Steel-plastic composite pipe spraying device

A technology for spraying equipment and steel-plastic pipes, which is applied in the direction of liquid spraying equipment, coatings, and devices for coating liquid on the surface. It can solve problems such as poor effects, and achieve good powder spraying effects, reasonable structure, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

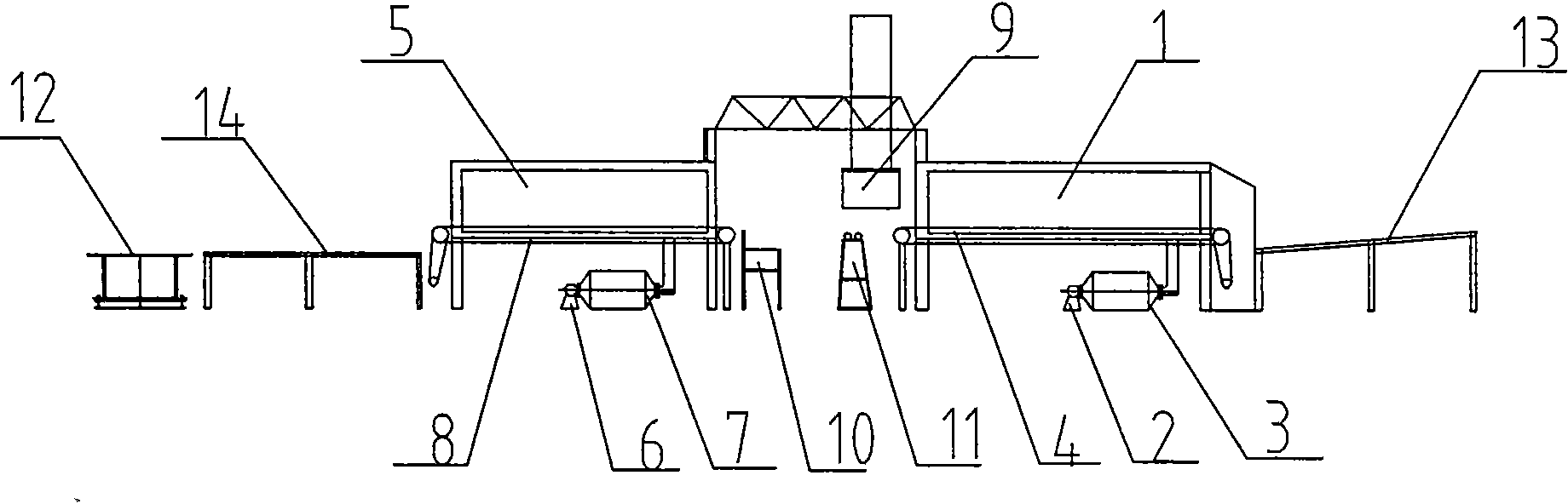

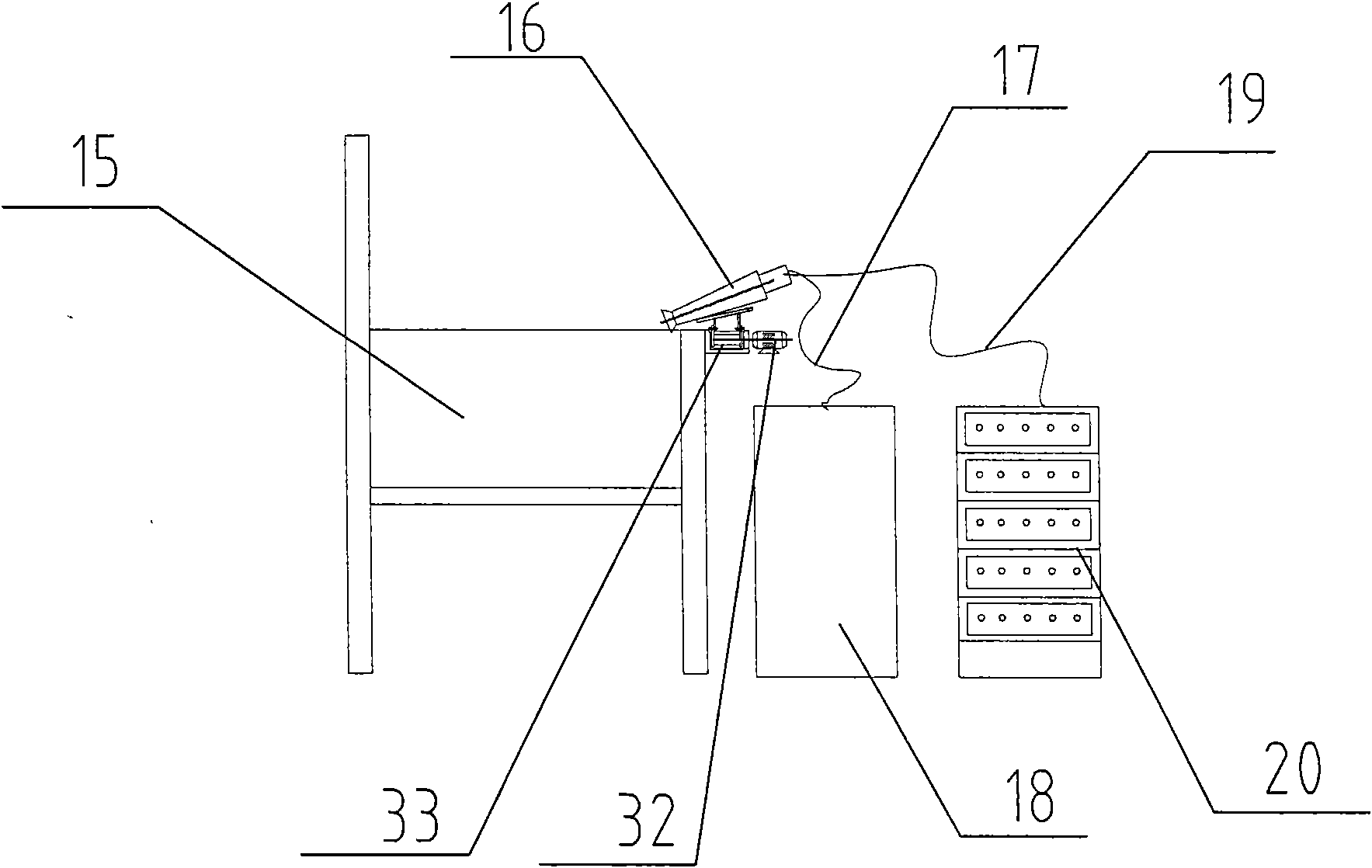

[0014] Embodiment one: if figure 1 , one end of the present invention is provided with loading frame 13, and loading frame 13 is connected with preheating system, comprises preheating furnace 1, and preheating furnace 1 communicates with fan 2 of preheating system and heater 3 of preheating system, and inside preheating furnace 1 There is a preheating system transmission track 4 for transmitting steel-plastic pipes; the preheating system leads to the spraying system, including the internal powder spraying system 11 and the electrostatic spraying system 10, and then leads to the curing system, including the curing furnace 5, and the curing furnace 5 is connected The curing system fan 6 and the curing system heater 7, the curing system transmission track 8 for transmitting steel-plastic pipes are arranged in the curing furnace 5;

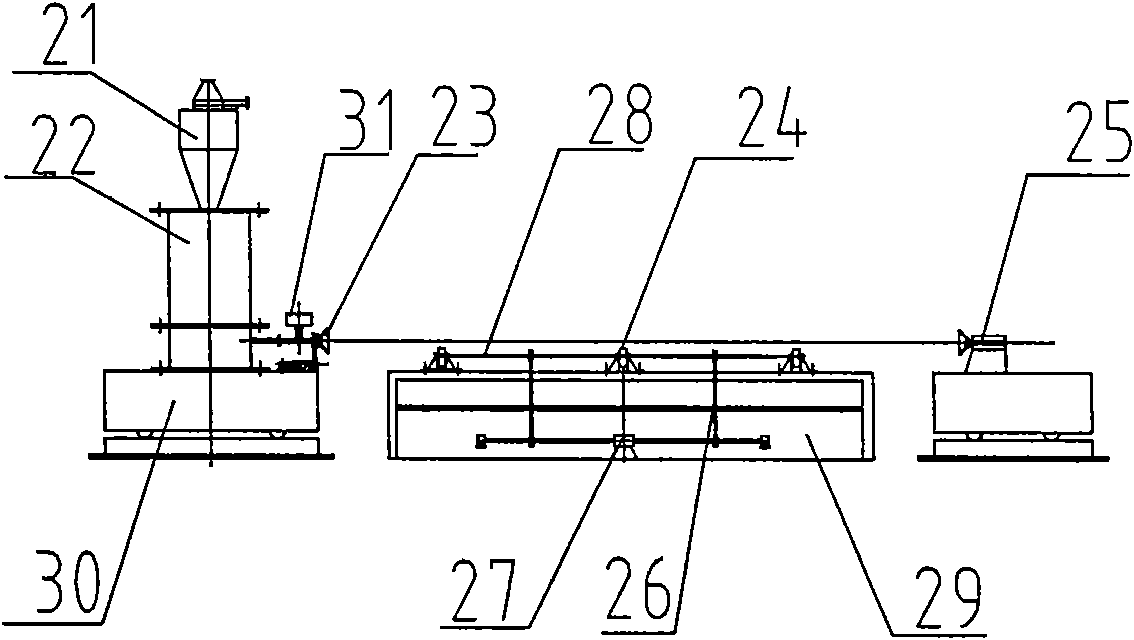

[0015] Such as figure 2 , wherein the internal powder spraying system 11 includes a roller frame 29, two groups are installed in parallel on the ro...

Embodiment 2

[0021] Embodiment 2: The heater 3 of the preheating system and the heater 7 of the curing system use natural gas to heat the air. Each group of rollers 24 on the interior powder spraying system 11 is made up of 2, to adapt to the steel-plastic pipe with shorter length. All the other are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com