Patents

Literature

966 results about "Living space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

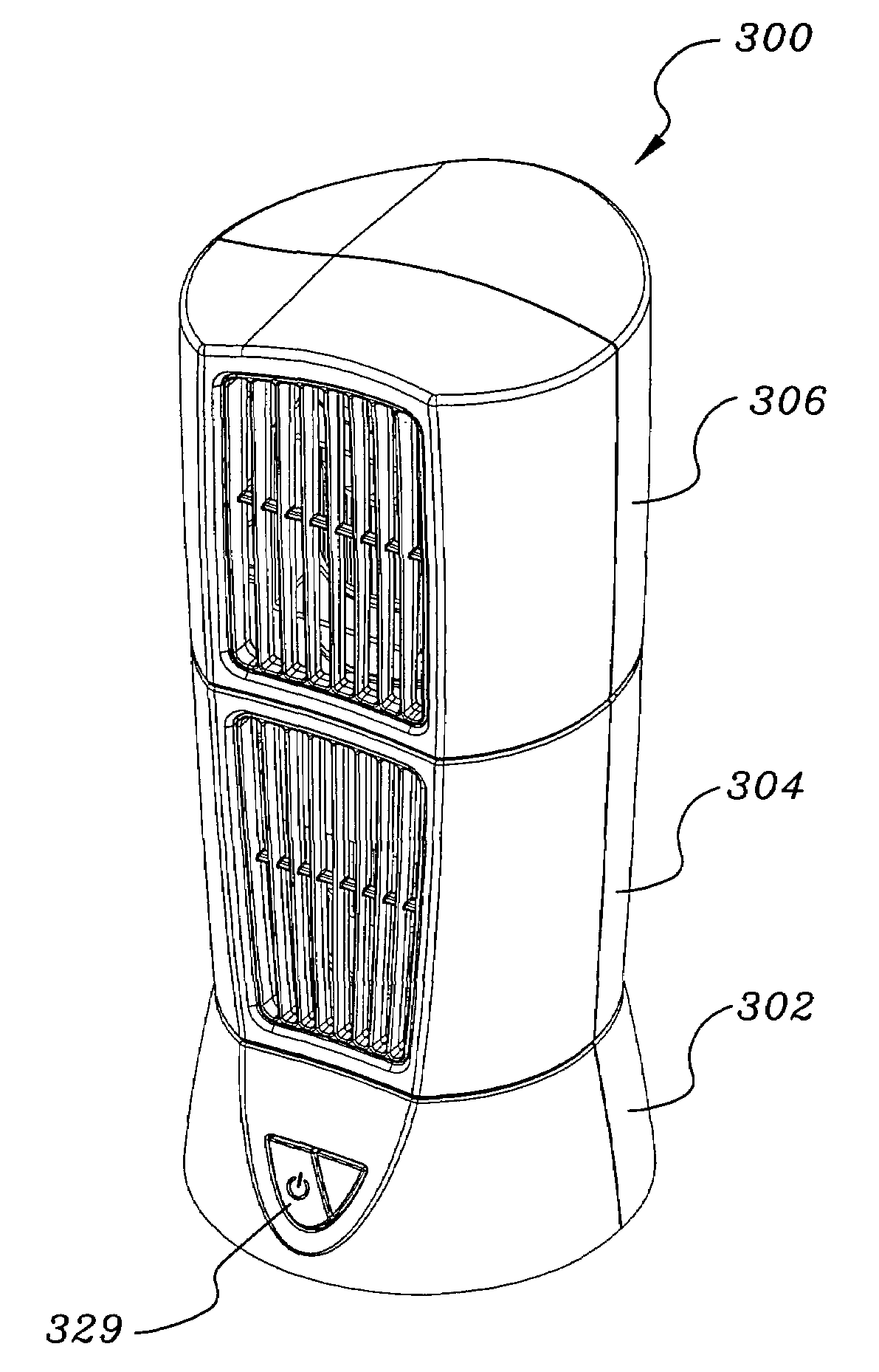

Multi-directional air circulating fan

Owner:LASKO OPERATION HLDG LLC

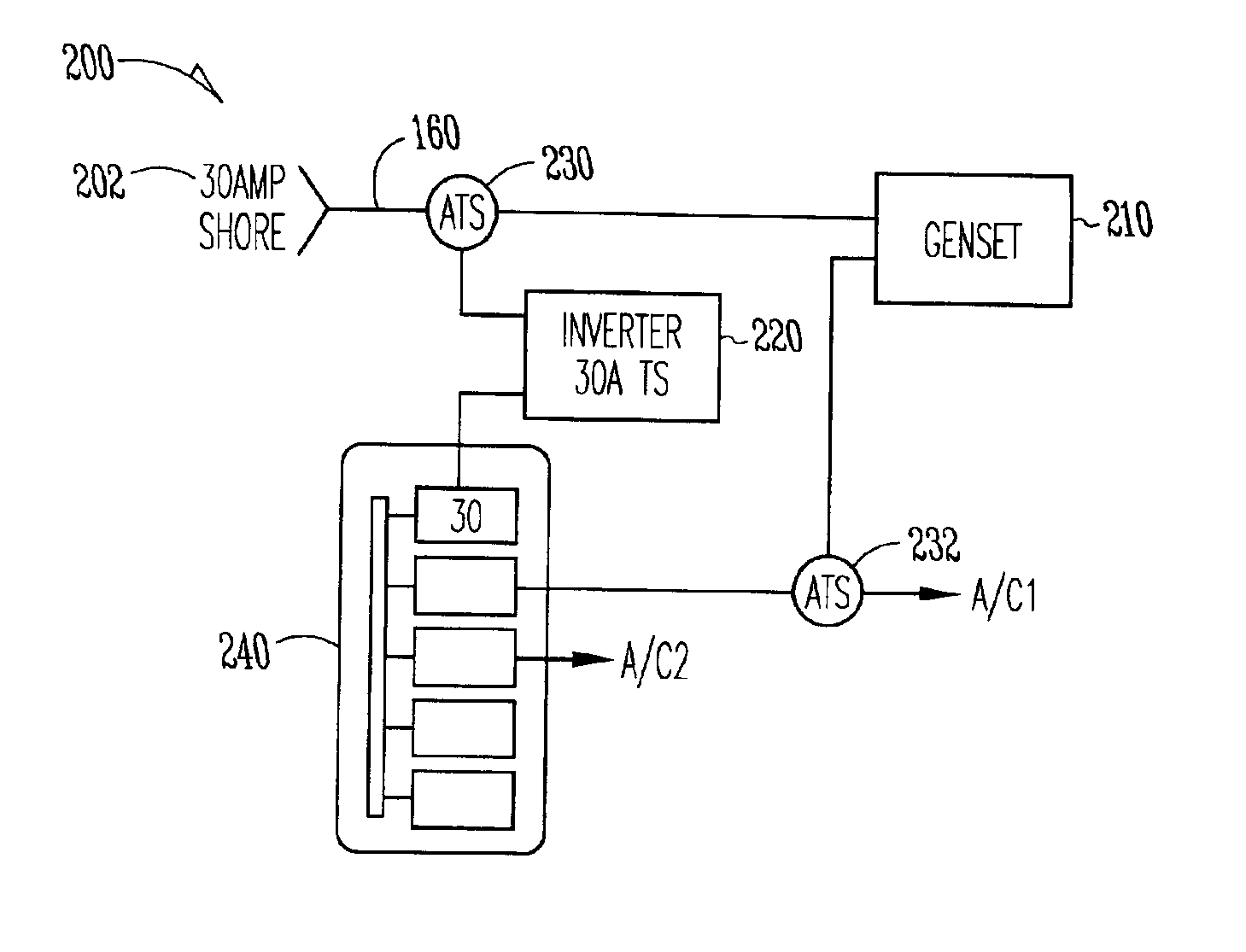

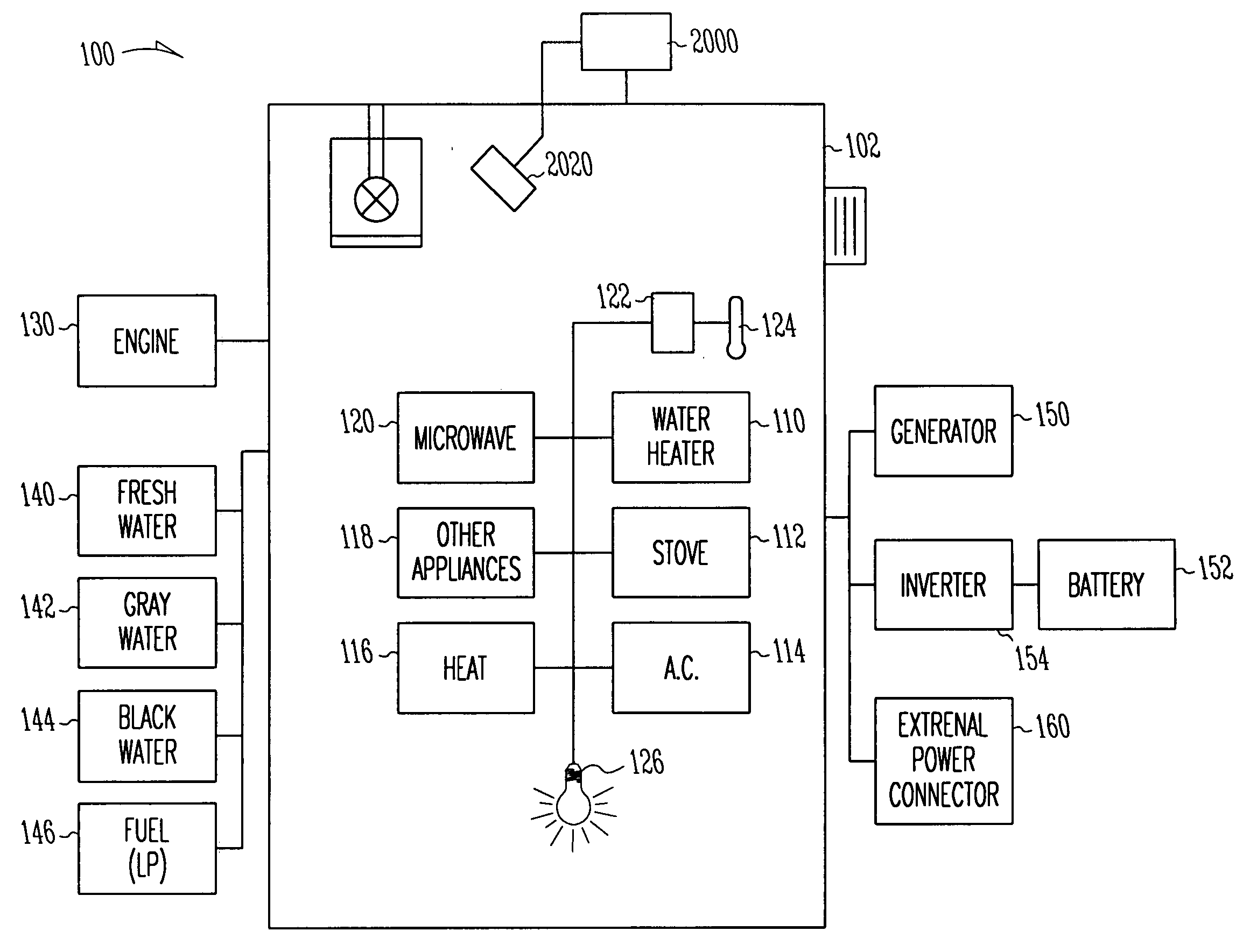

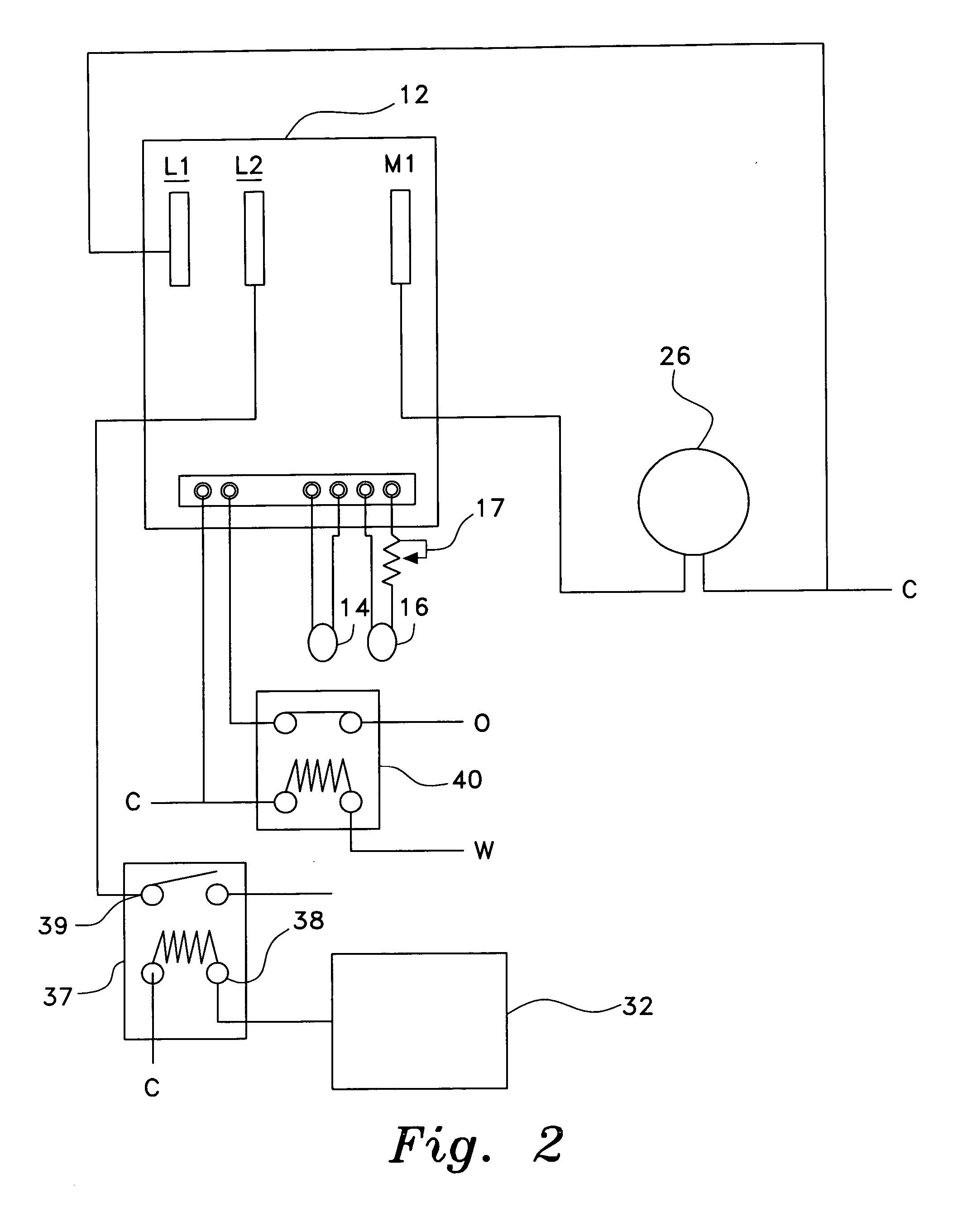

Mobile energy management system

InactiveUS6965818B2Easy to useDigital data processing detailsElectric power transfer ac networkElectricityDisplay device

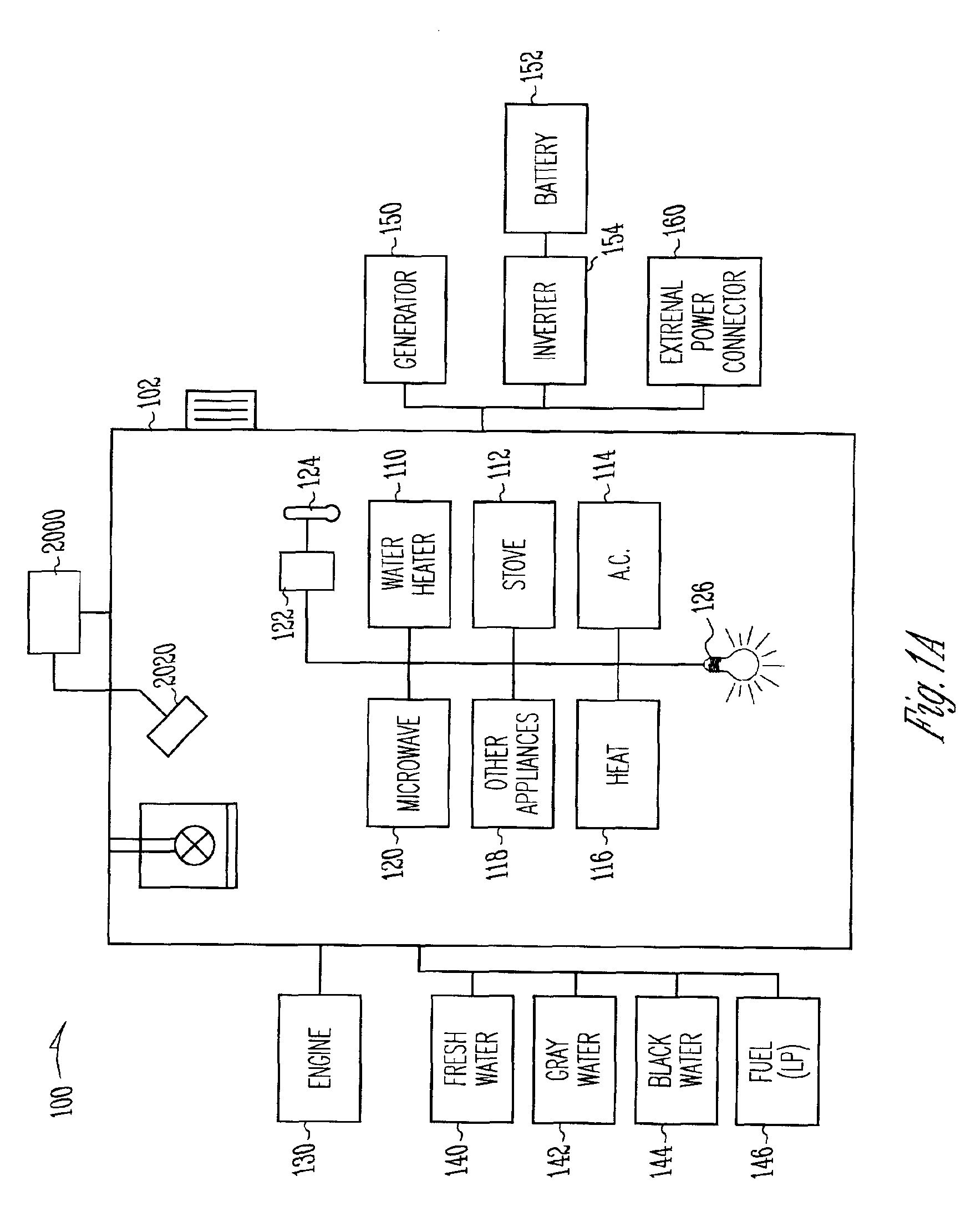

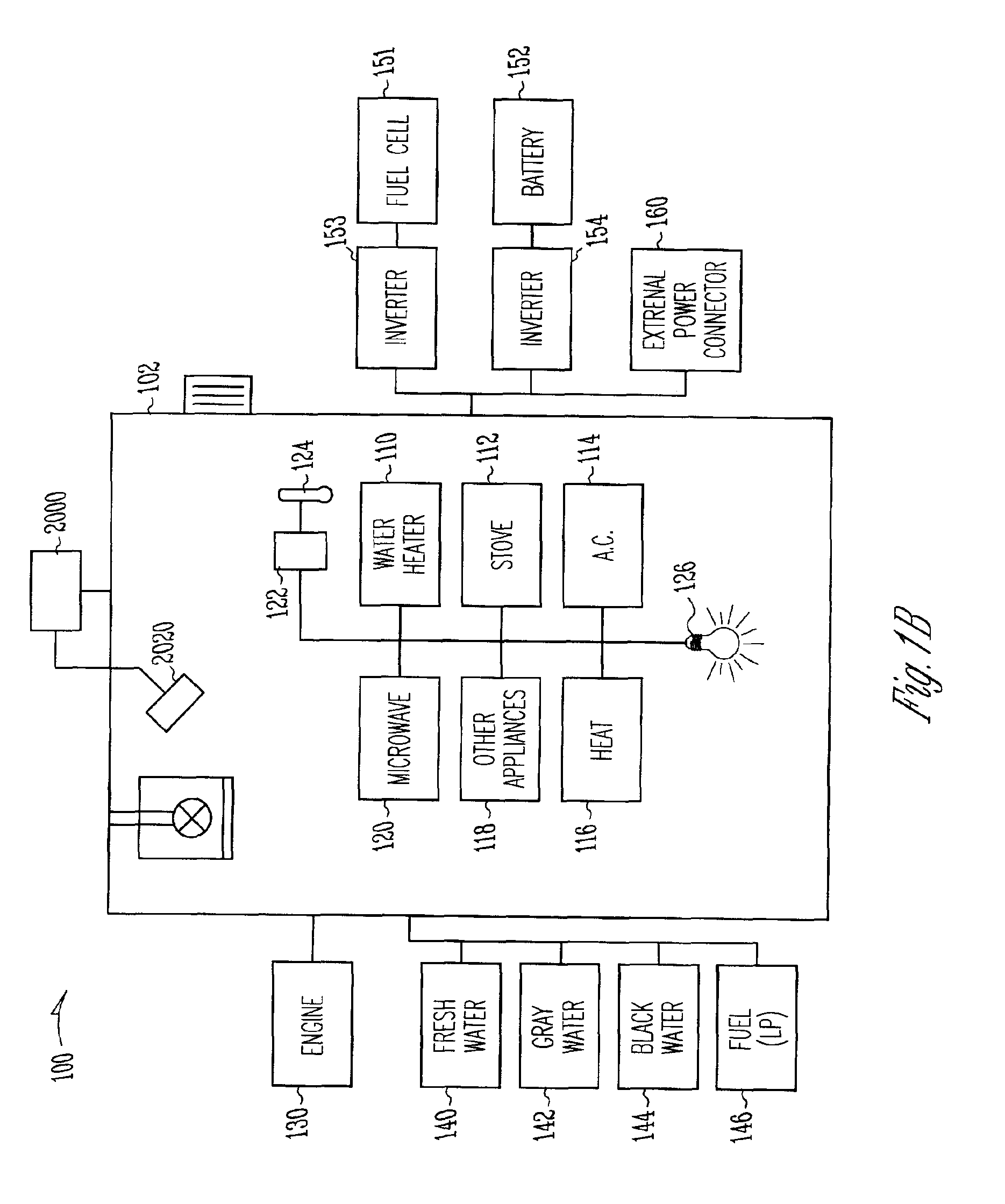

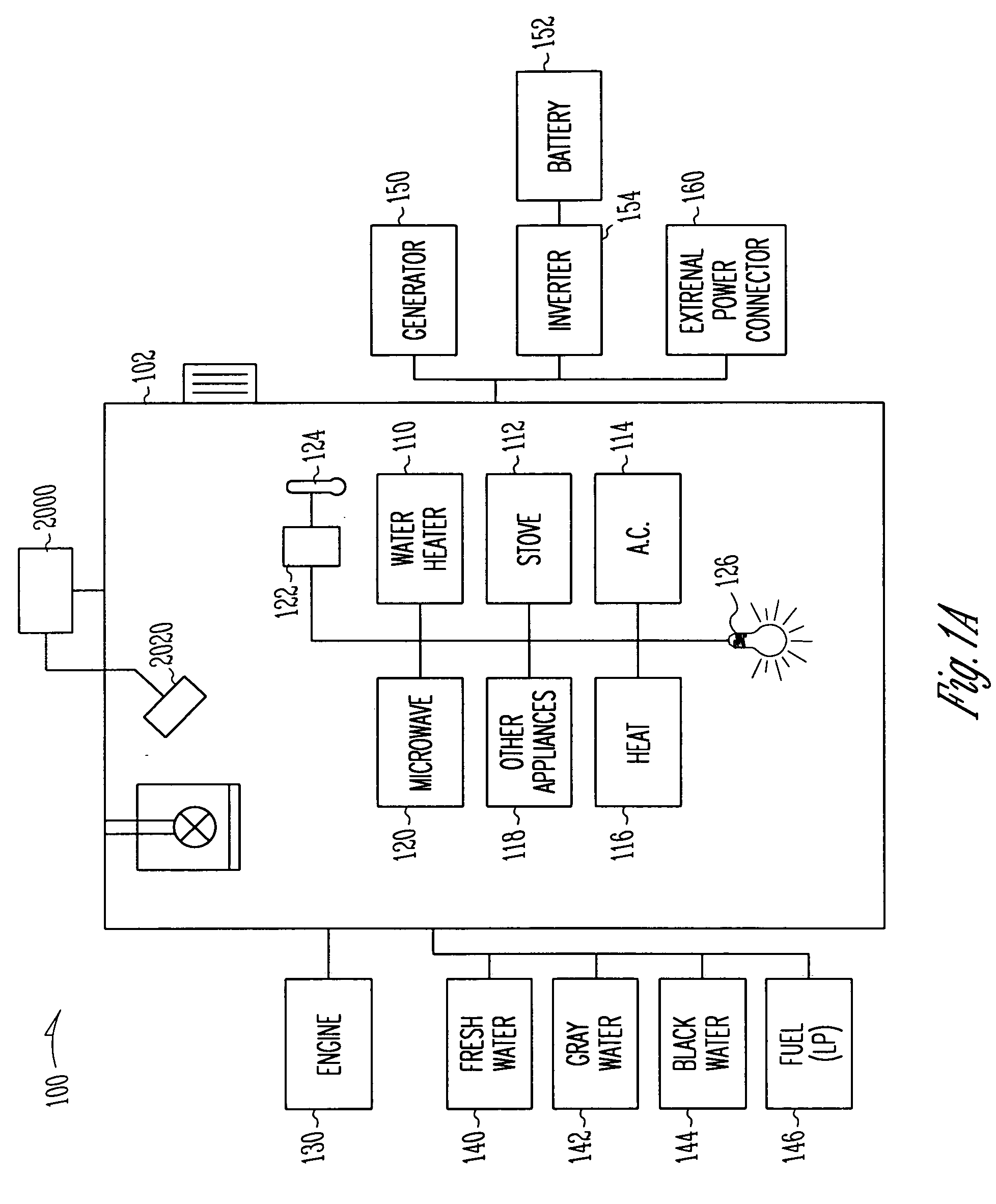

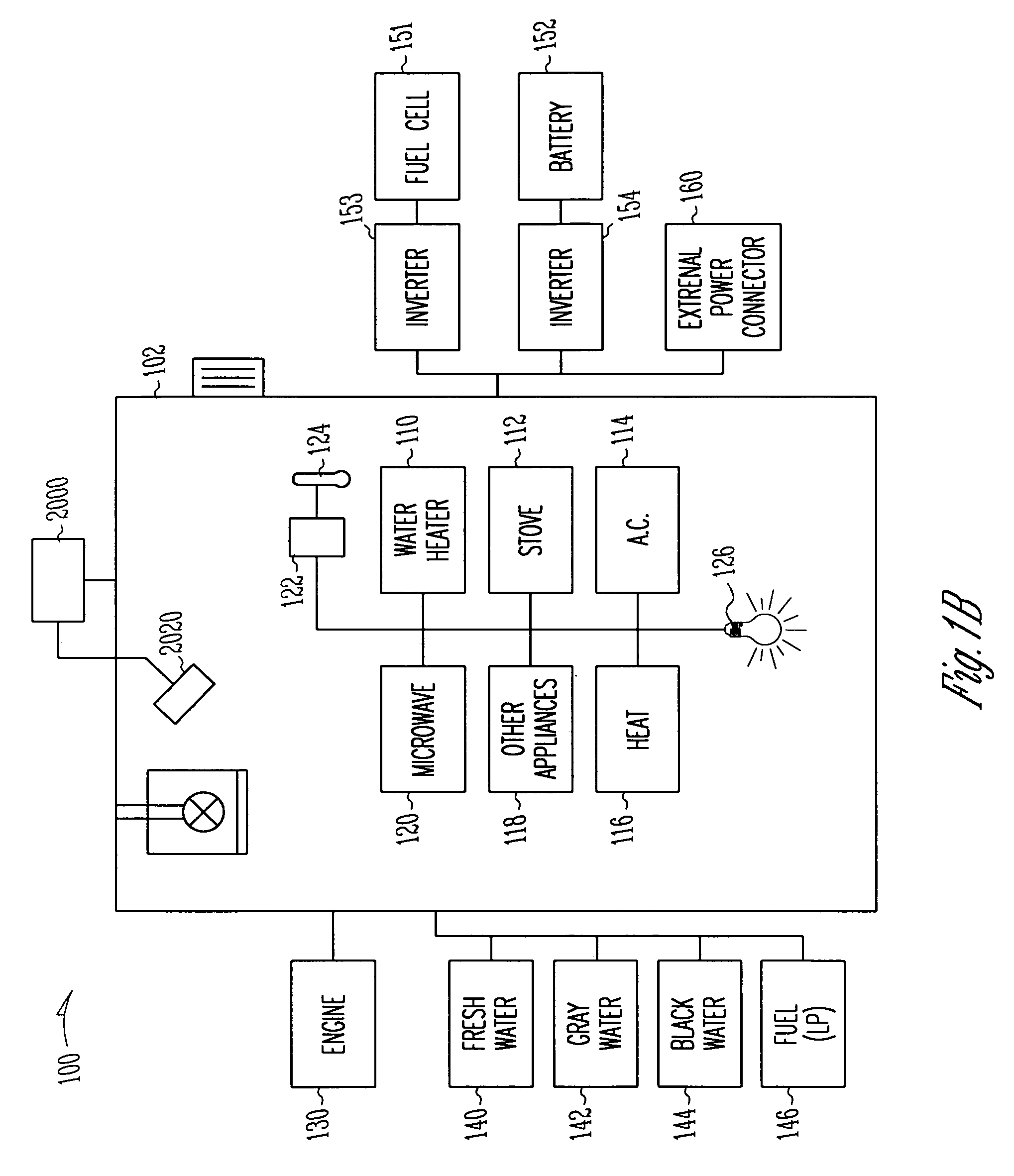

A recreational vehicle includes a chassis having a living space, an electrical system for providing electrical power to the living space, an air conditioner for cooling the living space, a heater for heating the living space, and a plurality of appliances within the living space attached to the electrical system. The recreational vehicle also includes an engine for moving the recreational vehicle, a motor generator for supplying power to the recreational vehicle, a connector for connecting the electrical system of the recreational vehicle to an external power source, and a local area network system electrically connected to the air conditioner, the heater, the plurality of appliances, and the motor generator. The local area network manages the power provided to the to the electrical appliances. A display positioned within the living space shows data related to the air conditioner, the heater, the plurality of appliances, the motor generator and the engine.

Owner:ONAN

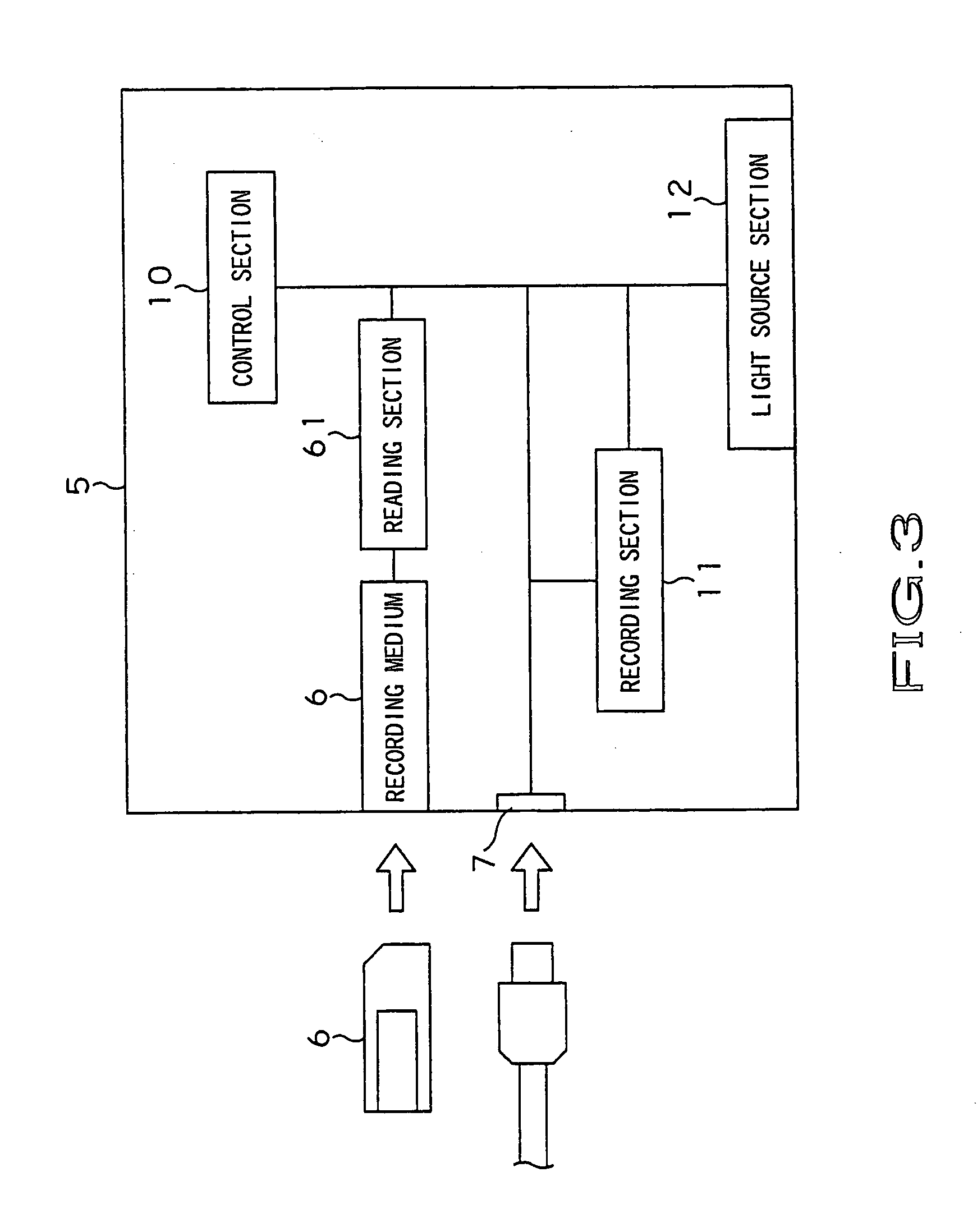

Communications system and communications lighting apparatus

InactiveUS20050002673A1Low costLow cost installationLine-of-sight transmissionClose-range type systemsCommunications systemLight equipment

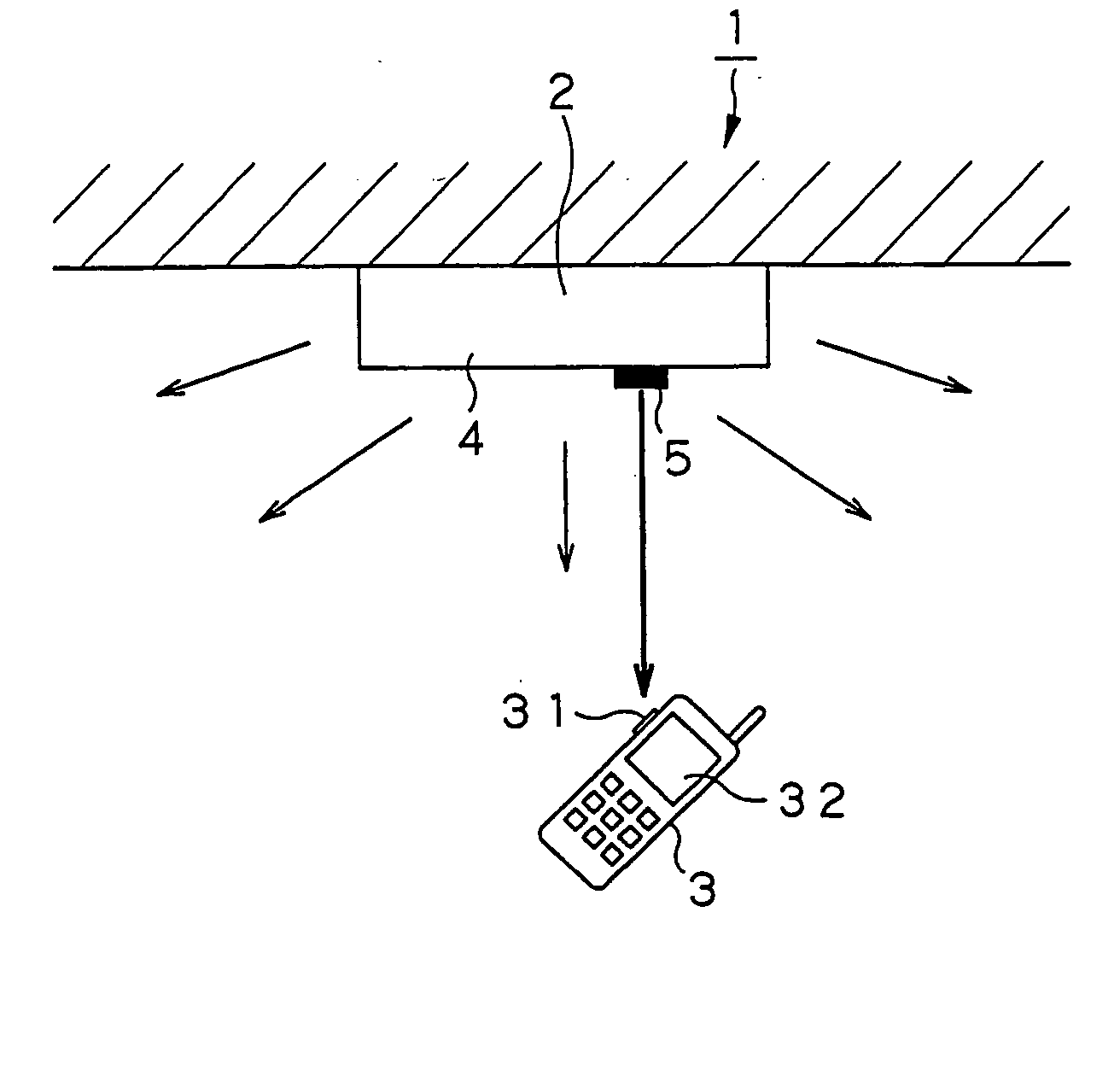

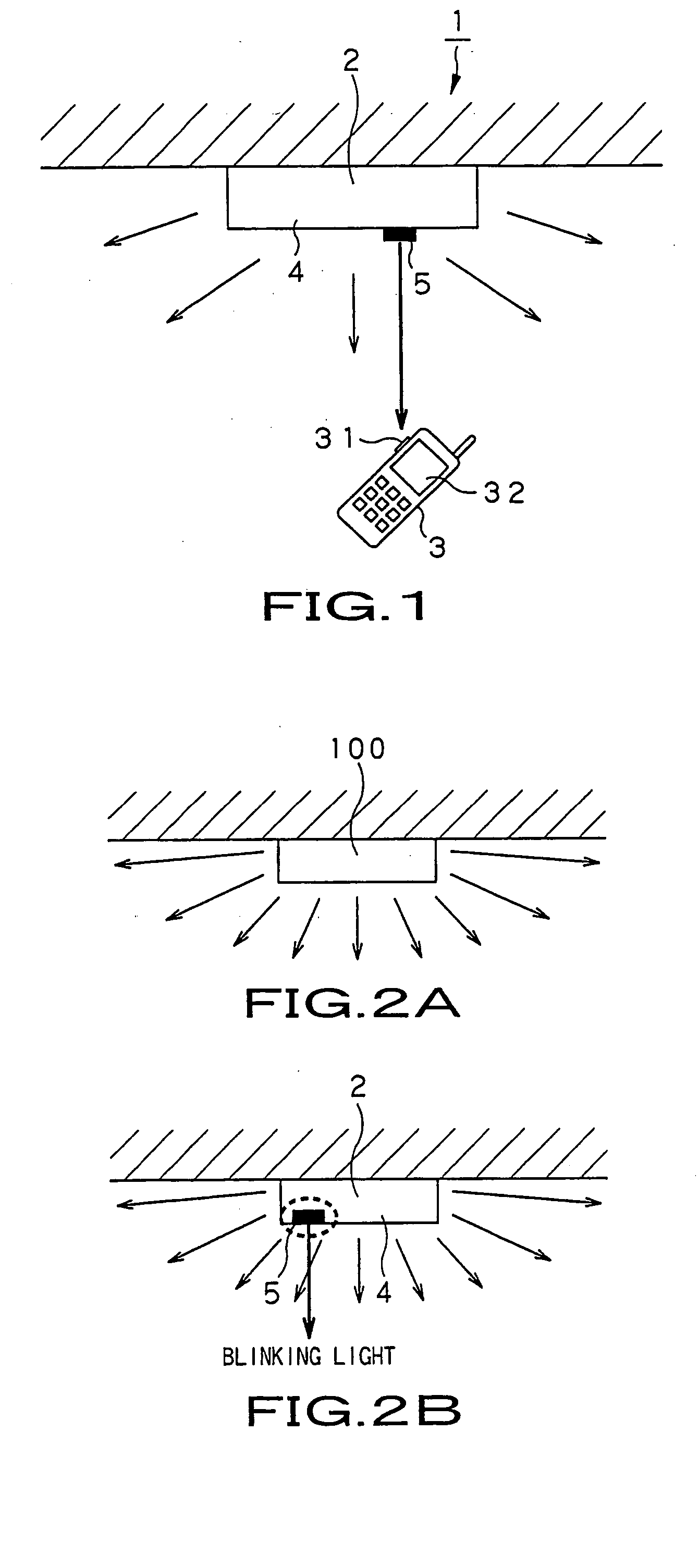

An optical-information transmitting, lighting apparatus 2 is installed in a place where a lighting apparatus of the existing type for applying light generally used is provided. The lighting apparatus 2 comprises an illumination light source 4 for applying light and an information-transmitting unit 5 for transmitting optical information. A person who may receive information from the lighting apparatus 2 has a mobile terminal 3, which receives the optical information transmitted from the information-transmitting unit 5. Since the lighting apparatus of the existing type is widely used in our living space. Hence, the optical-information transmitting, lighting apparatus 2 can convert every place where an existing type lighting apparatus is used, into an optical communications space.

Owner:SONY CORP

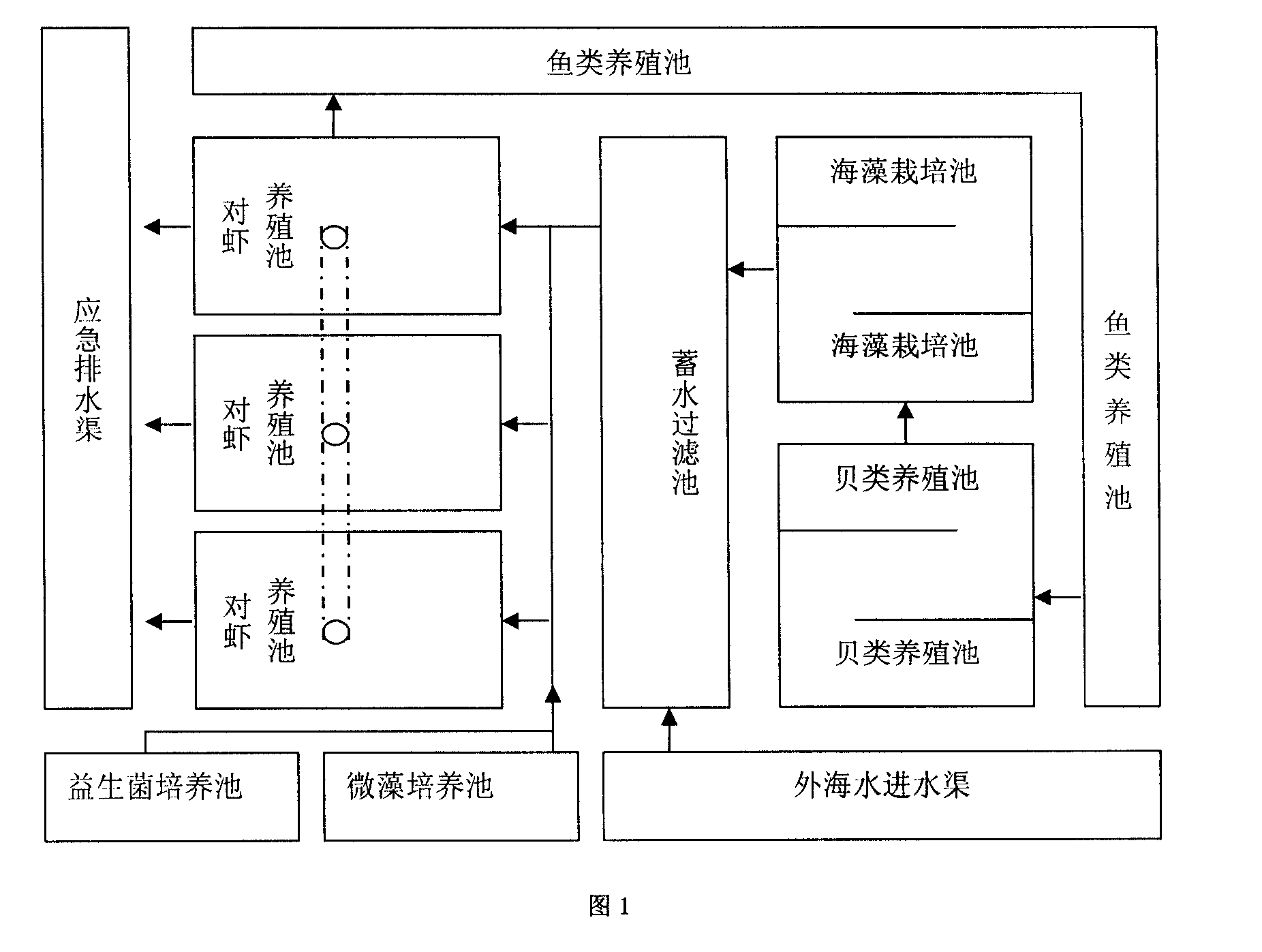

Shrimp-fish-shellfish-algae multiple cultivation and water quality biological regulate and control system thereof

InactiveCN101248766AAvoid direct competitionReduce mutual harmClimate change adaptationMultistage water/sewage treatmentMacrocystis pyriferaWater quality

The invention provides a shrimp-fish-shellfish-alga multi-unit culture and aquatic organism regulation system thereof. A shrimp culture zone, a fish culture zone, a shellfish culture zone, a large scale alga cultivation zone, a probiotics and microalga culture zone, a water processing zone and an emergency drainage system are arranged in a closed water circulation culture system, wherein the culture water circulates in different culture and water processing units. As the water circulates in different culture units and is utilized in multiple levels by various aquatic organisms of different trophic level and ecological niche, the system gives the various aquatic organisms full play to the positive bait resource complementarity, prevents the aquatic organisms from directly competing on living space and dissolved oxygen and reduces the mutual damage caused by organic remains and metabolic waste, achieves the 'self-modification' and 'biomanipulation' of the culture environment, enables the environment itself to recover from the pollution in culture process, and decontaminates the seawater culture environment.

Owner:GUANGDONG OCEAN UNIVERSITY

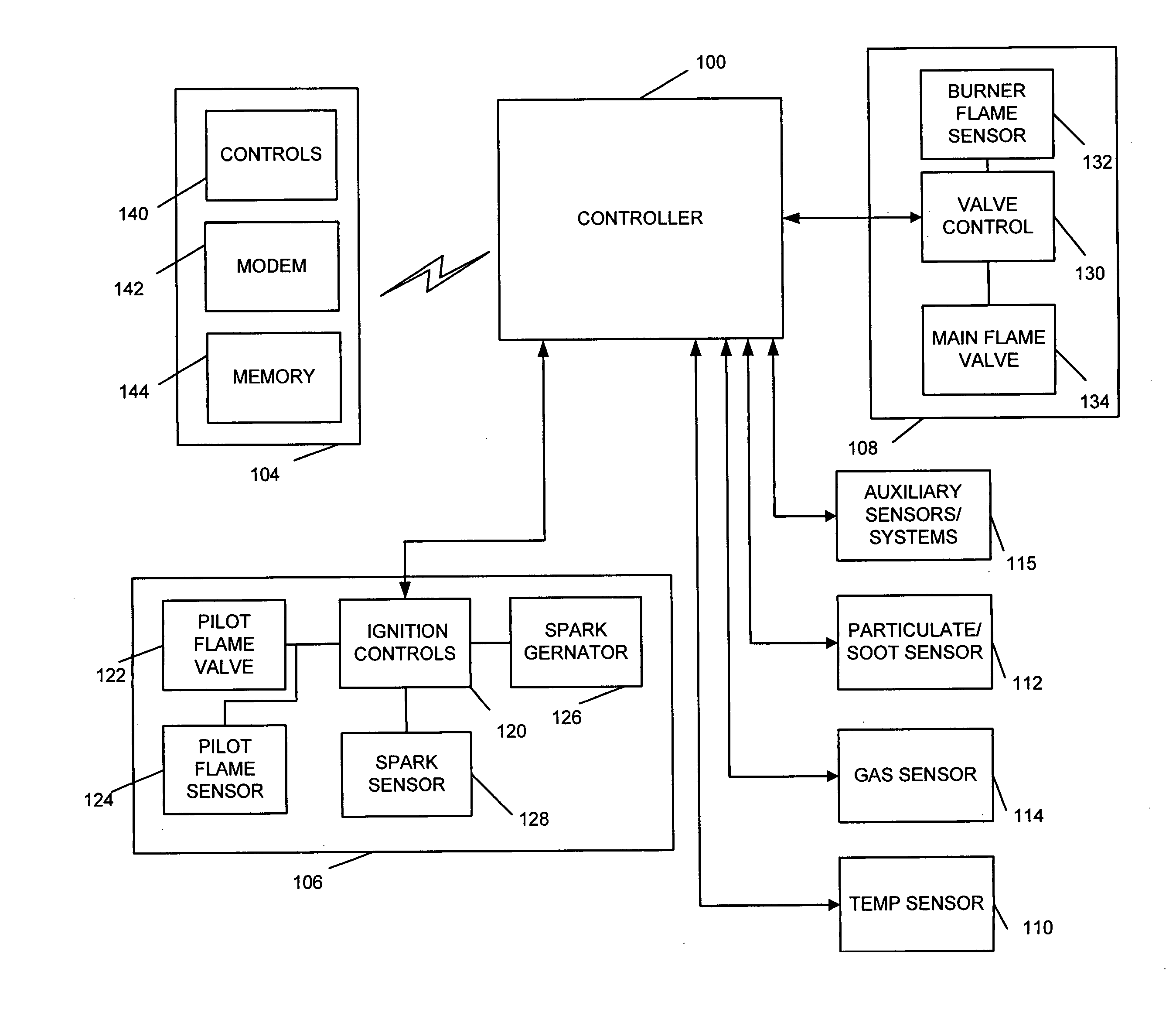

Gas fireplace monitoring and control system

A monitoring and control system for use with a decorative heating appliance such as a fireplace, stove, or fireplace insert. The monitoring and control system includes a sensor module, a computer system, a controller, and a communication system. The sensor module is configured to monitor a burner, gas valve, and ignition system of the heating appliance and generate monitoring signals. The controller is configured to generate fault condition signals based on the monitoring signals. The communication system is configured to communicate the fault condition signals to the computer system, wherein the computer system is located remotely from a living space within which the heating appliance resides. The computer system is configured to generate control signals in response to predetermined fault condition signals and communicate those signals to the controller via the communication system for control of at least one of the burner, gas valve, and ignition system or other functions of the heating appliance.

Owner:HNI TECH INC

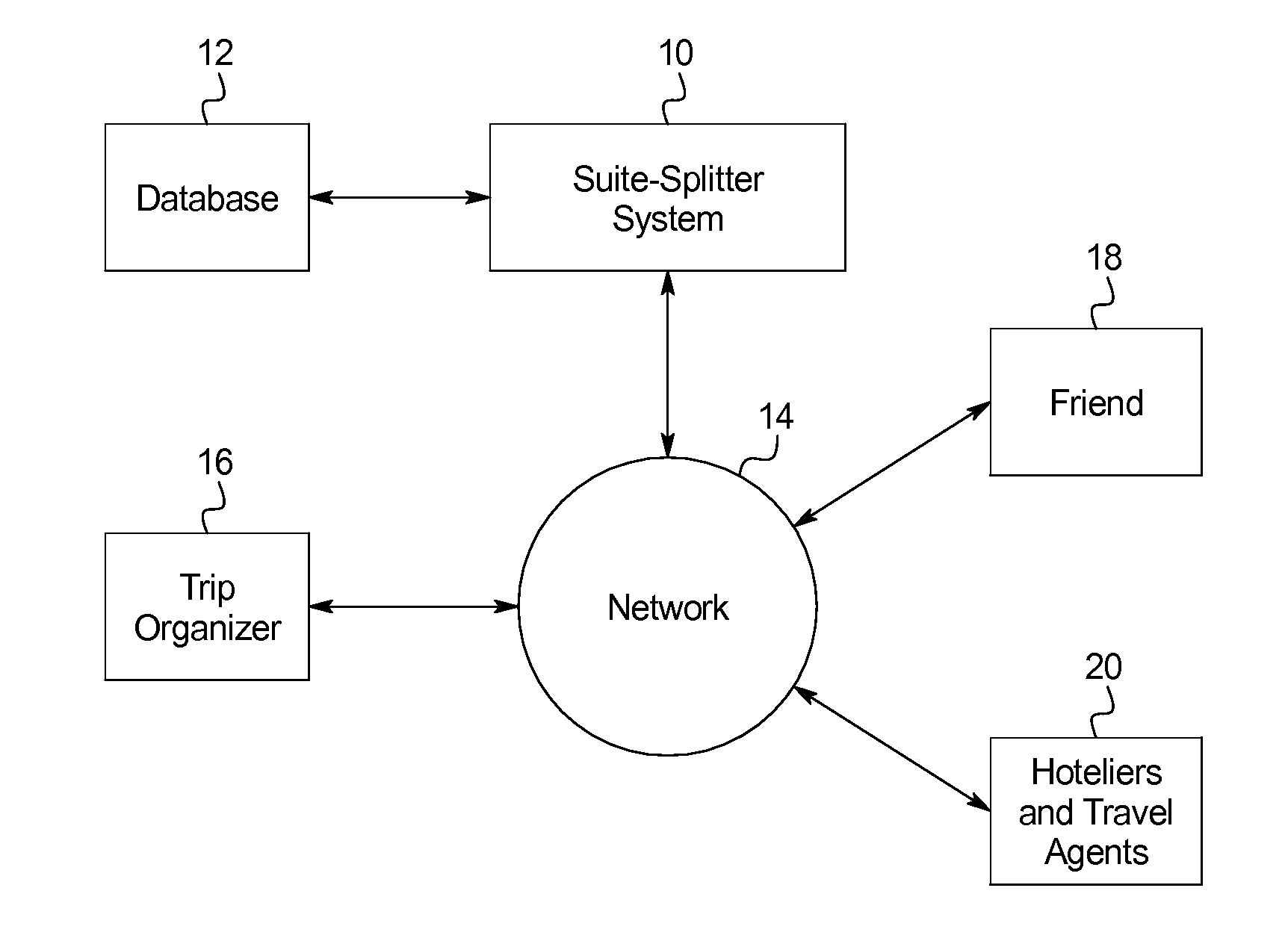

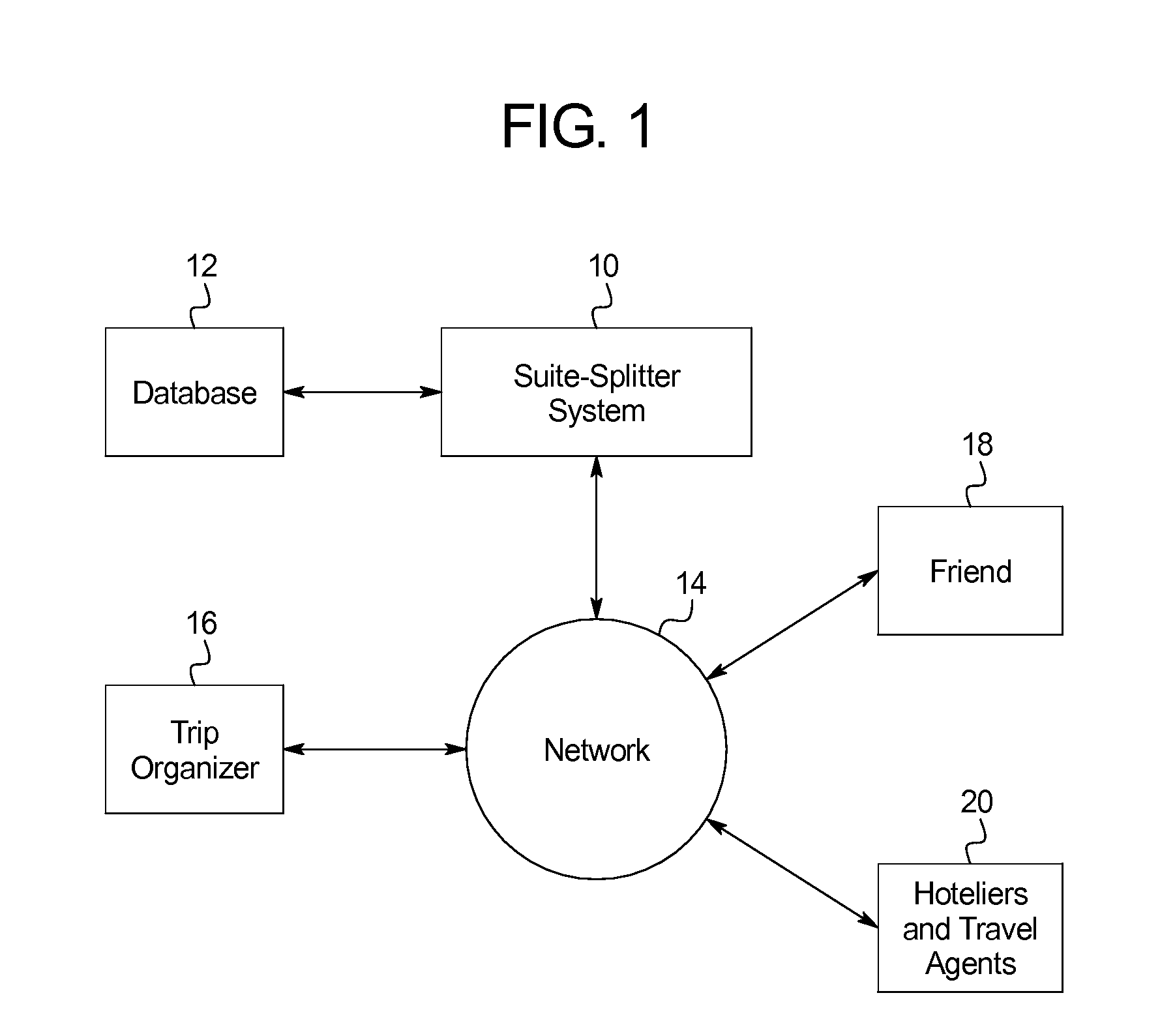

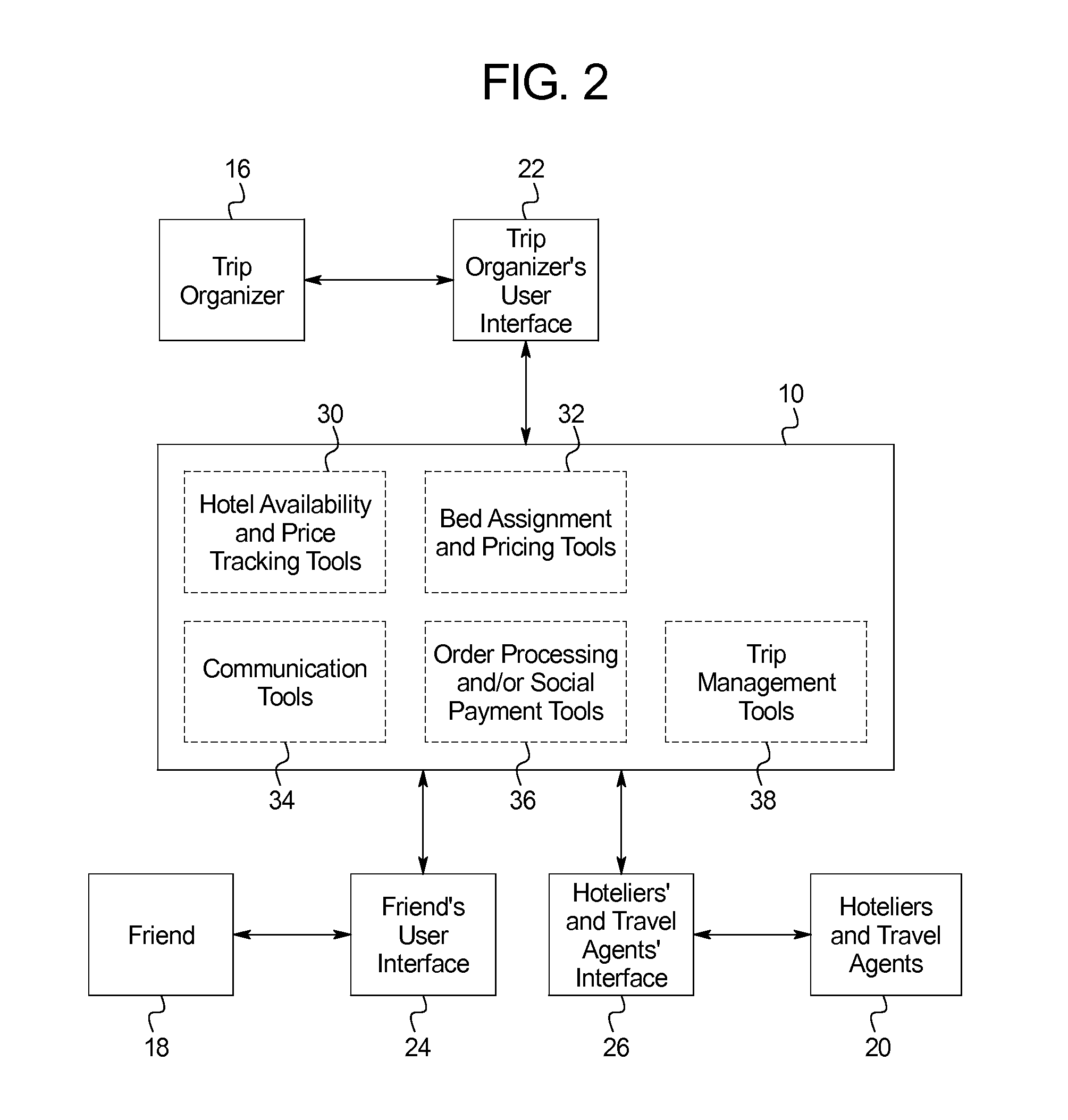

Systems and methods for optimizing markets for temporary living space

A computer implemented method of allocating costs of a rentable unit across two or more users includes the steps of: assigning two or more users to an event; assigning a date range to the event; assigning a rentable unit to the event, wherein the rentable unit includes two or more heterogeneous sleeping areas and a total price for the assigned date range; assigning a sleeping area to each of the users; and allocating a sub-total to each of the users based on relative value of the assigned heterogeneous sleeping area, wherein the sum of the allocated sub-totals equals the total price of the rentable unit for the assigned date range.

Owner:SUITEST IP GRP

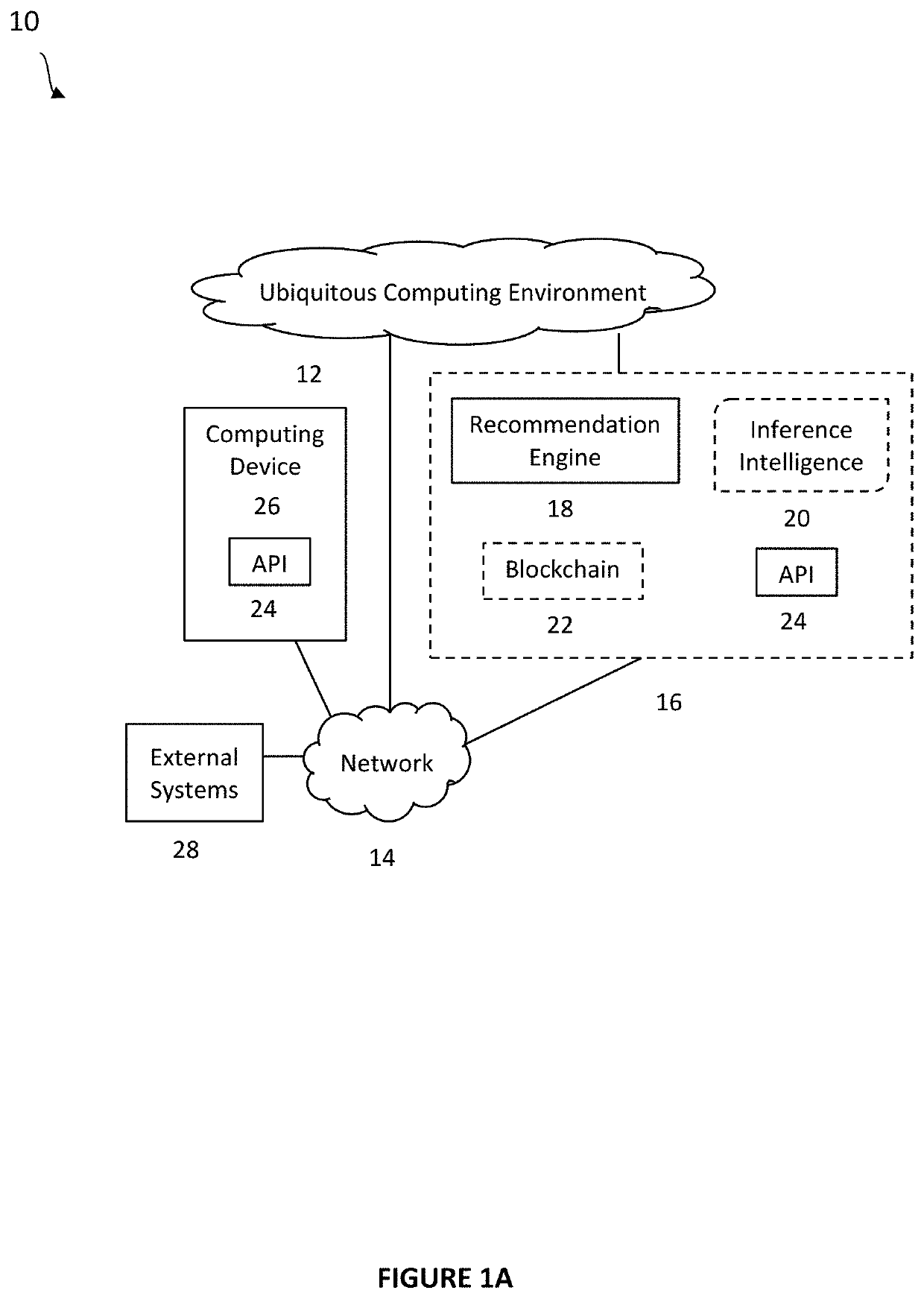

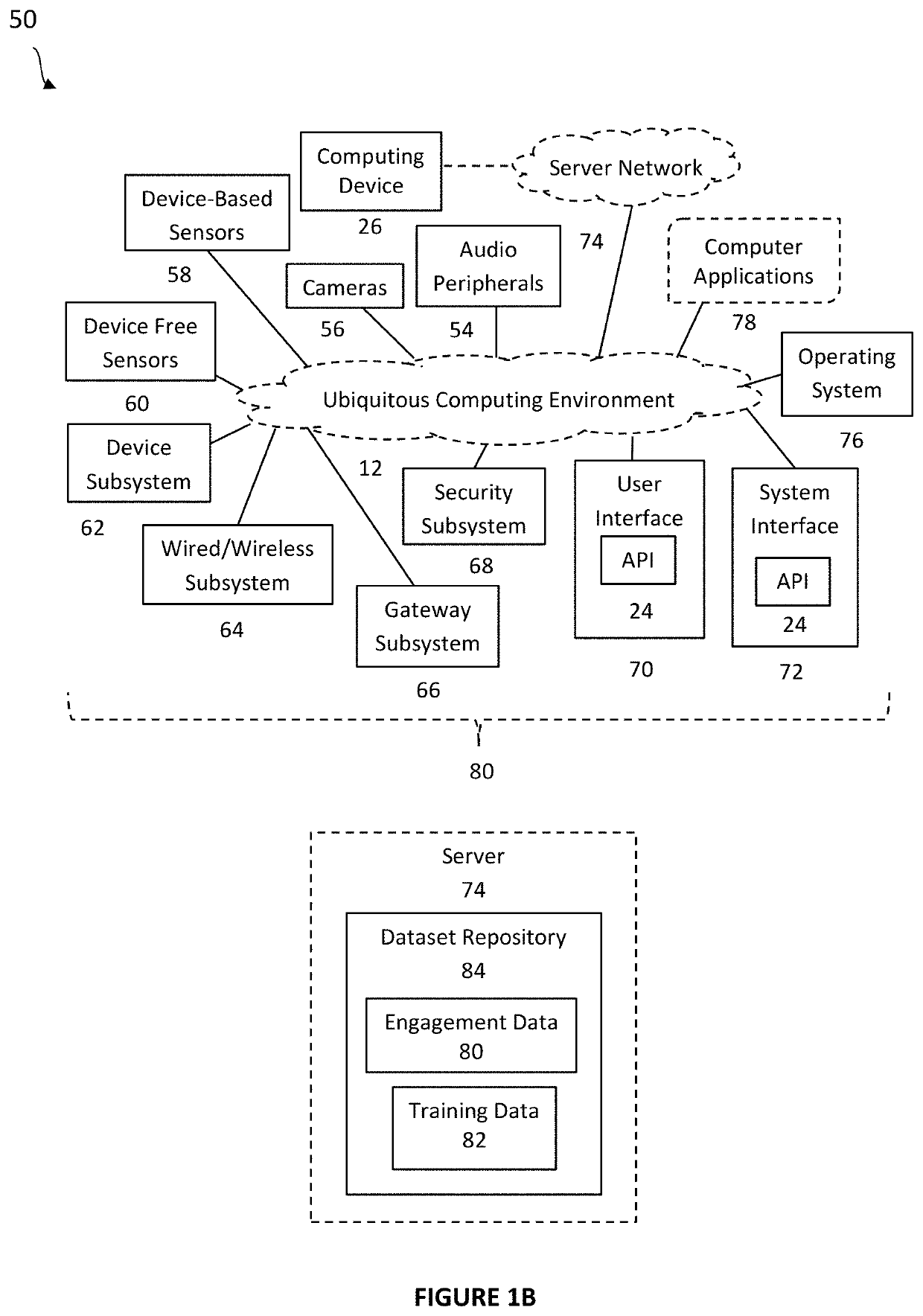

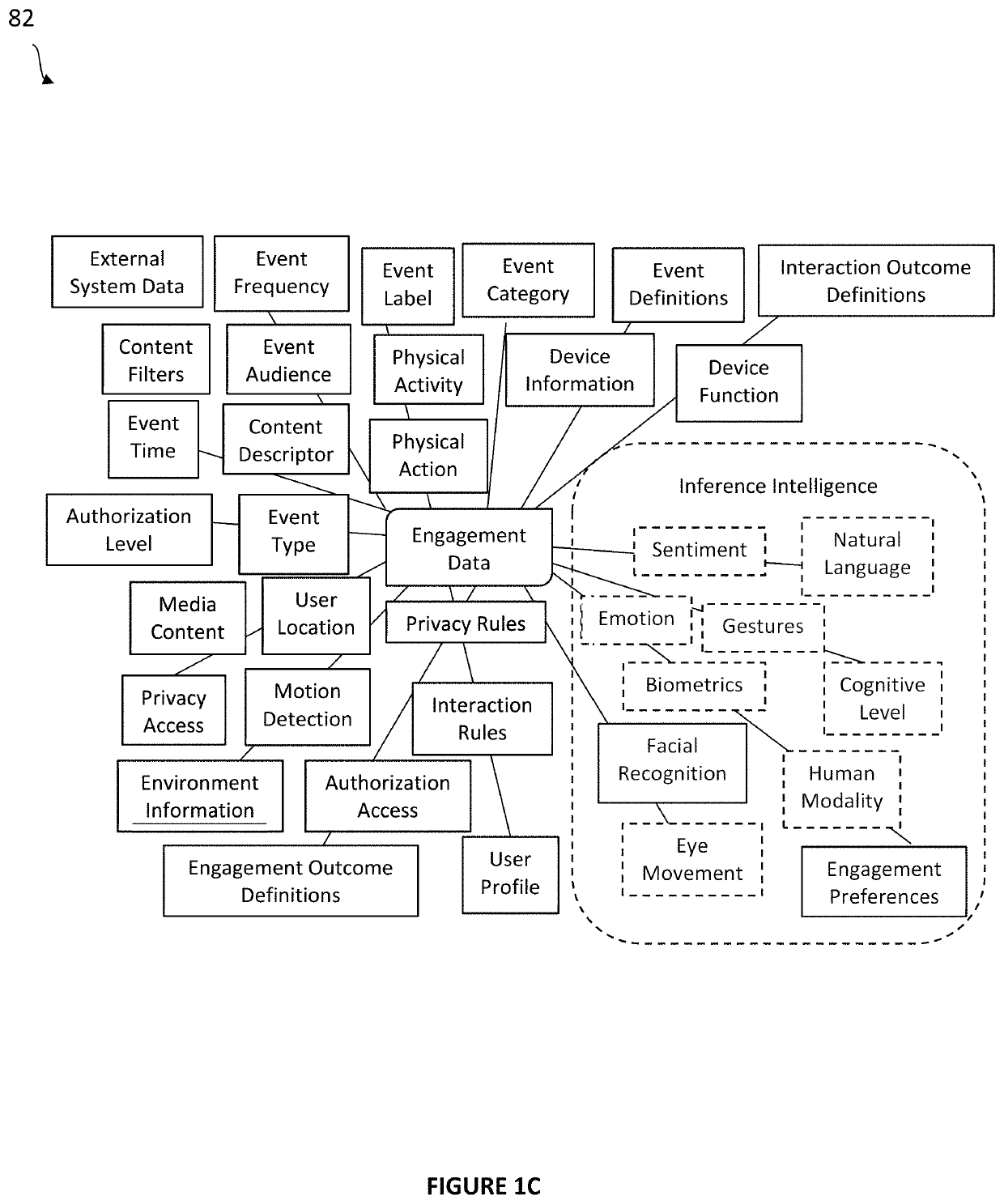

System and method for recommendations in ubiquituous computing environments

ActiveUS20200364588A1Particular environment based servicesCharacter and pattern recognitionEngineeringBehavioral data

Systems and methods for creating an ad hoc pervasive computing environment comprised of an inference recommendation engine coupled to commodity devices and sensors that passively collect human activity and behavioral data. Methods include machine learning and deep learning applications that analyze data to generate preference based recommendations to assist, inform, and guide subjects interacting with a connected living space and their connected social network.

Owner:KNOX GREGORY

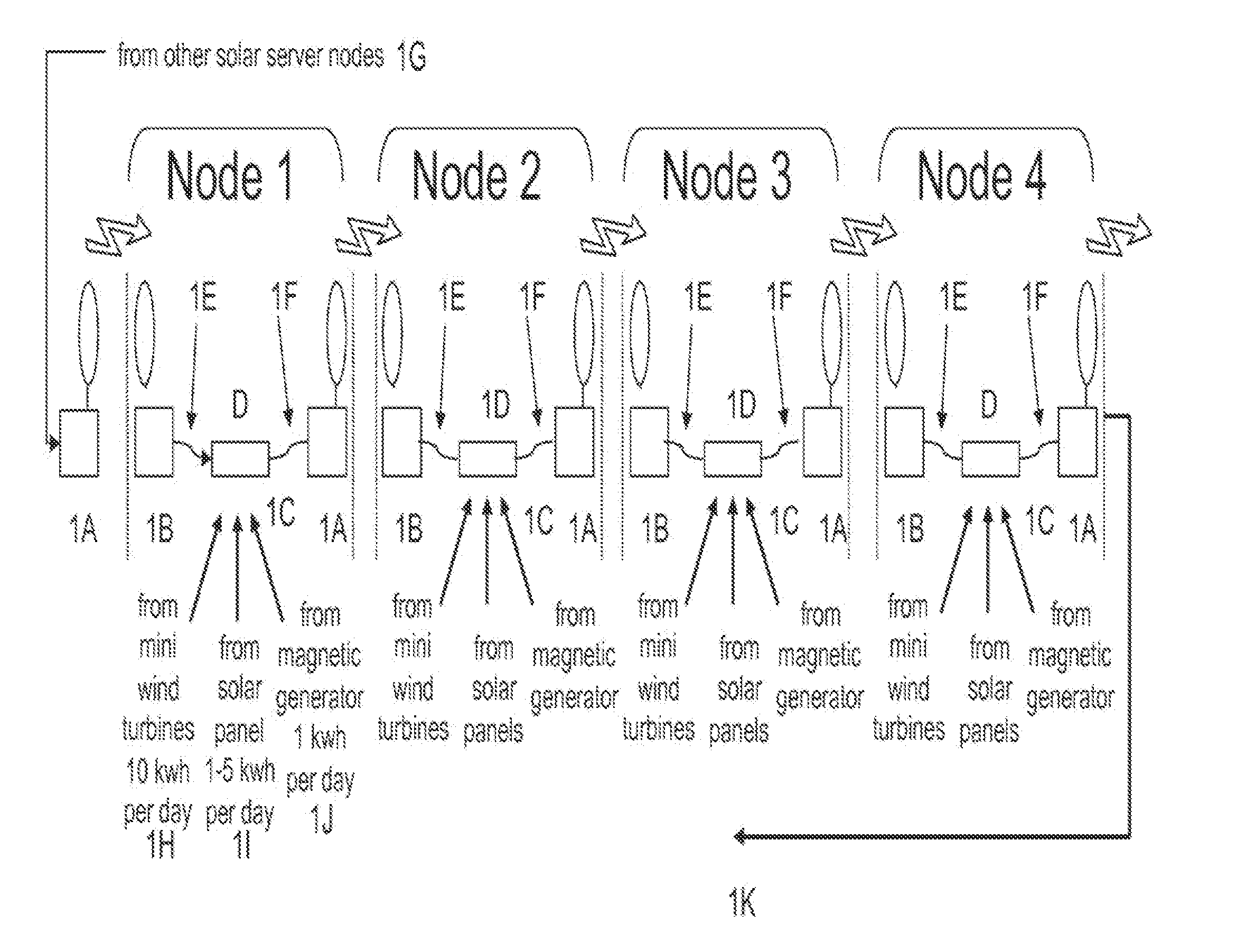

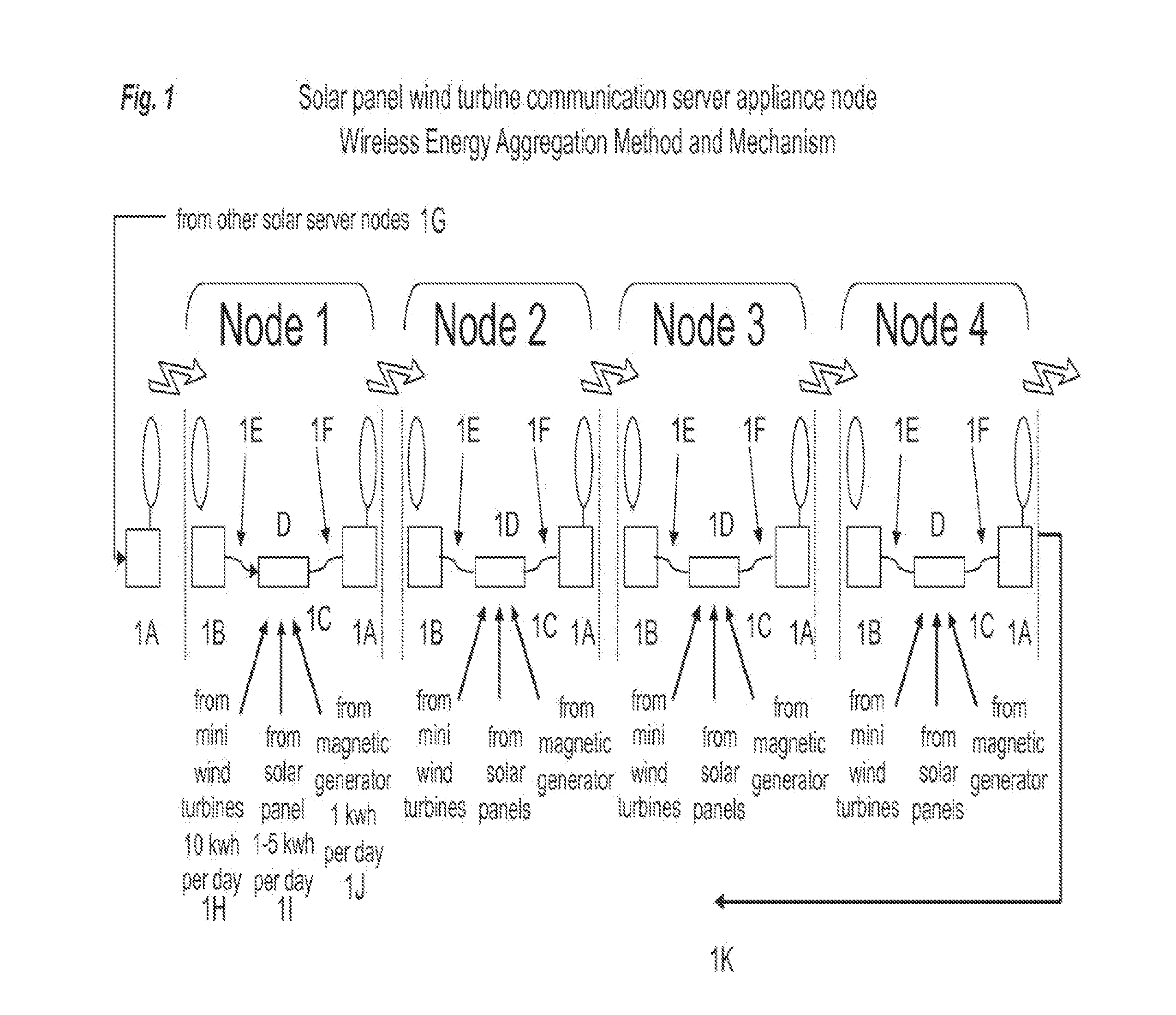

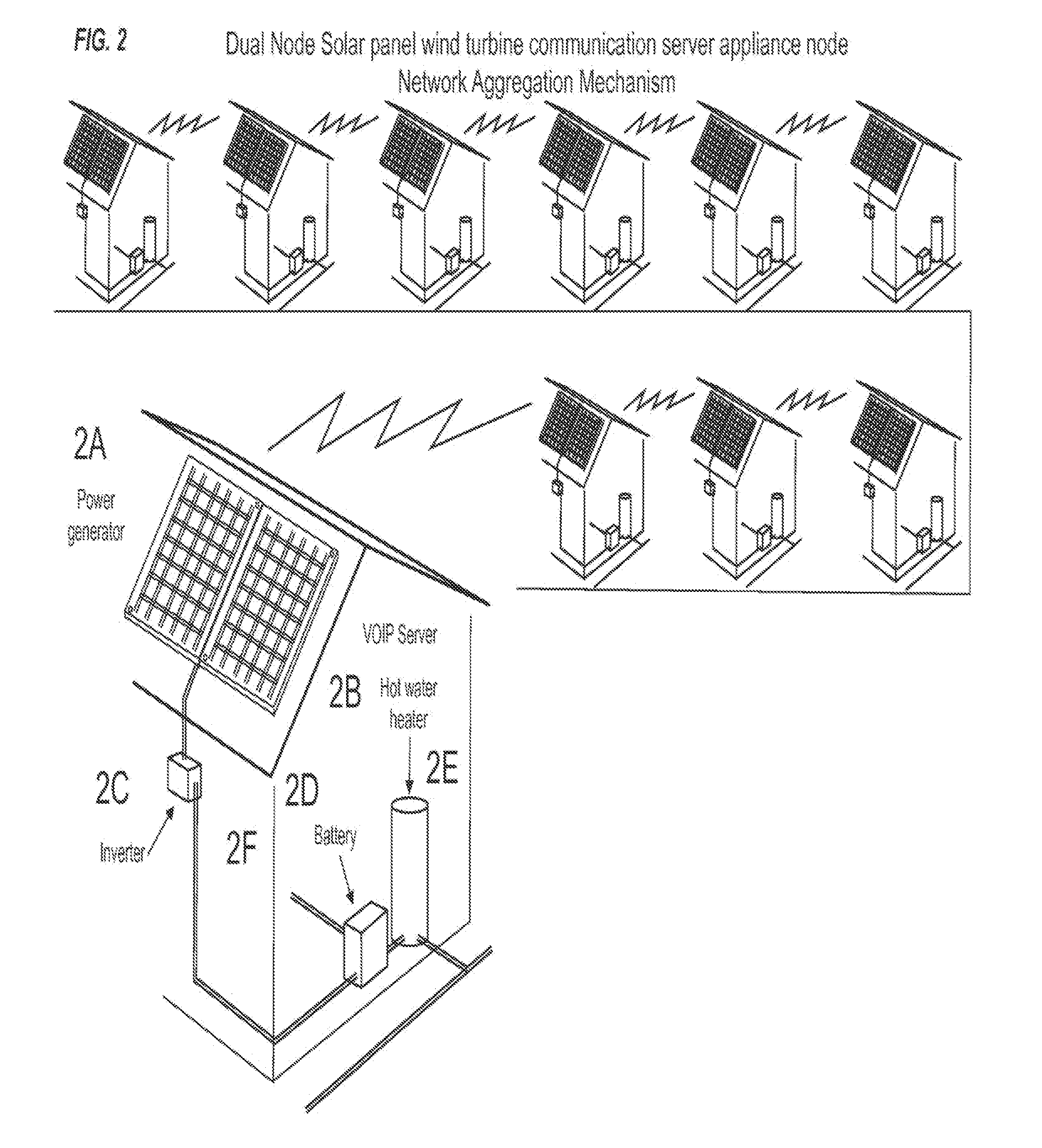

Solar panel wind turbine communication server network apparatus method and mechanism

InactiveUS20140176337A1Reduce energy costsConsume energySolar heating energyElectric signal transmission systemsOnline and offlineEngineering

The method included herein is an alternative energy wireless solar panel wind turbine communication server appliance node mechanism with built in communications server array, wireless energy and communications mechanism with protection, sharing, storage, accessing, authentication, battery management, certification, processing attachment and tracking mechanisms. The method and mechanism is utilized via networked servers, solar panels, and wireless electronic devices (online and offline) as well as mobile (wireless) communications devices built into one waterproof, temperature, controlled self-sensing hardware package. The method and mechanism also works as part of a kilowatt hour banking system, and thermal passive solar control mechanism for living spaces.

Owner:VALIN DAVID +1

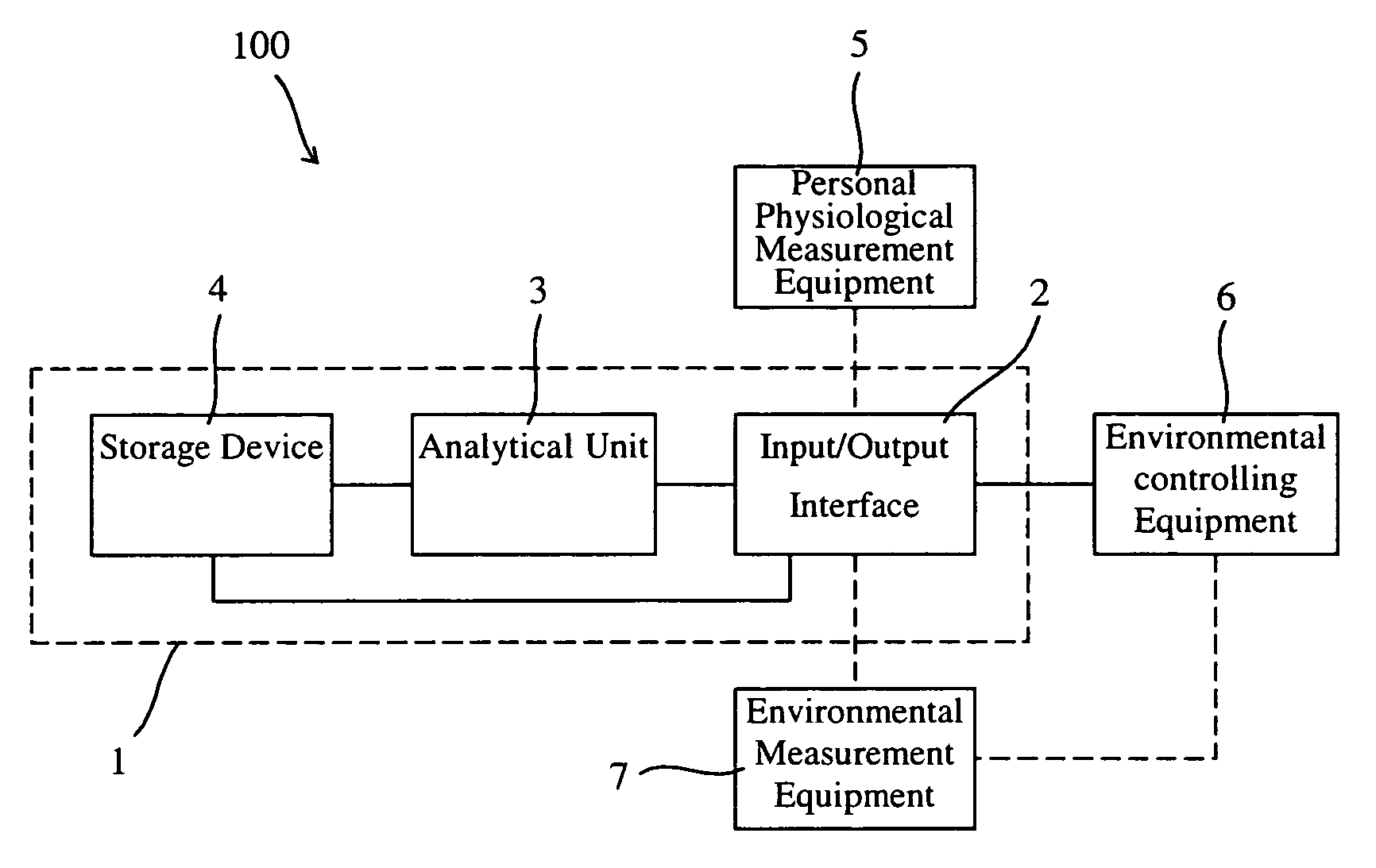

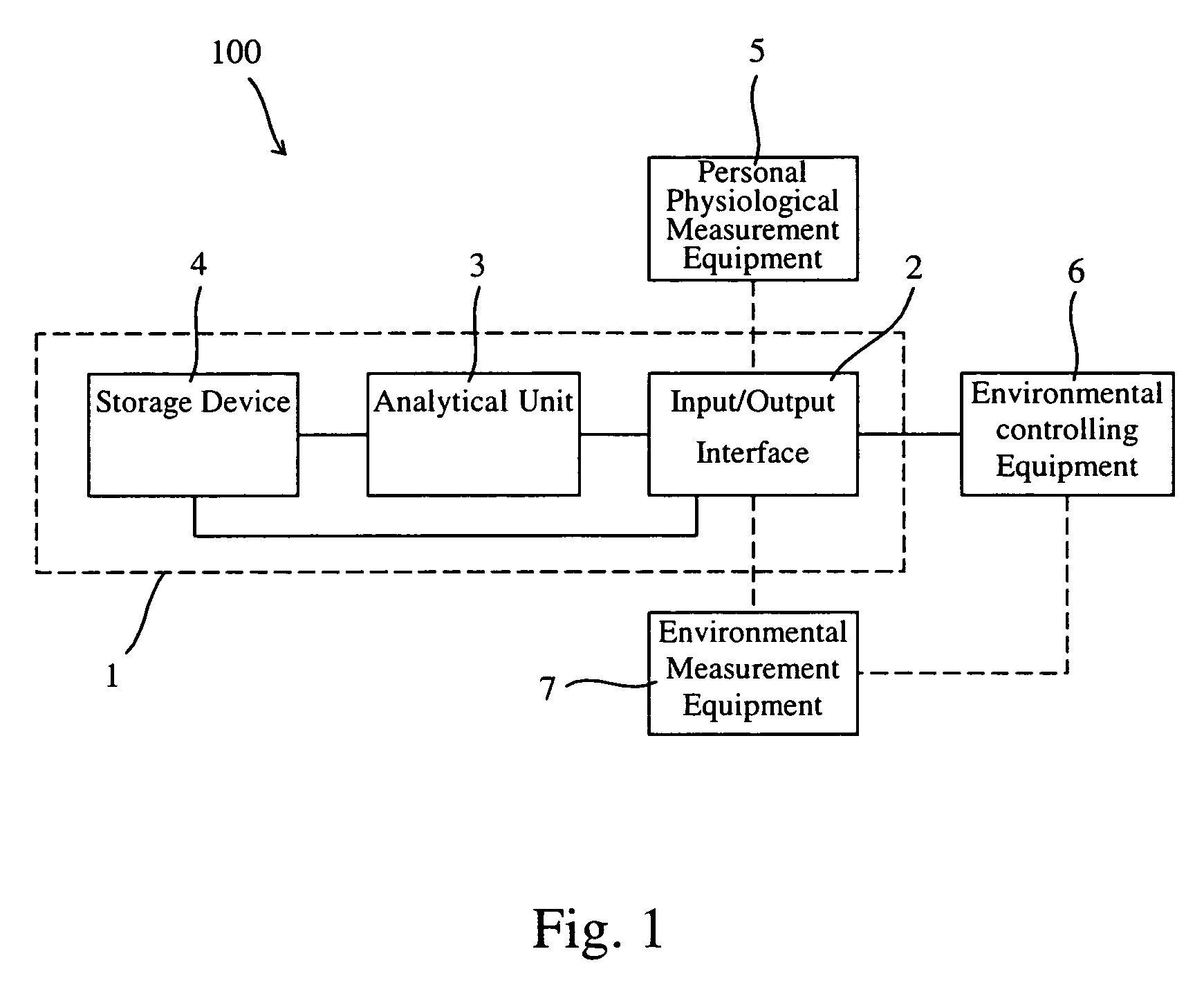

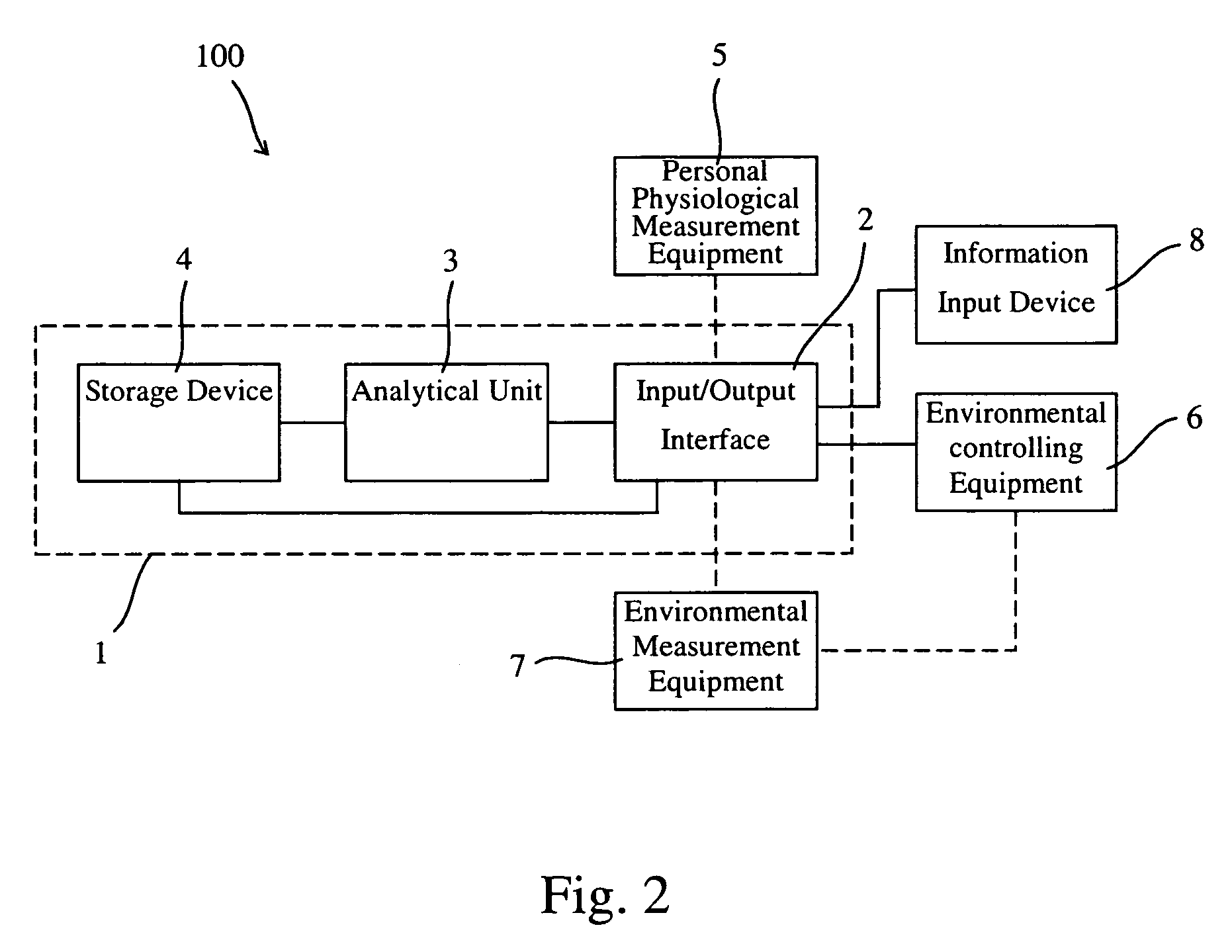

Environment controlling system and method thereof

InactiveUS7764180B2Improve the living environmentAir-treating devicesMechanical apparatusControl systemEngineering

This invention provides an environment controlling system and method thereof. The present system integrates and analyzes an individual's physiological and health information as well as environment information on a real-time basis to control environmental conditions and determine a living space beneficial to personal health. A healthy living space suitable for home care and disease management can be established by controlling environmental factors such as temperature, humidity, light, sound, etc.

Owner:IND TECH RES INST

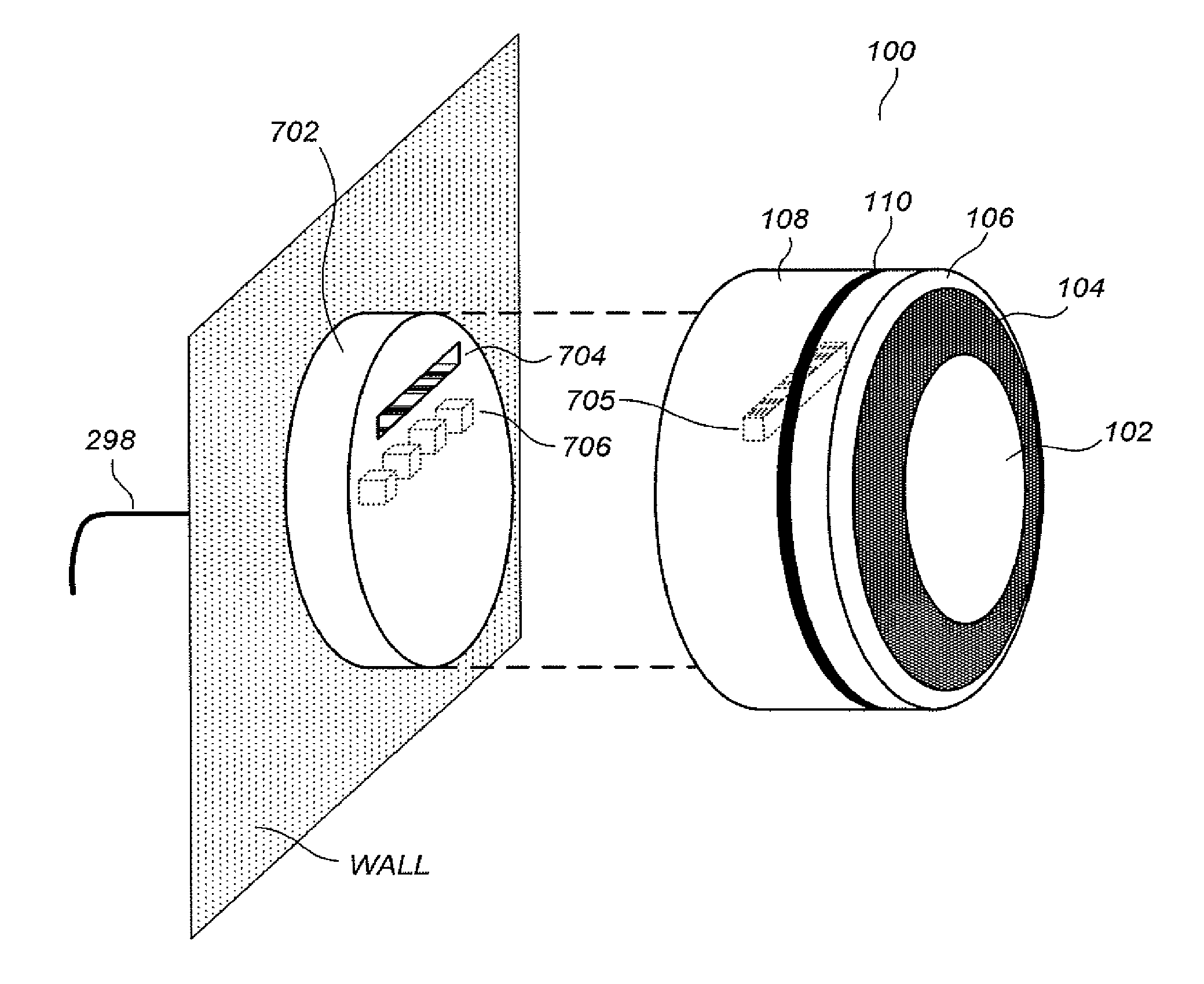

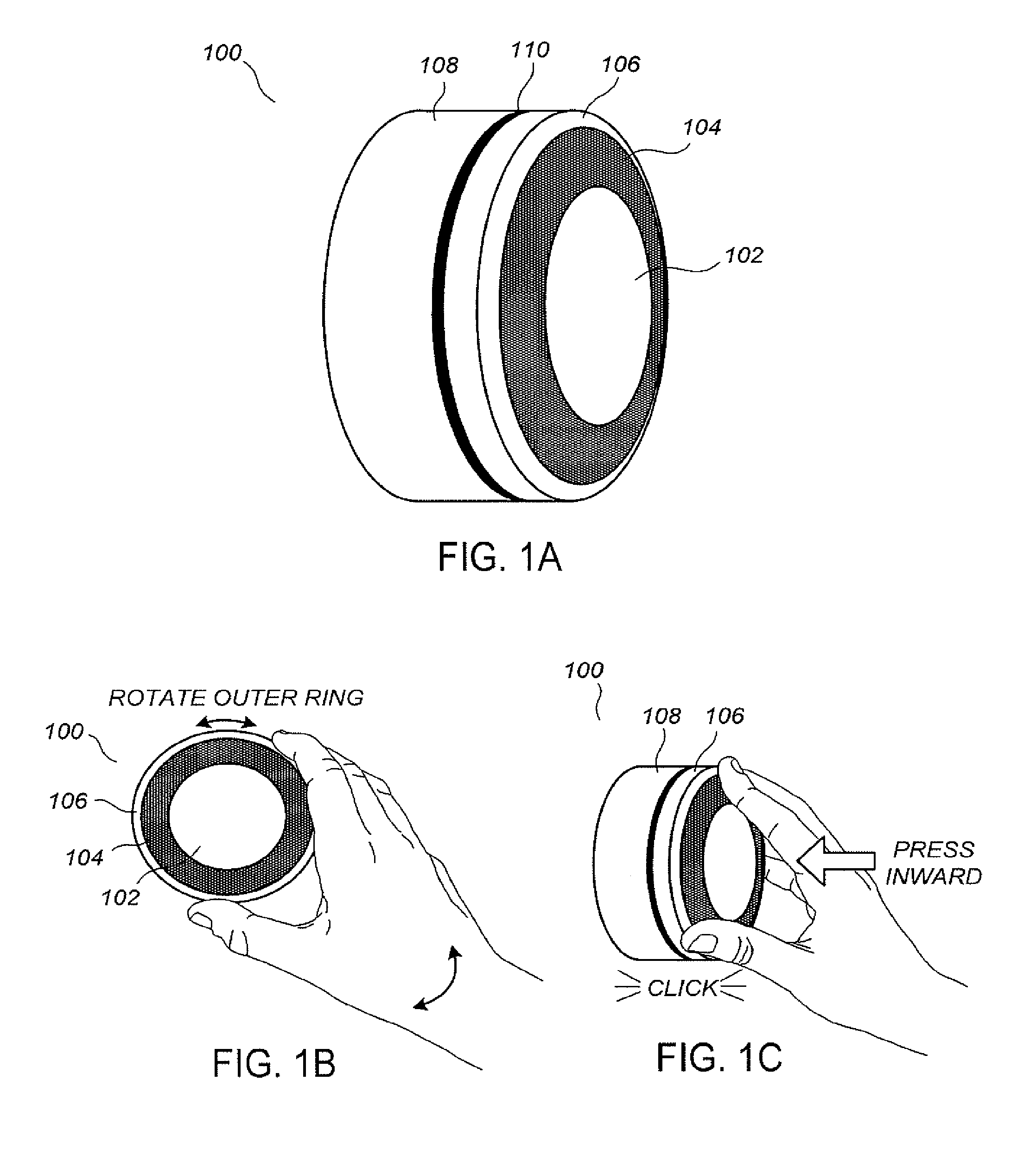

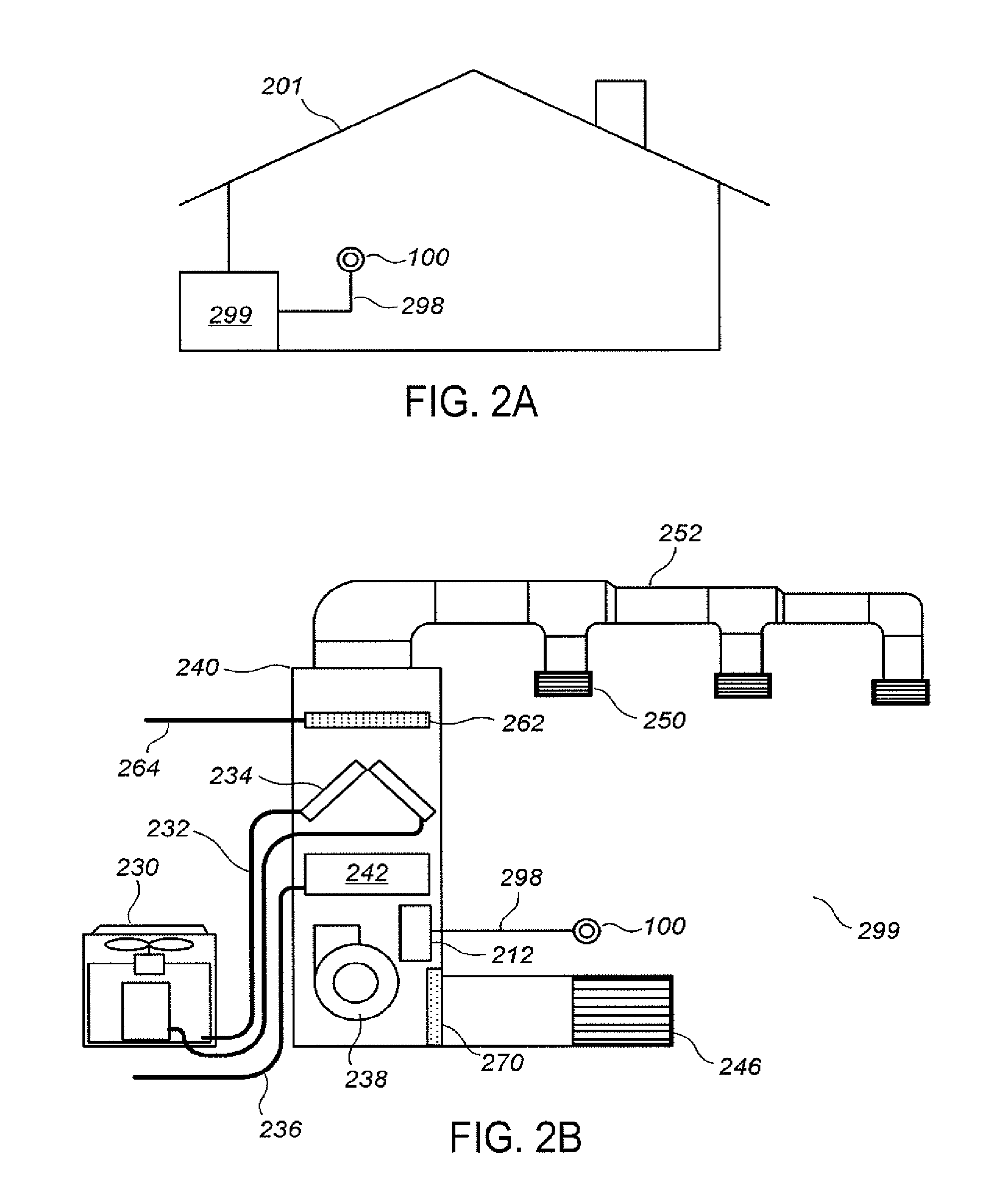

Continuous intelligent-control-system update using information requests directed to user devices

An intelligent control system includes intelligent thermostats and controls an environment, such as a residential living space, commercial building, or another environment. The intelligent control system obtains information related to the controlled environment by collecting sensor data, obtaining data from users during interactive information-exchange sessions, and by directing information queries to users on one or more user devices.

Owner:GOOGLE LLC

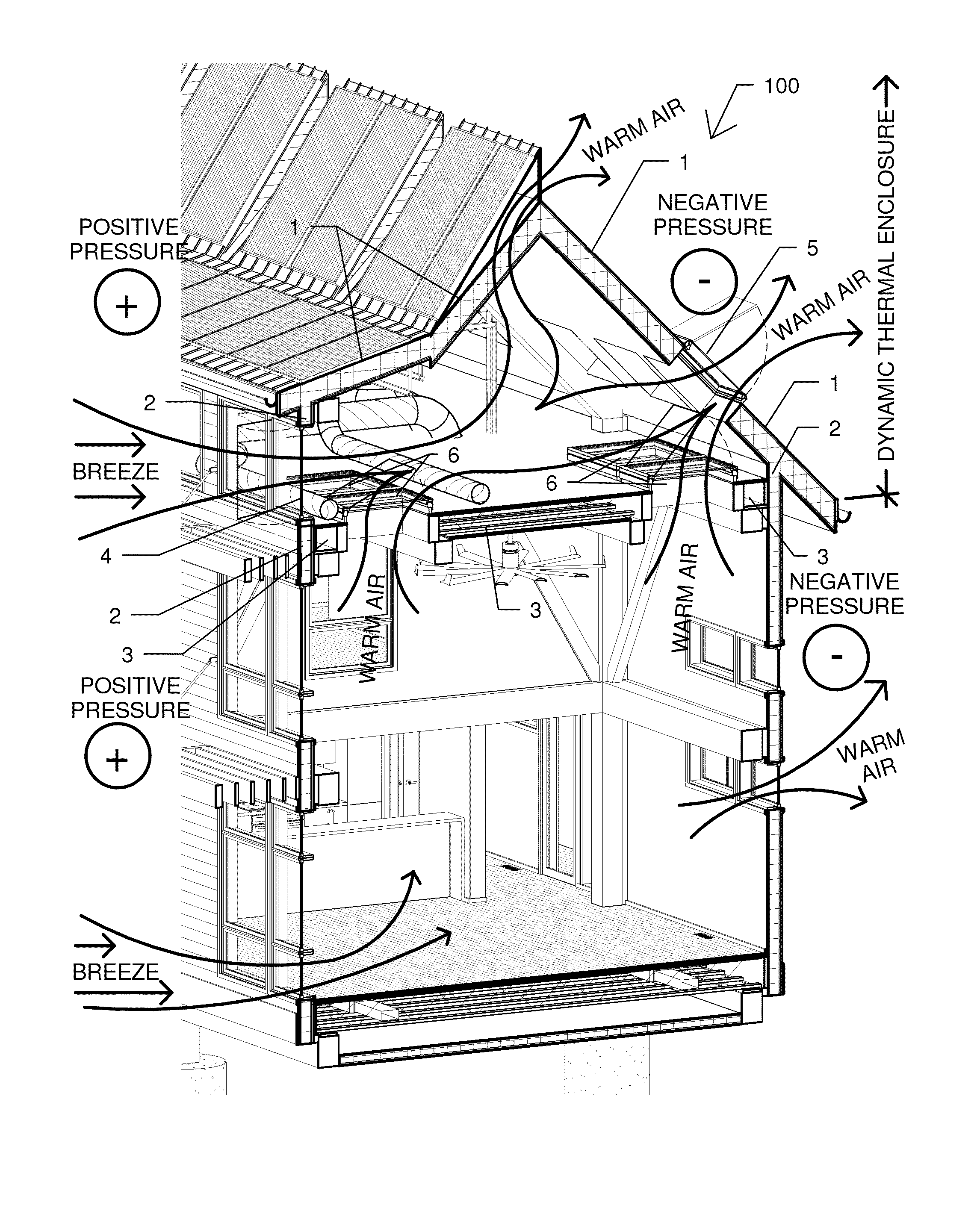

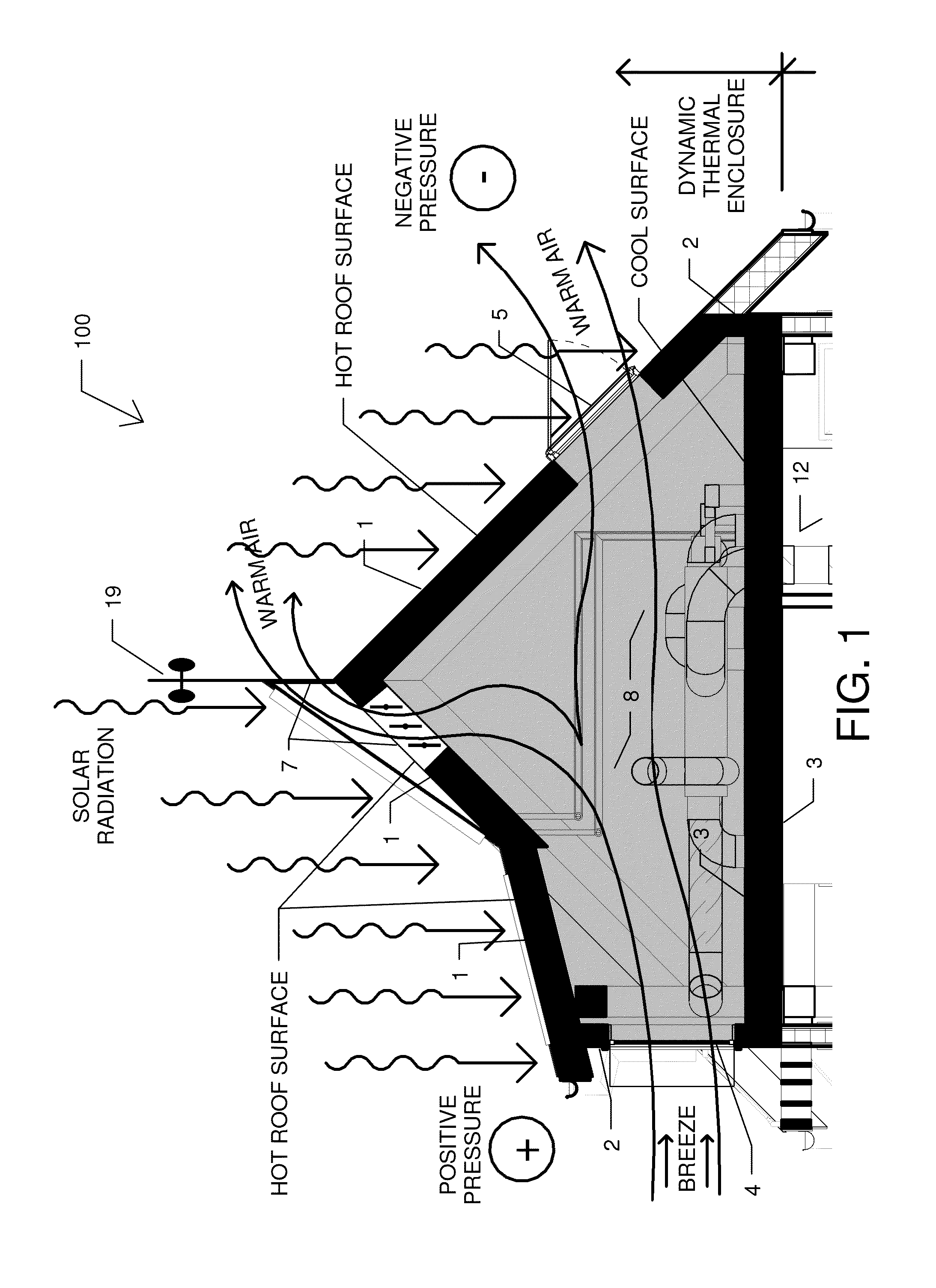

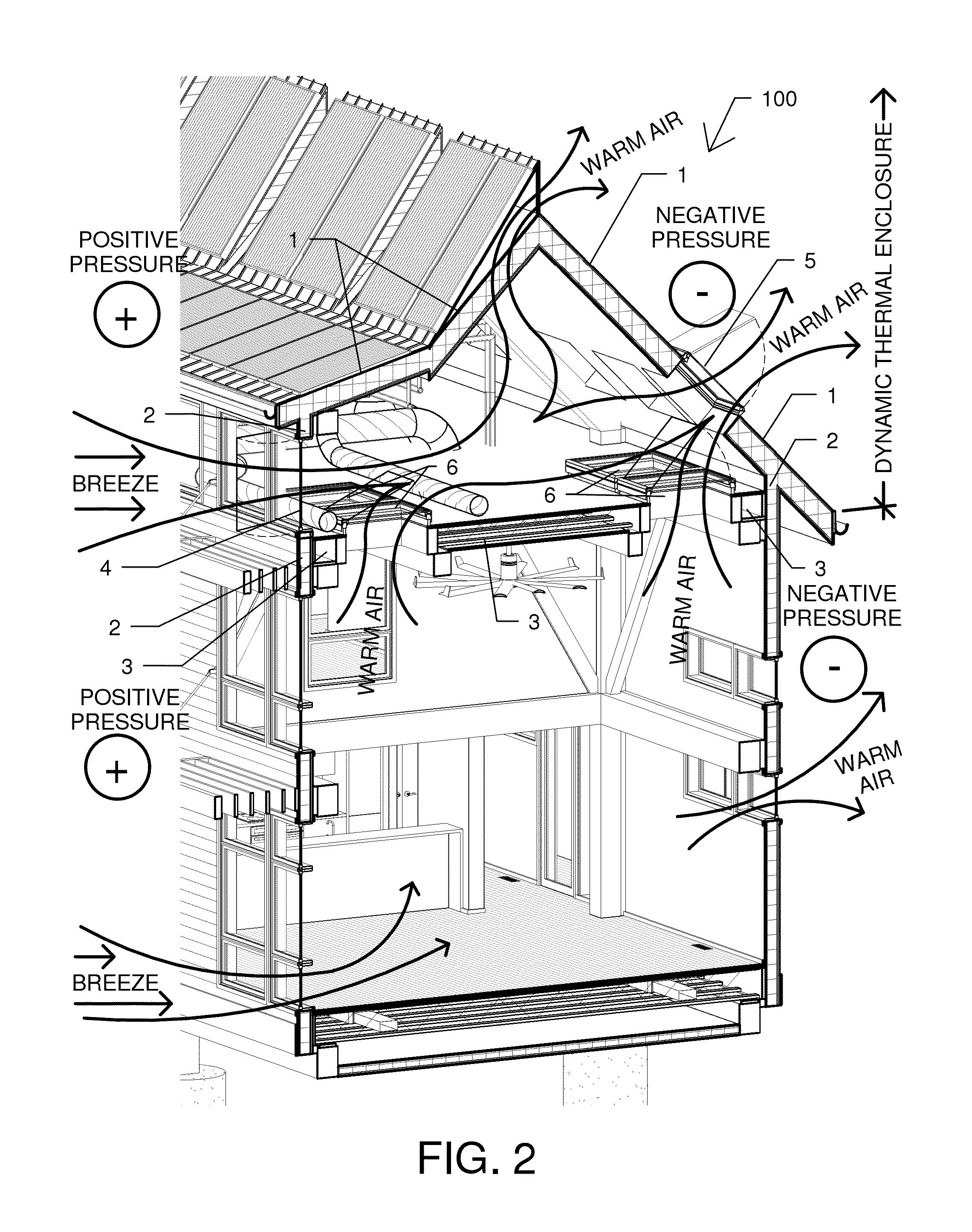

Energy-efficient building structure having a dynamic thermal enclosure

ActiveUS8726586B1Eliminate the problemEasy to disassembleLighting and heating apparatusSpace heating and ventilation detailsControl cellFresh air

A constructed enclosure, adjacent to an interior habitable space, uses a microprocessor-based control unit to operate enclosure openings to provide a multi-layer insulation barrier containing or creating heat, or providing a radiant barrier, isolating by open air, a thermal insulating layer from warm exterior surfaces, maximizing insulation values. The enclosed space, through the use of openings, which in one embodiment are windows, skylights and dampers connected to louvers, is heated by radiant exposure or cooled by natural air flow or exhaust fan. Return air is heated upstream from a forced air heating unit by traversing ductwork heated by the enclosure and by direct solar exposure from enclosure windows. Enclosure openings to the habitable interior spaces create air displacement drawing warm air out of the interior and fresh air in through exterior windows. The energy efficient system is tailored for immediate climate specific conditions.

Owner:STEVENS KIRK RUSSELL +4

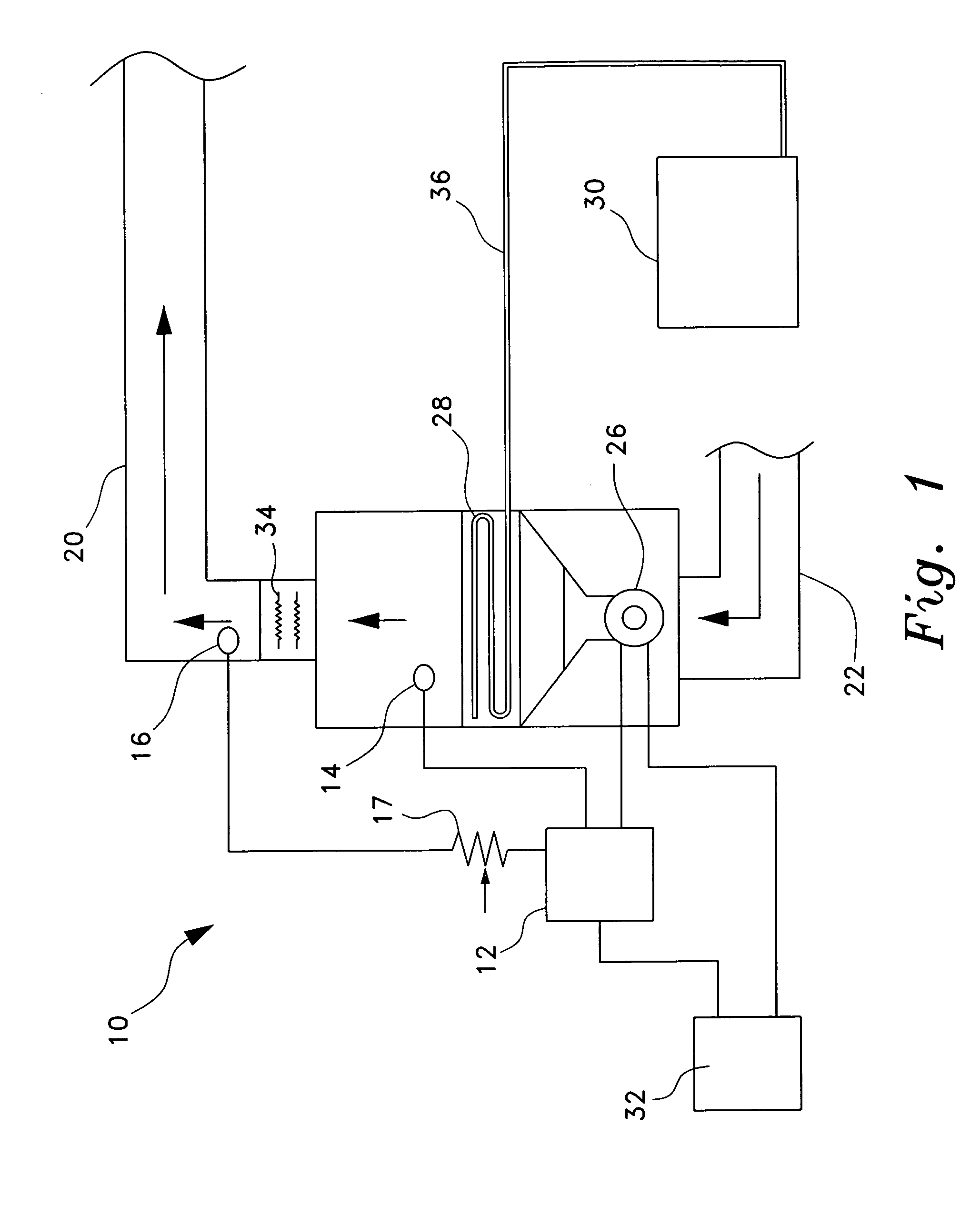

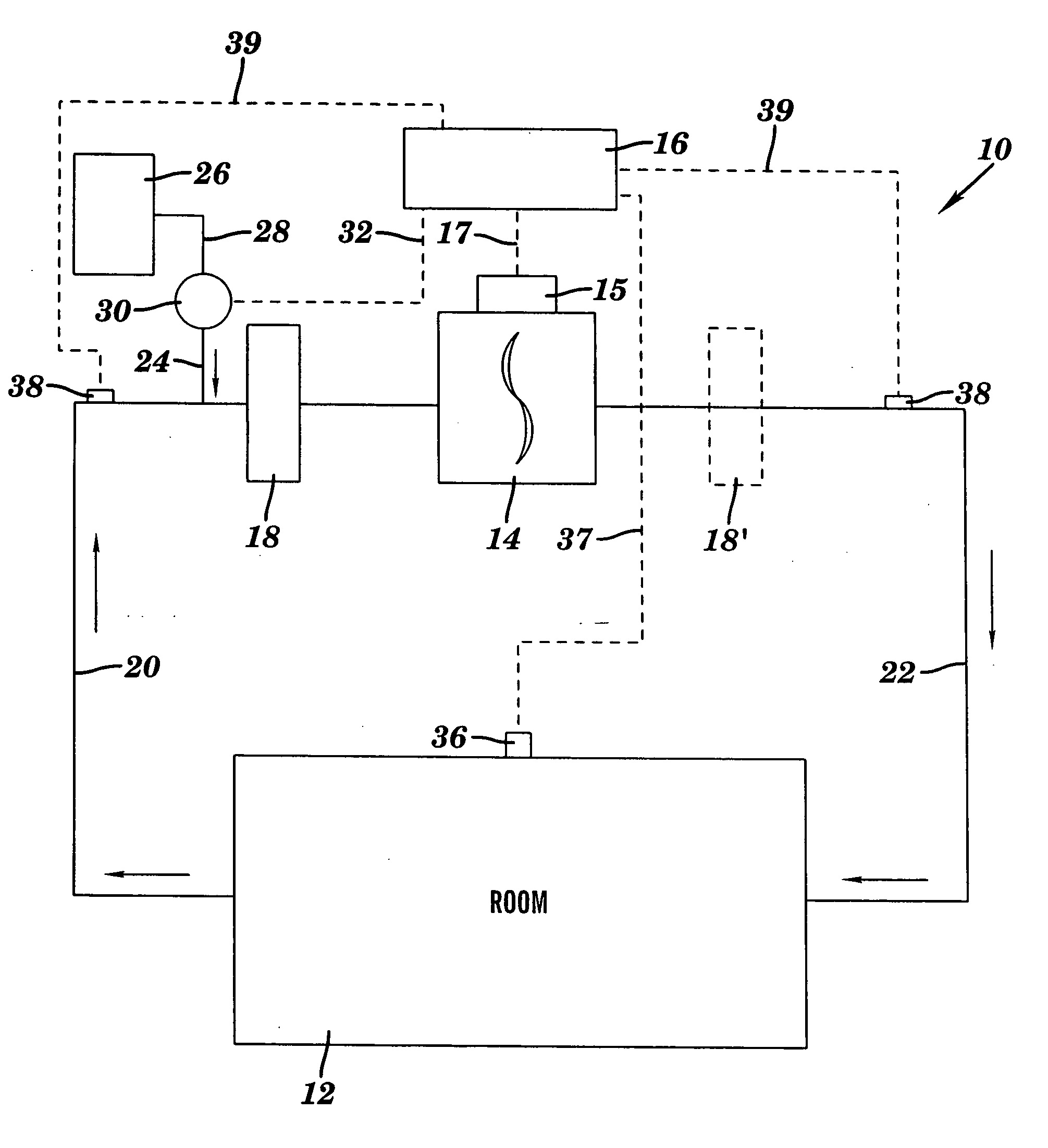

Mobile energy management system

InactiveUS20060052922A1Digital data processing detailsElectric power transfer ac networkElectricityDisplay device

A recreational vehicle includes a chassis having a living space, an electrical system for providing electrical power to the living space, an air conditioner for cooling the living space, a heater for heating the living space, and a plurality of appliances within the living space attached to the electrical system. The recreational vehicle also includes an engine for moving the recreational vehicle, a motor generator for supplying power to the recreational vehicle, a connector for connecting the electrical system of the recreational vehicle to an external power source, and a local area network system electrically connected to the air conditioner, the heater, the plurality of appliances, and the motor generator. The local area network manages the power provided to the to the electrical appliances. A display positioned within the living space shows data related to the air conditioner, the heater, the plurality of appliances, the motor generator and the engine.

Owner:CUMMINS POWER GENERATION

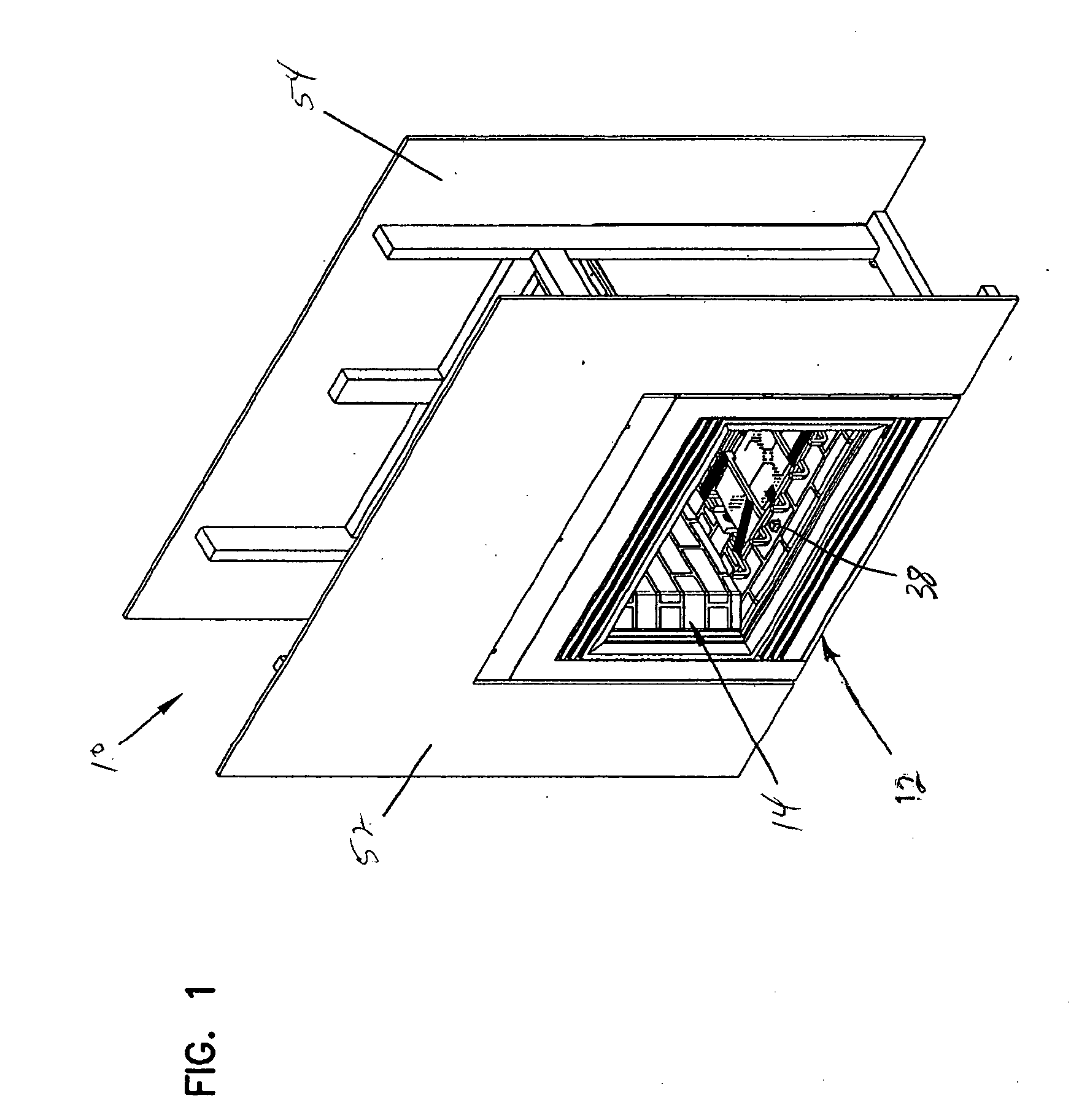

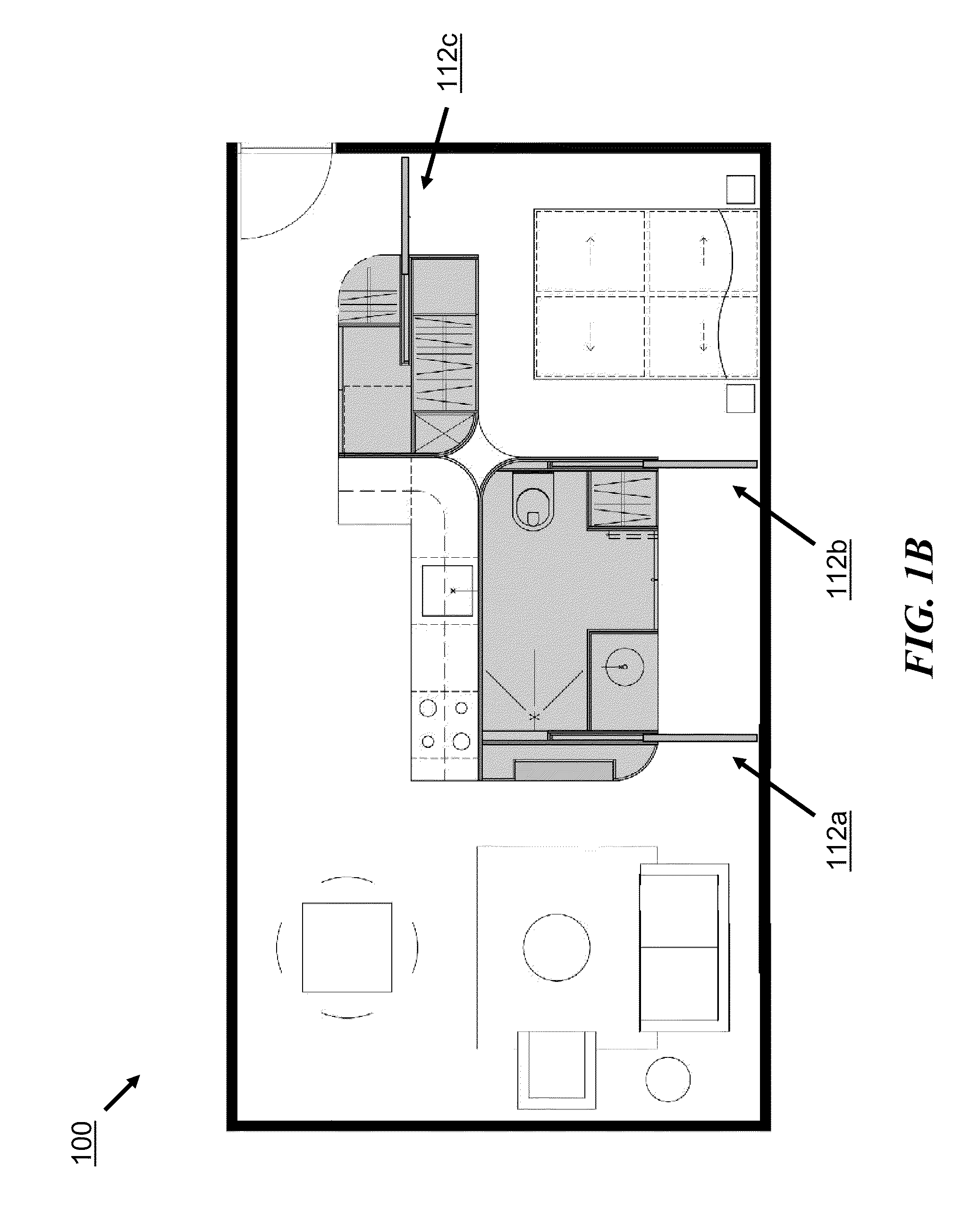

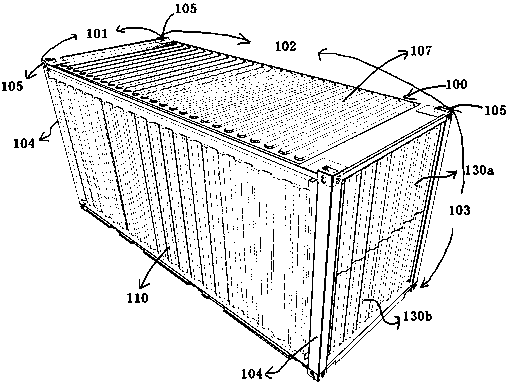

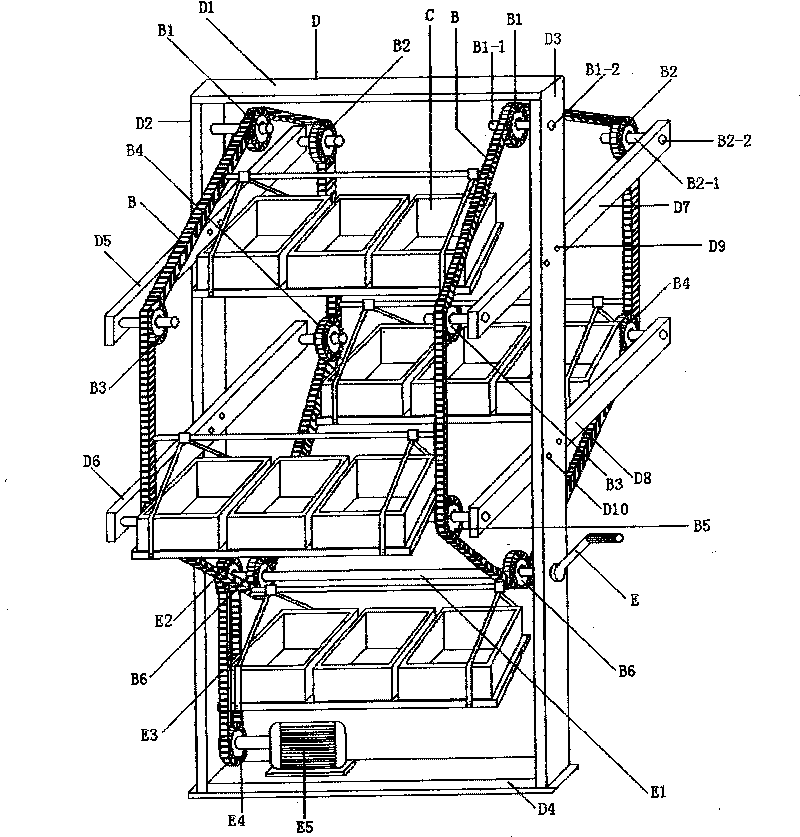

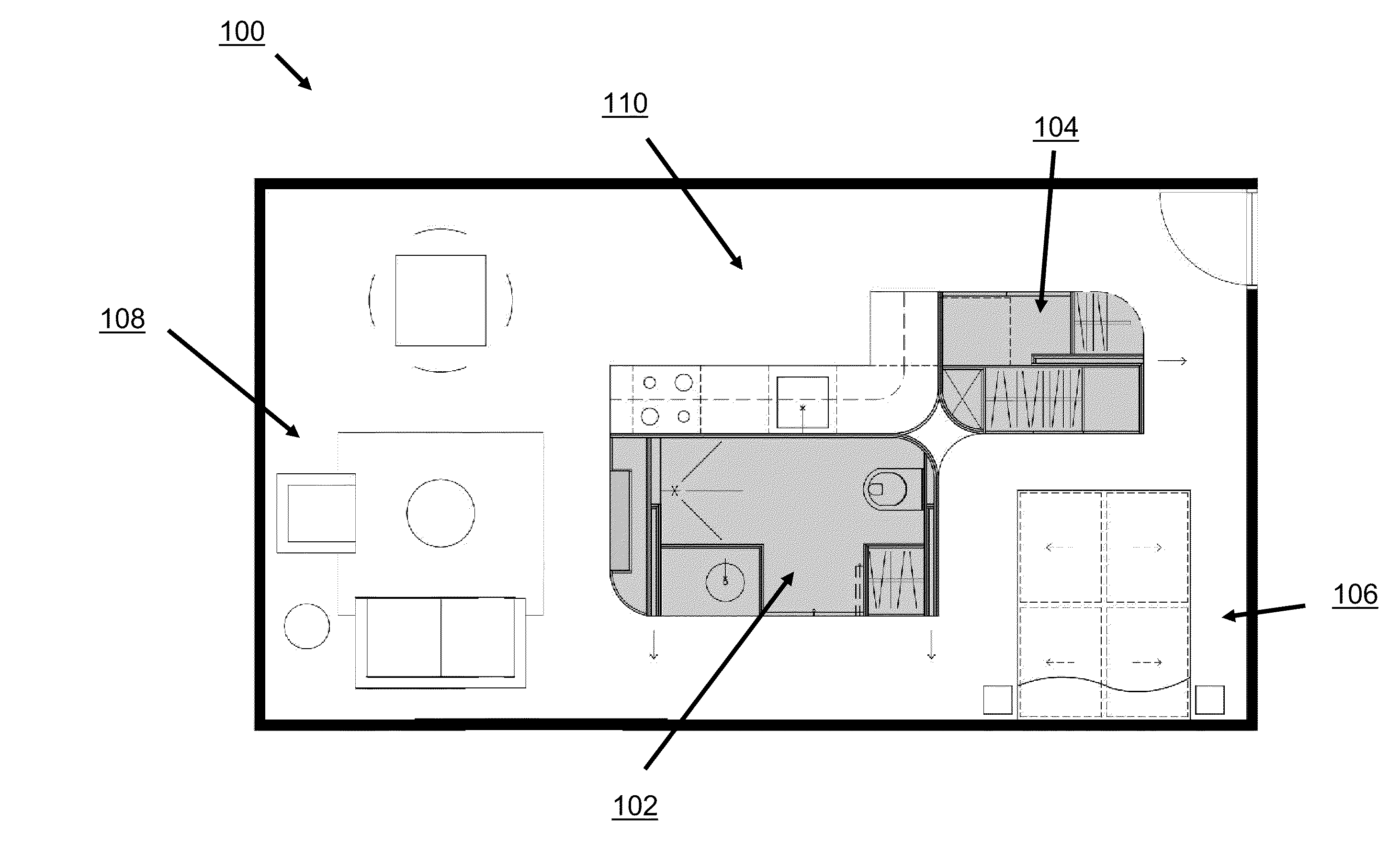

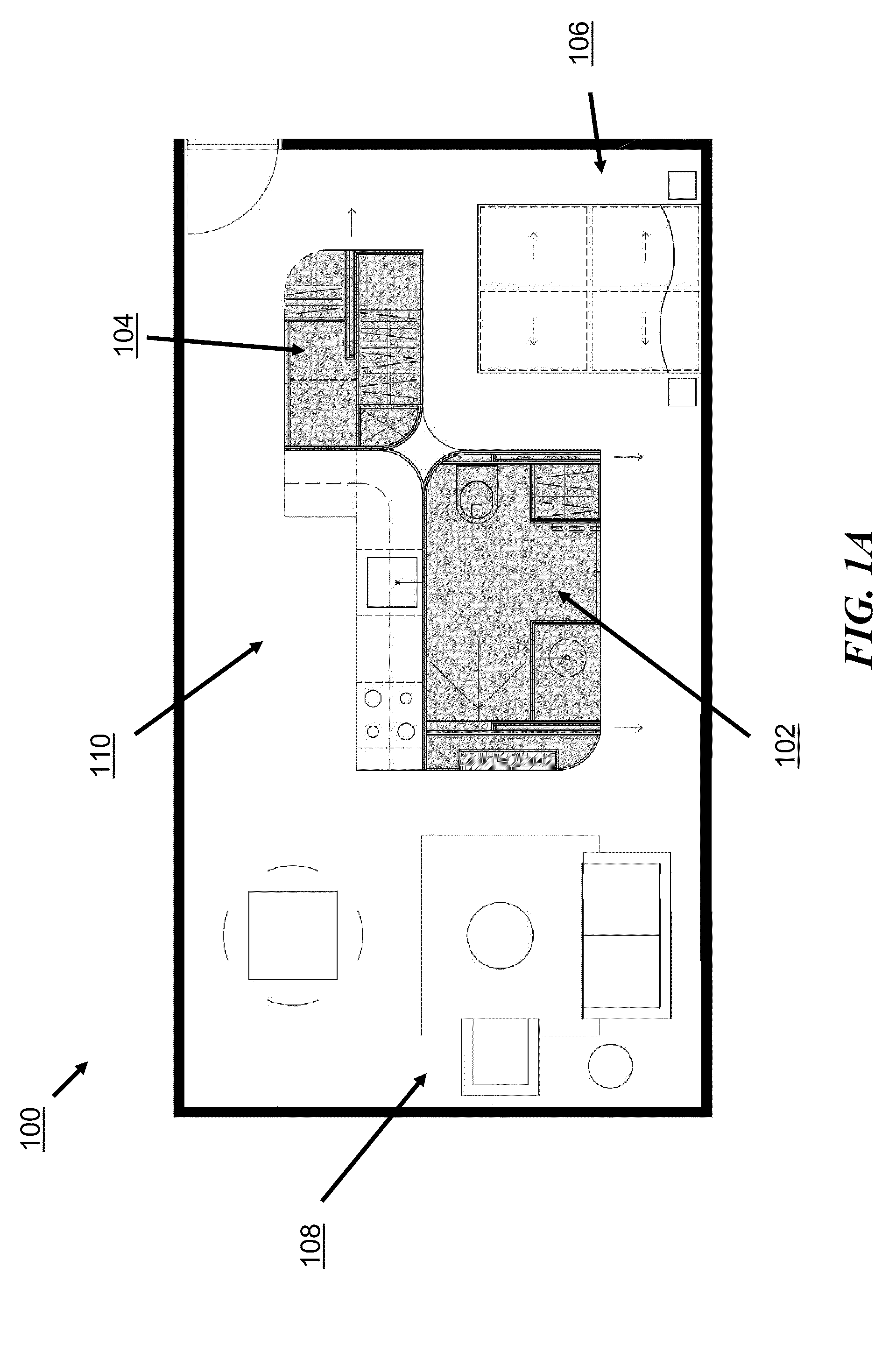

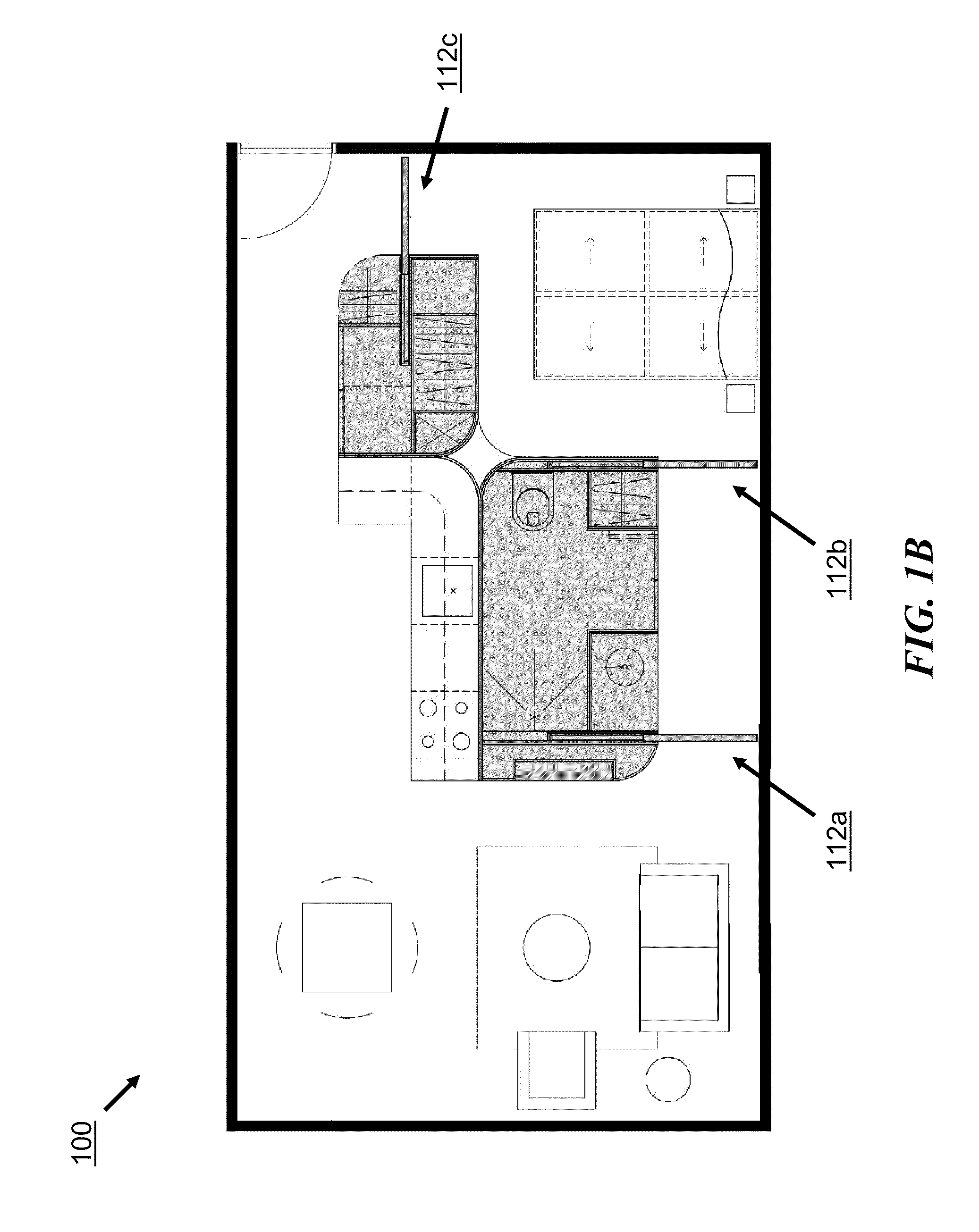

Prefabricated building modules for multi-unit housing

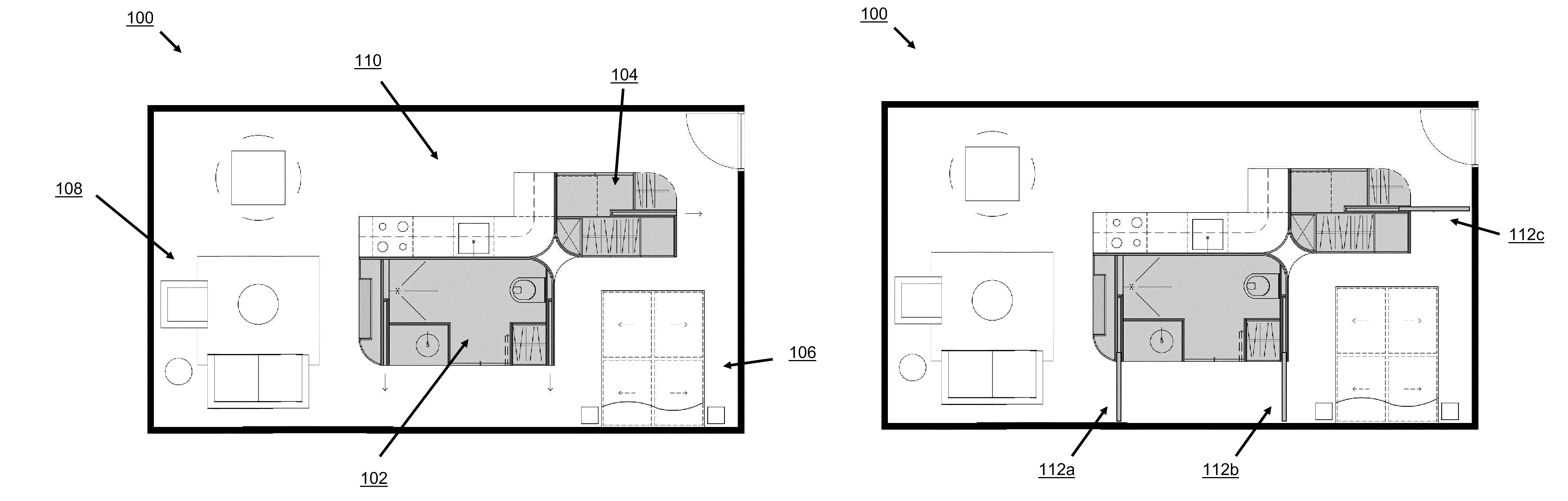

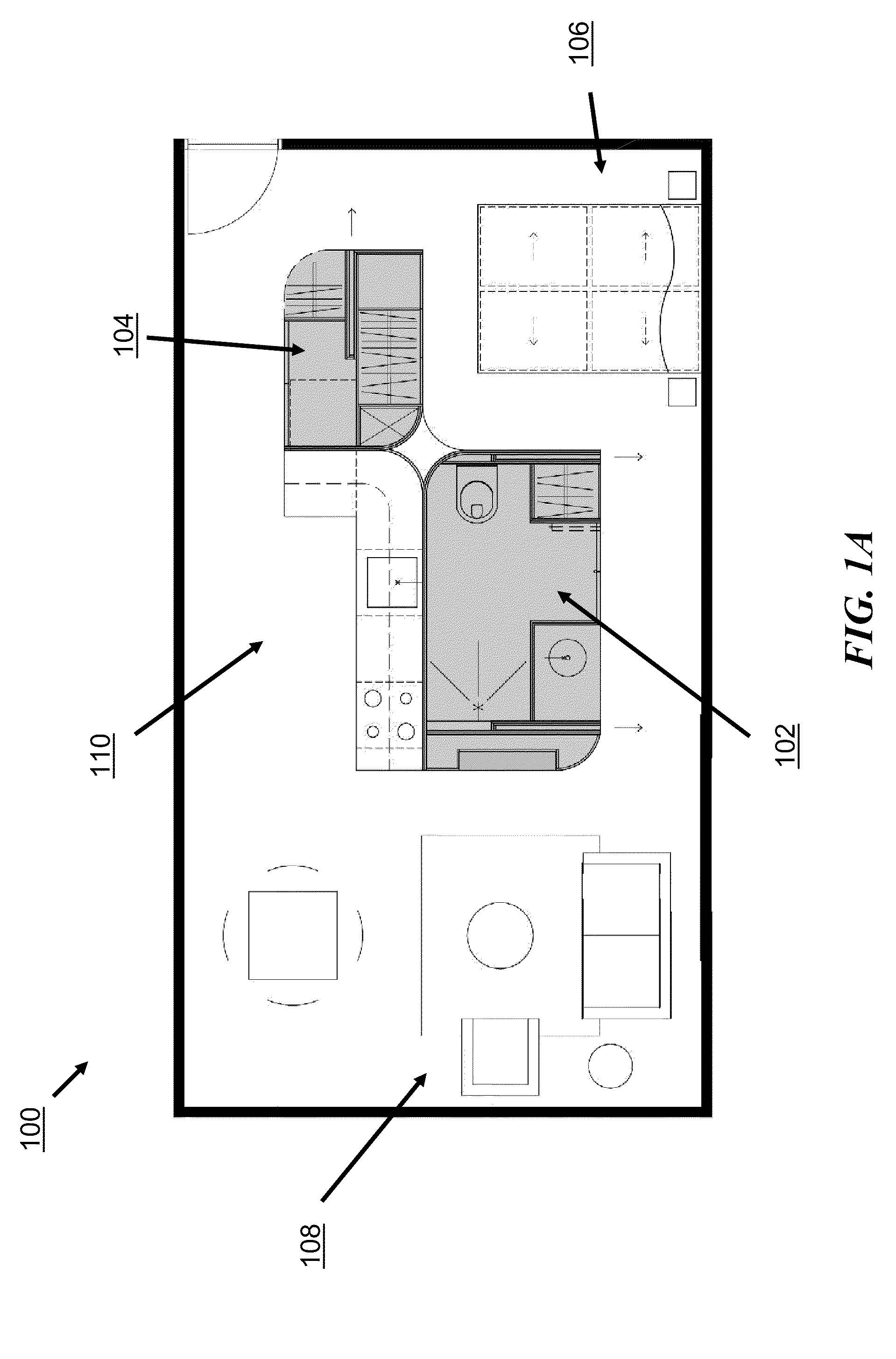

ActiveUS8621787B2Reduce impactReduces marketabilityPublic buildingsBuilding repairsArchitectural engineeringBuilding unit

The present application is directed towards systems and methods for building a living space during construction of a multi-unit housing structure. In particular, the present application describes various embodiments of prefabricated building modules that may be built and equipped with plumbing, HVAC and / or electrical fixtures prior to installation in a multi-unit housing structure. Because modules may be configured prior to installation in a housing structure, the use of prefabricated building modules may increase efficiency of construction and provide enhanced customization over other non-configurable building units.

Owner:IRONSTATE DEV

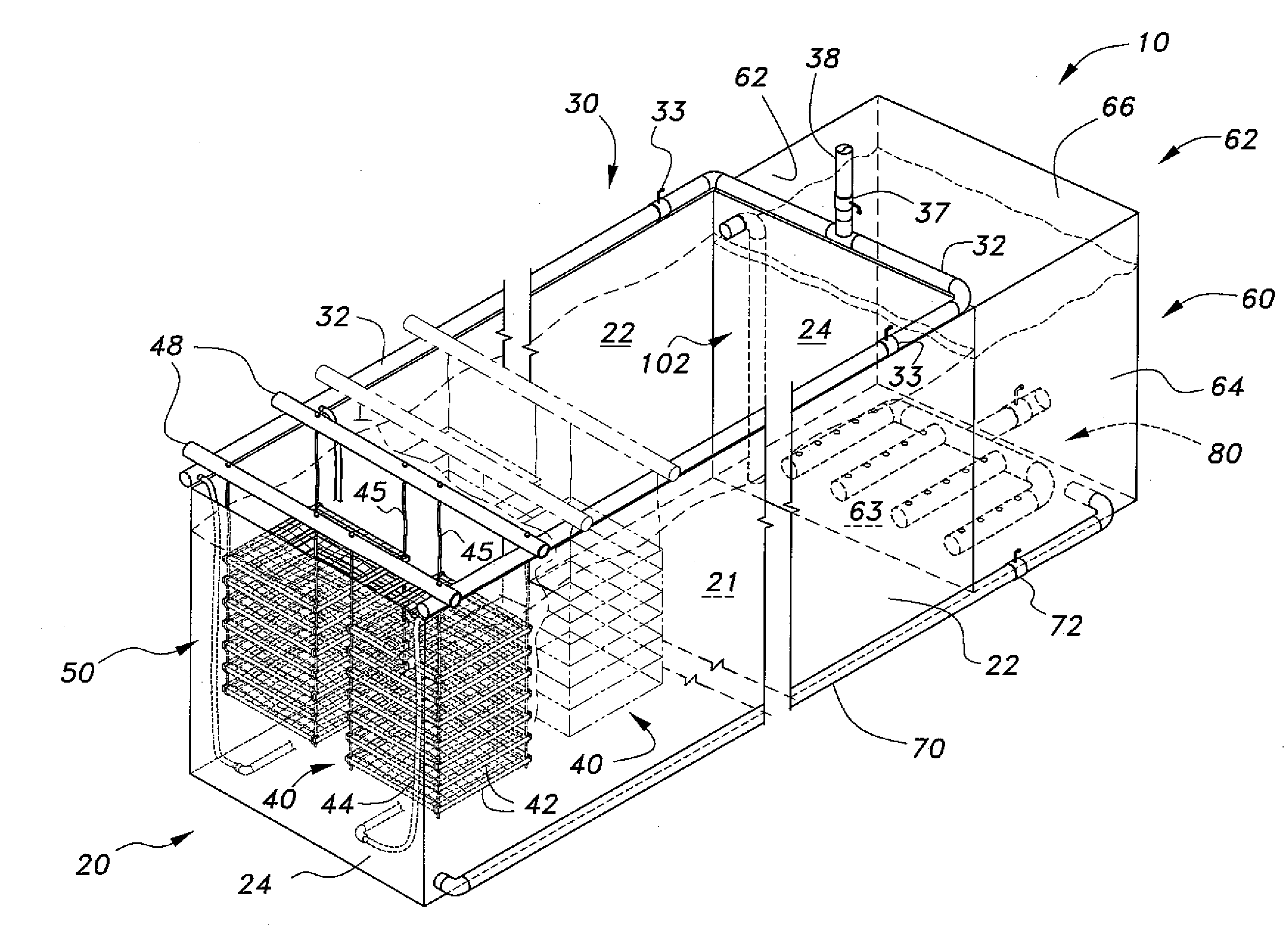

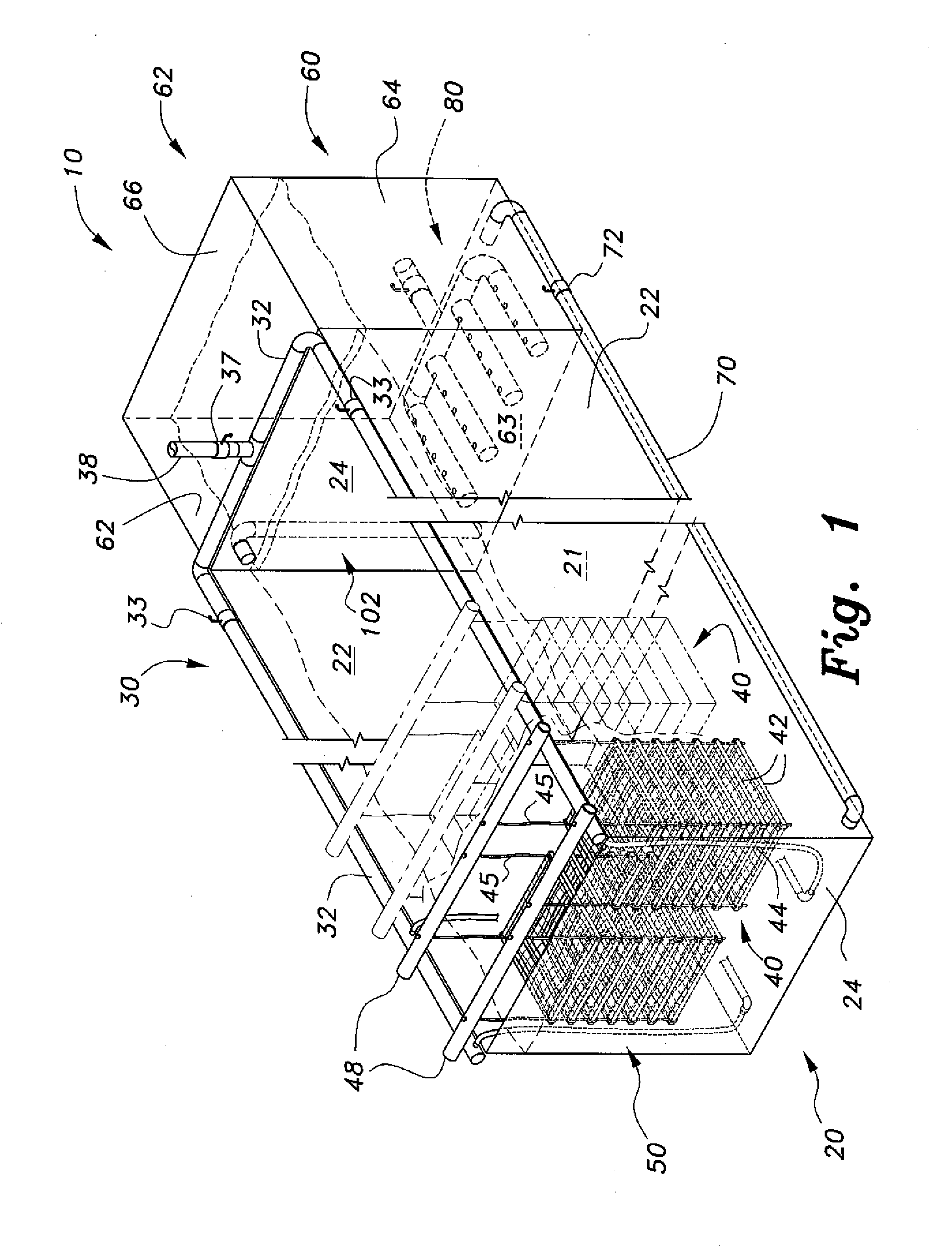

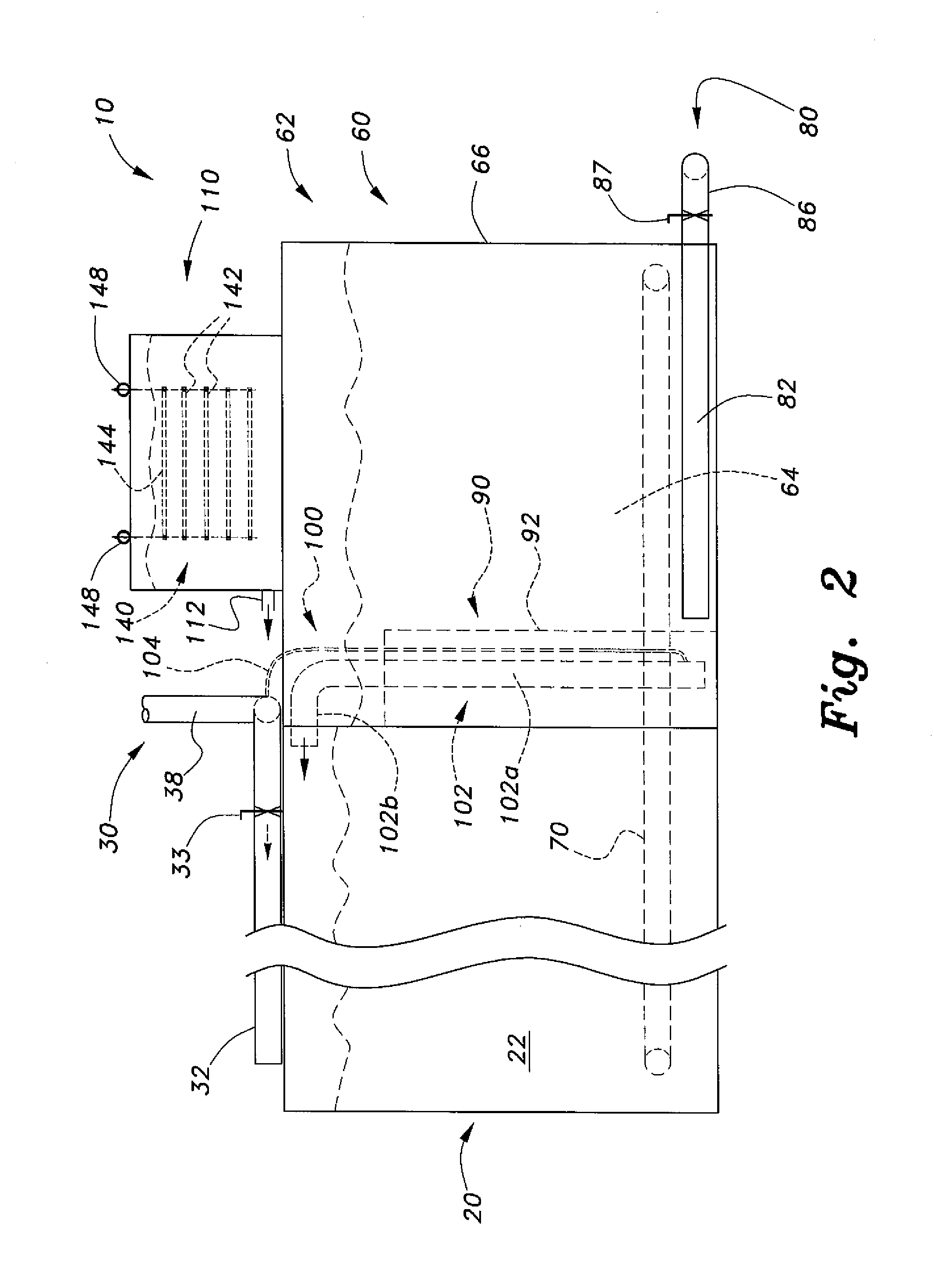

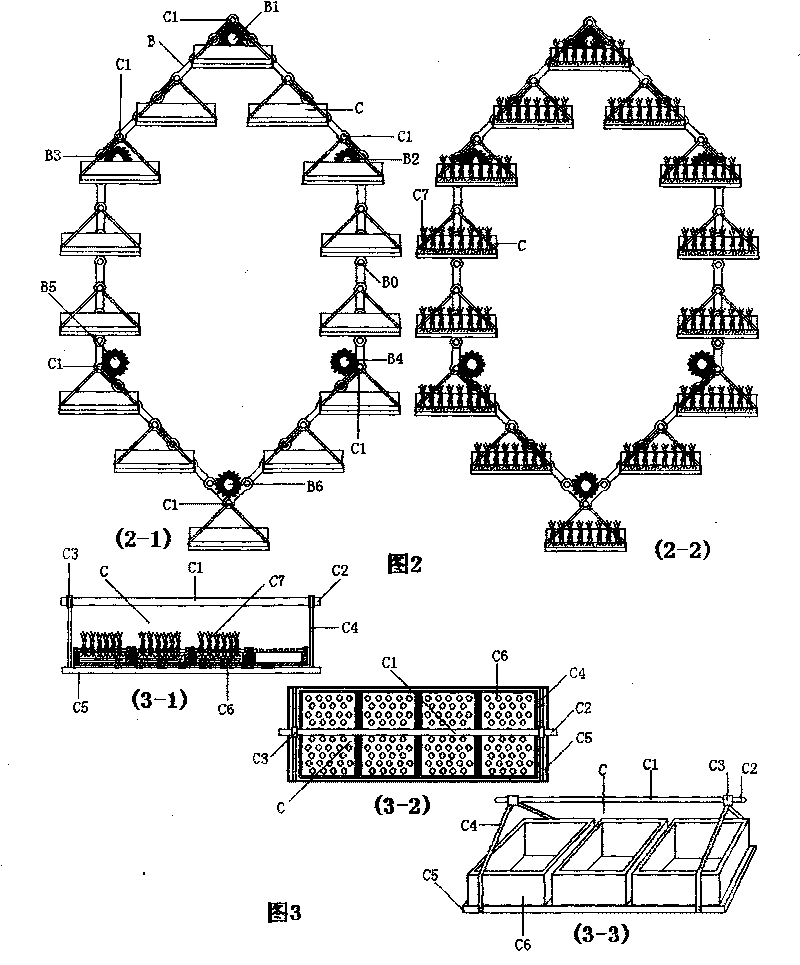

Shrimp culturing system

The shrimp culturing system includes a culturing tank and a clarifier tank. A plurality of shrimp cubes are suspended in the culture tank by set pairs of support bars. Each shrimp cube includes a plurality of stacked frames set at predetermined intervals. Each frame supports a mesh therein providing living space for the shrimp, and each stack is interconnected by ropes, which connect to the support bars to be suspended thereby. The shrimp cubes provide maximal space for culturing shrimp. The waste water from the culture tank cycles into the clarifier tank, which nurtures a biofloc to consume the waste and assimilate nitrogen, thereby producing their own waste that can be consumed by the shrimp. Excess solid waste drains via a solids removal manifold, and clarified water is airlifted back into the culture tank. A post-larval tank can be stacked onto the clarifier tank to introduce new batches of shrimp.

Owner:SHERIFF RICHARD L

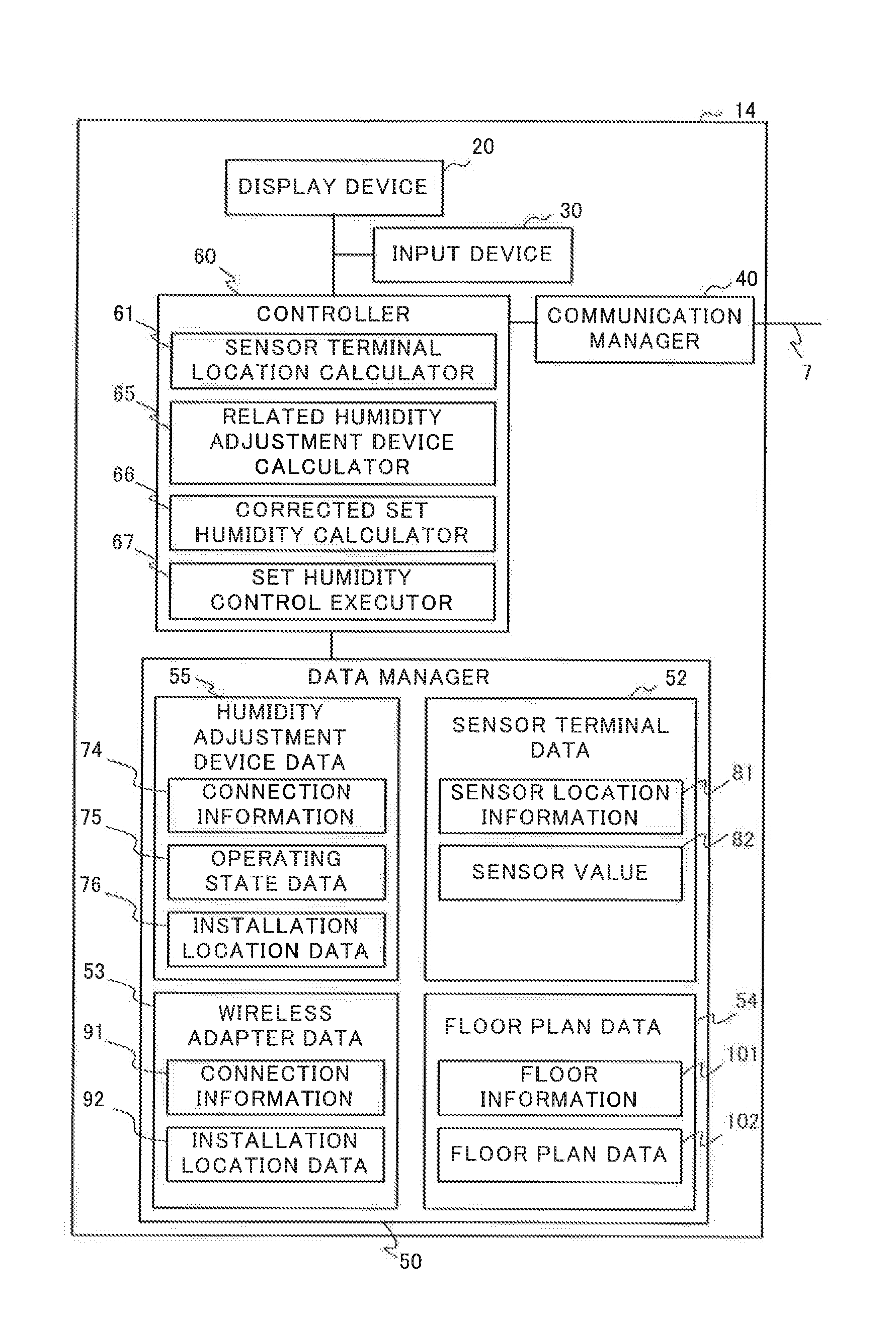

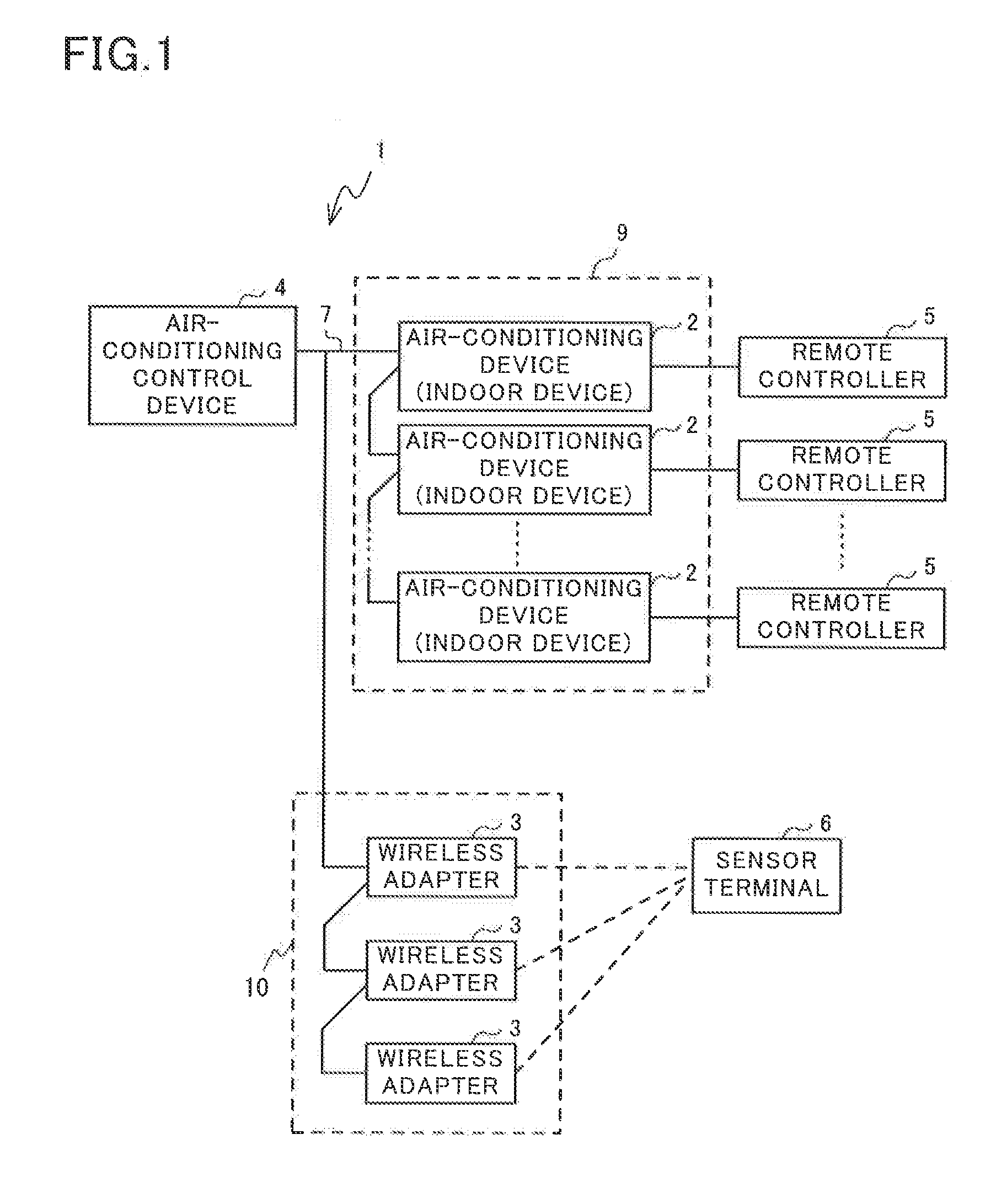

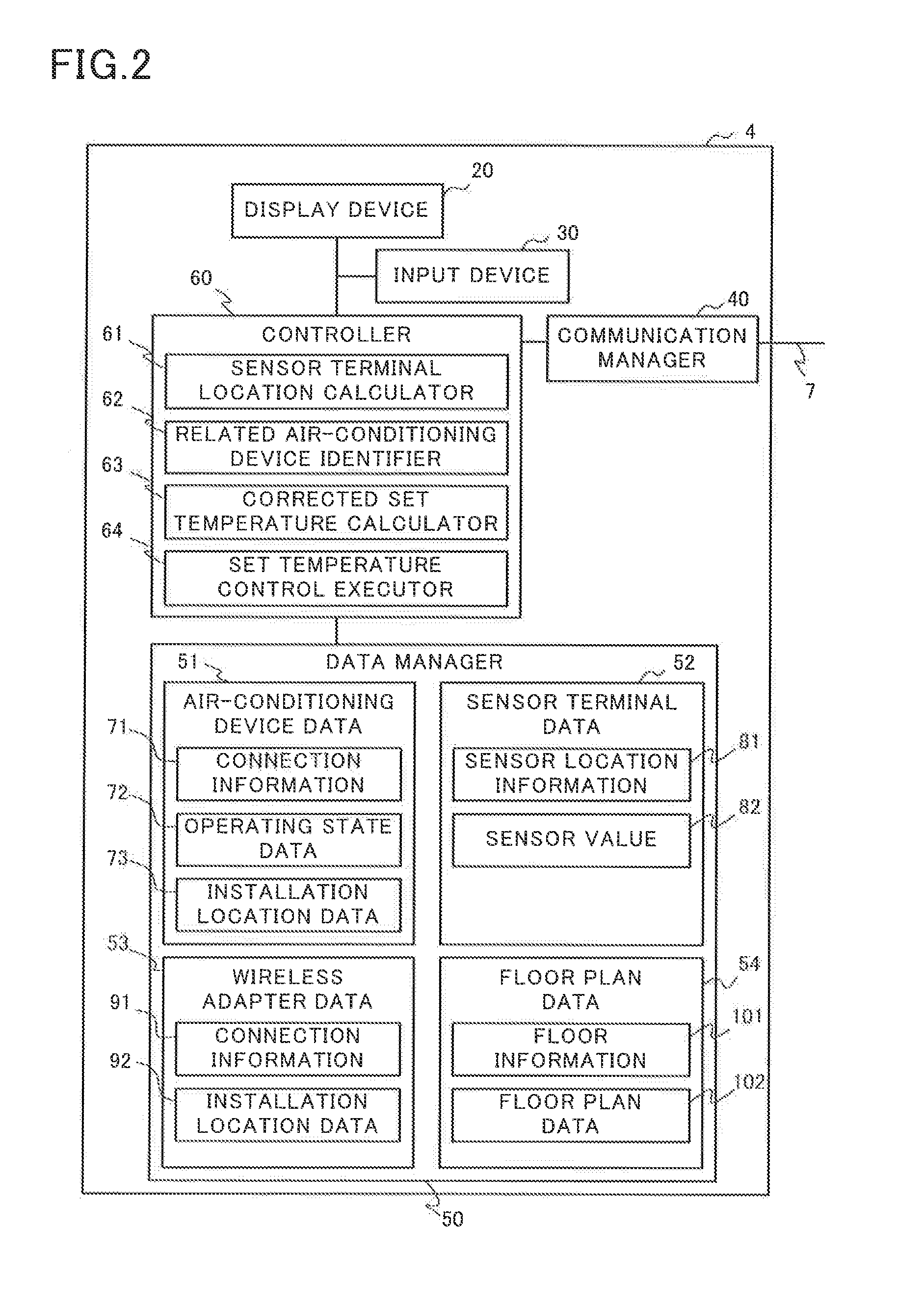

Control device, control method, and program

InactiveUS20130289778A1Improve comfortReduce workloadSampled-variable control systemsMechanical apparatusTemperature controlAir conditioning

A sensor terminal location calculator calculates the location of a sensor terminal based on the distance to the sensor terminal obtained by each of a plurality of wireless adapters installed in a living space. Based on the calculated sensor terminal location and installation location information for each air-conditioning device (indoor device), a related air-conditioning device identifier identifies from among the plurality of air-conditioning devices (indoor devices), a related device that influences the environment in the vicinity of the sensor terminal. Based on the difference between the temperature detected by the identified related device and the temperature detected by the sensor, a corrected set temperature calculation unit corrects a target value for the temperature used by the related device for environmental control. A set temperature control executor controls the related device based on the corrected target value.

Owner:MITSUBISHI ELECTRIC CORP

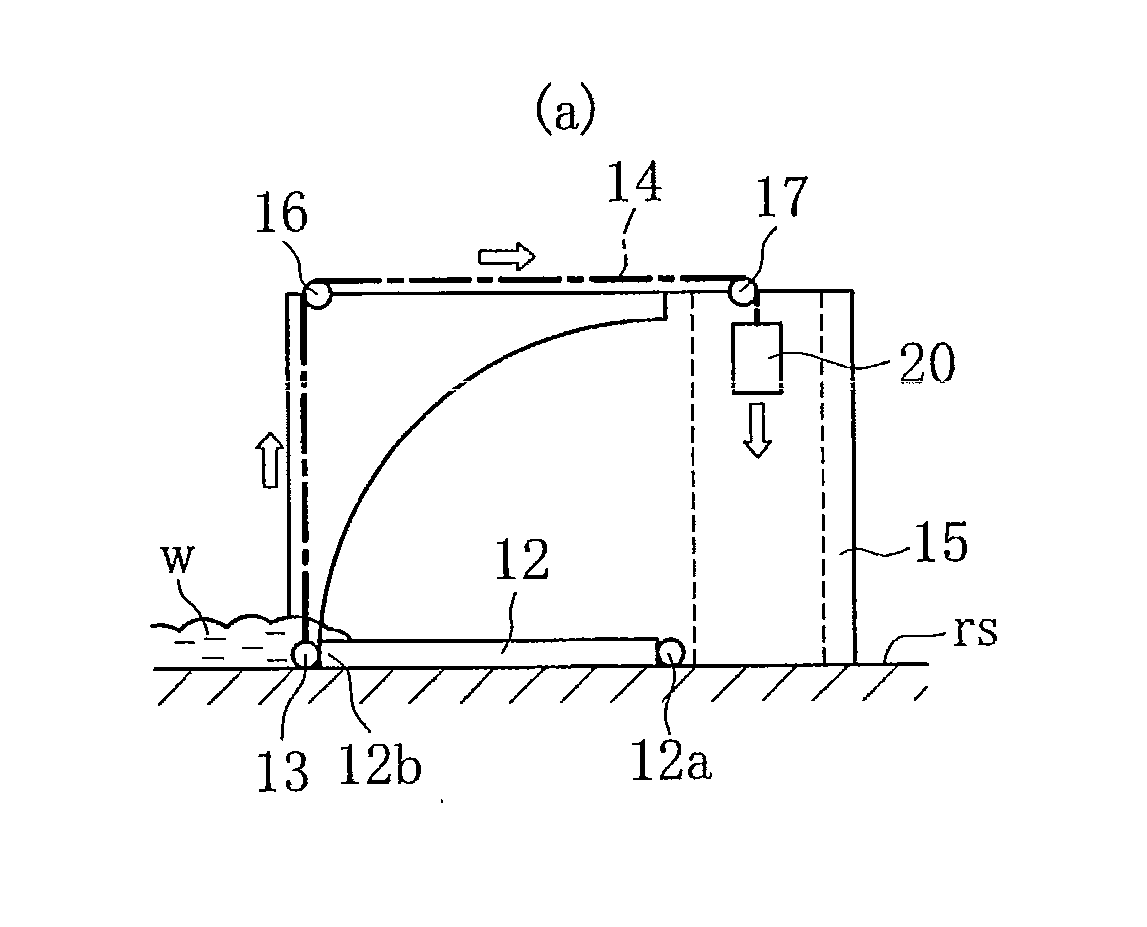

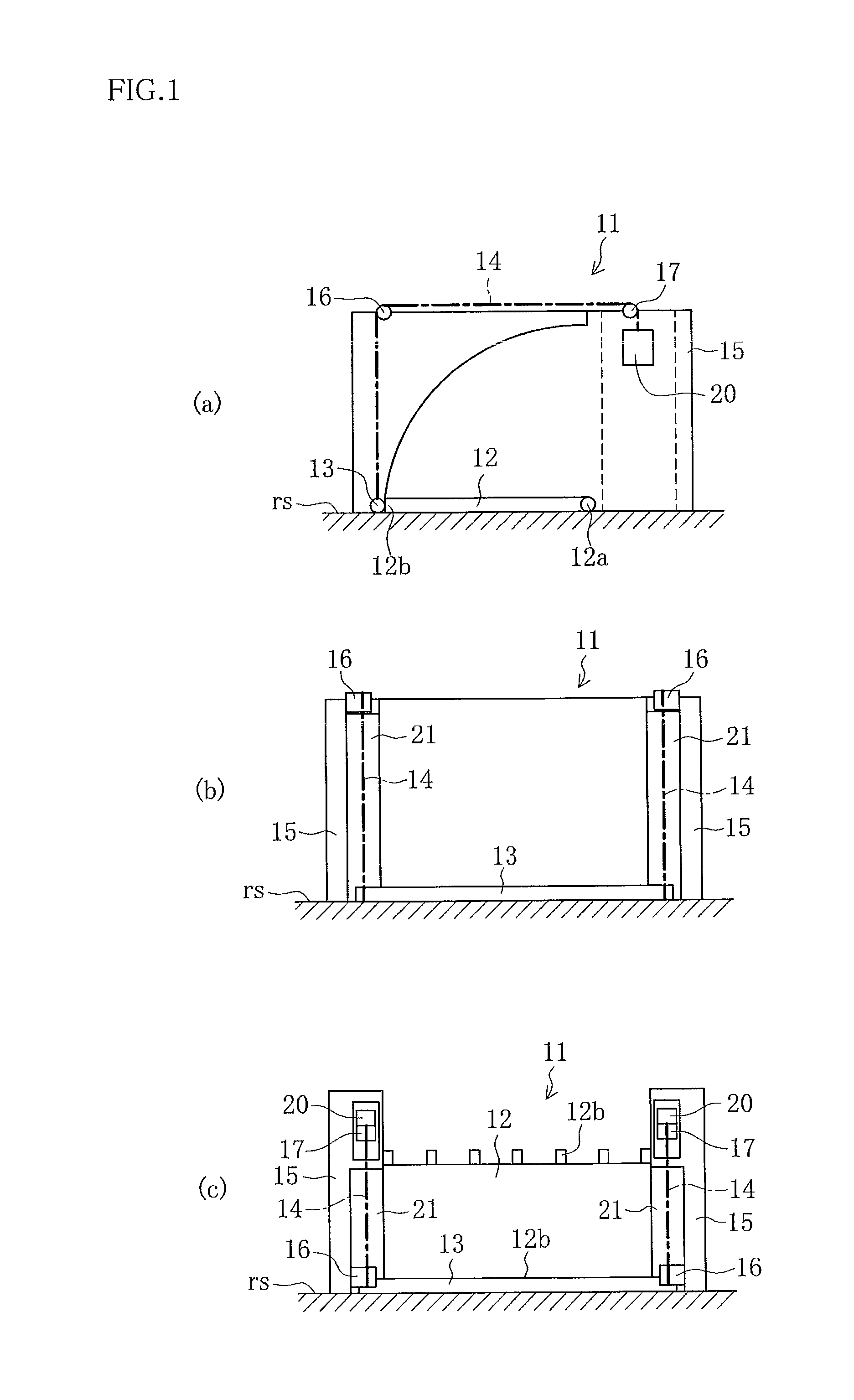

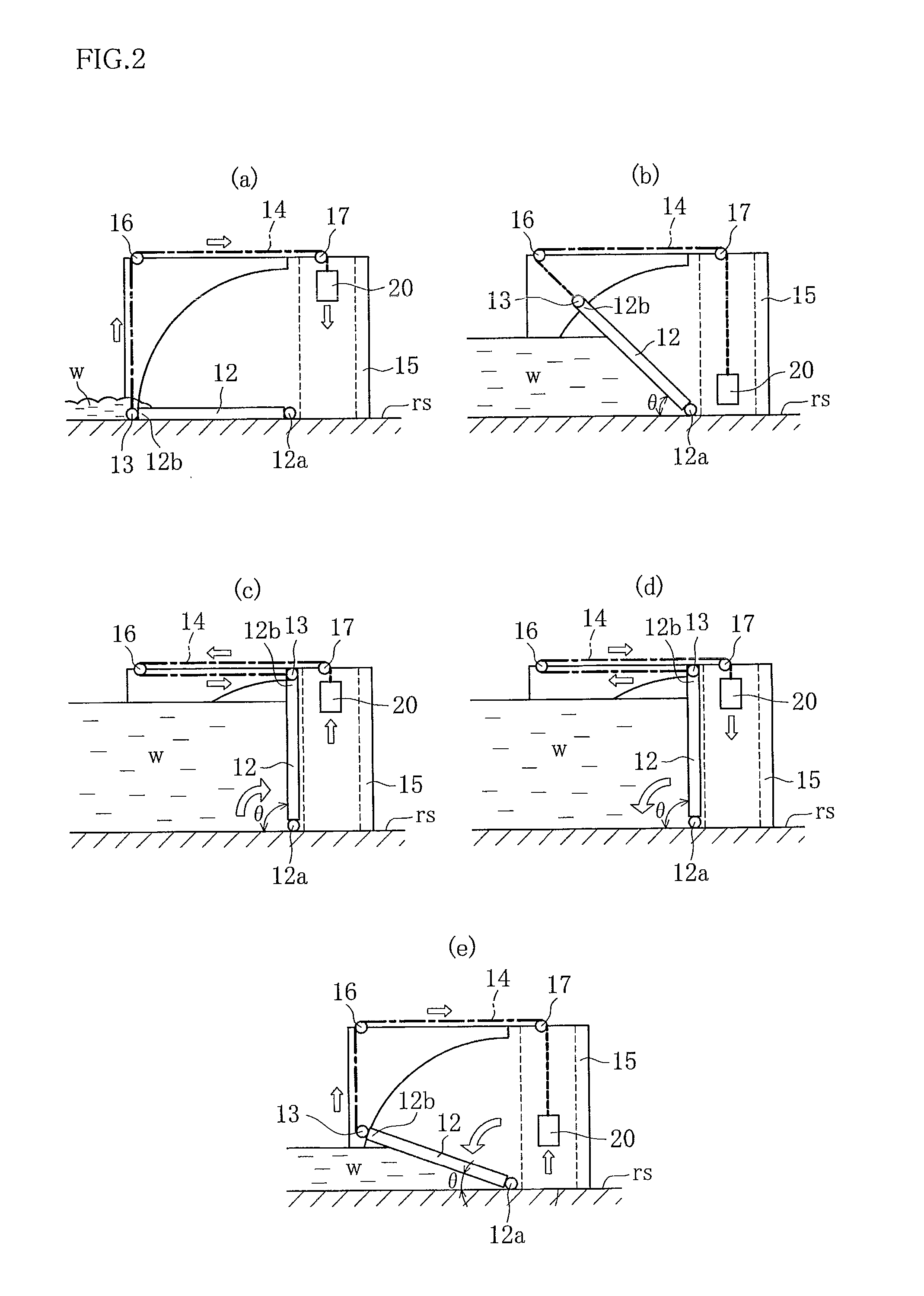

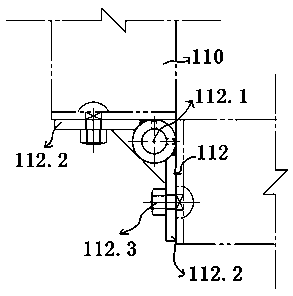

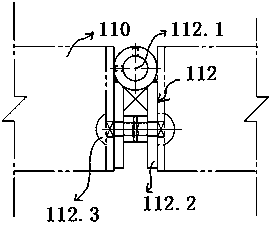

Floating flap gate

ActiveUS20140140770A1Prevent water from overflowingReduce shockFlood panelsDamsWater flowEngineering

The object of the present invention is to prevent an overflow of water into living spaces and underground spaces, to prevent difficulties in lower the door body when the water level has dropped, and to prevent the door body from suddenly falling. This is achieved by a floating flap gate 11 which is disposed at an opening or at an access way, so as to block the opening or the access way when water w flows in, and comprises a door body 12 with a forward end which is able to swing upwards, within in a plane in a height direction in a direction in which the water flows in around a base end thereof serving as a fulcrum. A rod 13 is attached to the forward end of the door body 12. One end of a wire rope 14 is attached to the rod 13, and the other end is attached to a counterweight 20 via fixed pulleys 16, 17. The fixed pulley 16 is arranged so that the counterweight 20 is at its lowest point when the angle of inclination of the door body 12 with respect to a horizontal plane reaches within a range from 10° to 80° during raising or lowering of the door body 12.

Owner:HITACHI ZOSEN CORP

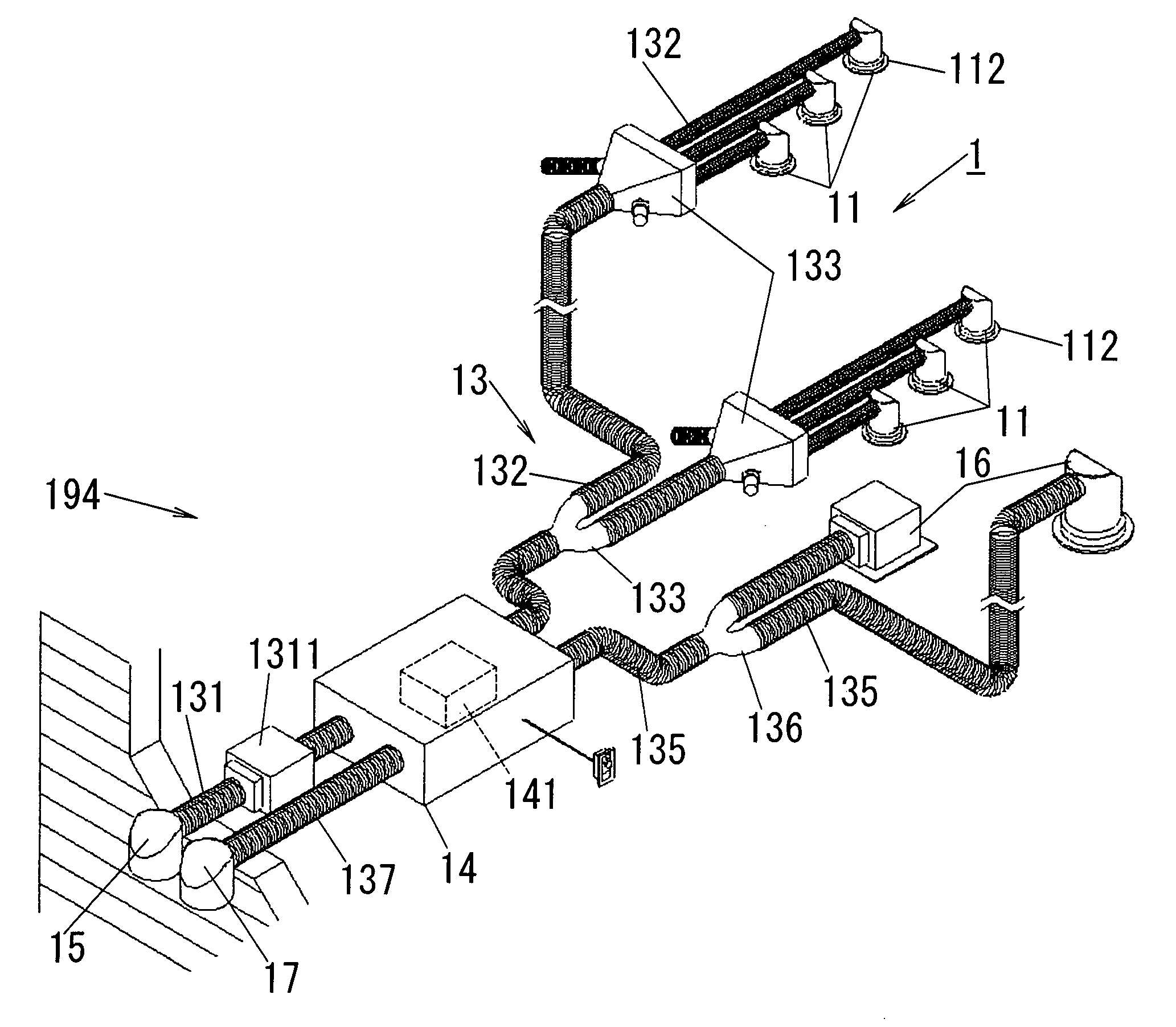

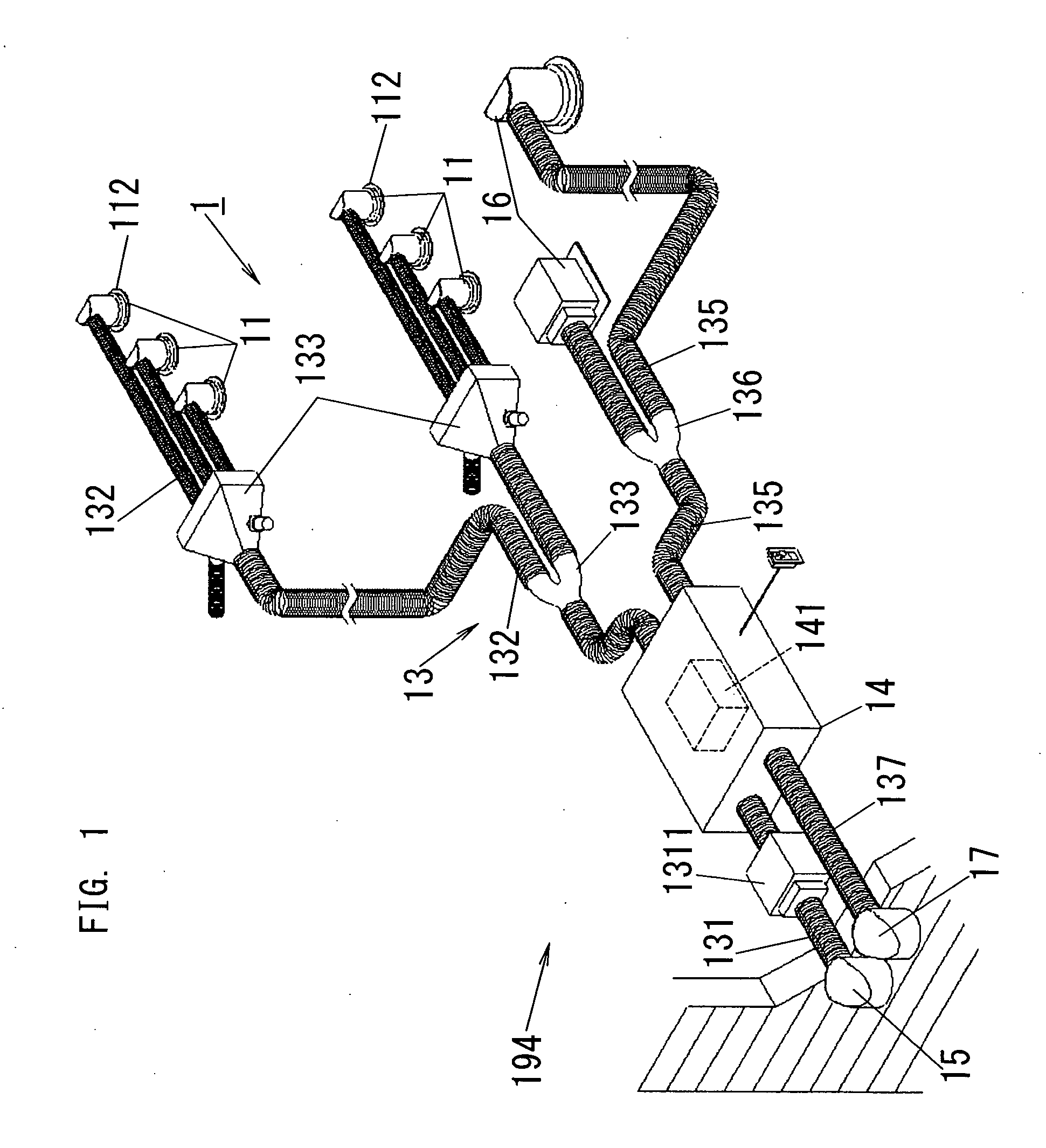

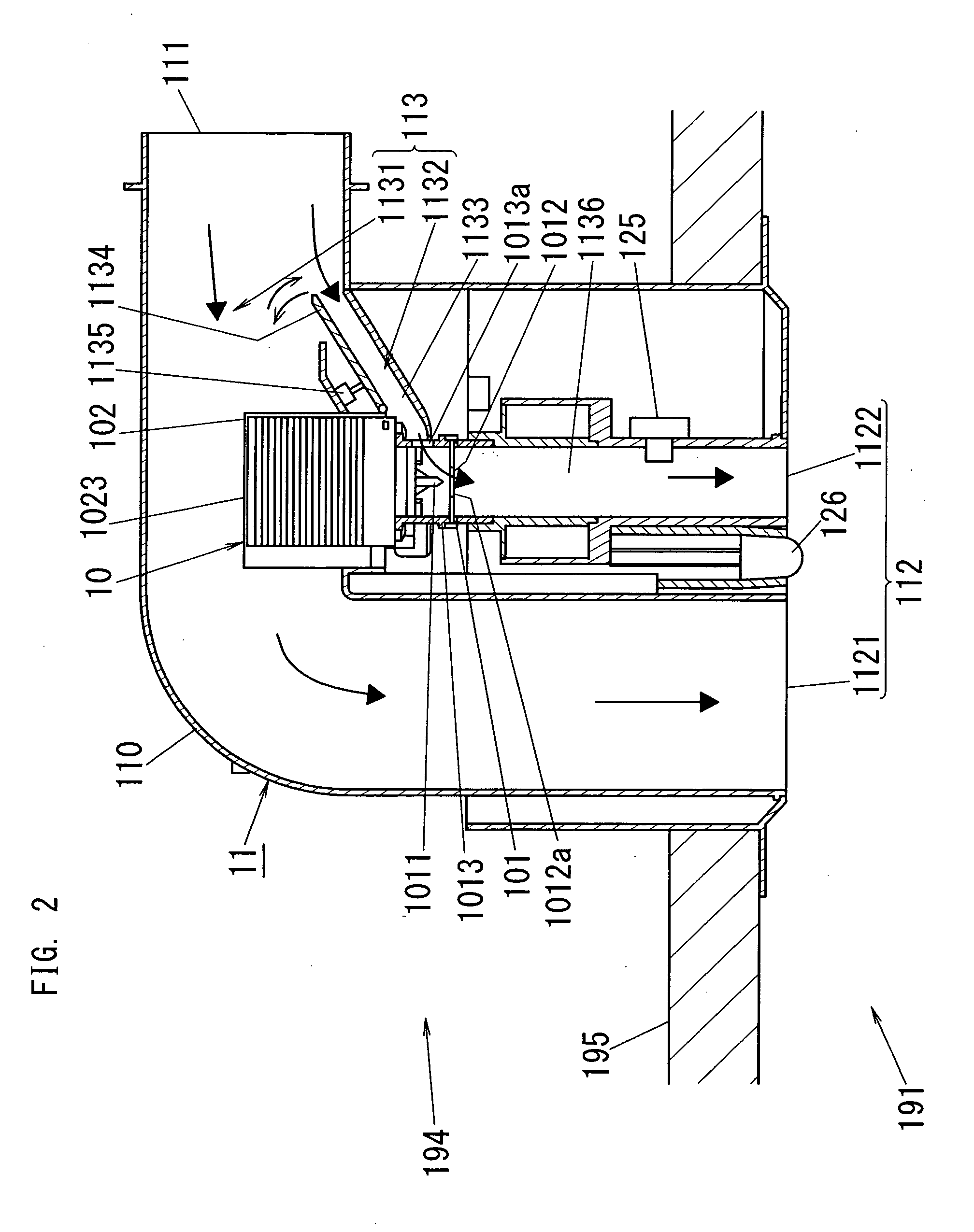

Ventilation system

InactiveUS20080242218A1Reduce living spaceEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringWater particle

A ventilation system comprises ductwork, a fan for creating a current of air passing through the ductwork, and an air supply outlet for supplying outdoor air into a living space of a house by means of the current of air. The ventilation system further comprises an electrostatic atomizer located at the side of the air supply outlet. The electrostatic atomizer is configured to produce mist of charged fine water particles by means of electrostatic atomization to spray the mist into the living space.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Foldable container house capable of being conveniently moved and transported

InactiveCN103953117AEnsure overlapLarge internal spaceBuilding constructionsDwelling buildingInterior spaceResidence

The invention relates to a foldable container house capable of being conveniently moved and transported. The foldable container house comprises a container house, wherein the container house is a standard 20-foot container high cabinet for transportation, communicated insertion openings are formed in two box bottom long edge steel components, the other side of a container house long edge is connected with a long edge reversible platform through a connecting hinge, one side of a container house short edge is connected with a short edge upward and downward reversible platform through a connecting hinge, an outward moving box body is arranged in a position, positioned at one side of a rigid side plate, of the container house, a moving box body and a peripheral side plate are arranged in a position positioned at one side of the long edge reversible platform, an inward opening inner reverse door is arranged on the peripheral side plate, and a double-leaf door is arranged in a position positioned at one side of the short edge upward and downward reversible platform. The foldable container house belongs to a container house which conforms to the standard transportation requirements and can expand the internal space. The foldable container house can be singly used as a residence and can also be combined and assembled with a plurality of container unit bodies to form a multi-story and yard living space.

Owner:沈姗姗

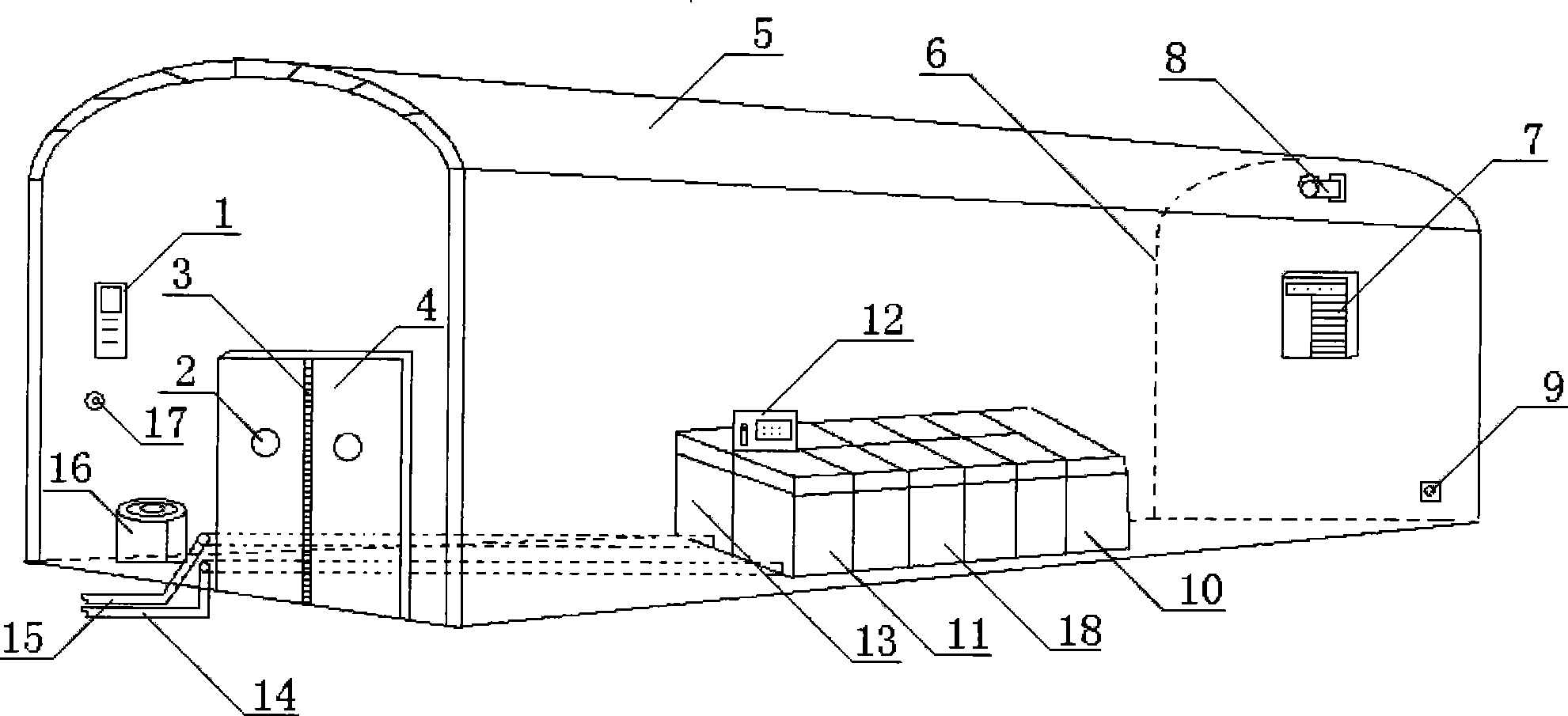

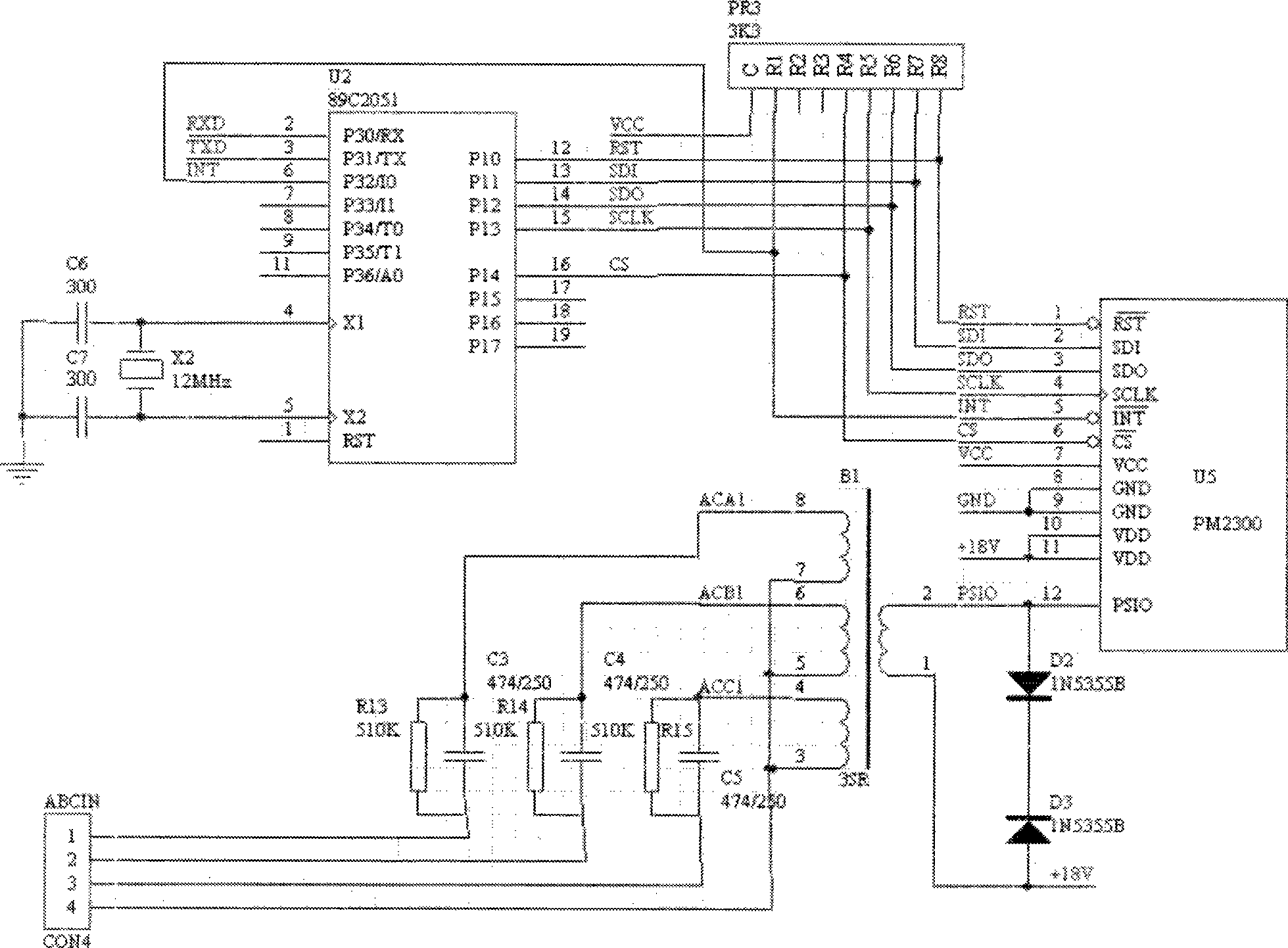

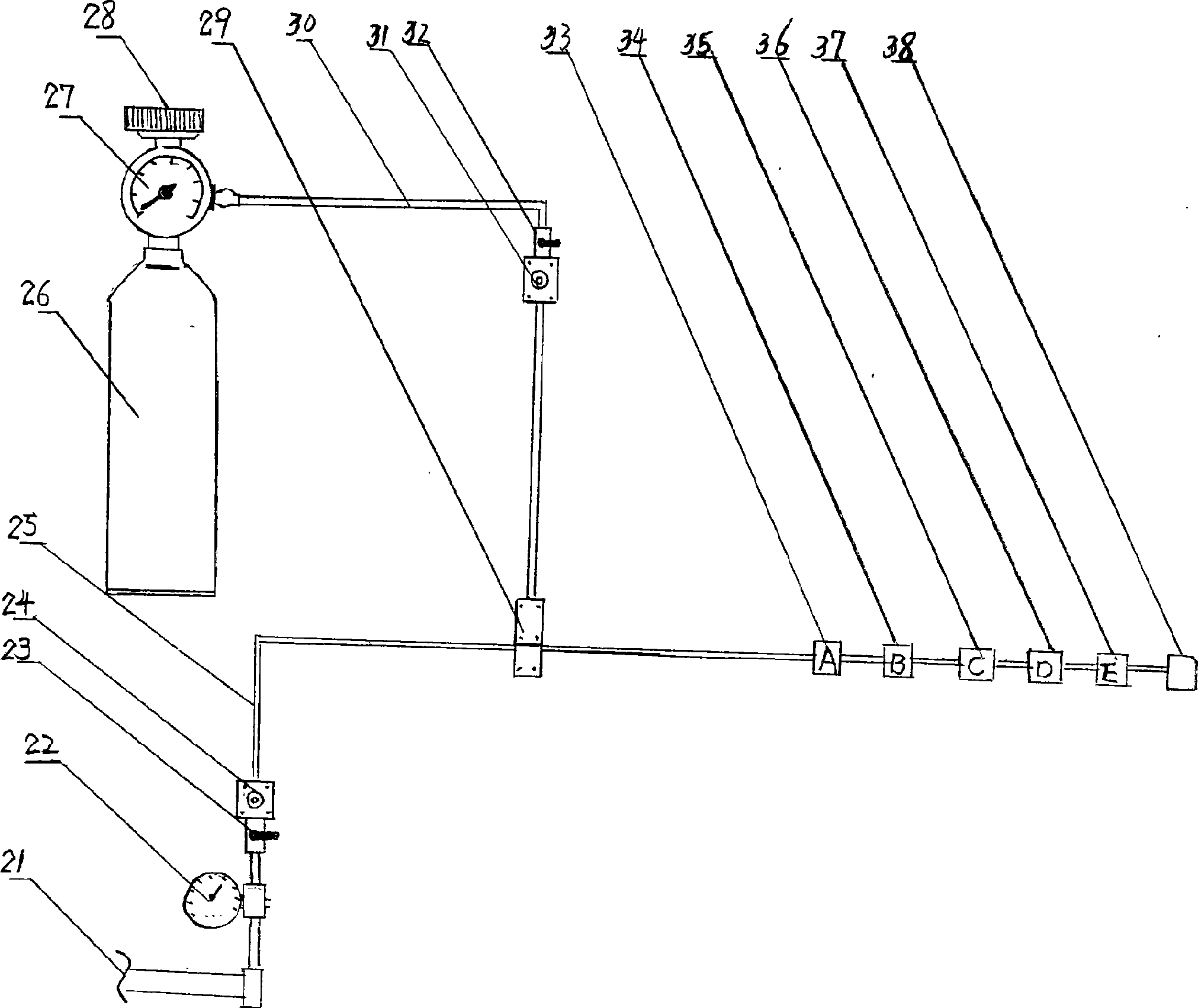

Double-gas path centralized oxygen supply life saving system of embedded type mine refuge underground chamber

InactiveCN101368484AEasy to remove and moveEasy to installSafety equipmentsGas detectorCo2 absorption

Owner:HARBIN INST OF TECH +2

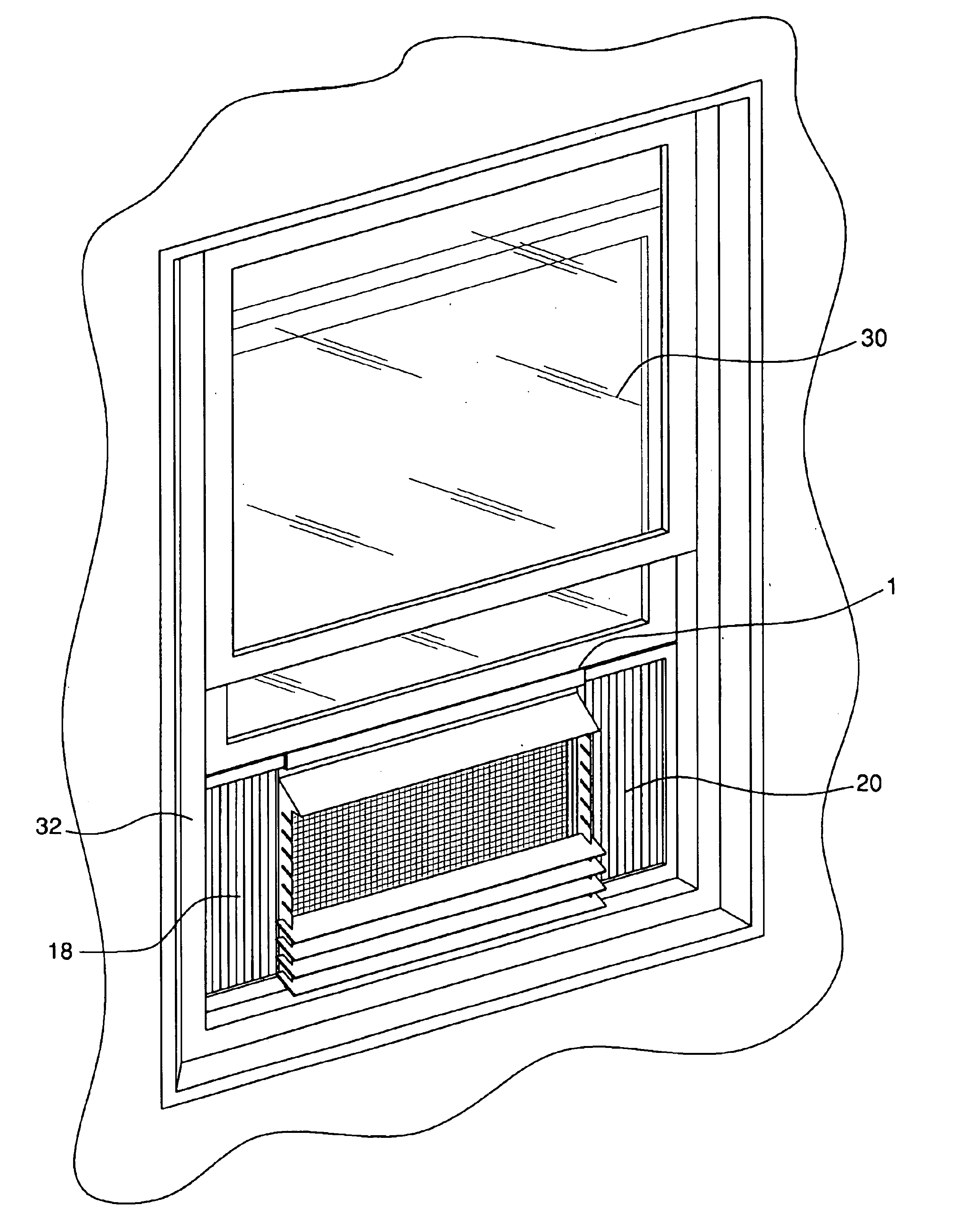

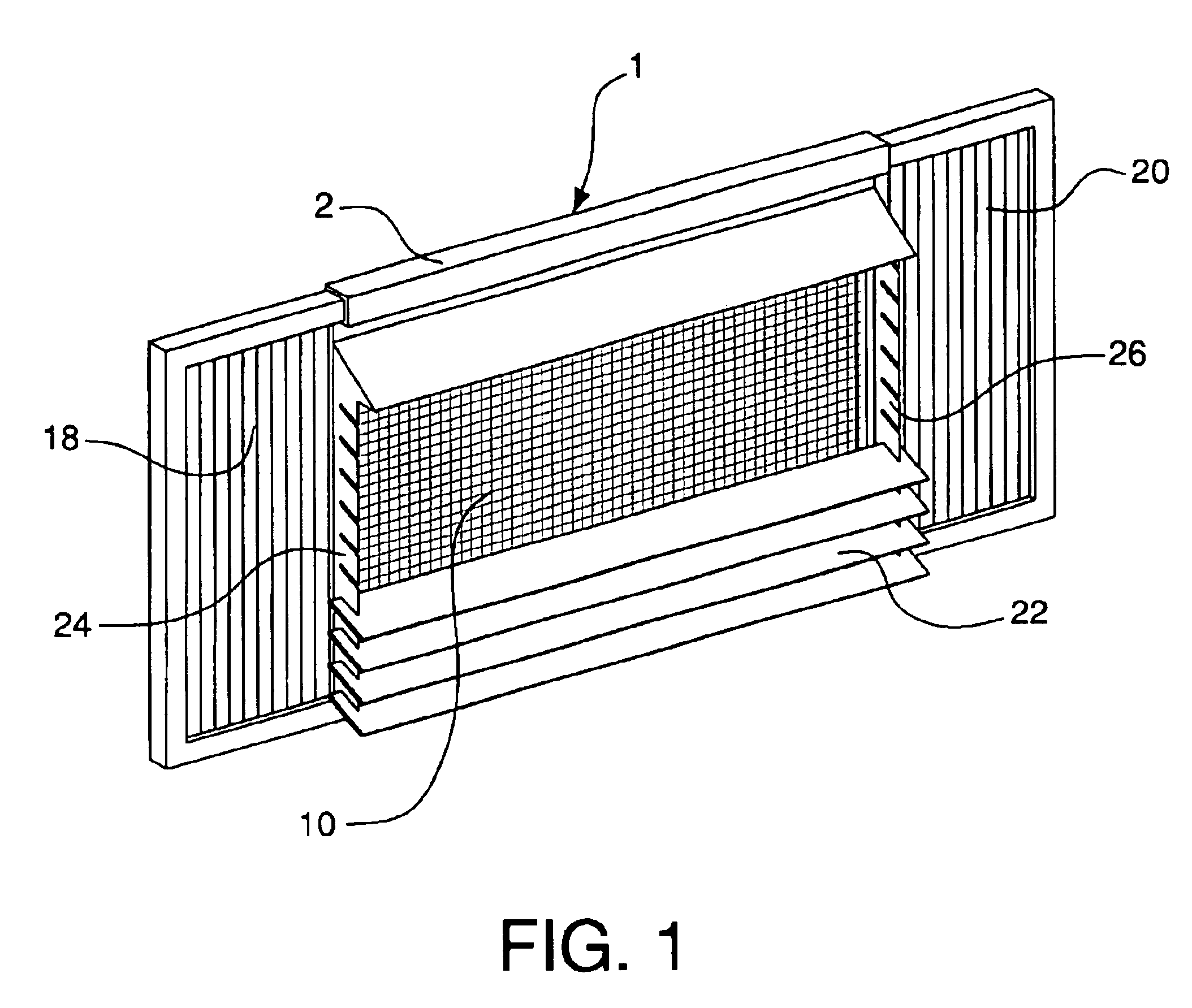

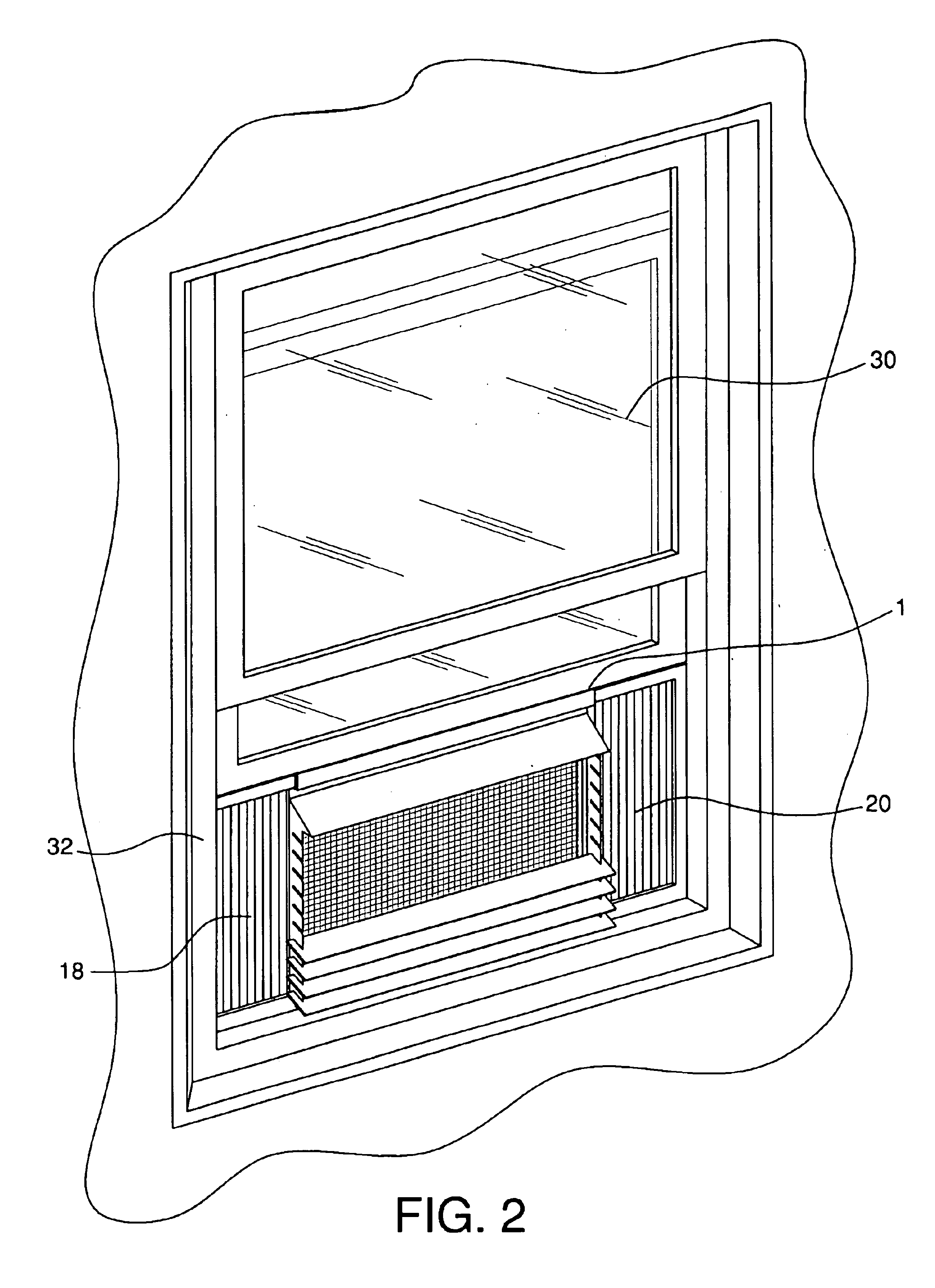

Portable window unit for killing insects

InactiveUS6874273B1Easily and readily insertable intoEasily and readily and removedElectric shock equipmentsInsect catchers and killersTransformerEngineering

A portable, self-contained unit has two spaced apart electrical wire grid screens. One of the screens has a positive charge and the other has a negative charge. Electrical power is provided to a transformer which provides the necessary electrical current to the grid screens. Flying insects attempting to pass between the dual electrified grid screens are electrocuted. A third screen is located behind the dual electrical screens, at the rear of the unit, adjacent to the living space. The dual screens are secured within a frame which is made of a non-electrical conducting material. The entire unit is configured to be positioned within a window opening and secured within the opening by slideably adjustable wing elements which moveably extend laterally from the frame.

Owner:WEISENBURG III EDWARD F

System and method of increasing efficiency of heat pumps

InactiveUS20050268628A1Increased and efficient and heat transferEffectively warm airHeat pumpsTemperatue controlEngineeringRefrigerant

The system and method for increasing efficiency of heat pumps employs temperature sensors to measure the indoor refrigerant coil (indoor heat exchanger) and supply duct air temperature in a heat pump system to vary the indoor air flow rate based on the amount of heat being supplied by the heat pump. By monitoring the indoor refrigerant coil temperature, and the supply duct air temperature near the unit, the airflow can be adjusted to match the BTU (heat) output of the heat pump system. Less air flow over a cooler indoor refrigerant coil temperature allows increased, more efficient, heat transfer, allowing the cooler indoor refrigerant coil temperature to more effectively warm the air. Additionally, with airflow reduced when the indoor refrigerant coil is operating at lower than optimal temperatures or during a defrost cycle, the reduced airflow into living spaces presents a less drafty and more comfortable condition.

Owner:THOMPSON THOMAS W

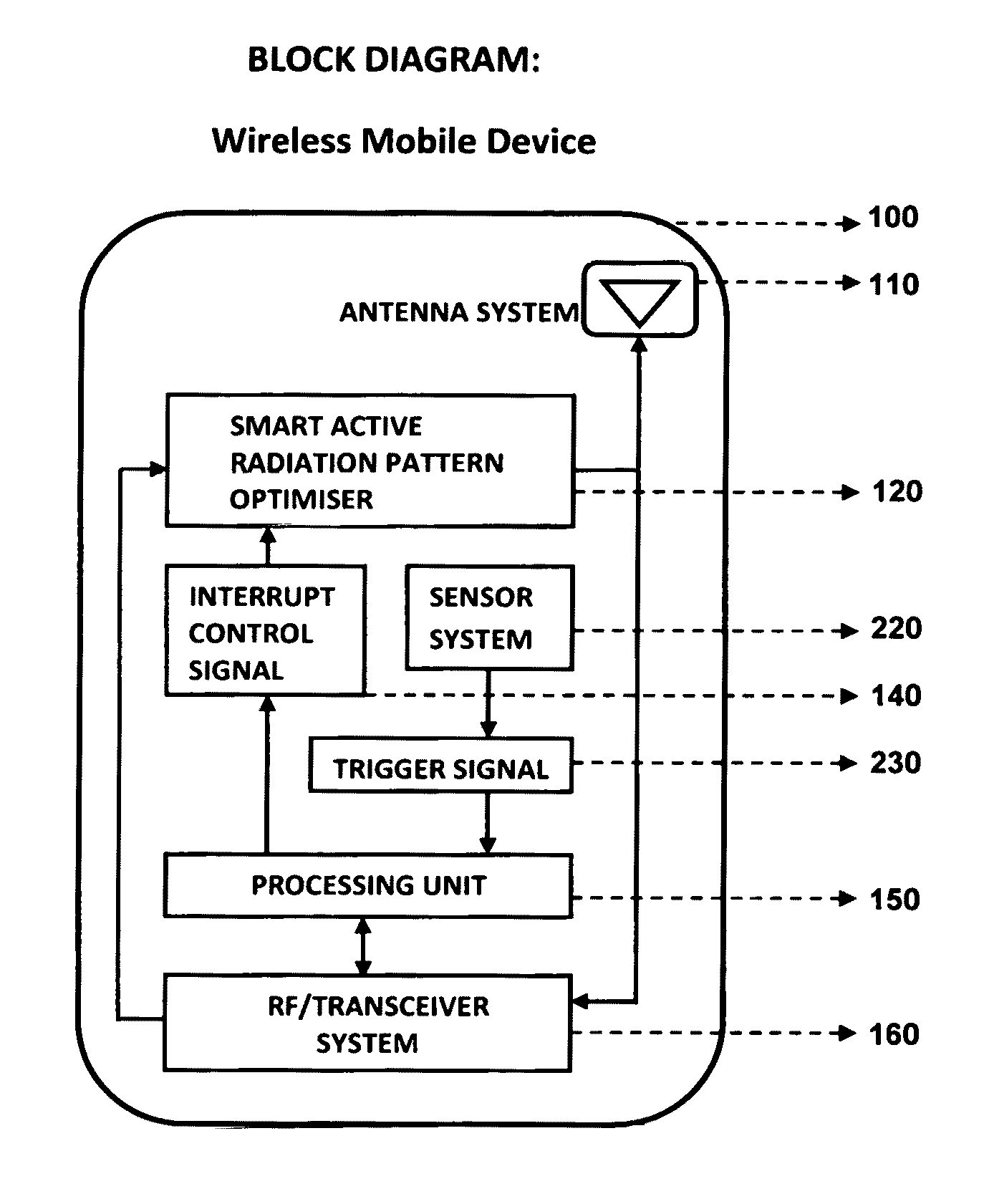

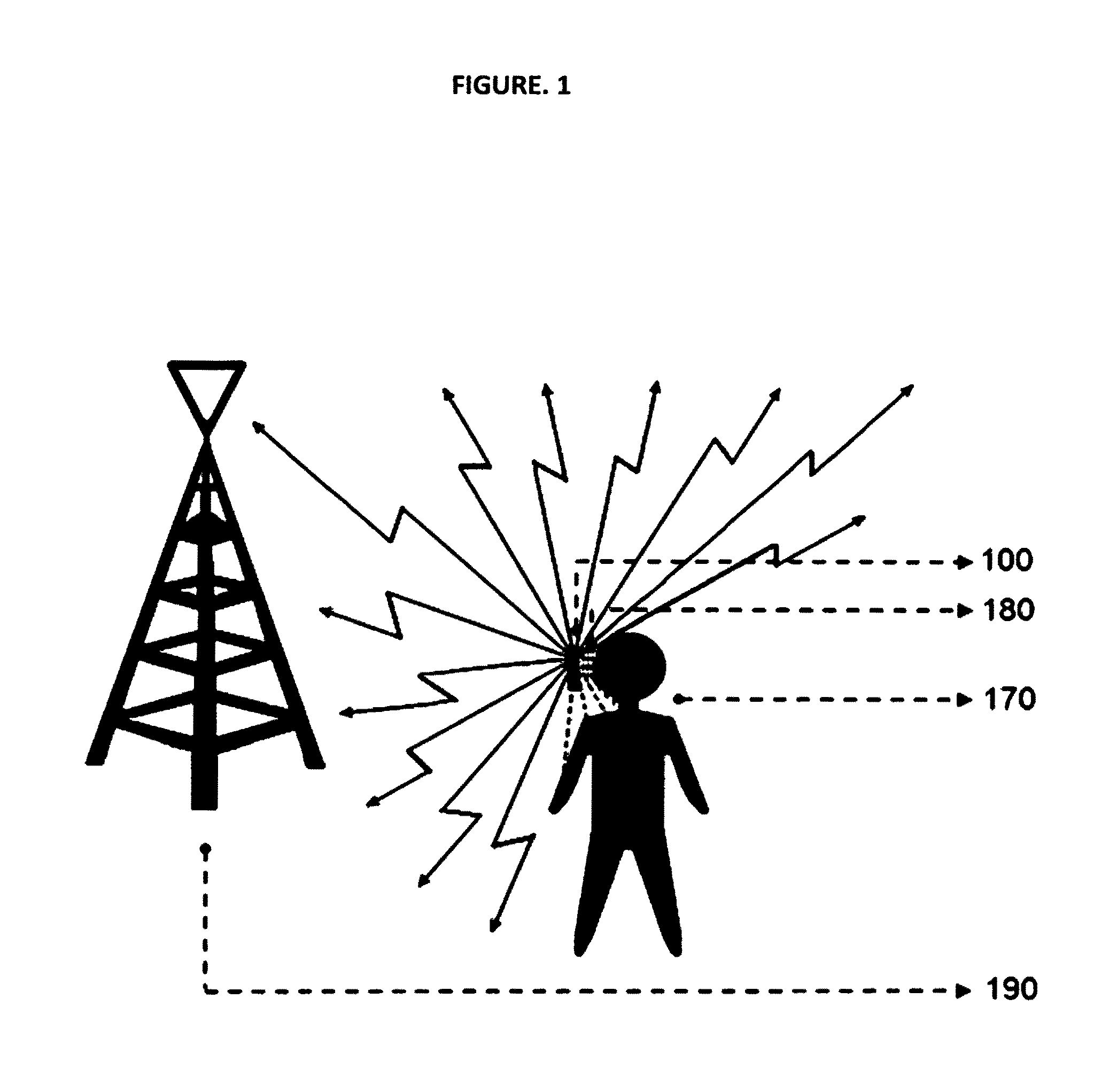

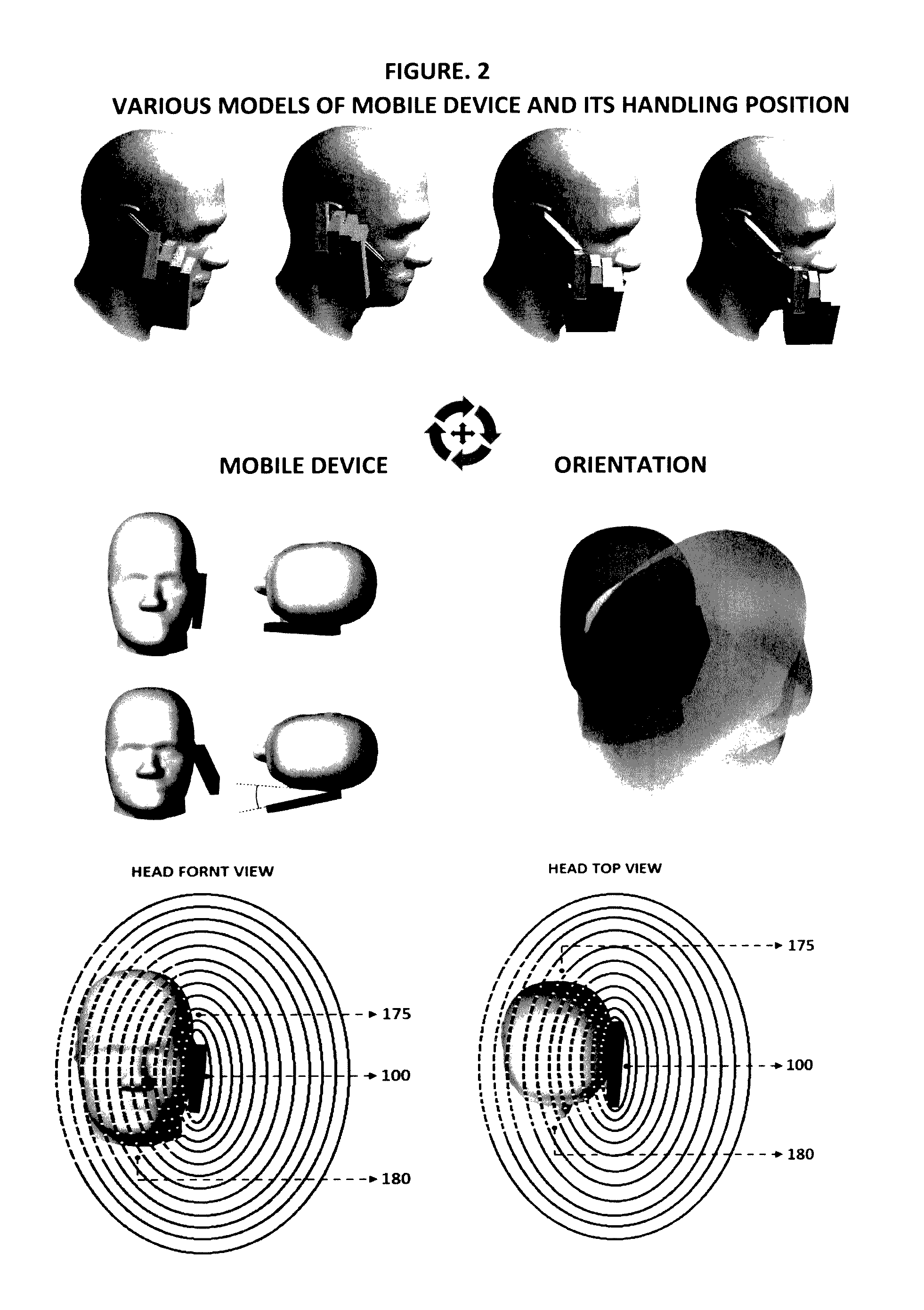

Environment property based antenna radiation pattern optimizing system

ActiveUS9515378B2Save battery powerOptimizationSpatial transmit diversityAntenna supports/mountingsSignal qualityAntenna radiation patterns

Mobile devices are handled in different environments which influence an antenna's performance due to electromagnetic interaction. Environment Property based Antenna Radiation Pattern Optimizing System (EPARPOS) is a system that actively varies, controls, directs, shapes and optimizes the antenna radiation pattern of mobile device in a closed loop manner controlled by precisely sensing the environment's property comprising dielectric nature, permittivity-∈, permeability-μ, conductivity-σ, susceptibility, direction, dimension, range, orientation, position, location, utilizing visual sensing, infrared sensing and signal quality parameters are all to determine the effect of the environment and effect on environment in order to enhance signal quality, protect the users by controlling radiation exposure in a user facing direction while maintaining radiations in other directions to sustain communication and to save battery power by controlling radiation in less effective directions. The system is utilized for guiding the user to locate and position the mobile device in a living space to achieve optimized performance.

Owner:PRASAD MUTHUKUMAR

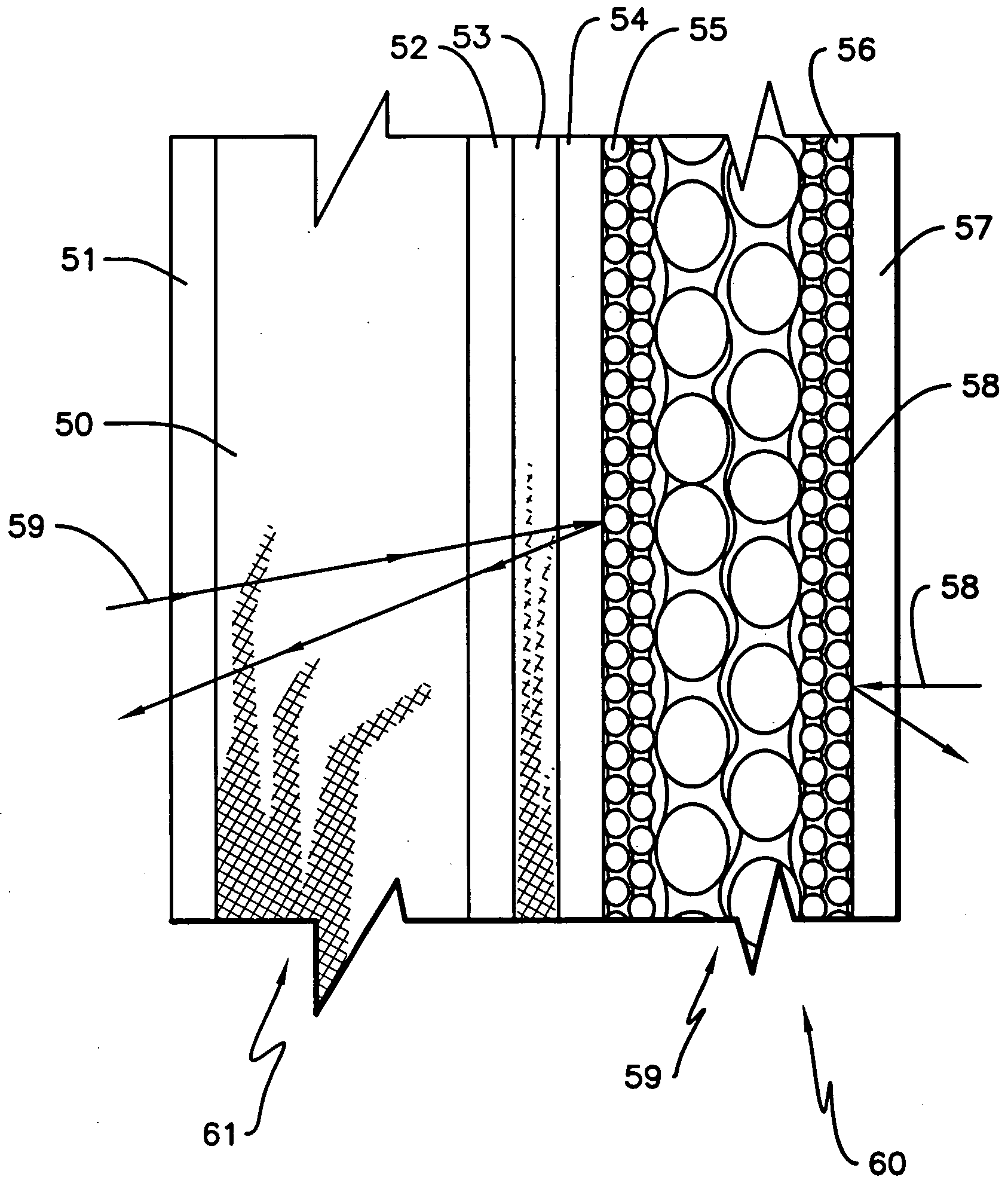

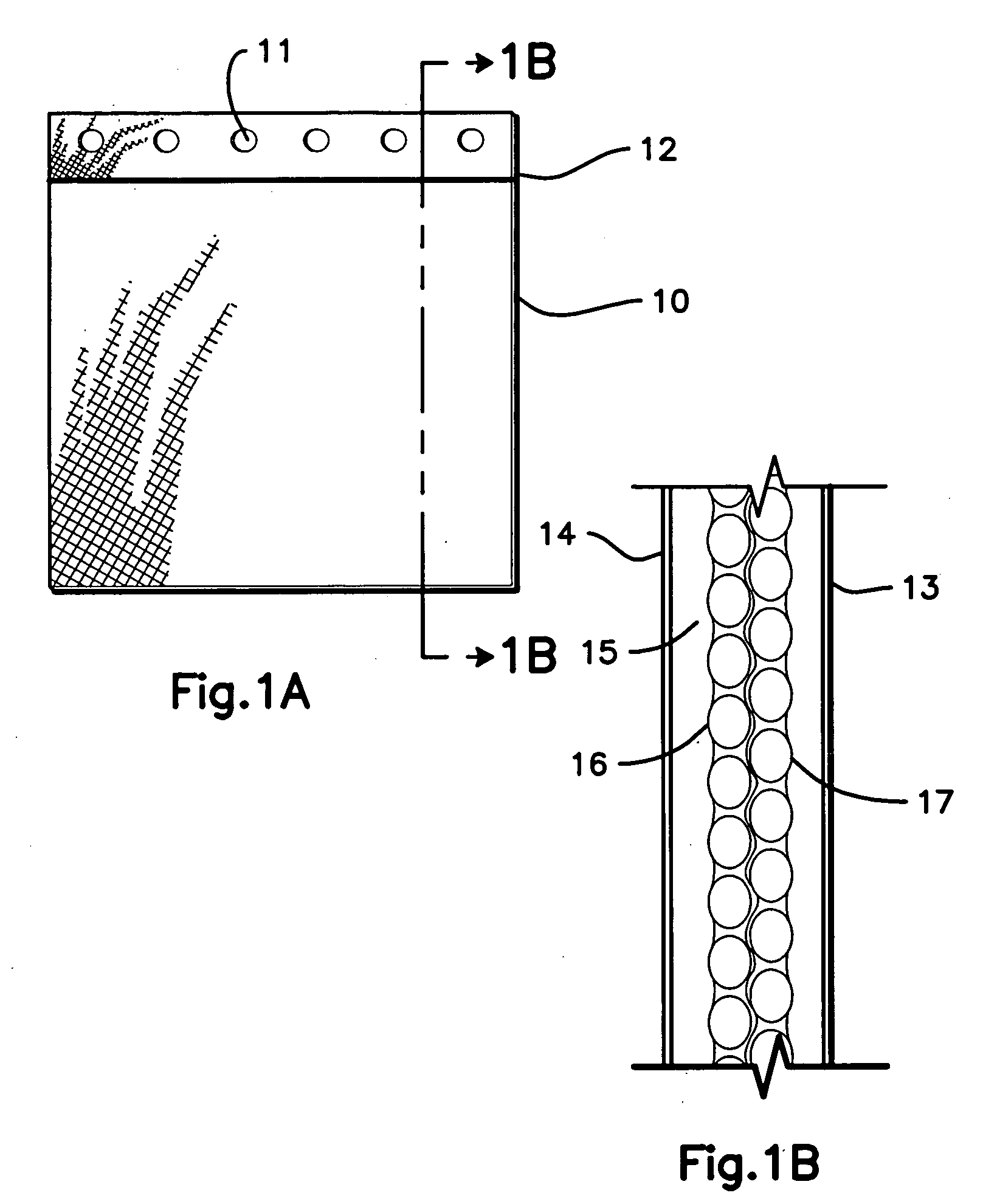

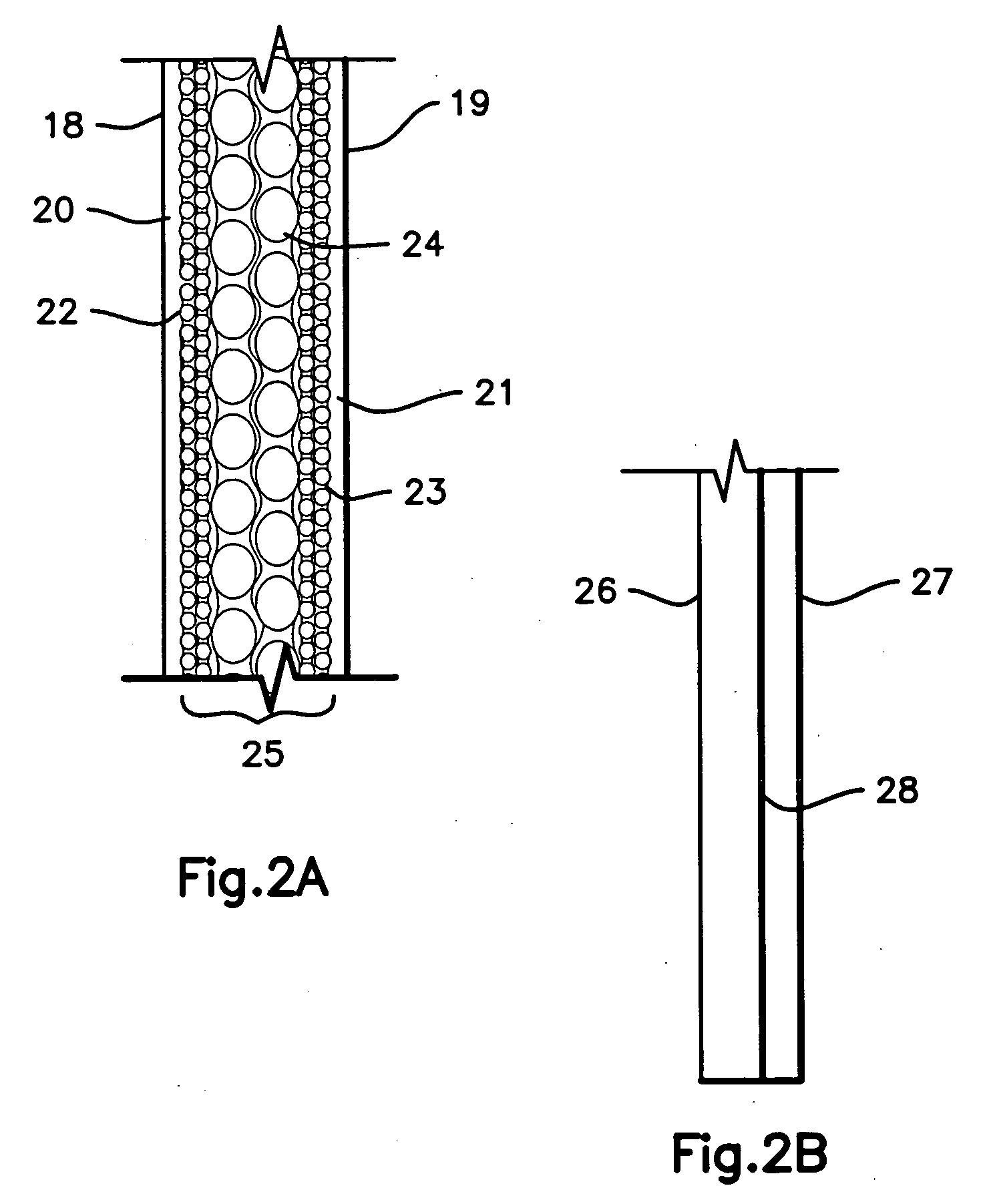

Insulated fabric pocket panels

Insulated Fabric Pocket Panels were designed to provide safe, economical, portable energy saving insulation for the interior living spaces of un-insulated or under insulated structures. The embodiments inserted into the fabric pocket panel include the following but not limited to either one layer of double bubble reflective foil insulation (15), an insulation bundle (25) or foil radiant barrier (28) inserted inside the pocket.The insulated fabric pocket panels insulate against heat and cold transfer through perimeter interior surfaces from outside weather. Heat and cold are reflected out of the interior of the structure to the outside environment. The reflective foil on the interior side of the panel reflects heated furnace air or cooled air conditioning air away from interior surfaces back into the interior or center of the rooms. Furnaces or air conditioners do have to heat or cool the interior finished wall surfaces. Only the air is heated or cooled. This process uses less energy, saves money, and protects the environment.Due to climate change, rising oil prices, stagnated wages and an increase in low-wage earners, environmental experts have said that within the next ten to fifteen years 30% of all Americans will not be able to heat or cool their residences. No American family should have to choose between heating or cooling their residence and buying food or medication(s). These panels are essential to middle class families, the elderly and disabled on fixed incomes, and poverty stricken families because they reduce energy use, save money and help protect the environment.

Owner:3M INNOVATIVE PROPERTIES CO

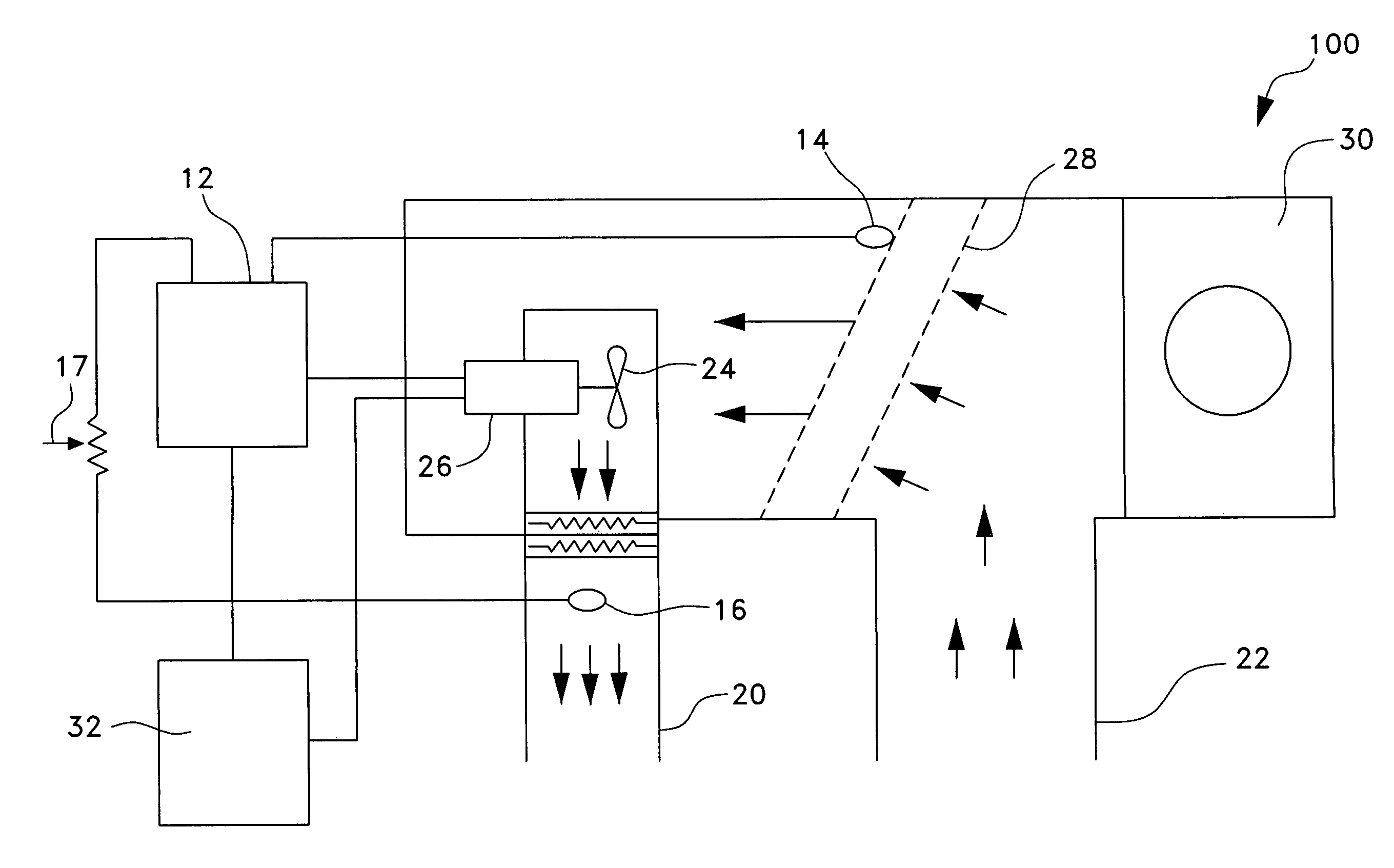

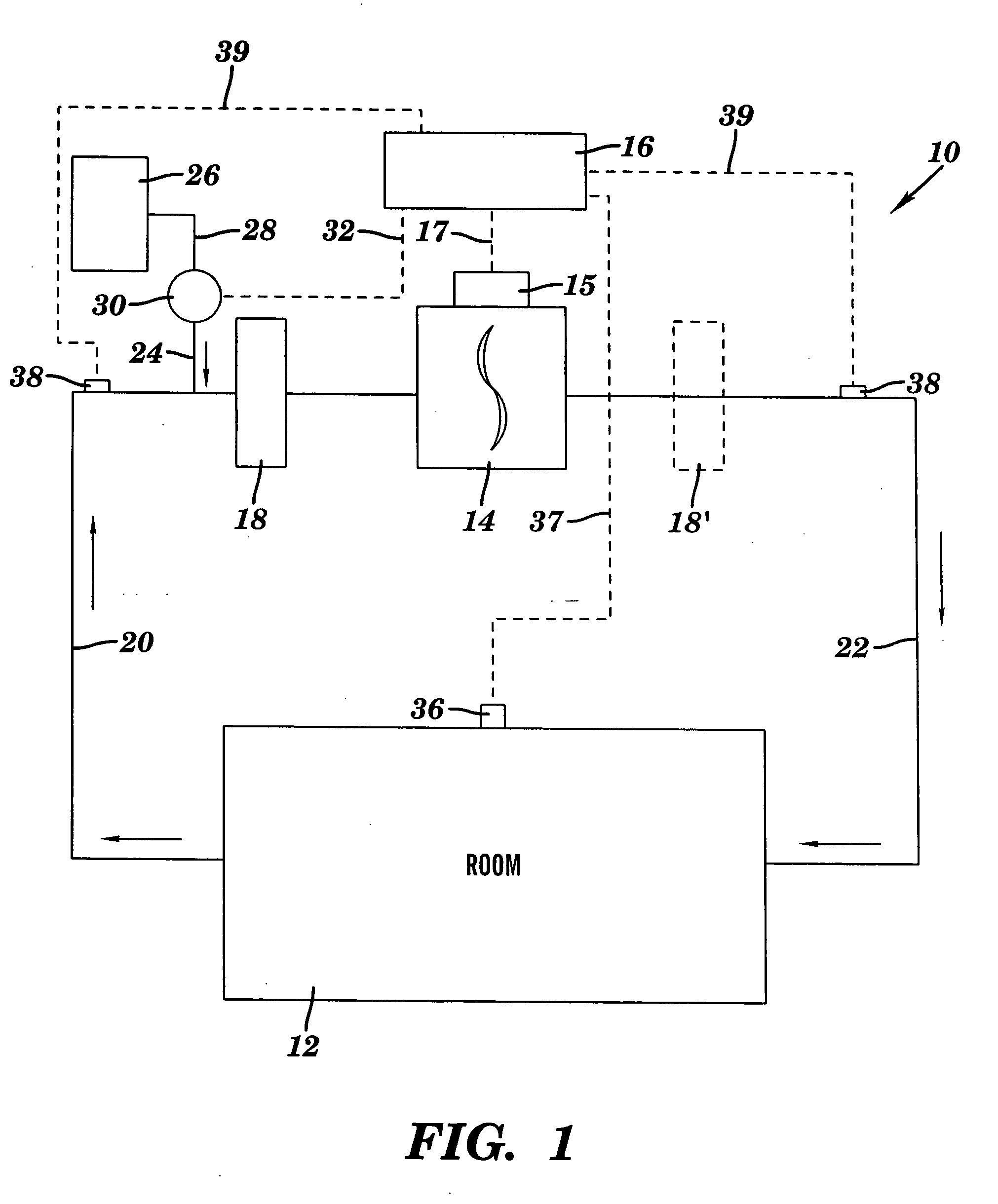

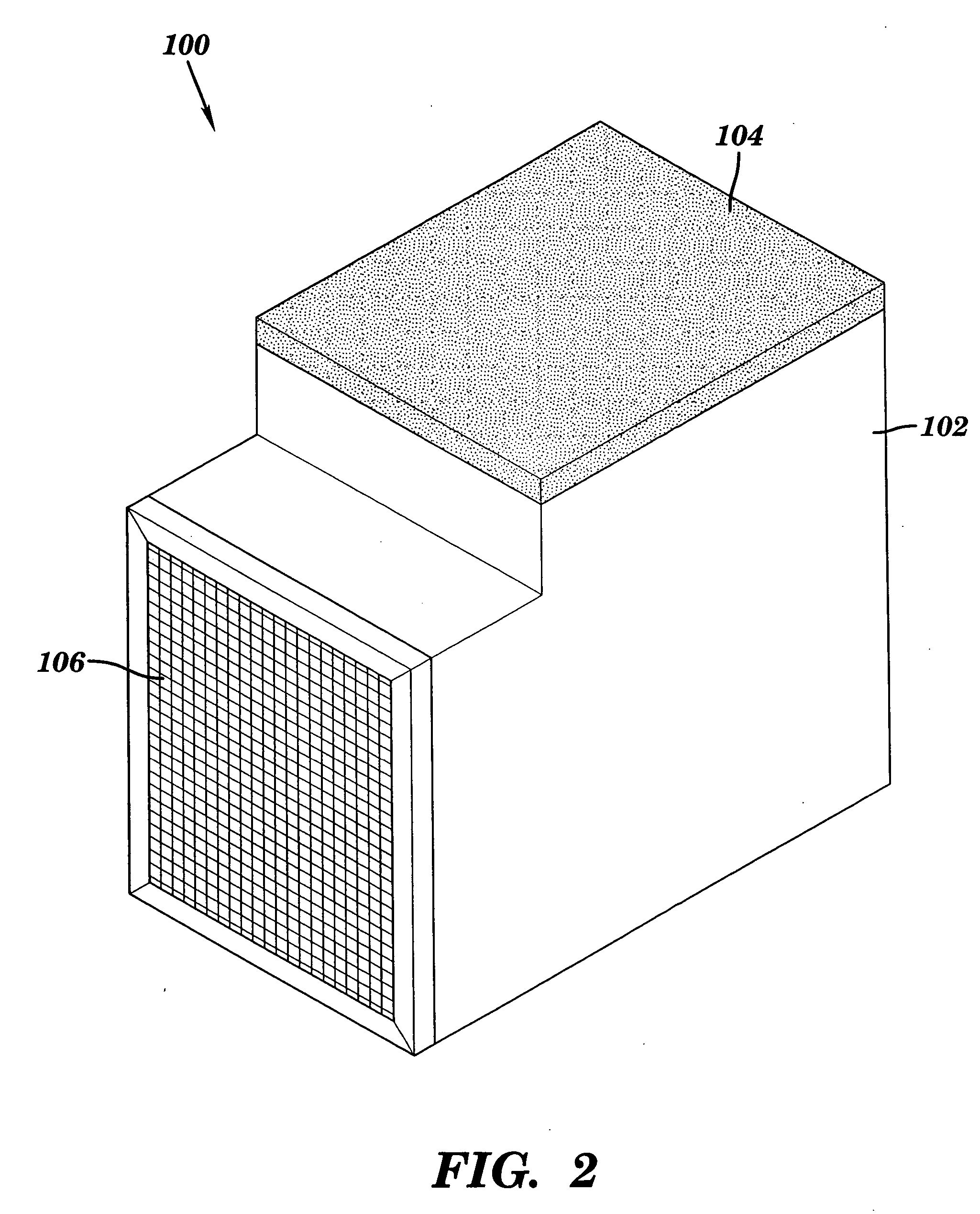

Systems and methods for controlling room air quality

InactiveUS20060162552A1Quantity minimizationMinimize the speed of the air moving deviceMechanical apparatusSpace heating and ventilation safety systemsIndoor air qualityAir handler

Systems and methods for improving the air quality of living spaces are provided. These systems and methods utilize improved filtration media and electronic control of the speed of the air handler to minimize the presence of contaminants in the air while optimizing the efficiency of the operation to the air handler. In one aspect, the speed of the air-handling device is controlled in response to the concentration of a contaminant in the living space. In another aspect, the speed of the air-handling device is controlled to optimize the filtration efficiency of the filtering medium. The systems and methods disclosed may be used in residential, commercial, and industrial settings, for example, in hotel rooms as well as for an entire home.

Owner:MOHAWK VALLEY ENERGY SOLUTIONS

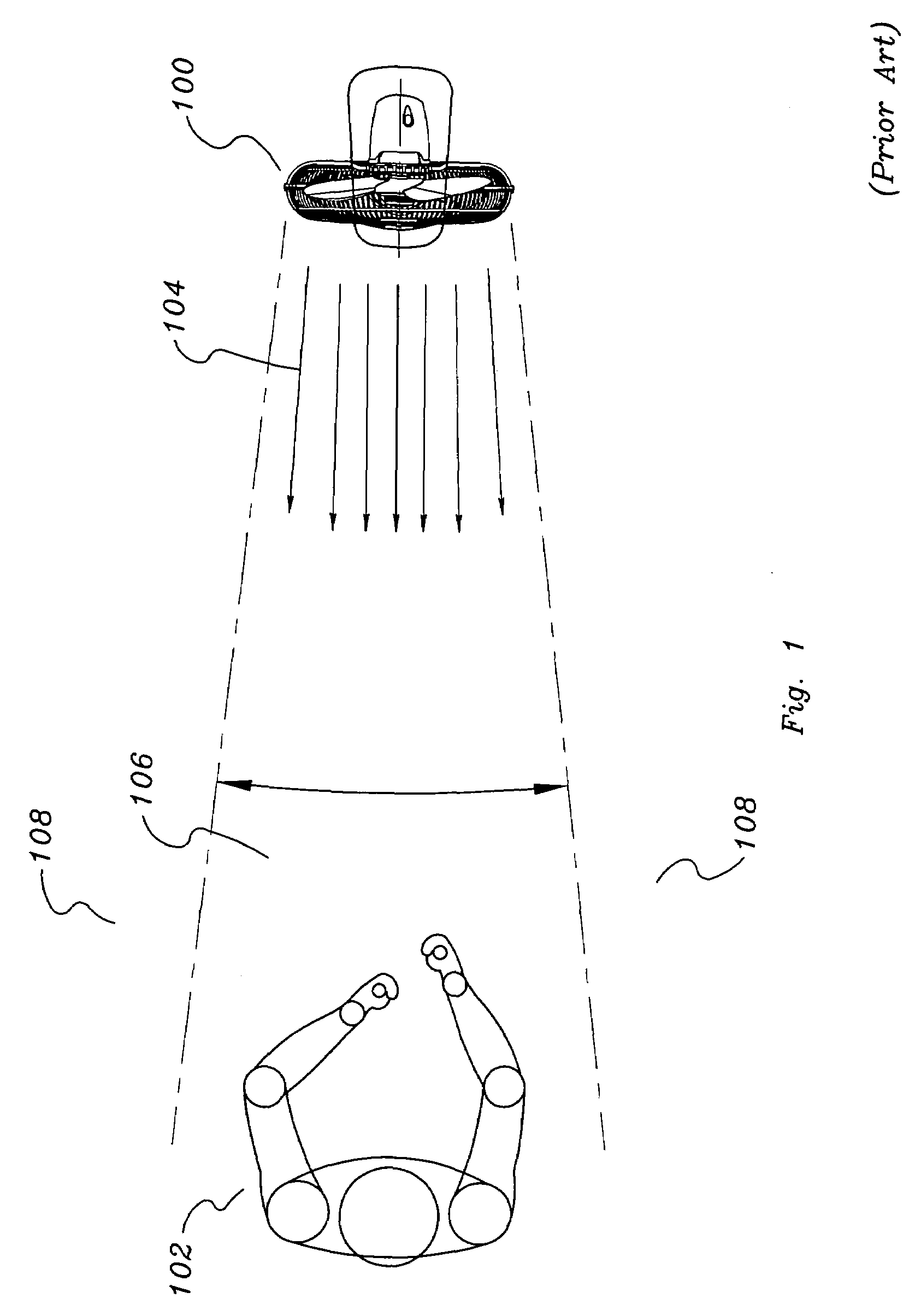

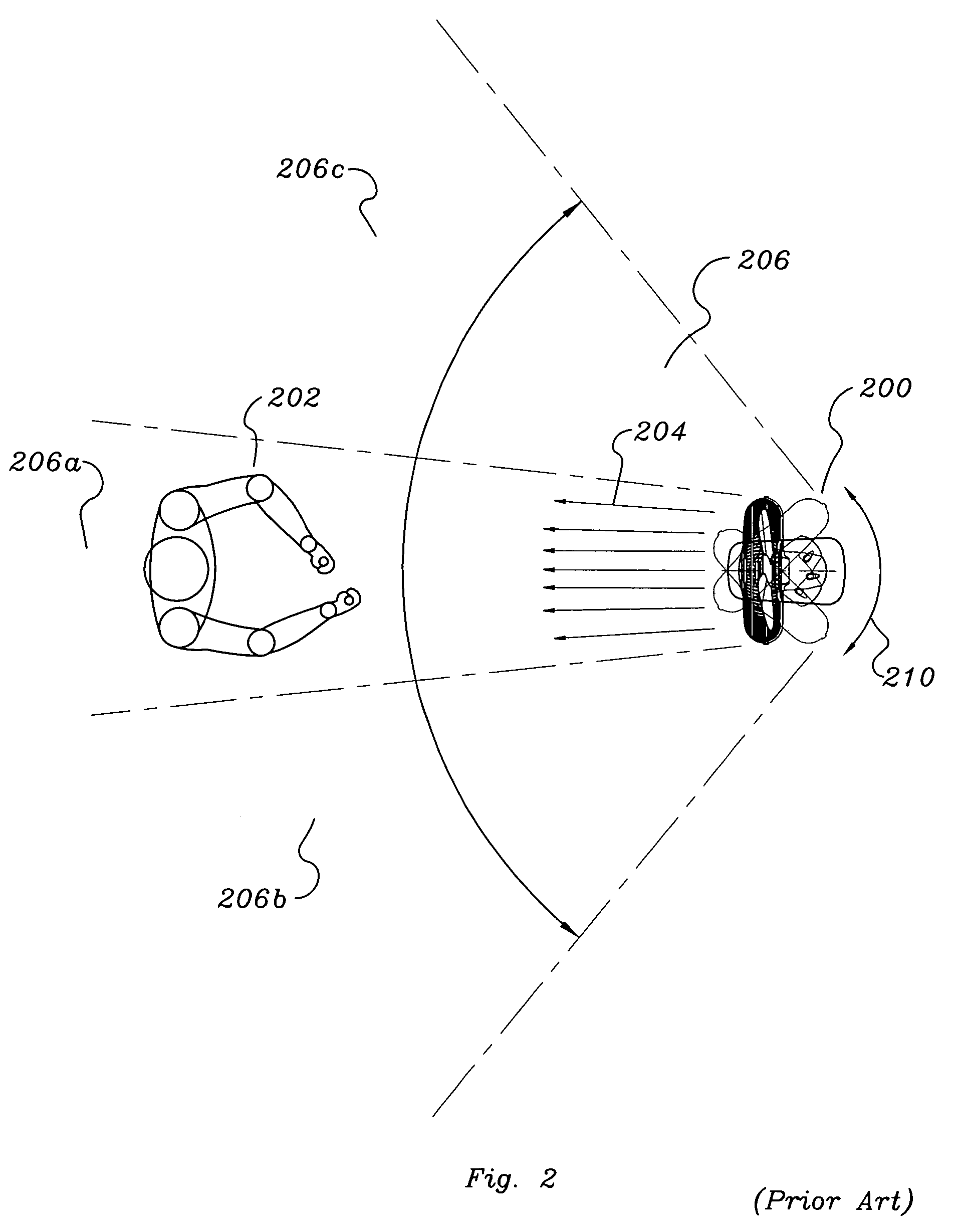

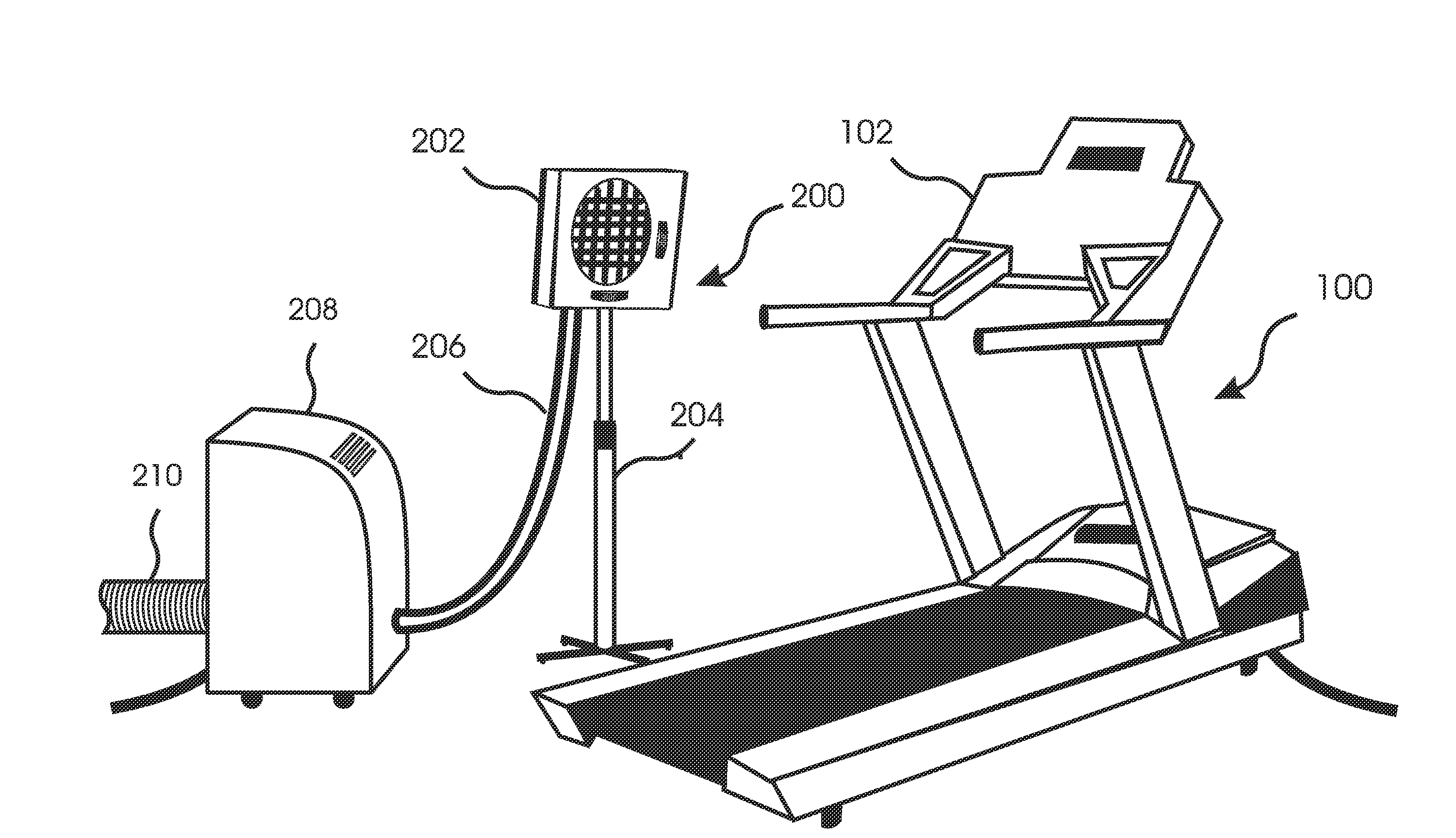

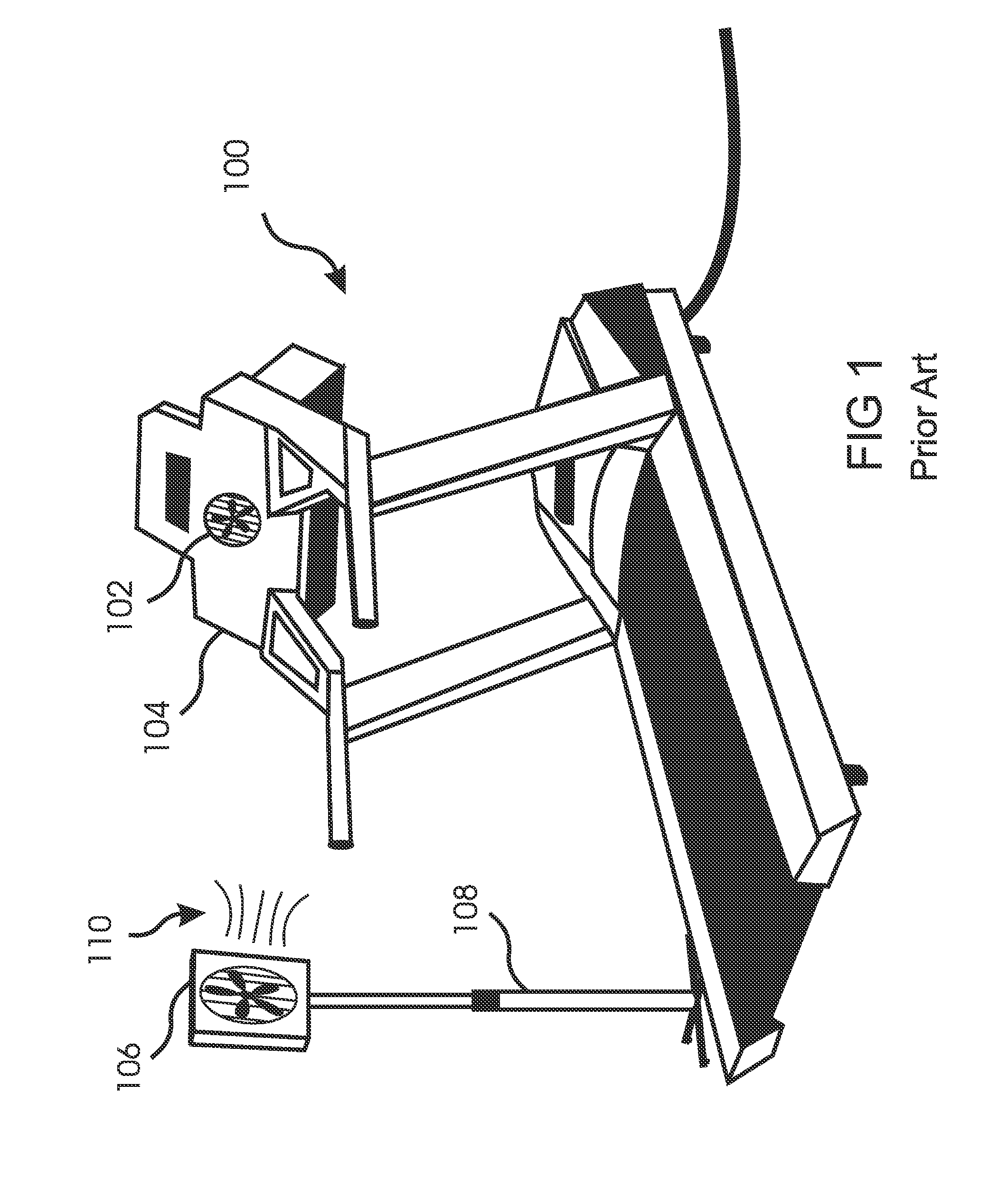

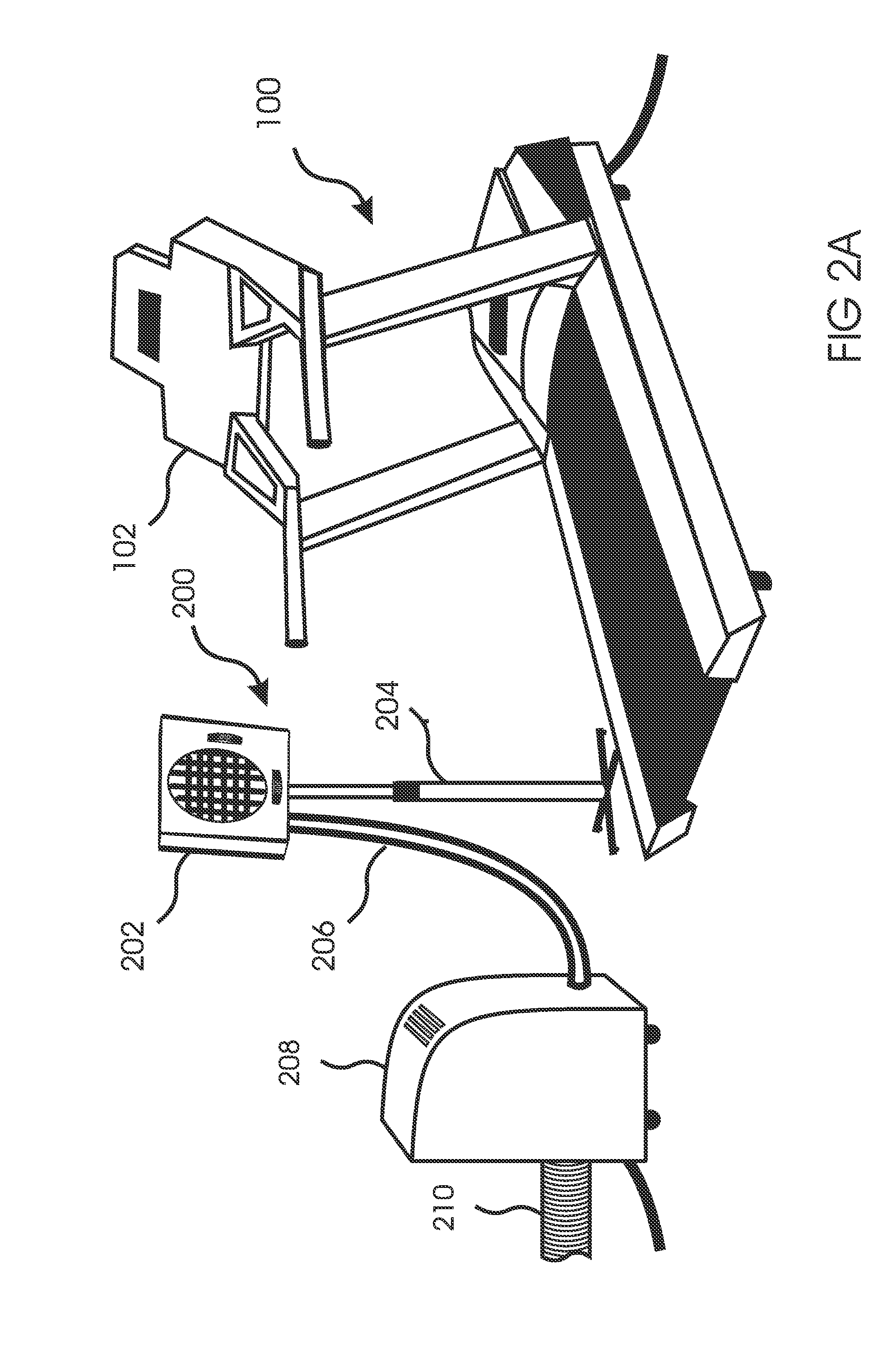

Apparatus for cooling an exerciser for use with an exercise machine

InactiveUS20100227542A1Improve efficiencyImprove uniformityDucting arrangementsMechanical apparatusEngineeringExercise machine

An apparatus is disclosed that cools an exerciser using an exercise machine by blowing chilled air directly onto the exerciser from an airflow director that is independent of the exercise machine. The airflow director is either located within the living space of the exercise room, or able to project a directed stream of chilled air into the living space of the exercise room. The airflow director can include adjustments for chilled air direction, flow rate, and other qualities. The chilled air source can include adjustments for temperature, humidity, and other qualities. A plurality of airflow directors can be included, so as to provide uniform cooing and / or to deliver chilled air to a plurality of exercise machines. A barrier and / or chilled air return vent can be included, so as to save energy and enhance the localization of the chilled air. Some embodiments can also warm the exerciser using warmed air.

Owner:GOLDMANN RICHARD DR

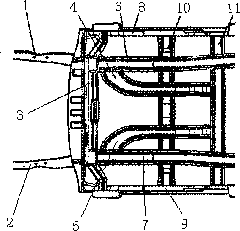

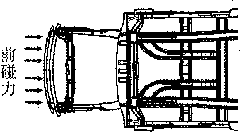

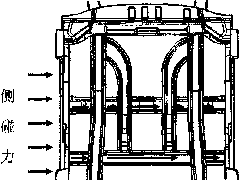

Automobile front floor framework

ActiveCN101823509APromote absorptionReduce the amount of living space compressionSuperstructure subunitsChinese charactersEngineering

The invention provides an automobile front floor framework structure, which has strong integral rigidity, can reduce the compression amount of the living space of passengers when colliding, and protects the safety of the passengers. The automobile front floor framework comprises a framework structure which is in a shape like a Chinese character 'mu' and is formed by overlapping a front beam, a left longitudinal beam and a right longitudinal beam, a left door sill inner plate and a right door sill inner plate as well as a rear beam, wherein the front part of the front beam is overlapped with the left and the right front longitudinal beam, the key point is that the invention further comprises a left middle longitudinal beam and a right middle longitudinal beam as well as a middle beam arranged between the front beam and the rear beam, the front ends of the left and the right middle longitudinal beams are respectively overlapped with the front beam or the left and the right longitudinal beams, and the rear ends thereof are respectively overlapped with the rear beam; and the middle beam is respectively overlapped with the left door sill inner plate, the left longitudinal beam, the left middle longitudinal beam, the right middle longitudinal beam, the right longitudinal beam and the right door sill inner plate along the left and the right directions of a vehicle body. The invention adds the left and the right middle longitudinal beams and the middle beam, effectively enhances the framework, can better absorb the collision energy during the processes of front side collision and side collision, reduces the compression amount of the living space of the passengers, and protects the safety of the passengers.

Owner:CHERY COMML VEHICLE ANHUI

A kind of manufacture method of carbonized bamboo chopsticks

InactiveCN102267151AConsistent colorImprove appearance qualityWood treatment detailsWood charring/burningFiberBrick

The invention discloses a method for manufacturing carbonized bamboo chopsticks, which comprises the steps of: sawing bamboo into sections, splitting pieces to make bamboo strips; processing the bamboo strips into bamboo chopsticks with a chopstick forming machine; placing the processed bamboo chopsticks on a mass The percentage concentration is 1~2% Na2S2O5 solution for 24~30 hours; take it out and soak it in clean water for 4~5 times; dry the bamboo chopsticks at 60~120°C to make the moisture content below 10%; The bamboo chopsticks are stacked neatly, placed in the carbonization furnace, and water vapor is introduced, the pressure of the carbonization furnace is controlled at 0.18~0.2MPa, the temperature is 128~135°C, and carbonization takes 1.5~3 hours; take out the bamboo chopsticks and dry them. Carbonizing bamboo chopsticks under high temperature and high pressure can carbonize all nutrients such as insect eggs, fat, sugar, and protein in the bamboo material, fundamentally eliminate the living space of insects and bacteria, and make the material lighter. Arranged in the shape of "hollow bricks", the tensile and compressive strength and waterproof performance are greatly improved. The bamboo chopsticks prepared by using the invention have properties such as anti-corrosion, insect-proof, mildew-proof and moisture-proof, and the bamboo chopsticks have beautiful and consistent colors.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

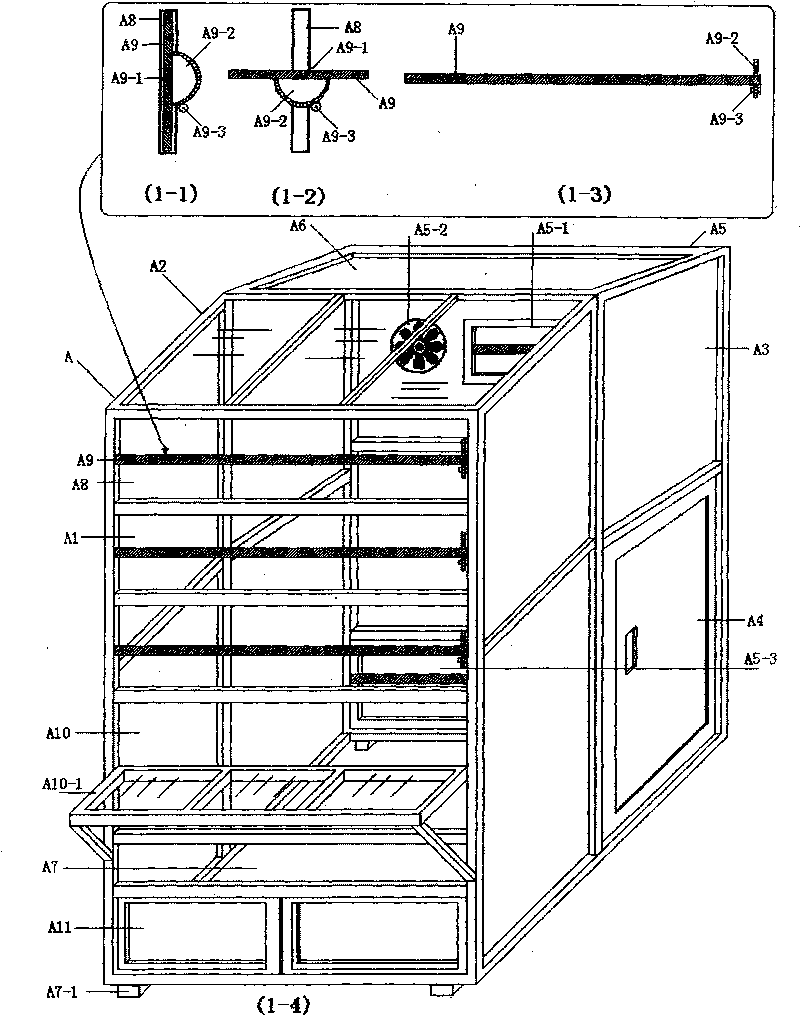

Solar facility of high industrial production line of forage grass, vegetable, flower and medical material

InactiveCN101743897AFast growthNo diseaseRenewable energy machinesAgriculture gas emission reductionDiseaseNutrient solution

The invention relates to a solar facility of a high industrial production line of forage grasses, vegetables, flowers and medical materials, which consists of an insulating production room, a chain ring cycle framework, a nutrient solution culturing plate, carbon dioxide gas, a thermocouple generator, a solar lens thermoelectric generator, a solar cooker thermoelectric generator, a solar lens thermoelectric generator, a heating bag and an LED power generation lamp. The facility can provide renewable energy sources and translucent insulation effect for the high industrial production line. The all-weather heating, insulation and light supplementation can be realized in the facility. The adoption of nutrient solution for culture increases the growth speed and prevents diseases and pests, and the forage grasses, vegetables, flowers and medical materials can be harvested all year round. Another significant feature of the facility is special development. The facility can save a large quantity of farmland, water resources and fertilizers, and can be used for all-weather production in any place (deserts, mountain areas, areas without power supply and areas in front of and behind houses). Moreover, the facility is a significant subject studied around the world at present. The invention can develop new living space for human beings, and has incalculable environmental, economic and social benefits.

Owner:陈绍勇

Environment-friendly healthy anionic coating material for building interior walls

InactiveCN104804624AImprove the living environmentPurify indoor airPolyester coatingsResidencePolyester resin

The invention discloses an environment-friendly healthy anionic coating material for building interior walls. The environment-friendly healthy anionic coating material contains the following ingredients in parts by weight: 25-35 parts of polyester resin, 10-25 parts of anion additive, 3-12 parts of nano-TiO2, 3-9 parts of titanium white, 1-5 parts of pigment, 5-15 parts of nano filler, 2-7 parts of dispersant, 3-8 parts of thickener, 2-10 parts of antifoamer and 20-30 parts of deionized water. The environment-friendly healthy anionic coating material for the building interior walls, disclosed by the invention, can be used for releasing negative ions continuously, dispelling indoor toxic and harmful gases, such as formaldehyde and phenol, purifying indoor air, improving an indoor living environment and providing a natural and environment-friendly living space and is applied to the field of interior decoration and finishing of residences, schools and shopping malls.

Owner:黎司华

Prefabricated building modules for multi-unit housing

ActiveUS20110179721A1Less-expensive to installImprove coordinationPublic buildingsBuilding repairsMulti unitArchitectural engineering

The present application is directed towards systems and methods for building a living space during construction of a multi-unit housing structure. In particular, the present application describes various embodiments of prefabricated building modules that may be built and equipped with plumbing, HVAC and / or electrical fixtures prior to installation in a multi-unit housing structure. Because modules may be configured prior to installation in a housing structure, the use of prefabricated building modules may increase efficiency of construction and provide enhanced customization over other non-configurable building units.

Owner:IRONSTATE DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com