Patents

Literature

434 results about "Water particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

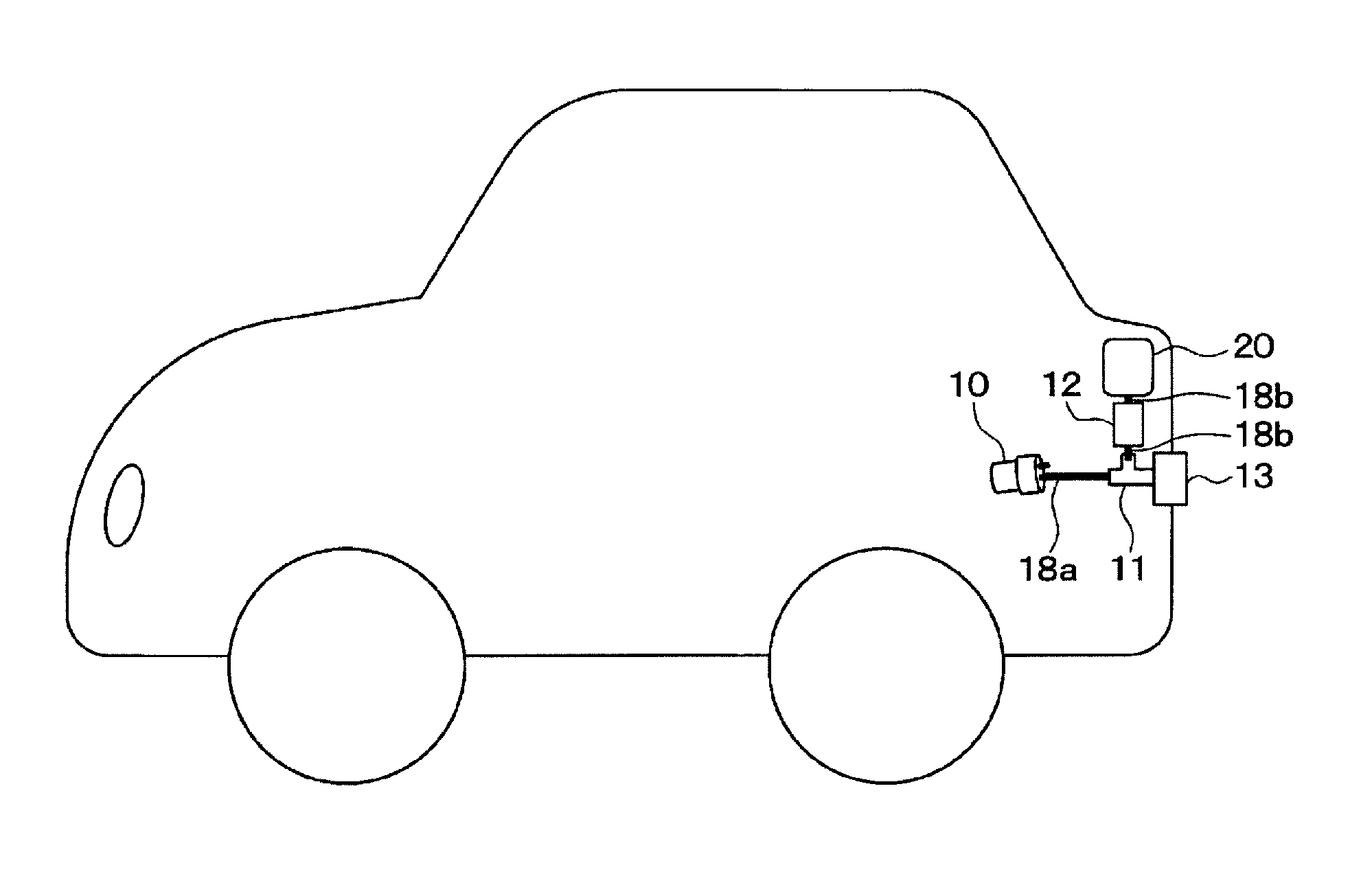

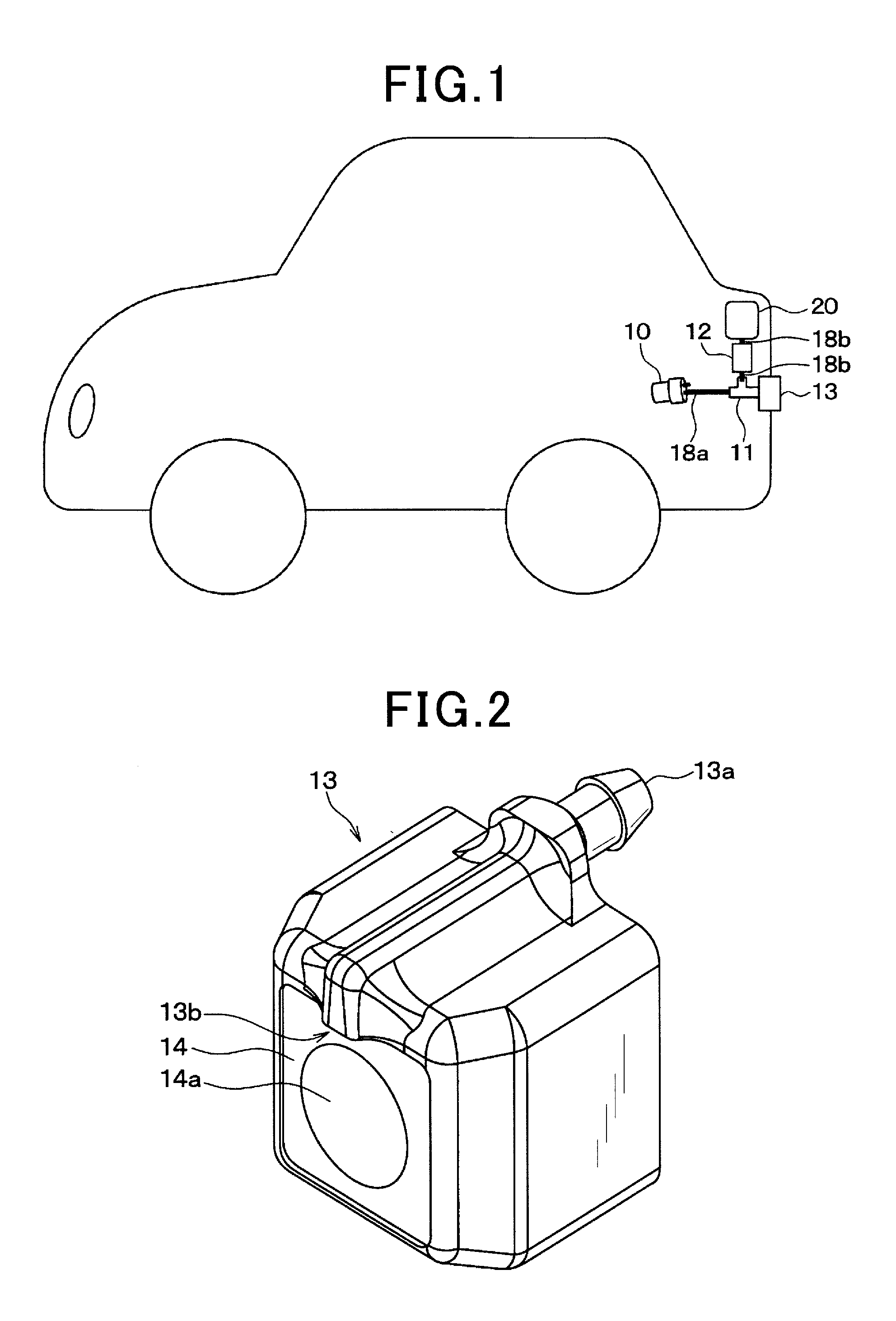

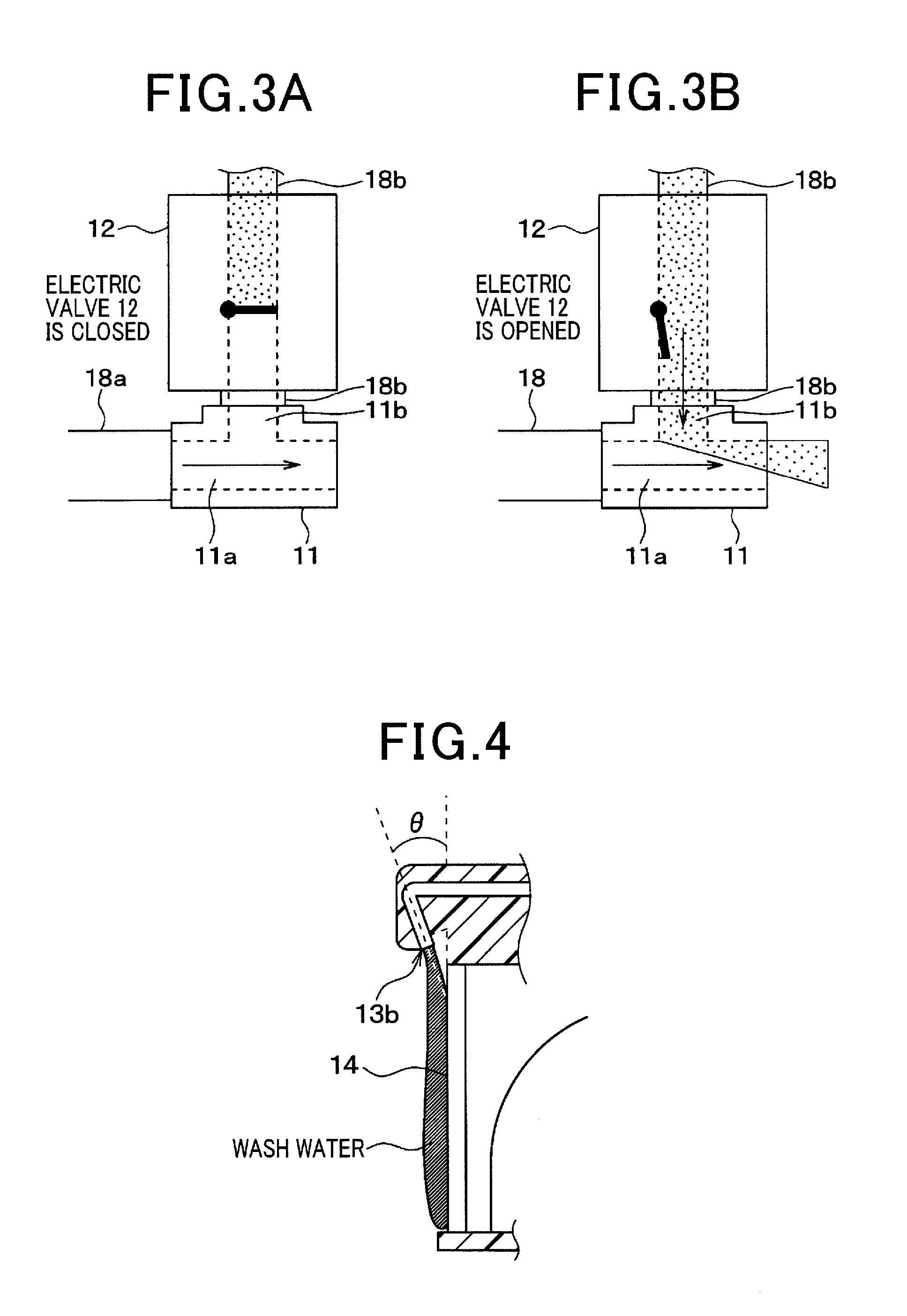

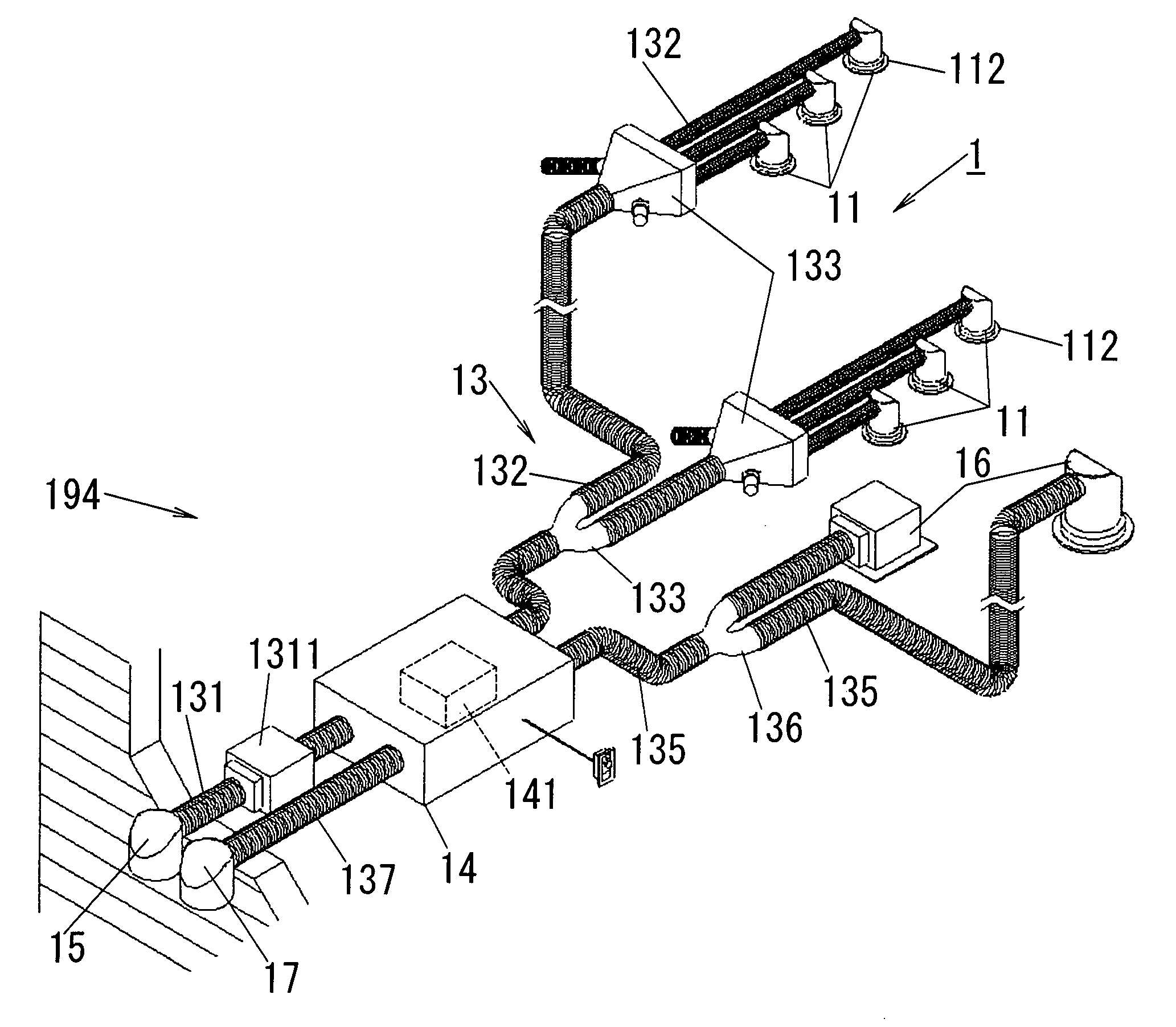

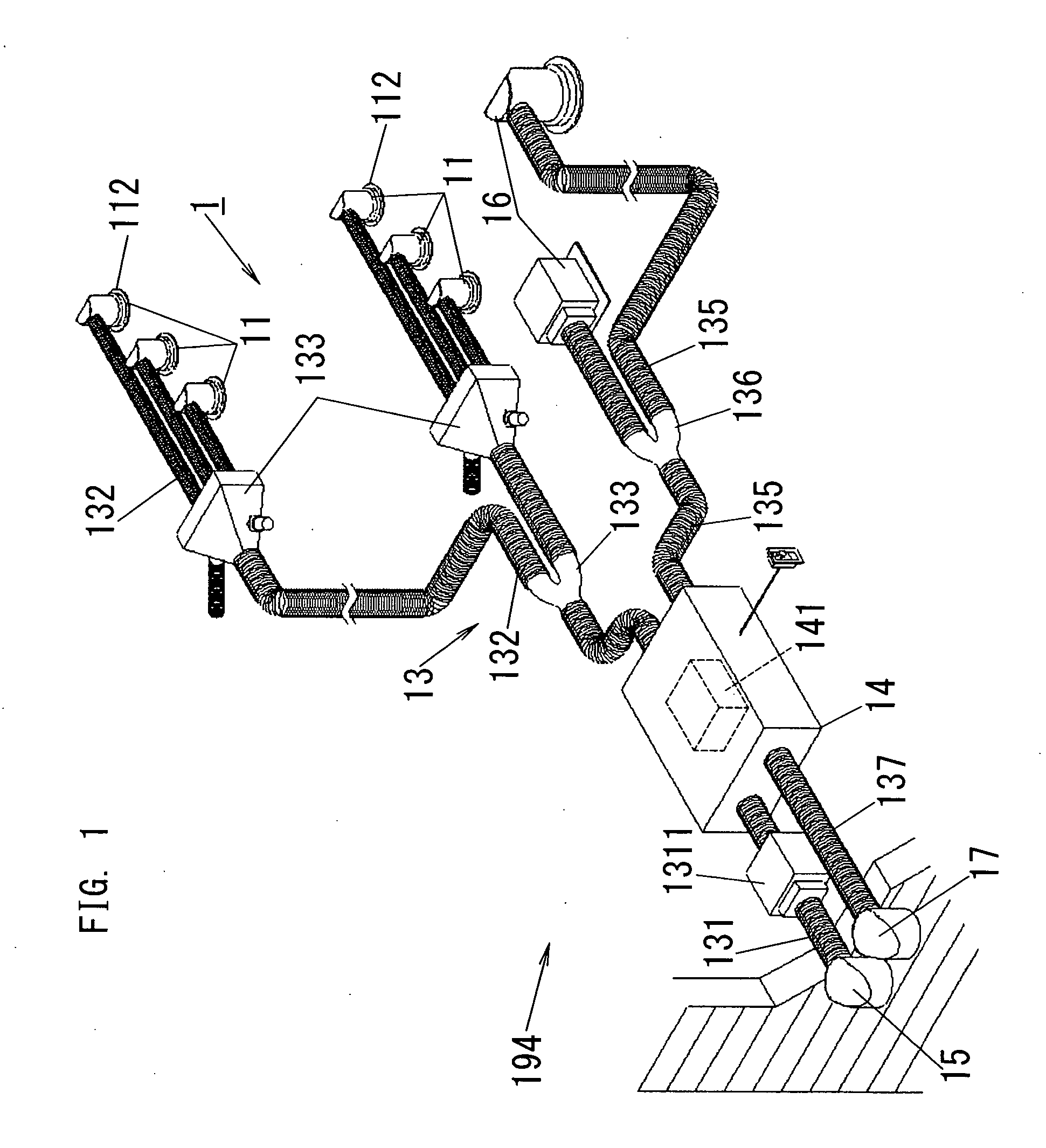

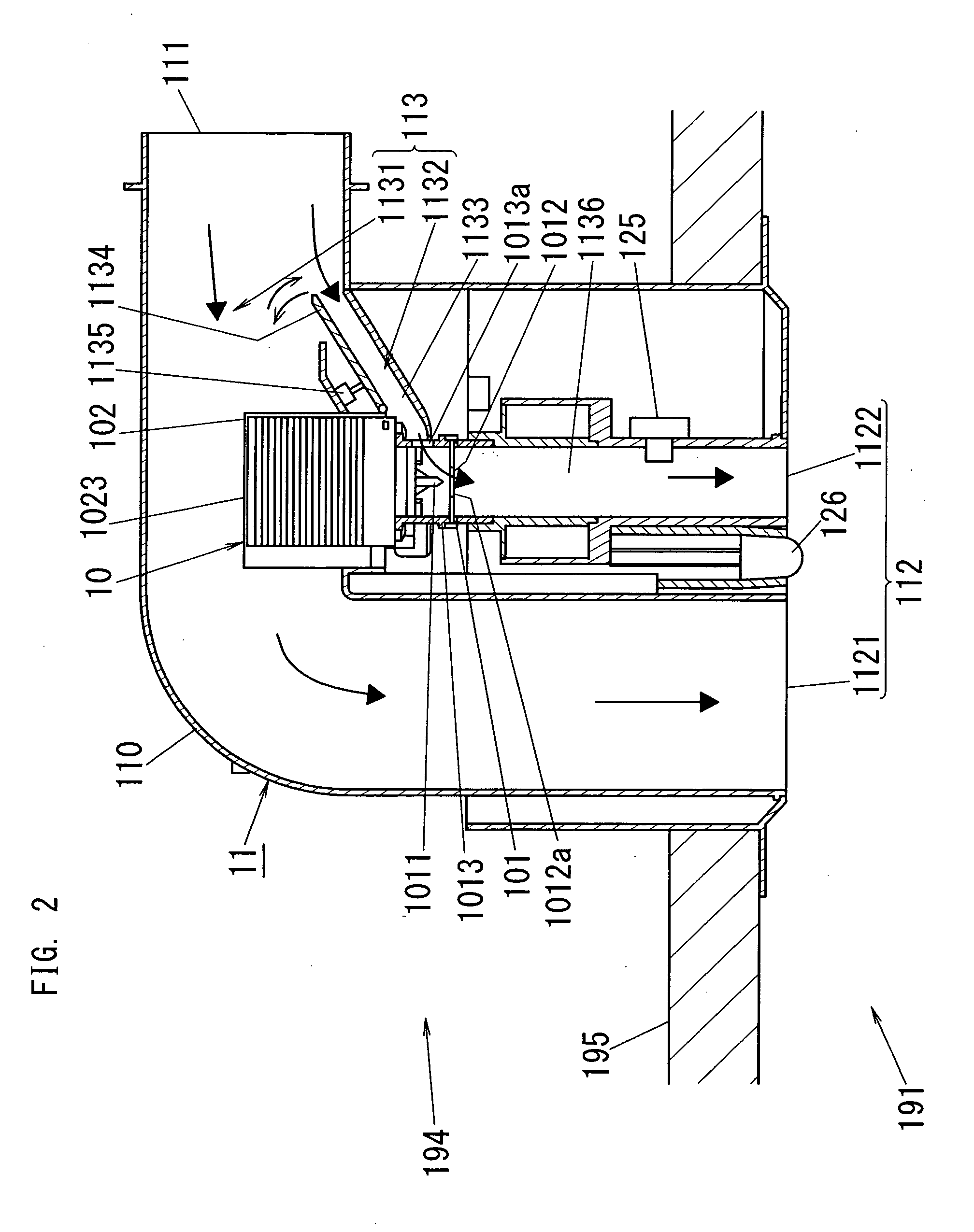

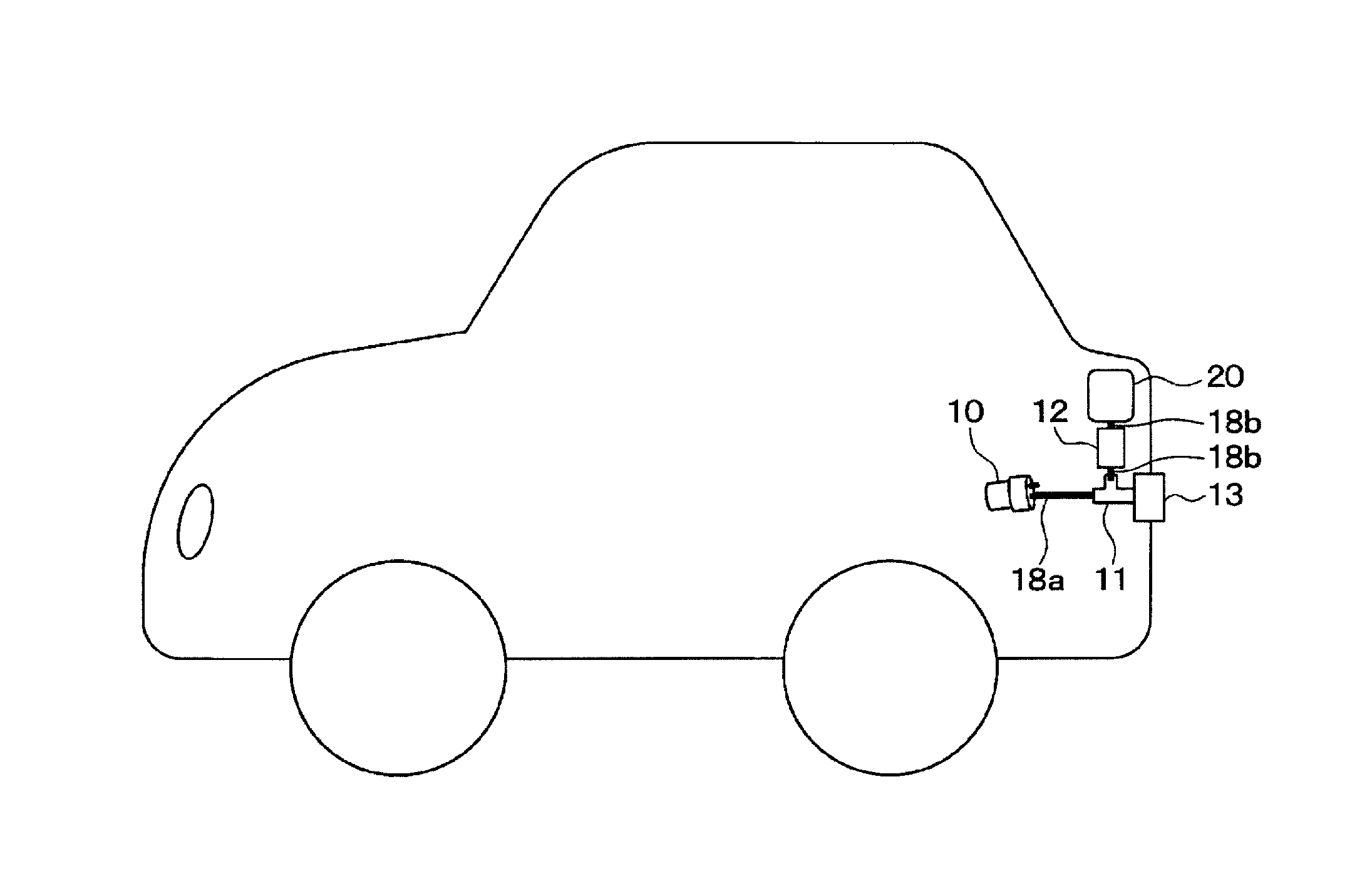

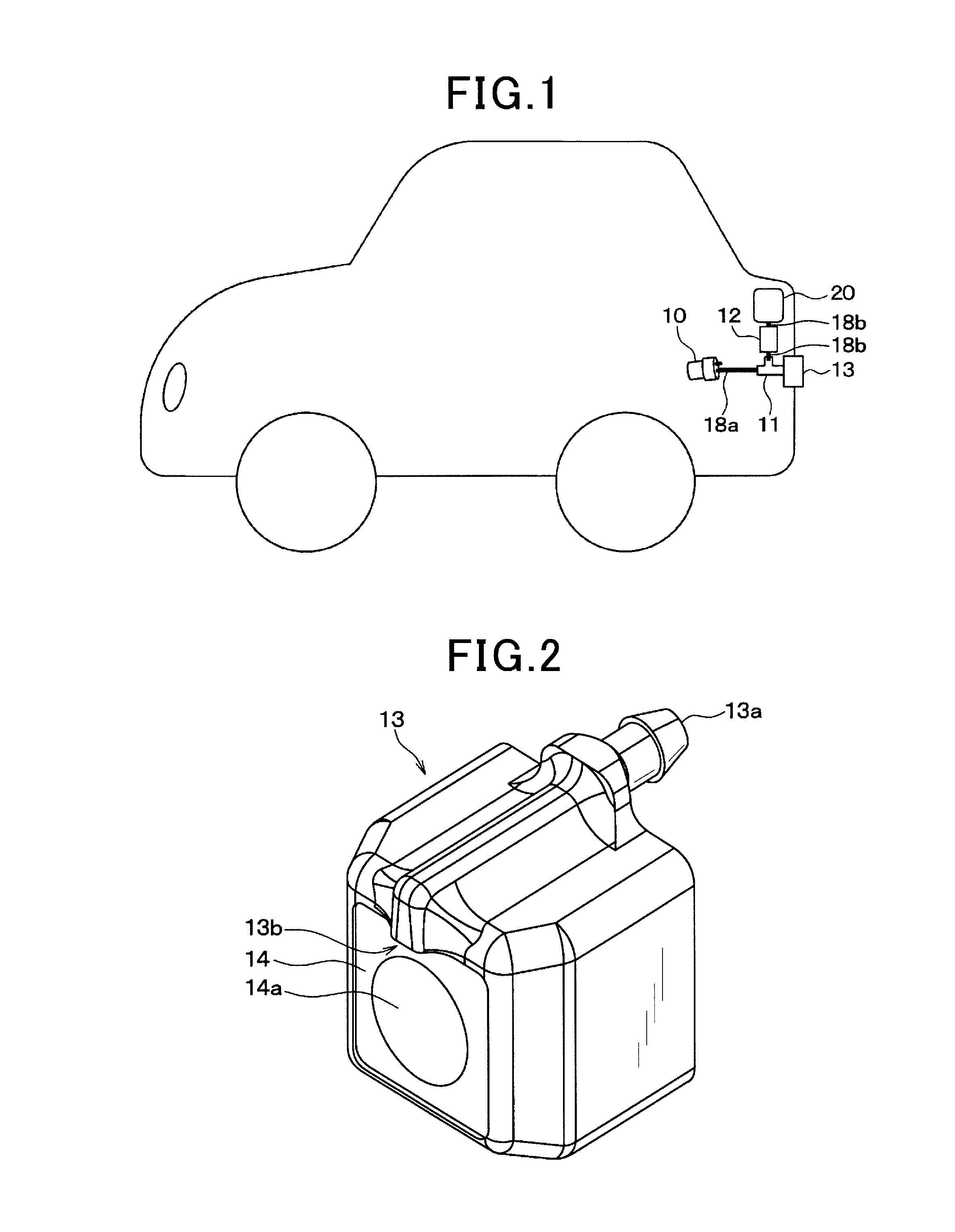

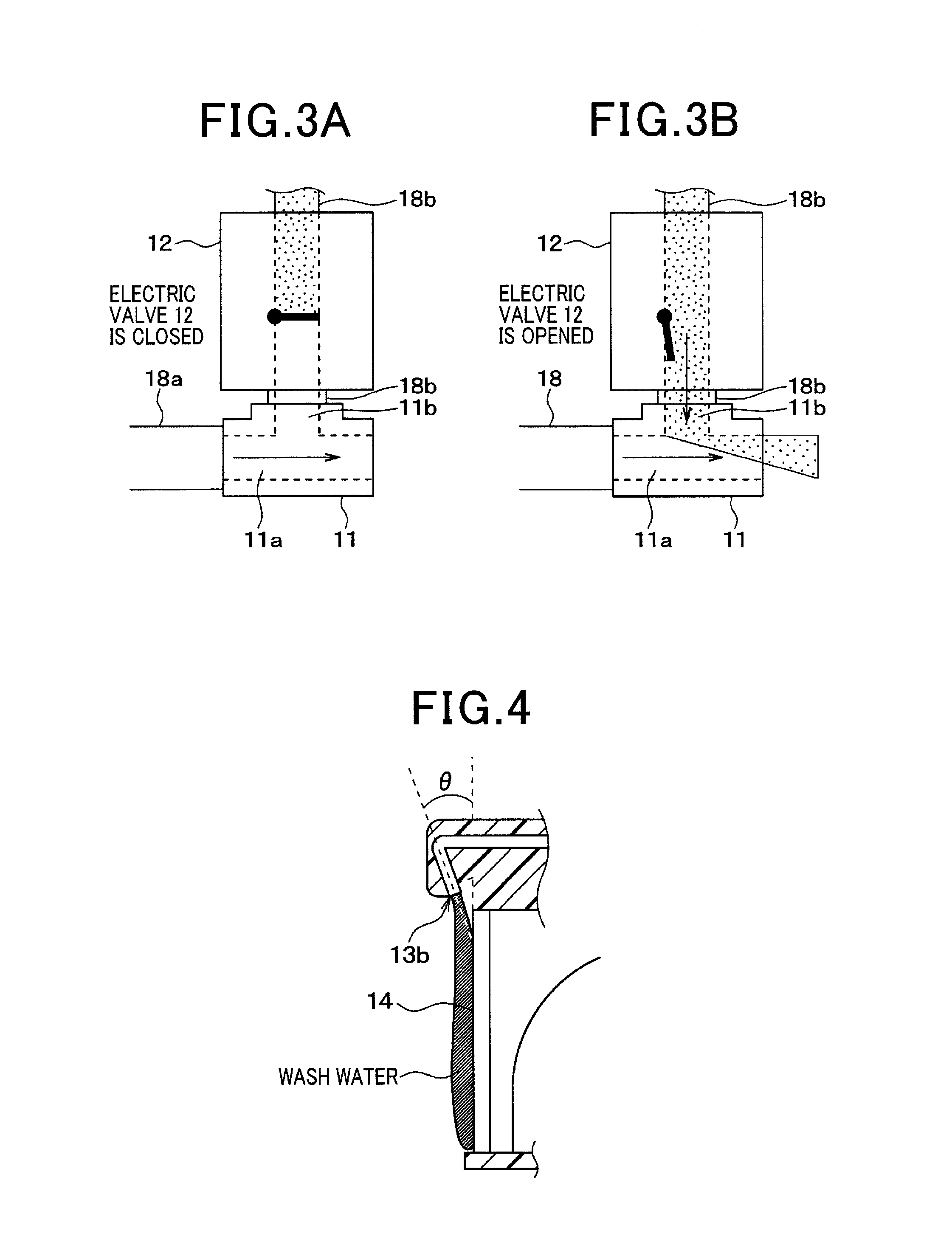

Camera washing device for camera lens

ActiveUS20130092758A1Reduce water consumptionShorten the time periodSpray nozzlesVehicle cleaningCamera lensWash water

A camera washing device has an air pump, a wash water tank storing wash water, an injection nozzle with an injection part, a junction joint having a high-pressure air passage and a wash water passage, and an electromagnetic valve. The air pump generates and supplies high-pressure air to the high-pressure air passage. When the control part instructs the electromagnetic valve to be switched to an open state, the wash water and the high-pressure air are mixed in the junction joint to generate water particles. The generated water particles are supplied to the injection nozzle. When the electromagnetic valve is switched to the open state after injecting the high-pressure air only to a lens of a rear camera, the injection part injects the water particles to the lens of the camera.

Owner:DENSO CORP

Continuous manufacture of superabsorbent/ion exchange sheet material

InactiveUS20020007166A1Increase in sizeNon-fibrous pulp additionWood working apparatusPapermakingIon exchange

A continuous sheet having a combination of acidic and basic water-absorbing resin particles that are essentially not neutralized and can be continuously manufactured on conventional papermaking apparatus, using a wet, dry, or wet-dry process to manufacture a water-absorbent sheet-like substrate containing 50%-100% by weight of the combination of acidic and basic water-absorbent particles. The acidic and basic essentially unneutralized resins can be contained in the sheet material articles of the present invention as separate acidic and basic resin particles, or as multicomponent particles containing both the acidic and basic resins. The sheet materials can be manufactured having new and unexpected structural integrity, with little or no shakeout or loss of superabsorbent particles during or after manufacture while exhibiting exceptional water absorption and retention properties. The sheet materials have an ability to absorb liquids quickly, demonstrate good fluid permeability and conductivity into and through the resin particles, and have a high gel strength such that the hydrogel formed from the SAP particles resists deformation under an applied stress or pressure, when used alone or in a mixture with other water-absorbing resins.

Owner:BASF AG

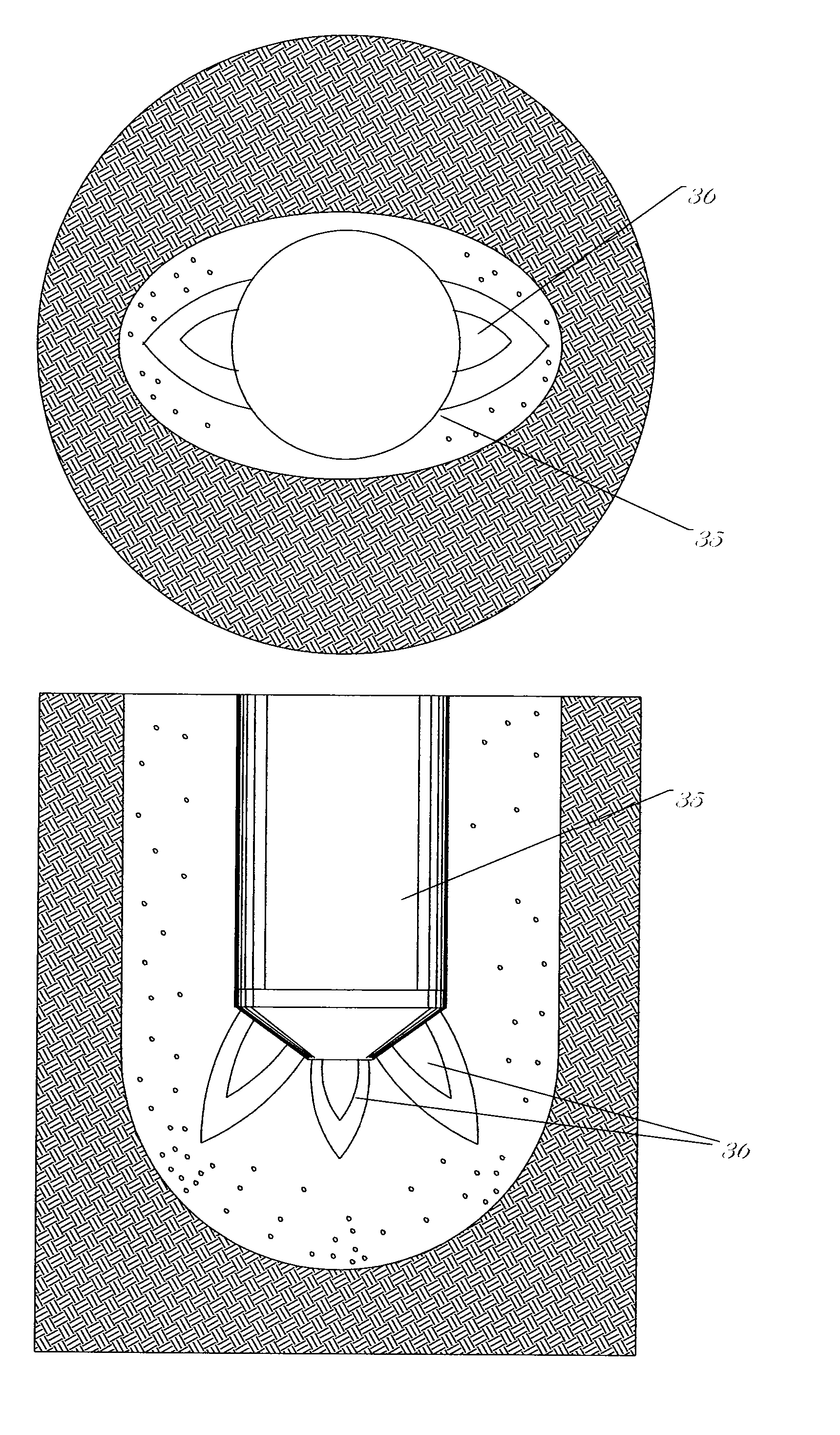

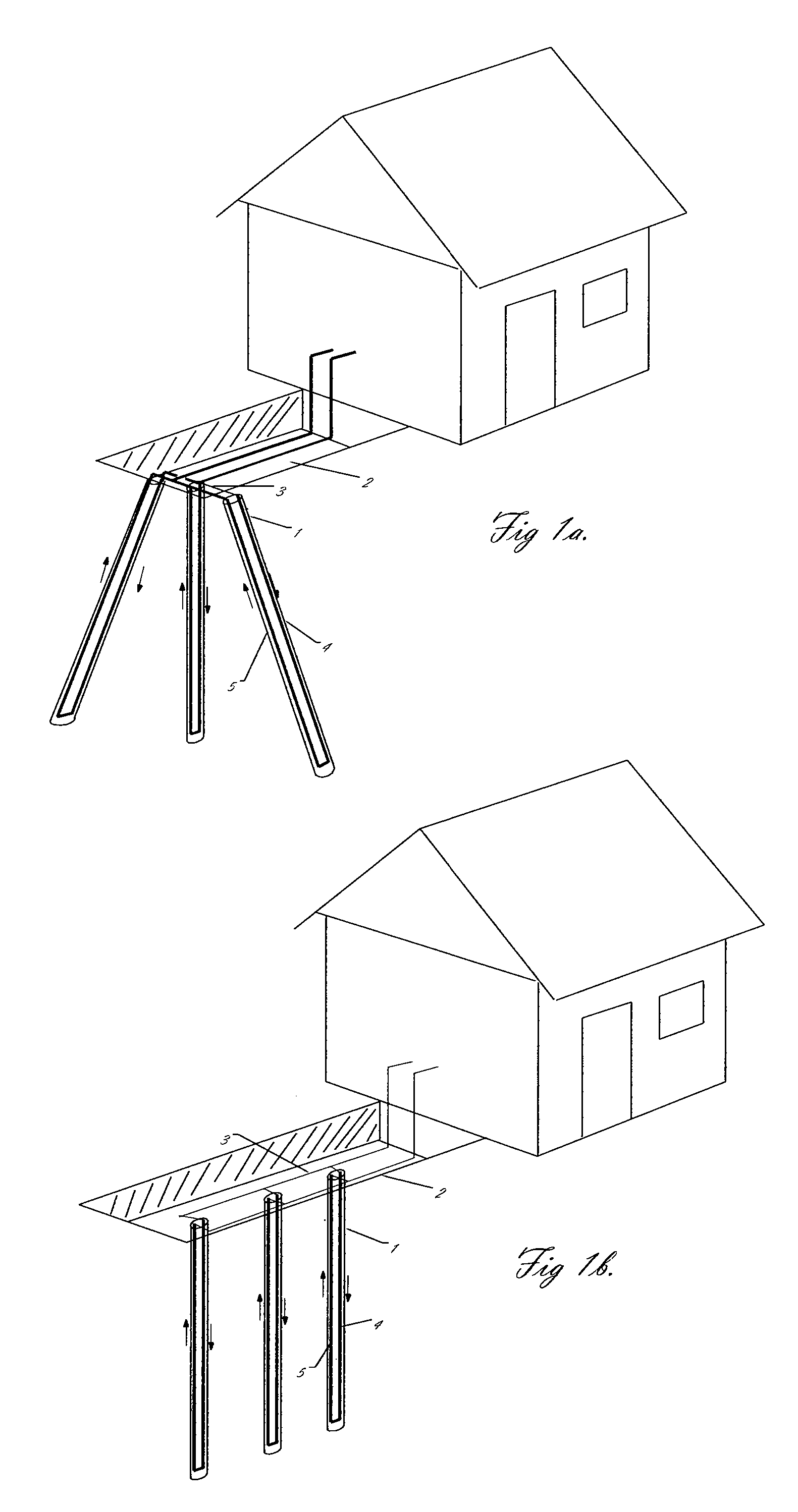

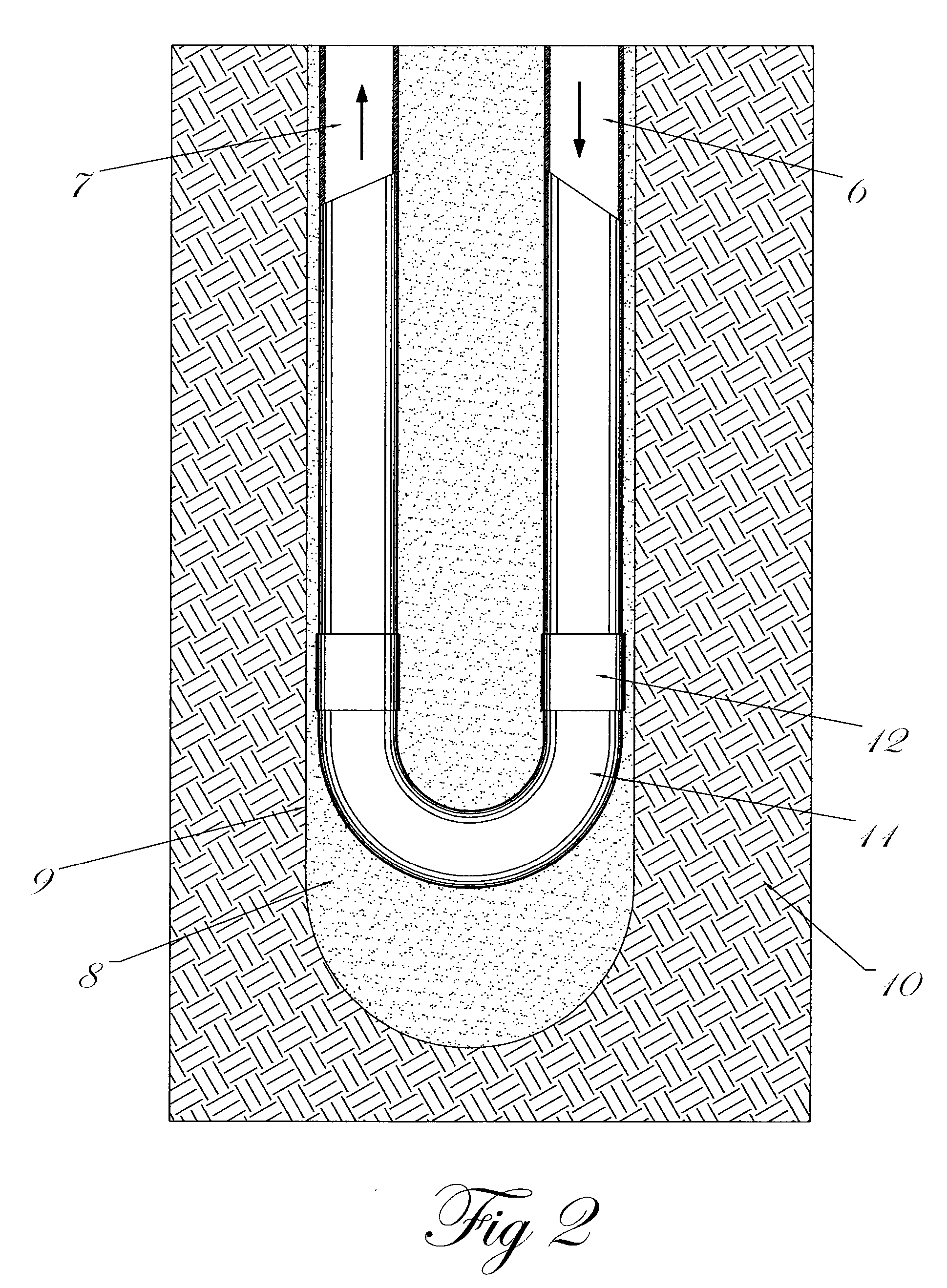

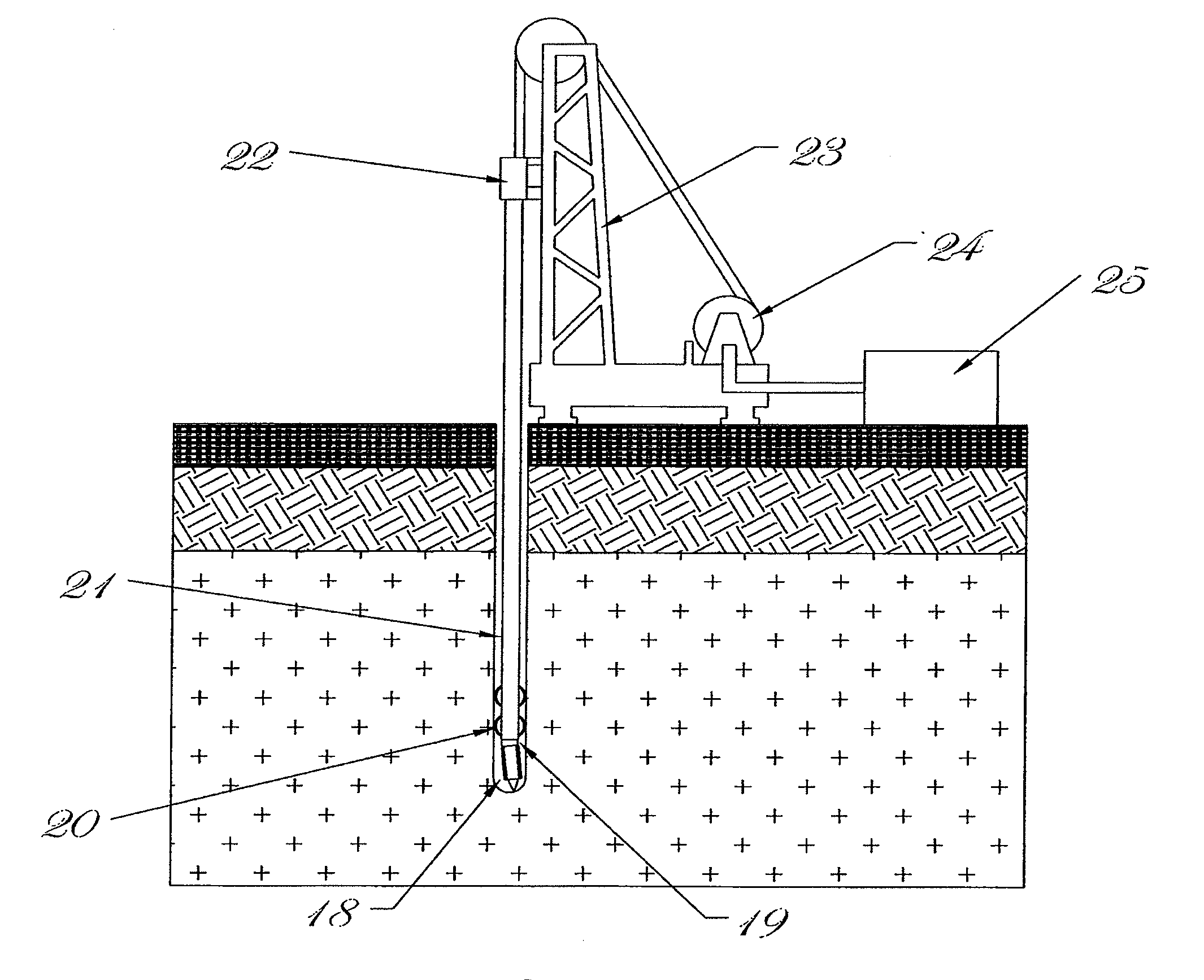

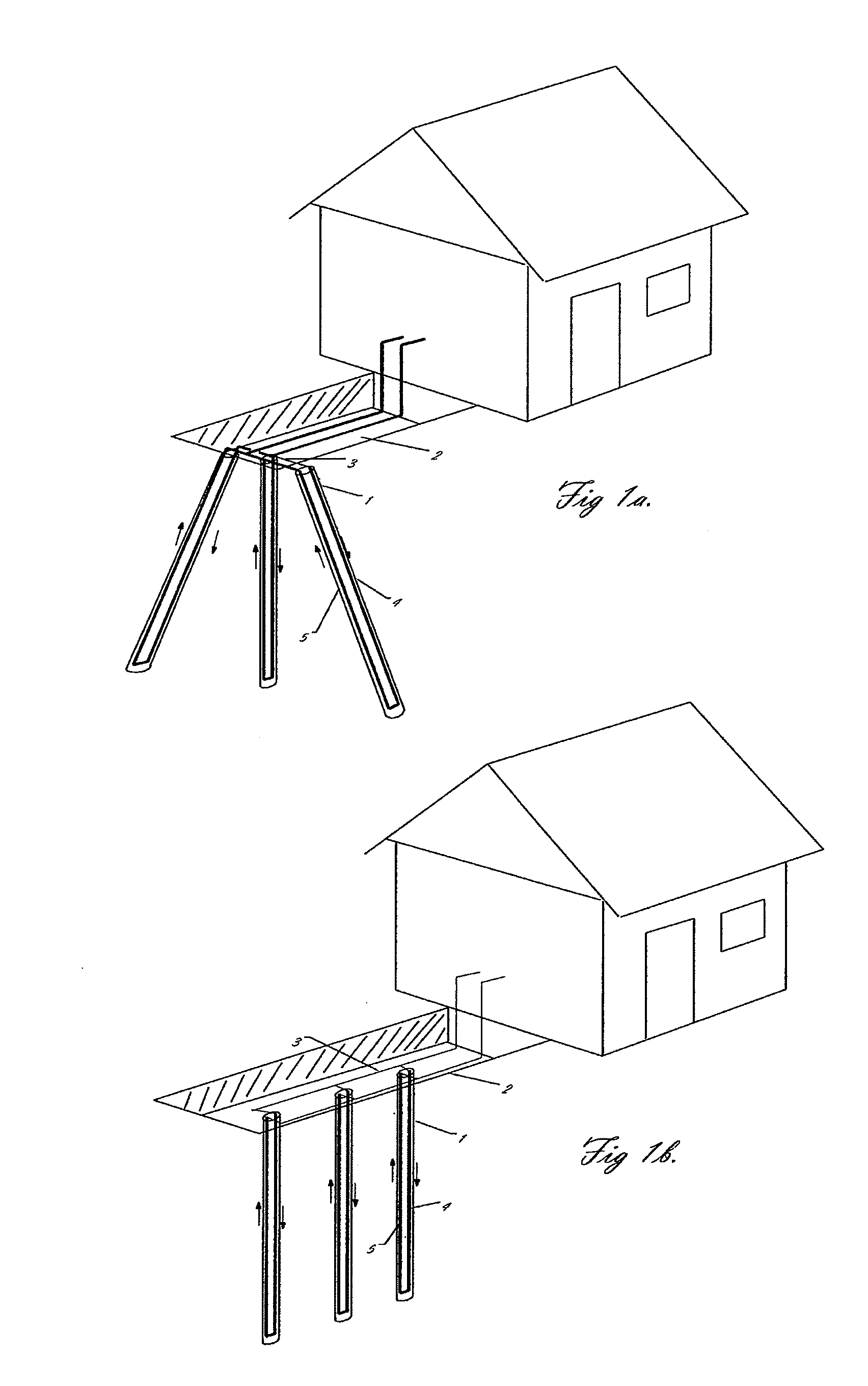

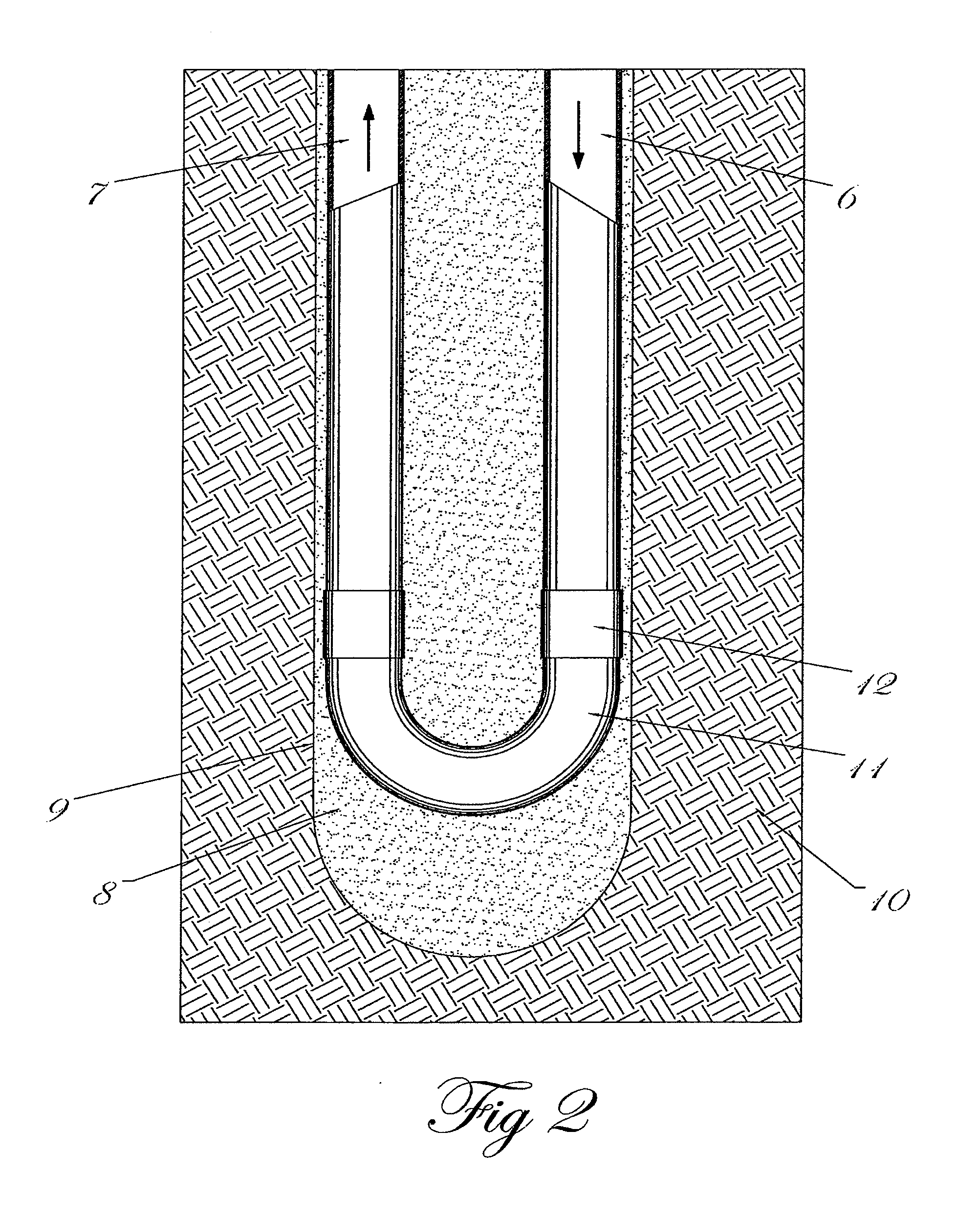

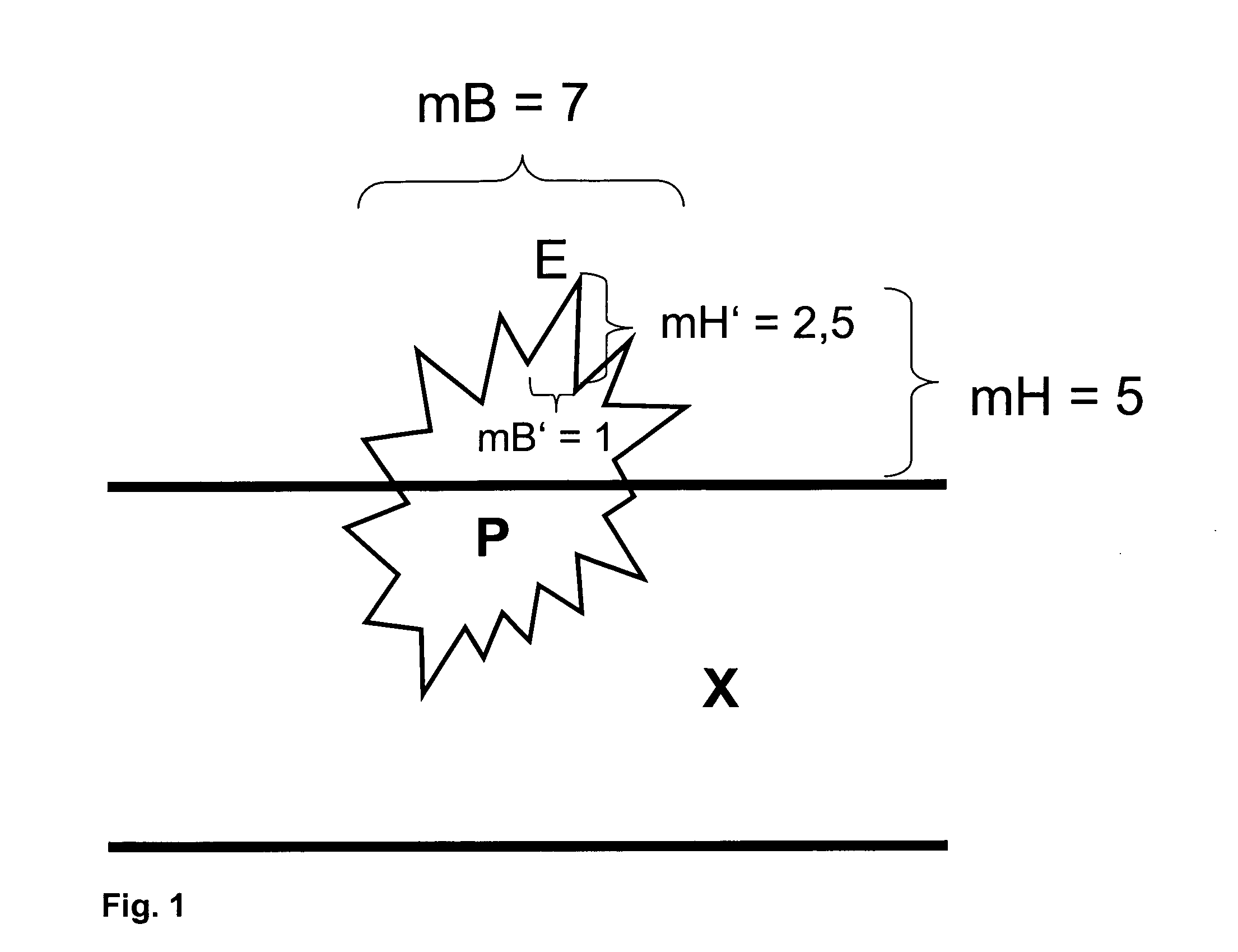

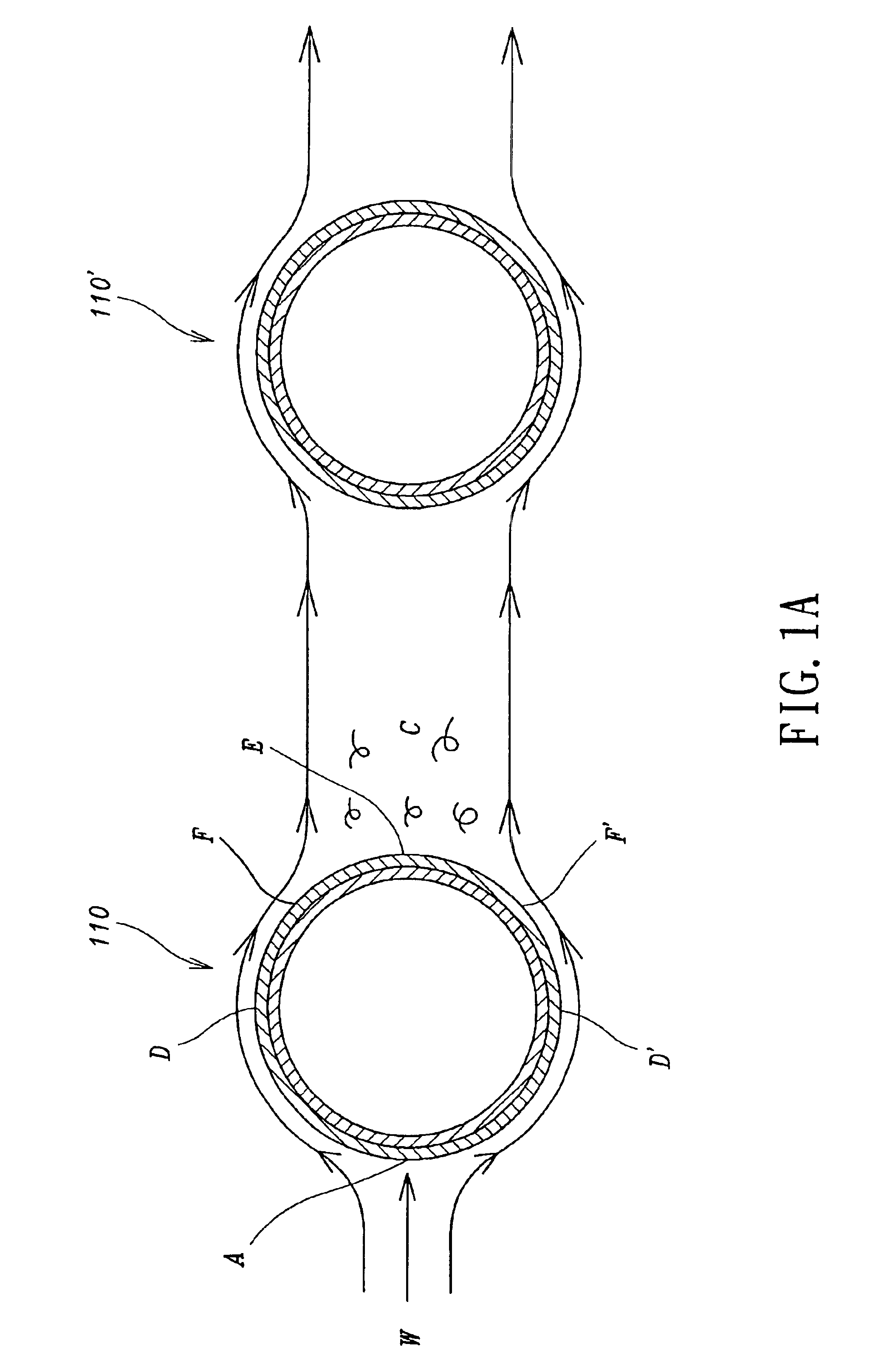

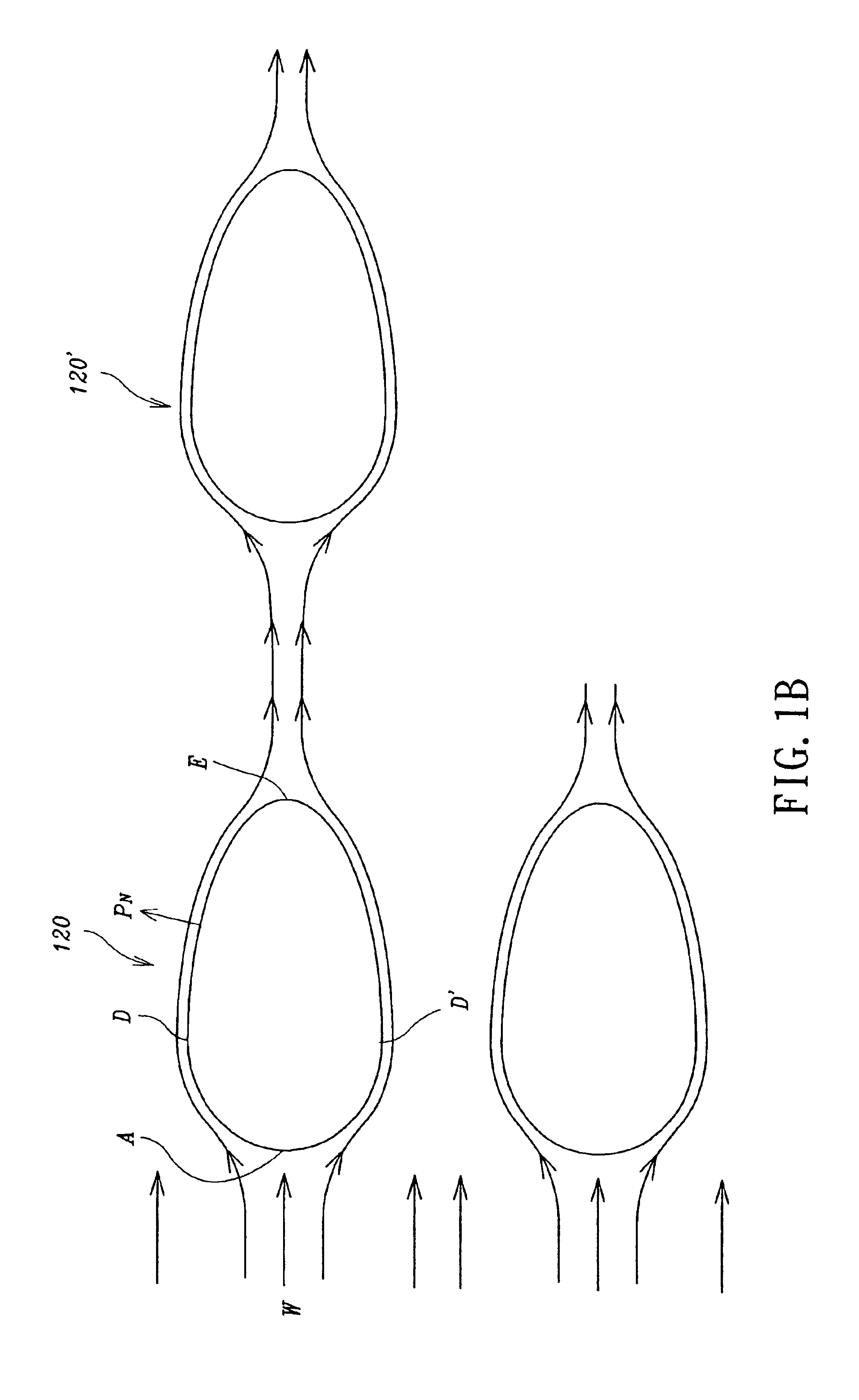

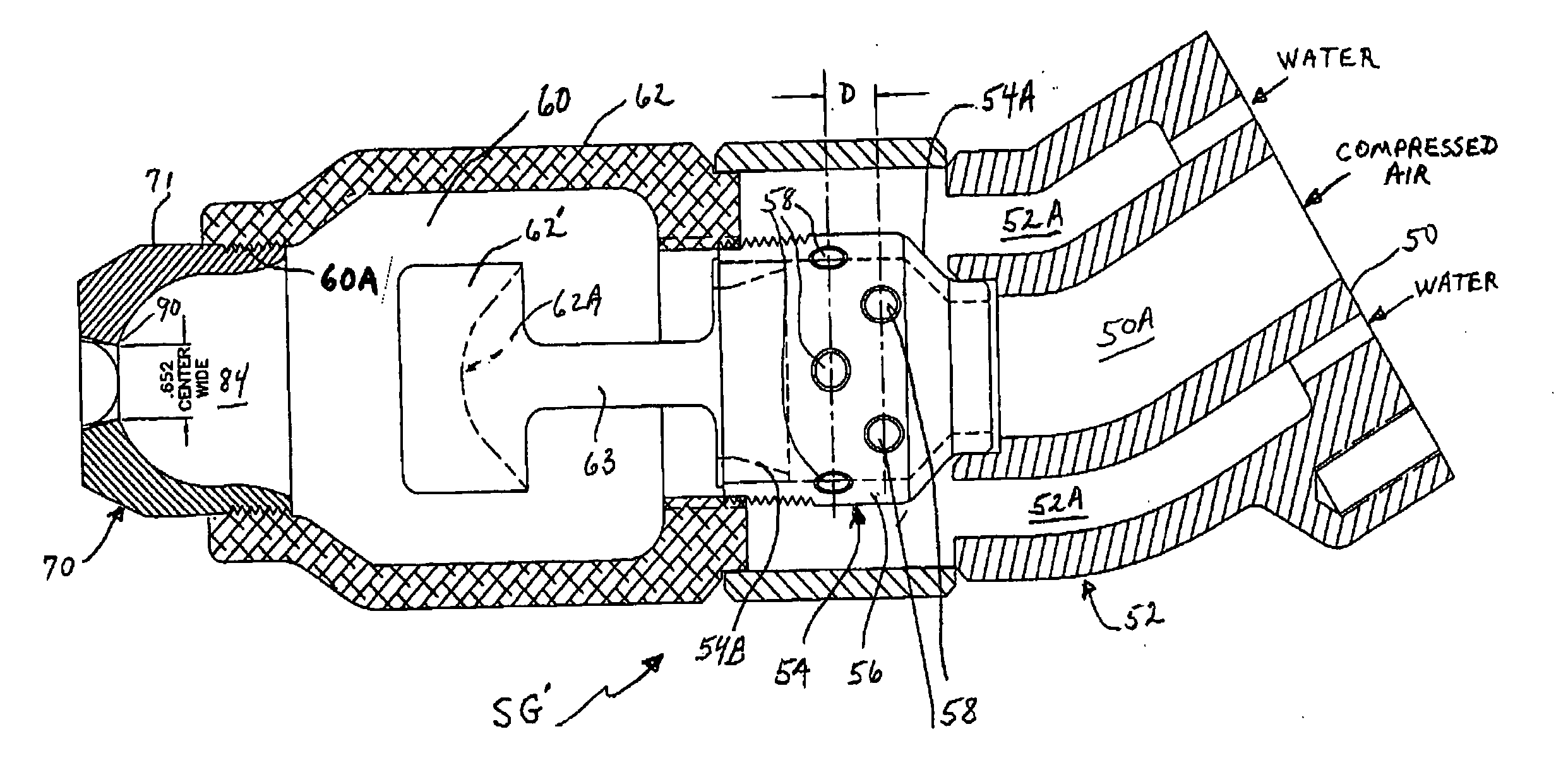

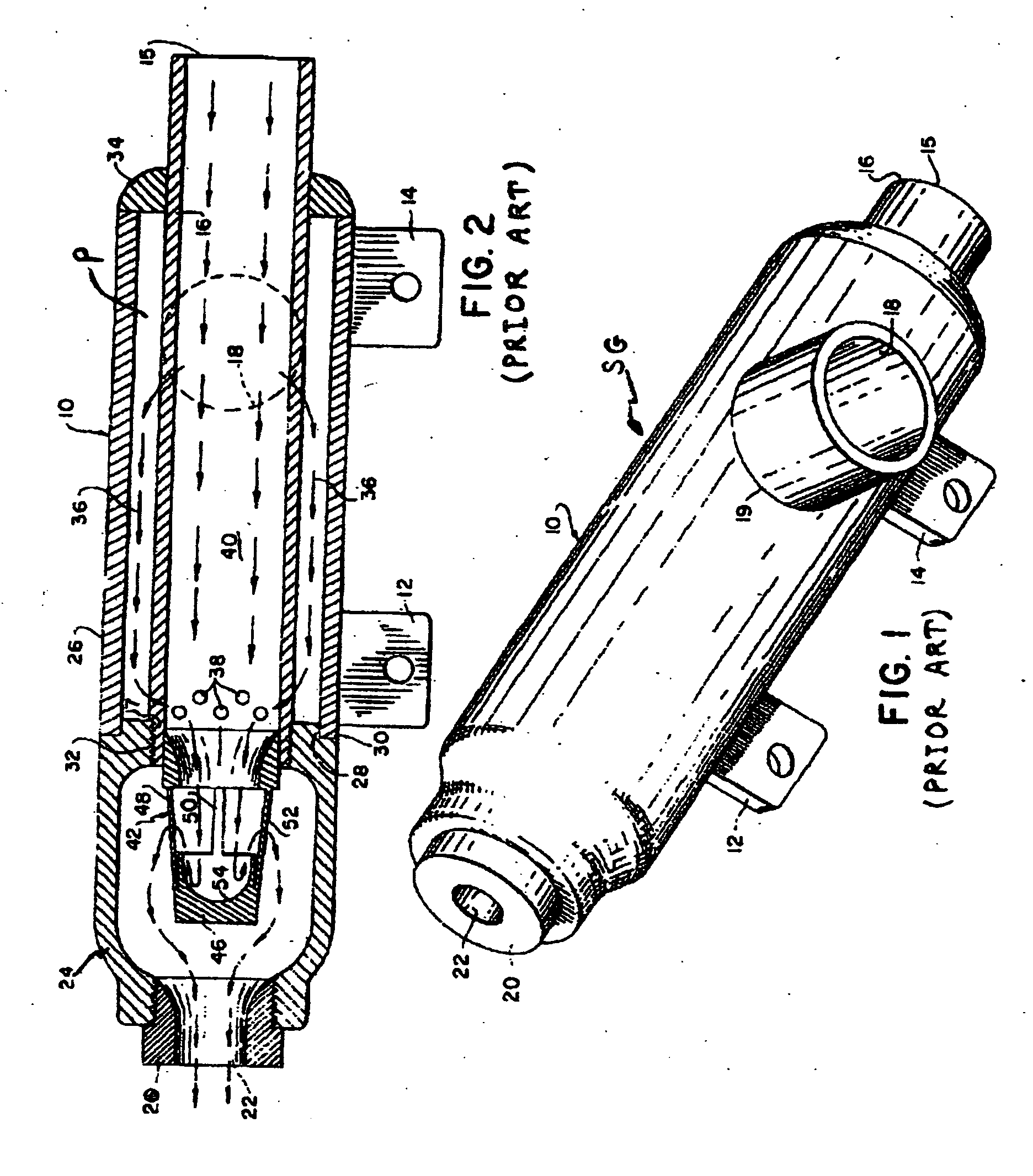

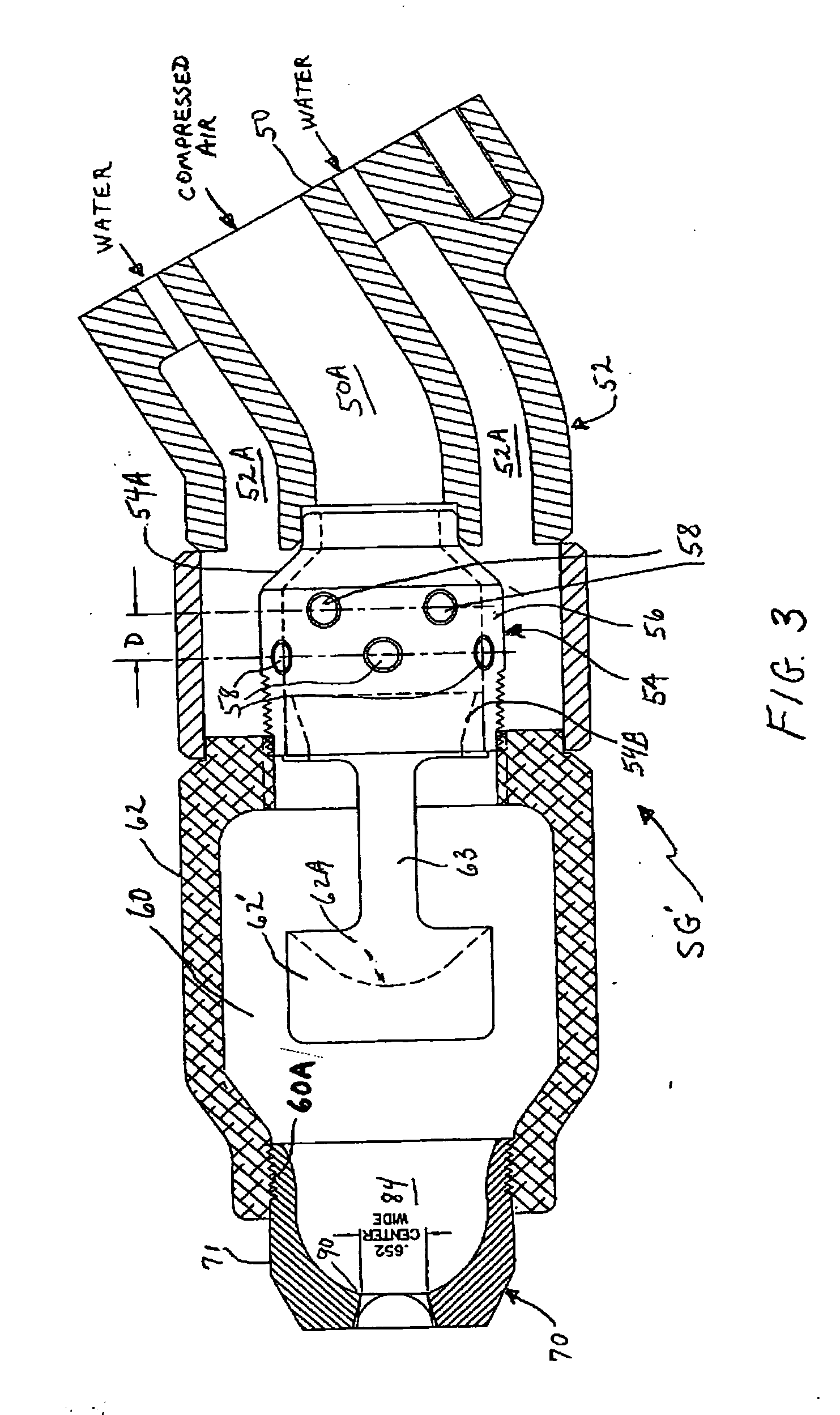

Method and System for Forming a Non-Circular Borehole

InactiveUS20080093125A1Prevent outbreakEasy to installEarth drilling toolsDrill bitsDissolutionGeothermal heat pump

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER DRILLING

Method and System for Forming a Non-Circular Borehole

InactiveUS20100032207A1Easy to installEasy to operateCollector components/accessoriesLighting and heating apparatusEngineeringDissolution

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER JARED MICHAEL +3

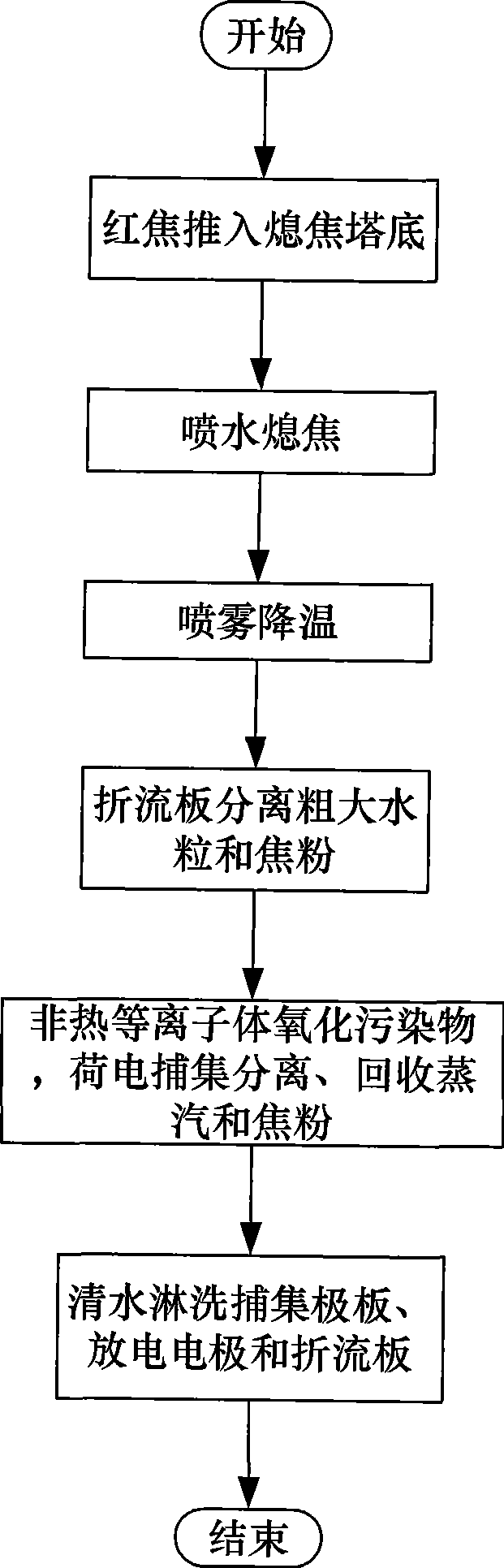

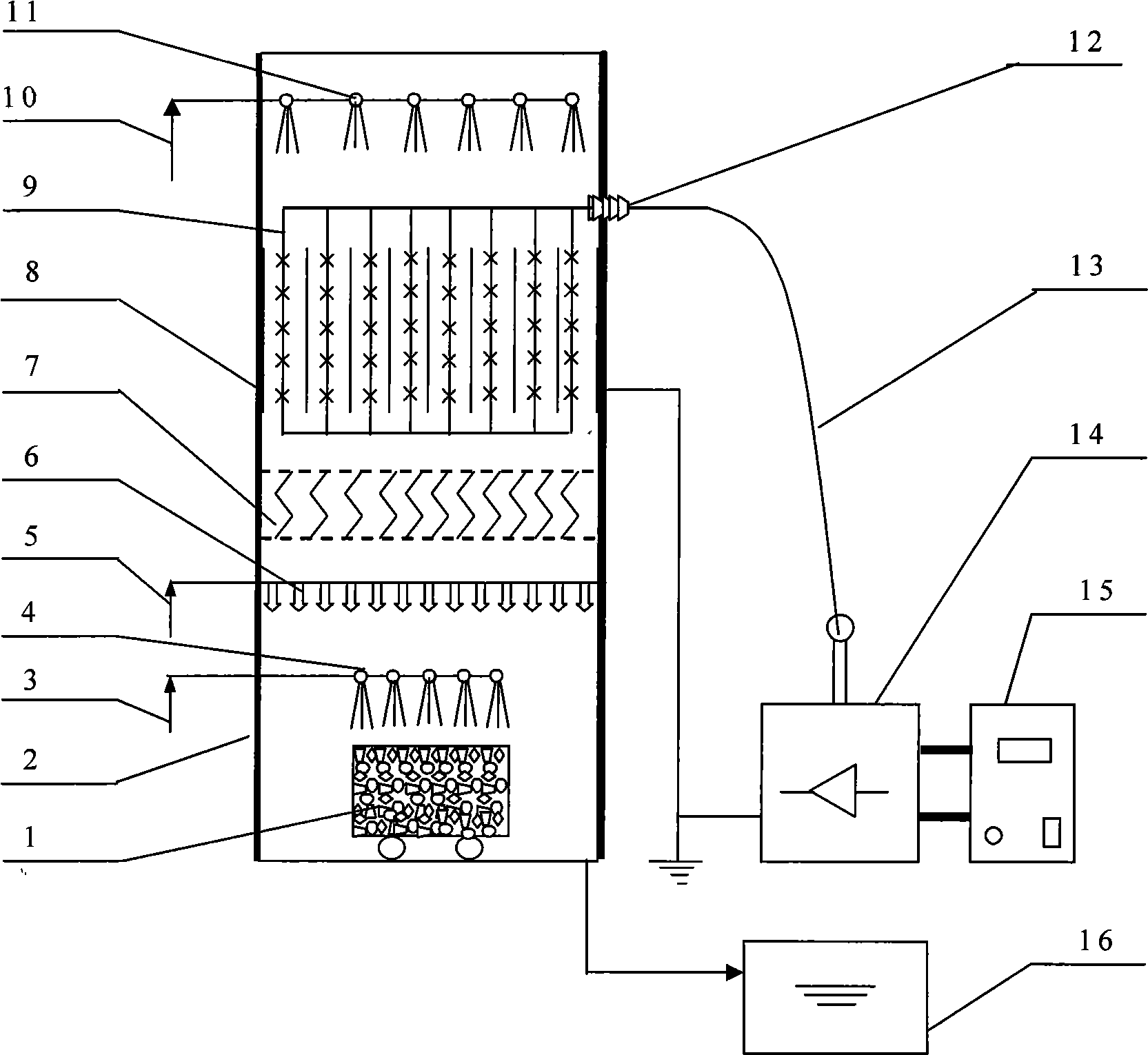

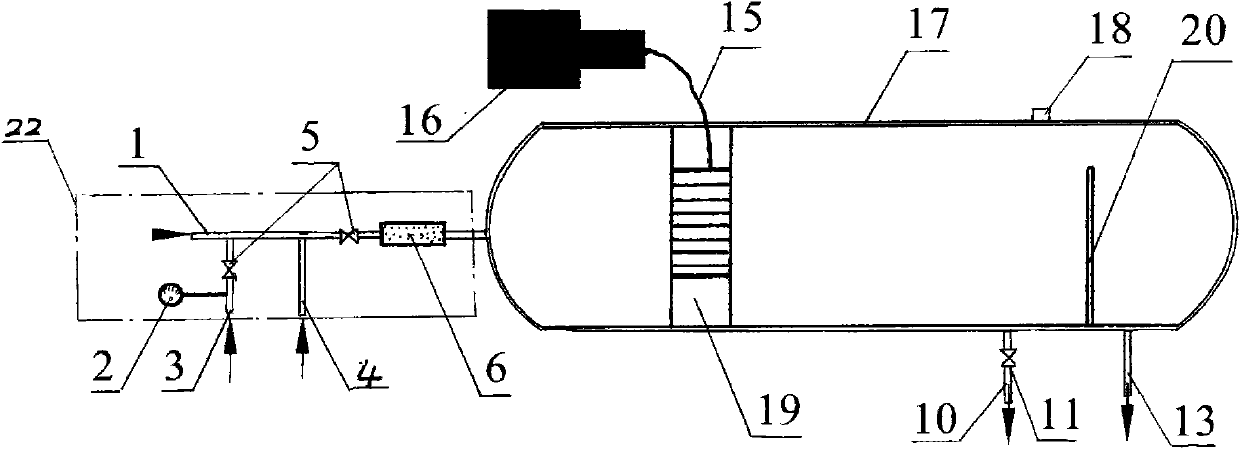

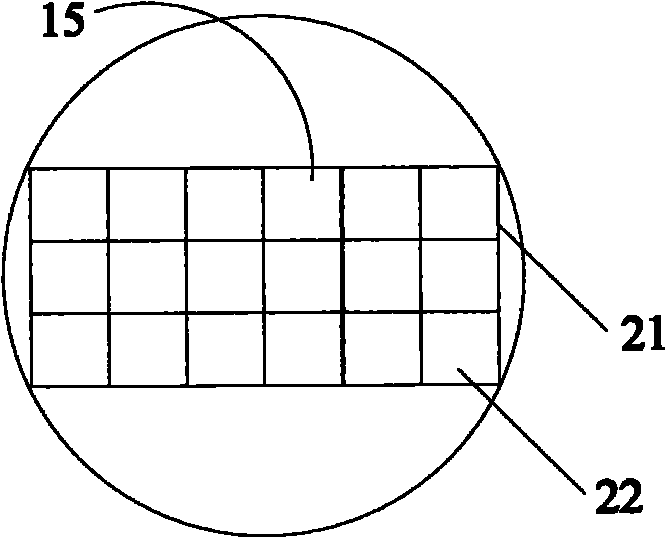

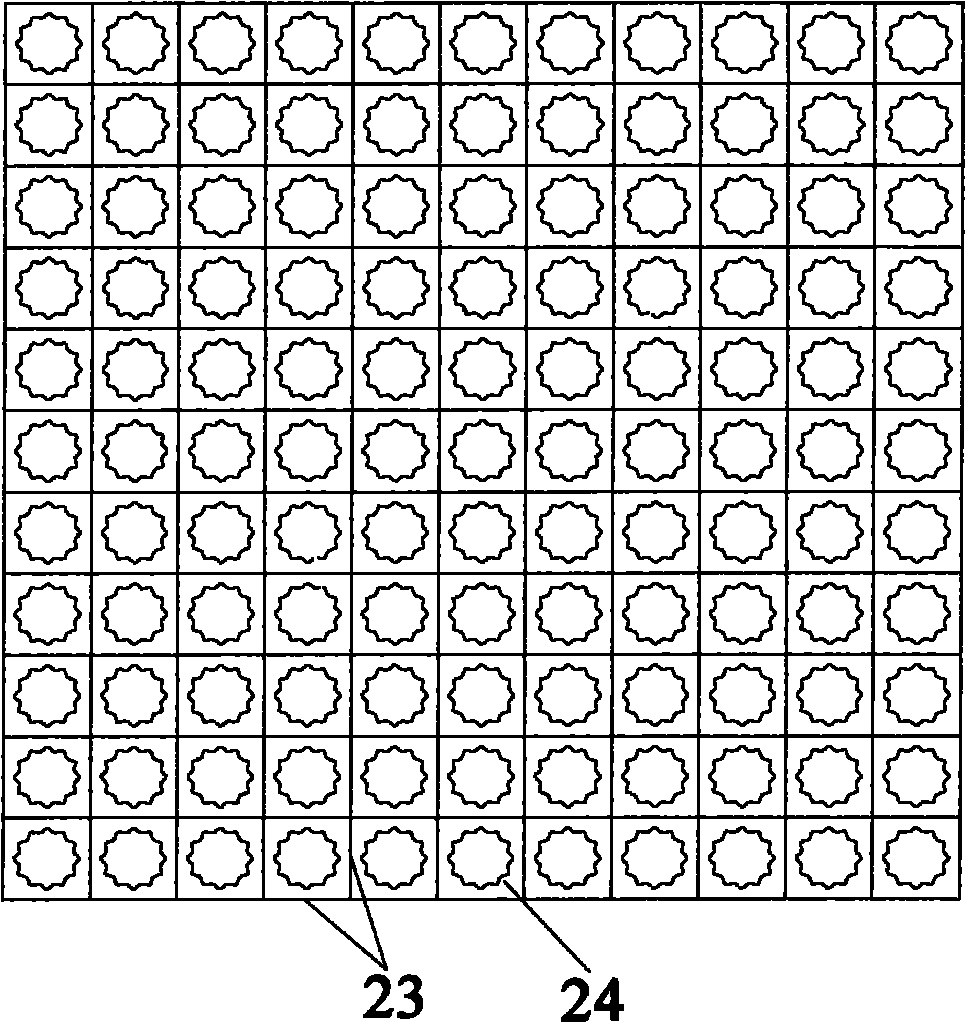

Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

InactiveCN101486017AReduce the amount of pollutantsPrevent diverted emissionsCombination devicesCoke quenchingWater vaporHigh pressure

The invention discloses a method and a device for processing wet quenching coke gas fog on the basis of athermal plasma injection. The method comprises the following steps that: in the ascending process, the hot gas fog generated by wet quenching coke sequentially passes through three processing steps including spray cooling, pre-dedusting on a baffle plate and athermal plasma purification, and is cooled in a spray cooling area; the cooled gas fog enters a pre-dedusting area on the baffle plate where the thicker and bigger water particles and coke powder in the gas fog are separated from the gas fog and impact to the baffle plate under the action of inertia; the remaining gas fog continues to ascend and enter an athermal plasma purification area where organic components, ammonia nitrogen and cyanide in the gas fog are oxidized by the athermal plasma; the water particles and the coke powder are charged and are transferred to a trapping pole plate directionally under the action of a high voltage electric field; and then the gas flow after subjected to the athermal plasma purification area continuous to ascend to the top of a coke quenching tower to be discharged. After the processing steps, the contents of water vapor and the coke powder discharged outside after one ton of coke is produced are controlled to be less than 0.05 ton and 5 grams respectively, and the removal rate of the organic components, the ammonia nitrogen and the cyanide can reach more than 80 percent.

Owner:BEIHANG UNIV

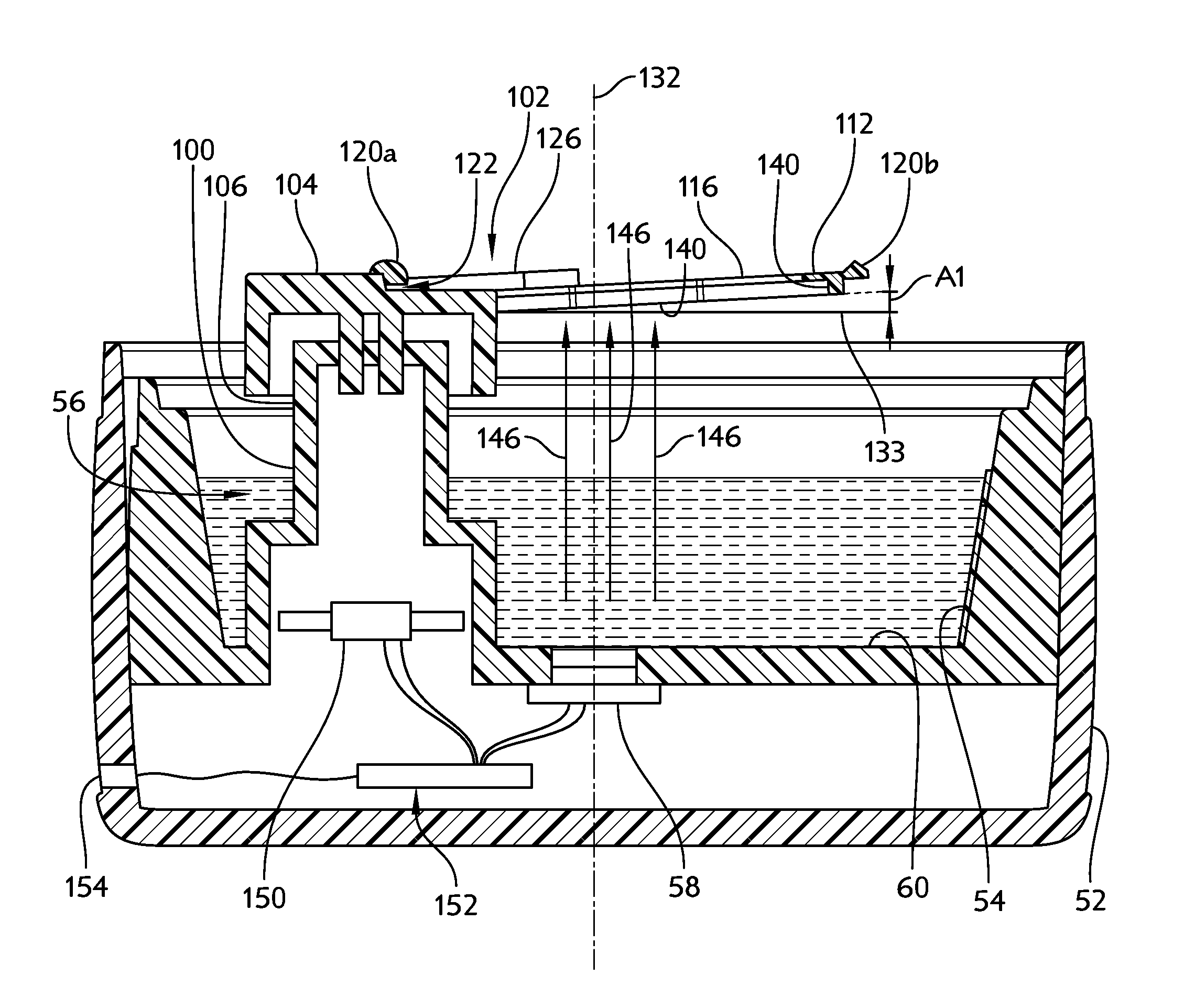

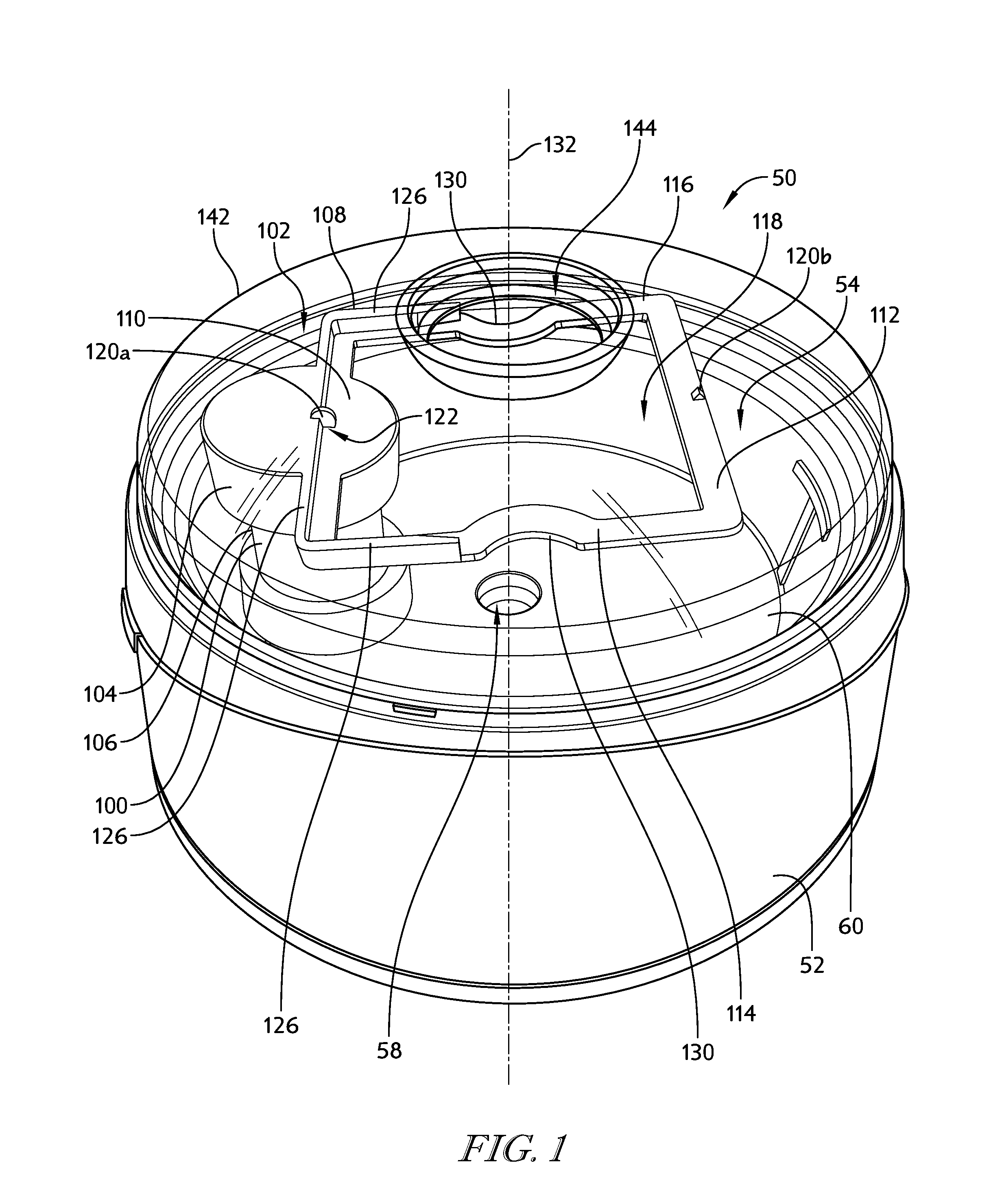

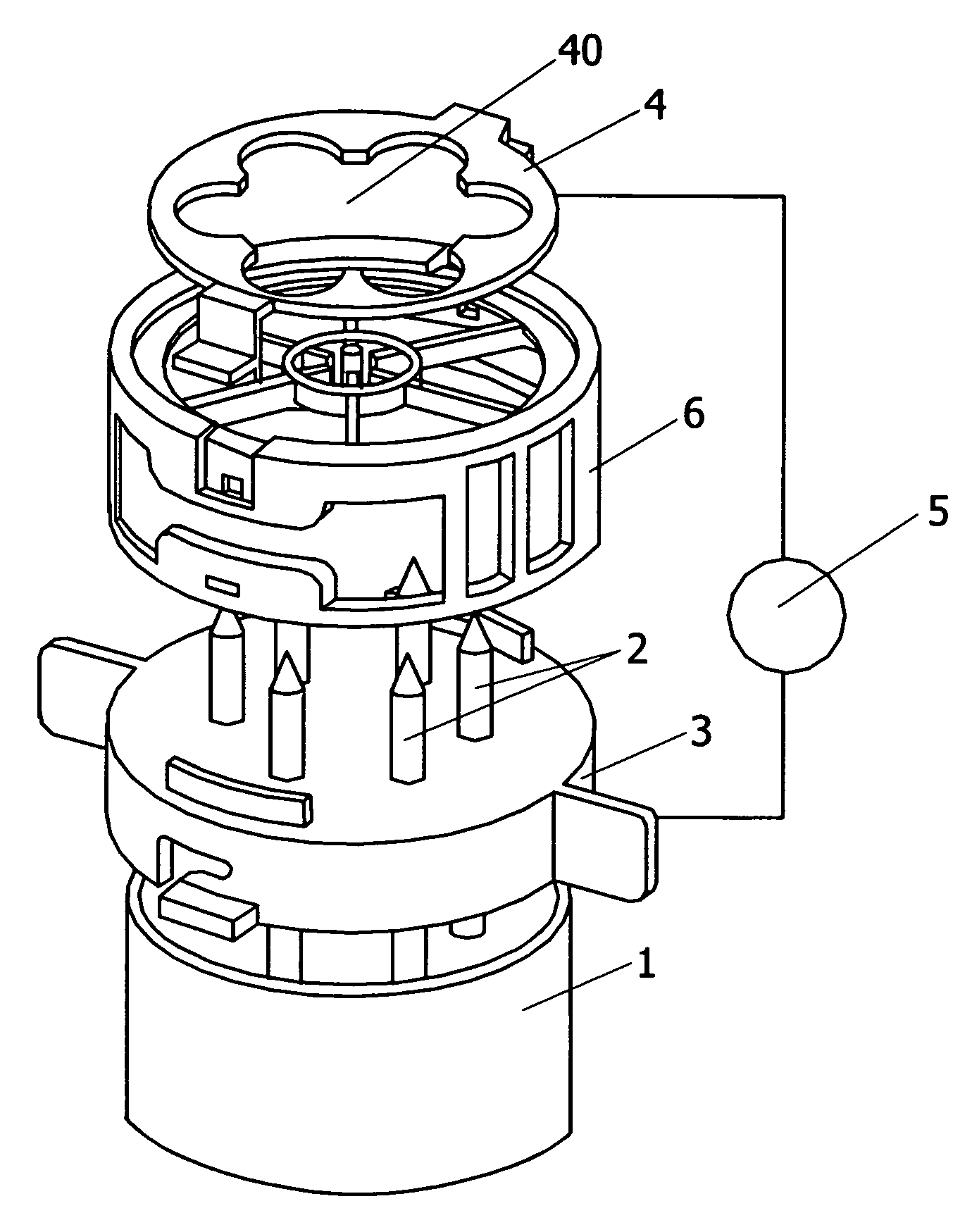

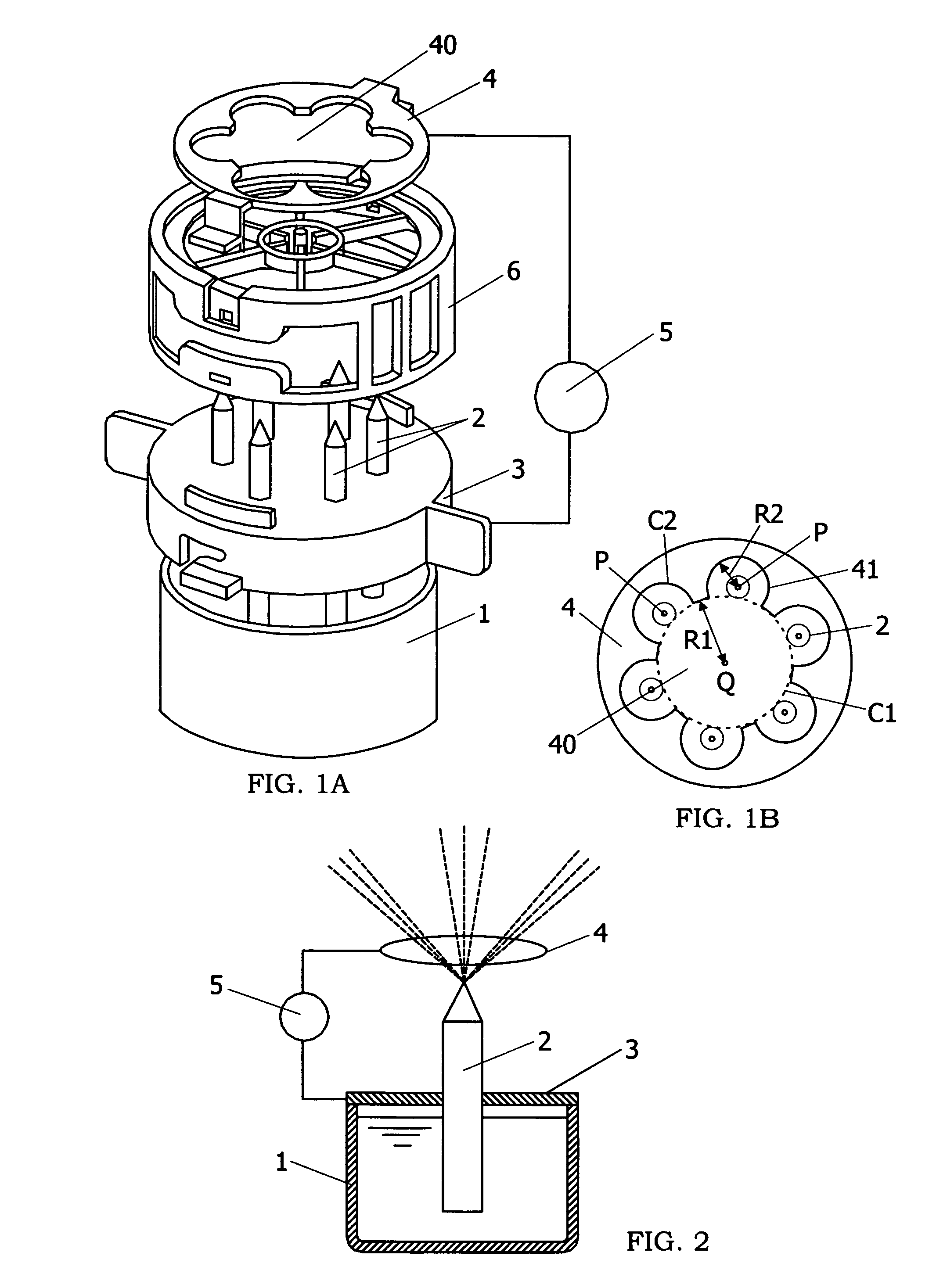

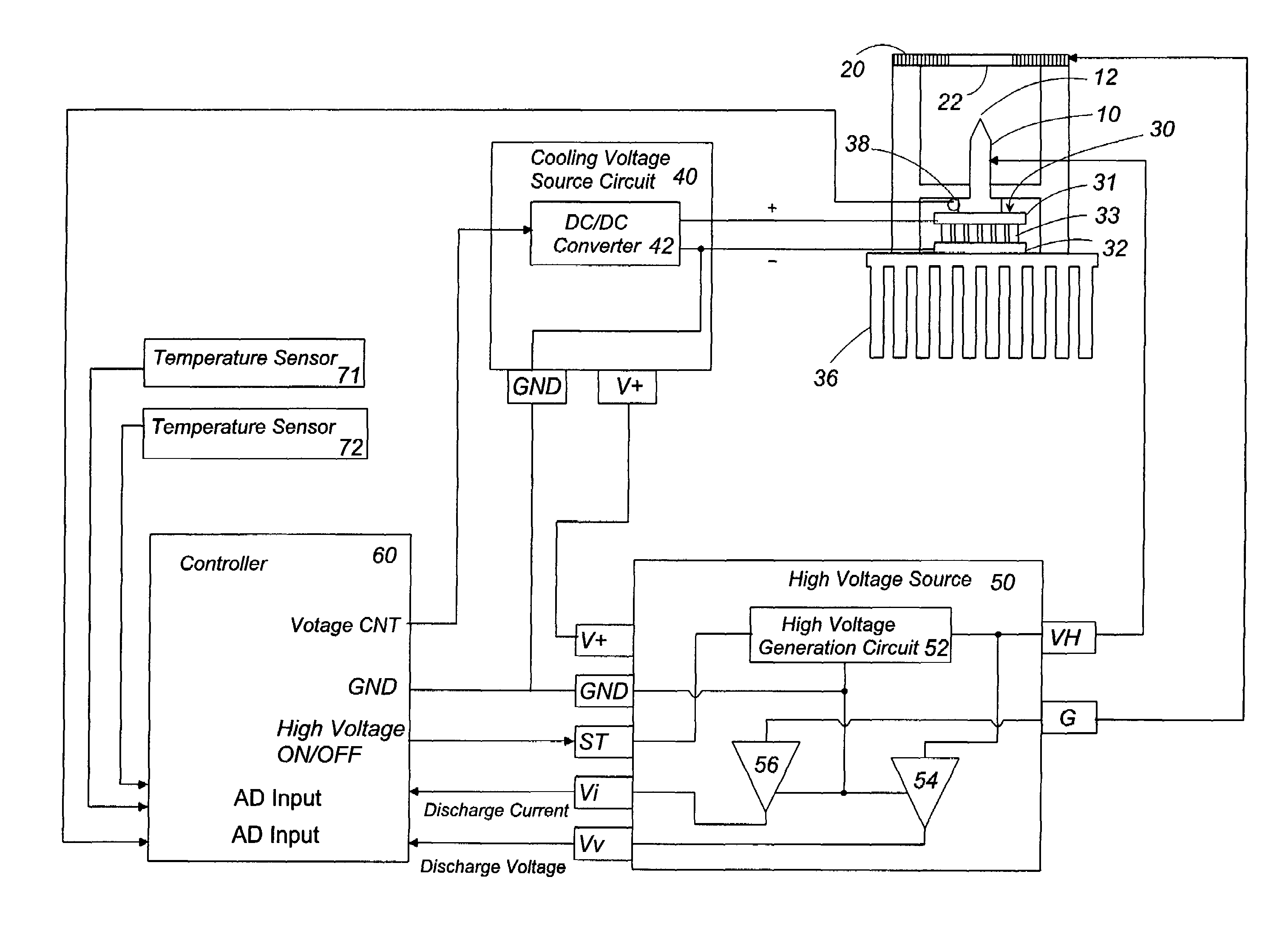

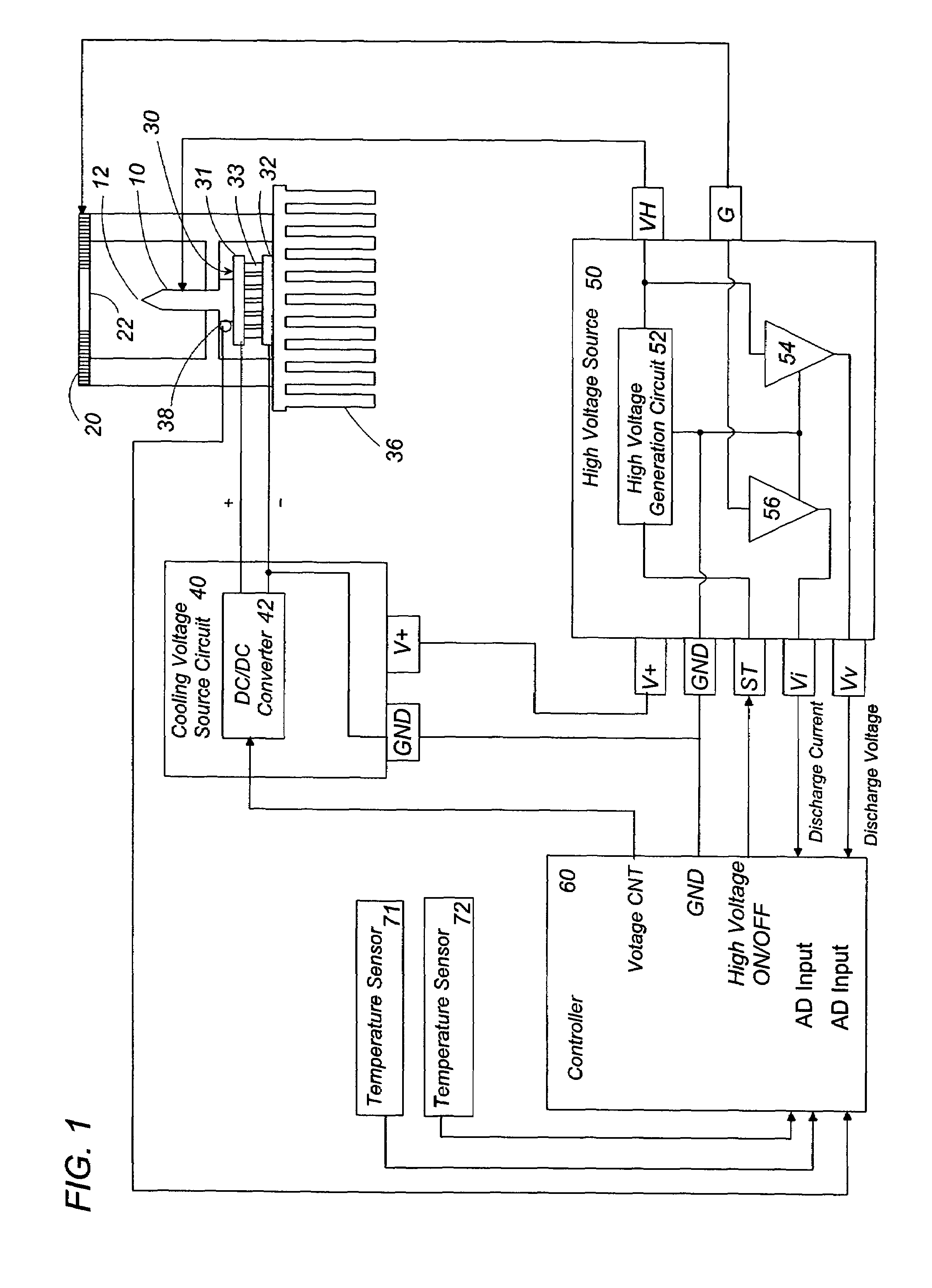

Electrostatically Atomizing Device

The present invention provides an electrostatically atomizing device capable of instantly giving an electrostatically atomizing effect without requiring a water tank. The electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, a water feeder configured to give water on the emitter electrode, and a high voltage source configured to apply a high voltage across said emitter electrode and said opposed electrode to electrostatically charge the water on the emitter electrode for spraying charged minute water particles from a discharge end of the emitter electrode. The water feeder is configured to condense the water on the emitter electrode from within the surrounding air, enabling to supply the water on the emitter electrode in a short time without relying upon an additional water tank. Thus, an atomization of the charged minute water particles can be obtained immediately upon use of the device.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Article for use in washing in sheet form

InactiveUS6818606B1Improve solubilityDetergent preparation by chemical meansDetergent powders/flakes/sheetsSolubilityWater soluble

Owner:KAO CORP

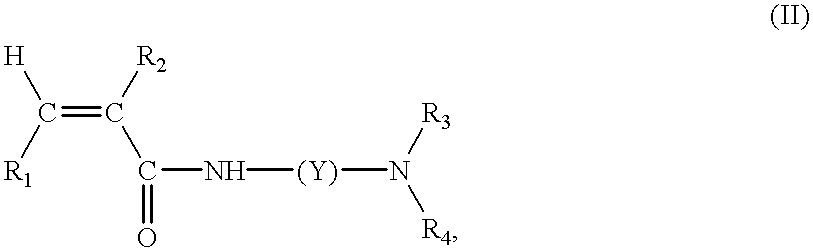

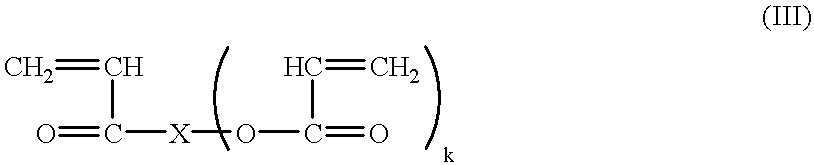

Enhancing the watertightness of textile sheetlike constructions, textile sheetlike constructions thus finished and use thereof

InactiveUS20060141223A1Improve water vapor permeabilityReduce penetrationLiquid surface applicatorsFibre treatmentFiberEngineering

The present invention relates to textile sheetlike constructions having an enhanced watertightness and also to a process for producing them. It was found that, surprisingly, the watertightness of porous textile sheetlike constructions is enhanced when a coating of hydrophobic particles having an average particle size in the range from 0.02 to 100 μm is applied to the surfaces of the fibers. The textile sheetlike constructions can be used for example as textile building materials or for producing tents, umbrellas or the like.

Owner:CARL FREUDENBERG KG PARTIAL INTEREST

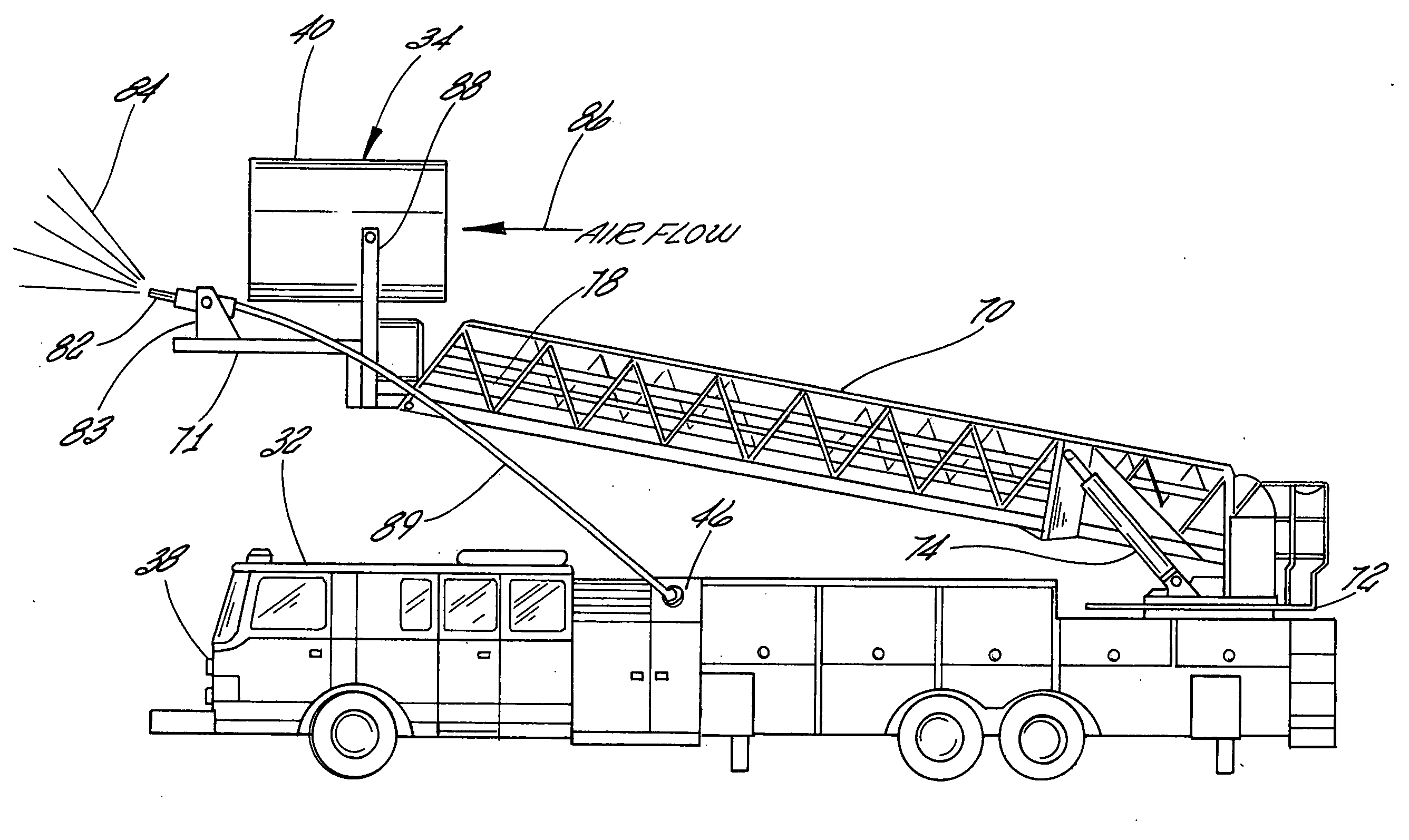

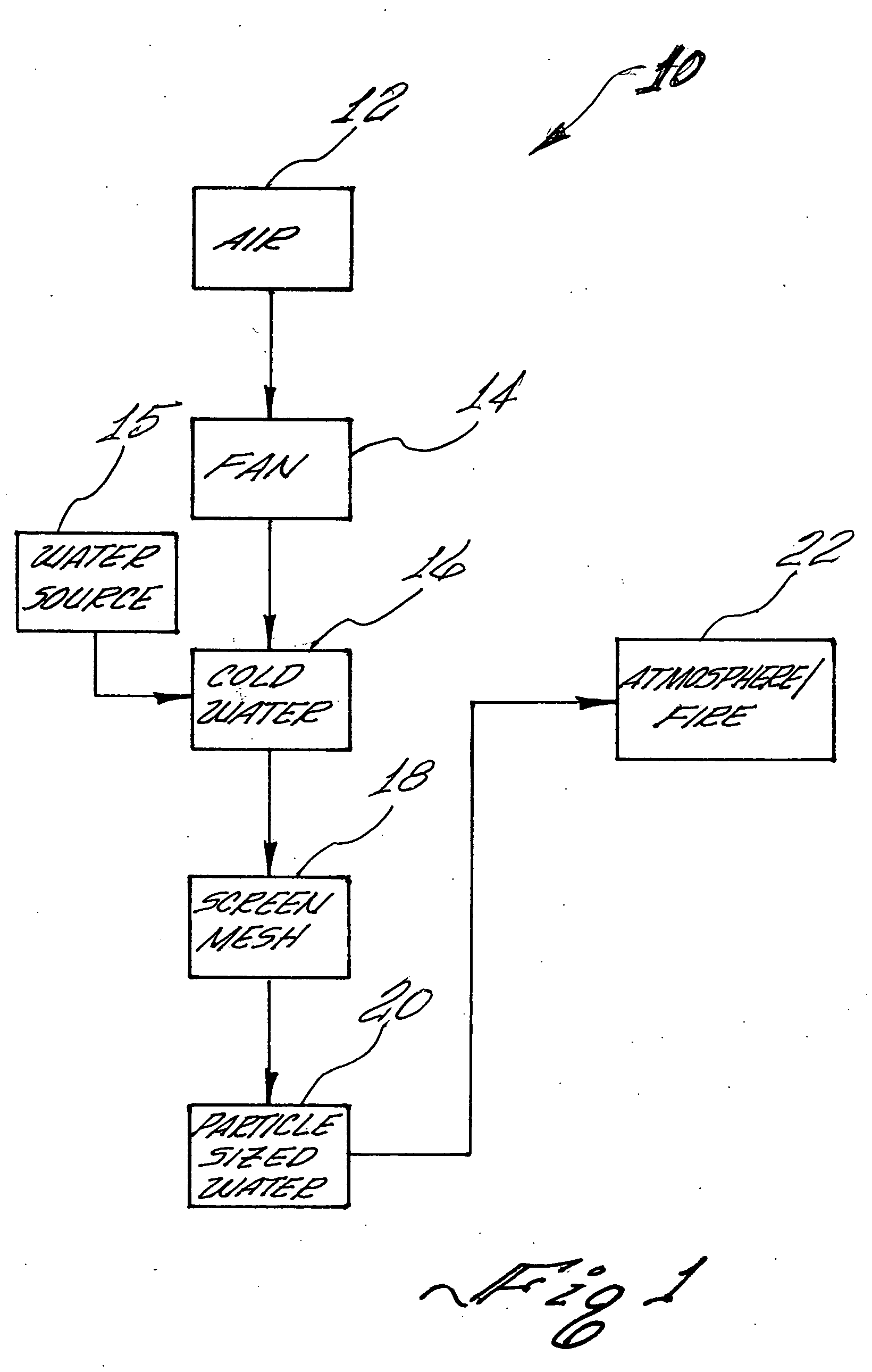

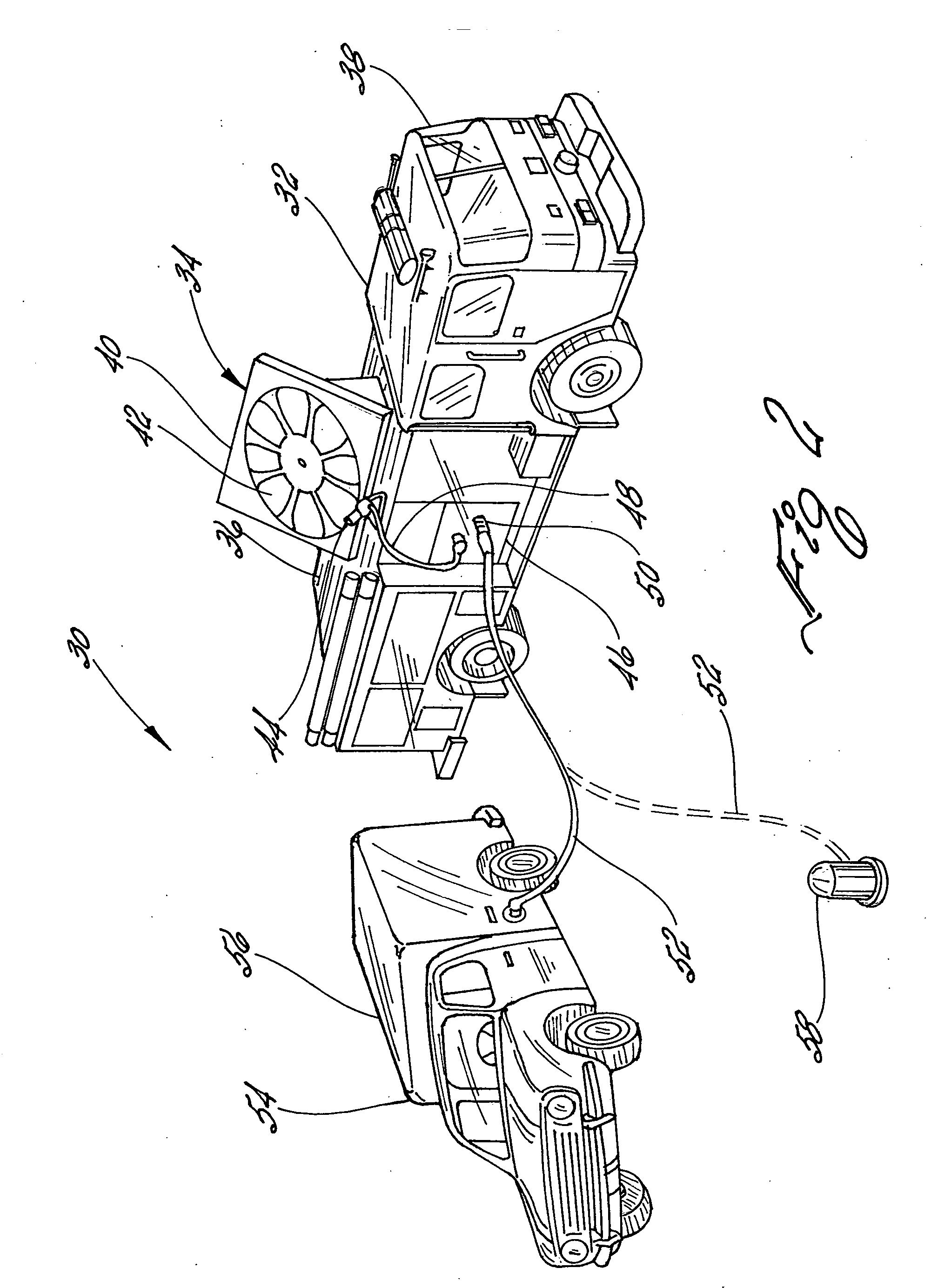

Weather adjustment system for fighting fires

InactiveUS20060213672A1Highly effectiveOvercome difficultiesFire rescueBoring toolsWater sourceWater flow

A weather adjustment system for fighting forest and brush fires under dry, hot and winding conditions which includes a fan / blower for generating wind at extremely high speeds, a water source which supplies cold water into the wind forming a stream of cold water particles and a screen mesh which provides very fine particles of water within the stream. The stream is directed to a forest or brush fire dropping the temperature at the edge of the fire which eventually extinguishes the fire.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

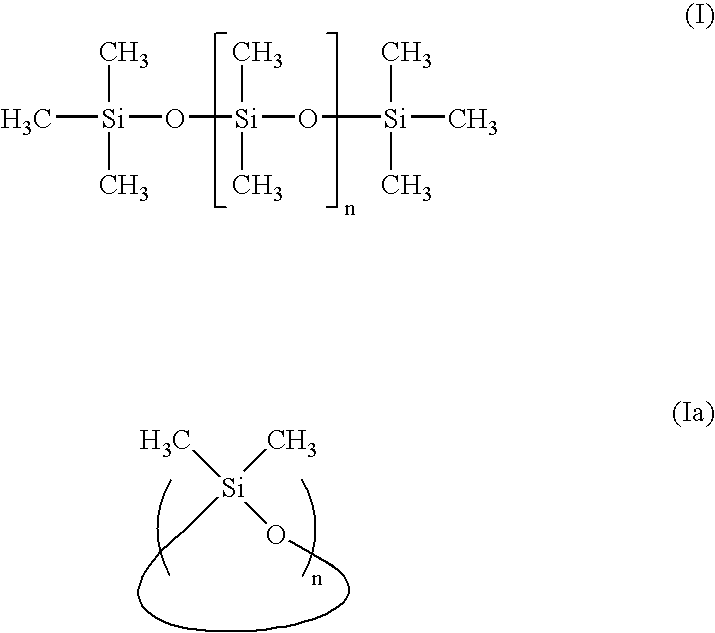

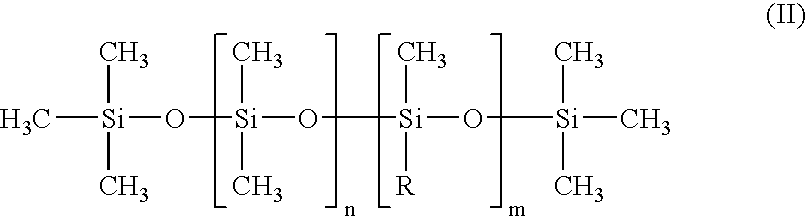

Process for producing detachable dirt- and water-repellent surface coatings

ActiveUS20060235143A1Good removal effectSimple wayFouling preventionSolid waste managementWaxSurface structure

Process for producing detachable dirt- and water-repellent surface coatings on articles, wherein during the coating process, hydrophobic particles are applied to the surface of the articles, thus generating a surface structure with elevations on that surface of the articles that has dirt- and water-repellent properties, which comprises suspending the hydrophobic particles in a solution of a silicone wax in a highly volatile siloxane, and applying this suspension to at least one surface of an article, and then removing the highly volatile siloxane.

Owner:EVONIK DEGUSSA GMBH

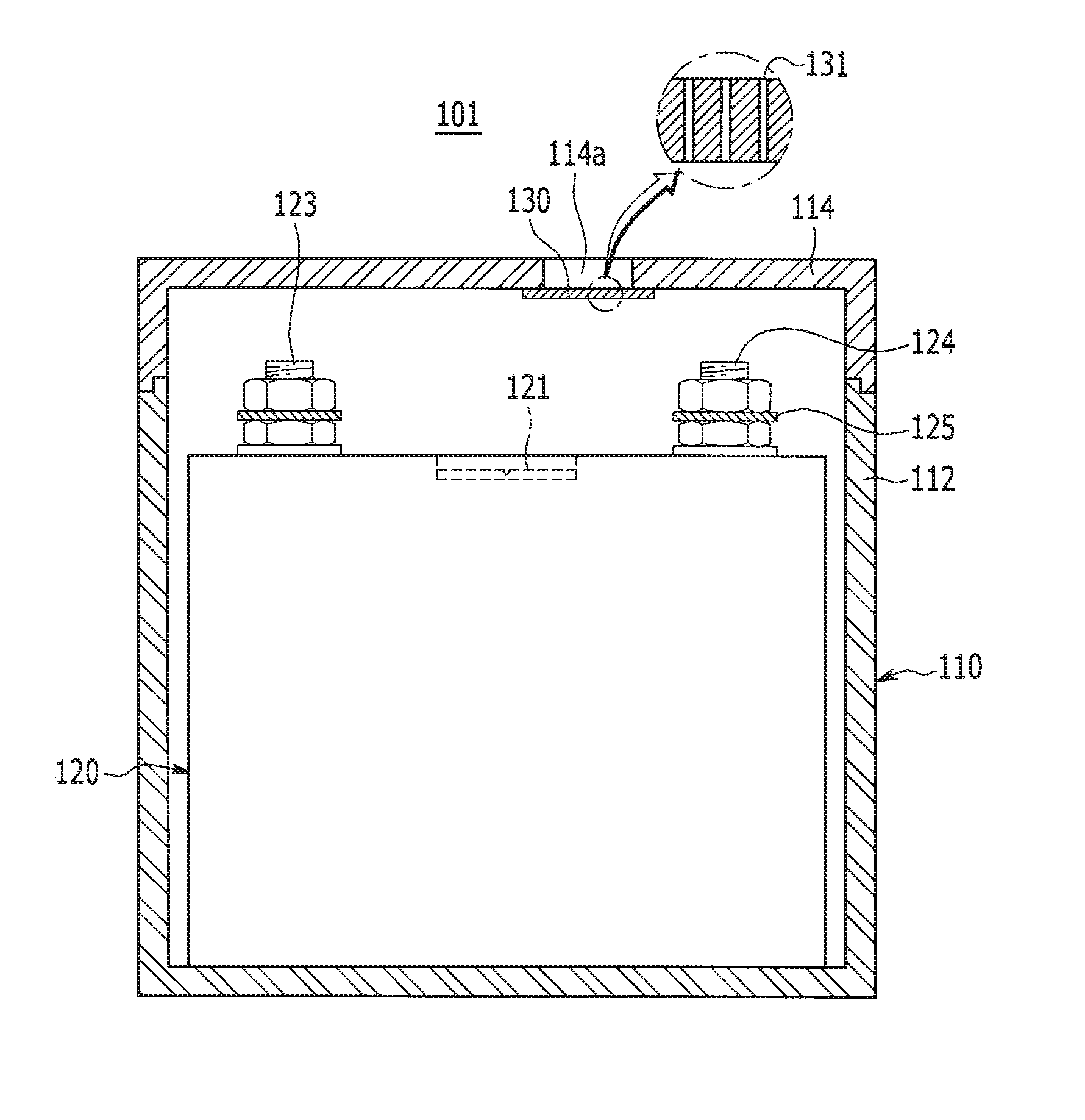

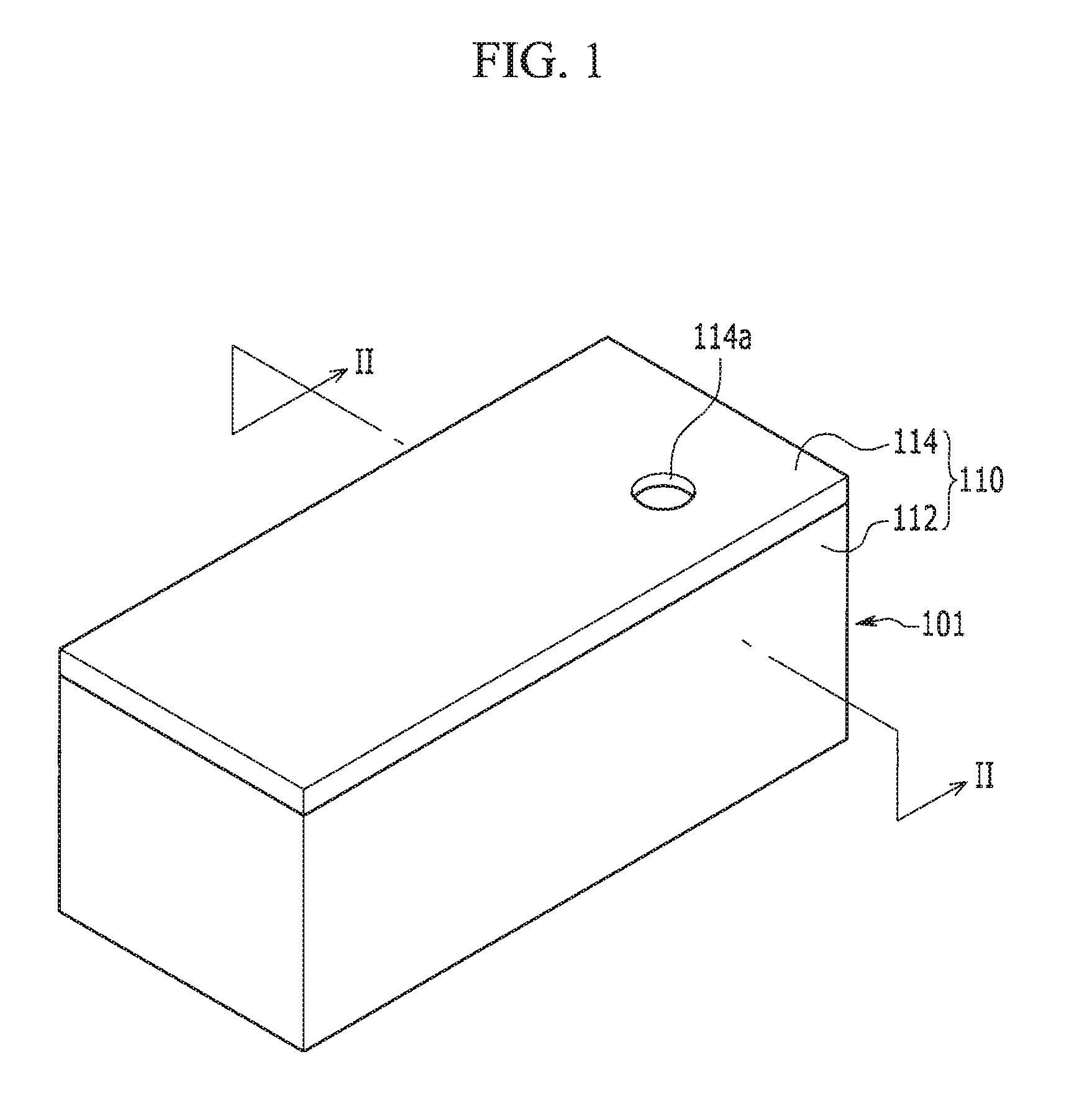

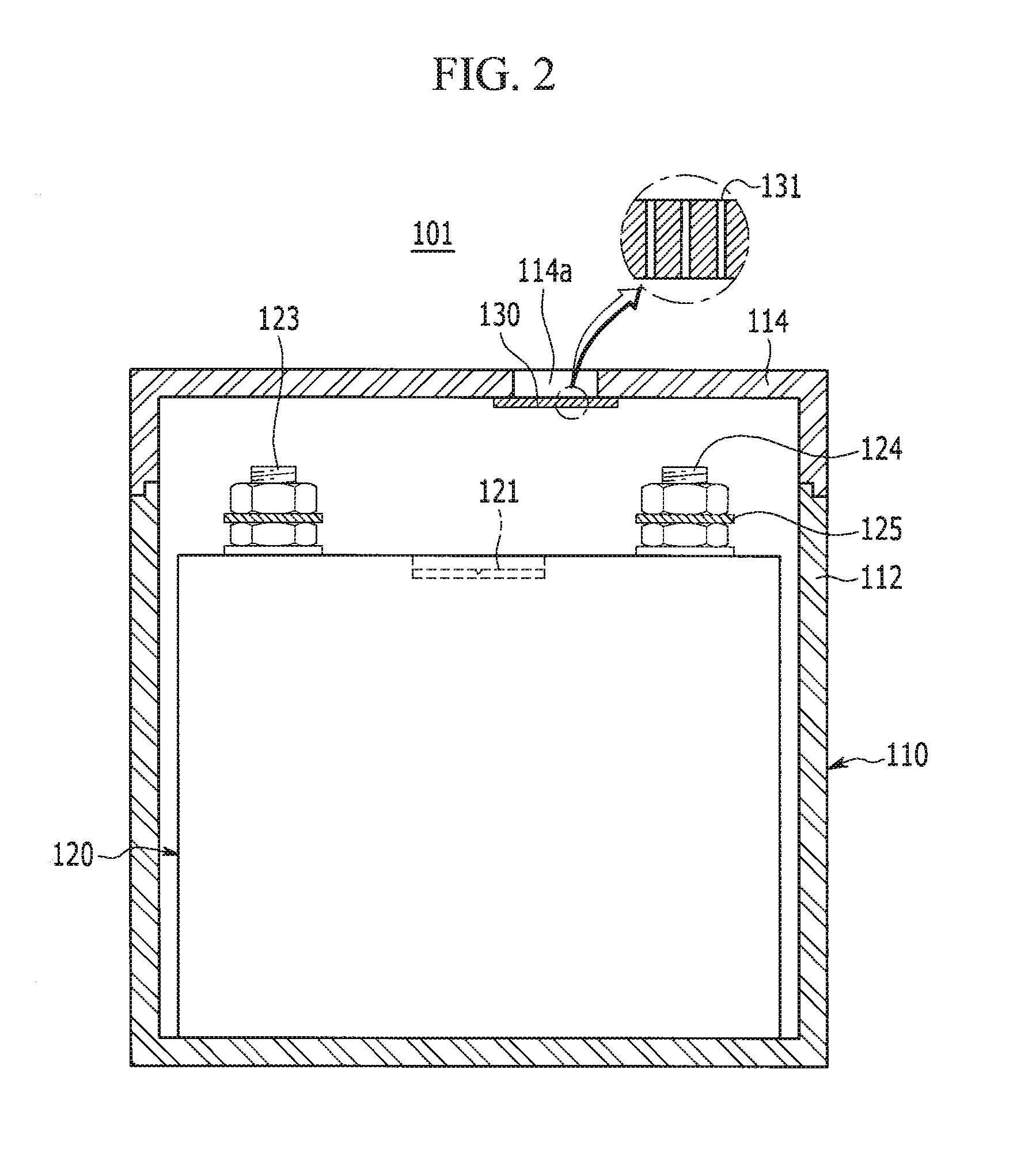

Battery module

ActiveUS20120015218A1Improve securitySmooth dischargeVent arrangementsLi-accumulatorsRechargeable cellWater particle

A battery module includes a plurality of rechargeable batteries and a housing configured to receive the rechargeable batteries, wherein the housing has a vent opening; and a valve configured to close the vent opening, wherein the valve includes a porous film with pores having a diameter larger than that of gas molecules and smaller than that of water particles.

Owner:ROBERT BOSCH GMBH +1

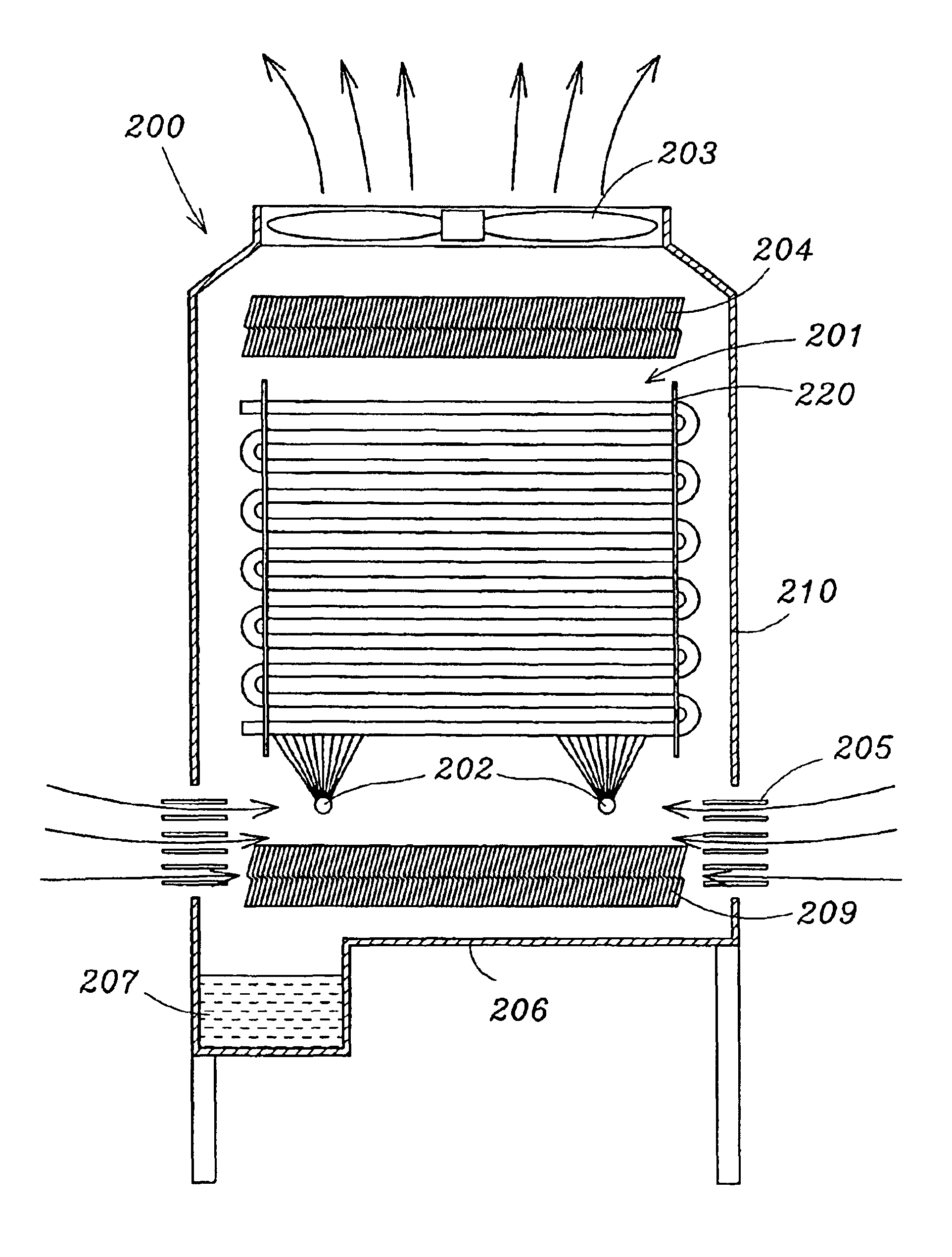

Evaporative condenser without cooling fins

InactiveUS6766655B1Solve the low heat dissipation efficiencyLong lastingEvaporators/condensersSteam/vapor condensersEvaporative coolerEvaporation

An evaporative type medium condenser without the using of conventional cooling fins comprises: characteristically a plurality of streamline cross sectional bare metal tubes disposed in parallel for medium coils to instead the conventional round sectional tubes thereof; a recycling water supply system having a plurality of water spray nozzles for spraying fine water particles onto the surface of coil tubes formed a water film continuously held thereon; a fan system to provide a wind flow blowing over the streamline tubes in a direction from a large head front portion of the streamline cross section to a gradual reduced rear portion thereof and to provide a low pressure area thereat so as to speedy the evaporation of the water film on the surface of the coils tubes for improving a high cooling efficiency to reach a high E.E.R. therefore.

Owner:WU HO HSIN

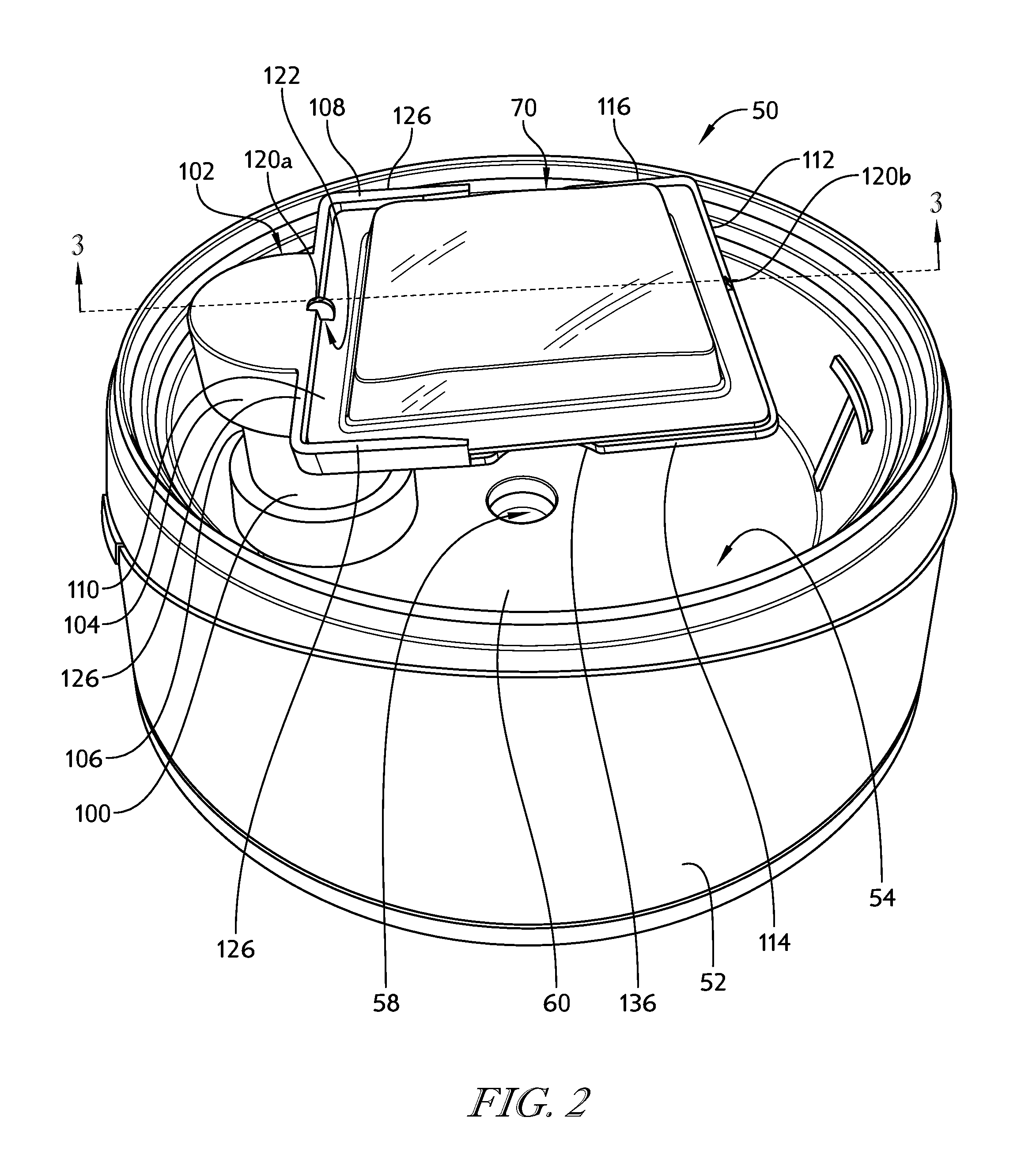

Volatile material dispenser and method of emitting a volatile material

A method of dispensing a fragrance having at least one aroma chemical includes the step of providing a frame adapted to be attached to a dispenser for dispensing fluids and a cartridge including a volatile material containing a fragrance comprising at least one aroma chemical, wherein the cartridge is adapted for attachment to the frame. The method of dispensing further includes the steps of nebulizing water to create nebulized water particles, directing the nebulized water particles at the cartridge, and entraining volatile material from the cartridge in at least some of the nebulized water particles upon collision with the cartridge to create volatile material-infused water particles.

Owner:SC JOHNSON & SON INC

Snow-gun

ActiveUS20060071091A1Improve efficiencyRecreational ice productionSpray nozzlesWater featureWater particle

Owner:RATNIK IND

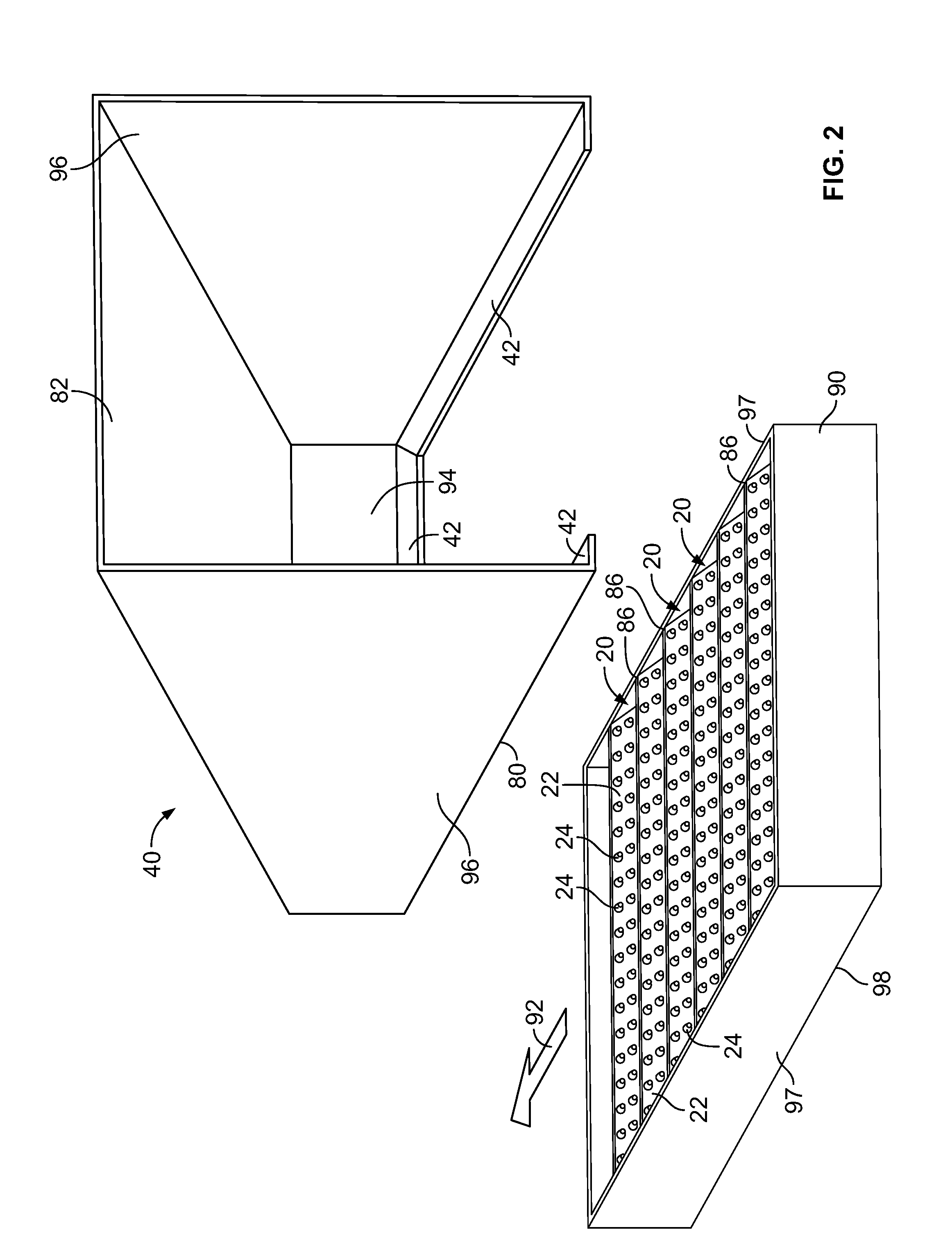

Mist eliminator, moisture removal system, and method of removing water particles from inlet air

InactiveUS8273158B2Reducing performance and efficiencyCombination devicesGas treatmentEnvironmental engineeringEngineering

Owner:BHA ALTAIR

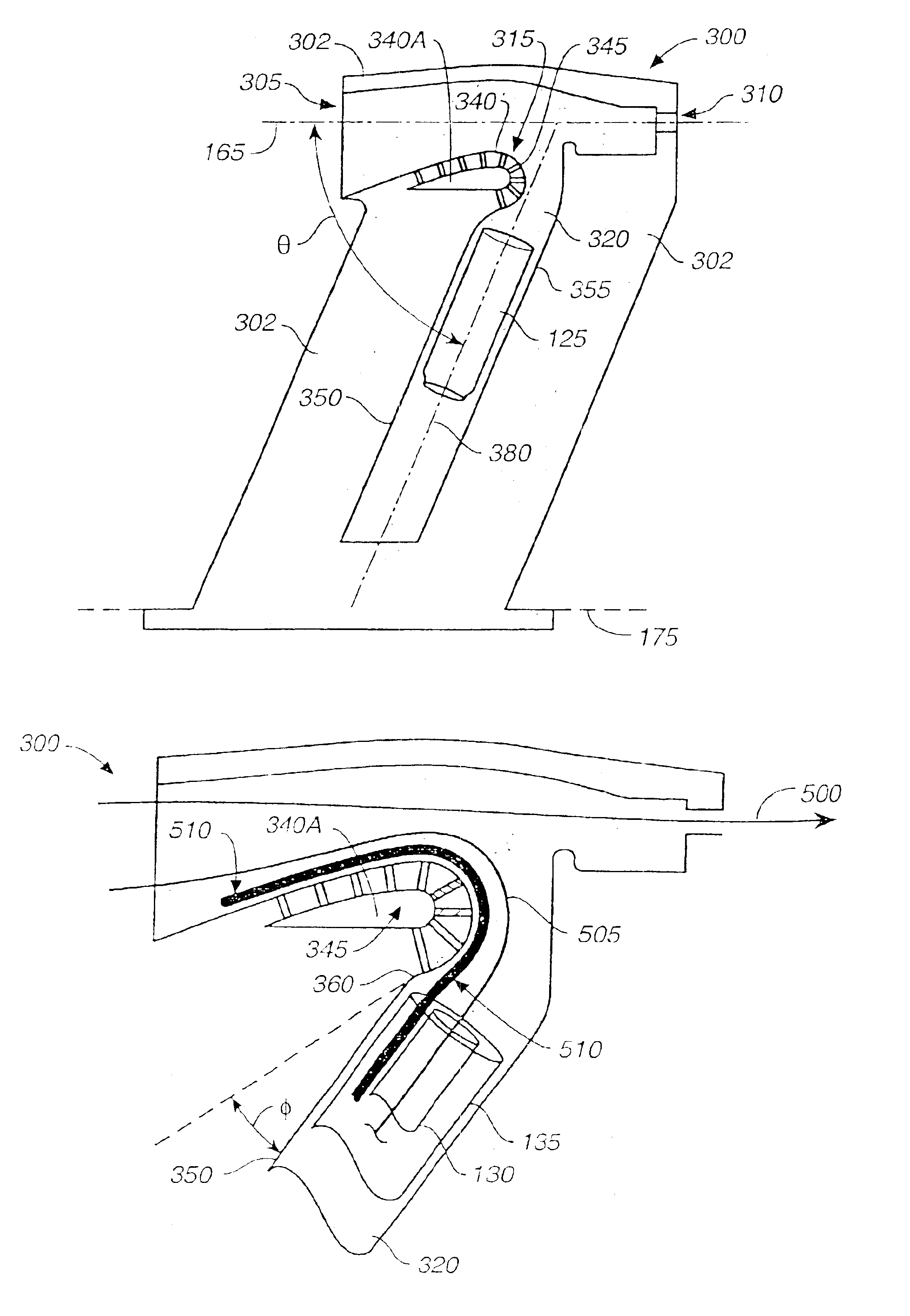

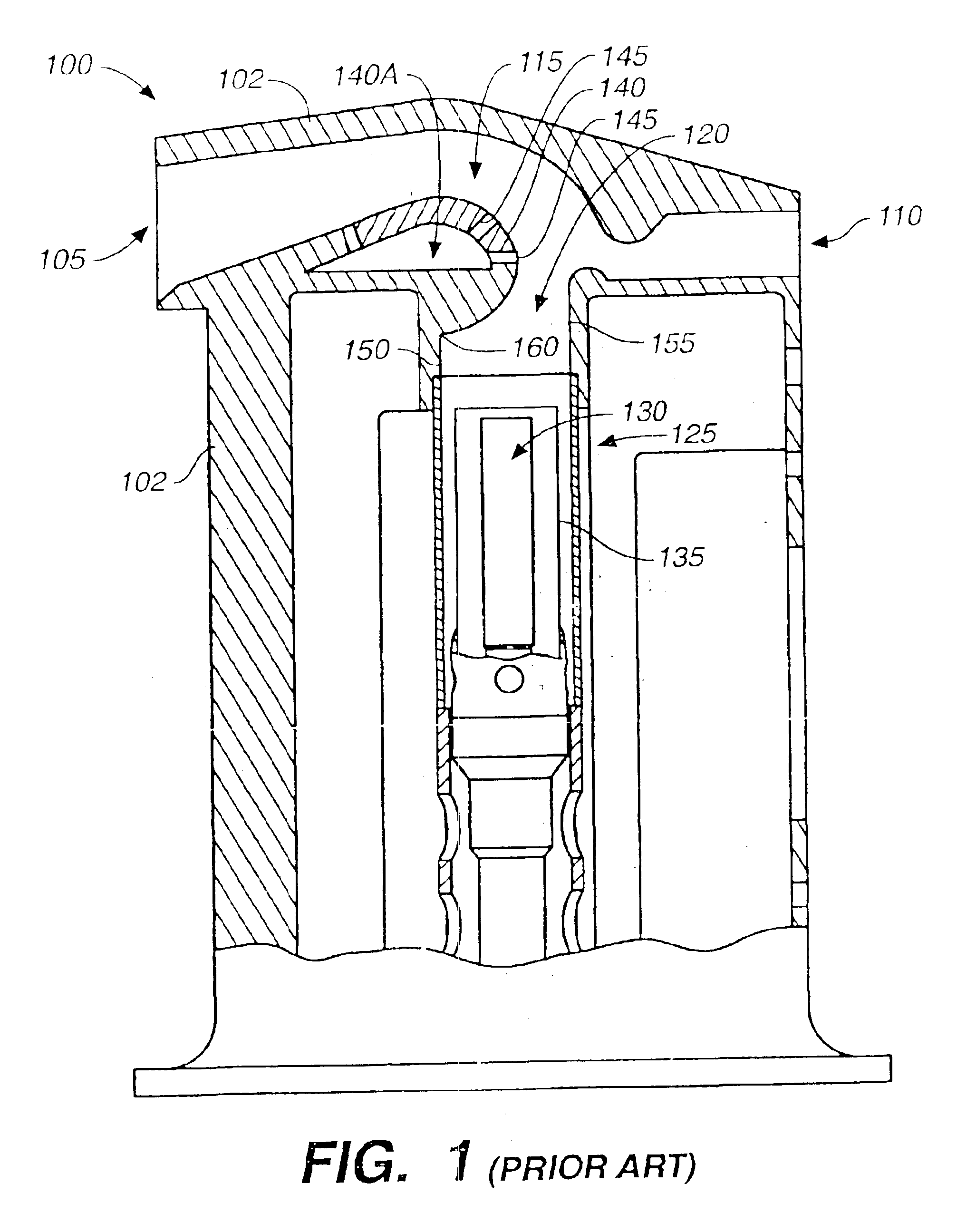

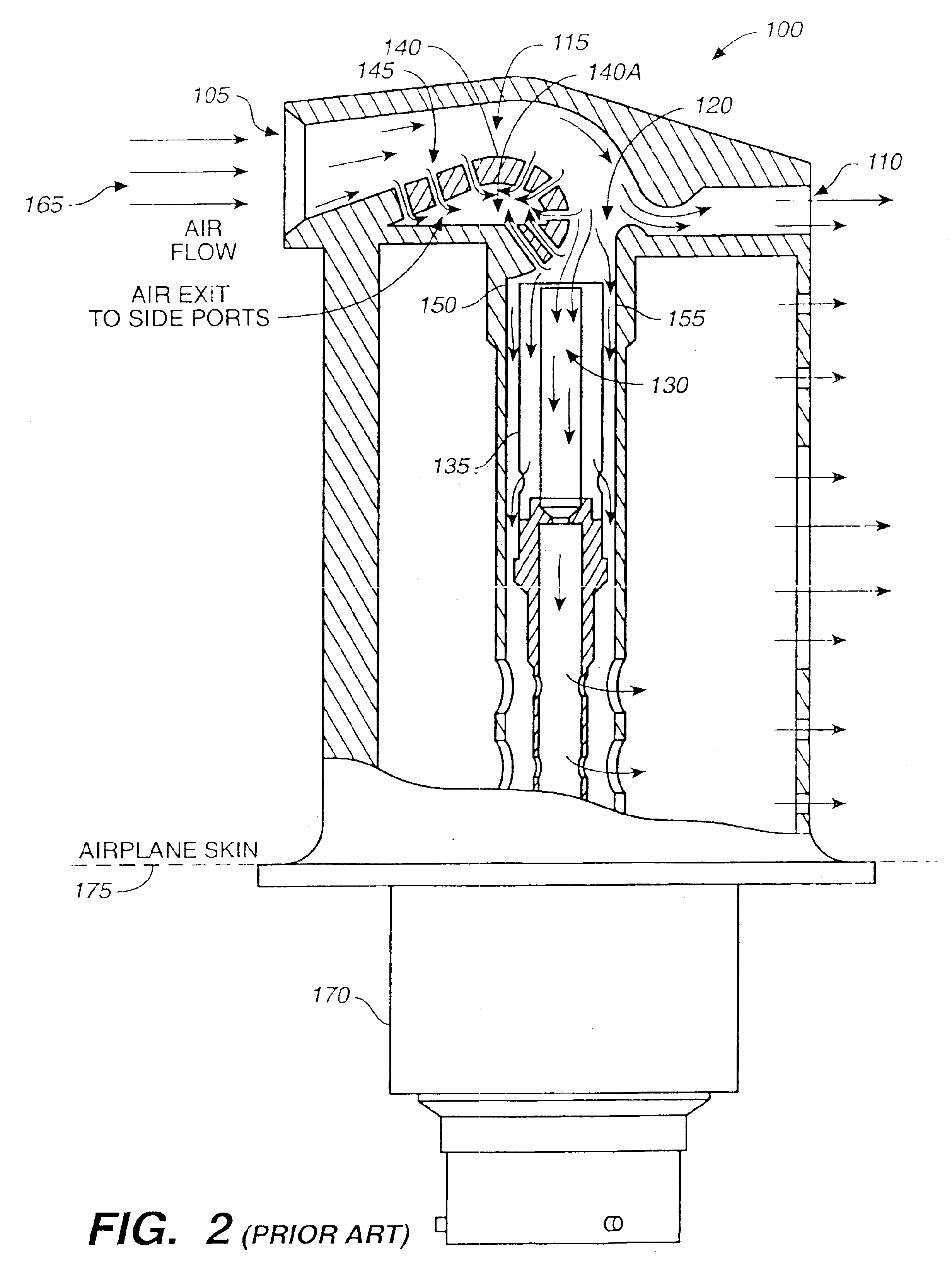

Total air temperature probe providing improved anti-icing performance and reduced deicing heater error

InactiveUS6840672B2Inertial extractionReduce cloggingThermometer detailsTemperature measurement of flowing materialsEngineeringIce accretion

A total air temperature (TAT) probe for measuring TAT includes an inlet scoop which receives airflow from free stream airflow moving toward the inlet scoop from a first direction. A first portion of the airflow entering the inlet scoop exits the probe through a main exit channel. A second portion of the airflow enters a TAT sensor flow passage, which extends longitudinally along an axis. This axis is oriented to form an angle of less than 90 degrees with the first direction from which the free stream airflow moves toward the inlet scoop. A sensor assembly extends longitudinally in the sensor flow passage and measures a total air temperature of airflow through the sensor flow passage. By increasing the angle through which the internal air turns, better inertial extraction of ice and water particles is realized. As a result, sensor clogging from accreted ice is significantly reduced. A second improvement is achieved by repositioning the sensor element to be more in-line with the internal airflow direction. This helps lower DHE by minimizing heated boundary layer spillage onto the sensing element.

Owner:ROSEMOUNT AEROSPACE

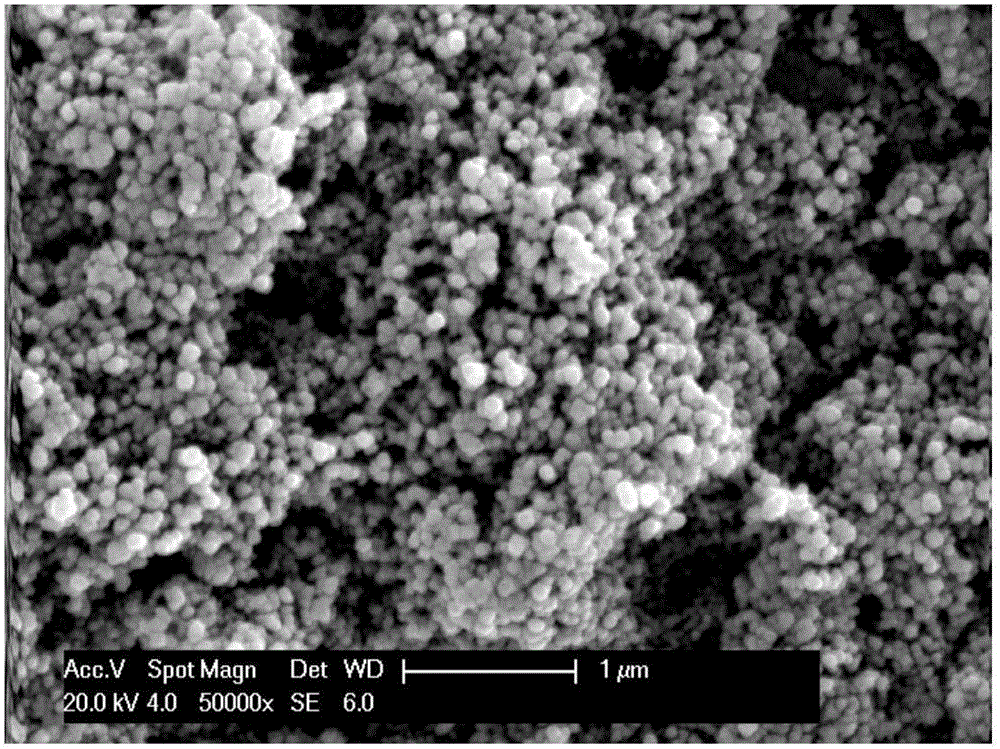

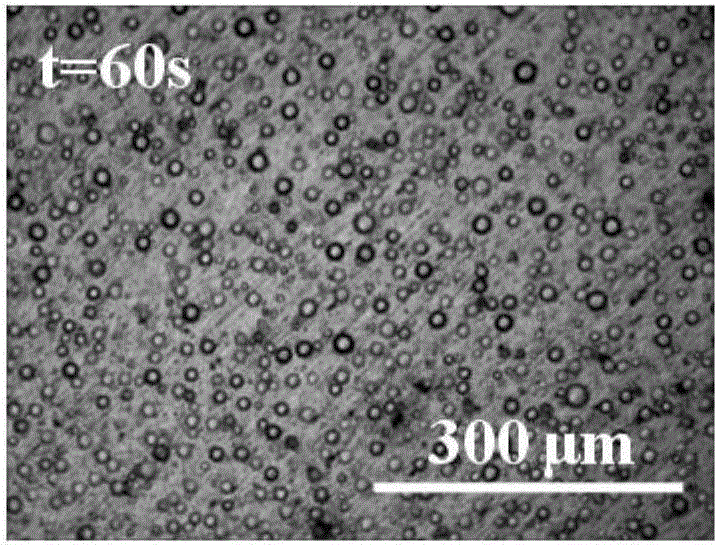

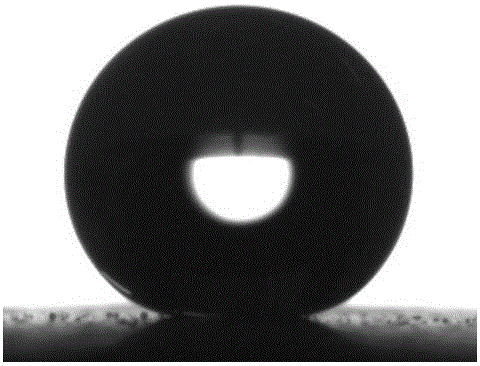

Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophilic particle hybridized super-hydrophobic coating and a preparation method thereof. A substrate is ultrasonically cleaned through acetone, absolute ethyl alcohol and deionized water in sequence for 15 min, and oil stain and dust on the surface are removed; then, absolute ethyl alcohol is used for elution, and cold-blast air is used for drying for use. Nanometer SiO2 sol is subjected to fluoroalkyl silane modification, a super-hydrophobic coating spraying solution is obtained, a super-hydrophilic monodisperse sphere type nanometer SiO2 solution, silica powder and glass beads are added into the super-hydrophobic coating spraying solution, stirred to be uniform and sprayed on the substrate, and after solidification, the super-hydrophilic particle hybridized super-hydrophobic coating is obtained. The coating has the low adhesion and super-hydrophobicity, and the condensation and dewfall efficiency and the dewdrop adsorption amount are remarkably high compared with a super-hydrophobic coating. The preparation technology is simple, no pollution is caused, operation is easy, the apparent mass is good, the cost is low, and wide application prospect and huge market benefits are achieved on the aspects of heat exchangers, water collection, seawater desalination and the like.

Owner:SOUTHEAST UNIV

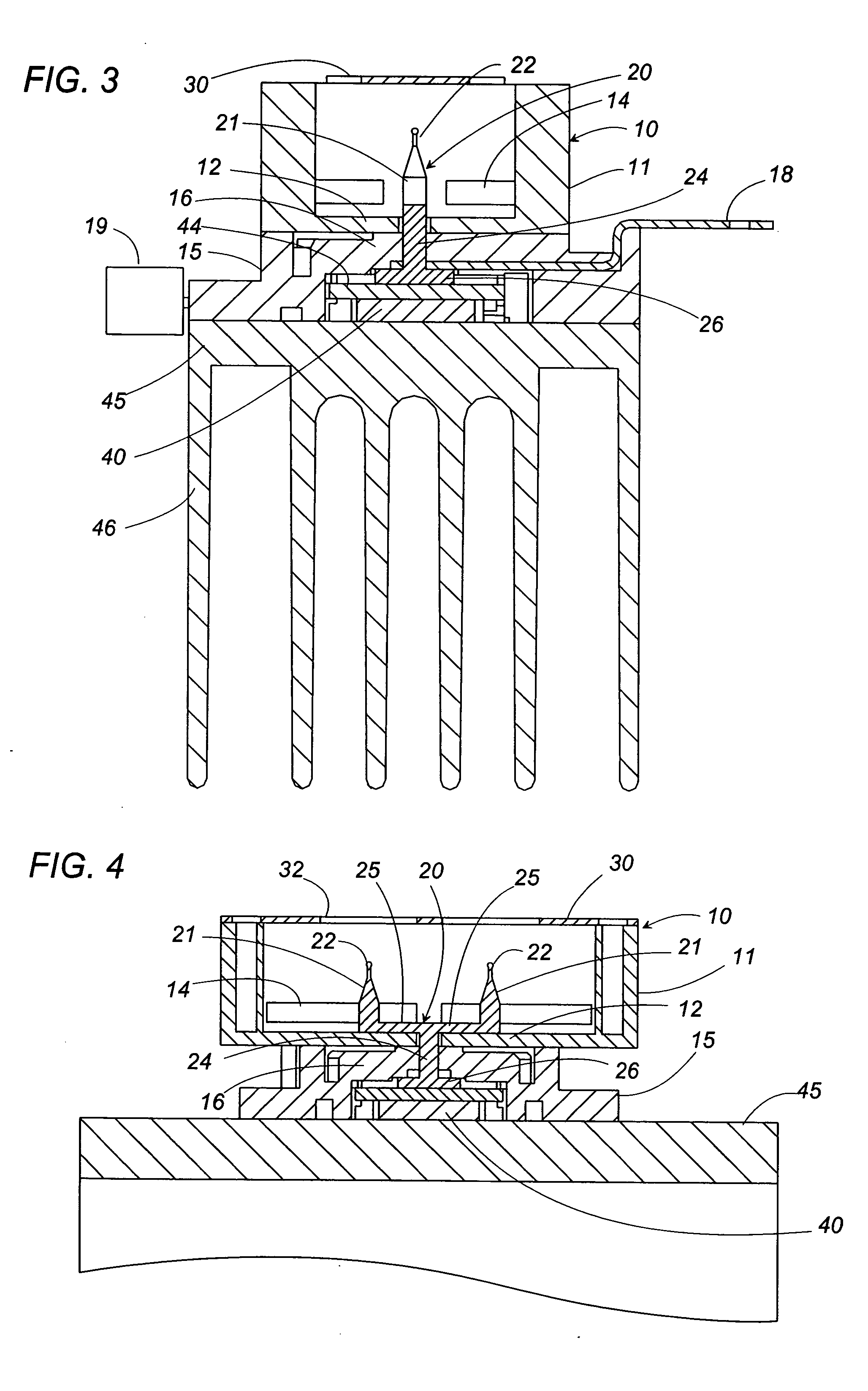

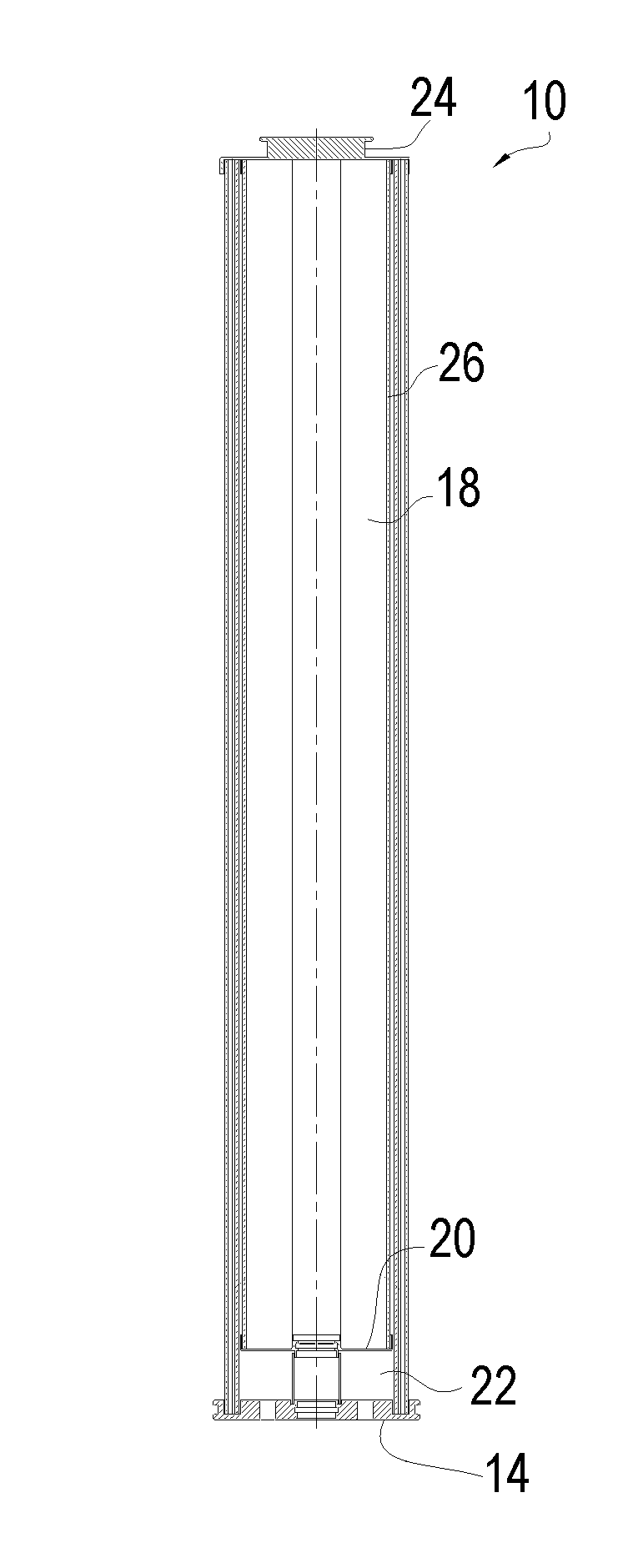

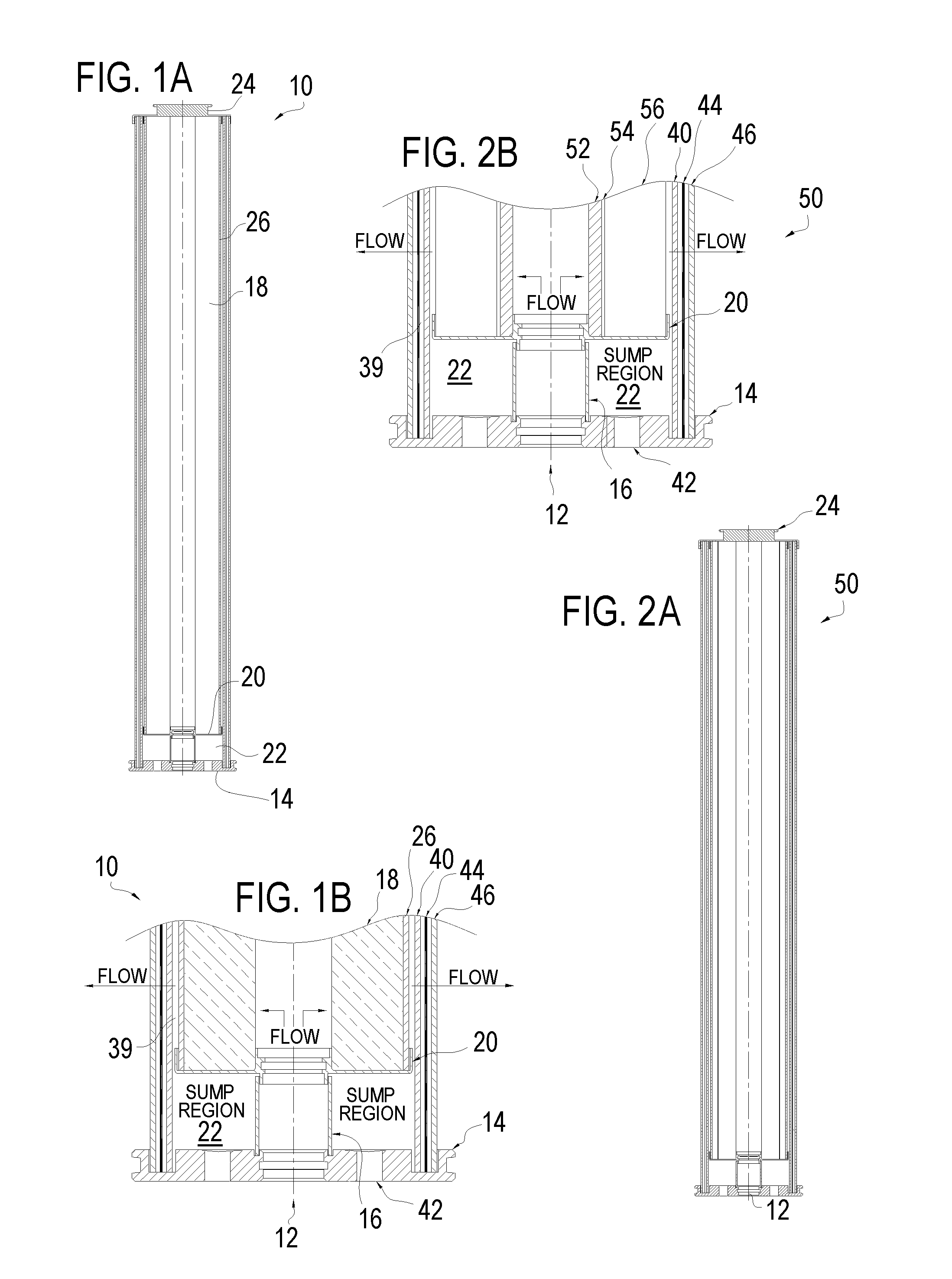

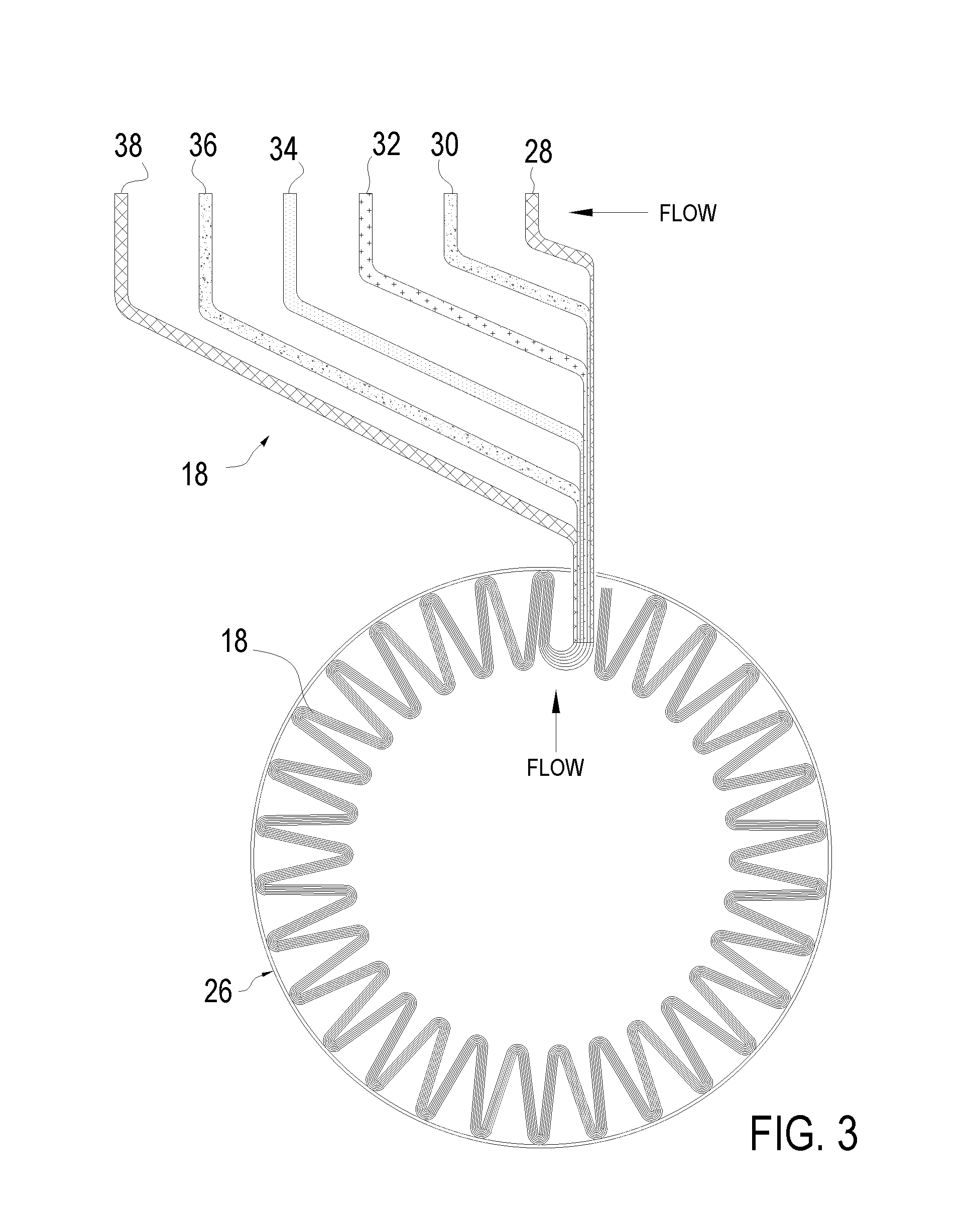

Coalescing filter element and filter assembly therefore

ActiveUS20140311963A1Efficient and cost-effectiveDewatering/demulsification with mechanical meansSeparation devicesParticulatesFiltration

A coalescing filter element provides an integrated filter element with a three stage design with a hydrophobic or hydrophilic coalescing layer. A coalescing filter element comprises: a) At least one particulate filtration layer; b) A coalescing layer promoting coalescing of water particles, wherein the coalescing layer is downstream of the at least one particulate filtration layer relative to the flow of fluid through the element; c) An annular coalescing space downstream of the coalescing layer; d) A sump in a lower portion of the filter element in fluid communication with the annular coalescing space; and e) A hydrophobic layer downstream of the annular coalescing space, wherein fluid being cleaned by the element flows through the hydrophobic layer. The coalescing layer may be a hydrophobic or a hydrophilic coalescing layer. A filter assembly will include the coalescing filter element of the present invention.

Owner:SCHROEDER INDS L L C

Ventilation system

InactiveUS20080242218A1Reduce living spaceEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringWater particle

A ventilation system comprises ductwork, a fan for creating a current of air passing through the ductwork, and an air supply outlet for supplying outdoor air into a living space of a house by means of the current of air. The ventilation system further comprises an electrostatic atomizer located at the side of the air supply outlet. The electrostatic atomizer is configured to produce mist of charged fine water particles by means of electrostatic atomization to spray the mist into the living space.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Camera washing device for camera lens

ActiveUS9180840B2Shorten the maintenance periodReduce in quantitySpray nozzlesVehicle cleaningCamera lensWash water

Owner:DENSO CORP

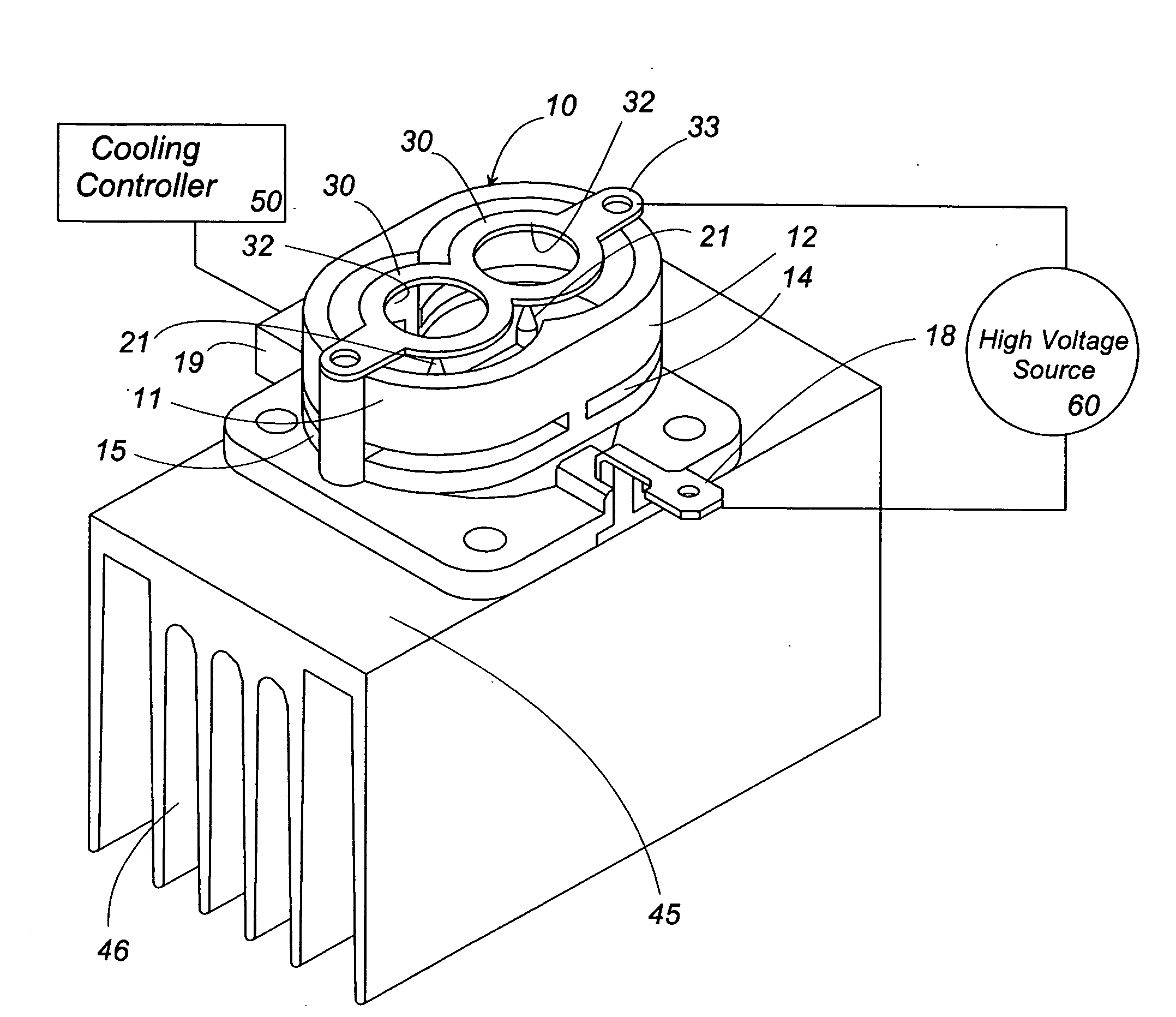

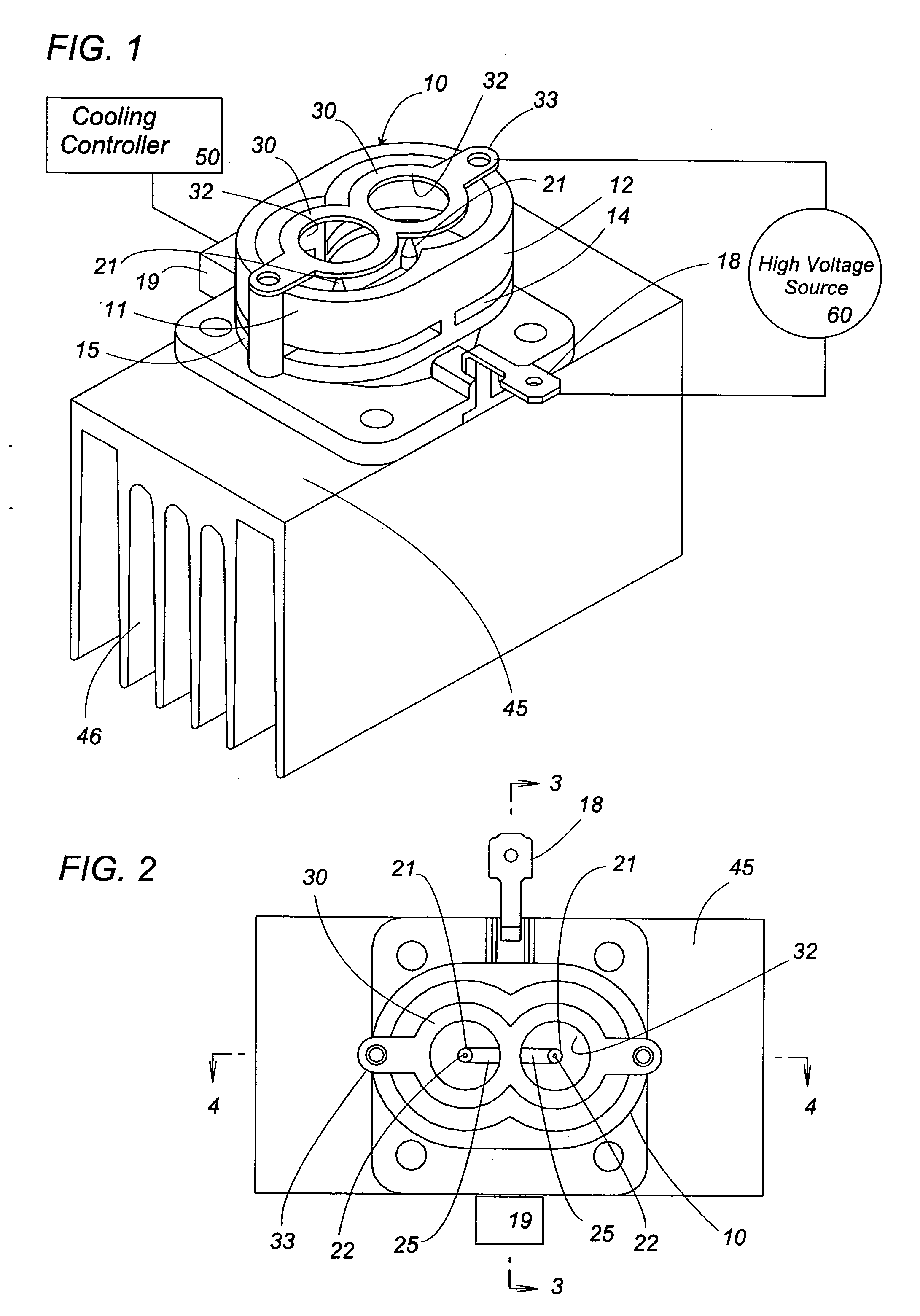

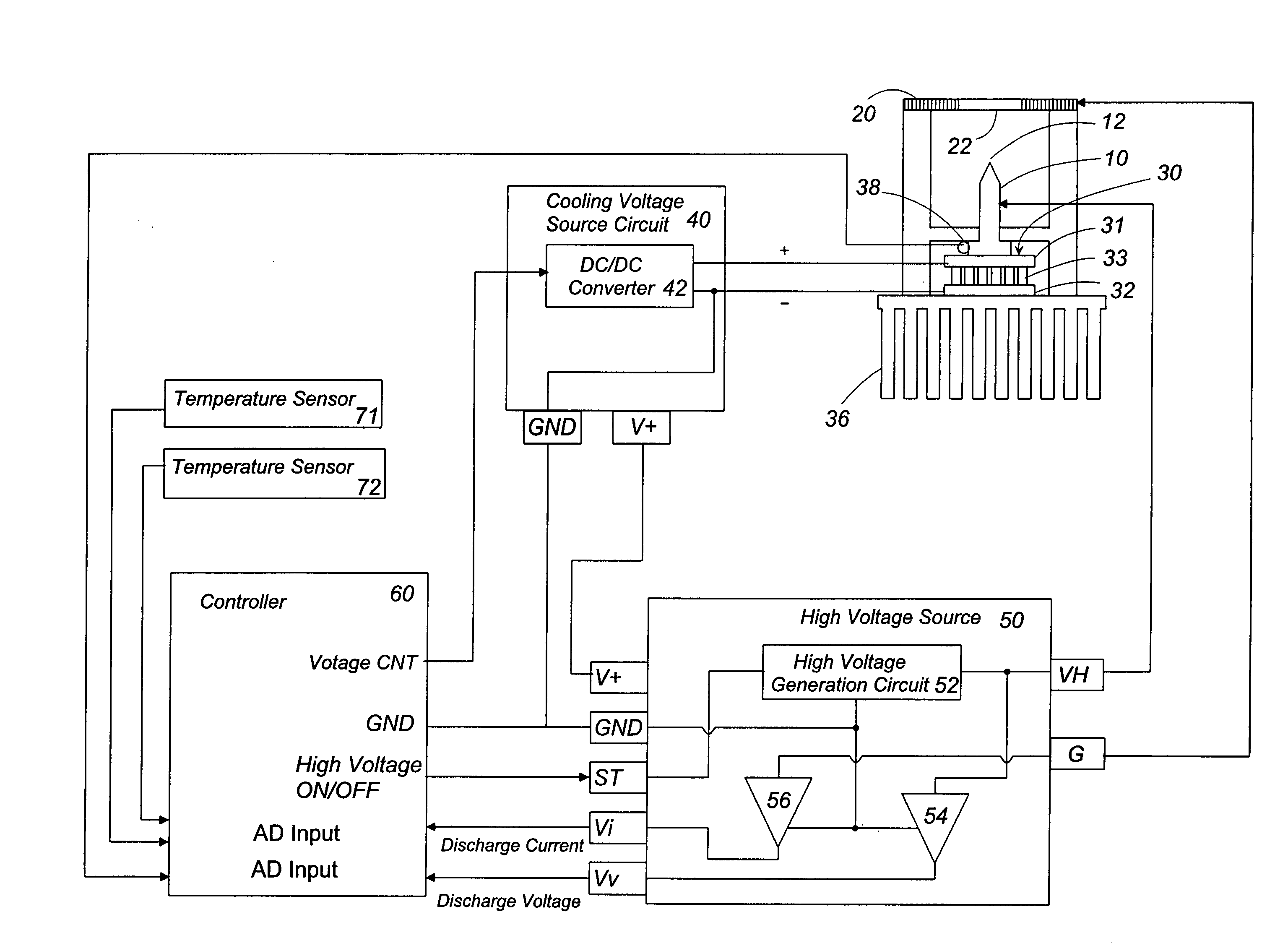

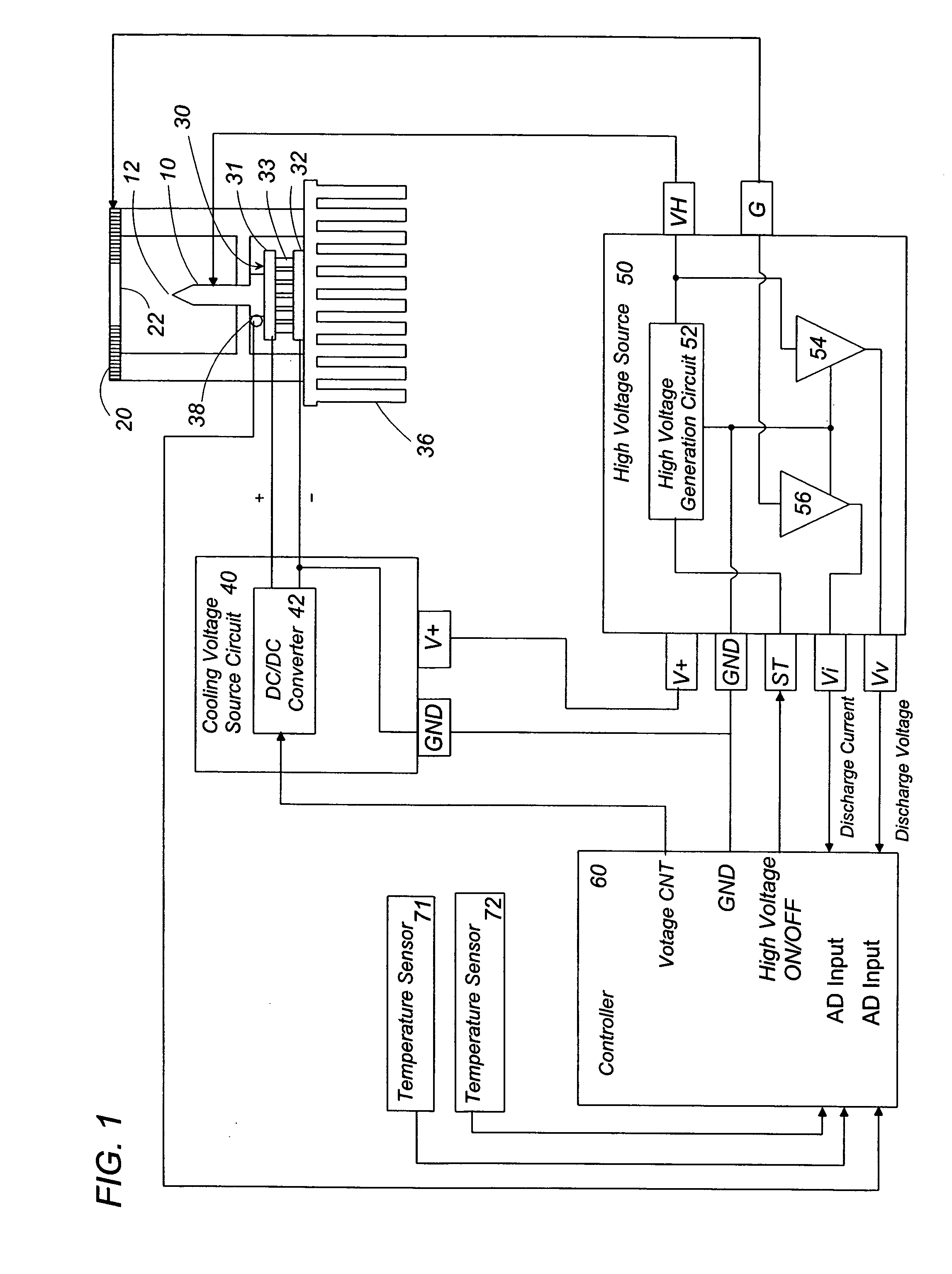

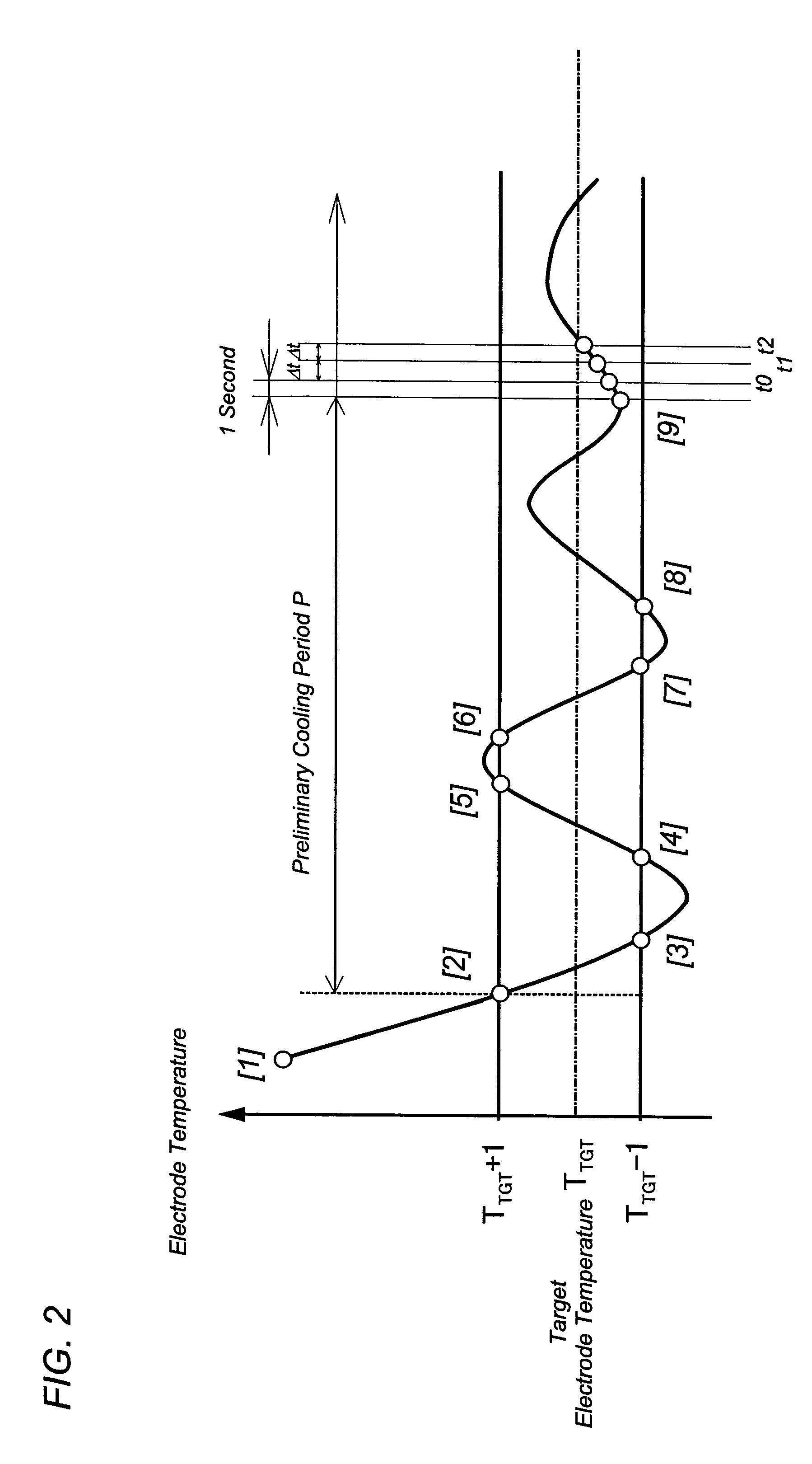

Electrostatically Atomizing Device

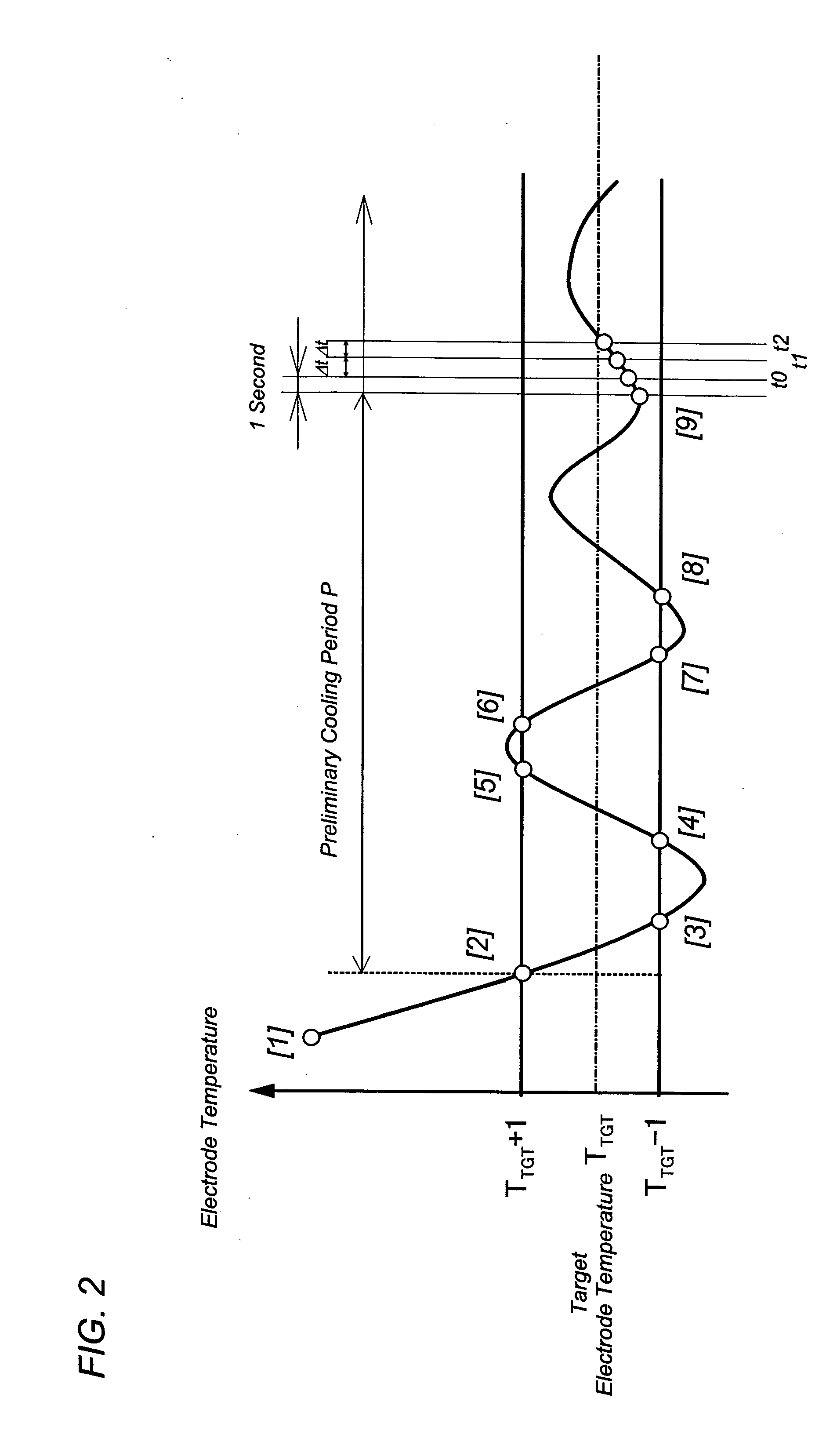

ActiveUS20080130189A1Guaranteed uptimeStable conditionLiquid spraying plantsSpraying power supplyHigh pressureWater particle

An electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, and a cooling means which condenses the water on the emitter electrode from within the surrounding air, and a high voltage source applying a high voltage across the emitter electrode and the opposed electrode to electrostatically charge the water for atomizing charged minute water particles from a discharge end of the emitter electrode. The device further includes a controller for discharging the charged minute water particles in a stable manner. The controller monitors a discharge current flowing between the two electrodes to control the cooling means for keeping the discharge current at a predetermined level, thereby regulating the atomizing amount of the charged minute particles from the emitter electrode.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Charged water particle, and method for creating environment where mist of charged water particle is dispersed

ActiveUS7473298B2Effectively inactivate bacteriaGood moisturizing effectHydrogen peroxideBurnersSuperoxideFine particulate

Owner:MATSUSHITA ELECTRIC WORKS LTD

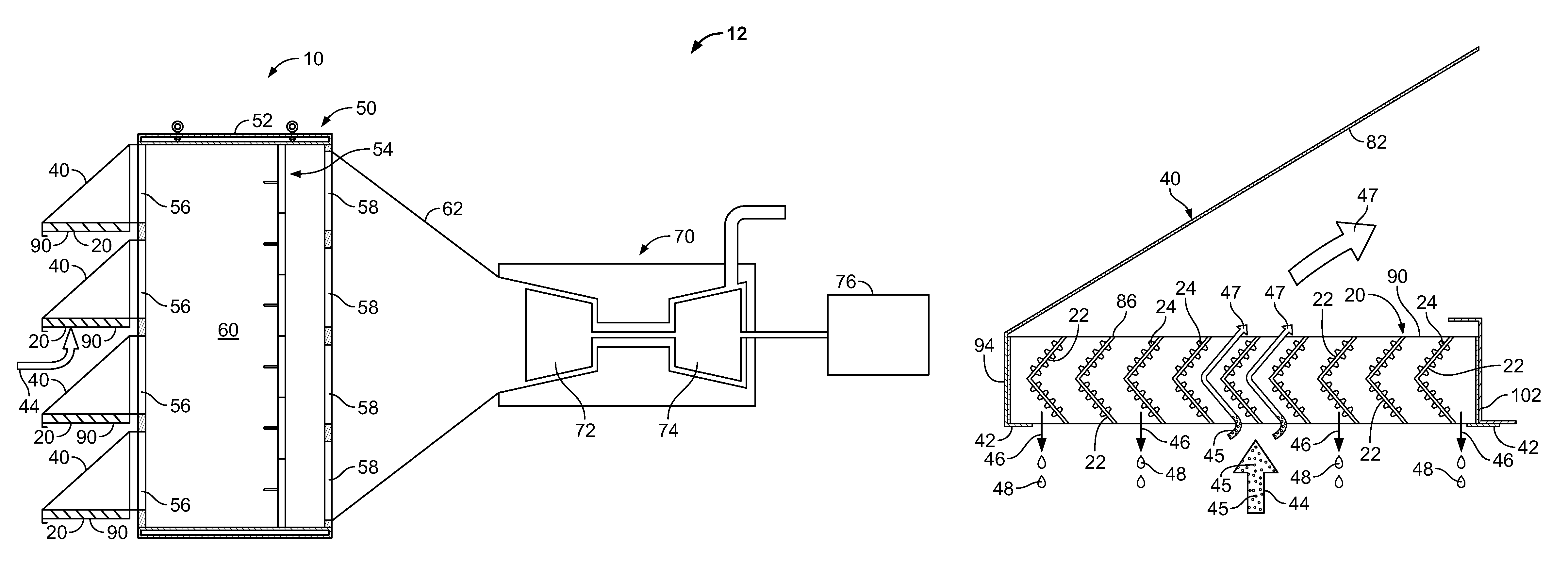

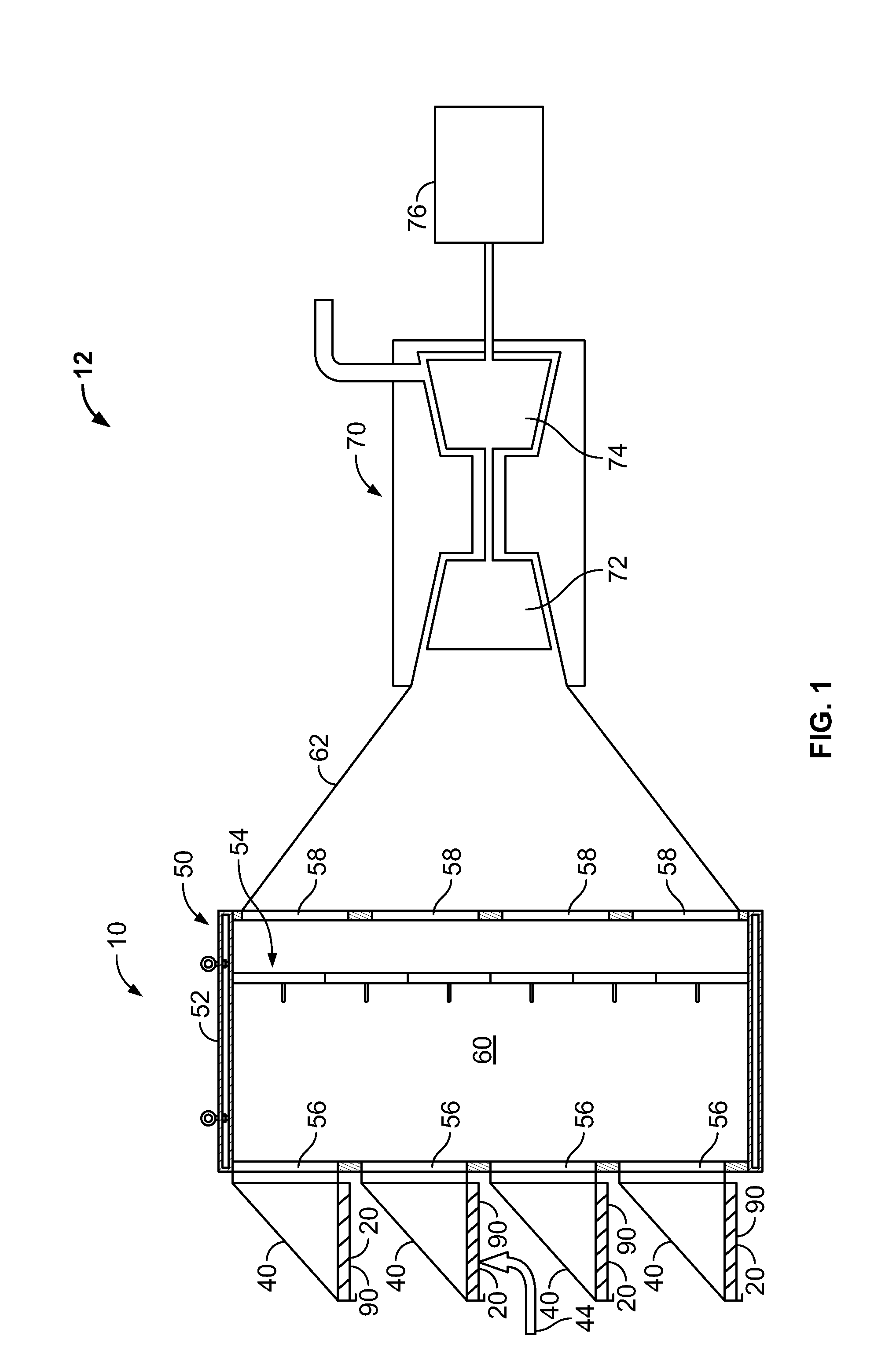

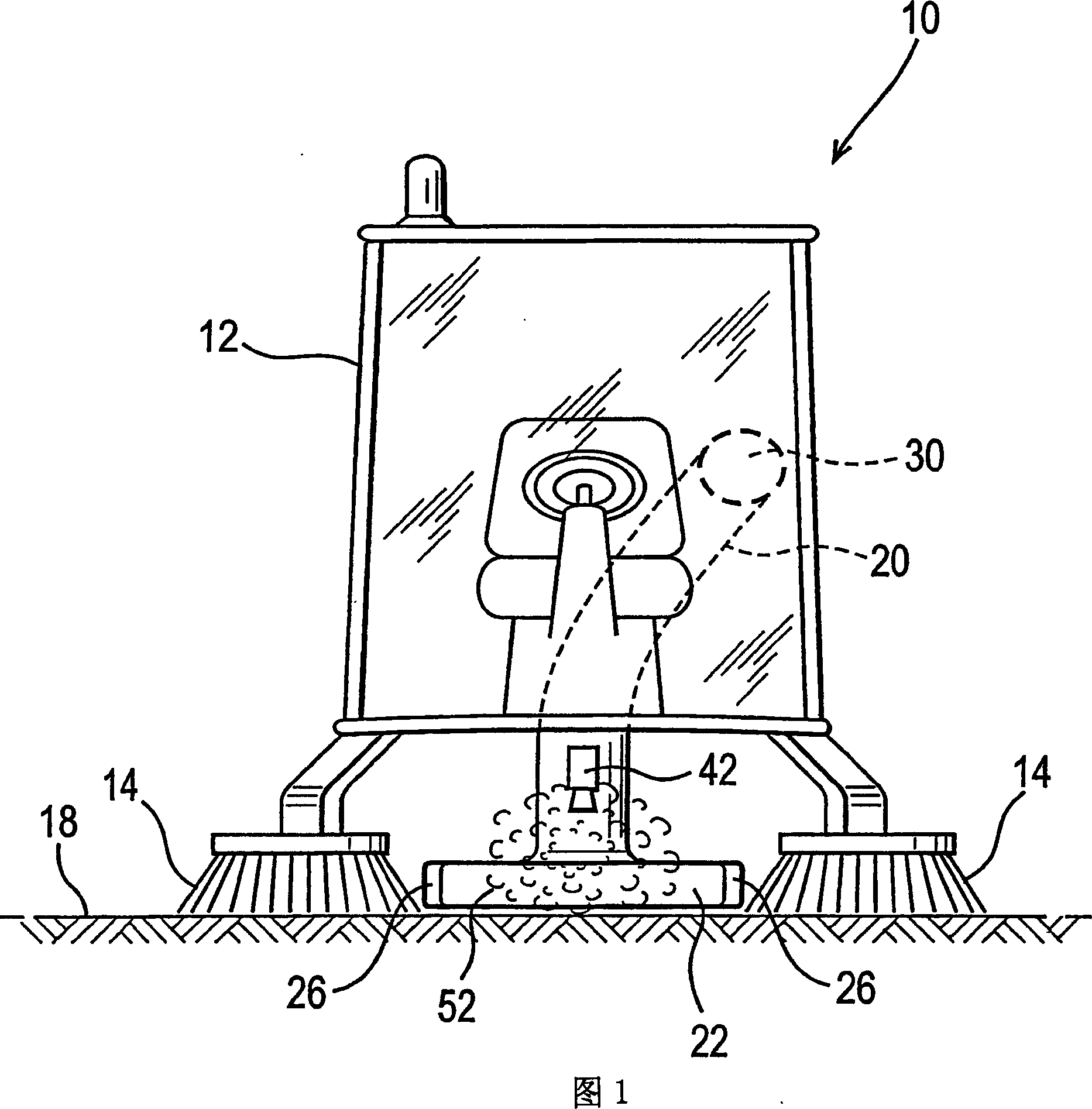

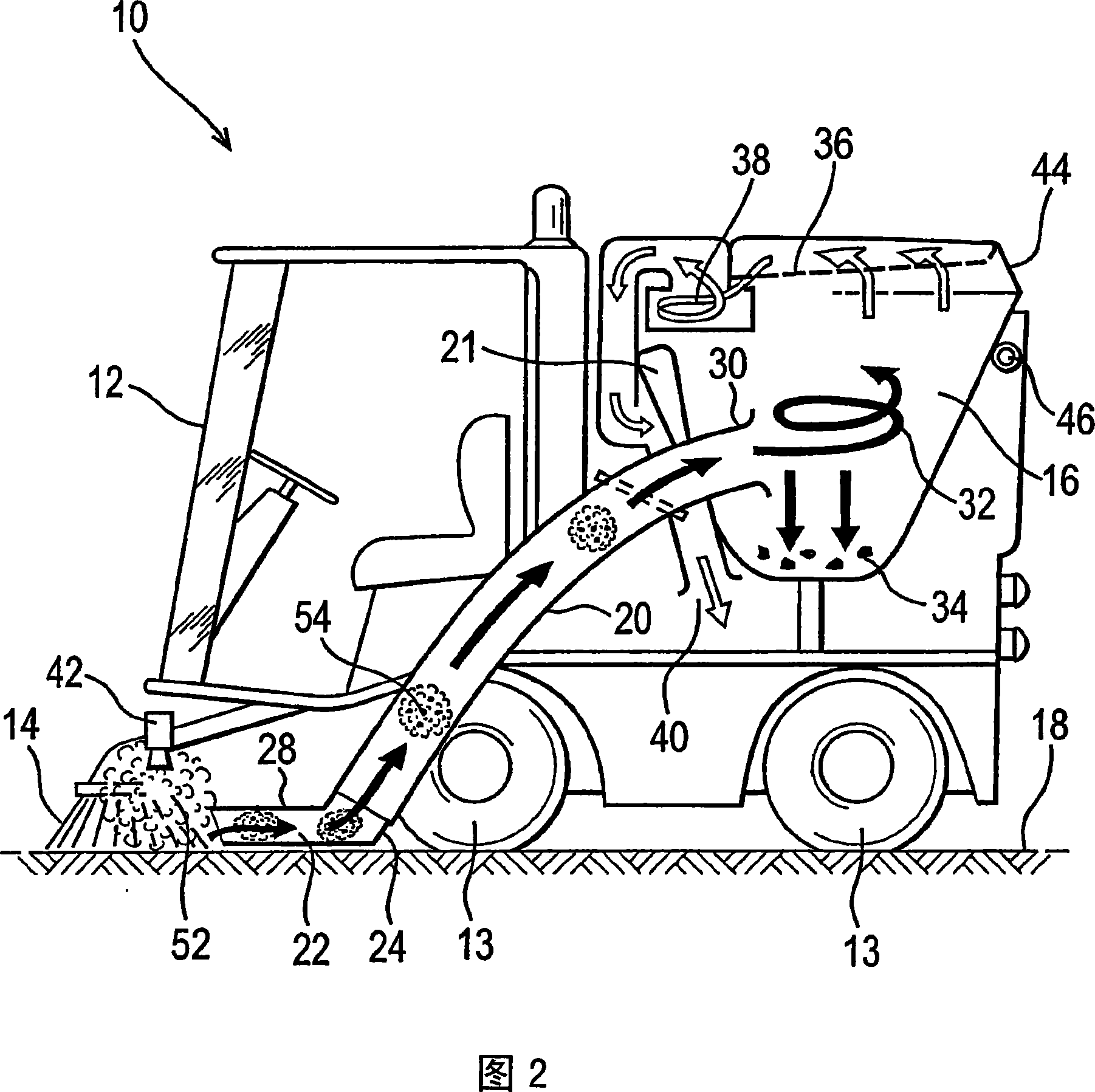

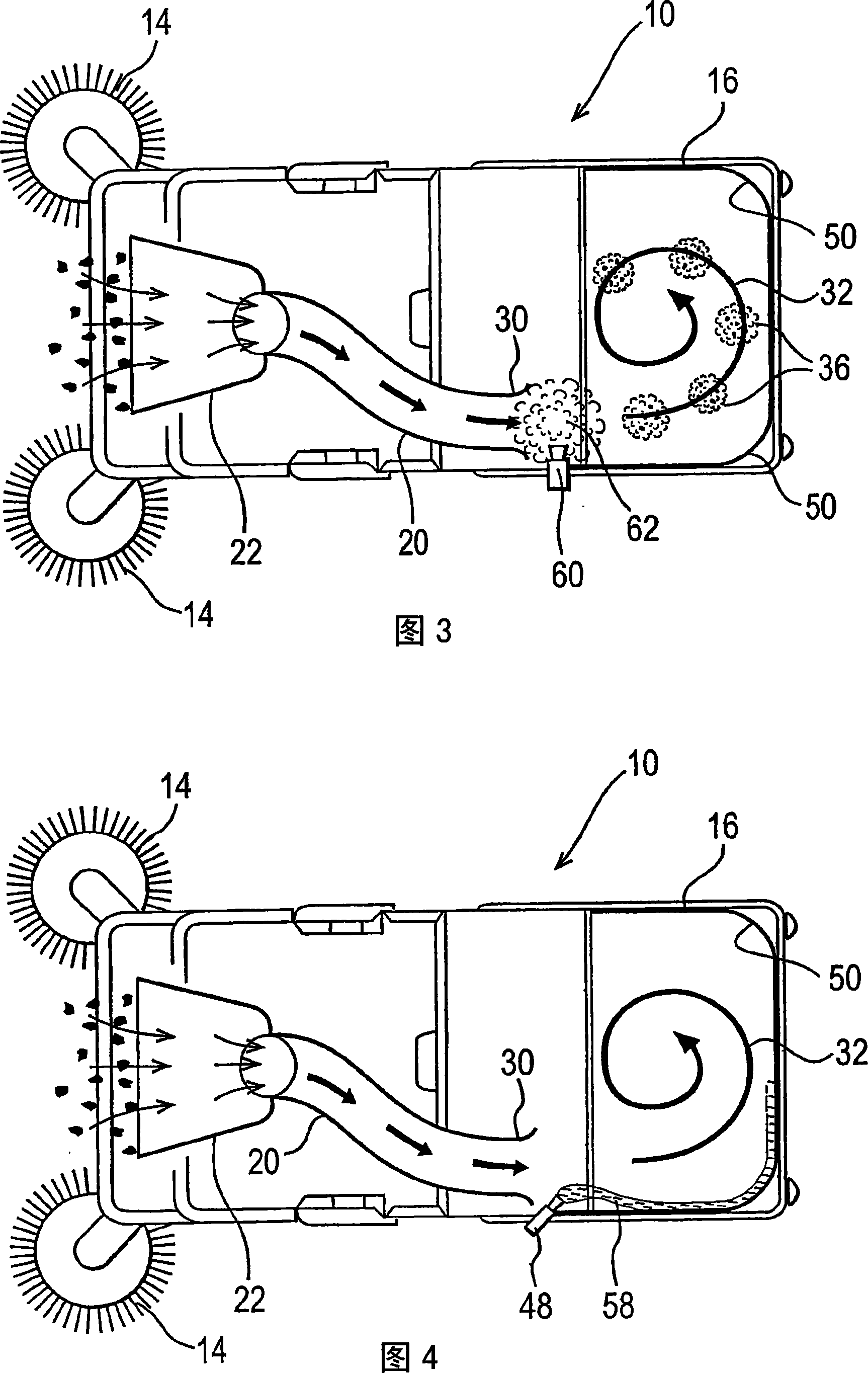

Dust control system

A road cleaning or sweeping machine (10) fitted with a dust control system using a water atomiser (42, 60). The atomiser (42, 60) creates water particles of a similar size to dust, and by entraining atomised water through the road sweeping machine's dust handling systems, i.e. from the brushes (14), through a suction pipe (20) and into a hopper (16), dust control is established. A method of improving dust separation in a hopper (16) of a road sweeping machine (10) using a water atomiser to reduce dust or a spray to wet the walls of the hopper (16).

Owner:TENNANT COMPANY

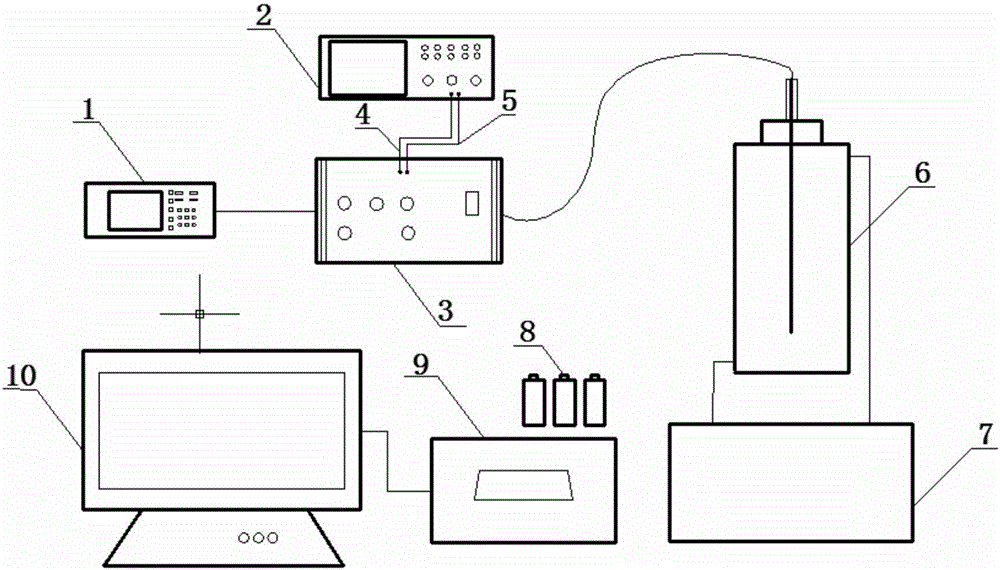

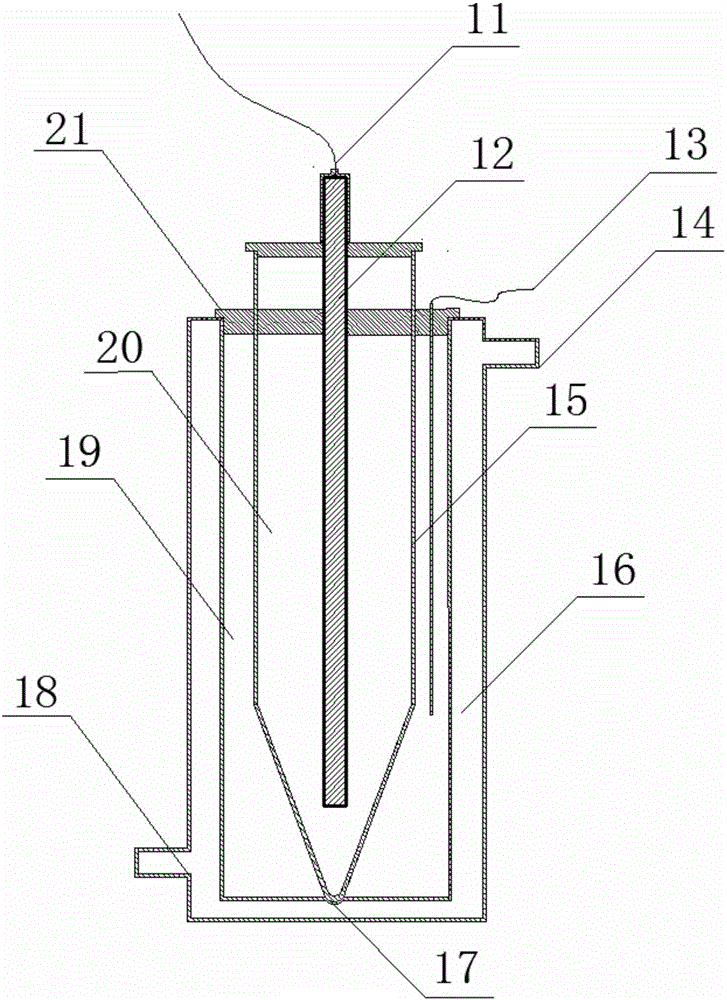

Quantitative evaluation system and method of crude oil emulsion stability

InactiveCN105158212ARapid quantitative demulsification and dehydration effectEase of evaluationScattering properties measurementsParticle size analysisWater bathsEmulsion test

The invention discloses a quantitative evaluation system and method of a crude oil emulsion stability. The system comprises a signal generator, an oscilloscope, a voltage amplifier, a bottle-test type demulsification dehydrator, a constant-temperature water bath, an emulsion test bottle, a kinetic stability analyzer and a computer, wherein the signal generator generates electric signals with a specific waveform, voltage and frequency, signal amplification is performed through the voltage amplifier, and then an asymmetric high-intensity electric field is applied to crude oil emulsion in the bottle-test type demulsification dehydrator to enable water particles therein to produce electrostatic coalescence and further to accelerate gravity settlement; or under the situation that no electric field is applied, a demulsification agent is directly added into the crude oil emulsion in the bottle-test type demulsification dehydrator to perform chemical demulsification; quantitative analysis and evaluation are performed on the demulsification effect by calculating emulsion dehydration rate or by using the kinetic stability analyzer. The evaluation system and method are convenient, quick, accurate and reliable to use, and can provide convenience for evaluation work of the emulsion demulsification effect under various conditions in laboratories and engineering fields.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

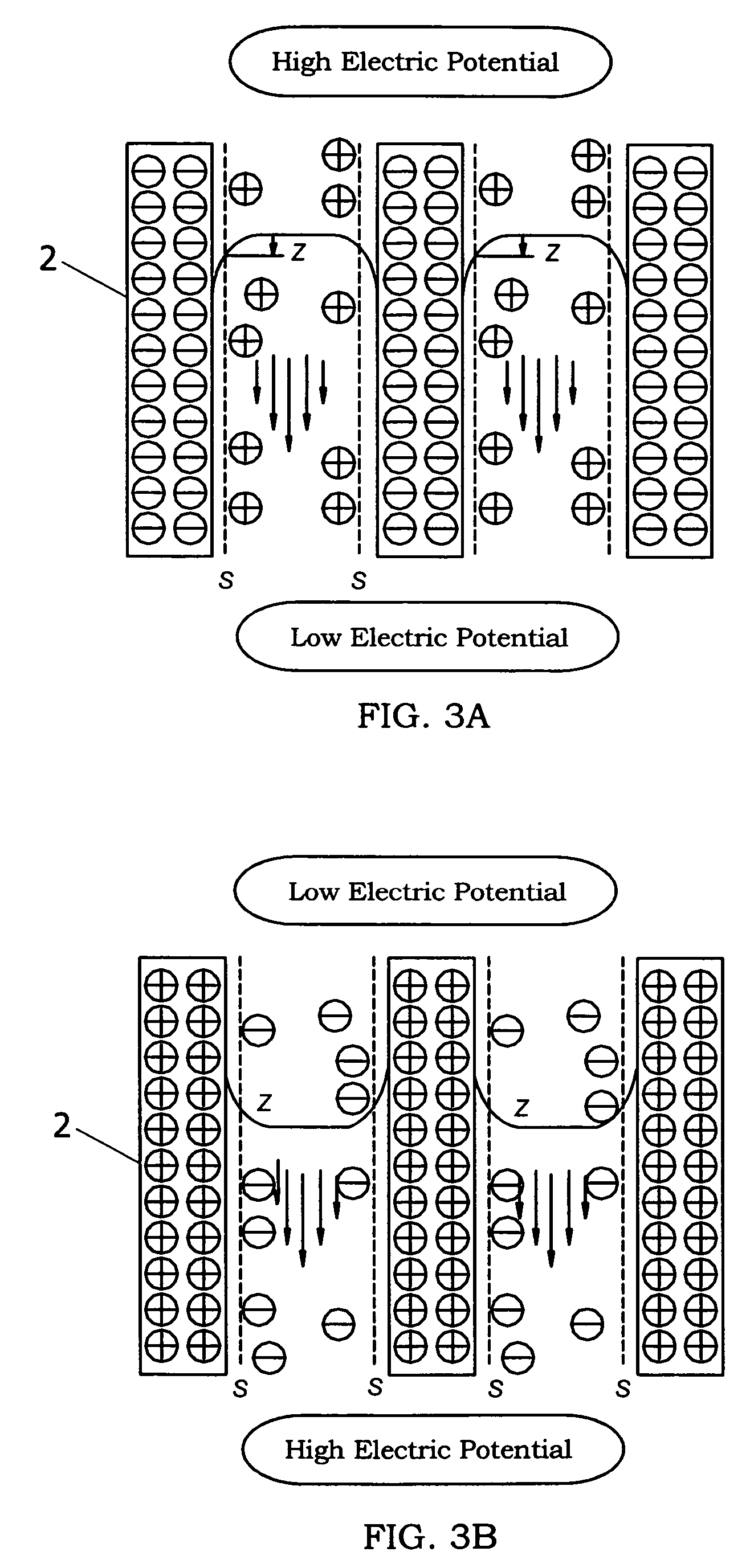

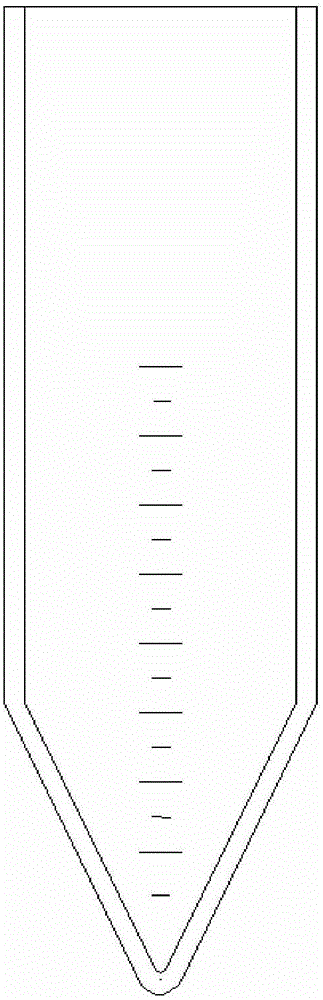

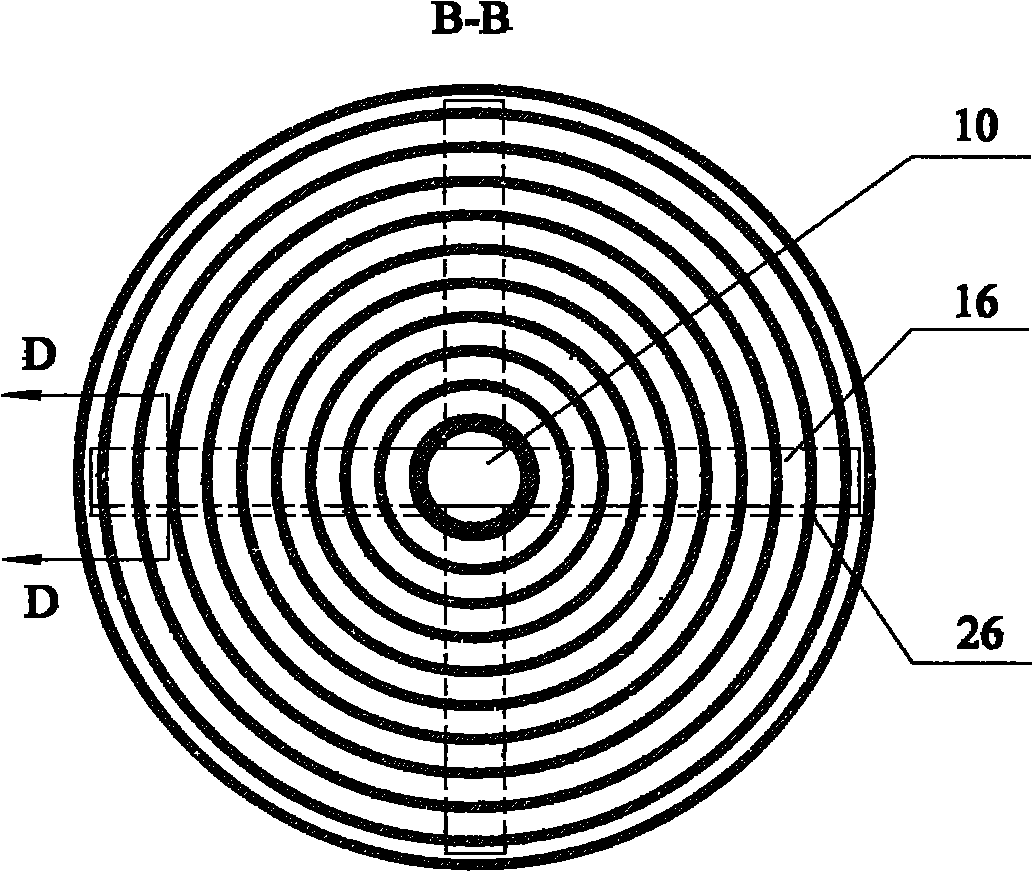

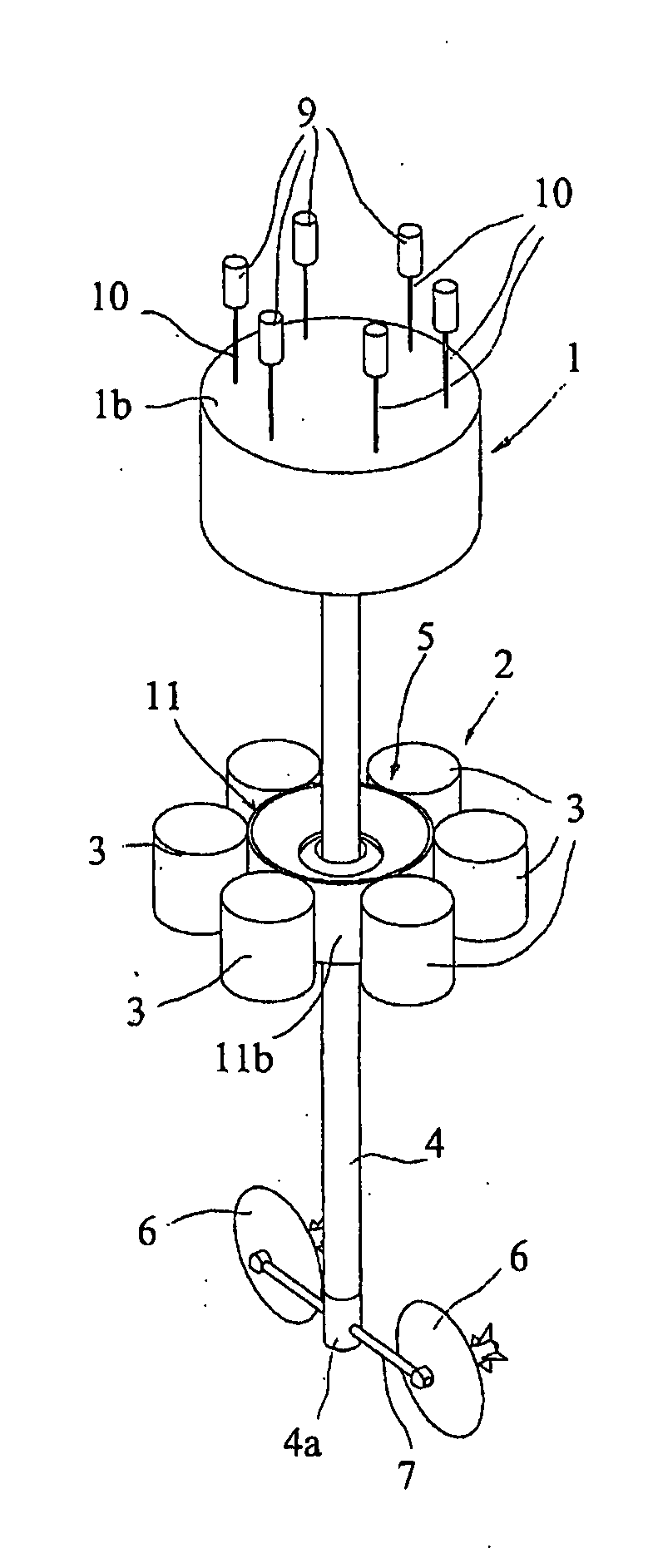

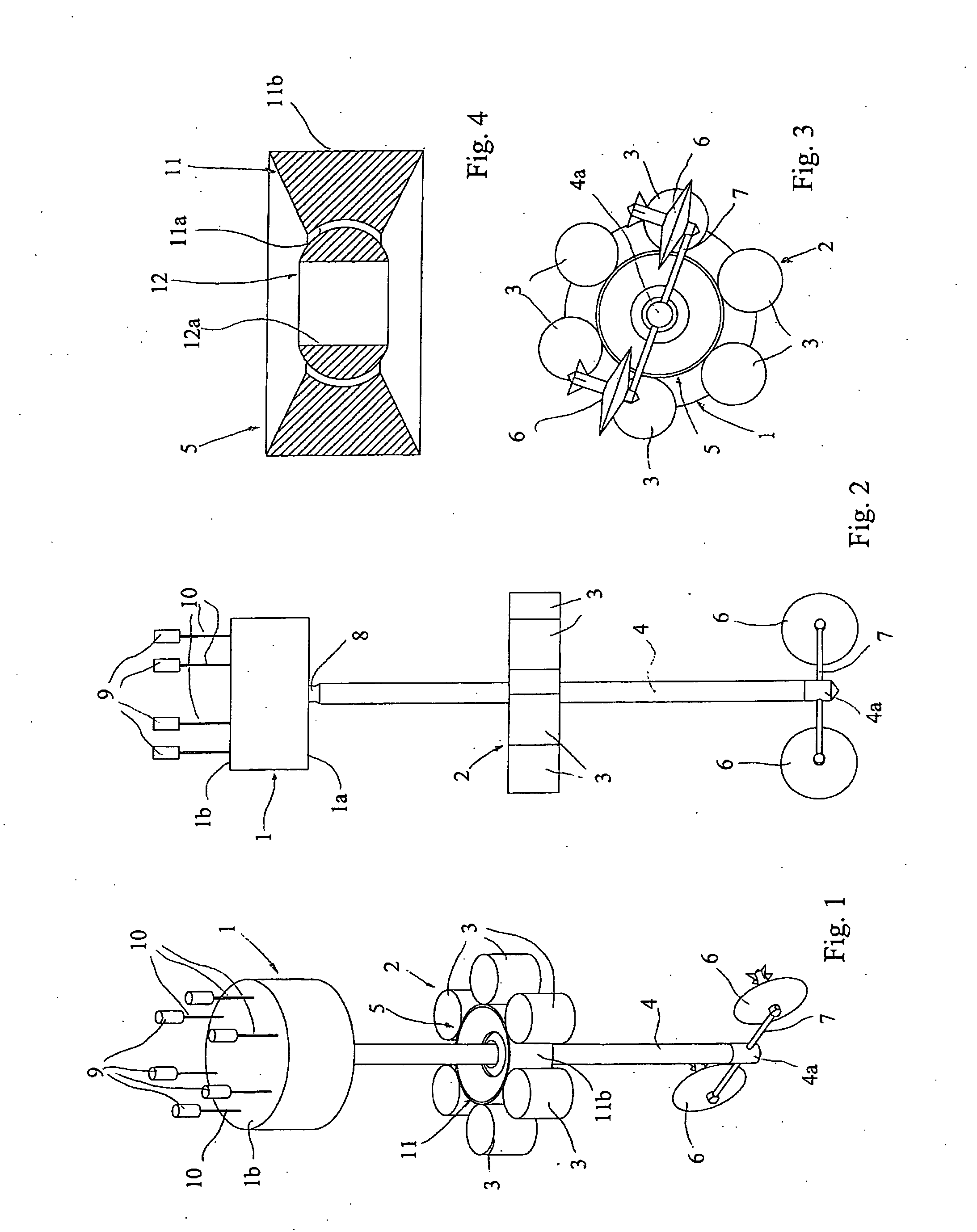

Novel and efficient electrostatic pre-coalescence method and device applied to dehydration and desalt of crude oil

InactiveCN102021018AAvoid short circuitReduce dosageLiquid separation by electricityDewatering/demulsification with electric/magnetic meansEngineeringHigh pressure

The present invention discloses a novel and efficient electrostatic pre-coalescence method and a device applied to dehydration and desalt of crude oil. The invention is used for dehydration of crude oil in the system of oil-gas gathering and transportation in oil fields and for dehydration and desalination of oil refineries, therefore enables the small water particle dispersed phase in the crude oil emulsion to coalesce and grow. The core part of the device is an electrode assembly comprising an electrically conductive metal rod, multilayer cannular electrodes vertically and coaxially mounted, and tabular electrodes parallelly mounted. When high pressure alternating current is applied to the electrode assembly, the dispersed phase water particles in the crude oil emulsion undergo demulsification because of the mechanism of dielectrophoresis coalescence and vibration coalescence, thereby the dispersed phase water particles coalescing and growing up, the subsequent time of gravity settling being reduced notably and the process efficiency being improved. Moreover, the device is compact and efficient. On the basis of the mechanism of dielectrophoresis phenomenon, the dosage of chemical demulsifiers and the total operating cost can be reduced and the economical benefit of oil refineries can be improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Completely submerged wave energy converter

InactiveUS20100164227A1Satisfactory resistanceImprove efficiencyGas turbine plantsEngine componentsEngineeringWater particle

A wave energy converter apparatus comprising at least two members joined mutually by a connector movable so as to allow mutual displacement of the members in response to waves in water where the apparatus is located. The apparatus also includes an energy converter for converting motion of the connector to electrical energy, and a device for storing and / or transporting elsewhere the energy produced. Preferably, the members are non-floating and completely submerged, thereby causing the apparatus, as a whole, to be neutrally buoyant. A member is additionally provided for maintaining each of the submerged members substantially at rest relative to the surrounding water with which they are in contact, such that the members move under wave action substantially in the same manner as an undisturbed water particle located in the same region, the at least two submerged members being spaced mutually by the connector so as to assume respective positions affected differently by the wave-induced water motion.

Owner:40SOUTH ENERGY

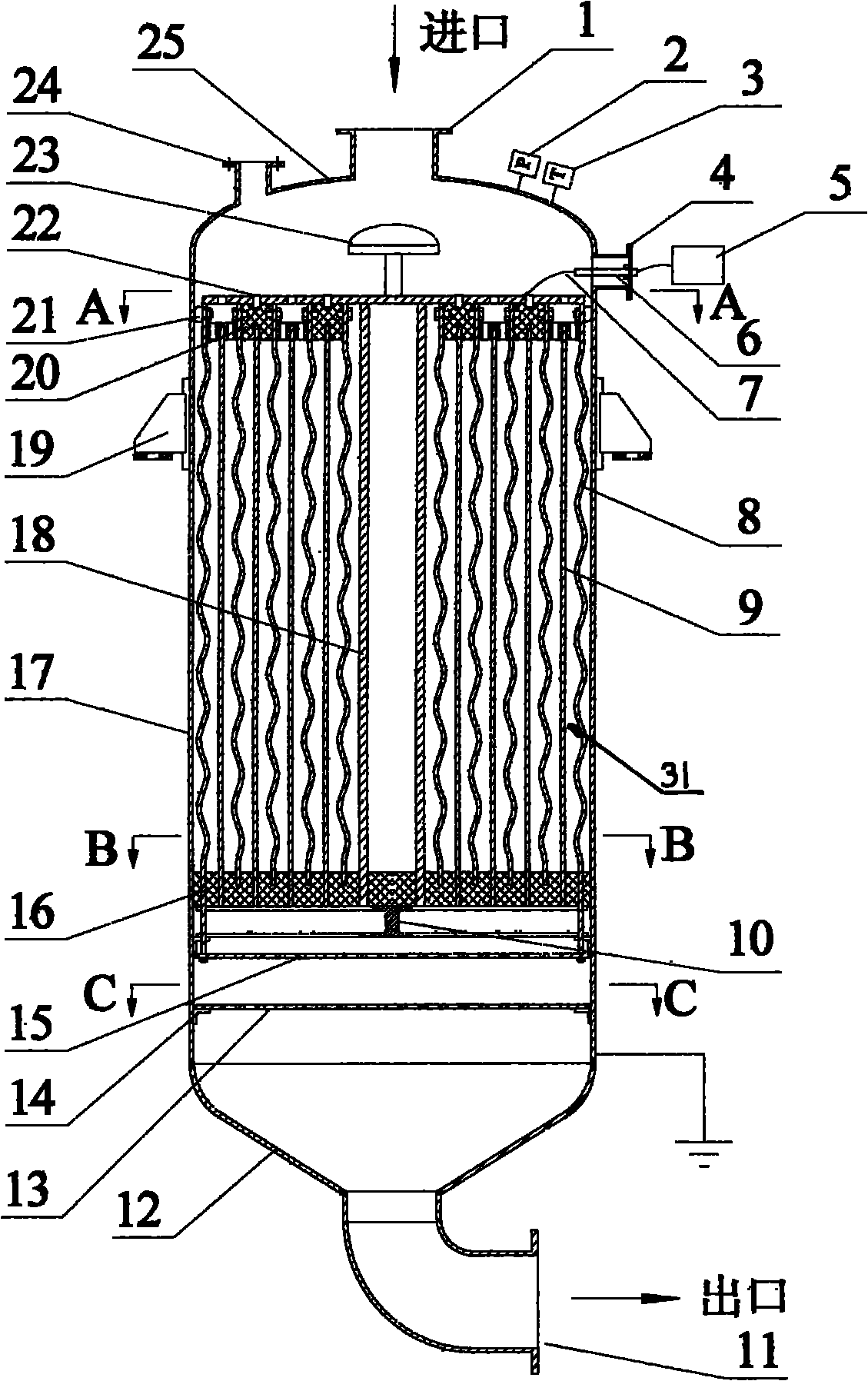

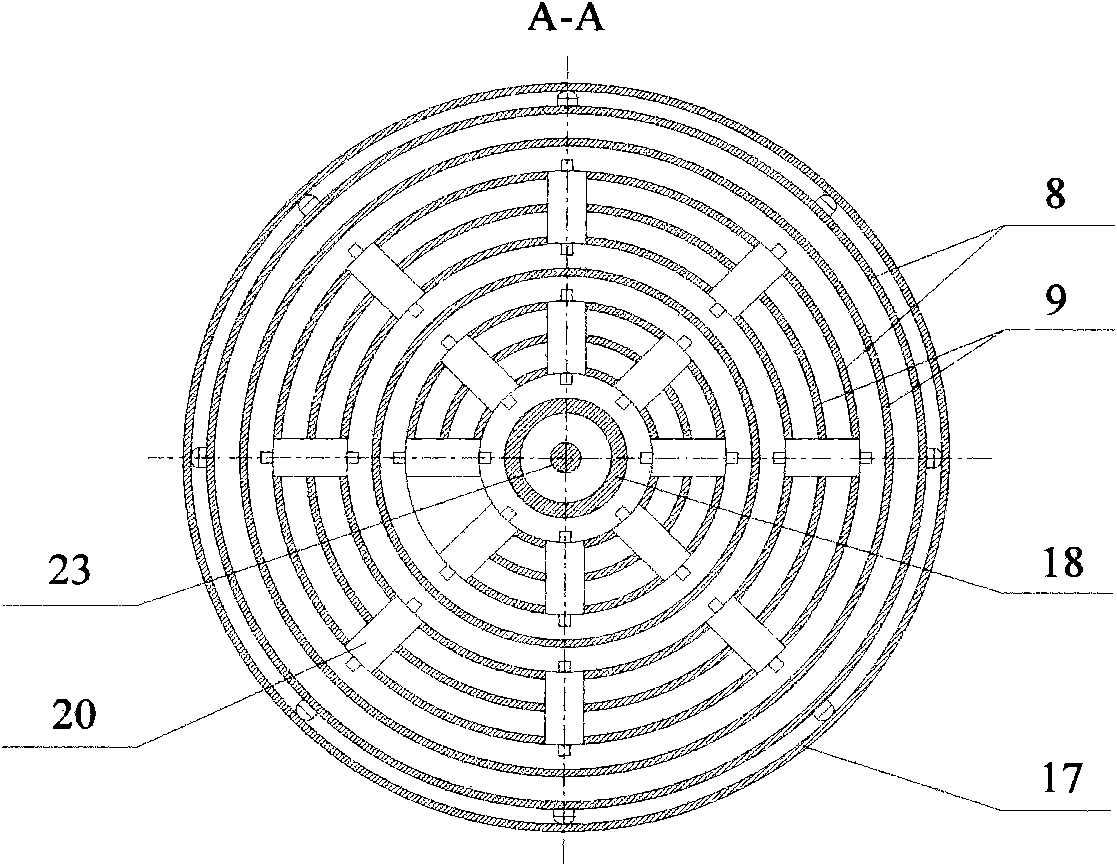

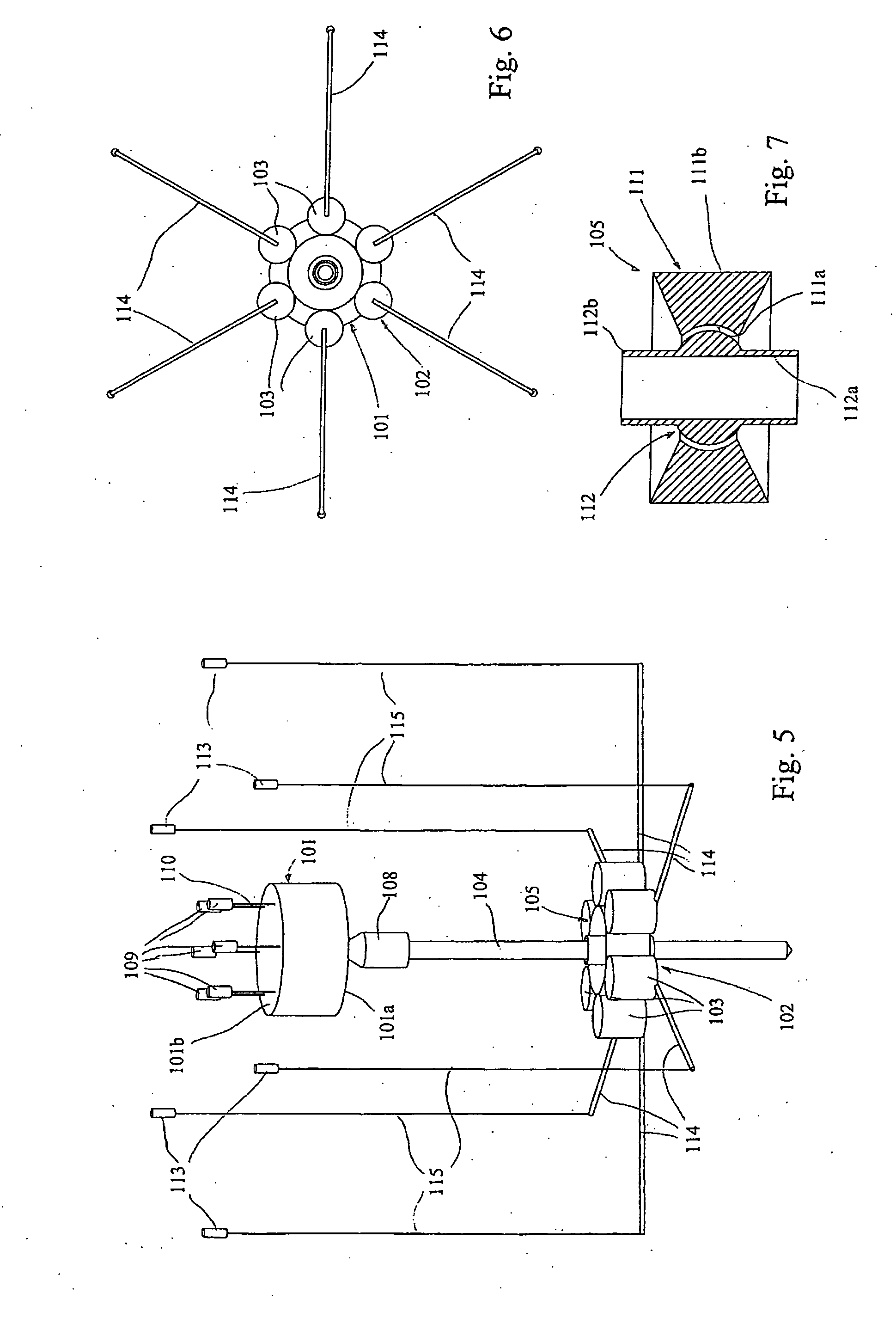

Novel high-efficiency crude oil electric dehydration and desalination method and equipment

InactiveCN102021019AEnough time to stayThoroughly dehydratedLiquid separation by electricityDewatering/demulsification with electric/magnetic meansDielectrophoresisHigh pressure

The invention discloses a novel high-efficiency crude oil electric dehydration and desalination method and novel high-efficiency crude oil electric dehydration and desalination equipment, which can be used for dehydrating and desalinating crude oil emulsion in oil refineries. The processing equipment mainly comprises an inlet component, a tank and an electrostatic precoalescer; when a high-voltage explosion-proof transformer outside the device applies high-voltage alternating current to the crude oil emulsion in a corrugated hollow tube through metal electrode plates by a high-voltage insulating wire, a non-uniform alternating current field is produced between the electrode plates to cause dielectrophoresis coalescence of dispersed phase water particles; the flow state of the crude oil emulsion in the hollow tube is turbulent flow, and the turbulent flow increases the collision probability of the dispersed phase water particles in the crude oil emulsion and obviously shortens hydraulic retention time; and a flowing passage in the electrostatic precoalescer can be designed to be corrugated circular or wavelike quasi-rectangular. By using the method and the equipment, the dispersed phase water particles subjected to electrostatic precoalescence can obviously reduce subsequent gravity settling time and improve the processing efficiency; and after the crude oil emulsion enters the tank from the inlet component at the left end, the crude oil emulsion flows along the horizontal direction and can reduce the power consumption of an inlet.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Electrostatically atomizing device

ActiveUS7567420B2Stable conditionReduce necessityLiquid spraying plantsSpraying power supplyHigh pressureWater particle

An electrostatically atomizing device includes an emitter electrode, an opposed electrode opposed to the emitter electrode, and a cooling means which condenses the water on the emitter electrode from within the surrounding air, and a high voltage source applying a high voltage across the emitter electrode and the opposed electrode to electrostatically charge the water for atomizing charged minute water particles from a discharge end of the emitter electrode. The device further includes a controller for discharging the charged minute water particles in a stable manner. The controller monitors a discharge current flowing between the two electrodes to control the cooling means for keeping the discharge current at a predetermined level, thereby regulating the atomizing amount of the charged minute particles from the emitter electrode.

Owner:MATSUSHITA ELECTRIC WORKS LTD

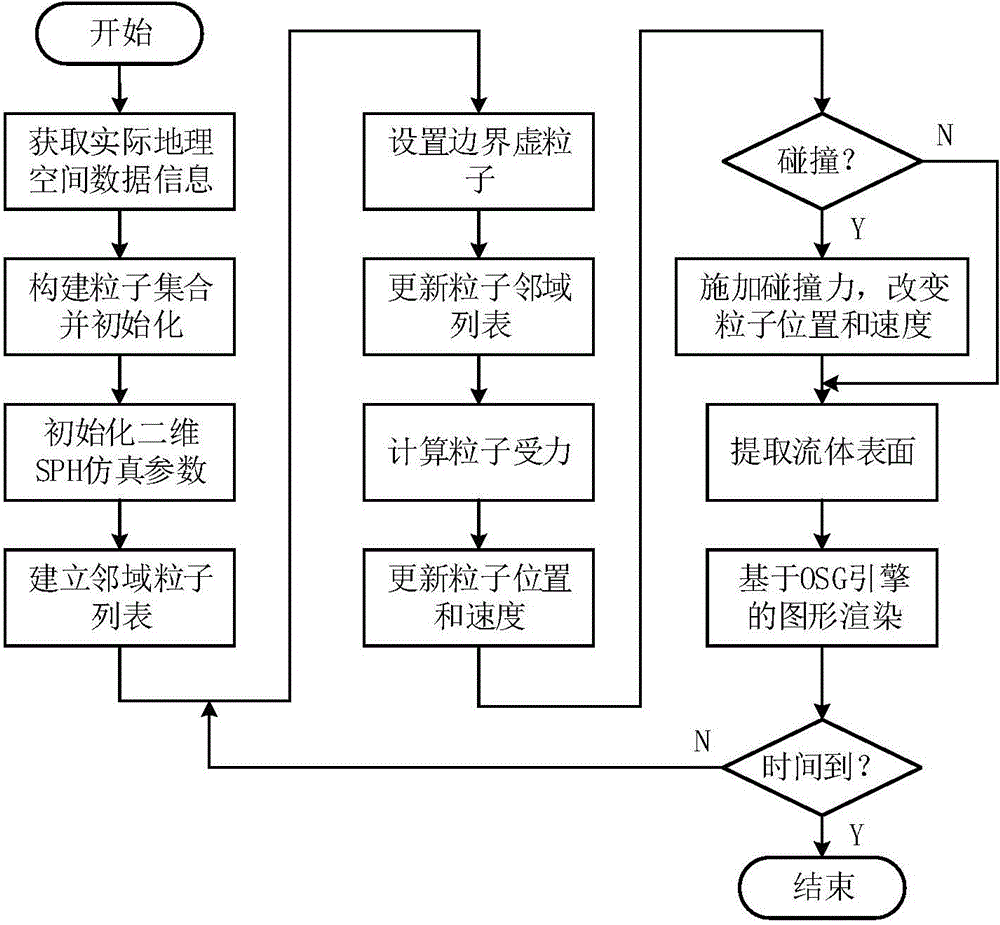

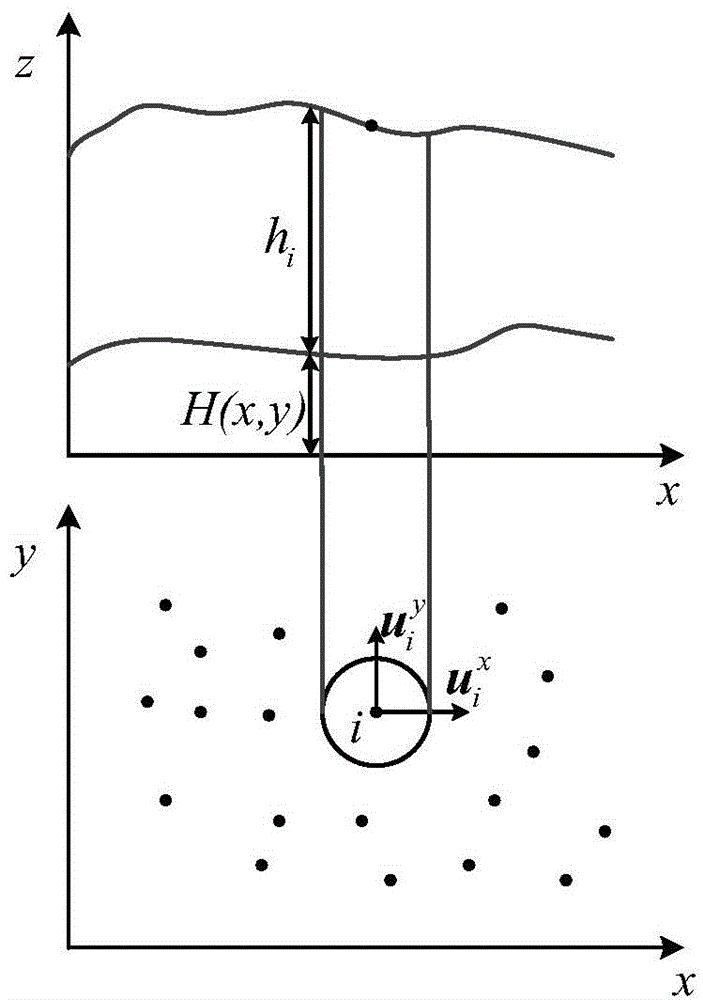

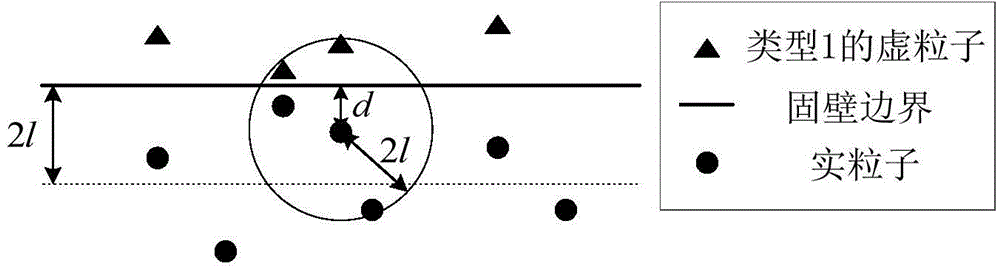

Dam bursting flood routing simulation method based on two-dimensional SPH

InactiveCN104991999AMake up for lack of precisionMake up for the huge amount of calculationClimate change adaptationSpecial data processing applicationsData informationCollision detection

A dam bursting flood routing simulation method based on two-dimensional SPH belongs to the technical field of geographic-science course simulation and geographic information systems. By the method, data information of a reservoir and downstream geographic space is obtained firstly, a flood routing two-dimensional mode based on a shallow water equation is established according to the obtained data, and a simulation course undergoes initialization which comprises initial configuration of particle properties, establishment of a neighborhood particle list of particles and setting of parameters; simulation circulation is started then, wherein whether boundary virtual particles are set is determined according to positions of the particles, and the neighborhood particle list of each water particle is updated; force borne by each water particle is calculated, and then the position and the speed of each water particle at the next time step are calculated; and collision detection is carried out, boundary punishment force is applied to change the position and the speed of the particle in case of a boundary, a fluid surface is extracted according to particle distribution, and the extracted fluid surface is rendered. The method provided by the invention can realize the relatively real analogue simulation of the large-scale dam bursting flood routing situations.

Owner:DALIAN UNIV OF TECH

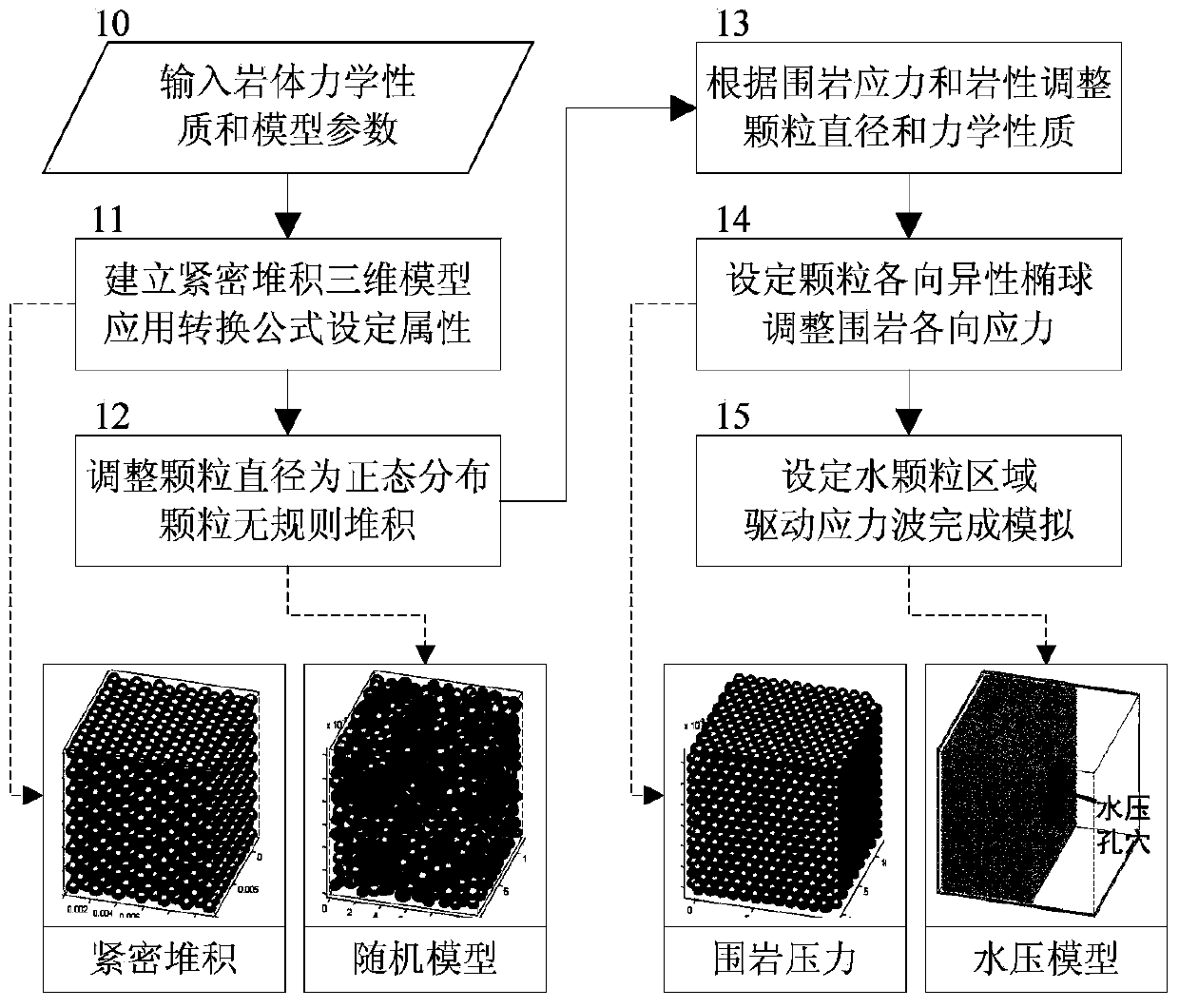

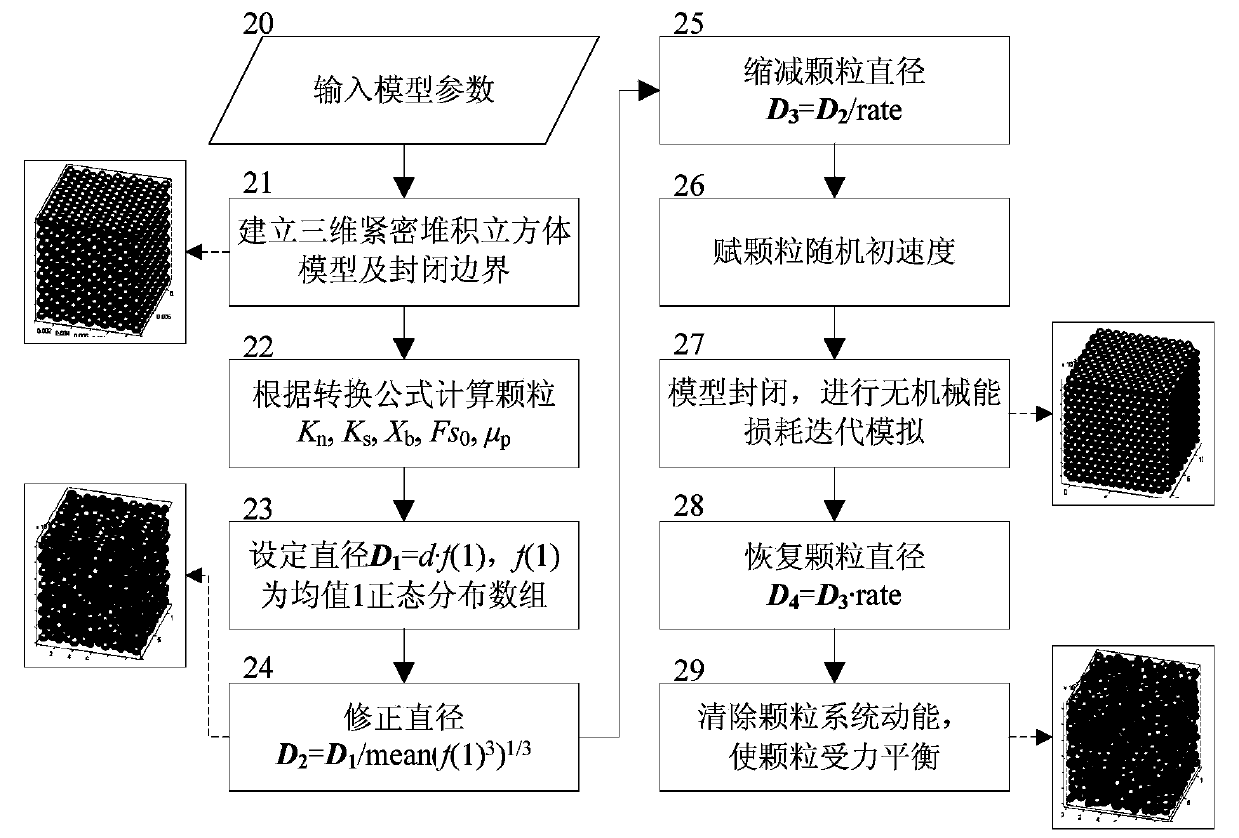

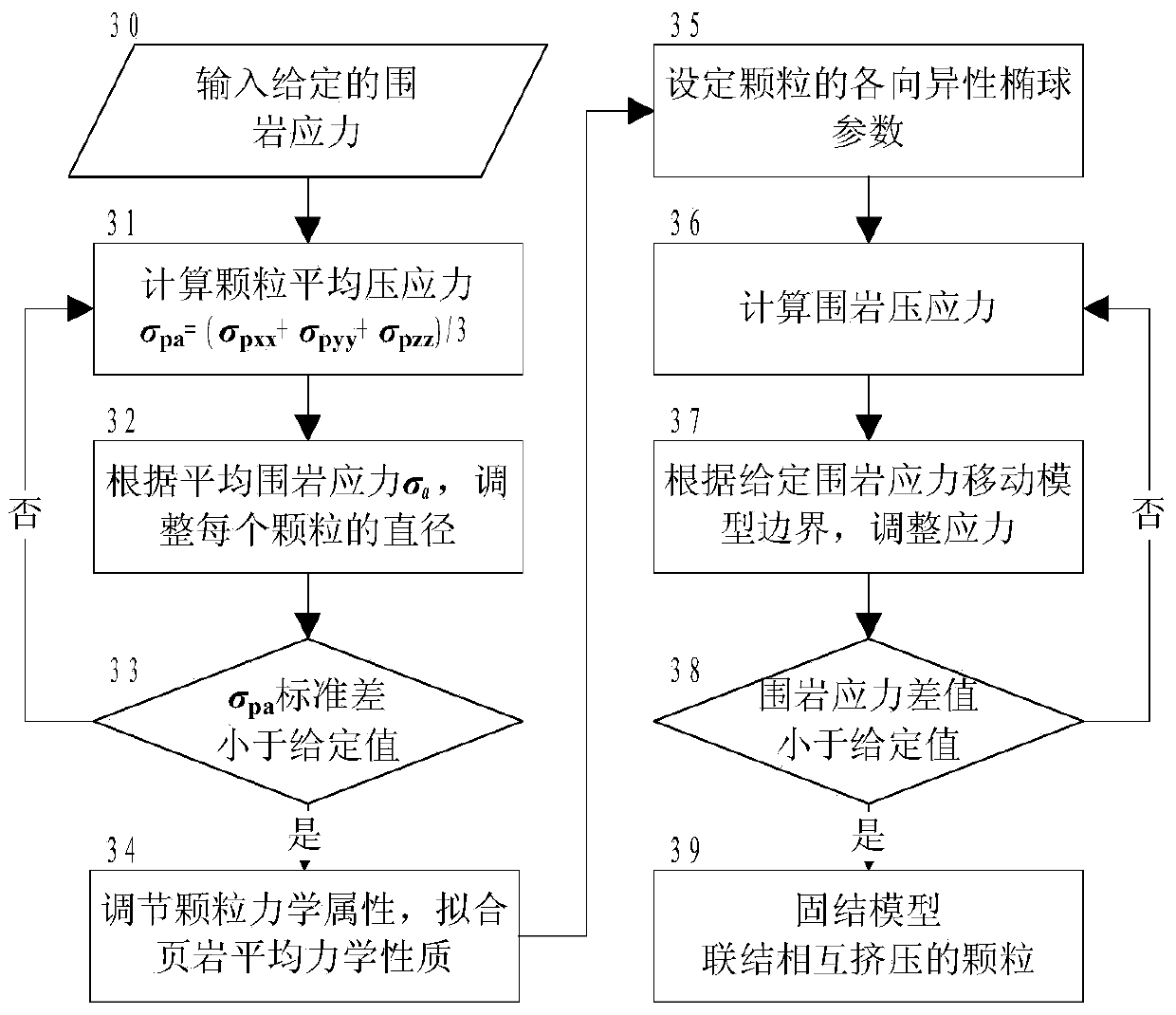

Method for modeling and simulating three-dimensional discrete element for shale pneumatic and hydraulic fracturing

ActiveCN103425899AAvoid it happening againAvoid the law of developmentFluid removalSpecial data processing applicationsHydraulic fracturingEngineering

The invention provides a method for modeling and simulating a three-dimensional discrete element for shale pneumatic and hydraulic fracturing. The method includes the steps of (1) establishing a three-dimensional close packing model with specific elastic property and destructive property according to a conversion formula, and establishing an integrated isotropic random module through particle diameter normal distribution adjustment and random packing, (2) adjusting the diameter of particles according to given confining pressure, setting particle anisotropic ellipsoid parameters, moving the boundary of the models, adjusting the confining pressure to the given value, and finally connecting a particle solidification model to obtain an anisotropic shale model with specific confining pressure and mechanical property, (3) establishing a hydraulic pressure cavity model and a hydraulic pressure boundary model according to requirements, generating hydraulic pressure and stress waves through mutual extrusion of water particles, and simulating generation and development of hydraulic fractures. The method avoids human influences of a traditional method based on continuity mechanics, can simulate the processes of hydraulic pressure propagation and hydraulic fracturing more really, and achieves predication of shale pneumatic and hydraulic fracturing.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com