Patents

Literature

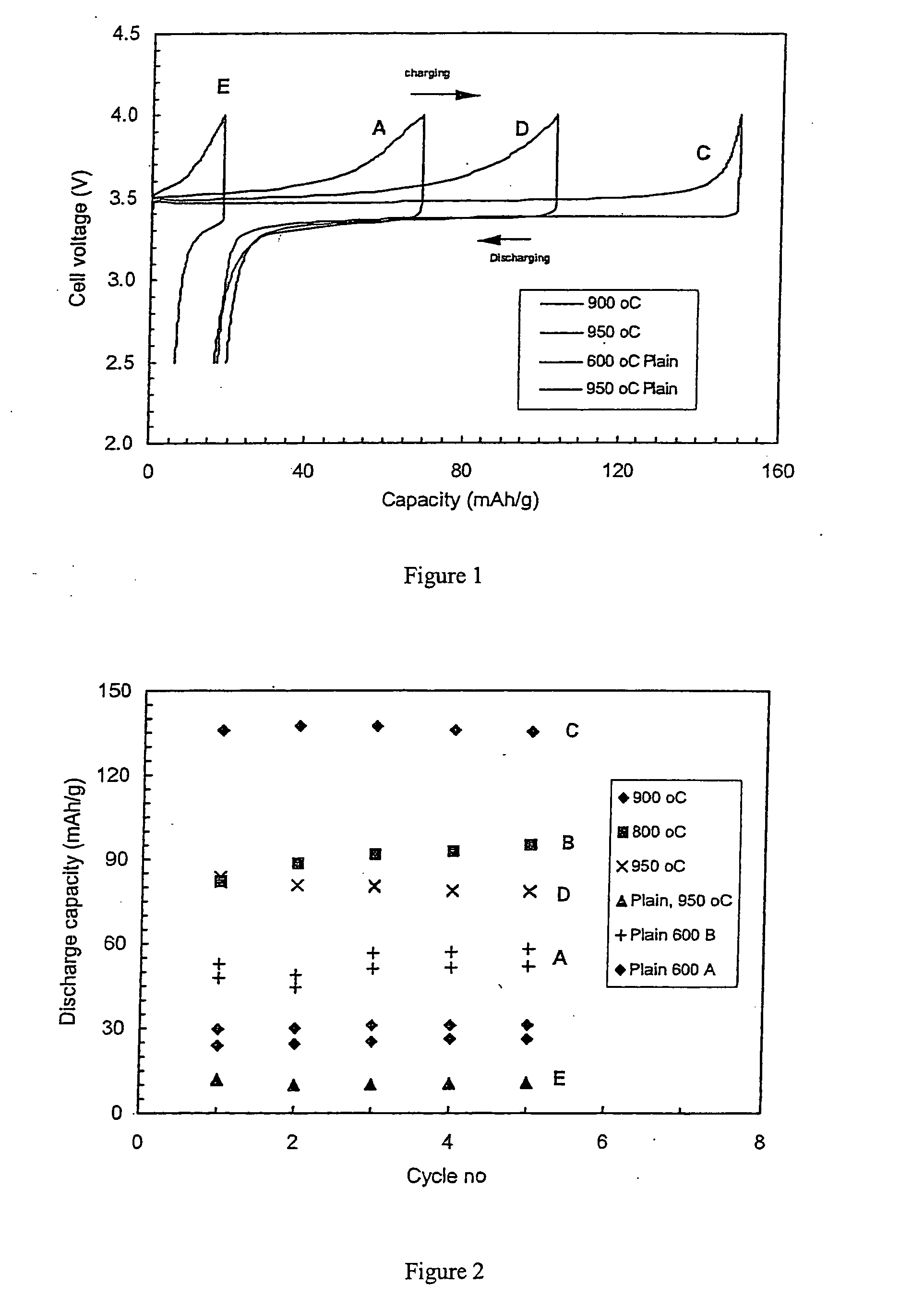

1999 results about "Carbon coated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

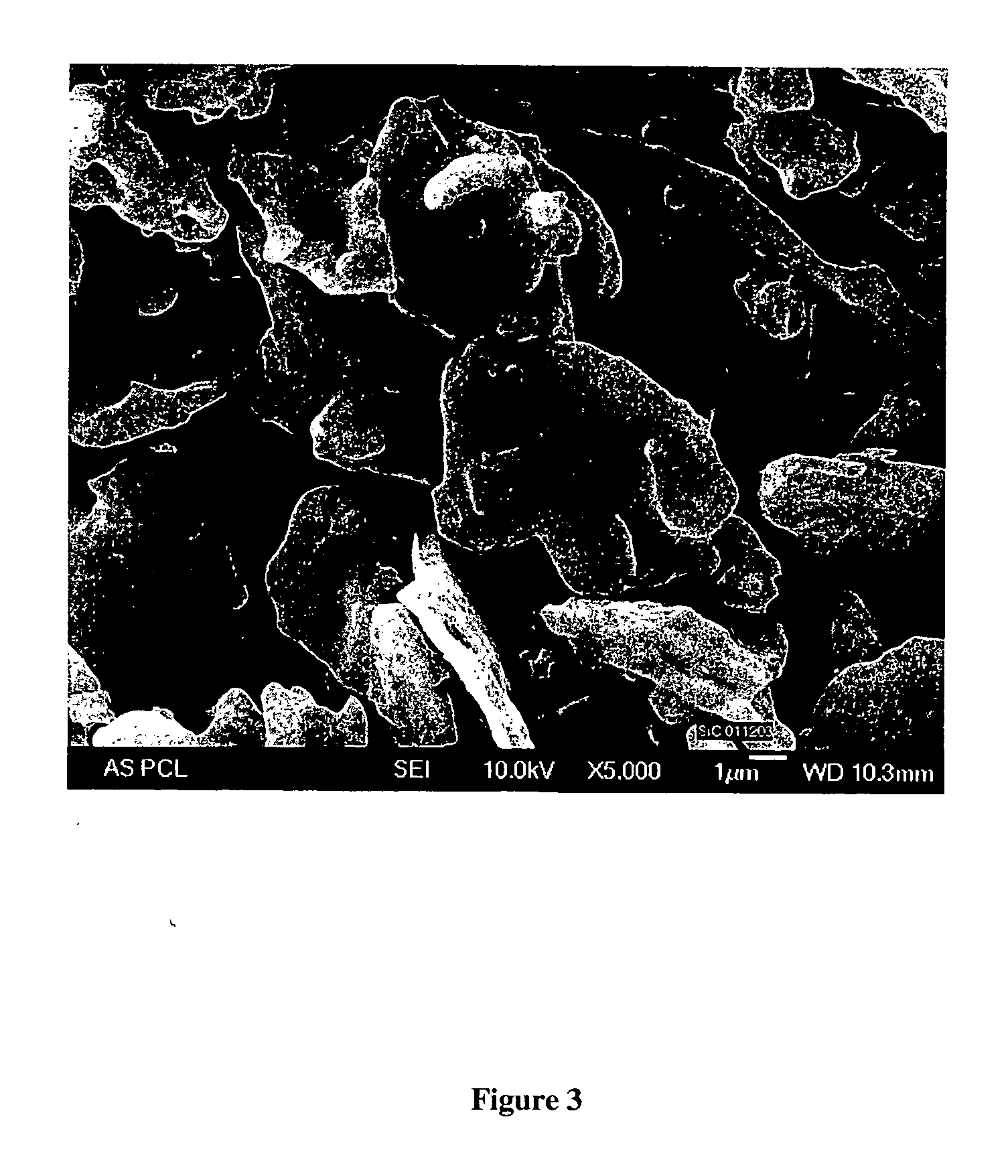

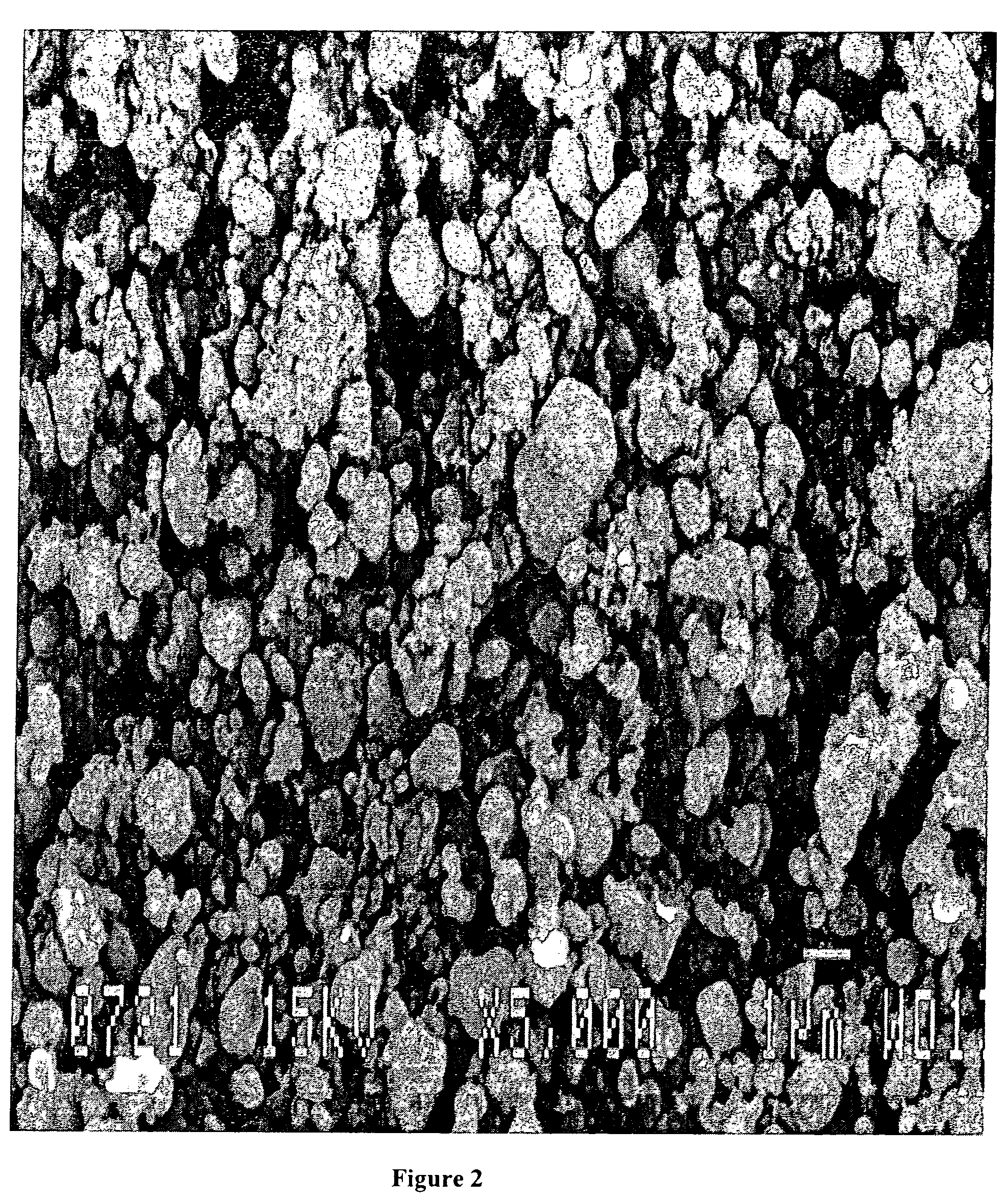

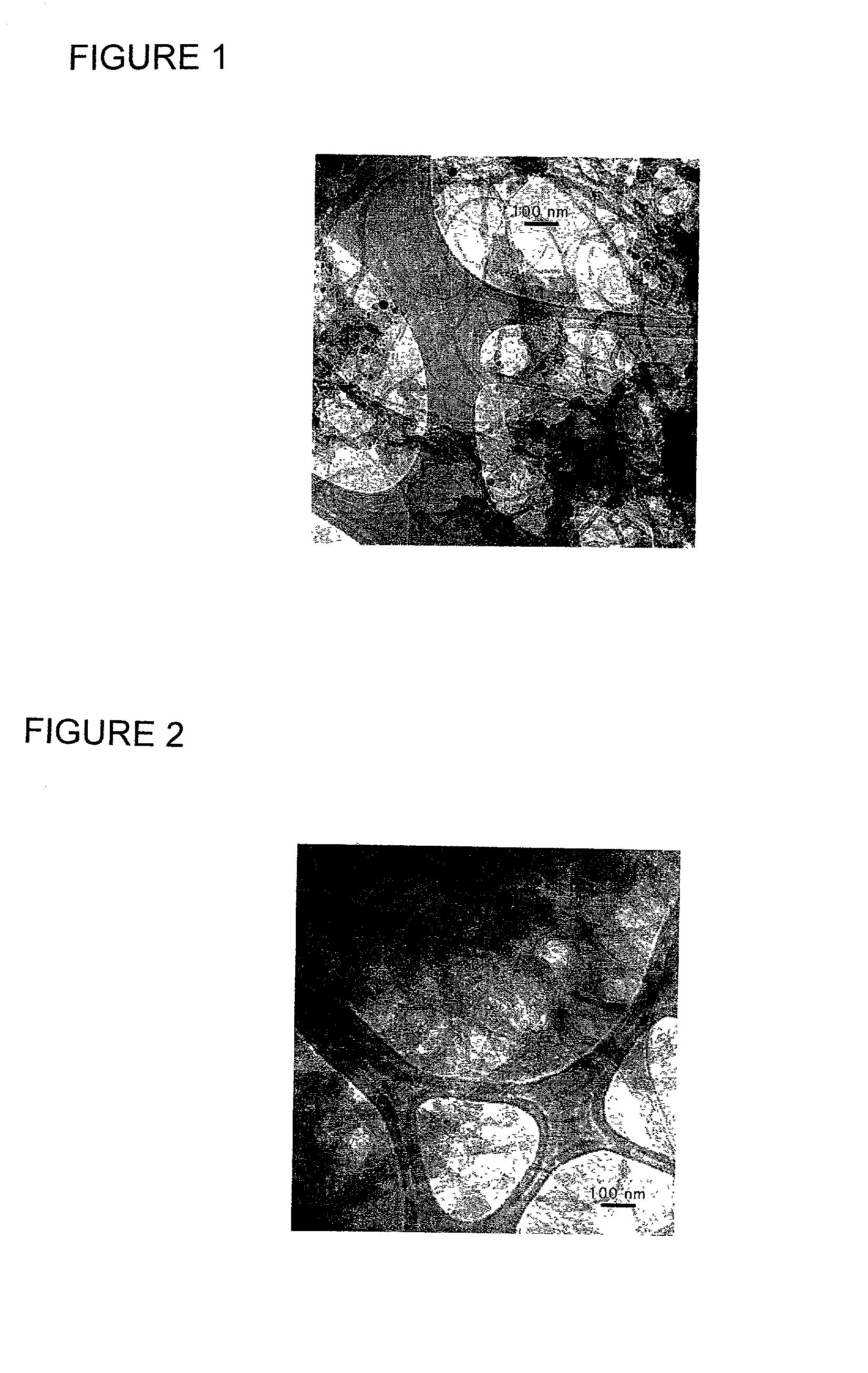

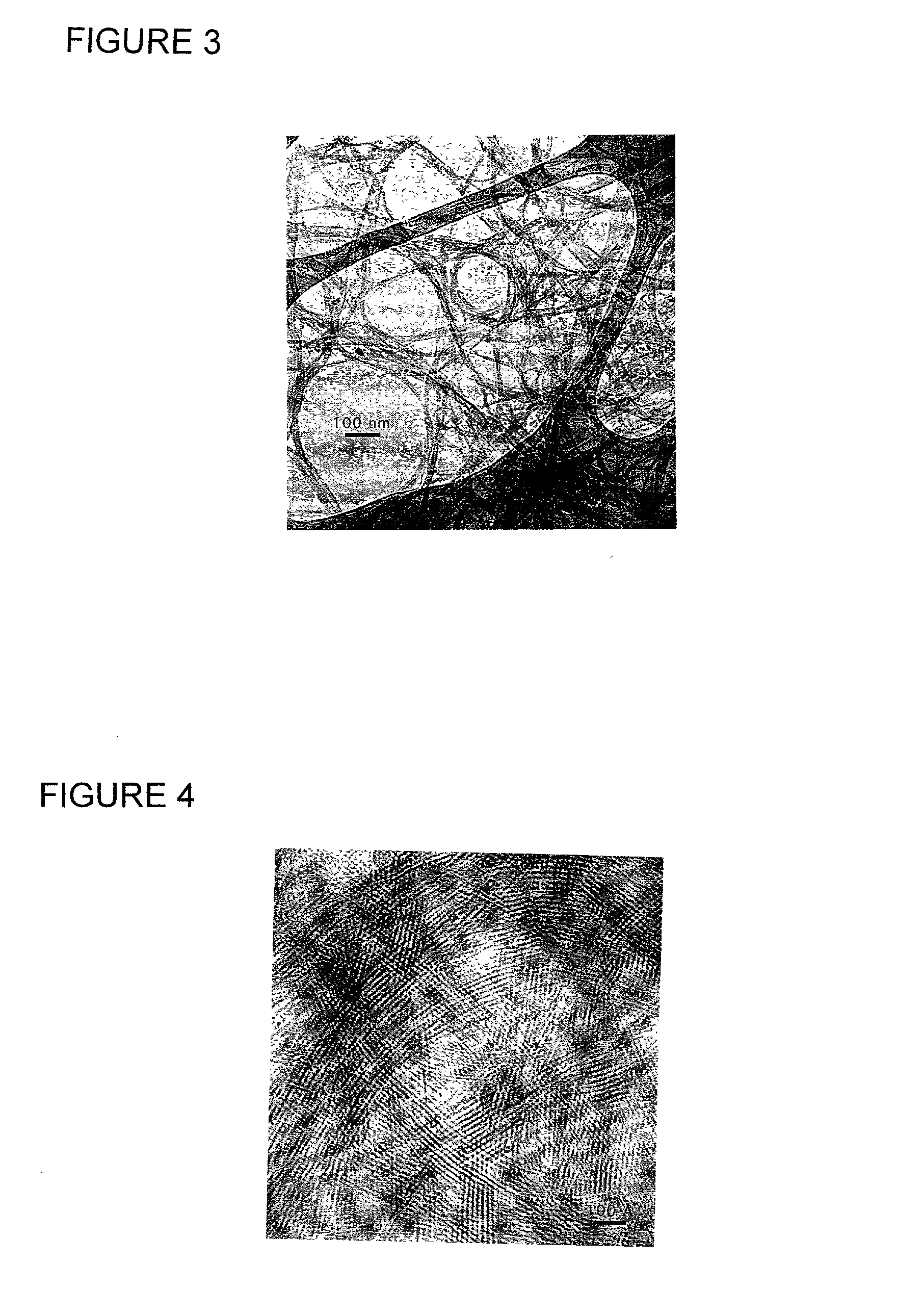

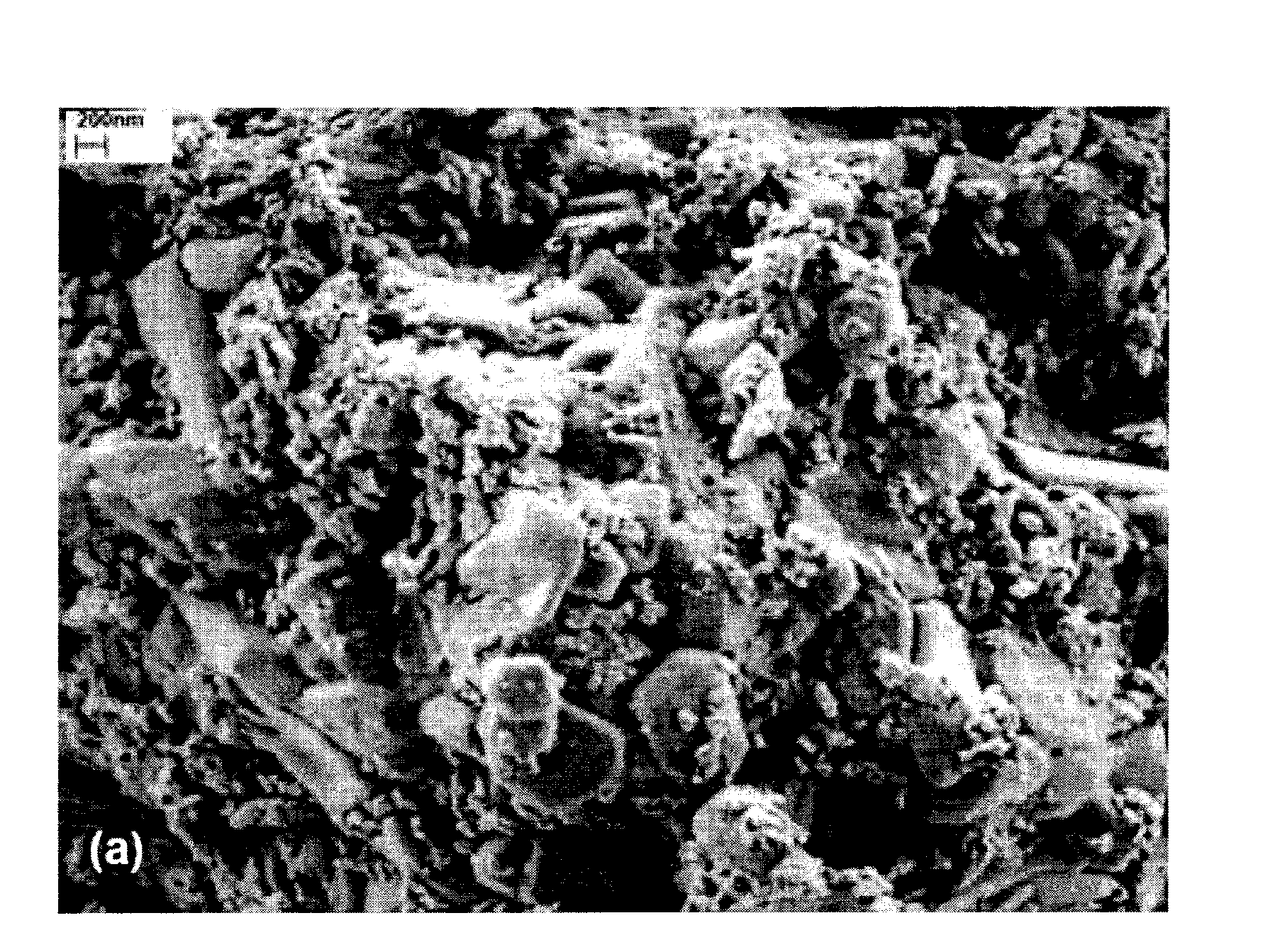

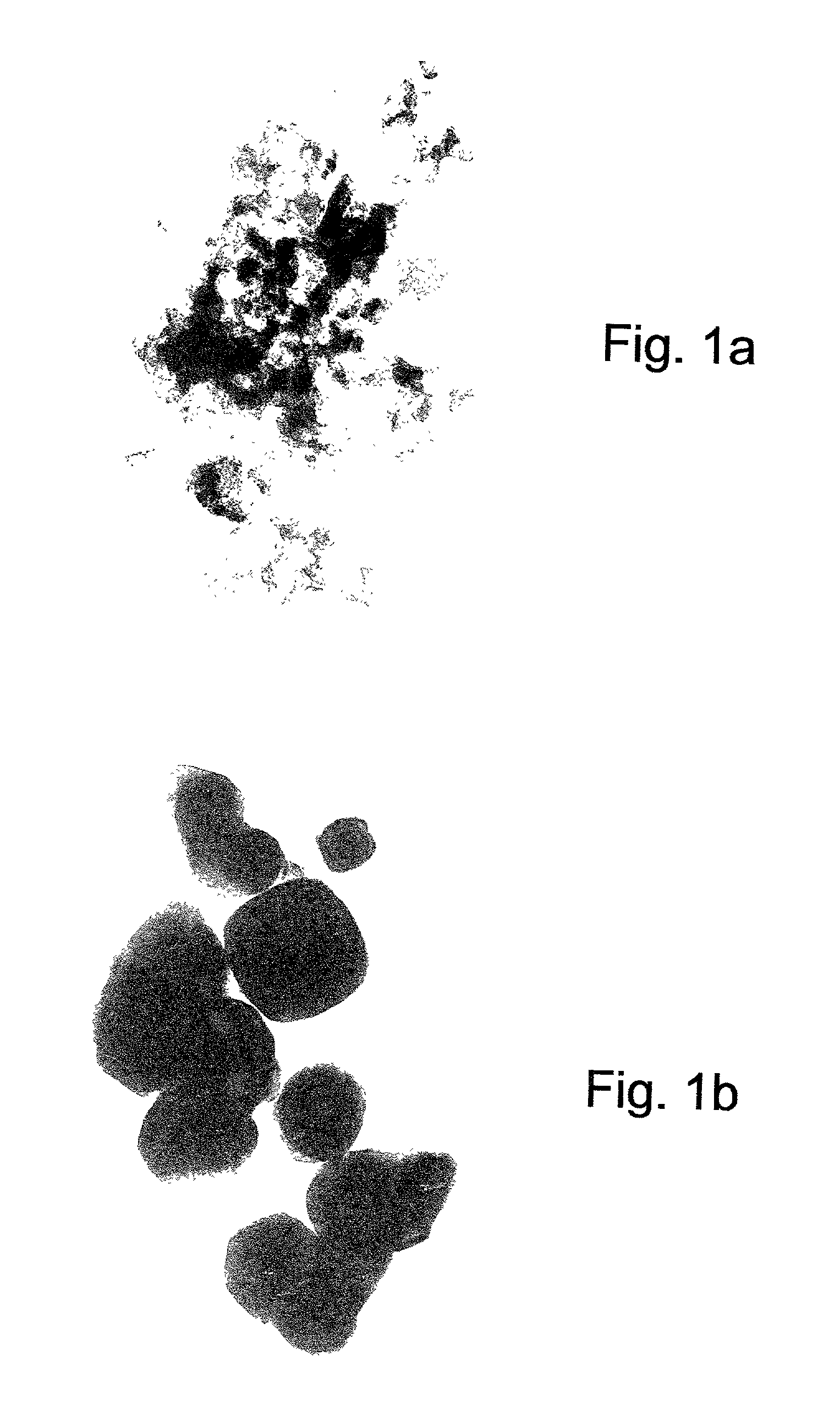

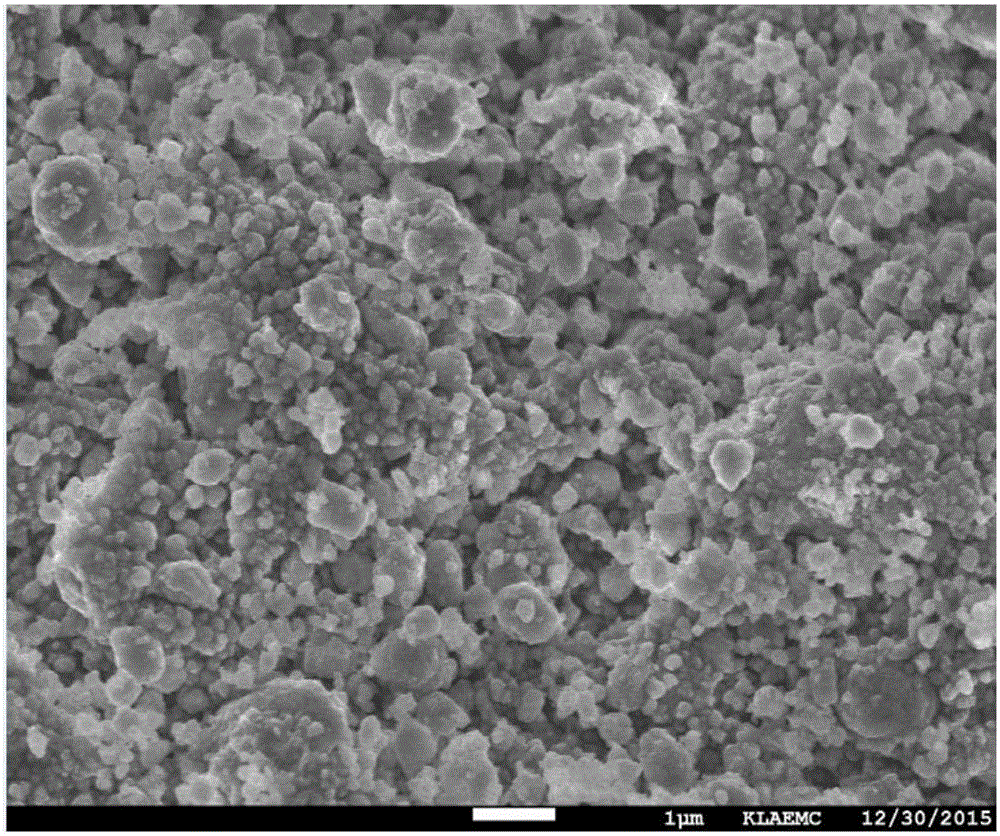

Carbon coating. Carbon coating is applied for SEM and TEM insulating samples. It is suitable for high resolution observation. The use of Carbon Films in Electron Microscopy with their LOW background signal, and relatively good electrical conductivity is well known.

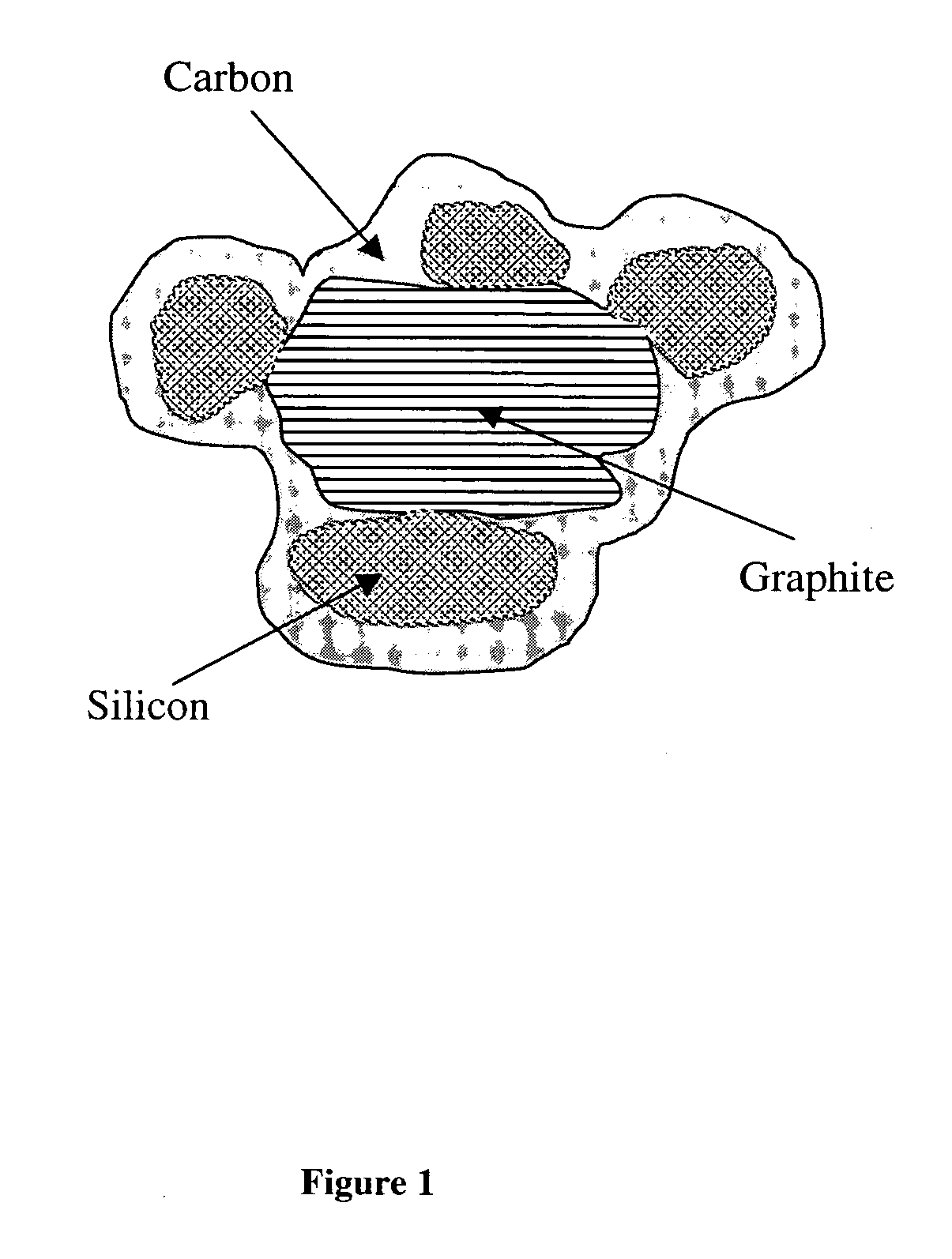

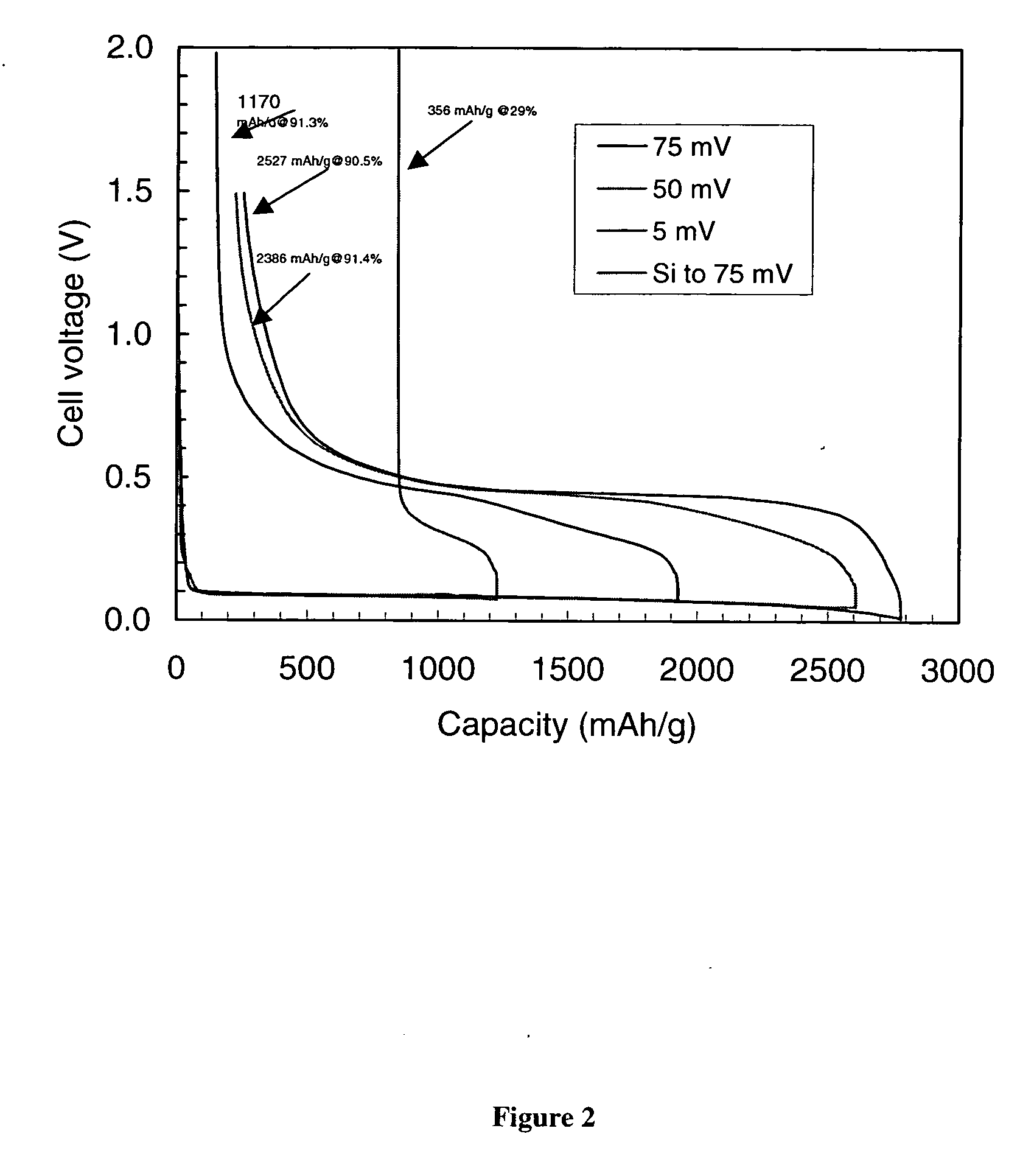

Carbon-coated silicon particle power as the anode material for lithium batteries and the method of making the same

InactiveUS20050136330A1Large capacityImprove efficiencyElectrode thermal treatmentElectrode carriers/collectorsCarbon compositesSilicon particle

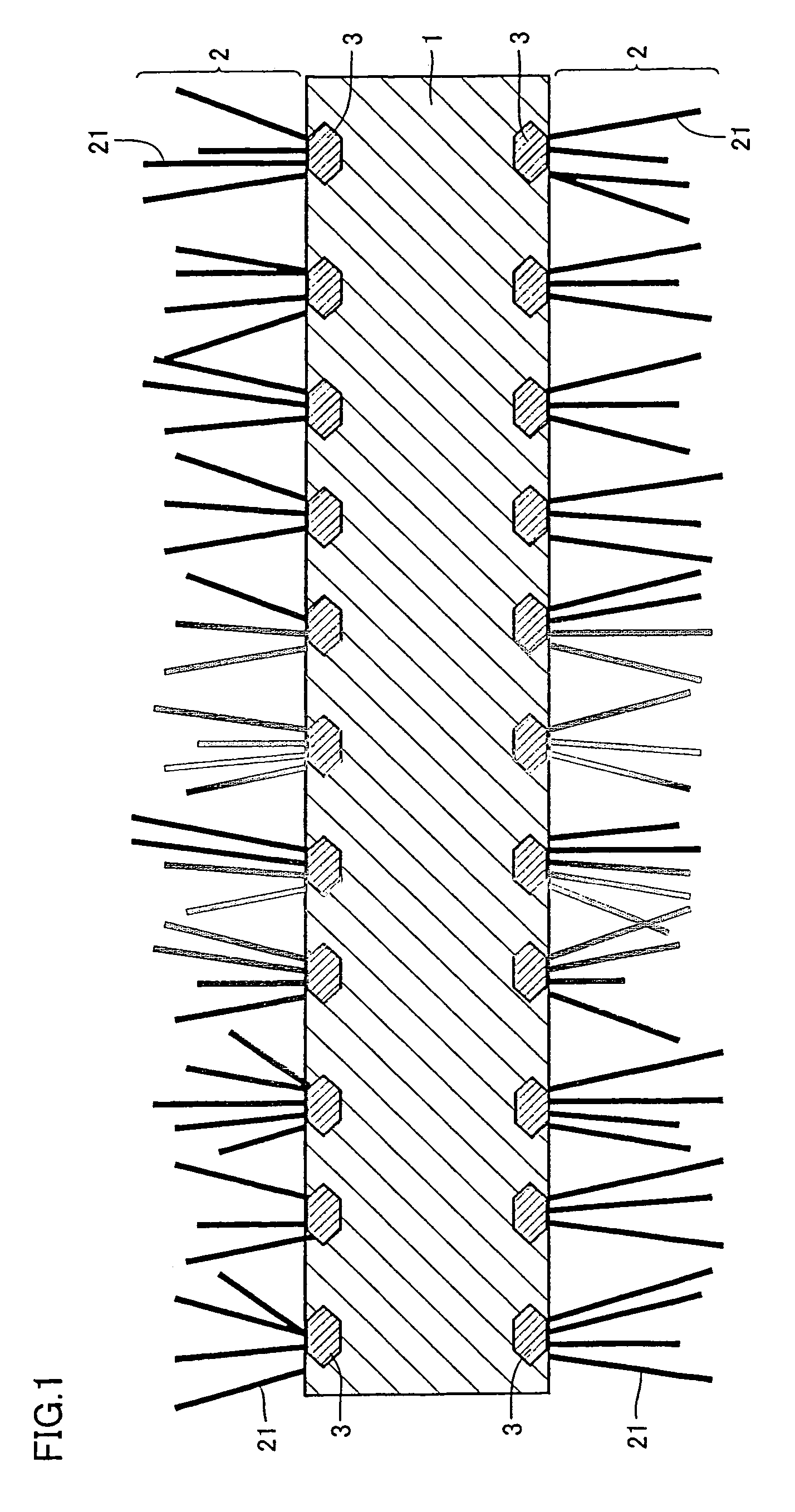

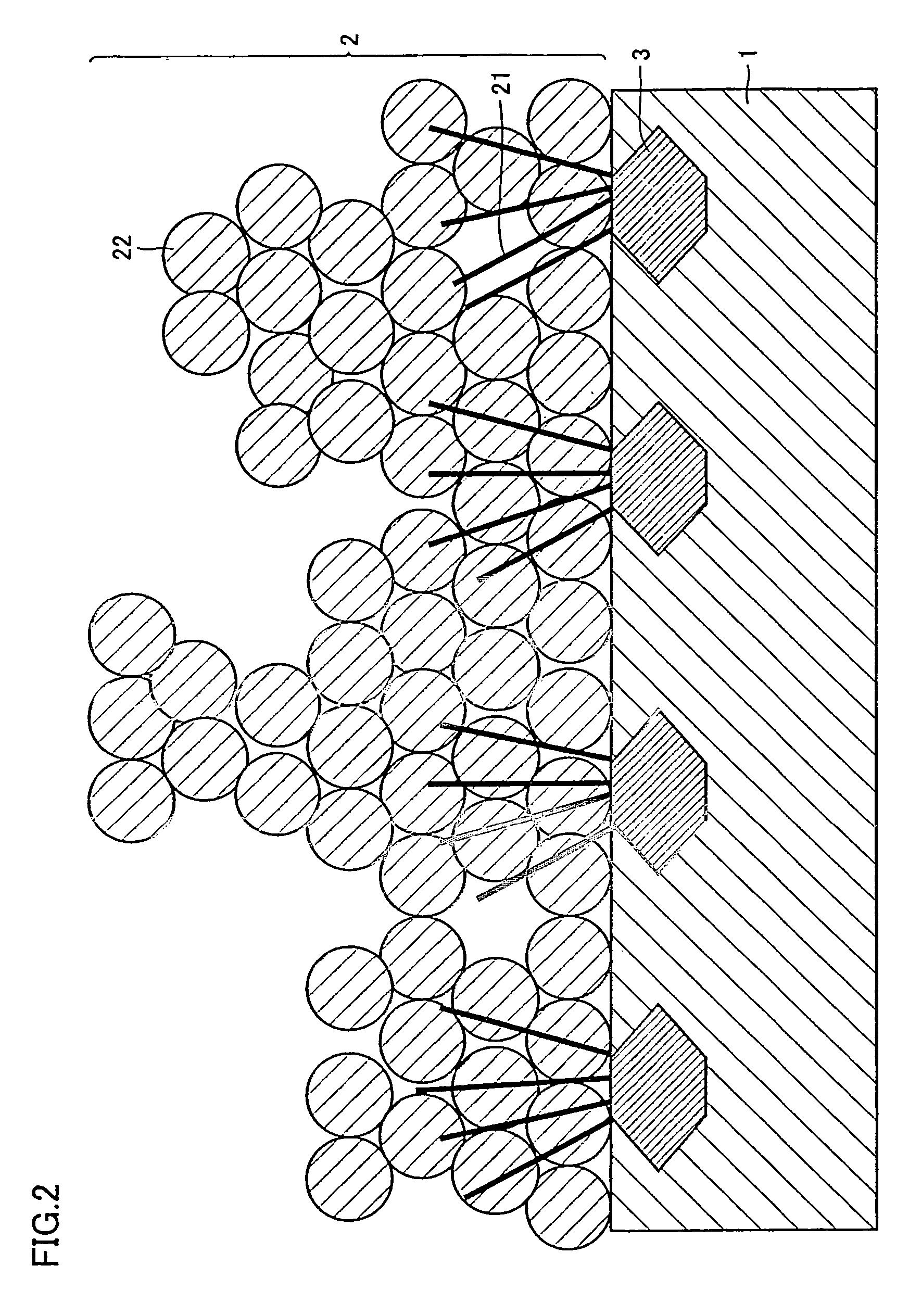

A process for the production of coated silicon / carbon particles comprising: providing a carbon residue forming material; providing silicon particles; coating said silicon particles with said carbon residue forming material to form coated silicon particles; providing particles of a carbonaceous material; coating said particles of carbonaceous material with said carbon residue forming material to form coated carbonaceous particles; embedding said coated silicon particles onto said coated carbonaceous particles to form silicon / carbon composite particles; coating said silicon / carbon composite particles with said carbon residue forming material to form coated silicon / carbon composite particles; and stabilizing the coated composite particles by subjecting said coated composite particles to an oxidation reaction. The coated composite particles will have a substantially smooth coating. The particles may be coated with multiple layers of carbon residue forming material /

Owner:PYROTECK INC

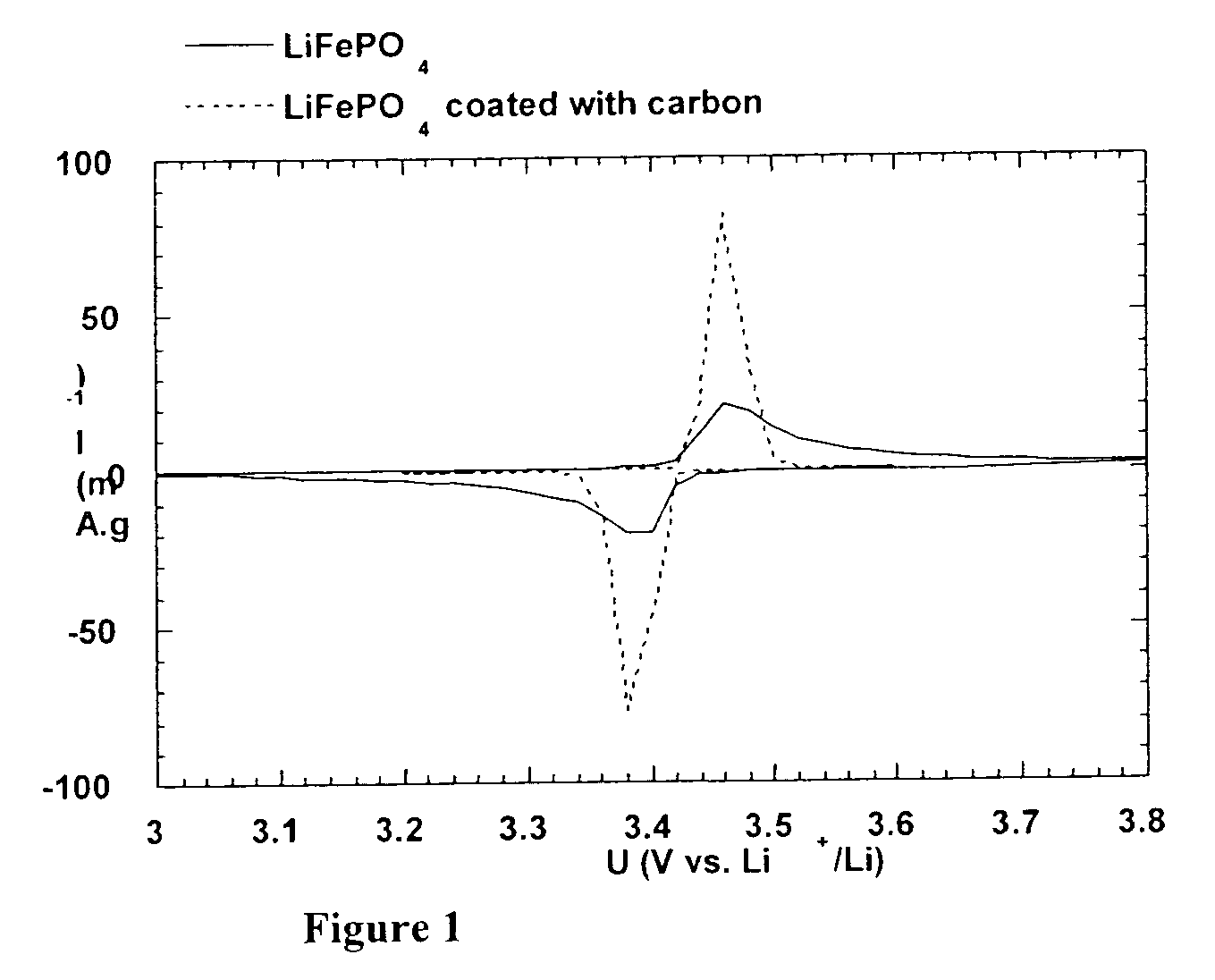

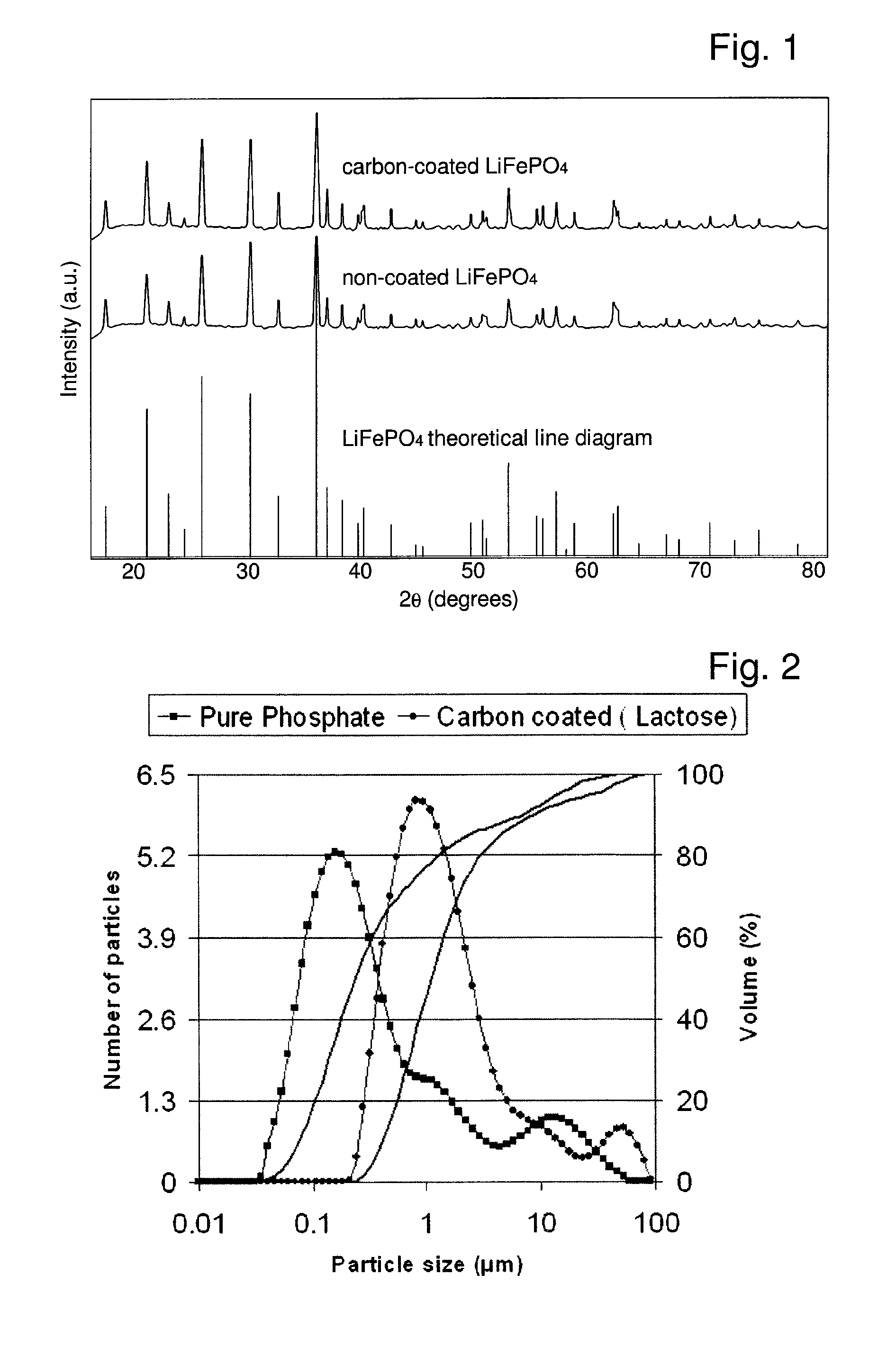

Method for synthesis of carbon-coated redox materials with controlled size

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

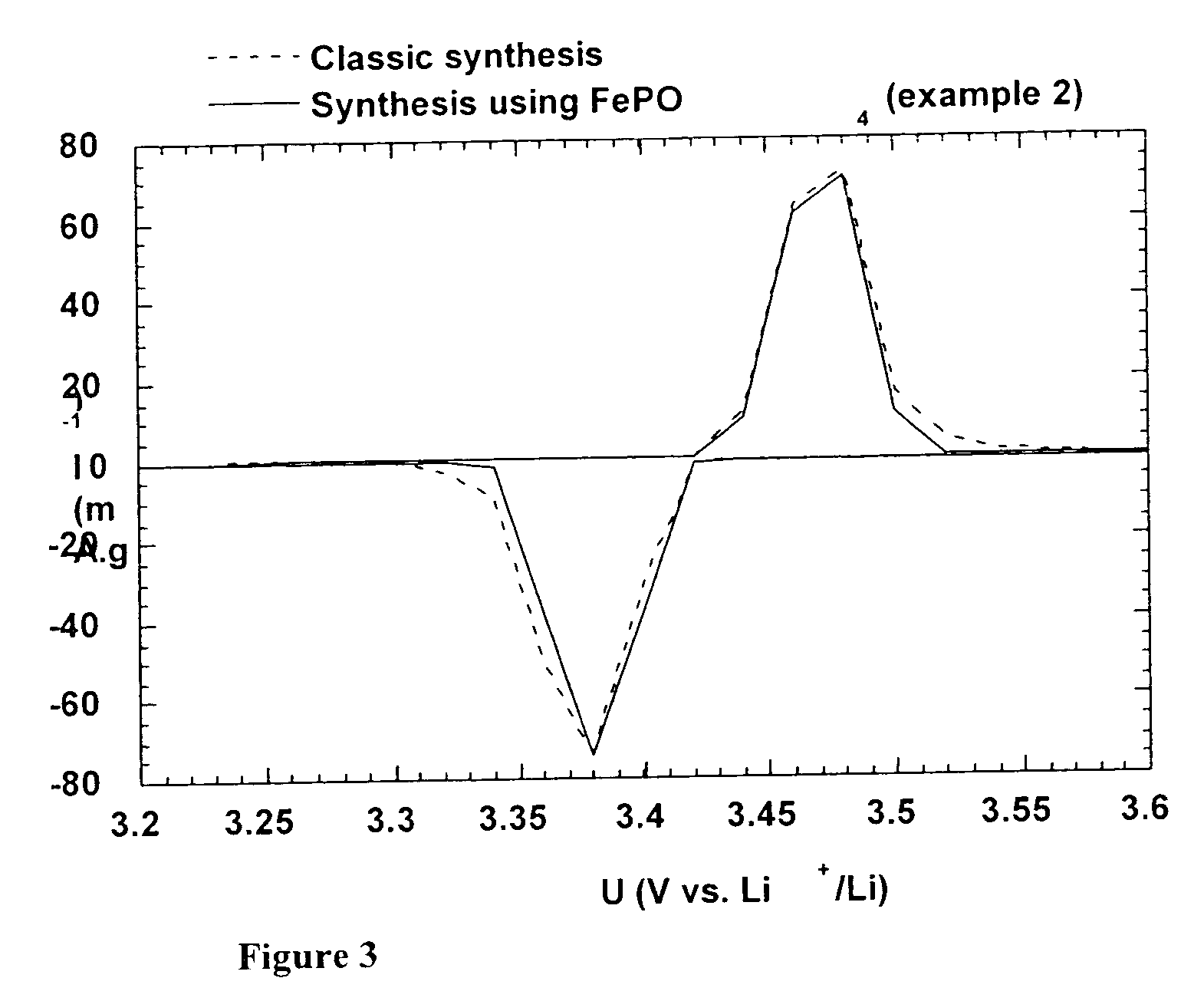

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Graphite alkene iron lithium phosphate positive active material, preparing method thereof, and lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material

InactiveCN101752561AImprove conductivityImprove cycle stabilityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

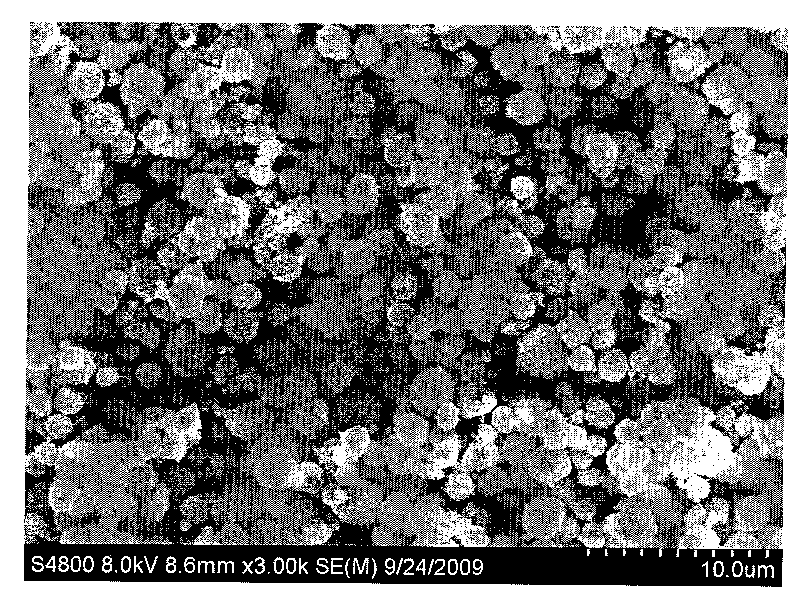

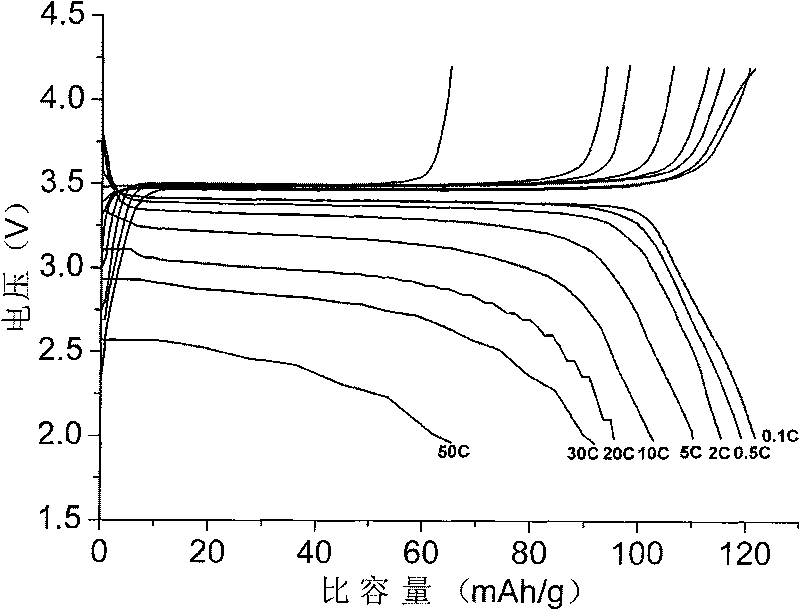

The present invention relates to graphite alkene iron lithium phosphate positive active material, a preparing method thereof, and a lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material. Graphite alkene and iron lithium phosphate are dispersed into water solution to be mixed evenly by stirring and ultra audible sound, then, are dried to obtain iron lithium phosphate material compounded by the graphite alkene and the iron lithium phosphate to be annealed by high temperature, and finally, the graphite alkene modified iron lithium phosphate positive active material is obtained. Compared with traditional carbon coated and conductive polymeric adulteration modified lithium batteries, the lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material has the advantages of high battery capacity, good charging-discharging circulating performance, long life and high circulating stability, and has great utility value.

Owner:宁波艾能锂电材料科技股份有限公司

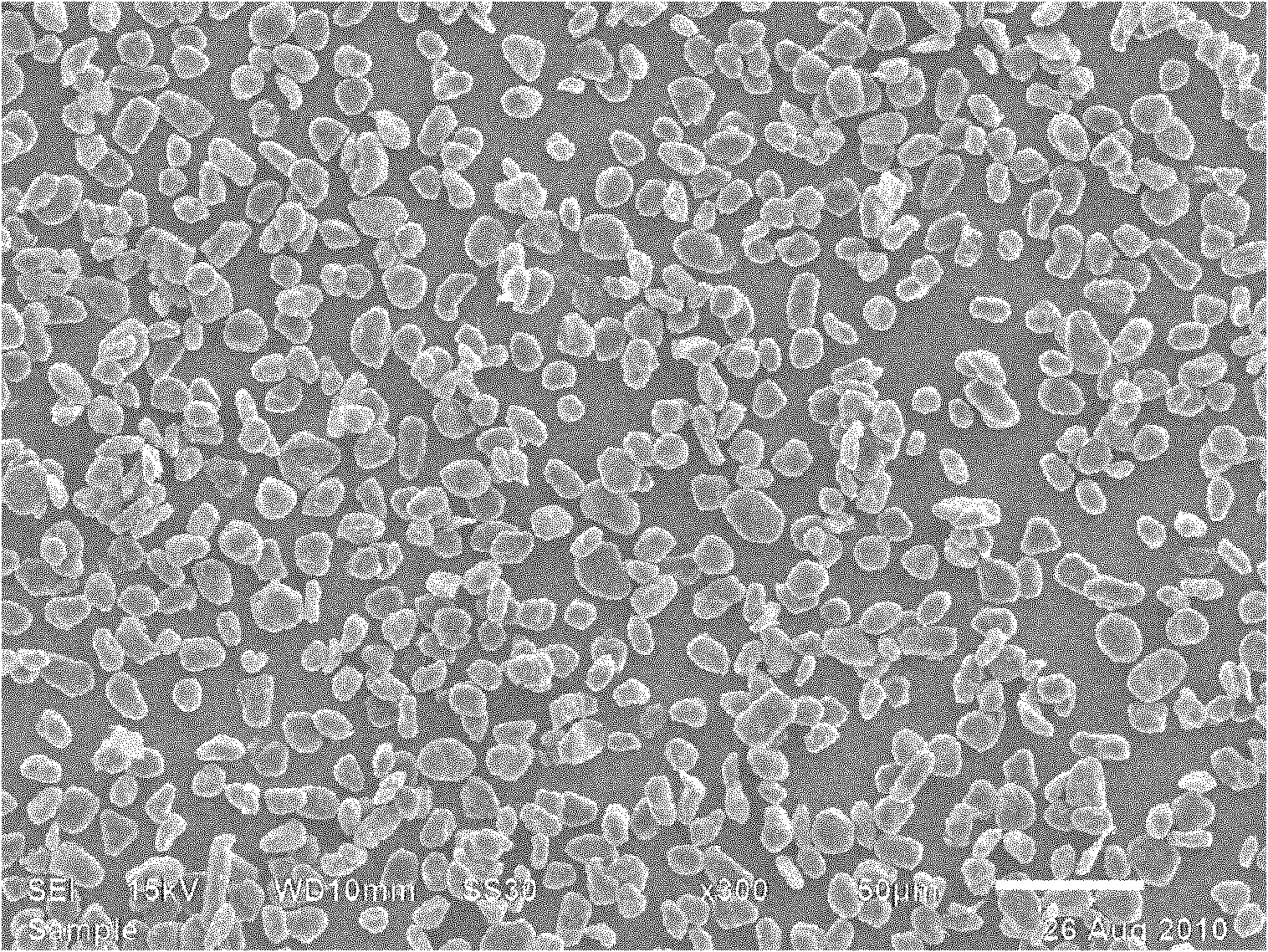

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

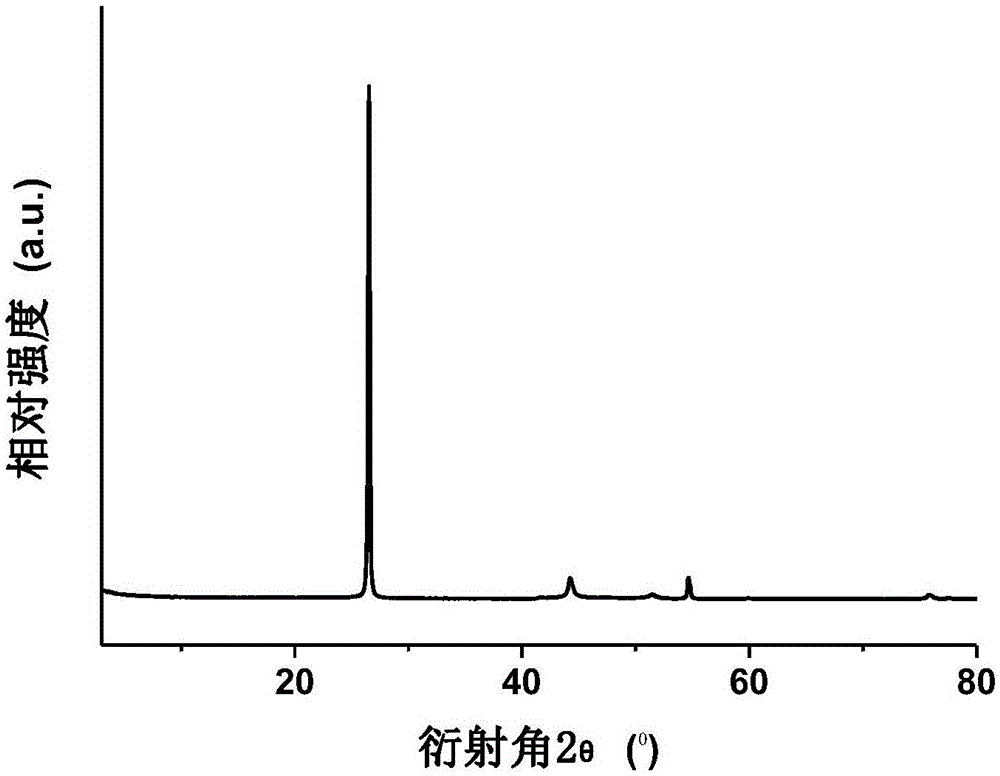

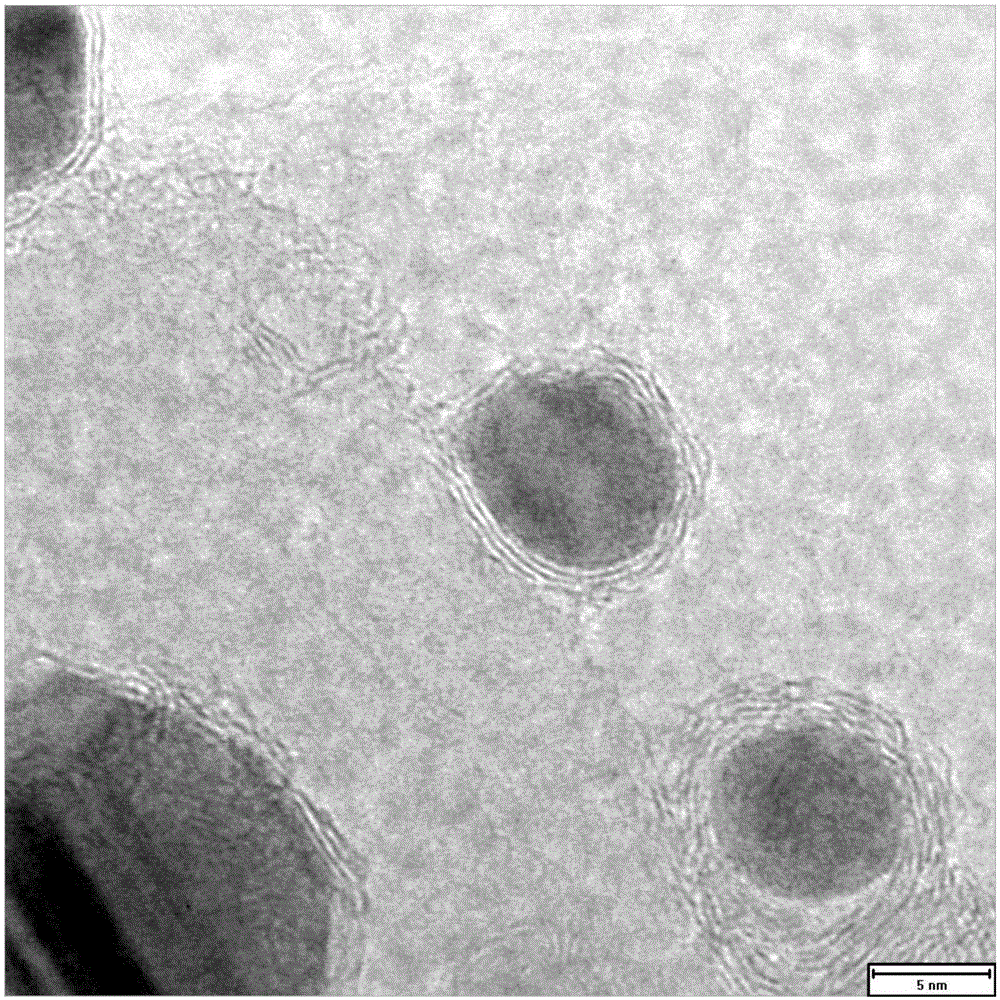

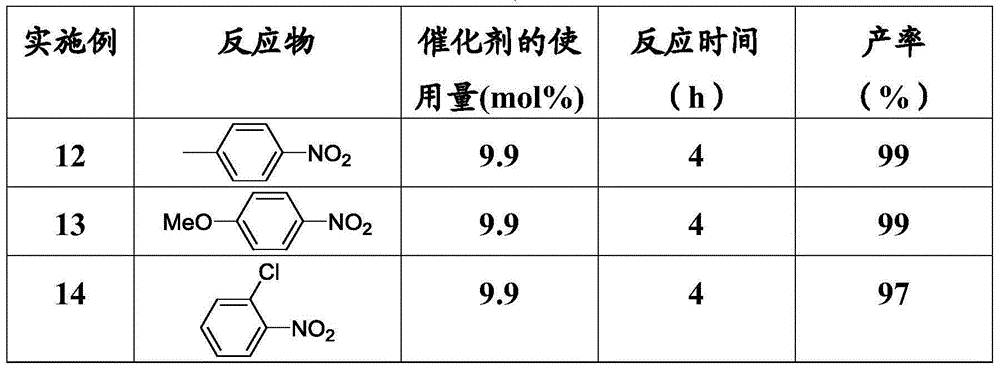

Catalyst for selective hydrogenation reaction of aromatic nitrocompound and preparation method of catalyst

InactiveCN105032424AEasy to storeLow costCarboxylic acid nitrile preparationOrganic compound preparationNitro compoundAlcohol

The invention relates to a catalyst for selective hydrogenation reaction of an aromatic nitrocompound and a preparation method of the catalyst. The catalyst consists of a catalyst carrier and active metal coated with carbon, wherein the catalyst carrier includes a carbon-base carrier, SiO2, TiO2 or Al2O3; the active metal is selected from Co, Fe, Ni or Cu and other poor and noble metals. The catalyst is prepared by adopting a Pechini type sol-gel process which comprises the steps of dispersing an active metal precursor to water containing a coordination compound, adding a polyhydric alcohol solution and a macromolecule auxiliary, then adding the carrier, stirring for dispersion, carrying out hydrothermal reaction, separating out solid on the lower layer, and calcining in the inert atmosphere to obtain the catalyst in which carbon coats the active metal. Compared with the prior art, the catalyst can realize the hydrogenation reaction of a substituted aromatic nitrocompound in the mild condition; substrate conversion rate and production selectivity are high; the catalyst has recyclable economy and good application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

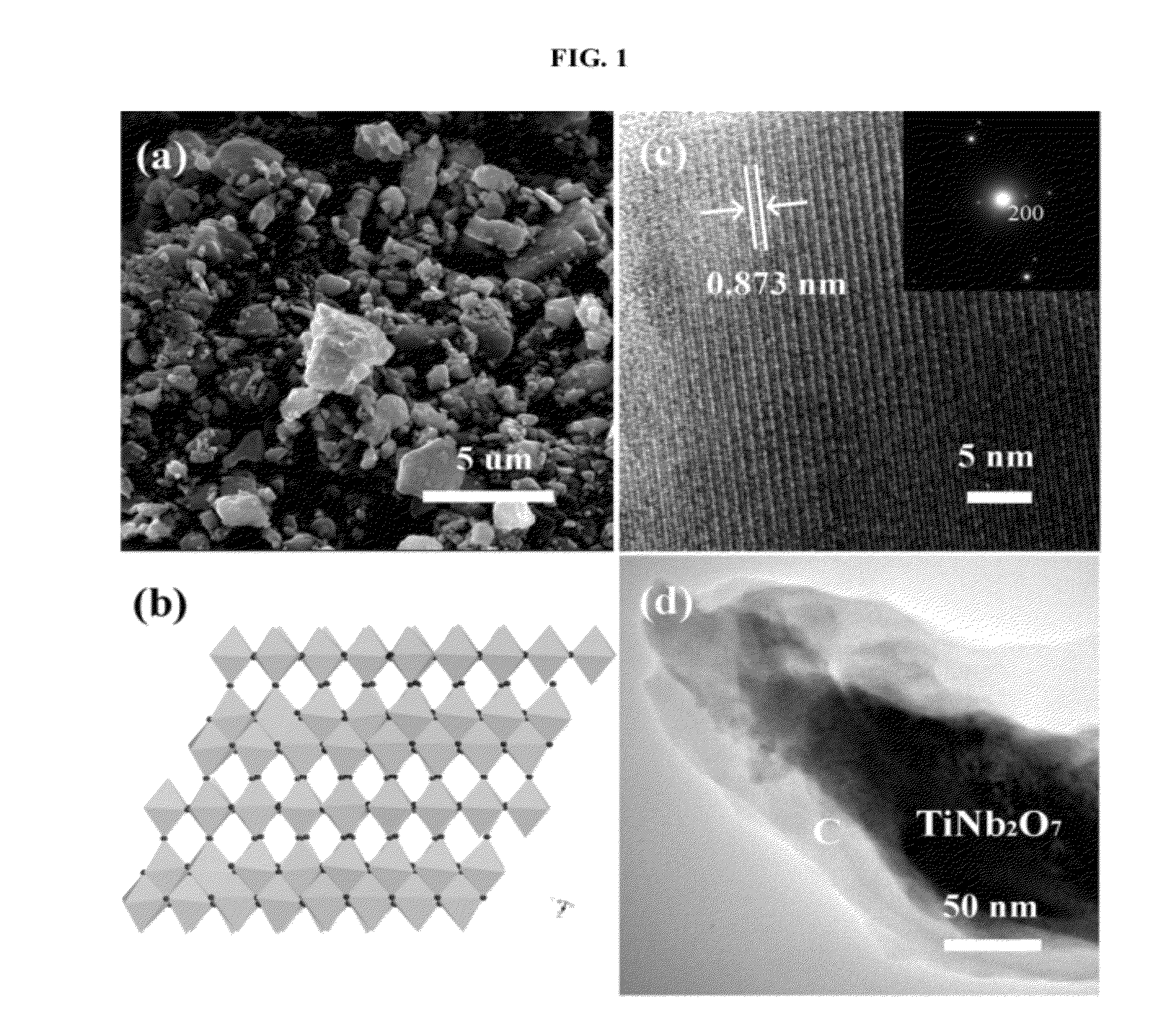

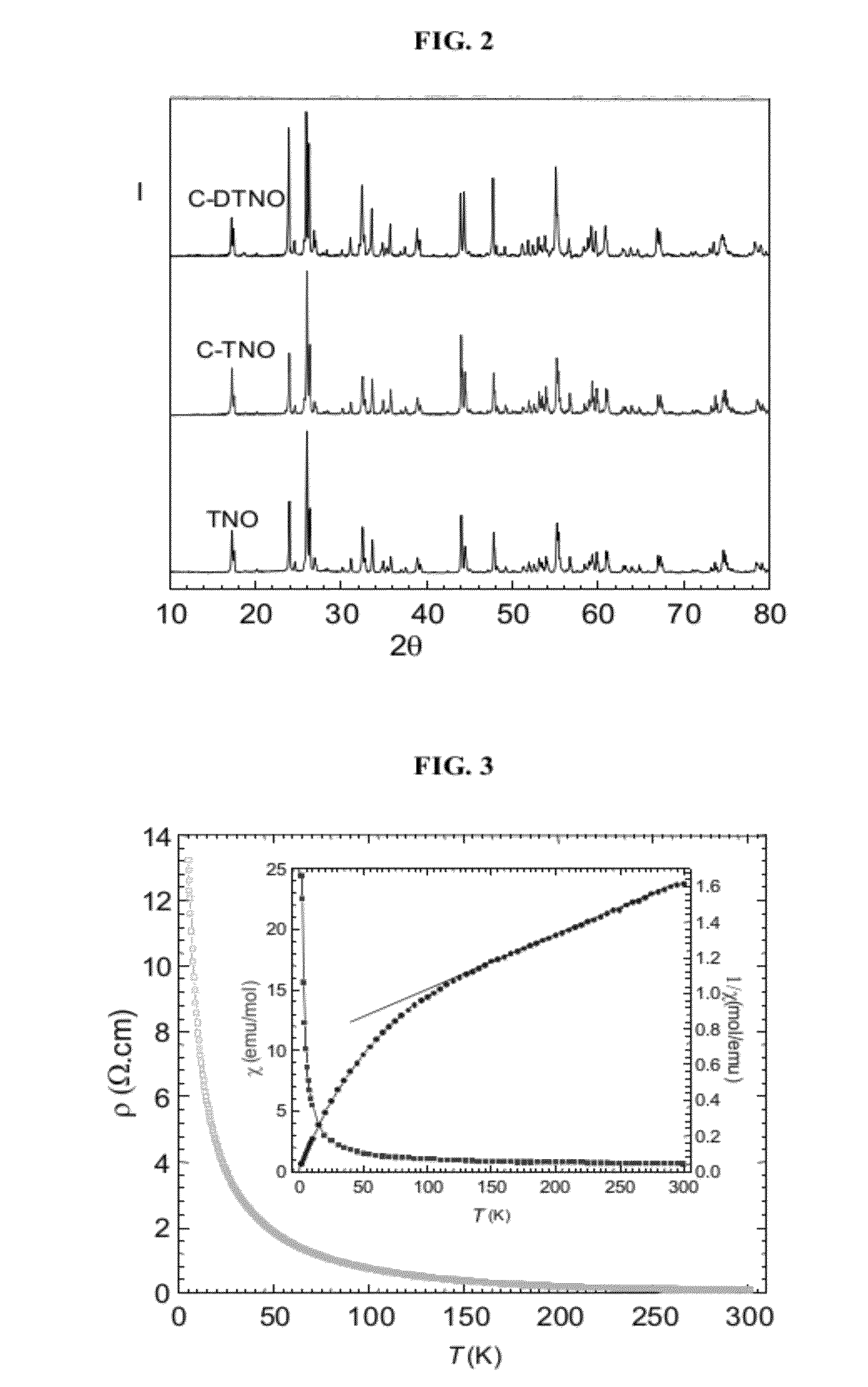

Niobium Oxide Compositions and Methods for Using Same

ActiveUS20120052401A1Alkaline accumulatorsElectric discharge heatingLithium-ion batteryCarbon coated

The disclosure relates a niobium oxide useful in anodes of secondary lithium ion batteries. Such niobium oxide has formula LixM1−yNbyNb2O7, wherein 0≦x≦3, 0≦y≦1, and M represents Ti or Zr. The niobium oxide may be in the form of particles, which may be carbon coated. The disclosure also relates to an electrode composition containing at least one or more niobium oxides of formula LixM1−yNbyNb2O7. The disclosure further relates to electrodes, such as anodes, and batteries containing at least one or more niobium oxides of formula LixM1−yNbyNb2O7. Furthermore, the disclosure relates to methods of forming the above.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Light-transmitting and/or coated article with removable protective coating and methods of making the same

InactiveUS6849328B1Heating evenlyIncrease heat absorptionSynthetic resin layered productsPaints with biocidesCombustionPolyvinyl alcohol

A method and coating are provided for temporarily protecting a substrate or article during shipping, handling or storage by applying a removable protective coating over at least a portion of the substrate. The substrate may be flat or curved and may have zero, one or more functional coatings. A plurality of substrates with the protective coating of the invention may be arranged in a shipping container so that the protective coating reduces the possibility of damage to the substrate or optional functional coating. In one embodiment, the protective coating is the evaporation or reaction product of an aqueous coating composition containing a polyvinyl alcohol polymer which may be subsequently removed by aqueous washing, thermal decomposition or combustion. In another embodiment, the protective coating is formed by sputtering a substantially carbon coating onto the substrate. The carbon coating is subsequently removed by combustion. The protective coating may have identification materials, such as colorants or fragrance materials, such that different types of substrates and / or functional coatings can be distinguished from each other. Additionally, the temporary protective coating can improve the heating of a functionally coated glass substrate.

Owner:VITRO FLAT GLASS LLC

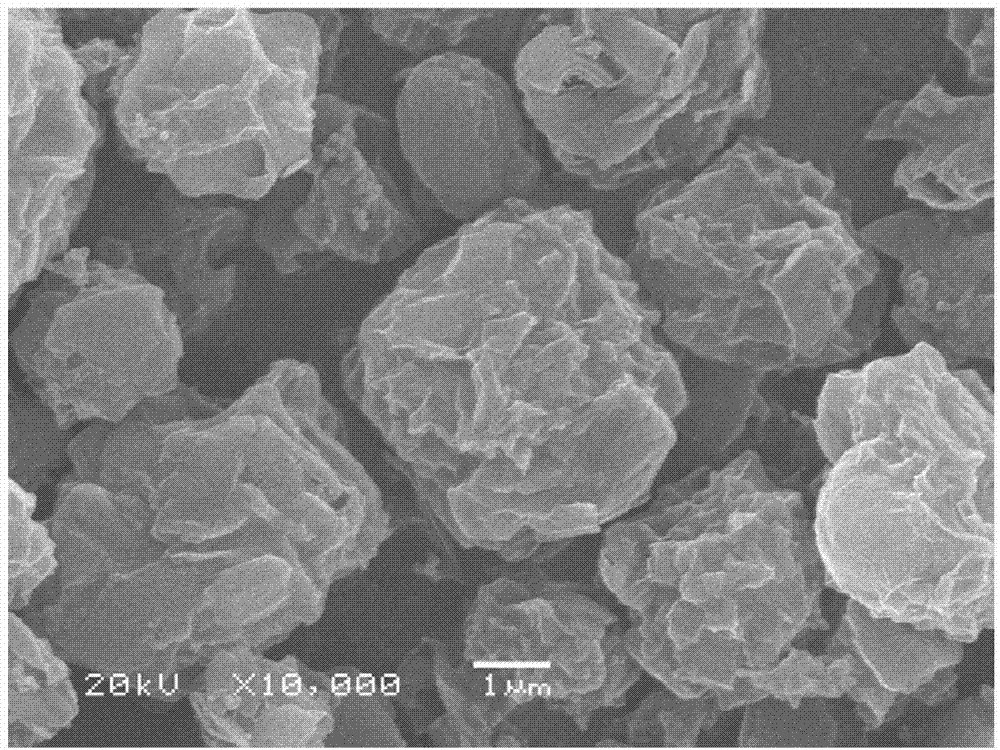

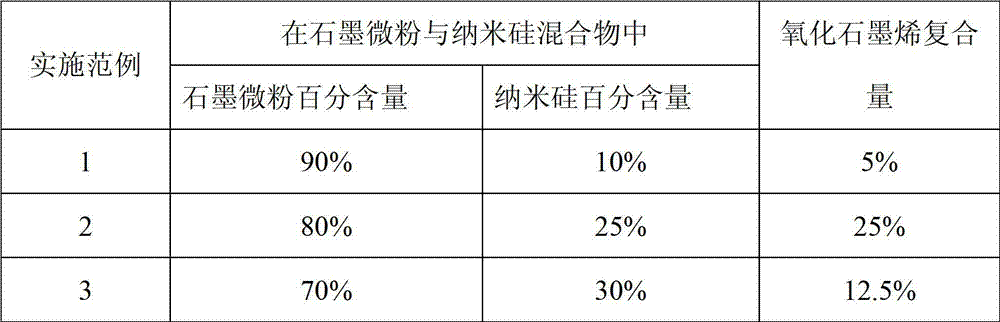

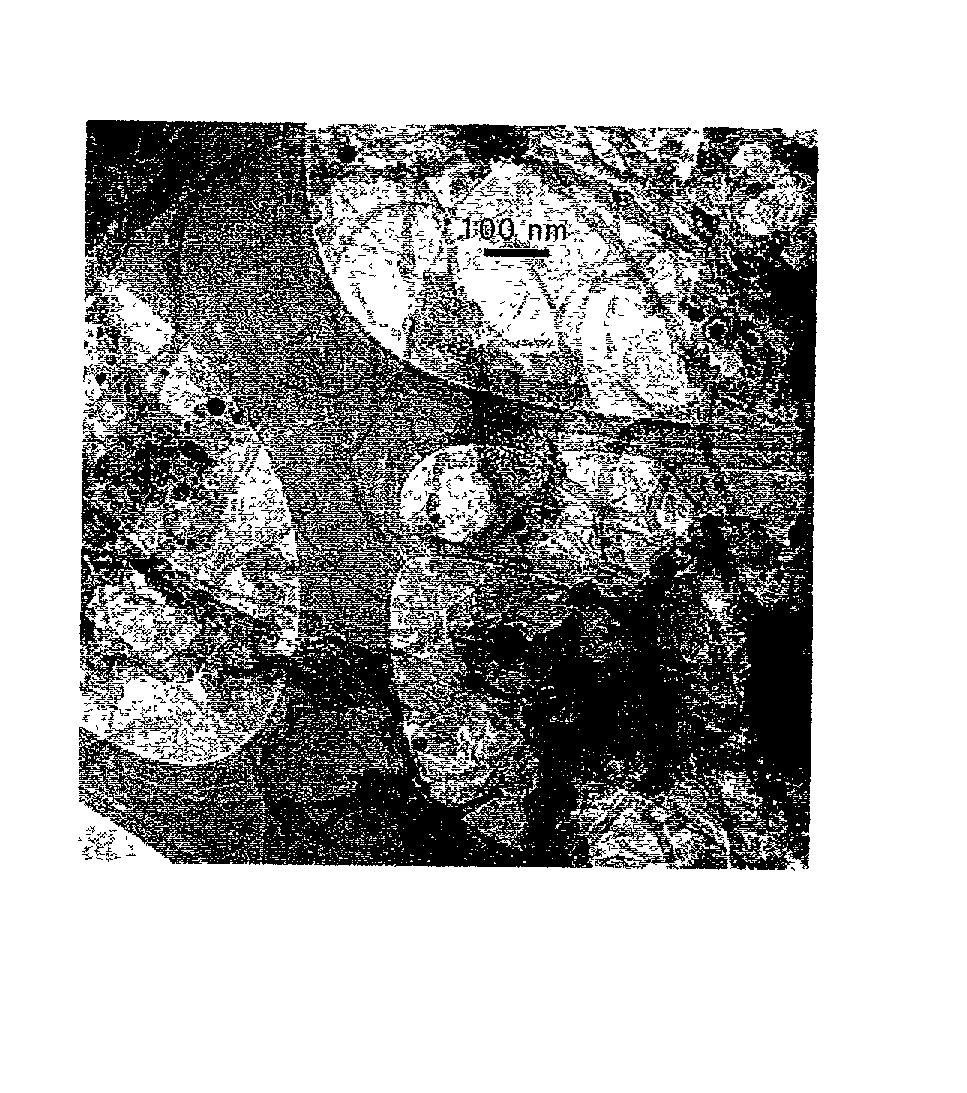

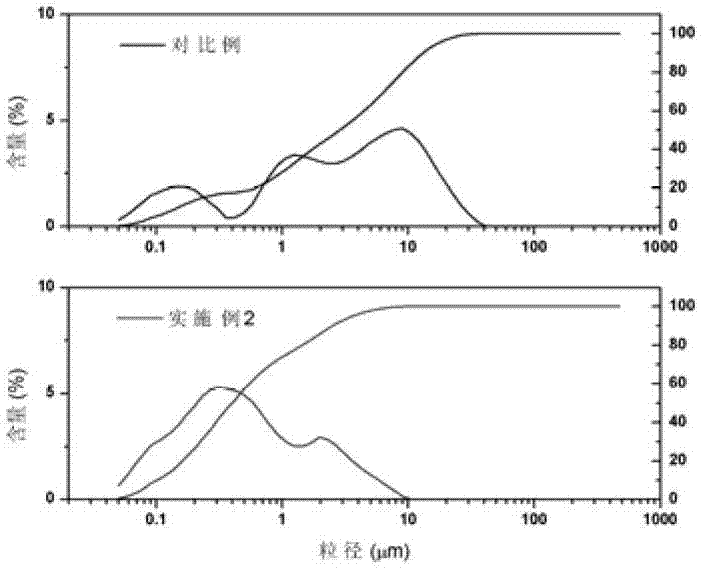

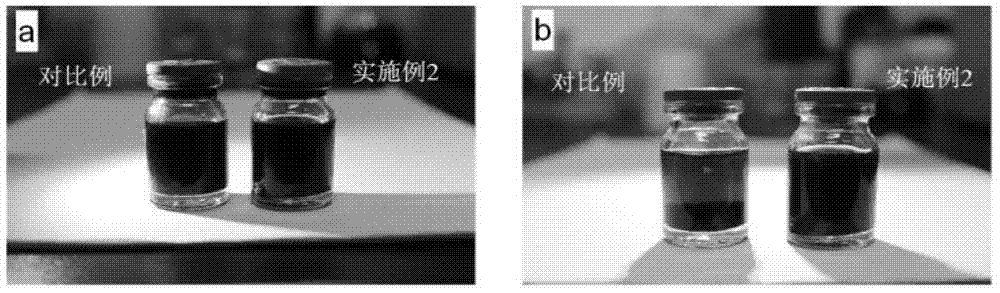

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Highly purified single-wall carbon nanotubes and production thereof

Highly purified single-wall carbon nanotubes (SWNTs) and production thereof. The highly purified single-wall carbon nanotubes may be produced according to one embodiment of the invention by generating a crude SWNT material having a carbon nanotube fraction and a non-nanotube carbon fraction, refluxing the crude SWNT material in an acid solution to redistribute the non-nanotube carbon fraction as a uniform carbon coating on the carbon nanotube fraction, and oxidizing the refluxed SWNT material to remove the uniform carbon coating formed thereon. Preferably, metal is also removed during reflux.

Owner:MIDWEST RES INST

Rare earth doped carbon clad type nanometer anode material iron lithium phosphate and its preparation method

InactiveCN1830764AIncrease capacityImprove cycle lifeCell electrodesPhosphorus compoundsEpoxyRare earth

A carbon-coated RE-doped iron lithium phosphate nano-particle used for positive electrode of battery is prepared from FeC2H4, H2O, Li2CO3, NH4H2PO4, Y2O3, CeO2 and epoxy resin through proportional mixing, ball grinding, baking, sieving, calcining in N2 atmosphere at 350 deg.C and 600-750 deg.C respectively, and keeping the temp for a certain time.

Owner:TSINGHUA UNIV +1

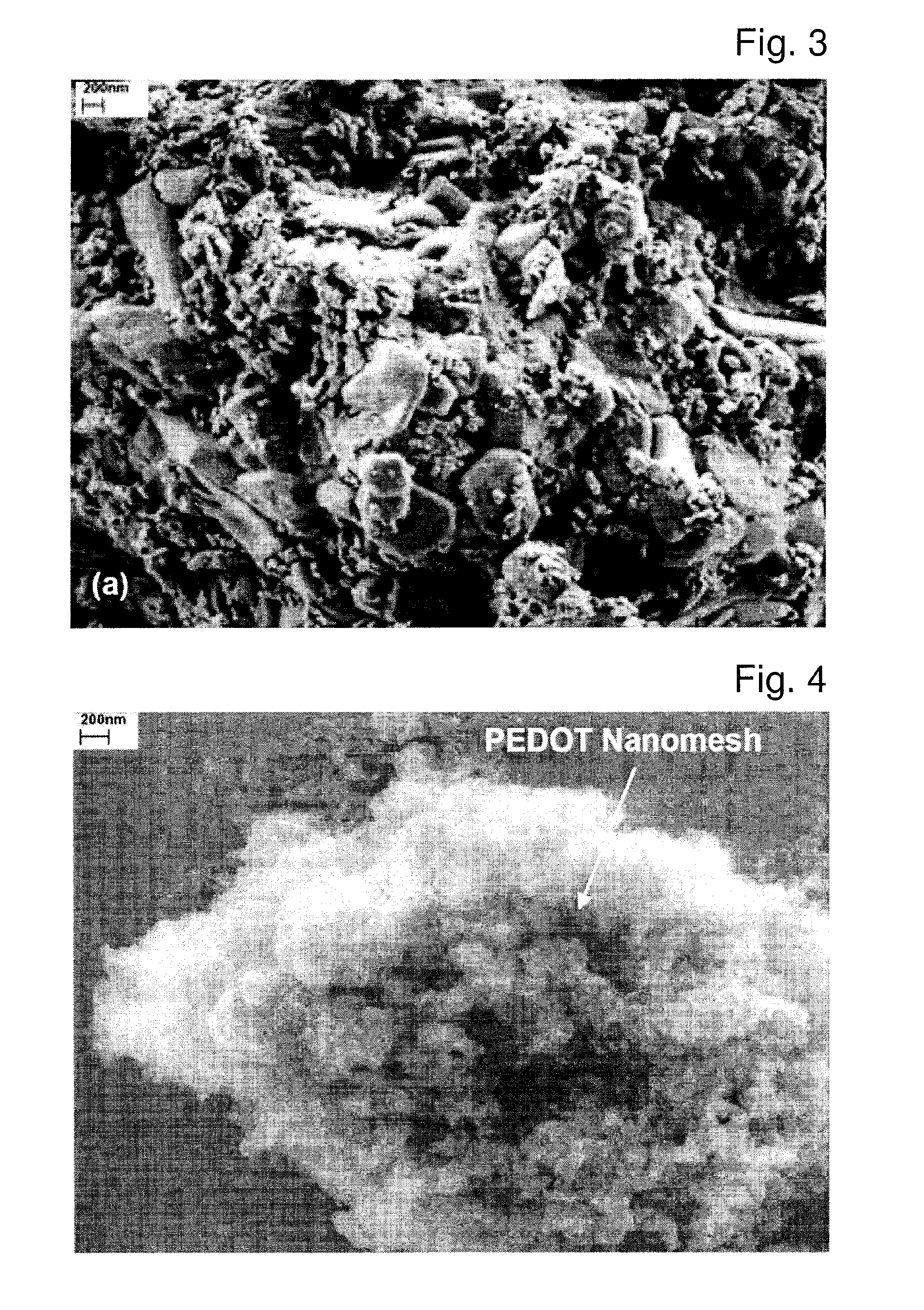

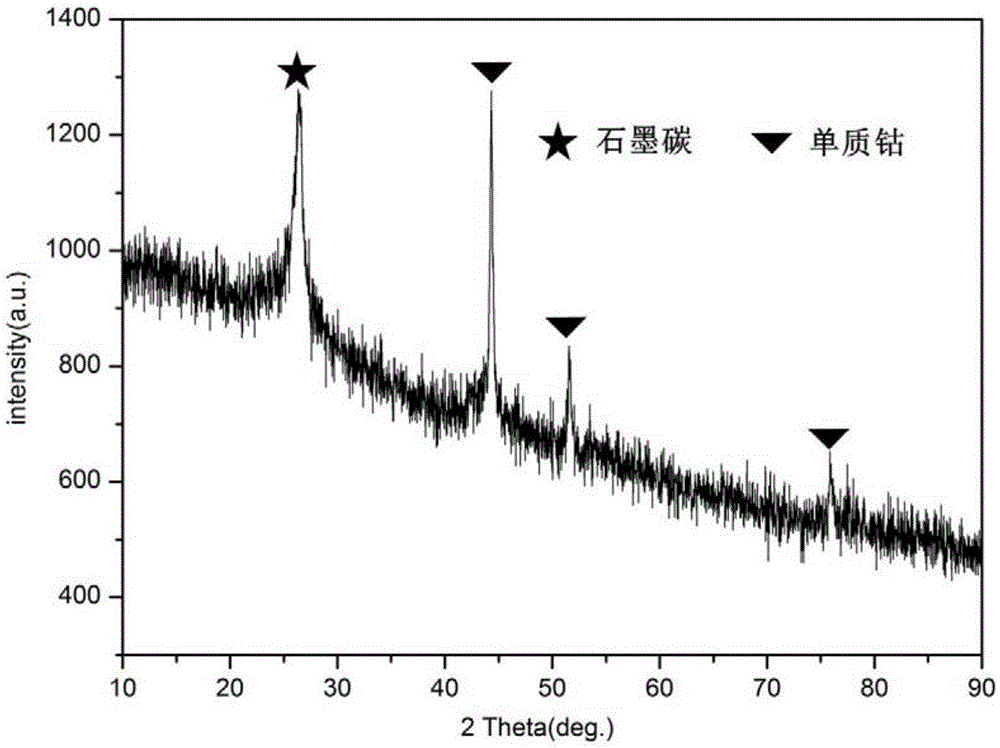

Open porous electrically conductive nanocomposite material

ActiveUS20100233538A1Easy to getFaster and energy efficientElectrode manufacturing processesFinal product manufactureHigh energyConductive polymer

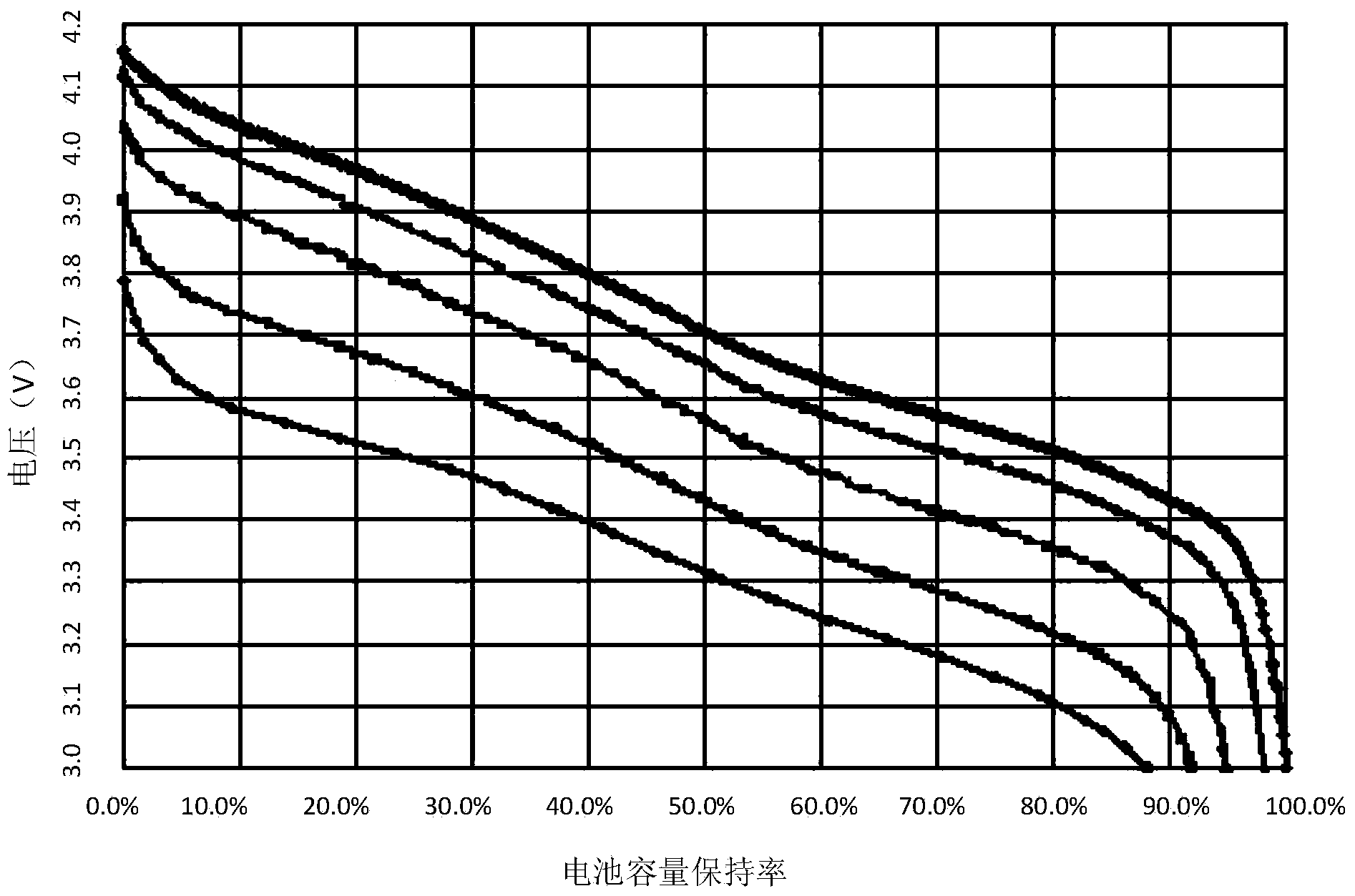

Nanocomposits of conductive, nanoparticulate polymer and electronically active material, in particular PEDOT and LiFePO4, were found to be significantly better compared to bare and carbon coated LiFePO4 in carbon black and graphite filled non conducting binder. The conductive polymer containing composite outperformed the other two samples. The performance of PEDOT composite was especially better in the high current regime with capacity retention of 82% after 200 cycles. Hence an electrode based on composite made of conductive, nanoparticulate polymer and electronically active material, in particular LiFePO4 and PEDOT nanostubs, with its higher energy density and increased resistance to harsh charging regimes proved to dramatically extend the high power applicability of materials such as LiFePO4.

Owner:BELENOS CLEAN POWER HLDG

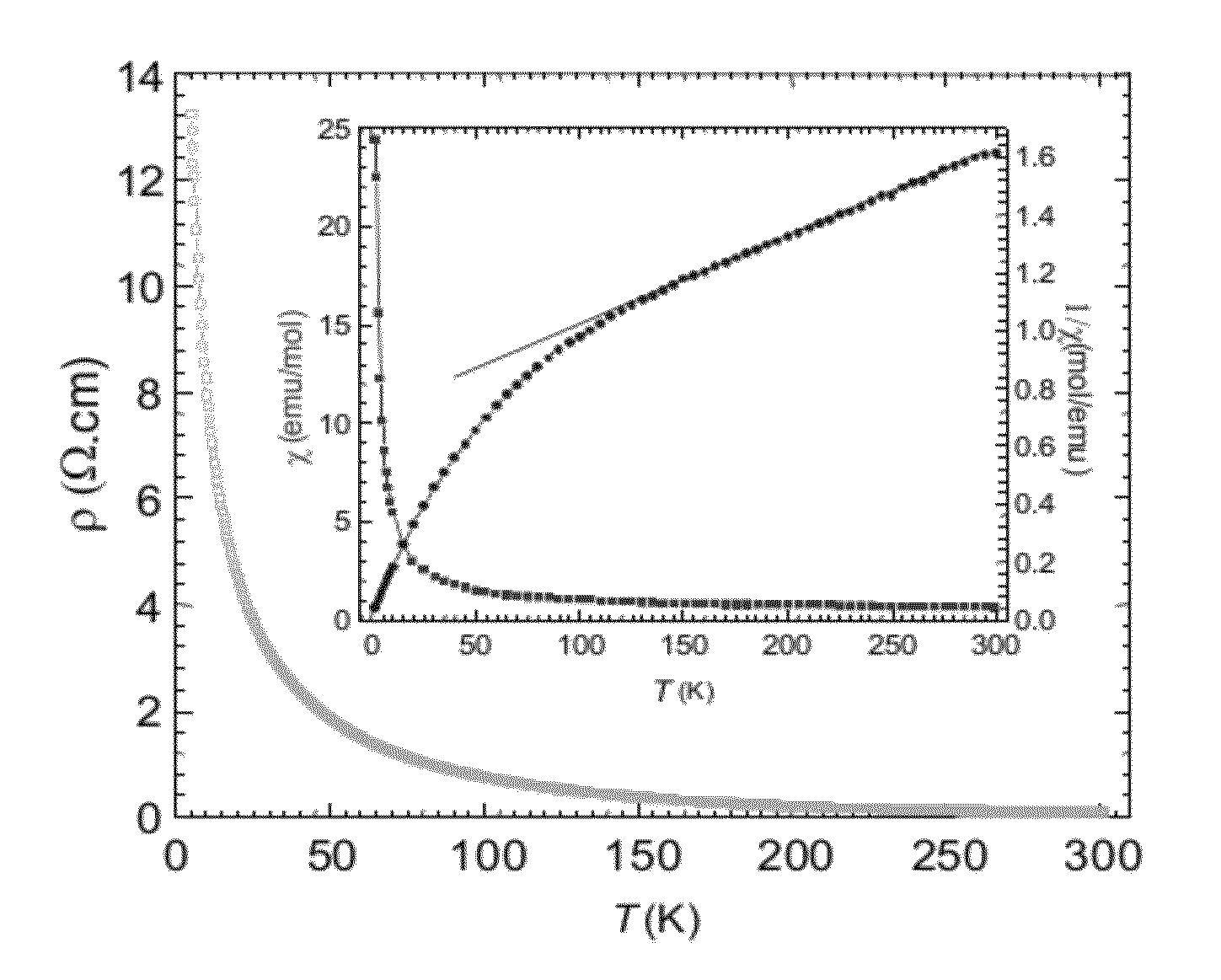

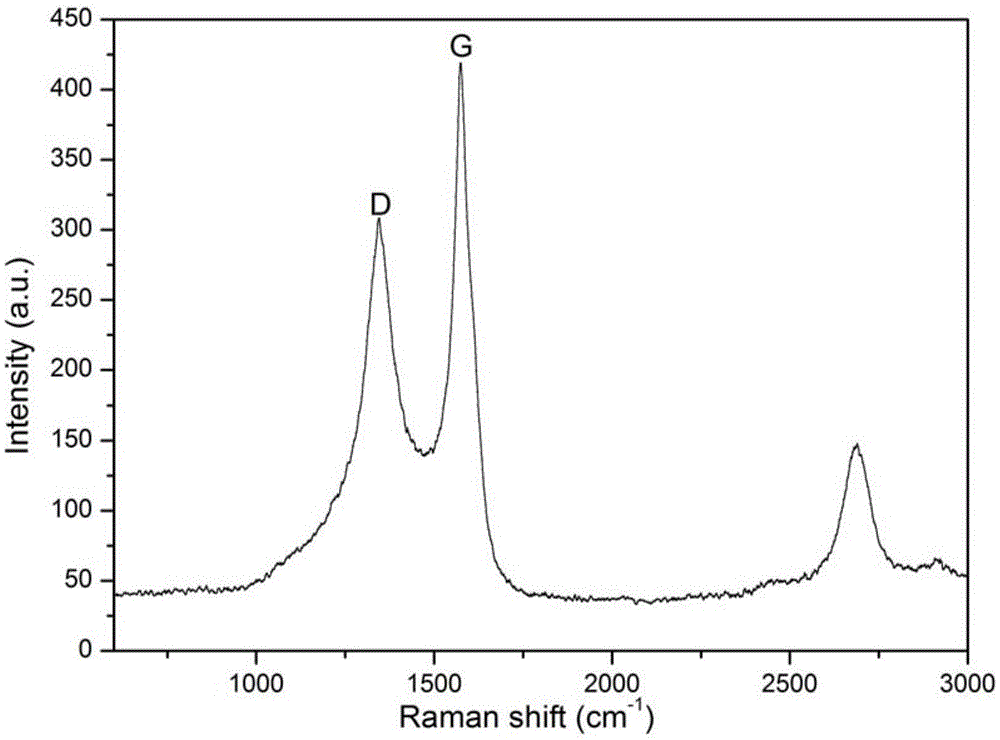

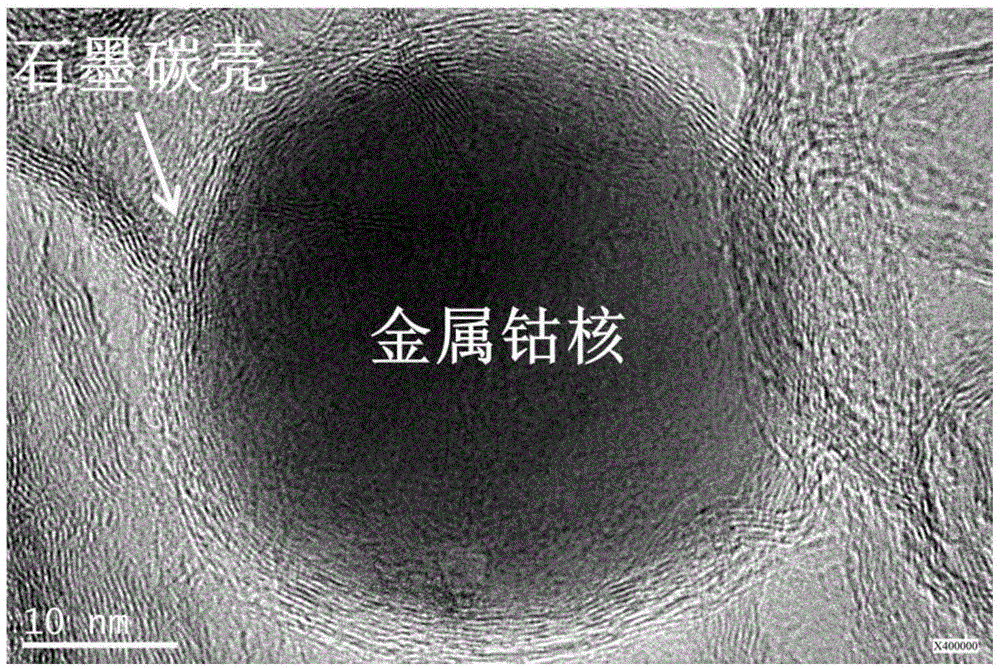

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

Nanoscale metal particles and method of preparing same

A process of preparing individually-isolated, carbon-coated nanoscale metal particles is disclosed. The process is effected by sonicating a mixture of a metal carbonyl and a hydrocarbon solvent that is selected so as to polymerize during sonication. Air-stable and aqueous solution-stable, carbon-coated nanoscale metal particles and a process of preparing same are also disclosed.

Owner:BAR ILAN UNIV

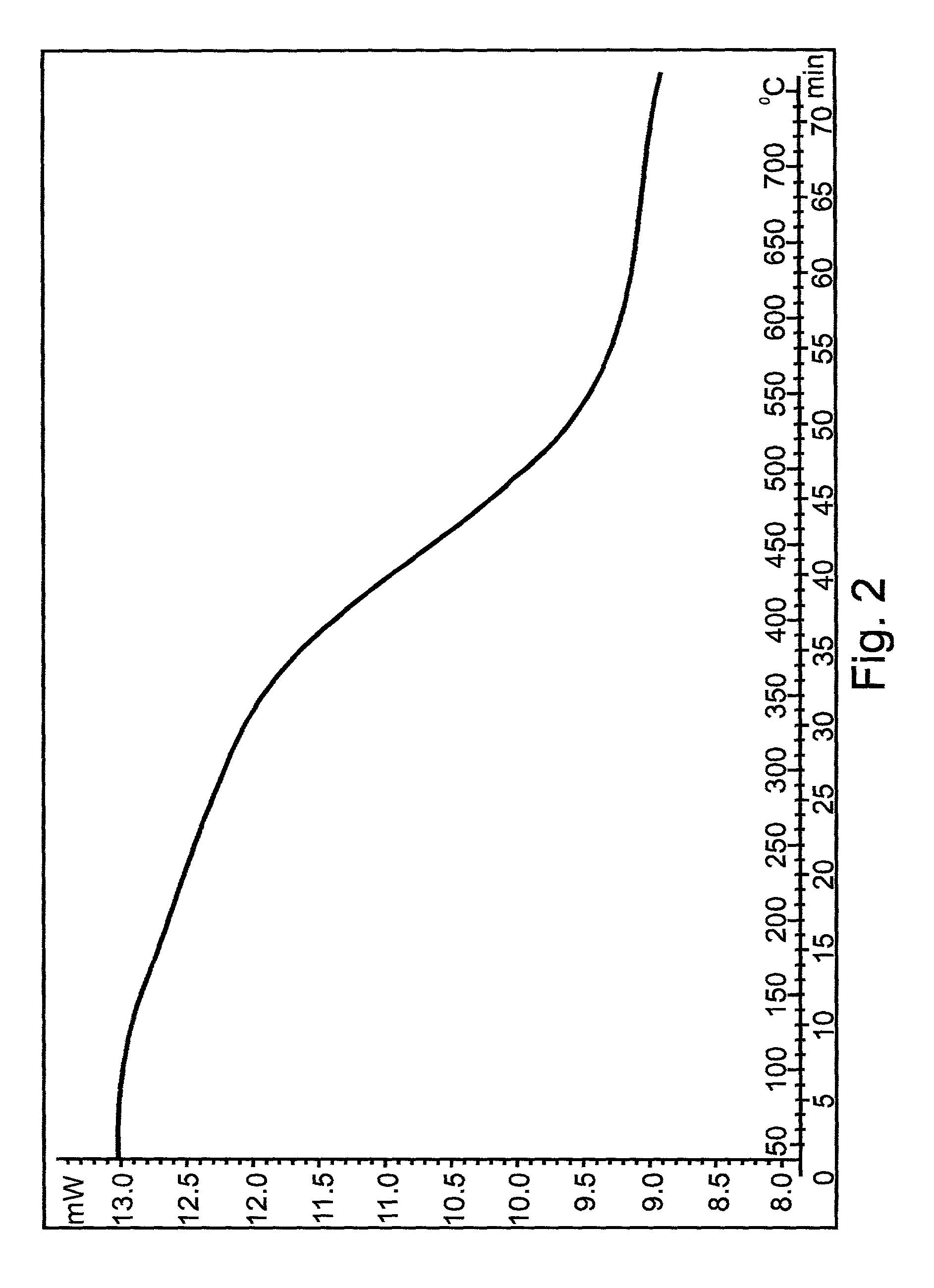

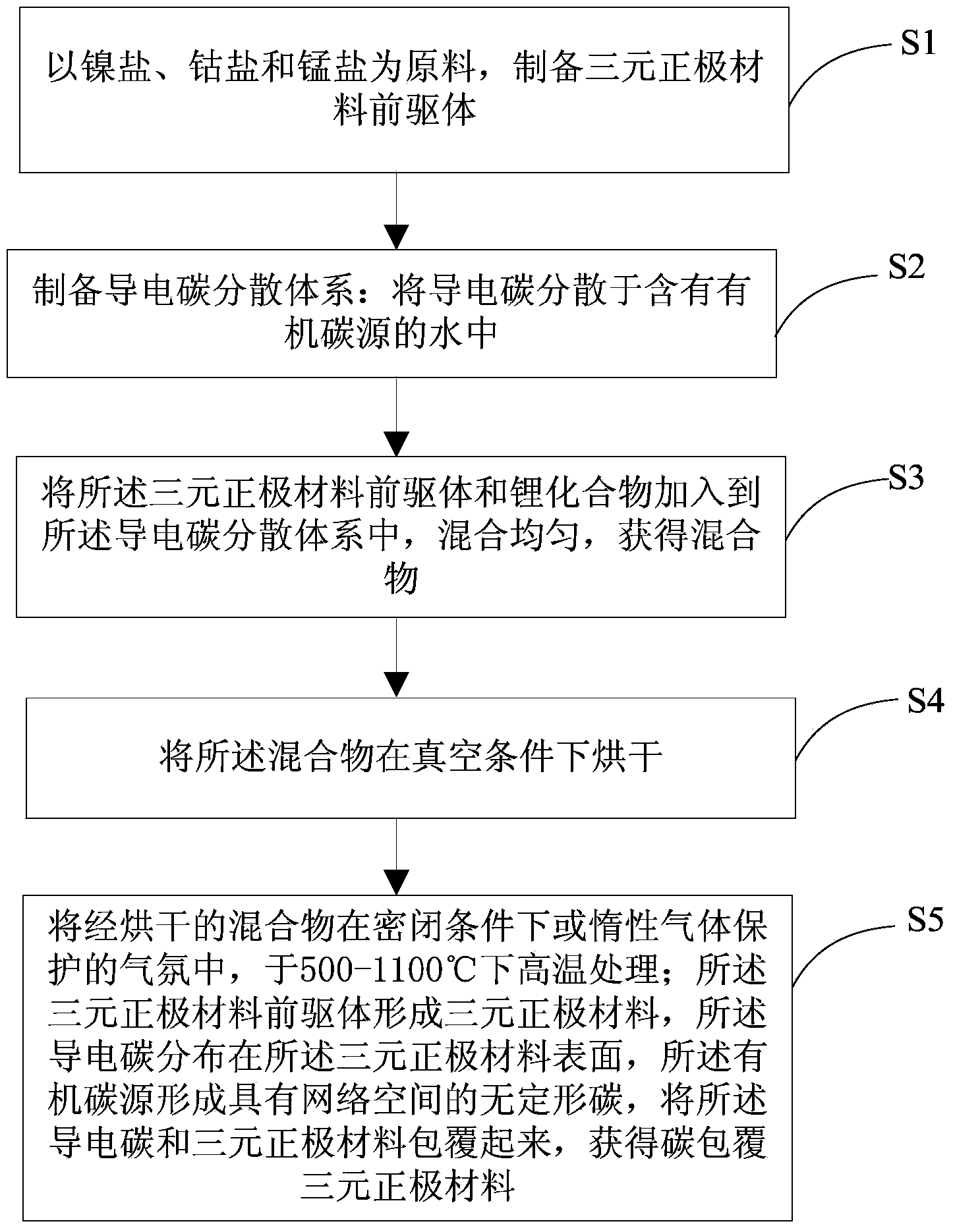

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

Nitride and Carbide Anode Materials

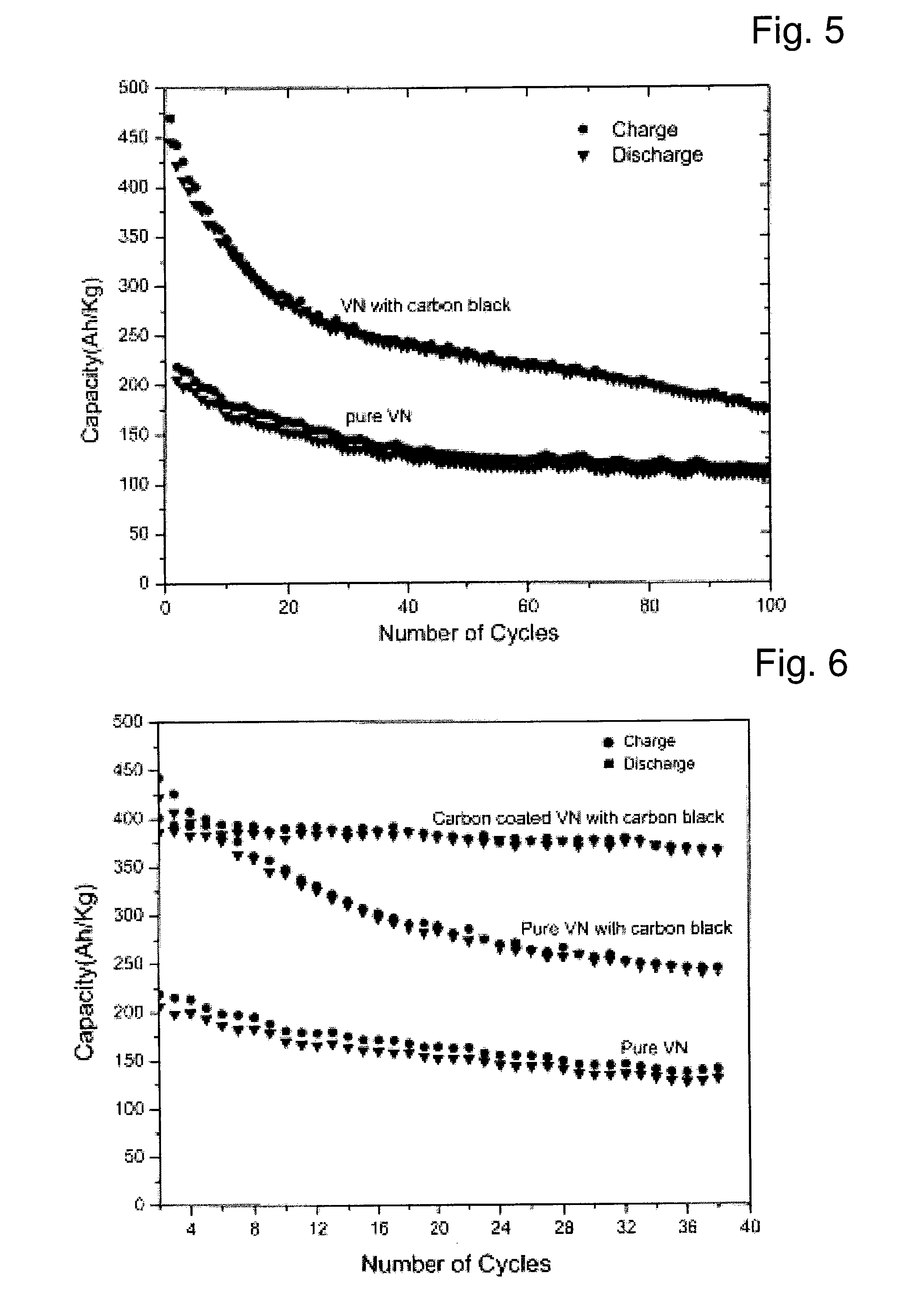

ActiveUS20100233546A1High chemicalHigh environmental stabilityFinal product manufactureConductive materialNanoparticleVanadium nitride

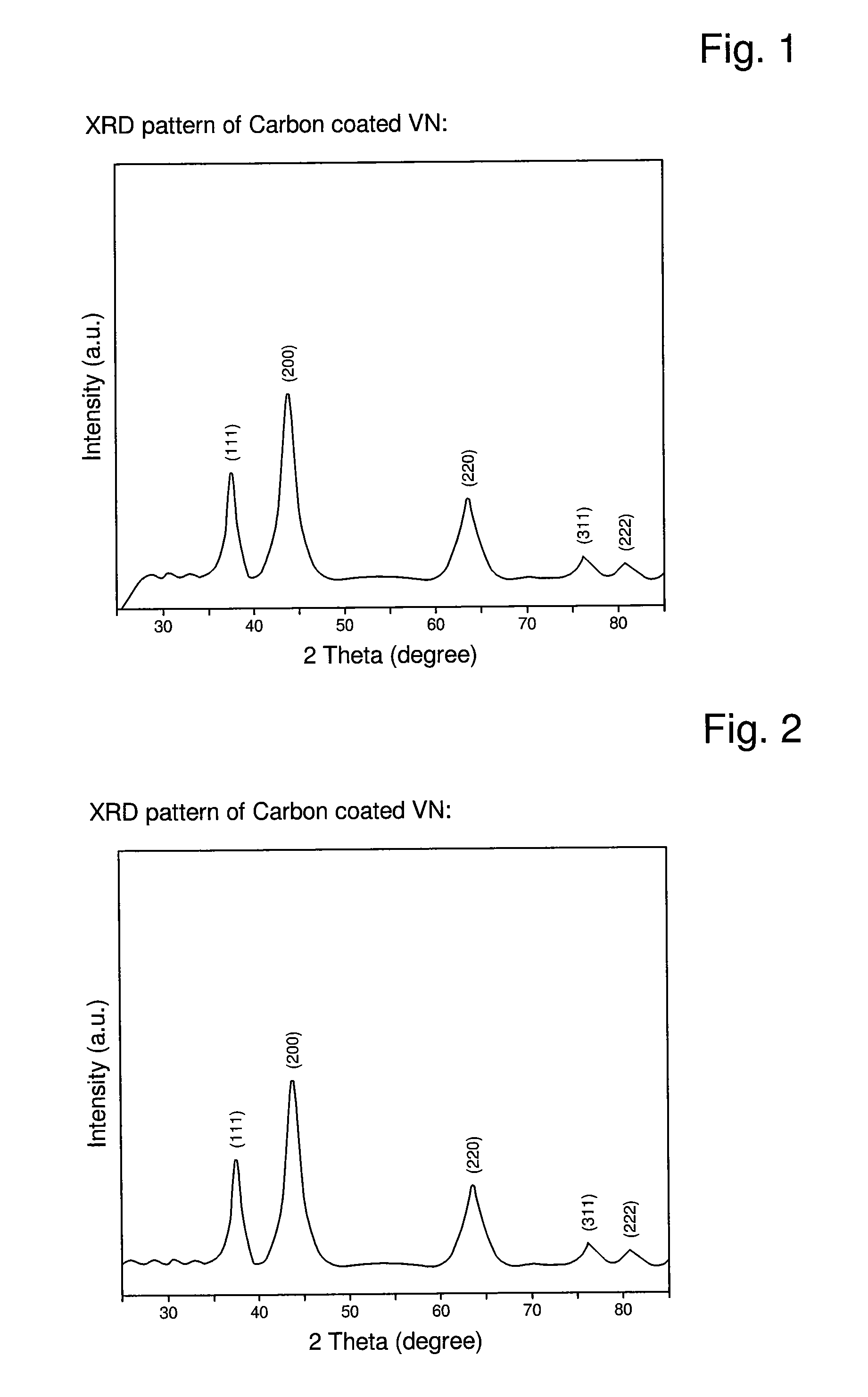

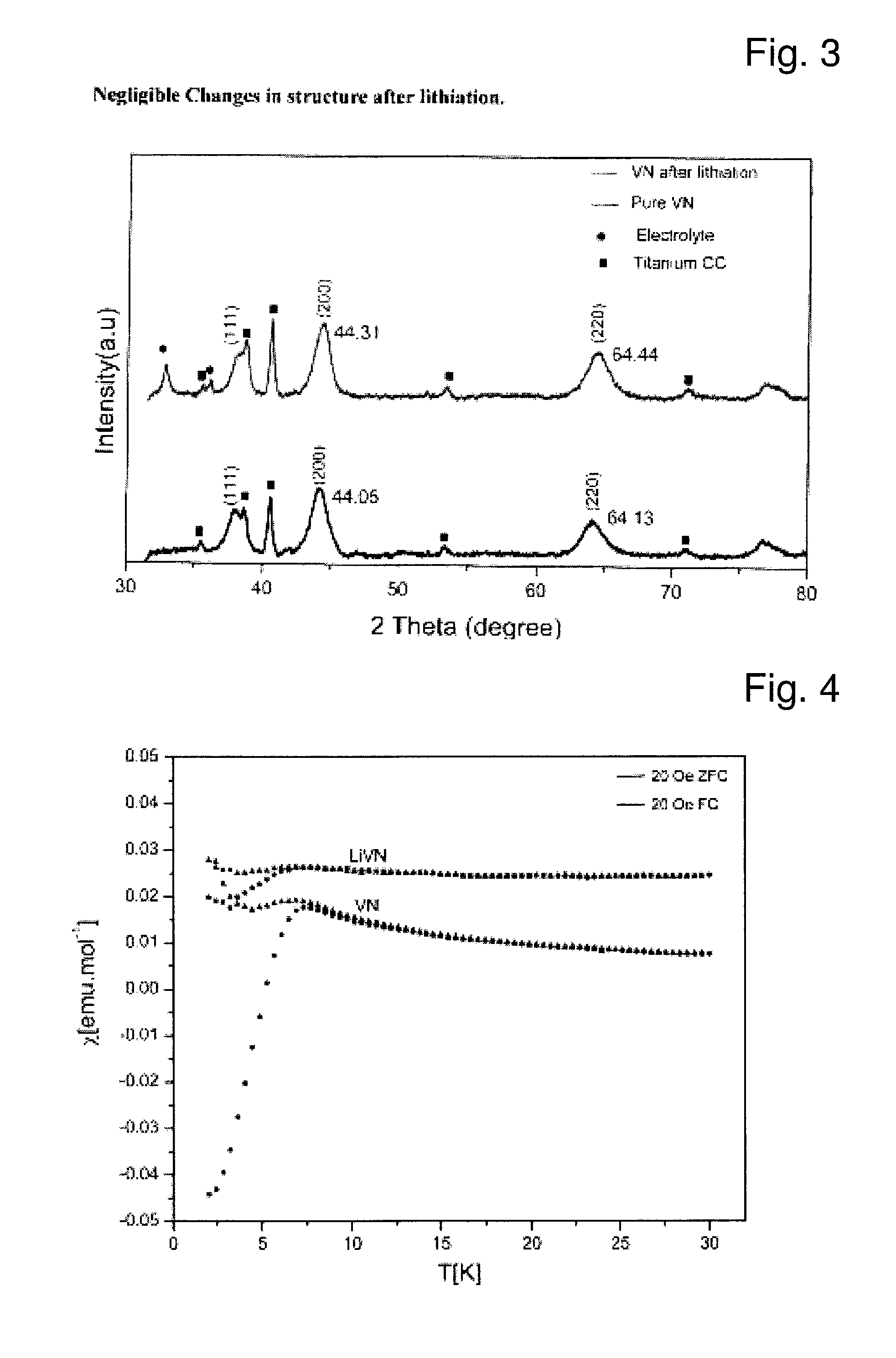

Described is an anode material which is a transition metal nitride or carbide in form of nanoparticles, preferably a nitride or carbide with one nitrogen or carbon per metal, and especially a nitride or carbide having rock salt structure. A preferred anode material is vanadium nitride, in particular carbon coated vanadium nitride having a mean particle size of <500 nm. Embedded in an electrically conducting environment, such nanoparticulate material, in particular the vanadium nitride shows exceptional good charging-discharging cycle stability.

Owner:BELENOS CLEAN POWER HLDG

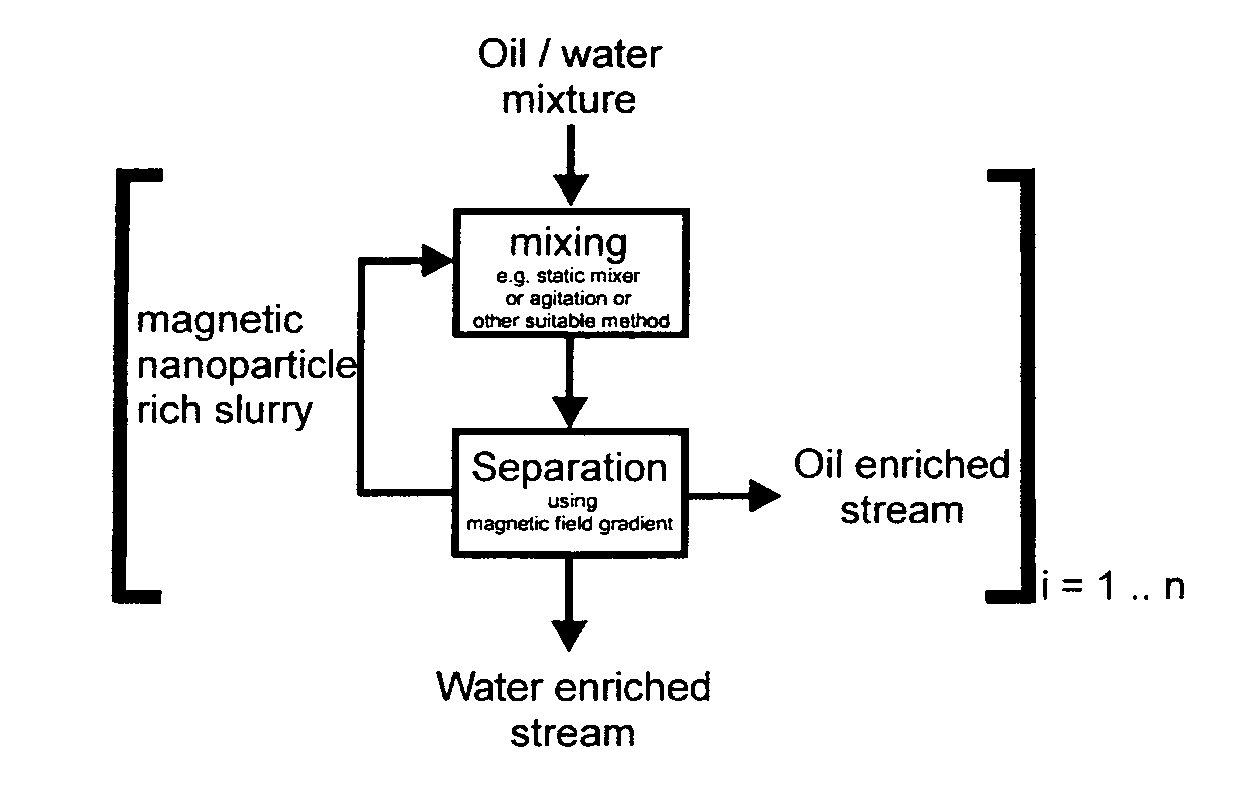

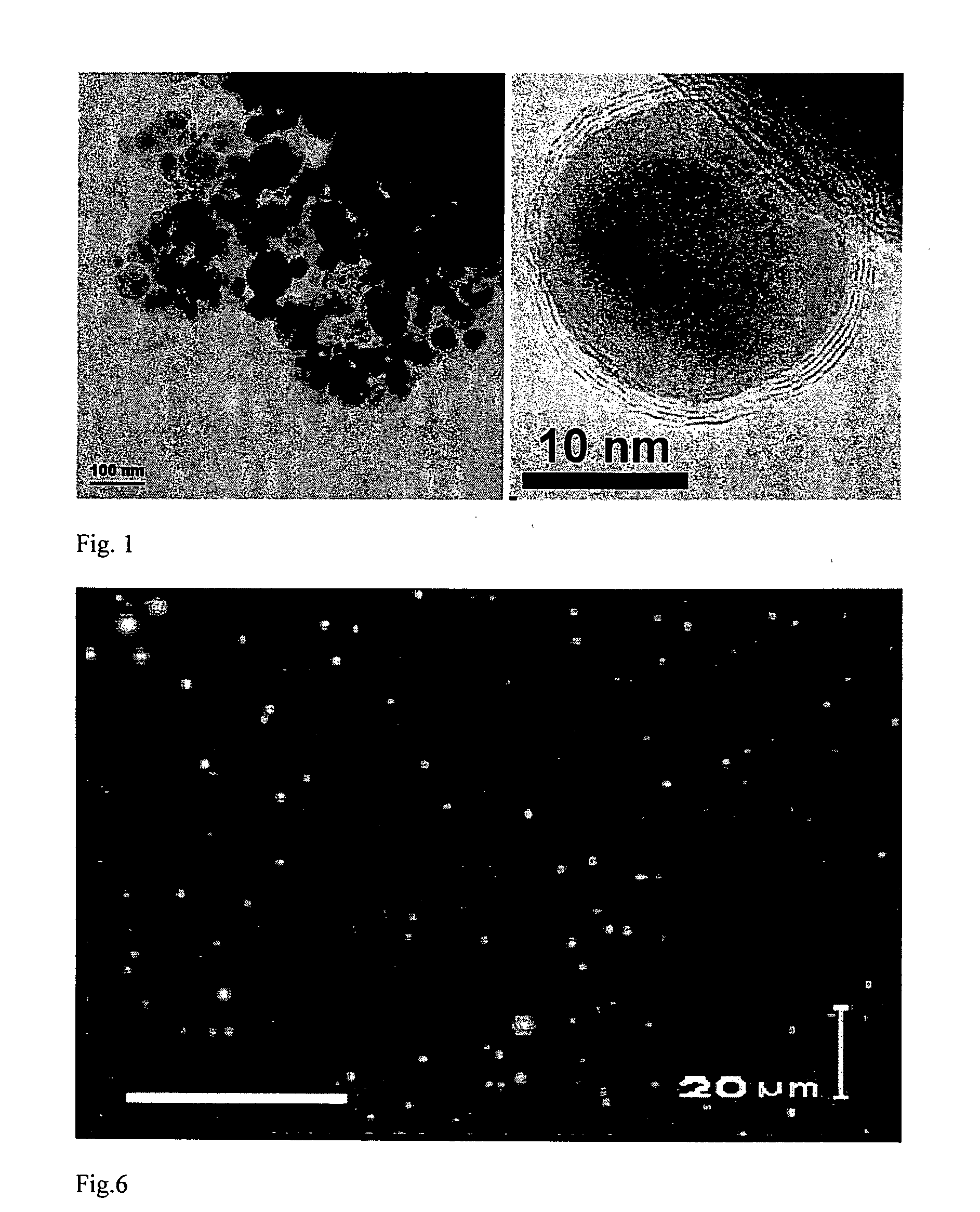

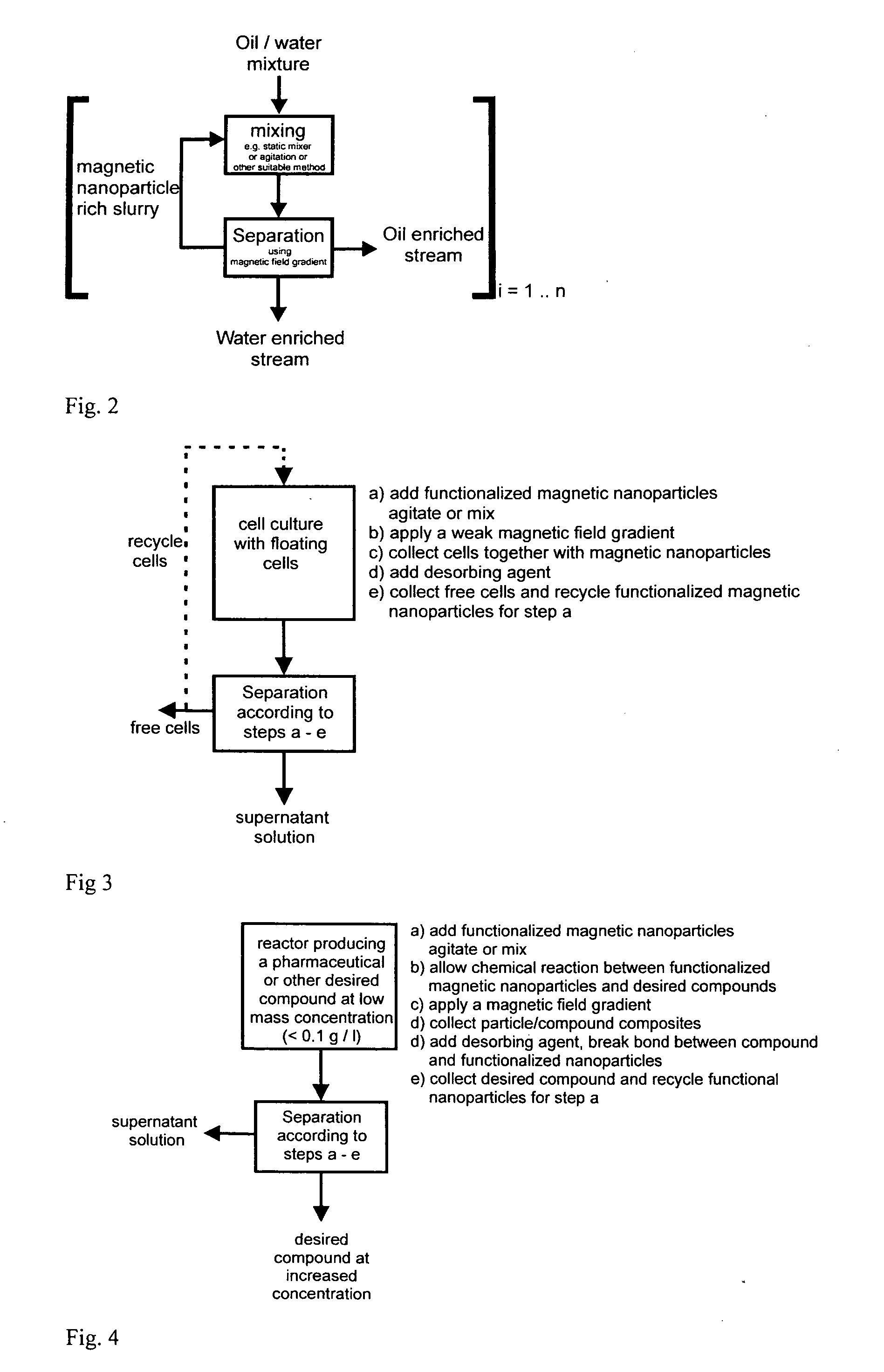

Carbon Coated Magnetic Nanoparticles and Their Use in Separation Processes

ActiveUS20100059449A1Improve mobilityRapidity and efficiencyNanomagnetismLiquid separation by electricityMagnetic field gradientMagnetite Nanoparticles

The invention relates to a process for separating a dispersed phase from a continuous phase comprising the steps of i) contacting said phases with an effective amount of nanoparticles; ii) applying a magnetic field gradient to the obtained system; iii) separating the obtained phases wherein said nanoparticles are of the core shell type, said core consists of a metal or alloy having soft magnetic properties and said shell contains a graphene layers which are optionally functionalized; to new nanoparticles and method of manufacturing such nanoparticles.

Owner:ETH ZZURICH

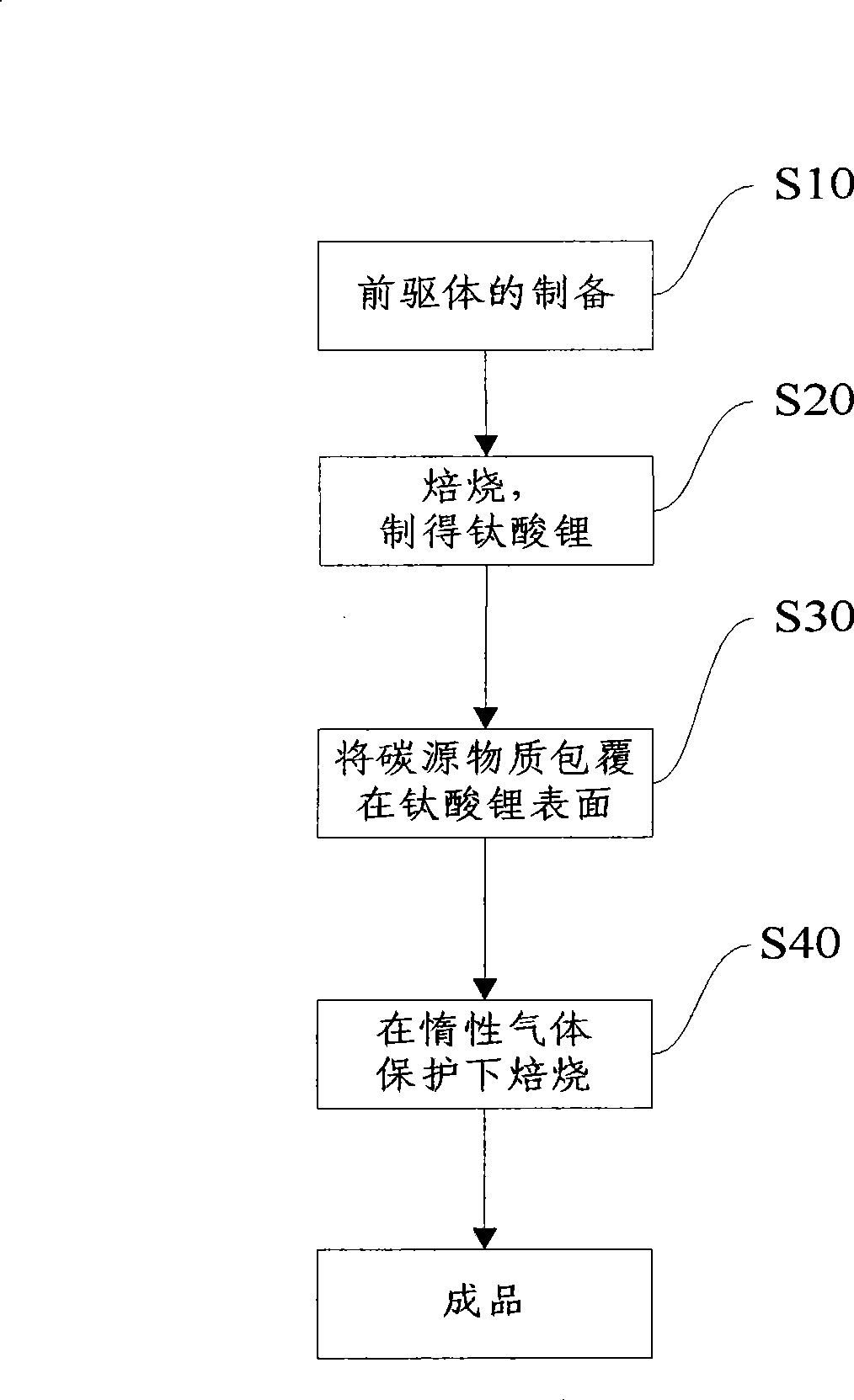

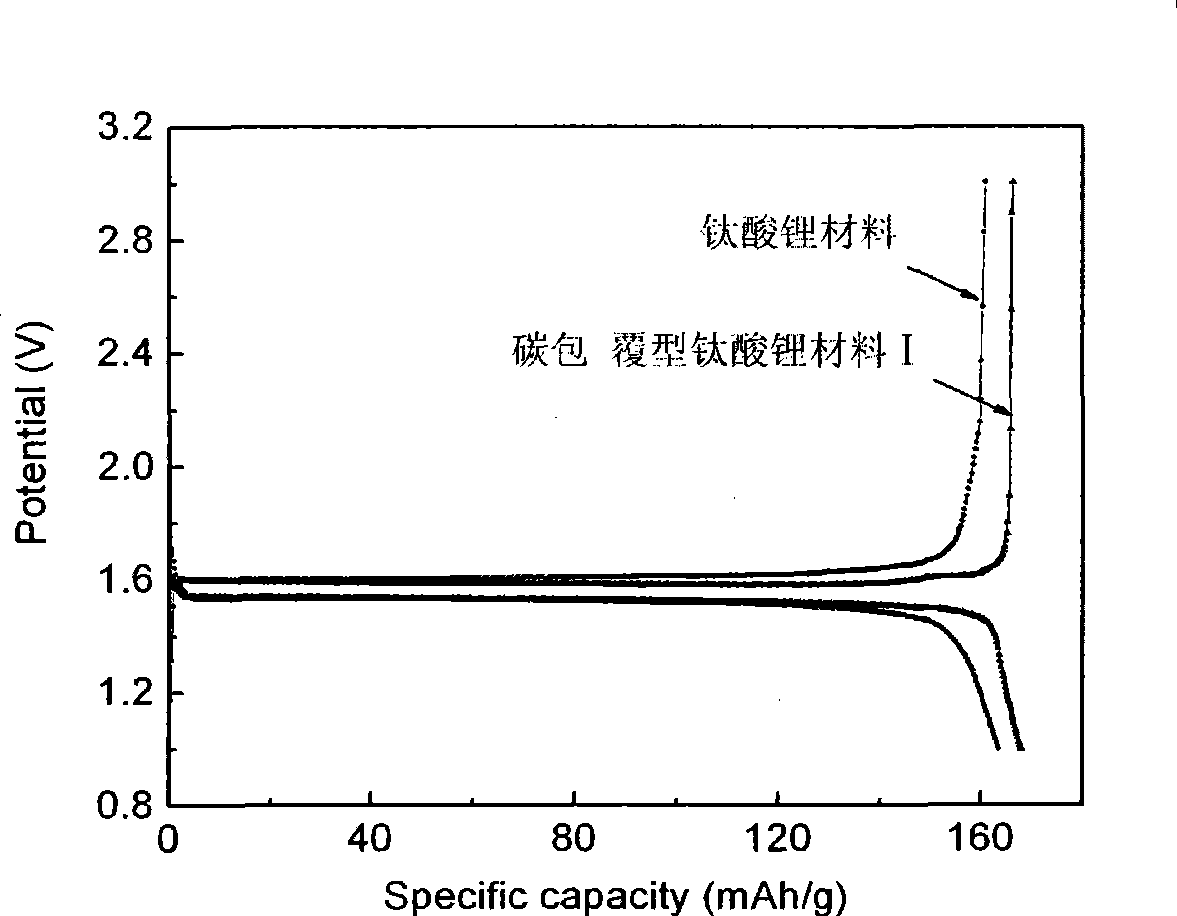

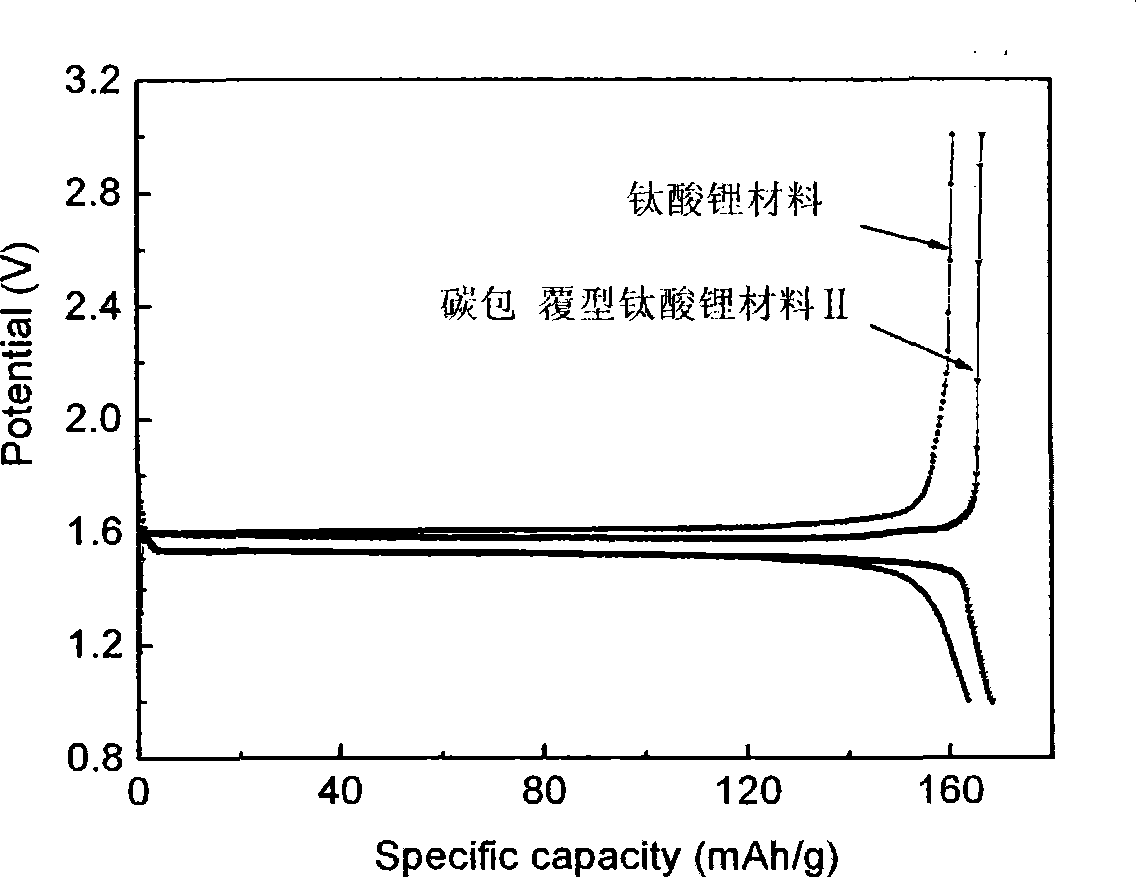

Method for preparing carbon-coating type lithium titanate for lithium ion battery

InactiveCN101378119AImprove electronic conductivityImprove rate charge and discharge performanceElectrode manufacturing processesCarbon coatedElectron

The invention discloses a preparation method of carbon-coated lithium titanate used for a lithium ion battery; the method comprises the following steps: (1) lithium salt and titanium dioxide are weighted according to proportion, a dispersing agent is added, a ball milling method is used for mixing fully and then the obtained mixture is dried in vacuum, thus obtaining a precursor; (2) the obtained precursor is roasted for 8 to 20 hours at the temperature of 750 to 1000 DEG C so as to prepare lithium titanate; (3) carbon source materials are coated on the surface of the prepared lithium titanate by a dipping and steaming method; and (4) the lithium titanate coated with the carbon source materials is placed in a tubular furnace, and is roasted for 0.5 to 5 hours at the temperature of 750 to 1000 DEG C under the protection of inert gas so as to obtain the carbon-coated lithium titanate. The preparation method of the invention forms chemically coated carbon on the surface of the lithium titanate by the pyrolytic reaction of the carbon-coated materials, and the surface contact of the coated carbon and the lithium titanate material is more firm and tight, thus improving the electron conductivity of the materials greatly and enhancing the charge and discharge performance of magnification of the materials.

Owner:TIANJIN B&M SCI & TECH

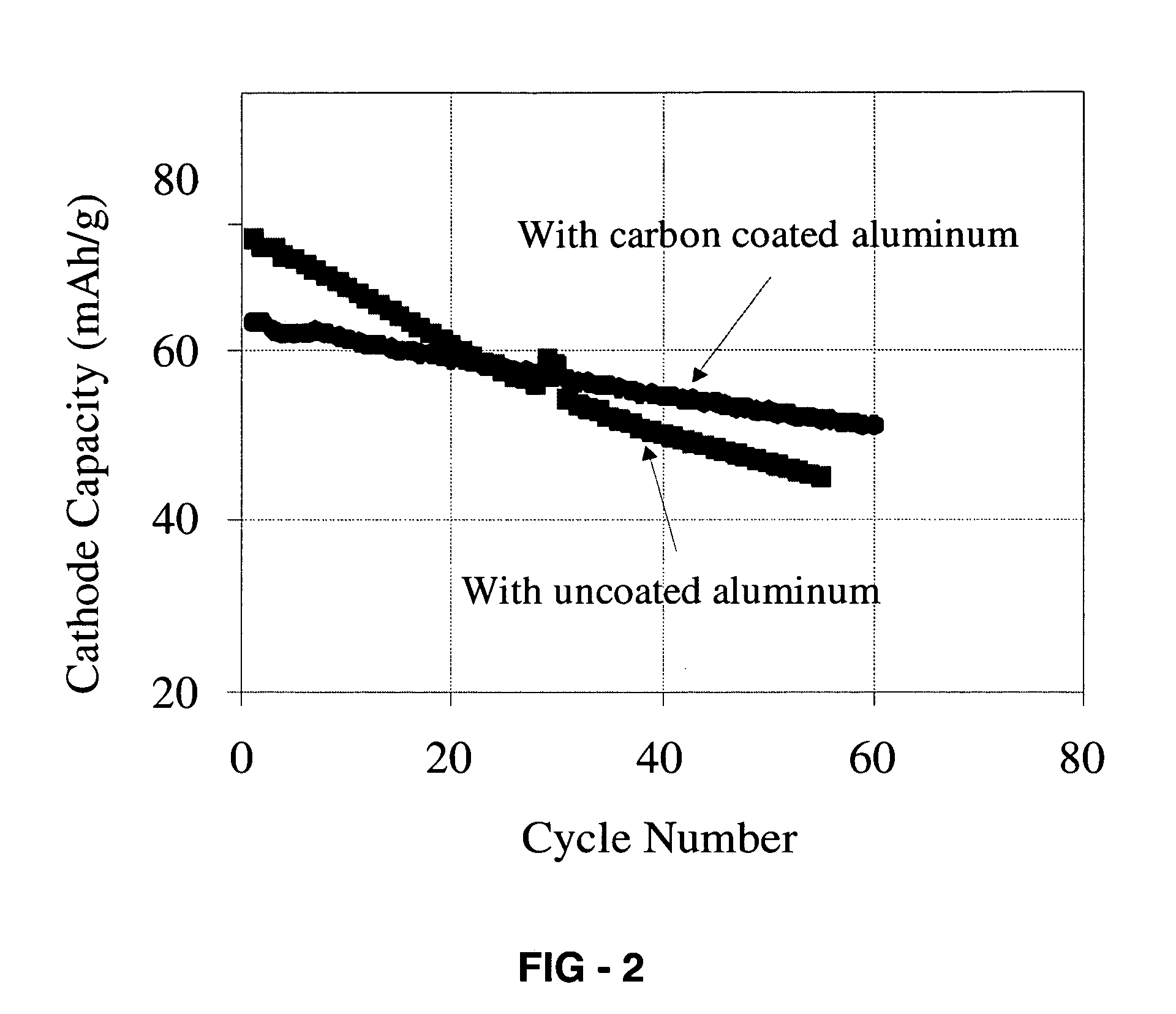

Carbon-coated aluminum and method for producing same

ActiveUS7327556B2Improve adhesionHybrid capacitor electrodesElectrode carriers/collectorsCarbon coatedHydrocarbon

Owner:TOYO ALUMINIUM KK

Carbon-coated metal oxide nanoparticles

InactiveUS6843919B2Effective airborne decontaminationProvide protectionMaterial nanotechnologySolid sorbent liquid separationMetal oxide nanoparticlesToxin

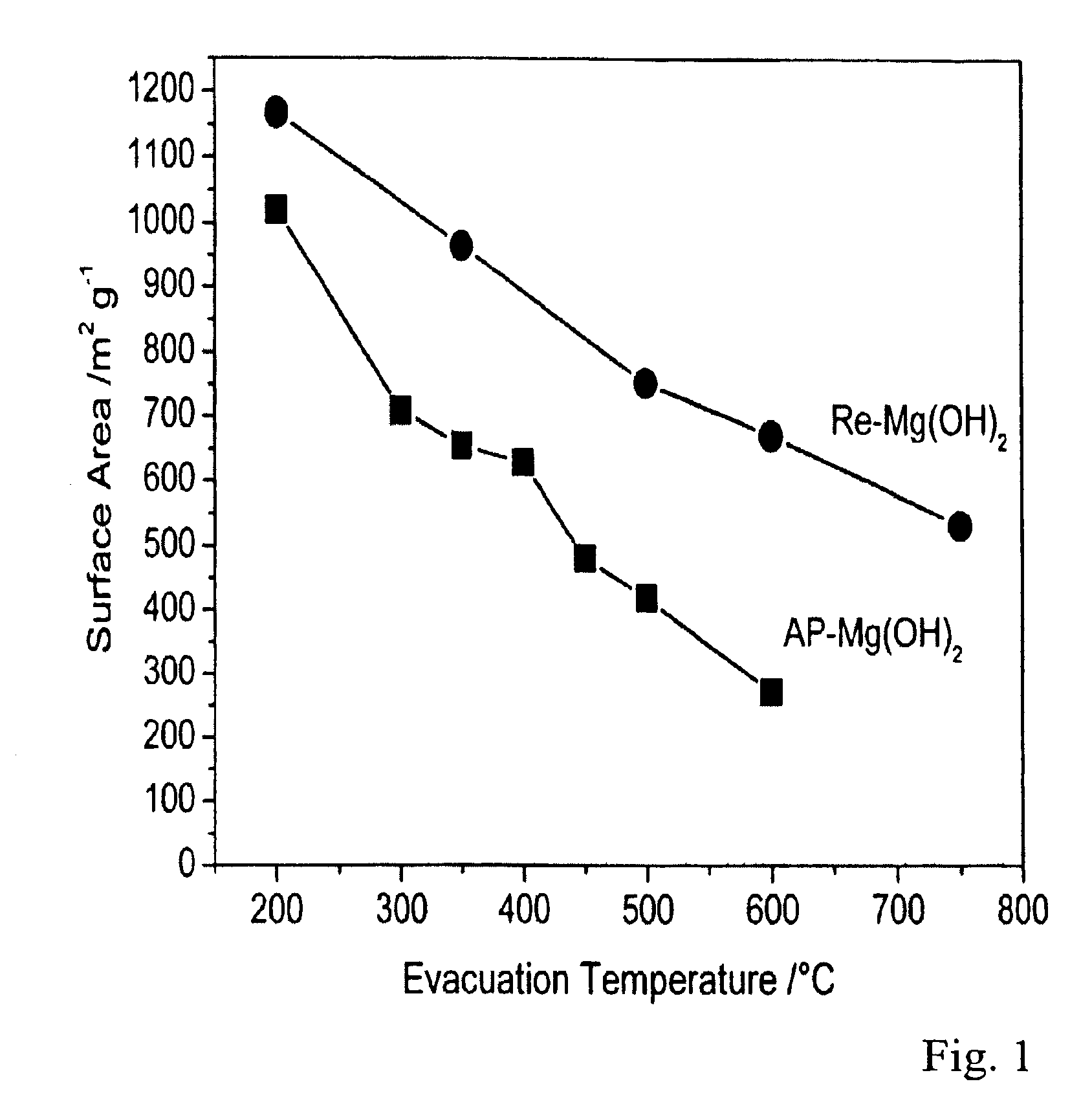

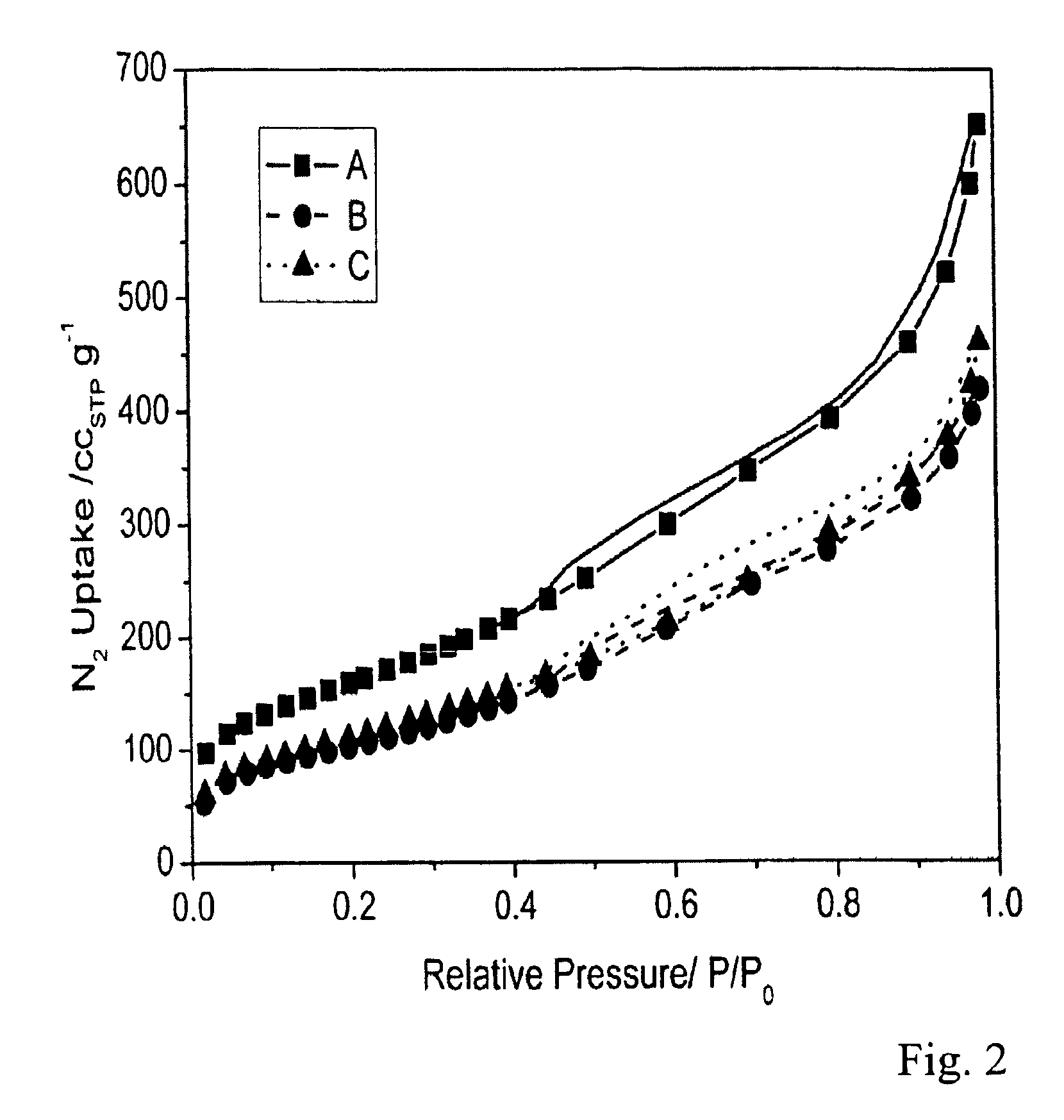

Composites for destroying chemical and biological agents such as toxins and bacteria, and methods of preparing and using those composites are provided. According to the invention, the substance to be destroyed is contacted with the inventive composites which comprise finely divided metal oxide nanoparticles at least partially coated with carbon. Advantageously, the composites exclude water while not excluding the target compound or adsorbates. The desired metal oxide nanoparticles can be pressed into pellets for use when a powder is not feasible. Preferred metal oxide nanoparticles include MgO, SrO, BaO, CaO, TiO2, ZrO2, FeO, V2O3, V2O5, Mn2O3, Fe2O3, NiO, CuO, Al2O3, SiO2, ZnO, Ag2O, and mixtures thereof.

Owner:KANSAS STATE UNIV RES FOUND

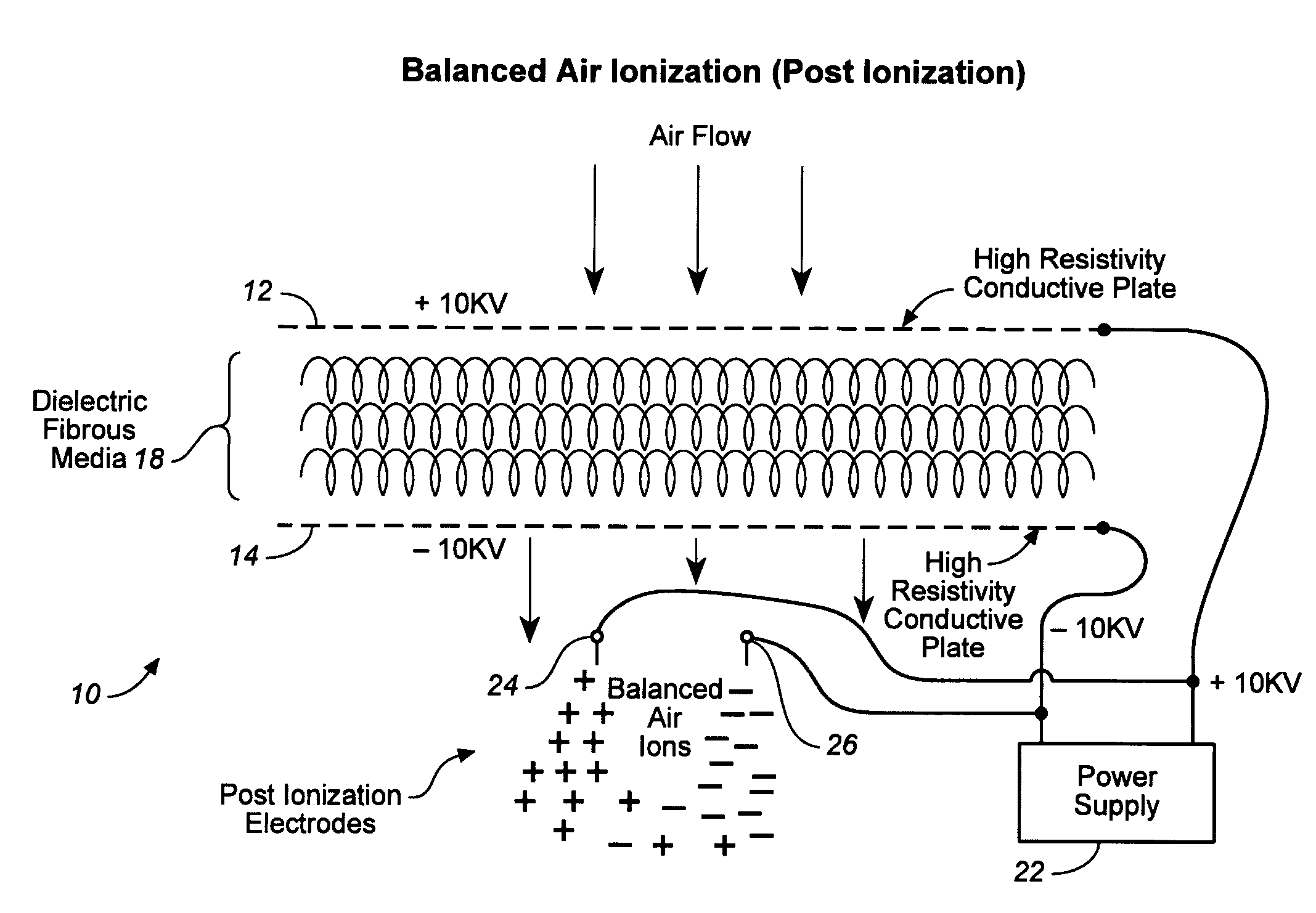

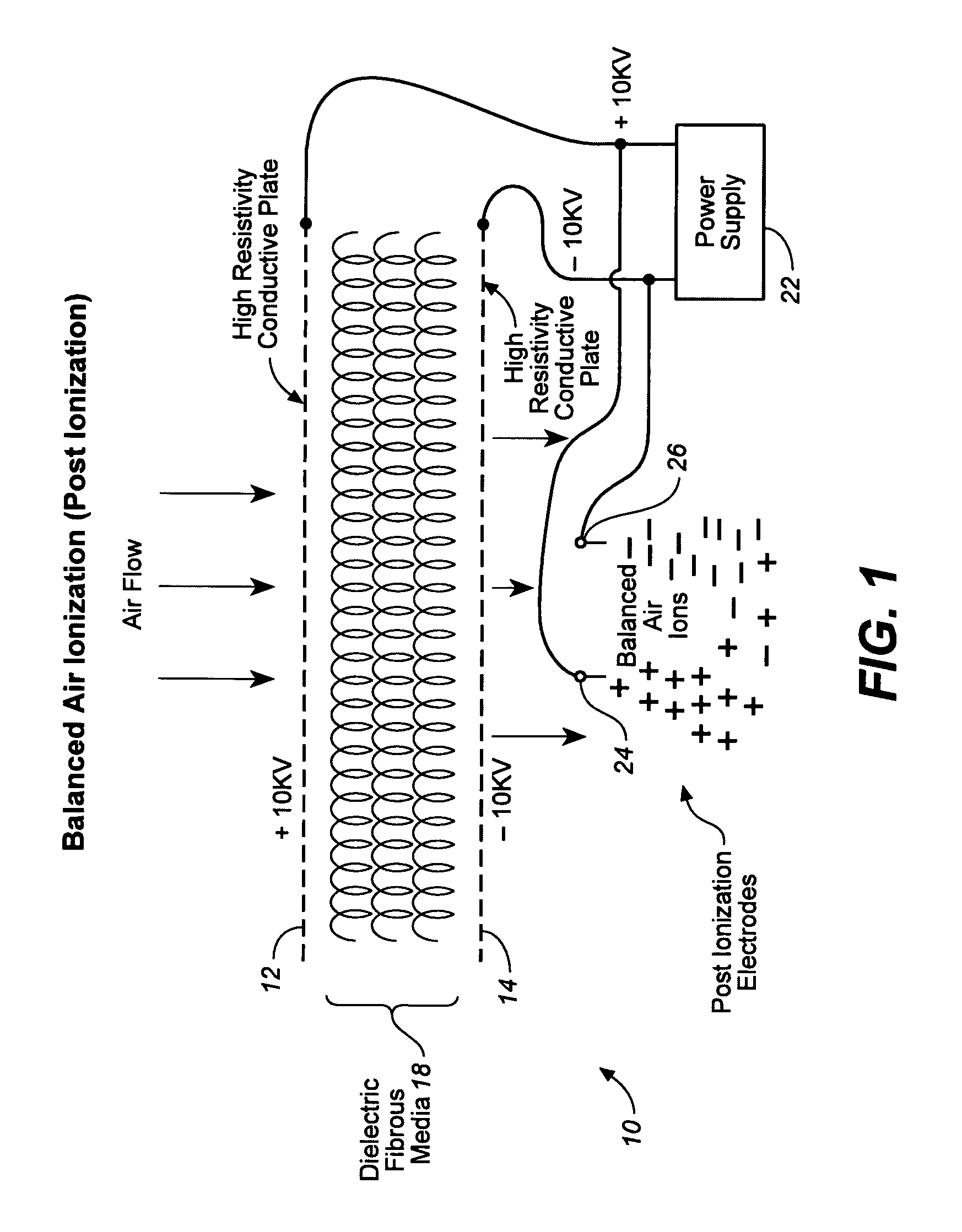

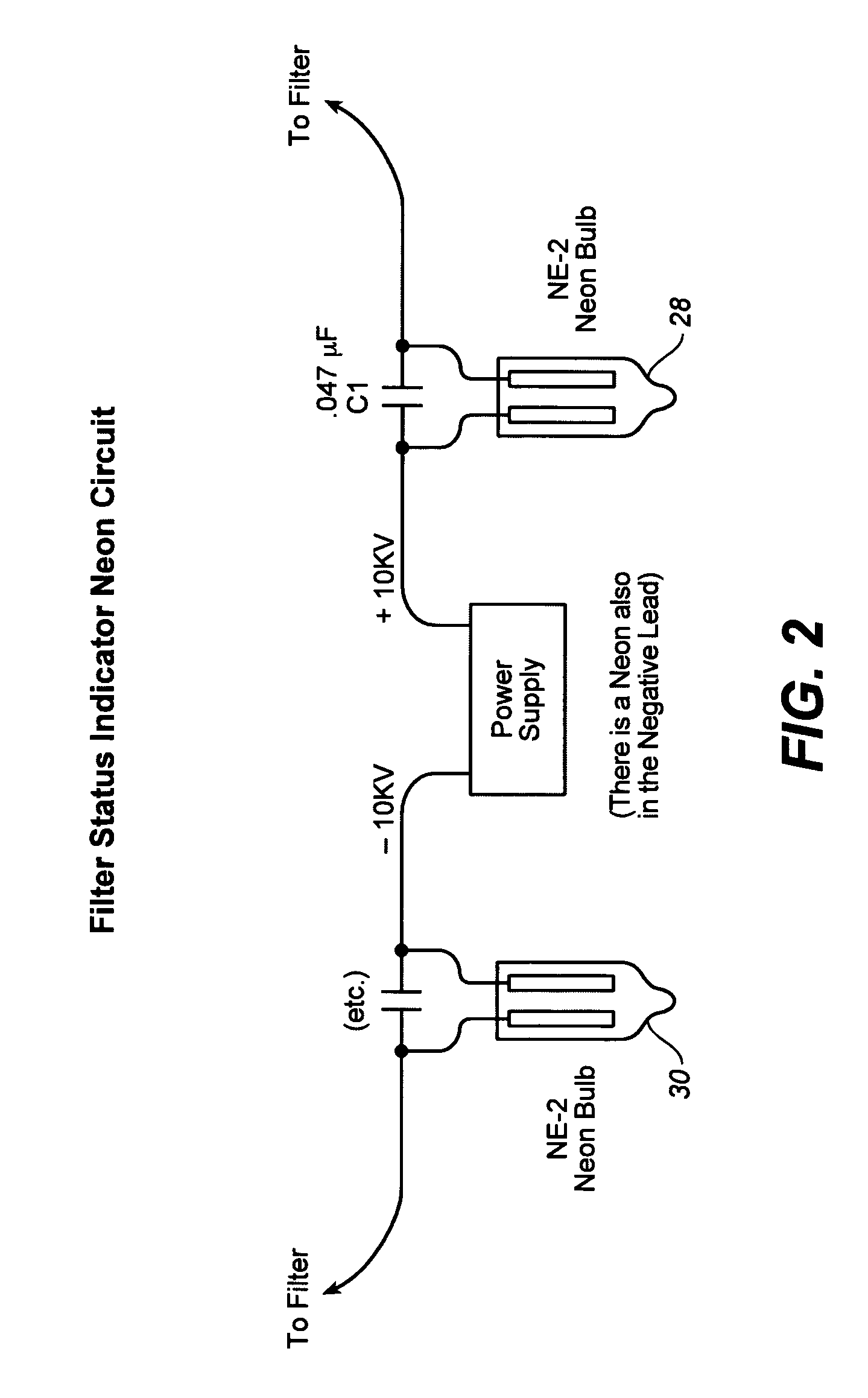

Electronic bi-polar electrostatic air cleaner

InactiveUS7258729B1Prevent surfaceImprove the level ofCombination devicesAuxillary pretreatmentFiberDielectric

An electro-mechanical electrostatic air cleaner that combines a low air resistance dielectric fibrous filter material positioned between and electrically charged by two electrically resistant carbon coated screens. The screens are charged by a remotely mounted bi-polar power supply. A pair of post ionization electrodes charge particles in the air with opposite charges, causing the particles to agglomerate. A plurality of screens may be placed in an array for increased one-pass filtration.

Owner:AIR ION DEVICES

Process for producing carbon coated iron lithium phosphate

InactiveCN101172599AElectrode manufacturing processesPhosphorus compoundsShortest distancePhosphate ion

The invention relates to a preparation method of lithium iron phosphate for the carbon cladding of a lithium ion battery. The prior lithium iron phosphate preparation technical art is complex, and has high cost. The invention has the synthetic process that: ferric oxide, phosphoric acid, simple organics and doped element compound are mixed and dried, the mol ratio of phosphate radical ion, ferric ion and doped element ion is 1:y:z, wherein, y is larger than or equal to 0.95 and smaller than or equal to 1, and y plus z is equal to 1; the mixture is added with lithium source compound, added with water to be mixed and dried, the mol ratio of lithium ion and phosphate radical ion is x:1, and x is larger than or equal to 0.95 and smaller than or equal to 1.05; the mixture which reacts for 2 to 20 hours under 500 to 800 DEG C is cooled in a furnace. The invention finally produces the precursor uniformly mixed with superfine crystal grain, and during the subsequent high temperature solid phase reaction, the end product lithium iron phosphate can be produced through shorter distance diffuseness of atoms. The end product has high purity, the crystallisation is good, the capacity is high, and the cycle stability is good.

Owner:HANGZHOU DIANZI UNIV

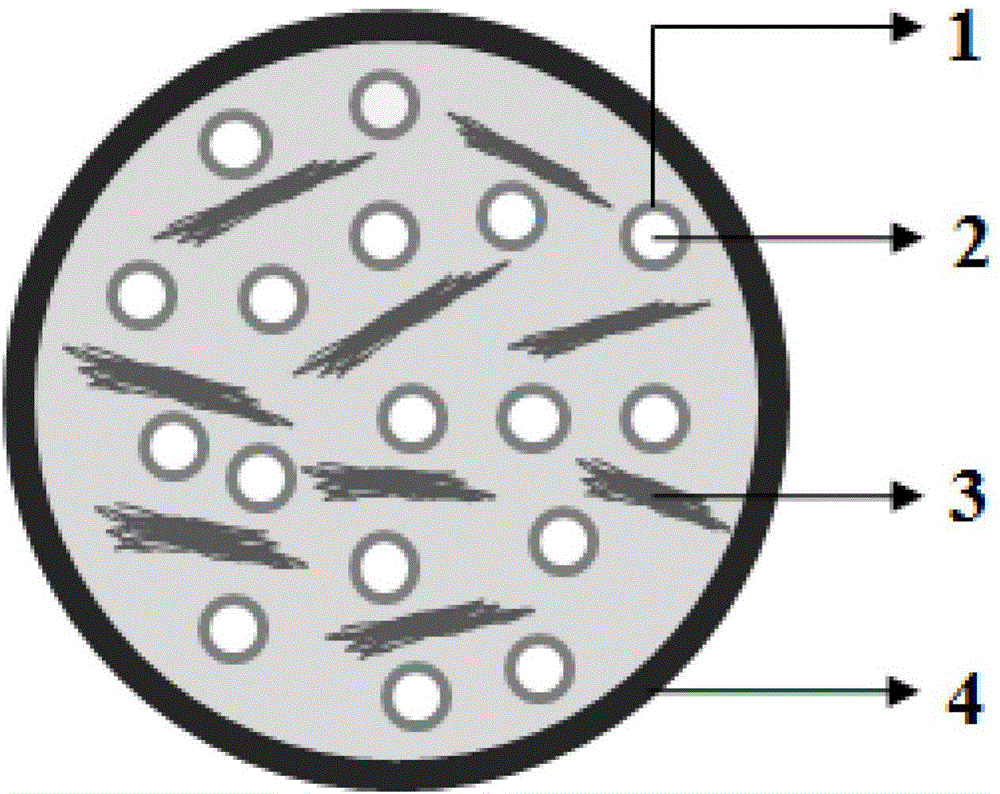

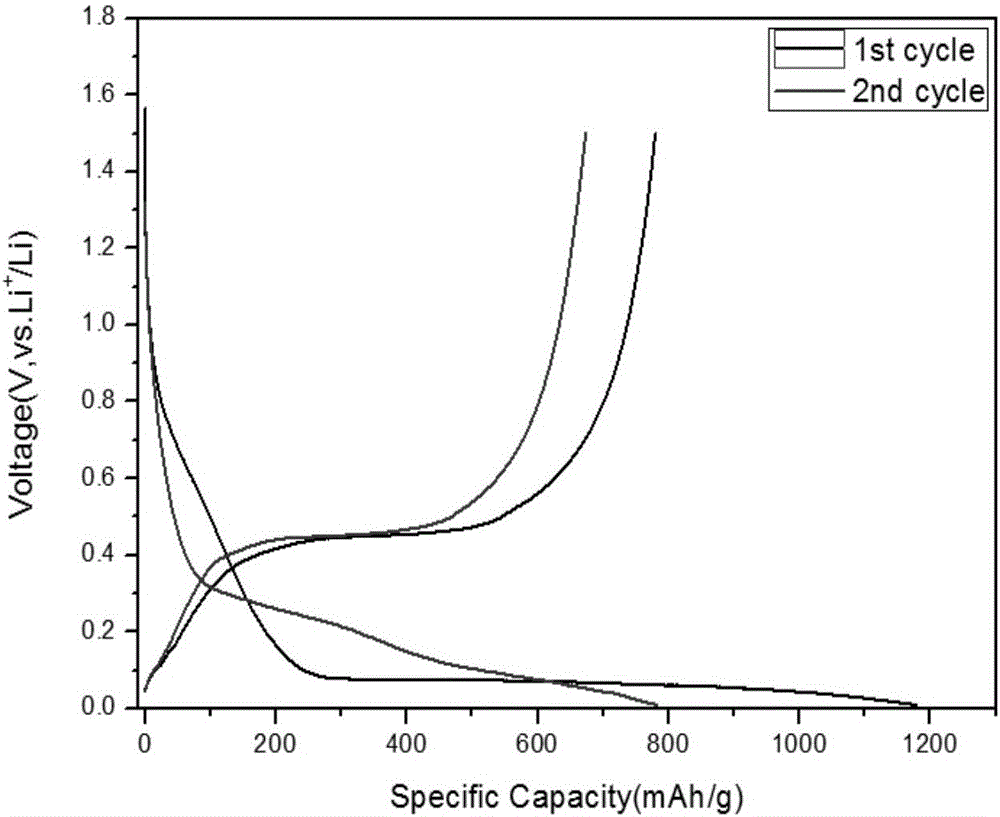

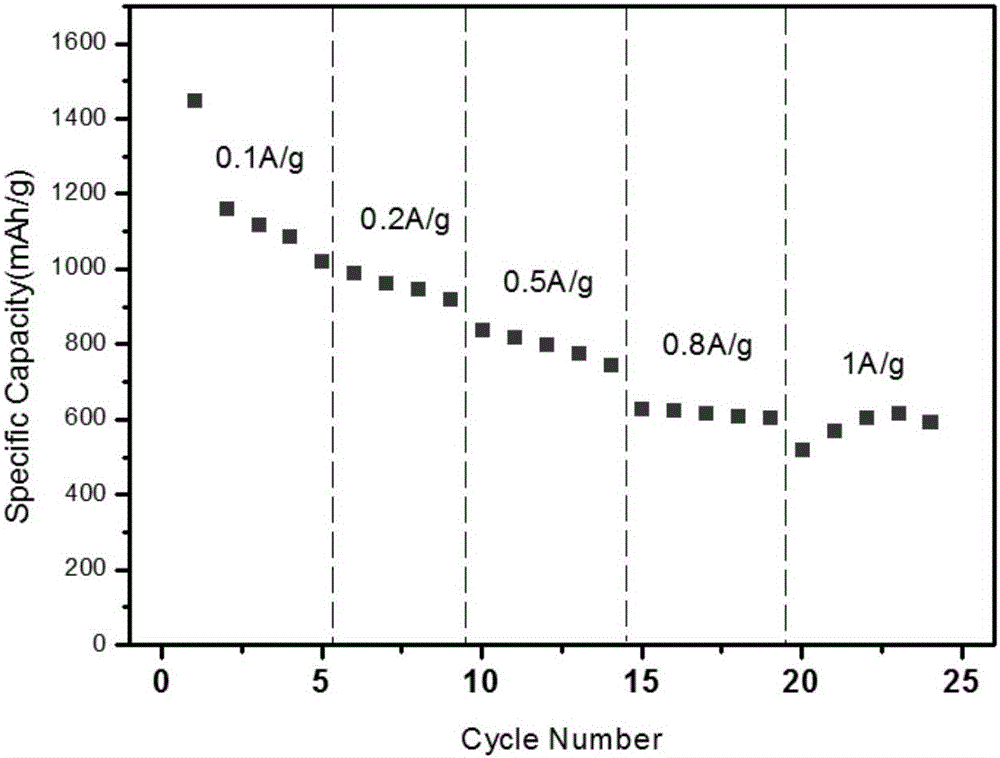

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

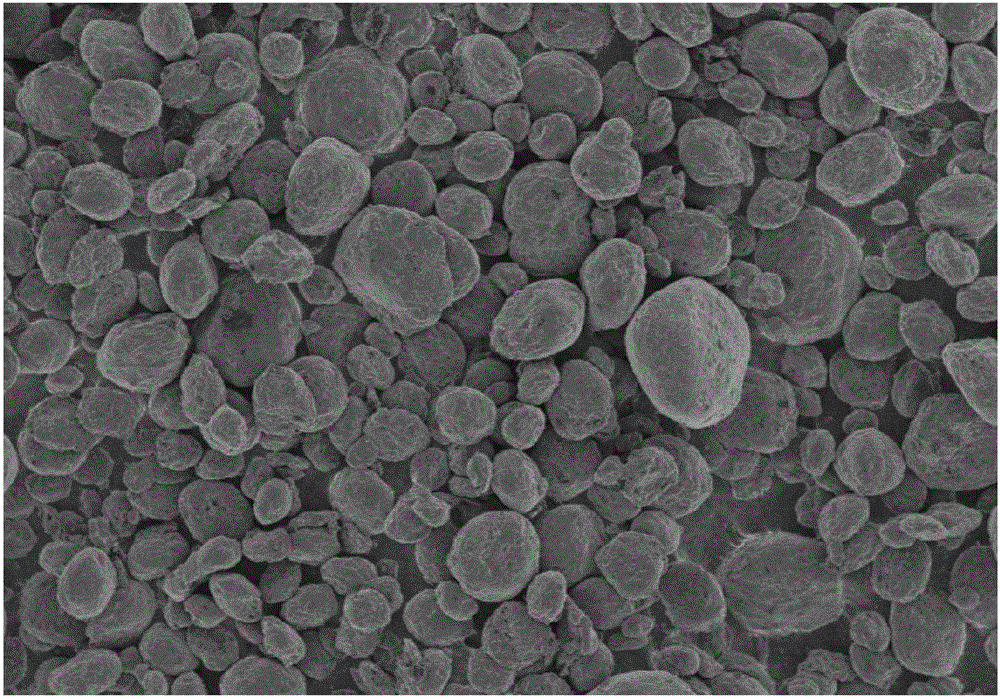

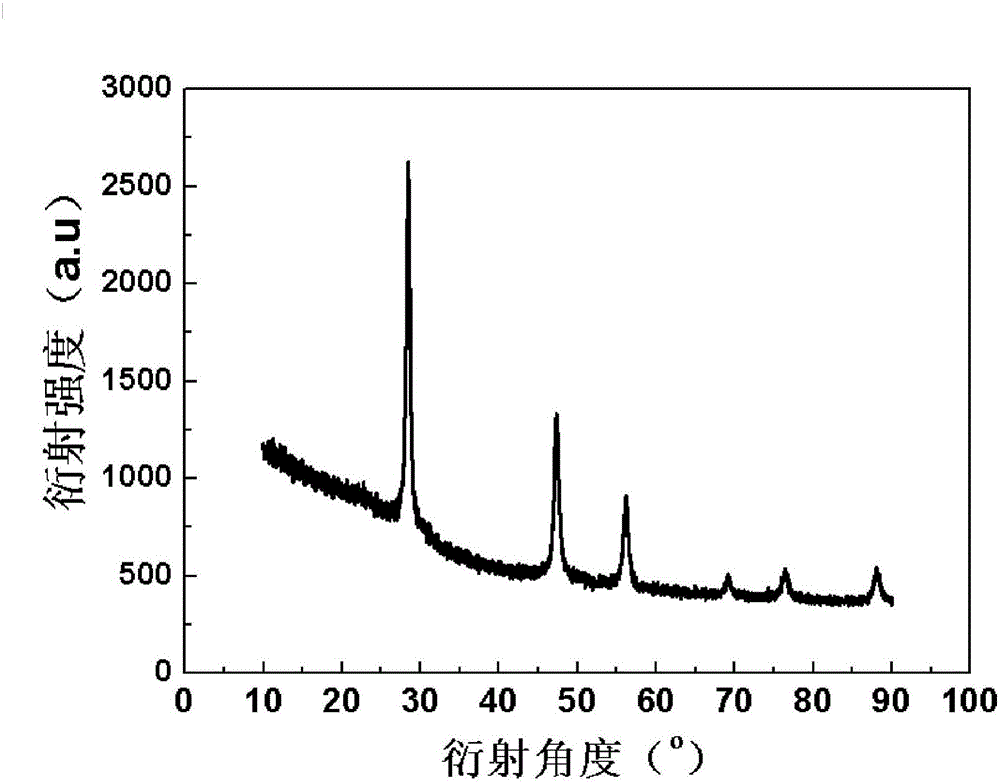

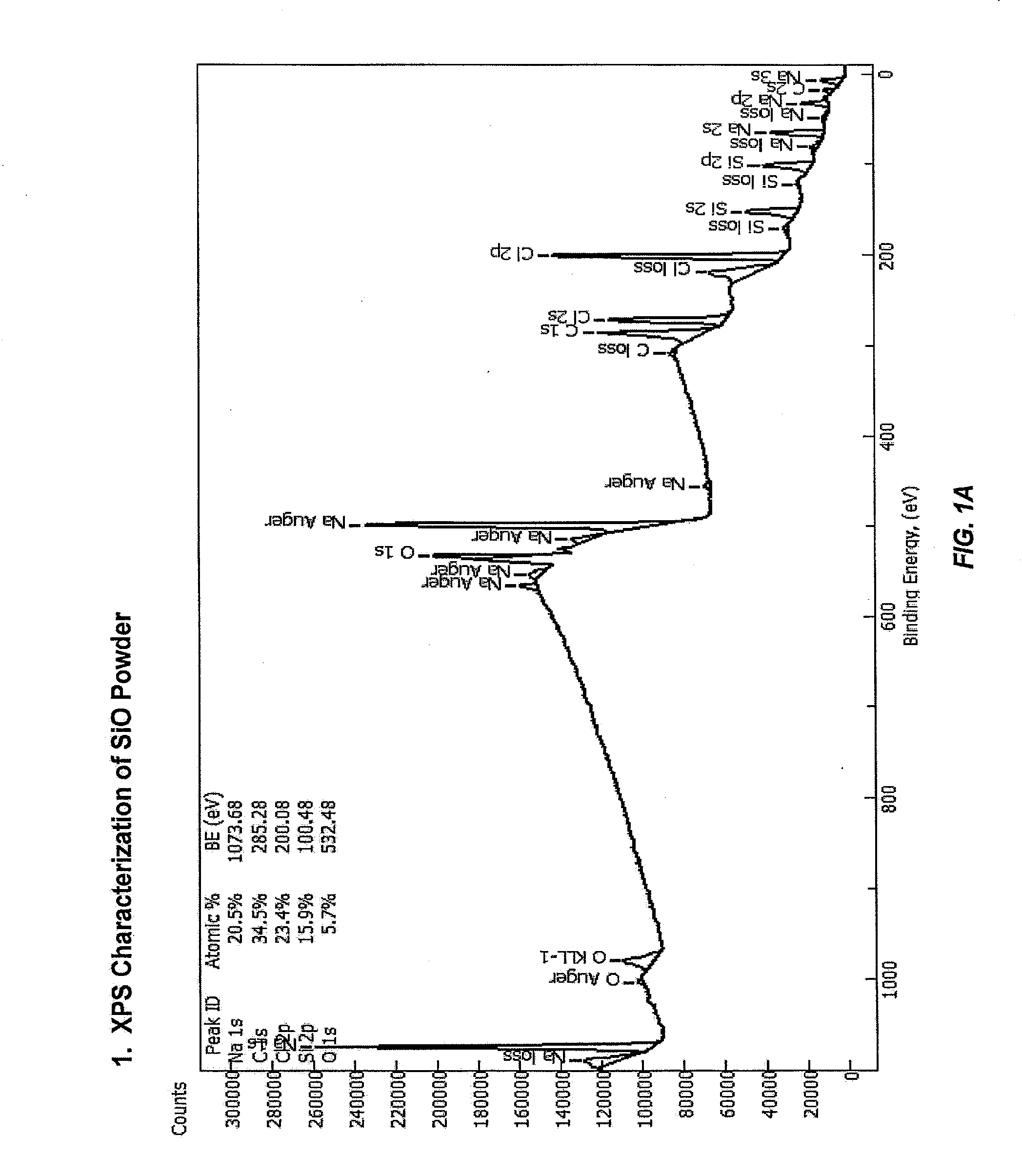

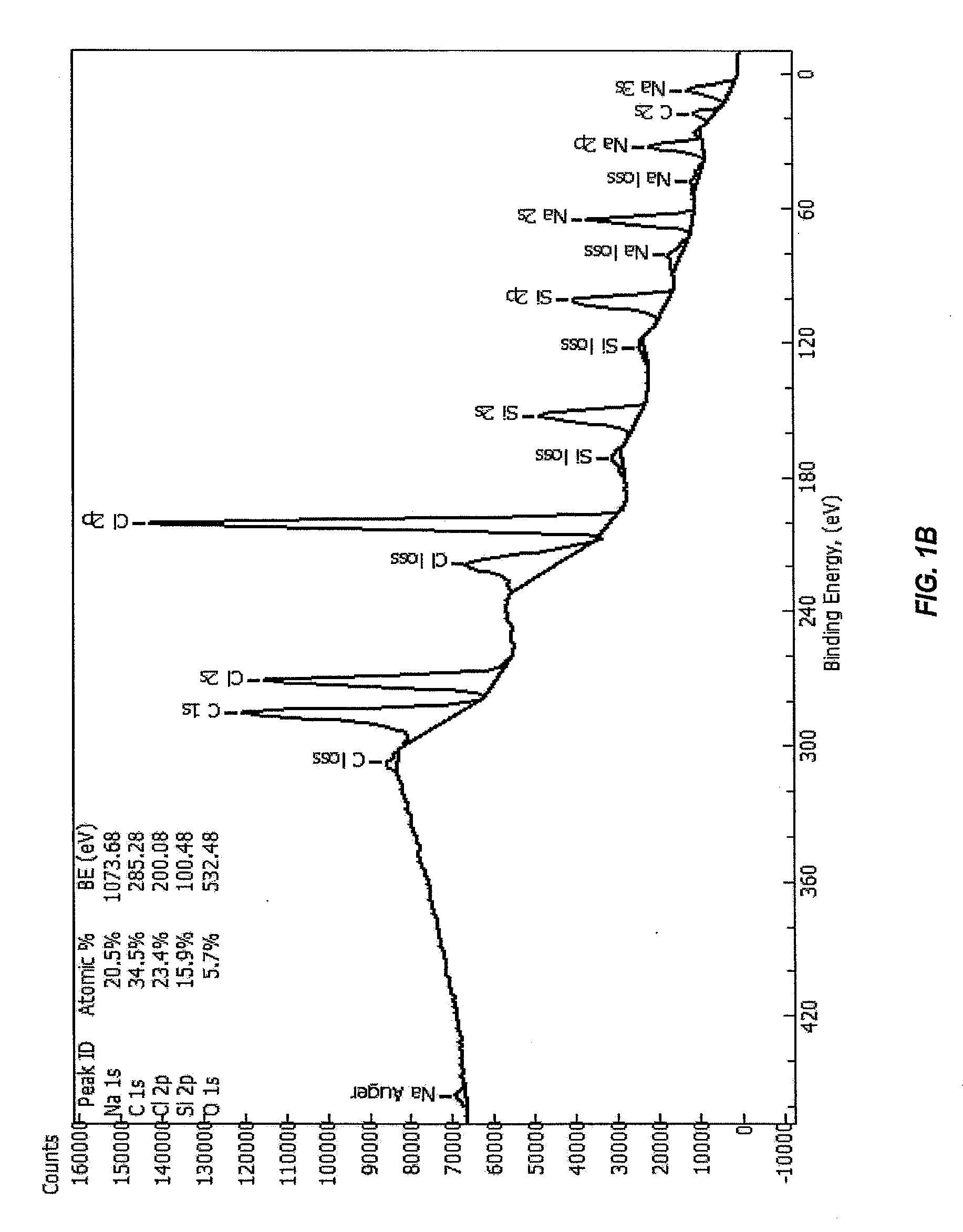

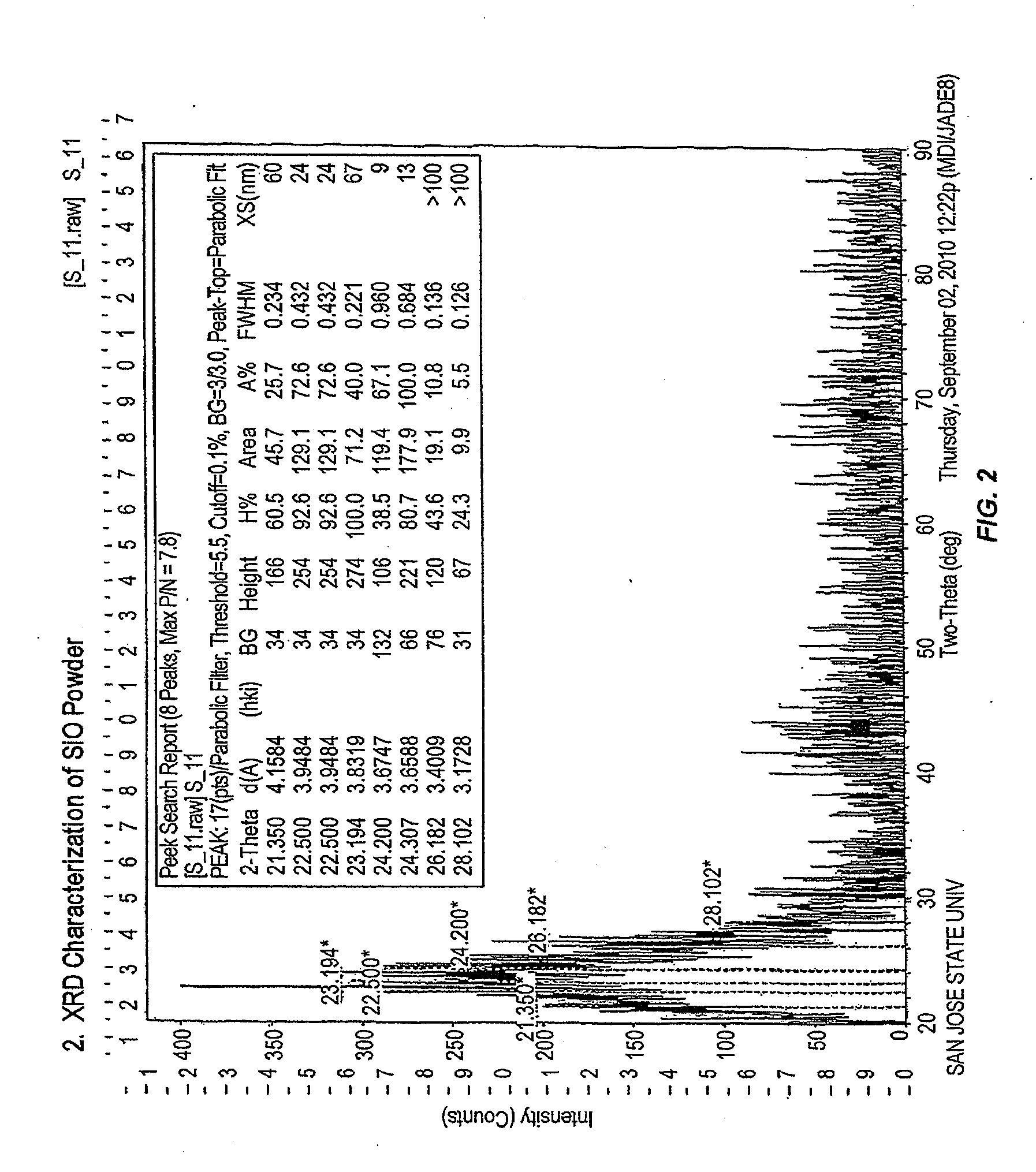

Fabrication and use of carbon-coated silicon monoxide for lithium-ion batteries

ActiveUS20140004426A1Smooth connectionNanotechPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSilicon monoxideMetallurgy

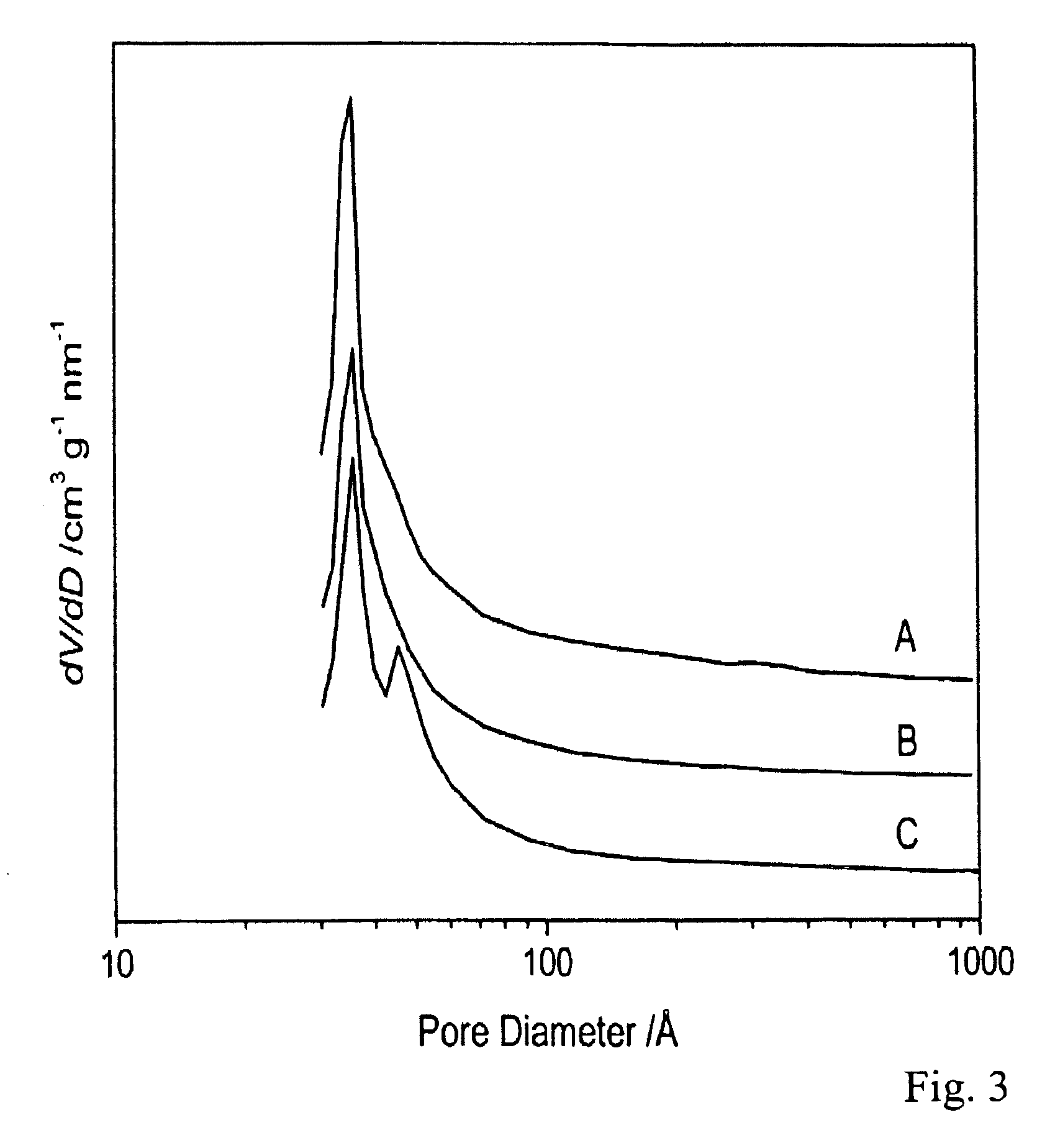

The present invention provides anode materials, methods of producing them, anodes, methods of producing them, electrochemical cells, and lithium-ion batteries, where the anode material comprises a silicon monoxide nanoparticle. In certain embodiments, the silicon monoxide is porous or mesoporous. In certain embodiments, the porous or mesoporous silicon additionally comprises other materials within its pores, such as lithium.

Owner:NEXEON LTD

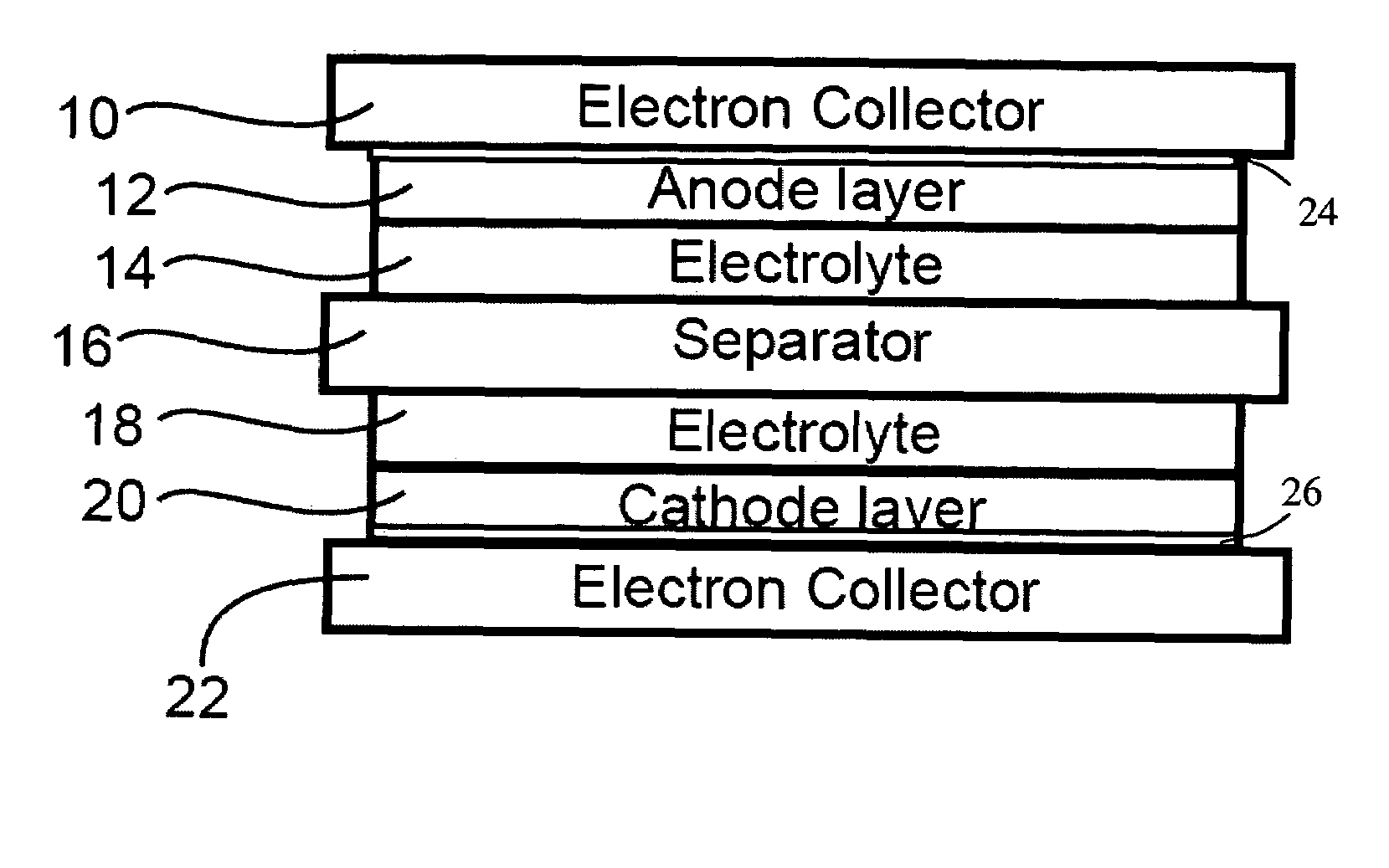

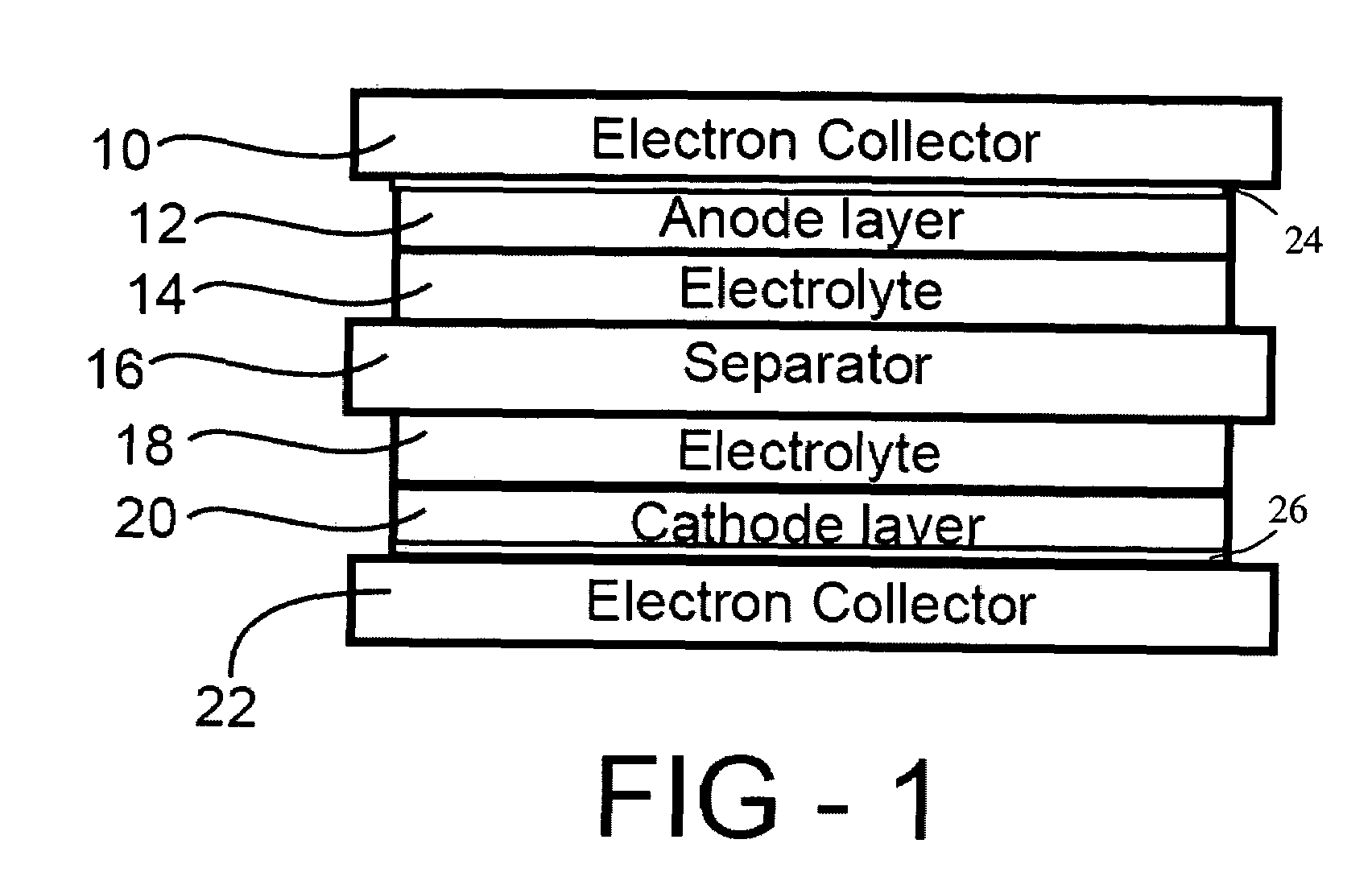

Corrosion protection using carbon coated electron collector for lithium-ion battery with molten salt electrolyte

InactiveUS7348102B2Material nanotechnologyElectrode carriers/collectorsConductive polymerCarbon nanotube

A battery, such as a lithium-ion battery, comprises a first electrode, a second electrode, a molten salt electrolyte, and an electron collector, associated with the first electrode, the electron collector comprising an electrically conducting film. The battery further includes a protection layer separating the electron collector and the first electrode, the protection layer comprising a carbon-containing material. The electron collector may be an electrically conducting material such as aluminum, aluminum alloy, copper, nickel, other metal (such as alloys), conducting polymer, and the like. In one example, the protection layer is a graphite layer. In other examples, the protection layer may be a fullerene film, carbon nanotube film, or other carbon-containing material.

Owner:TOYOTA MOTOR CO LTD +2

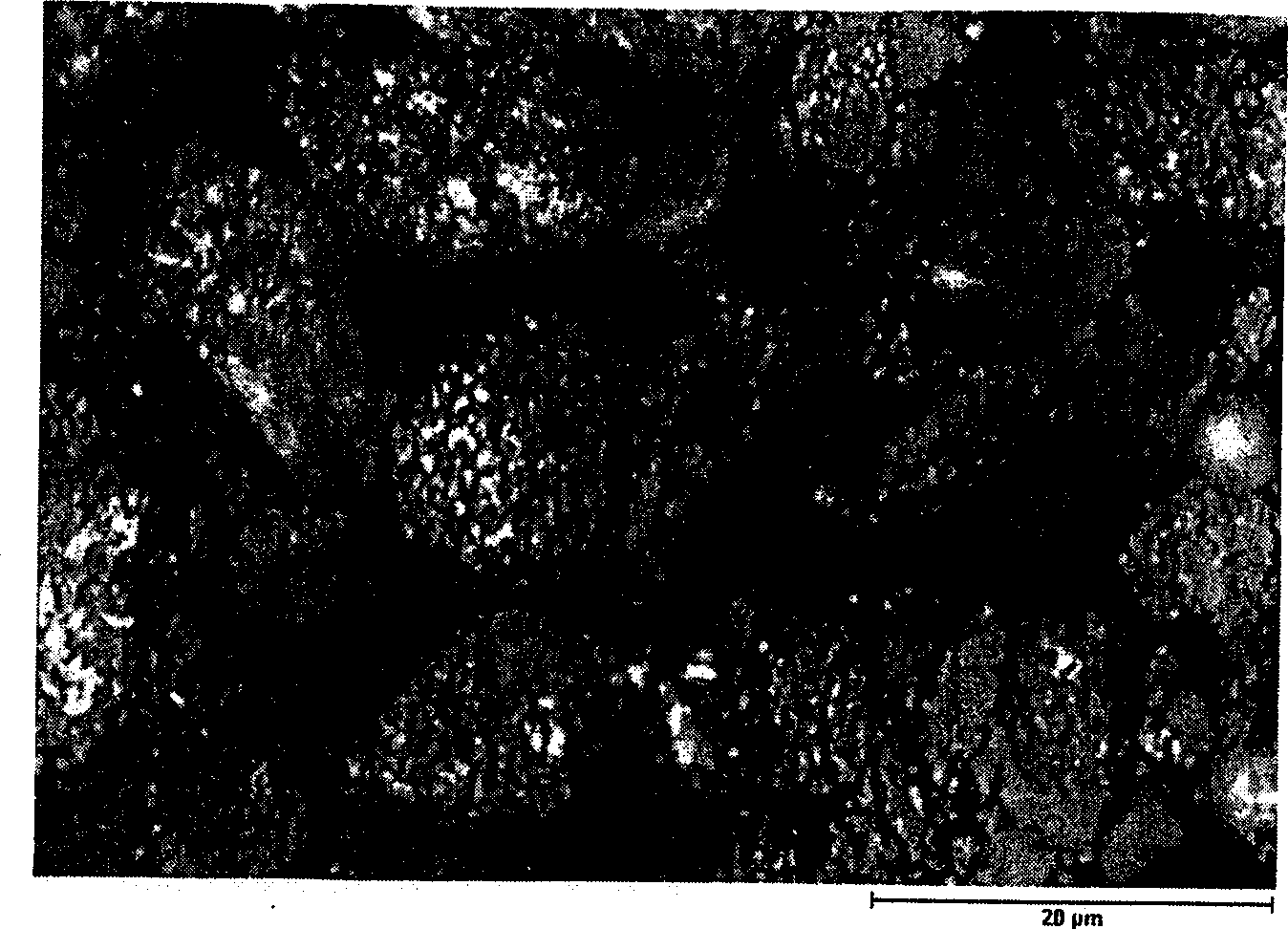

Preparation method for carbon-coated silicon negative electrode material for lithium ion battery

InactiveCN105958036ALow costAlleviate volume changesCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention provides a preparation method for a carbon-coated silicon negative electrode material for a lithium ion battery. The negative electrode material for the lithium ion battery with excellent performance is obtained from silicon powder by two times of carbon coating; the preparation method comprises the following steps of carrying out liquid phase dispersion on the silicon powder, then carrying out dispersion on the silicon powder, the first carbon coating layer and a dispersing agent; removing the solvent, and carrying out high-temperature carbonization treatment on the obtained solid material to obtain primary carbon-coated silicon negative electrode material; preparing a dispersion solution of a second carbon-coated material, dispersing the primary carbon-coated silicon material to the dispersion solution of the second carbon-coated material, and then removing the solvent and carrying out secondary roasting to obtain the secondary carbon-coated silicon negative electrode material. According to the preparation method, the raw materials are low in cost and easily available; the ratio of silicon to carbon can be optionally regulated and controlled; and the preparation method is simple in equipment, easy to implement the technological process, and suitable for scale production.

Owner:天津普兰能源科技有限公司

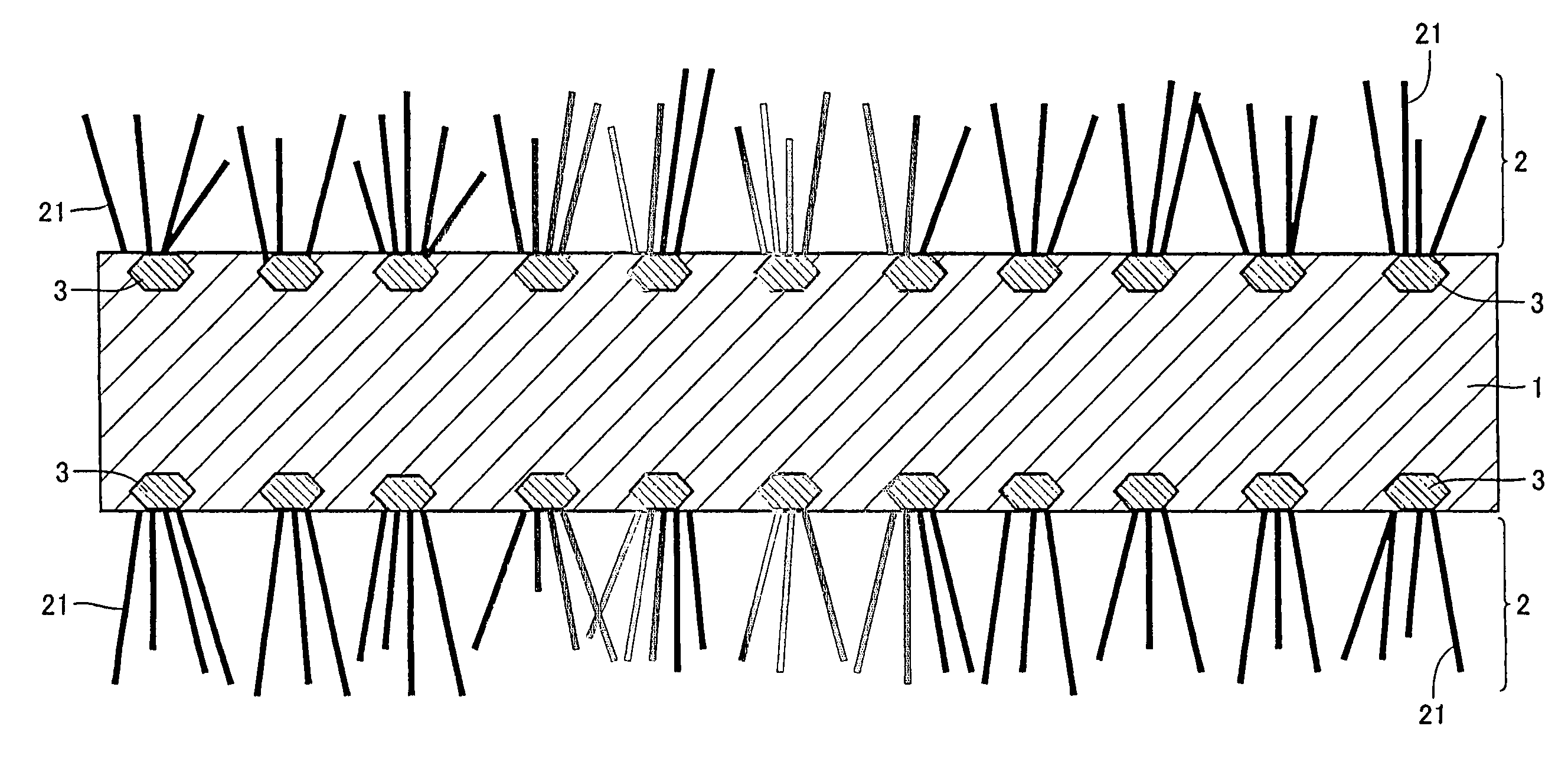

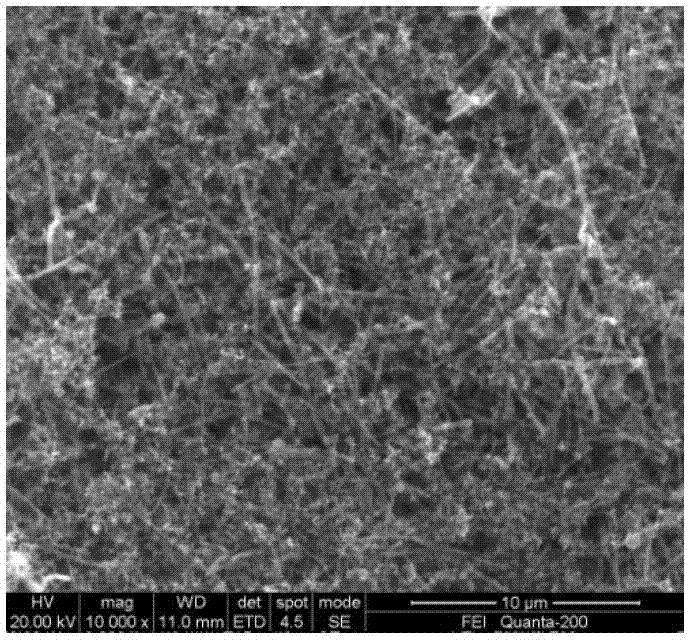

Current collector carbon coated aluminum foil and its preparation method

InactiveCN102832392AGood adhesionImprove conductivityElectrode manufacturing processesElectrolytic capacitorsInterface impedanceInternal resistance

The invention discloses a current collector carbon coated aluminum foil and its preparation method. A carbon-containing composite layer is arranged on the substrate of the current collector carbon coated aluminum foil, and is combined with the substrate through a binder, wherein the thickness of the carbon-containing composite layer is 1-100mum; the carbon-containing composite layer comprises granular conductive carbon black pre-dispersed by a dispersant, and fibrous conductive carbon; the granular conductive carbon black and the fibrous conductive carbon filled between the layers of the granular conductive carbon black form a netted node form conductive network. The composite layer is tightly combined with the substrate of the aluminum foil, so the conductivity and the corrosion resistance of the aluminum foil are improved, and the aluminum foil is protected from oxidation or chemical corrosion. The preparation method of the aluminum foil comprises the following operations: mixing the conductive carbon black with the dispersant in an organic solvent to pre-disperse, adding the fibrous conductive carbon, uniformly mixing, adding the binder to prepare a slurry, coating on the aluminum foil, and carrying out vacuum drying. The current collector carbon coated aluminum foil enables the interface impedances of the current collector and an active layer to be reduced, the internal resistance of a battery to be reduced, and the cycle life and the ratio performances of the battery to be improved when the aluminum foil is used as a lithium ion battery anode current collector. The aluminum foil has the advantages of simple technology, low cost and wide application prospect.

Owner:HUNAN CMAX NEW ENERGY TECH

Hard carbon coated lithium ion battery anode material and preparation method thereof

InactiveCN102082272AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesHeteroatomGraphite particle

The invention discloses a hard carbon coated lithium ion battery anode material and a preparation method thereof. The anode material is characterized in that the coating material is formed by a heteroatom modifier, a hard carbon precursor material and a soft carbon precursor material, wherein the weight ratio of the heteroatom modifier to the hard carbon precursor to the soft carbon precursor is 1:(2-3.3):(3-9). The preparation method is mainly characterized by comprising the following steps: fully mixing graphite and the coating material, and then carrying out heat treatment on the mixture under the protection of inert atmosphere; preserving the temperature for 0.5-6 hours, and then cooling; and carrying out secondary high-temperature graphitization treatment under the protection of inert atmosphere. The heteroatom modifier can change the structure of the hard carbon in the coating material, and the hard carbon precursor has the characteristics of dissolvability and condensation polymerization with the soft carbon precursor asphalt, thus improving the uniformity and operability of the coated graphite particles; and the ratio of the heteroatom modifier to the hard carbon precursor to the soft carbon precursor has an important effect on the performance of the three. By optimizing the ratio of the heteroatom to the hard carbon precursor to the soft carbon precursor in the coated graphite material, the aims of increasing the capacity of the anode material and improving the cycle performance of the anode material are achieved.

Owner:湖南摩根海容新材料有限责任公司

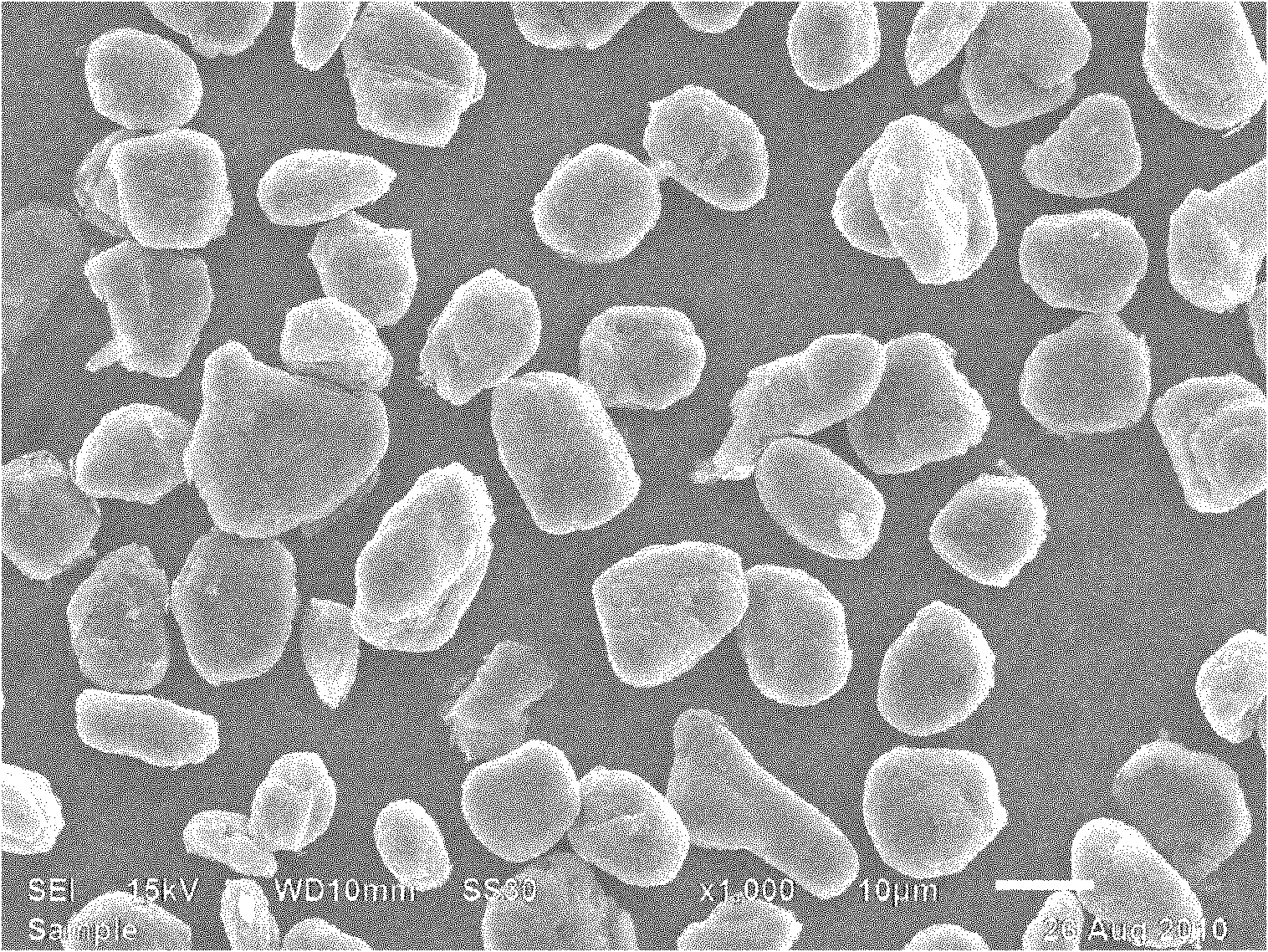

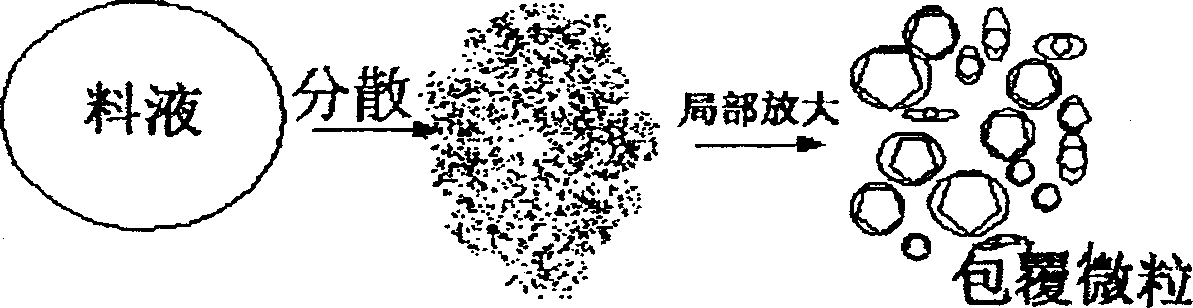

Process for preparing carbon coated graphite microparticles

InactiveCN1397598AReduce the first irreversible capacityLow charge and discharge voltagePigment treatment with macromolecular organic compoundsMicroparticleGraphite

A process for preparing carbon coated graphite microparticles used as negative electrode material of Li-ion battery features use of spray granulating method. It can elongate the service life of Li-ion battery.

Owner:TSINGHUA UNIV

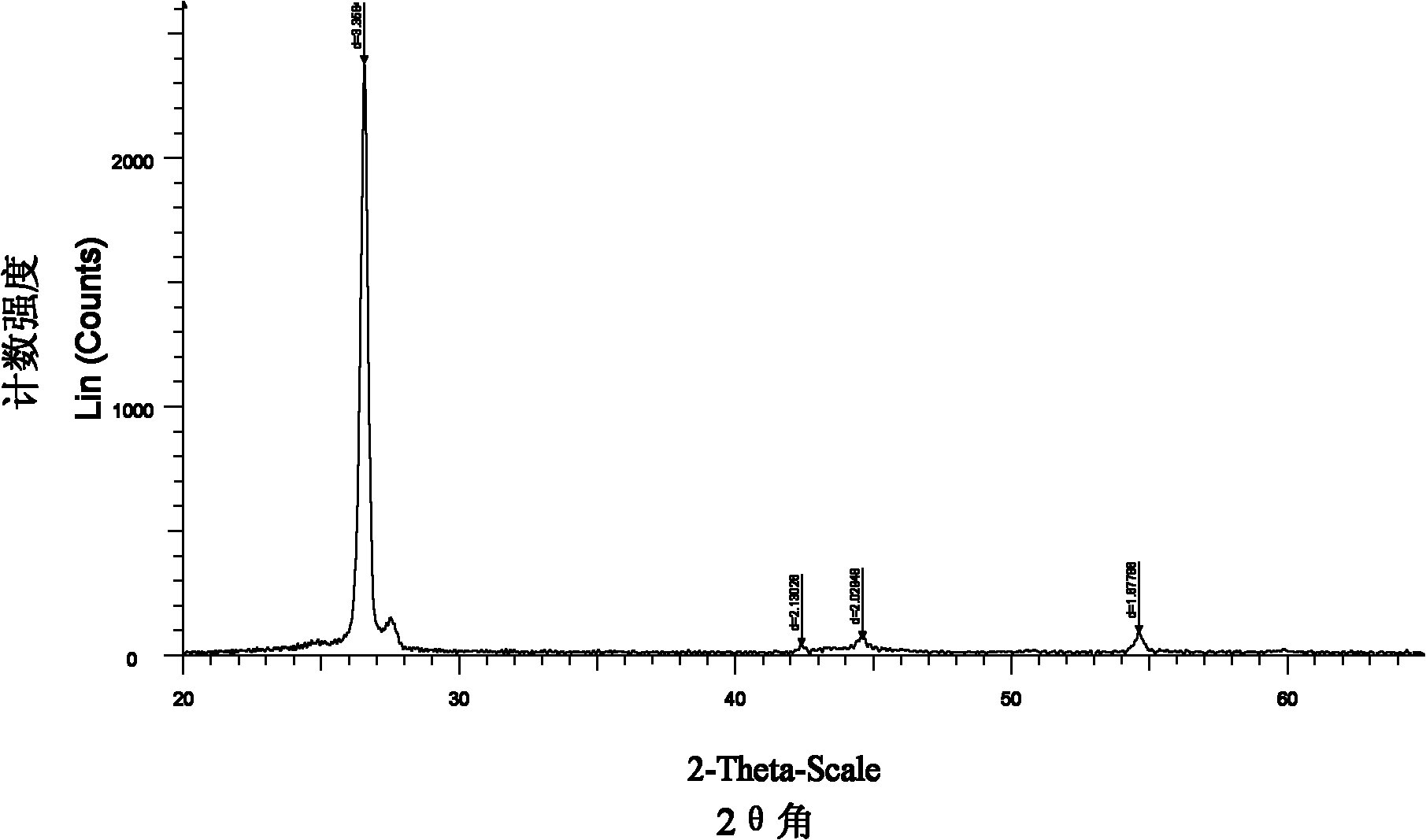

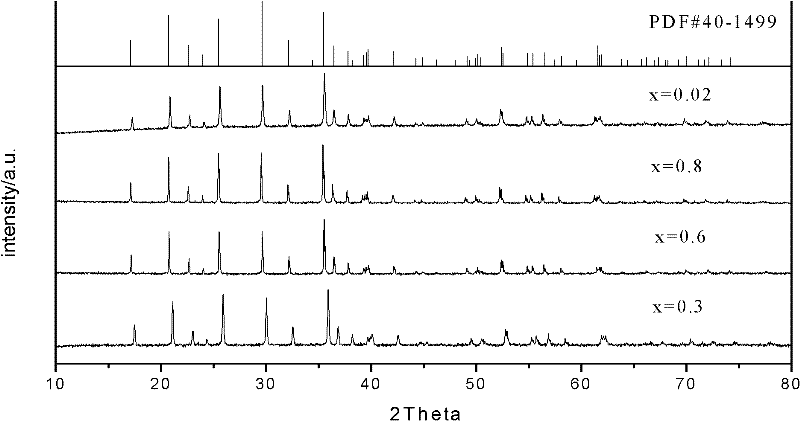

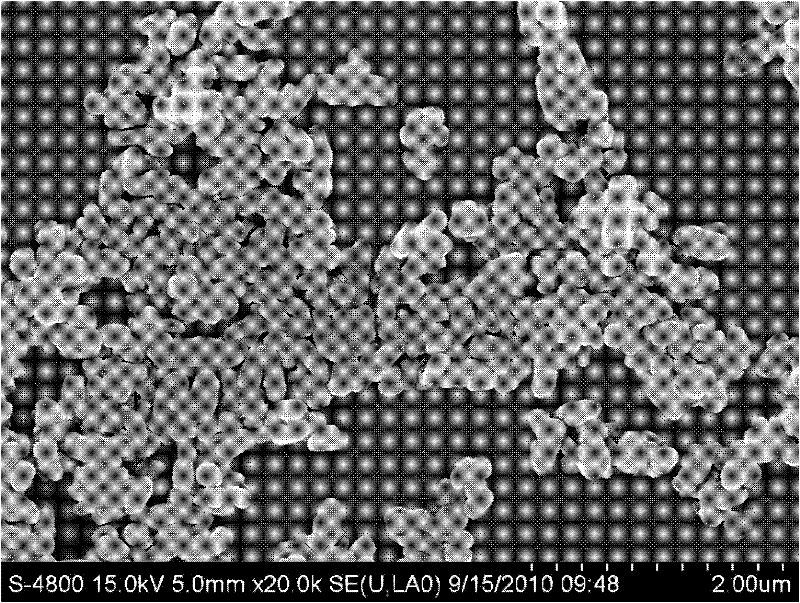

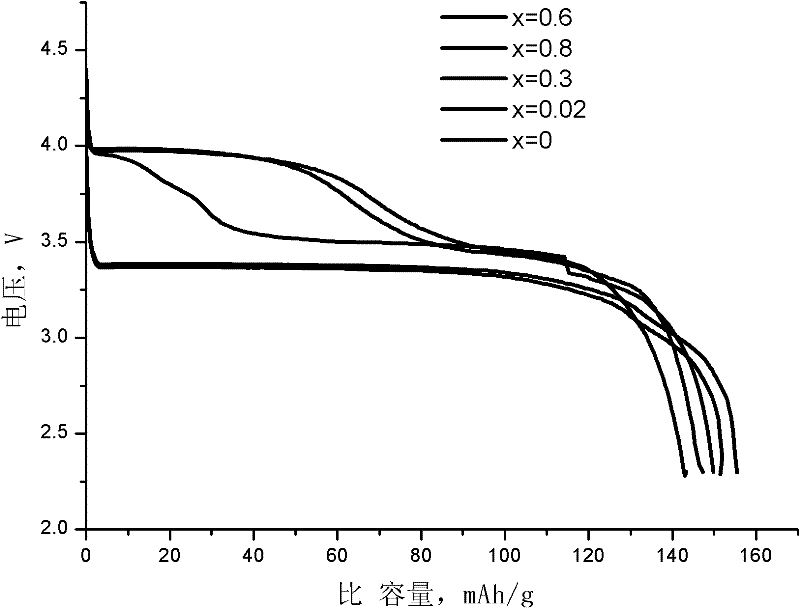

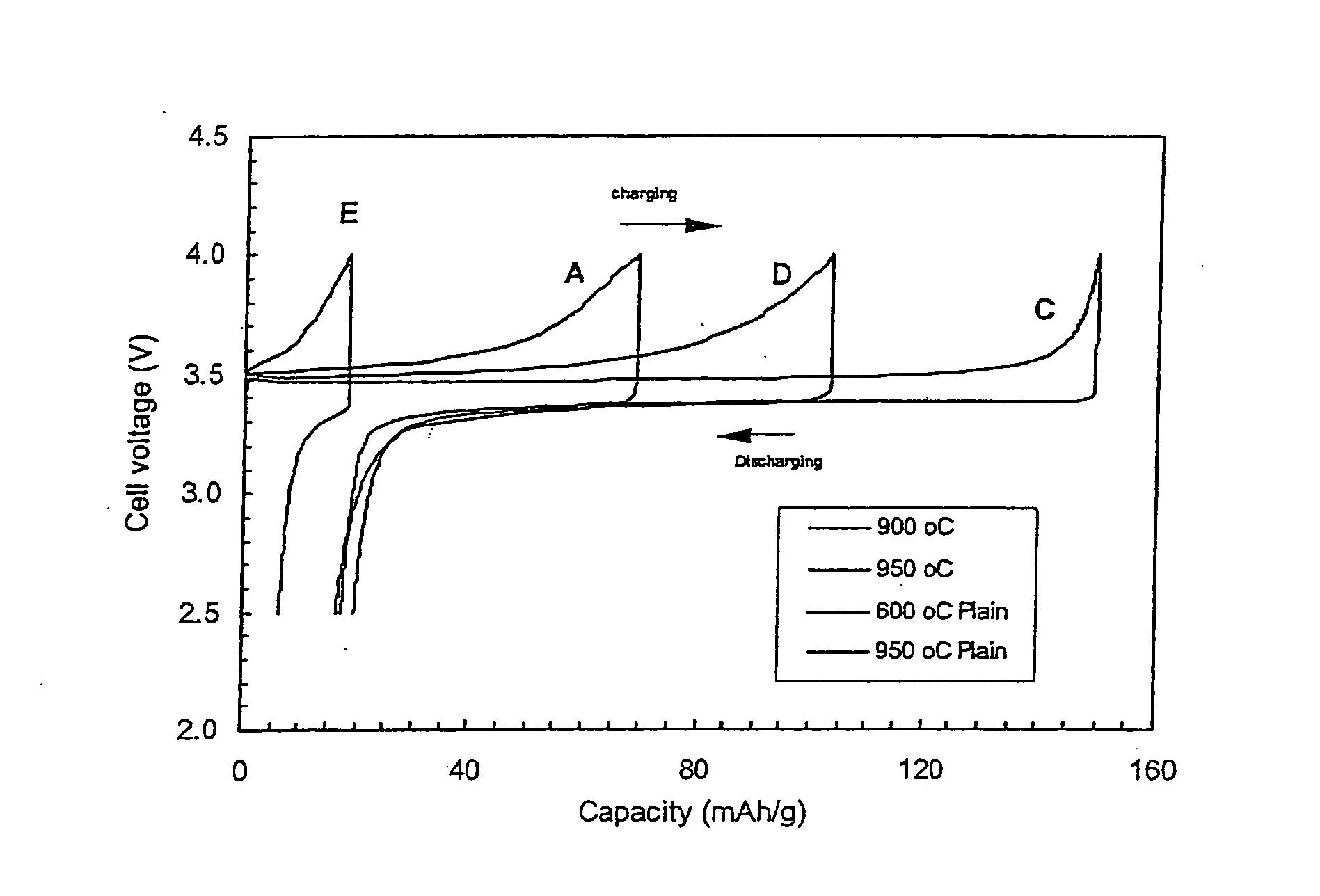

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

Process of making carbon-coated lithium metal phosphate powders

InactiveUS20070160752A1Improve material performanceThe process is simple and fastLiquid surface applicatorsCell electrodesLithium metalPhosphate

The present invention provides a process for making uniform carbon-coated LiMPO4 powders for use as a cathode material in lithium ion batteries. In one embodiment, the process comprises synthesizing a LiMPO4 powder. The process further comprises coating a carbonaceous coating on to the LiMPO4 powder to form a coated LiMPO4 powder. Additionally, the process comprises carbonizing the coated LiMPO4 powder.

Owner:CONOCOPHILLIPS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com