Patents

Literature

76results about How to "Single phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

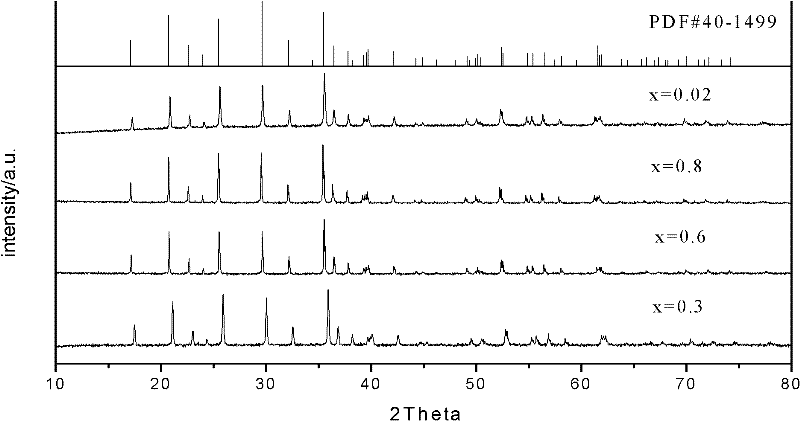

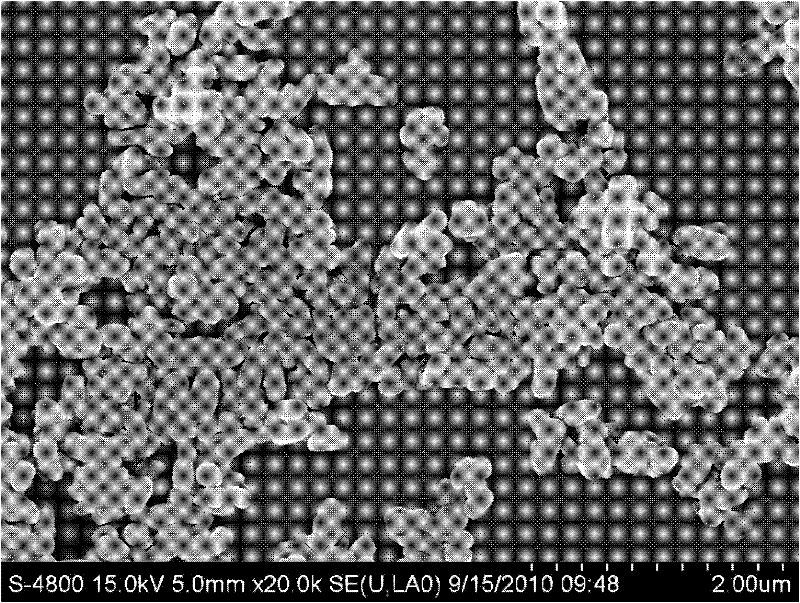

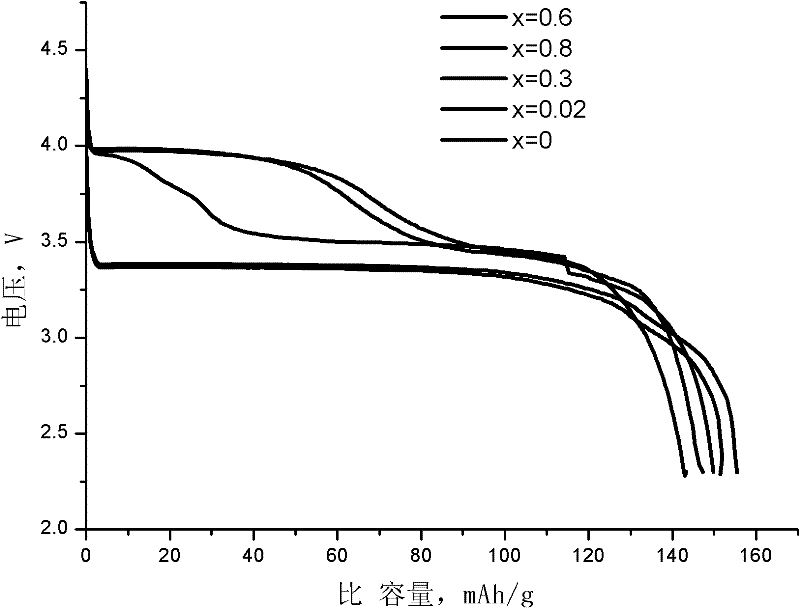

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

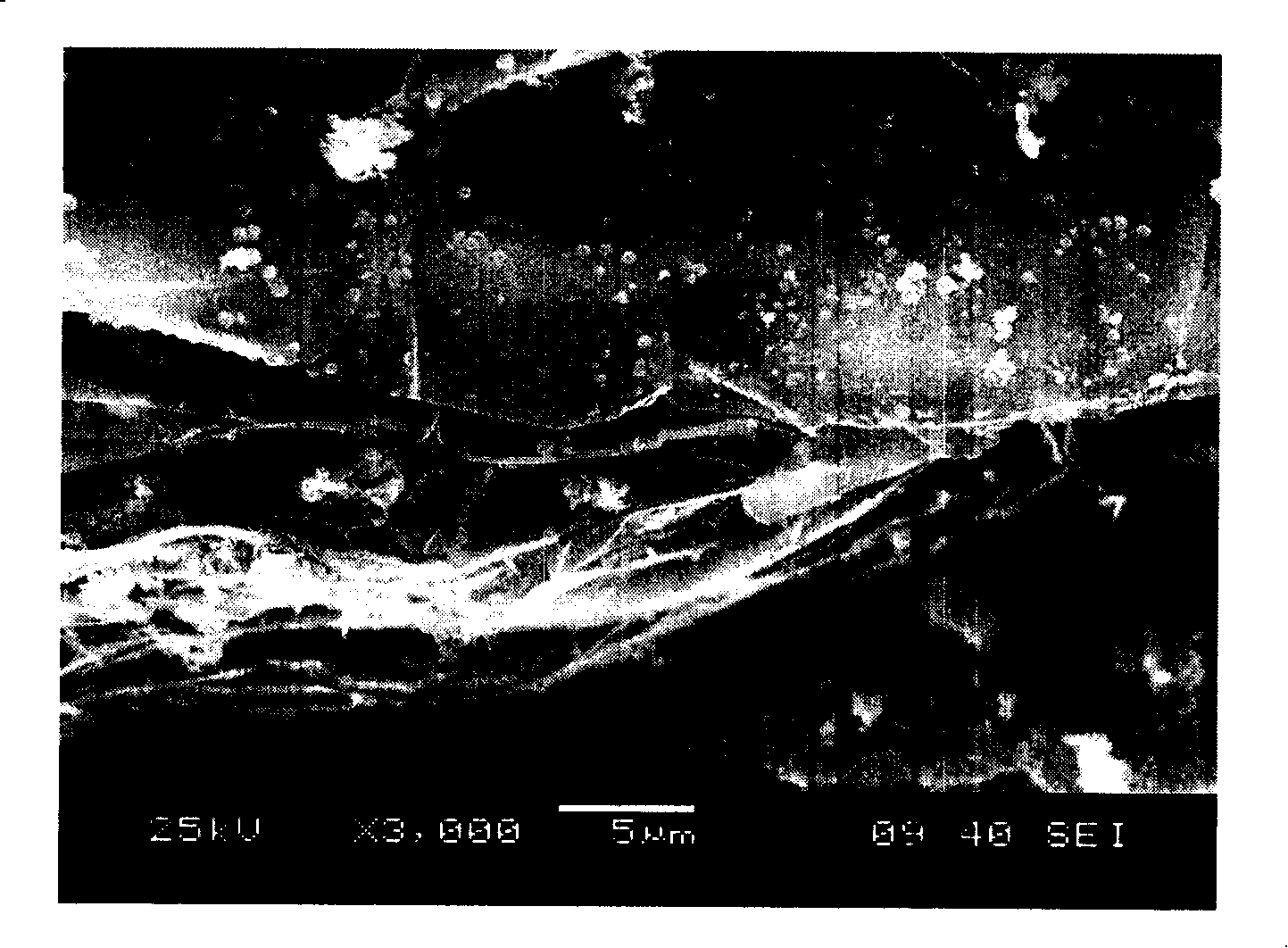

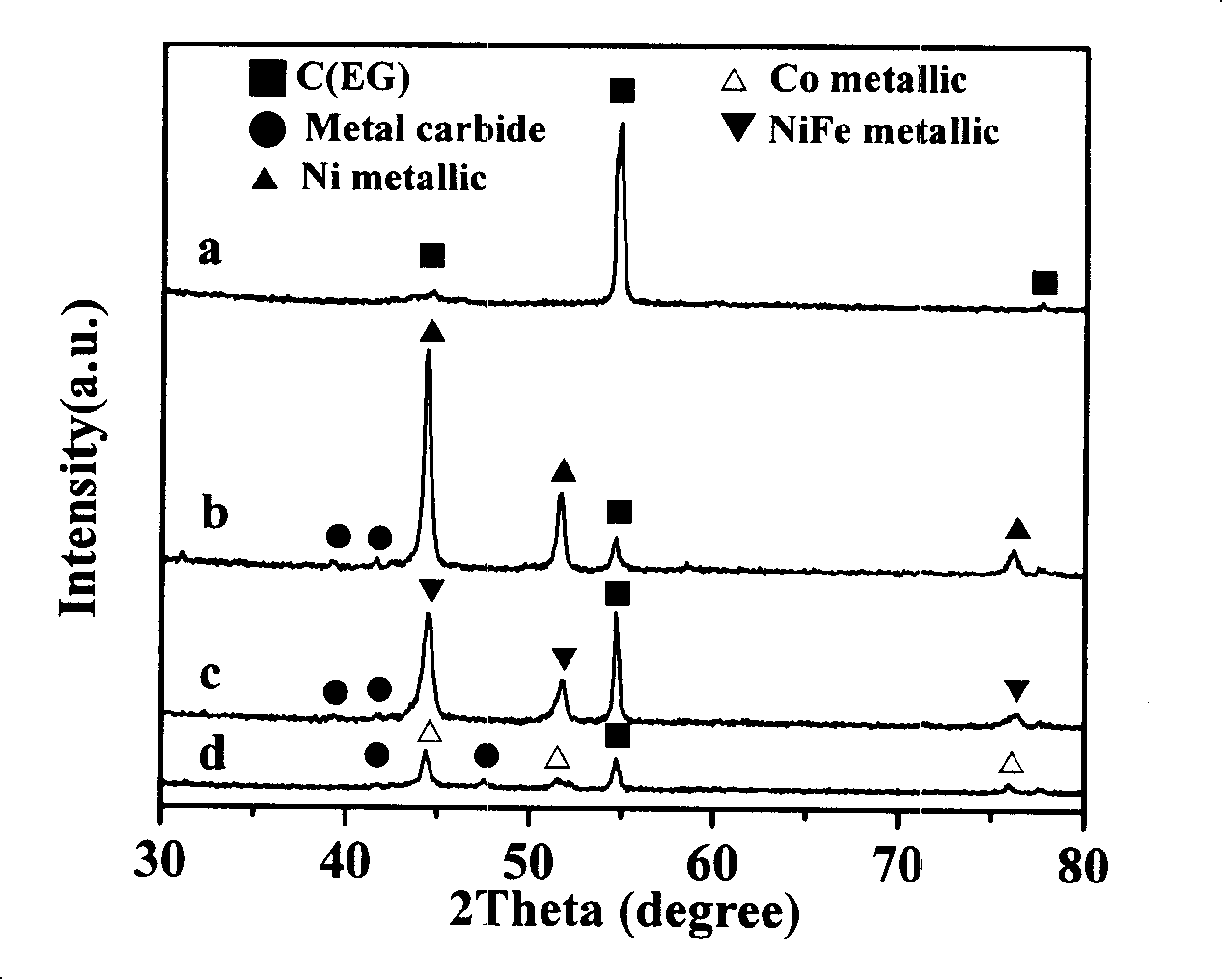

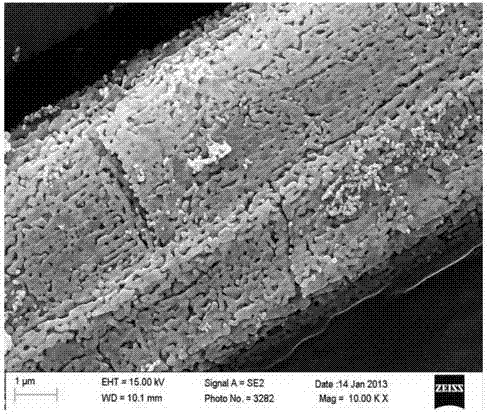

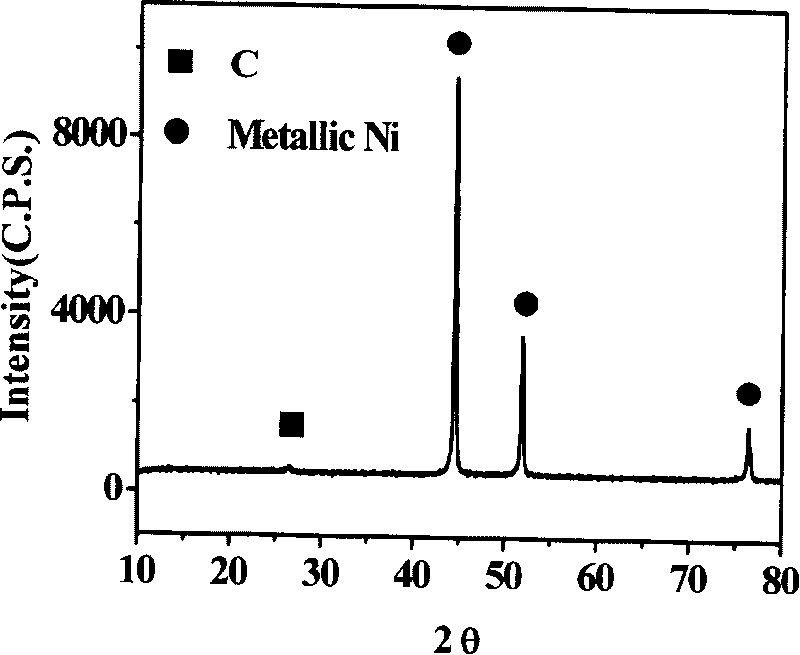

Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

InactiveCN101179921AStir and disperse evenlyEnable mass manufacturingMagnetic/electric field screeningScreening apparatusLow frequency bandElectromagnetic shielding

The invention relates to a preparation method of a lightweight graphite-based nano-magnetic metal composite material used for electromagnetic shielding, which belongs to the related field of electromagnetic shielding materials; the precursor solution of expanded graphite and magnetic metal is mixed and stirred evenly, and dried after evaporating the solvent. The obtained mixture is treated in a reducing atmosphere at 300°C-1000°C, passivated with ordinary nitrogen and cooled to room temperature to obtain a composite material of expanded graphite and magnetic nanometer metal, and the relative content of the two can be adjusted. The composite material is light in texture, has excellent electromagnetic properties, and can be pressed into various shapes required. The material has excellent electromagnetic shielding performance in the range of 300kHz-1.5GHz, reaching 70-105dB, and the addition of magnetic metal improves the electromagnetic shielding performance of the expanded graphite in the low-frequency band. The method is simple and efficient, suitable for mass preparation, and the obtained product is expected to be applied in aerospace, military, electronic and electrical products.

Owner:NANJING UNIV

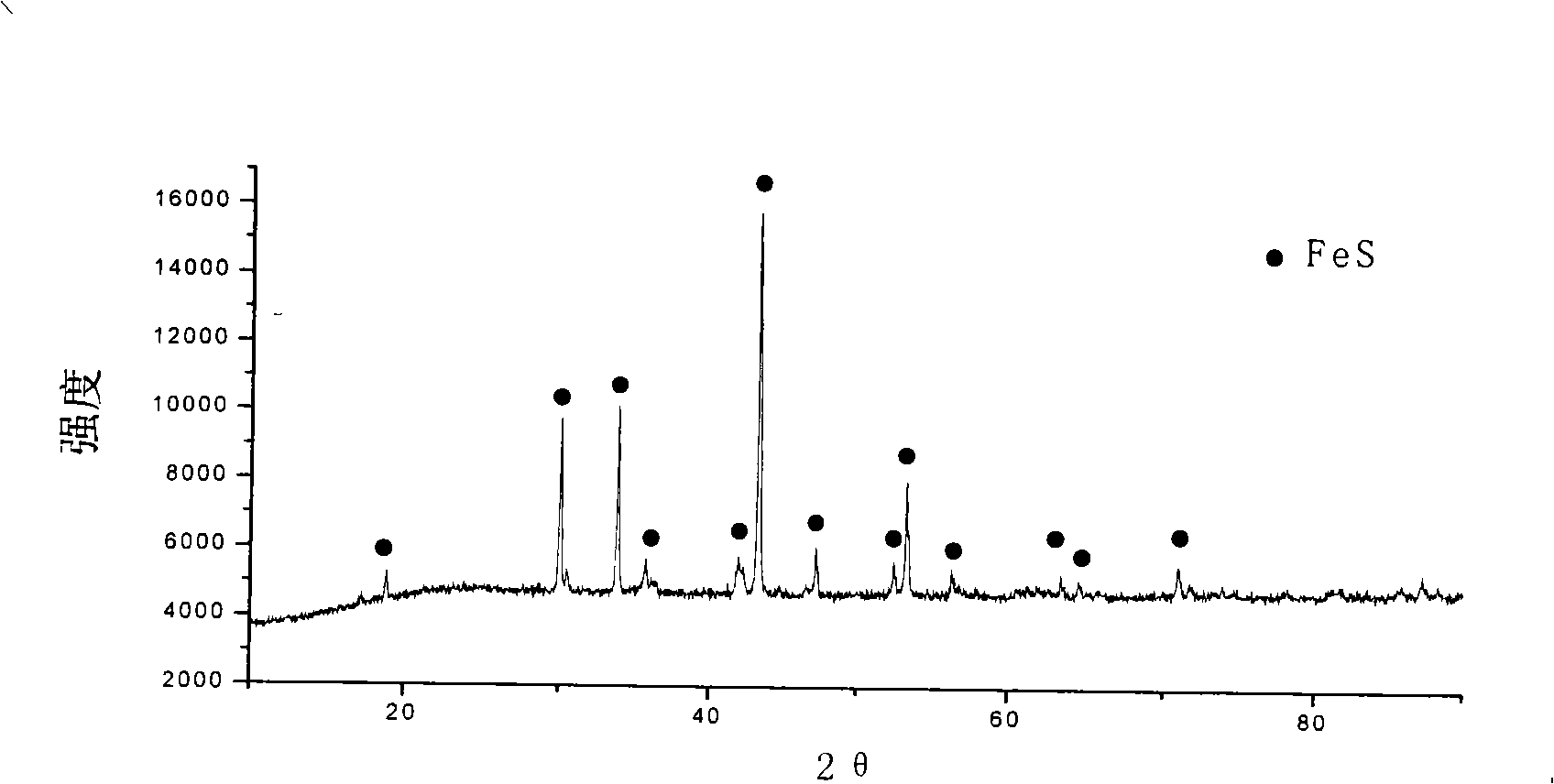

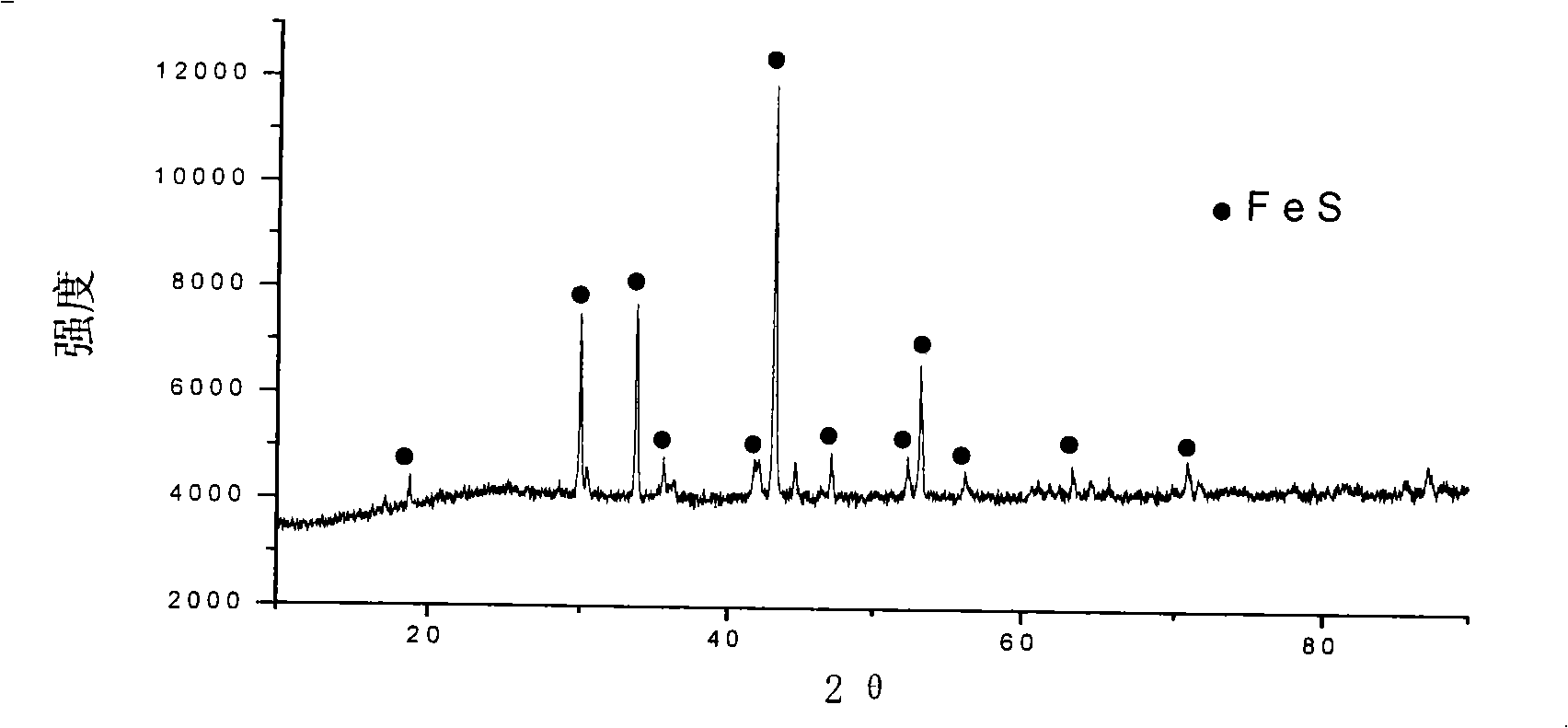

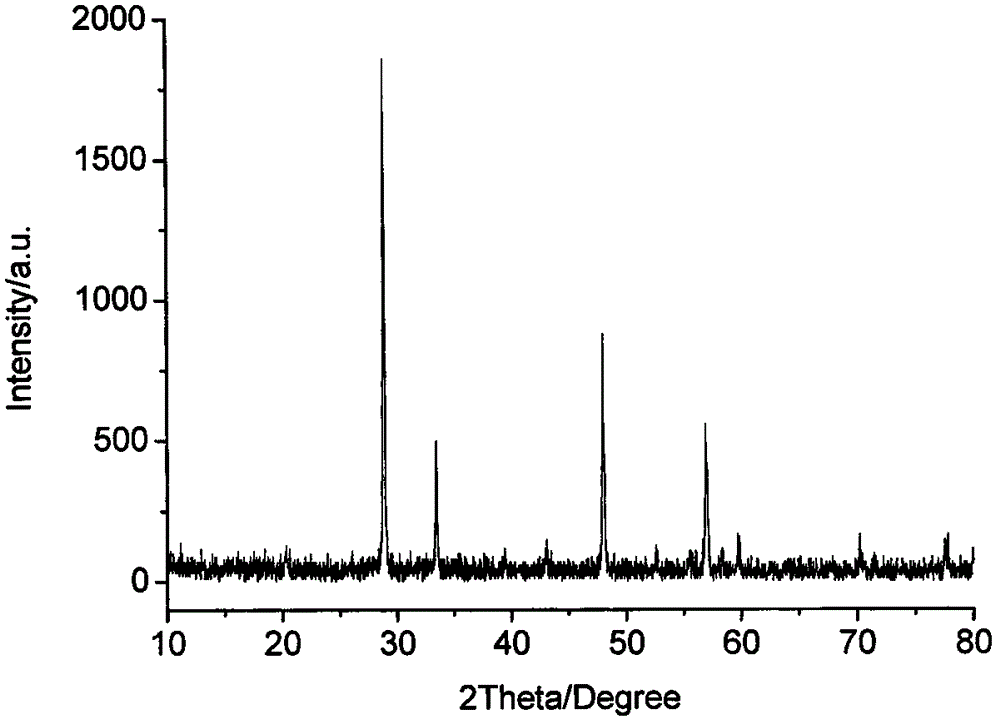

Process for preparation of iron sulfide

InactiveCN101311122AAvoid the disadvantage of "partial sintering"Avoid the disadvantage of easy oxidation of wet FeSIron sulfidesIron sulfideMedicinal chemistry

The invention discloses a method for synthesizing ferrous sulfide material, which adopts green vitriol and carbon powder as raw materials that are evenly mixed and then synthesized by high-temperature solid-phase reaction under the protection of inert gases to obtain the product of the invention. The obtained ferrous sulfide powder by adopting the method of the invention has high purity, single phase, simple preparation conditions and low cost, which can be synthesized in batch.

Owner:GRIMAT ENG INST CO LTD

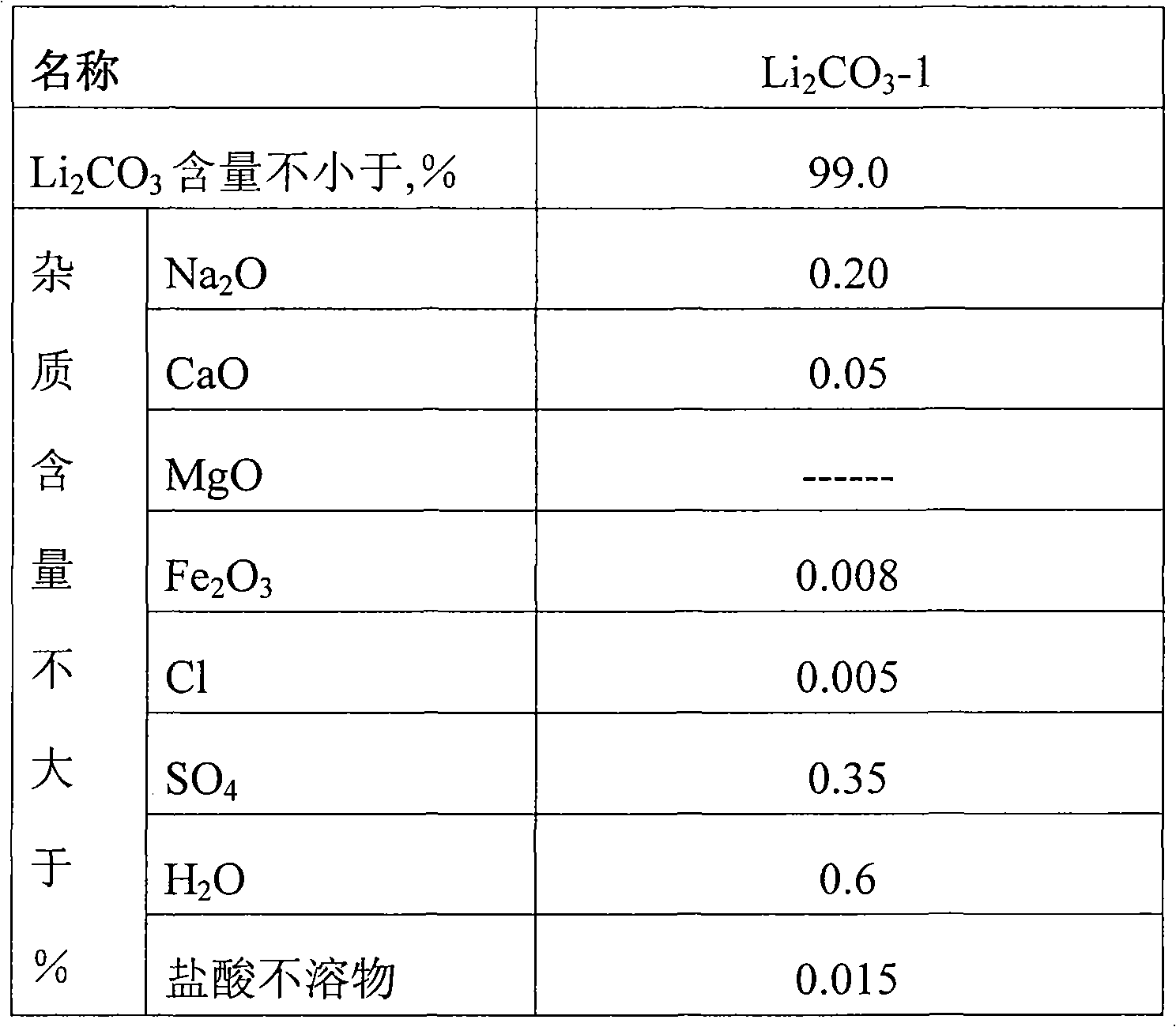

Preparation method of lithium phosphate

The invention provides a preparation method of lithium phosphate. The method comprises the following steps: (1) introducing carbon dioxide into water, adding industrial level lithium carbonate, further adding a precipitating agent, continuously introducing the carbon dioxide till the pH value of solution is 8-9, filtering and collecting lithium bicarbonate solution, wherein the raw material lithium carbonate is the industrial level lithium carbonate; (2) adding phosphoric acid into the lithium bicarbonate solution in the step (1) till the pH value of the solution is 6-6.5, heating to 65-70 DEG C, stirring, using ammonia water to regulate the pH value of the solution to 8-8.5, and then carrying out solid-liquid separation at the temperature of 90-95 DEG C, thus obtaining a lithium phosphate wet material; and (3) carrying out vacuum drying on the lithium phosphate wet material, thus obtaining the product. By utilizing the preparation method, the shortcomings of the traditional production process can be solved, the process is simple, the material phase is single, the preparation method ensures not to introduce a large number of other impurity elements, hydrochloric acid is not used during the process, special anti-corrosion treatment does not need to be carried out on reaction equipment, the environment is not influenced basically, and the yield of the process can be more than 97%.

Owner:SHANGHAI CHINA LITHIUM INDAL

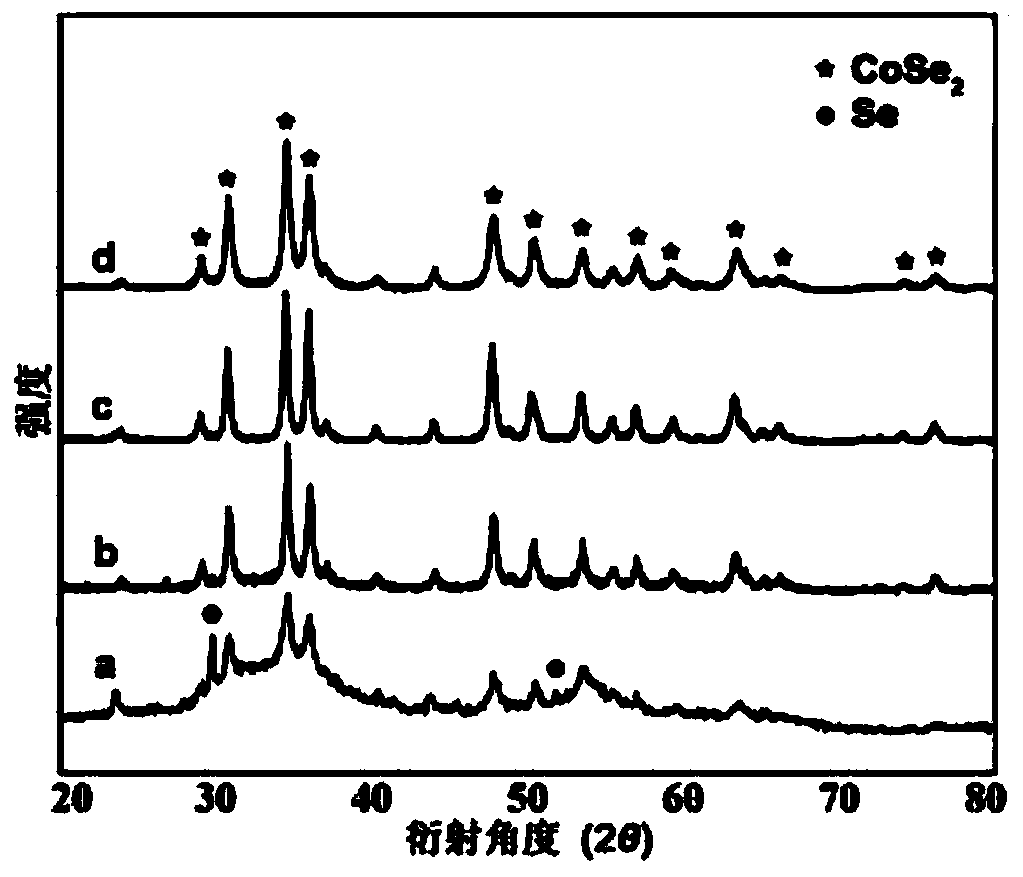

Method for synthesizing cobalt diselenide nanocrystal in polyalcohol-base solution

InactiveCN103466566AMild reaction conditionsLow costMaterial nanotechnologyBinary selenium/tellurium compoundsRefluxNanocrystal

The invention discloses a method for synthesizing a cobalt diselenide nanocrystal in a polyalcohol-base solution, which comprises the following steps: (1) weighing 0.25mmol of cobalt chloride, and dissolving in 10ml of triethylene glycol to obtain a cobalt precursor cation source solution; adding 40ml of triethylene glycol into a three-neck flask, adding selenium powder, and adding 0.1g of polyvinylpyrrolidone to obtain an anion source solution, wherein the Co / Se mol ratio is respectively 1:2, 1:1.9, 1:1.8, 1:1.7, 1:1.5 and 1:1; and (2) slowly heating the anion solution to 210-270 DEG C while quickly injecting the cation source solution, and reacting under reflux to synthesize the CoSe2 nanocrystal solution. The method has the advantages of mild reaction conditions, high safety, low toxicity, low cost, single and stable product phase and favorable repetitiveness, and is simple to operate; and the stoichiometric proportion and material feeding have favorable consistency.

Owner:TIANJIN UNIV

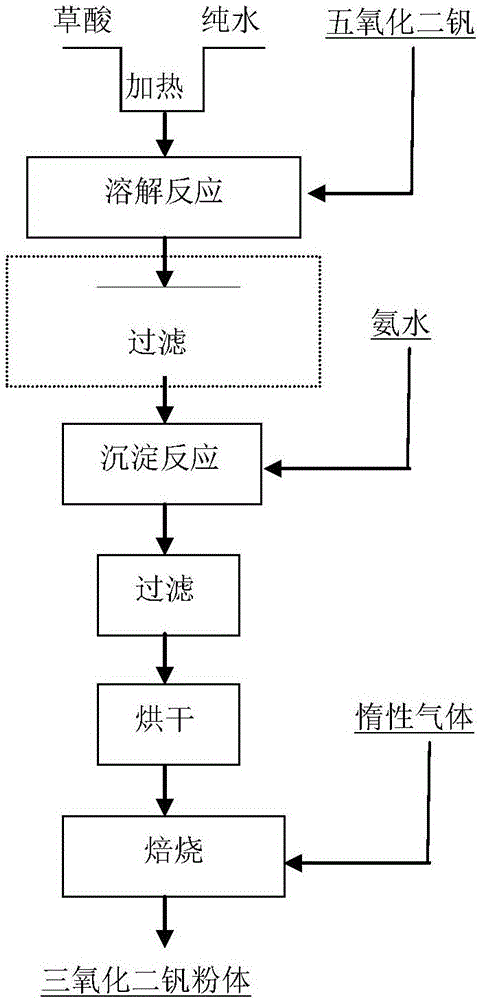

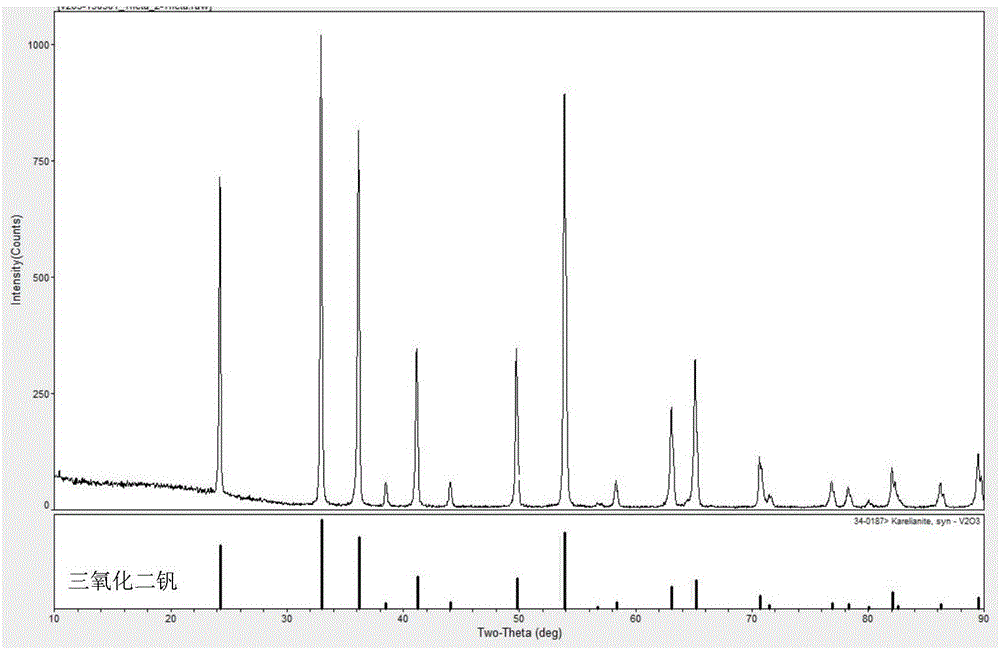

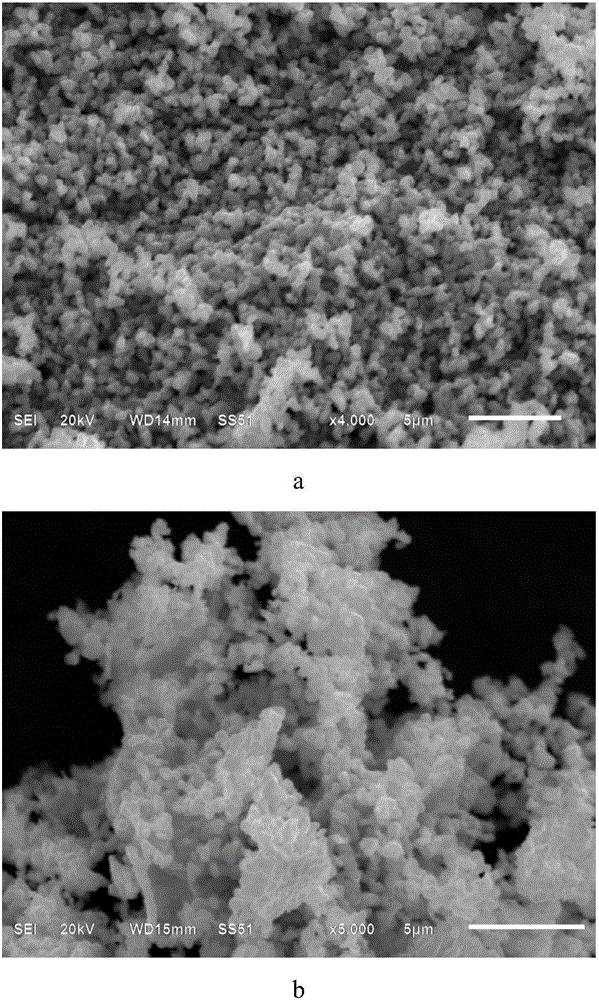

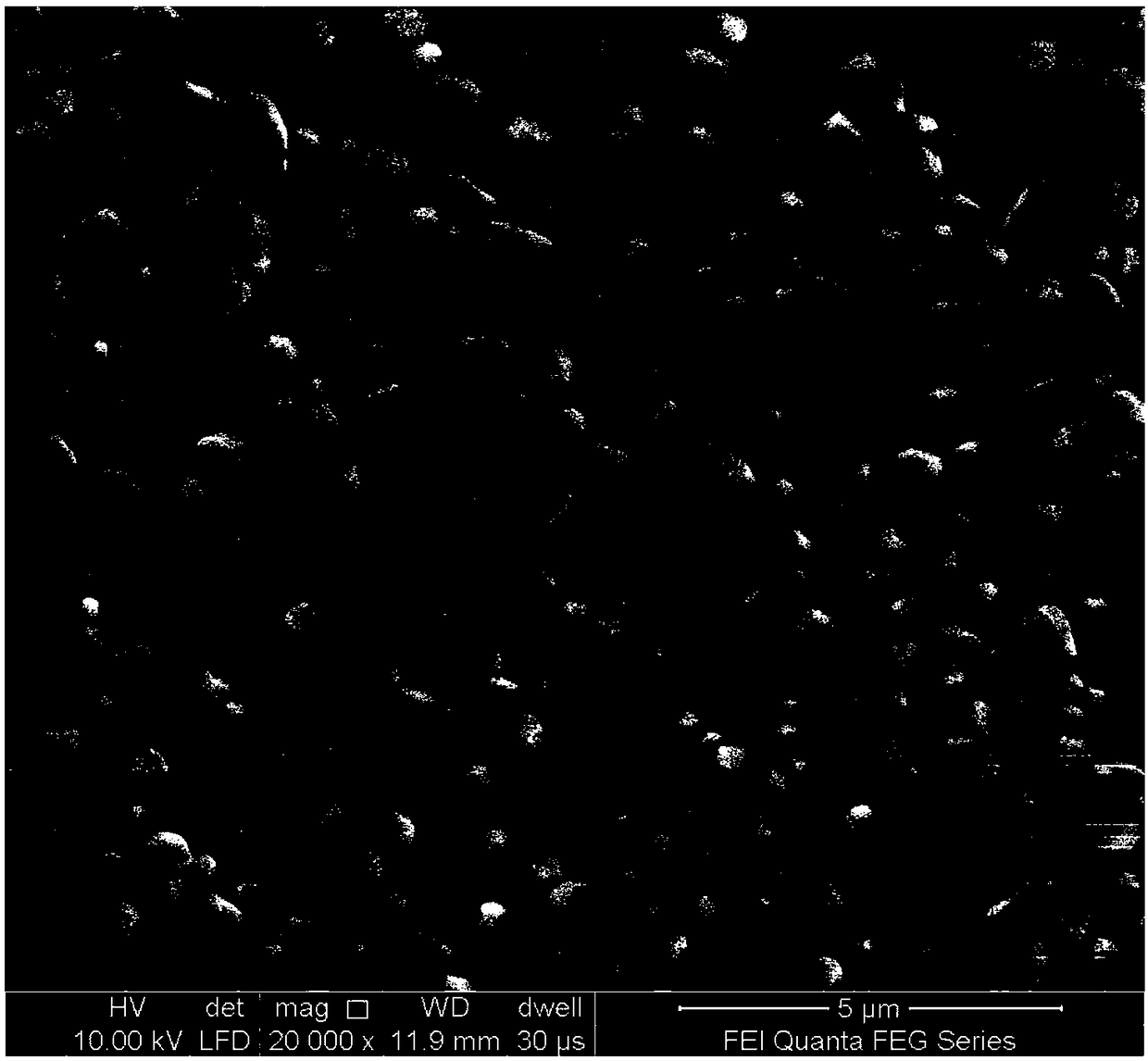

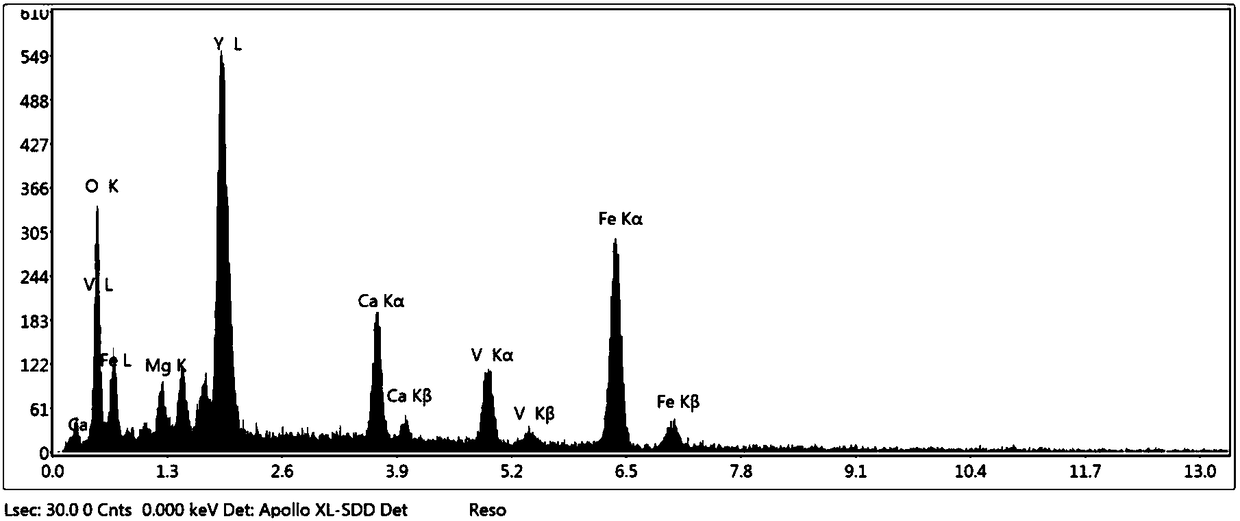

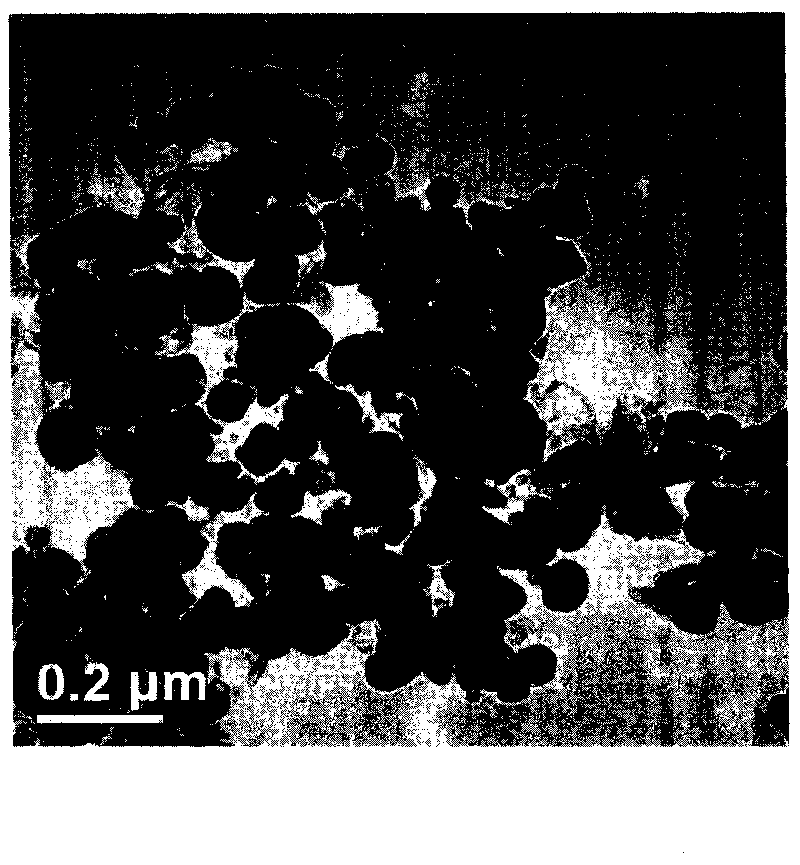

Preparation method of submicron-level vanadium trioxide powder

The invention relates to a preparation method of submicron-level vanadium trioxide powder. The preparation method comprises 1, preparing an oxalic acid solution, 2, heating the oxalic acid solution, adding vanadium pentoxide powder into the oxalic acid solution, and carrying out a stirring reaction process until complete dissolution to obtain a vanadyl oxalate solution, 3, slowly adding ammonium hydroxide into the vanadyl oxalate solution and carrying out stirring for a reaction to obtain precipitates, 4, filtering the precipitates and carrying out drying to obtain a high-activity precursor and 5, roasting the high-activity precursor in an inert atmosphere to obtain submicron-level vanadium trioxide powder. The submicron-level vanadium trioxide powder has high product purity and a single phase, contains submicron-level spherical particles with the uniform sizes less than 1 microns and high particle surface activity and is conducive to further processing and use. The preparation method has simple processes, can be operated easily, has a low cost, is free of hydrogen or other reducing atmospheres, has high safety and a low three waste treating capacity and can be easily industrialized.

Owner:有研资源环境技术研究院(北京)有限公司

Preparation method of magnesium oxide porous fiber

The invention discloses a preparation method of magnesium oxide porous fiber and relates to the material technology. The preparation method comprises the following steps of: (1), dissolving a certain amount of PEG (Polyethylene Glycol) with molecular weight of 6000 in deionized water, adding a proper amount of MgSO4.7H2O, stirring under room temperature, dropwise adding a proper amount of precipitant NaOH solution slowly while stirring to obtain a mixed solution, wherein the molar ratio of the MgSO4 to the PEG to the NaOH is x to y to z, wherein x is not smaller than 1.85 and not bigger than 2.05, y is not smaller than 0.01 and not bigger than 0.02 and z is not smaller than 0.85 and not bigger than 1.05; and the concentration of the MgSO4.7H2O in the mixed solution is 1.5mol / L-2mol / L; (2), carrying out hydro-thermal treatment on the mixed solution for 10-12 hours, naturally cooling the mixed solution to the room temperature, filtering and washing the mixed solution after aging the mixed solution for 12-15 hours, and drying the mixed solution at 80 DEG C to 100 DEG C to obtain precursor alkali magnesium oxide fiber. The magnesium oxide porous fiber obtained by the preparation method disclosed by the invention has a length of 100 microns to 200 microns, a slenderness ratio of 40-50, obvious porous structure characteristics and a bore diameter of 50nm-500nm.

Owner:SOUTHWEAT UNIV OF SCI & TECH

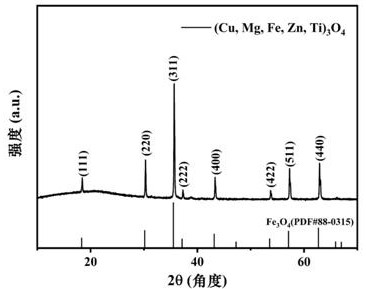

Preparation method of high-entropy ceramic material with good light absorption performance

The invention discloses a preparation method of a high-entropy ceramic material with good light absorption performance, the preparation method comprises the following steps: taking any five of CuO, MnO2, Fe2O3, Cr2O3, Co3O4, TiO2, ZnO and MgO powder as raw materials, carrying out ball-milling mixing, drying and grinding, then carrying out high-temperature calcination in an air atmosphere, and then cooling and grinding to obtain high-entropy ceramic with a spinel structure. The high-entropy ceramic is prepared by combining a mechanical wet grinding method and a solid-phase synthesis method, metal elements can be sufficiently and uniformly mixed, the method has the advantages of simple preparation technology, high repeatability, high production efficiency, suitability for industrial production and the like, and the prepared high-entropy ceramic is single in phase, high in purity, small in particle size and uniform in element distribution, the material has high solar energy absorptivity and good thermal stability, and can ensure the photo-thermal conversion efficiency of a solar energy absorbing material as a solar energy absorbent.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for hydrothermal growth of hydrated di-strontium-11-borate single crystal

InactiveCN101775653ANot easy to deliquescenceNot easy to dehydratePolycrystalline material growthFrom normal temperature solutionsDissolutionSingle crystal

The invention relates to a method for hydrothermal growth of a hydrated di-strontium-11-borate single crystal, which comprises selecting strontium salt and a boron-containing compound as raw materials, taking mineralizer solution or pure water as a dissolving medium, and preparing the hydrated di-strontium-11-borate single crystal through dissolution, hydration and crystallization of the strontium salt and the boron-containing compound in the hydrothermal medium. The specific steps are as follows: mixing the strontium salt and the boron-containing compound with the molar ratio of strontium and boron being 1:4-1:12, adding the mixture into a high-pressure reactor, and adding aqueous solution with 0-2.0mol / L of mineralizer with the filling degree of the high-pressure reactor being 50-80 percent; sealing the high-pressure reactor, placing the high-pressure reactor into the constant-temperature drying box with the temperature of 200-300 DEG C to keep the high-pressure reactor at the constant temperature for 3-14 days, switching off the power supply of the constant-temperature drying box, and lowering the temperature in the constant-temperature drying box to the room temperature; and taking out the product, washing the incompletely reacted raw materials with water, and drying the product, thereby obtaining the hydrated di-strontium-11-borate single crystal. The crystal has the advantage of powder frequency-doubling effect, and can not be easily deliquesced and dehydrated. Moreover, the operating conditions can be easily realized.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

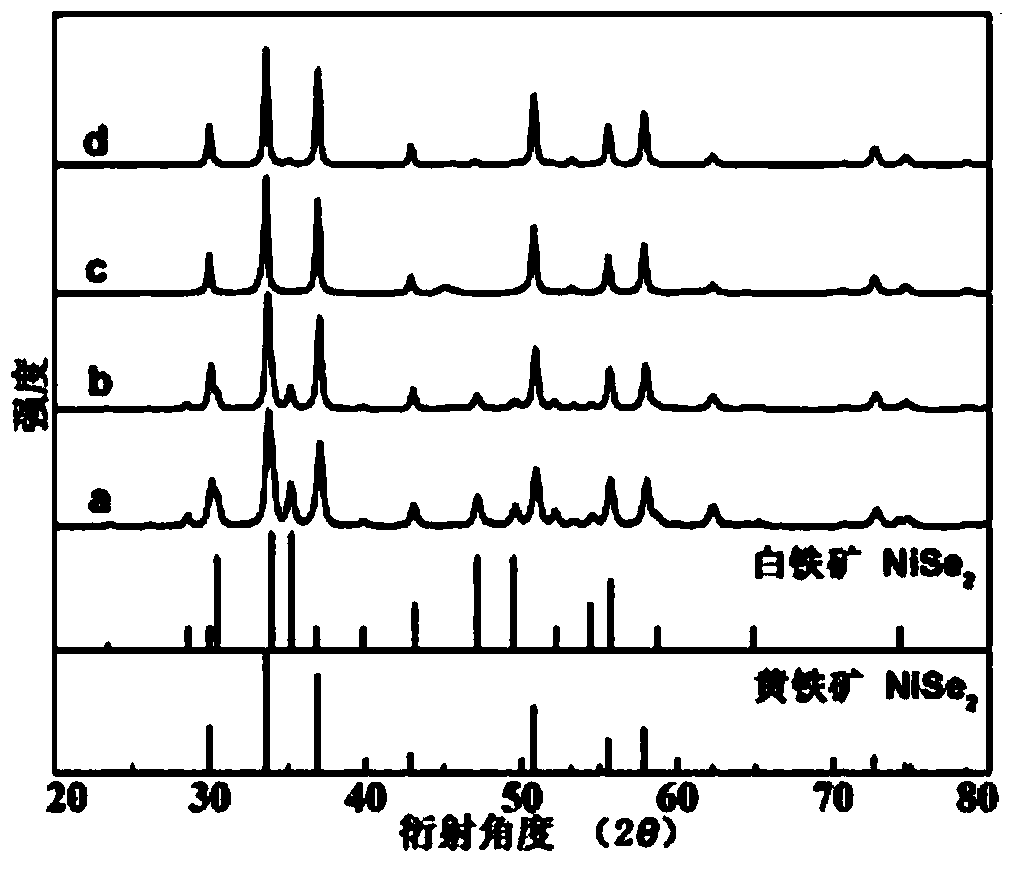

Method for synthesizing nickel diselenide nanocrystal in polyalcohol-base solution

InactiveCN103466563ASingle phasePhase stableMaterial nanotechnologyBinary selenium/tellurium compoundsChemical measurementSe element

The invention discloses a method for synthesizing a nickel diselenide nanocrystal in a polyalcohol-base solution, which comprises the following steps: (1) weighing 0.25mmol of nickel nitrate hexahydrate, and dissolving in 10ml of triethylene glycol to obtain a nickel precursor cation source solution; adding 40ml of triethylene glycol into a three-neck round-bottom flask, adding selenium powder, and adding 0.1g of polyvinylpyrrolidone to obtain an anion source solution, wherein the Ni / Se mol ratio is respectively 1:2, 1:1.9, 1:1.8 and 1:1.7; and (2) slowly heating the anion solution to 210-270 DEG C while quickly injecting the cation source solution, and reacting under reflux to synthesize the NiSe2 nanocrystal solution. The method has the advantages mild whole reaction conditions, high safety, low toxicity, low cost, single and stable product phase and favorable repetitiveness, and is simple to operate, and the stoichiometric proportion and material feeding have favorable consistency.

Owner:TIANJIN UNIV

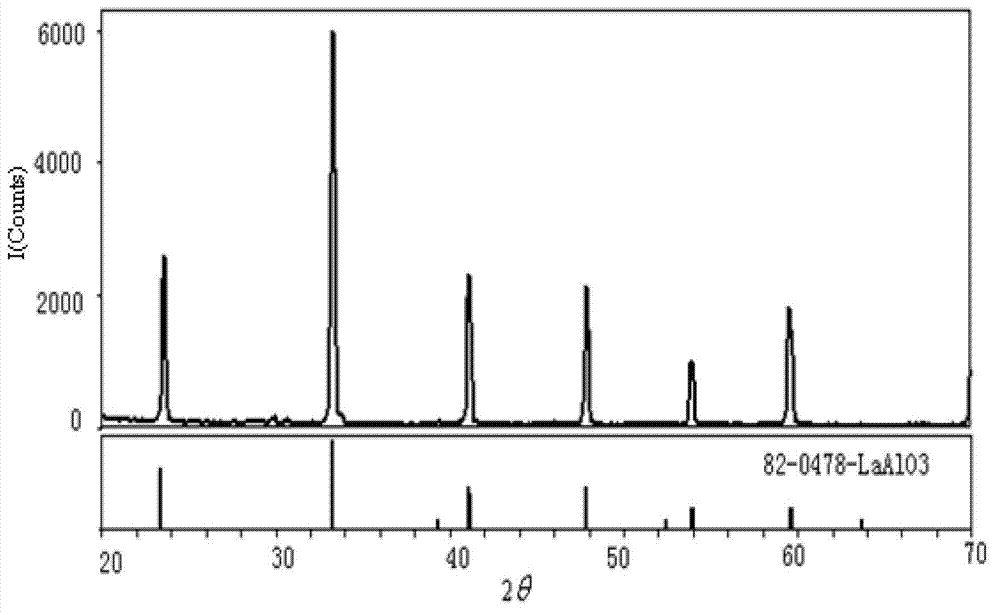

Method for preparing lanthanum aluminate powder efficiently

InactiveCN103112881ASmall granularityIncrease contact areaMaterial nanotechnologyRare earth metal compoundsAluminium hydroxideLanthanum hydroxide

The invention relates to a method for preparing lanthanum aluminate powder efficiently. The method comprises the following steps: (1) adding water into lanthanum oxide, wherein the mass of the added water is 1-20 times more than that of the lanthanum oxide, stirring, controlling the material temperature to be 30-250 DEG C and keeping warm for 1-8 hours, thus obtaining lanthanum hydroxide by the hydrothermal method; (2) adding aluminum hydroxide into a system of lanthanum hydroxide obtained by the hydrothermal method and water, wherein the mole ratio of the aluminum hydroxide to the lanthanum oxide is 2:1, using the water as medium, fully mixing the aluminum hydroxide with the lanthanum hydroxide by stirring, and filtering after stirring for 1-10 minutes; and (3) keeping the mixture of the aluminum hydroxide and the lanthanum hydroxide at the temperature of 1000-1400 DEG C for 1-5 hours, and thereby obtaining the lanthanum aluminate powder. The method for preparing lanthanum aluminate powder efficiently has the advantages that (a) the preparation technology is environment-friendly; and (b) the preparation efficiency is high. The aluminum hydroxide and the lanthanum hydroxide are fully mixed and the mixture is easy to filter, the calcination temperature is low, and the combining time is short. The method for preparing lanthanum aluminate powder efficiently is suitable for preparing lanthanum aluminate powder in large scales.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Simple preparation method of aluminate electron-emission substance for hot cathode

ActiveCN108394922ASimple preparation processUniform compositionDischarge tube/lamp detailsAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateEthylene diamine

The invention discloses a simple preparation method of an aluminate electron-emission substance for a hot cathode, and belongs to the technical field of preparation of the electron-emission materialsfor the hot cathodes. The preparation method comprises the following steps: taking Ba(NO3)2, Ca(NO3)2.4H2O and Al(NO3)3.9H2O as raw materials and taking EDTA (Ethylene Diamine Tetraacetic Acid) as a complexing agent to prepare precursor powder of salt by a sol-gel method; roasting the precursor powder to obtain final aluminate, wherein after the cathode is fully activated, the pulse emission current density under 950 DEG C b can reach 100A / cm<2> or above and emission slope reaches 1.4 or above. The aluminate prepared by the method has the advantages of simple preparation process, uniform components, single phase, low melting point, good emission performance and the like and is expected to be used in the fields such as microwave vacuum electronic devices.

Owner:BEIJING UNIV OF TECH

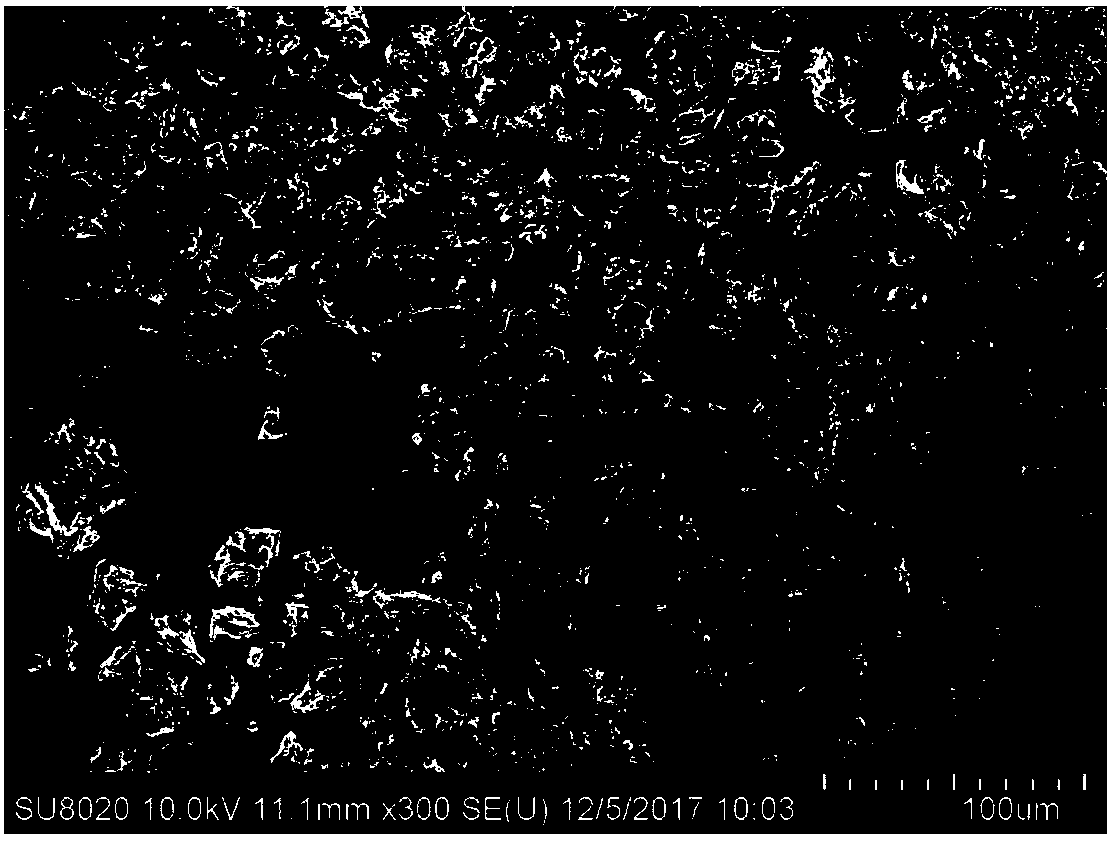

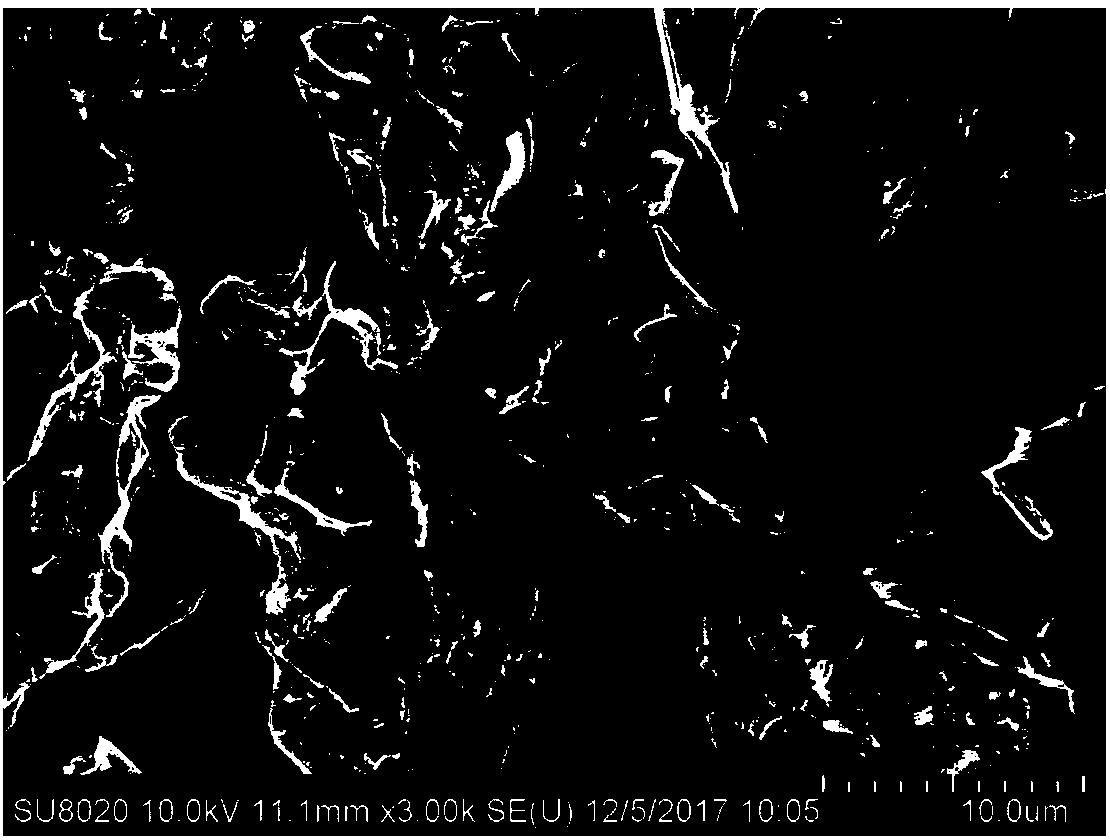

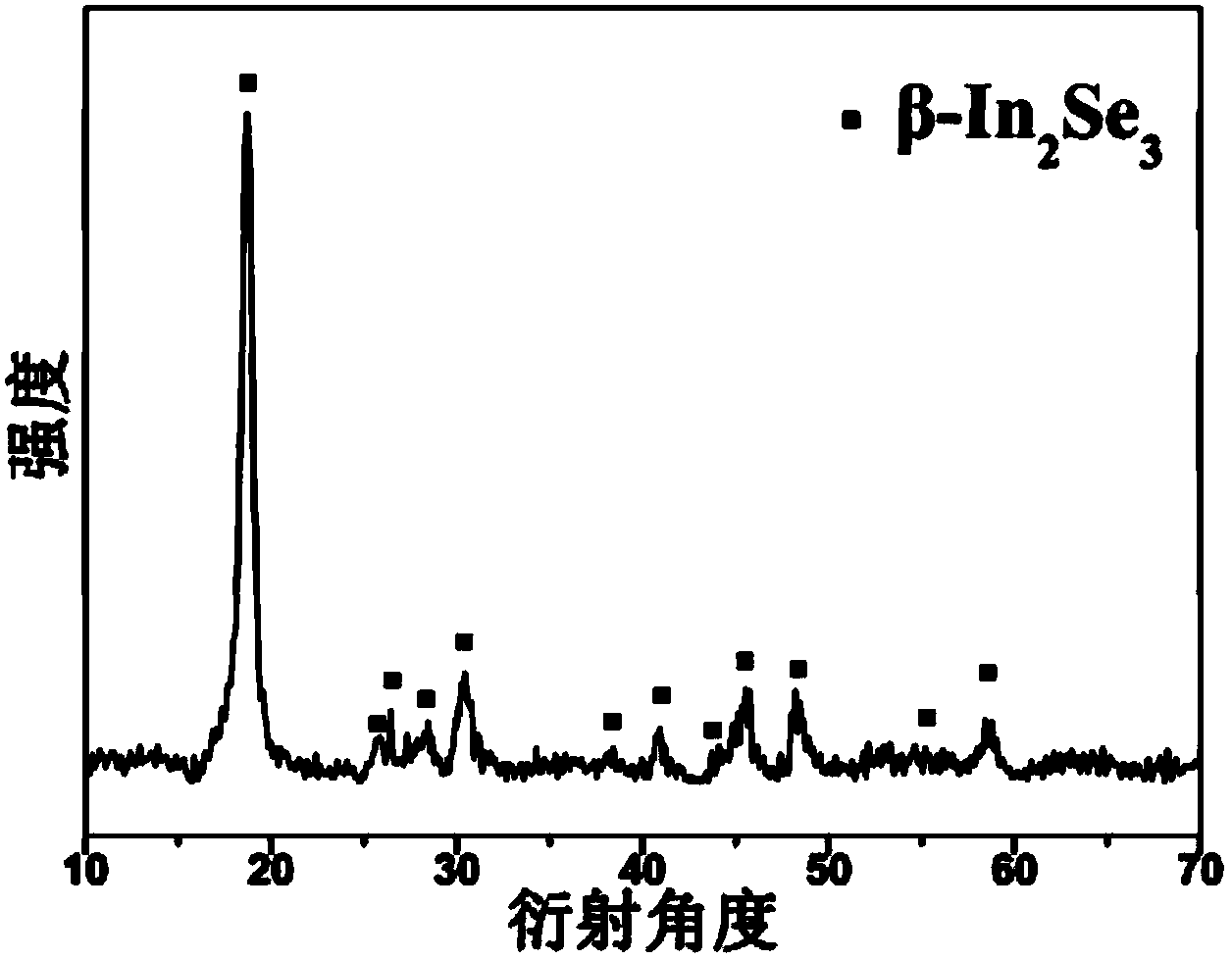

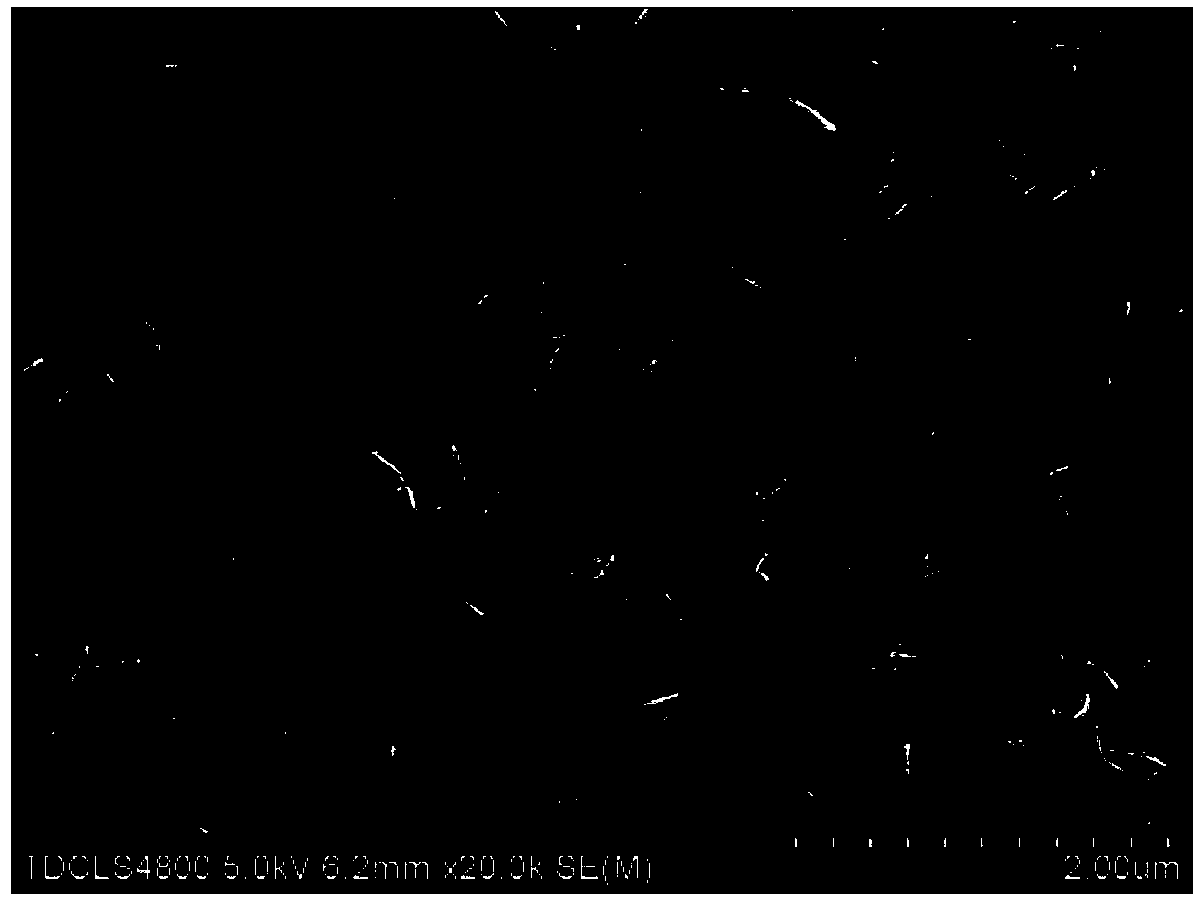

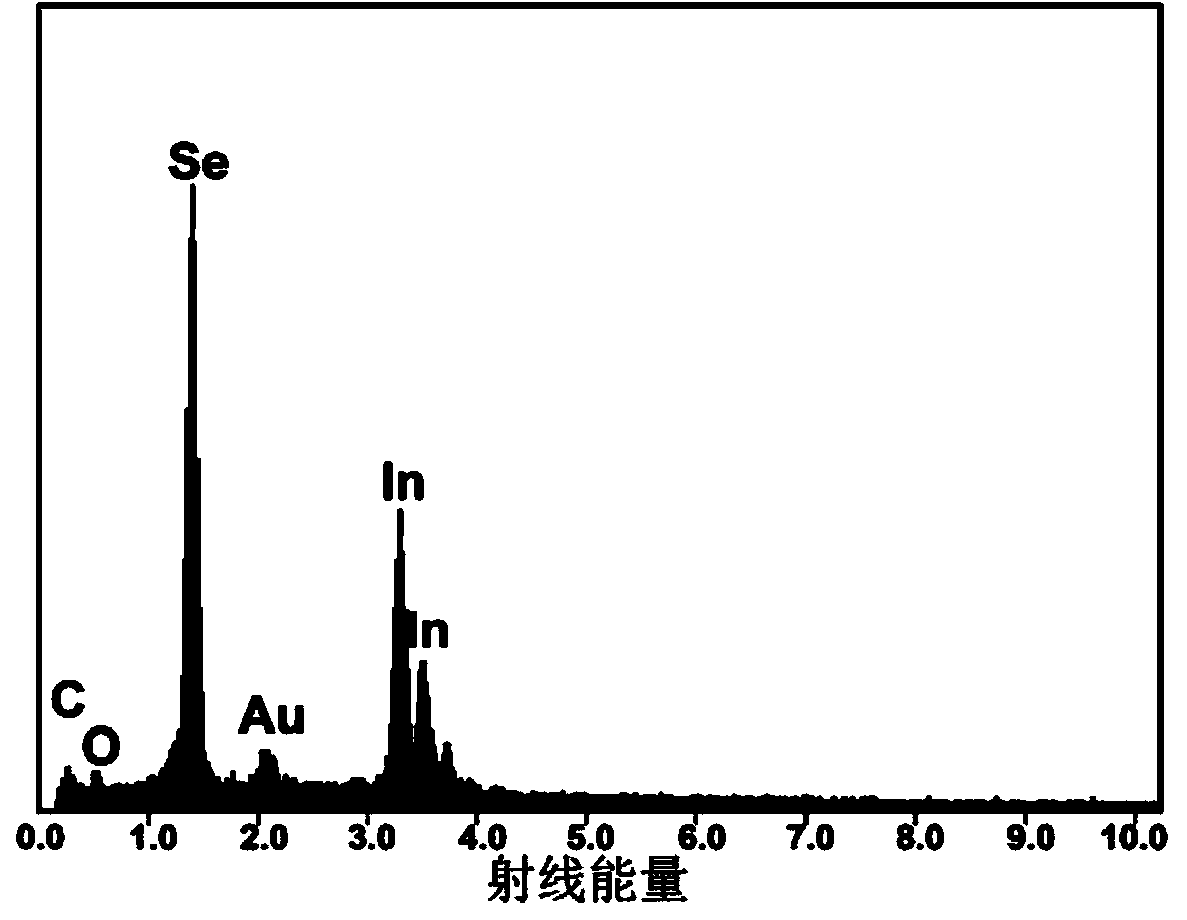

Method for synthesizing beta-phase indium selenide flaky nanocrystalline by using hydrazine hydrate-assisted polyhydric alcohol solution

InactiveCN104291278ASingle phaseMild reaction conditionsMaterial nanotechnologyBinary selenium/tellurium compoundsBottleNitrogen gas

The invention discloses a method for synthesizing beta-phase indium selenide flaky nanocrystalline by using a hydrazine hydrate-assisted polyhydric alcohol solution. The method comprises the following steps: firstly, weighing 0.1mol of tetrahydrate indium chloride and dissolving into 10ml of triethylene glycol to obtain a cationic precursor solution; additionally, adding 40ml of triethylene glycol to a three-necked round-bottomed flask; adding 0.15mmol of selenium powder, adding 0.1ml of hydrazine hydrate and introducing nitrogen to obtain an anionic source reaction base fluid; putting the three-neck bottle into a thermal reaction reflux device, introducing nitrogen, slowly heating the anionic source reaction base fluid, quickly injecting the cationic precursor solution until the injection temperature / reflux temperature ranges from 250 / 250 DEG C to 270 / 270 DEG C, so as to obtain a reaction solution containing indium selenide nanocrystalline; and centrifugally separating and purifying the reaction solution to prepare In2Se3 nanocrystalline. The entire reaction of the method is mild in condition, safe, low in toxicity, simple and convenient to operate and low in cost; the product is single and stable in phase and relatively good in repeatability, and the stoichiometric ratio accords with the standard ratio.

Owner:TIANJIN UNIV

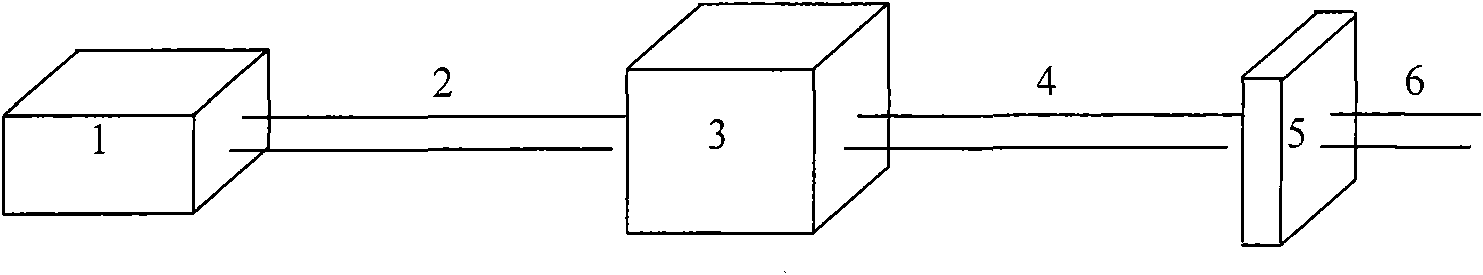

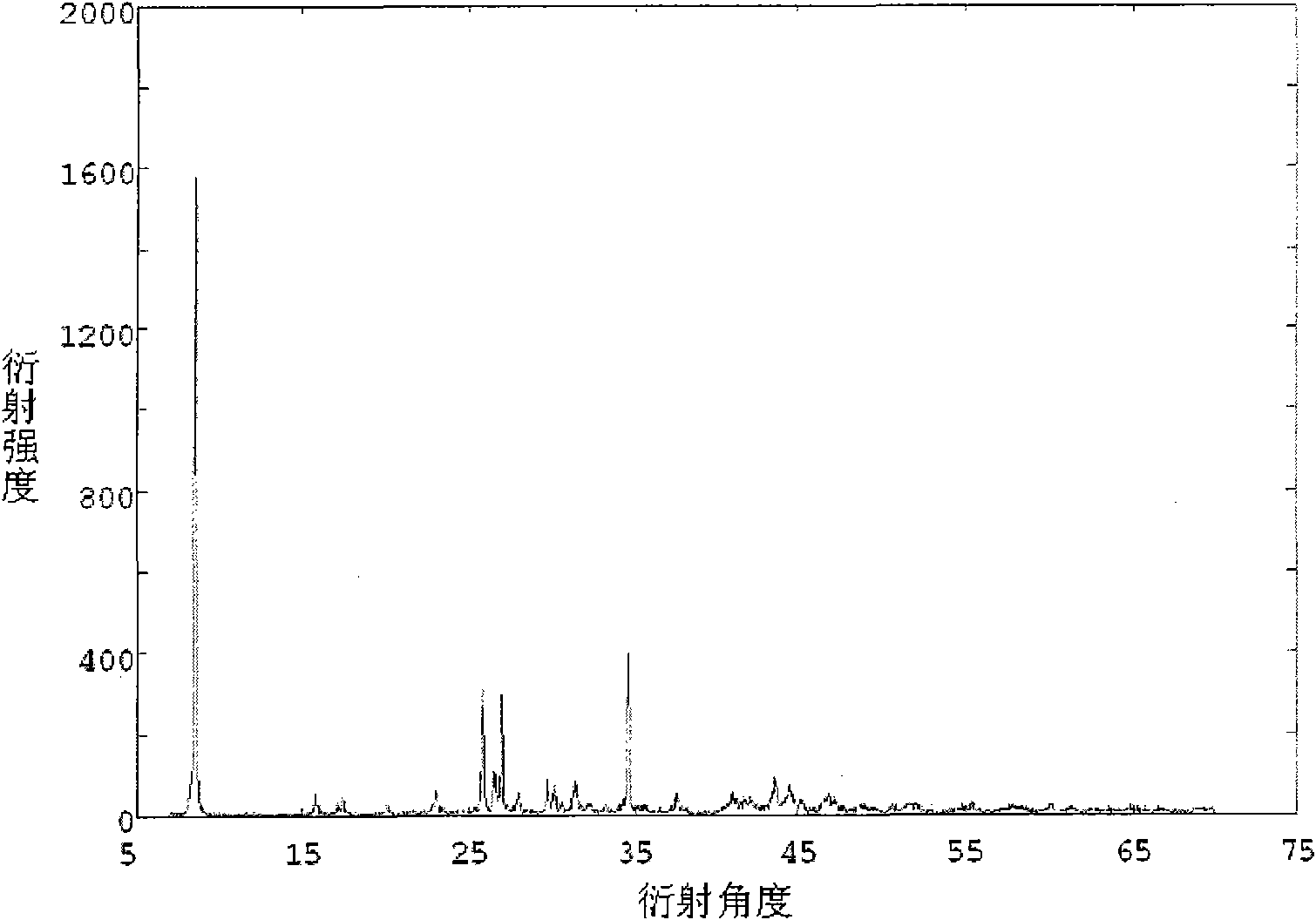

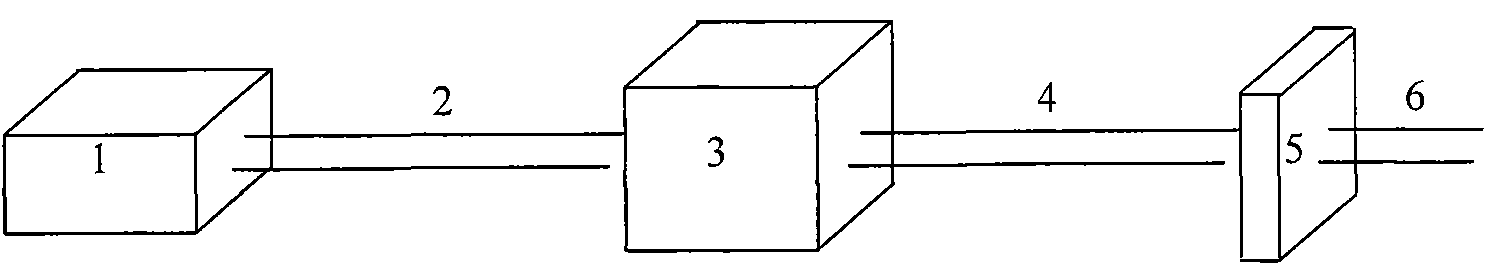

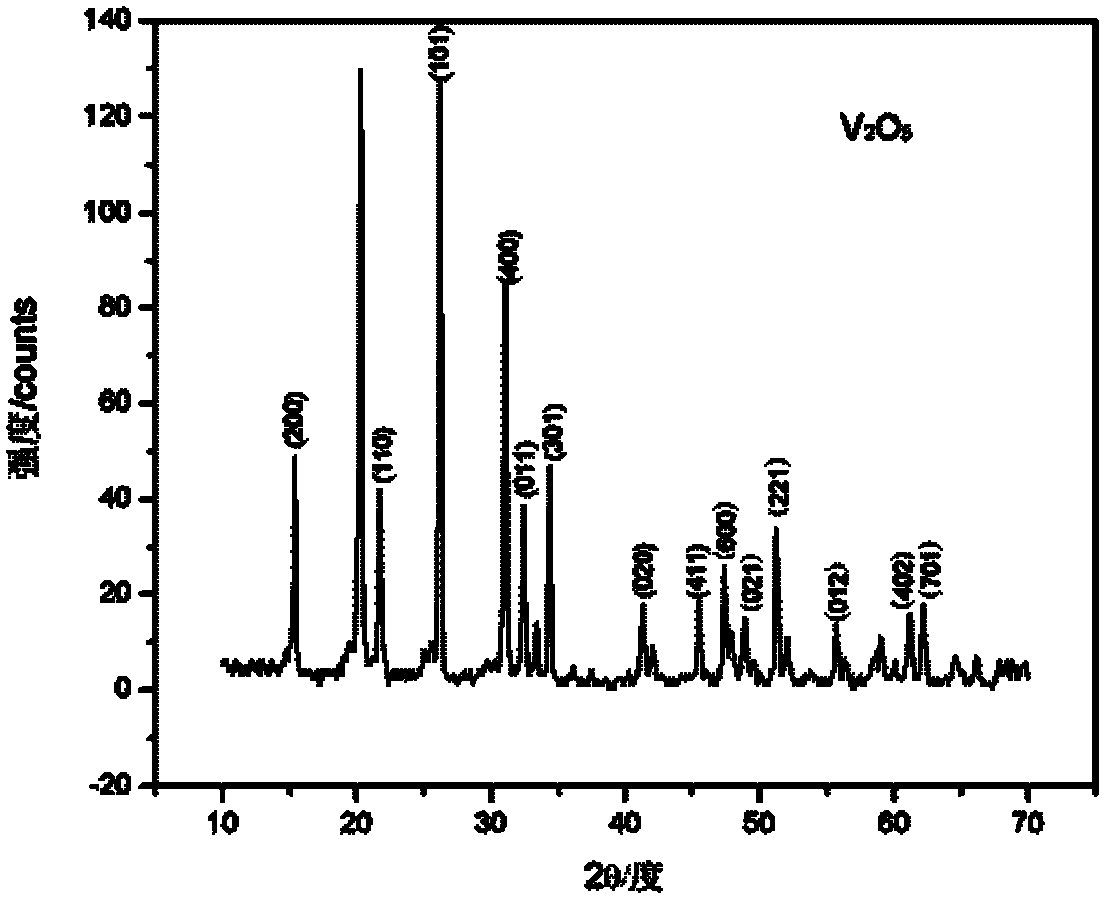

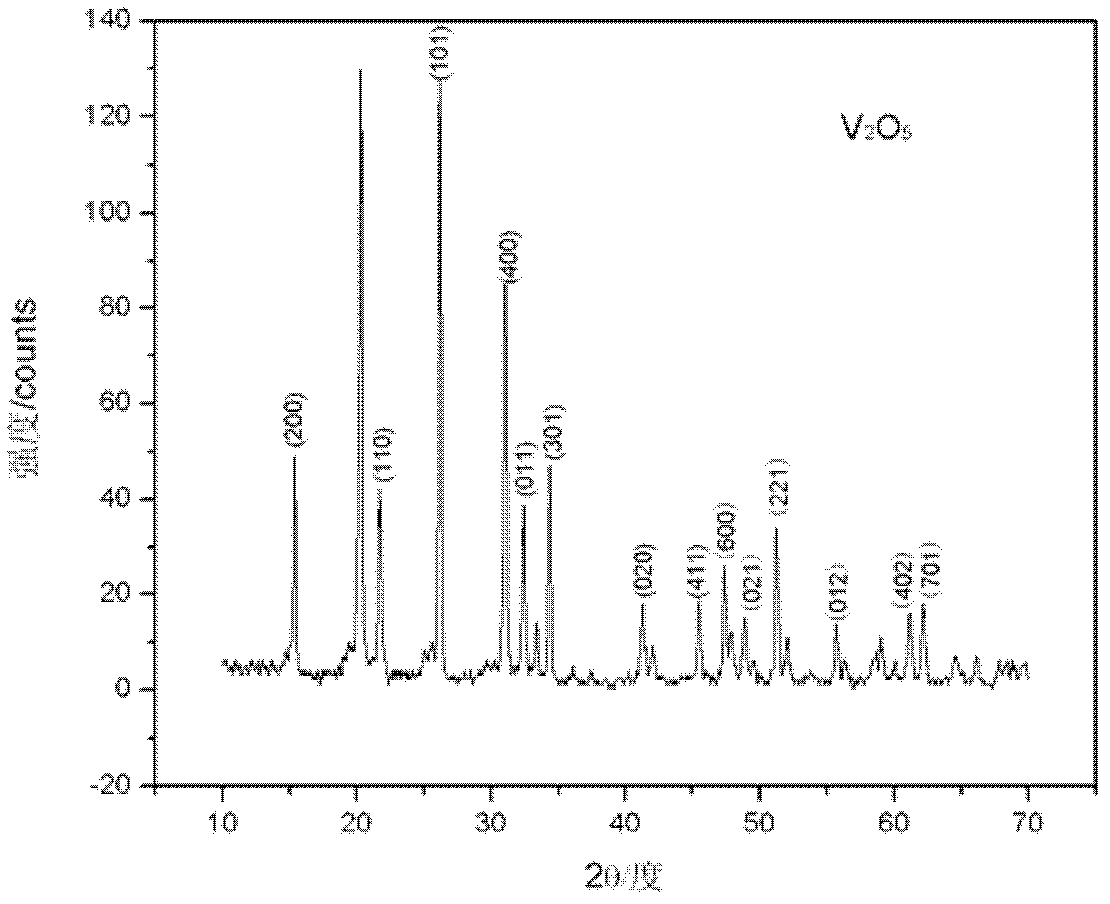

Method for preparing V2O5 nano-powders

ActiveCN102502827ASingle phaseAvoid generatingNanotechnologyVanadium oxidesUltrasonic cavitationAmmonia

A method for preparing V2O5 nano-powders comprises the following steps: firstly, de-ionized water, NH4VO3, ammonia water and dimethyl sulfoxide are stirred uniformly to obtain a solution A; the solution A is filled into an ultrasonic generator, and a hydrogen peroxide solution is also added into the ultrasonic generator to obtain a suspension liquid B; the suspension liquid B is centrifugally separated and washed repeatedly by de-ionized water and isopropanol to obtain light yellowish-red fine powders, and the fine powders obtained are soaked into isopropanol, and then are dried to obtain theV2O5 nano-powders. In the invention, an ultrasonic sol-gel method combining an ultrasonic cavitation technology and a sol-gel method is adopted to prepare the V2O5 nanocrystal with low cost. The method not only reduces the reaction time but also can prepare the V2O5 nano-powders with uniform sizes and single phase.

Owner:启东晟涵医疗科技有限公司

Corrosion-resistant high-strength neutron shielding alloy material and preparation method thereof

The invention discloses a corrosion-resistant high-strength neutron shielding alloy material which is composed of the following elements including, by mass, 49%-51% of Hf and the balance Zr and inevitable impurities. The invention also provides a preparation method of the corrosion-resistant high-strength neutron shielding alloy material. The method comprises the following steps of mixing sponge zirconium and sponge hafnium, conducting pressing and vacuum consumable electrode smelting to obtain an alloy cast ingot, sequentially machining and chamfering the alloy cast ingot, carrying out three-heating-number forging to obtain a forged alloy ingot, carrying out heat treatment on the forged alloy ingot, and cooling to obtain the alloy material. According to the corrosion-resistant high-strength neutron shielding alloy material and the preparation method, the Zr serves as a matrix, the Hf serves as a main alloy element, the alloy material is prepared through vacuum consumable electrode smelting and three-heating-number forging, and the prepared alloy material is single in phase and uniform in structure, has excellent neutron shielding performance and strength and meanwhile has extremely high corrosion resistance and machinable performance.

Owner:西安稀有金属材料研究院有限公司

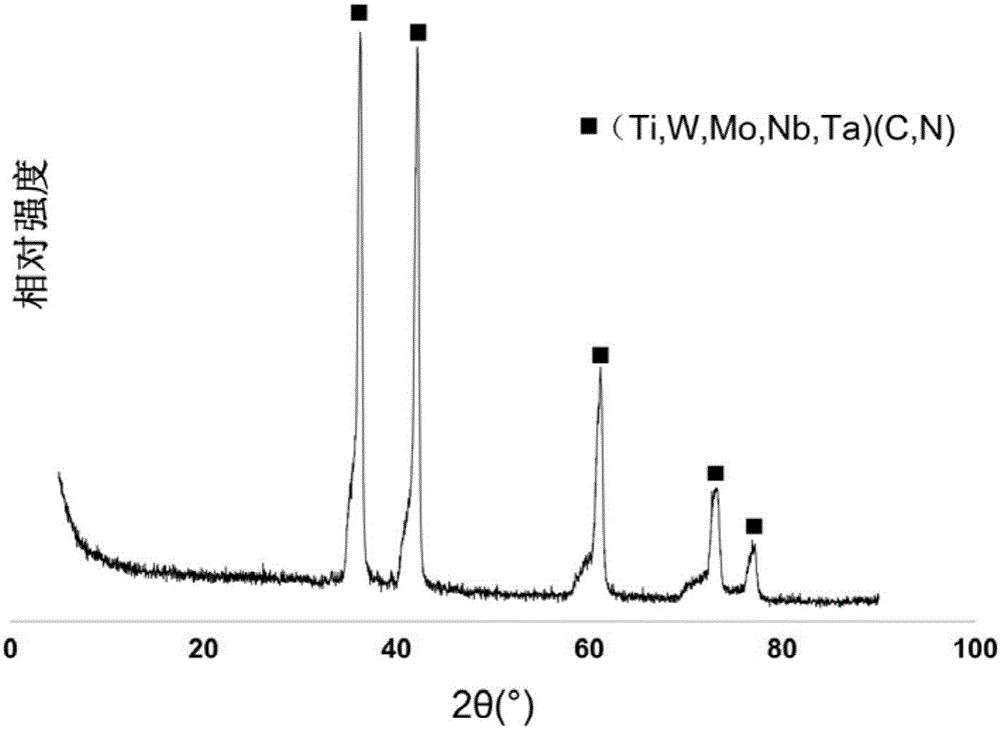

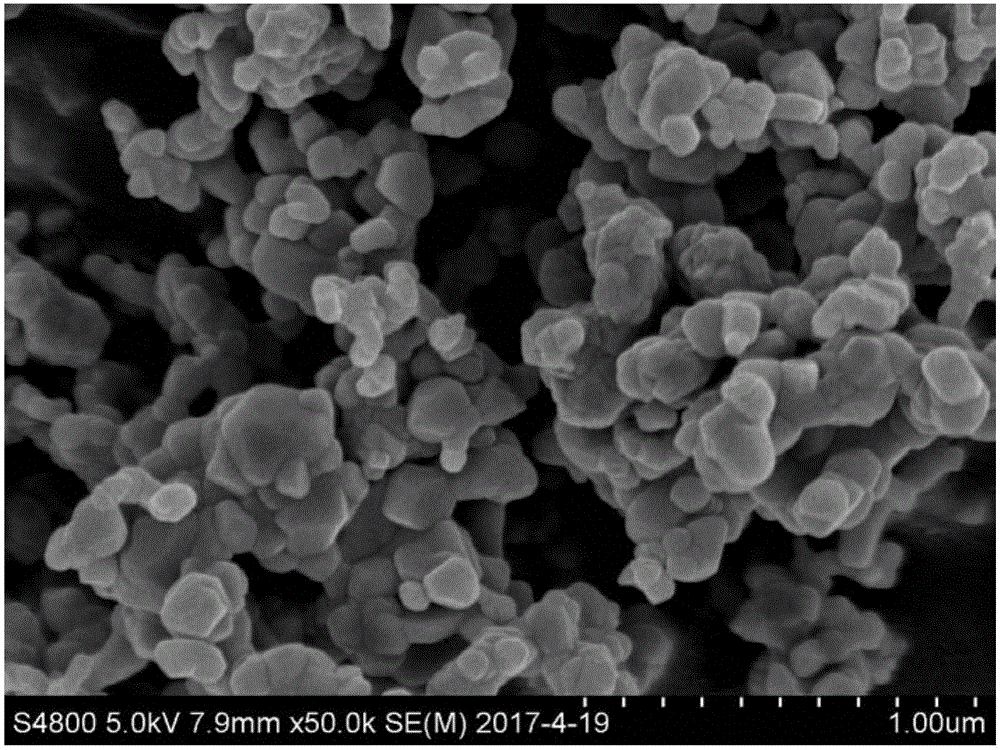

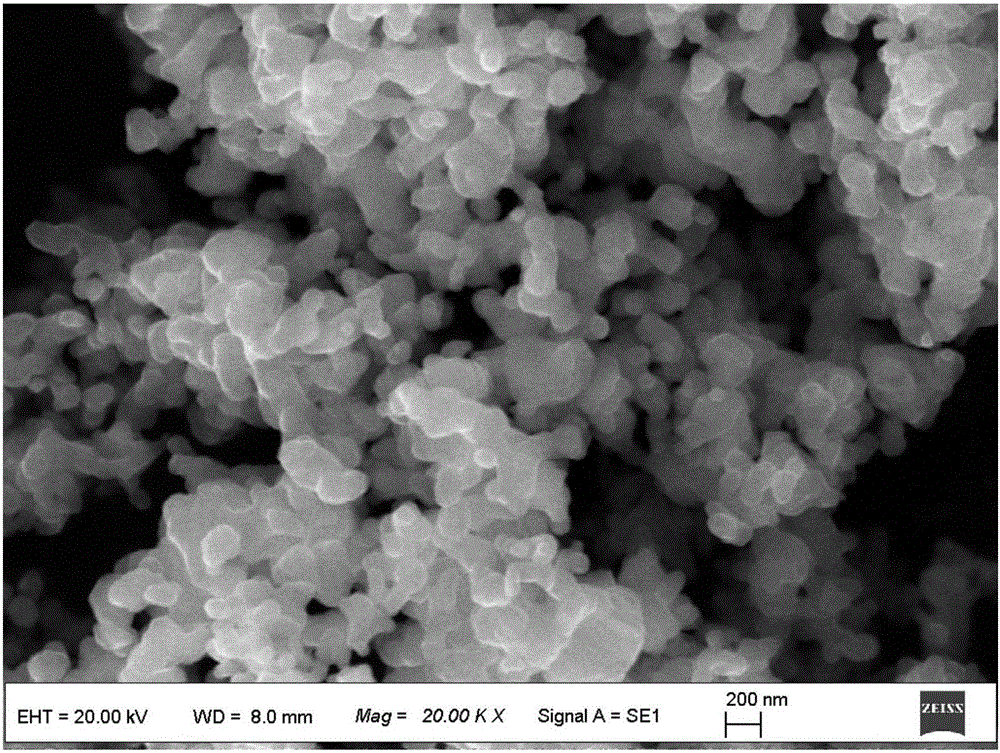

Solid solution type (Ti, Mo, Ta, Me) (C, N) nanopowder and preparing method thereof

The invention provides solid solution type (Ti, Mo, Ta, Me) (C, N) nanopowder and a preparing method thereof, and relates to the technical field of composite materials. The preparing method comprises the following steps that oxide of each element serves as a raw material, and carbon black serves as a reducing agent and a carbonization agent; then water or alcohol serve as a ball-milling medium, and a slurry is obtained after ball-milling for 1-4h under the condition of 200-300 r / min; a mixture is obtained after the slurry is dried and granulated; finally, the mixture is transferred to a vacuum reaction device, and the final reaction temperature is raised to 1350-1500 DEG C by a programmed temperature raising system; and the solid solution type nanopowder is obtained after reacting in an N2 atmosphere for 2.5-4h. The obtained solid solution type nanopowder is a single phase with the particle size of 150-300 nm. Through regulating for various parameters and controlling for the process, solid solution of an obtained product is complete, the particle size reaches the nano level, the production cost is low, the process is simple, and the solid solution type (Ti, Mo, Ta, Me) (C, N) nanopowder and the preparing method thereof are suitable for industrialized scale production.

Owner:XIAMEN UNIV OF TECH

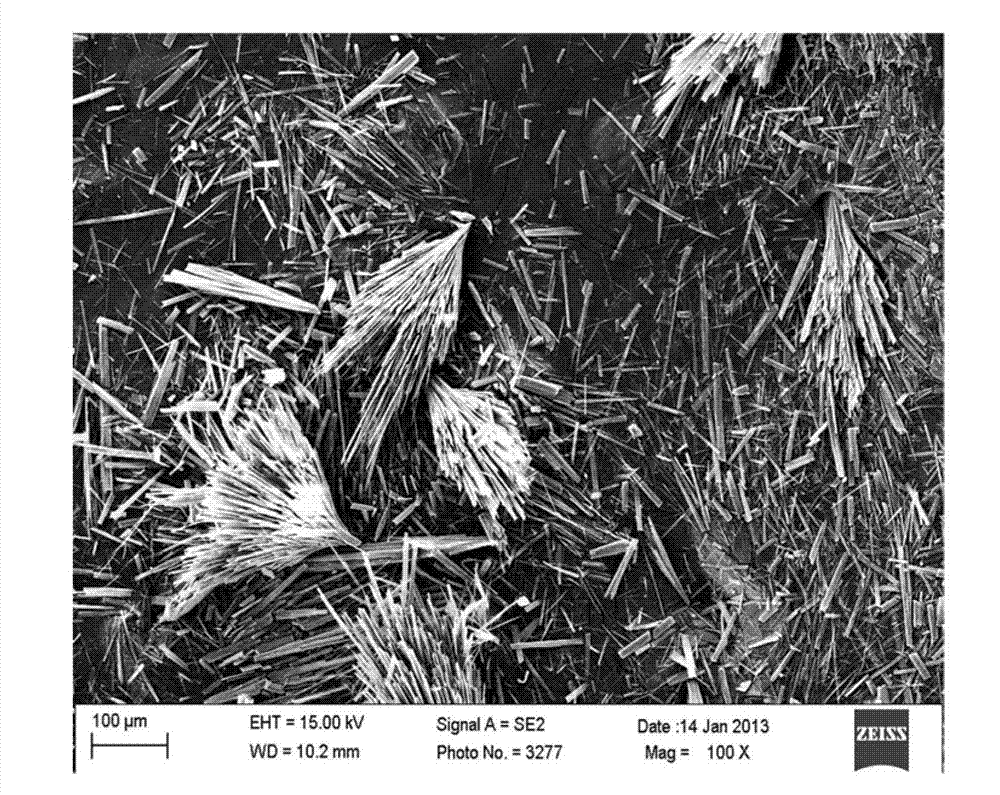

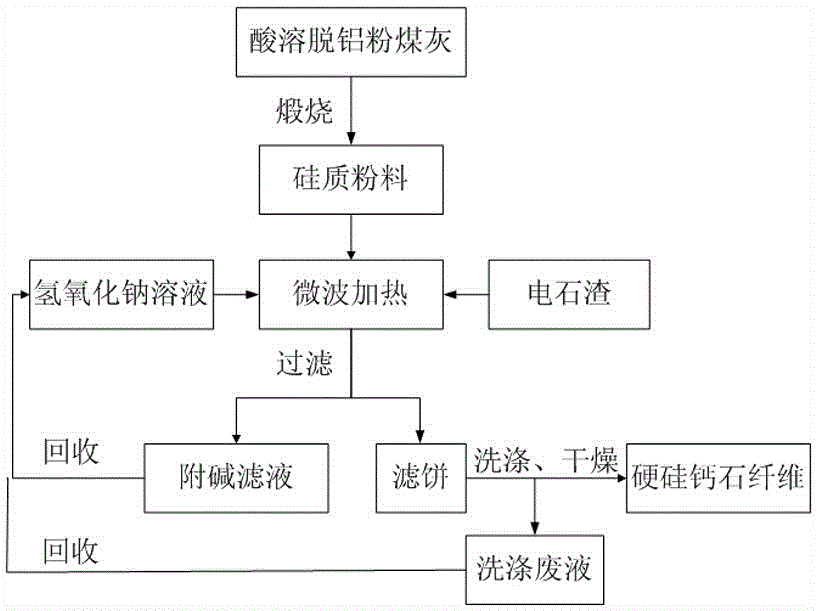

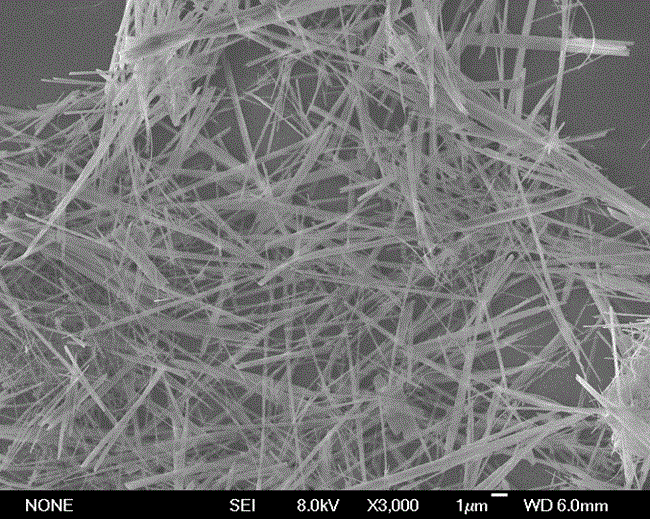

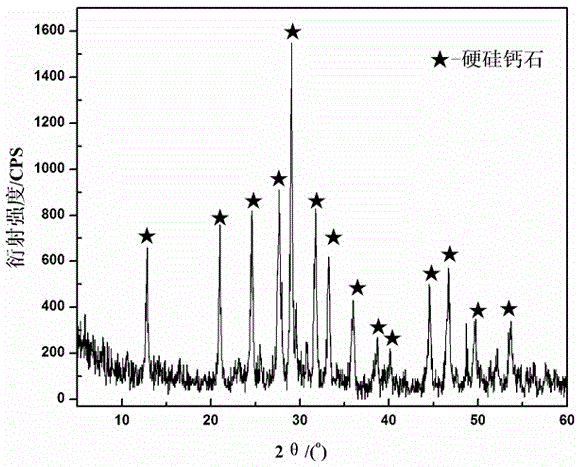

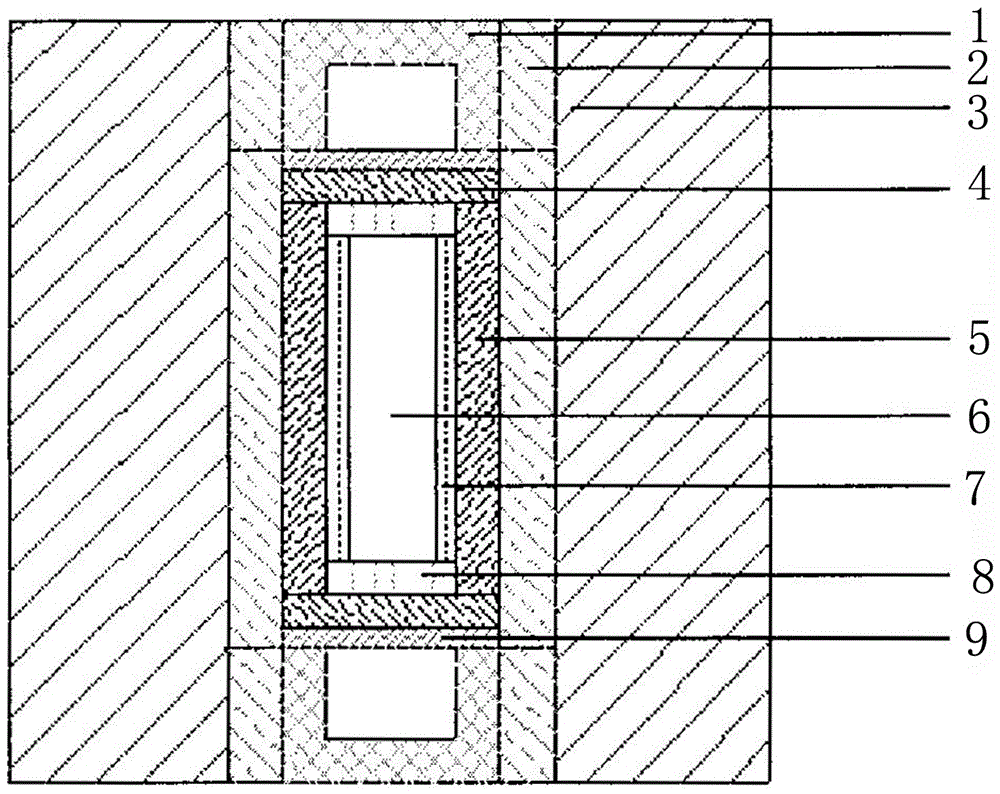

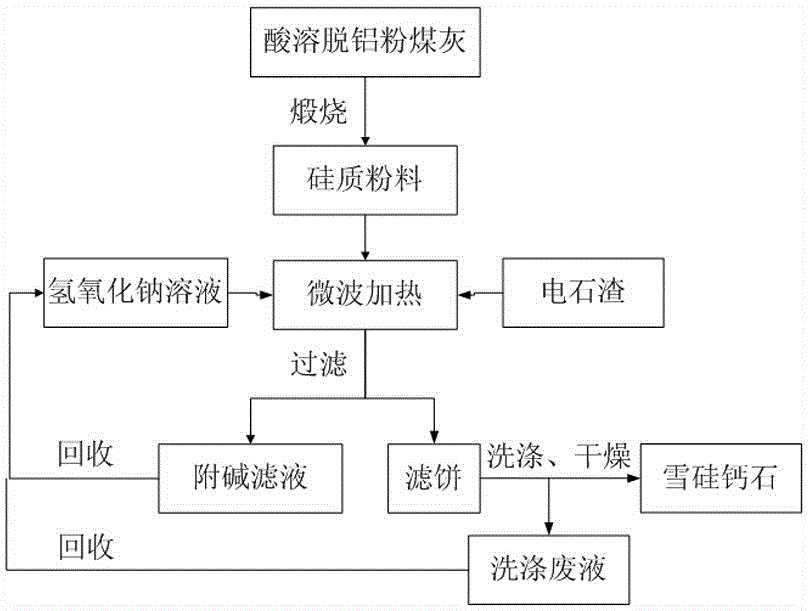

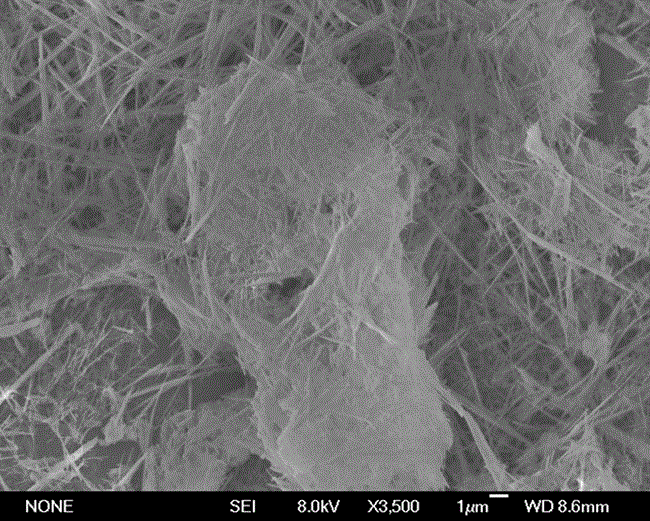

Silicon carbide fiber production method using acid soluble dealuminized fly ash and carbide slag

InactiveCN106495172ALow reaction temperatureShorten the timeAlkaline-earth metal silicatesFiberCalcium silicate

The invention provides a silicon carbide fiber production method using acid soluble dealuminized fly ash and carbide slag. The method comprises the steps of (1) incinerating acid soluble dealuminized fly ash to acquire silicious powder, (2) mixing the silicious powder, carbide slag and sodium hydroxide solution uniformly, conducting microwave heating for synthetic reaction, (3) after the completion of the reaction, filtering the mixed slurry to acquire filtered cakes and alkaline filtrate, (4) washing and drying the filtered cakes to acquire silicon carbide fiber, recycling the filtered cake washing waste solution and alkaline filtrate to the sodium hydroxide solution. The invention has the advantages of being low in reaction temperature, short in time, simple in process, and mild in conditions. The acquired silicon carbide fiber has the advantages of being high in purity, singular in material phase without impurities, high in crystallization rate, and big in length-diameter ratio, having the performance full satisfying or surpassing the standard of light calcium sillicate, and at the same time providing a novel solution to the solid waste emission problem involving acid soluble dealuminized fly ash and carbide slag.

Owner:LIAONING TECHNICAL UNIVERSITY

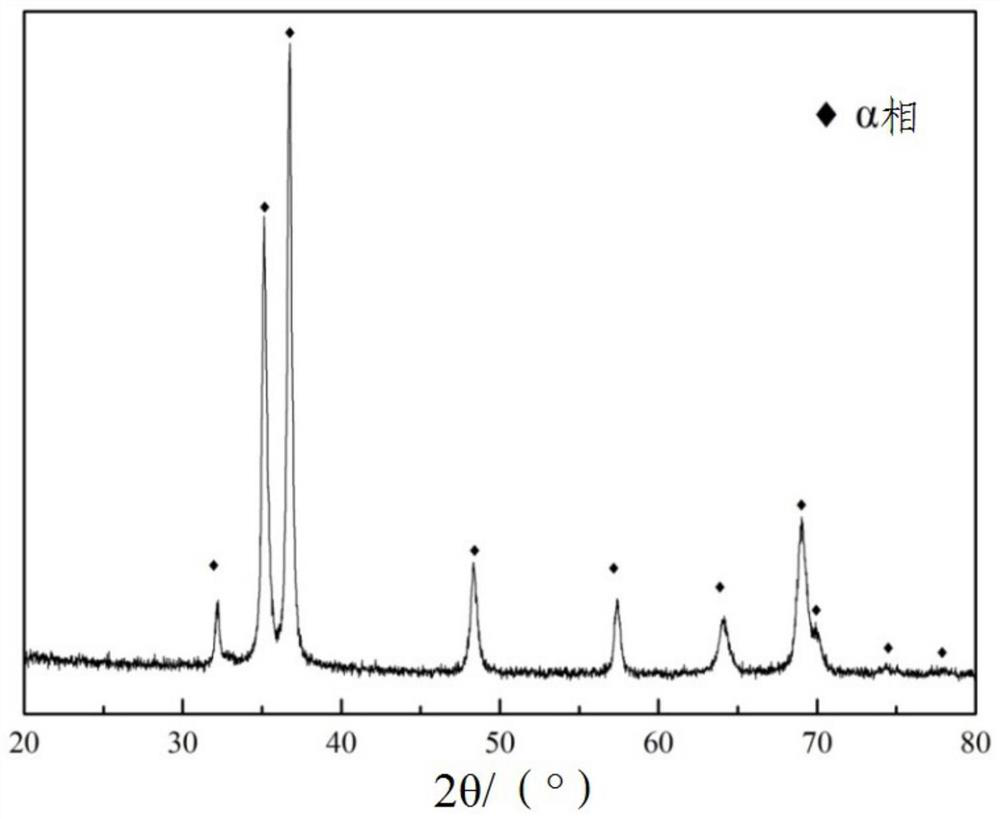

Method or adopting high-pressure phase-change method to prepare polycrystal alpha-aluminum oxide

The invention relates to a method for adopting a high-pressure phase-change method to prepare polycrystal alpha-aluminum oxide. According to the method, gamma-aluminum oxide is adopted as a raw material, through purification treatment and prepressing forming of the raw material, and after assembly of a sintering unit, sintering is conducted on high-temperature and super-high pressure condition in which the temperature is 300-1500 DEG C and the pressure is 1-25 GPa, and a follow-up sample is then subjected to treatment and performance detection. According to the method for adopting the high-pressure phase-change method to prepare polycrystal alpha-aluminum oxide, gamma-aluminum oxide is directly converted into polycrystal alpha-aluminum oxide, and thus a polycrystal alpha-aluminum oxide material which is single in phase, uniform in structure, has good performance like high rigidity and density, and is high in purity can be prepared.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

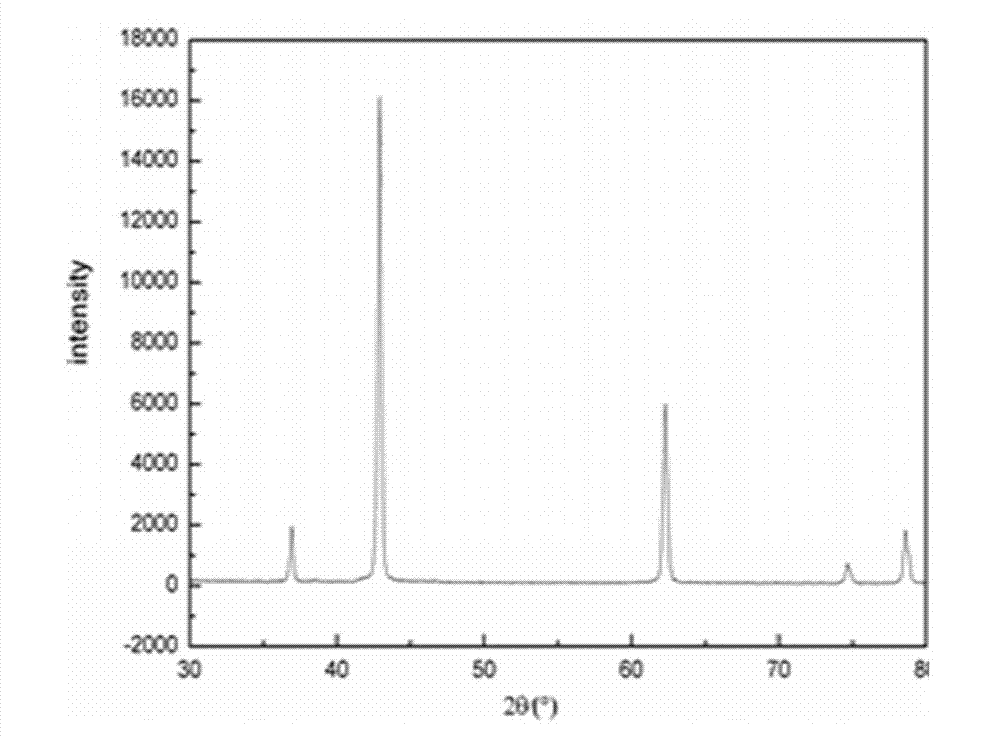

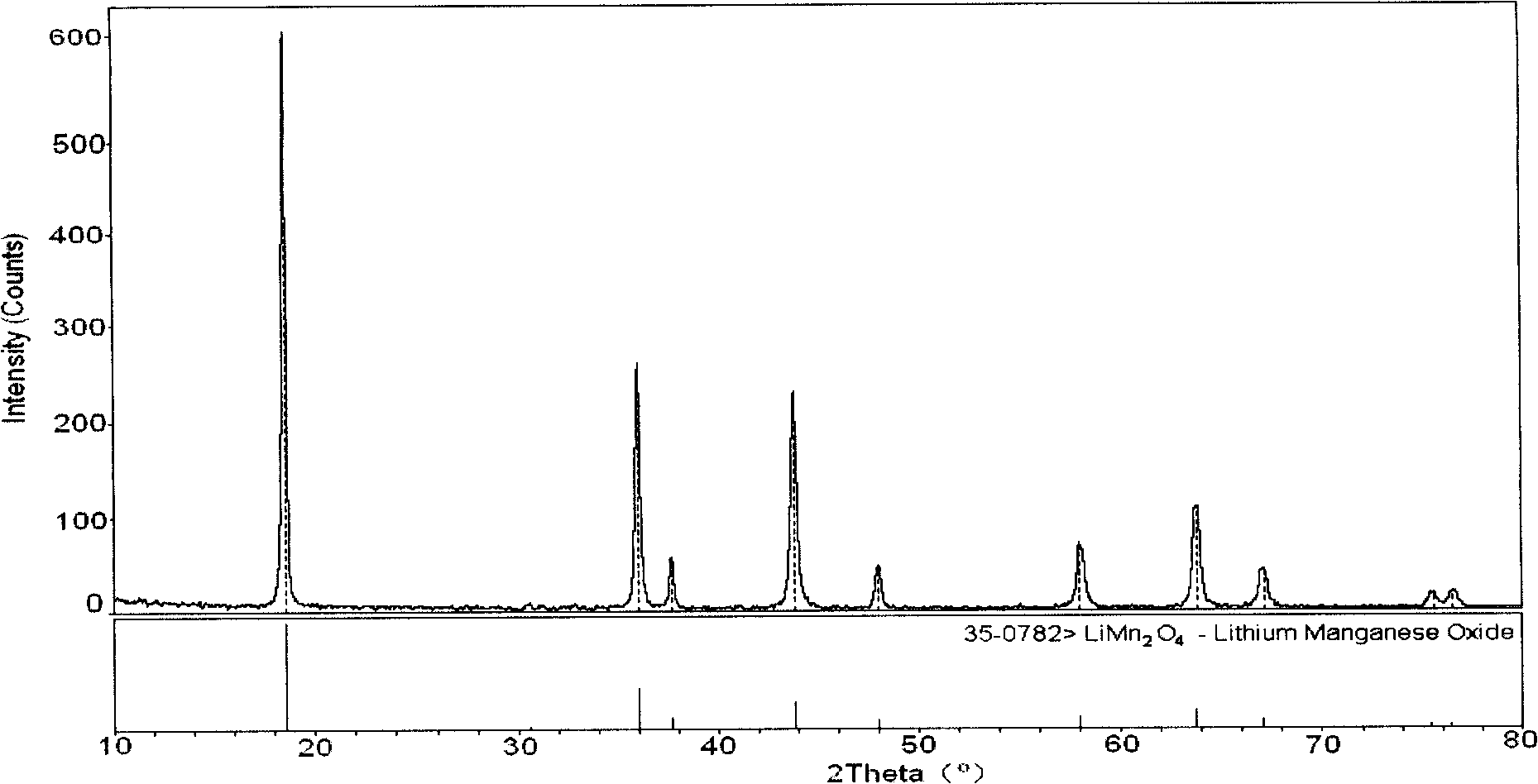

Method of producing silicon doped LiMn2O4 lithium ion battery anode material

InactiveCN101179125BTo achieve the purpose of dopingAvoid the disadvantage of not being able to enter the lattice structure of lithium manganese oxideElectrode manufacturing processesLithium compoundsManganeseSolvent

Owner:LUDONG UNIVERSITY +1

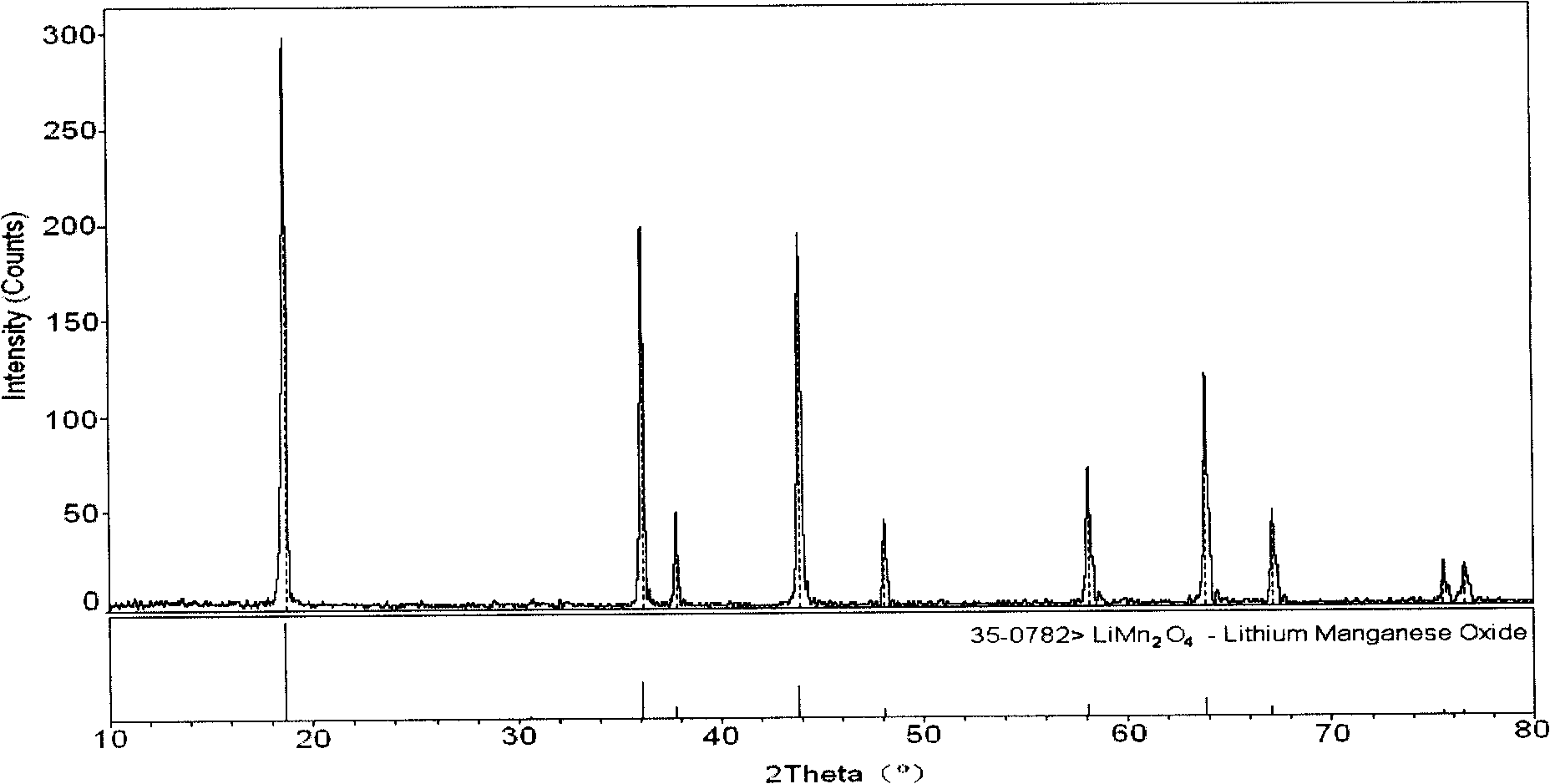

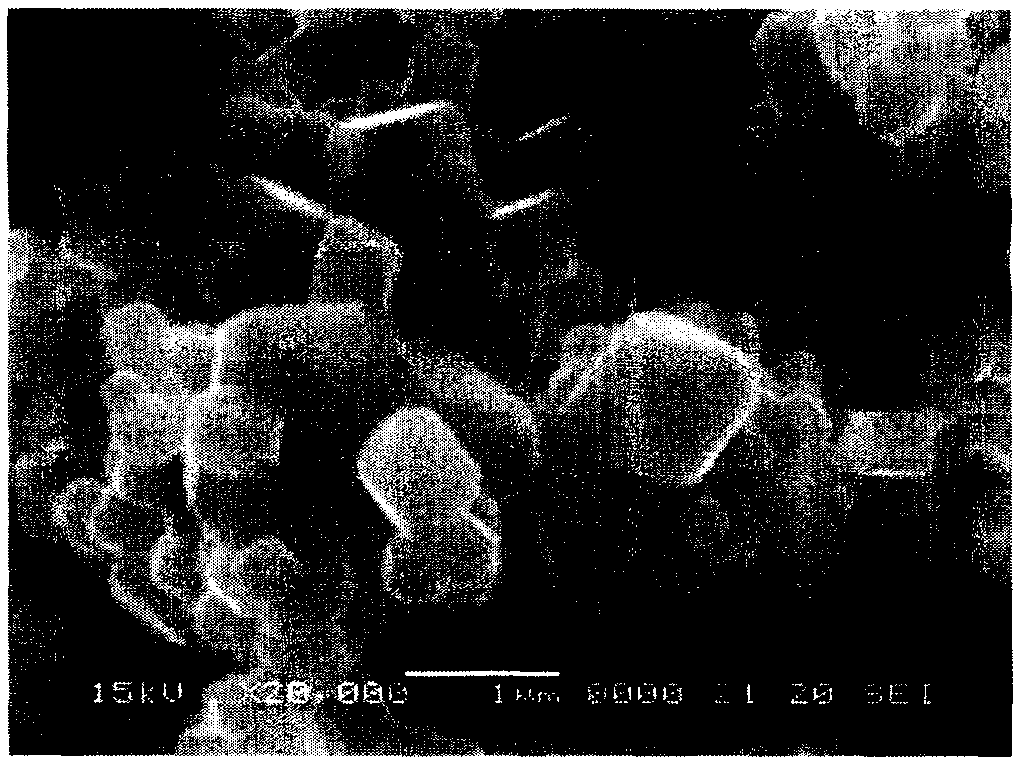

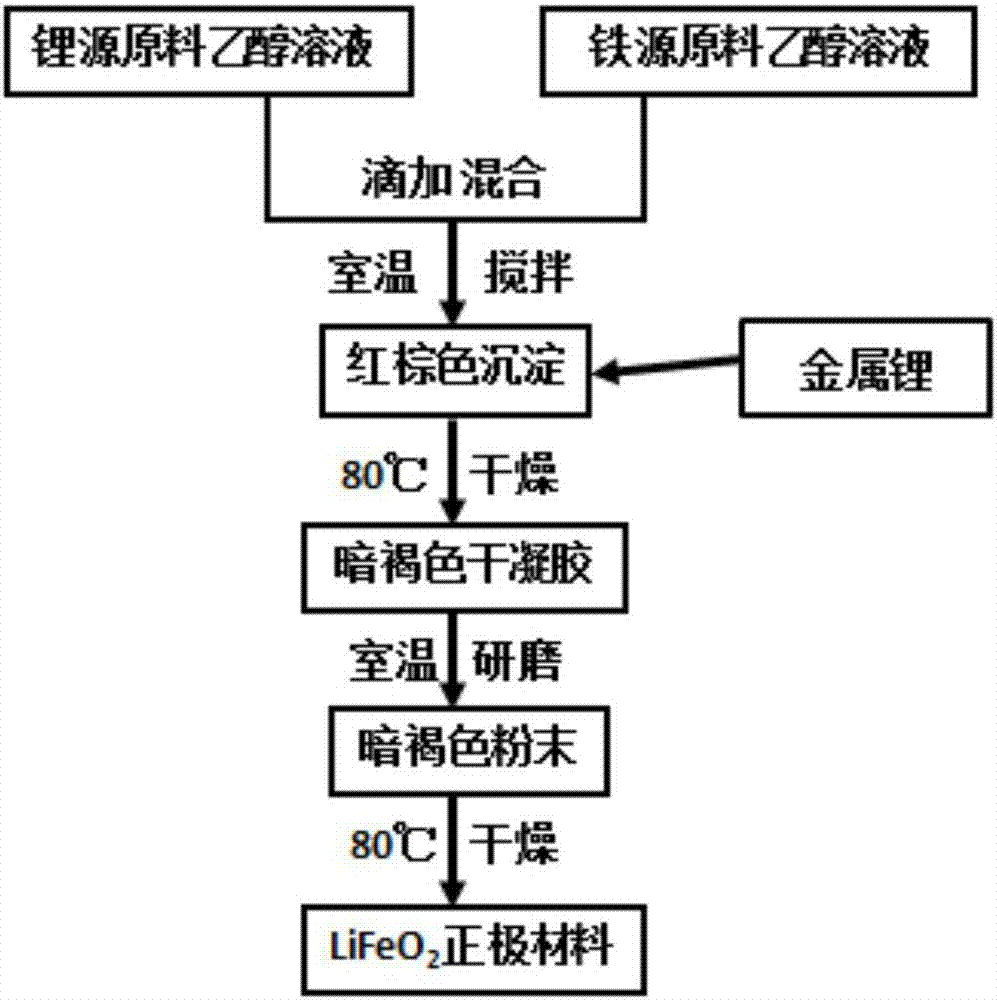

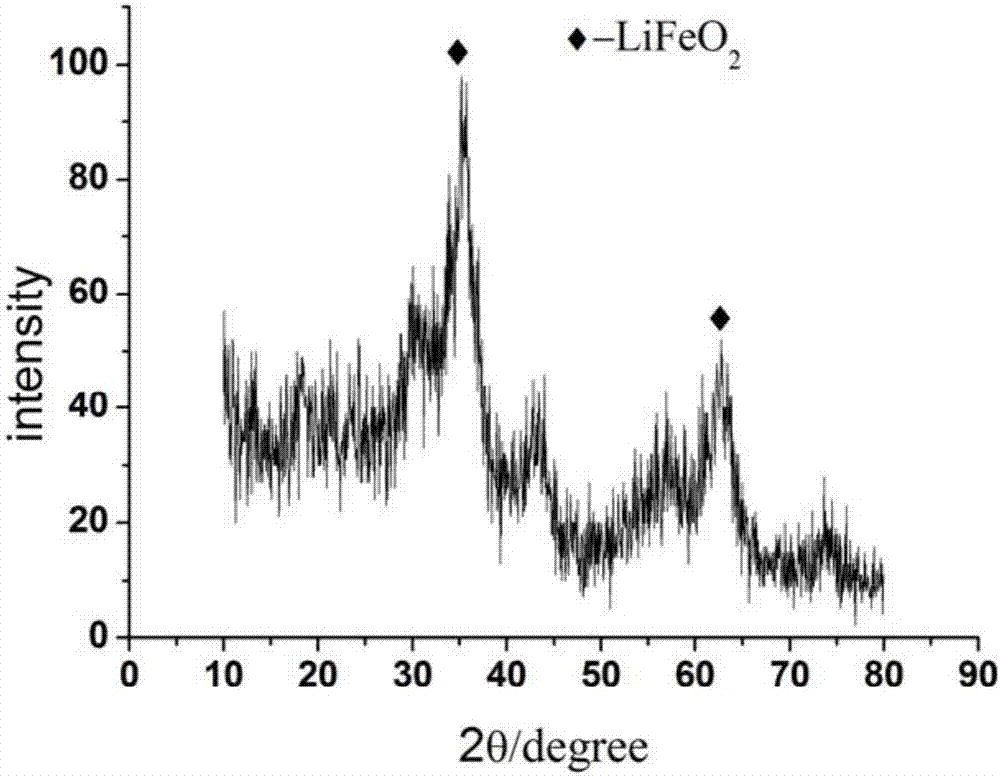

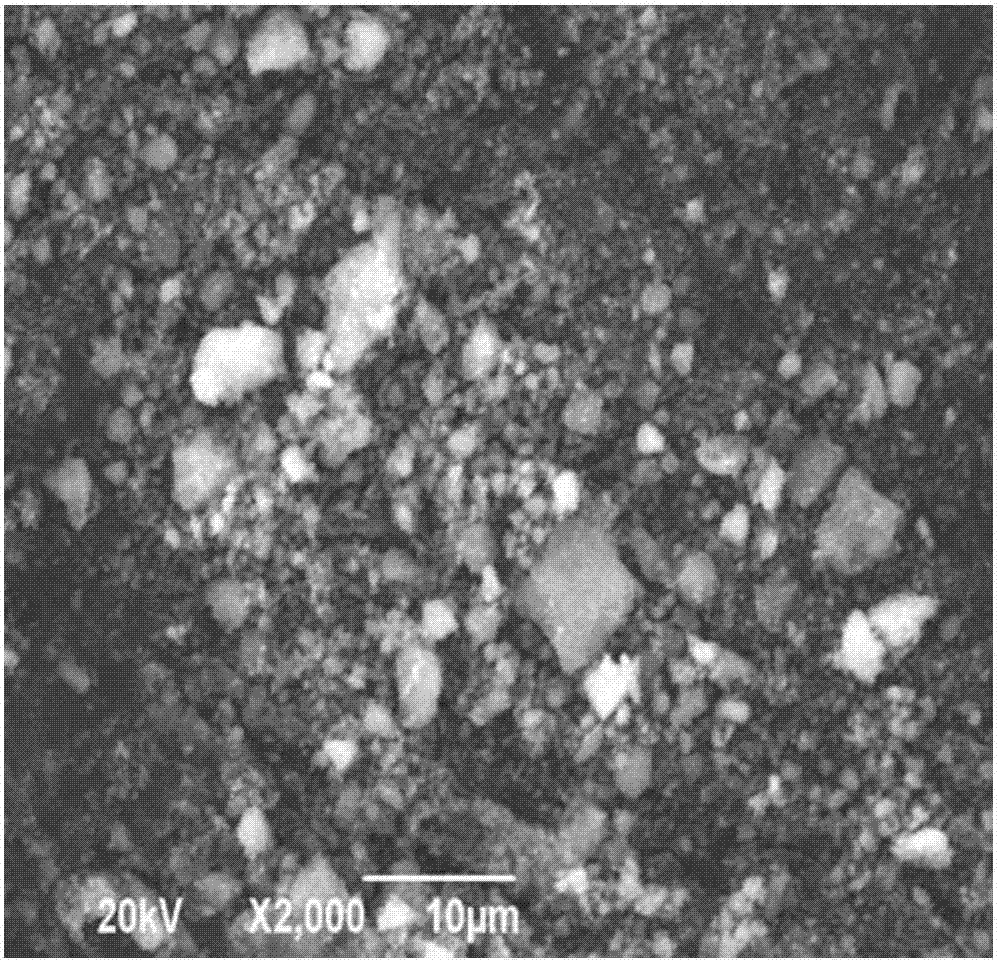

Preparation method of high-capacity iron-based lithium ion battery cathode material alpha-LiFeO2

ActiveCN107445210AUniform particle size distributionNo impuritiesIron oxides/hydroxidesCell electrodesSynthesis methodsCharge discharge

The invention belongs to the field of lithium batteries, and provides a preparation method of a high-capacity iron-based lithium ion battery cathode material, that is, alpha-LiFeO2 to overcome the defects of the complicated synthesis method of the existing alpha-LiFeO2 cathode material, low electrochemical performance, complicated structure, unpurified product and the like. The method for synthesizing at the room temperature is adopted, alpha-LiFeO2 is prepared by strictly controlling the molar ratio of Li<+> / Fe<3+>, various reactants are dissolved into absolute ethyl alcohol and are directly synthesized into alpha-LiFeO2 at the room temperature through magnetic stirring, metal lithium is introduced in the reaction process to serve as a reduction protective agent, an alpha-LiFeO2 product rich in lithium is obtained, the product is centrifuged, separated, washed, dried, grinded, refined and dried to obtain the lithium ion battery cathode material alpha-LiFeO2; the material has no impurity, is high in purity, single in phase and even in particle size distribution, the first specific discharge capacities respectively reach 450 mAh / g, 260 mAh / g and 202 mAh / g at the charge-discharge rates of 0.1 C, 0.2 C and 0.5 C; and in addition, the manufacturing cost is low, the synthesis method is simple, and the preparation method is suitable for large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

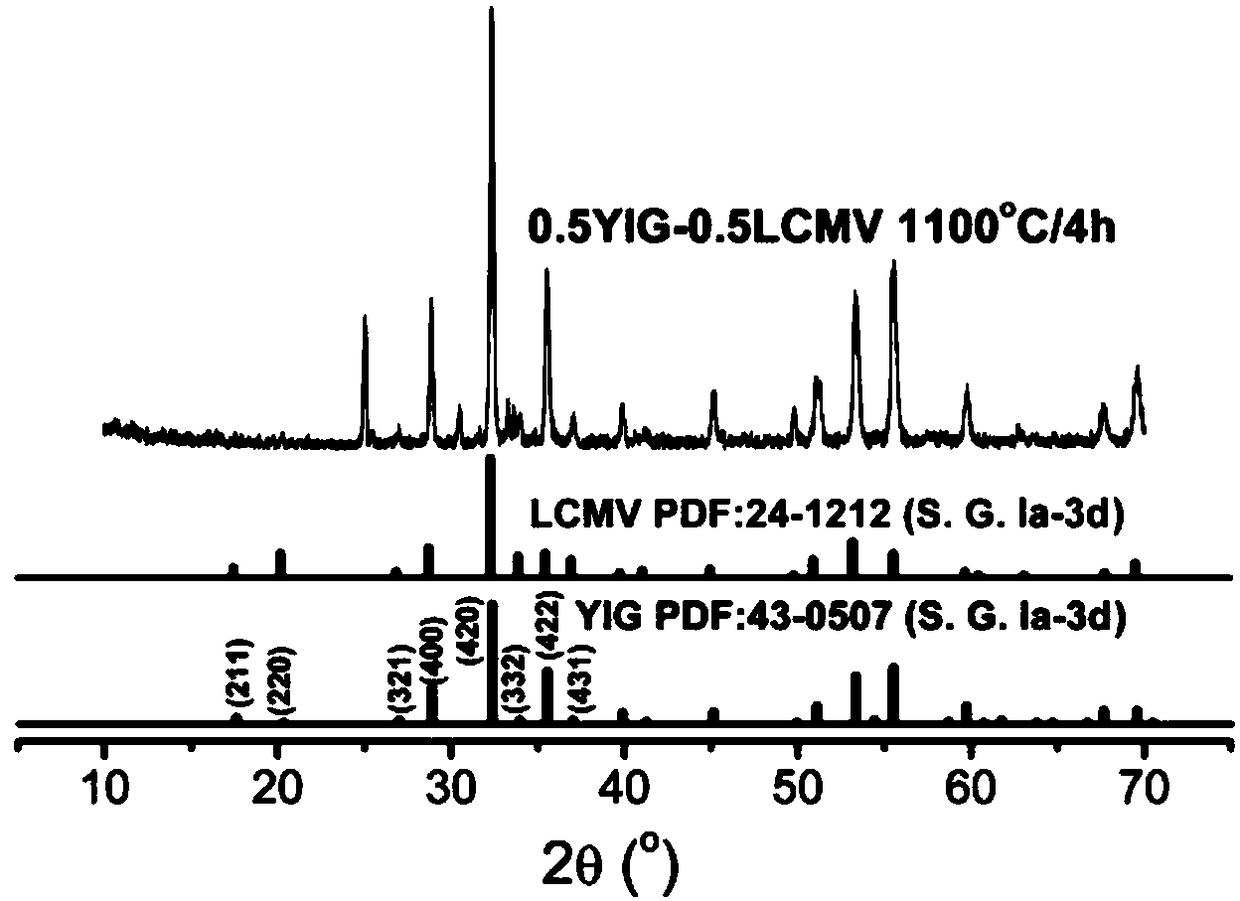

Garnet type solid solution magnetic dielectric functional medium ceramic material and preparation method thereof

InactiveCN108424134AImprove permeabilityHigh dielectric constantFixed capacitor dielectricStacked capacitorsDielectricMicrowave

The invention discloses a garnet type solid solution magnetic dielectric functional medium ceramic material and a preparation method thereof. garnet type ferrite ceramic Y3Fe5O12 and garnet type microwave dielectric ceramic Ca3LiMgV3O12 are used as the raw materials, the raw material ratio of ferrite-microwave dielectric ceramic is adjusted to synthesize a solid solution at one time, and a seriesof magnetic dielectric functional medium ceramic materials with magnetic properties, excellent dielectric properties and microwave properties can be obtained, and the specific structural expression general formula is: xY3Fe5O12-(1-x)Ca3LiMgV3O12, wherein x is greater than or equal to 0.01 and smaller than or equal to 0.99. Moreover, the ceramic material provided by the invention has a sintering temperature of 1000-1450DEG C, and has the characteristics of simple chemical composition and preparation process, and single phase.

Owner:XIAN UNIV OF TECH

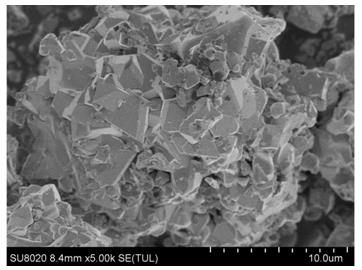

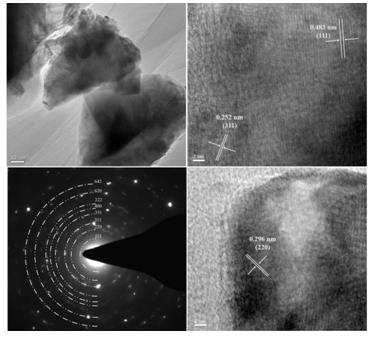

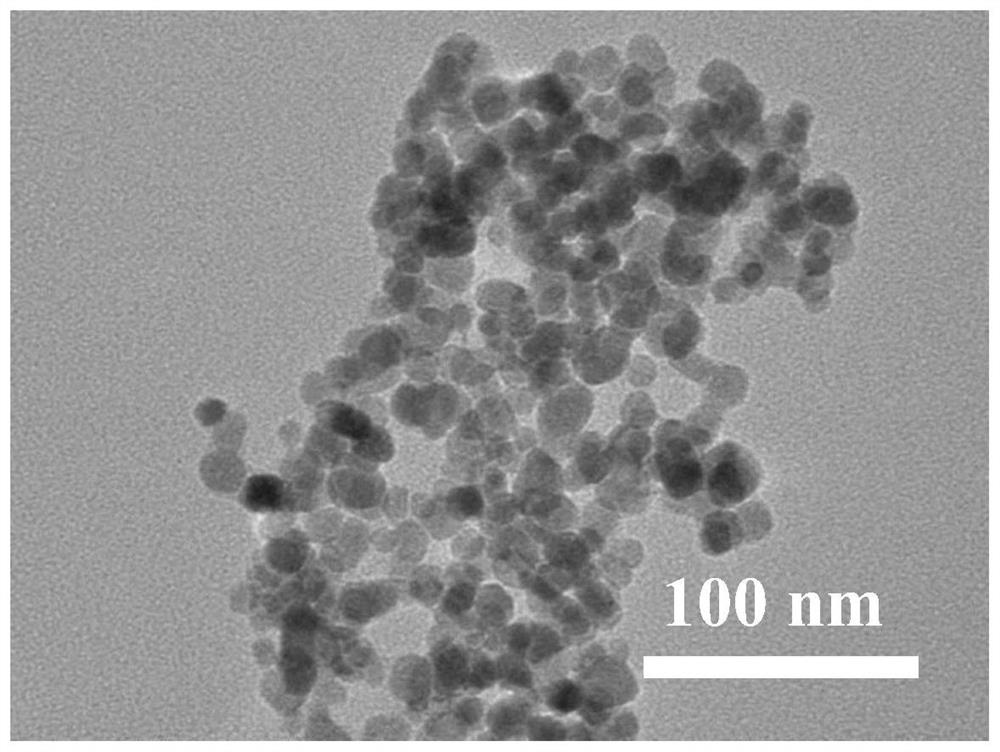

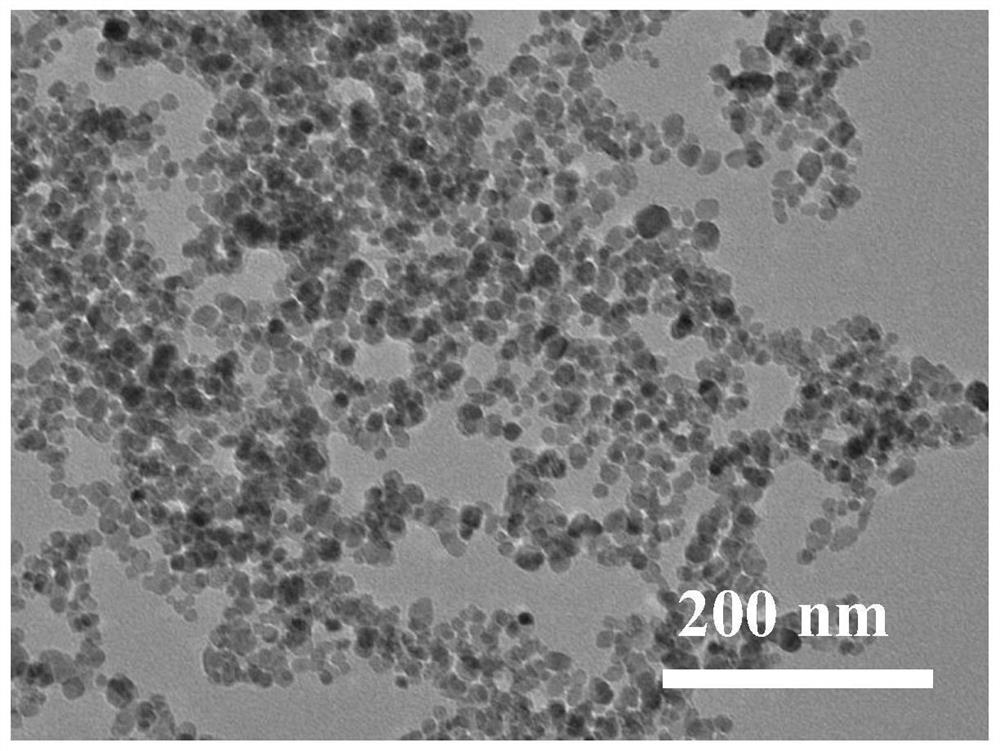

Preparation method of water-based nano magnetic fluid

PendingCN112309669AGood dispersionSingle phaseMagnetic liquidsInductances/transformers/magnets manufactureFerrous saltsActive agent

The invention discloses a preparation method of a water-based nano magnetic fluid. The method comprises the following steps of: dissolving ferrous salt and ferric salt in an acidic solution to preparea ferric salt mixed solution, and marking the ferric salt mixed solution as a feed liquid A; dissolving an alkali source in deionized water to prepare alkali liquor, and marking the alkali liquor asfeed liquid B; under the reaction condition of introducing inert gas N2, mixing the feed liquid B with the feed liquid A, heating the mixed solution in a water bath, and performing stirring to carry out a full reaction; adding a surfactant, heating an obtained mixed solution in a water bath, performing stirring, generating black precipitated nano ferroferric oxide particles after finishing the reaction, continuously introducing N2, and cooling to room temperature; collecting the black precipitates, and carrying out centrifugal washing by using a mixed solution of an organic solvent and water;and dispersing the precipitates in deionized water, removing the organic solvent, and carrying out ultrasonic dispersion to obtain the water-based nano magnetic fluid. The water-based magnetic fluid product is uniform in size, and the average particle size of the product is 5-25 nm; the water-based magnetic fluid product is good in dispersion, single in phase and good in stability; and stable dispersion of the product for more than or equal to 6 months can be realized after the product is modified.

Owner:BEIJING UNIV OF CHEM TECH +1

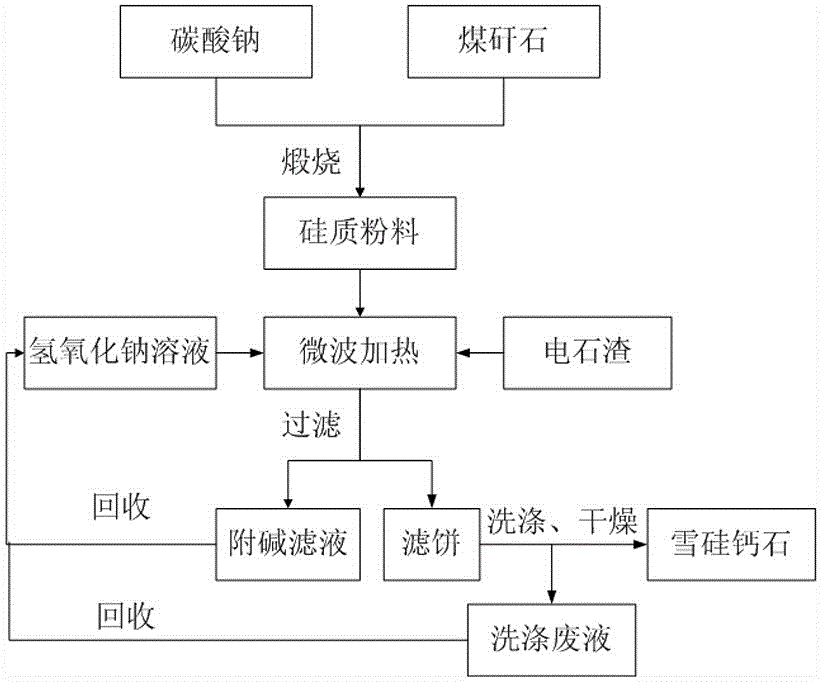

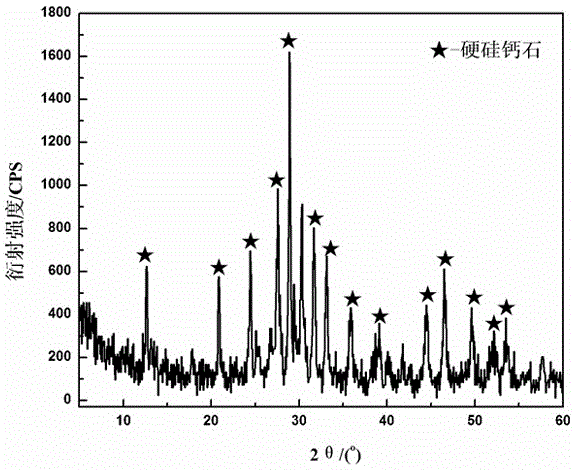

Method for producing tobermorite by conducting microwave heating on siliceous waste and carbide slag

ActiveCN106495173ALow reaction temperatureShorten the timeAlkaline-earth metal silicatesSynthesis methodsSlag

The invention provides a method for producing tobermorite by conducting microwave heating on siliceous waste and carbide slag. The method comprises the following technological steps that 1, siliceous waste is calcined and activated to obtain siliceous powder; 2, the siliceous powder, the carbide slag and a sodium hydroxide solution are mixed to be uniform, and a microwave heating synthesis reaction is conducted; 3, after the reaction is completed, mixed slurry is filtered to obtain a filter cake and filtrate with alkali; 4, the filter cake is washed and dried to obtain the tobermorite, and filter cake washing waste liquid and the filtrate with alkali are recycled and reused in the sodium hydroxide solution. Compared with an existing synthesis method, the method has the advantages that the reaction temperature is low, the time is short, the technology is simple, the conditions are mild, the obtained tobermorite is high in purity, single in physical phase, free of impurities and high in crystallinity, the production cost is significantly reduced, resources are significantly saved, and meanwhile a new solving way is provided for the discharge problem of three bulk solid waste including coal gangue, acid-soluble aluminum fly ash and carbide slag.

Owner:大连锡安科技有限公司

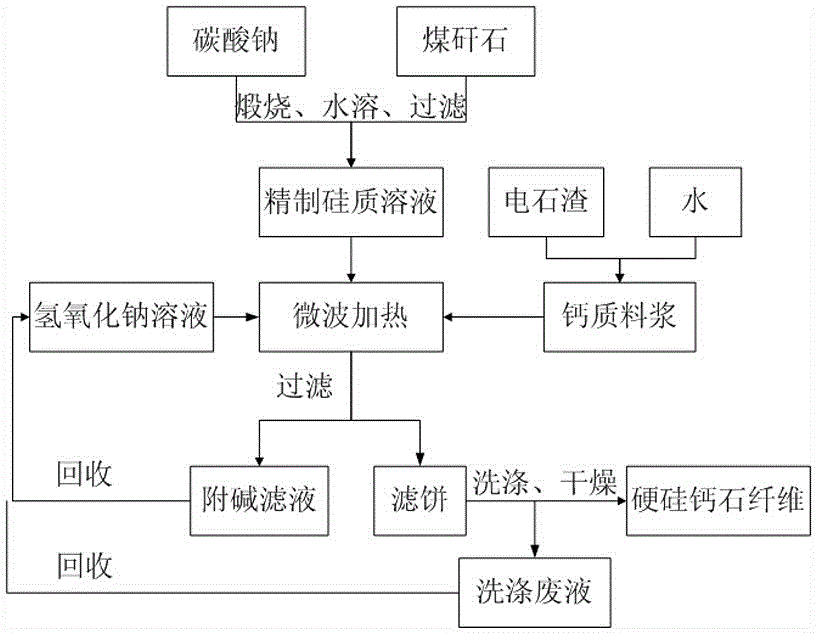

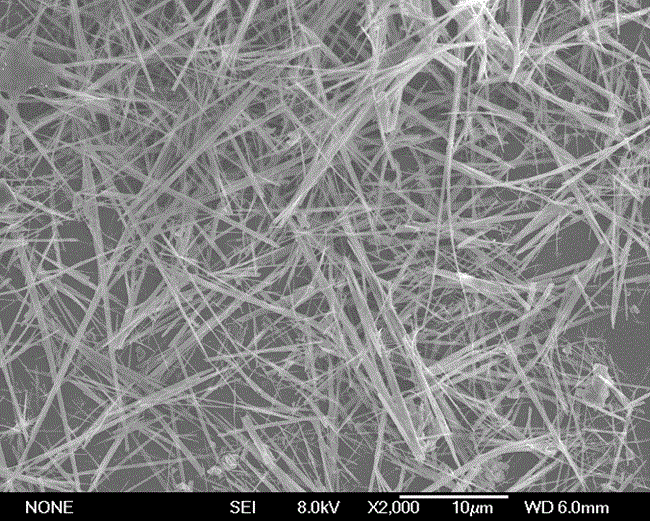

Microwave-assisted method for compounding gangue and acetylene sludge into xonotlite fiber

InactiveCN106517223ALow reaction temperatureShorten the timeTransportation and packagingSolid waste disposalLiquid wasteCalcium in biology

The invention provides a microwave-assisted method for compounding gangue and acetylene sludge into a xonotlite fiber. The method comprises the following steps: (1) mixing acetylene sludge with water, thereby preparing a calcium pulp; (2) alkalizing, calcining and activating gangue, uniformly mixing the activated product with water and then filtering, thereby obtaining a refined siliceous solution; (3) uniformly mixing the calcium pulp, the refined siliceous solution and a sodium hydroxide solution and performing microwave heating synthetic reaction; (4) after completing reacting, filtering a mixed slurry, thereby obtaining a filter cake and aqueous alkali; (5) washing the filter cake and drying, thereby obtaining the xonotlite fiber, and then recycling the filter cake washing effluent and the aqueous alkali into the sodium hydroxide solution. Compared with the existing compounding method, the method has the advantages of low reaction temperature, short time, simple process and mild condition; the obtained xonotlite fiber is high in purity; the phase is single and impurity-free; the degree of crystallinity is high; the performance can fully meet and even exceed the standard for light calcium silicate thermal insulation materials.

Owner:LIAONING TECHNICAL UNIVERSITY

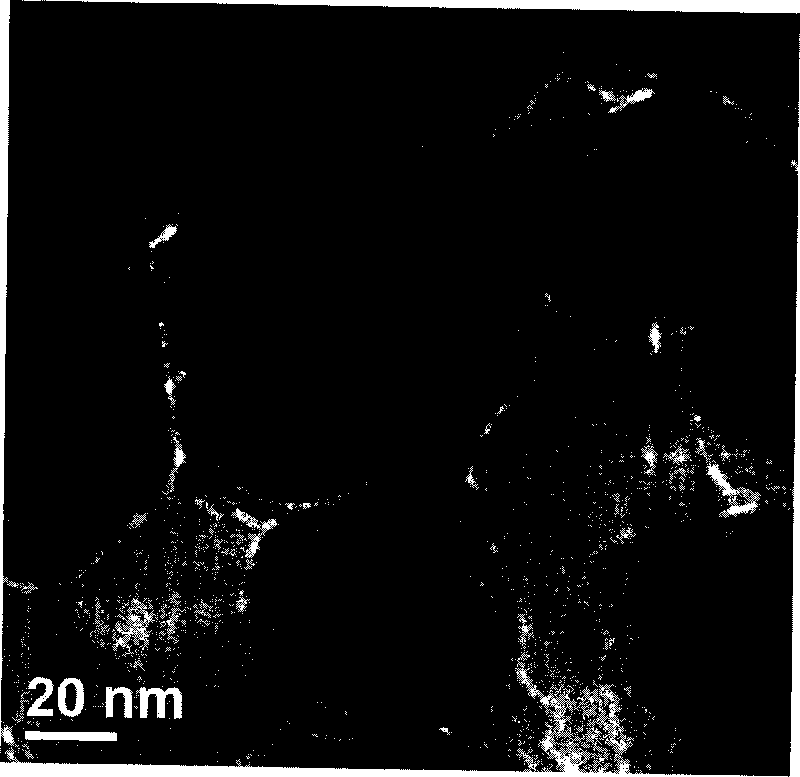

Method for preparing nano metallic nickel granular material coating with carbon

InactiveCN101176915BSolve the problem of easy oxidation in airSimple methodCoatingsCarbon layerMagnetic storage

Owner:NANJING UNIV

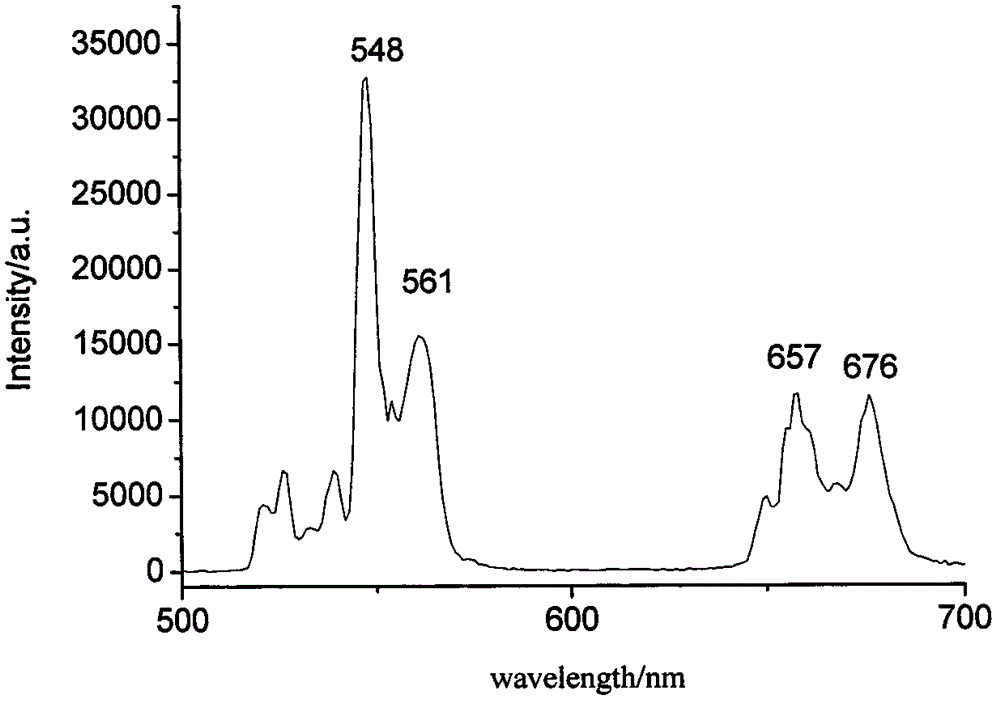

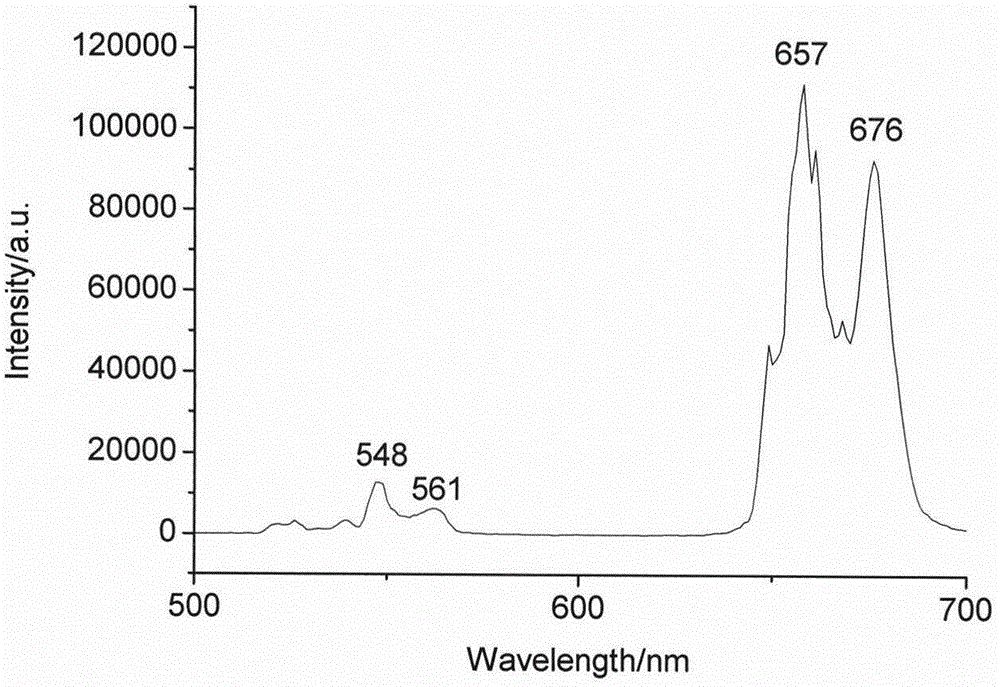

Yttrium-cerium composite oxide-based up-conversion luminescent material and preparation method thereof

ActiveCN107523298ASimple preparation processSmall powder particlesLuminescent compositionsCeriumUp conversion

In order to solve the problems that an oxide-based up-conversion luminescent material in the field of up-conversion luminescent materials has low luminous efficiency and luminescent intensity which cannot meet the practical application requirement, the invention provides an yttrium-cerium composite oxide-based up-conversion luminescent material and a preparation method thereof. The luminescent material has a chemical formula as Y(2-x-y)RExYbyCeO5, wherein x is larger than or equal to 0.0002 and smaller than or equal to 0.035, and y is larger than or equal to 0.01 and smaller than or equal to 0.25. The preparation method comprises the steps of adopting a sol-gel method for preparing a precursor, drying, grinding, calcining at 900 to 1300 DEG C for 1 to 4h, and obtaining a series of rare-earth-doped yttrium-cerium composite oxide-based up-conversion luminescent material. The luminescent material has the advantages of simple preparation process, small powder particle, single material phase, good chemical stability, high luminescent intensity under 980nm infrared light stimulation and the like, can meet the requirement of practical application fields such as anti-counterfeit technology, and has a wide application prospect.

Owner:WENZHOU UNIVERSITY

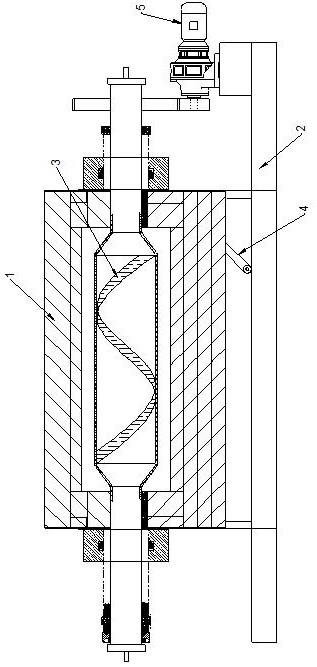

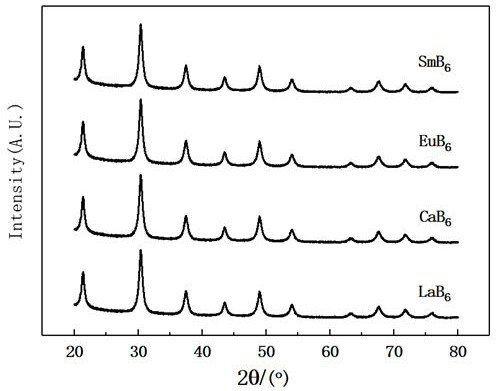

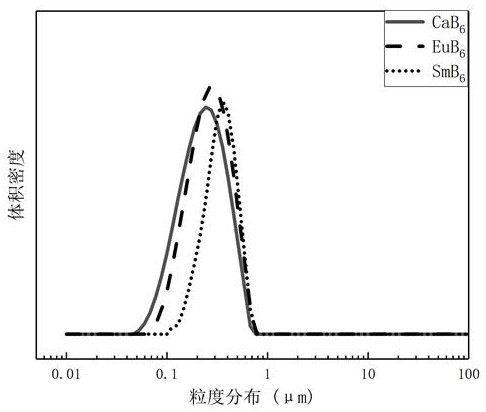

Preparation method of dispersed fluffy MB6 nano low-heat-transfer powder material

ActiveCN114524439ASmall particle sizeLow costChemical industryNanotechnologyHeat conservationRotary furnace

The invention provides a preparation method of a dispersed fluffy MB6 nano low-heat-transfer powder material. The preparation method comprises the following steps: step 1, grinding metal M cations and a boron source to obtain an MB6 precursor; 2, the MB6 precursor is loaded into a rotary furnace to be calcined, hydrogen and nitrogen mixed gas is introduced into the rotary furnace, the temperature is increased to 850-1200 DEG C, heat preservation is conducted for 30-450 min, and a head product is obtained after cooling; and step 3, removing impurities from the primary product to obtain the dispersed and fluffy MB6 nano low-heat-transfer powder material. The powder material disclosed by the invention is loose and fluffy in powder, small in particle size, relatively low in required temperature, low in energy consumption, low in cost of required raw materials, simple in batch preparation and suitable for large-scale industrial production.

Owner:TIANJIN BAOGANG RES INST OF RARE EARTHS

Method for preparing V2O5 nano-powders

ActiveCN102502827BSingle phaseAvoid generatingNanotechnologyVanadium oxidesUltrasonic cavitationUltrasonic generator

A method for preparing V2O5 nano-powders comprises the following steps: firstly, de-ionized water, NH4VO3, ammonia water and dimethyl sulfoxide are stirred uniformly to obtain a solution A; the solution A is filled into an ultrasonic generator, and a hydrogen peroxide solution is also added into the ultrasonic generator to obtain a suspension liquid B; the suspension liquid B is centrifugally separated and washed repeatedly by de-ionized water and isopropanol to obtain light yellowish-red fine powders, and the fine powders obtained are soaked into isopropanol, and then are dried to obtain the V2O5 nano-powders. In the invention, an ultrasonic sol-gel method combining an ultrasonic cavitation technology and a sol-gel method is adopted to prepare the V2O5 nanocrystal with low cost. The method not only reduces the reaction time but also can prepare the V2O5 nano-powders with uniform sizes and single phase.

Owner:启东晟涵医疗科技有限公司

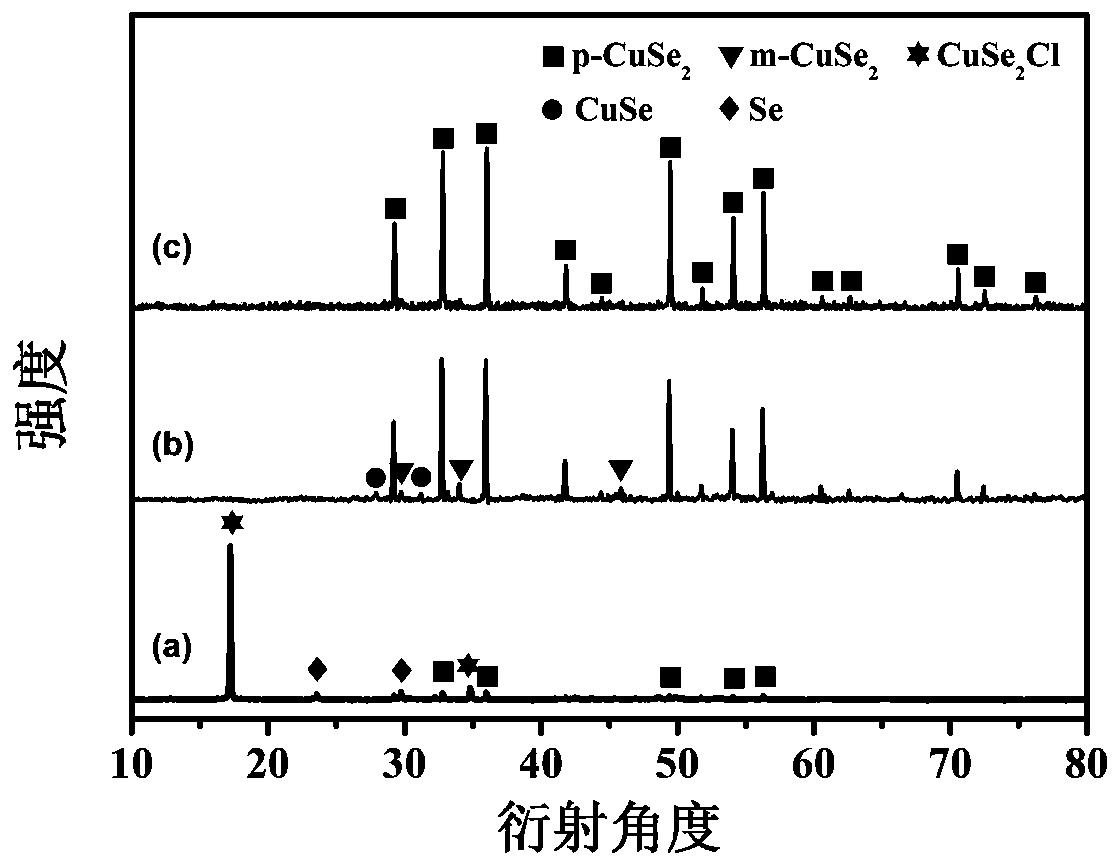

P-CuSe2 (pyrite CuSe2) and preparation method thereof

ActiveCN109384203ASingle phaseUniform phaseMetal selenides/telluridesBinary selenium/tellurium compoundsPyriteCopper(II) chloride

The invention belongs to the technical field of metastable crystal materials and particularly relates to p-CuSe2 (pyrite CuSe2) and a preparation method thereof. According to the preparation method ofp-CuSe2, CuCl is used as a Cu source, triethylene glycol is used as a solvent and a reducing agent, CuCl and triethylene glycol are mixed, and a cationic precursor solution is obtained. Glucose is used as an auxiliary reducing agent and matched with triethylene glycol, Se powder is reduced to Se2<2-> under the action of polyvinylpyrrolidone, an anionic precursor solution is obtained, auxiliary reducing agents with higher toxicity are avoided, the glucose has proper reducibility and cannot produce Se<2-> and other impure phases due to too high reducibility, and product purity can be improved.The cationic precursor solution and the anionic precursor solution are mixed to be subjected to a replacement reaction, and the p-CuSe2 with single and stable phase is obtained.

Owner:QINGHAI UNIV FOR NATITIES

Application and preparation method for molybdenum-based low temperature sintering microwave dielectric ceramic material

The invention discloses an application and a preparation method for a molybdenum-based low temperature sintering microwave dielectric ceramic material, and belongs to the technical field of electronic ceramics and manufacturing techniques thereof. According to the preparation method, a composition expression of the ceramic material is (1-x)Bi2O3-(x)Ln2O3-MoO3, wherein the Ln is equal to La or Nd, and each x is equal to or greater than 0.001 and equal to or smaller than 0.3; the ceramic material can be prepared into a ceramic by sintering at the temperature range of 800-1000 DEG C, has excellent microwave dielectric properties, and can be used as a microwave dielectric material. The ceramic material has the following advantages: 1, adjustable dielectric constant (Epsilonr is equal to or greater than 21 and equal to or smaller than 31); 2, high quality factor (Qf is equal to 20, 300-32, 300 GHz); 3, low sintering temperature (800-1000 DEG C); 4, simple preparation technology; 5, wide application range.

Owner:XIAN TECHNOLOGICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com