Flat-pressing top-covering type autoclaved brick manufacturing device

A manufacturing device and a technology for autoclaved bricks, which are applied in the field of flat-pressed top-type autoclaved brick manufacturing devices, can solve the problem of increasing the time for making electrolytic manganese slag autoclaved bricks, reducing the efficiency of electrolytic manganese slag autoclaving bricks, and reducing electrolytic manganese slag. Dispersion difficulties and other problems, to achieve the effect of excellent quality, saving the process of manual sand sweeping, and sufficient brick materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

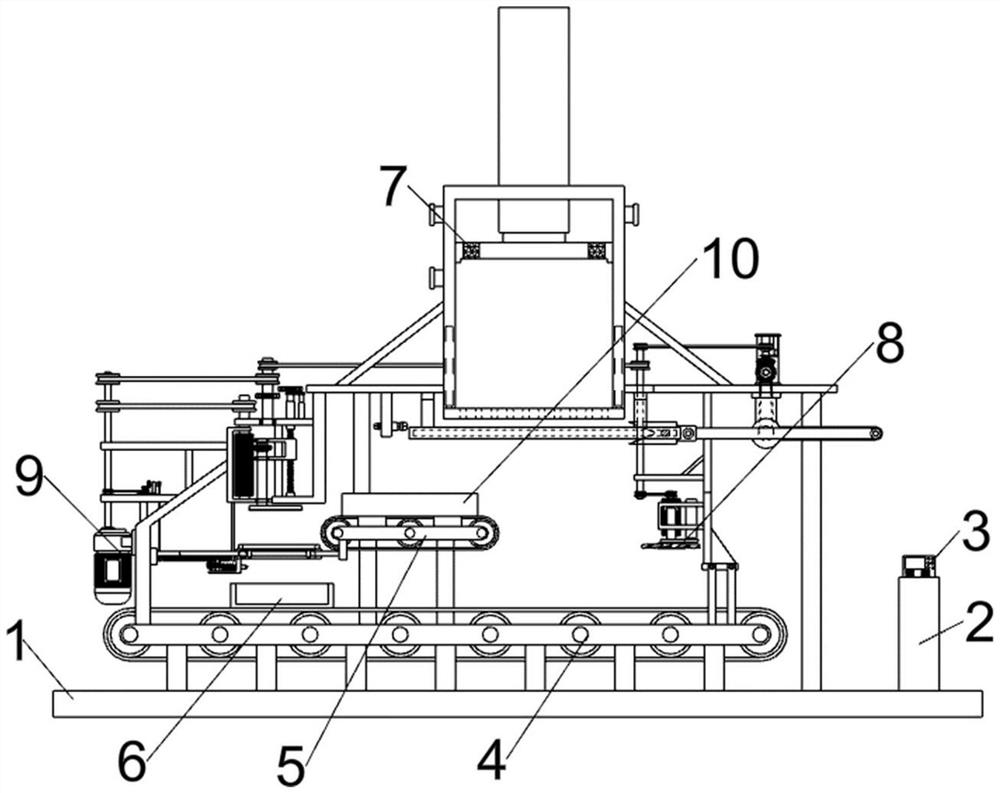

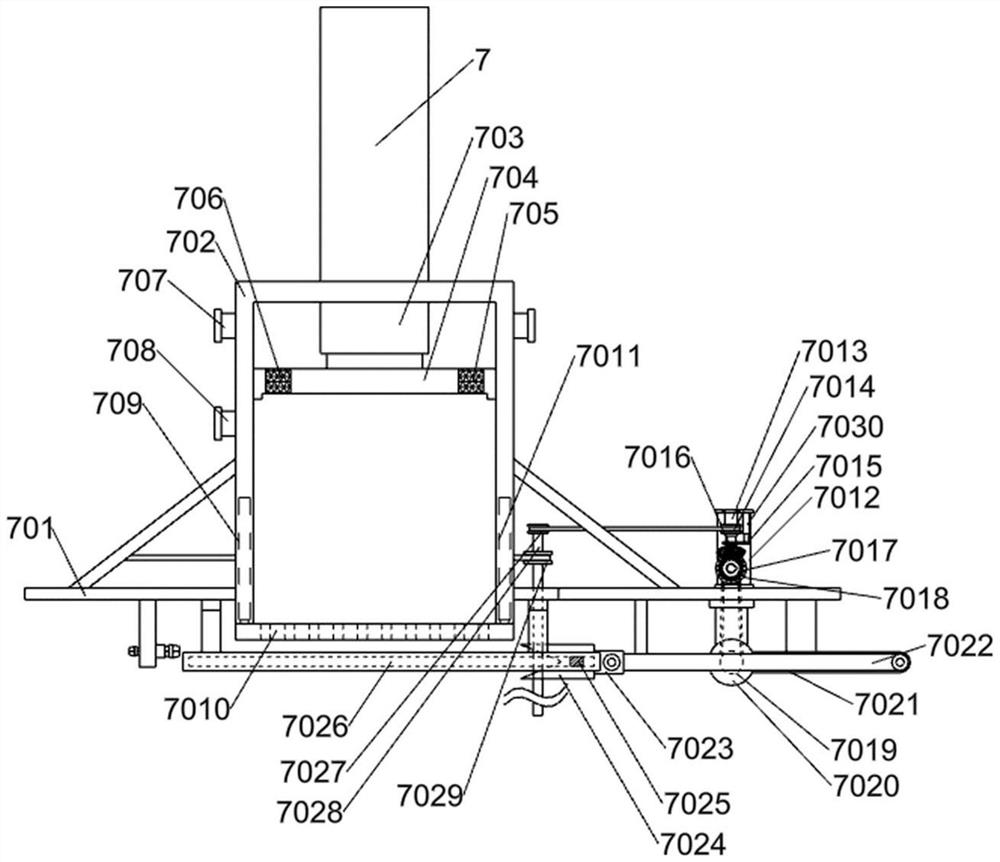

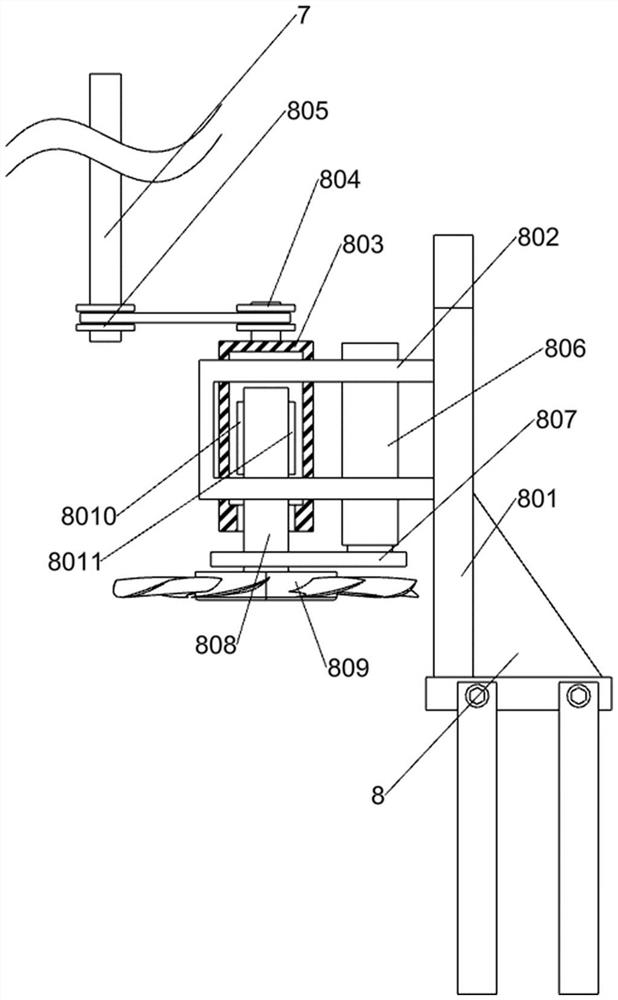

[0028] A flat-press roofing type autoclaved brick manufacturing device, such as Figure 1-6 As shown, it includes a working machine bottom plate 1, an operating table 2, an operation control panel 3, a first transmission mechanism 4, a second transmission mechanism 5, a mixing cabin 6, an extrusion granulation system 7, a stirring and mixing system 8, and a material spreading system. The system 9 and the protective side plate 10; the upper part of the working machine bottom plate 1 is connected with the operating platform 2 by bolts; the upper part of the operating platform 2 is connected with the operation control panel 3; the upper part of the working machine bottom plate 1 is connected with the first transmission mechanism 4 by bolts; the first The transmission mechanism 4 is connected with the second transmission mechanism 5; the second transmission mechanism 5 is bolted to the protection side plate 10; the second transmission mechanism 5 is connected with the extrusion gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com