Patents

Literature

3064 results about "Powder Spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

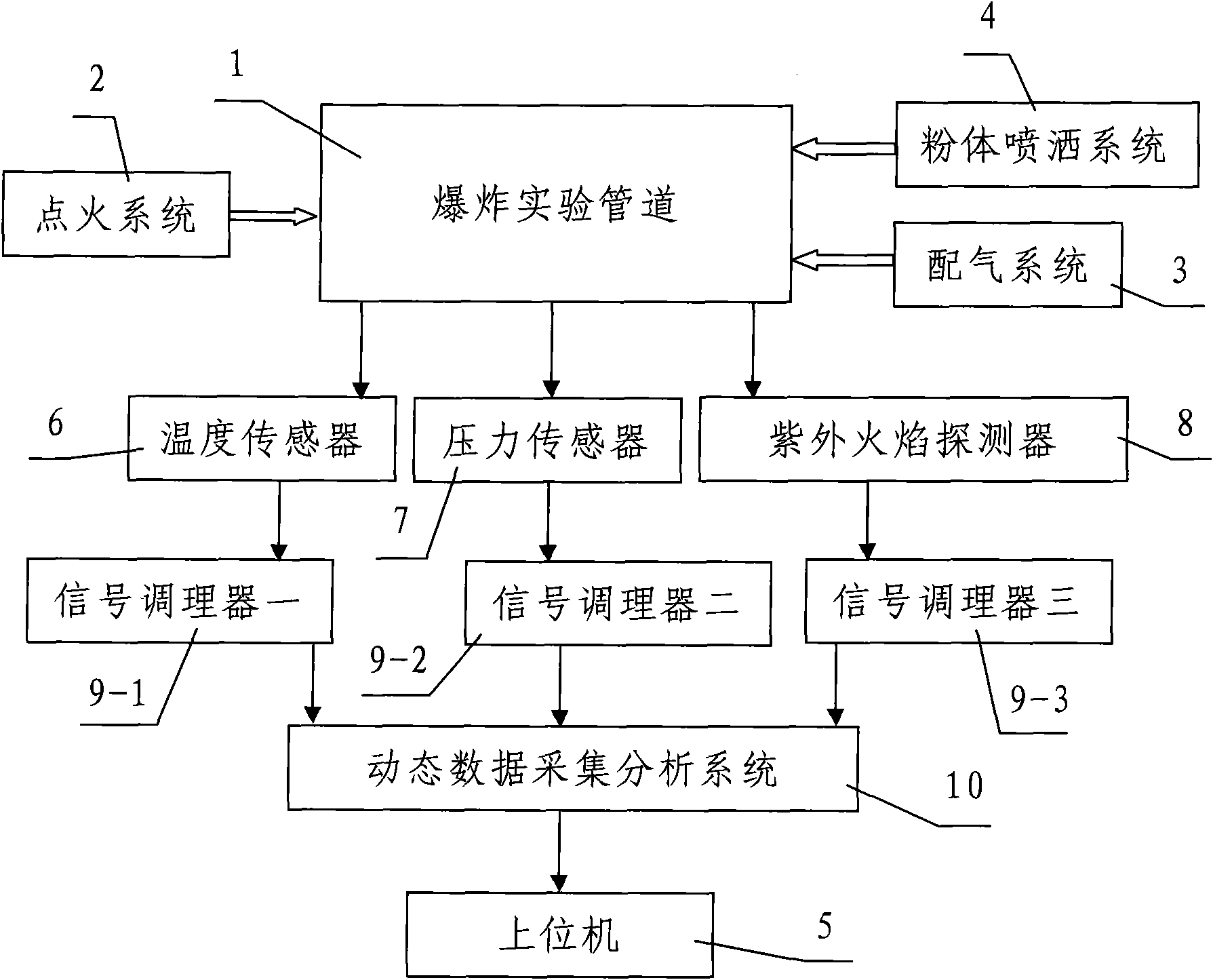

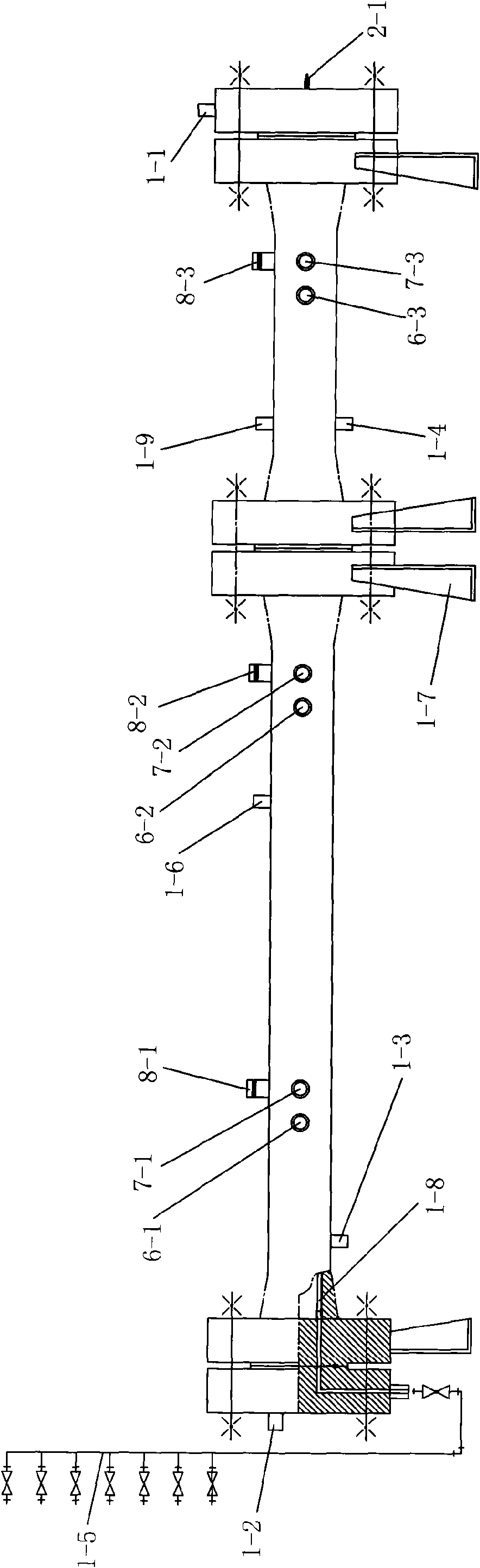

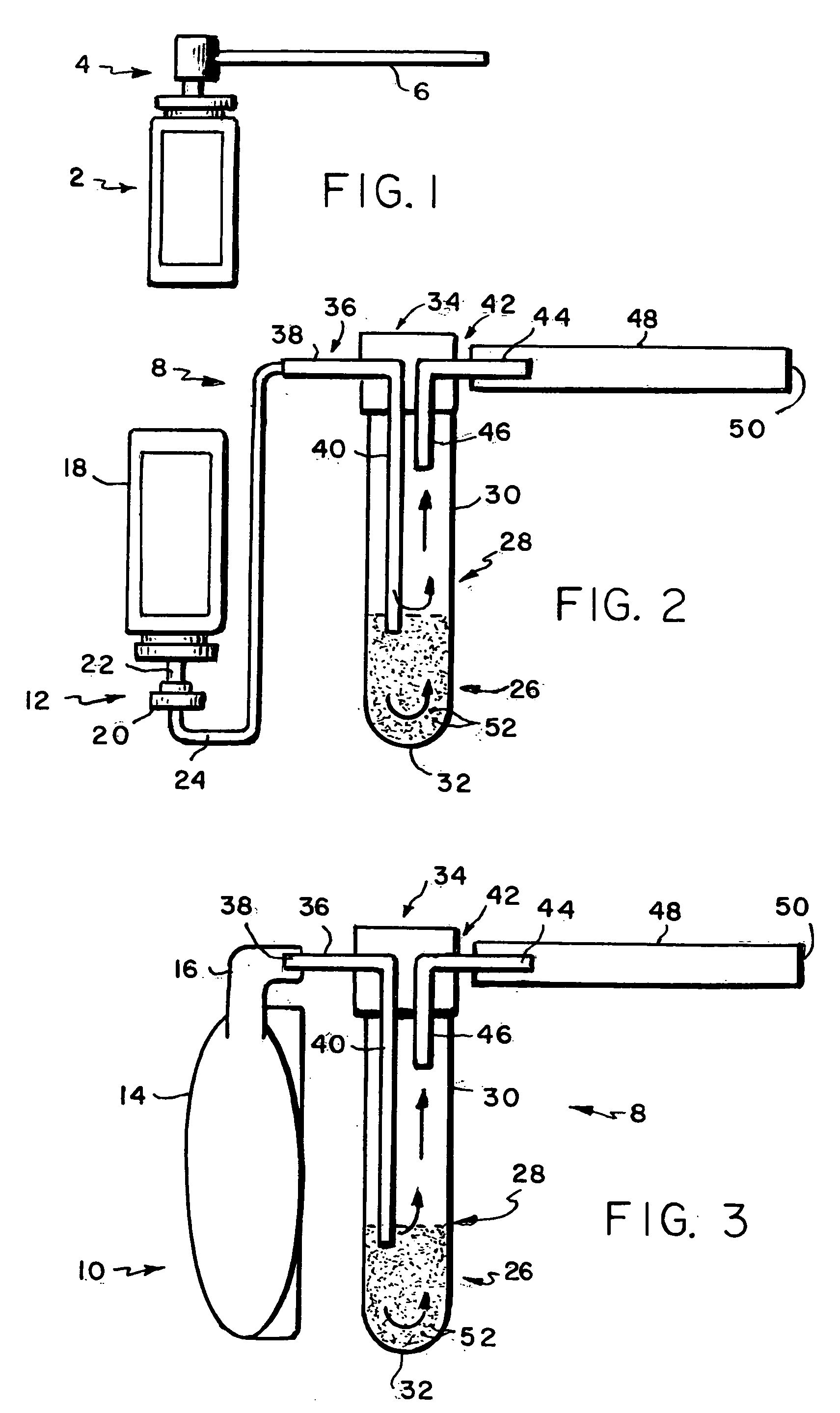

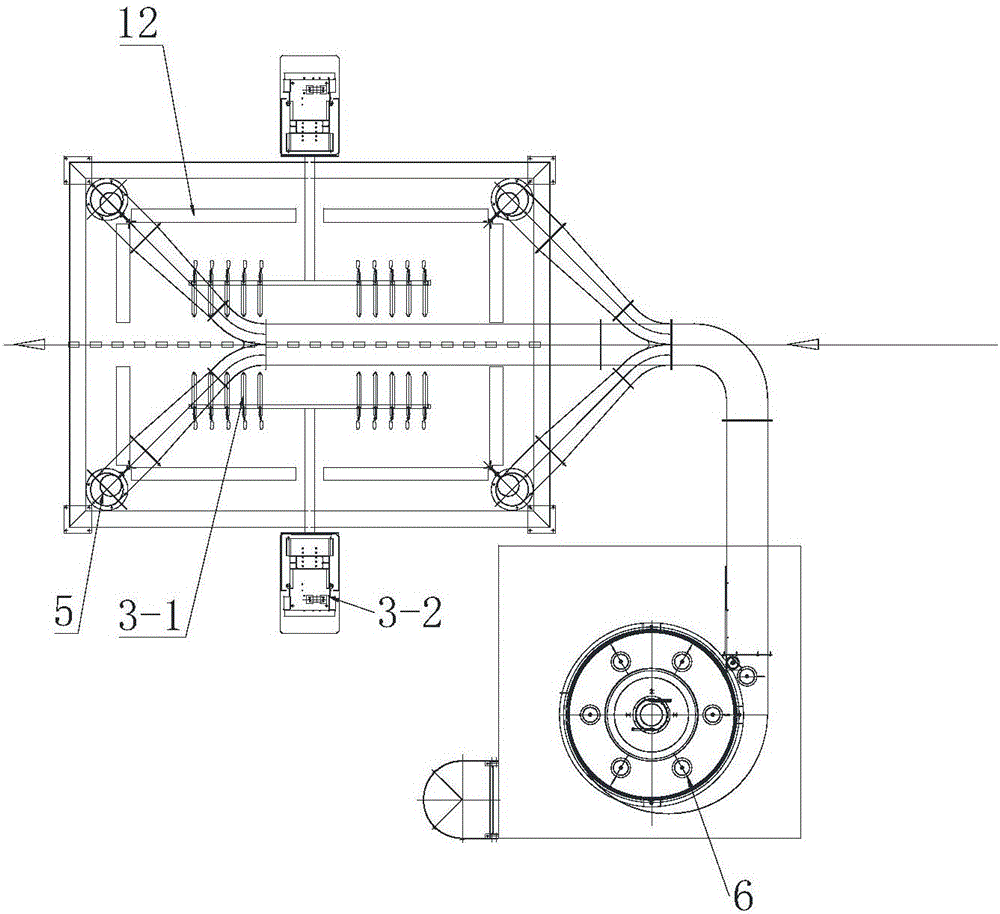

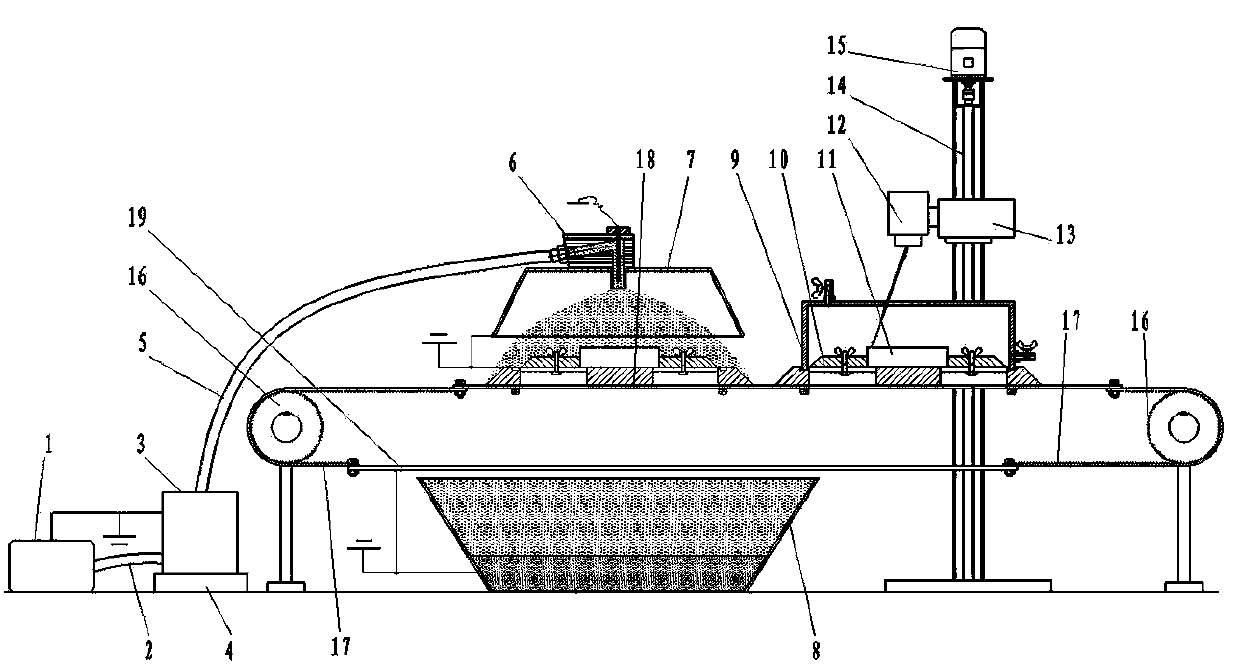

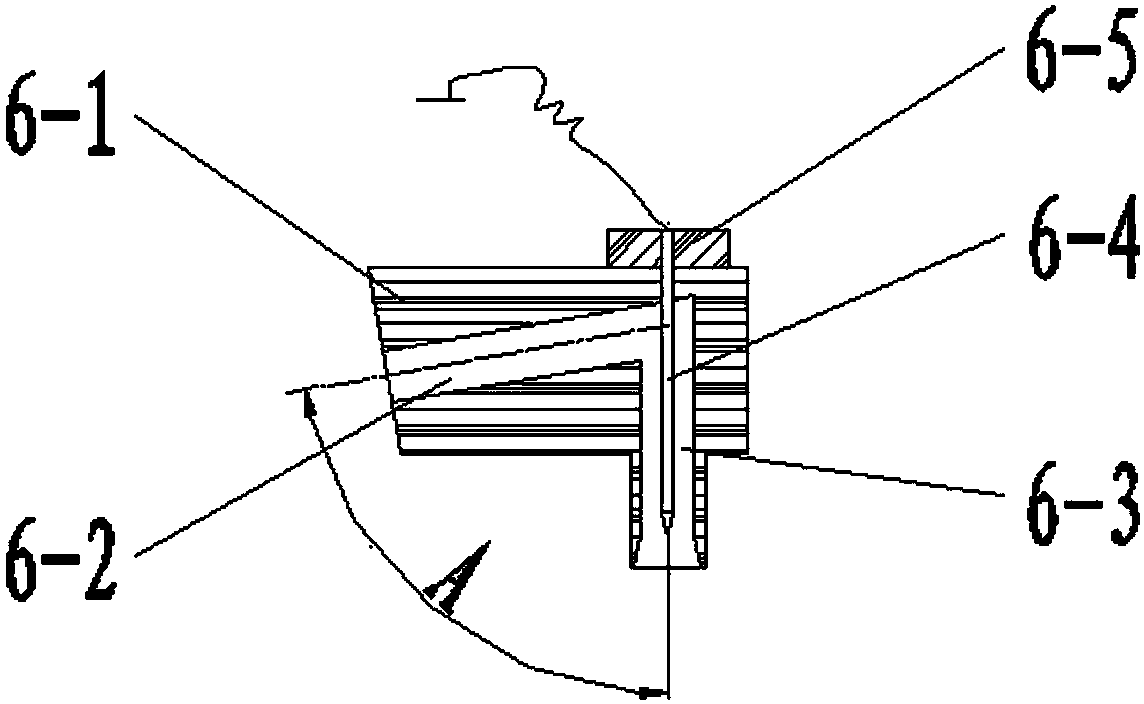

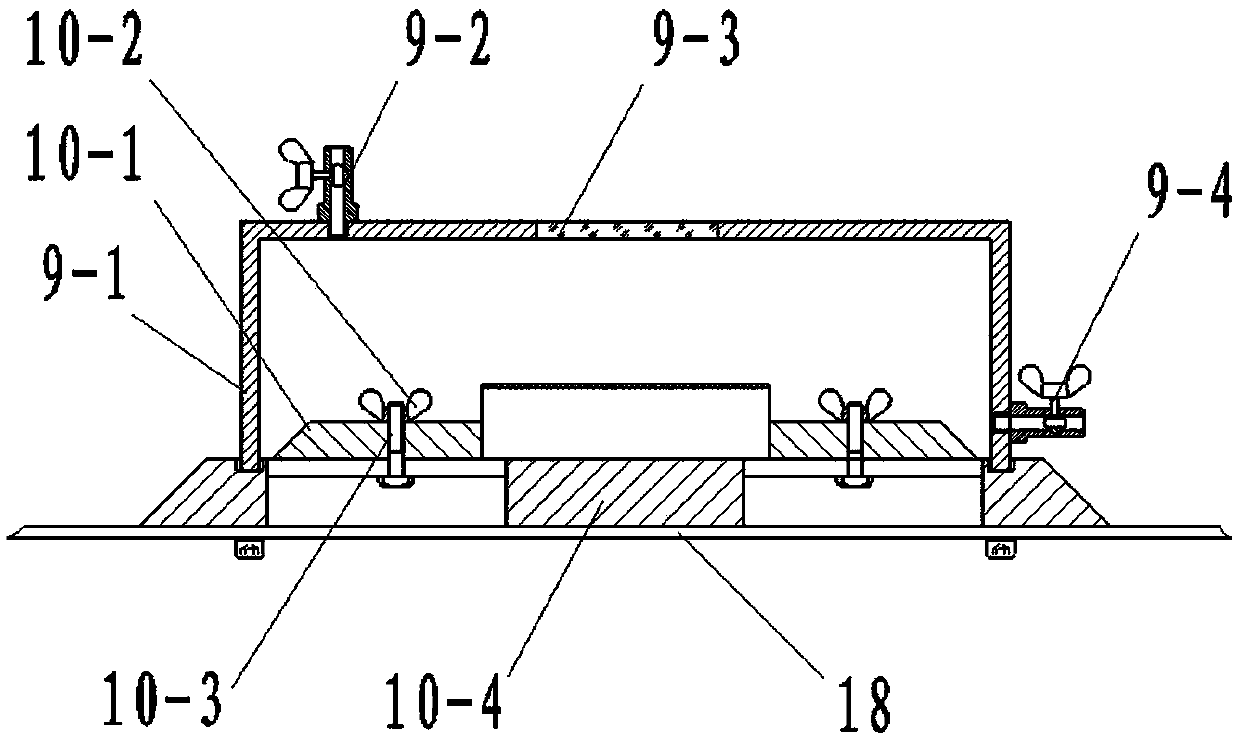

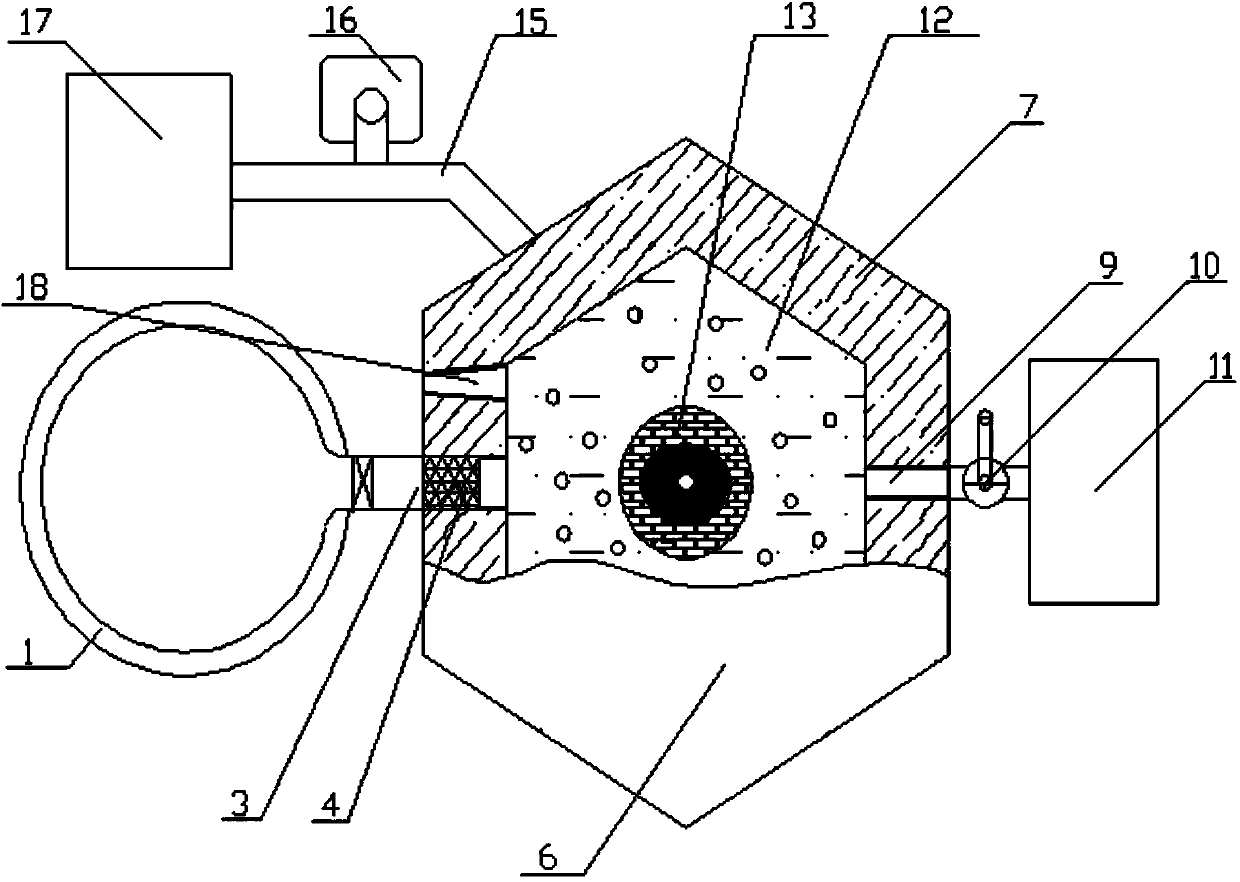

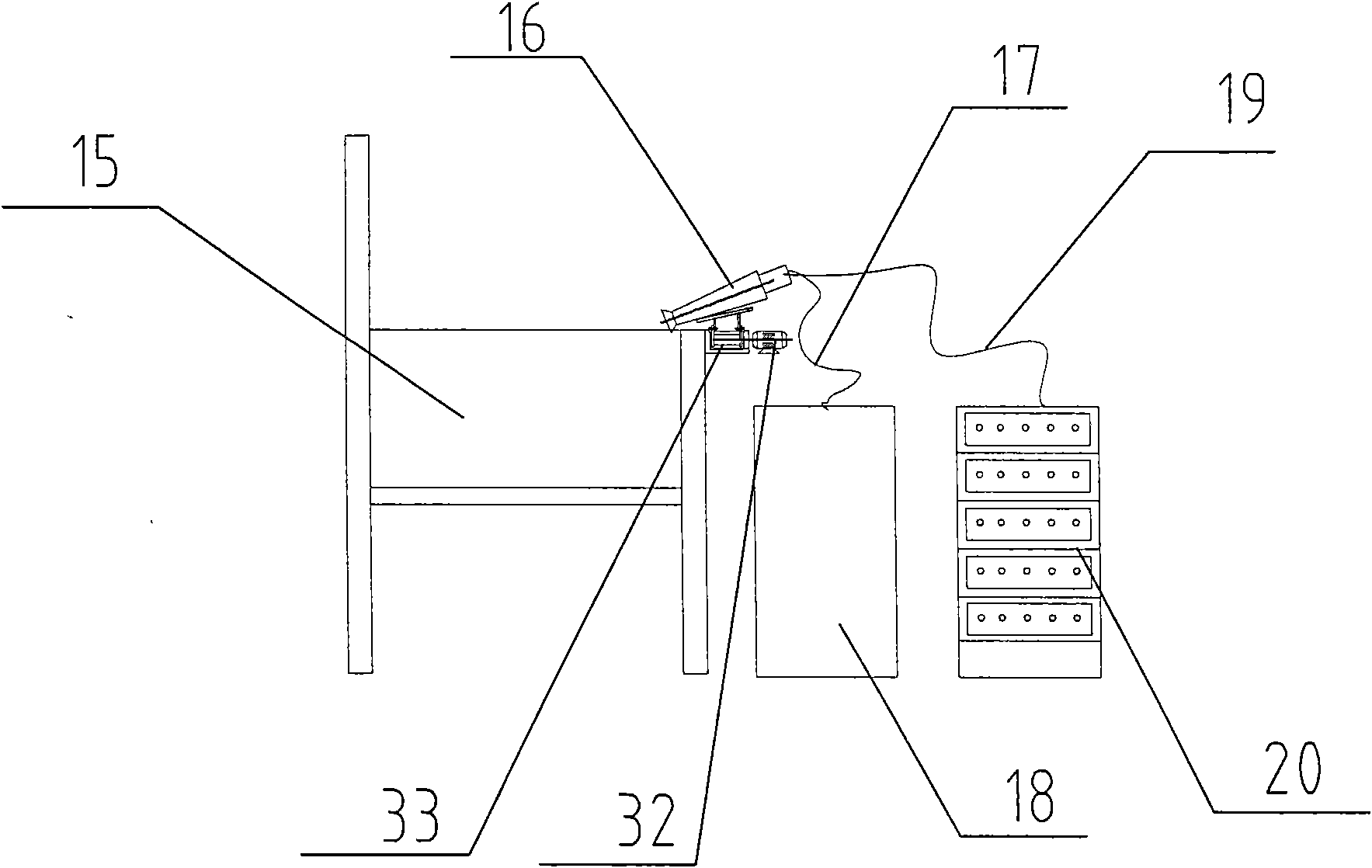

Device for testing explosion, spreading and explosion suppression characteristics of inflammable gas and dust

InactiveCN101576521AVariable volumeSolve the problem of airtightnessMaterial exposibilityDistribution systemTest fixture

The invention discloses a device for testing explosion, spreading and explosion suppression characteristics of inflammable gas and dust, which comprises an explosion test pipeline, a gas distribution system and a powder spraying system communicated with the explosion test pipeline respectively, an ignition system for igniting the inflammable gas or dust introduced into the explosion test pipeline, a data test acquisition system, and a host computer connected with the data test acquisition system, wherein the data test acquisition system comprises a sensor group distributed on the explosion test pipeline, a signal conditioner and a dynamic data acquisition analysis system. The device has the advantages of reasonable design, simple and convenient operation and use, more test functions and good test effects, and can effectively solve various practical problems of the prior experimental devices.

Owner:XIAN UNIV OF SCI & TECH

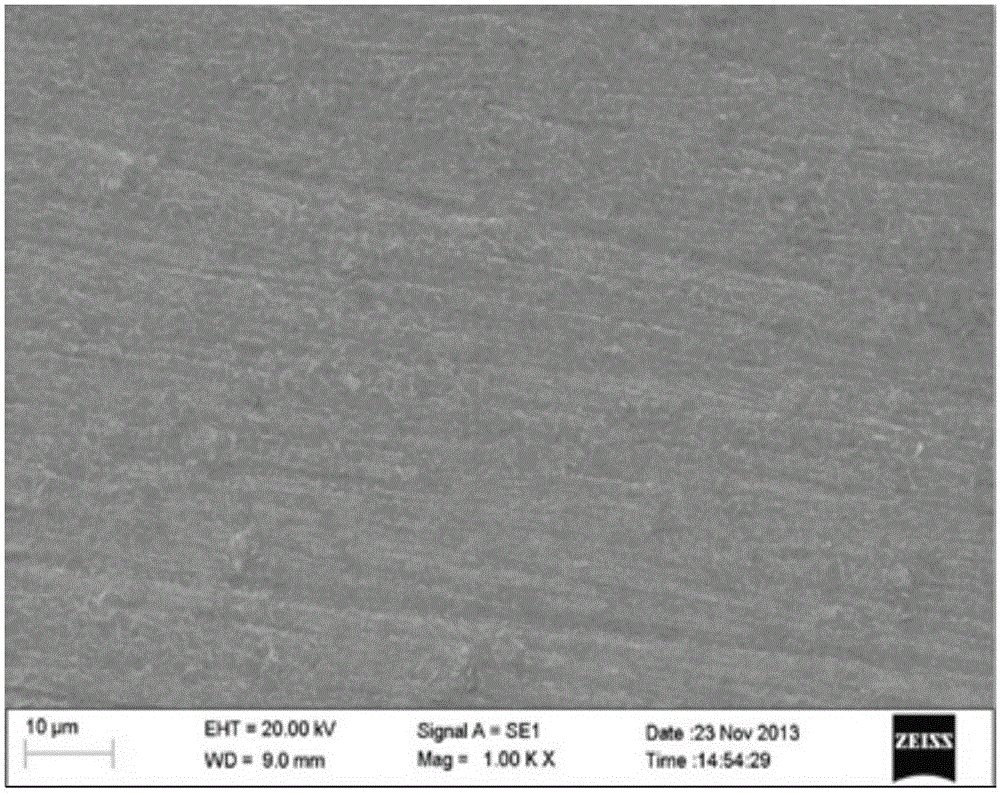

Rare earth element oxyflouride powder spray material and sprayed article

InactiveUS20140057078A1Increase resistanceImprove corrosion resistanceFireproof paintsMolten spray coatingRare-earth elementHigh resistance

A spray material comprising rare earth element oxyfluoride particles having an aspect ratio of up to 2, an average particle size of 10-100 μm, and a bulk density of 0.8-2 g / cm3, and containing not more than 0.5 wt % of carbon and 3-15 wt % of oxygen is suitable for air plasma spraying. An article having a sprayed coating of rare earth element oxyfluoride has high resistance against plasma etching and a long lifetime.

Owner:SHIN ETSU CHEM IND CO LTD

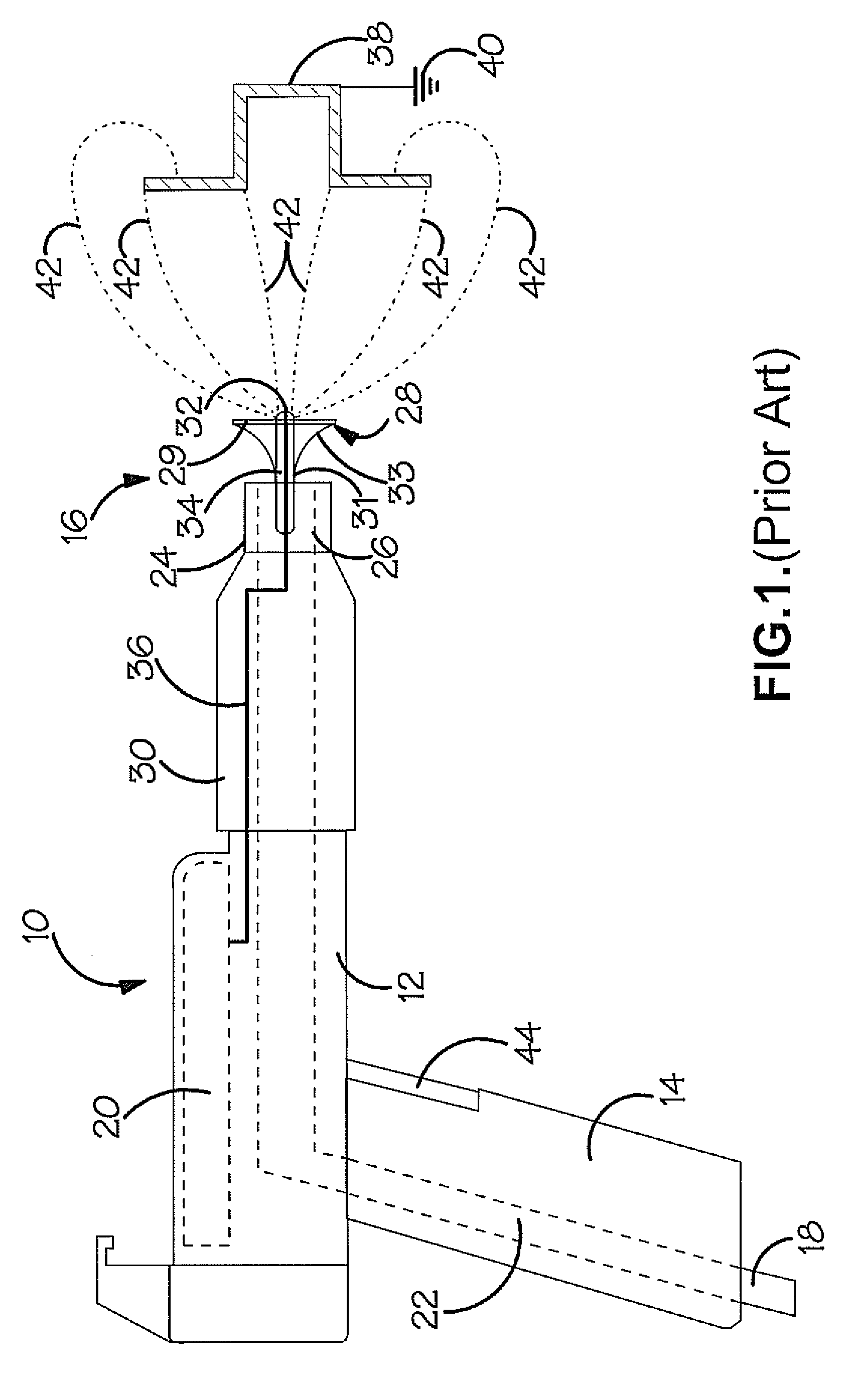

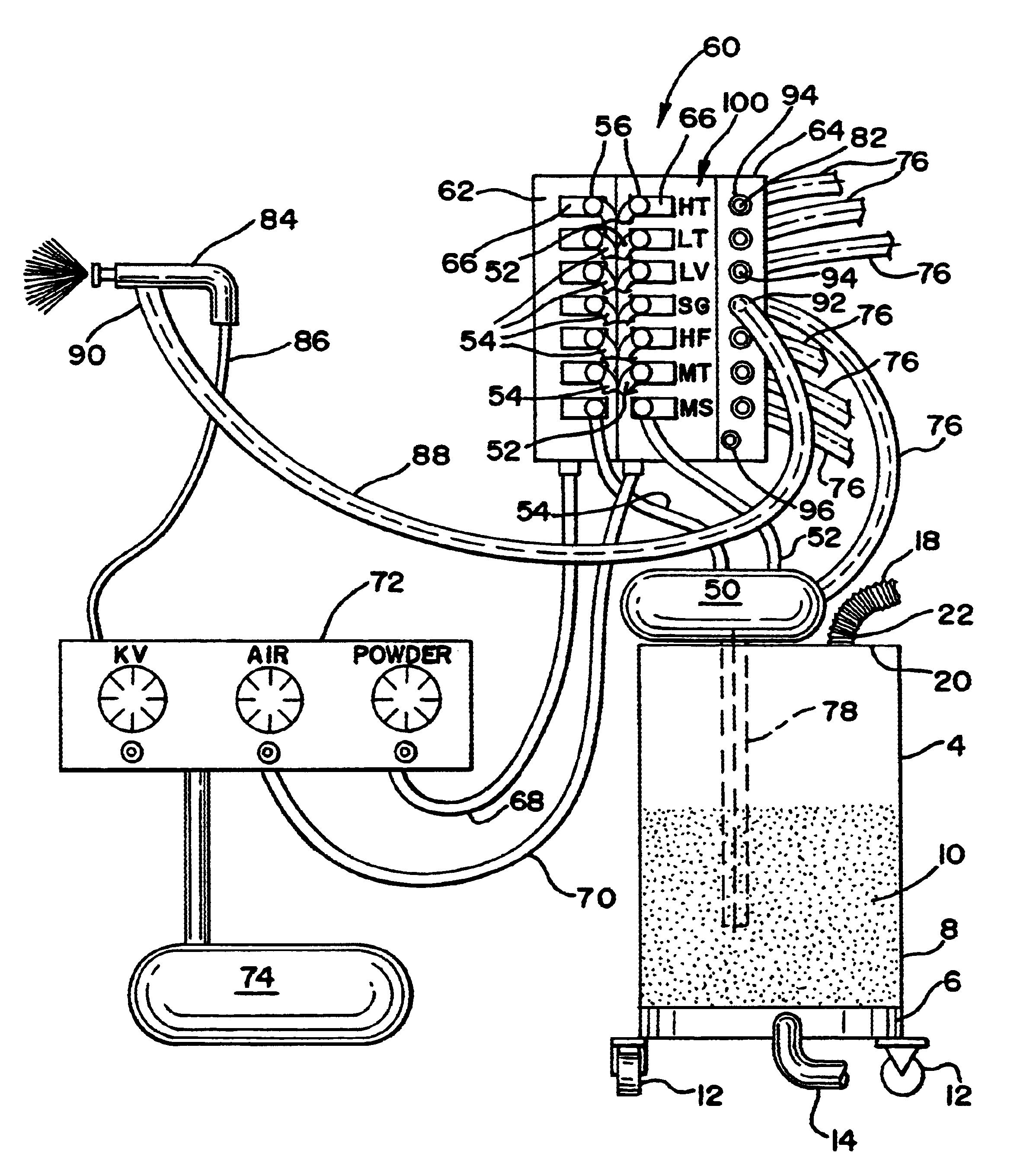

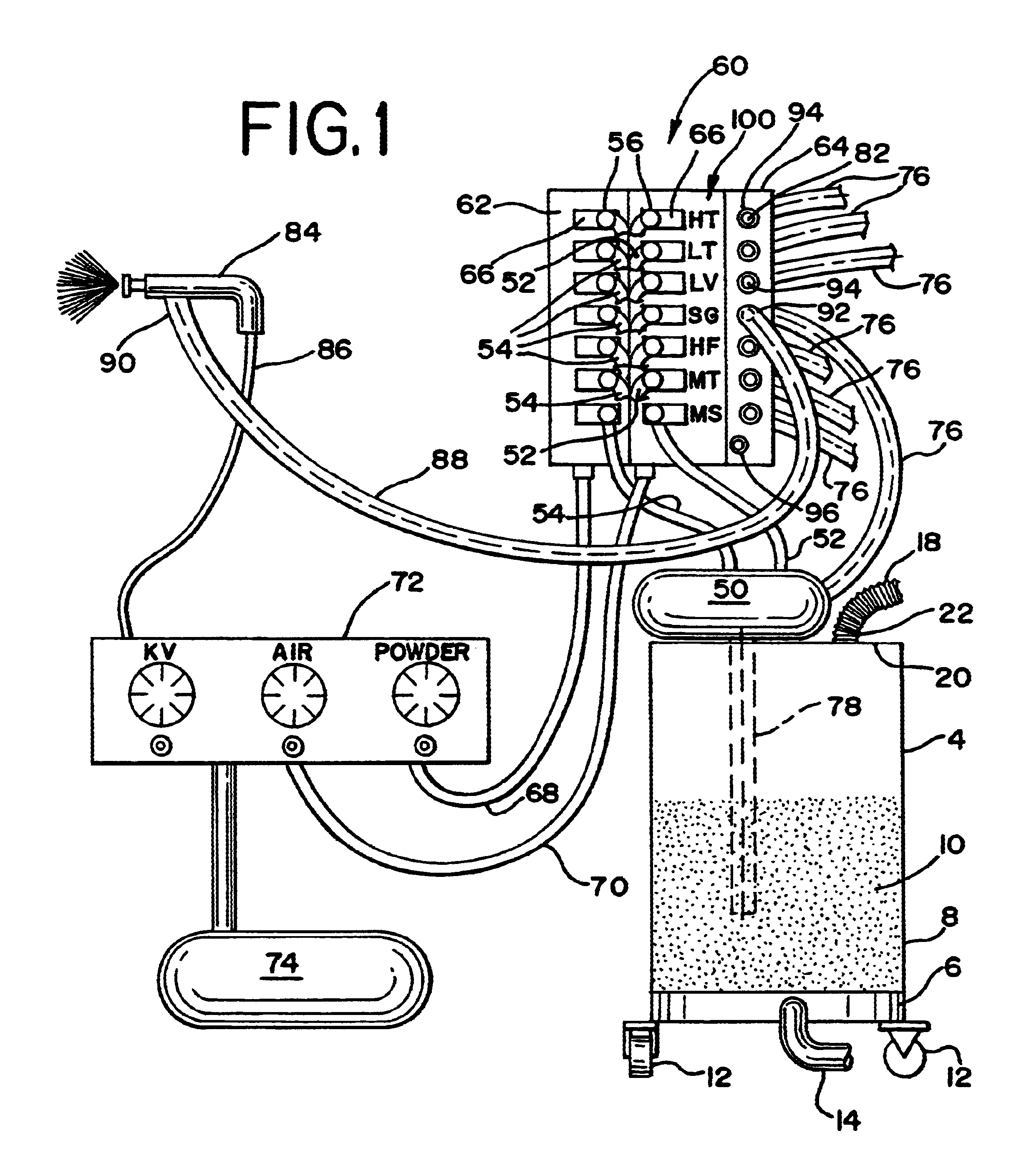

Particulate material applicator and pump

InactiveUS20050229845A1Good cleanabilityShorten color change timeLiquid surface applicatorsLiquid supply arrangementsEngineeringExpansion chamber

A nozzle assembly for a material application device includes an expansion chamber for slowing down the velocity of powder fed to the nozzle from a dense phase pump. The nozzle assembly includes a nozzle insert that forms the expansion chamber and provides air assist function. The nozzle includes an integral deflector, and further includes a passageway for a charging electrode so that the electrical path is routed away from the powder path, while permitting the electrode tip to be centered in the powder spray pattern from the nozzle. The nozzle also includes air wash for the electrode. The nozzle outlet orifice has a cross-sectional area that is equal to or greater than the inlet cross-sectional area so that a slow moving dense phase powder cloud is produced by the nozzle.

Owner:NORDSON CORP

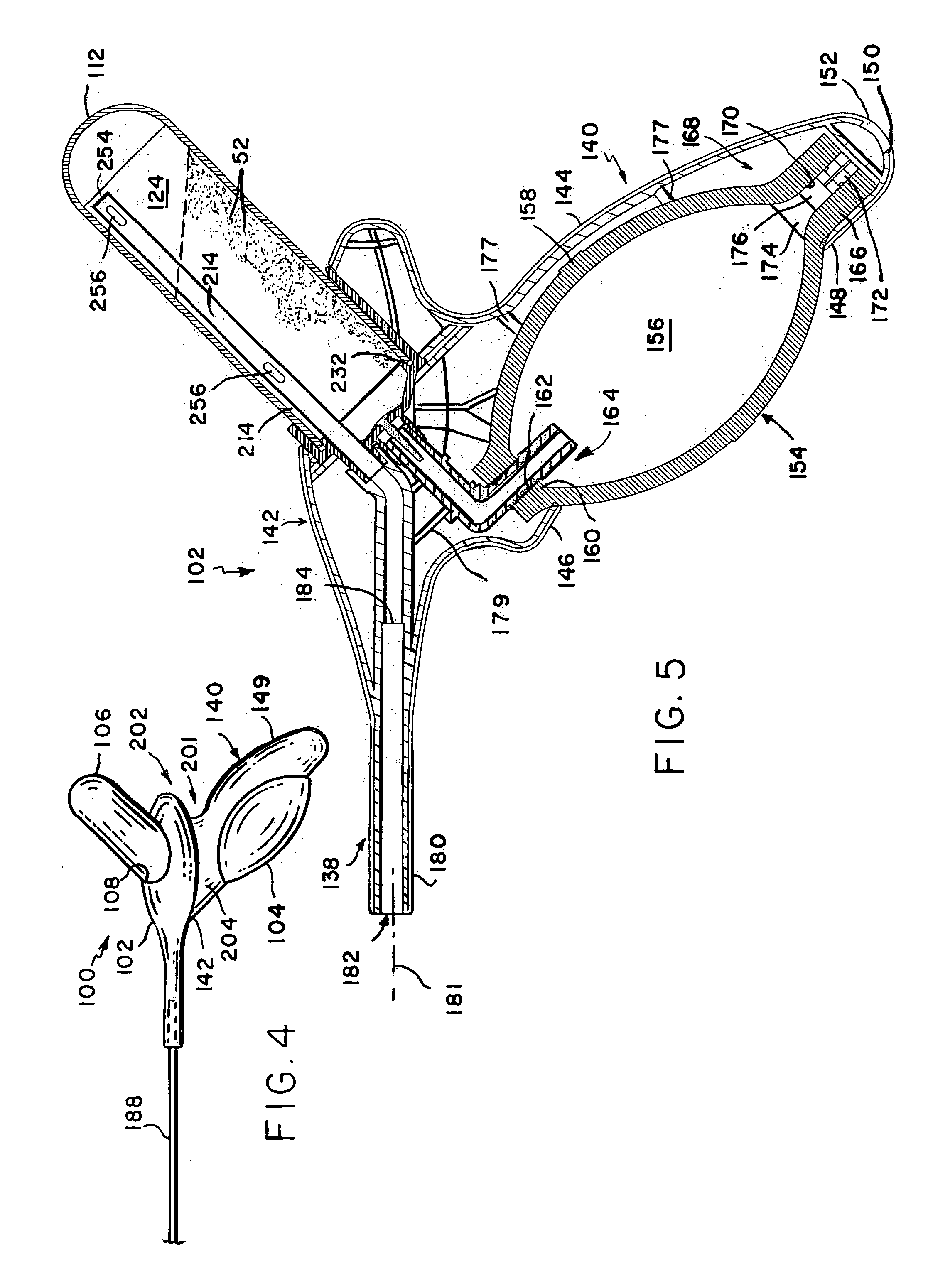

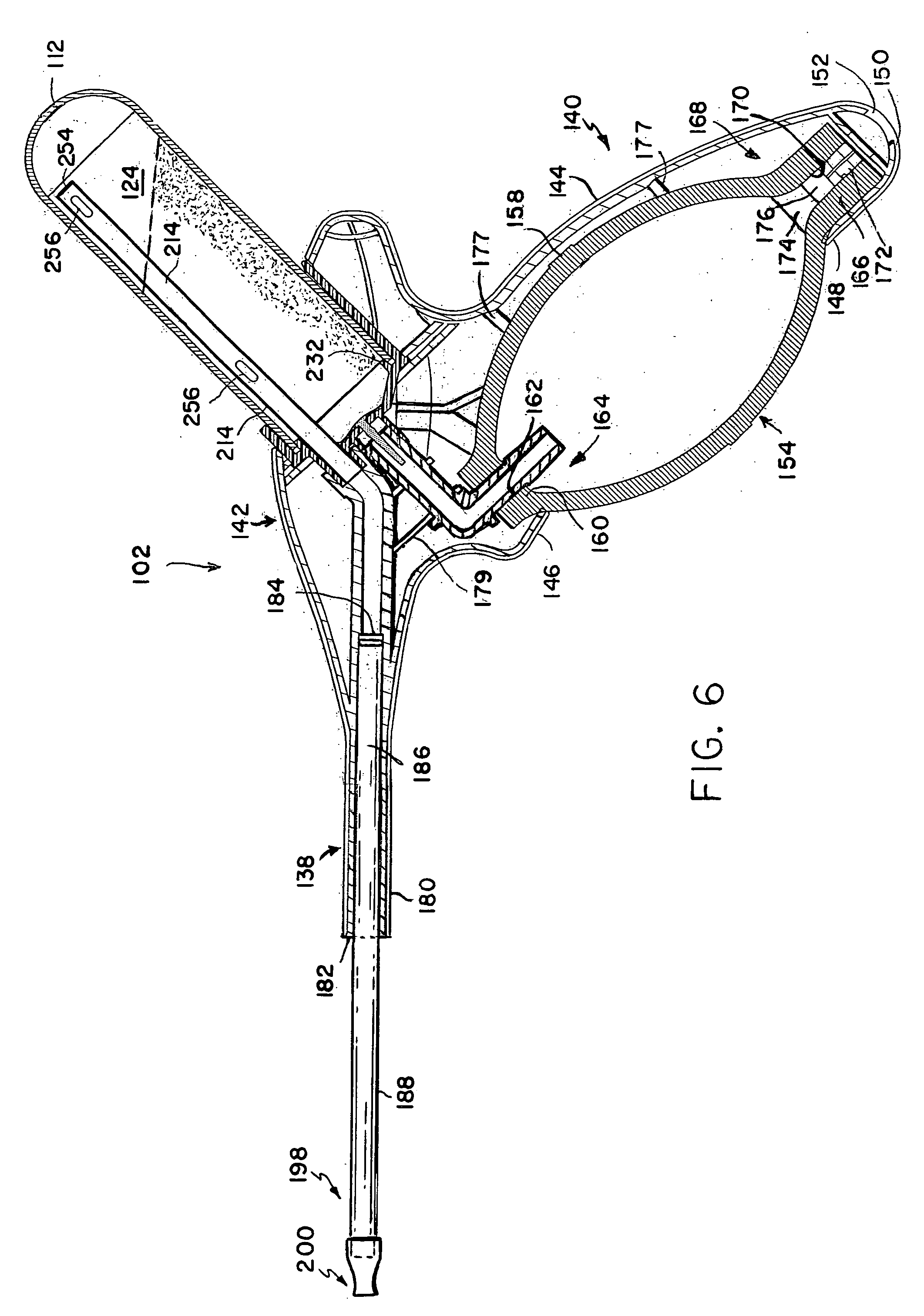

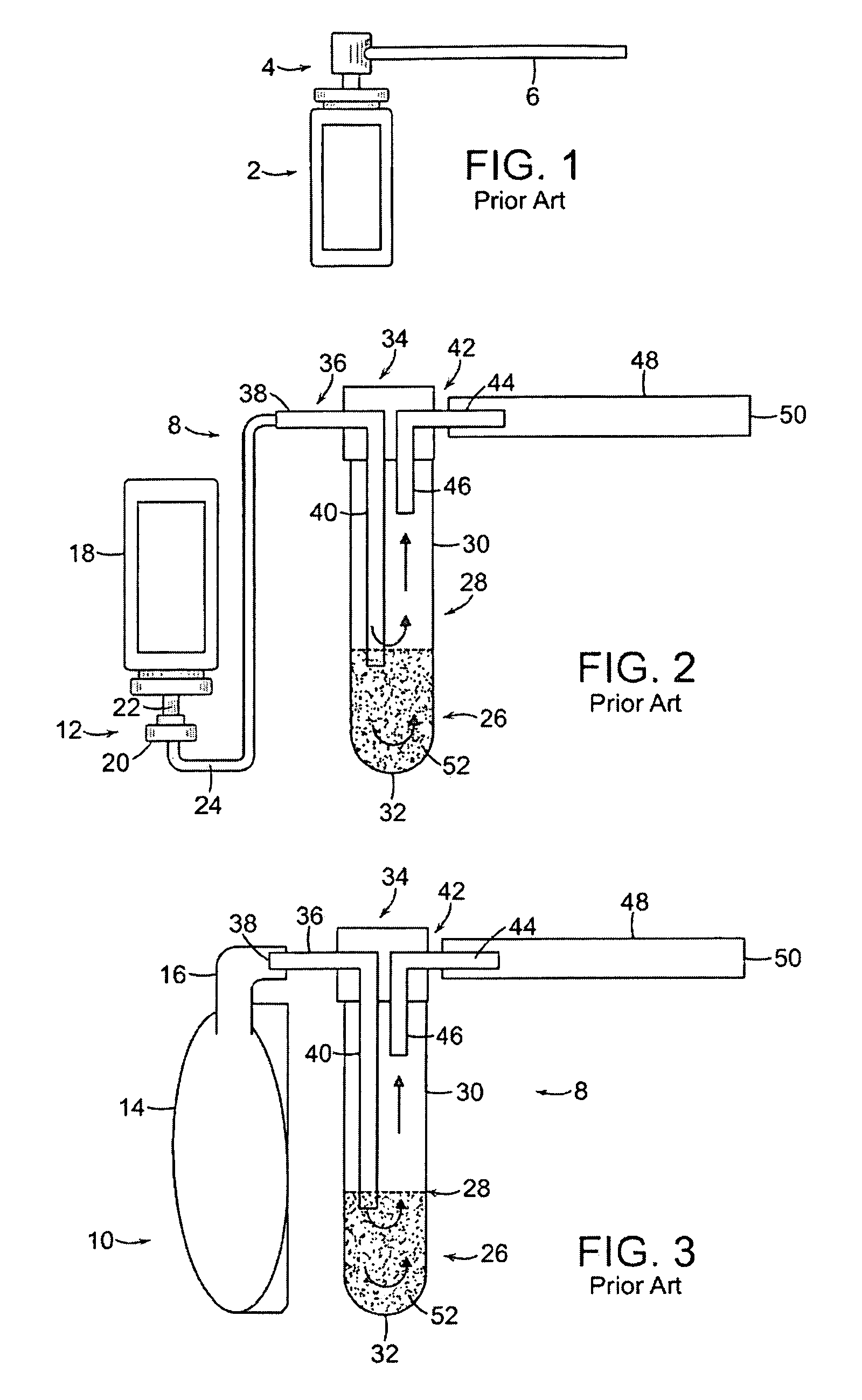

Powder delivery device

ActiveUS20050205087A1Easily and advantageously manufacturedEasily and advantageously and distributedPowder deliverySurgeryHand heldEngineering

A pistol-shaped powder delivery device consolidates propellant pulse creation, powder storage, powder aerosolization and aerolsolized powdered delivery in a single device while providing dose, pattern and coverage control of the output spray. The single-hand-held, single-hand-operated device includes a housing having a handle portion that is selectively collapsed to generate a propellant pulse that is conveyed into and through powder stored in a reservoir mounted at an upward angle to the horizontal in a receptacle provided in the housing. Powder in the reservoir is caused to be aerosolized by the propellant pulse whereupon aerosolized powder exits the reservoir through an open end of, and elongate slots provided in the sidewall of, an elongate hollow member extending from an outlet in the receptacle through the stored powdered material into a head space in the reservoir. The outlet is connected a barrel portion for output of the aerosolized powder spray.

Owner:GENZYME CORP

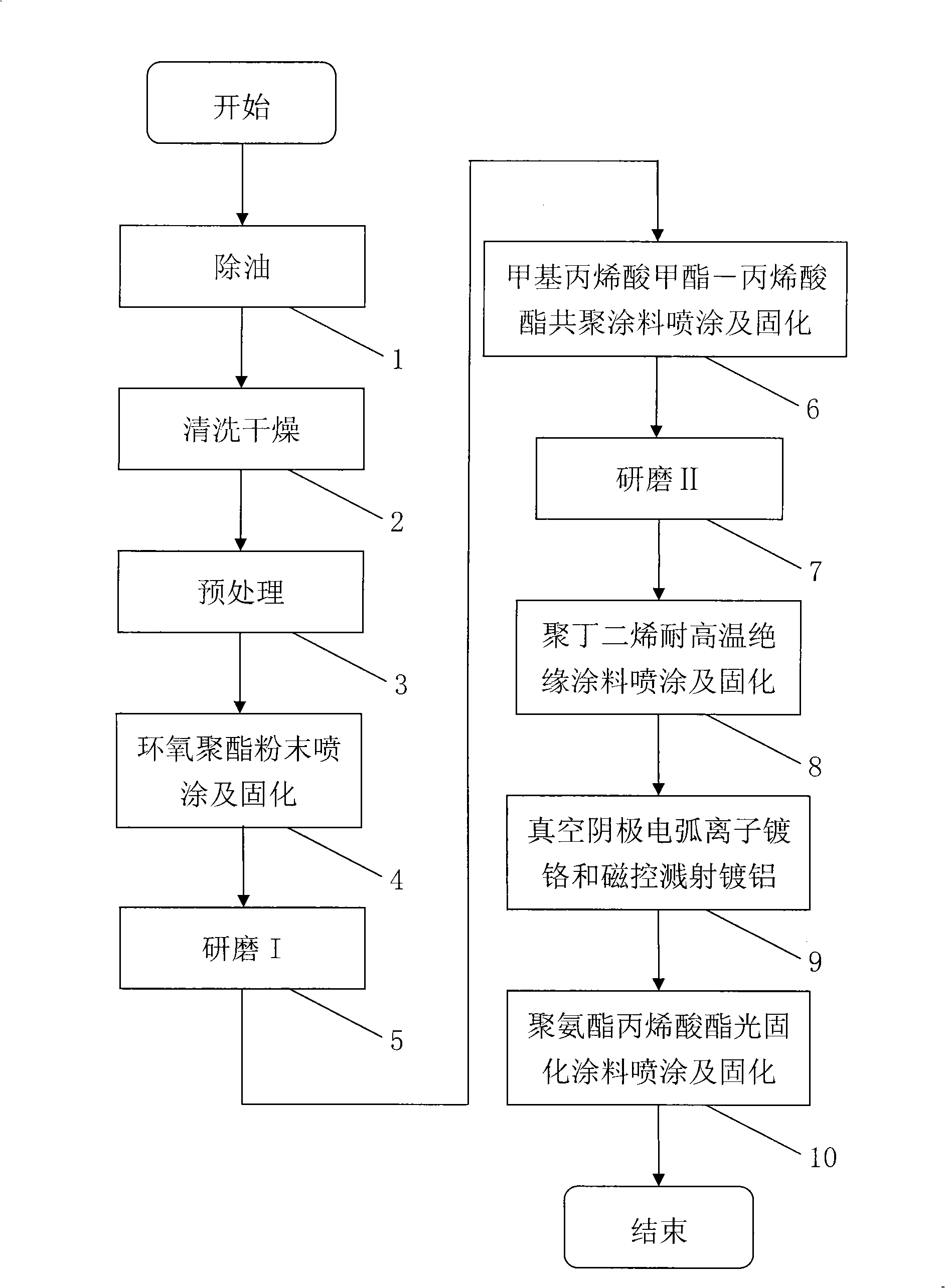

Film coating process for aluminium alloy wheel hub

InactiveCN101343740AReduce pollutionReduce energy consumptionVacuum evaporation coatingSputtering coatingPolyesterFilm coating

The invention discloses an aluminum alloy wheel hub coating technology. The aluminum alloy wheel hub coating technology comprises the procedures of oil removing, cleaning and drying, pre-treating, epoxy polyester powder spraying and solidifying, grinding I, methyl methacrylate-acrylate copolymer paint spraying and solidifying, grinding II, polybutadiene high temperature resistant insulating coating spraying and solidifying, vacuum cathode arc ion chromium plating and magnetism control sputtering aluminum plating, and polyurethane methacrylate light solidifying paint spraying and solidifying in sequence. The aluminum alloy wheel hub coating technology adopts dry electric plating to replace the traditional wet electric plating, the plating layer surface quality and the physical and chemical properties are approximately equivalent to the wet electric plated aluminum alloy wheel hub, the chromium consumption is reduced to about one fifth of the wet electric plating, the water consumption is reduced to about one seventh of the wet electric plating, precious nickel and copper are not utilized, the poisonous metal substance such as hexavalent chromium is not contained, the pollution to the environment is reduced, the energy, water and precious metal consumption is remarkably reduced, the technological flow is simplified, the production efficiency is enhanced, the heavy polishing working sequence is omitted, the working condition is remarkably improved, and the cost is reduced.

Owner:HUZHOU JINTAI PLATING IND

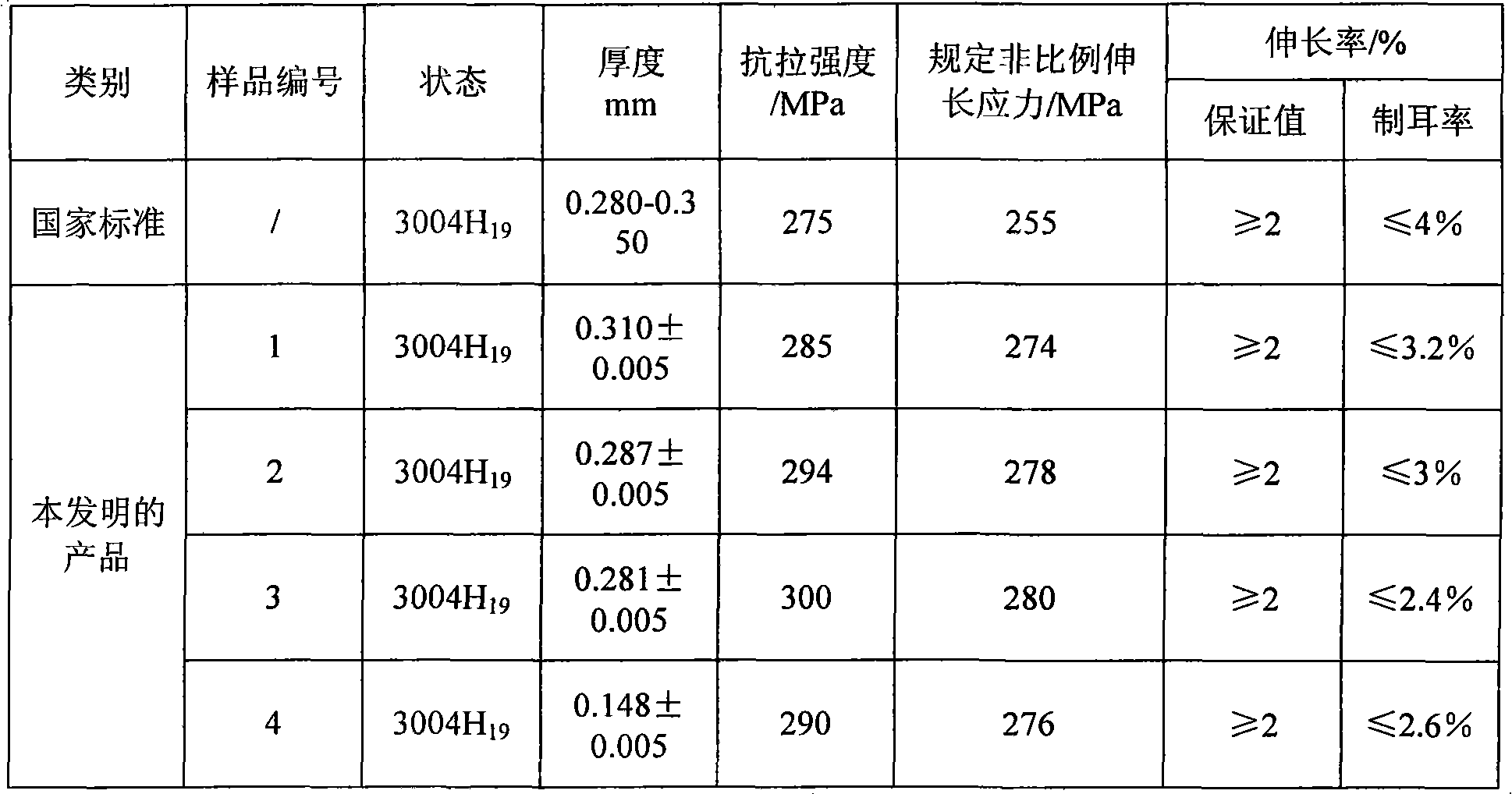

Engineering process for producing low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid

The invention relates to an engineering process for producing a low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid. The process comprises the procedures of alloy aluminium melting, ingredient adjusting, on-line refining for three times, standing, outgassing, grain refining, filtering, tilting cast-rolling, homogenizing, cold rolling, intermediate annealing, another cold rolling, full annealing, recoiling and packaging. The refining comprises powder spraying refining in a melting furnace and combined refining of on-line argon and carbon tetrachloride introducing. The annealing comprises high-temperature quick annealing, the intermediate annealing and the full annealing. During the cast-rolling, the temperature in a front box is 710-720 DEG C, and the cast-rolling speed is 600-900 mm / min. The product is the low-iron low-silicon 3004 alloy. The low-iron low-silicon 3004 alloy comprises 0.06-0.14 wt% of Si, 0.25-0.43 wt% of Fe, 0.012-0.14 wt% of Cu, 1.0-1.2 wt% of Mn, 0.8-1.0 wt% of Mg, at most 0.02 wt% of Zn, 0.015-0.03 wt% of Ti and the balance of Al. The invention has the characteristics of simple procedure, energy saving, emission reduction, goodalloy performance and low earring rate.

Owner:SNTO TECH GRP

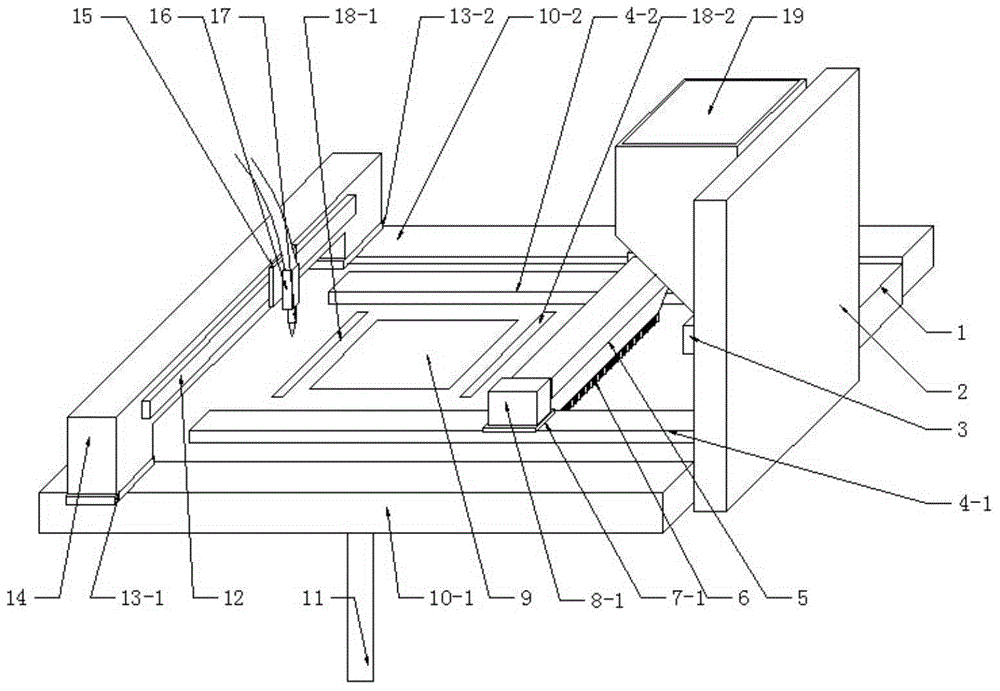

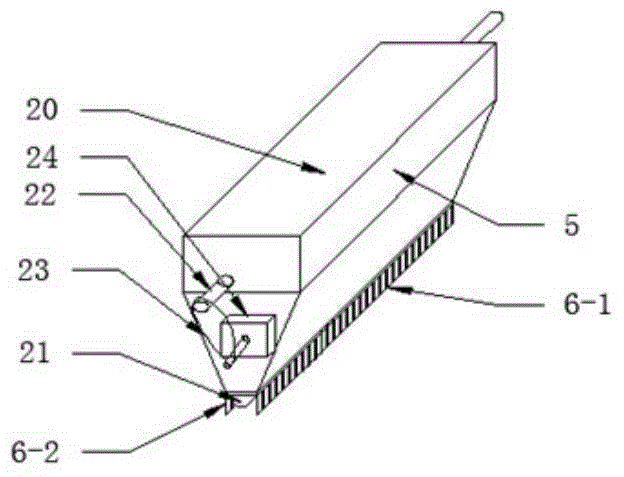

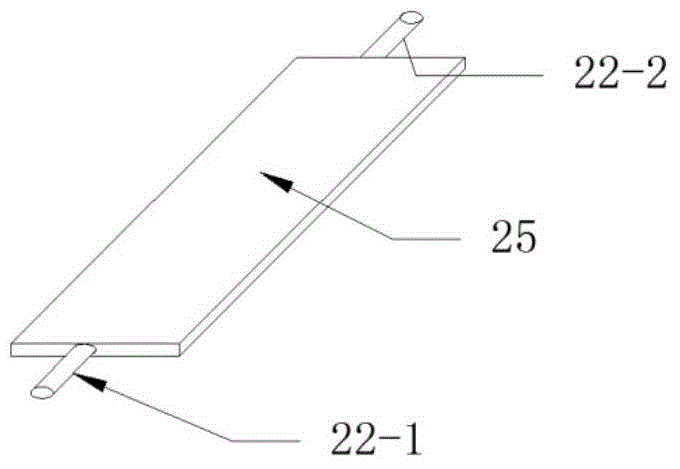

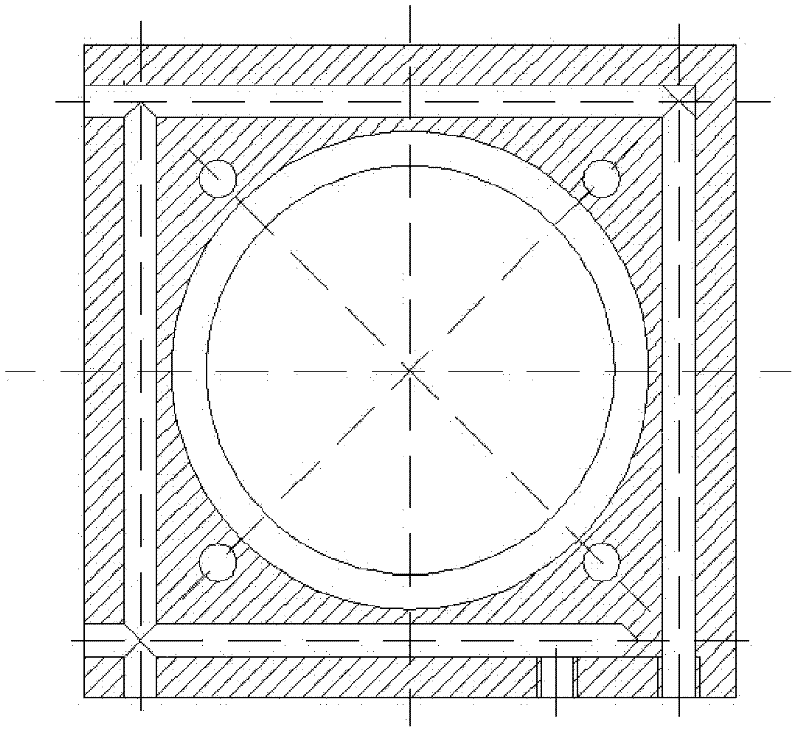

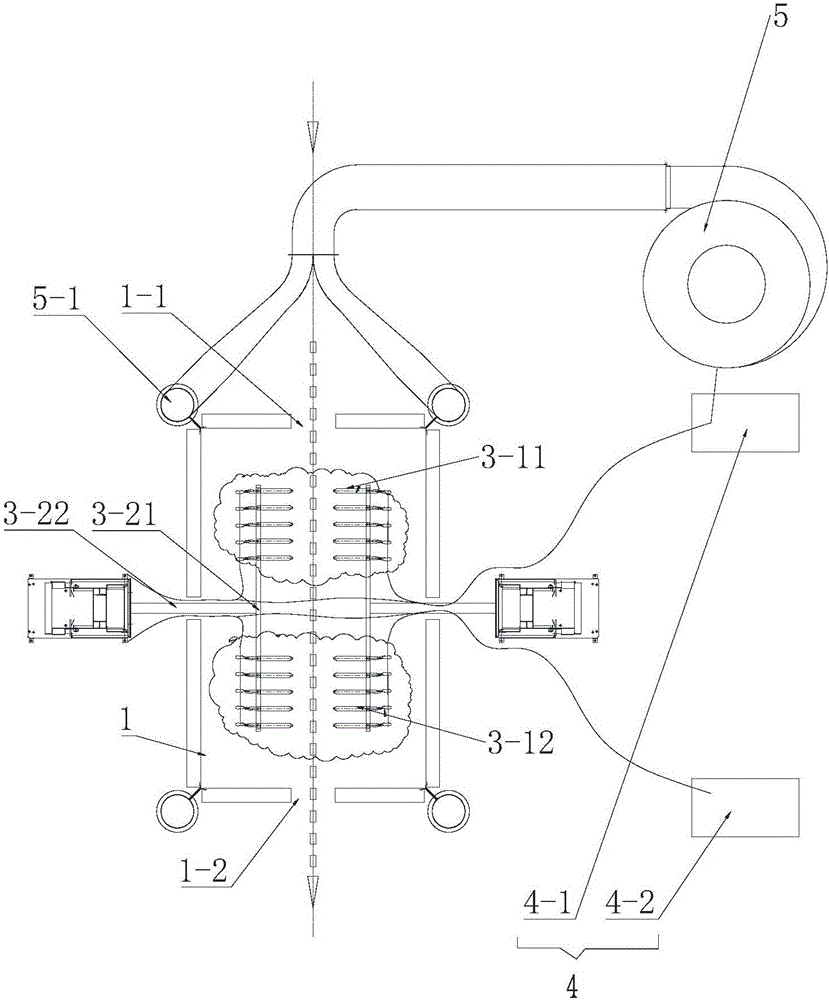

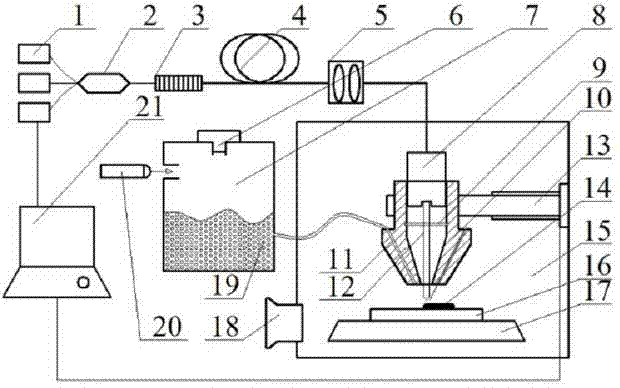

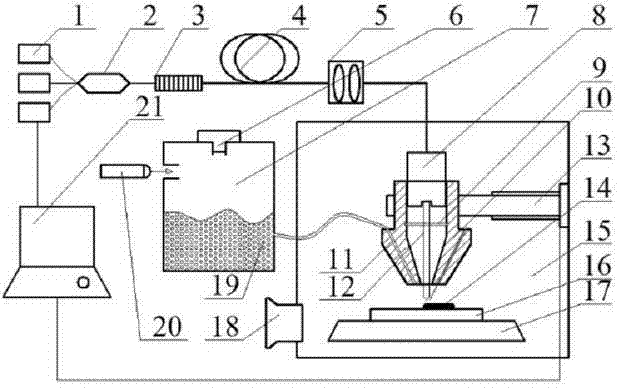

Selective laser melting powder sending and laying device used for compounding of different types of powder

ActiveCN105562687ASolve recycling difficultiesReduce consumptionIncreasing energy efficiencySelective laser meltingMetallurgy

The invention discloses a selective laser melting powder sending and laying device used for compounding of different types of powder. The selective laser melting powder sending and laying device comprises a worktable, a forming cylinder, a powder spraying device and a powder laying device. The upper surface of the forming cylinder is arranged on the worktable. The powder spraying device and the powder laying device are arranged on the two sides of the forming cylinder. The powder spraying device is characterized in that powder spraying electric guide rails, a support, a nozzle electric guide rail and a nozzle are included; the nozzle is arranged on the nozzle electric guide rail; the nozzle electric guide rail is arranged on the powder spraying electric guide rails through the support; and the powder spraying electric guide rails are fixed to the worktable. The powder laying device comprises a powder hopper, a powder scraping electric guide rail and a supporting frame; the powder hopper is arranged on the powder scraping electric guide rail through the supporting frame; and the powder scraping electric guide rail is fixed to the worktable. According to the selective laser melting powder sending and laying device used for compounding of different types of powder, the selective laser melting technology and the laser cladding coaxial powder sending technology are combined, and the purposes of effectively recovering powder during compound additive manufacturing of gradient materials and forming parts with complex gradients in any direction are achieved.

Owner:NANJING UNIV OF SCI & TECH

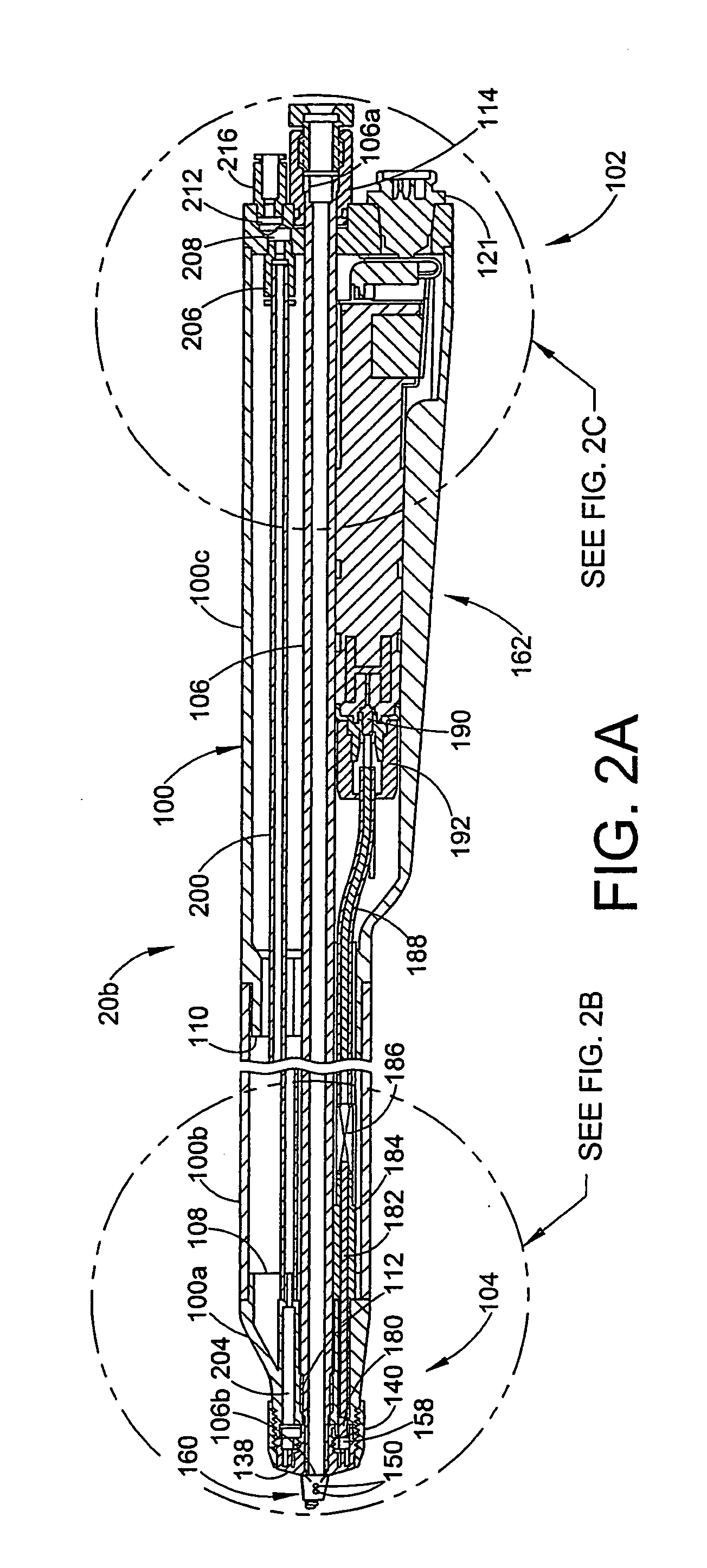

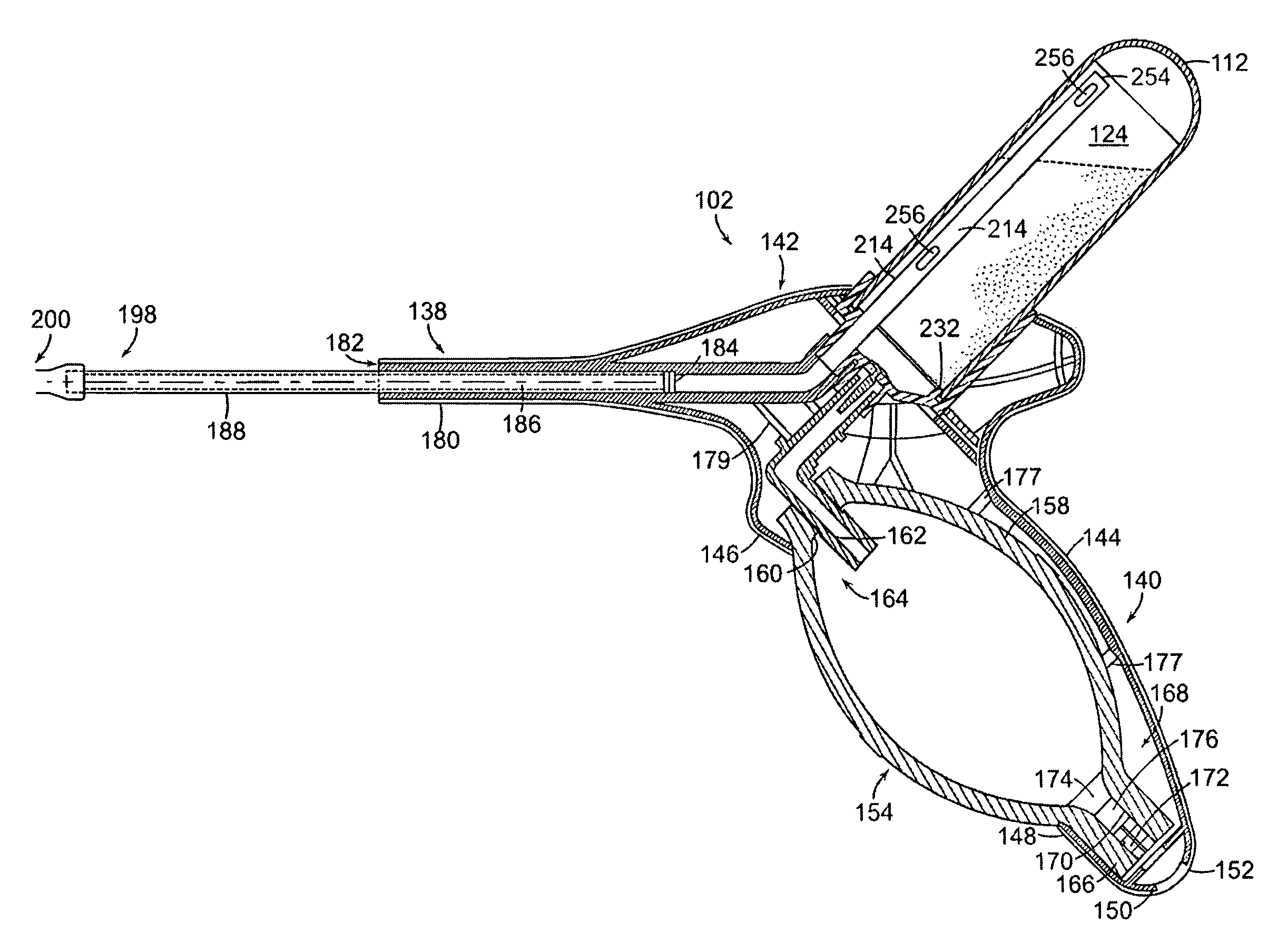

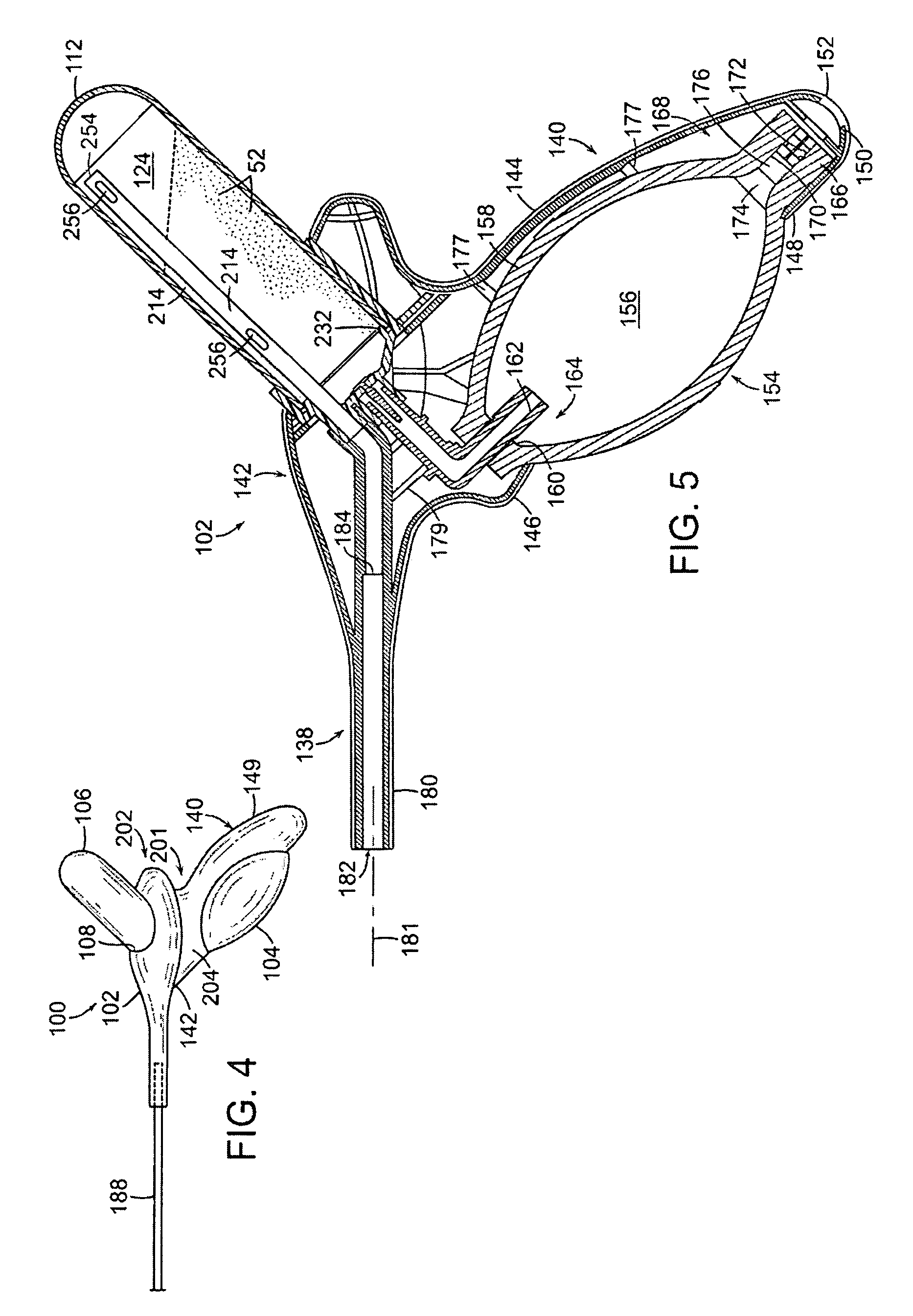

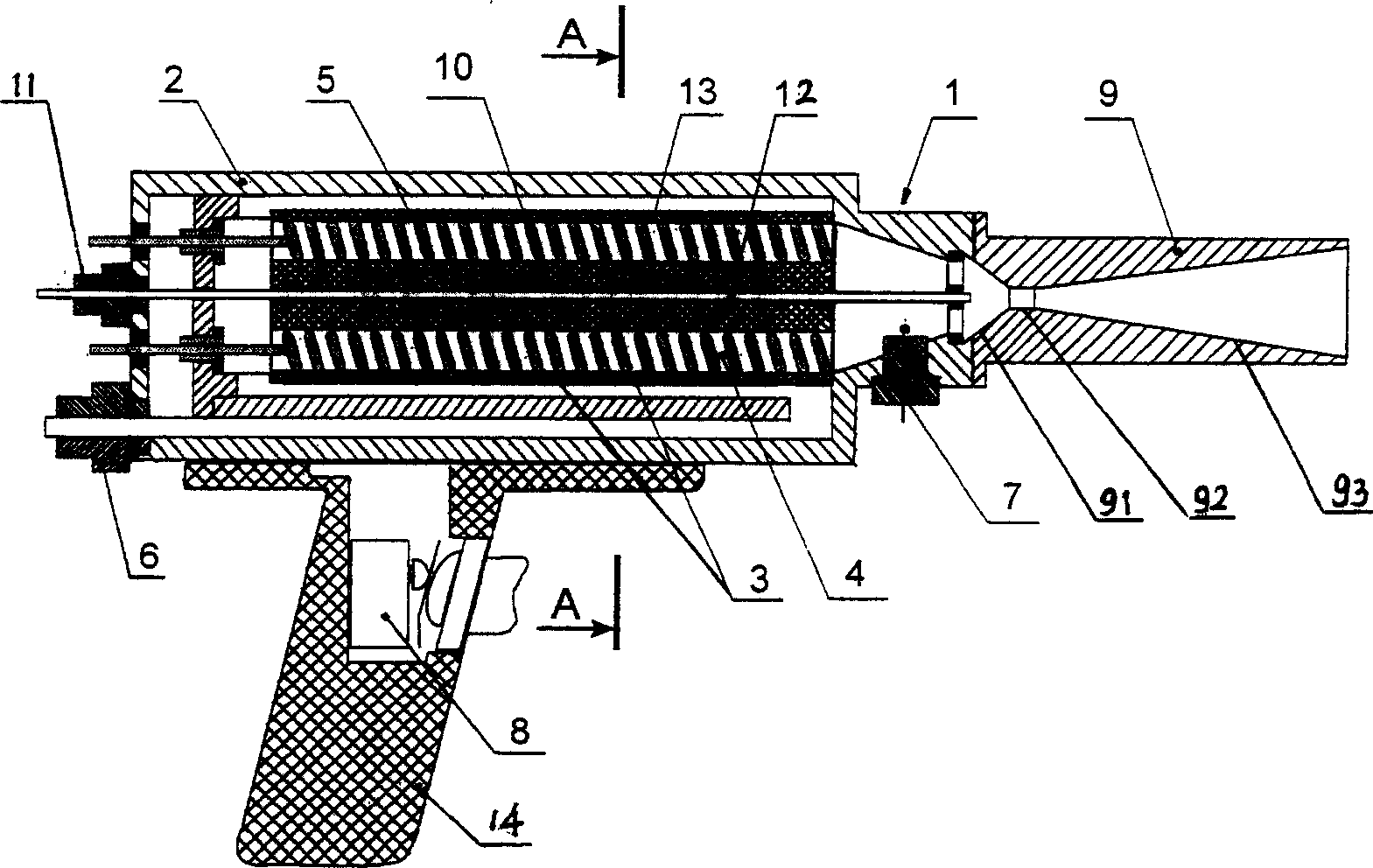

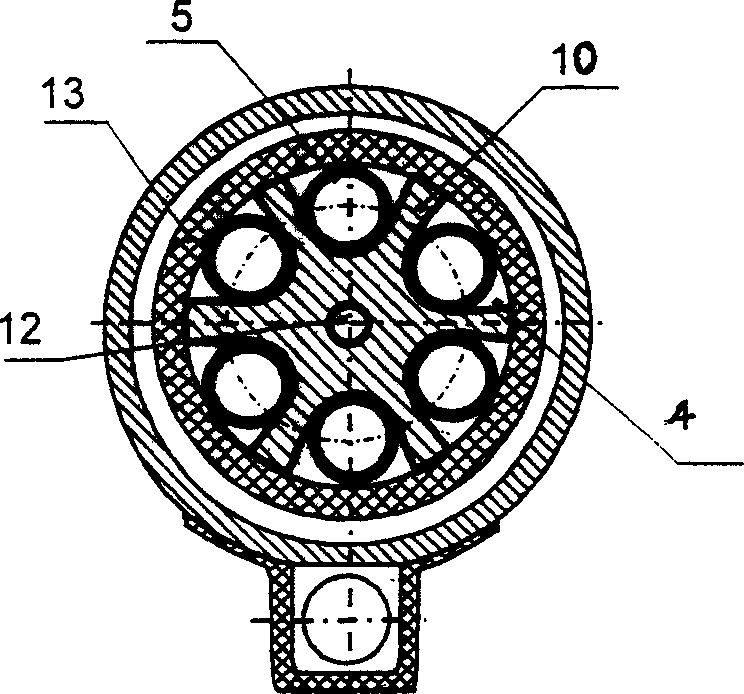

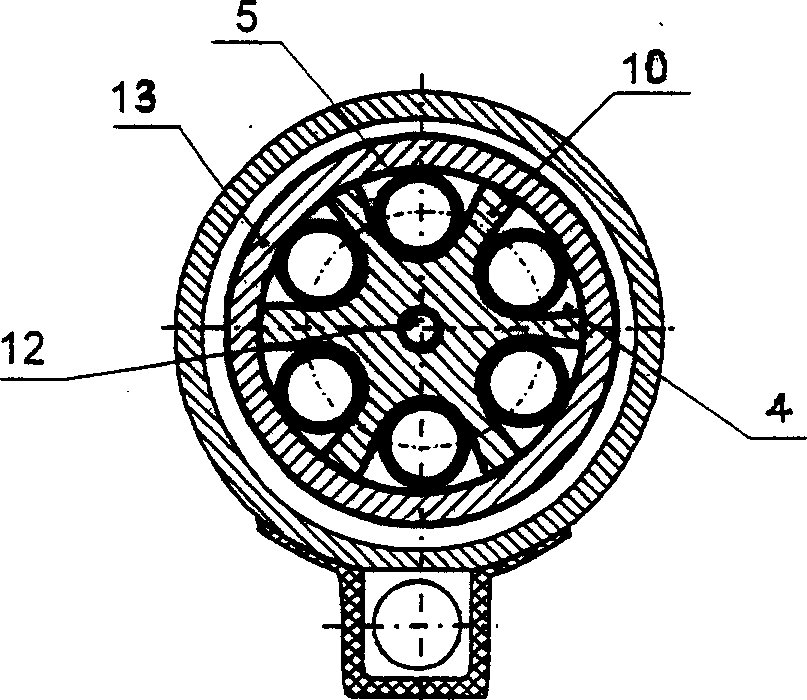

Powder delivery device

ActiveUS7455248B2Efficiently and satisfactorily operablePowder deliverySurgeryHand heldCoverage control

A pistol-shaped powder delivery device consolidates propellant pulse creation, powder storage, powder aerosolization and aerolsolized powdered delivery in a single device while providing dose, pattern and coverage control of the output spray. The single-hand-held, single-hand-operated device includes a housing having a handle portion that is selectively collapsed to generate a propellant pulse that is conveyed into and through powder stored in a reservoir mounted at an upward angle to the horizontal in a receptacle provided in the housing. Powder in the reservoir is caused to be aerosolized by the propellant pulse whereupon aerosolized powder exits the reservoir through an open end of, and elongate slots provided in the sidewall of, an elongate hollow member extending from an outlet in the receptacle through the stored powdered material into a head space in the reservoir. The outlet is connected a barrel portion for output of the aerosolized powder spray.

Owner:GENZYME CORP

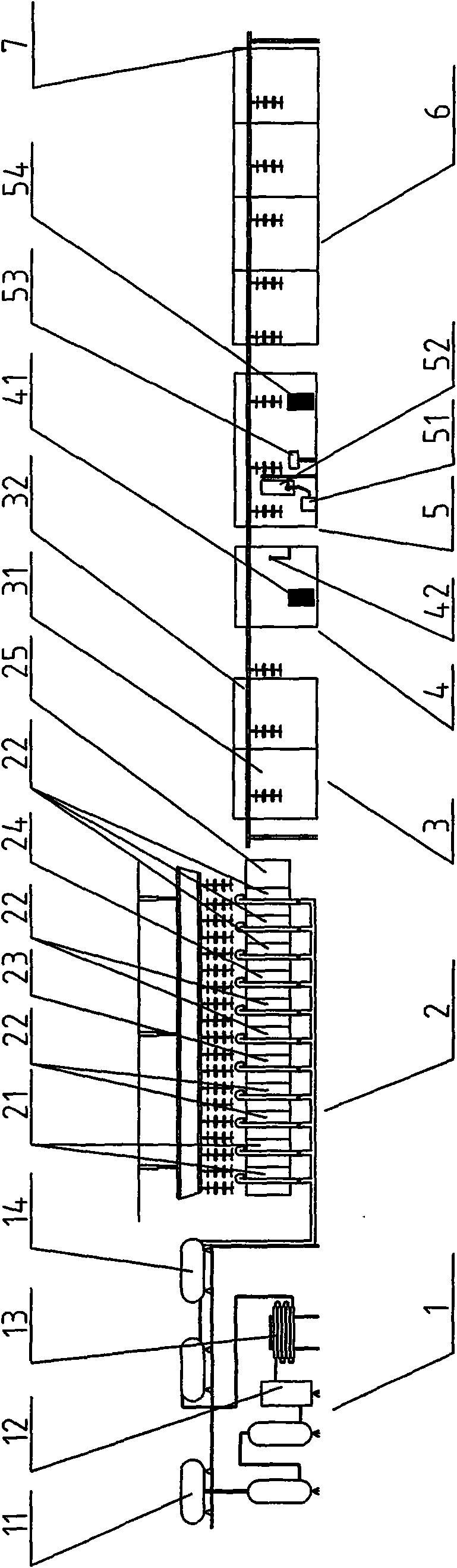

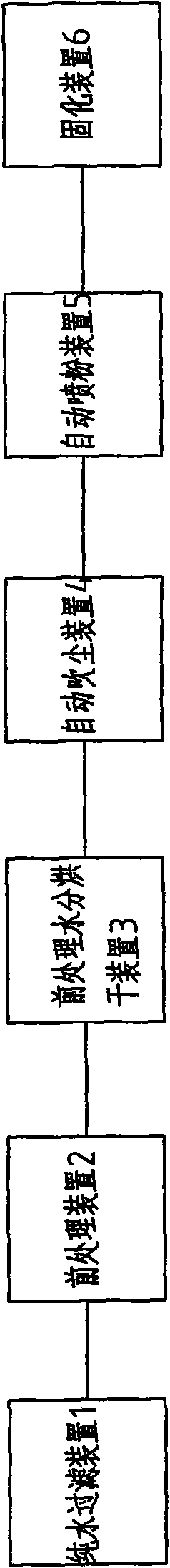

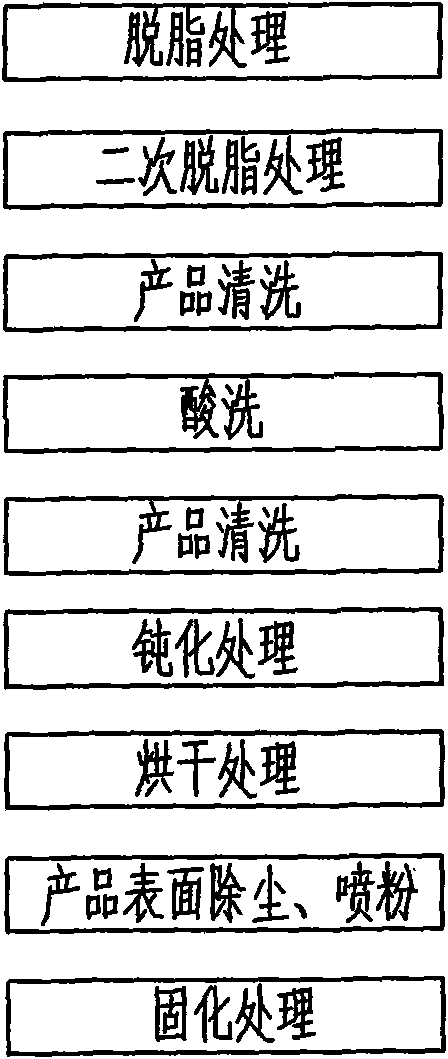

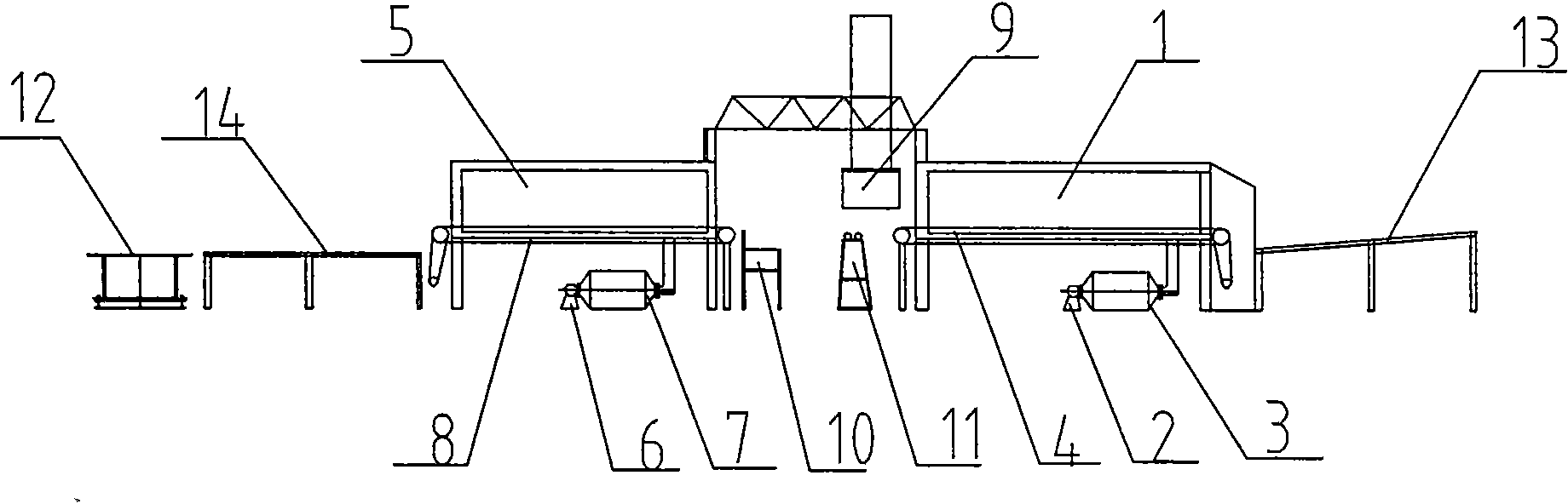

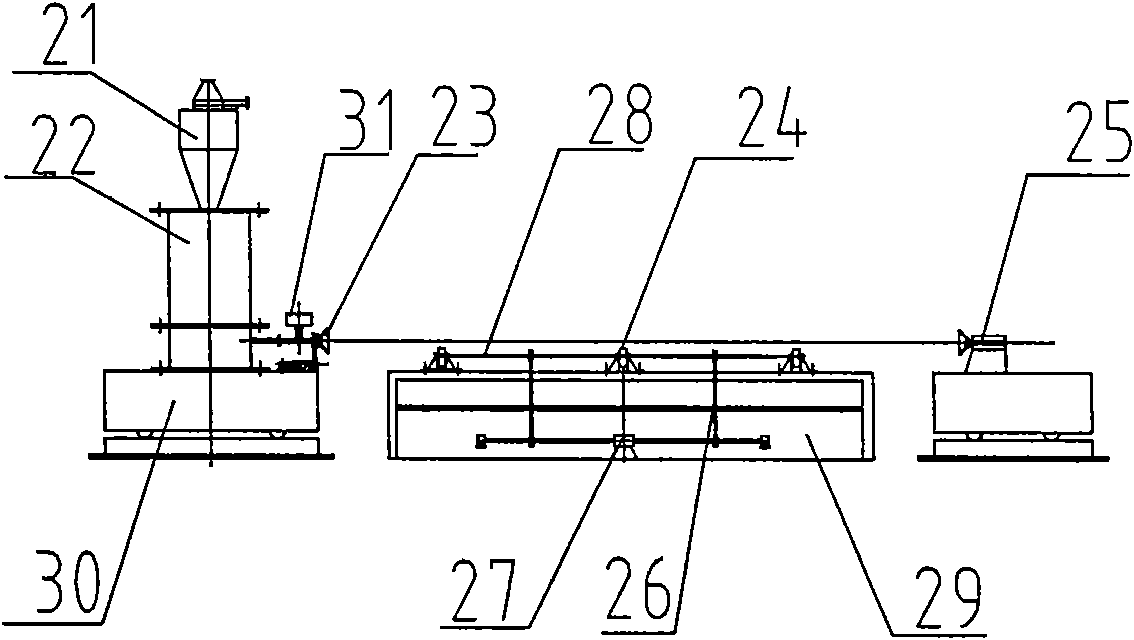

Automatic powder spraying line for automobile wheel hub finishing components and technique thereof

ActiveCN101602042AEvenly distributedSave resourcesLiquid spraying plantsPretreated surfacesSurface cleaningFiltration

The invention relates to an automatic powder spraying line for automobile wheel hub finishing components and a technique thereof; the production line comprises a pure water filtration system for providing pure water for the power spraying line, a pretreatment device, a pretreatment water content drying device, an automatic dust blowing device, an automatic powder spraying device, a solidifying device and a conveying lead rail; wherein, the pretreatment device sequentially comprises a pickling tank, alkaline wash tank and a passivation tank; the automatic powder spraying device comprises a tank body, a powder spraying gun, a powder storage tank, a powder sucking device, a constant temperature and humidity device. The production technique has the following steps: 1) alkali degreasing, 2) product surface cleaning, 3) drying, 4) dust abatement, 5) power spraying, 6) solidification. The production line of the invention features high degree of automation, suitability for mass production, high output benefits and low cost; in addition, the production technique equipped with the production line is more reasonable, components produced by the coating method of powder spraying has more uniform surface color and thickness.

Owner:GUANGZHOU JINZHONG AUTO PARTS MFG

Stained paper for decorating glass inter space, glass mirror face surface and manufacturing process thereof

InactiveCN101497502AExquisite decorationColorfulGlass/slag layered productsTectorial membraneEngineering

The invention provides a stained paper for glass partition or surface decoration of glass or a mirror surface, and provides a method for making the same. The stained paper mainly comprises a protective film layer, an adhesive layer, a base material layer and a process layer. The process layer is arranged on the upper surface of the base material layer which is a transparent plastic film material; the lower bottom of the base material layer is provided with the adhesive layer; the lower bottom of the adhesive layer is provided with the protective film layer; the process layer is prepared based on a UV printing ink process combining with a powder spraying process, a powdering process, a flocking process, a roller hot printing process, or the combination of the processes. A glass wall paper prepared by the method has the advantages of strong decorative effect, high grade, and convenient assembly and replacement, and is a preferably selected replacing product for the complanation of process glass.

Owner:陈威

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

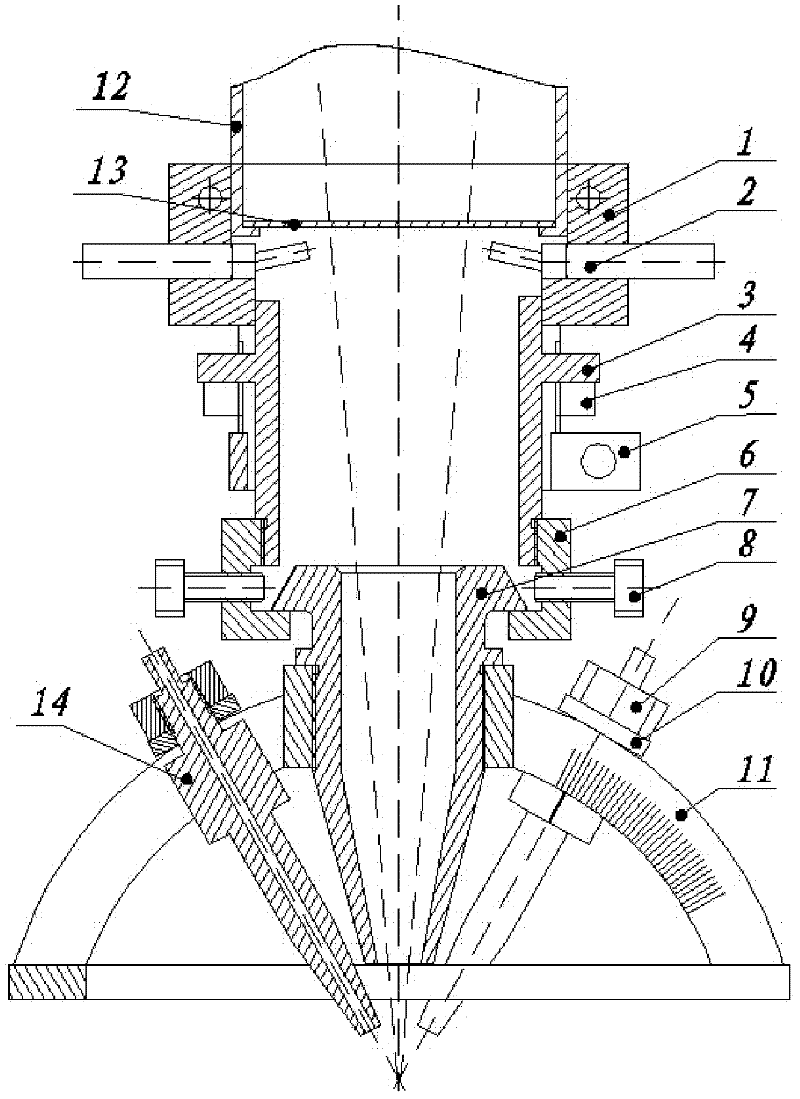

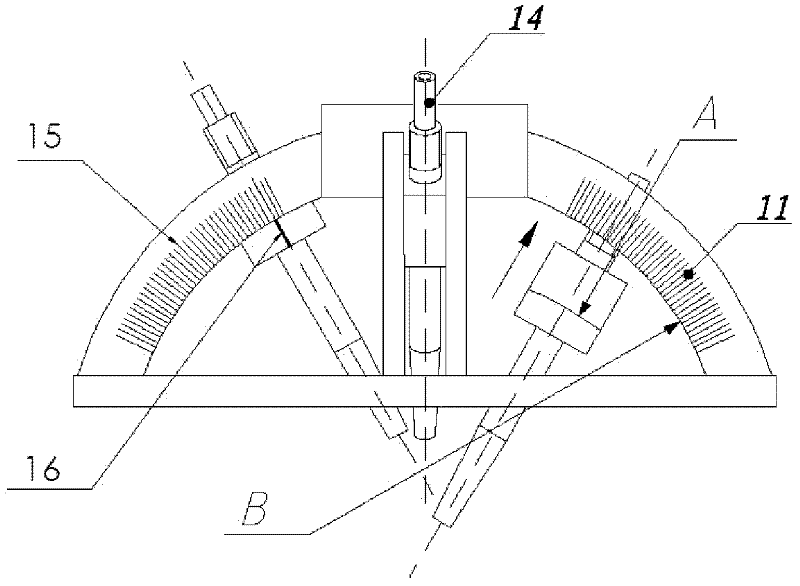

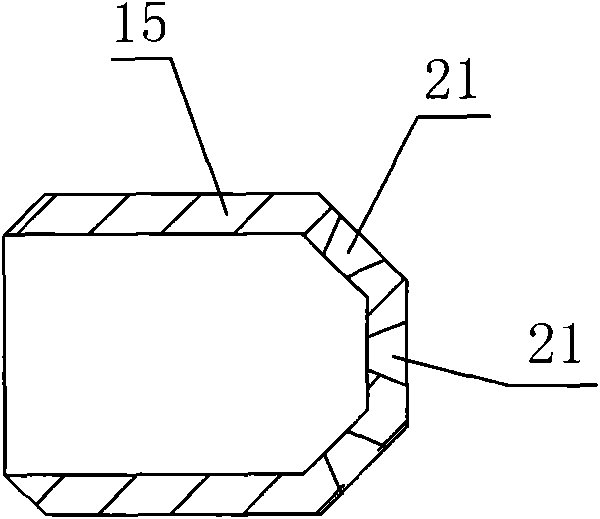

Angle-adjustable four-pipe powder feeding nozzle for laser direct forming

InactiveCN102554471AEasy fine-tuningStable positionMetallic material coating processesLaser beam welding apparatusMetallurgyProtective glasses

The invention discloses an angle-adjustable four-pipe powder feeding nozzle for laser direct forming, which comprises an upper portion, a middle portion and a lower portion, wherein the upper portion comprises an upper connecting sleeve and a protective glass decontamination nozzle, the middle portion comprises a sliding sleeve, a powder defocus adjusting nut, a locking sleeve and a central adjusting device, and the lower portion comprises a conical laser sleeve, a powder spraying pipe and a powder spraying pipe rail frame. The angle-adjustable four-pipe powder feeding nozzle is characterized in that the powder spraying pipe is capable of sliding on the powder spraying pipe rail frame so that the injection angle of powder can be continuously adjusted, positive and negative defocus values of powder collection points can be continuously adjusted by means of vertical movement of the sliding sleeve, and coaxiality of laser and powder can be adjusted by a coaxiality adjusting device. The nozzle not only can be used as a coaxial powder feeding nozzle, but also can be used as a paraxial powder feeding nozzle, the inner surface of a powder spraying pipe hole is extremely smooth and as smooth as a mirror surface, and collectability of the powder is improved.

Owner:XI AN JIAOTONG UNIV +1

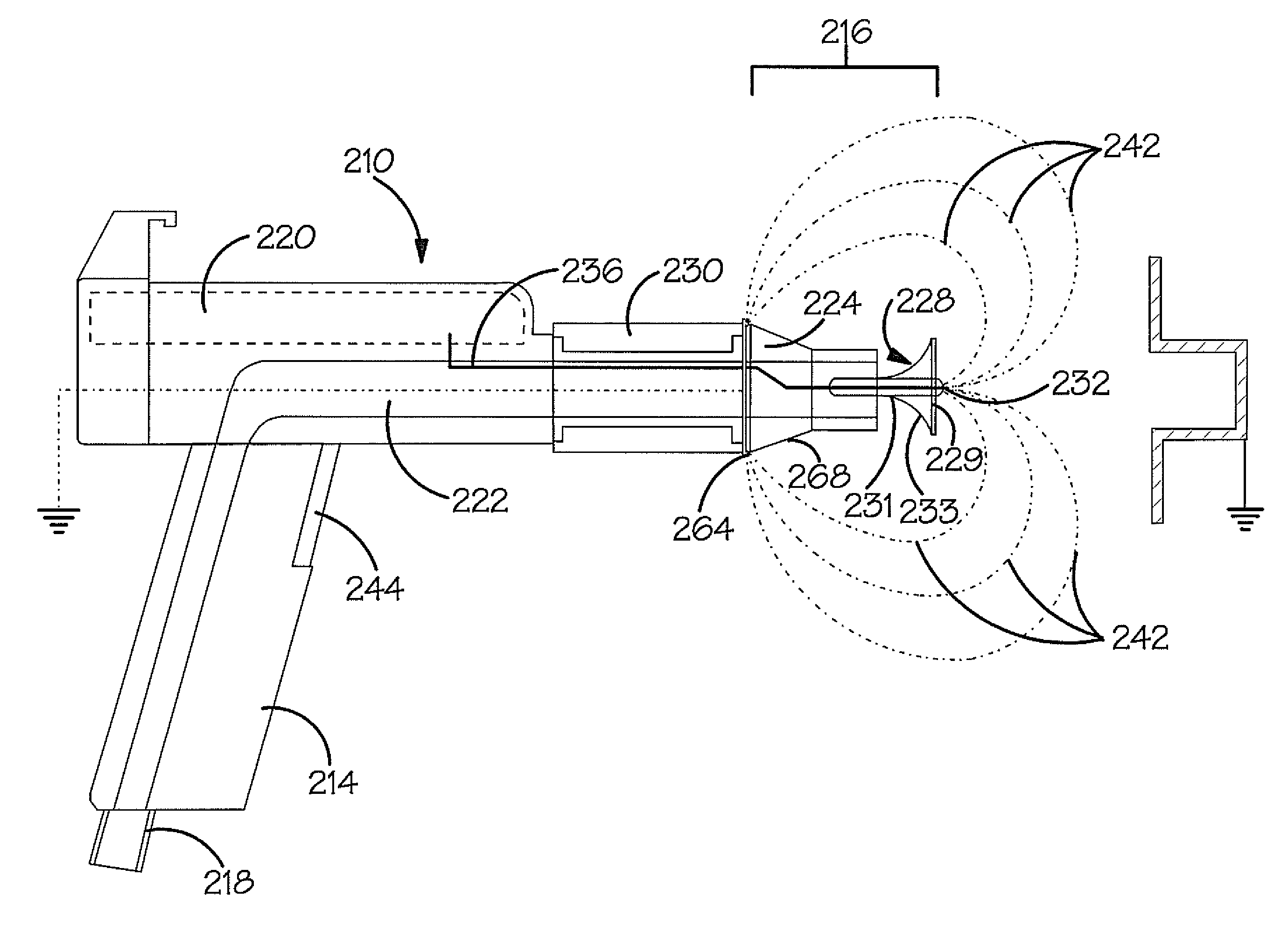

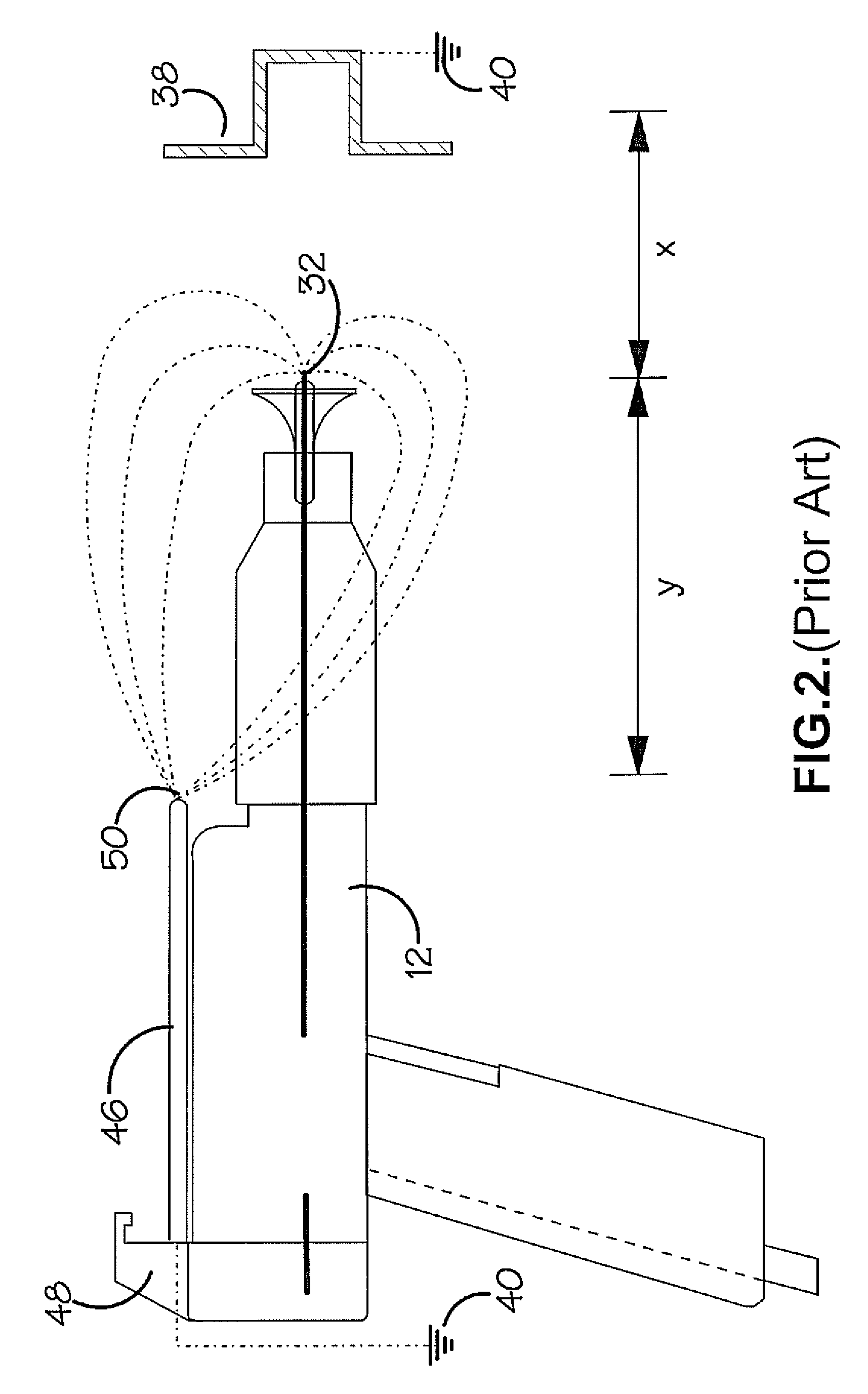

Powder spray coating discharge assembly

InactiveUS20090229517A1Reduce discharge currentImprove conductivityLiquid spraying plantsLiquid surface applicatorsSpray coatingElectrical connection

A powder spray coating discharge assembly (230, 260, 216, 228, 232) for connection to an electrostatic spray coating gun (210), the gun (210) having a gun body (212), means for connecting to a supply of coating powder and means for supplying a voltage (20) at first and second potentials respectively to first (292) and second electrical connections (294) each for connection to a respective one of a discharge electrode (232) and a counter electrode (260), the means for supplying the voltage (20) comprising: a variable voltage power supply (114) having an input connected to an electrical power source (110), an output connected to each of the first and second electrical connections (292, 294), a control circuit (128) for controlling the variable voltage power supply (20) and means (120) for sensing an output load, wherein the control circuit (128) is adapted to adjust the variable voltage power supply (20) to reduce the voltage and current in proportion to a sensed increase in load, or vice-versa.

Owner:YU TUNG INVESTMENT HLDG

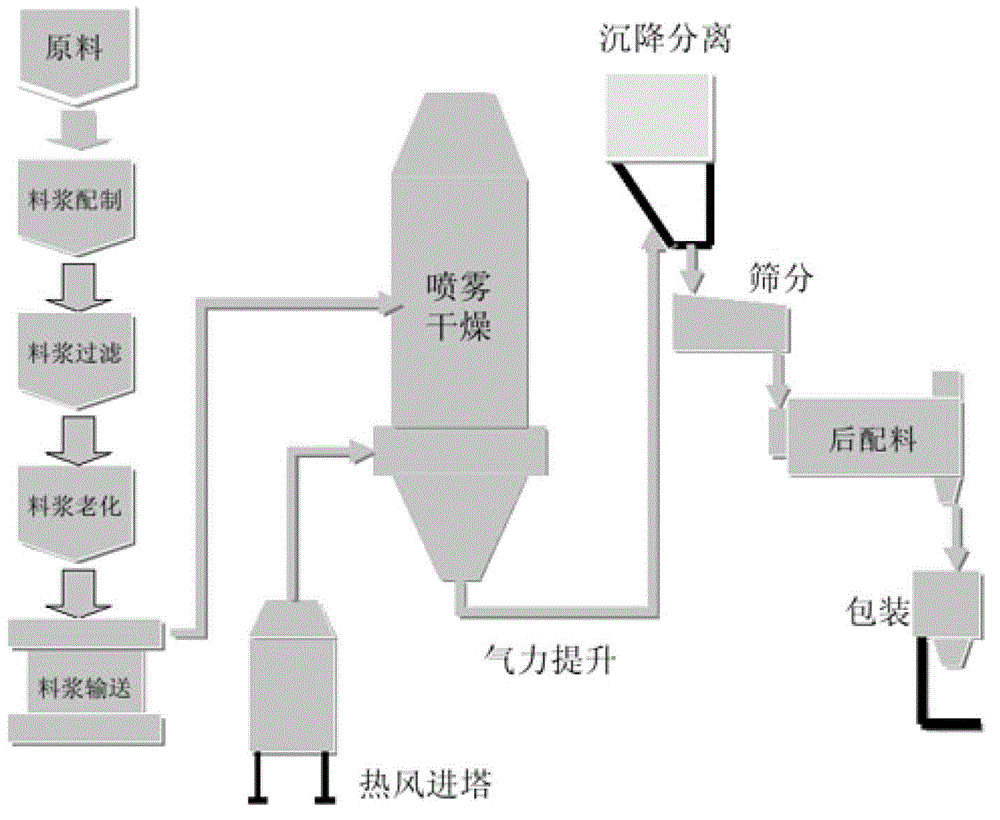

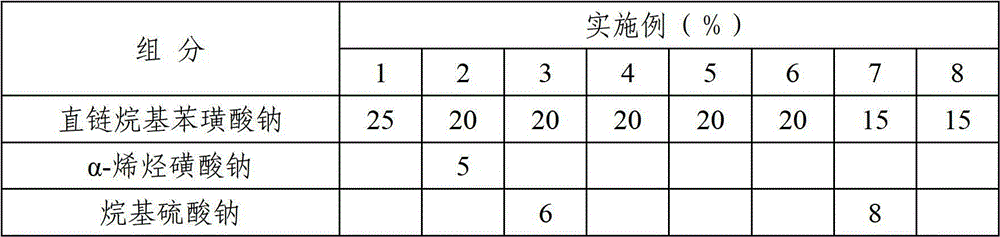

Neutral washing powder and preparation method thereof

ActiveCN102876489AStrong decontaminationImprove liquidityOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic acidSolubility

The invention provides a neutral washing powder with a new compound formula. The washing powder contains neutralizing agents and powder spraying and forming auxiliaries, namely organic acids and does not contain such alkaline materials as sodium silicate and sodium carbonate. The washing powder can effectively protect fabric fibers, care clothes, is truly inirritative in hand washing, has good dissolubility, is quickly dissolved under low temperature and adopts the spray drying production process. The specific feeding sequence is adopted during slurry mixing, so that the washing powder particles with moderate strength and good flowability can be produced with the formulas under the conditions of high active agent system and absence of powder spraying skeleton sodium silicate materials. The washing powder has strong detergency under neutral condition and achieves the effect of washing and caring unification.

Owner:NICE GROUP

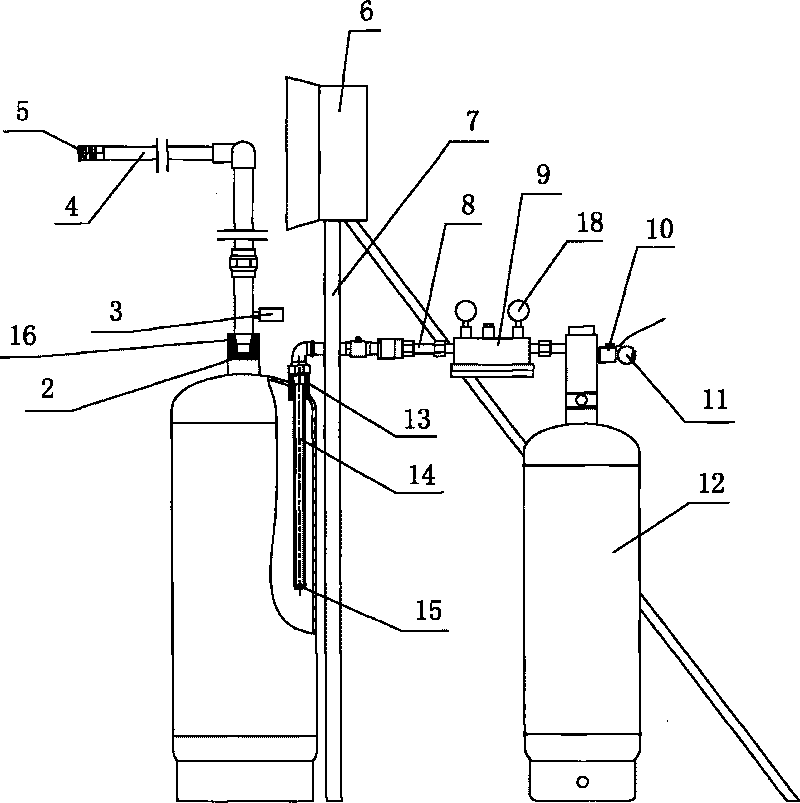

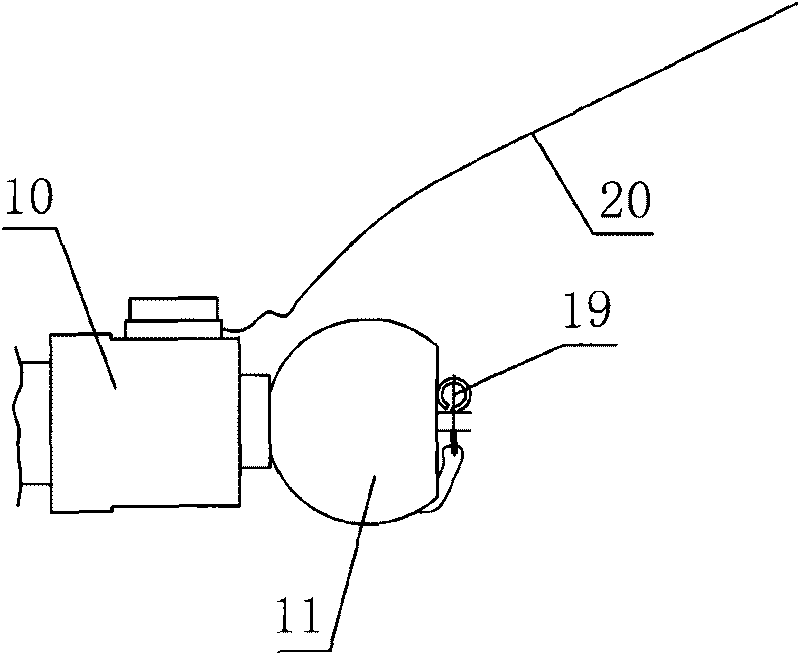

Ultrafine dry powder cold gas sol fire extinguishing device

The invention discloses an ultrafine dry powder cold gas sol fire extinguishing device which comprises an ultrafine dry powder fire-extinguishing agent storing container, an ultrafine dry powder spray device and a high-pressure gas drive device, wherein the ultrafine dry powder fire-extinguishing agent storing container is provided with a gas inlet and a powder spray opening; the ultrafine dry powder spray device is sealed and connected with the powder spray opening; the high-pressure gas drive device is sealed and connected with the gas inlet; the ultrafine dry powder spray device comprises a powder spray pipe, an ultrafine dry powder outlet nozzle, a dry powder spray sealing membrane which is arranged in the powder spray pipe and a fan which is arranged in the front or the back of the ultrafine dry powder outlet nozzle; and the high-pressure gas drive device comprises a gas storing bottle which is connected with the gas inlet through a gas inlet pipeline, a gas circuit control valve and an inflating and connecting pipe which is inserted into the storing container and is provided with a gas inlet nozzle. The invention has reasonable design, simple structure, low processing and manufacture cost, simple and convenient use and operation, convenient distribution, high fire extinguishing speed, high fire extinguishing efficiency, environmental protection and no pollution, and simultaneously can be effectively suitable for areas needing fire extinguishment, such as wells, roads, cable chutes, tunnels, subways, and the like.

Owner:国兴一实安防科技实业(浙江)有限公司

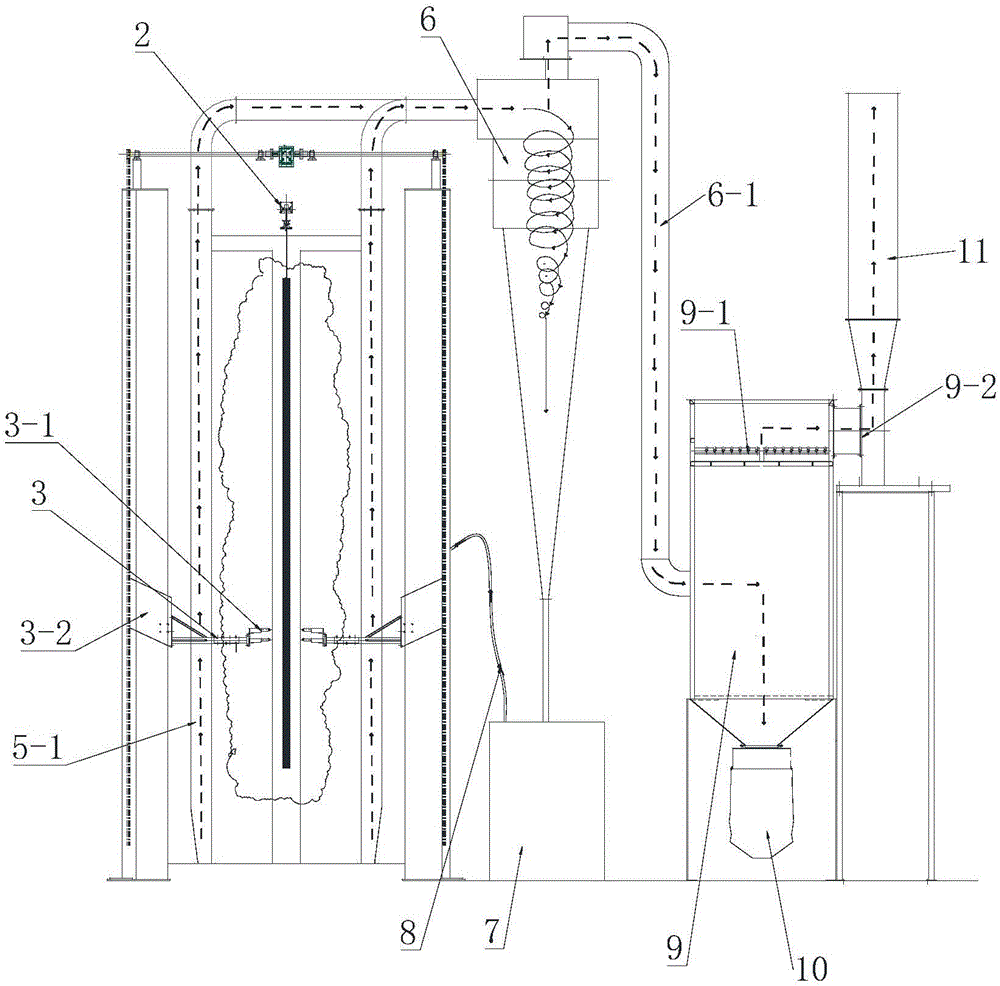

Electrostatic powder vertical type spraying device

ActiveCN105964435AEasy to closePrevent spillageLiquid spraying plantsLiquid surface applicatorsMetallurgyExhaust pipe

The invention discloses an electrostatic powder vertical type spraying device. The electrostatic powder vertical type spraying device comprises a powder spraying house, a conveying device for conveying workpieces, a powder spraying device, a powder supplying device and a powder recycling device. The powder spraying house is provided with a workpiece input port and a workpiece output port both of which correspond to the conveying device. The electrostatic powder vertical type spraying device is characterized in that the powder recycling device comprises exhaust pipes arranged at the four corners of the powder spraying house respectively, and each exhaust pipe is provided with a gap for exhausting air from bottom to top, so that air flow in the powder spraying house is uniform and the negative pressure of air needing to be exhausted is reduced; the powder spraying device comprises electrostatic spray gun sets oppositely arranged on the two sides of the conveying device and a lifting device driving the electrostatic spray guns on the two sides to synchronously ascend and descend. The electrostatic powder vertical type spraying device is simple in structure and convenient to use and install; in the powder spraying production process, powder consumption is low, the one-time powder coating rate is high, the time taken to clean the powder house and the time taken to change powder are shortened, electric energy is saved, fewer operating workers are needed, and the production cost is greatly reduced.

Owner:佛山市安邦得机械设备有限公司

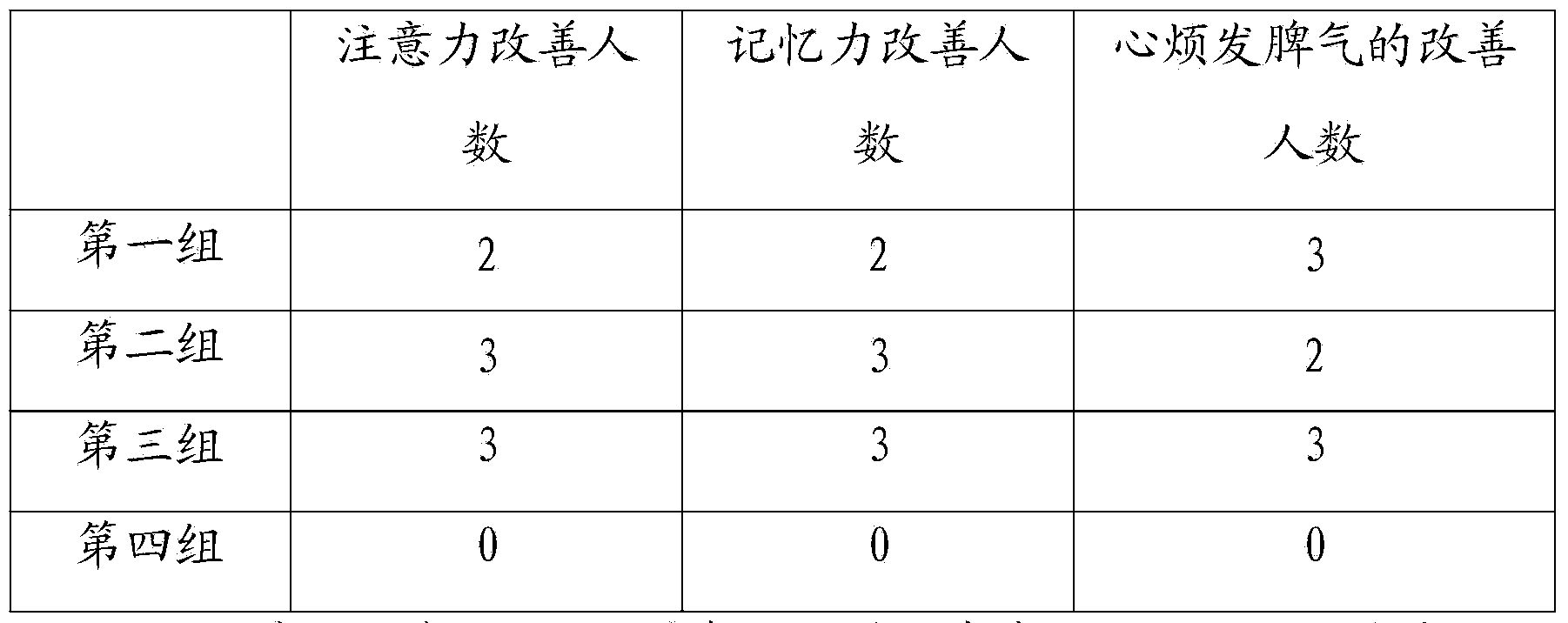

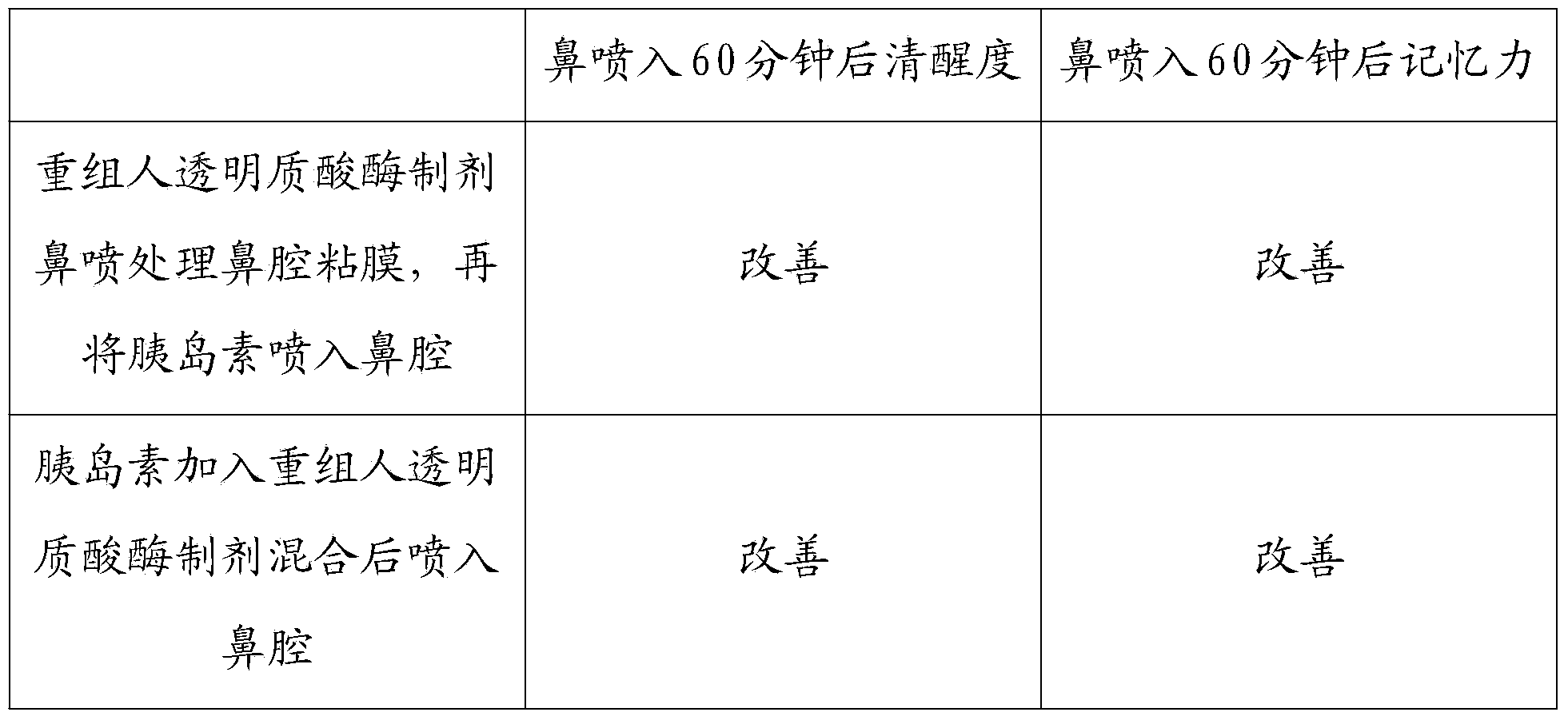

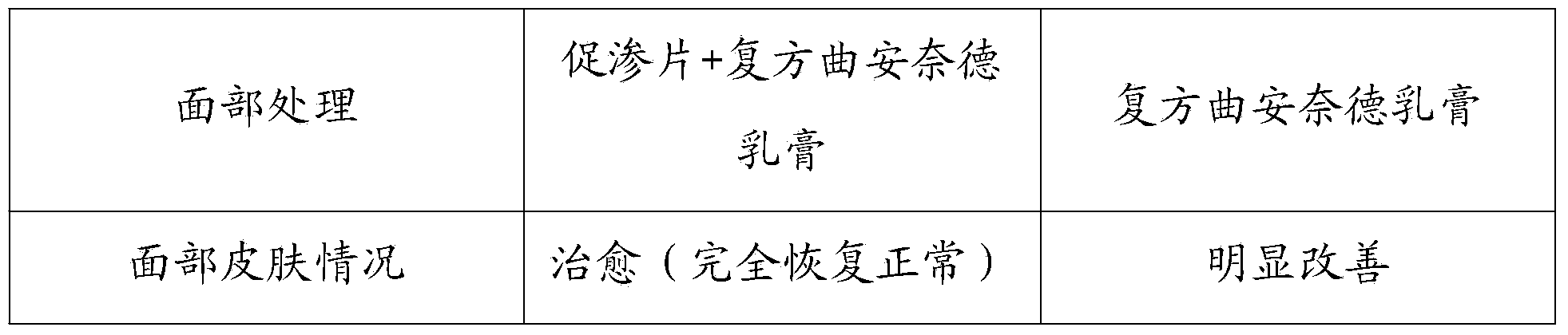

Recombined human hyaluronidase, production and purification method and preparations thereof, use method and application

InactiveCN103468662AImprove permeabilityPharmaceutical non-active ingredientsEnzymesNasal cavityDisease

The invention discloses a recombined human hyaluronidase, a production and purification method and preparations of the recombined human hyaluronidase, a use method and application. Recombined human hyaluronidase PH20 or human hyaluronidase human albumin fusion protein PH20-HSA or human hyaluronidase human immunoglobulin IgG2Fc fragment fusion protein PH20-IgFc is adopted by the recombined human hyaluronidase and used in the mucosa or the surface of the skin. The preparations of the recombined human hyaluronidase can be made into different types such as membrane preparations, spray preparations, lotion and freeze-dried powder spray and used for skin infiltration promotion of beauty nutrient substances, skin mucosa infiltration promotion of surface anesthetic, infiltration promotion of skin disease therapeutic medicine, mucosa infiltration promotion of biological tranquillizer, mucosa skin infiltration promotion of growth factors, mucosa infiltration promotion of hypoglycemic drug, mucosa nasal cavity infiltration promotion of nervous centralis nutrient substances and the like.

Owner:惠觅宙

Quick laser cladding device and cladding method of flat metal parts

ActiveCN103741139AImprove surface qualityPrecise and controllable thicknessMetallic material coating processesGalvanometerRapid scan

The invention relates to a quick laser cladding device of flat metal parts. The quick laser cladding device comprises five modules, namely an electrostatic powder spraying device, a quick laser galvanometer scanning device, a gas protection module, a parts conveying module, and a parts fixing clamp. The quick laser cladding device has the advantages of low equipment building and operating costs, fast powder adding method, fast cladding speed, good cladding layer surface quality, accurate and controllable cladding layer thickness and the like. According to the quick laser cladding device, the system building and operating costs are reduced, the production efficiency is improved, and good cladding quality is also obtained. By adopting the method, the requirements of cladding the flat metal parts at low cost, large batch, high speed and high quality can be met.

Owner:苏州科弗曼机械有限公司

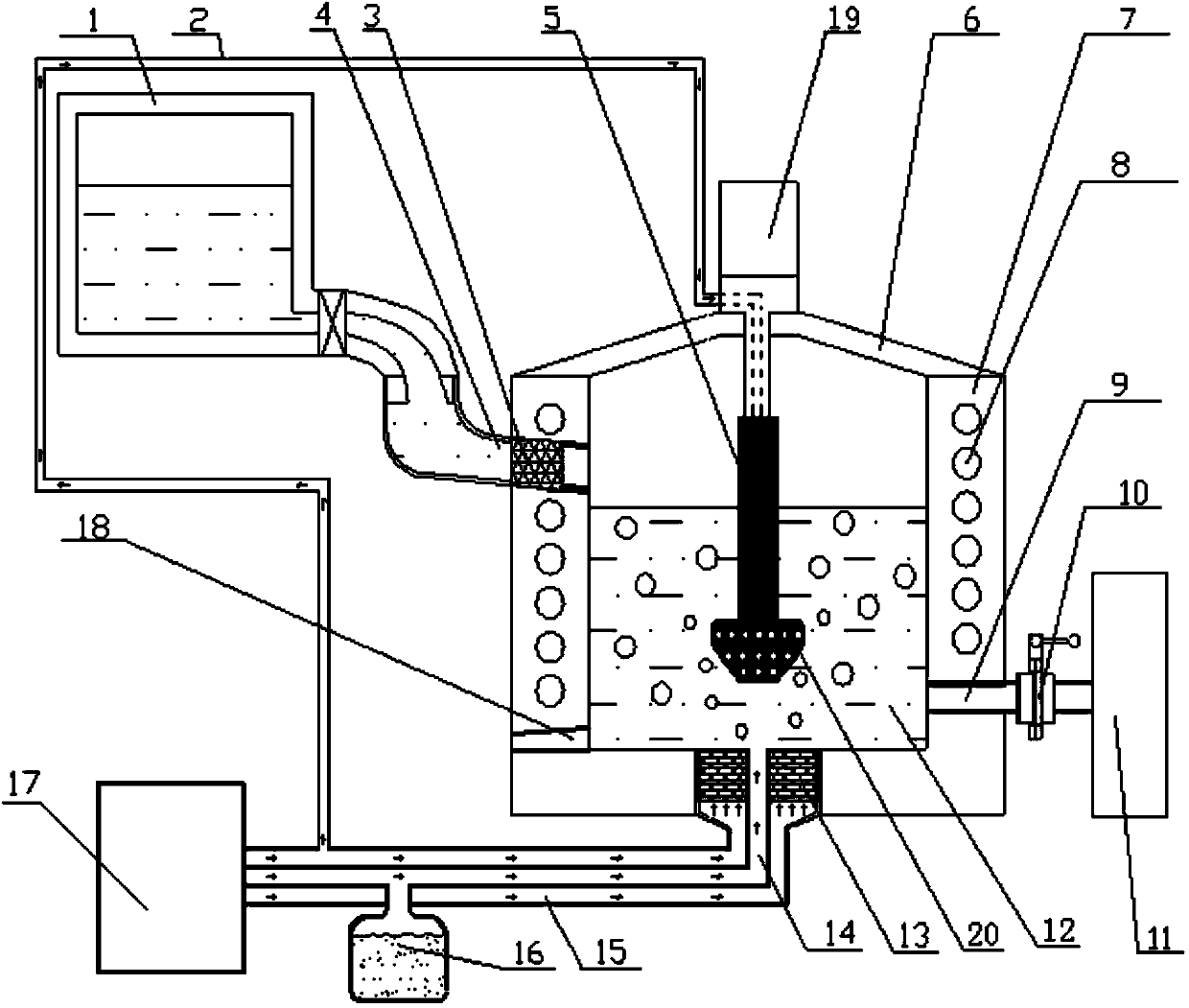

Manufacturing device for light alloy or light metal semi-solid slurry and manufacturing method

The invention discloses a manufacturing device for light alloy or light metal semi-solid slurry and a method for manufacturing the semi-solid slurry through the device. The manufacturing device for the light alloy or light metal semi-solid slurry comprises a smelting furnace, a runner, a mechanical stirring device, an inert gas stirring device, a powder spray device and a heating device. The semi-solid slurry manufacturing device reasonable in structure is designed, continuity for manufacturing the semi-solid slurry is good, and products can be cast industrially and continuously in a large scale by applying a semi-solid pressure casting or squeeze casting forming method. According to the manufacturing method for the semi-solid slurry, efficiency for manufacturing the light alloy or light metal semi-solid slurry is high, energy consumption is less, cost is low, and the manufactured semi-solid slurry cannot generate oxide inclusions, and is even in organization and excellent in quality.

Owner:机械科学研究总院(将乐)半固态技术研究所有限公司

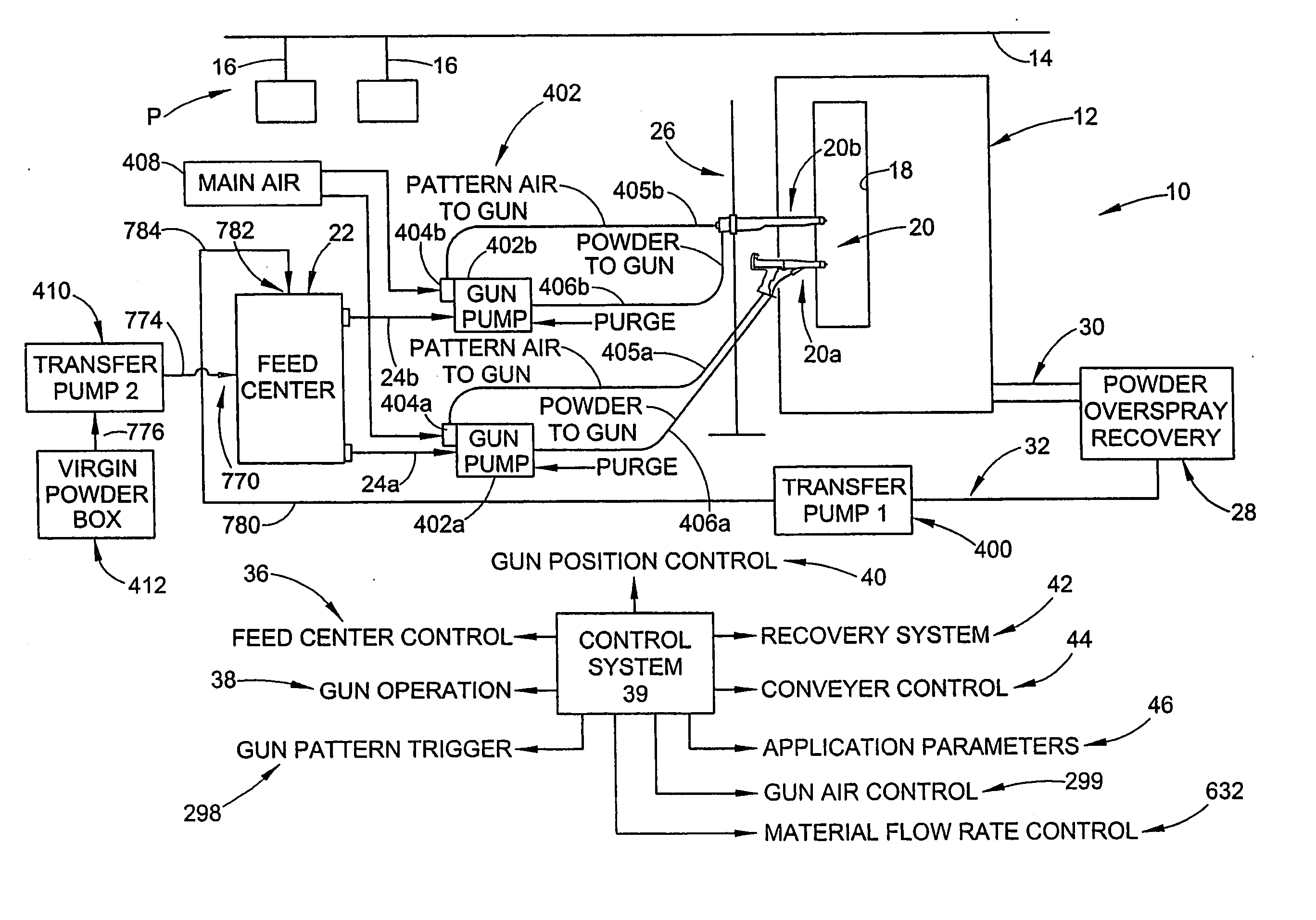

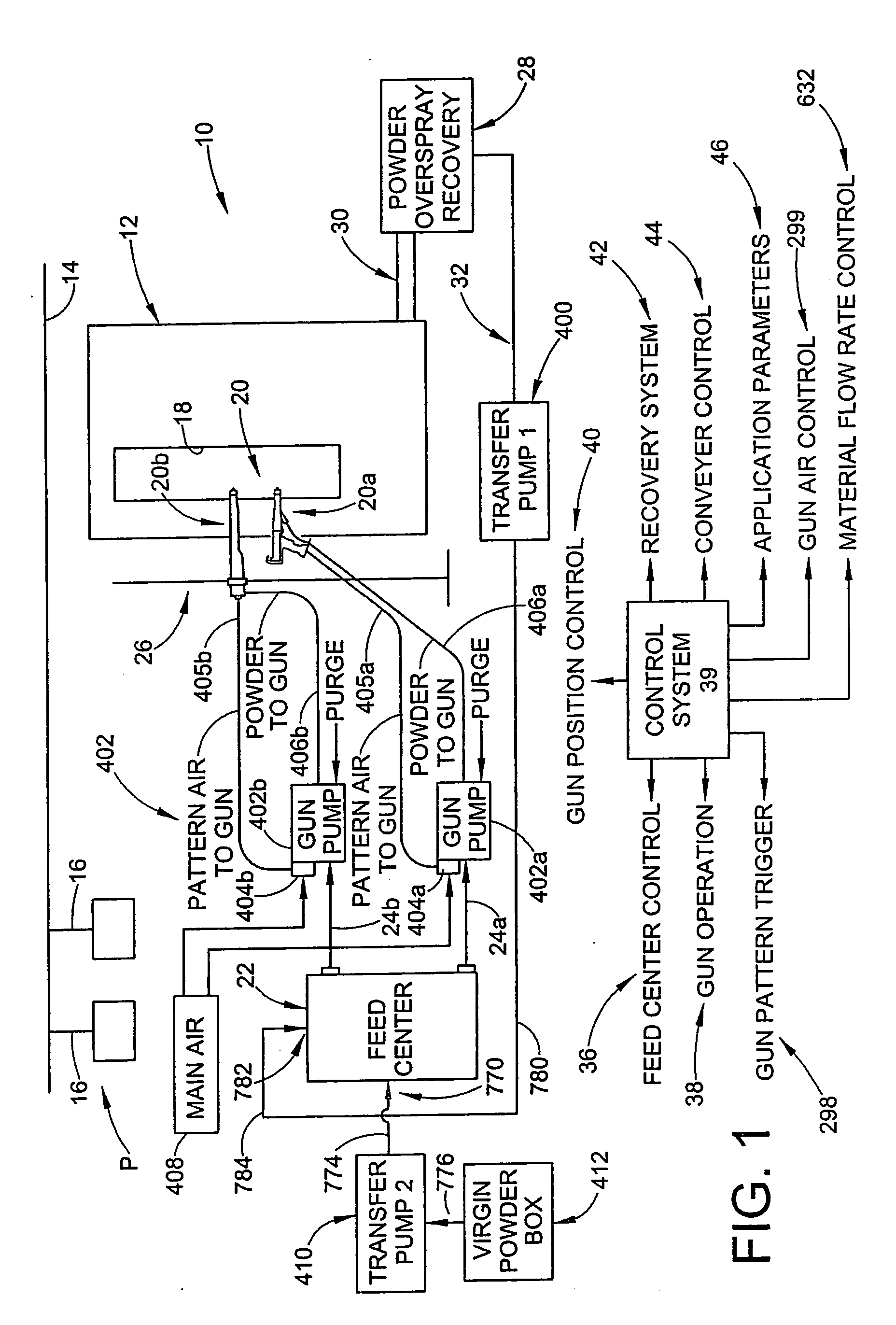

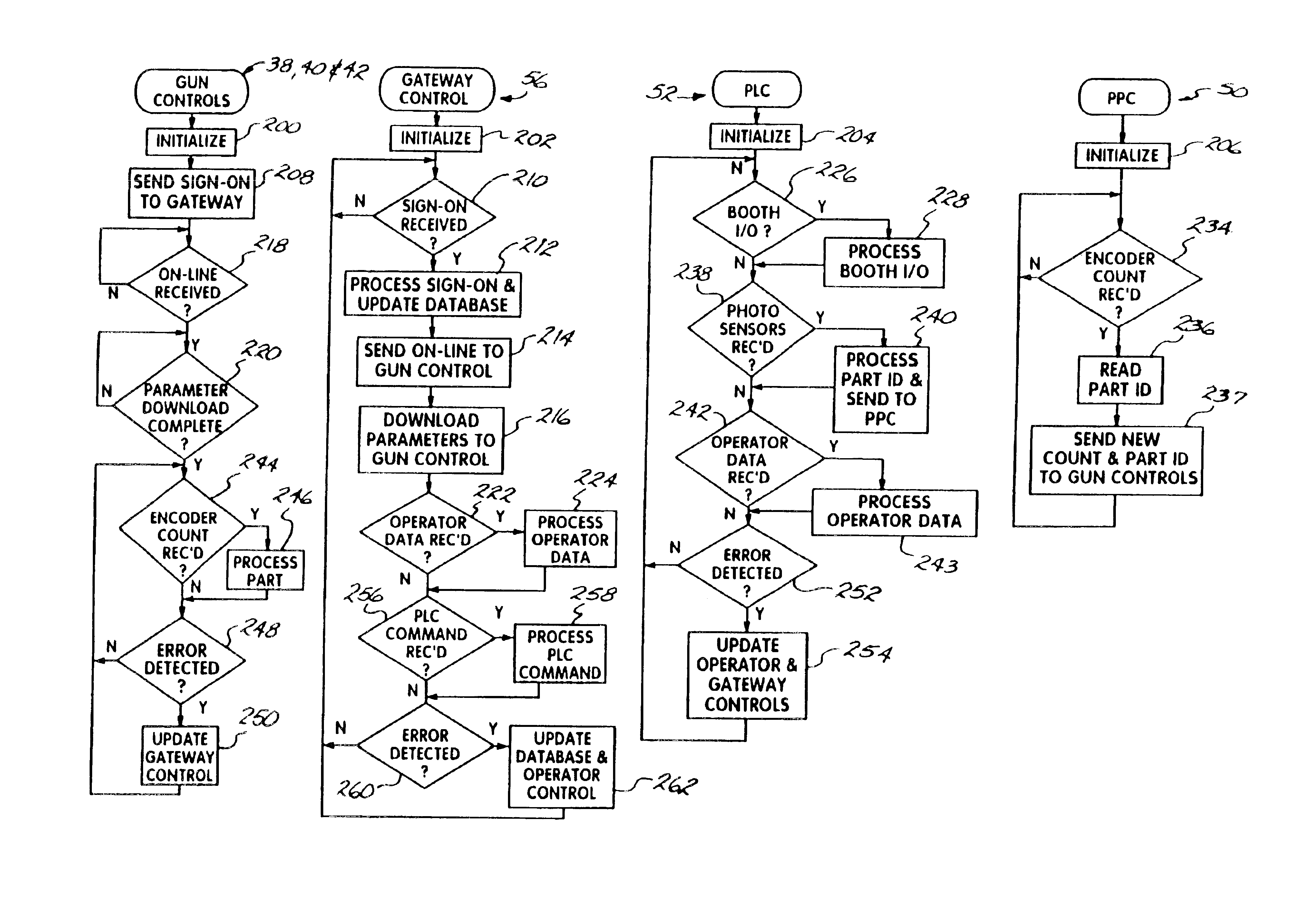

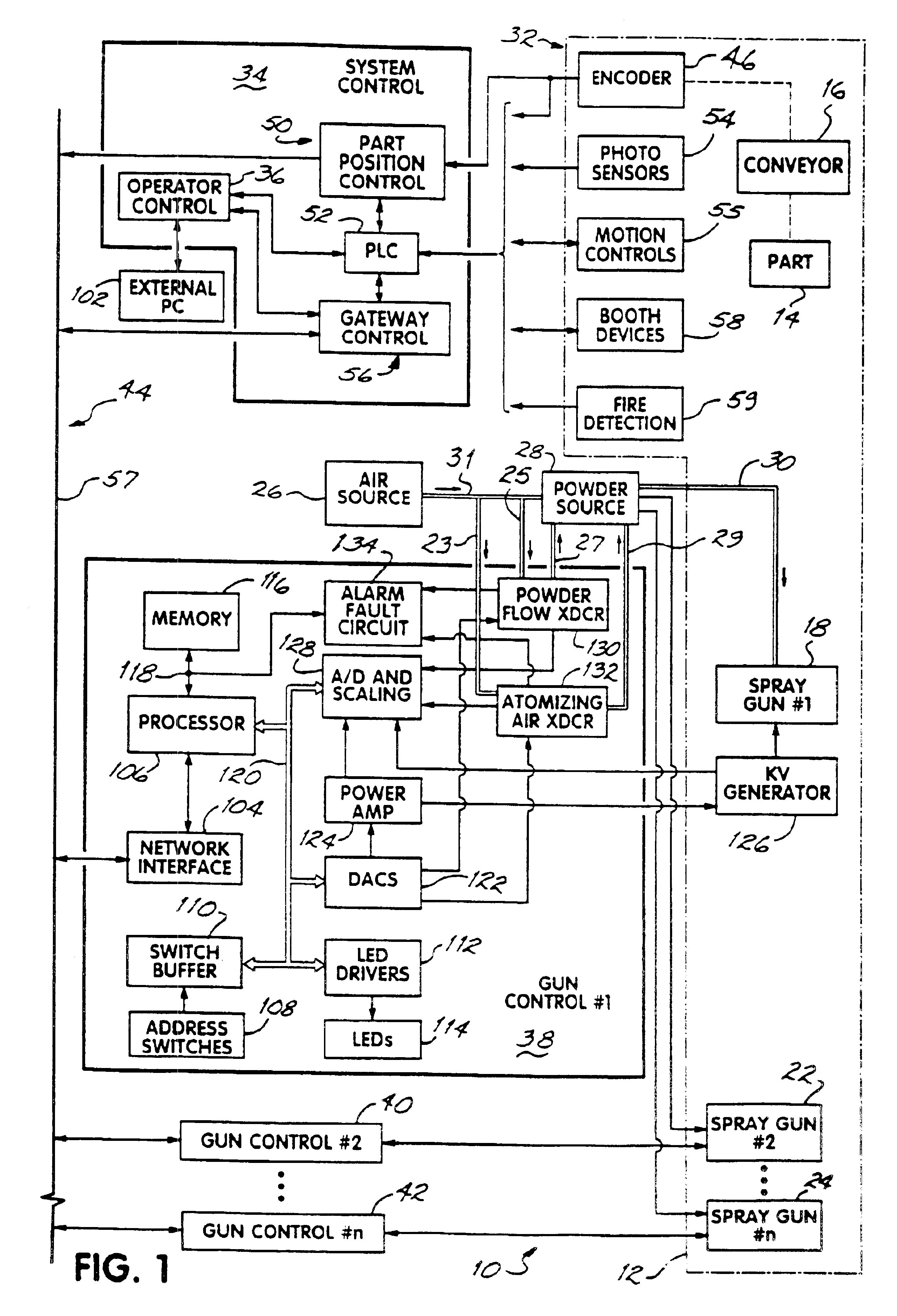

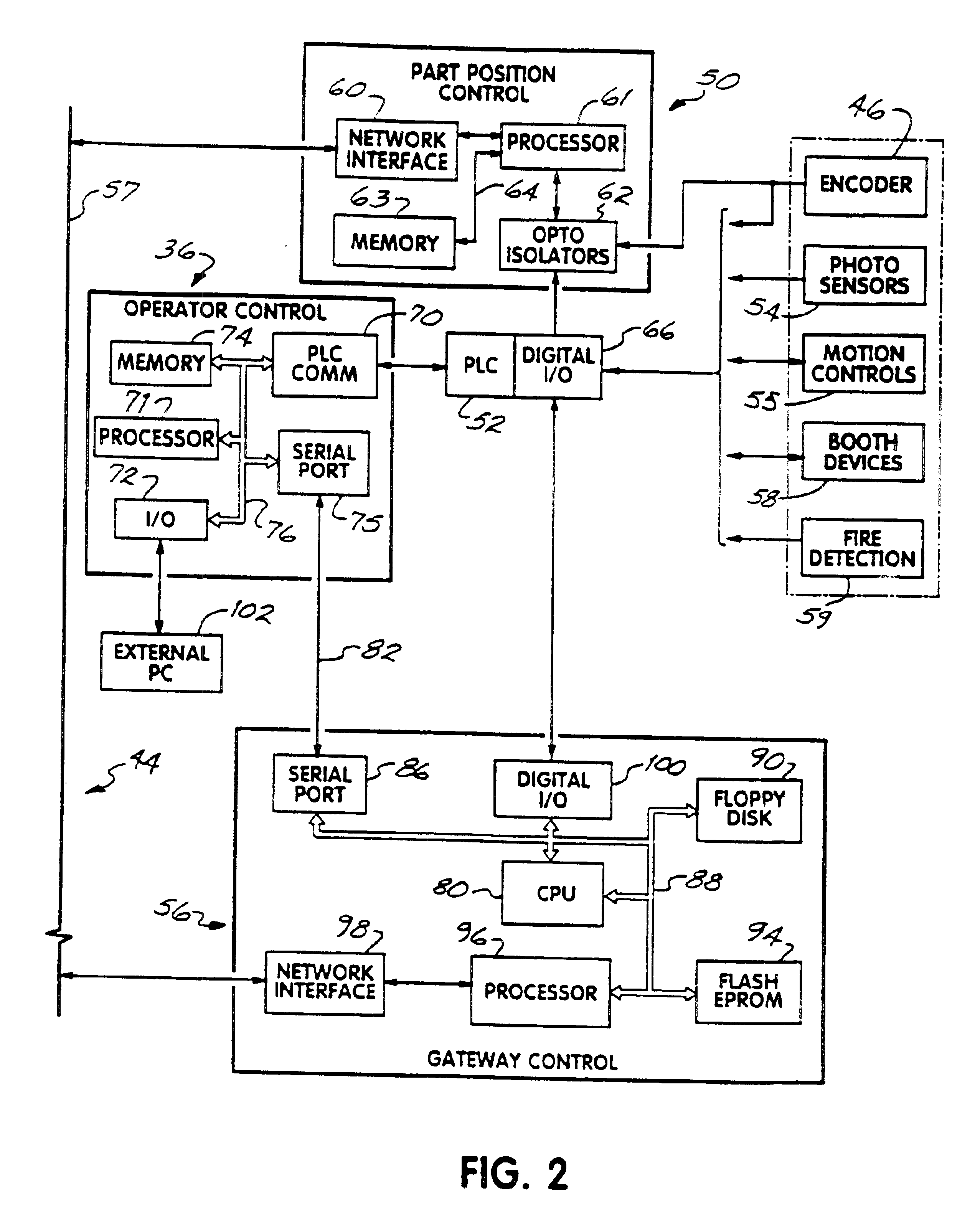

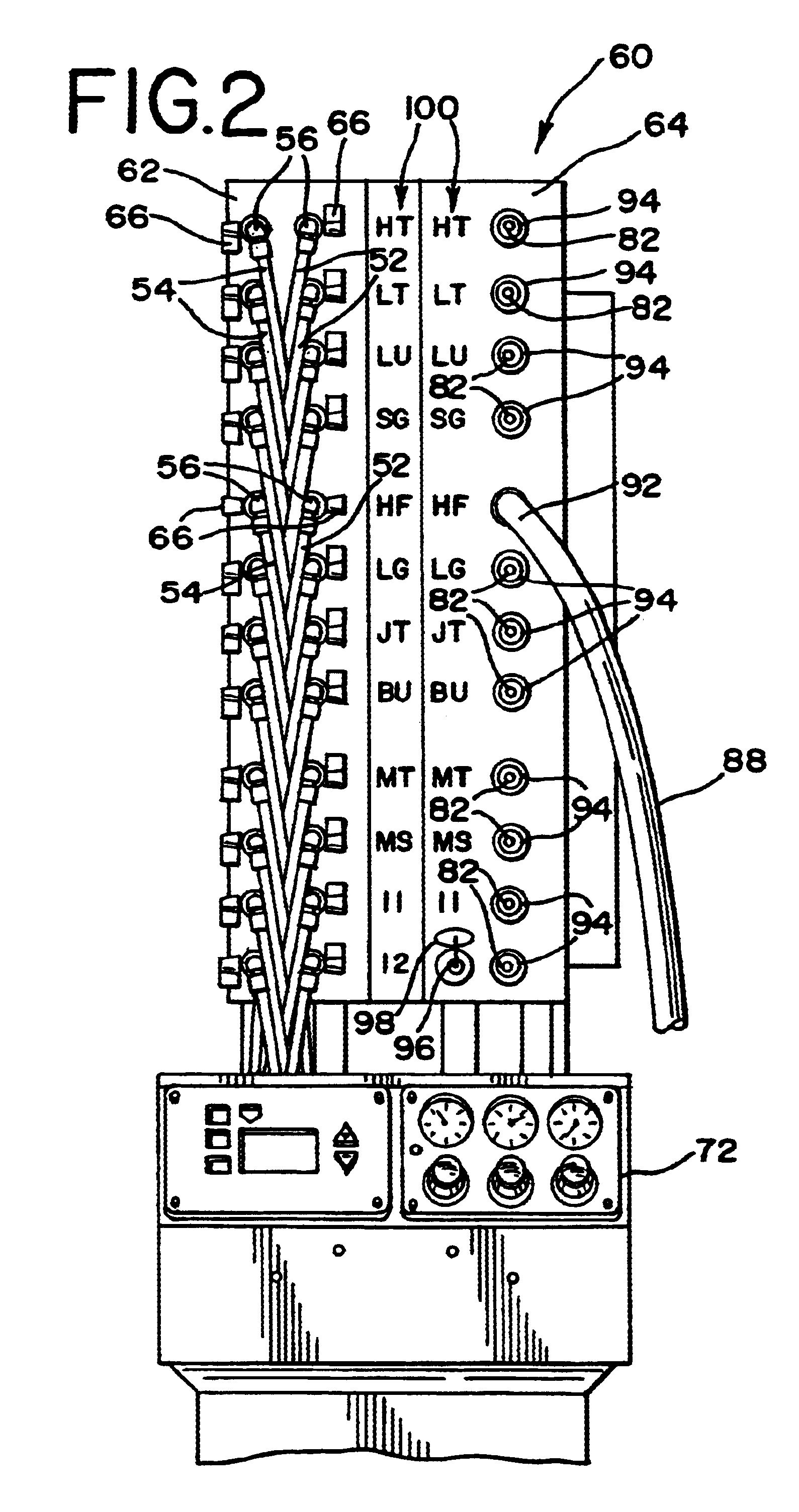

Distributed control system for powder coating system

InactiveUS6863920B2Save operator timeHuge savingsLiquid spraying plantsLiquid surface applicatorsDistributed control systemSystem controller

A powder coating control system comprising a plurality of gun controls associated with a like plurality of powder spray guns. Each of the gun controls stores a plurality of presets spray parameters. Each of the gun controls responds to part identification signals and part position signals to select in real time one of the stored presets of spray parameters and trigger its respective powder spray gun ON and OFF to apply a powder coating to the moving part in accordance with the selected set of spray parameters. The control system further permits a gun purge cycle to be programmed either before or after the powder coating process is executed. The control system automatically initializes and brings each of the gun controls to an operable state on-line with the system control.

Owner:NORDSON CORP

Pneumatic powder spraying apparatus

InactiveCN1603008ABroaden the scope of industrial applicationsEasy to carryLiquid spraying apparatusPressure inorganic powder coatingGas heaterMechanical energy

This invention opens one kind of gas dynamic powder spraying device which is composed with compression gas source,powder feed unit and spray mechanism.The spray mechanism includes gas heater and supersonic nozzle that is rigid linkage structure of coaxial setting.Gas heater includes metal shell,heat element and electrothermal insulator.One end of metal shell is fixed coaxial with the supersonic nozzle,the other end of metal shell is equipped with carrier gas joint and feed powder joint.The electrothermal insulator which is installed in the metal shell is composed with two coaxial emboitement internal and external tube,the center of the internal tube has a channel which two ends respectively connect powder feed unit and supersonic nozzle.In the exine of the internal tube,there are agroove gas direct channels which connect to the compress gas source,the heat element lies in the agroove gas direct channals.This invention which can be used to prepared monolayer and multi-layer coating widens industry application,reduces equipment weight,simplifies design structure and equipment maintanance and improves the spraying efficiency,being suitable for mechanical energy and metallurgy etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Steel-plastic composite pipe spraying device

InactiveCN101862725AReasonable structureHigh degree of automationLiquid spraying plantsLiquid surface applicatorsEconomic benefitsElectrical control

The invention relates to a steel-plastic composite pipe spraying device, which comprises an electrostatic spraying system for spraying the outer surface of a steel-plastic composite pipe, an inner powder spraying system for spraying the inner wall of the steel-plastic composite pipe, a pre-heating system, a solidifying system, a transportation system and an electric control system for controlling the entire device, wherein the pre-heating system consists of a pre-heating furnace, a pre-heating system fan and a pre-heating system heater, which are connected with the pre-heating furnace; the solidifying system consists of a solidifying furnace, and a solidifying system fan and a solidifying system heater, which are connected with the solidifying furnace; the transportation system consists of a feeding bracket, a discharging bracket, and a pre-heating system transportation track and a solidifying system transportation track, which hare driven by a motor, and a translation bracket for controlling the steel pipe to move among the pre-heating system, the solidifying system, the electrostatic spraying system and the inner powder spraying system, the pre-heating system is arranged behind the feeding bracket, the electrostatic spraying system and the inner powder spraying system are arranged between the pre-heating system and the solidifying system, and the discharging bracket is arranged behind the solidifying system. The steel-plastic composite pipe spraying device has the advantages of reasonable structure, high automation and high efficiency, has good powder spraying effect, can realize the automatic, continuous and stable production, and has good energy conservation and environmental protection as well as good economic benefit.

Owner:鼎顺钢塑管设备材料(杭州)有限公司

High-corrosion-resistant and wear-resistant coating and preparation method thereof

ActiveCN104673069AImprove corrosion resistance and wear resistanceGood corrosion resistance and wear resistanceAnti-corrosive paintsPolyether coatingsEpoxyDefoaming Agents

The invention discloses a high-corrosion-resistant and wear-resistant coating and a preparation method thereof. The coating comprises a base layer and a surface layer, wherein a base layer paint coats a base material to form the base layer, and a surface layer paint coats the base layer to form the surface layer; the base layer paint comprises the following components in percentage by weight: 50-60% of polyether ketone, 20-30% of fluororesin, 10-20% of epoxy resin, 2.0-8.0% of organic silicon resin, 0.1-0.4% of a leveling agent, 0.5-1.5% of a wetting agent and 0.1-0.4% of a defoaming agent; and the surface layer paint comprises the following components in percentage by weight: 8-16% of polyether ketone, 75-85% of fluororesin, 3.0-7.0% of nano-titanium dioxide, 0.5-1.5% of a wetting agent, 0.1-0.4% of a leveling agent, 0.1-0.4% of a defoaming agent and 0.3-1.0% of a pigment. The preparation method comprises the following steps: uniformly spraying the base layer paint by using a corona discharge type electrostatic powder spray gun, then baking under the condition that the baking temperature is 240-330 DEG C, so as to form the base layer, directly spraying the surface layer paint without cooling after the base layer is formed, spraying the surface layer paint, and baking to form the surface layer so as to ensure that the high-corrosion-resistant and wear-resistant coating disclosed by the invention is prepared. According to the high-corrosion-resistant and wear-resistant coating disclosed by the invention, the base material and the base layer are closely combined, and the base layer and the surface layer are also closely combined, so that the high-corrosion-resistant and wear-resistant coating has the advantages of high adhesive force, high corrosion resistance, abrasion resistance and impact resistance.

Owner:广州穗剑实验室科技有限公司

Method and device for preparing diamond-like carbon coating by cladding fiber laser

ActiveCN102409339AShort reaction timeFast binding strengthMaterial nanotechnologyMetallic material coating processesCarbon coatingDiamond-like carbon

The invention relates to a method and device for preparing a diamond-like carbon coating by cladding a carbon nanotube with fiber laser. The carbon nanotube is cladded with a fiber laser; the carbon nanotube is molten quickly by absorbing laser energy to form liquid carbon, and is cooled at an extremely high cooling speed; a diamond core grows, and undergoes phase change within an extremely short period of time; a part of carbon nanotube phases turn into diamond phases; the slightly-molten surface layer of a substrate material undergoes molecular level and atomic level diffusion, so that a strong metallurgically-bonded diamond-like carbon coating is formed; unbalanced condensation is led by an extremely high cooling speed; and an obtain diamond structure is fine and is approximate to a nanostructure. A used fiber laser head is coaxially connected with a powder spray head; processing is performed in a vacuum cavity; a laser beam is fully superposed with a carbon nanotube beam; and preparation of diamond-like carbon coatings of any shape and three-dimensional processing can be performed in cooperation with a flexible processing system of a six-degree-of-freedom robot.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

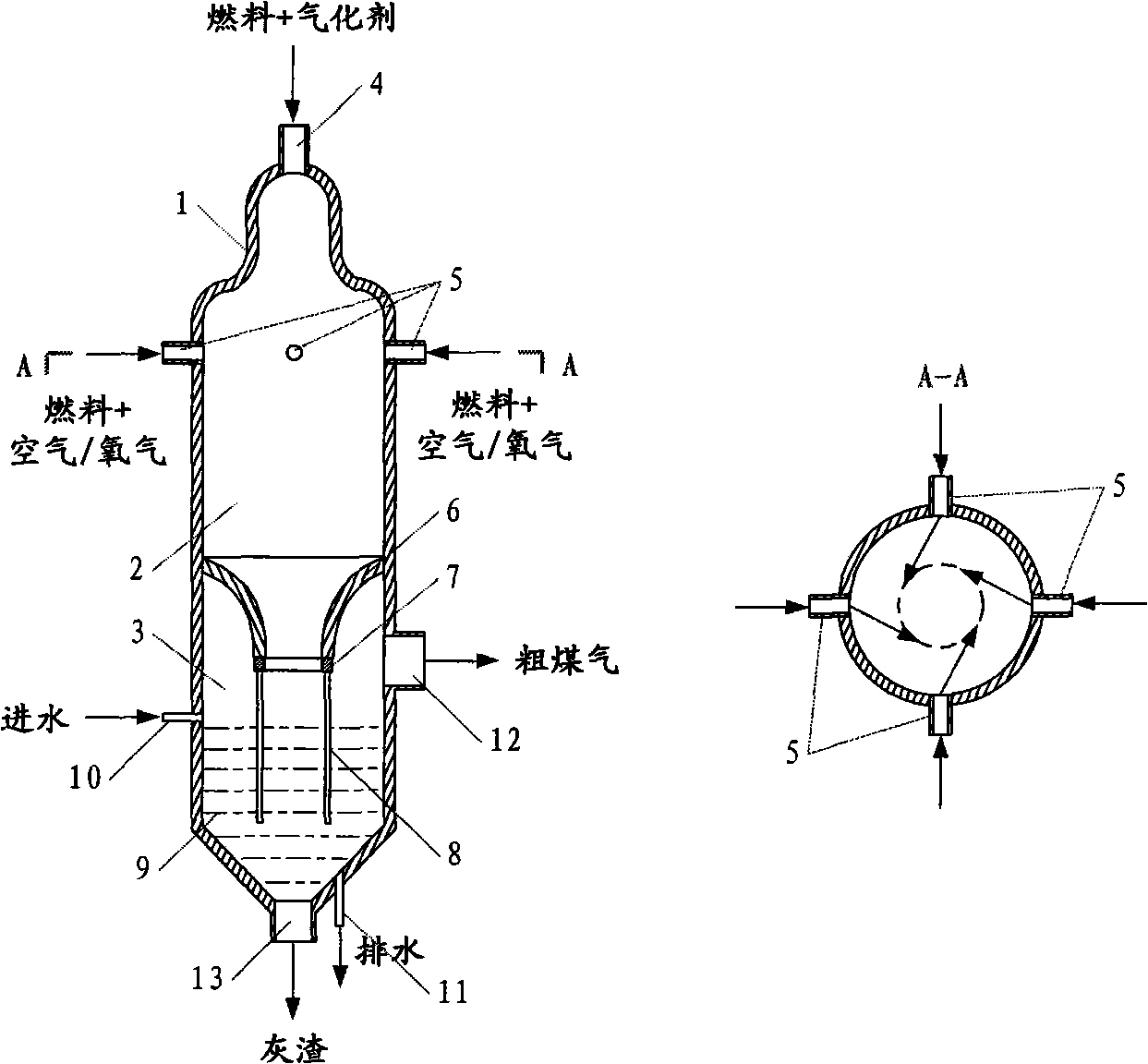

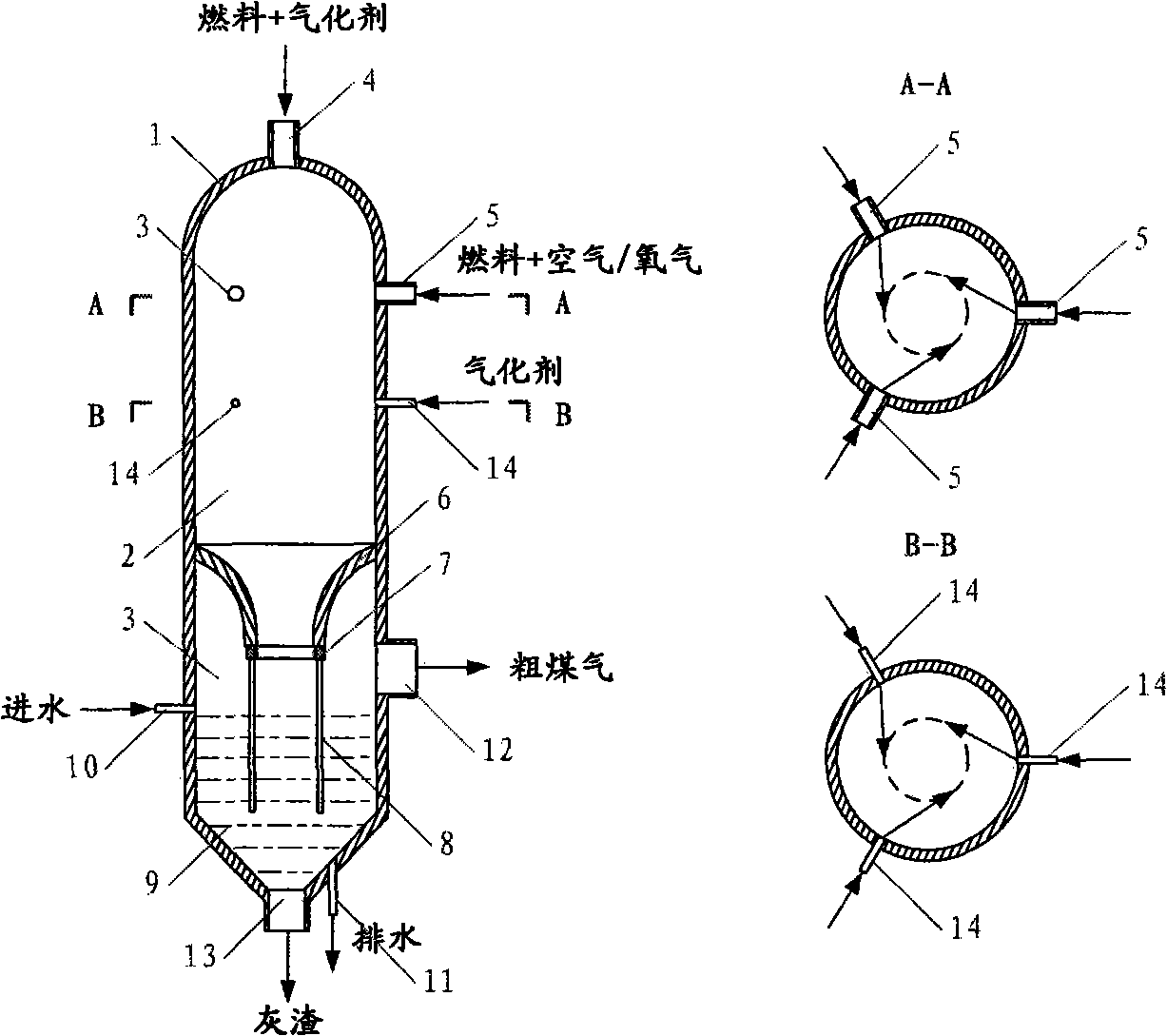

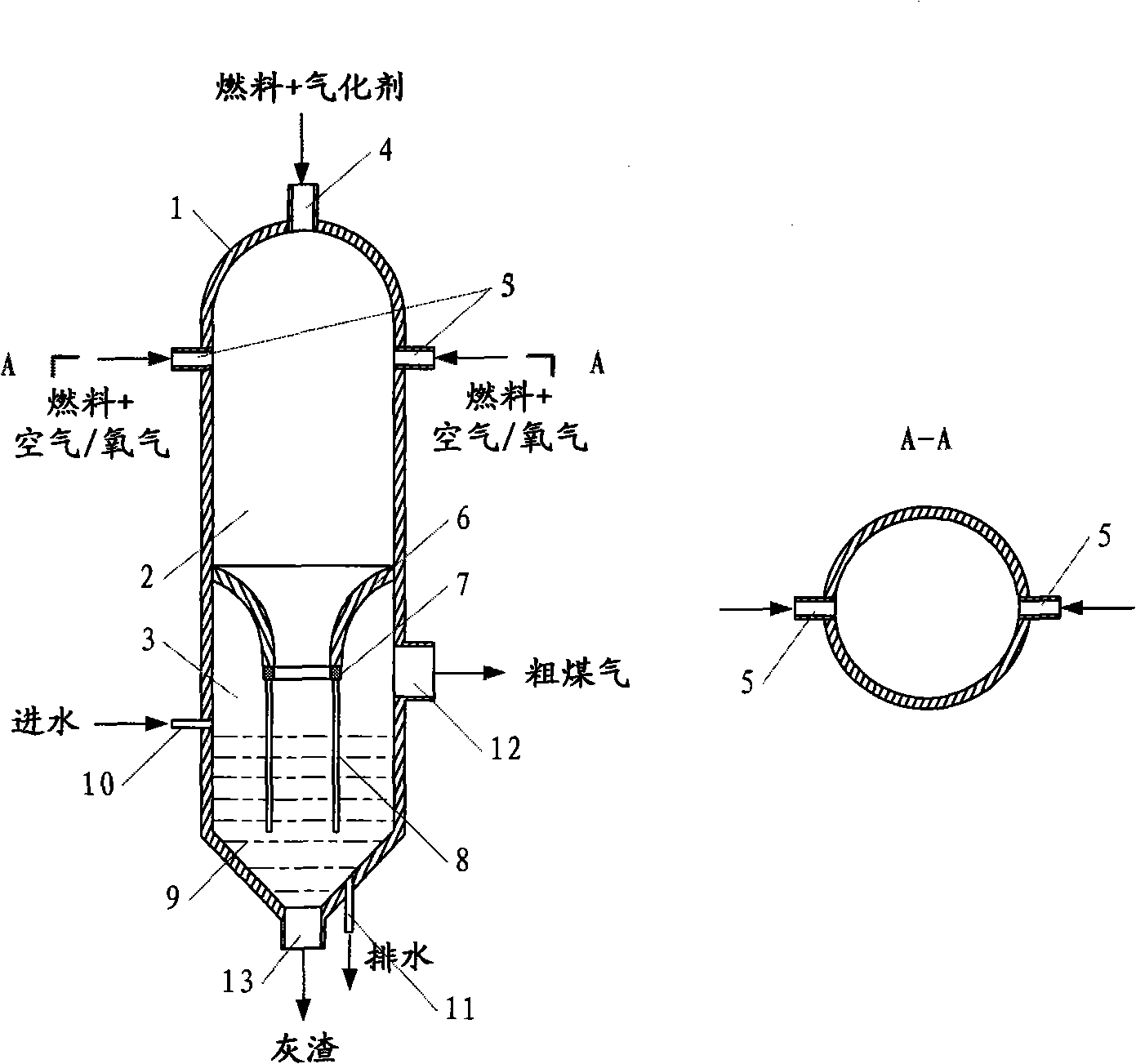

Staged powder spraying entrained bed gasification furnace and gasification method thereof

InactiveCN102134512AExtended service lifeSimple structureGranular/pulverulent flues gasificationSpray nozzleSolid fuel

The invention relates to a staged powder spraying entrained bed gasification furnace, which comprises a gasification chamber and a quench chamber, and is characterized in that: the gasification chamber also comprises a gasification nozzle which is formed on the top of the gasification chamber and of which the axis is overlapped with the axis of the gasification chamber; the gasification chamber also comprises a plurality of combustion nozzles which are uniformly arranged on the upper wall of the gasification chamber along the upper periphery of the gasification chamber, and of which the axes form an angle of 0-90 degrees with the axis of the gasification chamber. The invention also relates to a method for gasifying powdery solid fuel in the gasification furnace. One part of fuel is sprayed together with an oxidant into the gasification chamber through the combustion nozzles, and is combusted, and a high temperature area is formed on the upper part of the gasification chamber; and the other part of fuel and a gasification agent are sprayed into the gasification chamber through the gasification nozzle, preheated on the top of the gasification chamber, and enters the high-temperature area for gasification. The service life of the nozzles can be effectively prolonged, the retention period of the fuel in the gasification chamber can be prolonged, higher carbon conversion rate can be achieved, and the gasification furnace can treat fuel with higher caking property.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

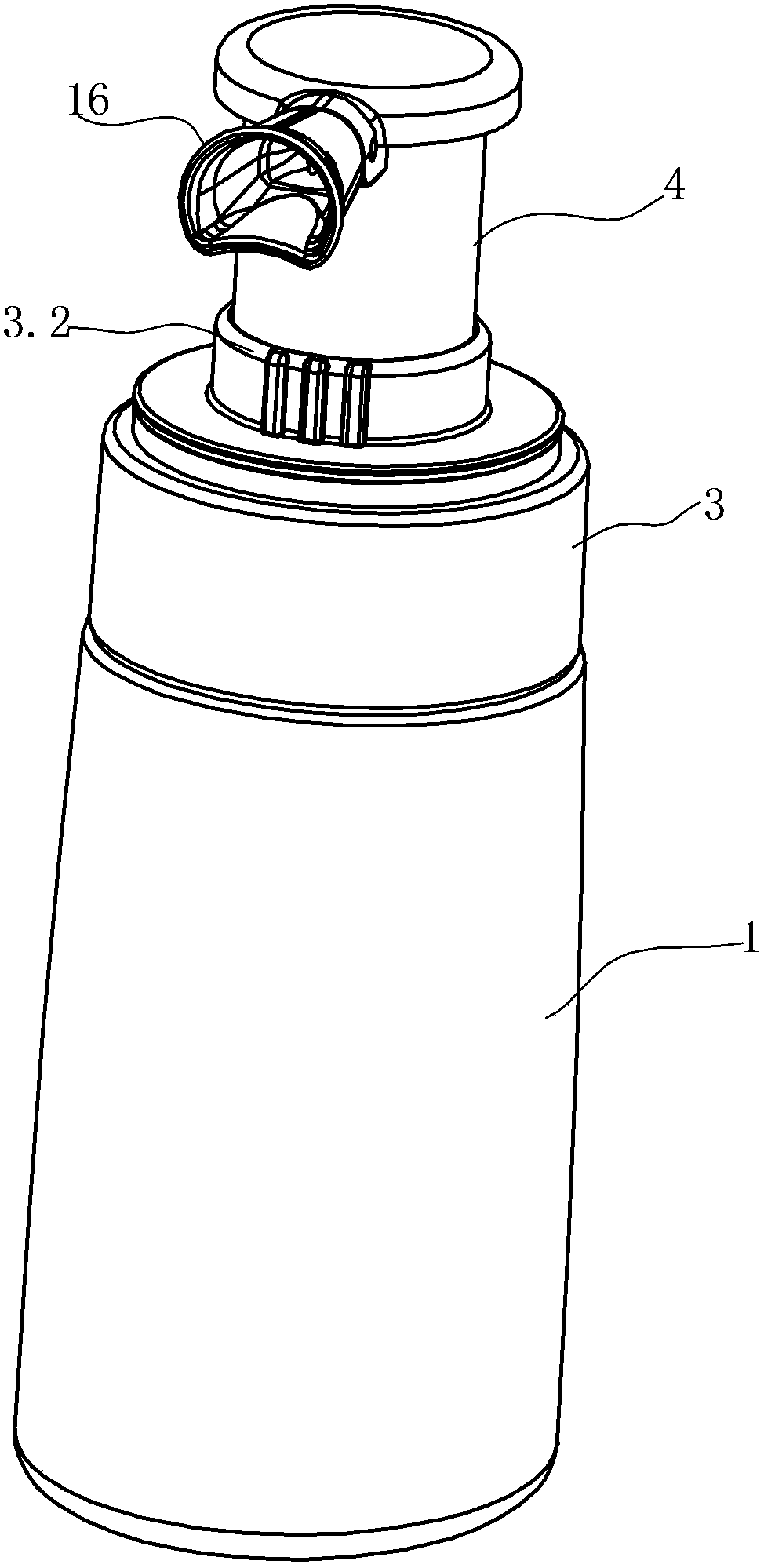

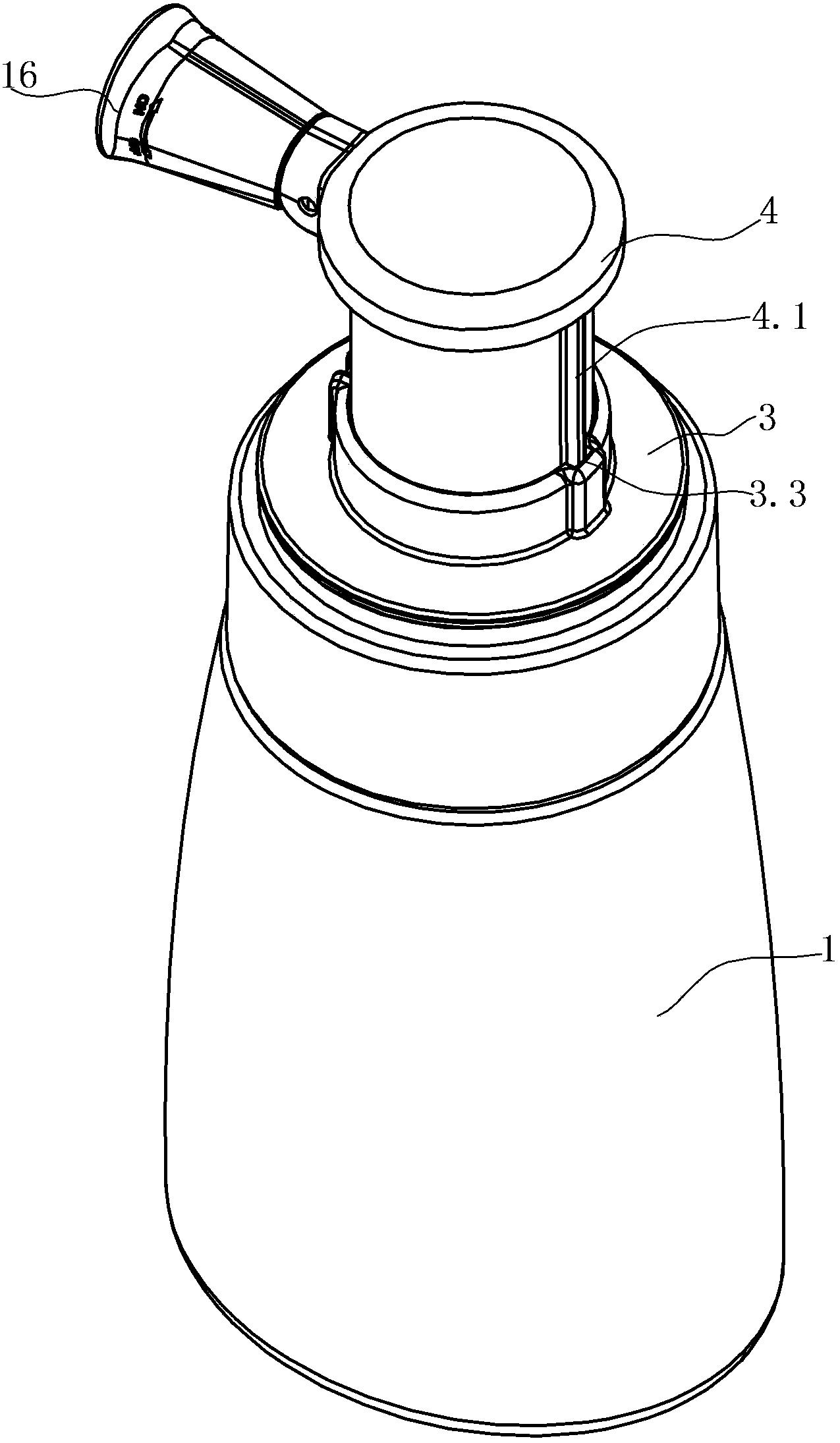

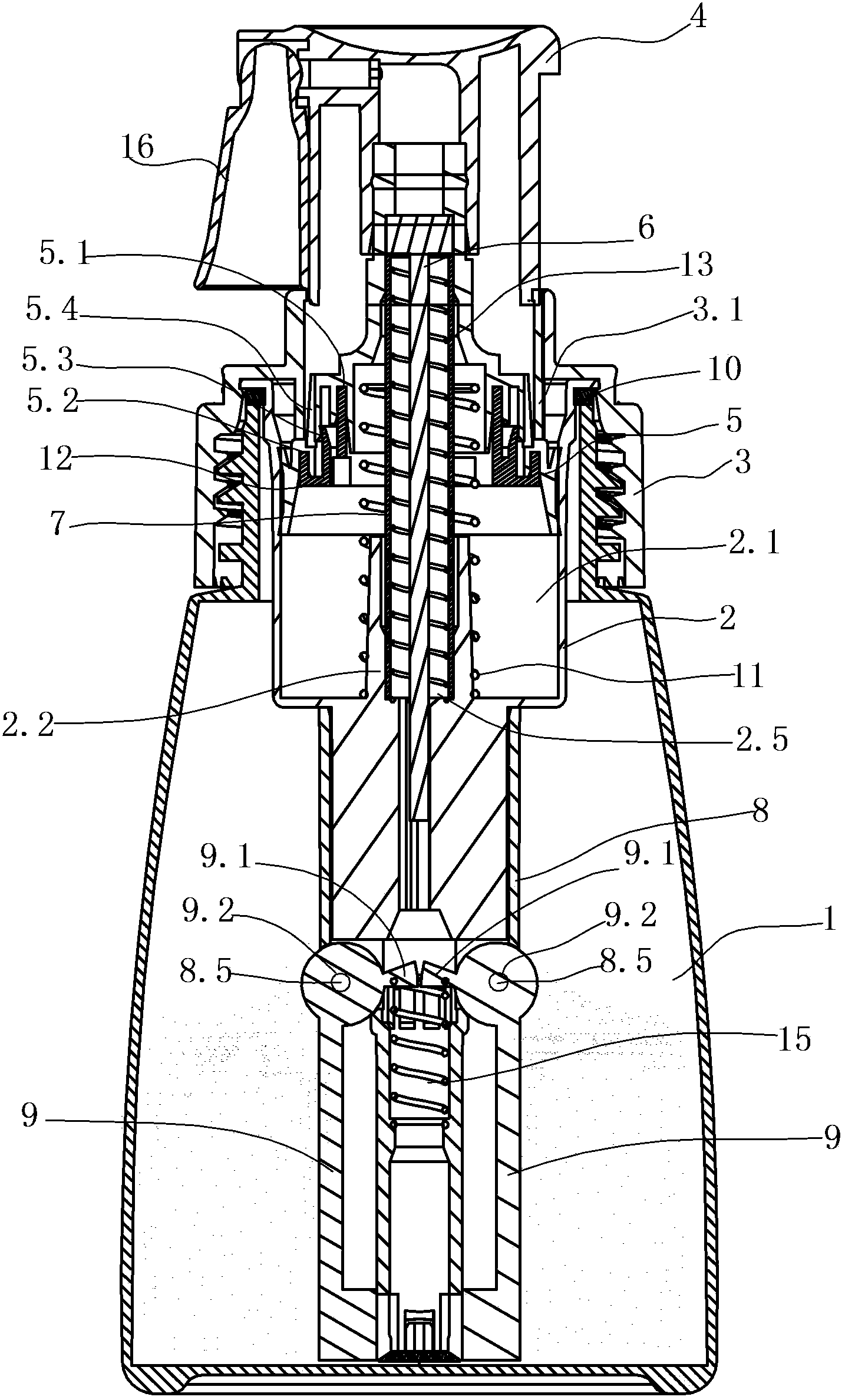

Powder sprayer

A powder sprayer comprises a bottle body, a pump body, a piston and an elastic element and is characterized in that a hollow delivery pipe is arranged in a piston of the pump body, the upper end of the hollow delivery pipe is communicated with a nozzle of a cap, and the lower end of the delivery pipe is communicated with a middle hole in the pump body. The upper end of a connector is connected with the lower end of the pump body, the connector comprises a powder outlet channel communicated with the delivery pipe, a base used for mixing powder and air flow is arranged at the bottom of the powder outlet channel, and a powder inlet is formed and communicated with a bottle body inner cavity. The connector further comprises an air flow channel, an air inlet of the air flow channel is communicated with a piston cavity, and an air outlet is communicated with the base. A manipulator mechanism is arranged in the bottle body inner cavity and at least comprises a manipulator, and the upper end of the manipulator is connected with the cap or the piston through a transmission mechanism. The powder sprayer has the advantages of being simple in structure, convenient and quick to use and good in powder spraying effect.

Owner:ZHEJIANG JM IND

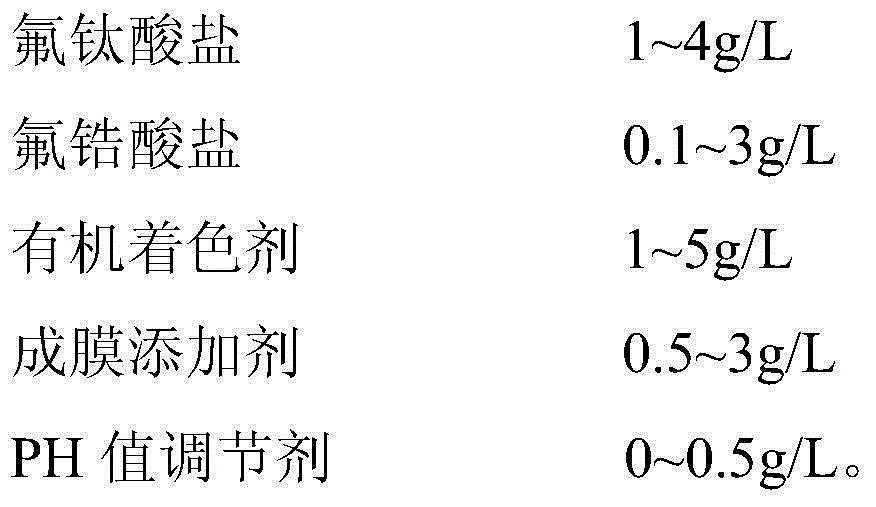

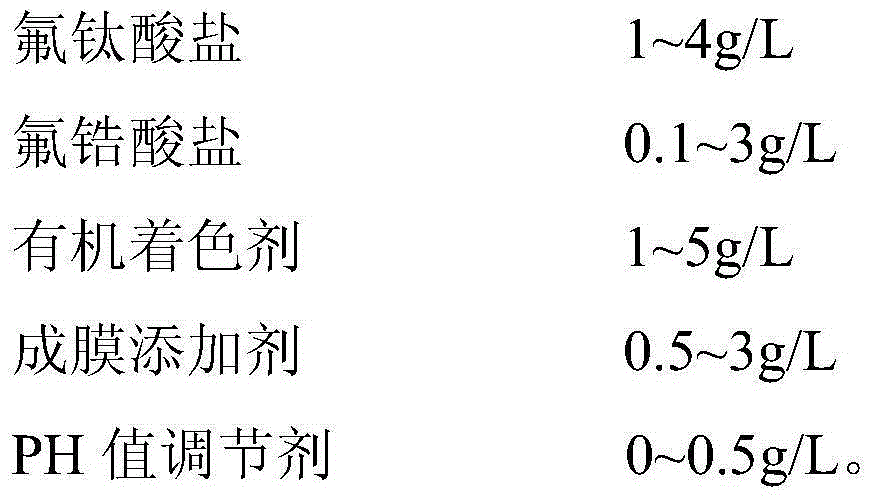

Anticorrosion treatment process for converting/electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys

ActiveCN105132900AEasy to operateLow film forming temperatureLiquid surface applicatorsMetallic material coating processesCompound (substance)Titanium

The invention belongs to the technical field of chemical materials and discloses an anticorrosion treatment process for converting / electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys. The anticorrosion treatment process comprises the following steps: (1) carrying out surface pretreatment on the aluminum alloys; (2) converting the surfaces of the aluminum alloys, putting the aluminum alloys subjected to surface pretreatment into a zirconium titanate converting solution, soaking, washing, standing and drying the aluminum alloys to obtain conversion films; (3) suspending the dried aluminum alloys in a powder spraying room and electro-statically spraying organic powder on the aluminum alloys; and (4) standing, preserving heat at 180-200 DEG C, then cooling to obtain anticorrosion coatings. According to the anticorrosion treatment process, the conversion treatment is low in film-forming temperature and short in film-forming time; the zirconium titanate treatment solution is stable, chromium-free and environmentally-friendly; through the treatment process, the surfaces of the aluminum alloys are high in corrosion resistance; the conversion films are excellent in combination with the aluminum alloys and the organic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Powder spray coating system

InactiveUS6695220B2Quickly and easily turned to isolate any particular hopperEasy to removeBurnersLiquid supply arrangementsCoating systemEngineering

Owner:MILLERKNOLL INC

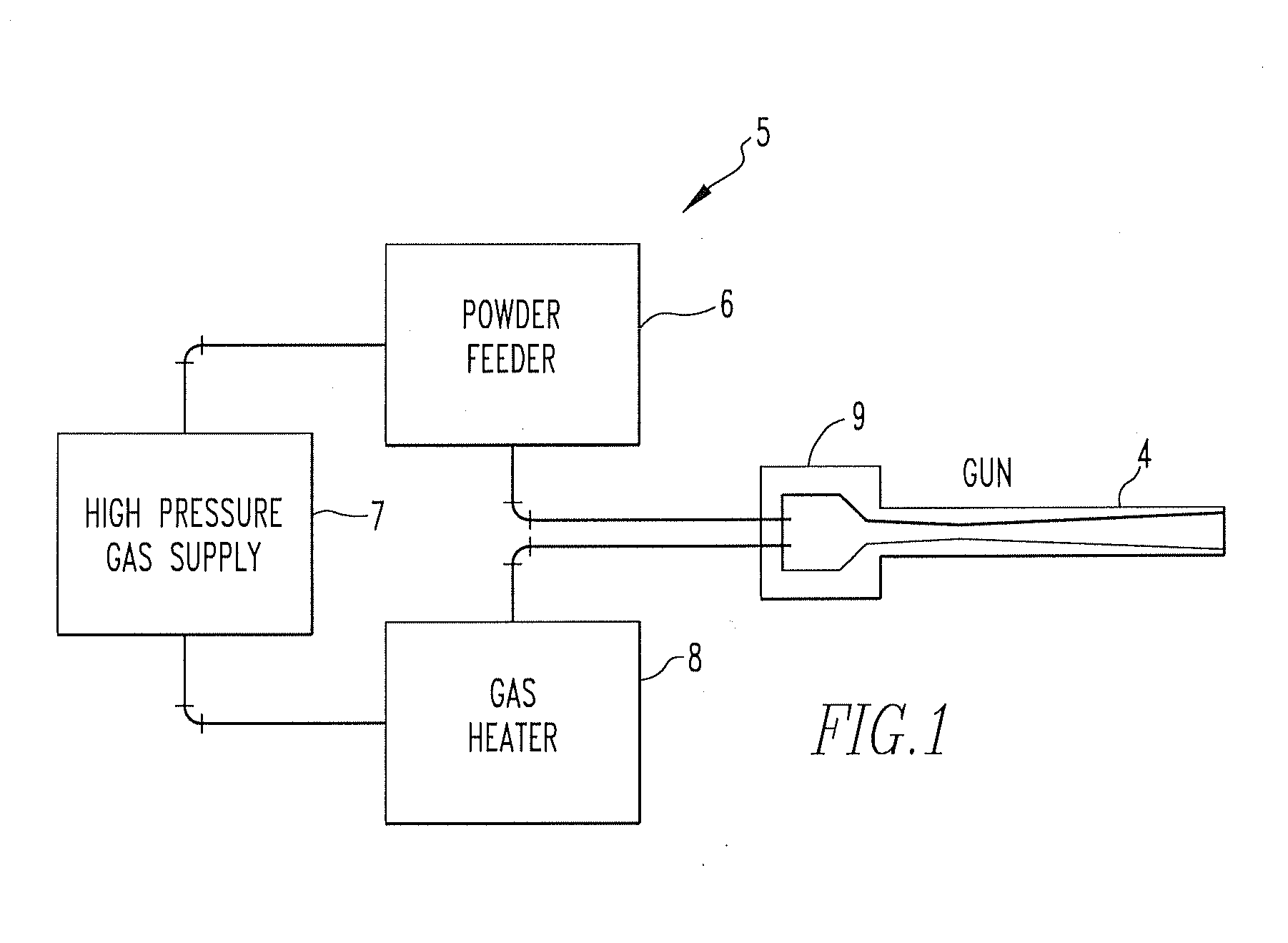

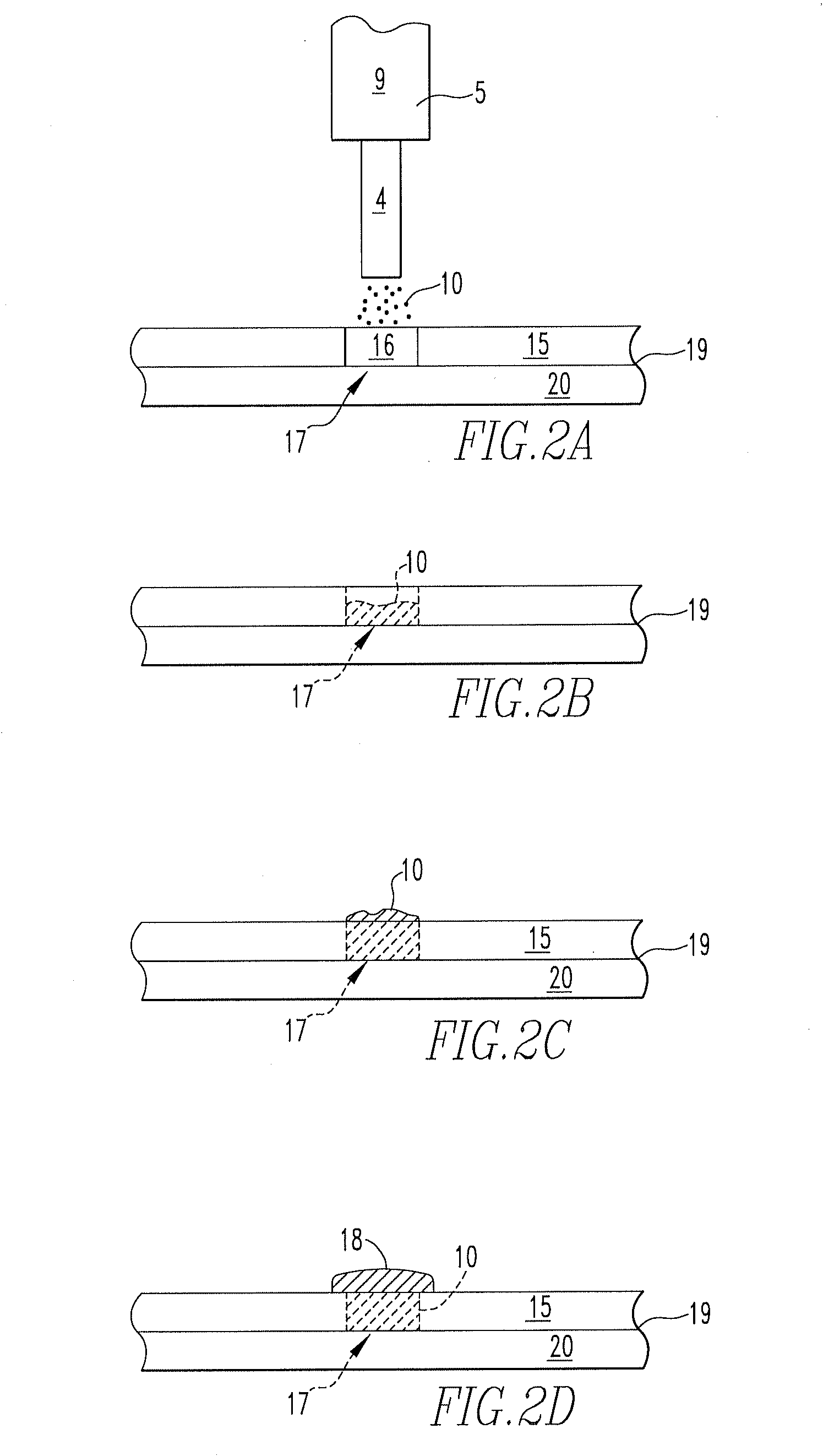

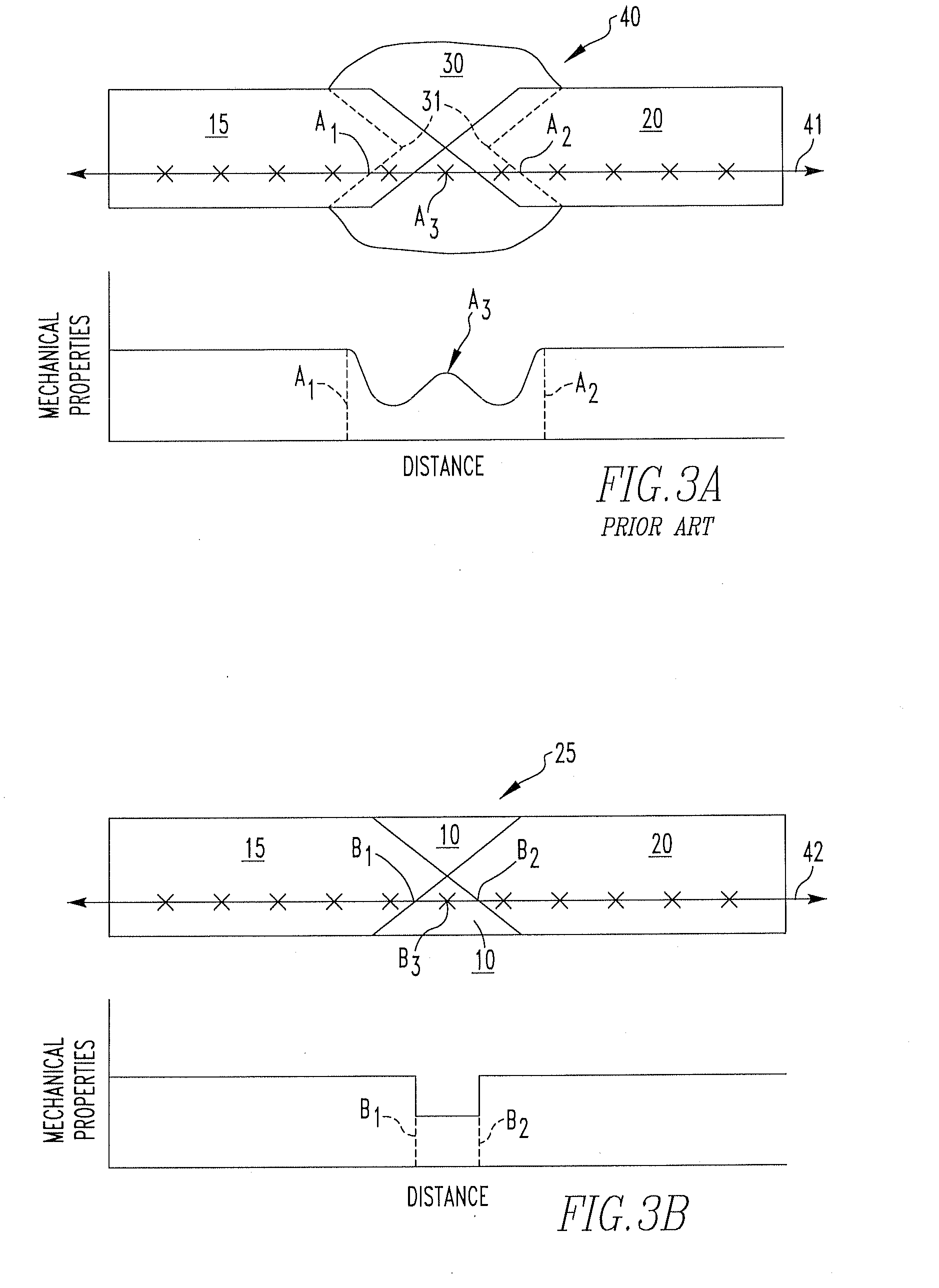

High velocity metallic powder spray fastening

InactiveUS20070194085A1Uniform mechanical propertiesCooking-vessel materialsLiquid spraying apparatusMulti materialMetallic bonding

The present invention provides a low temperature joining method that is compatible with multiple materials and results in a bond between joined structures without reducing the mechanical properties of the joined structures base materials. The method of the present invention includes the steps of contacting a first structure to a second structure; and directing particles of a metallic bonding material towards an interface between the first structure and second structure at a velocity to cause the particles of the metallic bonding material form a molecular fusion between the first structure and second structure.

Owner:ARCONIC INC

Vanadium iron spraying powder refining technique

InactiveCN101148733AImprove reaction kinetic conditionsHigh recovery rateProcess efficiency improvementAlloyPowder Spray

The present invention discloses one kind of powder spraying ferrovanadium refining process. During electro alumino-thermic process, and after completing alumino-thermic reaction, separating slag from the alloy and stopping heating, reductive powder material is sprayed through the spray gun inserted into the slag layer and the furnace body is rotated so that the sprayed powder material is well mixed to the slag. Then, the electrode is re-inserted for further smelting for one other 20-25 min, so as to make the residual vanadium in the slag reduced to produce ferrovanadium. The present invention has effectively improved reaction dynamic condition of the refined material, complete reaction, high vanadium recovering rate and lowered production cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com