Patents

Literature

1792results about "Preparation from carboxylic acid esters/lactones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

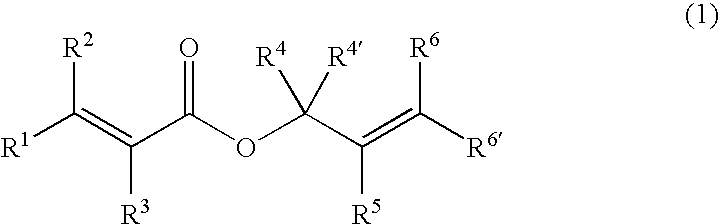

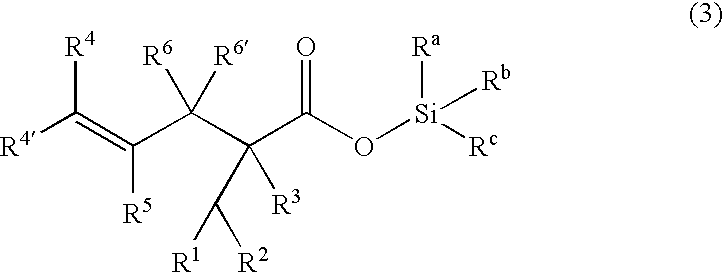

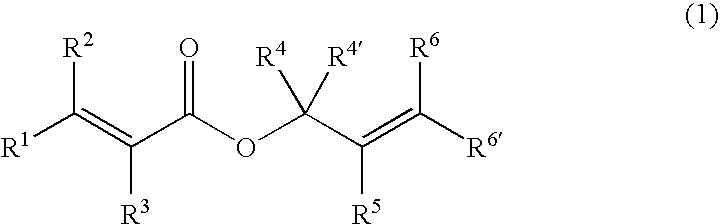

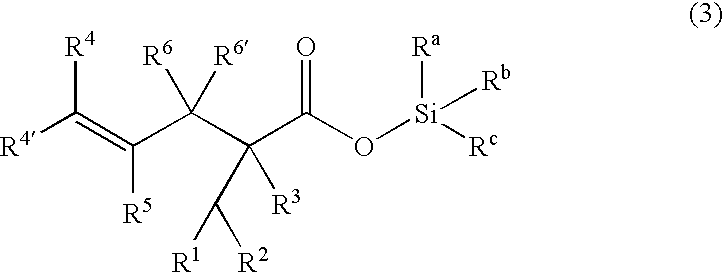

Processes of making gamma,delta-unsaturated carboxylic acid and silyl ester thereof, carboxyl group-containing organosilicon compound and process of making

ActiveUS7307178B2Few stepsHigh yieldSilicon organic compoundsPreparation from carboxylic acid esters/lactonesCarboxyl radicalPerylene derivatives

A γ,δ-unsaturated carboxylic acid silyl ester is prepared by reacting an α,β-unsaturated carboxylic acid ester with a hydrosilane or hydrosiloxane in the presence of tris(pentafluorophenyl)borane. γ,δ-Unsaturated carboxylic acid derivatives are readily prepared through fewer steps and in high yields.

Owner:SHIN ETSU CHEM CO LTD

Processes of making gamma,delta-unsaturated carboxylic acid and silyl ester thereof, carboxyl group-containing organosilicon compound and process of making

ActiveUS20050070729A1High yieldFew stepsSilicon organic compoundsPreparation from carboxylic acid esters/lactonesCarboxyl radicalPerylene derivatives

A γ,δ-unsaturated carboxylic acid silyl ester is prepared by reacting an α,β-unsaturated carboxylic acid ester with a hydrosilane or hydrosiloxane in the presence of tris(pentafluorophenyl)borane. γ,δ-Unsaturated carboxylic acid derivatives are readily prepared through fewer steps and in high yields.

Owner:SHIN ETSU CHEM IND CO LTD

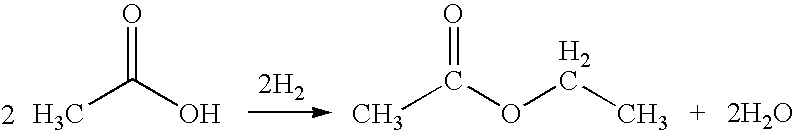

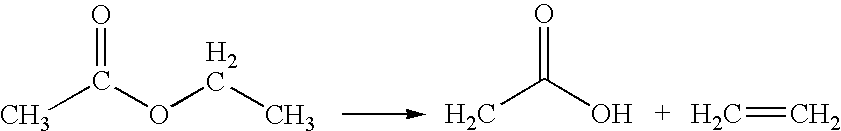

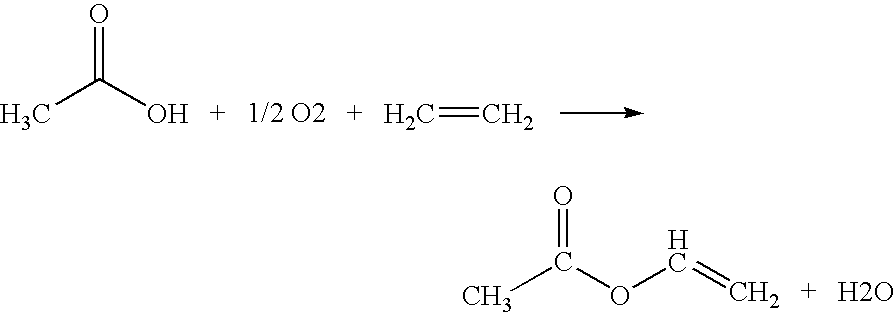

Integrated process for the production of viny acetate from acetic acid via ethy acetate

This invention provides an integrated three step economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form ethyl acetate which is cracked to form ethylene and acetic acid in the second step and in a subsequent step so formed ethylene and acetic acid is reacted with molecular oxygen over a suitable catalyst to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C., which is cracked over a NAFION catalyst to form ethylene and acetic acid at a temperature of about 185° C., which is mixed with molecular oxygen and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

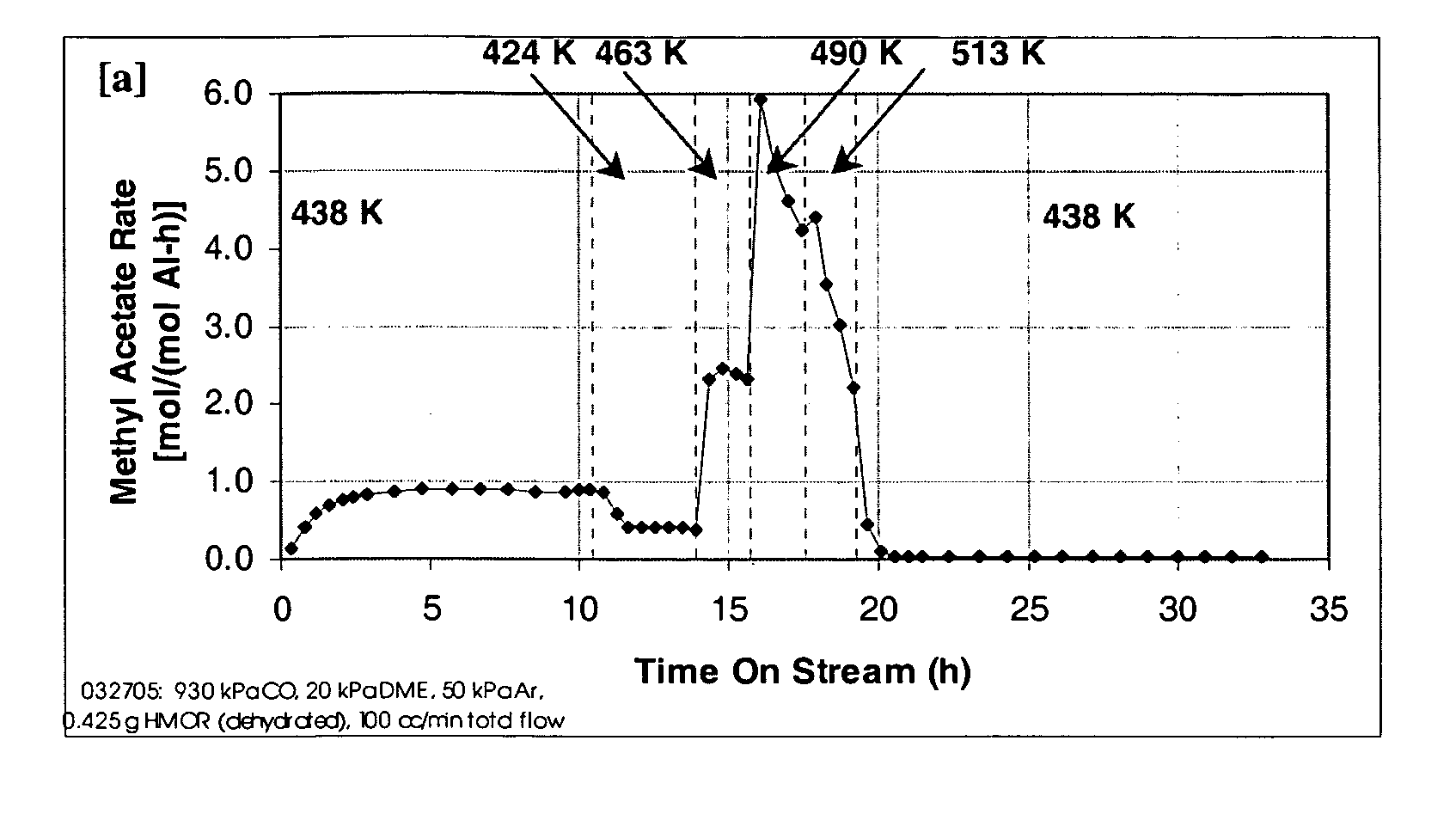

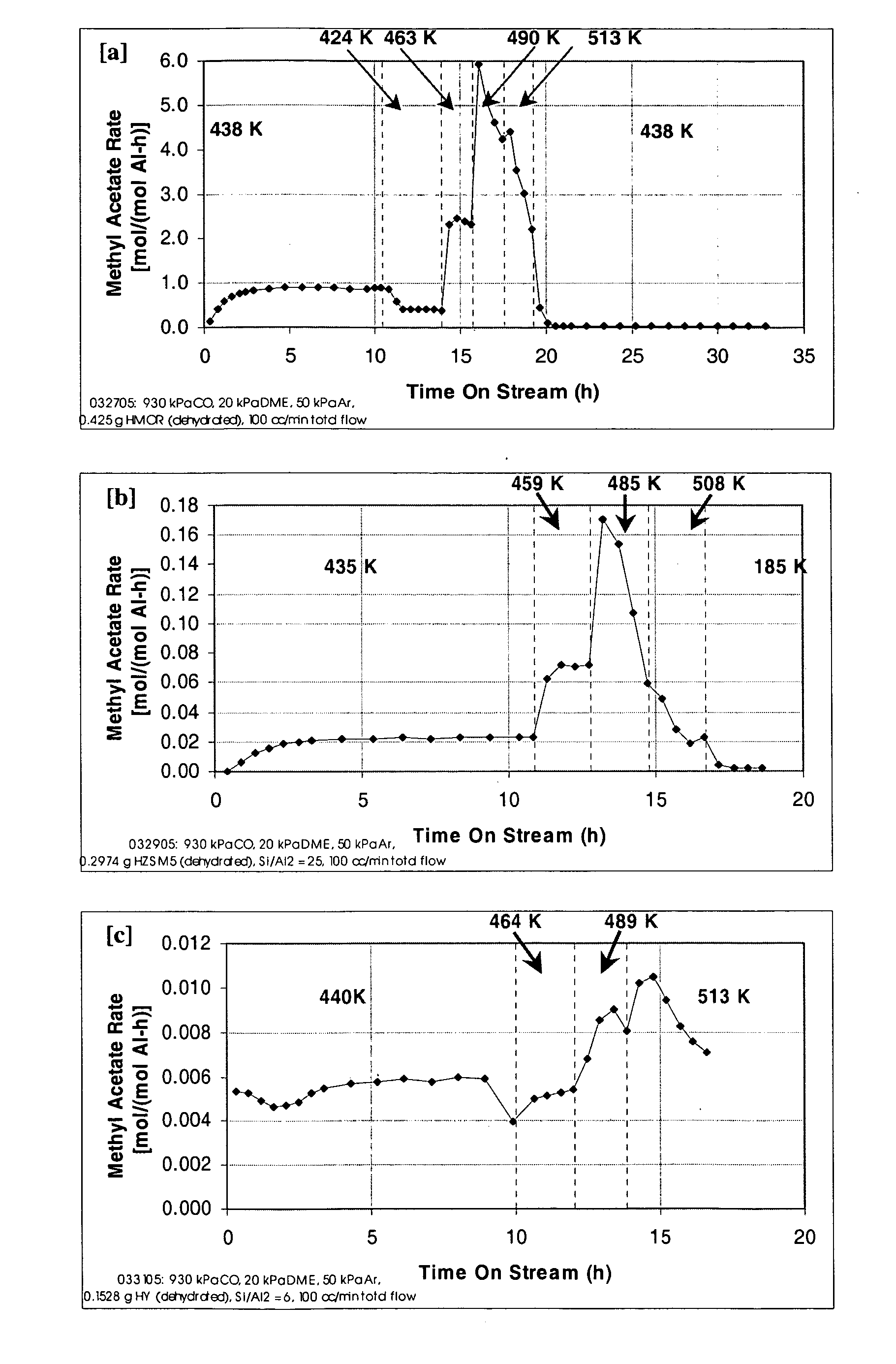

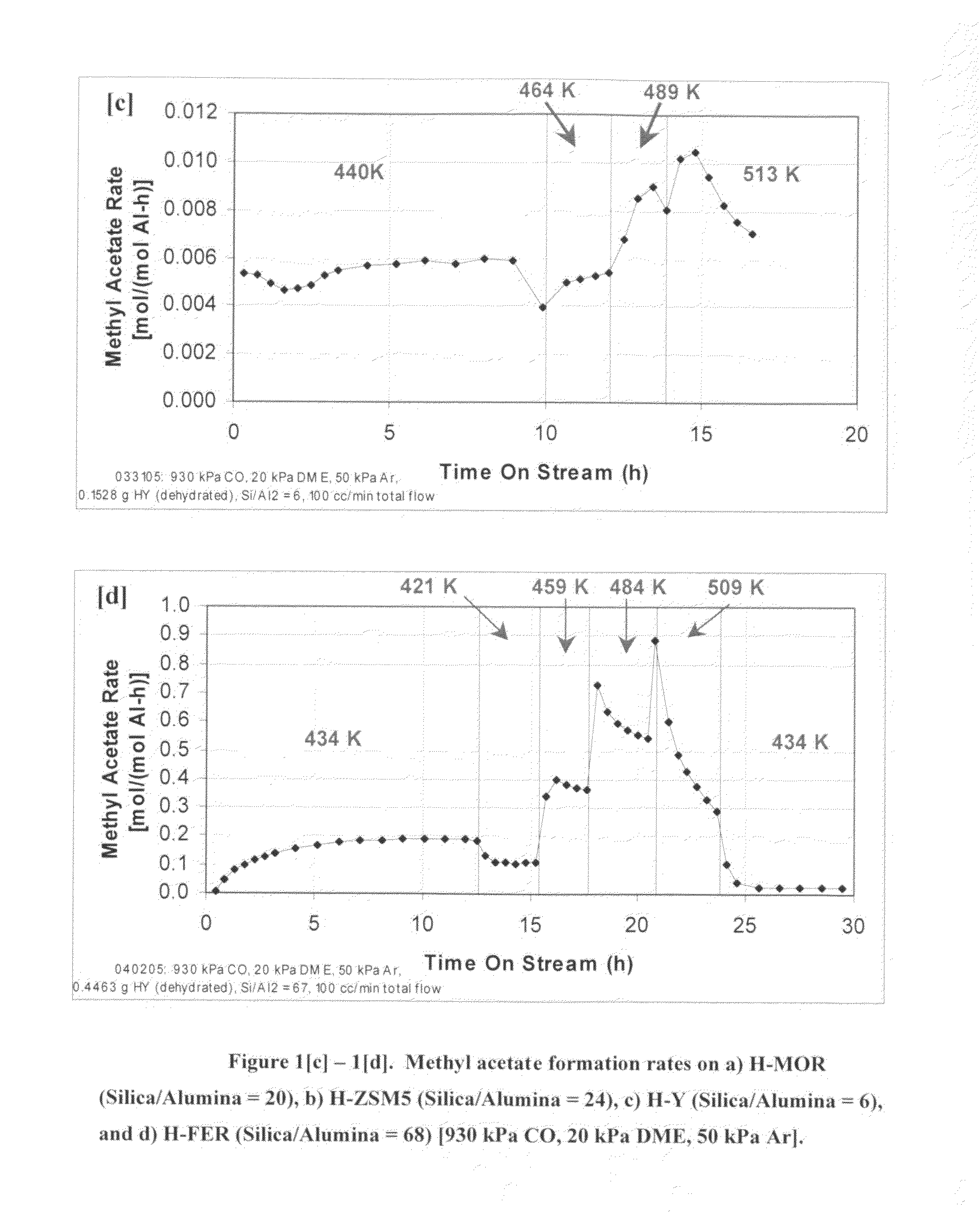

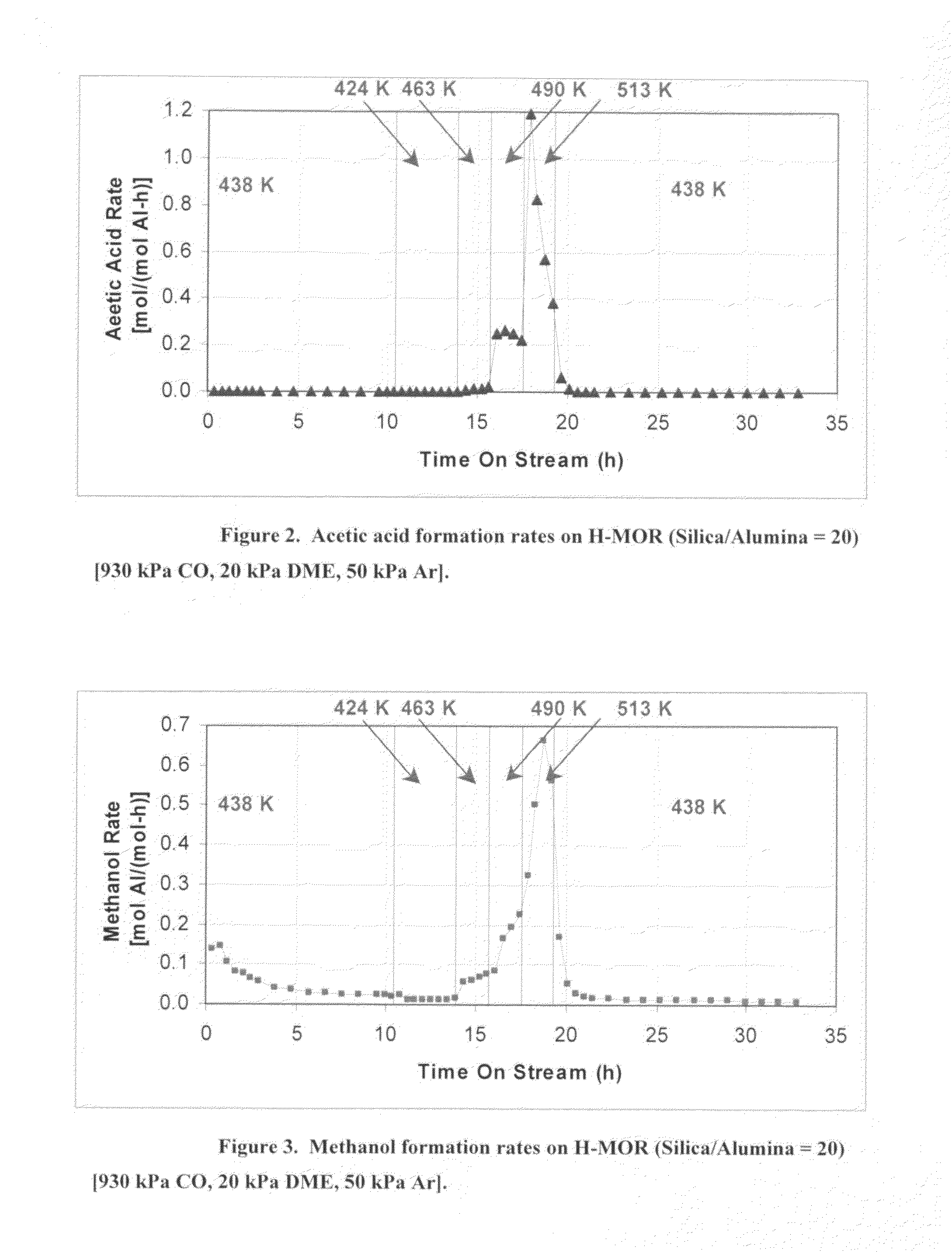

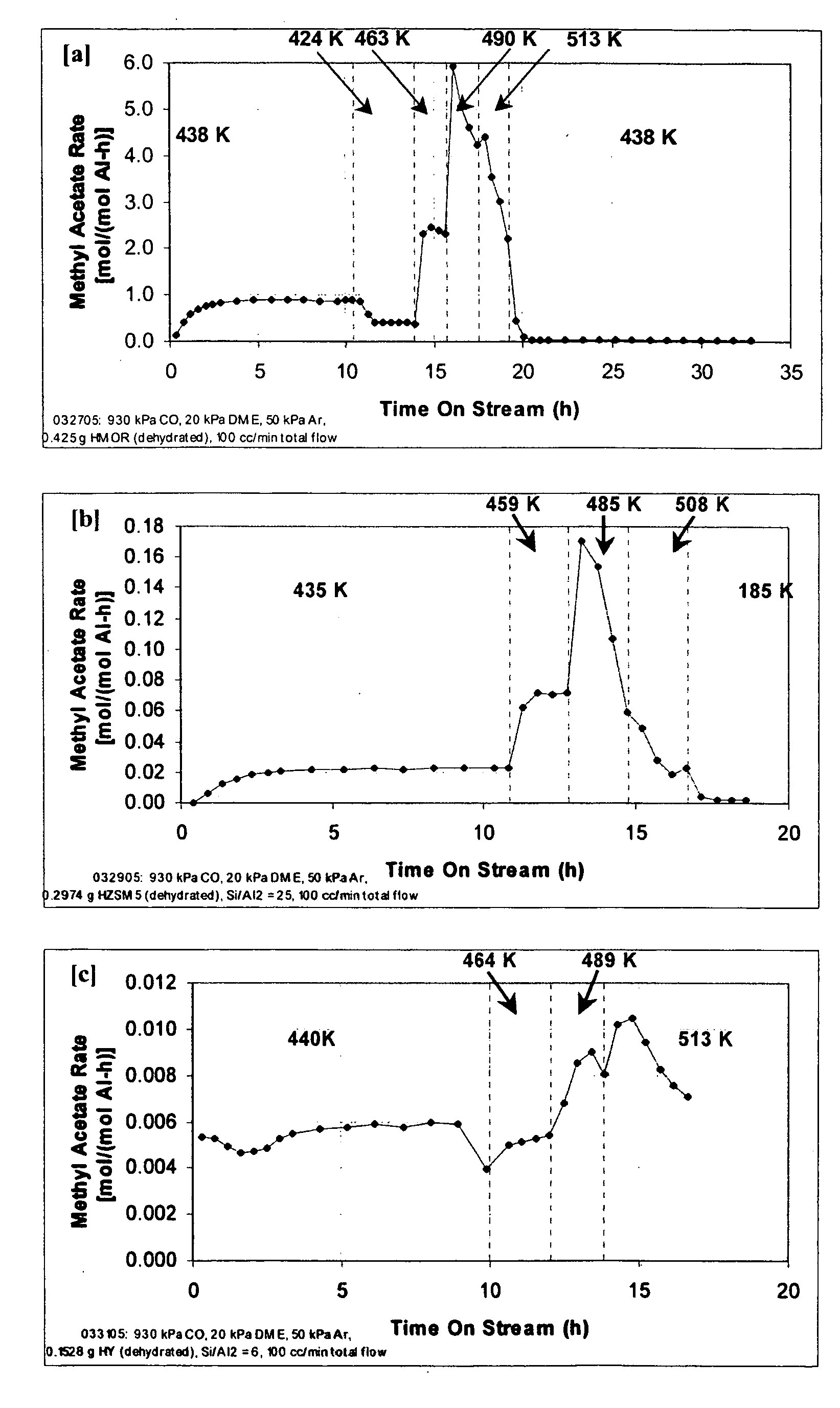

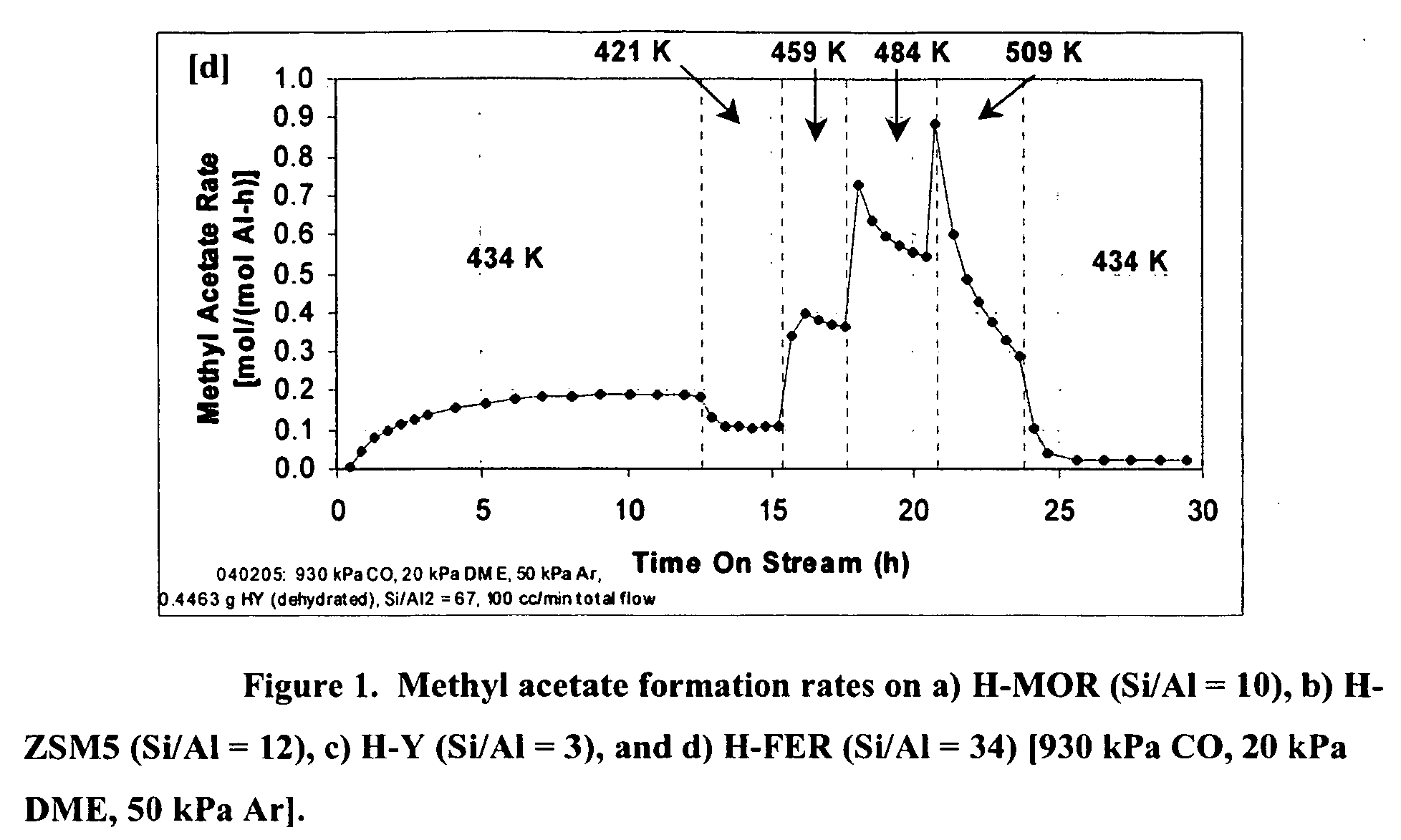

Process for carbonylation of alkyl ethers

ActiveUS20070238897A1Organic compound preparationPreparation from carboxylic acid esters/lactonesCarboxylic acidCarbonylation

A product comprising a lower alkyl ester of a lower aliphatic carboxylic acid is produced by a process comprising reacting under substantially anhydrous conditions a lower alkyl ether with carbon monoxide in the presence of a zeolite catalyst having an 8-member ring channel which is interconnected with a channel defined by a ring with greater than or equal to 8 members, the 8-member ring having a window size of at least 2.5 Angstroms×at least 3.6 Angstroms and at least one Brønsted acid site and the zeolite having a silica:X2O3 ratio of at least 5, wherein X is selected from aluminum, boron, iron, gallium and mixtures thereof.

Owner:THE BRITISH PETROLEUM CO LTD +1

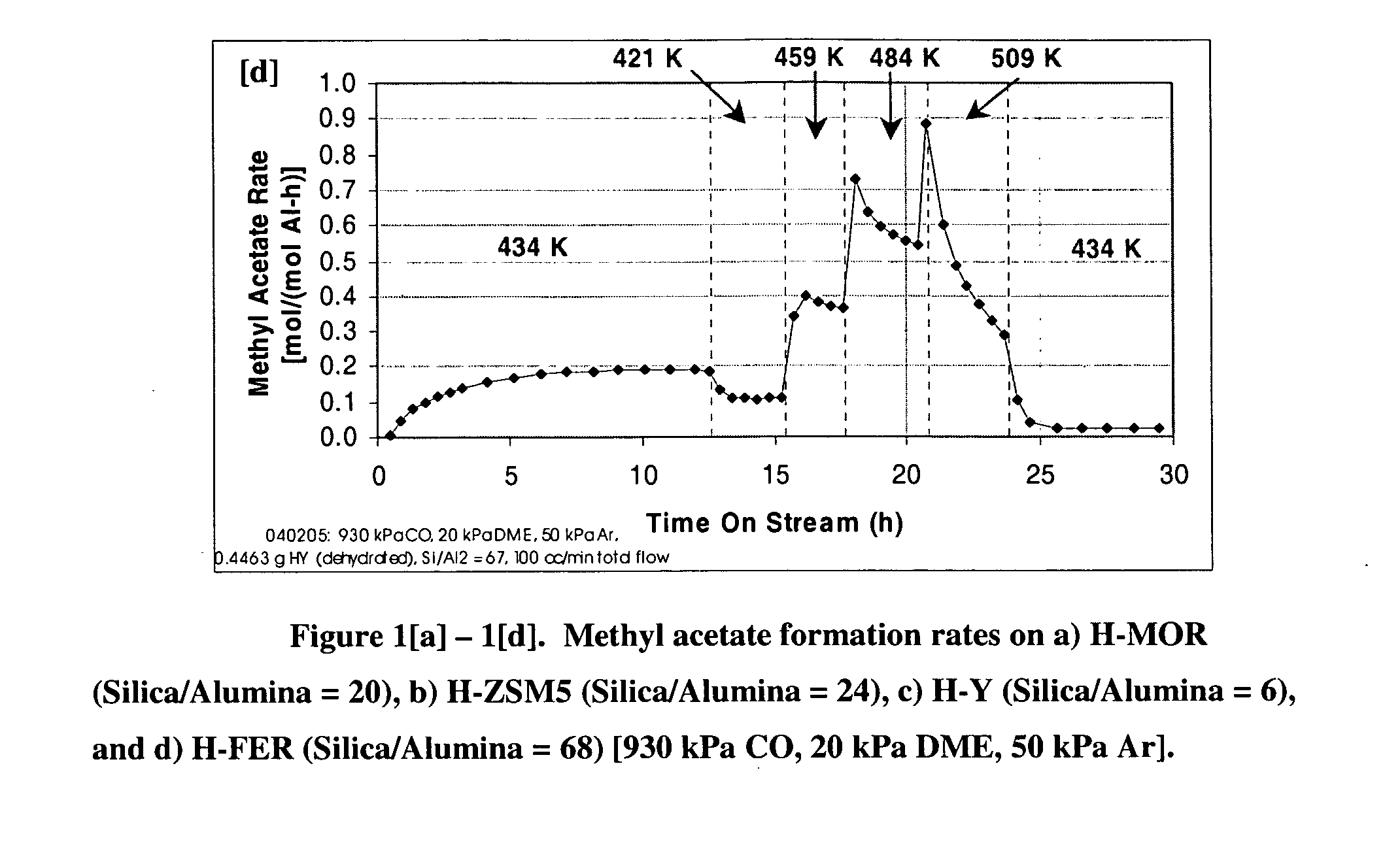

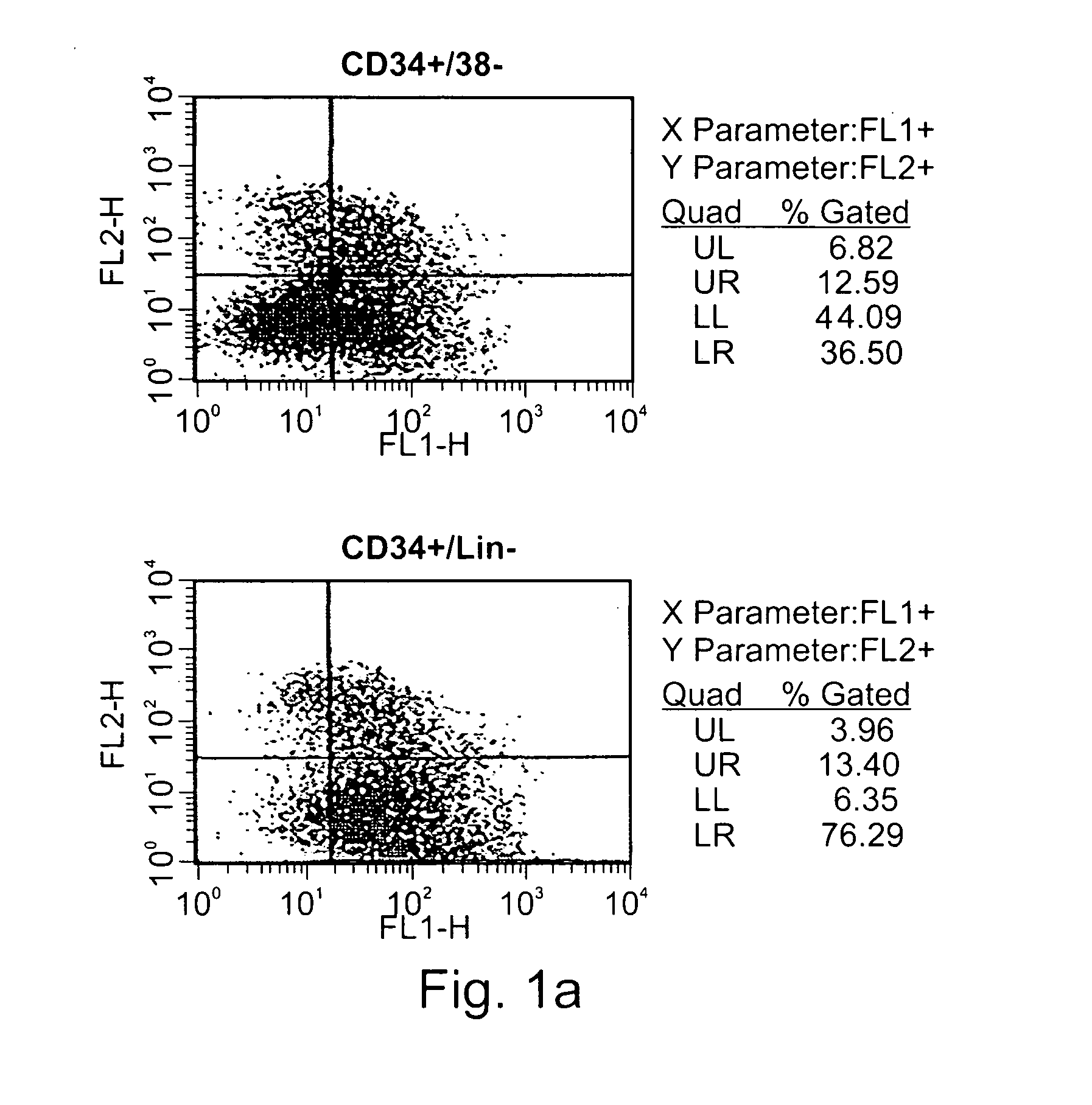

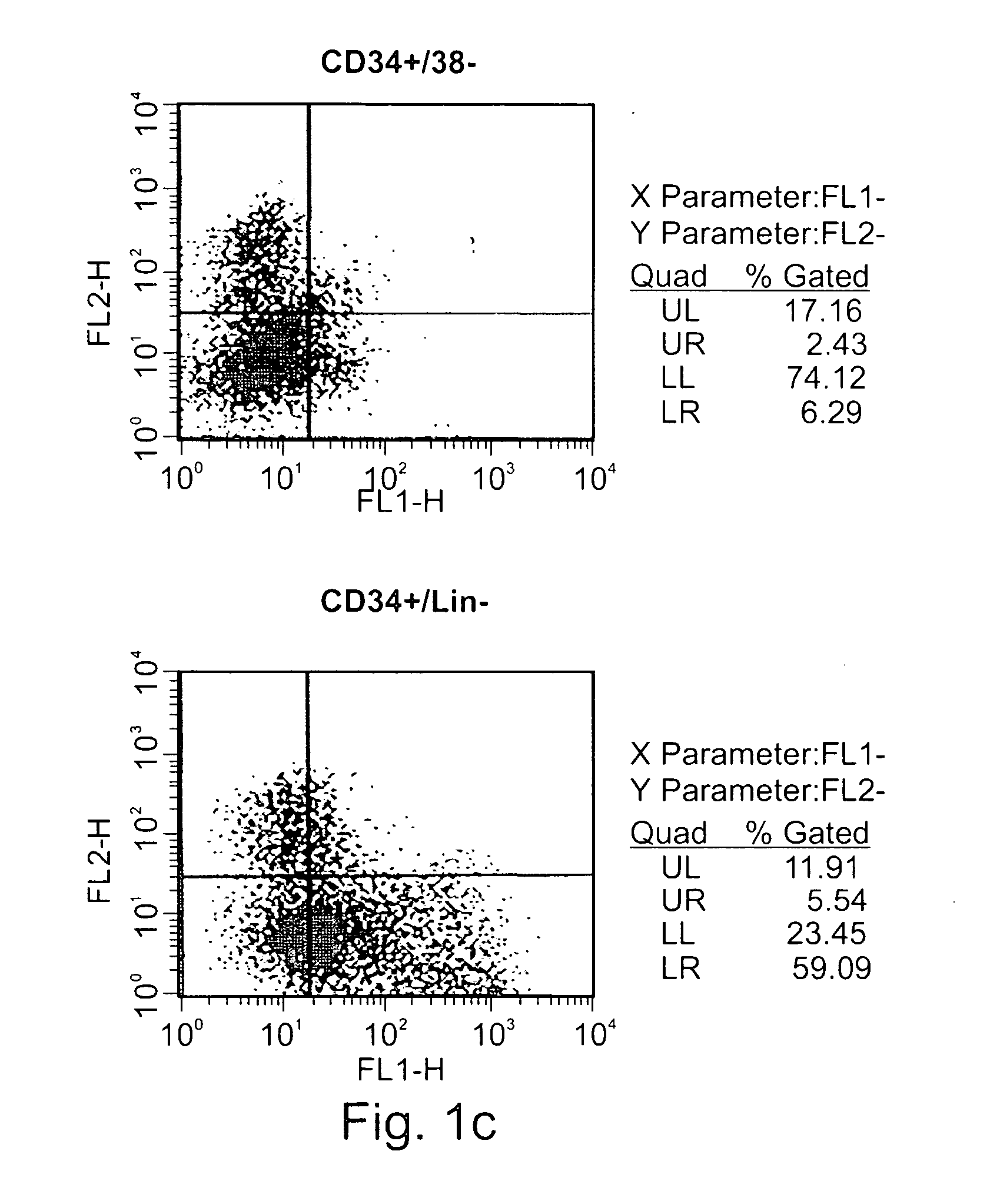

Expansion of renewable stem cell populations

ActiveUS20050008624A1Maximize expansionReduce capacityBiocideGenetic material ingredientsEx vivoImmunology

Owner:GAMIDA CELL

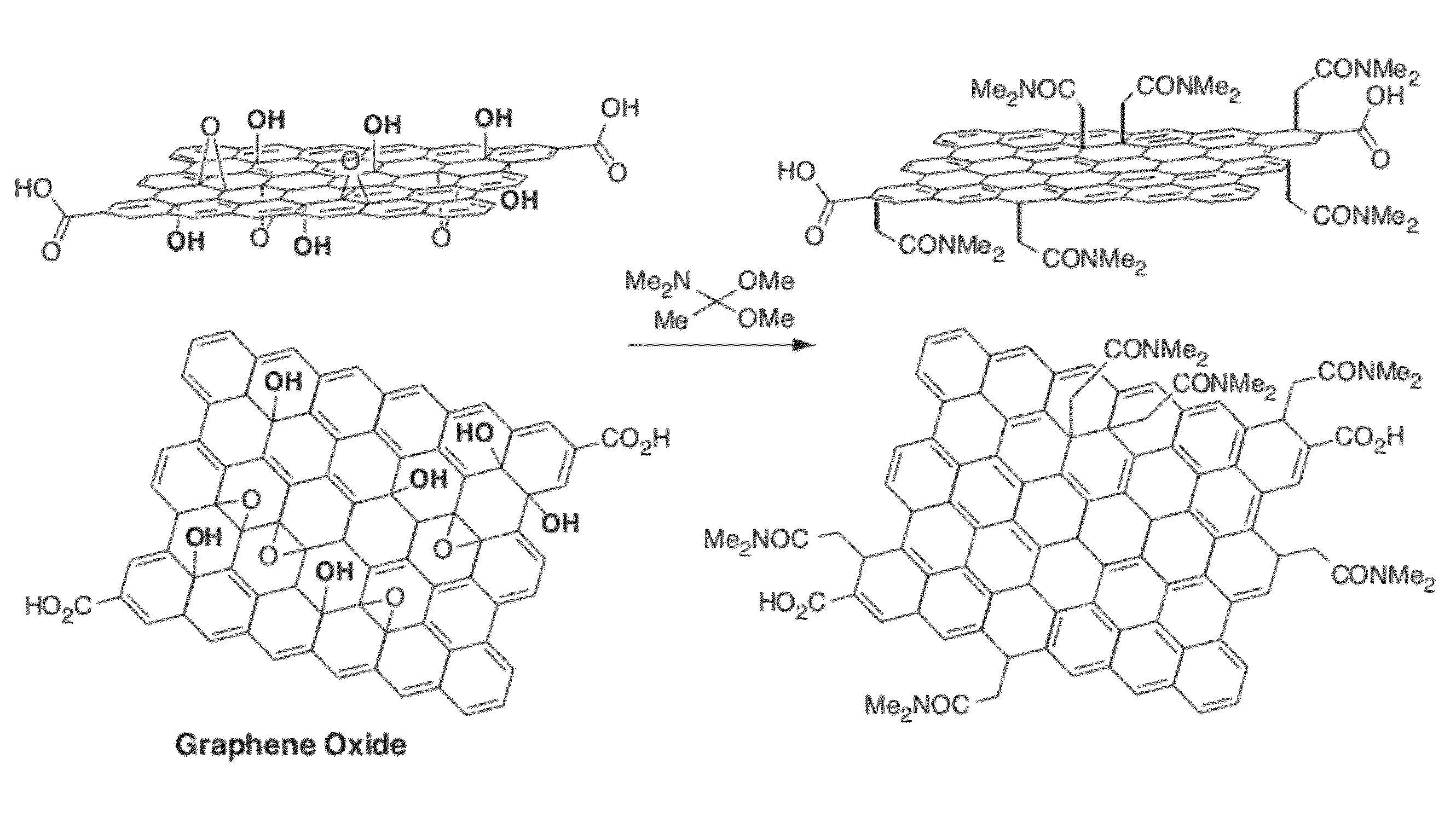

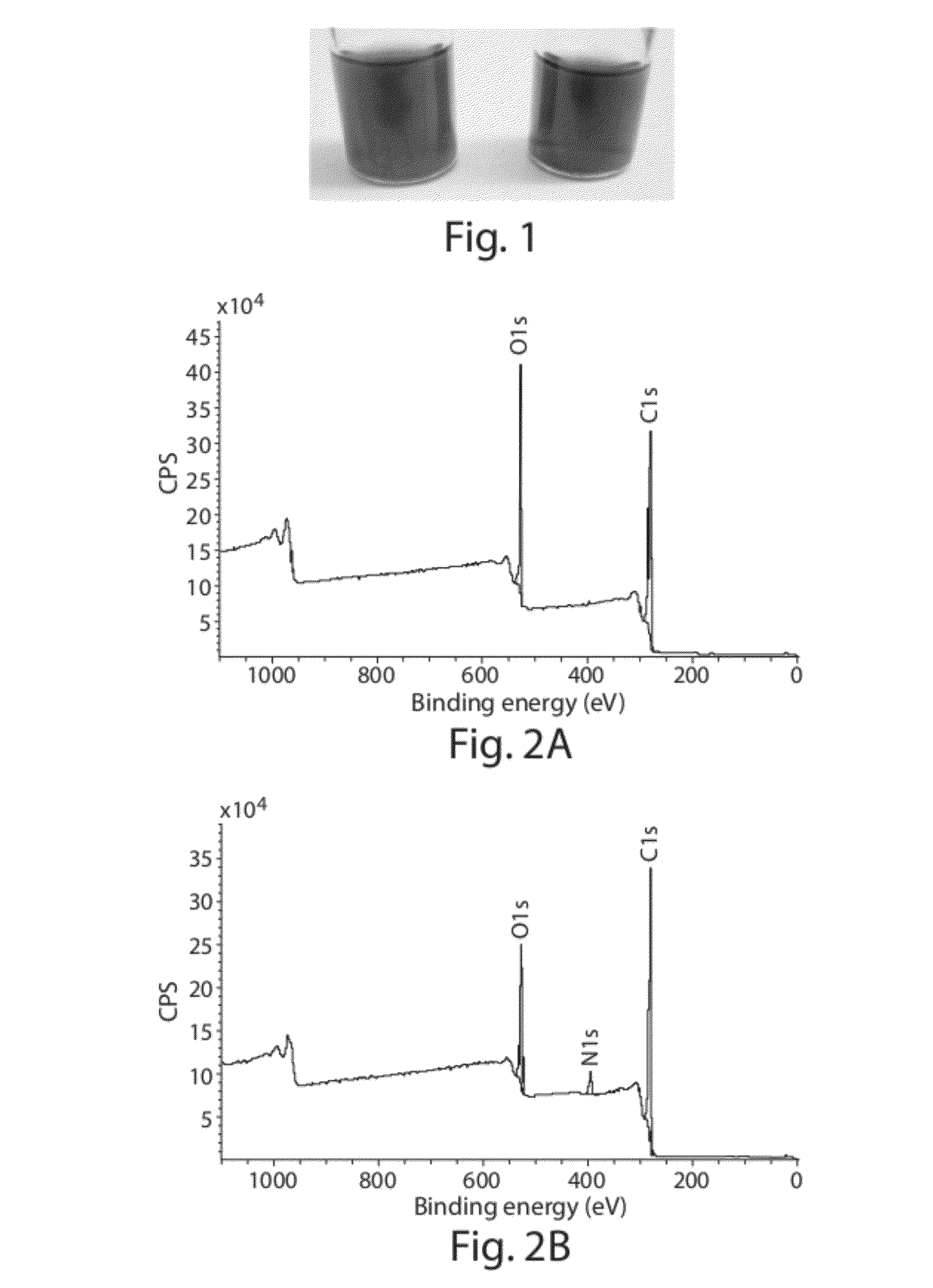

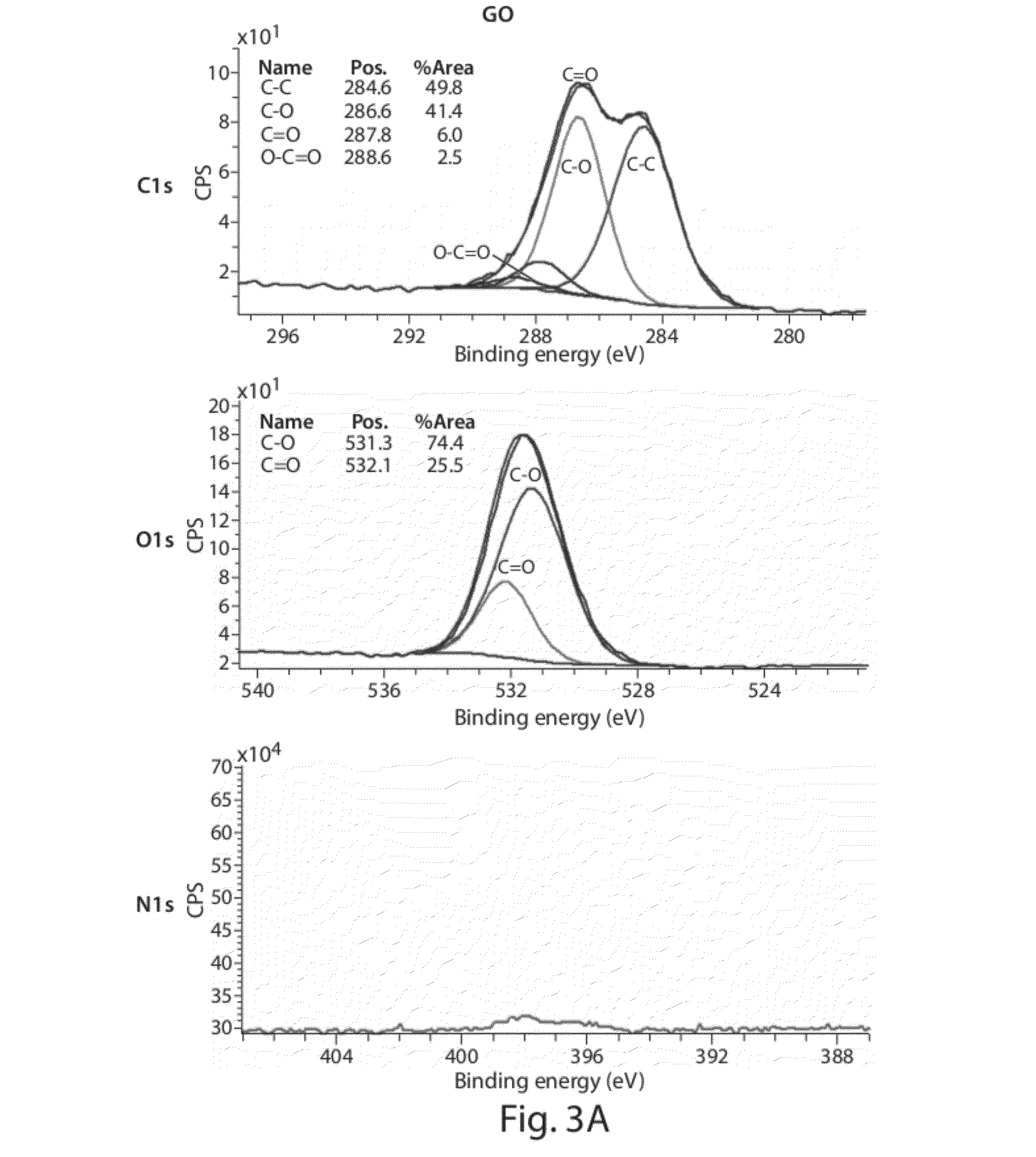

Compositions comprising and methods for forming functionalized carbon-based nanostructures

InactiveUS20120116094A1Reduce the amount requiredReduce concentrationMaterial nanotechnologyCarbon compoundsNanostructureMaterials science

Owner:MASSACHUSETTS INST OF TECH

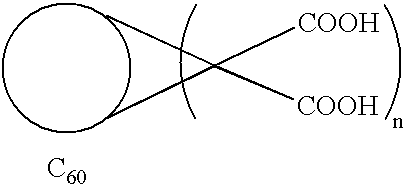

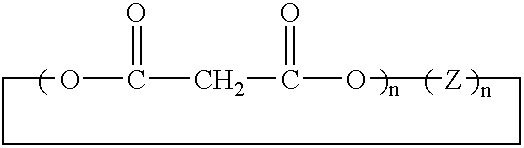

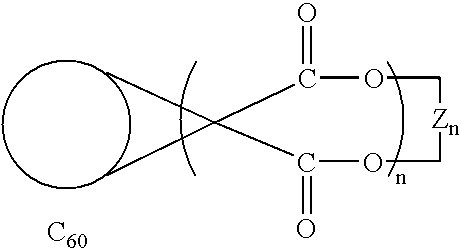

Method of synthesis of water soluble fullerene polyacids using a macrocyclic malonate reactant

InactiveUS6538153B1Increase productionInhibit productionNanotechPreparation from carboxylic acid esters/lactonesArylWater soluble

A method for synthesizing compounds of the formulawhere C60 is a C60 fullerene. The method comprises the steps of forming a macrocyclic malonate compound of the formulawhere each Z is the same or different and is a straight-chain or branched-chain aliphatic radical having from 1-30 carbon atoms which may be unsubstituted or monosubstituted or polysubstituted by identical or different substitutents, in which radicals up to every third CH2 unit can be replaced by O or NR where R is alkyl having 1-20 carbon atoms or a chain containing unsubstituted or substituted aryl or other cyclic groups and n is an integer from 2 to 10; reacting said macrocyclic malonate compound with C60 to form an adduct of the formulawhere the Z radicals are linked together to form said macrocycle adduct; and hydrolyzing said macrocycle adduct to form a compound of the formula

Owner:LUNA LABS USA LLC

Process for carbonylation of alkyl ethers

ActiveUS7465822B2Organic compound preparationPreparation from carboxylic acid esters/lactonesCarboxylic acidCarbonylation

A product comprising a lower alkyl ester of a lower aliphatic carboxylic acid is produced by a process comprising reacting under substantially anhydrous conditions a lower alkyl ether with carbon monoxide in the presence of a zeolite catalyst having an 8-member ring channel which is interconnected with a channel defined by a ring with greater than or equal to 8 members, the 8-member ring having a window size of at least 2.5 Angstroms×at least 3.6 Angstroms and at least one Brønsted acid site and the zeolite having a silica:X2O3 ratio of at least 5, wherein X is selected from aluminum, boron, iron, gallium and mixtures thereof.

Owner:BP CHEM LTD +1

Compounds that modulate PPAR activity and methods for their preparation

InactiveUS6875780B2BiocideOxygen-containing compound preparationAcute hyperglycaemiaHypertriglyceridemia

This invention relates to compounds that alter PPAR activity. The invention also relates to pharmaceutically acceptable salts of the compounds, pharmaceutically acceptable compositions comprising the compounds or their salts, and methods of using them as therapeutic agents for treating or preventing dyslipidemia, hypercholesterolemia, obesity, hyperglycemia, atherosclerosis, hypertriglyceridemia and hyperinsulinemia in a mammal. The present invention also relates to methods for making the disclosed compounds.

Owner:WARNER-LAMBERT CO

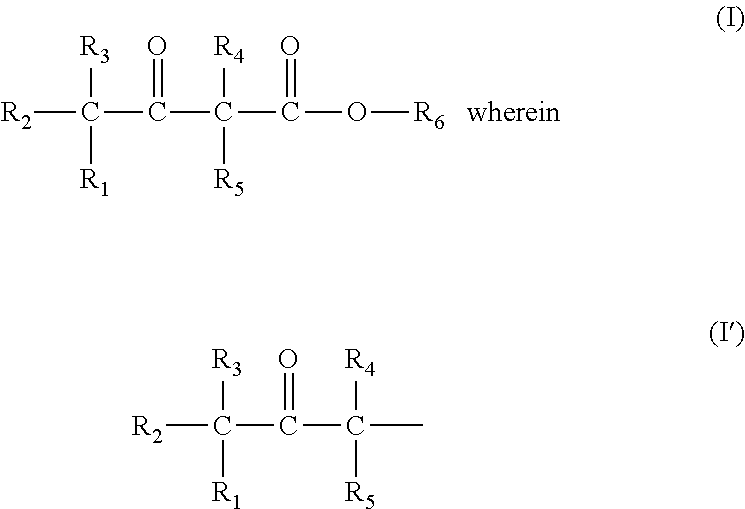

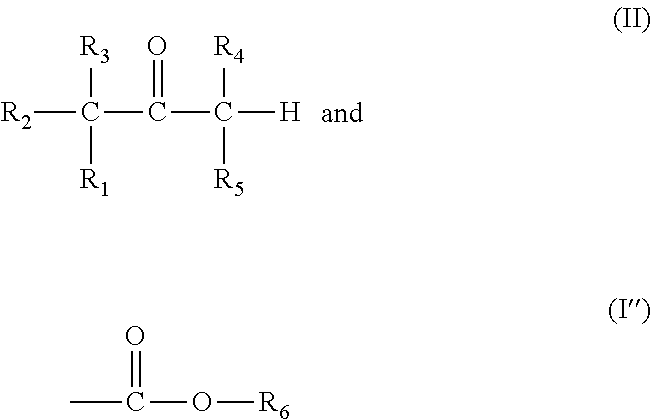

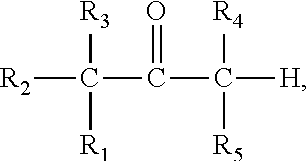

Prodrug comprising beta-keto carboxylic acid, beta-keto carboxylic acid salt or beta-keto carboxylic acid ester for drug delivery

InactiveUS20120065179A1Improve bioavailabilityGood water solubilityBiocideOrganic compound preparationActive agentCarboxylic acid

There is provided a prodrug of a pharmaceutically active agent, such prodrug comprising a beta-keto carboxylic acid, a beta-keto carboxylic acid salt or a beta-keto carboxylic acid ester functional group, a pharmaceutical composition comprising the prodrug, and to the use of the prodrug or composition for treatment of a mammalian subject suffering from a condition which can be cured or alleviated by administration of the pharmaceutically active agent. There is further provided a method of inhibiting decarboxylation of a compound comprising a beta-keto carboxylic acid or a salt thereof with a monovalent cation, characterized in that a dry salt of the beta-keto carboxylic acid with a divalent or polyvalent cation is prepared.

Owner:INFINITON

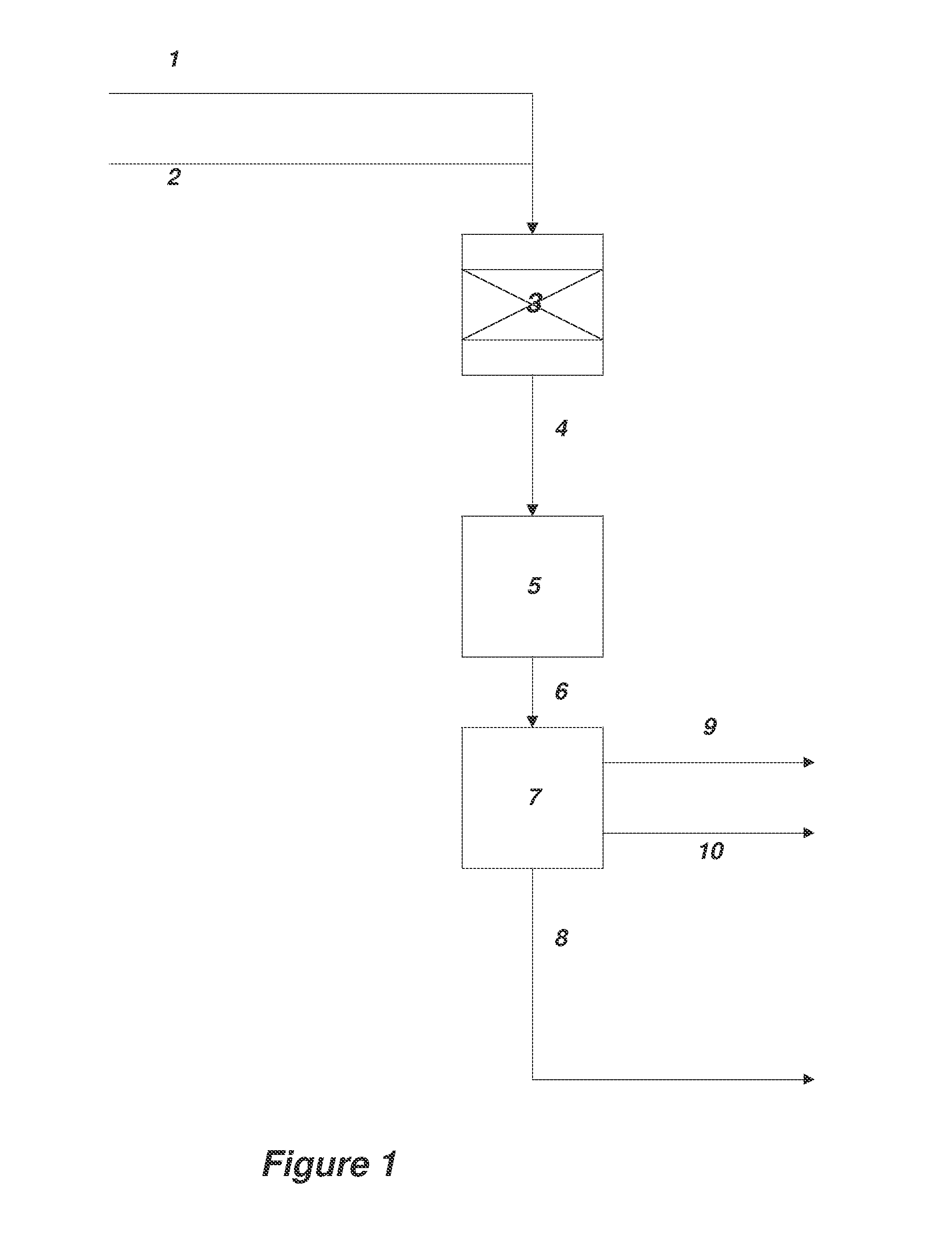

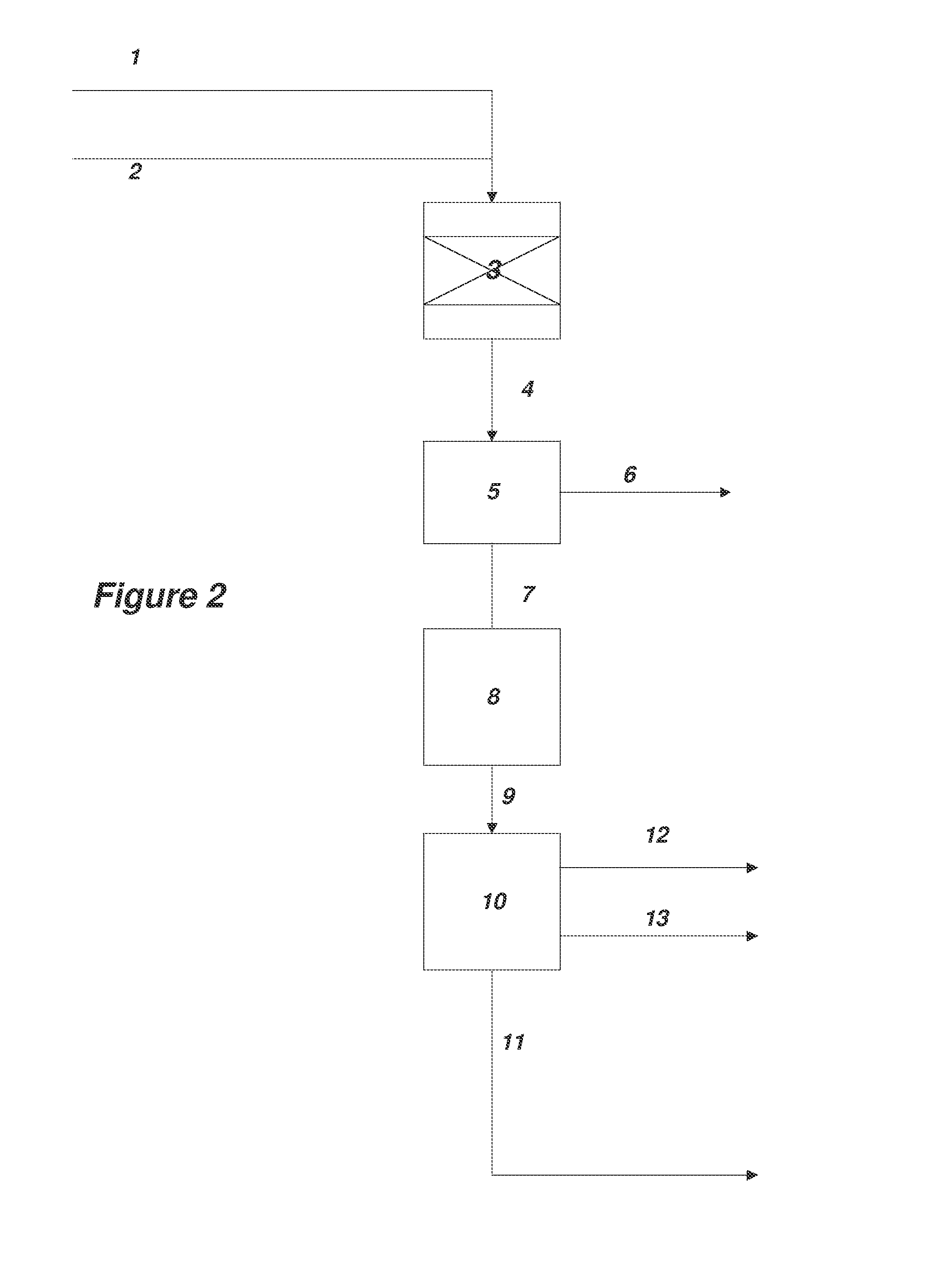

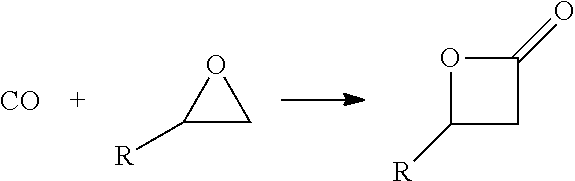

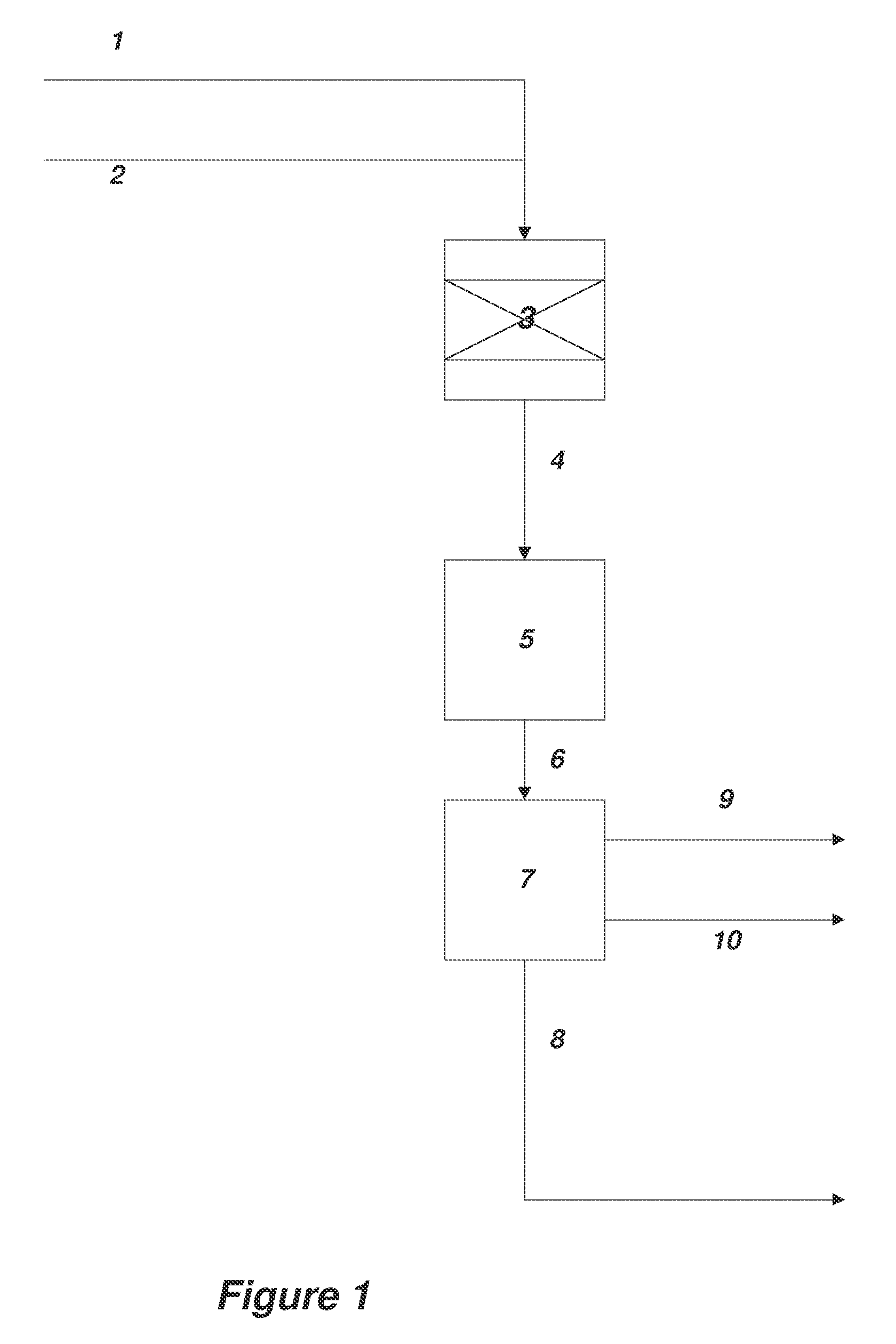

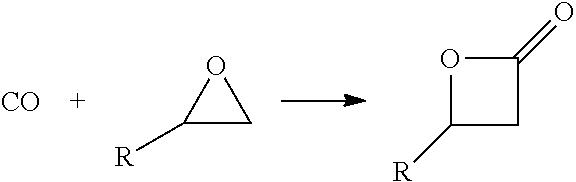

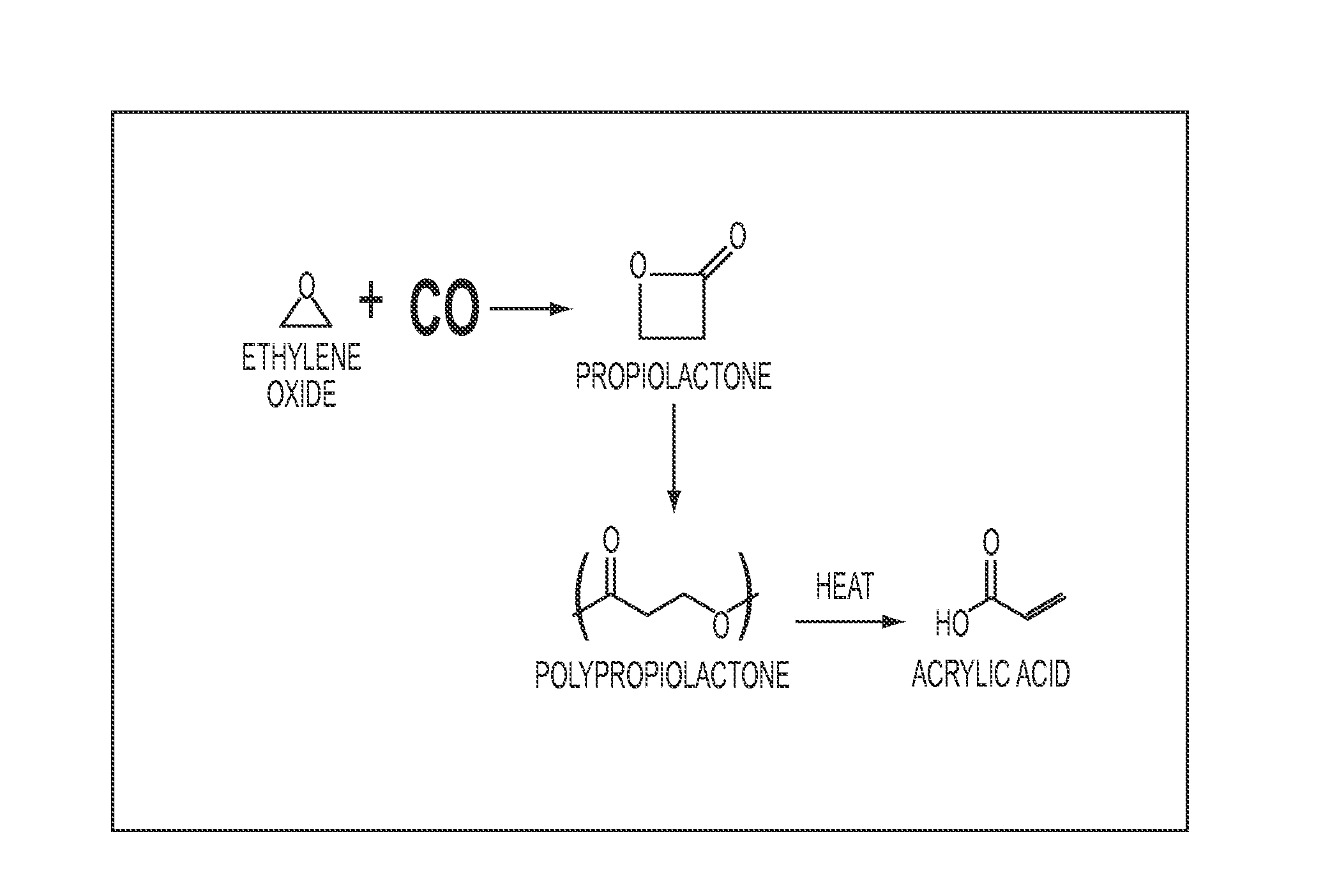

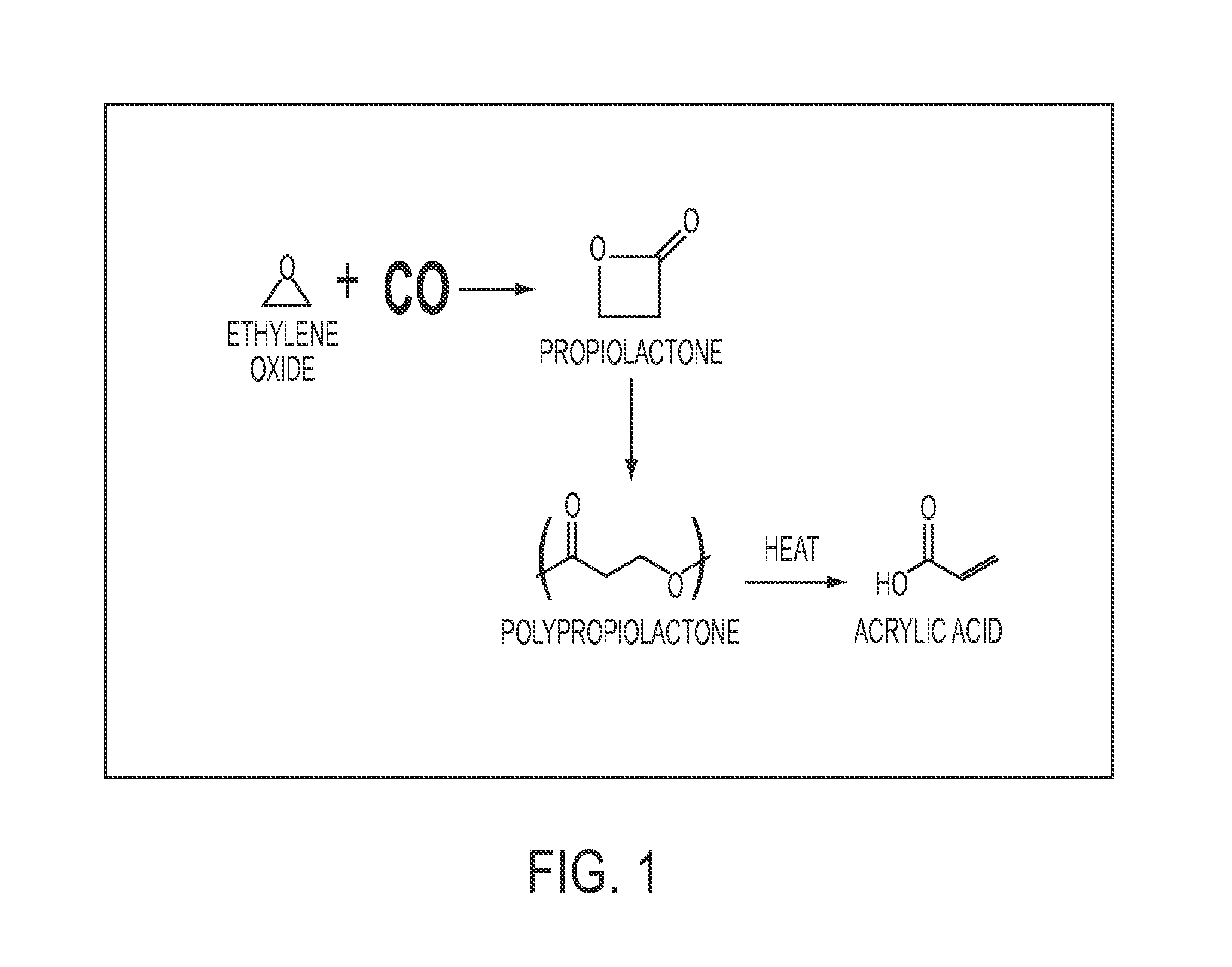

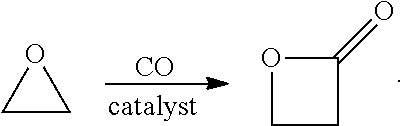

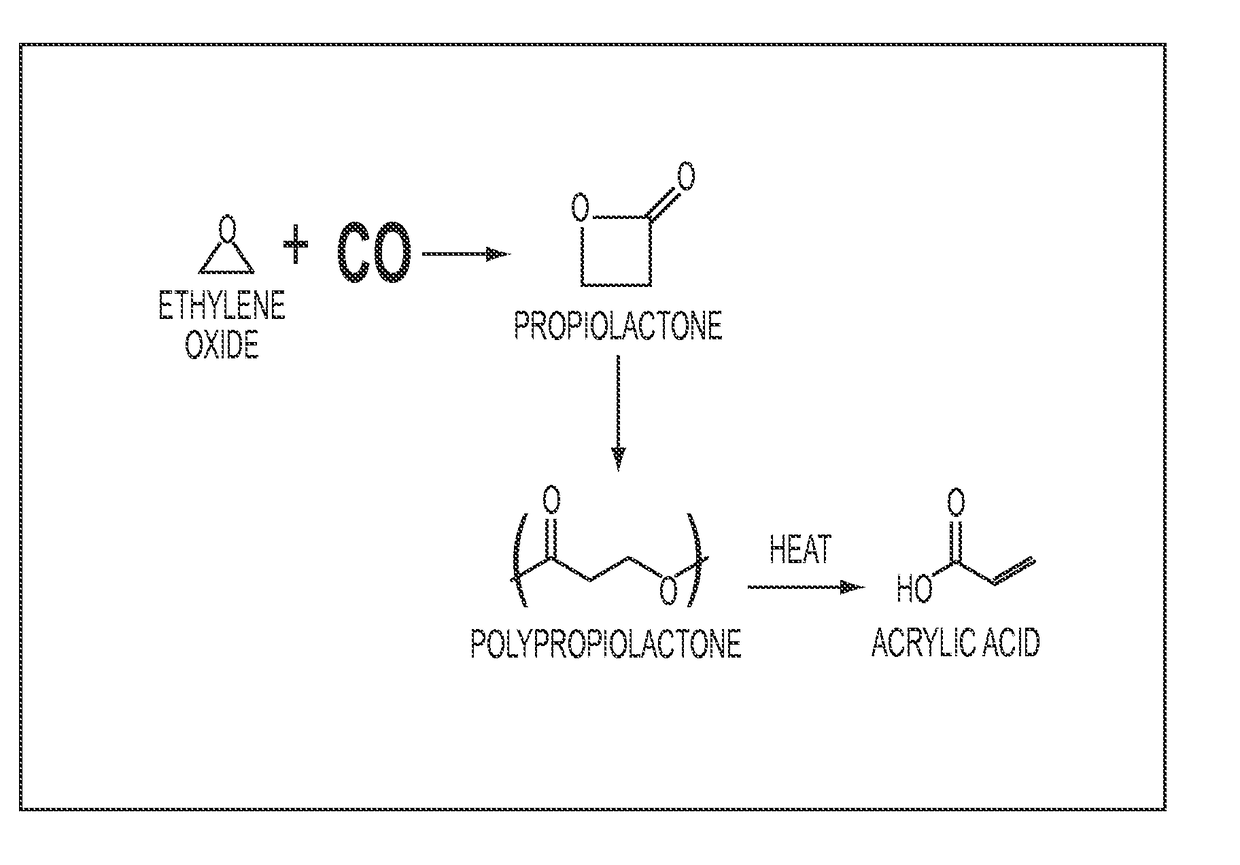

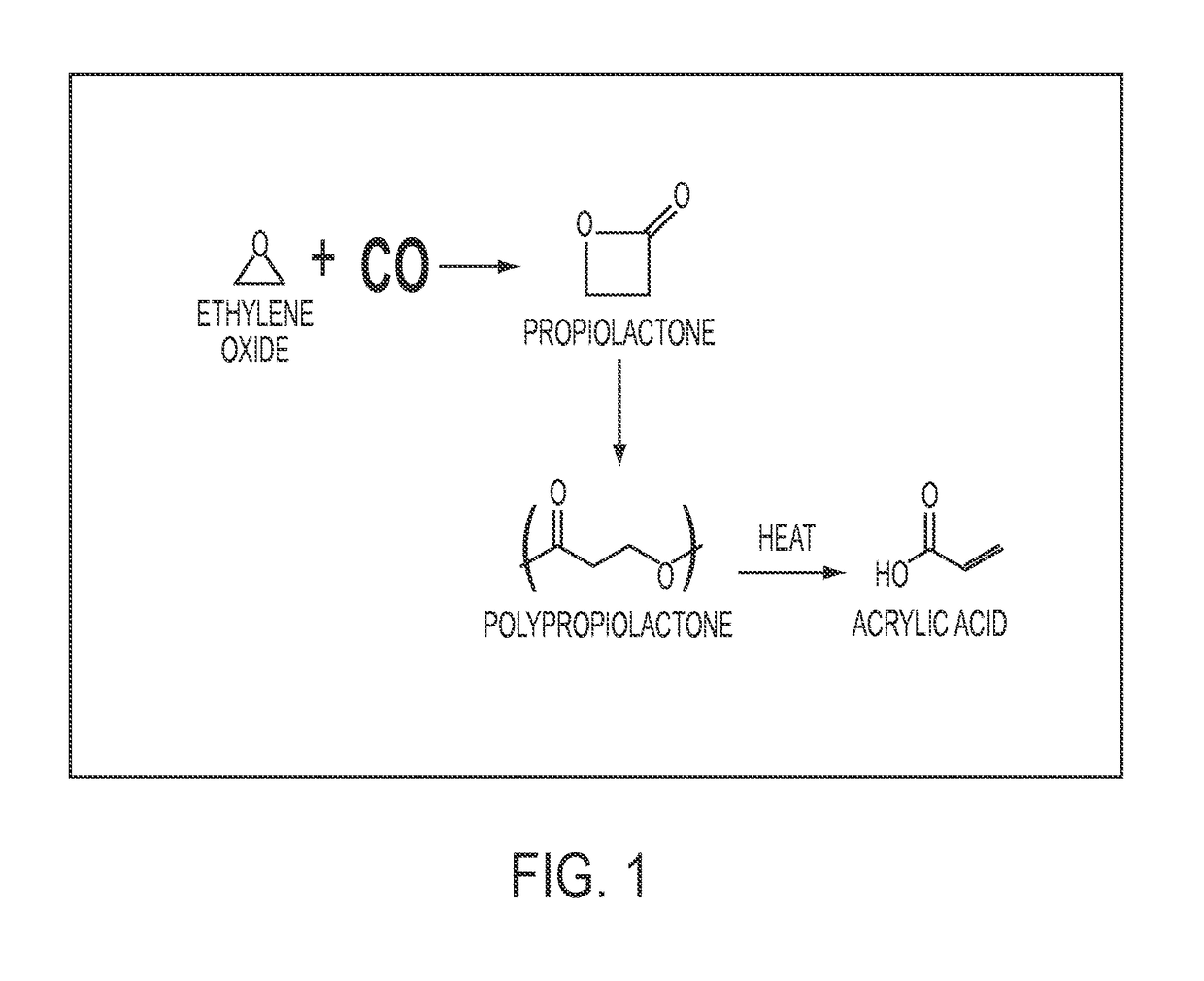

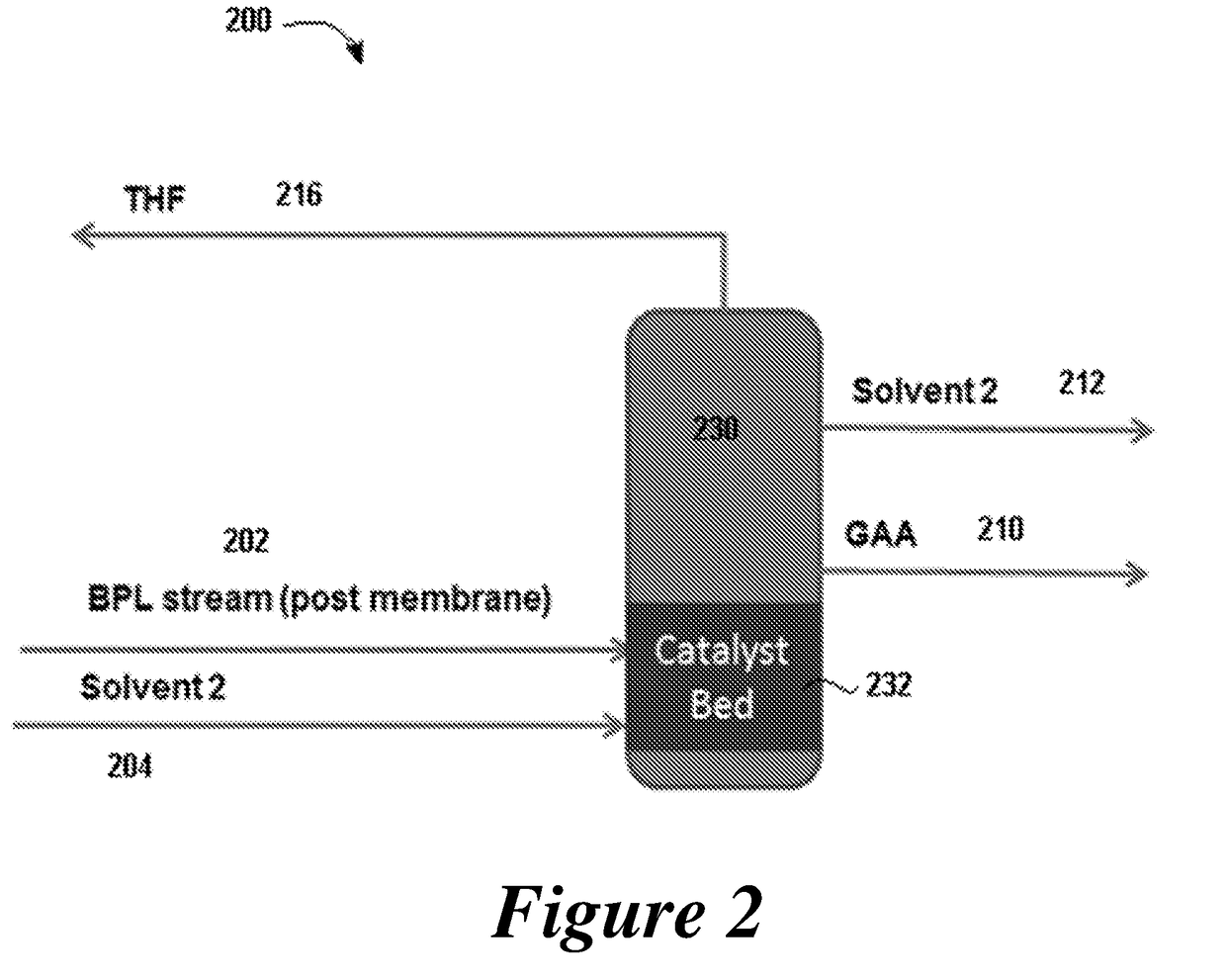

Process for production of acrylates from epoxides

ActiveUS20140309399A1Low costAvoiding isolation and storageOrganic compound preparationPreparation by ester-hydroxy reactionReaction zoneMetal carbonyl

The methods of the present invention comprise the steps of: providing a feedstock stream comprising an epoxide and carbon monoxide; contacting the feedstock stream with a metal carbonyl in a first reaction zone to effect conversion of at least a portion of the provided epoxide to a beta lactone; directing the effluent from the first reaction zone to a second reaction zone where the beta lactone is subjected to conditions that convert it to a compound selected from the group consisting of: an alpha beta unsaturated acid, an alpha beta unsaturated ester, an alpha beta unsaturated amide, and an optionally substituted polypropiolactone polymer; and isolating a final product comprising the alpha-beta unsaturated carboxylic acid, the alpha-beta unsaturated ester, the alpha-beta unsaturated amide or the polypropiolactone.

Owner:NOVOMER INC

Process for production of acrylates from epoxides

ActiveUS9096510B2Low costAvoiding isolation and storageOrganic compound preparationPreparation by ester-hydroxy reactionReaction zoneMetal carbonyl

The methods of the present invention comprise the steps of: providing a feedstock stream comprising an epoxide and carbon monoxide; contacting the feedstock stream with a metal carbonyl in a first reaction zone to effect conversion of at least a portion of the provided epoxide to a beta lactone; directing the effluent from the first reaction zone to a second reaction zone where the beta lactone is subjected to conditions that convert it to a compound selected from the group consisting of: an alpha beta unsaturated acid, an alpha beta unsaturated ester, an alpha beta unsaturated amide, and an optionally substituted polypropiolactone polymer; and isolating a final product comprising the alpha-beta unsaturated carboxylic acid, the alpha-beta unsaturated ester, the alpha-beta unsaturated amide or the polypropiolactone.

Owner:NOVOMER INC

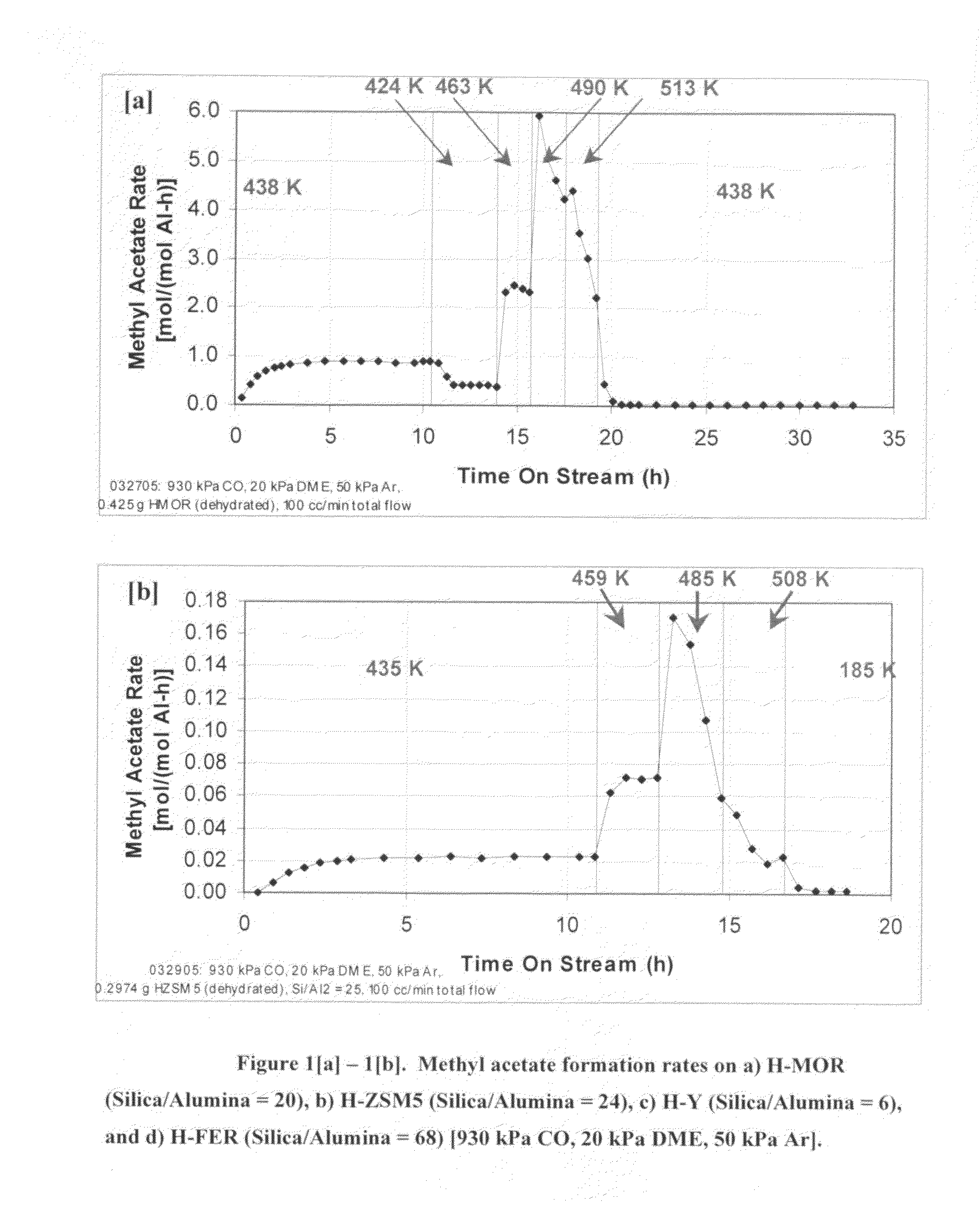

Process for carbonylation of alkyl ethers

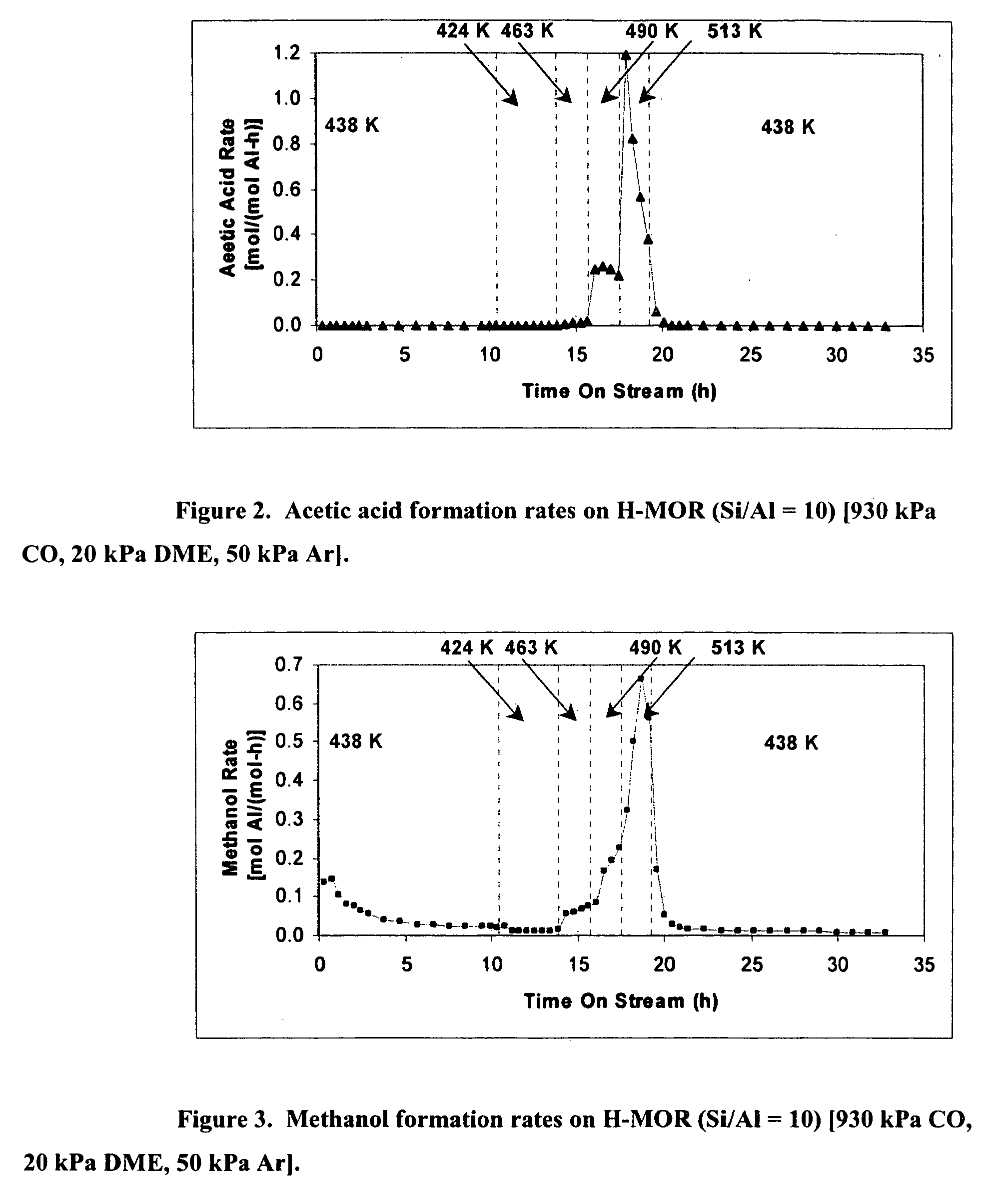

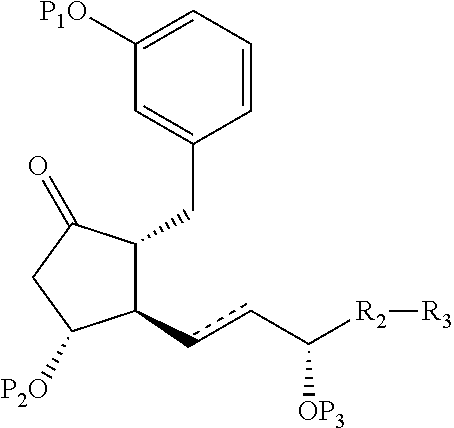

InactiveUS20060252959A1Organic compound preparationPreparation from carboxylic acid esters/lactonesMordeniteMethyl acetate

A product comprising a lower alkyl ester of a lower aliphatic carboxylic acid is produced by a process comprising reacting a lower alkyl ether with carbon monoxide in the presence of a catalyst comprising mordenite and / or ferrierite, under substantially anhydrous conditions. More specifically, methyl acetate is selectively produced by reaction of dimethyl ether with carbon monoxide in the presence of a catalyst comprising mordenite or ferrierite, under substantially anhydrous conditions.

Owner:RGT UNIV OF CALIFORNIA +1

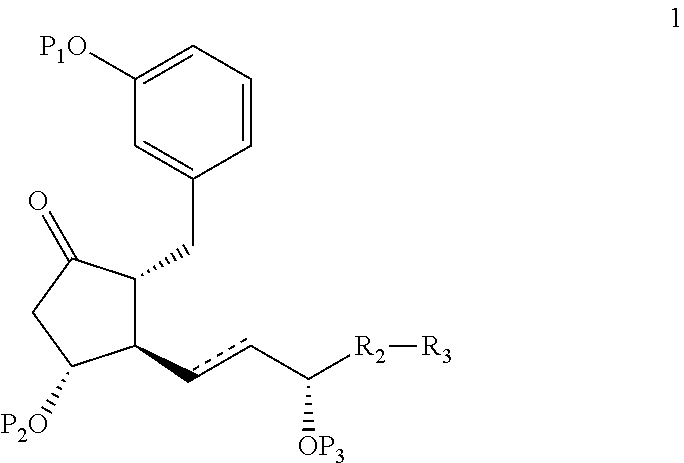

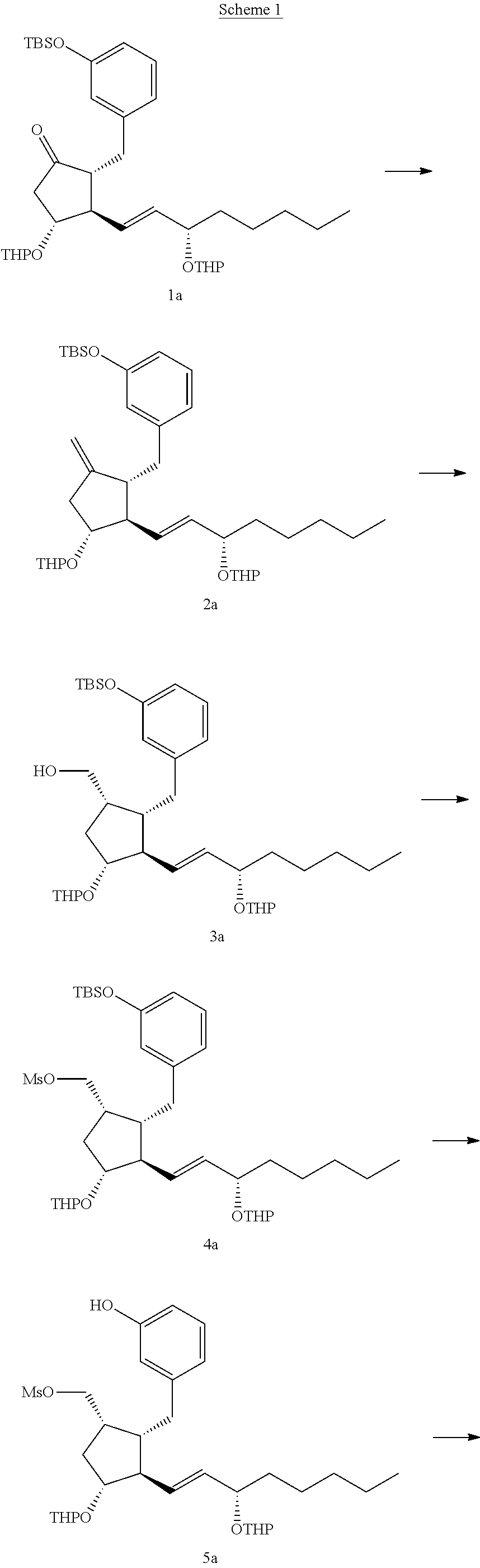

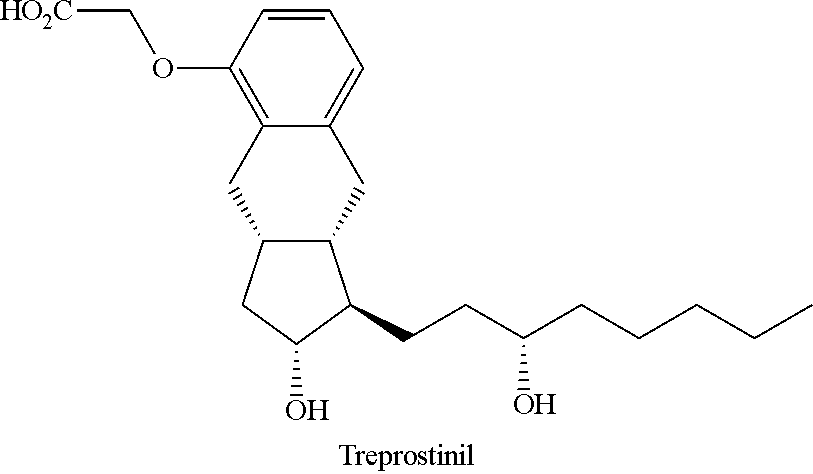

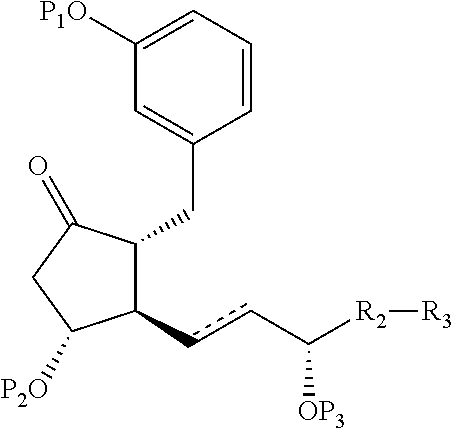

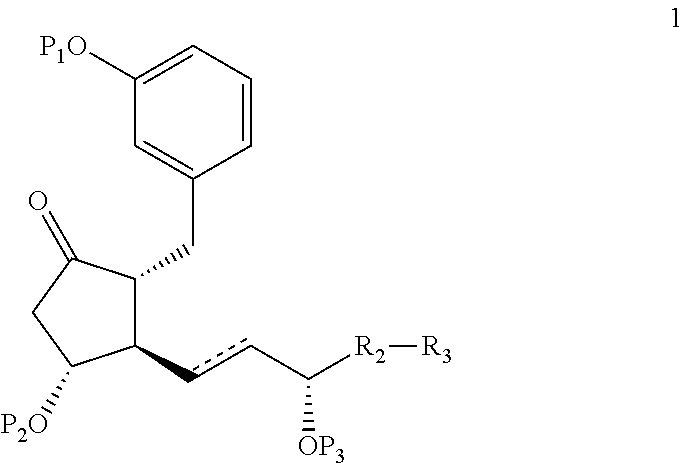

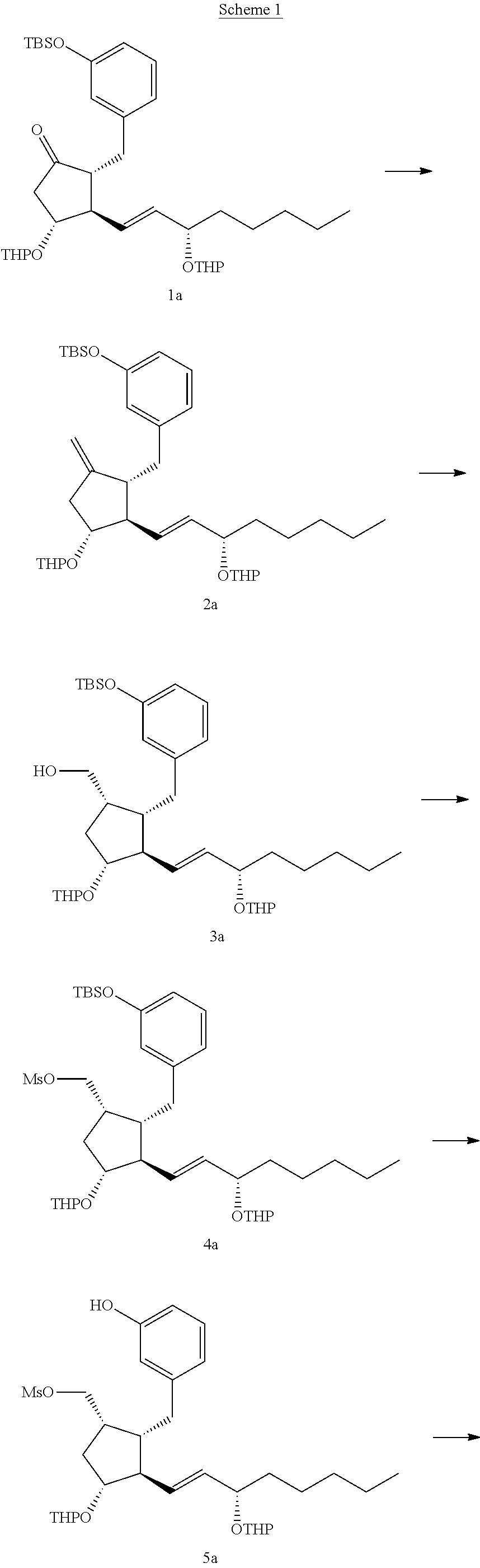

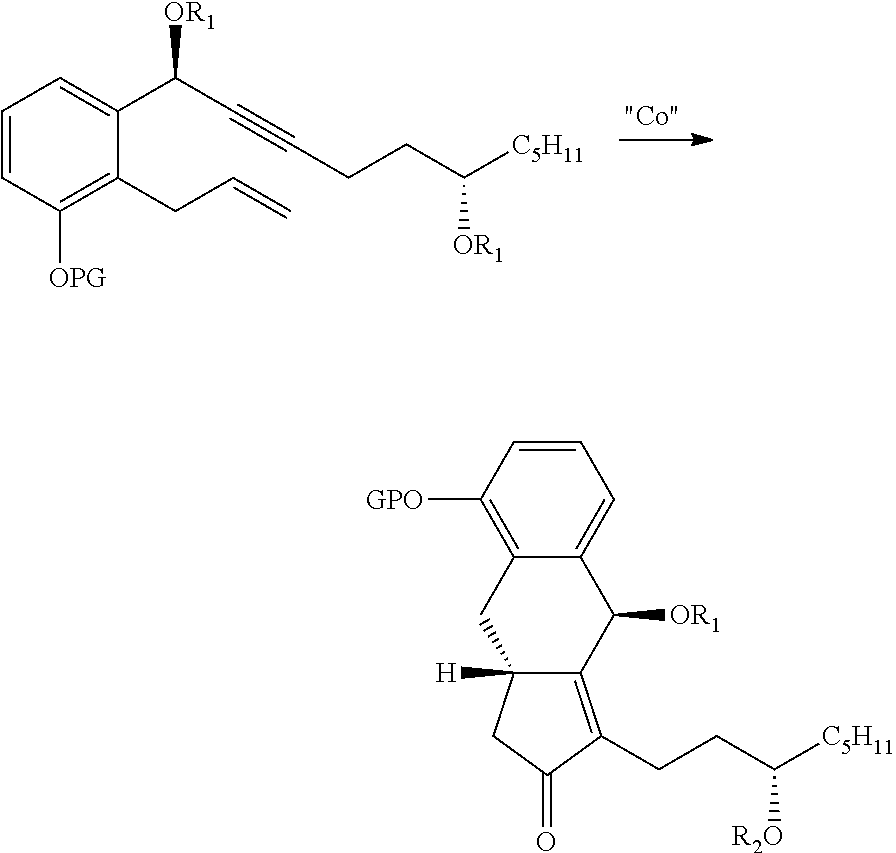

Intermediates for the synthesis of benzindene prostaglandins and preparations thereof

ActiveUS20130053581A1Silicon organic compoundsOrganic compound preparationPhotochemistryProstaglandin

Novel processes for preparing optically active cyclopentanones 1which are useful for the preparation of benzindene Prostaglandins and novel cyclopentanones are provided. The invention also provides novel processes of preparing benzindene Prostaglandins and novel intermediates for benzindene Prostaglandins.

Owner:CHIROGATE INT

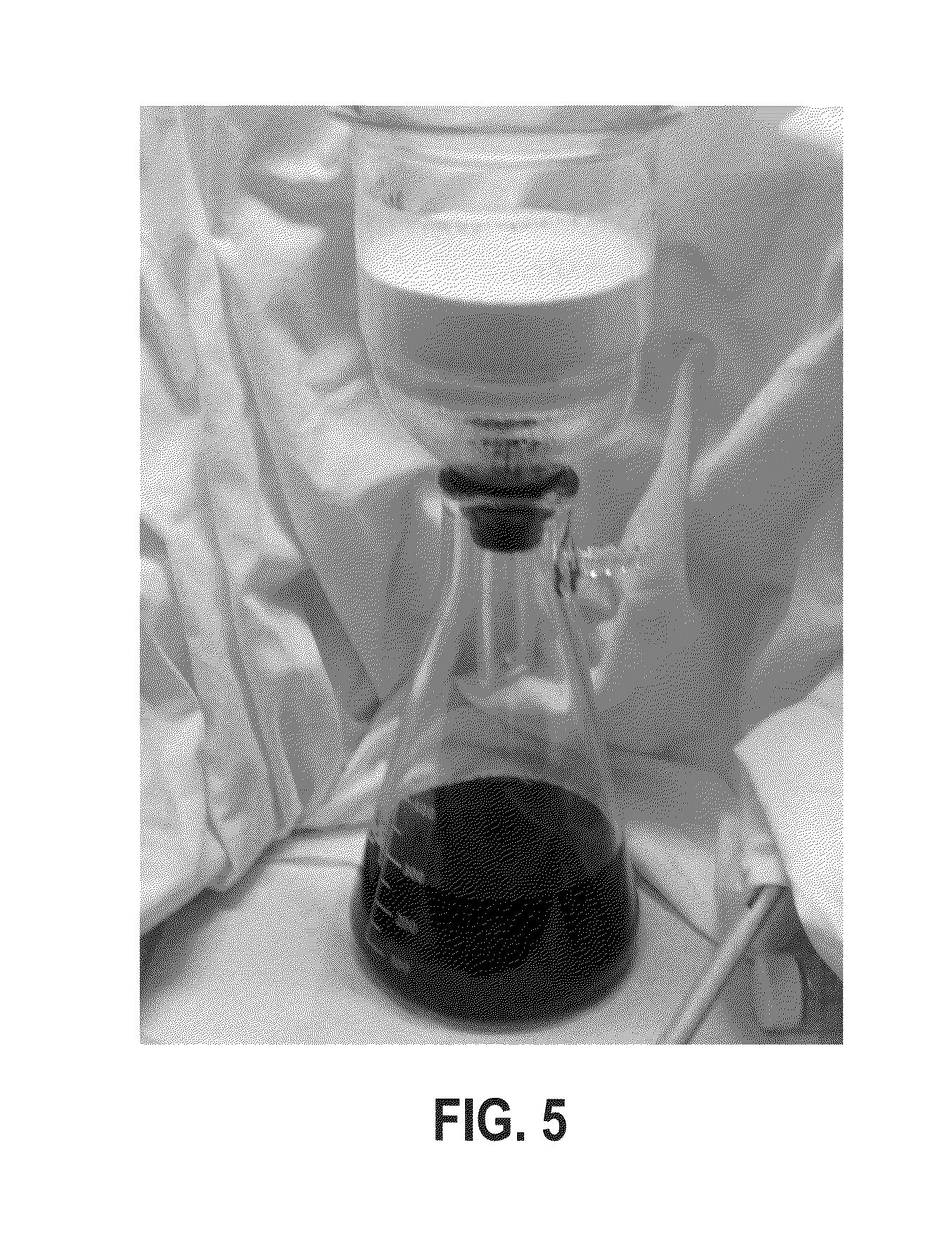

Methods and materials for depolymerizing polyesters

Provided is a method of depolymerizing polyesters from post-consumer products, such as beverage bottles, to produce a high purity reaction product. For the depolymerization reaction, the polyesters are reacted with an alcohol having 2 to 5 carbons and an amine organocatalyst at a temperature of about 150° C. to about 250° C. In one application, the use an organocatalyst with a boiling point significantly lower than the boiling point of the reactant alcohol allows for the ready recycling of the amine organocatalyst. In another application, performing the depolymerization reaction under pressure at a temperature above that of the alcohol allows for accelerated depolymerization rates and the recovery of the organocatalyst with no further heat input. In a further application, glycolytic depolymerization of poly(ethylene terephthalate) (PET) from post-consumer beverage bottles produces a pure reaction product of bis(2-hydroxyethyl)terephthalate (BHET), which may in turn be used to produce high purity beverage bottle grade PET, in a closed loop process with minimal output and waste.

Owner:IBM CORP

Poly(Acrylic Acid) From Bio-Based Acrylic Acid And Its Derivatives

ActiveUS20130274697A1Organic compound preparationHeterogenous catalyst chemical elementsAcid derivativeSuperabsorbent polymer

Bio-based glacial acrylic acid, produced from hydroxypropionic acid, hydroxypropionic acid derivatives, or mixtures thereof and having impurities of hydroxypropionic acid, hydroxypropionic acid derivatives, or mixtures thereof, is polymerized to poly(acrylic acid) or superabsorbent polymer using the same processes as petroleum-derived glacial acrylic acid.

Owner:THE PROCTER & GAMBLE COMPANY

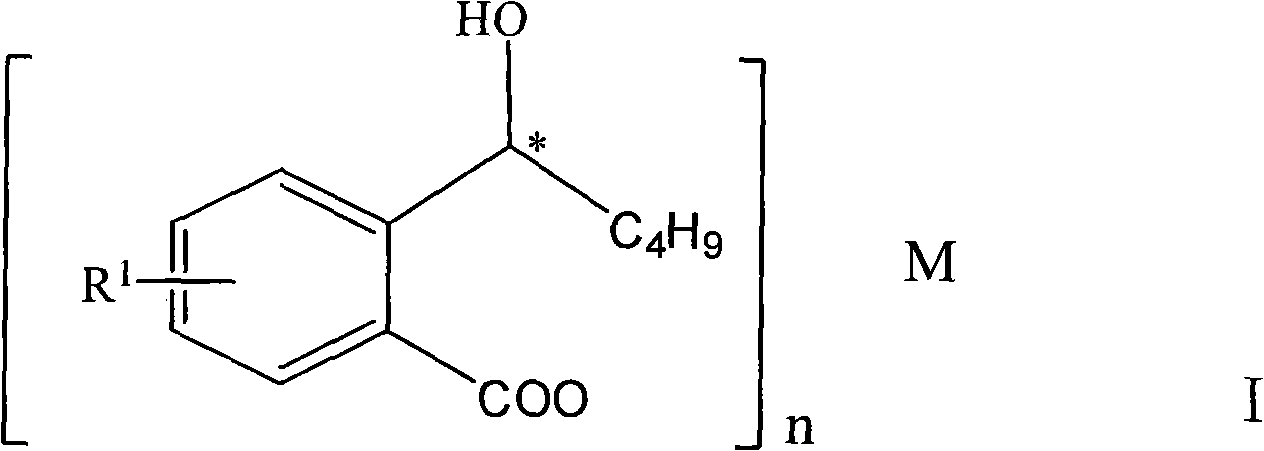

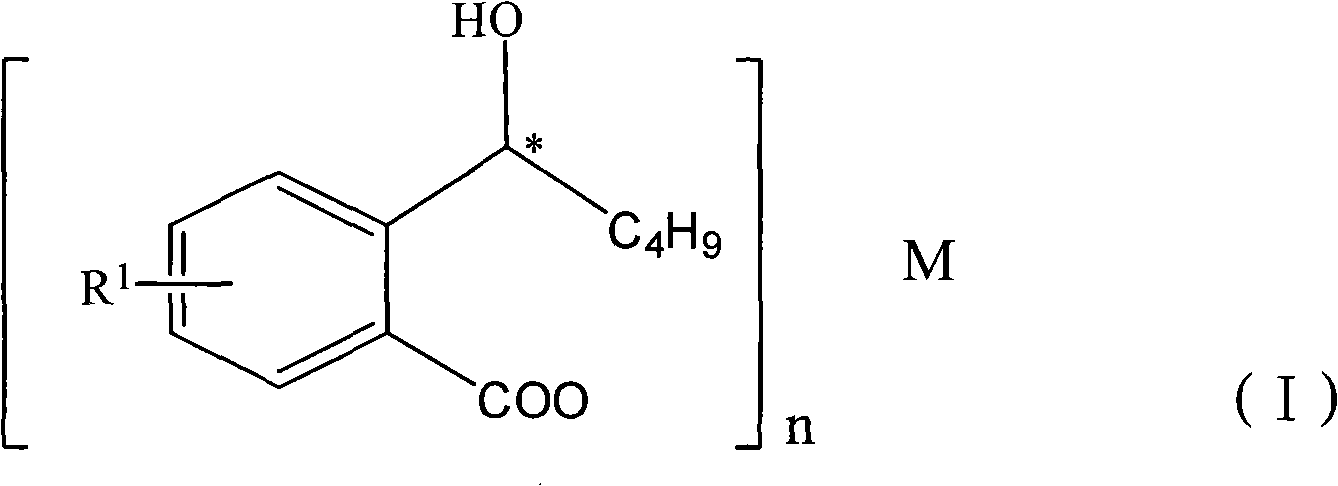

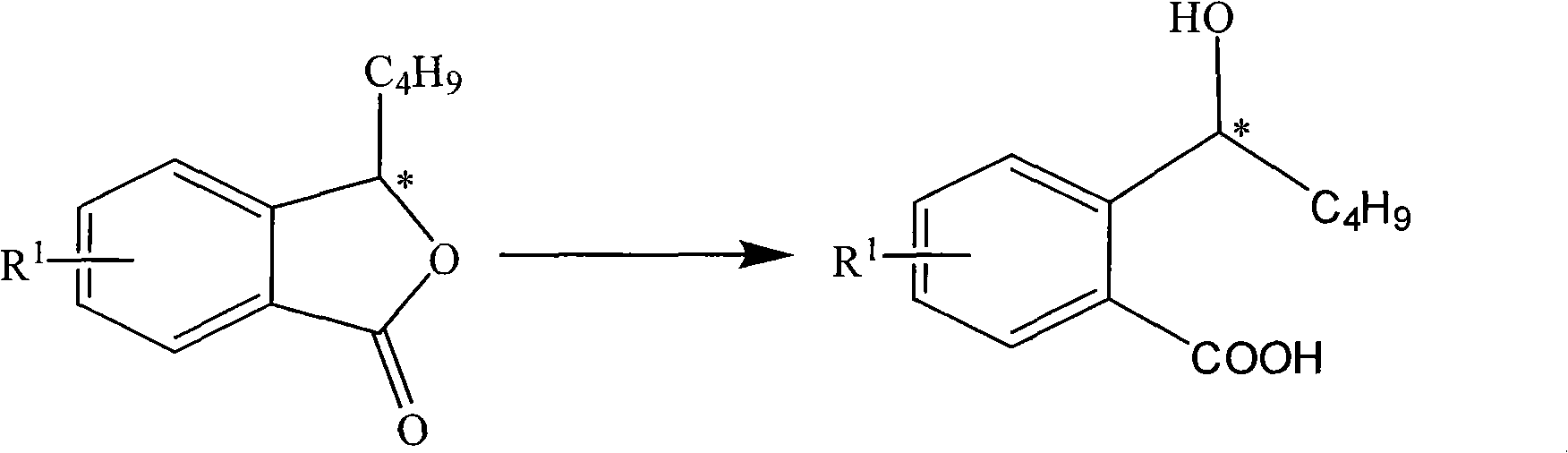

Halogenated 2-(a-hydroxyl pentyl) benzoate, production method and uses thereof

ActiveCN101402565ASuitable for storageSuitable for processingOrganic active ingredientsNervous disorderDiseaseBenzoic acid

The invention discloses a halogen substituted 2-(a-hydroxyl amyl) benzoate compound, a preparation method and medicinal application thereof, which belong to the technical field of organic chemical synthesis. The structural formula of the compound which is showed as above has an antimer structure, wherein <R1> represents a halogen atom; n is equal to 1 to 3; and M represents a univalent metallic ion or a bivalent metallic ion or a trivalent metallic ion or an organic base. The compound has the advantages of better activity on preventing and treating cardio-cerebral ischemia diseases, improving cardio-cerebral circulation disturbance and resisting thrombus, and the like.

Owner:ZHEJIANG AUSUN PHARMA

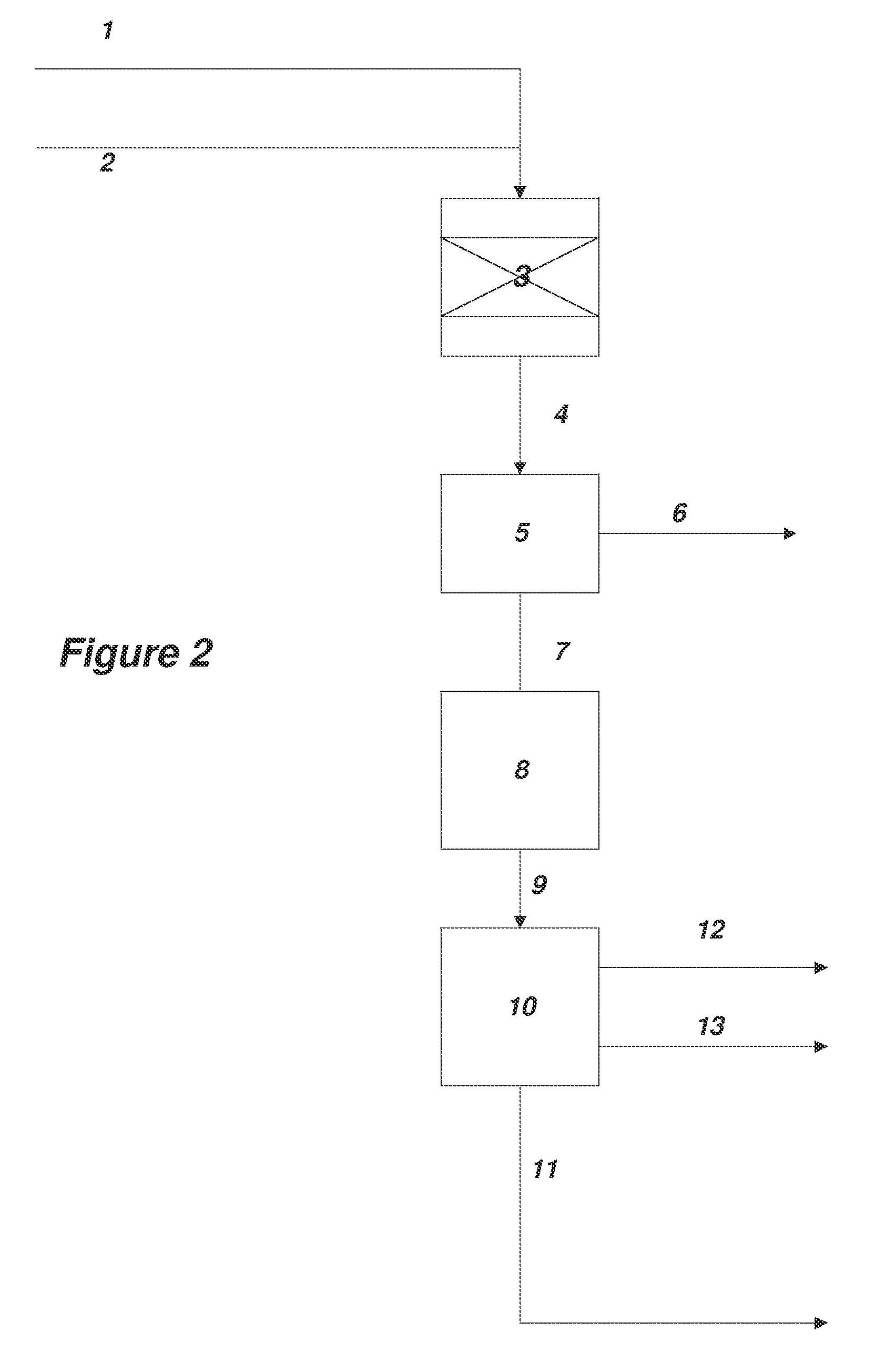

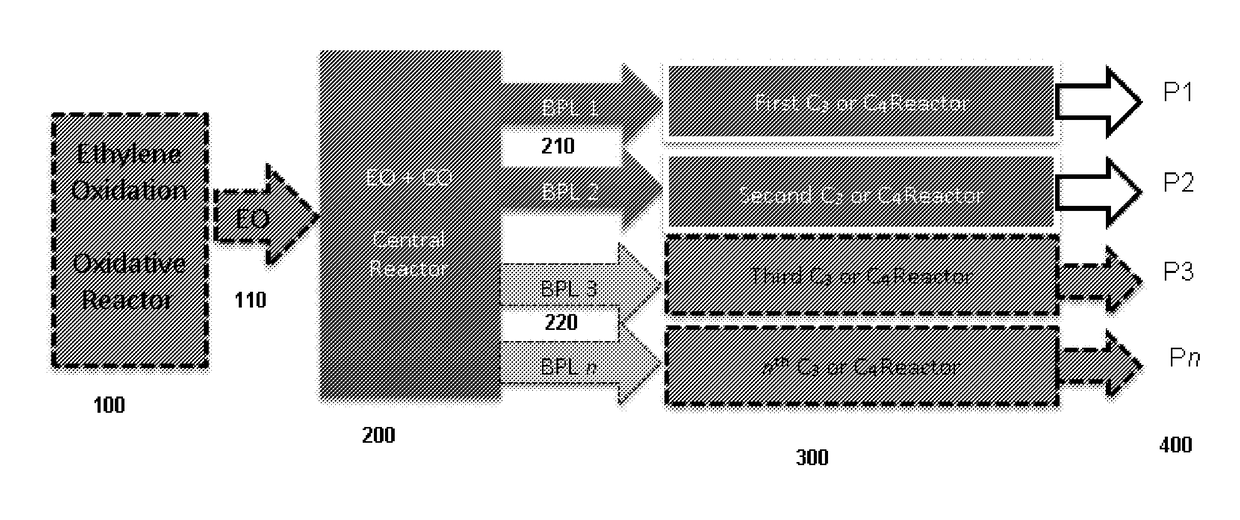

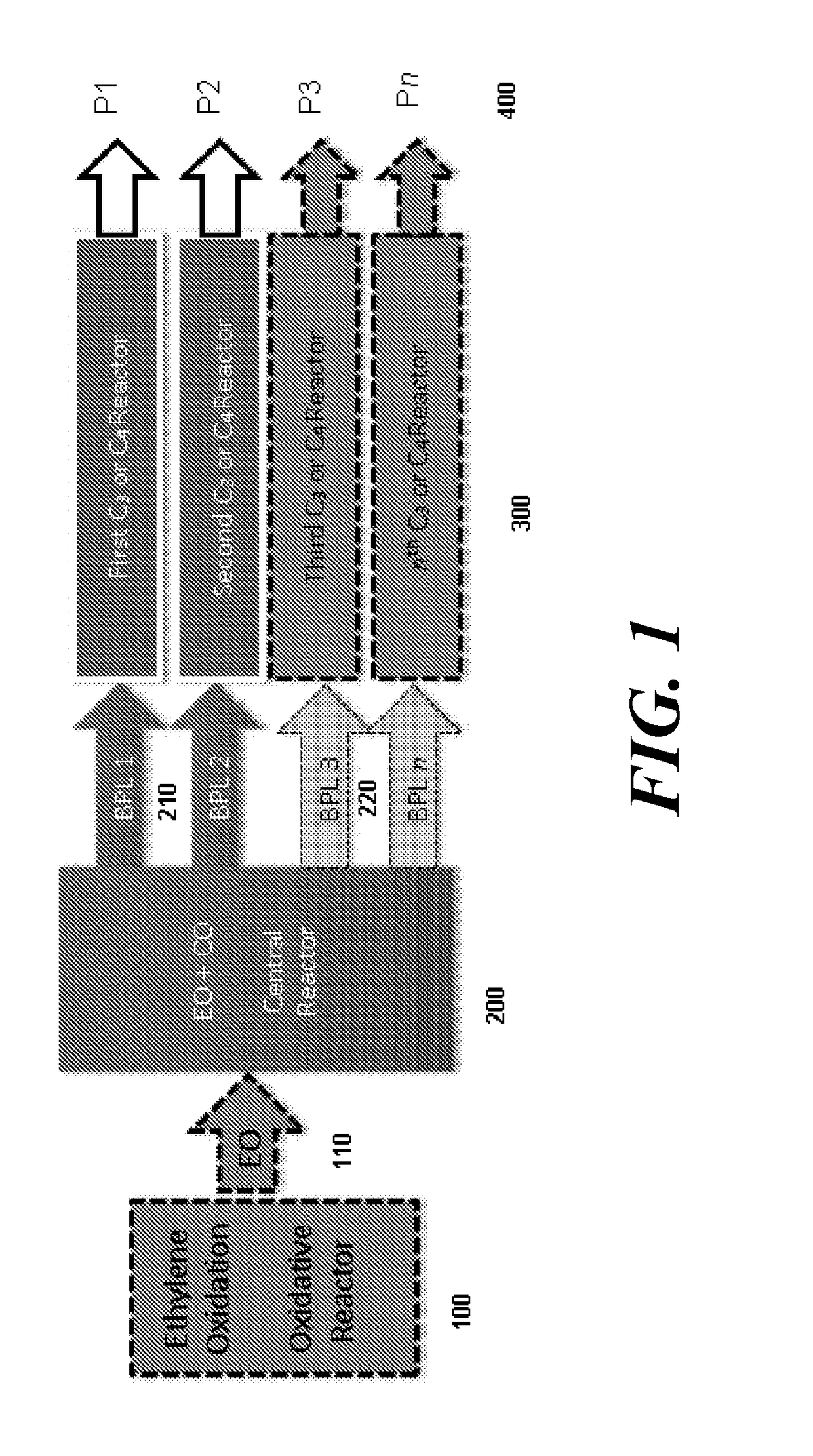

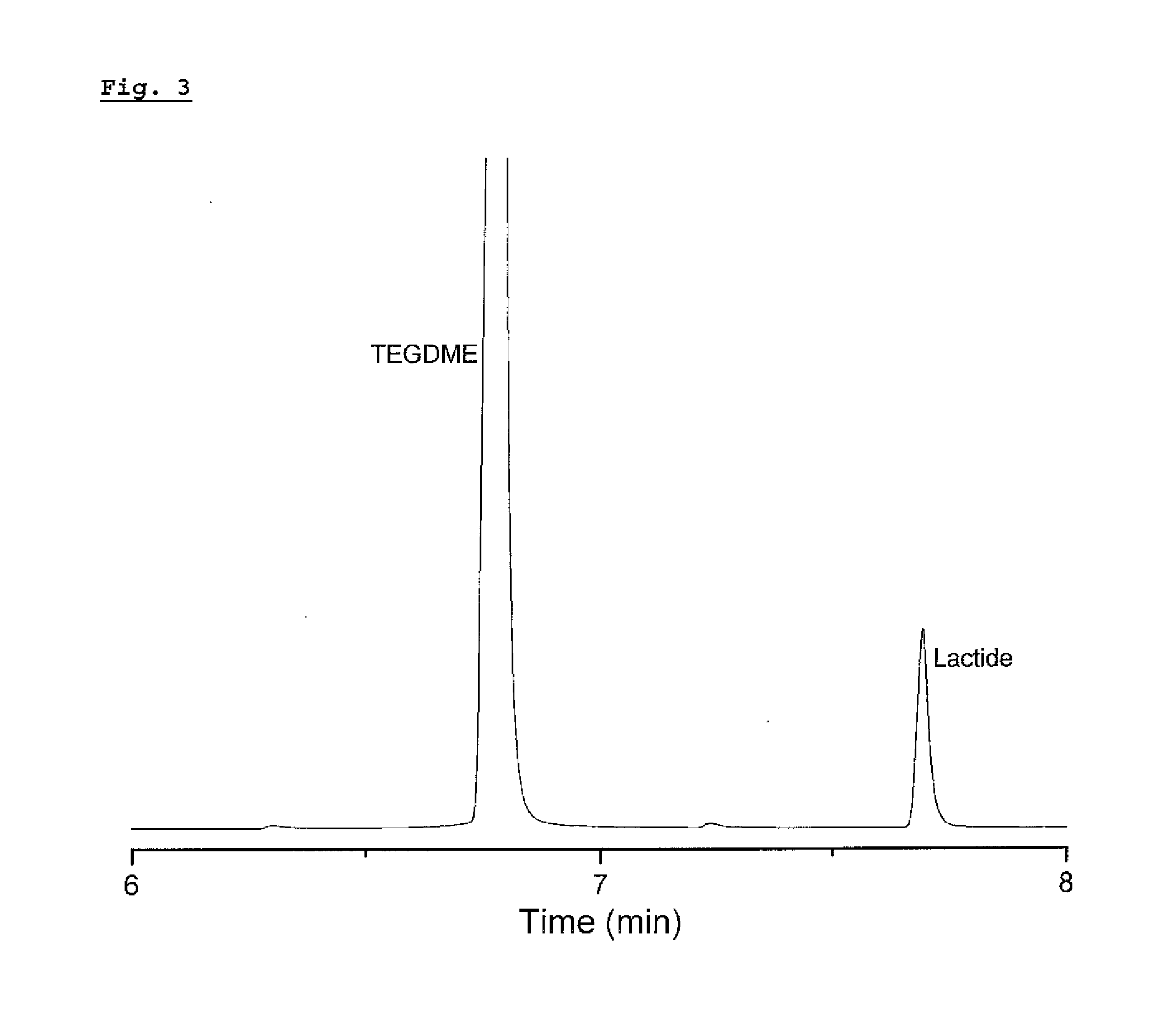

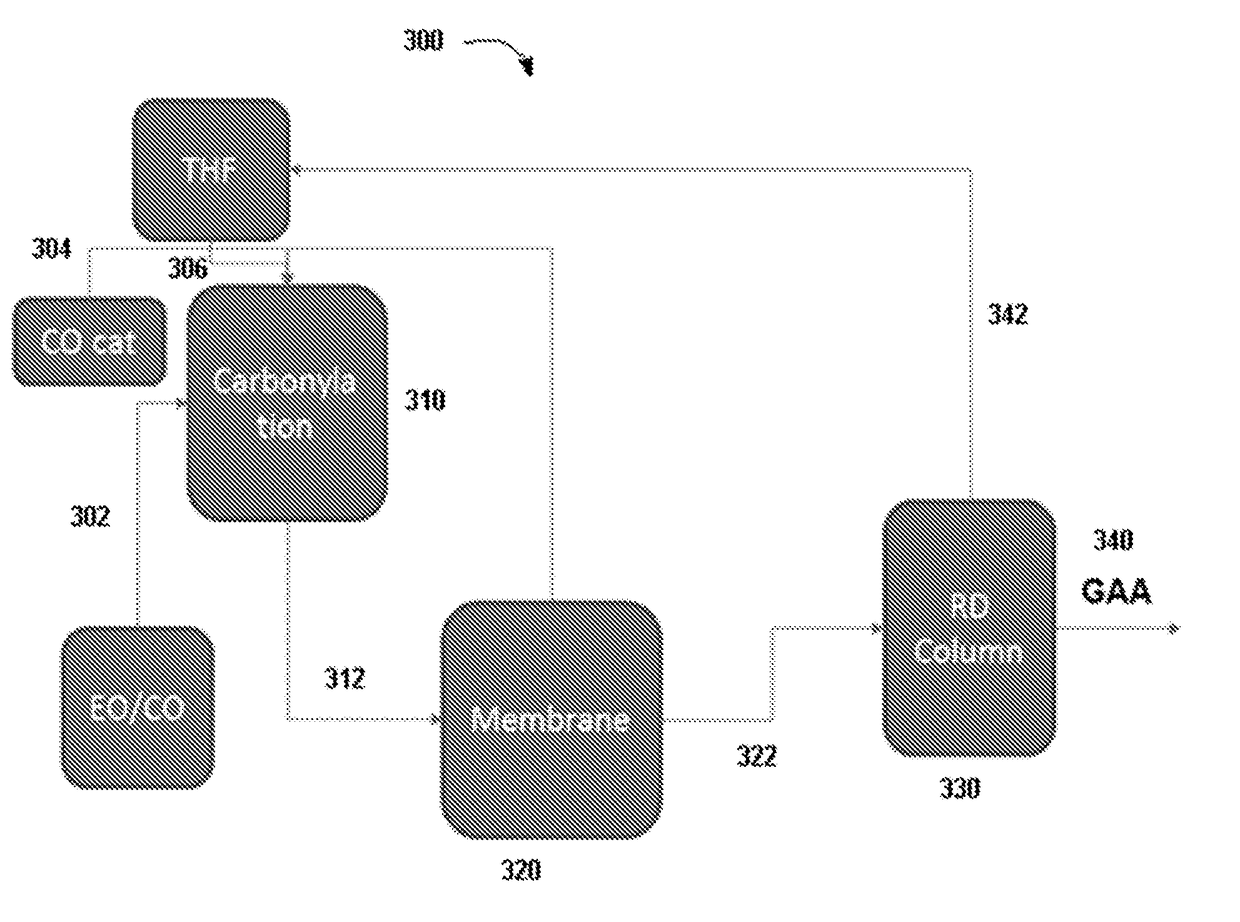

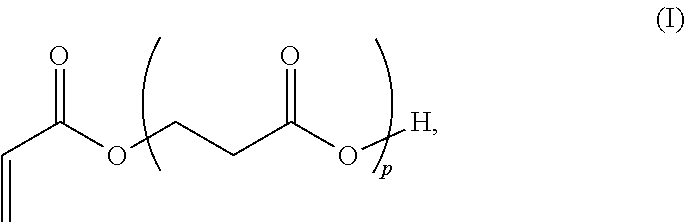

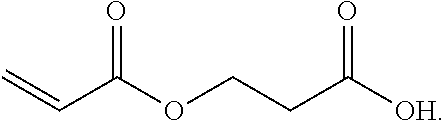

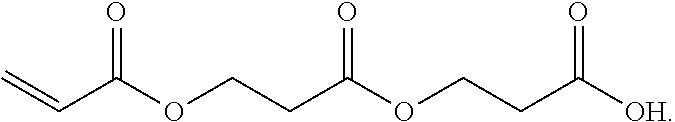

Systems and processes for polymer production

ActiveUS20180094100A1Higher and smoother conversion to acrylic acidHigh degreePreparation from carboxylic acid esters/lactonesPolymer sciencePolymer

Owner:NOVOMER INC

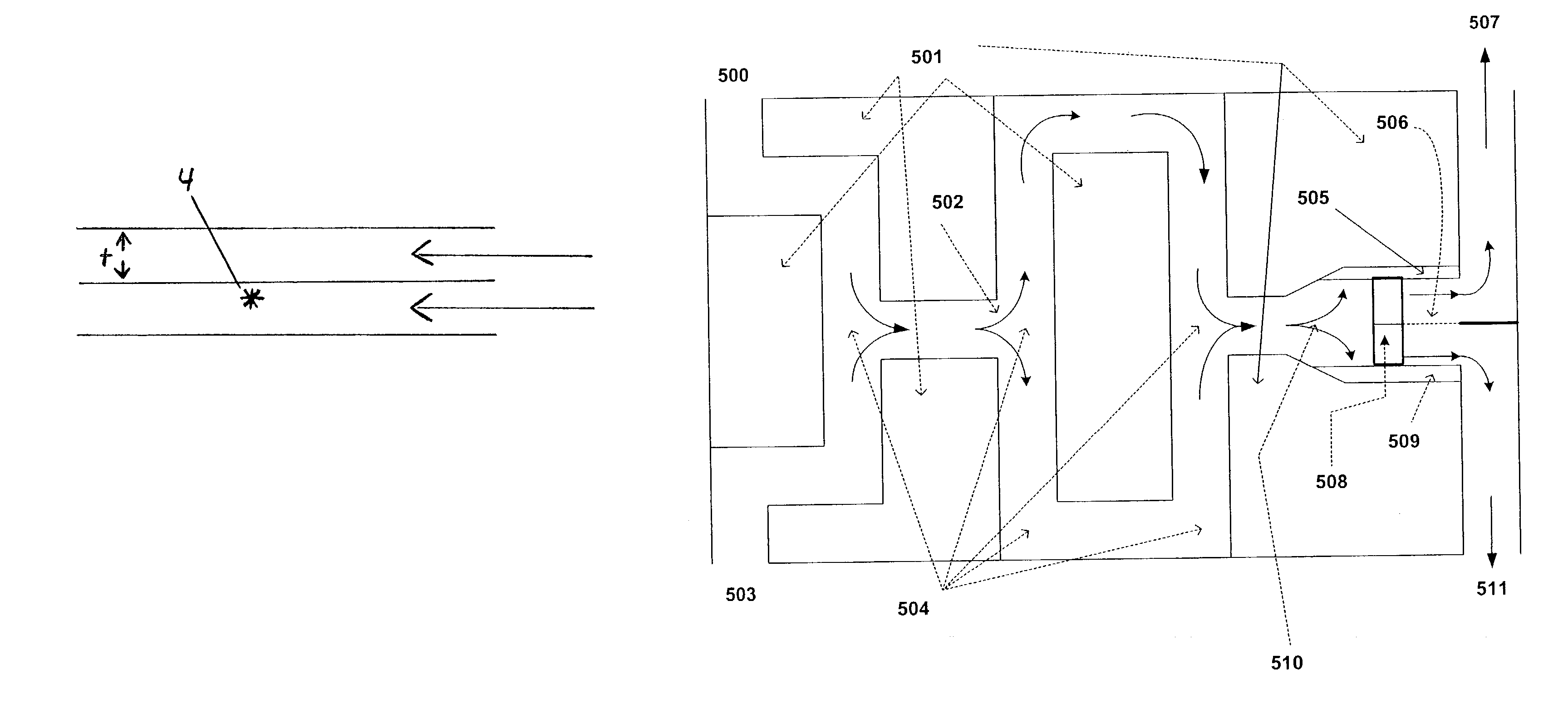

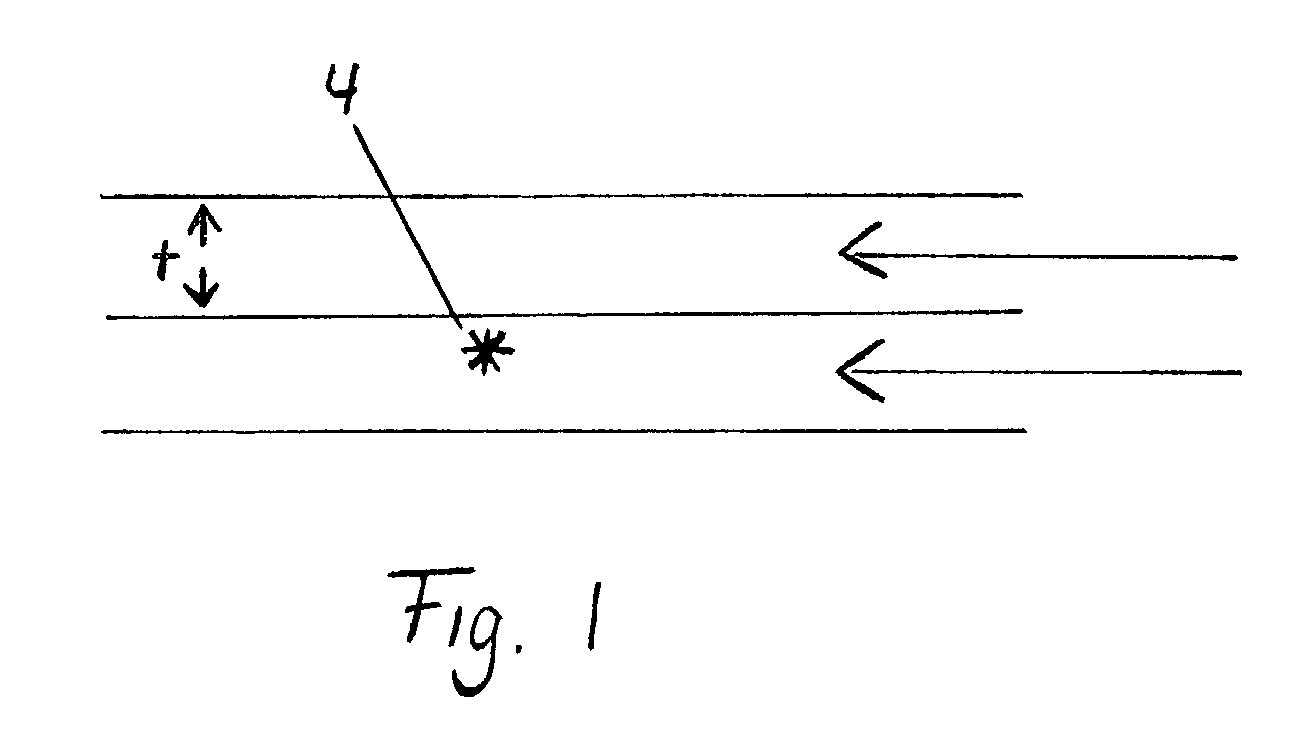

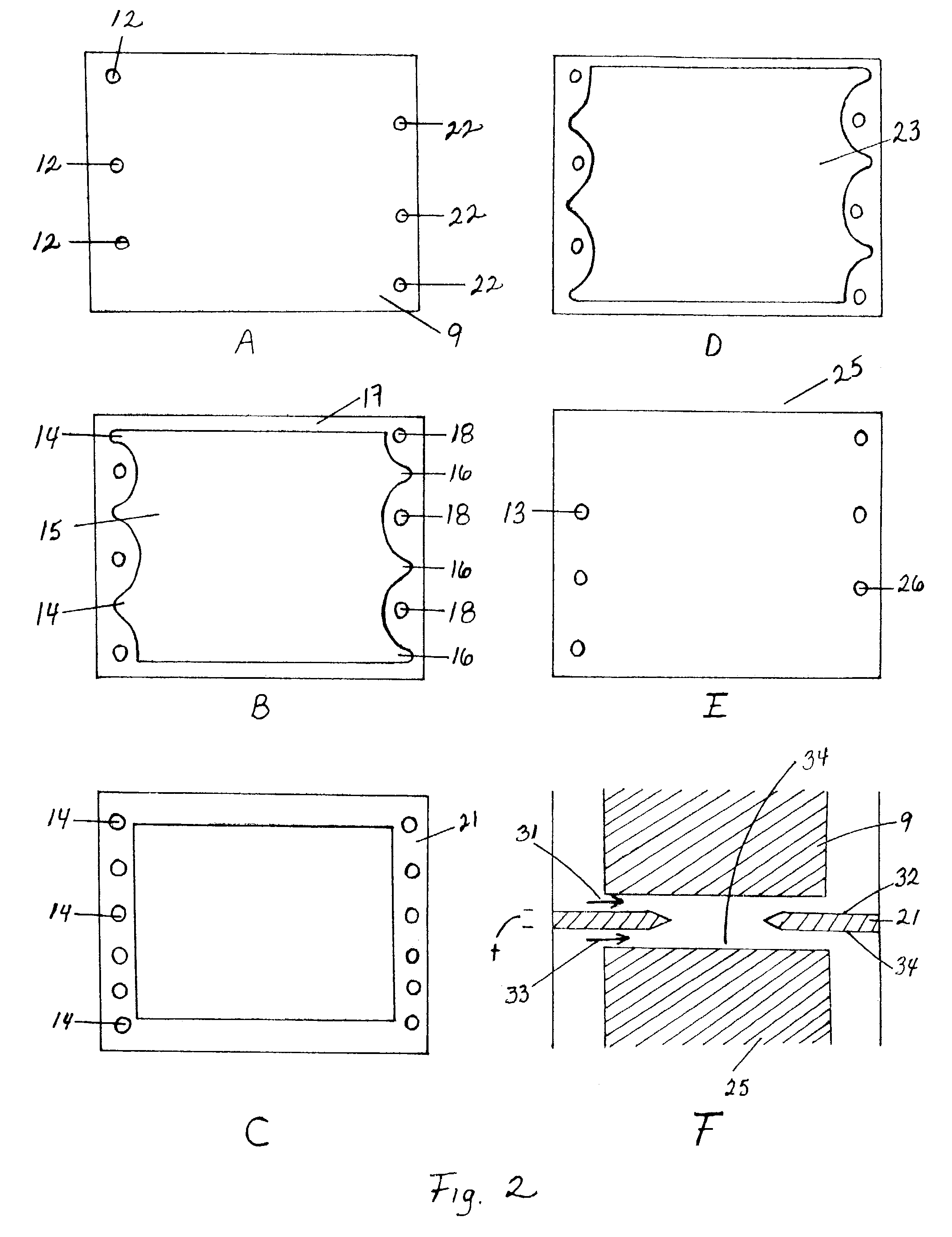

Multiphasic microchannel reactions

InactiveUS7118920B2Improved fluid separationHigh reactivityPreparation by oxidation reactionsOrganic chemistry methodsUnit operationPhase-transfer catalyst

Multiphasic reactions, especially those reactions using a phase transfer catalyst, are conducted in microchannel apparatus. Advantageously, these reactions can be conducted with two, planar microlayers of reactants in adjacent laminar flow streams. Microchannel apparatus and methods for conducting unit operations such as reactions and separations in microchannel apparatus is also described. Microchannel apparatus can provide advantages for controlling reactions and separating products, solvents or reactants in multiphase reactions.

Owner:BATTELLE MEMORIAL INST

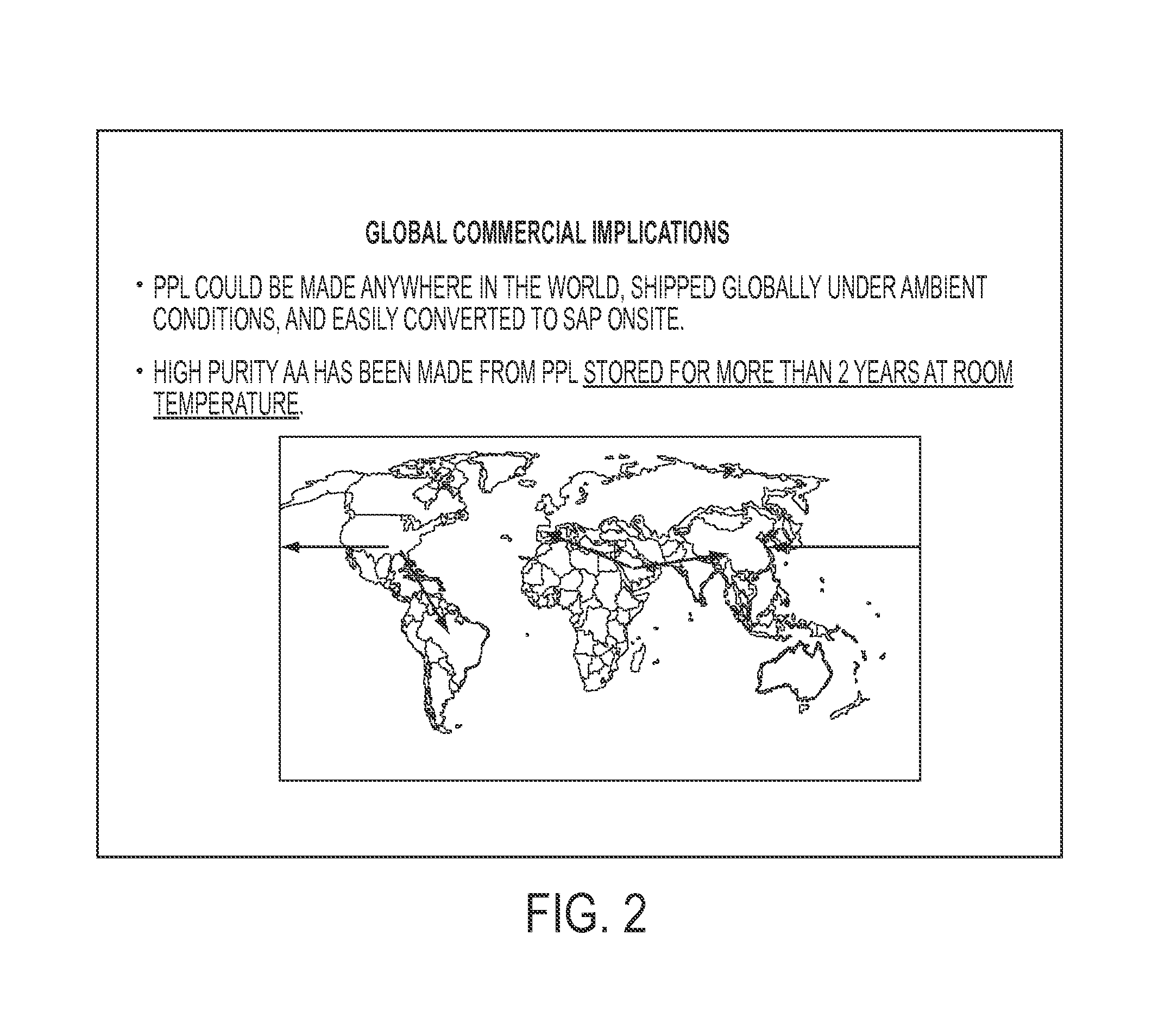

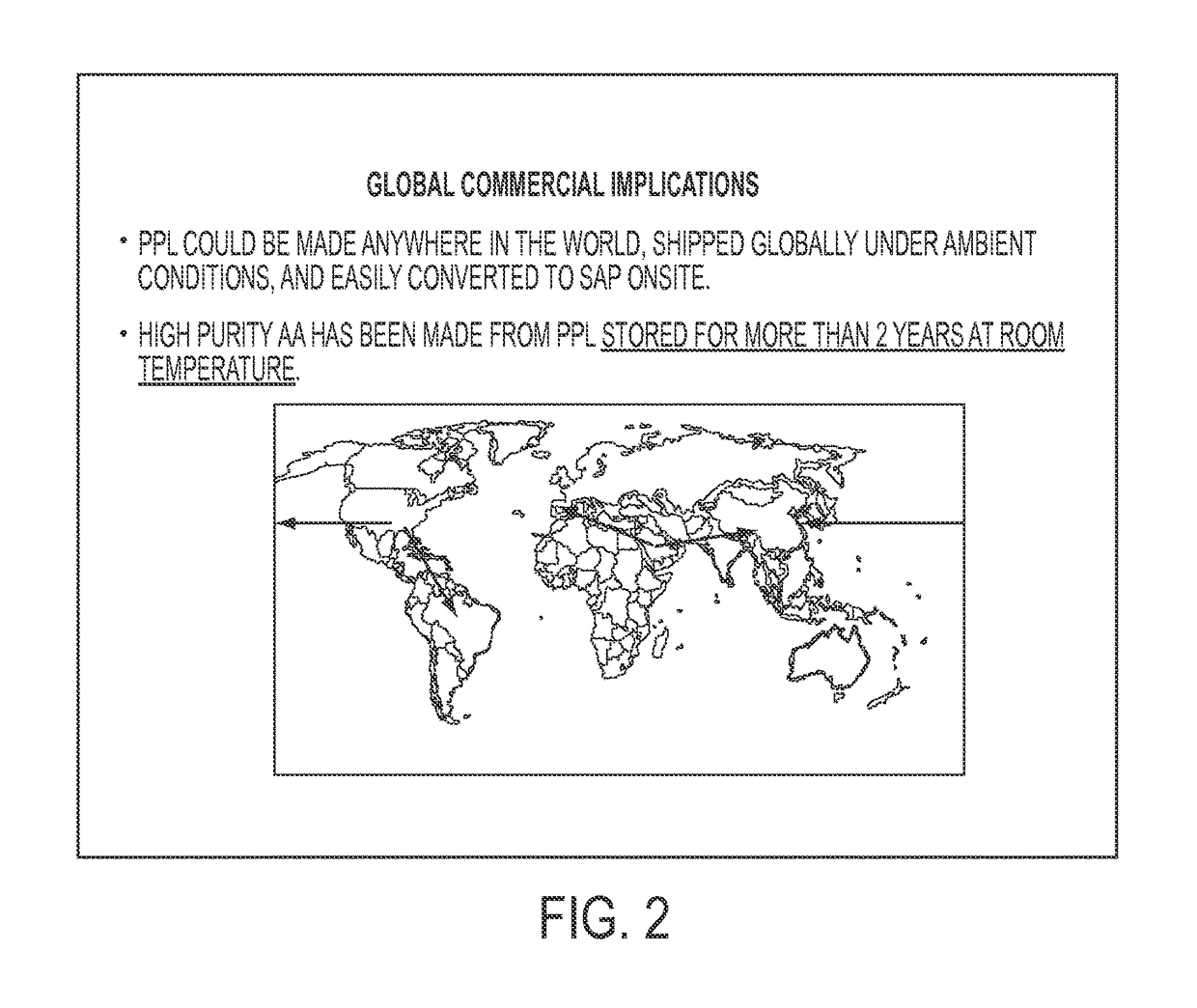

Acrylic acid production methods

InactiveUS20160016876A1Transportation safetyLess expensiveMarket predictionsOrganic compound preparationEthylene oxidePolymerization

In one aspect, the present invention encompasses safe and efficient methods for providing highly pure acrylic acid. In certain embodiments, the inventive methods include the step of producing polypropiolactone from ethylene oxide at a first location, transporting the polymer to a second location and pyrolyzing the polypropiolactone to provide glacial acrylic acid. In certain embodiments, the step of pyrolyzing the polymer is performed continuously in conjunction with a polymerization process to make SAPs.

Owner:NOVOMER INC

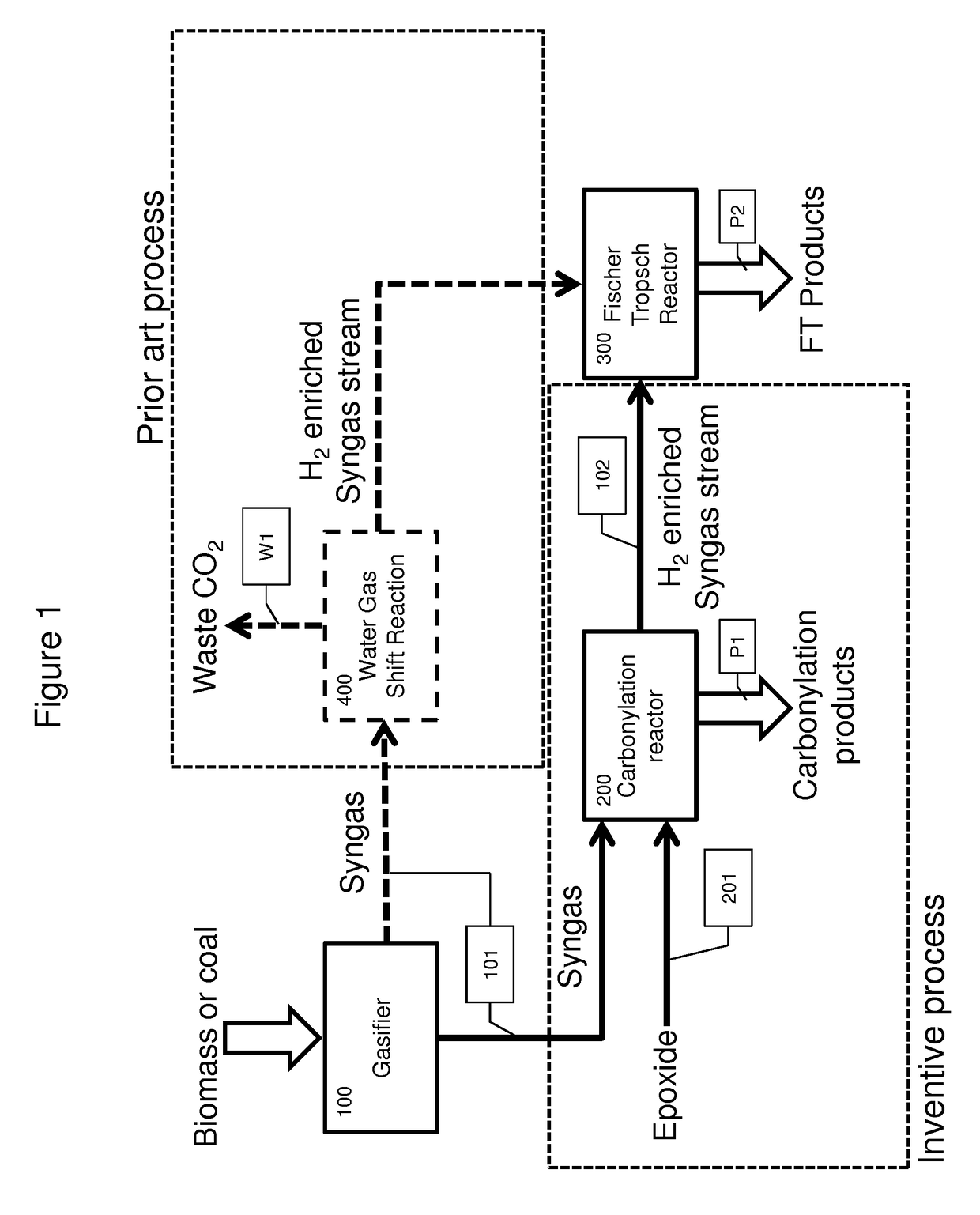

Flexible chemical production platform

InactiveUS20180029005A1Reduce their present relianceProcess control/regulationOrganic compound preparationBiochemical engineeringProcess engineering

Disclosed are integrated systems and methods for the conversion of epoxides to beta lactones and to multiple C3 products and / or C4 products.

Owner:NOVOMER INC

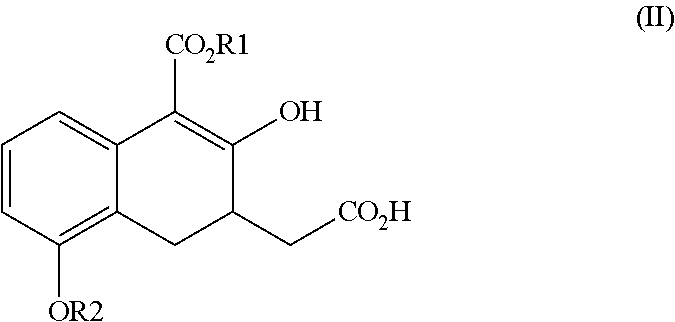

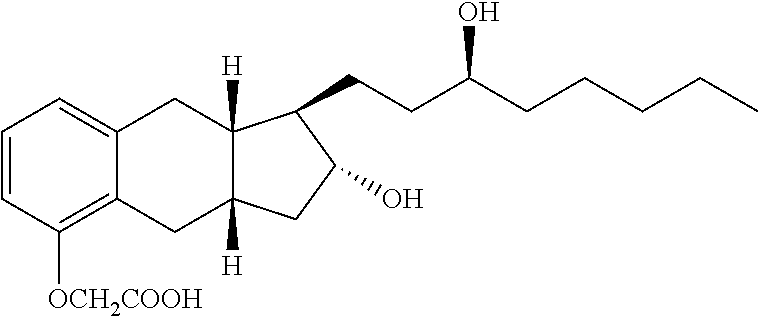

Novel intermediate for synthesizing treprostinil diethanolamine and method for preparing the same

ActiveUS20160152548A1High optical purityHigh purityOrganic compound preparationPreparation by ester-hydroxy reactionCombinatorial chemistryEthanolamine synthesis

The present invention relates to a method for treprostinil diethanolamine synthesis. The present invention also relates to a novel intermediate used in the method for treprostinil diethanolamine synthesis. The novel intermediate is shown in the following formula (II):wherein R1 and R2 are described in the description.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

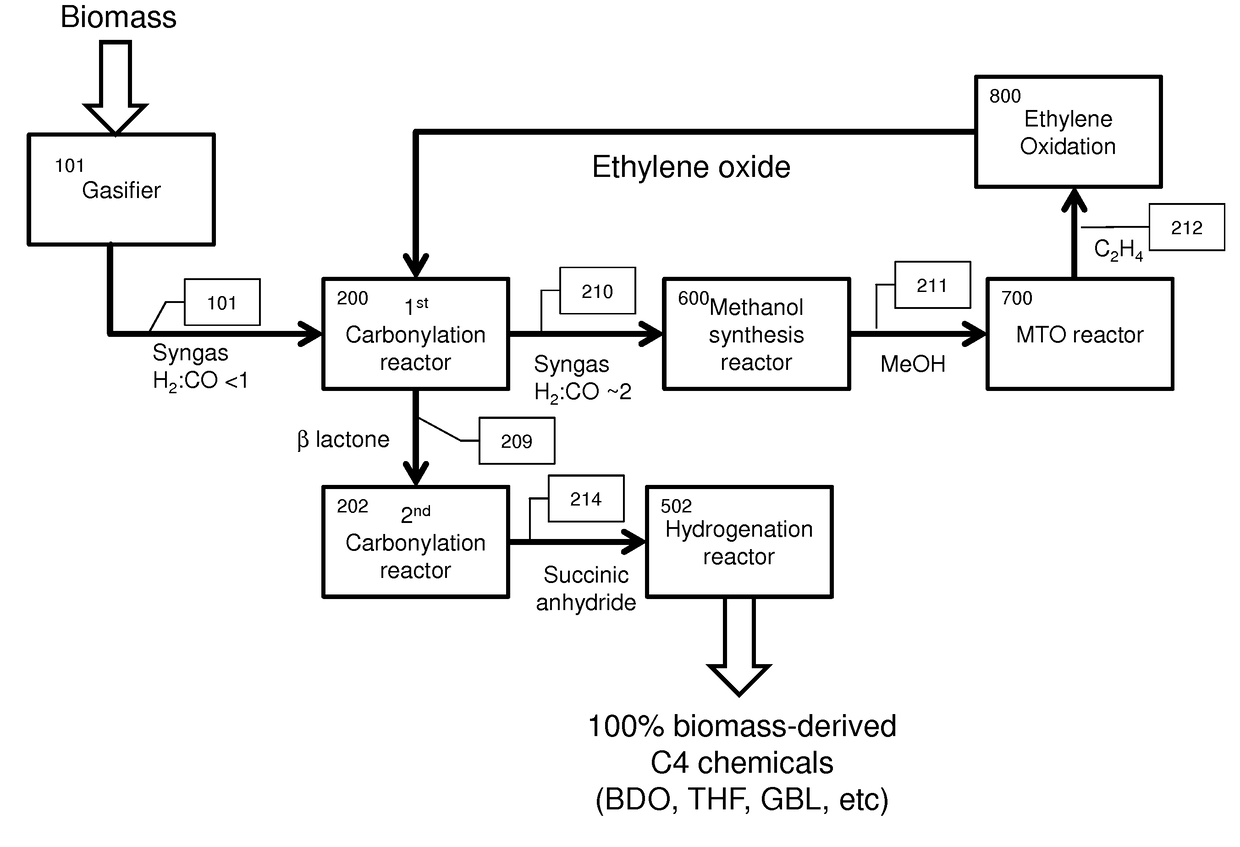

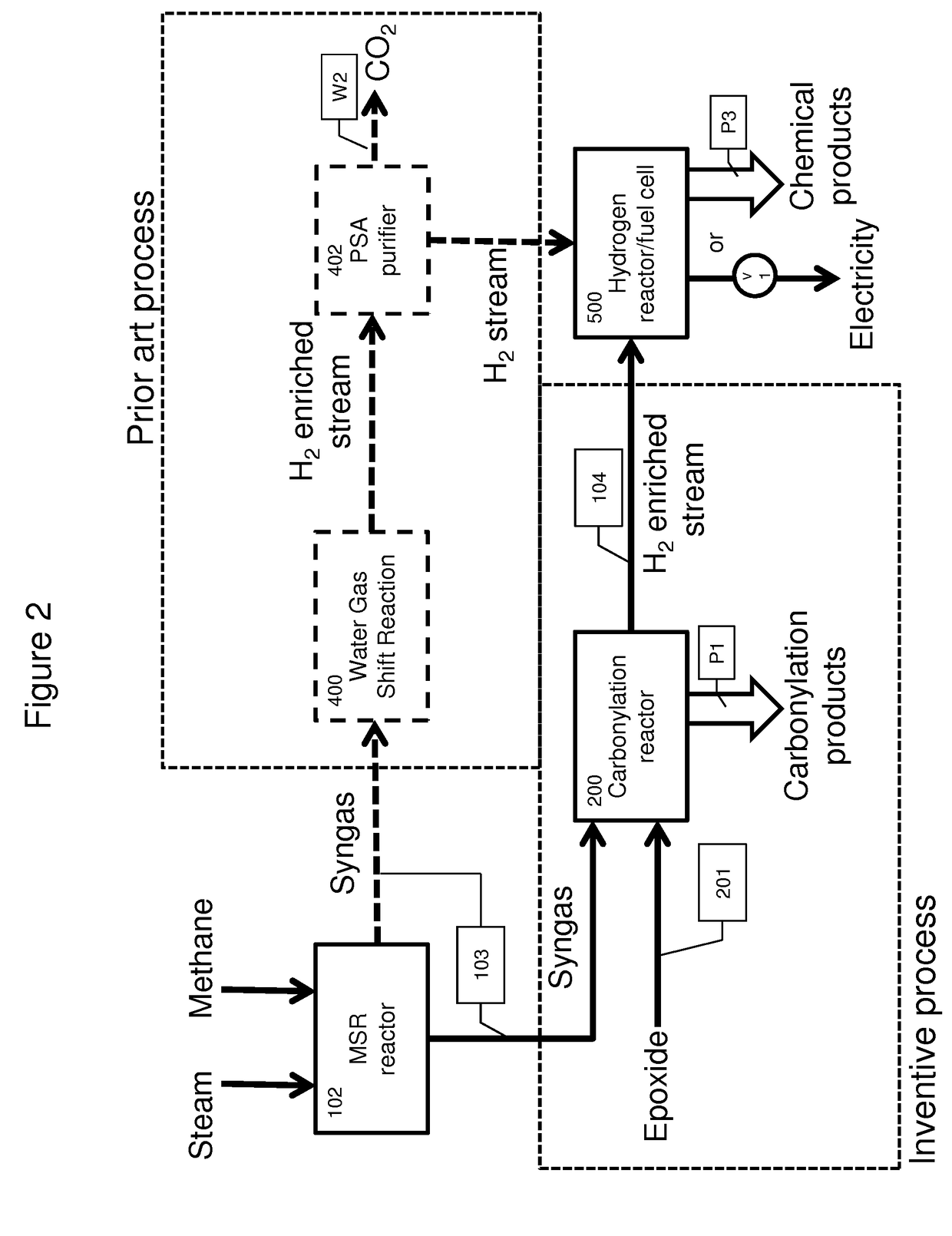

Integrated methods for chemical synthesis

ActiveUS20170107103A1Improve carbon efficiencyQuantity maximizationBiofuelsPreparation from carboxylic acid esters/lactonesChemical synthesisSyngas

Among other things, the present invention encompasses the applicant's recognition that epoxide carbonylation can be performed industrially utilizing syngas streams containing hydrogen, carbon monoxide and varying amounts carbon dioxide. Contrary to expectation, the epoxide carbonylation reaction proceeds selectively in the presence of these mixed gas streams and incorporates excess CO in the syngas stream into valuable chemical precursors, resulting in hydrogen streams substantially free of CO. This is economically and environmentally preferable to performing WSGR which releases the excess carbon as CO2. The integrated processes herein therefore provide improved carbon efficiency for processes based on coal or biomass gasification or steam methane reforming.

Owner:NOVOMER INC

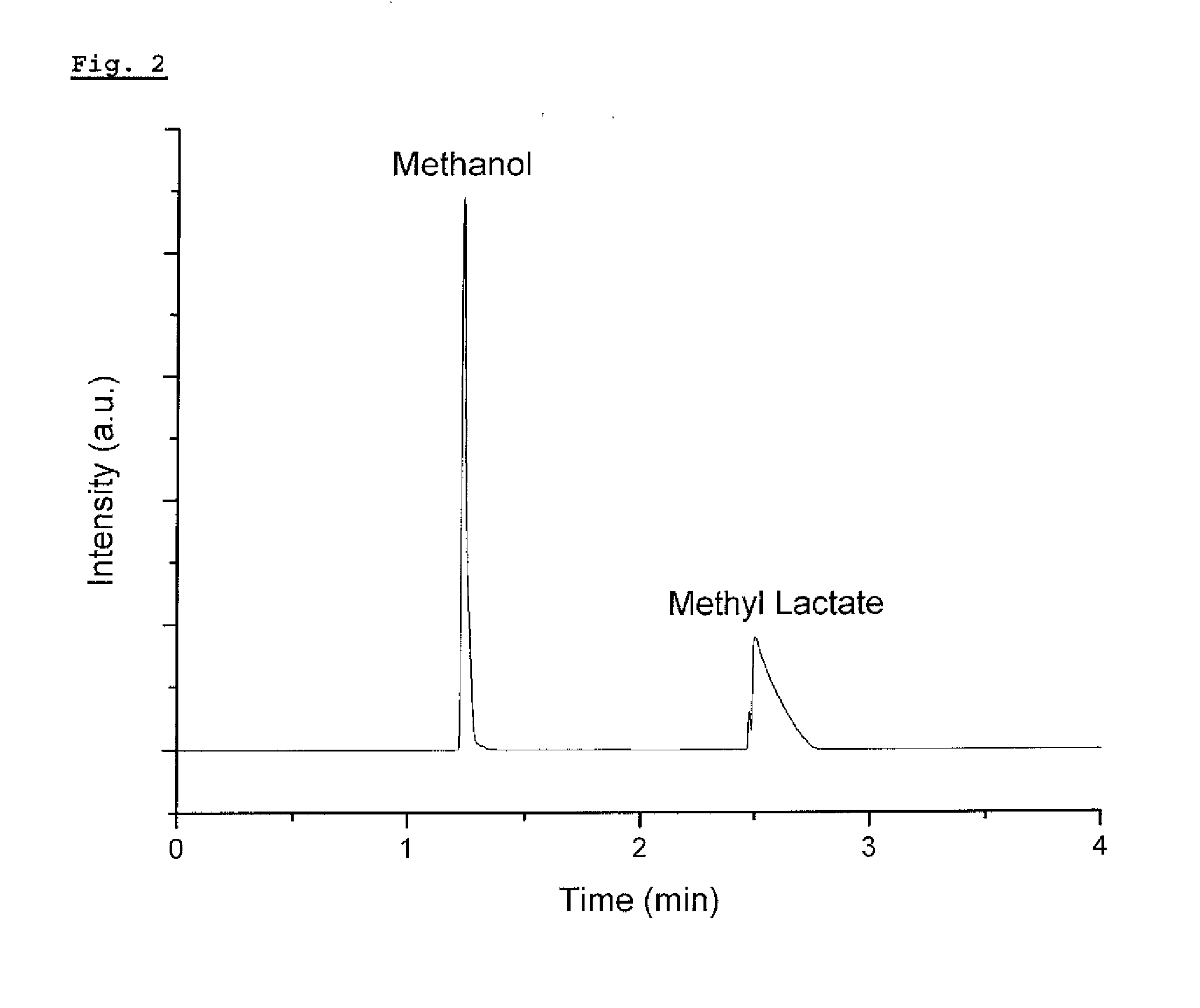

Recovery method of highly pure lactic acid and alkyl lactate

InactiveUS20120142945A1Efficient separationRecovering highly pure lactic acid more economicallyOrganic compound preparationCarboxylic acid esters preparationLiquid productRecovery method

A method for recovery of highly pure alkyl lactate and lactic acid is provided, which includes a step 1 for producing source liquid comprising lactic acid or ammonium lactate; a step 2 for dehydrating the source liquid product of step 1; a step 3 for producing liquid mixture by sequentially adding and stirring alcohol and acid solution to the dehydrated source liquid; a step 4 for separating and removing ammonium salt precipitation from the liquid mixture of step 3; a step 5 for producing alkyl lactate from ammonium salt-free liquid mixture by esterification reaction; and a step 6 for separating alcohol and alkyl lactate by distillation from the mixture of step 5.

Owner:KOREA RES INST OF CHEM TECH

Acrylic acid production methods

InactiveUS20170145126A1Transportation safetyLess expensiveMarket predictionsPreparation from carboxylic acid esters/lactonesEthylene oxideLactone

In one aspect, the present invention encompasses safe and efficient methods for providing highly pure acrylic acid. In certain embodiments, the inventive methods include the step of producing polypropiolactone from ethylene oxide at a first location, transporting the polymer to a second location and pyrolyzing the polypropiolactone to provide glacial acrylic acid. In certain embodiments, the step of pyrolyzing the polymer is performed continuously in conjunction with a polymerization process to make SAPs.

Owner:NOVOMER INC

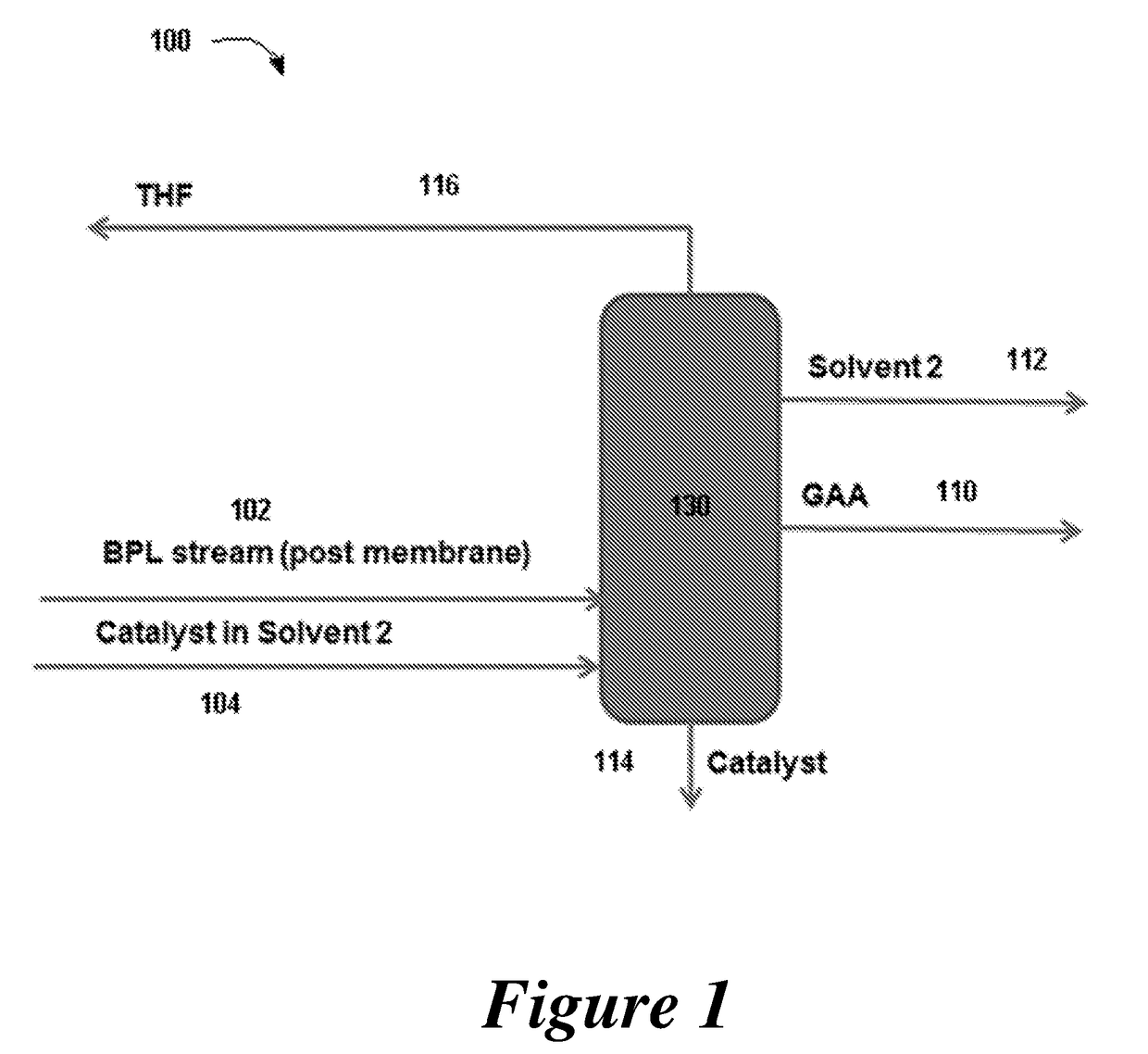

Distillation process for production of acrylic acid

ActiveUS20180022677A1Chemical industryPreparation from carboxylic acid esters/lactonesDistillationBeta-Propiolactone

Provided are integrated processes for the conversion of beta propiolactone to acrylic acid. Systems for the production of acrylic acid are also provided.

Owner:NOVOMER INC

Intermediates for the synthesis of benzindene prostaglandins and preparations thereof

Novel processes for preparing optically active cyclopentanones 1which are useful for the preparation of benzindene Prostaglandins and novel cyclopentanones are provided. The invention also provides novel processes of preparing benzindene Prostaglandins and novel intermediates for benzindene Prostaglandins.

Owner:CHIROGATE INT

Process for production of acrylic acid

ActiveUS20180016219A1Promote aggregationReduce adverse effectsChemical industryPreparation from carboxylic acid esters/lactonesBiochemistryBeta-Propiolactone

Provided are integrated processes for the conversion of beta propiolactone to acrylic acid. Systems for the production of acrylic acid are also provided.

Owner:NOVOMER INC

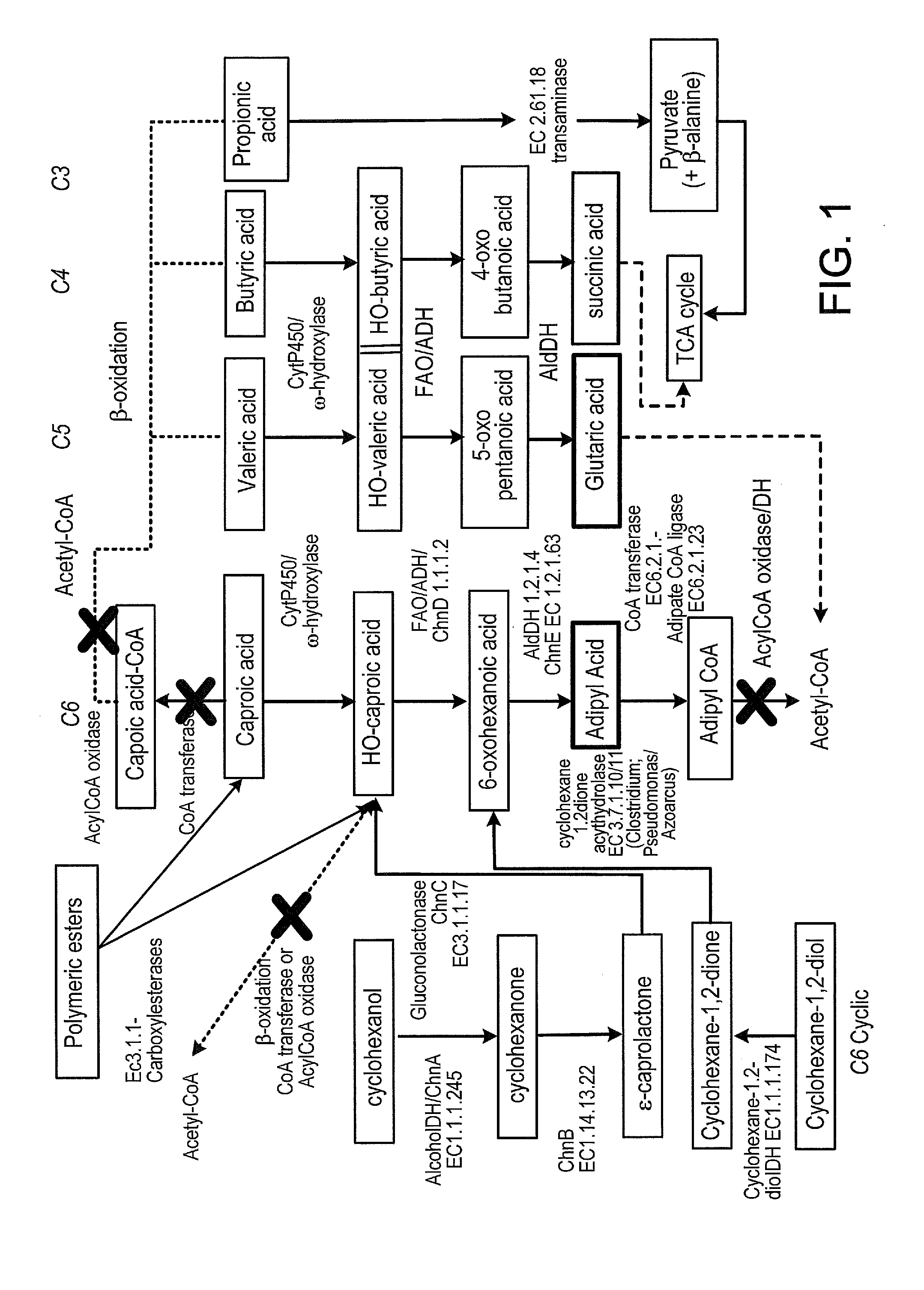

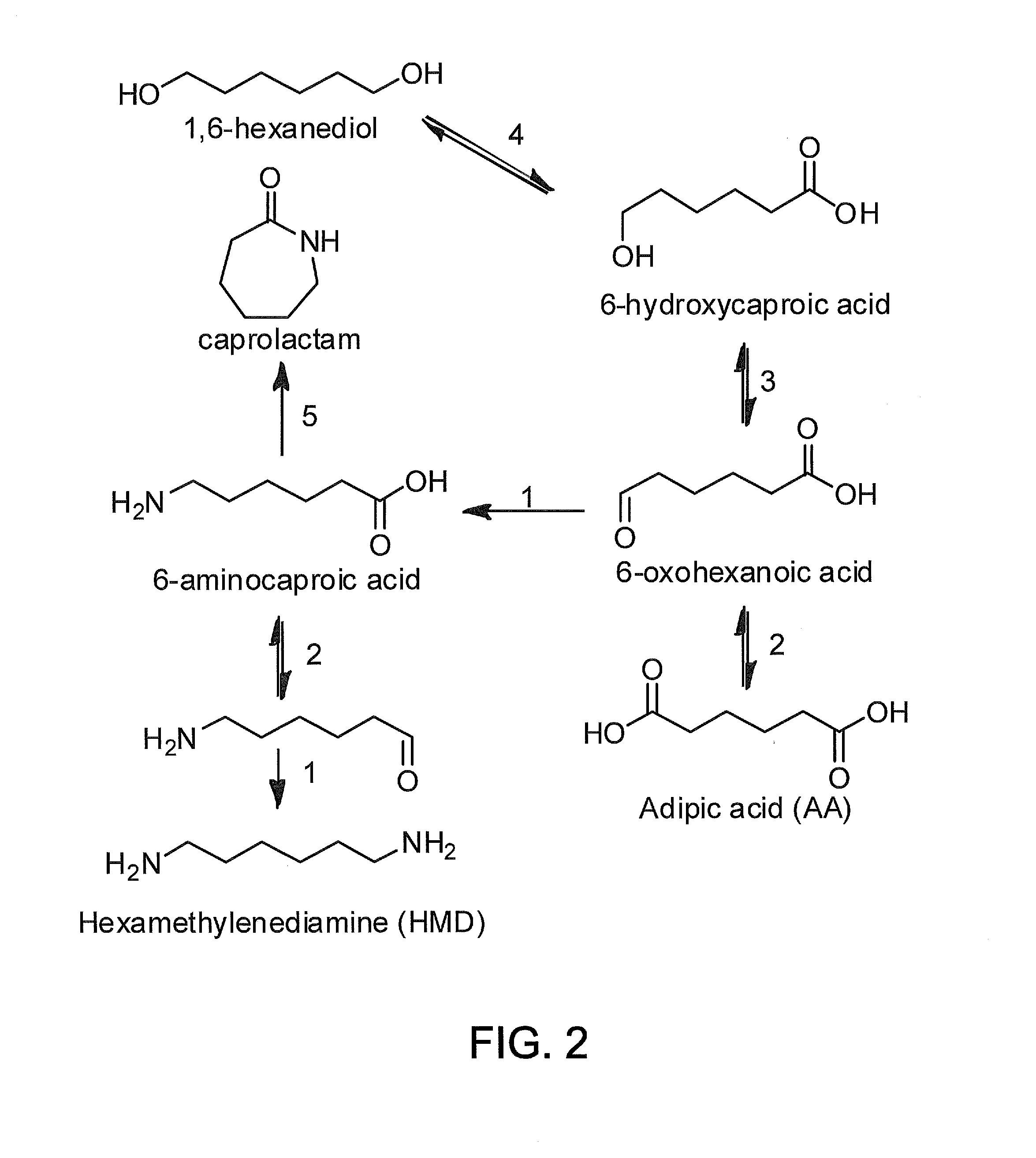

Methods of producing carboxylic acids

The invention relates to methods for enriching monomer content in a cycloalkane oxidation process mixed organic waste stream. In particular, the methods involve combining a biocatalyst with a mixed organic waste stream from a cycloalkane oxidation process, and enzymatically converting dimeric and / or oligomeric components of said waste stream into monomeric components. The methods may enrich the content of diacids, adipic acid, and / or other α,ω-difunctional C6 alkanes in the mixed organic waste stream. Additionally, the treated mixed organic waste streams may have improved burning efficiency.

Owner:INV NYLON CHEM AMERICAS LLC

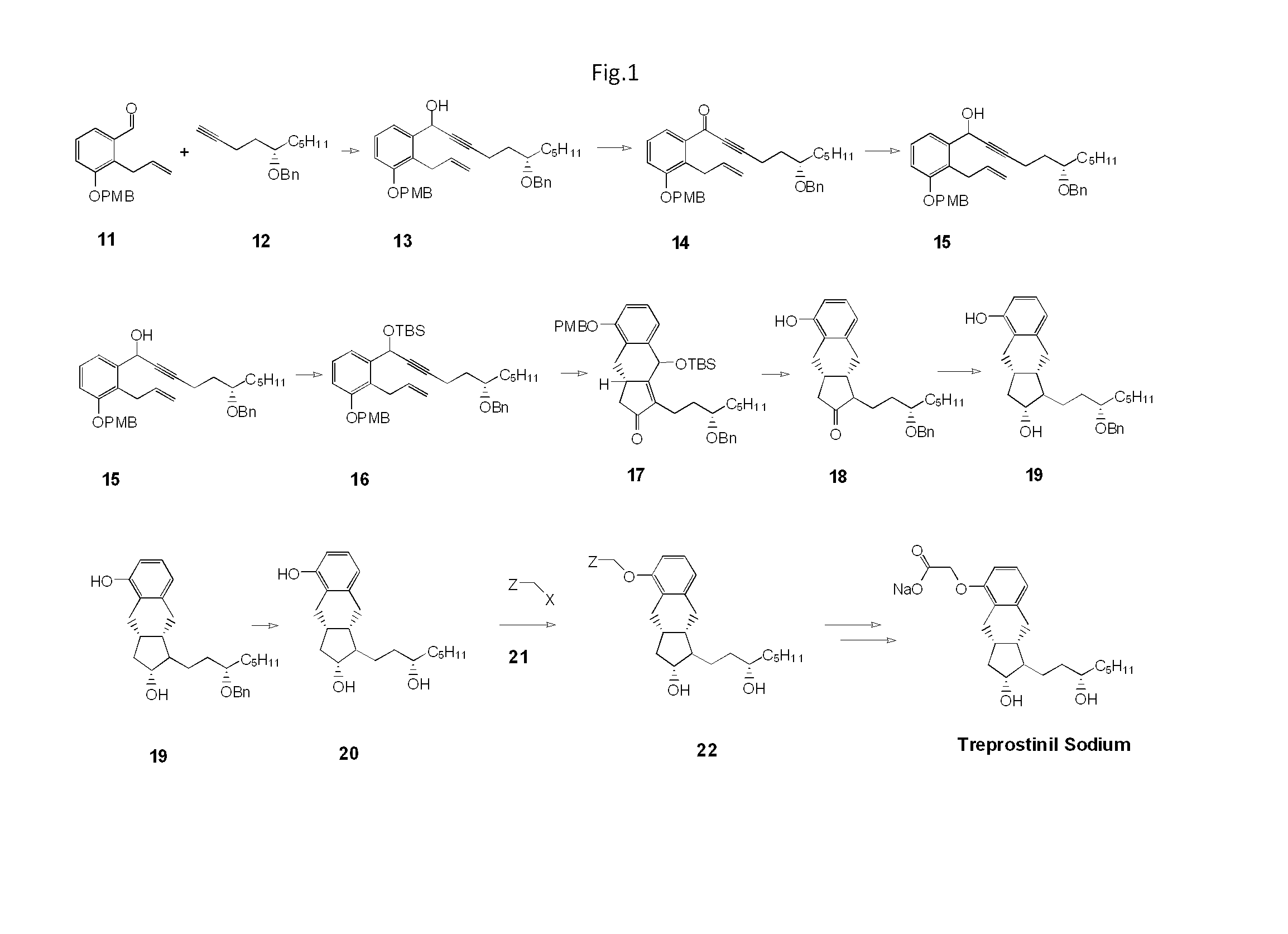

Synthesis Of Treprostinil And Intermediates Useful Therein

InactiveUS20130331593A1Enhanced chromatographic propertyGood flexibilitySilicon organic compoundsOrganic compound preparationAlkyneHydrolysis

Treprostinil is prepared by a process which involves Pauson-Khan cyclization of an an alkene-substituted, alkyne-substituted benzene corresponding to formula: (I) where PMB represents para-methoxy benzyl protecting group and R1 and R2 are alcohol protecting groups. Following cyclization, the resulting compound can be subjected to several chemical trans-formations followed by alkylation, hydrolysis and salt formation to yield treprostinil sodium. The use of para-methoxybenzyl group as the phenolic protecting group confers several process advantages that result in simplified purification of the final product and improved yields.

Owner:EON LABS

Popular searches

Energy input Catalyst activation/preparation Metal/metal-oxides/metal-hydroxide catalysts Preparation by transesterification Preparation by carbon monoxide or formate reaction Carboxylic preparation from carbon monoxide reaction Drug screening Dead animal preservation Mammal material medical ingredients Blood/immune system cells

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com