Patents

Literature

58results about How to "Stir and disperse evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

InactiveCN101179921AStir and disperse evenlyEnable mass manufacturingMagnetic/electric field screeningScreening apparatusLow frequency bandElectromagnetic shielding

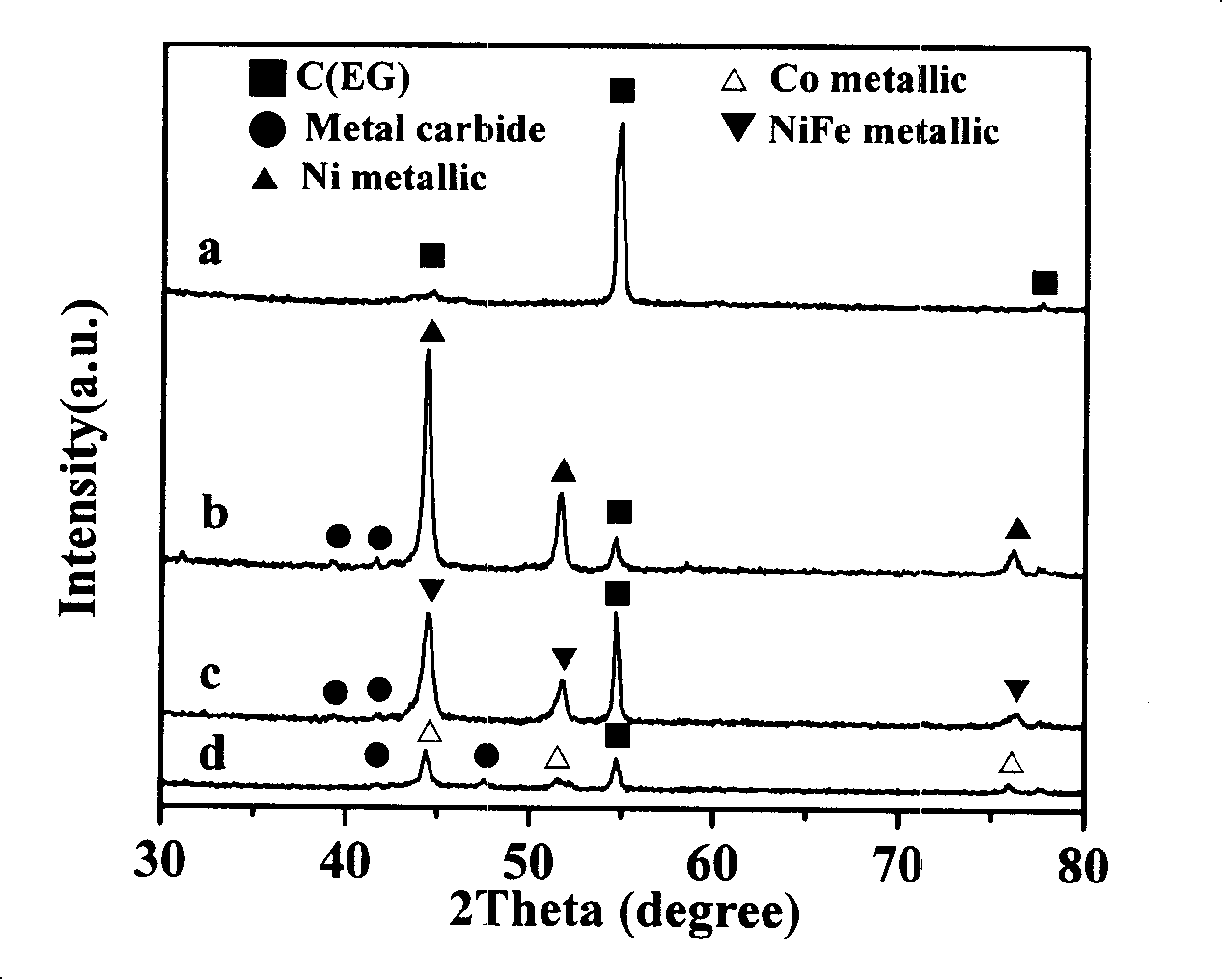

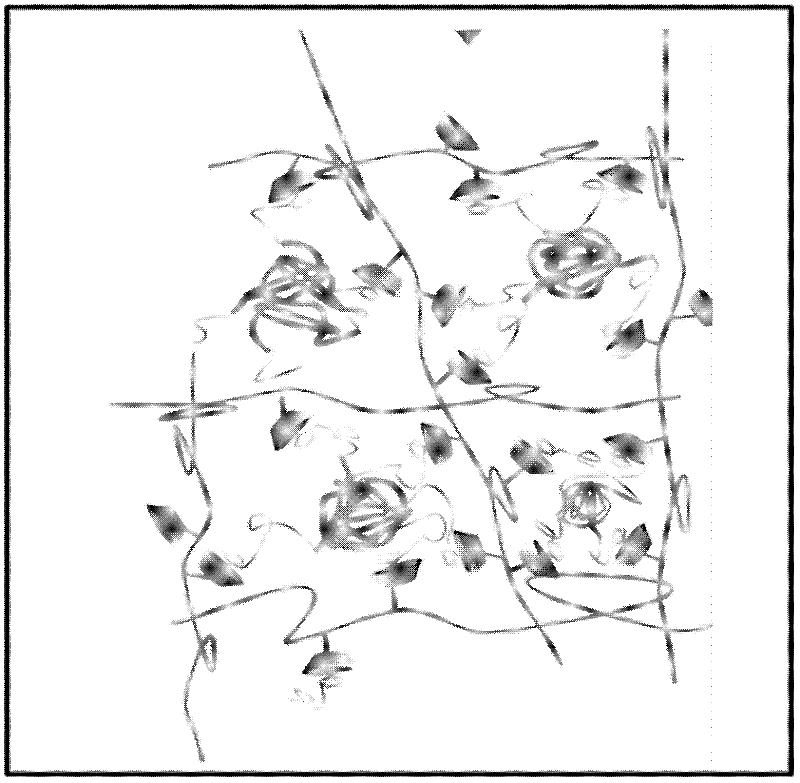

The invention relates to a preparation method of a lightweight graphite-based nano-magnetic metal composite material used for electromagnetic shielding, which belongs to the related field of electromagnetic shielding materials; the precursor solution of expanded graphite and magnetic metal is mixed and stirred evenly, and dried after evaporating the solvent. The obtained mixture is treated in a reducing atmosphere at 300°C-1000°C, passivated with ordinary nitrogen and cooled to room temperature to obtain a composite material of expanded graphite and magnetic nanometer metal, and the relative content of the two can be adjusted. The composite material is light in texture, has excellent electromagnetic properties, and can be pressed into various shapes required. The material has excellent electromagnetic shielding performance in the range of 300kHz-1.5GHz, reaching 70-105dB, and the addition of magnetic metal improves the electromagnetic shielding performance of the expanded graphite in the low-frequency band. The method is simple and efficient, suitable for mass preparation, and the obtained product is expected to be applied in aerospace, military, electronic and electrical products.

Owner:NANJING UNIV

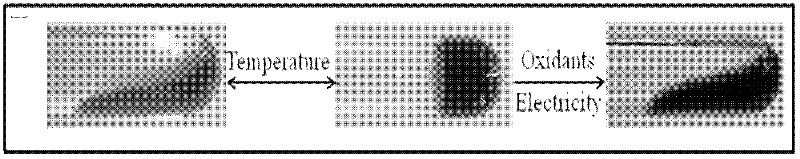

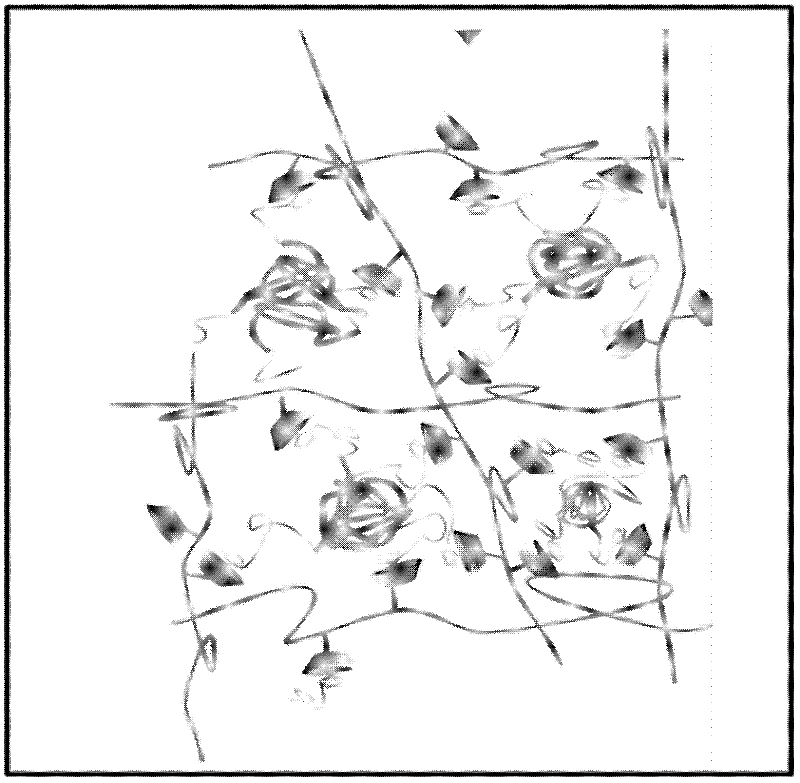

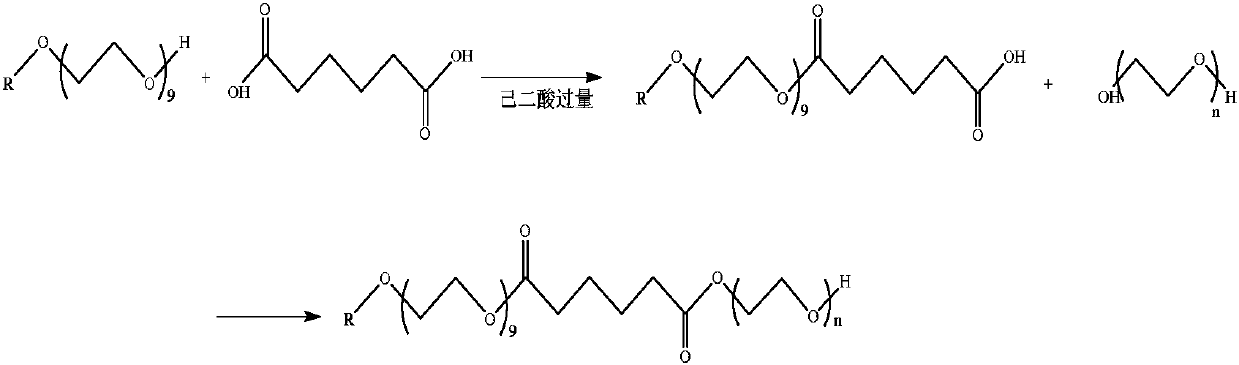

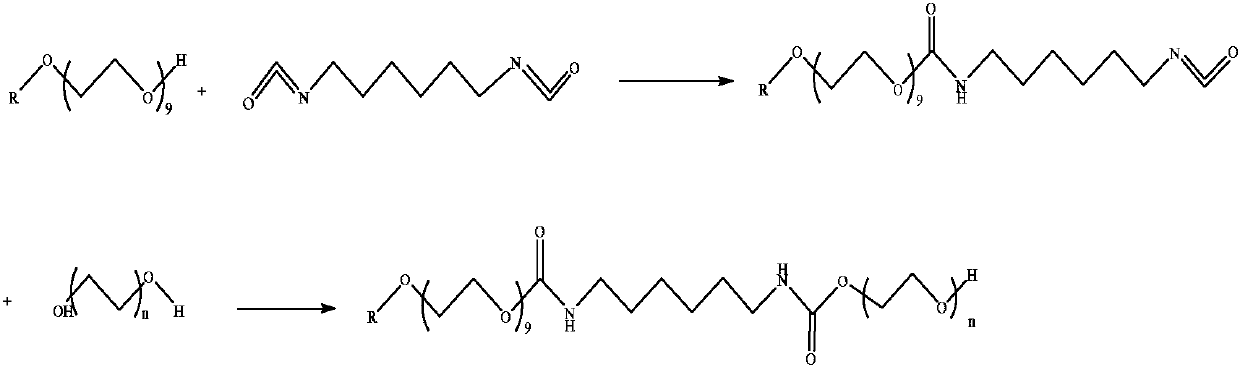

Multiple sensitive hydrogel material and preparation method thereof

InactiveCN102516739AObservation specific shiftStir and disperse evenlyMaterial analysis by electric/magnetic meansMaterial thermal analysisConcentrations glucoseCyclodextrin

The invention belongs to the technical field of high-molecular chemistry and relates to a multiple sensitive hydrogel material and a preparation method thereof. The hydrogel material comprises a polymer with cyclodextrin (subject) and polyether pluronic modified by ferrocene (object) group. A gel formation method comprises steps of: simultaneously dissolving the polymer with cyclodextrin and the polyether pluronic with ferrocene group in water; and stirring and dispersing thoroughly under certain solution condition, so as to form a large amount of crosslinking netted organizations based on subject and object identification in the solution. The gel material can response to environment temperature change, oxidizing agent, existence of electric field or change of glucose concentration to generate gel-sol conversion. The invention has advantages of simple preparation method, environment-friendliness and thrift, and has huge application value in biomedicine.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

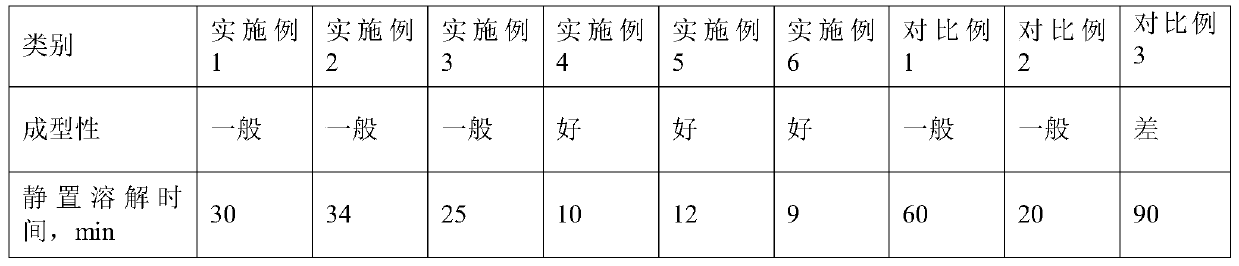

Clothes aroma-retaining bead and preparation method thereof

ActiveCN111286414AIncrease aromaGood decontamination effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolymer scienceActive agent

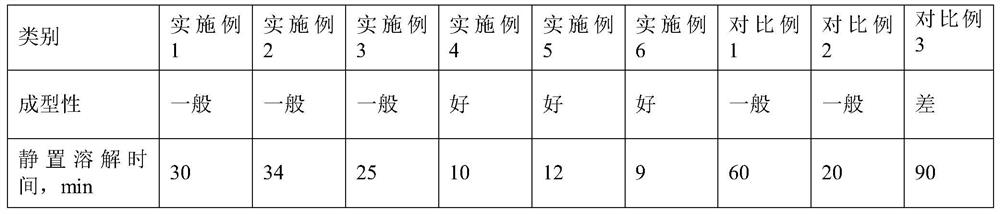

The present invention relates to the field of detergents, and discloses a clothes aroma-retaining bead and a preparation method thereof. According to the invention, a specific type of nonionic surfactant is added and compounded with polyethylene glycol in the mating process of the clothing aroma-retaining beads, or the nonionic surfactant is directly added to modify polyethylene glycol, so that the clothing aroma-retaining bead is easy to form during processing and forming, and the technical problem that a surfactant cannot be added to the existing clothing aroma-retaining bead is solved.

Owner:NICE ZHEJIANG TECH CO LTD

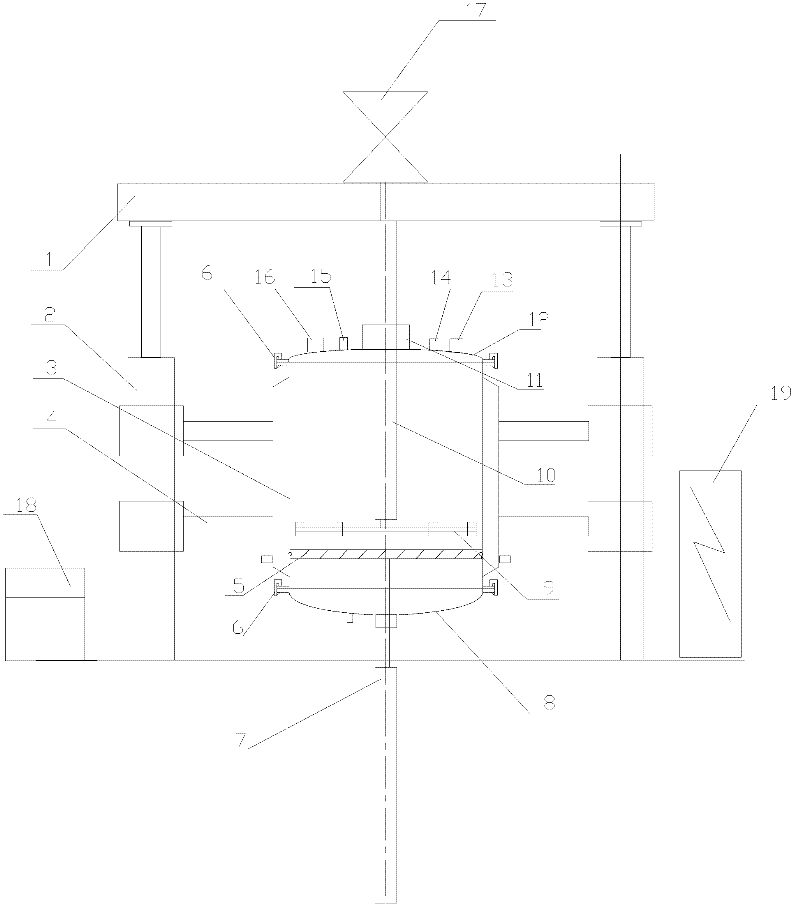

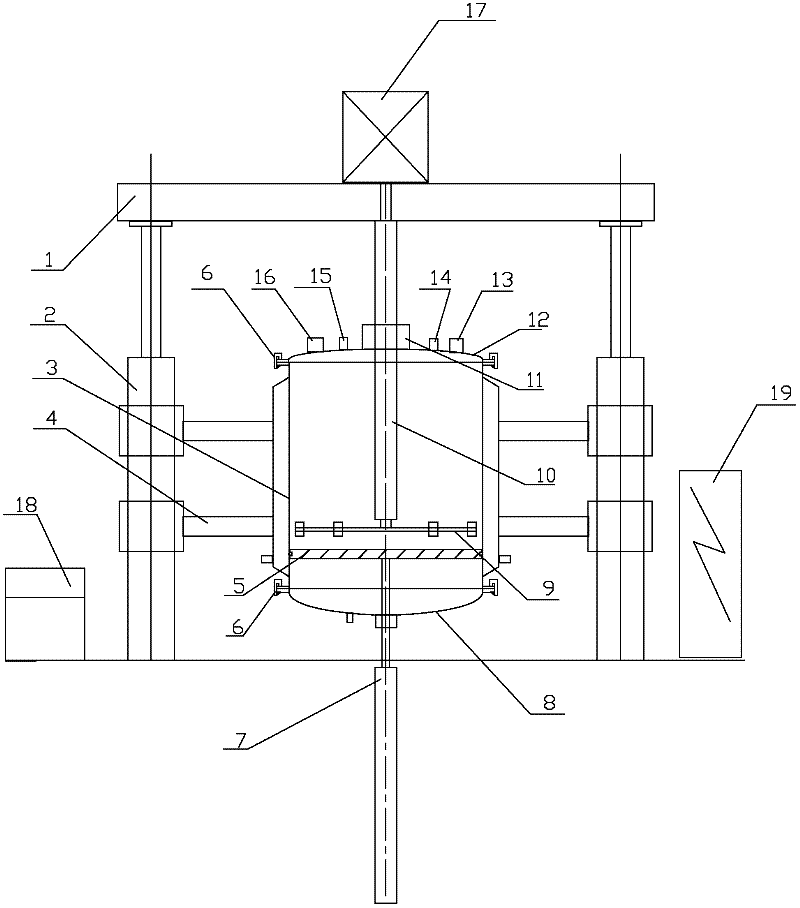

A new type of mixer

InactiveCN102266732AChange volumeStir quicklyRotary stirring mixersTransportation and packagingDrive shaftEngineering

The invention discloses a new type of mixer, which includes a tank body and a stirring paddle driven by a power machine through a transmission shaft to rotate and stir materials in the tank body, and also includes a first lifting mechanism, a second lifting mechanism and a pressure plate. The first lifting mechanism drives the stirring paddle to move up and down in the tank, and the second lifting mechanism drives the pressure plate to move up and down in the tank, and the pressure plate moves up and down in the tank. below. Compared with the prior art, the novel mixer provided by the invention can improve the mixing efficiency of highly viscous materials and improve product quality.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

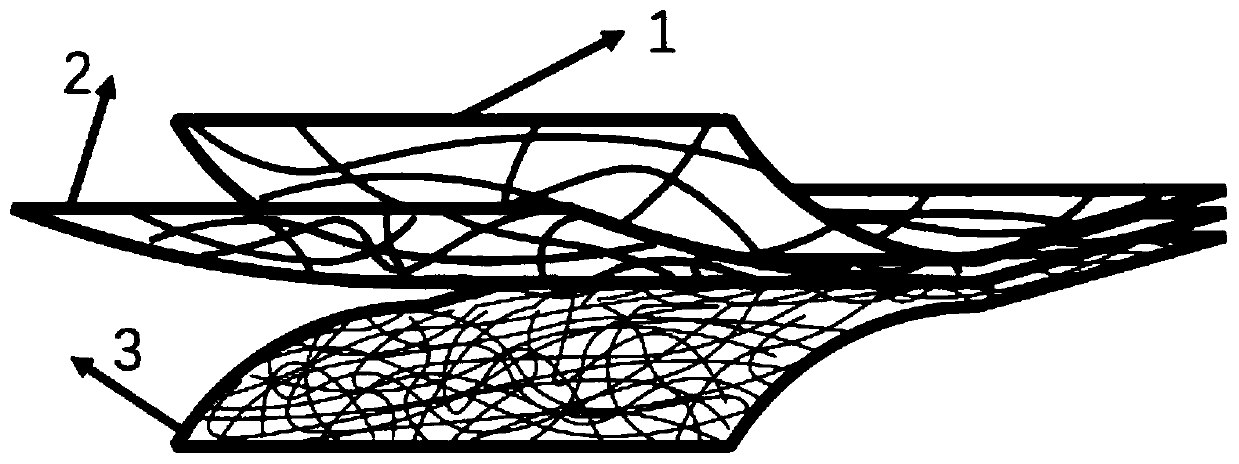

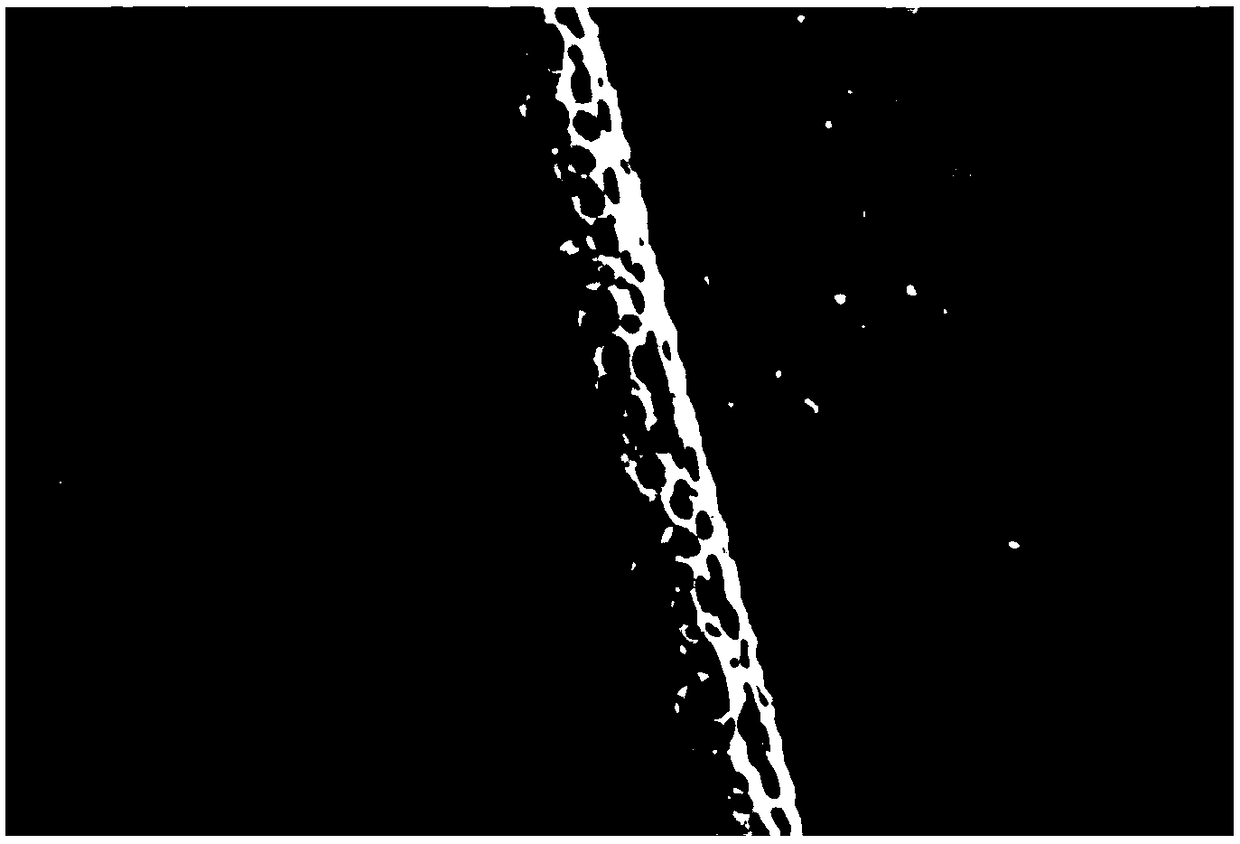

Composite fiber film which can be used for high-efficiency low-resistance smog prevention mask and preparation method

ActiveCN109572082AImprove filtration efficiencyHEPA filterSynthetic resin layered productsLaminationFiberNanofiber

The invention discloses a composite fiber film which can be used for a high-efficiency low-resistance smog prevention mask. The composite fiber film has a three-layer structure formed by compounding non-woven fabrics, meltblown cottons and a porous nanofiber film through ultrasonic hot pressing, wherein the outer layer is the non-woven fabrics, the middle layer is the meltblown cottons, and the inner layer is the porous nanofiber film; the porous nanofiber film is made of porous nanofibers, the nanofibers have a porous structure, the diameter of the porous nanofibers is 100-900 nm, the diameter of the nanofibers is 50-400 nm, and the humidity responsive intelligent sterilization efficiency is 98-99.9%. The composite fiber film can effectively improve the filtering efficiency of smog and reduce resistance, and has the characteristics of high-efficiency filtering and ultra-low resistance.

Owner:山东蓝色时光新材料有限公司

Prepn process of higher alpha-olefin low-viscoelasticity bulk polymer

ActiveCN1673237AReduced impact of polymerization reactionsStir and disperse evenlyPolymer scienceAlpha-olefin

The present invention is the preparation process of higher alpha-olefin low-viscoelasticity bulk polymer for reducing resistance of pipeline conveyed oil product. Under the conditions of low temperature and isolating air, refined monomer is reacted under stirring and in the presence of main catalyst and co-catalyst. In the first 1-3 hr of the reaction, antisticking powder in certain proportion is added; in the subsequent 3-6 hr, the reaction system is further stirred; and after that, the reaction is continued at 5-20 deg.c for 3-10 days to obtain the low-viscoelasticity solid bulk polymer. The process of the present invention is simple, and the product is easy to crush, high in storage stability and simple in application.

Owner:PIPECHINA SOUTH CHINA CO

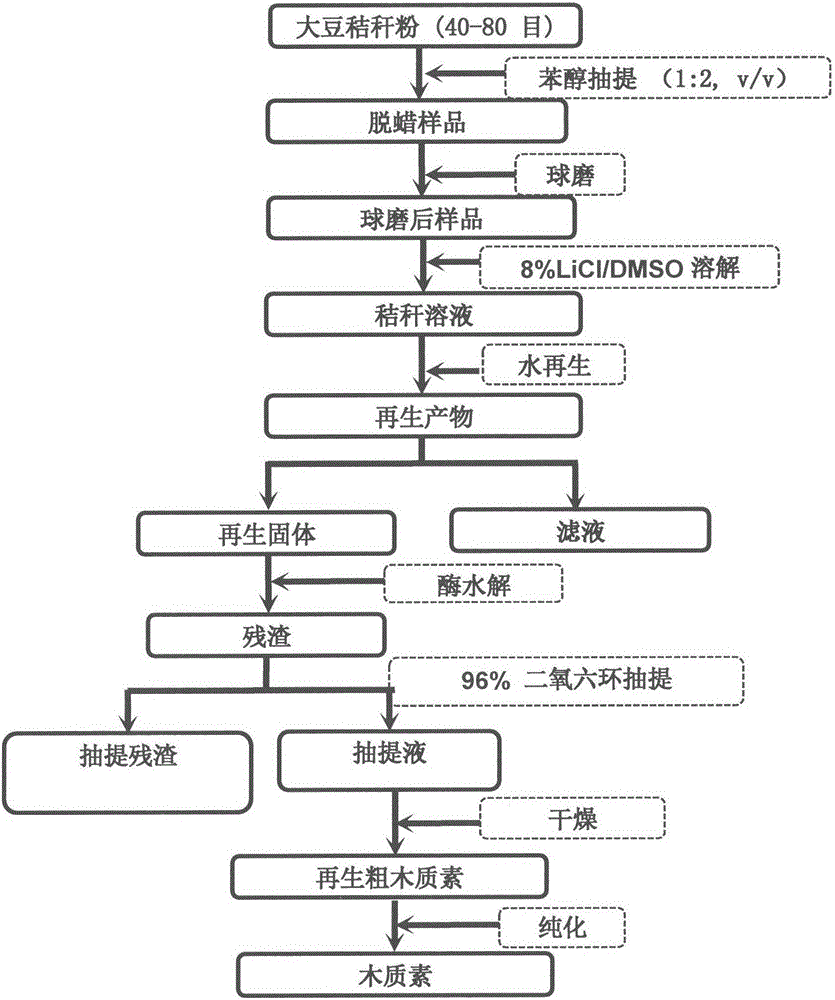

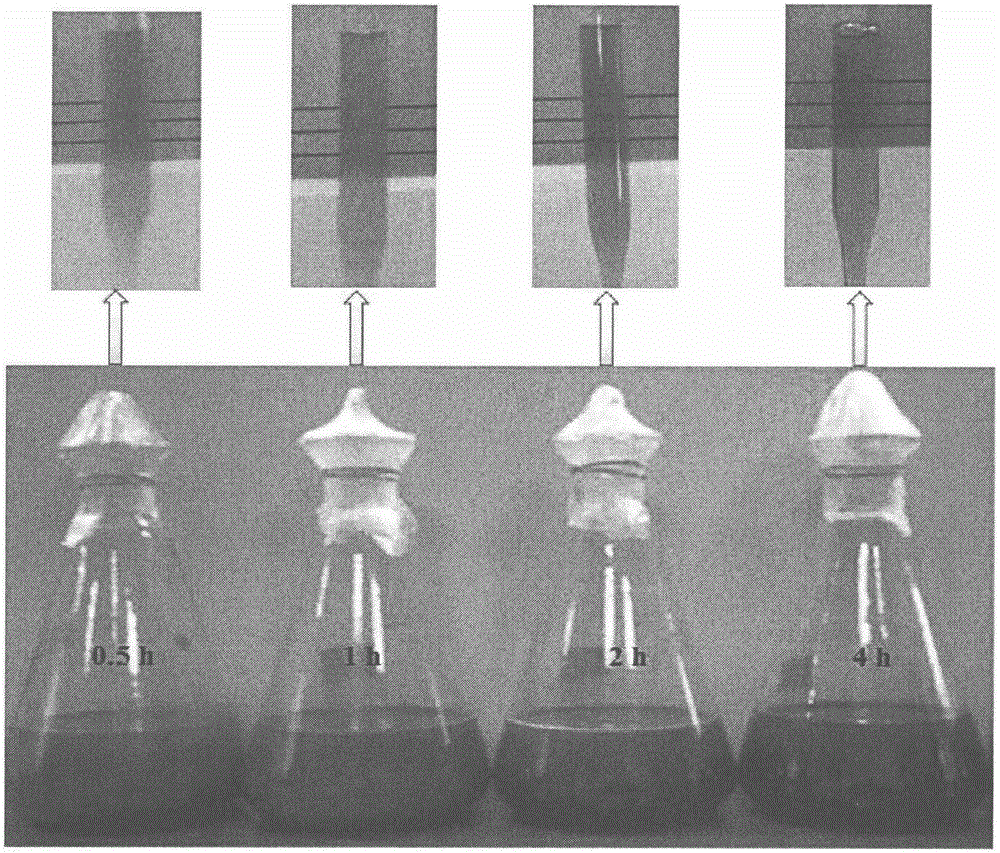

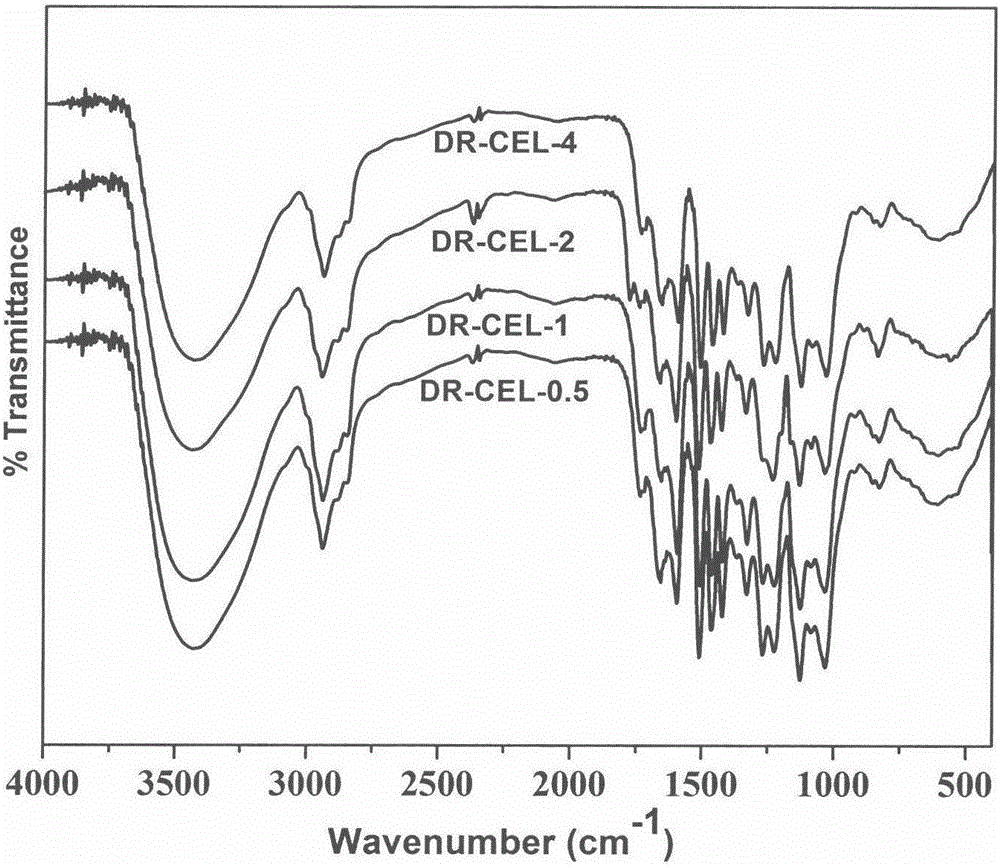

Extraction method for dissolved-regenerated lignin

The invention relates to an extraction method for dissolved-regenerated lignin. The method consists of: crushing lignocellulose and conducting ball milling treatment, then dissolving the ball milled lignocelluloses powder in a 8% LiCl / DMSO mixed solution, carrying out magnetic stirring at room temperature for 24h to obtain a lignocellulose solution, adding the lignocellulose solution into certain amount of distilled water, performing stirring to disperse it uniformly, conducting centrifugal separation on regenerated lignocellulose and performing washing with distilled water, hydrolyzing the regenerated lignocelluloses in enzyme, then carrying out centrifugal separation on the regenerated supernatant and insoluble enzymolysis residue, washing the insoluble residue with a buffer solution, and then performing washing with deionized water so as to obtain enzyme hydrolysis residue, using a dioxane aqueous solution to extract the enzyme hydrolysis residue, then performing rotary evaporation to remove the dioxane aqueous solution therein to obtain crude lignin, and dissolving the crude lignin in acetic acid, then adding the mixture into a large amount of distilled water to precipitate and regenerate lignin, thus obtaining the wood fiber dissolved-regenerated lignin. The method provided by the invention has a simple process and can extract lignin efficiently.

Owner:NANJING FORESTRY UNIV

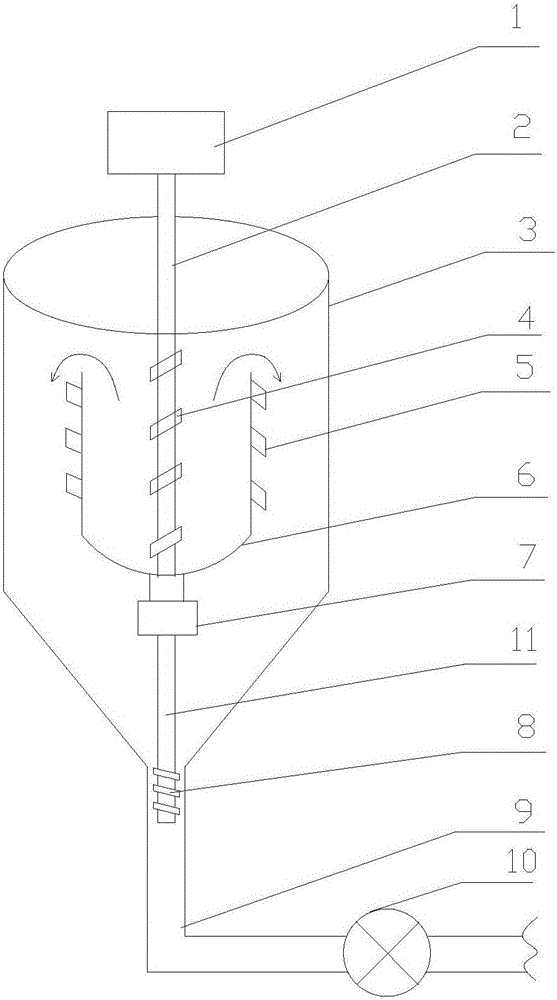

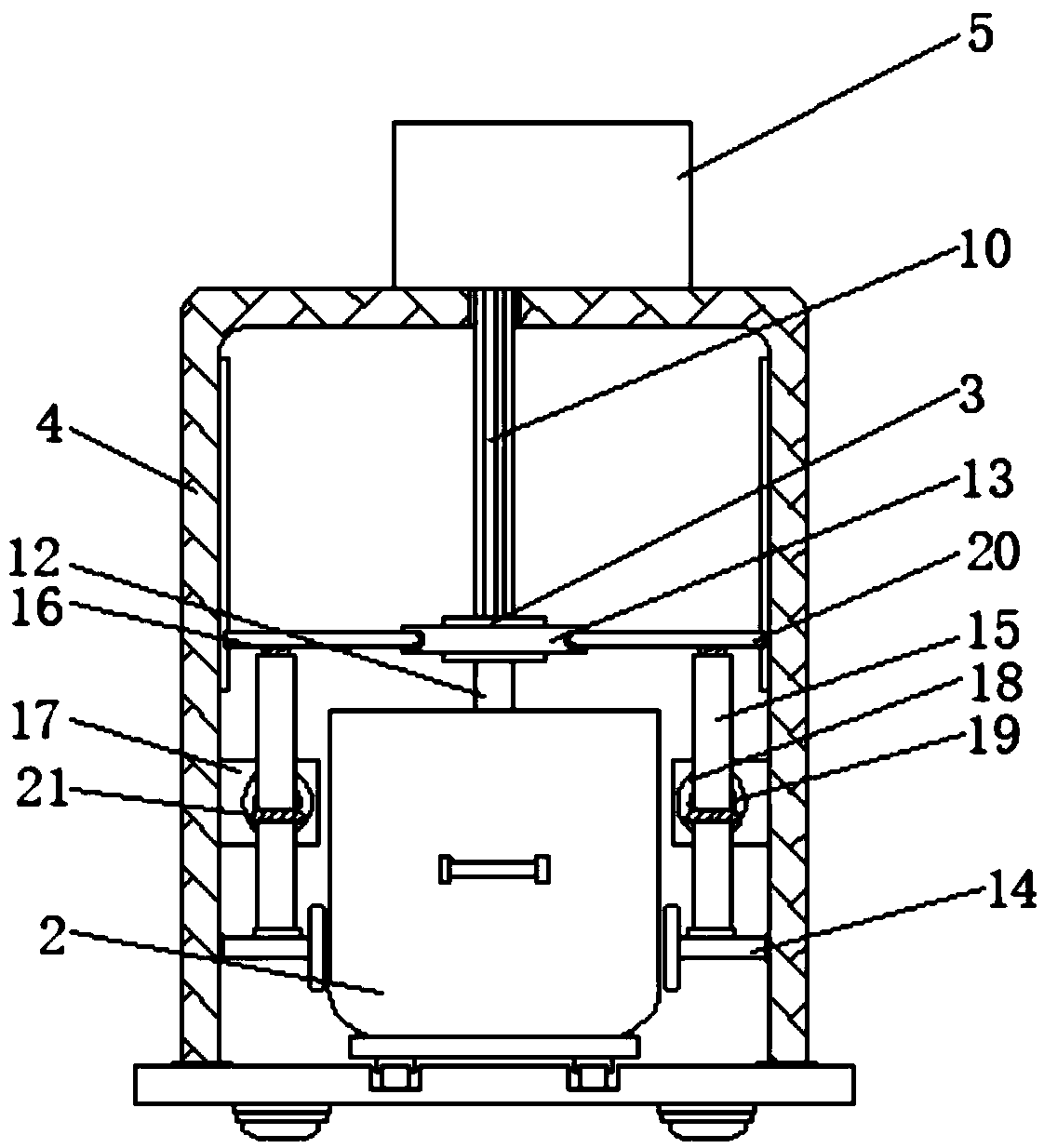

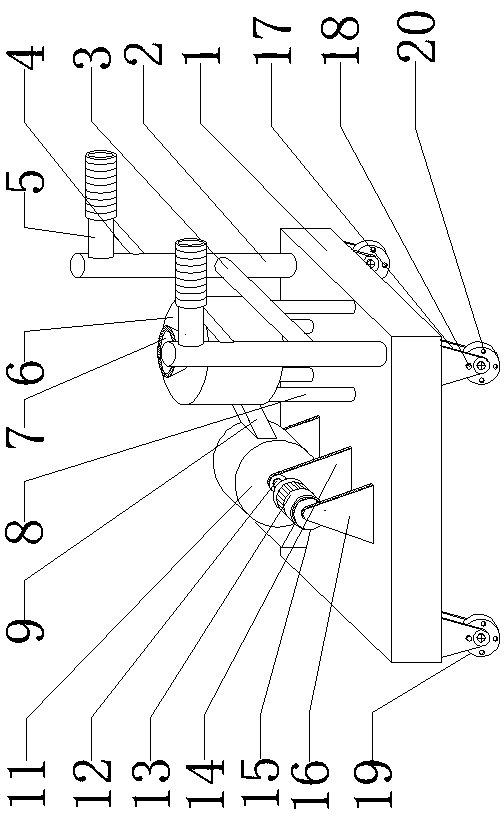

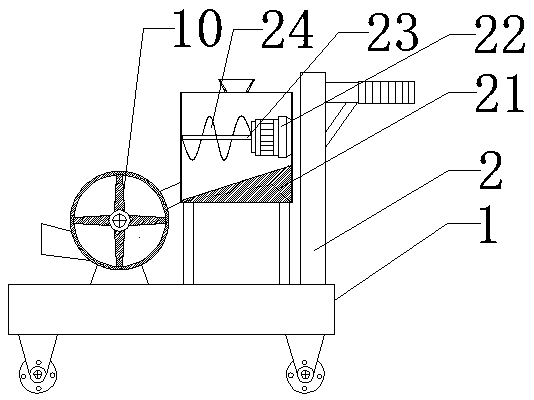

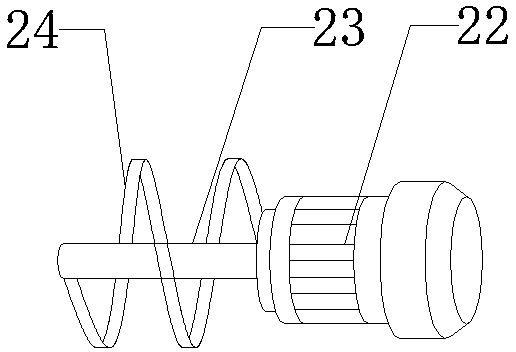

Reactive extrusion liquid feeding tank device

ActiveCN105797630AImprove stirring efficiencyAvoid orifice cloggingRotary stirring mixersTransportation and packagingFeed tankReactive extrusion

The invention discloses a reactive extrusion liquid feeding tank device.The reactive extrusion liquid feeding tank device comprises a feeding tank and a stirring device, an output pipeline is arranged below the feeding tank, a metering pump is arranged on the output pipeline, and the stirring device is arranged in the feeding tank and comprises a first stirring shaft, a second stirring shaft, a first motor, a second motor and a stirring tank, wherein the first motor is fixedly arranged on the first stirring shaft, the second motor is fixedly arranged at the upper end of the second stirring shaft, the stirring tank is arranged above the second motor, the first stirring shaft is provided with a spiral thread, spiral threads are formed at the lower ends of the stirring tank and the second stirring shaft, the first stirring shaft and the second stirring shaft rotate oppositely to enable liquid in the stirring tank to flow upwards and liquid outside the stirring tank to flow downwards.Compared with the prior art, the reactive extrusion liquid feeding tank device has the advantages that owing to the stirring device, liquid stirring uniformity is achieved, stirring efficiency is improved, and a generated internal liquid flow system is capable of forming a certain push force at a pipe orifice to prevent the pipe orifice from being blocked.

Owner:江苏苏能新材料科技有限公司

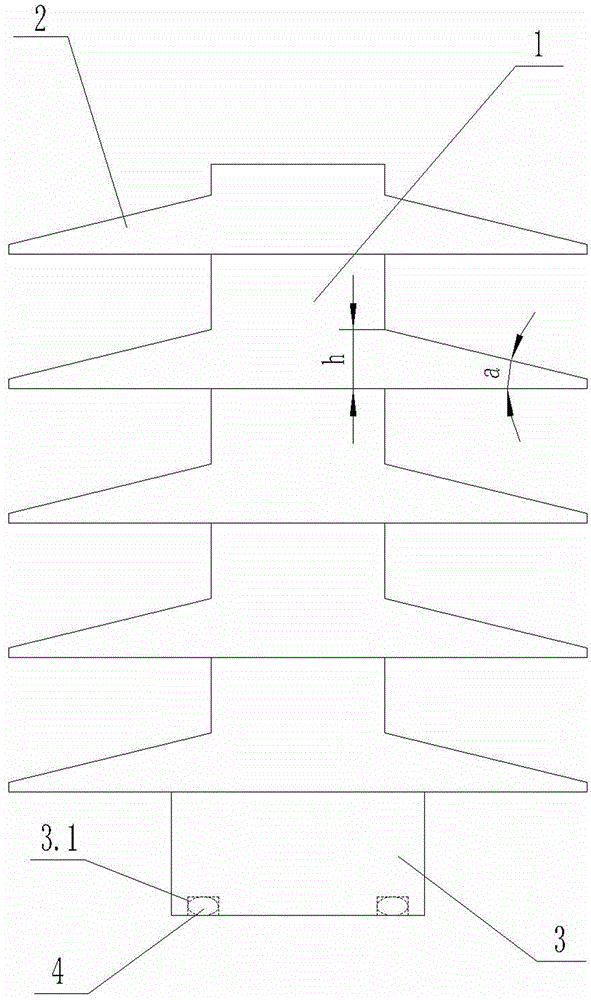

Insulation column for power equipment

InactiveCN103956240AExtended service lifeImprove insulation performanceSupporting insulatorsEpoxy resin coatingsElectric power equipmentPower equipment

The invention discloses an insulation column for power equipment. The insulation column for the power equipment comprises a ceramic insulator. The two ends of the ceramic insulator are respectively provided with a threaded hole. The ceramic insulator comprises an insulator body (1) and an insulation umbrella (2) arranged on the insulator body (1). The inclination angle (a) of the umbrella skirt of the insulation umbrella (2) ranges from 12 degrees to 15 degrees. The thickness (h) of the root of the umbrella skirt ranges from 8 mm to 10 mm. The outer surface of the ceramic insulator is coated with a layer of insulating paint. The insulation column for the power equipment can prevent the creepage phenomenon.

Owner:甘肃兴通电力安装工程有限公司

Scratch-resisting polyurethane acrylic coating and preparation method thereof

InactiveCN107987719AImprove toughnessHigh hardnessPolyurea/polyurethane coatingsChemical industryAcrylic coating

The invention discloses scratch-resisting polyurethane acrylic coating and a preparation method thereof and belongs to the technical field of chemical industry. The prepared coating can give consideration to rigidity and toughness. The coating disclosed by the invention is prepared from the following components in percentage by mass: 10 percent to 15 percent of an active diluting agent, 30 percentto 50 percent of a soft component, 30 percent to 50 percent of a hard component, 2 percent to 3 percent of a photoinitiator and 0.1 percent to 0.5 percent of a flatting agent. Correspondingly, the invention further discloses the preparation method of the scratch-resisting polyurethane acrylic coating; the preparation method comprises the following steps: uniformly mixing all the components and filtering a mixture with 200-mesh filter paper and coating the surface of a product; finally, curing in a UV (Ultraviolet) light source under the protection of nitrogen gas. According to the scratch-resisting polyurethane acrylic coating, a coating film formed on the surface of a base material has good scratch resistance and good ductility after the coating is cured, and the coating has a smooth surface; meanwhile, the rigidity and toughness ratio of the coating can be blended according to different purposes of the coating; the coating is wide in application range and low in cost.

Owner:无锡特丽斯新材料科技有限公司

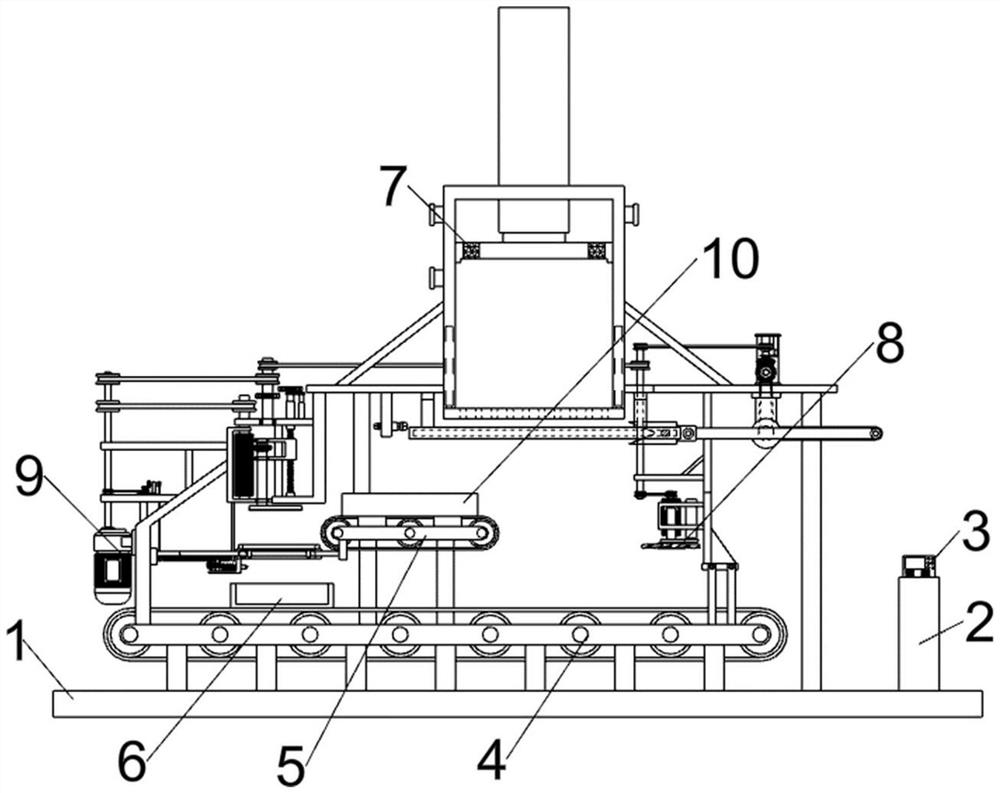

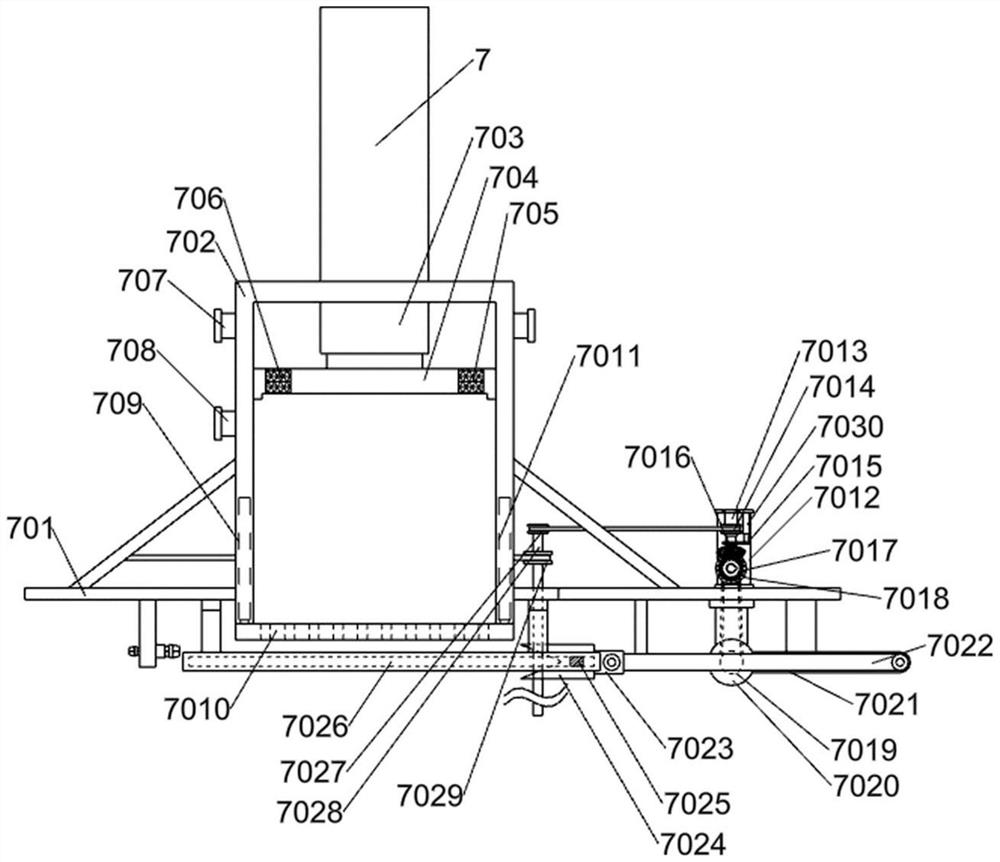

Flat-pressing top-covering type autoclaved brick manufacturing device

InactiveCN112339104AProcessing speedReduce wasteCeramic shaping plantsFeeding arrangmentsManufacturing engineeringPowder Spray

The invention relates to the field of autoclaved bricks, in particular to a flat-pressing top-covering type autoclaved brick manufacturing device. The technical problem to be solved by the invention is to provide the flat-pressing top-covering type autoclaved brick manufacturing device. According to the technical scheme, the flat-pressing top-covering type autoclaved brick manufacturing device comprises an operation control screen, a first conveying mechanism, a second conveying mechanism, a mixing cabin, an extrusion granulation system, a stirring and mixing system, a spreading system, a protection side plate and the like; and the upper portion of a working machine bottom plate is in bolted connection with a console. Electrolytic manganese residues are extruded and granulated before autoclaved brick processing and then mixed with other powder to be stirred and mixed, so that the phenomenon of powder spraying in the brick pressing process is avoided, and the powder waste is reduced; and meanwhile, a capping block can adhere to the powder around the top after being pressed into the top of a brick body, so that a large amount of residual sand is prevented from being generated at thetop of the brick body after brick discharging, and the brick making speed is increased.

Owner:上海储络信息科技有限公司

High-toughness PVC drainage-pipe material, and preparation method and application thereof

The invention relates to a high-toughness PVC drainage-pipe material, and a preparation method and application thereof. The PVC drainage-pipe material is prepared according to the following preparation method: taking nanometer calcium carbonate and chlorinated polyethylene as raw materials to prepare a compound modified particle with a core-shell structure through an emulsion polymerization method; and blending the compound modified particle with PVC through melting, so as to prepare a ternary nanometer compound material. By selecting a specific nanometer particle to organically combine with an elastomer, the core-shell structural compound modified particle taking nanometer calcium carbonate as a core and CPE as a shell, then the compound modified particle and PVC resin are subjected to melt blending, so that the compound modified particles are well dispersed in PVC matrix, and give play to toughening reinforcing modification effect on PVC.

Owner:HENAN LIANSU IND

Synthetic method of poly-alpha-olefin lubricating oil with oxidation resistance

ActiveCN105294904ASolve the precipitation problemGood compatibilityBase-materialsPropanoic acidEnd-group

The invention relates to a preparation method of poly-alpha-olefin lubricating oil with oxidation resistance. The method comprises the following steps: partially esterifying beta-3,5-di-tert-4-hydroxy phenyl propionic acid and hexanediol, trimethylolpropane, pentaerythritol or dipentaerythritol to obtain a hydroxyl compound containing an antioxidant radical; sufficiently esterifying the hydroxyl compound and acrylic acid to obtain a reaction-type antioxidant with end-group double-bond; during the polymerization process of the alpha olefin that is octylene, decene and laurylene direct olefin, adding the reaction-type antioxidant with the end-group double-bond, and after the polymerization, obtaining the poly-alpha-olefin lubricating oil basic oil with oxidation resistance. The prepared poly-alpha-olefin lubricating oil has good oxidation resistance; the structure of the poly-alpha-olefin contains a great amount of antioxidant radicals, and the content of the antioxidant radicals can be adjusted according to different application requirements. During the application process, no phenol antioxidant is needed.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

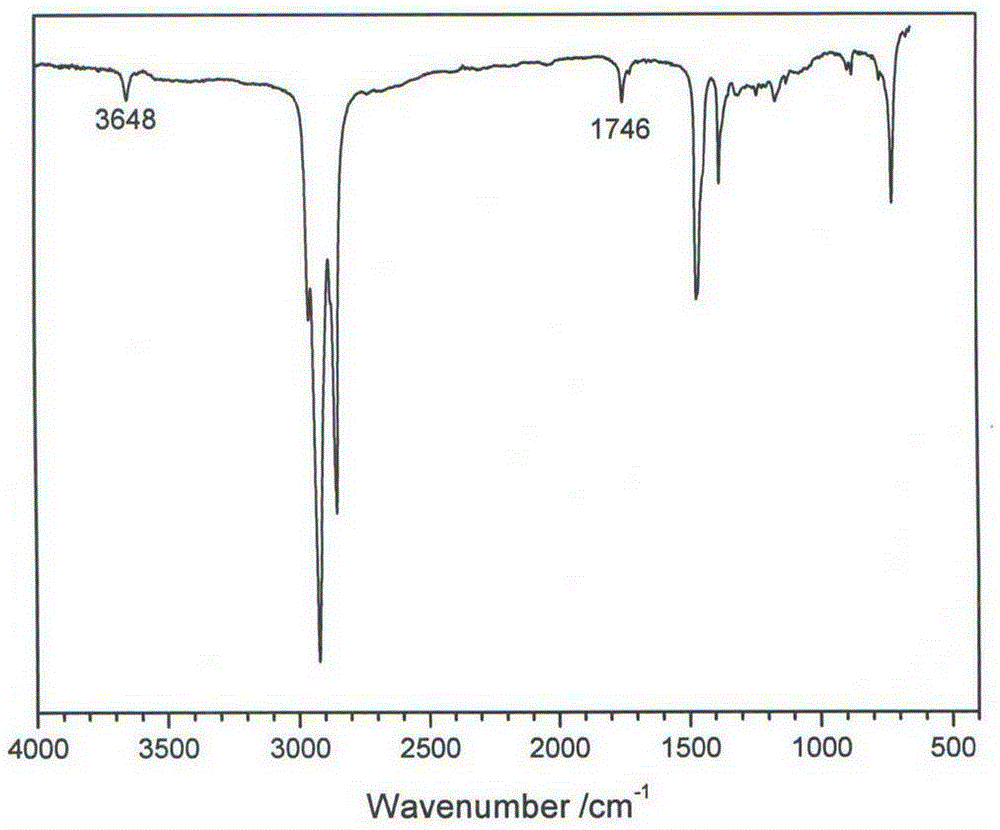

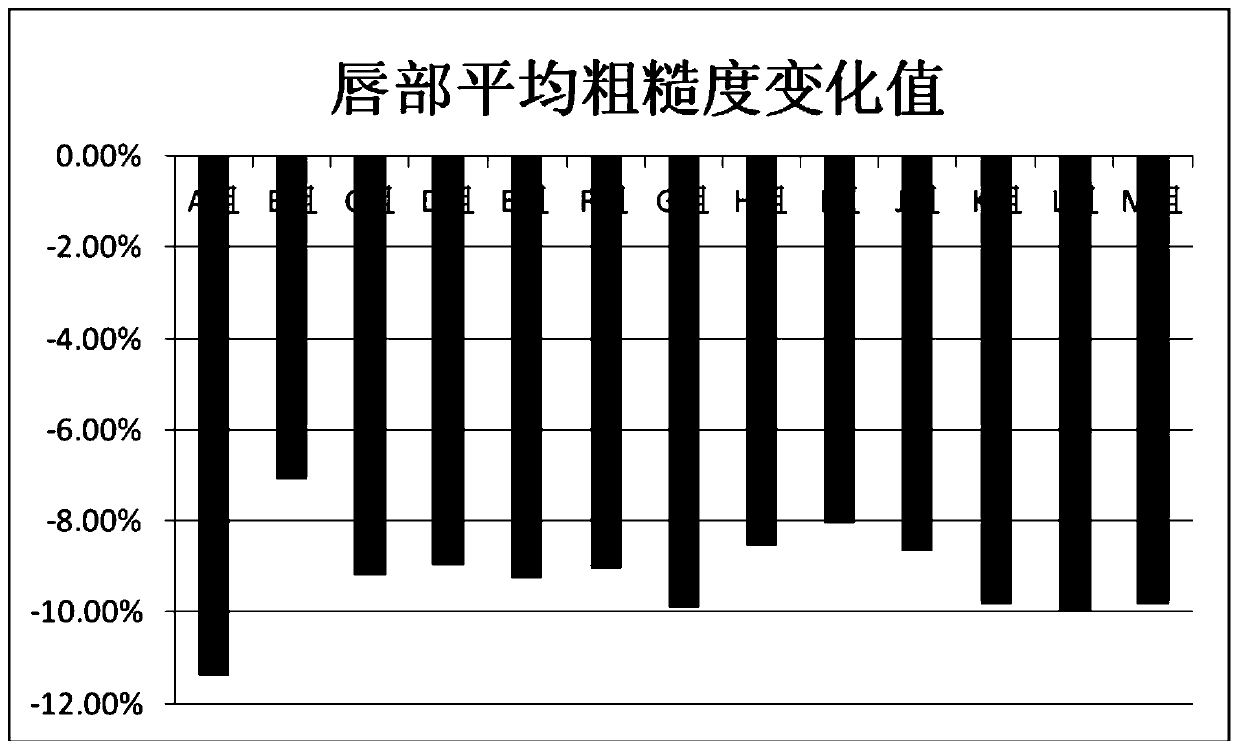

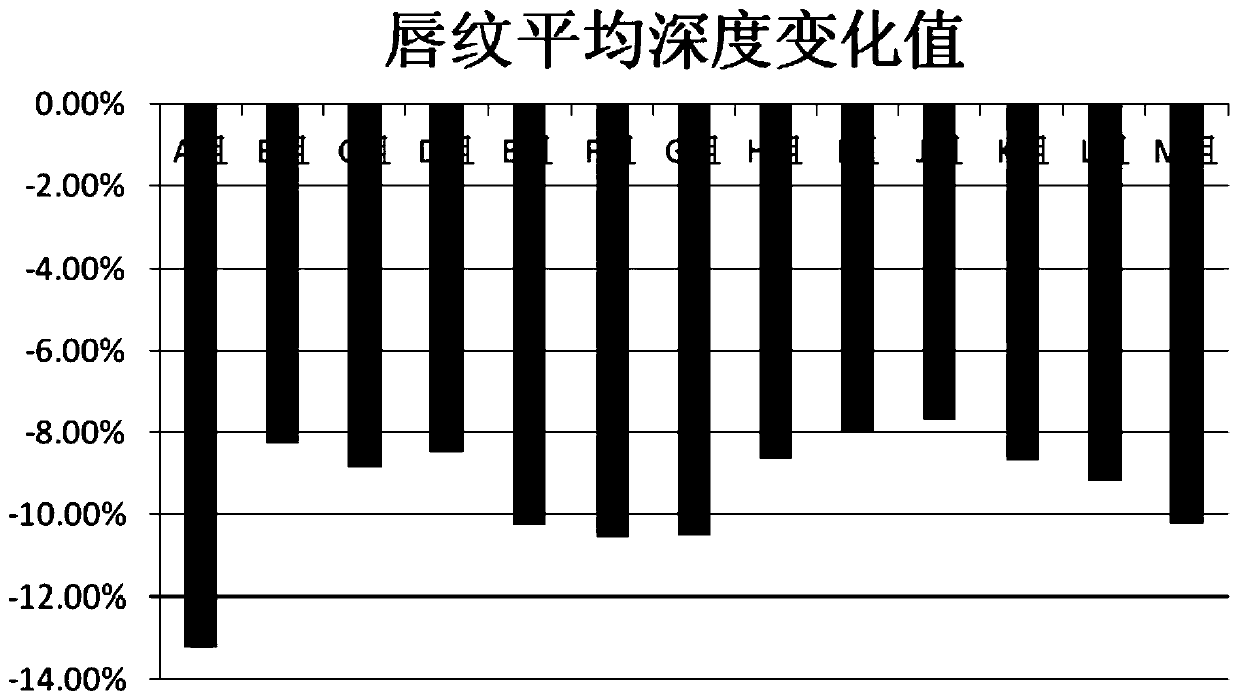

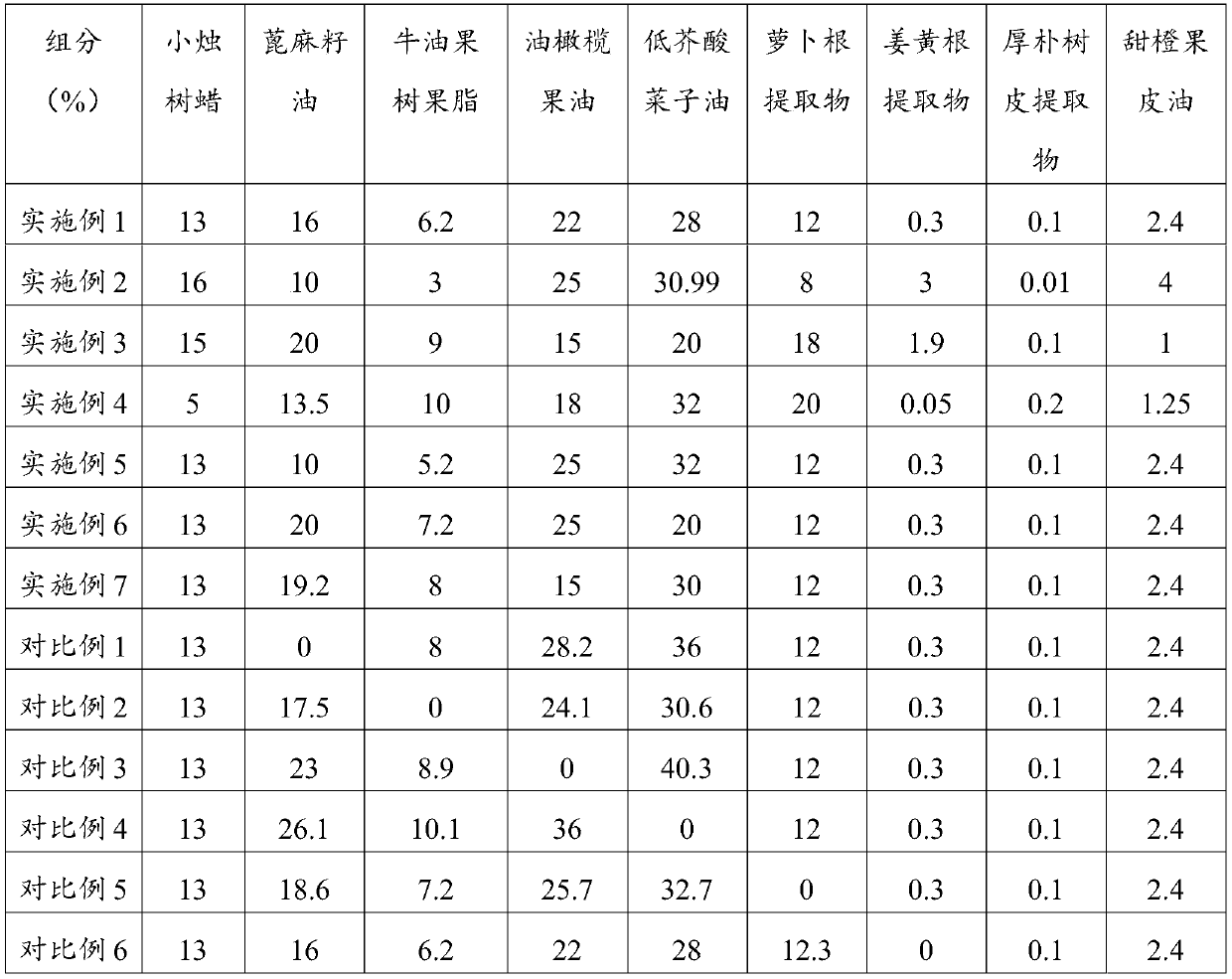

Pure natural plant lipstick and preparation method thereof

ActiveCN110448484AImprove antibacterial propertiesAntioxidantCosmetic preparationsMake-upBiotechnologyWrinkle skin

The invention discloses a pure natural plant lipstick which comprises 5-16% of candelilla wax, 48-87% of vegetable oils and 8-20% of a radish root extract. The vegetable oils include castor oil, avocado butter, olive fruit oil and canola oil. According to the pure natural plant lipstick, the radish root extract and the vegetable oils are added into the lipstick, the radish root extract not only can provide a smearing color for the lipstick, but also has strong coloring power and color development degree, and can cooperate with other vegetable oils to repair skin, promote collagen synthesis, resist wrinkles, preserve moisture and relax the skin; in addition, essence, synthetic pigments or preservatives are not added into the lipstick. The lipstick is environmentally friendly and healthy, and all raw materials are from pure plants, have good affinity with skin and are safe and natural. The invention also discloses a preparation method of the pure natural plant lipstick. The preparation method is simple and suitable for industrial production.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

Skin-touch and scratch-resistant film and preparation method of skin-touch and scratch-resistant surface film

InactiveCN108454213AImprove flatnessNo smellSynthetic resin layered productsPolyurea/polyurethane coatingsWater basedPolymer science

The invention discloses a skin-touch and scratch-resistant film and a preparation method of a skin-touch and scratch-resistant surface film and belongs to the field of functional films. The preparation method is simple in process and high in safety, and is capable of reducing cost and preparing the skin-touch and scratch-resistant film with high ductility. The skin-touch and scratch-resistant filmcomprises a nano coating, a skin-touch and scratch-resistant surface film, a water-based ink layer and a PVC printing bottom film which are successively arranged from top to bottom; the skin-touch and scratch-resistant surface film takes a delustering sheet as a substrate; an adhesion layer, a transparent layer and a skin-touch layer are successively arranged on the surface of the substrate frombottom to top; a coating of the transparent layer is prepared from the following component in percentage by mass: 10-15% of reactive diluent, 40-80% of soft component, 10-30% of hard component, 2-5% of photoinitiator and 0.1-0.5% of flatting agent; a coating of the skin-touch layer is prepared from 3-5% by mass of elastic fluff powder. The preparation method of the skin-touch and scratch-resistantsurface film comprises the following steps: coating a mixed coating on the substrate by using a micro-gravure precise coating method, drying by using a suspended drying box, and finally carrying outoxygen-free ultraviolet curing to obtain the skin-touch and scratch-resistant surface film.

Owner:无锡特丽斯新材料科技有限公司

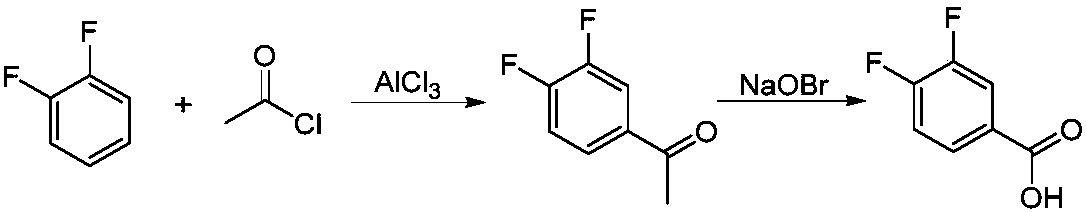

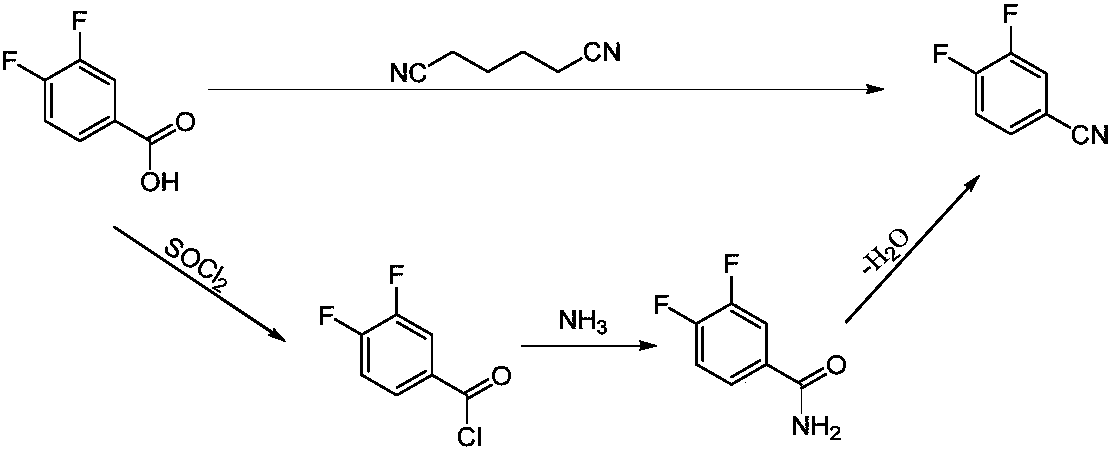

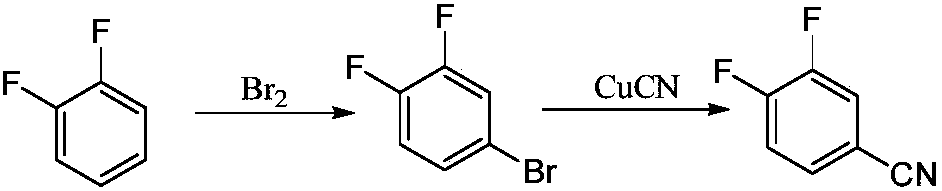

3,4-difluorobenzonitrile preparation method

ActiveCN108409605AHigh activityLow reaction temperatureCarboxylic acid nitrile preparationOrganic compound preparationPotassium fluoridePotassium

The invention discloses a 3,4-difluorobenzonitrile preparation method. The 3,4-difluorobenzonitrile preparation method comprises the following steps of taking 3,4-difluorobenzonitrile as a raw material, potassium fluoride as a fluorinated reagent and bis-(N,N'-1,3-dimethyl-2-imidazolinyl)-chloride ammonium salt as a phase transfer catalyst, then adding a reducing agent and a dispersant, and performing reaction to prepare the 3,4-difluorobenzonitrile. In the method, the temperature of fluorination reaction is relatively low, the reaction time is short, the total molar yield can reach about 90 percent, and the solvents and the catalyst can be recycled; produced potassium chloride in reaction becomes a pure product with the purity being 99 percent or above after recrystallization, and the pure product can be directly sold, so that the production cost is reduced; in addition, the technology is safe and environmentally friendly, is small in quantities of three wastes (waste water, waste solid and waste gas) and is suitable for industrial production.

Owner:江苏丰山生化科技有限公司

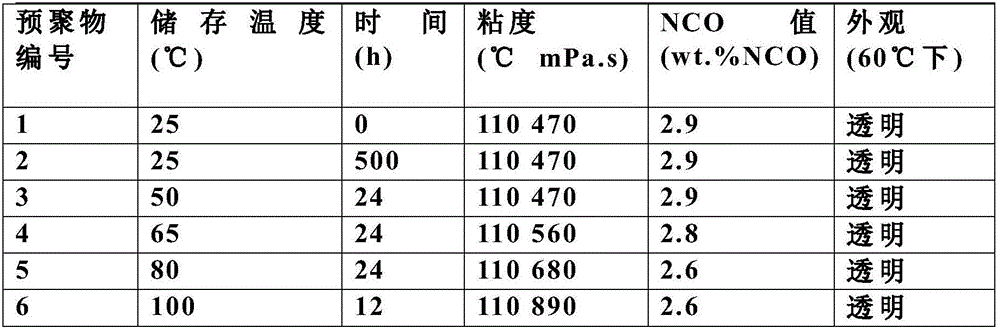

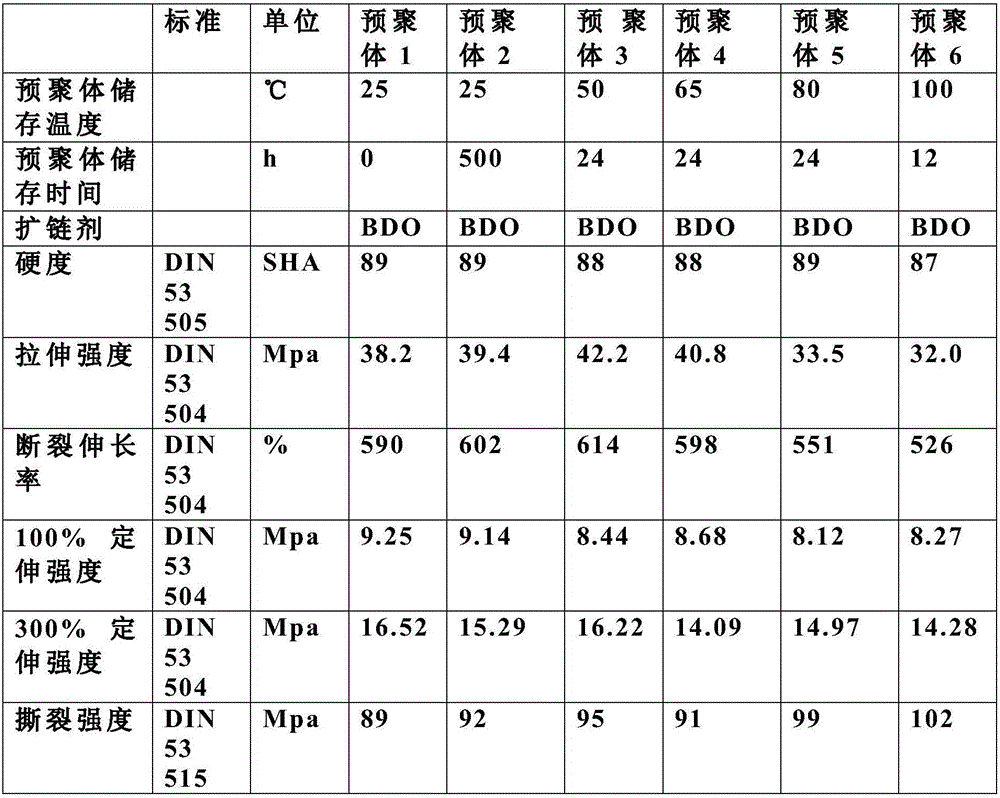

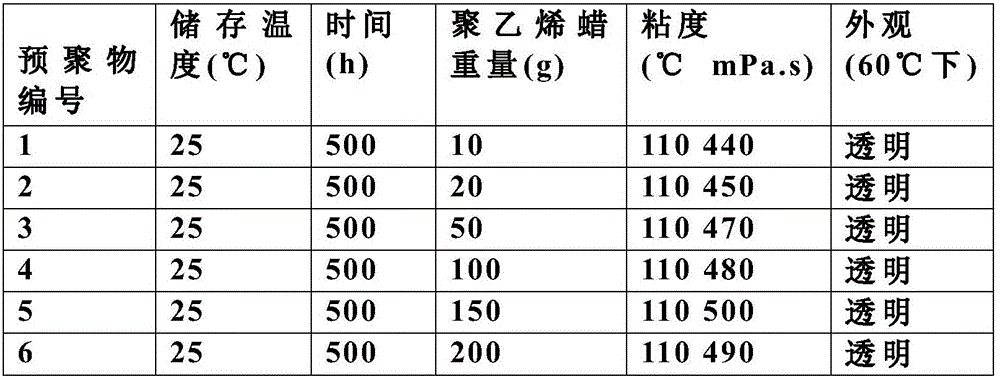

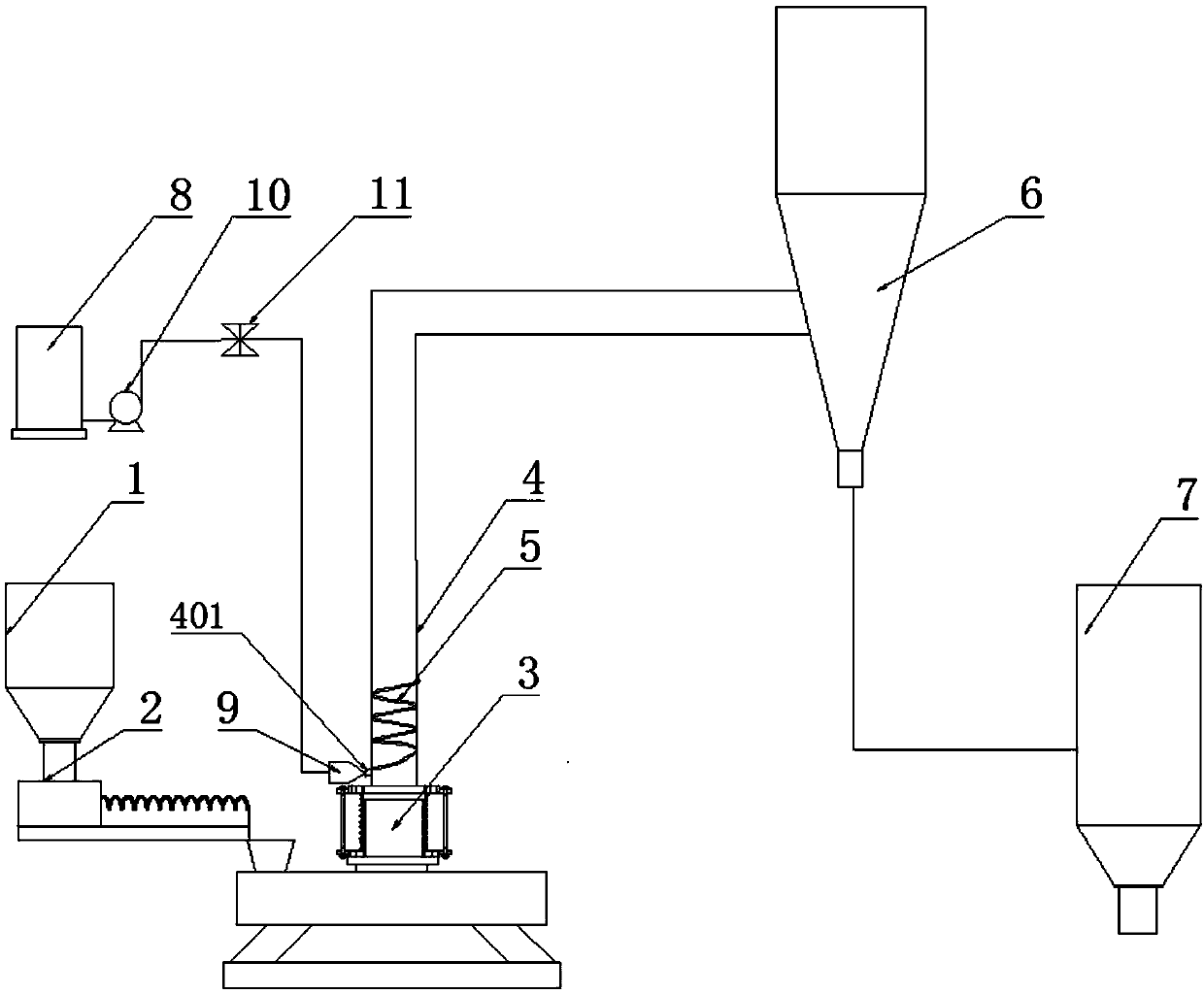

A stable NCO prepolymer, a preparing method thereof and use of the prepolymer

The present invention relates to a stable NCO prepolymer and its preparation method and application. The content of NCO in the prepolymer is 1.2~30wt.%, the viscosity at 110°C is less than 4500mPa.s, and at least one kind of Between ~8000g / mol, a mixture of polyols and waxes with a functionality of 1.95 to 3.15, the polyols are selected from polyester polyols, poly‑ε‑caprolactone polyols, polycarbonate polyols, polyether polyols and polyols Tetrahydrofuran ether diol; and the reaction product of 1,5-naphthalene diisocyanate and the blocking agent mixture, the molar ratio of 1,5-naphthalene diisocyanate and the blocking agent is 1:0.1~0.4. The prepolymer of the present invention is stable and uniform, can form a stable and transparent melt, and can have suitable viscosity at processing temperature.

Owner:苏州绿朗工程技术有限公司

Coffee cream and preparation method thereof

InactiveCN103355435AEasy to operateRich coffee cream flavorEdible oils/fats ingredientsEdible oils/fats production/working-upFreeze thawingSodium Caseinate

The invention designs a coffee cream. The coffee cream is characterized by comprising the following components in percentage by weight: 16-30% of vegetable fat, 0.02-0.5% of sorbitan monostearate, 0.02-0.1% of lecithin, 0.02-0.5% of mono-glycerate lactate, 0.02-0.5% of sodium stearyl lactate, 0.02-0.6% of polyglycerol ester, 0.1-1.0% of microcrystalline cellulose, 0.02-1.0% of modified cellulose, 0.3-2.0% of sodium caseinate, 0.02-0.2% of monopotassium phosphate, 3-16% of sugar, 3-12% of glucose syrup, 1.0-10.0% of coffee extract and 38-60% of water. Compared with existing like products, the coffee cream disclosed by the invention has the following advantages that the coffee extract is directly added in the ingredients and the problems of the stability of a cream emulsifying system and the freeze-thaw stability in the storage after the coffee extract is added are solved through a special emulsification stabilizing system and process conditions.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

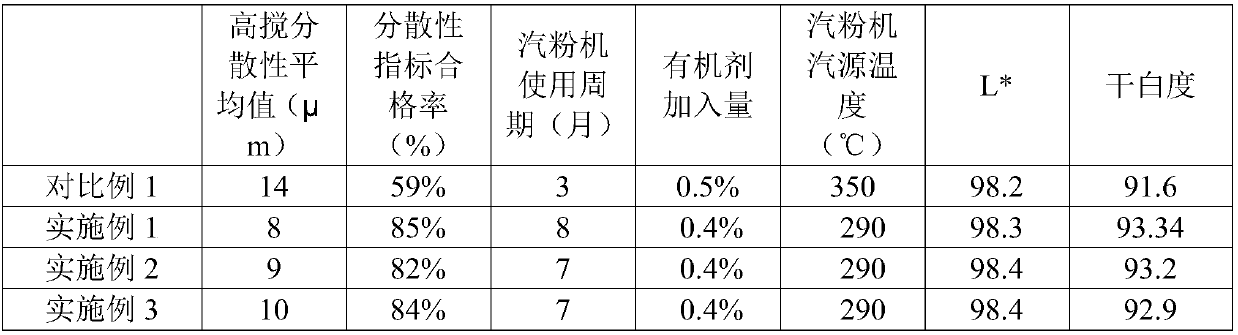

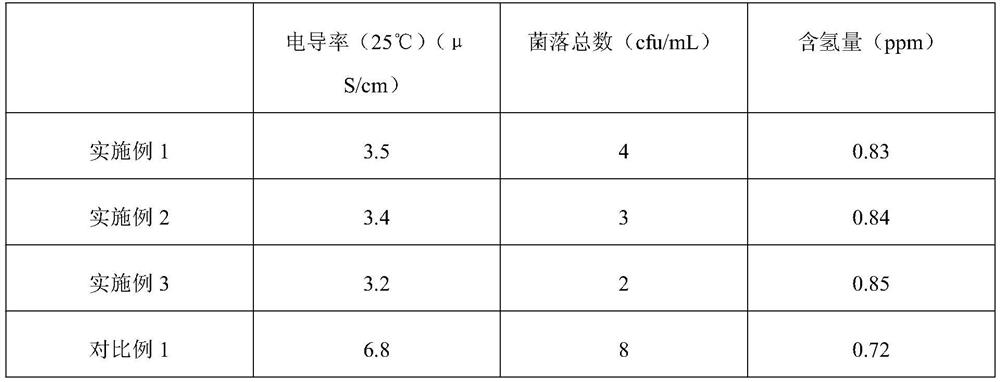

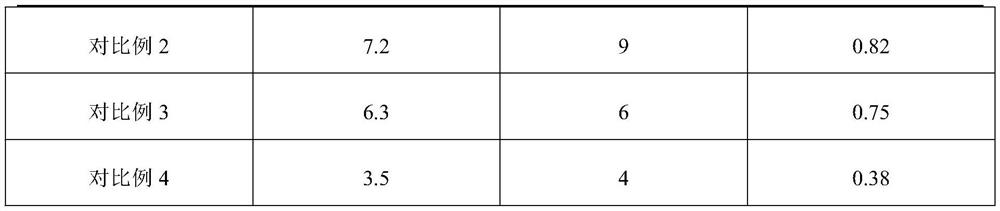

Organic coating treatment method of titanium dioxide

ActiveCN110655808AReduce wearReduce frequencyPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPhysical chemistryTitanium oxide

The invention relates to an organic coating treatment method of titanium dioxide, which comprises the following steps: carrying out steam powder treatment on titanium dioxide by a steam powder machineto obtain titanium dioxide fine powder, and feeding the titanium dioxide fine powder into a conveying ascending pipeline from a discharge port of the steam powder machine; atomizing an organic coating agent in an organic silicon material tank by using an atomizing spray gun; spraying the atomized organic coating agent into the conveying ascending pipeline using a nozzle of the atomizing spray gunthrough an organic agent inlet, coating titanium dioxide organic agent obtained through steam powder treatment in the conveying ascending pipeline, wherein the total adding amount of an organic agentaccounts for 0.4% of the weight of titanium dioxide, and the adding speed is controlled to be 0.01 m<3> / h-0. 013 m<3> / h; the pressure of the atomization spray gun is controlled to be 0.3-0.5 Mpa; feeding an obtained product into a steam powder bag filter for gas separation, and feeding organically coated titanium dioxide into a finished product bin from an outlet in the bottom of the steam powderbag filter. The method has the advantages of reasonable process, good coating effect, uniform coating of the organic agent on the surface of titanium dioxide, and qualified and stable product quality.

Owner:中信钛业股份有限公司

Seawater desalination composite membrane for producing hydrogen-rich direct drinking water and preparation method of seawater desalination composite membrane

InactiveCN111729520AImprove desalination separation effectStir and disperse evenlySemi-permeable membranesGeneral water supply conservationTetrafluoroborateMeth-

The invention provides a seawater desalination composite membrane for producing hydrogen-rich direct drinking water and a preparation method of the seawater desalination composite membrane. The preparation method comprises the steps: firstly, stirring and hydrolyzing acrylic resin, tetraethyl orthosilicate, butyl titanate and N-methyl pyrrolidone, then adding polyethersulfone micro powder and 1-butyl-3-methylimidazole tetrafluoroborate, uniformly stirring and dispersing to obtain slurry, and preparing a base film from the slurry; uniformly spraying a surface coating on one surface of the basemembrane to finally prepare the seawater desalination composite membrane. The seawater desalination composite membrane has proper filter holes, allows water molecules to pass through and intercepts other impurity molecules to pass through, thereby greatly enhancing the seawater desalination separation effect and enable the obtained product to be directly drunk. In addition, hydrogen is properly generated while hydrogen in seawater is promoted to pass through the membrane, so that the product has relatively high hydrogen content.

Owner:长沙三思新材料科技有限公司

New material processing device based on energy-saving and environment-friendly concept design

InactiveCN109107438AEasy to moveReduce security risksRotating receptacle mixersTransportation and packagingEngineeringNew materials

The invention discloses a new material processing device based on energy-saving and environment-friendly concept design. The new material processing device comprises a bottom plate, an agitation barrel and a movement block, wherein the top of the bottom plate is fixedly connected with a frame; the top of the frame is fixedly connected with a protective cover; a first motor is fixedly connected onto one side of the top of the frame and further located inside the protective cover; one end of an output shaft of the first motor is fixedly connected with a first belt pulley; the top of the inner wall of the protective cover is rotationally connected with a rotation rod through a bearing; the surface of the rotation rod is fixedly connected with a second belt pulley; and the surface of the second belt pulley is connected with the surface of the first belt pulley through a belt in a drive manner. The invention relates to the technical field of the production of latex paint. The new material processing device based on the energy-saving and environment-friendly concept design can be used for realizing quickly and uniformly agitating and dispersing a coating inside the agitation barrel, andmeanwhile, can be used for preventing the coating from being easily adhered to the inner wall of the agitation barrel to accordingly influence the dispersion work of the coating.

Owner:合肥瀚鹏新能源有限公司

Method for preparing high-efficiency filtration and intelligent antibacterial porous nanofiber membrane

ActiveCN109468748AGood filtering effectReduce resistanceElectro-spinningFiltration separationChemistryDichloromethane

The invention discloses a method for preparing a high-efficiency filtration and intelligent antibacterial porous nanofiber membrane. A polymer polylactic acid-glycolic acid copolymer and polycaprolactone are dissolved in a mixed solvent of dichloromethane and N.N-dimethylformamide, a dissolved solution is then divided into two portions, citric acid and sodium chlorite are separately added and stirred uniformly to prepare two different solutions, and polyvinyl alcohol microspheres are added in the two different solutions to prepare two different polymer solutions; the above two polymer solutions are separately added to an electrospinning machine storage tank, and the two different polymer solutions are simultaneously spun to obtain a mutually interlaced and entangled porous nanofiber membrane. The porous nanofiber membrane has the advantages of high-efficiency filtration and ultra-low resistance, and the filter membrane has better filtering effect and lower resistance in fields of air filtration, fresh air system, wastewater treatment and the like. The method is simple, efficient and easy to industrialize.

Owner:山东蓝色时光新材料有限公司

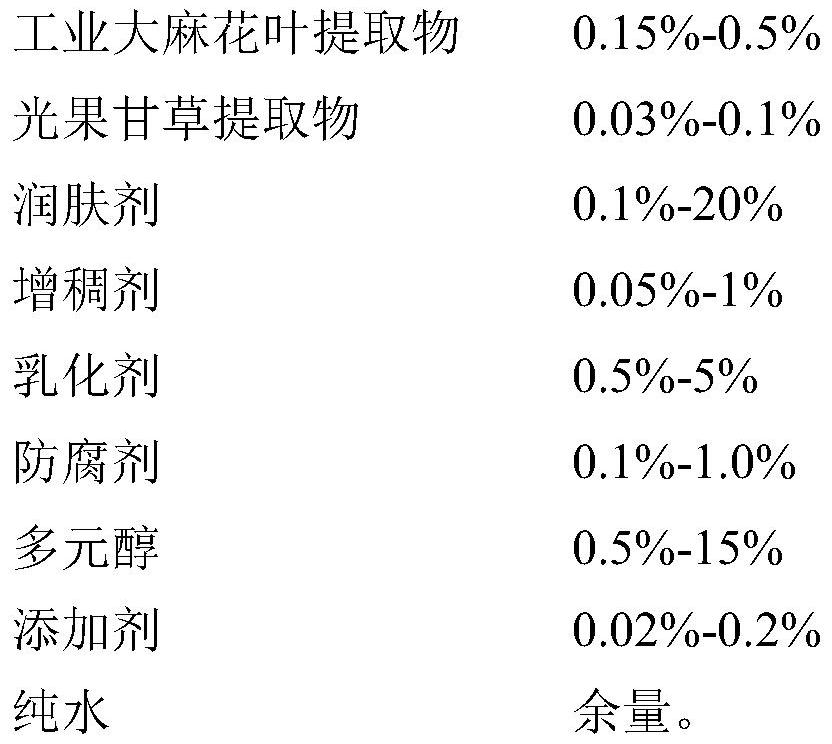

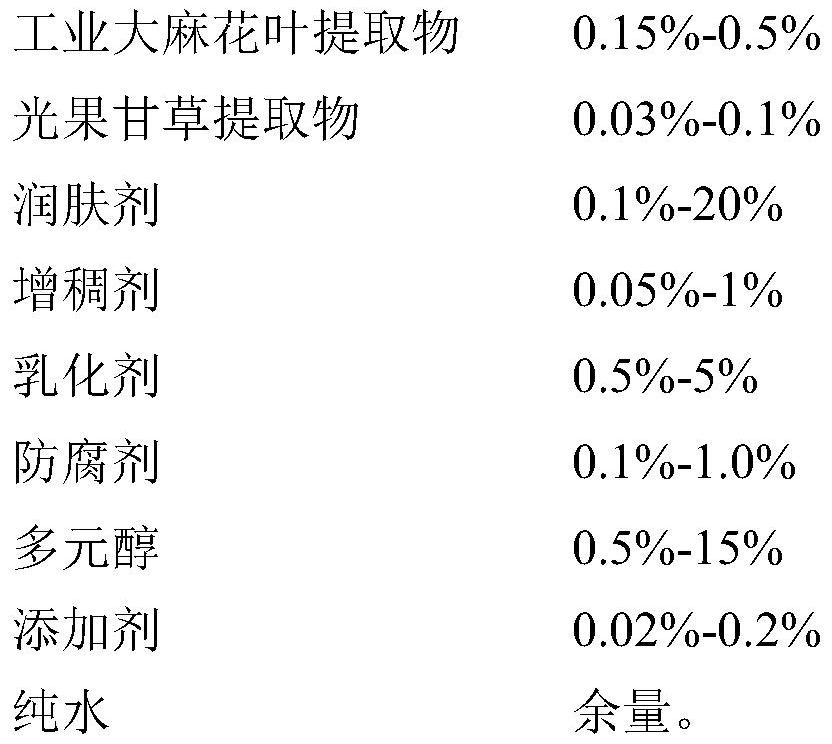

Skin care composition and preparation method thereof

InactiveCN111773149ASuppress generationAnti-inflammatory effectCosmetic preparationsAntipyreticBiotechnologyBiology

The invention discloses a skin care composition and a preparation method thereof. The skin care composition comprises an industrial hemp flower and leaf extract and a glycyrrhiza glabra extract, and the mass ratio of the industrial hemp flower and leaf extract to the glycyrrhiza glabra extract is (1.5-16): 1. Specifically, the skin care composition can be composed of the following components in percentages by weight: 1% to 20% of an emollient, 0.05% to 1% of a thickening agent, 0.5% to 5% of an emulsifying agent, 0.15% to 0.5% of a hemp flower and leaf extract, 0.03% to 0.1% of a glycyrrhiza glabra extract, 0.1% to 1.0% of a preservative, 0.5% to 15% of polyhydric alcohol, 0.02% to 0.2% of an additive and the balance of pure water. According to the skin care composition disclosed by the invention, the industrial hemp flower and leaf extract and the glycyrrhiza glabra extract have a synergistic effect, so that multiple skin care effects of whitening, removing freckles, removing wrinkles, diminishing inflammation, brightening the skin color, homogenizing the skin color and the like are achieved.

Owner:KPC PHARM INC

Nano-carbon-containing refractory castable for desulfurization stirrer and preparation method of nano-carbon-containing refractory castable

PendingCN111689783AImprove performanceImprove dispersion uniformityRotary stirring mixersTransportation and packagingCarbon filmMullite

The invention discloses a nano-carbon-containing refractory castable for a desulfurization stirrer. The castable comprises raw materials with the particle size being 1 mm or above, raw materials withthe particle size being larger than or equal to 0.1 mm and smaller than 0.1 mm and raw materials with the particle size being smaller than 0.1 mm. The raw materials with the particle size being smaller than 0.1 mm are prepared from pure fused mullite with the particle size being 325 mesh and dense corundum fine powder with the particle size being 325 mesh. The 325-mesh pure fused mullite and the 325-mesh dense corundum fine powder are carbon film nano-coated pure fused mullite and carbon film nano-coated dense corundum fine powder respectively. The invention also discloses a preparation methodof the castable. According to the castable disclosed by the invention, the thermal shock stability and the slag and molten iron erosion penetration resistance of the castable are improved, so that the castable is good in comprehensive performance and low in raw material cost, and a prepared stirrer is long in service life and low in consumption cost.

Owner:武汉钢铁有限公司

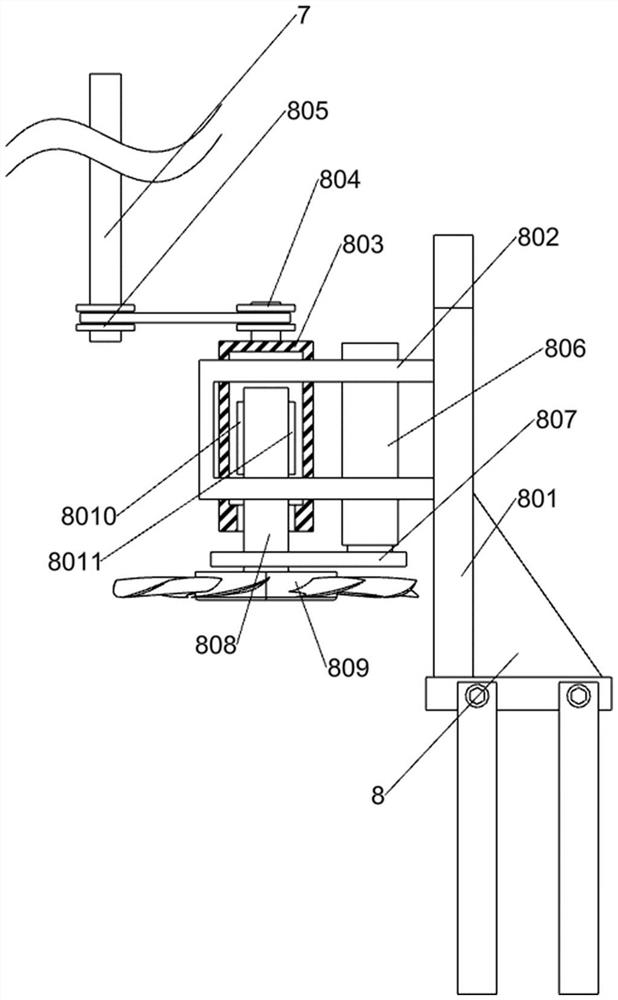

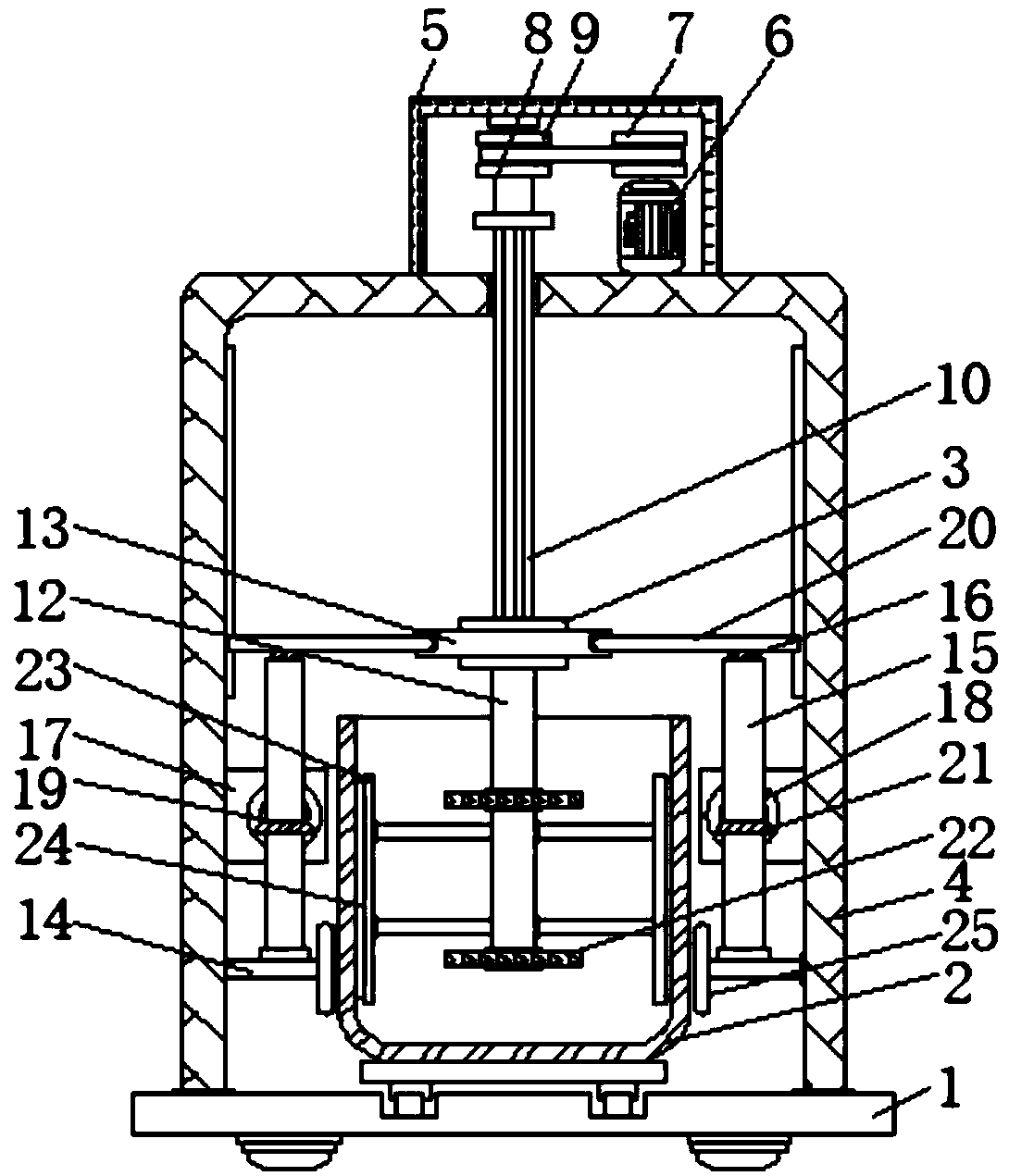

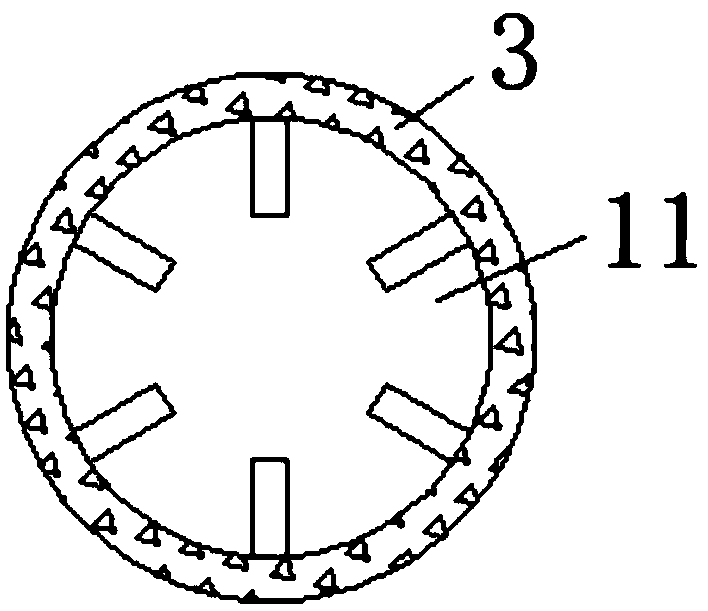

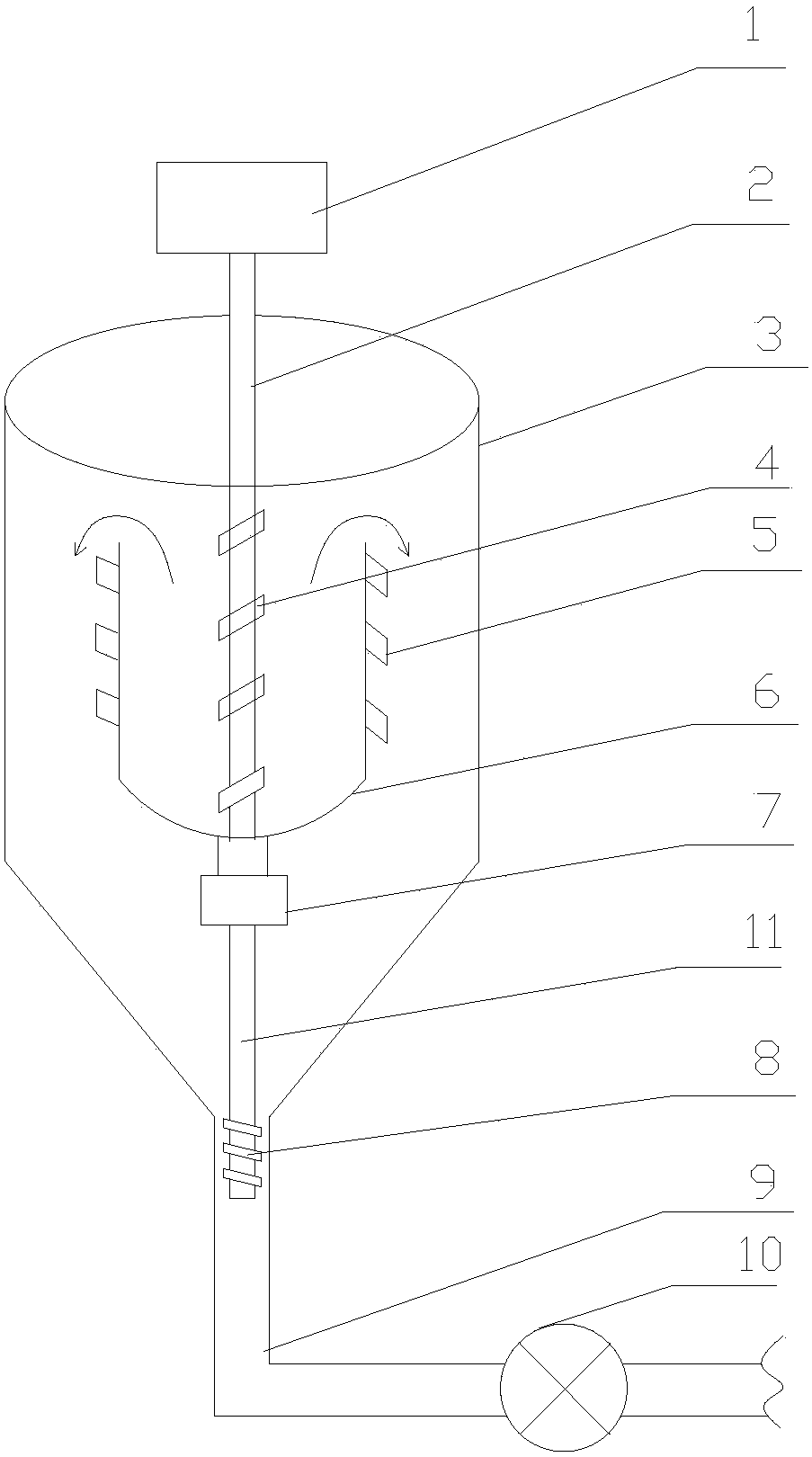

A reaction extrusion liquid feeding tank device

ActiveCN105797630BStir and disperse evenlyStir to disperse and mix evenlyRotary stirring mixersTransportation and packagingEngineeringMetering pump

The invention discloses a reaction extrusion liquid feeding tank device, comprising a feeding tank body and a stirring device, an output pipeline is located below the feeding tank body, a metering pump is arranged on the output pipeline, and the stirring device is arranged in the feeding tank Inside the body, the stirring device includes a first stirring shaft, a second stirring shaft, a first motor fixed on the upper end of the first stirring shaft, a second motor fixed on the upper end of the second stirring shaft, and a second motor fixed on the upper end of the second stirring shaft. A stirring tank; the first stirring shaft is provided with a set of spiral threads, and the lower end of the stirring tank and the second stirring shaft is provided with a set of spiral threads, and the first stirring shaft and the second stirring shaft rotate in opposite directions, so that the stirring The liquid in the tank flows upwards, and the liquid outside the stirred tank flows downwards. Compared with the prior art, the present invention not only makes the liquid evenly stirred by the stirring device, improves the stirring efficiency, but also can form a certain driving force at the nozzle of the generated liquid internal flow power system to prevent the nozzle from being blocked.

Owner:江苏苏能新材料科技有限公司

Odor-removing and bacteria-removing aqueous latex paint and preparation method thereof

InactiveCN110093076AGood antibacterial and bactericidal effectReduce corrosionAntifouling/underwater paintsPaints with biocidesEmulsionBacteria

The invention discloses odor-removing and bacteria-removing aqueous latex paint which comprises the following raw materials in parts by weight: 28-35 parts of emulsion, 20-30 parts of titanium dioxide, 25-28 parts of a filler, 10-13 parts of hexacyclic stone, 0.5-1.2 parts of sodium humate, 0.5-1.0 parts of an activator, 5-8 parts of an oxidant, 3-5 parts of a buffer, 0.2-0.5 parts of a surfactantand 90-105 parts of water. The odor-removing and bacteria-removing aqueous latex paint provided by the invention is suitable for various environmental places, achieves odor-removing and bacteria-removing effects through interaction between far infrared rays released by latex paint and substances, and has good brushing performance.

Owner:夏战利

Self-cleaning scratch-resistant film and preparation method of its surface film

InactiveCN109021423AImprove flatnessEnvironmentally friendly and odorlessPolyurea/polyurethane coatingsUltravioletReactive diluent

The invention discloses a self-cleaning scratch-resistant film and a preparation method of its surface film, which belong to the field of a functional film. The preparation method has the advantages of simple process, high safety, environmental friendliness and cost saving, and the obtained coating film is scratch-resistant and has a self-cleaning function. The film of the invention comprises a nano-coating, a self-cleaning scratch-resistant surface film, an aqueous ink layer and a PVC printing base film from top to bottom; the self-cleaning scratch-resistant surface film takes PVC sheet as abase material, and the surface of the base material is an adhesion layer and a transparent layer from bottom to top; the transparent layer paint comprises the following components by mass ratio: 10% to 20% of a reactive diluent, 5% to 20% of a soft component, 50% to 80% of a hard component, 2% to 5% of a light-induced agent, and 0.1% to 0.5% a defoamer; a mixed paint is applied on the substrate bya micro-concave precision coating method, and then is dried by a suspension oven, and finally, oxygen-blocking ultraviolet curing is carried out to obtain the self-cleaning scratch-resistant surfacefilm.

Owner:无锡特丽斯新材料科技有限公司

Transformer oil not prone to yellowing

The invention discloses transformer oil not prone to yellowing. The transformer oil is prepared from, by weight, 4-5 parts of zinc acetylacetonate, 0.7-1 part of oleic acid, 20-24 parts of ethyl alcohol, 2-3 parts of polyimide, 0.2-0.4 part of ethylene diamine, 0.4-0.6 part of silane coupling agent KH570, 1000-1100 parts of transformer base oil, 2-3 parts of polyethyleneimine, 0.5-0.6 part of dodecyl selenium, 3-4 parts of aluminum nitride, 2-3 parts of cobalt oxide, 3-4 parts of silicon dioxide, 0.3-0.4 part of stearic acid and 0.2-0.5 part of sodium tripolyphosphate.

Owner:TONGLING SANJIA TRANSFORMER

Perfume beads for clothes and preparation method thereof

ActiveCN111286414BStir and disperse evenlyStir wellInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolymer scienceActive agent

The invention relates to the field of detergents, and discloses a fragrance-retaining beads for clothing and a preparation method thereof. The invention adds a specific type of non-ionic surfactant to compound polyethylene glycol in the breeding of the fragrance-retaining beads for clothing, or directly adds non-ionic surfactants. The polyethylene glycol modified by the agent can make the clothing fragrance beads easy to form during processing and molding, and solve the technical problem that surfactants cannot be added to the existing clothing fragrance beads.

Owner:NICE ZHEJIANG TECH CO LTD

Granule casting machine for livestock of breeding industry

The invention discloses a granule casting machine for livestock of the breeding industry. The granule casting machine comprises a machine body, wherein vertical rods and a support rack are separatelyconnected with one side of the top of the machine body; and a transverse rod is connected in the middle of the outer surfaces of the vertical rods. The granule casting machine for livestock of the breeding industry is provided with a first motor, a first rotating shaft, a casting cabin, a casting hole and a casting impeller, when granules are cast, the casting impeller is driven to rotate by the first motor through the first rotating shaft, then the granules are pushed to rotate through the casting impeller, the granules are subjected to the action of centrifugal force and are finally uniformly cast out from the casting hole, the feeding efficiency can be improved, and livestock can be fed uniformly; and meanwhile, a second motor, a second rotating shaft and a stirring impeller are arranged, after a fed is fed into a stirring cabin, the stirring impeller is driven to uniformly stir and disperse the granules by the second motor through the second rotating shaft, then the granules are not easy to cake, the casting hole is not easily blocked, and the casting machine is simple, convenient and rapid to operate when being operated by a user.

Owner:XUZHOU JIAHE FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com