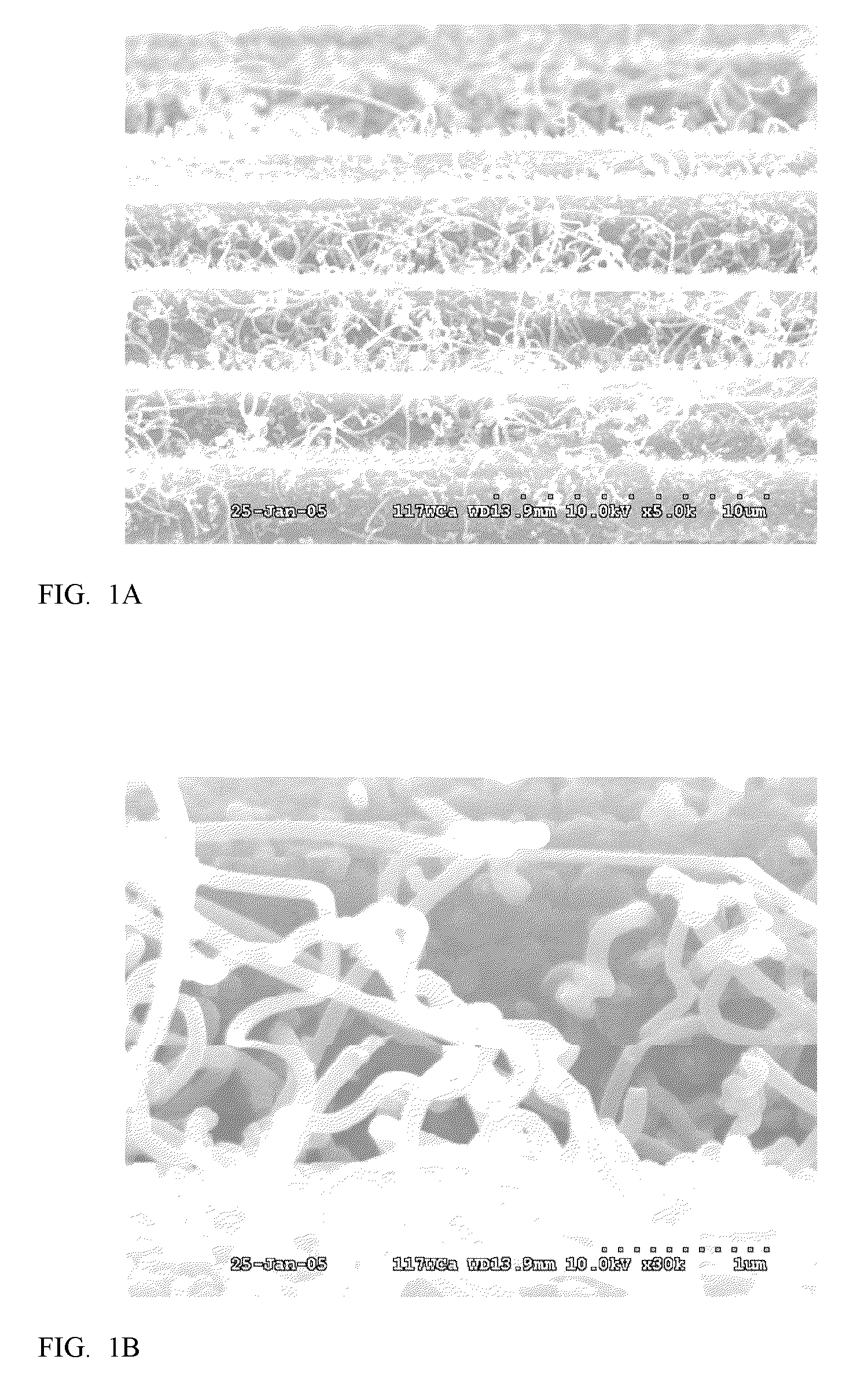

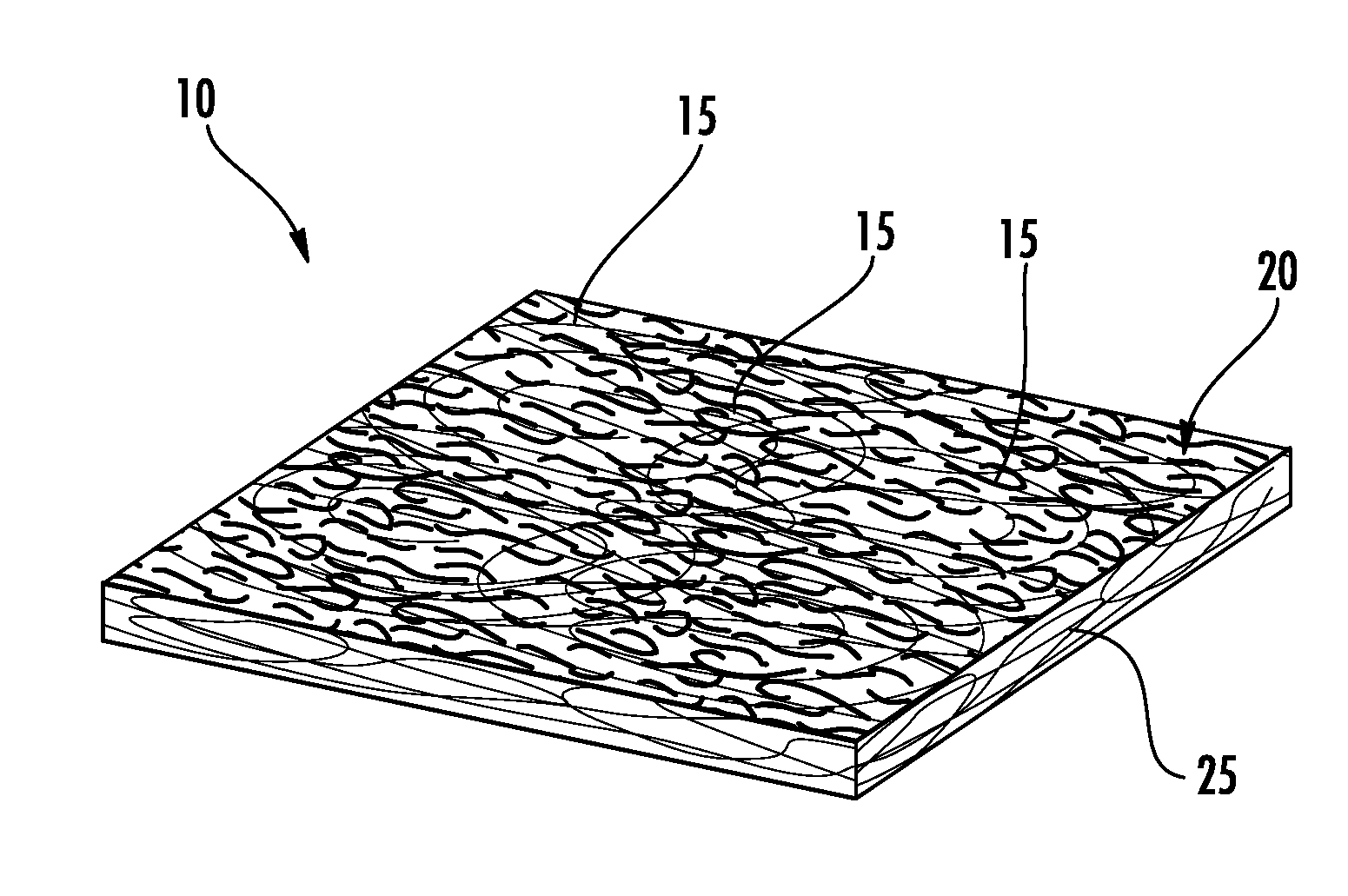

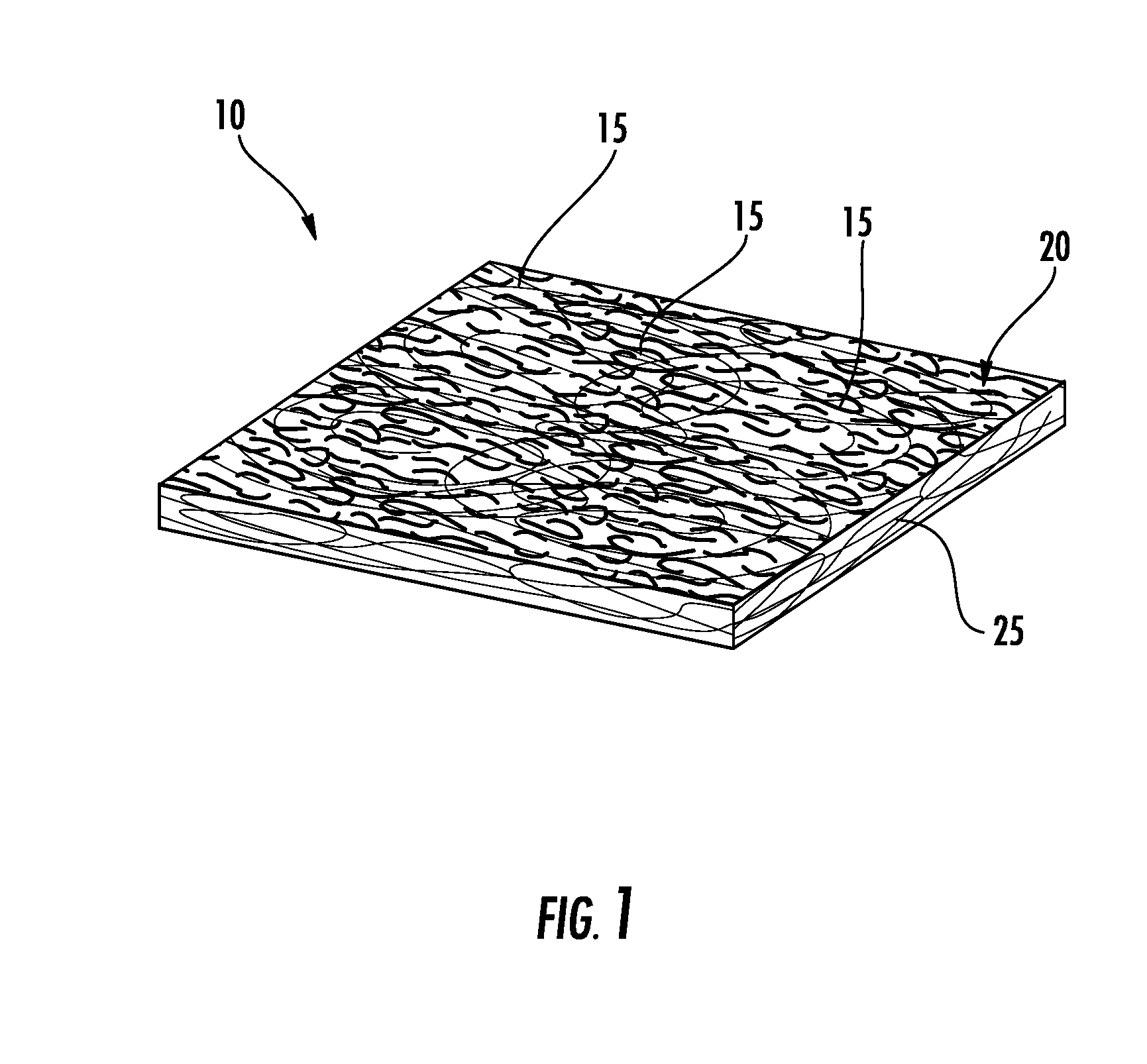

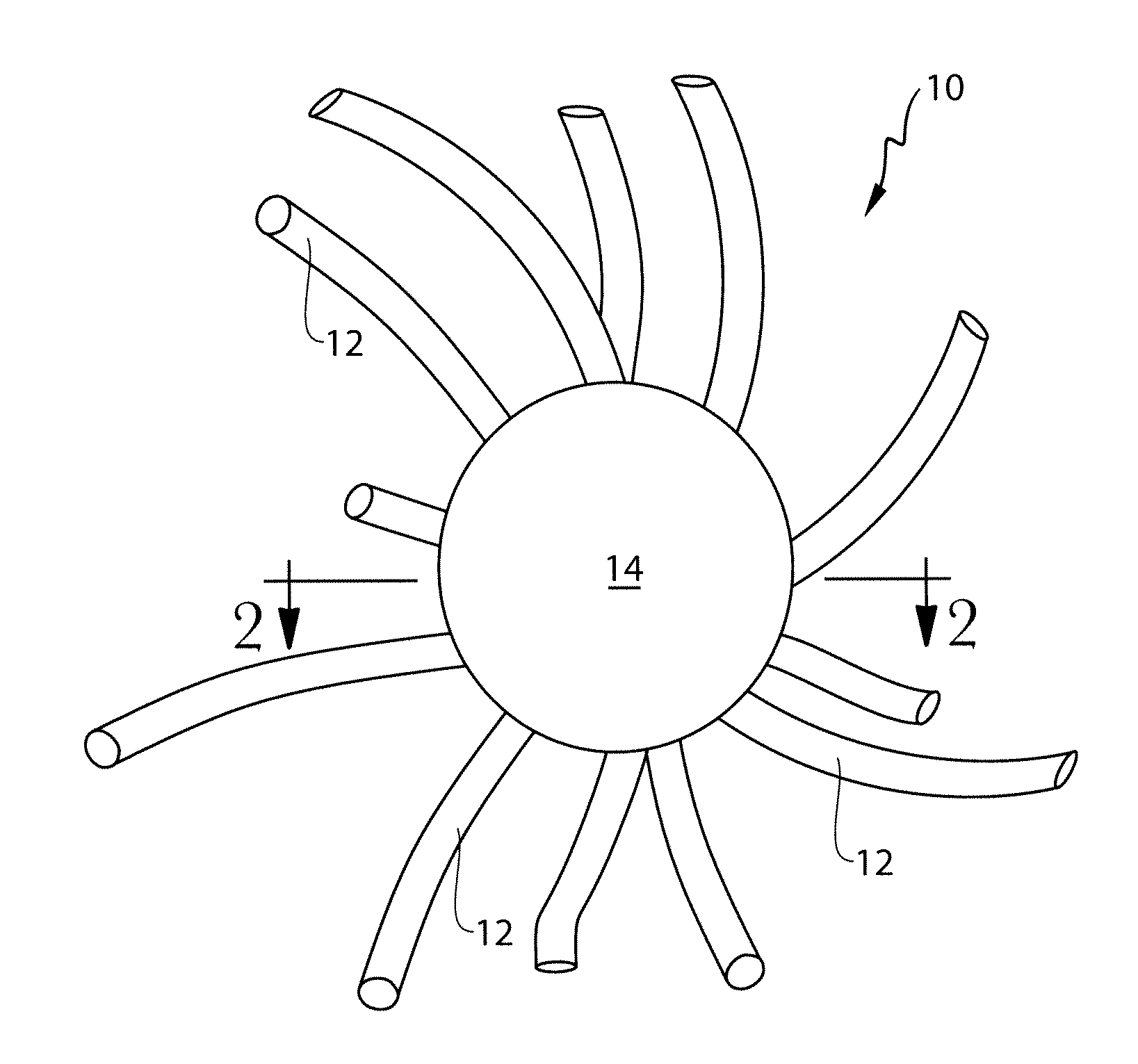

Nanofibrillar structure and applications including cell and tissue culture

ActiveUS20050095695A1Reduce usageBioreactor/fermenter combinationsNanostructure manufactureLipid formationNanofiber

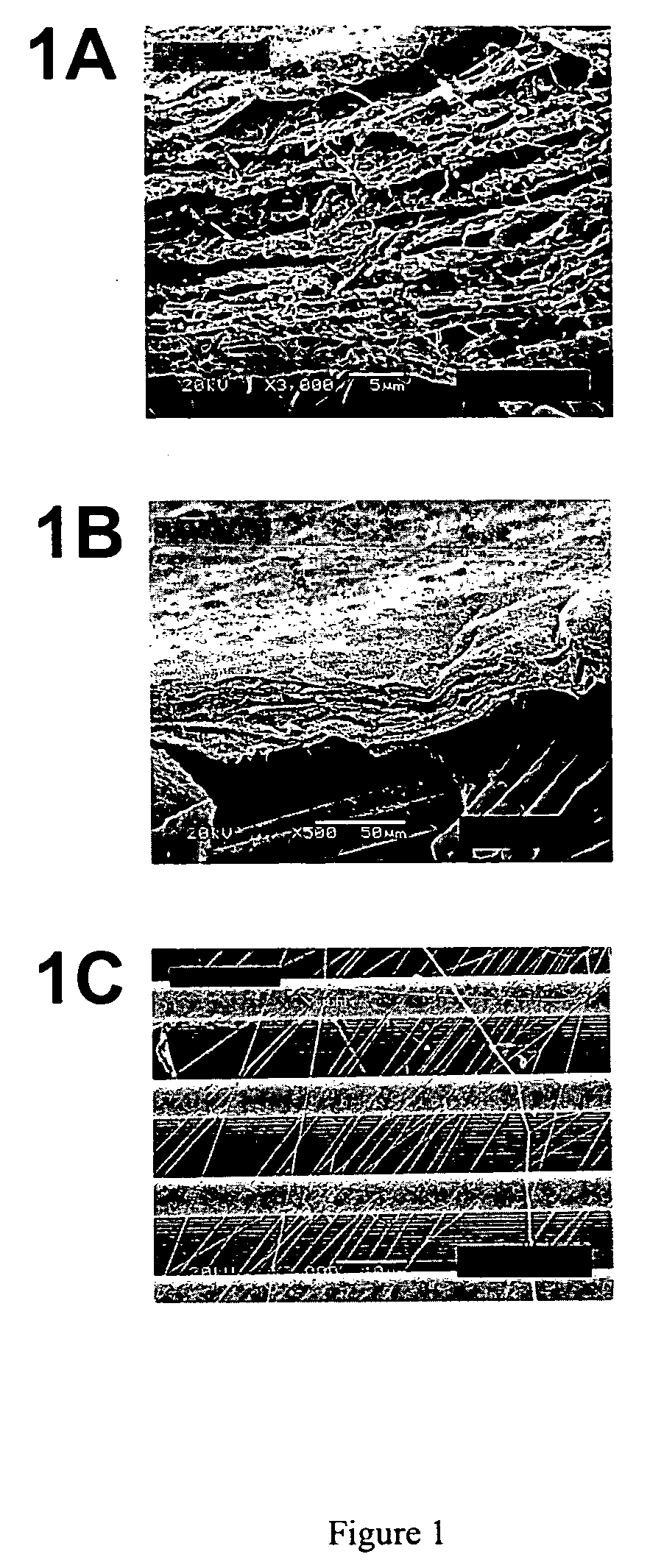

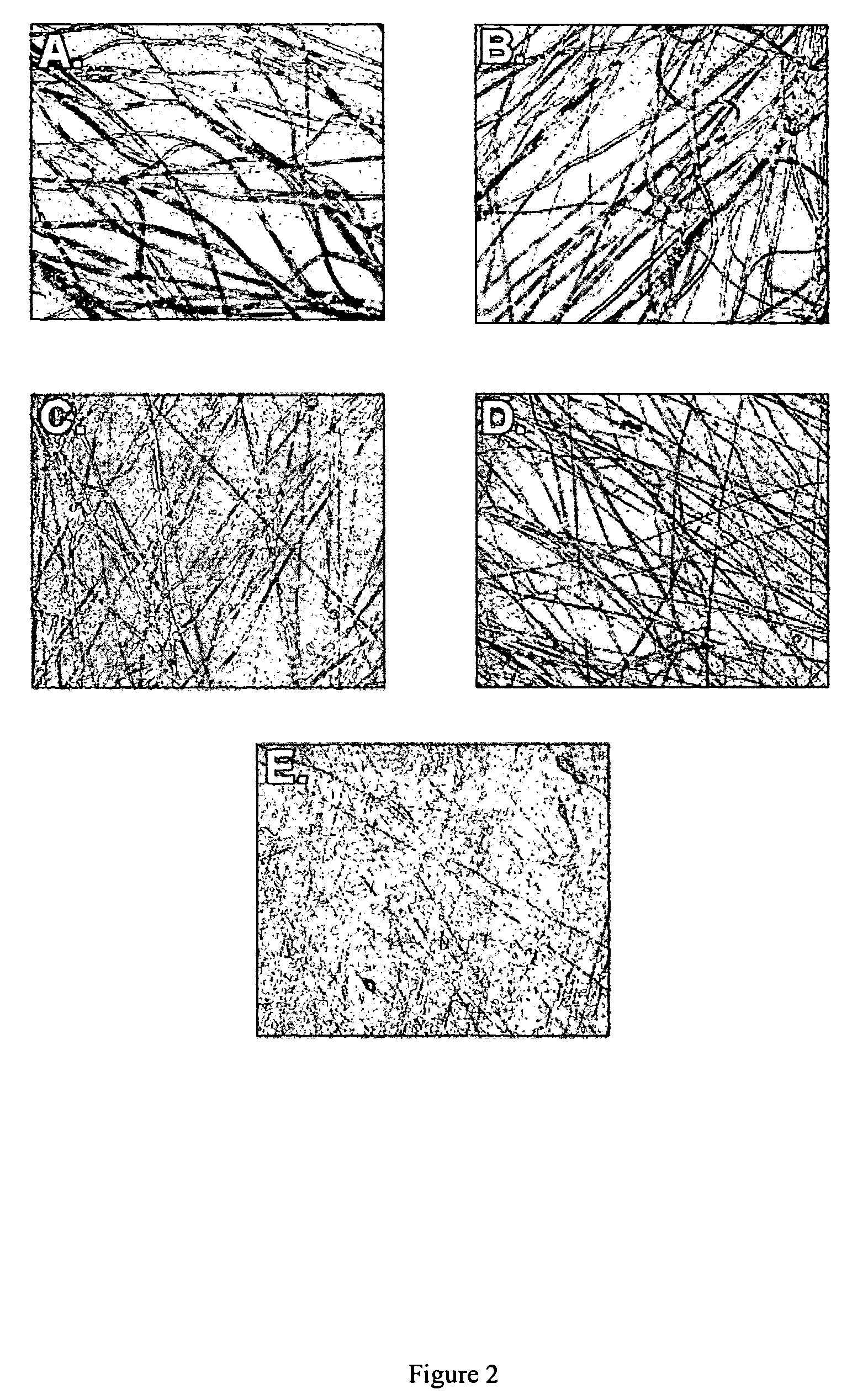

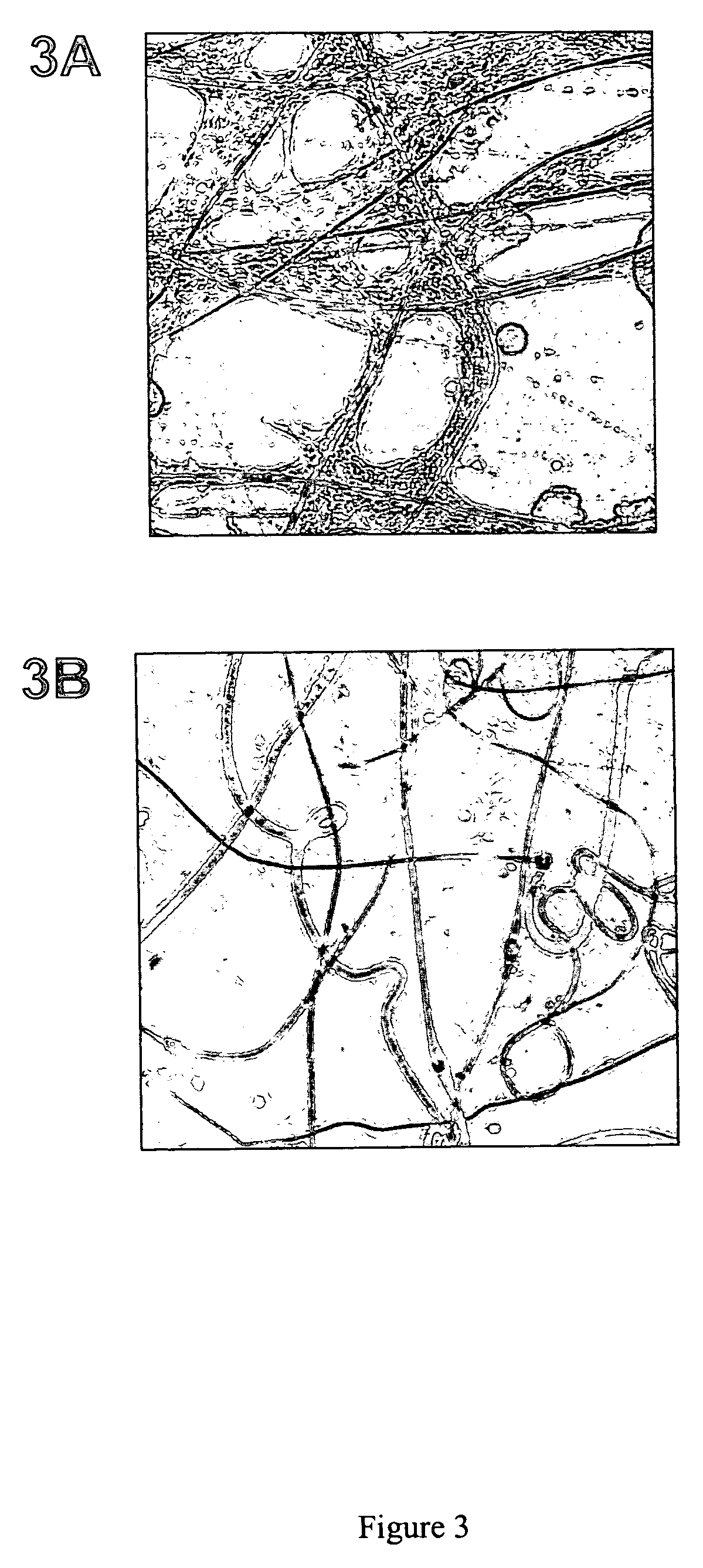

A nanofibrillar structure for cell culture and tissue engineering is disclosed. The nanofibrillar structure can be used in a variety of applications including methods for proliferating and / or differentiating cells and manufacturing a tissue. Also disclosed is an improved nanofiber comprising a lipid, lipophilic molecule, or chemically modified surface. The nanofibers can be used in a variety of applications including the formation of nanofibrillar structures for cell culture and tissue engineering.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

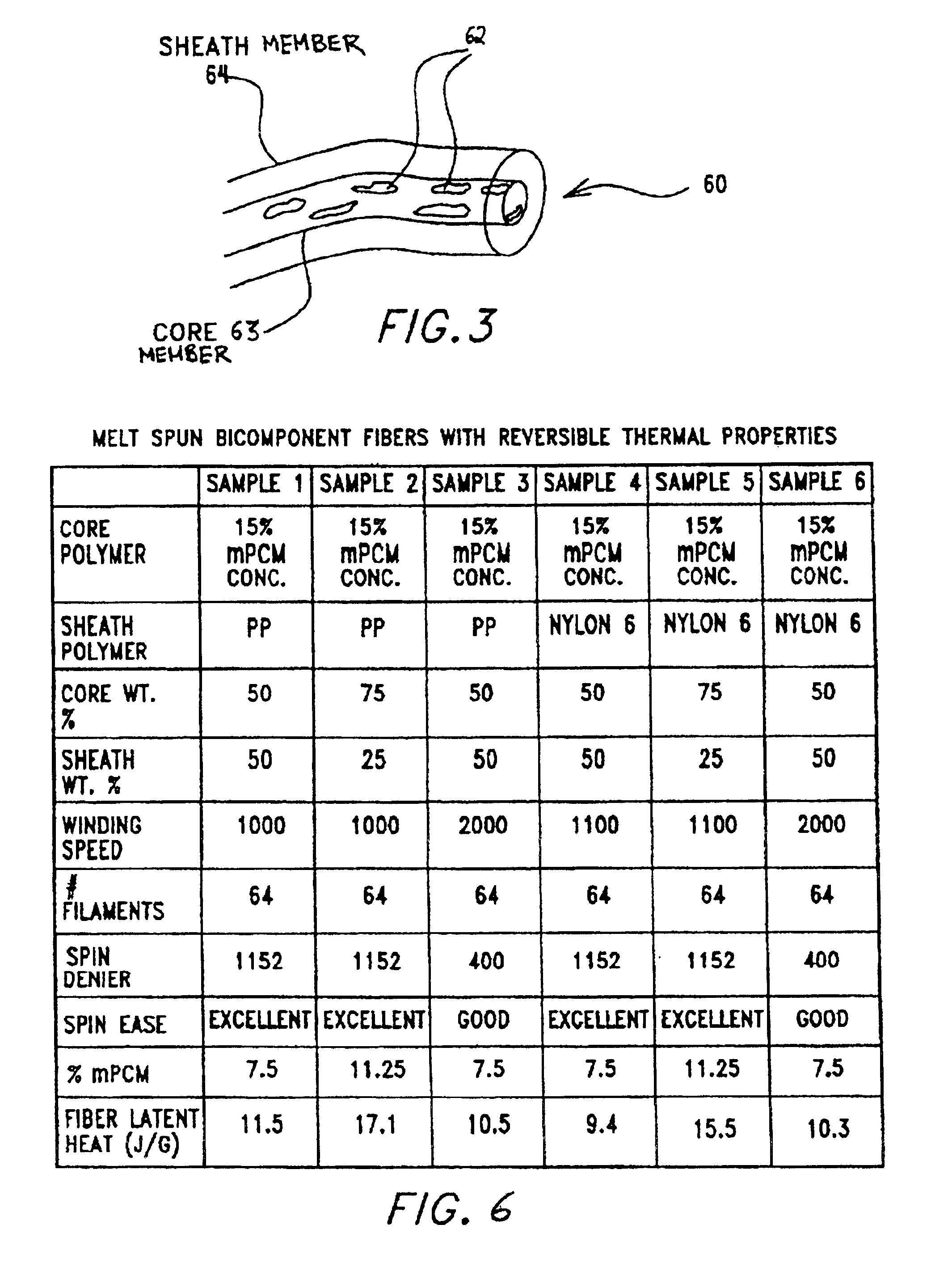

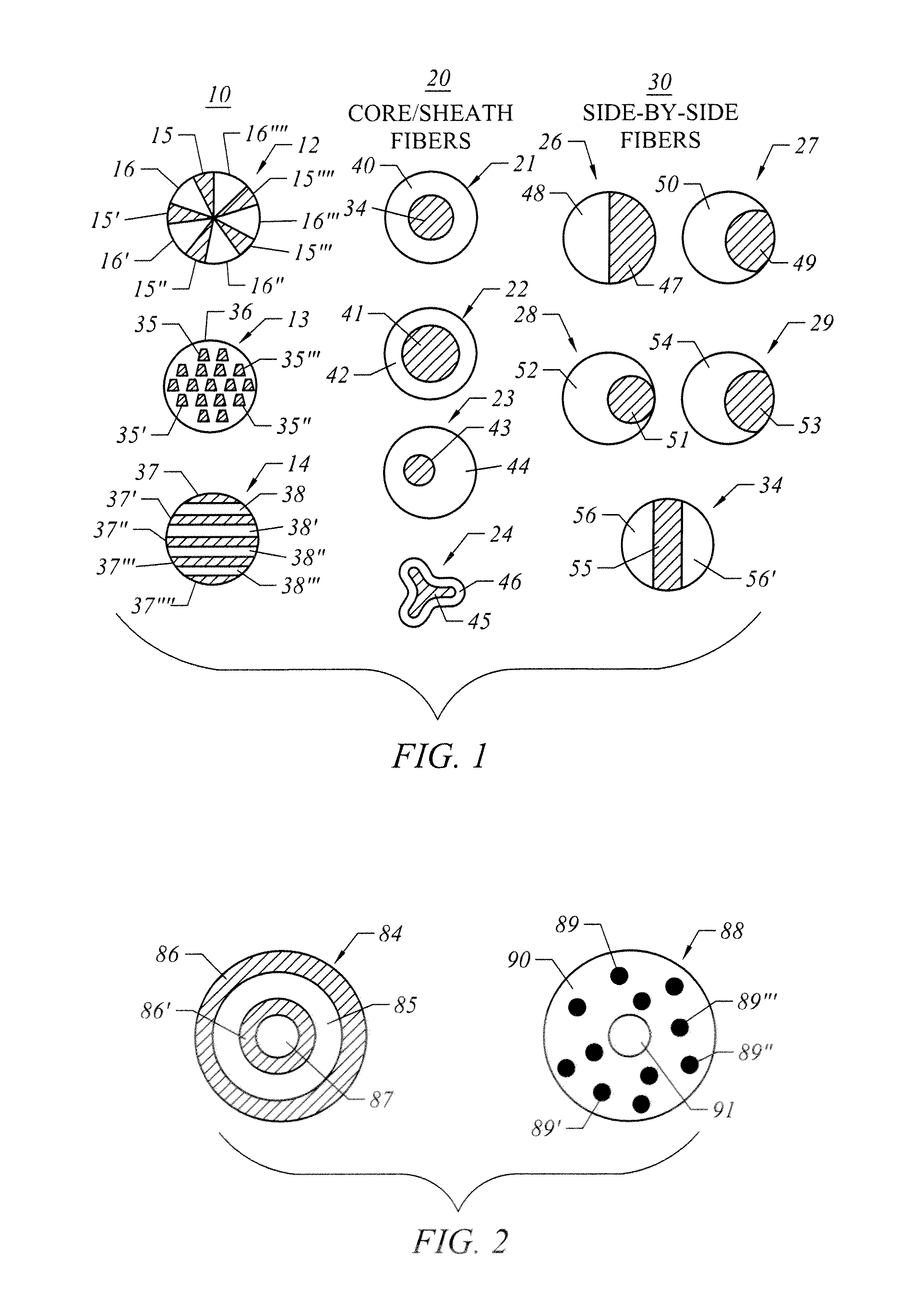

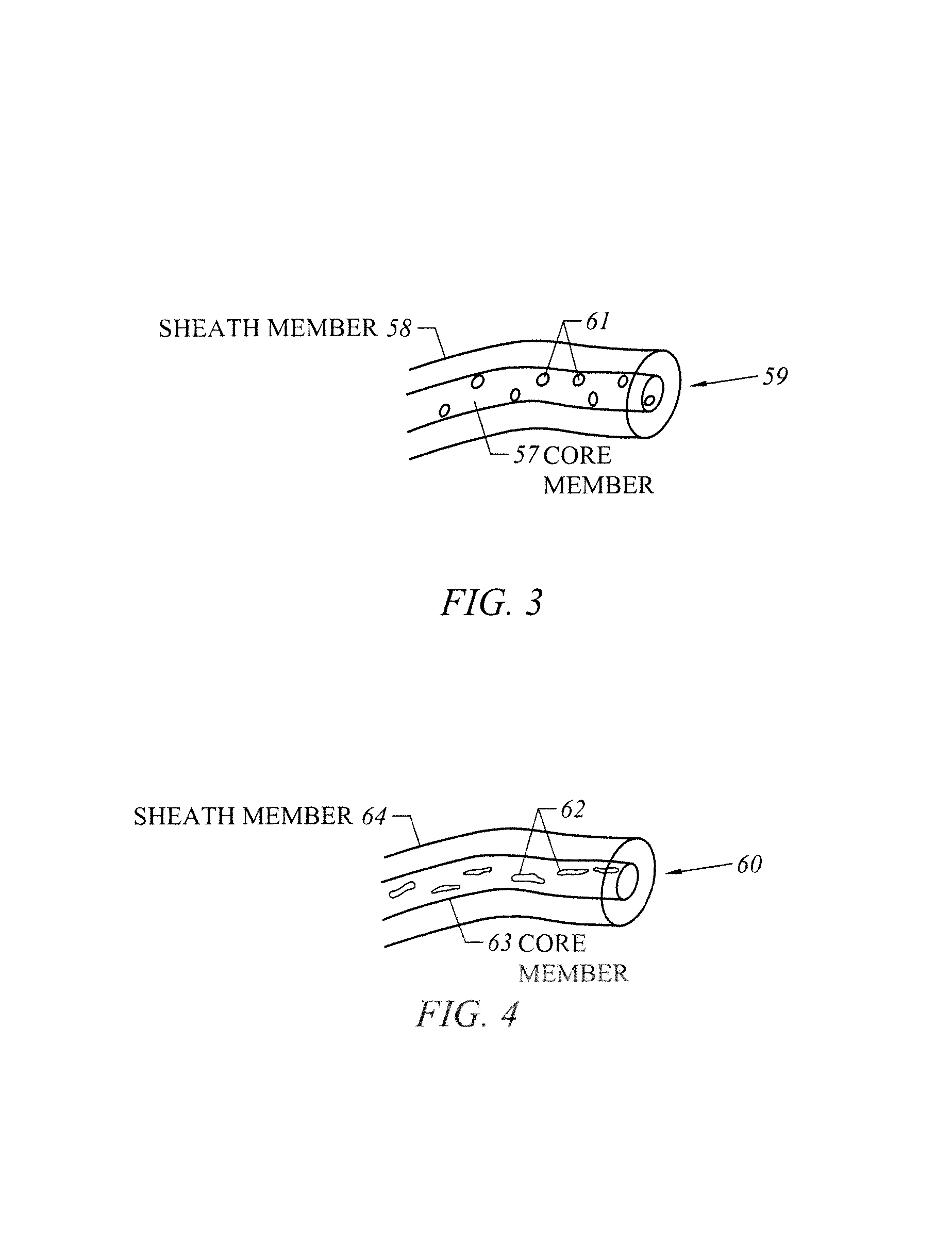

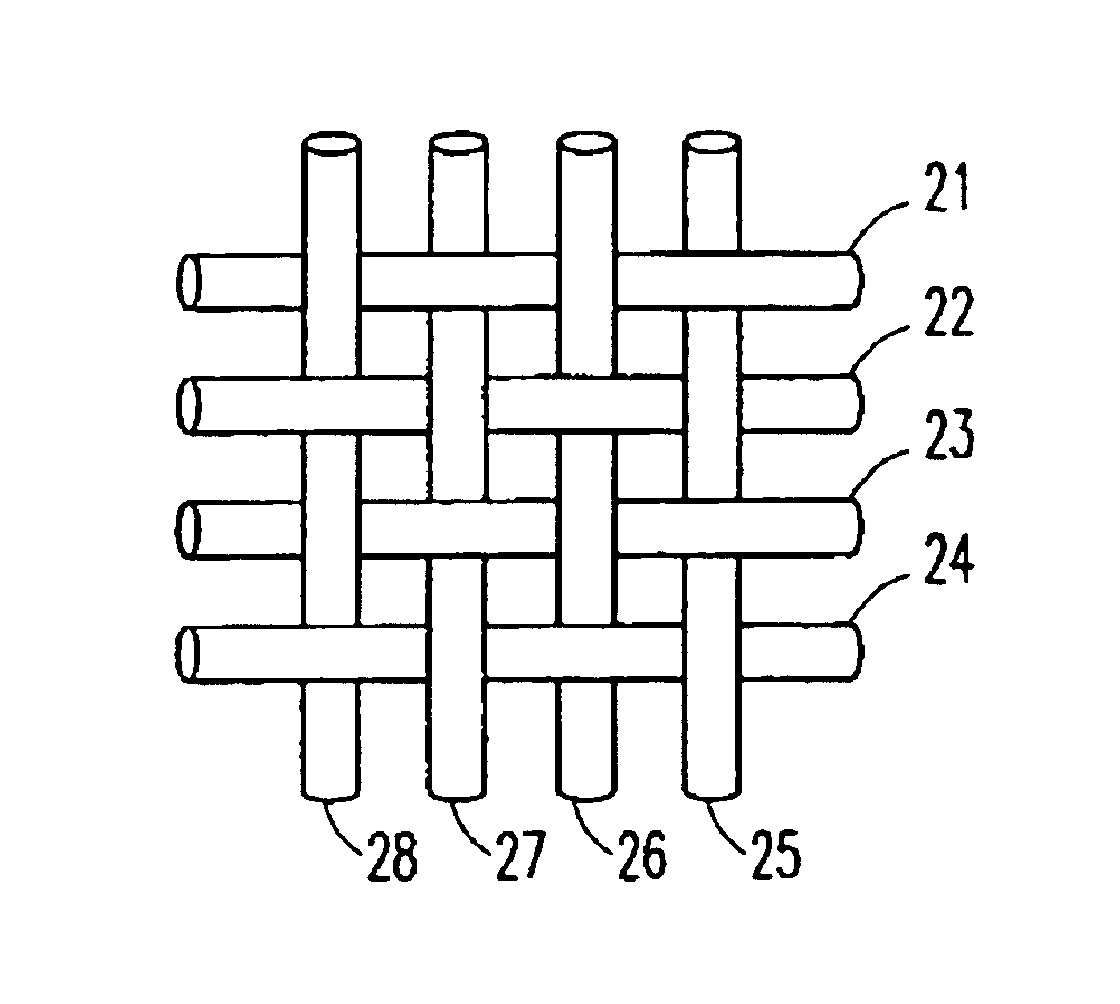

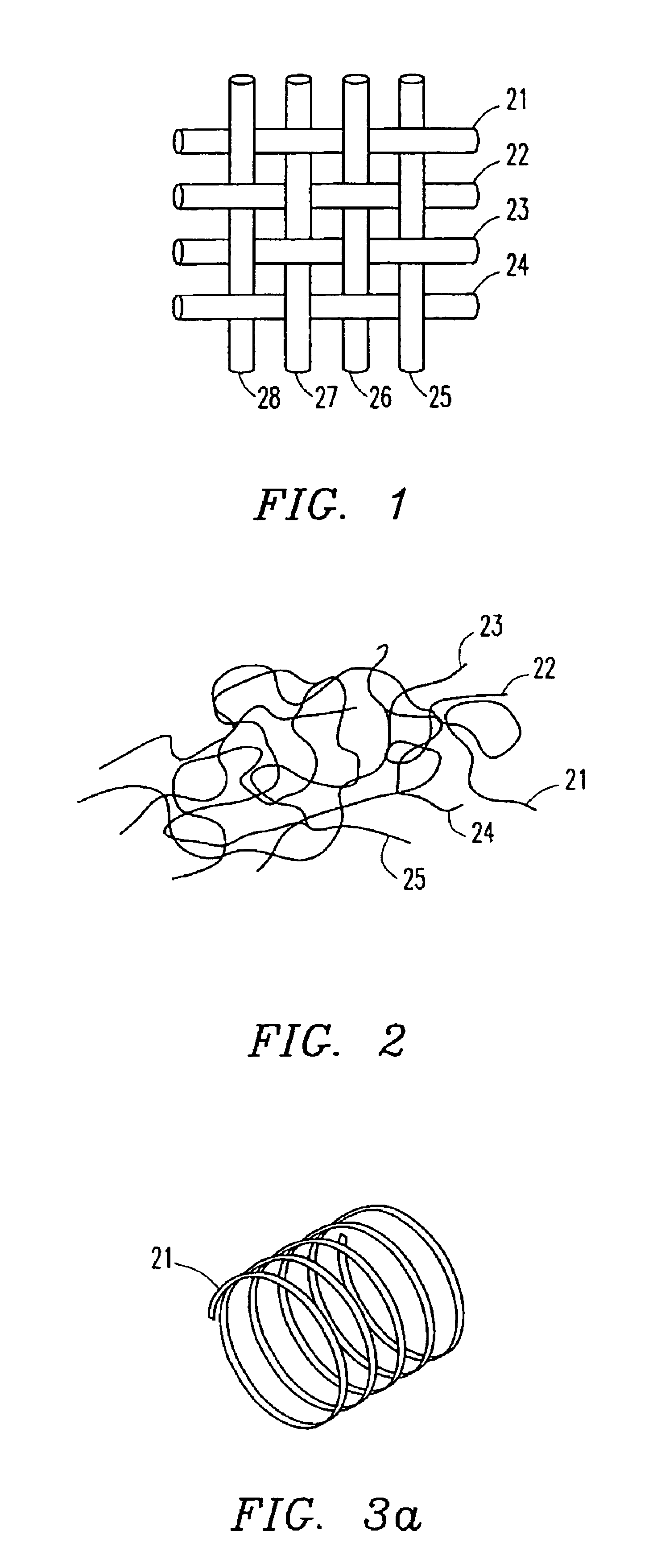

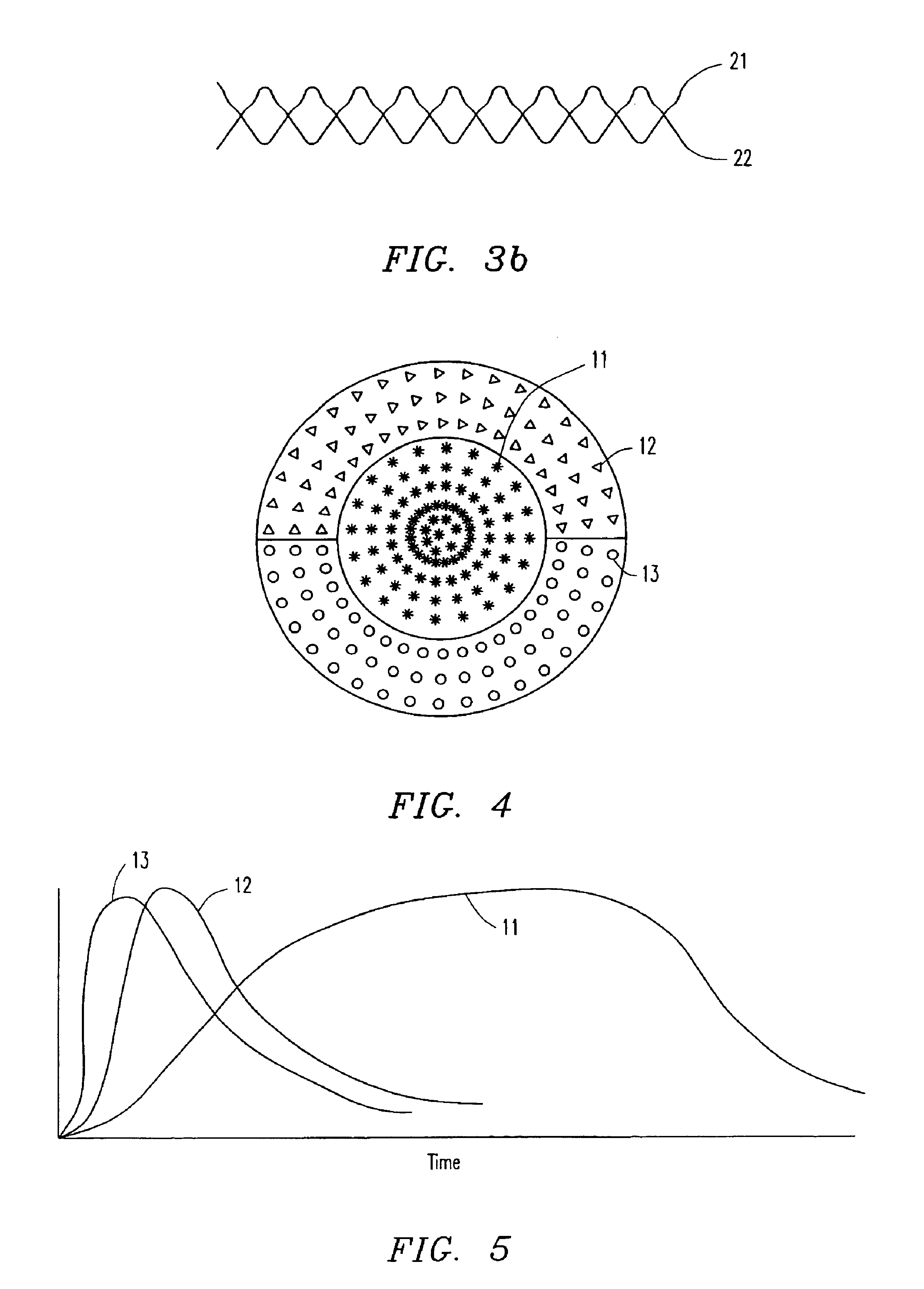

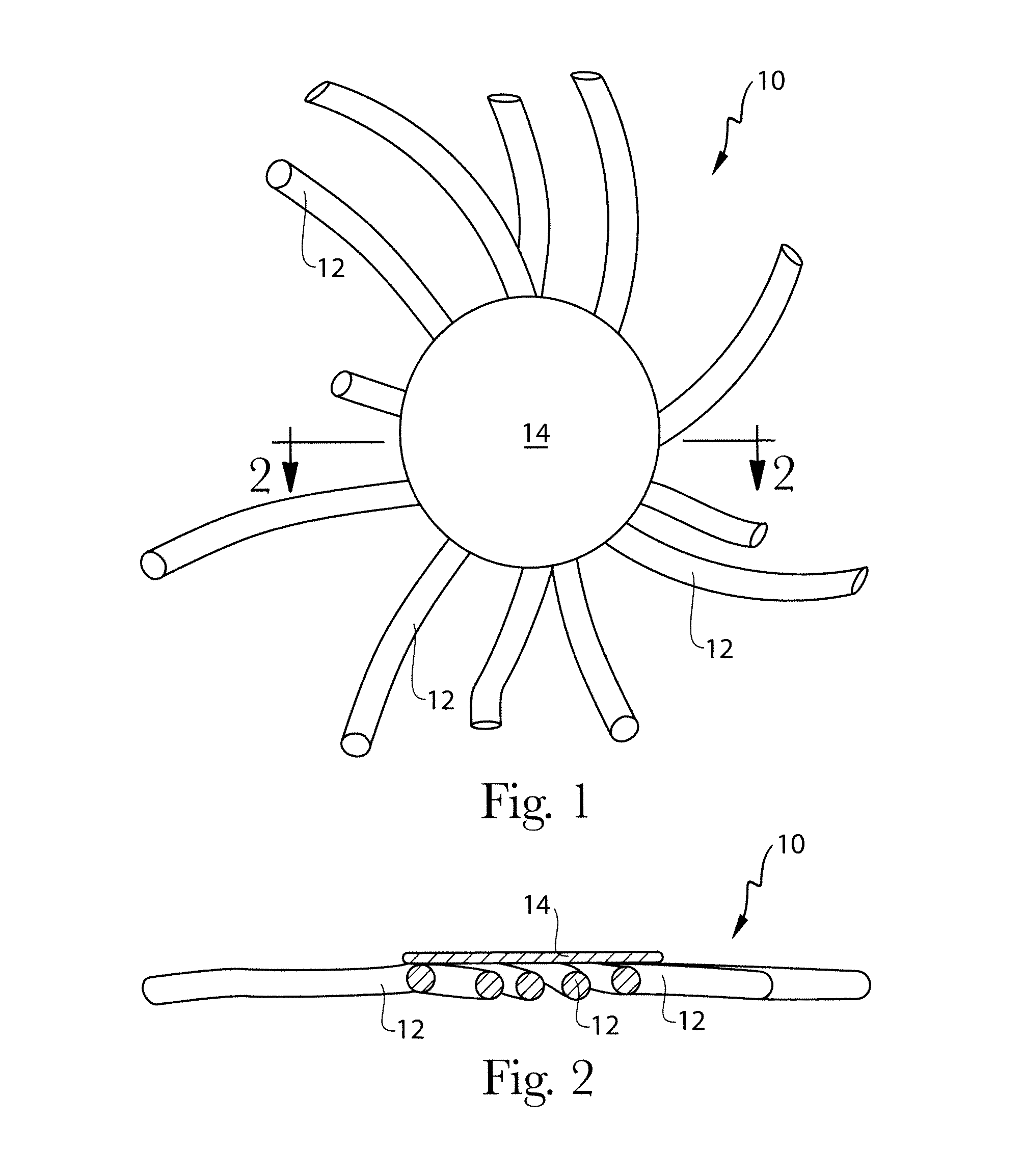

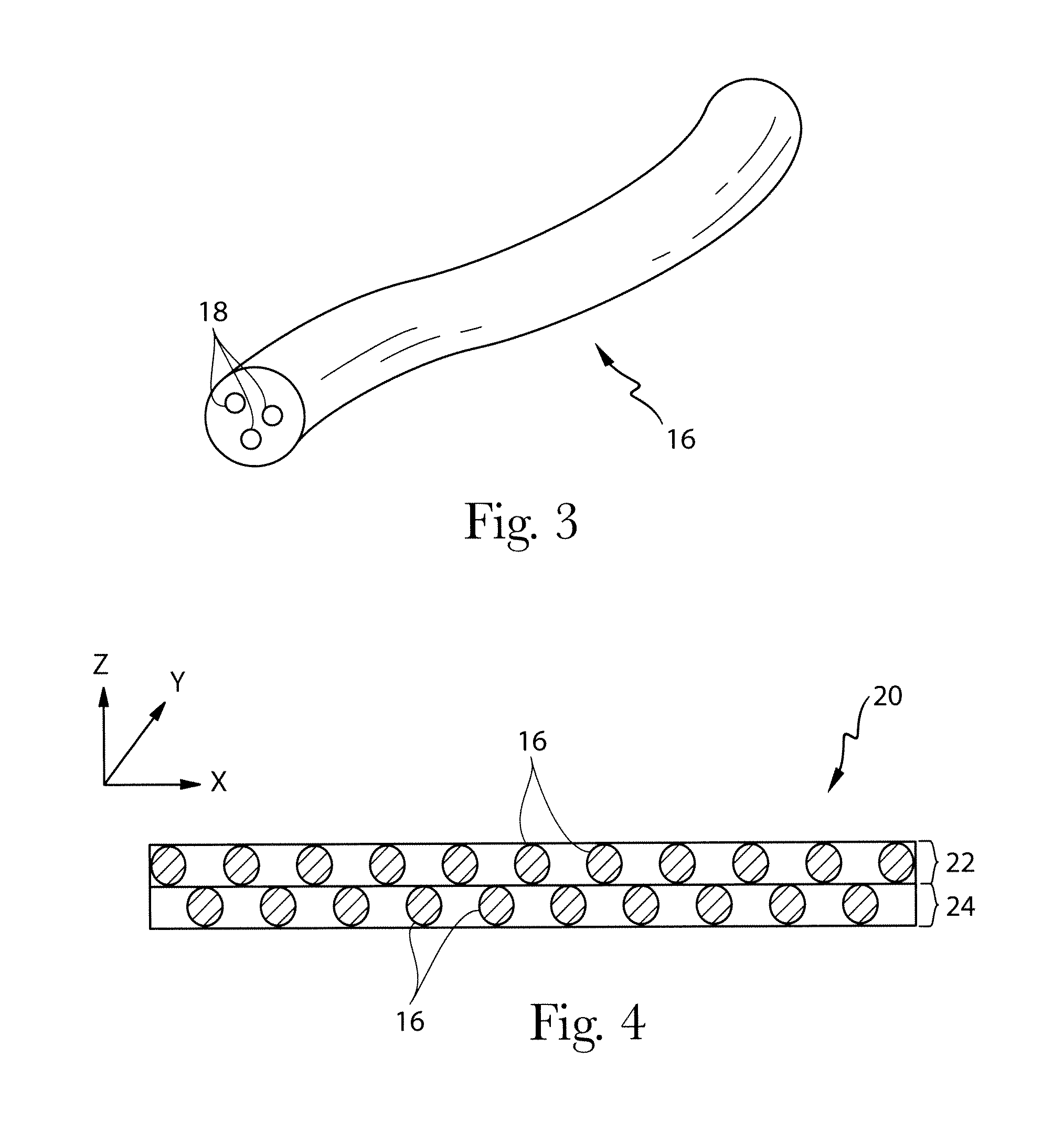

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

InactiveUS6855422B2Easy to processImprove propertiesHeat storage plantsWarp knittingMedical productPhase-change material

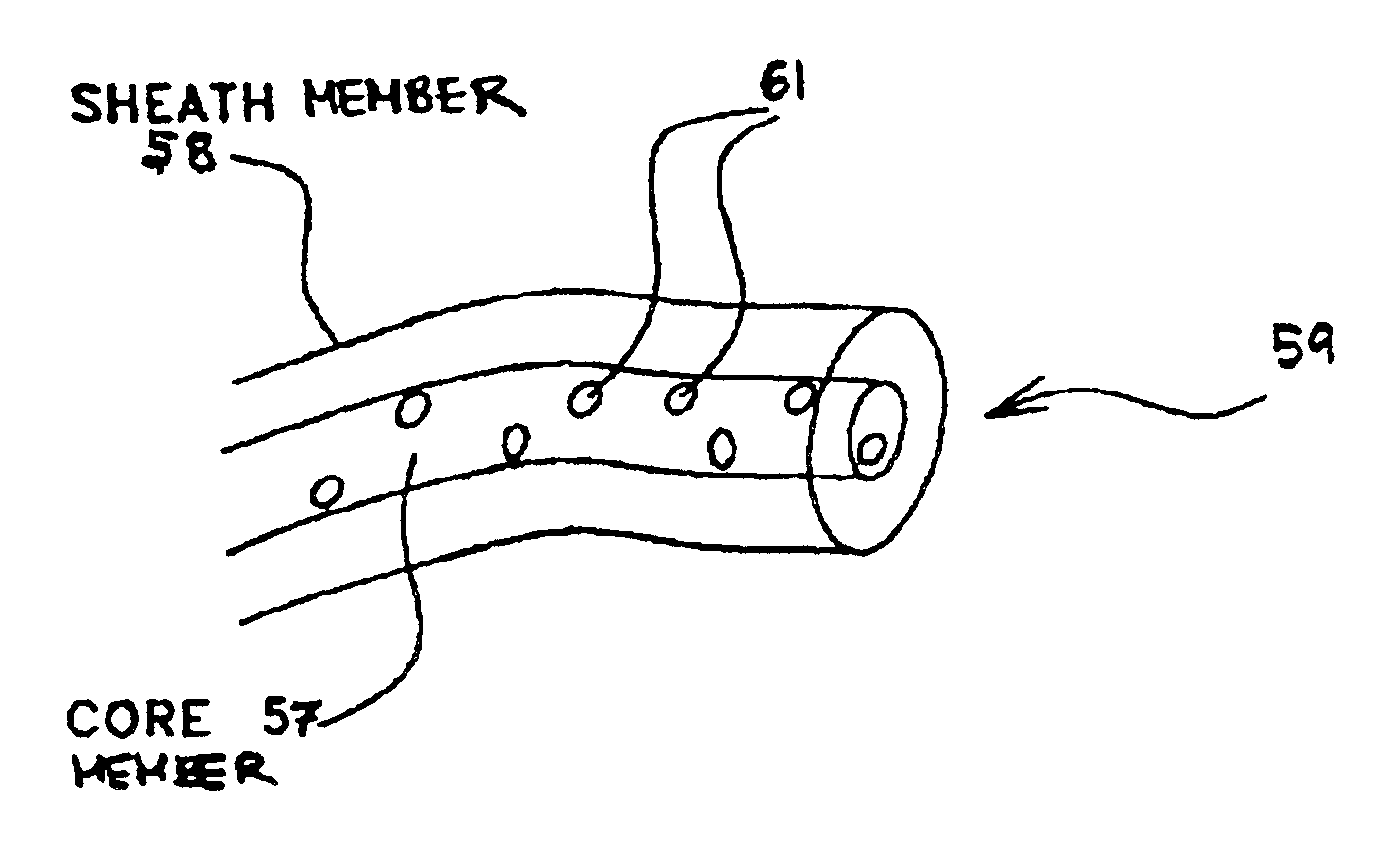

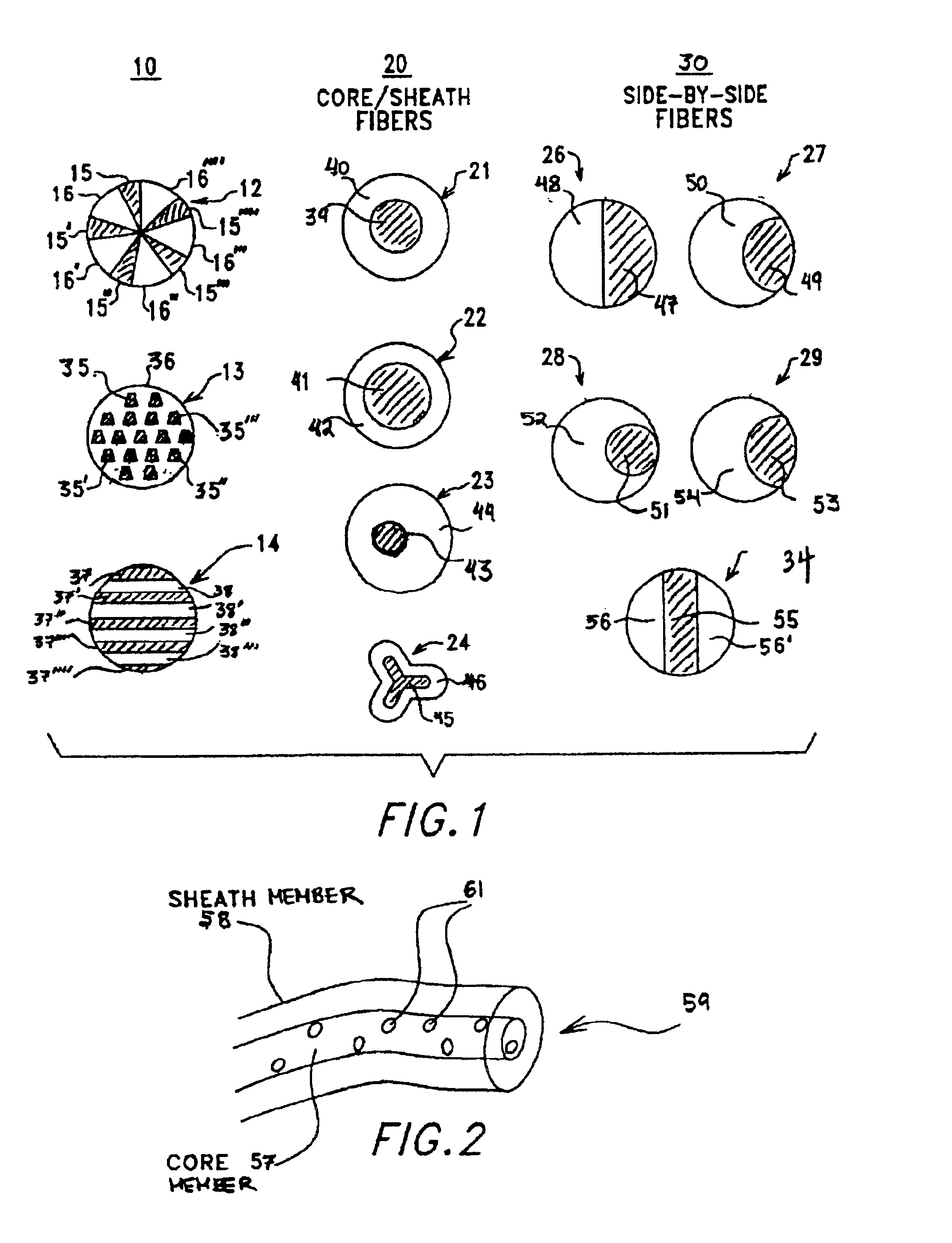

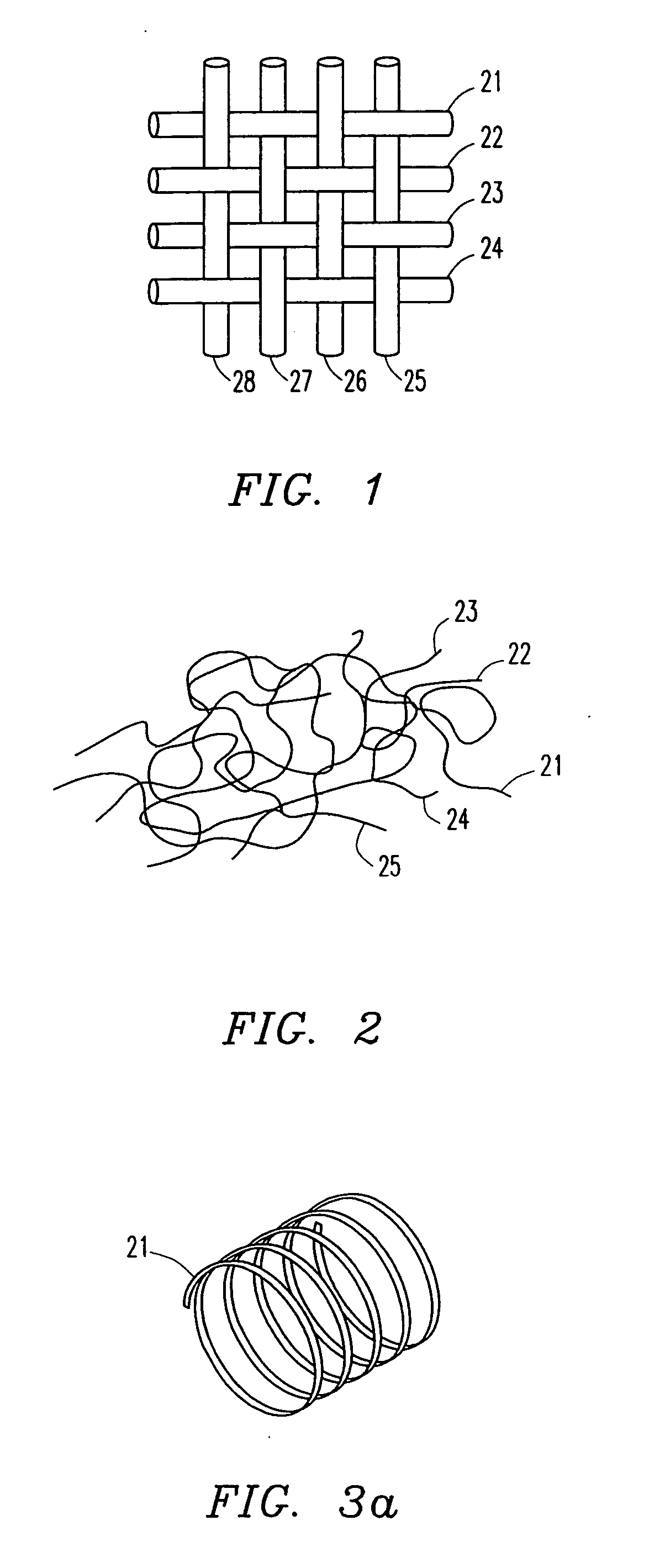

The invention relates to a multi-component fiber having enhanced reversible thermal properties and methods of manufacturing thereof. The multi-component fiber comprises a fiber body formed from a plurality of elongated members, at least one of the elongated members comprising a temperature regulating material dispersed therein. The temperature regulating material comprises a phase change material. The multi-component fiber may be formed via a melt spinning process or a solution spinning process and may be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber may be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

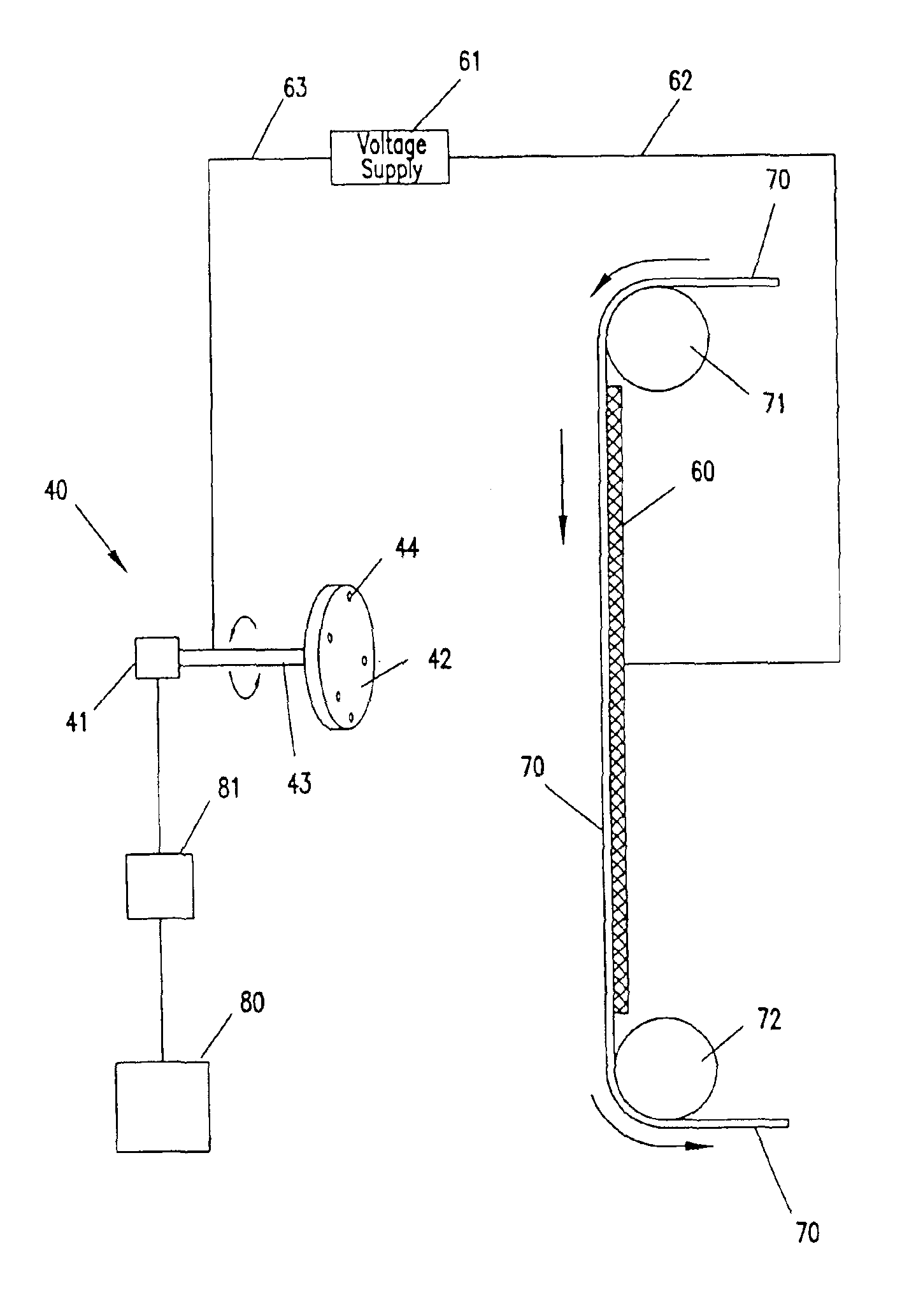

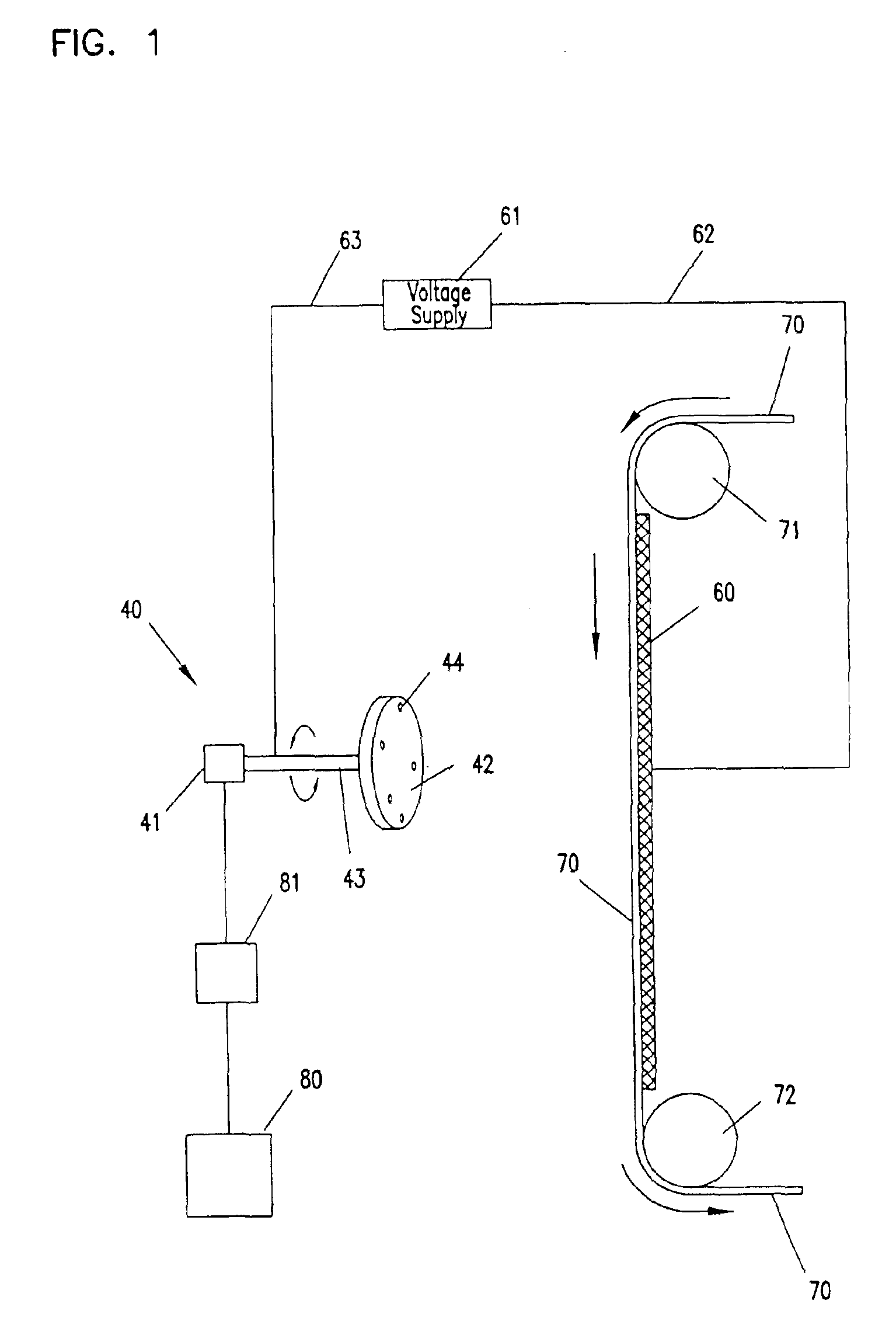

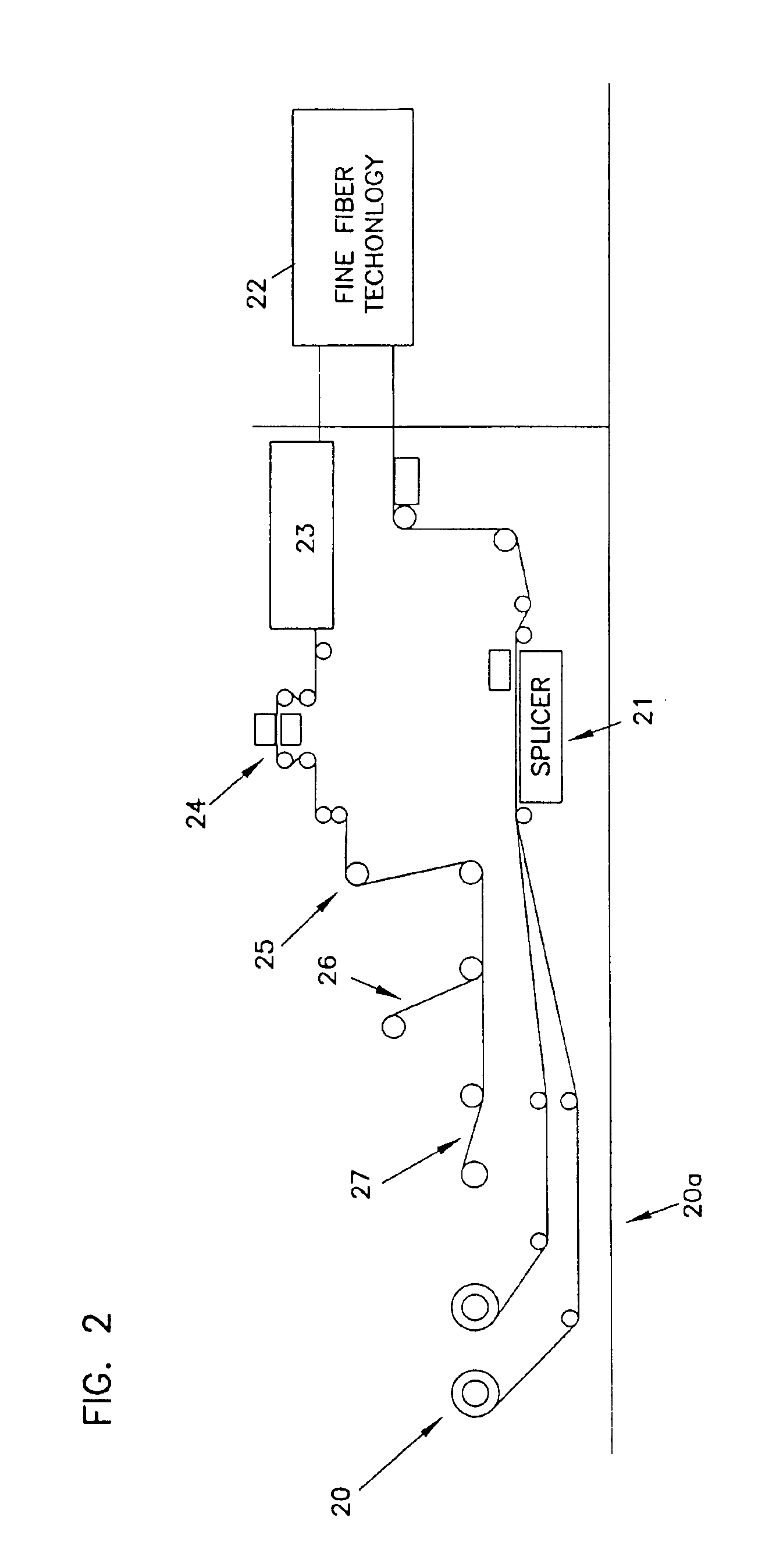

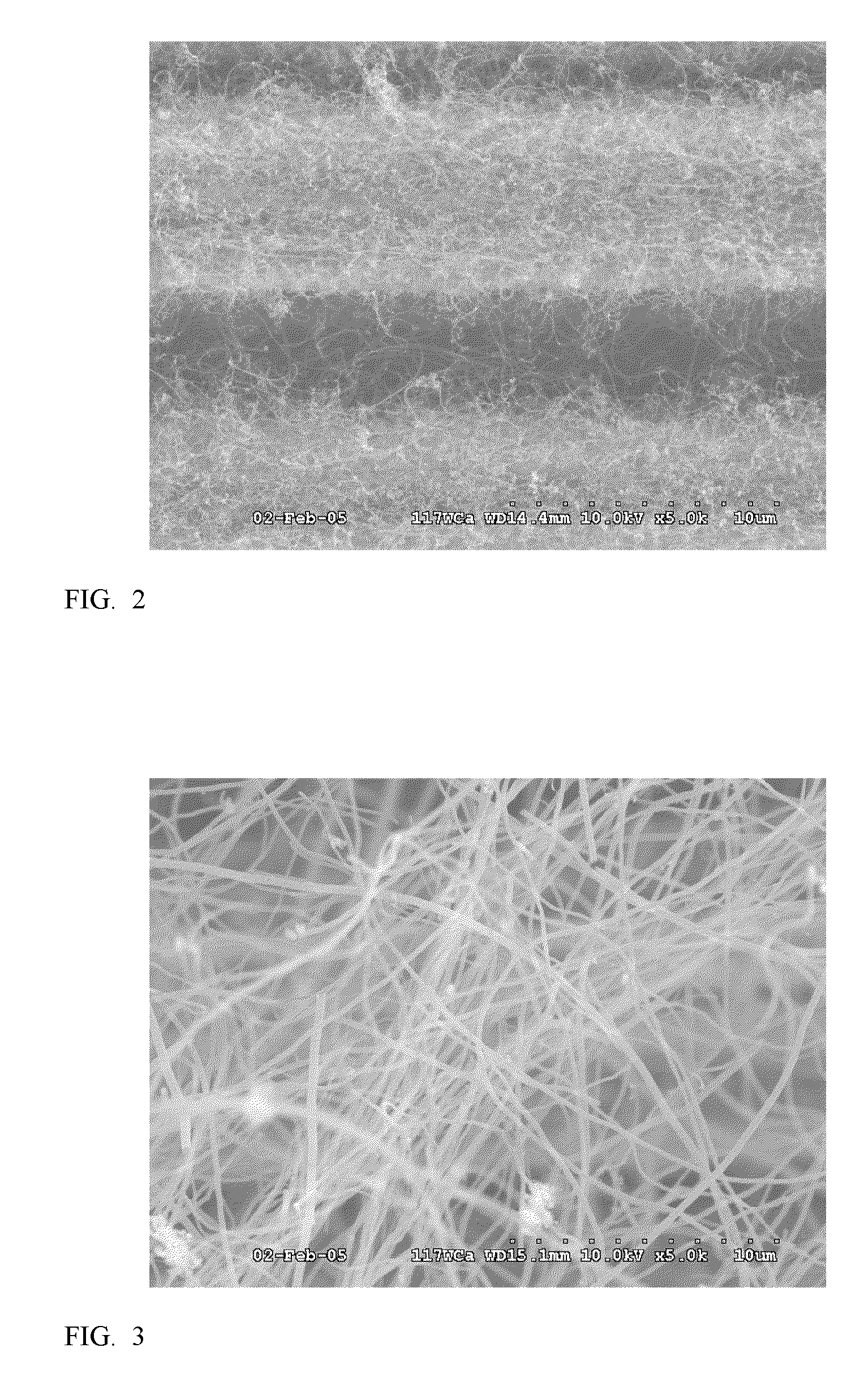

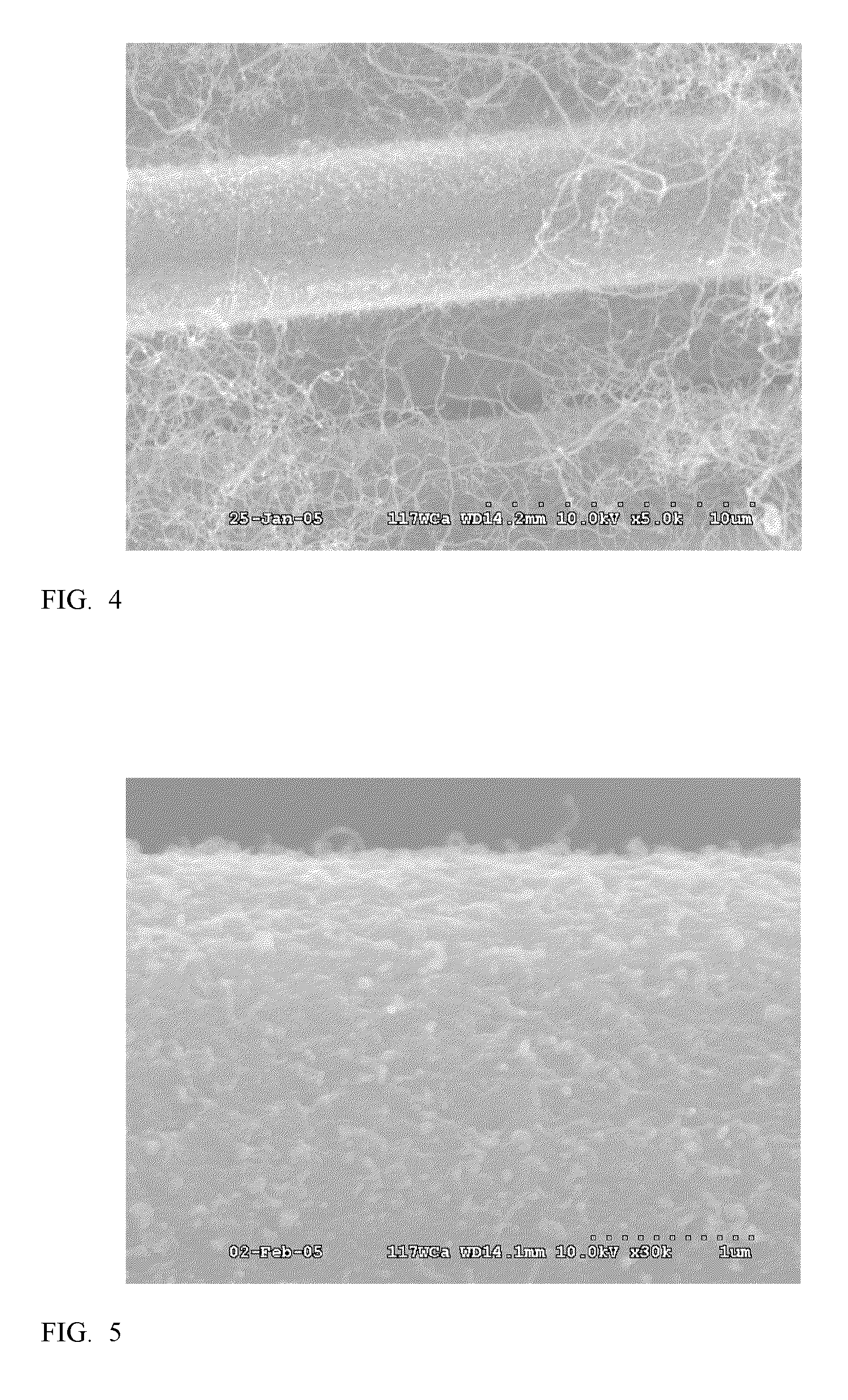

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

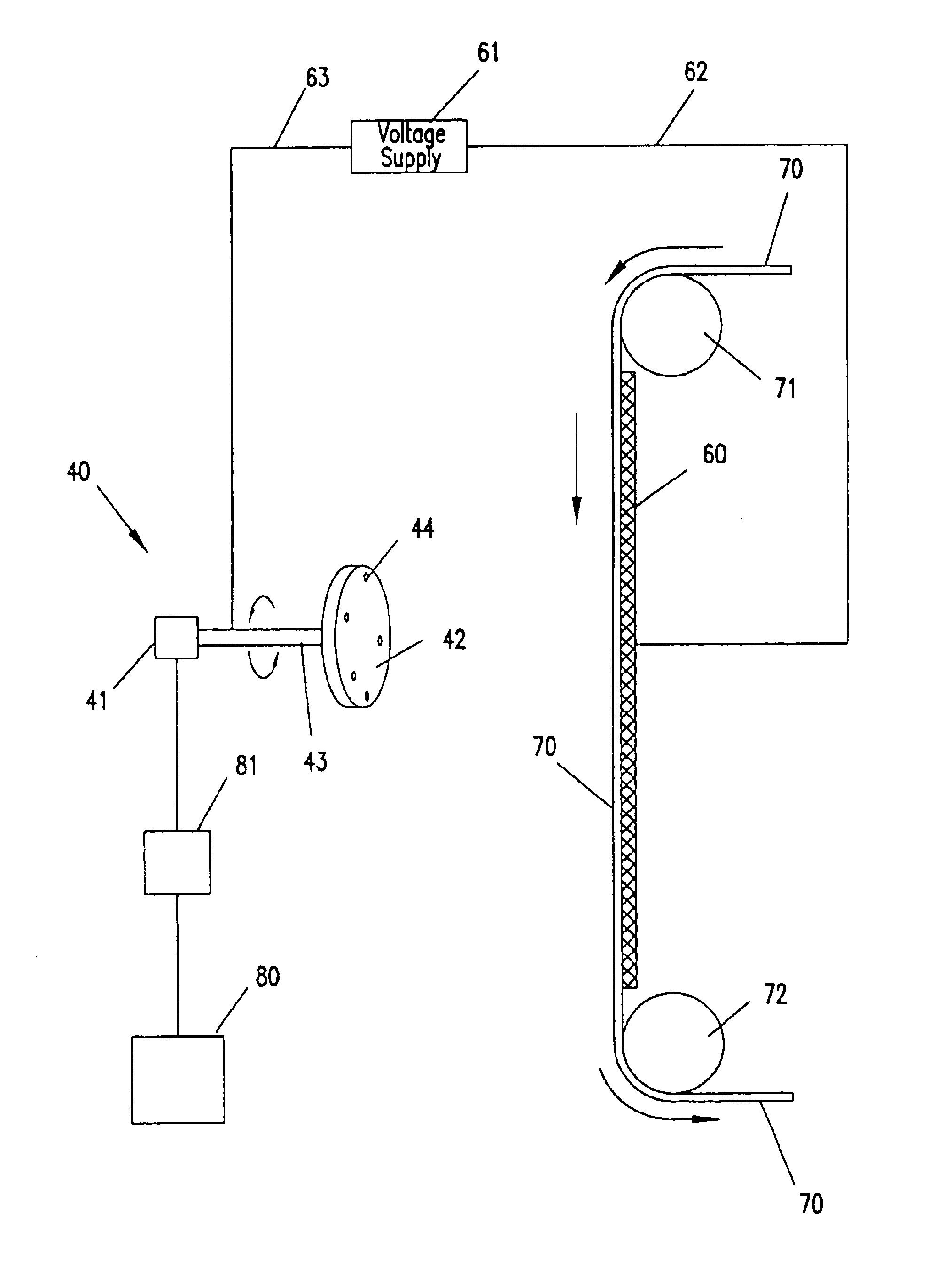

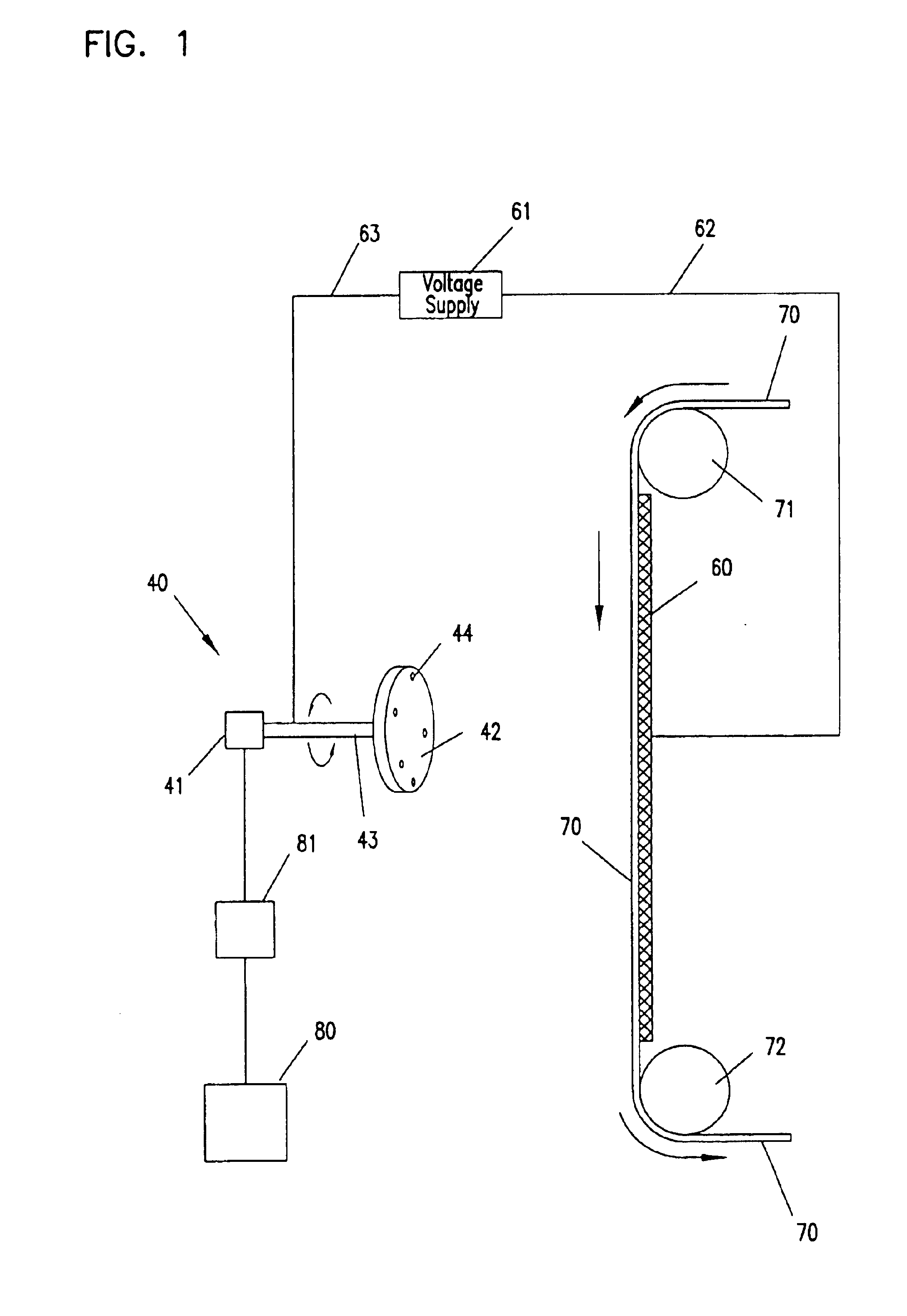

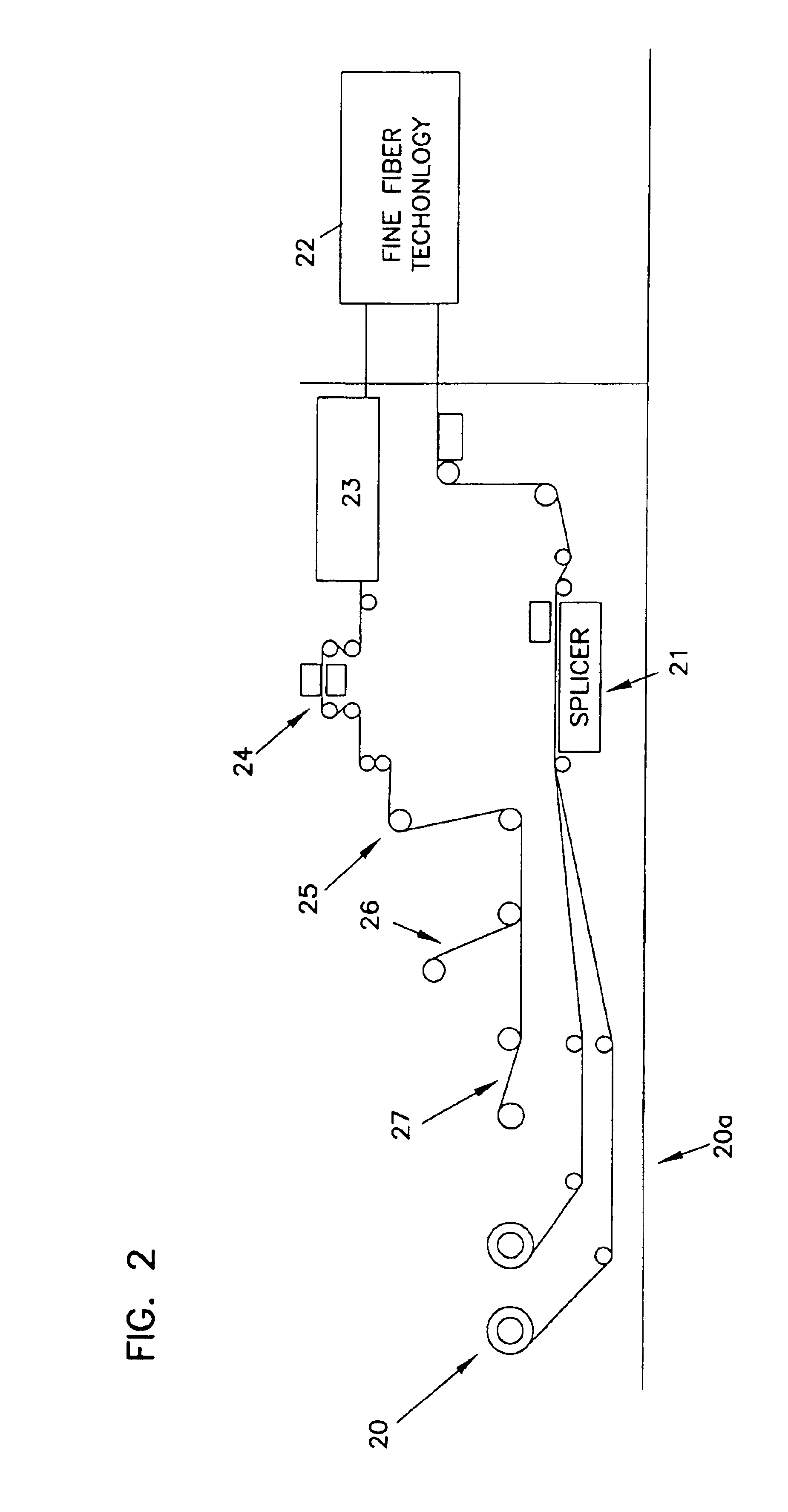

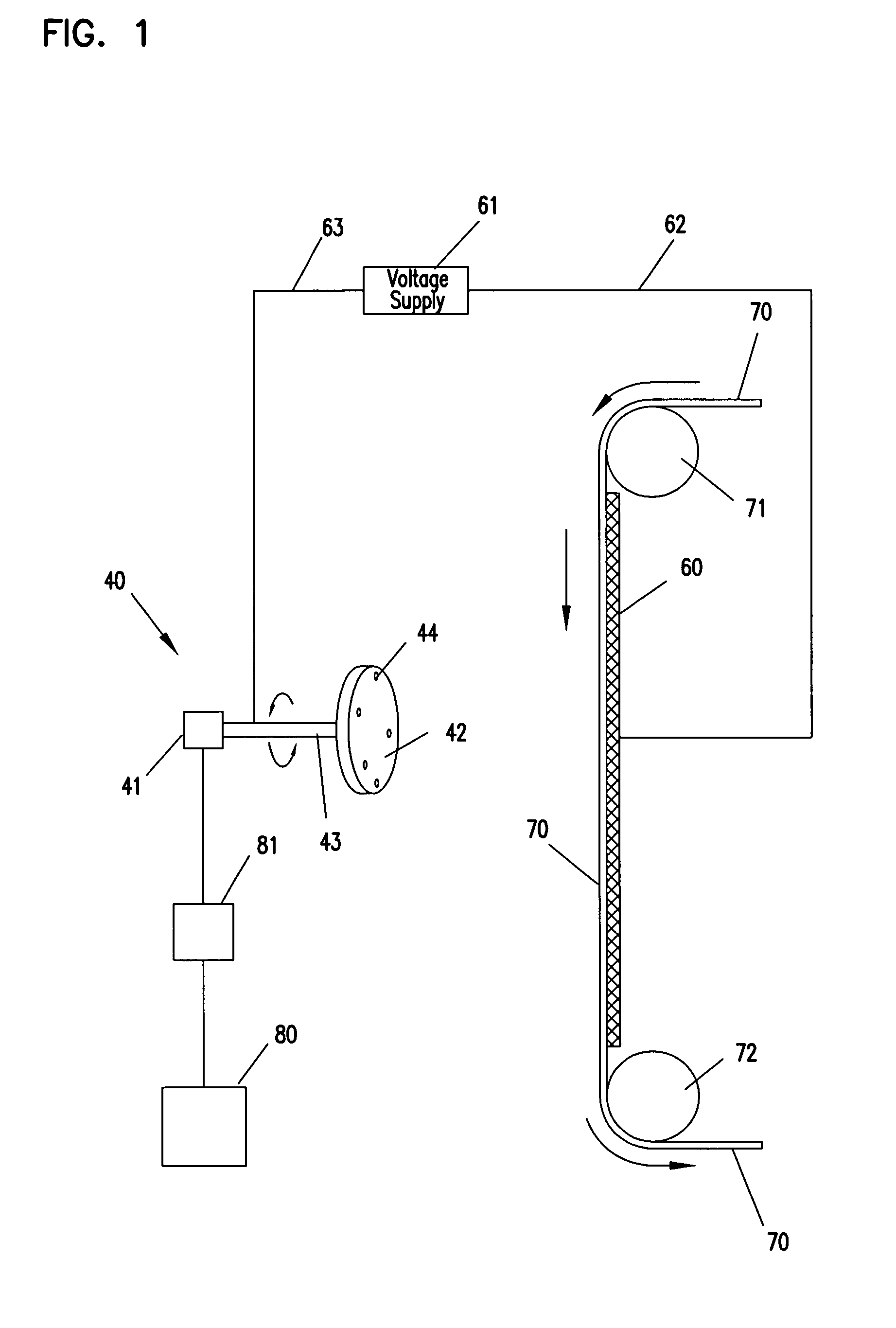

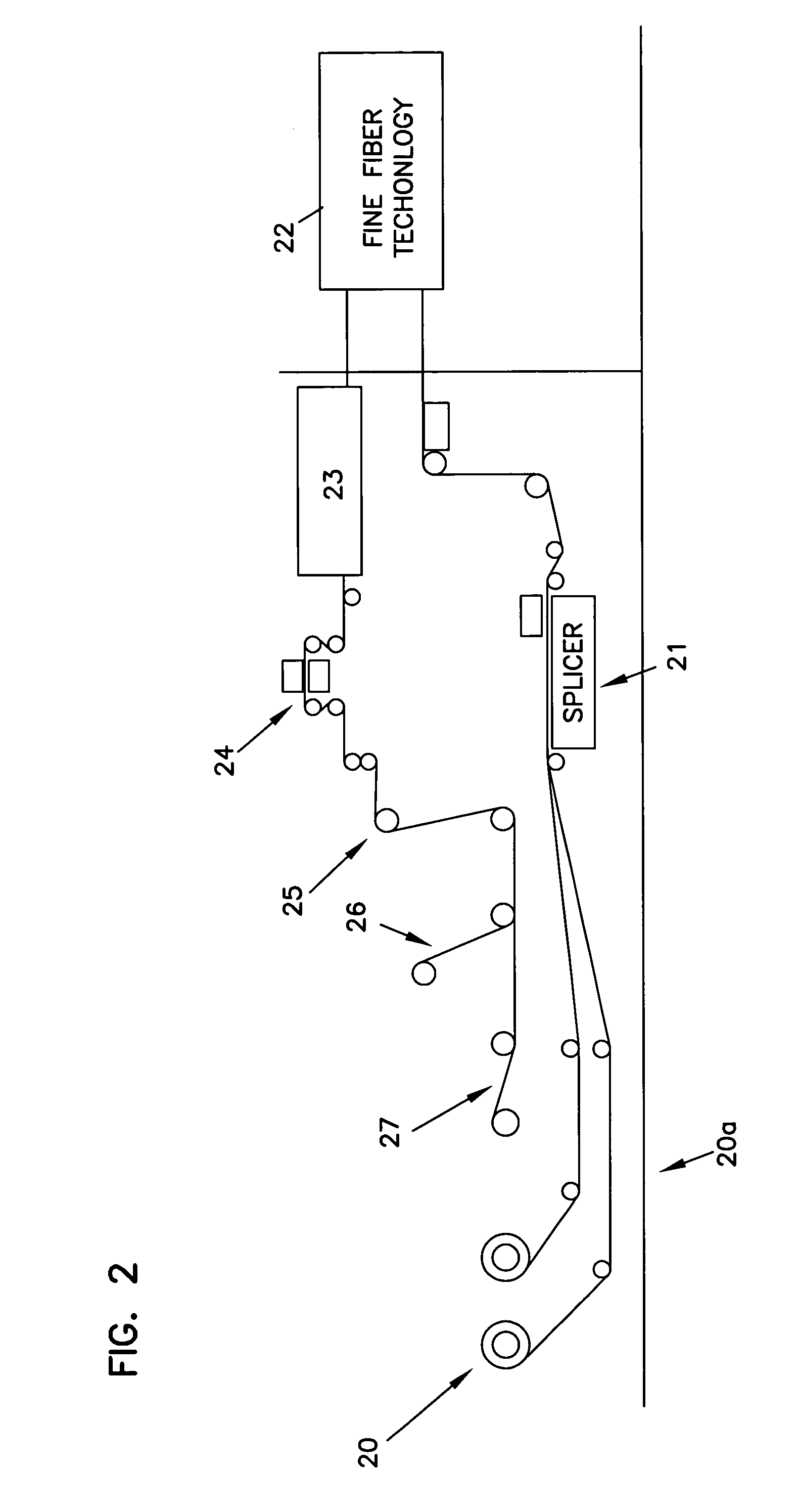

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

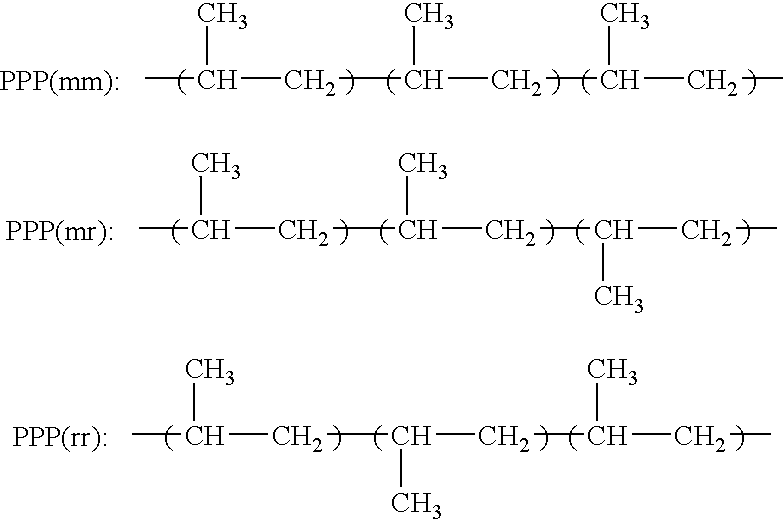

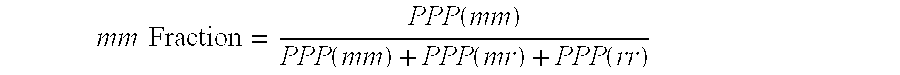

Plasticized polyolefin compositions

InactiveUS20060135699A1Monocomponent polyolefin artificial filamentArtifical filament manufacturePolyolefinPlasticizer

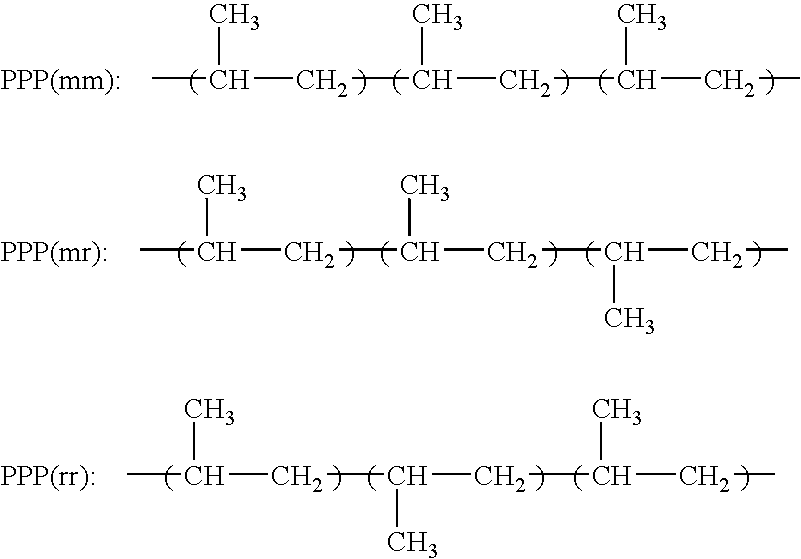

The present invention relates to a composition comprising 1) from 1 to 98 weight % of a first propylene polymer having a melting point of 100° C. or more, 2) from 5 to 98 weight % of a second propylene polymer having a heat of fusion of 70 J / g or less and a tacticity index of 75% or more, 3) from 0.5 to 75 weight % of a non-functionalized plasticizer (“NFP”) having a viscosity index of 120 or more, based upon the weight of the first polymer, second polymer, and the NFP, and articles therefrom

Owner:EXXONMOBIL CHEM PAT INC

Silk biomaterials and methods of use thereof

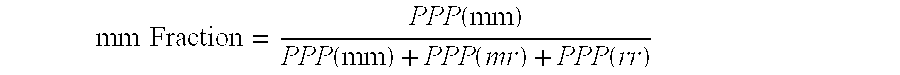

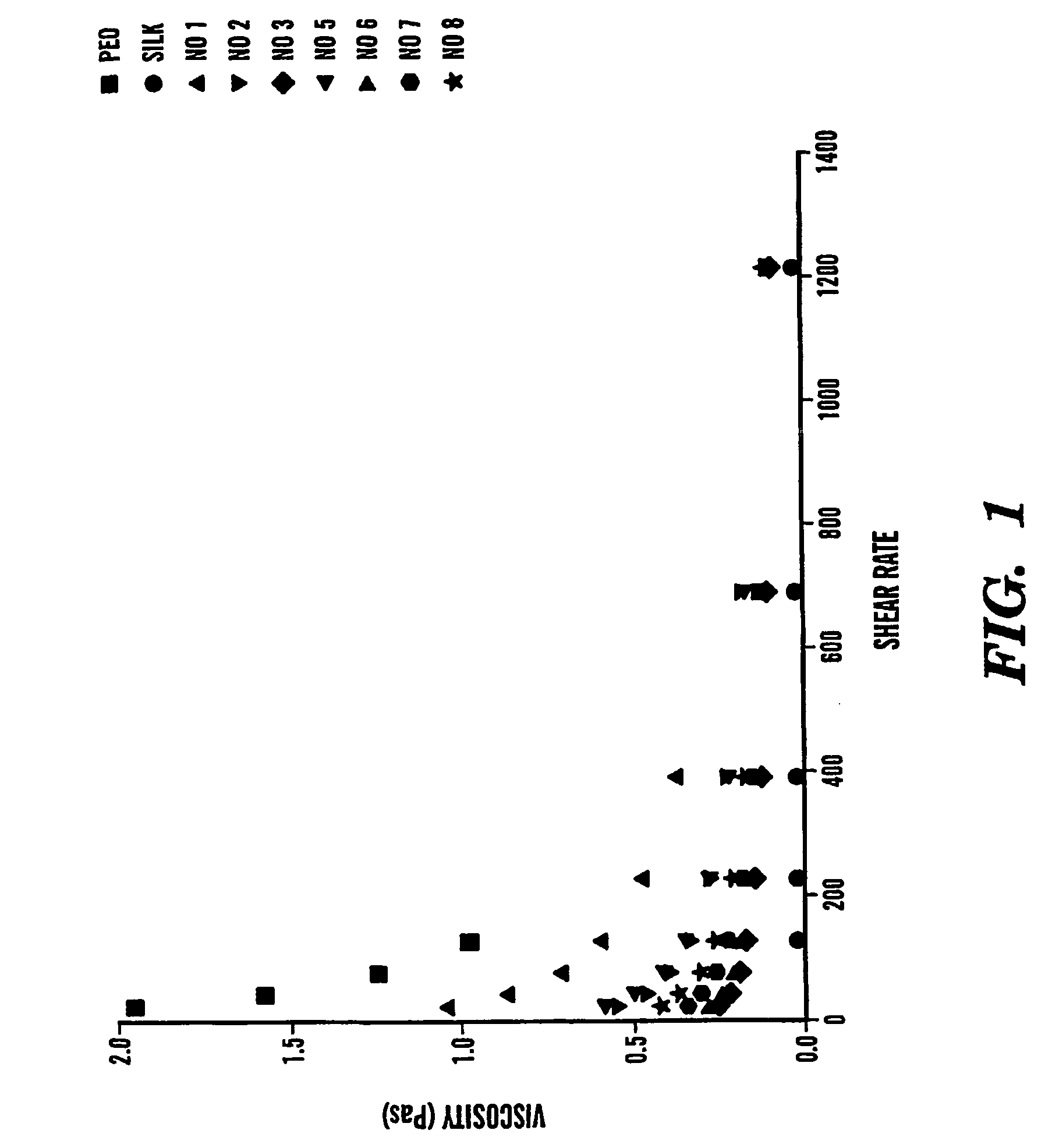

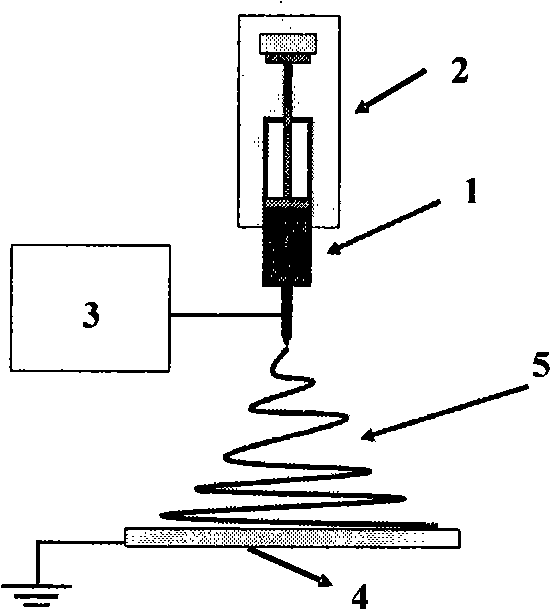

ActiveUS7674882B2Avoid problemsReduce usagePeptide/protein ingredientsFilament/thread formingFiberIn vivo

The present invention provides an all-aqueous process and composition for production of silk biomaterials, e.g., fibers, films, foams and mats. In the process, at least one biocompatible polymer, such as poly(ethylene oxide) (PEO) (a well-documented biocompatible material), was blended with the silk protein prior to processing e.g., electrospinning. We discovered that this step avoids problems associated with conformational transitions of fibroin during solubilization and reprocessing from aqueous solution which lead to embrittled materials. Moreover, the process avoids the use of organic solvents that can pose problems when the processed biomaterials are exposed to cells in vitro or in vivo.

Owner:MASSACHUSETTS INST OF TECH +1

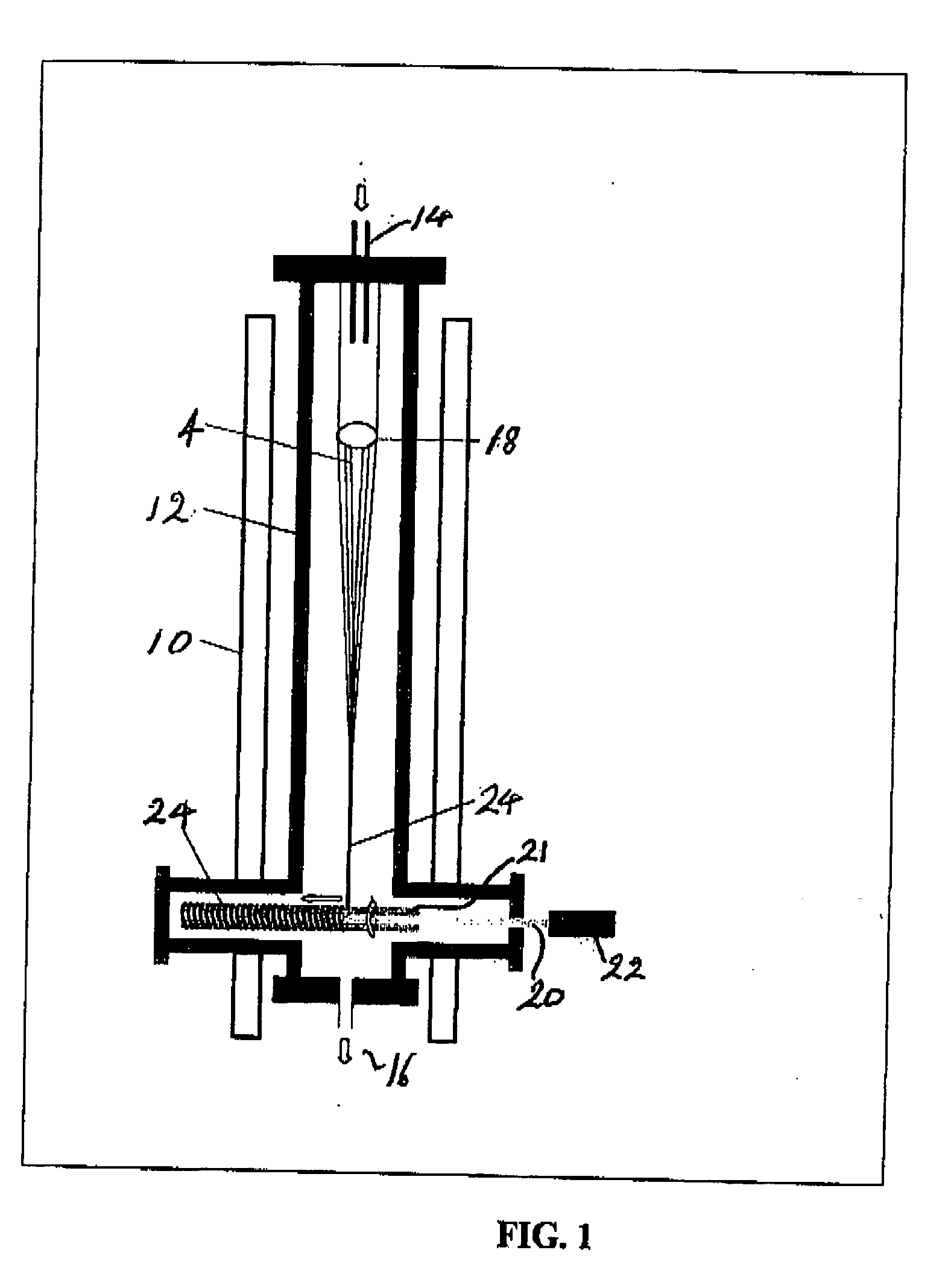

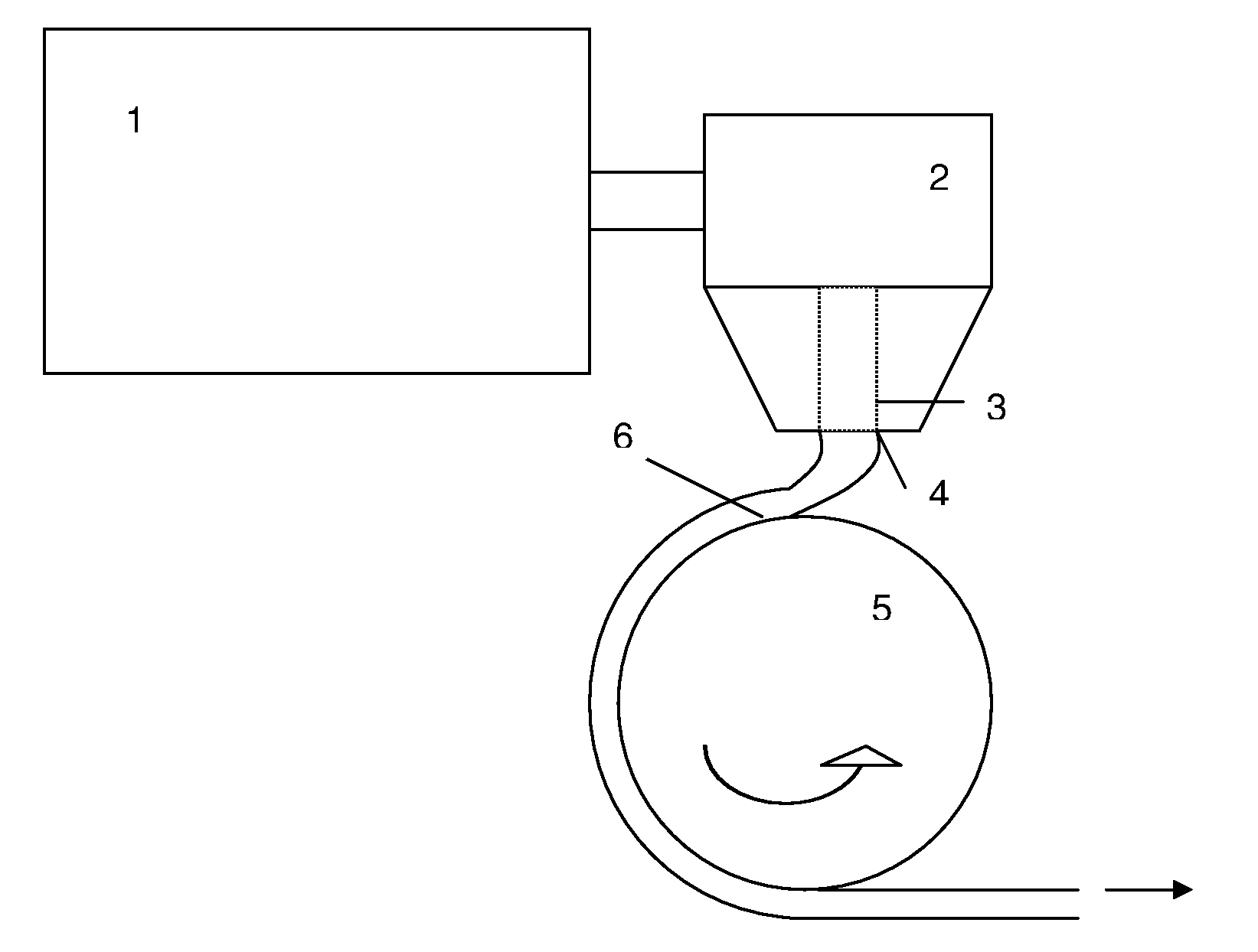

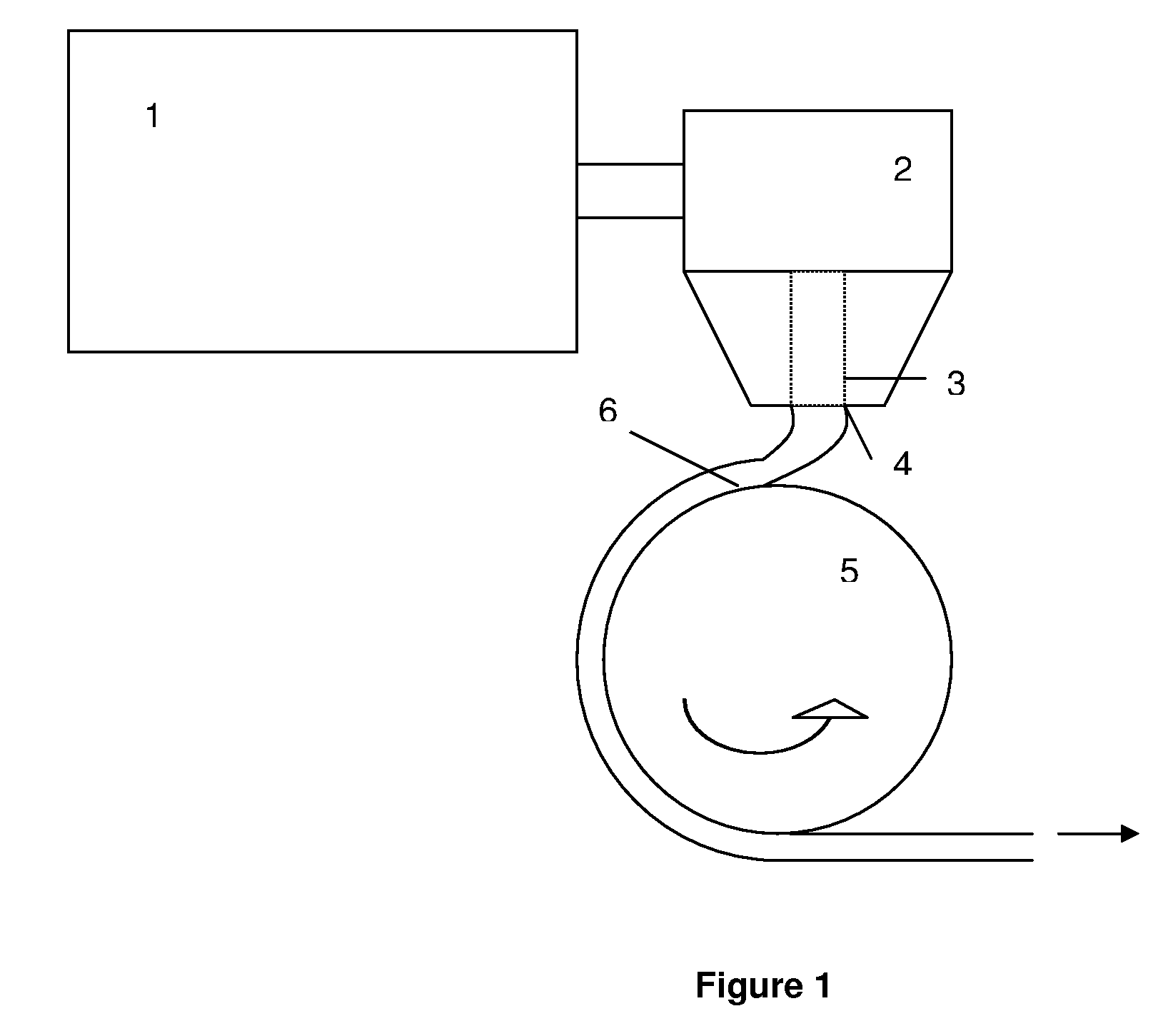

Production of agglomerates from gas phase

ActiveUS20050006801A1Avoid enteringImprove mechanical propertiesMaterial nanotechnologyMulti-walled nanotubesGas phaseReaction zone

A process for production of an agglomerate comprises the steps of: passing a flow of one or more gaseous reactants into a reactor; reacting the one or more gaseous reactants within a reaction zone of the reactor to form product particles; agglomerating the product particles into an agglomerate; and applying a force to the agglomerate to displace it continuously away from the reaction zone.

Owner:CAMBRIDGE ENTERPRISE LTD

Reinforced polymers

InactiveUS6331265B1Less tangleImprove mechanical propertiesMaterial nanotechnologyWood working apparatusPolymer scienceNanotube

Provided is a method for the production of a reinforced polymer, which method comprises:(a) introducing carbon nanotubes into a polymer to provide a mixture of the polymer and the nanotubes;(b) stretching the mixture at or above the melting temperature (Tm) of the polymer to orient the carbon nanotubes; and(c) stretching the mixture in the solid state to further orient the carbon nanotubes.

Owner:FINA RES SA

Dissolvable Fibrous Web Structure Article Comprising Active Agents

The personal care compositions of the present invention are in the form of an Article comprising a dissolvable fibrous web structure. The fibers of the dissolvable fibrous web structure comprise a surfactant; a water soluble polymeric structurant; and a plasticizer. Additionally the ratio of the water soluble water soluble polymeric structurant to the active agent in the fiber is 3.5 or less.

Owner:THE PROCTER & GAMBLE COMPANY

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Surface modified particulate and sintered or injection molded products

ActiveUS20150080495A1Simple technologyWeaken energyConductive materialCeramic shaping apparatusParticulatesPolymer science

Disclosed are interfacially modified particulate and polymer composite material for use in injection molding processes, such as metal injection molding and additive process such as 3D printing. The composite material is uniquely adapted for powder metallurgy processes. Improved products are provided under process conditions through surface modified powders that are produced by extrusion, injection molding, additive processes such as 3D printing, Press and Sinter, or rapid prototyping.

Owner:TUNDRA COMPOSITES LLC

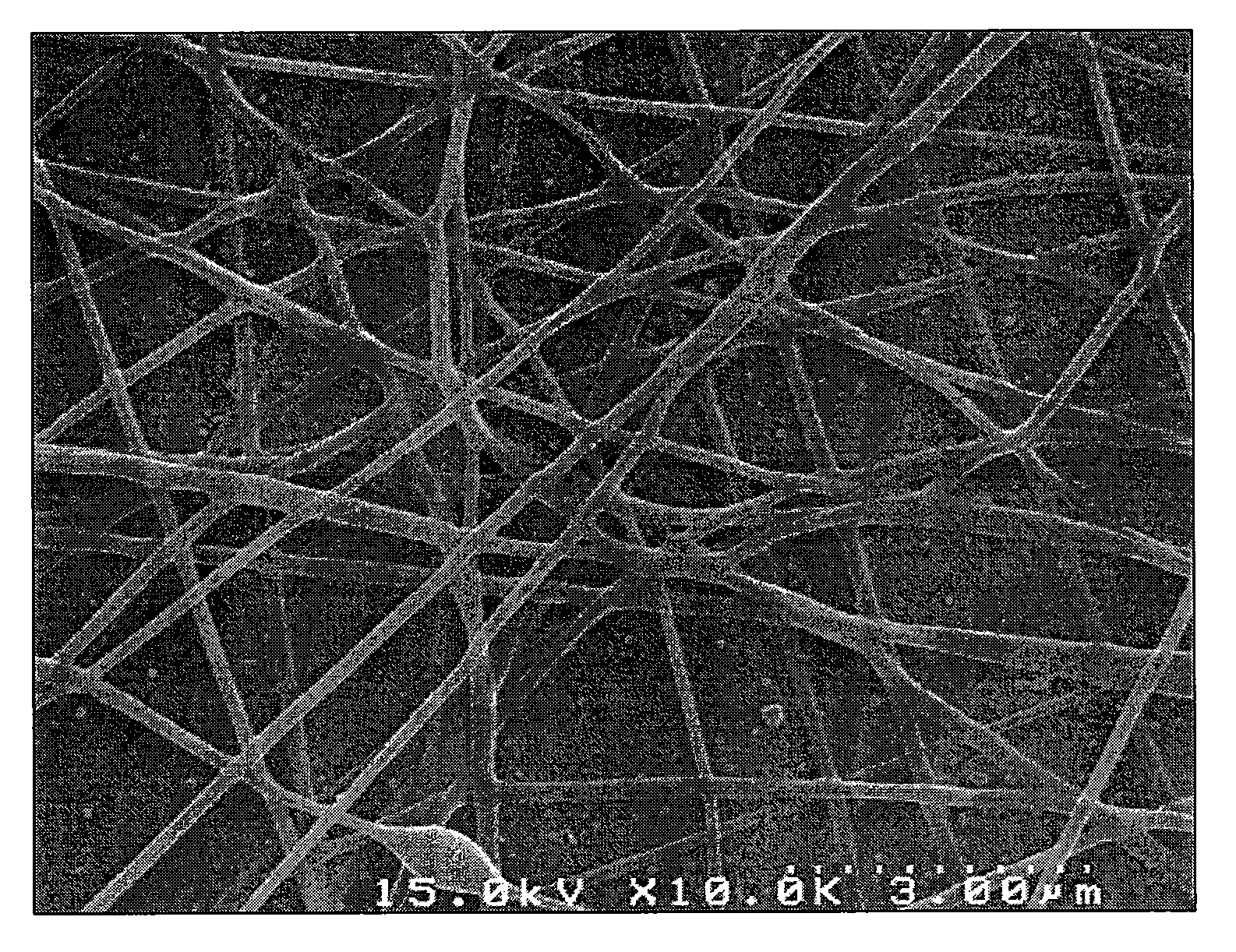

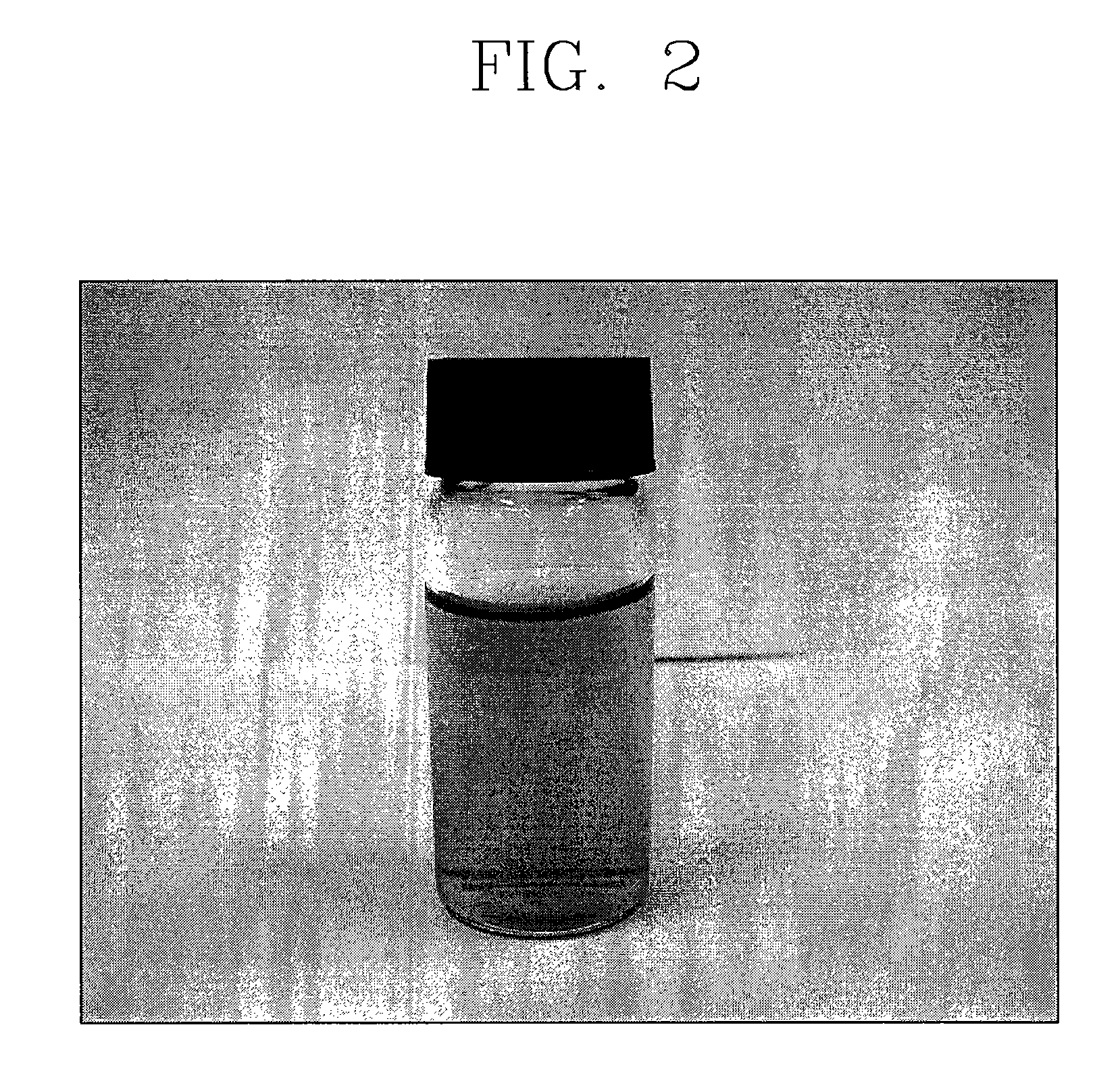

Graphene composite nanofiber and preparation method thereof

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

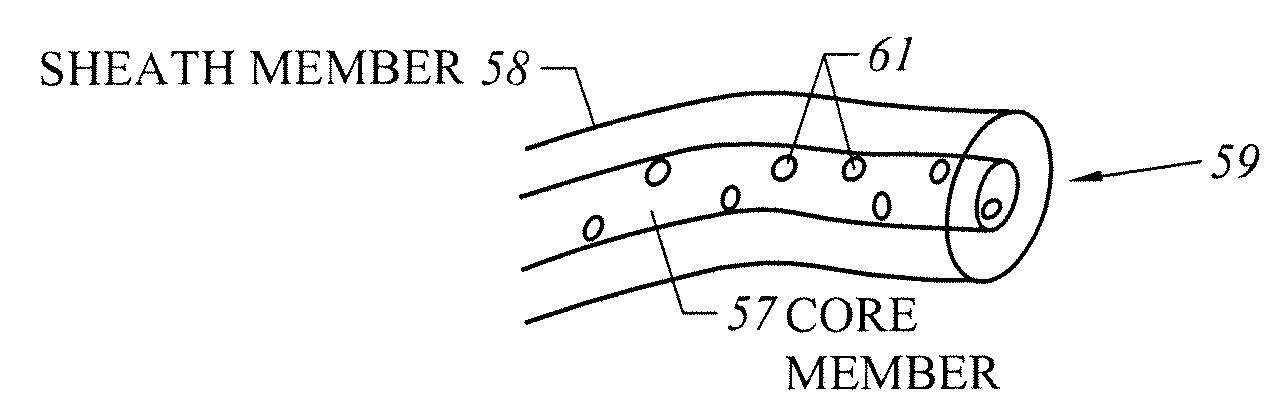

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof are described. In one embodiment, a multi-component fiber includes a fiber body formed from a set of elongated members, and at least one of the set of elongated members includes a temperature regulating material having a latent heat of at least 40 J / g and a transition temperature in the range of 22° C. to 40° C. The temperature regulating material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. The multi-component fiber can be formed via a melt spinning process or a solution spinning process and can be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber can be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

Polypropylene based fibers and nonwovens

InactiveUS20060008643A1Great contributionSynthetic resin layered productsWoven fabricsFiberPolyolefin

The present invention relates to fibers and nonwovens made from plasticized polyolefin compositions comprising a polyolefin, a non-functionalized hydrocarbon plasticizer and a slip agent.

Owner:EXXONMOBIL CHEM PAT INC

Nano copolymer fibrous membrane material capable of being biodegraded and absorbed and preparation process and use thereof

InactiveCN1961974AOvercome the technical problem of difficult spinningSurgical adhesivesPharmaceutical containersFiberAqueous solution

The invention relates to a gelatin nanometer fiber film which can biologically degrade and absorb, and relative preparation, wherein it via the control on static spin realizes the static spin on gelatin water solution and gelatin / macromolecule mixture water, to obtain the nanometer fiber, which comprises: 0 A61L 27 / 14 A61K 45 / 00 D01D 5 / 00 D01F 1 / 00 A61L 27 / 60 A61L 33 / 06 A61L 24 / 04 A61L 15 / 22 A61F 2 / 02 2 14 3 2005 / 11 / 9 1961974 2007 / 5 / 16 000000000 Institute of Chemistry Chinese Academy of Science Beijing 100080 Han Zhichao He Aihua Li Junxing libai 31002 Shanghai Patent Agency of the Chinese Academy of Sciences No.319 Yueyang Road, Shanghai 200031

Owner:INST OF CHEM CHINESE ACAD OF SCI

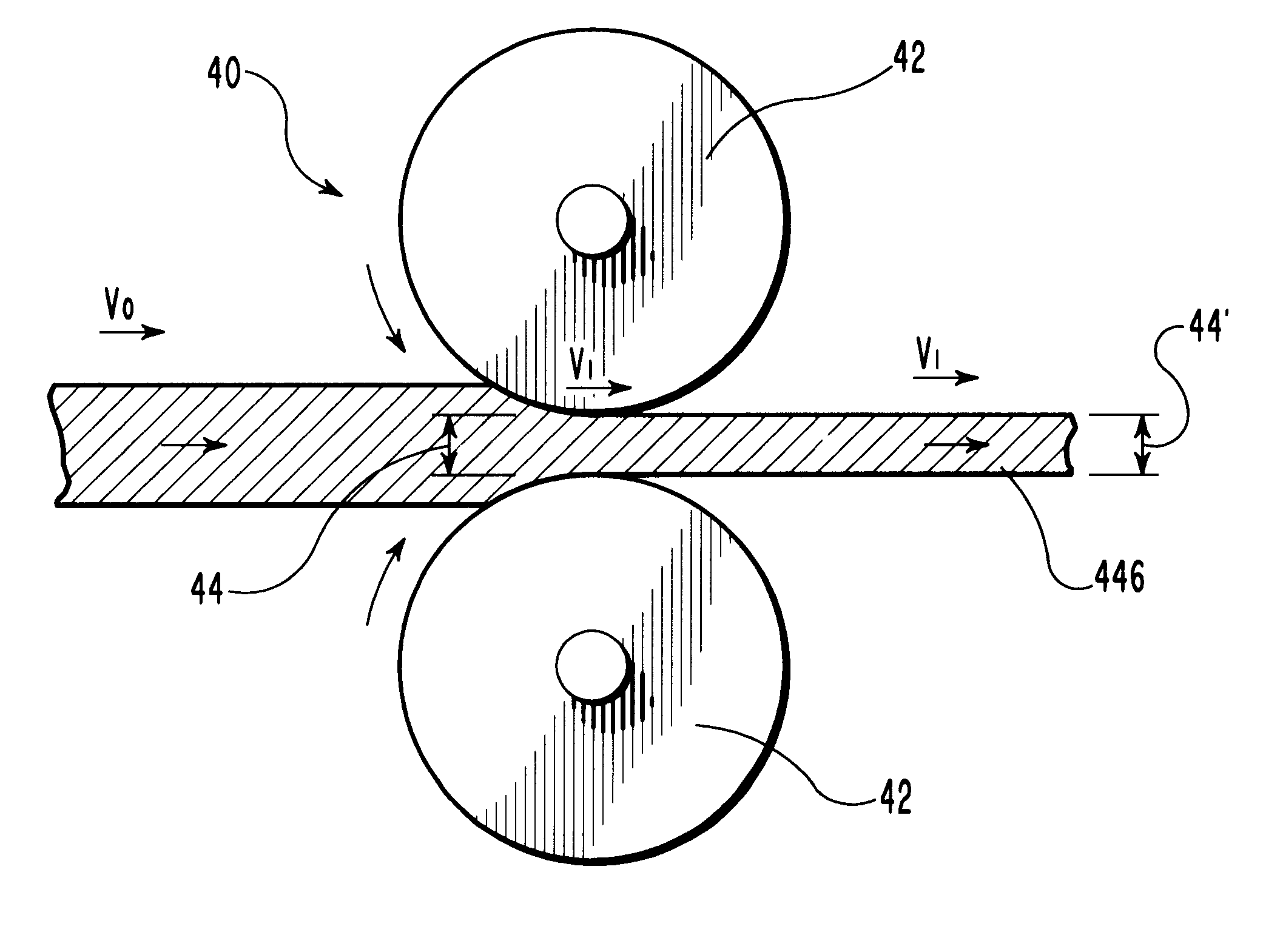

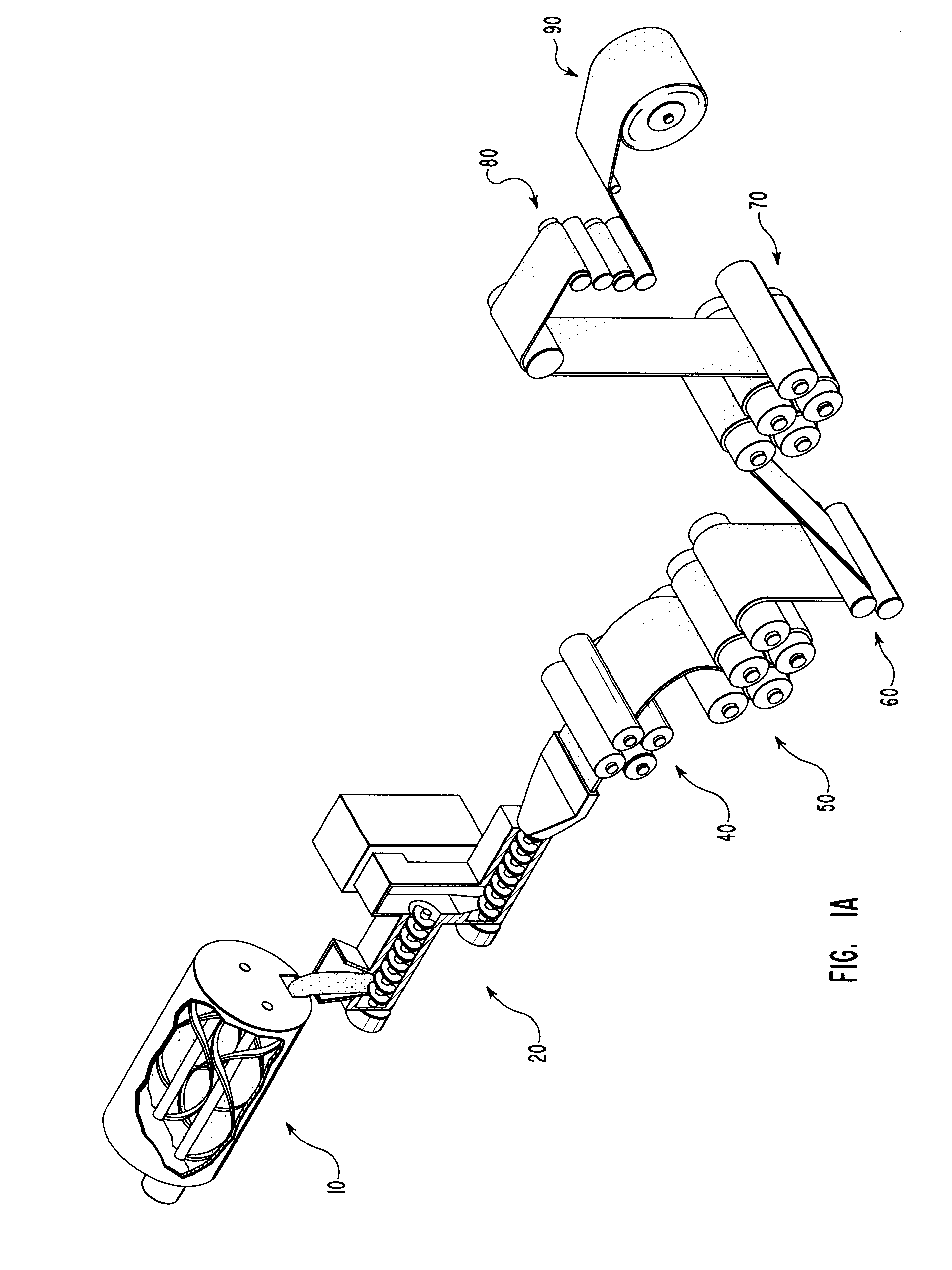

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Dissolvable Nano Web Porous Film and Method of Preparing the Same

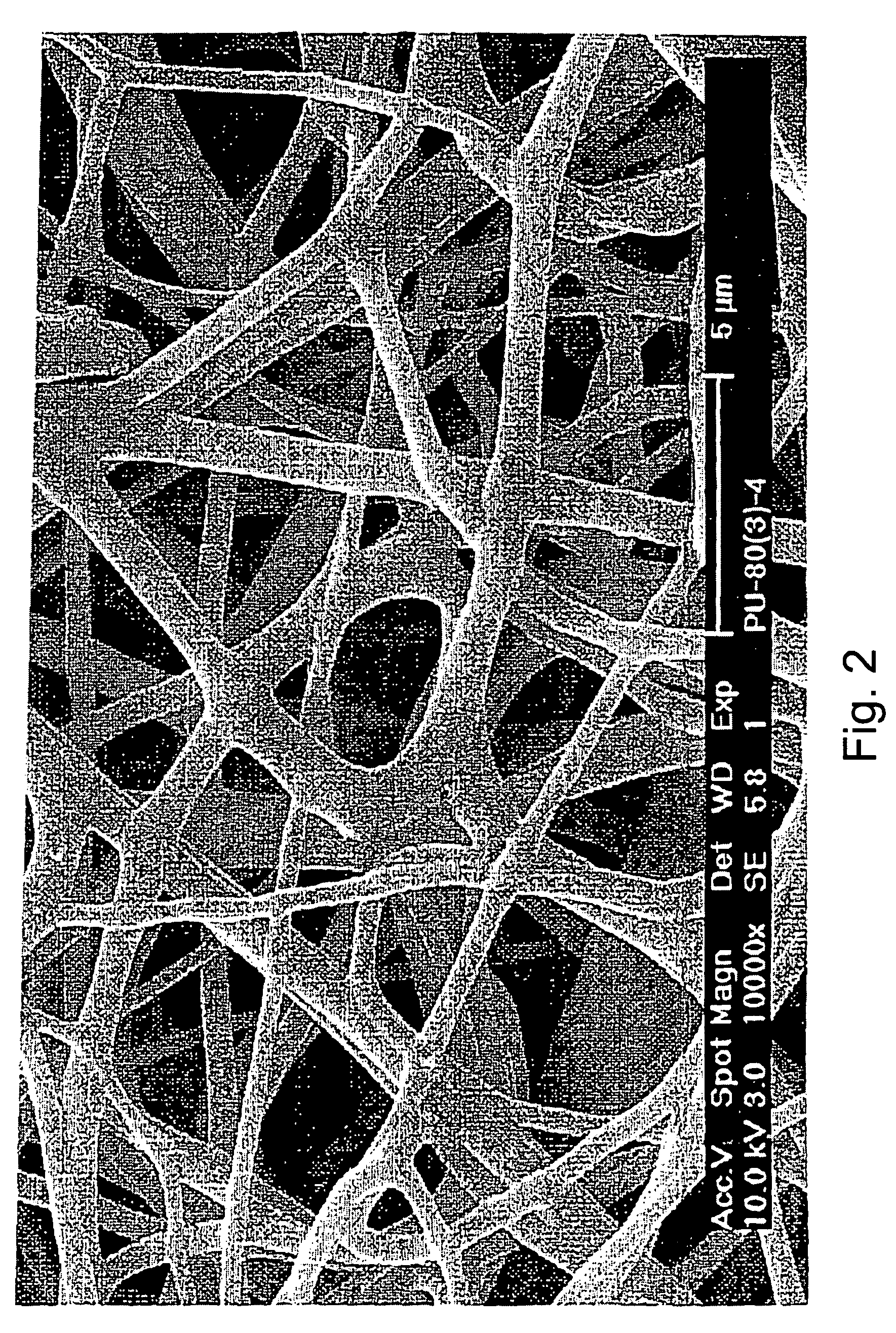

InactiveUS20110250256A1Excellent in dissolvabilityImprove solubilityBiocideElectric discharge heatingSolubilityFiber

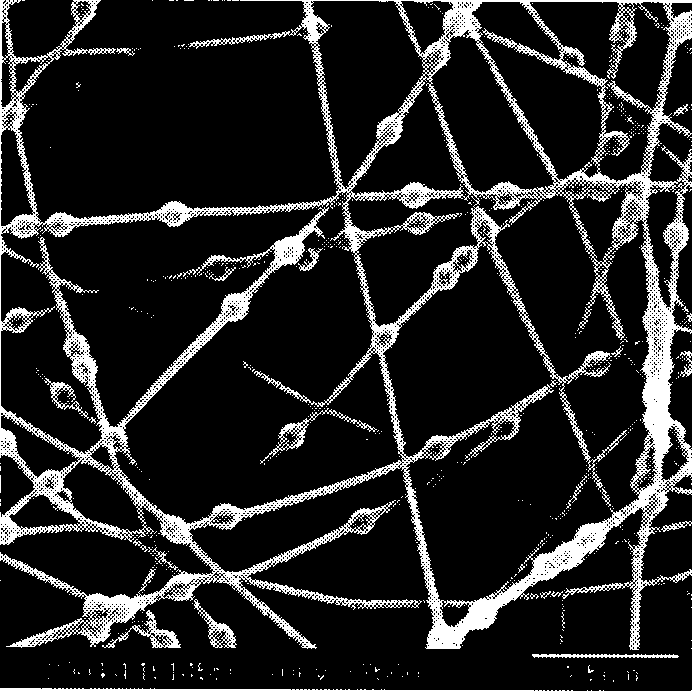

A dissolvable nano web porous film has a network structure and a large specific surface area. The network structure is formed by stacking nano fibers that have a thickness of 10˜50,000 nm. The nano fibers are formed of a composition comprising nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and an optional additive. A method of preparing a dissolvable nano web film comprises producing a polymer melt or solution formed of a composition that comprises a nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and additives, spinning the melt or solution to form a nano web porous film having nano webs stacked in a network structure, drying the nano web porous film, and stabilizing the nano web porous film. The porous film has a 5˜5000 times higher specific surface area and a 2˜20 times faster dissolving time than a conventional film. The dissolvable nano web porous film has excellent dissolvability and solubility.

Owner:GENIC

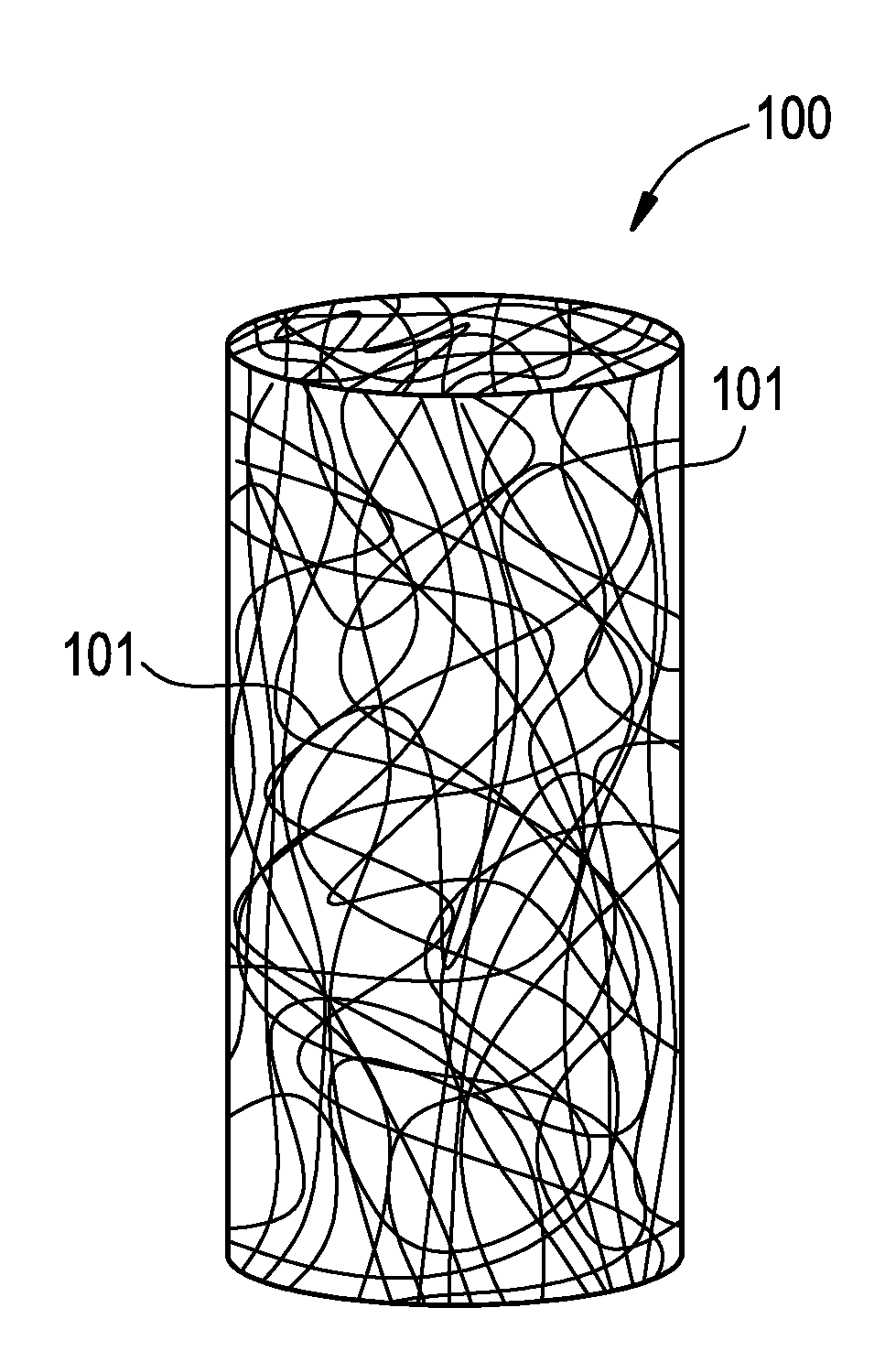

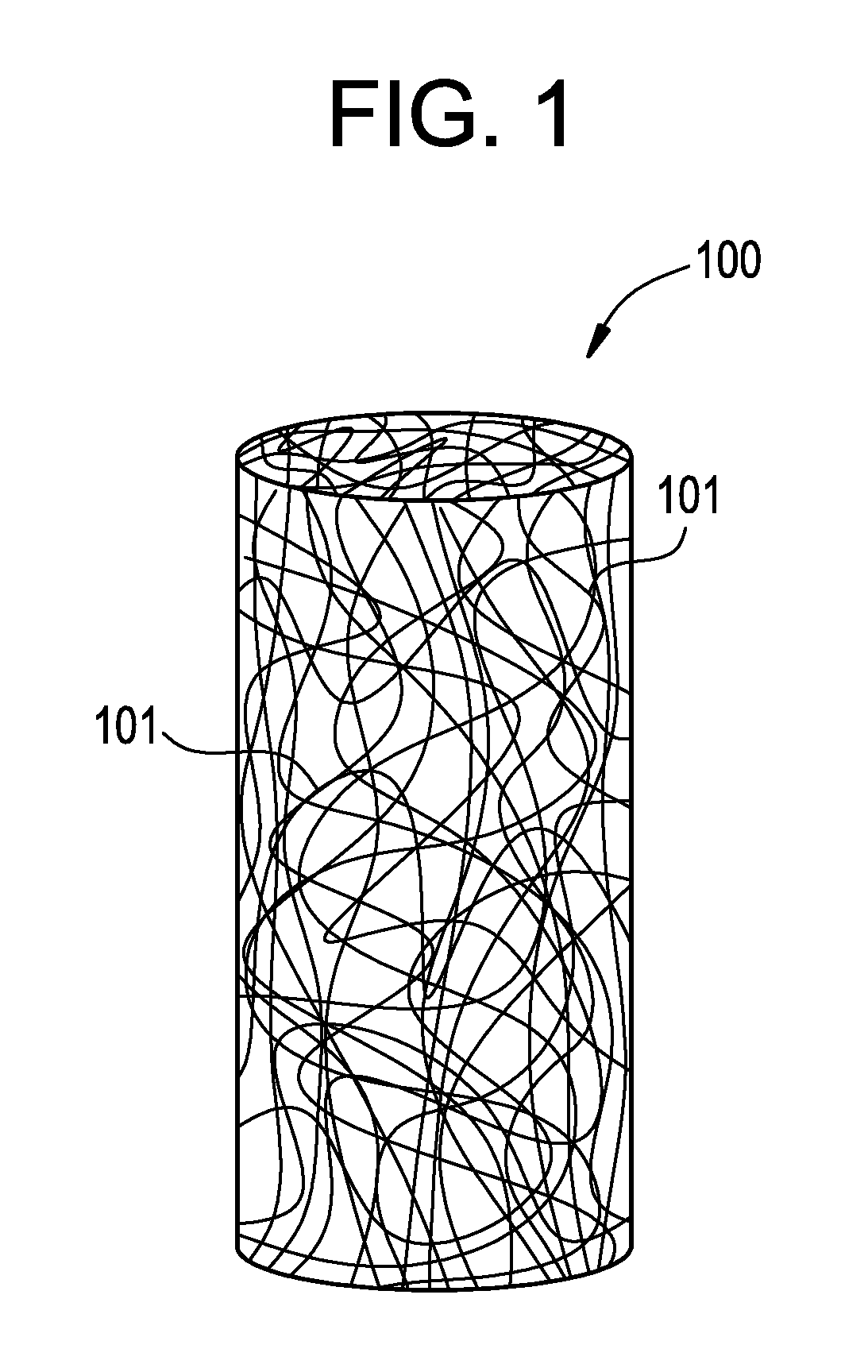

Vascular prosthesis and method for production thereof

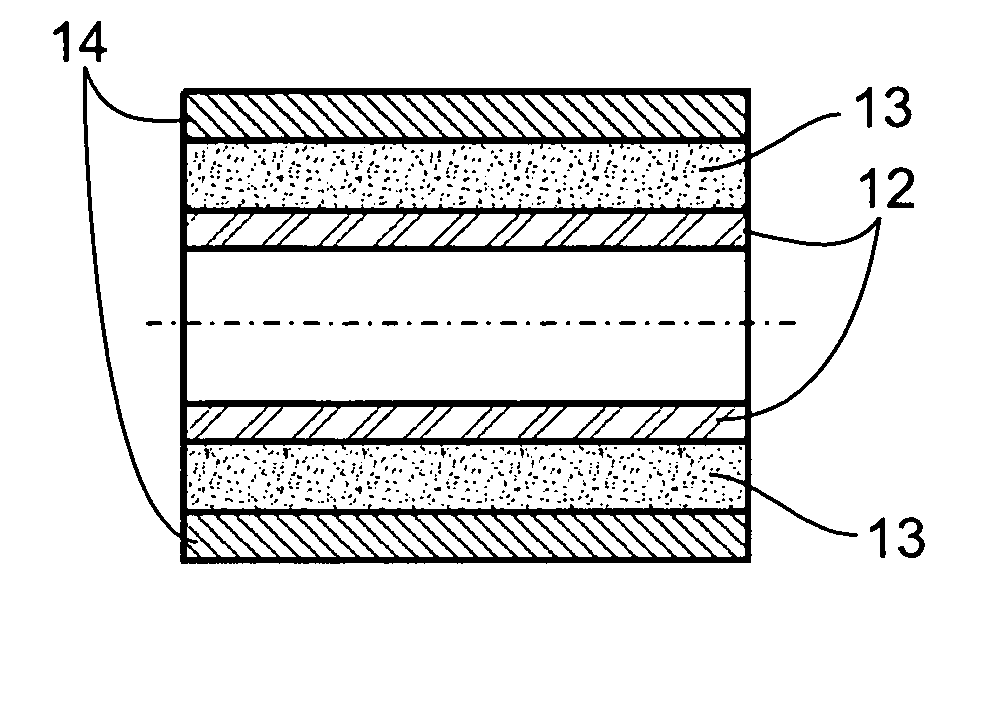

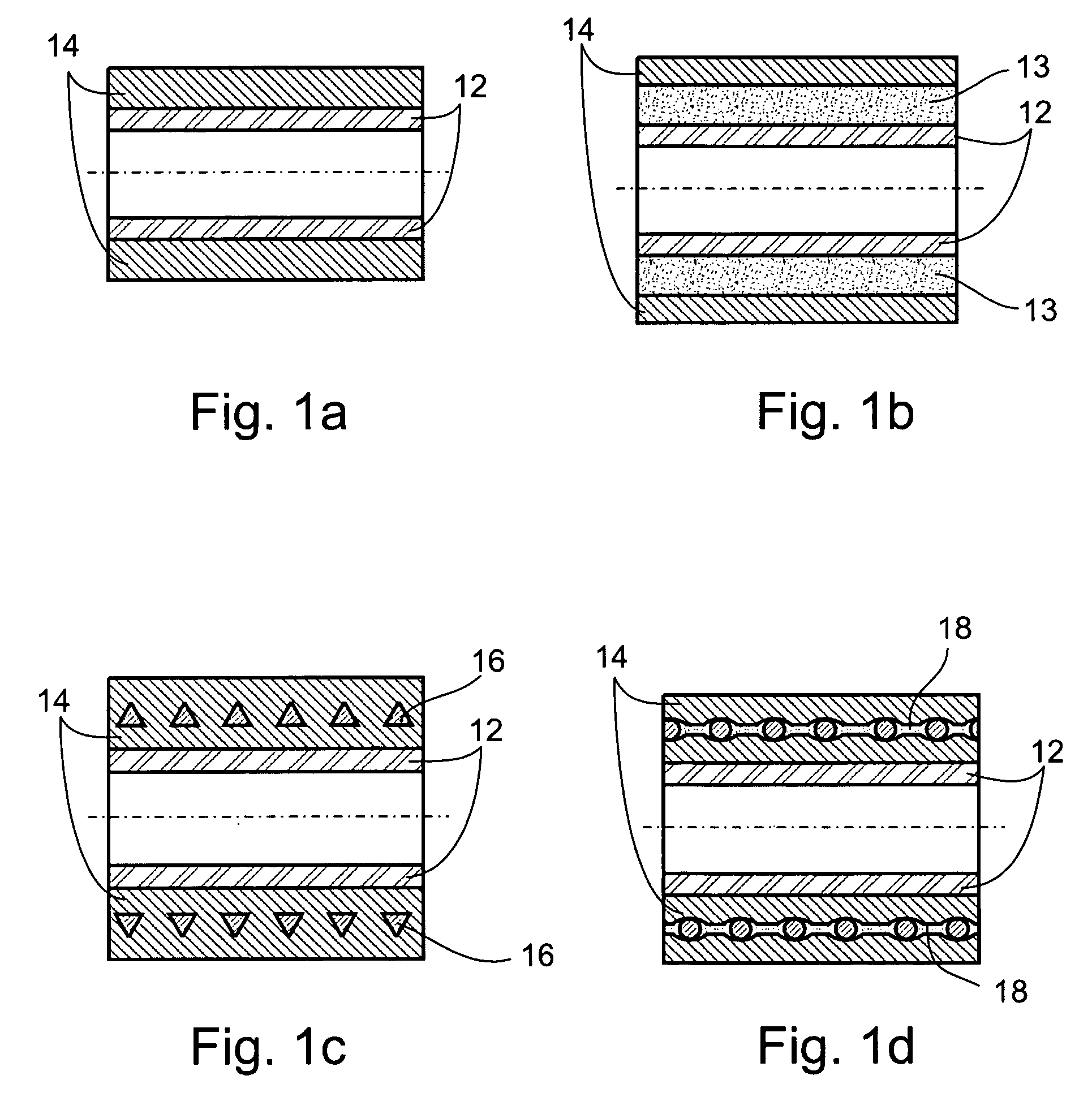

A vascular prosthesis comprising a first layer having a predetermined first porosity and a second layer having a predetermined second porosity, wherein the first layer and the second layer are each made of first and second electrospun polymer fibers.

Owner:NICAST LTD

Antibacterial nano fiber material and preparation method thereof

InactiveCN101358382ANo side effects on the human bodyContinuous and stable releaseFilament/thread formingMacromolecular non-active ingredientsFiberSide effect

The invention relates to an antibacterium nano fiber material and a preparation method thereof; the material comprises polymer superfine fiber and antibacterial agent, and the weight ratio is 60 to 98: 2 to 40; the preparation method comprises the following steps: (1) the antibacterial agent is dissolved in distilled water to prepare solution; the polymer superfine fiber is dissolved in methylene dichloride or chloroform organic solvent, emulsifier is added to be mixed evenly, to obtain solution which is dispersed evenly; (2) the two types of solution are mixed to obtain even water-in-oil W / O latex, and then electrostatic spinning is conducted to the latex, to obtain the antibacterium nano fiber material. The nano fiber material has good ventilation property and filterability, still has bacteriostasis and sterilization functions for a long time after stably releasing the antibacterial agent, has simple preparation method, adopts the biodegradable and bioabsorbable polymer as carrier materials, can be absorbed by the human body after fully releasing, is not left, does not need secondary operation and has no side effect.

Owner:DONGHUA UNIV

Core-shell composite micron/nano fiber and preparation method thereof

ActiveCN1807707AAvoid sex changeStable structure and performanceOther chemical processesFilament/thread formingFiberPolymer science

The invention discloses a core-shell structure composite fiber and preparing method in the functional fibre preparing technique domain, which is characterized by the following: the material of composite fiber is functional microballoon / microcapsule; the shell material is oil soluble high molecular polymer or water-soluble high molecular polymer; the embedded functional microballoon / microcapsule is distributed over the inner fibre of high molecular polymer to form core-shell structure composite fiber; the polymer fluid of multiphase component forms composite embedding structure directly by the action of high-voltage electric field.

Owner:重庆大清医疗器械有限公司

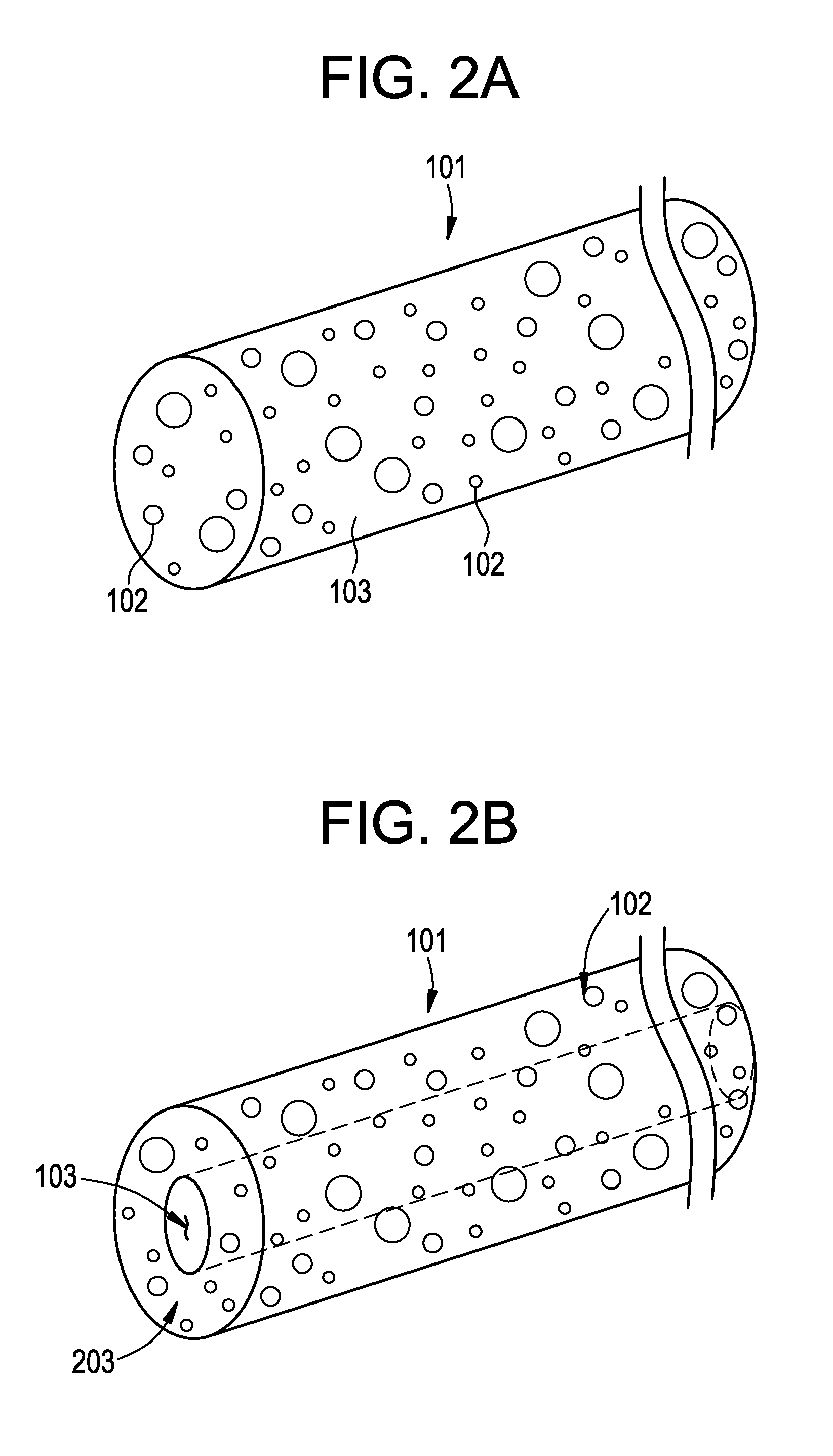

Fabrication of drug loaded biodegradable polymer fibers

InactiveUS20050106211A1Organic active ingredientsPeptide/protein ingredientsFiberThree dimensional matrix

The invention provides tissue engineering compositions and methods wherein three-dimensional matrices for growing cells are prepared for in vitro and in vivo use. The matrices comprise biodegradable polymer fibers capable of the controlled delivery of therapeutic agents. The spatial and temporal distribution of released therapeutic agents is controlled by use of defined nonhomogeneous patterns of therapeutic agents in the matrices.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

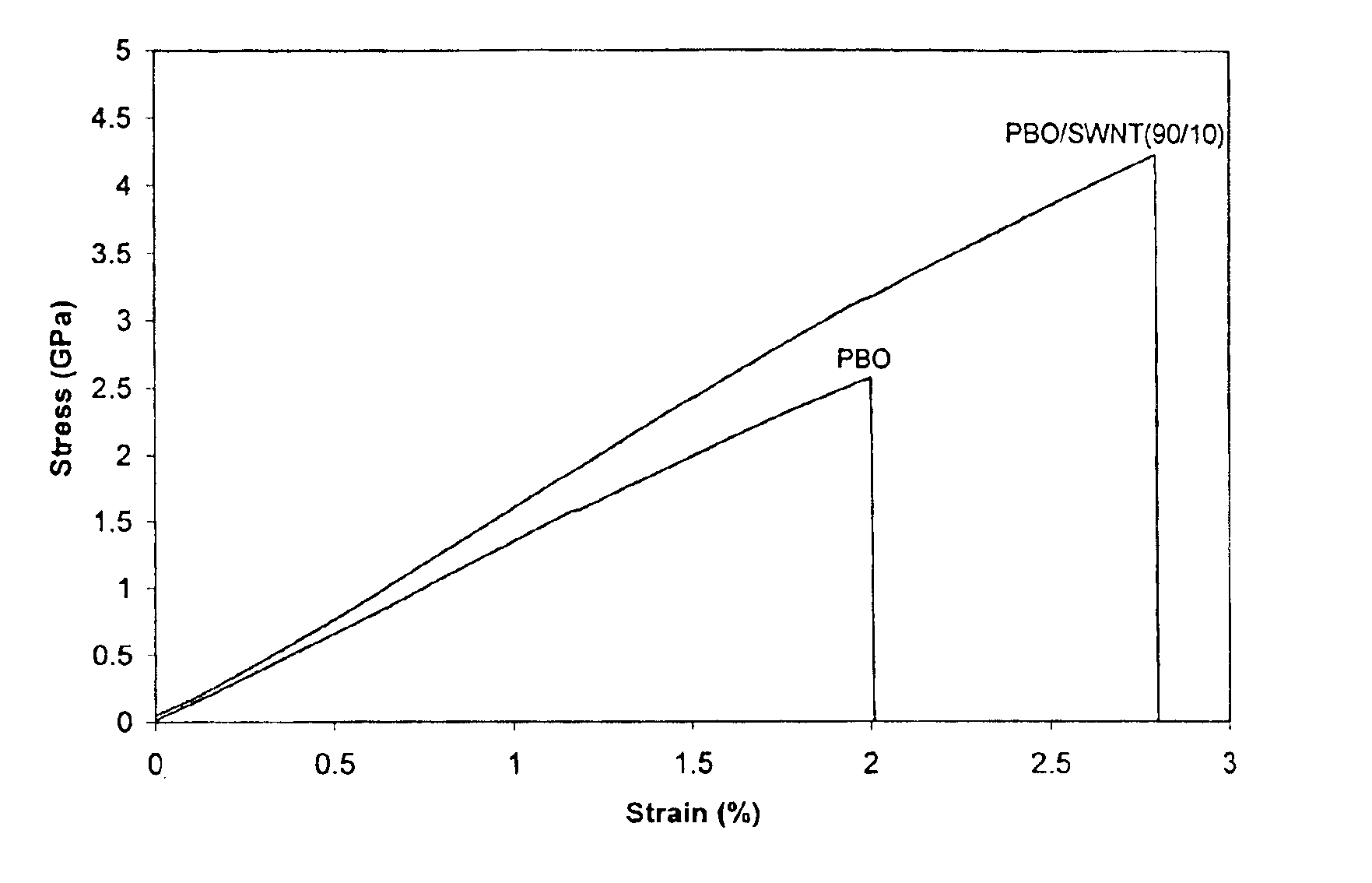

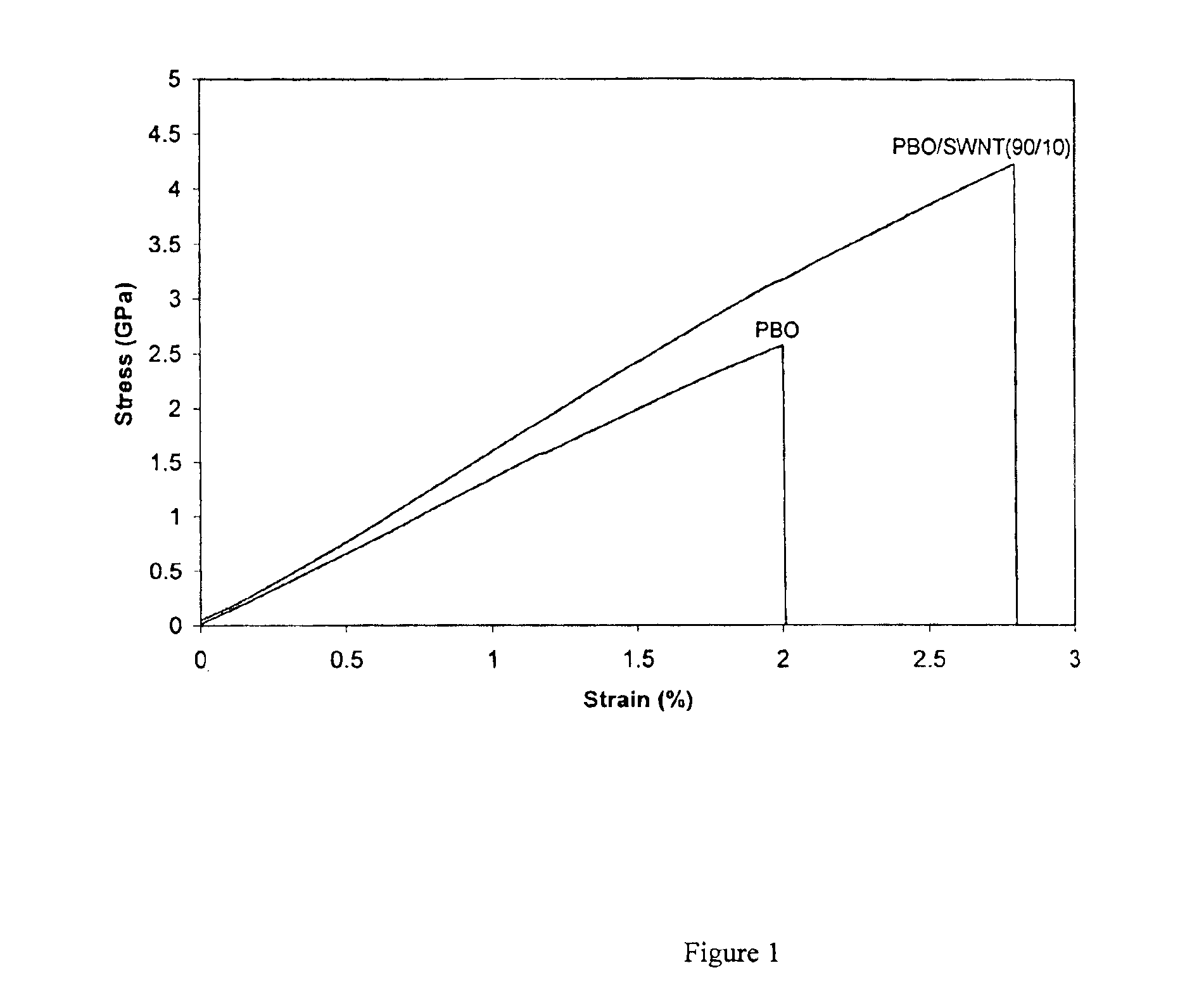

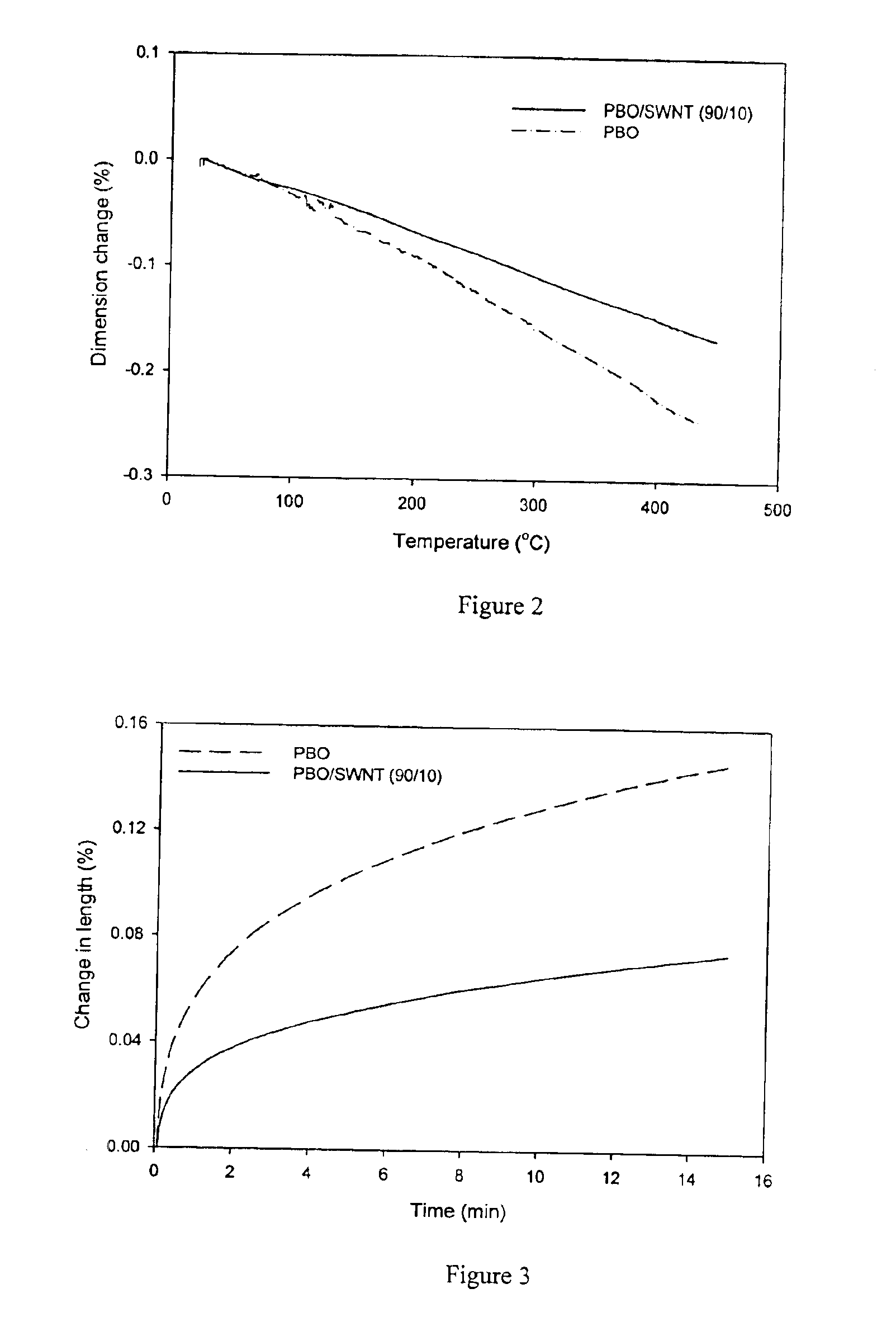

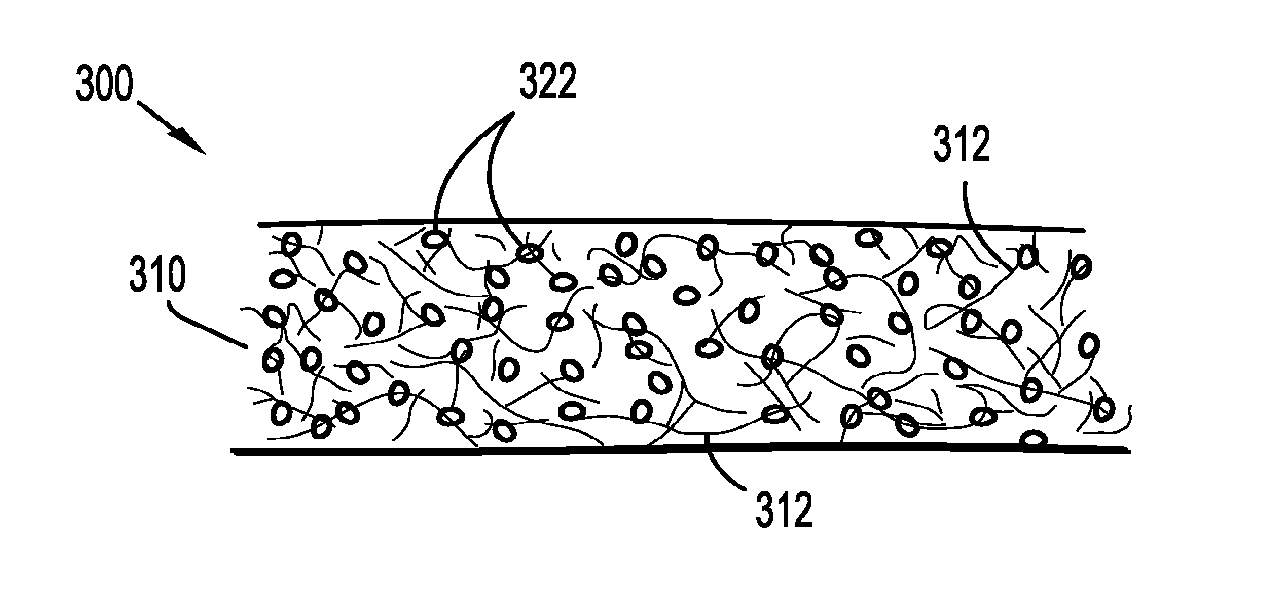

Compositions comprising rigid-rod polymers and carbon nanotubes and process for making the same

InactiveUS6900264B2High modulusHigh stiffnessMaterial nanotechnologySpecial tyresFiberLiquid crystalline

The present invention relates to compositions comprising rigid-rod polymers and carbon nanotubes. The compositions comprise dispersed carbon nanotubes aligned with rigid-rod polymers. The alignment of the nanotubes and polymers can be liquid crystalline. The rigid-rod polymers of this invention include, but are not limited to, polymers and copolymers comprising benzobisazole, pyridobisimidazole and benzamidazobenzo-phenanthroline repeat units. Dispersion of carbon nanotubes is achieved by in-situ polymerization in the presence of the carbon nanotubes, which may be either single-wall or multi-wall or a combination of both. The polymer compositions comprising carbon nanotubes may be spun into fibers or formed into films. The strength of the resulting fibers of the present invention is significantly greater than that of fibers without carbon nanotubes.

Owner:GEORGIA TECH RES CORP

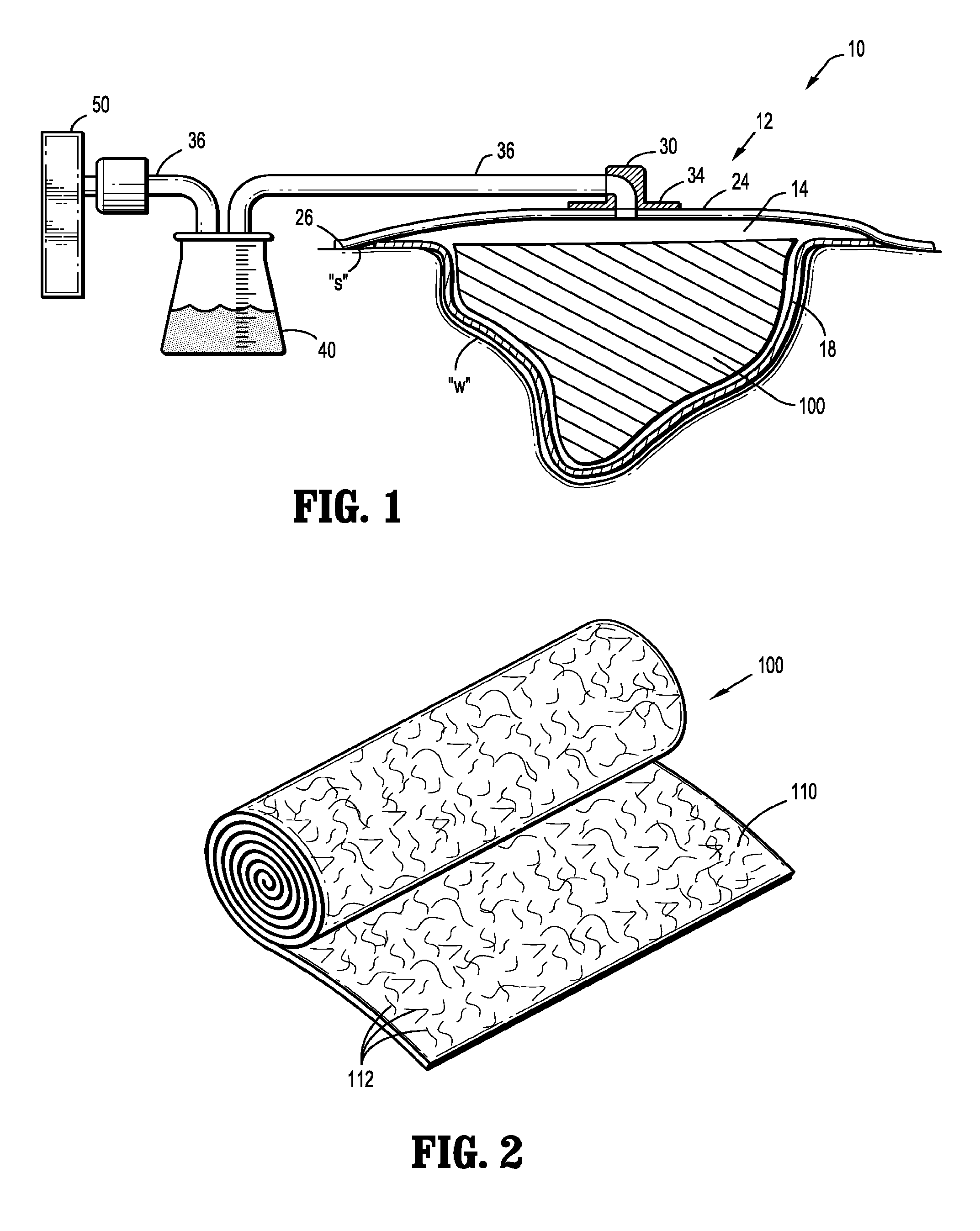

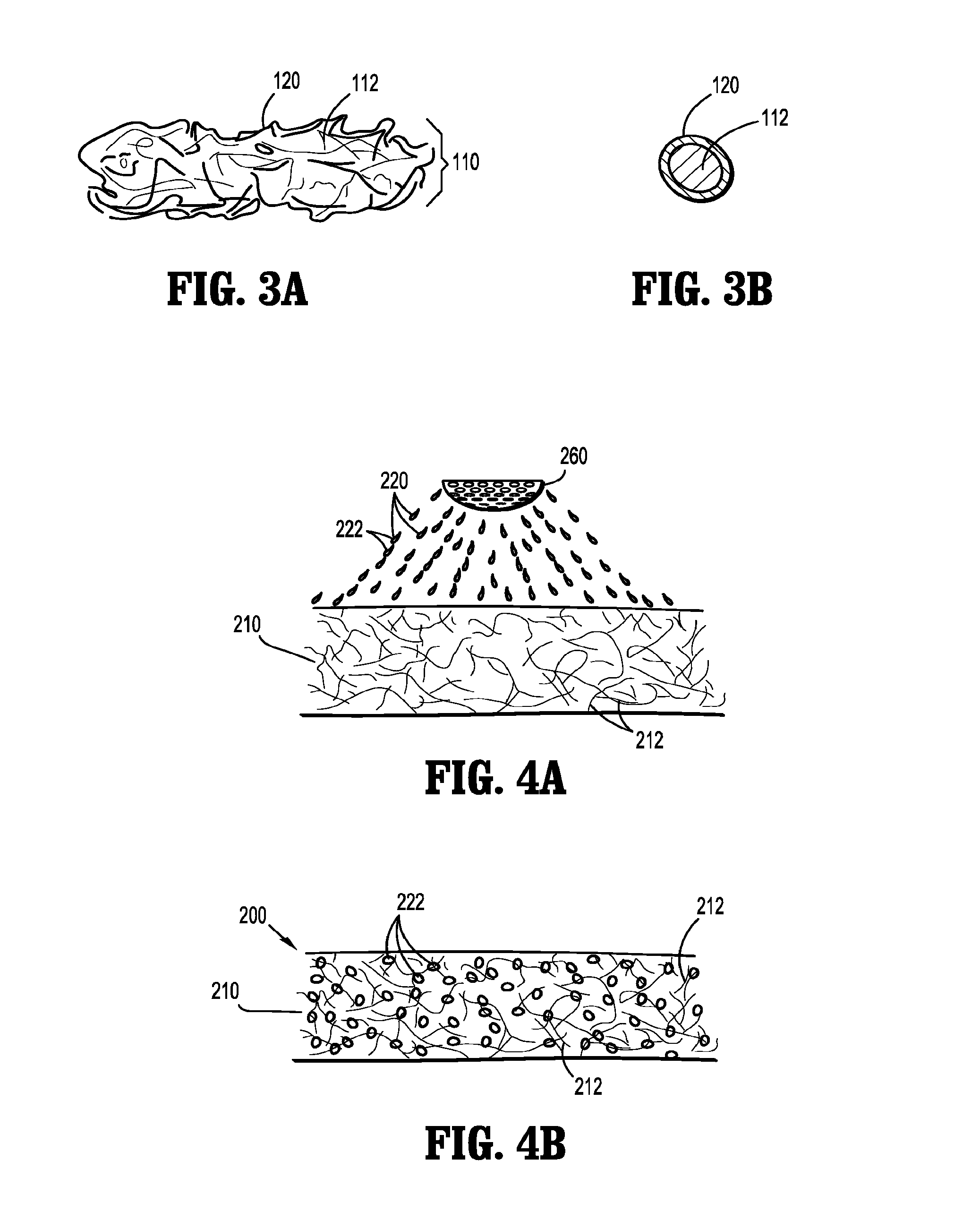

Wound Filler Material with Improved Nonadherency Properties

InactiveUS20130165878A1Improves nonadherencyImprove featuresFibre treatmentPretreated surfacesWound healingFiber

An apparatus for promoting the healing of an exuding wound includes a wound cover for defining a reservoir over a wound in which a negative pressure may be maintained. The cover may form a substantially fluid-tight seal around the wound and permit fluid communication between the reservoir and a vacuum source suitable for providing an appropriate negative pressure to the reservoir to stimulate healing of the wound. A wound filler positioned between the wound and the wound cover includes a fibrous material treated with a surface modification additive.

Owner:SMITH & NEPHEW INC

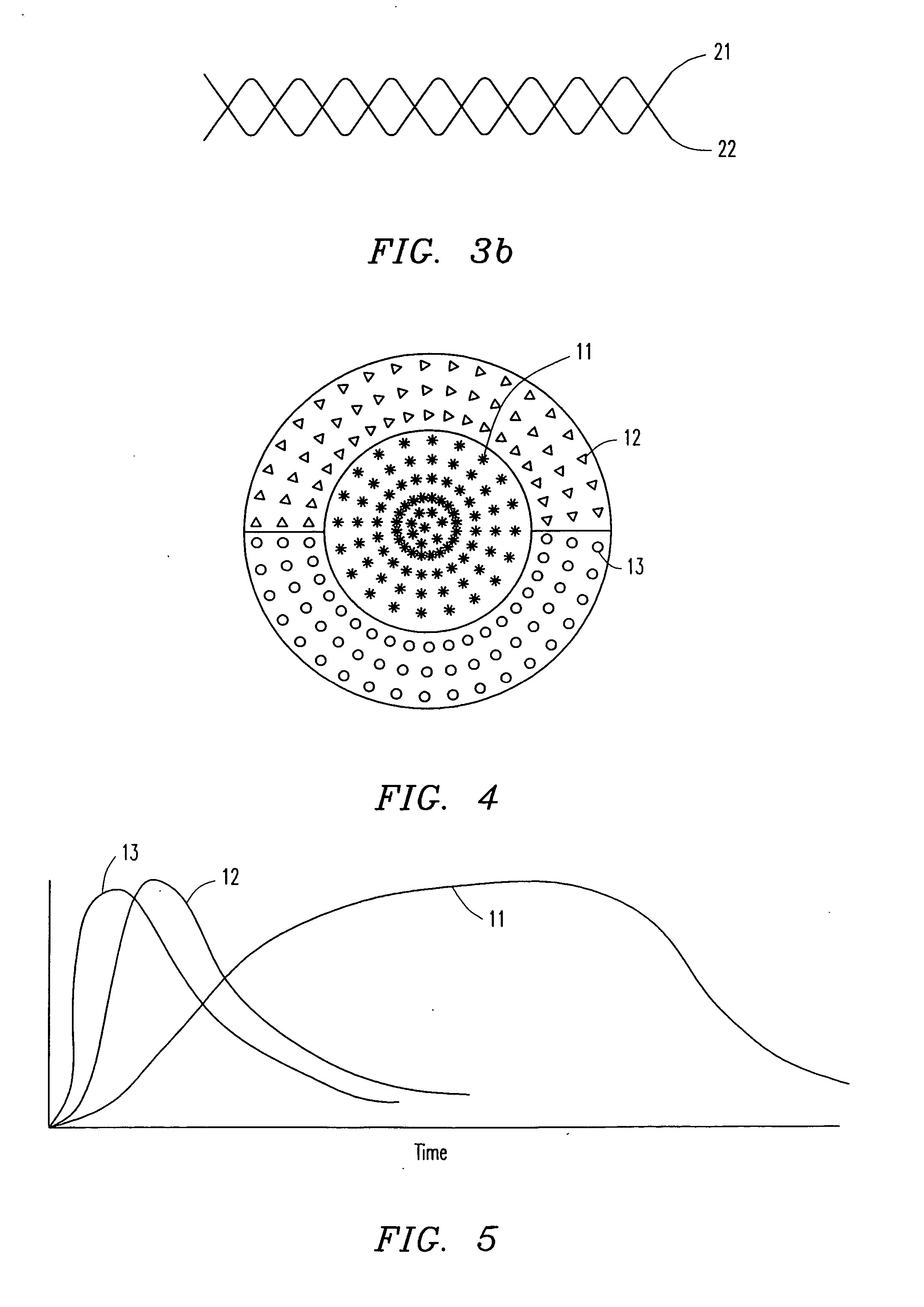

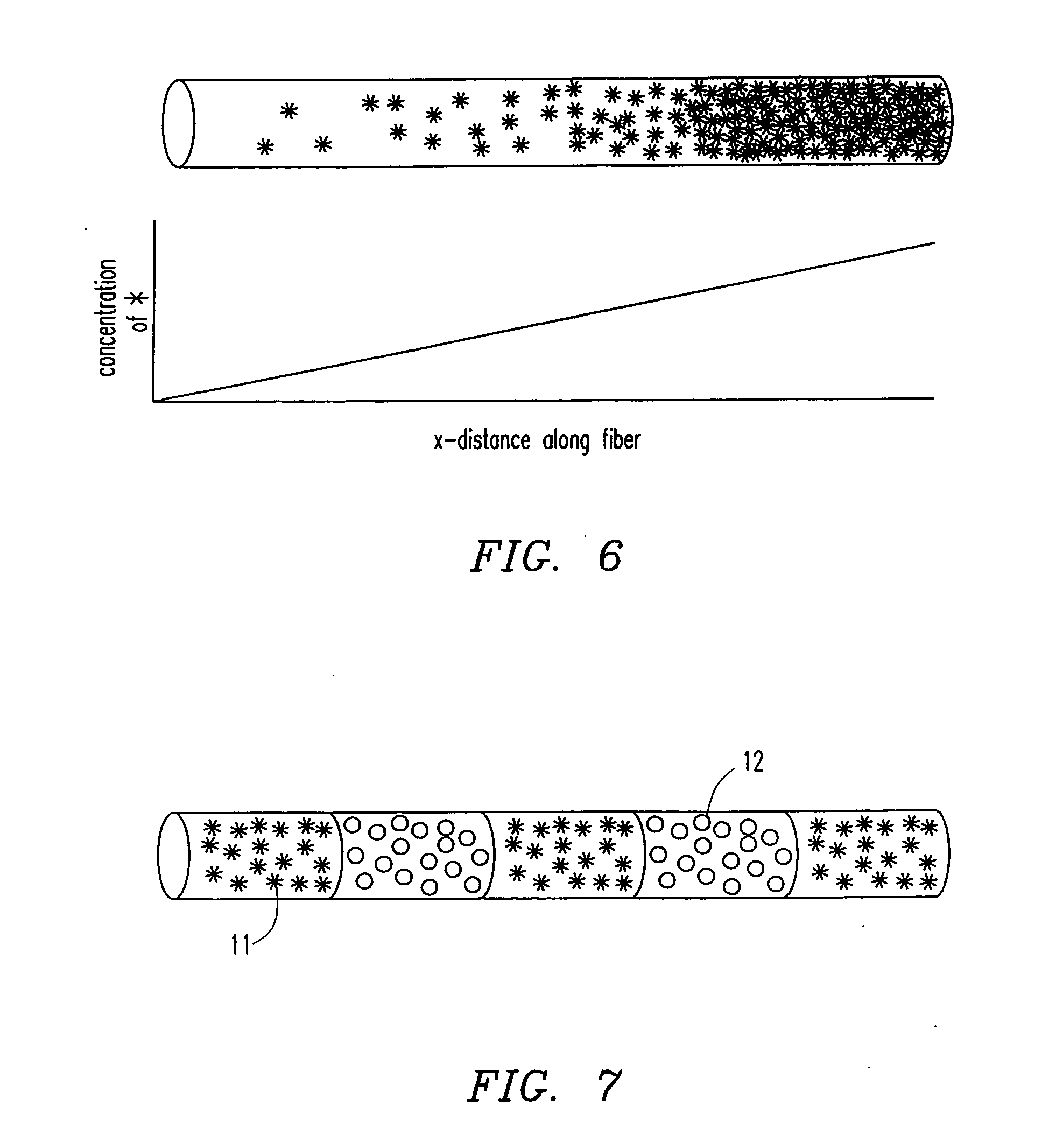

Fabrication of drug loaded biodegradable polymer fibers

InactiveUS6858222B2Limit maximum numberOrganic active ingredientsPeptide/protein ingredientsFiberControlled release

The invention provides tissue engineering compositions and methods wherein three-dimensional matrices for growing cells are prepared for in vitro and in vivo use. The matrices comprise biodegradable polymer fibers capable of the controlled delivery of therapeutic agents. The spatial and temporal distribution of released therapeutic agents is controlled by use of defined nonhomogeneous patterns of therapeutic agents in the matrices.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

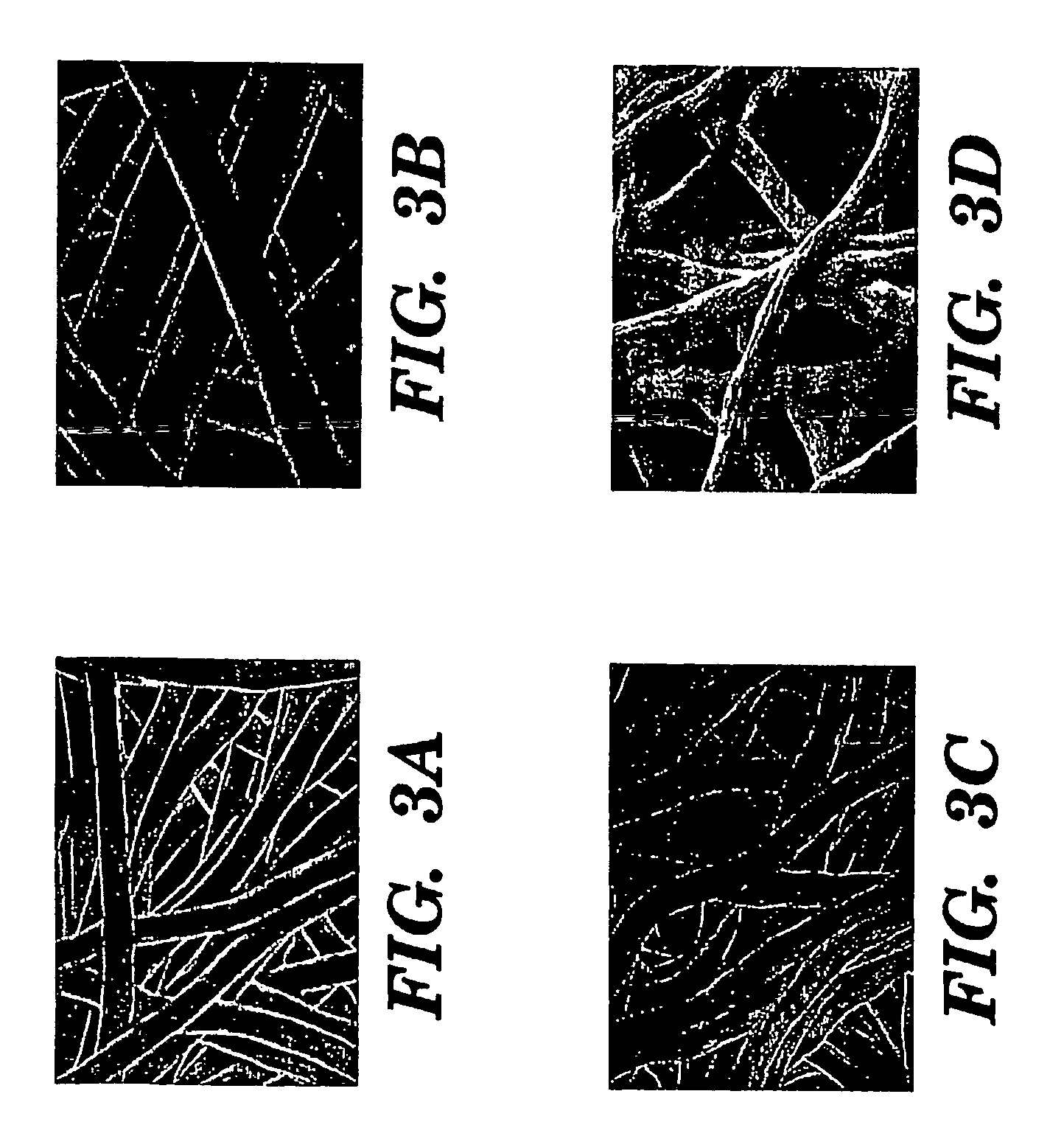

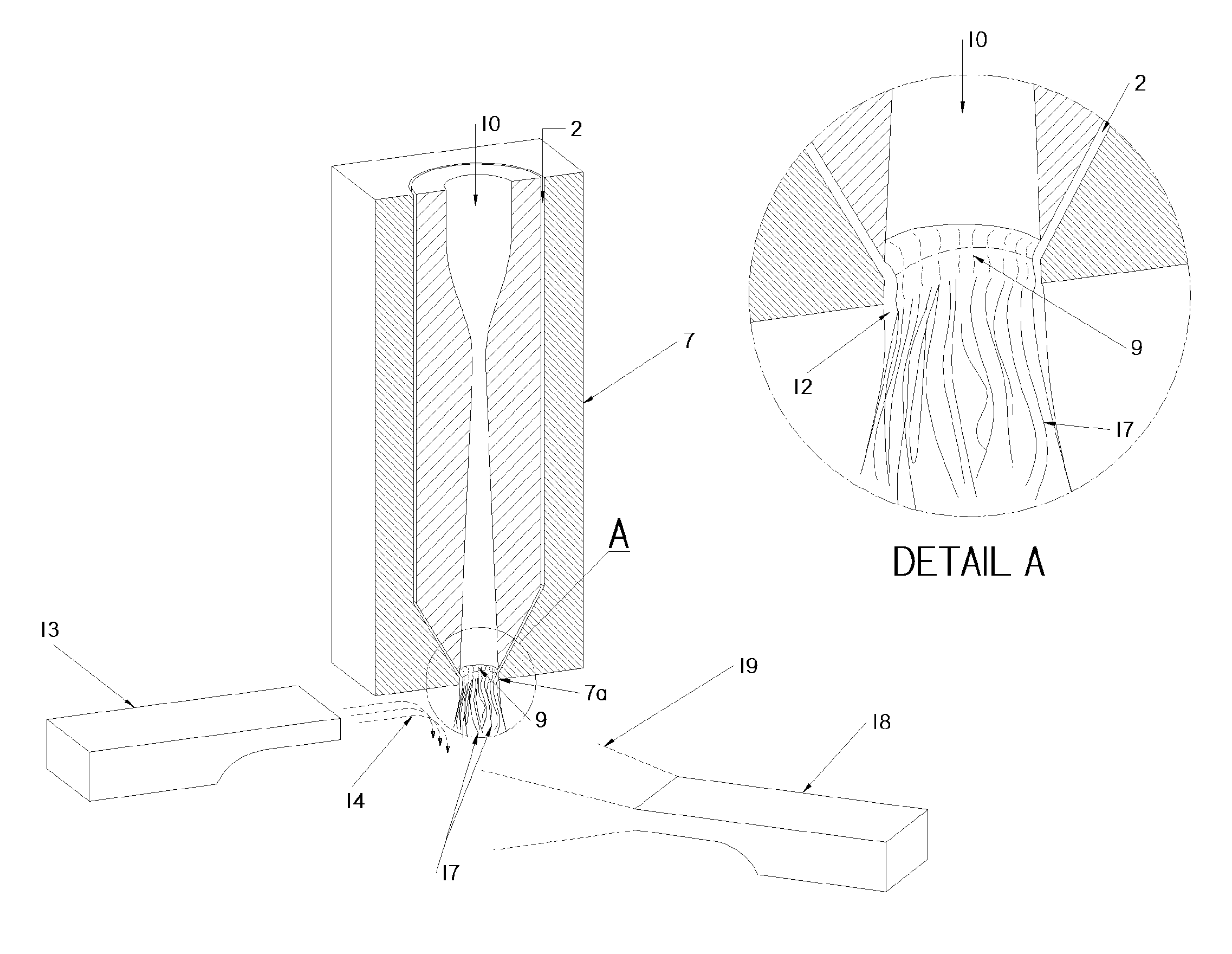

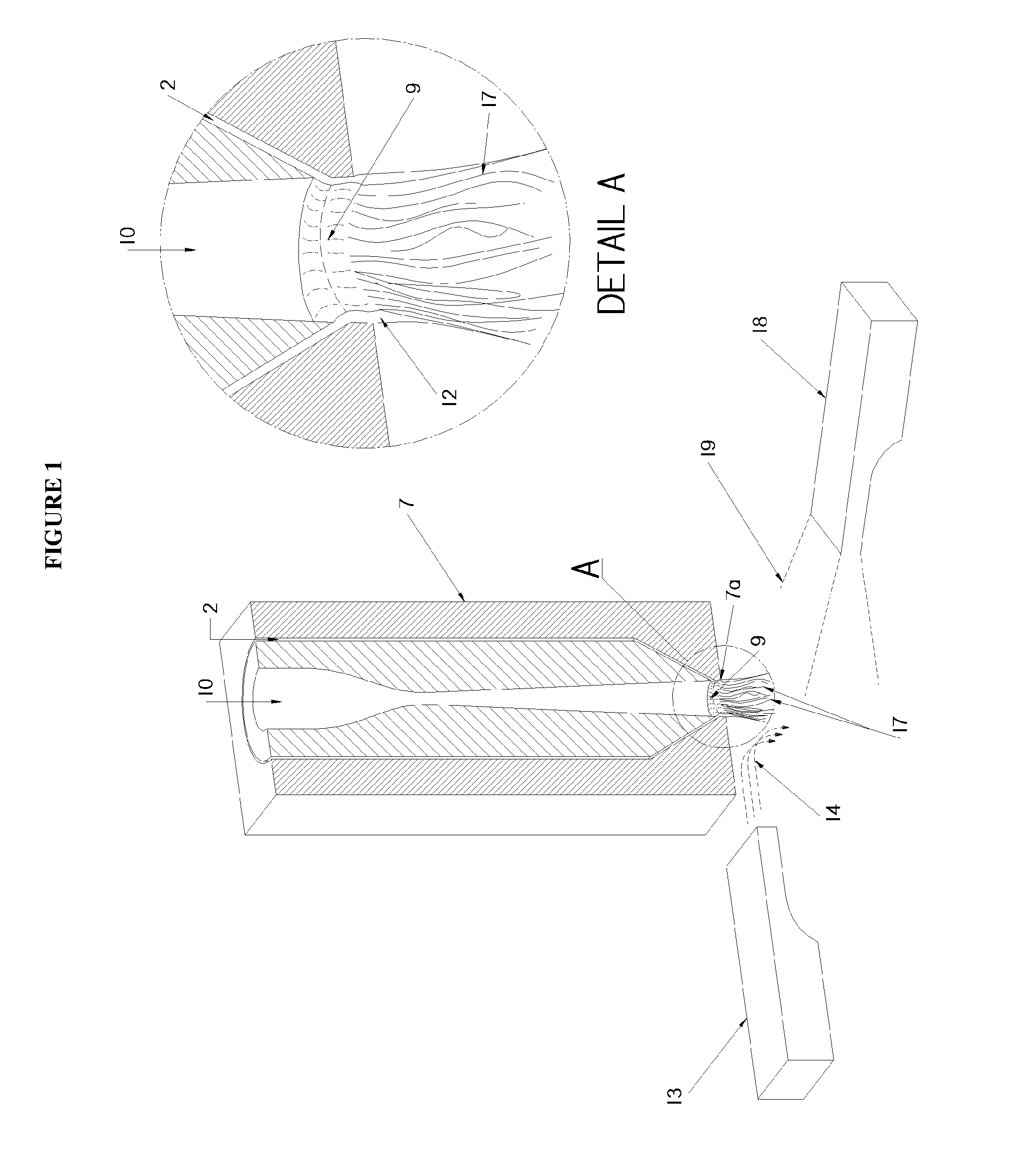

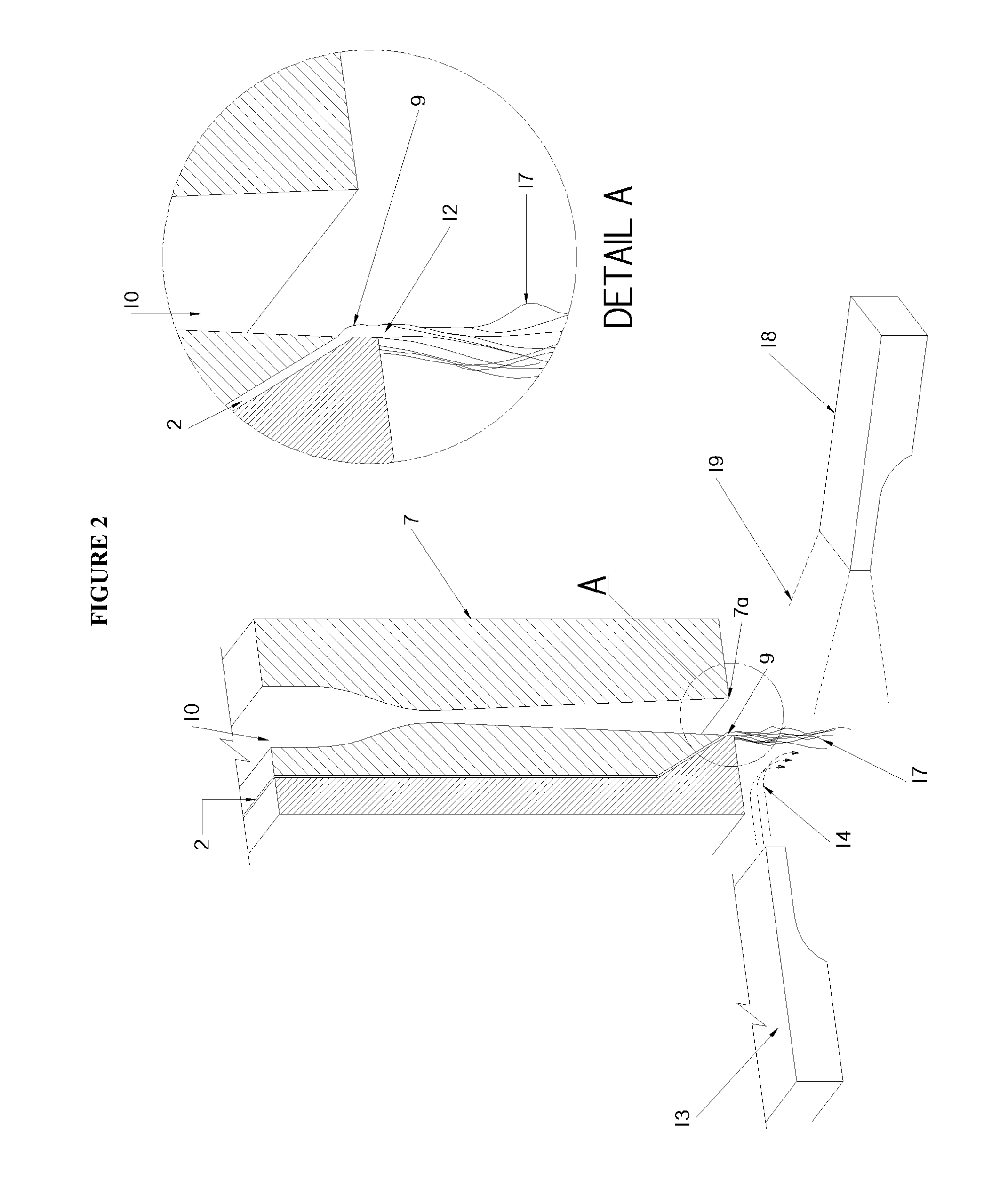

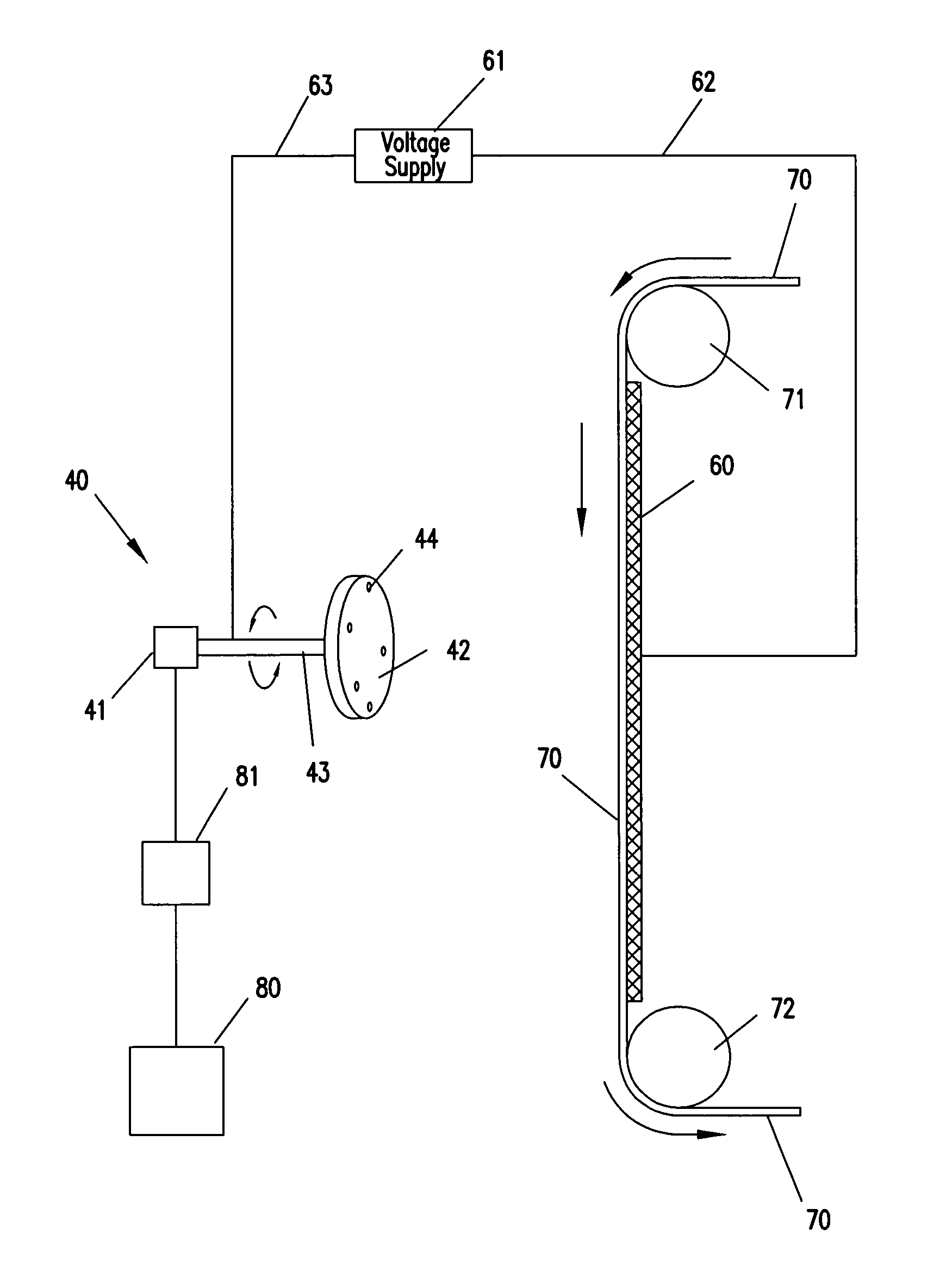

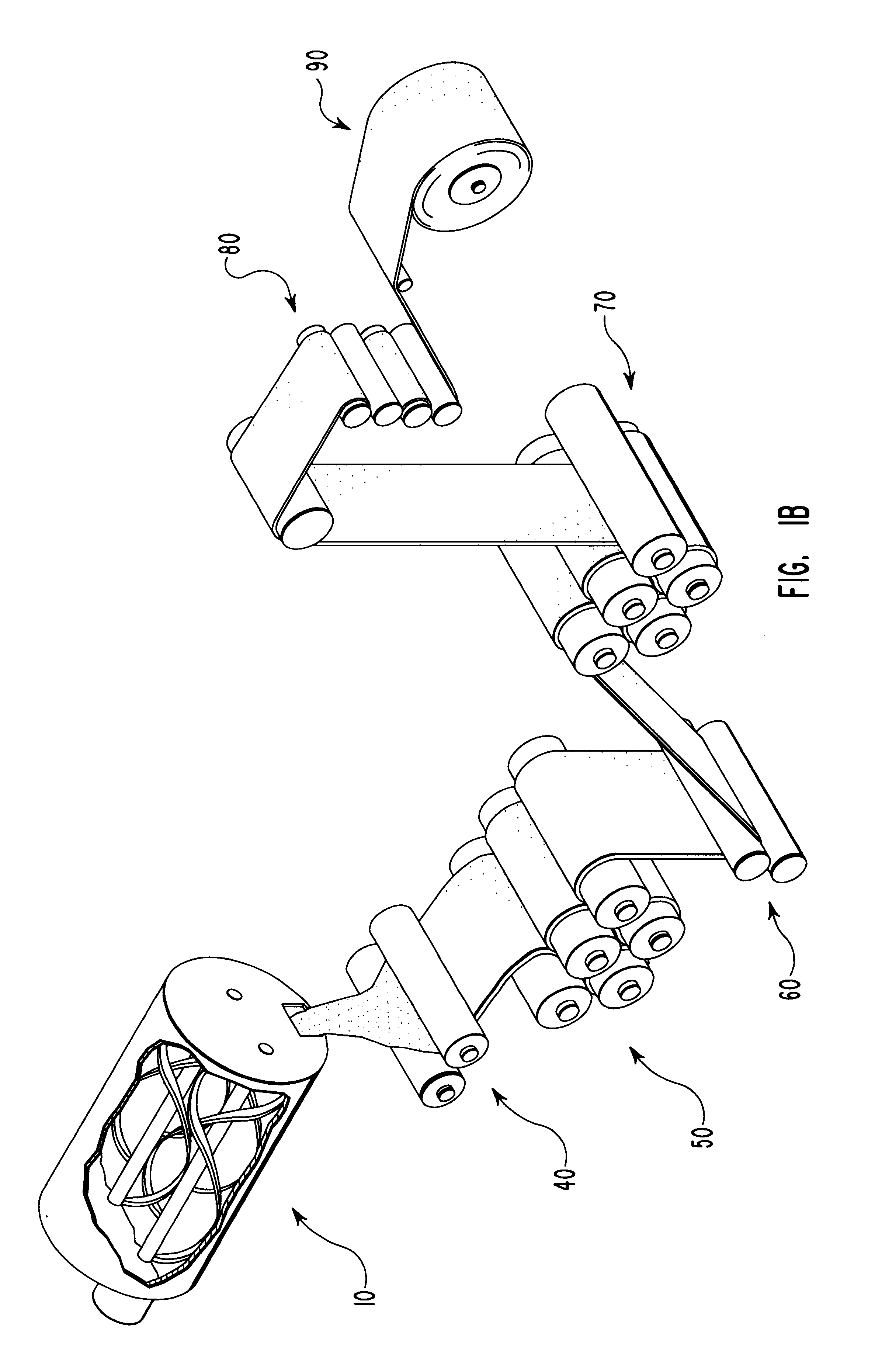

Continuous process for the production of carbon nanofiber reinforced continuous fiber preforms and composites made therefrom

ActiveUS20090220409A1Limited utilityLow yieldMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

This invention provides a continuous process for the growth of vapor grown carbon fiber (VGCNT) reinforced continuous fiber preforms for the manufacture of articles with useful mechanical, electrical, and thermal characteristics. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCNT produced in situ resulting in a highly entangled mass of VGCNT infused with the continuous fiber preform. The continuous process disclosed herein provides denser and more uniform carbon nanotubes and provides the opportunity to fine-tune the variables both within an individual preform and between different preforms depending on the characteristics of the carbon nanotubes desired. The resulting continuous fiber preforms are essentially endless and are high in volume fraction of VGCNT and exhibit high surface area useful for many applications. The invention also provides for composites made from the preforms.

Owner:PERFORMANCE POLYMER SOLUTIONS

Vascular closure device

ActiveUS20090171388A1Minimize potential for infectionFilament/thread formingAntiinfectivesVascular closure deviceVascular device

A biocompatible material may be configured into any number of implantable medical devices including a vascular closure device. The vascular closure device includes a fibrous structure formed from at least one randomly oriented fiber, the randomly oriented fiber comprising at least one polymer, and at least one agent, in therapeutic dosage, incorporated into at least one of the fibrous structure and the at least one randomly oriented fiber.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

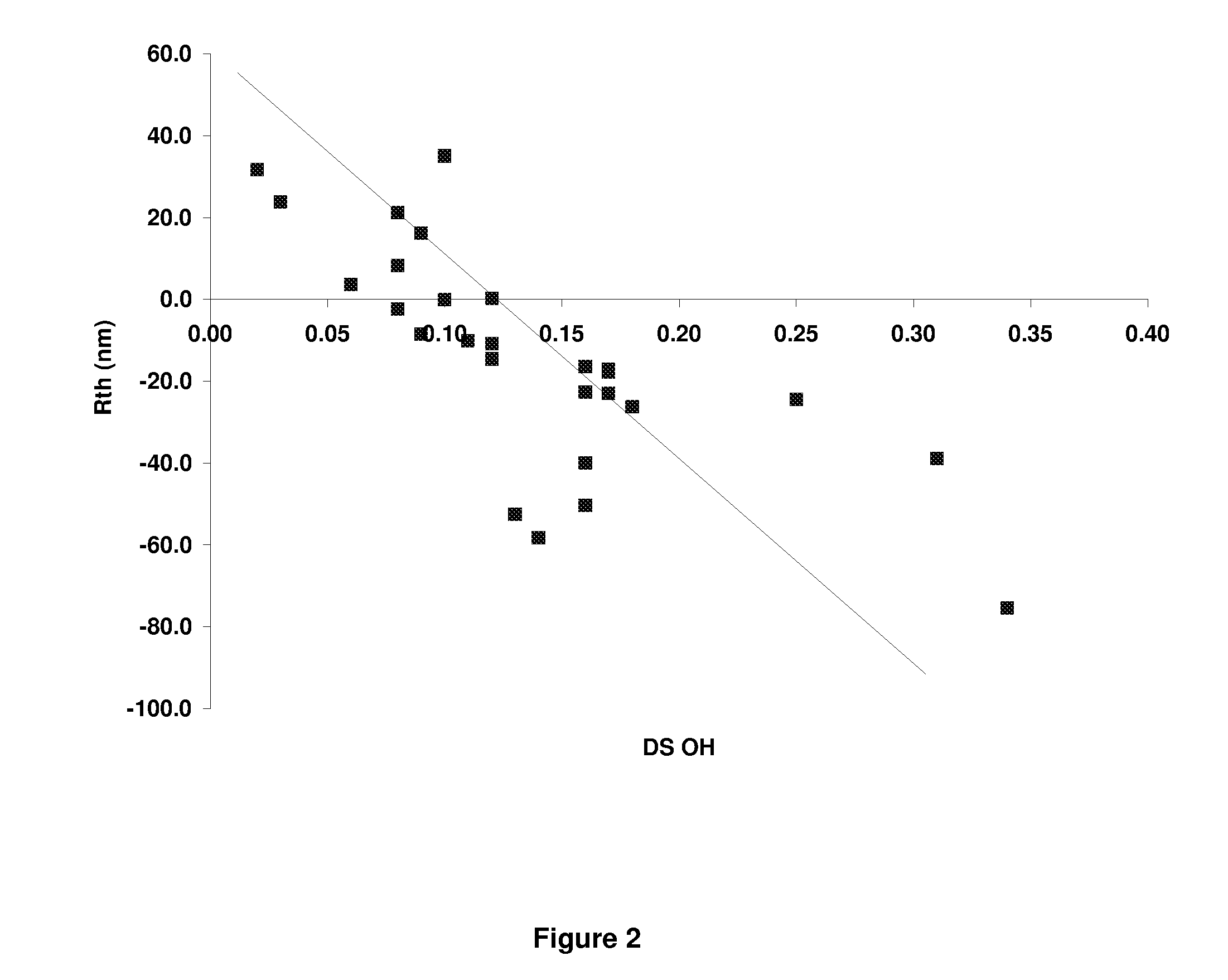

Cellulose Ester Compositions Having Low Bifringence and Films Made Therefrom Comprising a Plasticizer

The present invention relates to cellulose esters having low hydroxyl content for use in optical applications, such as liquid crystal display (LCD) films. Films made with low hydroxyl levels and a given ratio of non-acetyl ester to hydroxyl level have been found to have low intrinsic birefringence. Therefore, these films can be cast, molded, or otherwise oriented without an appreciable birefringence or optical distortion (i.e. retardation). Such features make these films useful in polarizer, protective, and compensator films as well as molded optical parts, such as lenses. Furthermore, it has also been found that resins of the present invention can also be made to have “+C plate” behavior either by melt or solvent based processing, a characteristic which is not typical of cellulose esters. Such +C behavior allows films to be produced having unique compensatory behavior. Other embodiments of the invention relate to methods melt casting films while minimizing birefringence formation. Another embodiment of the invention is directed to films made from the cellulose esters described herein further comprising a plasticizer.

Owner:EASTMAN CHEM CO

Methods of Applying Skin Wellness Agents to a Nonwoven Web Through Electrospinning Nanofibers

Generally, the present invention is directed to, in one embodiment, a method for forming a composite nonwoven web configured to deliver skin wellness agents to the skin of a user. According to the method, an aqueous system of a hydrophilic polymer and a skin wellness agent is formed. The aqueous system is then electrospun onto a surface of a nonwoven web containing synthetic fibers. The resulting nanofibers have an average diameter of from about 50 nanometers to about 5000 nanometers, such as from about 200 nanometers to about 700 nanometers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Antibacterial polypropylene melt-blow non-woven filter material and preparation method thereof

ActiveCN102836594AImprove filtering effectImprove filtration efficiencyFiltration separationNon-woven fabricsPolymer sciencePolypropylene

The invention relates to a polypropylene melt-blow non-woven filter material, in particular to an antibacterial polypropylene melt-blow non-woven filter material and a preparation method thereof. The polypropylene melt-blow non-woven filter material is prepared from the following raw materials in parts by weight: 85-95 parts of melt-blow polypropylene slices, 1-5 parts of nanometer tourmaline, 1-3 parts of nanometer titanium oxide, 1-3 parts of nanometer zinc oxide, 0.1-3 parts of a coupling agent, 0.1-2 parts of a dispersing agent and 0-0.5 part of an antioxidant. According to the antibacterial polypropylene melt-blow non-woven filter material prepared with the method, a formula and a preparation process are improved, so that the electret polarity time of the prepared filter material can be up to 5-6 years, and the antibacterial performance is superior to the prior art.

Owner:XINGNUO ECONOMIC & TRADE DEV SHANGHAI

Filaments comprising an active agent nonwoven webs and methods for making same

Owner:GLENN JR ROBERT WAYNE +11

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com