Patents

Literature

1143results about "Liquid spraying plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

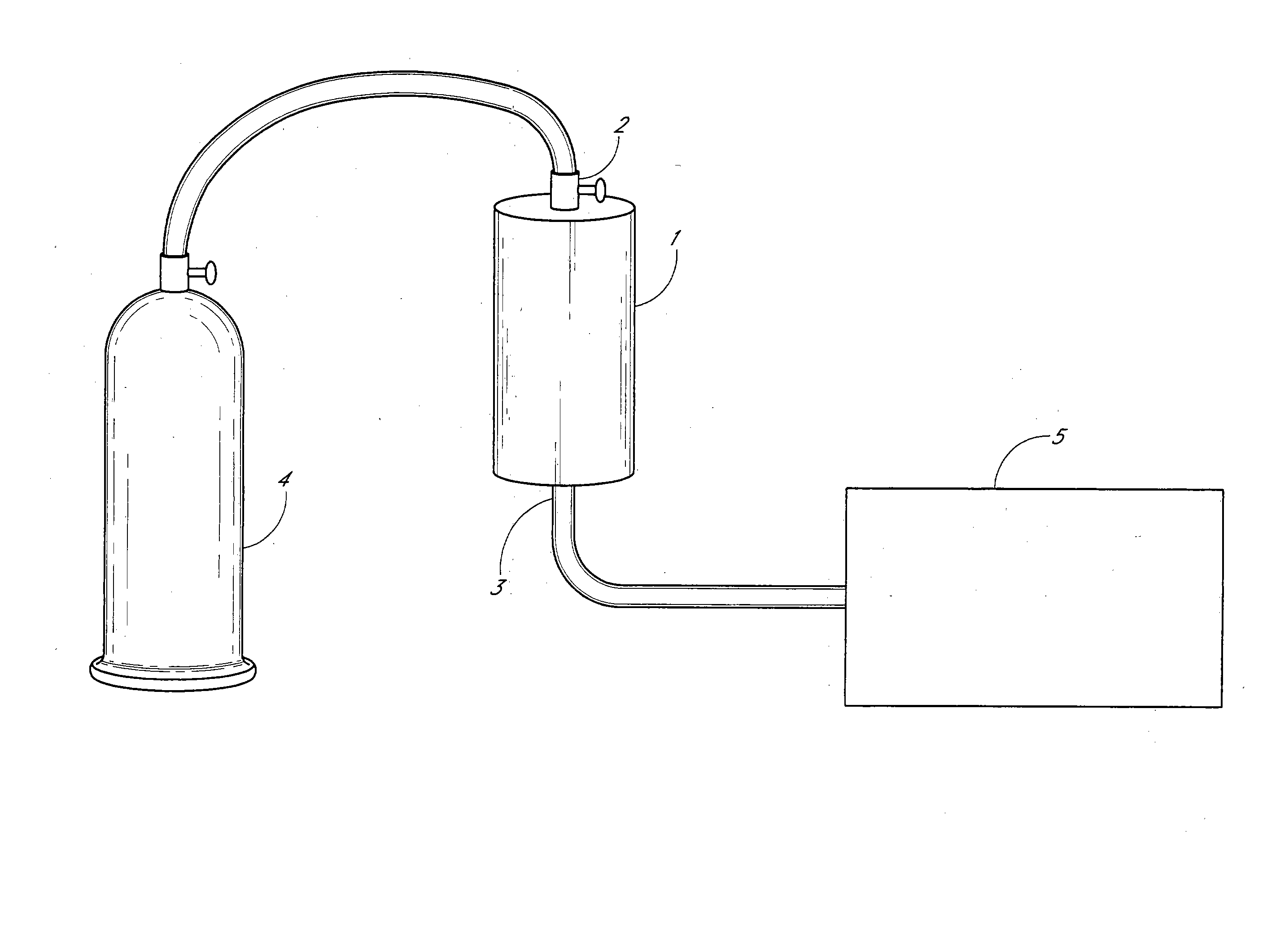

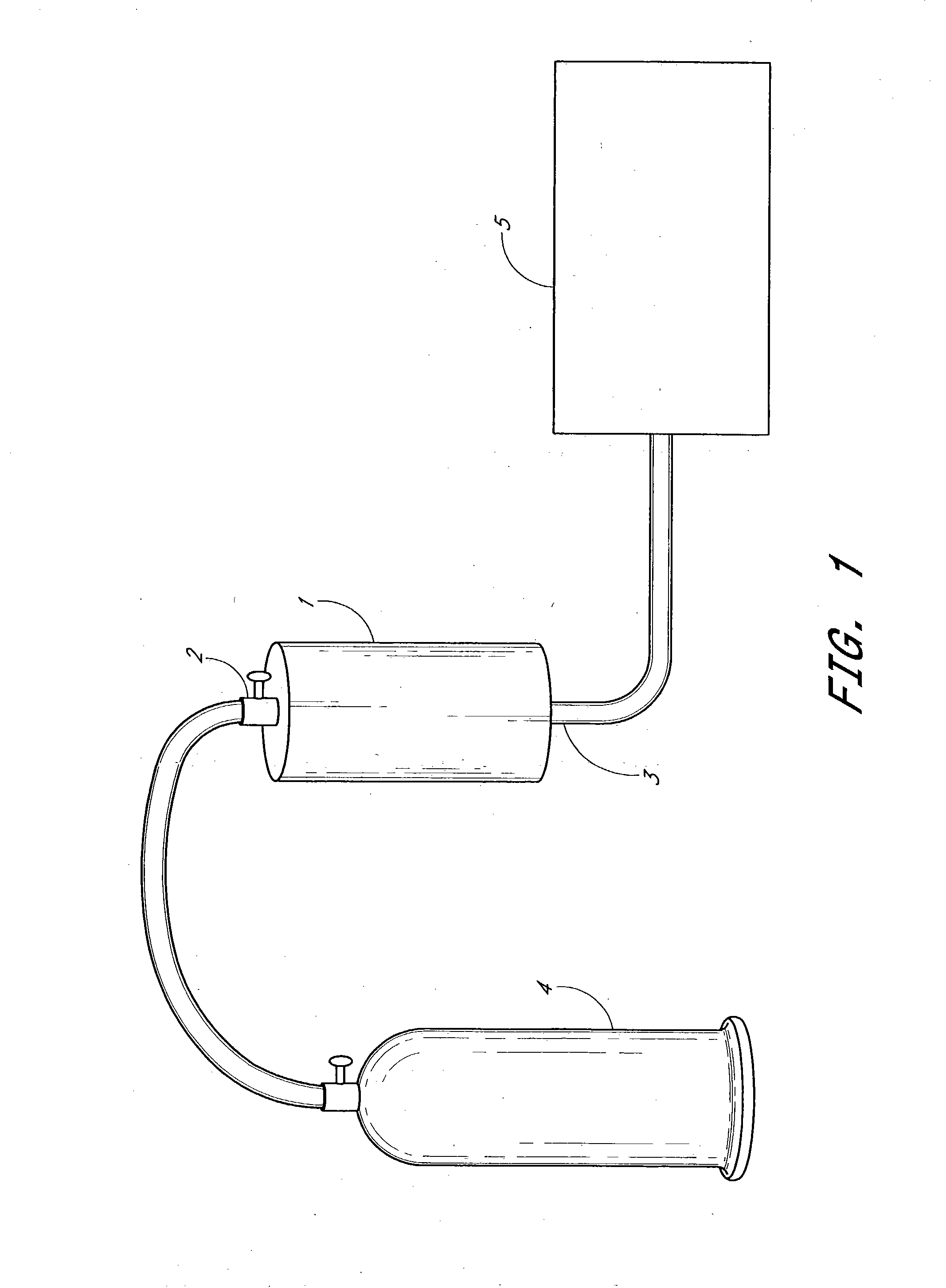

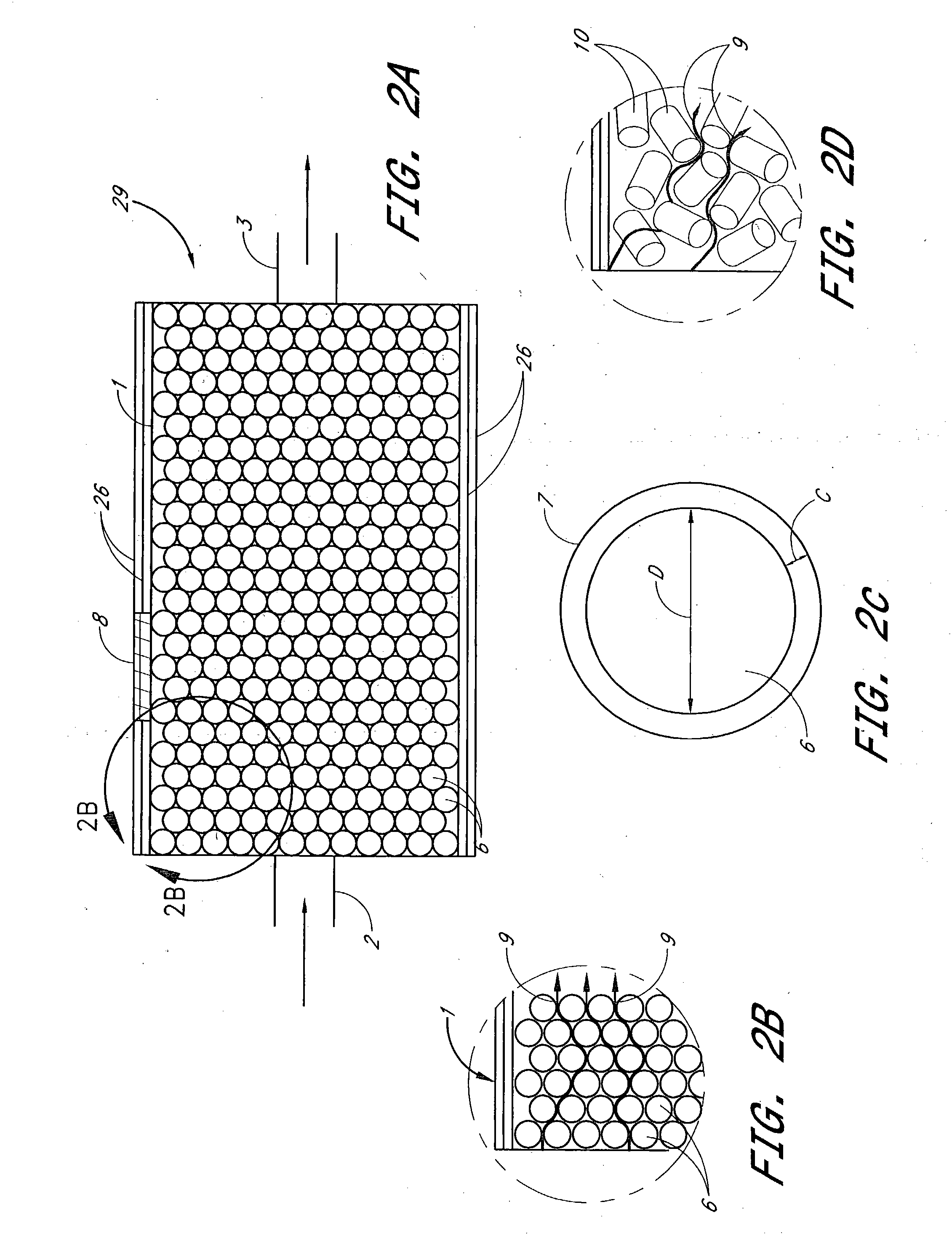

Sublimation bed employing carrier gas guidance structures

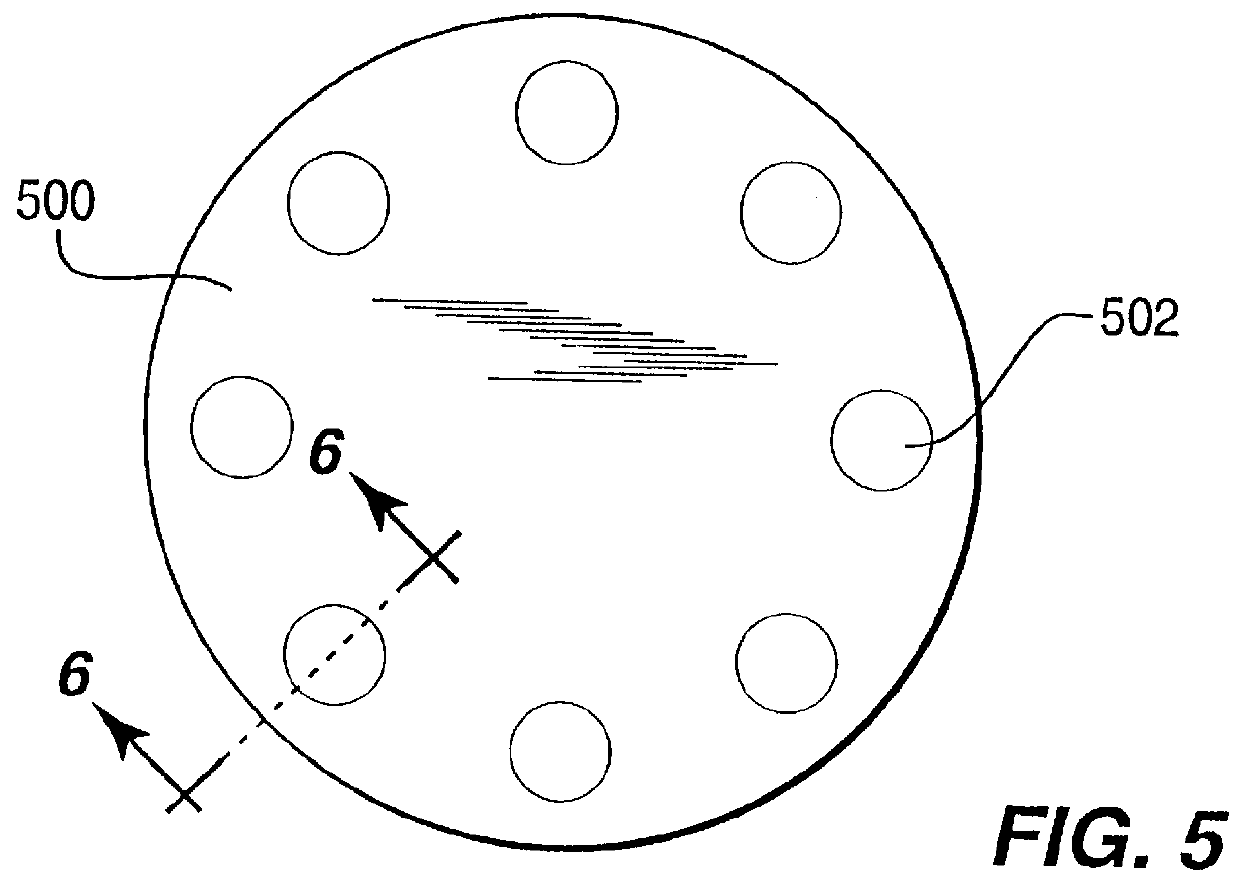

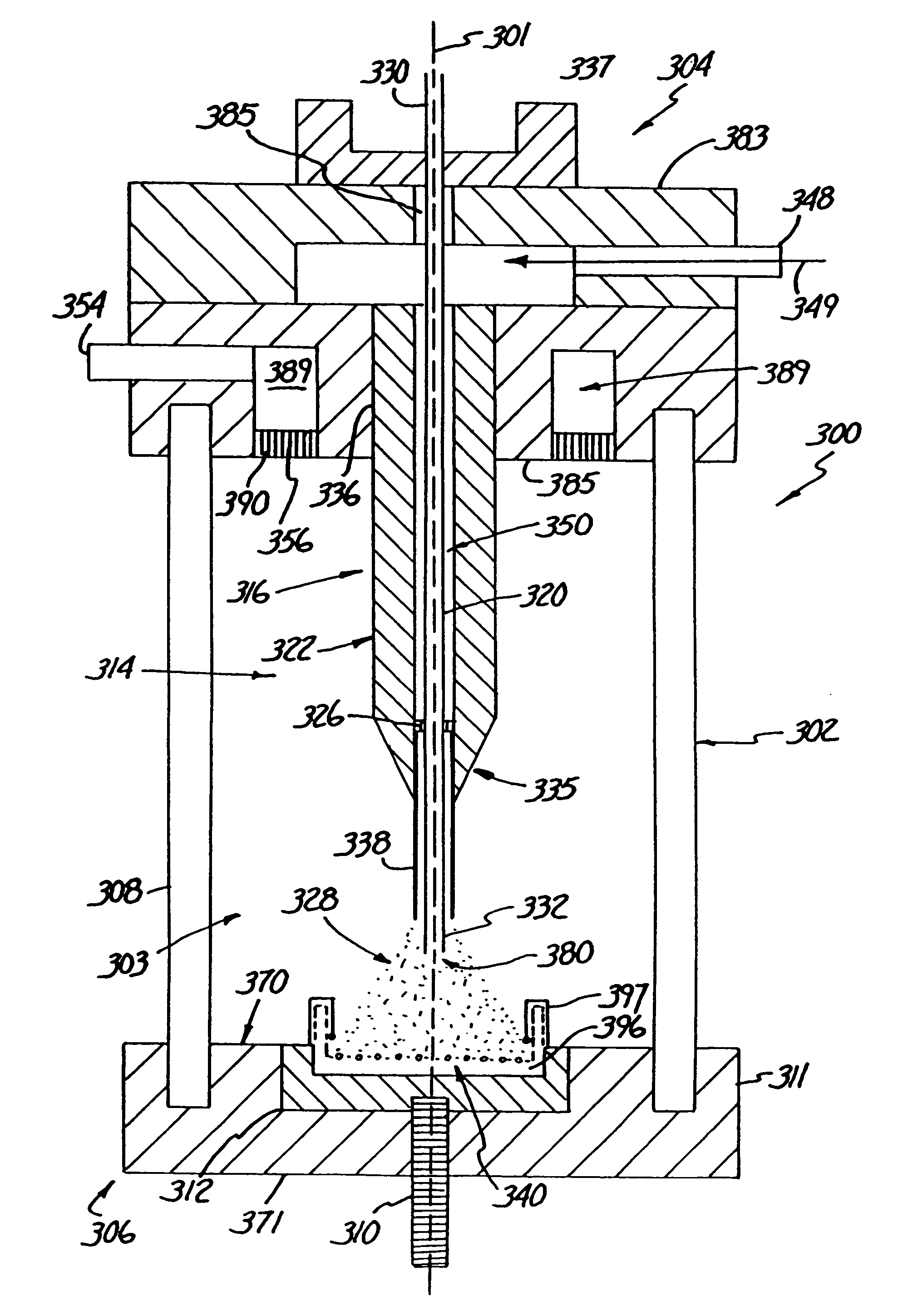

ActiveUS20050072357A1Raise the ratioIncrease contact timeLiquid spraying plantsLiquid surface applicatorsSource materialEngineering

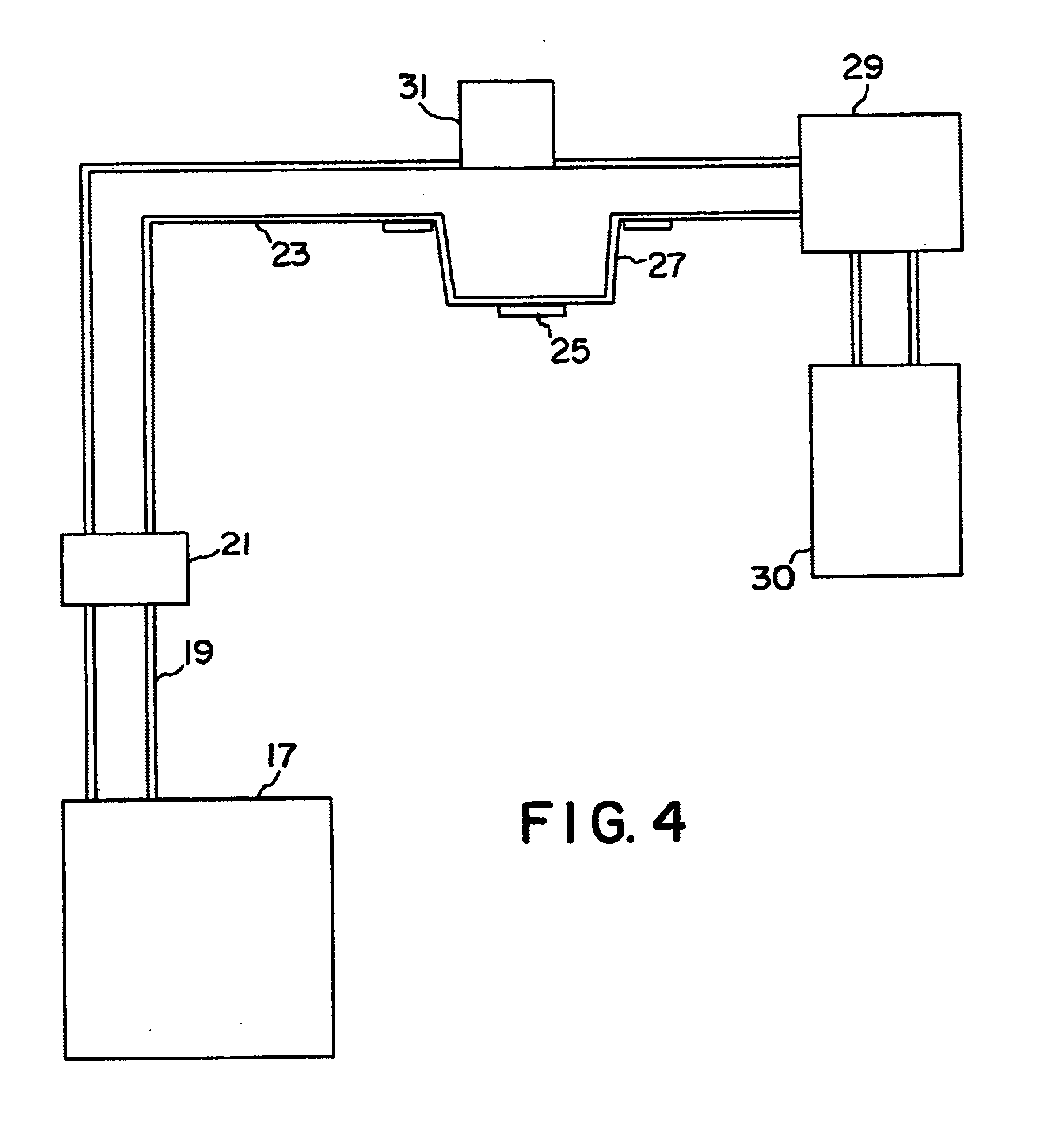

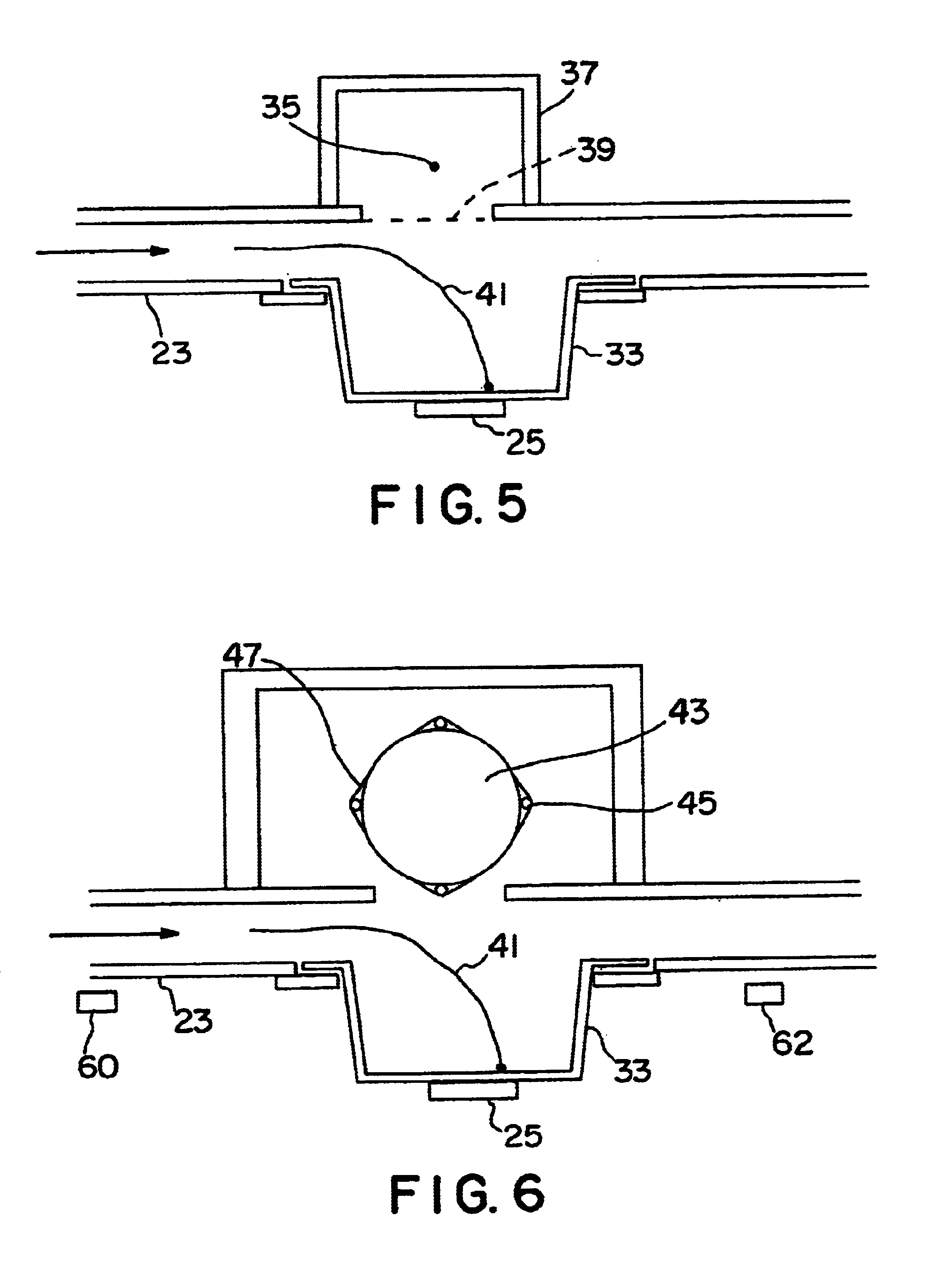

Preferred embodiments of the present invention provides a sublimation system employing guidance structures including certain preferred embodiments having a high surface area support medium onto which a solid source material for vapor reactant is coated. Preferably, a guidance structure is configured to facilitate the repeated saturation of the carrier gas with the solid source for a vapor reactant. Methods of saturating a carrier gas using guidance structures are also provided.

Owner:ASM IP HLDG BV

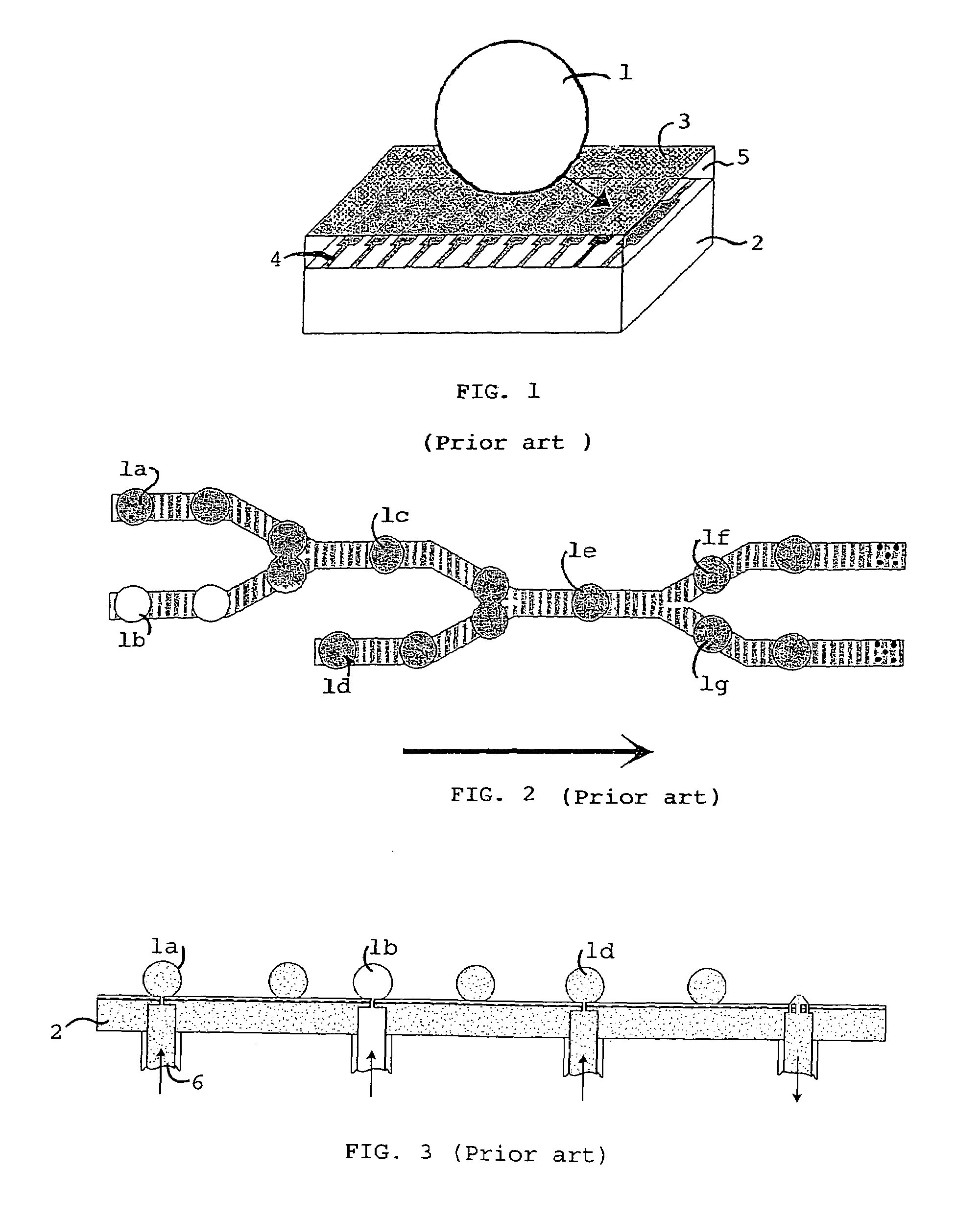

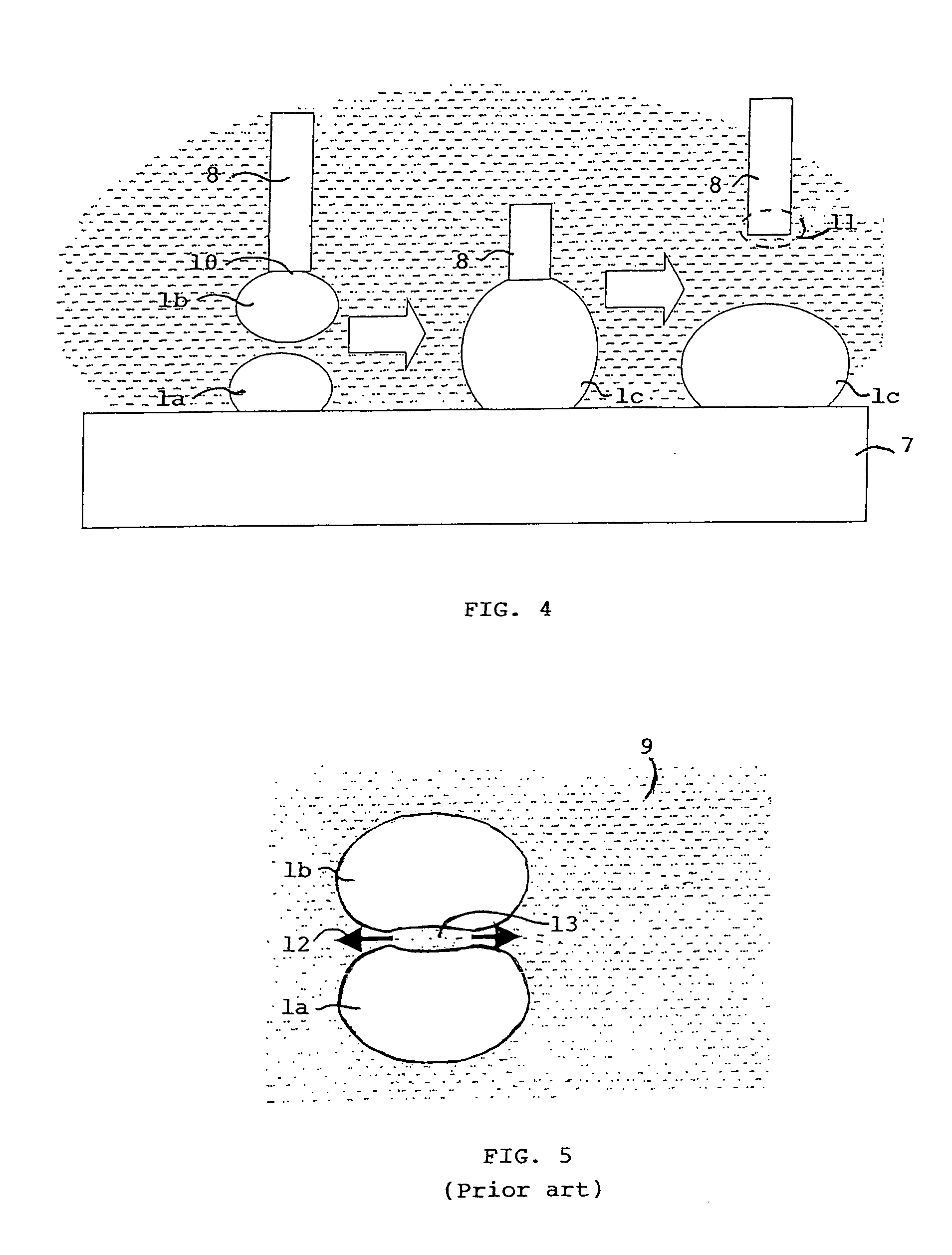

Coating medical devices

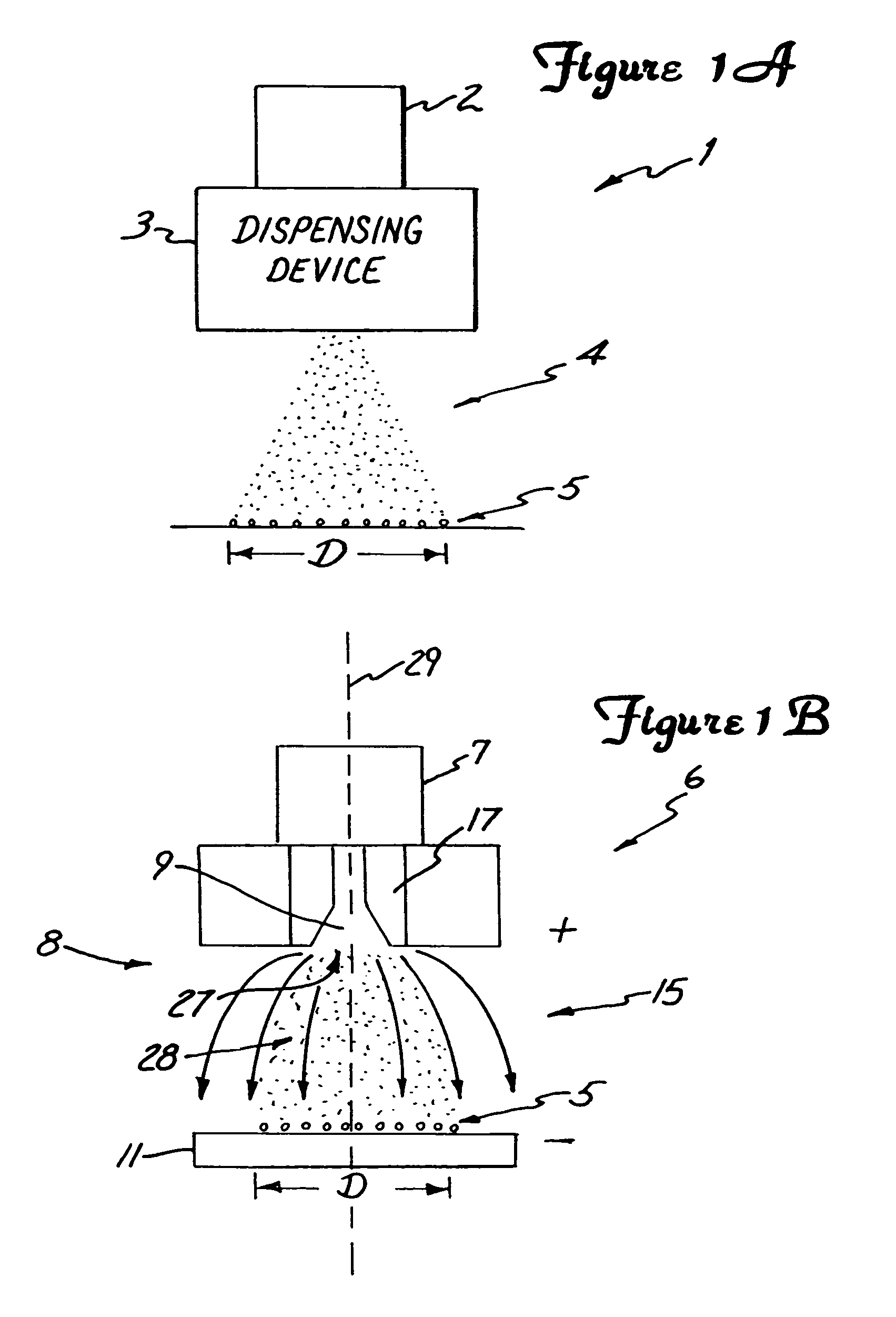

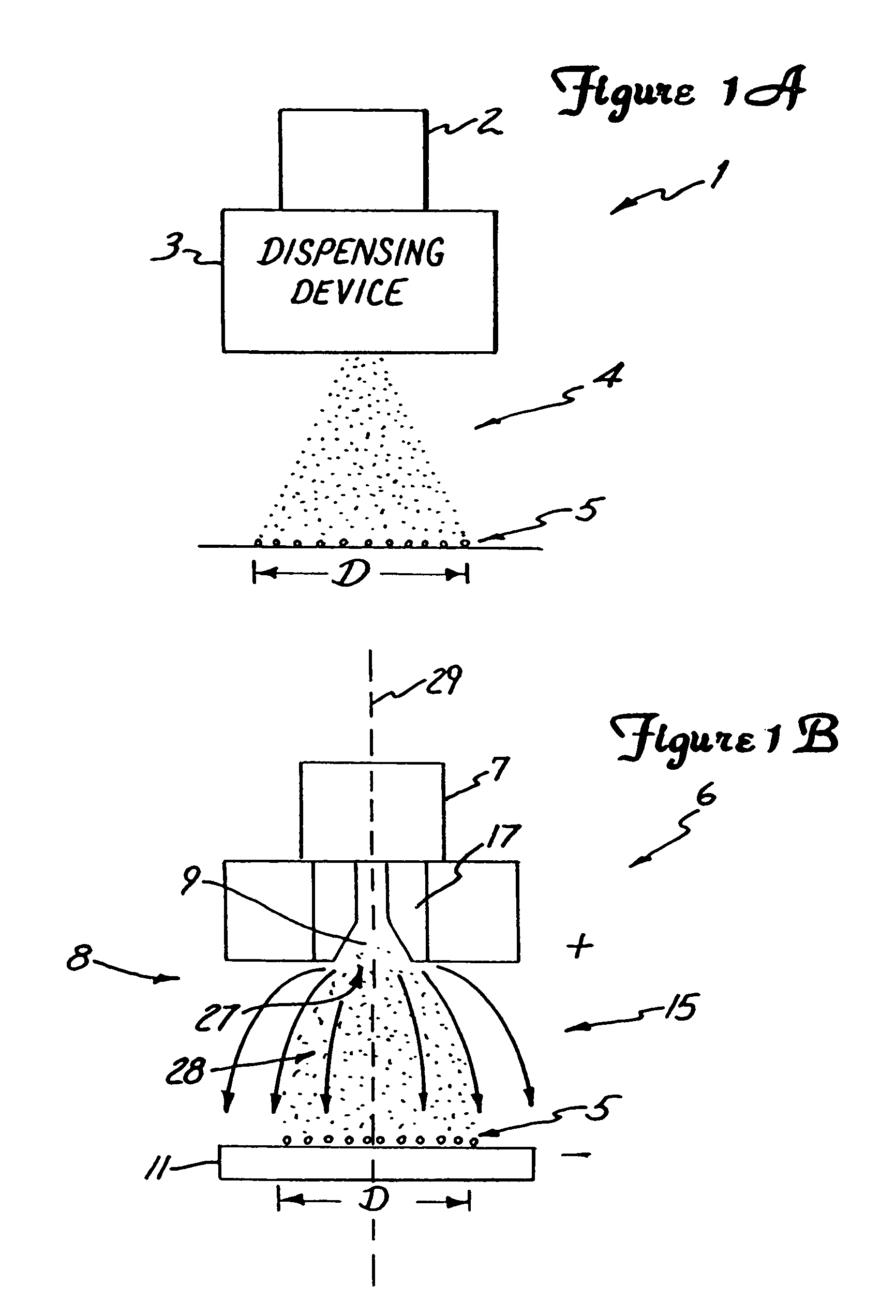

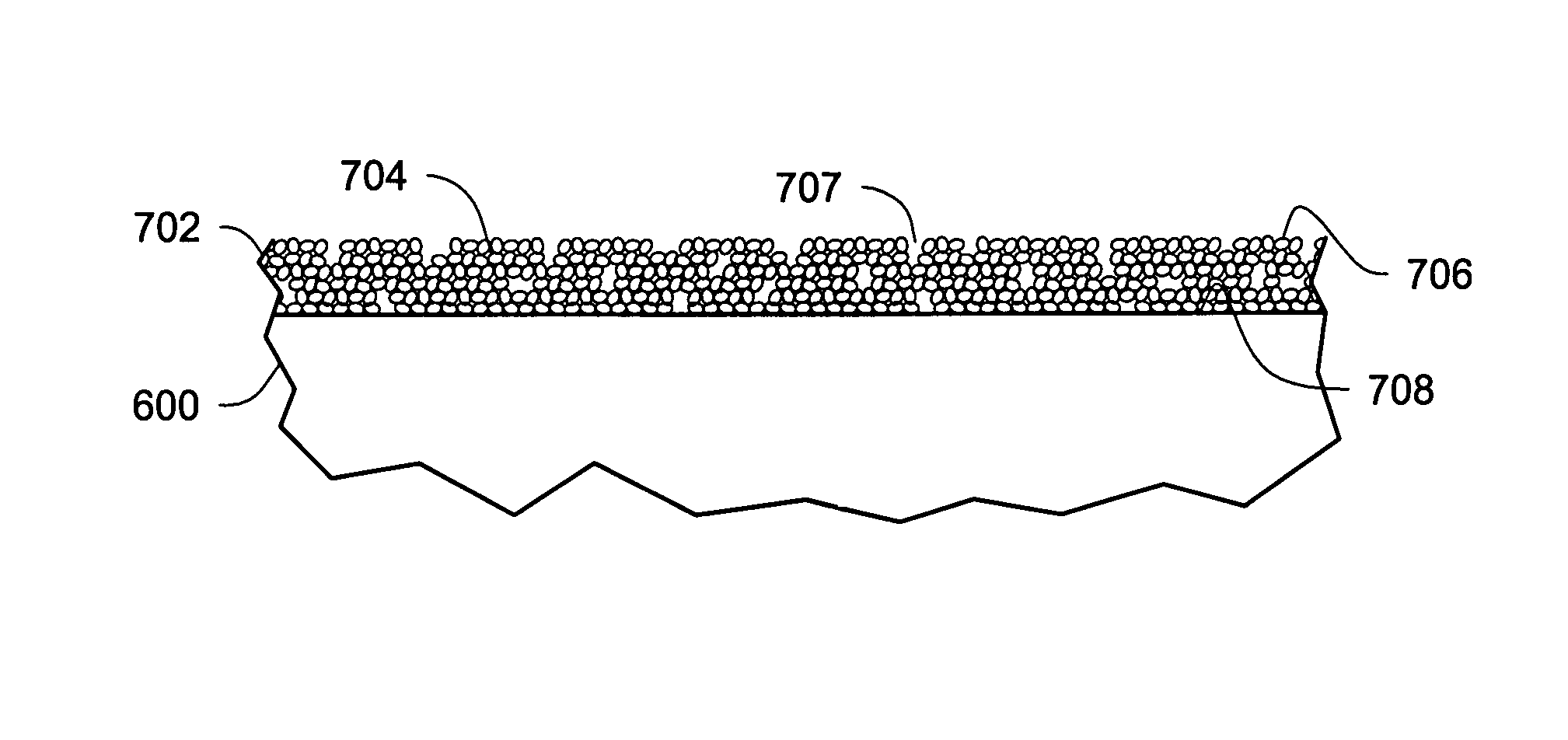

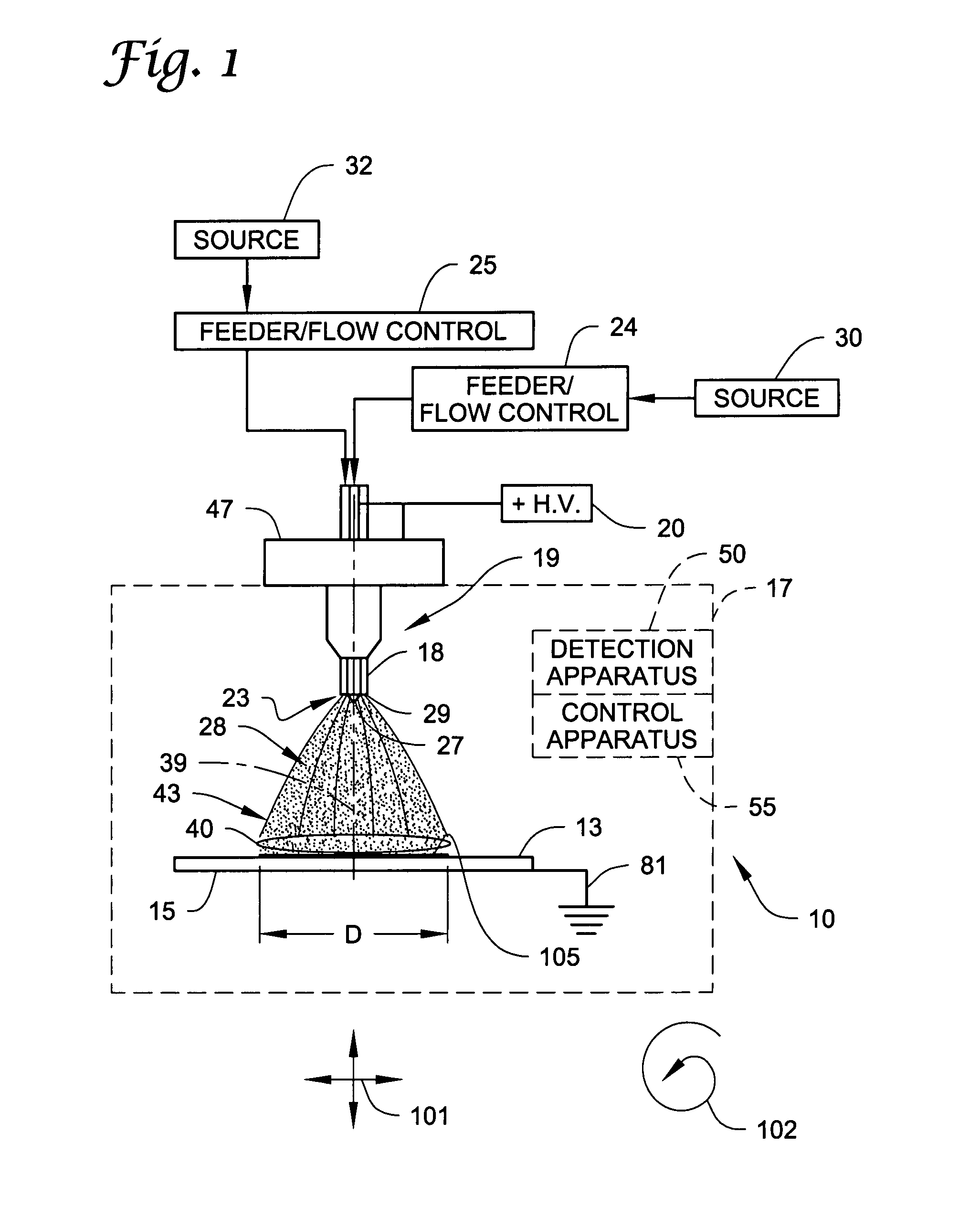

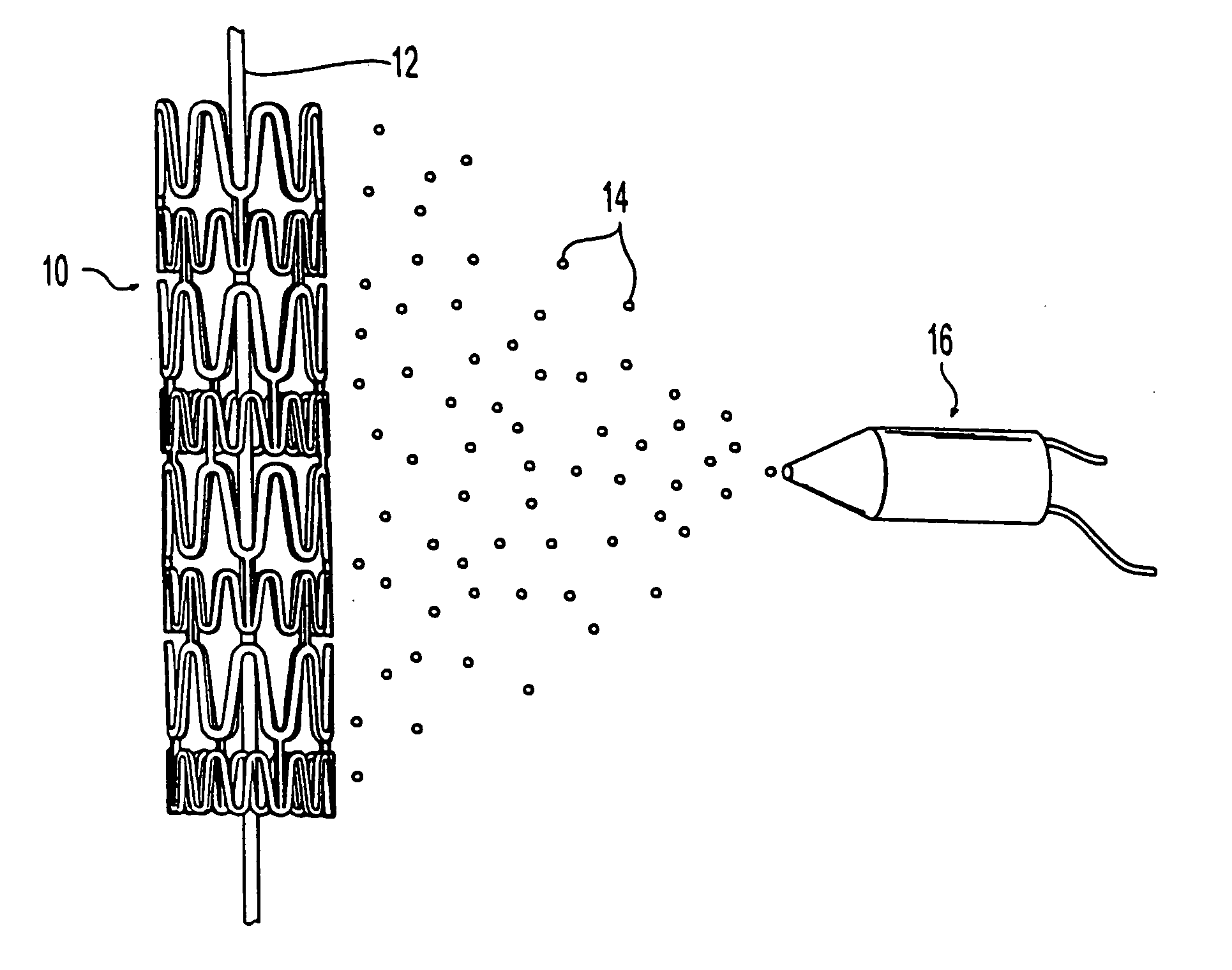

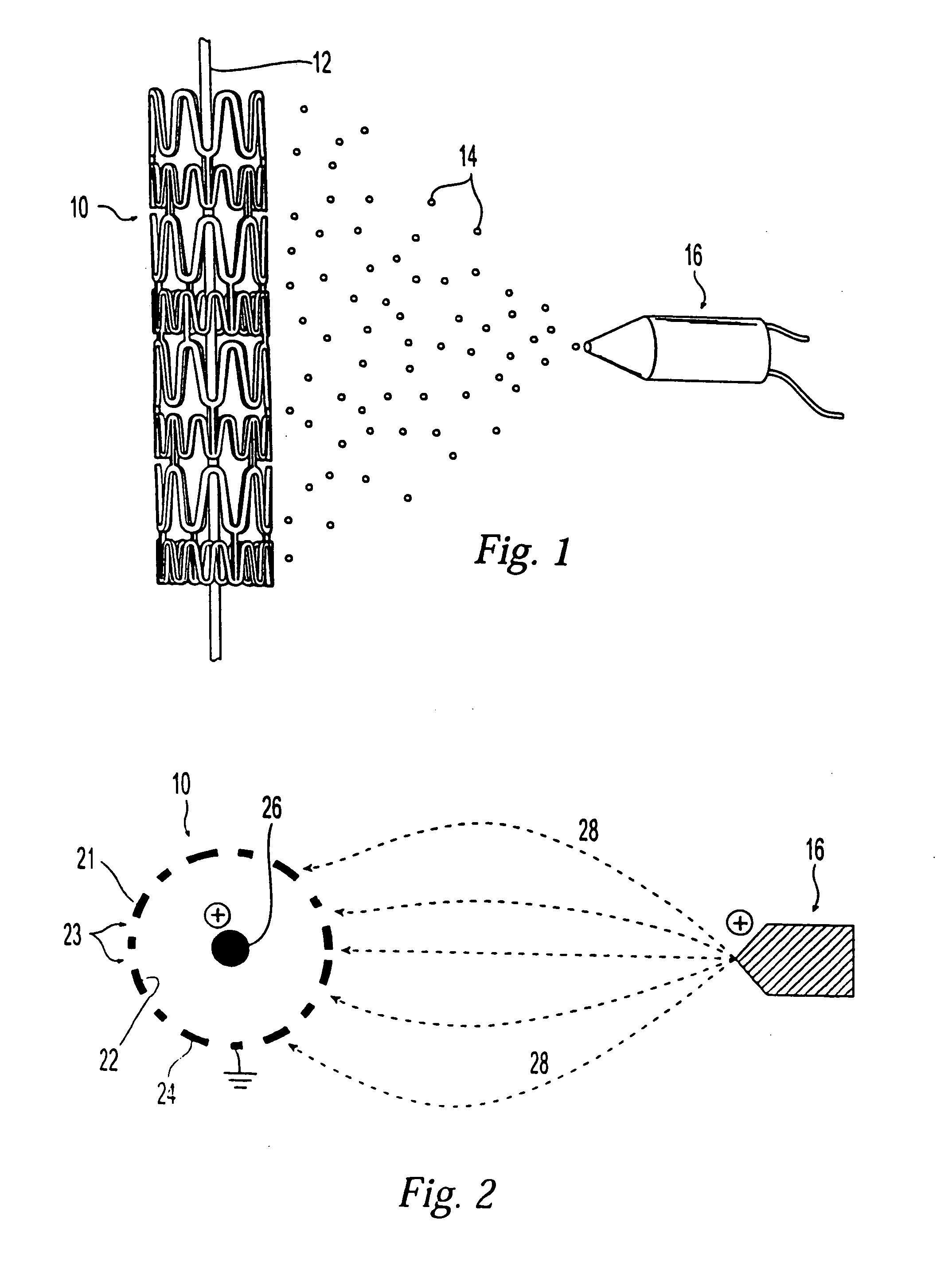

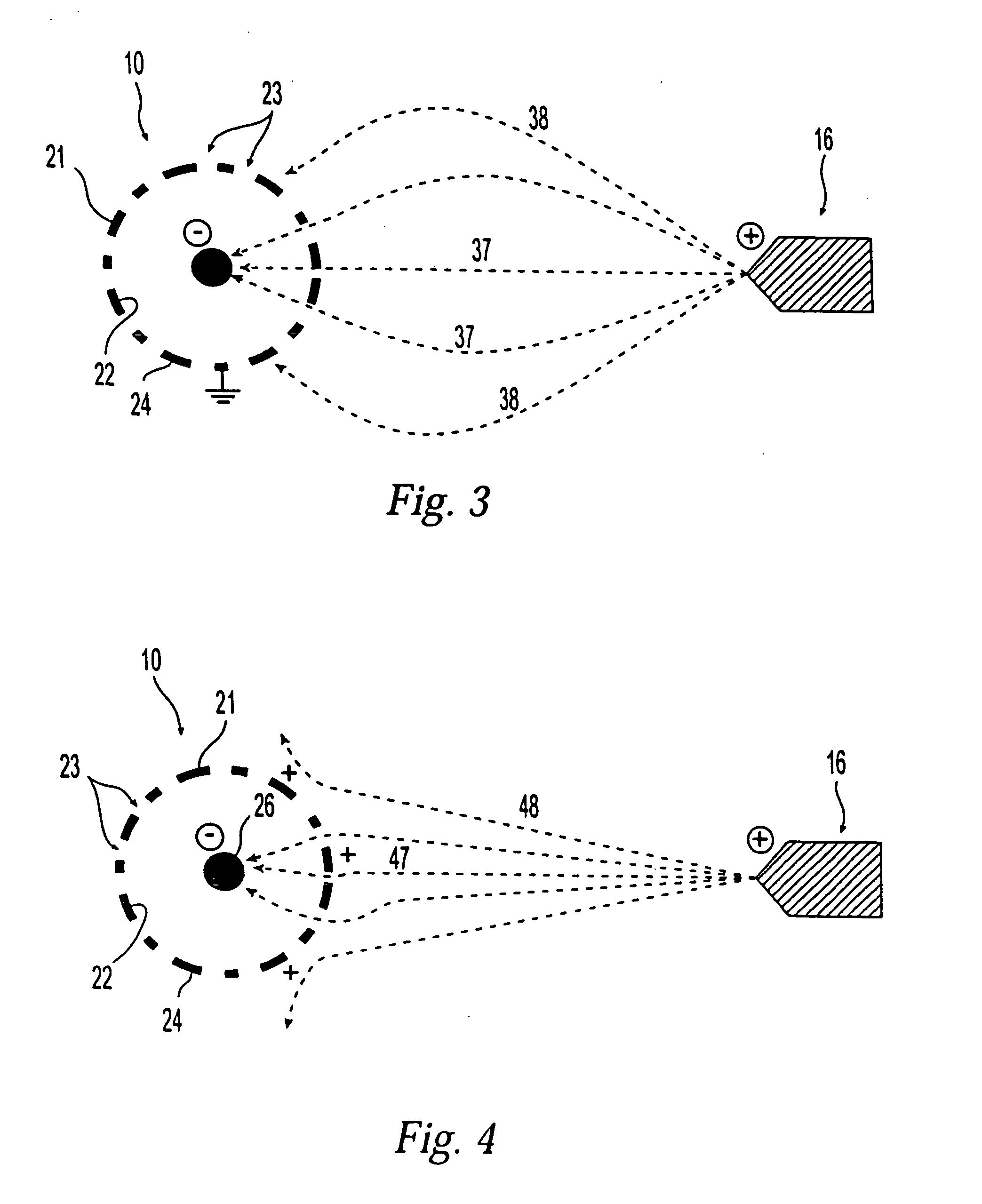

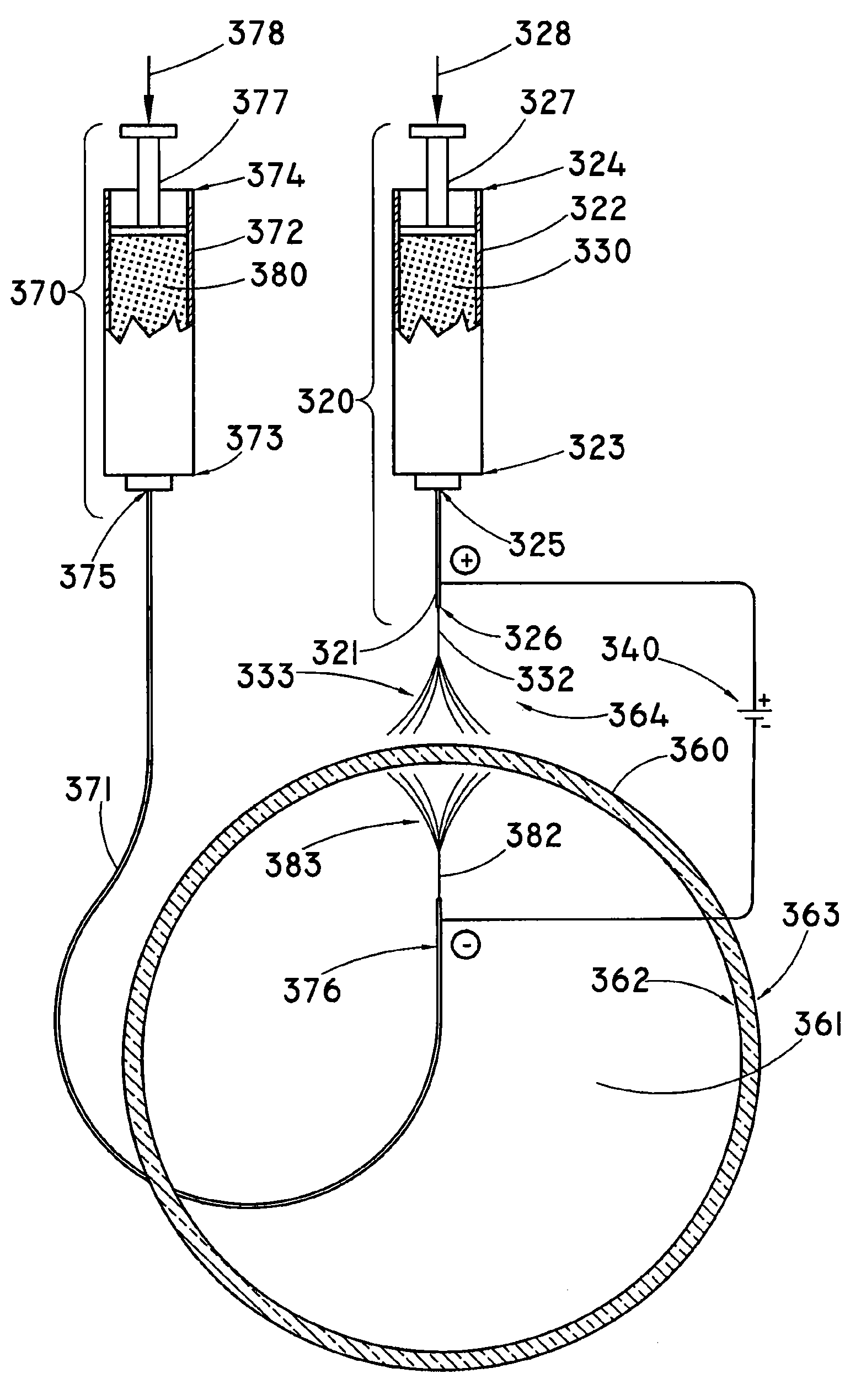

Methods and systems for coating at least a portion of a medical device (e.g., a stent structure) include providing a plurality of coating particles (e.g., monodisperse coating particles) in a defined volume. For example, the particles may be provided using one or more nozzle structures, wherein each nozzle structure includes at least one opening terminating at a dispensing end. The plurality of coating particles may be provided in the defined volume by dispensing a plurality of microdroplets having an electrical charge associated therewith from the dispensing ends of the one or more nozzle structures through use of a nonuniform electrical field between the dispensing ends and the medical device. Electrical charge is concentrated on the particle as the microdroplet evaporates. With a plurality of coating particles provided in the defined volume, such particles can be moved towards at least one surface of the medical device to form a coating thereon (e.g., using an electric field and / or a thermophoretic effect).

Owner:RGT UNIV OF MINNESOTA

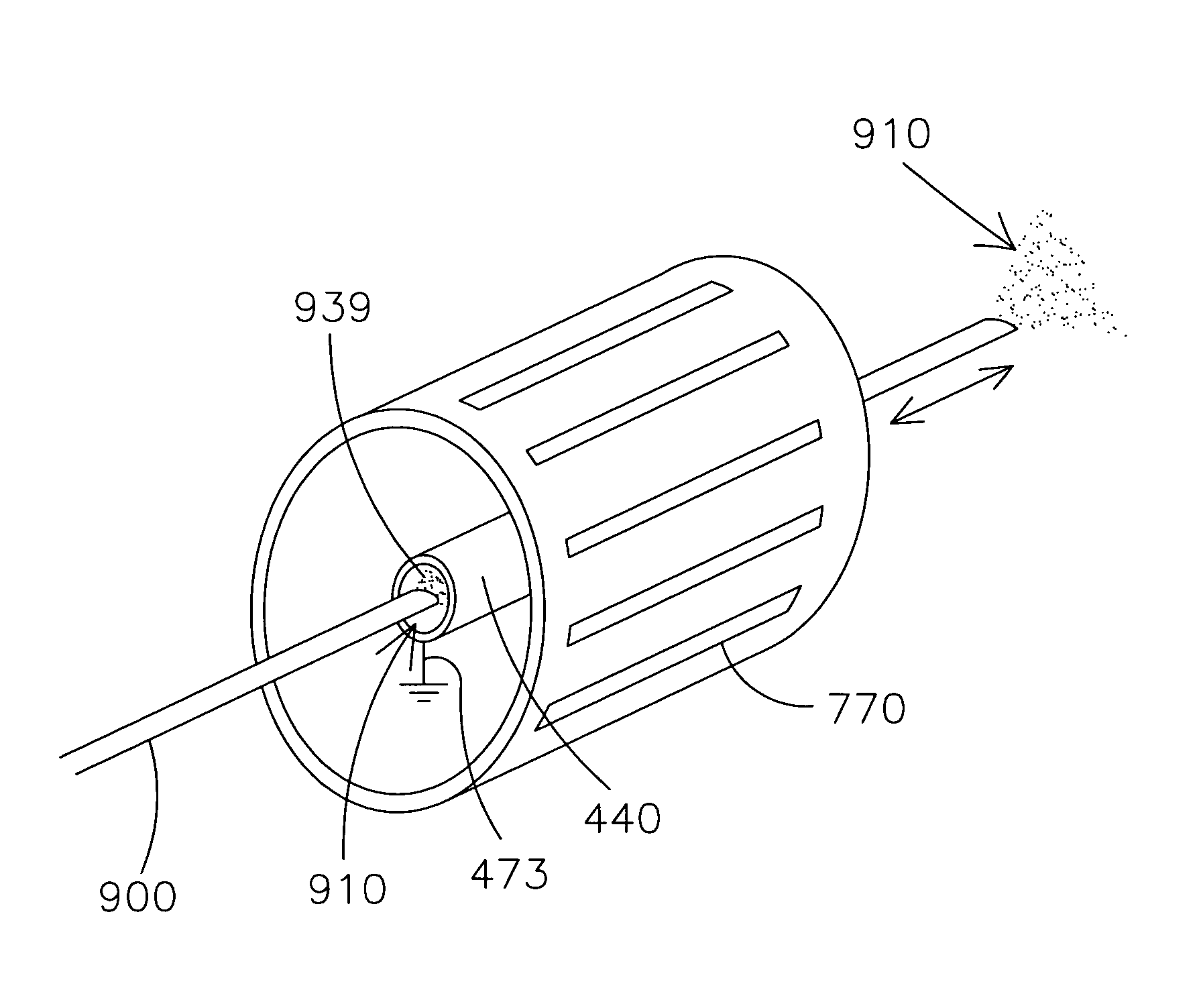

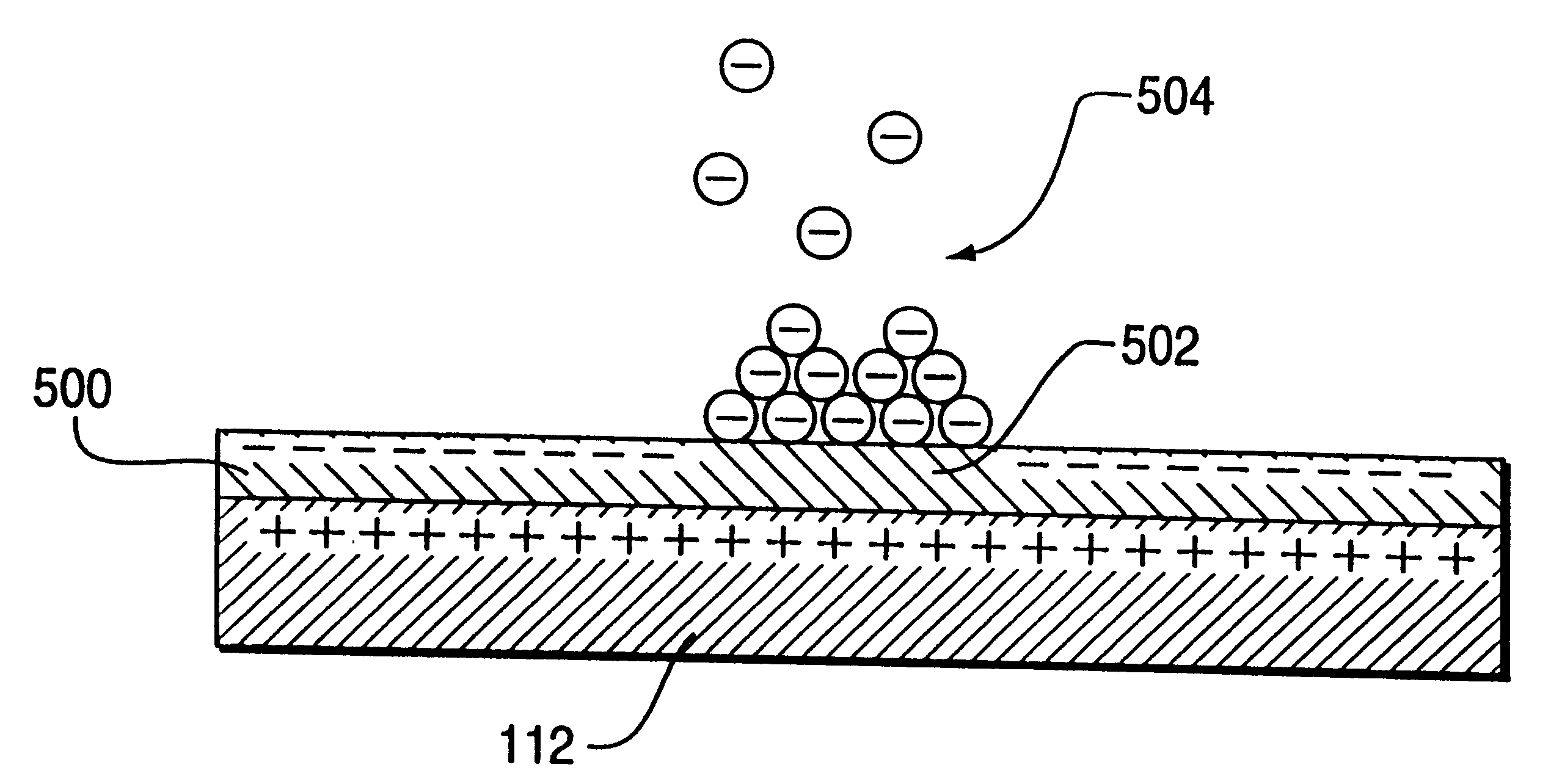

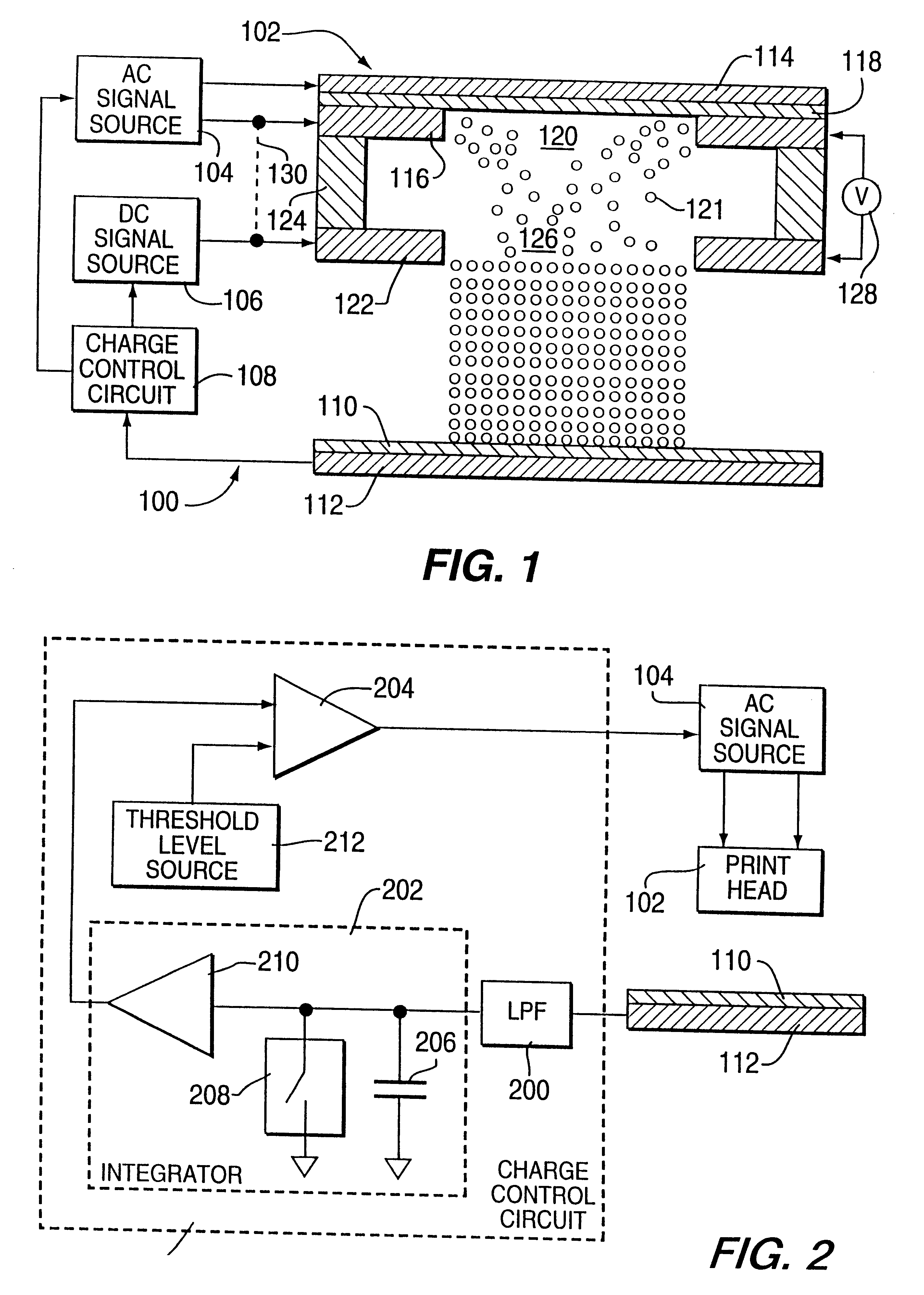

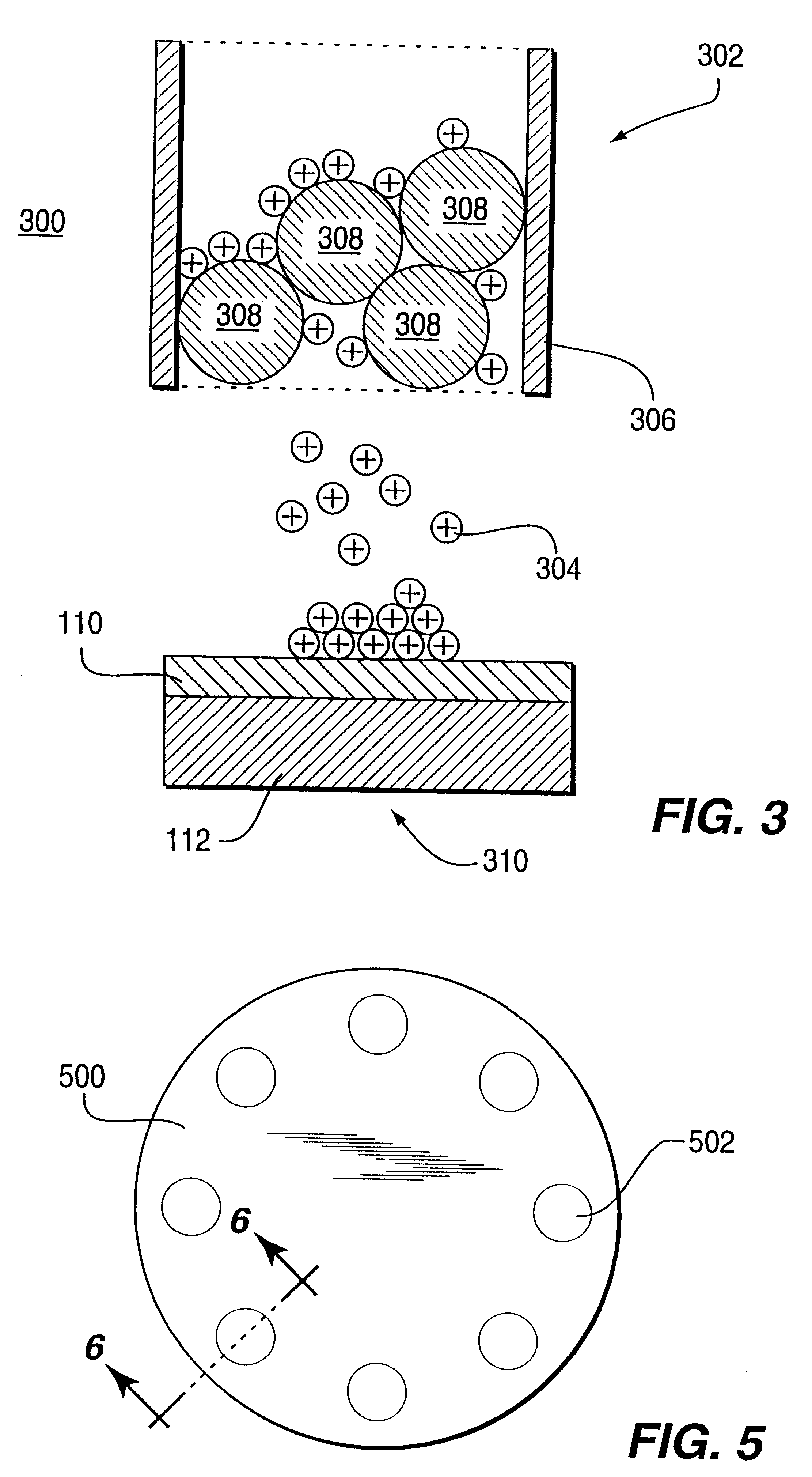

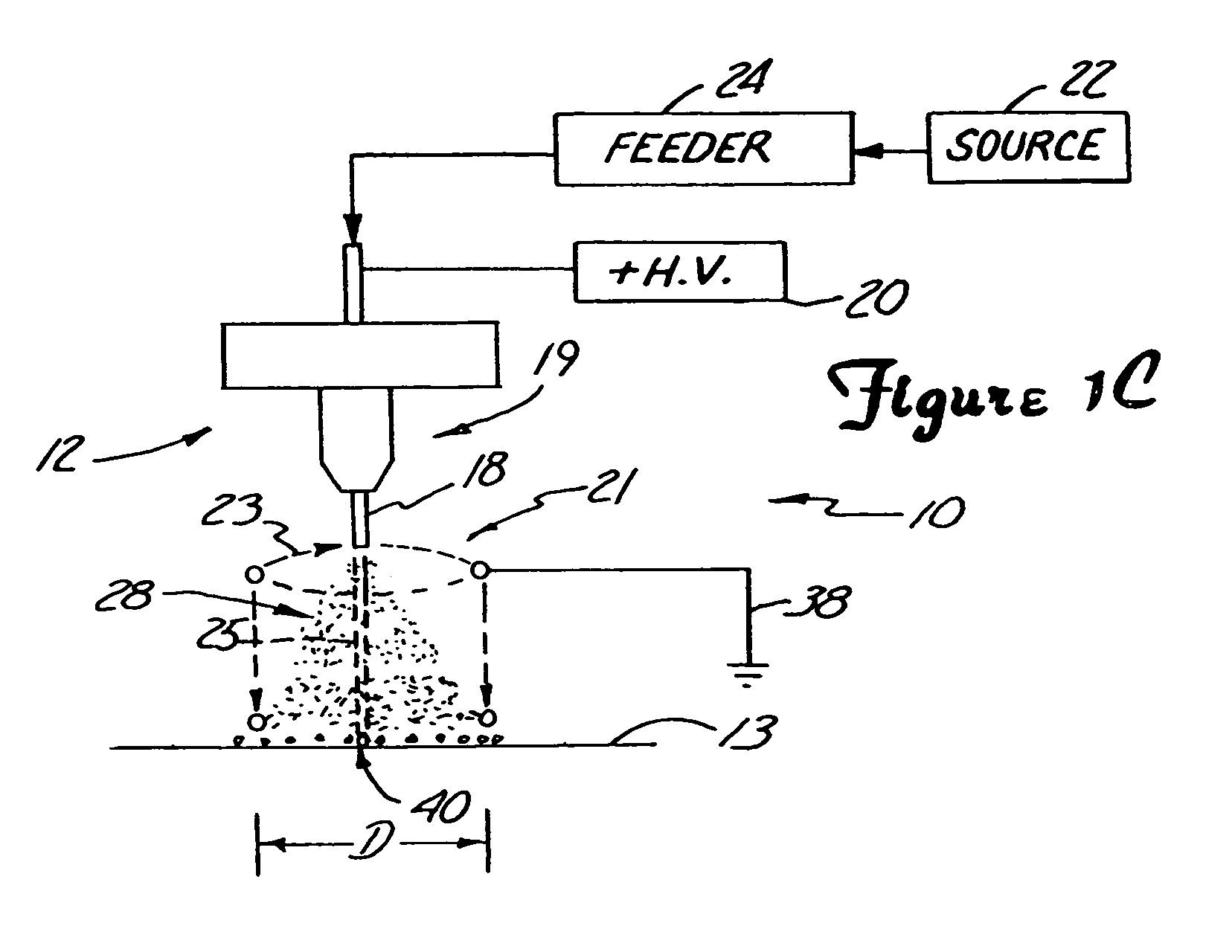

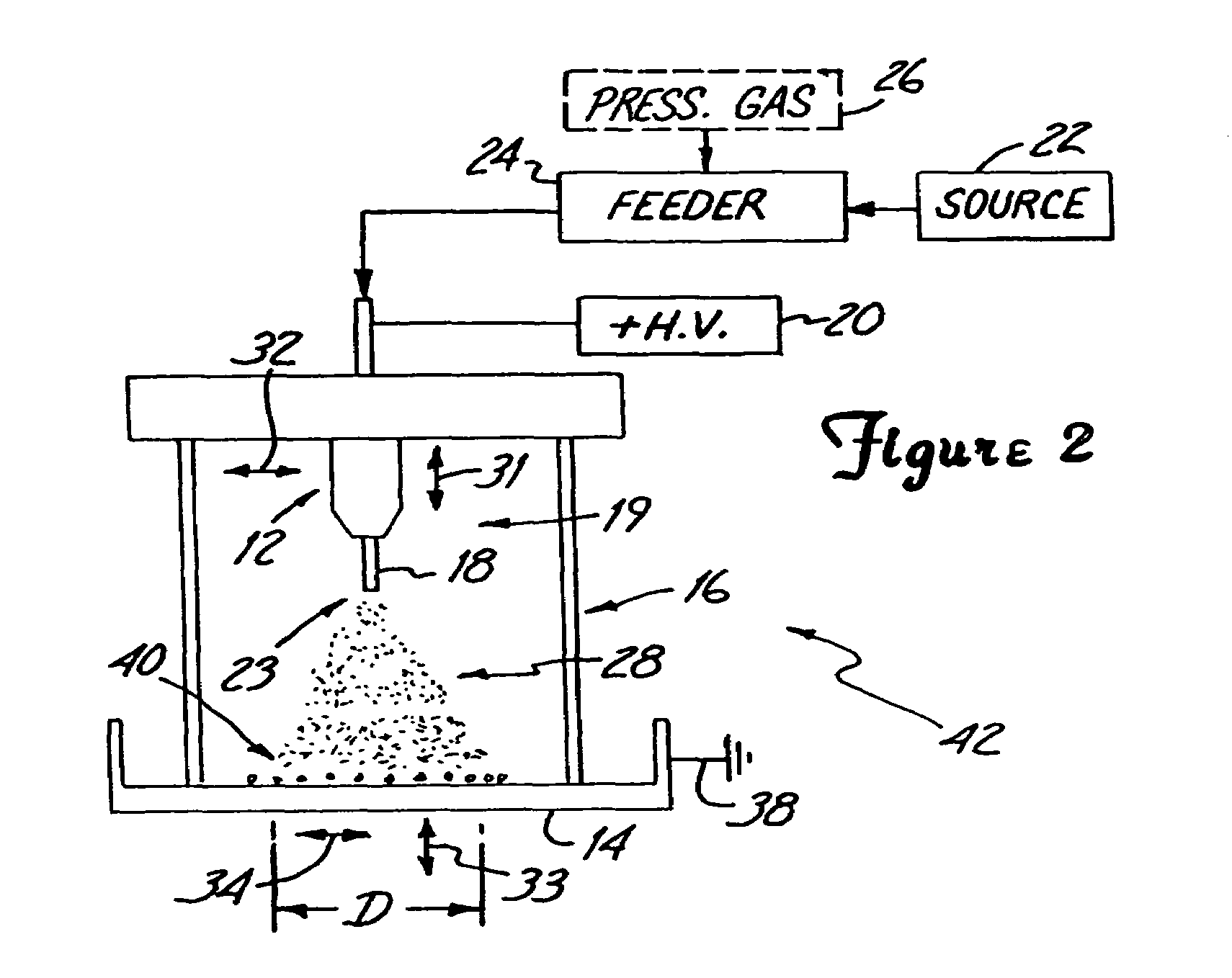

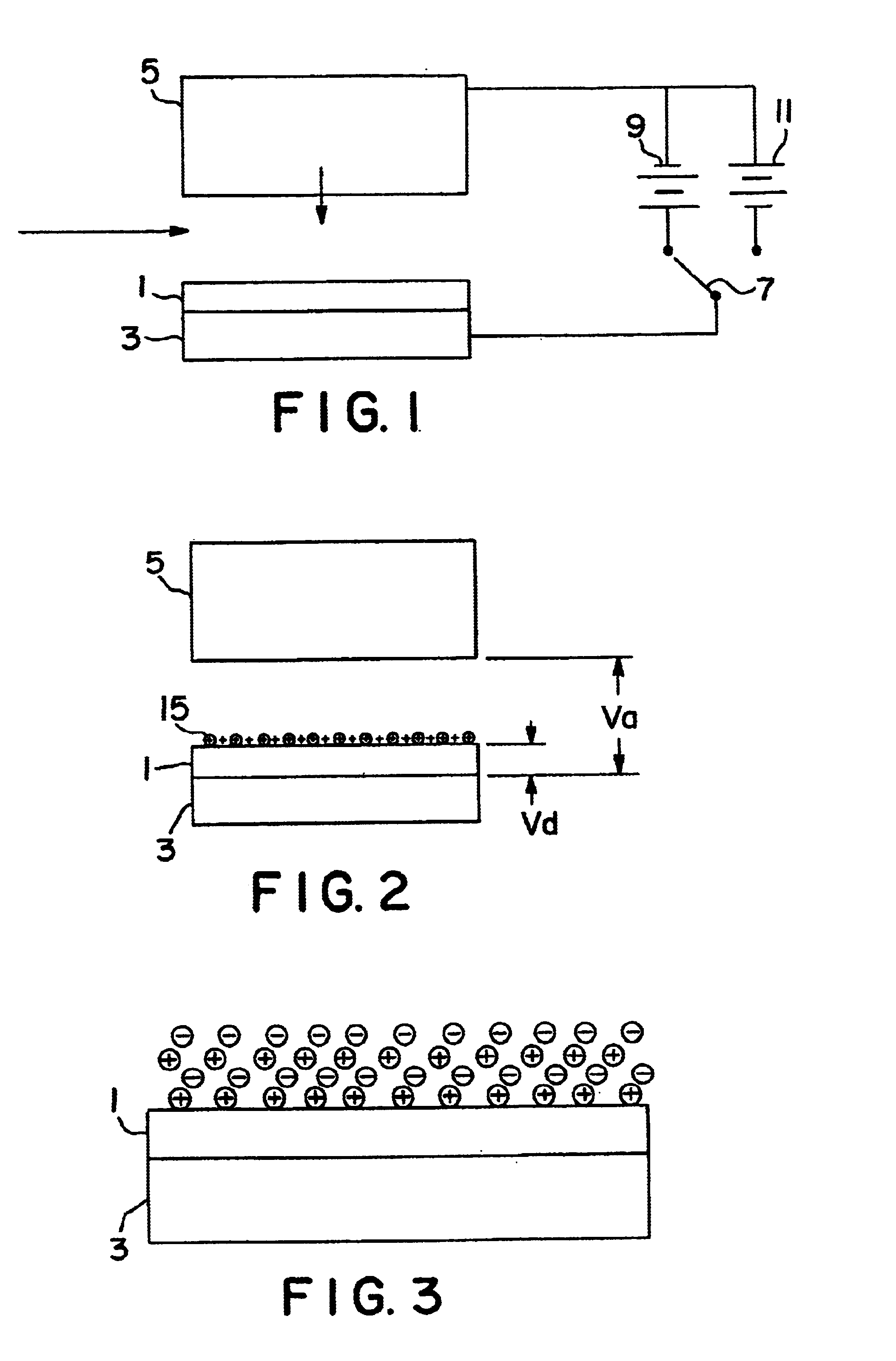

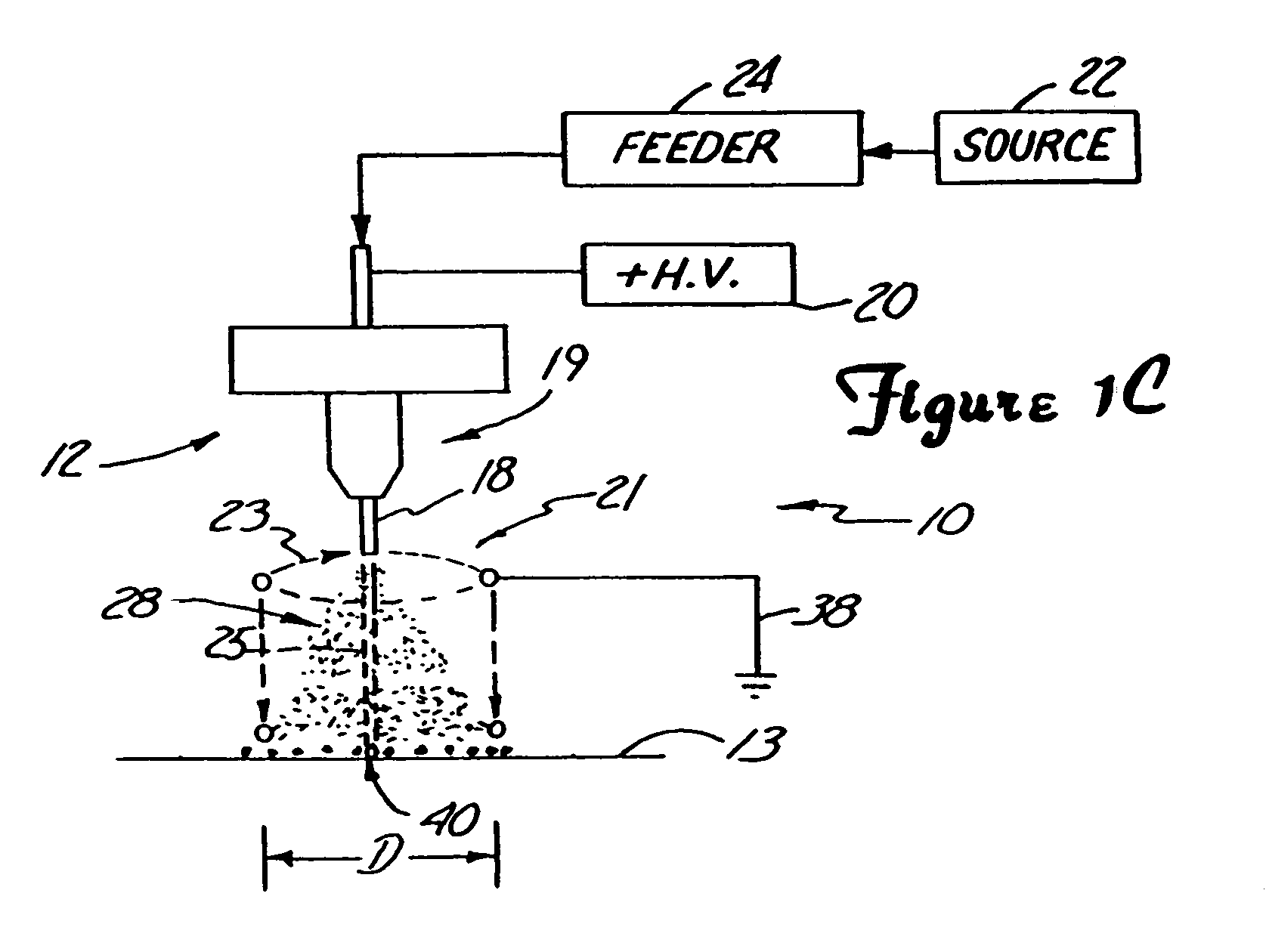

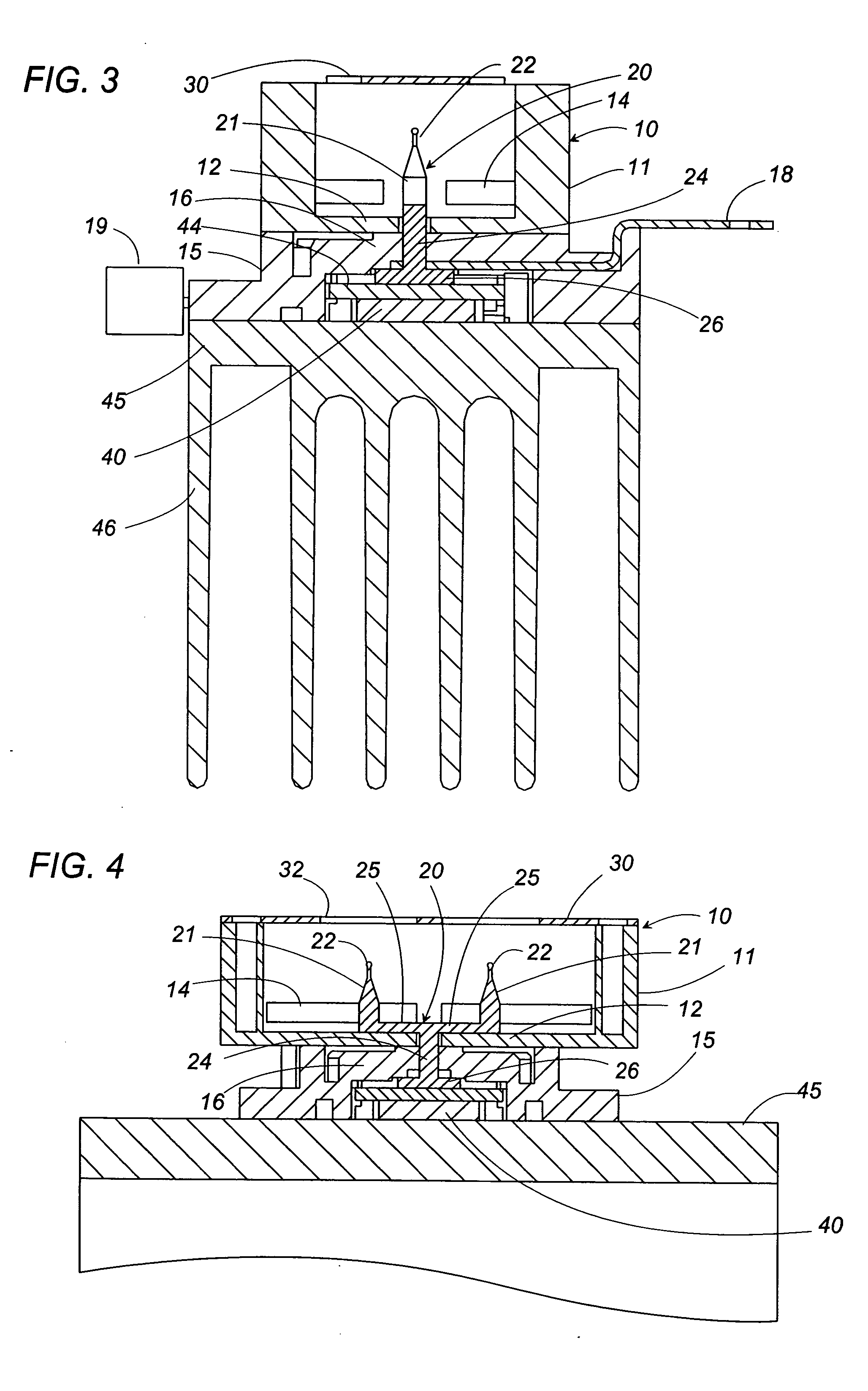

Method for electrostatically depositing a medicament powder upon predefined regions of a substrate

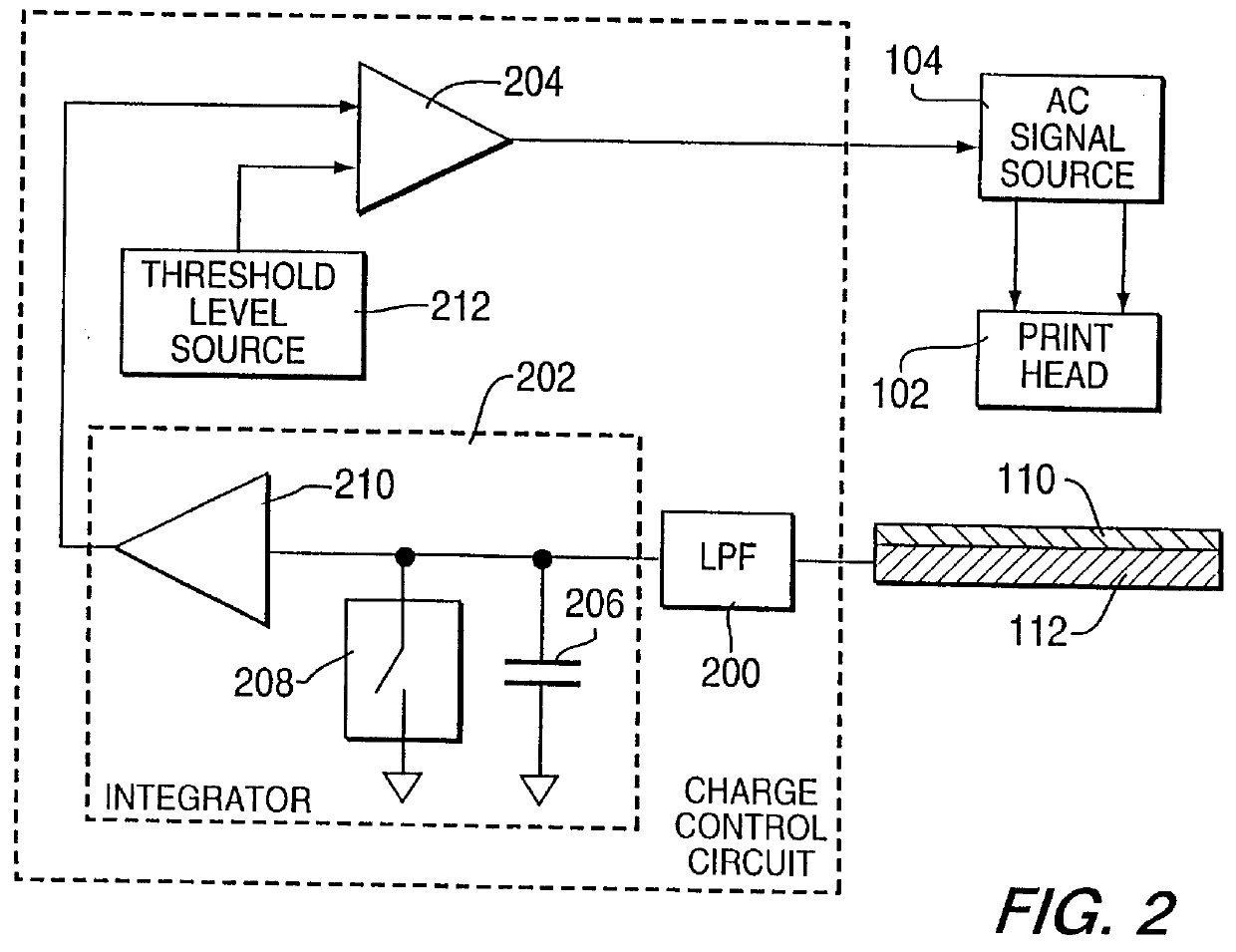

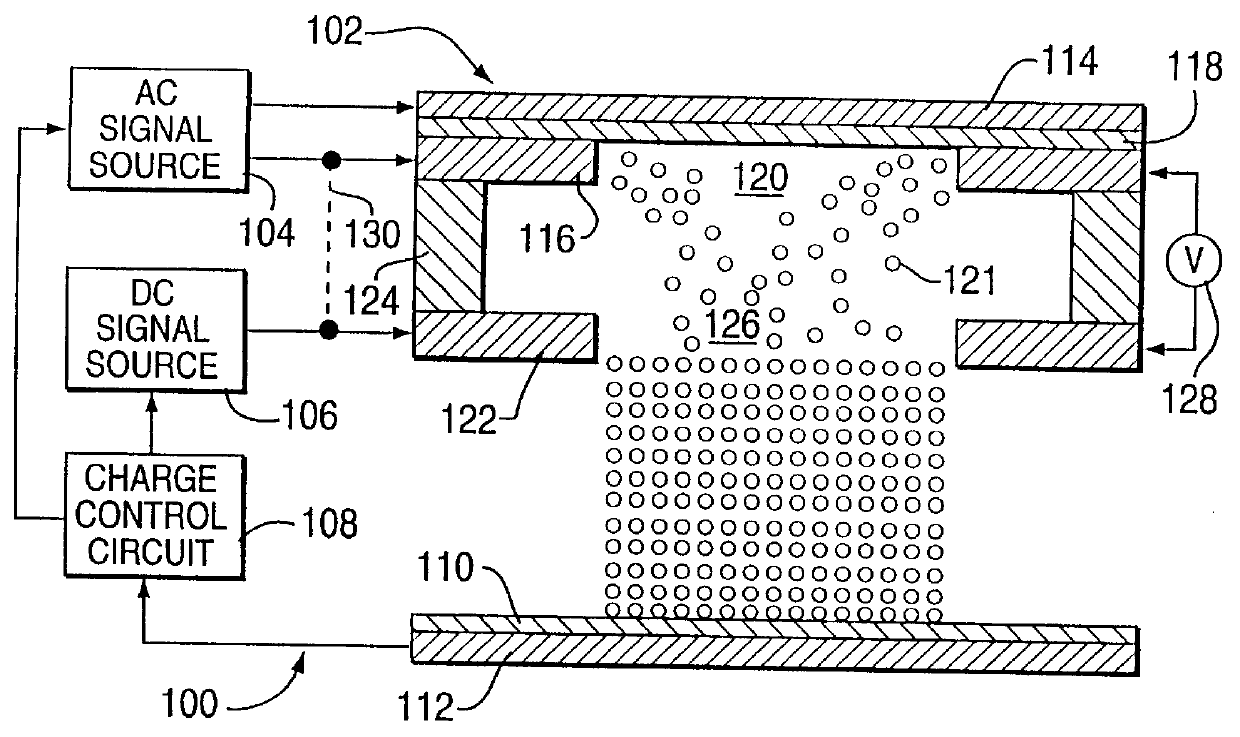

Method for electrostatically depositing select doses of medicament powder at select locations on a substrate. Specifically, the apparatus contains a charged particle emitter for generating charged particles that charge a predefined region of a substrate and a charge accumulation control circuit for computing the amount of charge accumulated upon the substrate and deactivating the emitter when a selected quantity of charge has accumulated. Additionally, a triboelectric charging apparatus charges the medicament powder and forms a charged medicament cloud proximate the charged region of the substrate. The medicament particles within the medicament cloud electrostatically adhere to the charged region. The quantity of charge accumulated on the substrate at the predefined region and the charge-to-mass ratio of the medicament powder in the cloud control the amount (dose) of medicament deposited and retained by the substrate. Consequently, this apparatus accurately controls both medicament dosage and deposition location. Furthermore, since the substrate can be of any dielectric material that retains an electrostatic charge, the apparatus can be used to deposit medicament on substrates that are presently used in oral medicament consumption, e.g., substrates that are used to fabricate suppositories, inhalants, tablets, capsules and the like.

Owner:DELSYS PHARMA

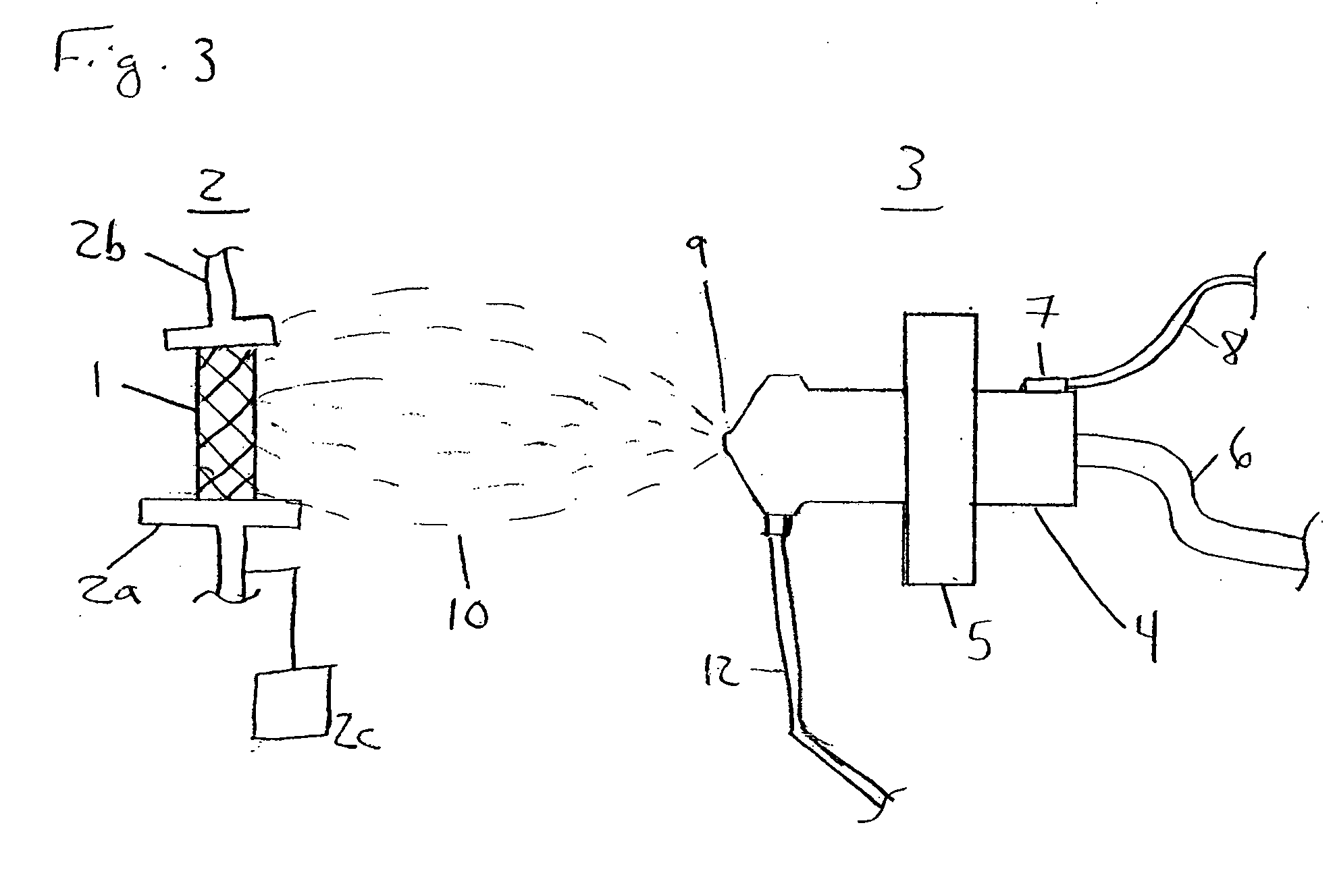

Device for injection and mixing of liquid droplets

ActiveUS7211223B2Avoid biological contaminationPreventing evaporation of the dropsLiquid spraying plantsTransportation and packagingElectricityViscous liquid

Owner:CENT NAT DE LA RECHERCHE SCI

Method and apparatus for electrostatically depositing a medicament powder upon predefined regions of a substrate

A method for electrostatically depositing select doses of medicament powder at select locations on a substrate. Specifically, an apparatus contains a charged particle emitter for generating charged particles that charge a predefined region of a substrate and a charge accumulation control circuit for computing the amount of charge accumulated upon the substrate and deactivating the emitter when a selected quantity of charge has accumulated. Additionally, a triboelectric charging apparatus charges the medicament powder and forms a charged medicament cloud proximate the charged region of the substrate. The medicament particles within the medicament cloud electrostatically adhere to the charged region. The quantity of charge accumulated on the substrate at the predefined region and the charge-to-mass ratio of the medicament powder in the cloud control the amount (dose) of medicament deposited and retained by the substrate. Consequently, this apparatus accurately controls both medicament dosage and deposition location. Furthermore, since the substrate can be of any dielectric material that retains an electrostatic charge, the apparatus can be used to deposit medicament on substrates that are presently used in oral medicament consumption, e.g., substrates that are used to fabricate suppositories, inhalants, tablets, capsules and the like.

Owner:DELSYS PHARMA

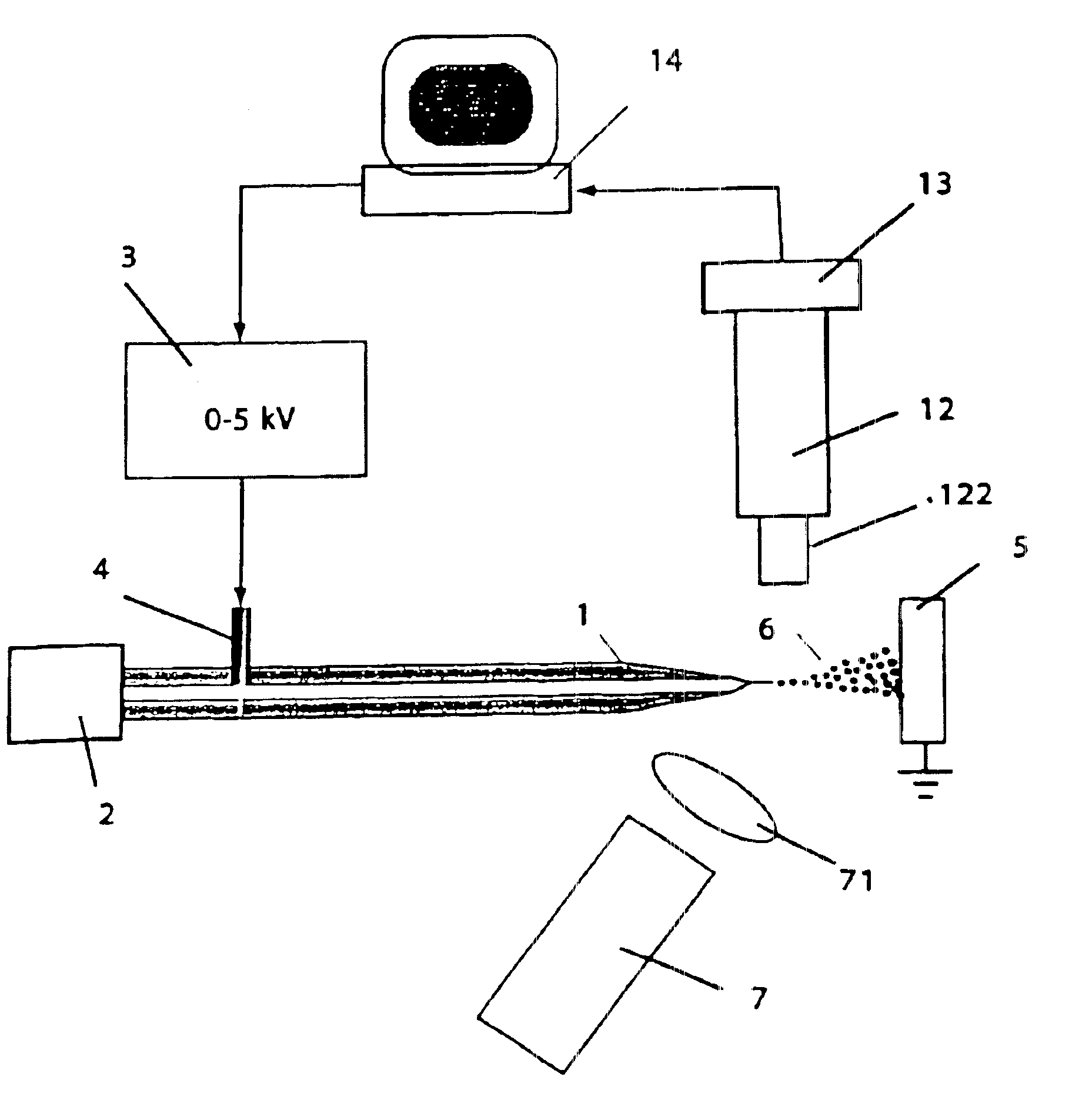

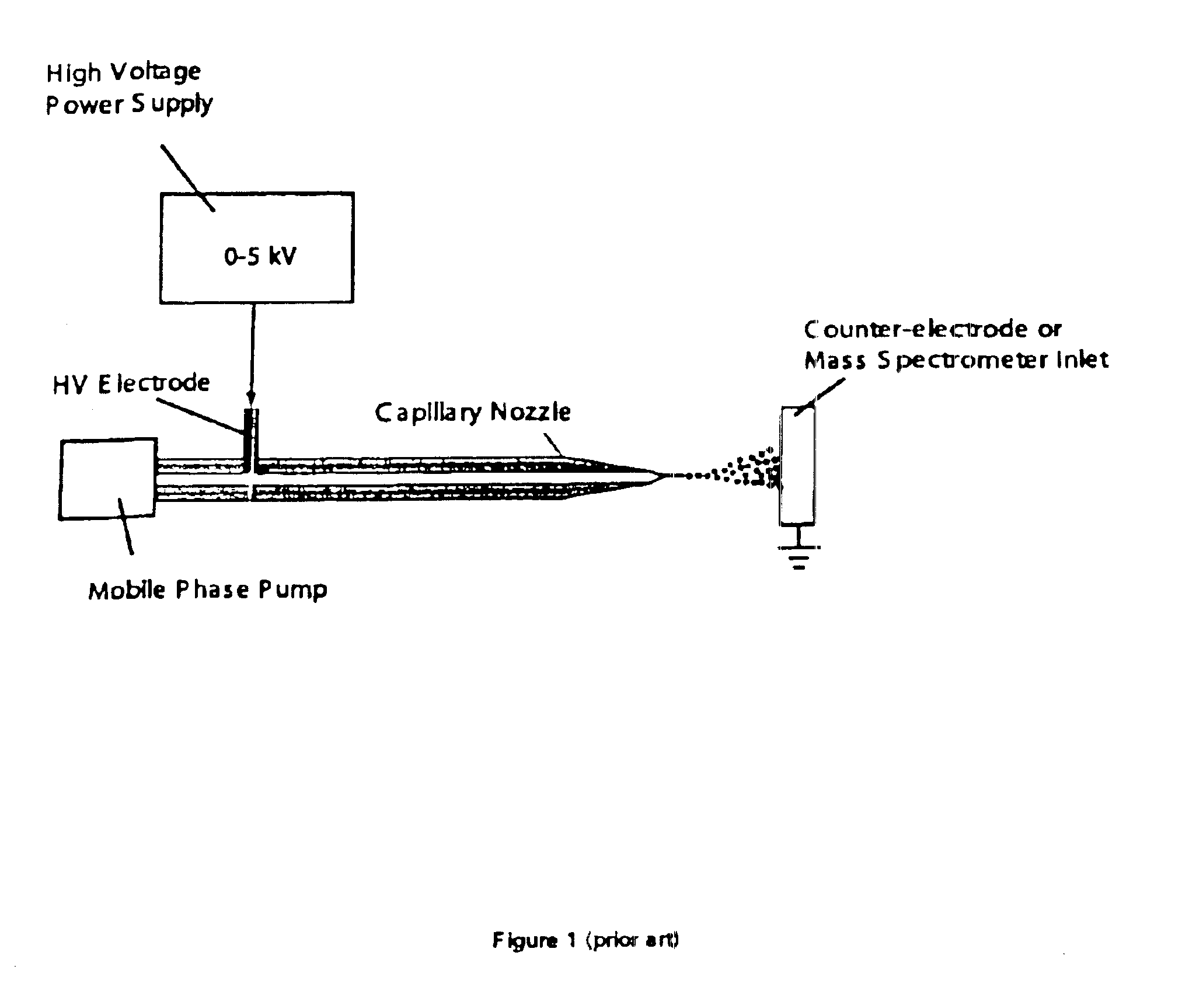

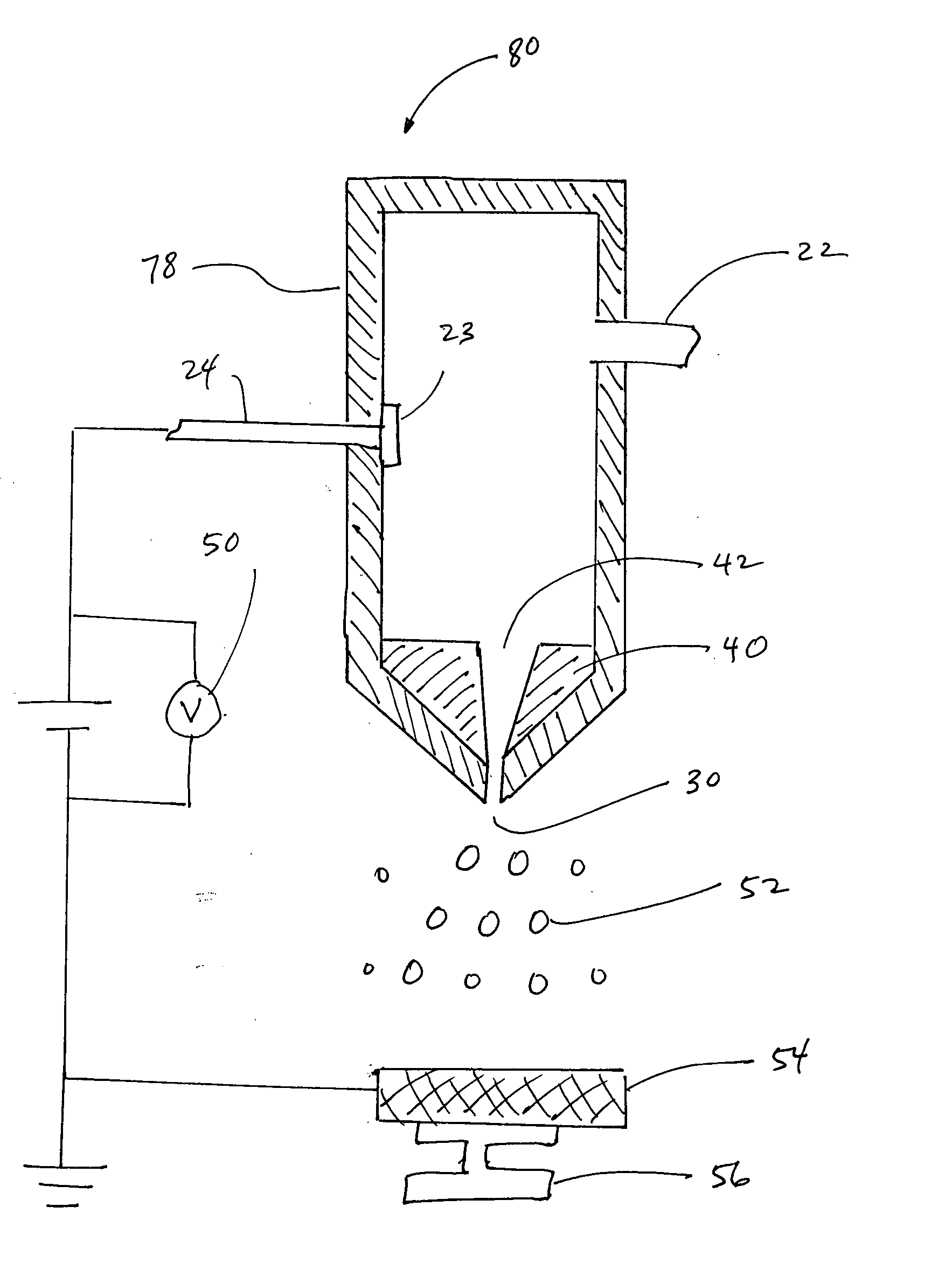

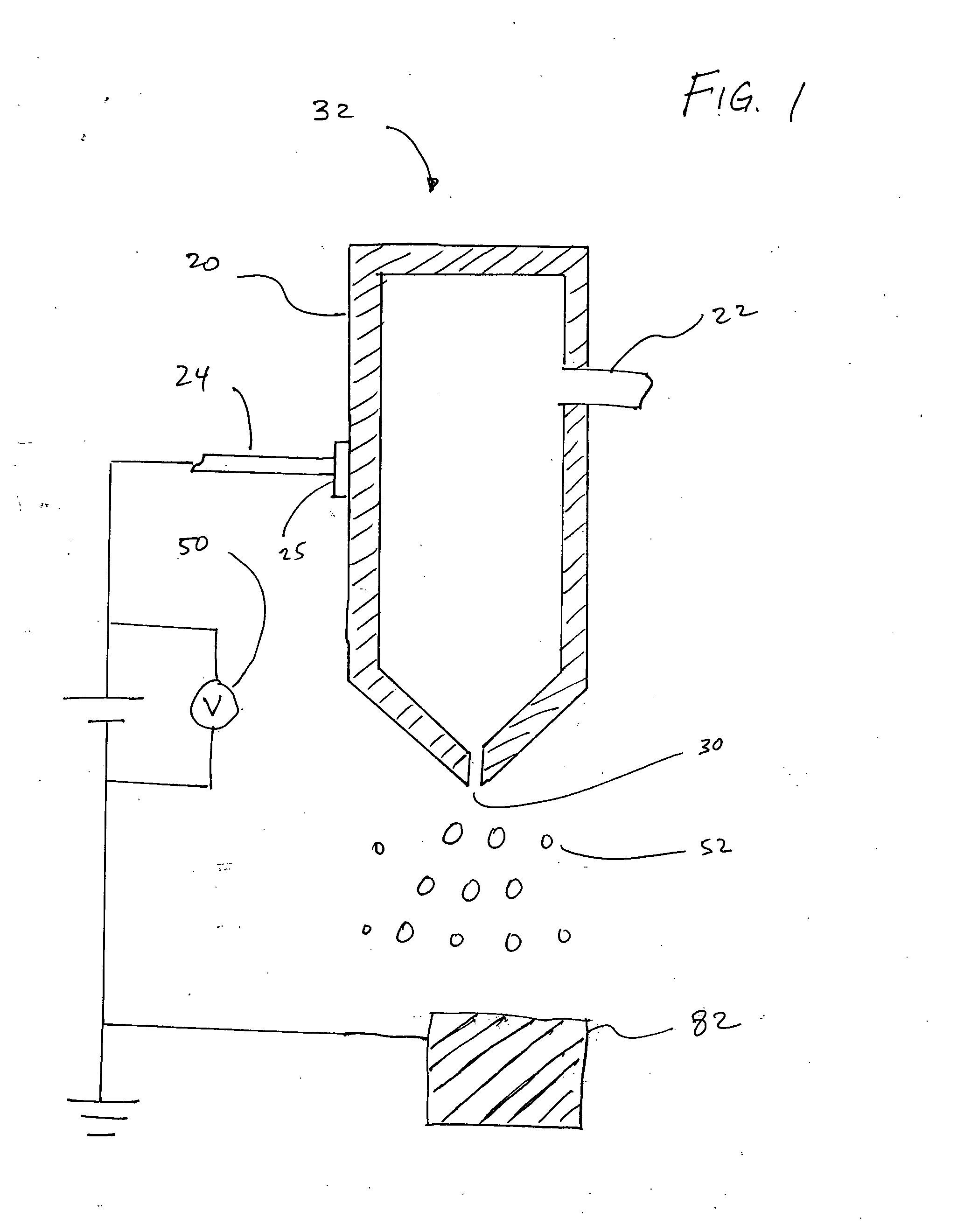

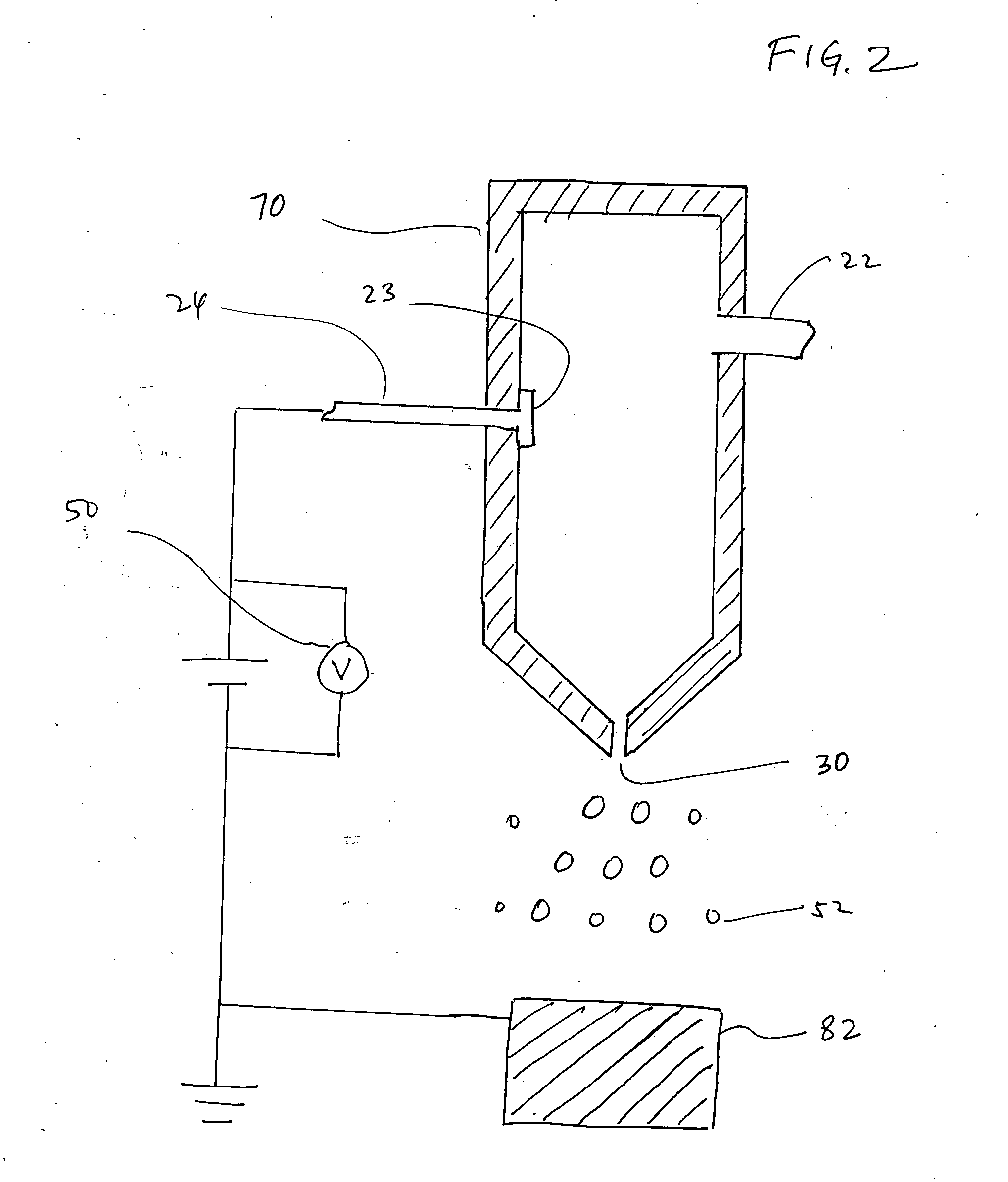

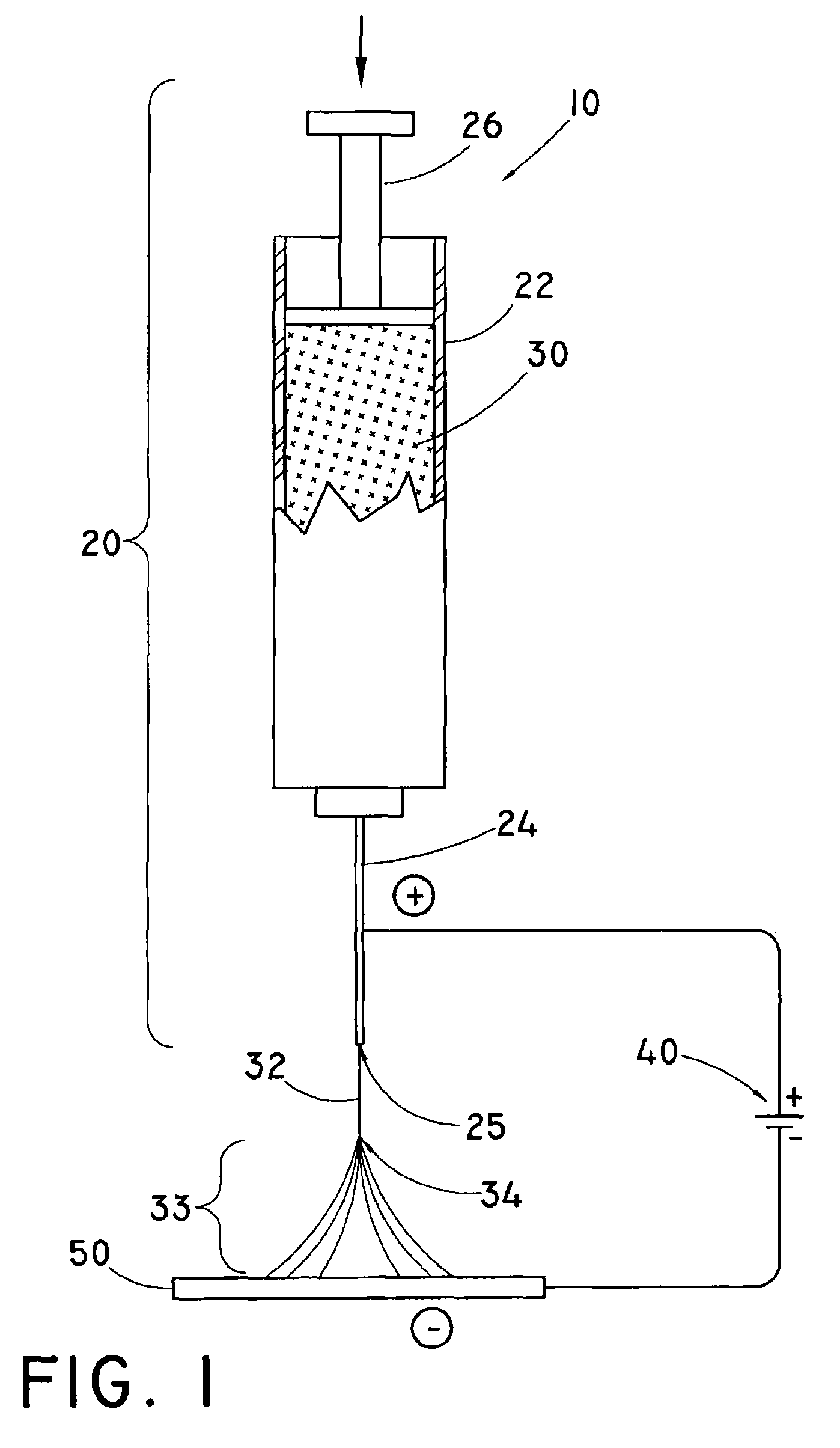

Electrospraying apparatus and method for coating particles

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

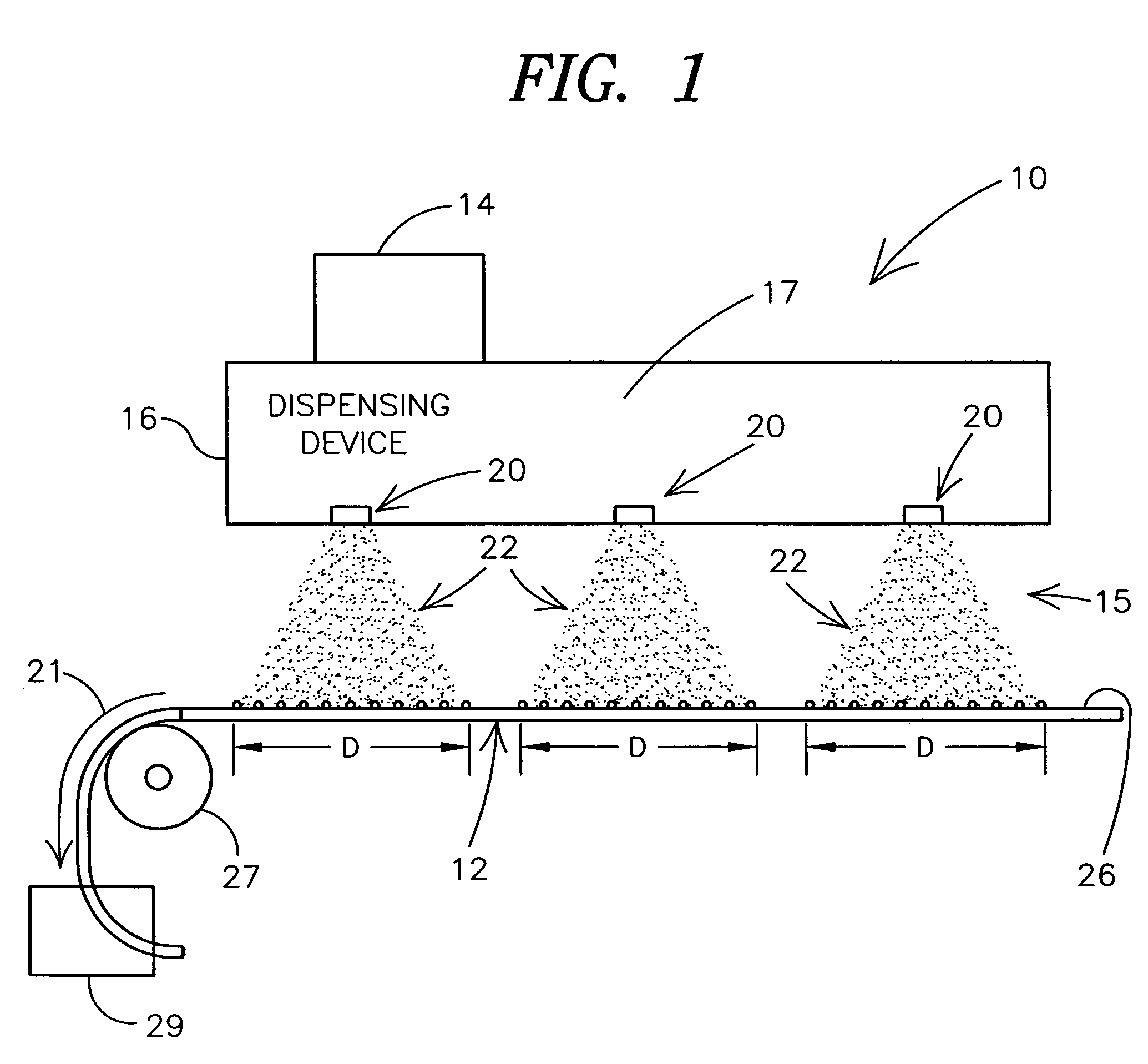

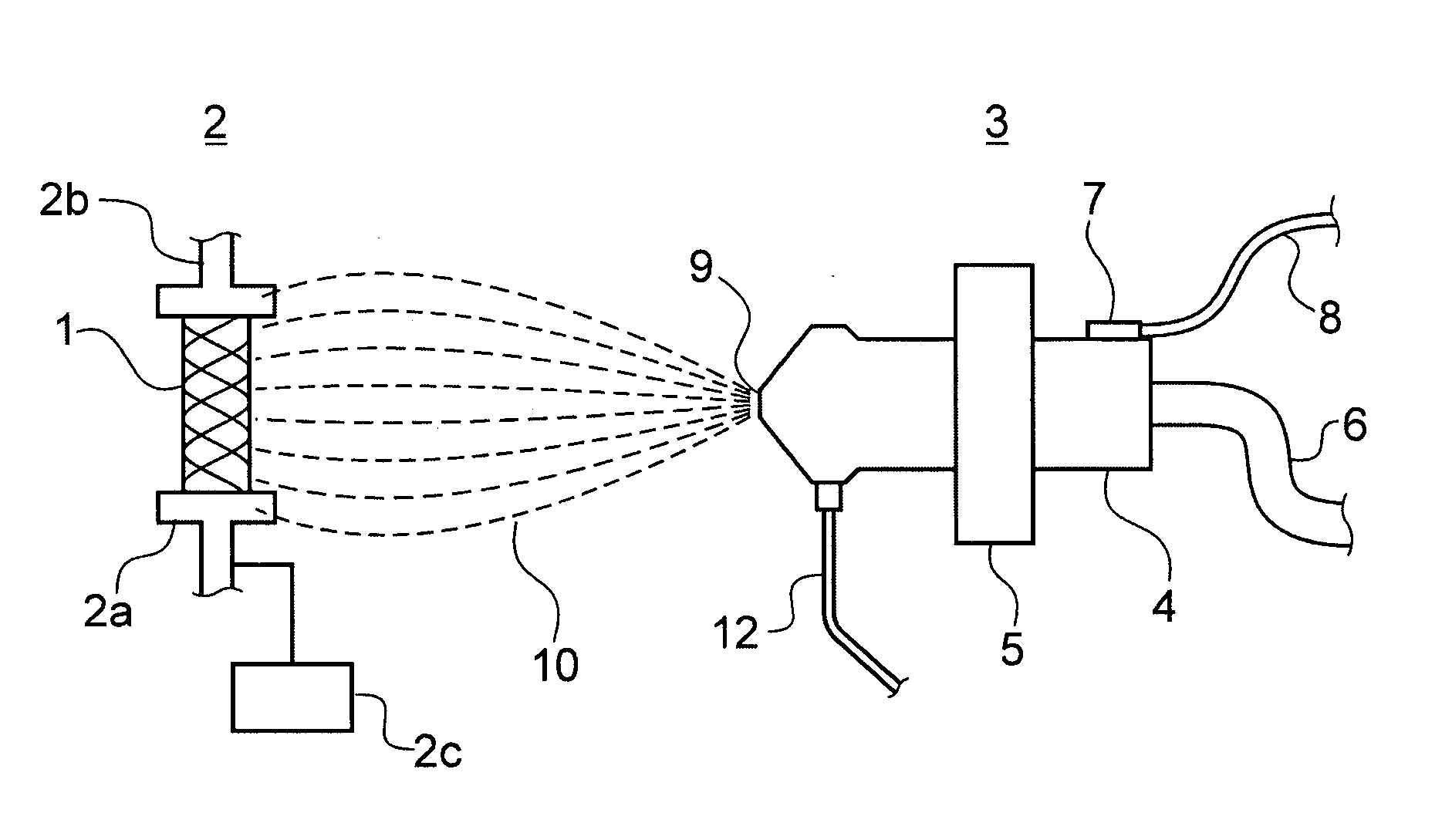

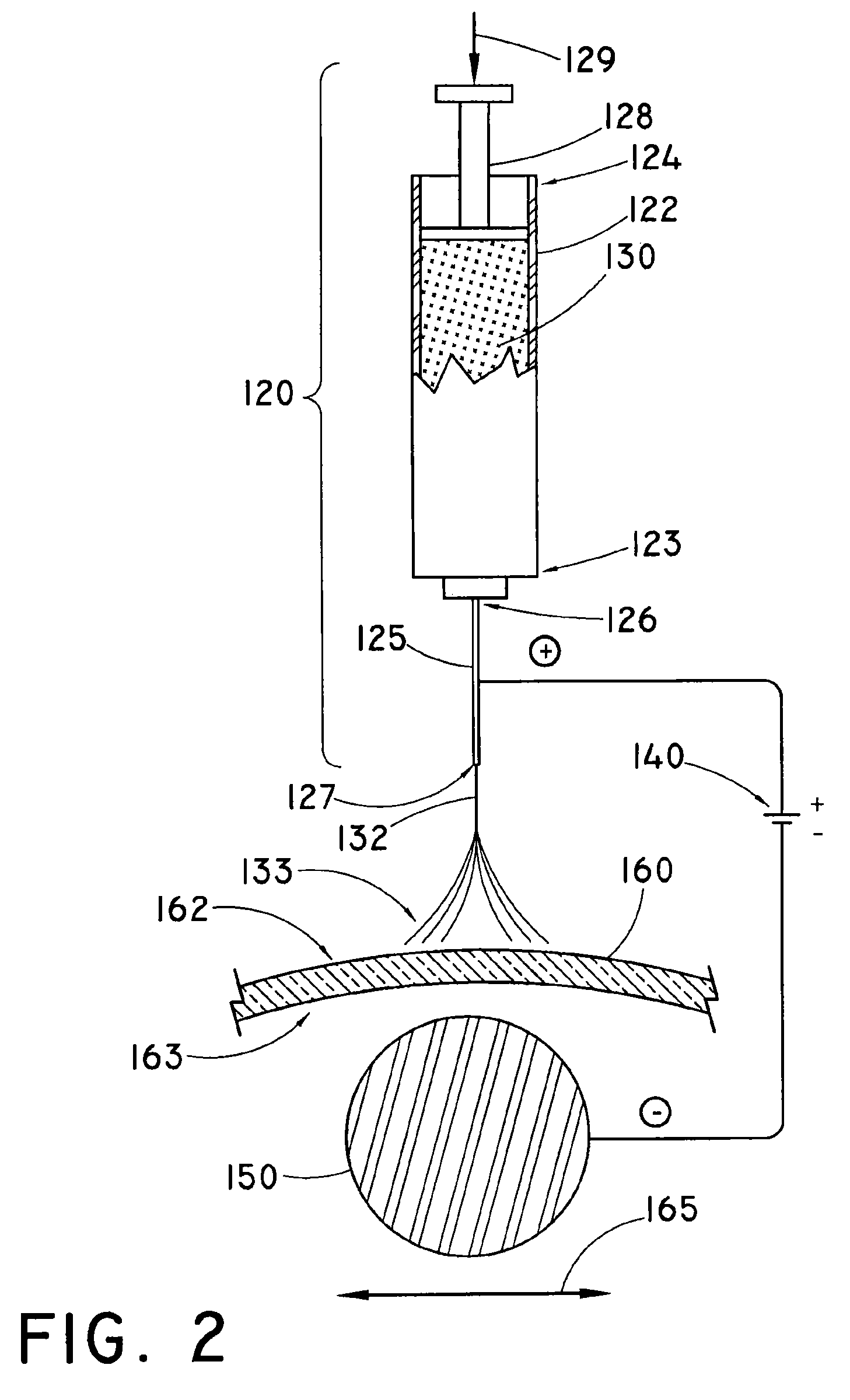

High mass throughput particle generation using multiple nozzle spraying

InactiveUS7498063B2High mass throughputImprove throughputSurgeryPretreated surfacesElectricityNanoparticle

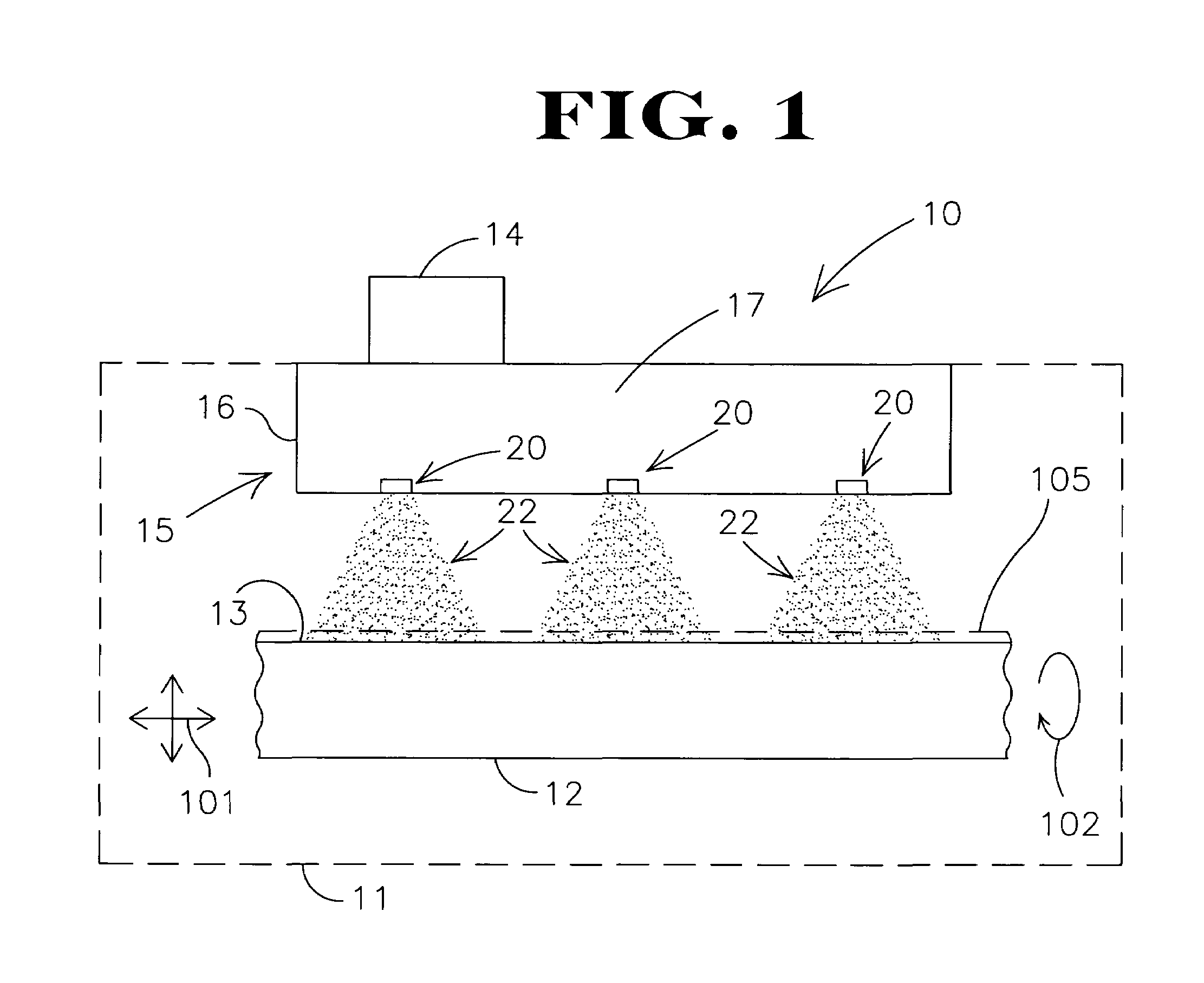

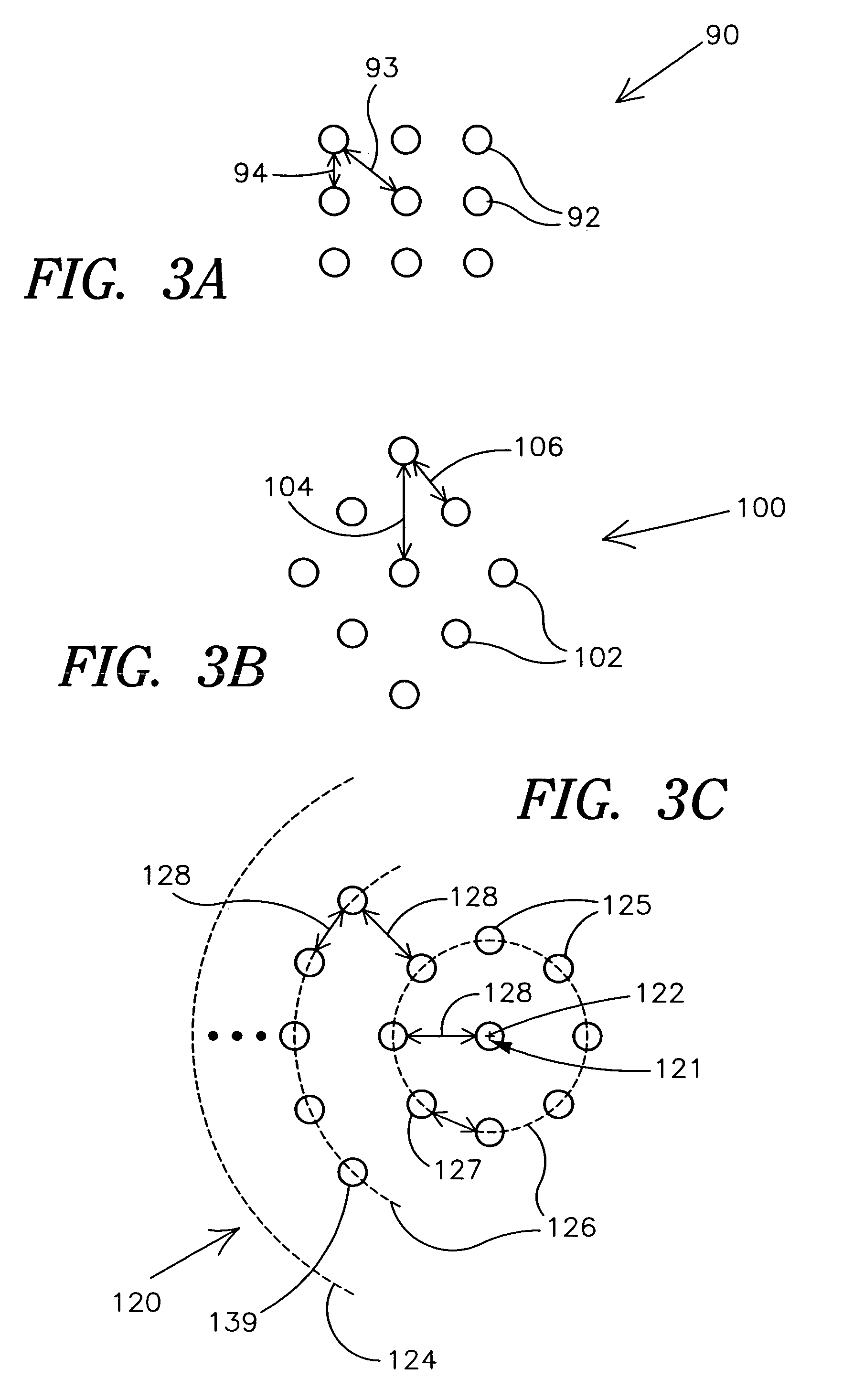

Spraying apparatus and methods that employ multiple nozzle structures for producing multiple sprays of particles, e.g., nanoparticles, for various applications, e.g., pharmaceuticals, are provided. For example, an electrospray dispensing device may include a plurality of nozzle structures, wherein each nozzle structure is separated from adjacent nozzle structures by an internozzle distance. Sprays of particles are established from the nozzle structures by creating a nonuniform electrical field between the nozzle structures and an electrode electrically isolated therefrom.

Owner:RGT UNIV OF MINNESOTA

Method and apparatus for coating medical implants

InactiveUS20070031607A1Reduce unevennessMinimize volume chargeLiquid spraying plantsLiquid surface applicatorsFiberBiomedical engineering

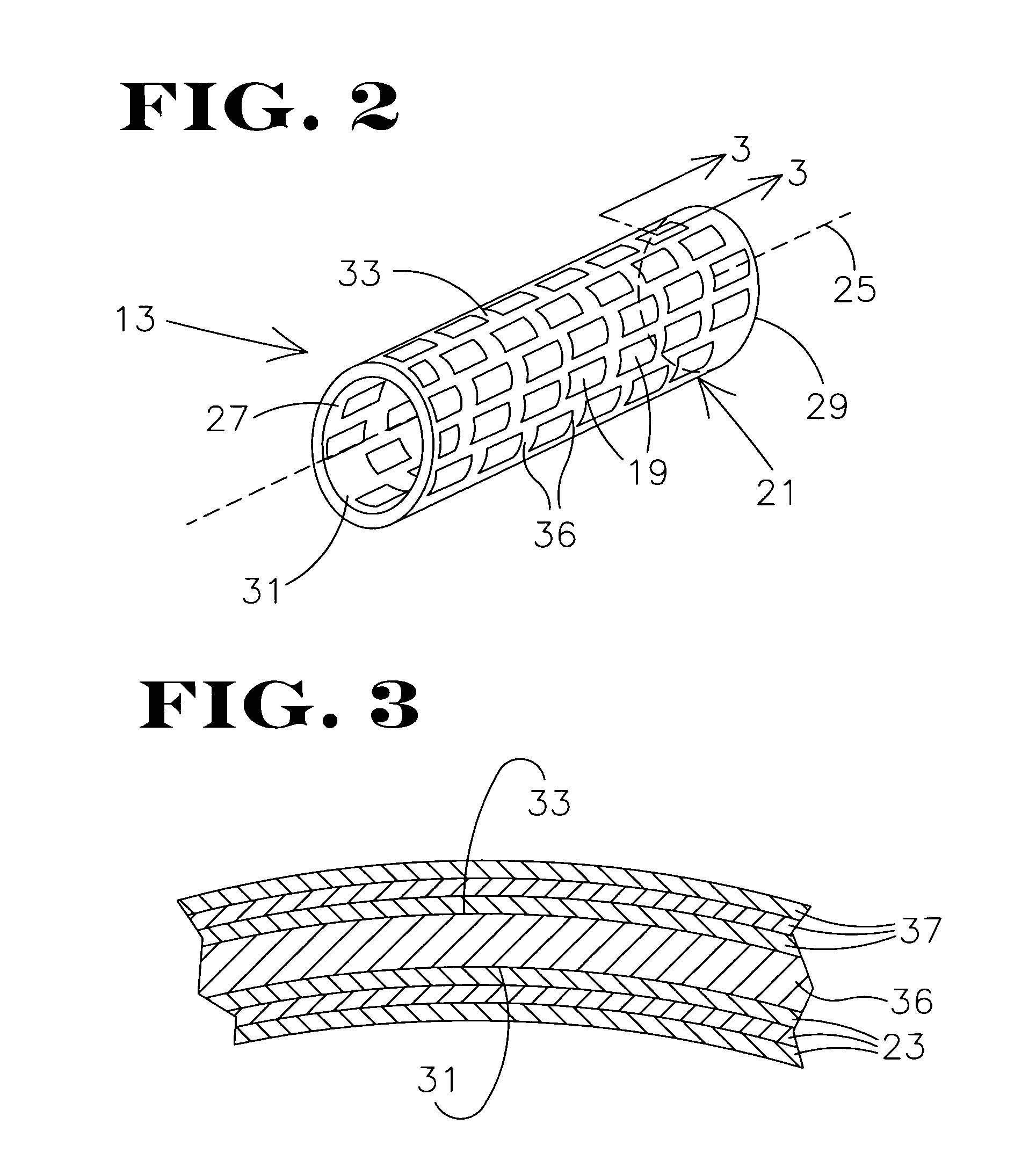

A method of coating a non-rotary object with an electrospun coat, the method comprising, dispensing a charged liquefied polymer through at least one dispensing element within an electric field to thereby form a jet of polymer fibers, and moving the dispensing element relative to the object so as to coat the object with the electrospun coat.

Owner:NICAST LTD

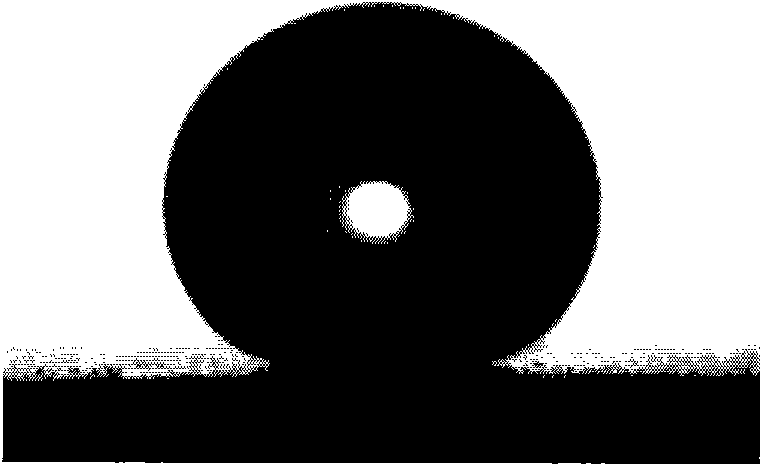

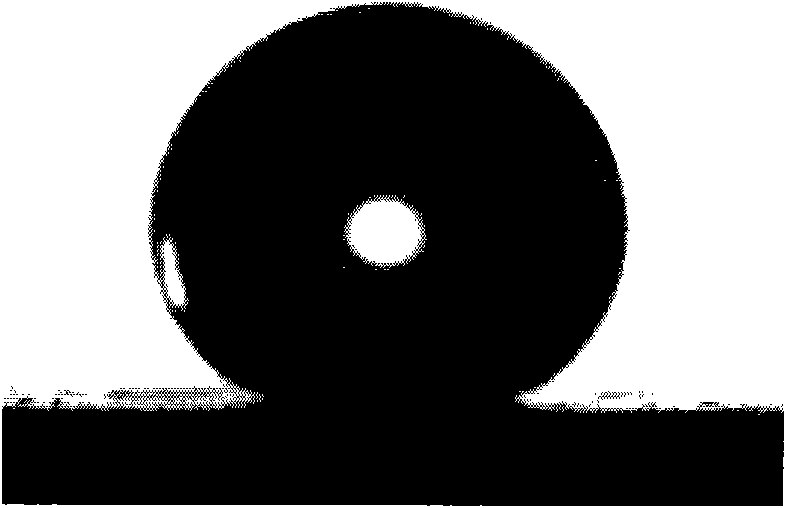

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

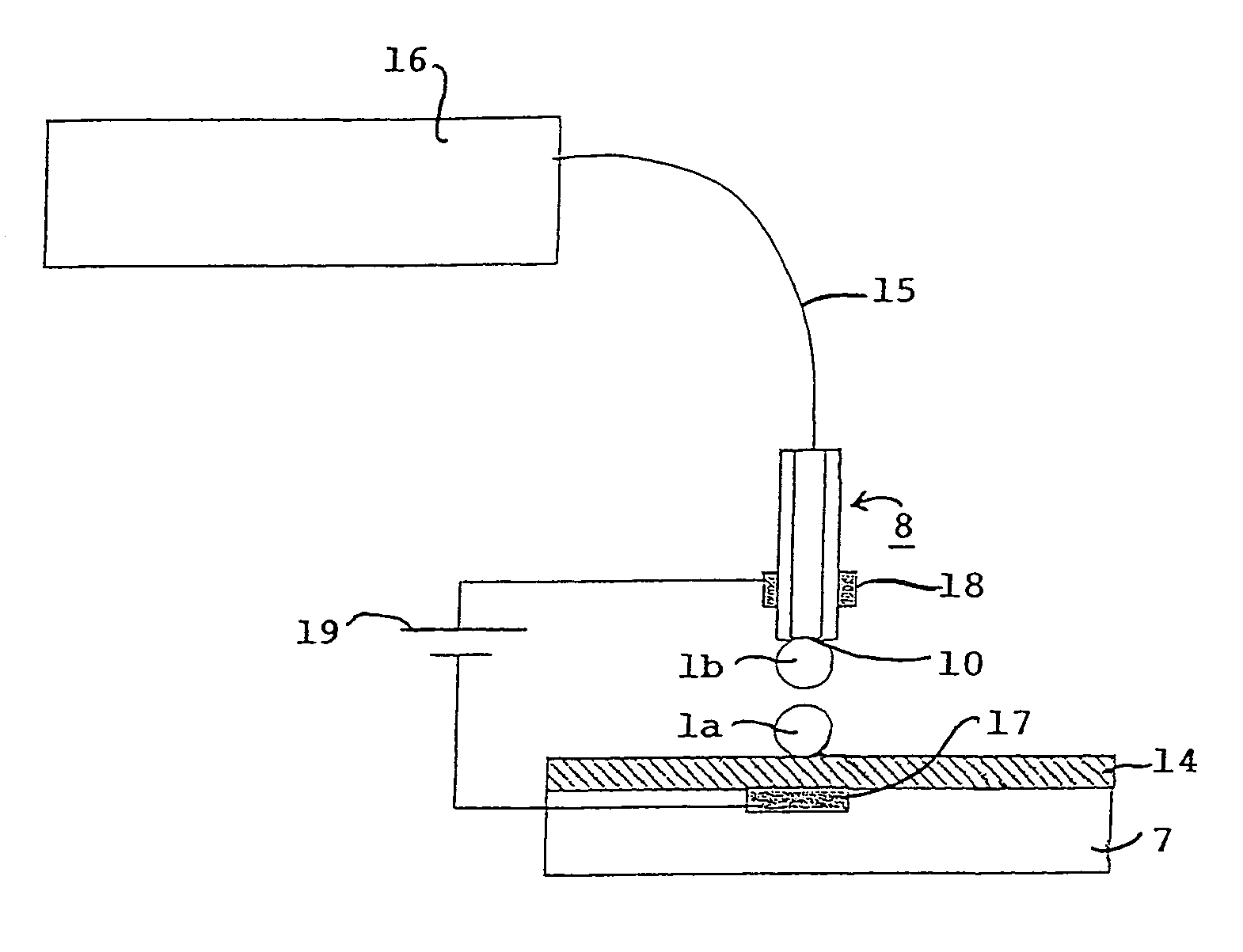

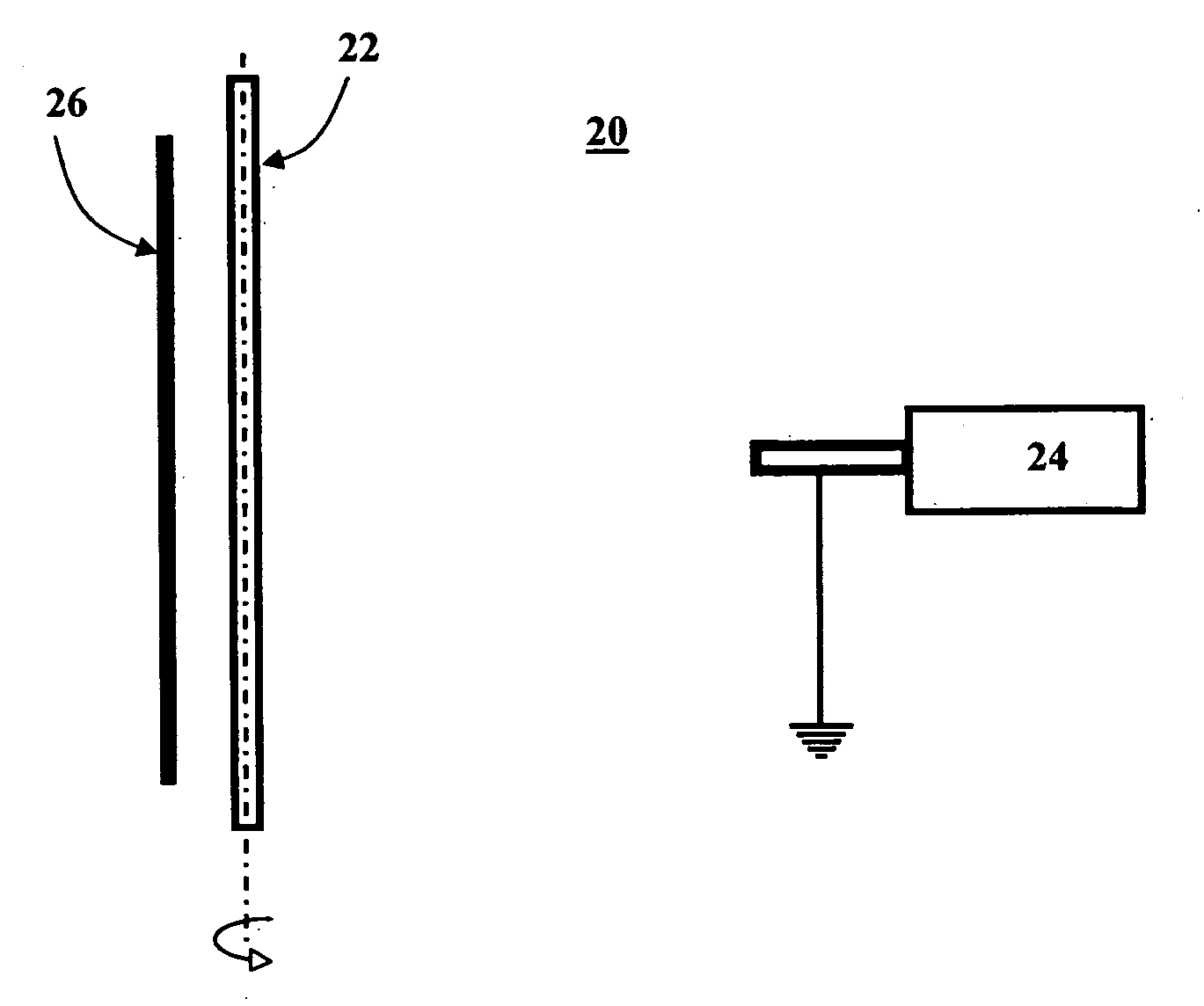

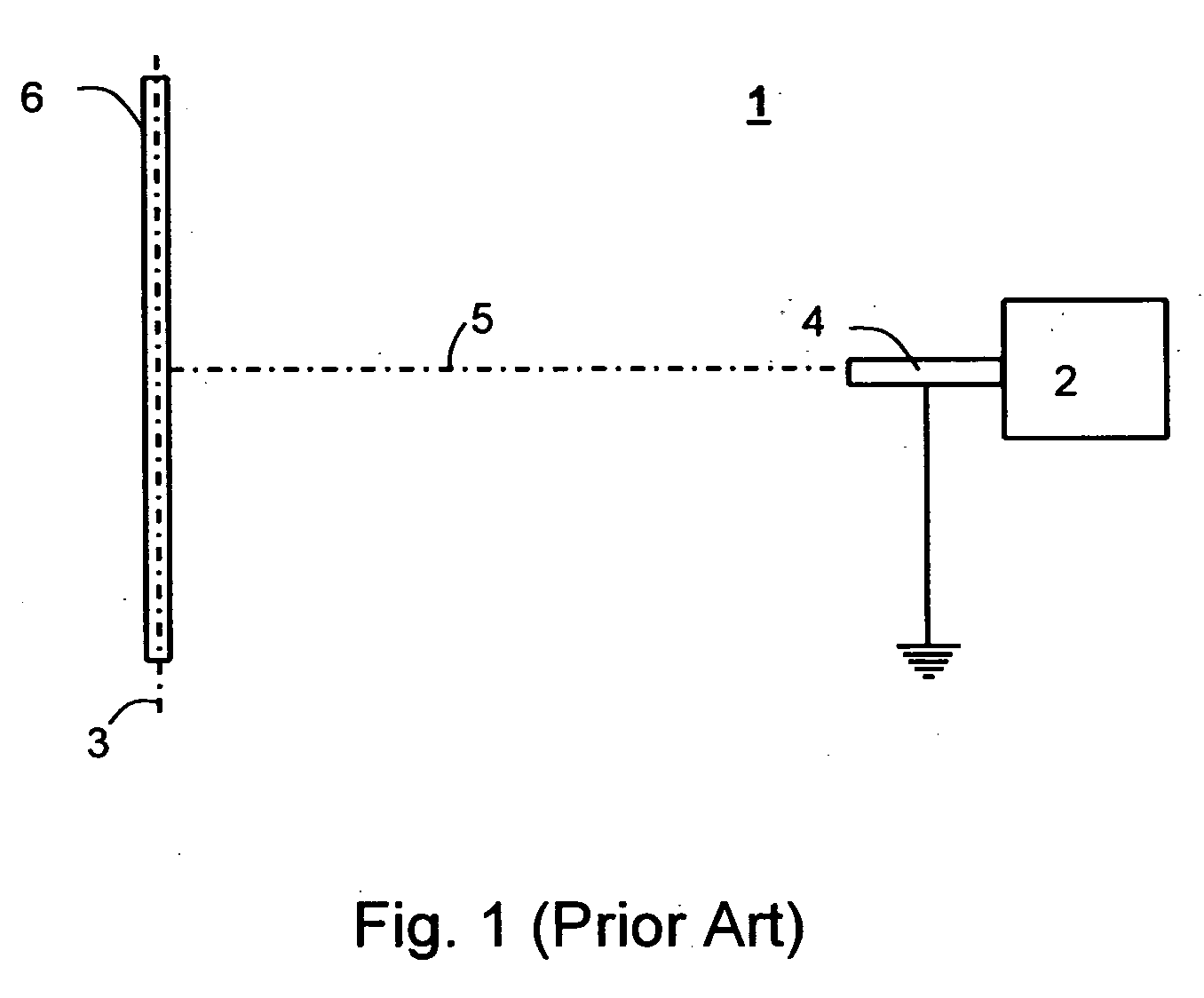

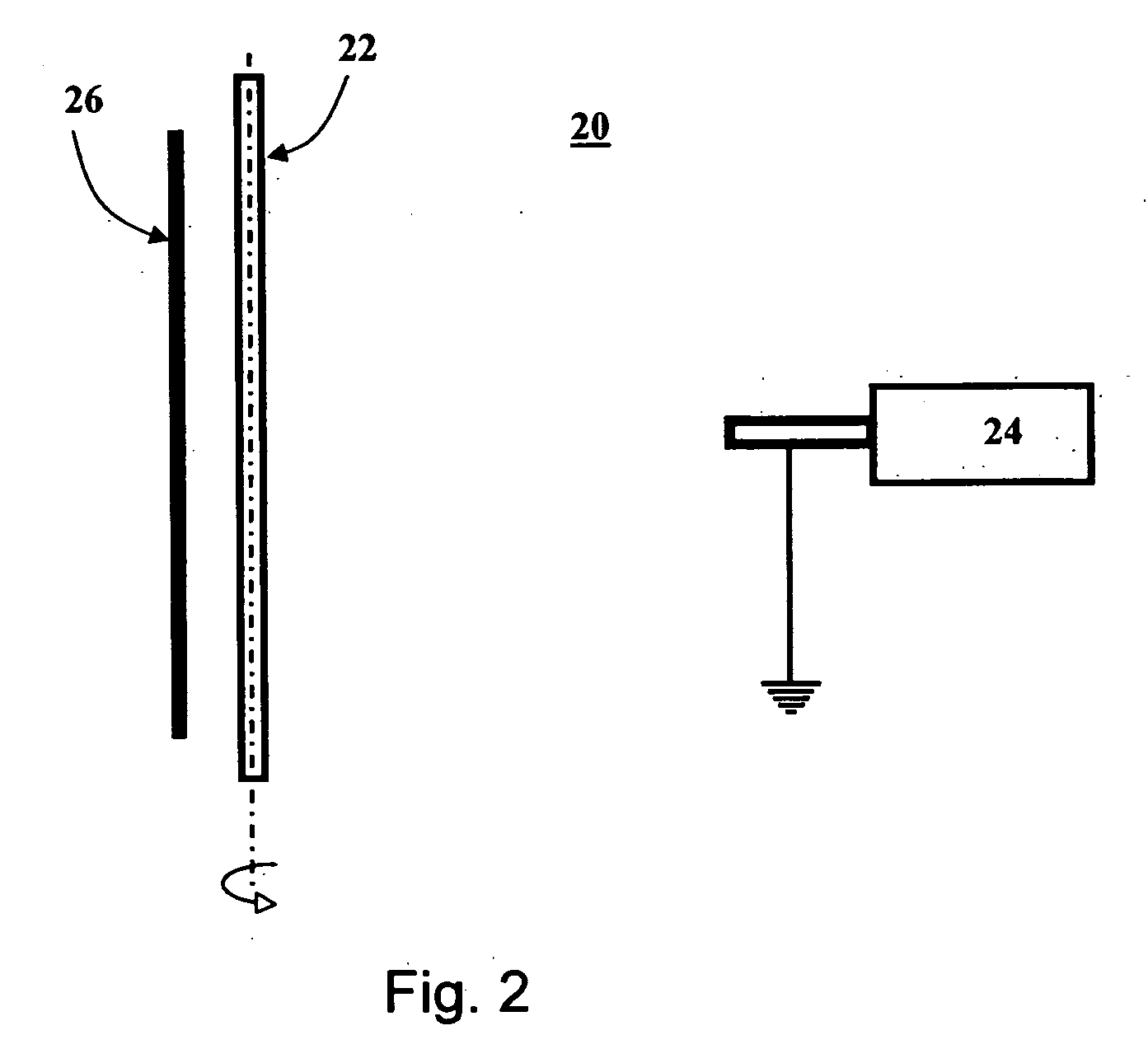

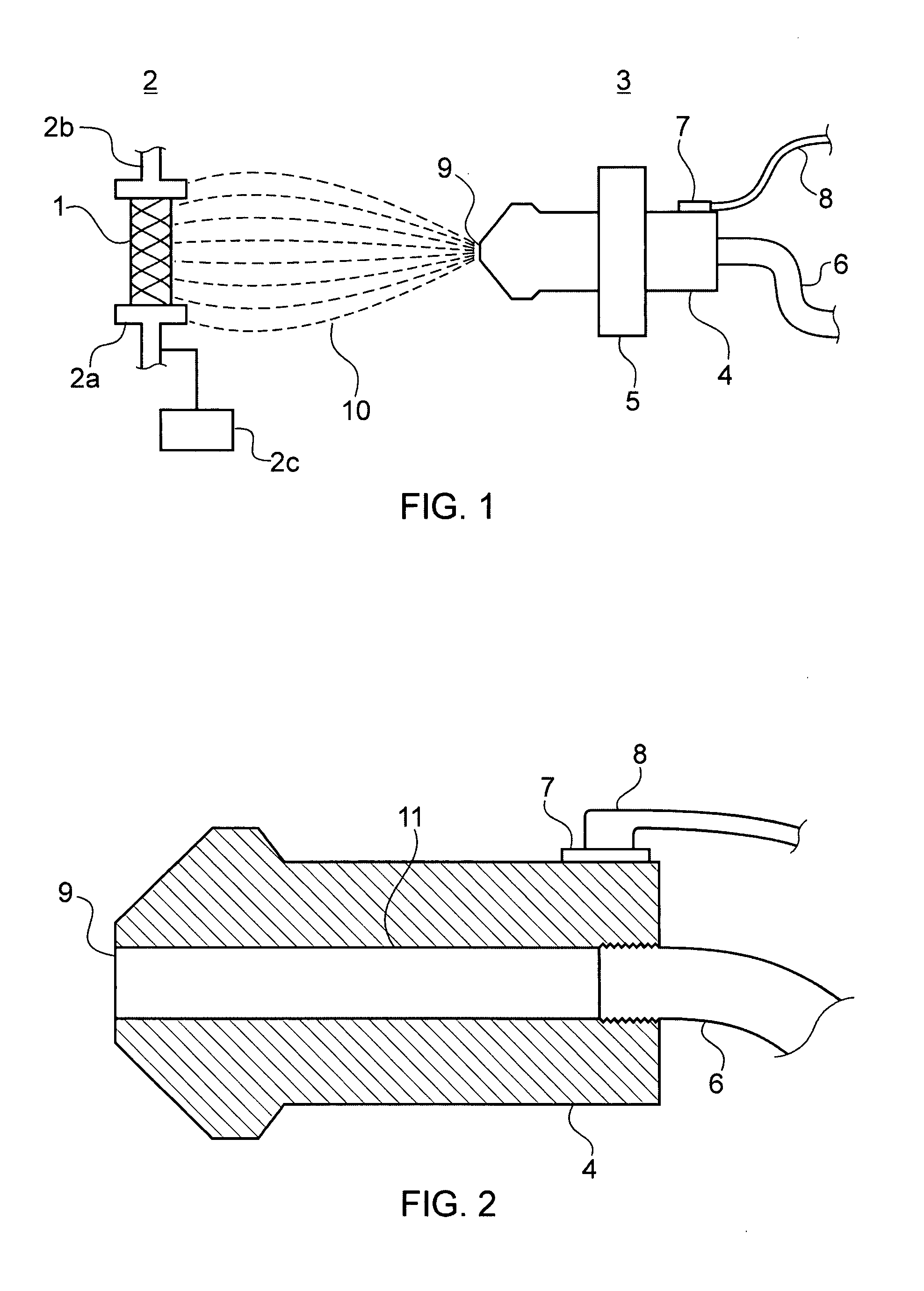

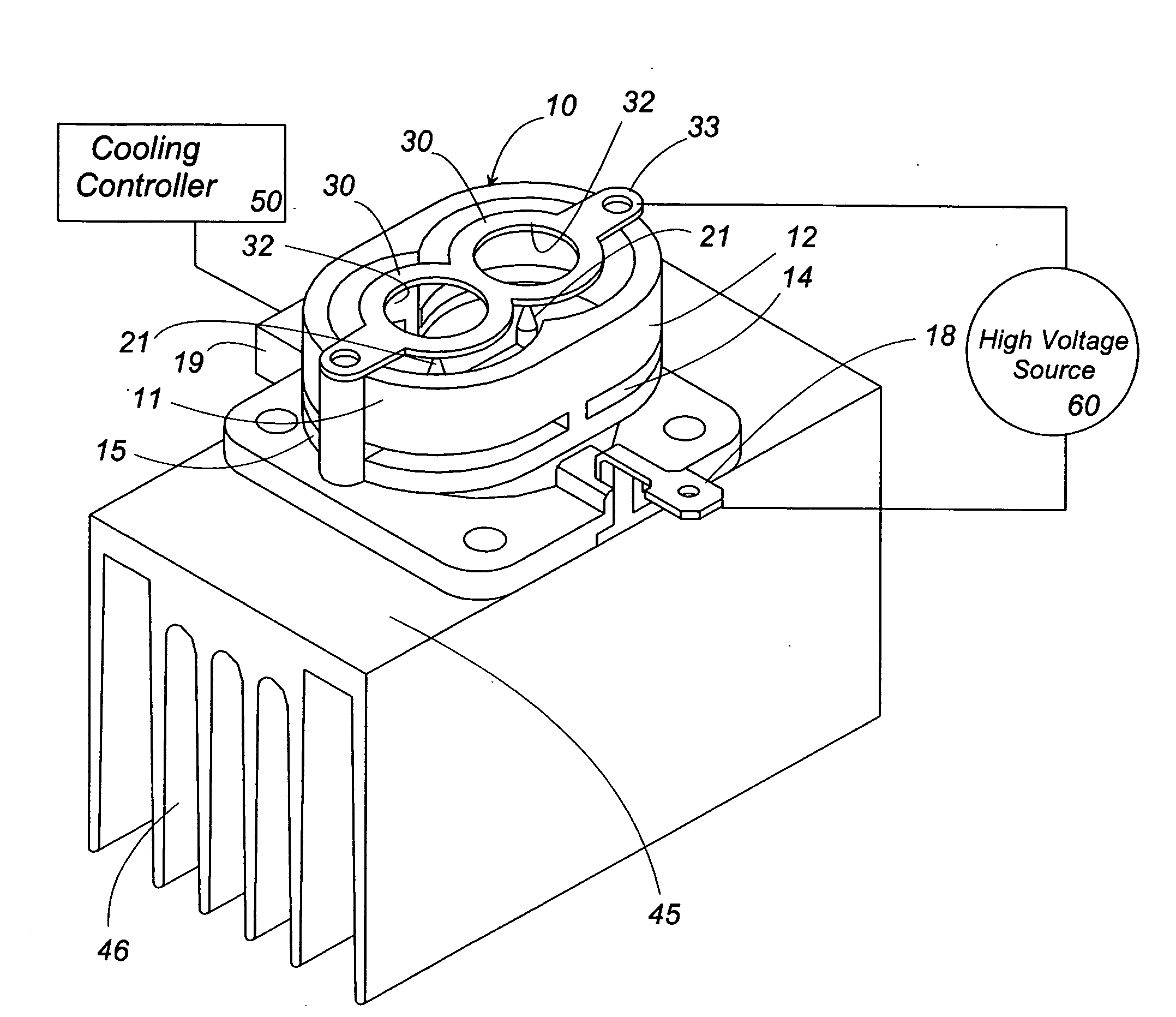

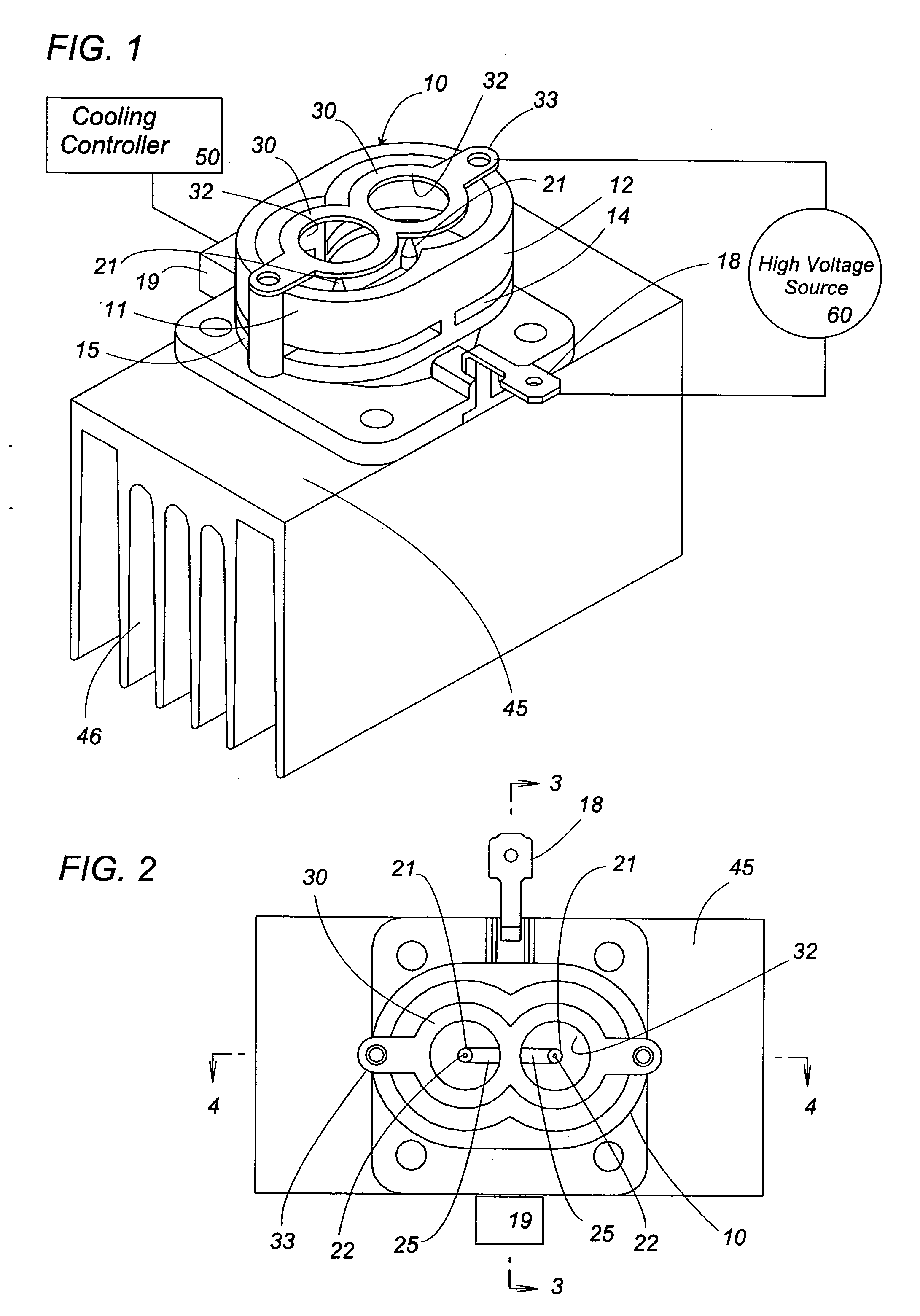

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS20050175772A1Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

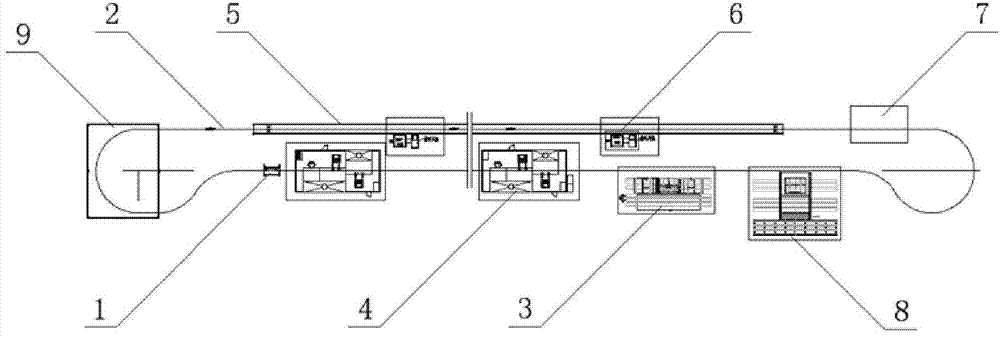

Production line for automatically coating profile steel and coating method thereof

ActiveCN104759383ASolve puzzlesFully automatedLiquid spraying plantsPretreated surfacesProduction lineIndustrial engineering

The invention discloses a production line for automatically coating a profile steel and a coating method thereof, wherein a suspension conveying line (2) runs through the central axis of a coating chamber (4). A loading mechanism (3) is installed on the front end of the coating chamber (4); and the suspension conveying line (2) on the back end of the coating chamber (4) is provided with a drying channel (5). A back output end of the drying channel (5) is connected with a cooling area (7); and an unloading mechanism (8) is installed behind the cooling area (7). By utilizing the head-to-tail closed loop suspension conveying line and the tandem type hanging manner of hanging multiple workpieces on one hanger, procedures such as loading, finishing coat spraying, priming paint spraying, drying, cooling, unloading and storing are all finished automatically, accordingly achieving the automatic spraying of the profile steel having a long length, and optimizing the conventional profile steel coating technology. By utilizing electrostatic spraying in association with the position and the angle of the spraying gun, the coating problem of coating dead angle at inside corners of the profile steel is solved better, accordingly improving the coating quality of the entire profile steel.

Owner:HUBEI ABSOLUTE SINCERITY STEEL STRUCTURE +1

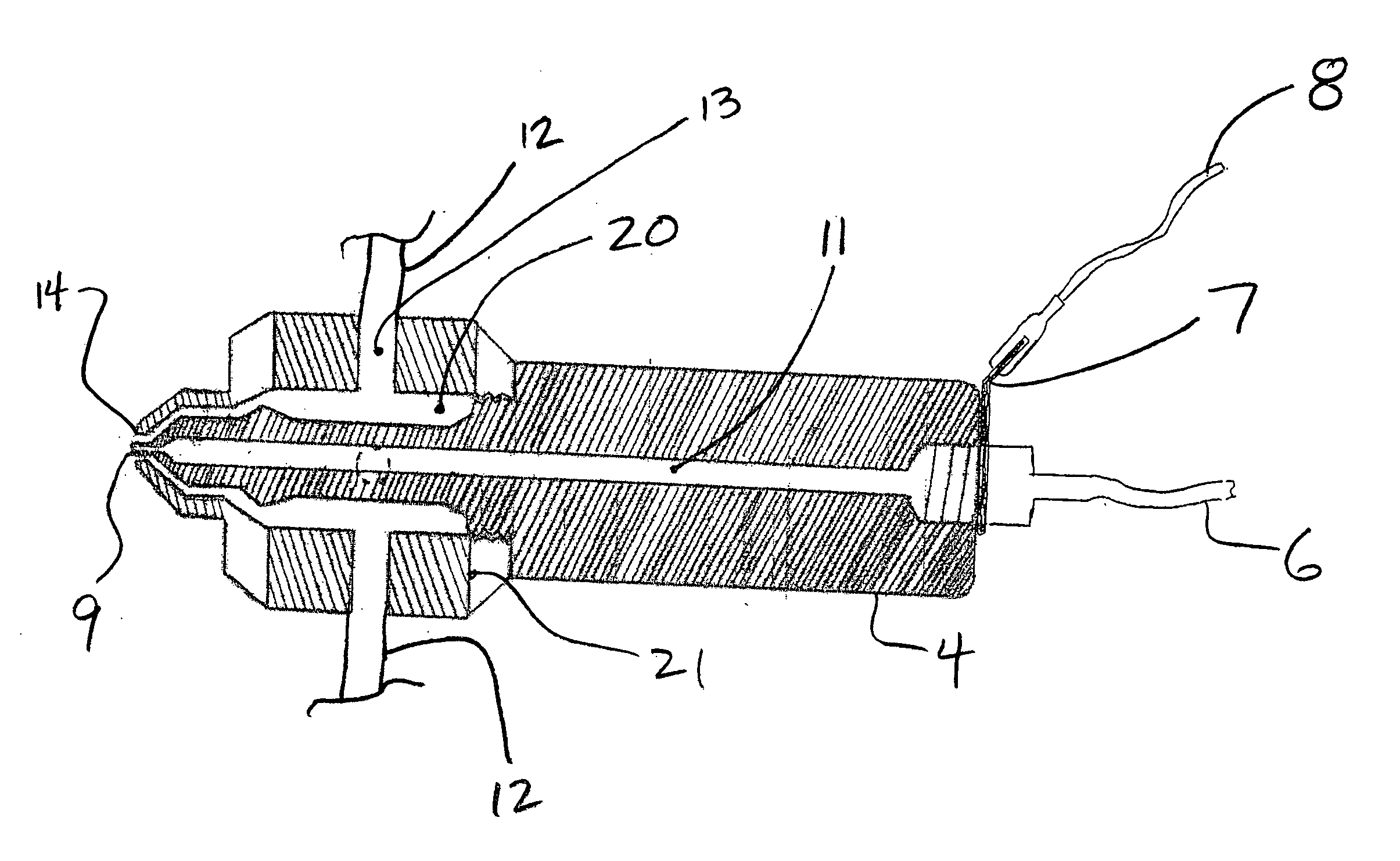

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS7241344B2Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

Method for depositing particles onto a substrate using an alternating electric field

InactiveUS6923979B2Quality improvementAvoid charge accumulationPowder deliveryPretreated surfacesElectrical polarityElectric field

Owner:MICRODOSE THERAPEUTX INC

Method for feedback controlled electrospray

Owner:NEW OBJECTIVE INC

System and method for electrostatic-assisted spray coating of a medical device

A system and method for the electrostatic spray application of a coating material onto a medical device. The coating material is electrically charged and an atomizer is used to atomize the coating material, creating electrically charged droplets which coat the medical device. In alternate embodiments, a swirl atomizer, a pressure atomizer, an ultrasound atomizer, a rotary atomizer, and an effervescent atomizer are used to atomize the coating material.

Owner:BOSTON SCI SCIMED INC

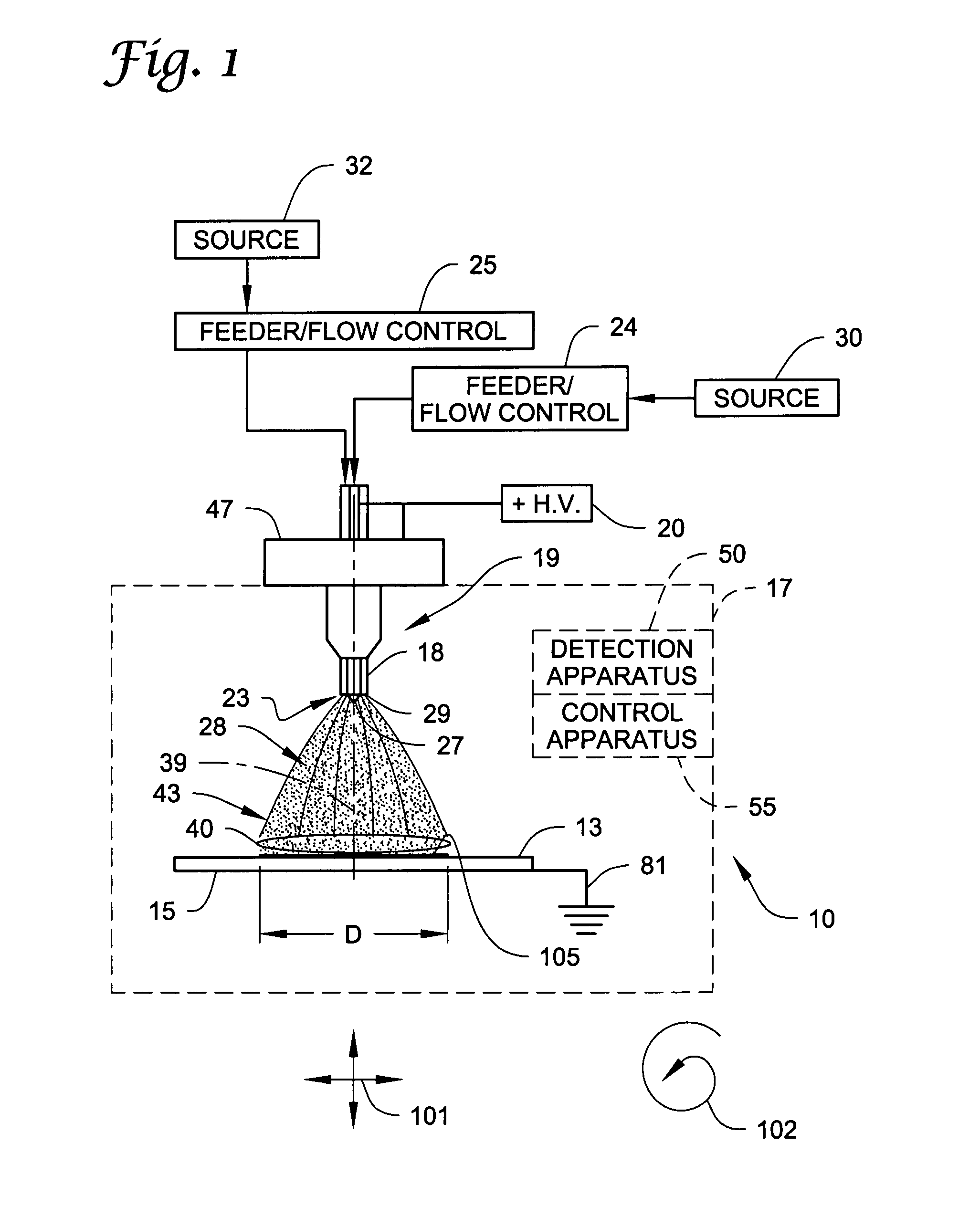

Electrospraying method with conductivity control

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

Open-hole wellbore lining

InactiveUS20090090514A1Control moreLiquid spraying plantsLiquid surface applicatorsLength waveFluid composition

Embodiments of the present invention provide systems and methods for lining a wellbore. In certain aspects, the systems and methods comprise providing a fluid composition that is solidifiable or gellable on exposure to actinic radiation of a predetermined wavelength at the wall of open-hole wellbore and providing actinic radiation at the predetermined wavelength to solidify or gel the composition.

Owner:SCHLUMBERGER TECH CORP

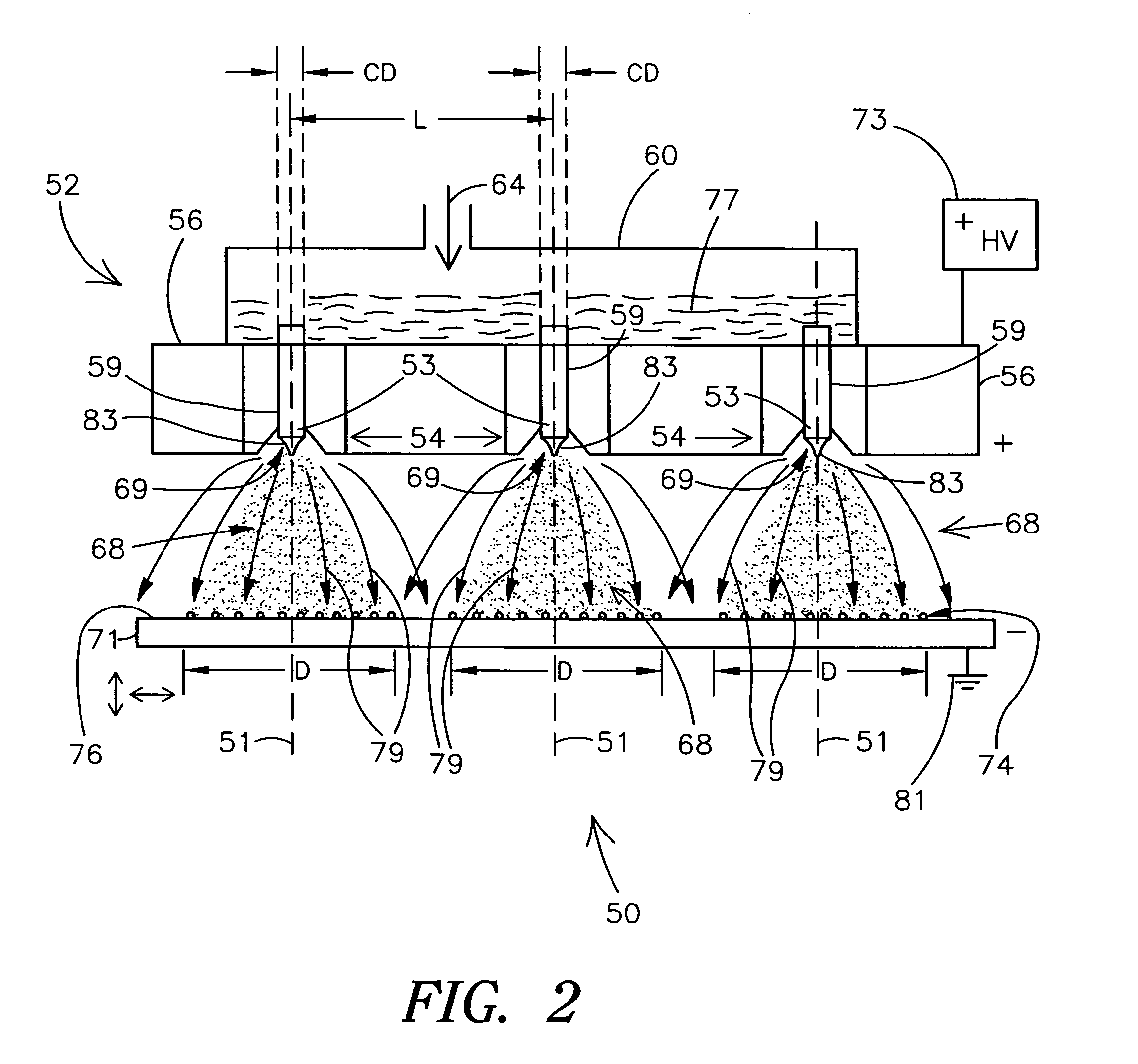

Electrospray coating of objects

Electrospray methods and systems for coating of objects (e.g., medical devices such as a stent structure) with an open matrix coating. The open matrix coating is formed by electrospray using one or more nozzle structures each having at least an inner and outer opening. A first flow of a liquid spray composition is provided to the inner opening and a second flow of a liquid diluent composition is provided to the outer opening (e.g., the liquid diluent composition including at least one solvent, such as a composition having a dielectric constant equal to or greater than 10).

Owner:RGT UNIV OF MINNESOTA +1

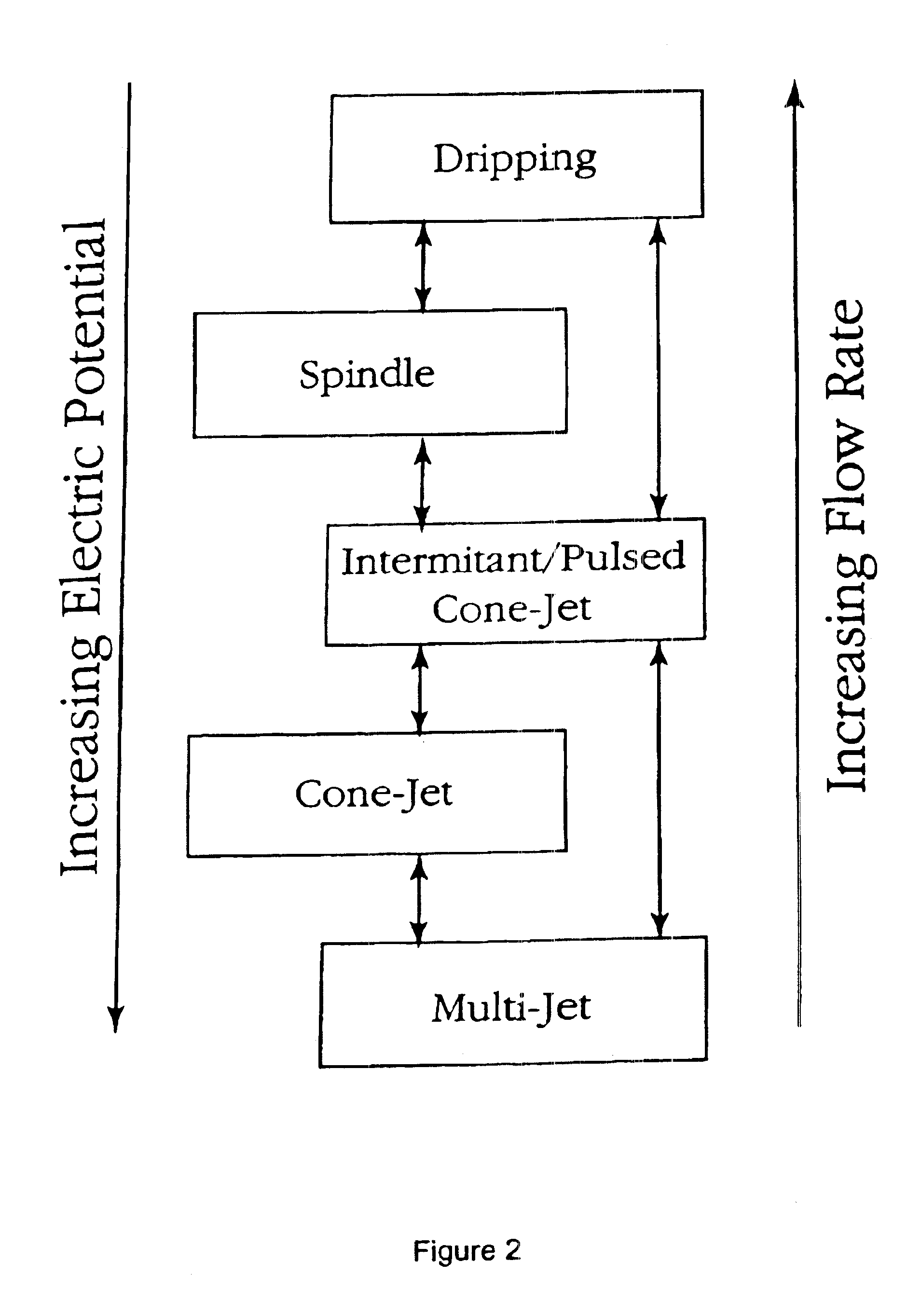

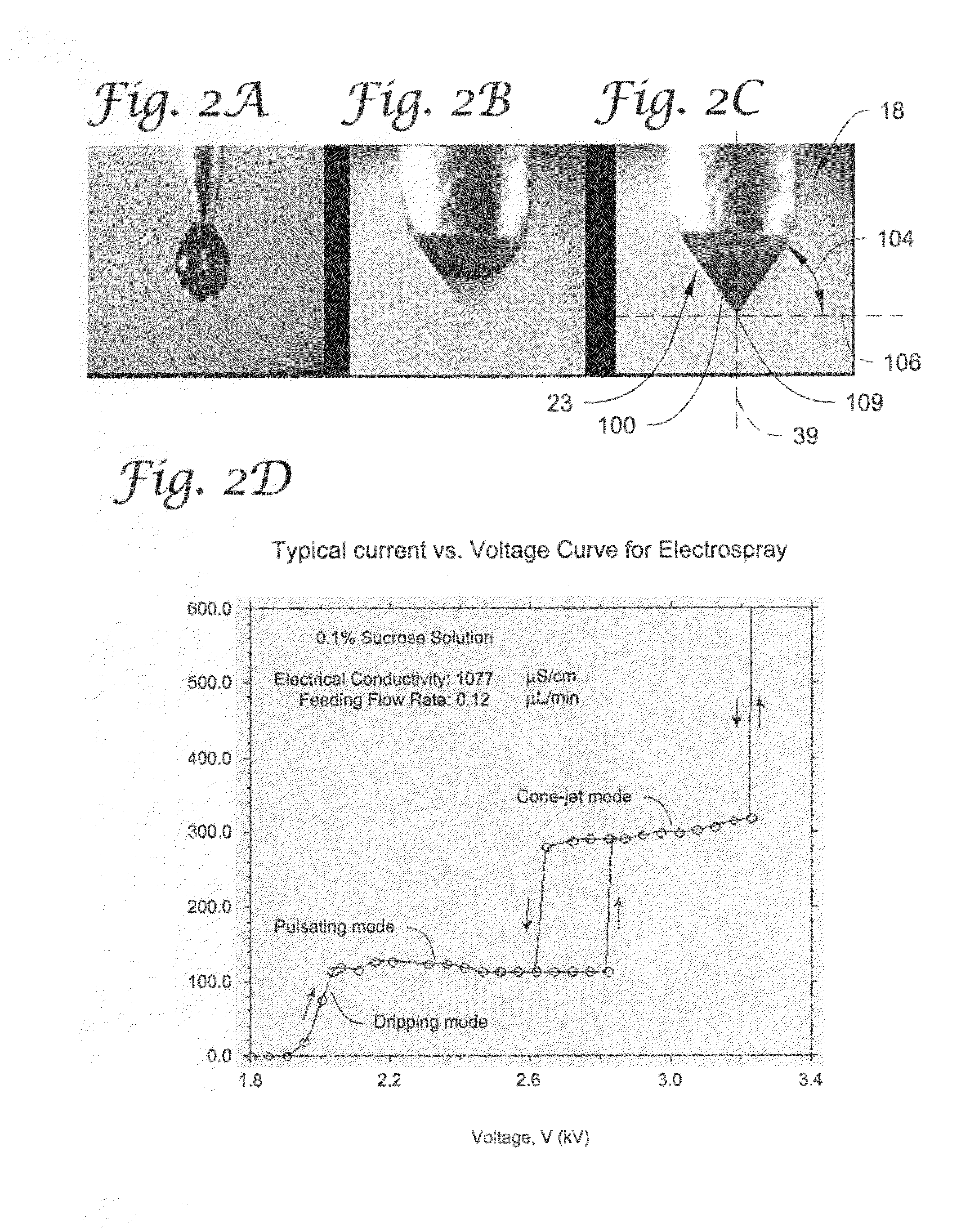

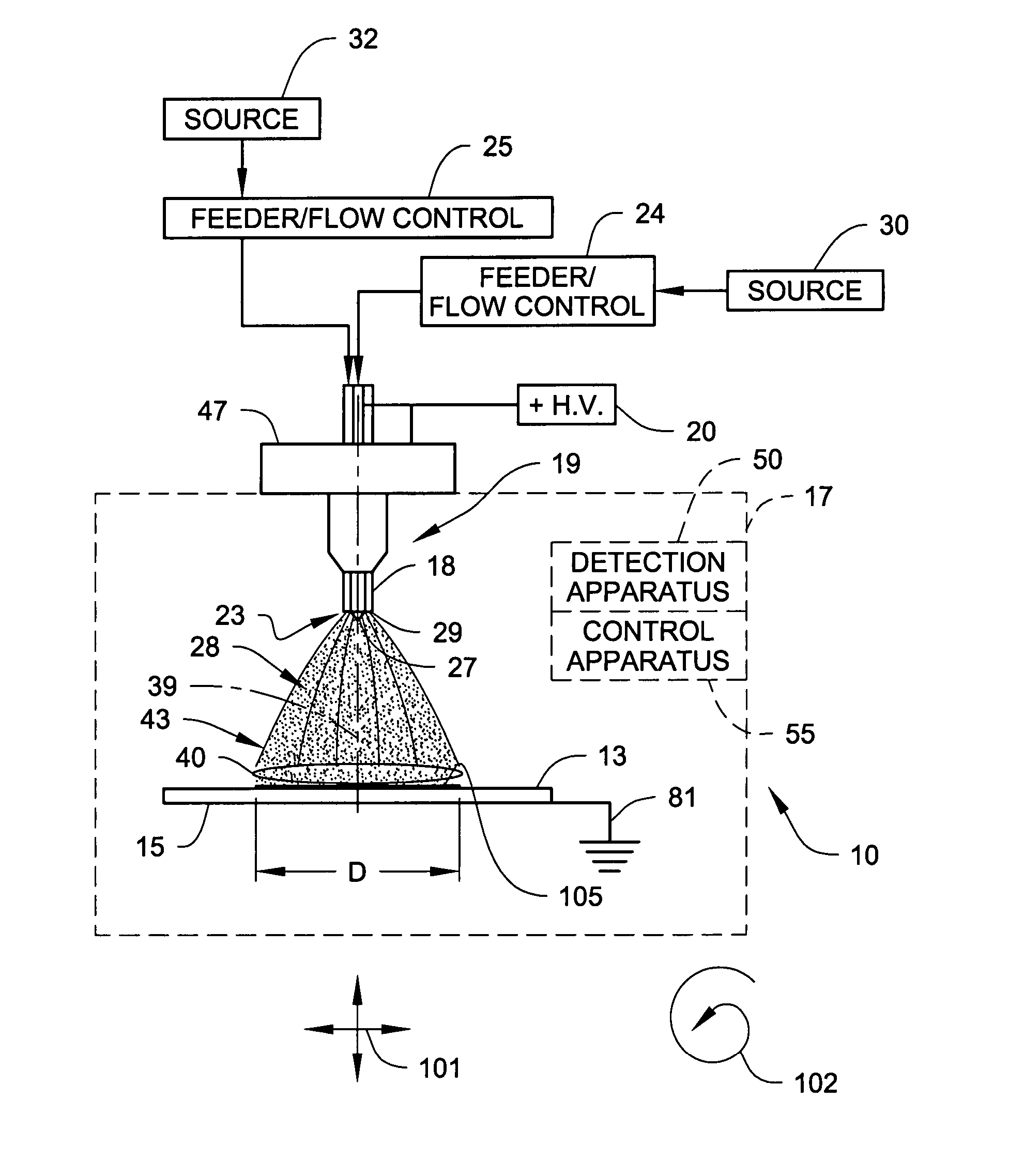

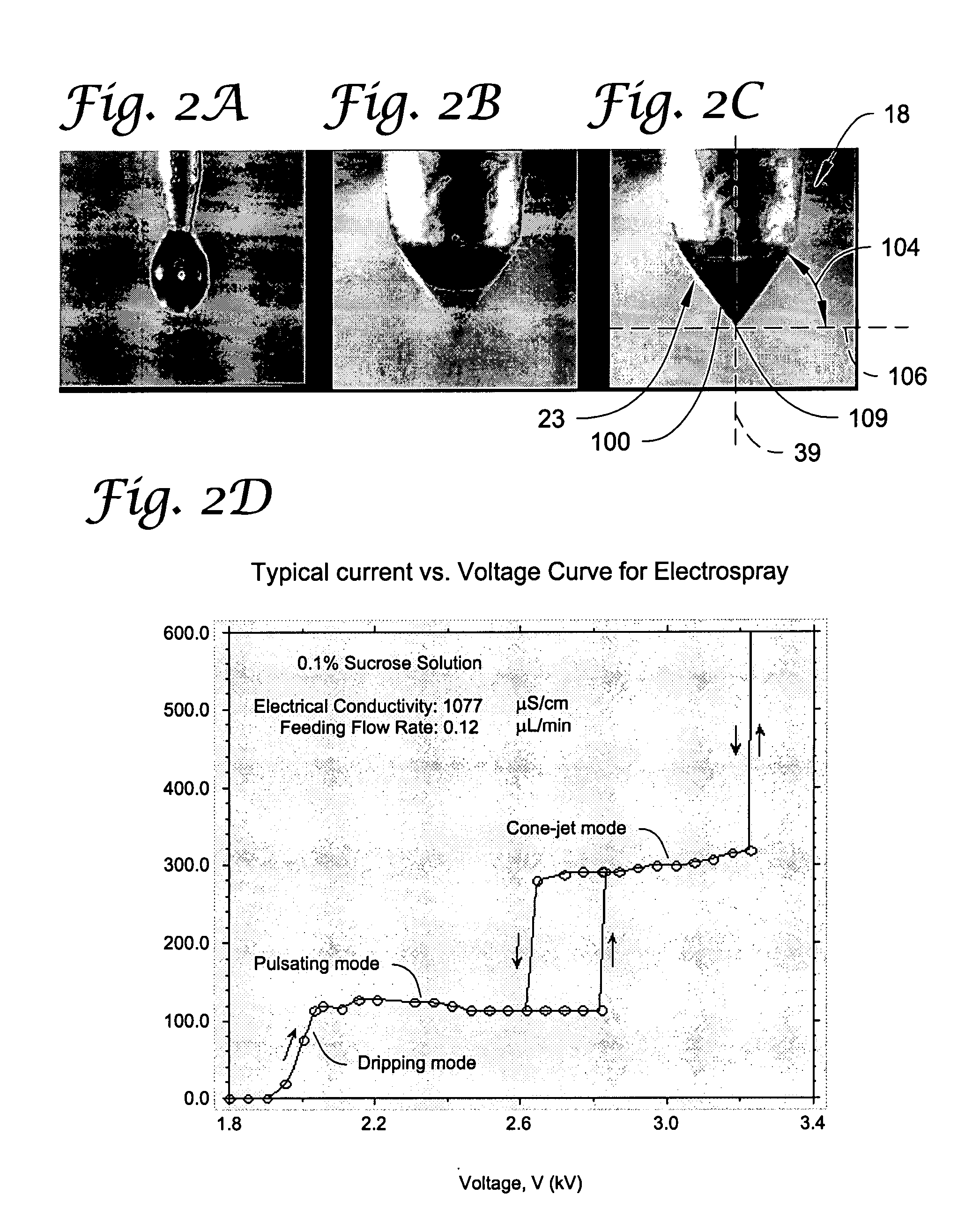

Electrospray coating of objects

InactiveUS20070199824A1Stable cone-jetPretreated surfacesSurface layering apparatusMedical deviceFilm-coated tablet

Electrospray methods and systems for coating of objects (e.g., medical devices such as a stent structure) with selected types of coatings (e.g., open matrix coating and closed film coating)

Owner:RGT UNIV OF MINNESOTA +1

Method for spray-coating a medical device having tubular wall such as a stent

InactiveUS20050149177A1Pretreated surfacesInductances/transformers/magnets manufactureInsertion stentSpray coating

Owner:BOSTON SCI SCIMED INC

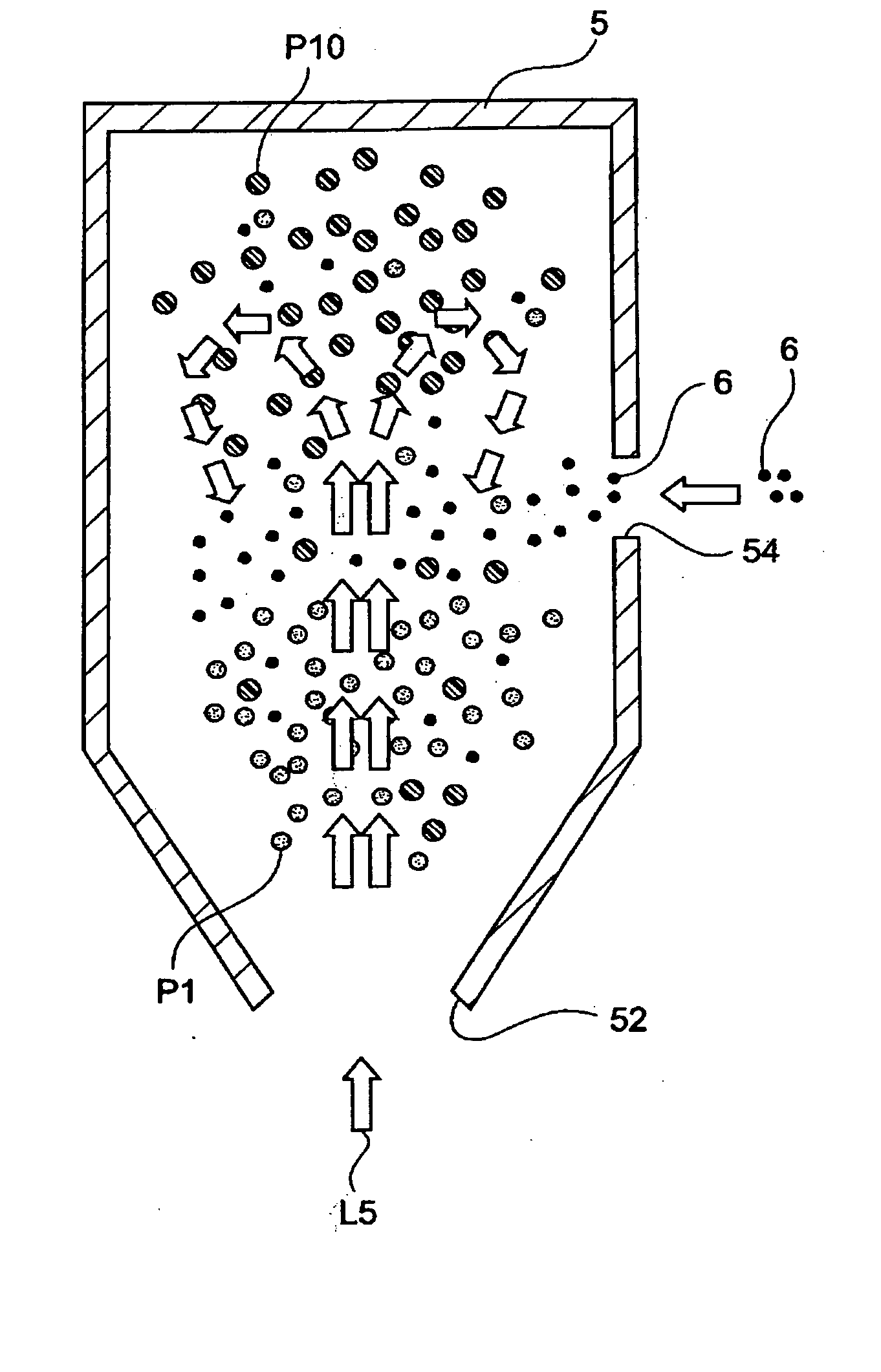

Electrostatically Atomizing Device

The present invention provides an electrostatically atomizing device capable of instantly giving an electrostatically atomizing effect without requiring a water tank. The electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, a water feeder configured to give water on the emitter electrode, and a high voltage source configured to apply a high voltage across said emitter electrode and said opposed electrode to electrostatically charge the water on the emitter electrode for spraying charged minute water particles from a discharge end of the emitter electrode. The water feeder is configured to condense the water on the emitter electrode from within the surrounding air, enabling to supply the water on the emitter electrode in a short time without relying upon an additional water tank. Thus, an atomization of the charged minute water particles can be obtained immediately upon use of the device.

Owner:MATSUSHITA ELECTRIC WORKS LTD

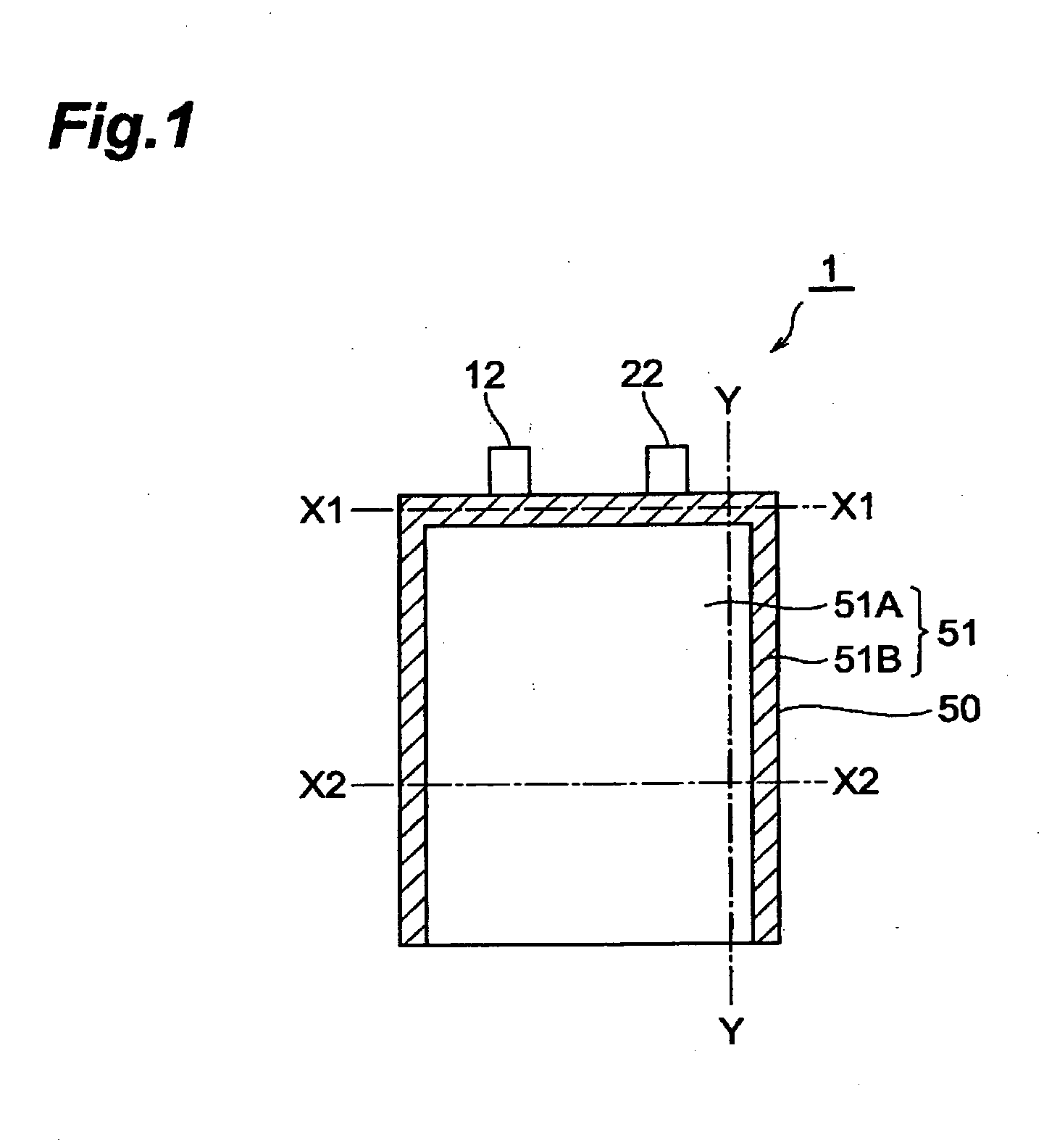

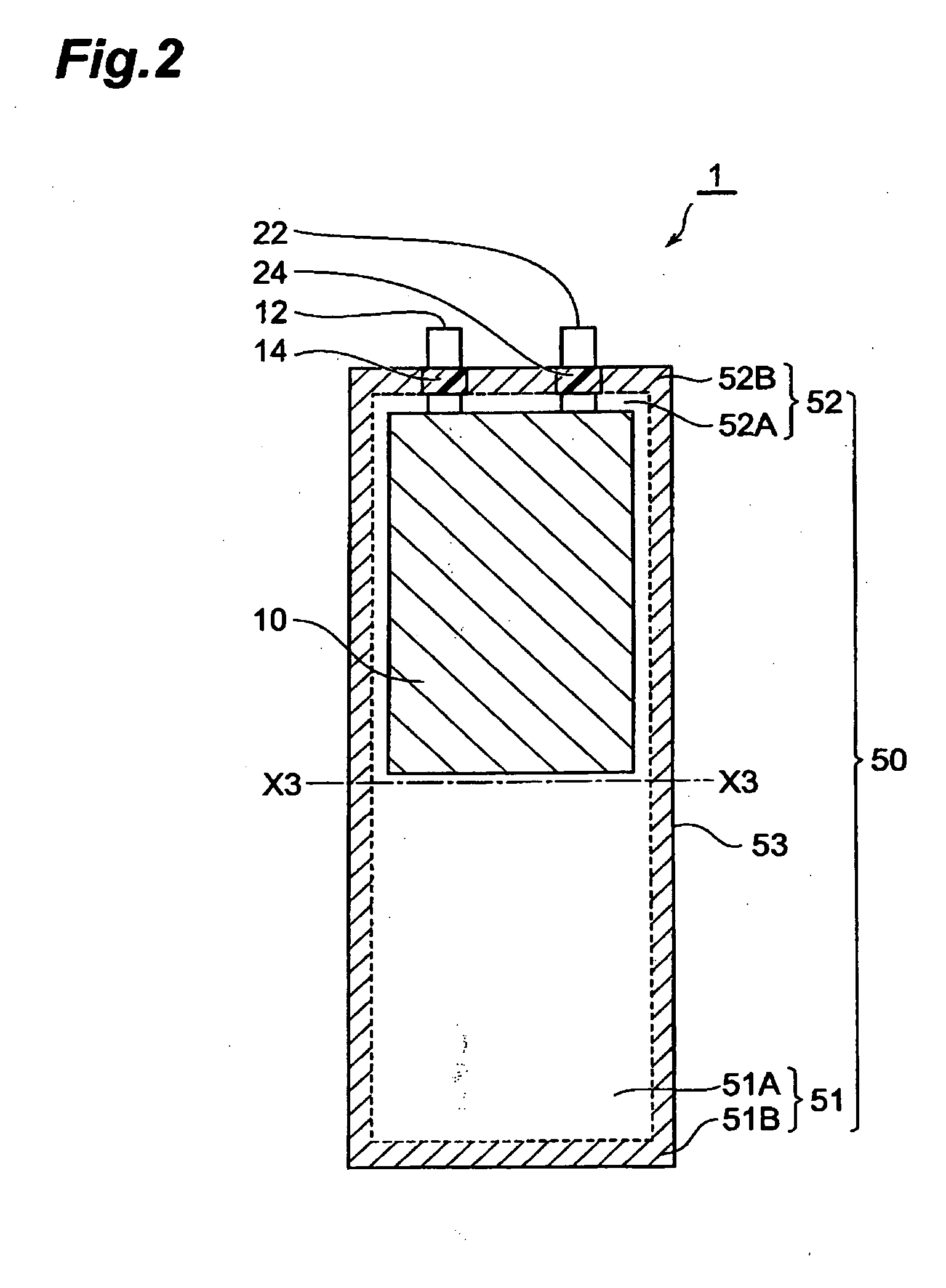

Method of making composite particle for electrode, method of making electrode, method of making electrochemical device, apparatus for making composite particle for electrode, apparatus for making electrode, and apparatus for making electrochemical device

InactiveUS20050064096A1Characteristic easily and reliablyExcellent charge and discharge characteristicsElectrolysis componentsPretreated surfacesElectrochemistryMaterials science

The method of making a composite particle for an electrode in accordance with the present invention comprises a granulating step of integrating a conductive auxiliary agent and a binder adapted to bind the conductive auxiliary agent and an electrode active material together with a particle made of the electrode active material while in close contact with each other in an inert gas atmosphere so as to form a composite particle for an electrode containing the electrode active material, conductive auxiliary agent, and binder. When the composite particle obtained by this method is used as a constituent of an electrode, an electrode having an excellent electrode characteristic and an electrochemical device having excellent electrochemical characteristics can be formed easily and reliably.

Owner:TDK CORPARATION

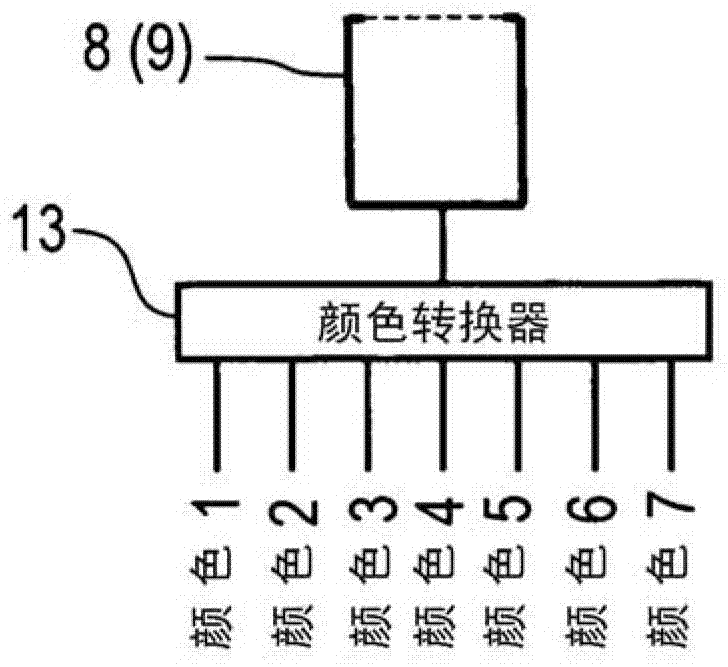

Paint spraying device

InactiveUS6010084AQuick changeEasy to changeLiquid spraying plantsMovable spraying apparatusCoated surfaceSolvent

PCT No. PCT / JP97 / 02446 Sec. 371 Date Mar. 18, 1998 Sec. 102(e) Date Mar. 18, 1998 PCT Filed Jul. 15, 1997 PCT Pub. No. WO98 / 03268 PCT Pub. Date Jan. 29, 1998A paint spraying apparatus on which a number of paint applicator units of different types can be selectively and replaceably mounted depending upon conditions of a paint coating operation required. A color changing valve assembly is provided in a valve casing which serves as a common base assembly for a number of paint applicator units to be chosen from, including rotary atomizing head type electrostatic paint applicator units and spray gun type electrostatic paint applicator units. Accordingly, depending upon conditions of coating operation, such as shape of a coating surface, nature of paint, properties of solvent etc., a suitable paint applicator unit, selected from the paint applicator units, can be easily and replaceably mounted in position on the valve casing. The color changing valve assembly which is provided within the valve casing can be shared as a common mount base by a plural number of paint applicator units of different types.

Owner:ABB IND

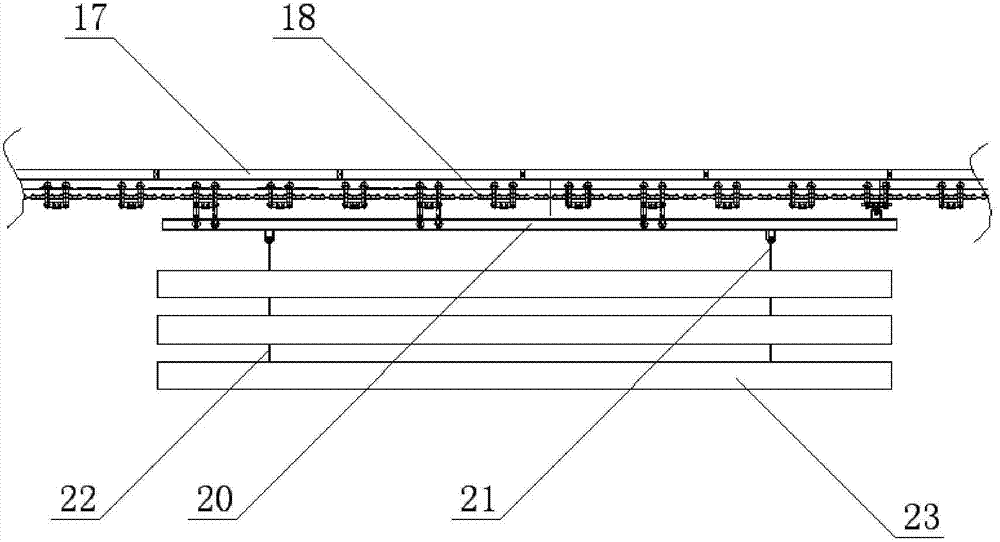

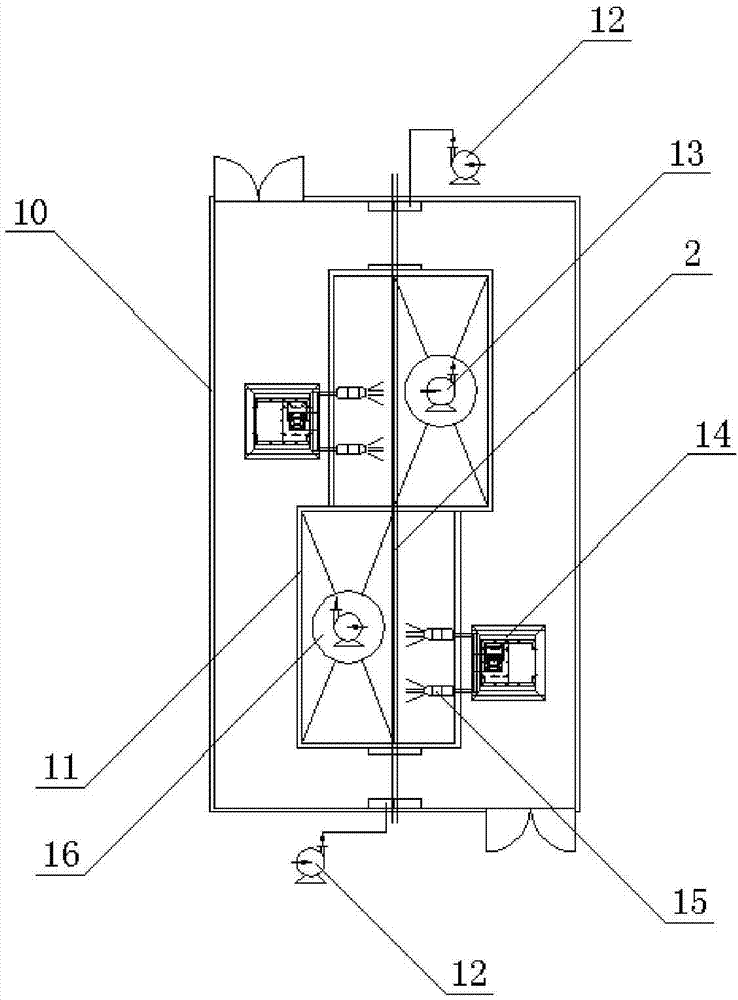

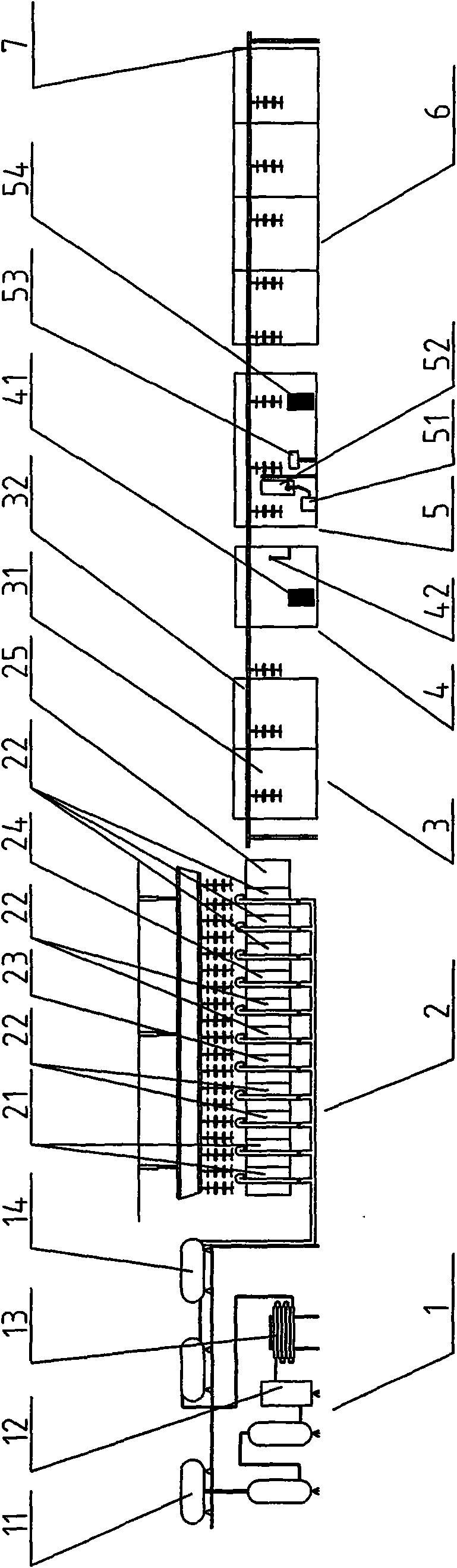

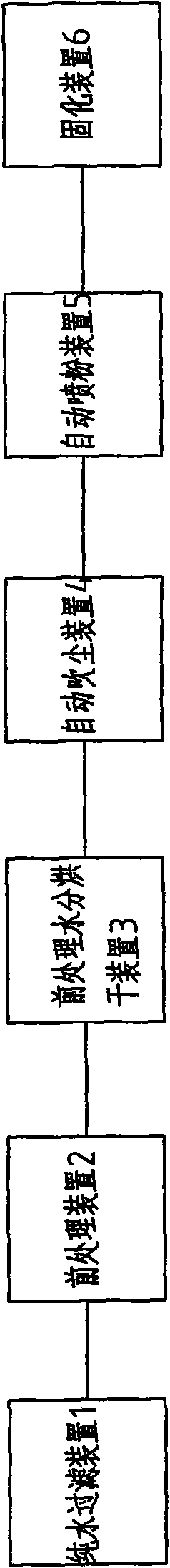

Automatic powder spraying line for automobile wheel hub finishing components and technique thereof

ActiveCN101602042AEvenly distributedSave resourcesLiquid spraying plantsPretreated surfacesSurface cleaningFiltration

The invention relates to an automatic powder spraying line for automobile wheel hub finishing components and a technique thereof; the production line comprises a pure water filtration system for providing pure water for the power spraying line, a pretreatment device, a pretreatment water content drying device, an automatic dust blowing device, an automatic powder spraying device, a solidifying device and a conveying lead rail; wherein, the pretreatment device sequentially comprises a pickling tank, alkaline wash tank and a passivation tank; the automatic powder spraying device comprises a tank body, a powder spraying gun, a powder storage tank, a powder sucking device, a constant temperature and humidity device. The production technique has the following steps: 1) alkali degreasing, 2) product surface cleaning, 3) drying, 4) dust abatement, 5) power spraying, 6) solidification. The production line of the invention features high degree of automation, suitability for mass production, high output benefits and low cost; in addition, the production technique equipped with the production line is more reasonable, components produced by the coating method of powder spraying has more uniform surface color and thickness.

Owner:GUANGZHOU JINZHONG AUTO PARTS MFG

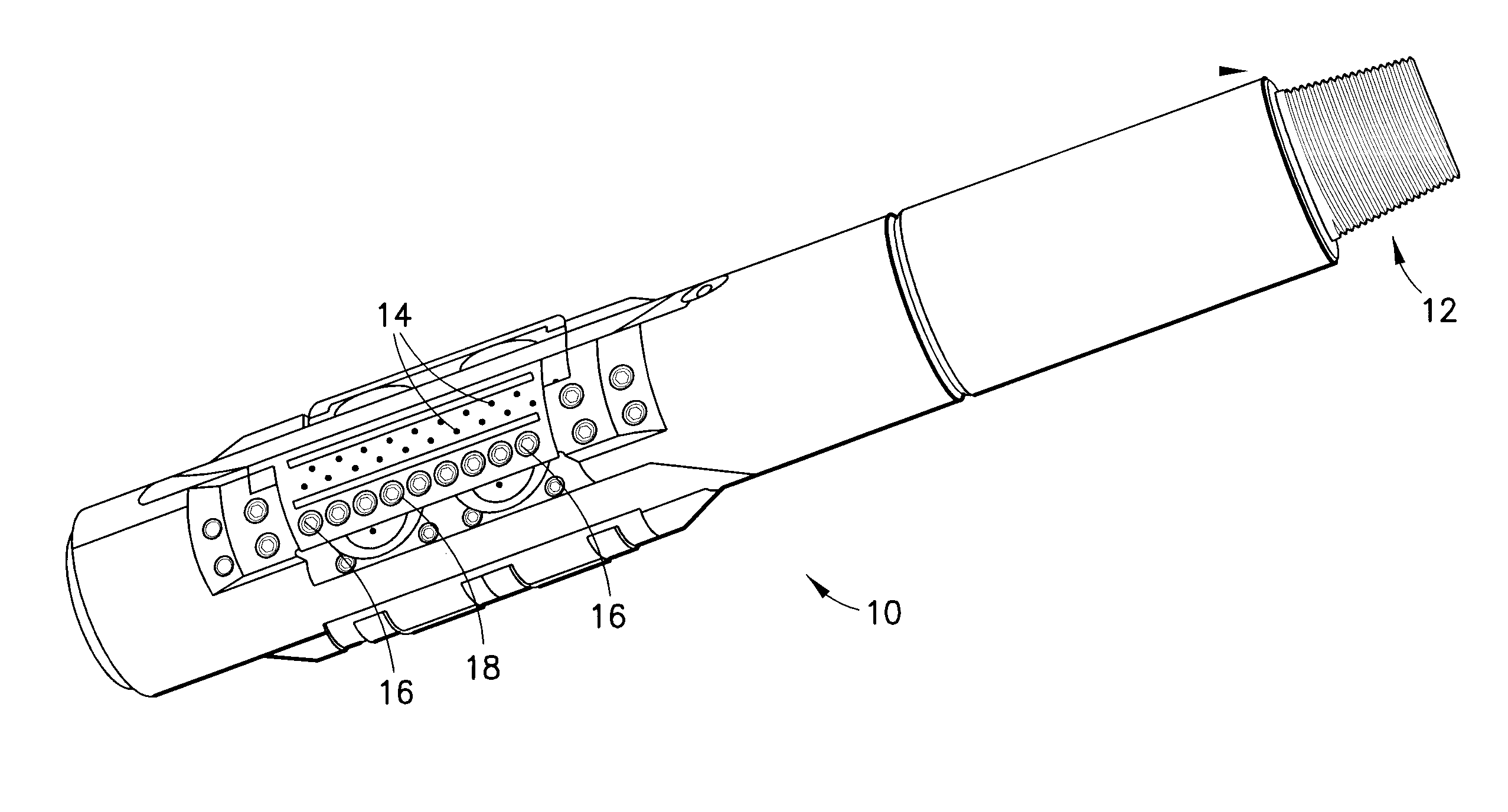

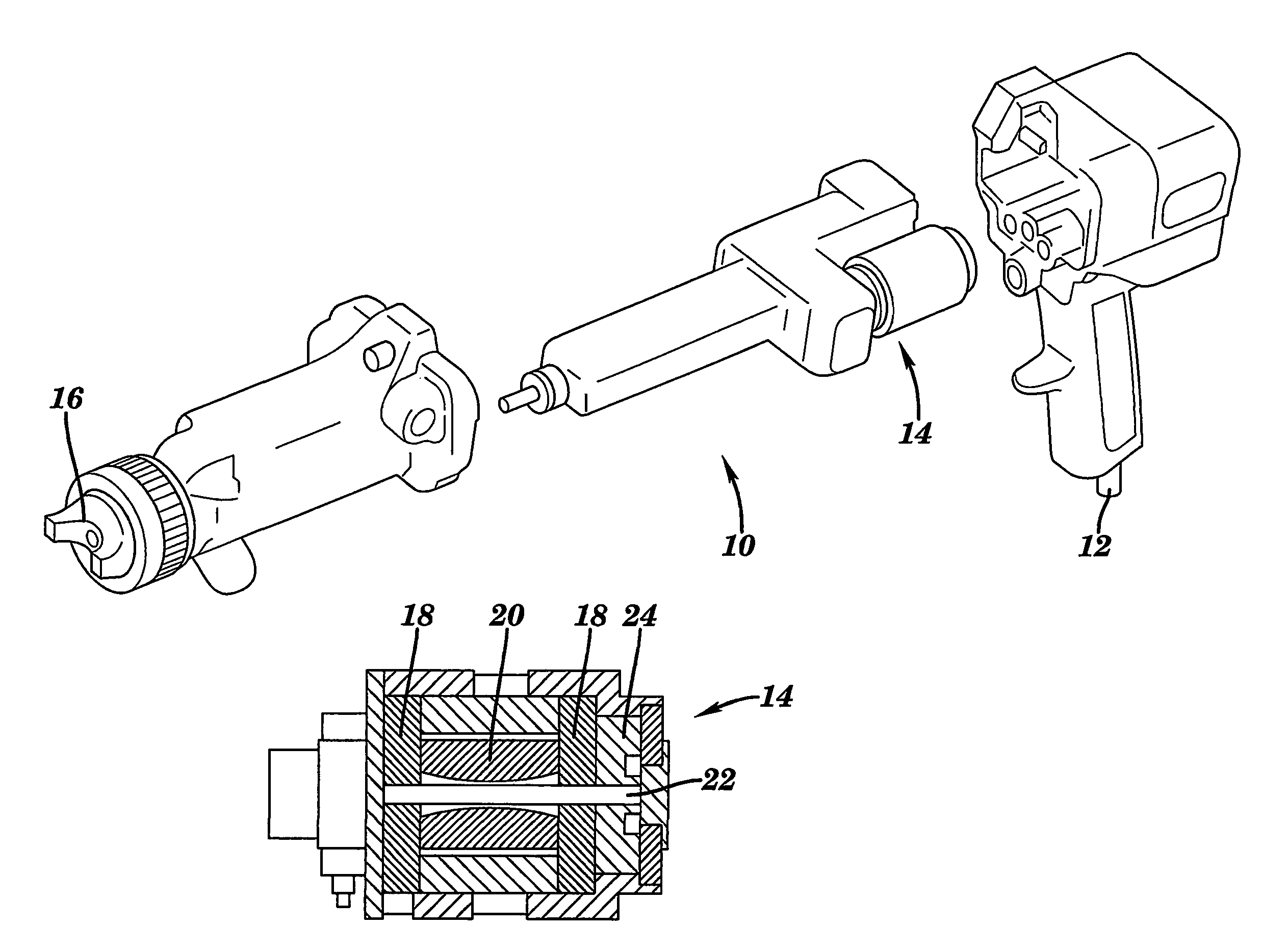

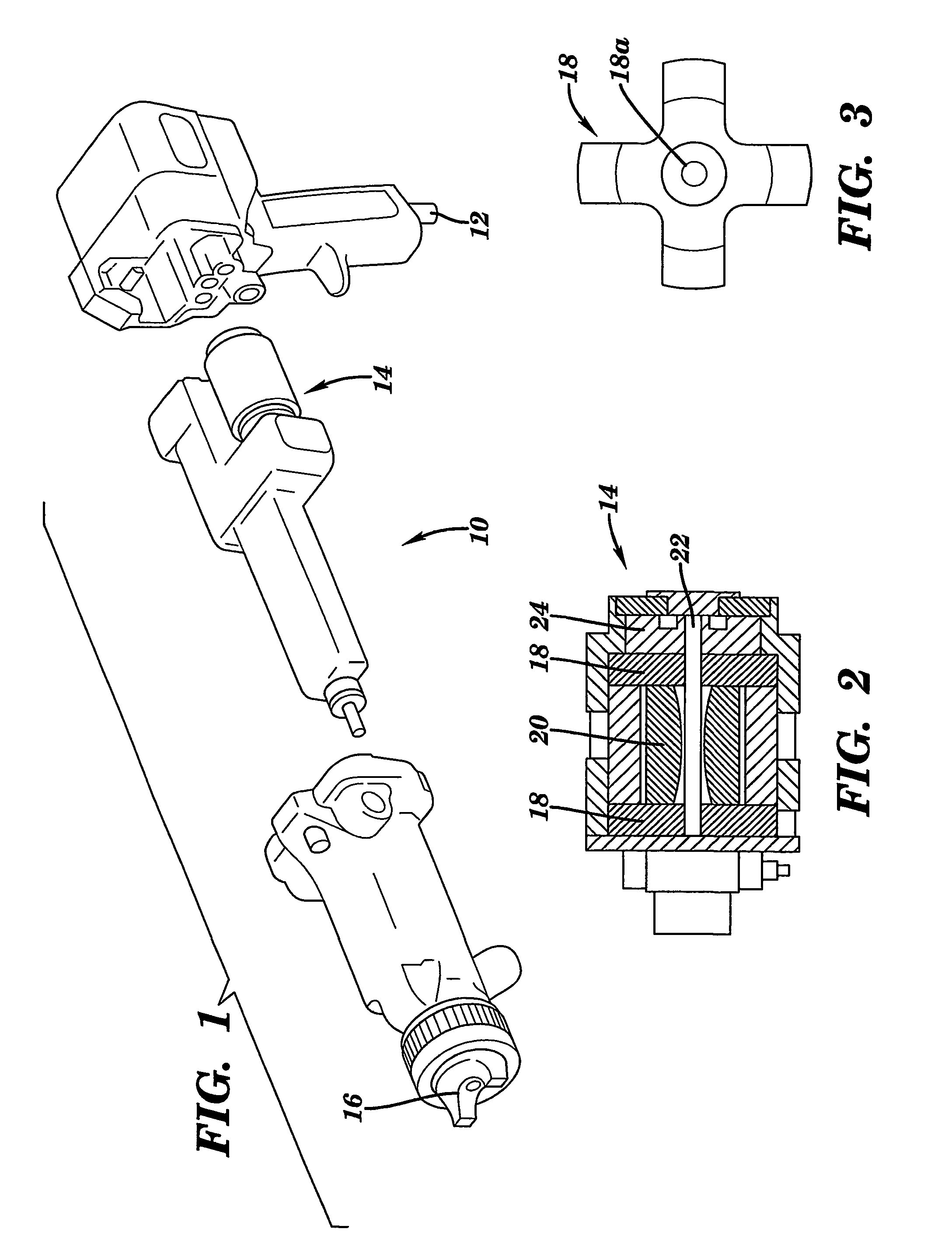

Solvent resistant bearings for self-generating electrostatic spray gun

InactiveUS7226004B2Improve bearing lifeFailure can be causedBurnersLiquid spraying plantsImpellerAlternator

An electrostatic spray gun (10) having an air powered alternator-turbine (14) with a rotating impeller (24) therein mounted in bearings (18) is provided with bearings (18) which are coated with a solvent resistant material. This coating is provided on all surfaces of the bearing (18) except for the inner diameter (18A) which contains the impeller (24). This construction prevents leaching of the oil out of the bearing (18) and into the airstream and also is resistant to paint should the spray gun (10) become immersed in such.

Owner:GRACO INC

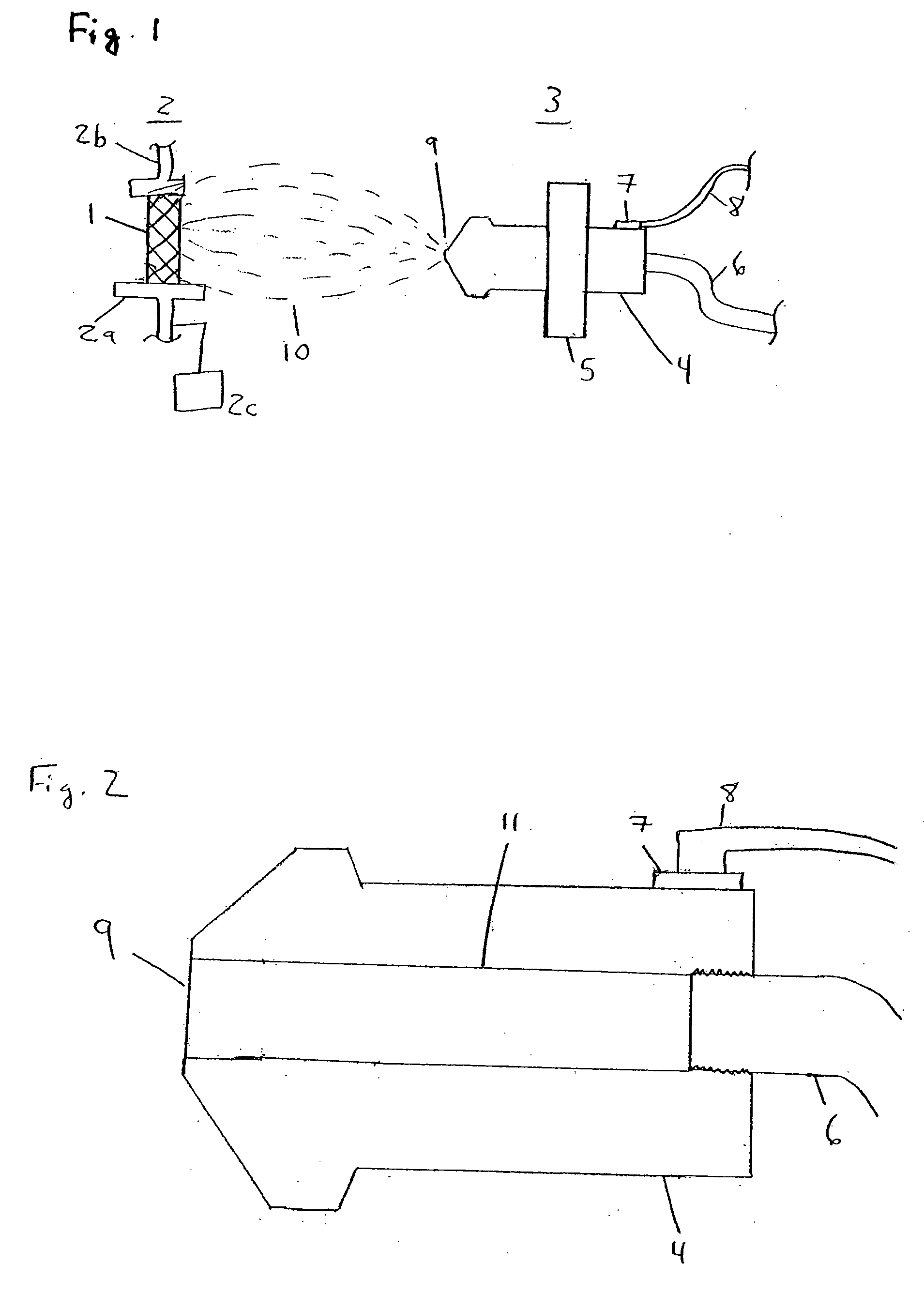

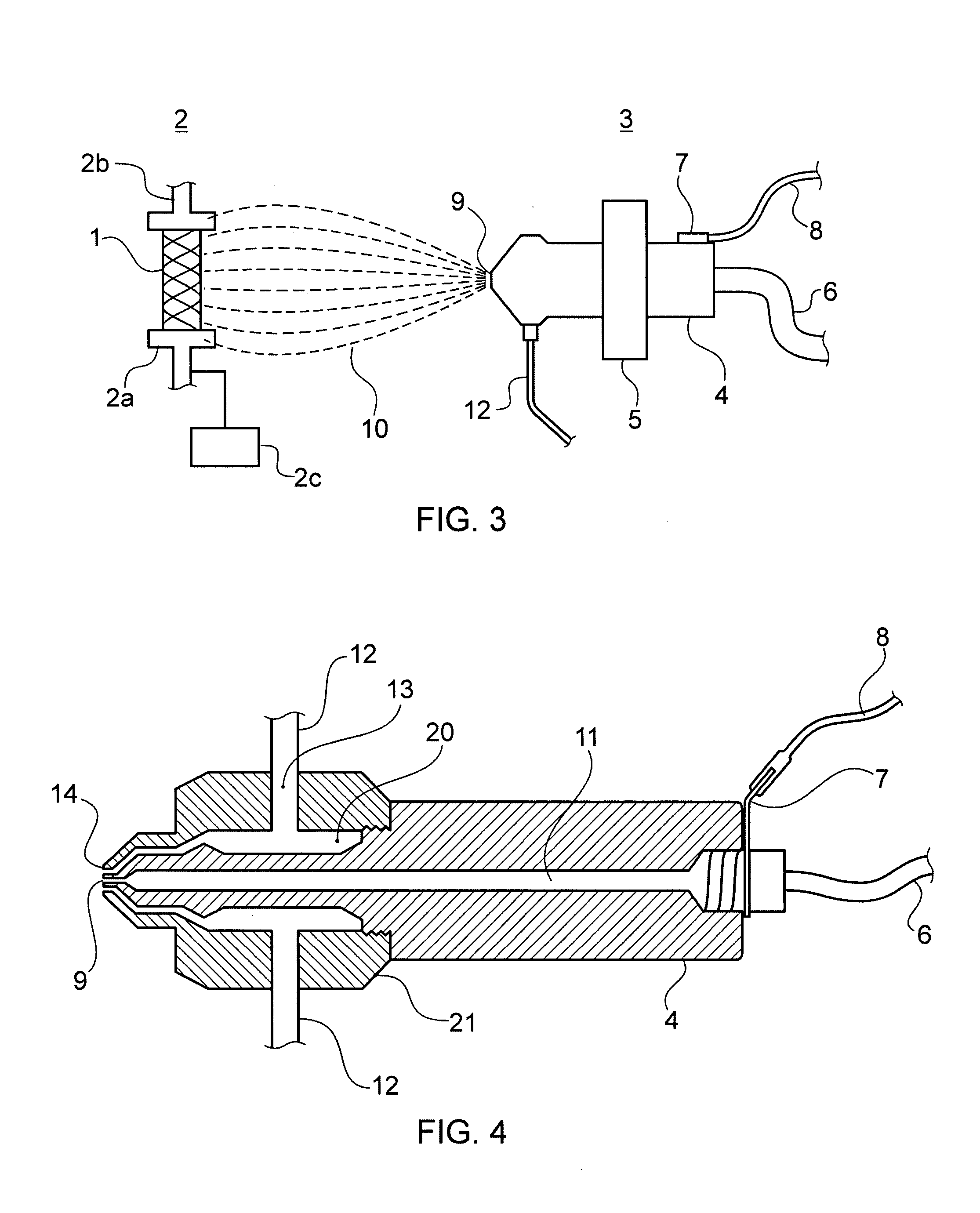

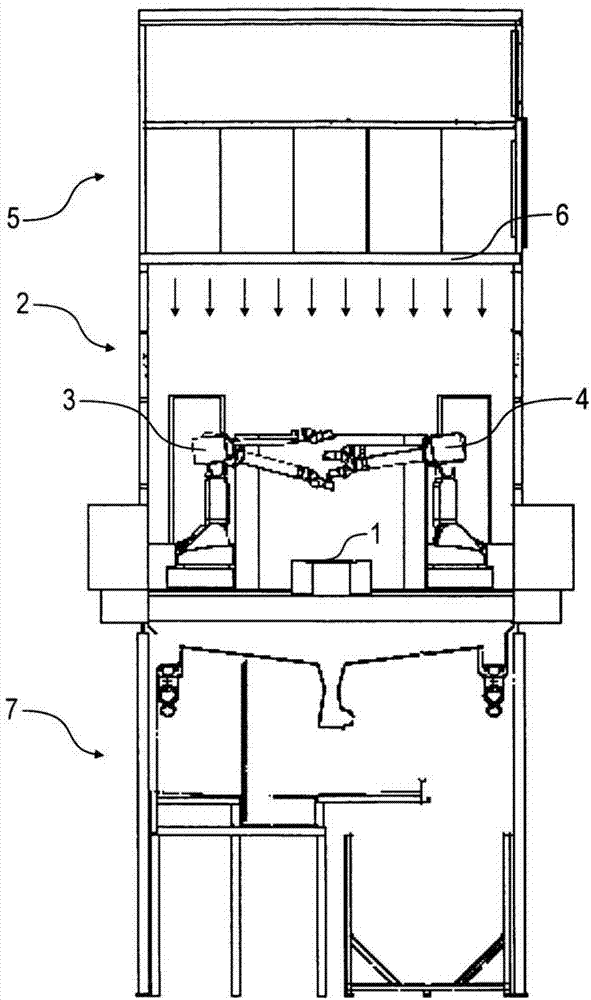

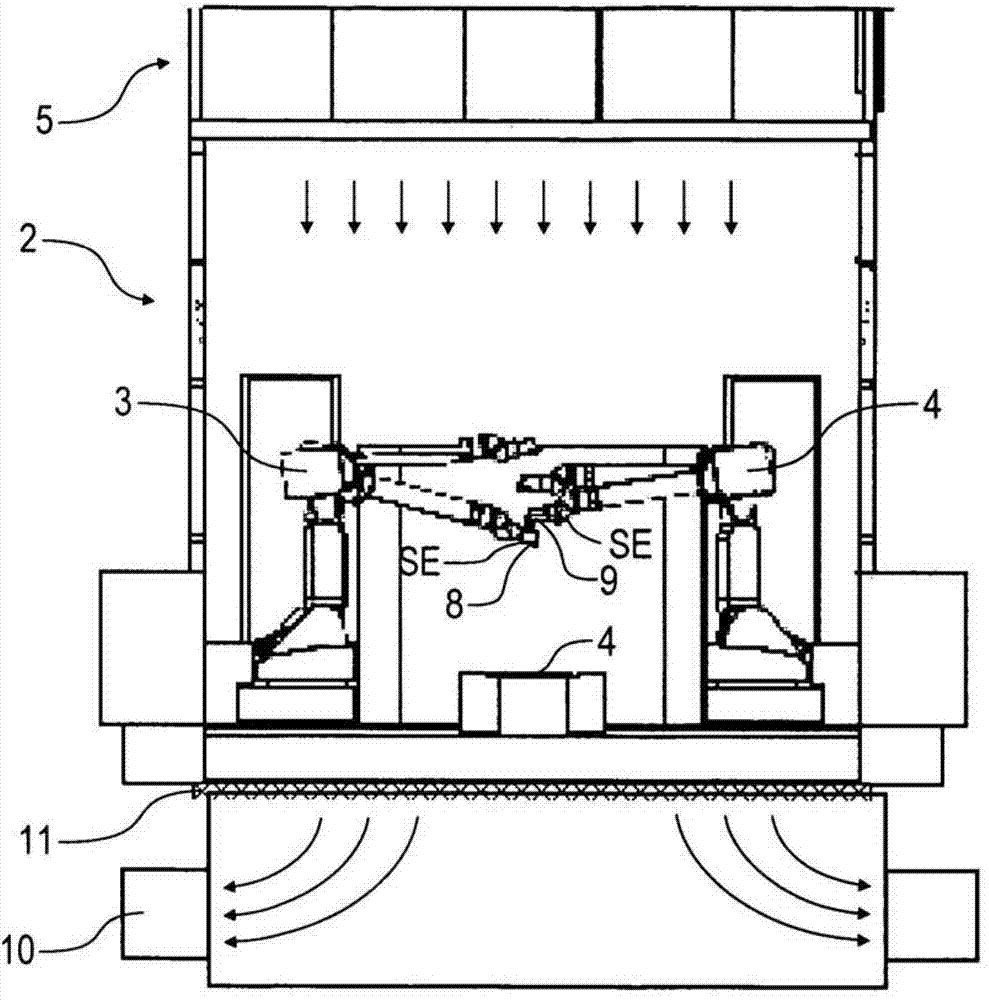

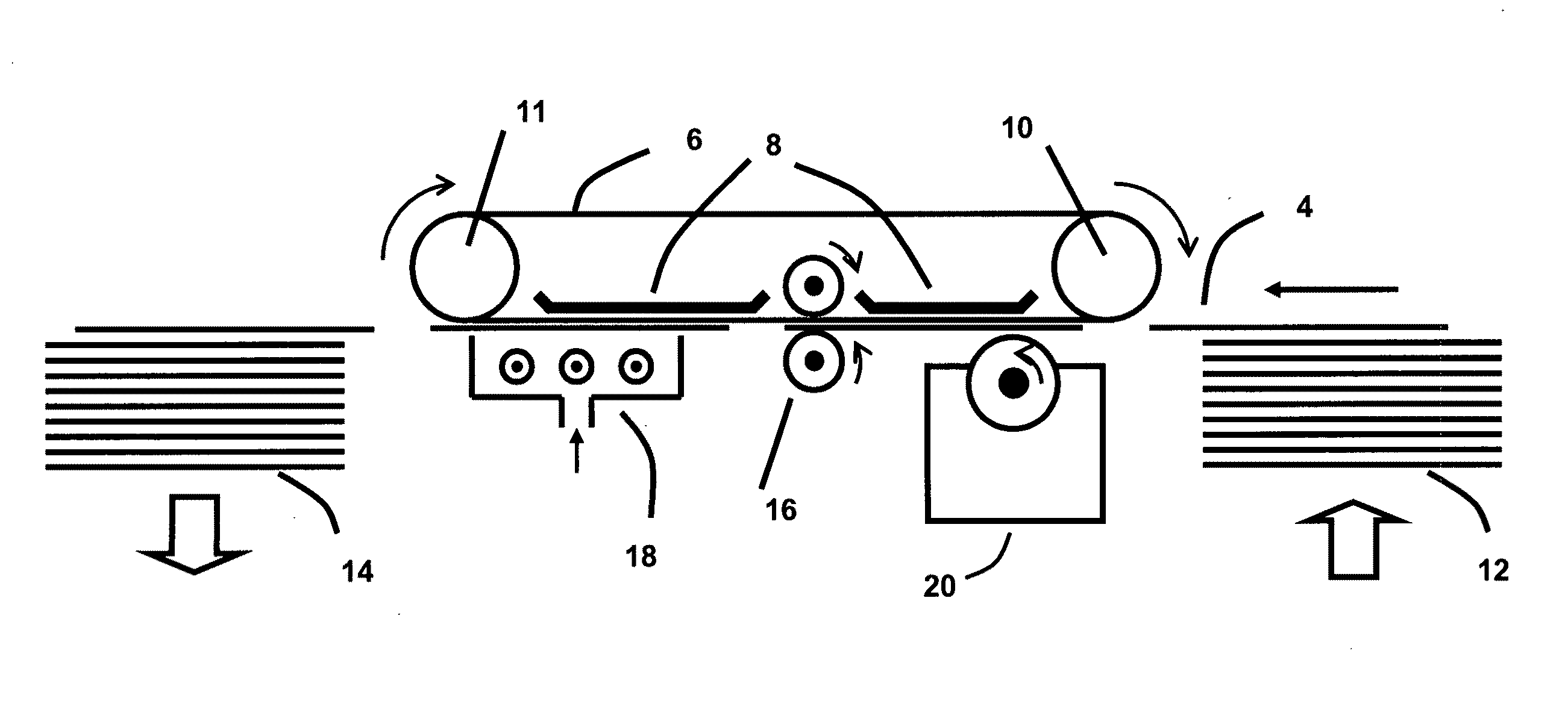

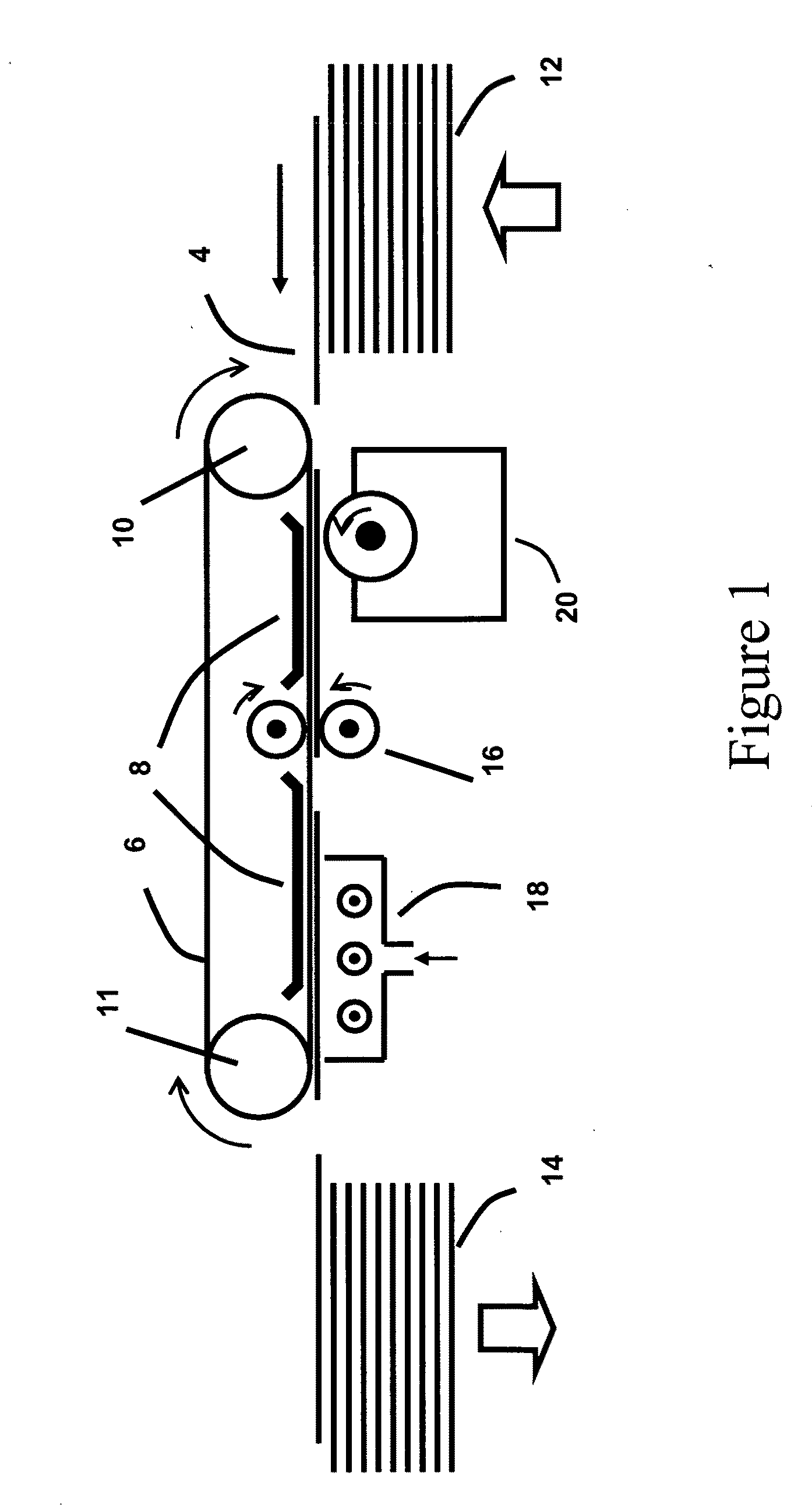

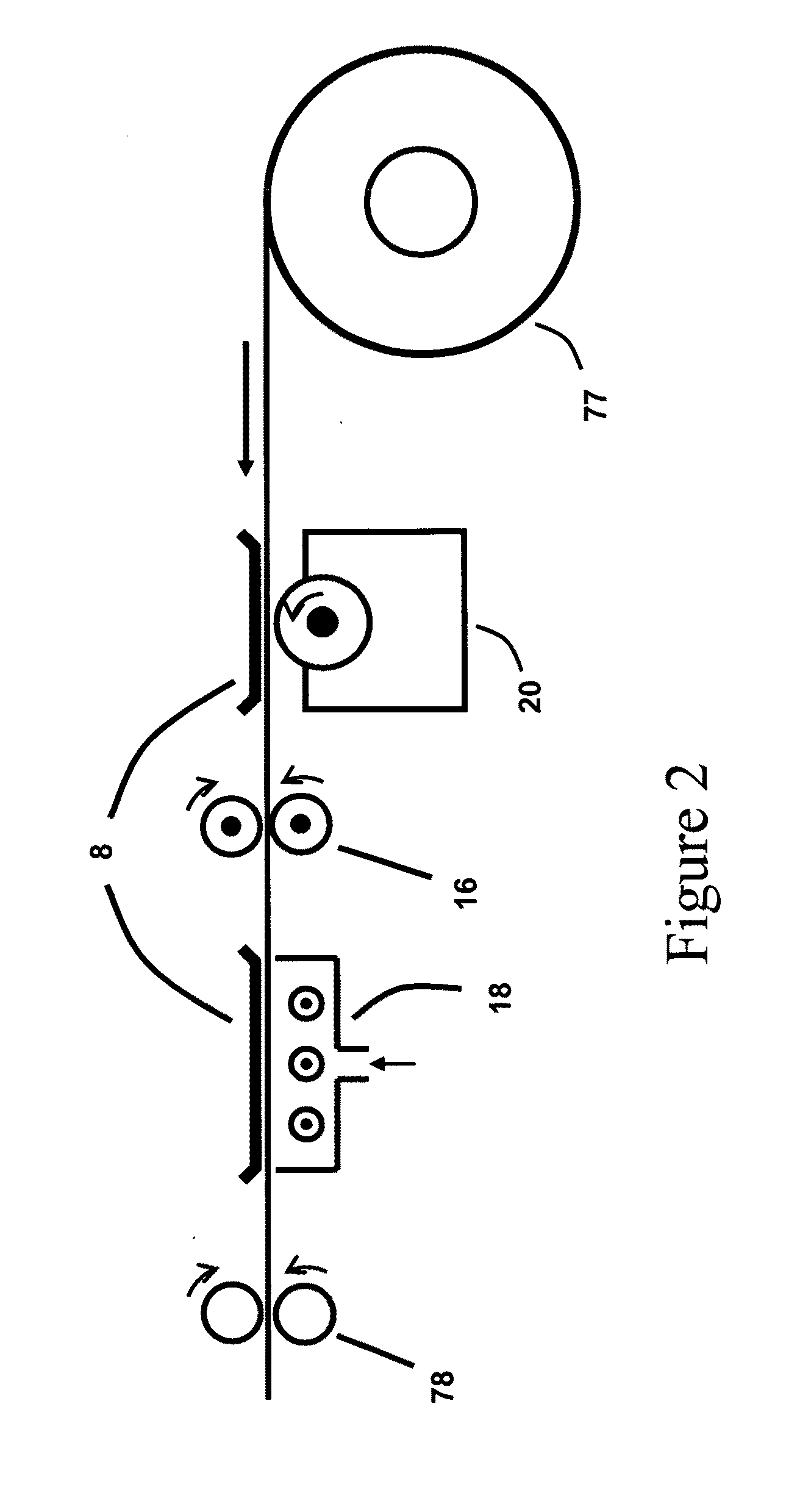

Coating device comprising a jet of coating medium which is broken down into drops

InactiveCN102971080AReduce volumeSave energyLiquid spraying plantsLiquid surface applicatorsInstabilityEngineering

The invention relates to a coating device and to an associated coating method for coating components with a coating medium, in particular for painting motor vehicle body components and / or motor vehicle accessories with a paint. The coating device comprises at least one applicator unit (8, 9) for expelling the coating medium from at least one coating medium nozzle. Furthermore a drop generator (TE; TE') can be provided in order to impose a vibration and / or an instability on the coating medium in order to generate coating agent drops (70) and / or to break down the coating medium into drops (70). The applicator unit (8, 9) is preferably provided in order to expel at least one coherent coating medium jet (70') which breaks down into drops (70).

Owner:DUERR SYST GMBH

Non-interactive electrostatic deposition of induction charged conductive powder

A method for manufacturing electrodes using an electrostatic deposition unit. In the first step of the process a mixture of magnetic carrier beads and a conductive powder is prepared in the sump of the deposition unit; the mixture forms a magnetic brush on the sleeve of the deposition unit. In the second step of the process, the substrate is positioned away from the magnetic brush to form an air gap. In the third step of the process, a voltage is applied between the substrate and the sleeve of the deposition unit in order to produce a large asymmetry between the magnetic brush and said substrate such that the electric field at the magnetic brush is at least 3.0 times as great as the electric field at the substrate. In the fourth step of the process, conductive powder is deposited onto the substrate.

Owner:XACTIV

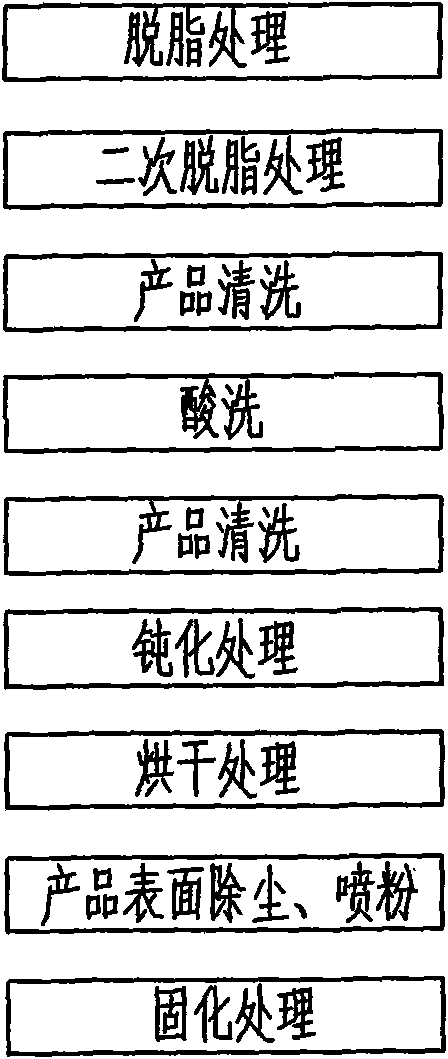

Copper imitation wire drawing process

InactiveCN101607501AStrong textureSimple processLiquid spraying plantsNatural patternsMetallic materialsHeat sensitive

The invention relates to a metal material surface coating process, in particular to a metal material surface copper imitation wire drawing process. The technical problem to be solved by the invention is to overcome the defects of the prior art and provide the metal material surface copper imitation wire drawing process with good copper imitation effect, strong copper metal texture, long light-keeping and color-keeping time and easy scale production. The technical proposal is as follows: the copper imitation wire drawing process comprises the following steps of: 1) carrying out conventional chemical pretreatment on the surface of a metal material and leading the metal surface to be clean, smooth and flat; 2) electrostatic spraying a transparent red outdoor powder coating or a pure transparent outdoor powder coating containing pigments; and 3) using a thermal-sensitive transfer paper with copper imitation bottom color of deep sky blue or black straight stripes for carrying out thermal transfer and obtaining the copper imitation wire drawing effect, wherein the straight-silkiness stripes with the color phase of deep sky blue or black silkiness straight textures are printed on the thermal-sensitive transfer paper with the copper imitation bottom color of deep sky blue or black straight stripes, the bottom color of the copper imitation color is light red purple or red purple or light yellow. In addition to the advantages, the copper imitation wire drawing process is more conductive to environmental protection.

Owner:李宗炳

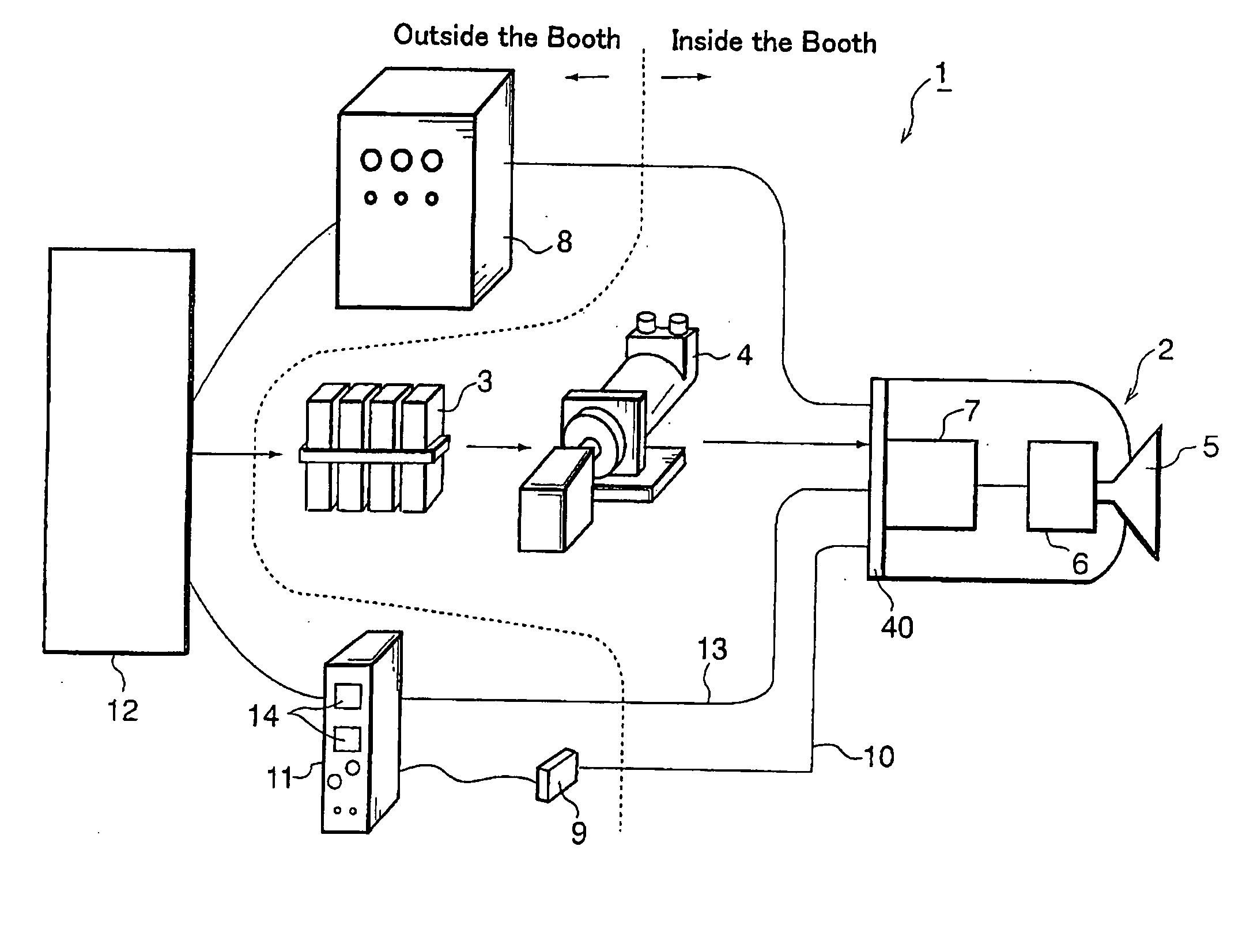

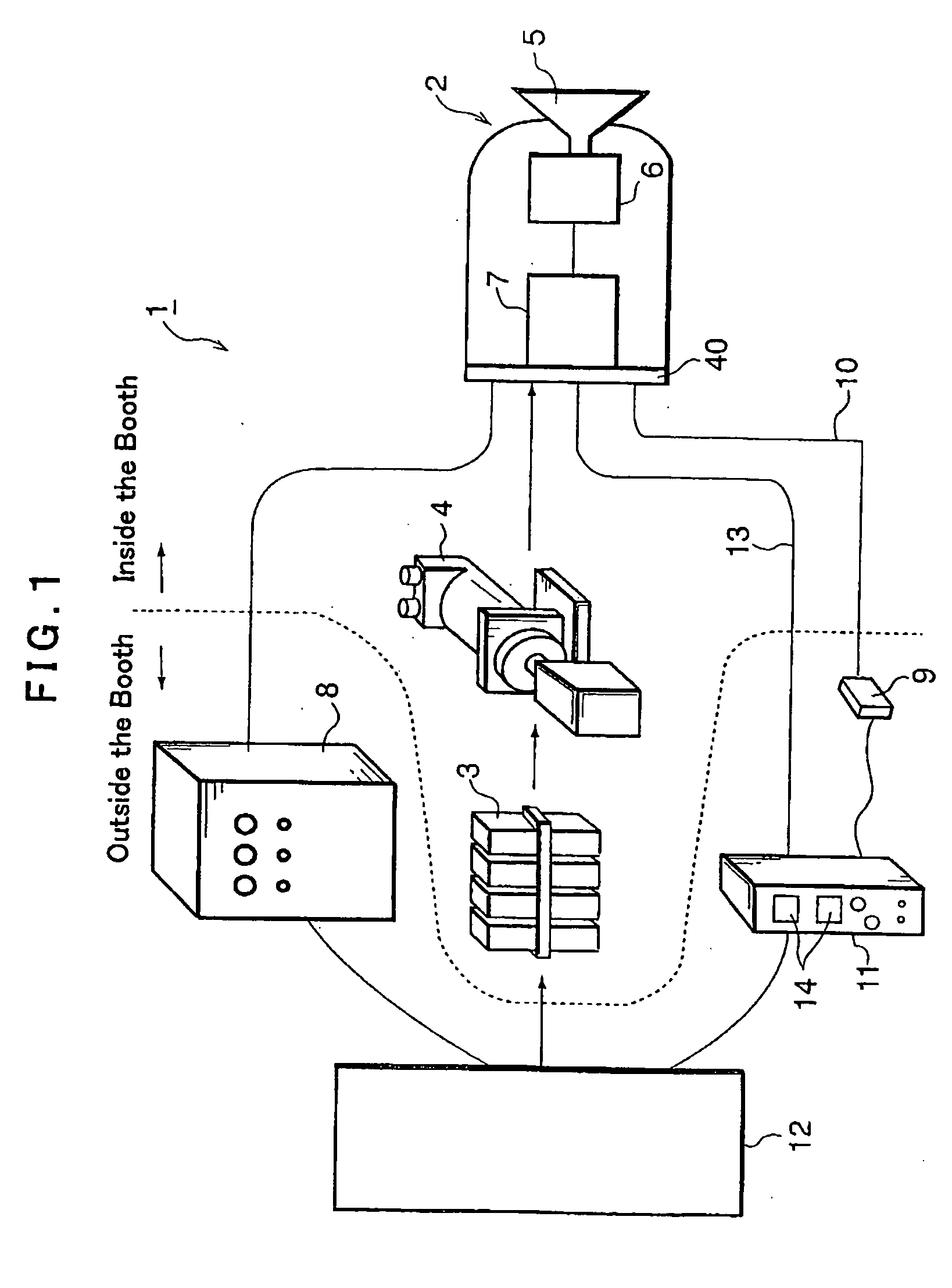

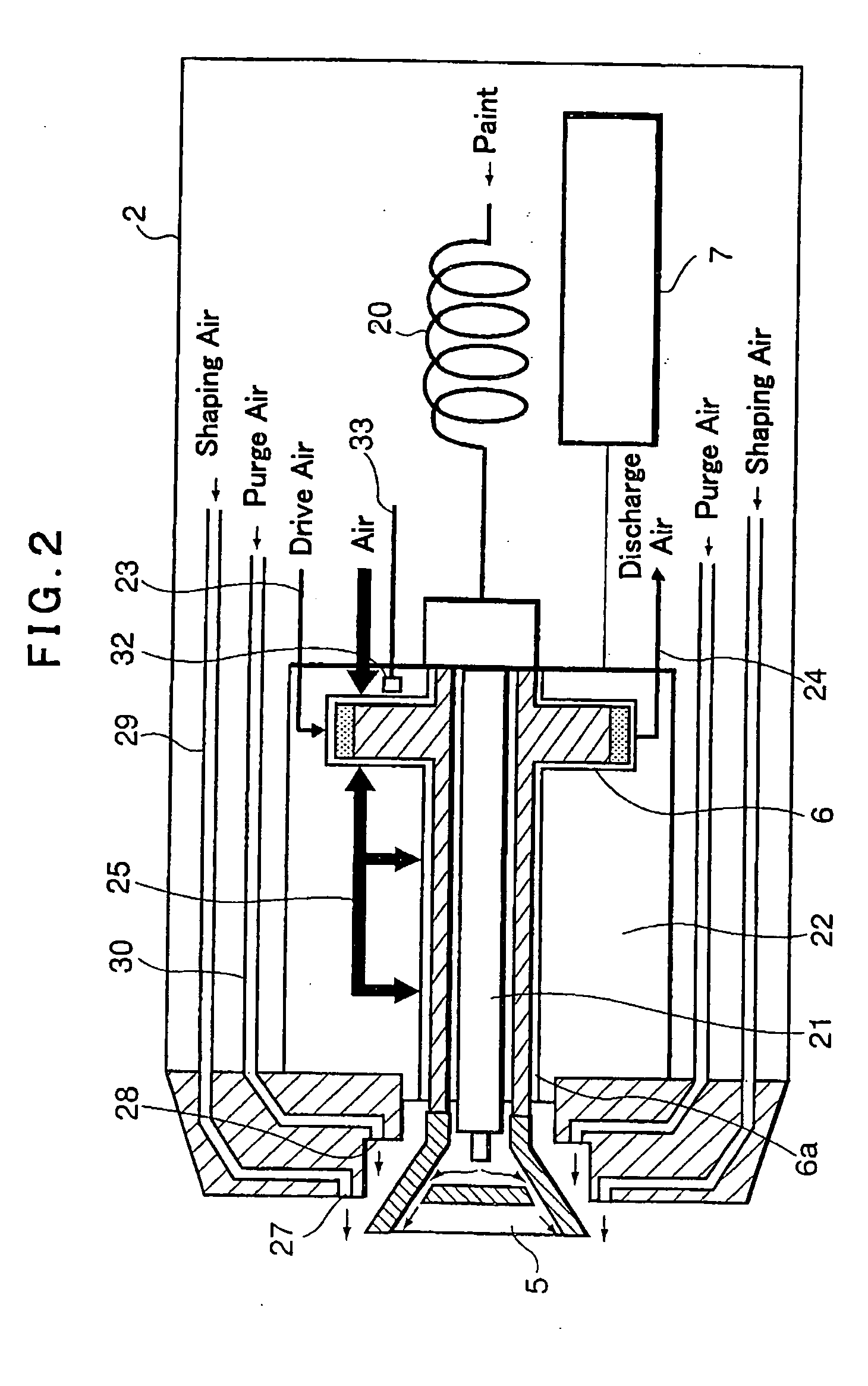

Electrostatic coating system

ActiveUS20050040262A1Guaranteed uptimeEasy to controlBurnersLiquid spraying plantsElectrostatic coatingTotal current

Total supplied current (I2) and high voltage (Vm) supplied to a rotary atomizer head (5) are detected by a total current sensor (115) and a high voltage sensor (116). Total leak current (I2) in paint paths, thinner paths and air paths inside an electrostatic atomizer (2) is detected via a metal back plate (40) of the electrostatic atomizer (2). When the total leak current value (I2) exceeds a threshold value (Ia), the level Vm of the high voltage applied to the rotary atomizer head (5) is lowered stepwise.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

Needle-to-needle electrospinning

The disclosure relates to a method and apparatus for coating a medical device. The method includes providing an electrospinning apparatus and simultaneously electrospinning at least one solution onto a first surface and an opposing second surface. The apparatus comprises a first spinneret and a second spinneret. An energy source is electrically coupled to the first spinneret and the second spinneret. The first spinneret and second spinneret comprise a reservoir and an orifice fluidly coupled to the reservoir. The first spinneret orifice is located substantially opposite the second spinneret orifice.

Owner:MED INST INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com