Patents

Literature

372 results about "Side stream" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Side·stream | \ˈsīd-ˌstrēm \. : relating to or being tobacco smoke that is emitted from the lighted end of a cigarette or cigar.

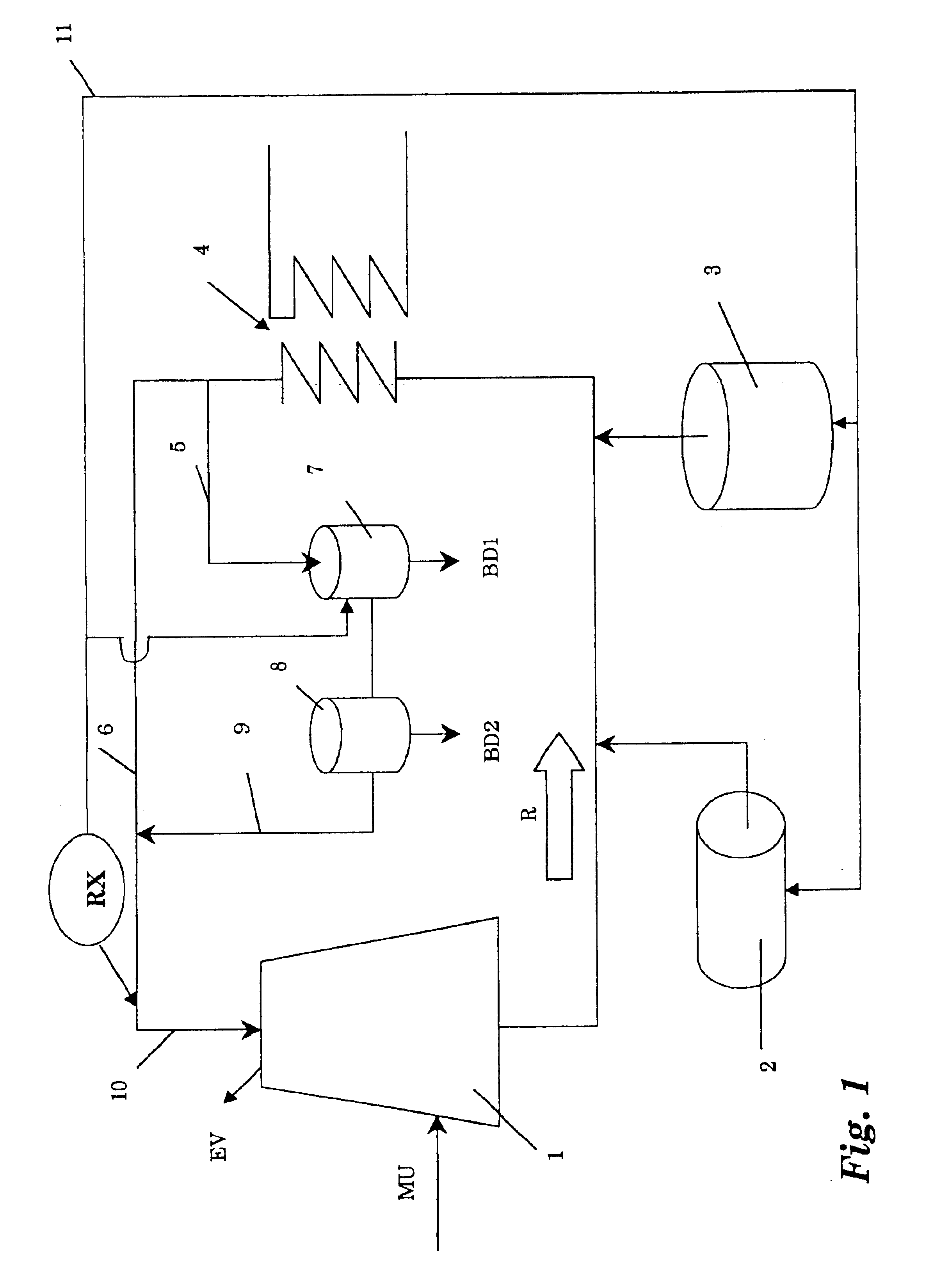

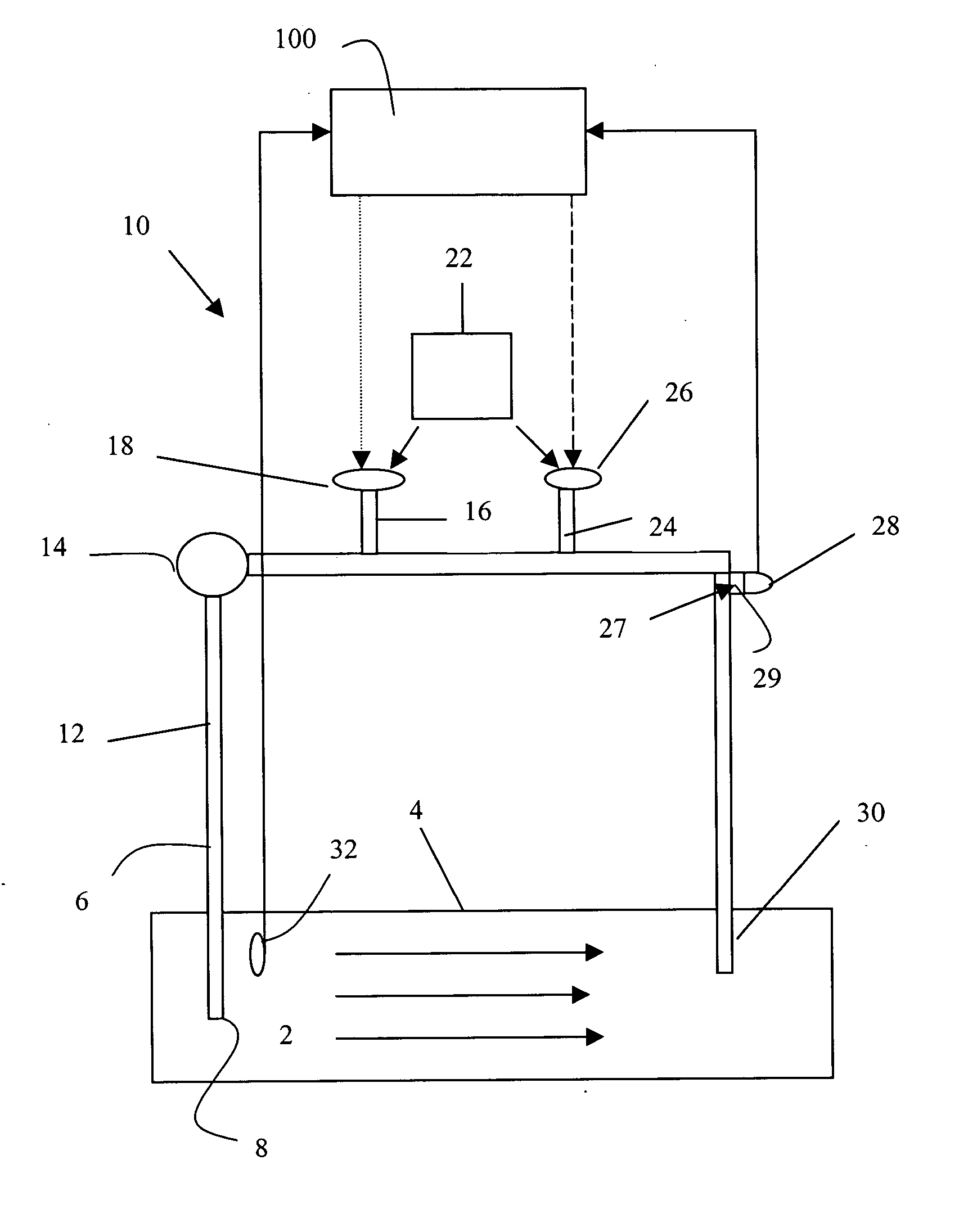

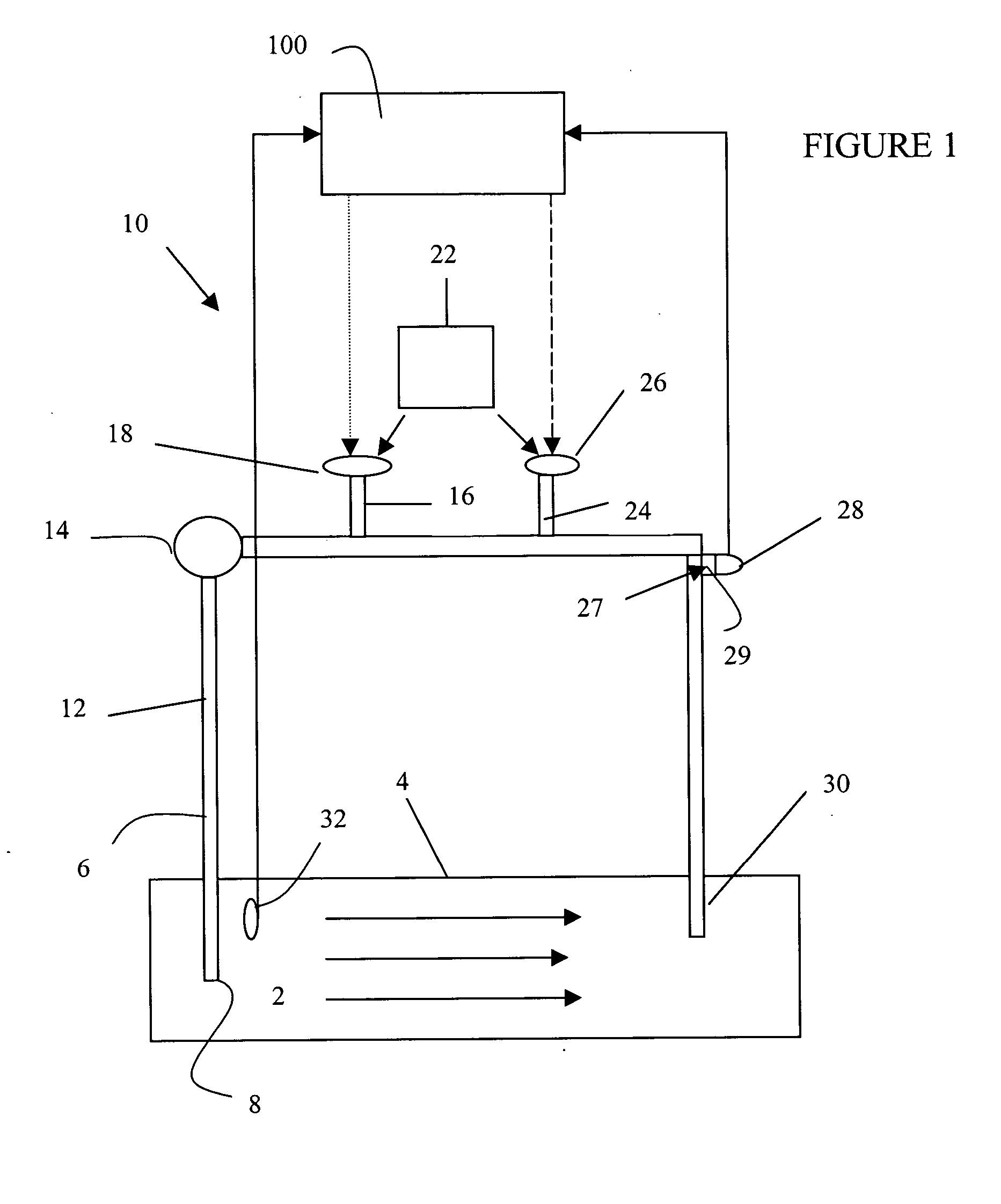

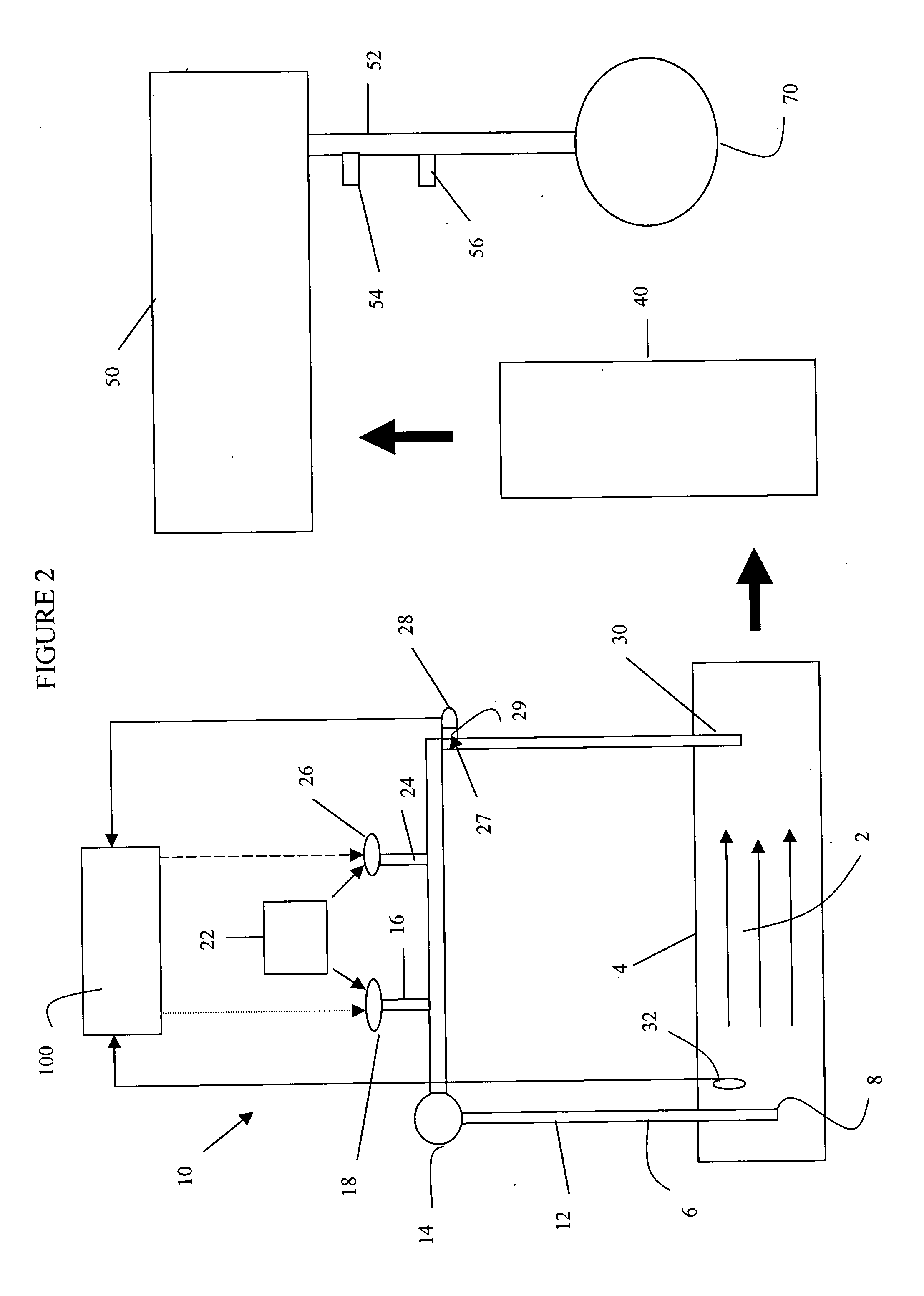

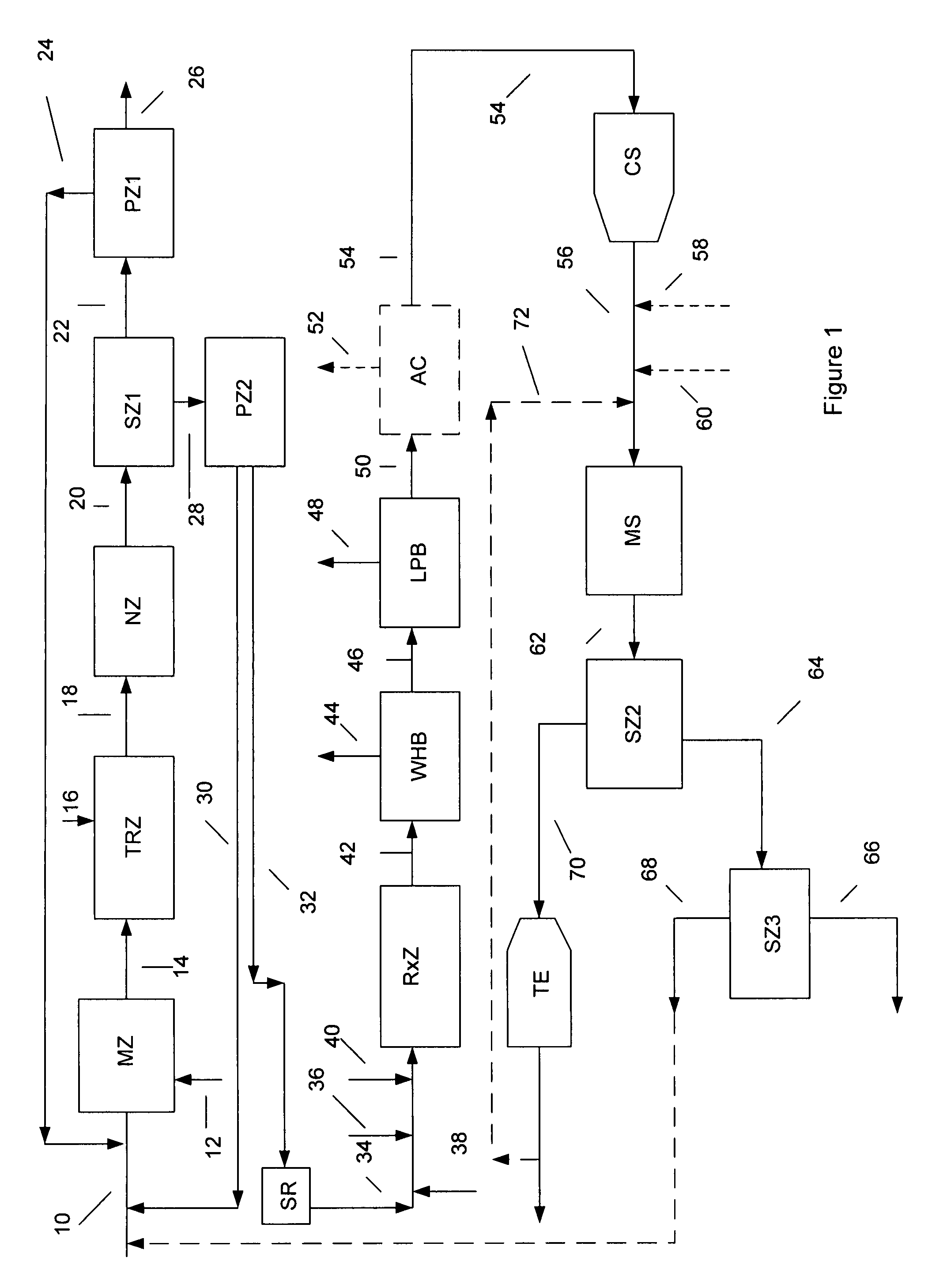

Methods and systems for improved dosing of a chemical treatment, such as chlorine dioxide, into a fluid stream, such as a wastewater stream

InactiveUS6949196B2Reduce consumptionQuantity minimizationWater treatment parameter controlOther chemical processesChemical treatmentChlorine dioxide

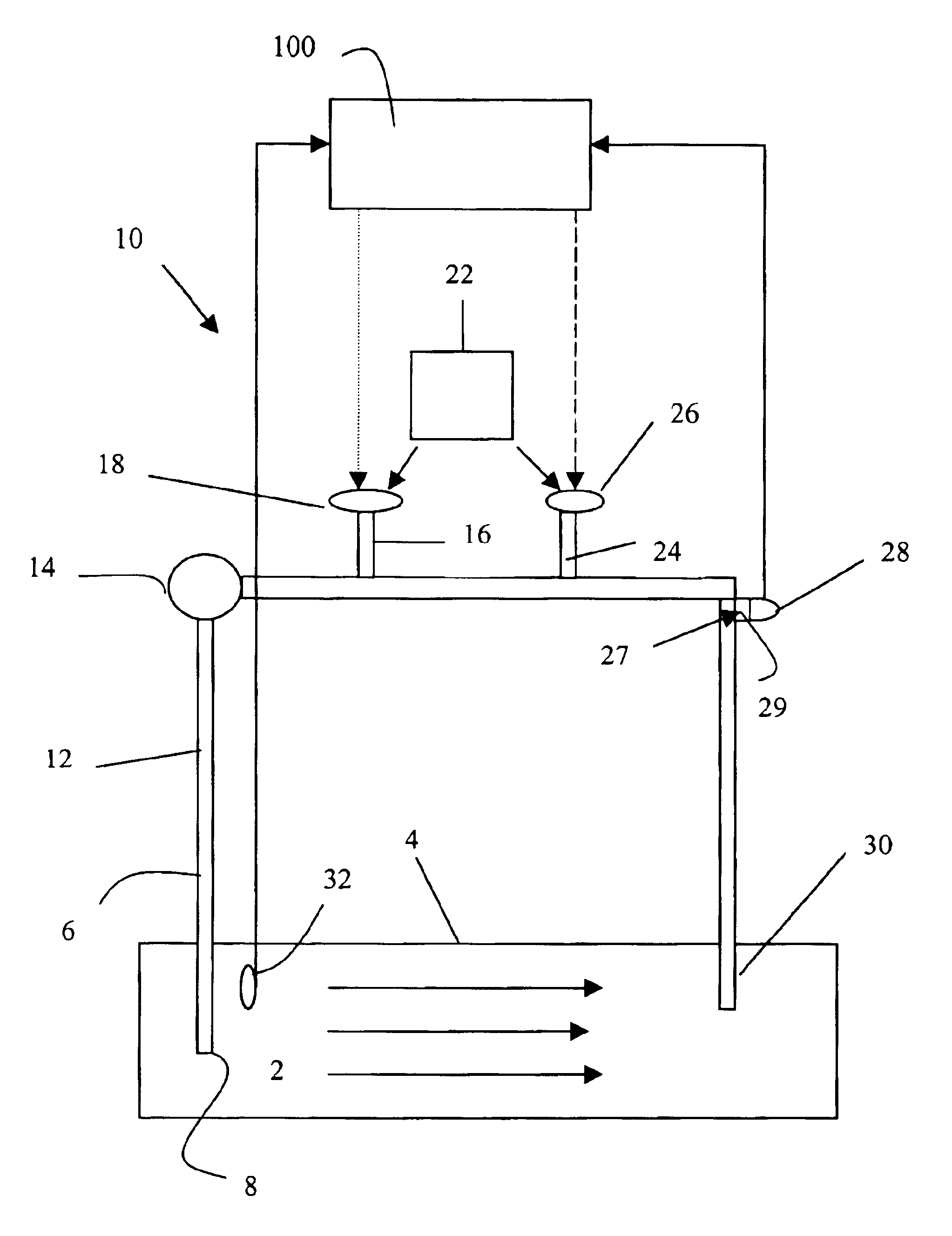

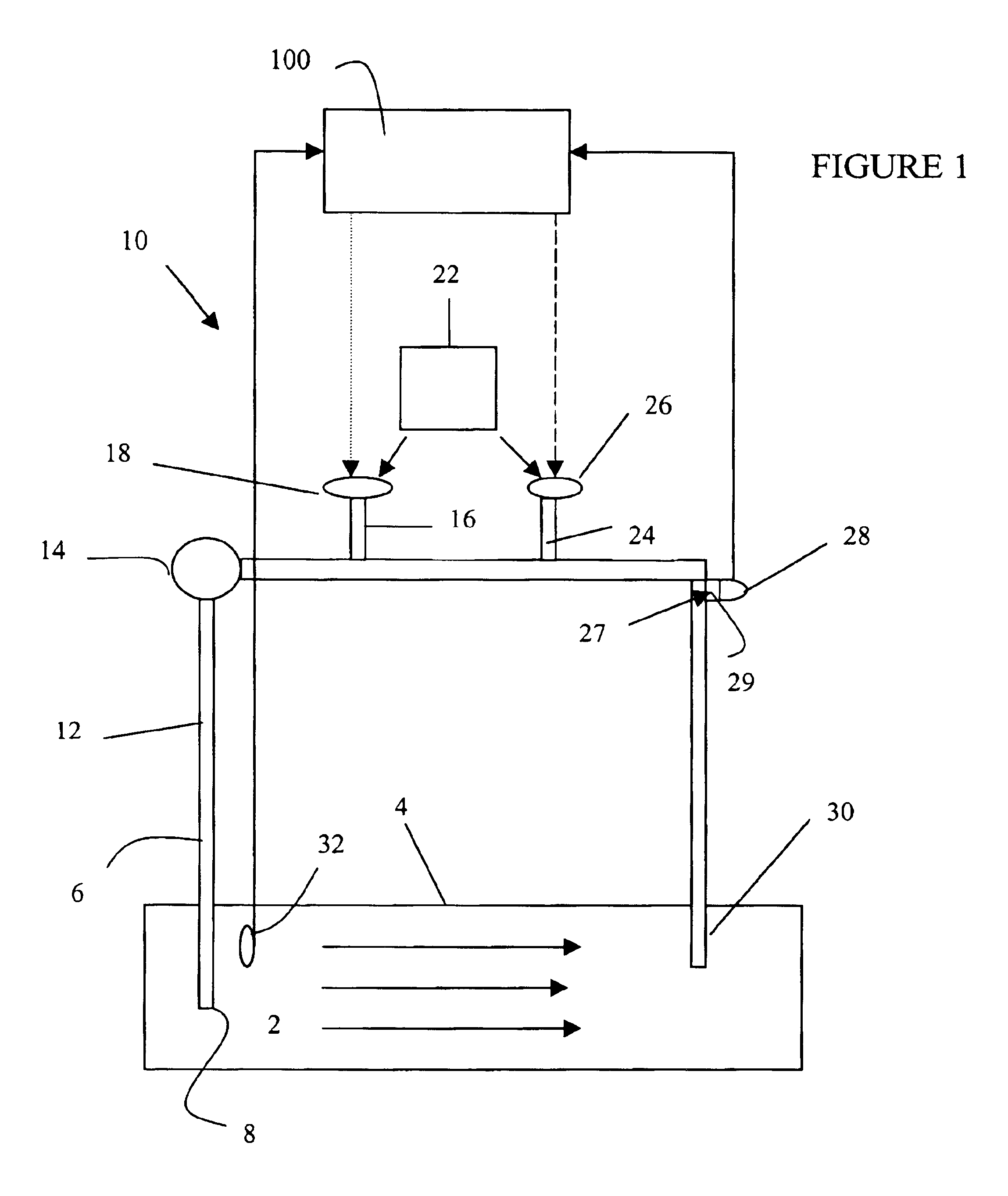

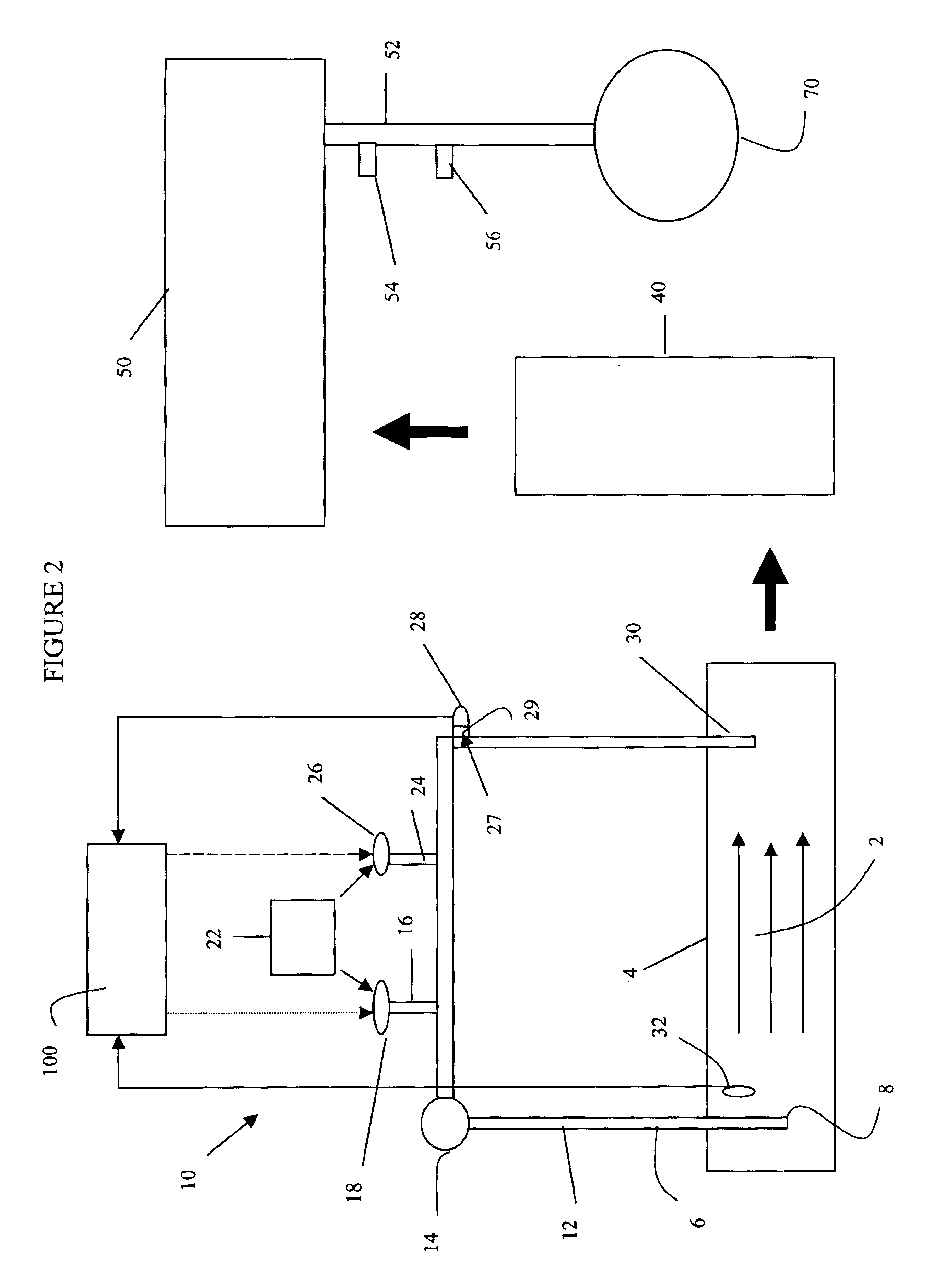

The invention is directed to methods, apparatuses, and systems for treatment of a liquid flow comprising addition of a chemical treatment at at least two locations along a side stream of a main flow of said liquid, in which the dosing by such additions is sufficient to treat the entire main flow upon return of the side stream to the main flow. Algorithms are utilized to control the additions at the locations of addition of chemical treatments. In a typical embodiment, one chemical addition is principally proportional to the flow rate of the liquid flow, and the other chemical addition is principally adjusted based on signals from a primary measuring device that measures a parameter in the flow after one or both chemical additions. The addition of chlorine dioxide as the chemical treatment, to disinfect wastewater, is discussed.

Owner:FKOS LLC +1

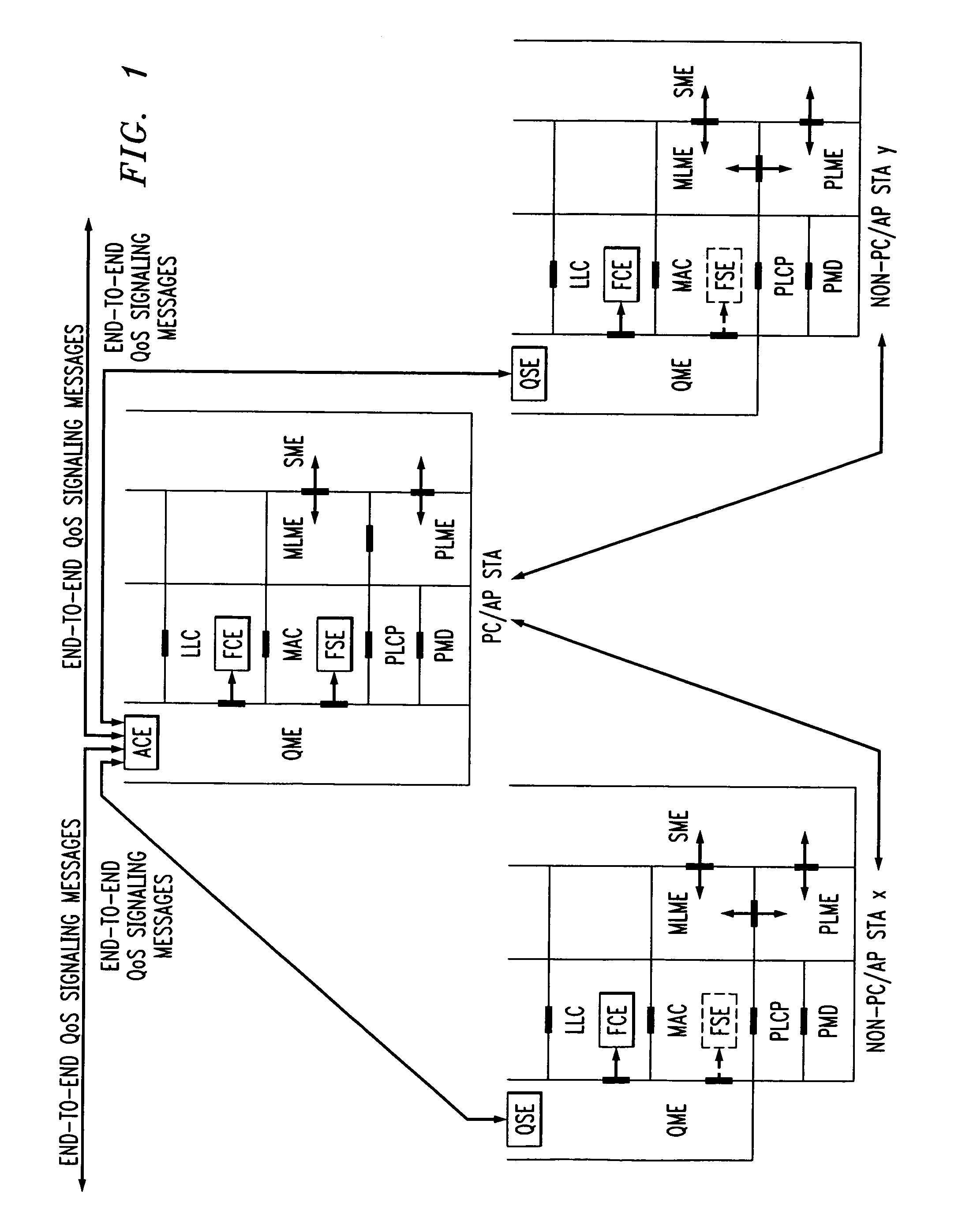

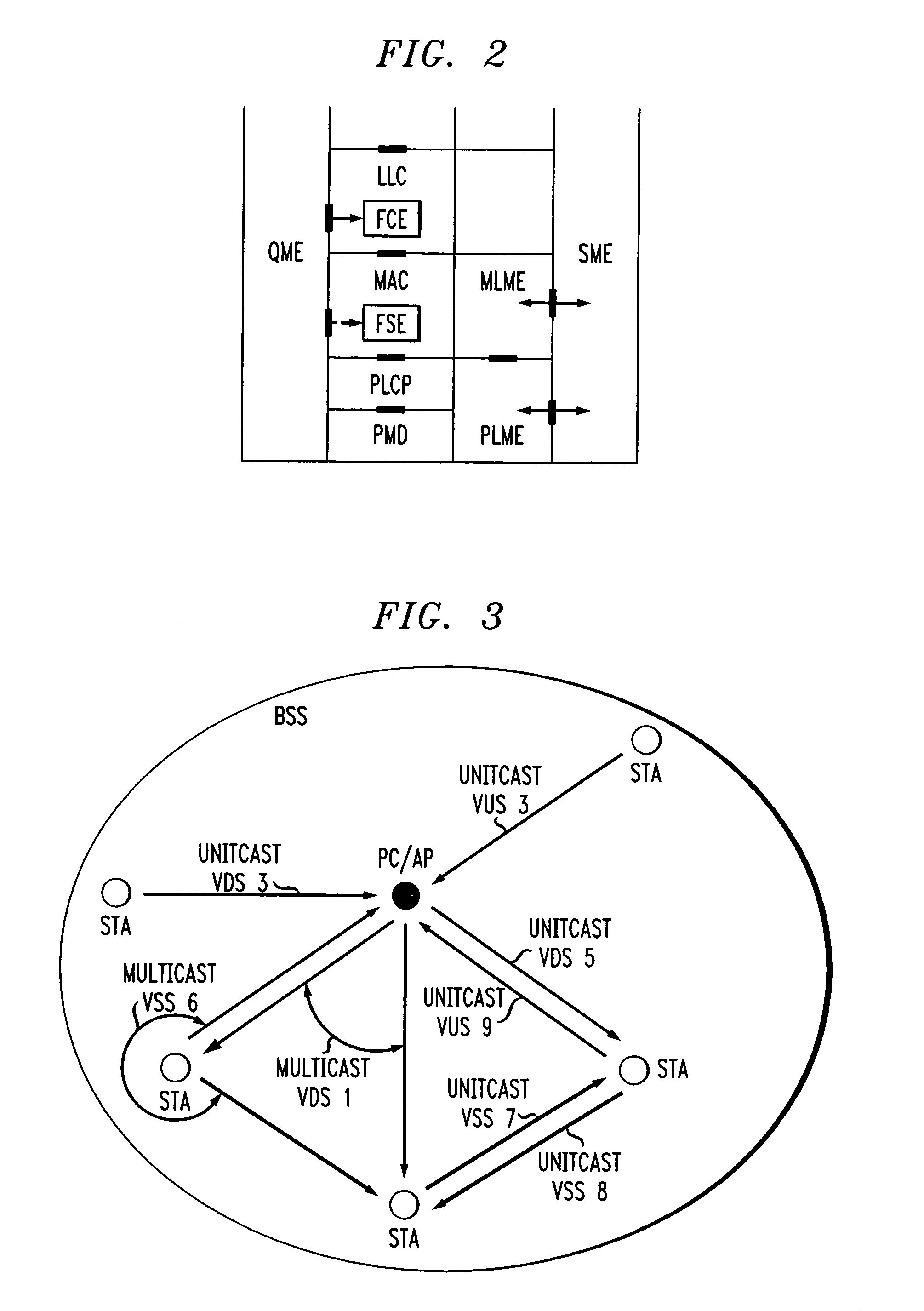

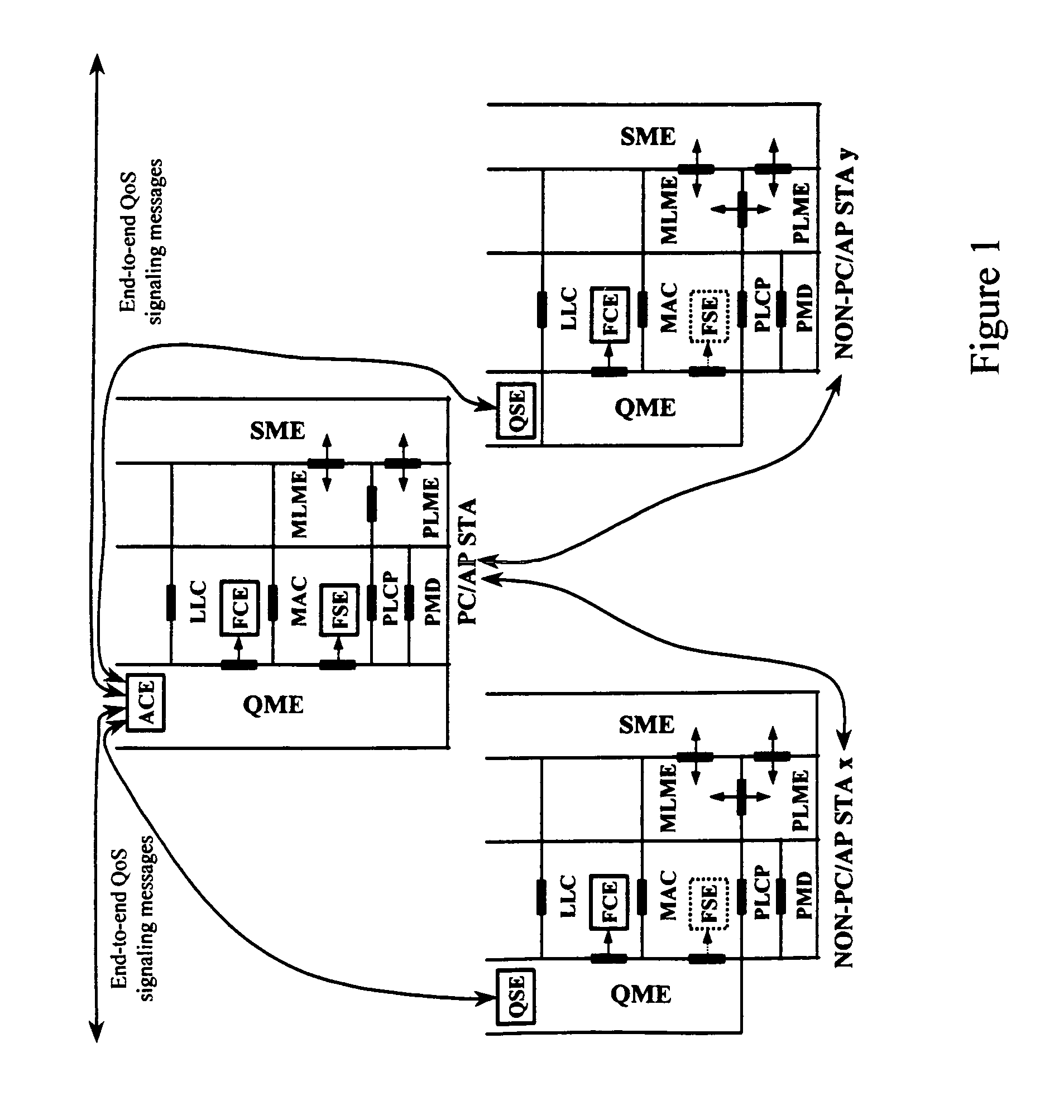

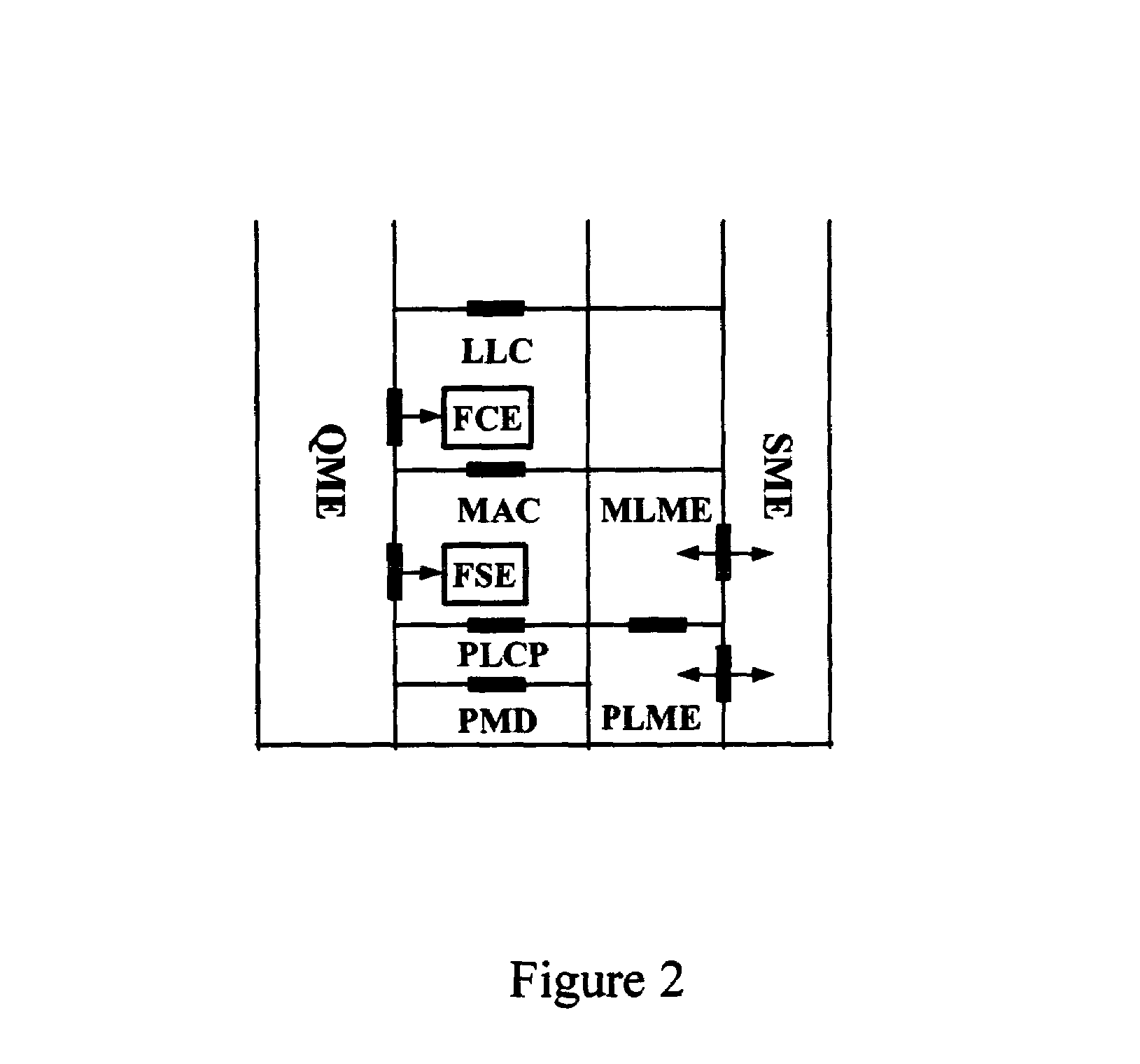

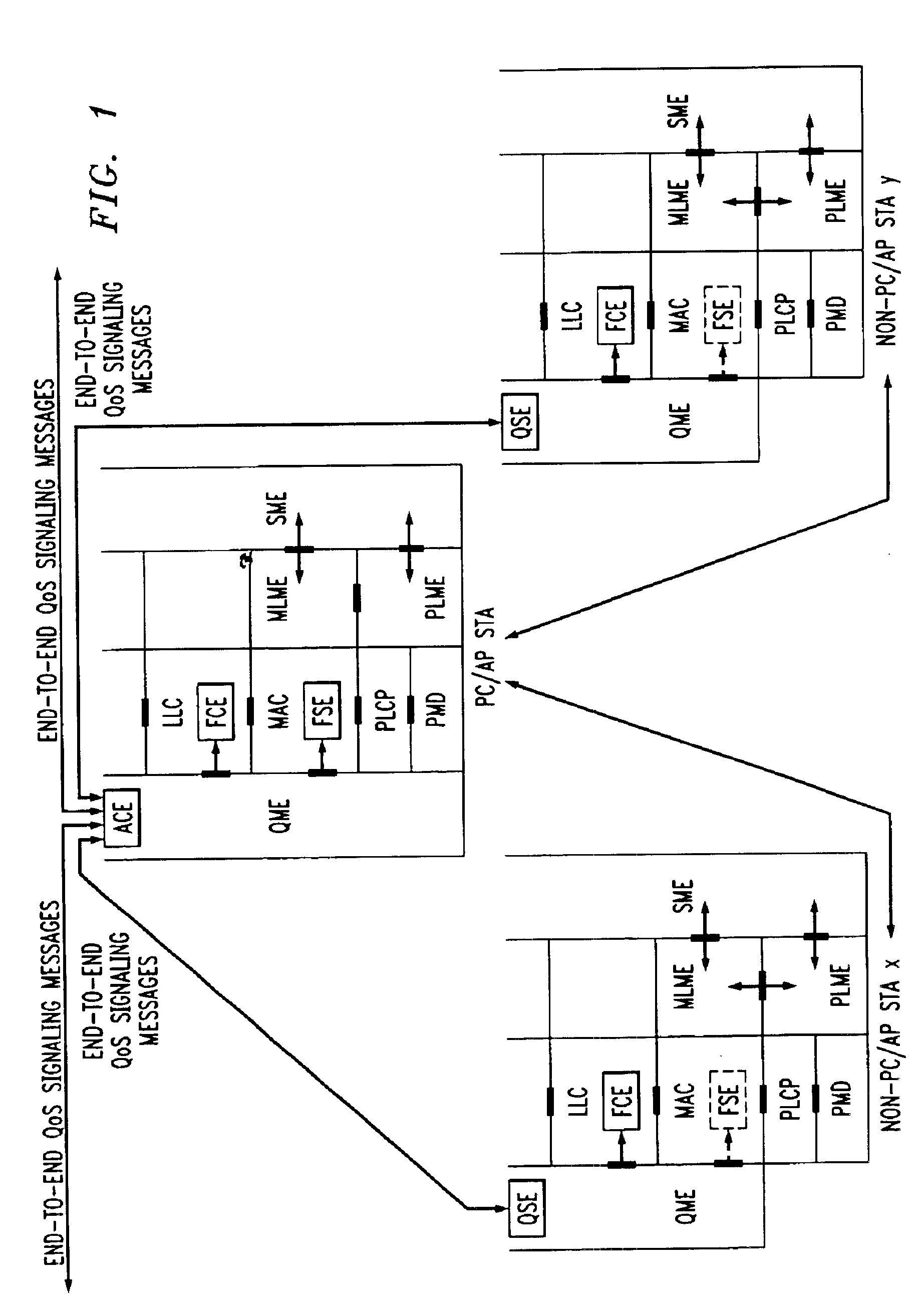

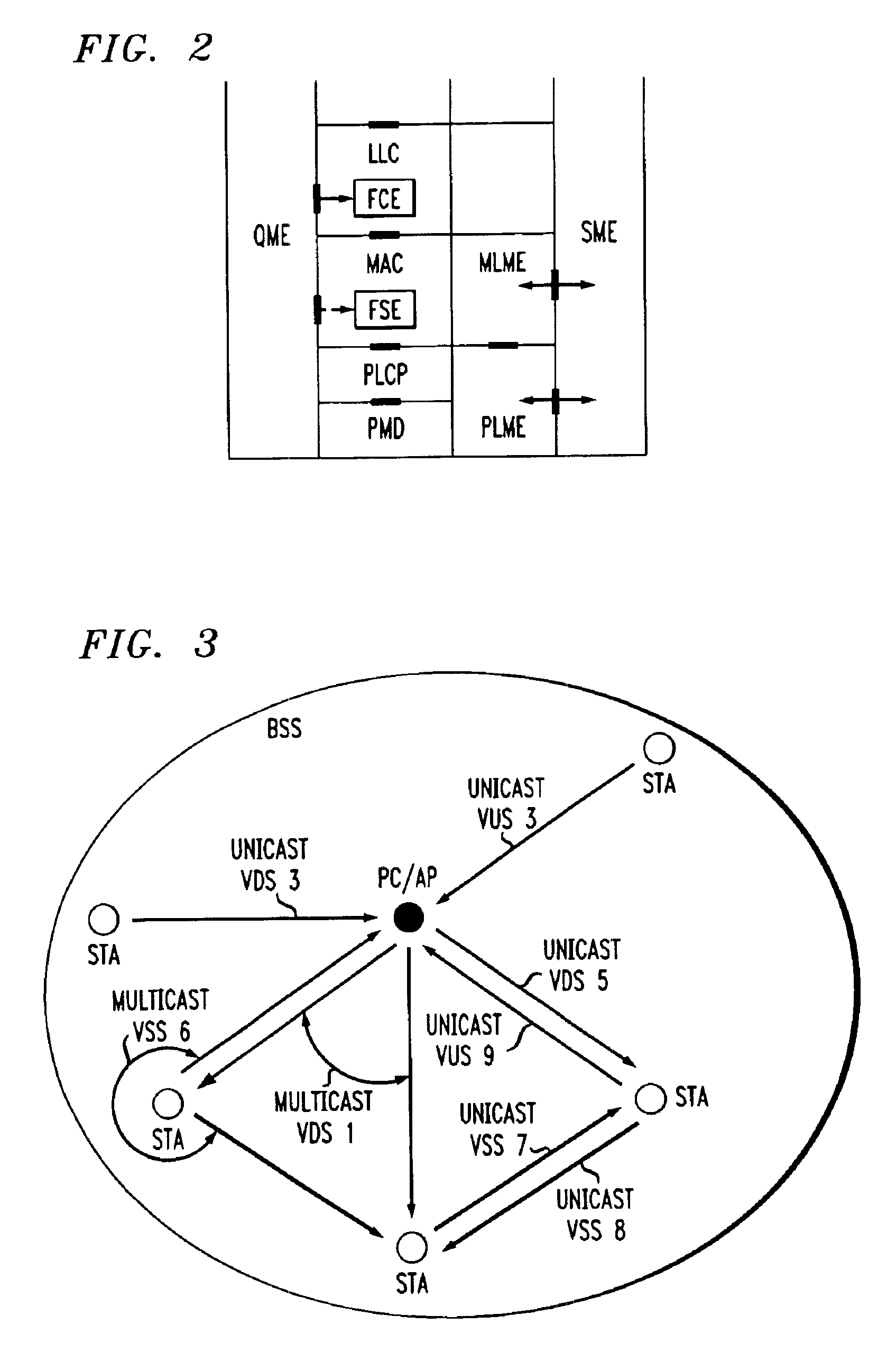

Virtual streams for QoS-driven wireless LANs

InactiveUS7151762B1Network traffic/resource managementNetwork topologiesQuality of serviceBasic service

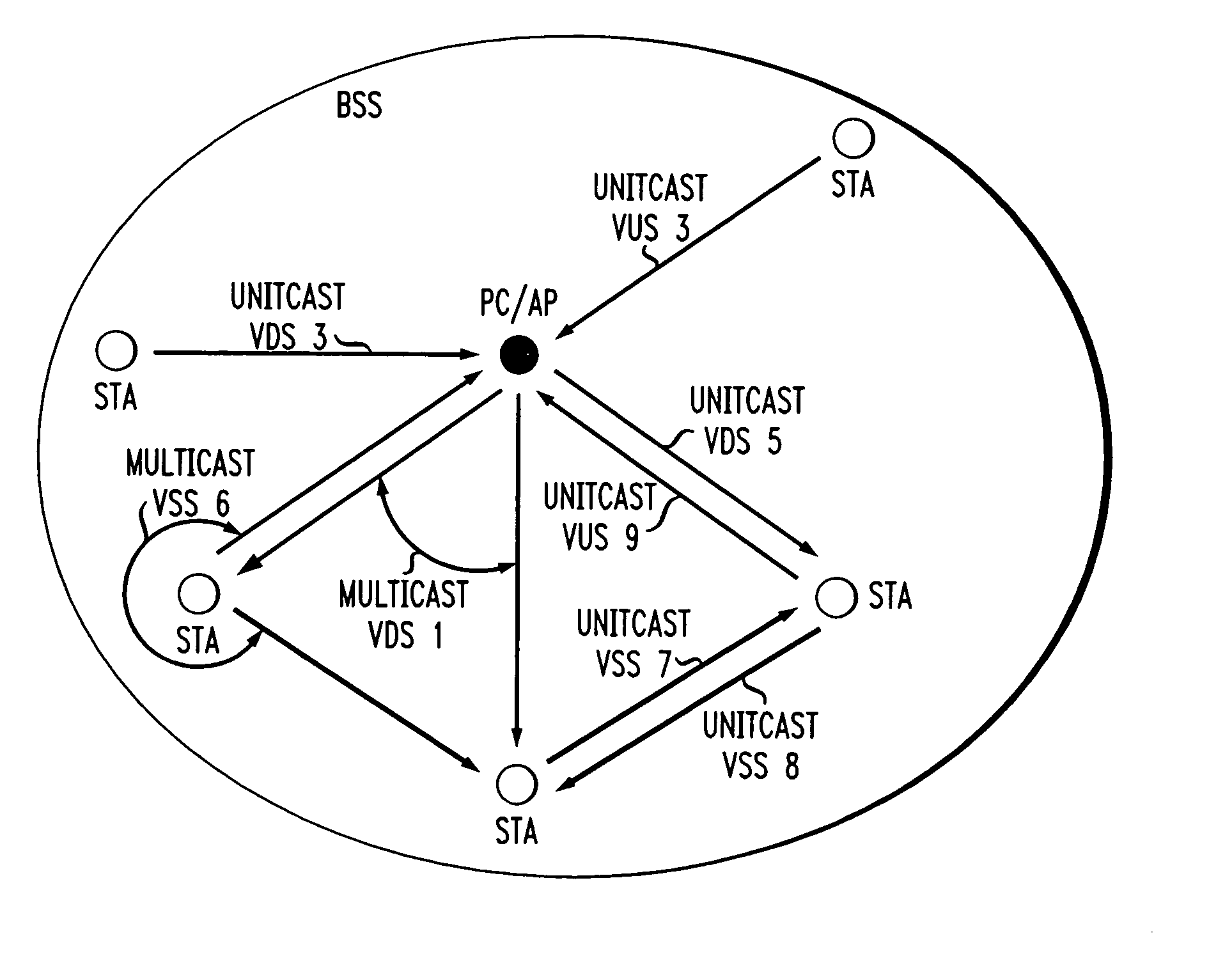

A virtual stream (VS) in a basic service set (BSS) in a wireless local area network (WLAN) that exists solely within the medium access control (MAC) sublayer of the WLAN. The VS includes a unidirectional path in the wireless network between a station sourcing a quality of service (QoS) session and at least one station receiving the QoS session in the same BSS. The VS is defined by a VS identifier (VSID) that is unique within and local to the BSS, an address of the sourcing station, and an address of the at least one receiving station. The VS can be a virtual down-stream (VDS), a virtual up-stream (VUS) or a virtual side-stream (VSS). The VS can be a unitcast or a multicast VS.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

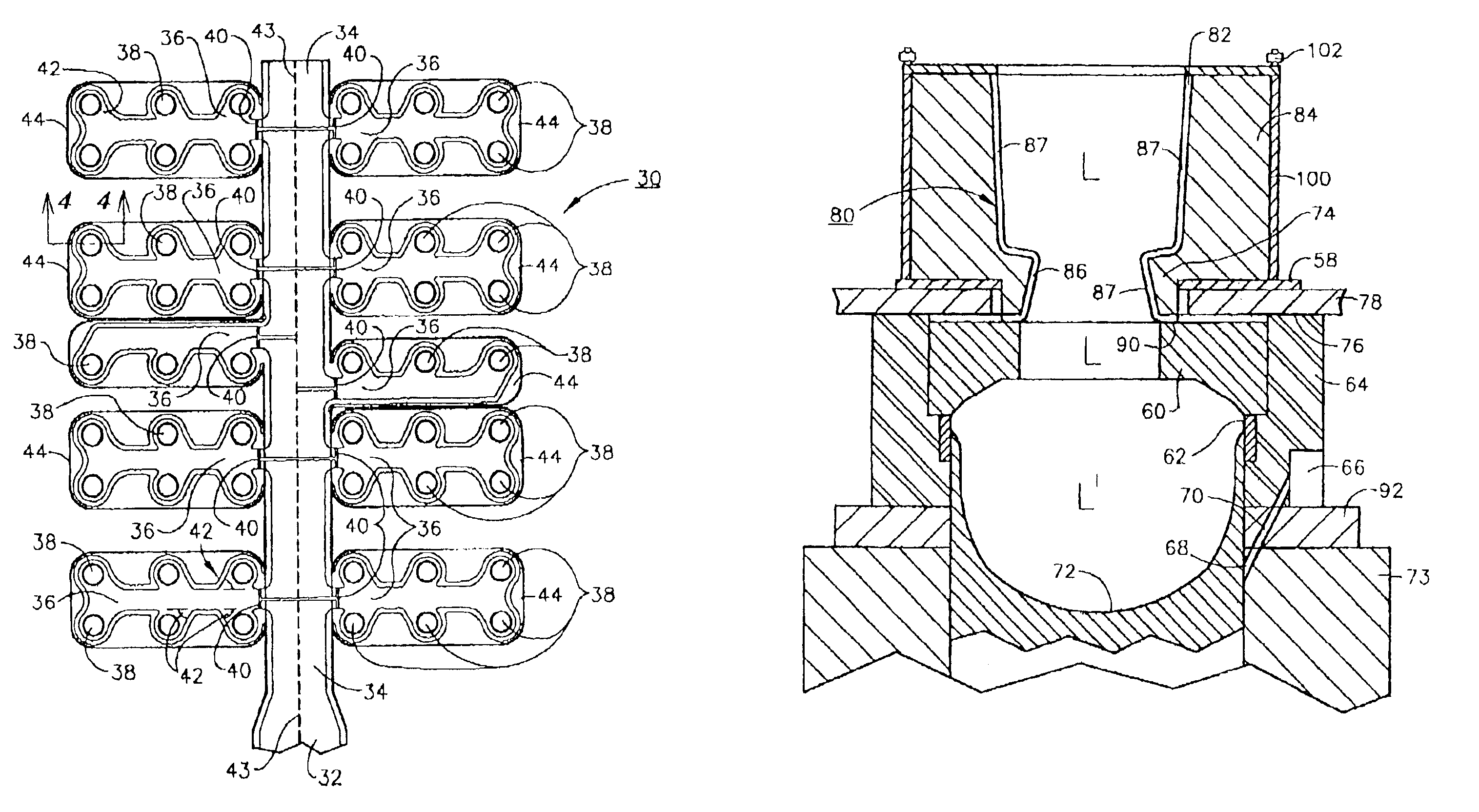

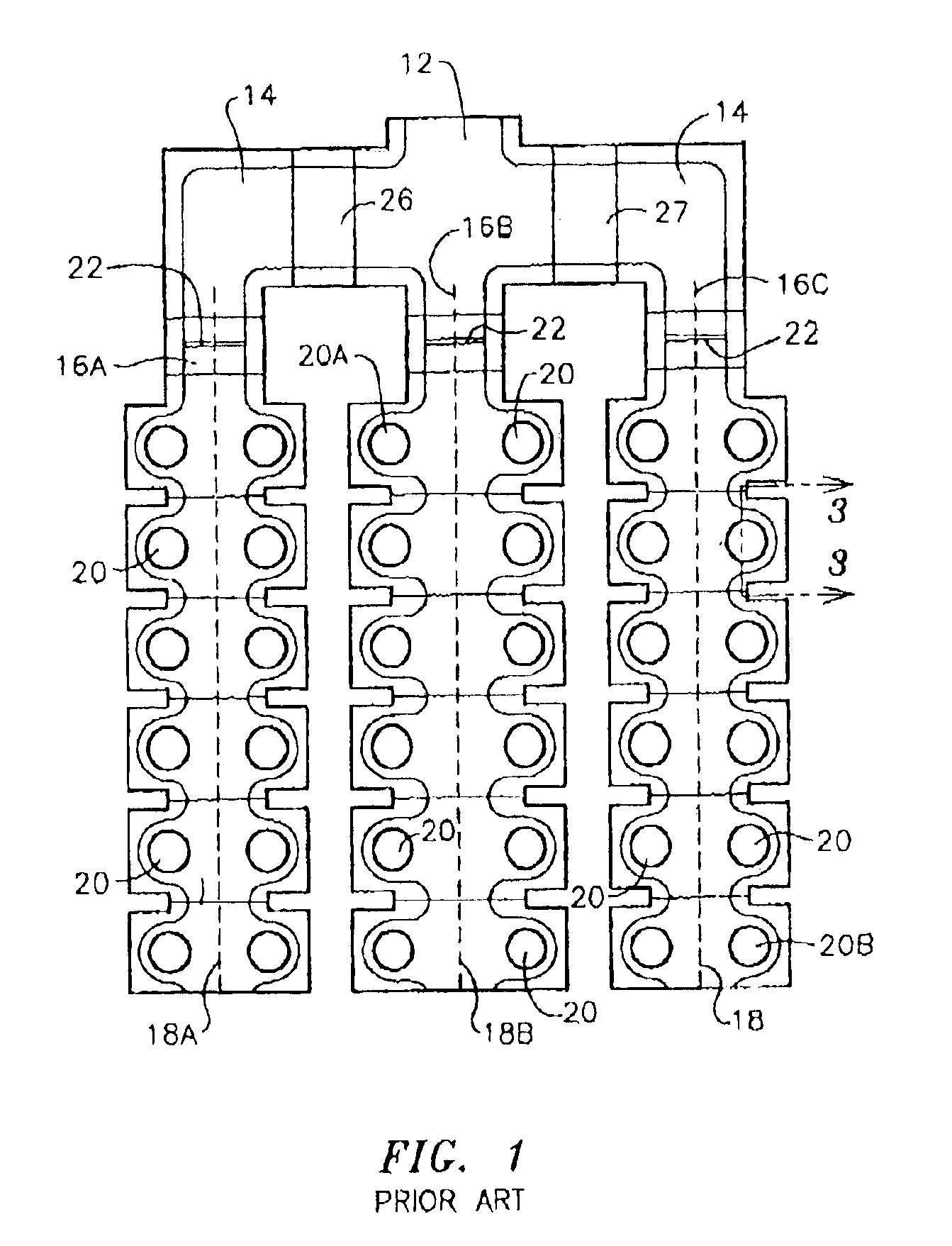

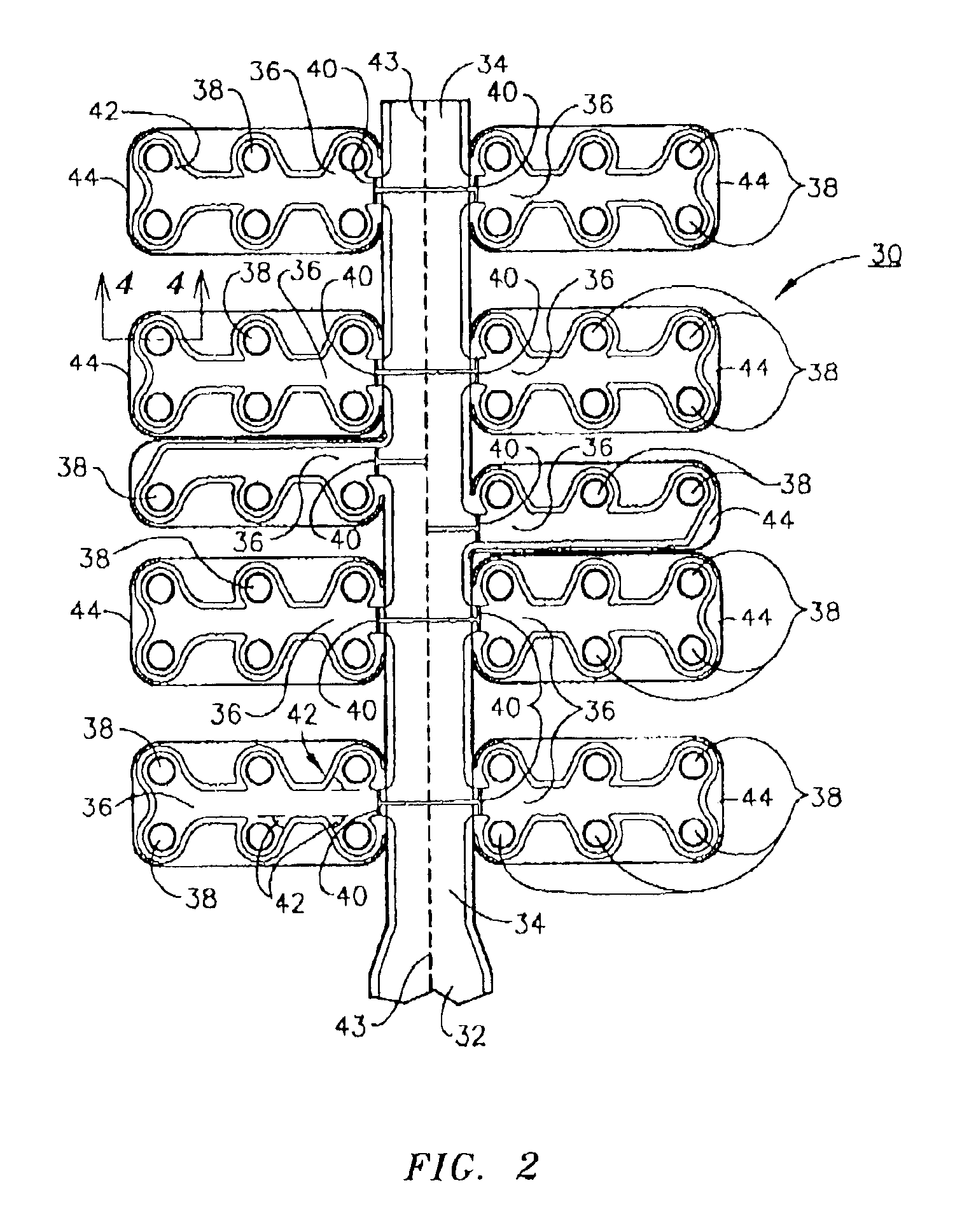

Casting apparatus

A metal distribution system for the simultaneous production of a plurality of logs or round billets from molten metal comprising: 1) a trough for the introduction of molten metal; 2) a plurality of side streams extending from the trough and each of the side streams including a plurality of opposing apertures each of the apertures including a thimble for the shaping of molten metal passing through the trough and the side streams and into the thimbles. A uniform flow of molten metal into the side streams and the individual apertures is provided by the controlled negative angular orientation of the most upstream opposing pair of apertures thereby providing relative uniformity of the temperature of molten metal reaching each of the plurality of apertures. A unique unitized thimble configuration and trough damming arrangement are also described.

Owner:PYROTECK INC

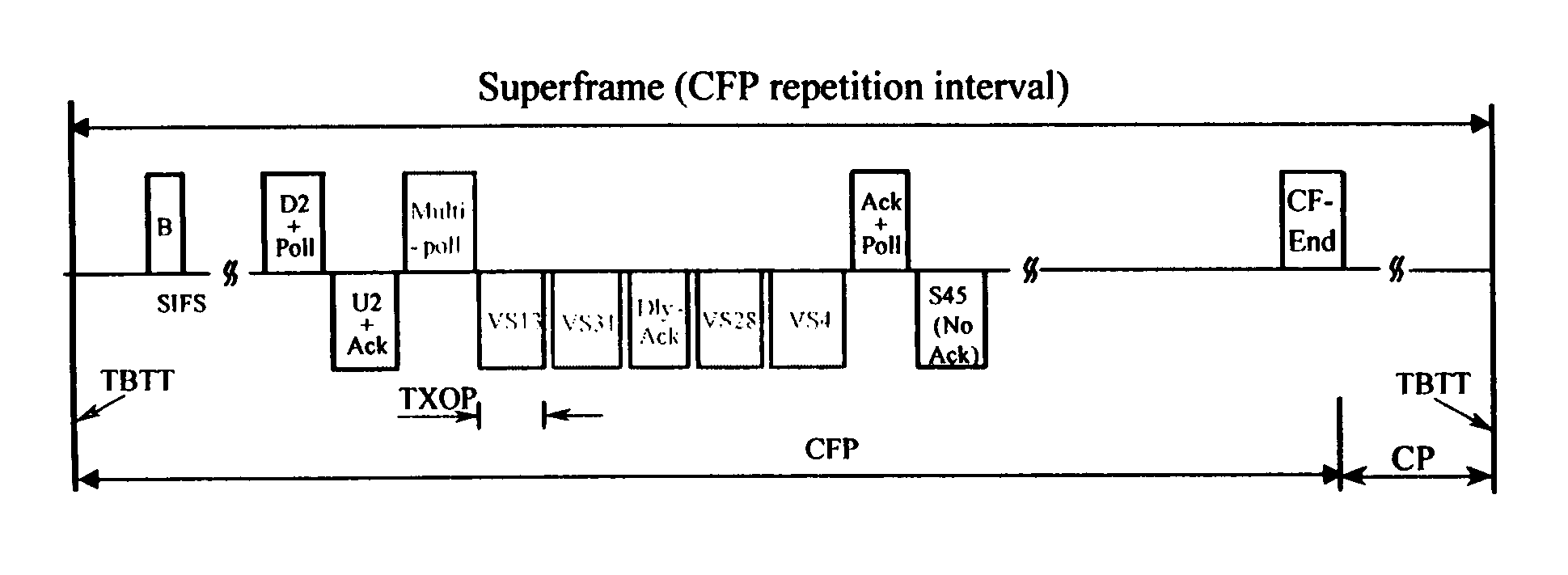

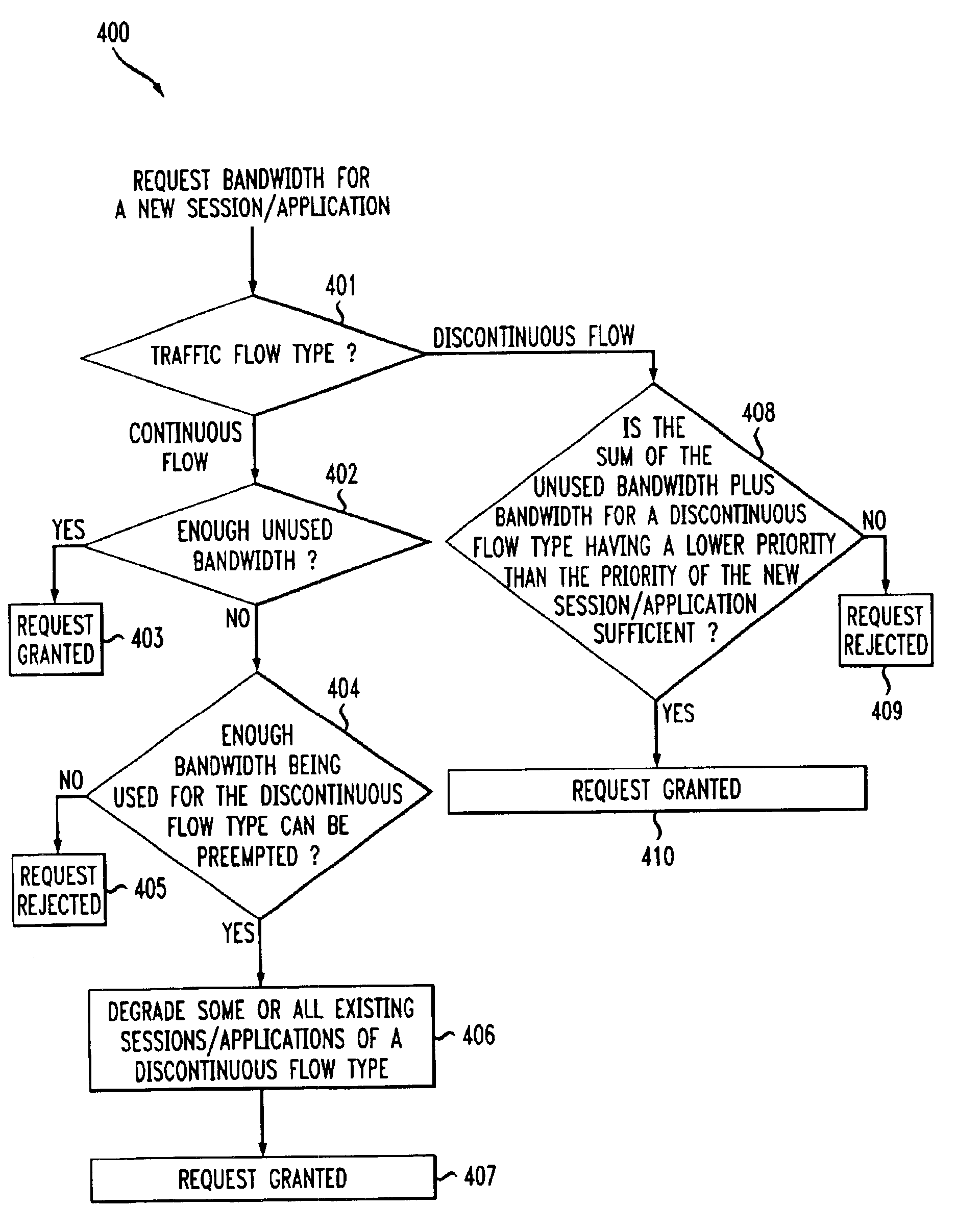

Multipoll for QoS-Driven wireless LANs

InactiveUS7039032B1Enhanced channel accessNetwork traffic/resource managementElectric testing/monitoringQuality of serviceWireless lan

A method and a system are disclosed for providing quality of service (QoS)-driven channel access within a basic service set (BSS) in a wireless network. A point coordinator (PC) station determines whether at least one of upstream traffic and side-stream traffic is scheduled to be transmitted from at least one non-PC station At least one available TO is allocated to each selected non-PC having at least one traffic to transmit. A multipoll frame containing information relating to at least two allocated TOs is then sent from the PC station containing information relating to each allocated TO.

Owner:AT&T INTPROP I L P

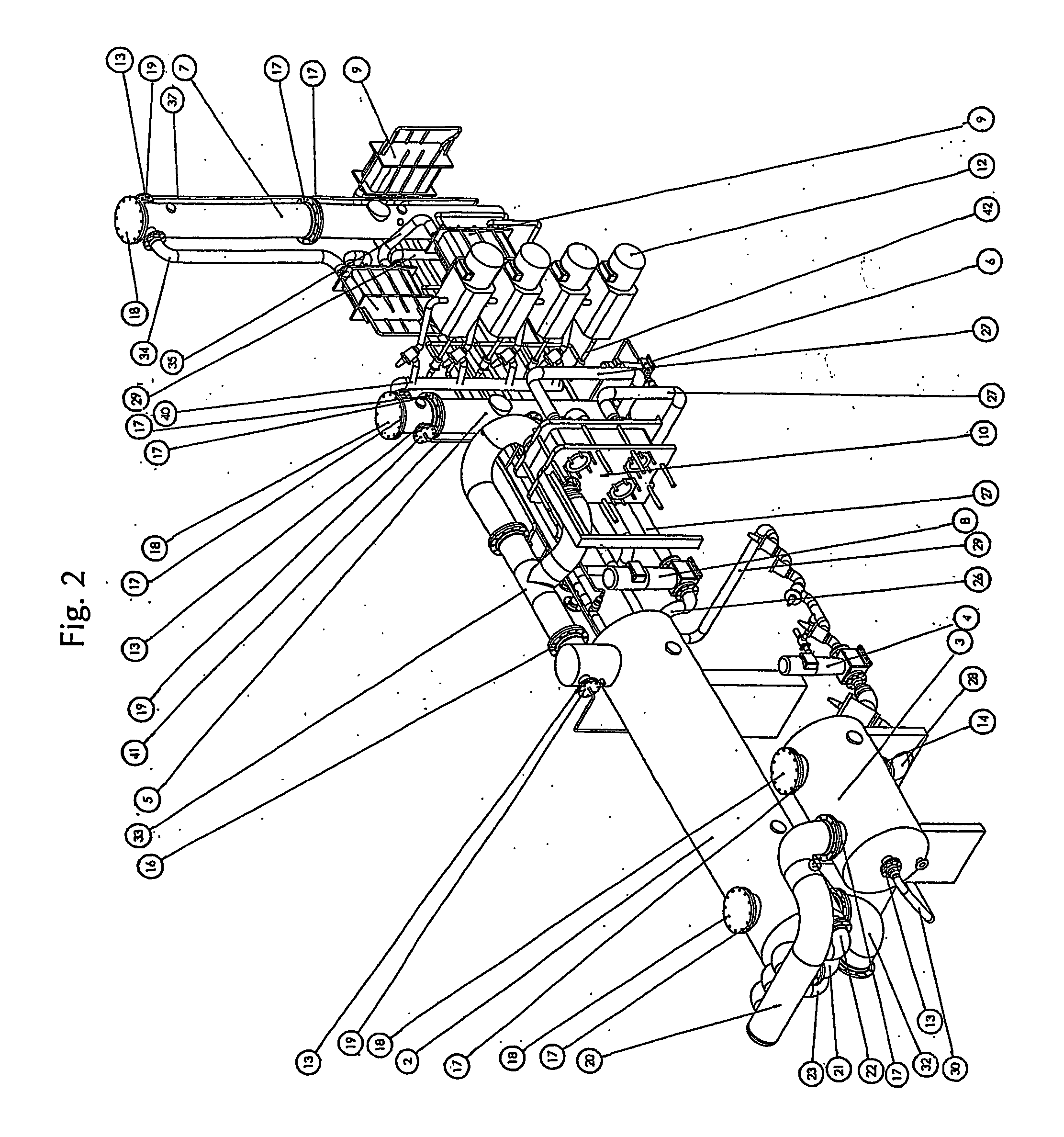

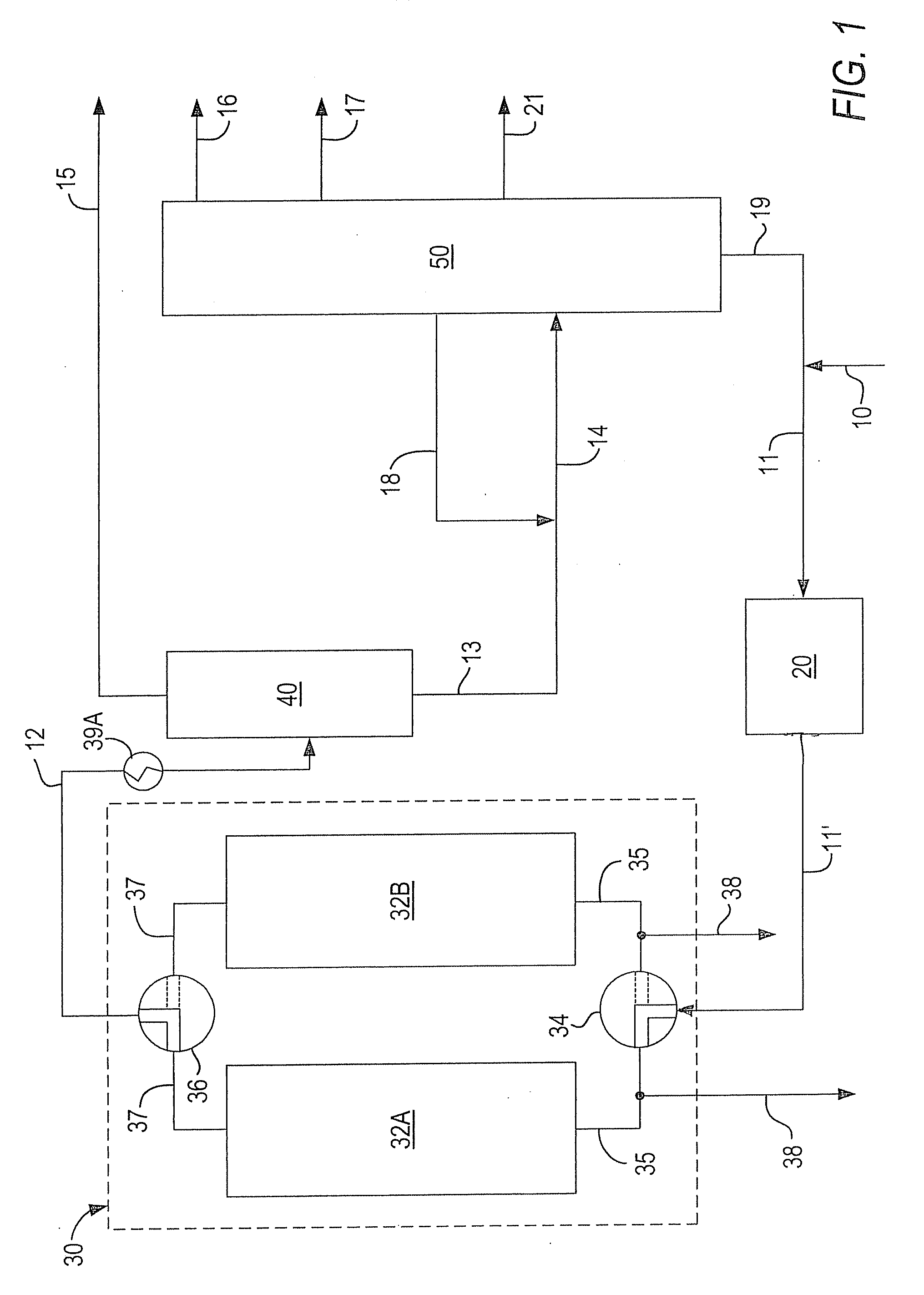

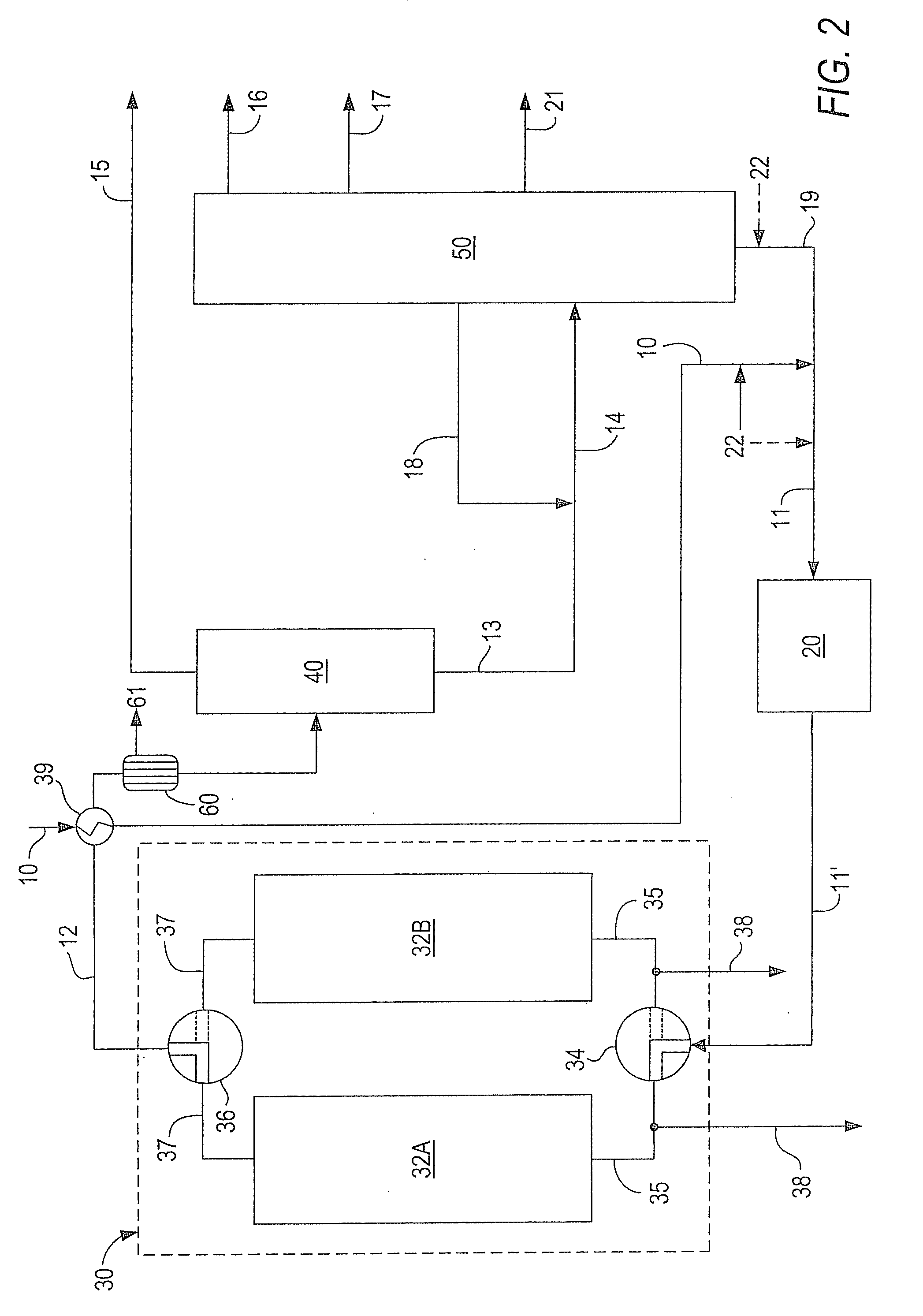

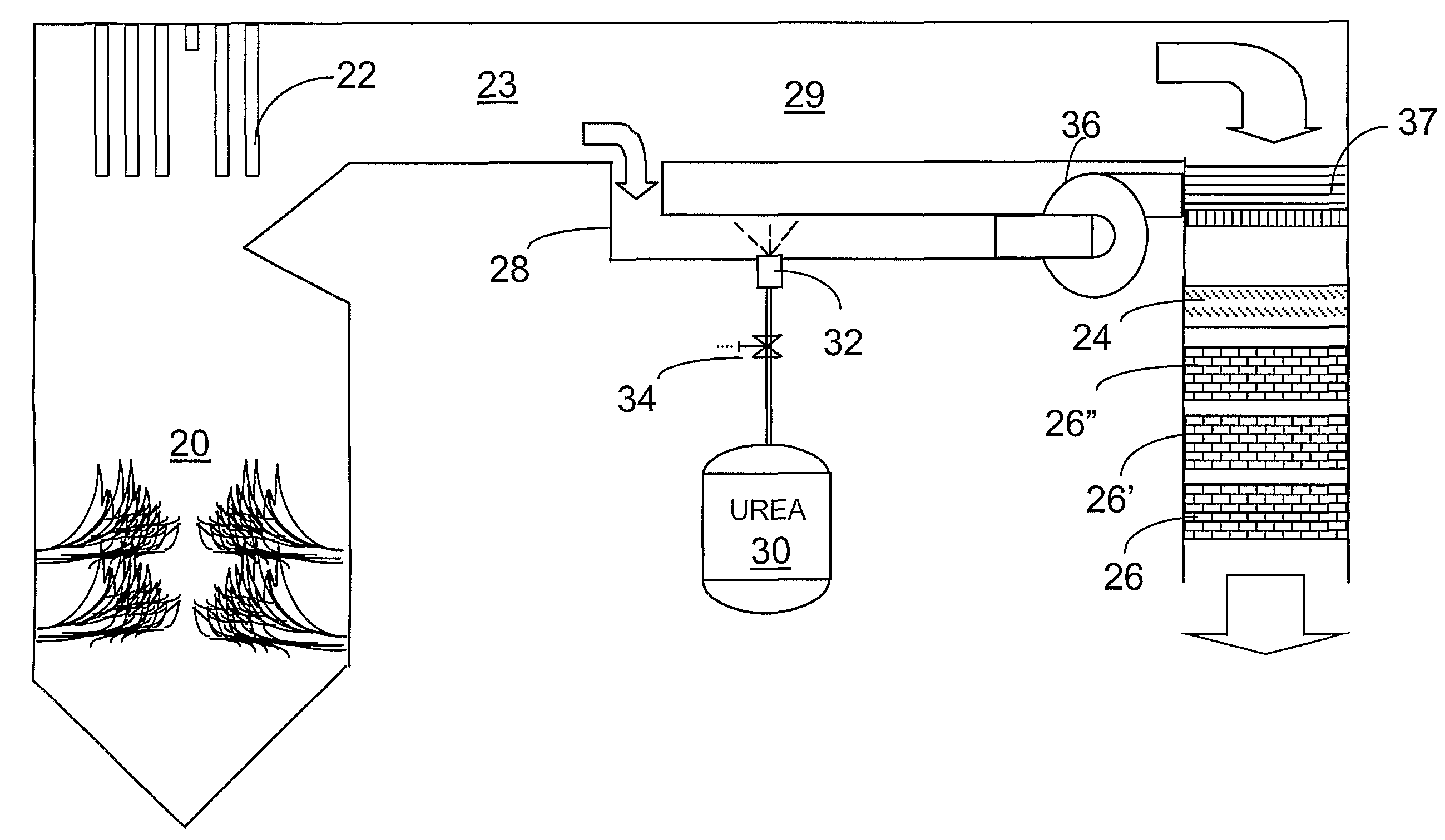

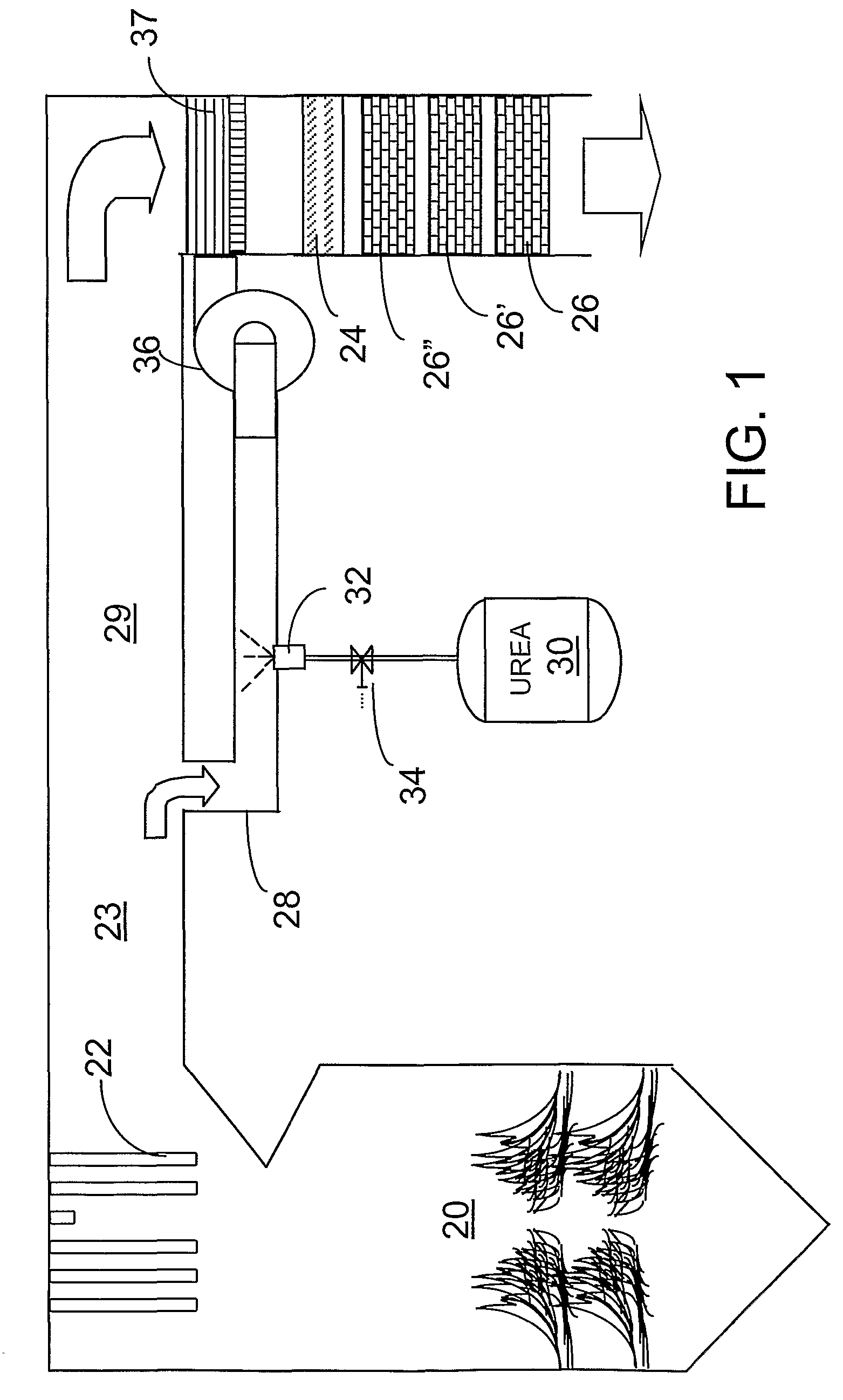

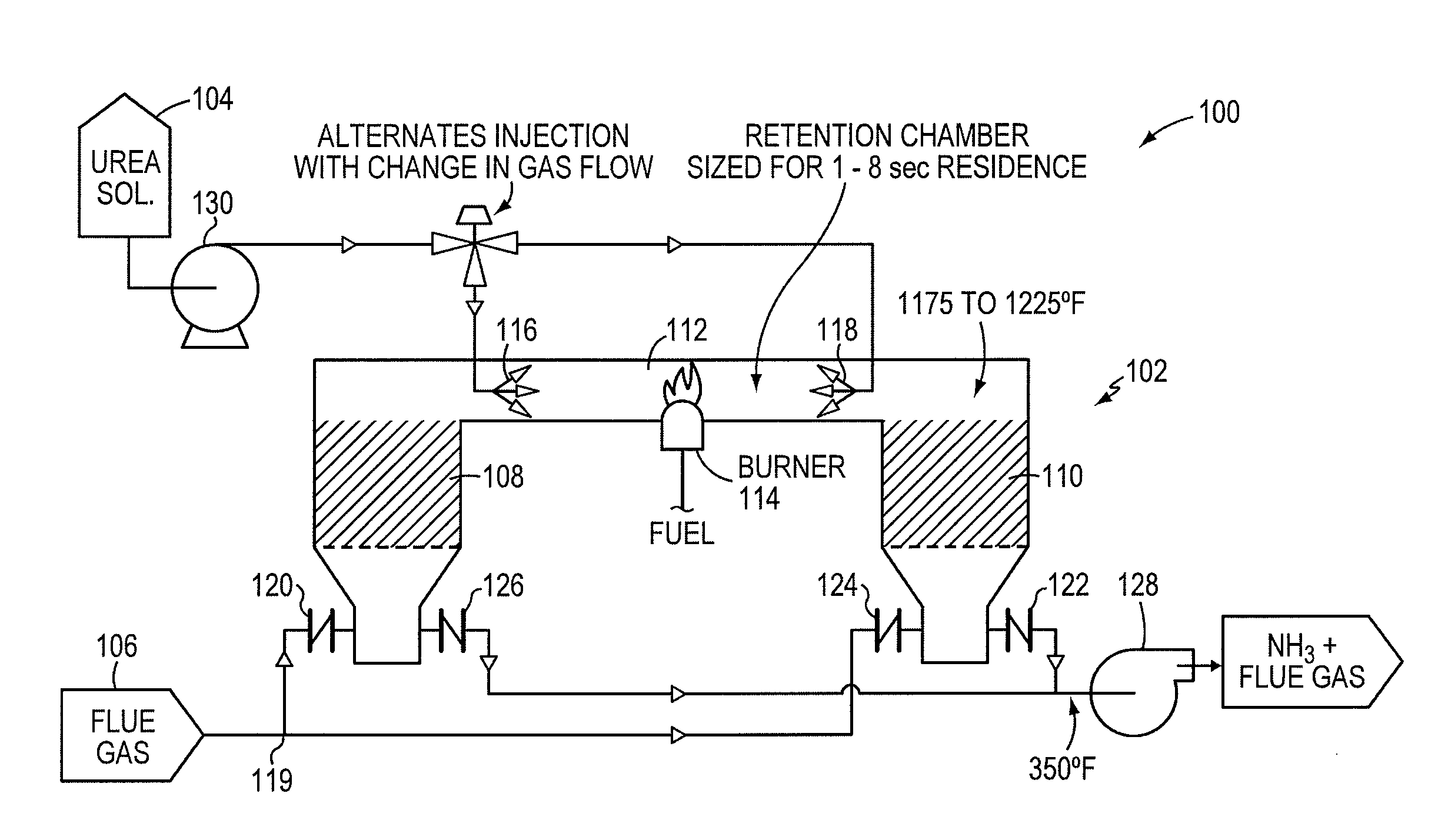

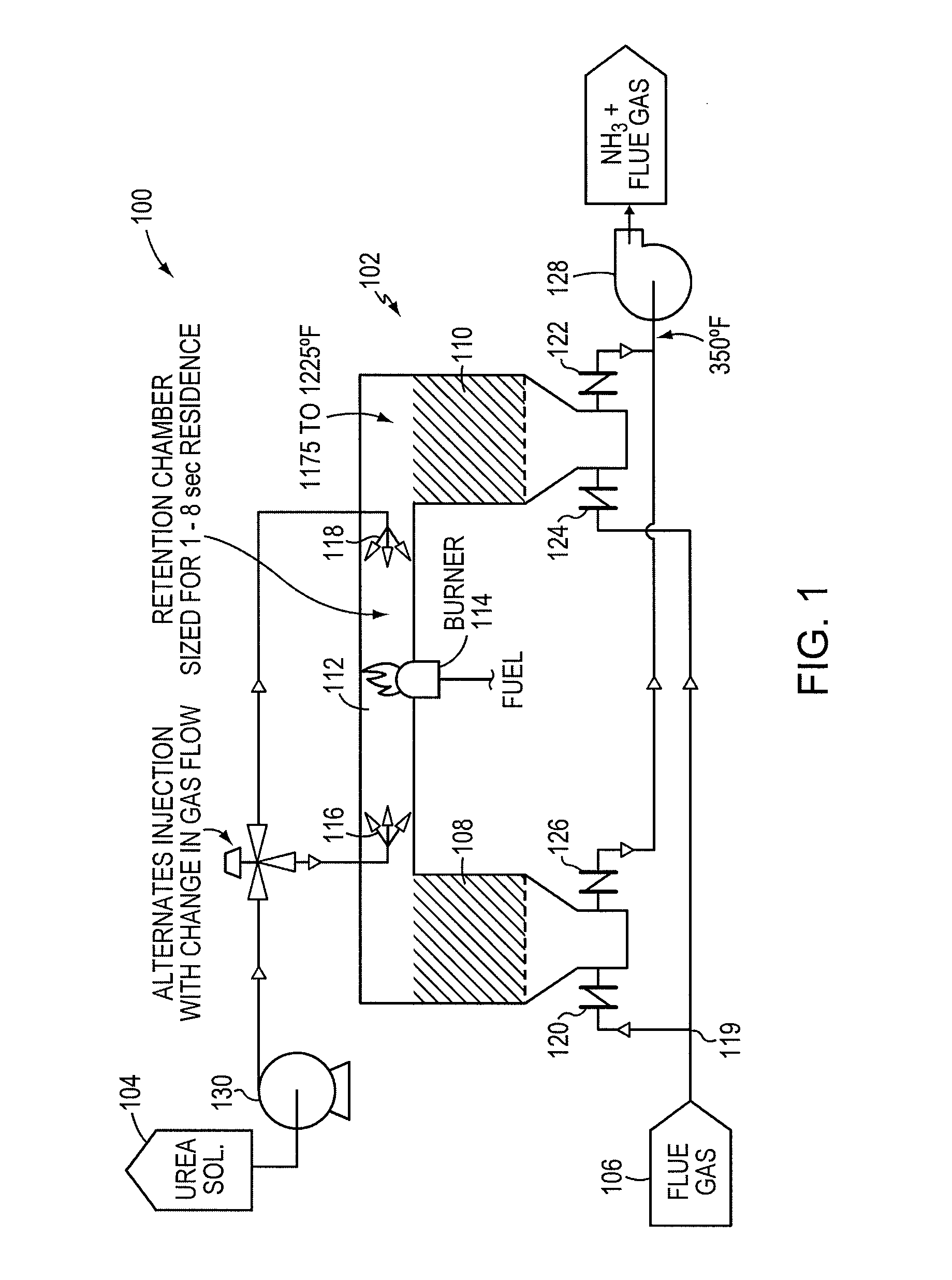

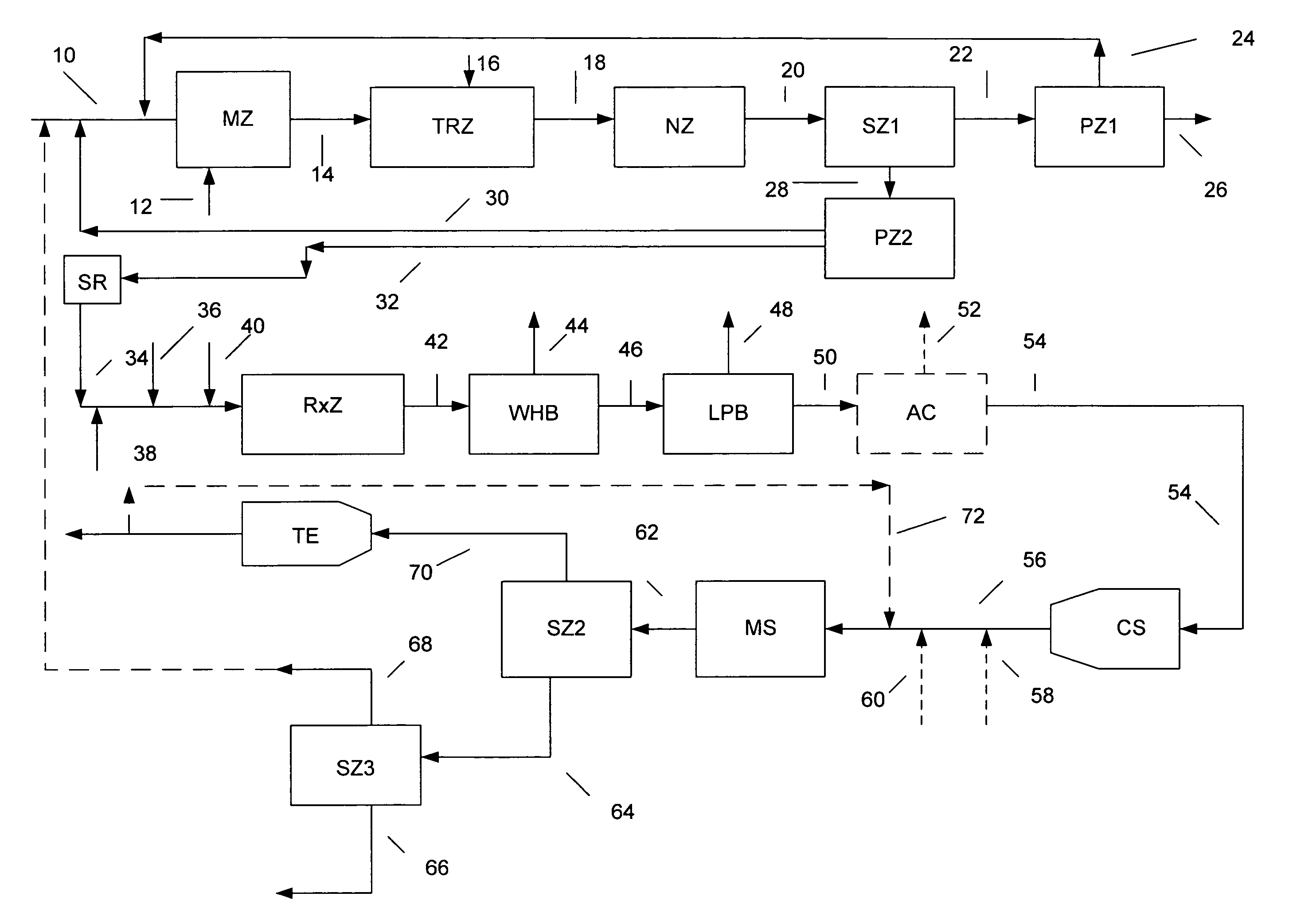

Selective catalytic reduction of nox enabled by sidestream urea decomposition

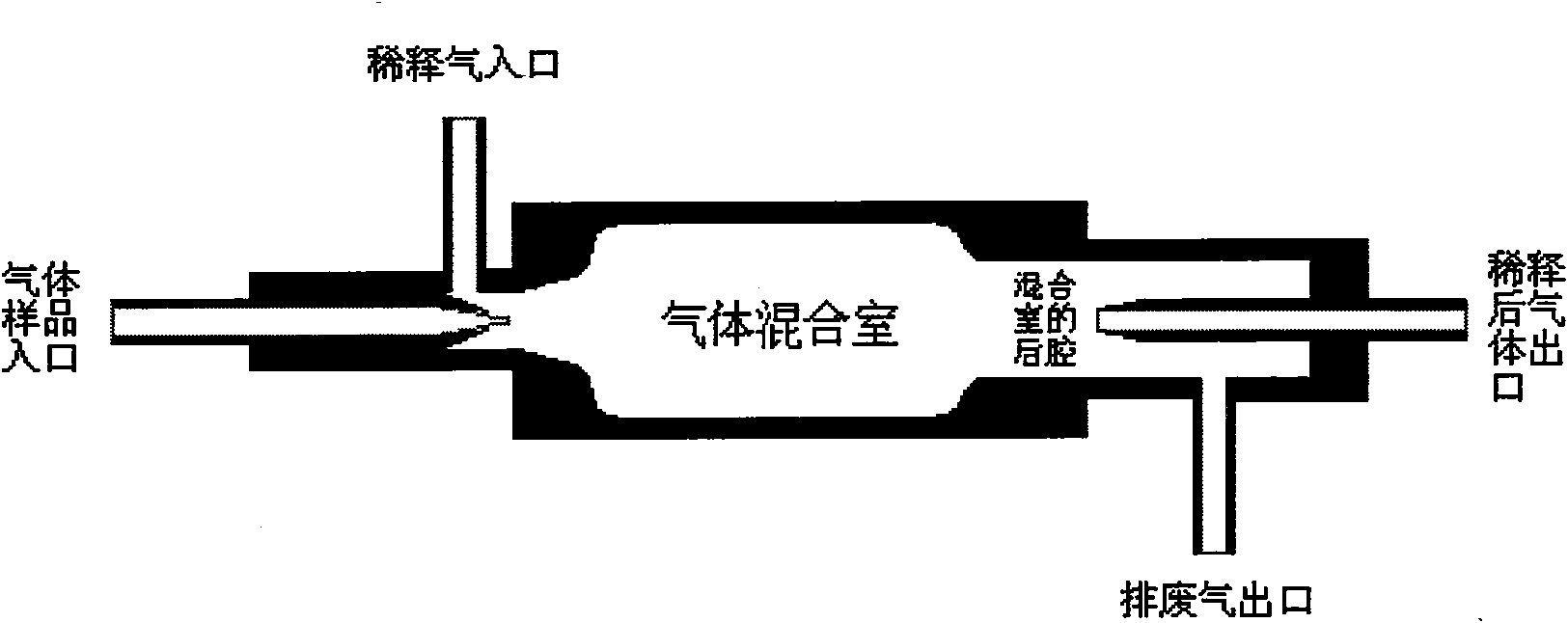

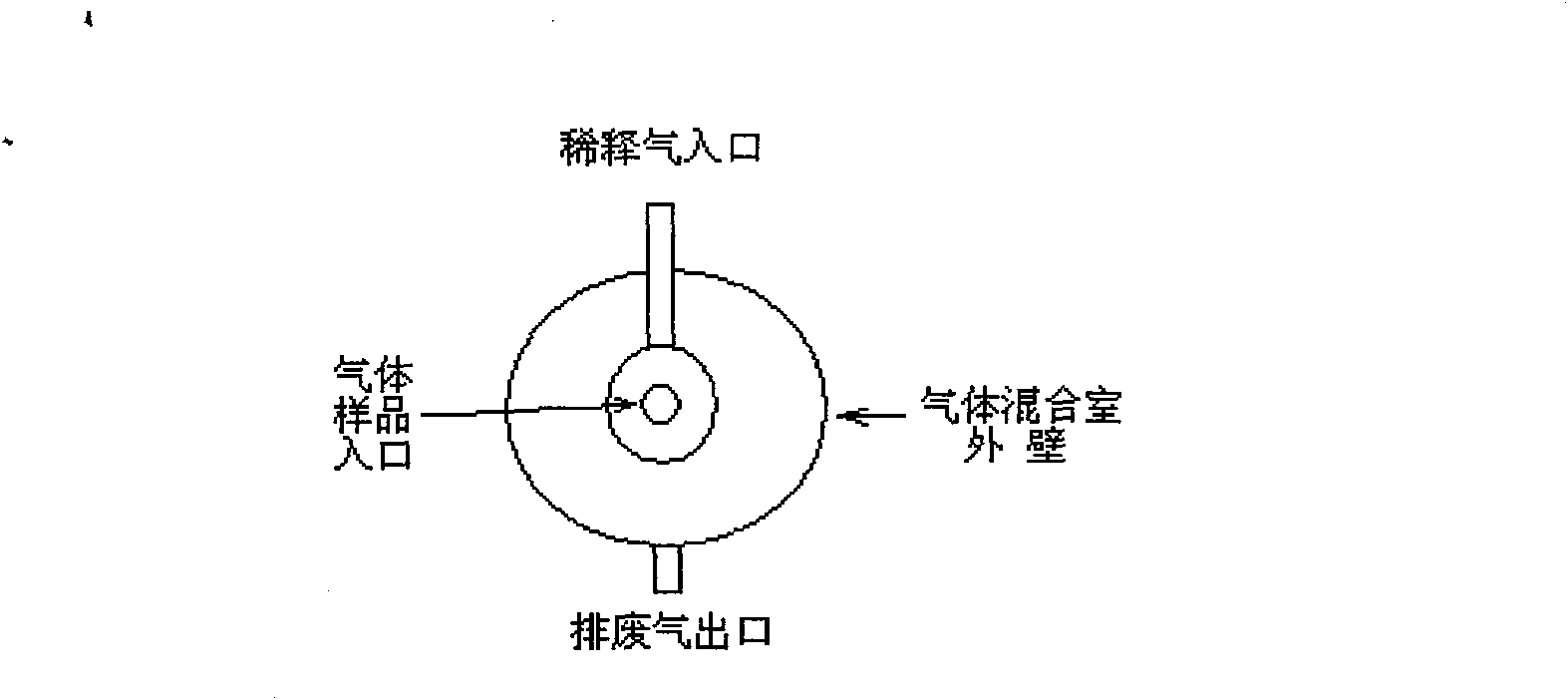

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

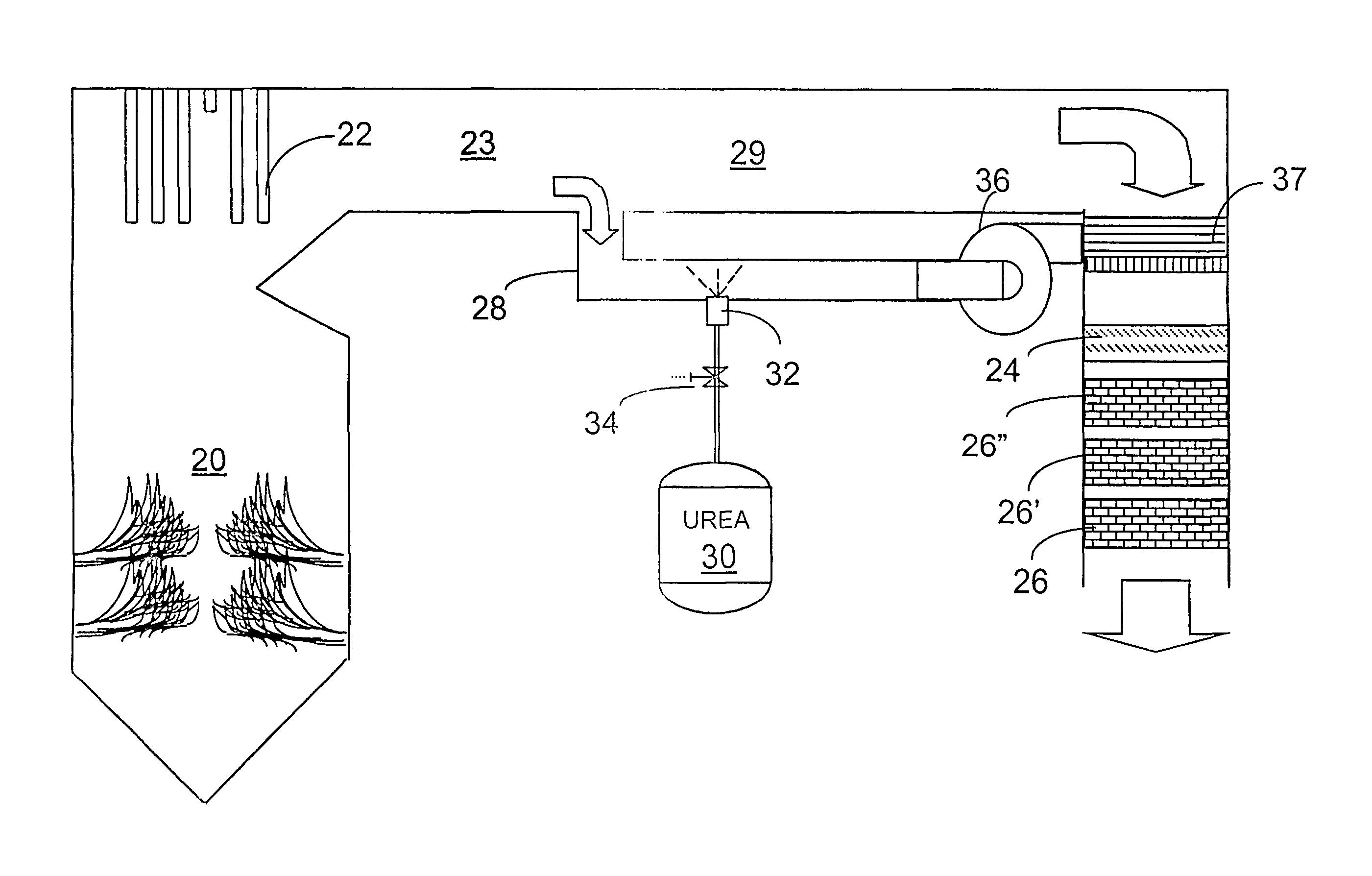

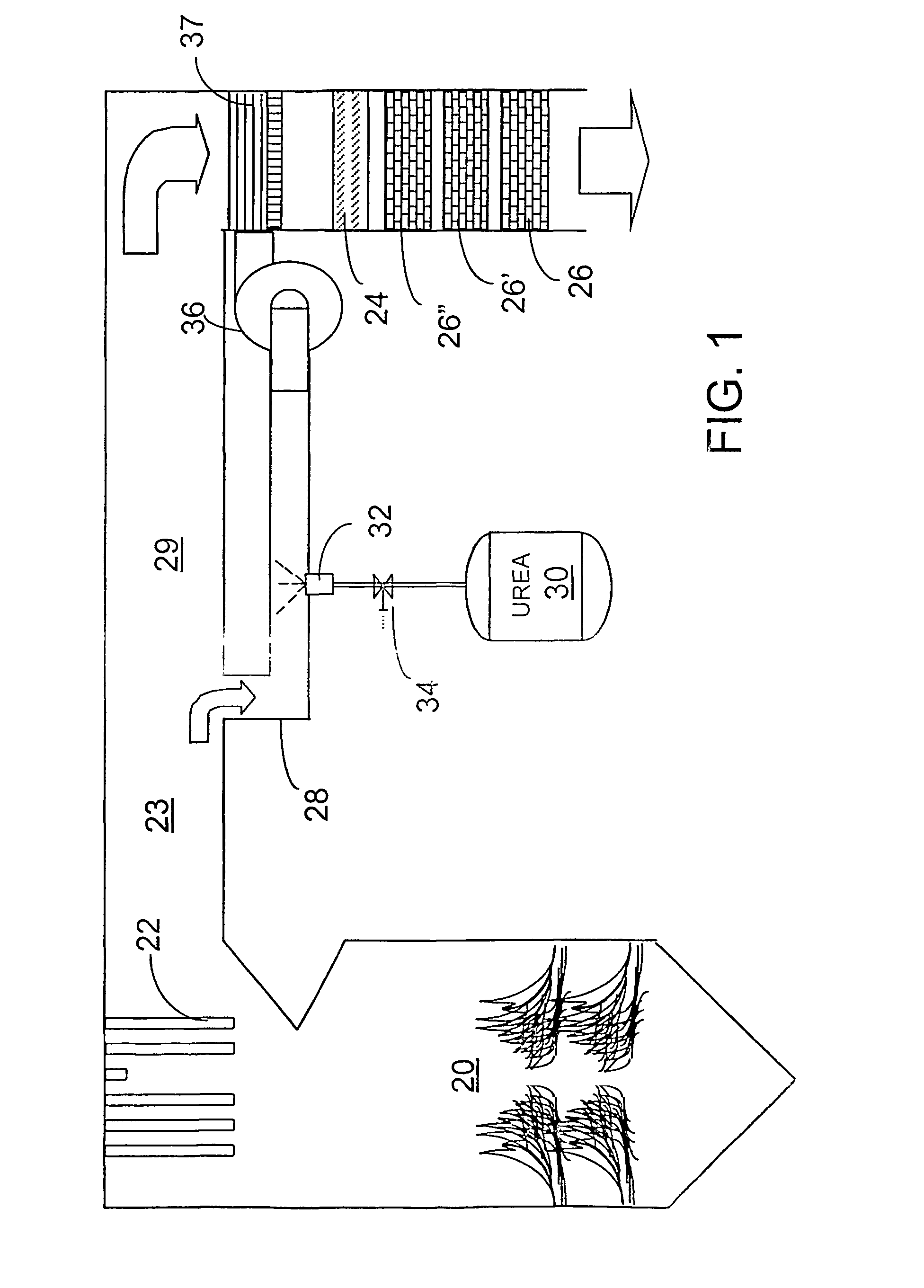

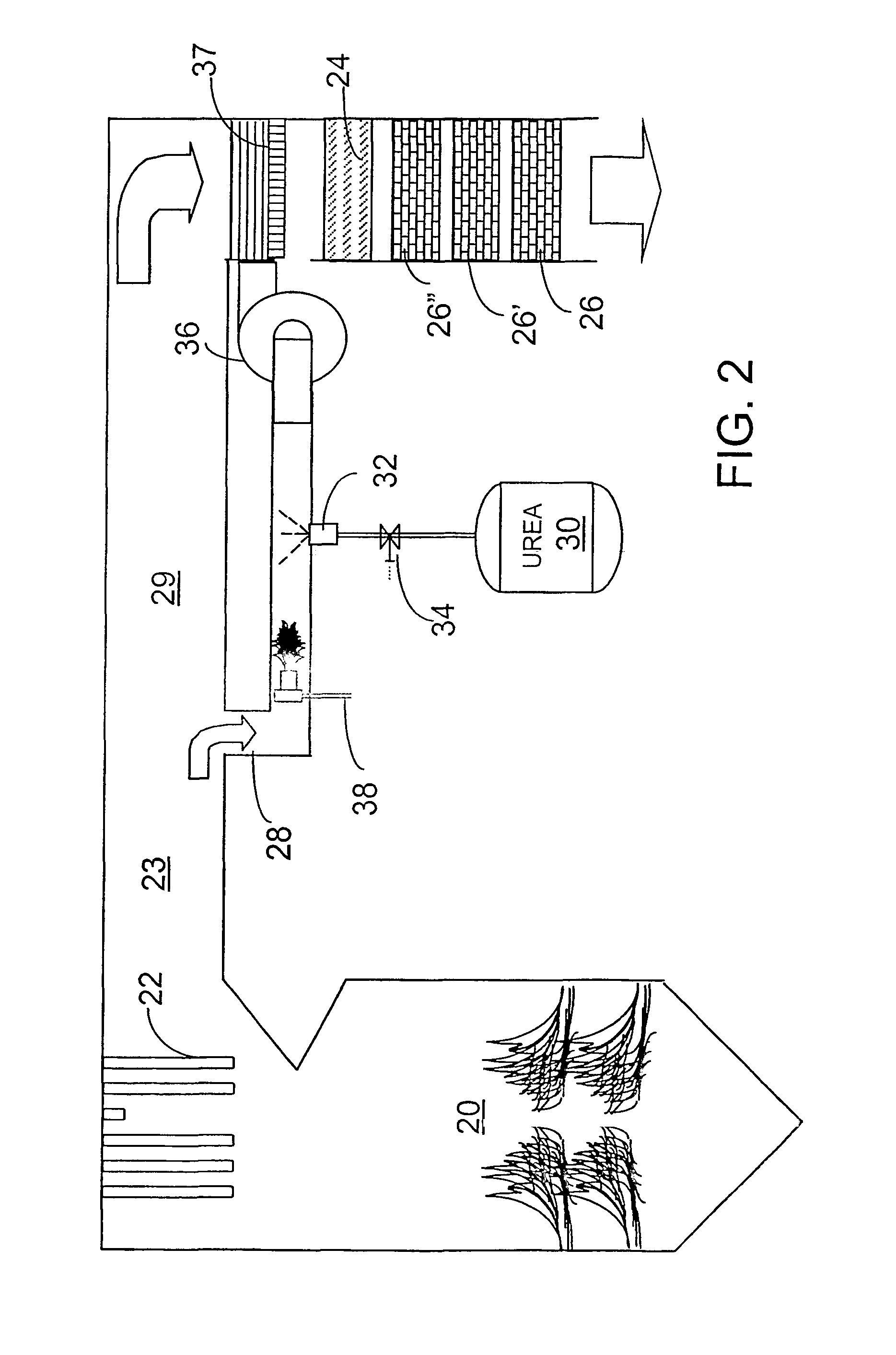

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

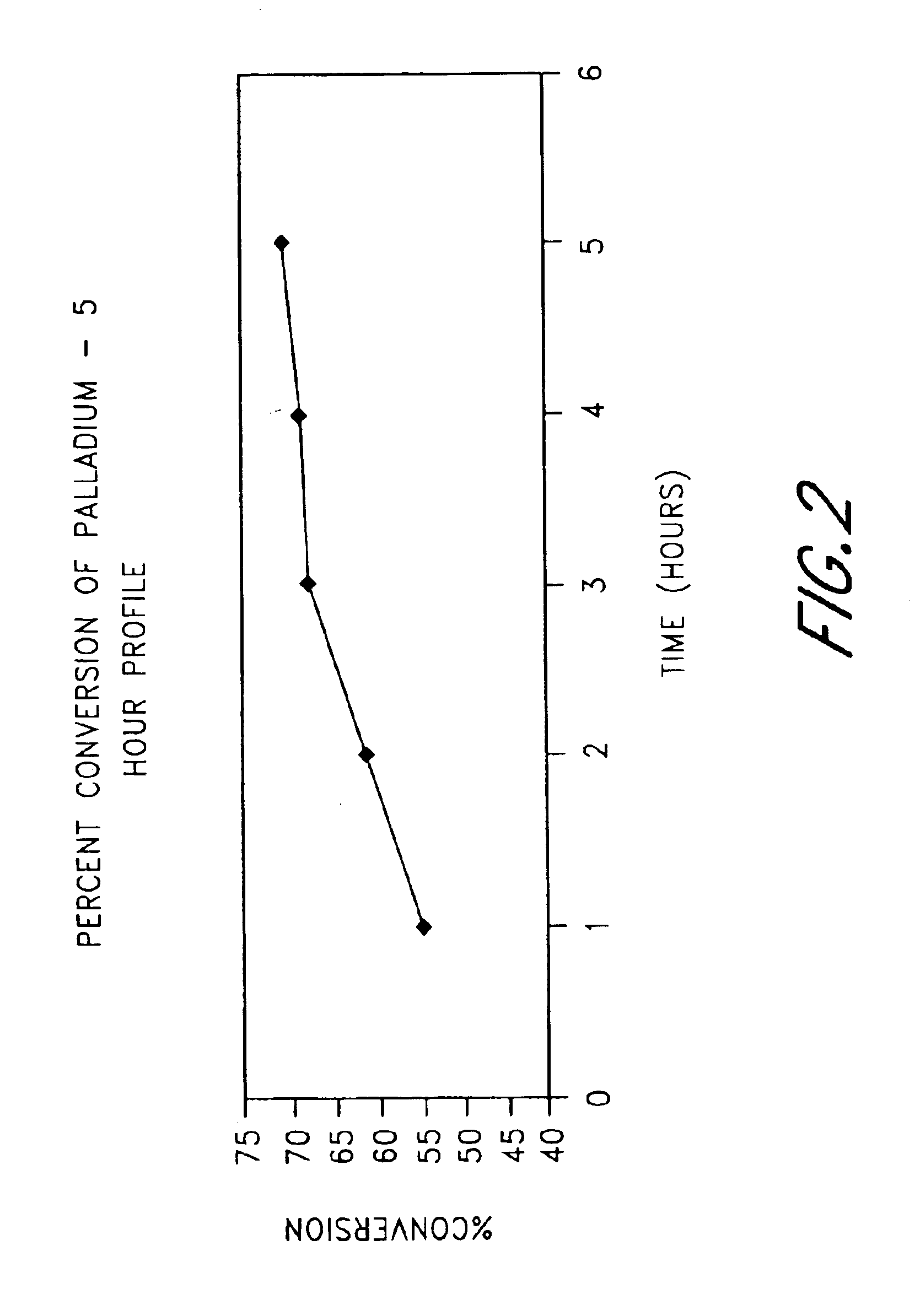

Method of making a smoking composition

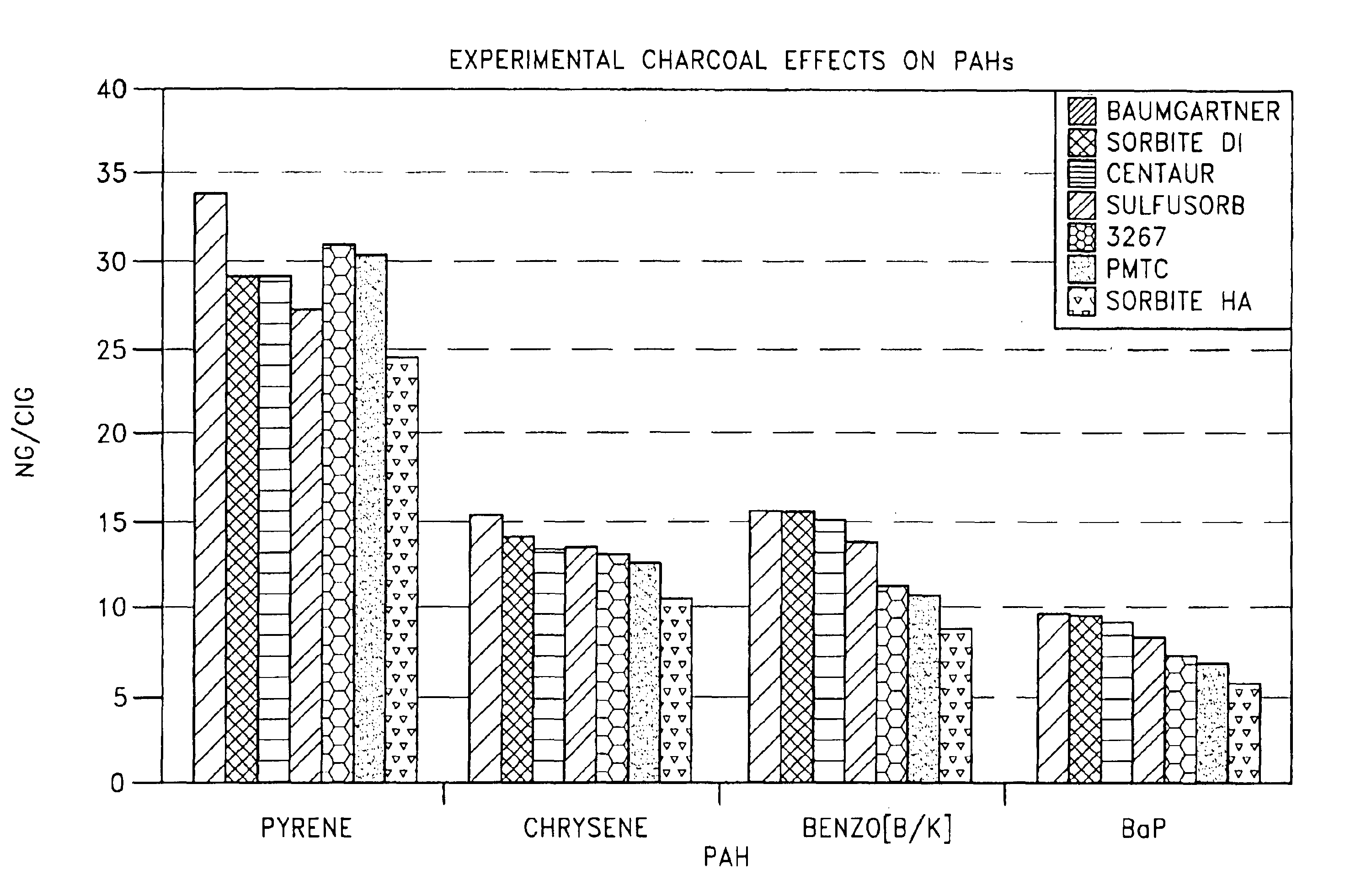

The present invention relates to smoking articles such as cigarettes, and in particular to catalytic systems containing metallic or carbonaceous particles that reduce the content of certain harmful or carcinogenic substances, including polyaromatic hydrocarbons, tobacco-specific nitrosamines, carbazole, phenol, and catechol, in mainstream cigarette smoke and in side stream cigarette smoke.

Owner:VECTOR TOBACCO LLC

RSVP/SBM based side-stream session setup, modification, and teardown for QoS-driven wireless lans

InactiveUS6950397B1Error preventionFrequency-division multiplex detailsQuality of serviceWireless lan

A method and a system are disclosed for setting up, modifying and tearing down a side-stream communication session in a basic service set (BSS) in a wireless network so that the communication session has a defined Quality of Service (QoS). Regarding setting up a side-stream communication session, a first Path message and a first Resv message (Path / Resv message) of a RSVP protocol is detected at a designated subnet bandwidth manager (DSBM) in a station having a point coordinator (PC). The first Resv message originates from a RSVP agent of a destination non-PC station in the BSS and requests resource reservation for setting up a side-stream session between a source non-PC station and at least one destination non-PC station in the same BSS. The DSBM extracts a QoS parameter set and a classifier from the first Path / Resv message for the session.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

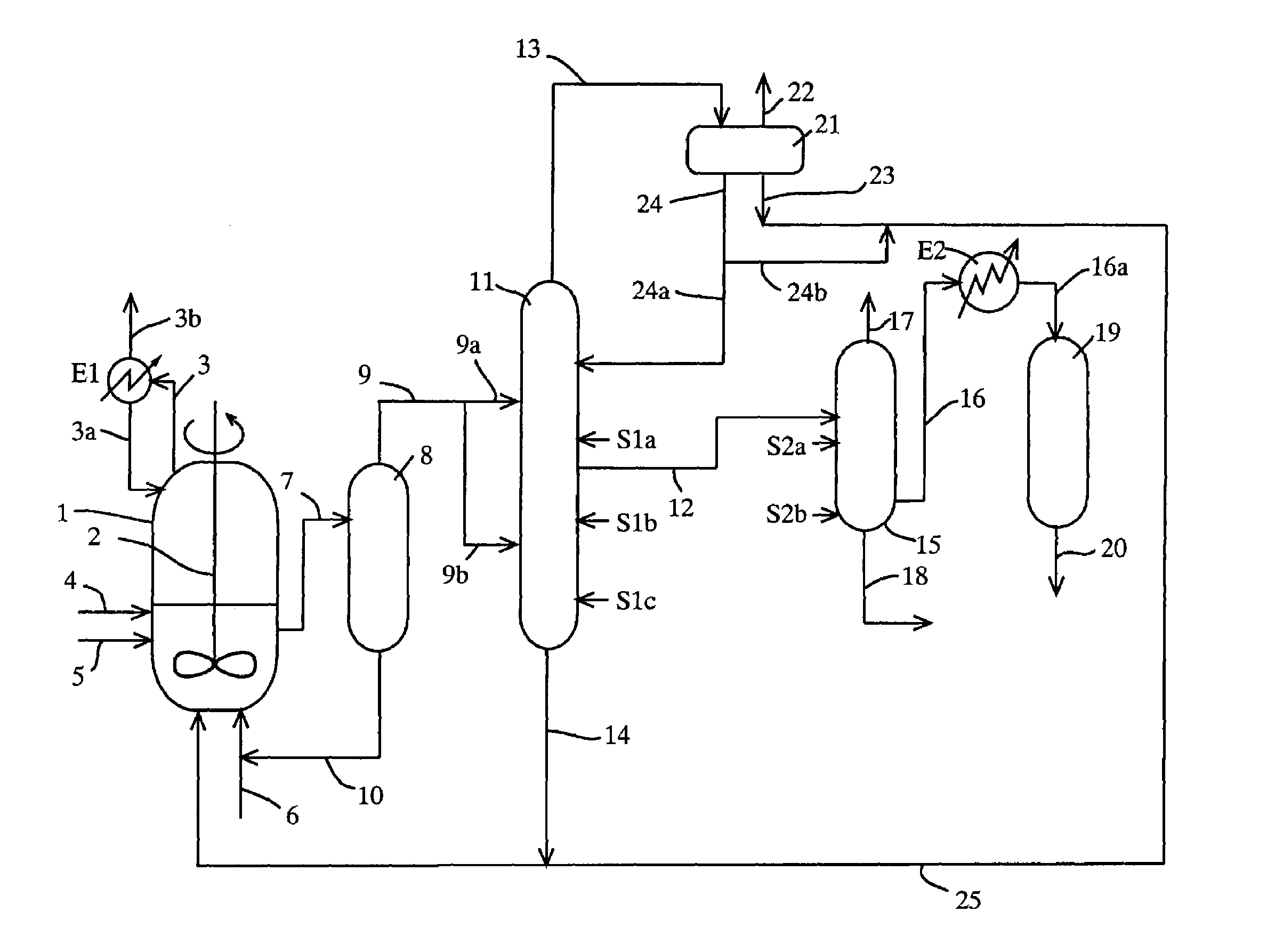

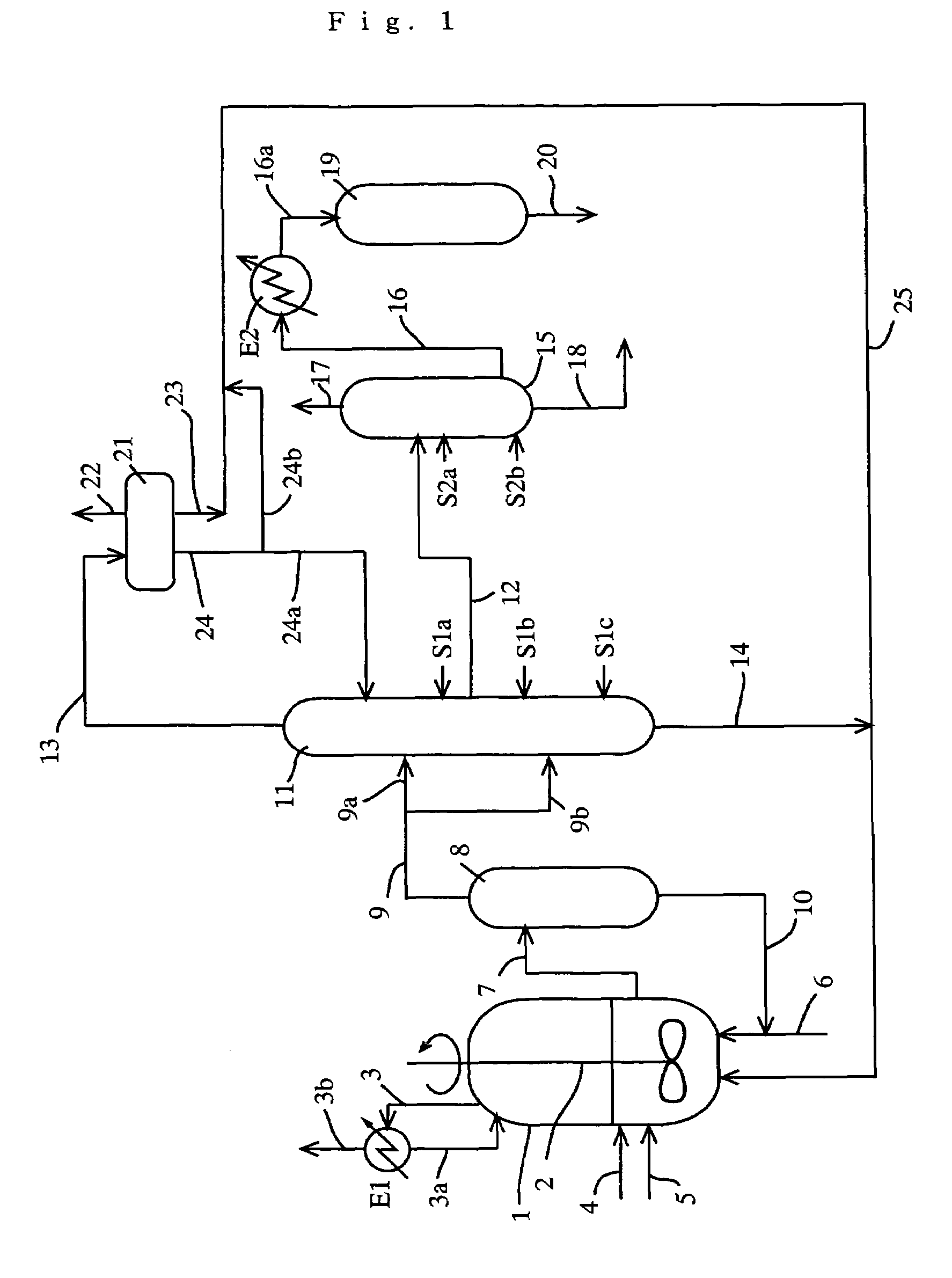

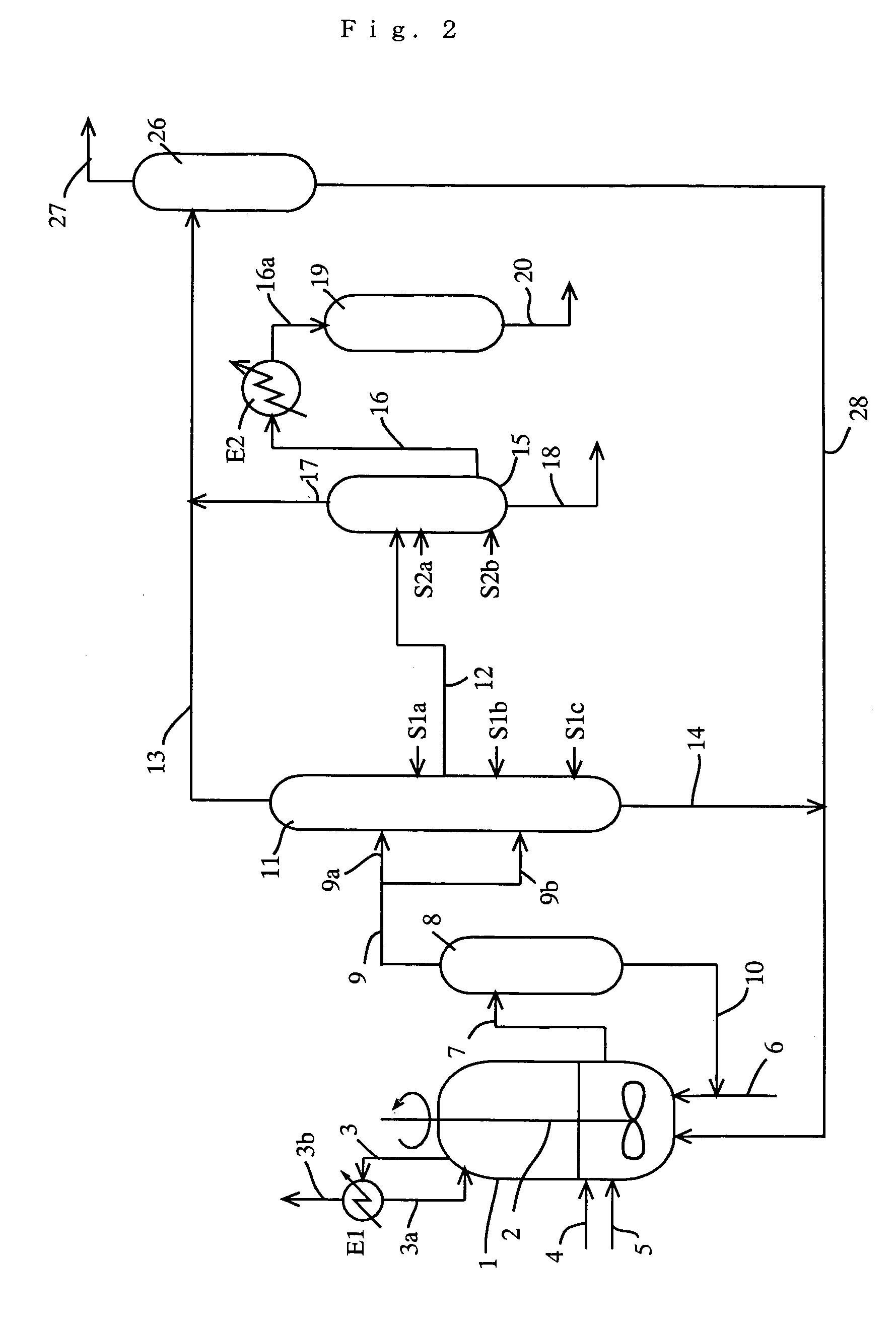

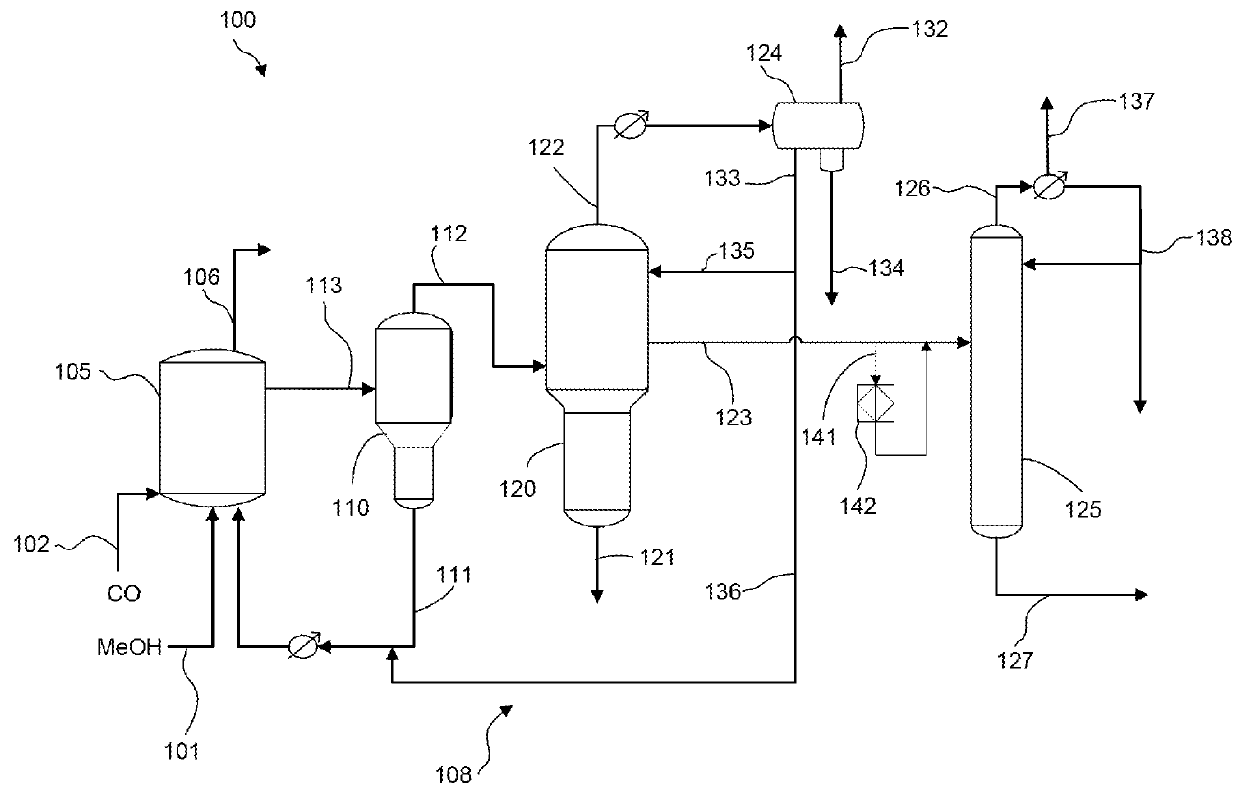

Process for producing carboxylic acid

InactiveUS7678940B2Efficient separationHigh purityOrganic compound preparationCarboxylic compound separation/purificationHydrogen halideAlcohol

A process for producing a purified carboxylic acid having “n+1” carbon atoms comprises feeding a carboxylic acid stream containing a carboxylic acid having “n+1” carbon atoms, a hydrogen halide, a lower boiling point (bp) component, a higher bp component, and others to a first distillation column; separating a lower bp fraction containing part of the lower bp component and a higher bp fraction containing part of the higher bp component in the first column; withdrawing a side stream containing at least the carboxylic acid by side cut from the first column; feeding the side stream to a second distillation column; separating a lower bp fraction containing part of the lower bp component and a higher bp fraction containing part of the higher bp component in the second column; and withdrawing a side stream containing the carboxylic acid by side cut from the second column to recover a purified carboxylic acid; and the process further comprises feeding at least one first component (A) selected from the group consisting of an alcohol, corresponding to the carboxylic acid, having “n” carbon atom(s), and an ester of the alcohol with the carboxylic acid to the first column, and if necessary water. Such a process ensures reduction of the concentration of the hydrogen halide in the purified carboxylic acid.

Owner:DAICEL CHEM IND LTD

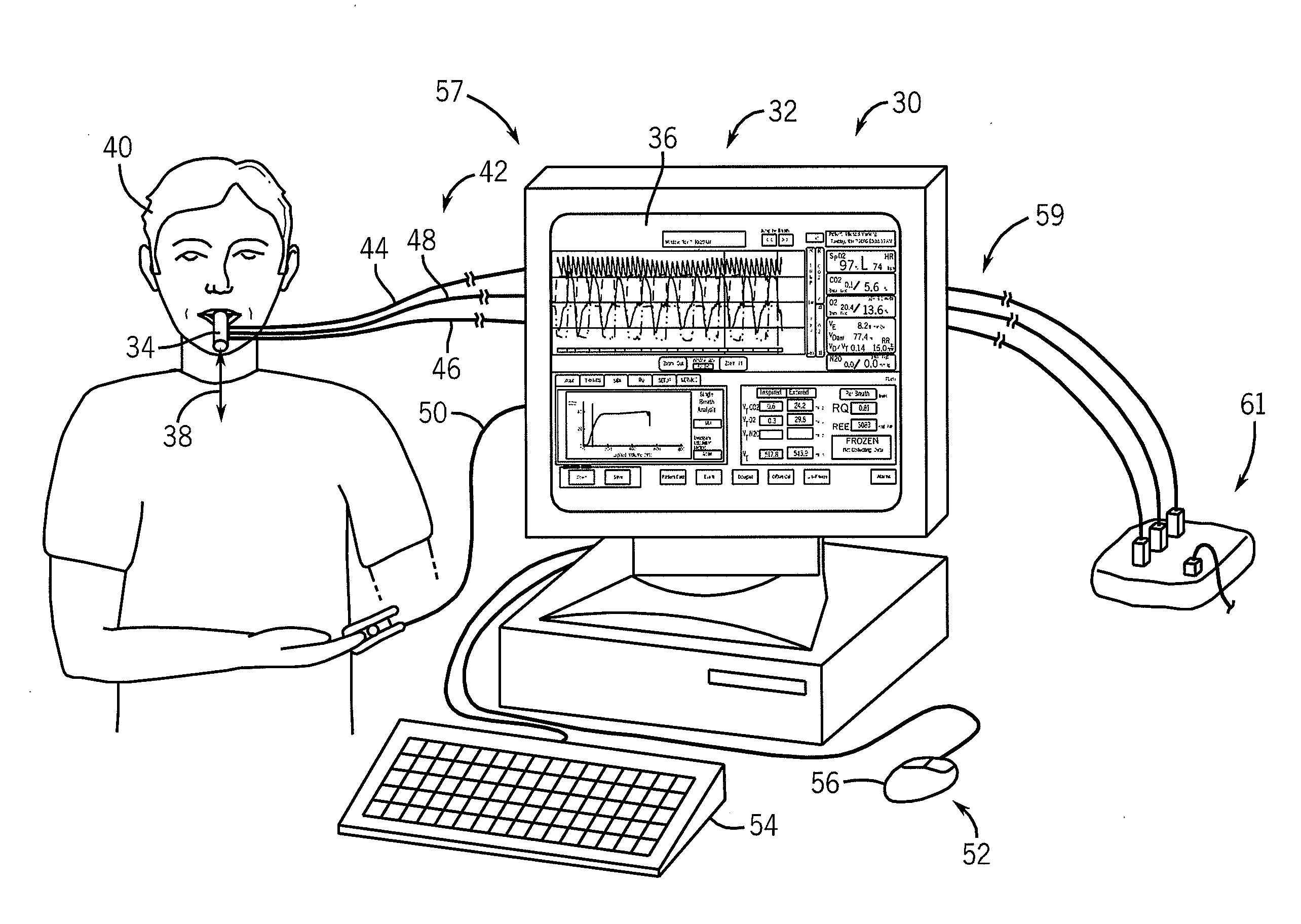

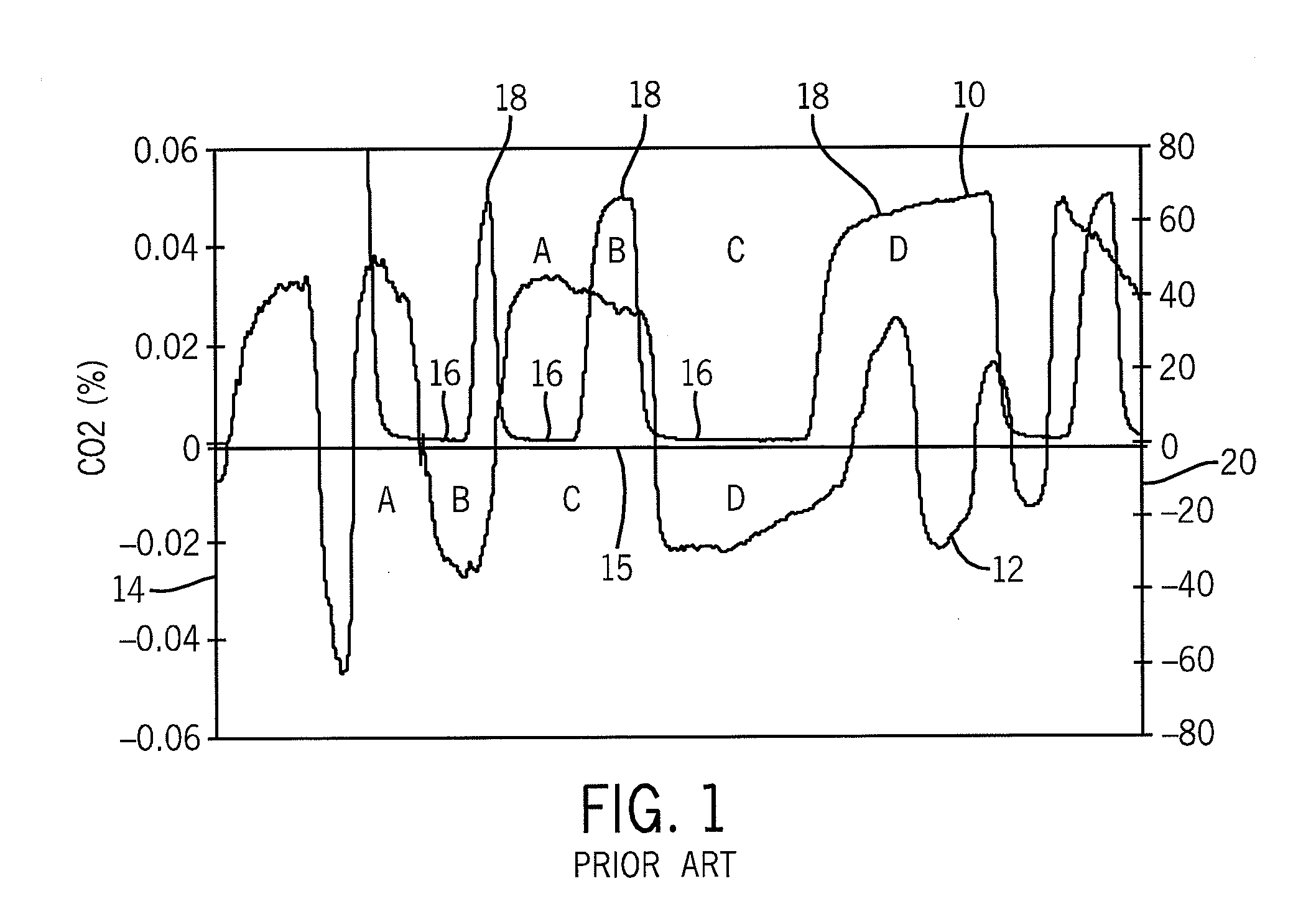

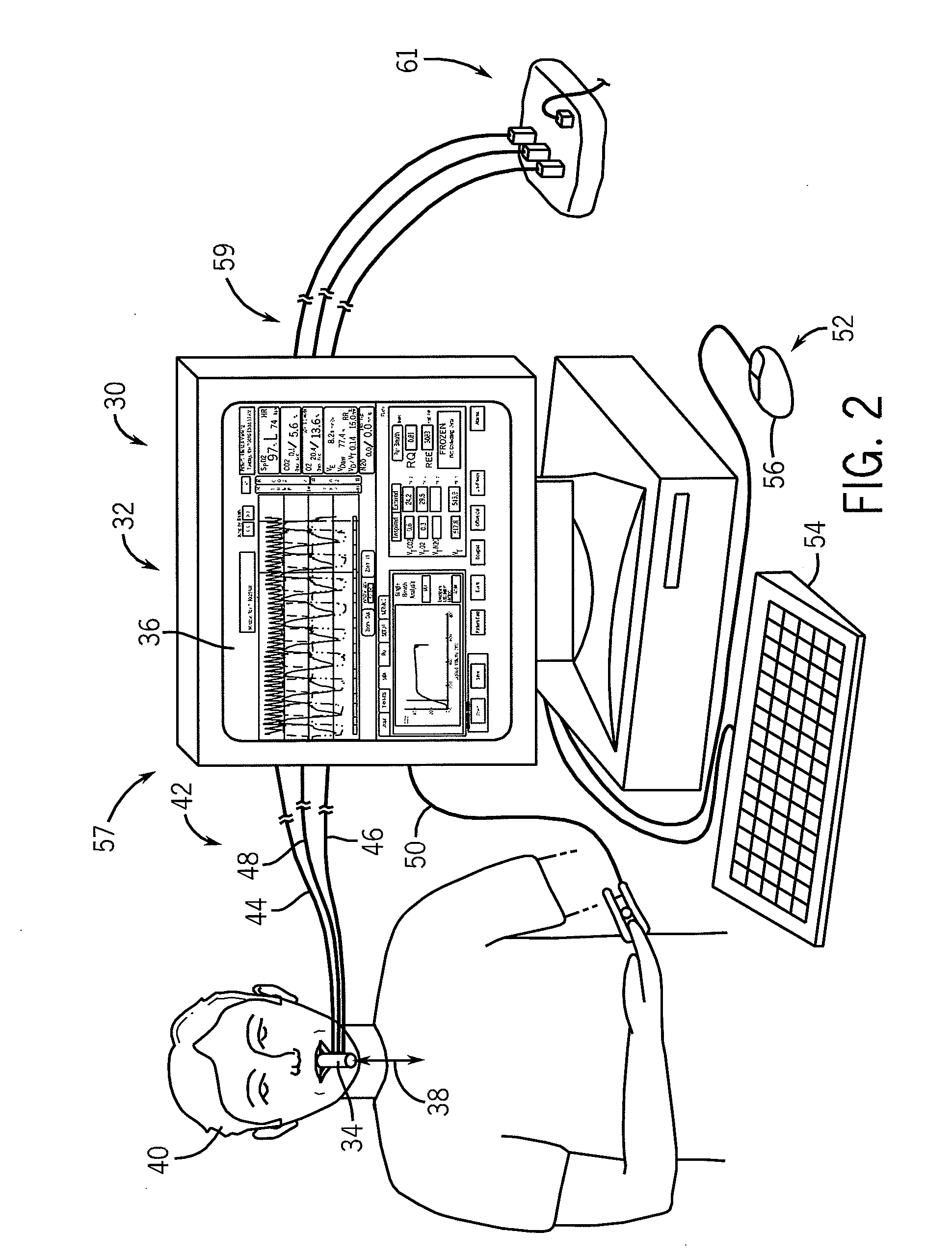

Premature infant side-stream respiratory gas monitoring sensor

InactiveUS20080119753A1Monitor performanceOvercomes drawbackRespiratory organ evaluationSensorsRespiratory gas monitoringEngineering

A side-stream respiration monitoring sensor includes a body having a first end, a second end, and a detecting section disposed between the respective ends. The detecting section includes a first port and a second port positioned on generally opposite sides of a restricting member. The restricting member extends into a flow path formed through the body such that a pressure differential is generated between the first port and the second port. A sampling port is positioned downstream relative to a patient from the first and the second port and configured to acquire a respiration sample. The sensor is constructed to monitor respiration performance of premature infants “preemies”, or the like.

Owner:CARDIOPULMONARY TECH

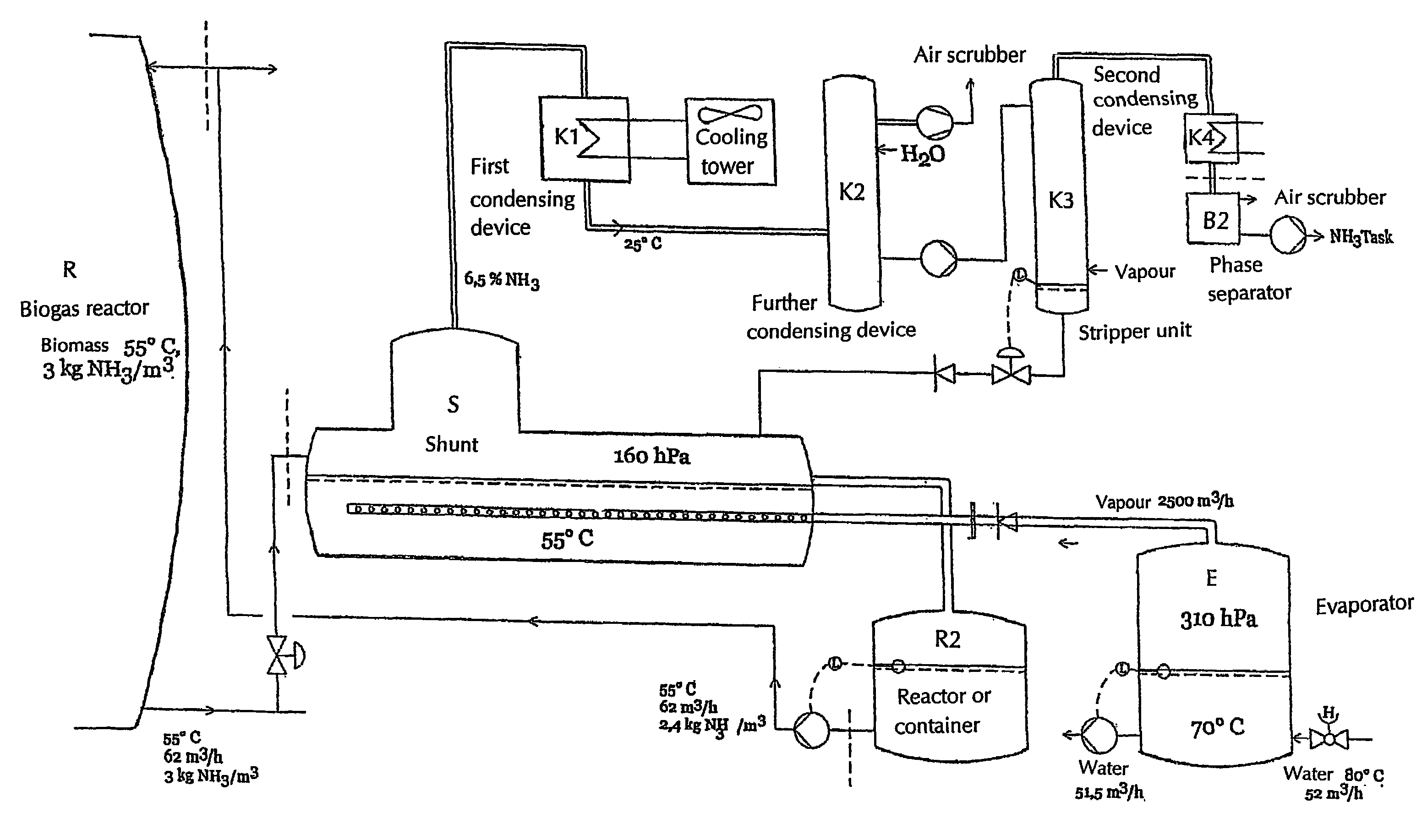

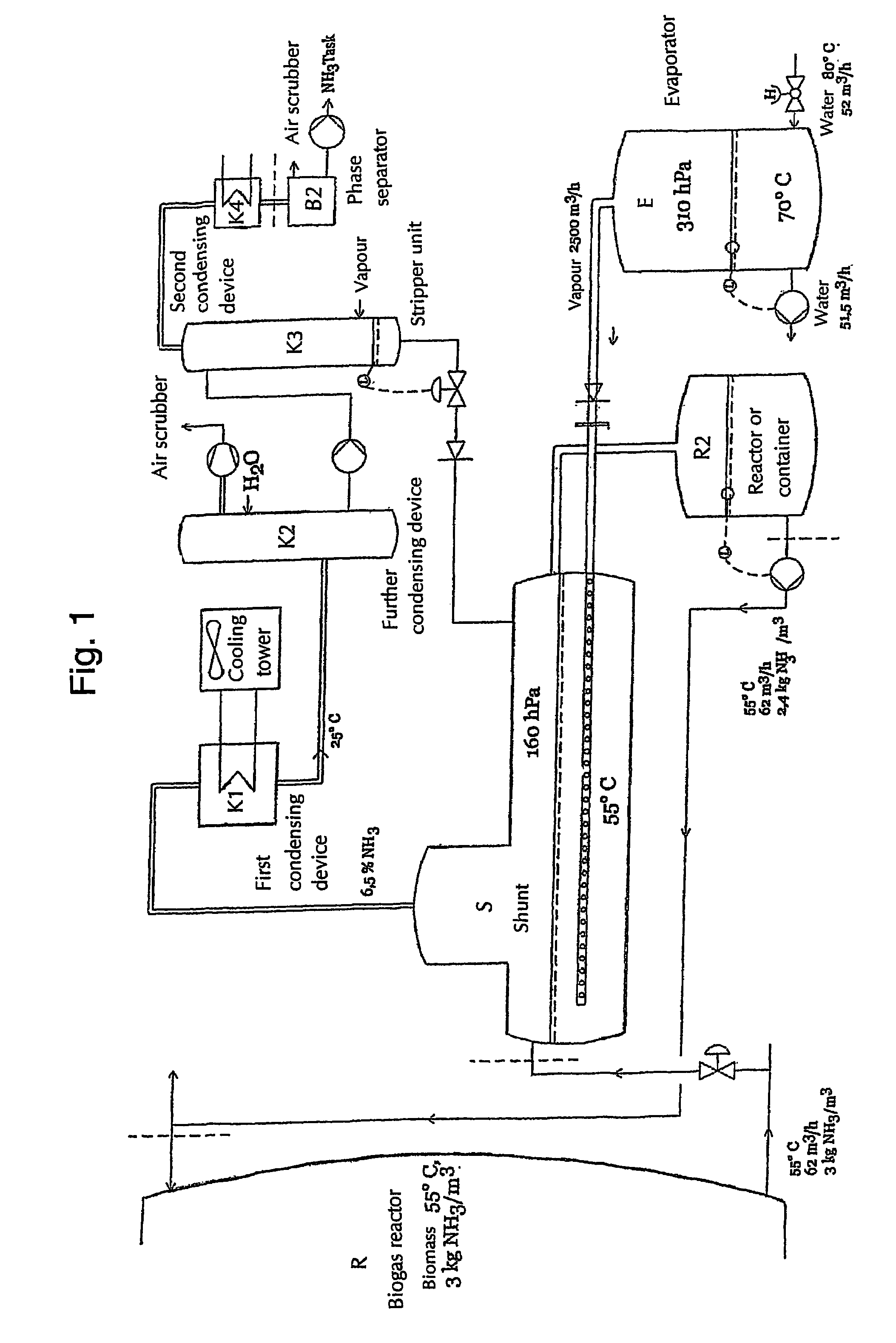

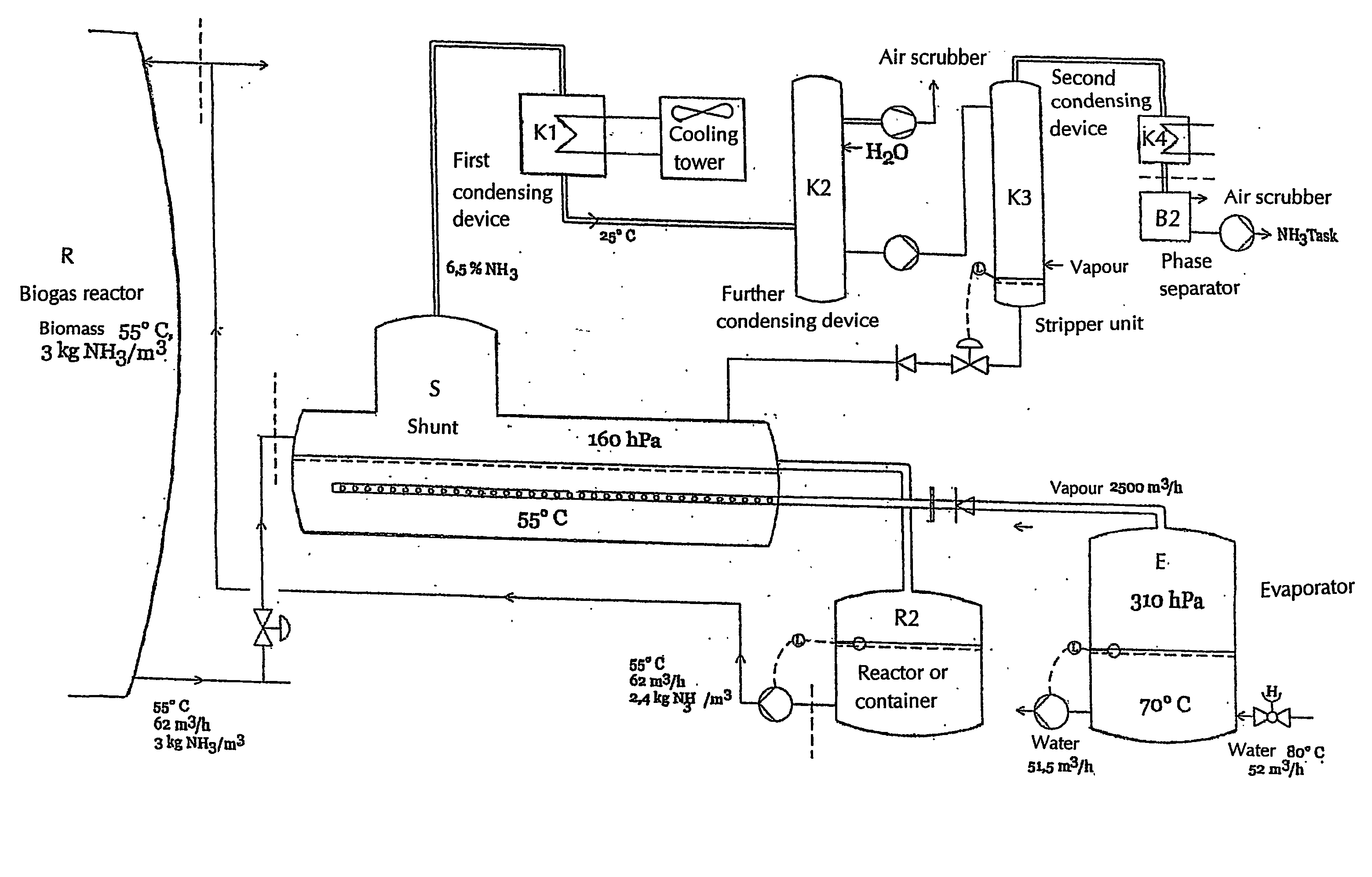

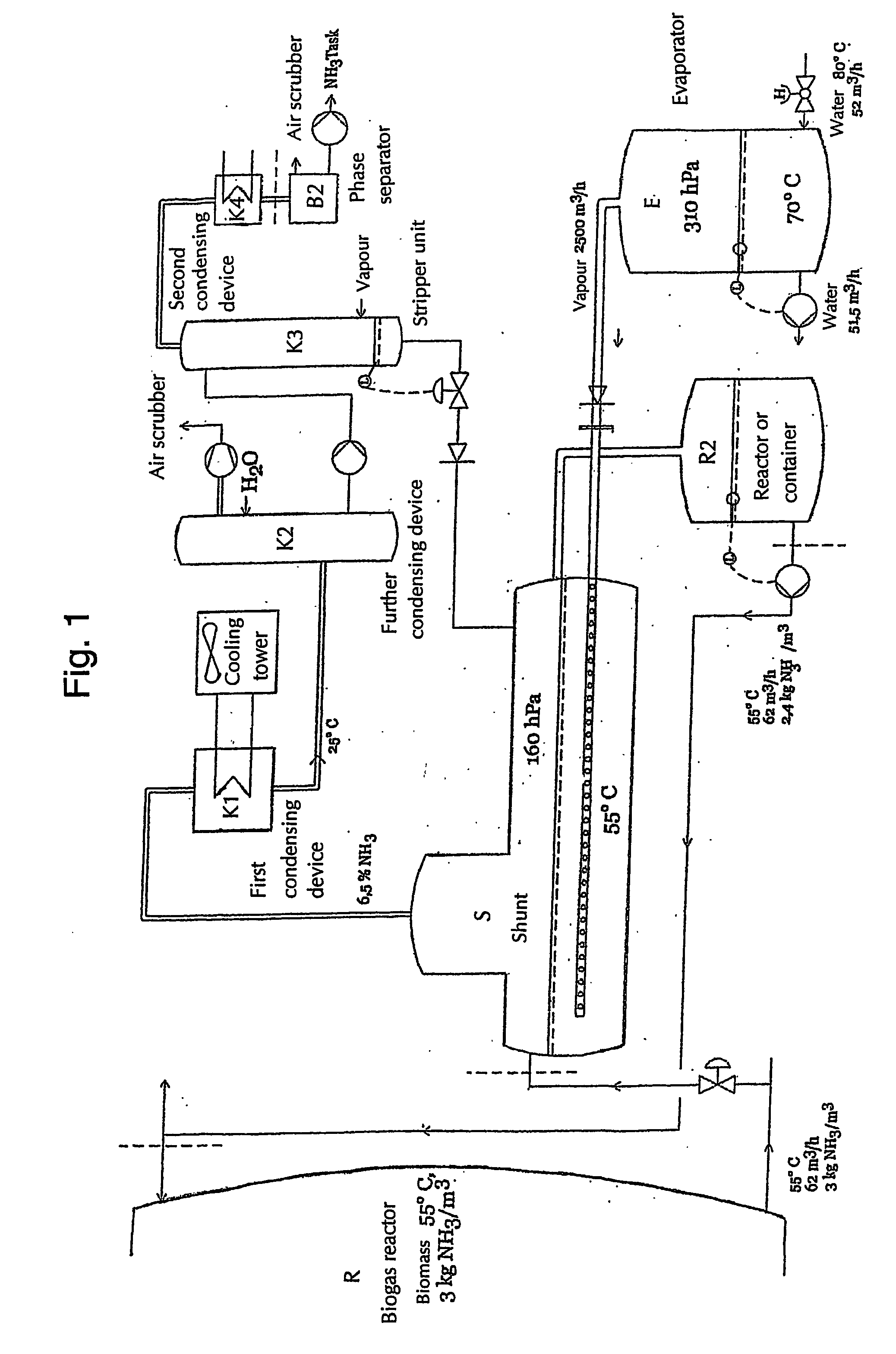

Method and device for stripping ammonia from liquids

InactiveUS7416644B2Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

Owner:GFE PATENT AS

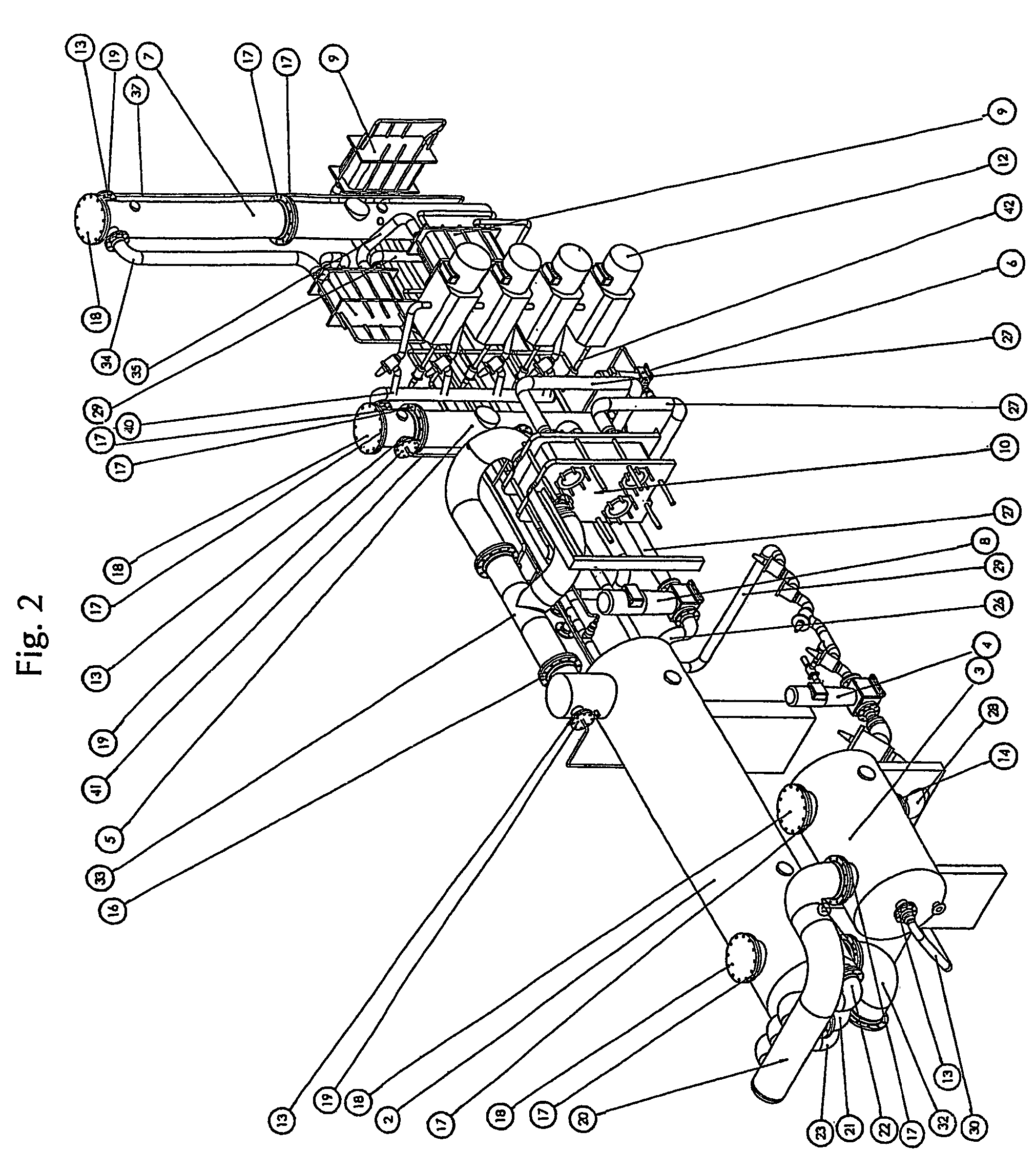

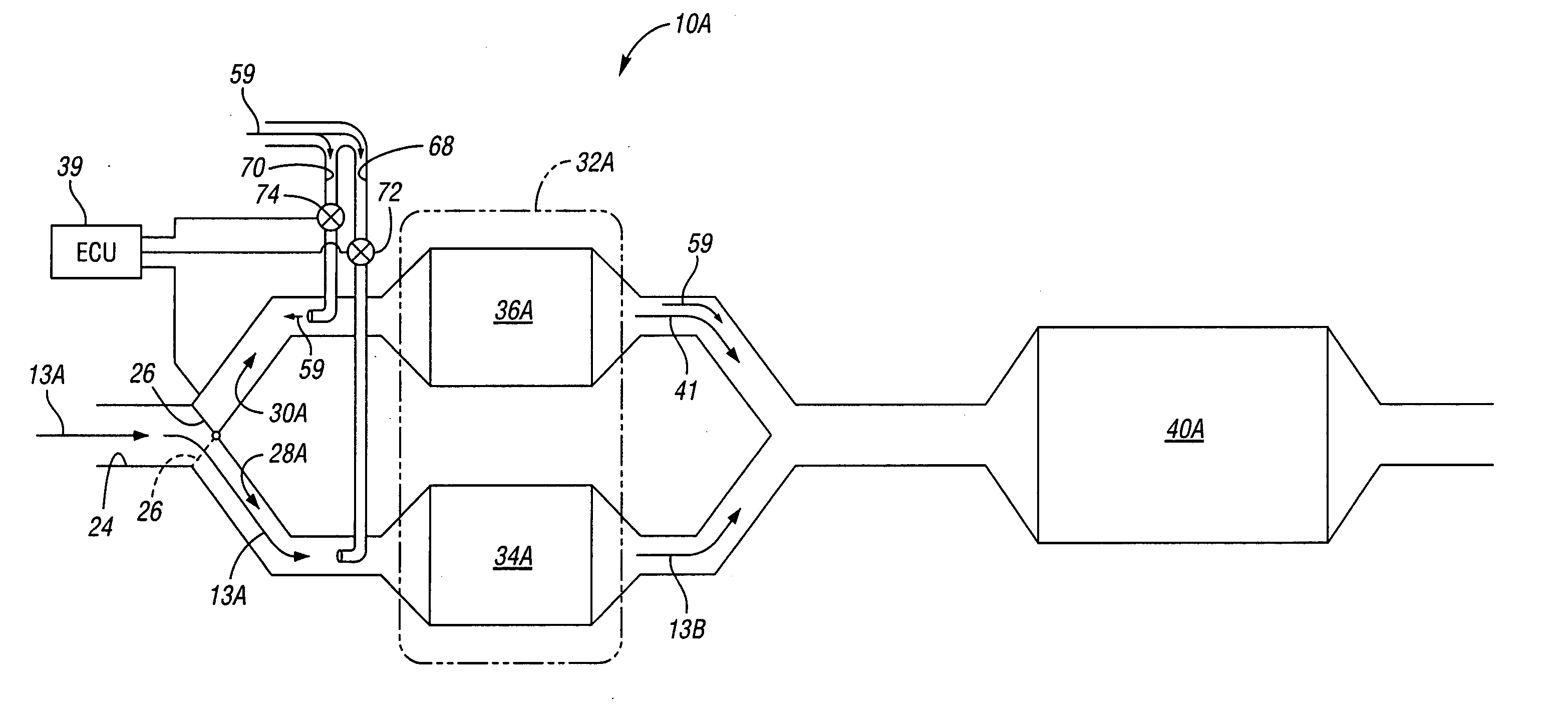

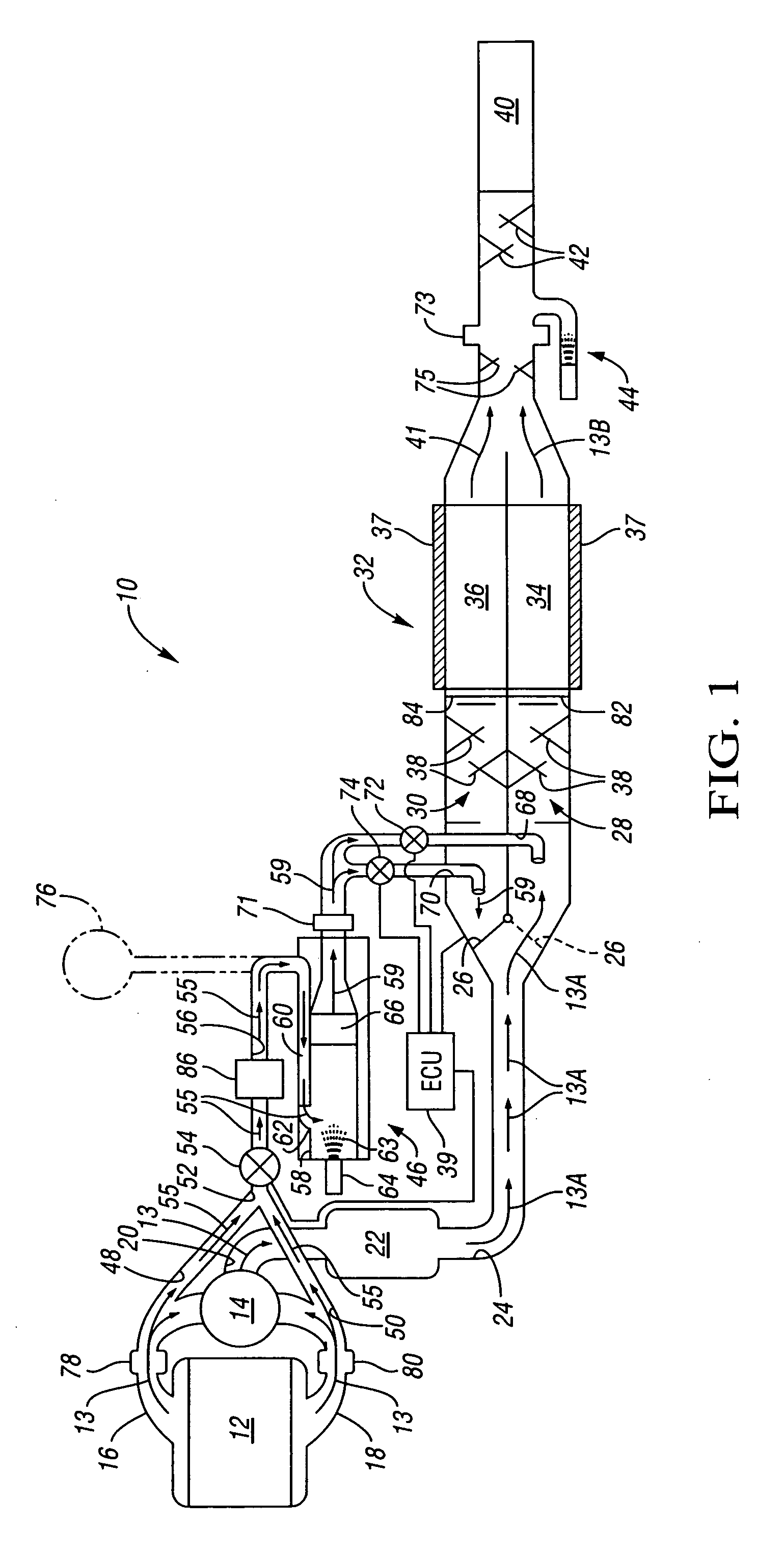

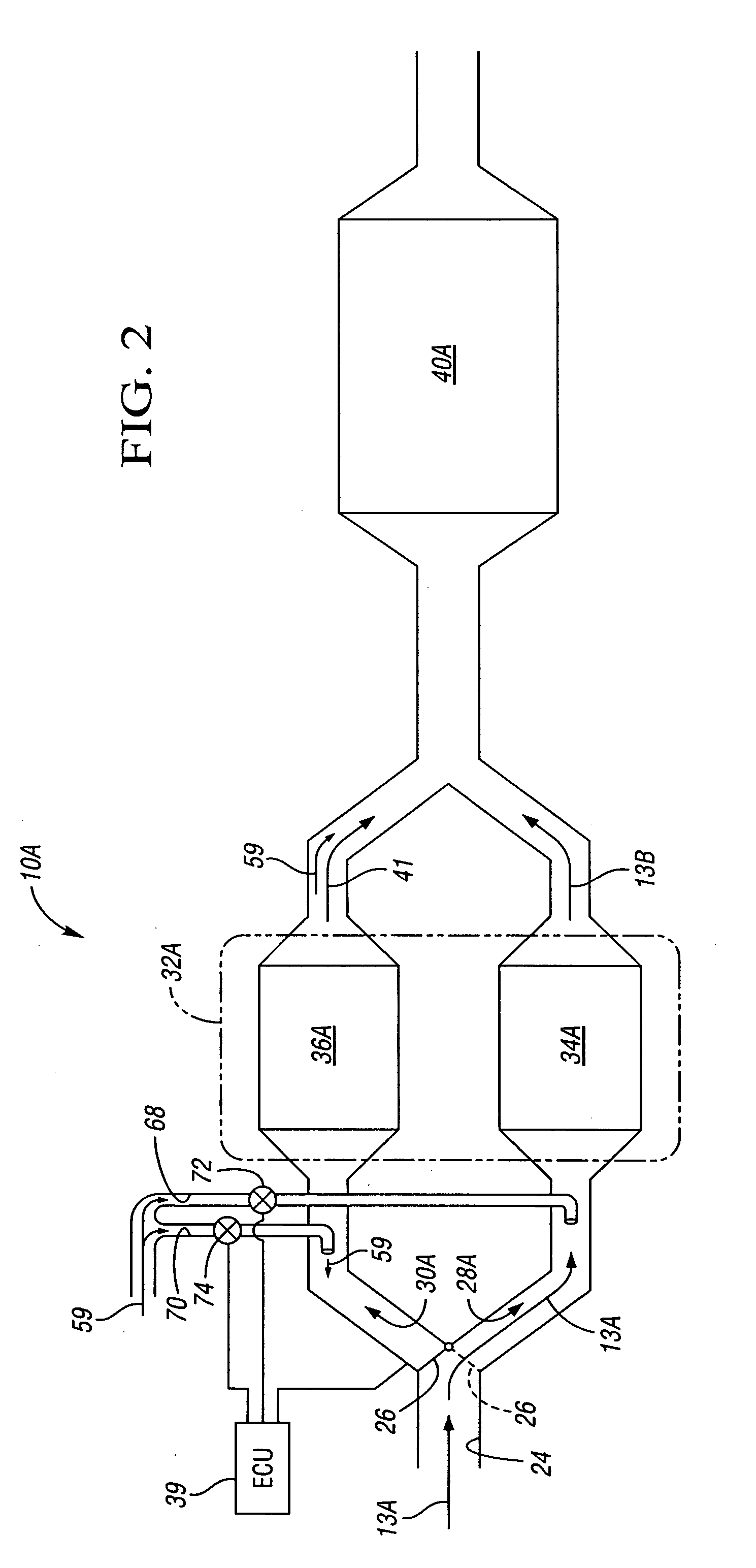

Exhaust aftertreatment system and method of use for lean burn internal combustion engines

The present invention is an aftertreatment system for lean burn internal combustion engines. The present invention provides a multiple branch lean NOx trap, or LNT, with a diverter valve operable to selectively direct lean exhaust flow to one portion of the LNT while another portion of the LNT regenerates in a low oxygen environment. Additionally, the present invention employees a continuously operating side stream exhaust fuel reformer that delivers a reductant, such as partially oxidized (POx) gas or reformate, to the LNT for regeneration. The present invention also provides a method of exhaust aftertreatment of a lean burn internal combustion engine utilizing the system provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and device for stripping ammonia from liquids

InactiveUS20060006055A1Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

The present invention in a first aspect provides a method and a system for stripping volatile compounds such as ammonia from e.g. fermentation liquids. Part of the ammonia is stripped from the liquid in a stripper system comprising a shunt through which liquid such as e.g. fermentation medium comprising a biomass can be diverted in the form of a side stream in liquid contact with a main fermentor(s). The stripper system is connected to an evaporator. In the evaporator aqueous liquid is heated at a pressure below atmospheric pressure whereby vapour is developed at a temperature below 100° C. The vapour from the evaporator is directed to the liquid medium comprising ammonia and this results in ammonia being stripped from the liquid and transferred to the vapour phase. The vapour phase is condensed in a first condenser at a low pressure, e.g. a pressure well below 1 bar, and the liquid thus obtained is further treated in a stripper unit at a higher pressure, such as e.g. a pressure at or above 1 bar, to obtain a more concentrated solution of ammonia. When stripped for at least part of the ammonia the liquid initially obtained from the biogas reactor and diverted to the shunt can be returned to the reactor.

Owner:GFE PATENT AS

Process for delayed coking of whole crude oil

ActiveUS20120298552A1Enhance thermal cracking reactionReduce coke yieldThermal non-catalytic crackingCatalytic crackingNaphthaFractionating column

An improved delayed coking process utilizing a coking unit and a coking unit product fractionating column which includes the steps of:heating a mixture of a fresh whole crude oil feedstream and the bottoms from the coking unit product fractionator in a furnace to a coking temperature in the range of 480° C. to 530° C. / 896° F. to 986° F.;introducing the heated mixed whole crude oil and bottoms feedstream directly into the delayed coking unit;optionally passing the vaporized liquid and gaseous coking unit product stream into a flash unit;recovering a light product gas stream that includes H2S, NH3 and C1 to C4 hydrocarbons from the flash unit;transferring the bottoms from the flash unit to the coking unit product fractionating column;recovering as separate side streams from the fractionating column naphtha, light gas oil and heavy gas oil;recycling a portion of the heavy gas oil by introducing it into the fractionating column optionally with the bottoms from the flash unit;mixing the fractionating column bottoms with the whole crude oil feedstream to form the mixed feedstream; andintroducing the mixed whole crude oil and fractionating column bottoms feedstream into the furnace.

Owner:SAUDI ARABIAN OIL CO

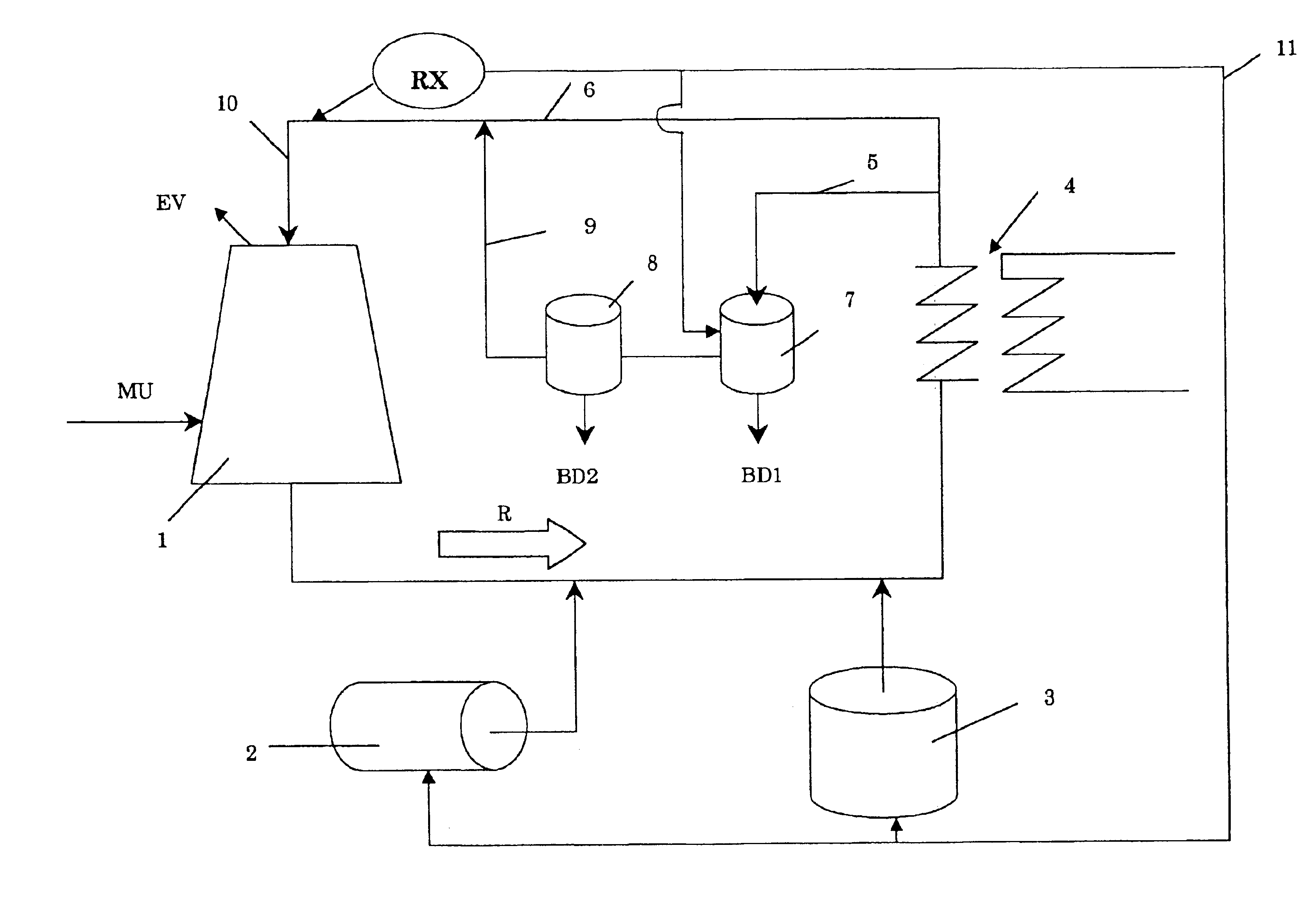

Water treatment method and apparatus

InactiveUS6733654B1Water treatment parameter controlNature of treatment waterCooling towerWater flow

A method of operating a cooling tower comprises feeding to the cooling tower a make-up stream of water containing organic and / or biological contaminants, causing a side stream taken from the recirculating stream to pass through an electrolytic cell, removing solids precipitating by the action of the cell, and remixing the treated side stream with the main stream, before feeding them to the cooling tower.

Owner:ARGAD EYAL

Devices for Analyzing the Presence and Concentration of Multiple Analytes Using a Diffusion-based Chemical Sensor

InactiveUS20020041827A1Rapid simultaneous measurementSimple and inexpensive to manufactureAnalysis using chemical indicatorsComponent separationDiffusionAnalyte

<heading lvl="0">Abstract of Disclosure< / heading> The present invention provides a microfabricated sensor and a method capable of rapid simultaneous measurement of multiple analytes in a fluid sample. The sensor is inexpensive, disposable and portable, and requires only microliters of sample, a particular advantage with precious fluids such as blood. The sensor utilizes diffusion between layered laminar streams rather than side by side streams. This allows multiple side by side channels for simultaneous detection of multiple analytes. In the sensor, a sample stream and a carrier stream flow in layers, one on top of the other, and one or more reagents are introduced to the bottom of the carrier stream through either a fluid or a solid reagent inlet. The reagent contains reagent particles which, in the presence of the analyte, have a detectable change in a property. The analyte diffuses into the carrier stream where it interacts with reagent particles and is detected by optical, electrochemical or other means.

Owner:UNIV OF WASHINGTON

Processing Of Whole Fruits And Vegetables, Processing Of Side-Stream Ingredients Of Fruits And Vegetables, And Use Of The Processed Fruits And Vegetables In Beverage And Food Products

ActiveUS20120088015A1Improve textureImprove dispersion propertyFruit and vegetables preservationAnimal feeding stuffAdditive ingredientPomace

Processing and use of whole fruits and vegetables or side-stream ingredients of juice extraction, paste, or ketchup process, or canning industry, in particular, the processing of the by-products, including pomace, and its use in beverage and food products.

Owner:TROPICANA PROD INC

Method for detecting tobacco-specific nitrosamines

The invention relates to a method for measuring tobacco-specific nitrosamines (TSNAs for short) by using a super efficient liquid chromatogram-tandem mass spectrum combined method, and belongs to a method for detecting TSNAs. The method comprises the following steps of: adding internal standard-containing aqueous solution of ammonium acetate into a filter sheet after trapping smoke and cigarette filters smoked completely under standard conditions or tobacco shreds, performing ultrasonic extraction, transferring 1 to 2mL of extract into a small solid-phase extraction column taking N-vinyl pyrrolidone-benzene sulfonic acid copolymer as filler, flushing the small column by using aqueous solution of methanoic acid and methanol, finally eluting the small column by using solution of aqueous ammonia and methanol solution, analyzing the eluant by using an ultra performance liquid chromatography-mass spectrometer / mass spectrometer (UPLC-MS / MS), and quantifying according to the area ratio of a component peak to an isotope internal standard peak. The detecting method can be used for detecting the TSNAs in cured and hybrid cigarette mainstream smoke, cigarette side-stream smoke, filter tip intercepting smoke and tobacco shreds, and has the advantages of simple pretreatment, accurate quantification, high instrument analysis speed, low detection limit, high sample treatment flux and the like.

Owner:HONGTA TOBACCO GRP

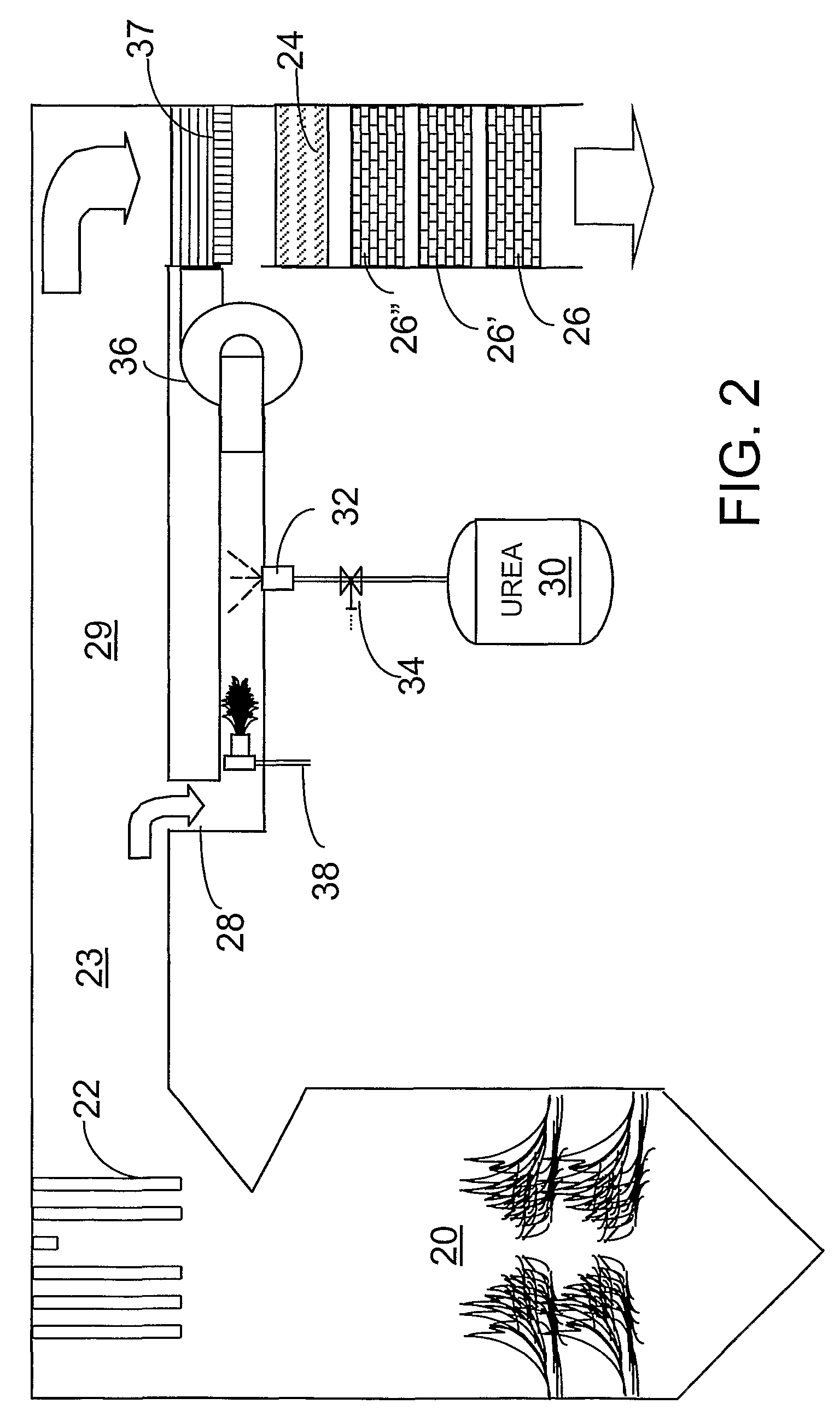

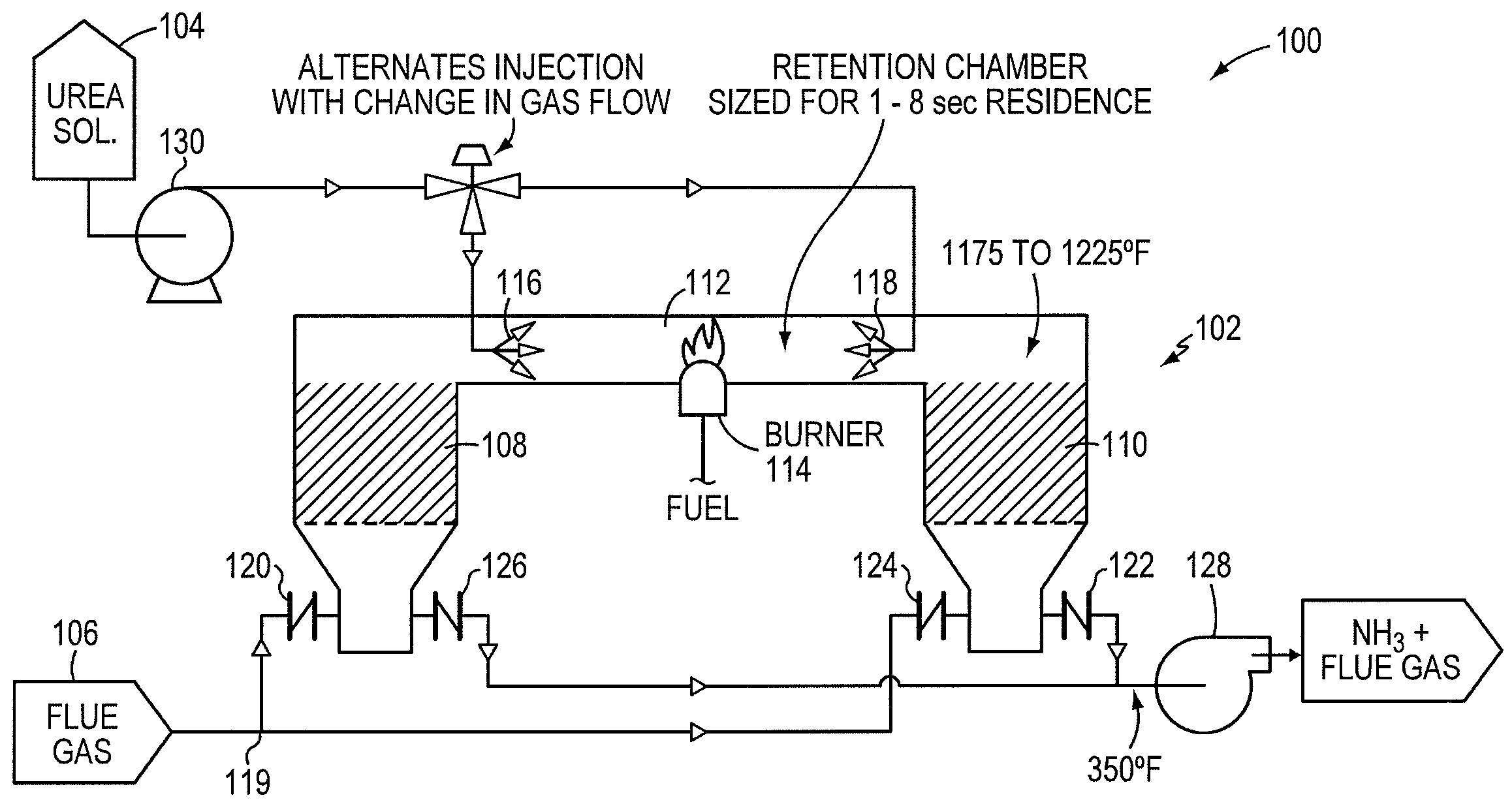

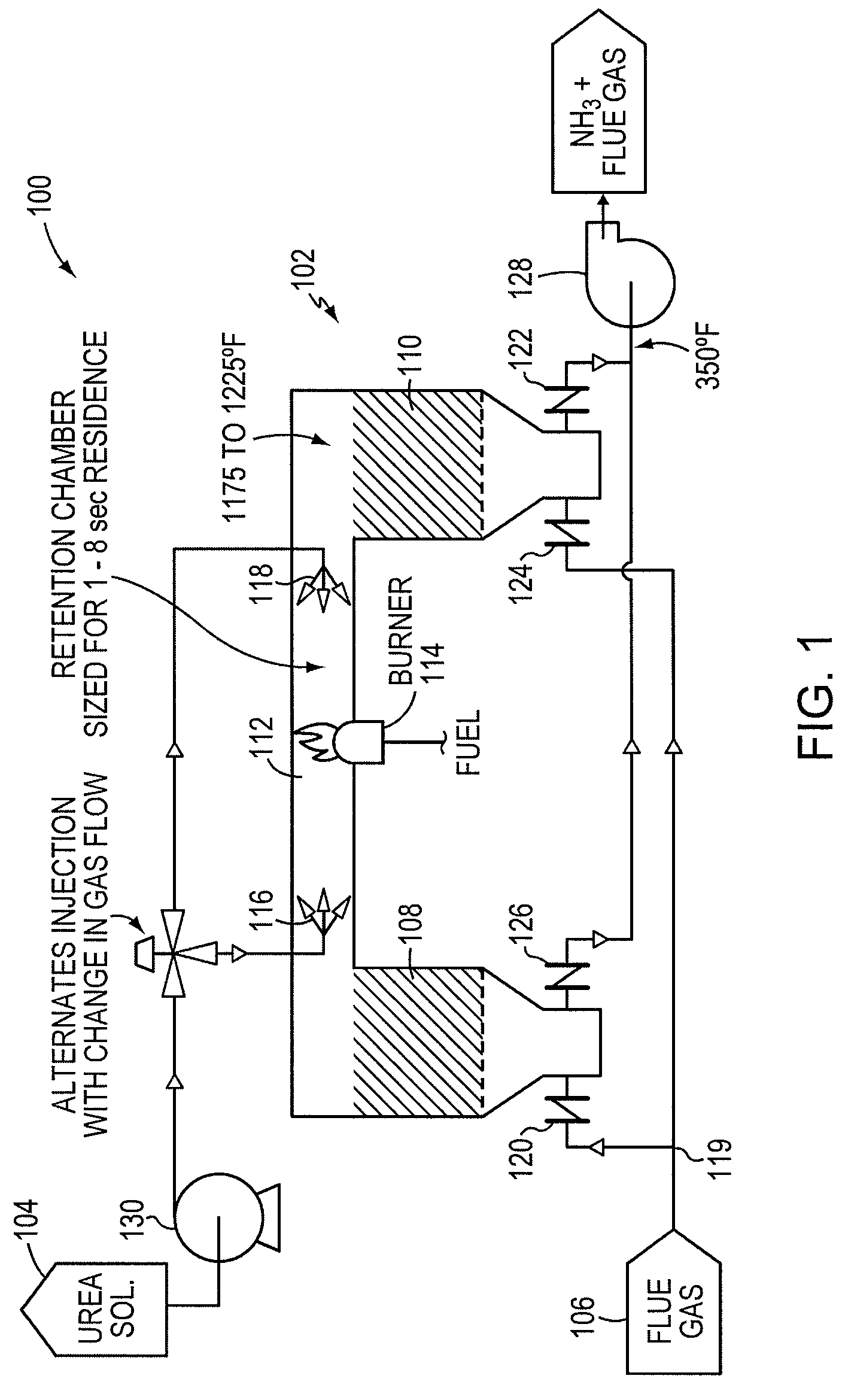

SELECTIVE CATALYTIC REDUCTION OF NOx ENABLED BY SIDESTREAM UREA DECOMPOSITION

ActiveUS20060115402A1Well mixedAccurate temperatureCombination devicesNitrogen compoundsParticulatesSuperheater

A preferred apparatus arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140.degree. C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

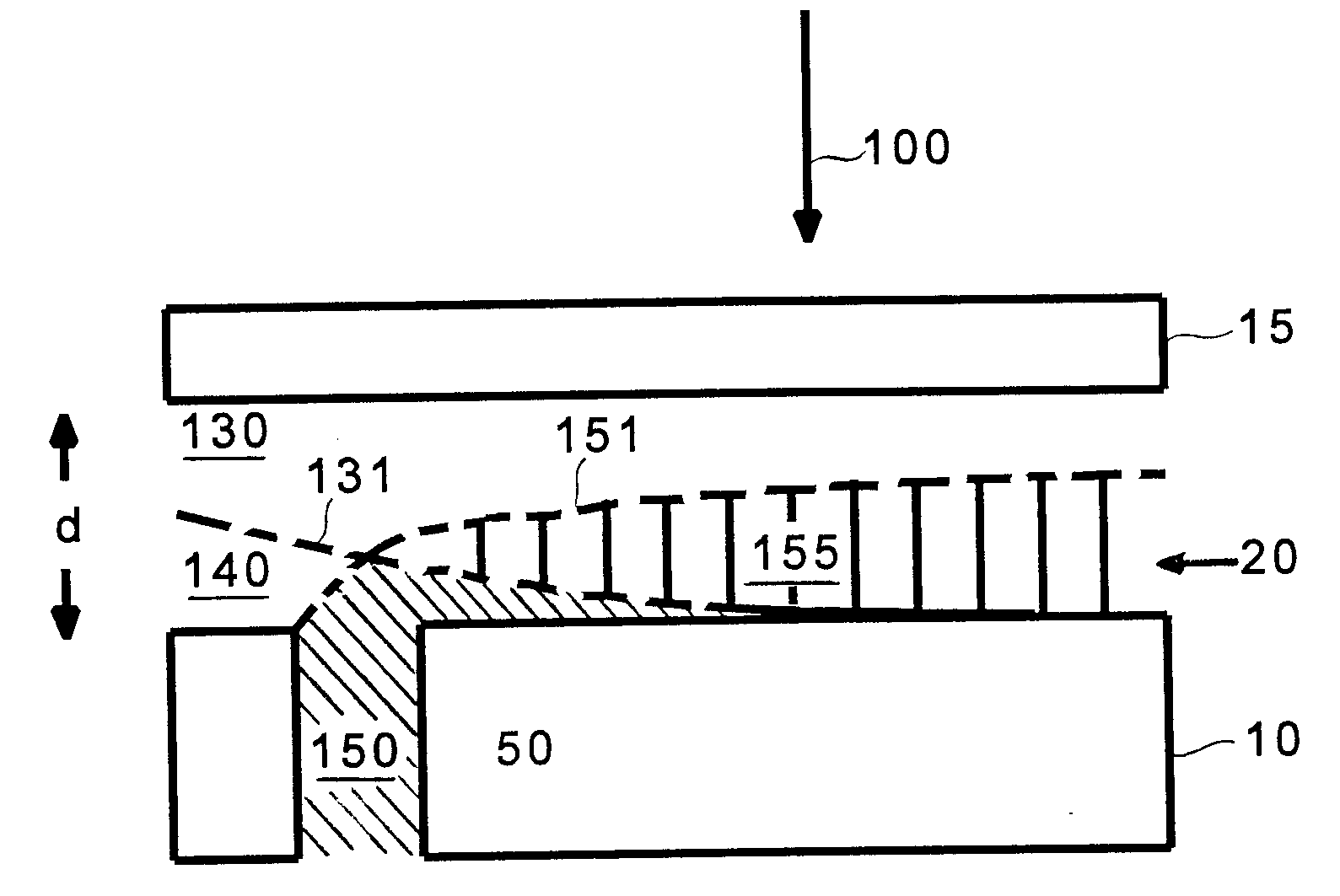

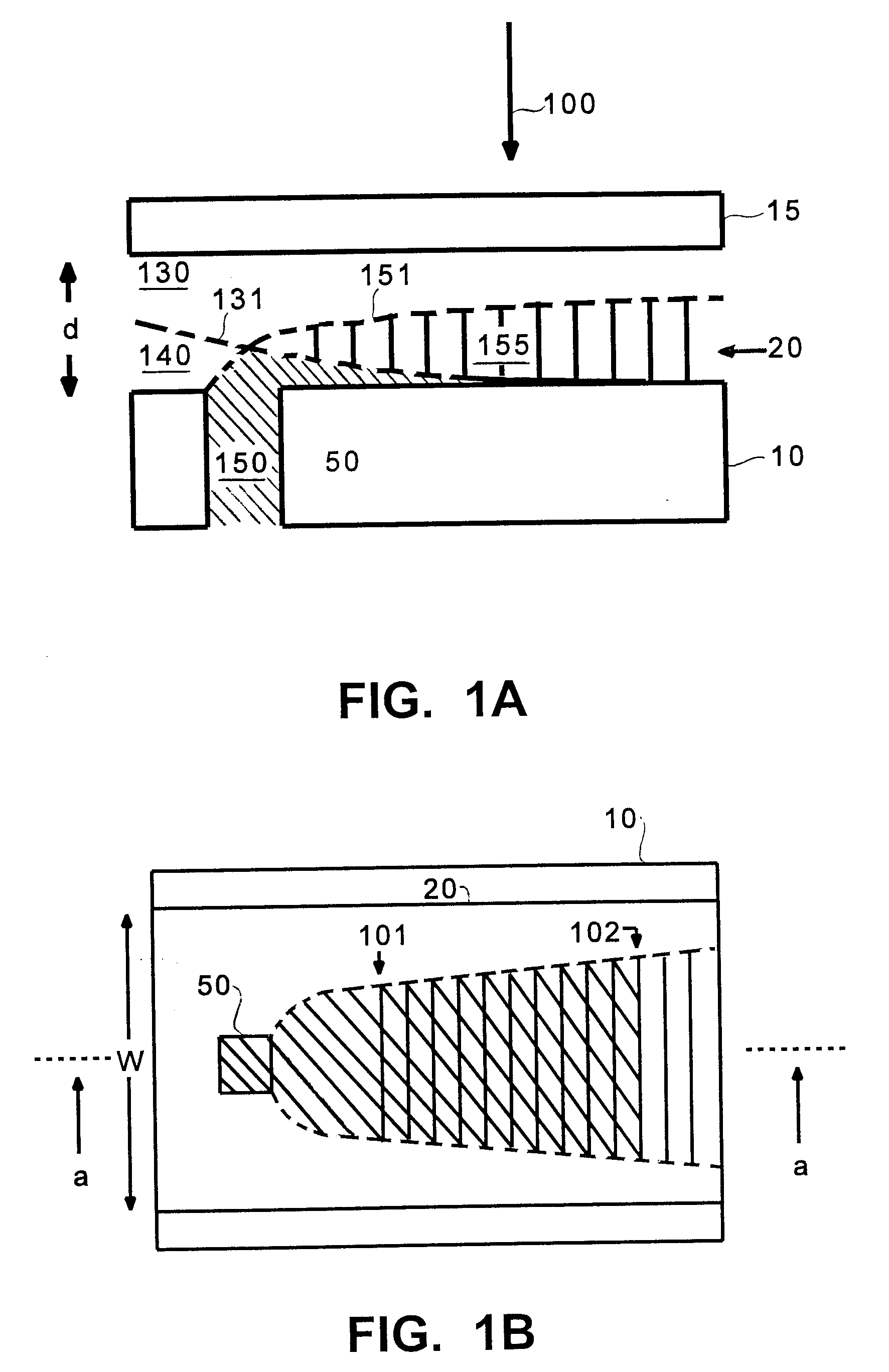

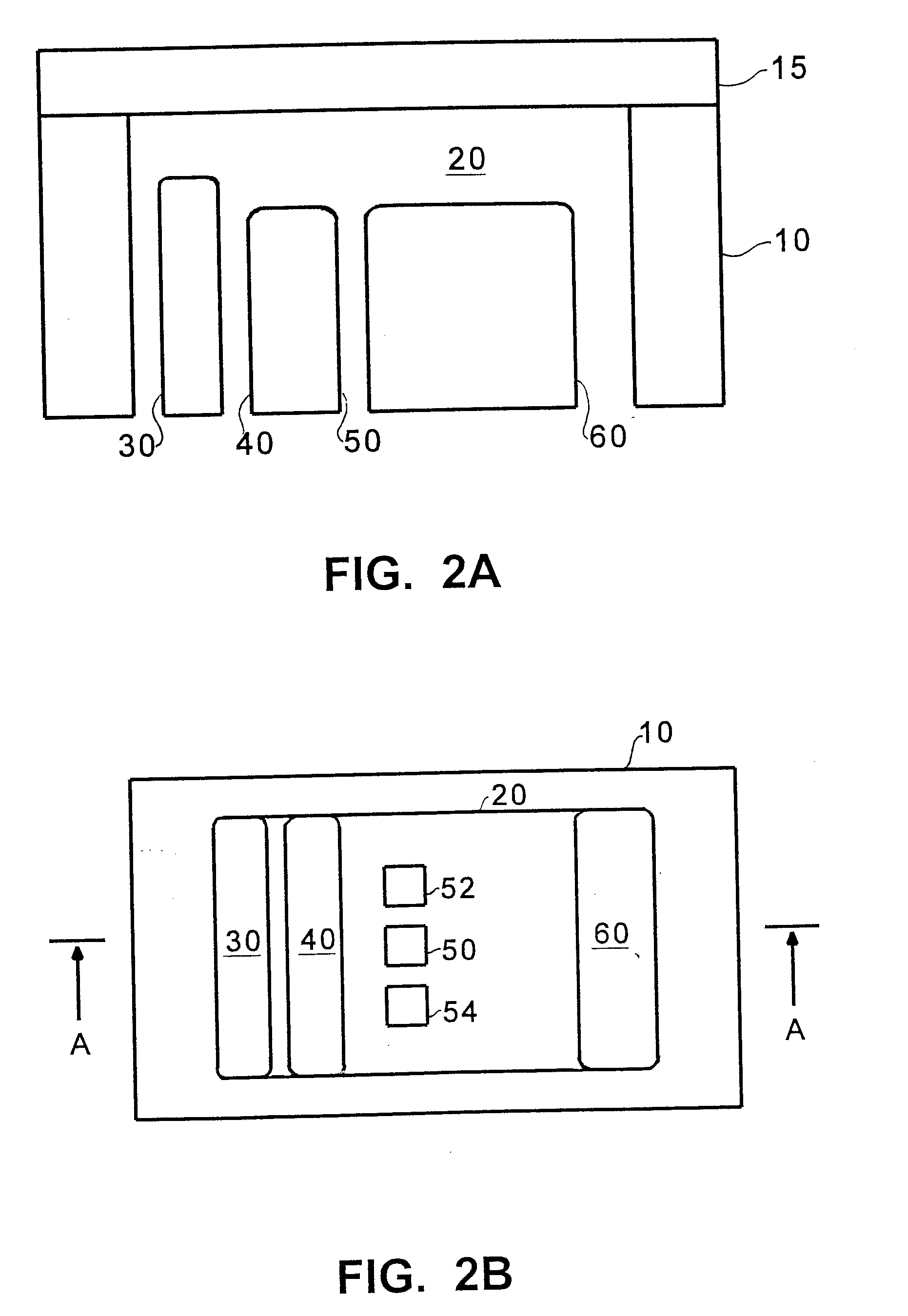

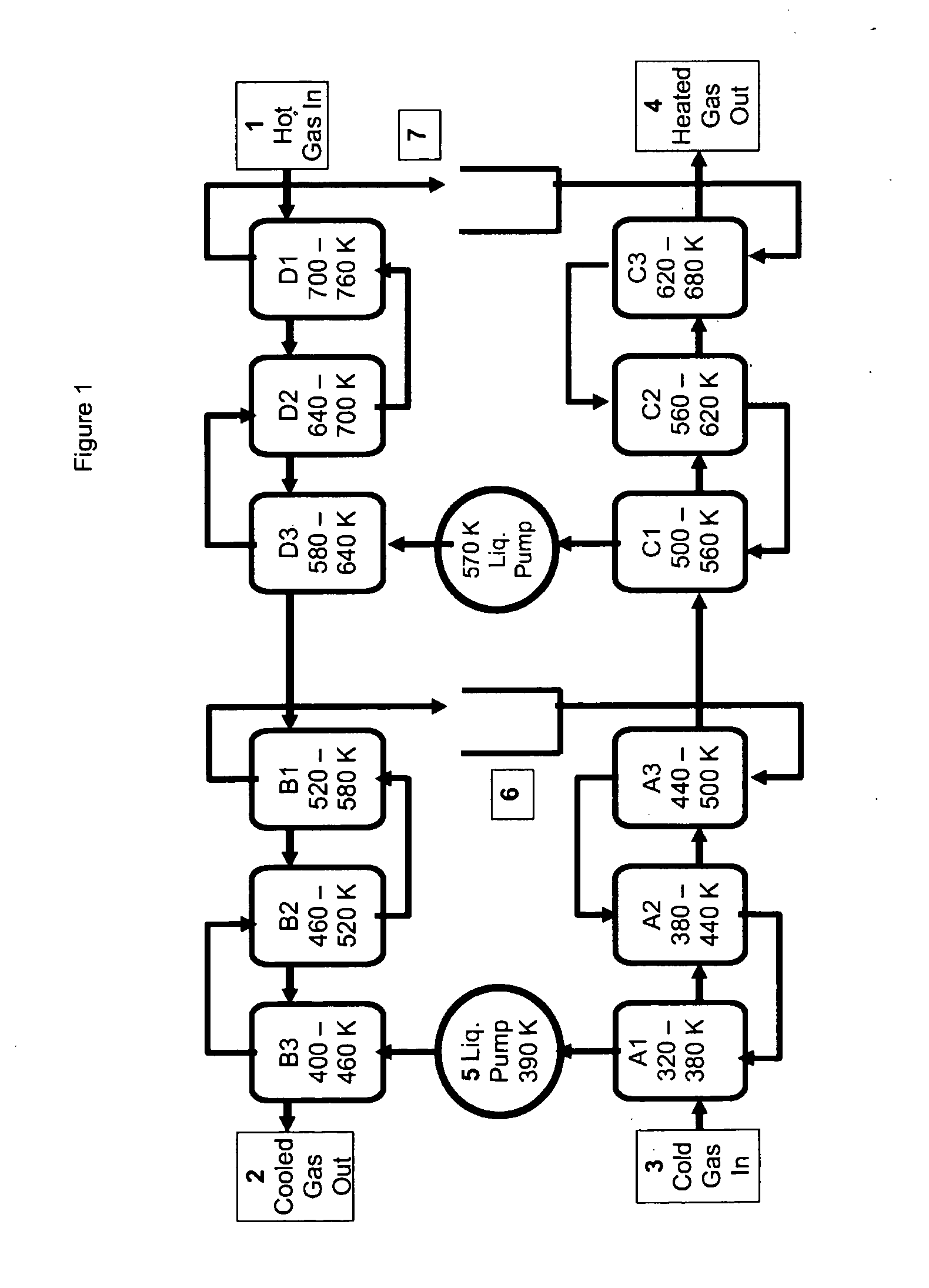

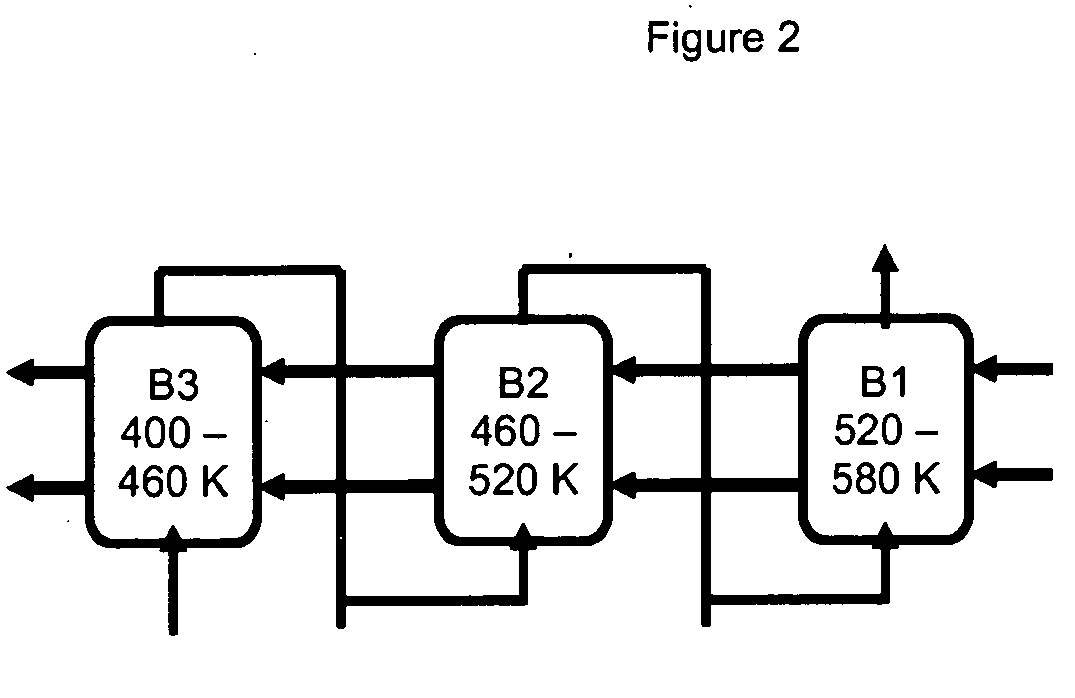

Thermal Decomposition of Urea in a Side Stream of Combustion Flue Gas Using a Regenerative Heat Exchanger

InactiveUS20080050297A1Avoid insufficient temperatureImprove thermal efficiencyNitrogen compoundsExhaust apparatusFlue gasThermal efficiency

This invention relates generally to the treatment of NOx in combustion flue gas. In certain embodiments, the invention relates to the use of a regenerative heat exchanger (RHE) to convert urea to ammonia in a side stream of flue gas. Ammonia and / or other urea decomposition products exit the heat exchanger, are mixed with the rest of the flue gas, and enter a selective catalytic reduction (SCR) unit for reduction of NOx in the flue gas. The use of an RHE significantly improves the thermal efficiency of the overall process. More particularly, in certain embodiments, the regenerative heat exchanger is a dual chamber RHE.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

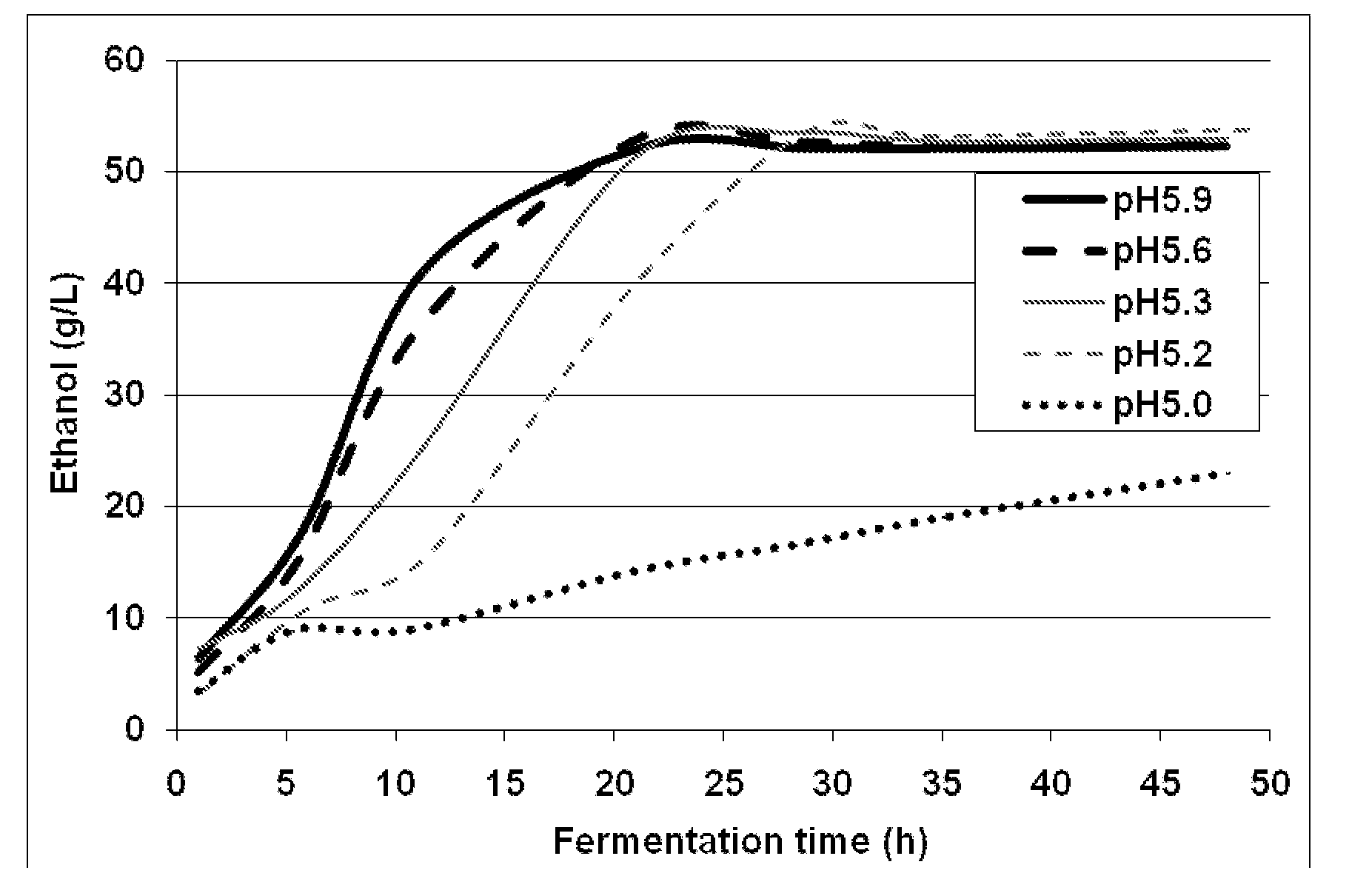

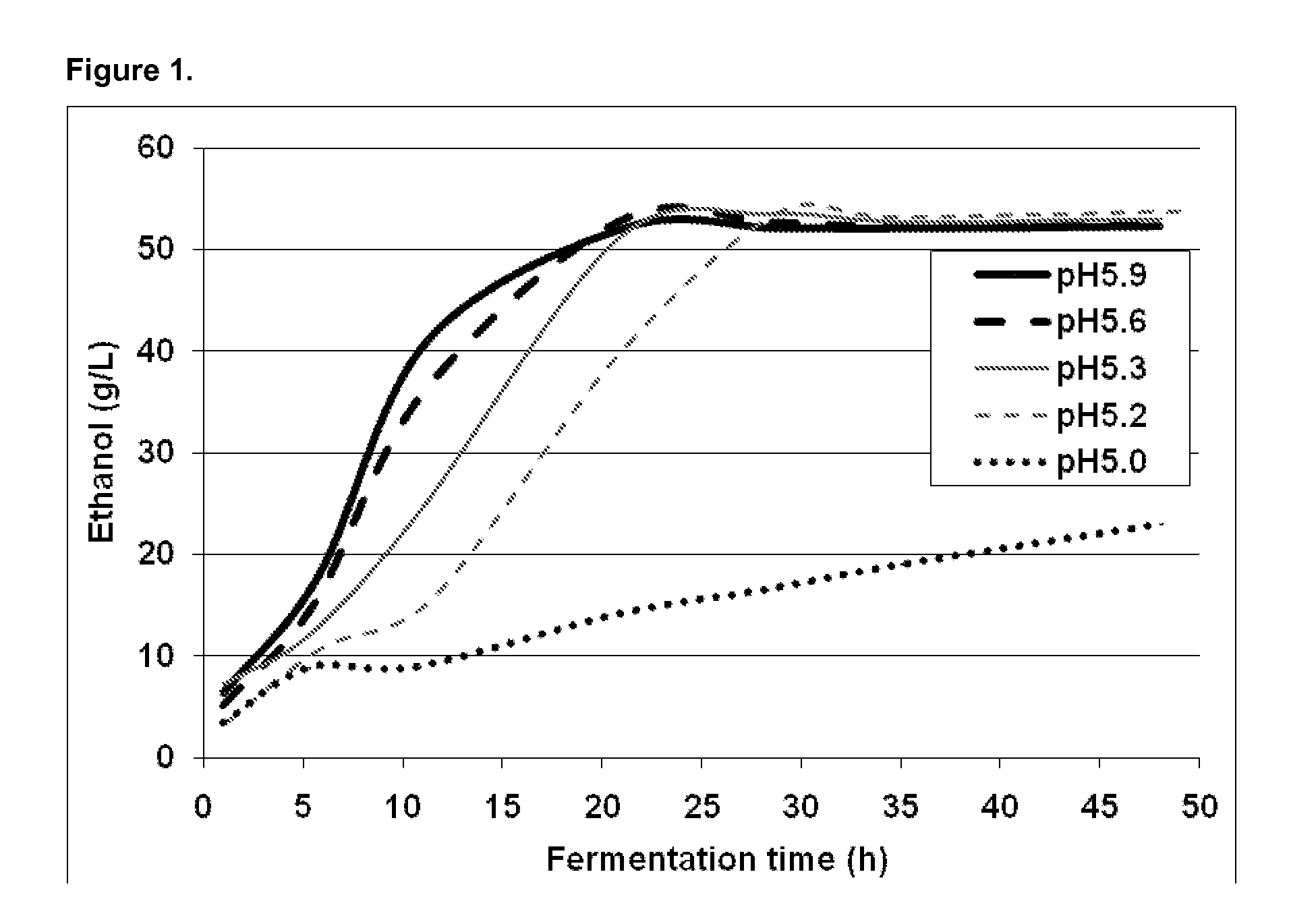

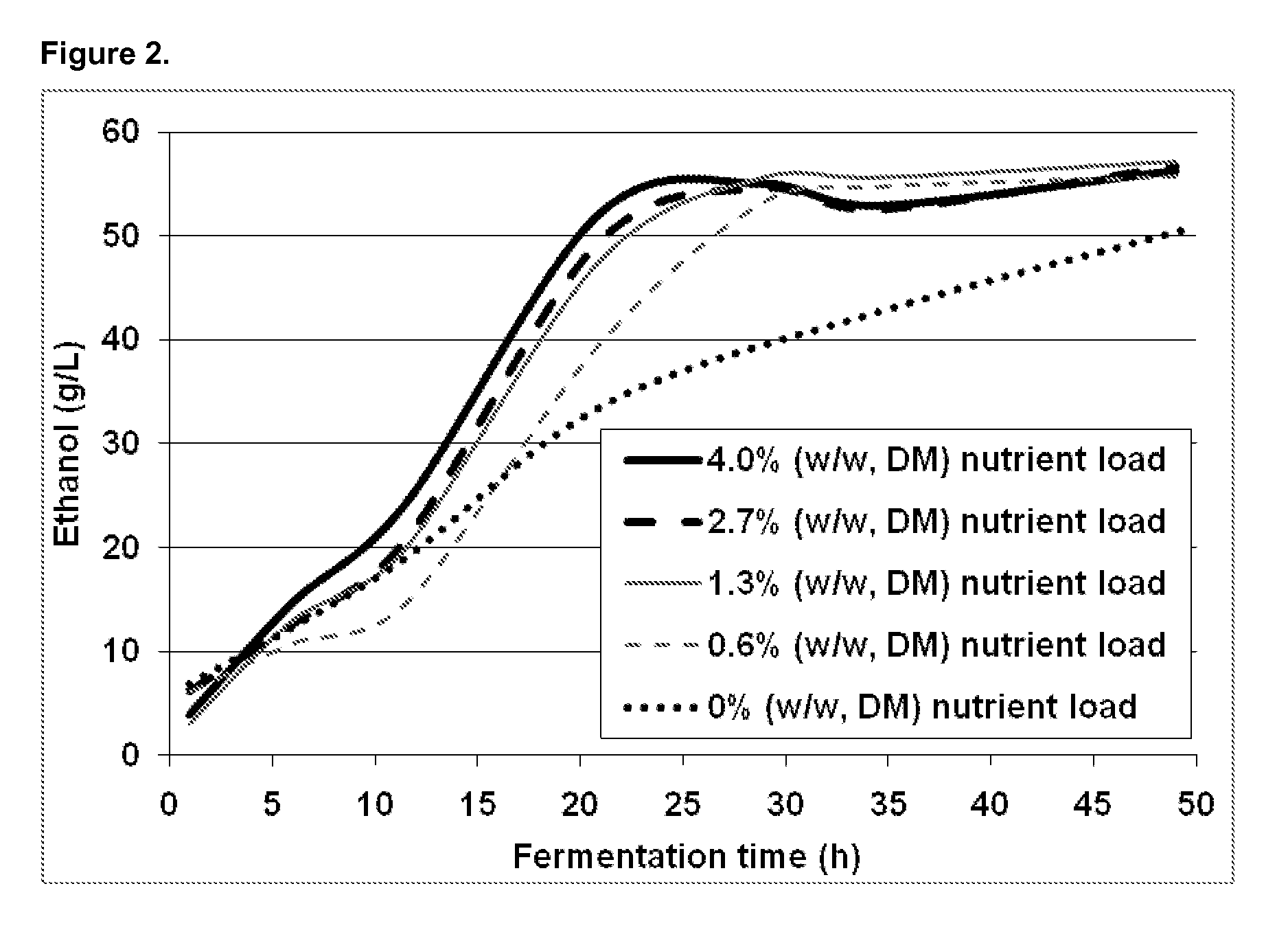

Process for alcoholic fermentation of lignocellulosic biomass

InactiveUS20100159552A1Lower cost of capitalReduce operating costsBiofuelsFermentationCelluloseHydrolysate

A process for the production of ethanol wherein a hydrolyzed lignocellulosic biomass is fermented in the presence of a stillage residue. The fermentation of cellulosic hydrolysates is improved by adding prior to and / or during fermentation a stillage residue side stream from a corn starch-to-ethanol process as a nutrient source for the yeast organisms used in the fermentation. Stillage residues from the grain dry mill ethanol producing process, including the whole stillage, wet cake, thin stillage, and / or syrup are added to assist as a nitrogen and nutrient source for the fermentive processes. The stillage residue is produced by any grain-to-ethanol process.

Owner:GREENFIELD SPECIALTY ALCOHOLS

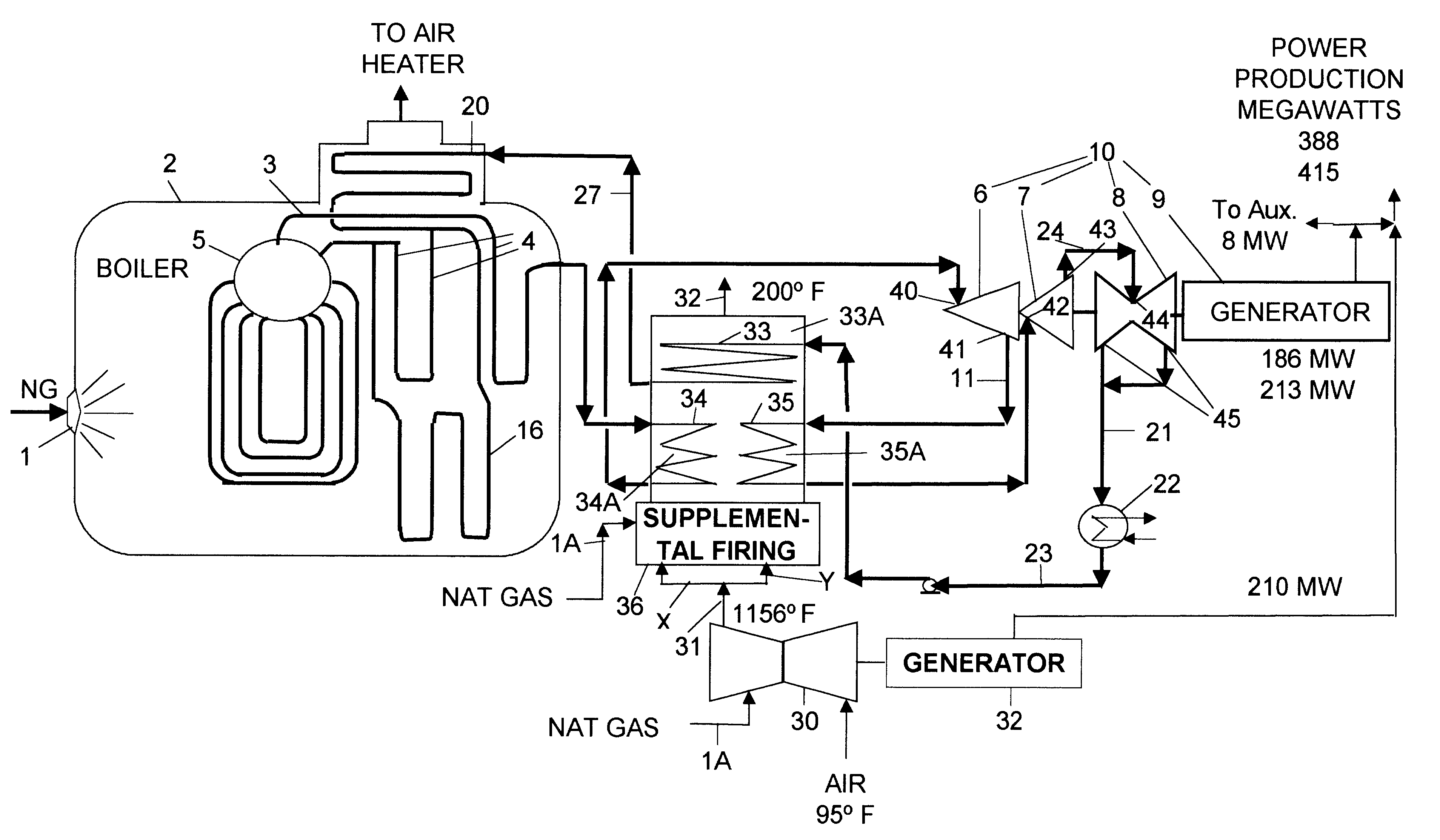

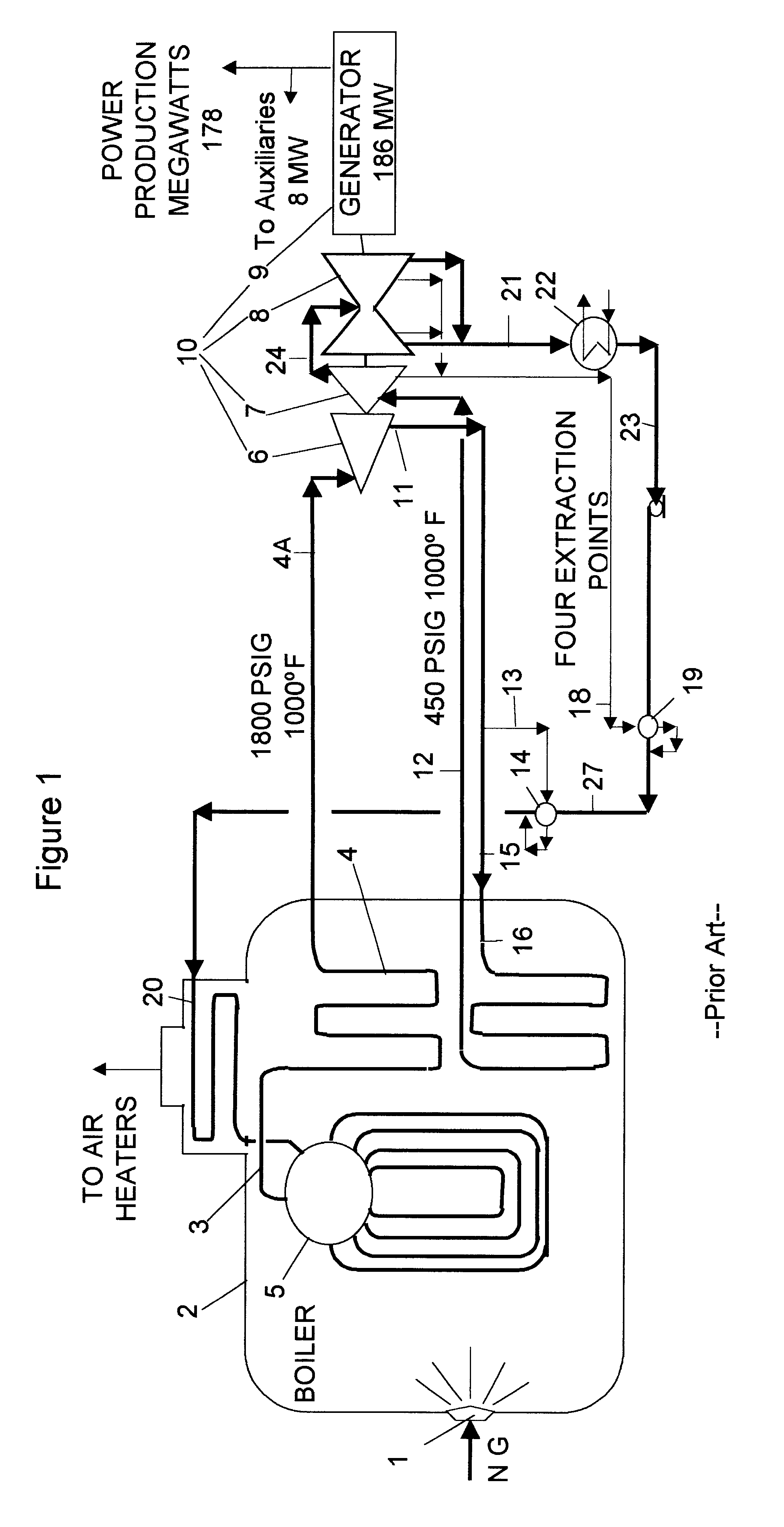

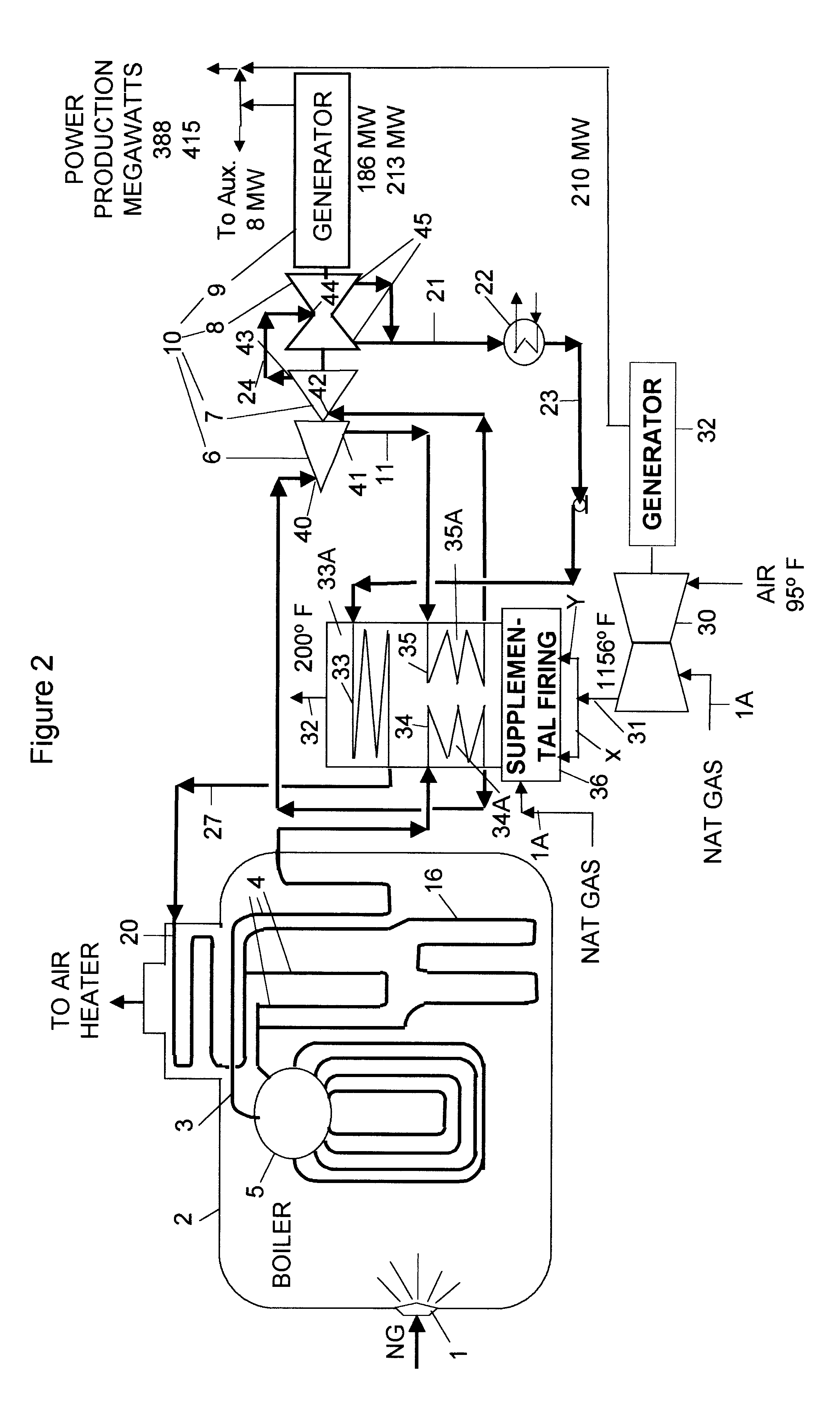

Process for generating electric power

A process for a steam turbine-generator system that includes a boiler and a train of steam turbines and a gas turbine generator system. Exhaust gas from the gas turbine superheats the high pressure steam produced by the boiler in the steam generator system and reheats a steam side stream extracted at an intermediate point on the steam turbine train in the steam generator system after which the reheated steam side stream is fed back into the steam turbine train downstream of the extraction point. Further, the exhaust gas preheats a steam condensate stream formed by condensing the exhaust steam from the downstream steam outlet on the steam turbine train after which the preheated condensate is recycled back to the boiler. The gas turbine exhaust gas superheats the high pressure steam and reheats the steam side stream before it preheats the steam condensate stream. A second embodiment of the invention includes firing supplemental fossil fuel to provide additional heat to superheat the high pressure steam, and / or to reheat the intermediate pressure steam stream, and / or to preheat the steam condensate stream.

Owner:WYLIE ROGER

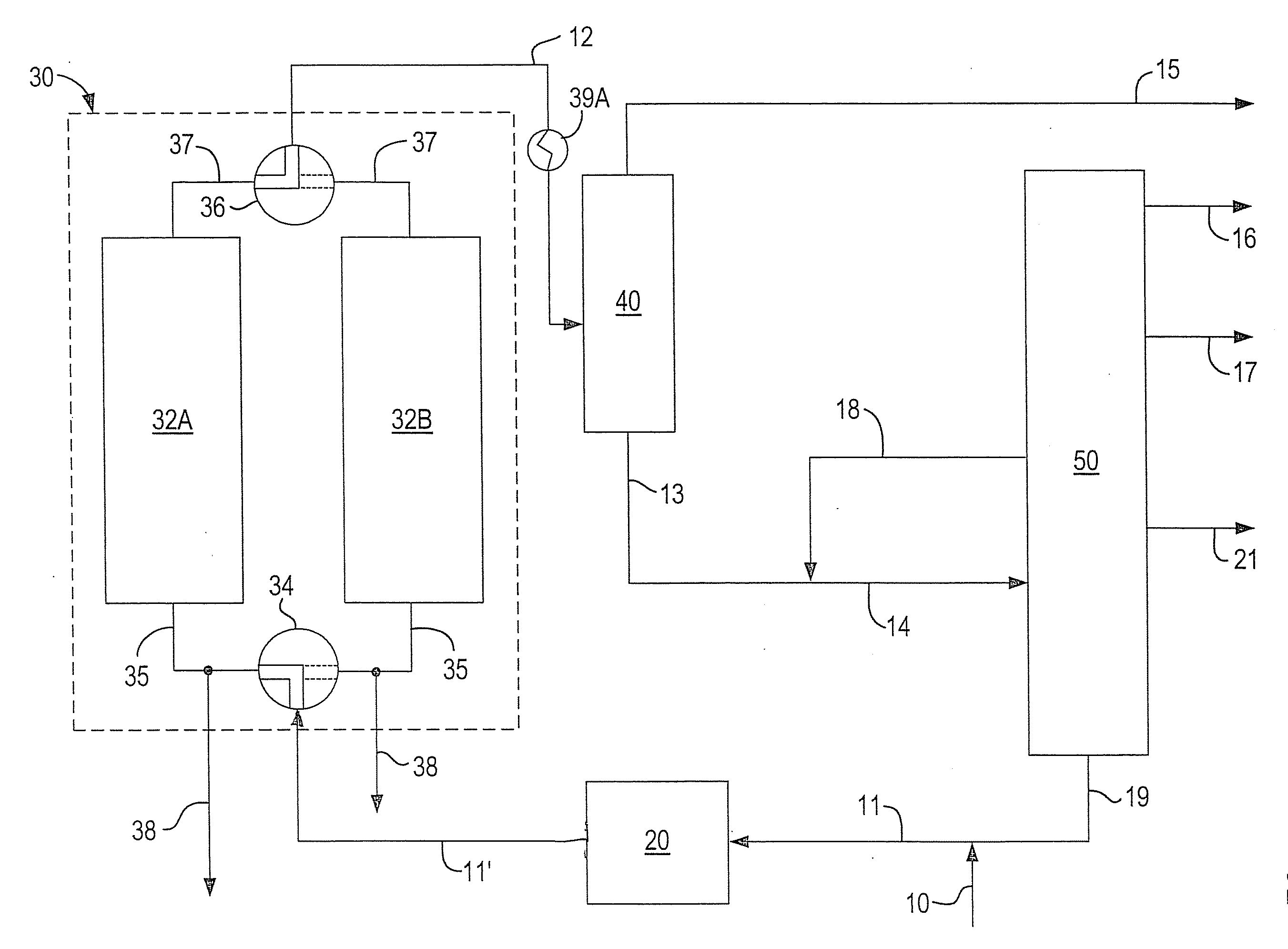

Methods and systems for improved dosing of a chemical treatment, such as chlorine dioxide, into a fluid stream, such as a wastewater stream

InactiveUS20050023224A1Reduce and eliminate needReliable treatmentWater treatment parameter controlOther chemical processesChemical treatmentChlorine dioxide

The invention is directed to methods, apparatuses, and systems for treatment of a liquid flow comprising addition of a chemical treatment at at least two locations along a side stream of a main flow of said liquid, in which the dosing by such additions is sufficient to treat the entire main flow upon return of the side stream to the main flow. Algorithms are utilized to control the additions at the locations of addition of chemical treatments. In a typical embodiment, one chemical addition is principally proportional to the flow rate of the liquid flow, and the other chemical addition is principally adjusted based on signals from a primary measuring device that measures a parameter in the flow after one or both chemical additions. The addition of chlorine dioxide as the chemical treatment, to disinfect wastewater, is discussed.

Owner:FKOS LLC +1

Production of biodiesel and a side stream of crude glycerol which is converted to methanol

Owner:GD SPA

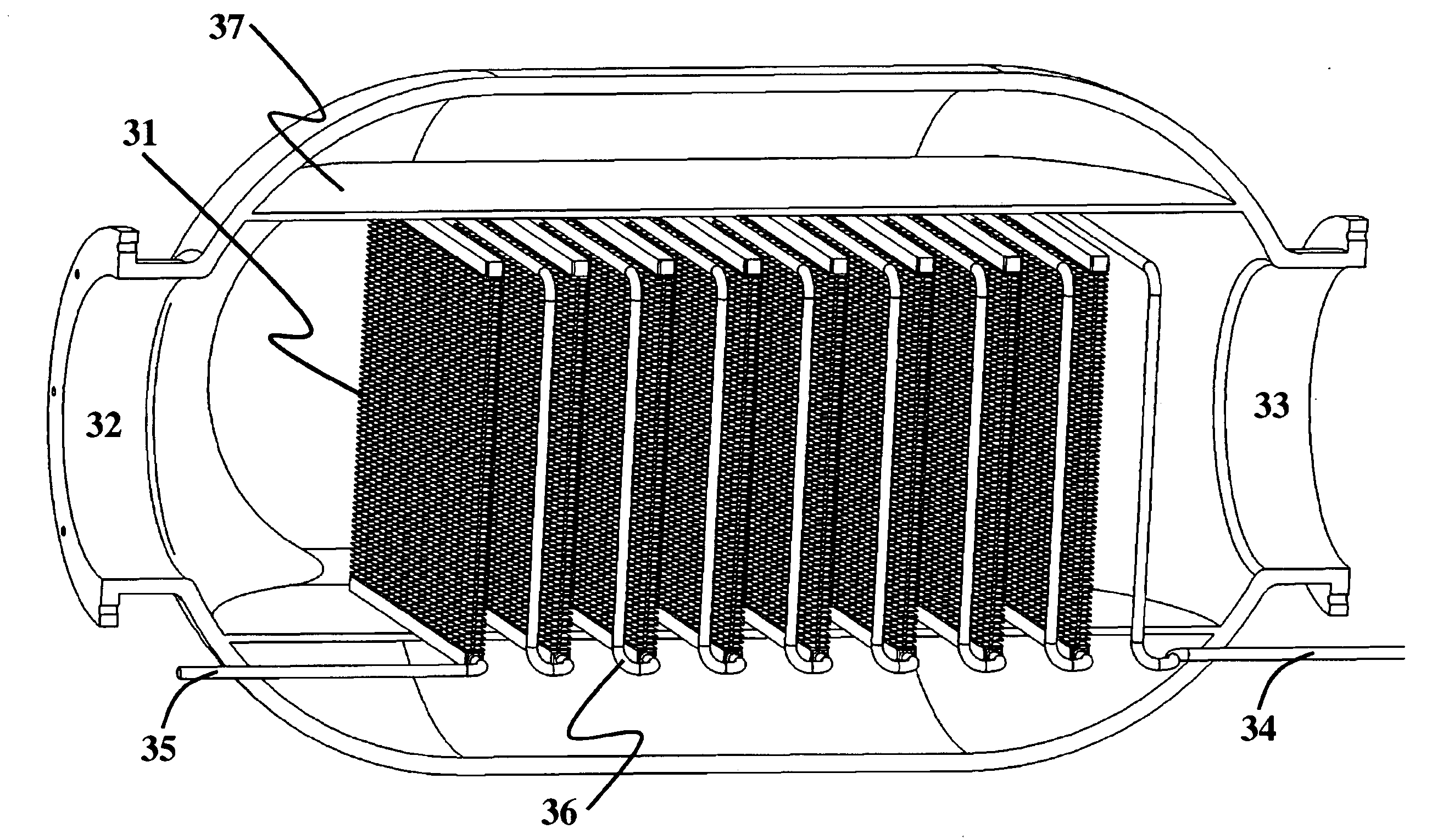

Compact, high-effectiveness, gas-to-gas compound recuperator with liquid intermediary

InactiveUS20100276119A1Efficient exchangeStationary conduit assembliesStationary tubular conduit assembliesOrganic fluidMolten salt

A liquid-loop compound recuperator is disclosed for high-ε heat exchange between a first shell-side fluid stream and a second shell-side fluid stream of similar thermal capacity rates (W / K). The compound recuperator is comprised of at least two fluid-to-liquid (FL) recuperator modules for transfer of heat from a shell-side fluid, usually a gas, to an intermediary tube-side heat transfer liquid (HTL). Each FL module includes a plurality of thermally isolated, serially connected, adjacent exchanger cores inside a pressure vessel. The cores are rows of finned tubes for cross-flow transfer of heat, and they are arranged in series to effectively achieve counterflow exchange between the HTL and the shell-side stream. The HTL may be water, an organic liquid, a molten alloy, or a molten salt.

Owner:DOTY SCI

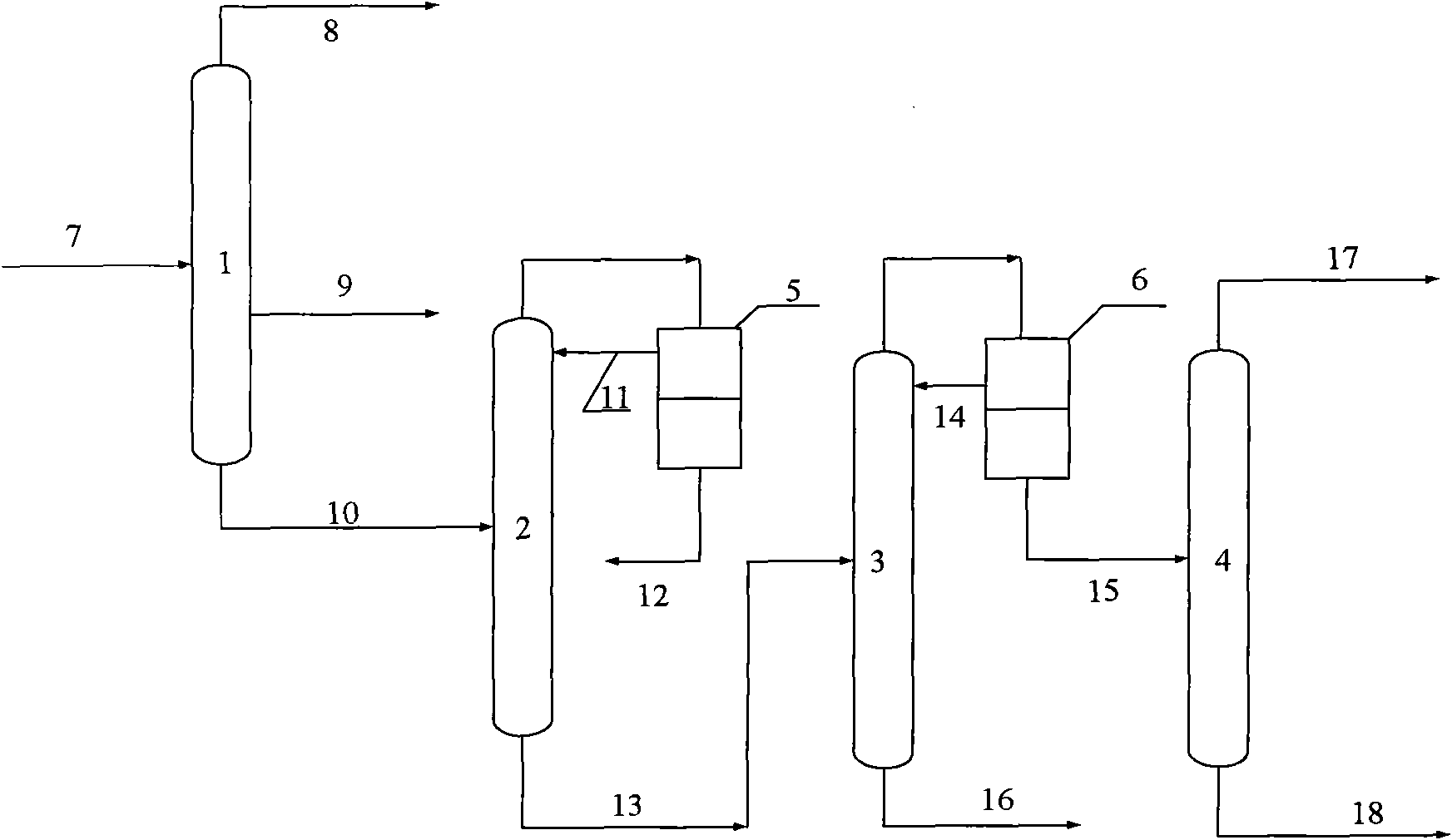

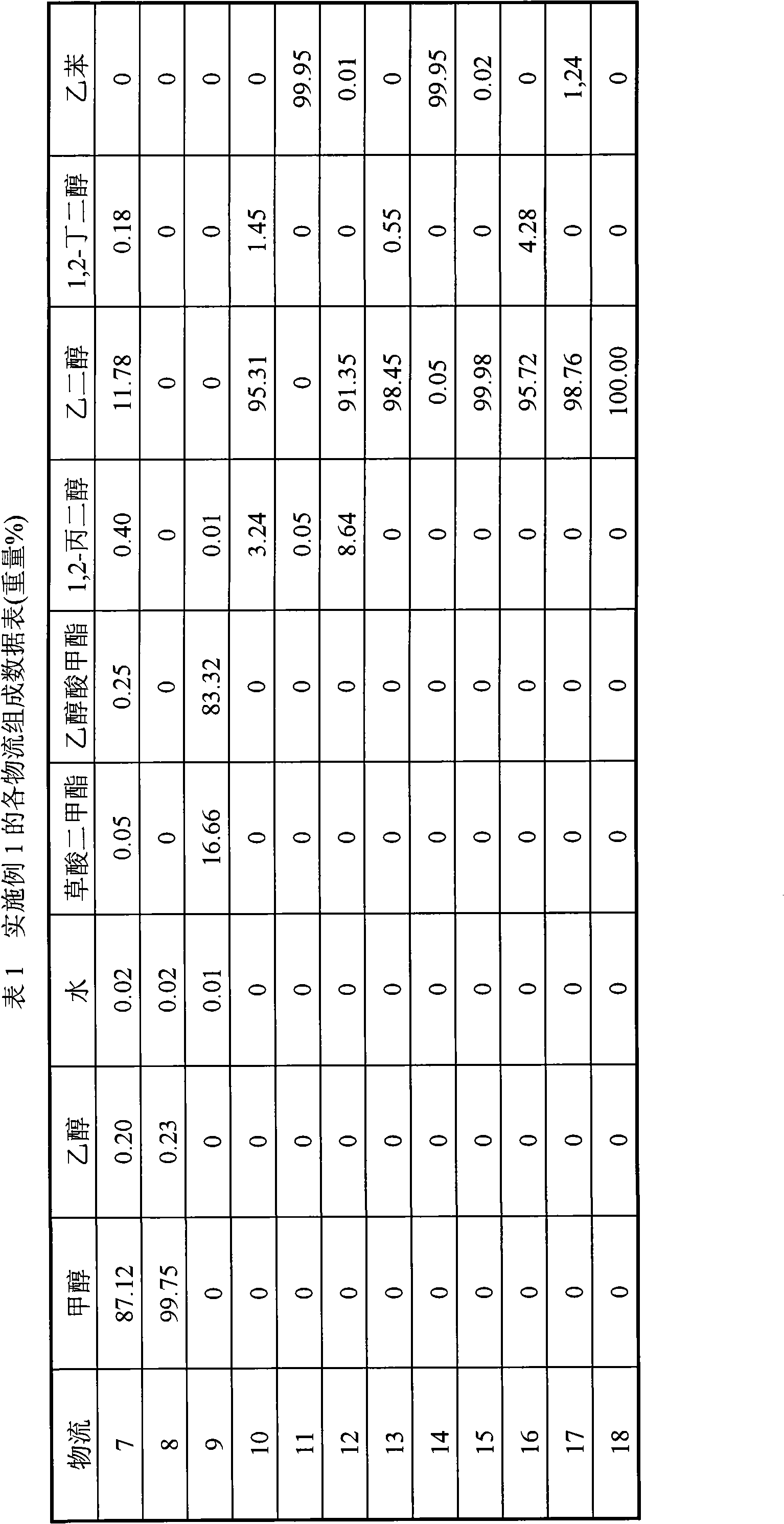

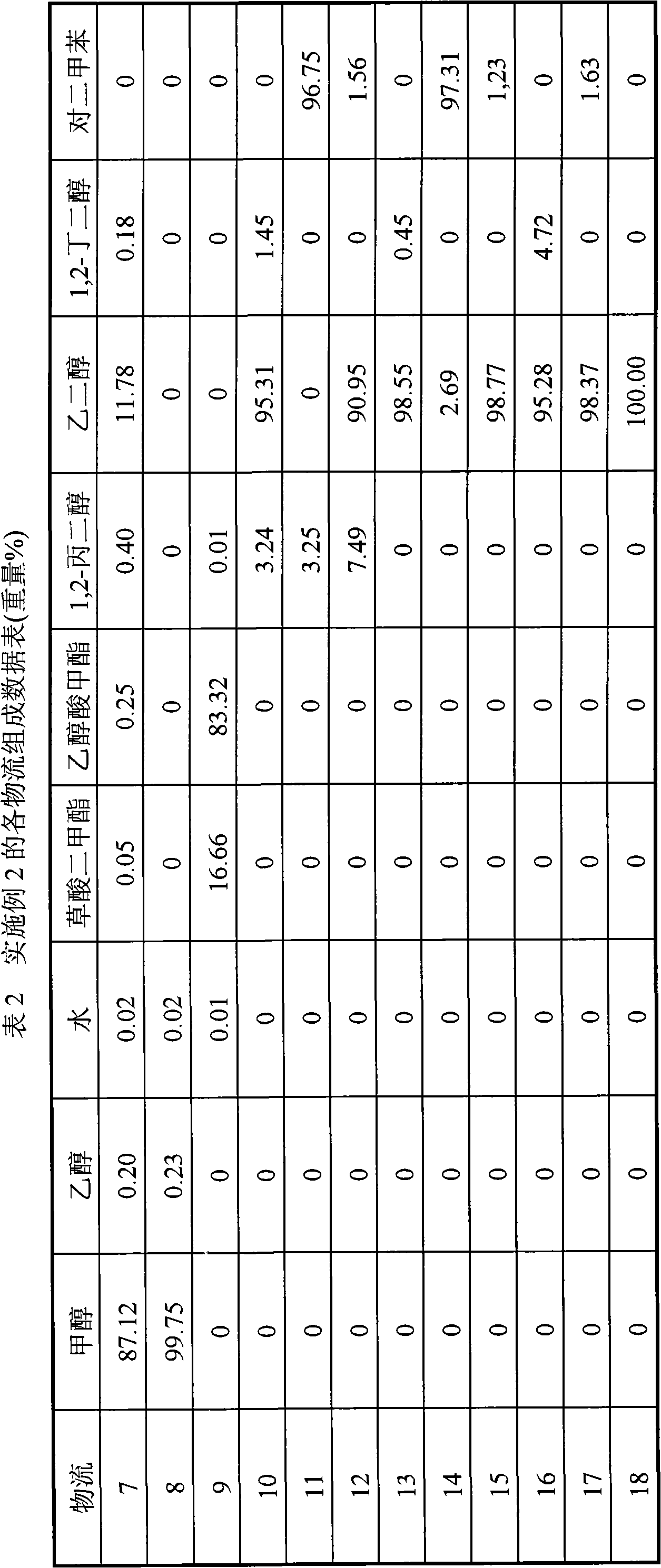

Method for producing glycol product by separating synthetic gas

ActiveCN102372596AAchieve separationOrganic compound preparationHydroxy compound preparationSyngasSeparation technology

The invention relates to a method for producing a glycol product by separating synthetic gas, which mainly solves the problem of no relative separation technology report on the glycol products prepared by synthetic gas. The method of the invention comprises the following steps: the glycol product prepared by synthetic gas enters in a fraction cutting tower (1) for separating, a material flow I is obtained from the top of the tower, a material flow II is collected from the side stream, a material flow III is obtained from a tower kettle; the material flow III and an entrainer I enter in a first azeotropic rectification tower (2) for separating, a glycol solution comprising 1,2-propylene glycol is collected from the top of the tower, a material flow IV is obtained from the tower kettle; the material flow IV and an entrainer II enter in a second azeotropic rectification tower (3) for separating, a material flow V is collected from the top of the tower, the glycol solution comprising 1,2-butylene glycol is obtained from the tower kettle; a material flow V enters in a central section of a product tower (4), the glycol solution comprising light components is collected from the top of the tower, and a glycol product is obtained from the tower kettle. The technical scheme better solves the problem, and can be used in industrial production for separating glycol products by synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

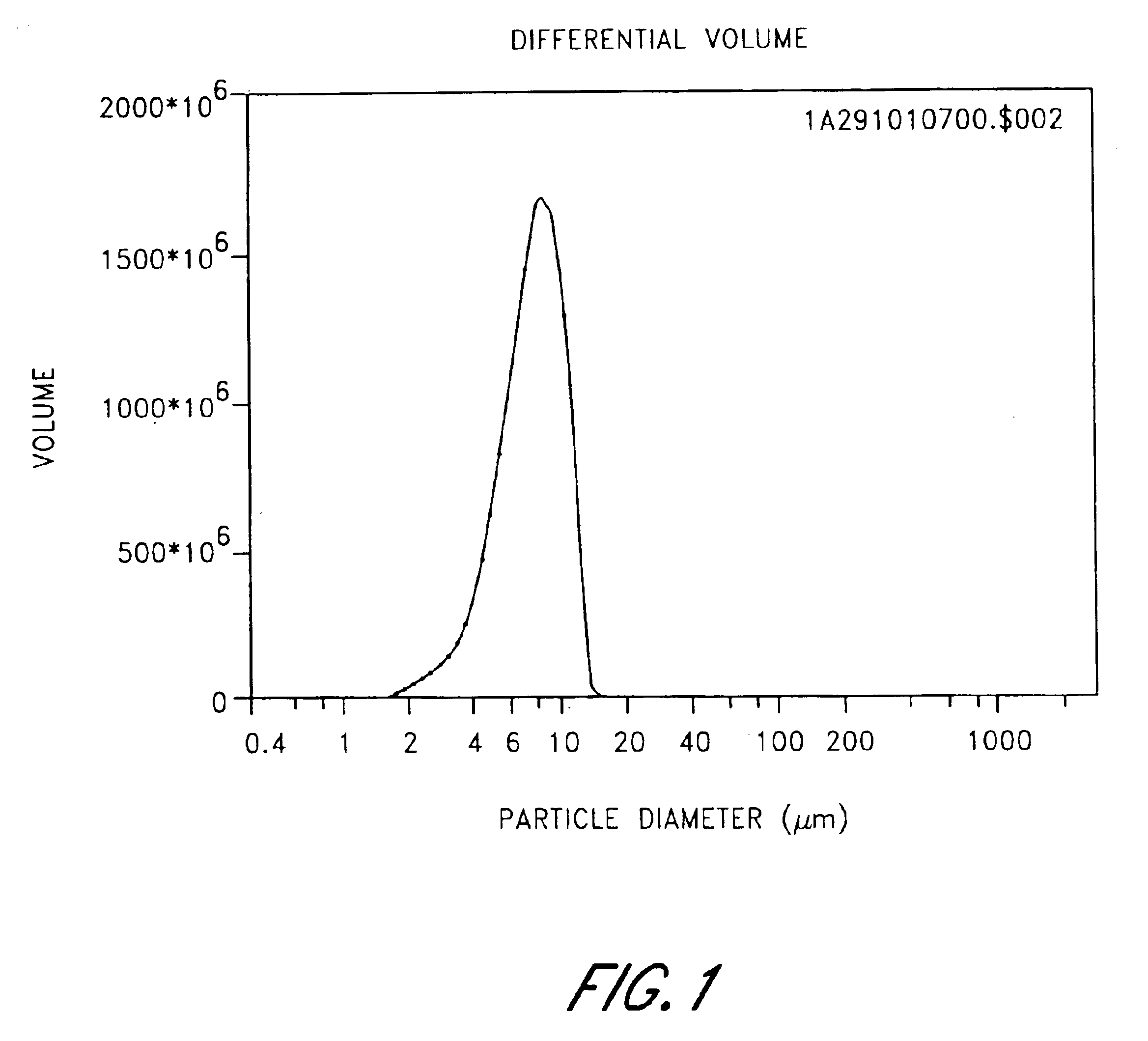

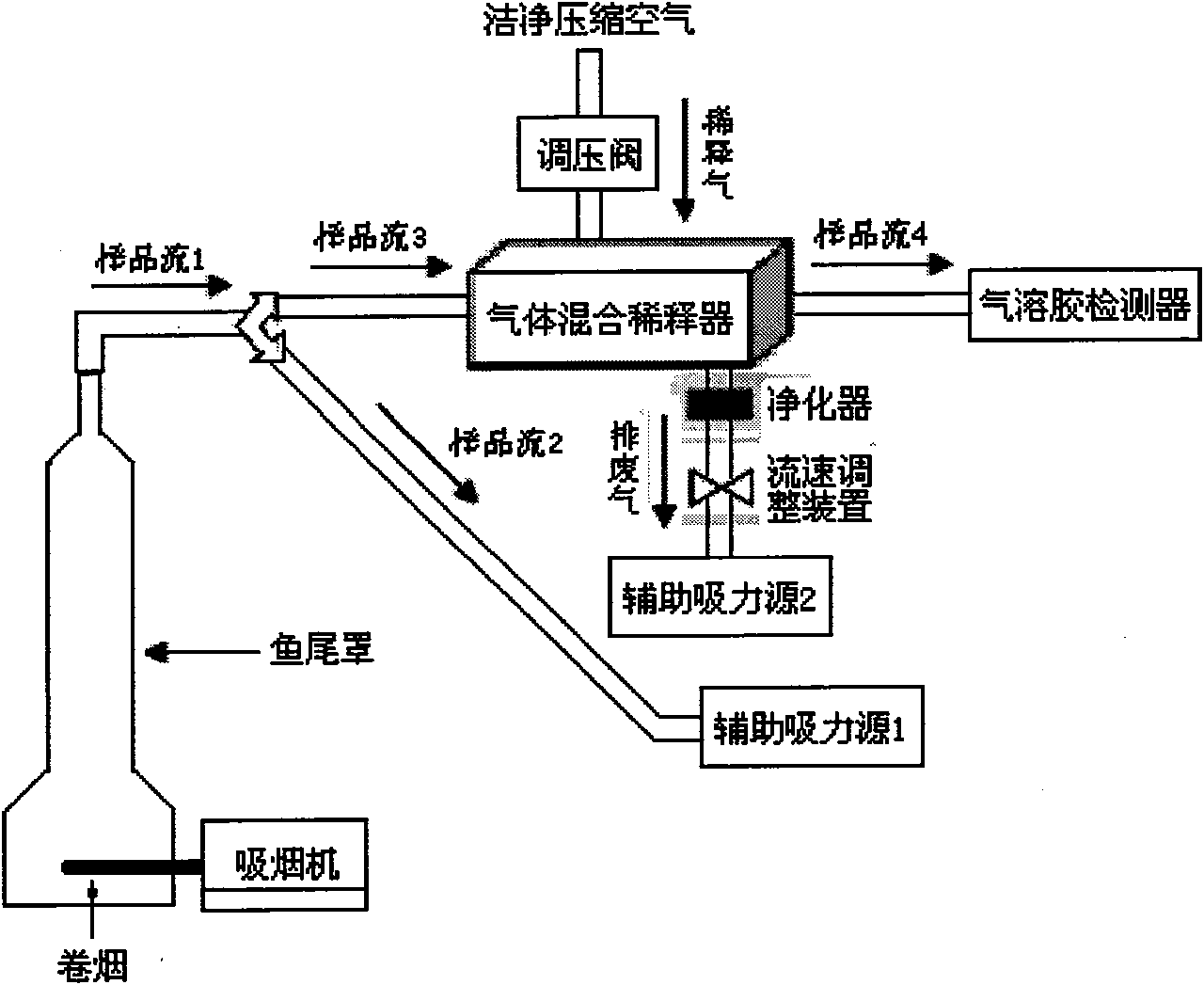

Method for collecting and detecting aerosol in side-stream smoke applicable to cigarettes having different concentrations of tar

ActiveCN101923035ASave money and material resourcesReasonable settingPreparing sample for investigationParticle size analysisEnvironmental engineeringBiology

Owner:CHINA TOBACCO GUANGDONG IND

Insulation boards and methods for their manufacture

A method for producing polyisocyanurate insulation foams, the method comprising contacting an A-side stream of reactants that includes an isocyanate with a B-side stream of reactants that include a polyol and a blowing agent, where the blowing agent includes isopentane and n-pentane in a substantial absence of cyclopentane.

Owner:HOLCIM

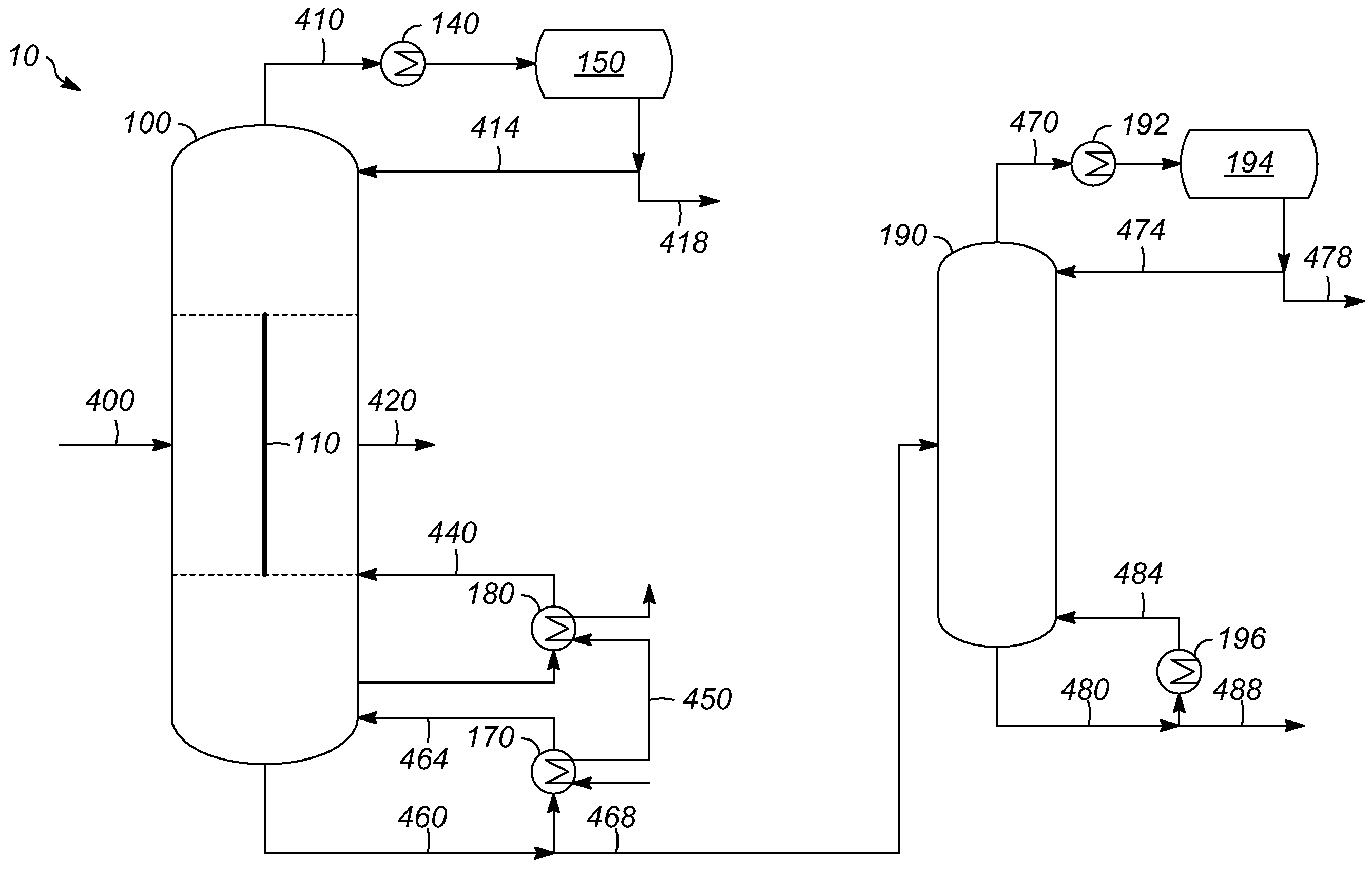

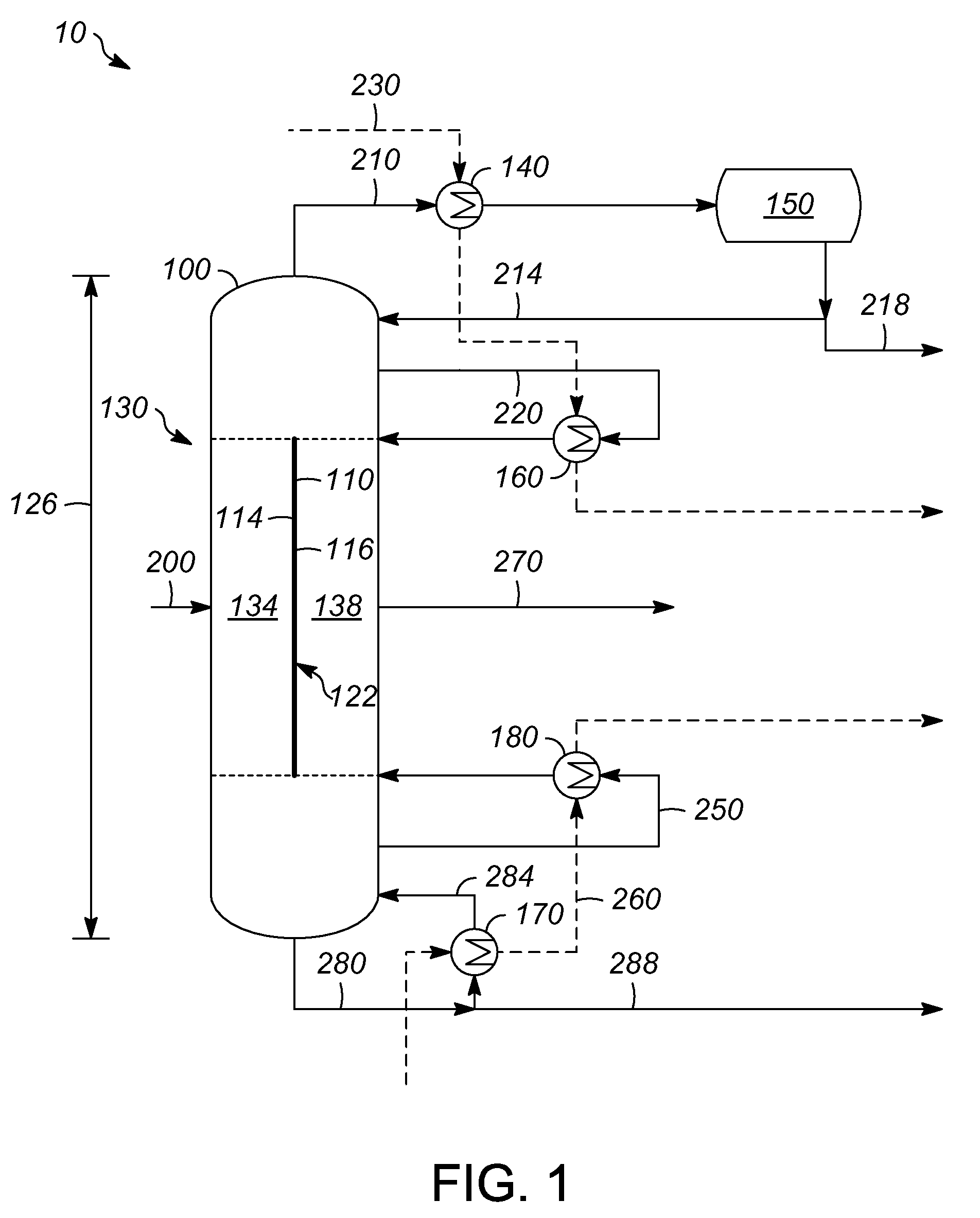

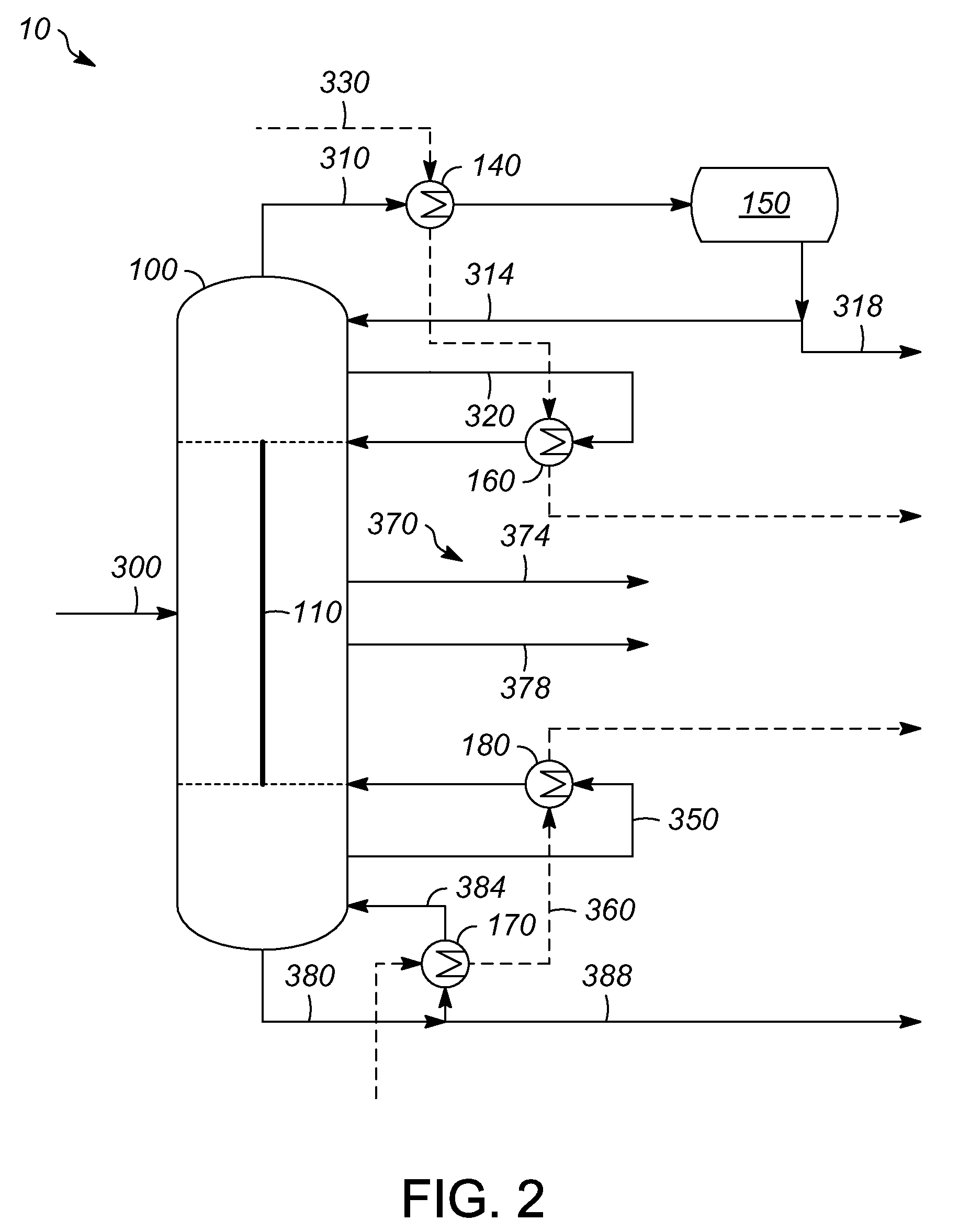

Process and system for heating or cooling streams for a divided distillation column

ActiveUS20100224536A1Reduce dutyEfficiently provideHydrocarbon distillationSteam distillationNaphthaDistillation

One exemplary embodiment can be a system for separating a plurality of naphtha components. The system can include a column, an overhead condenser, and a side condenser. Generally, the column includes a dividing imperforate wall with one surface facing a feed and another surface facing at least one side stream. Typically, the wall extends a significant portion of the column height to divide the portion into at least two substantially vertical, parallel contacting sections. Typically, the overhead condenser receives an overhead stream including a light naphtha from the column. Usually, a side condenser receives a process stream from the column and returns the stream to the column to facilitate separation. A cooling stream may pass through the overhead condenser and then the side condenser.

Owner:UOP LLC

Process for producing acetic acid

ActiveUS9382186B1Stay focusedPreparation from carboxylic acid esters/lactonesCarboxylic preparation from carbon monoxide reactionAcetic acidWater concentration

A process for producing acetic acid is disclosed in which the water concentration is controlled in the side stream between two columns. Controlling the water concentration by the liquid light phase recycle controls the hydrogen iodide concentration in the side stream to be less than or equal to 50 wppm.

Owner:CELANESE INT CORP

Thermal decomposition of urea in a side stream of combustion flue gas using a regenerative heat exchanger

InactiveUS7682586B2Avoid insufficient temperatureHeat produced by the burner is conservedNitrogen compoundsExhaust apparatusFlue gasThermal efficiency

This invention relates generally to the treatment of NOx in combustion flue gas. In certain embodiments, the invention relates to the use of a regenerative heat exchanger (RHE) to convert urea to ammonia in a side stream of flue gas. Ammonia and / or other urea decomposition products exit the heat exchanger, are mixed with the rest of the flue gas, and enter a selective catalytic reduction (SCR) unit for reduction of NOx in the flue gas. The use of an RHE significantly improves the thermal efficiency of the overall process. More particularly, in certain embodiments, the regenerative heat exchanger is a dual chamber RHE.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com