Patents

Literature

159 results about "Metal carbonyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal carbonyls are coordination complexes of transition metals with carbon monoxide ligands. Metal carbonyls are useful in organic synthesis and as catalysts or catalyst precursors in homogeneous catalysis, such as hydroformylation and Reppe chemistry. In the Mond process, nickel tetracarbonyl is used to produce pure nickel. In organometallic chemistry, metal carbonyls serve as precursors for the preparation of other organometalic complexes.

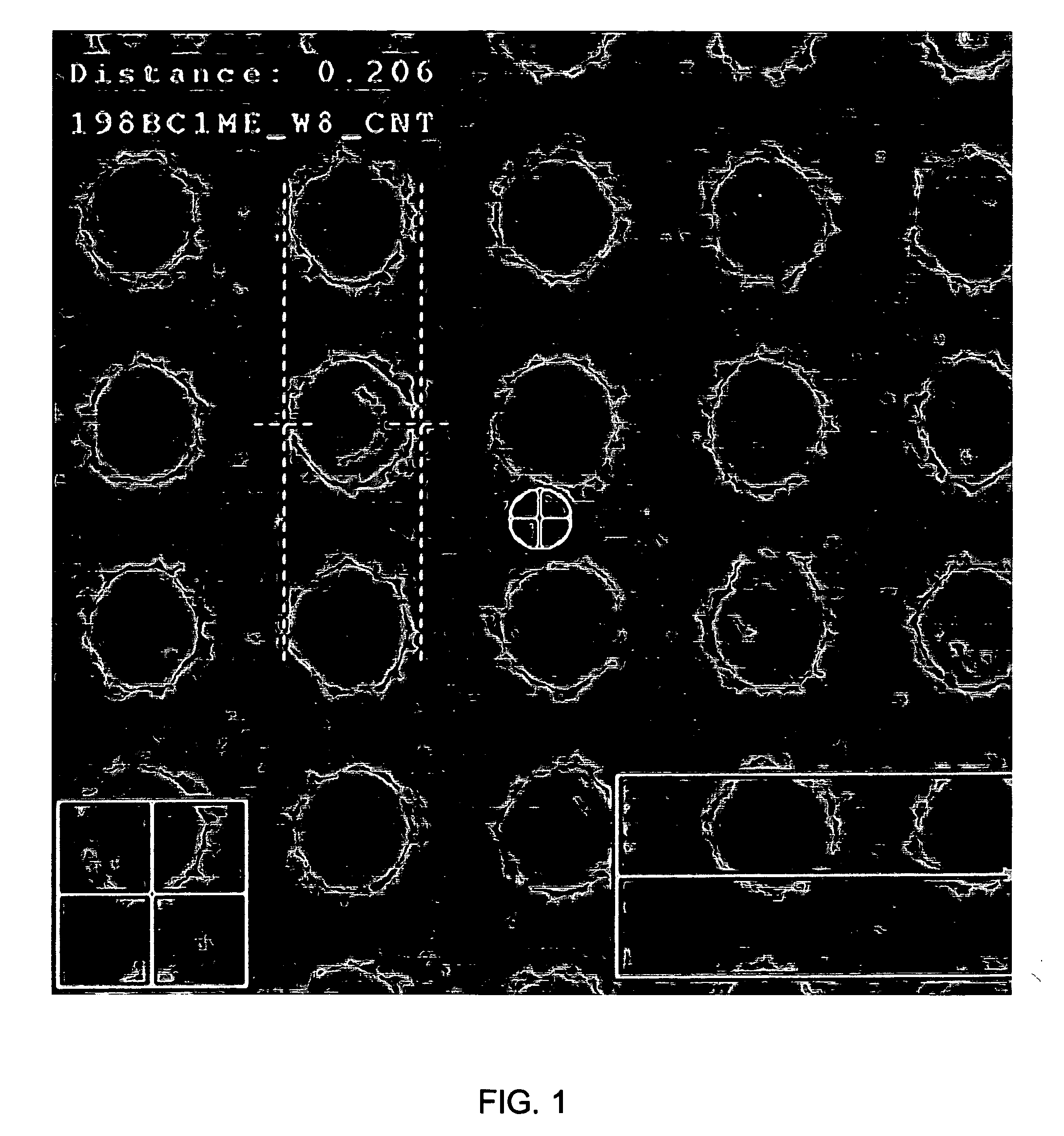

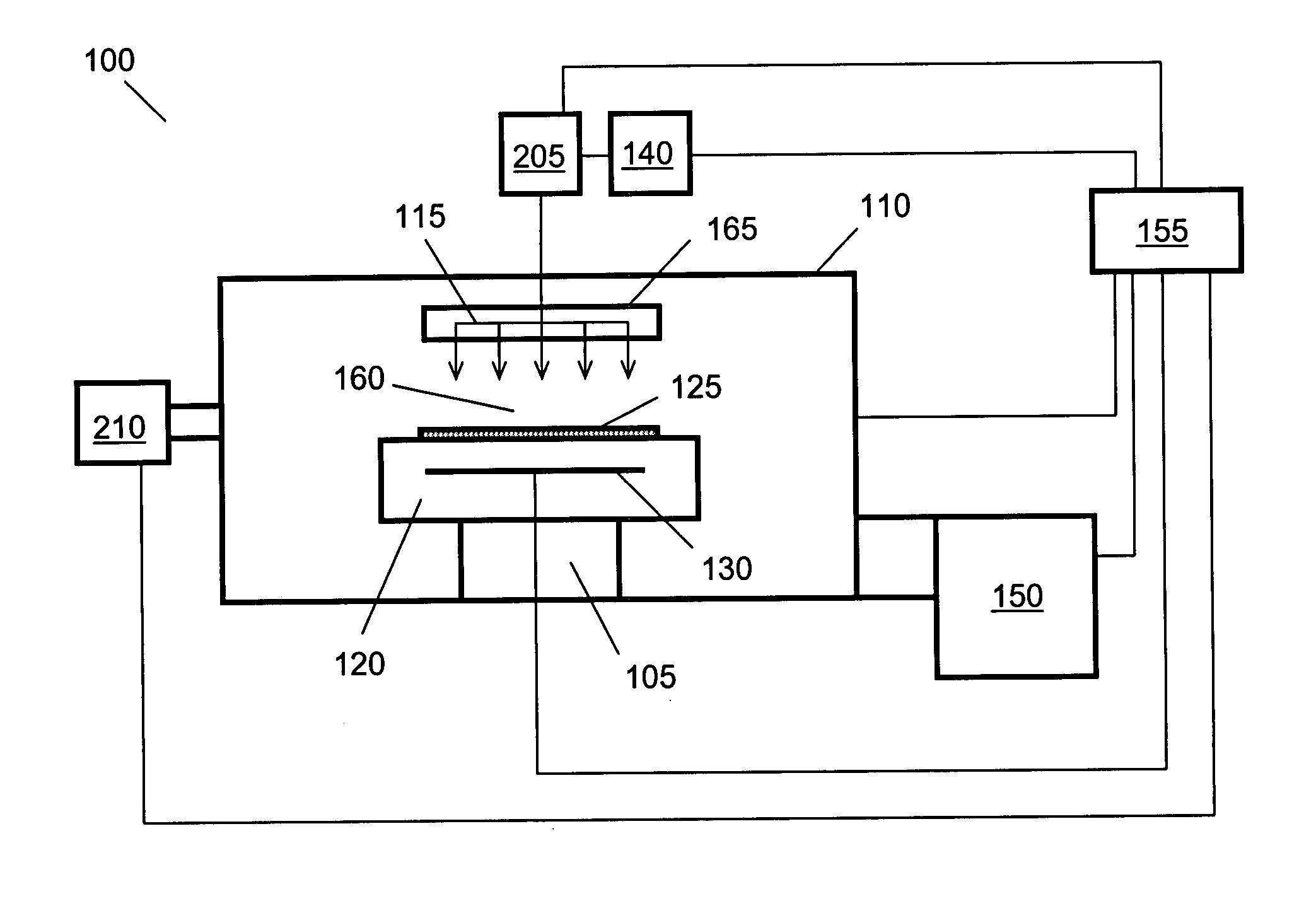

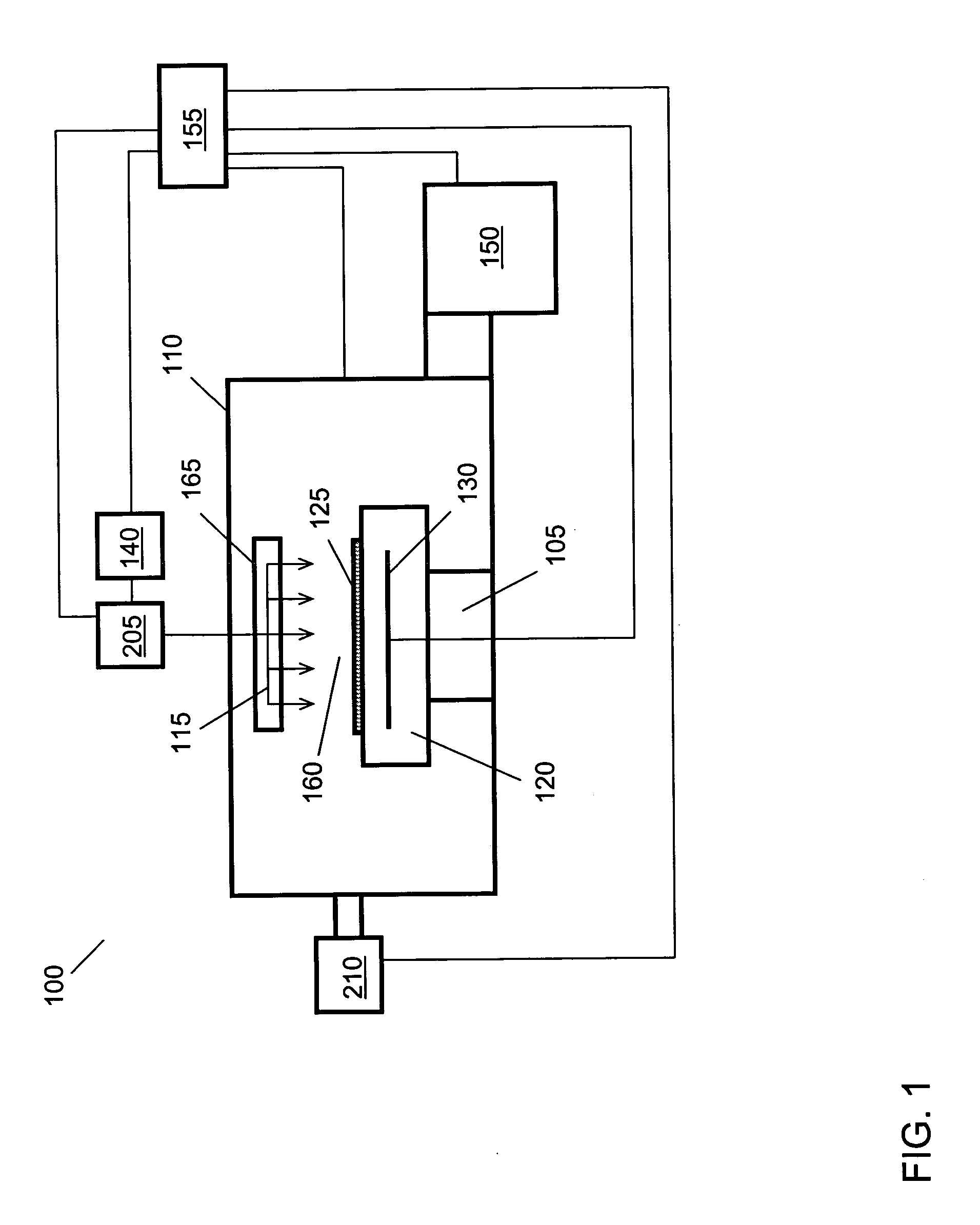

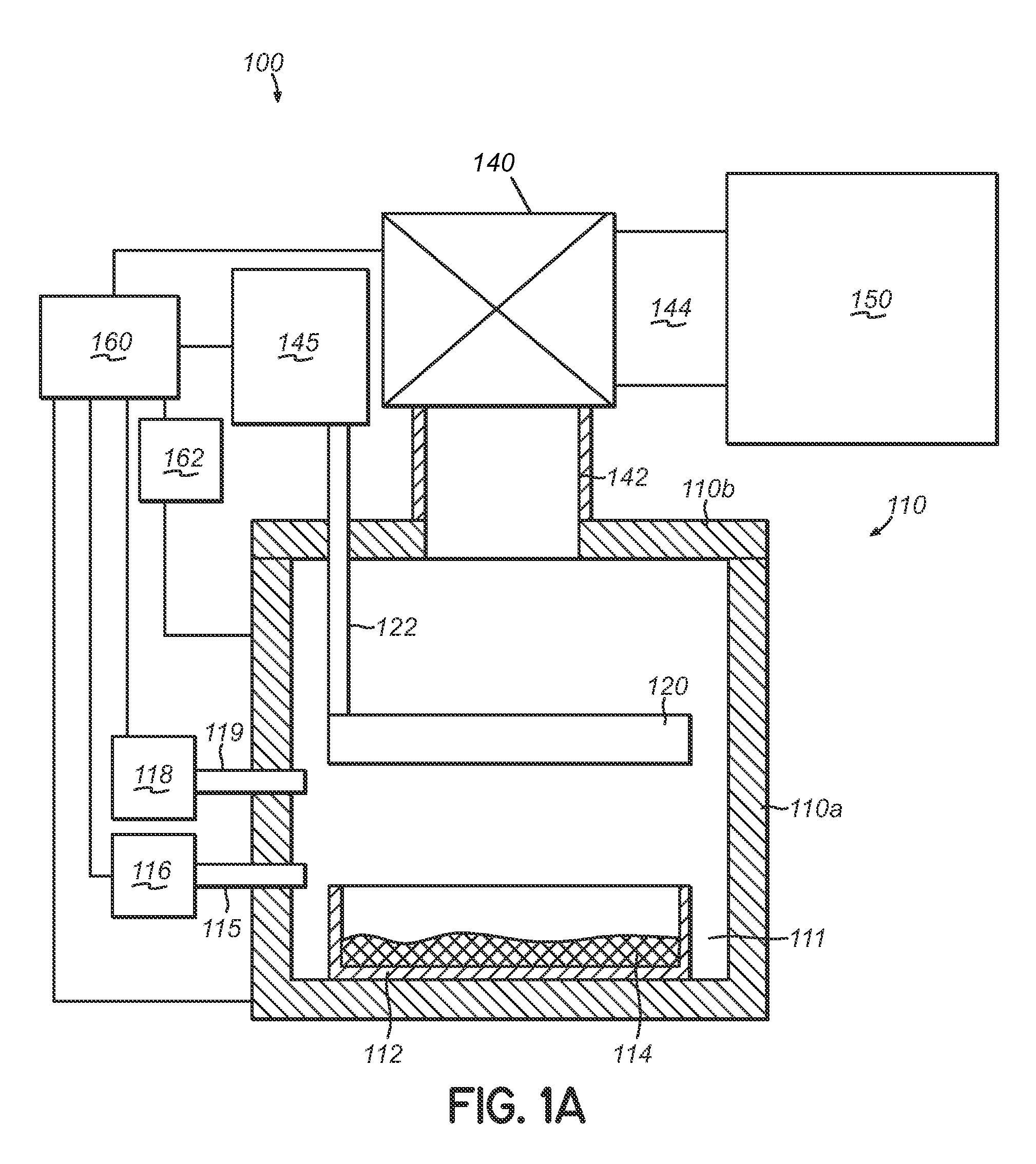

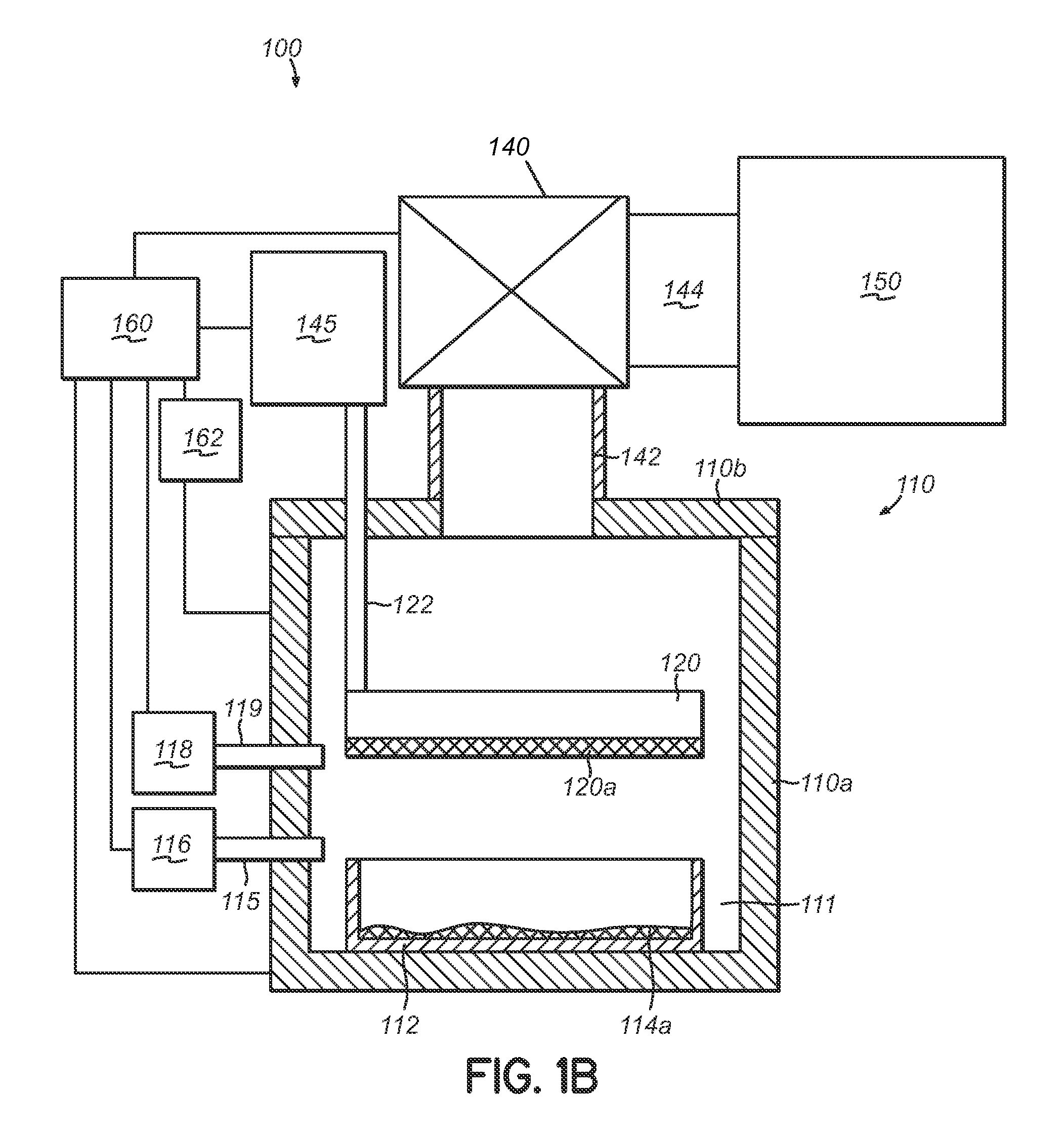

Method and apparatus for reducing carbon monoxide poisoning at the peripheral edge of a substrate in a thin film deposition system

InactiveUS20070234955A1Reduce CO poisoningSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCO poisoningOptoelectronics

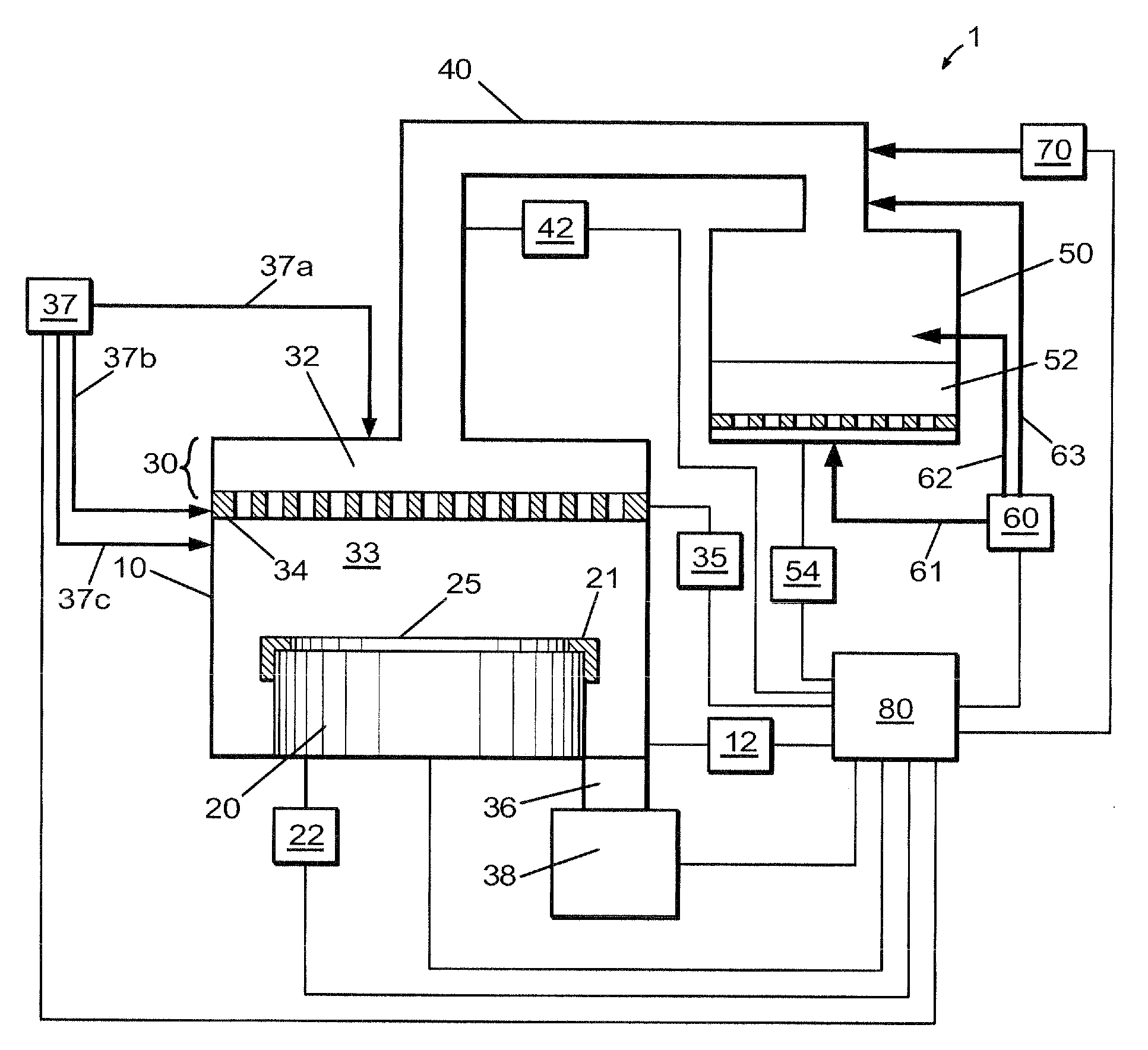

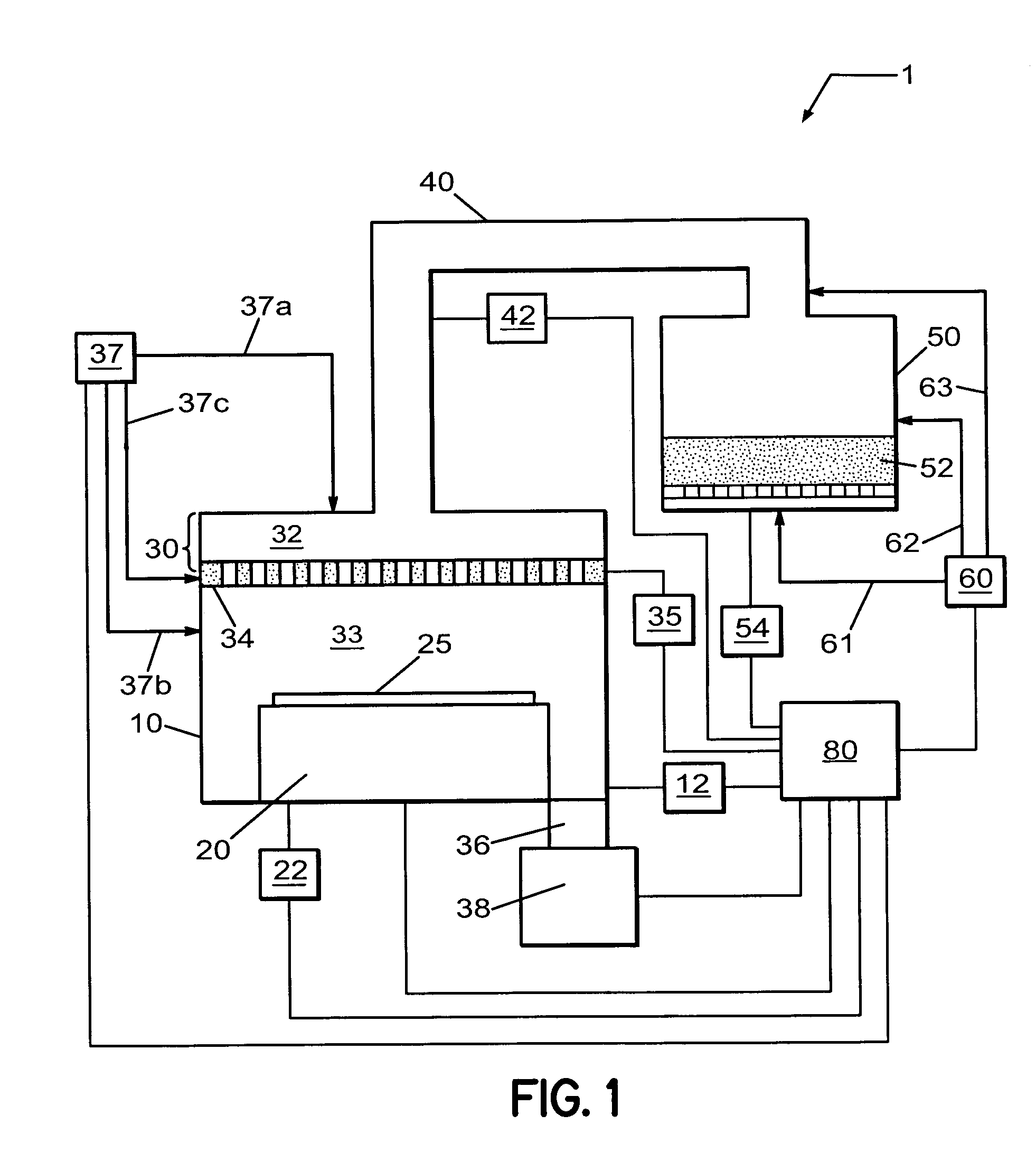

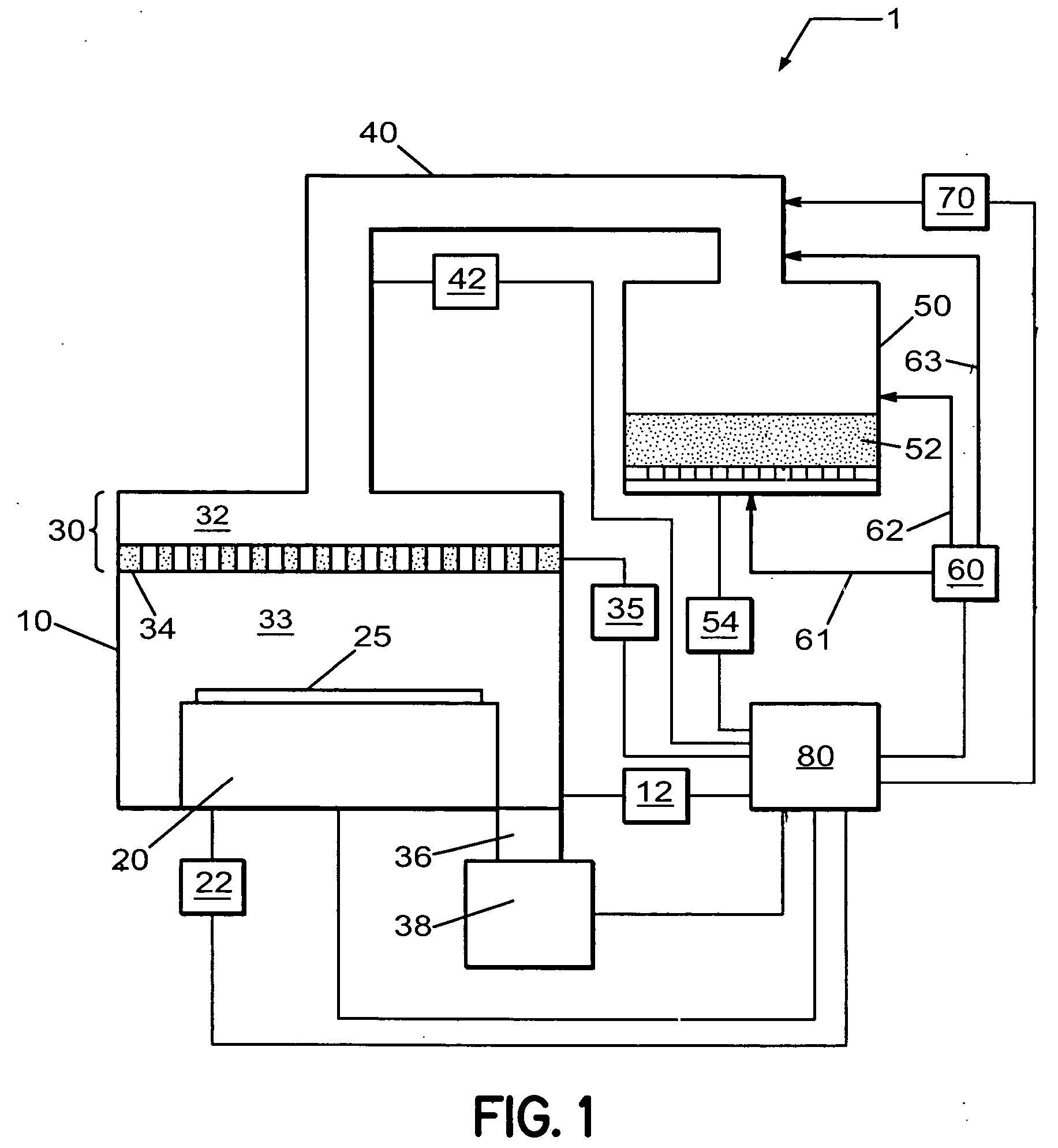

A method and apparatus is described for reducing CO poisoning of a thin metal film formed on a substrate using a metal carbonyl precursor. The thin metal film is formed on the substrate resting on a substrate holder in a thin film deposition system. The substrate holder comprises a shield ring positioned on a peripheral edge of the substrate holder and configured to surround the peripheral edge of the substrate, whereby the shield ring reduces the production of CO by-products at the peripheral edge of the substrate.

Owner:TOKYO ELECTRON LTD

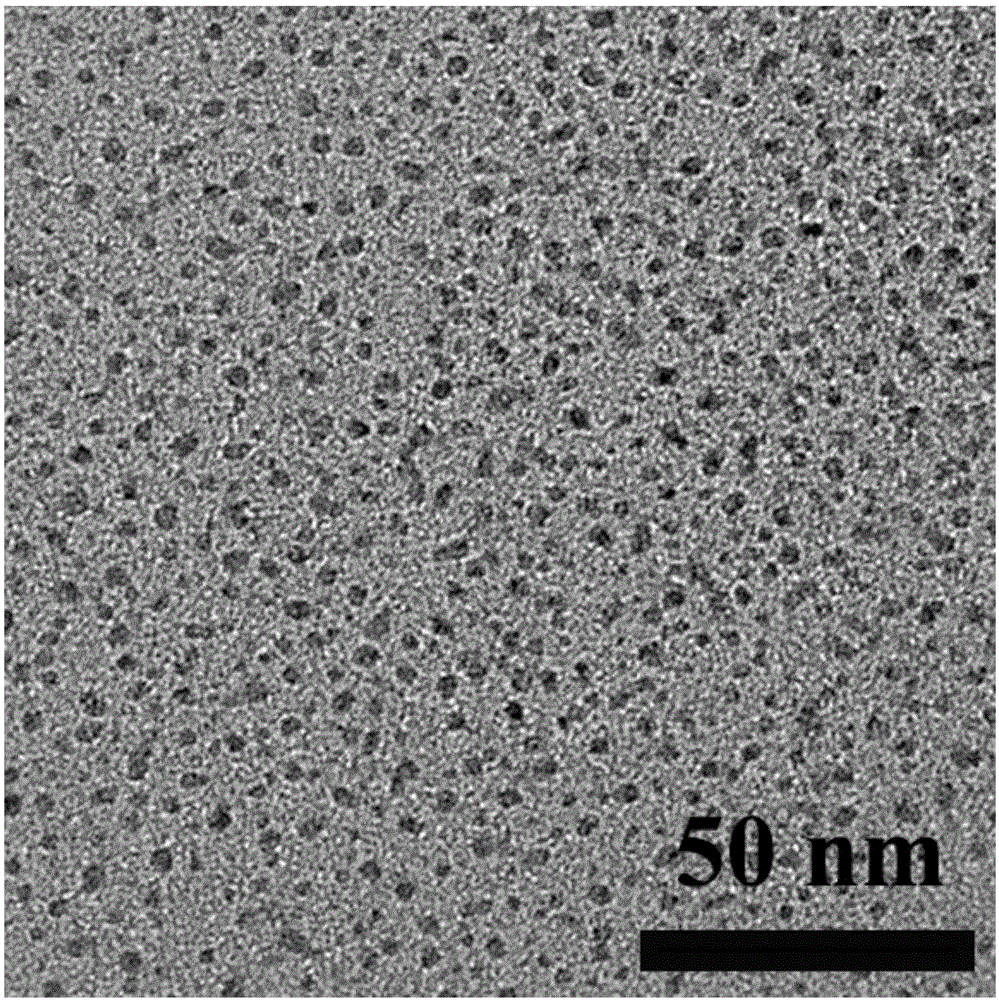

Nanoscale metal particles and method of preparing same

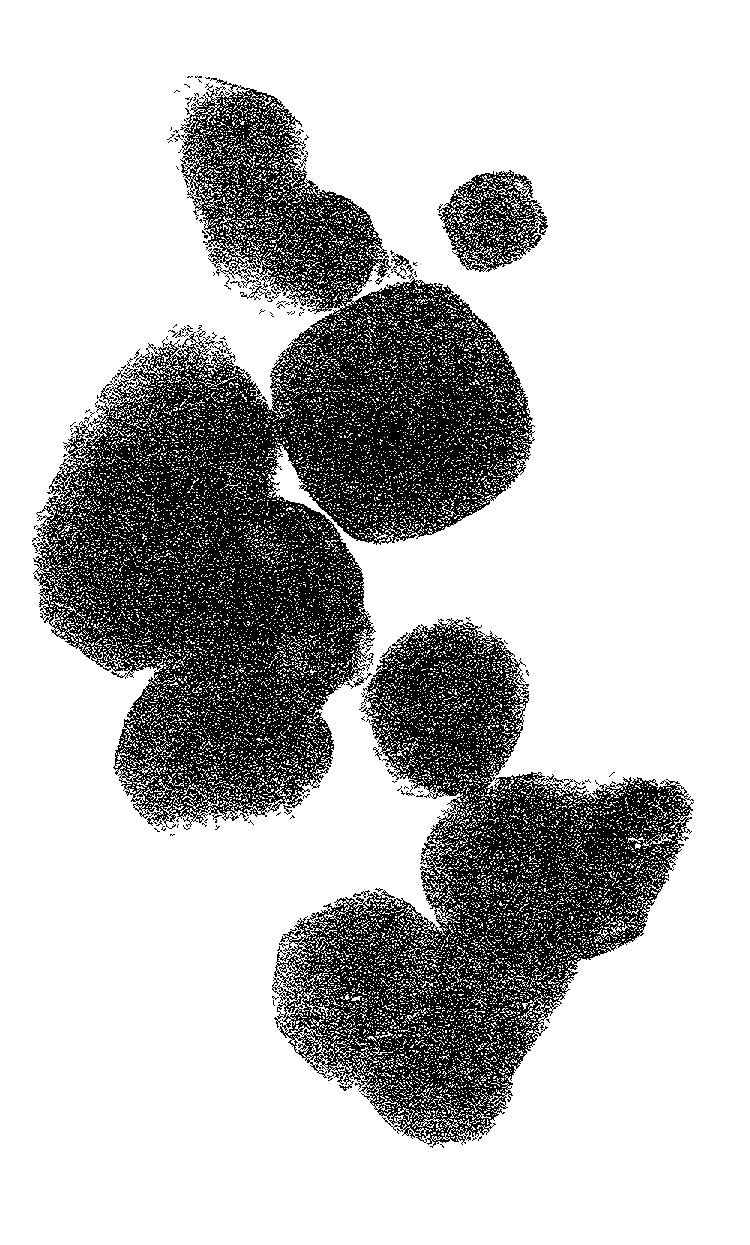

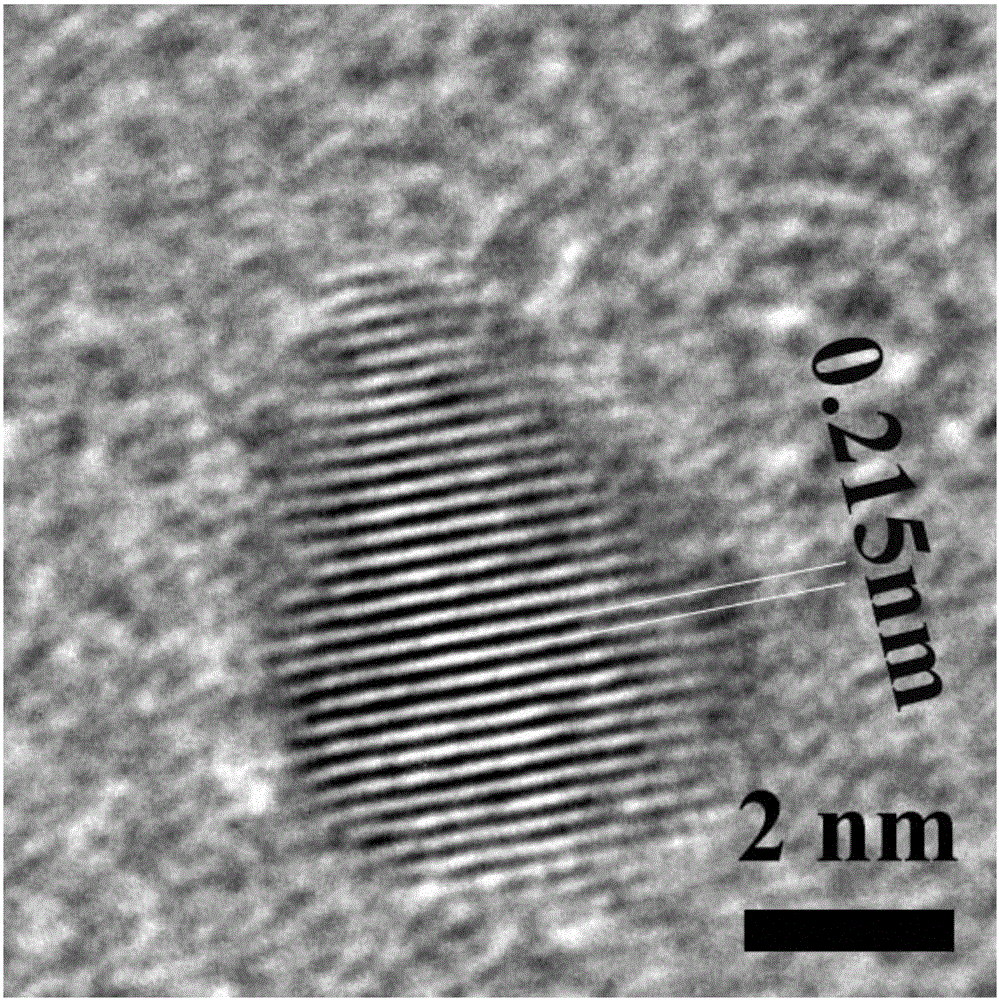

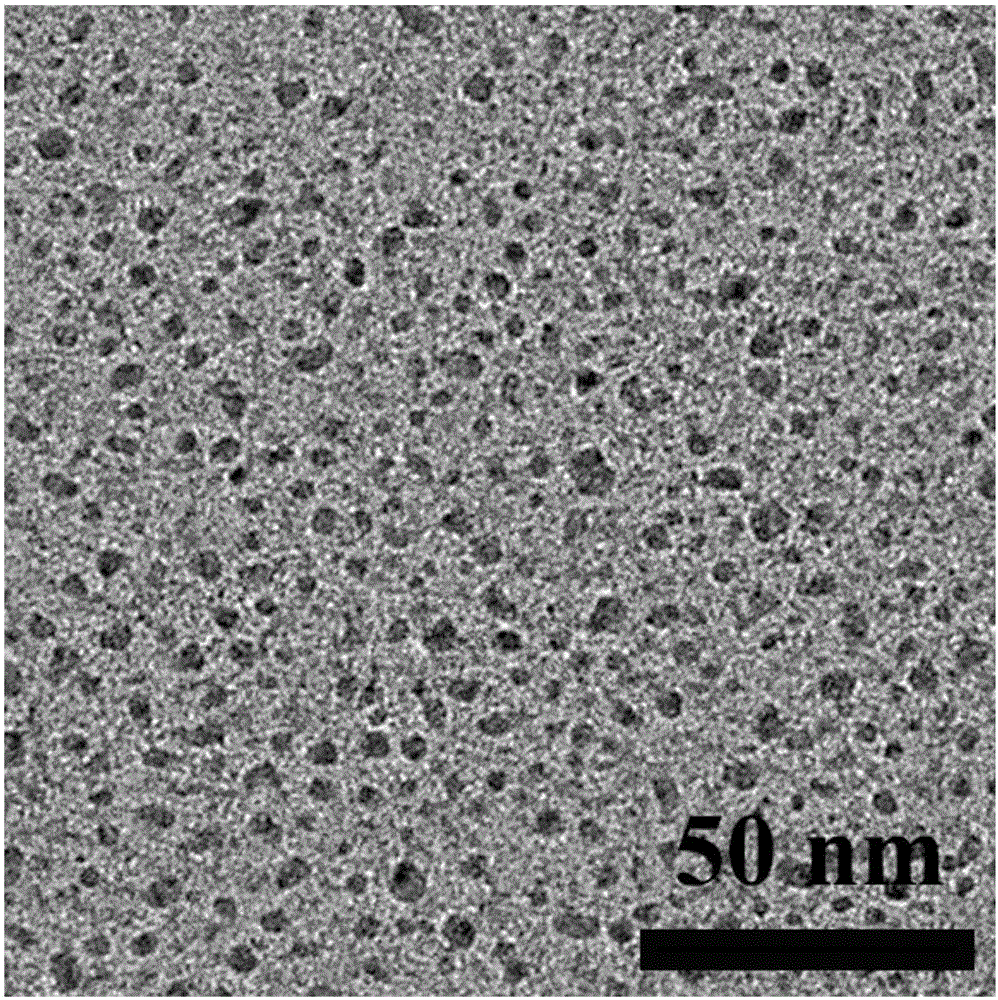

A process of preparing individually-isolated, carbon-coated nanoscale metal particles is disclosed. The process is effected by sonicating a mixture of a metal carbonyl and a hydrocarbon solvent that is selected so as to polymerize during sonication. Air-stable and aqueous solution-stable, carbon-coated nanoscale metal particles and a process of preparing same are also disclosed.

Owner:BAR ILAN UNIV

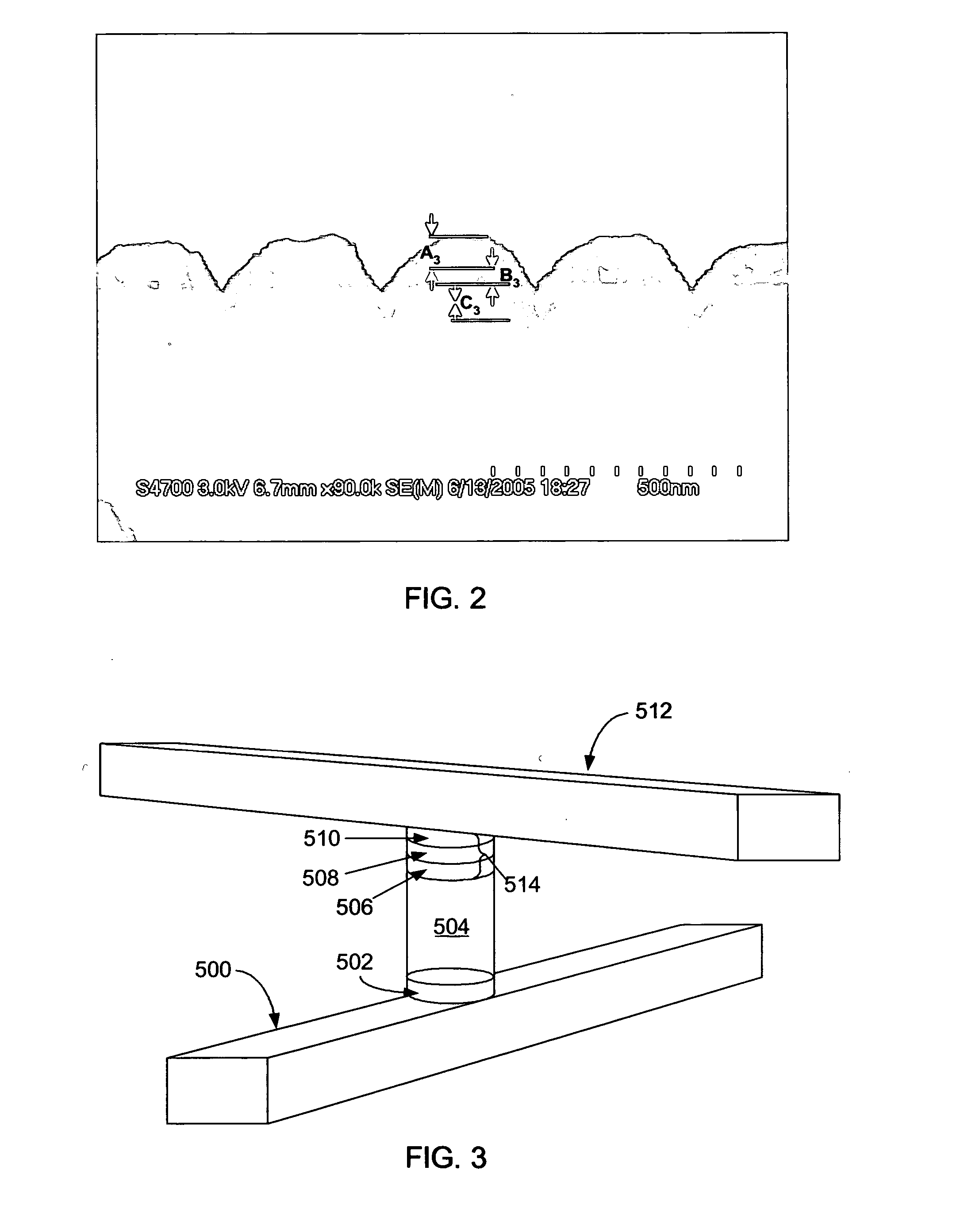

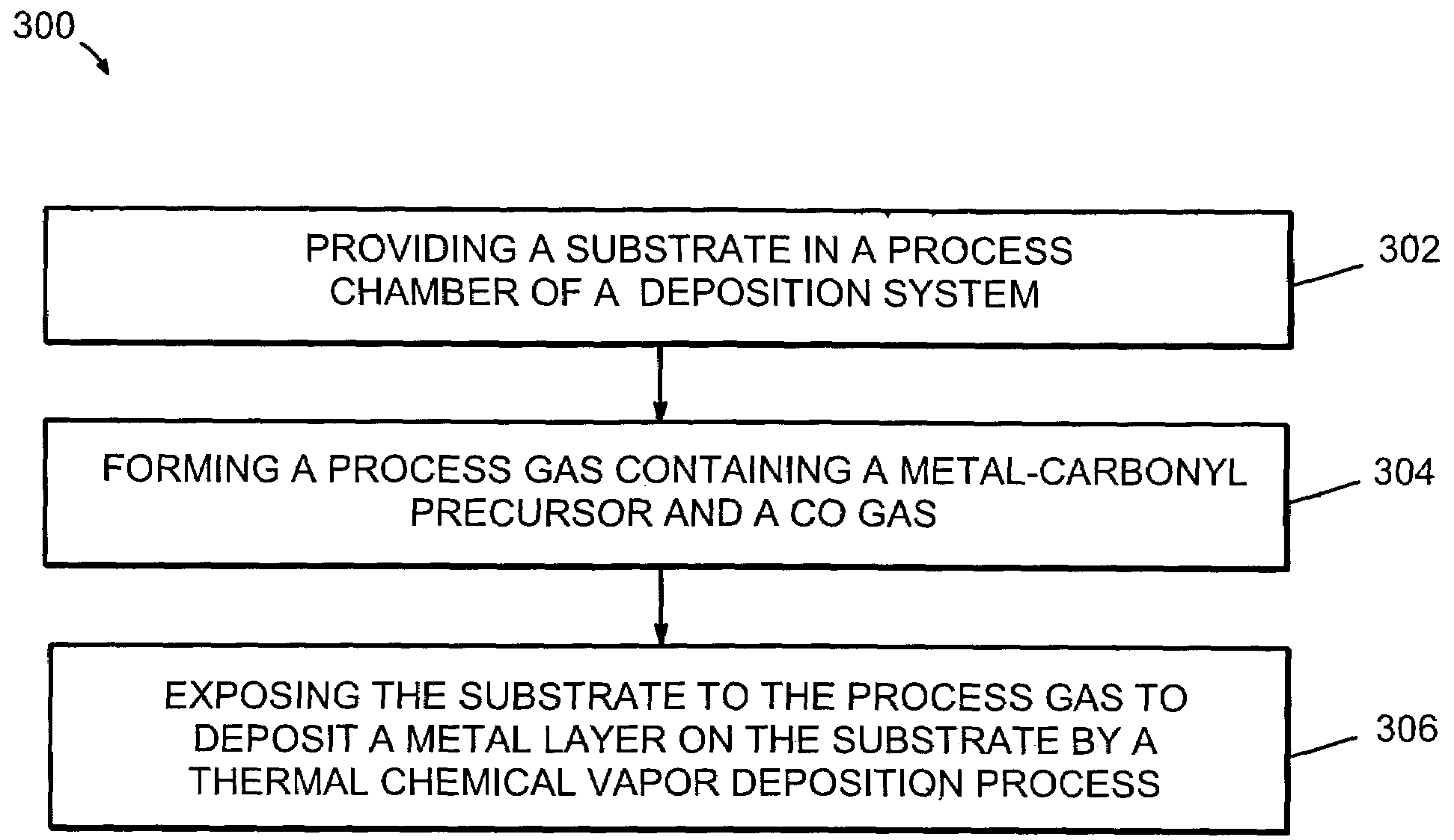

Method for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS20060110530A1Increase deposition rateRaise the evaporation temperatureVacuum evaporation coatingSputtering coatingGas phaseThermal chemical vapor deposition

A method for increasing deposition rates of metal layers from metal-carbonyl precursors by mixing a vapor of the metal-carbonyl precursor with CO gas. The method includes providing a substrate in a process chamber of a deposition system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, and exposing the substrate to the process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:IBM CORP +1

Metal Precursor Solutions For Chemical Vapor Deposition

InactiveUS20080254218A1Reduce deliverySemiconductor/solid-state device manufacturingAnti-corrosive paintsArylGas phase

Metal source containing precursor liquid solutions for chemical vapor deposition processes, including atomic layer deposition, for fabricating conformal metal-containing films on substrates are described. More specifically, the metal source precursor liquid solutions are comprised of (i) at least one metal complex selected from β-diketonates, β-ketoiminates, β-diiminates, alkyl metal, metal carbonyl, alkyl metal carbonyl, aryl metal, aryl metal carbonyl, cyclopentadienyl metal, cyclopentadienyl metal isonitrile, cyclopentadienyl metal nitrile, cyclopentadienyl metal carbonyl, metal alkoxide, metal ether alkoxide, and metal amides wherein the ligand can be monodentate, bidentate and multidentate coordinating to the metal atom and the metal is selected from group 2 to 14 elements, and (ii) a solvent selected from organic amides including linear amides and cyclic amides for such metal source containing precursors.

Owner:VERSUM MATERIALS US LLC

Method of plasma etching transition metals and their compounds

InactiveUS20070010100A1Efficient removalSolid-state devicesSemiconductor/solid-state device manufacturingCompound aMetal carbonyl

A method of plasma etching comprises using a primary etchant of carbon monoxide gas to etch a transition metal or transition metal compound and to form a volatile by-product of metal carbonyl.

Owner:SANDISK TECH LLC

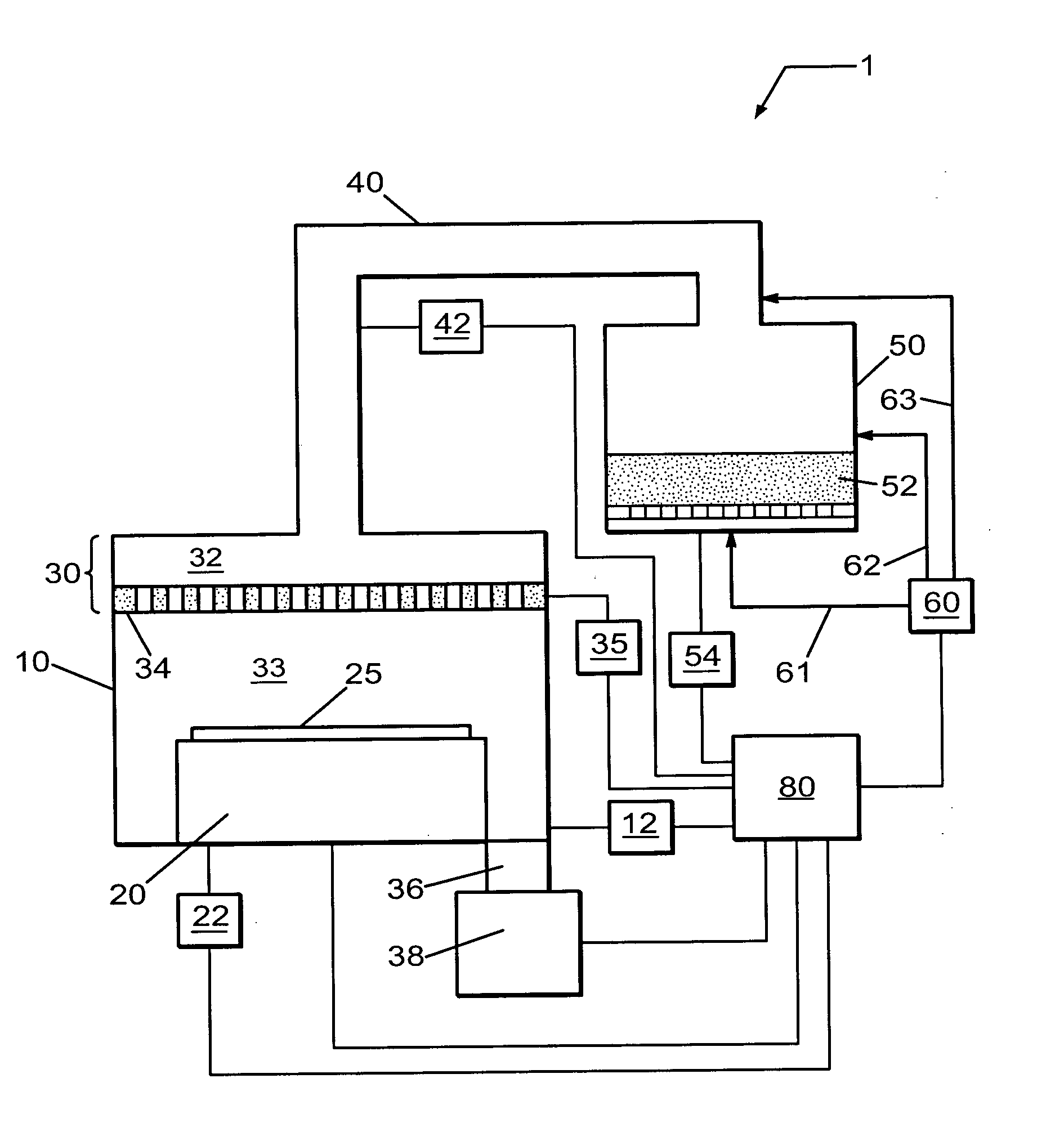

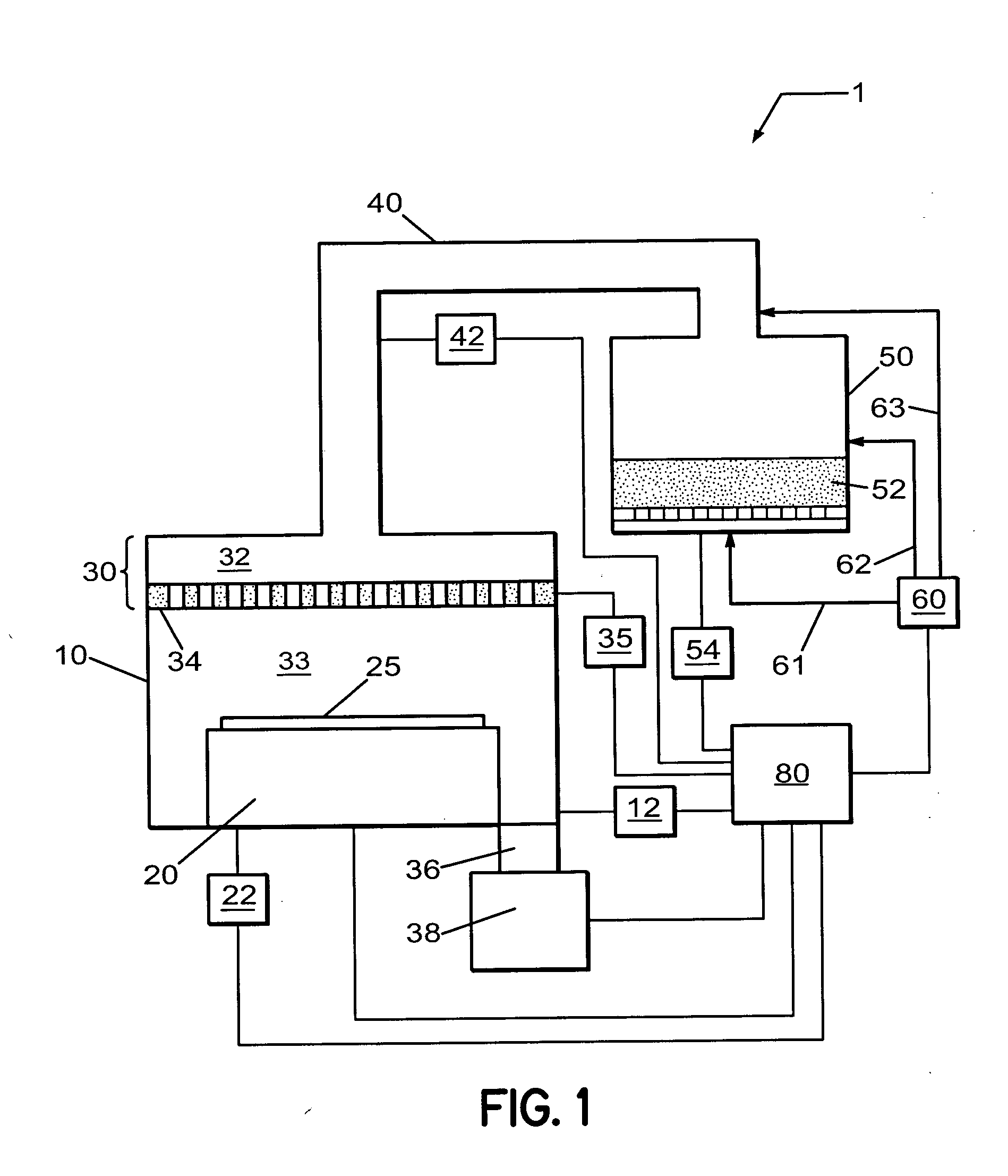

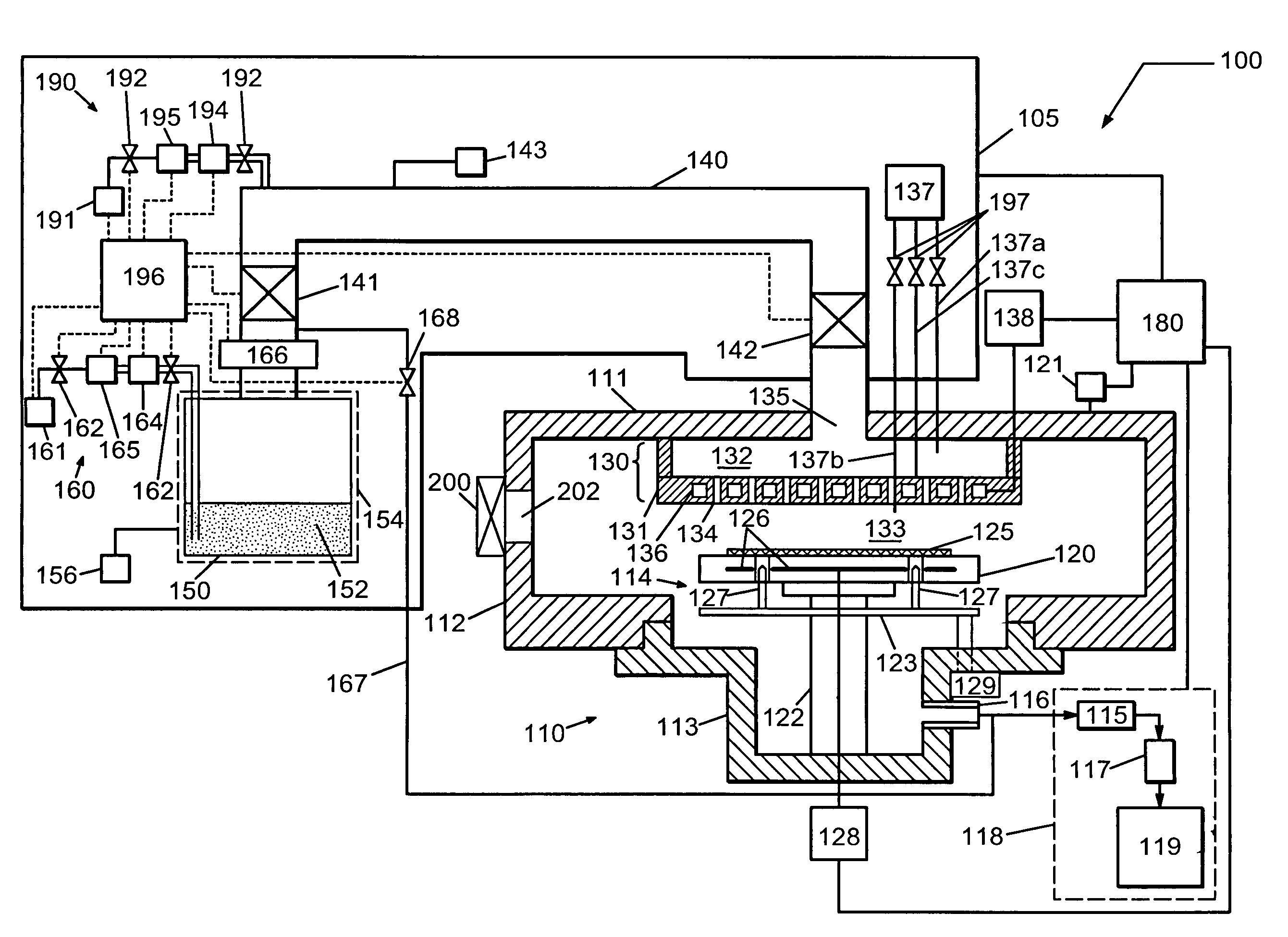

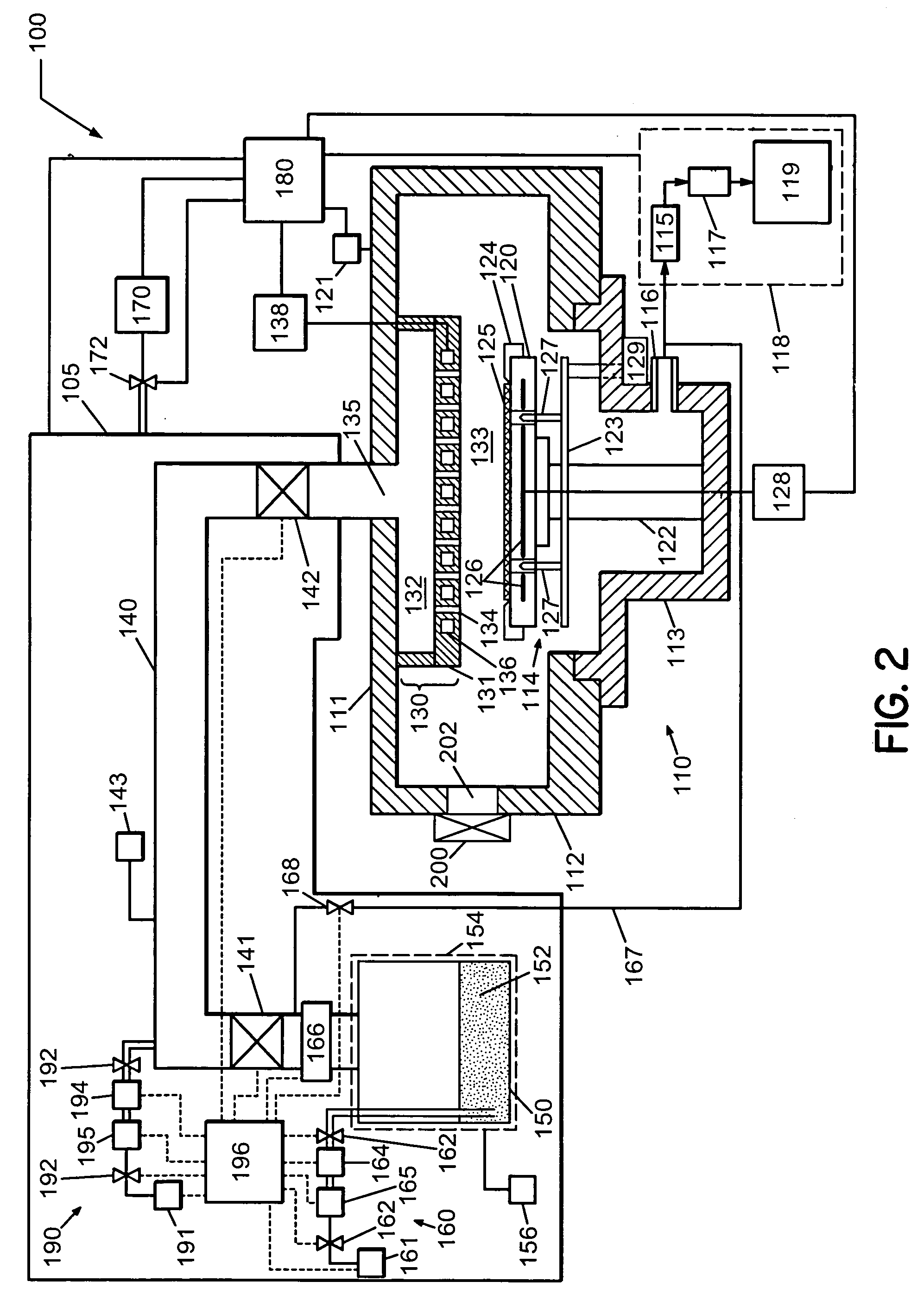

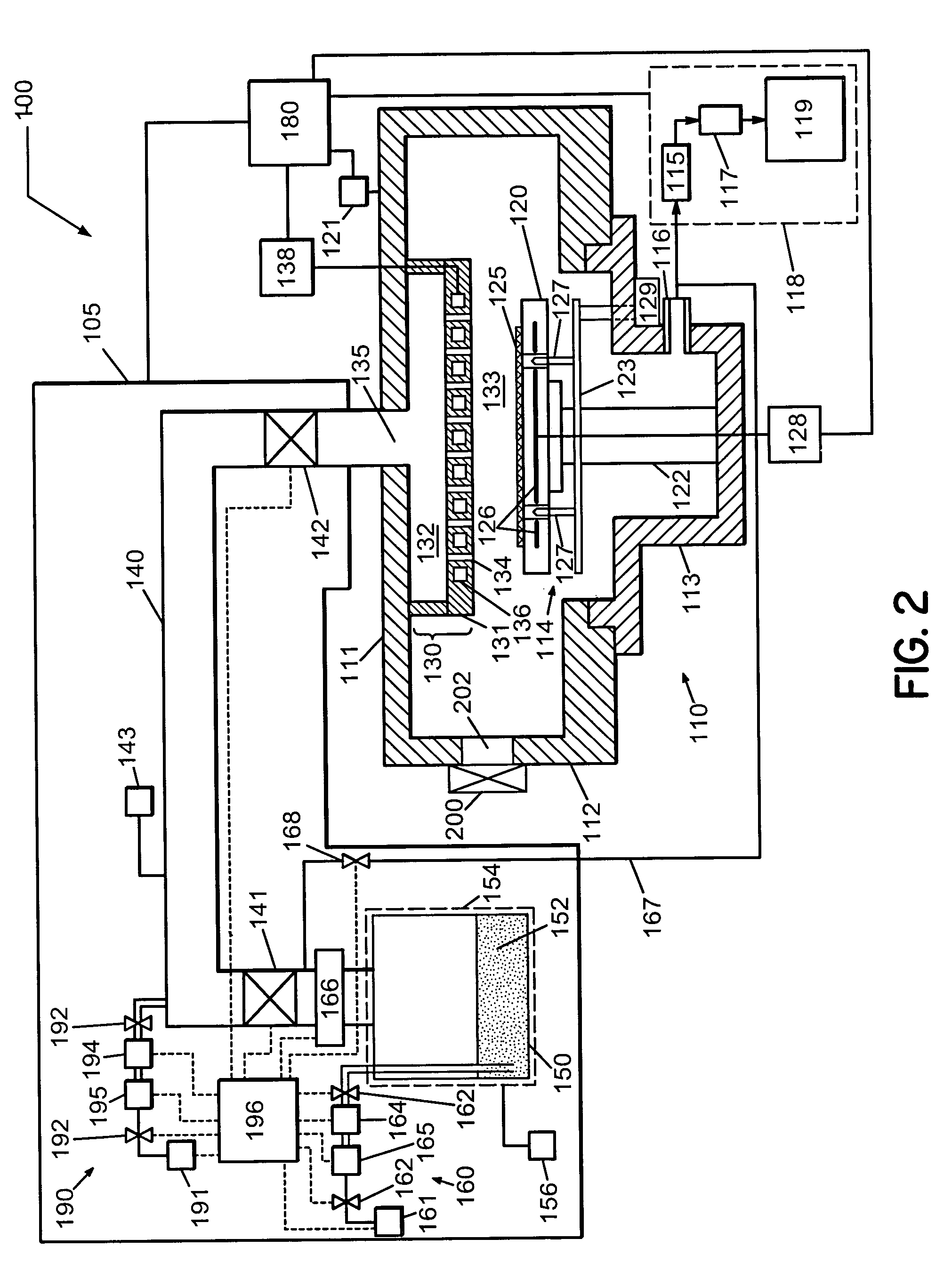

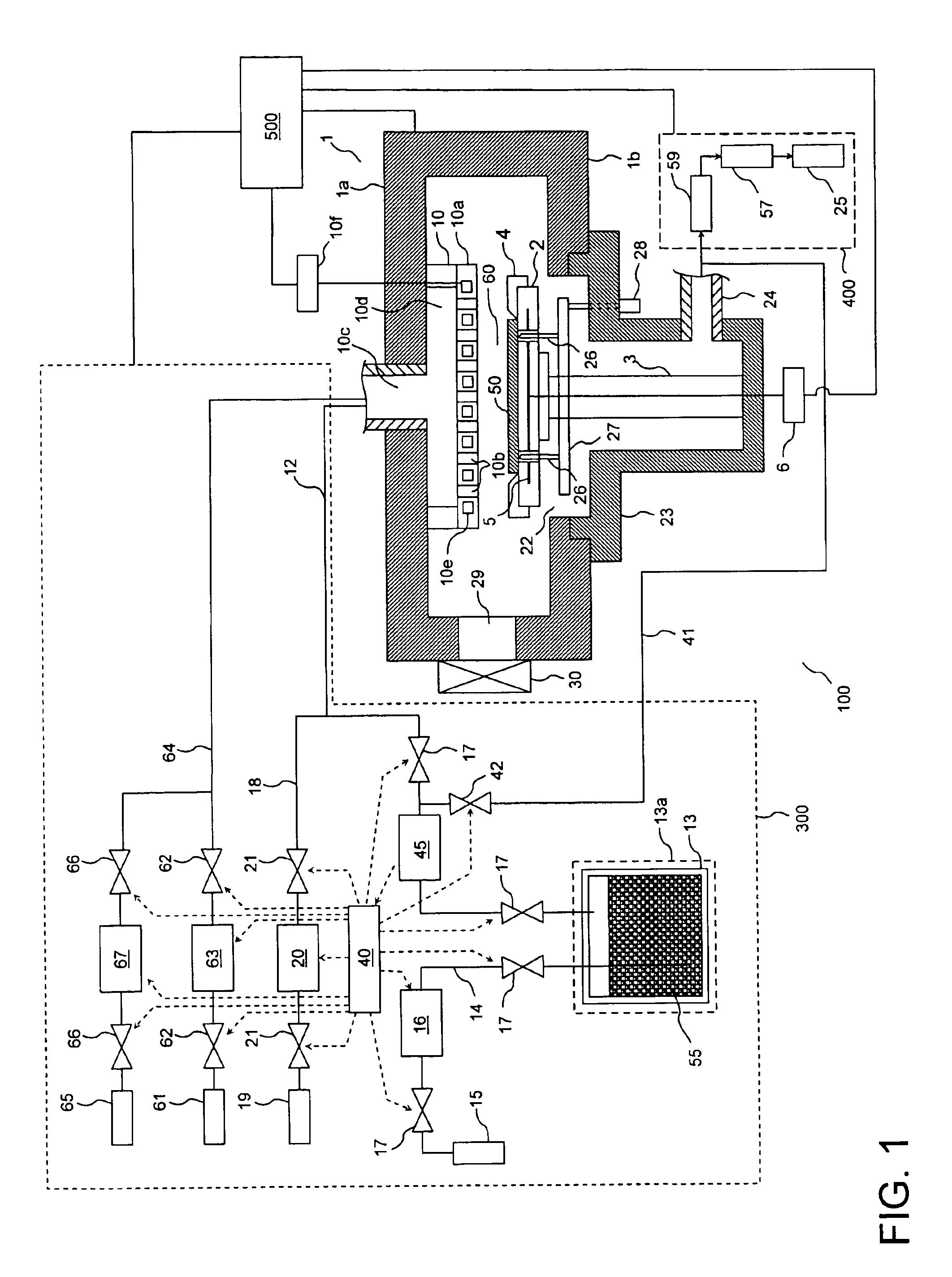

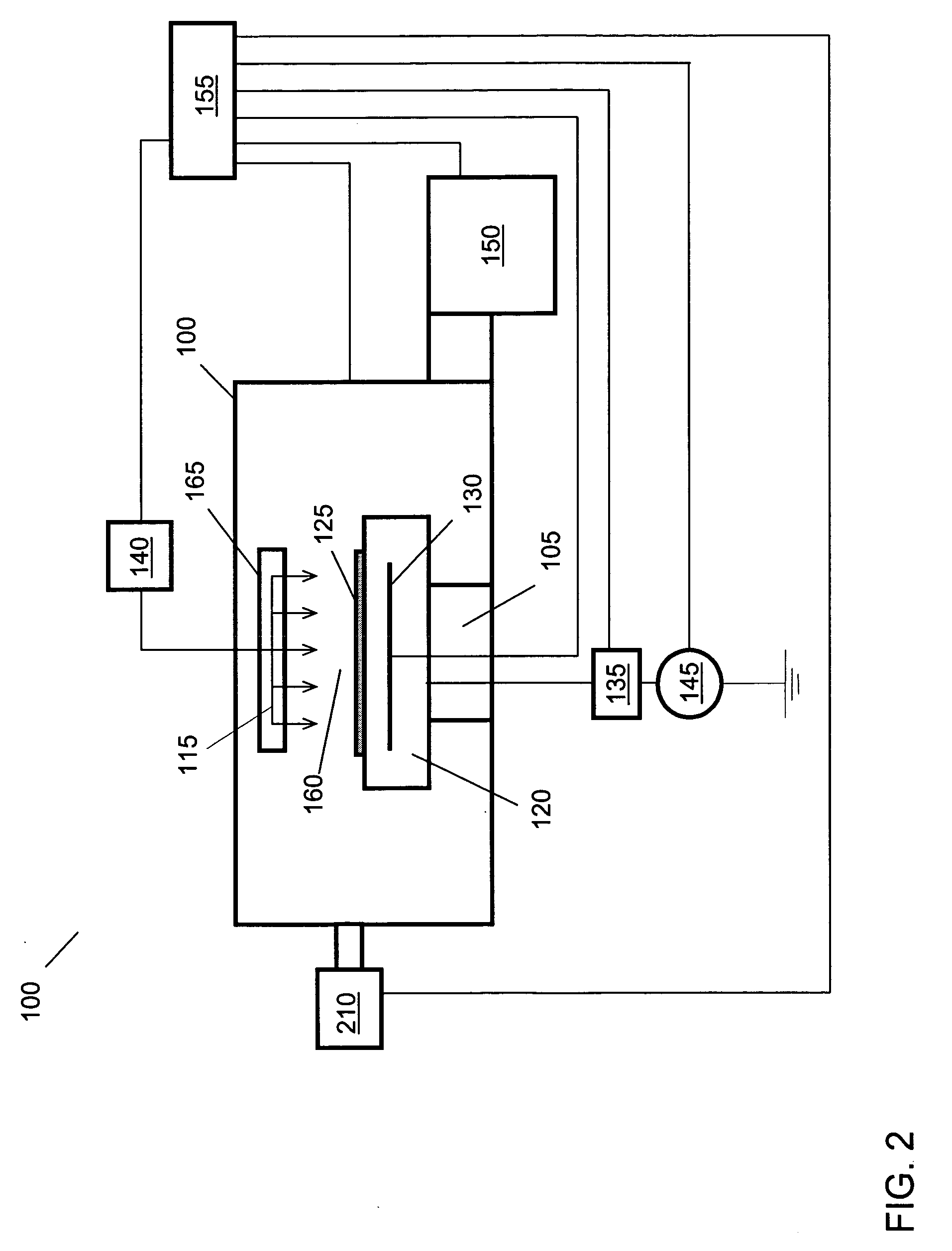

Method and deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS7279421B2Increase deposition rateRaise the evaporation temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal chemical vapor depositionGas phase

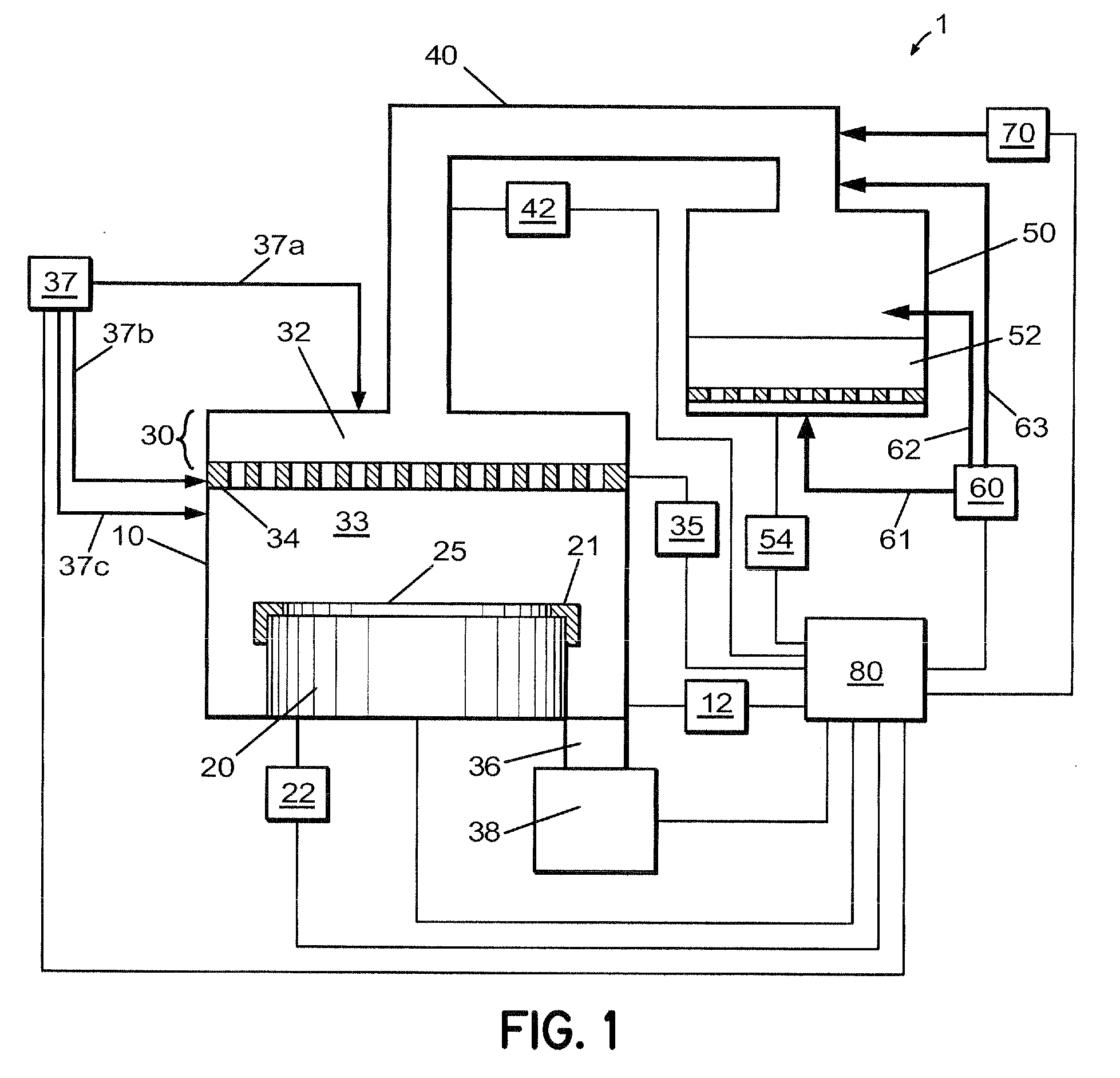

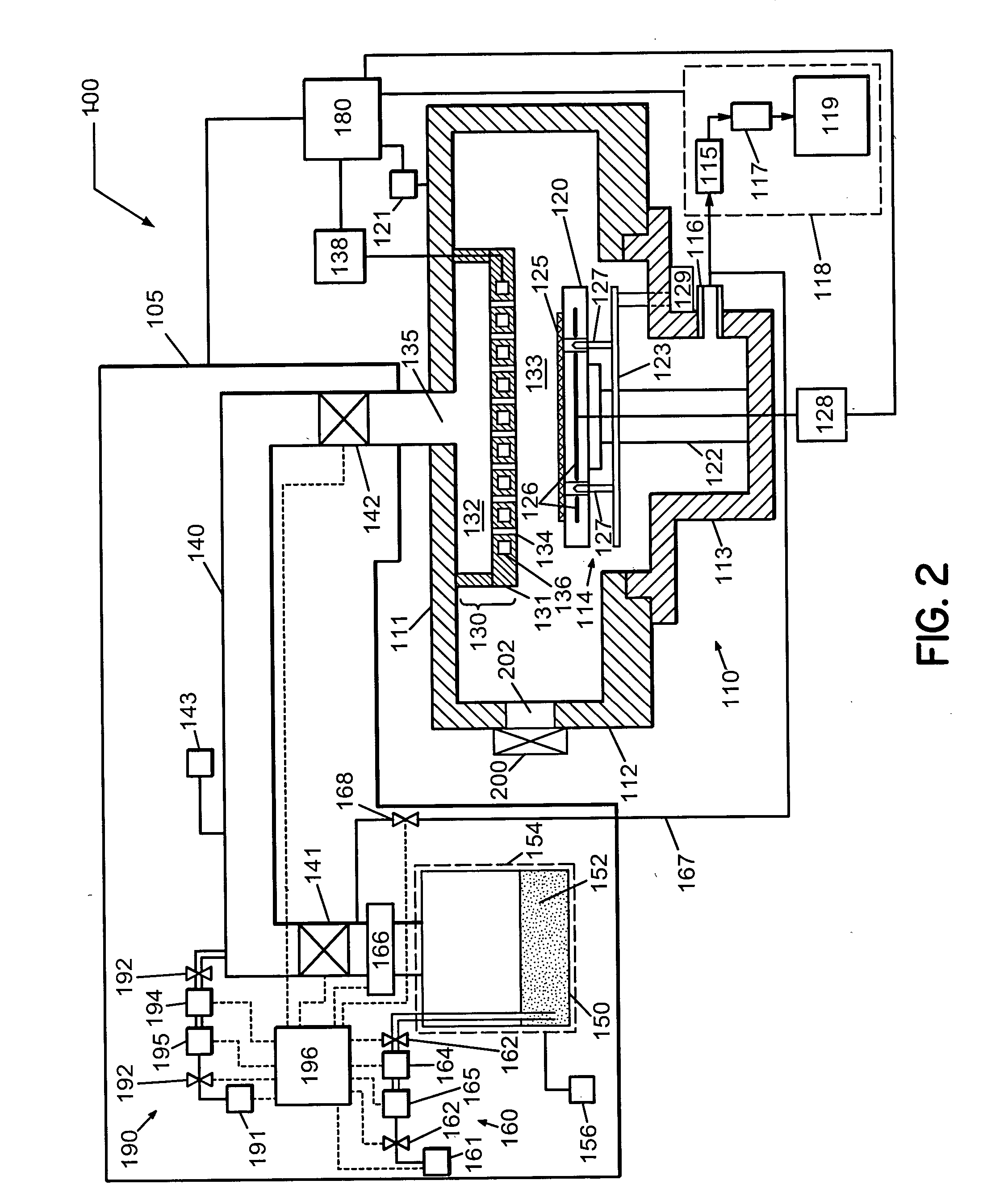

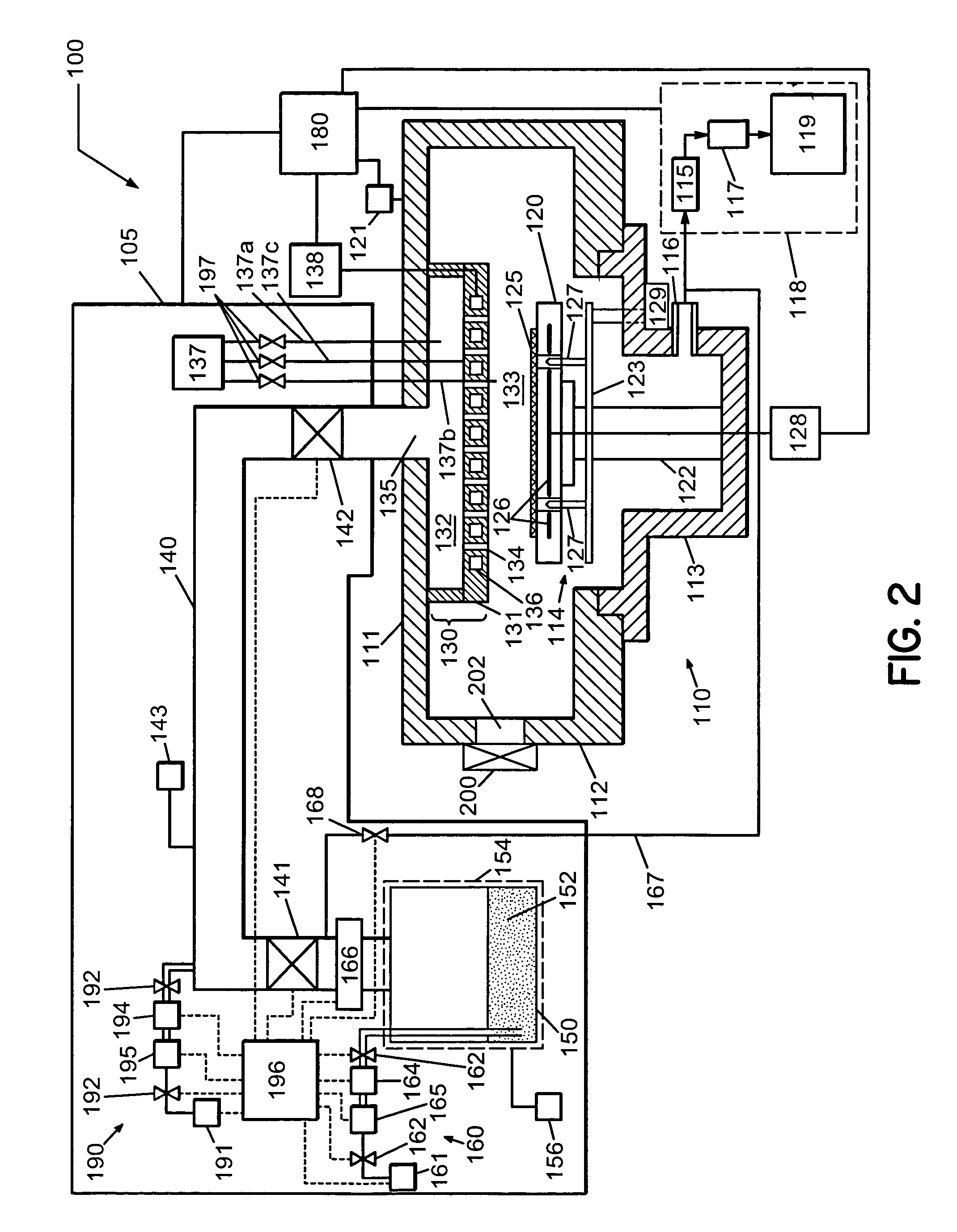

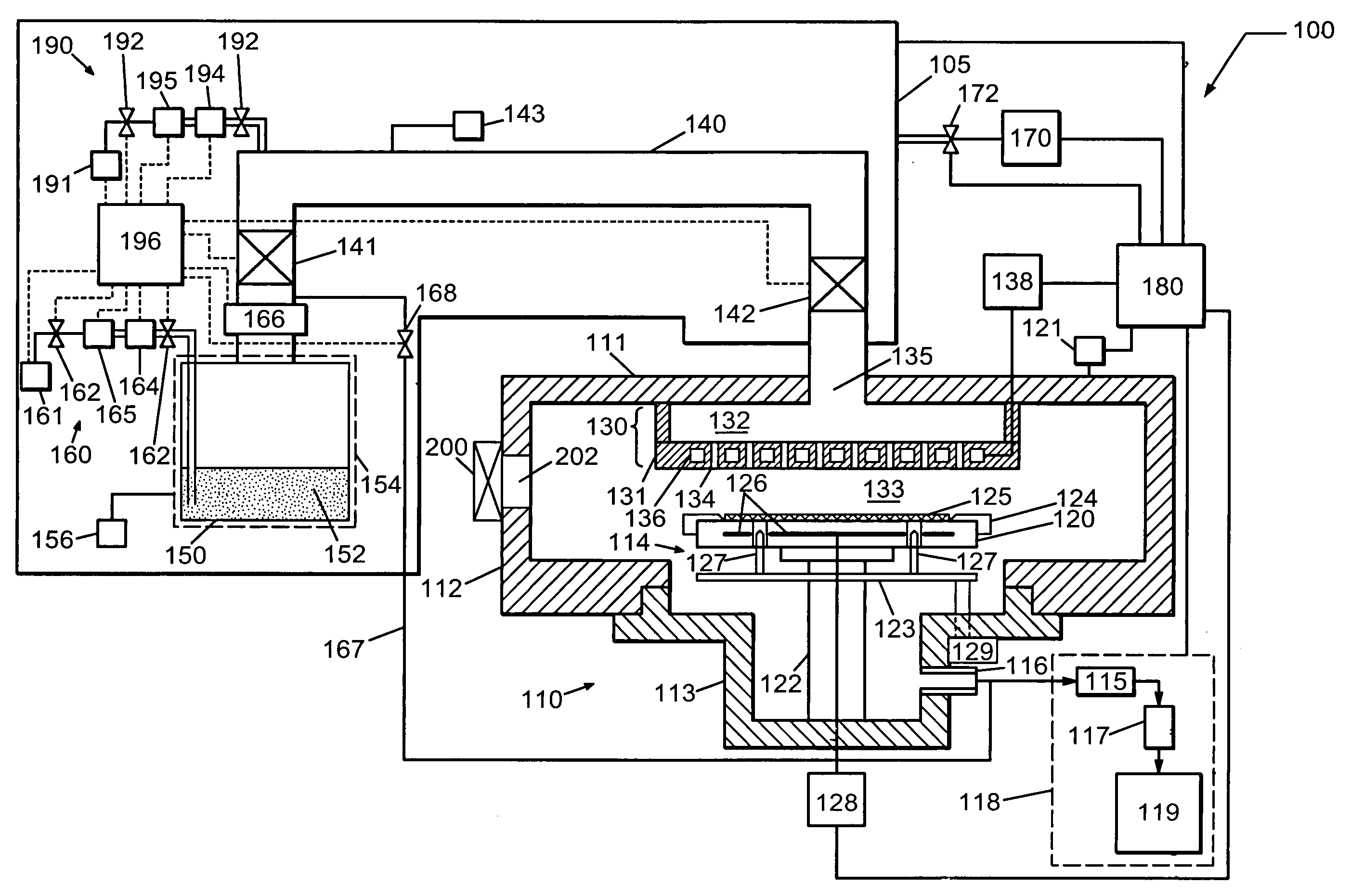

A method and a deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors using CO gas and a dilution gas. The method includes providing a substrate in a process chamber of a processing system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, diluting the process gas in the process chamber, and exposing the substrate to the diluted process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process. The deposition system contains a substrate holder configured for supporting and heating a substrate in a process chamber having a vapor distribution system, a precursor delivery system configured for forming a process gas containing a metal-carbonyl precursor vapor and a CO gas and for introducing the process gas to the vapor distribution system, a dilution gas source configured for adding a dilution gas to the process gas in the process chamber, and a controller configured for controlling the deposition system during exposure of the substrate to the diluted process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:TOKYO ELECTRON LTD

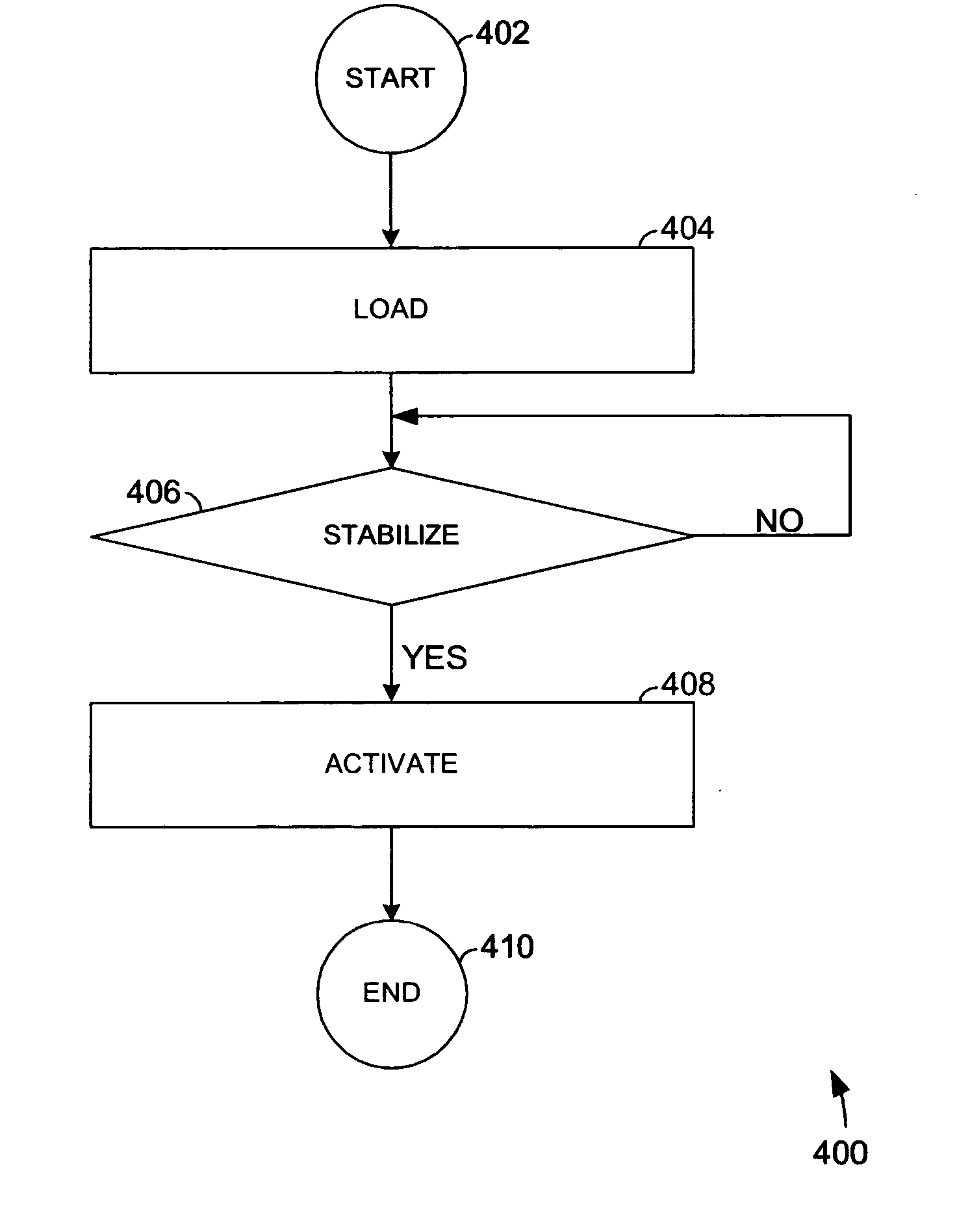

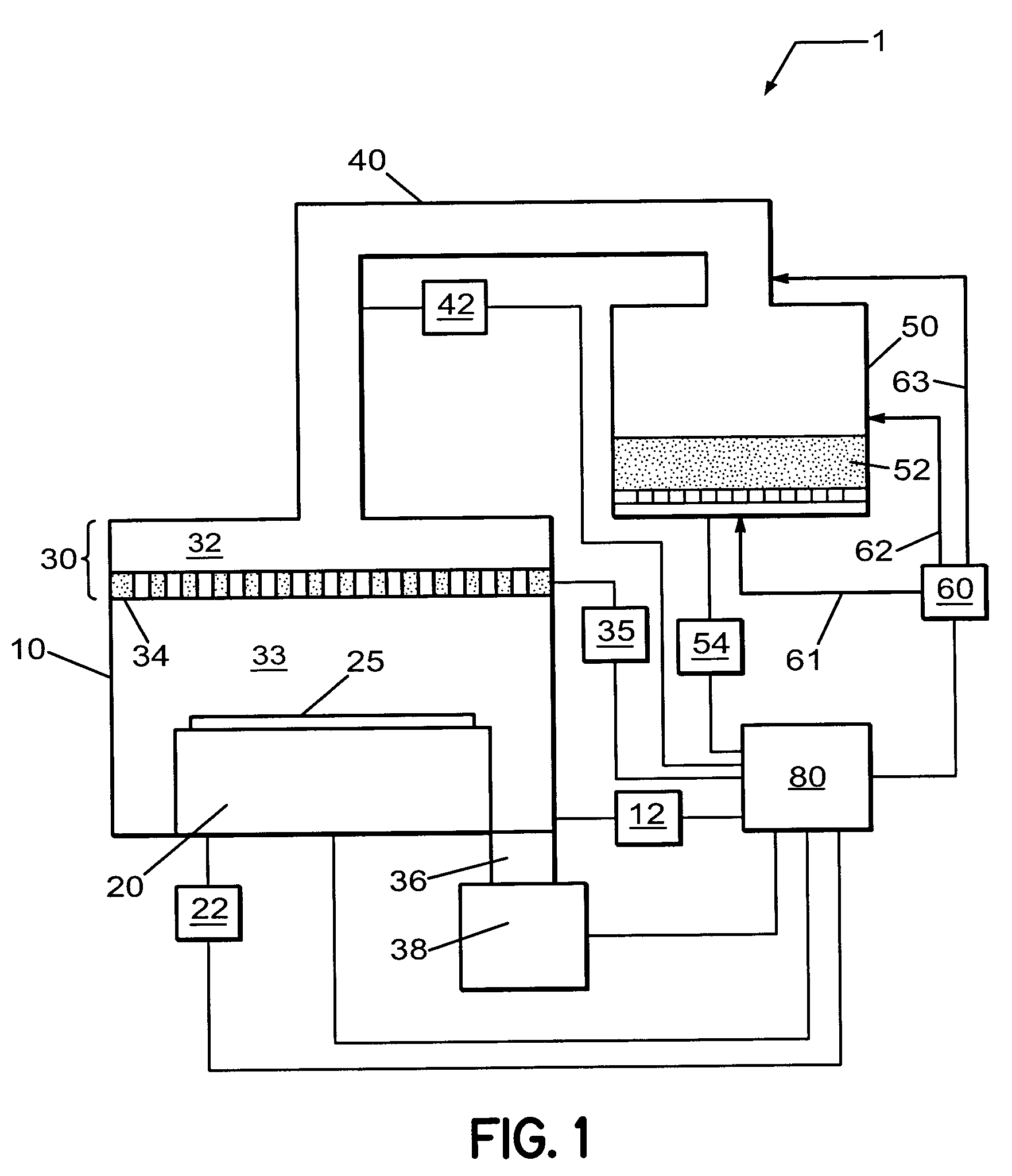

Method and system for performing in-situ cleaning of a deposition system

InactiveUS20060115590A1Increase deposition rateChemical vapor deposition coatingThermal chemical vapor depositionEvaporation

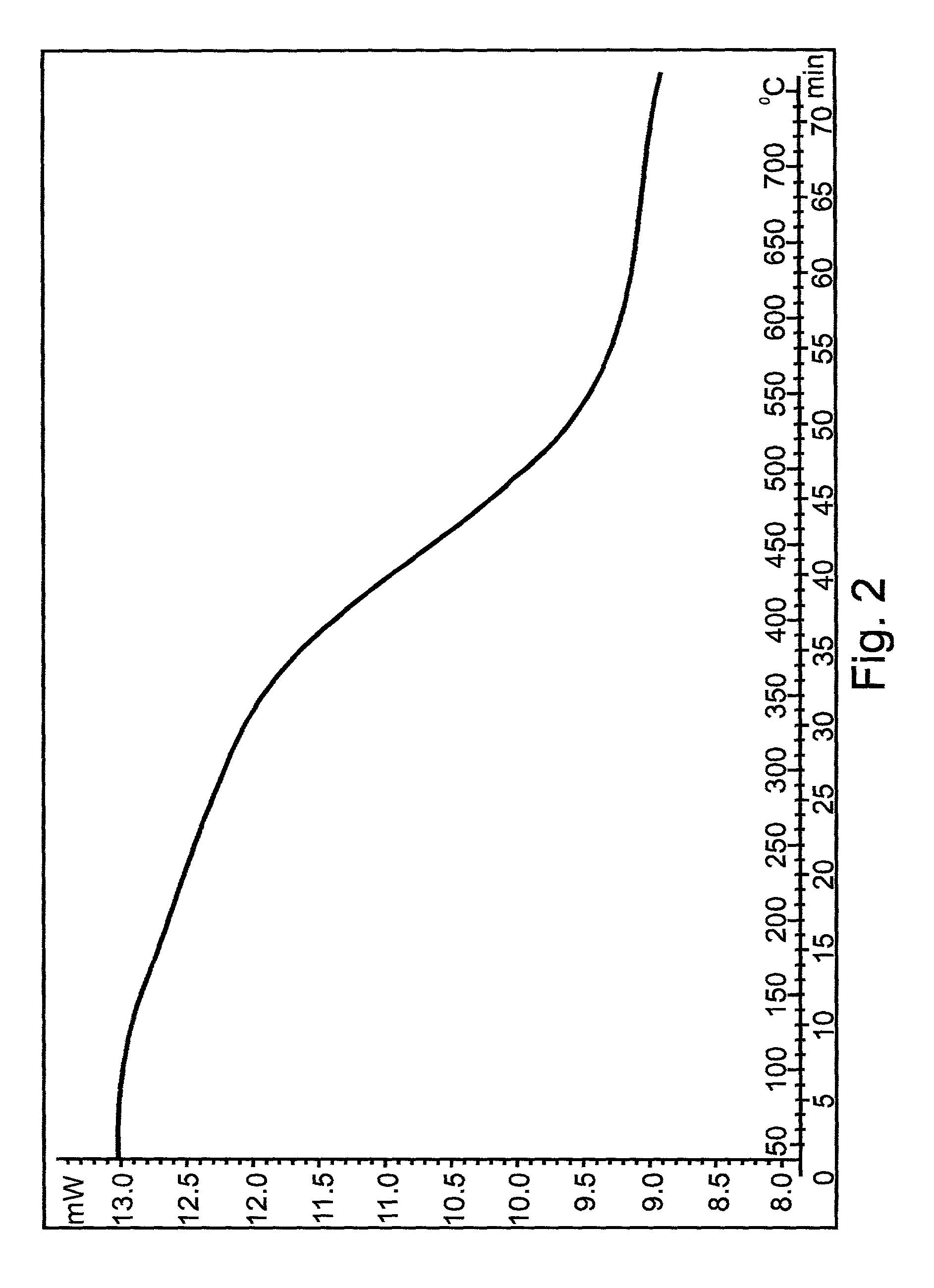

A method for depositing metal layers, such as Ruthenium, on semiconductor substrates by a thermal chemical vapor deposition (TCVD) process includes introducing a metal carbonyl precursor in a deposition system, and depositing a metal layer from the metal carbonyl on a substrate. The TCVD process utilizes a short residence time for the gaseous species in the processing zone above the substrate to form a low-resistivity metal layer. In the deposition system, the metal carbonyl is evaporated in a solid precursor evaporation system, and the precursor vapor is transported to the process chamber via a vapor delivery system. Further, an in-situ cleaning system is coupled to the vapor delivery system in order to perform periodic cleaning of the deposition system. Periodic in-situ cleaning permits achieving a greater deposition rate by operating the deposition system at higher temperature where precursor vapor can decompose and potentially deposit on surfaces of the deposition system.

Owner:GLOBALFOUNDRIES INC +1

Method for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS7270848B2Increase deposition rateRaise the evaporation temperatureVacuum evaporation coatingSemiconductor/solid-state device manufacturingThermal chemical vapor depositionMetal carbonyl

A method for increasing deposition rates of metal layers from metal-carbonyl precursors by mixing a vapor of the metal-carbonyl precursor with CO gas. The method includes providing a substrate in a process chamber of a deposition system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, and exposing the substrate to the process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:IBM CORP +1

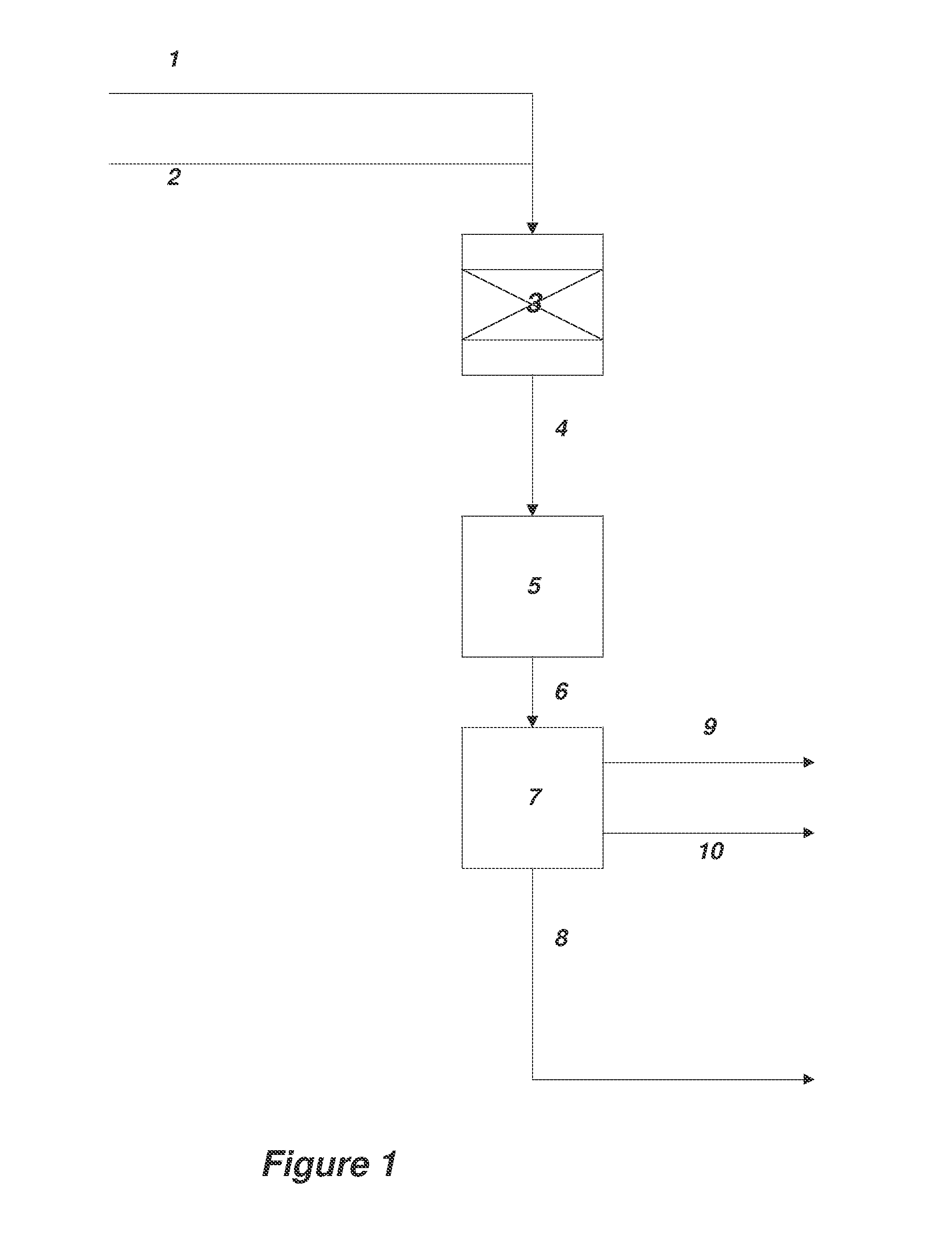

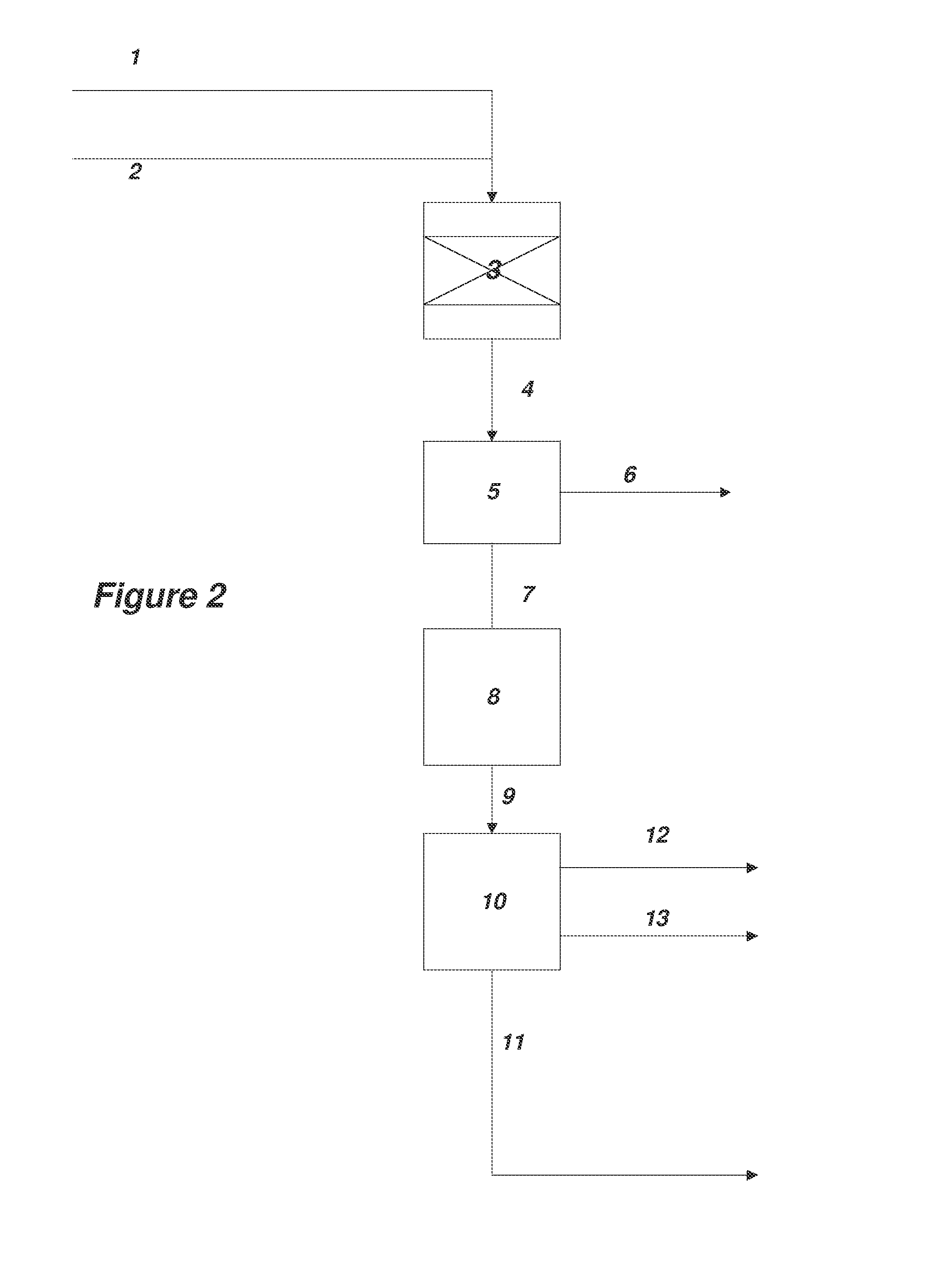

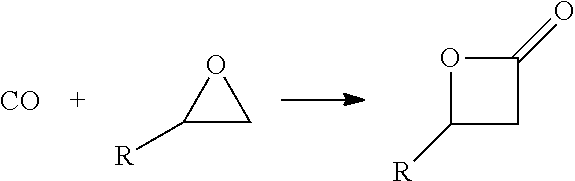

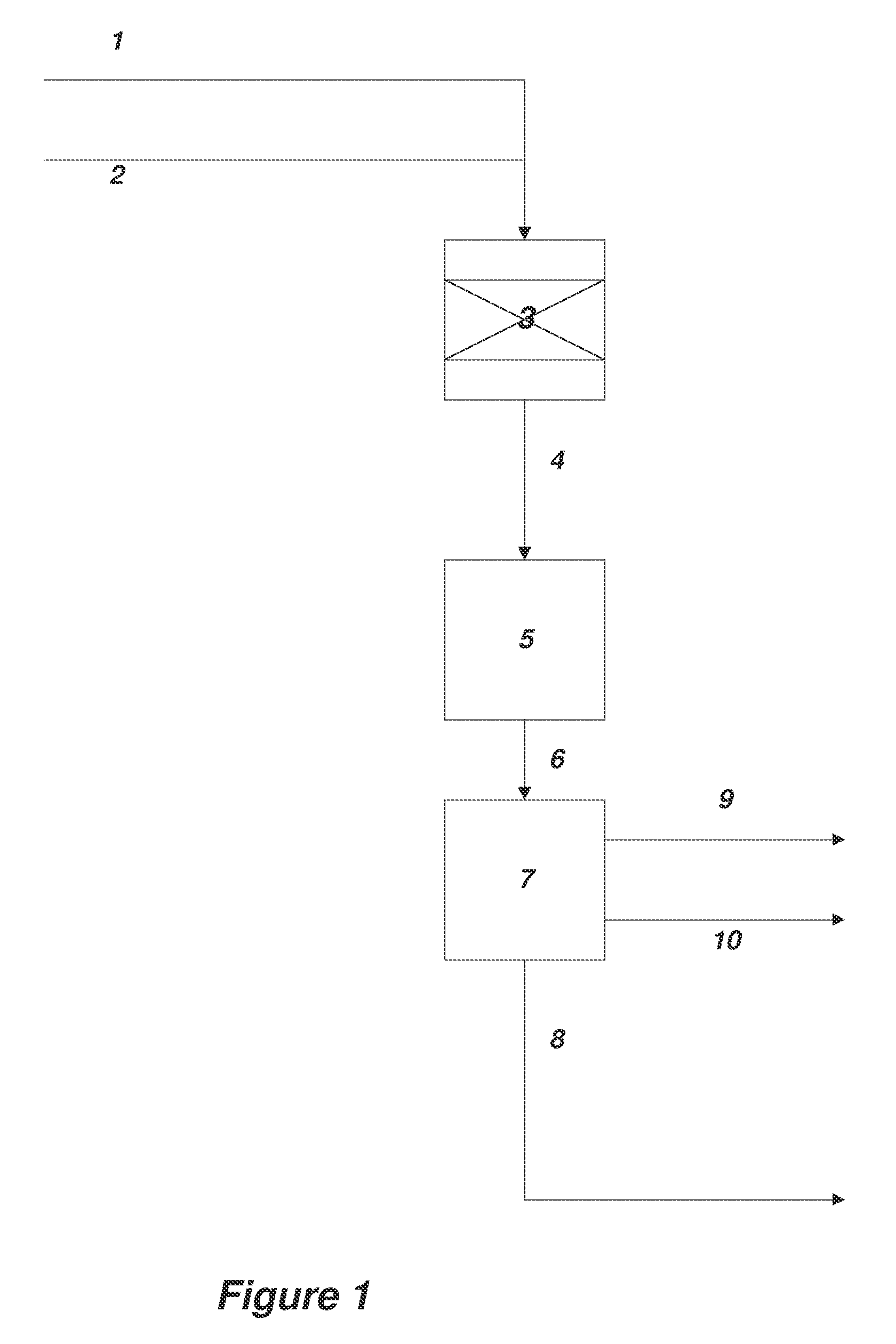

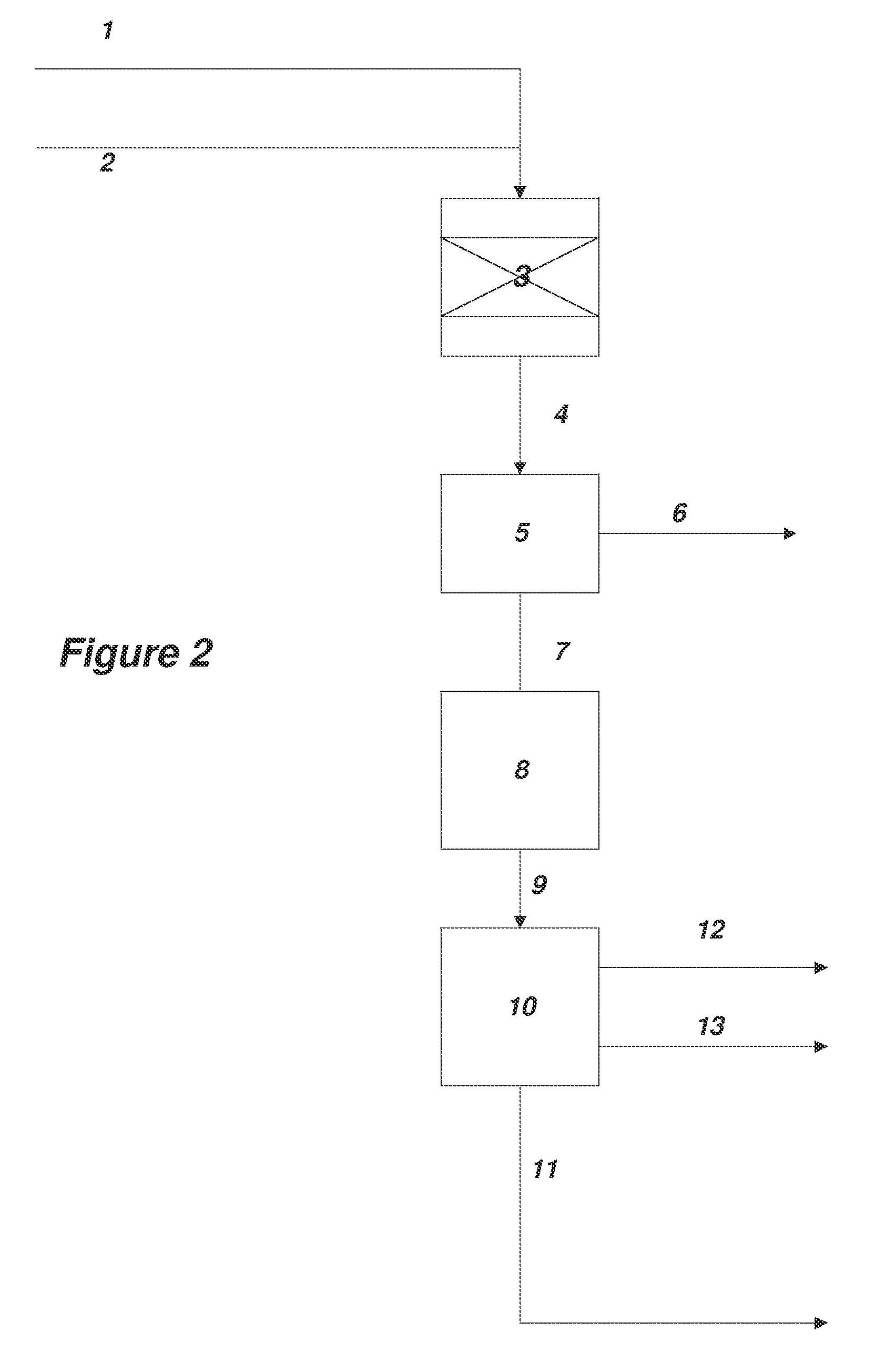

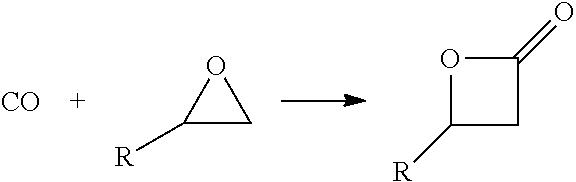

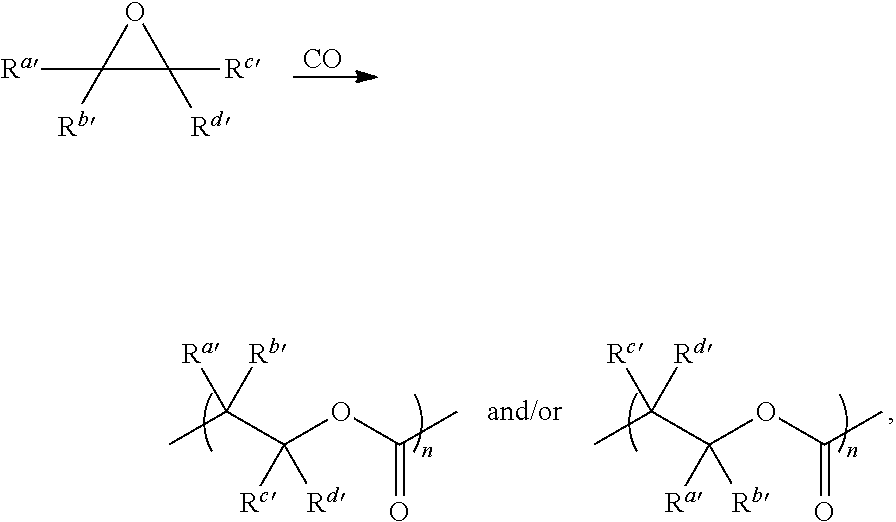

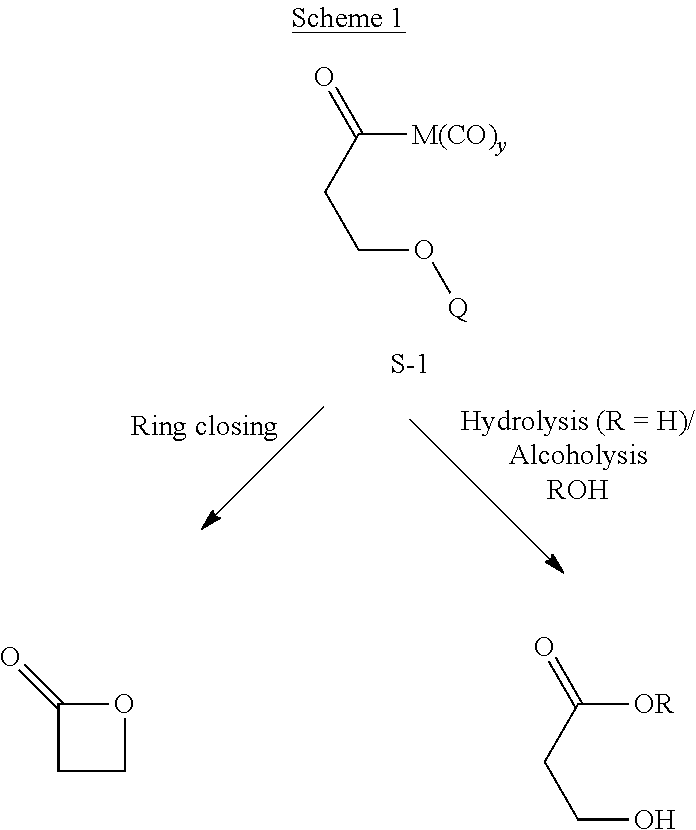

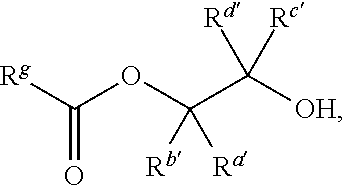

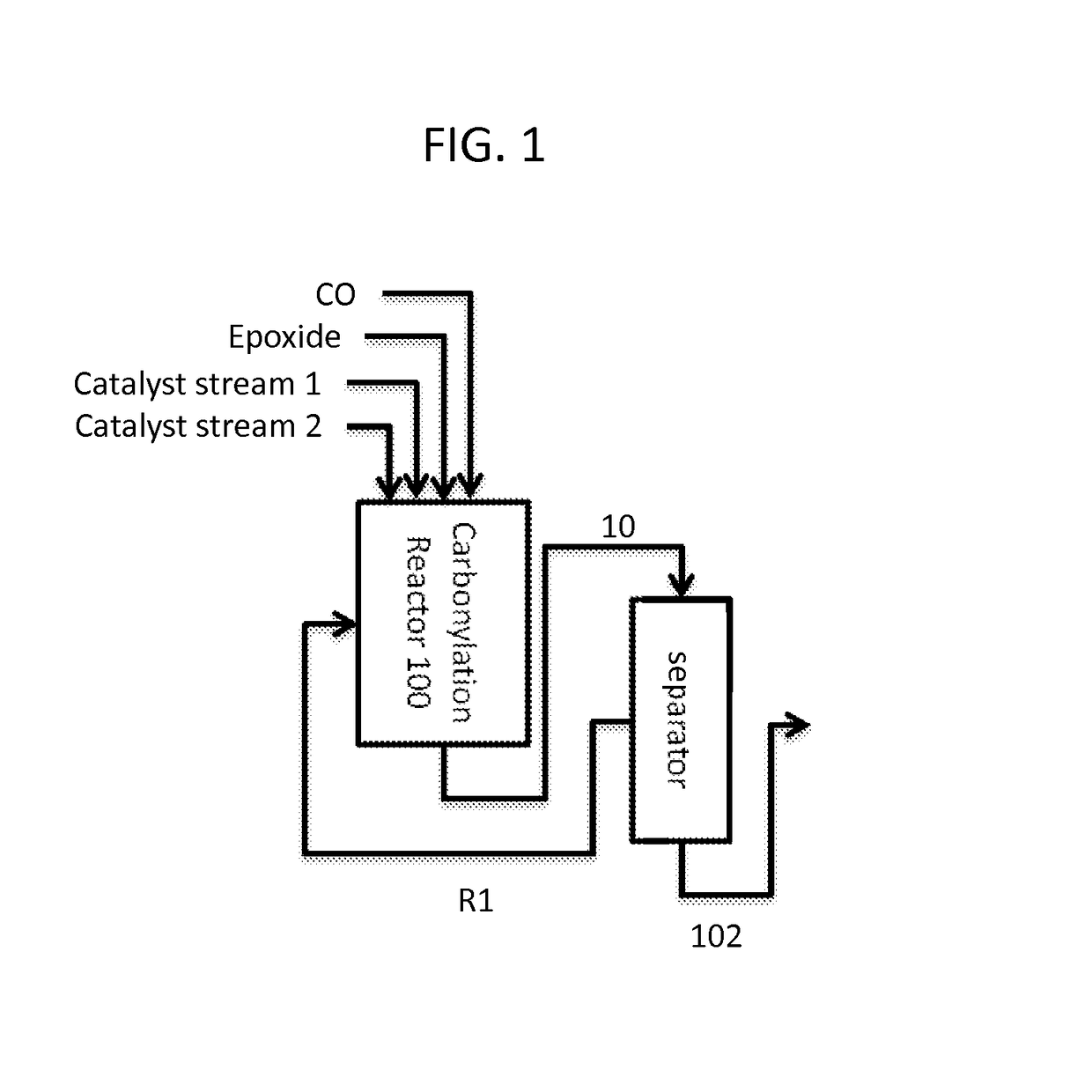

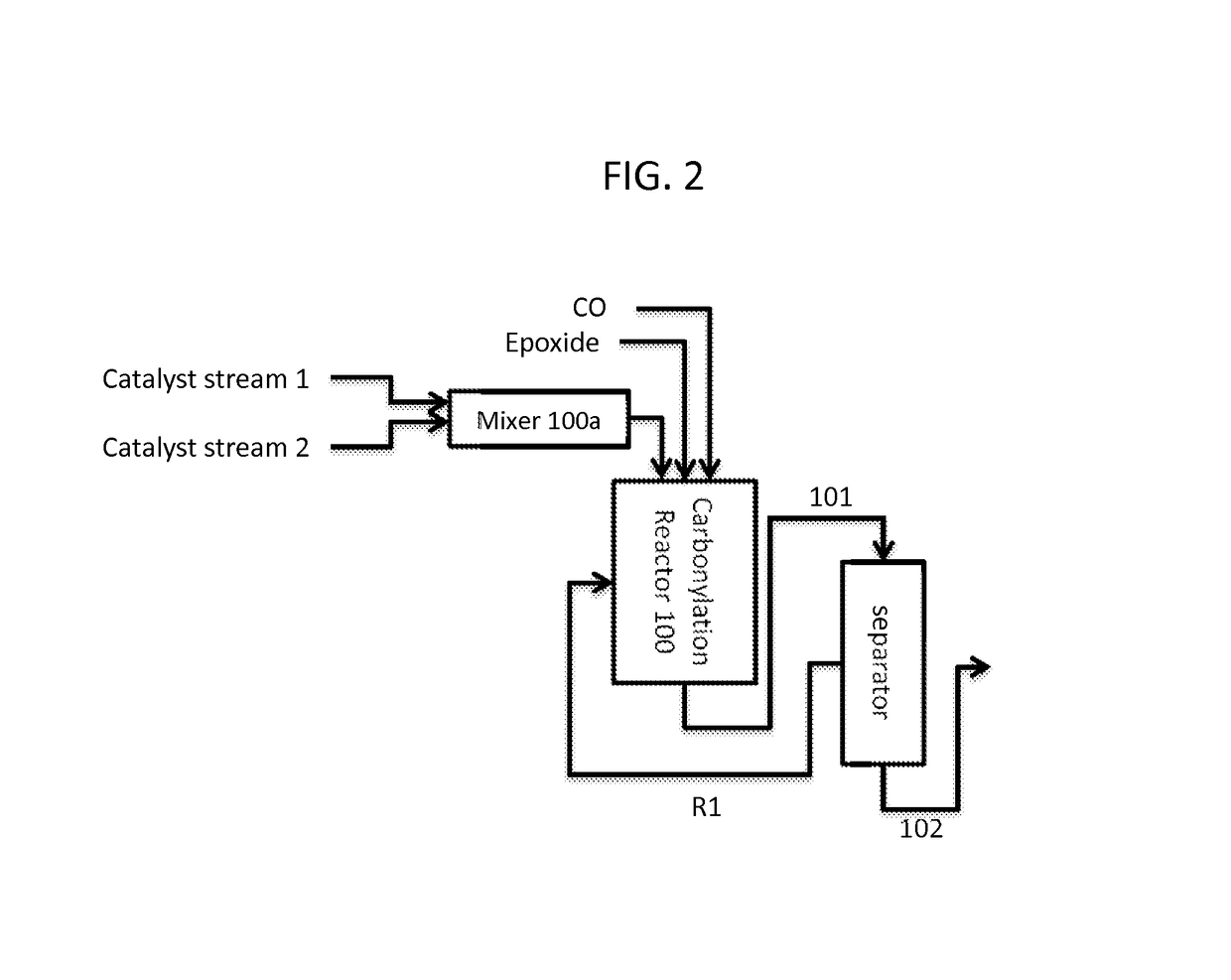

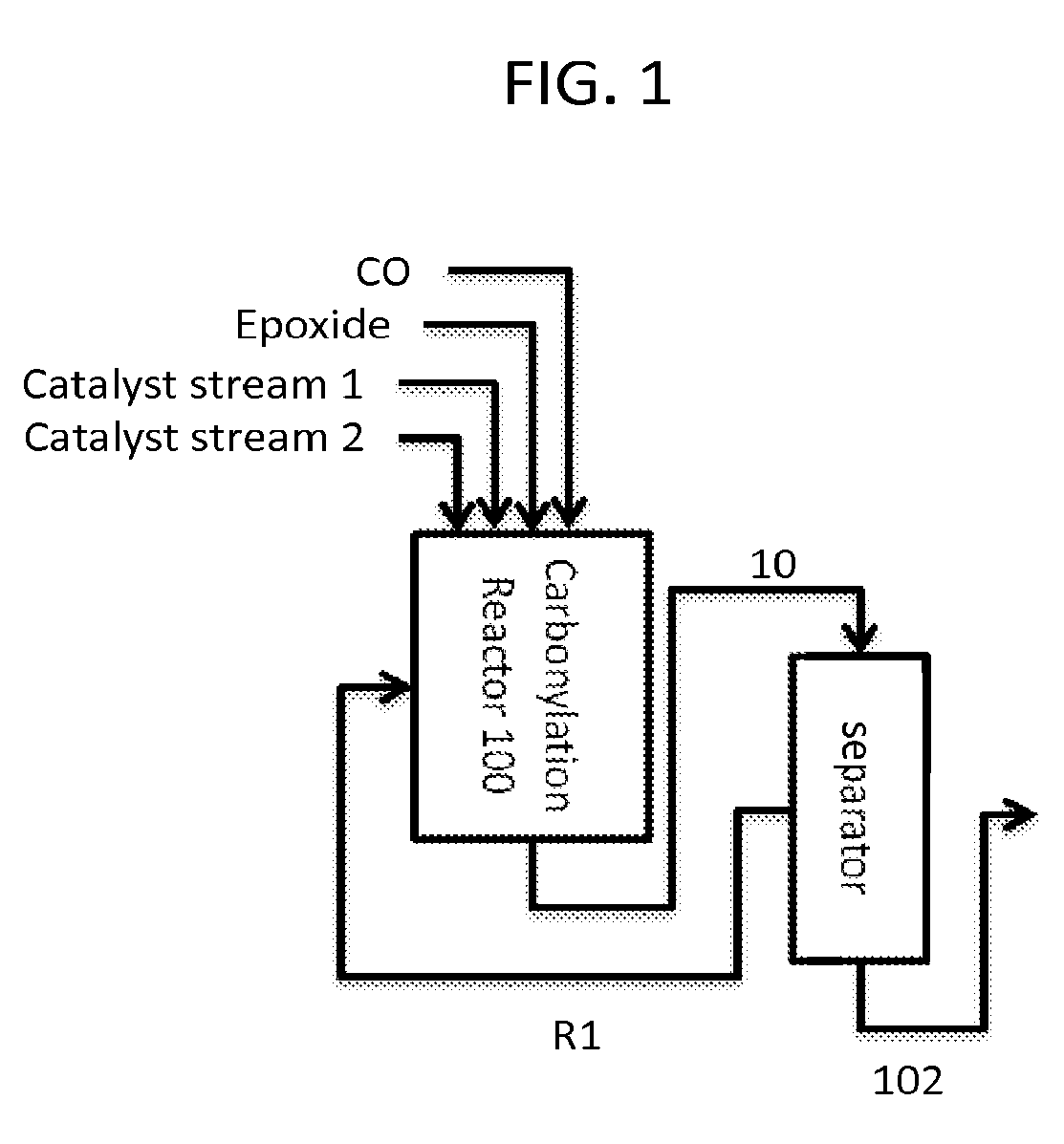

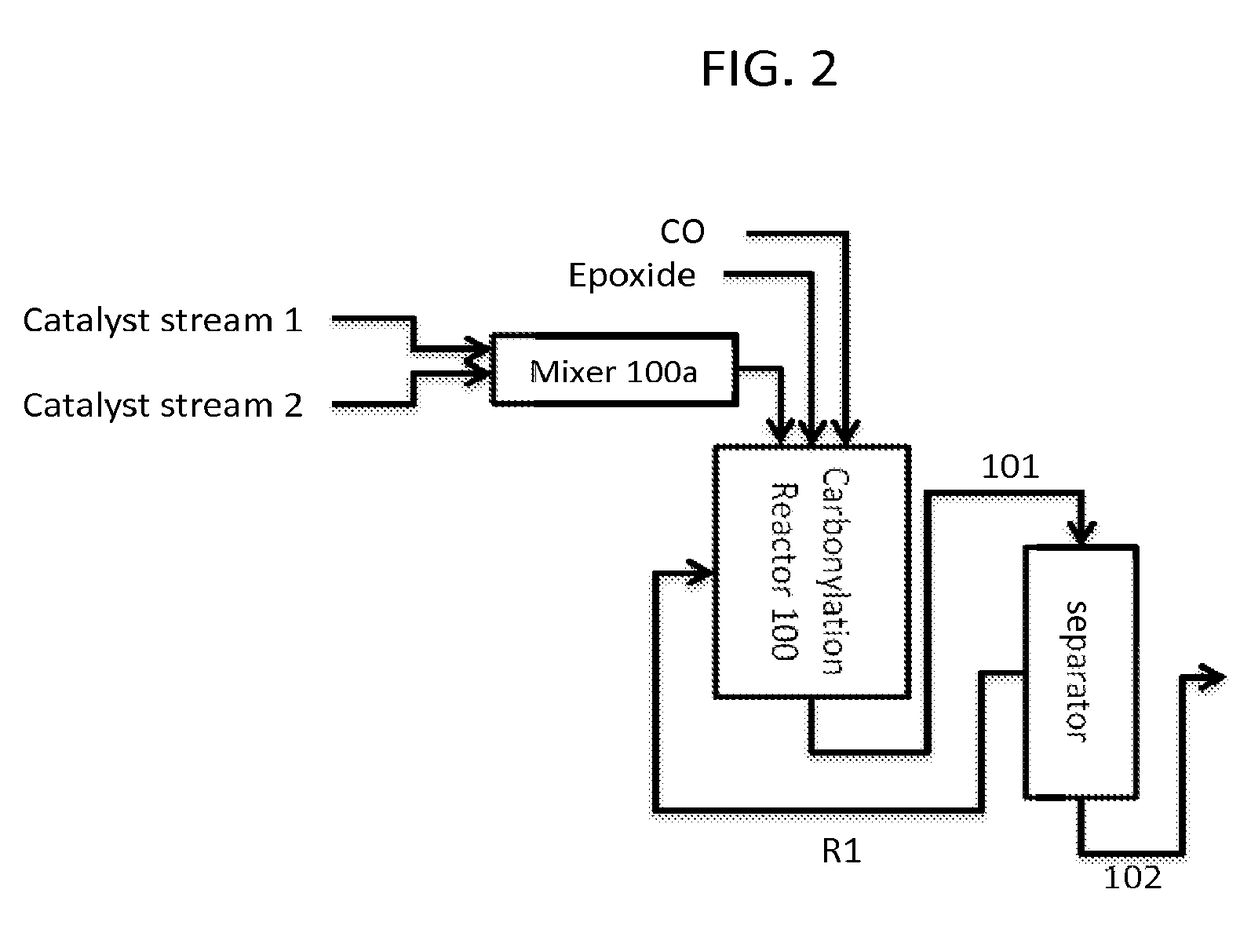

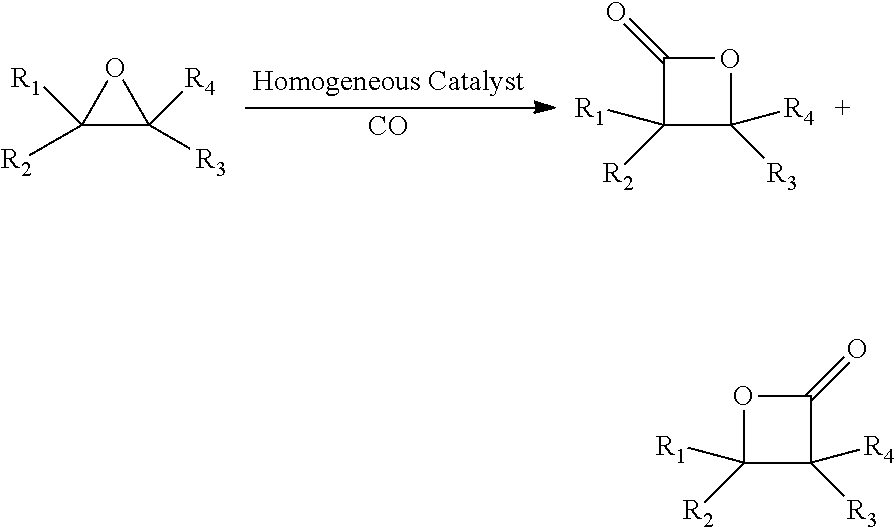

Process for production of acrylates from epoxides

ActiveUS20140309399A1Low costAvoiding isolation and storageOrganic compound preparationPreparation by ester-hydroxy reactionReaction zoneMetal carbonyl

The methods of the present invention comprise the steps of: providing a feedstock stream comprising an epoxide and carbon monoxide; contacting the feedstock stream with a metal carbonyl in a first reaction zone to effect conversion of at least a portion of the provided epoxide to a beta lactone; directing the effluent from the first reaction zone to a second reaction zone where the beta lactone is subjected to conditions that convert it to a compound selected from the group consisting of: an alpha beta unsaturated acid, an alpha beta unsaturated ester, an alpha beta unsaturated amide, and an optionally substituted polypropiolactone polymer; and isolating a final product comprising the alpha-beta unsaturated carboxylic acid, the alpha-beta unsaturated ester, the alpha-beta unsaturated amide or the polypropiolactone.

Owner:NOVOMER INC

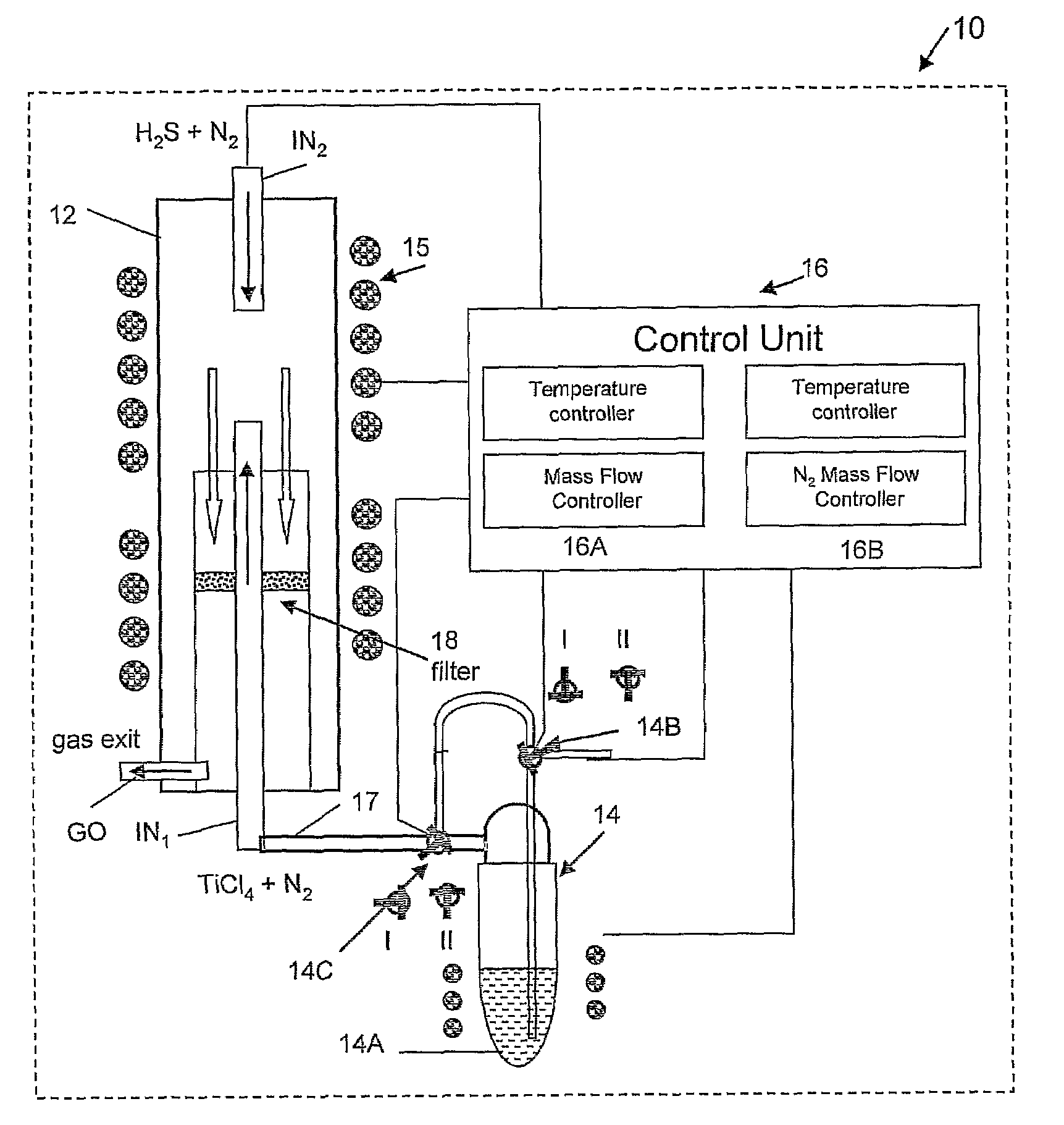

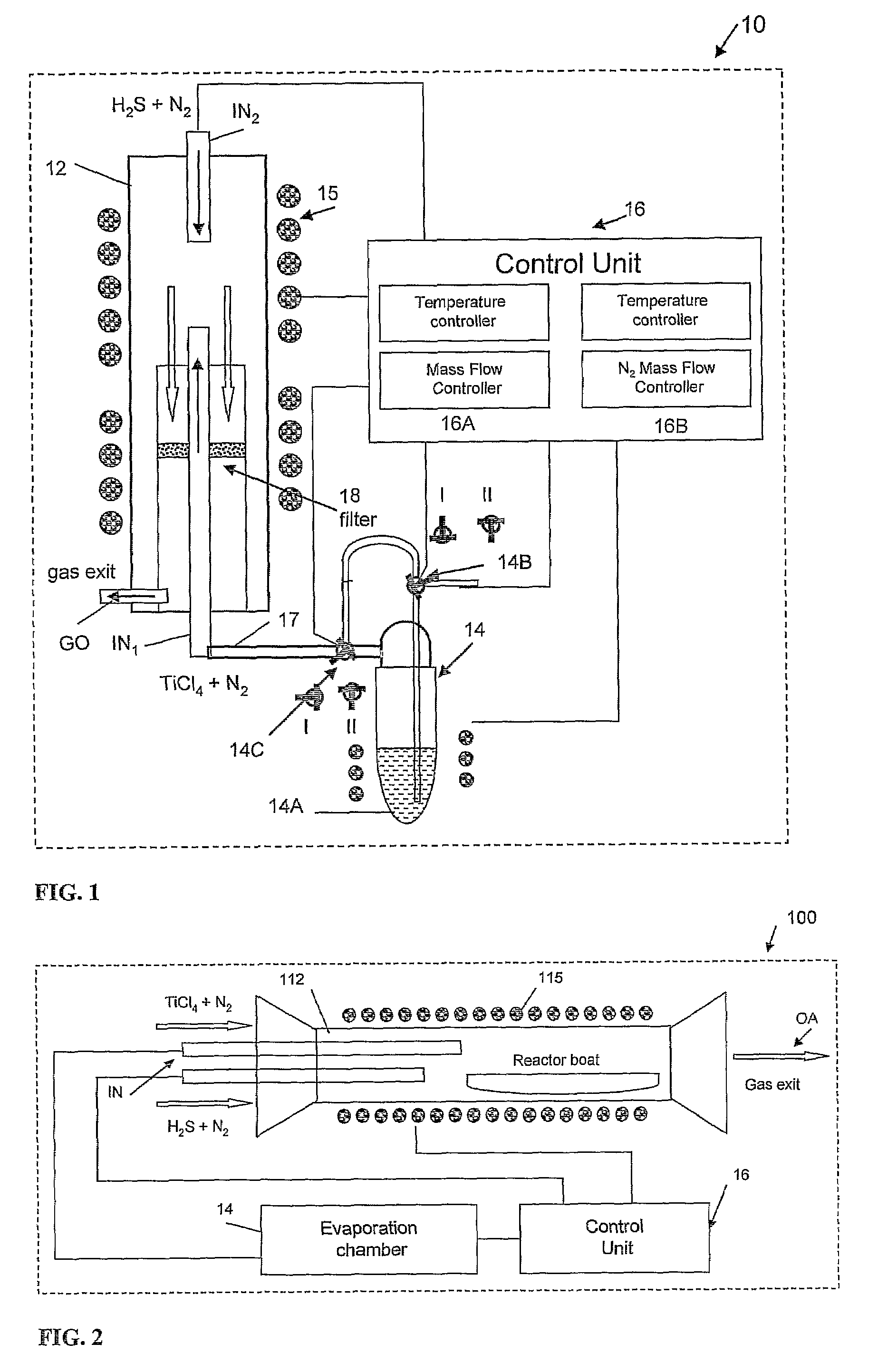

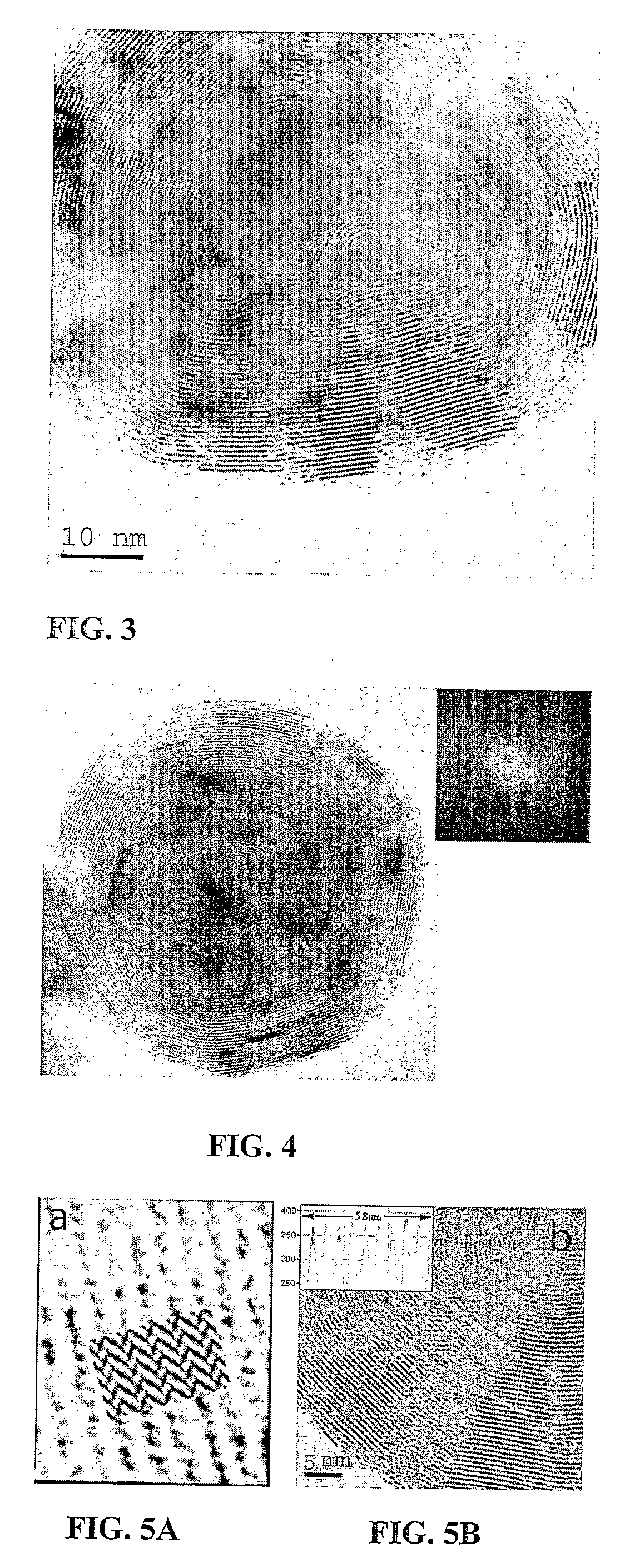

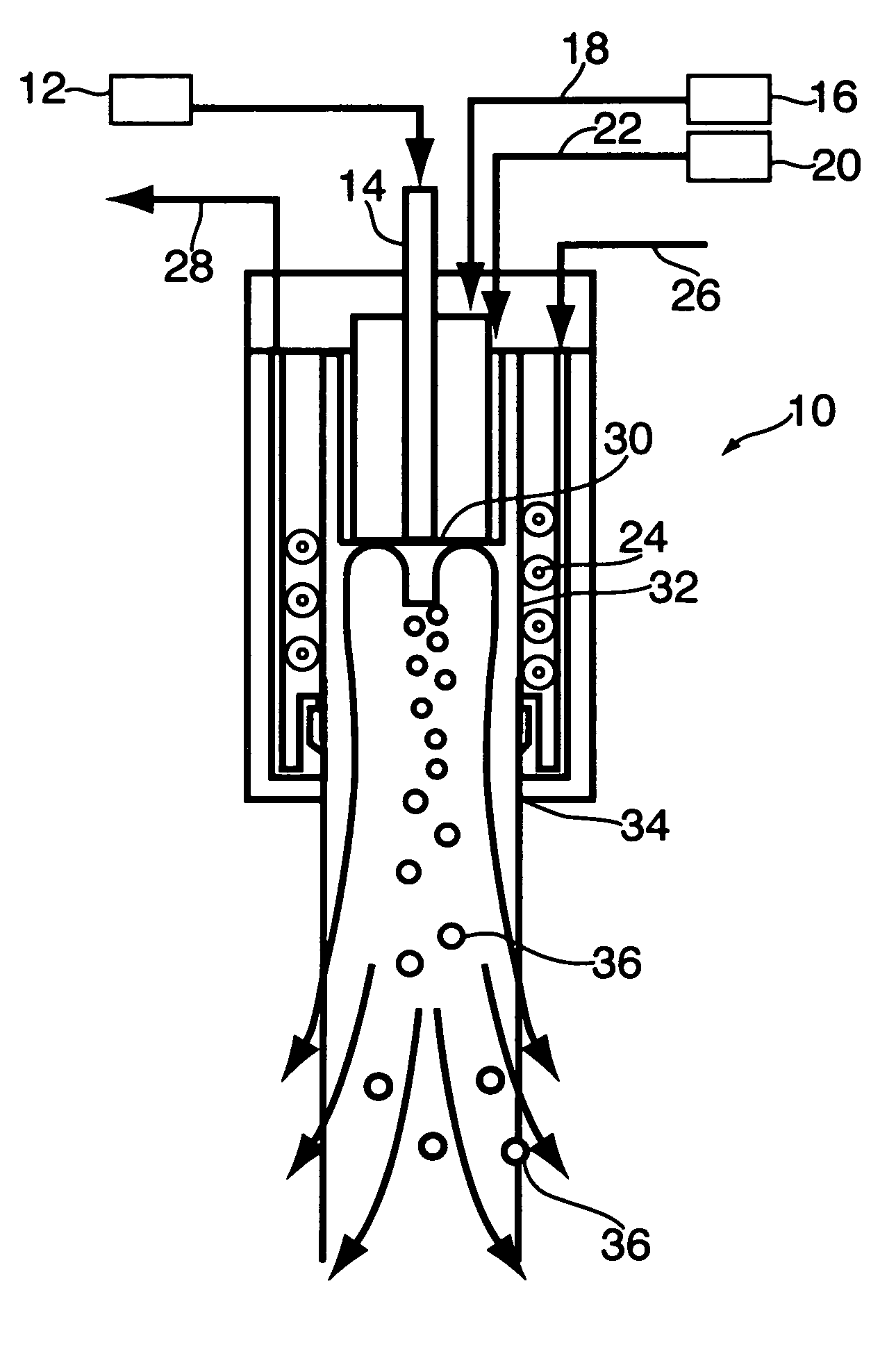

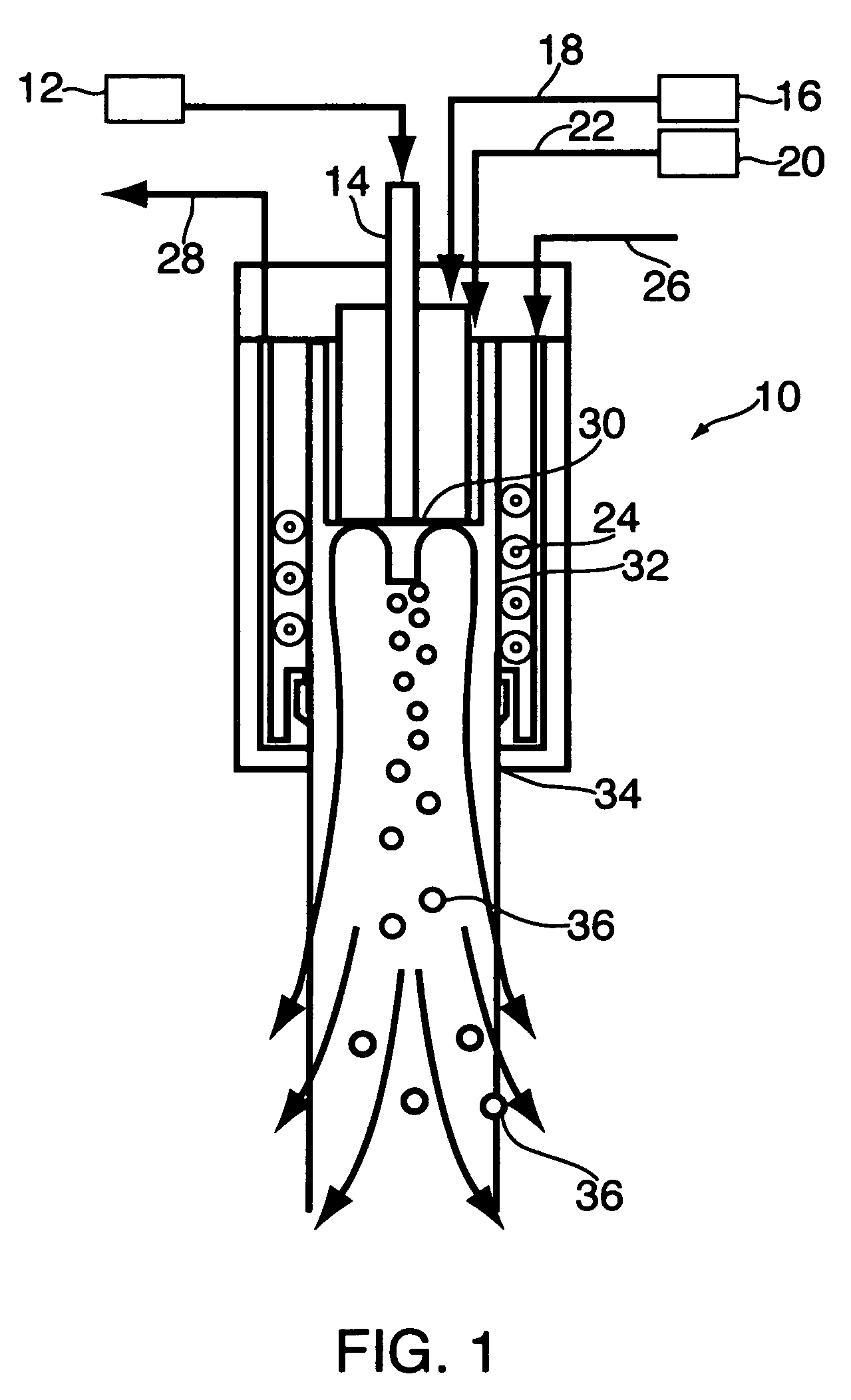

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

Process for production of acrylates from epoxides

ActiveUS9096510B2Low costAvoiding isolation and storageOrganic compound preparationPreparation by ester-hydroxy reactionReaction zoneMetal carbonyl

The methods of the present invention comprise the steps of: providing a feedstock stream comprising an epoxide and carbon monoxide; contacting the feedstock stream with a metal carbonyl in a first reaction zone to effect conversion of at least a portion of the provided epoxide to a beta lactone; directing the effluent from the first reaction zone to a second reaction zone where the beta lactone is subjected to conditions that convert it to a compound selected from the group consisting of: an alpha beta unsaturated acid, an alpha beta unsaturated ester, an alpha beta unsaturated amide, and an optionally substituted polypropiolactone polymer; and isolating a final product comprising the alpha-beta unsaturated carboxylic acid, the alpha-beta unsaturated ester, the alpha-beta unsaturated amide or the polypropiolactone.

Owner:NOVOMER INC

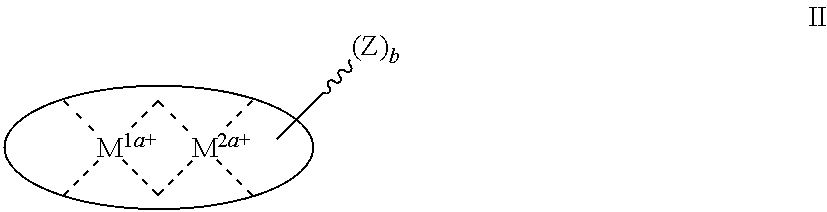

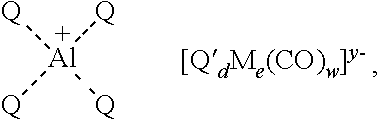

Catalysts for epoxide carbonylation

InactiveUS20170080409A1Use in synthesisIncrease the rate of chemical reactionsOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsPtru catalystEthylene oxide

The present invention encompasses catalysts for the carbonylation of heterocycles such as ethylene oxide, as well as methods for their use. The catalysts feature Lewis acidic metal complexes having one or more tethered metal-coordinating groups in combination with at least one metal carbonyl species. In preferred embodiments, the inventive catalysts have improved stability when subjected to product separation conditions in continuous ethylene oxide carbonylation processes.

Owner:NOVOMER INC

Catalysts and methods for polyester production

InactiveUS20150368394A1High yieldIncrease ratingsPhysical/chemical process catalystsOther chemical processesPolyesterMetal carbonyl

Disclosed are polymerization systems and methods for the formation of polyesters from epoxides and carbon monoxide. The inventive polymerization systems feature the combination of metal carbonyl compounds and polymerization initiators and are characterized in that the molar ratios of metal carbonyl compound, polymerization initiators and provided epoxides are present in certain ratios.

Owner:NOVOMER INC

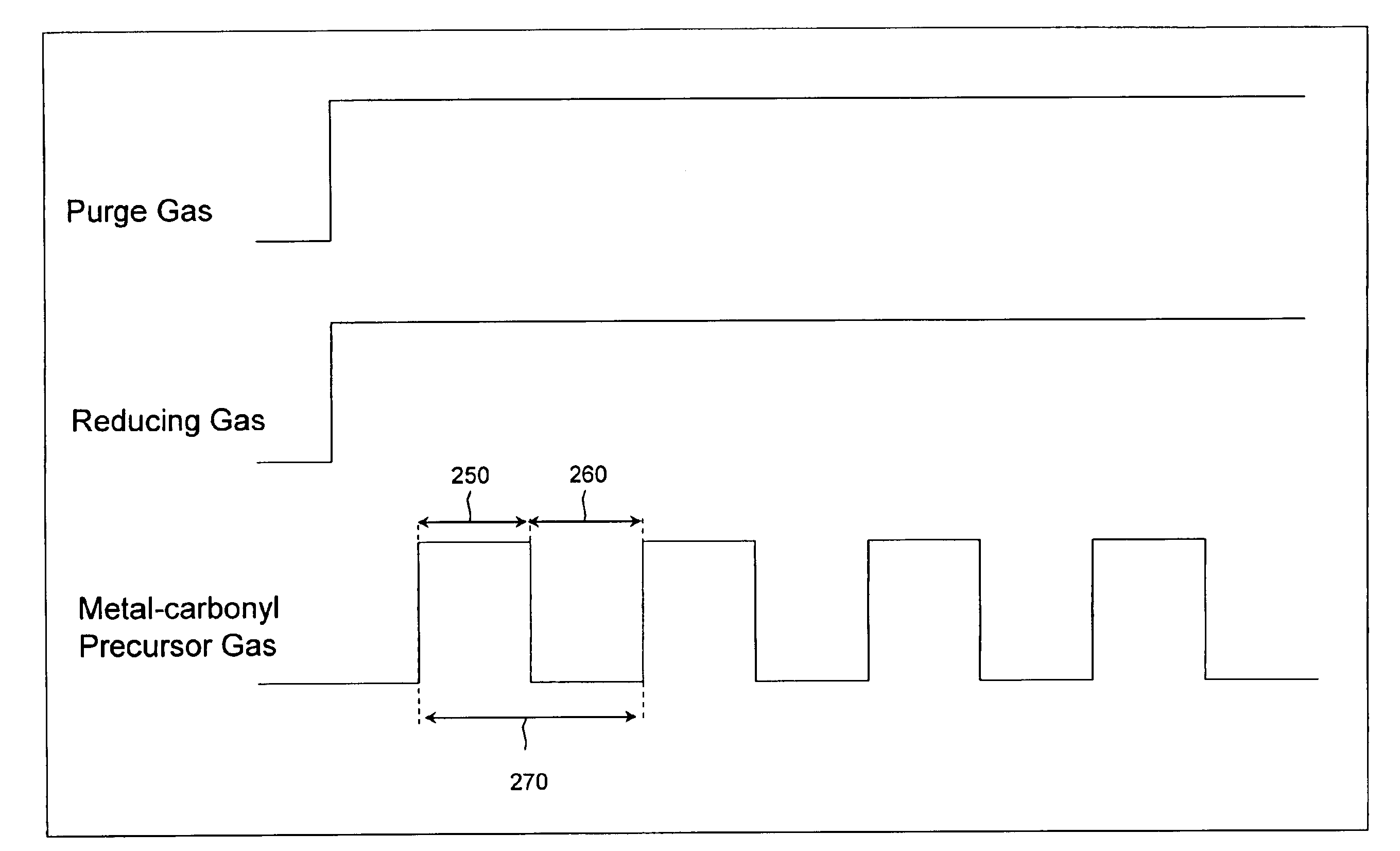

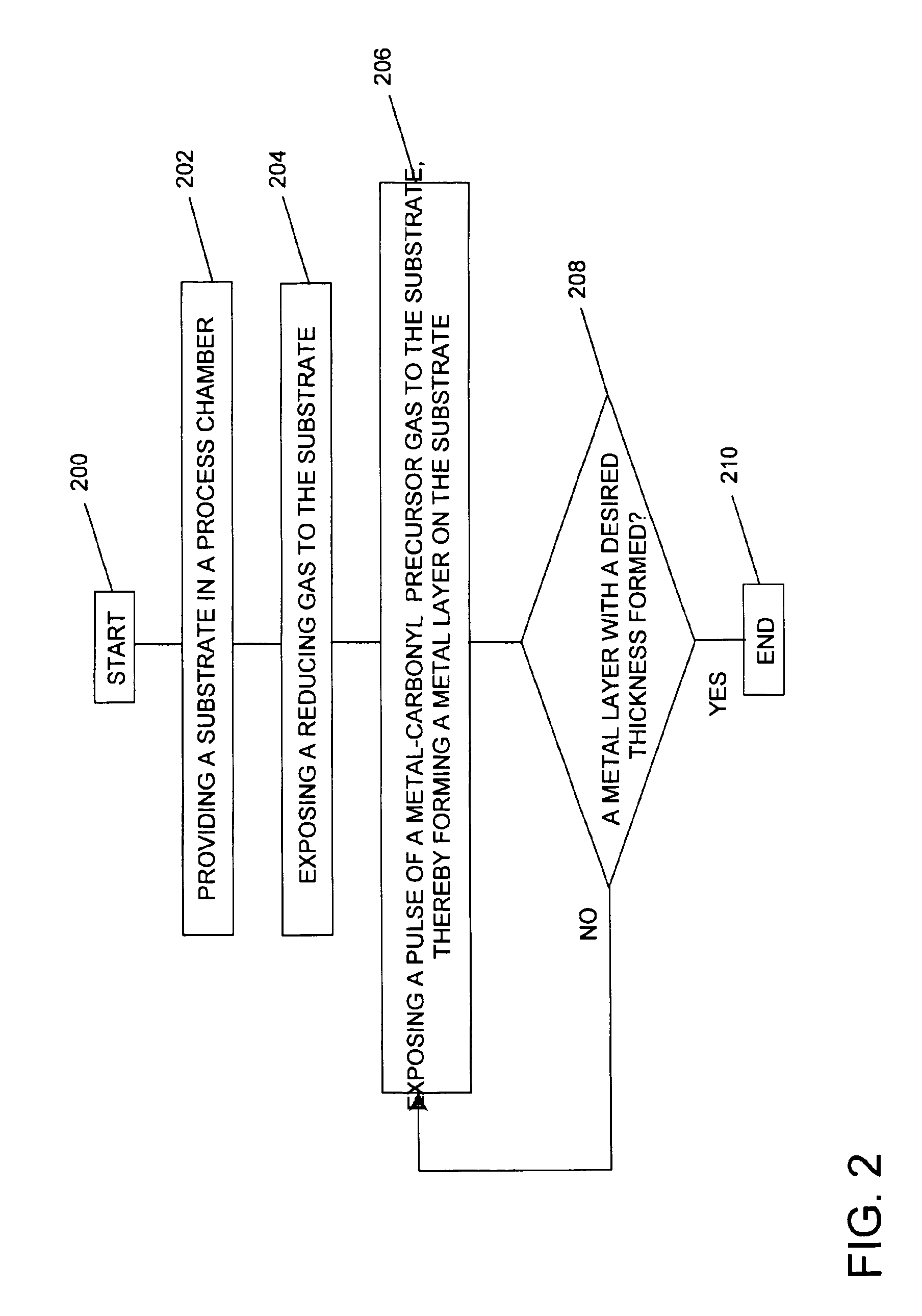

Method of forming a metal layer using an intermittent precursor gas flow process

InactiveUS6924223B2Semiconductor/solid-state device manufacturingSpecial surfacesProduct gasNucleation

A method is provided for forming a metal layer on a substrate using an intermittent precursor gas flow process. The method includes exposing the substrate to a reducing gas while exposing the substrate to pulses of a metal-carbonyl precursor gas. The process is carried out until a metal layer with desired thickness is formed on the substrate. The metal layer can be formed on a substrate, or alternately, the metal layer can be formed on a metal nucleation layer.

Owner:INT BUSINESS MASCH CORP +1

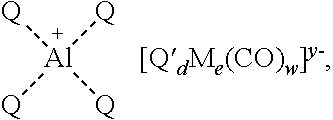

Synthesis of metal complexes and uses thereof

InactiveUS20170225157A1Little and no contaminationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsCarbonylationProtein carbonyl

The present disclosure provides novel methods of making aluminum complexes with utility for promoting epoxide carbonylation reactions. Methods include reacting neutral metal carbonyl compounds with alkylaluminum complexes.

Owner:NOVOMER INC

Synthesis of metal complexes and uses thereof

ActiveUS20190030520A1Little and no contaminationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCompound (substance)Carbonylation

The present disclosure provides novel methods of making aluminum complexes with utility for promoting epoxide carbonylation reactions. Methods include reacting neutral metal carbonyl compounds with alkylaluminum complexes.

Owner:NOVOMER INC

Method of forming a metal layer

A method and a processing tool are provided for forming a metal layer with improved morphology on a substrate. The method includes pre-treating the substrate by exposing the substrate to excited species in a plasma, exposing the pre-treated substrate to a process gas containing a metal-carbonyl precursor, and forming a metal layer on the pre-treated substrate surface by a chemical vapor deposition process. The metal-carbonyl precursor can contain W(CO)6, Ni(CO)4, Mo(CO)6, CO2(CO)8, Rh4(CO)12, Re2(CO)10, Cr(CO)6, or Ru3(CO)12 or any combination thereof, and the metal layer can contain W, Ni, Mo, Co, Rh, Re, Cr, or Ru, or any combination thereof, respectively.

Owner:GLOBALFOUNDRIES INC +1

Method and deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS20060110918A1Increase deposition rateReduce premature decompositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseThermal chemical vapor deposition

A method and a deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors using CO gas and a dilution gas. The method includes providing a substrate in a process chamber of a processing system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, diluting the process gas in the process chamber, and exposing the substrate to the diluted process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process. The deposition system contains a substrate holder configured for supporting and heating a substrate in a process chamber having a vapor distribution system, a precursor delivery system configured for forming a process gas containing a metal-carbonyl precursor vapor and a CO gas and for introducing the process gas to the vapor distribution system, a dilution gas source configured for adding a dilution gas to the process gas in the process chamber, and a controller configured for controlling the deposition system during exposure of the substrate to the diluted process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:TOKYO ELECTRON LTD

Processes for producing beta-lactone and beta-lactone derivatives with heterogenous catalysts

ActiveUS20190047972A1Efficient processingSmall carbon footprintOrganic chemistryMolecular sieve catalystsChemical compoundReaction zone

The present invention is directed to processes from producing beta-lactone and beta-lactone derivatives using heterogenous catalysts. In preferred embodiments of the present invention, the processes comprise the steps: passing a feed stream comprising an epoxide reagent and a carbon monoxide reagent to a reaction zone; contacting the epoxide reagent and the carbon monoxide reagent with a heterogenous catalyst to produce a beta-lactone product in the reaction zone; and removing the beta-lactone product from the reaction zone. In preferred embodiments, the heterogenous catalyst comprises a solid support containing a cationic Lewis acid functional group and a metal carbonyl compound comprising at least one of anionic metal carbonyl compound or a neutral metal carbonyl compound. In certain preferred embodiments, the epoxide reagent and carbon monoxide reagent have a biobased content.

Owner:NOVOMER INC

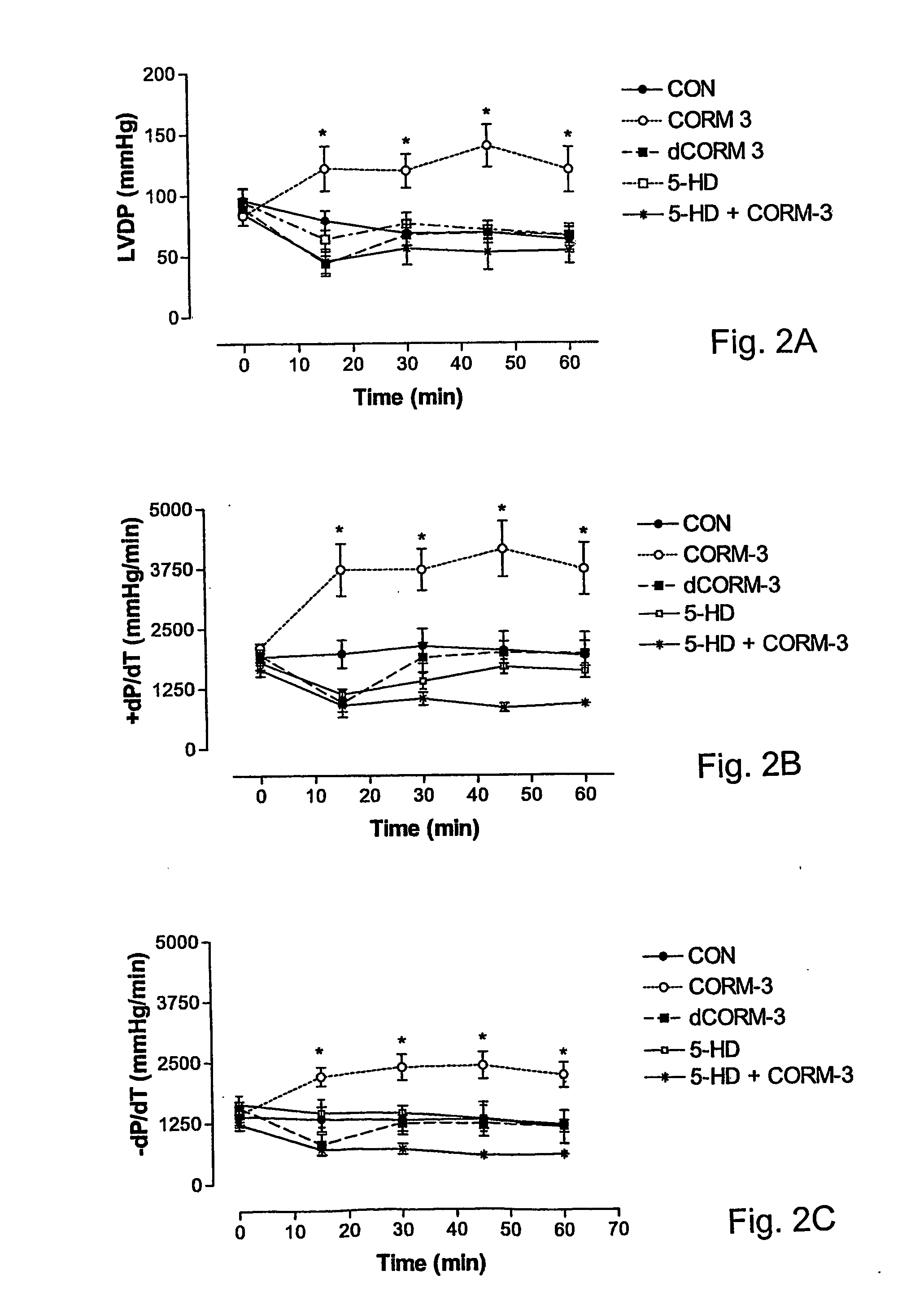

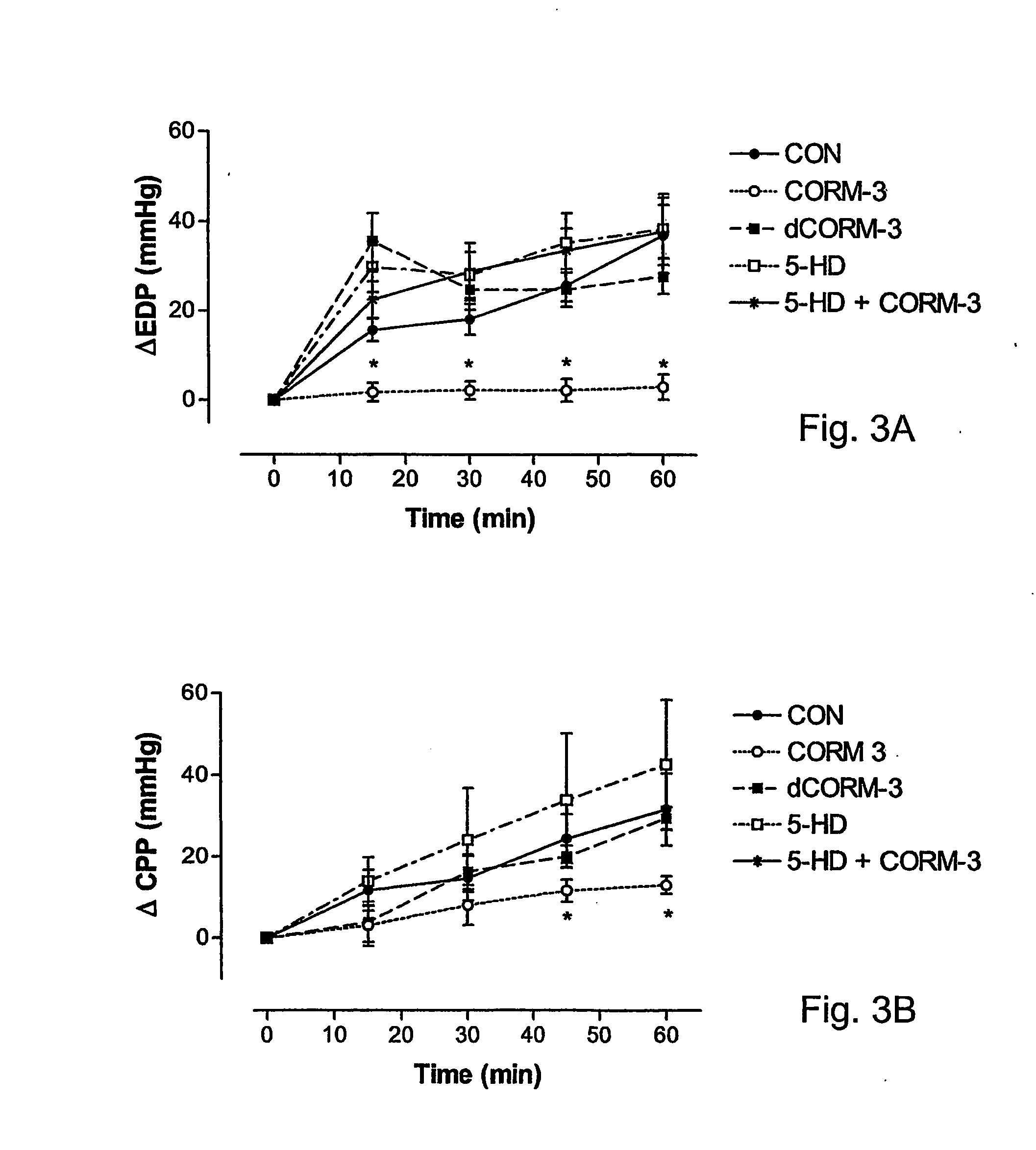

Therapeutic delivery of carbon monoxide

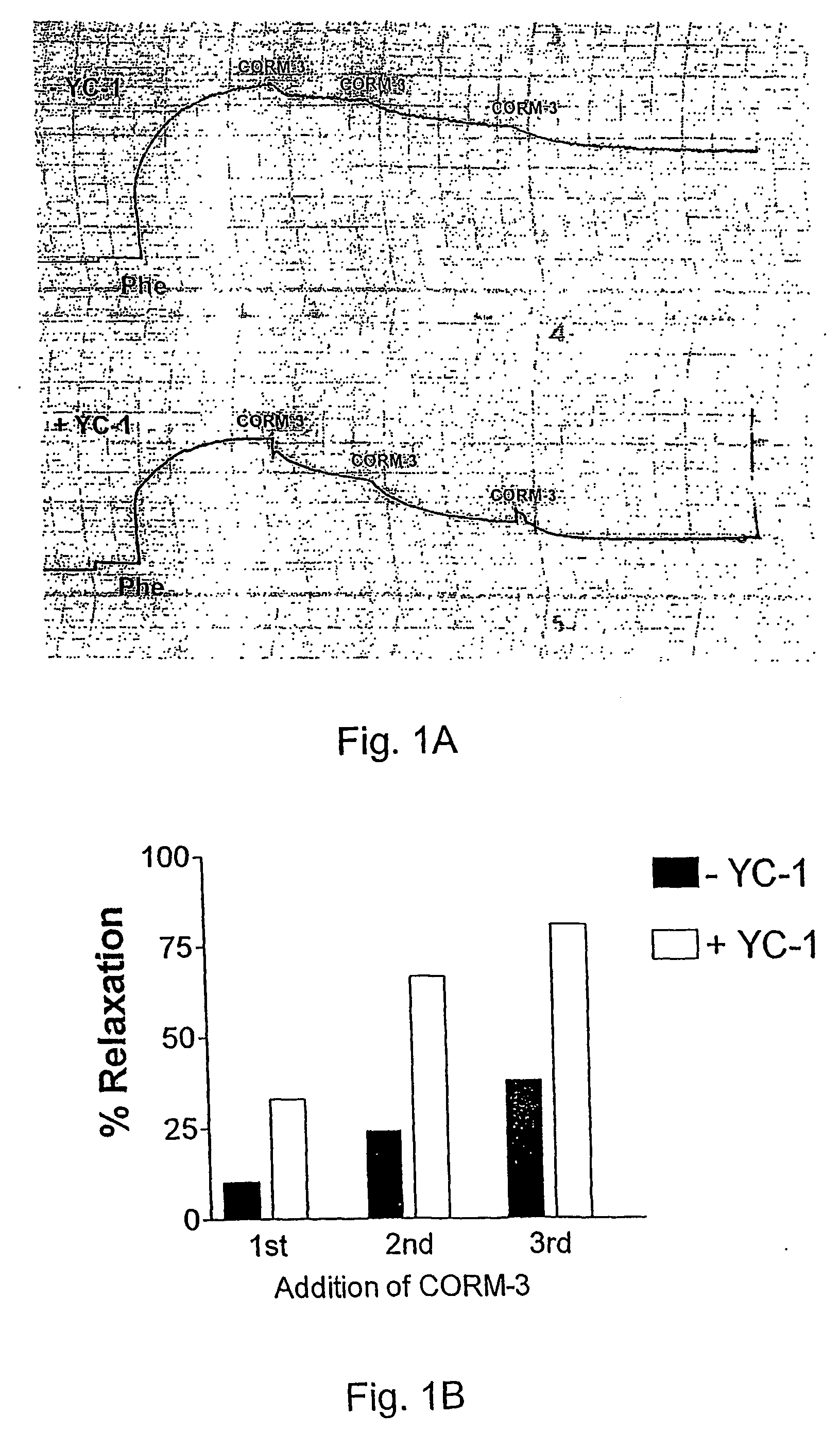

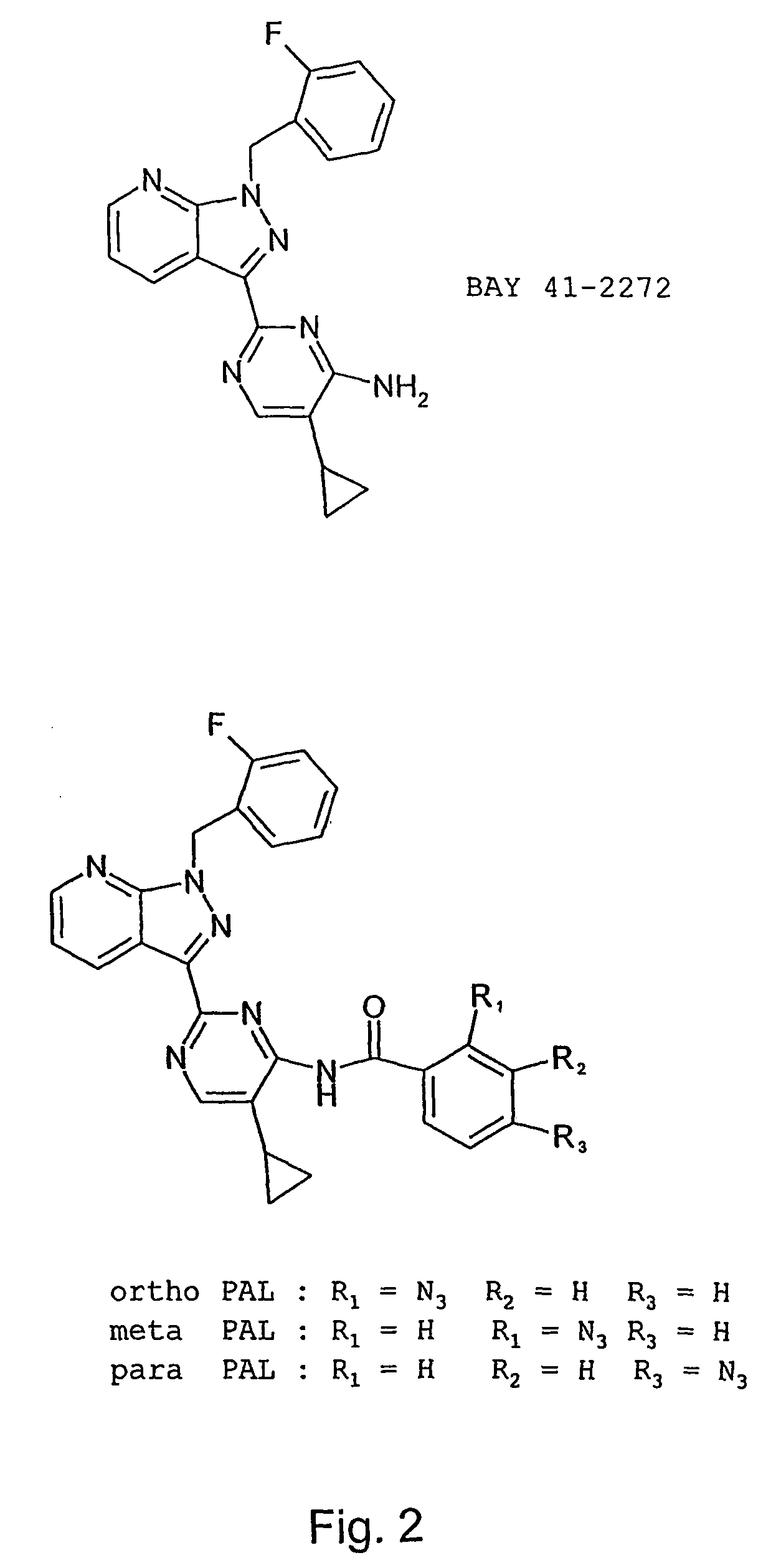

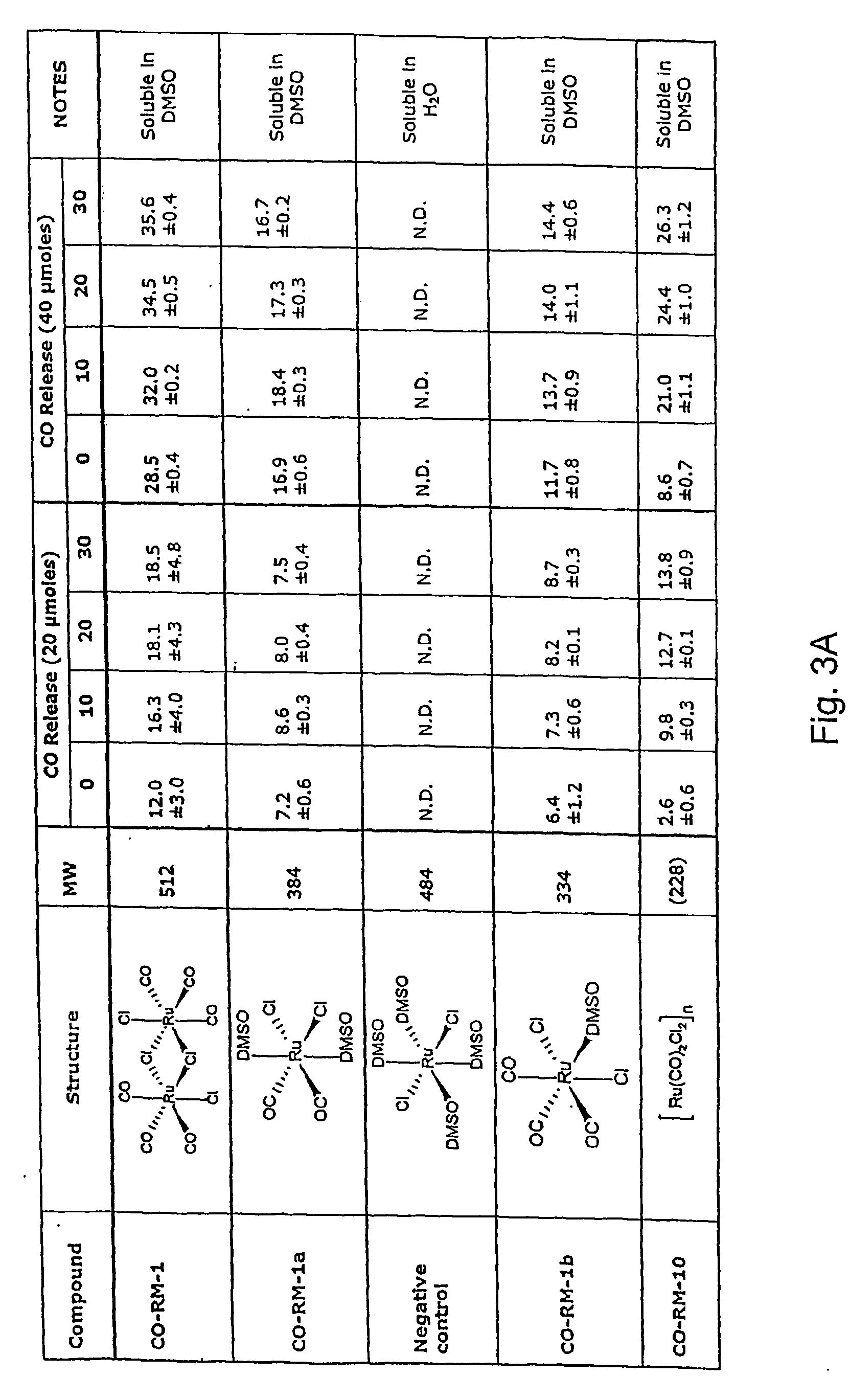

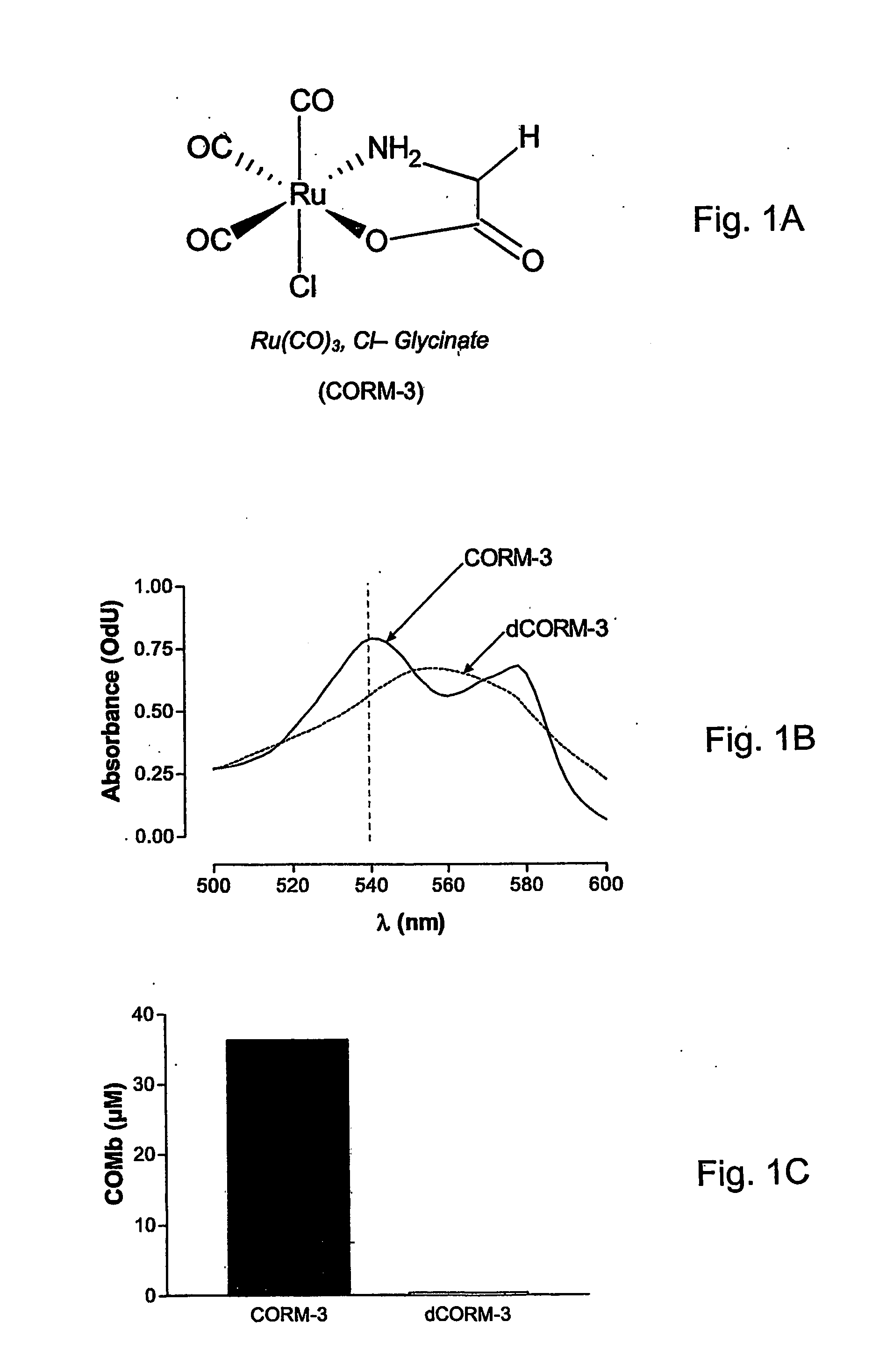

InactiveUS20060147548A1Good treatment effectPhysiological effect is goodBiocideHeavy metal active ingredientsGuanylate Cyclase StimulatorsStimulant

Metal carbonyls are used in combination with at least one guanylate cyclase stimulant / stabilizer to deliver CO having biological activity, for example vasodilatation and inhibition of platelet aggregation. The two components may be administered simultaneously or sequentially. A particular described combination is tricarbonylchloro(glycinato)ruthenium(II) and the drug YC-1.

Owner:HEMOCORM

Therapeutic delivery of carbon monoxide to extracorporeal and isolated organs

ActiveUS20060127501A1Increase stimulationAlter and enhance biological effectBiocideHeavy metal active ingredientsSolubilityBlood flow

Metal carbonyls are used to deliver CO to organs to limit post-ischaemic damage. The organ may be extracorporeal, e.g. for use in a transplant, or may be an isolated organ inside or attached to the body but isolated from the blood flow. The carbonyl preferably has one or more other ligands other than CO, such as amino acids, to modulate the CO release property and solubility.

Owner:HEMOCORM

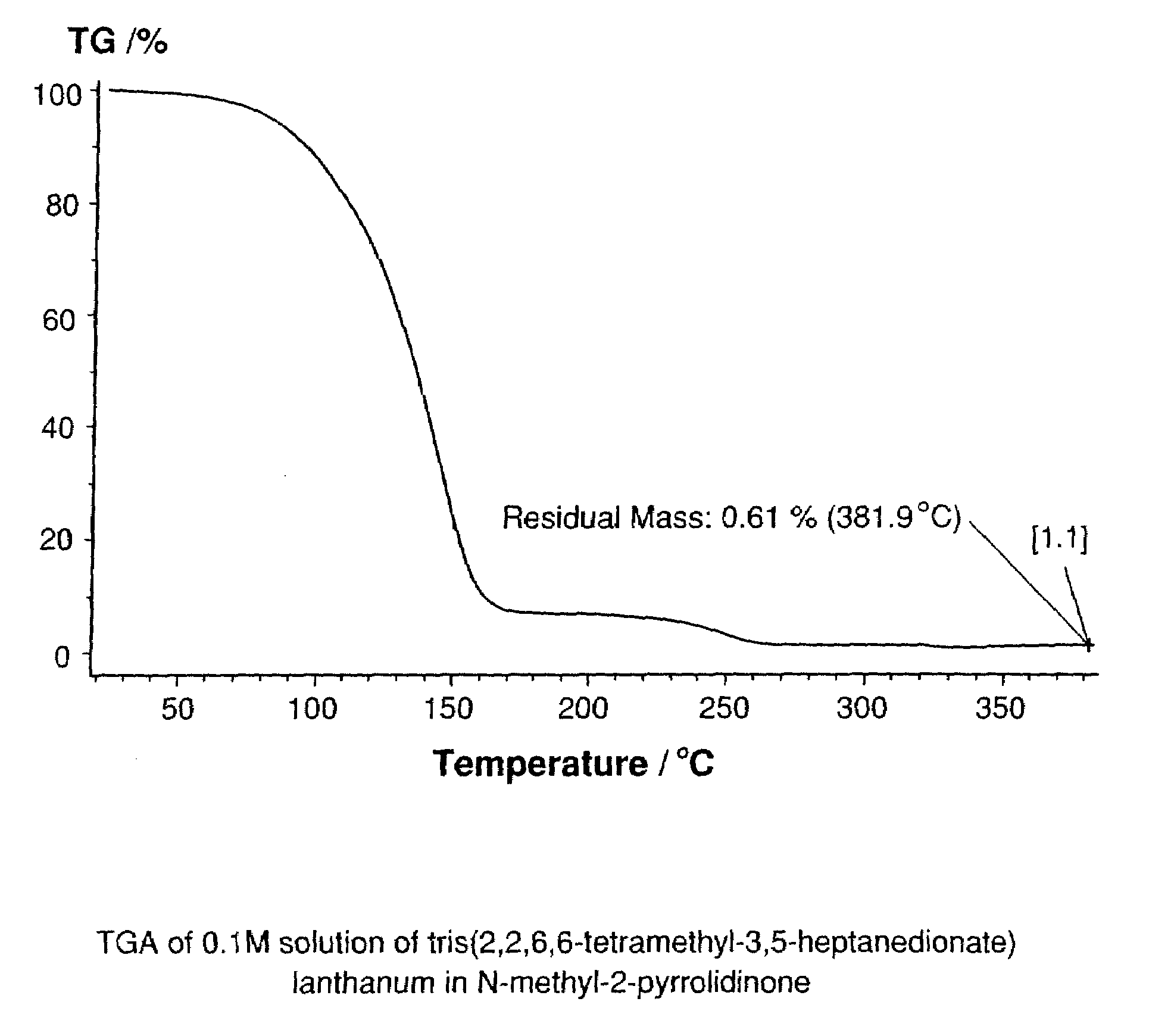

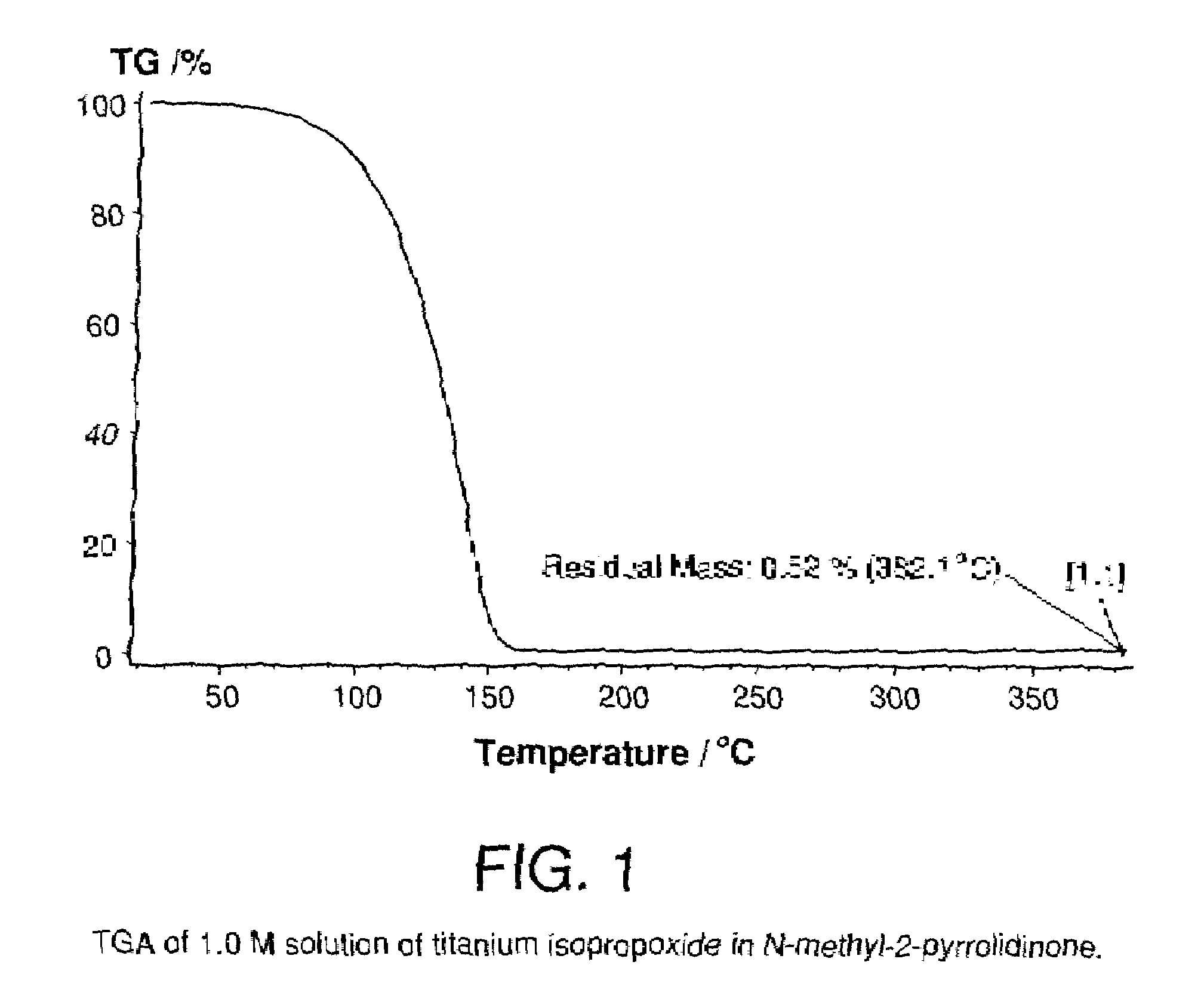

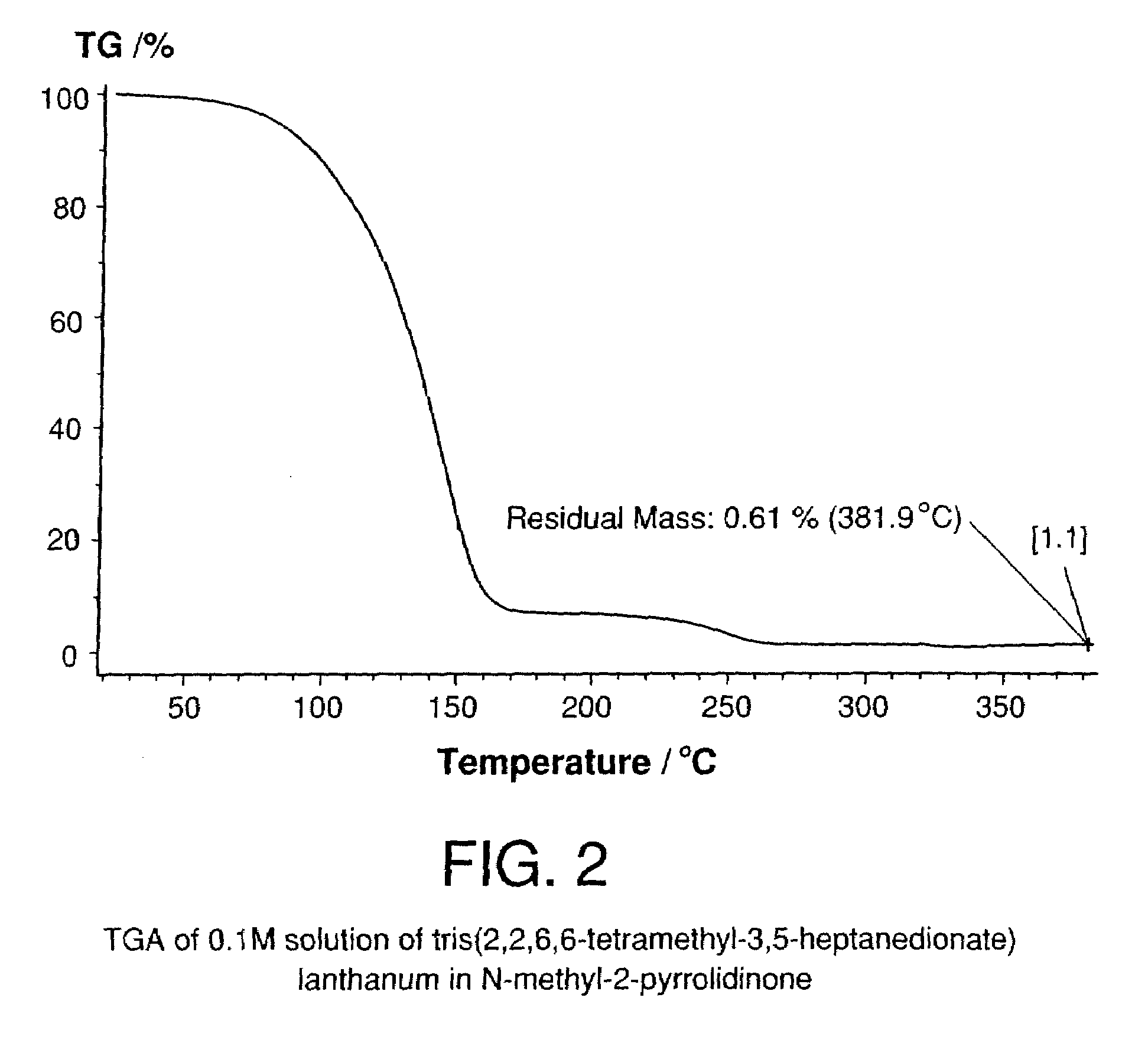

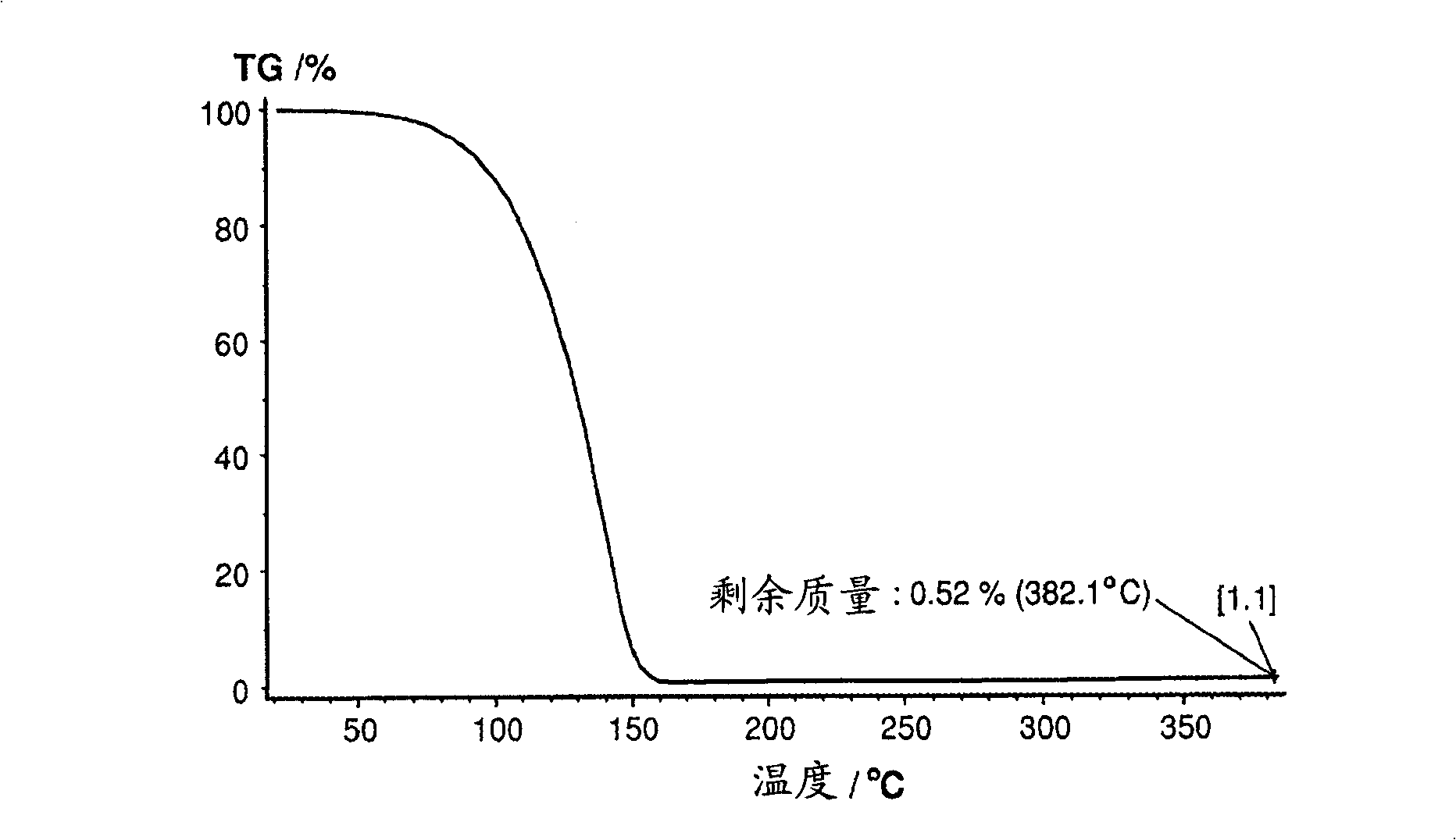

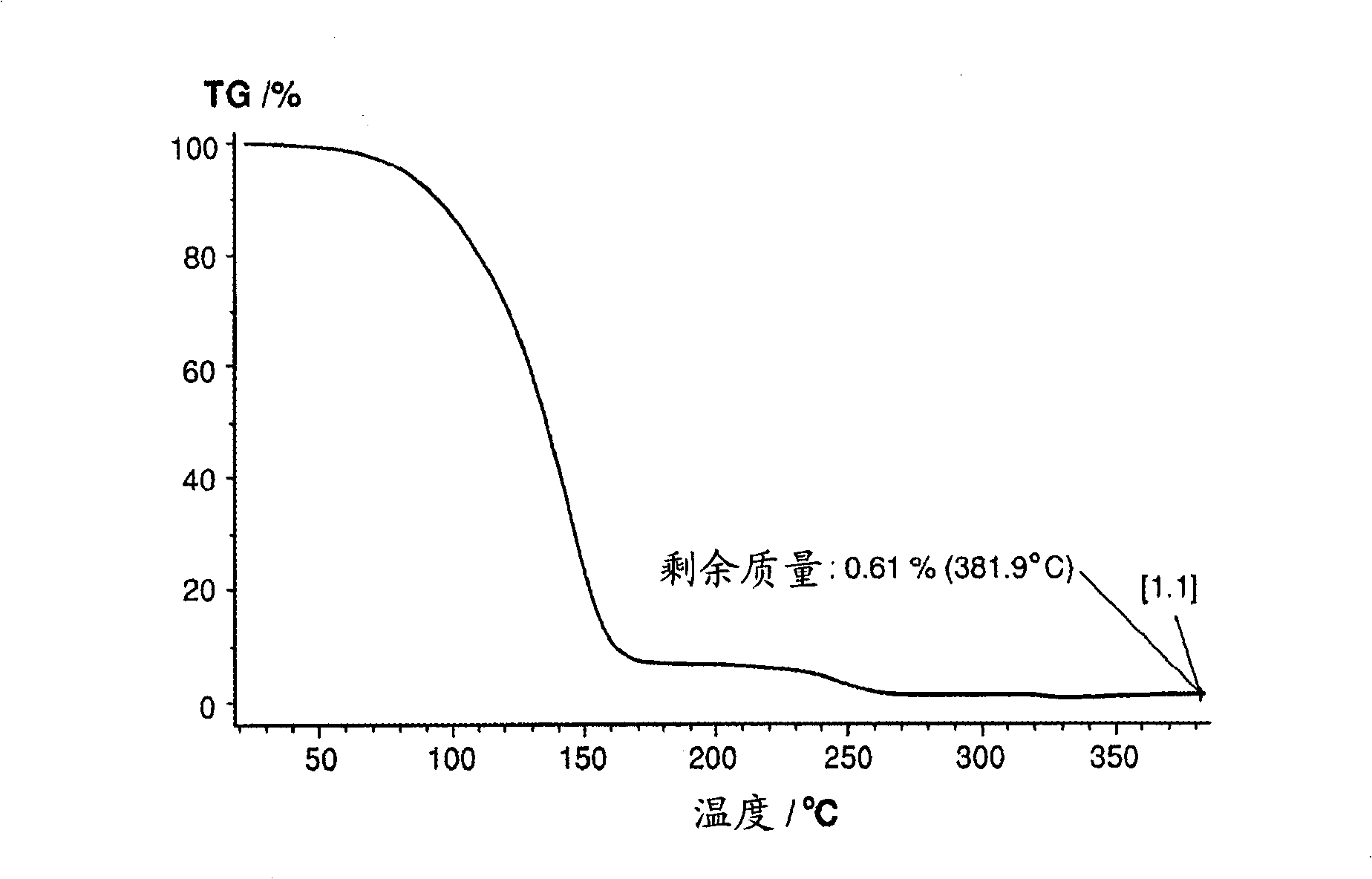

Metal precursor solutions for chemical vapor deposition

InactiveCN101343732AImprove gasification effectEasy to transportCopper organic compoundsChemical vapor deposition coatingArylGas phase

The present invention describes a metal precursor solution and metal source containing precursor liquid solutions for chemical vapor deposition processes, including atomic layer deposition, for fabricating conformal metal-containing films on substrates. More specifically, the metal source precursor liquid solutions are comprised of (i) at least one metal complex selected from -diketonates, -ketoiminates, -diiminates, alkyl metal, metal carbonyl, alkyl metal carbonyl, aryl metal, aryl metal carbonyl, cyclopentadienyl metal, cyclopentadienyl metal isonitrile, cyclopentadienyl metal nitrile, cyclopentadienyl metal carbonyl, metal alkoxide, metal ether alkoxide, and metal amides wherein the ligand can be monodentate, bidentate and multidentate coordinating to the metal atom and the metal is selected from group 2 to 14 elements, and (ii) a solvent selected from organic amides including linear amides and cyclic amides for such metal source containing precursors.

Owner:AIR PROD & CHEM INC

Catalyst for treating organic wastewater and preparation method thereof

InactiveCN102101053AHigh activityHigh removal rateMetal/metal-oxides/metal-hydroxide catalystsChemical oxygen demandRuthenium

The invention discloses a catalyst for treating organic wastewater and a preparation method thereof. The catalyst is a metal carbonyl loaded catalyst, a precursor of the catalyst is one or a combination of ruthenium carbonyl and cobalt carbonyl, a second component Ce or Fe is added at the same time, and a carrier of the catalyst is selected from one or a compound oxide of active carbon, gamma-Al2O3 and TiO2. The catalyst can be used for oxidizing and degrading different organic matters with various concentrations in water under a milder condition so as to greatly reduce COD (Chemical Oxygen Demand) in wastewater and improve the removal efficiency of the COD in the wastewater.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for the conversion of carbon monoxide

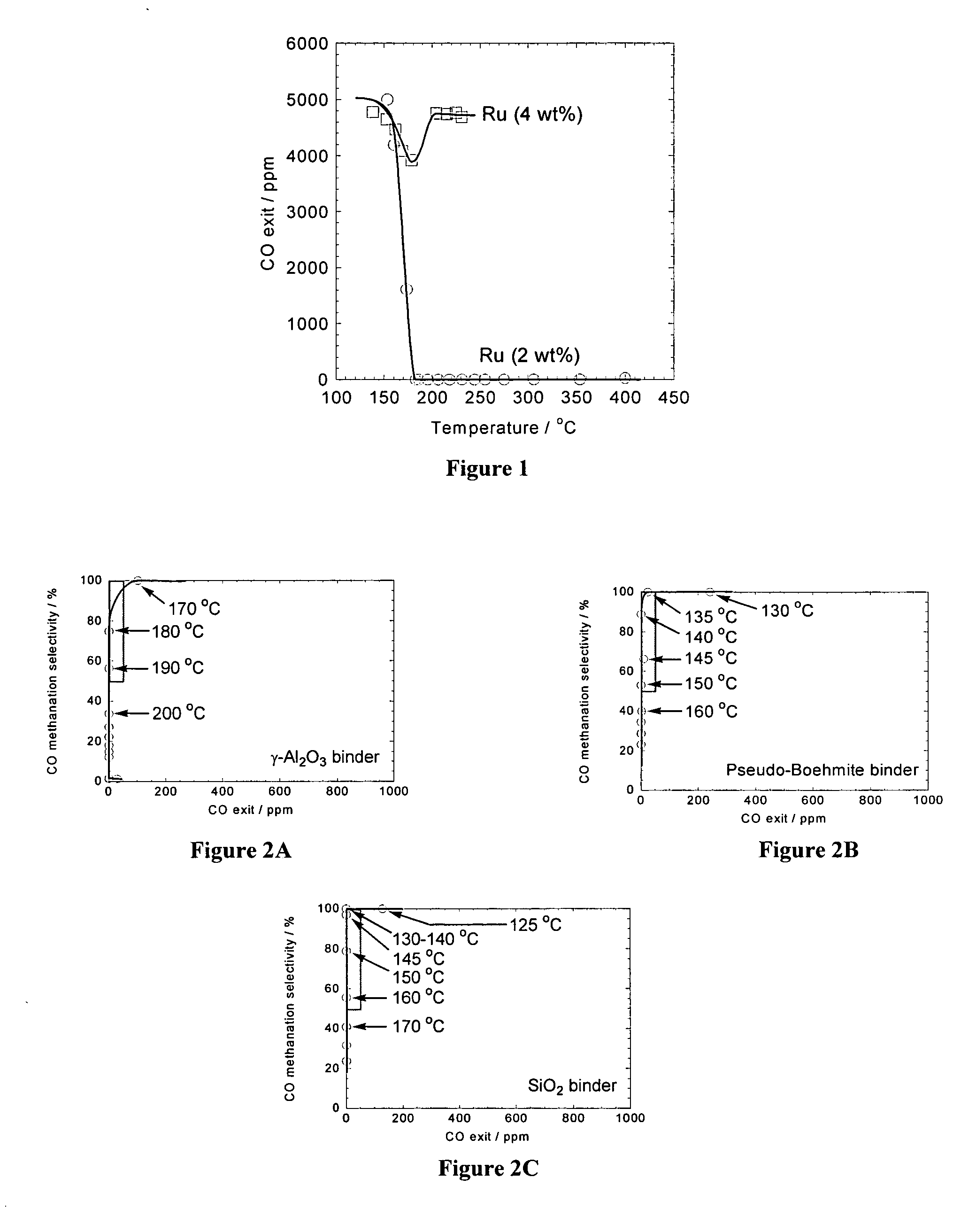

InactiveUS20050096212A1Facilitates selective hydrogenationReduce concentrationMolecular sieve catalystsRutheniumFaujasite

A catalyst for the conversion of carbon monoxide comprising a support having a predetermined pore size and a metal capable of forming a metal carbonyl species is described. In one embodiment, the catalyst of the present invention comprises a mordenite, beta, or faujasite support and ruthenium metal.

Owner:SUD CHEM INC

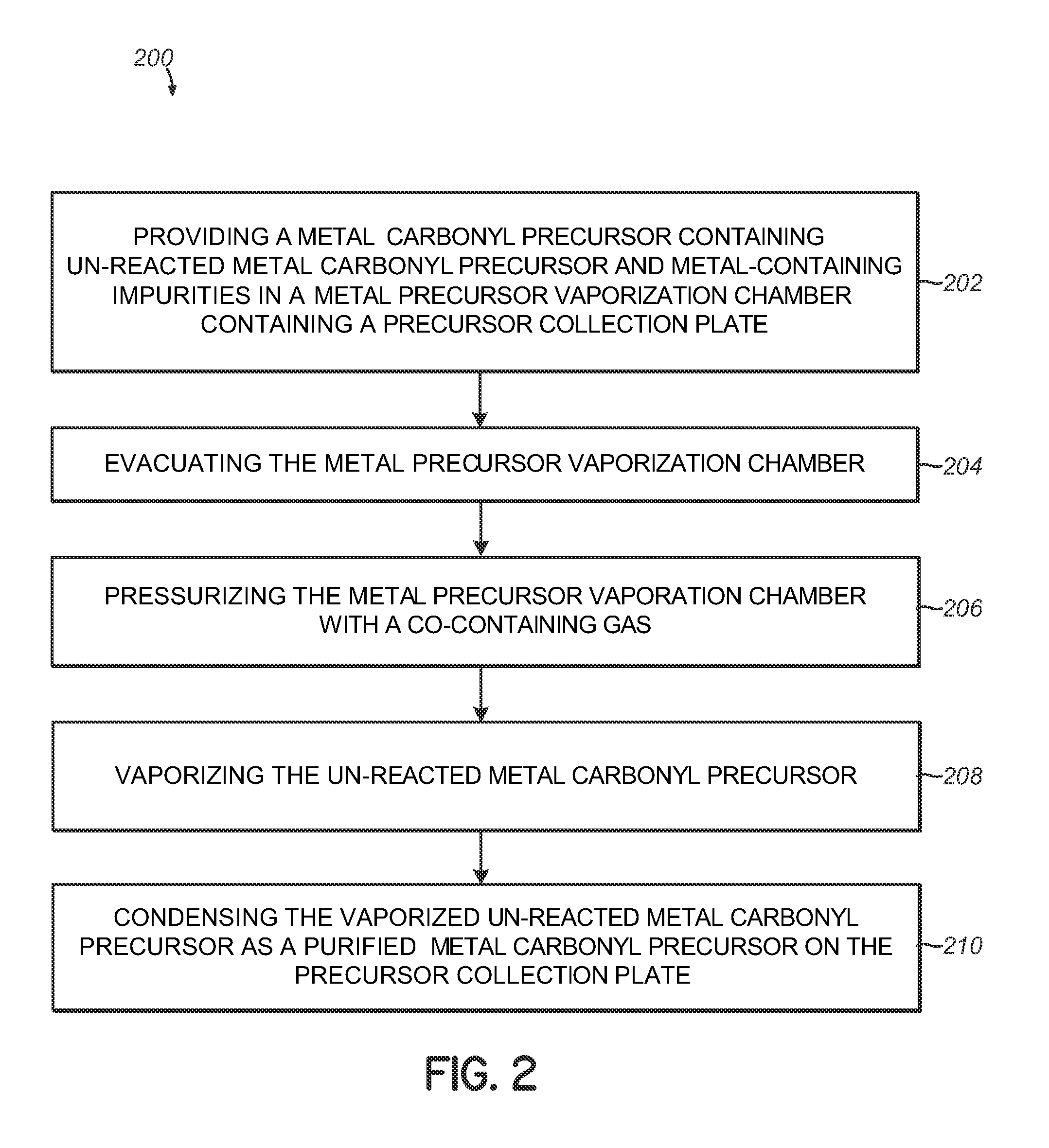

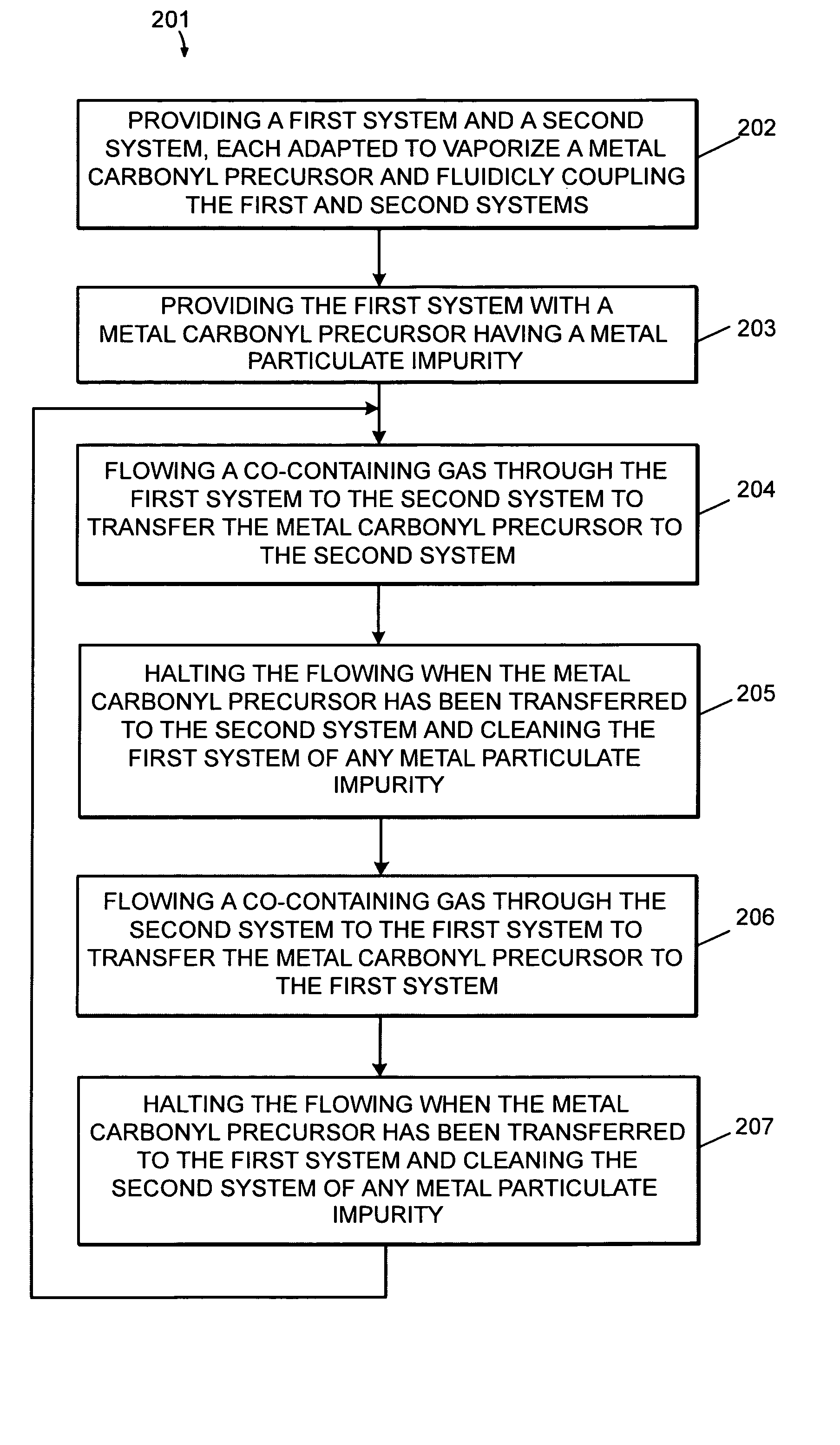

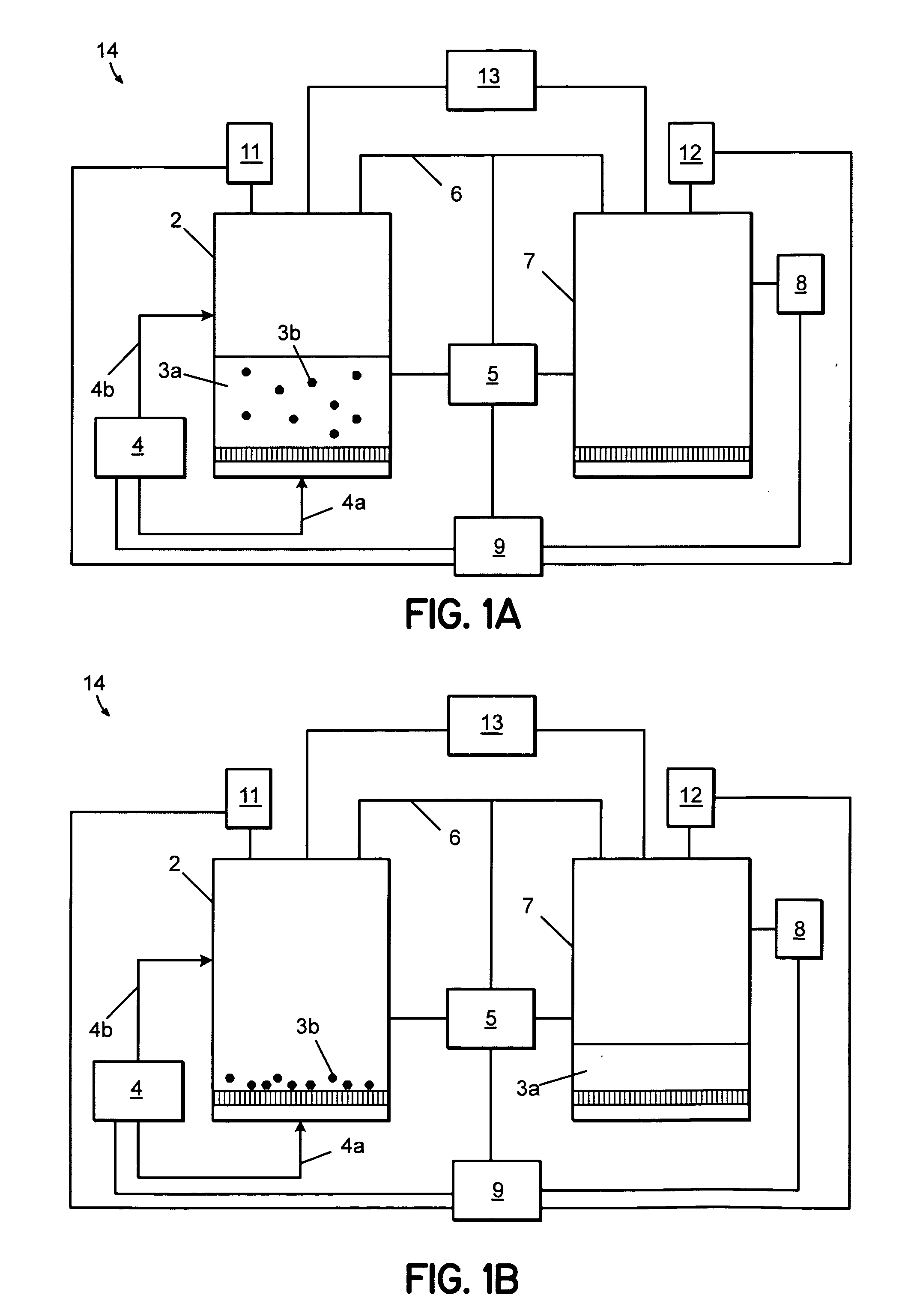

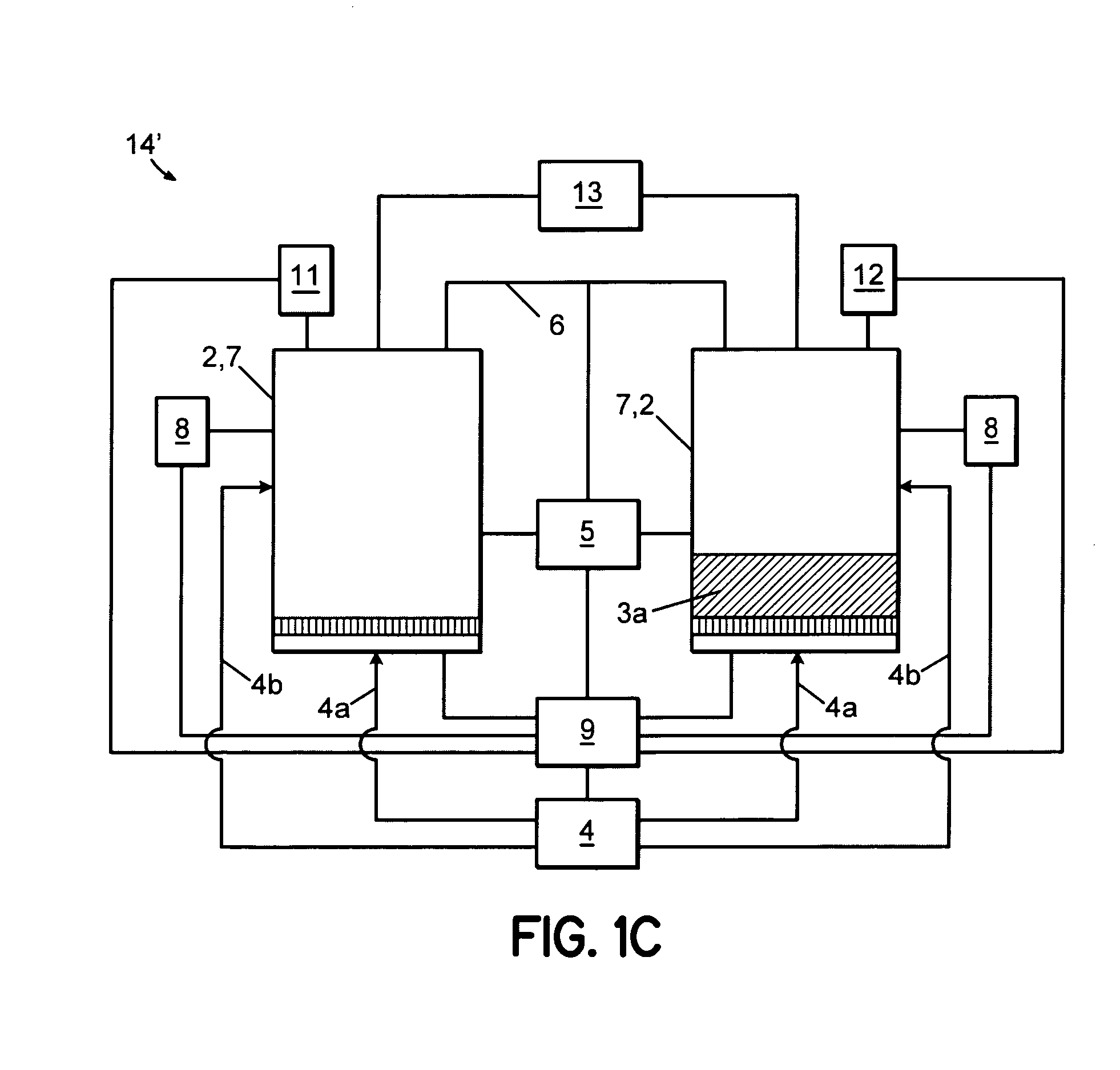

Method and integrated system for purifying and delivering a metal carbonyl precursor

InactiveUS20070231241A1Efficient deliveryOrganic compound preparationOxygen compounds preparation by reductionVaporizationMetal carbonyl

A method and integrated system are provided for purifying and delivering a metal carbonyl precursor utilized to process a substrate. The method includes providing the metal carbonyl precursor containing un-reacted metal carbonyl precursor and metal-containing impurities in a metal precursor vaporization chamber containing a precursor collection plate, evacuating the metal precursor vaporization chamber, pressurizing the metal precursor vaporization chamber with a CO-containing gas, vaporizing the un-reacted metal carbonyl precursor, and condensing the vaporized un-reacted metal carbonyl precursor as a purified metal carbonyl precursor on the precursor collection plate. The method may further include vaporizing the purified metal carbonyl precursor, and delivering a process gas containing the vapor of the purified metal carbonyl precursor by flowing a gas containing CO through the metal precursor vaporization chamber to a deposition system configured to expose a substrate to the process gas.

Owner:TOKYO ELECTRON LTD

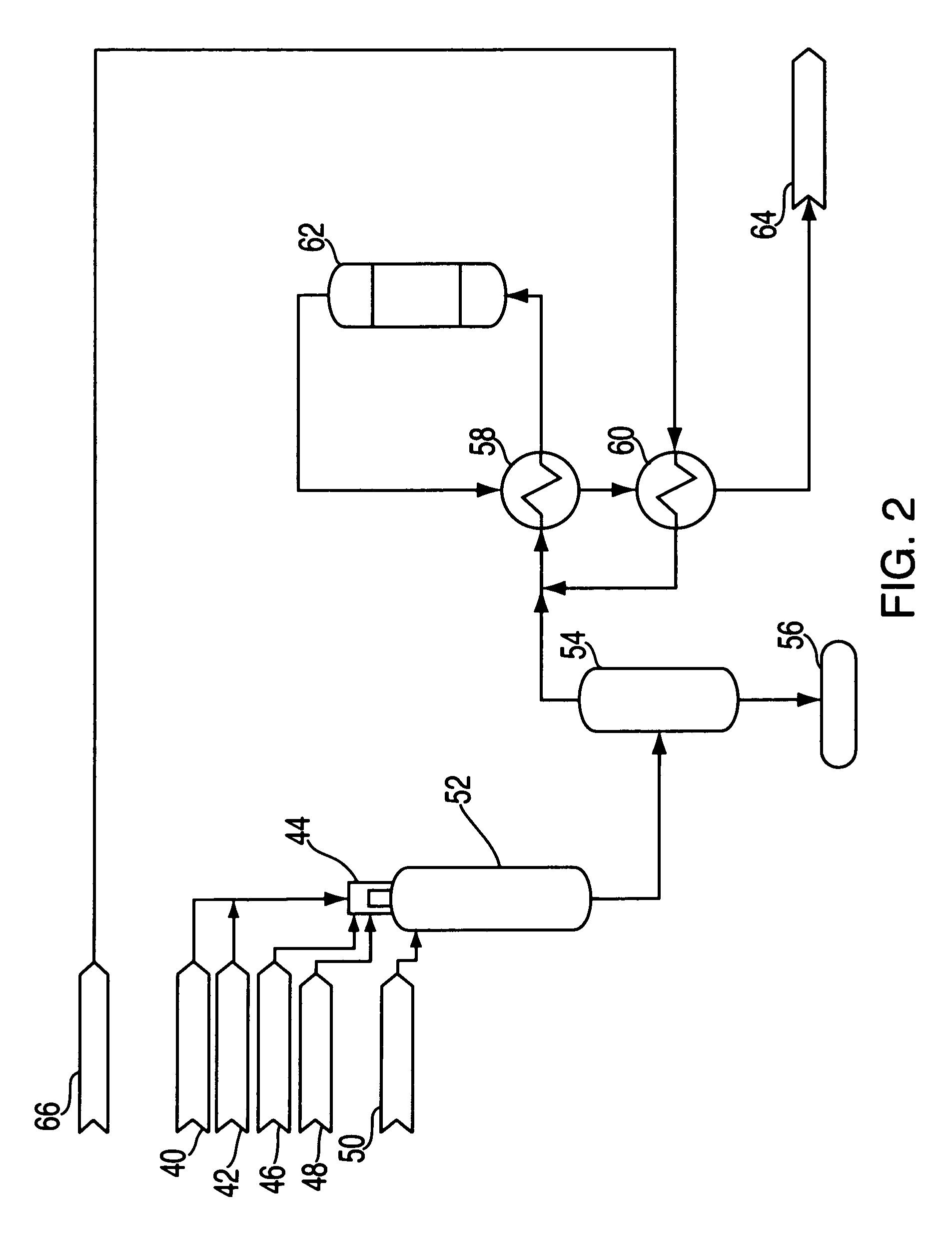

Method producing metal nanopowders by decompositon of metal carbonyl using an induction plasma torch

InactiveUS7967891B2Increase flexibilityImprove toleranceMaterial nanotechnologyTransportation and packagingMetallurgyInduction plasma technology

Owner:TEKNA PLASMA SYST INC

Method for purifying a metal carbonyl precursor

InactiveUS20070072401A1Increasing sublimation/evaporation temperatureReducing premature thermal decompositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingParticulatesCollection system

A method of purifying a metal carbonyl precursor in a metal precursor vaporization system where the metal carbonyl precursor comprises a metal particulate impurity. The method includes flowing a CO-containing gas through the metal precursor vaporization system to a precursor collection system in fluid communication with the metal precursor vaporization system to separate the metal carbonyl precursor from the metal particulate impurity and to transfer the metal carbonyl precursor to the precursor collection system, and collecting the transferred metal carbonyl precursor in the precursor collection system, where an amount of the metal particulate impurity is lower in the precursor collection system than in the precursor vaporization system and the precursor collection system is maintained at a lower temperature than the metal precursor vaporization system. A metal carbonyl precursor parameter may be monitored to determine a status of the metal carbonyl precursor and the need for purifying the metal carbonyl precursor.

Owner:TOKYO ELECTRON LTD

Method for preparing quantum dot of transitional metal chalcogenide compound

ActiveCN105129748AEasy to manufactureWide versatilityMaterial nanotechnologyBinary selenium/tellurium compoundsMetal chalcogenidesReaction temperature

The invention discloses a method for preparing a quantum dot of a transitional metal chalcogenide compound and belongs to the field of preparing functional nanomaterials by colloidal chemical methods. The method disclosed by the invention comprises the following steps: mixing a metal carbonyl compound and trioctylphosphine oxide, heating and dissolving the mixture as a metal source precusor, by taking octadecene as a reaction solvent, heating the mixture under inert gas protection to reaction temperature, and preparing a metal source reaction system; by taking organic phosphorus as a coorinating solvent, preparing non-metal source sulfur powder, selenium powder or tellurium powder into a precusor solution; injecting the non-metal source solution into the metal source reaction system under inert gas protection and maintaining the reaction temperature and carrying out a heating reaction; and carrying out high speed centrifugal separation, and adding a mixed solution of n-butylamine / n-hexane into the obtained solid product to obtain a quantum dot material of the transitional metal chalcogenide compound in a collide dispersing state. The preparation method for the quantum dot material of the transitional metal chalcogenide compound disclosed by the invention is good in universality, fast in reaction speed, high in reaction yield, simple to operate, mild in reaction condition and easy for large-scaled production.

Owner:NANJING UNIV OF POSTS & TELECOMM

Environment protection type polyurethane non-particle spray coating material for play ground layer and manufacture method thereof

InactiveCN101245223AImprove mechanical propertiesOvercome injuryGround pavingsPolyurea/polyurethane coatingsEpoxyCalcium bicarbonate

The invention discloses an environmental-friendly type polyurethane non particle spraying material used in stadium ground layer, which is formed by the mixing of component A and component B; wherein, the weight proportion of component A and component B is 1:3; the component A is obtained by mixing diphenylmethane diisocyanate and polyether glycol according to certain proportion; the component B is obtained by mixing polyether-tribasic alcohol, polyether glycol, dry process montmorillonite clay, 3, 5-methyl-sulfide base tolylene diamine, trimethylolpropane, epoxy resin, two-octyl, silica dioxide powder, calcium bicarbonate, organobentonite, iron oxide red or tartrazine-phthalo green mixture and metal carbonyl carboxylate according to certain proportion. The invention also discloses a preparation method of the material, which includes the steps: first preparing the component A and the component B respectively in specific condition, and mixing and stirring the component A and the component B to obtain the material of the invention. As the material of the invention contains no TDI and MOCA, the polyurethane non particle spraying material has no toxicity and safety hidden danger, and is an environmental-friendly material.

Owner:SICHUAN AOHAI SPORTS ENG

Catalyst for removing metal carbonyl, process for producing mixed reformed gas containing hydrogen, process for removing metal carbonyl, and fuel cells system

InactiveUS20070281203A1Efficient removalCell electrodesHydrogen/synthetic gas productionIridiumClay minerals

The present invention relates to a catalyst for removing a metal carbonyl which comprises a nickel-containing catalyst component and copper, said copper being present in an amount of 0.001 to 250% by weight in terms of metallic copper on the basis of a weight of the nickel contained in the catalyst component. The catalyst may further contain, if required, zinc oxide, a clay mineral, or a clay mineral supporting at least one element having an average particle diameter of not more than 50 nm which is selected from the group consisting of ruthenium, rhodium, iridium, platinum, gold, silver, palladium, nickel, cobalt, copper, iron, zinc, vanadium and manganese. When using the catalyst, it is possible to produce a mixed reformed gas from hydrocarbons, and remove a metal carbonyl in a reforming reaction field.

Owner:TODA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com