Antibacterial polypropylene melt-blow non-woven filter material and preparation method thereof

An antibacterial polypropylene and melt-blown polypropylene technology, applied in the field of polypropylene melt-blown non-woven filter material, can solve the problems of complex preparation process and unsatisfactory electret effect, and achieve the effect of excellent filtration performance and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0031] A kind of antibacterial polypropylene melt-blown non-woven filter material, its raw material is as shown in following table 1:

[0032] Table 1: Recipe

[0033]

Example 1

Example 2

Example 3

Example 4

Example 5

Melt blown polypropylene chips

85kg

90kg

95kg

96kg

93kg

Nano Tourmaline

1kg

2kg

3kg

4kg

5kg

[0034] Nano Titanium Dioxide

1kg

2kg

3kg

1kg

2kg

1kg

2kg

2kg

1kg

2kg

0.1kg

0.2kg

0.5kg

1kg

1.5kg

0.1kg

0.5kg

1kg

2kg

1kg

Antioxidant 1010

0

0.1kg

0.3kg

0.4kg

0.5kg

[0035] The particle size of the nano tourmaline is 300-350nm, the particle size of the nano-titanium dioxide is 50-75nm, and the particle size of the nano-zinc oxide is 50-75nm.

[0036] The preparation method of the an...

Embodiment 6~10

[0042] A kind of antibacterial polypropylene melt-blown non-woven filter material, its raw material is as shown in following table 2:

[0043] Table 2: Recipe

[0044]

Example 6

Example 7

Example 8

Example 9

Example 10

Melt blown polypropylene chips

91kg

91kg

91kg

91kg

92kg

Nano Tourmaline

4kg

5kg

5kg

4kg

4kg

Nano Titanium Dioxide

2kg

2kg

1kg

1kg

1kg

2kg

1kg

1kg

2kg

1kg

0.4kg

0.4kg

1kg

0.8kg

0.5kg

[0045] polyethylene wax

0.1kg

0.1kg

0.5kg

1kg

1kg

Antioxidant 1010

0.5kg

0.5kg

0.5kg

0.2kg

0.5kg

[0046] The particle size of the nano tourmaline is 300-350nm, the particle size of the nano-titanium dioxide is 50-75nm, and the particle size of the nano-zinc oxide is 50-75nm.

[0047] The preparation method of t...

experiment example 1

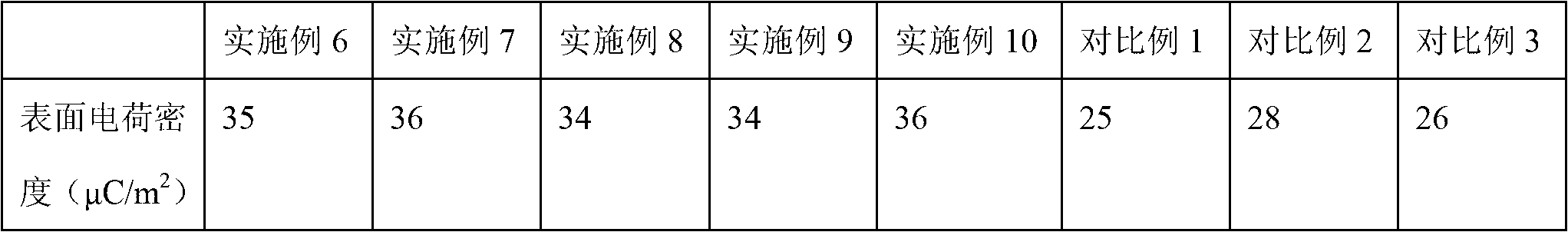

[0057] Experimental Example 1: Performance Testing

[0058] The performance of the antibacterial polypropylene melt-blown nonwoven fabric prepared by the present invention is detected:

[0059] 1. Adopt EST111 type digital charge meter to measure the surface charge density of the antibacterial polypropylene melt-blown nonwoven fabric prepared by the present invention and comparative examples, and the measurement time is after 48 hours after the electret:

[0060] Table 4: Experimental results

[0061]

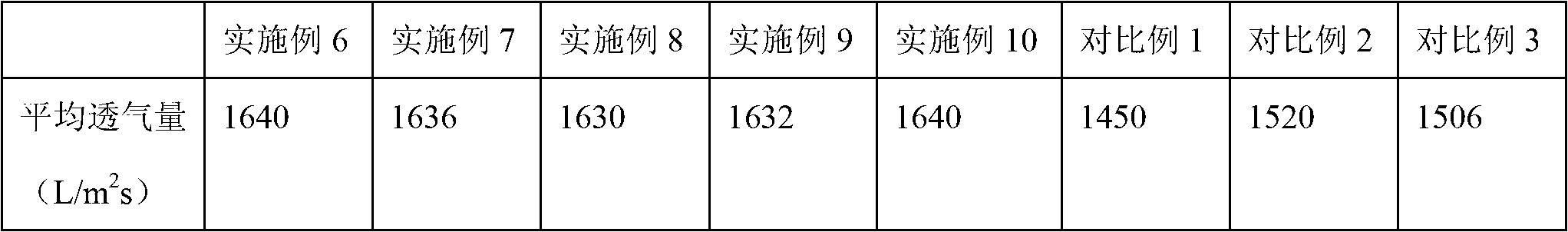

[0062] 2. The air permeability of the antibacterial polypropylene melt-blown nonwoven fabric prepared by the present invention and comparative examples is detected by a YG461 type fabric medium pressure air flow meter:

[0063] Table 5: Experimental results

[0064]

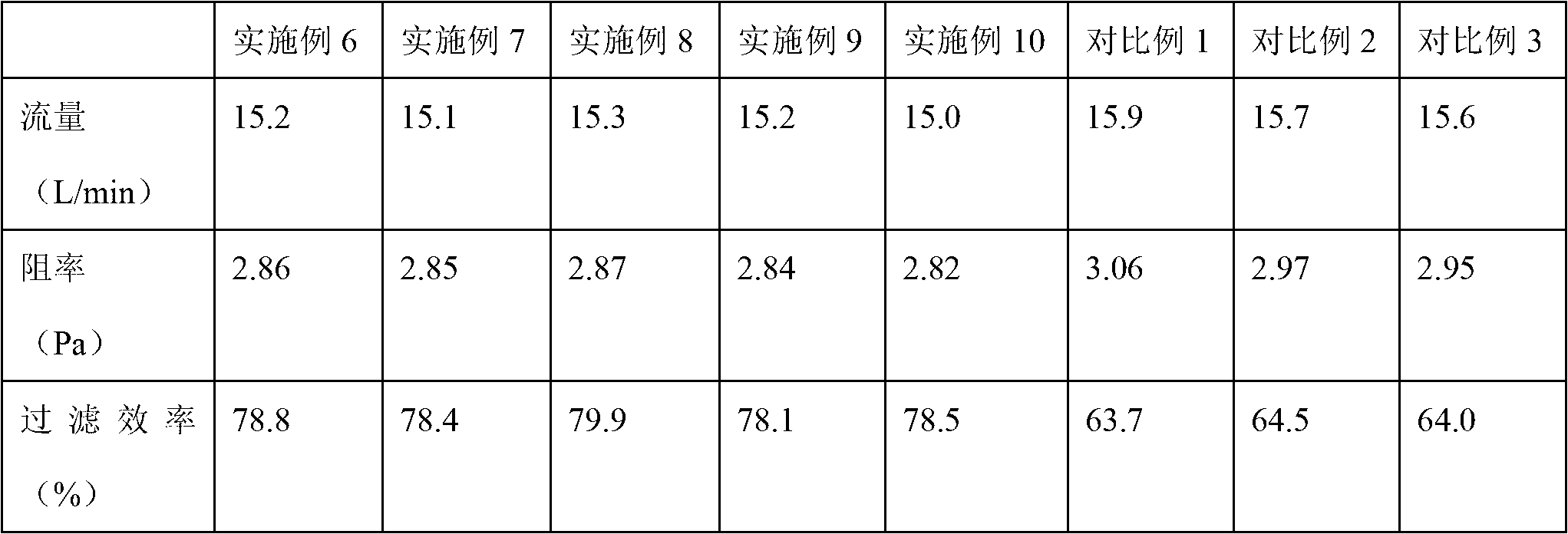

[0065] 3. The TSI-8130 type filterability detector that adopts U.S. production detects the antibacterial polypropylene melt-blown non-woven fabric that this detection present invention and comparative exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com