Patents

Literature

11805results about "Loose filtering material filters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

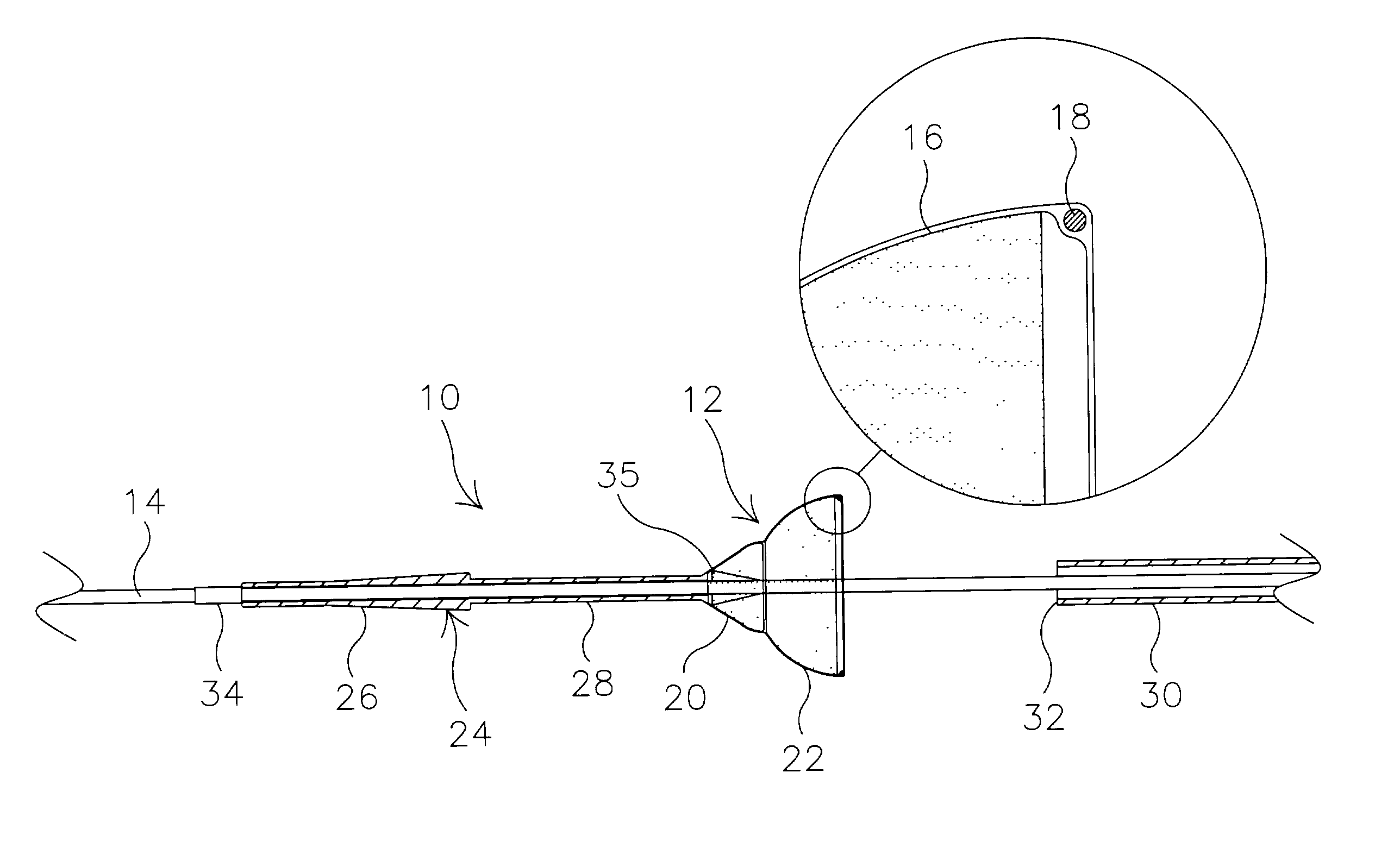

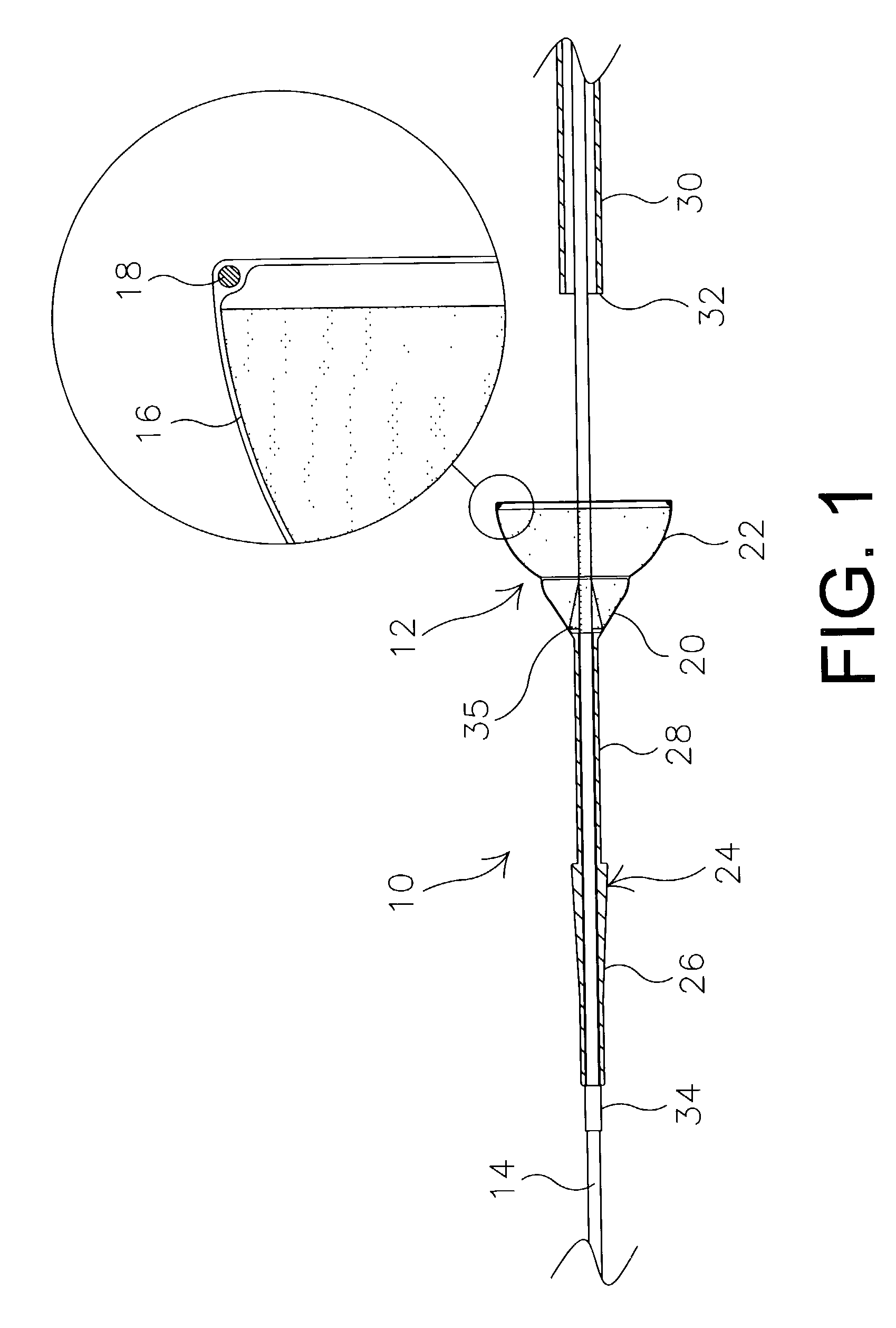

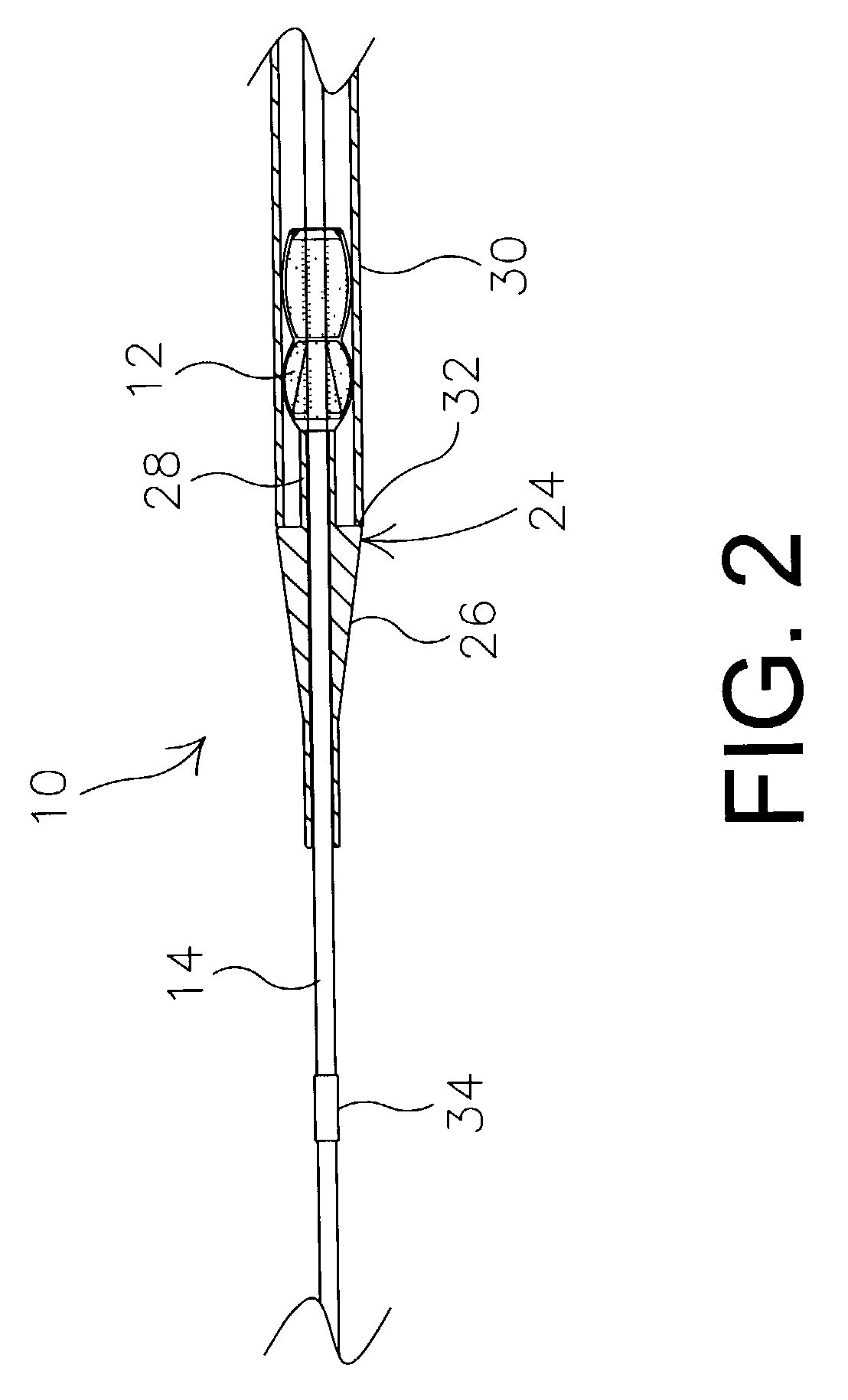

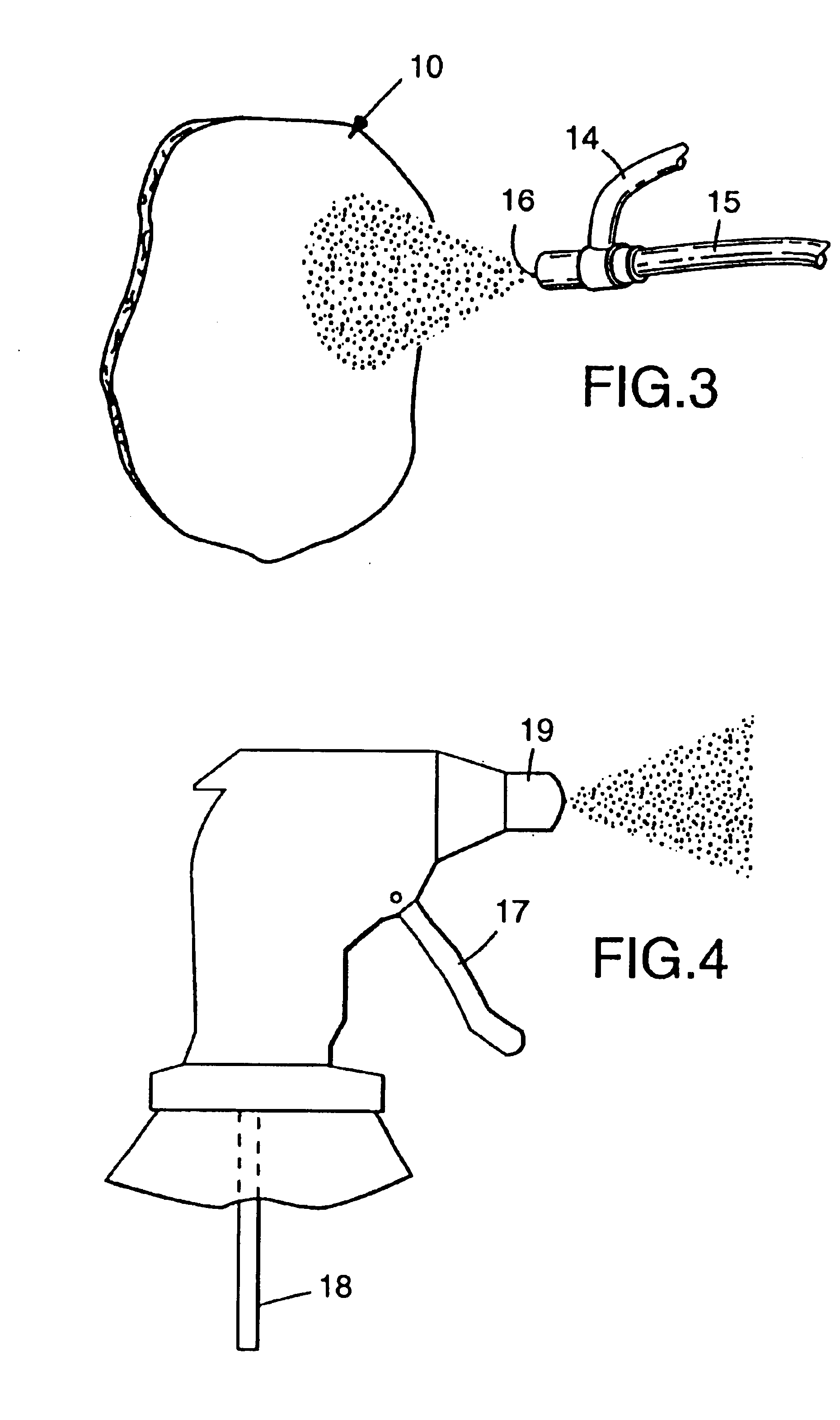

Method of making an embolic filter

Embolic protection filters and methods of making and using such devices are disclosed. An illustrative method of making a device for filtering embolic debris from a body may include the steps of molding a filter assembly that includes a distal tip and a filter portion, forming a plurality of apertures within the filter portion, and coupling a support member to the filter assembly that is adapted to shift the filter portion between a collapsed configuration and an expanded configuration.

Owner:BOSTON SCI SCIMED INC

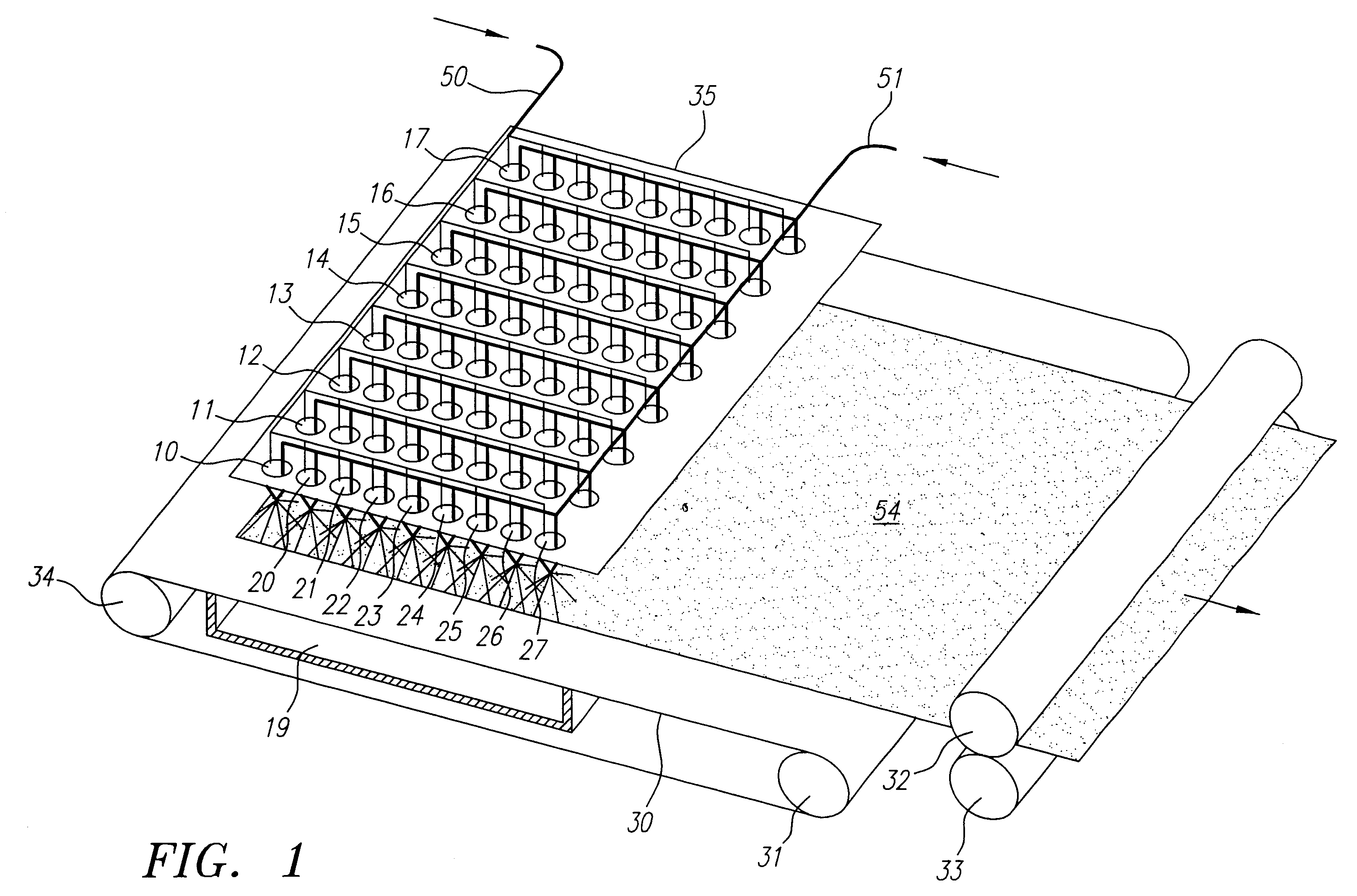

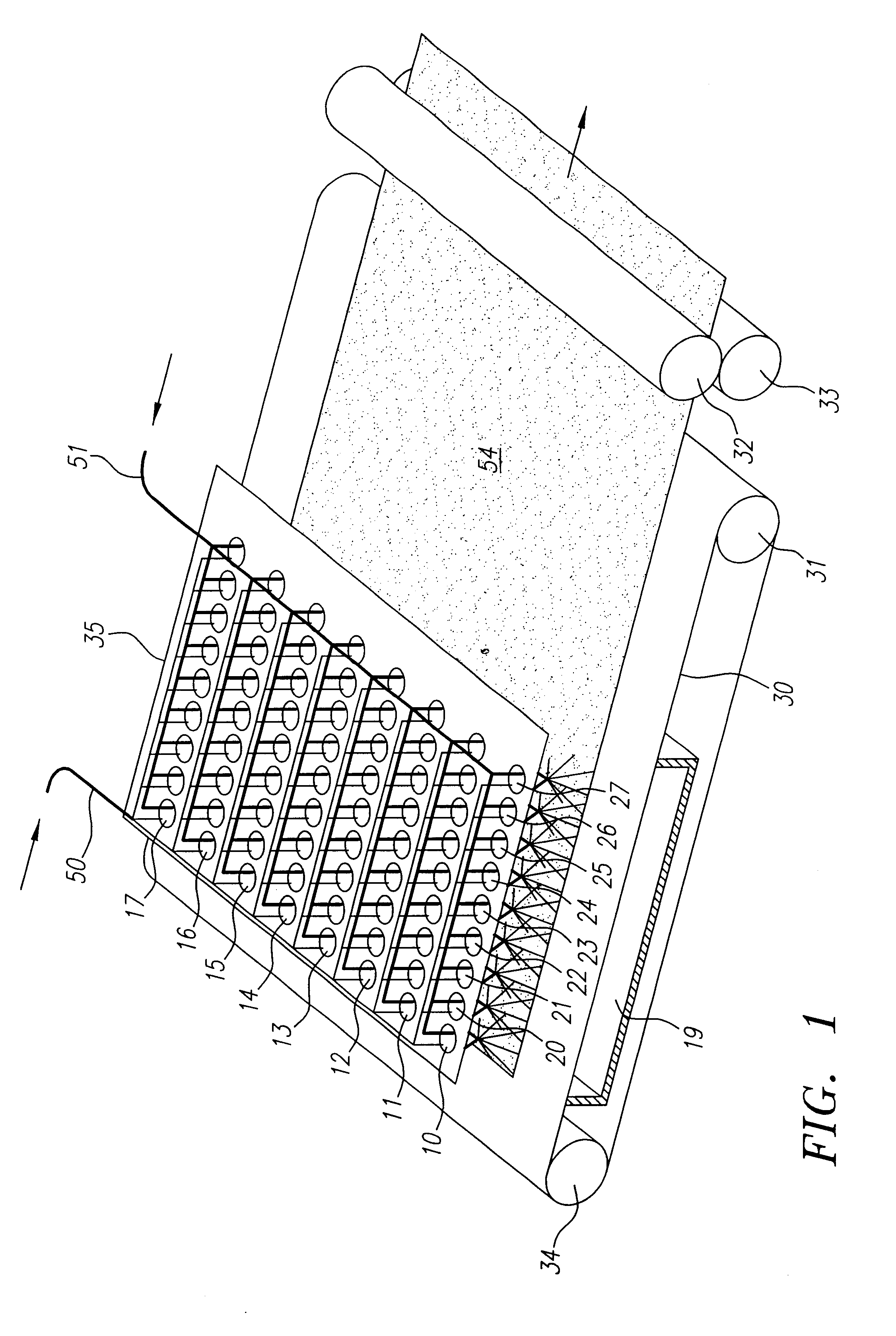

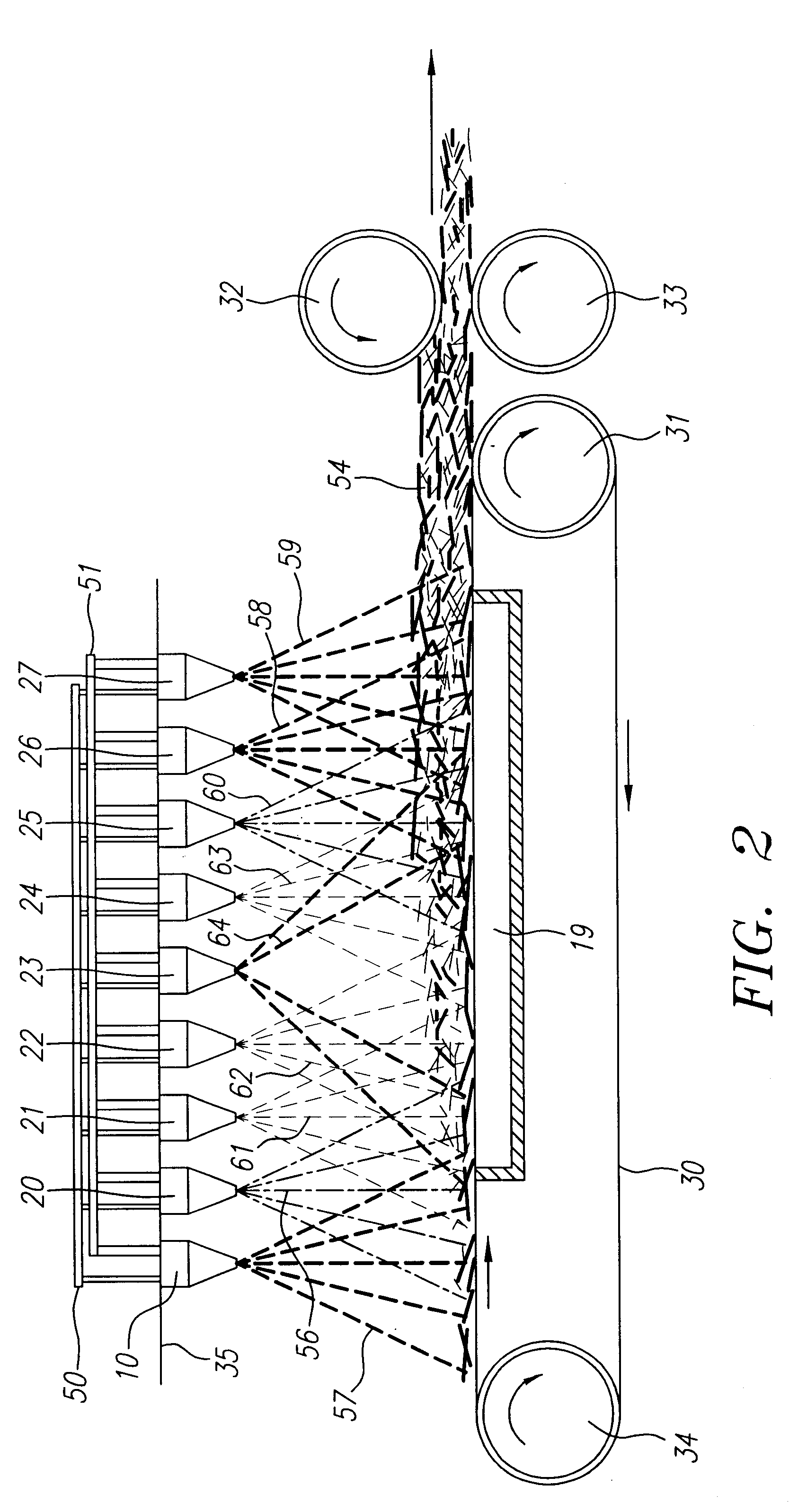

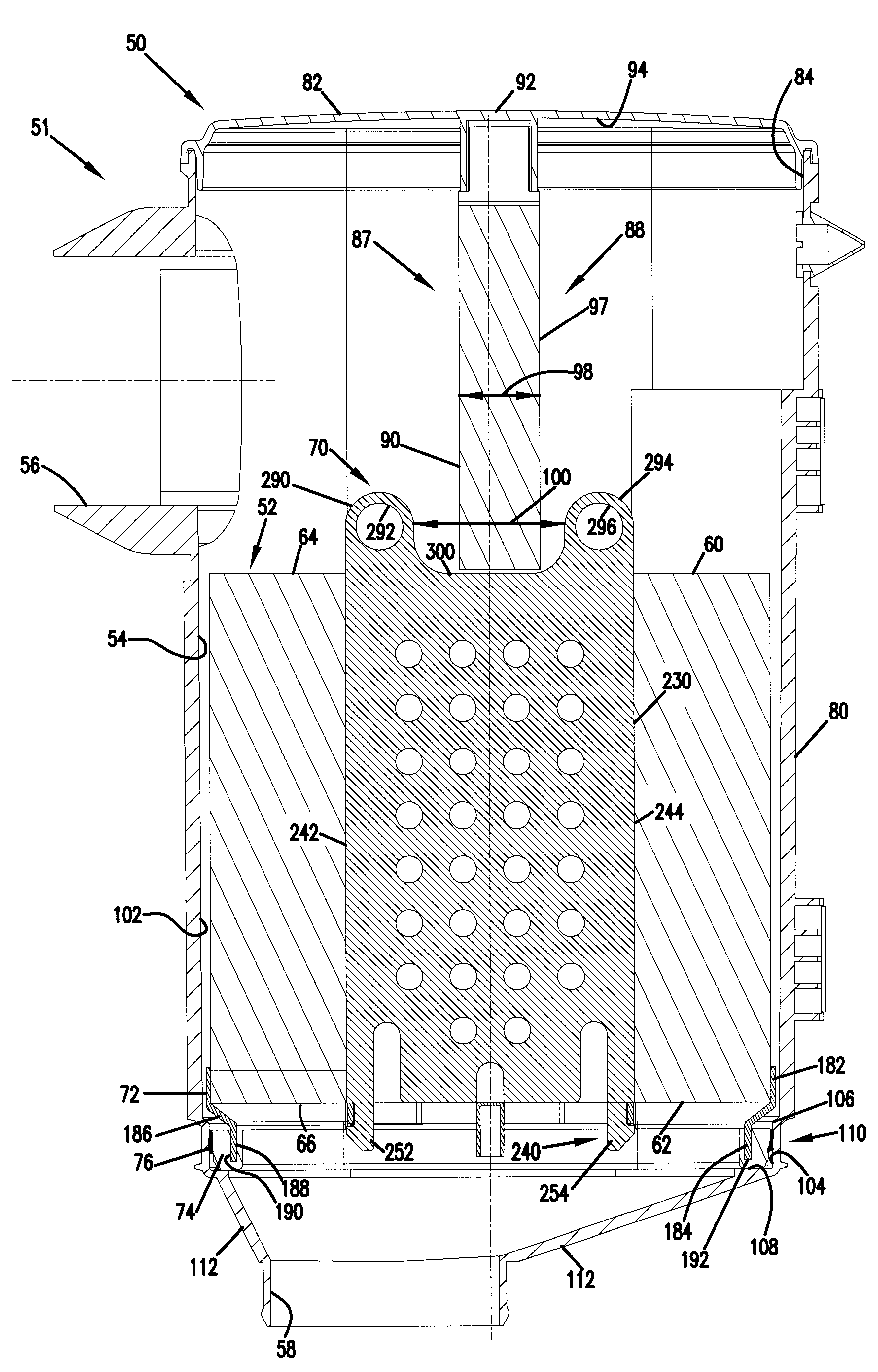

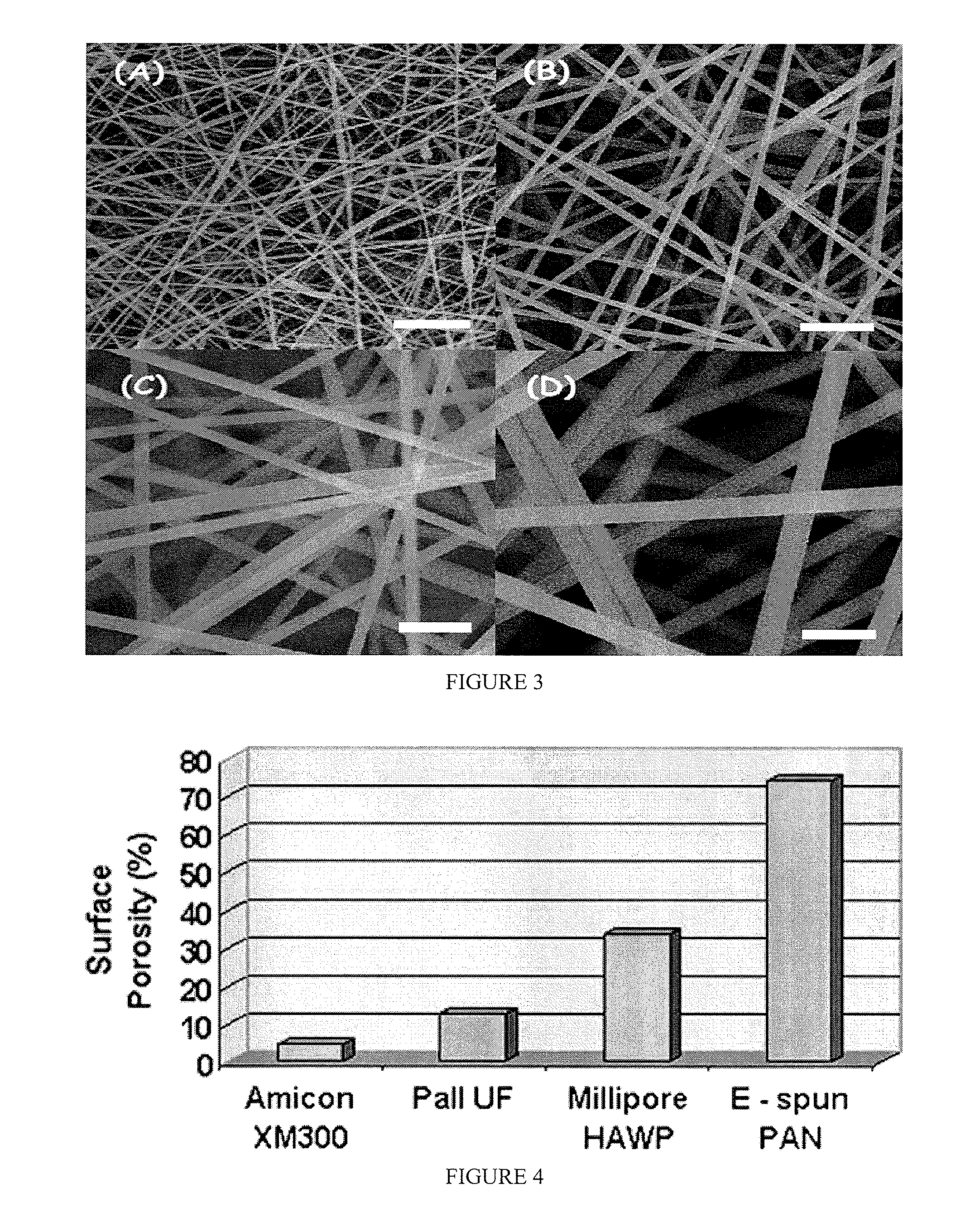

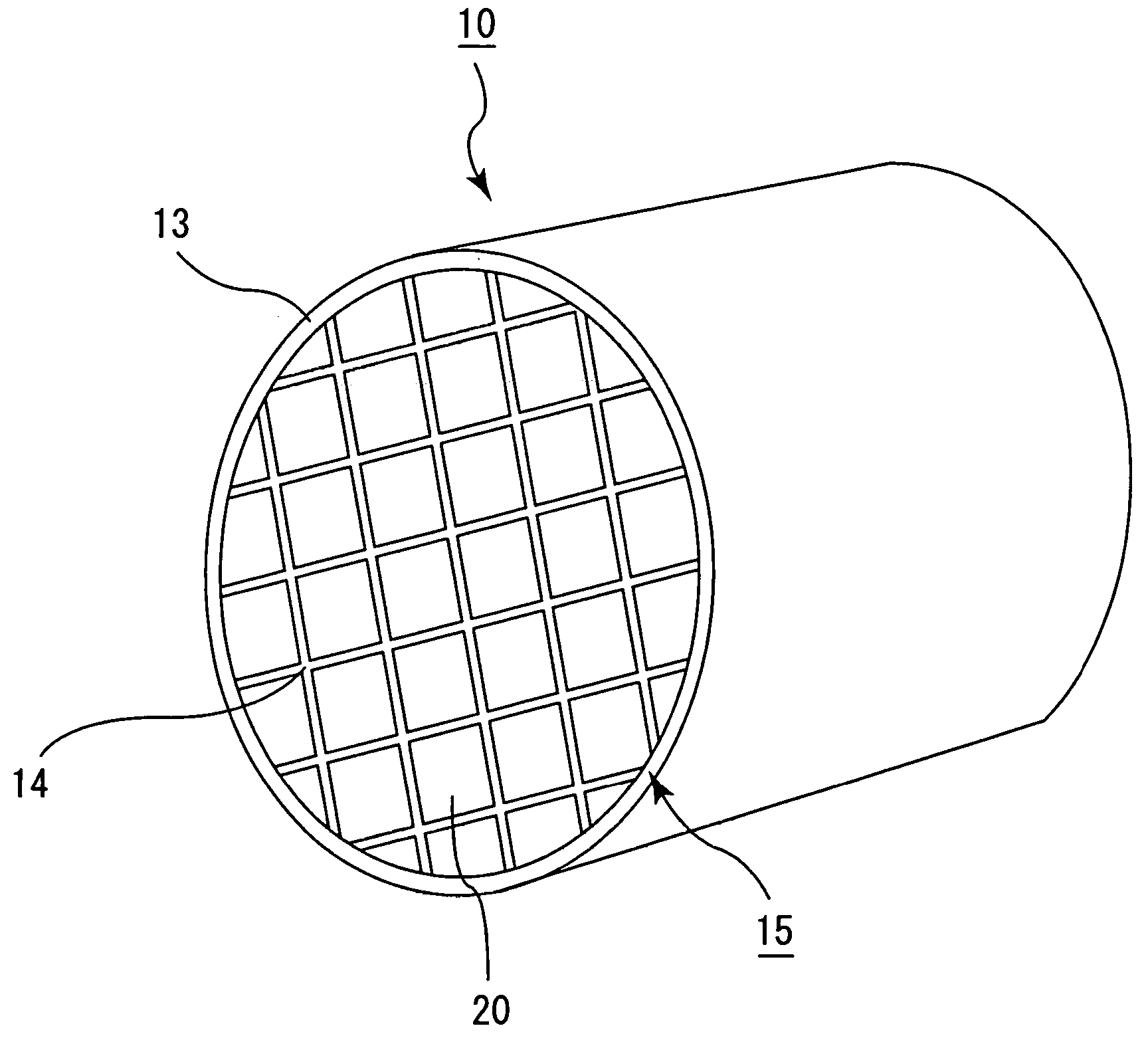

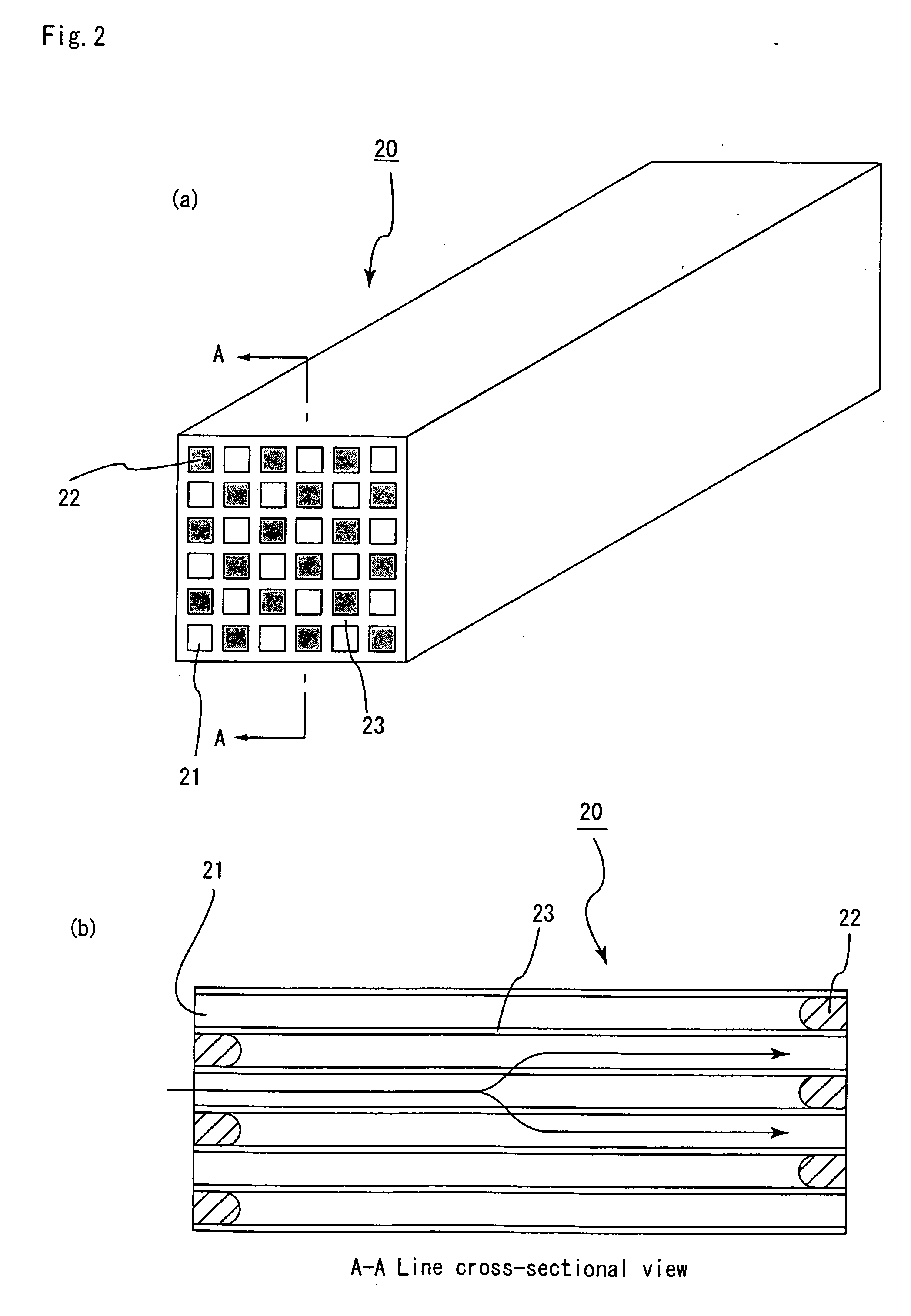

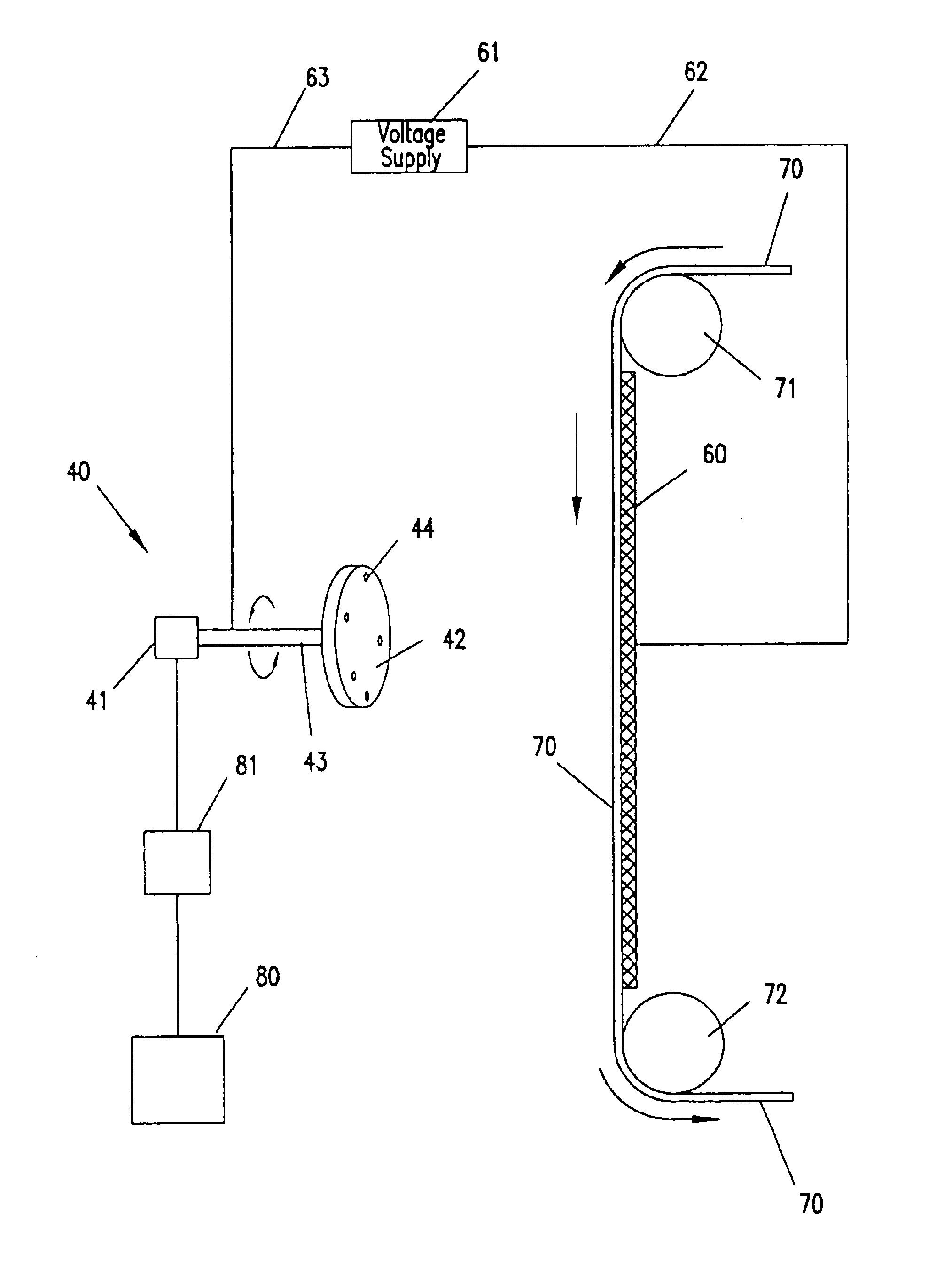

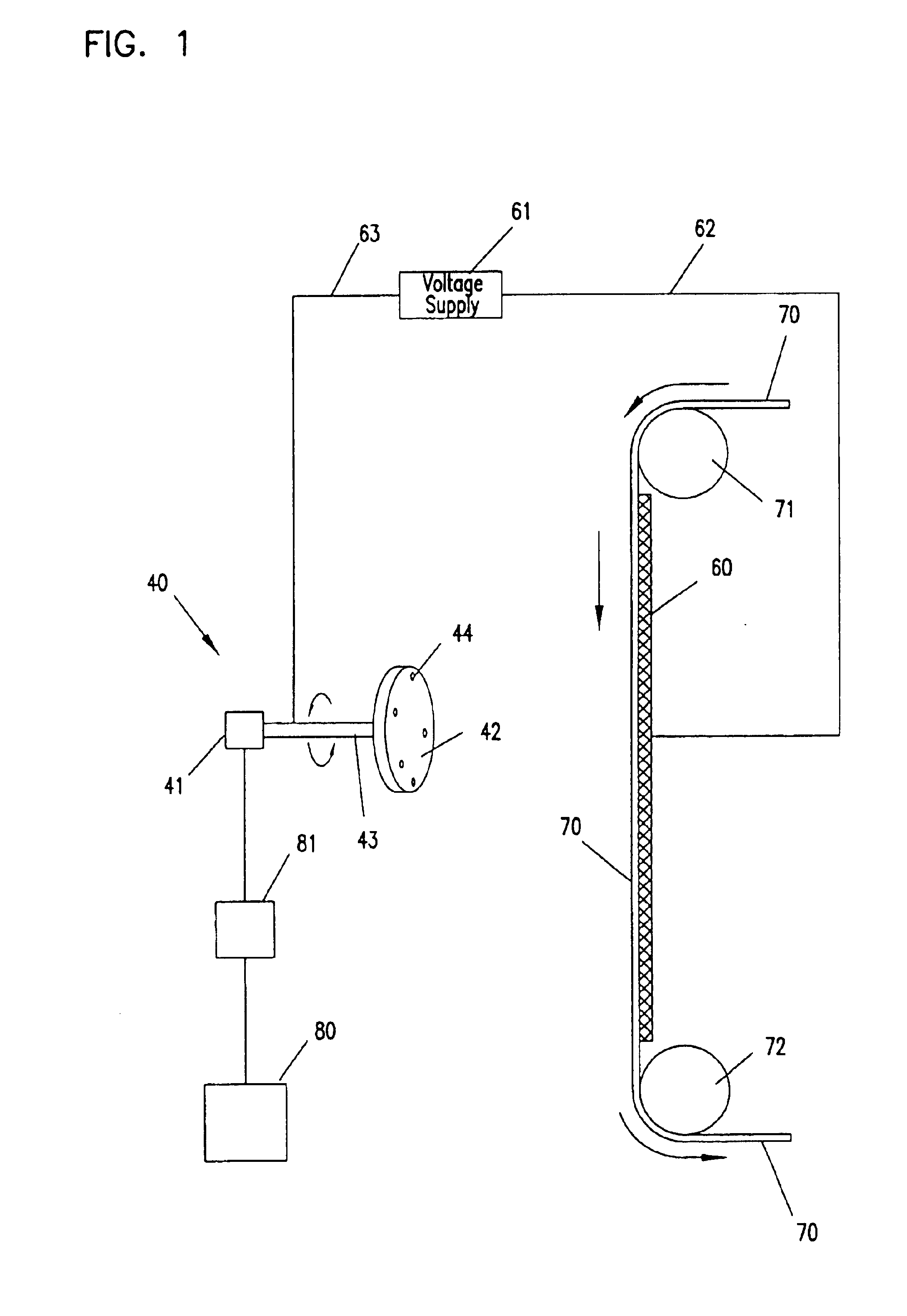

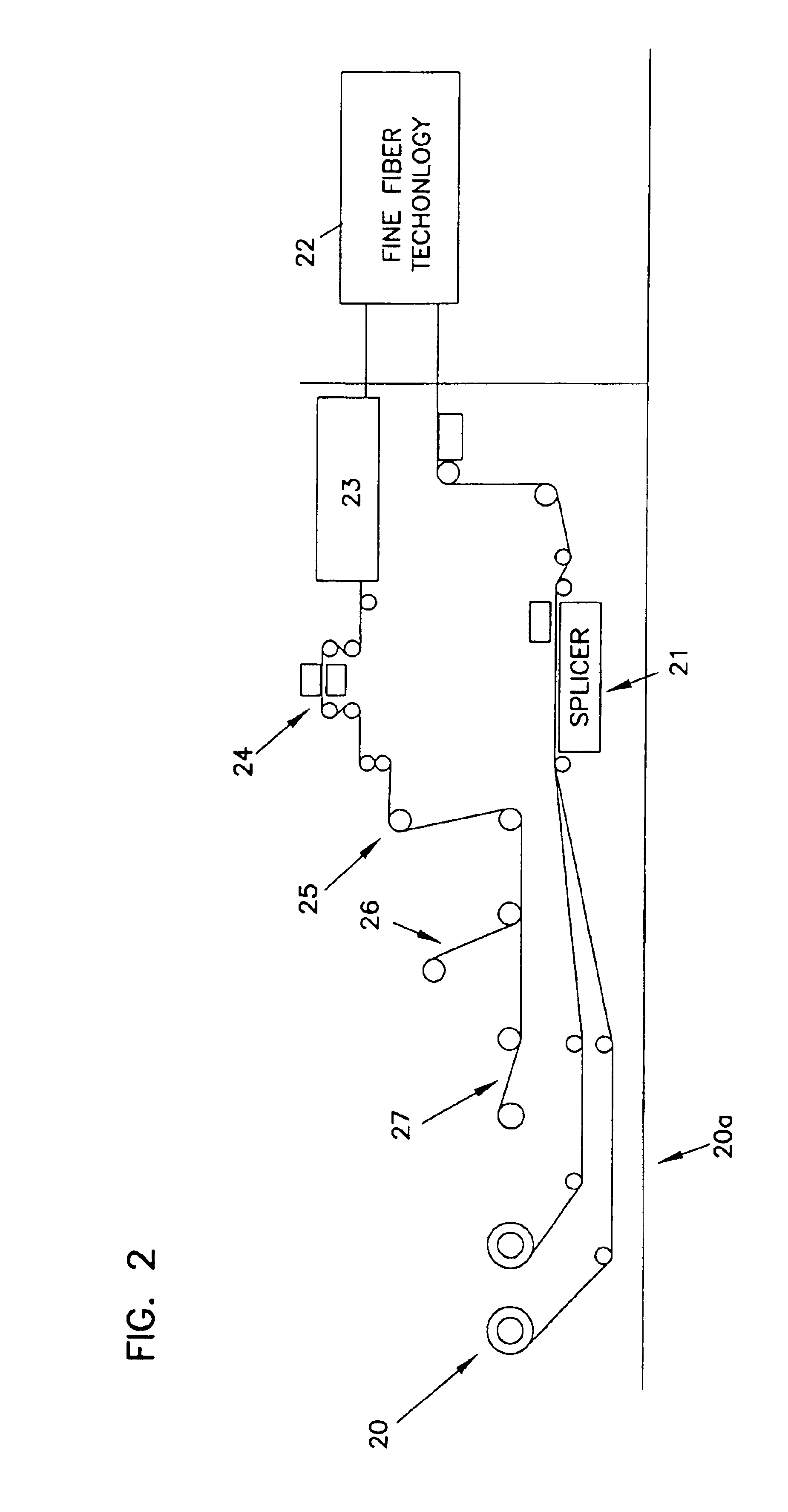

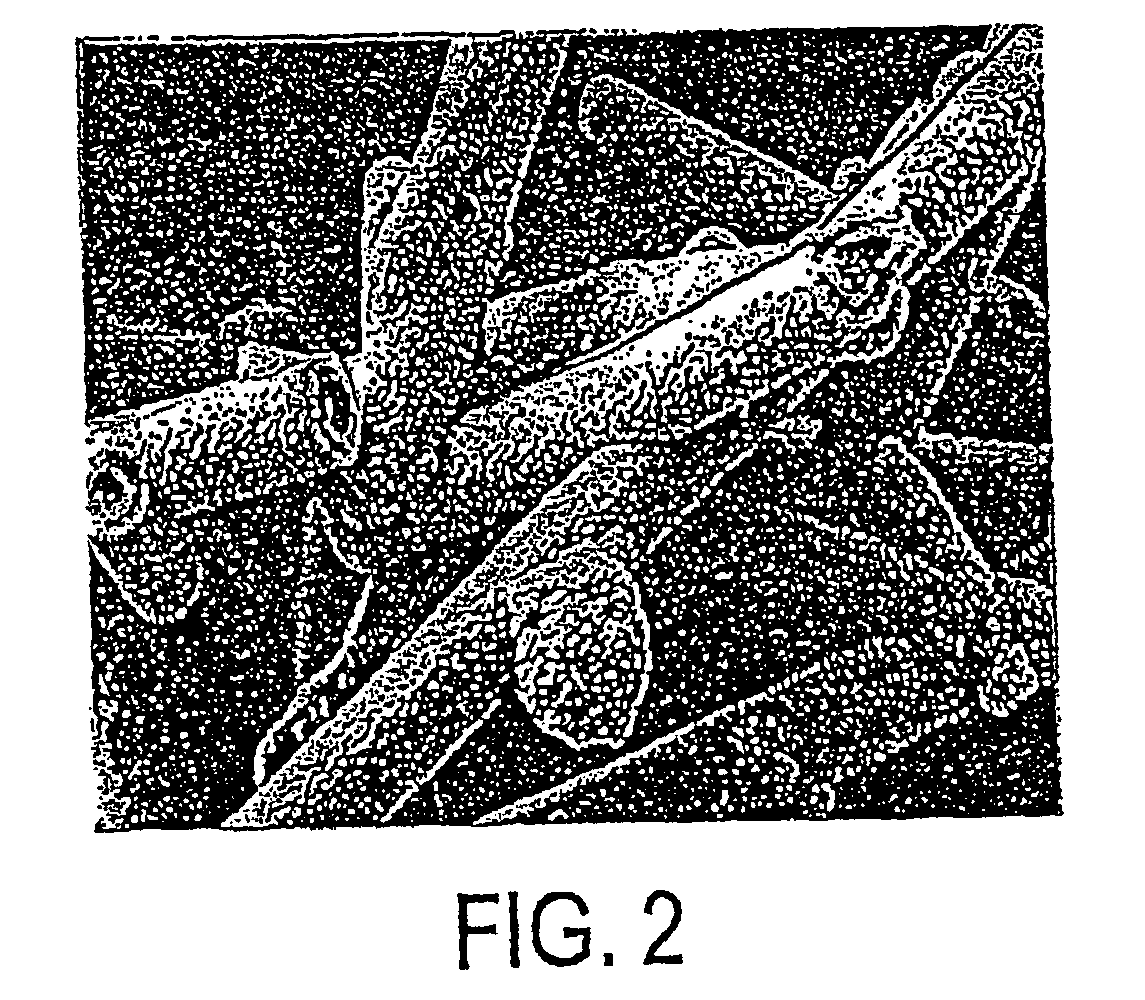

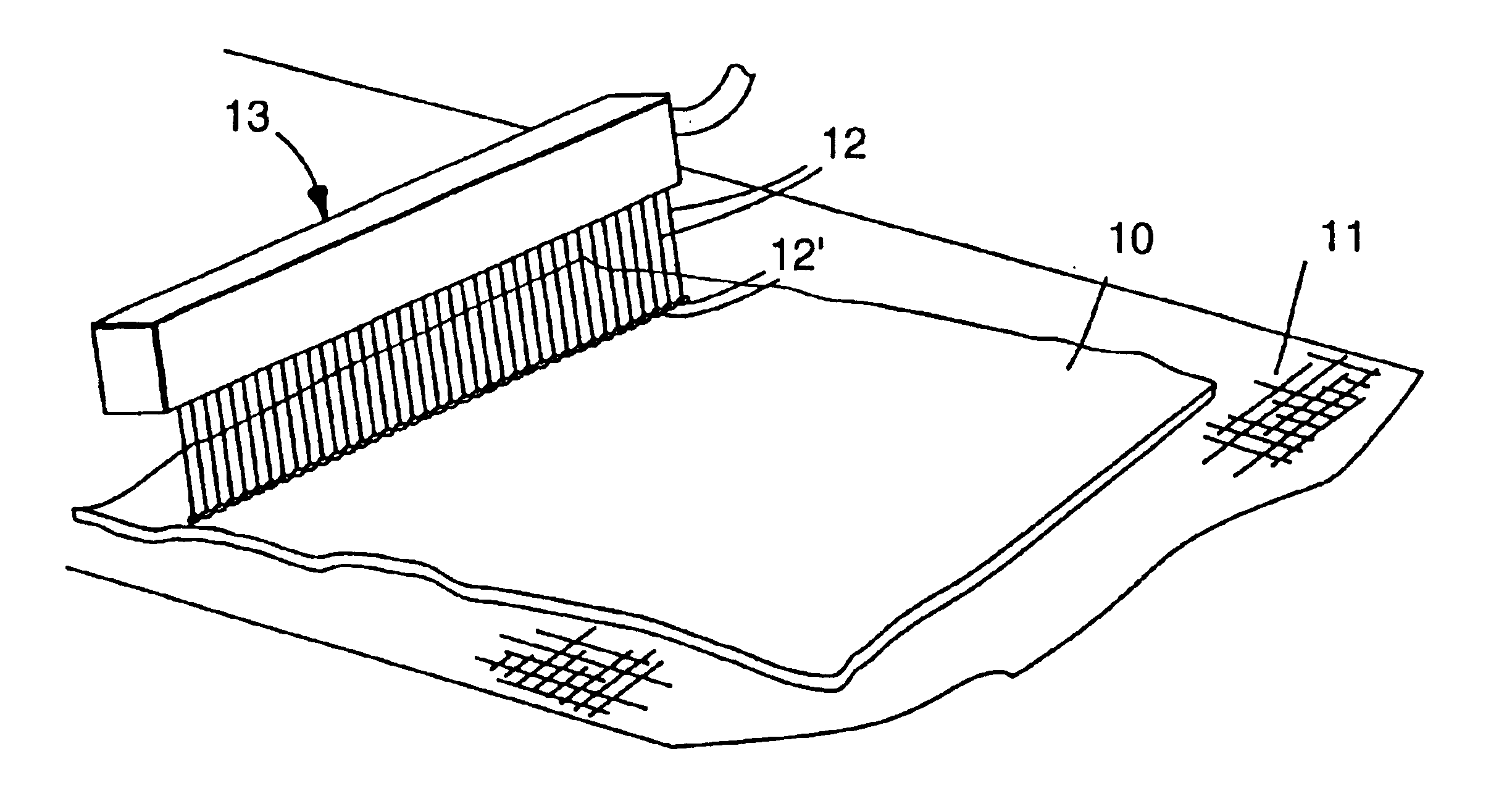

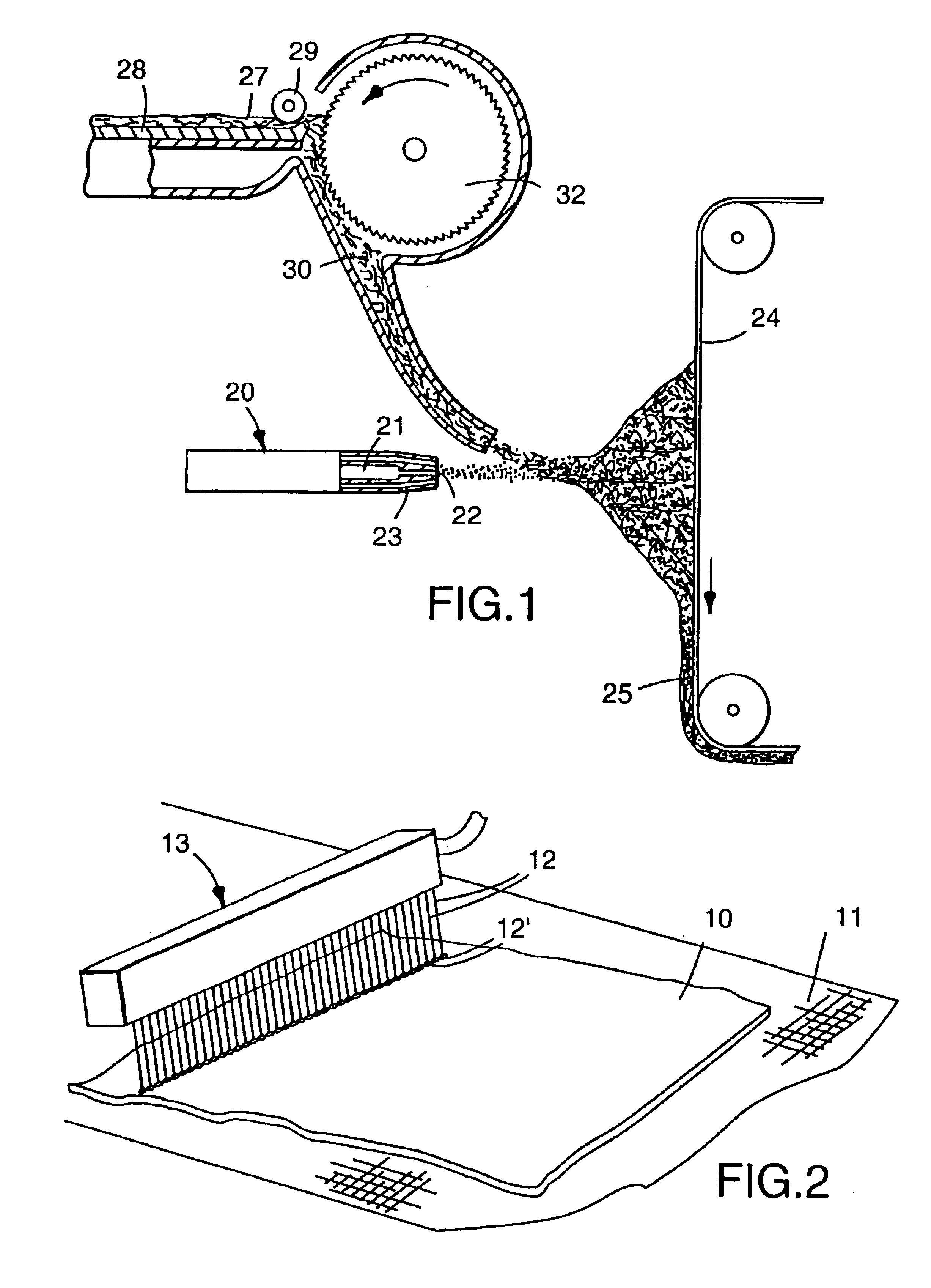

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Filter element, air cleaner, and methods

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

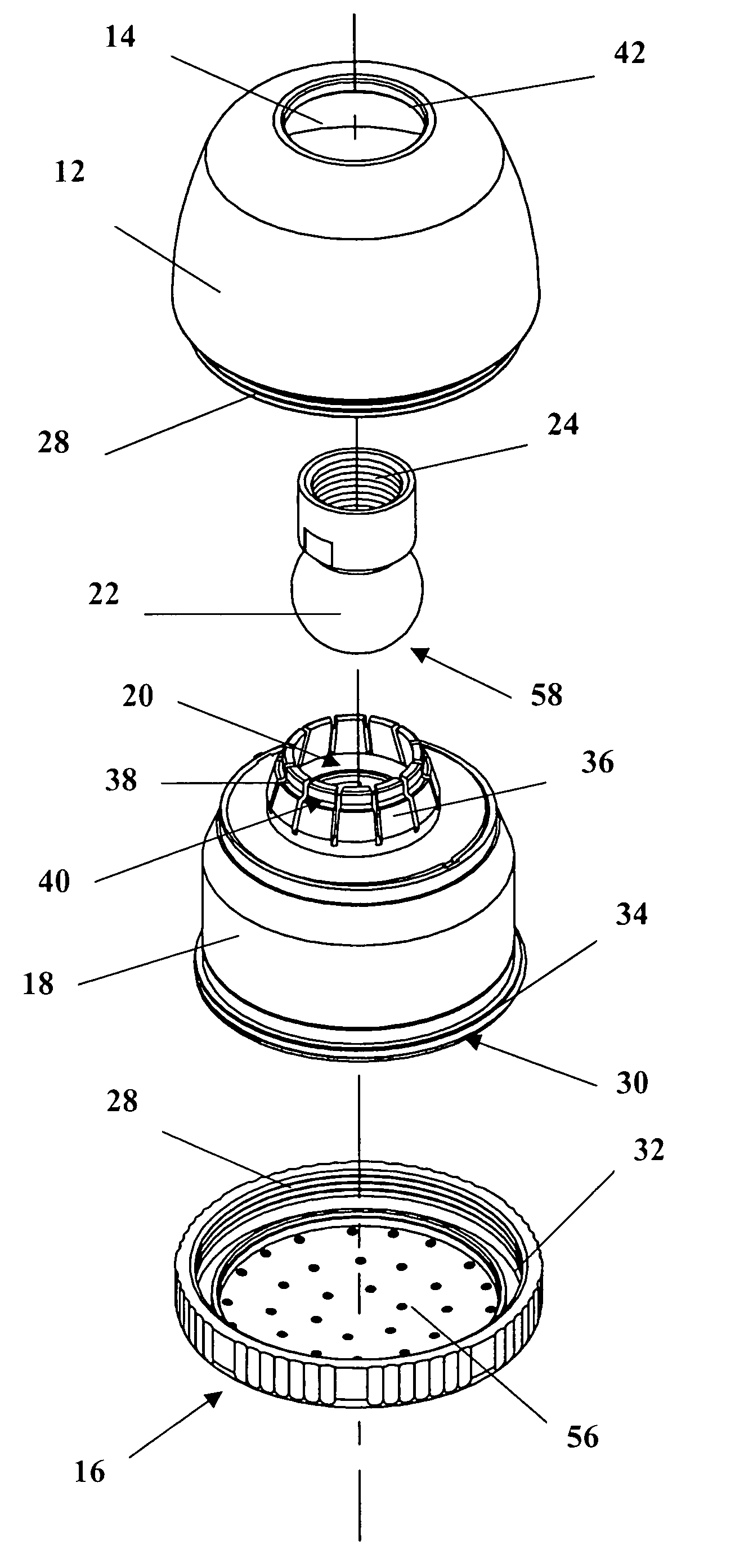

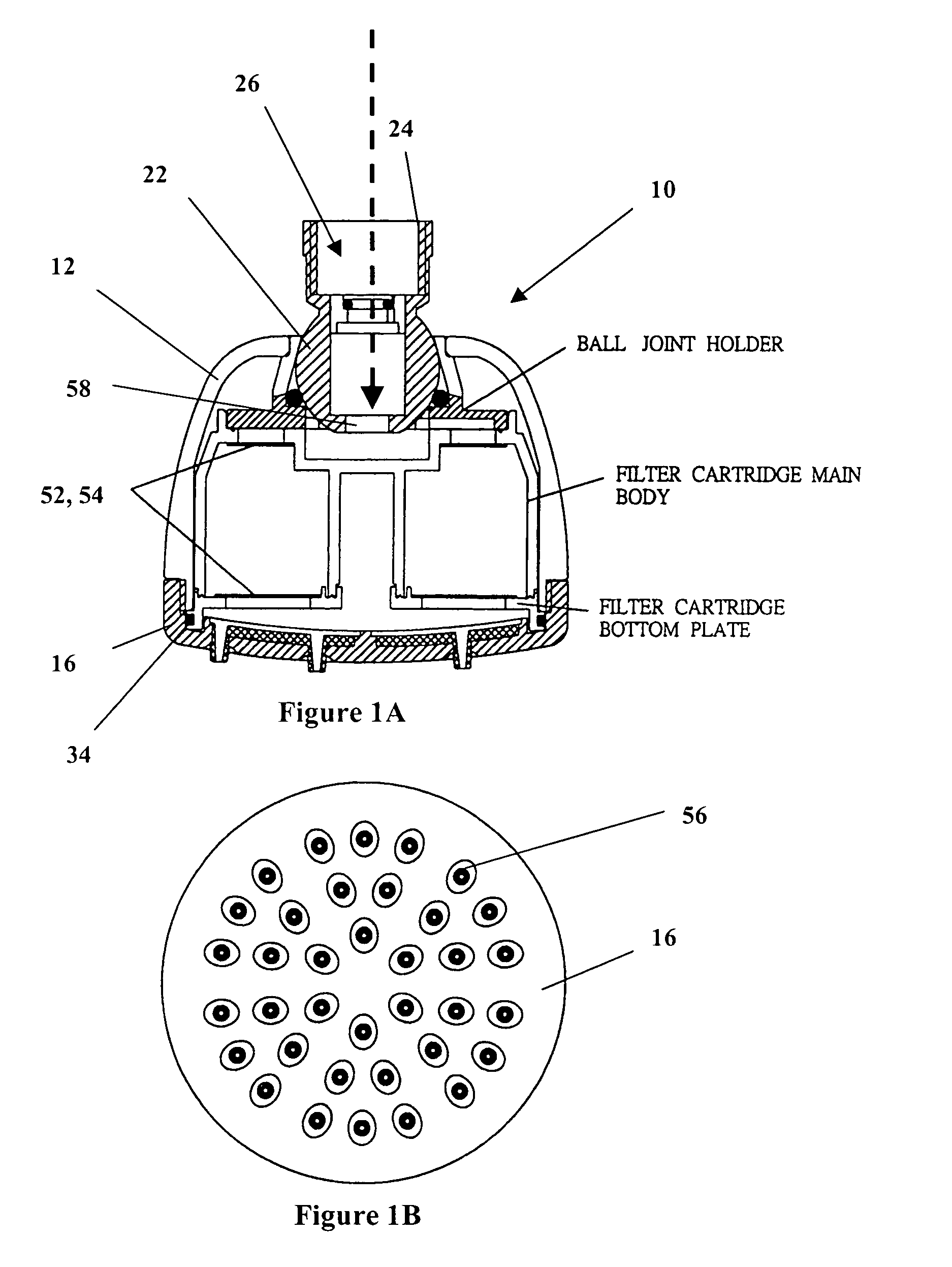

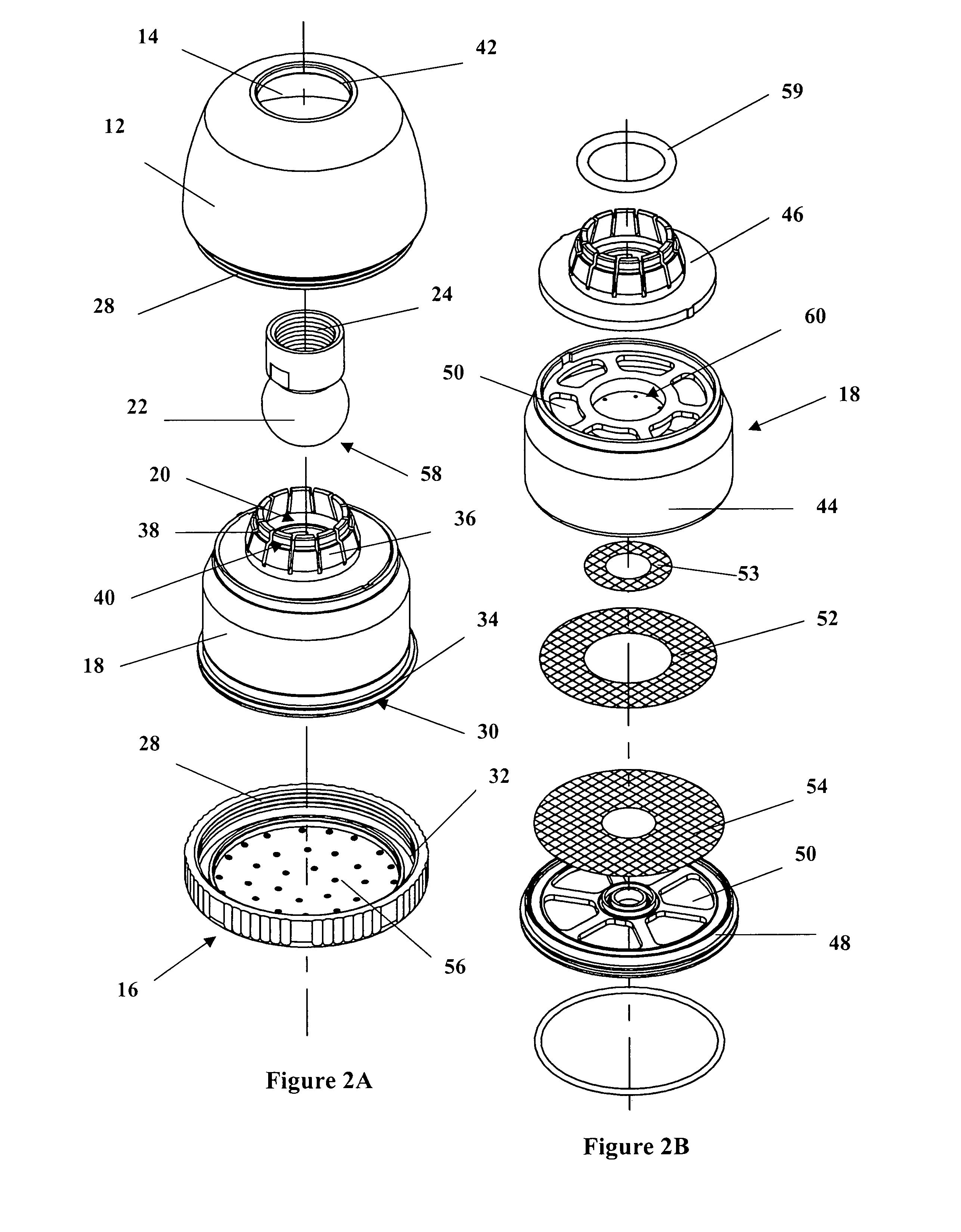

Water filter

A showerhead having a replaceable water filter assembly. The showerhead having a compact body with releasably coupled pivotable element connected to the water filter assembly.

Owner:H2O INT

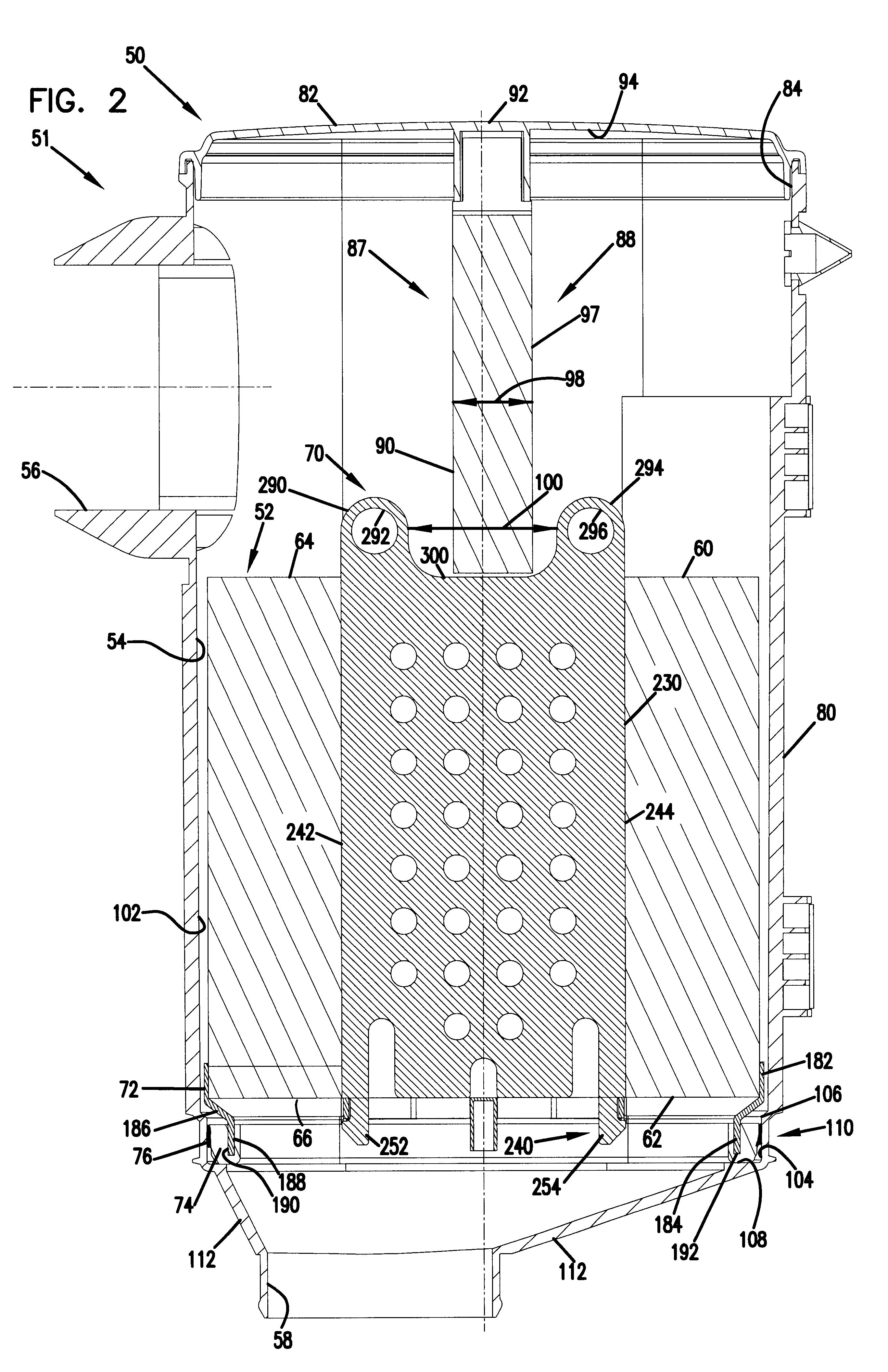

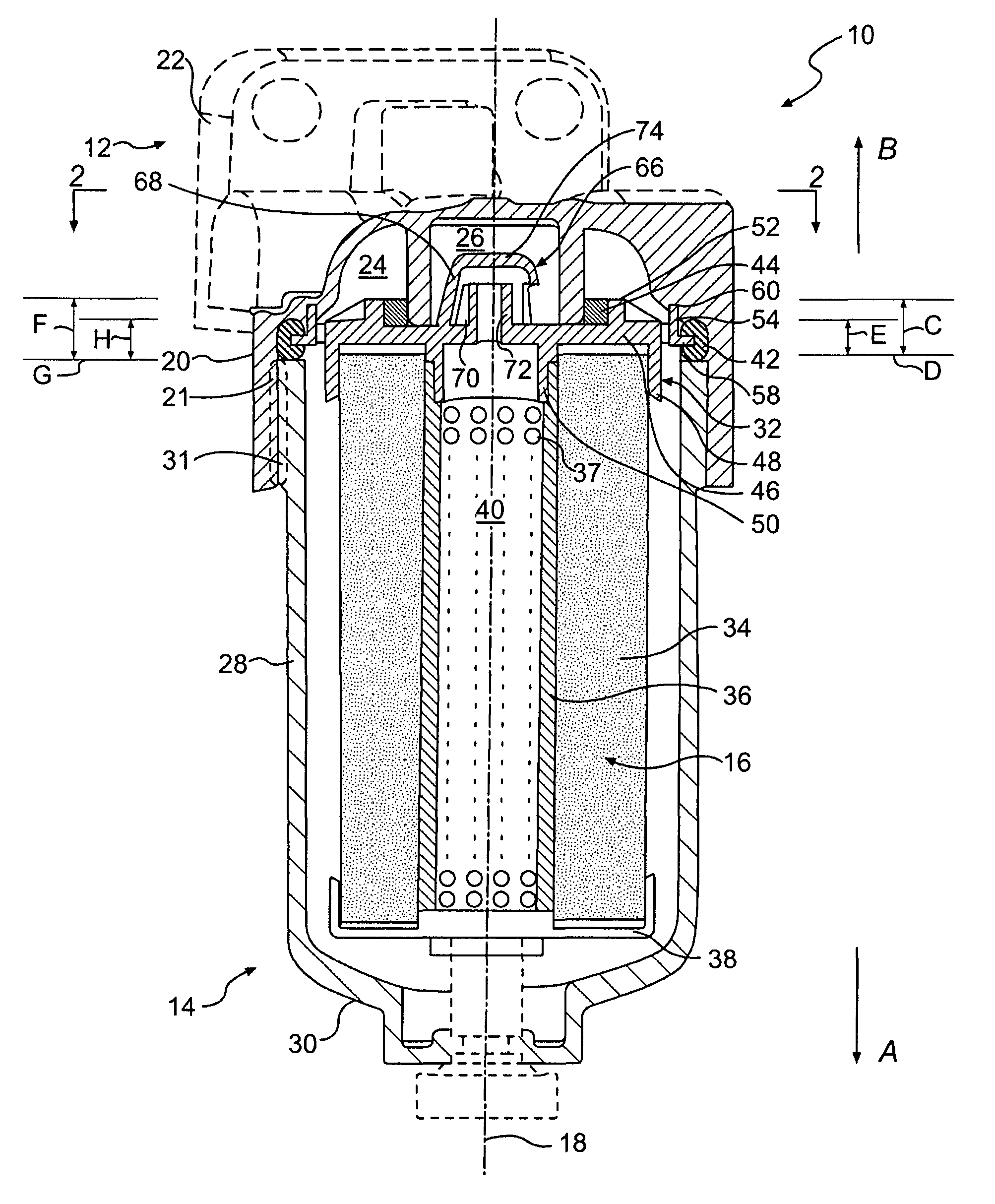

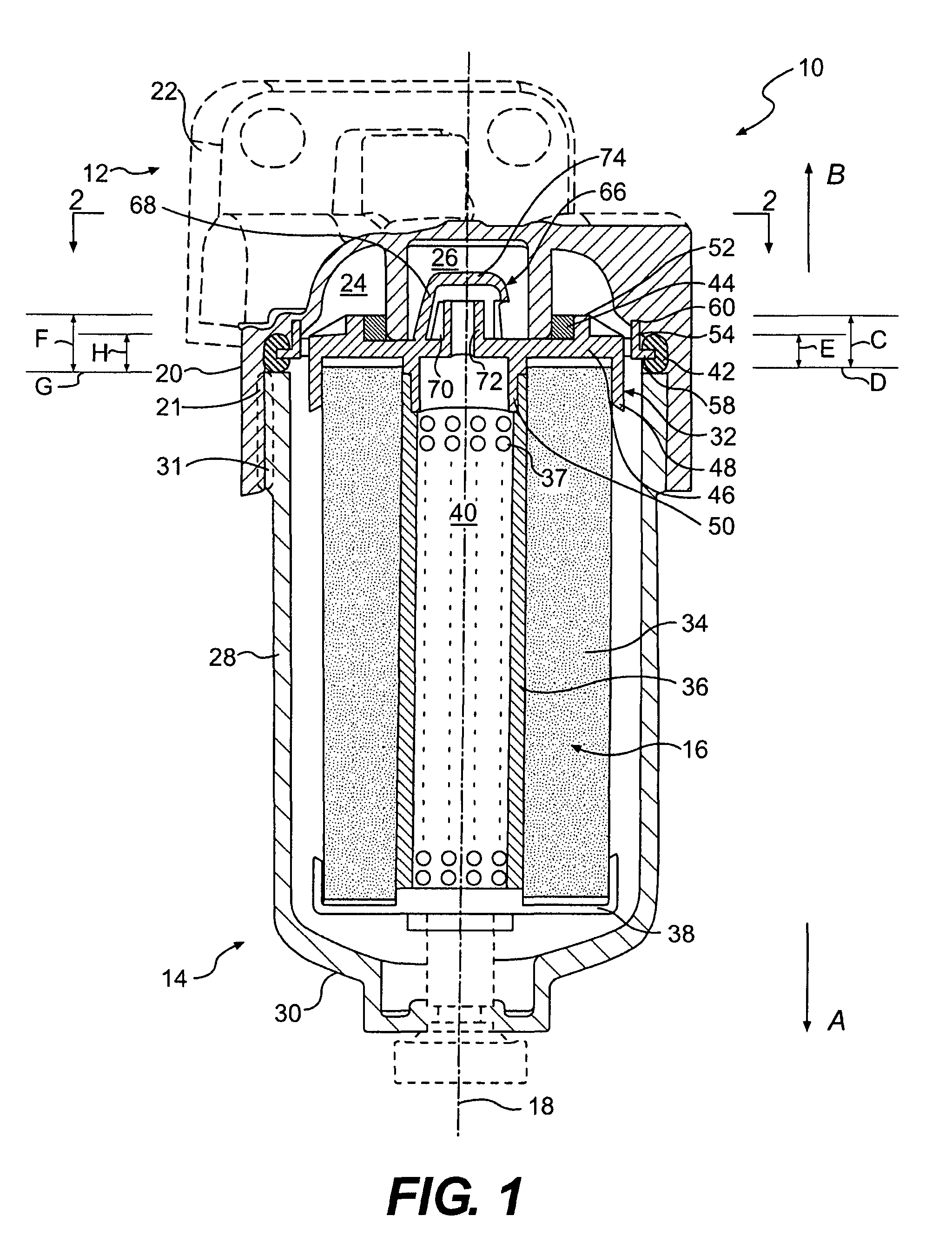

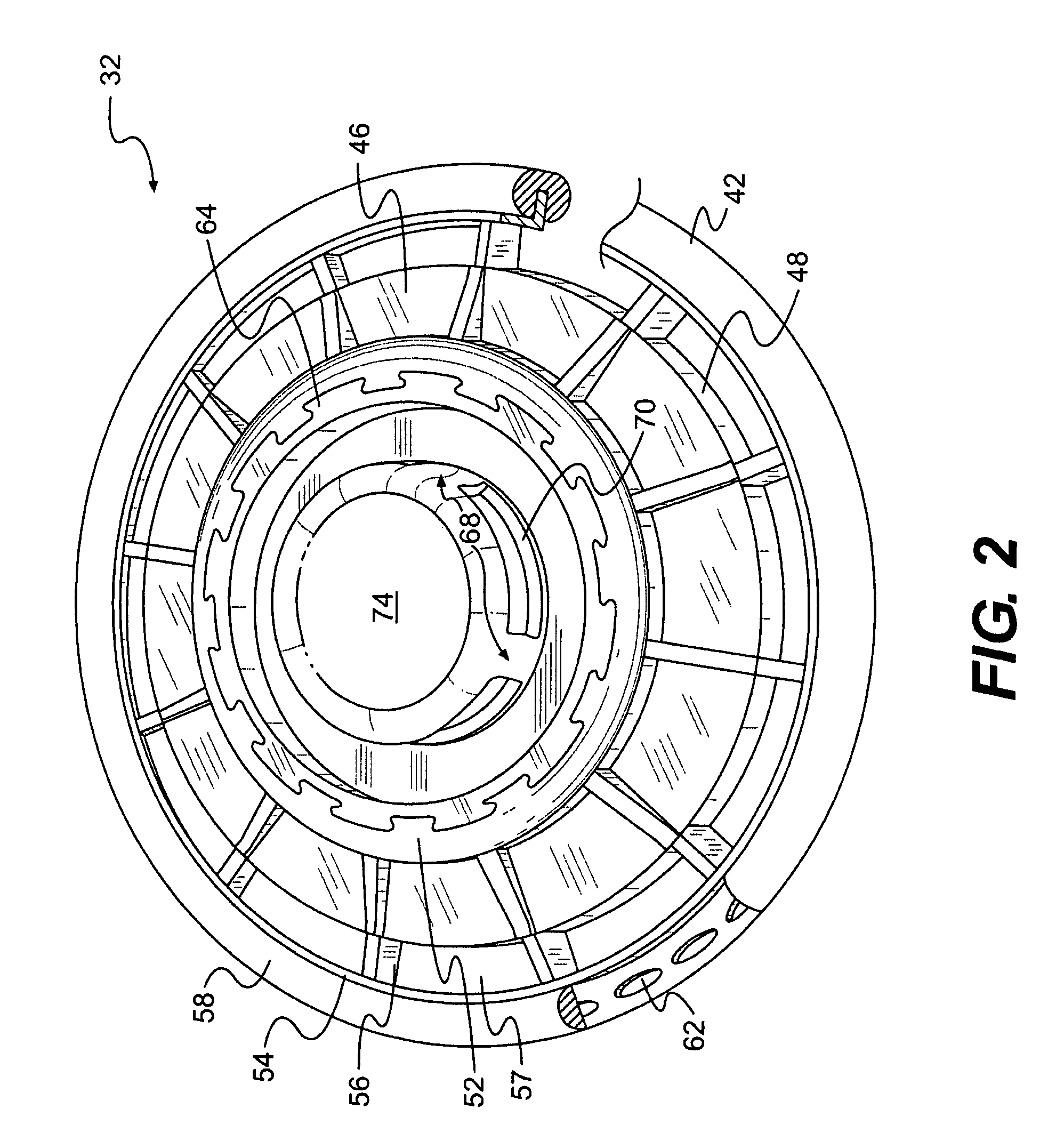

Fluid filter system

An endcap including a first plate member including a radial inner portion, a radial outer portion, and defining a longitudinal axis. The endcap also includes a flange disposed between the radial inner and outer portions of the first plate member and projecting axially along the longitudinal axis in a first direction. The endcap also includes a first seal member disposed adjacent the flange. The first seal includes a first portion thereof engaged with an axial facing surface of the first plate member and a second portion thereof engaged with a radially facing surface of the flange. The endcap further includes a second plate member disposed radially outward of the radial outer portion and a second seal member disposed adjacent the second plate member including at least a portion thereof axially spaced from the axially facing surface of the first plate member in a second direction along the longitudinal axis opposite the first direction.

Owner:DONALDSON CO INC +2

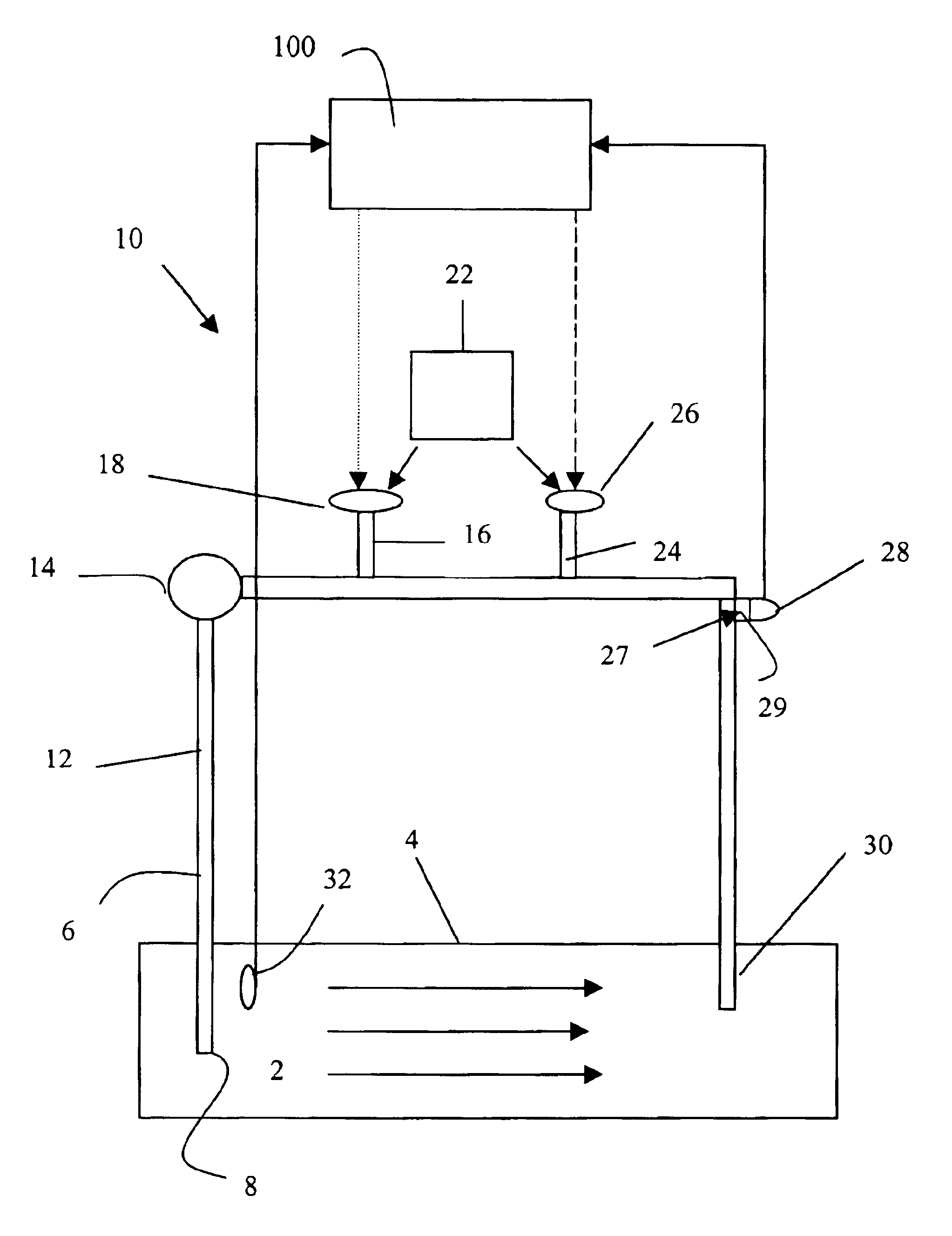

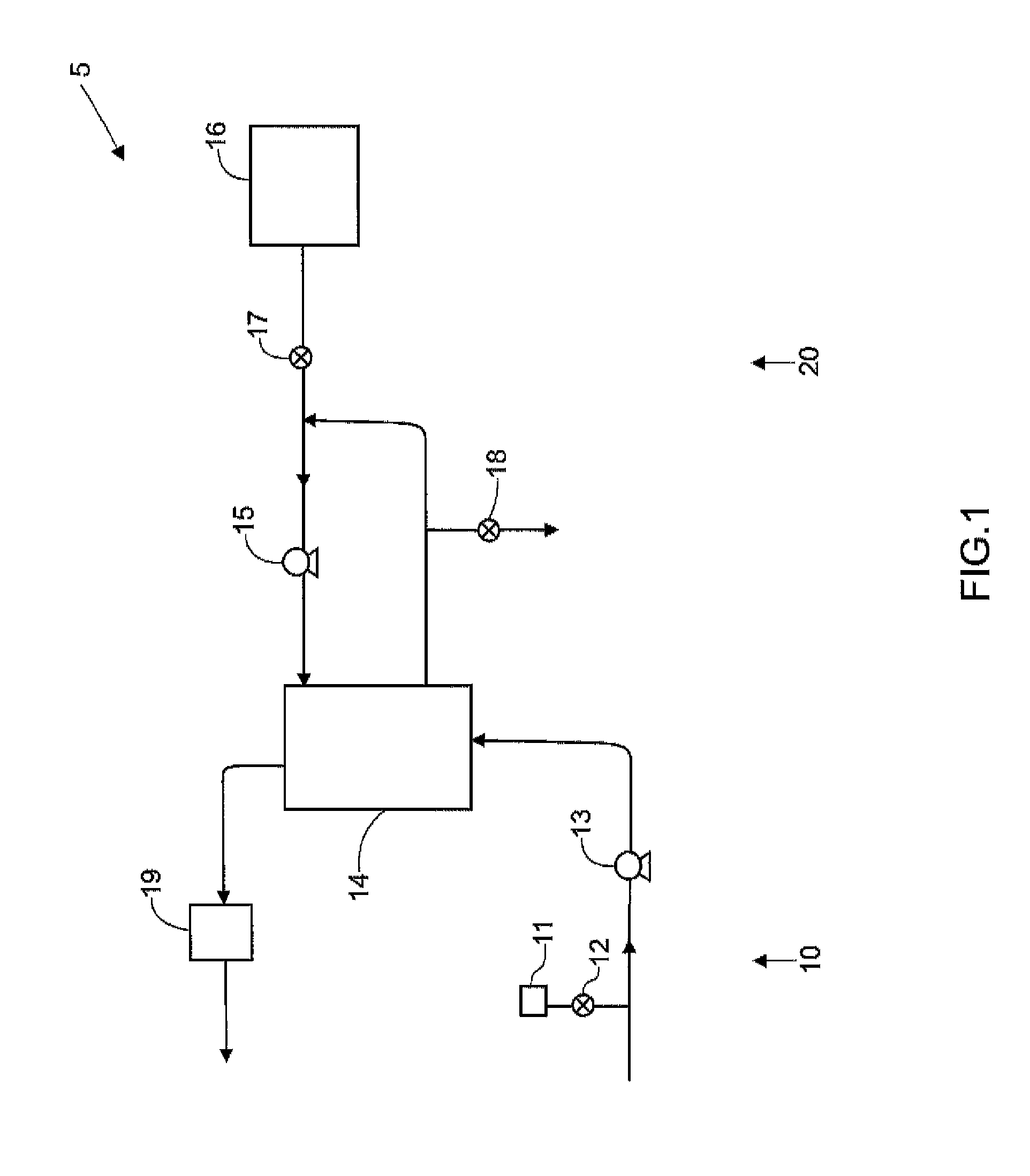

Methods and systems for improved dosing of a chemical treatment, such as chlorine dioxide, into a fluid stream, such as a wastewater stream

InactiveUS6949196B2Reduce consumptionQuantity minimizationWater treatment parameter controlOther chemical processesChemical treatmentChlorine dioxide

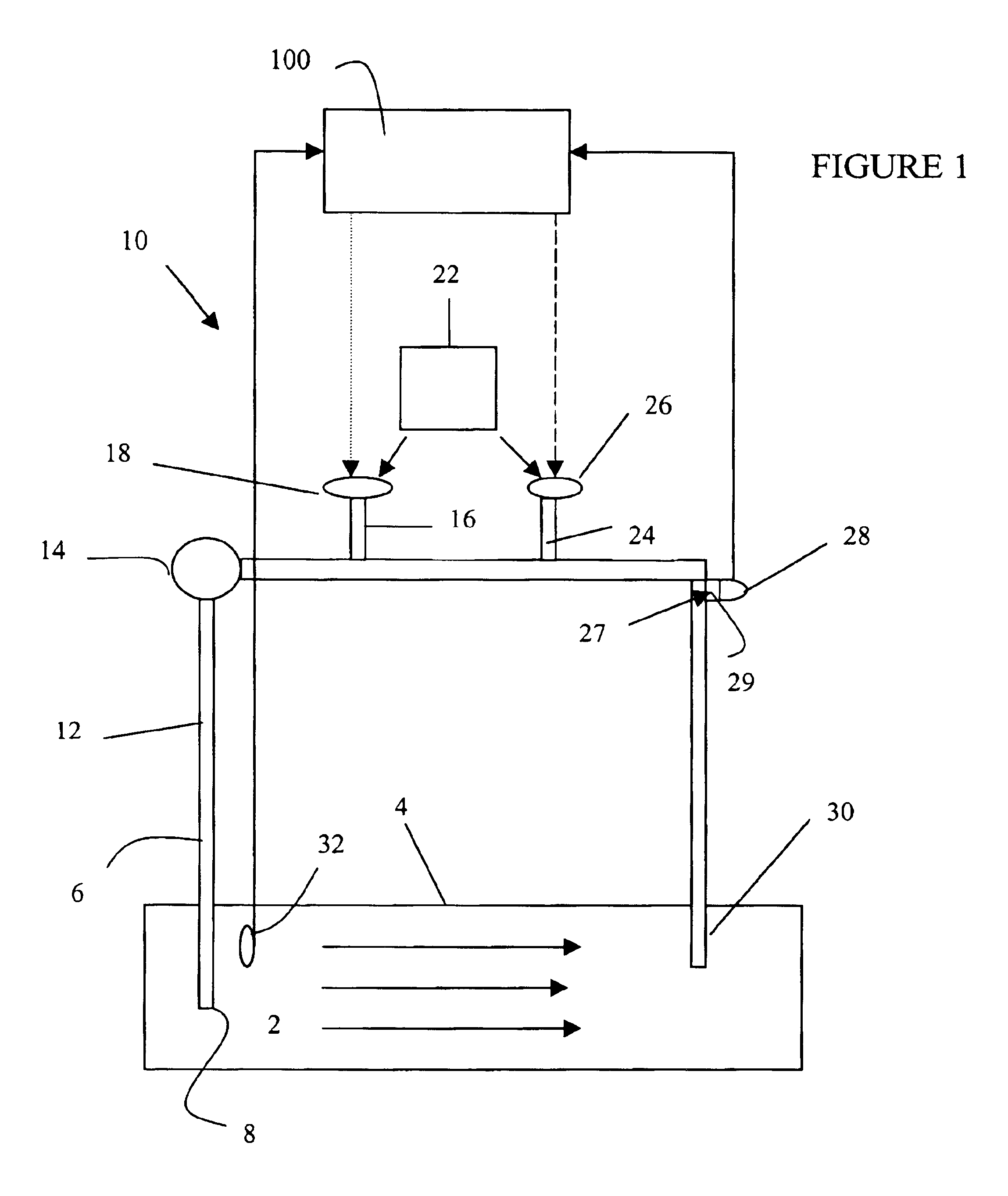

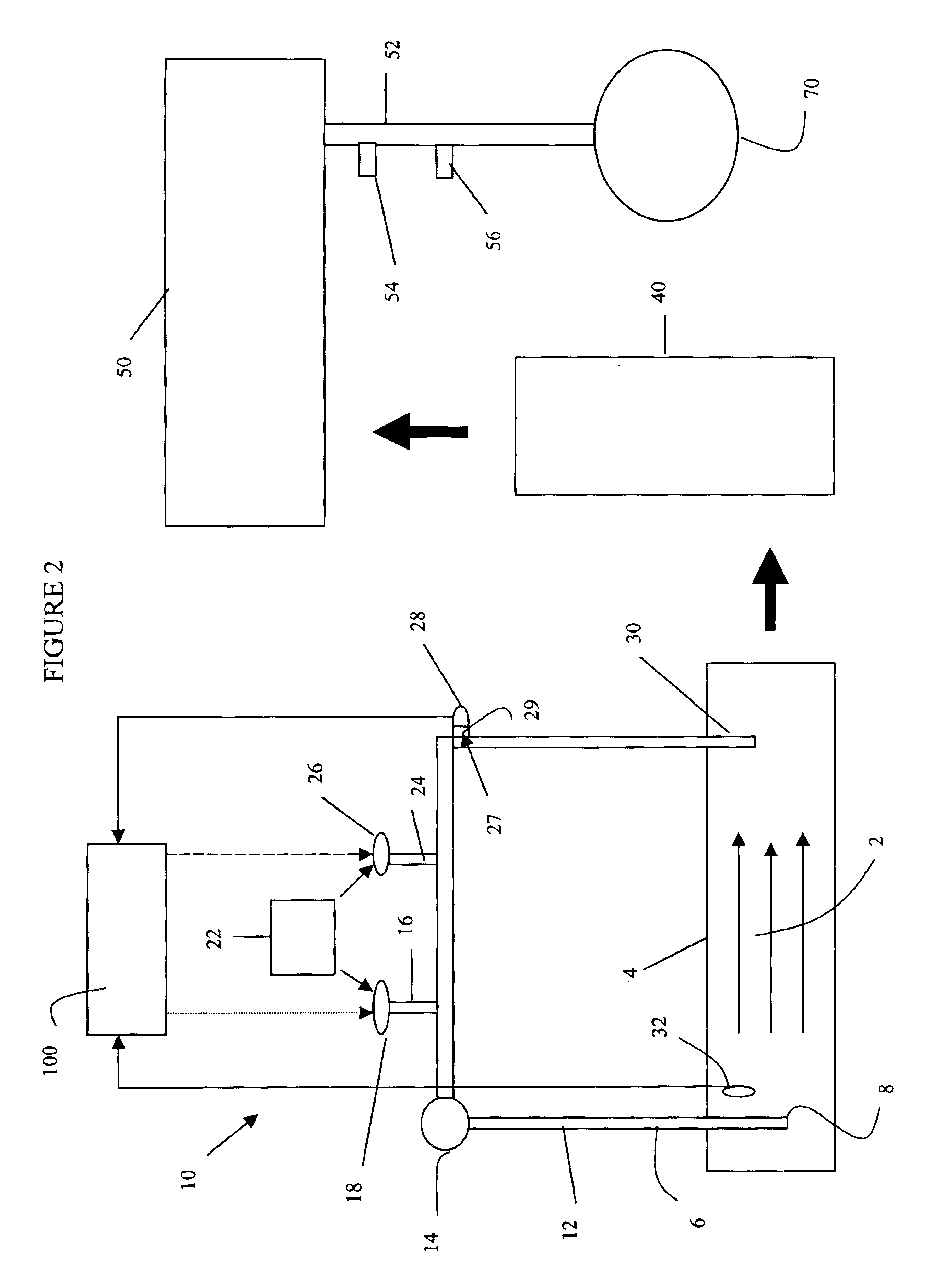

The invention is directed to methods, apparatuses, and systems for treatment of a liquid flow comprising addition of a chemical treatment at at least two locations along a side stream of a main flow of said liquid, in which the dosing by such additions is sufficient to treat the entire main flow upon return of the side stream to the main flow. Algorithms are utilized to control the additions at the locations of addition of chemical treatments. In a typical embodiment, one chemical addition is principally proportional to the flow rate of the liquid flow, and the other chemical addition is principally adjusted based on signals from a primary measuring device that measures a parameter in the flow after one or both chemical additions. The addition of chlorine dioxide as the chemical treatment, to disinfect wastewater, is discussed.

Owner:FKOS LLC +1

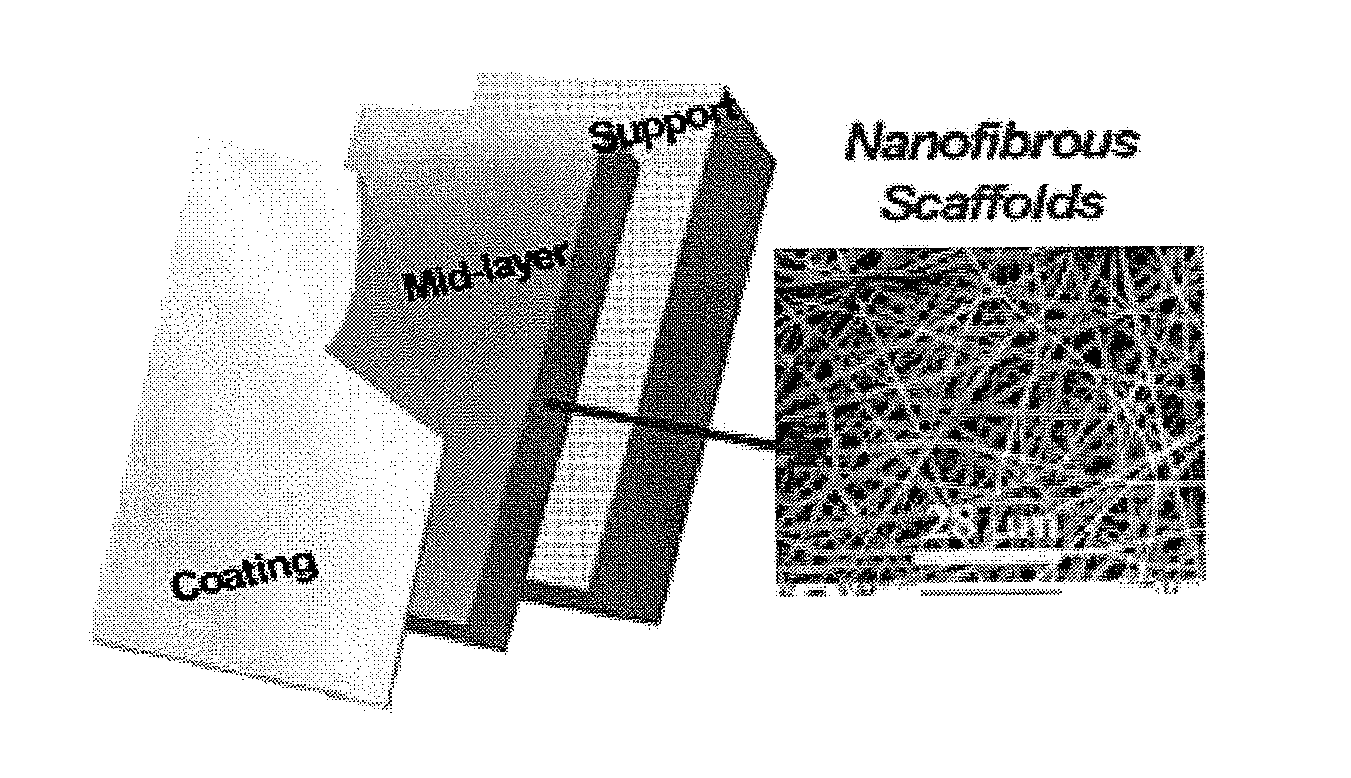

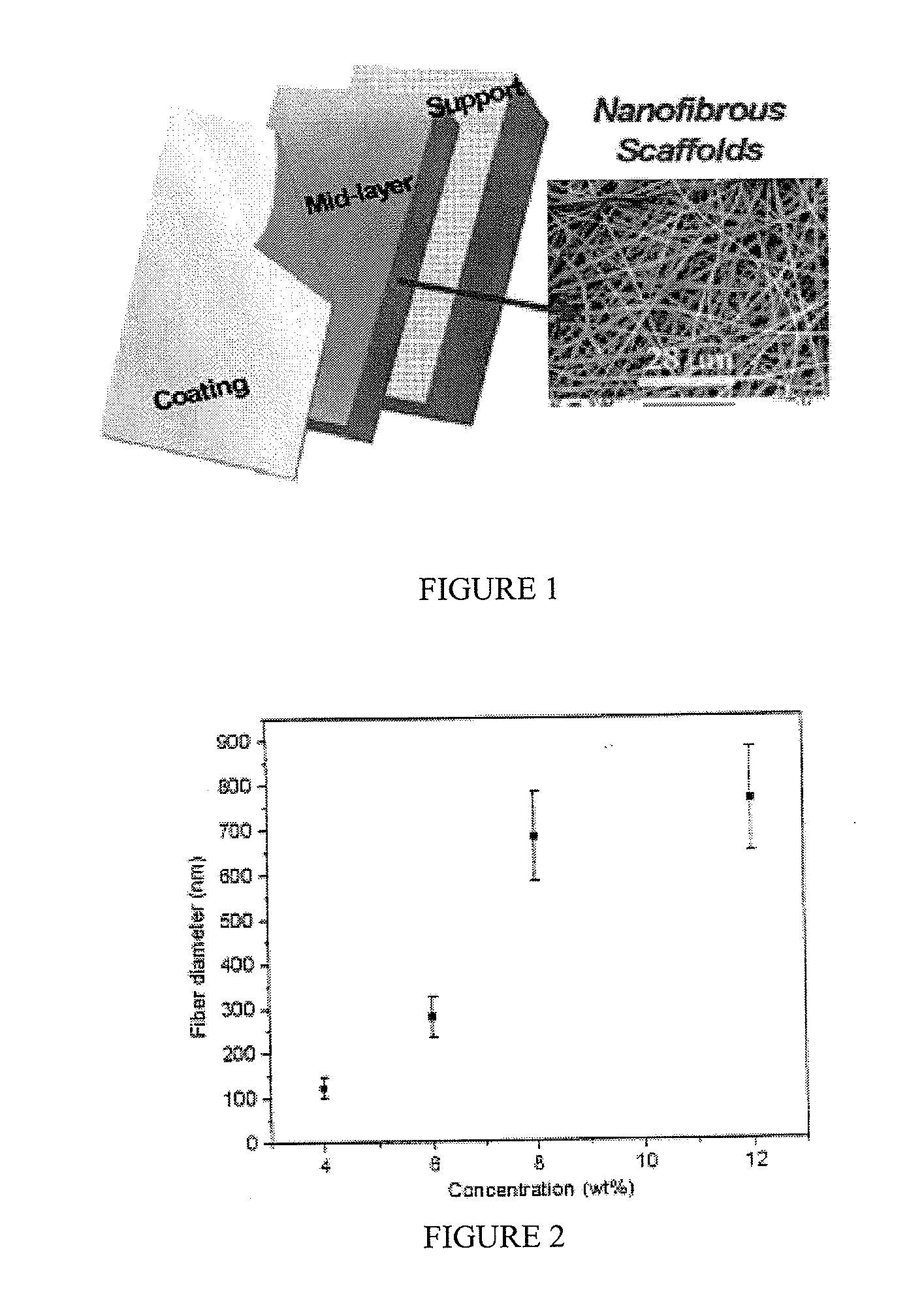

Articles Comprising a Fibrous Support

Articles comprising a fibrous support of nanofibers and an interfacially polymerized polymer layer disposed on a surface of the fibrous support are useful, e.g., as fluid separation membranes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

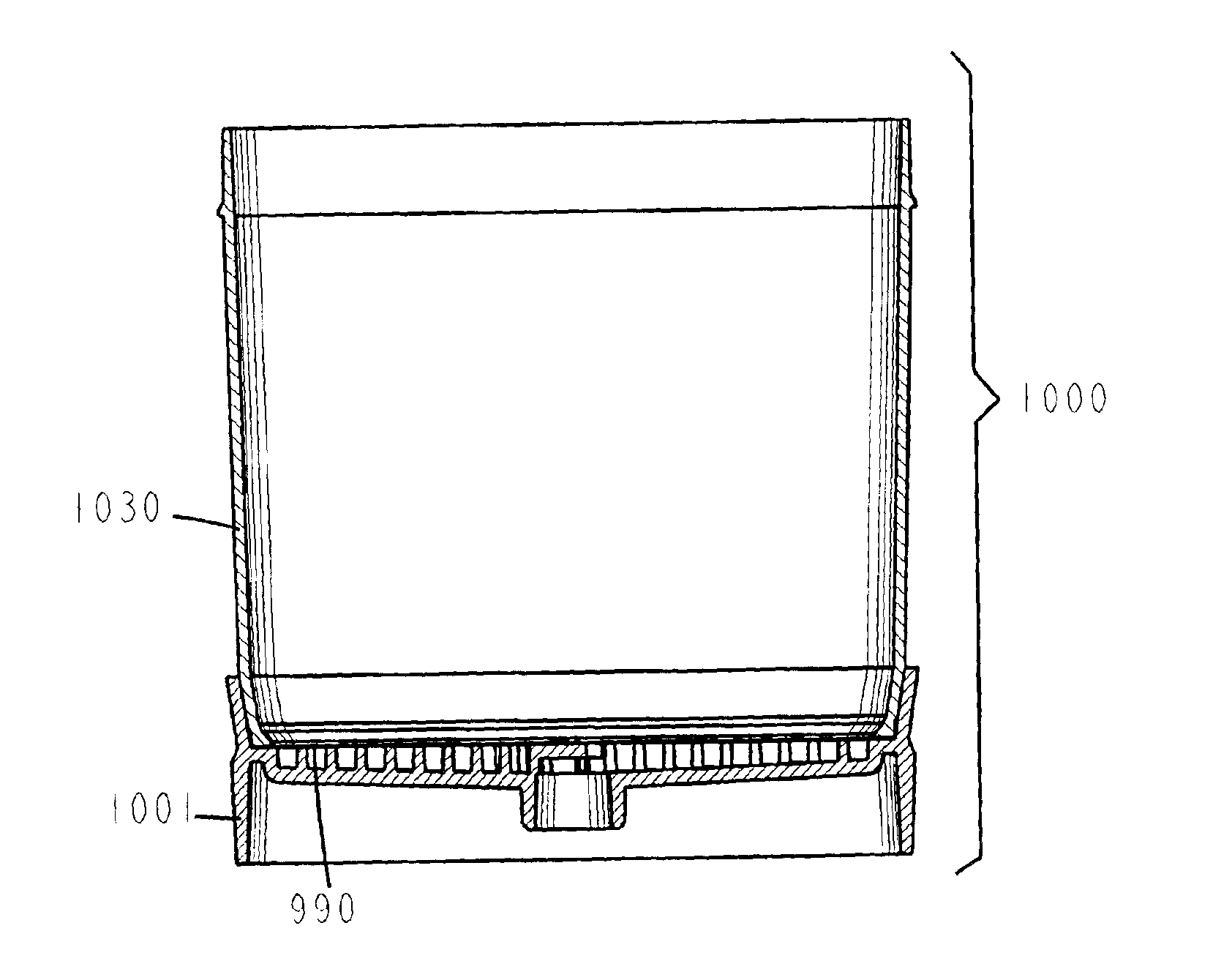

Disposable vacuum filtration apparatus capable of detecting microorganisms and particulates in liquid samples

InactiveUS6913152B2Increase valueEasy to disassemblePreparing sample for investigationUltrafiltrationMicroorganismWrinkle skin

A vacuum filtration apparatus (900) for detecting microorganisms and particulates in liquid samples. The apparatus includes a base (901), an absorbent pad (991), a filter (990), a funnel (930), and a lid (960). The funnel is releasably attached to the base, and may contain an integral flexible seal for releasably sealing the filter to the base. The outer wall of the lid may be segmented to make it flexible, this flexibility allows it to be releasably attached to the funnel or the base. The apparatus is designed so that any funnel will fit any base, and any lid will fit any base or any funnel when all parts are manufactured to normal tolerances. The apparatus may be configured to to keep the filter wrinkle free in both the dry and wet states.

Owner:FOXX LIFE SCI

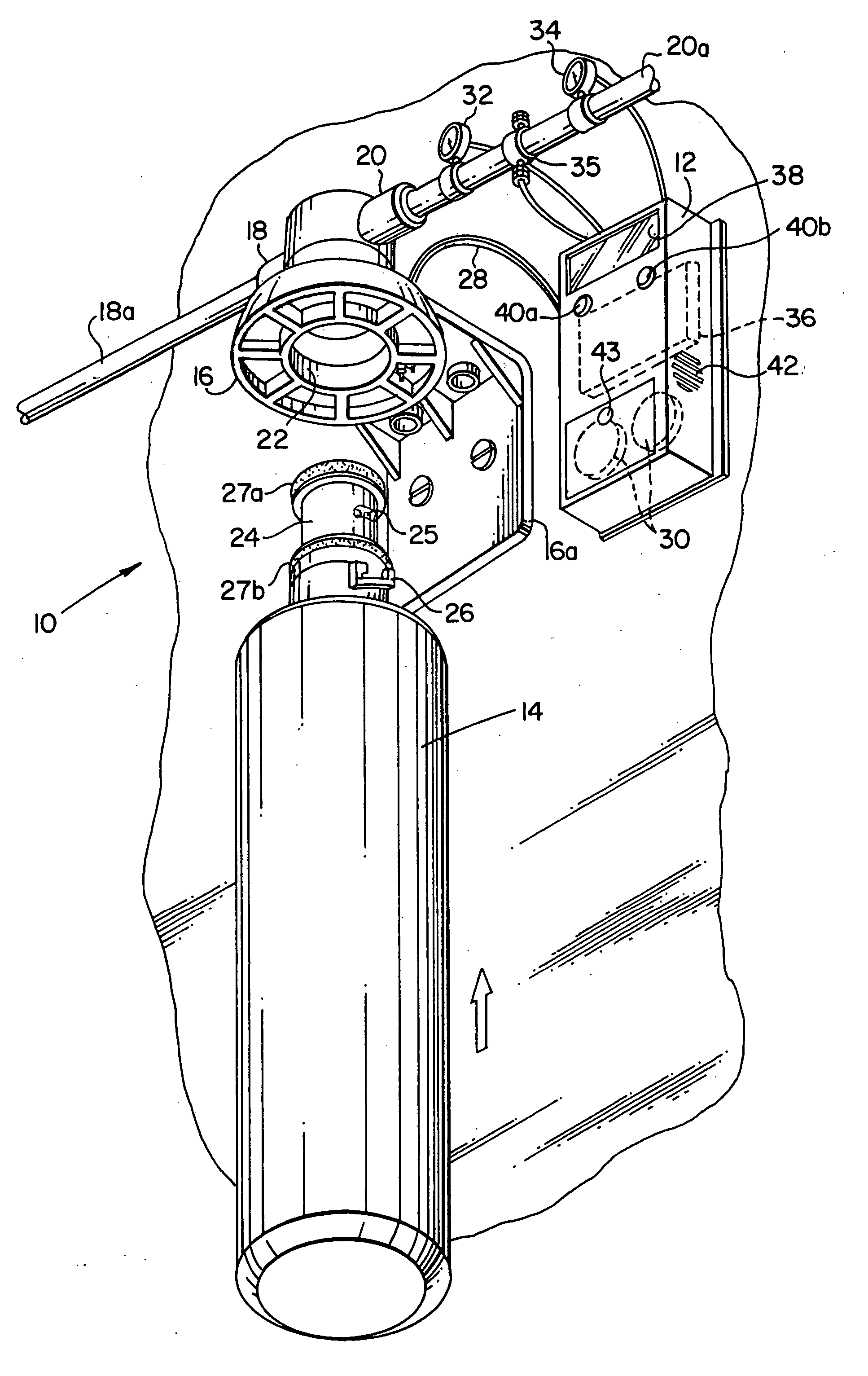

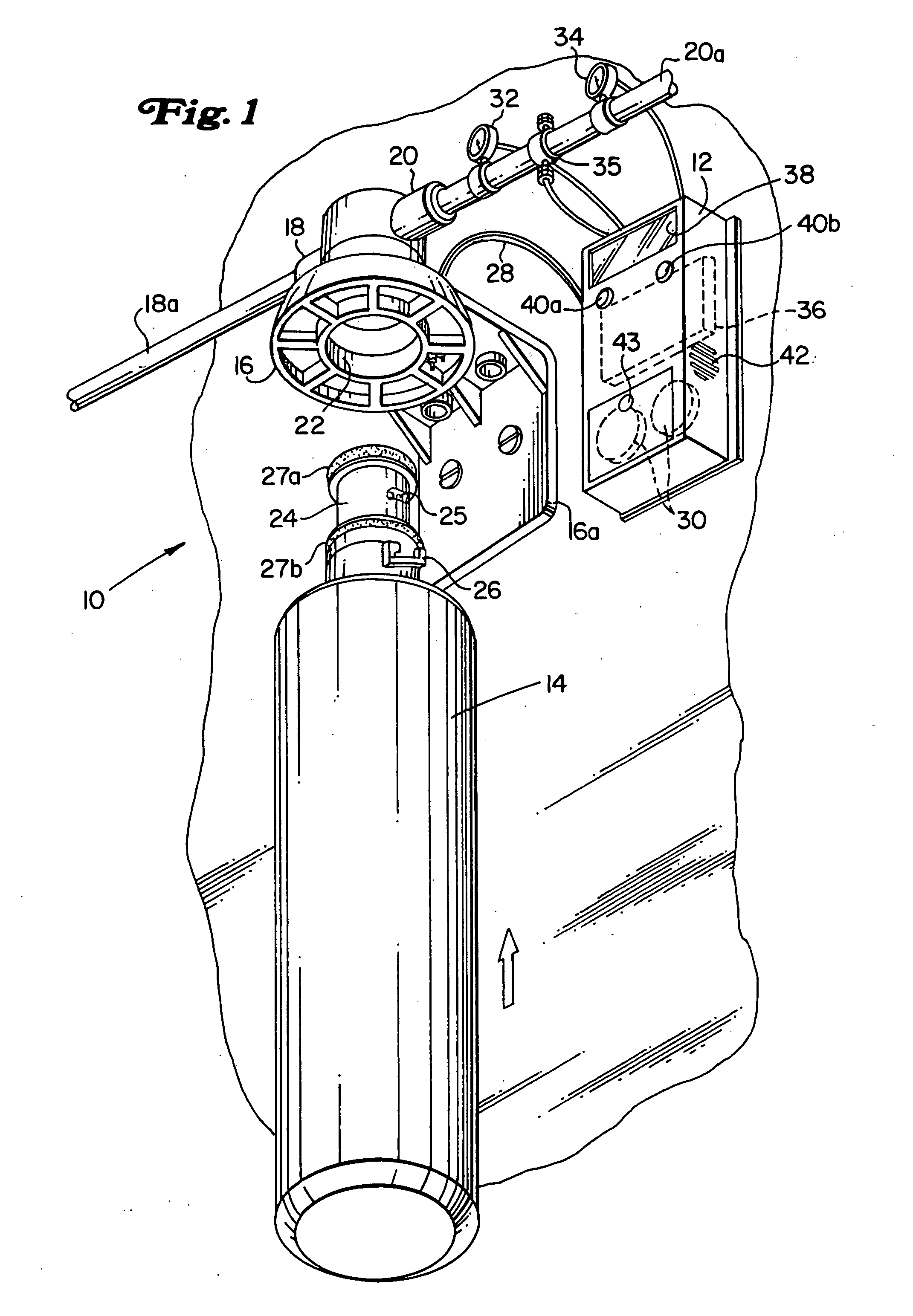

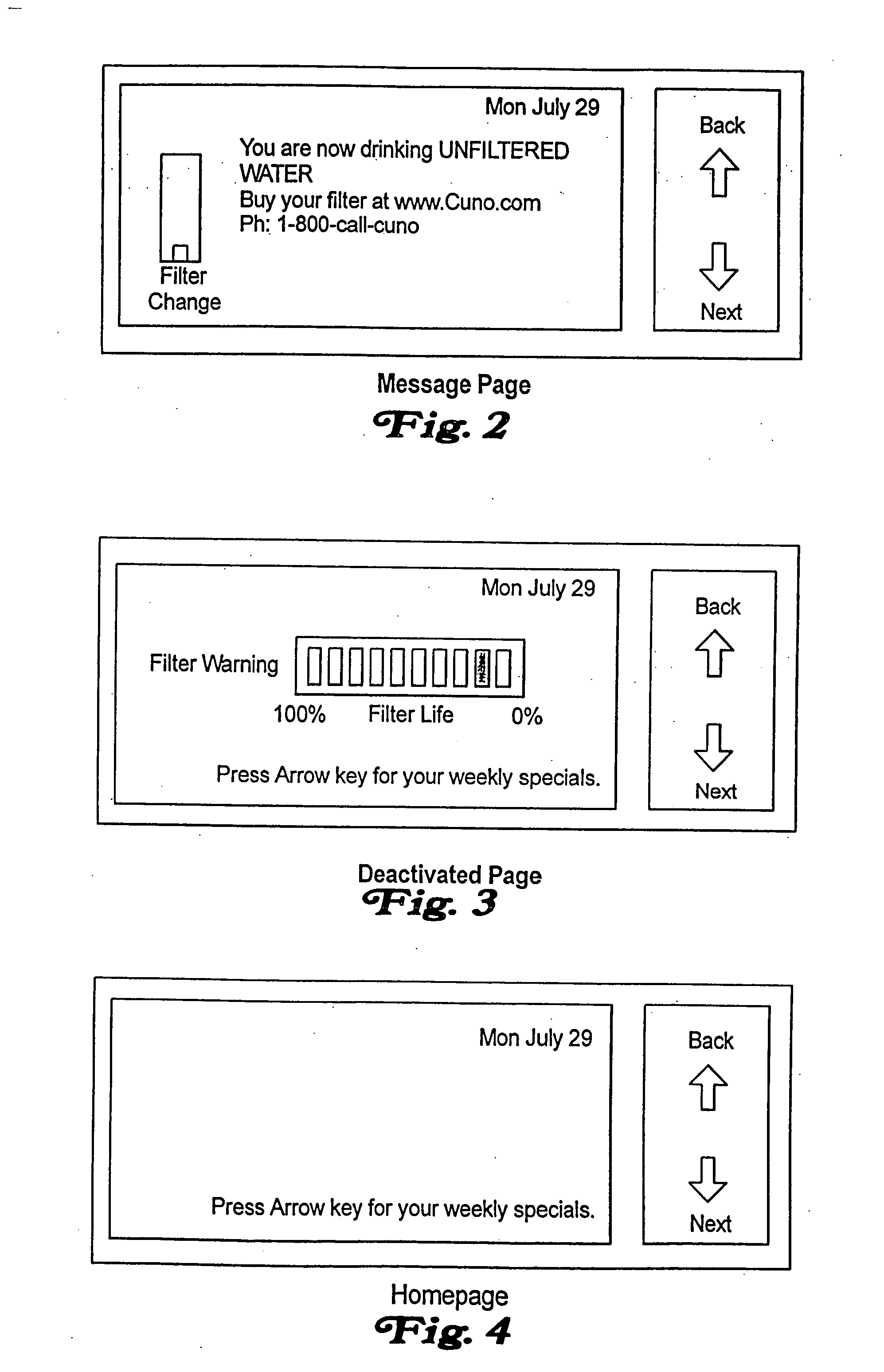

System for monitoring the performance of fluid treatment cartridges

InactiveUS20060060512A1Facilitate communicationWater treatment parameter controlIon-exchanger regenerationEngineeringData storing

A fluid treatment system is provided, the system including a fluid treatment cartridge for treating fluid passing therethrough. The cartridge has an inlet through which untreated fluid enters the cartridge and an outlet from which treated fluid exits the cartridge. The cartridge also has a radio frequency identification (RFID) tag for storing data. The fluid treatment system also includes a connection manifold configured to detachably support the fluid treatment cartridge. The connection manifold has an inlet flow path for directing untreated fluid to the inlet of the cartridge and an outlet flow path for directing treated fluid from the outlet of the cartridge, and a data sensor for reading data stored on the RFID tag. The fluid treatment system further includes means for evaluating the data stored on the RFID tag and read by the data sensor, as well as means for deterring fluid treatment system use based upon the evaluation of the data stored on the RFID tag and read by the data sensor.

Owner:3M INNOVATIVE PROPERTIES CO

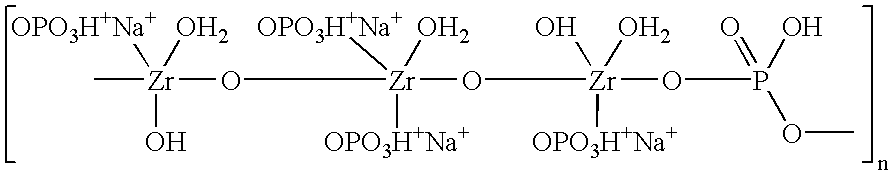

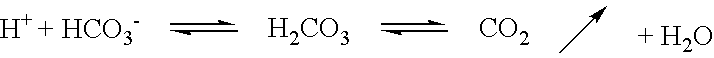

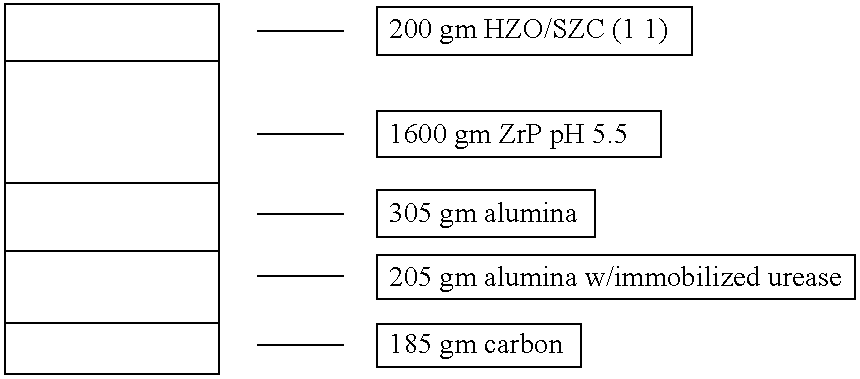

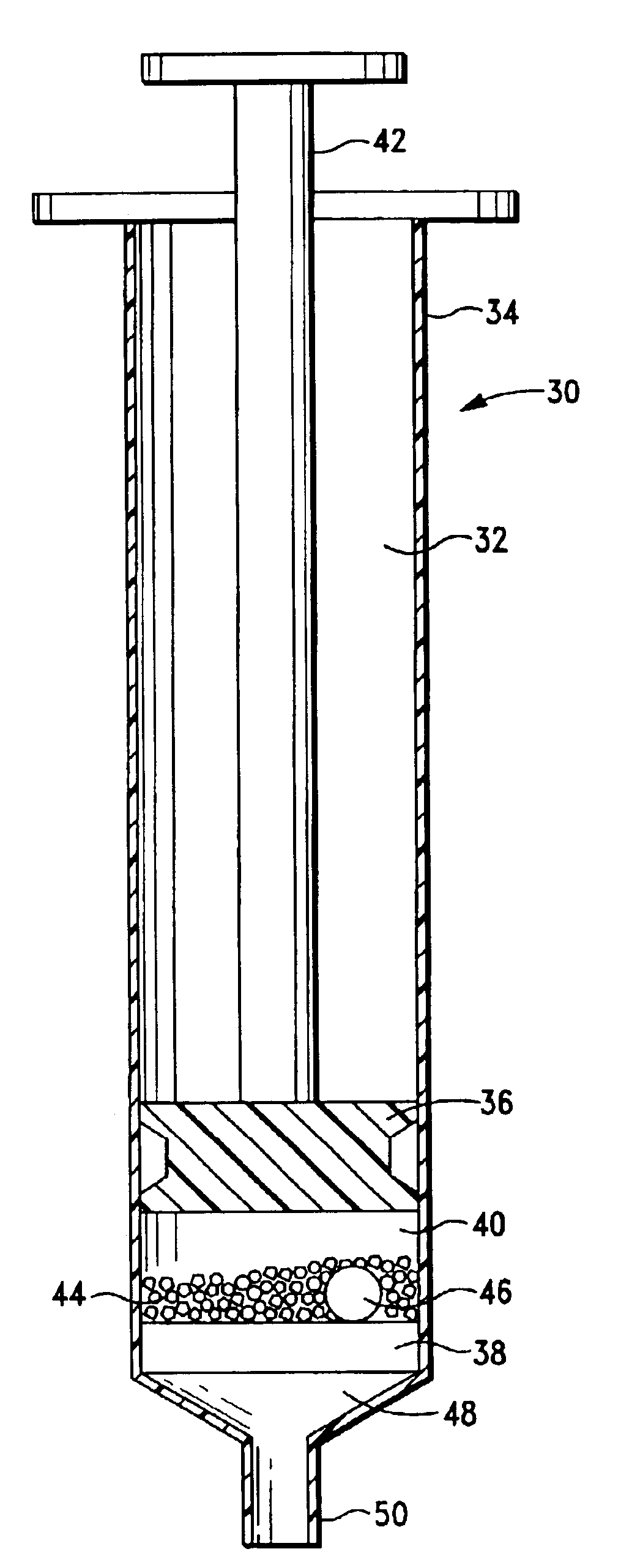

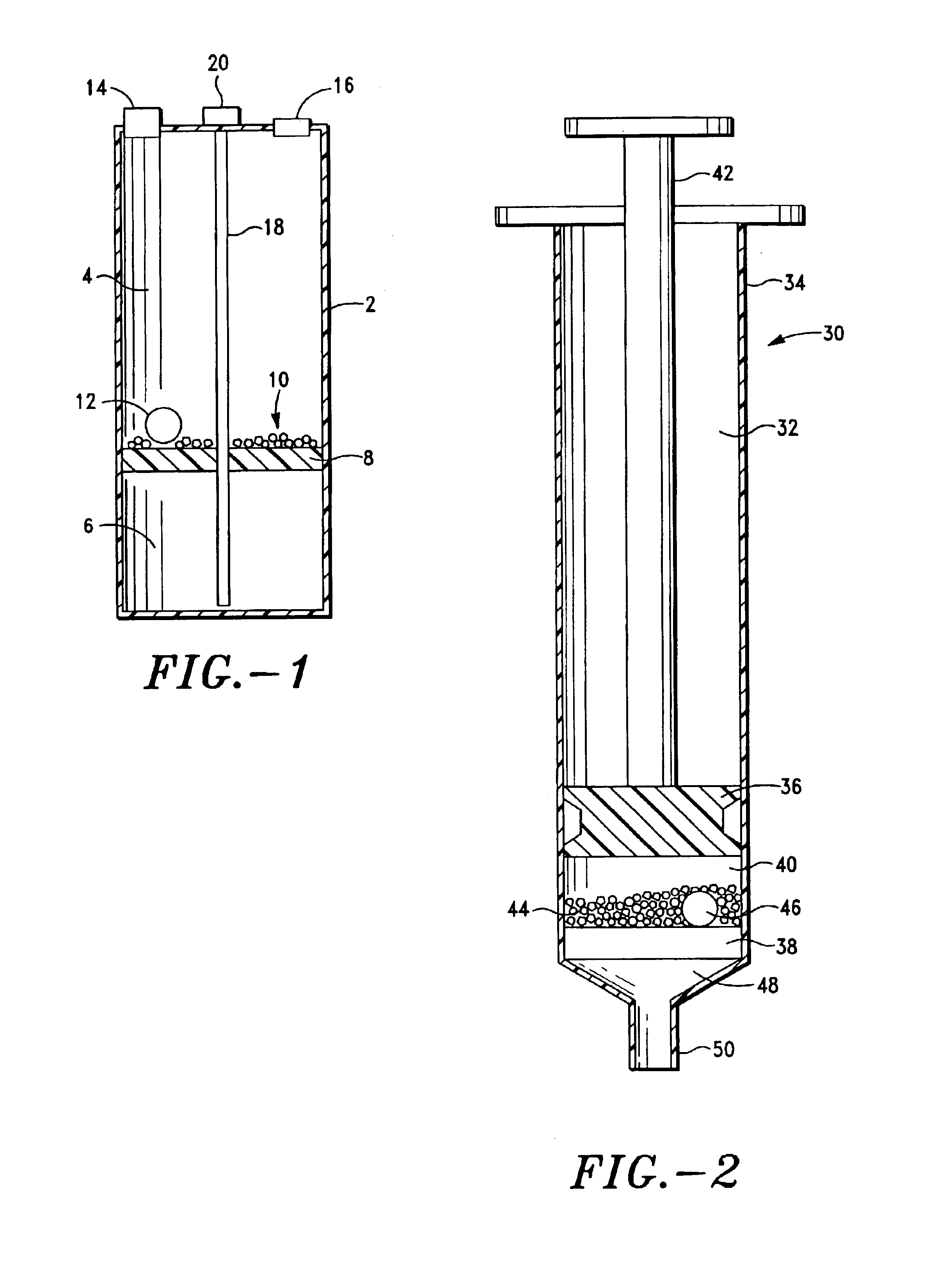

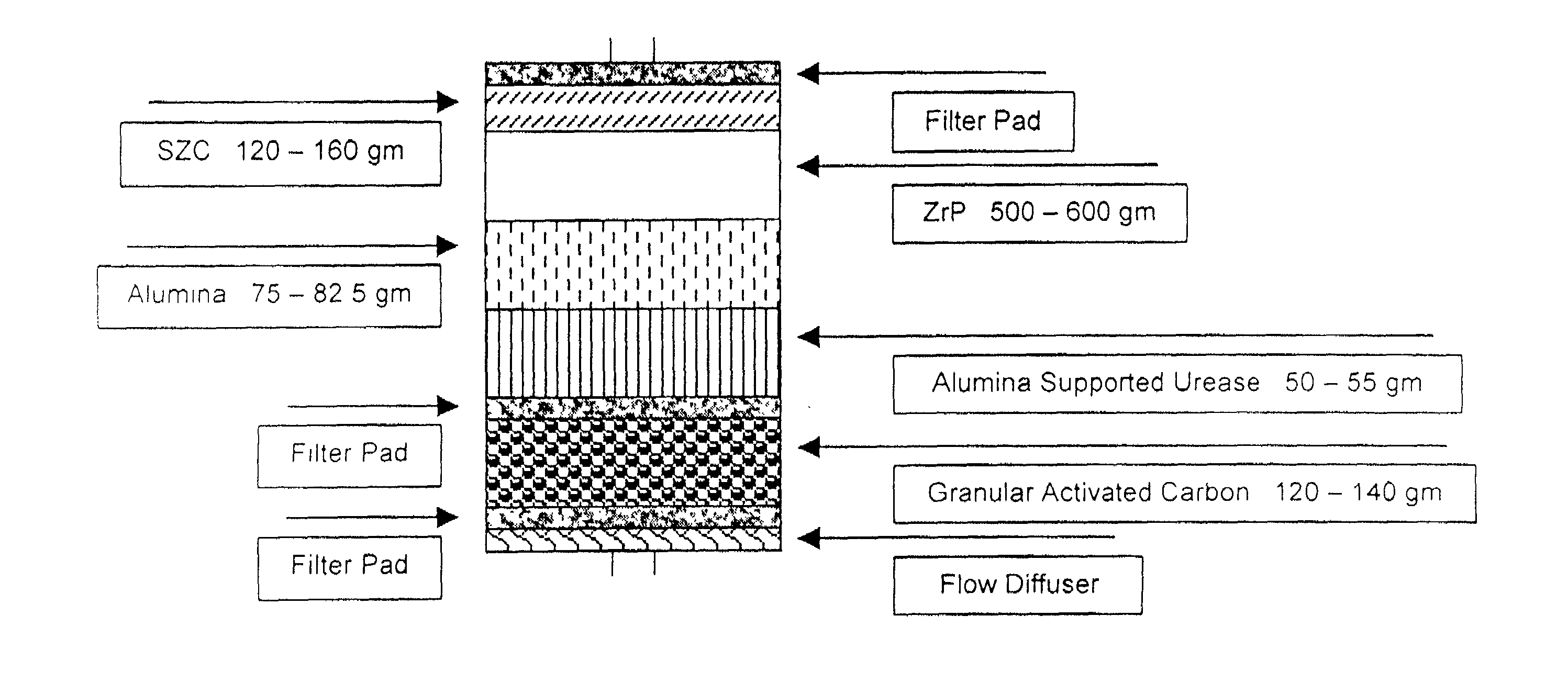

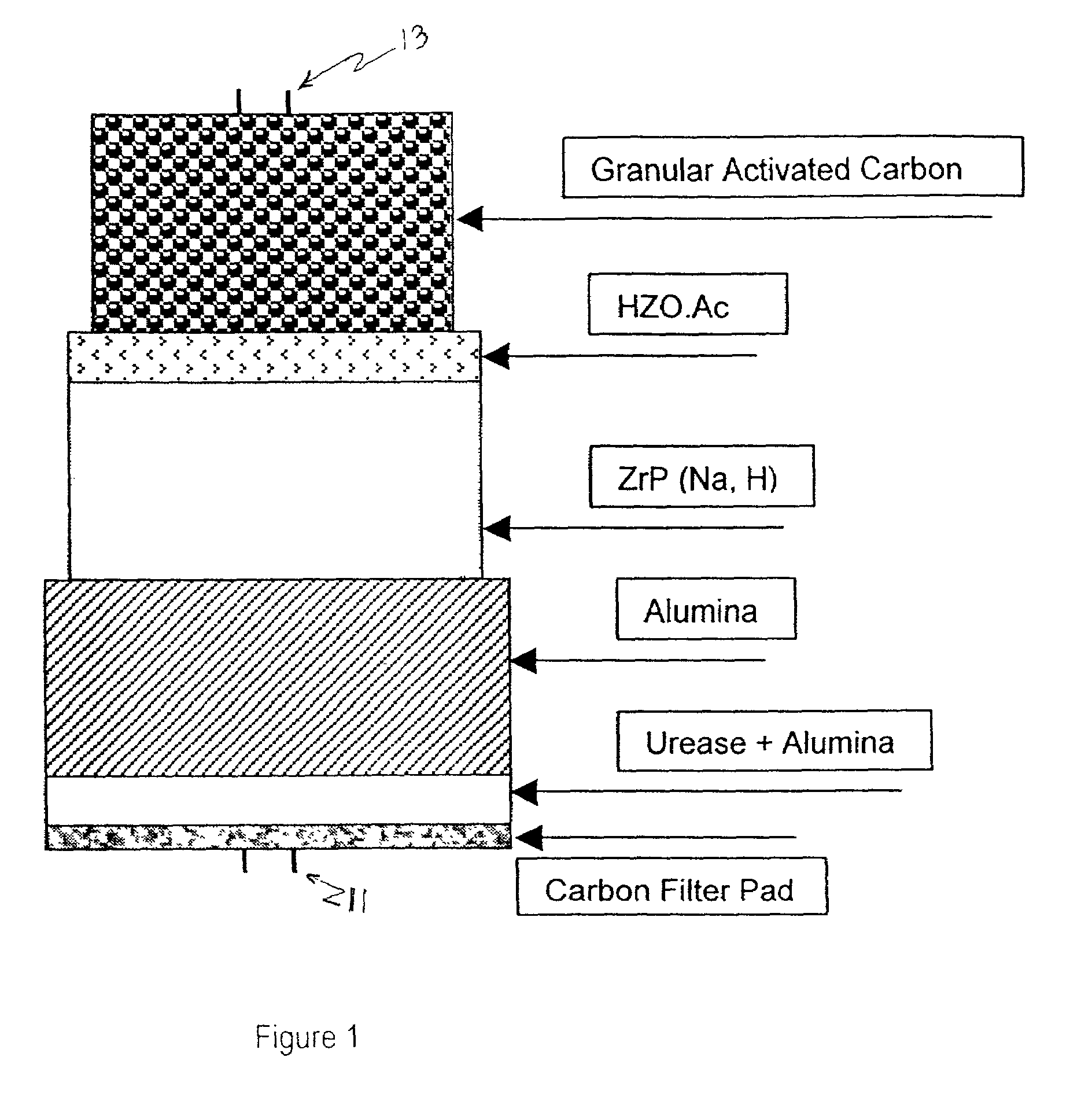

Cartridges useful in cleaning dialysis solutions

InactiveUS20020112609A1Avoid a lotSolve the blockageIsotope separationLoose filtering material filtersHemodialysis membraneChemistry

Owner:RENAL SOLUTIONS

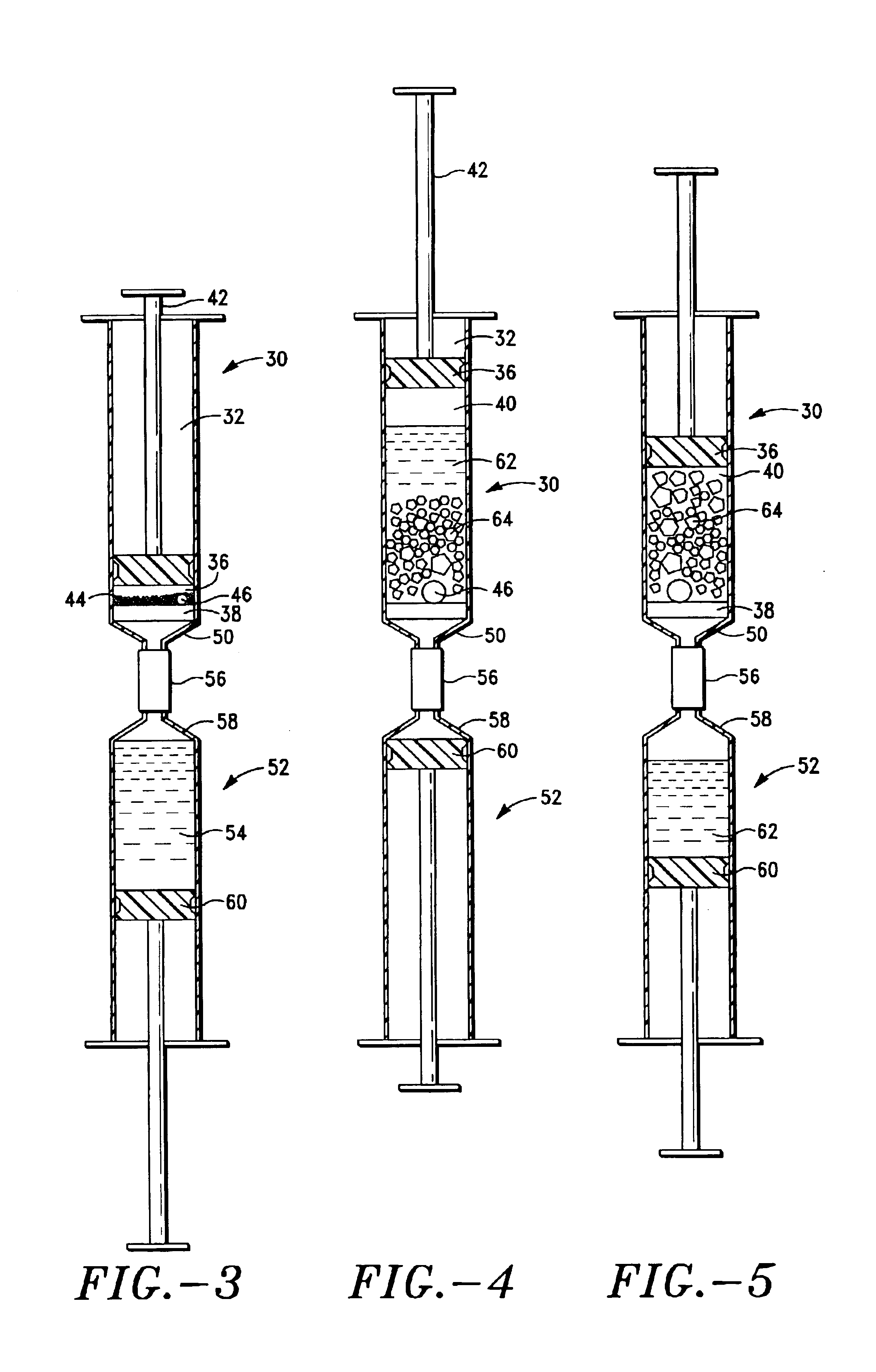

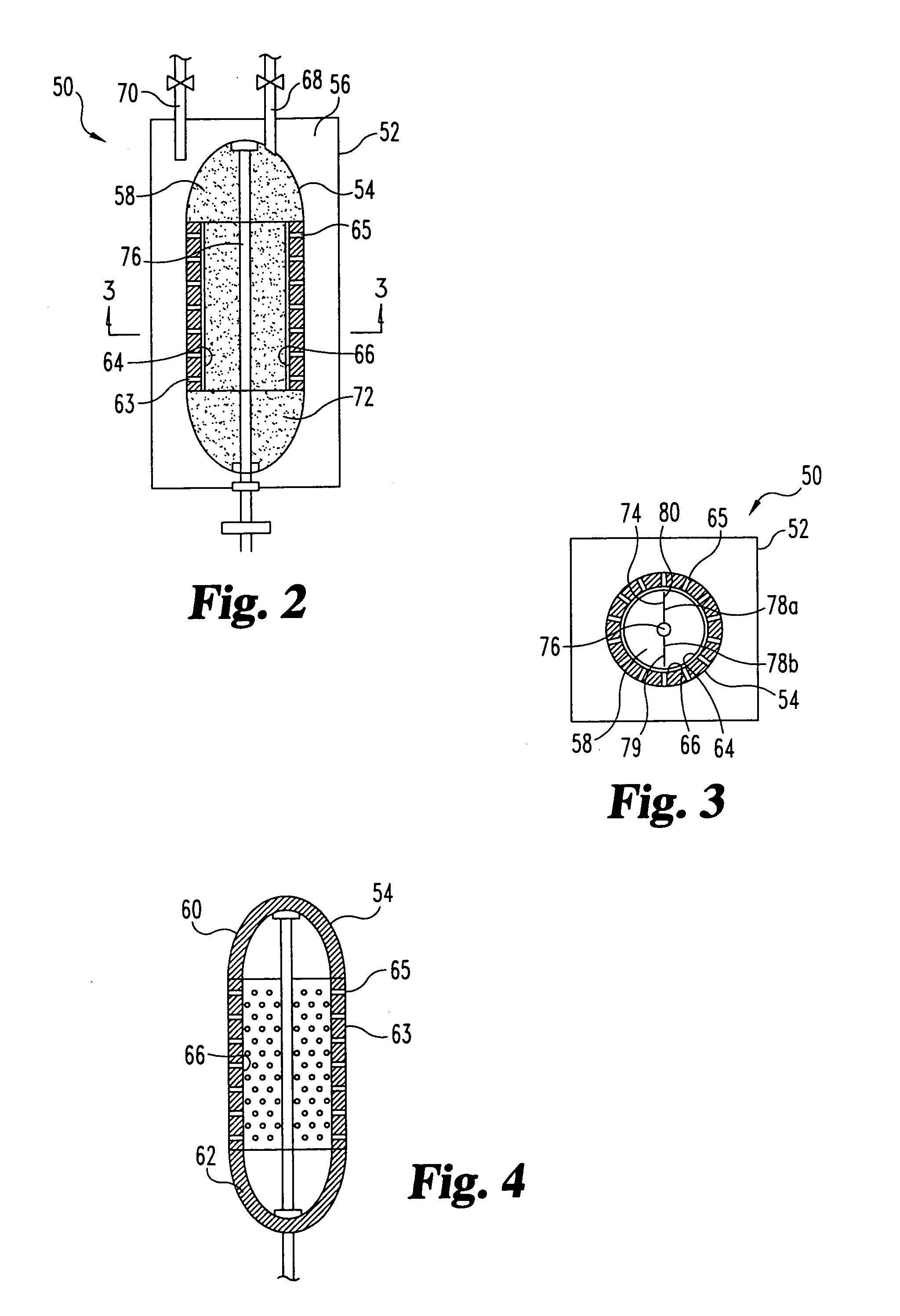

Plasma concentrate apparatus and method

ActiveUS6905612B2Effective absorptionPromote absorptionMixing methodsDead animal preservationRed blood cellAbsorption of water

A plasma concentrator for producing plasma concentrate from a plasma from which erythrocytes have been substantially removed. The device comprises a concentrating chamber having an inlet port and an concentrate outlet, the concentrating chamber containing hydrogel beads and at least one inert agitator; and a concentrate chamber having an inlet communicating with the concentrator outlet through a filter, and having an plasma concentrate outlet port. A process for producing plasma concentrate from plasma from which erythrocytes have been substantially removed, comprising the steps of a) moving the plasma into a concentrating chamber containing hydrogel beads and an agitator to form a hydrogel bead-plasma mixture; b) causing the agitator to stir the hydrogel bead-plasma mixture, facilitating absorption of water by the beads from the plasma, until a hydrogel bead-plasma concentrate is formed; and c) separating the plasma concentrate from the hydrogel beads by passing the plasma concentrate through a filter. The concentrator can be one or more syringe devices coupled for multiple concentrations.

Owner:HANUMAN

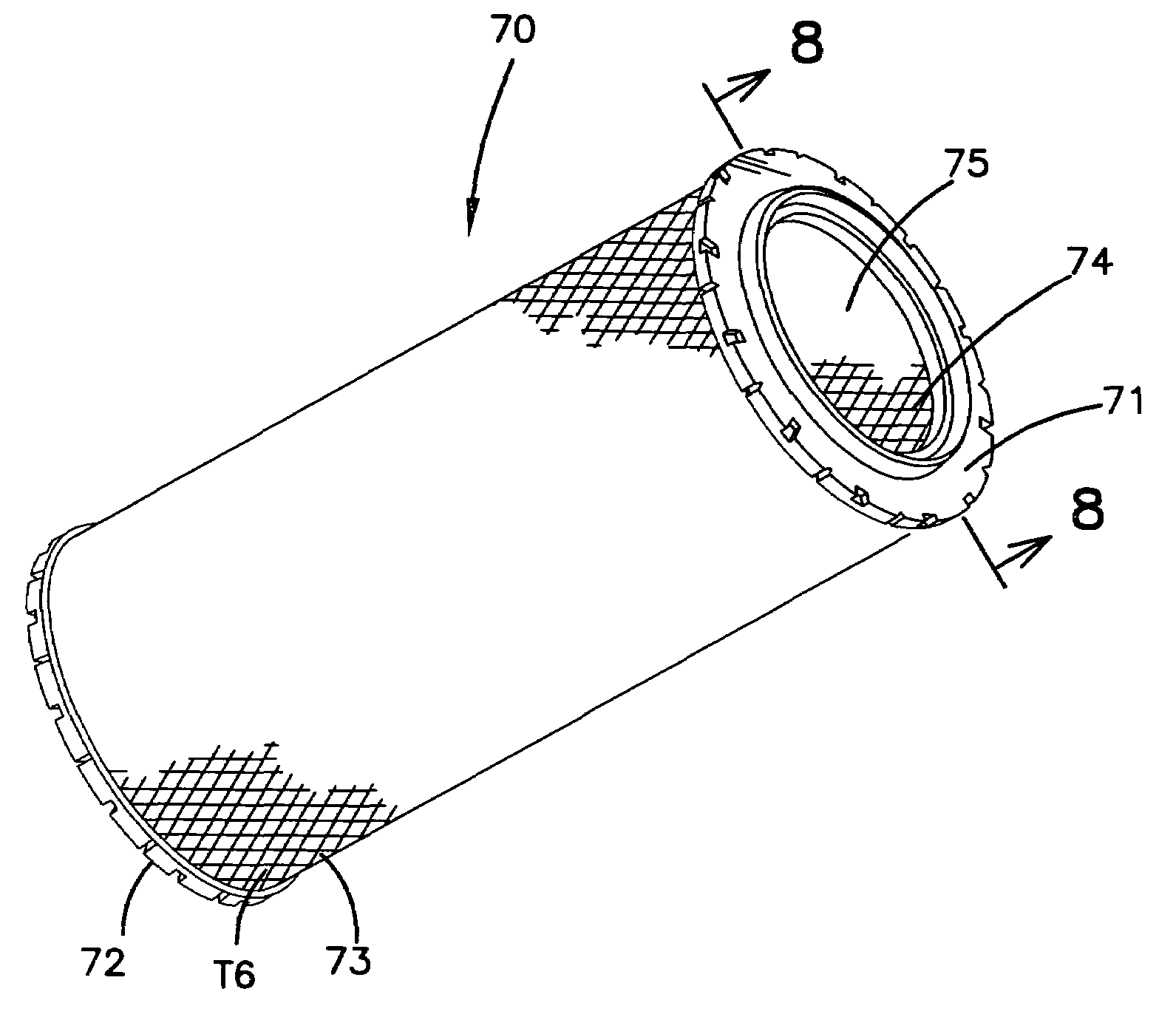

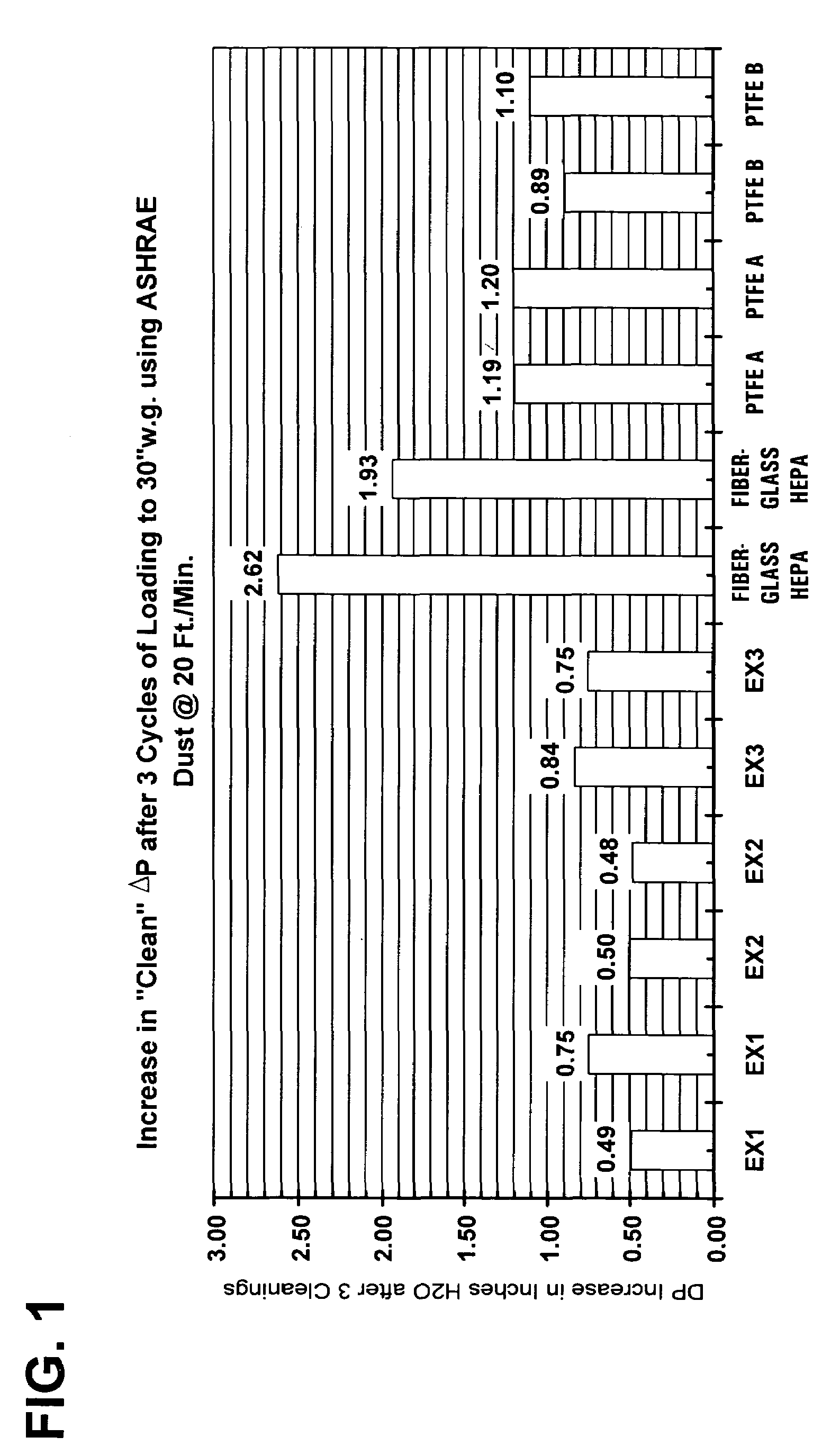

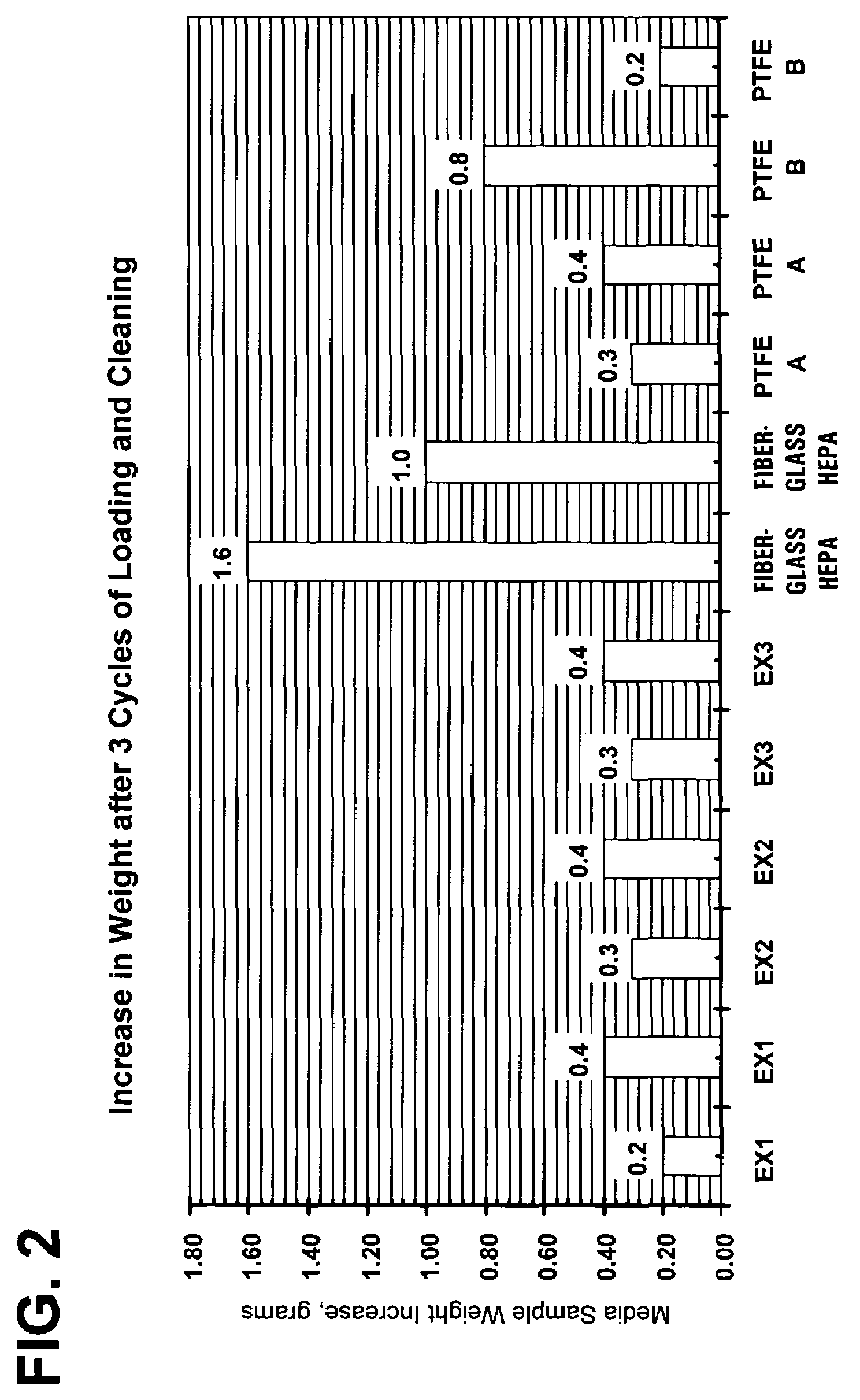

Cleanable high efficiency filter media structure and applications for use

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

Composite membrane and method for making the same

InactiveUS6878278B2Improve throughputEasy to adaptSemi-permeable membranesLoose filtering material filtersPolyamideReverse osmosis

A composite membrane and method for making the same, comprising a porous support and a polyamide surface. The subject membrane provides improved flux and / or rejection rates. The subject membrane is further capable of operating at lower operating pressures. The subject method includes reacting a polyfunctional amine with a polyfunctional acyl halide to form a polyamide. The method includes the step of contacting a complexing agent with the polyfunctional acyl halide prior substantial reaction between the polyfunctional acyl halide and a polyfunctional amine. The subject process is easily adapted to commercial scale manufacturing processes and is particularly suited for making nanofiltration and reverse osmosis composite membranes.

Owner:DOW GLOBAL TECH LLC

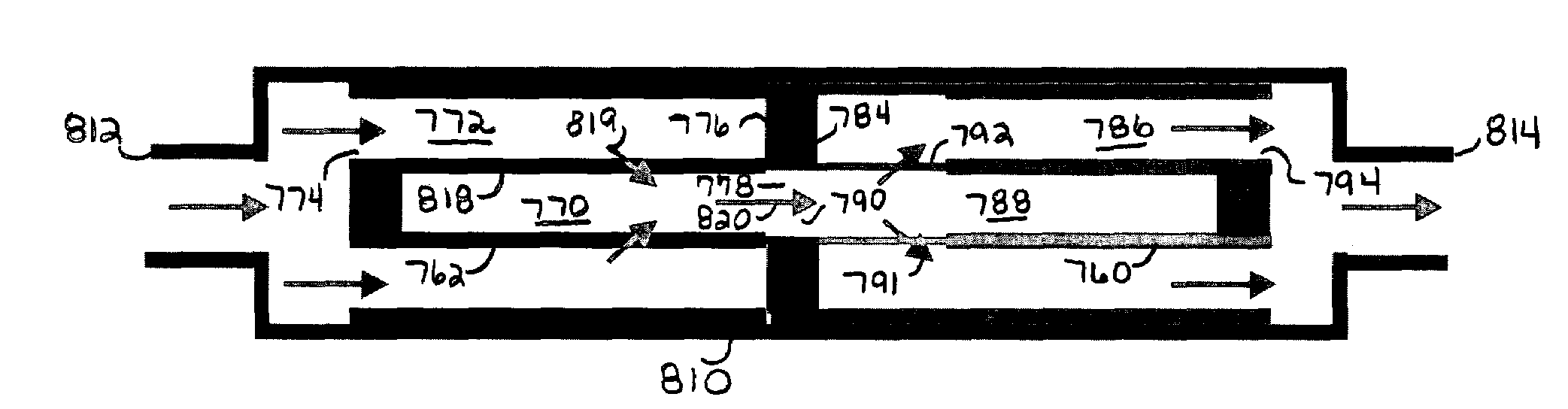

Filter cartridge assemblies and methods for filtering fluids

Filter cartridge assemblies and housings are provided and include a tubular housing having an inner wall, an outer wall, a first end, and a second end. The housings include inner walls with shoulders or other radially-inwardly extending flow directors at the intersections of adjacent sections of the tubular body. The assemblies include a plurality of filter media sections within the housing, and each of the plurality of filter media sections preferably has a different filter media composition. One or more of the filter media sections traverses one or more of the shoulders or other radially-inwardly extending flow directors such that the flow directors evenly direct the flow of fluid through the assembly. The assemblies find particular applicability in dialysis systems.

Owner:RENAL SOLUTIONS

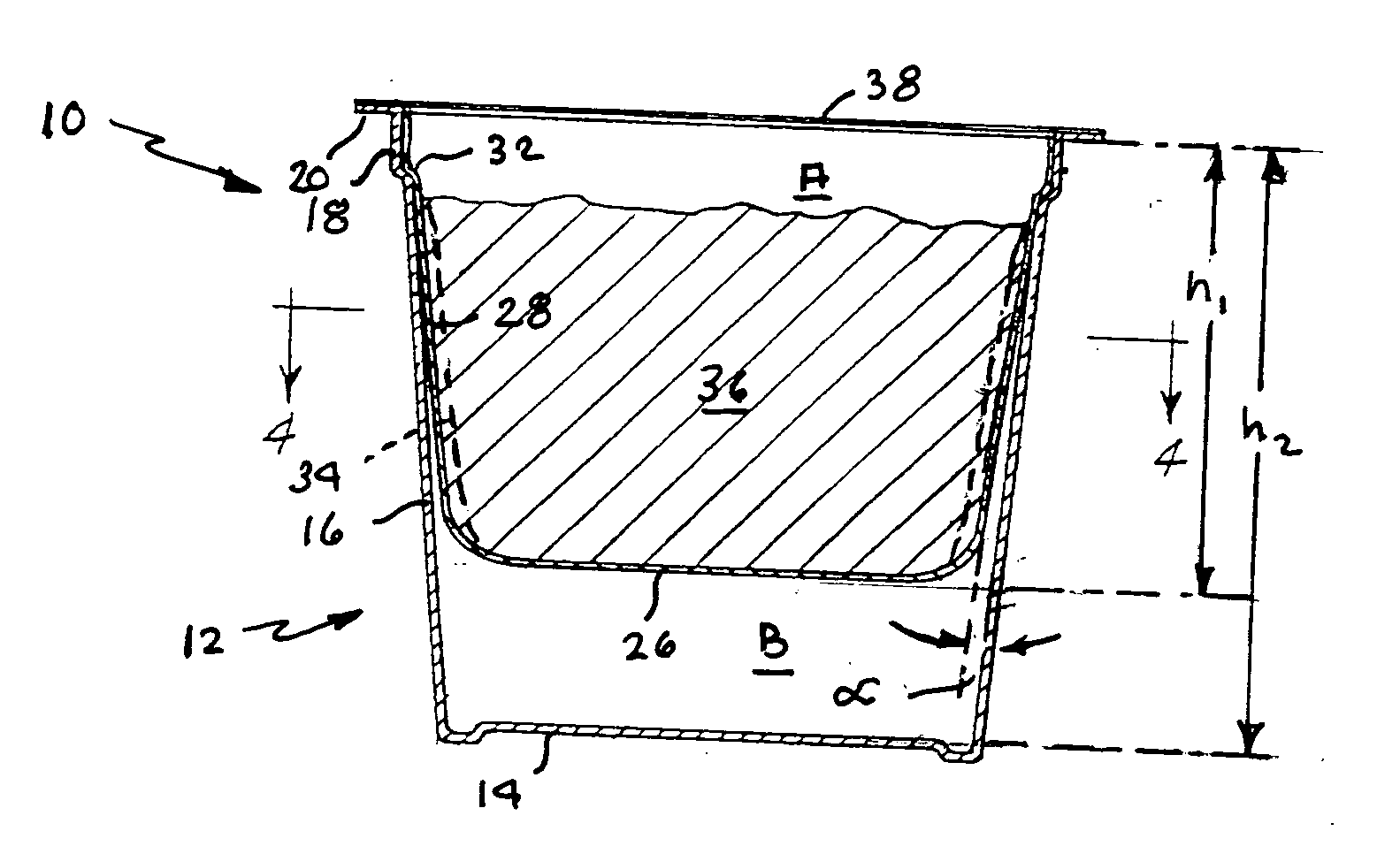

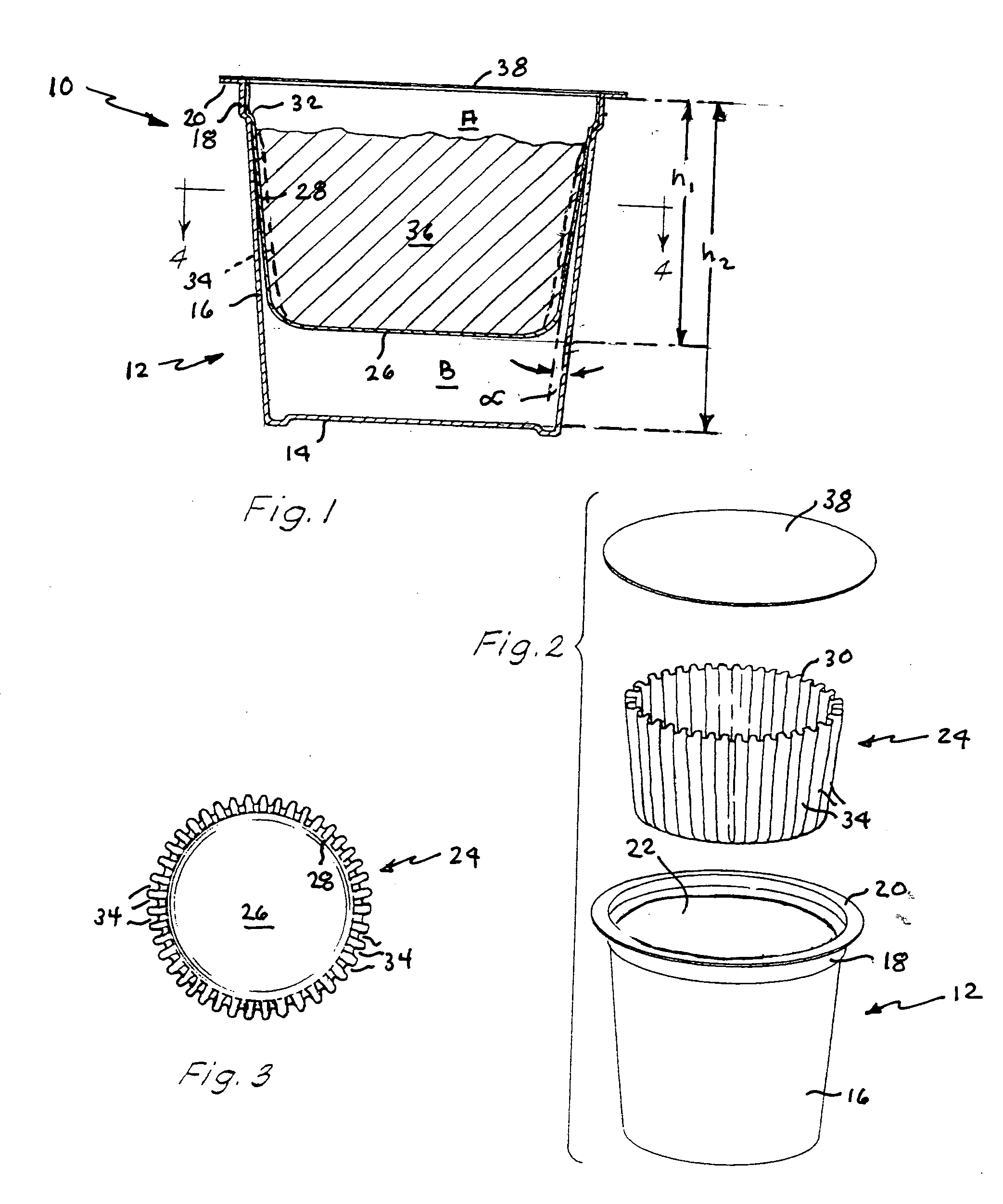

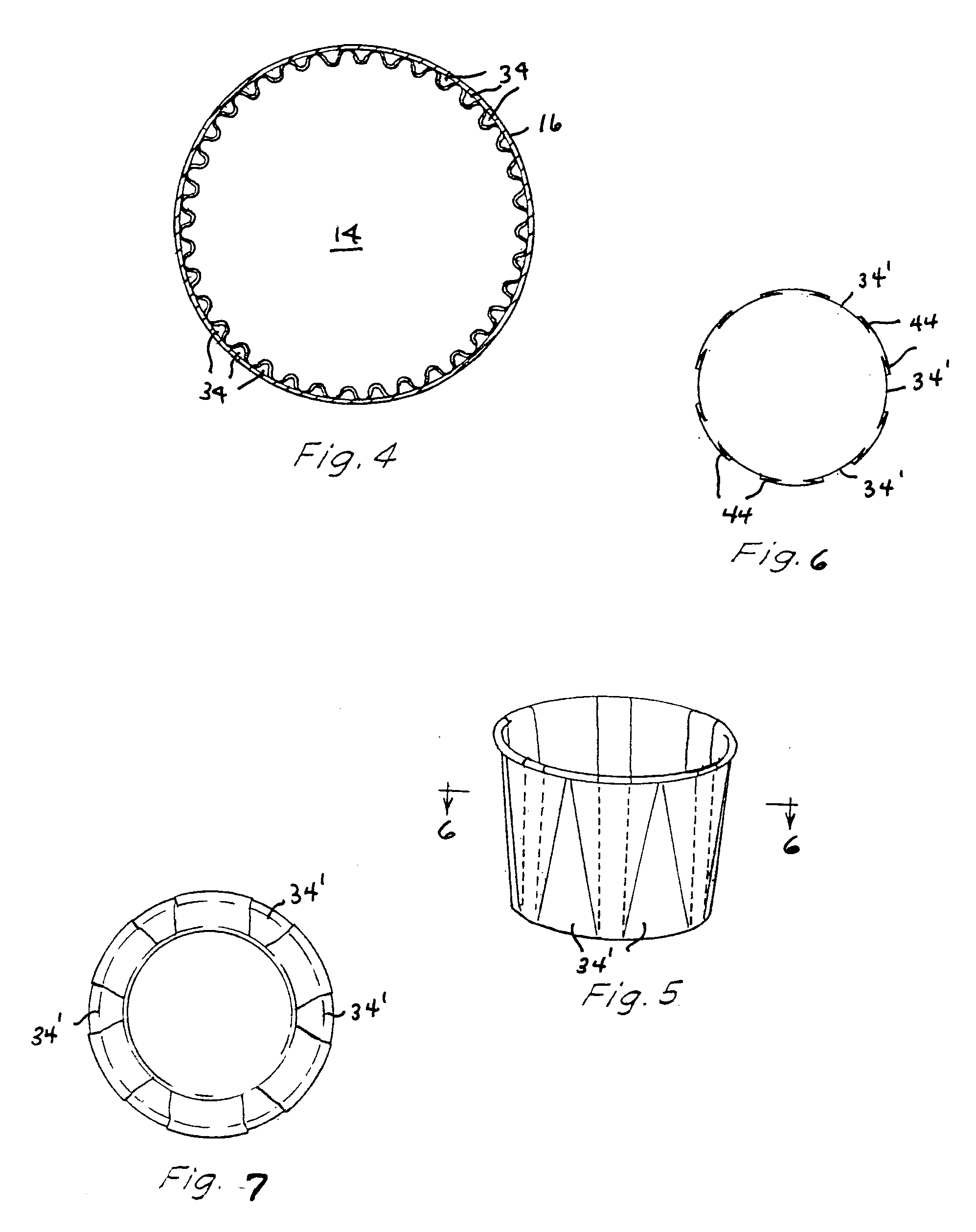

Beverage filter cartridge

A beverage filter cartridge has an impermeable cup-shaped out container internally subdivided by a generally cup-shaped filter element into a first chamber inside the filter and a second chamber located between the filter bottom and the container bottom. The upper rim of the filter is joined at a peripheral juncture to the container side wall, and the filter side wall has exterior channels that face the container side wall and lead downwardly from the peripheral juncture to the second chamber.

Owner:KEURIG GREEN MOUNTAIN INC

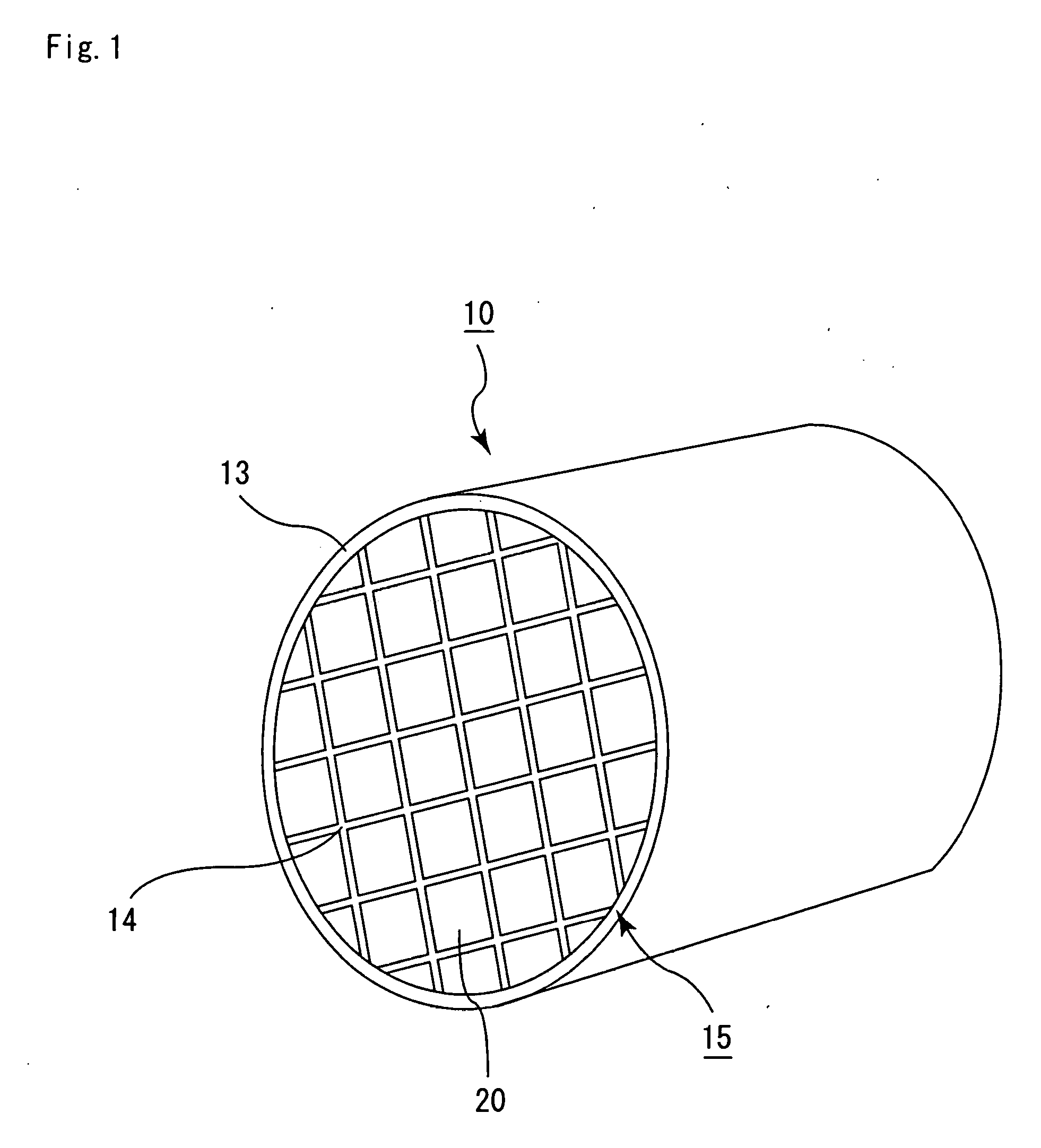

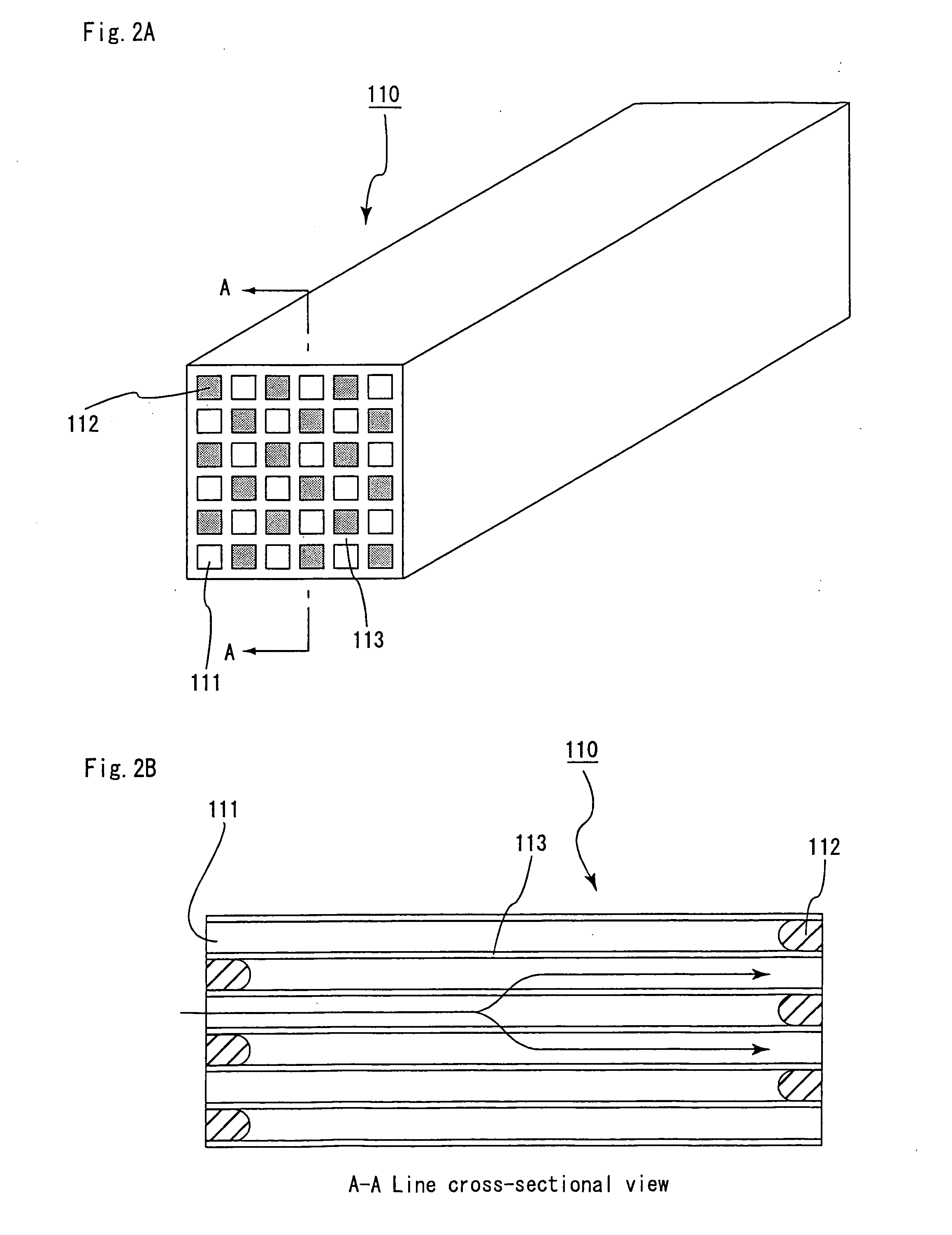

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

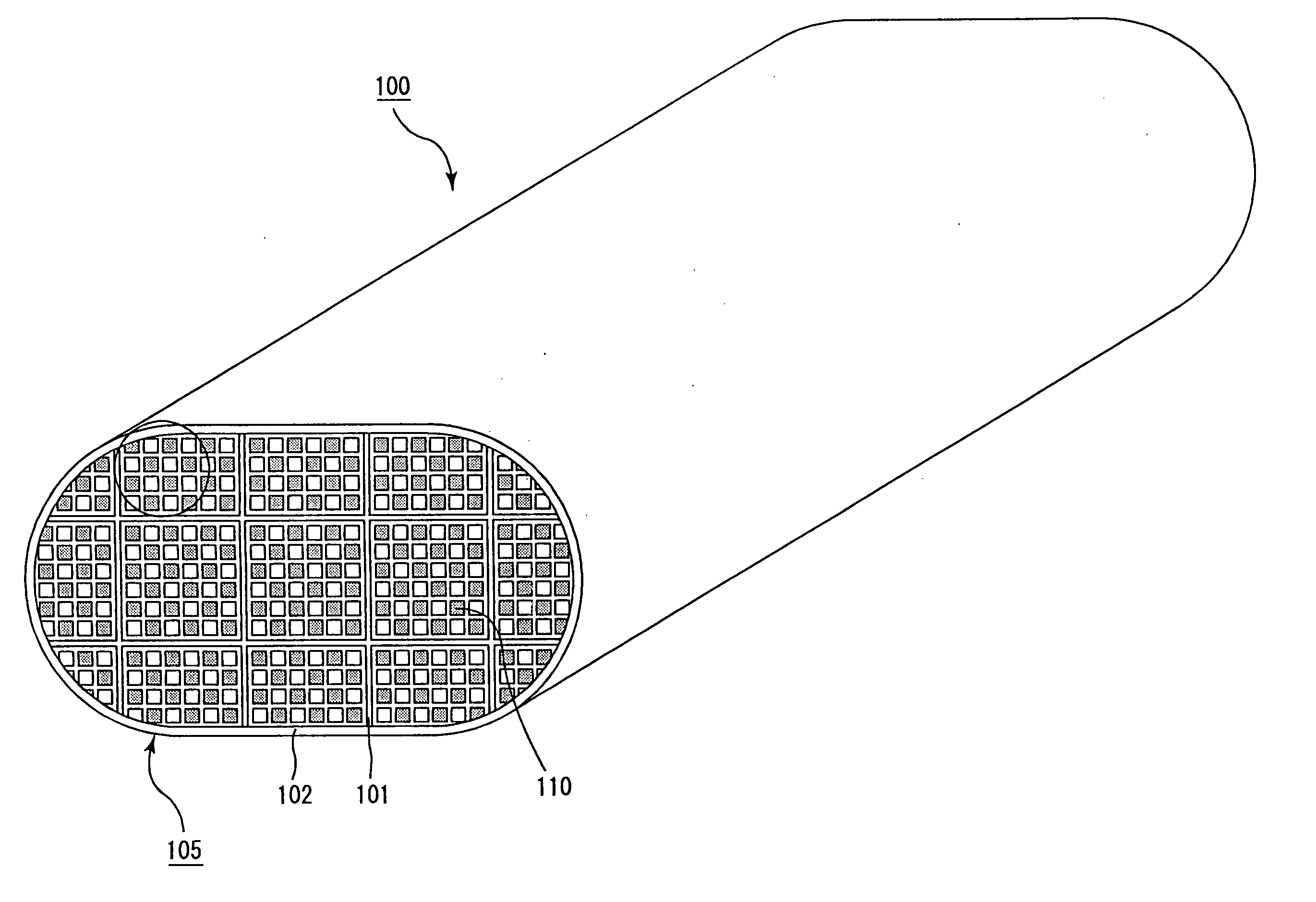

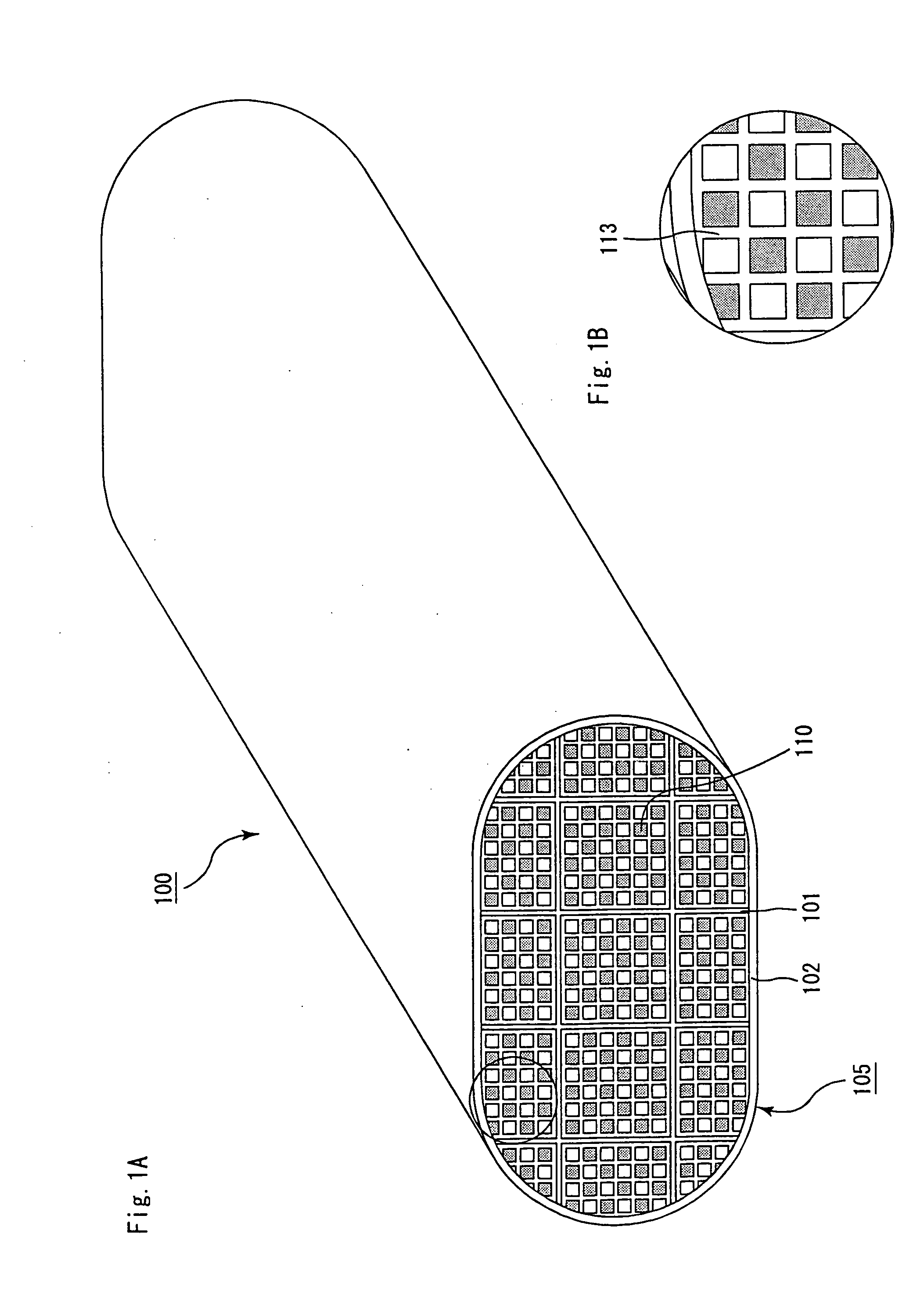

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

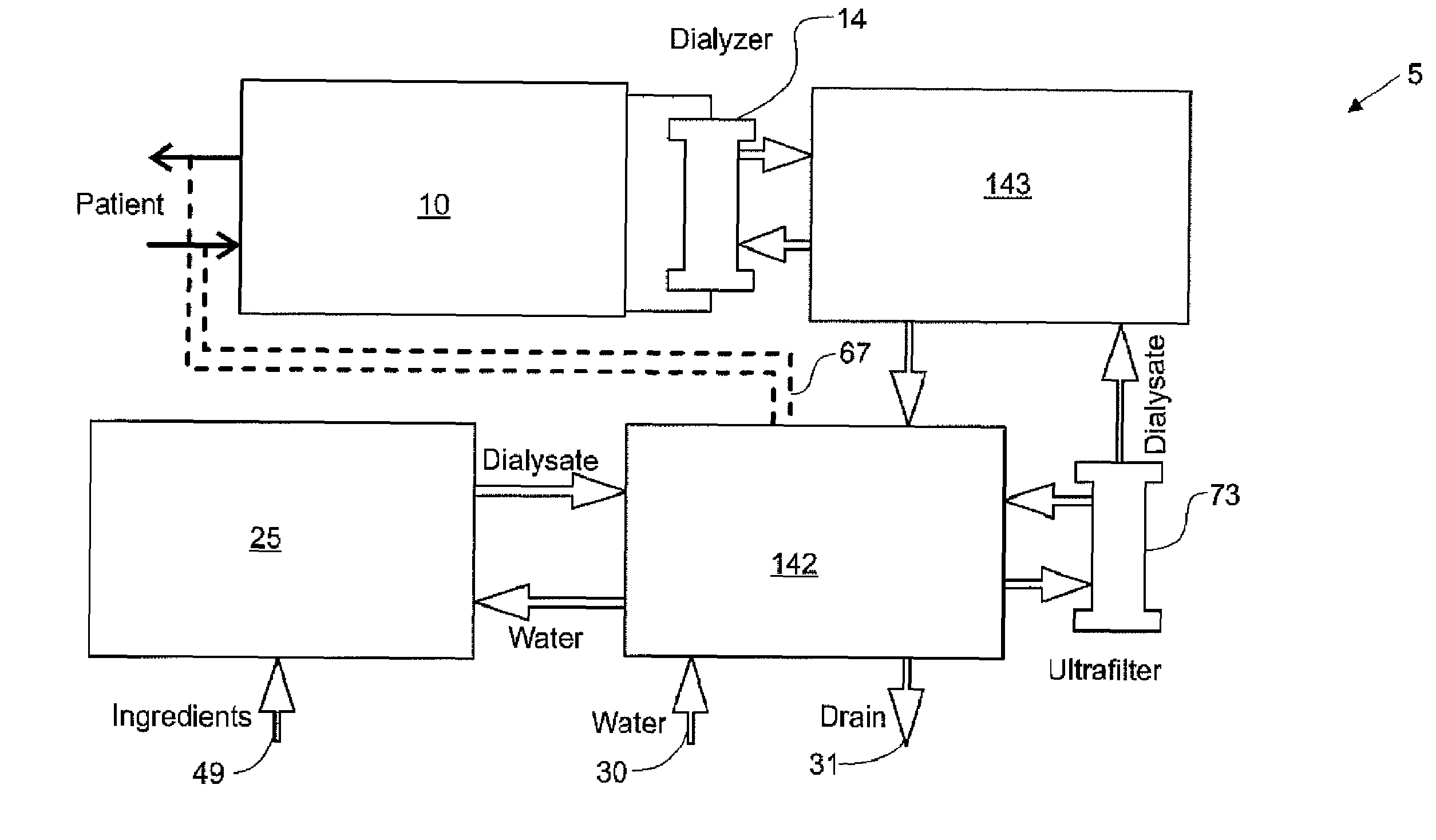

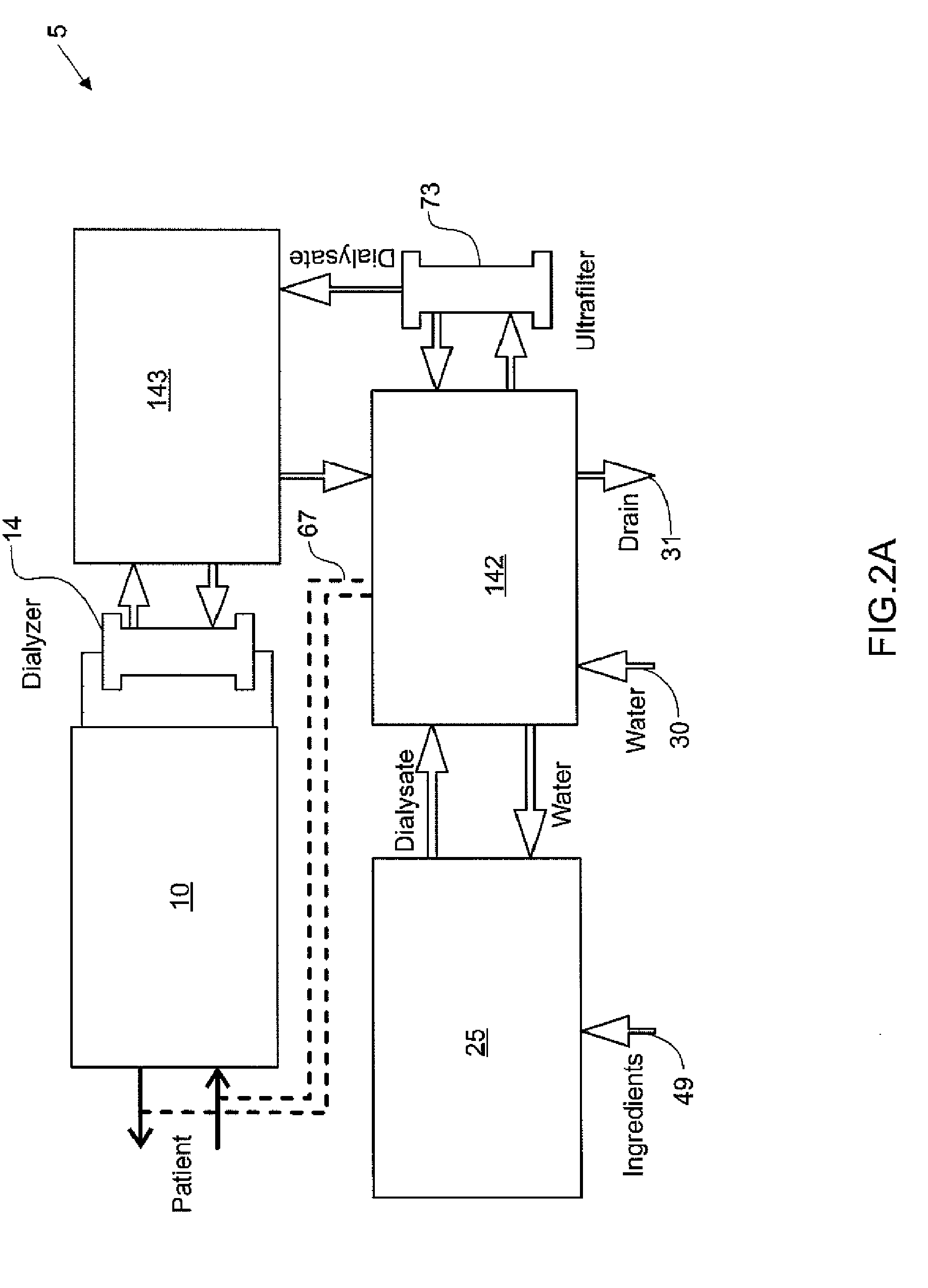

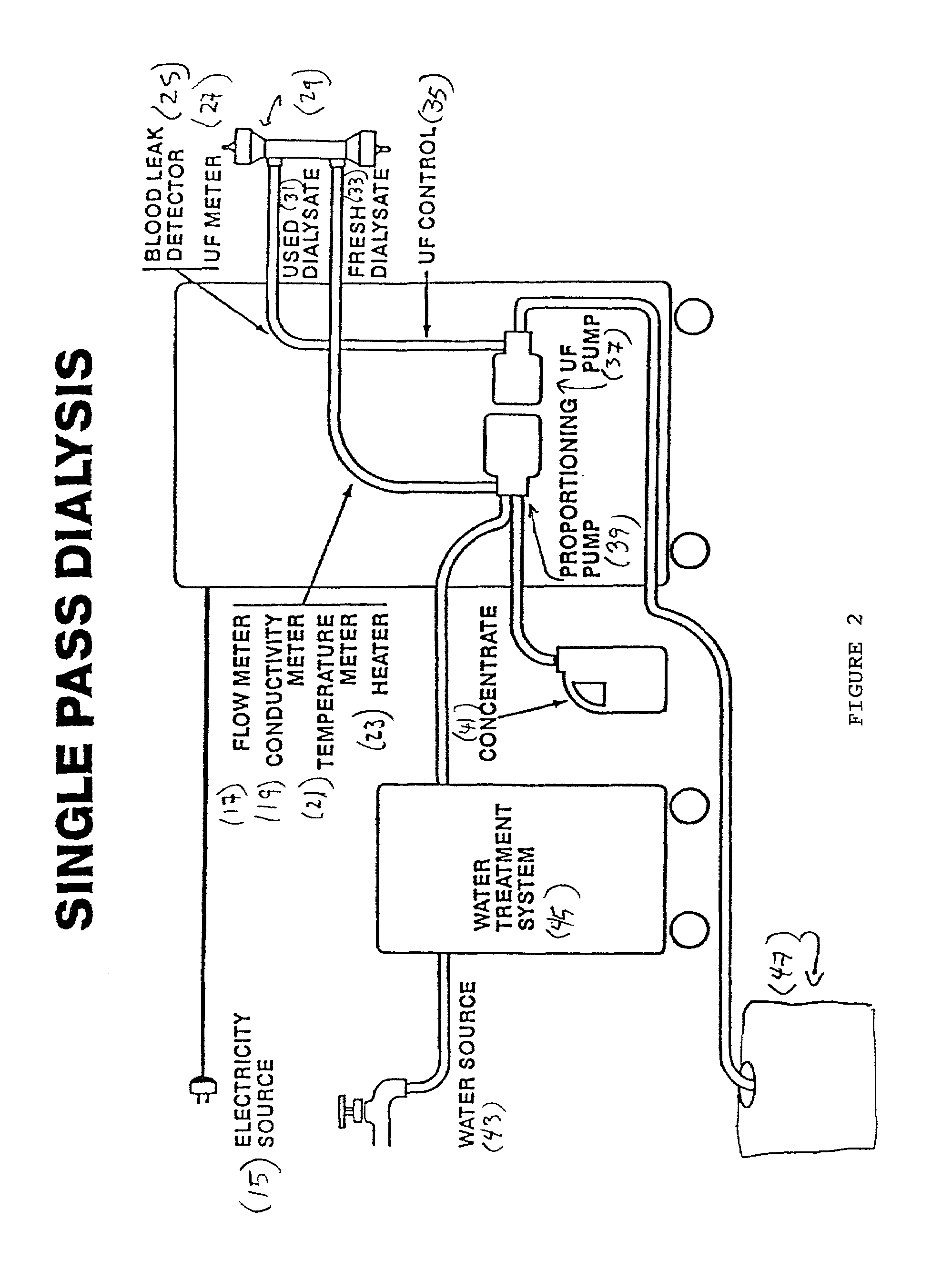

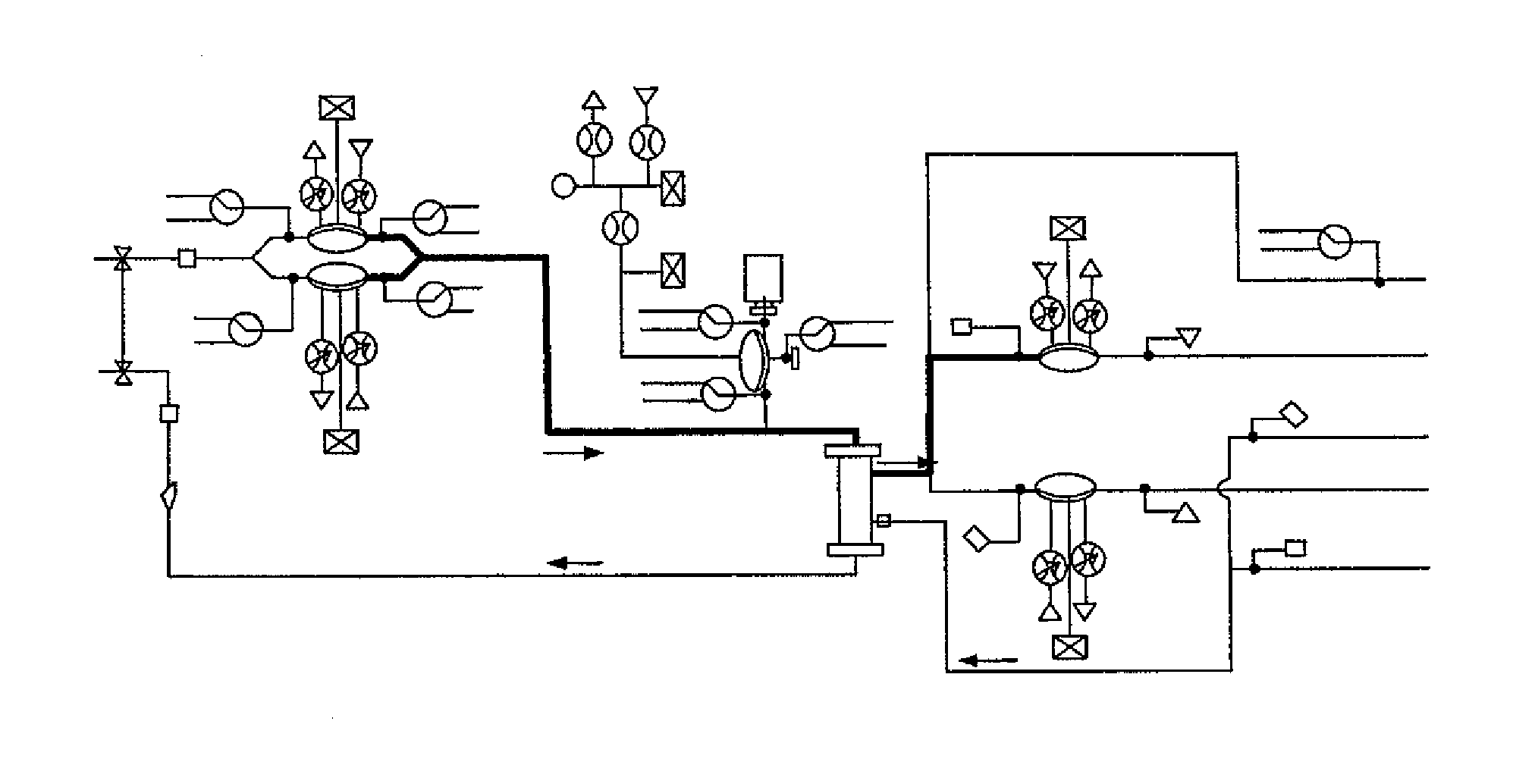

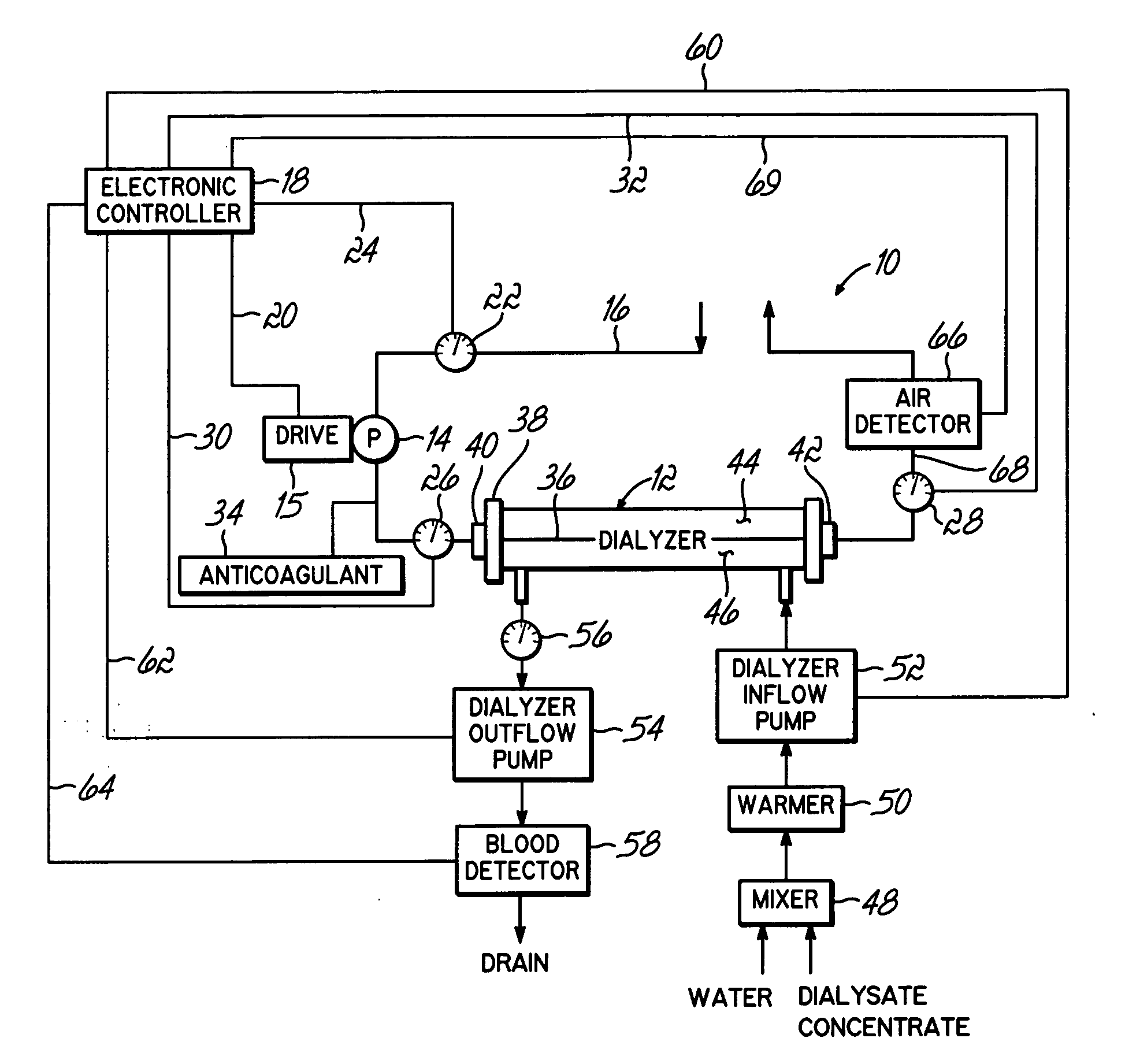

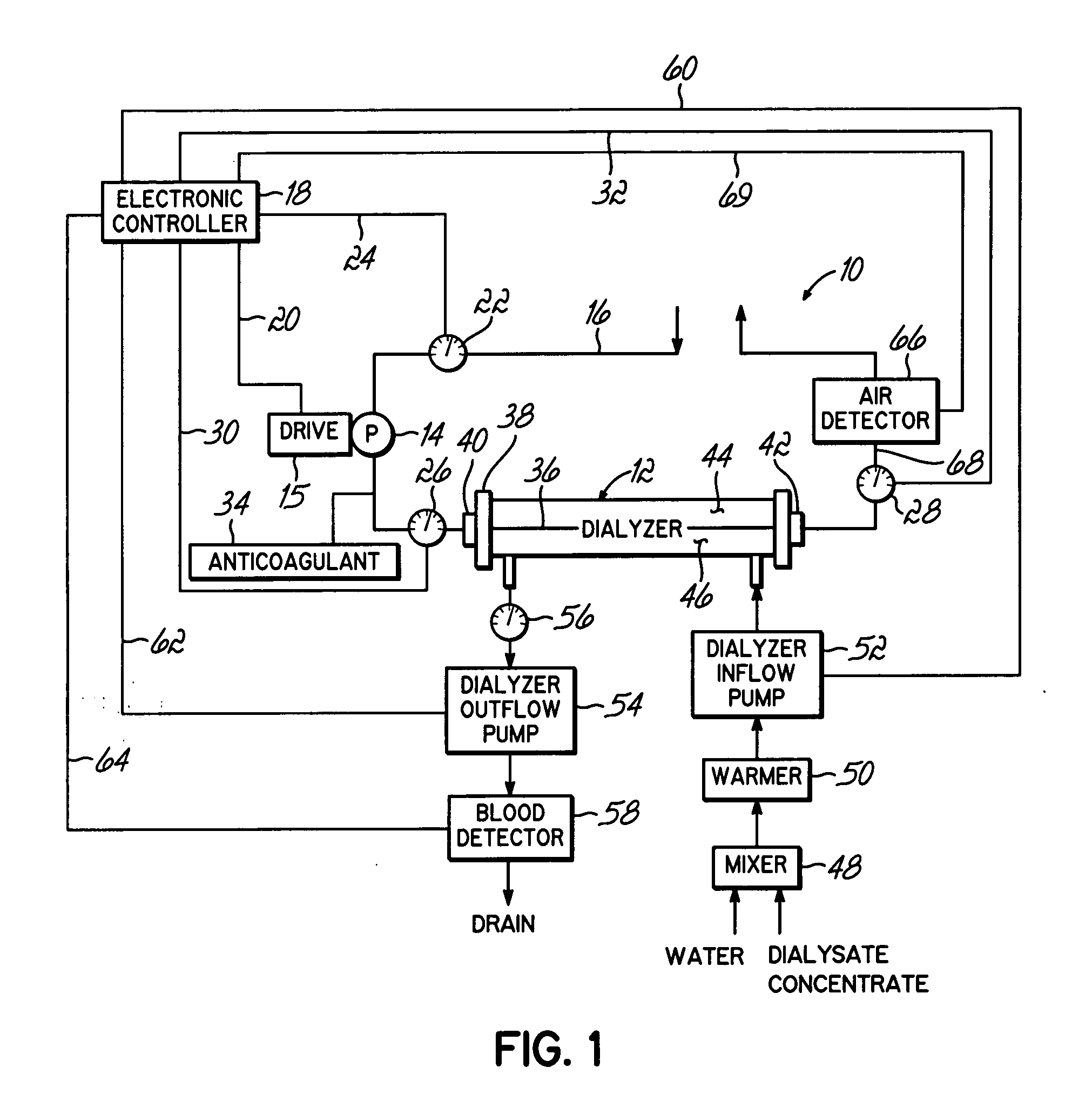

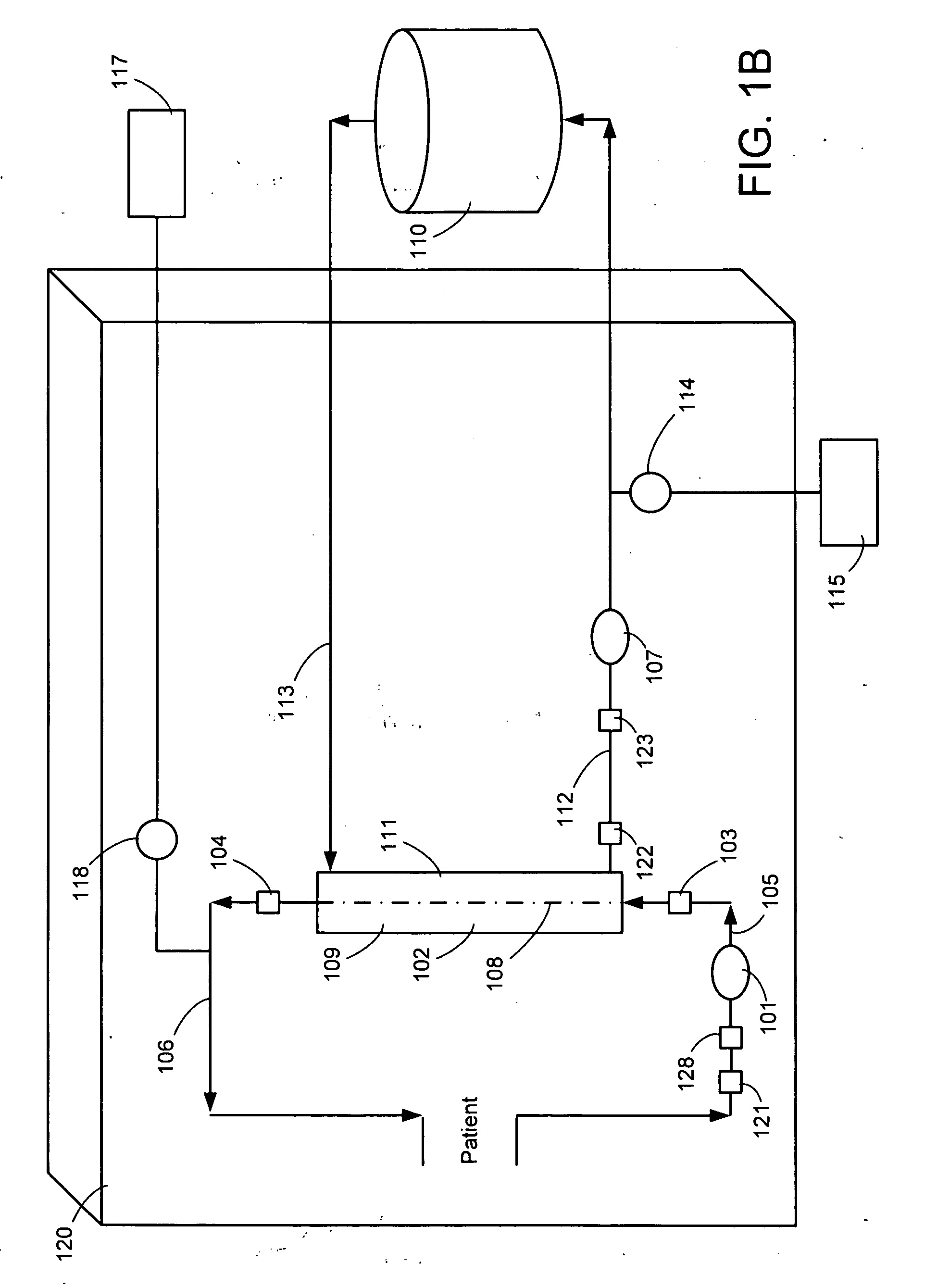

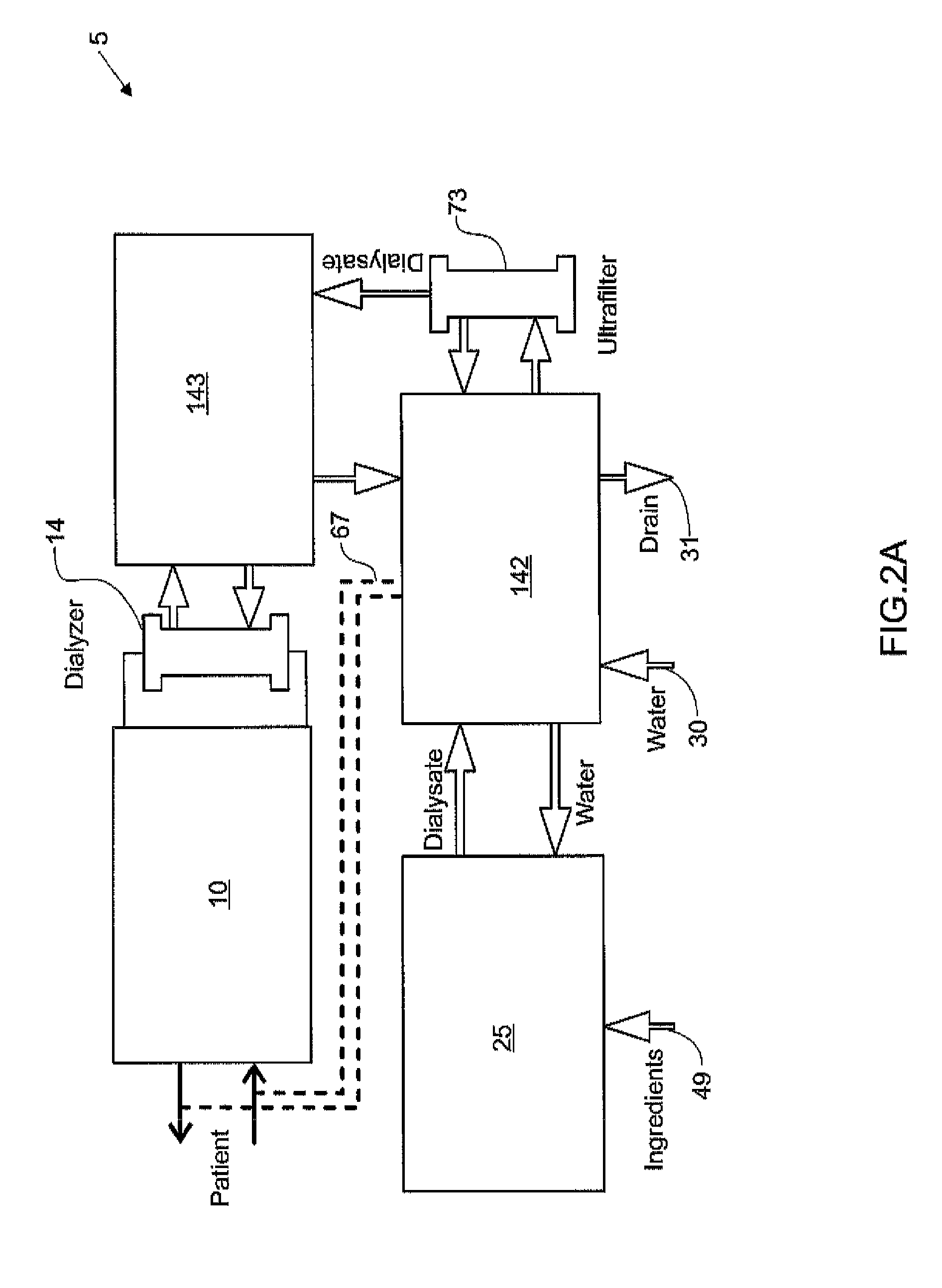

Hemodialysis systems and methods

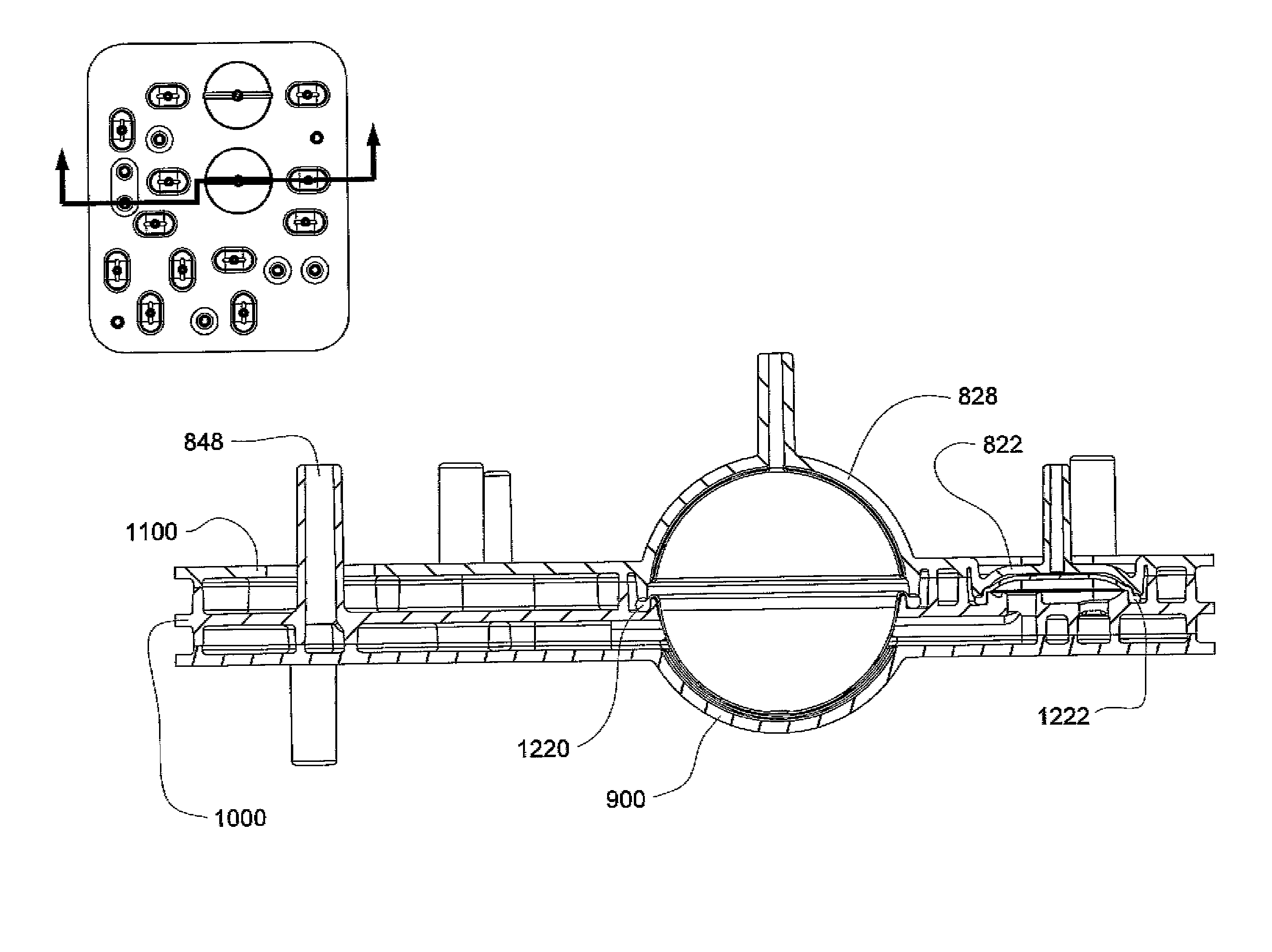

ActiveUS20090095679A1Mechanical/radiation/invasive therapiesSolvent extractionHaemodialysis machineDialysate flow

Hemodialysis dialysis systems are disclosed. Hemodialysis systems of the invention may include a dialysate flow path including a balancing circuit, a mixing circuit, and / or a directing circuit. The circuits may be defined within one or more cassettes. The fluid circuits may be at least partially isolated, spatially and / or thermally, from electrical components of the system. A gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer to urge dialysate through the dialyzer and blood back to the patient. The hemodialysis systems may include fluid handling devices, actuated using a control fluid, optionally delivered using a detachable pump. Fluid handling devices may be generally rigid and of a spheroid shape, optionally with a diaphragm dividing the device into compartments.

Owner:DEKA PROD LLP

Cartridges useful in cleaning dialysis solutions

InactiveUS7033498B2Avoid a lotSolve the blockageZirconium compoundsLoose filtering material filtersMedicineHemodialysis membrane

Owner:RENAL SOLUTIONS

Blood treatment systems and methods

ActiveUS8409441B2Increase pressureMechanical/radiation/invasive therapiesSolvent extractionBlood treatmentsGraphics

Dialysis systems comprising actuators that cooperate to perform dialysis functions and sensors that cooperate to monitor dialysis functions are disclosed. According to one aspect, such a hemodialysis system comprises a user interface model layer, a therapy layer, below the user interface model layer, and a machine layer below the therapy layer. The user interface model layer is configured to manage the state of a graphical user interface and receive inputs from a graphical user interface. The therapy layer is configured to run state machines that generate therapy commands based at least in part on the inputs from the graphical user interface. The machine layer is configured to provide commands for the actuators based on the therapy commands.

Owner:DEKA PROD LLP

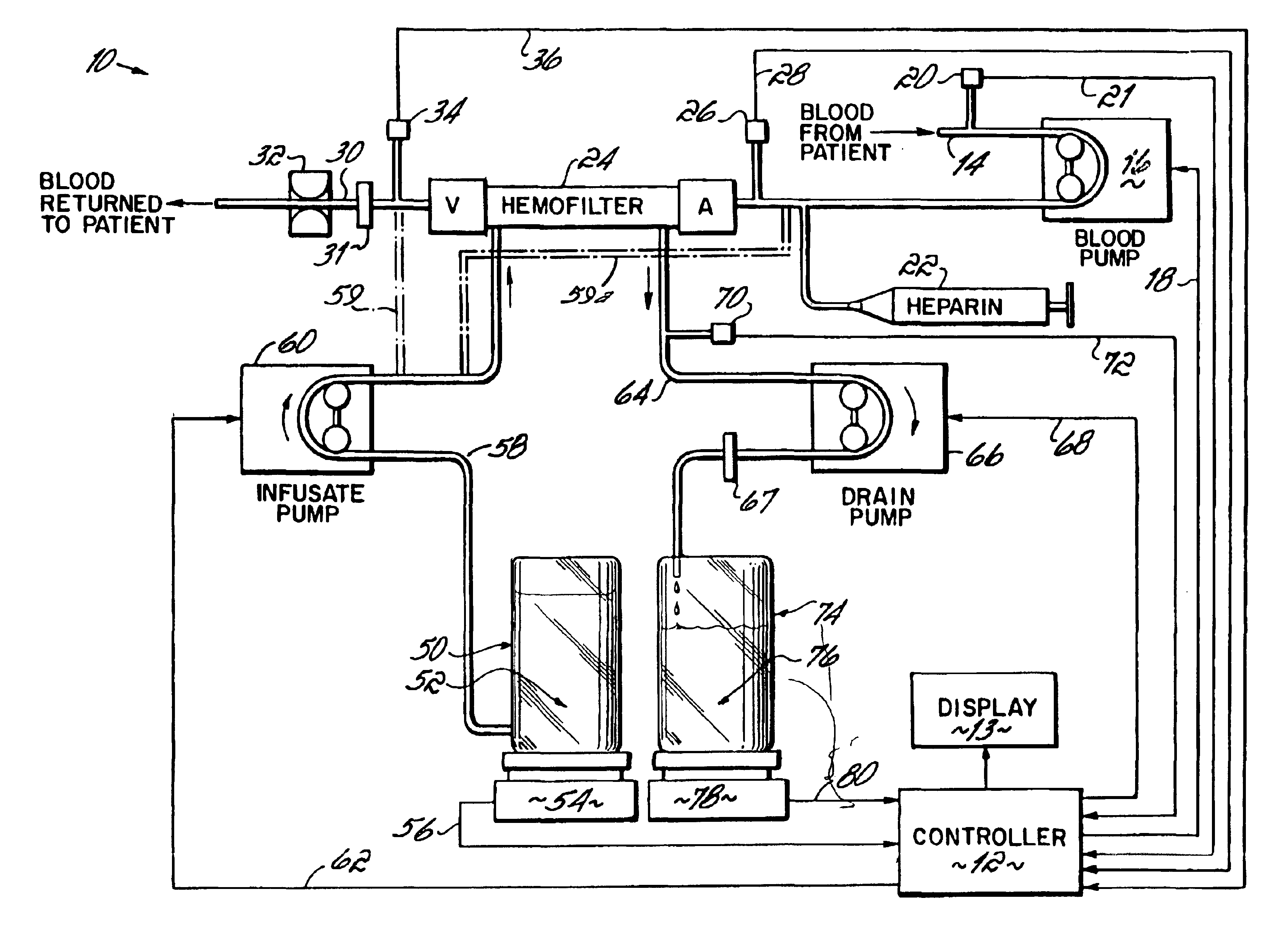

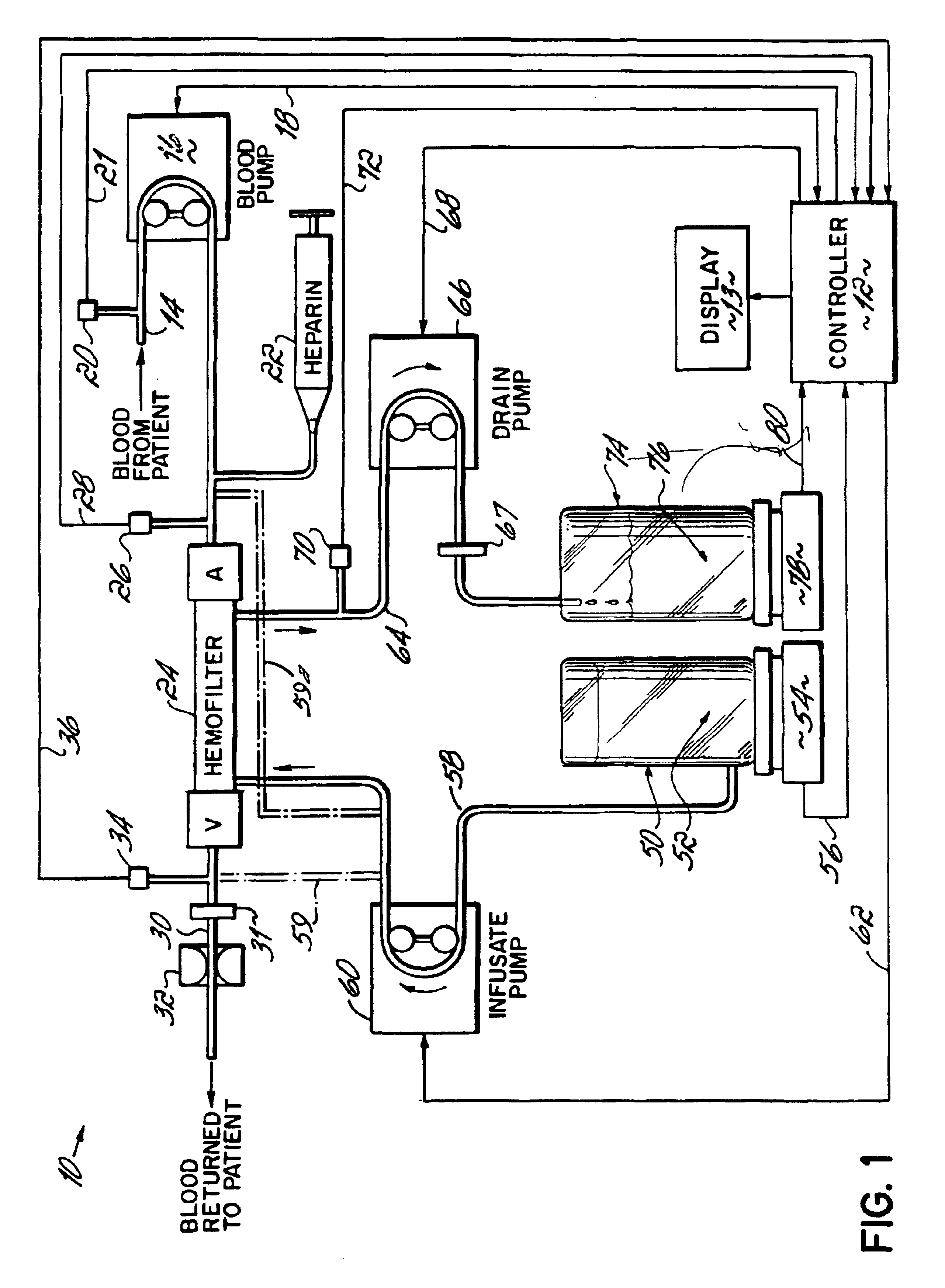

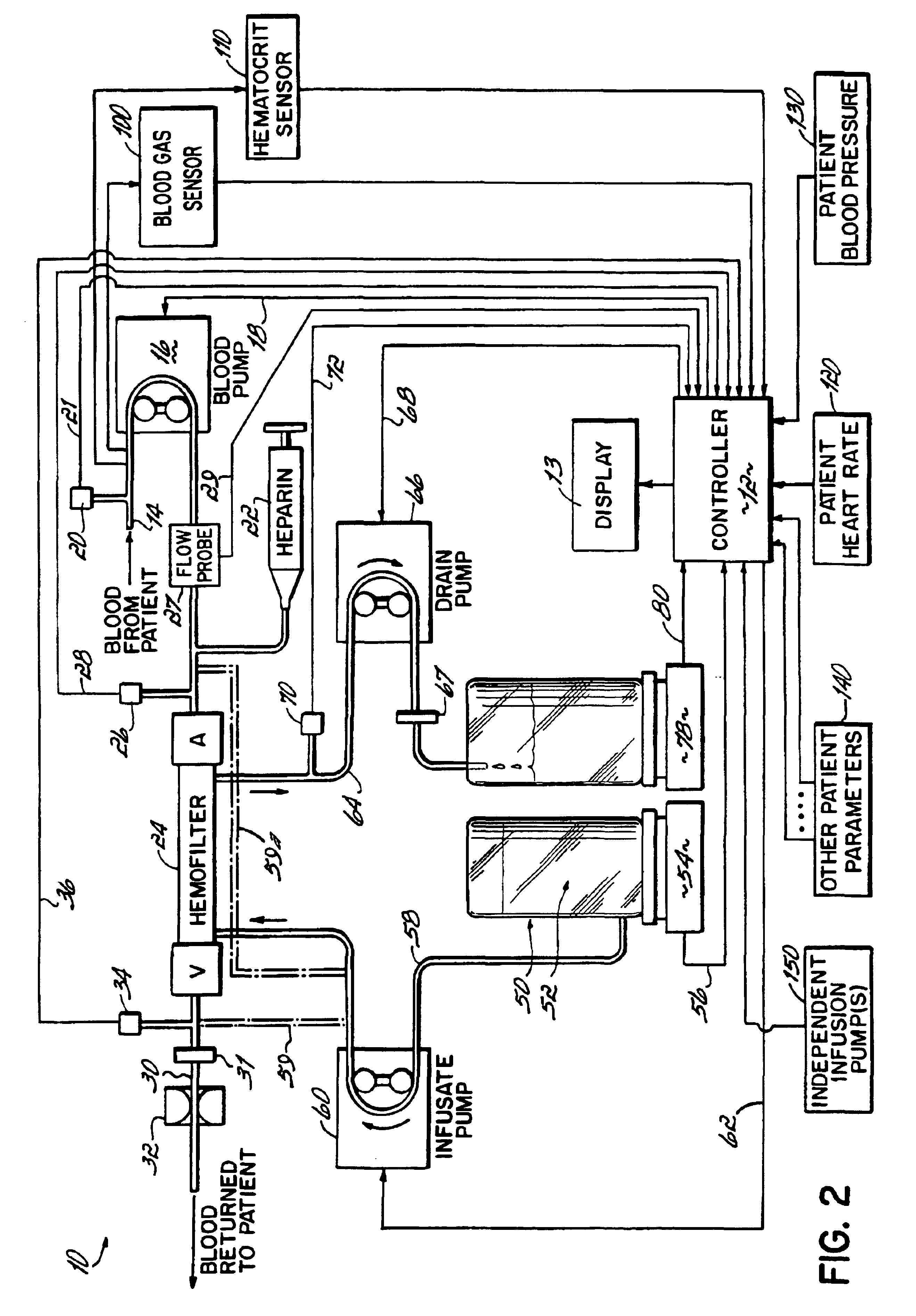

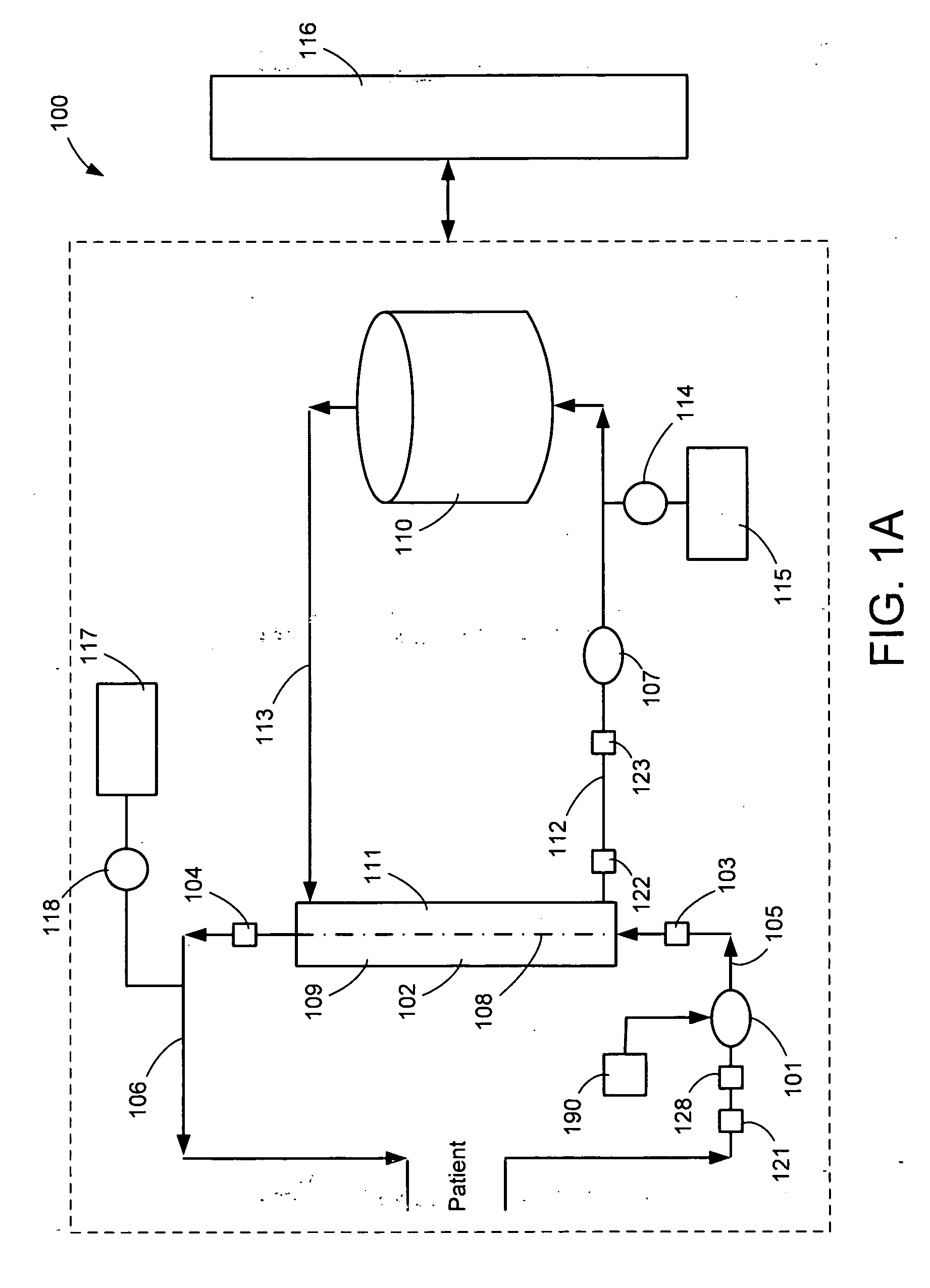

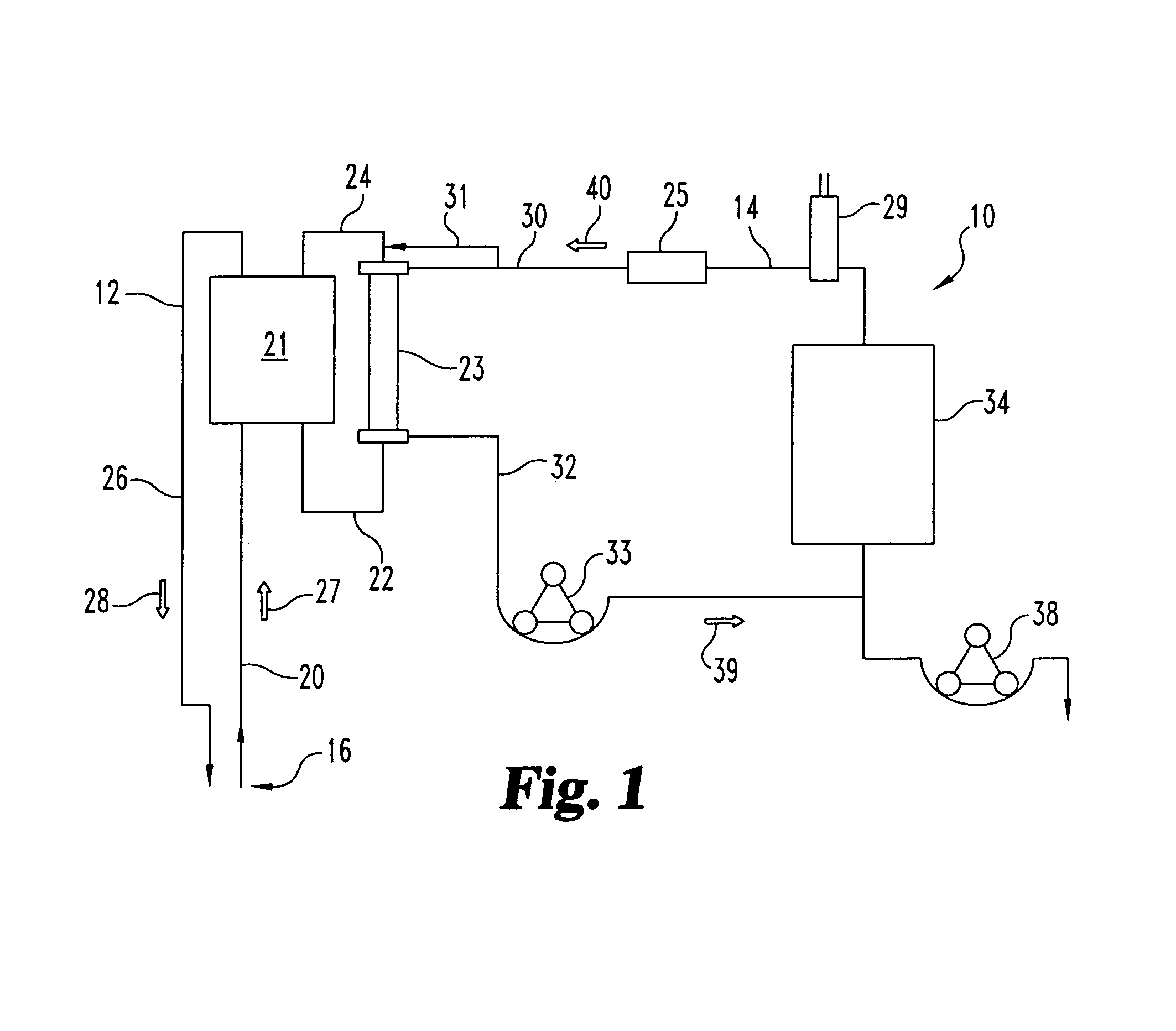

Hemofiltration system

InactiveUS6780322B1Reliable and long-term operationImprove accuracySolvent extractionUltrafiltrationMedicineTime changes

A multipurpose hemofiltration system (10) and method are disclosed for the removal of fluid and / or soluble waste from the blood of a patient. The system (10) continuously monitors the flow rates of drained fluid, blood, and infusate. When necessary, the pumping rates of the infusate, drained fluid and blood are adjusted to remove a preselected amount of fluid from the blood in a preselected time period. A supervisory controller (160) can monitor patient parameters, such as heart rate (120) and blood pressure (130), and adjust the pumping rates accordingly. The supervisory controller (160) uses fuzzy logic to make expert decisions, based upon a set of supervisory rules, to control each pumping rate to achieve a desired flow rate and to respond to fault conditions. An adaptive controller (162) corrects temporal variations in the flow rate based upon an adaptive law and a control law.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

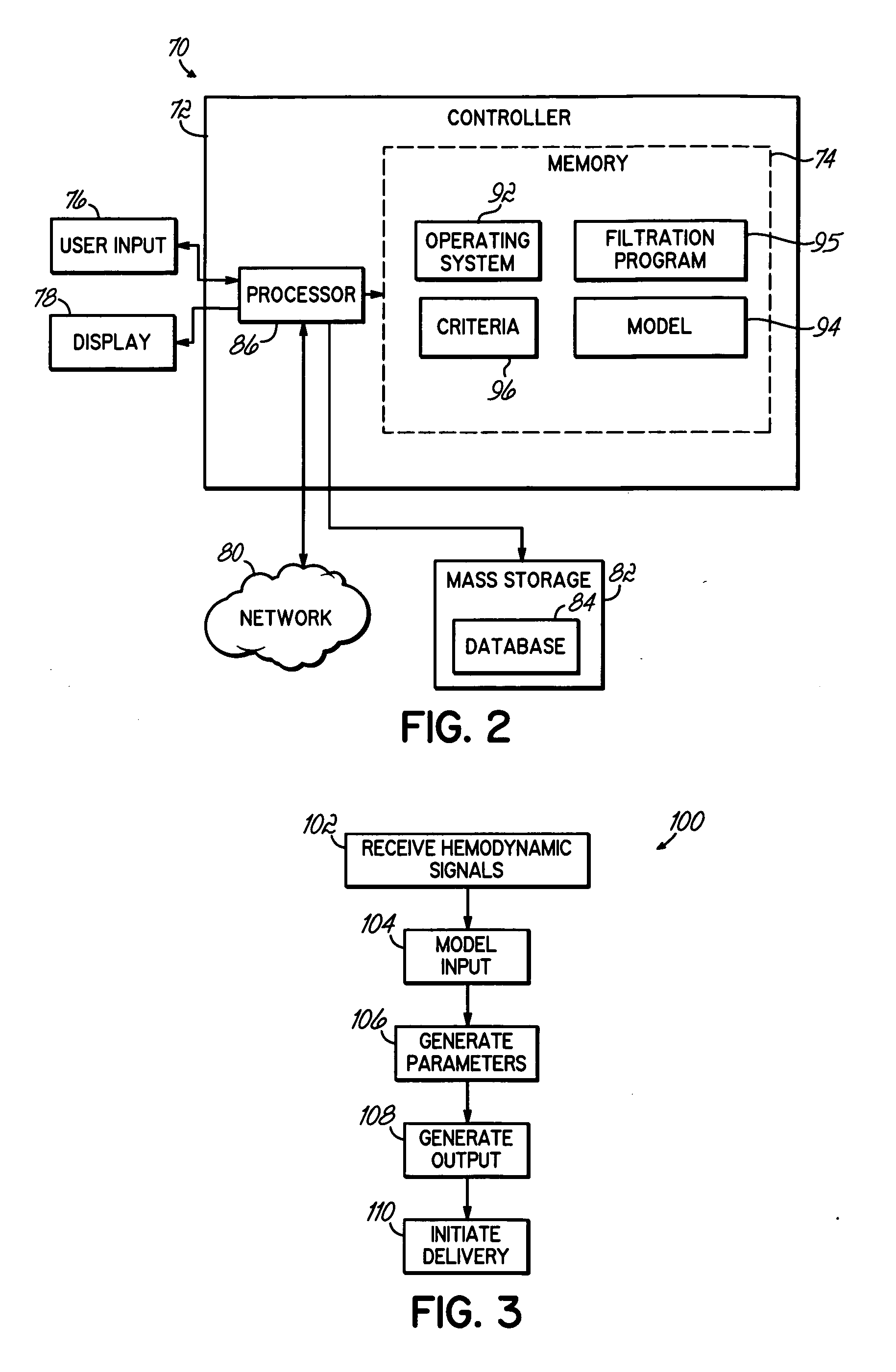

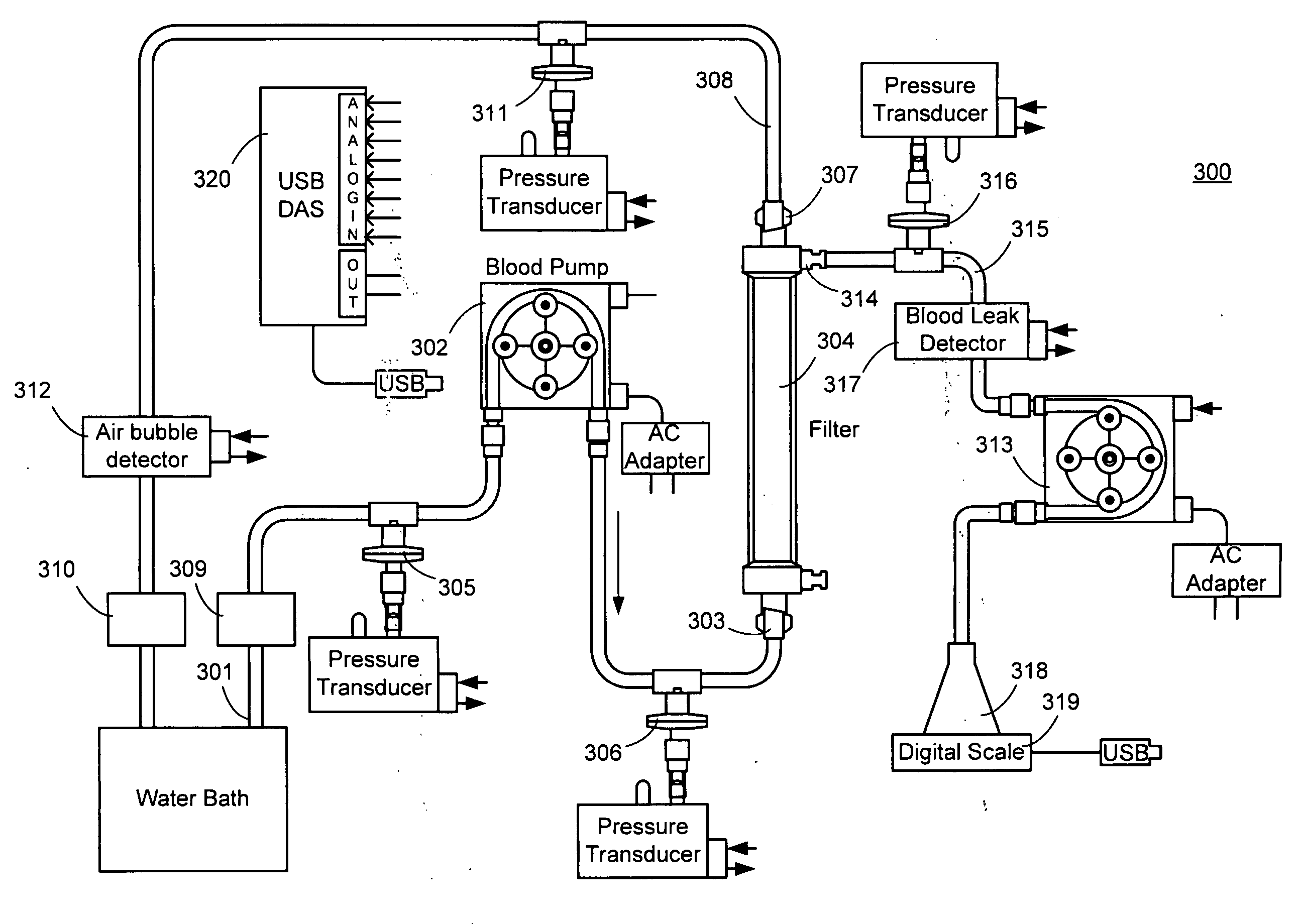

Extracorporeal renal replacement modeling system

InactiveUS20070215545A1AccuracyReduce decreaseSolvent extractionDialysis systemsUltrafiltrationMathematical model

A system, program product and method continuously optimize an ultrafiltration rate during an extracorporeal renal replacement process by modeling physiological and actual rate data. The system maps the sensed, physiological data to a mathematical model to assess the data in terms of the ultrafiltration rate. The model provides parameters used to predict where the treatment is headed based on current conditions. The system processes the parameters in terms of preset criteria to generate the optimized ultrafiltration rate. Where the system is networked, communication of the data may be accomplished using remote and online communication techniques.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

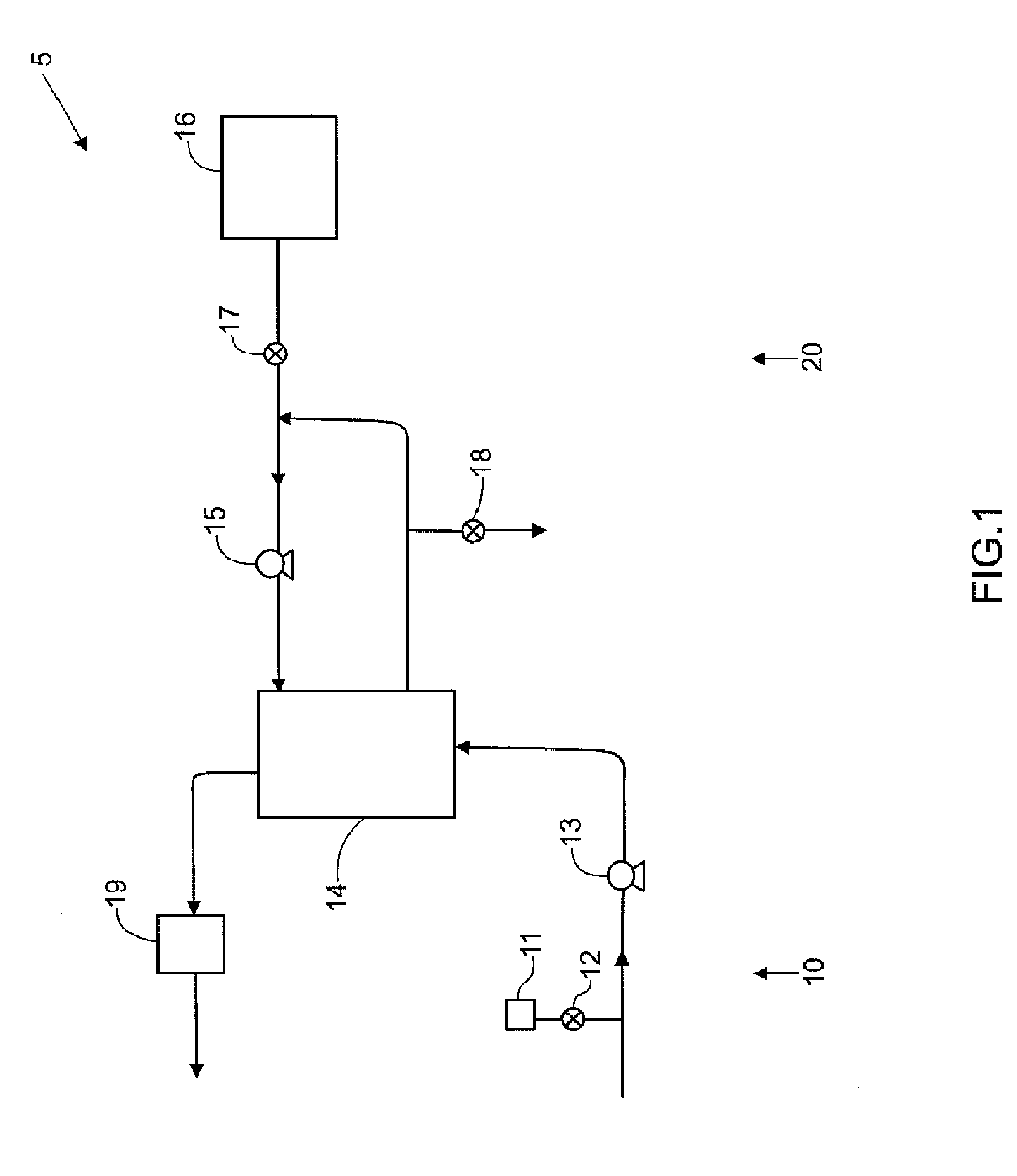

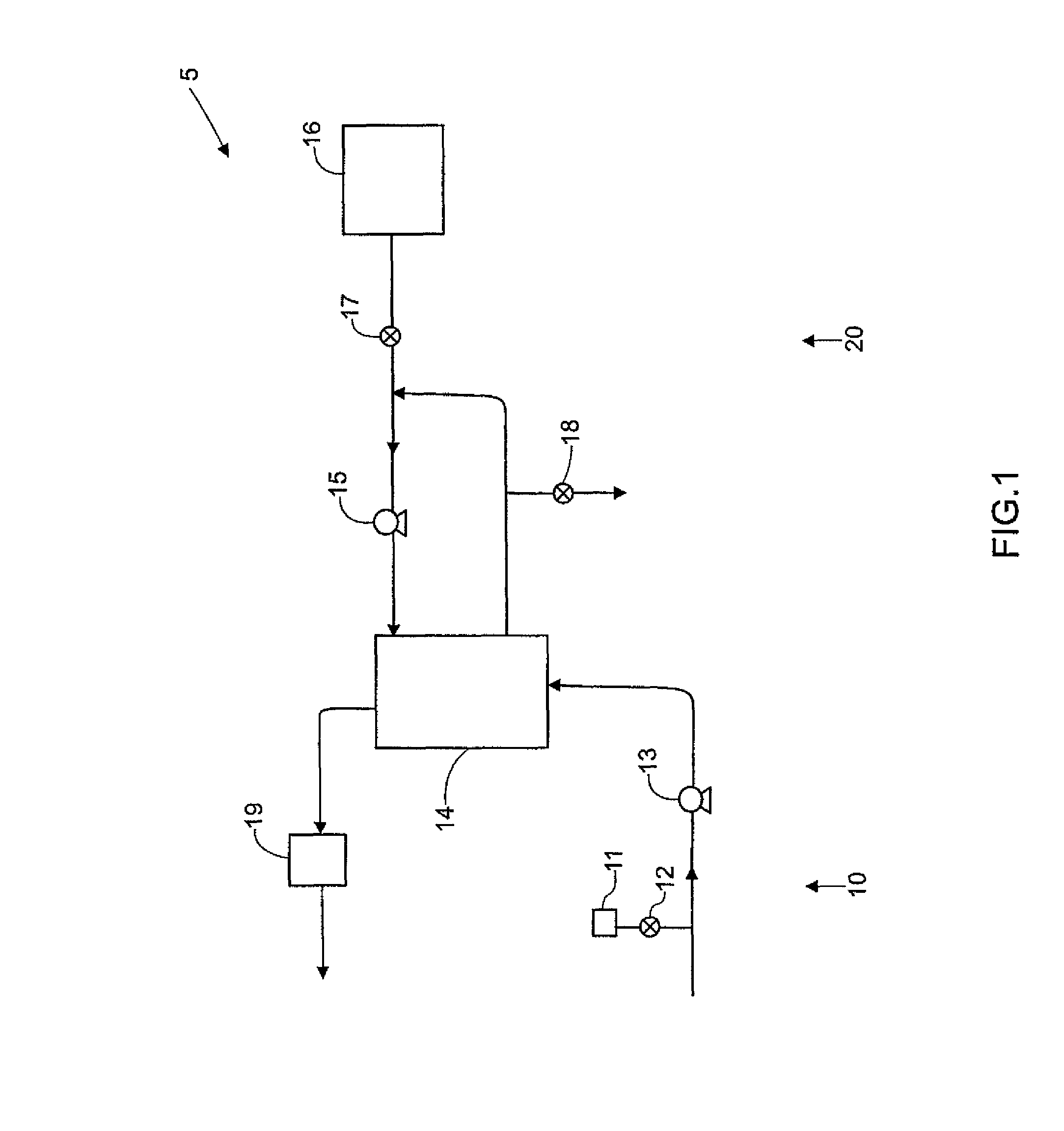

Filtration monitoring and control system

InactiveUS6077435AUseful controlAccurate CalibrationDispersed particle filtrationUltrafiltrationFouling indexFiltration

PCT No. PCT / AU96 / 00144 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 28236 PCT Pub. Date Sep. 19, 1996A method and apparatus for determining the fouling effect of a feedstream on a filter having known characteristics disclosed. The method comprises passing the feedstream through a filter (5) having known characteristics; determining the change in resistance to flow of the feedstream across the filter, either continuously or over a number of time intervals and from this data, calculating a feed fouling index (FFI) representative of the fouling characteristics of the feedstream with respect to the filter. A method and apparatus for monitoring the operation of a filtration system is also disclosed the method comprising sampling system parameter values at selected locations within the filtration system at a predetermined sampling rate; generating a parameter profile characteristic from the sampled parameter values at predetermined intervals of time; and analysing the parameter profile characteristic to determine correct operation of the filtration system. A further method and apparatus of monitoring and controlling a filtering system based on backwash efficiency is also disclosed, the method comprising determining resistance values of filtering elements used in the filtering system at predetermined times during the backwash cycle of the system by monitoring a number of operating parameters of the system; calculating a backwash efficiency value representative of the efficiency of the backwash cycle of the filtering system using the resistance values determined; and controlling the operation of the filtering system in dependence on the value of the backwash efficiency calculated.

Owner:EVOQUA WATER TECH LLC

Process if making fine fiber material

Improved polymer materials and fine fiber materials can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

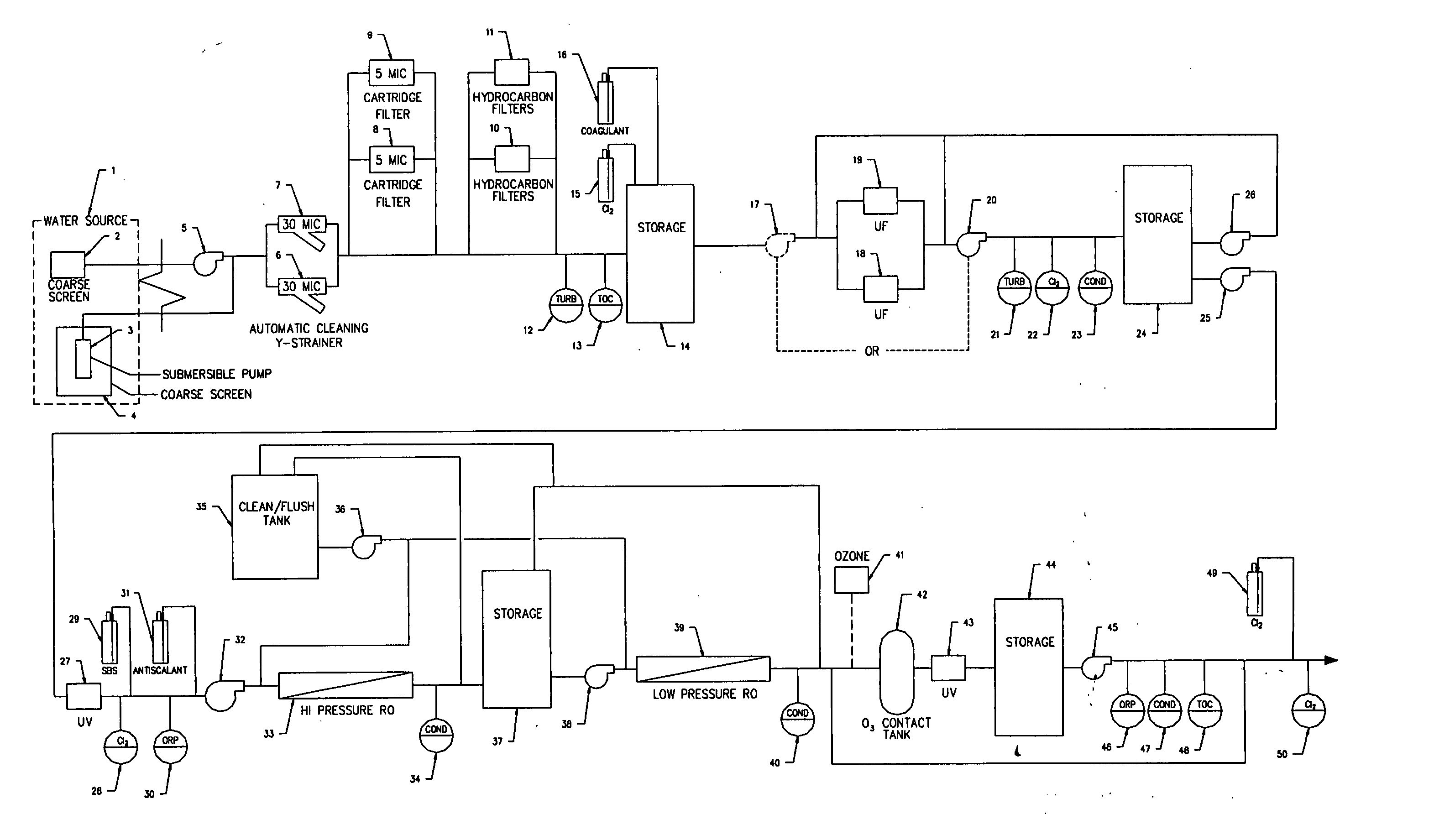

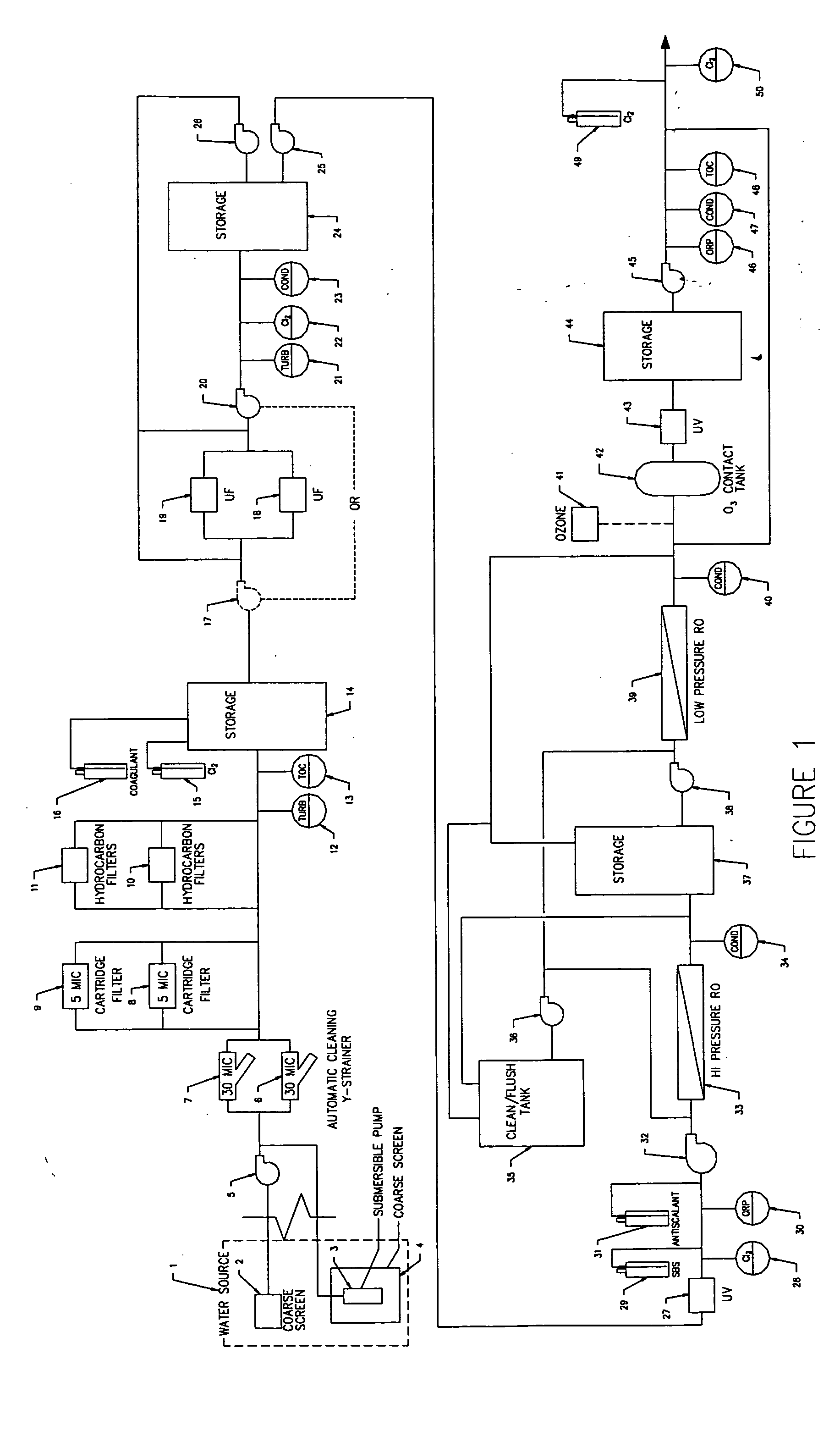

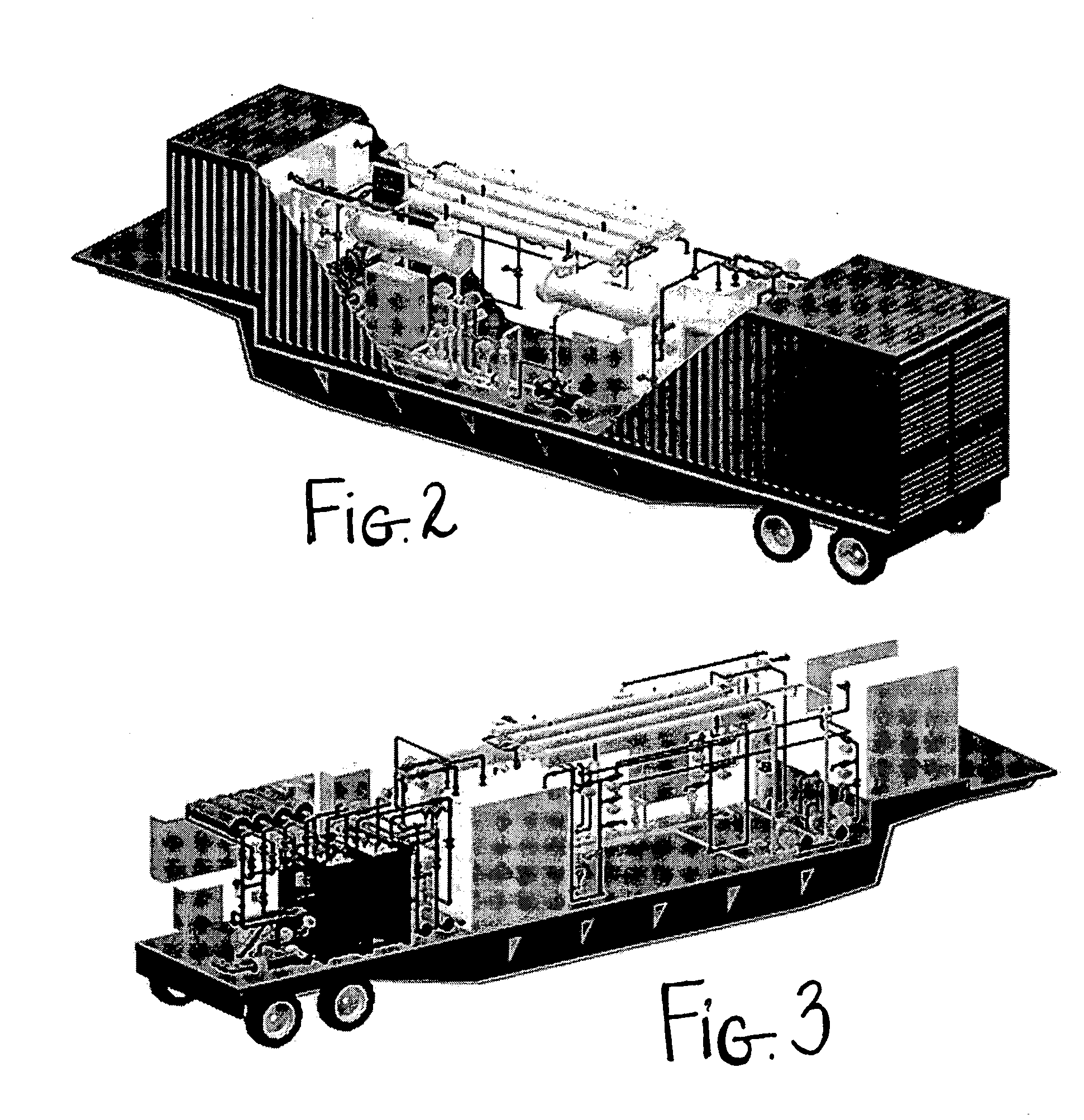

Water purifier and method of making and using the same

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

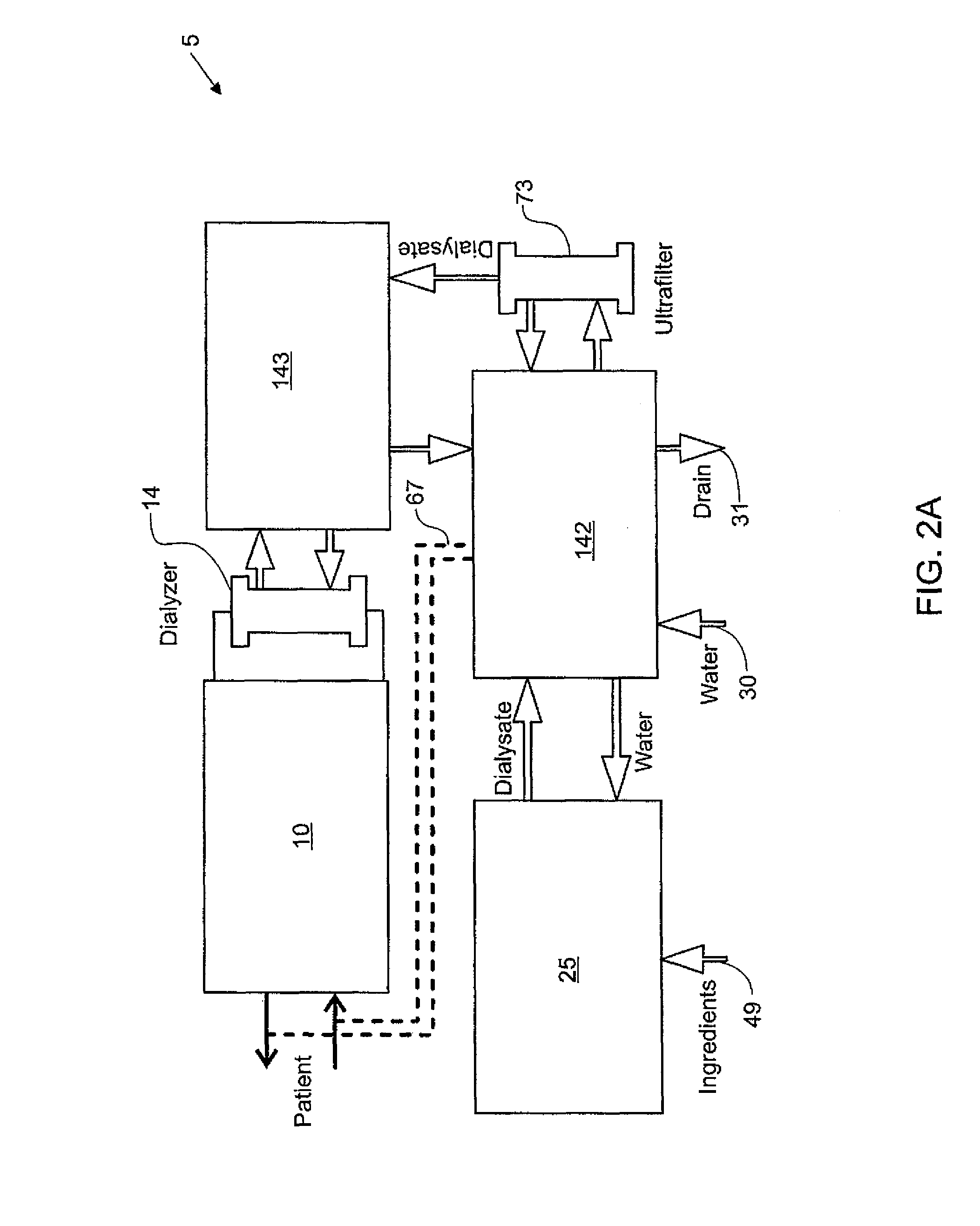

Manifolds for Use in Conducting Dialysis

The present invention is directed to novel systems for conducting the filtration of blood using manifolds. The manifolds integrate various sensors and have fluid pathways formed therein to direct fluids from various sources through the requisite blood filtration or ultrafiltration system steps.

Owner:FRESENIUS MEDICAL CARE HLDG INC

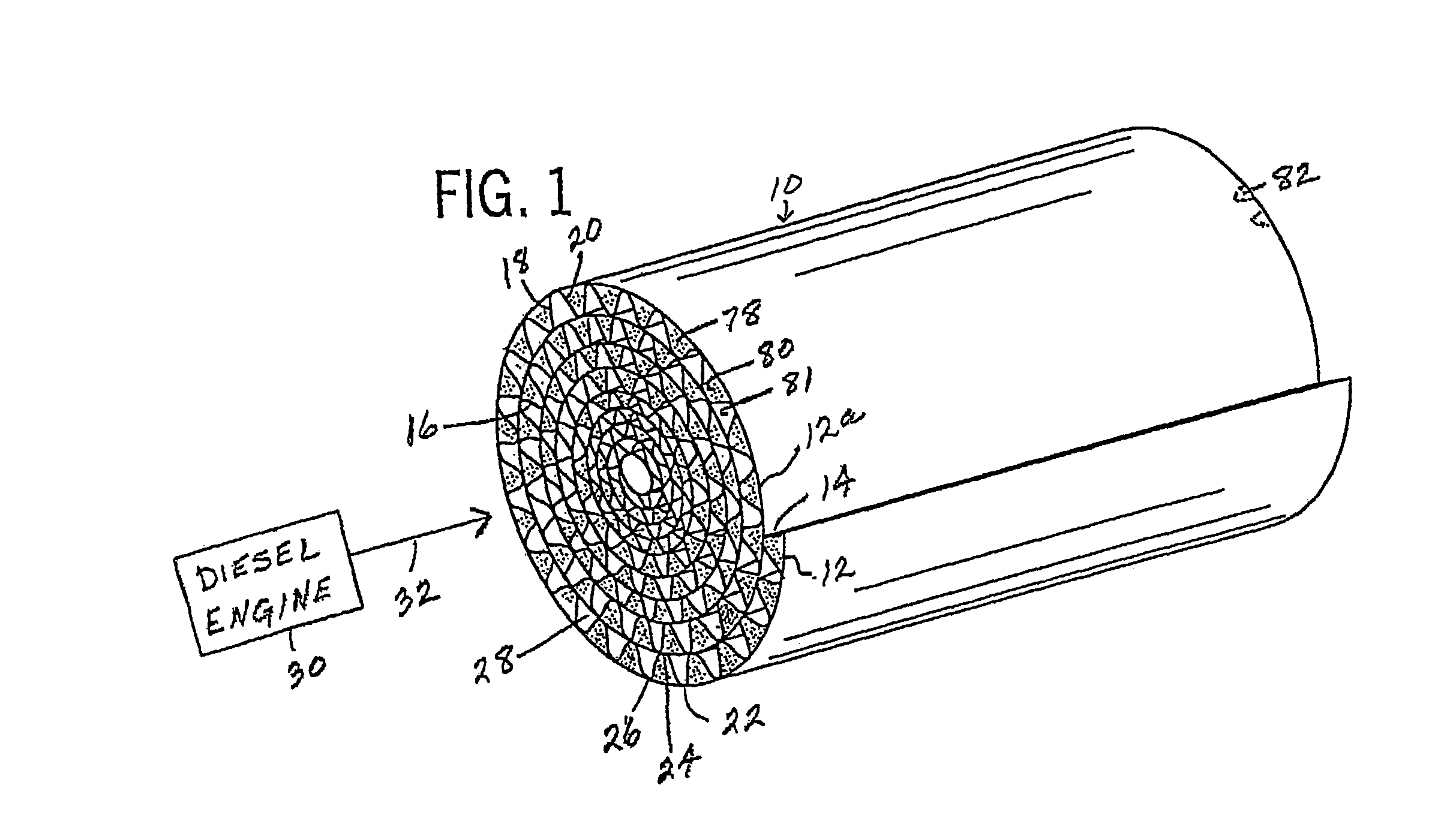

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

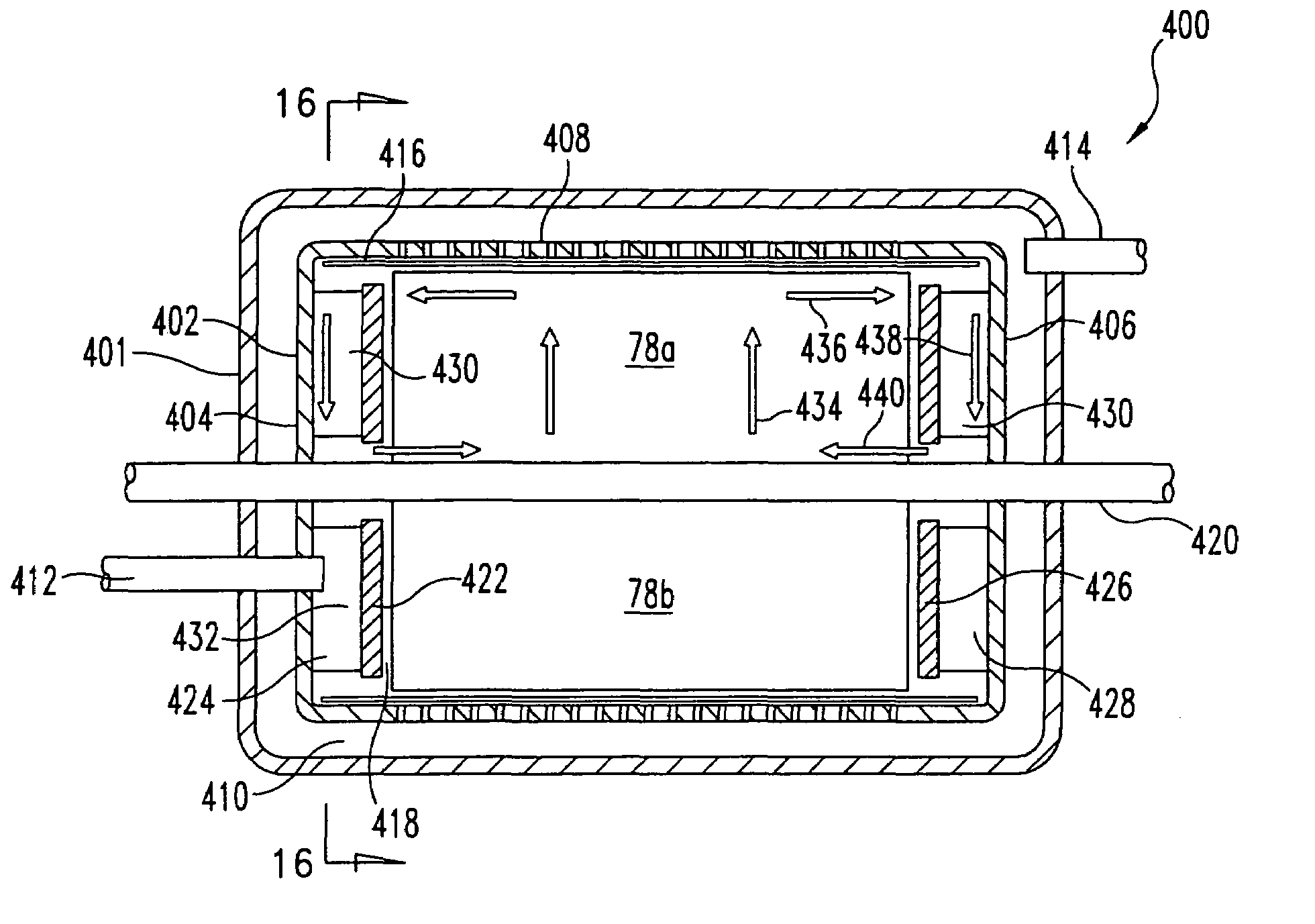

Hemodialysis systems and methods

The present invention generally relates to hemodialysis and similar dialysis systems, including a variety of systems and methods that would make hemodialysis more efficient, easier, and / or more affordable. One aspect of the invention is generally directed to new fluid circuits for fluid flow. In one set of embodiments, a hemodialysis system may include a blood flow path and a dialysate flow path, where the dialysate flow path includes one or more of a balancing circuit, a mixing circuit, and / or a directing circuit. Preparation of dialysate by the preparation circuit, in some instances, may be decoupled from patient dialysis. In some cases, the circuits are defined, at least partially, within one or more cassettes, optionally interconnected with conduits, pumps, or the like. In one embodiment, the fluid circuit and / or the various fluid flow paths may be at least partially isolated, spatially and / or thermally, from electrical components of the hemodialysis system. In some cases, a gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer that, when activated, is able to urge dialysate to pass through the dialyzer and urge blood in the blood flow path back to the patient. Such a system may be useful, for example, in certain emergency situations (e.g., a power failure) where it is desirable to return as much blood to the patient as possible. The hemodialysis system may also include, in another aspect of the invention, one or more fluid handling devices, such as pumps, valves, mixers, or the like, which can be actuated using a control fluid, such as air. In some cases, the control fluid may be delivered to the fluid handling devices using an external pump or other device, which may be detachable in certain instances. In one embodiment, one or more of the fluid handling devices may be generally rigid (e.g., having a spheroid shape), optionally with a diaphragm contained within the device, dividing it into first and second compartments.

Owner:DEKA PROD LLP

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

Sorbent reactor for extracorporeal blood treatment systems, peritoneal dialysis systems, and other body fluid treatment systems

InactiveUS7169303B2Facilitate homogeneous suspensionReduce probabilitySolvent extractionHaemofiltrationFluid balancePeritoneal dialysis

Systems and methods for extracorporeal processing of blood or other body fluid for the treatment of conditions, such as sepsis, autoimmune disease, or toxemia related to kidney failure, liver failure, or drug overdose are provided. In an extracorporeal treatment system, a fraction of a body fluid is passed into a treatment fluid, at least a portion of which is then passed through a sorbent suspension reactor for treatment by a sorbent suspension. The treatment fluid circuit can be maintained at a fixed volume, which enables accurate fluid balance between the patient and the extracorporeal circuit. Some or all of the treatment fluid, optionally also containing nutrients and / or therapeutic agents, is returned to the patient. In a peritoneal dialysis system, dialysate is passed into a patient's peritoneal cavity, recovered from the cavity, passed through a sorbent suspension reactor in accordance with the invention, and returned to the cavity.

Owner:HEMOCLEANSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com