Patents

Literature

240 results about "Kilowatt-Hour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The kilowatt hour (symbol kW⋅h, kWh, or kW h) is a unit of energy equal to 3.6 megajoules. If energy is transmitted or used at a constant rate (power) over a period of time, the total energy in kilowatt hours is equal to the power in kilowatts multiplied by the time in hours. The kilowatt hour is commonly used as a billing unit for energy delivered to consumers by electric utilities.

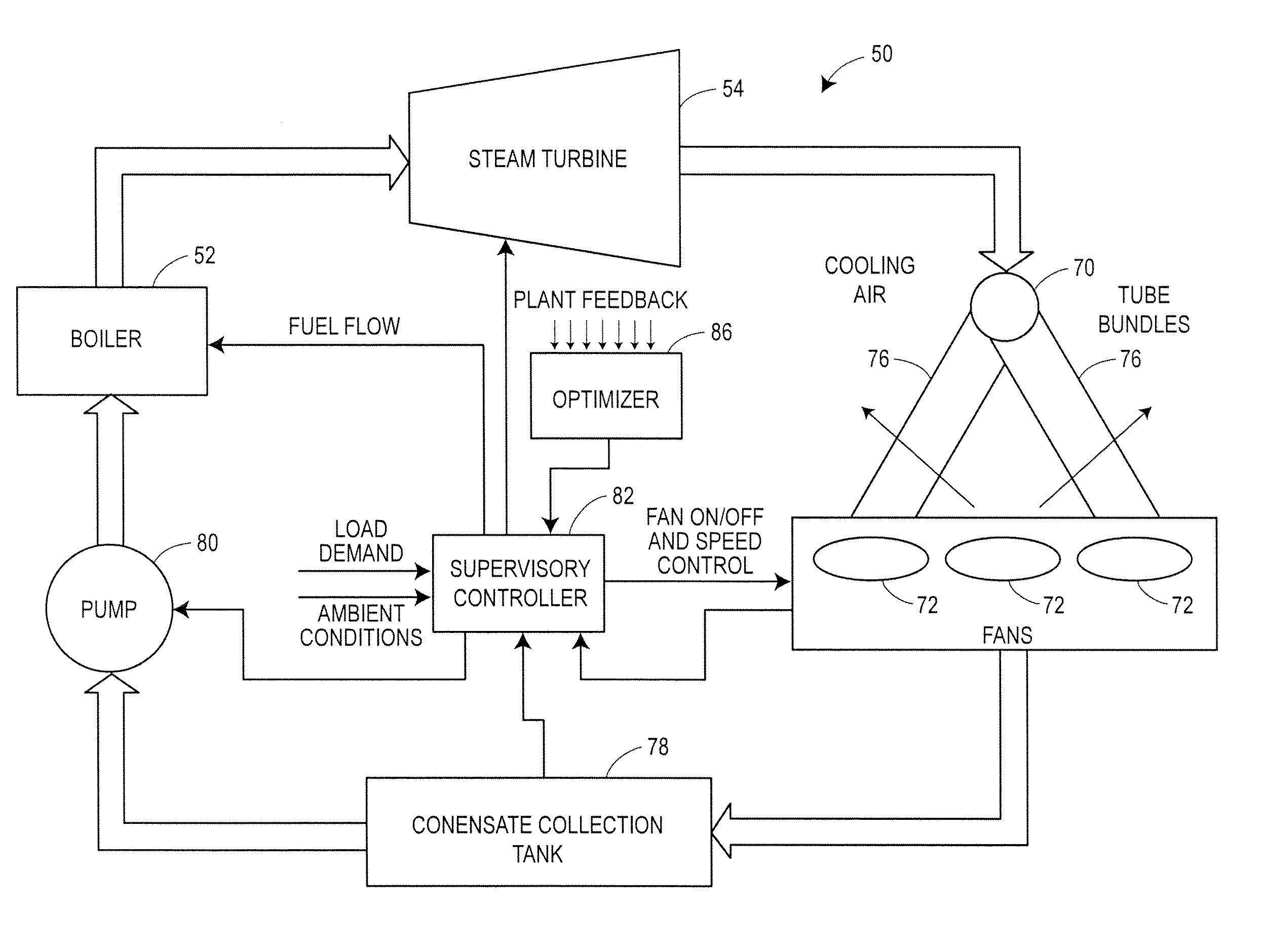

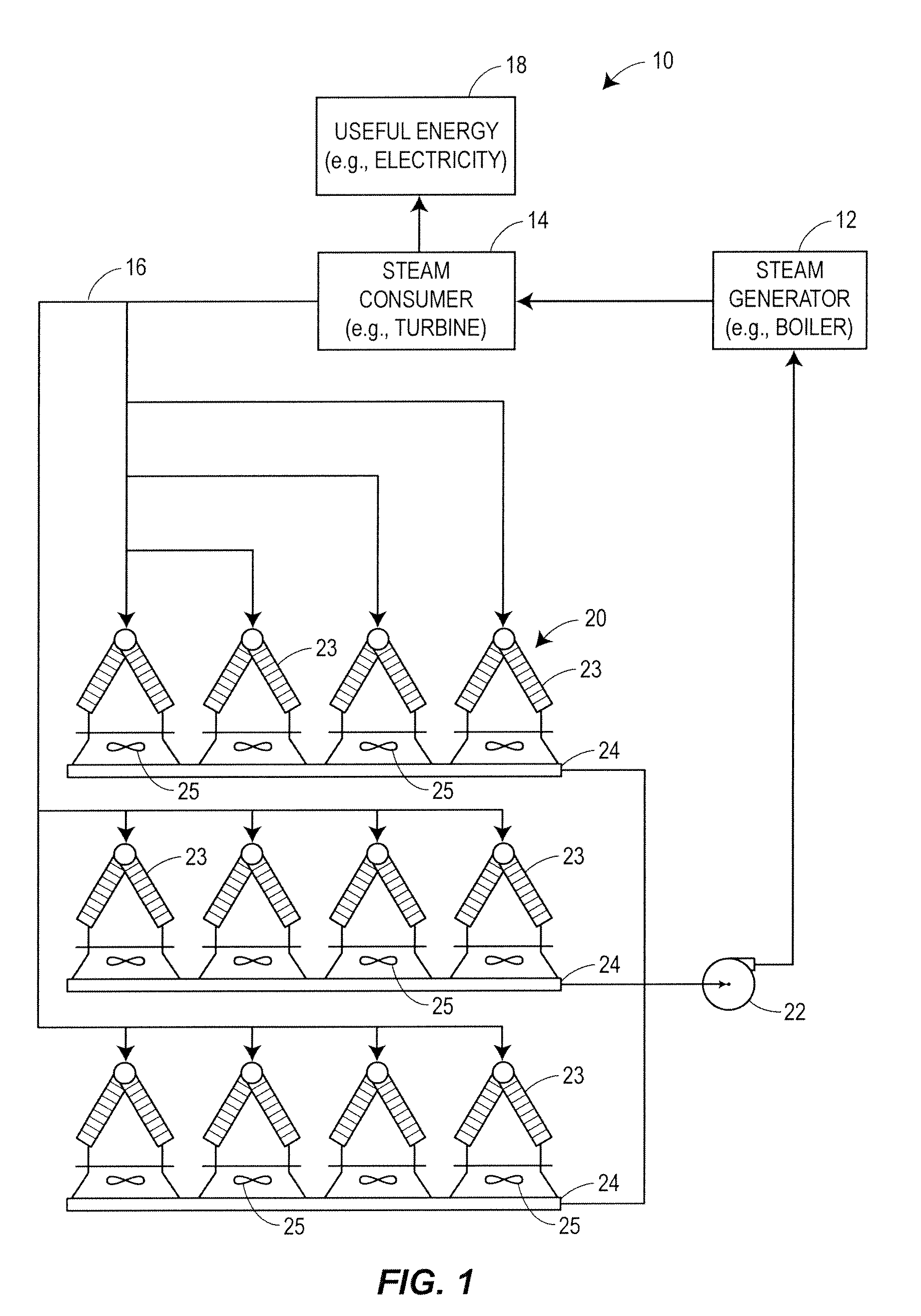

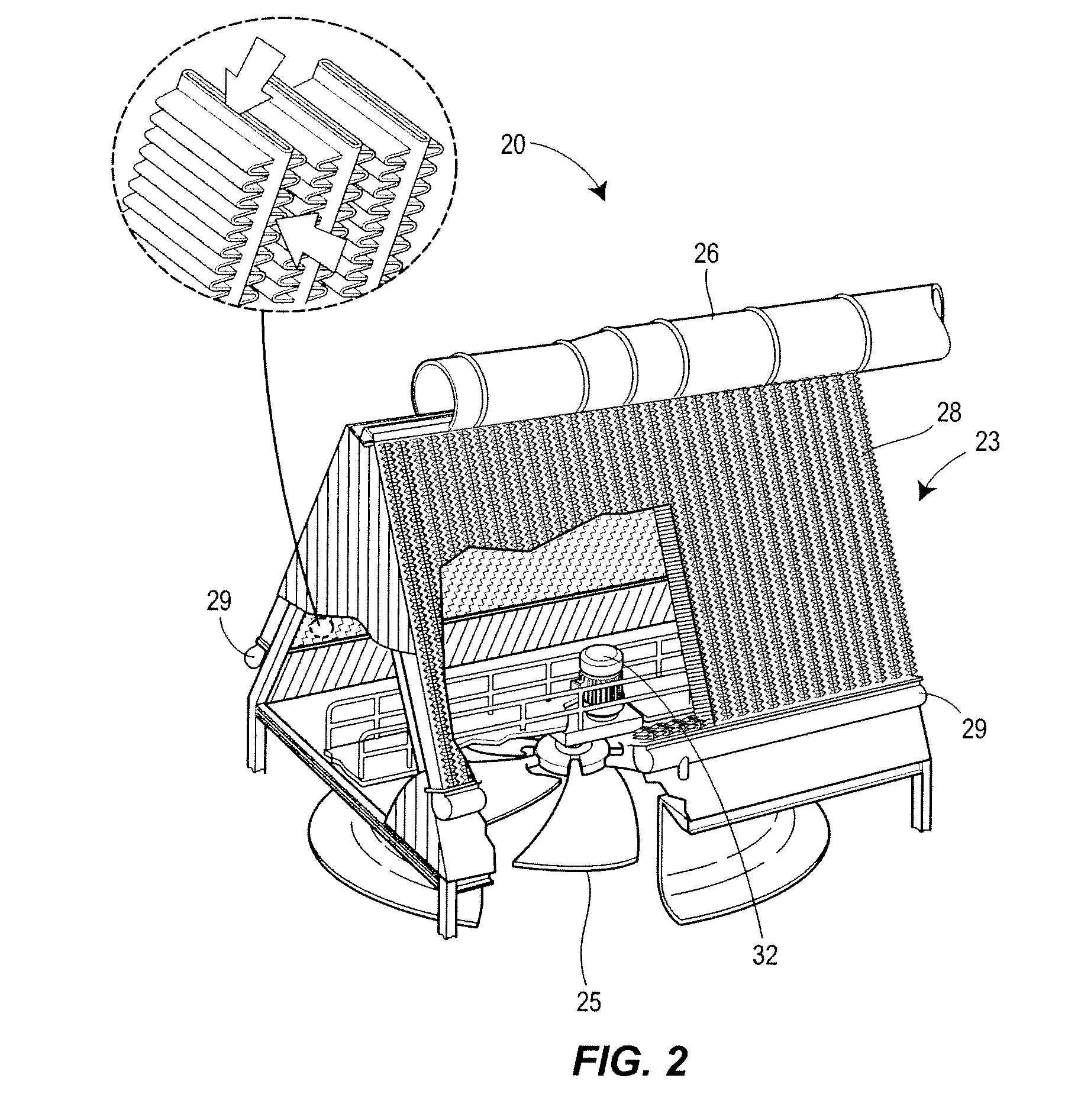

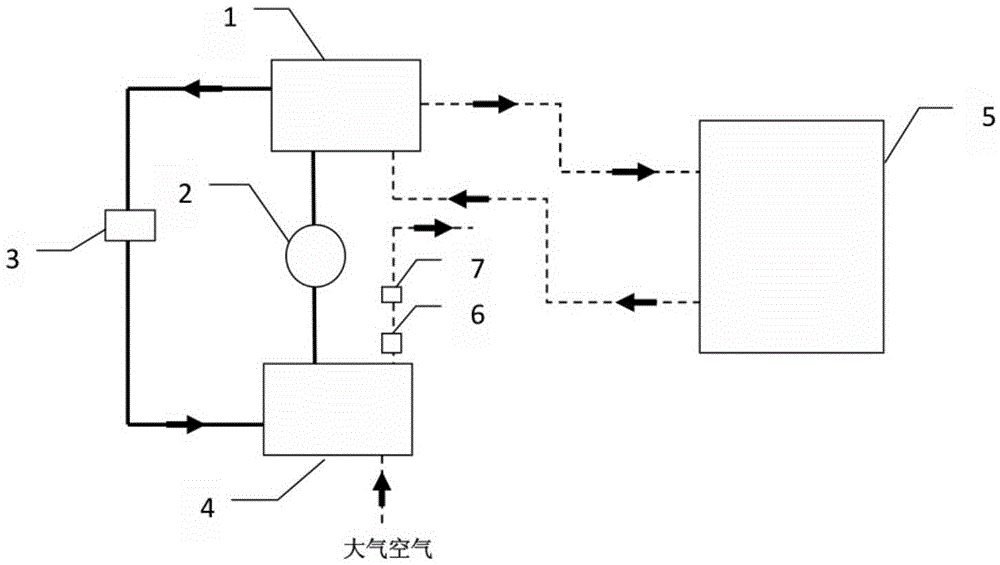

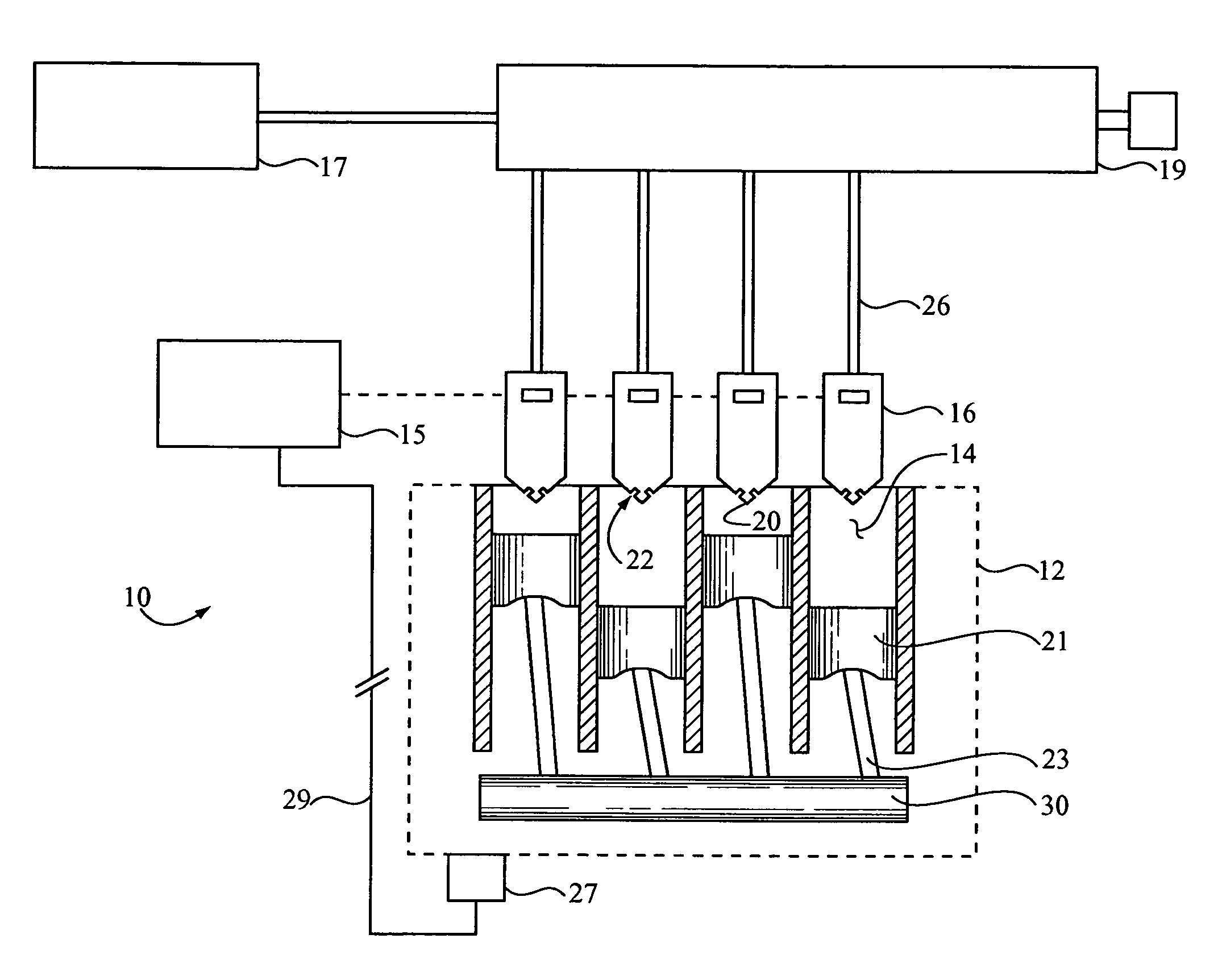

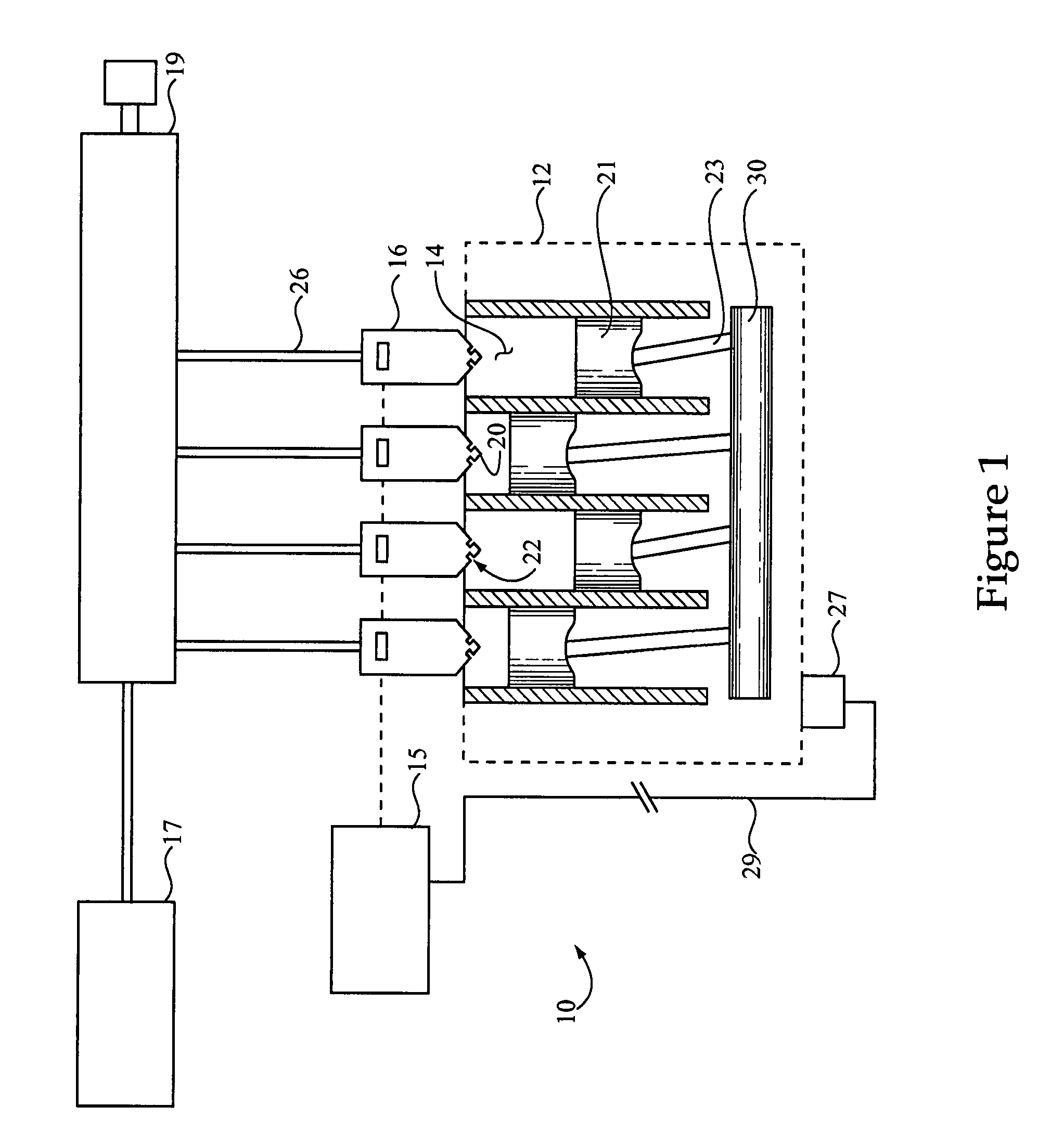

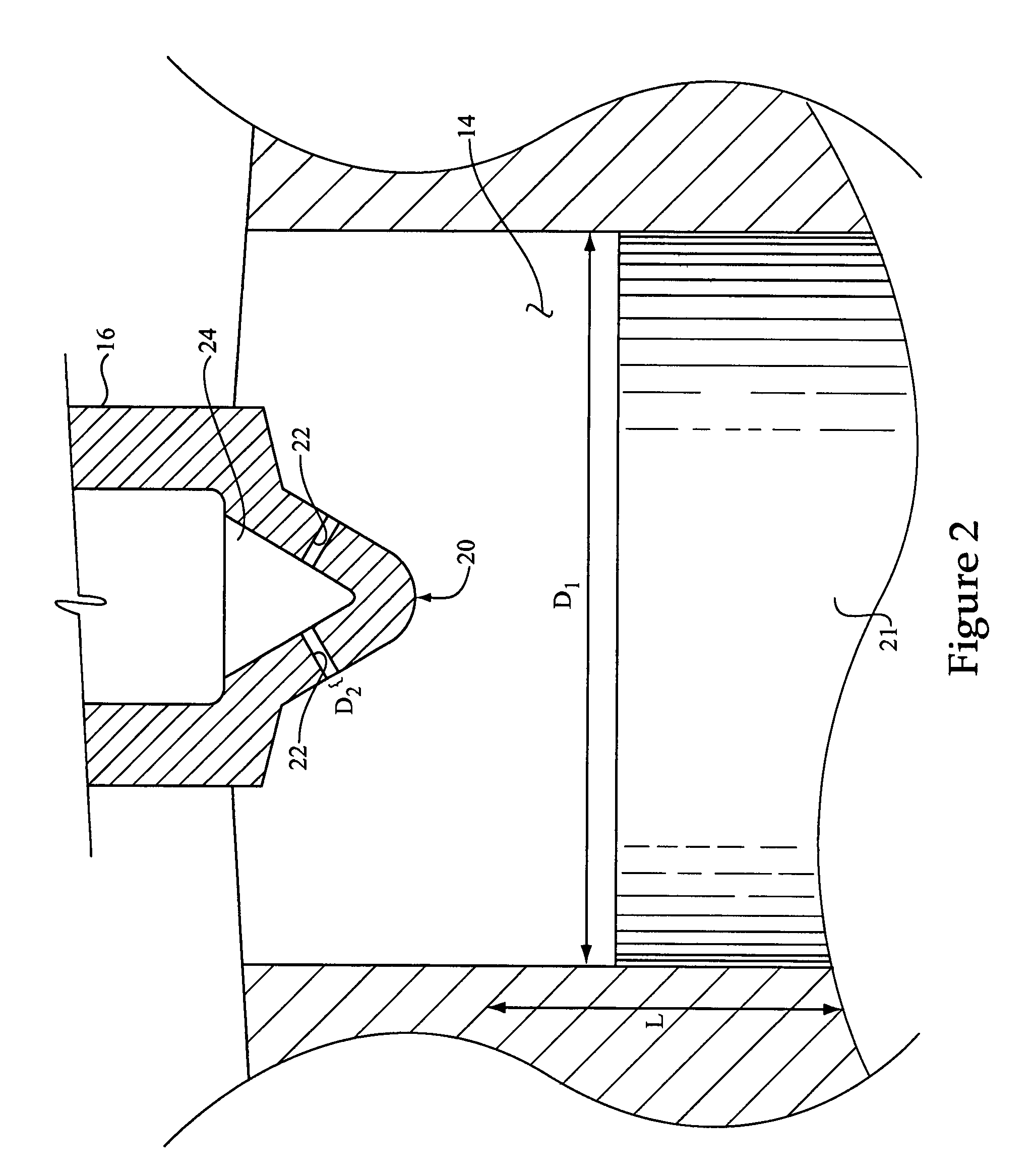

Optimized control of power plants having air cooled condensers

ActiveUS20110066298A1Cost can be reduced and minimizedLow costMechanical power/torque controlLevel controlOperating pointControl variable

An optimization and control system for a utility plant that uses fan based air cooled condensers controls the operation of the power generation system at the plant in conjunction with the operation of the air cooled condensers so as to run the power plant at an optimum operating point associated with minimizing or reducing the cost of each kilowatt-hour of energy or other useful energy produced by the plant. The optimization and control system includes an optimizer having a numerical solver that determines values for a set of control variables associated with an optimal operating point of the plant and an expert system that oversees and modifies the control variable settings prior to providing these settings to a plant controller. The numerical solver uses an objective function and one or more models of plant equipment to determine the operating point of the plant that minimizes the cost per unit of useful energy generated by the plant. As part of determining the optimal plant operating point, the numerical solver may determine the number of fans to run within the air cooled condensers of the plant and / or the speed of the fans to use in the air cooled condensers in conjunction with the amount of fuel to burn in the boiler, the desired temperature of the steam at the input of the steam turbine, etc., all required to produce a given amount of power (load demand) at the particular environmental conditions currently experienced at the plant. The expert system may modify these outputs by determining which fans to actually use at any particular time based on, for example, the availability of or the operational status of the fans, the wear of the fans and fan motors, etc.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

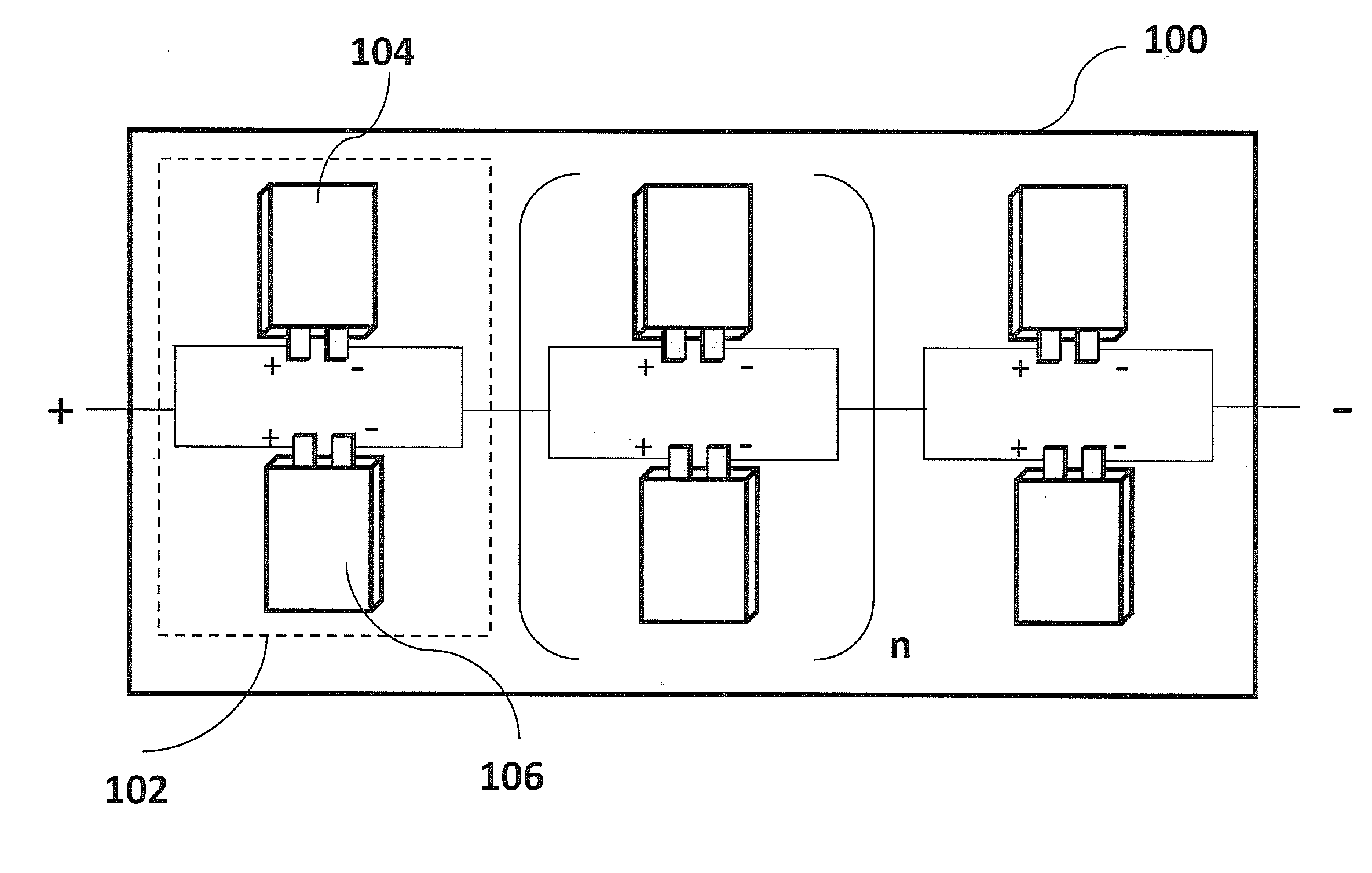

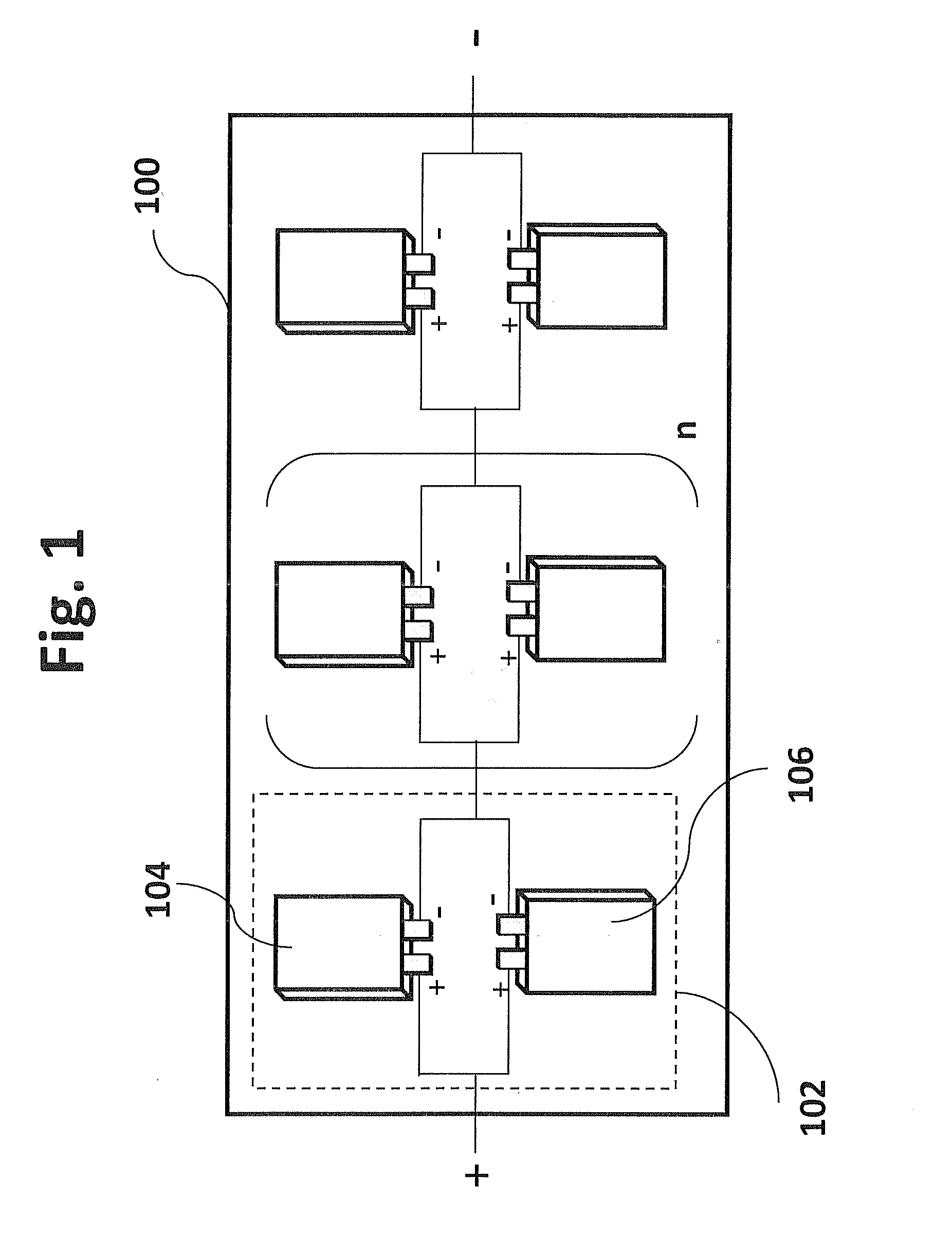

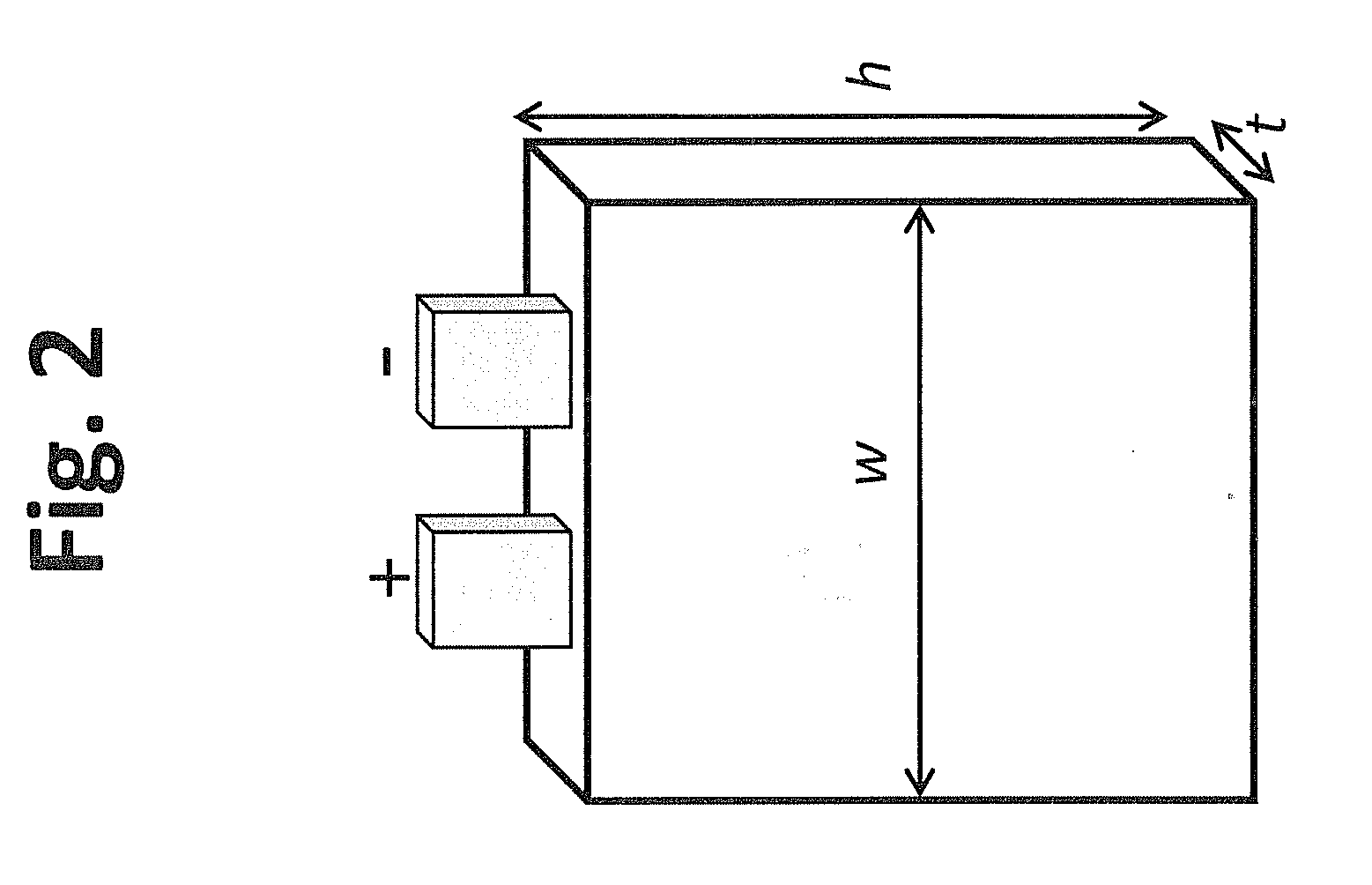

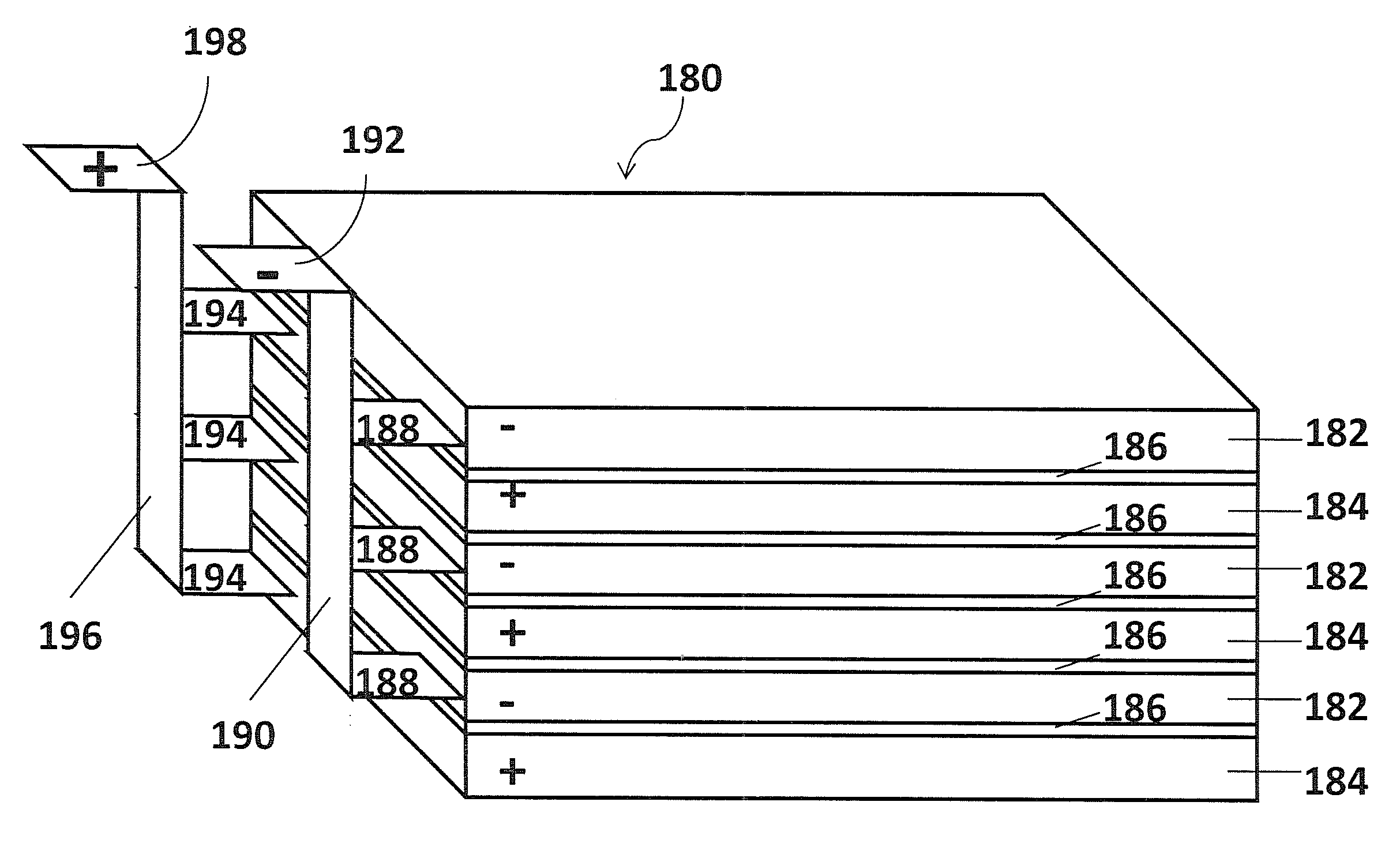

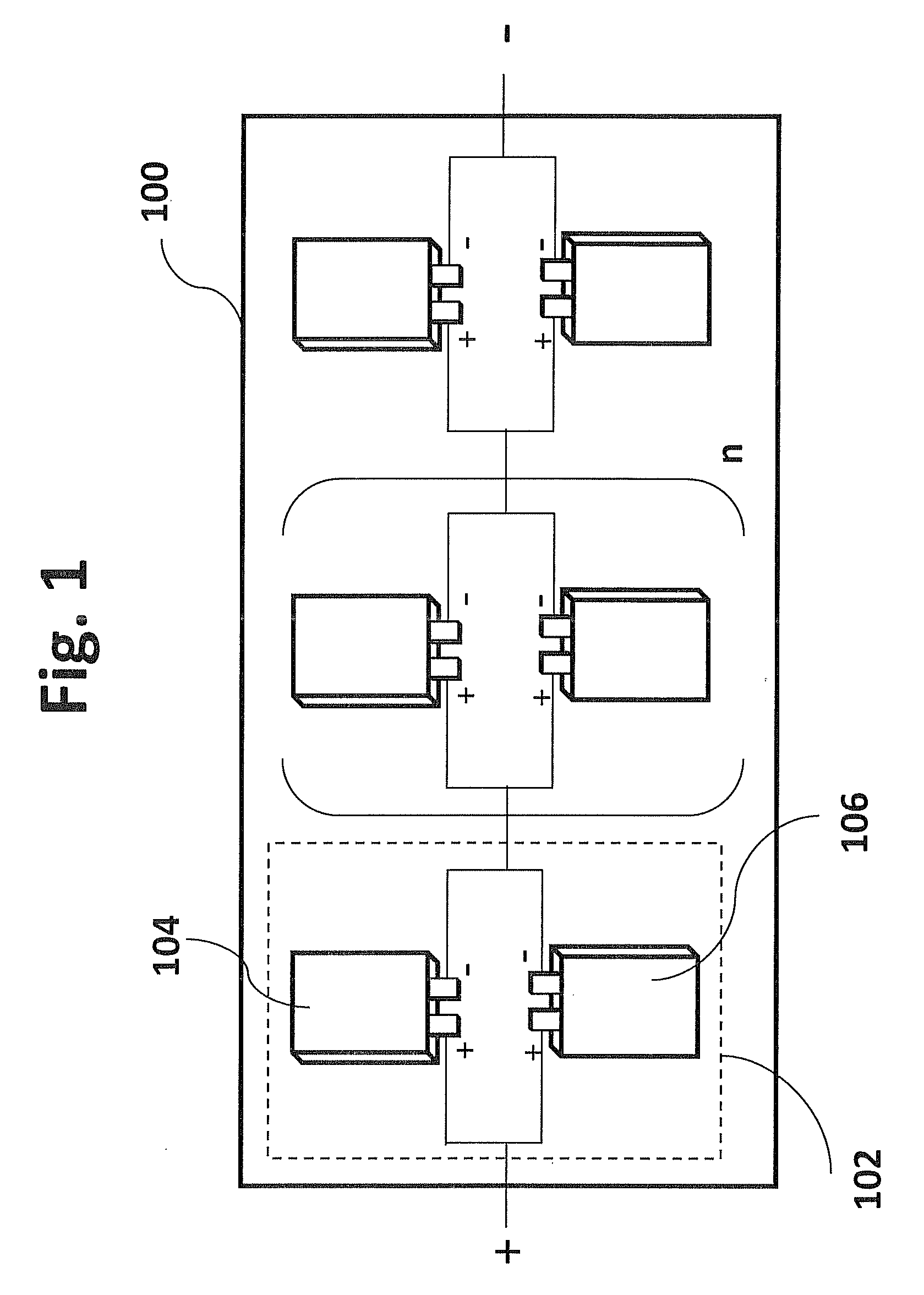

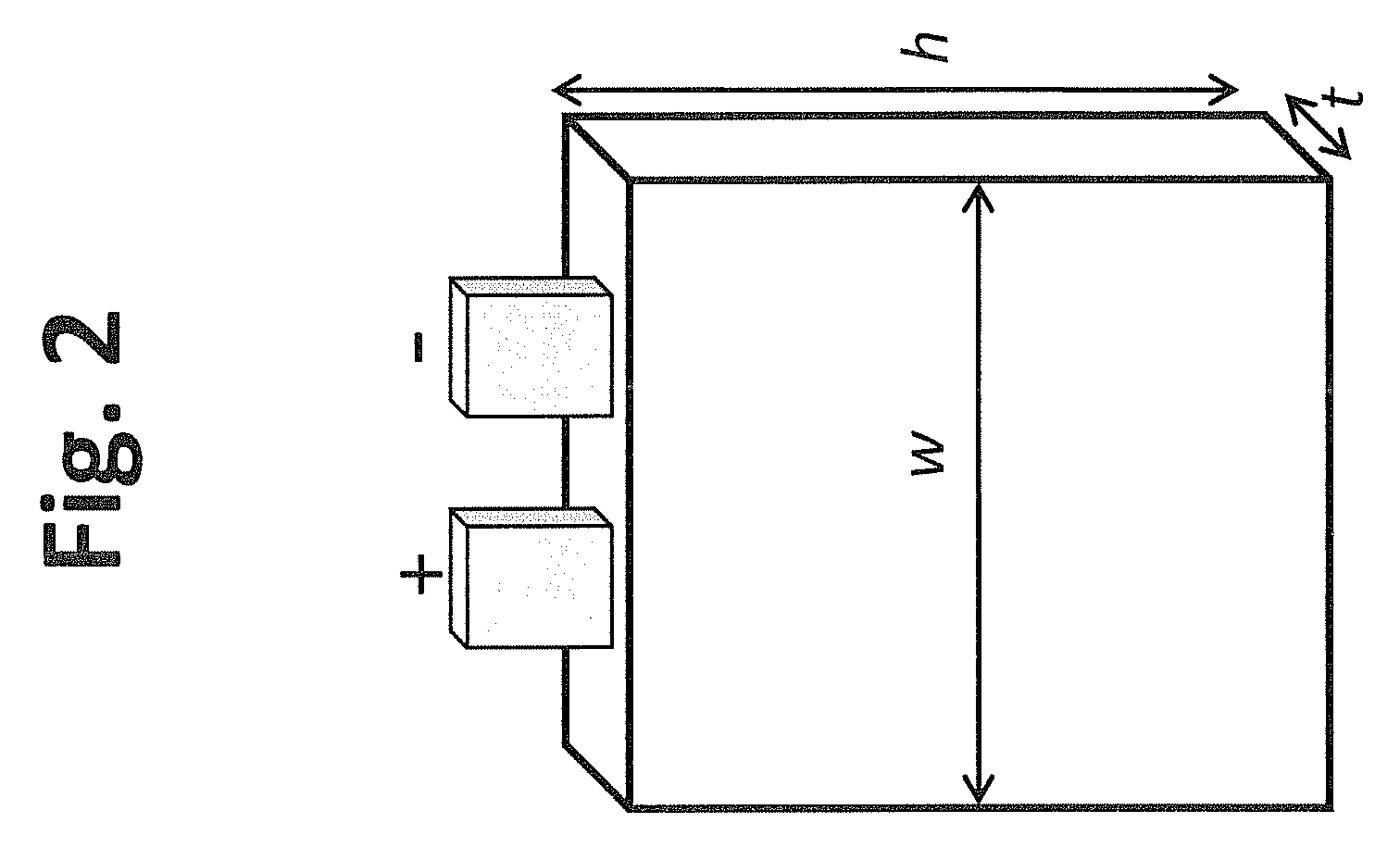

Battery Packs for Vehicles and High Capacity Pouch Secondary Batteries for Incorporation into Compact Battery Packs

High performance battery packs are described especially for use in electric vehicles and plug-in hybrid electric vehicles. Based on high energy lithium ion battery designs, the battery packs can have pairs of parallel connected batteries to supply an energy capacity at full discharge of at least about 40 kilowatt-hours or in alternative embodiments a set of all series connected batteries that can produce at full discharge at least about 15 kilowatt-hours. In some embodiments, lithium rich positive electrode active materials can be used to faun the batteries in which the material comprises a composition approximately represented by a formula xLi2M′O3.(1−x)LiMO2 with x from about 0.05 to about 0.8.

Owner:IONBLOX INC

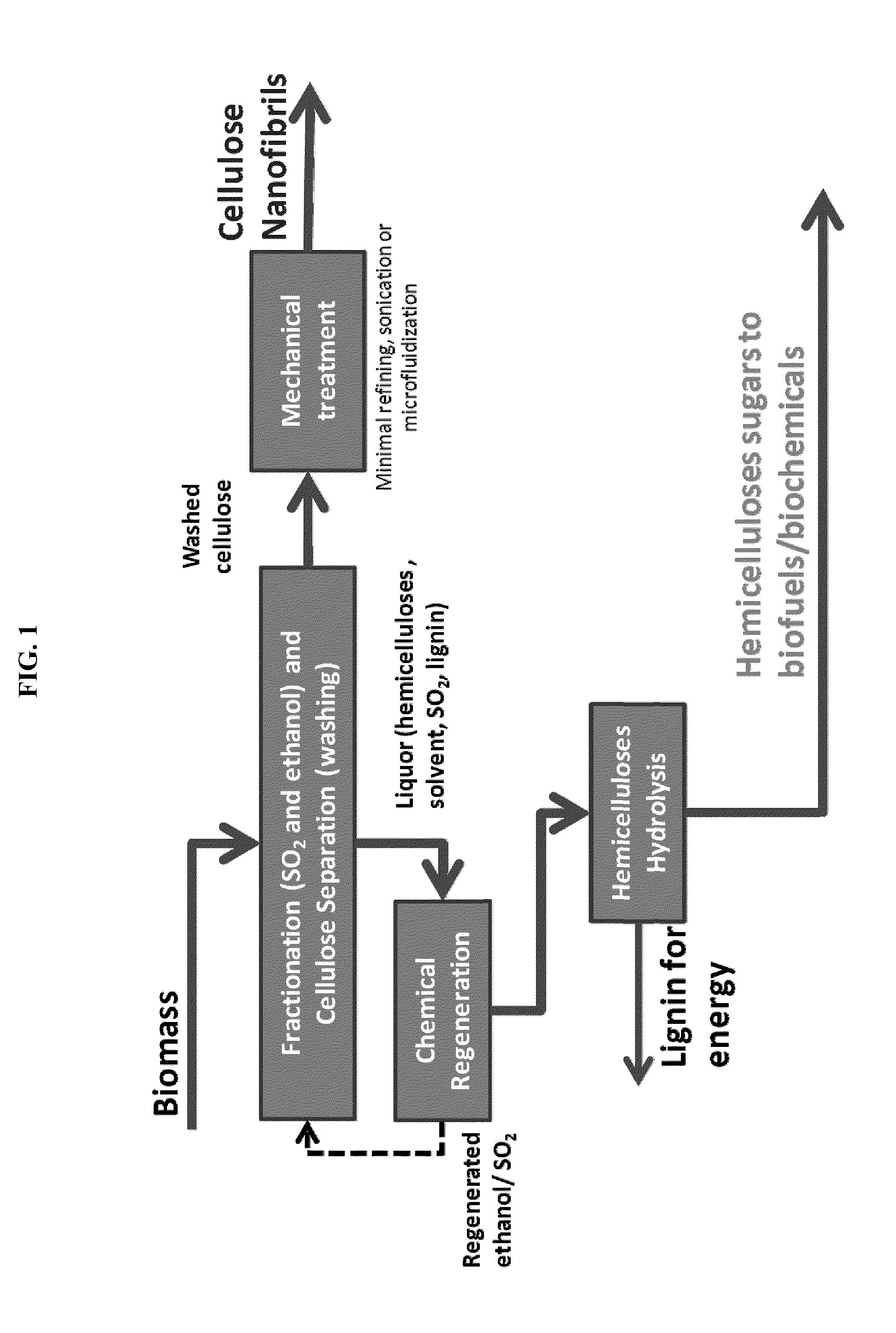

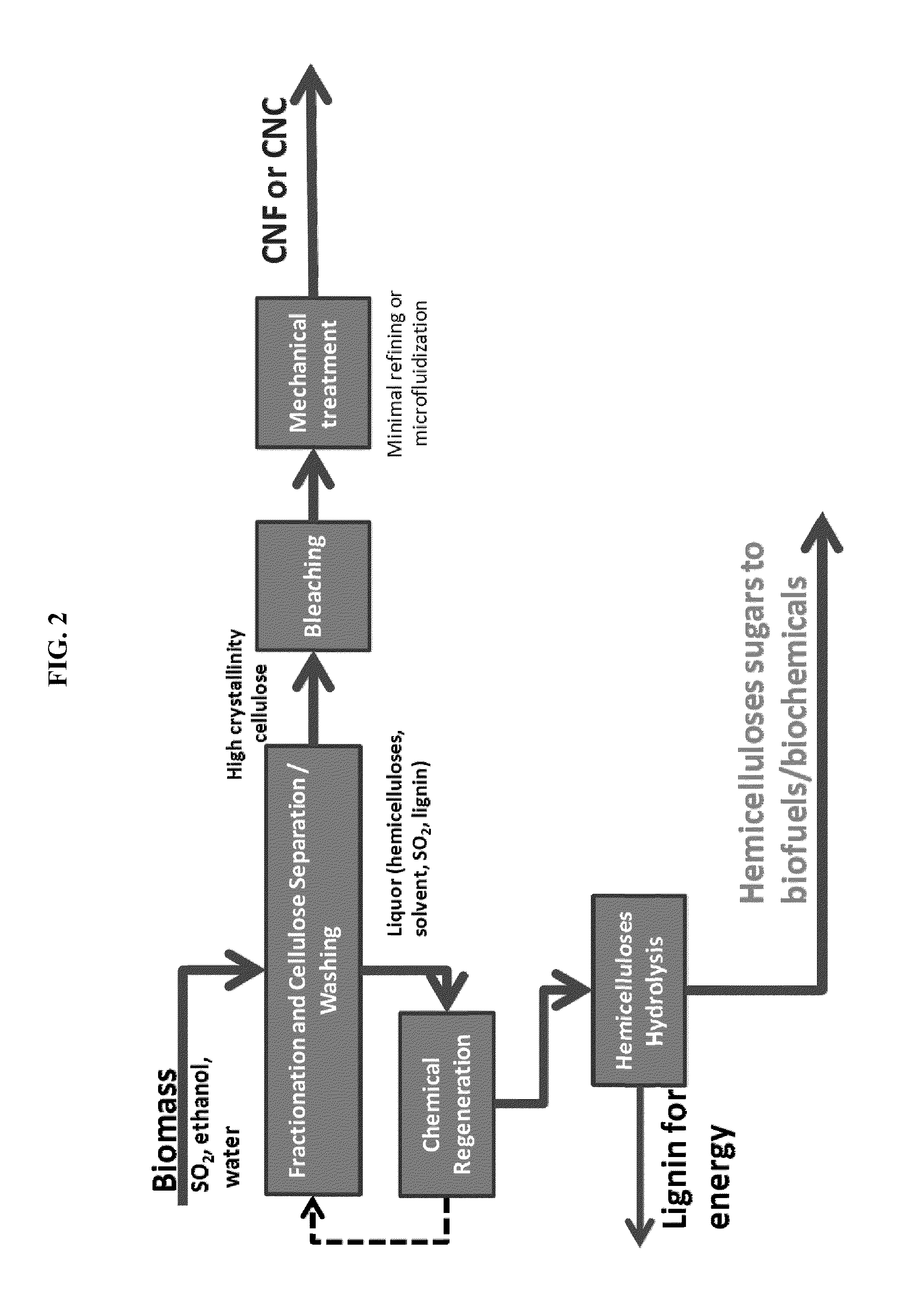

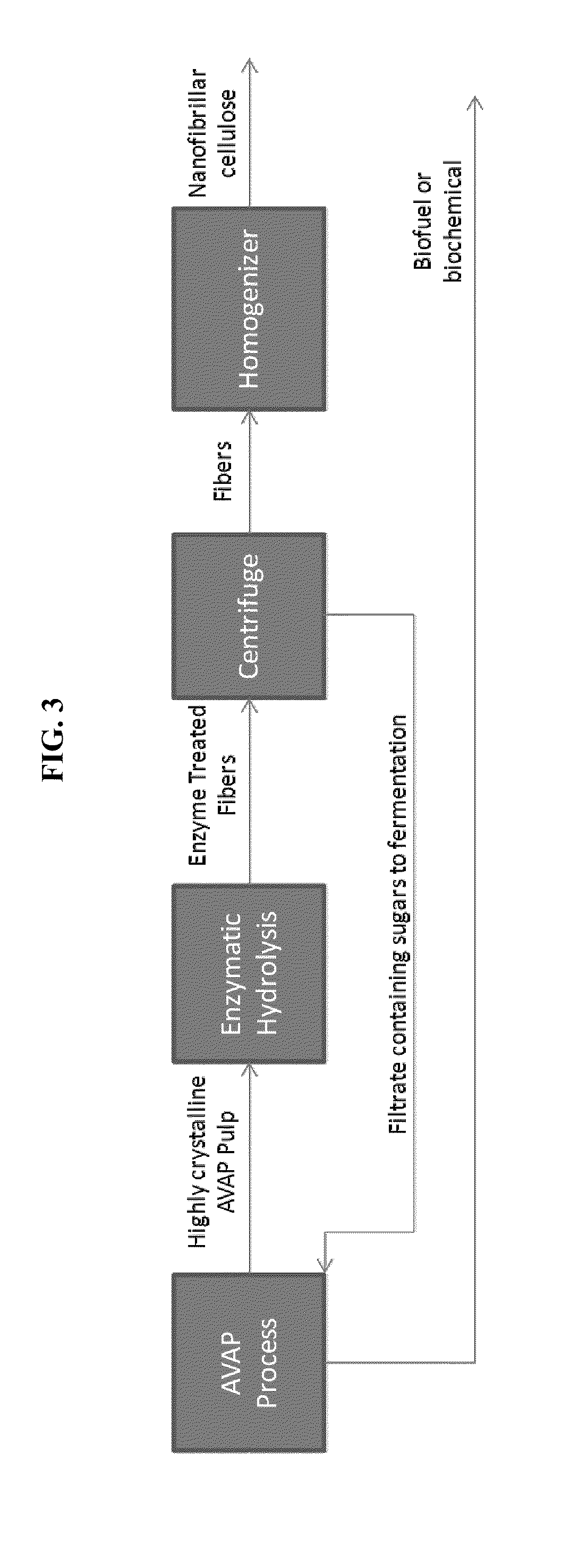

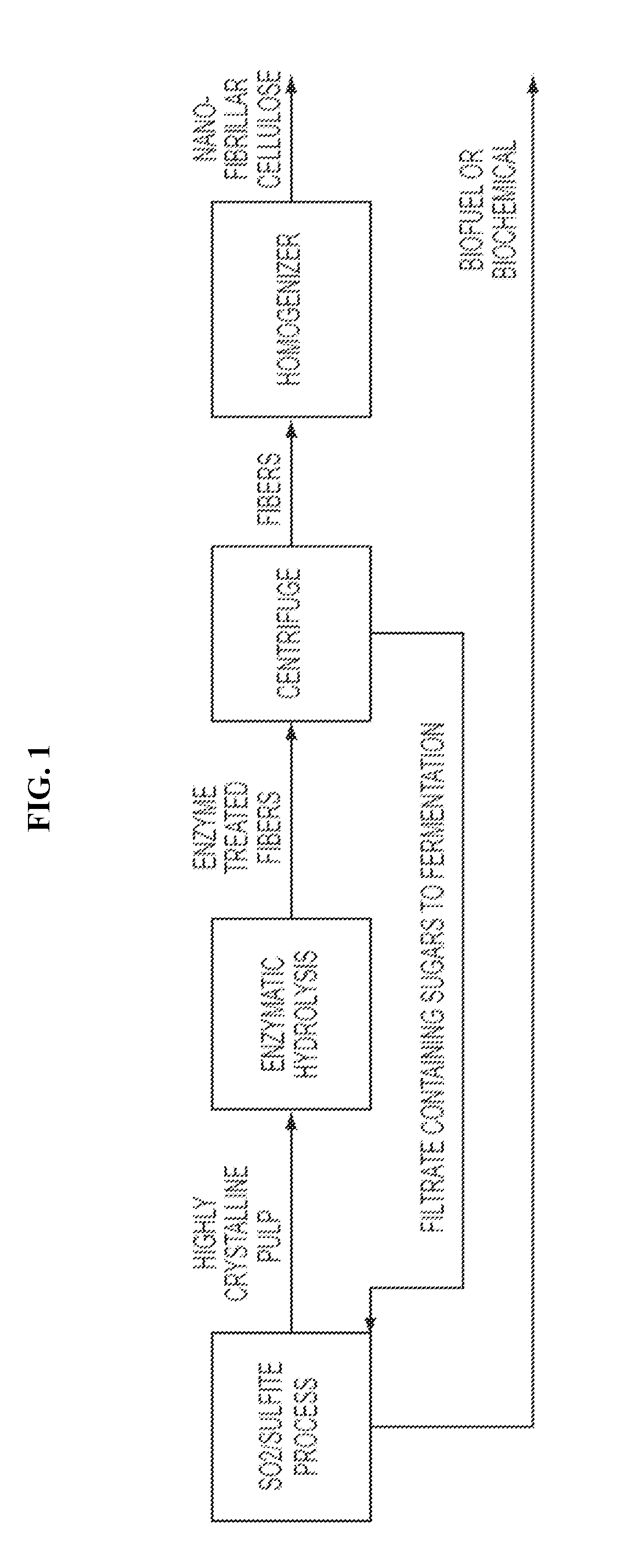

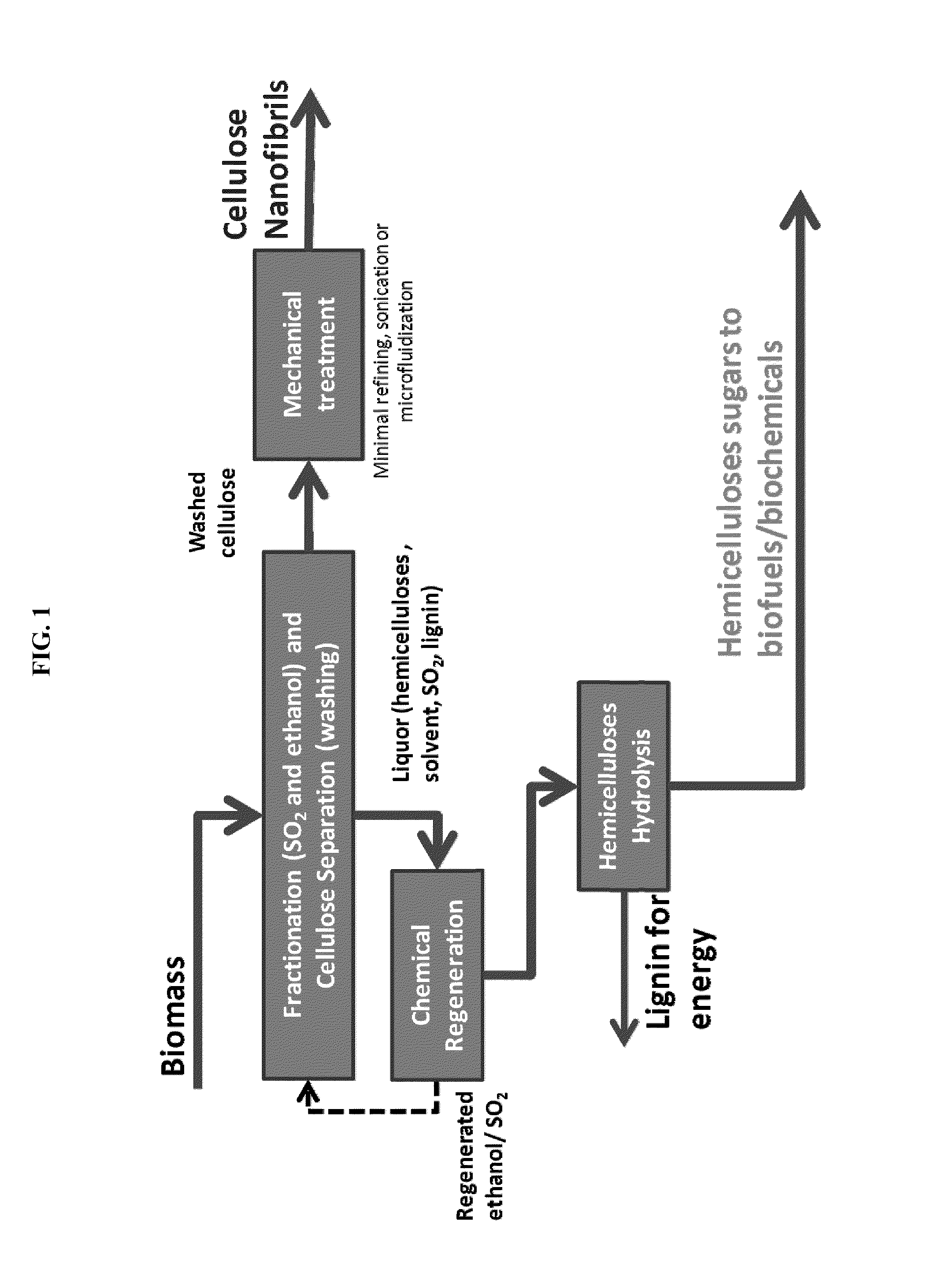

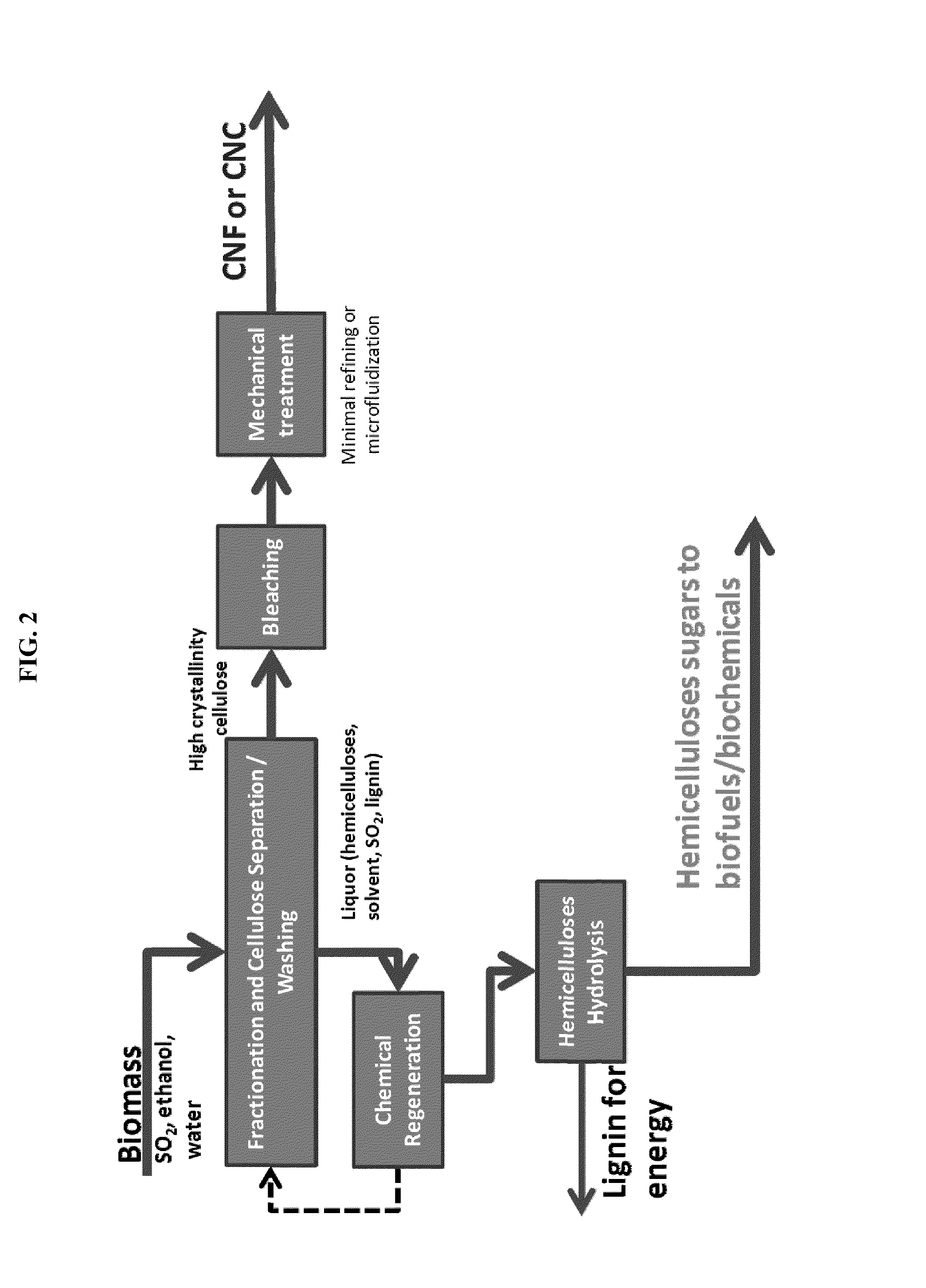

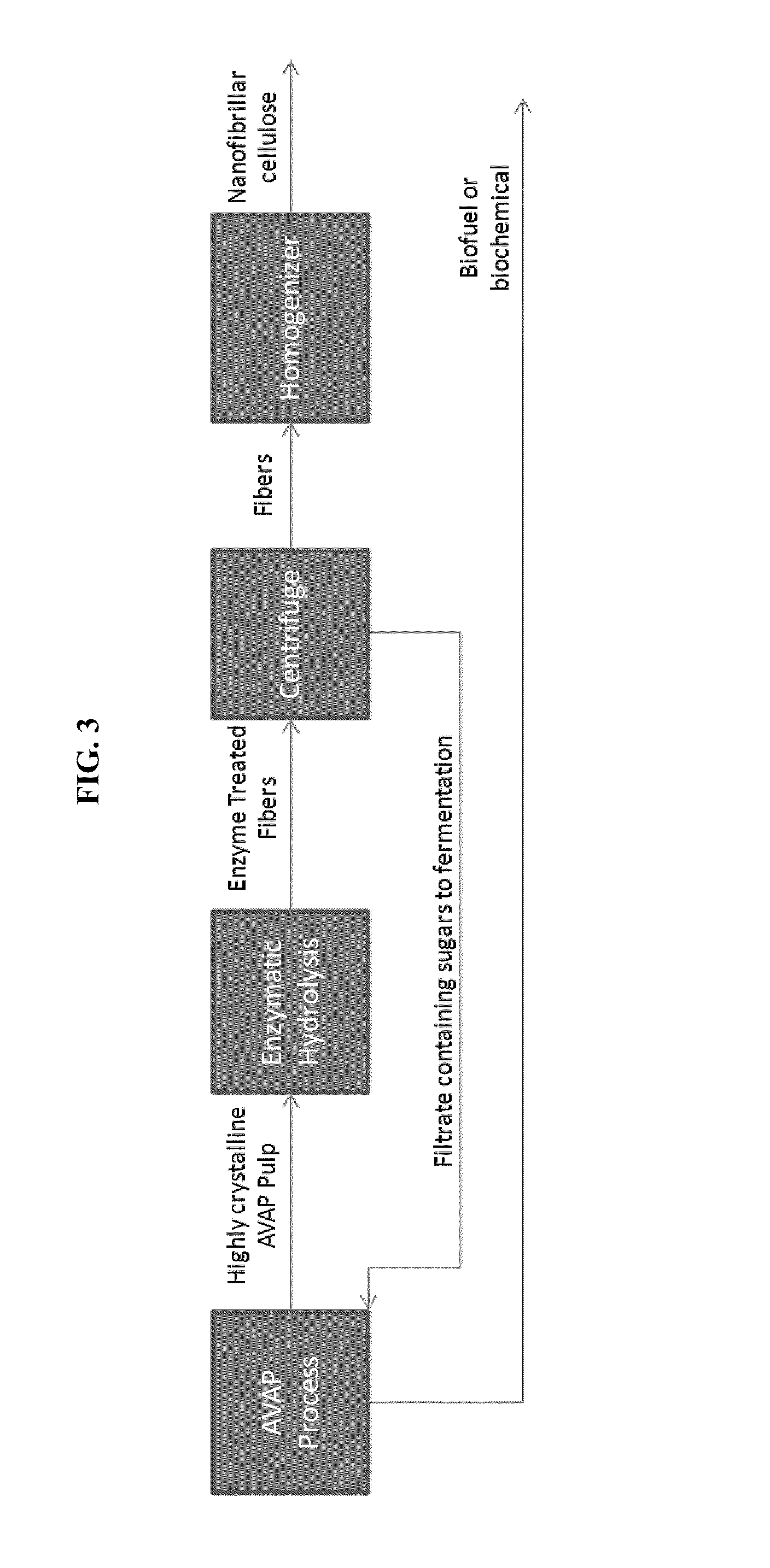

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

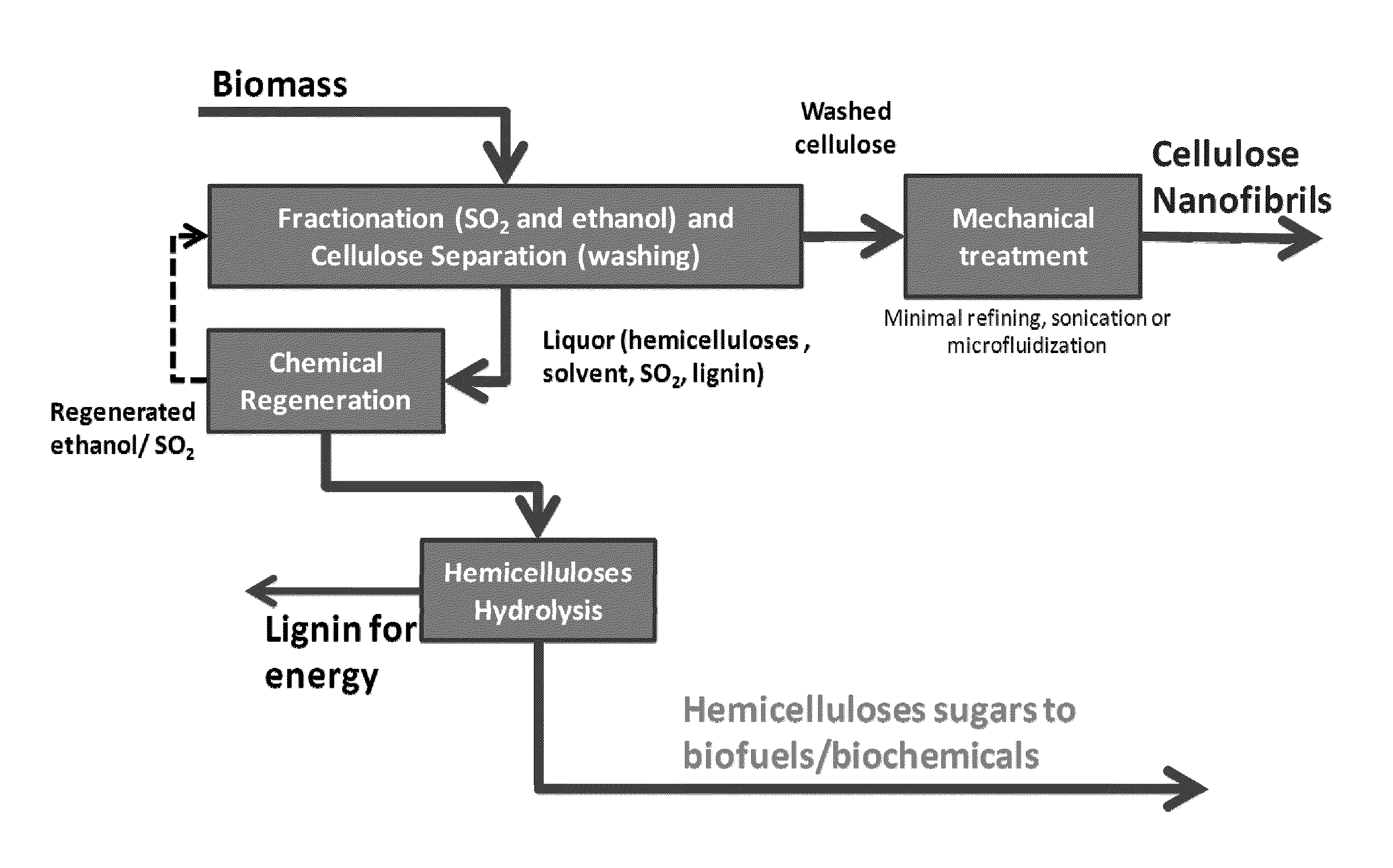

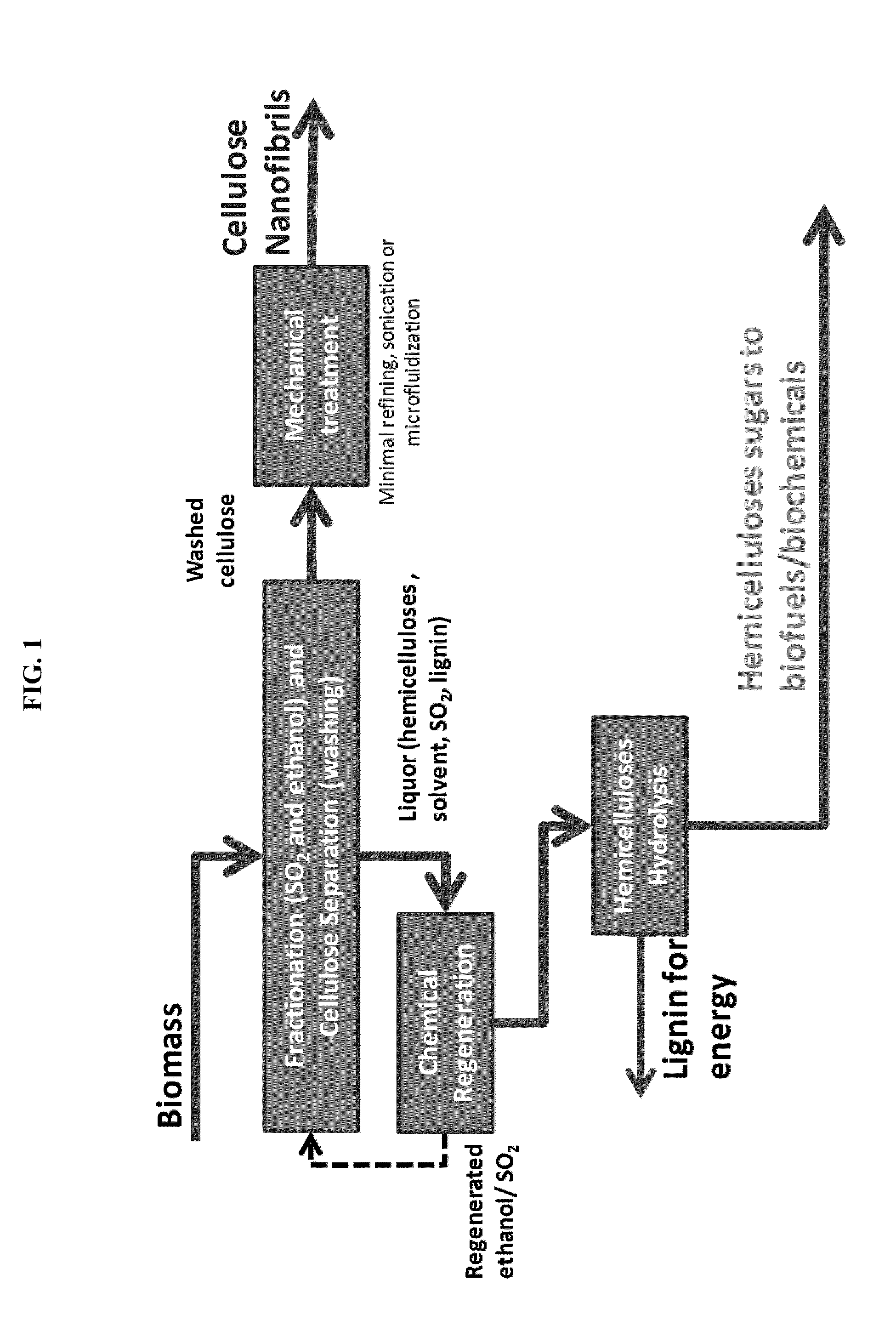

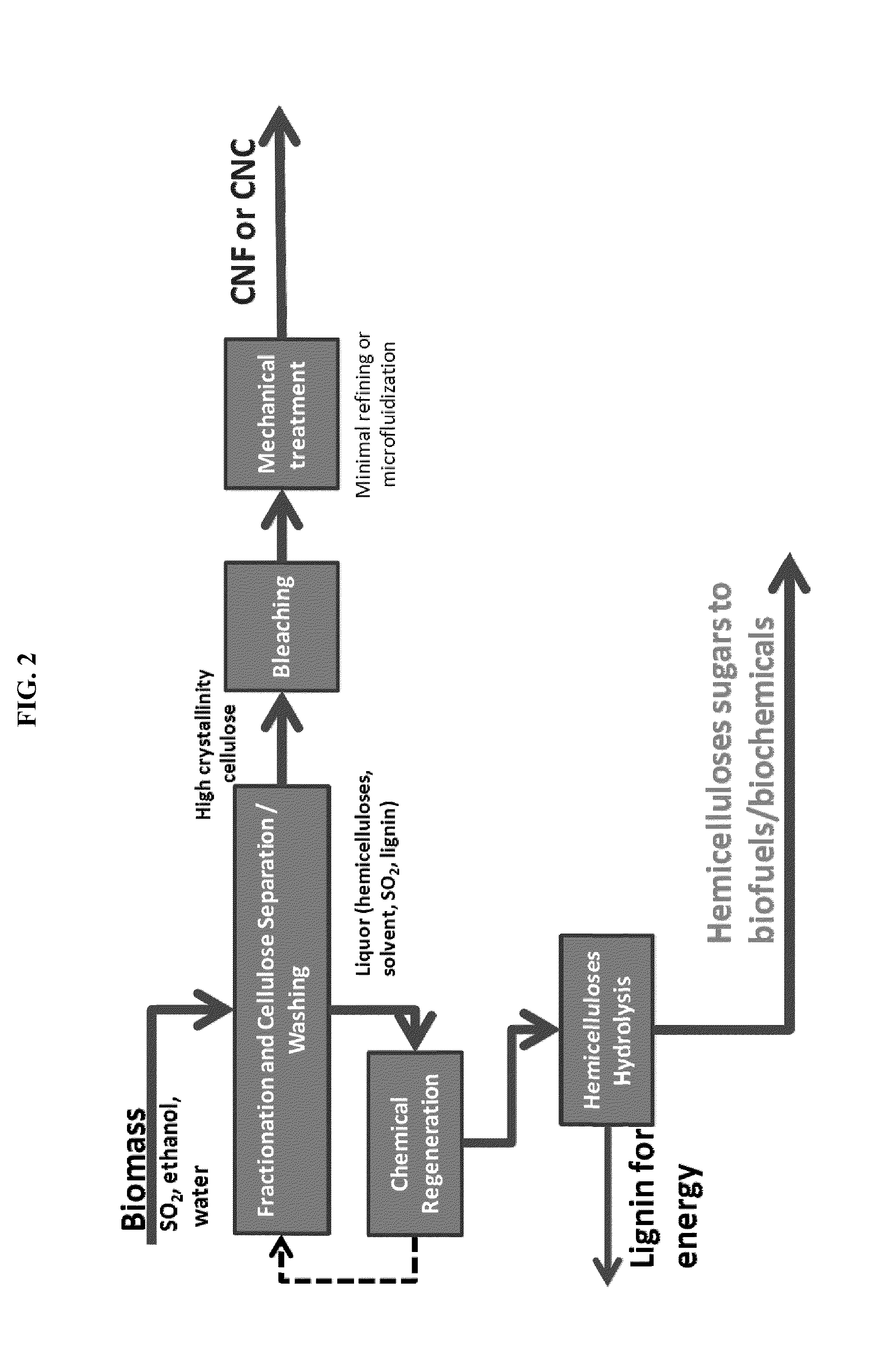

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

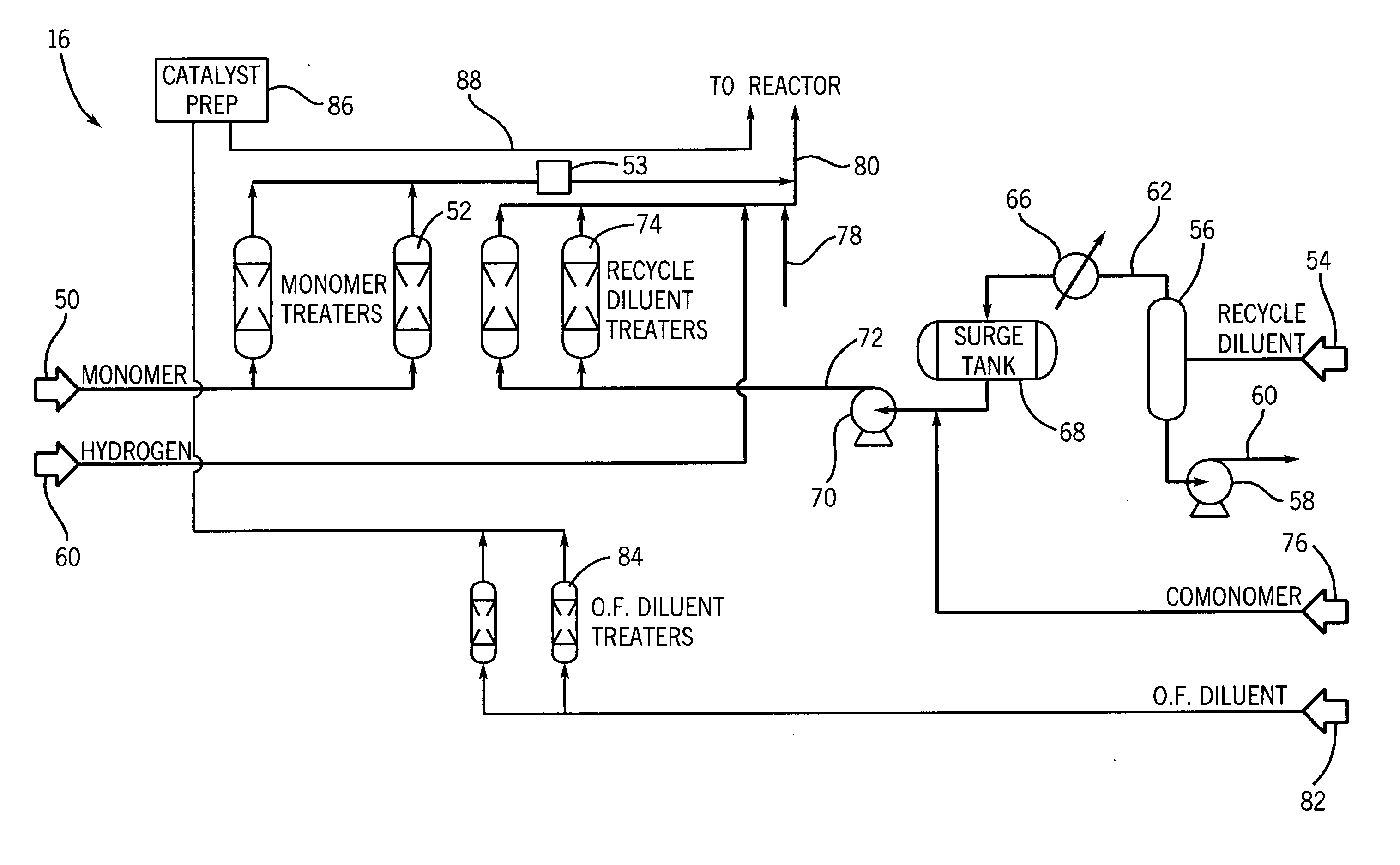

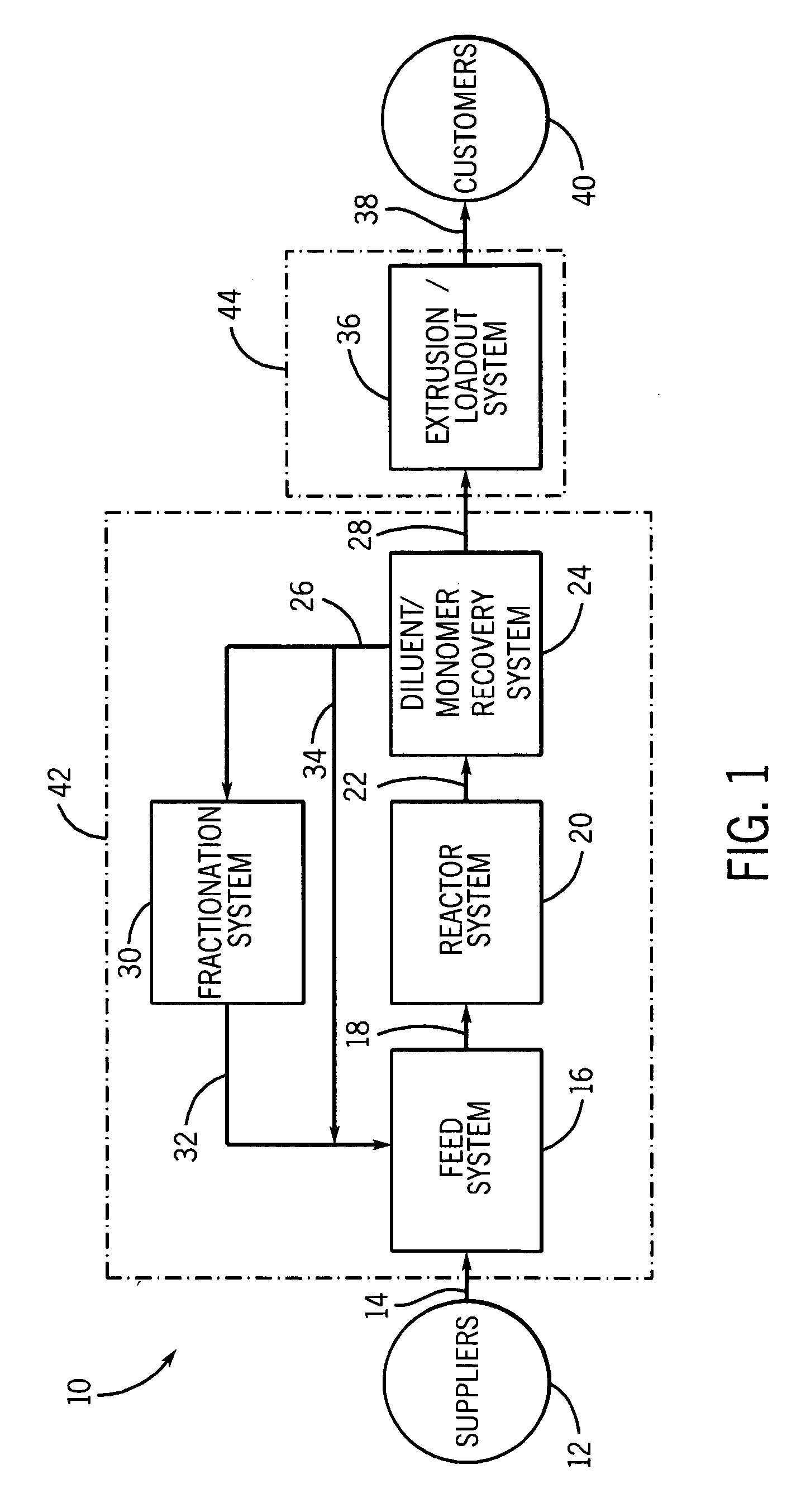

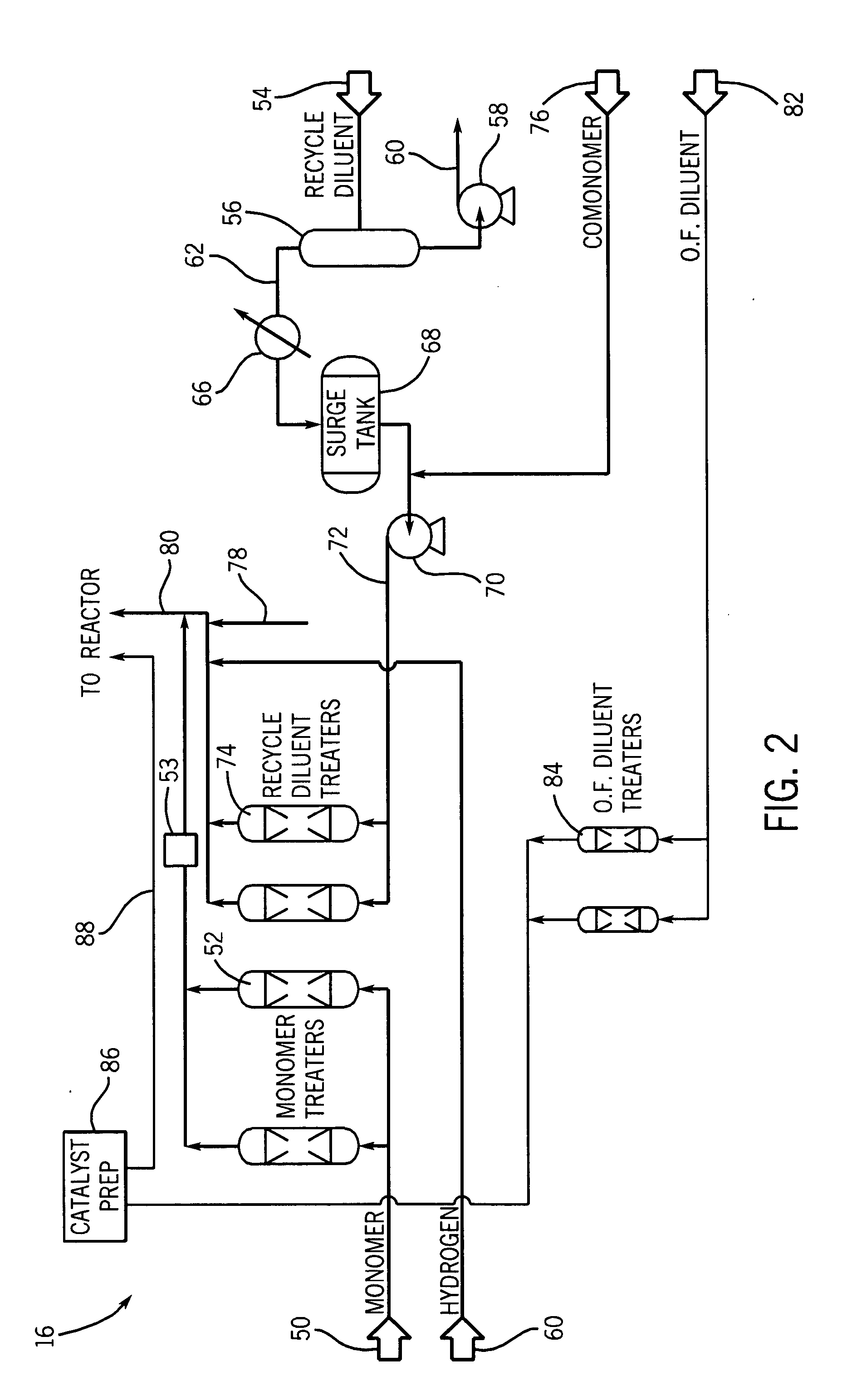

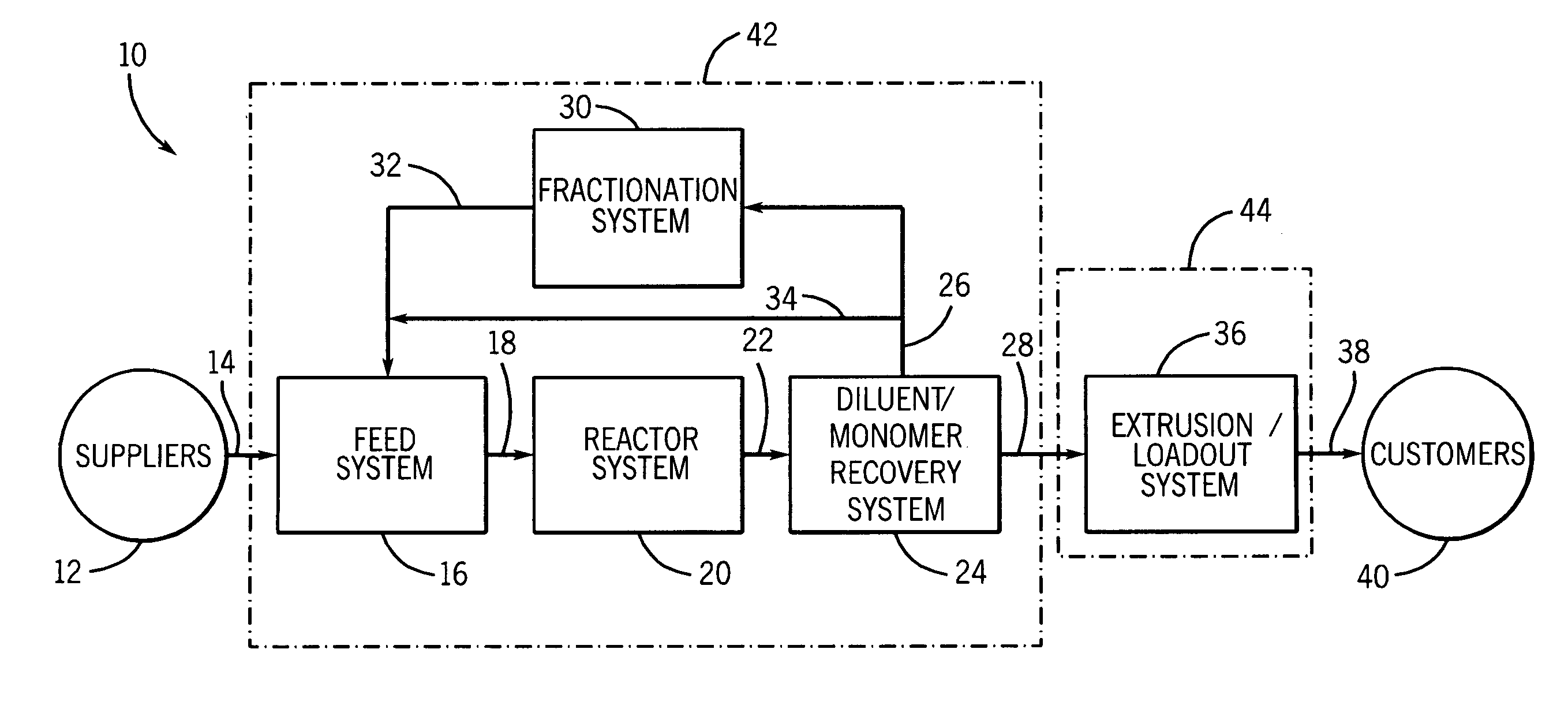

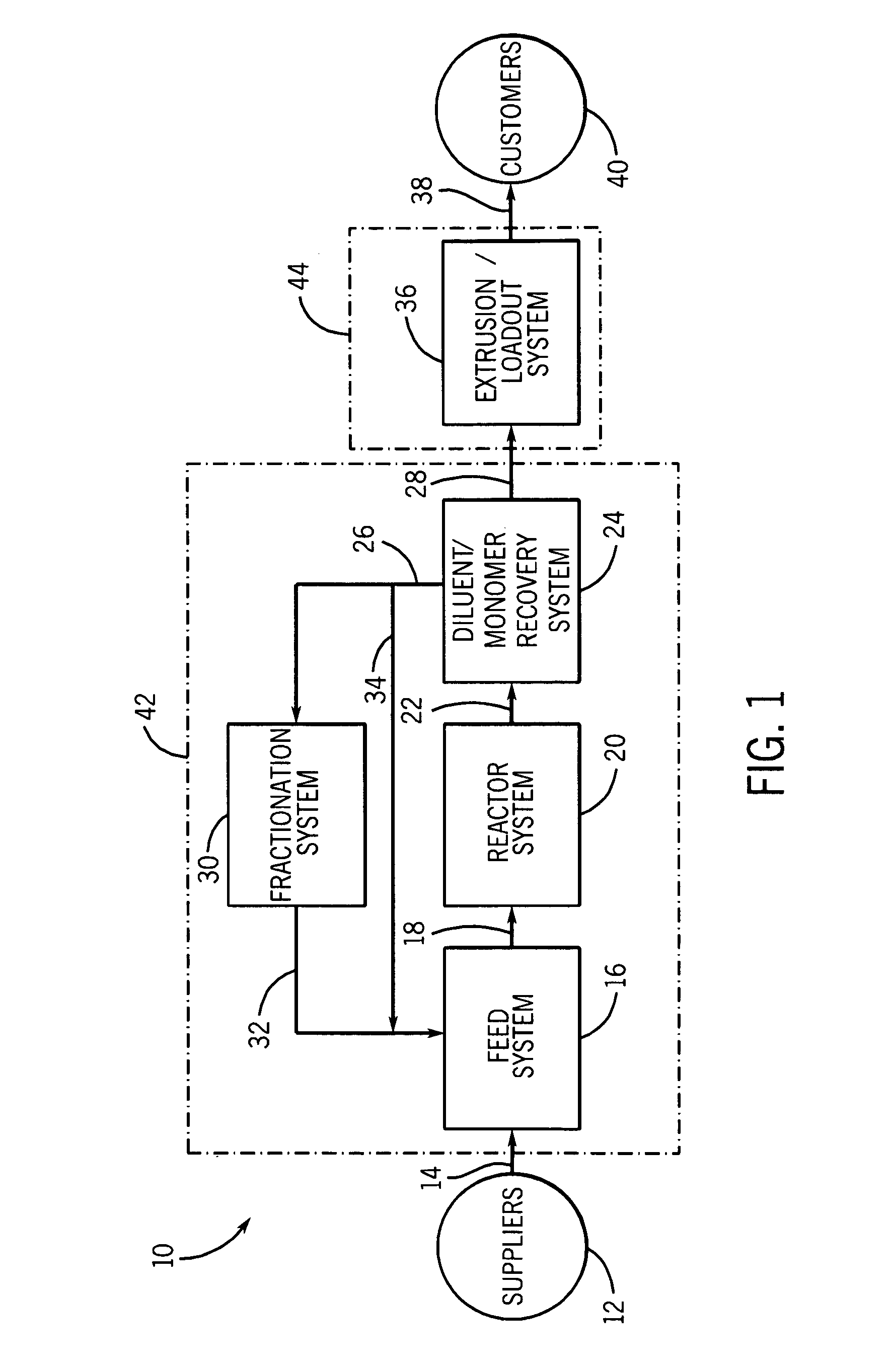

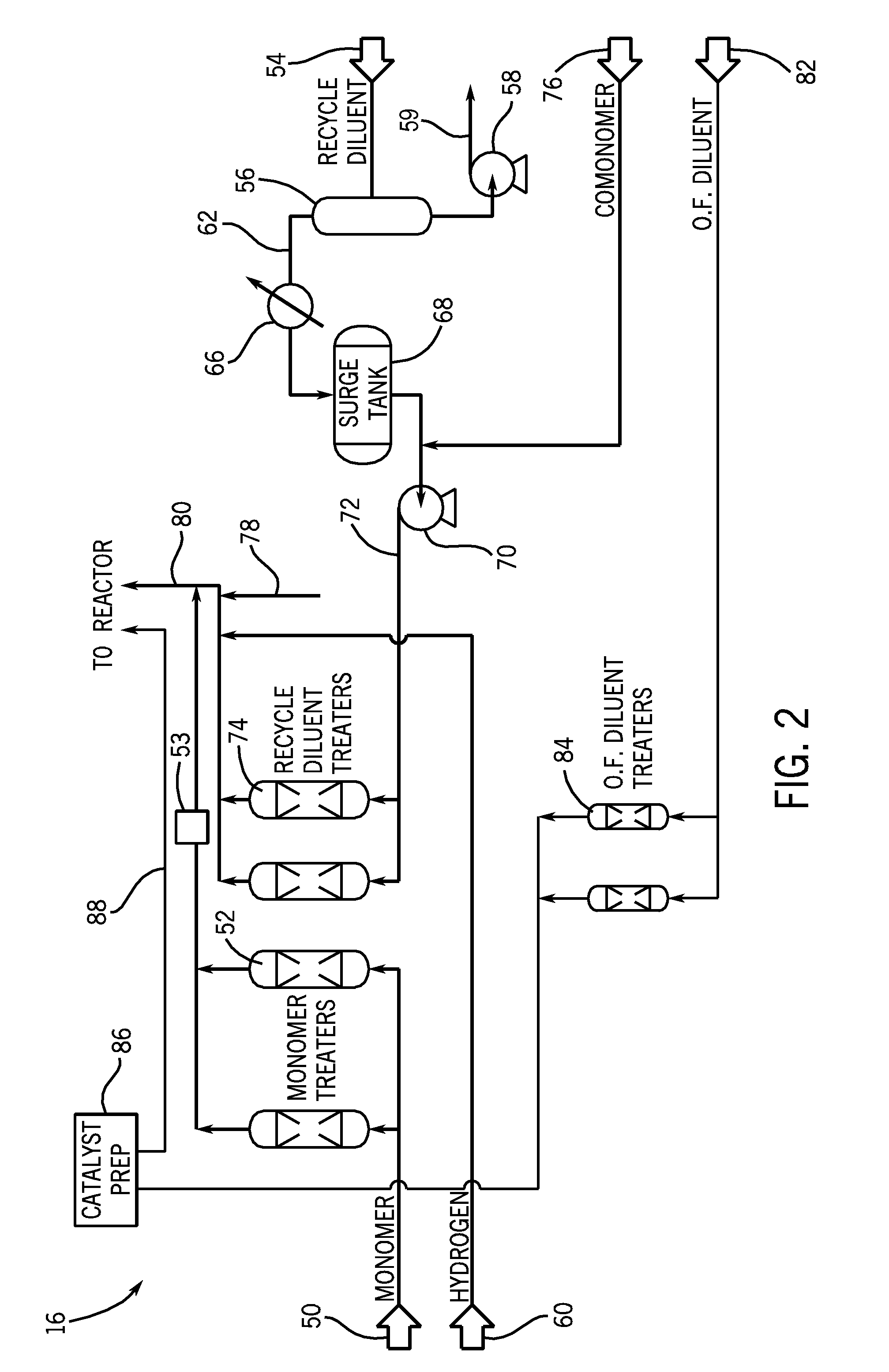

Energy efficient polyolefin process

A manufacturing process for producing polyolefin, having a feed system, a reactor system including at least one polymerization reactor, a diluent / monomer recovery system, a fractionation system, and an extrusion / loadout system having an extruder. The manufacturing process is configured to consume less than 325 kilowatt-hours of electricity per metric ton of polyolefin produced.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

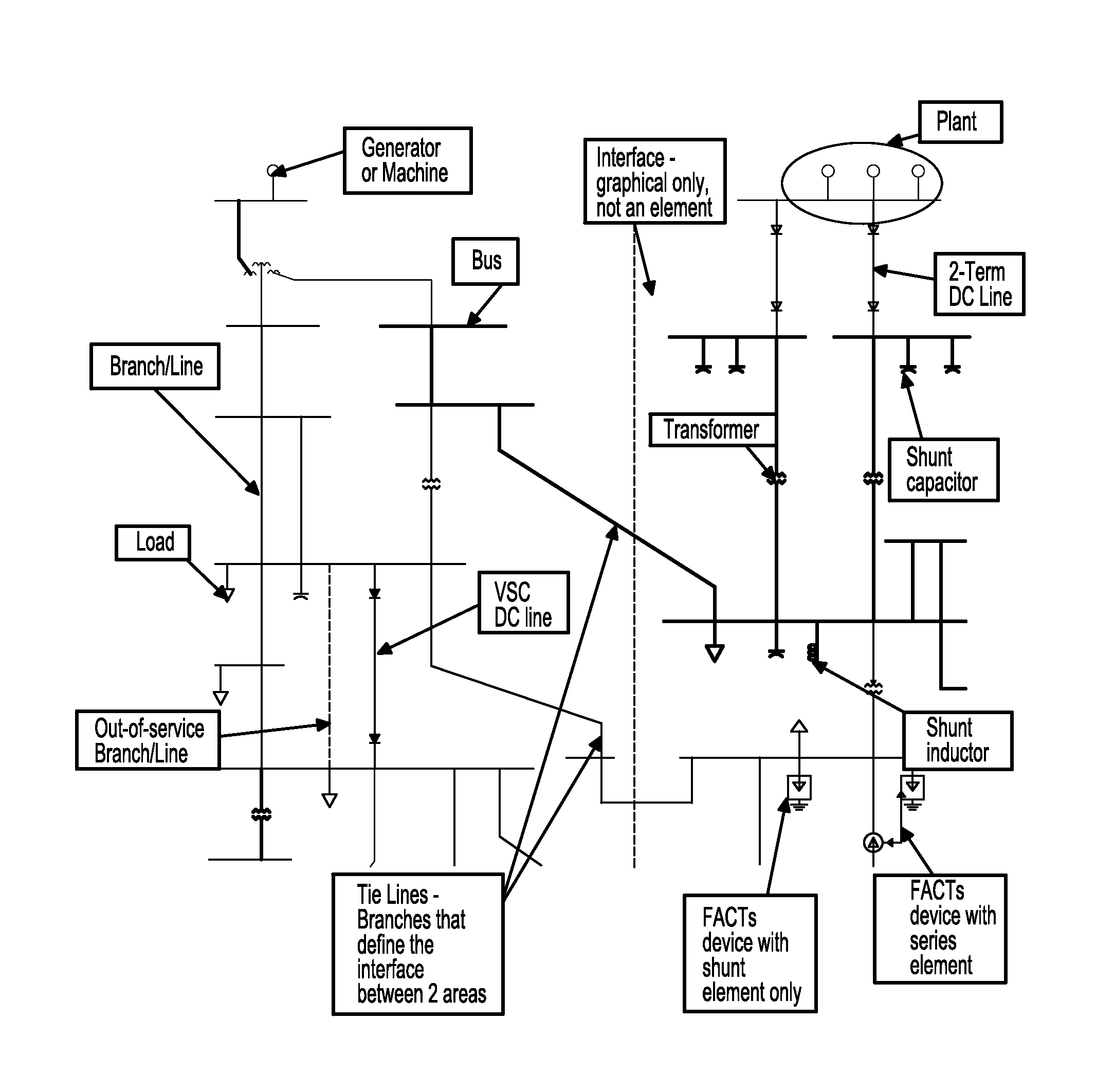

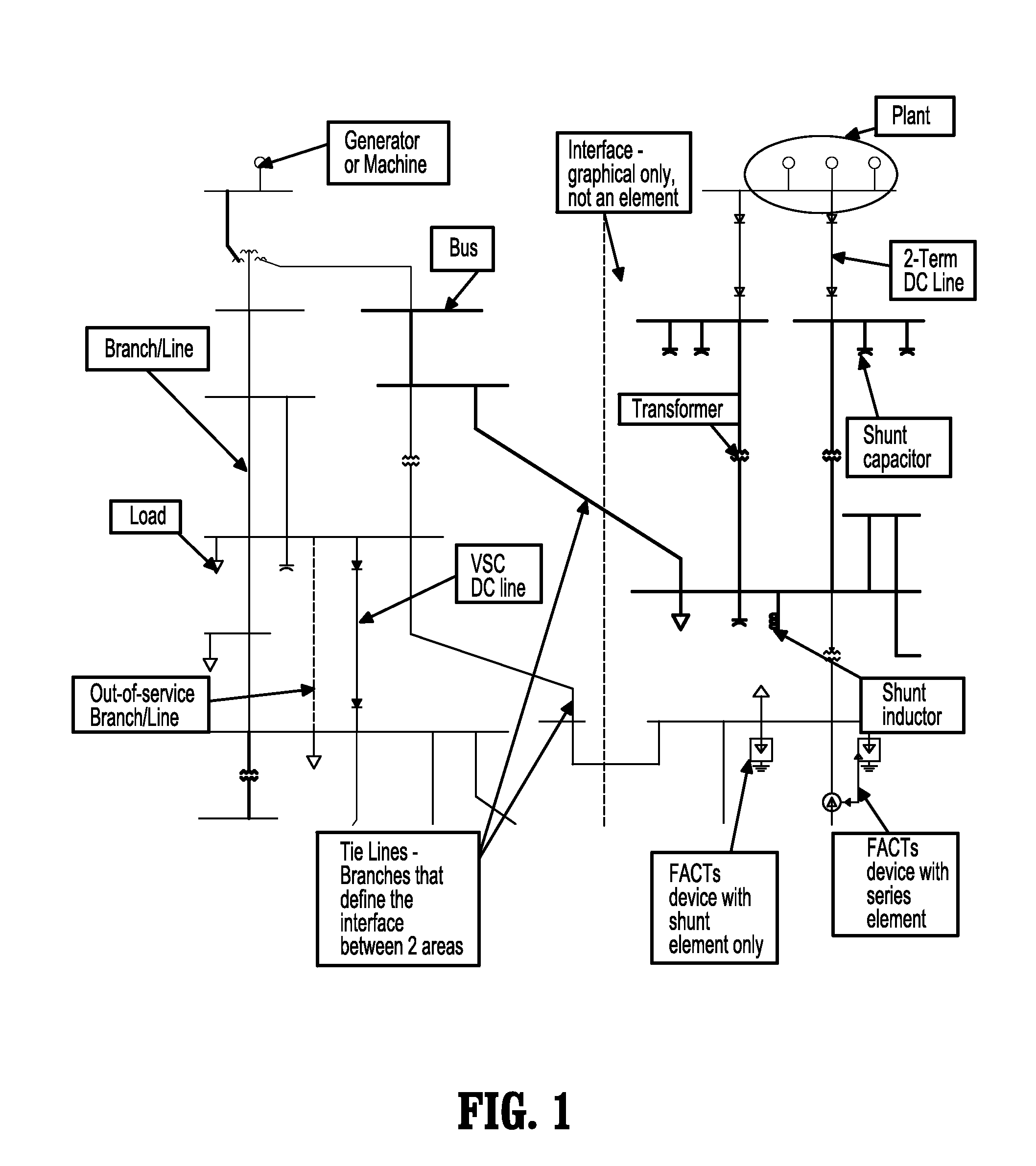

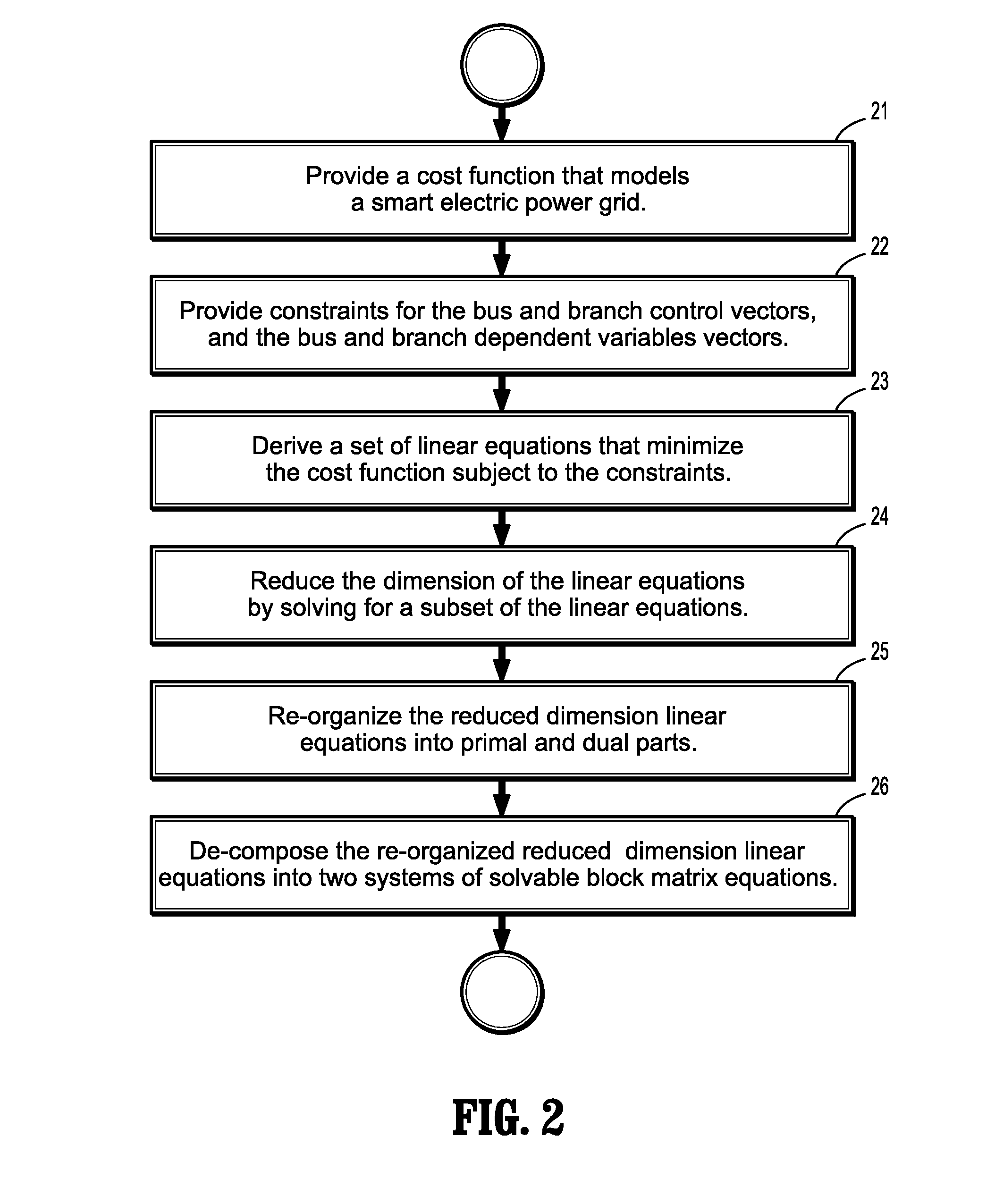

Interior point method for reformulated optimal power flow model

A method for approximating an optimal power flow of a smart electric power grid includes providing a cost function that models a smart electric power grid having buses connected by branches, deriving a set of linear equations that minimize the cost function subject to constraints from an expression of an extremum of the cost function with respect to all arguments, reducing a dimension of the linear equations by solving for a subset of the linear equations, re-organizing the reduced dimension linear equations into primal and dual parts, and decomposing the re-organized reduced dimensional linear equations into two systems of block matrix equations which can be solved by a series of back substitutions. A solution of the two systems of block matrix equations yields conditions for a lowest cost per kilowatthour delivered through the smart electric power grid.

Owner:SIEMENS AG

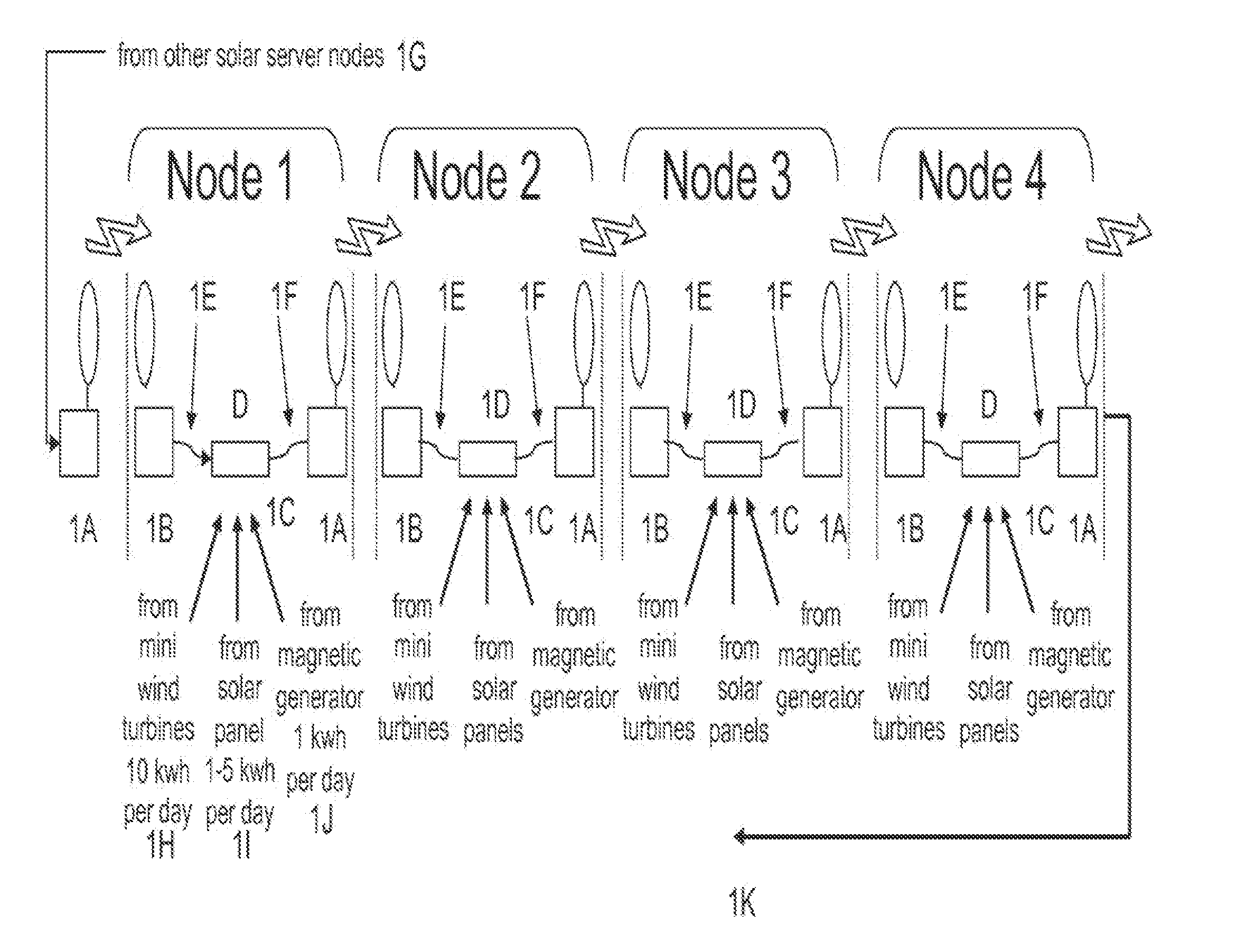

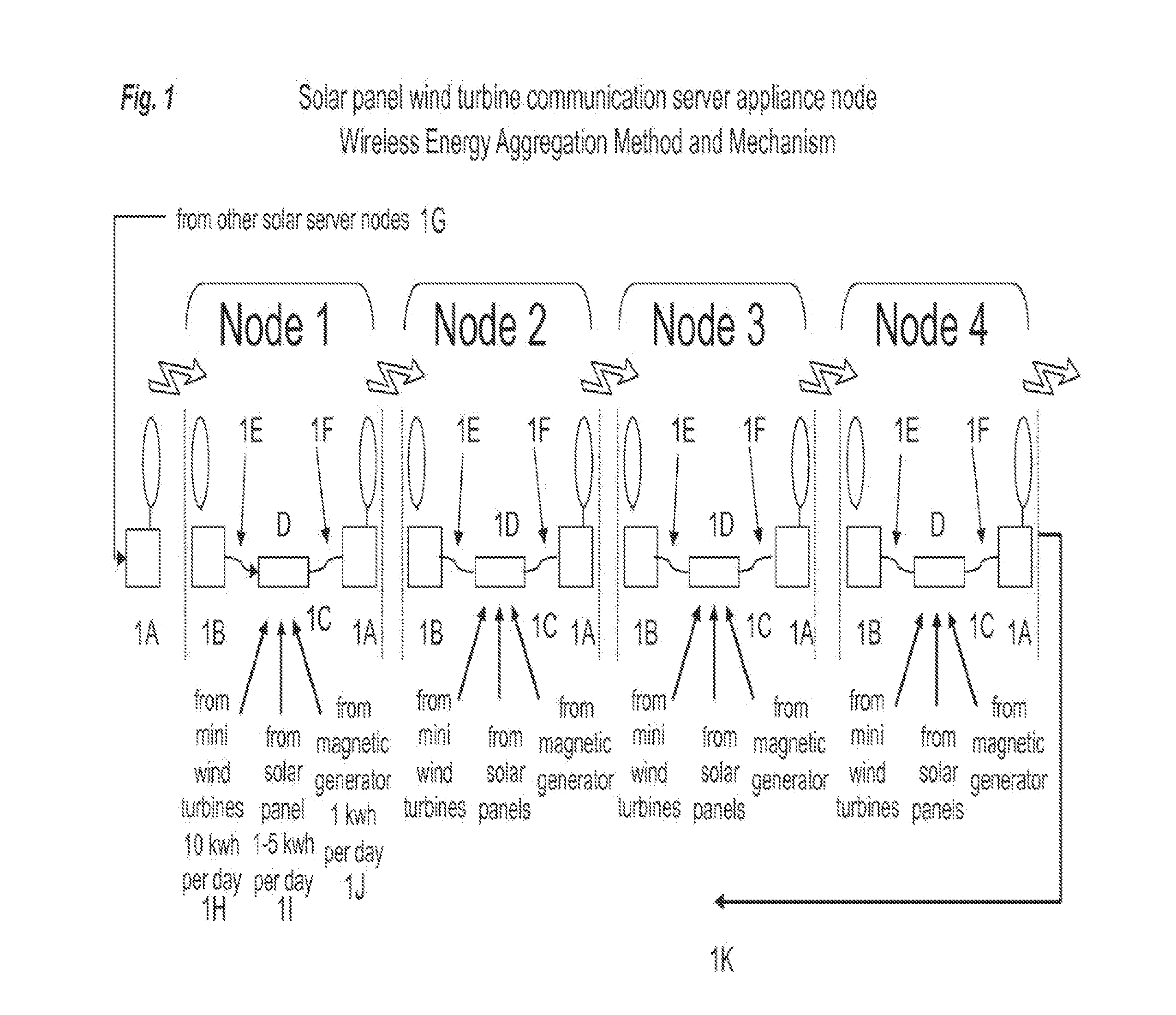

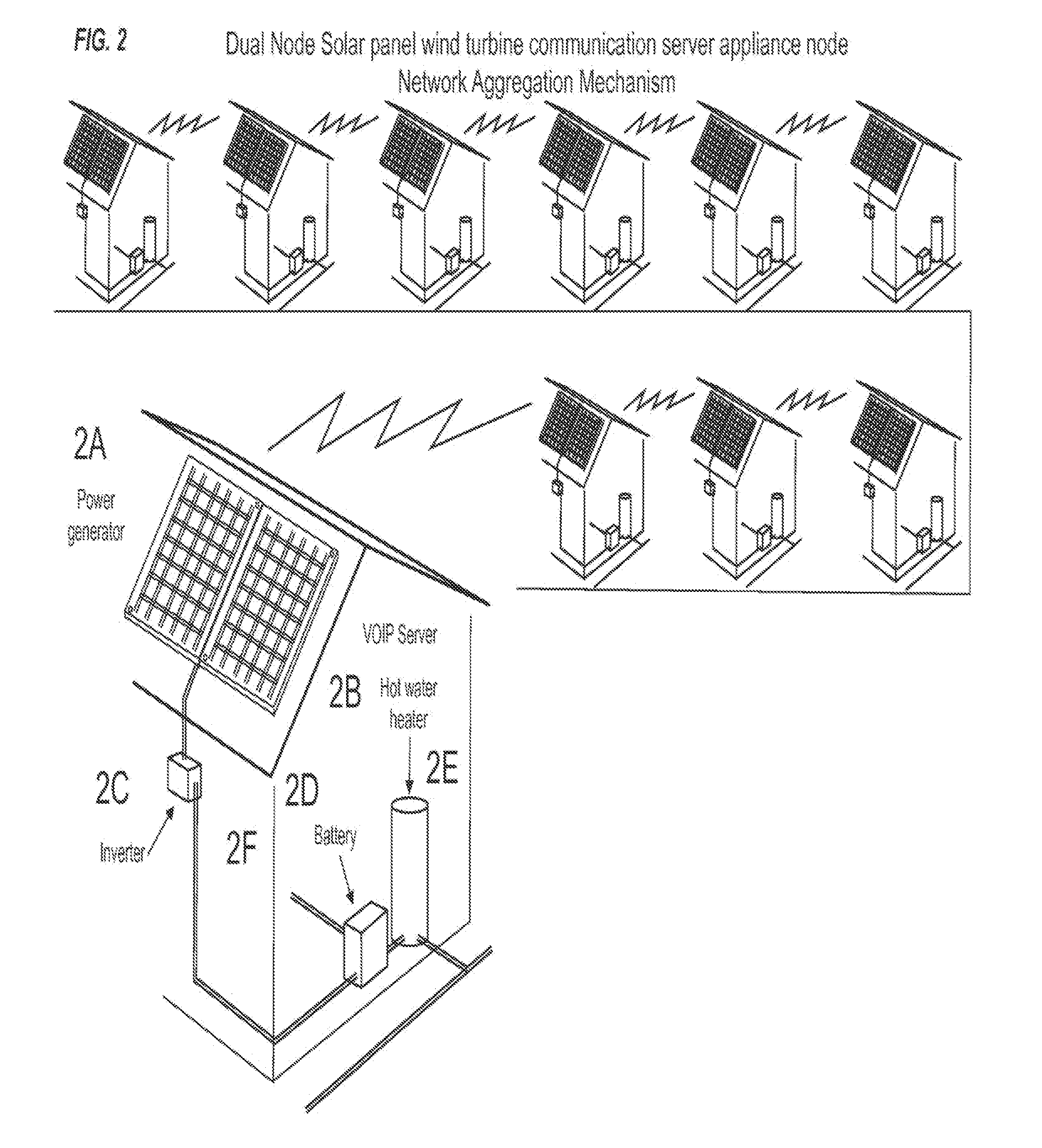

Solar panel wind turbine communication server network apparatus method and mechanism

InactiveUS20140176337A1Reduce energy costsConsume energySolar heating energyElectric signal transmission systemsOnline and offlineEngineering

The method included herein is an alternative energy wireless solar panel wind turbine communication server appliance node mechanism with built in communications server array, wireless energy and communications mechanism with protection, sharing, storage, accessing, authentication, battery management, certification, processing attachment and tracking mechanisms. The method and mechanism is utilized via networked servers, solar panels, and wireless electronic devices (online and offline) as well as mobile (wireless) communications devices built into one waterproof, temperature, controlled self-sensing hardware package. The method and mechanism also works as part of a kilowatt hour banking system, and thermal passive solar control mechanism for living spaces.

Owner:VALIN DAVID +1

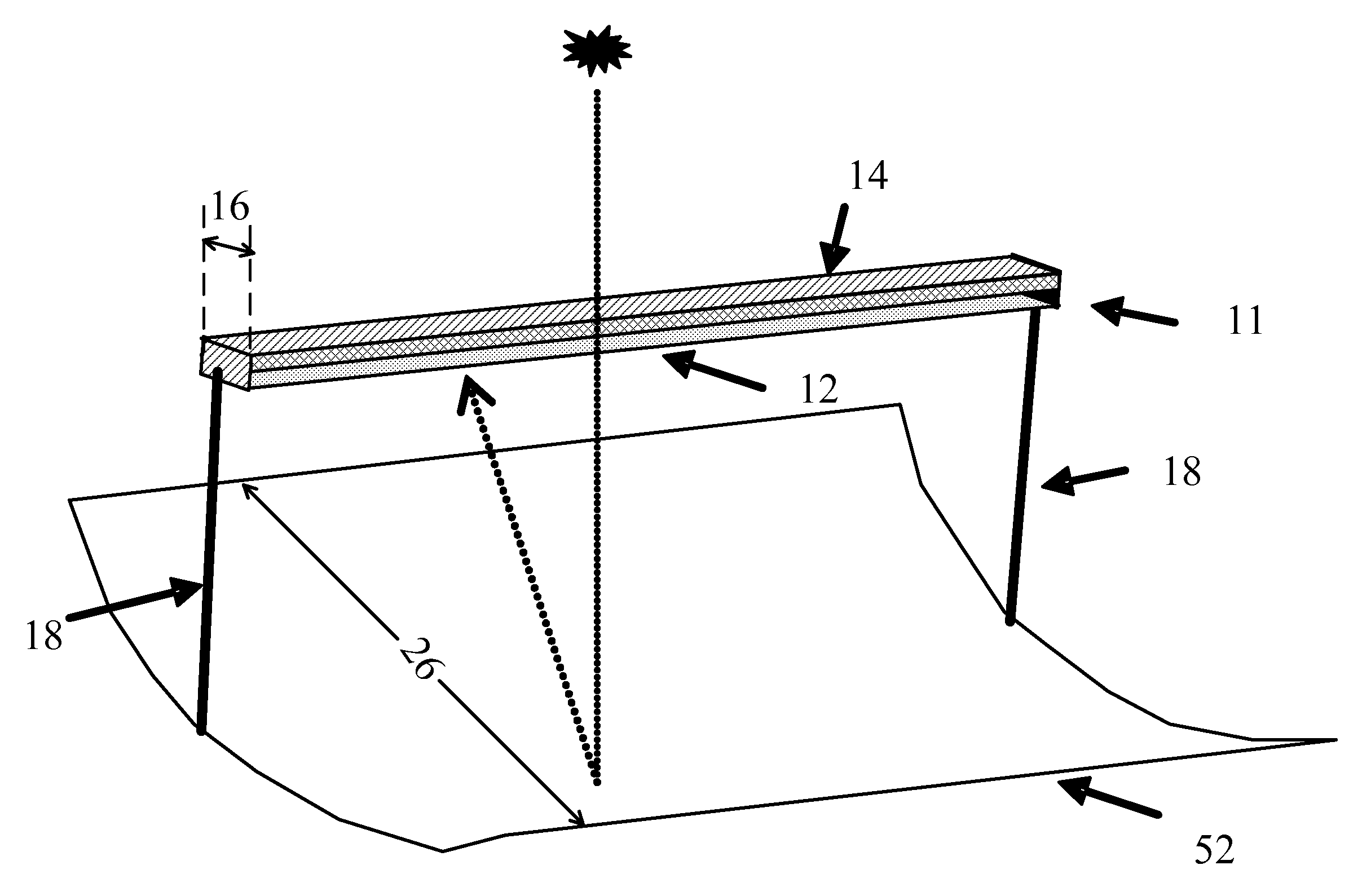

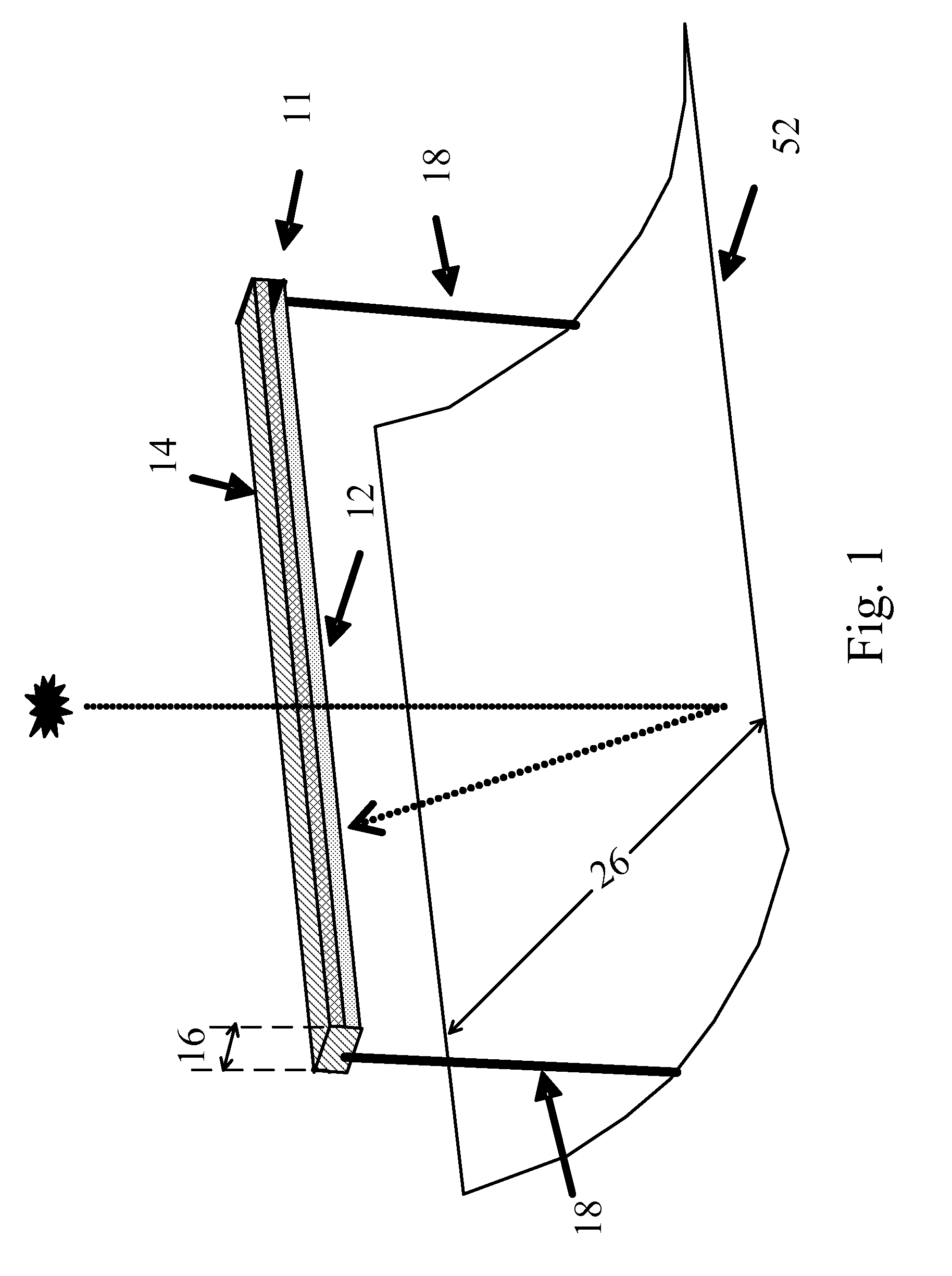

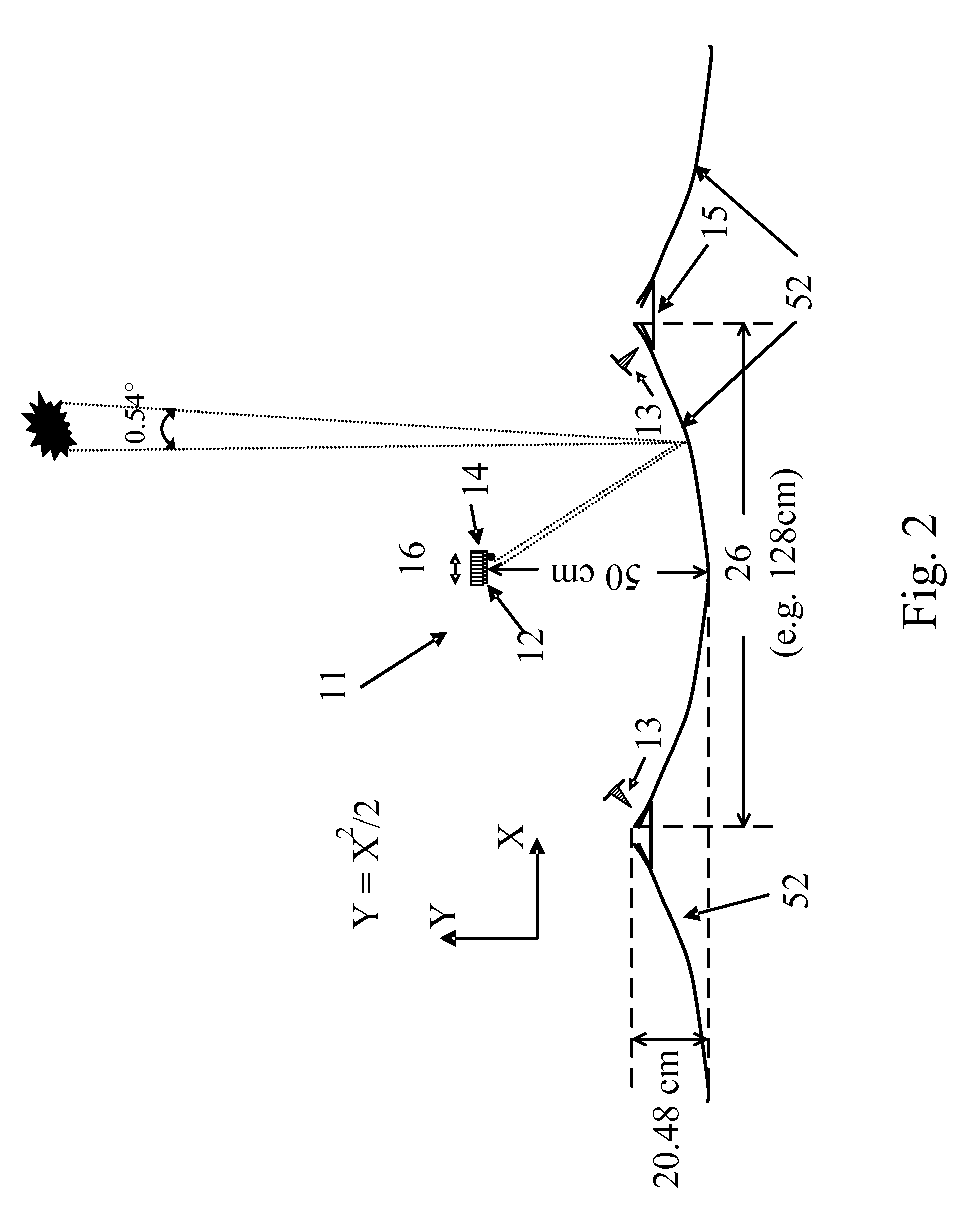

Method and Apparatus to Lower Cost Per Watt with Concentrated Linear Solar Panel

InactiveUS20110041894A1Reduce tracker costLarge energy outputSolar heating energySolar heat devicesPhotovoltaic solar energyCells panel

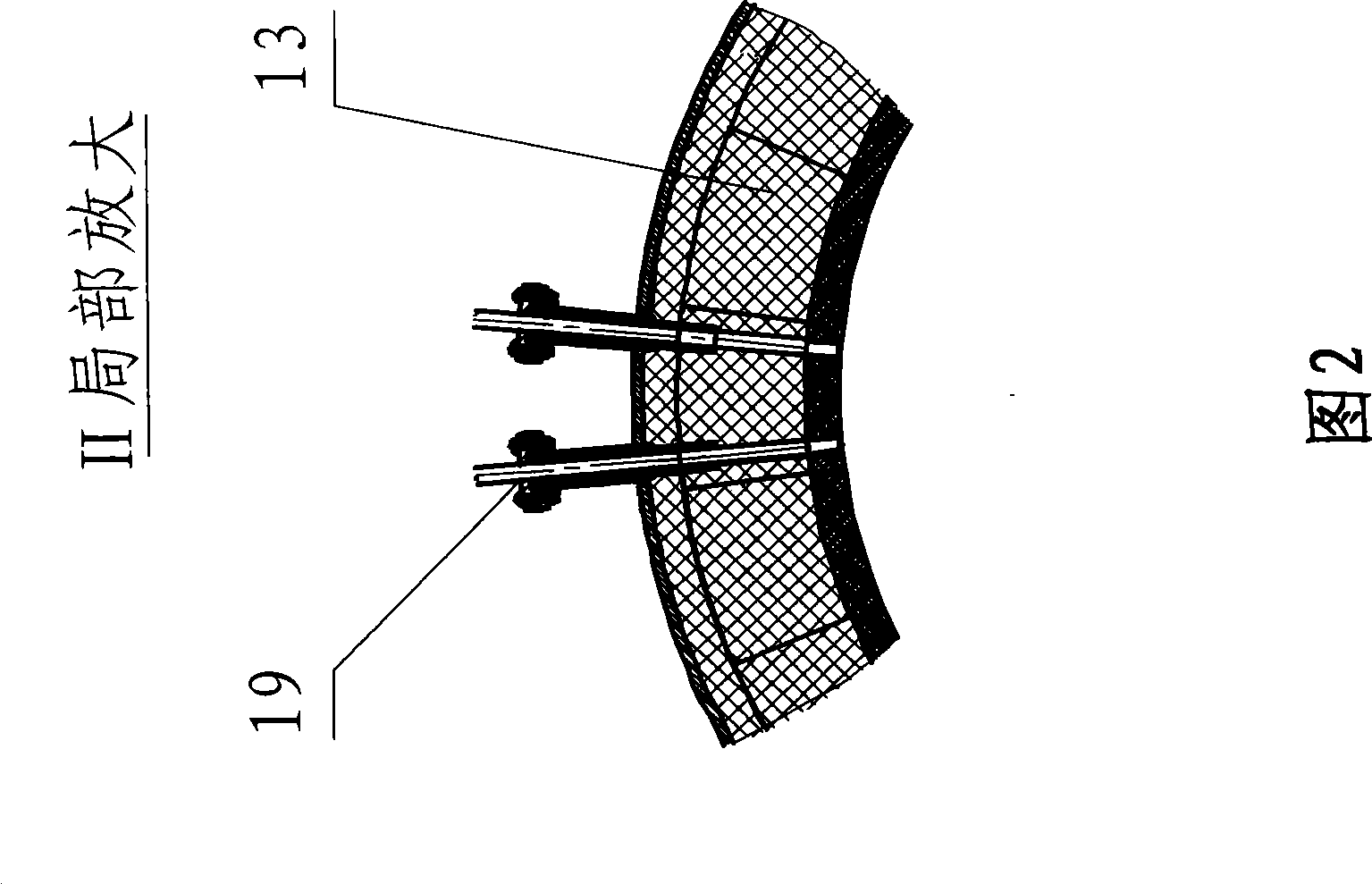

The present invention proposes a hybrid methodology and apparatus between photovoltaic (PV) and concentrated photovoltaic (CPV) solar panels to lower the photovoltaic solar energy production cost. In particular, the disclosed methodology addresses a simple quasi-parabolic trough PV (QPTPV) low concentration system with greater tolerance to tracker pointing errors. The quasi-parabolic trough (QPT) reflector is defocused to cover the width of a linear solar cells array, which is reduced from a large rectangular solar cells panel. In summary, the QPTPV system consists of low cost quasi-parabolic reflectors, a compact linear PV cells array and a lower cost relaxed pointing 2-axes tracker. The combination of these low cost technologies disclosed can achieve the lowest cost per kilowatt hour of photovoltaic energy production.

Owner:LIAO HENRY H

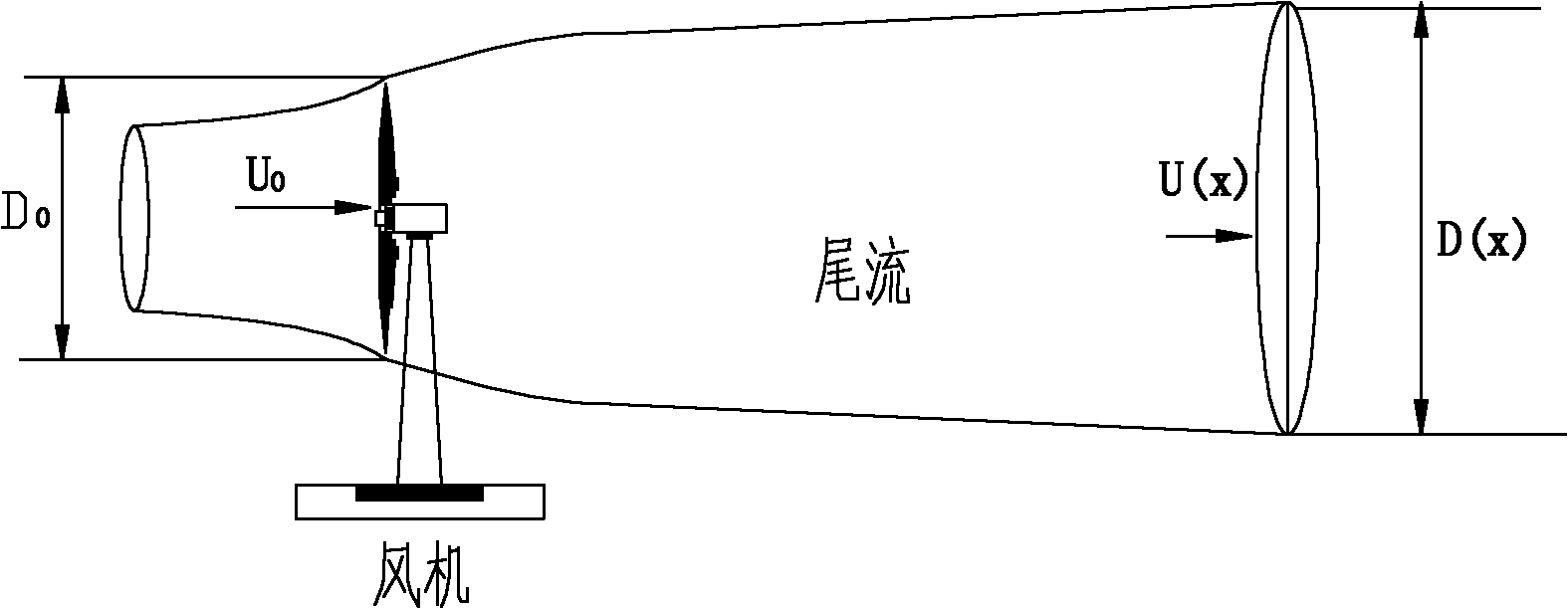

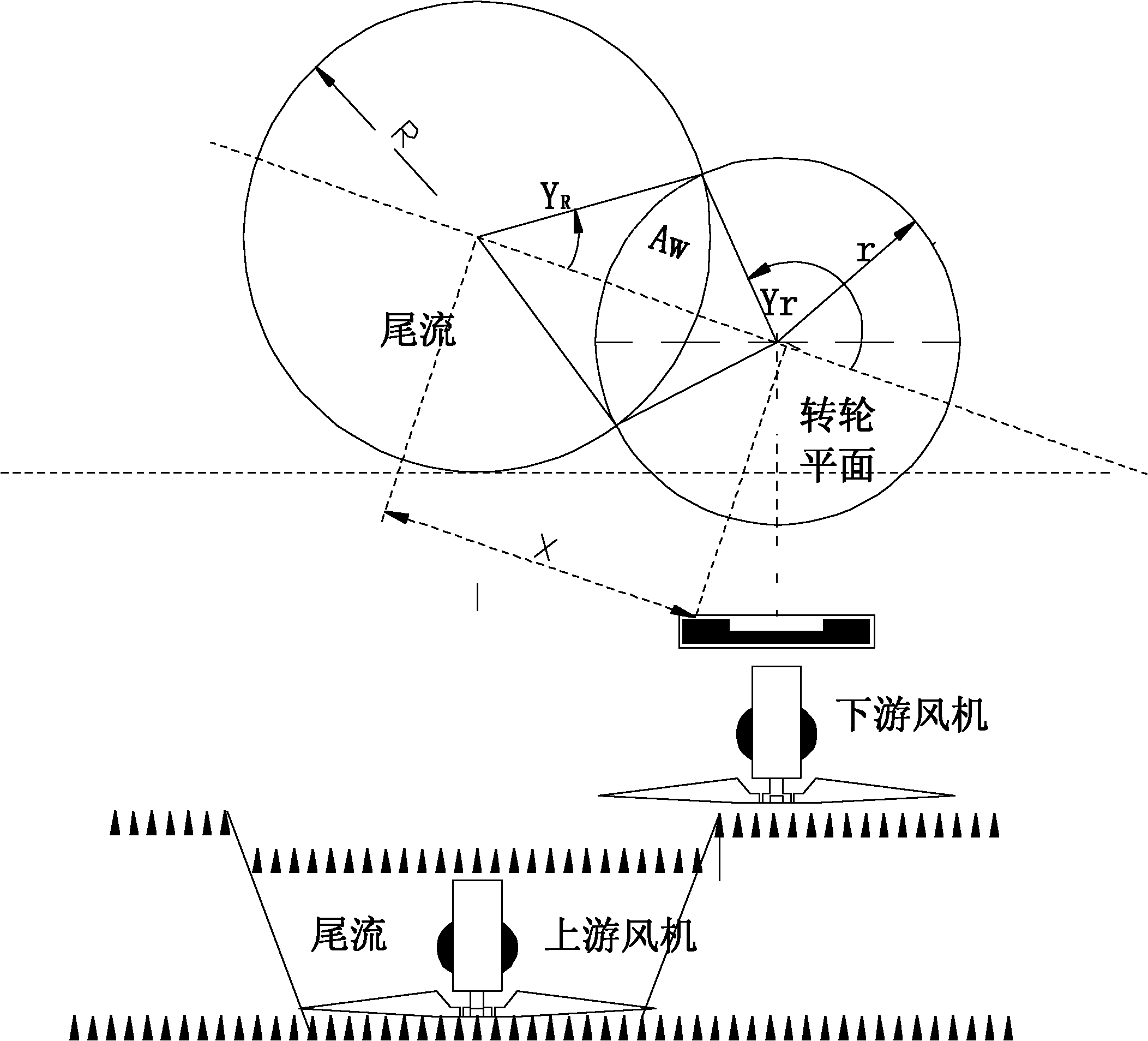

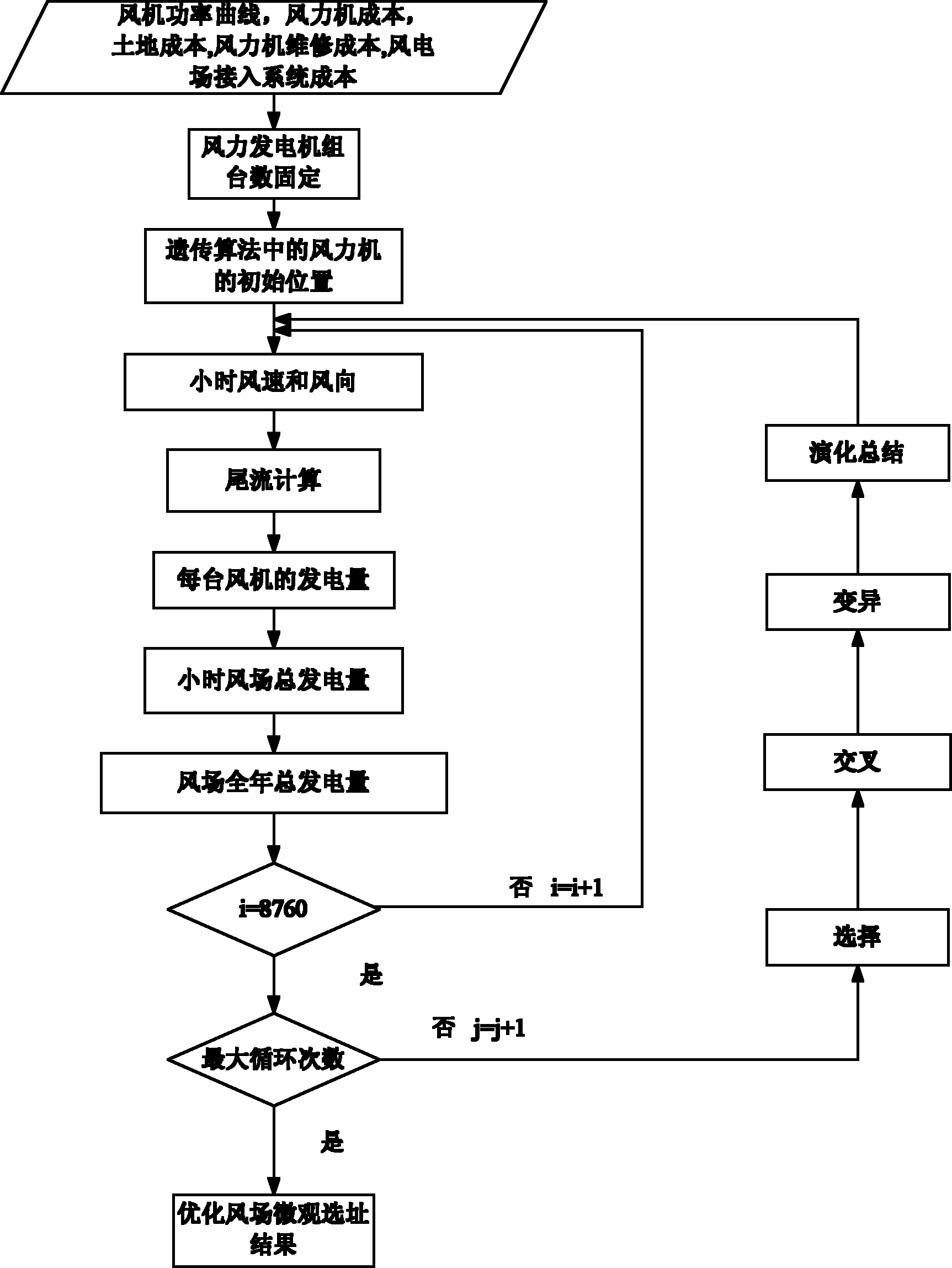

Real-coded genetic algorithm-based optimizing method for micrositing of wind power station

InactiveCN102142103AOptimizing Micro AddressesAccurate annual power generationGenetic modelsWind motor combinationsWinding machinePower station

The invention discloses a real-coded genetic algorithm-based optimizing method for the micrositing of a wind power station. In the method, the measured wind speed in the wind farm is corrected by an index model in the direction of relative height; a power characteristic curve of a wind machine is discretized by a linearized method; for the wake flow of the wind machine, a linearized wake flow model is adopted; the wind speed of the wind machines at the wake flow of a plurality of wind machines is solved by a method of the summation of squared differences, when part of the wind machines are positioned in the wake flow, the wind speed is revised by a method of area coefficients; based on an optimizing target function of the micrositing in the design of the wind power station, when the total number of the wind machines in the wind power station is determined, the total generated energy is used as the target function, and when the total number of the wind machines in the wind power station is not determined, the kilowatt-hour cost is used as the target function; and the microcosmic arrangement site of each wind machine in the wind power station is obtained by the real-coded genetic algorithm-based optimizing method. By the method, the reliability of forecast is high, the optimizing efficiency is high and results are accurate.

Owner:HOHAI UNIV

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

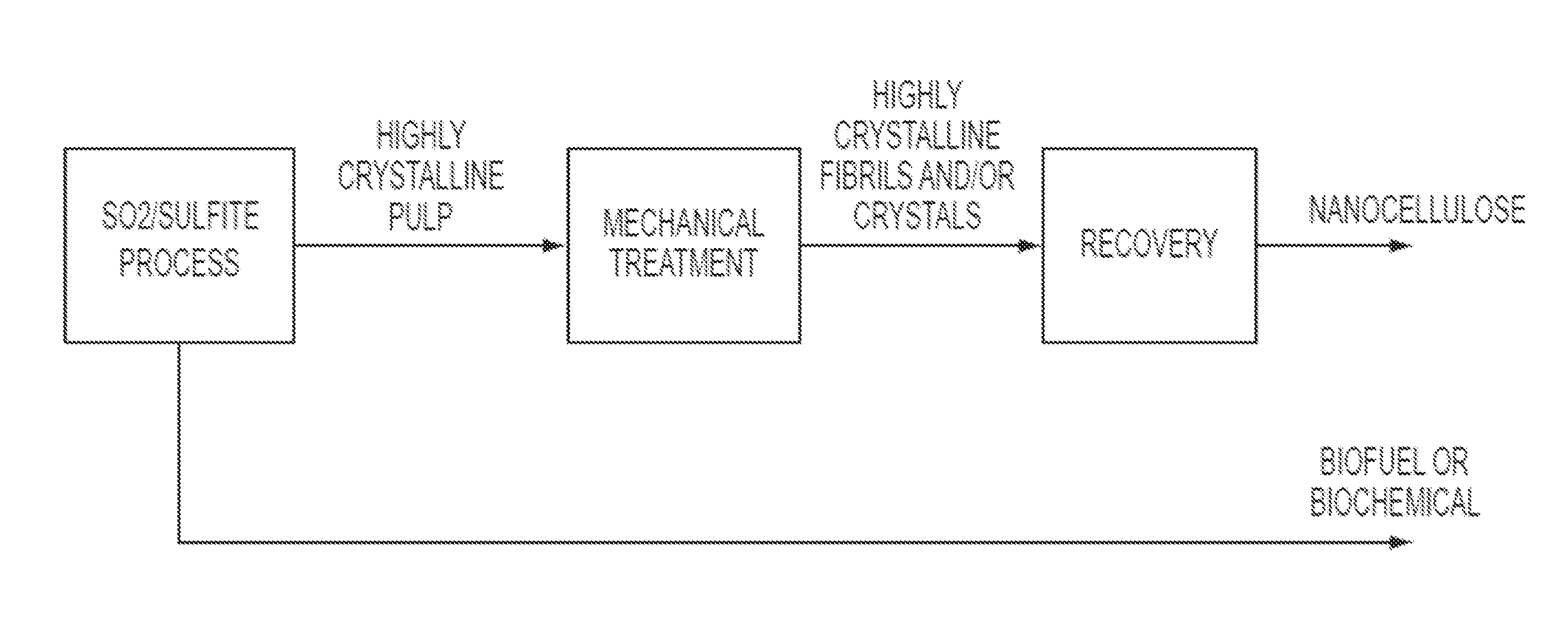

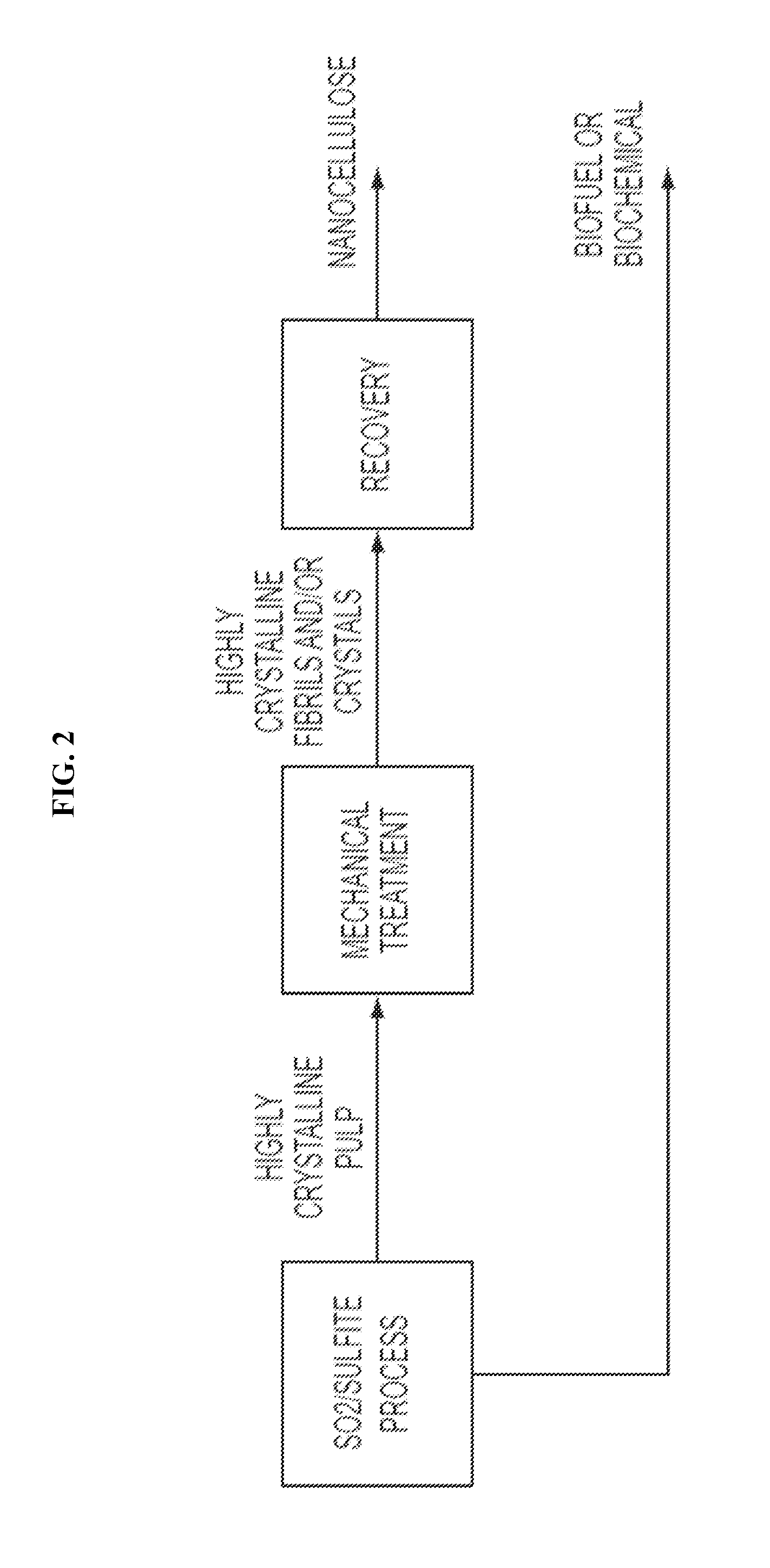

Sulfite-based processes for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with low mechanical energy input. In some variations, the process includes fractionating biomass with sulfur dioxide or a sulfite compound and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Kilowatt-hour meter image automatic identification method

The invention relates to a kilowatt-hour meter image automatic identification method which comprises the following steps: 1. image preprocessing: detecting vertical texture of a panel image by using Sobel operator, preliminarily removing the background area by a projection method, extracting the area with abundant vertical texture by an expansion method, and carrying out binarization treatment on the image by a adaptive threshold segmentation method based on an integral projection method; 2. precise positioning of indicating value and bar code: by combining an intelligent judgment method on the basis of indicating value intervals and length-width ratio characteristic of numeric characters under the complex image background, adapting to precise positioning of indicating values of different types of kilowatt-hour meters on the basis of vertical edge detection of the Sobel operator and morphological treatment; carrying out horizontal scanning on the bar code area to extract the bar code characteristic area; 3. bar code identification: identifying different character bar codes by using a similar edge distance normalization method; and 4. indicating value identification: extracting the indicating value by a PCA (principal component analysis) method. By using the PCA character recognition method, various character indicating values can be precisely identified, including identification of half-character.

Owner:BRINGSPRING SCIENCE & TECHNOLOGY CO LTD

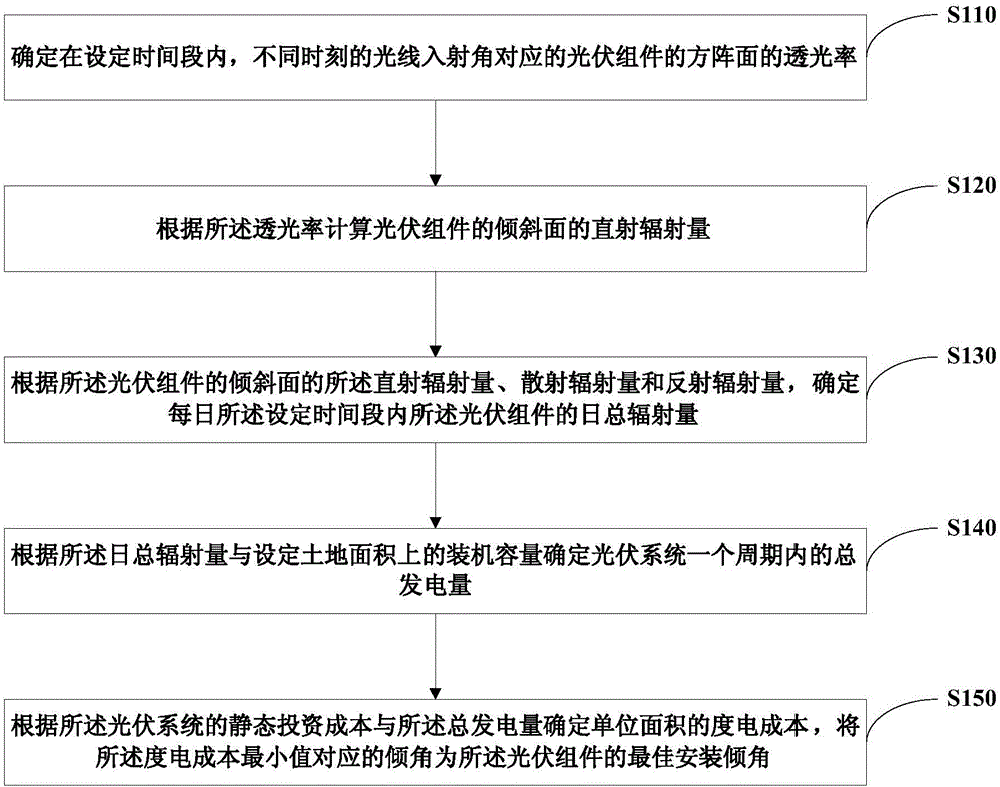

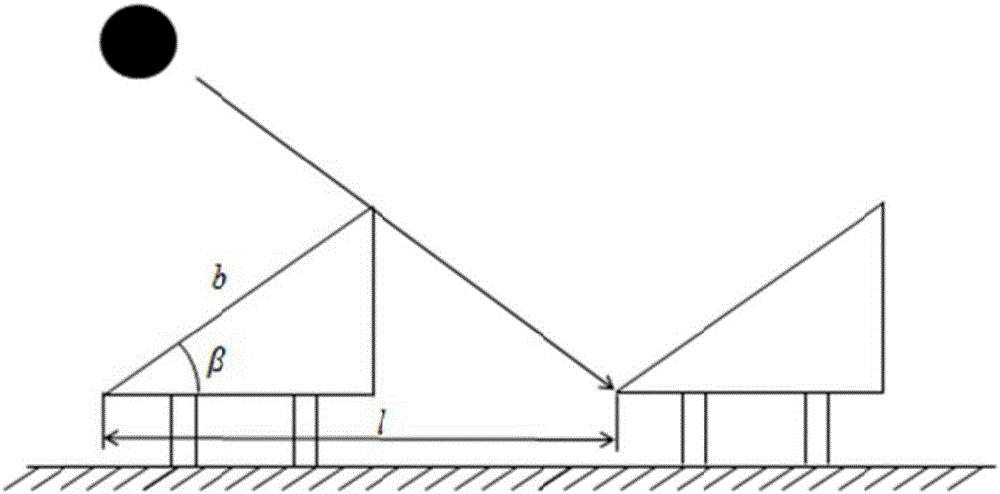

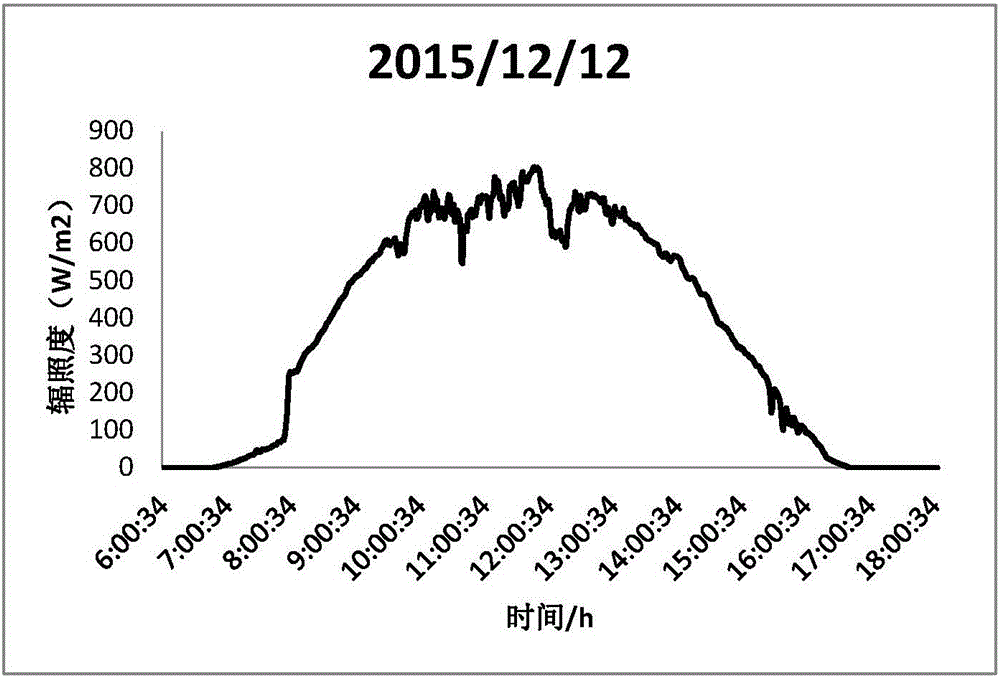

Determining method and device of optimal installing inclination angle of photovoltaic module

InactiveCN106372346AAccurate calculationLow investment costData processing applicationsDesign optimisation/simulationOptical transmittanceDirect radiation

The invention discloses a determining method and device of the optimal installing inclination angle of a photovoltaic module, and relates to a photovoltaic equipment arrangement technology. The method comprises the steps of determining the light transmittance of photovoltaic module square matrix surfaces corresponding to light ray incidence angles at different moments in the set time period; calculating the direct radiation quantity of the inclination area of the photovoltaic module according to the light transmittance; determining the total daily radiation quantity of the photovoltaic module in the daily set time period according to the direct radiation quantity, the scattering radiation quantity and the reflecting radiation quantity of the inclination area of the photovoltaic module; determining the total power generation quantity of a photovoltaic system in one period according to the total daily radiation quantity and the installed capacity on the set land area; determining the cost per kilowatt hour of electricity in unit area according to the total power generation quantity and the static investment cost of the photovoltaic system; determining the inclination angle corresponding to the minimum value of the cost per kilowatt hour of electricity as the optimal installing inclination angle of the photovoltaic module. The problem that a traditional optimal inclination angle calculation method does not consider the growing economy is solved; the effect that the cost per kilowatt hour of electricity is the lowest is achieved.

Owner:CSI CELLS CO LTD +1

Energy efficient polyolefin process

A manufacturing process for producing polyolefin, having a feed system, a reactor system including at least one polymerization reactor, a diluent / monomer recovery system, a fractionation system, and an extrusion / loadout system having an extruder. The manufacturing process is configured to consume less than 325 kilowatt-hours of electricity per metric ton of polyolefin produced.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

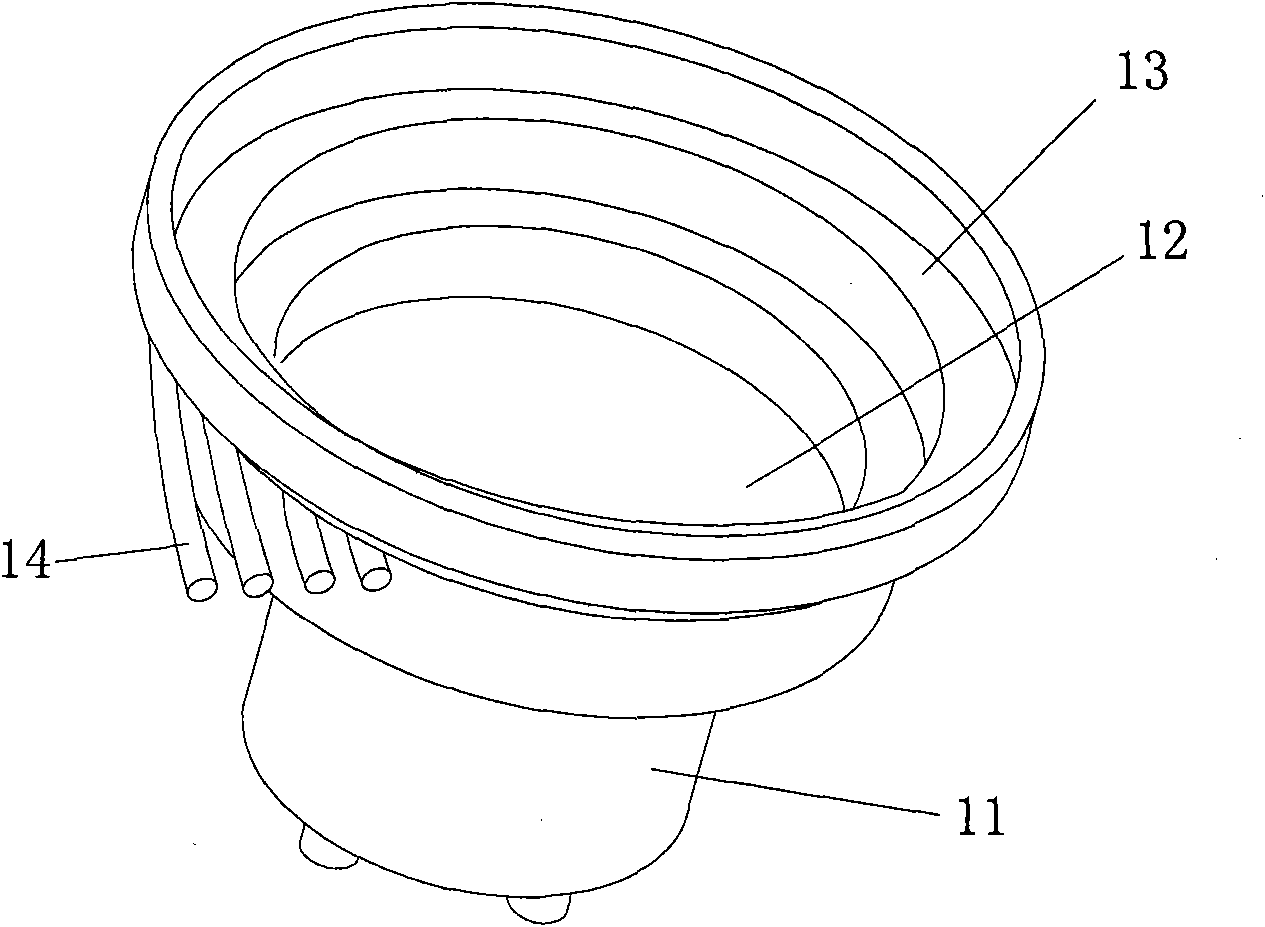

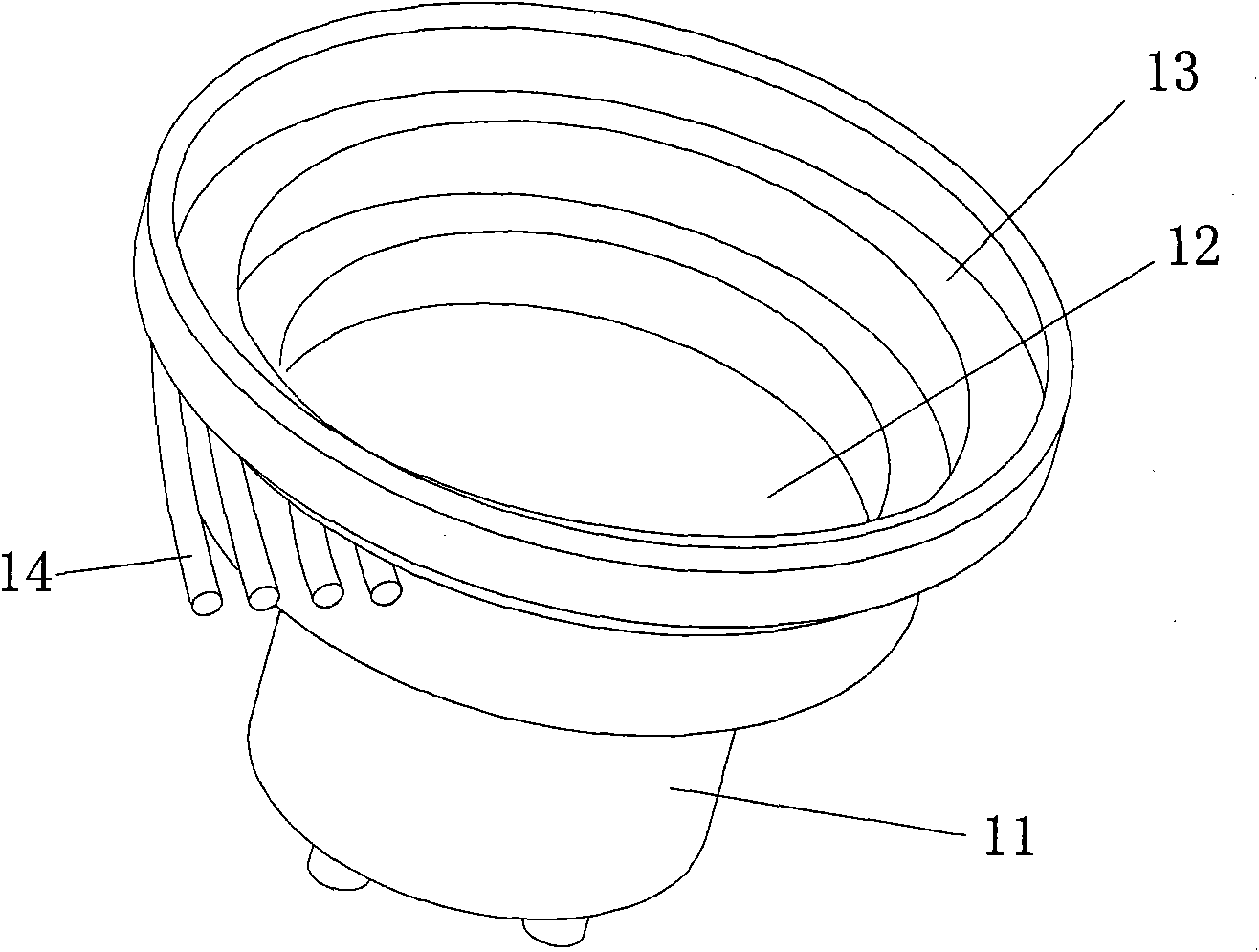

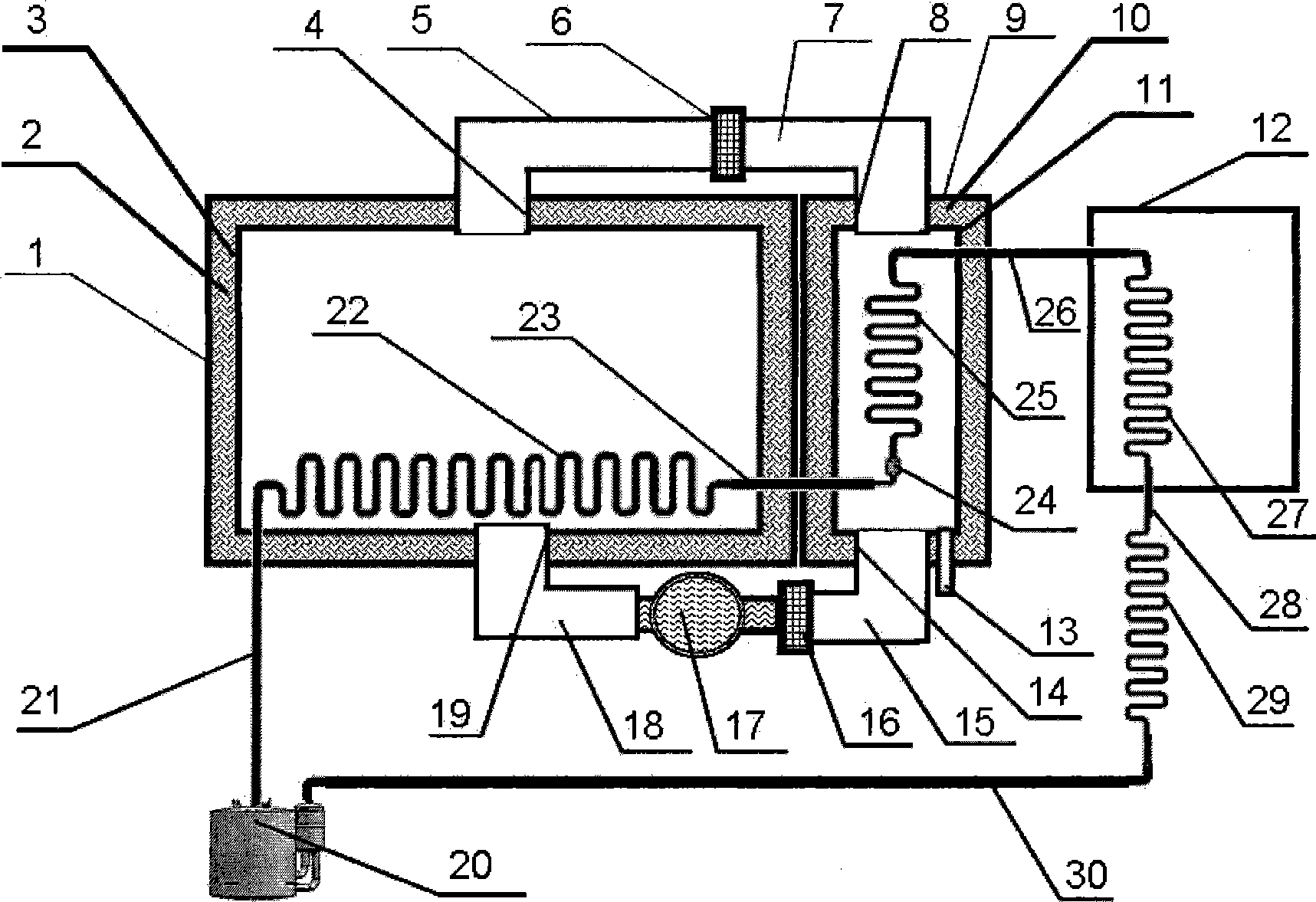

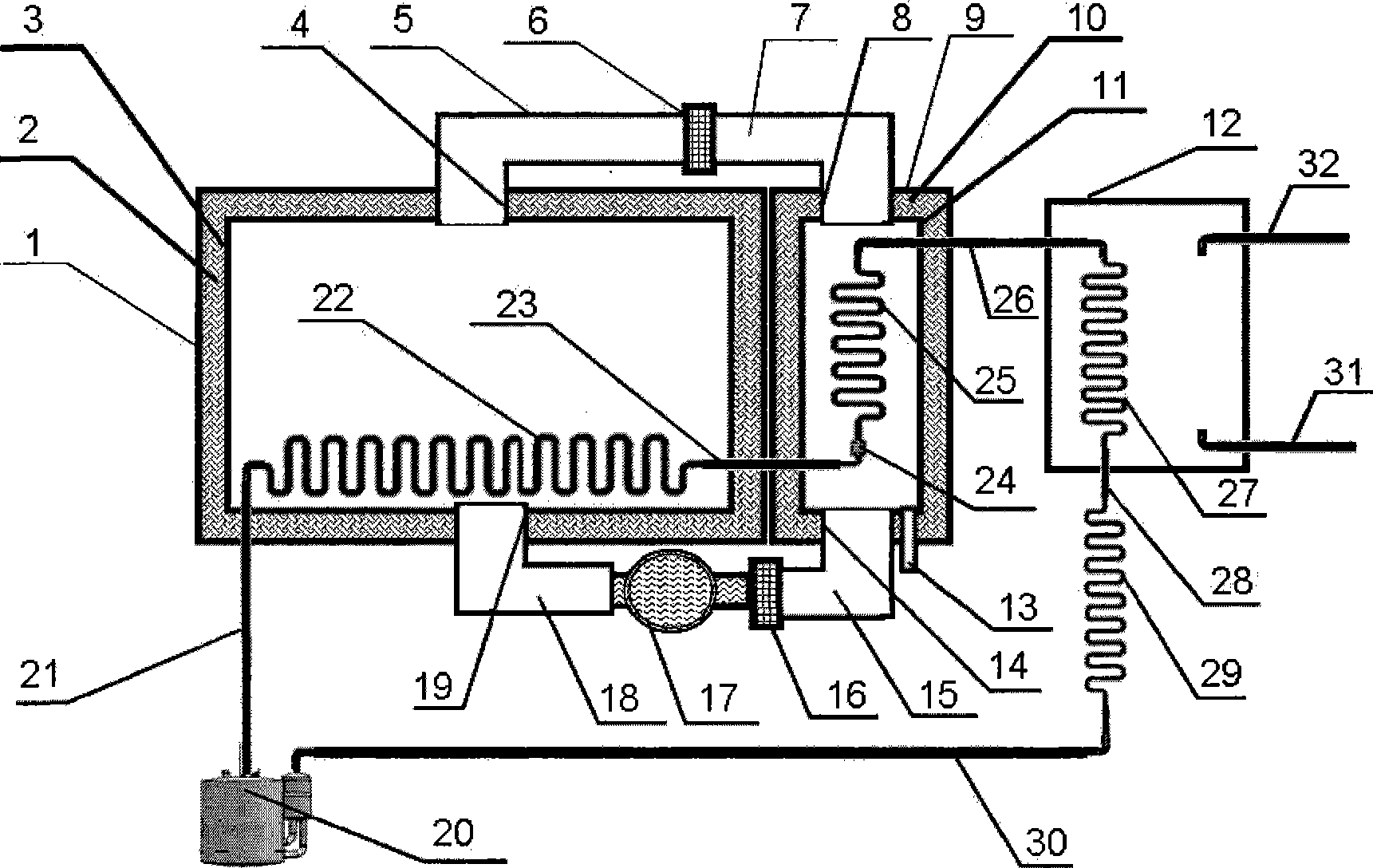

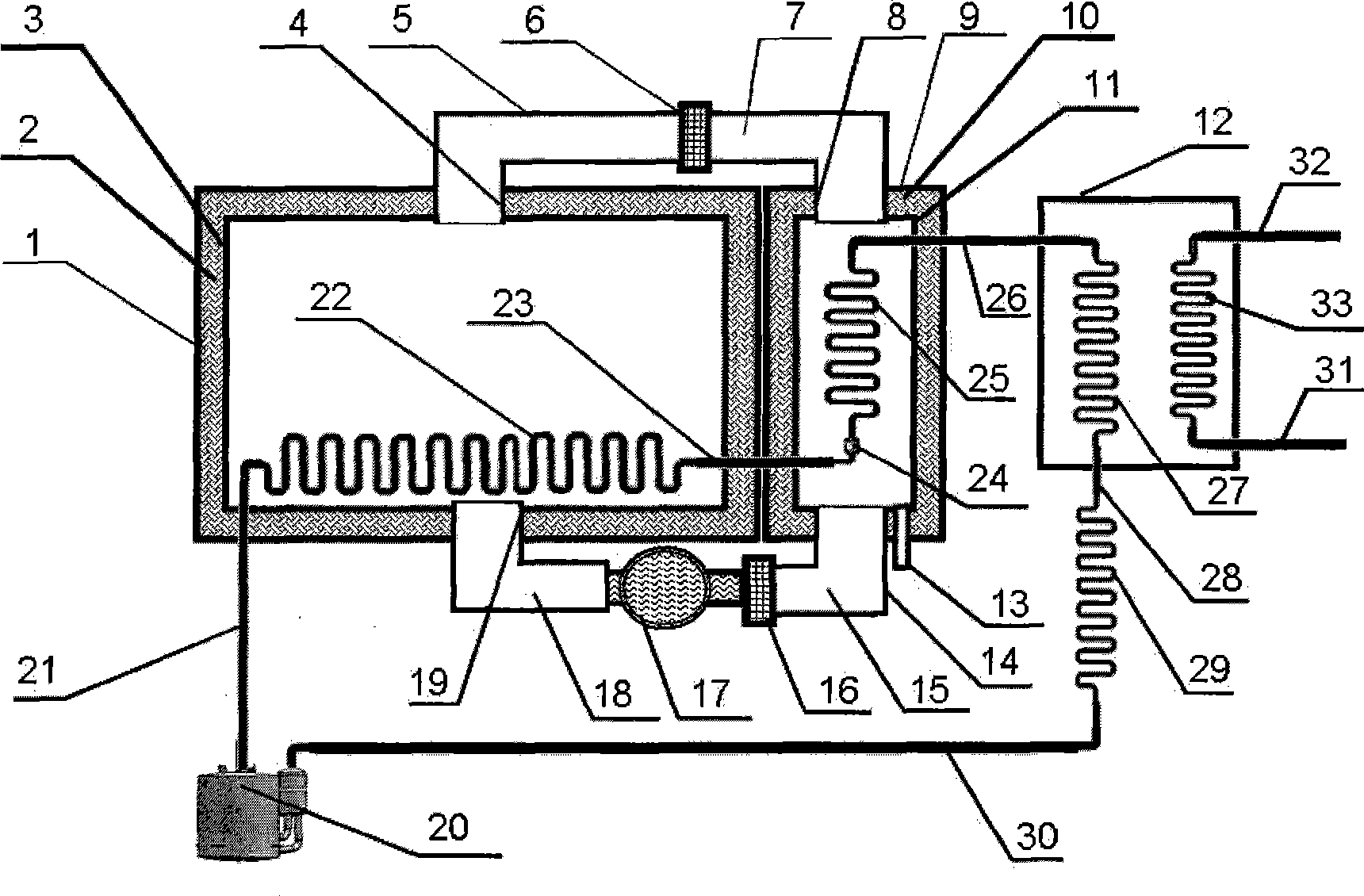

Operation modes and structure of heat-circulation heat pump drying unit

ActiveCN105605910AIncrease moisture contentIncrease enthalpyDrying gas arrangementsAir volumeAtmospheric air

The invention discloses operation modes and a structure of a heat-circulation heat pump drying unit. The structure is characterized in that the drying unit comprises a heat recovery air duct which forms a sealed air flow circulation loop with the inner cavity of the drying oven, an evaporator is installed in the air duct, and an air regulator for regulating and controlling the air flowing through the evaporator is arranged in the unit. The operation modes are a heating mode and a heat-circulation dehumidification mode. In the early operation stage of the unit, the heating mode is started, the heat pump system absorbs heat from the atmosphere, so that the air in the drying oven is heated to achieve the preset temperature; and then, the unit operates the heat-circulation dehumidification mode, the high-temperature high-humidity gas in the drying oven flows through the evaporator in the air duct to be cooled and dehumidified and then flows back to the drying oven, the sensible heat and latent heat absorbed by the evaporator are released into the drying oven by a condenser, and the air regulator enables the ratio of the condensation air quantity to evaporation air quantity to be greater than 2 and controls the inlet / outlet air temperature difference of the evaporator to be 10-25 DEG C. The unit has the advantages of high average COP and high latent heat ratio in the heat absorbed by the evaporator; and the dehydrating amount per kilowatt-hour is 5 kilograms or above, so that the efficiency is enhanced by 70-130% as compared with the conventional heat pump drying.

Owner:淄博绿爽食品有限公司

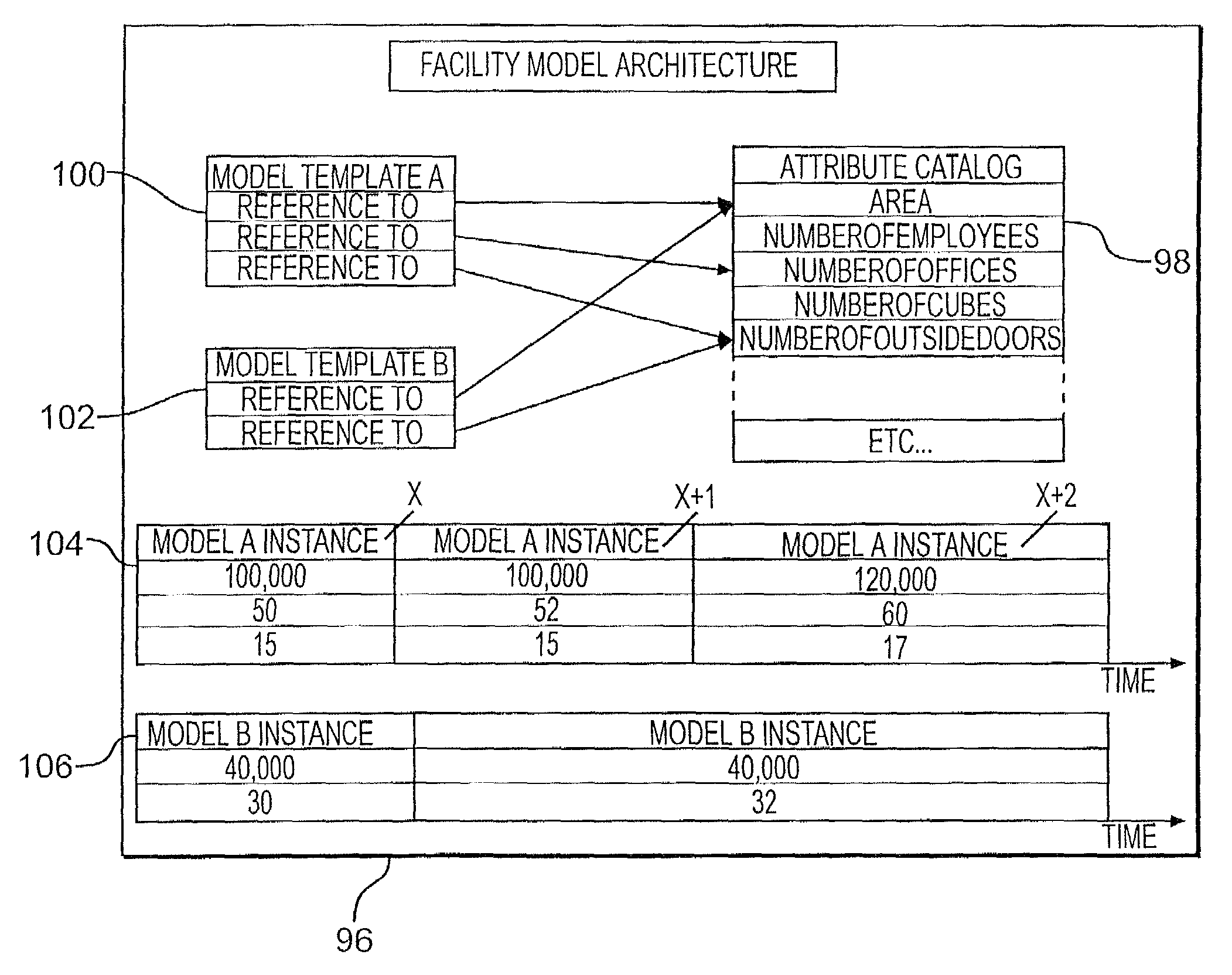

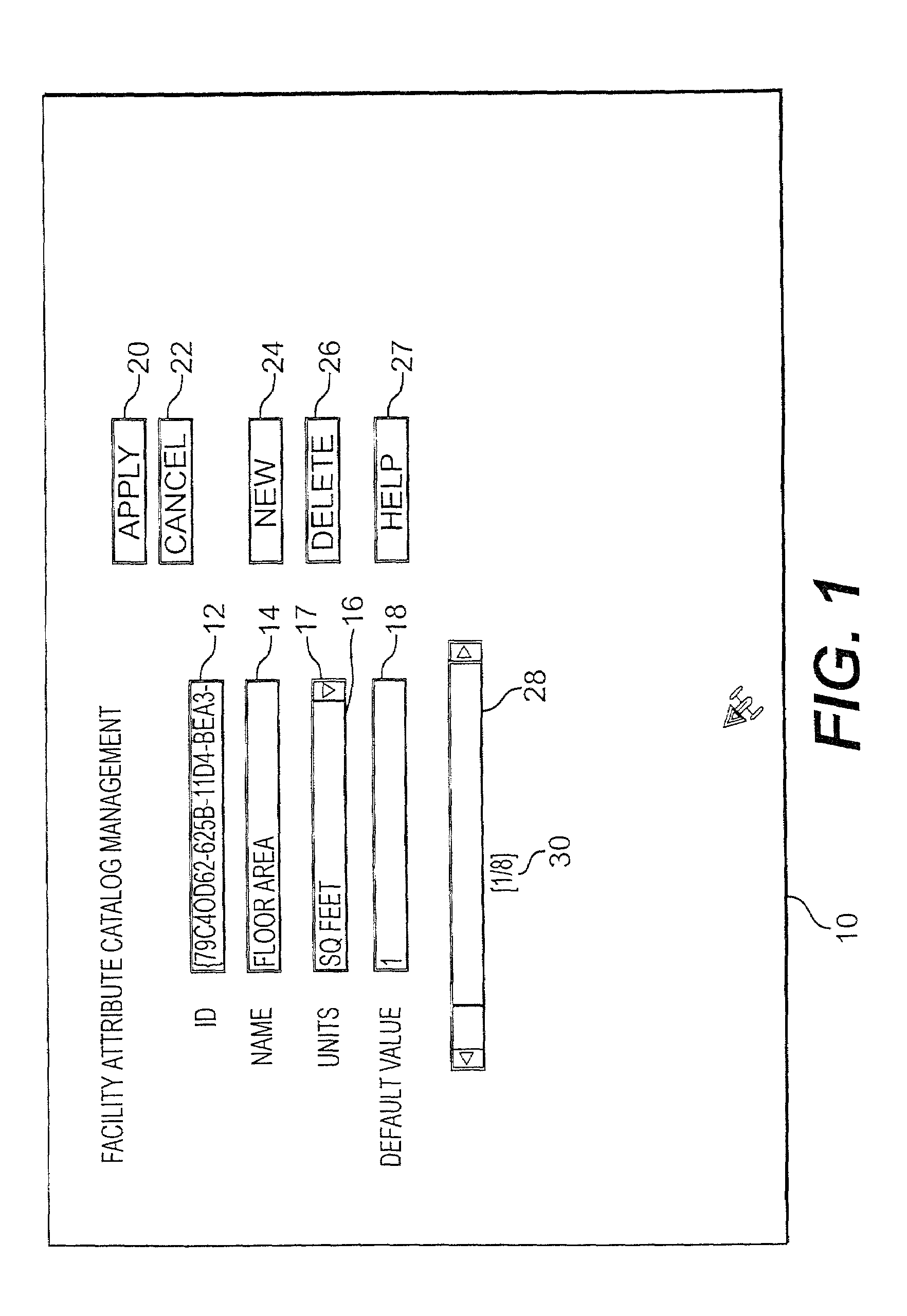

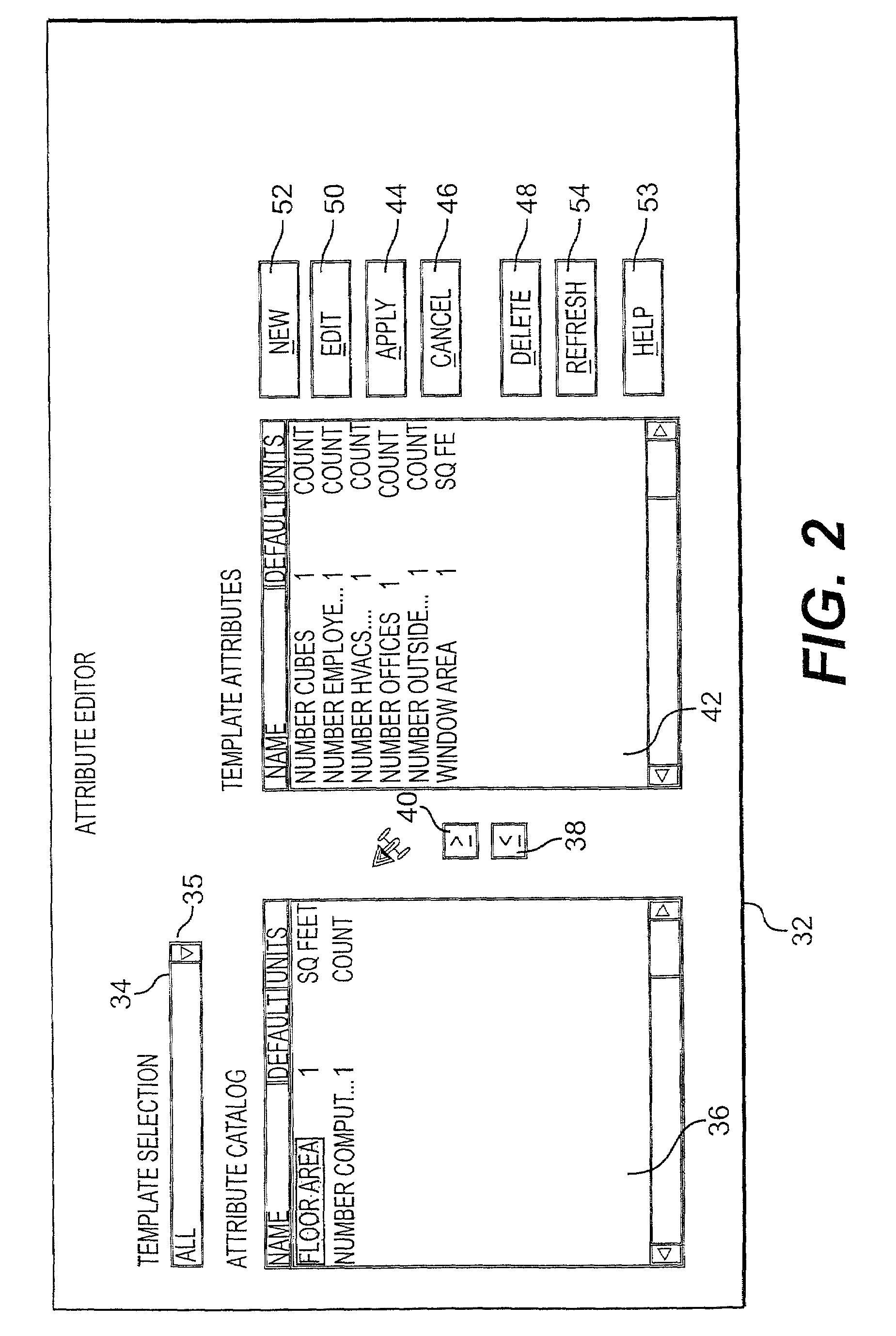

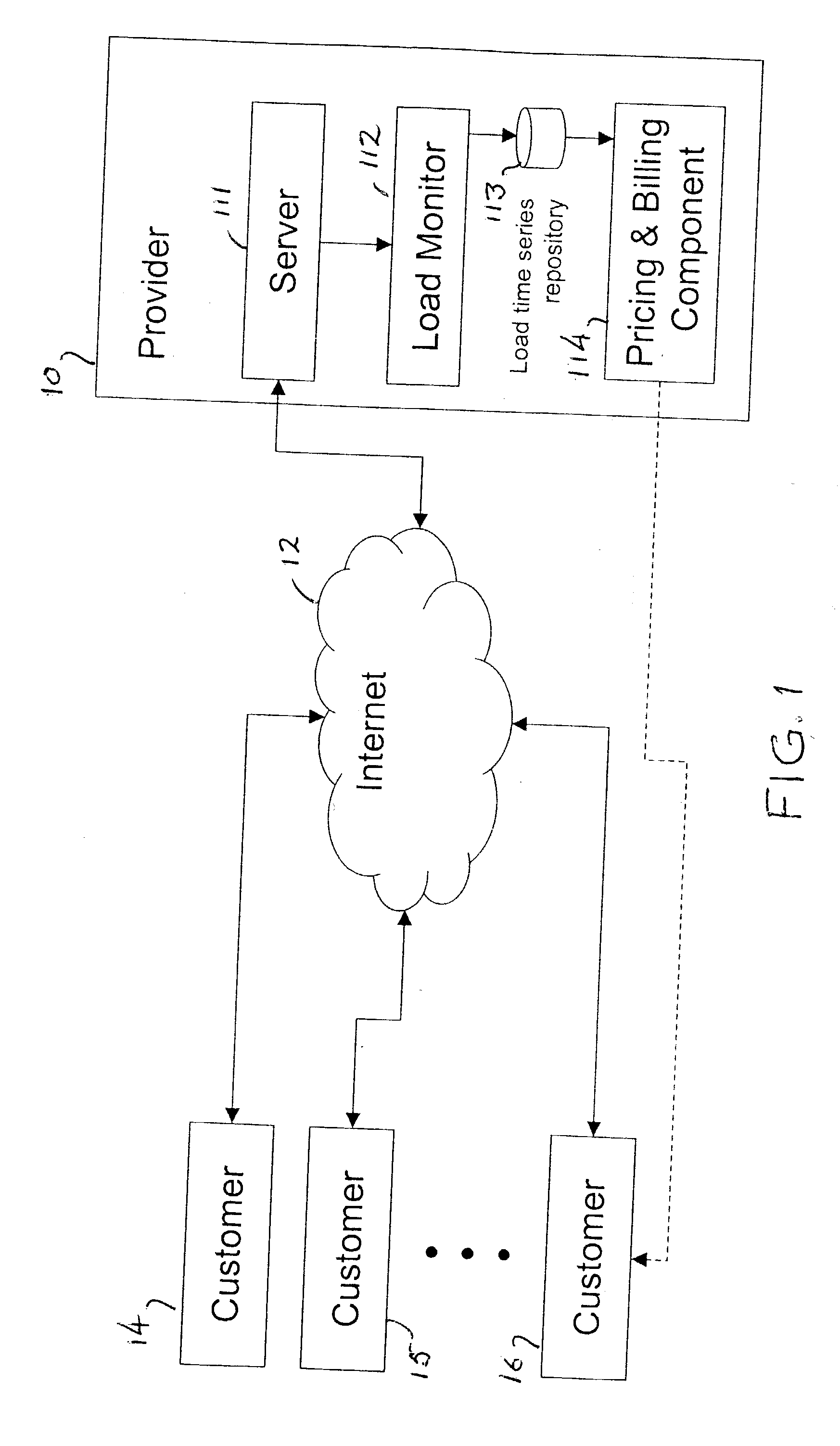

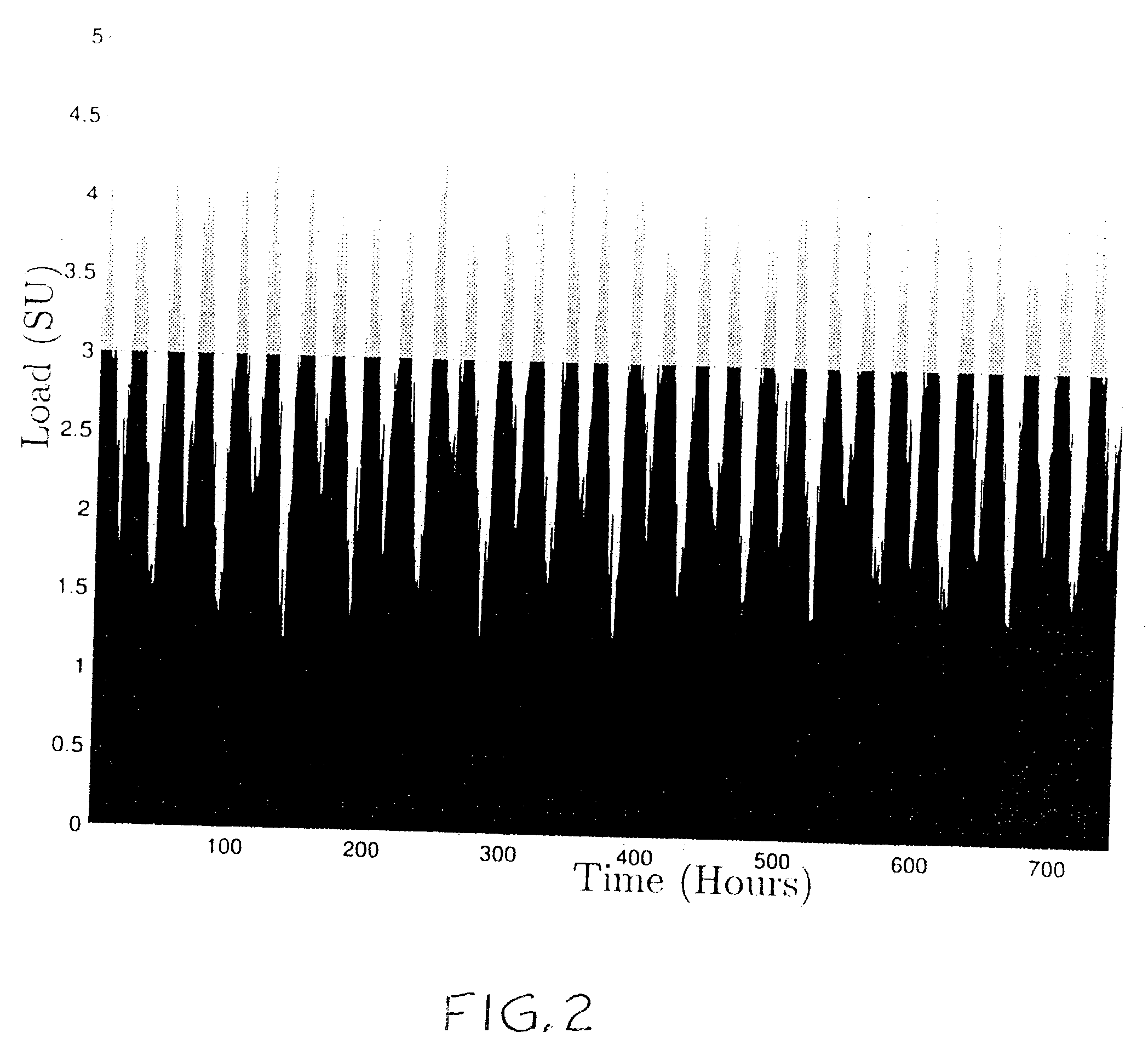

System and method for creating dynamic facility models with data normalization as attributes change over time

InactiveUS7219069B2Reduce resource consumptionCost-effectivelyResourcesSpecial data processing applicationsData setLoad profile

Users desire to normalize raw data from meter load profile acquisition systems against some attributes (i.e., properties) of a facility, such as the number of employees. The facility area, and the number of products produced would be additional potential attributes for consideration. Normalization involves dividing a load profile channel such as kiloWatt hours by a determined facility attribute to obtain a new data set, for example, such as “kWh / Employee.” The present modelization allows a user to define a set of attributes and manage their value over time to refine the facility model. Keeping track of the attributes over time provides increased accuracy in the resulting data. The model is managed by a user interface which can be refined over time as the facility evolves. Data comprising sets of attributes over time may persist within the system for later retrieval.

Owner:SCHLUMBERGER RESOURCE MANAGEMENT SERVICES

Internal combustion engine and operating method therefor

InactiveUS7597084B2Internal combustion piston enginesFuel injection apparatusGramExternal combustion engine

The present disclosure provides an engine operating method and high power density internal combustion engine, including an engine housing with a plurality of cylinders. Fuel injectors are provided and disposed at least partially within each cylinder, and configured to inject fuel such as diesel, JP8 or another fuel therein for compression ignition. The engine is configured to burn a quantity of injected fuel to yield at least about 150 horsepower per liter of engine displacement at a smoke output of less than about 0.4 grams, and in some cases less than about 0.75 grams, smoke per horsepower-hour, at a fuel consumption of less than about 250 grams fuel per kilowatt-hour output of the engine.

Owner:CATERPILLAR INC

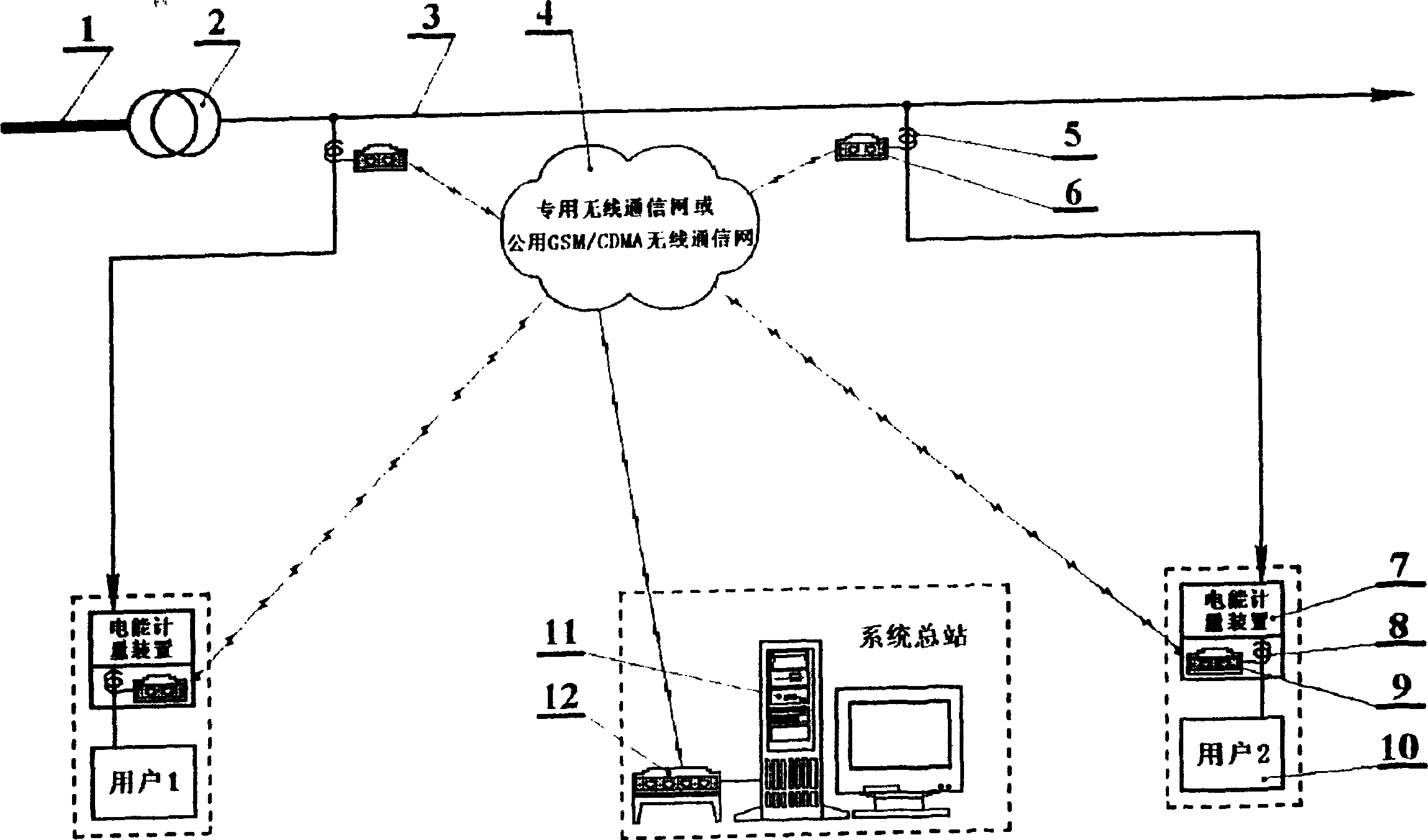

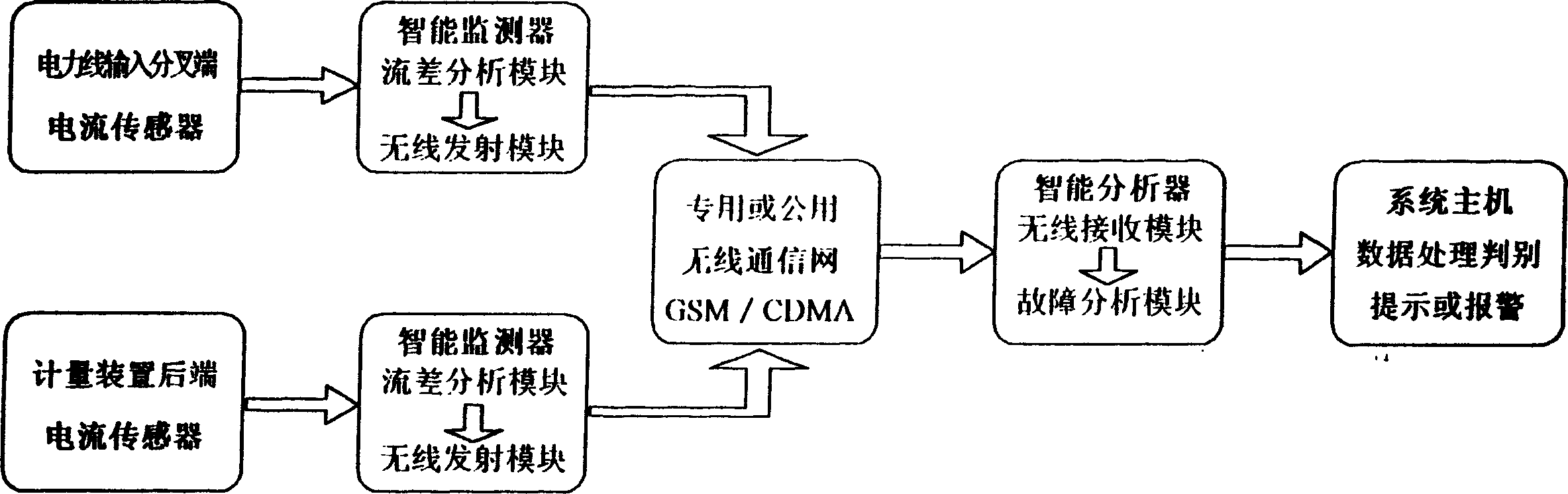

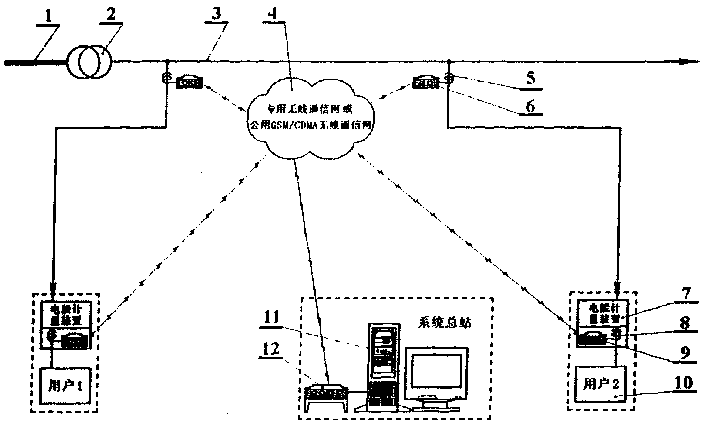

Failure analysis monitoring method and system device used on power supply network

InactiveCN1479107AReduce the likelihood of damageCall the police quicklyFault locationCurrent sensorMaster station

A method and system for monitoring and analyzing the failure of power supply network is disclosed. Said method includes such steps as installing the current sensors respectively at the input branch terminal of power transmission line to be monitored and the outlet terminal of user's electric kilowatt-hour meter, using intelligent monitor to calculate the current difference, transmitting the result to master station, analyzing data, drawing the current difference-time chart, and failure analysis while warning or alarming.

Owner:WAHLAP TECH CO LTD

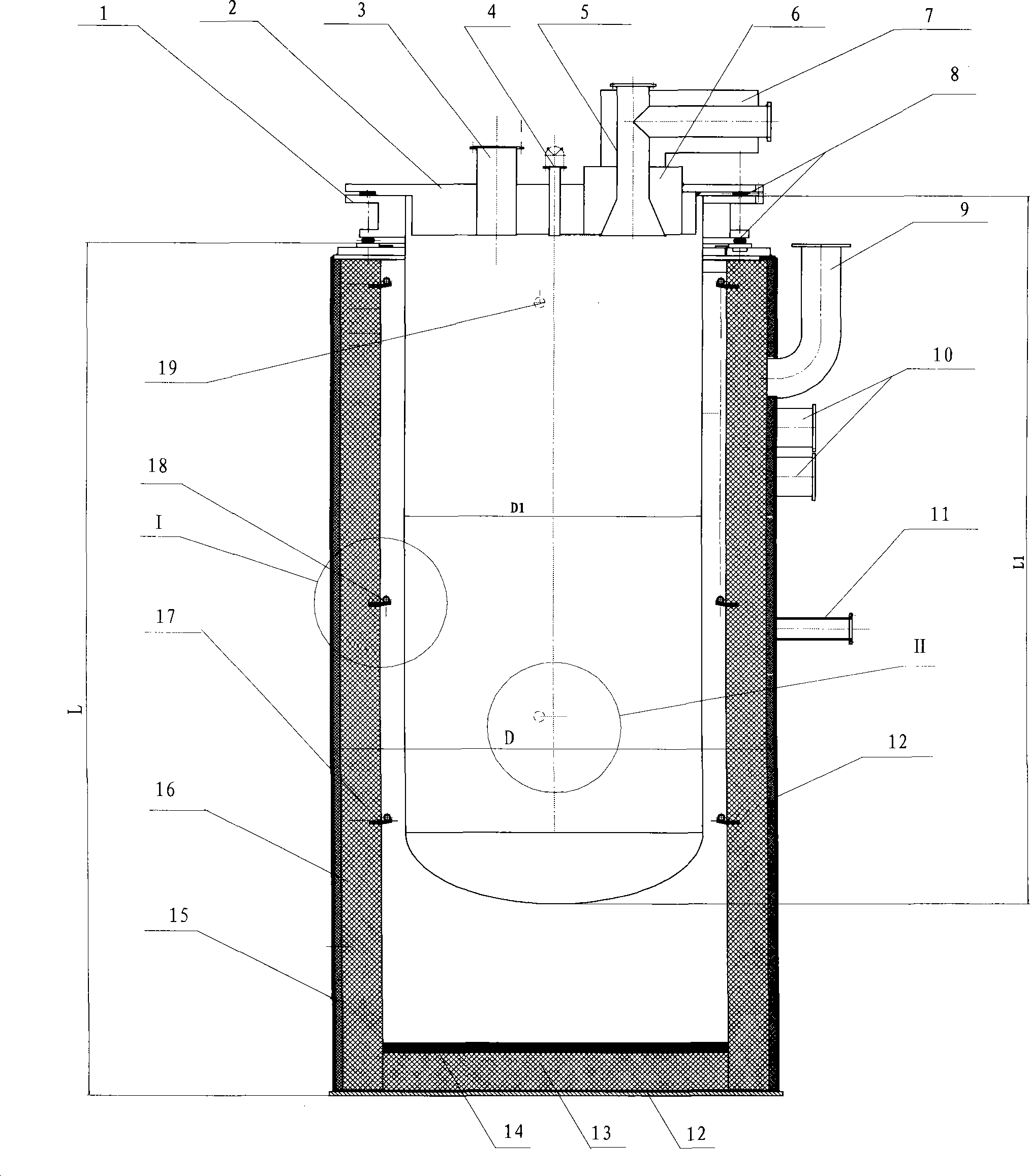

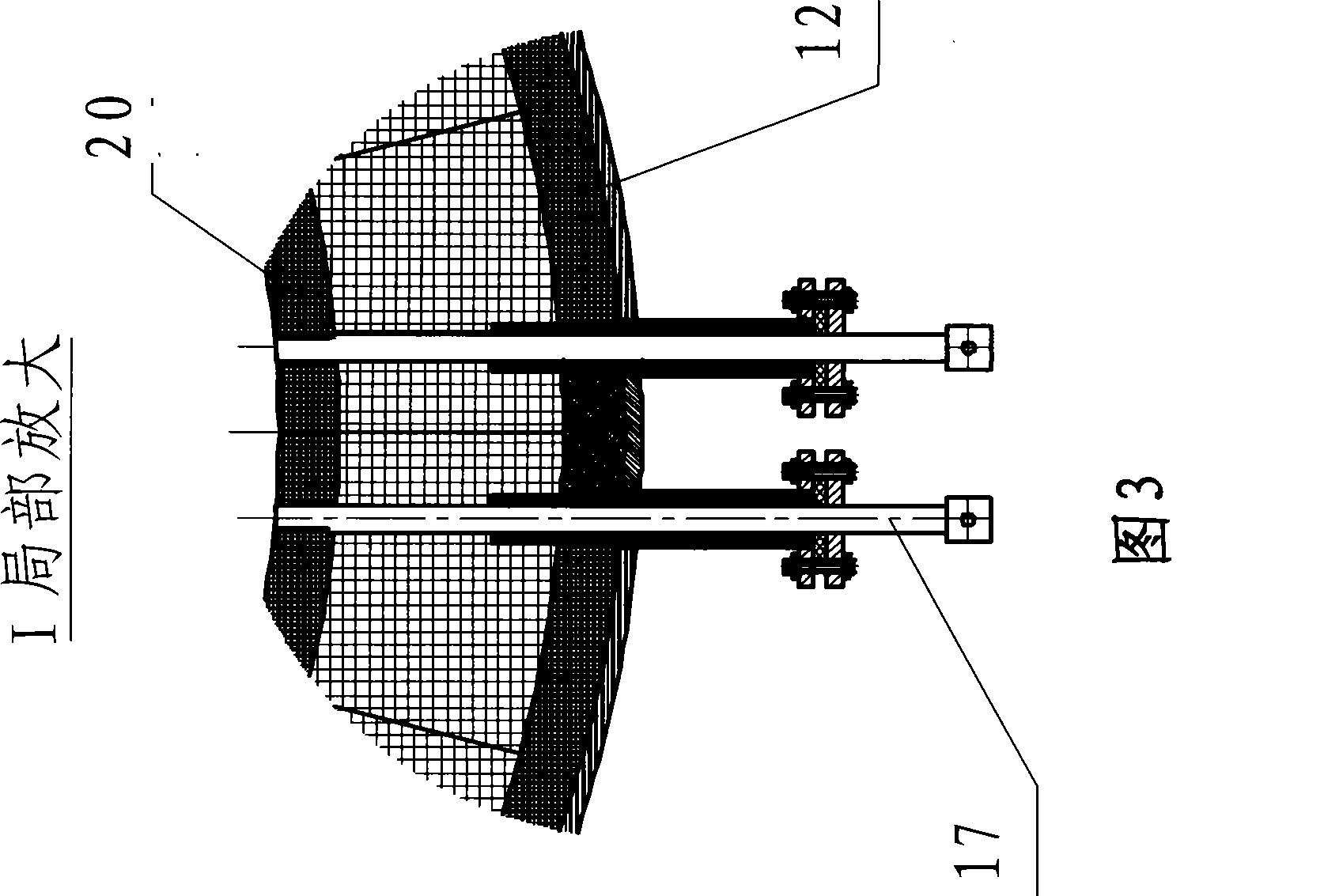

Titanium sponge 10-ton reduction-distillation furnace

The invention relates to a combined reduction steam furnace of 10 tons of sponge titanium, which mainly consists of a U-typed reactor 1, a reaction cover 2, a furnace body 16 and a conductive device 17. The ratio of the length to the diameter of the U-typed reactor is 2.43 and the ratio of the length to the diameter of the furnace body is 1.94; the U-typed reactor is vertically arranged in the furnace body; the flange of the U-typed reactor is arranged on the furnace body and sealed by a sealing ring 8; and the upper end of the U-typed reactor is covered by the reaction cover. When a magnesium reduction method is used for producing the sponge titanium, magnesium and titanium tetrachloride carry out reduction reaction in the reactor; the produced heat is transferred into a hearth by the wall of the reactor; the plugs of an air inlet / outlet pipe 10 are opened according to the setting of the temperature; and excess heat is discharged by an air outlet pipe 9. Heat radiation realizes heat exchanging according to the convection principle of cold air and the wall of the reactor. The electric consumption is 6500KWh per ton of titanium, each ton of products reduce the electricity by more than 1500 to 2000 kilowatt hour, the argon reduces the pressurizing time by 1 to 2 hours, the productivity is improved by 90 percent and the economic effect is very obvious.

Owner:洛阳双瑞万基钛业有限公司

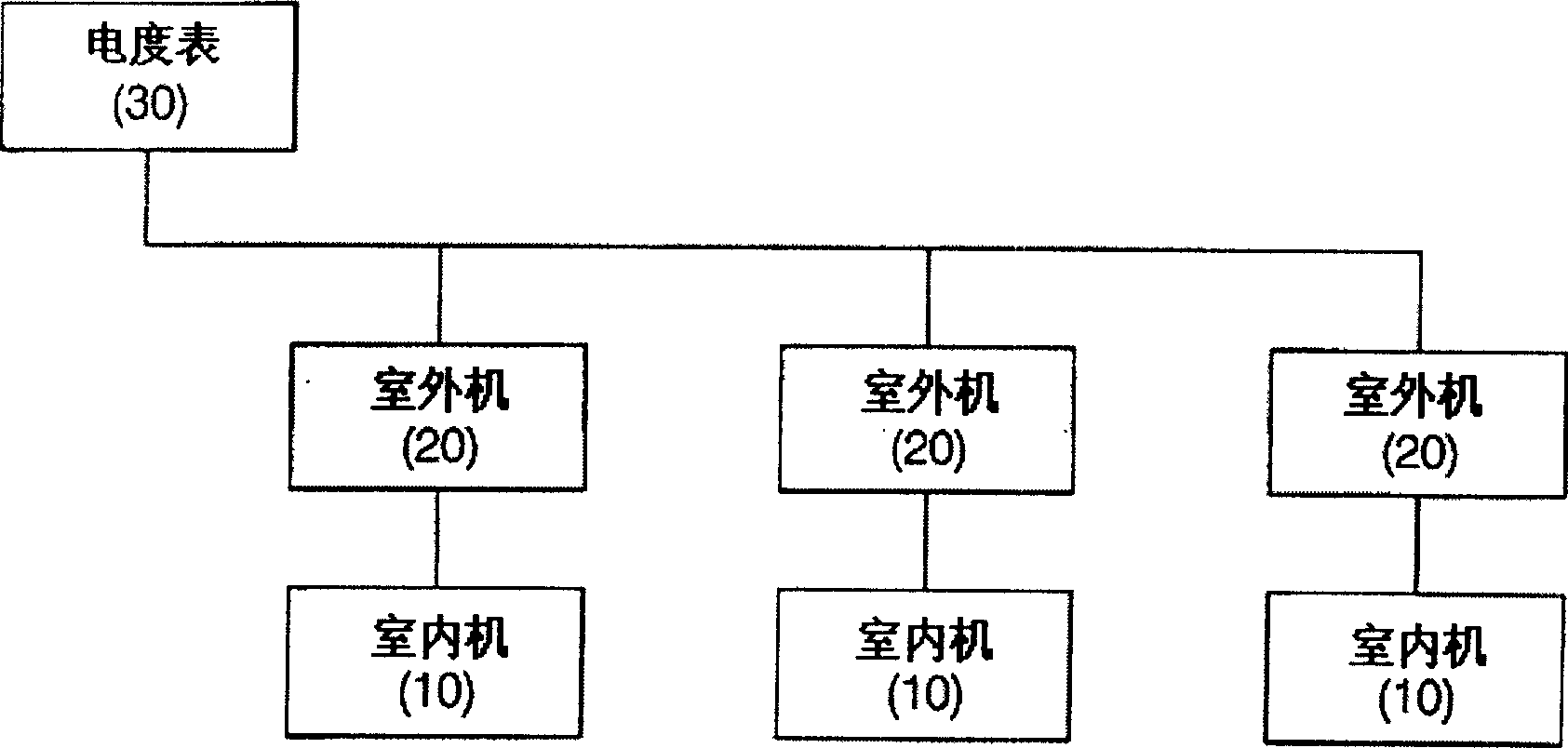

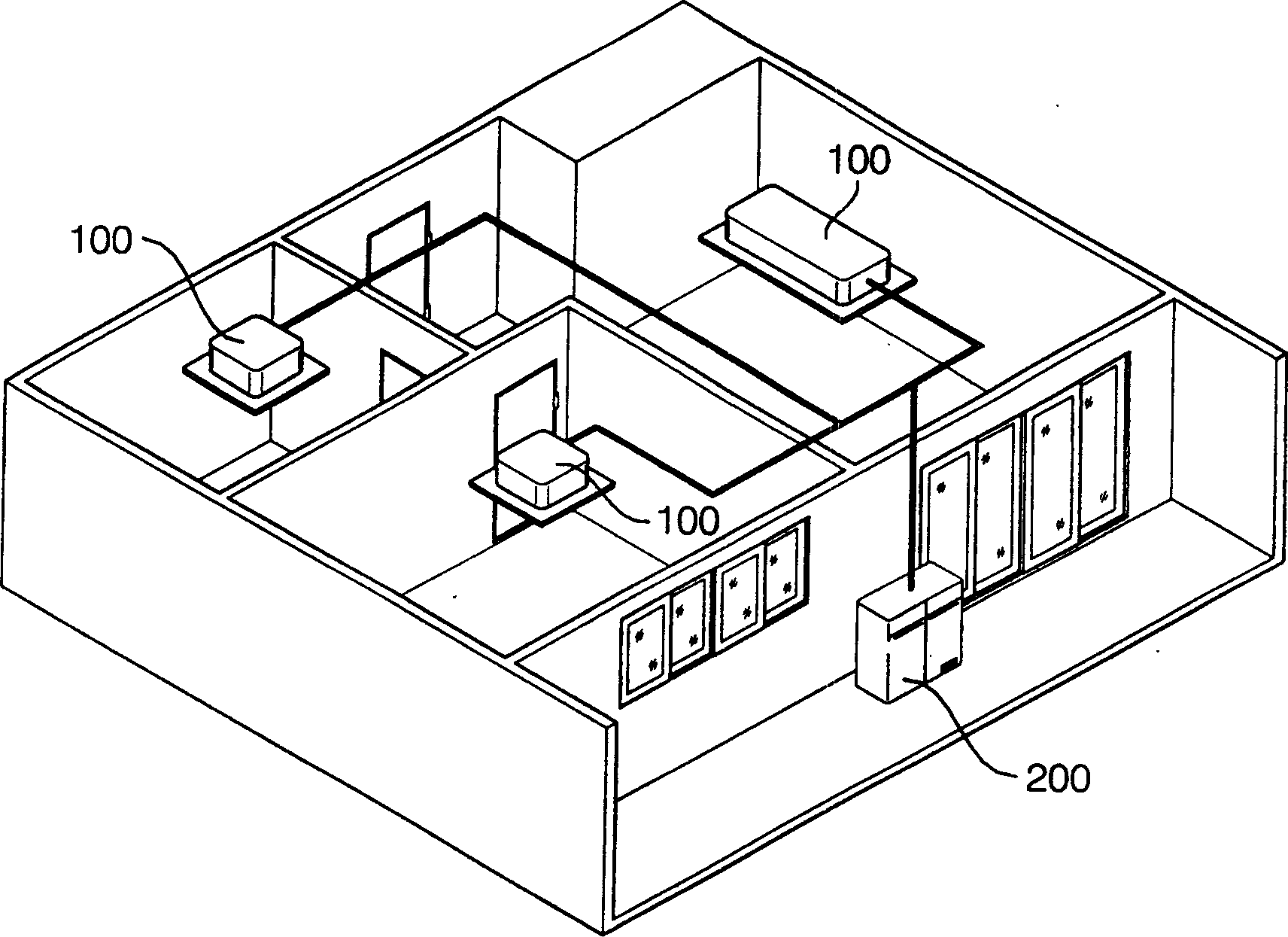

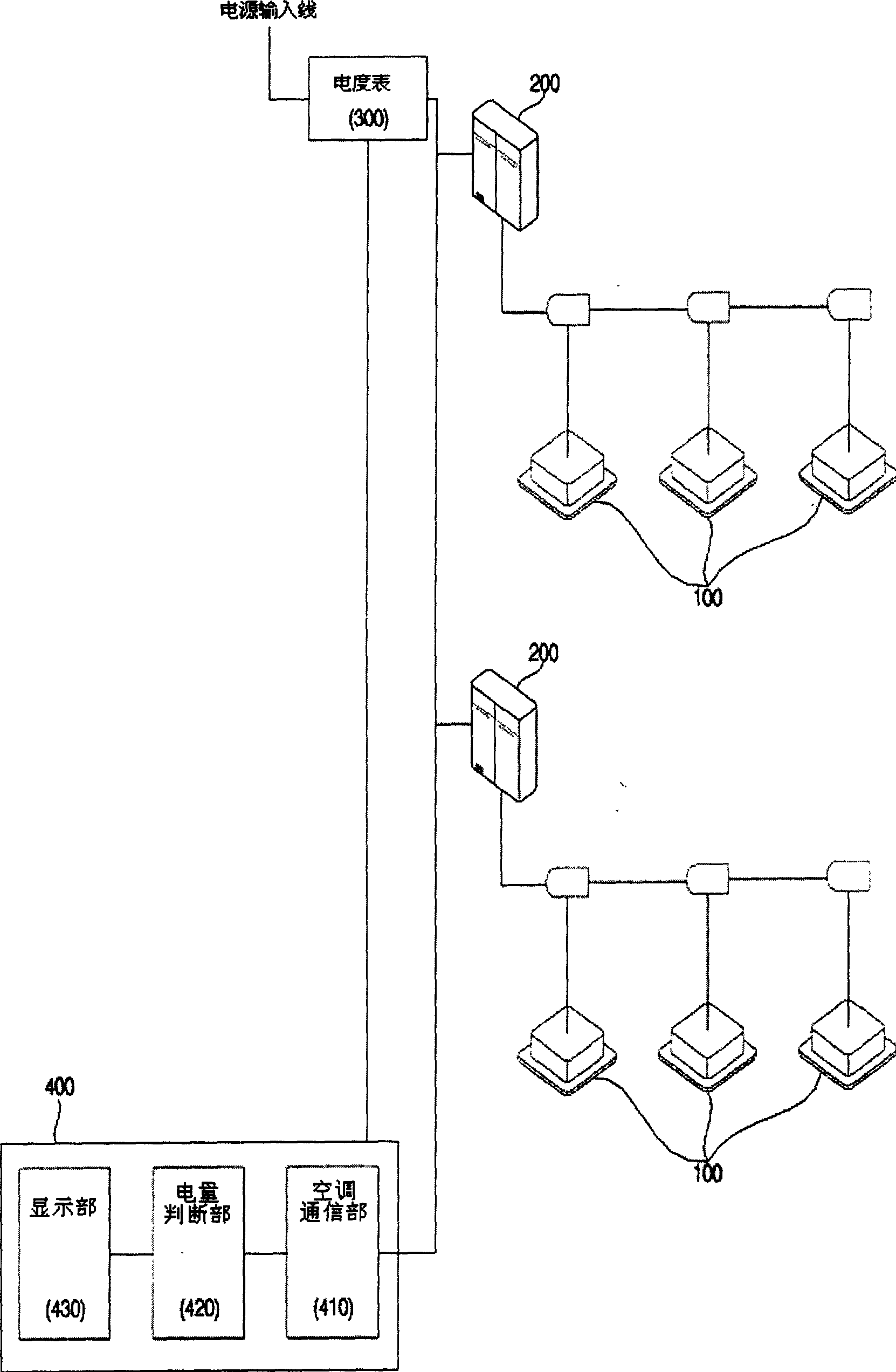

Air conditioning system with plural indoor units and its operation

InactiveCN1712843AEffective Power ManagementSpace heating and ventilation safety systemsLighting and heating apparatusDisplay deviceElectric consumption

An air conditioner system with multiple indoor units is composed of multiple indoor units, one outdoor unit shared by multiple indoor units, a kilowatt-hour meter for measuring the total electric consumption, and a display for displaying the electric consumption of each indoor and the total electric consumption of whole system. Its operation method is also disclosed.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

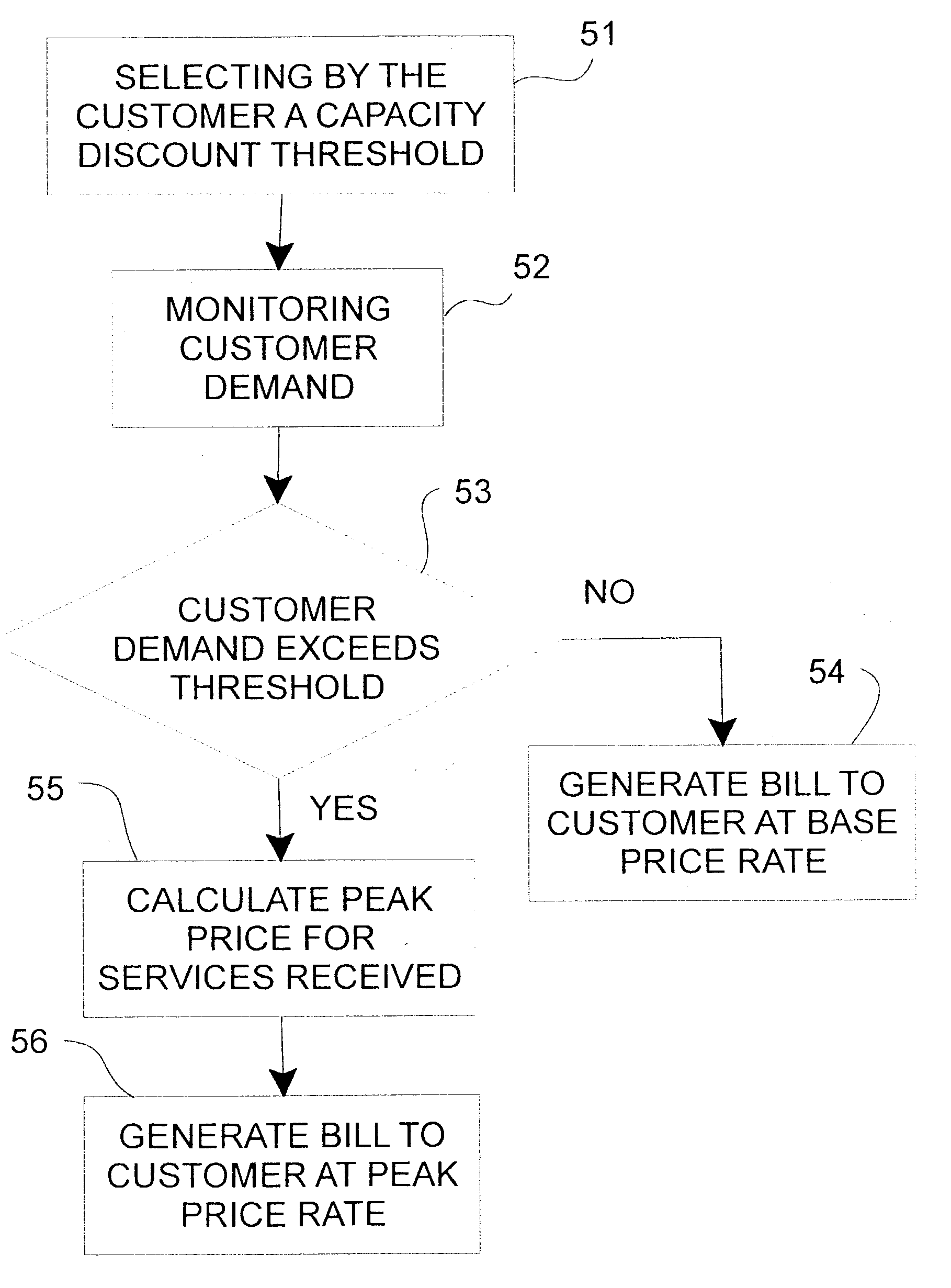

Method for design of pricing schedules in utility contracts

InactiveUS20040139037A1High possible utilitarian welfareElectric devicesSpecial tariff metersTime scheduleMegabyte

A provider of standardized services is provided with guidance on the design of pricing structures for contracts regulating the provision of a commodity good between a supplier and a customer. These are contracts characterized by long duration and dedicated infrastructure. The provision of the commodity good is variable over time, and the rate of provisioning is continuously monitored. Examples are kilowatt hours in the case of electric energy and megabytes / second in the case of Web hosting.

Owner:IBM CORP

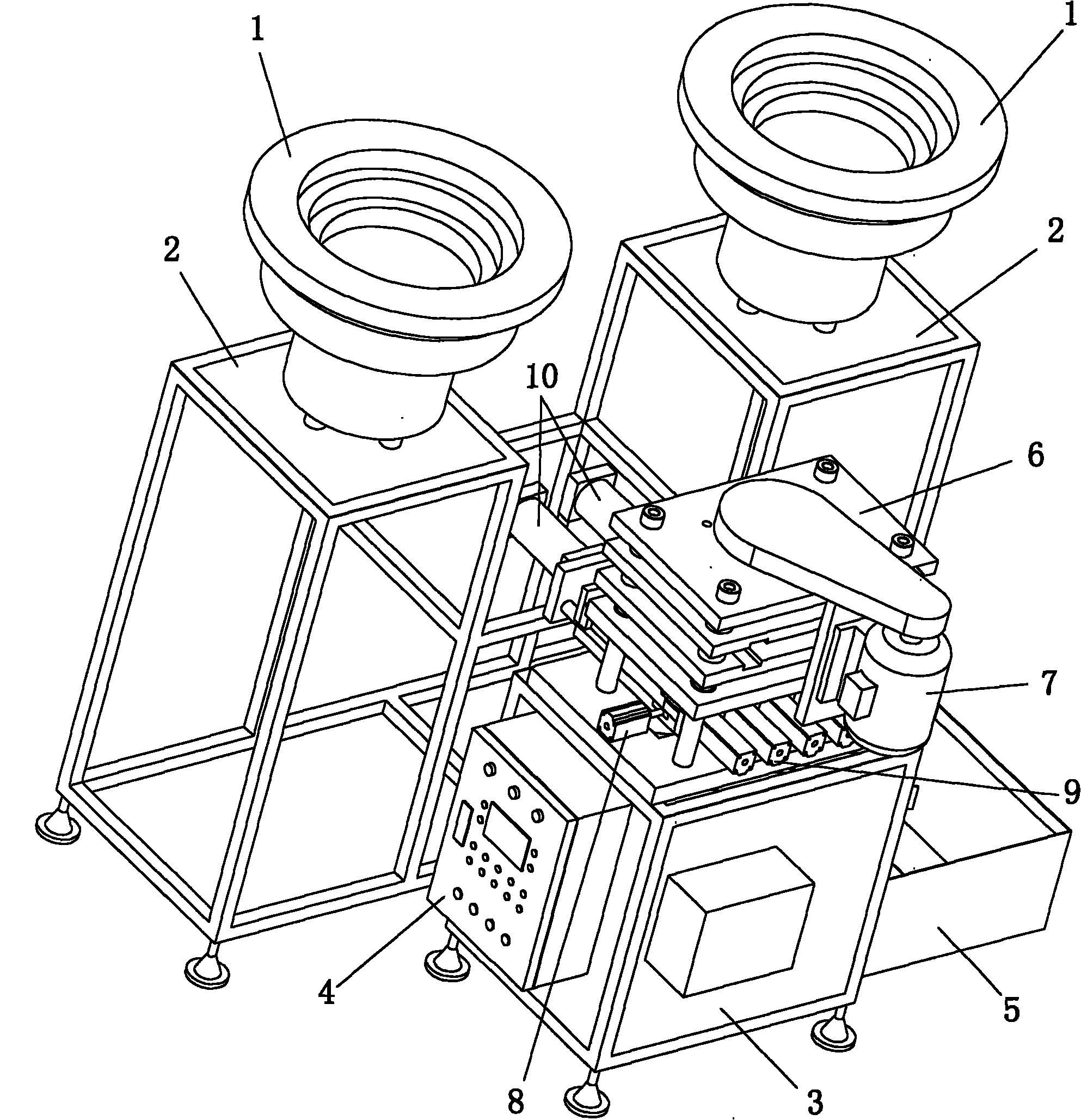

Multi-head fully-automatic feed tapping machine

ActiveCN101966612AReduce volumeIncrease productivityThread cutting feeding devicesThread cutting machinesProcess engineeringFully automatic

The invention discloses a multi-head fully-automatic feed tapping machine which comprises a feed part, a tapping part and a control part, wherein the feed part comprises a feed disk frame and a feed vibration disk, and a material delivery pipe is arranged on the feed vibration disk; the feed vibration disk comprises a vibration host, an inner vibration disk and a product splitter plate; a tapping mechanism and a motor of the tapping part are arranged on a host frame, and a clamping mechanism is arranged below the tapping mechanism; the motor is connected with the tapping mechanism, and the material delivery pipe is connected to the clamping mechanism; and a cooling oil channel is arranged below the clamping mechanism. In the invention, the clamping mechanism controlled through a vibration feed mechanism, hydraulic pressure and an air cylinder is matched with the multi-head tapping mechanism; on one hand, the volume of the whole machine is greatly reduced, and consumed materials are reduced; on the other hand, the production efficiency of the machine is greatly improved; by taking a frequently used eight-head mode as an example, 1,700 granules can be produced with each kilowatt-hour of electricity; and compared with the traditional technology, the electricity can be saved by more than 60 percent, and the working efficiency is improved by more than 7 times, thus the machine conforms to the requirement for energy saving and environmental protection and is beneficial to the popularization and the application.

Owner:江苏新岚实业有限公司

Waste heat cyclic utilization type high-efficiency energy-saving drying machine

The invention discloses an energy-efficient dryer featuring recyclable use of exhaust heat, comprising a high-temperature insulated cylinder assembly, a low temperature insulated cylinder assembly and a multi-source heat pump assembly. In the invention, the multi-source heat pump technology is adopted to improve heat efficiency, most importantly, previously unused hot air is used as a heat source, a heat absorption pipe coil is adopted to absorb heat in the hot air, meanwhile, moisture of the cooled hot air is condensed to water, as a result, the air is increasingly drier and the temperature is increasingly higher, when the temperature reaches the set value, a programming controller is adopted to regulate working frequency of a compressor via a frequency converter to keep the temperature optimal. By doing so, all driers can save electricity by over 80%, according to the annual consumption of 3 trillion kilowatt-hour of electricity for drying all objects in the world, if the electricity can be saved by 80%, then 2.4 trillion kilowatt-hour of electricity and 864 million tons of coal can be saved annually, which means carbon dioxide emission can be reduced by 1,468,800,000 tons.

Owner:凌建军

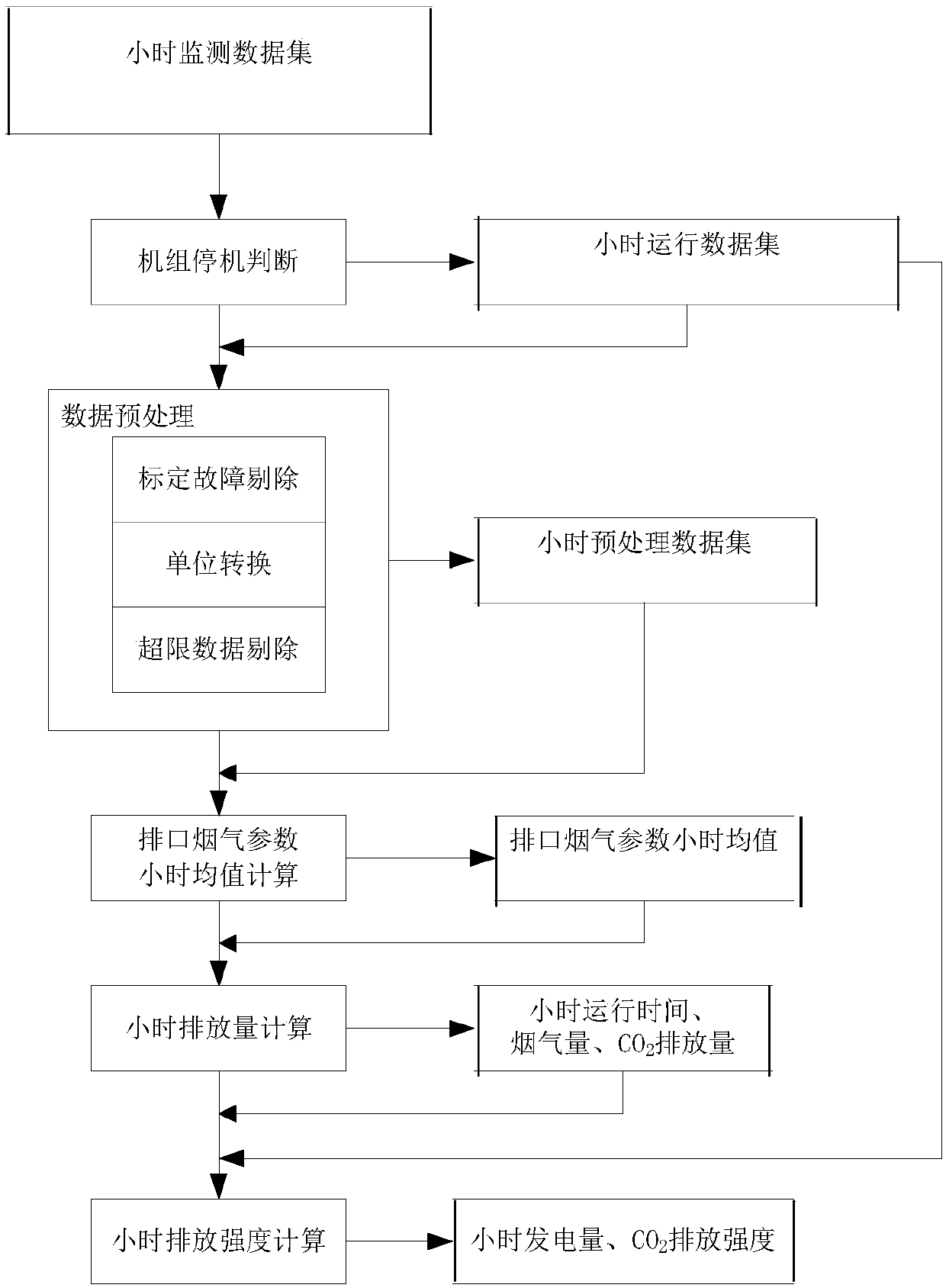

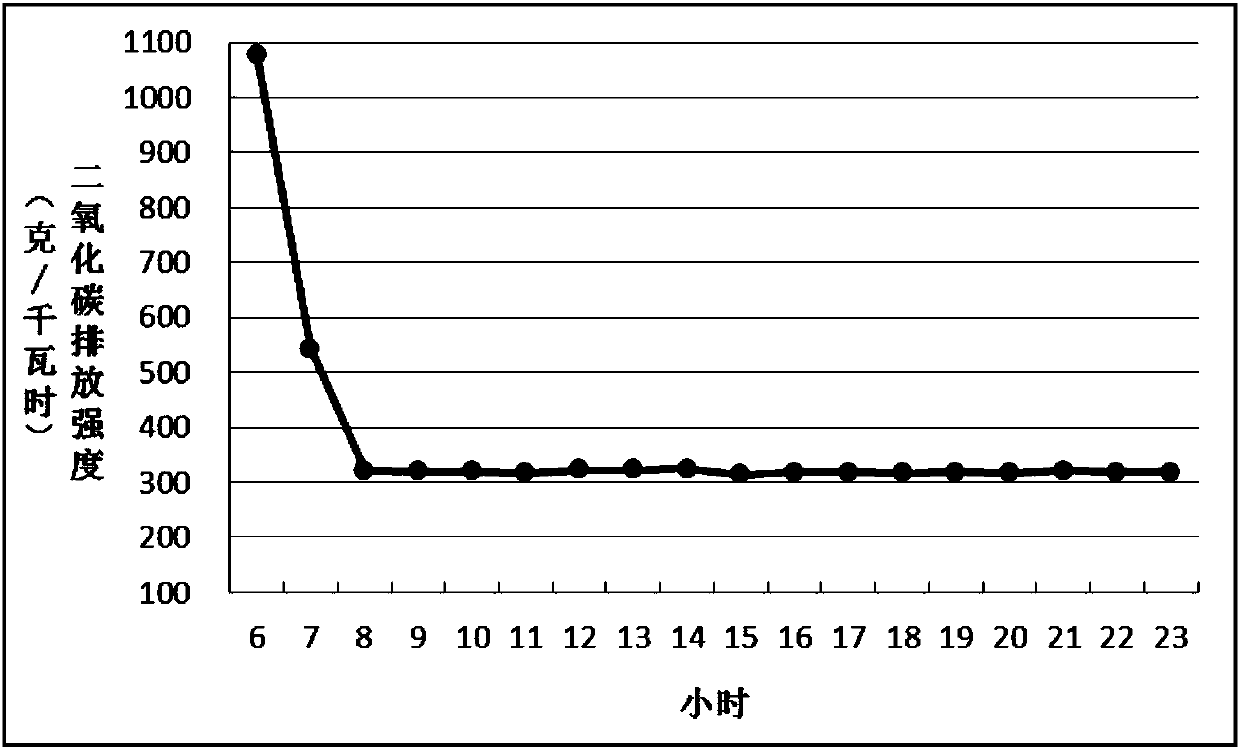

Thermal power generating unit carbon emission accounting method based on field monitoring data

InactiveCN108280047AImprove accuracyImprove timelinessAnalysing gaseous mixturesComplex mathematical operationsMeasuring instrumentData acquisition

The invention provides a thermal power generating unit carbon emission accounting method based on field monitoring data. The method comprises the following steps of 1, selecting monitoring points; 2,installing a CO2 measuring instrument at a thermal power generating unit chimney outlet; 2, collecting monitoring data, wherein the monitoring data monitored by a CEMS and the CO2 measuring instrumentwhich are arranged at the chimney outlet is transmitted to a main station after being collected by a data collection module, and is stored by the main station; 3, calculating the CO2 emission amountper hour, wherein one hour serves as a calculating cycle, the monitoring data collected within one hour serves as the basis, the halting data and ultralimit data in the data are removed, and then theCO2 emission amount per hour is calculated; 4, counting the CO2 emission amount, wherein the CO2 emission amount of the unit hour serves as the basis, and the summarizing value of the CO2 emission amount is obtained through a summing operation; 5, calculating the strength of CO2 emission, wherein the unit CO2 emission strength means the CO2 emission amount every time when the unit generates one kilowatt hour, namely the ratio of the CO2 emission amount within the duration to the power generation amount within the duration.

Owner:JIANGSU FRONTIER ELECTRIC TECH +2

Battery packs for vehicles and high capacity pouch secondary batteries for incorporation into compact battery packs

ActiveUS9083062B2Primary cell to battery groupingSmall-sized cells cases/jacketsHigh energyLithium-ion battery

High performance battery packs are described especially for use in electric vehicles and plug-in hybrid electric vehicles. Based on high energy lithium ion battery designs, the battery packs can have pairs of parallel connected batteries to supply an energy capacity at full discharge of at least about 40 kilowatt-hours or in alternative embodiments a set of all series connected batteries that can produce at full discharge at least about 15 kilowatt-hours. In some embodiments, lithium rich positive electrode active materials can be used to form the batteries in which the material comprises a composition approximately represented by a formula xLi2M′O3. (1−x)LiMO2 with x from about 0.05 to about 0.8.

Owner:IONBLOX INC

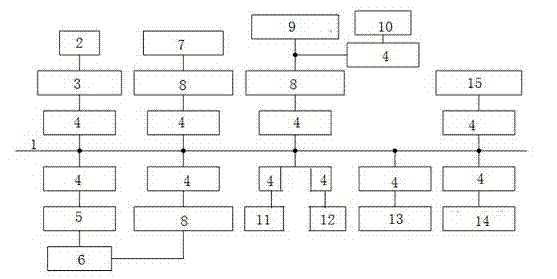

Laboratory microgrid system

ActiveCN102412578AFlexible AC transmissionSingle network parallel feeding arrangementsMicrogridSolar power

The invention discloses a laboratory microgrid system which can provide lots of theoretical and experimental bases for large-scale and high-efficiency utilization of renewable energy sources and construction of the microgrid in China. The laboratory microgrid system comprises a dummy bus; corresponding interconnection switches on the dummy bus are respectively connected with an analog wind power generation system, an analog solar power generation system, an analog generator system, an analog storage battery energy storage system, an analog load system and an analog electric power quality control system; the dummy bus is also connected with a power transmission network through a corresponding interconnection switch by virtue of a bidirectional kilowatt-hour meter; and thus the laboratory microgrid system is formed. A microgrid controller is connected with all the interconnection switches, carries out control operations according to one or more of grid-connected operation control strategy or stabilization control strategy during grid-isolated operation or active regulation and reactive optimization control strategy or grid-connected / isolated mode switching strategy or multi-power-supply coordination control strategy and energy optimal management strategy, and coordinates and controls a renewable energy source grid-connected device and an electric power quality control device so as to complete renewable energy source grid-connected harmonic suppression and voltage disturbance resistance.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

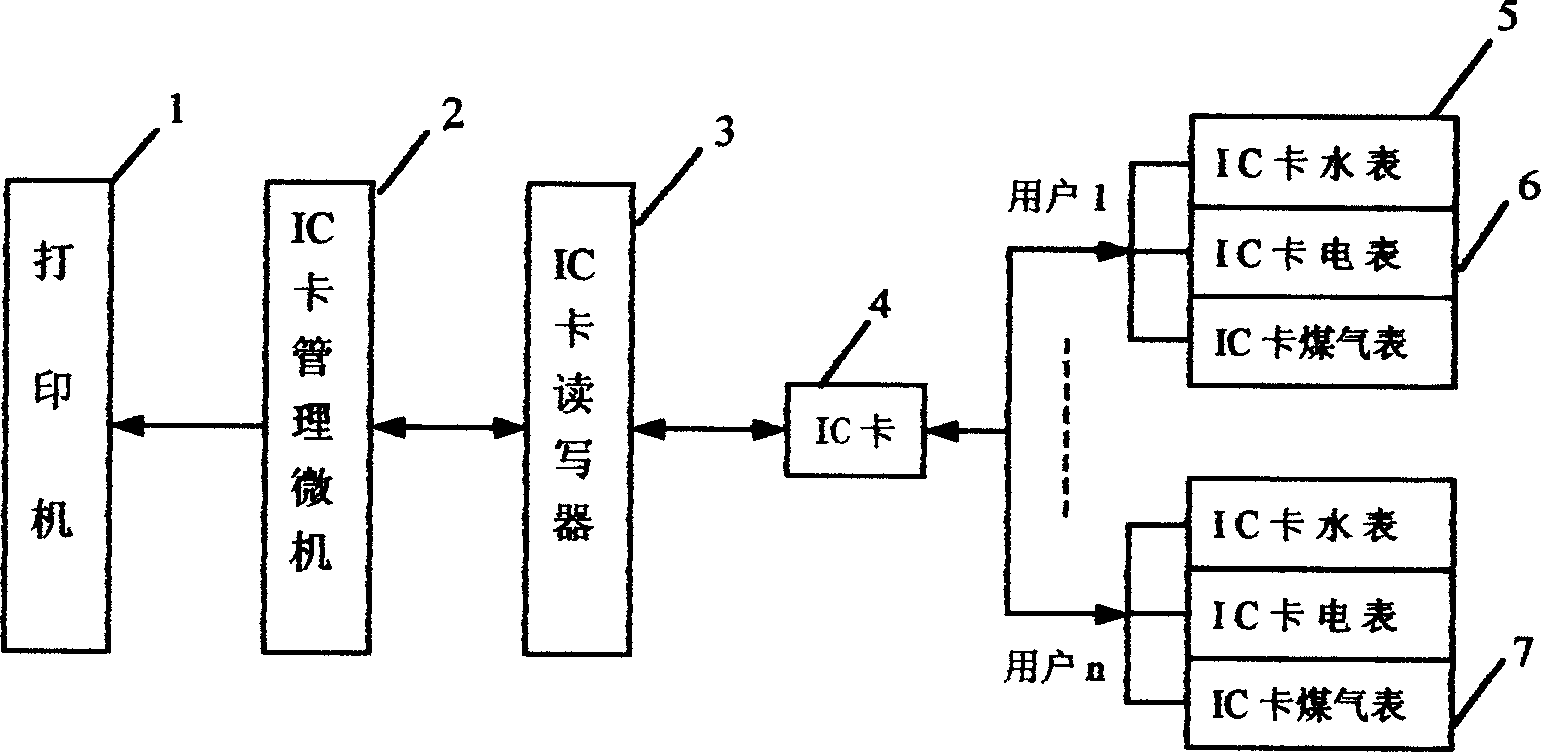

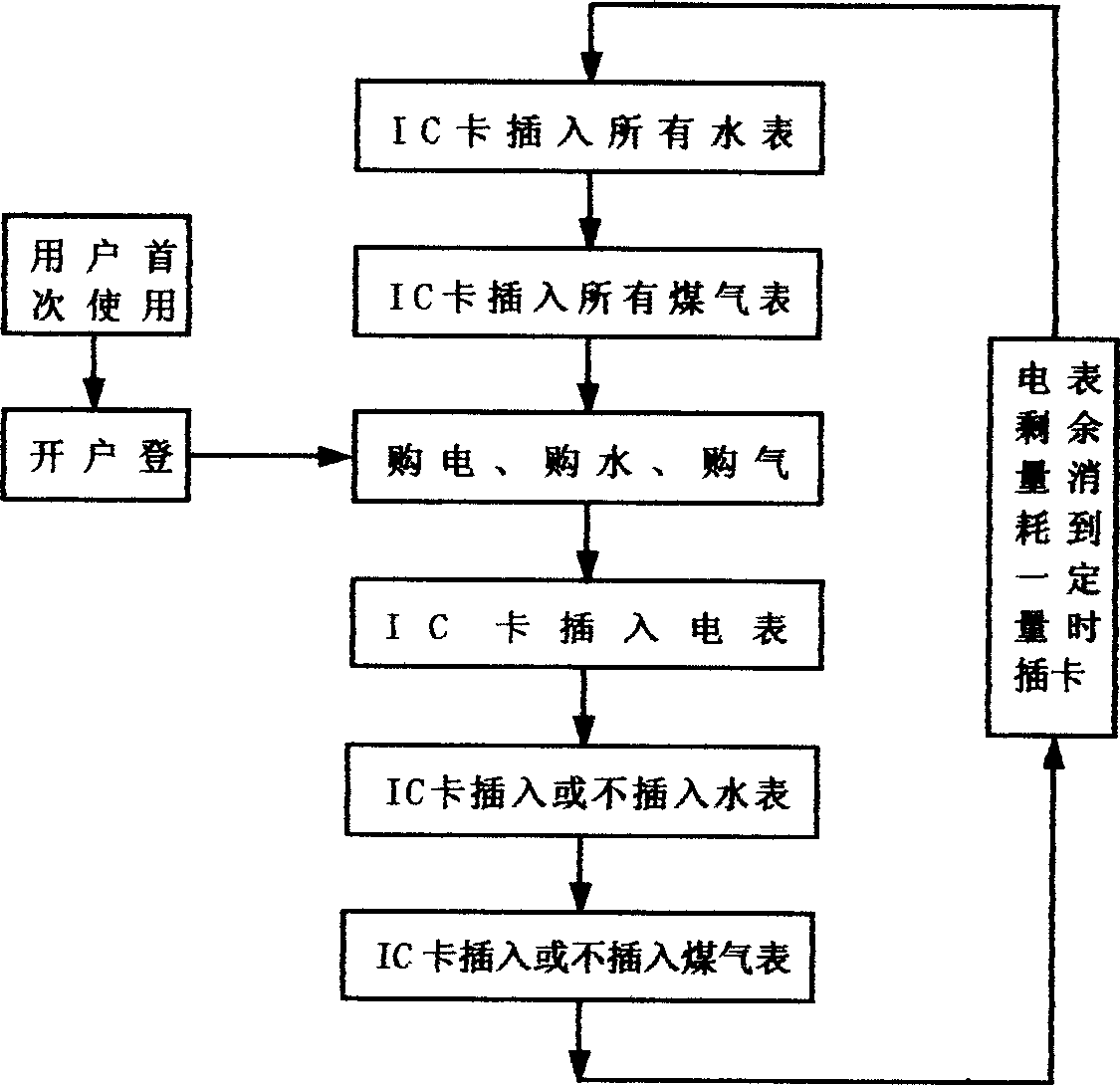

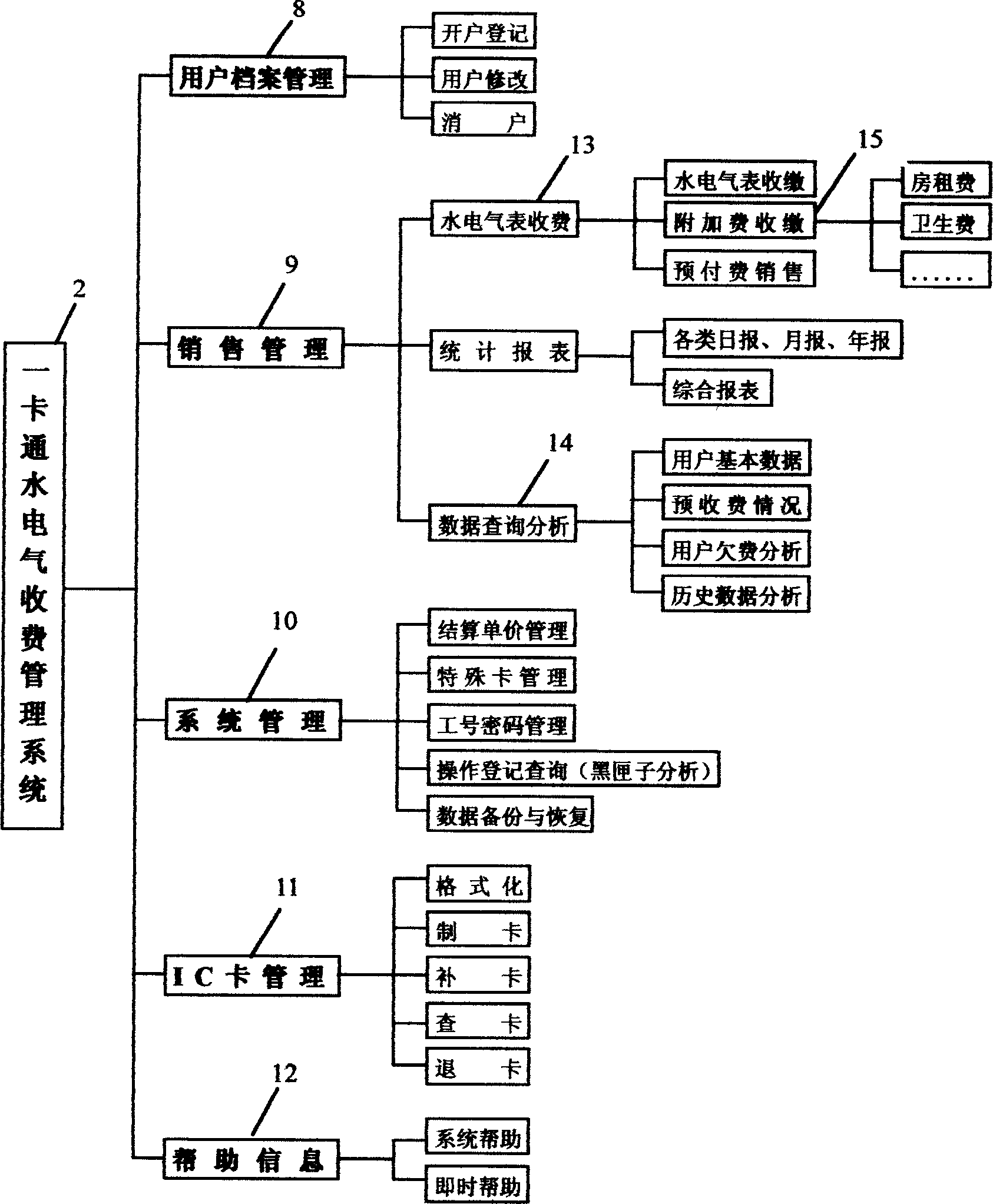

IC card water, electricity, gas 'one card for all' comprehensire chargeing management system

InactiveCN1475953ARealize charge managementAddress reliabilityMemory adressing/allocation/relocationSensing record carriersMicrocomputerCard reader

An integrated charge management system using IC card for water, electric and gas comsumptions is composed of IC card, the kilowatt-hour meter with IC card, IC card-type wate meter and gas meter, and a managing microcomputer with IC card reader, memory, comparing module and other modules. When the electric quantity bought by user has been consumed off, it is automatically cut off. The electric quantity can be bought again only after the fee for water and gas has been paid.

Owner:武汉阿迪克电子股份有限公司 +2

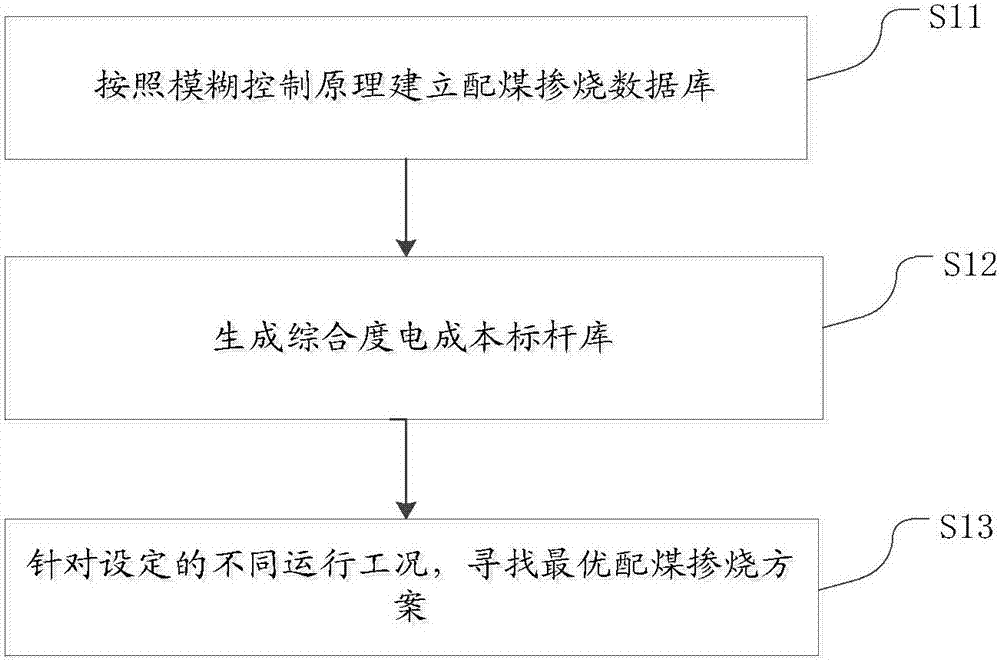

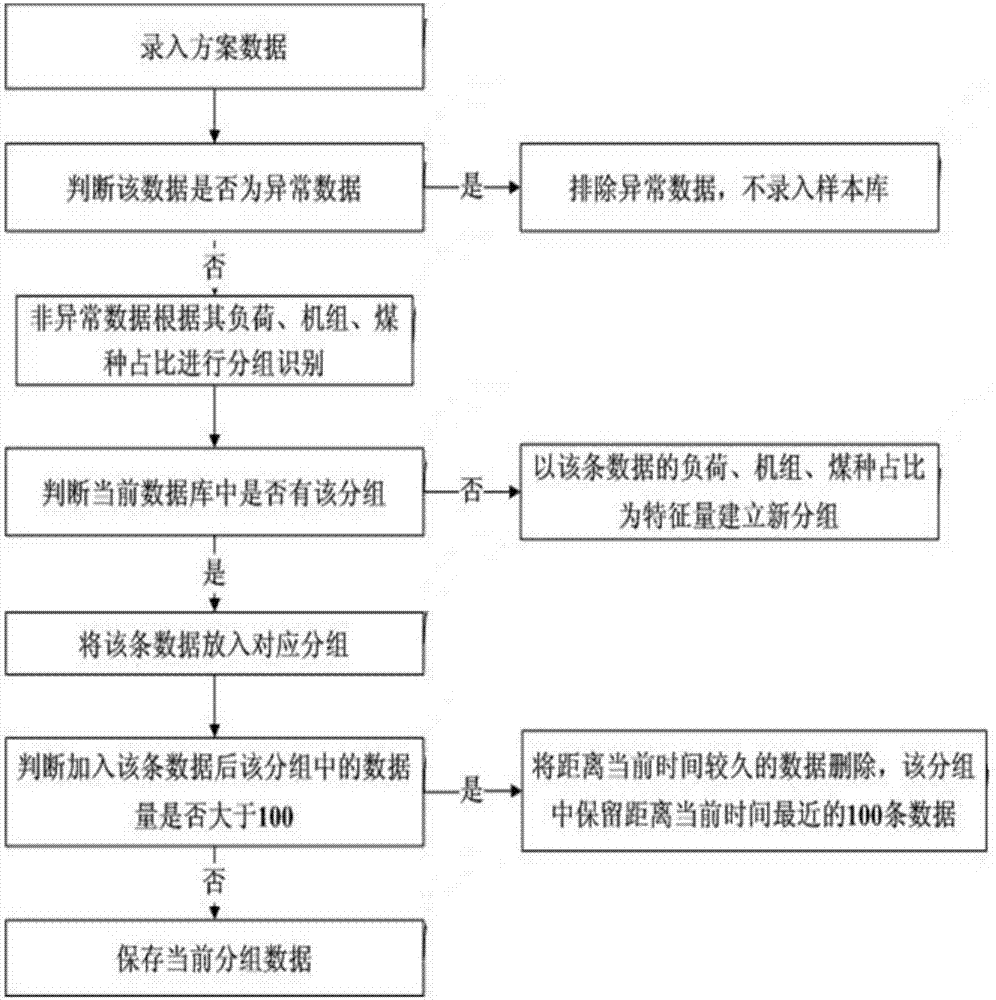

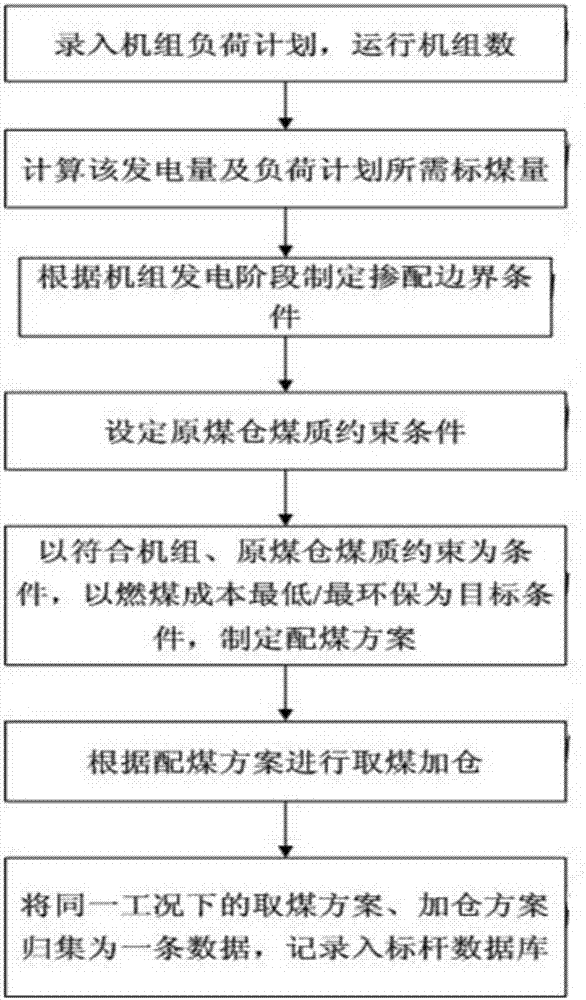

Multi-coal type blending combustion optimization method of coal-fired unit

InactiveCN107274027ALower coal costsSolve the problem of low combustion economyForecastingCombustionFuzzy control system

The invention discloses a multi-coal type blending combustion optimization method of a coal-fired unit. The method includes the following steps that: a coal blending combustion database is built according to a fuzzy control principle; a comprehensive cost per kilowatt hour benchmark library is generated; and an optimal mixed coal combustion scheme is searched according to different set work conditions. With the method adopted, the coal combustion cost of a power plant can be decreased.

Owner:HUNAN CHINA RESOURCES POWER LIYUJIANG CO LTD +1

Optimal selection method for wind generation sets in wind power farm

The invention discloses an optimal selection method for wind generation sets in a wind power farm. The method comprises the following steps of: (1) firstly, computing the annual equivalent full generation hours and the generating capacity coefficient of each alternative set of a proposed wind power farm, and computing difference kilowatt hour cost and full lifecycle difference kilowatt hour cost of each alternative set in the wind power farm according to a computational formula of the difference kilowatt hour cost and the full lifecycle difference kilowatt hour cost; (2) taking minimization of the expense of the kilowatt hour cost in the full lifecycle as the primary basis for making a decision, comparing the full lifecycle difference kilowatt hour cost of each alternative set, and selecting the alternative set with the minimal full lifecycle difference kilowatt hour cost as the determined set; (3) when the full lifecycle difference kilowatt hour costs of the alternative sets of different models are identical or approximate, selecting the set with lower difference kilowatt hour cost or the set with higher annual equivalent full generation hours and higher generating capacity coefficient. The method can effectively and quickly perform optimal selection on multiple models, thereby providing reliable basis for the developers to make decision on selection.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

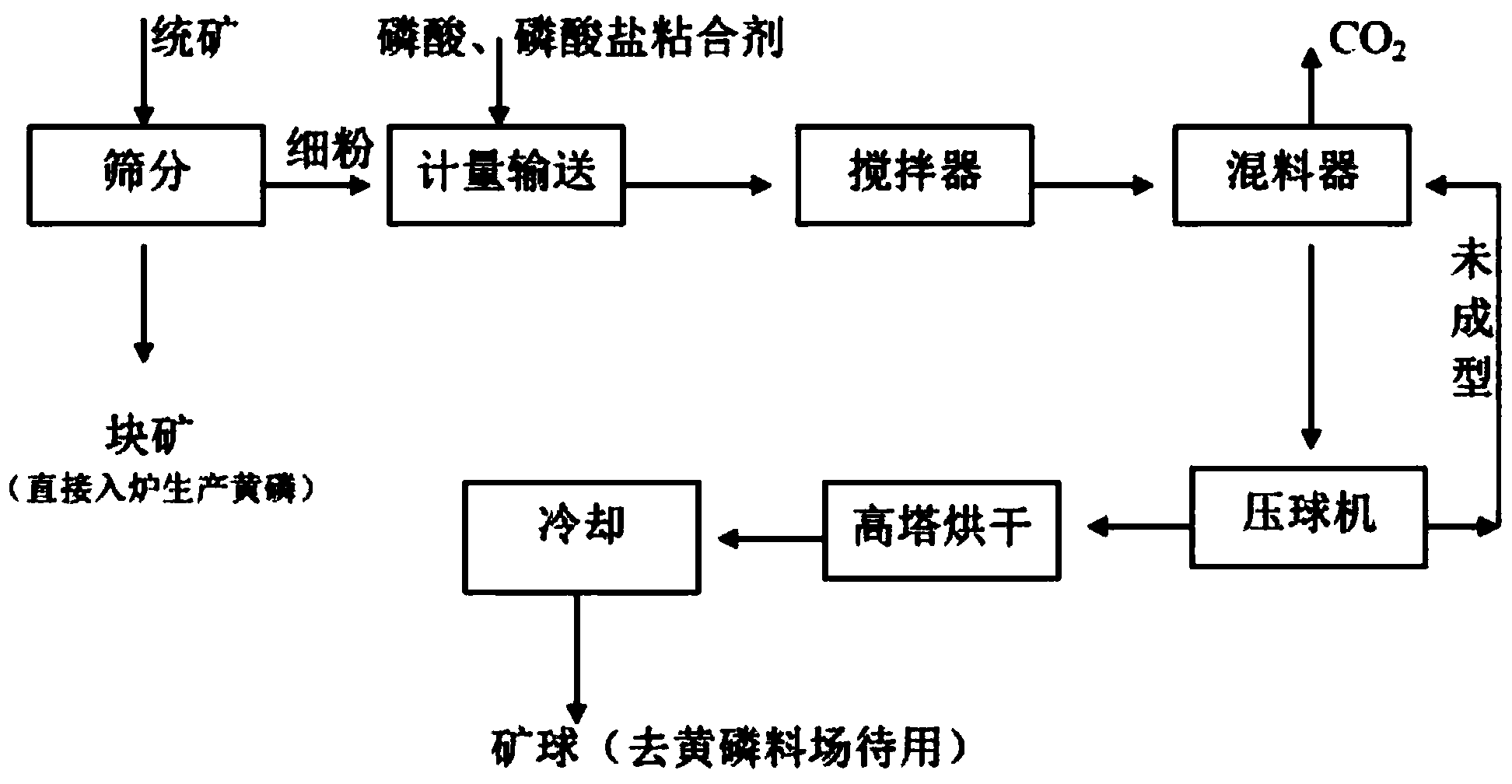

Method for producing powdered rock phosphate balls by using powdered rock phosphate

ActiveCN103964404AIncrease contentRaise the gradeRaw phosphate material treatmentCO2 contentCalcium Binder

The invention relates to the technical field of mineral processing, in particular to a method for producing powdered rock phosphate balls by using powdered rock phosphate screened out by enterprises or mineral powder left after mine production with low-concentration phosphoric acid. The method comprises the steps of screening, batching, mixing, ball pressing, drying and cooling; in the method, the content of P2O5 in phosphate rock is increased as a phosphate acid and phosphate binder is adopted and the P2O5 in the binder ultimately enters a furnace and participates the phosphorus producing reaction, and the quality of phosphate rock is improved; carbonate impurities in the added phosphoric acid and phosphate rock are subjected to chemical replacement reaction, and mixing is carried out by a double-roll mixer, so that carbon dioxide and organic matters harmful to the electric furnace during production can be fully released; in the production of yellow phosphor, the power consumption of the electric furnace can be reduced by 190 kilowatt hour as long as 1% of CO2 content is reduced, the consumption of coke can be reduced by 29 kilograms, and the production costs of the enterprises can be greatly reduced.

Owner:贵州福泉川东化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com