Patents

Literature

482results about How to "Consume energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

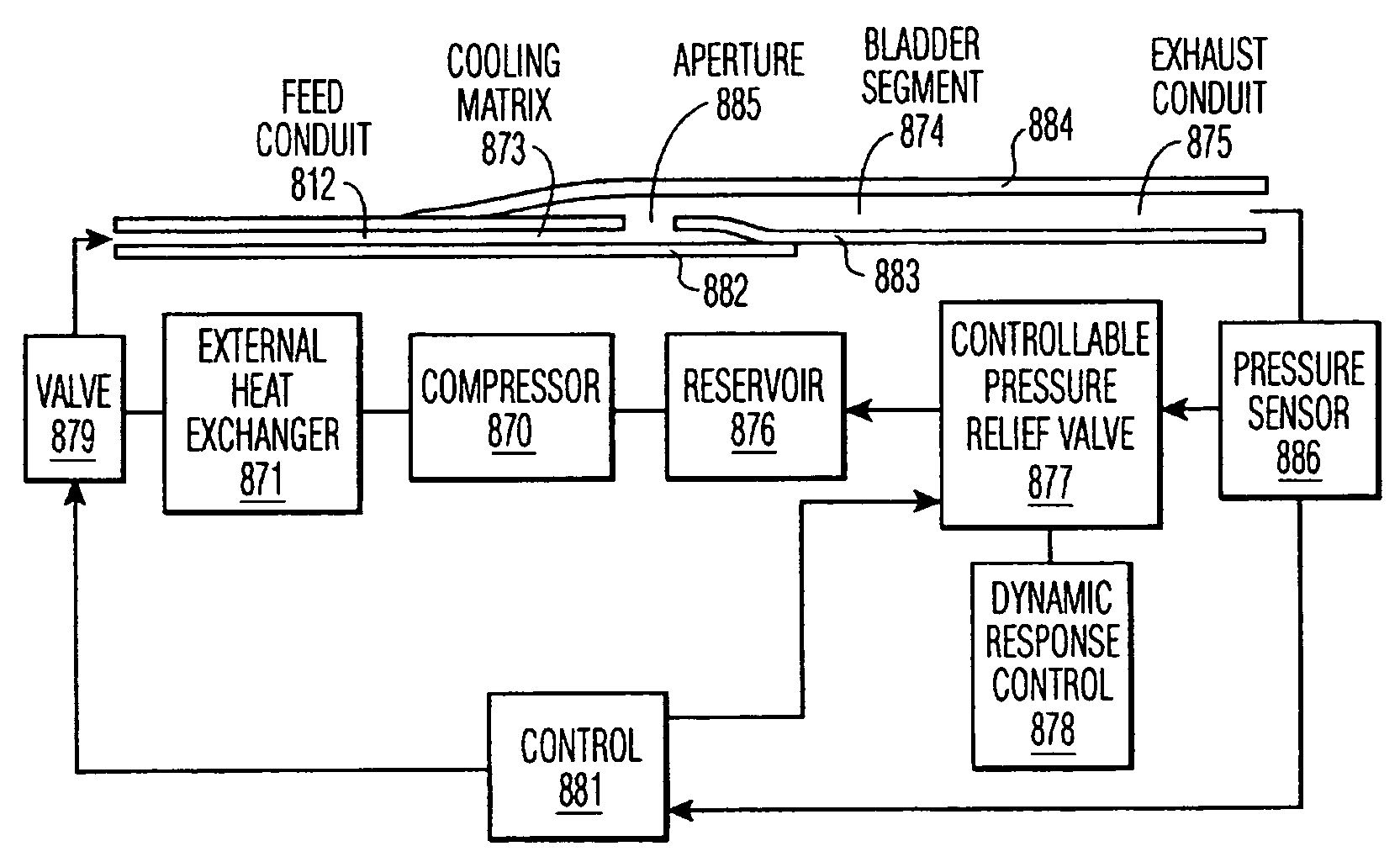

Adaptively controlled footwear

A method for controlling footwear, comprising cushioning a transient force during use of the footwear at a first period of a gait cycle, storing energy from said cushioning, and releasing the stored energy during use of the footwear at a second period of the gait cycle, and after said transient force has subsided. The control can be electronic, mechanical or hydraulic, and is preferably dependent on a sensed gait cycle phase. The control may be adaptive to the user or the use of the footwear. The stored energy can be used to assist in locomotion, to generate electrical energy, to drive a heat pump, or simply dissipated.

Owner:PROMDX TECH

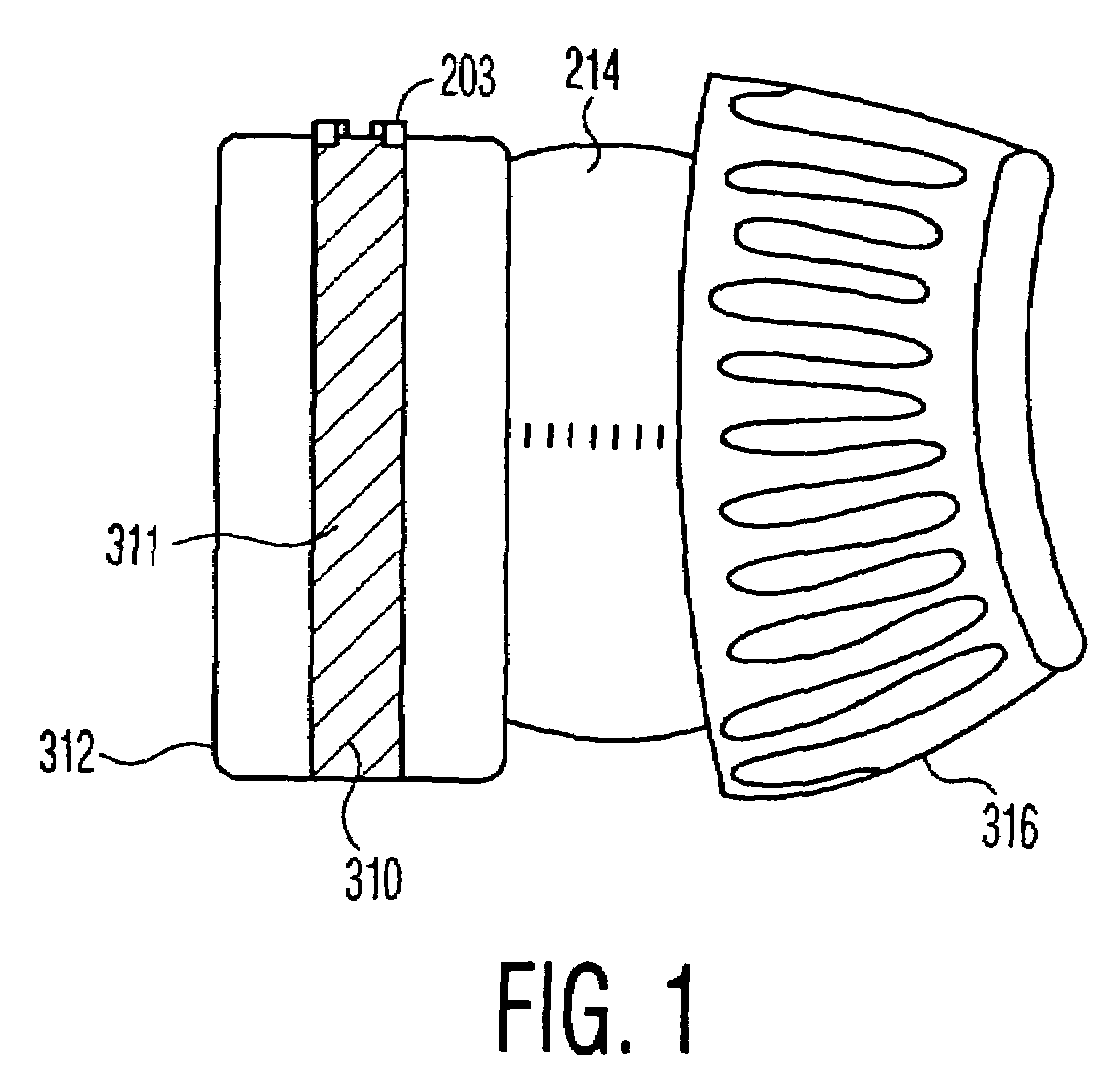

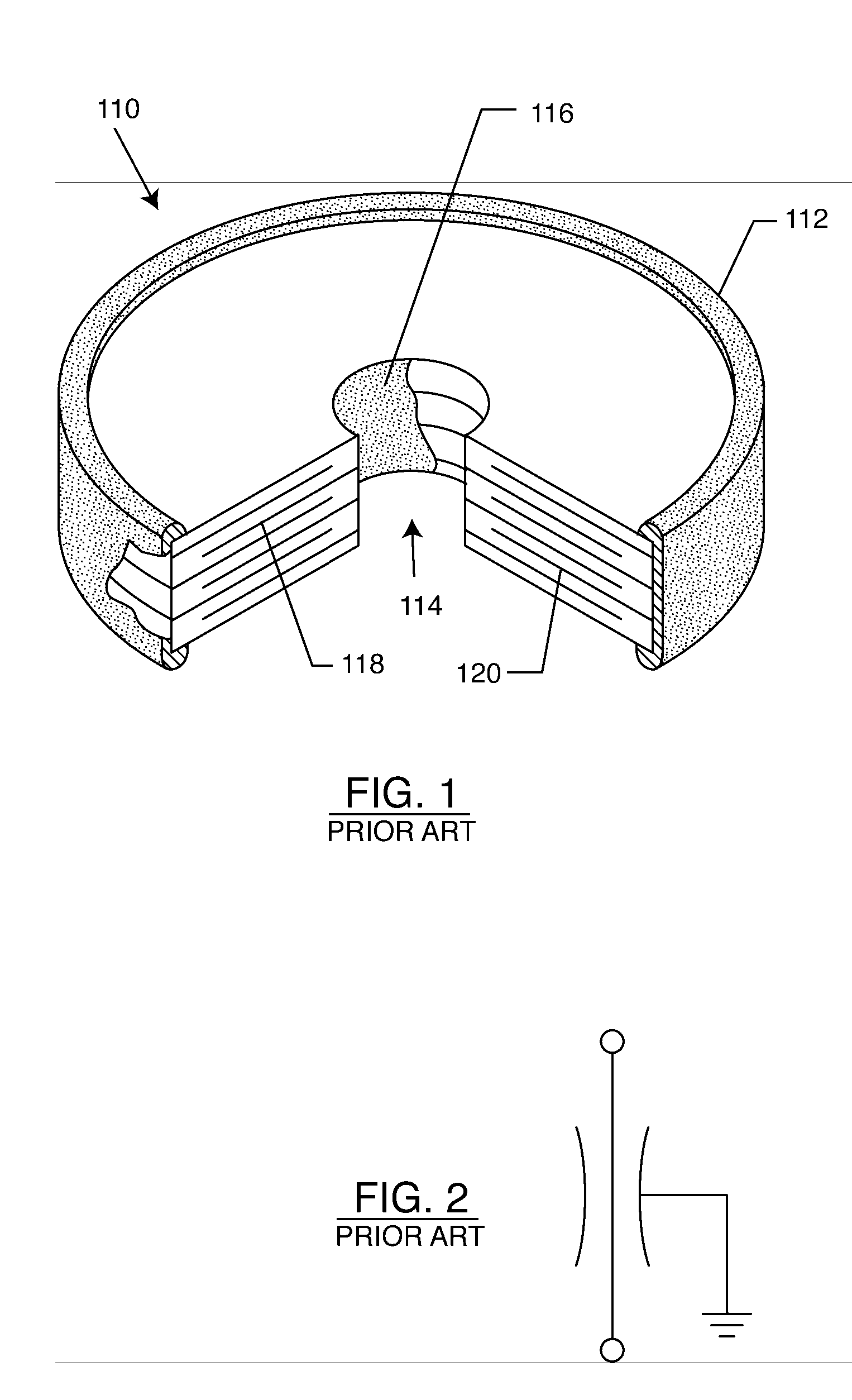

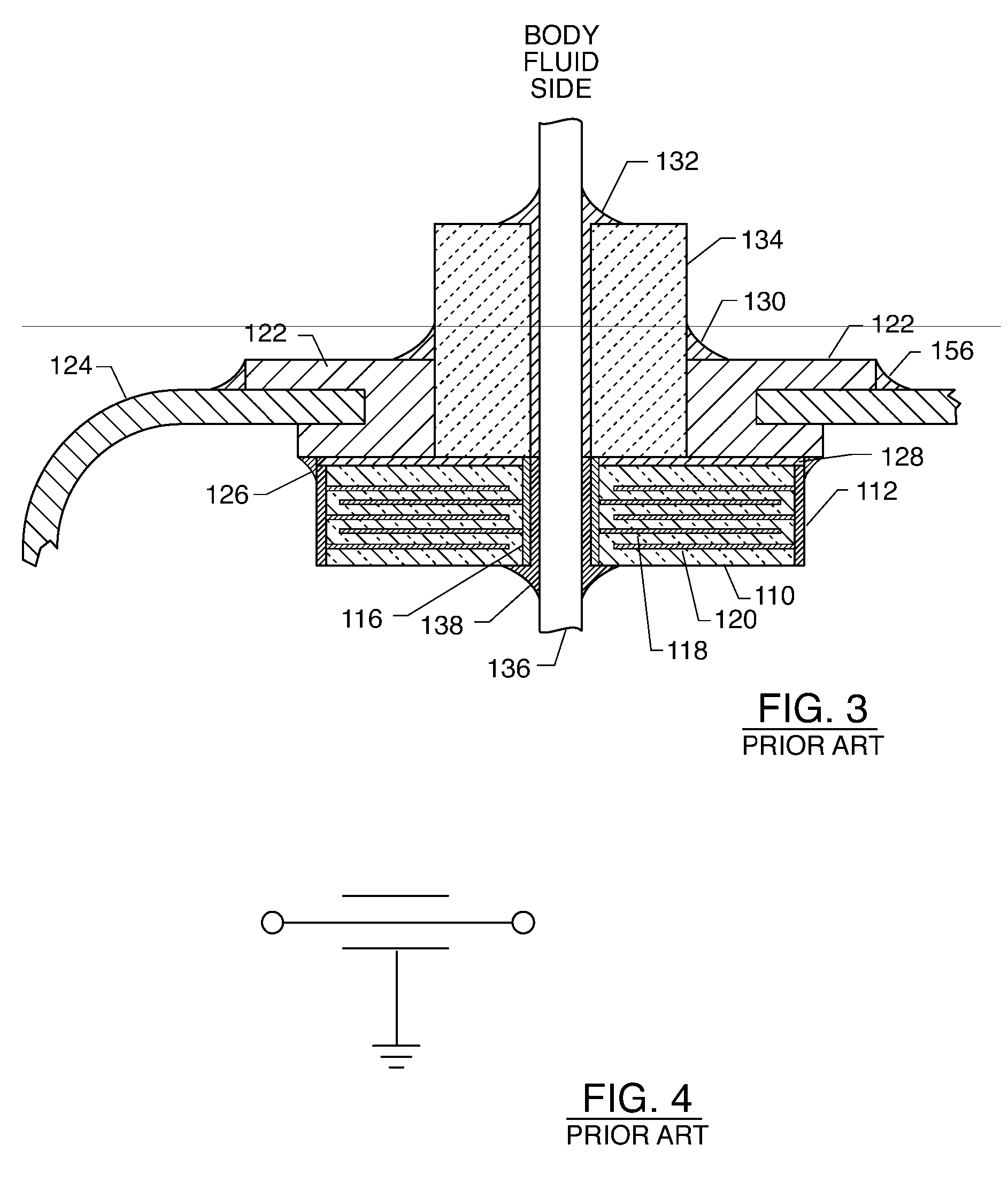

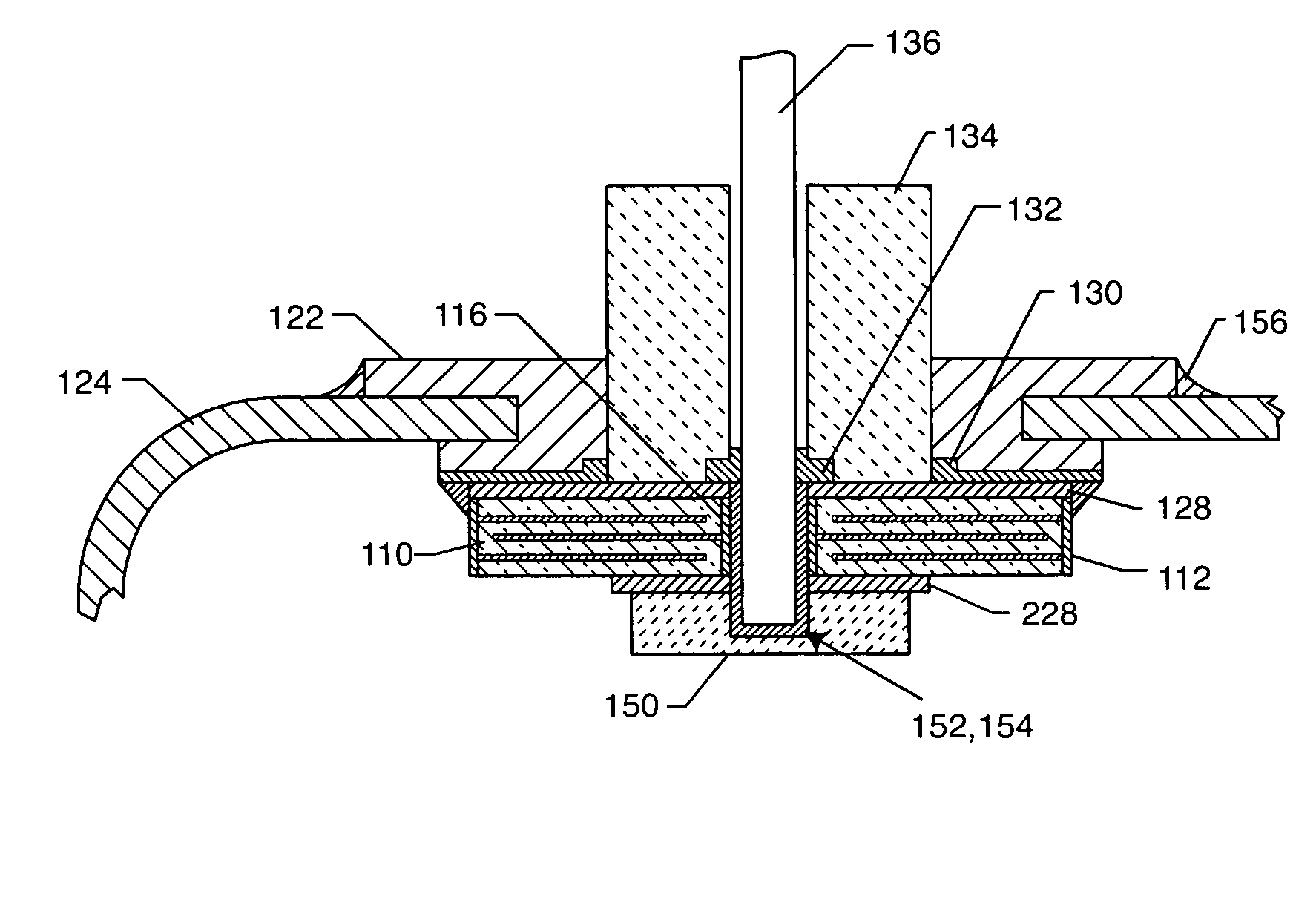

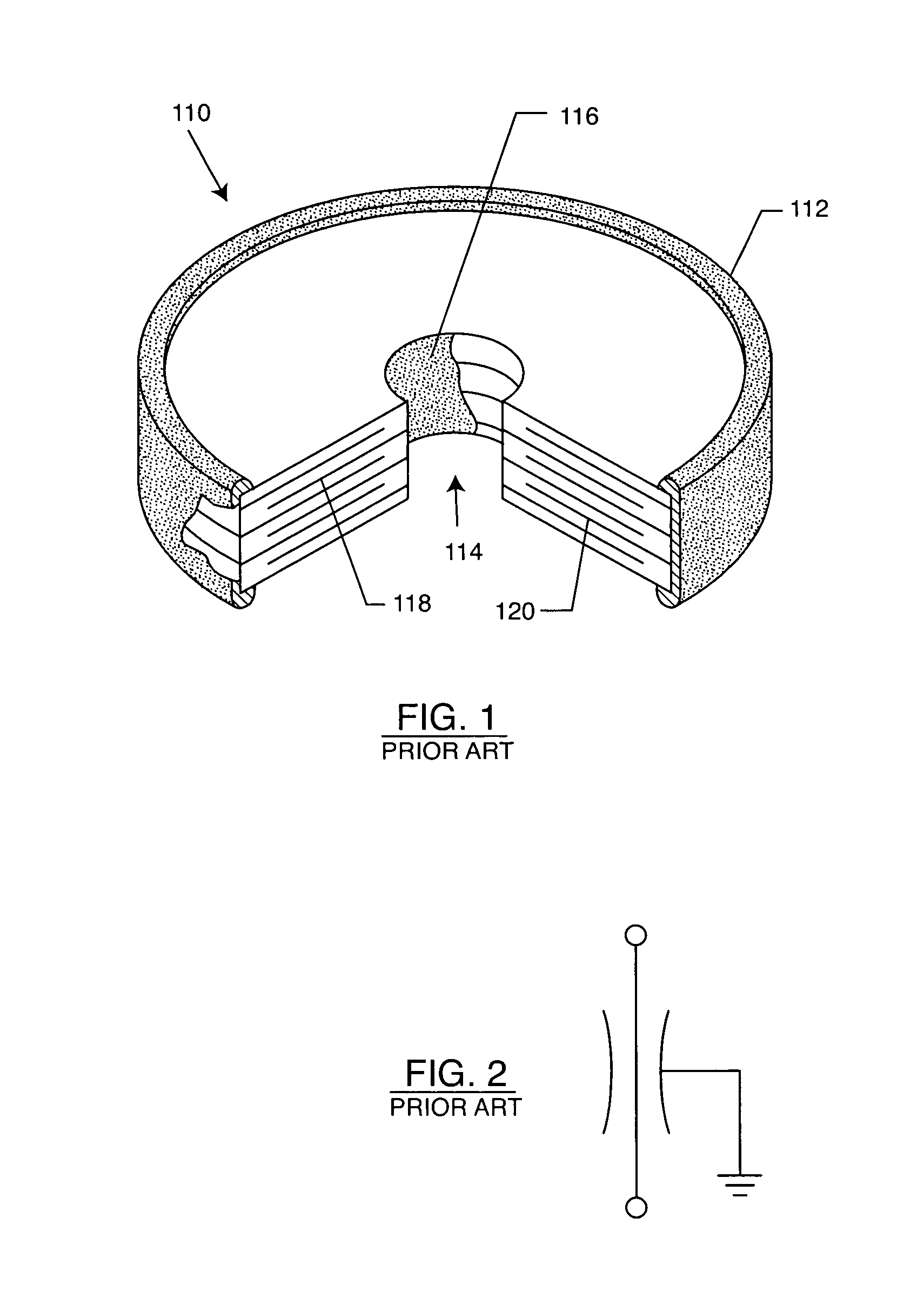

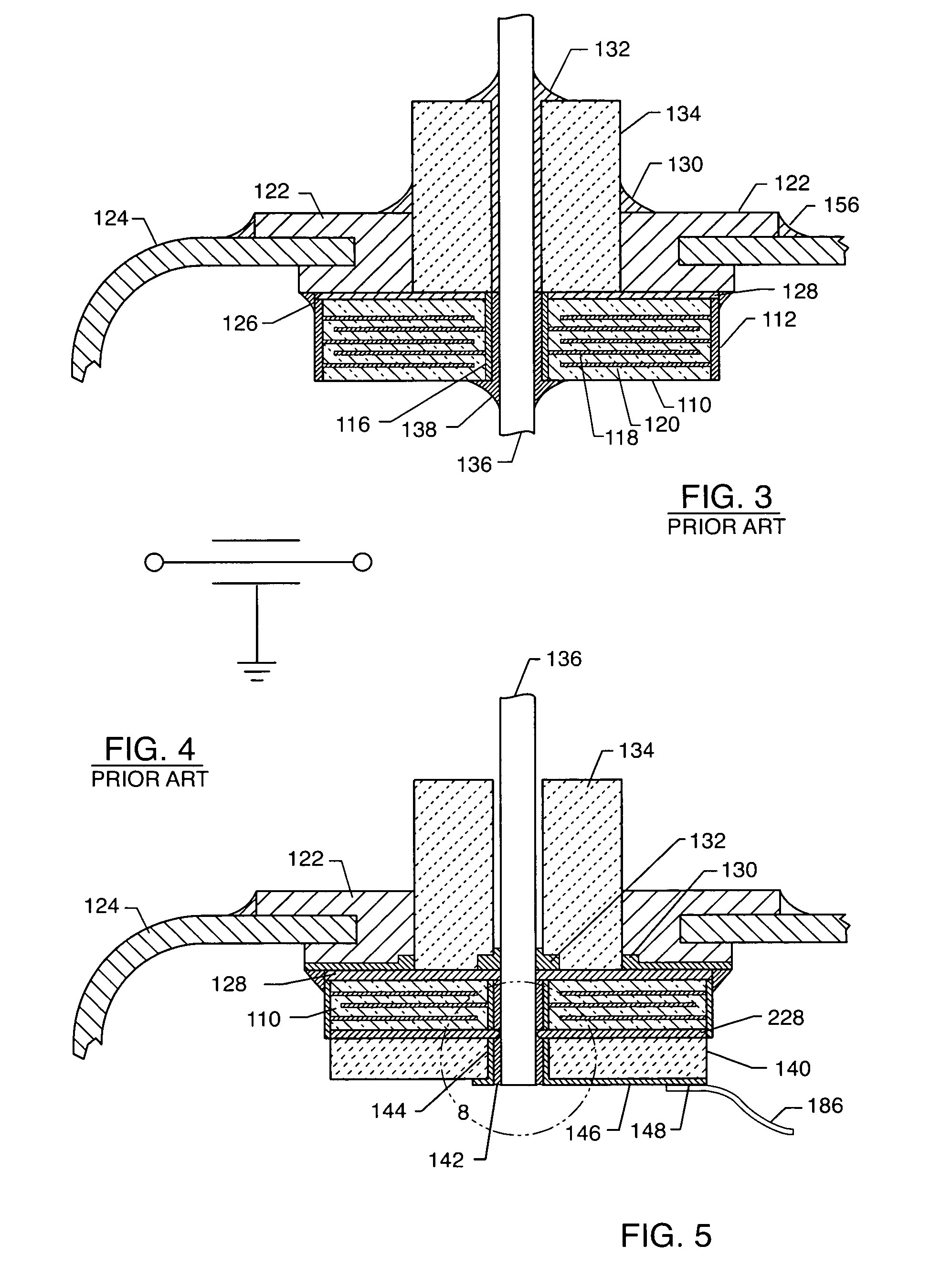

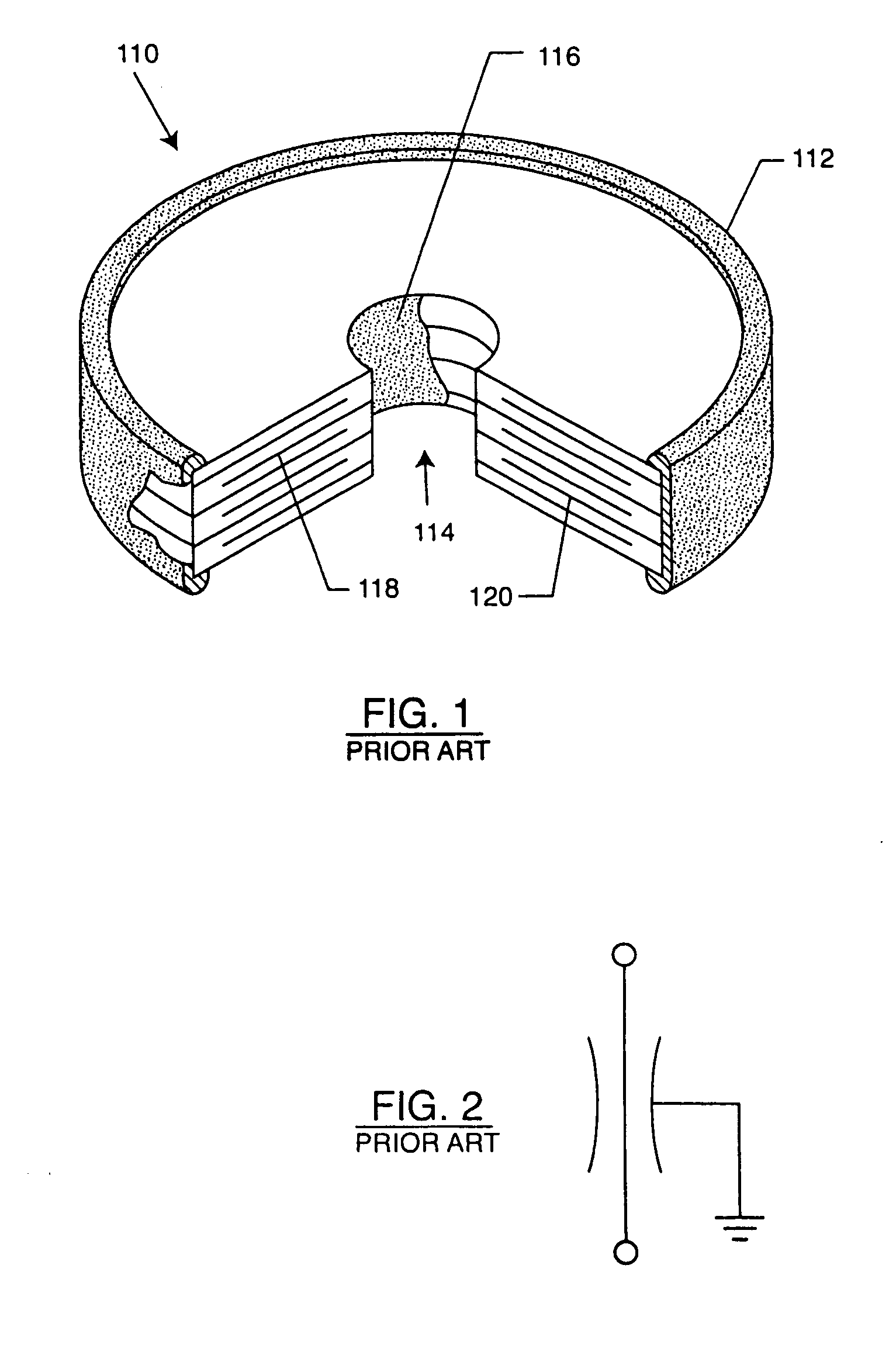

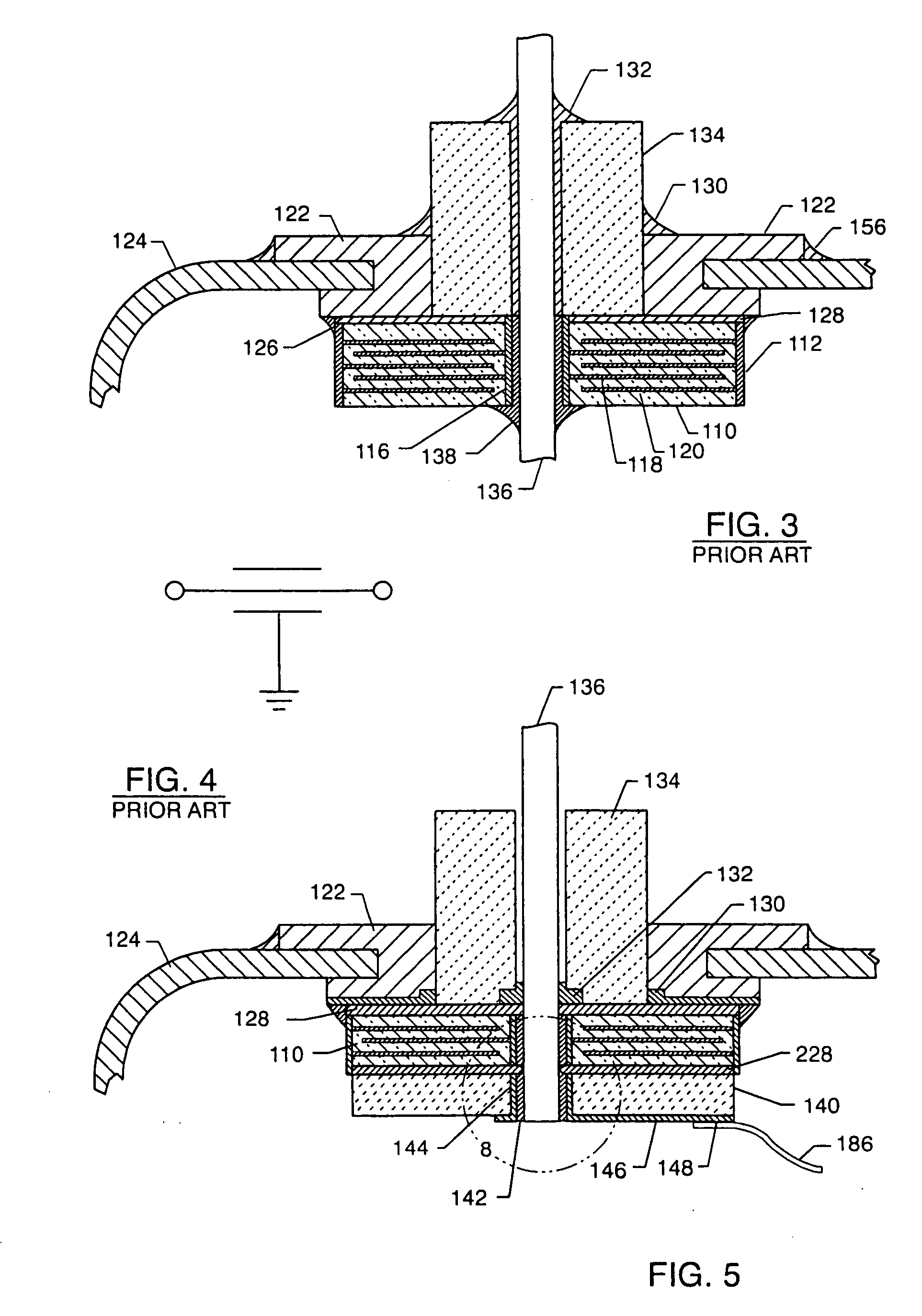

Hermetic feedthrough terminal assembly with wire bond pads for human implant applications

ActiveUS20060259093A1Consume energyReduce tensionMultiple-port networksAnti-noise capacitorsUltrasonic bondingMedical device

A feedthrough terminal assembly for active implantable medical devices includes a structural wire bond pad for a convenient attachment of wires from either the circuitry inside the implantable medical device or wires external to the device. Direct attachment of wire bond pads to terminal pins enables thermal or ultrasonic bonding of lead wires, while shielding the capacitor or other delicate components from the forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

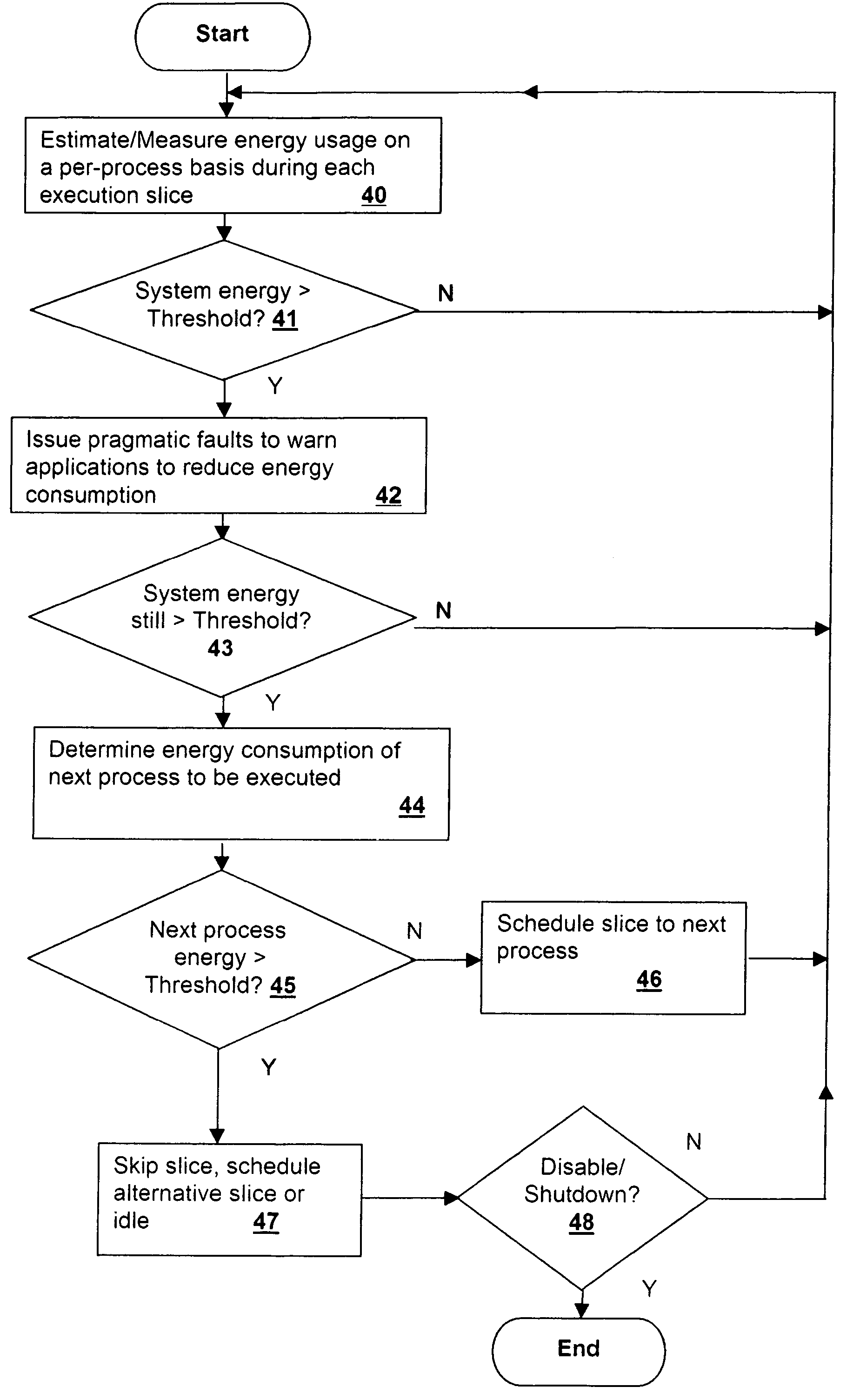

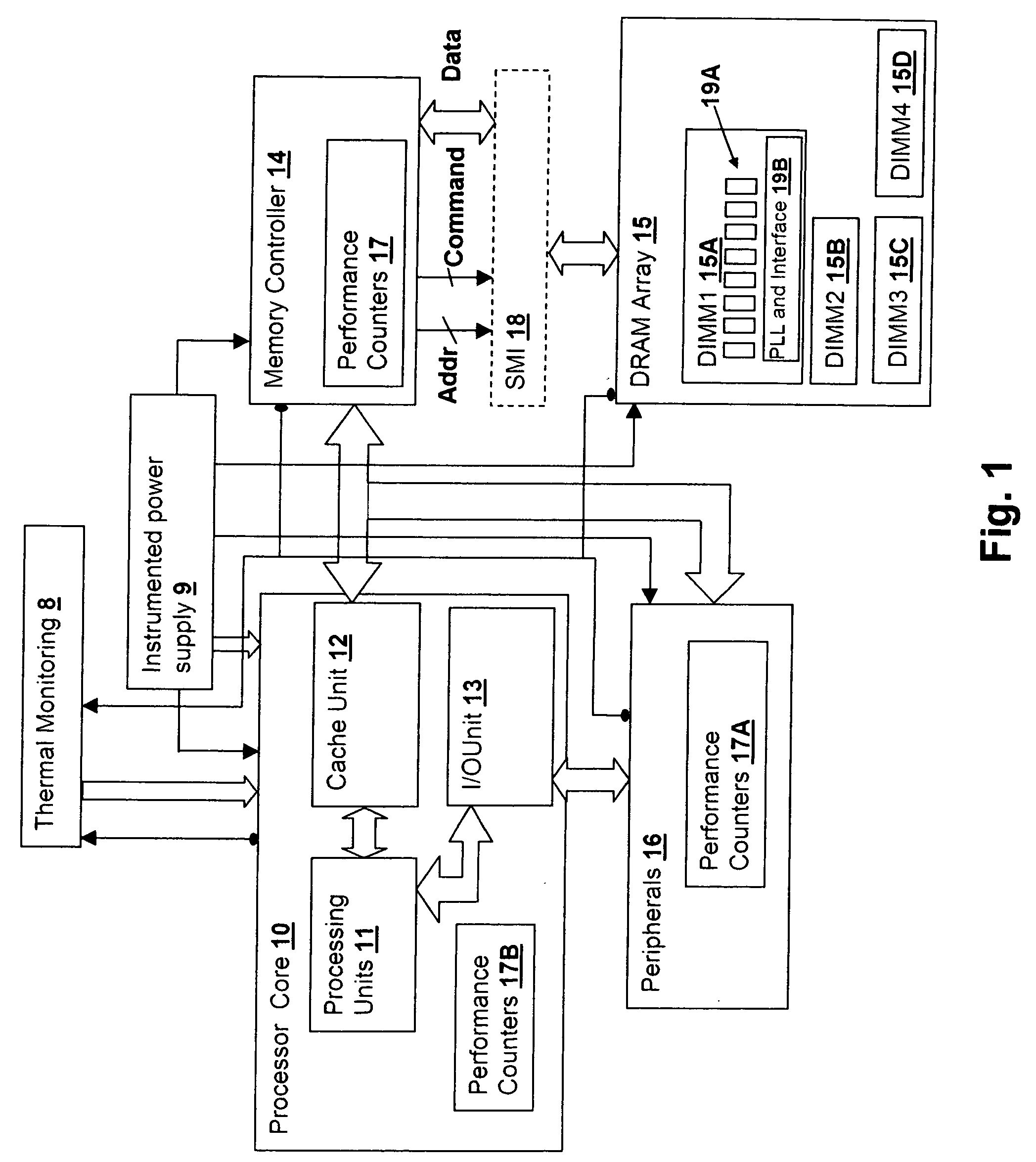

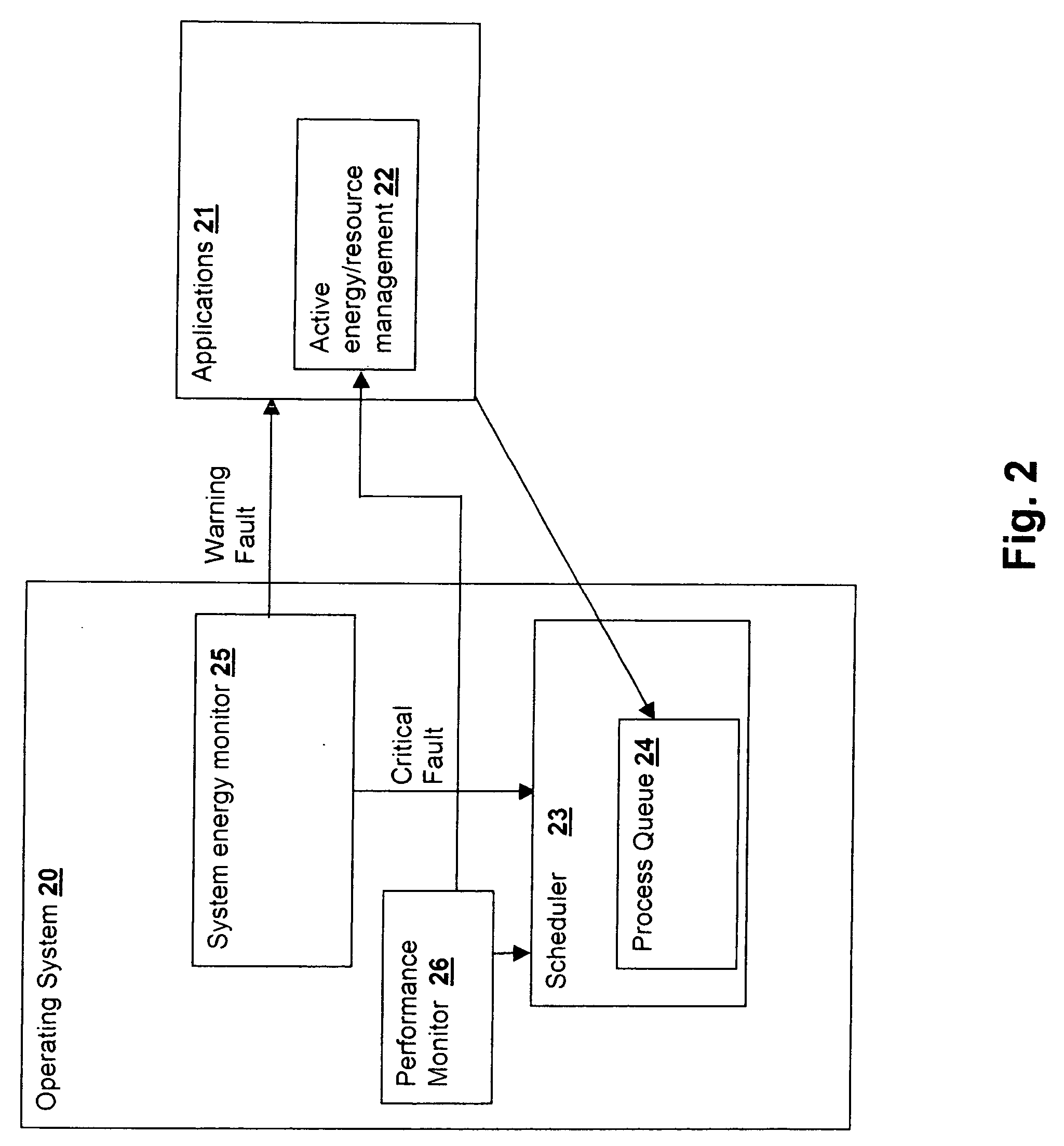

Method and system for energy management via energy-aware process scheduling

InactiveUS20050125701A1Weaken energyHigh degreeEnergy efficient ICTVolume/mass flow measurementOperational systemHigh energy

A method and system for energy management via energy-aware process scheduling provides per-process energy use / power dissipation control to manage system energy requirements and thermal conditions without throttling overall system performance. Use of energy by a particular process is measured or is estimated from resource requirements that are determined by the operating system or reported by the application owning the process. The scheduler then determines whether or not to allocate execution slices to the process in conformity with the measured or estimated energy requirements of the process. The scheduler may insert “idle” execution slices to reduce energy use / power dissipation or may prefer low energy-use processes over high energy-use processes. Pragmatic faults may be issued as warnings from the operating system to an application to indicate that energy requirements need to be curtailed. If the warning sent to the application does not result in sufficient energy use / power dissipation reduction, then the scheduler may implement the selective allocation of slices to processes that have an excessive energy requirement. The scheduler may be notified of such a condition through pragmatic “critical” faults that indicate a higher degree of severity than the previously-issued warning faults.

Owner:IBM CORP

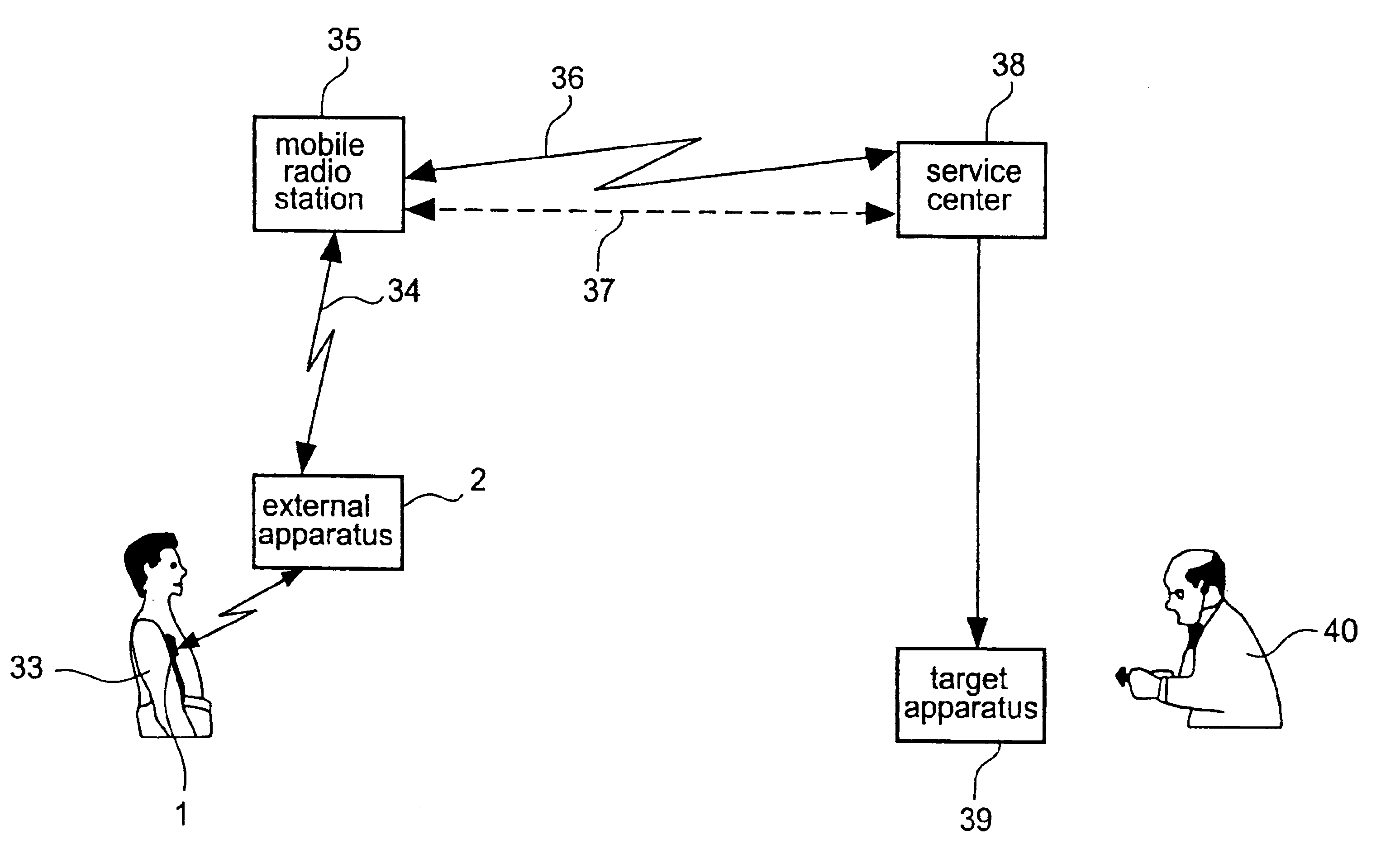

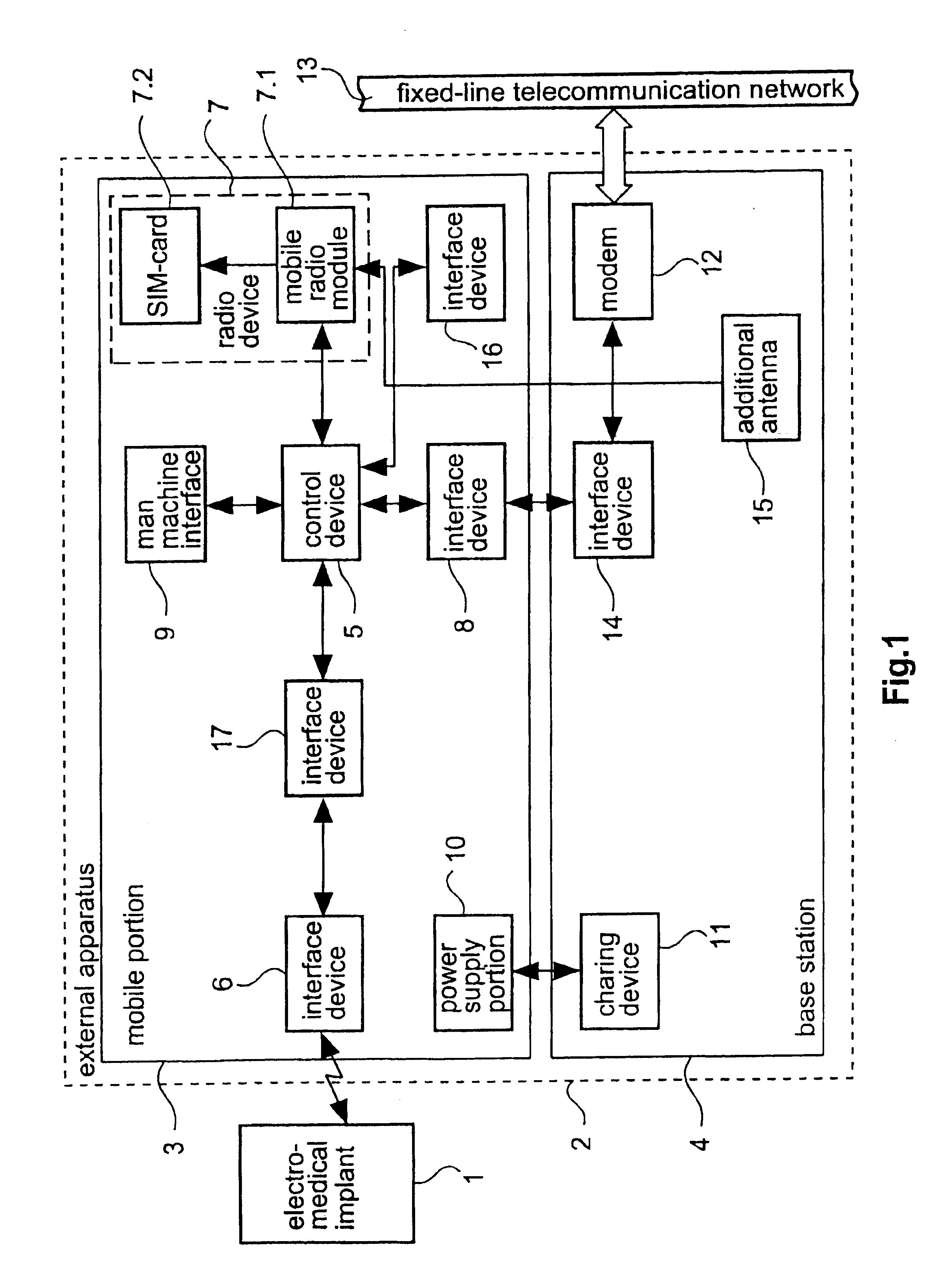

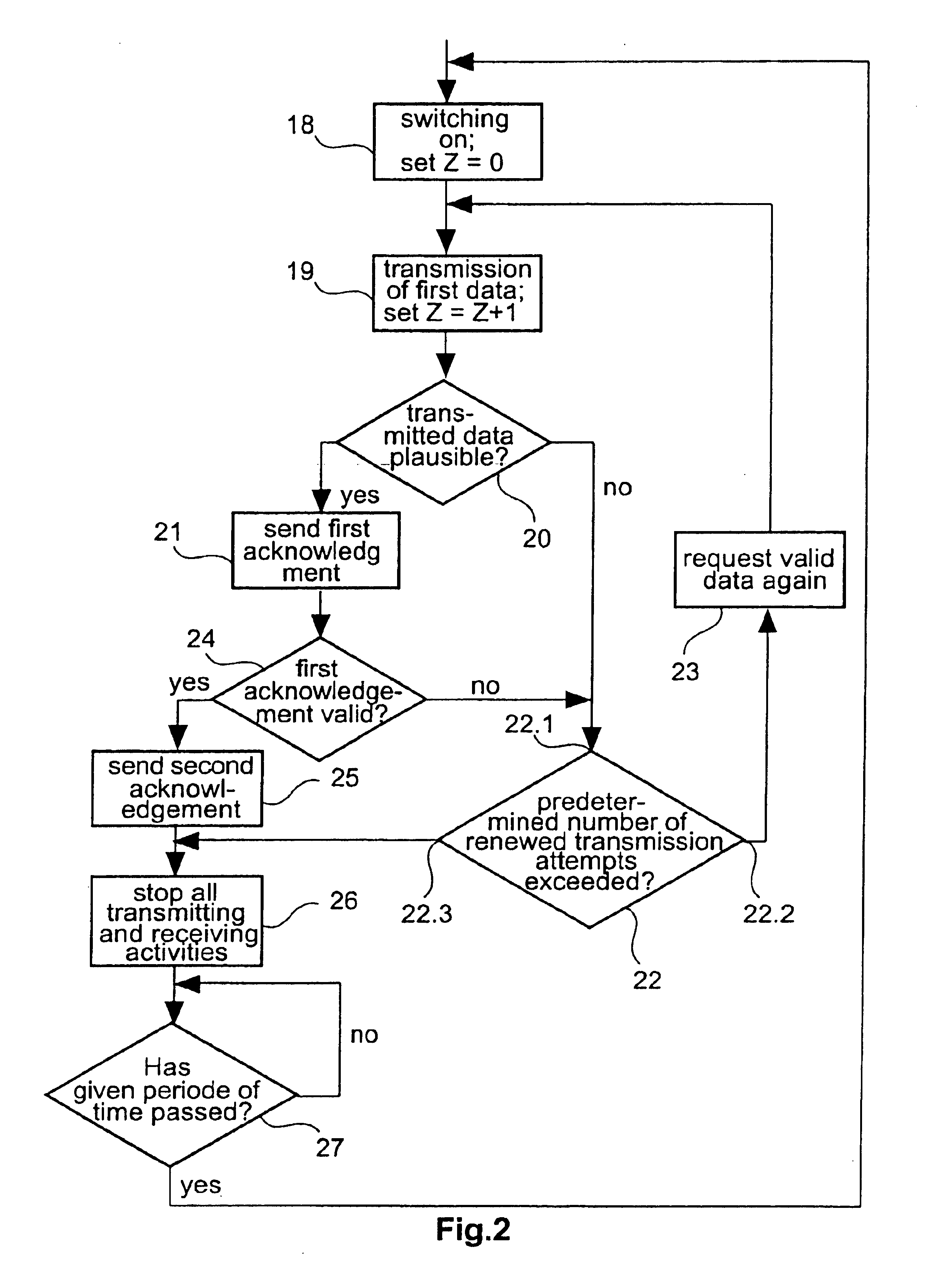

Method and apparatus for data transmission between an electromedical implant and an external apparatus

InactiveUS6893395B1Increase the lengthCompensating for such errorElectrotherapyDiagnostic recording/measuringEngineeringData transmission

A method and apparatus for data transmission between an electromedical implant having a first transmitter / receiver unit, such as a cardiological implant, and an associated external apparatus having a second transmitter / receiver unit. Data transmission begins with a triggering signal which is sent by the first transmitter / receiver unit in normal operation in predeterminable first intervals. Reception readiness of the first transmitter / receiver unit is maintained after emission of the triggering signal for a second time interval which is shorter than the first time interval.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

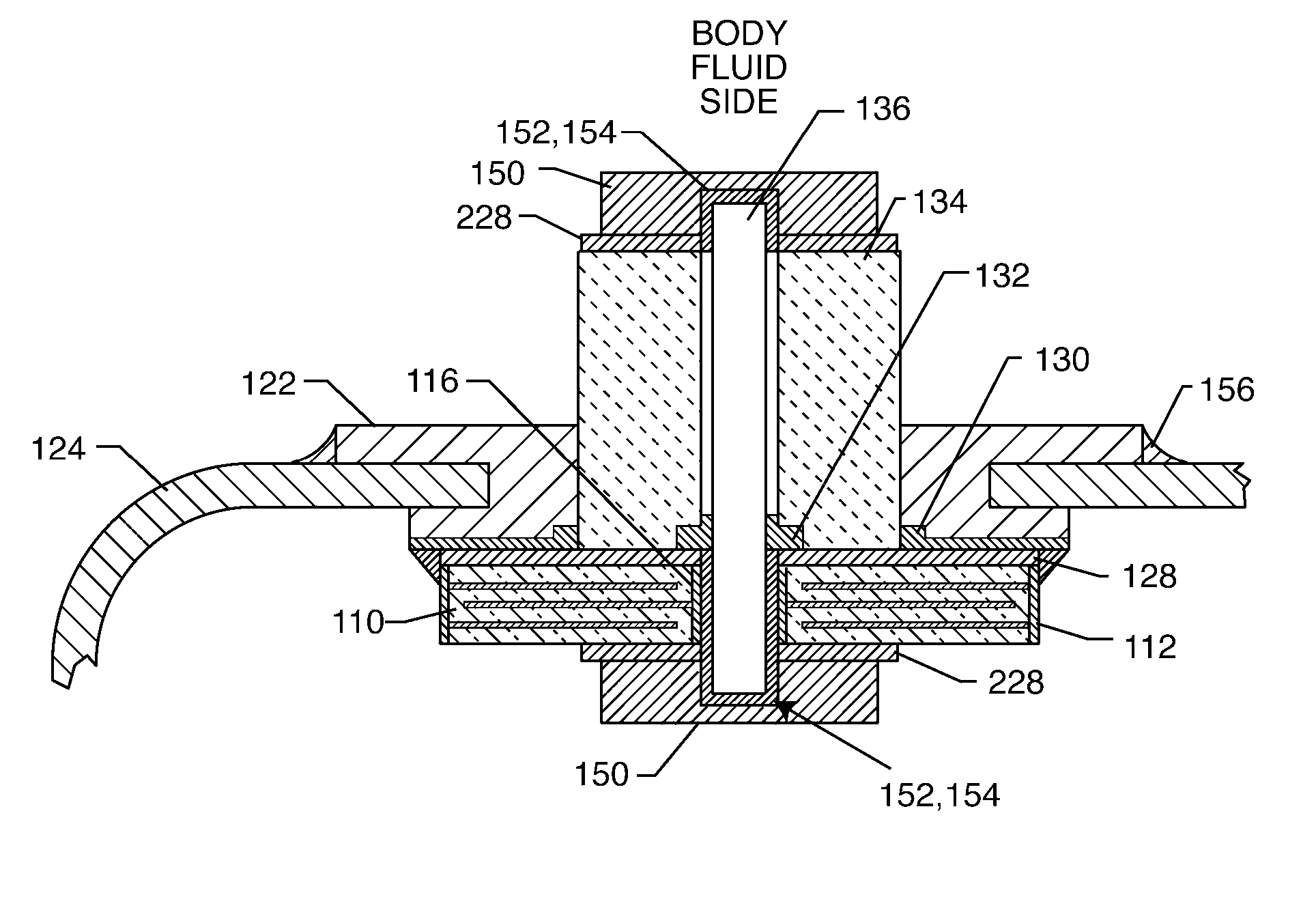

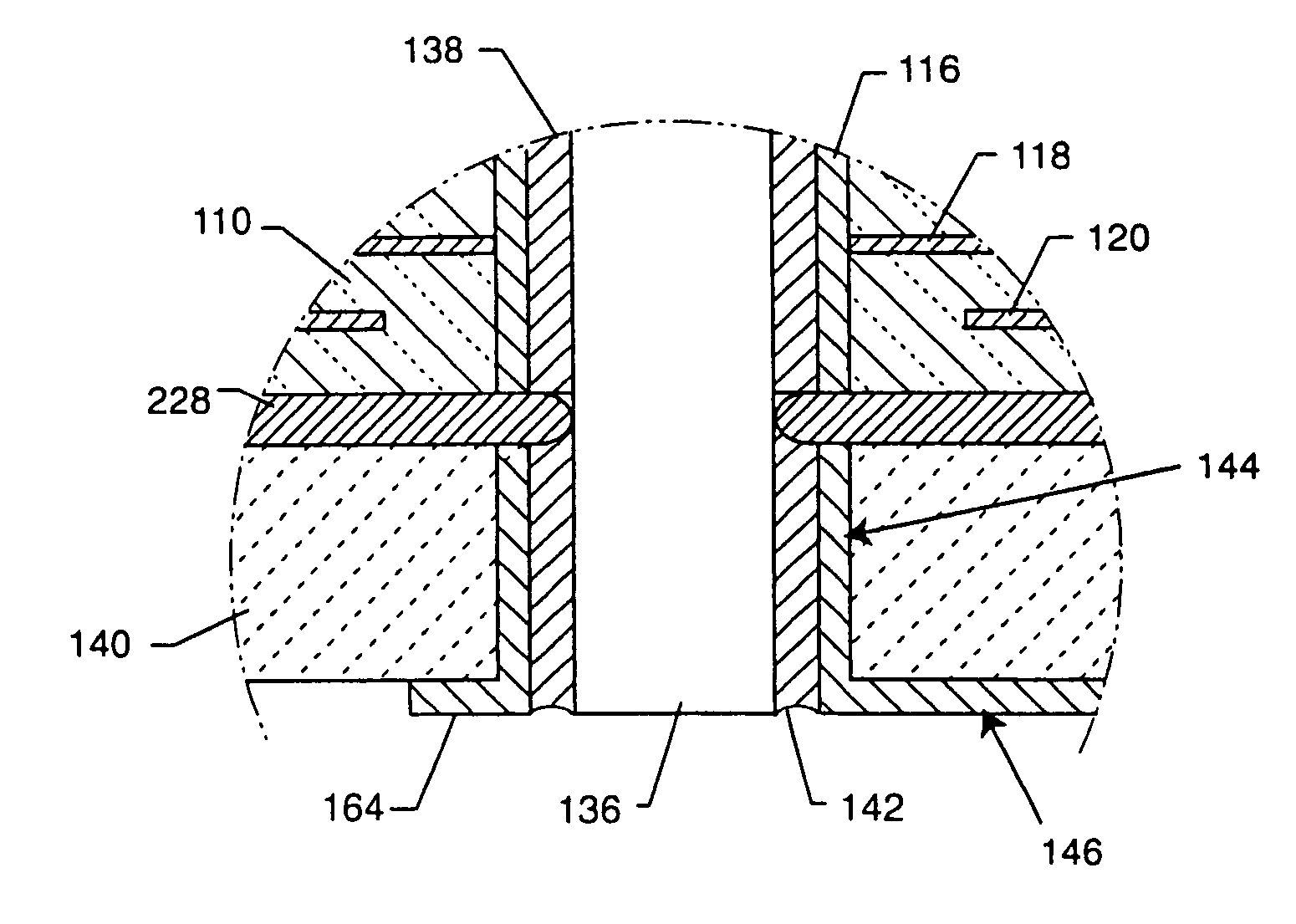

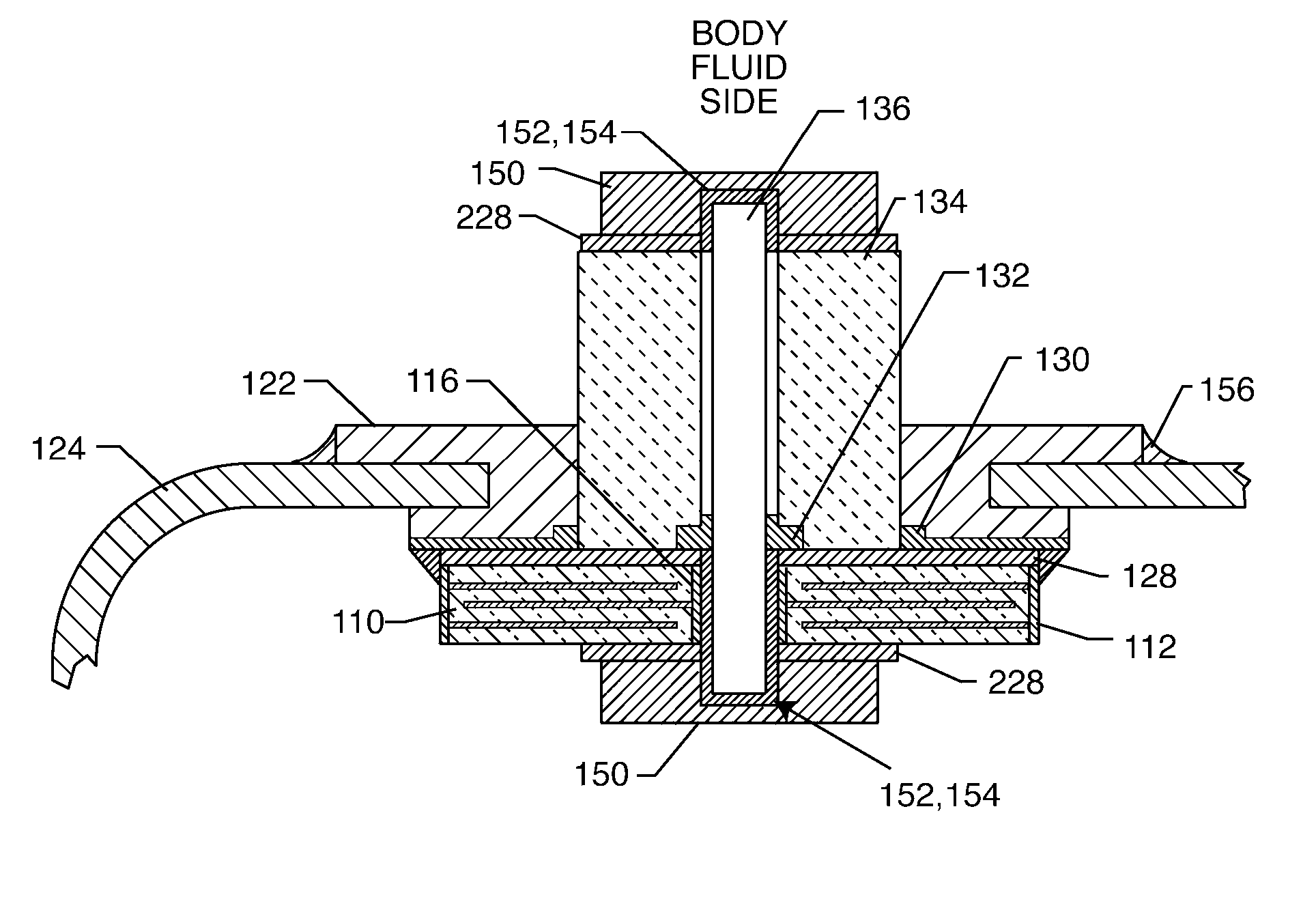

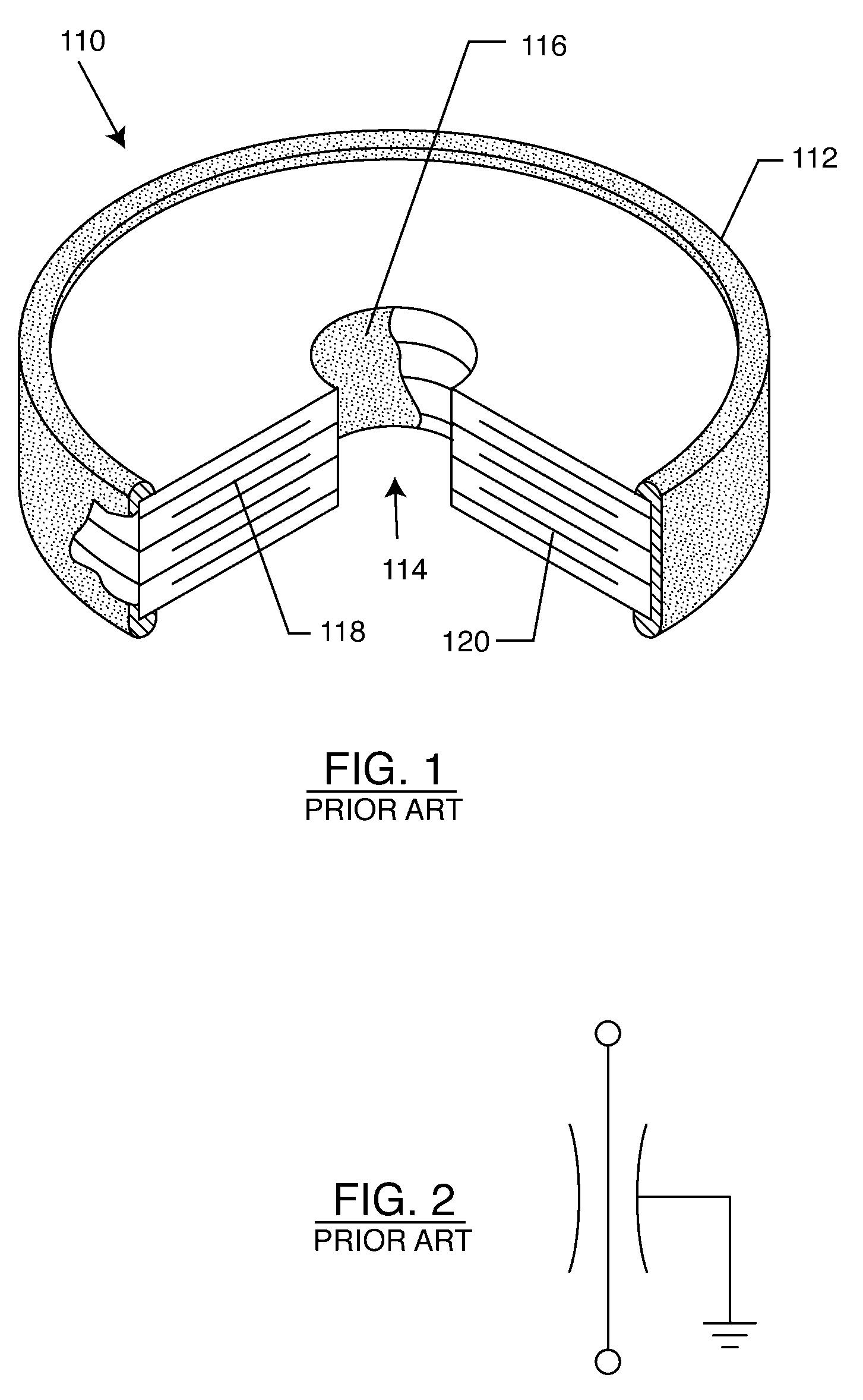

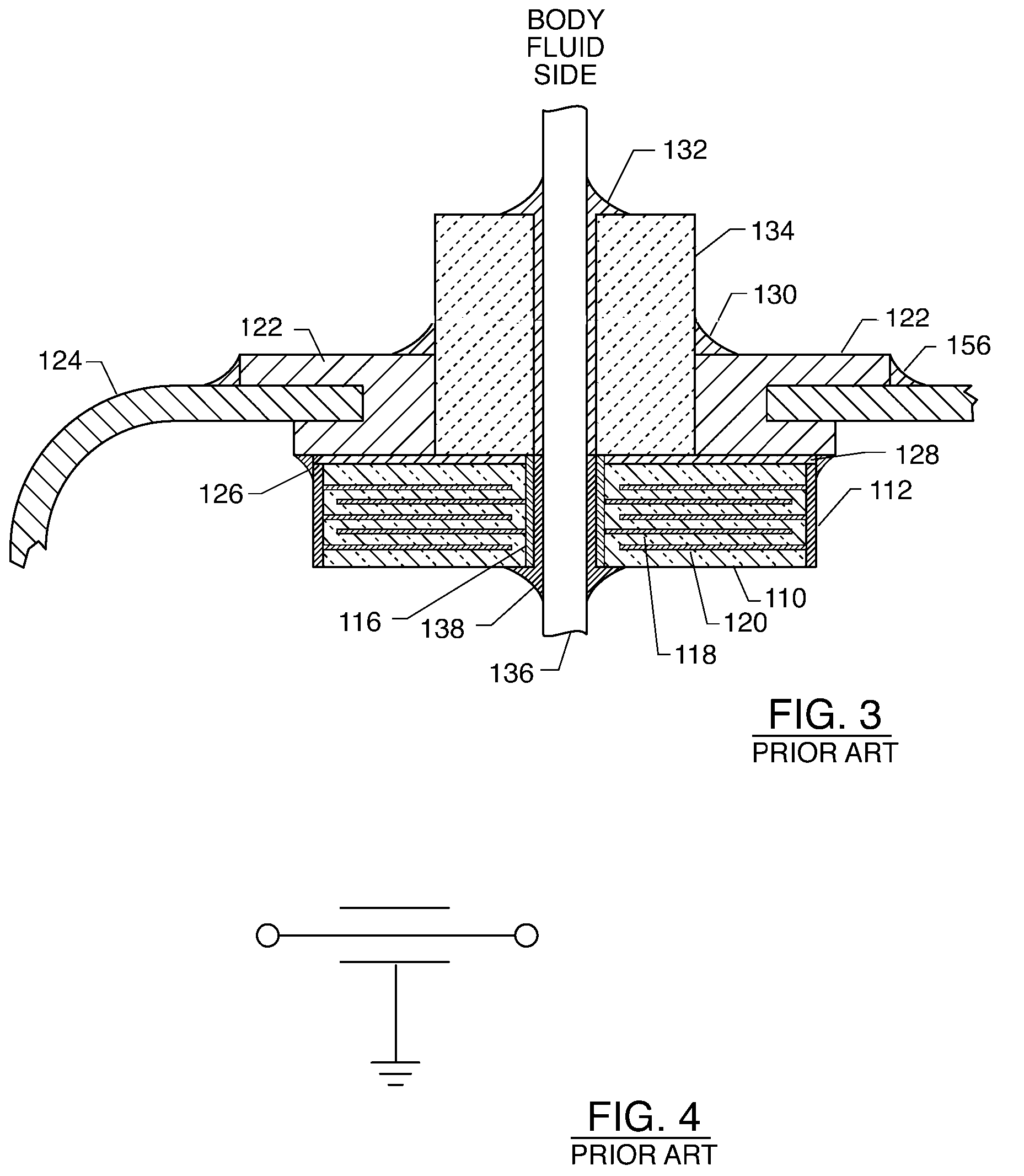

EMI filter terminal assembly with wire bond pads for human implant applications

ActiveUS20050007718A1Avoid crackingAbsorbs stressMultiple-port networksElectrotherapyElectromagnetic interferenceSoldering

An electromagnetic interference filter terminal assembly for active implantable medical devices includes a structural pad in the form of a substrate or attached wire bond pad, for convenient attachment of wires from the circuitry inside the implantable medical device to the capacitor structure via thermal or ultrasonic bonding, soldering or the like while shielding the capacitor from forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

Mosaic extremity protection system with transportable solid elements

InactiveUS7874239B2Suitable degree of flexibilityConsume energyPersonal protection gearWoven fabricsPlanar polygonFiber

Owner:WARWICK MILLS INC

Polymeric ballistic material and method of making

PendingUS20060013977A1Dissipating projectile energySlow its forward motionLayered productsArmour platesBallistic impactPolymer

This invention relates to a polymeric ballistic material comprising a high molecular weight, high density polyethylene (HMW-HDPE) and / or composite, and to articles made from this ballistic material suitable for stopping projectiles. The articles may include backstops for firing ranges and home use, armor for vehicles, personnel, and aircraft, training targets, protection for temporary or mobile military and / or police installations, buildings, bunkers, pipelines or any “critical” need equipment that might require protection from ballistic impact, and the like.

Owner:BALLISTICS RES +1

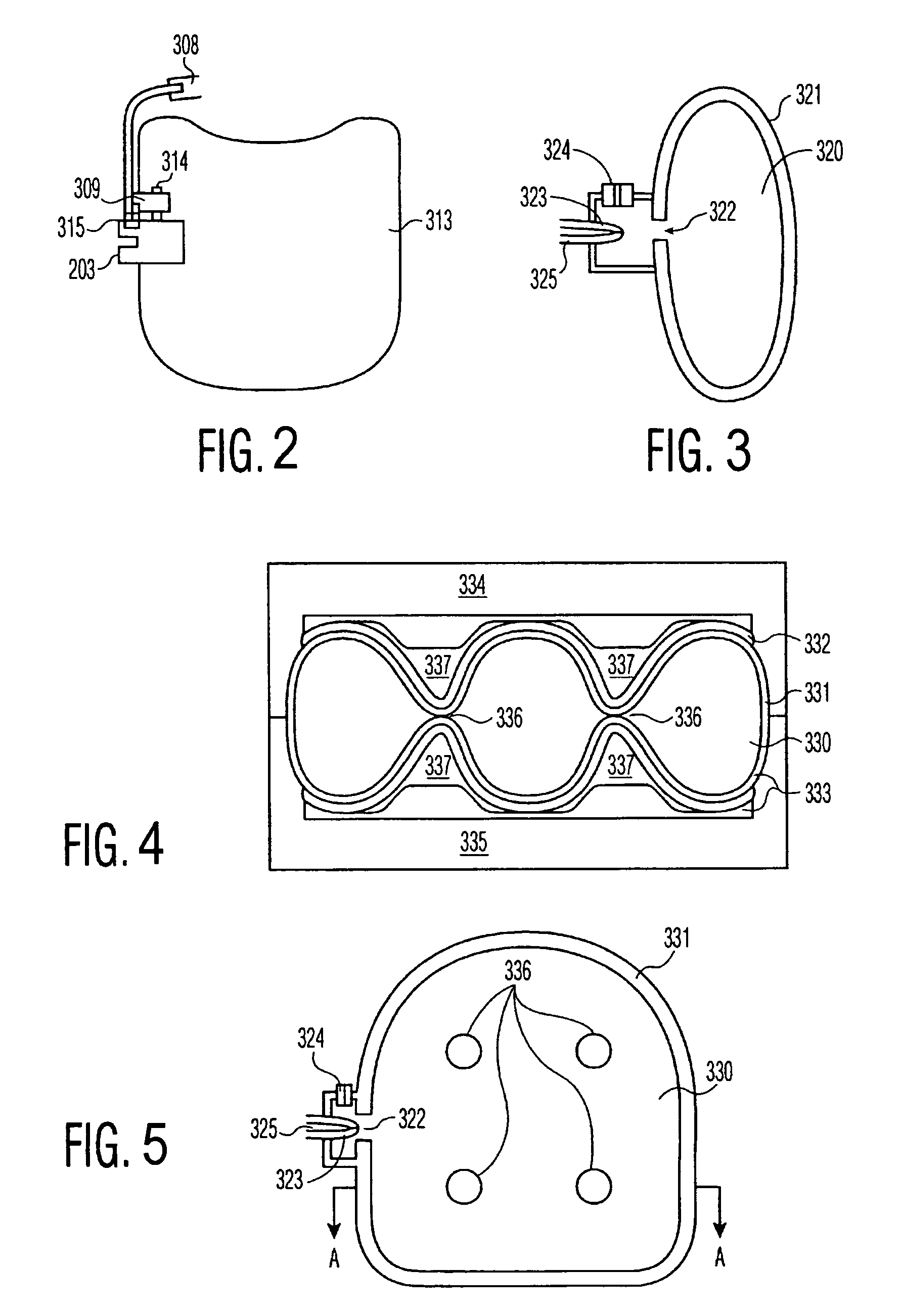

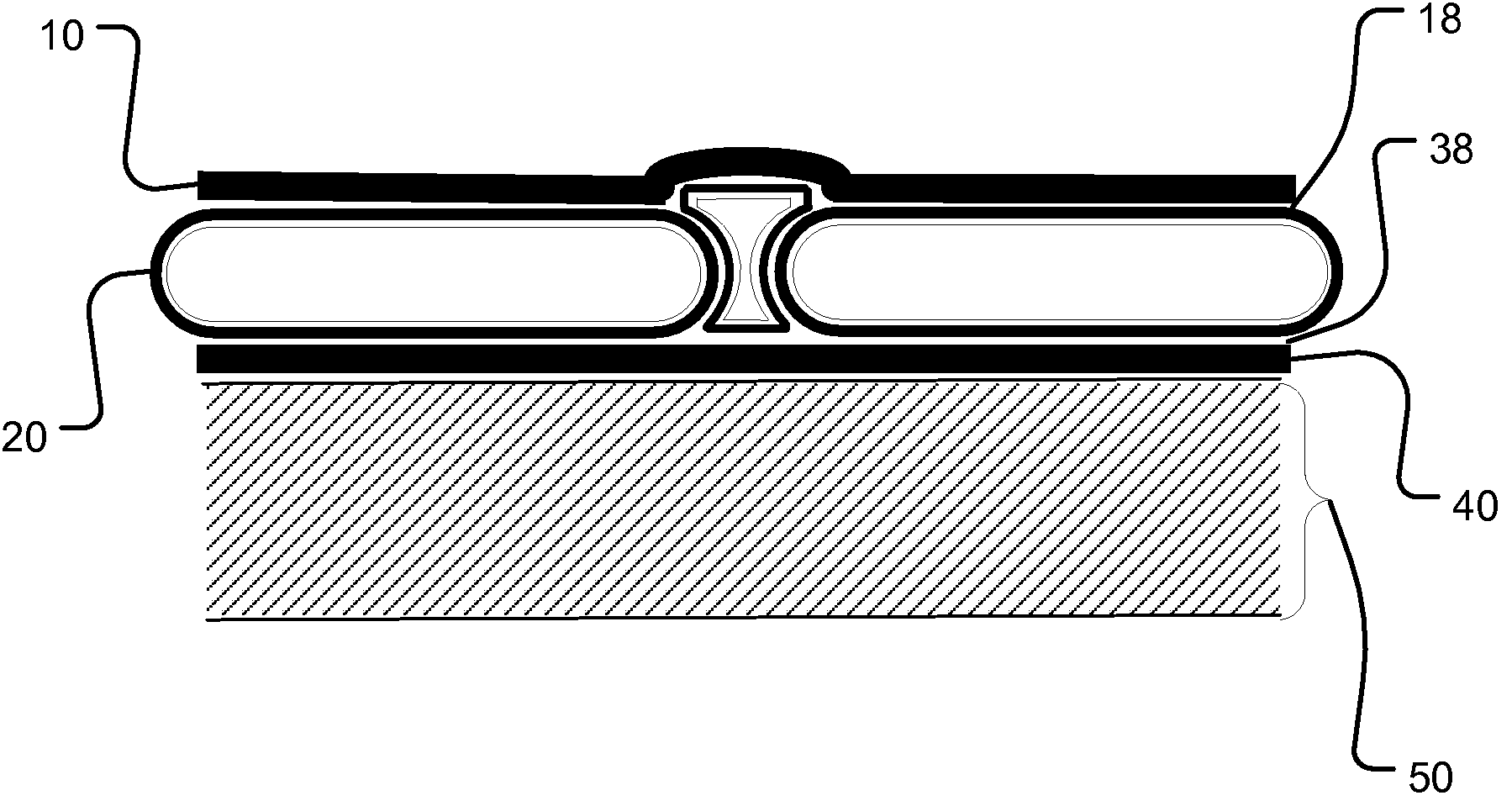

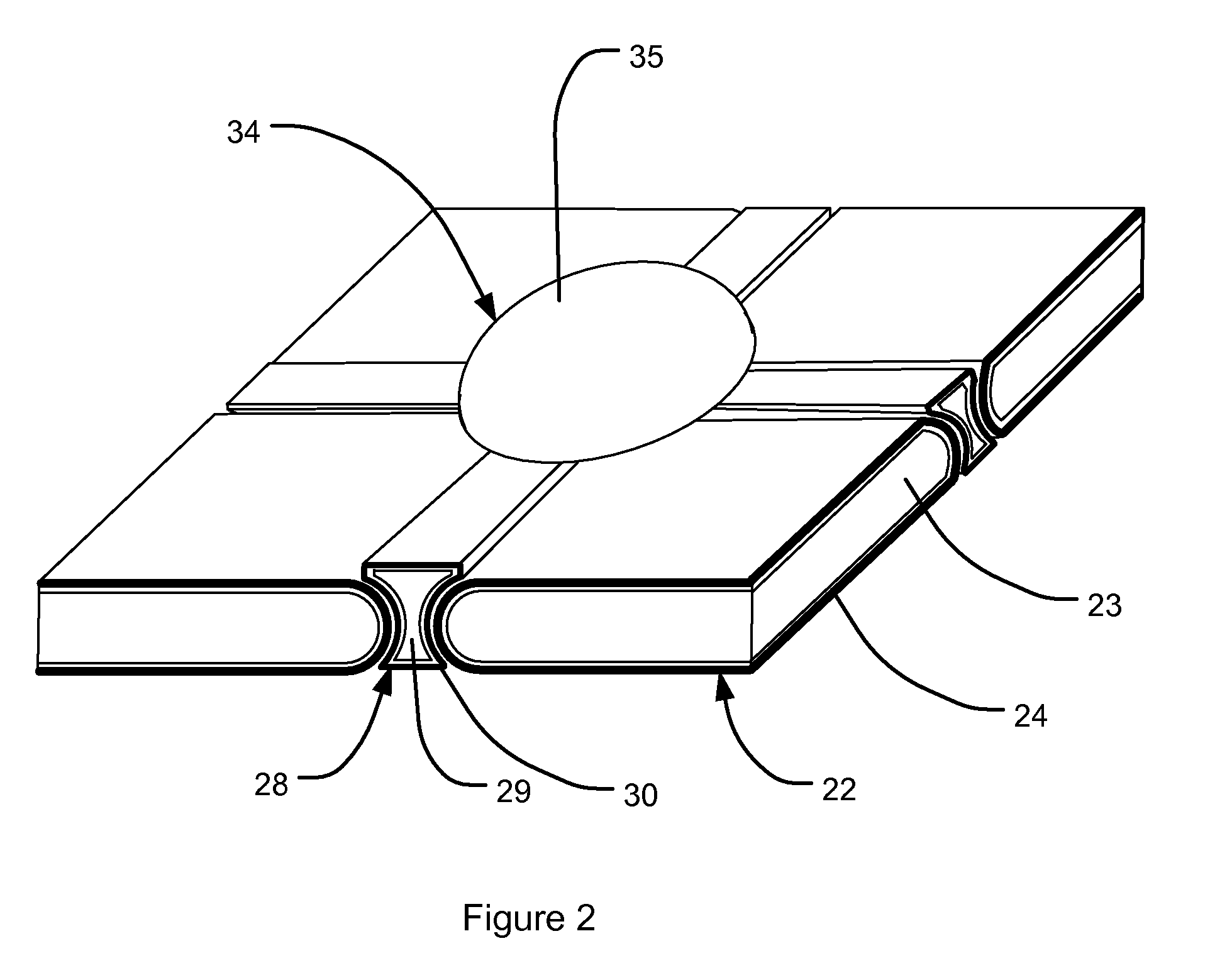

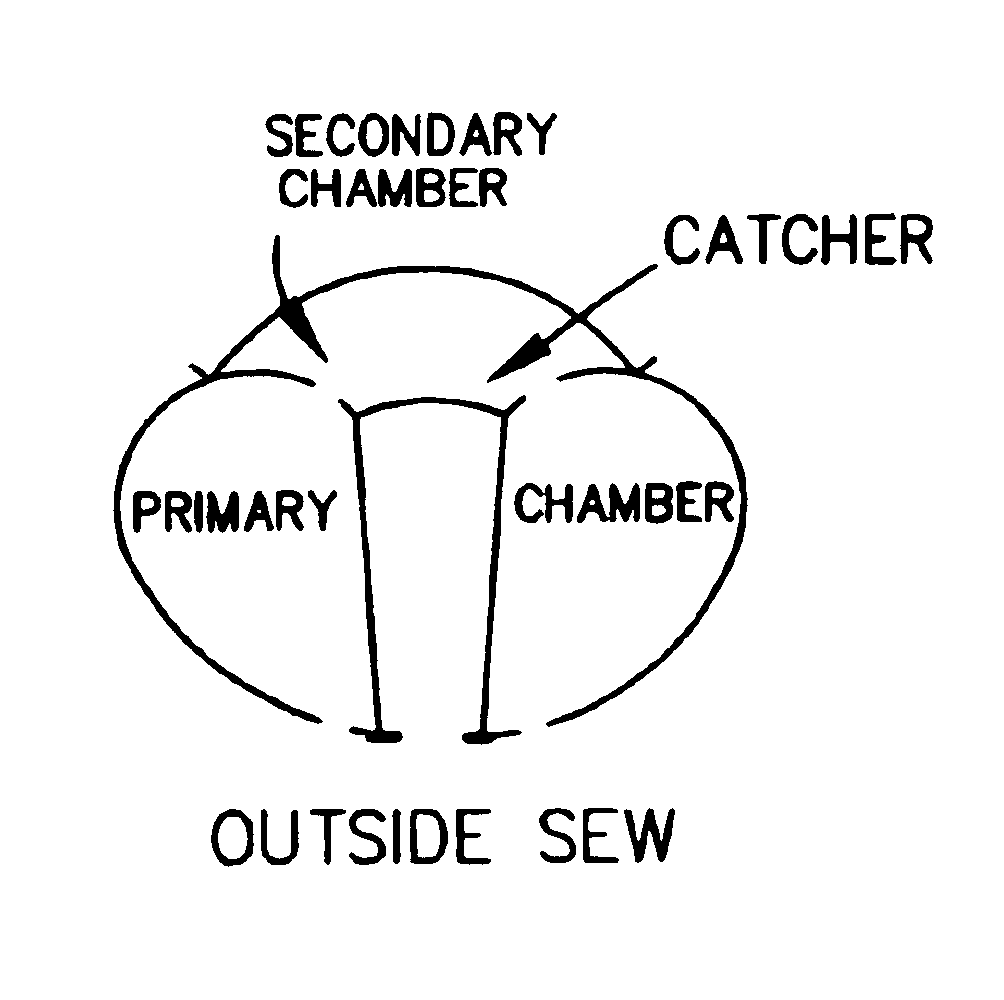

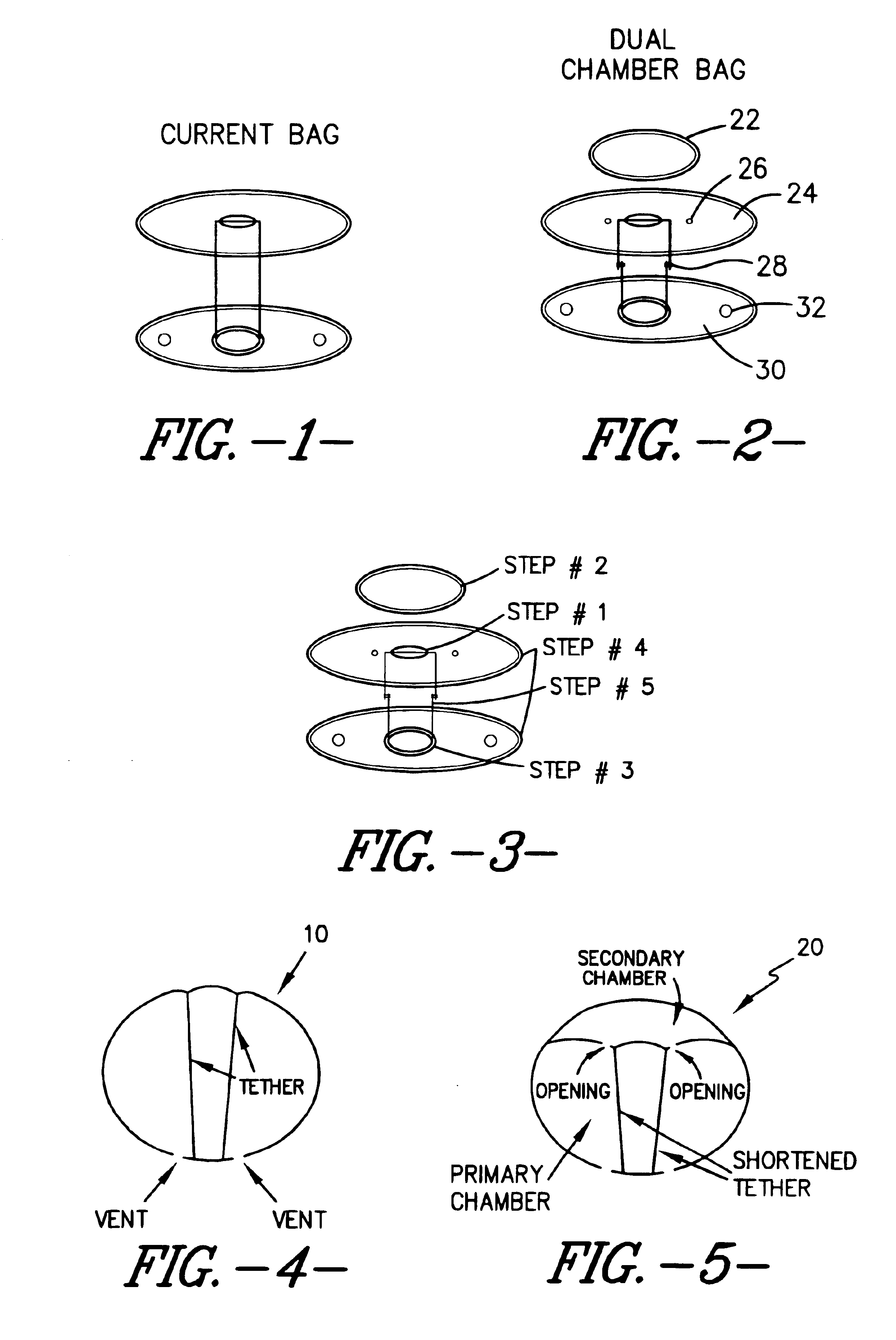

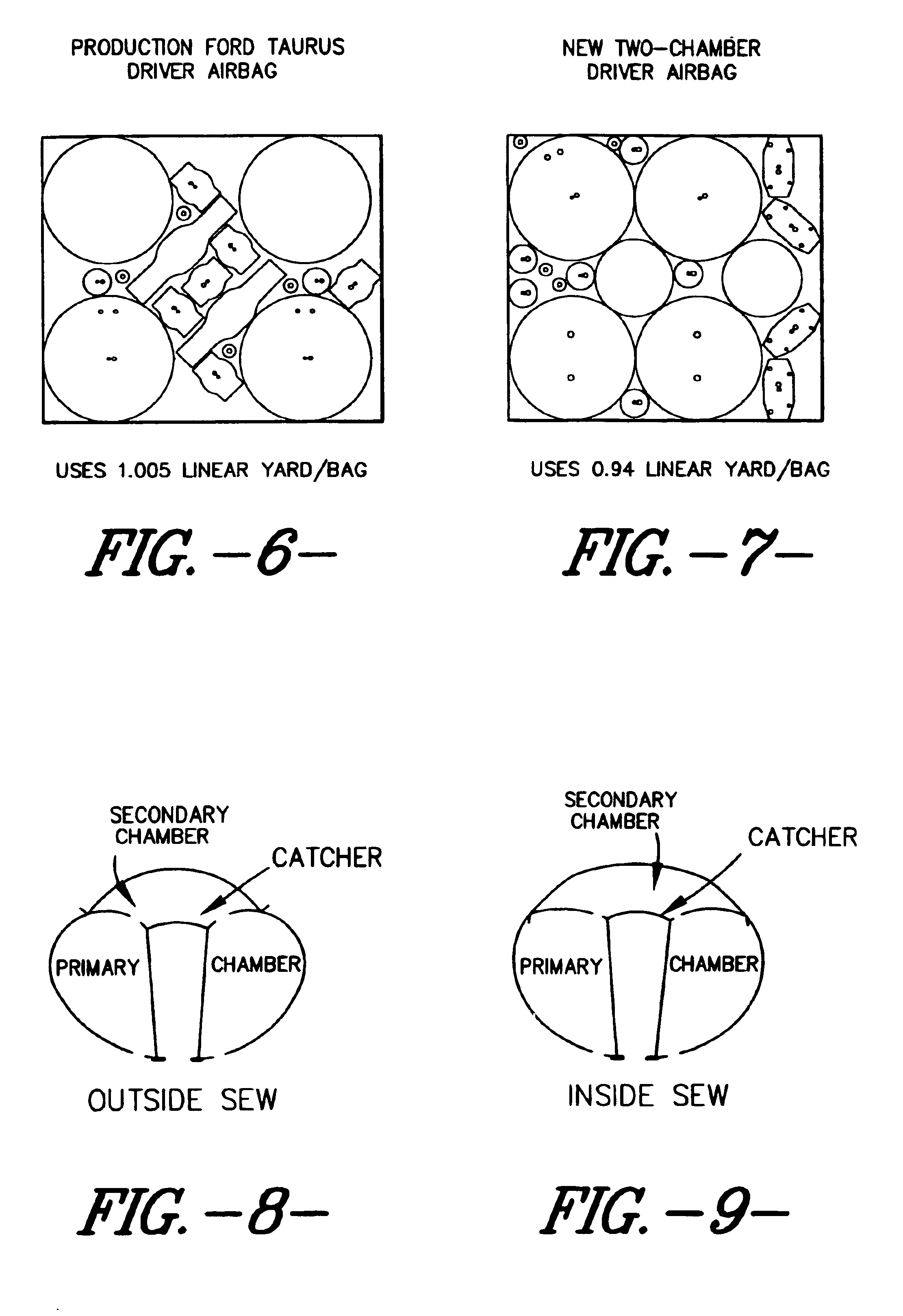

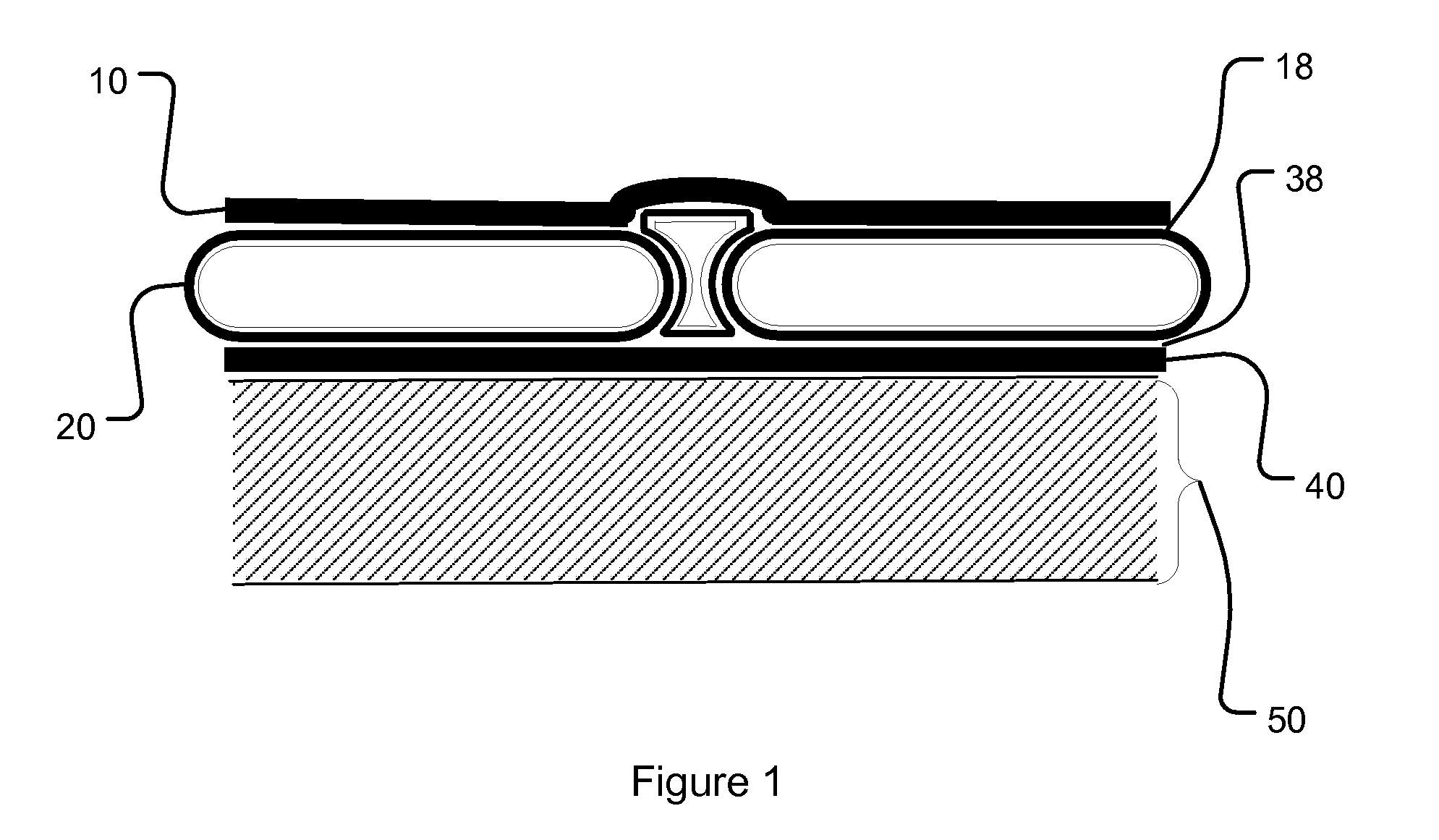

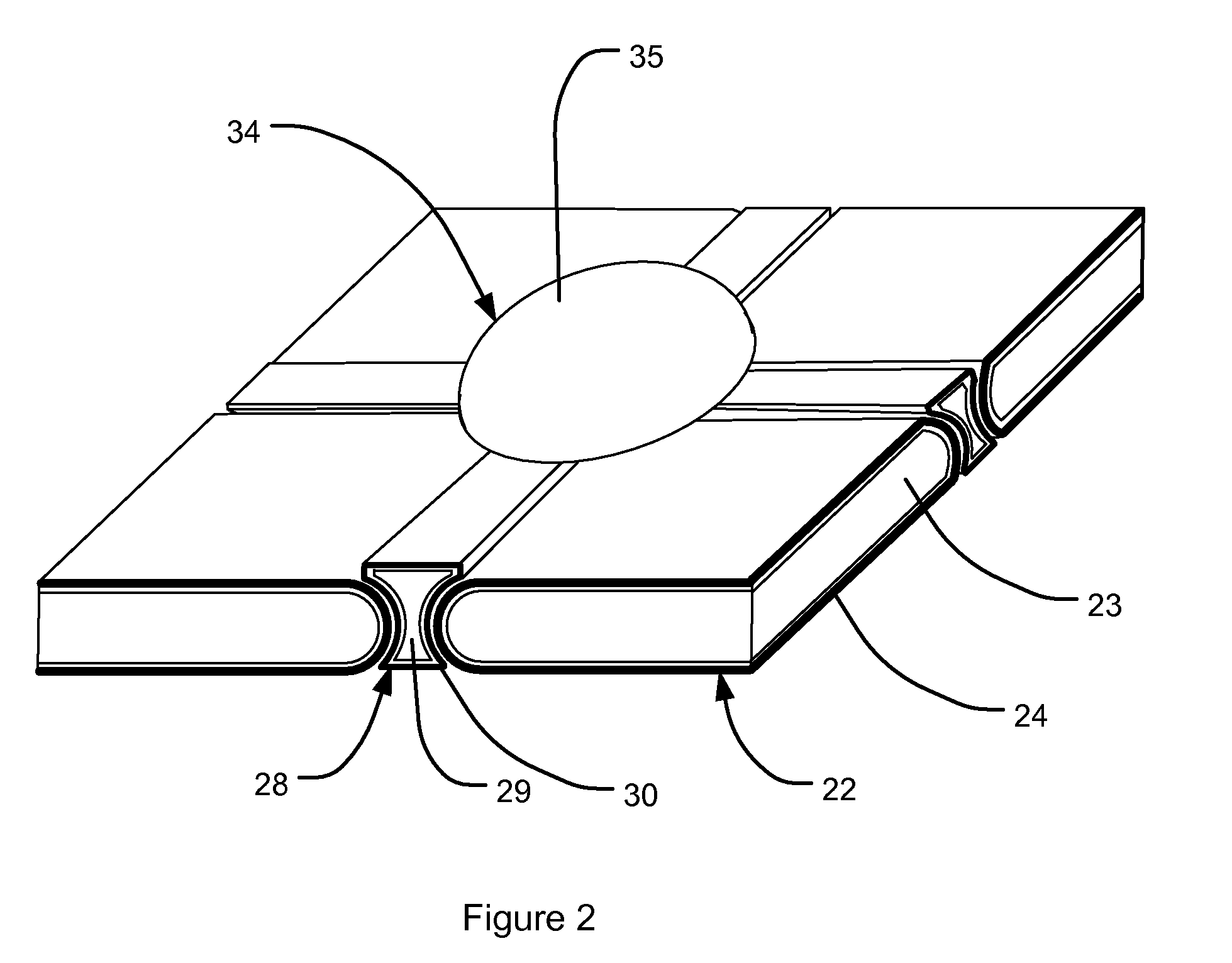

Multiple chamber airbags and methods

InactiveUS6962363B2Low amount and weightMinimally labor-intensive to manufacturePedestrian/occupant safety arrangementEngineeringSingle chamber

A two or more chambered airbag provides much improved safety and / or performance. A modified single chamber airbag can be used as the primary chamber of the two-chamber airbag. A piece of fabric of appropriate size is sewn to the inside or outside surface of the front panel of the primary chamber to create the secondary chamber. One or more apertures are opened between the primary and secondary chambers. In order for the secondary chamber to inflate properly, the tethers of the primary chamber are shortened to 50% to 80% of their original length. The size or location of the tether sewing to the inner surface of the front panel of the primary chamber is also adjusted to create a desired shape of the secondary chamber when deployed.

Owner:MILLIKEN & CO

Mosaic extremity protection system with transportable solid elements

A flexible armor system adaptable to a garment suitable for extremity protection uses planar, polygon-shaped solid elements made of ceramic cores wrapped in high strength fabric and arranged with rotable edge and intersection protection as a flexible mosaic array which is bonded between an elastic strike side spall cover and a high tensile strength flexible backer layer, further supported by a substantial fiber pack. A progressive mode of localized system failure during a ballistic strike includes: a projectile penetrating the spall cover, fracturing the ceramic core of a wrapped SE while being partially deformed; the deformed projectile accelerating the fractured but still wrapped solid element before it so as to free the solid element from the array and drive it through the flexible backer as a combined mass at a reduced velocity into the fiber pack.

Owner:WARWICK MILLS INC

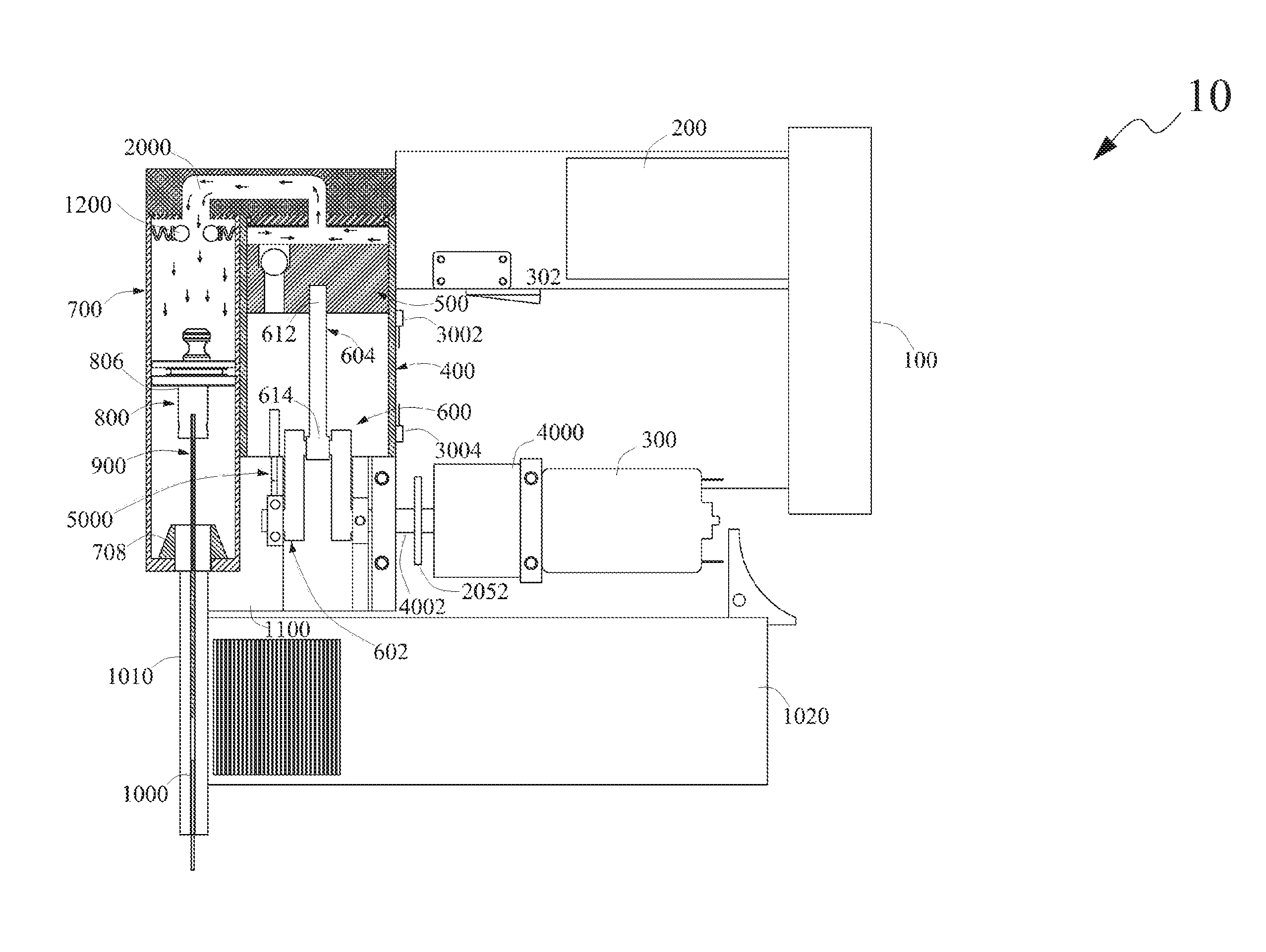

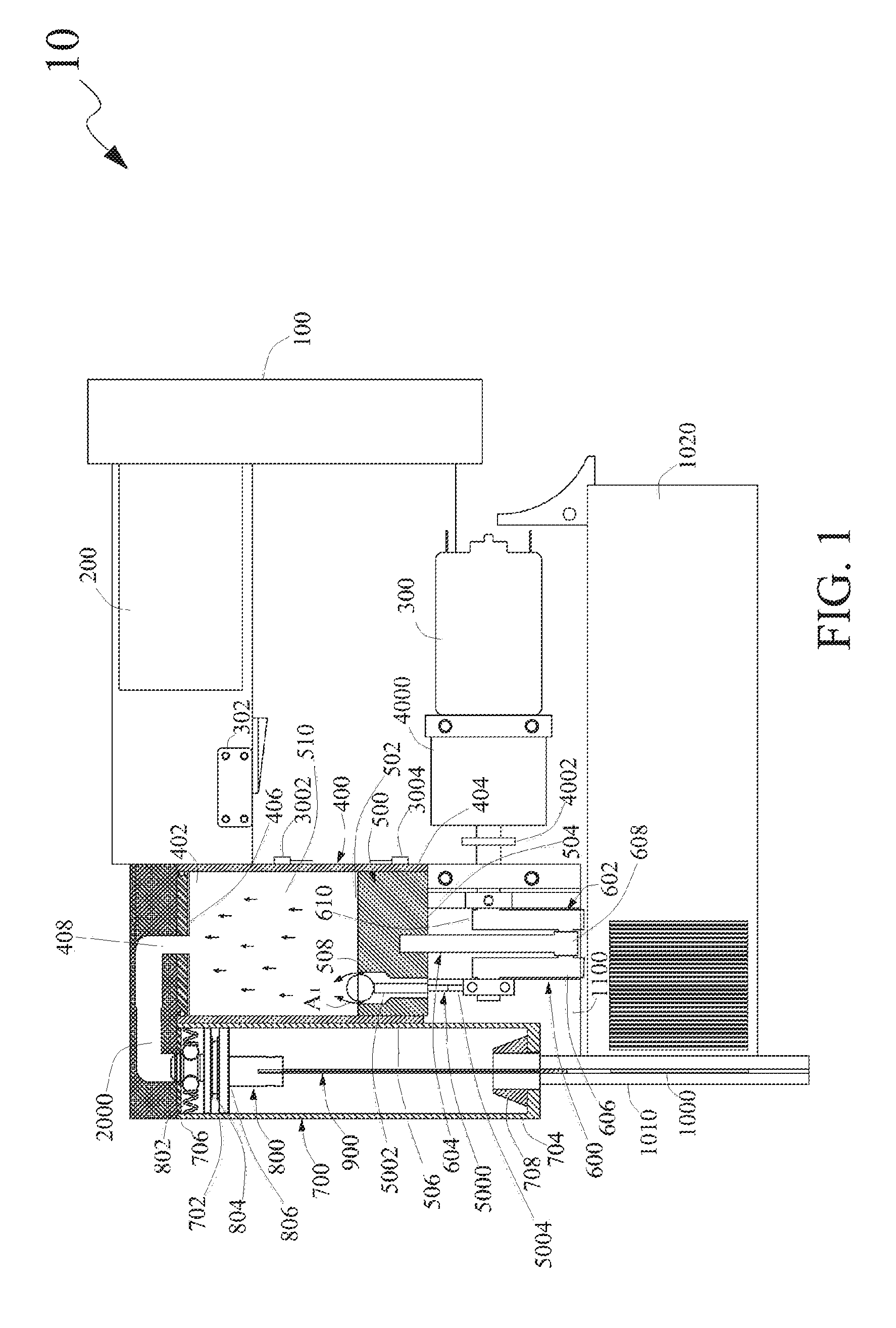

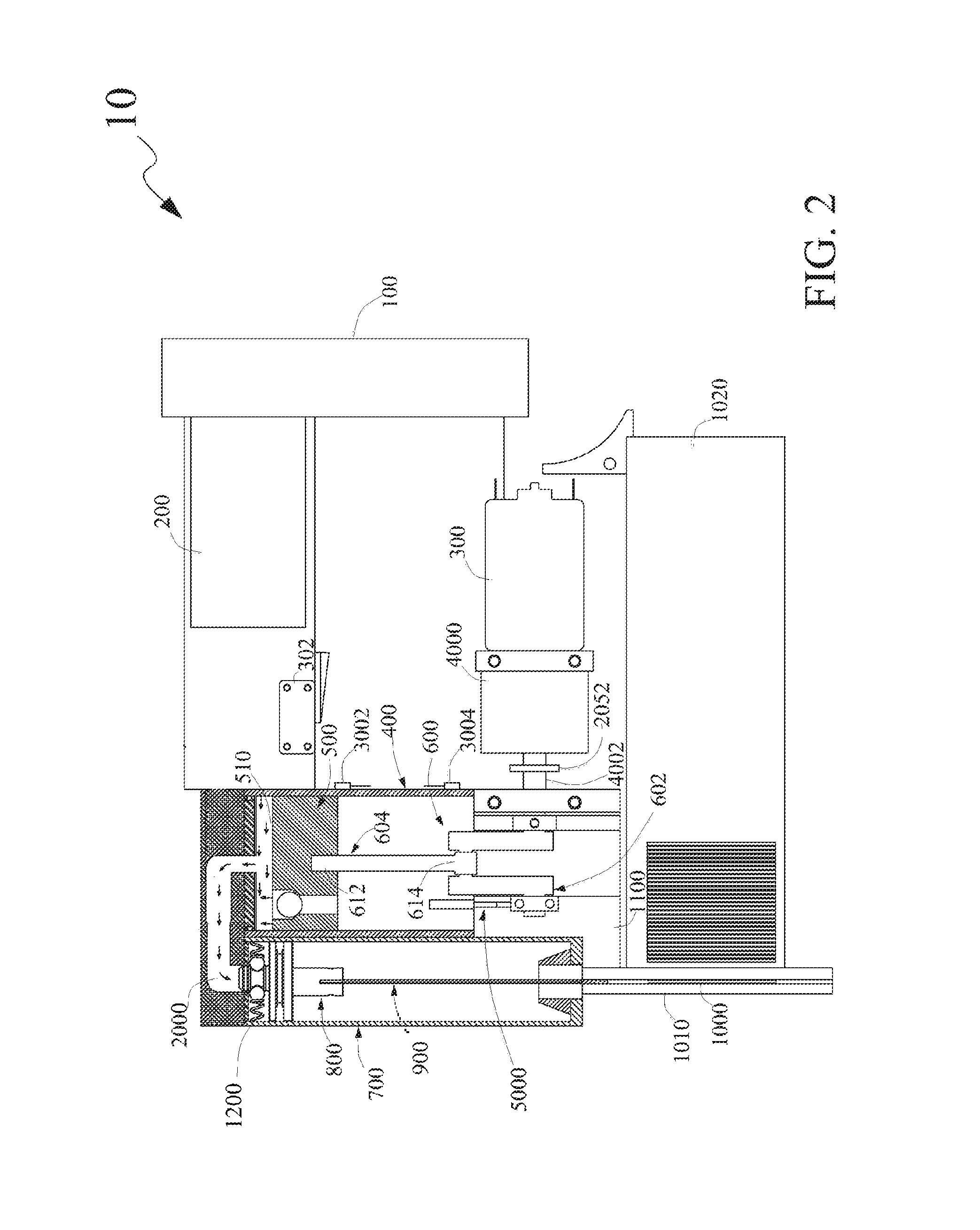

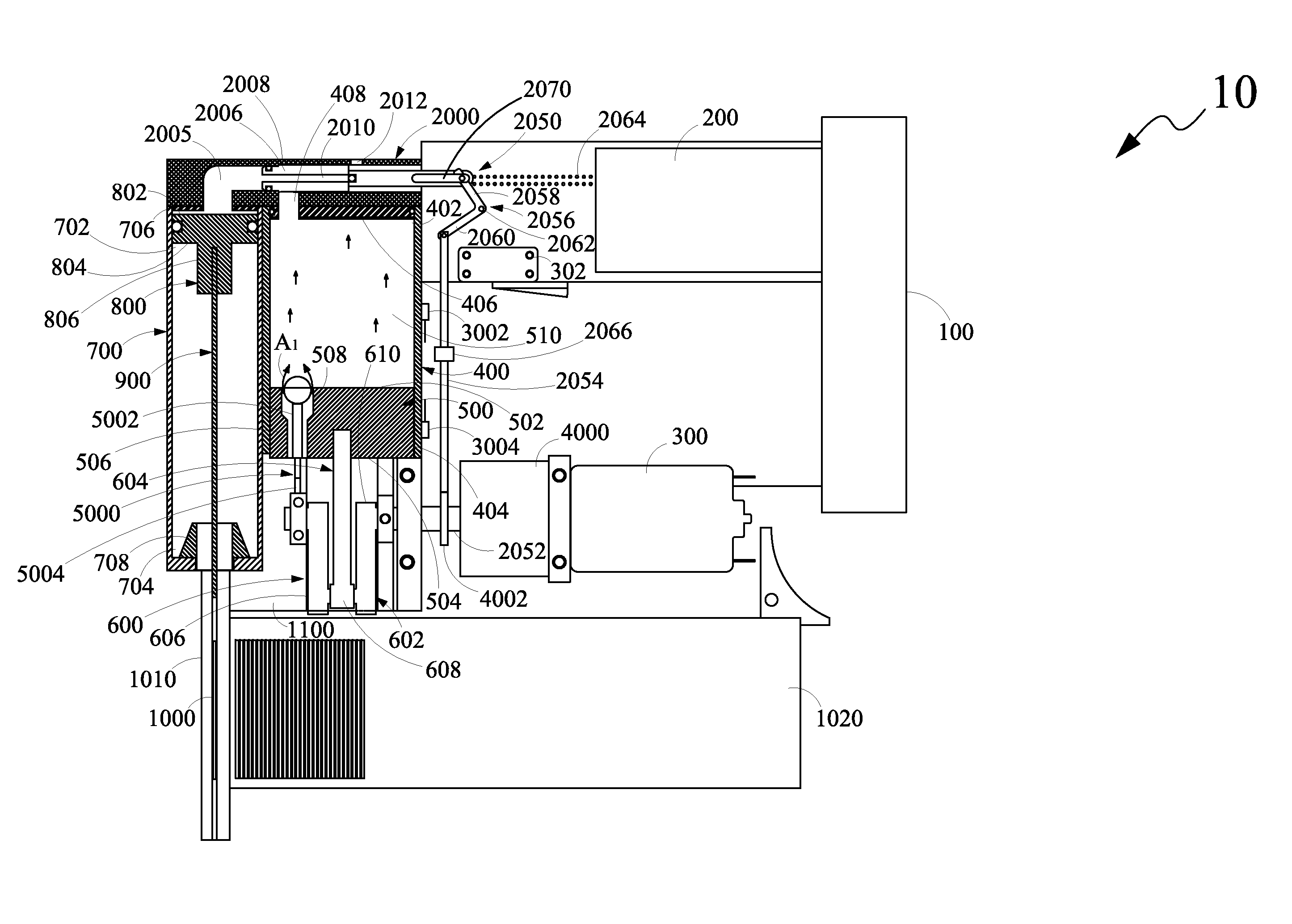

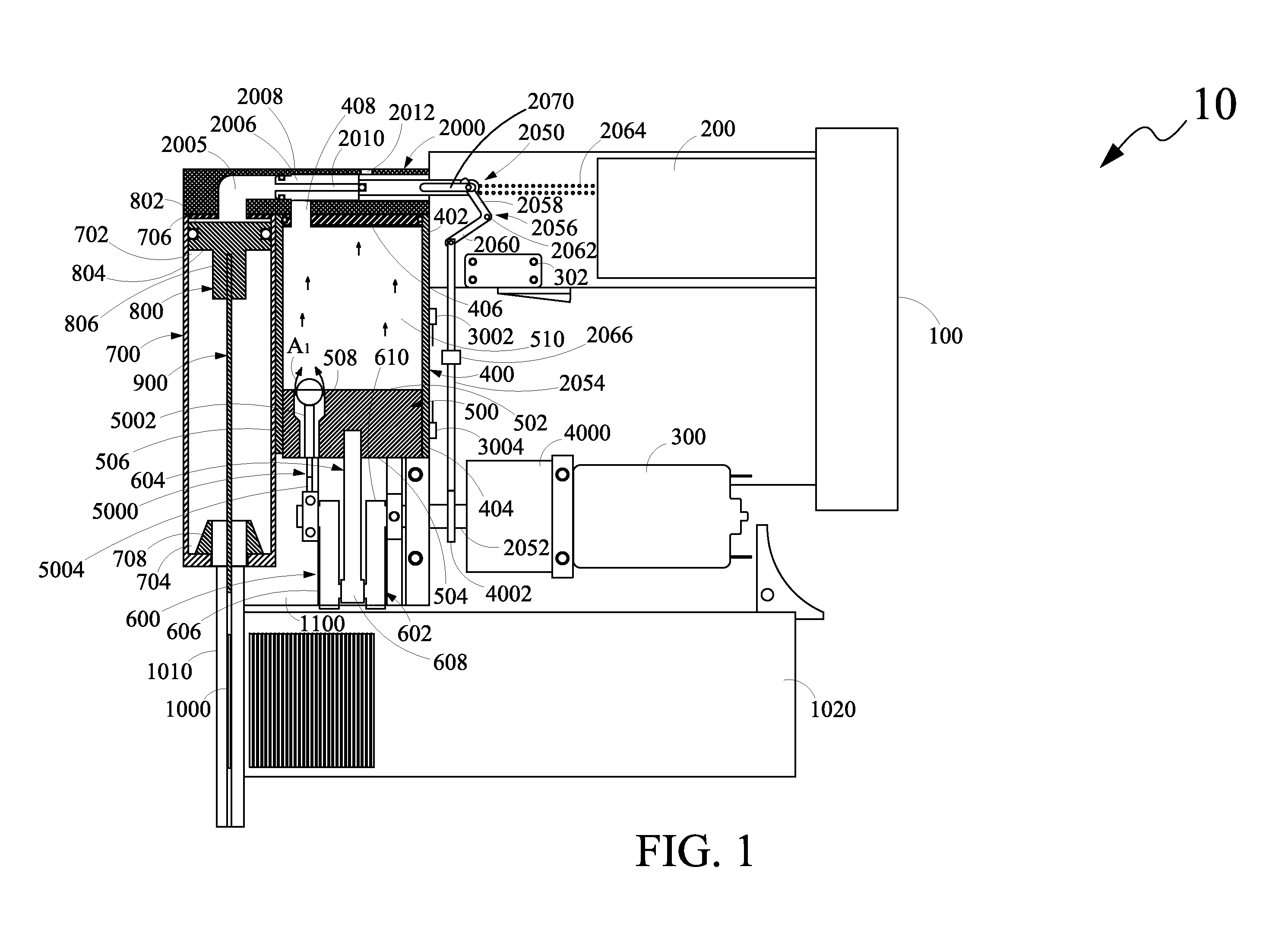

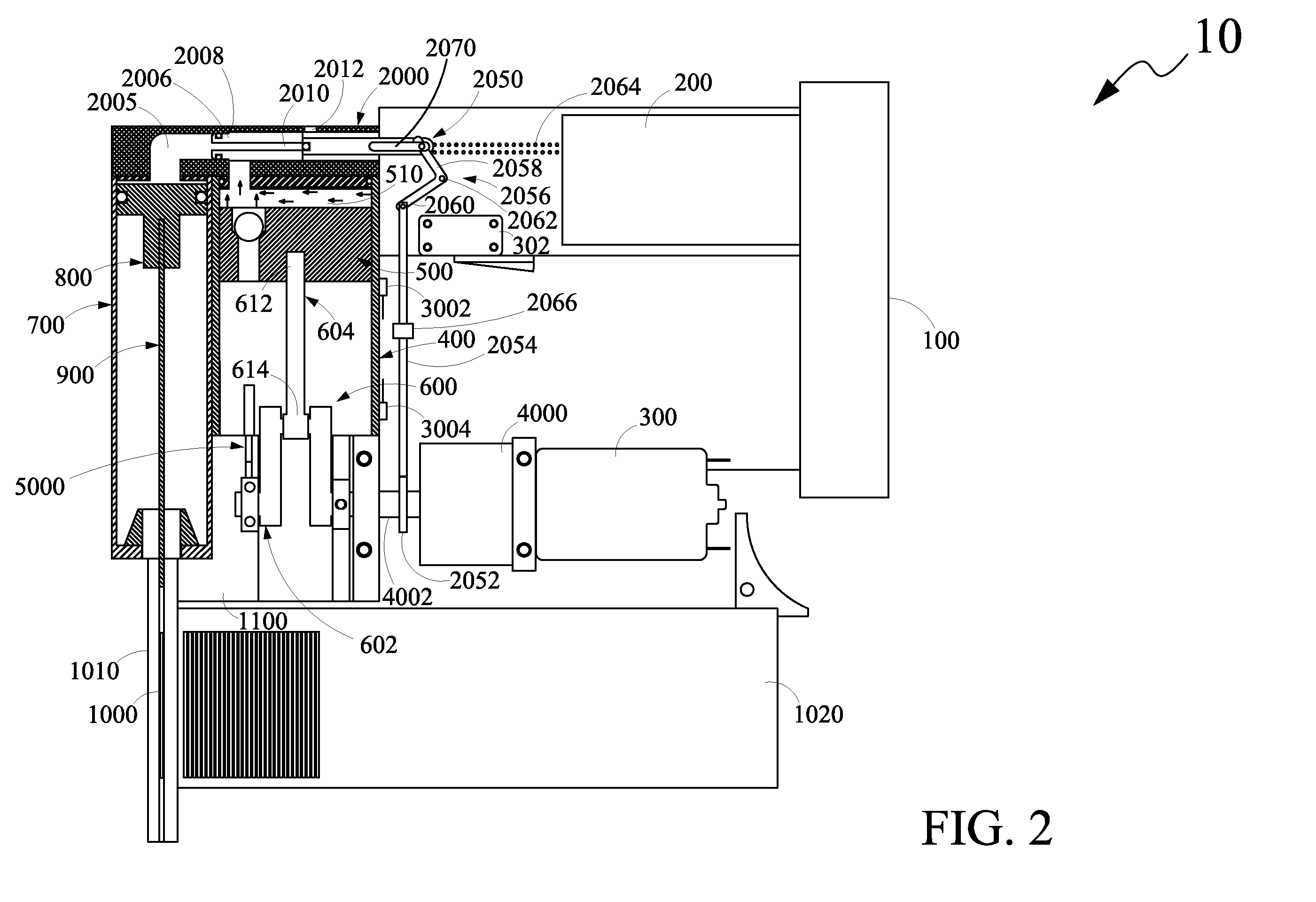

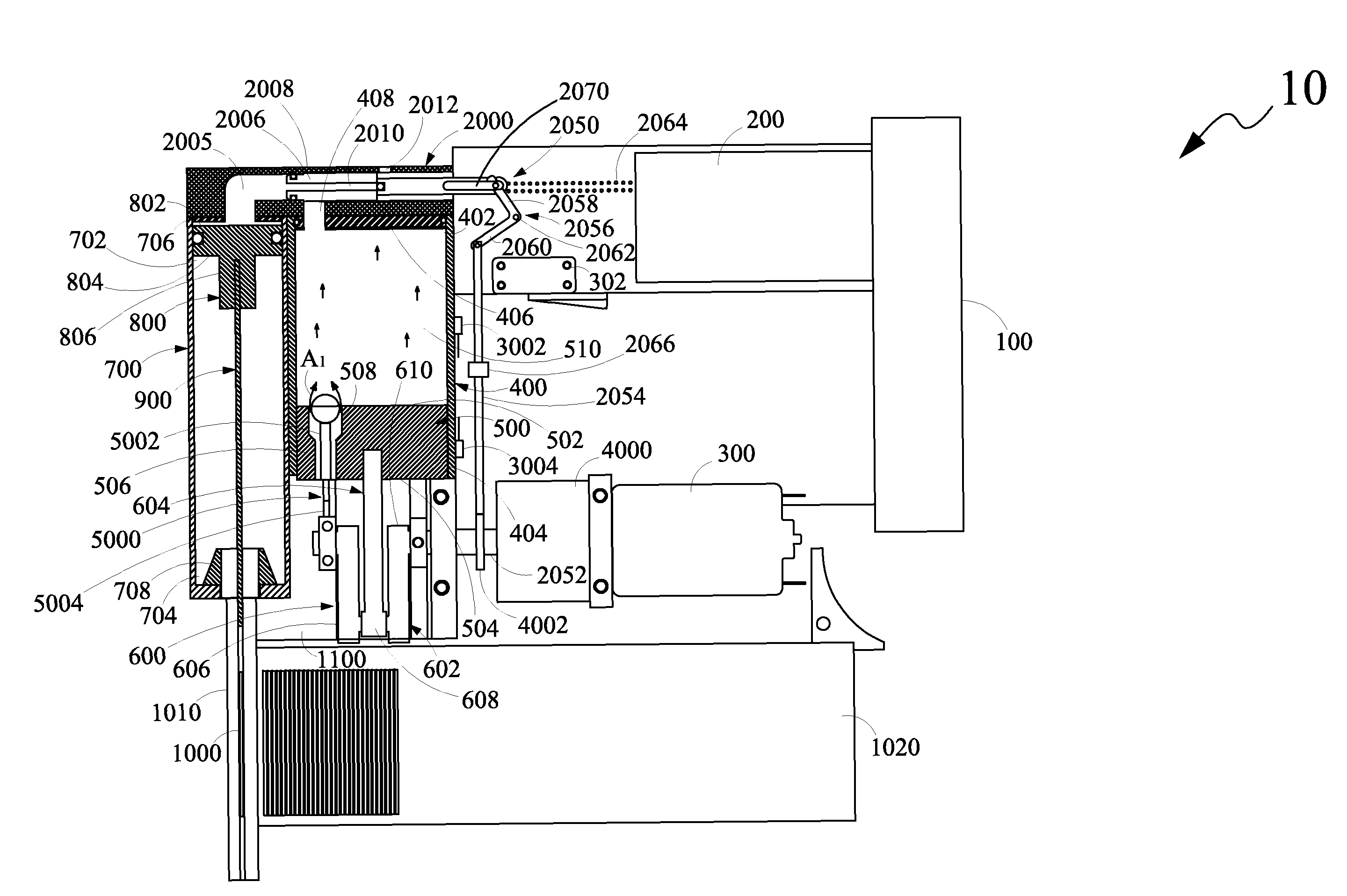

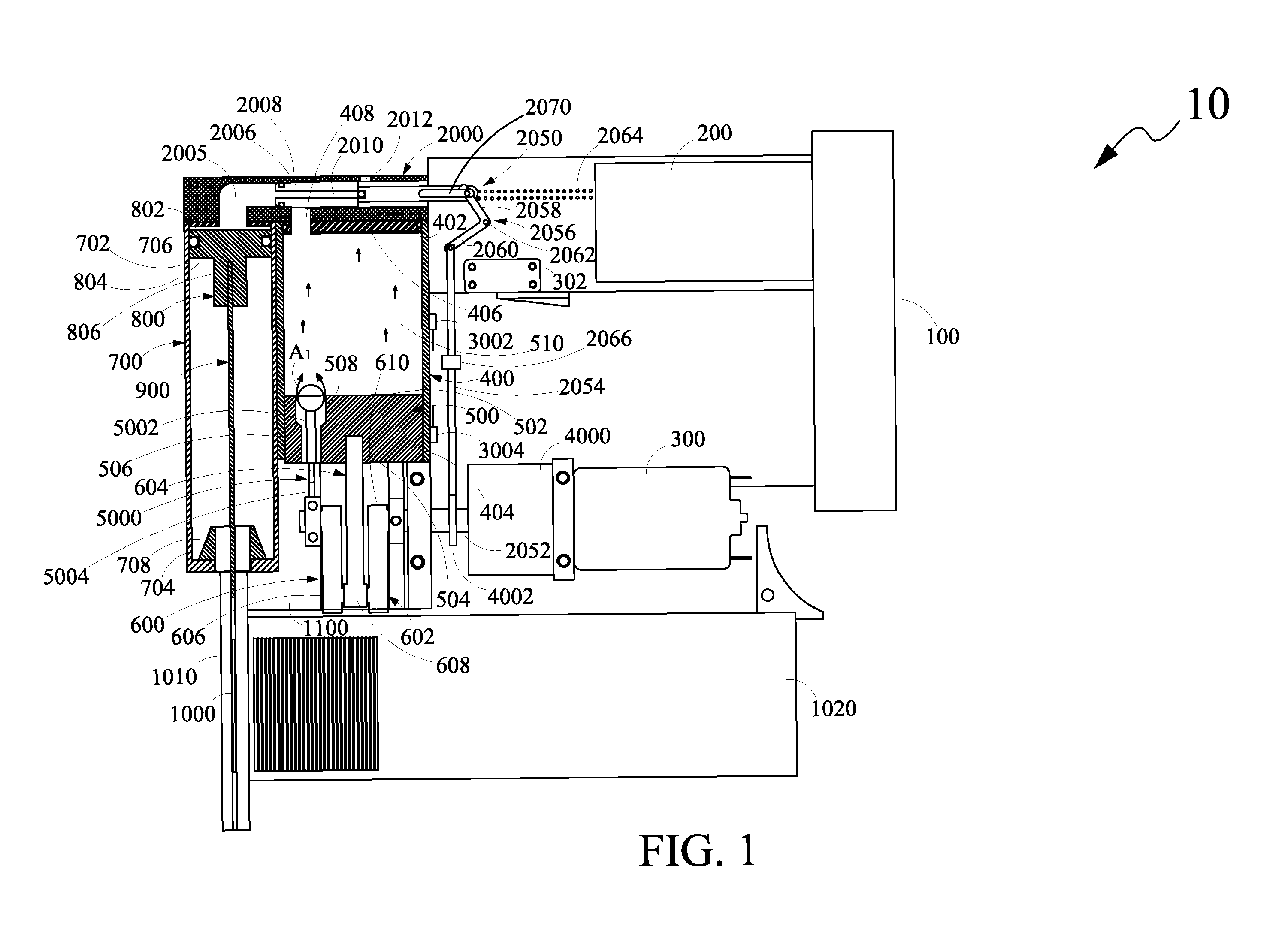

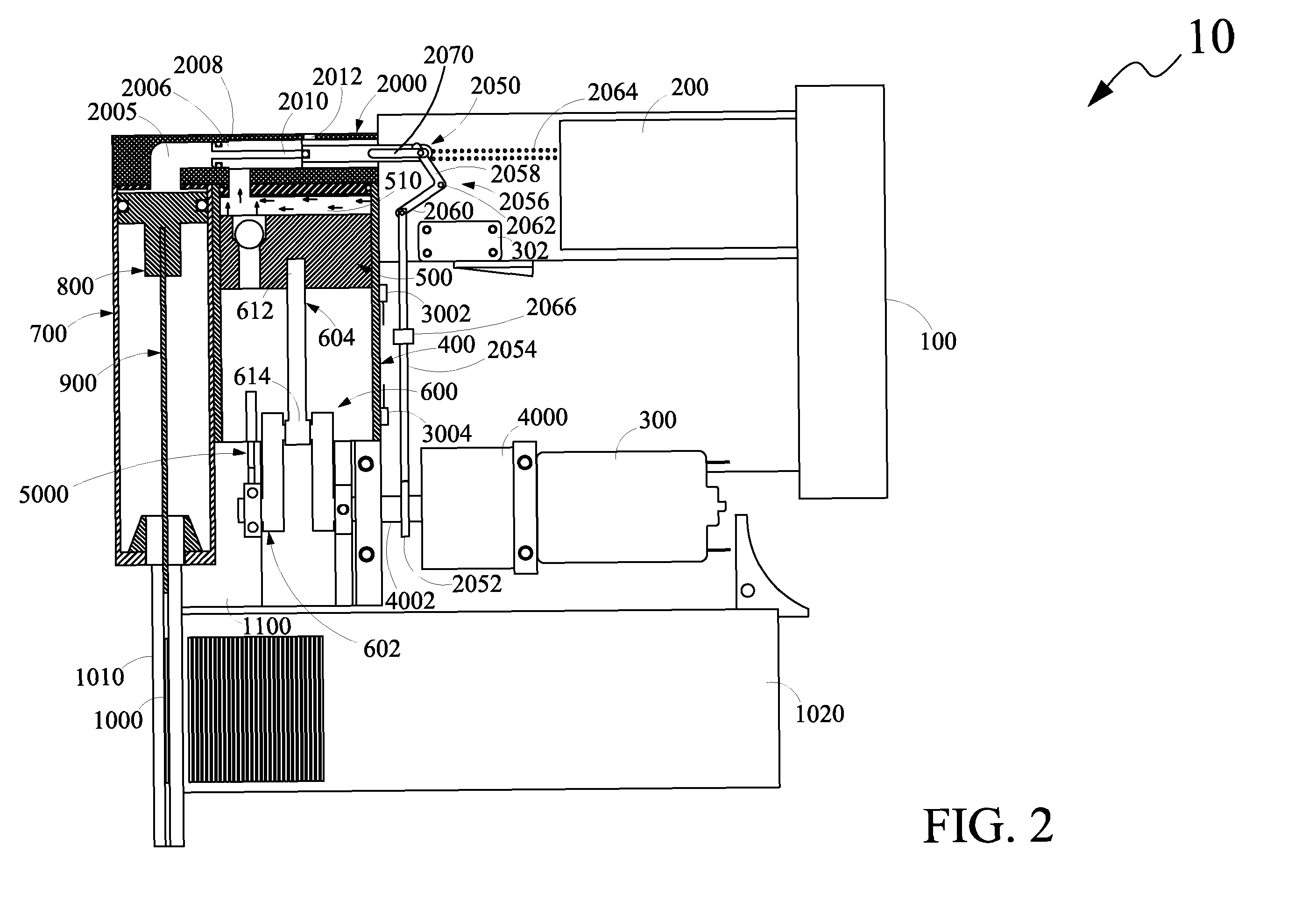

Fastener driving apparatus

ActiveUS8079504B1Avoid consumptionPrecludes of drive in drive speedStapling toolsFluid couplingsLinear motionEngineering

A fastener driving apparatus includes a power source, a control circuit, a motor, a first cylinder, a first piston, a linear motion converter, a second cylinder, a second piston, an anvil, a retention element retaining a component of the apparatus, and at least one sensor. During a compression stroke, the first piston compresses gas in a first cylinder to a predetermined pressure. Compressed gas is communicated to the second cylinder and the retention force of the retention element is overcome, to release the retained component of the apparatus, thereby causing the second piston to move linearly and enabling the anvil to drive the fastener into the workpiece. During a return stroke of the first piston, a vacuum created in the first cylinder is communicated to the second cylinder, causing the second piston and the anvil to retract to their initial positions.

Owner:TRICORD SOLUTIONS

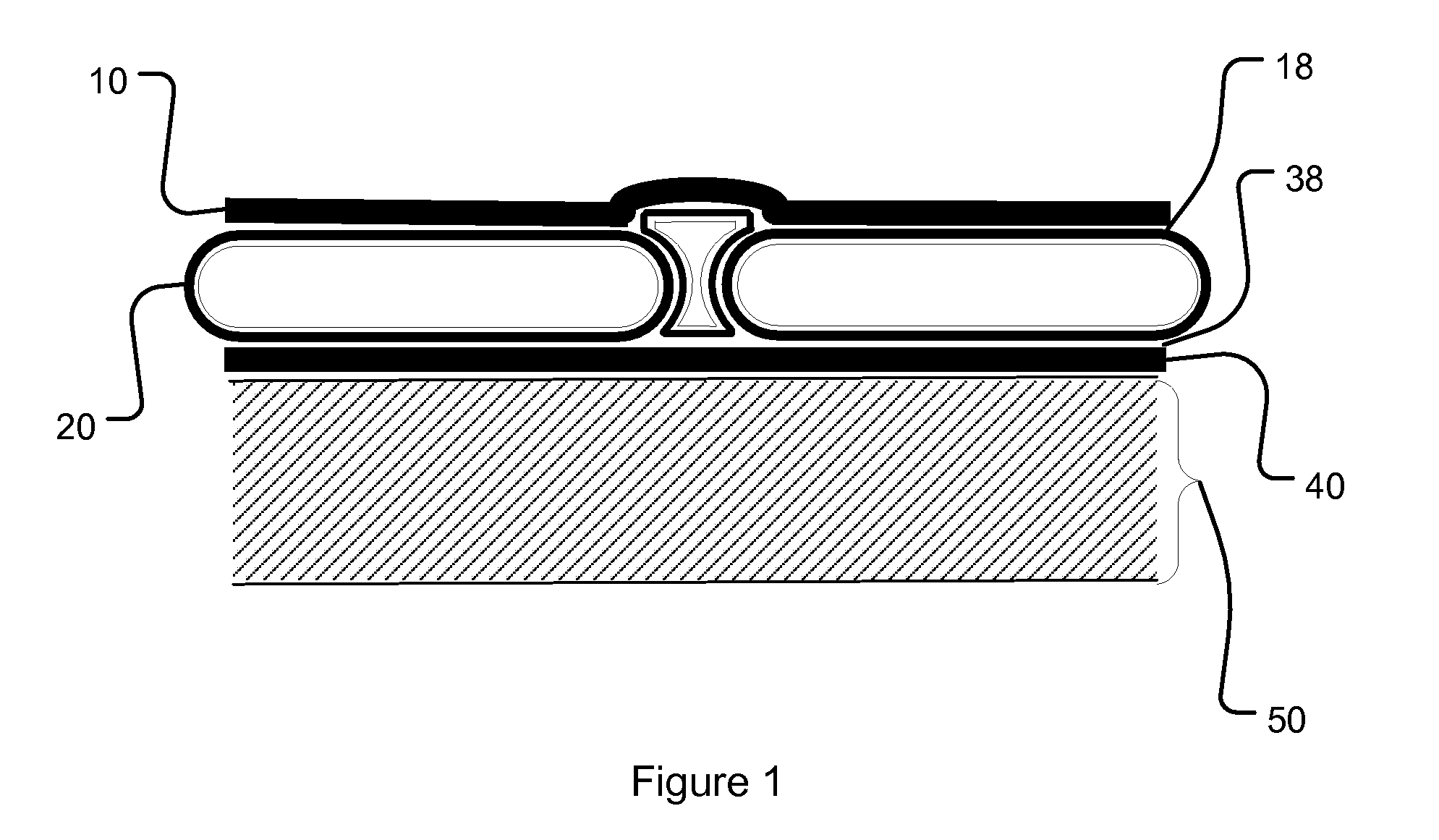

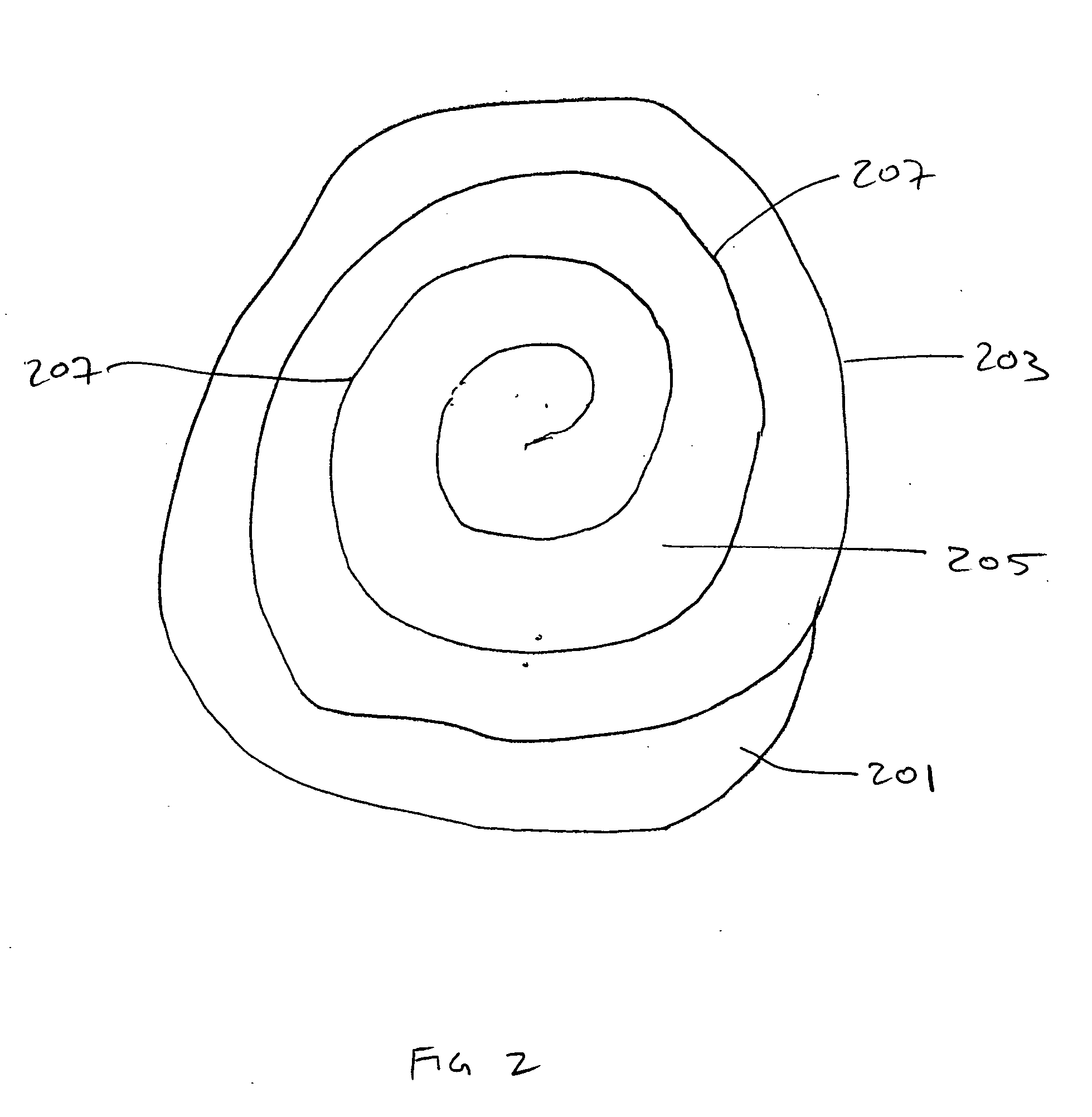

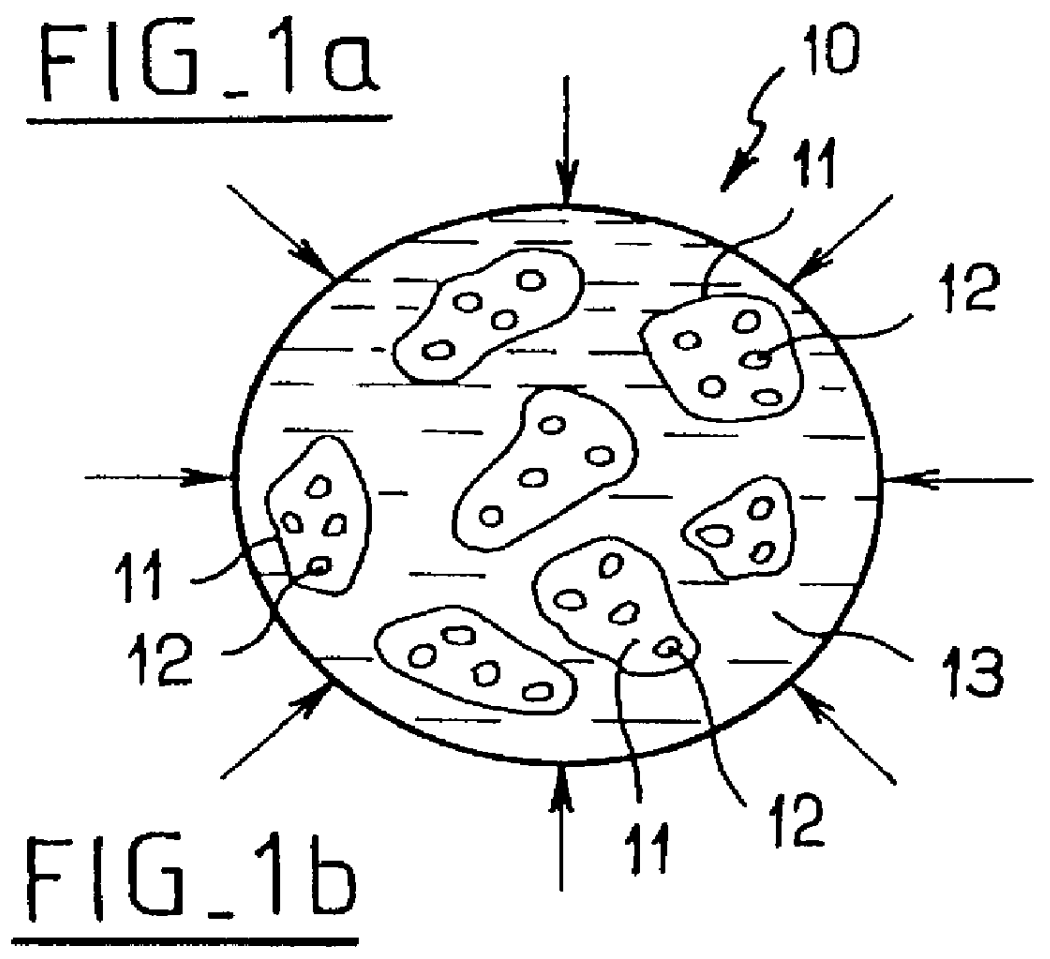

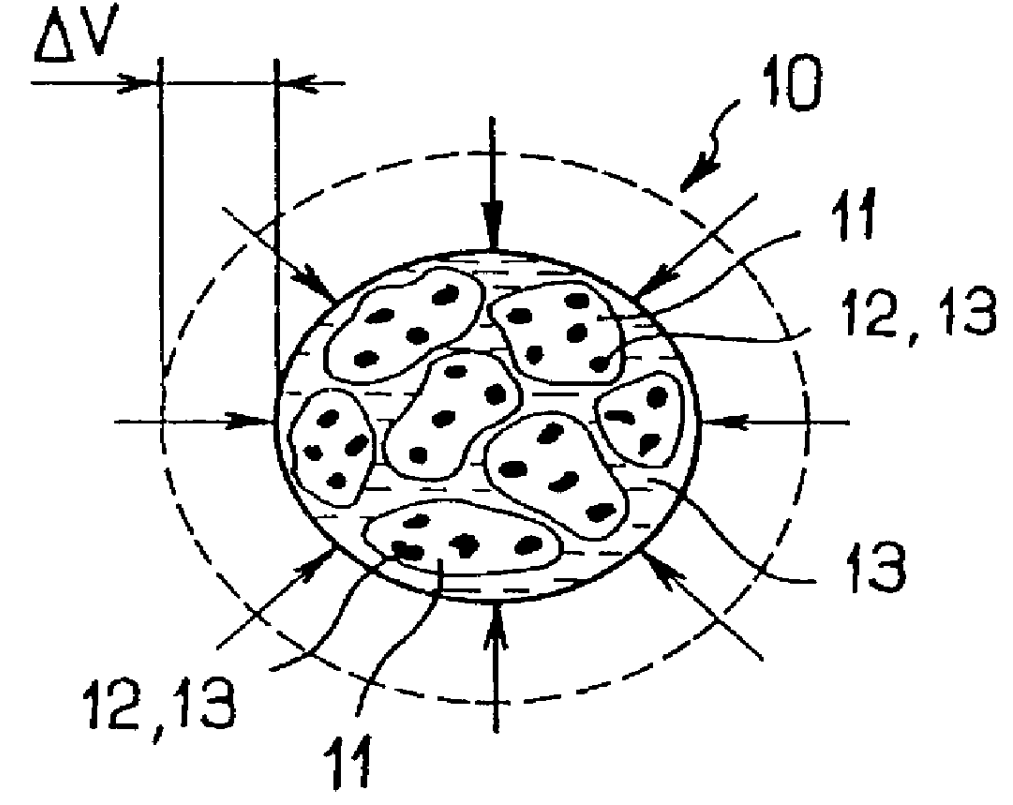

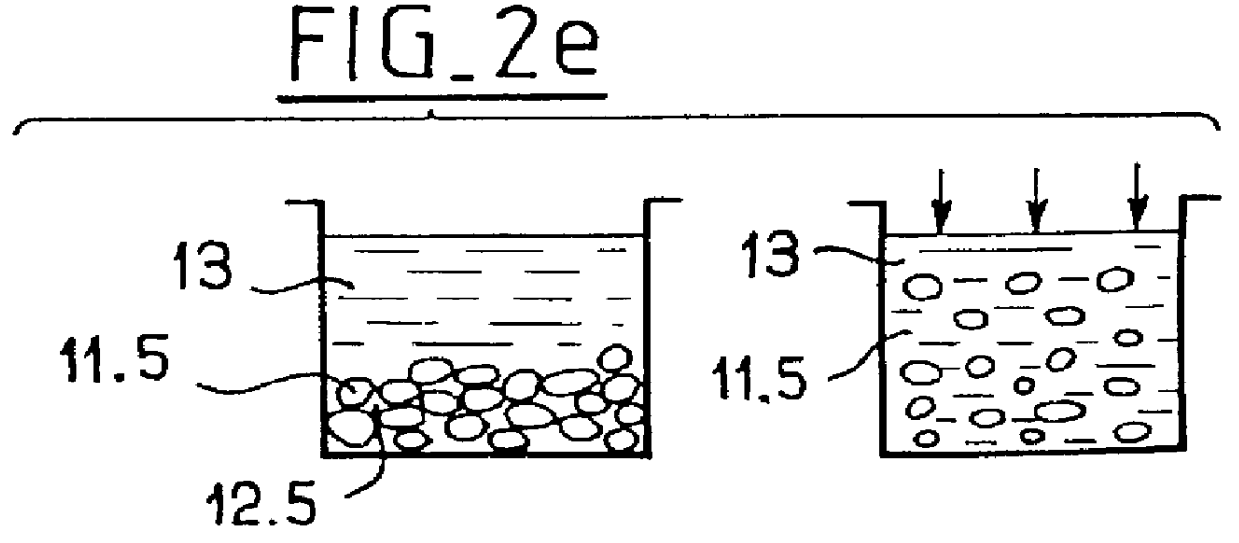

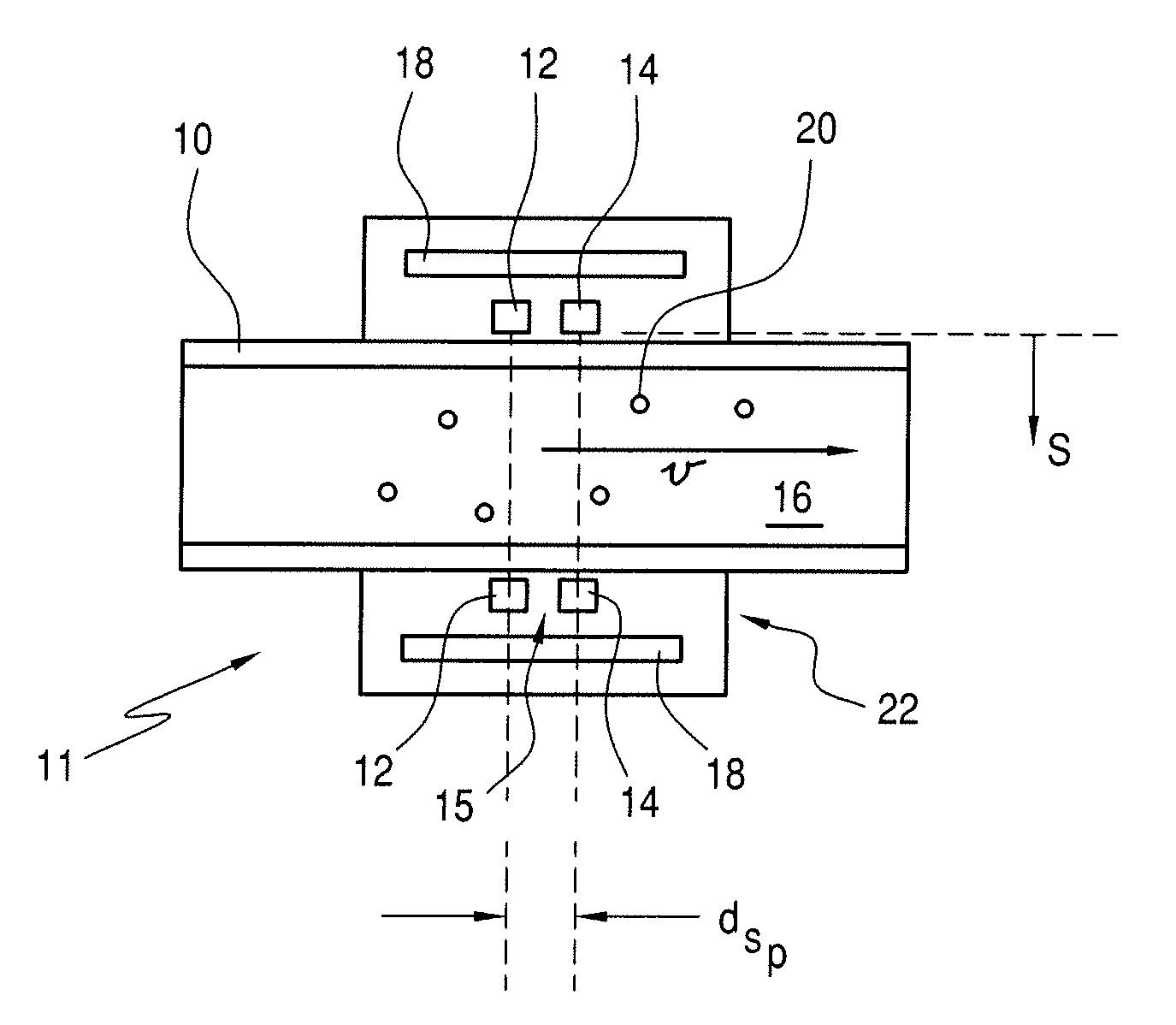

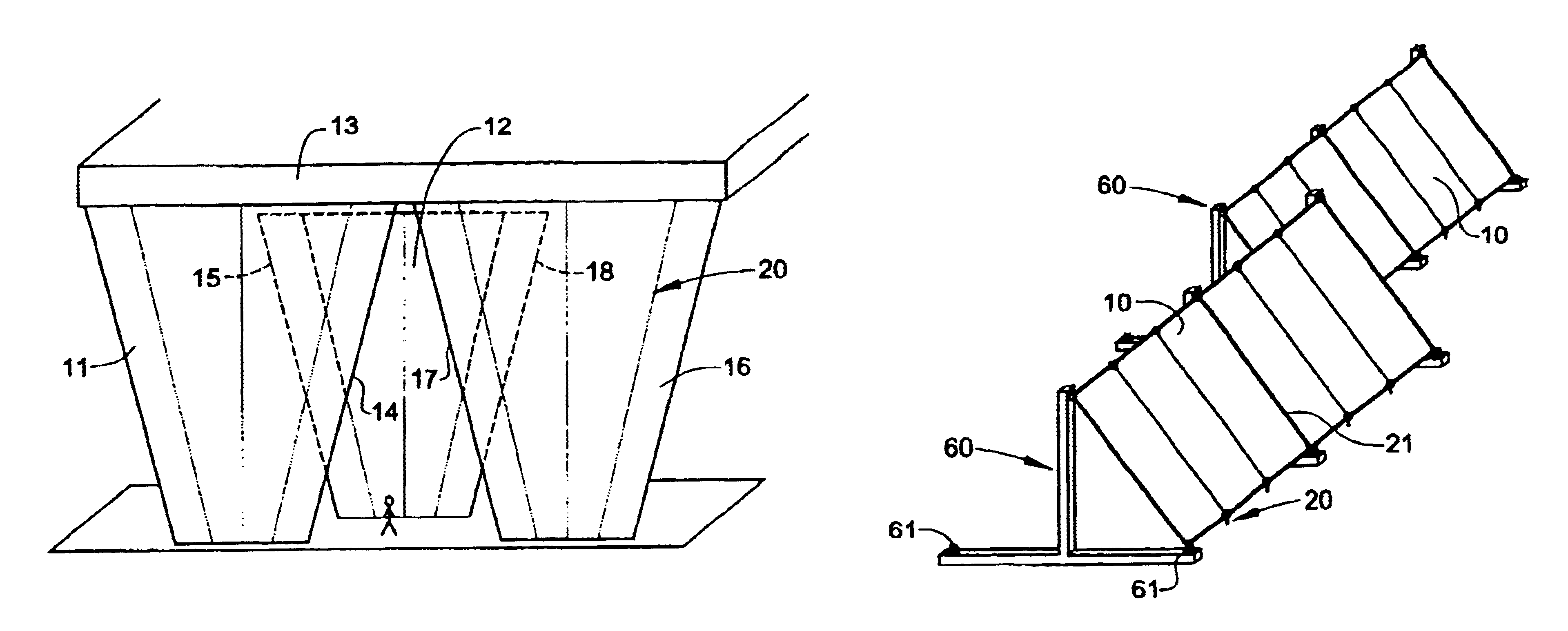

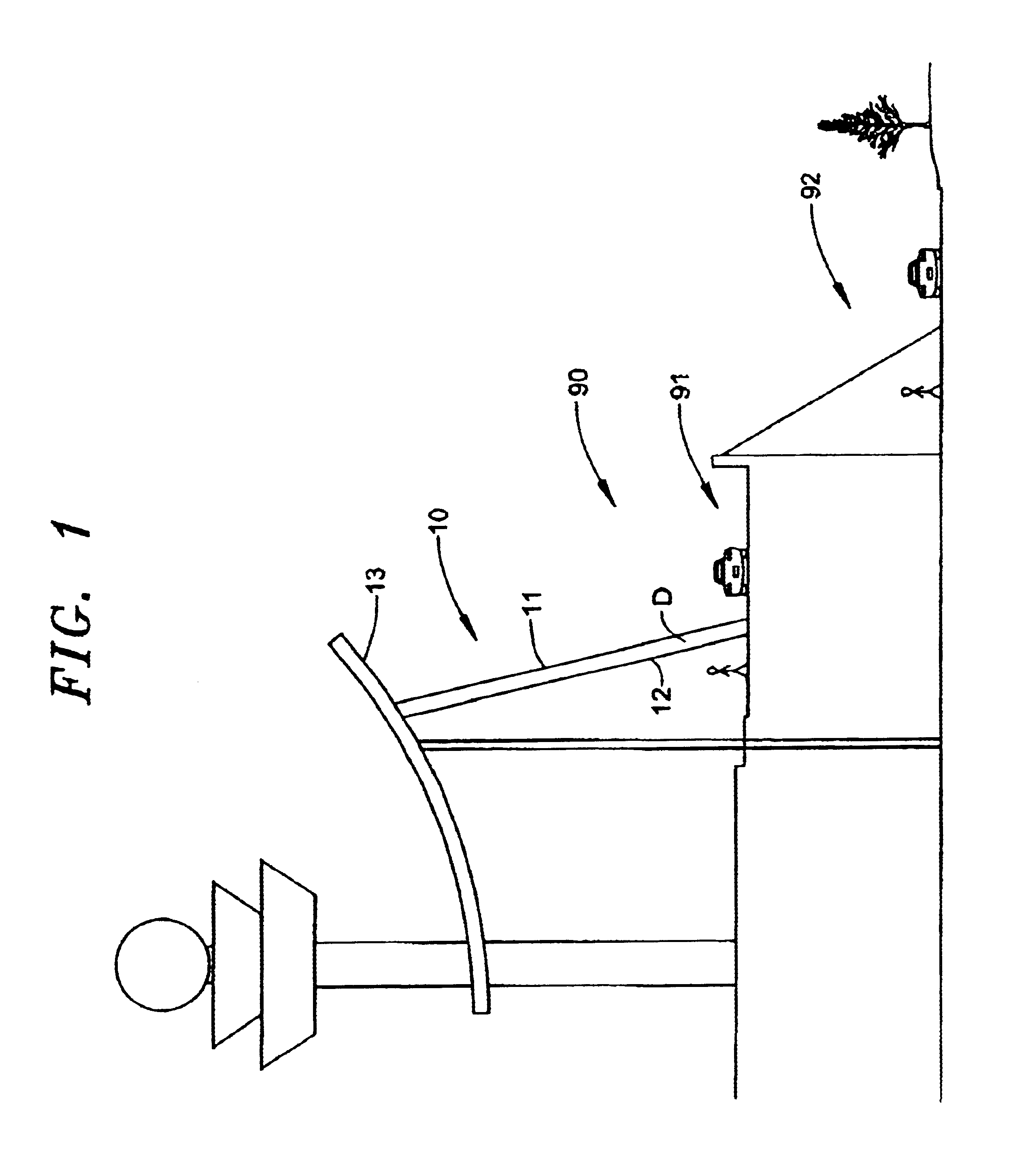

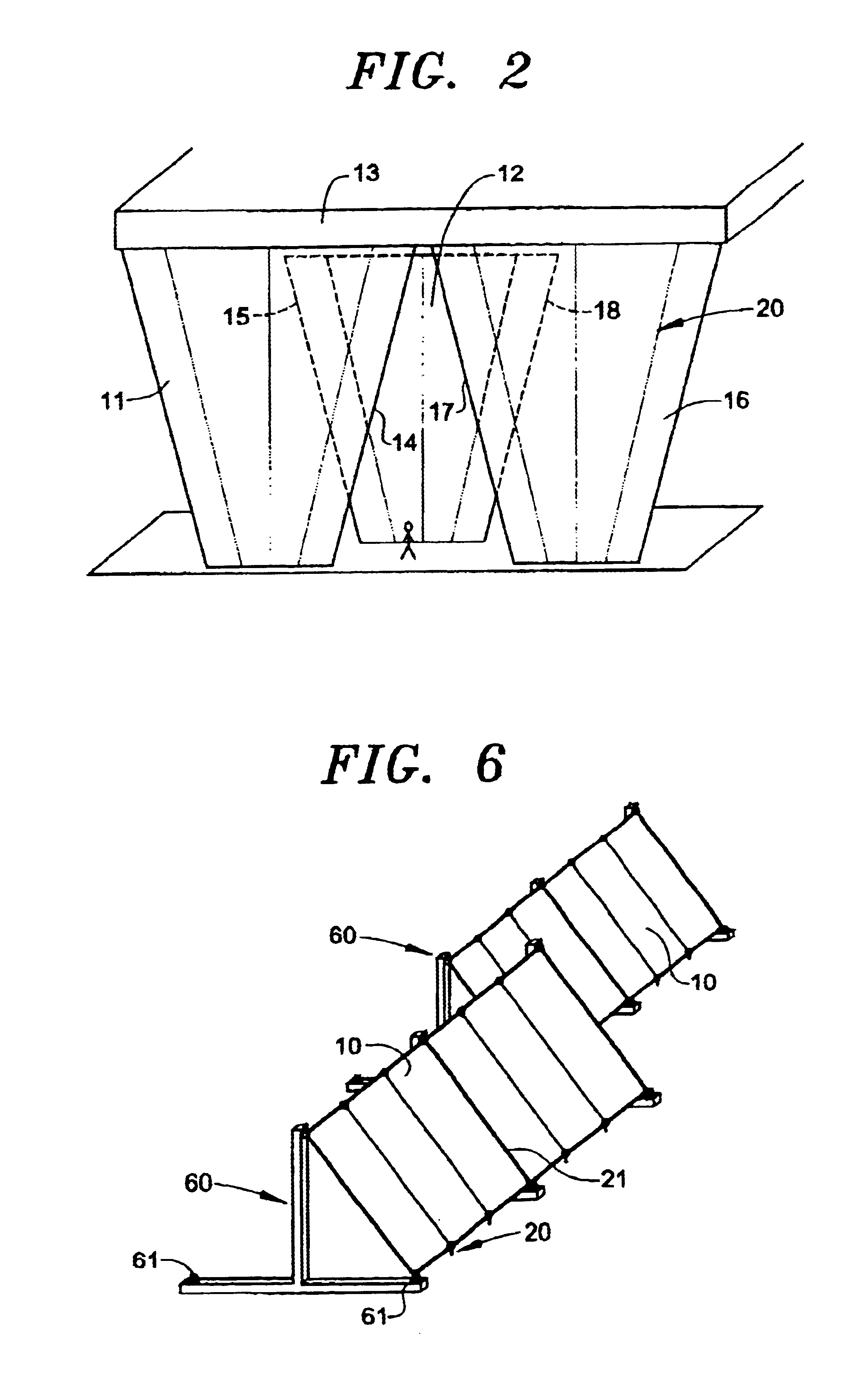

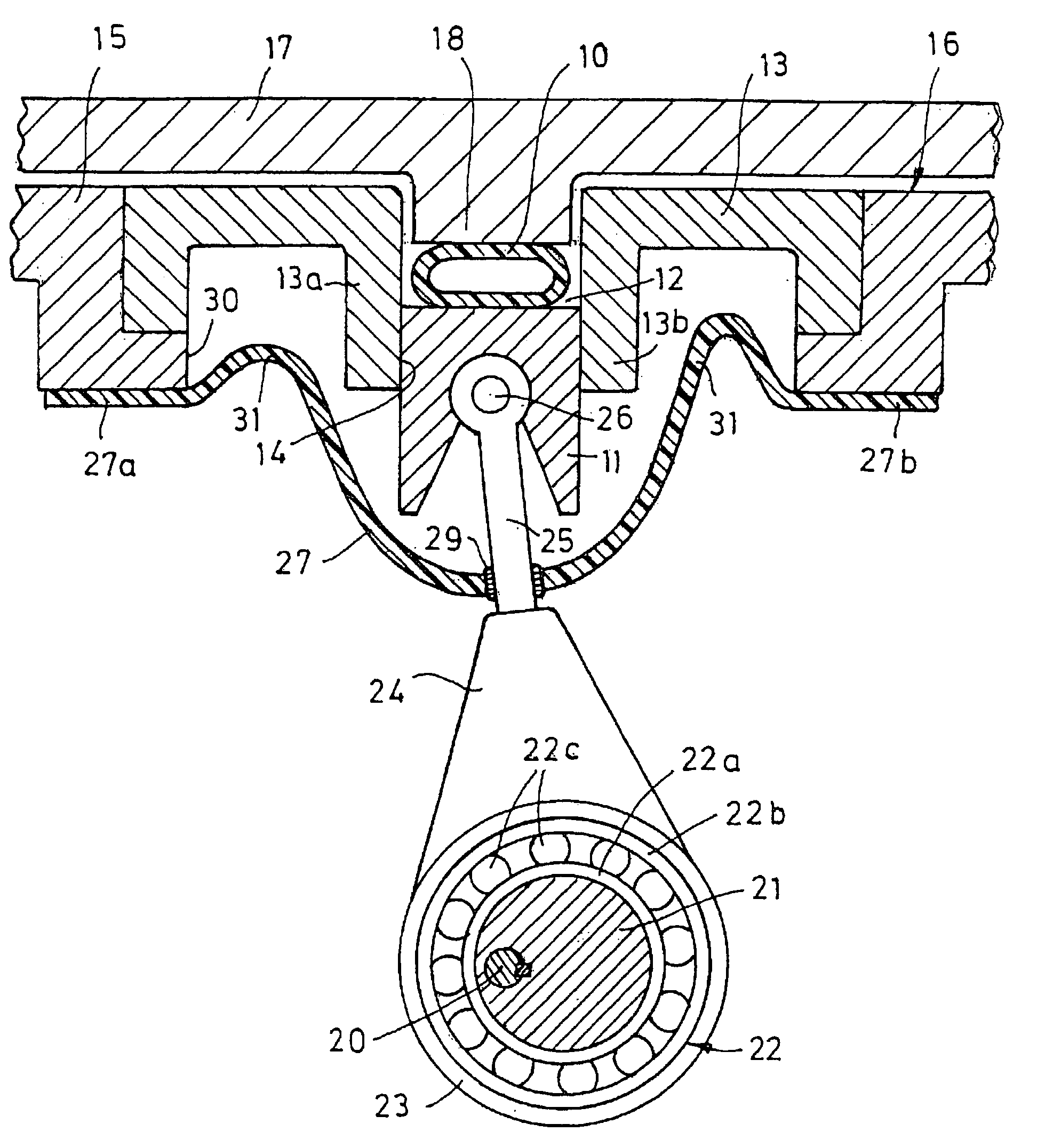

Heterogeneous structure for accumulating or dissipating energy, methods of using such a structure and associated devices

InactiveUS6052992AImprove performanceAvoid compressionHeat storage plantsLiquid springsExternal pressureEngineering

PCT No. PCT / FR95 / 01609 Sec. 371 Date Jun. 6, 1997 Sec. 102(e) Date Jun. 6, 1997 PCT Filed Dec. 6, 1995 PCT Pub. No. WO96 / 18040 PCT Pub. Date Jun. 13, 1996The invention relates to a heterogeneous structure for energy accumulation-dissipation (10), the structure being constituted by a porous capillary solid matrix (11) of open capillary porosity and of controlled topology, with capillary passages (12) of varying section and / or mutually interconnected to form labyrinths, and by a liquid (13) surrounding the porous capillary matrix and defining a liquid / solid separation surface, with the matrix (11) being lyophobic relative to said liquid. The area of the separation surface then varies isothermally and reversibly as a function of the external pressure to which the heterogeneous structure (10) is subjected.

Owner:D L D INT

EMI filter terminal assembly with wire bond pads for human implant applications

ActiveUS20050248907A1More stressImprove featuresAnti-noise capacitorsElectrotherapyElectromagnetic interferenceSoldering

An electromagnetic interference filter terminal assembly for active implantable medical devices includes a structural pad in the form of a substrate or attached wire bond pad, for convenient attachment of wires from the circuitry inside the implantable medical device to the capacitor structure via thermal or ultrasonic bonding, soldering or the like while shielding the capacitor from forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

Hermetic feedthrough terminal assembly with wire bond pads for human implant applications

ActiveUS7623335B2Increases moment of inertiaIncrease volumeMultiple-port networksAnti-noise capacitorsEngineeringUltrasonic bonding

A feedthrough terminal assembly for active implantable medical devices includes a structural wire bond pad for a convenient attachment of wires from either the circuitry inside the implantable medical device or wires external to the device. Direct attachment of wire bond pads to terminal pins enables thermal or ultrasonic bonding of lead wires, while shielding the capacitor or other delicate components from the forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

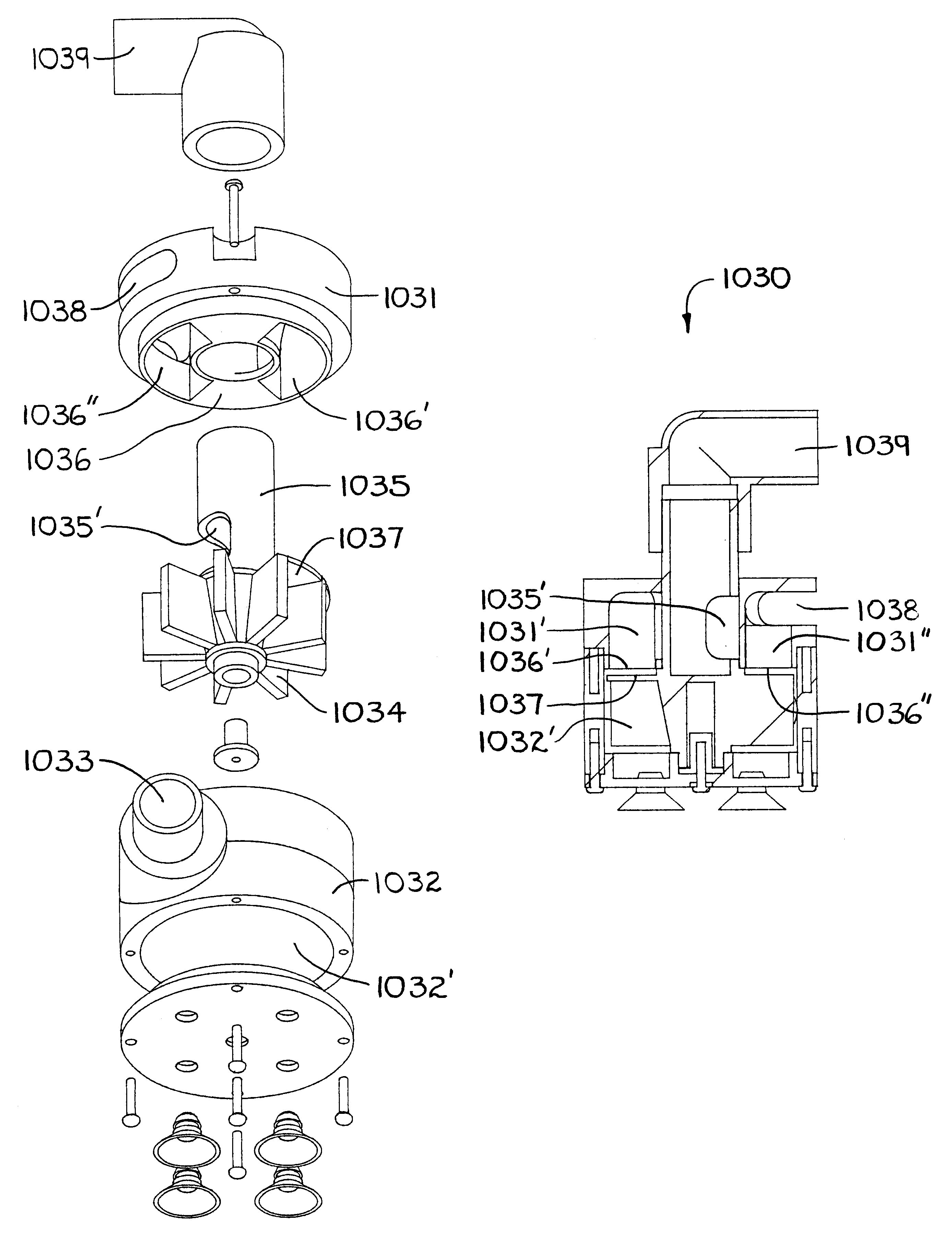

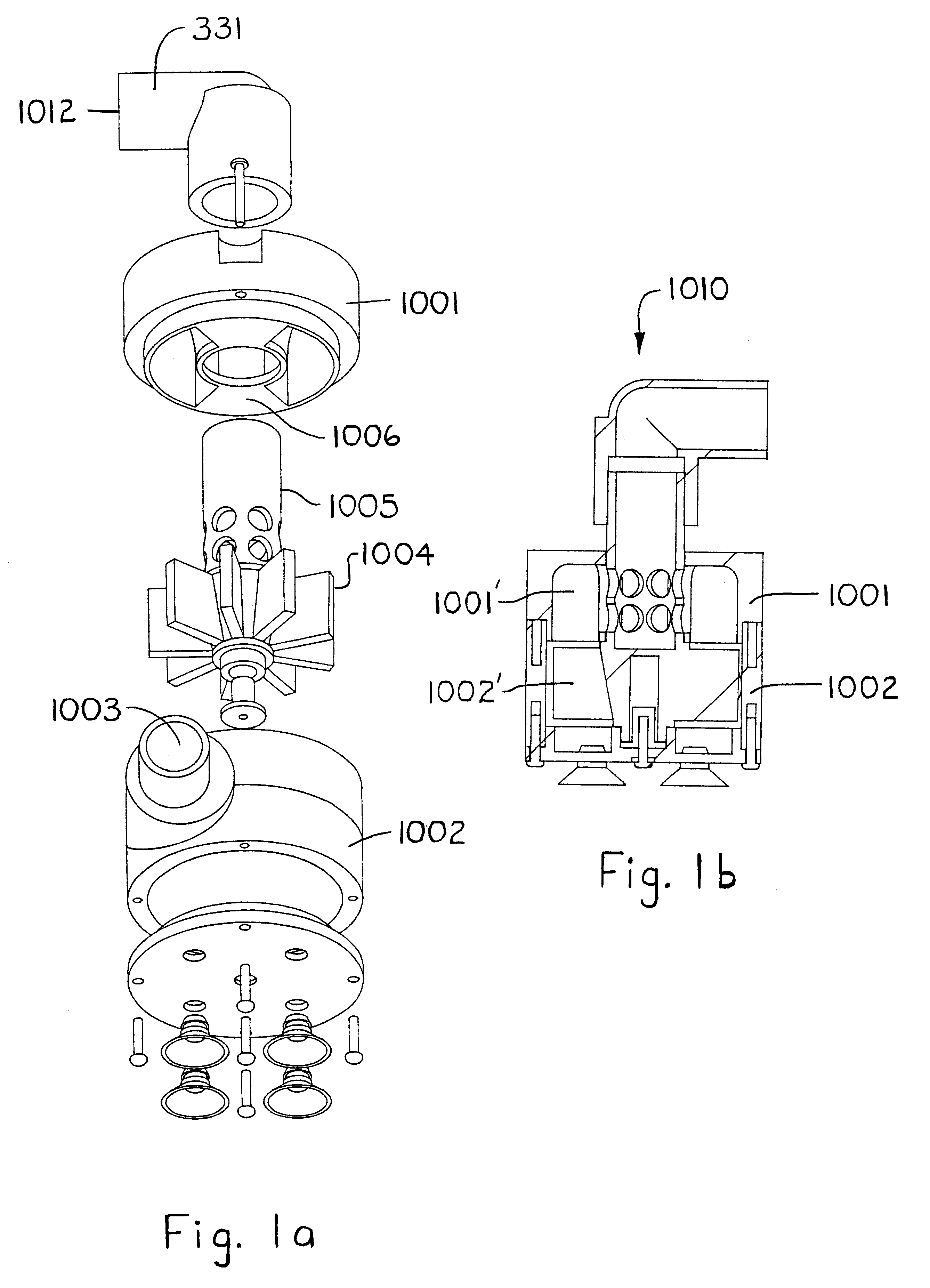

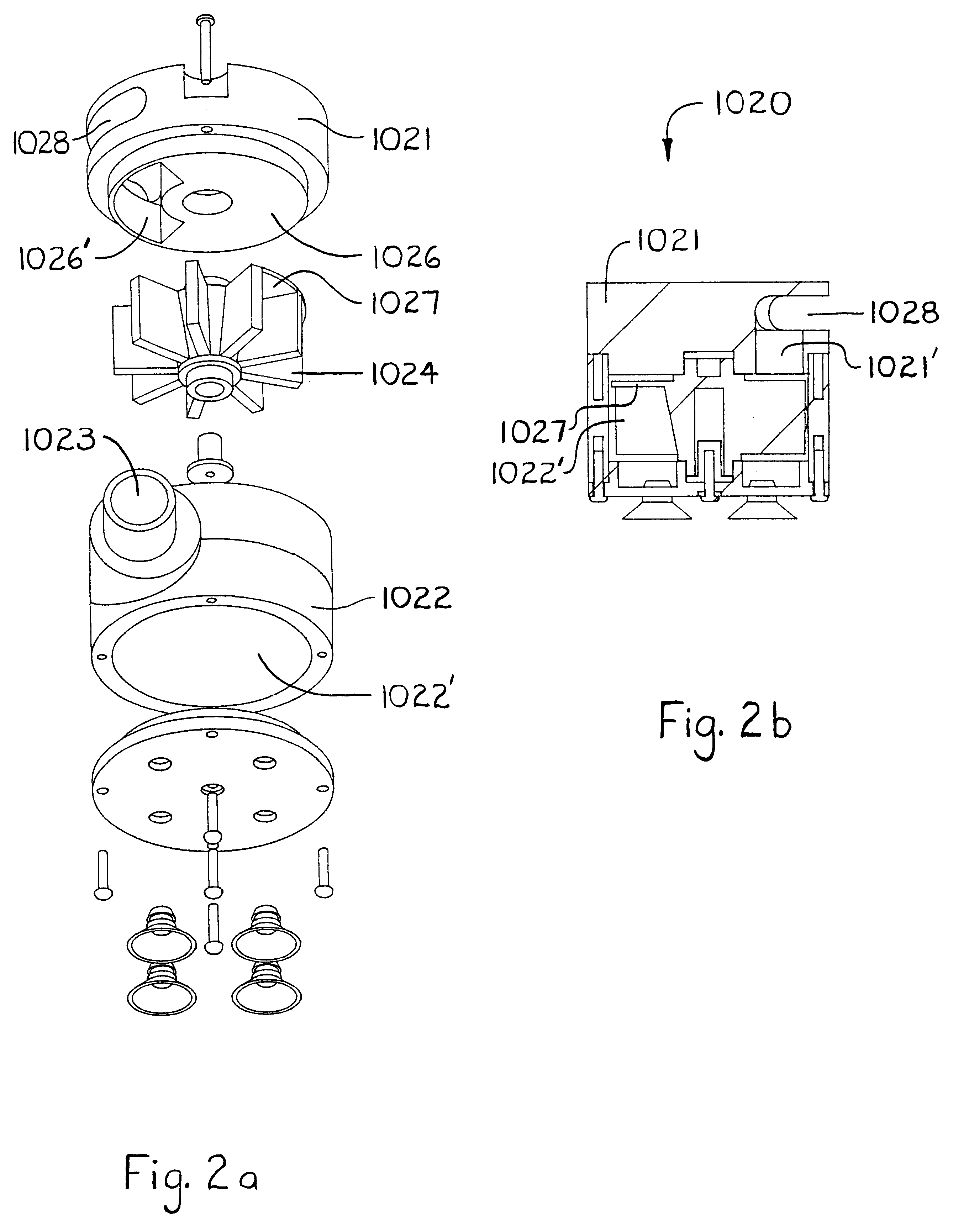

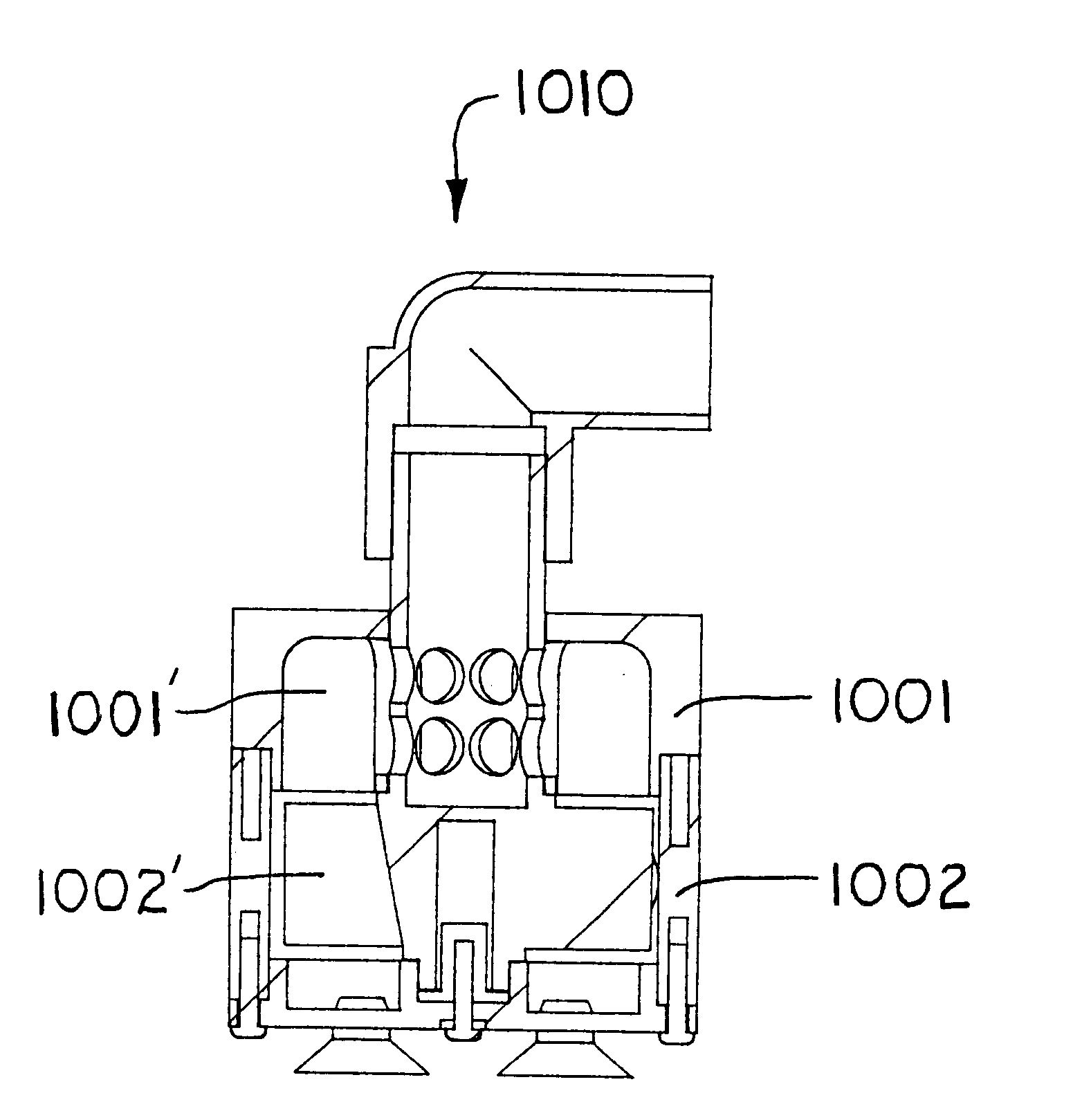

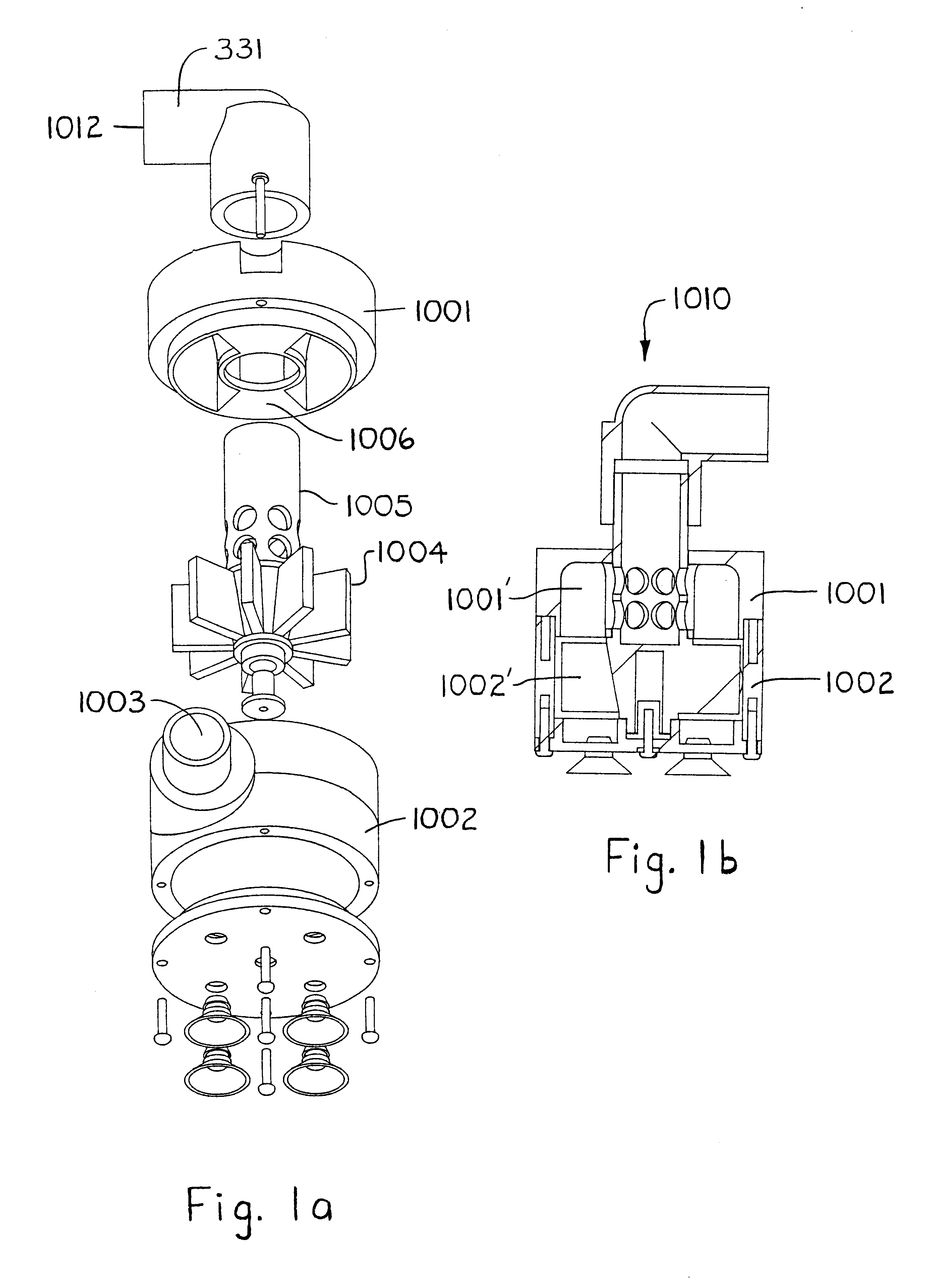

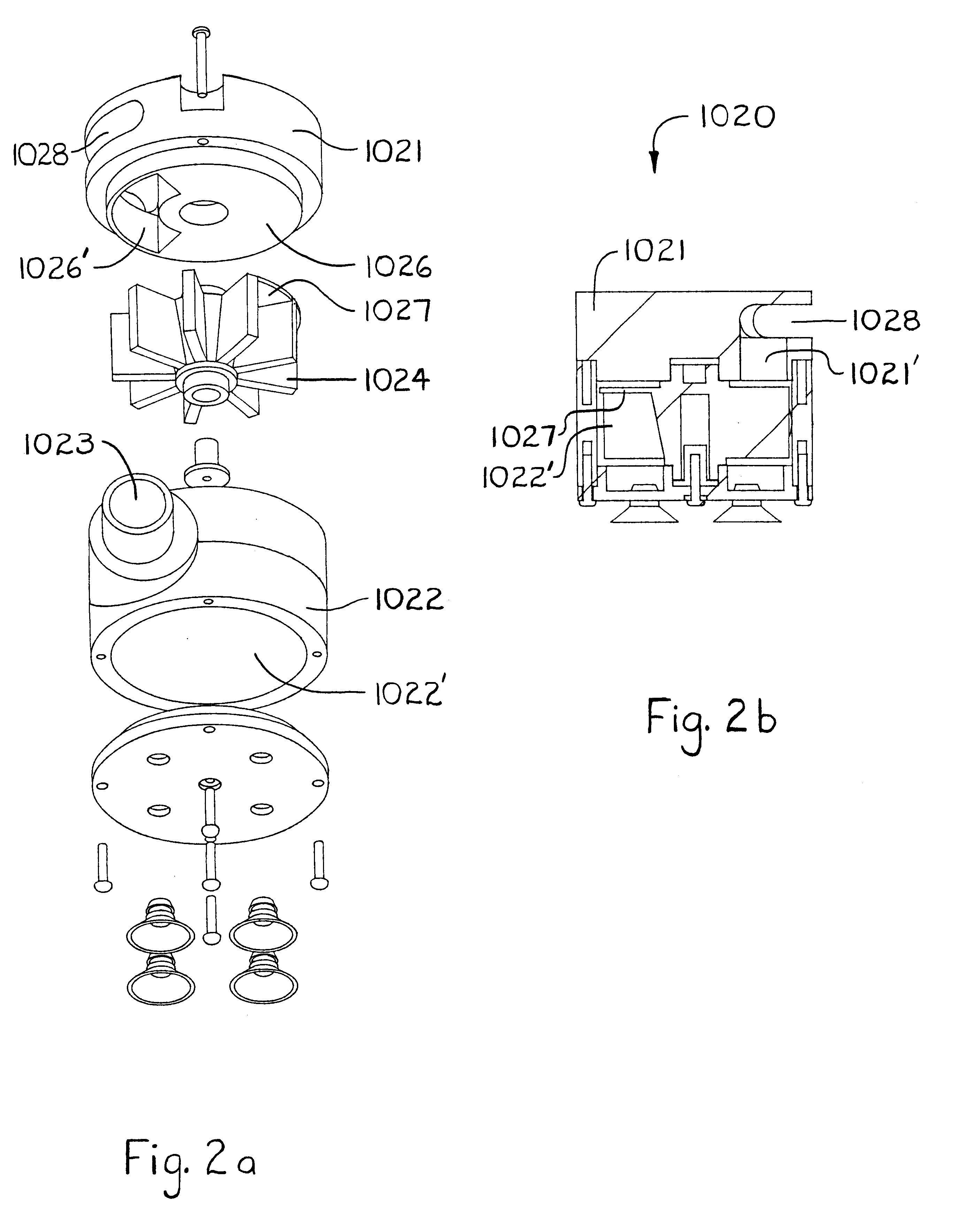

Agitators for wave-making or mixing as for tanks, and pumps and filters

A tank agitator connects to a low head feed and causes agitation by discharging through a port that might rotate, oscillate, or otherwise issue a pulsing stream. This agitator has a housing with a turbine plenum and an exhaust plenum. A turbine in the turbine plenum spins by the flowthrough of the feedwater and exhausts to the exhaust plenum. A hollow drive shaft is spun by the turbine and extends through the exhaust plenum and to terminate outside the housing. It has an aperture that allows water in the exhaust plenum to flow into its lumen. A nozzle caps the shaft and is bent such that the discharge issuing therefrom sweeps in circles with the spinning of the drive shaft. A variant form of the agitator includes a drive train that incorporates a drag link to convert the spinning input of the turbine into an oscillating output in the drive shaft. In another variant form, the discharge is pulsed. To do this, the exhaust plenum lies between an opening to the turbine plenum and a port in the housing wall to the outside. A blocker door is coupled to and driven by the spinning turbine to cycle between uncovering and covering one of the exhaust opening and the discharge port. Given the foregoing, the discharge stream issuing from the discharge port will pulse between alternating phases of flow and quiescence.

Owner:SEAMAN ANTHONY E

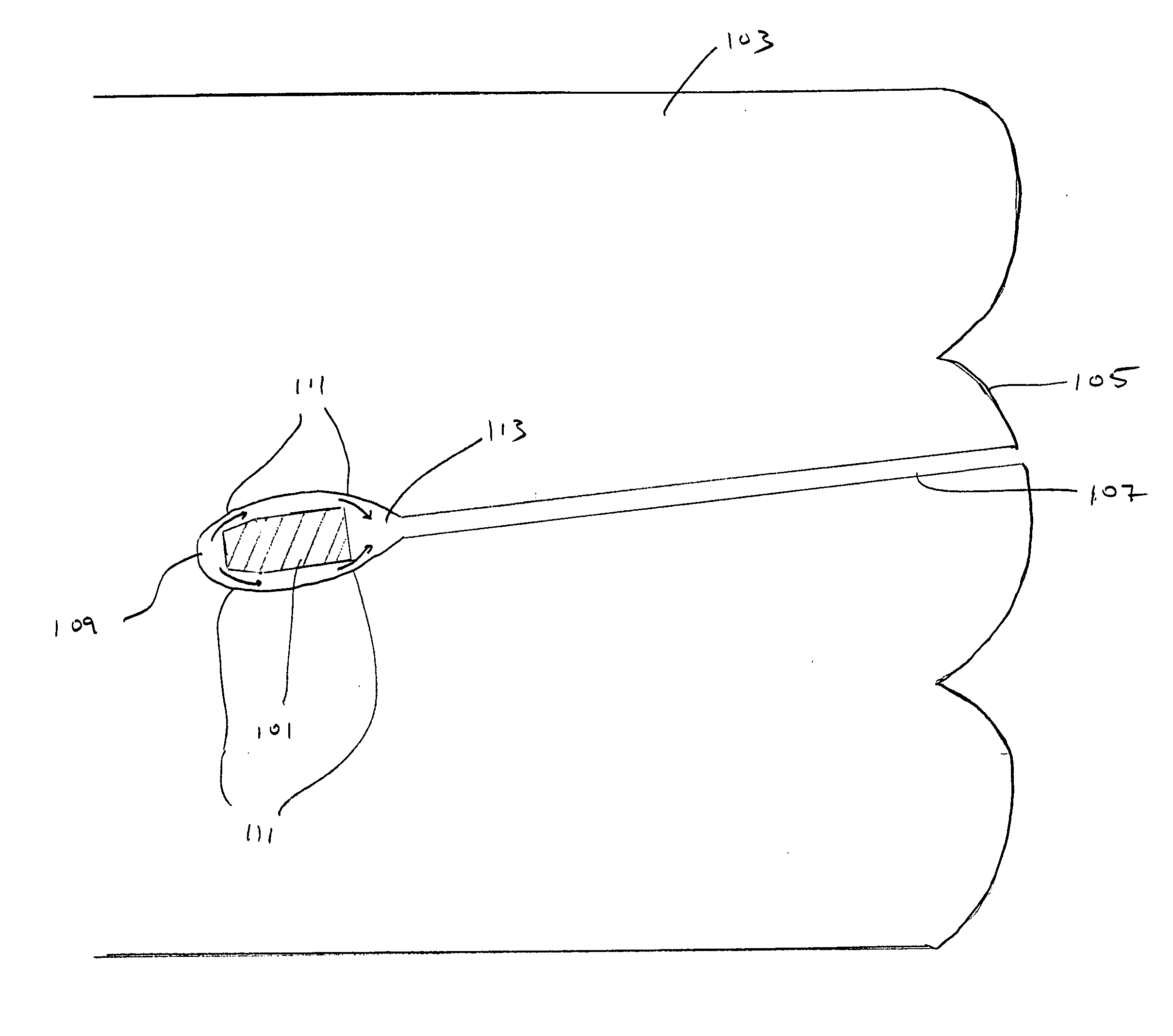

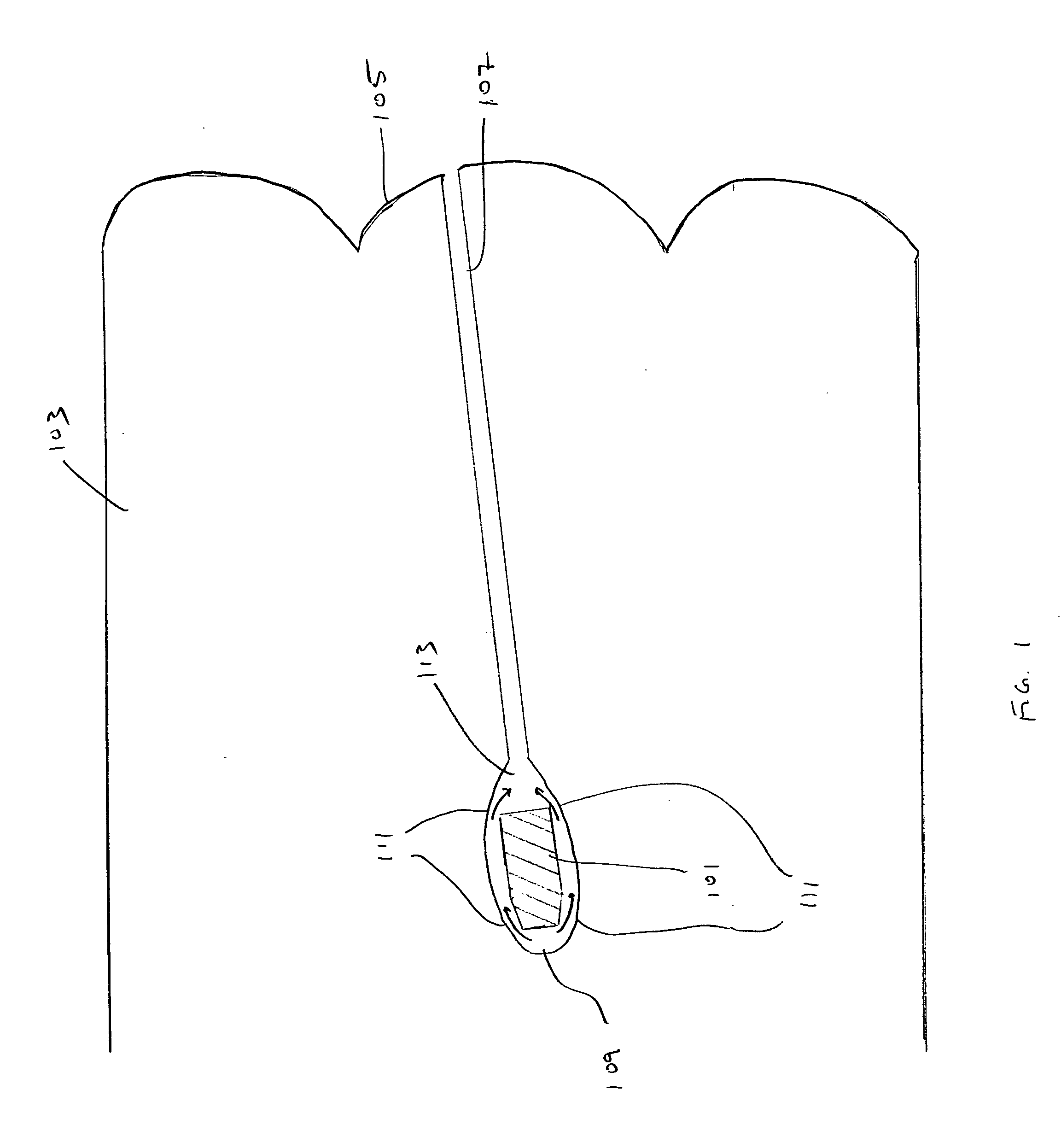

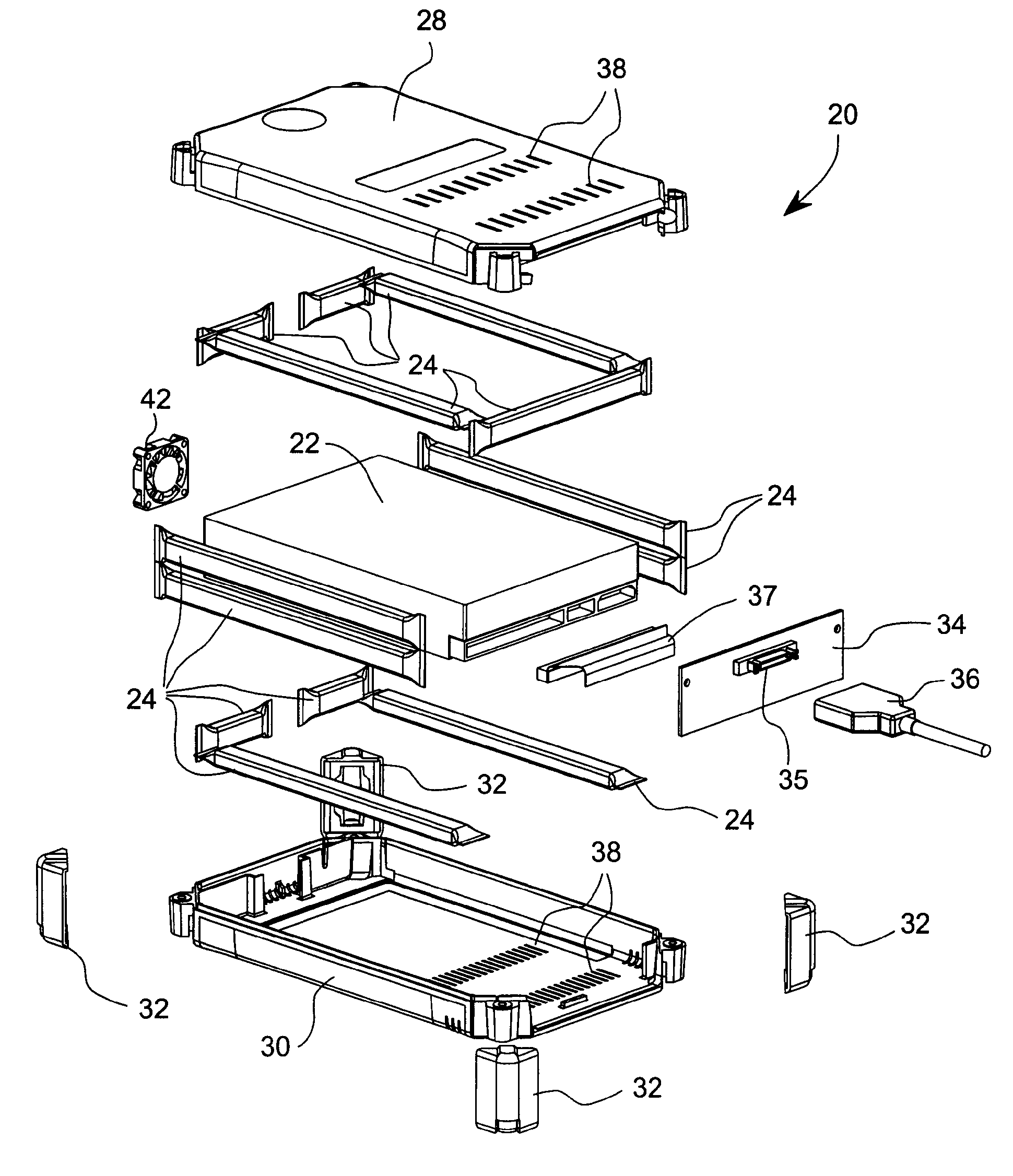

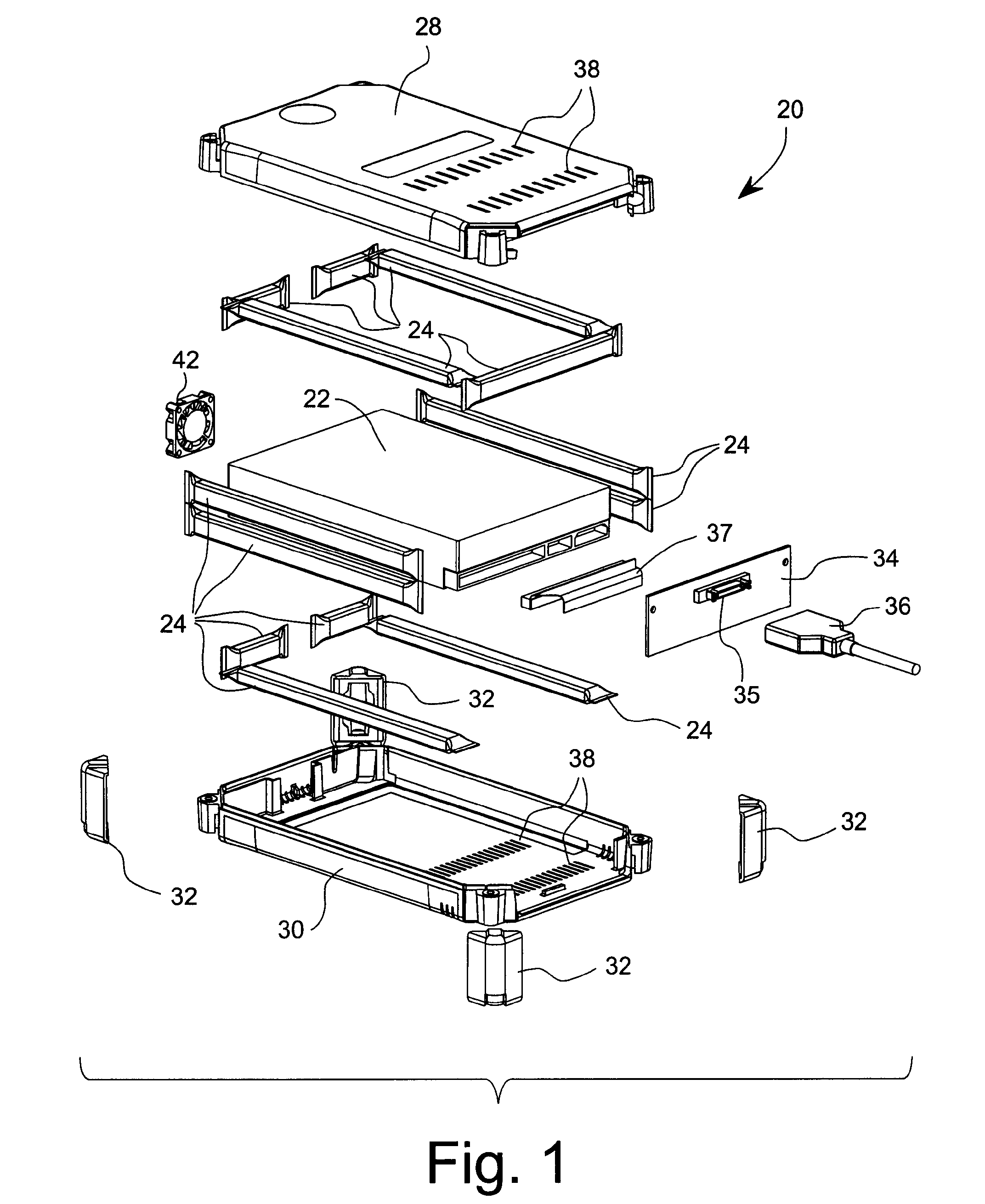

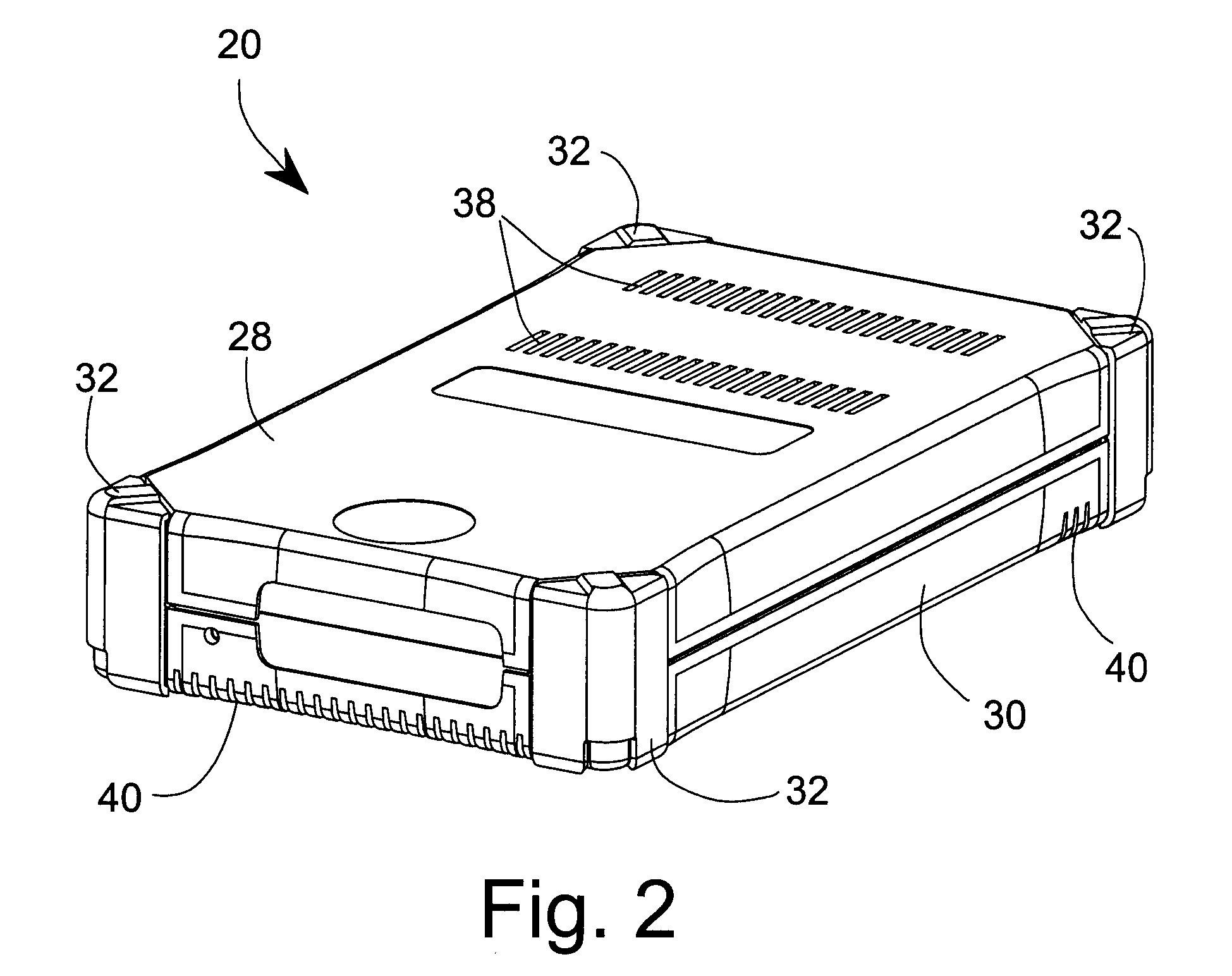

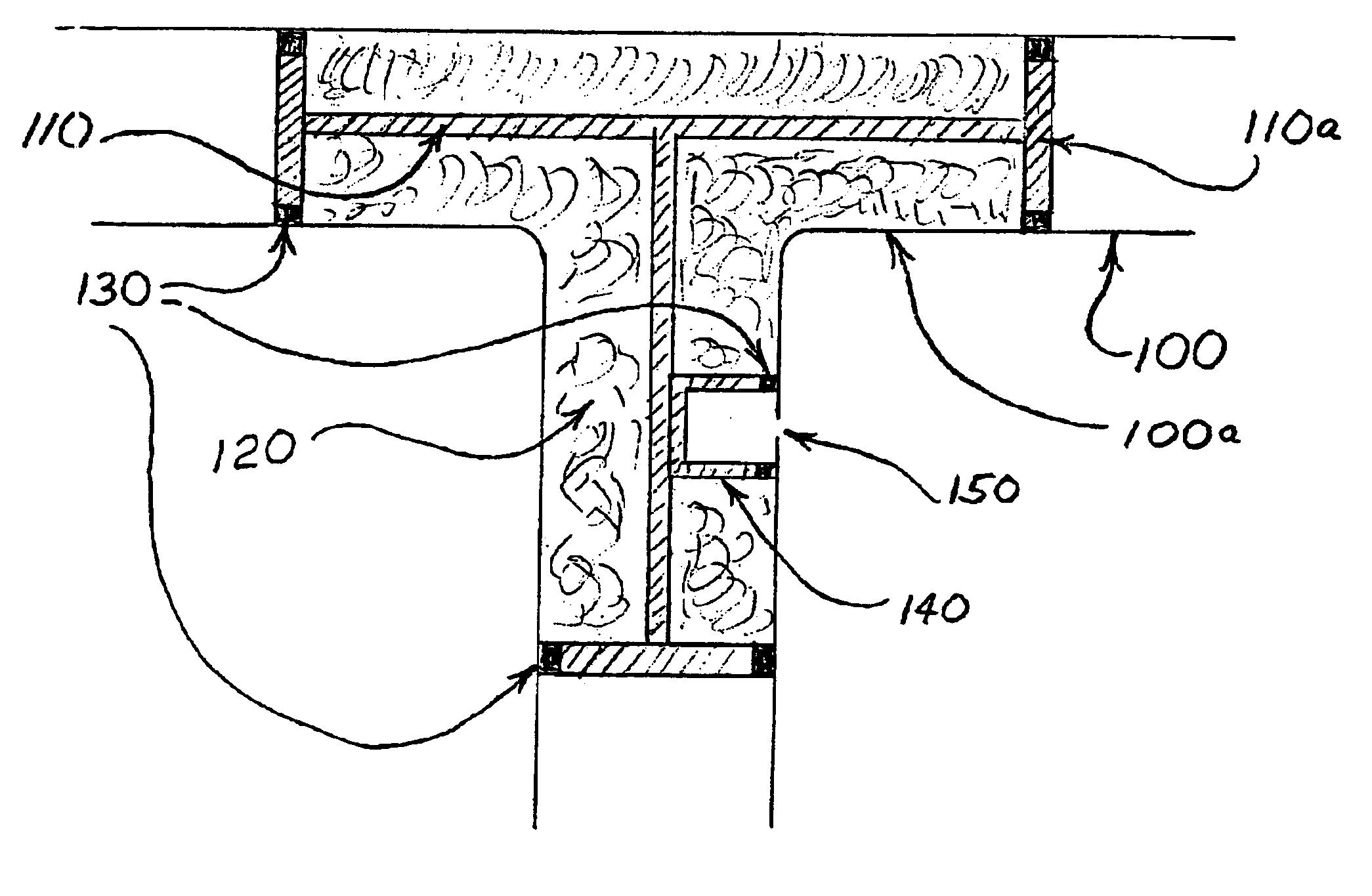

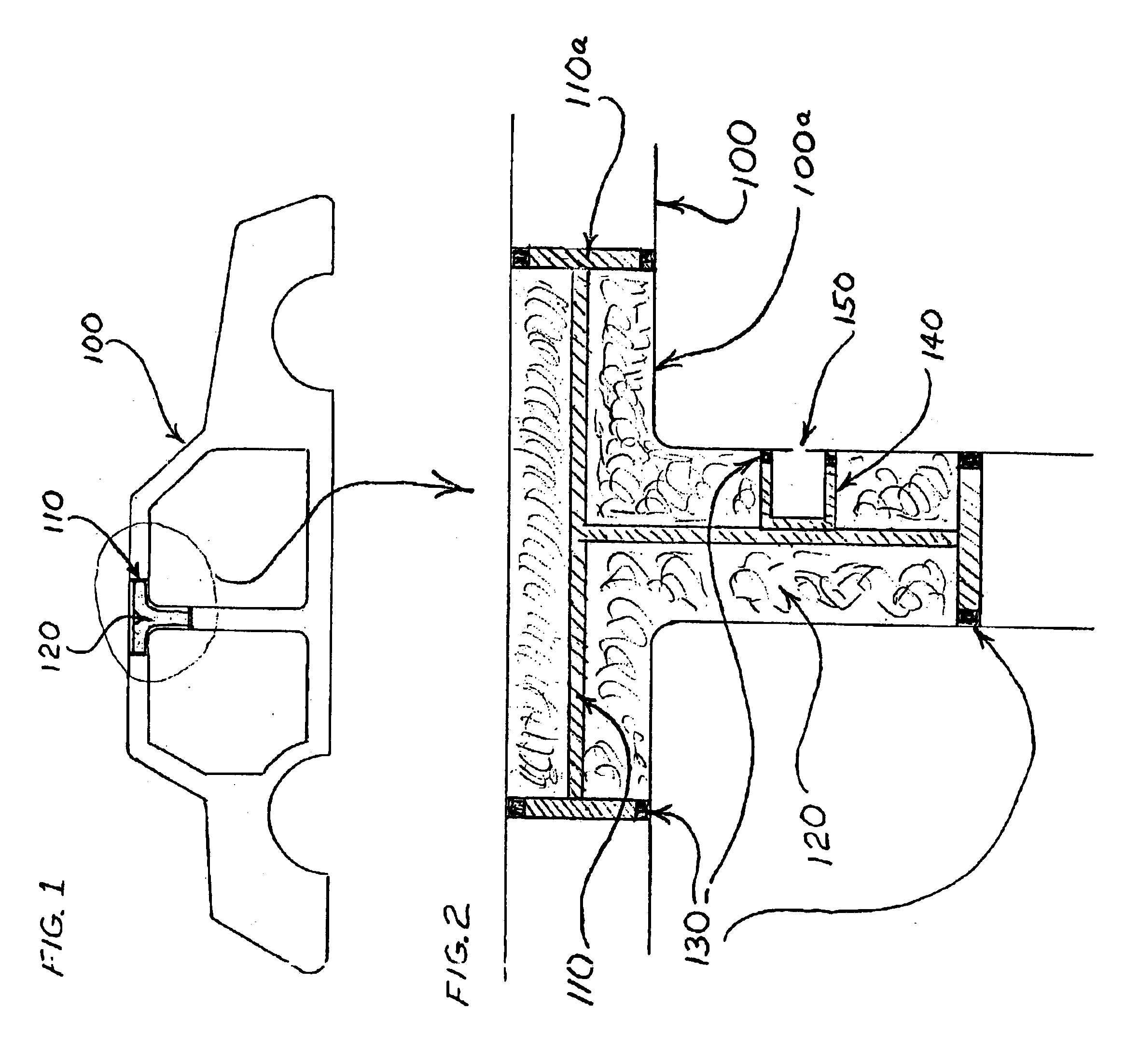

Ruggedized Host Module

ActiveUS20060181845A1Improve protectionIncrease vibrationDigital data processing detailsRecord information storageViscous liquidFlow through cell

An energy dissipative element (24) protects hard disk drives (22, 72, 92) from shocks and vibrations. A closed elastic envelope (48) houses a body of open cell foam (54), a volume of viscous liquid (56), and a compressible gas (64). Under compression or expansion of the foam (54), viscous liquid (56) flows through cell orifices and thereby dissipates energy resulting from external force applied against the elastic wall (48). The energy dissipative elements (24) are applied between a disk drive housing (22) and an outer case (26) to create a ruggedized portable disk drive module (20).

Owner:OLIXIR TECH CORP

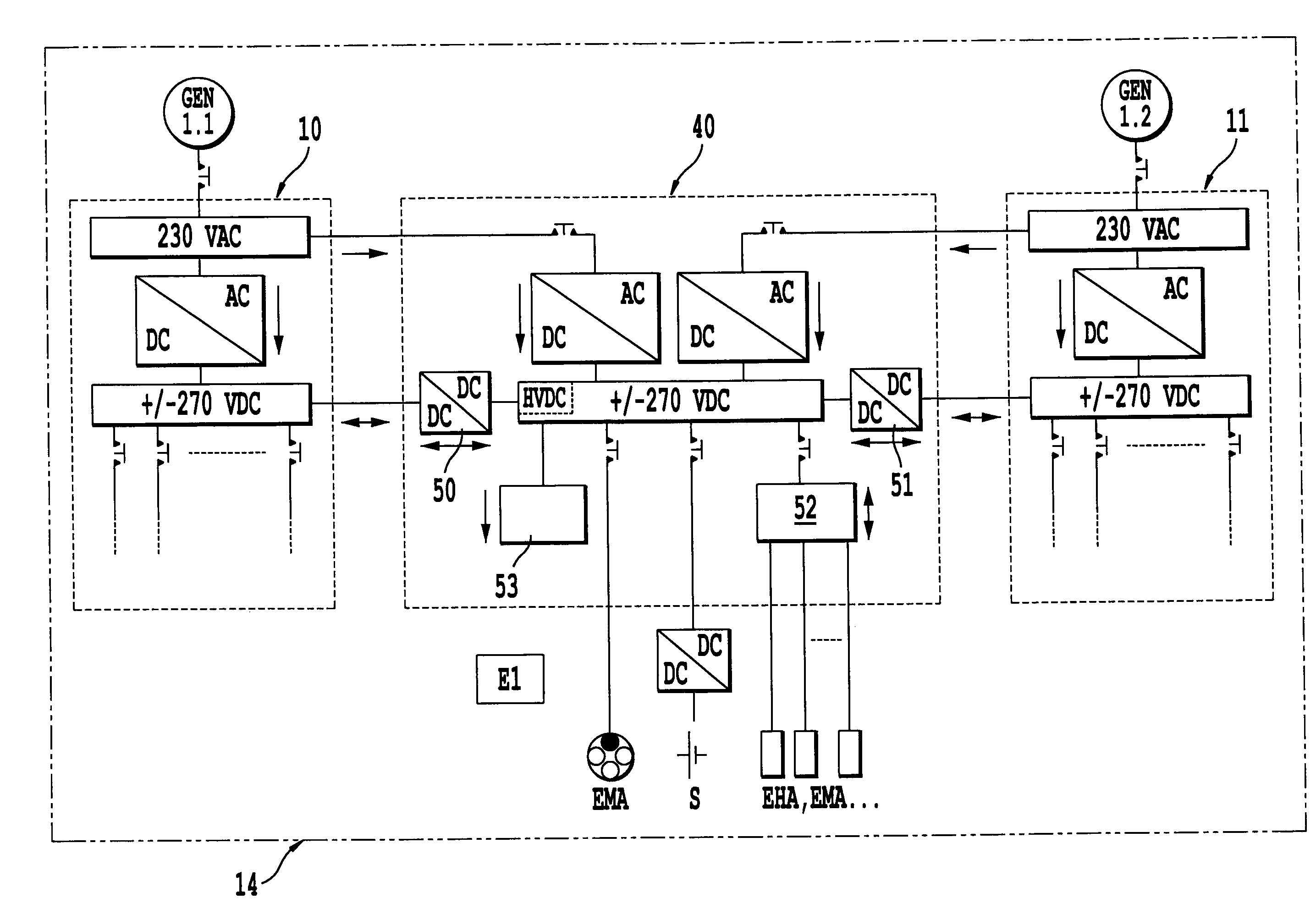

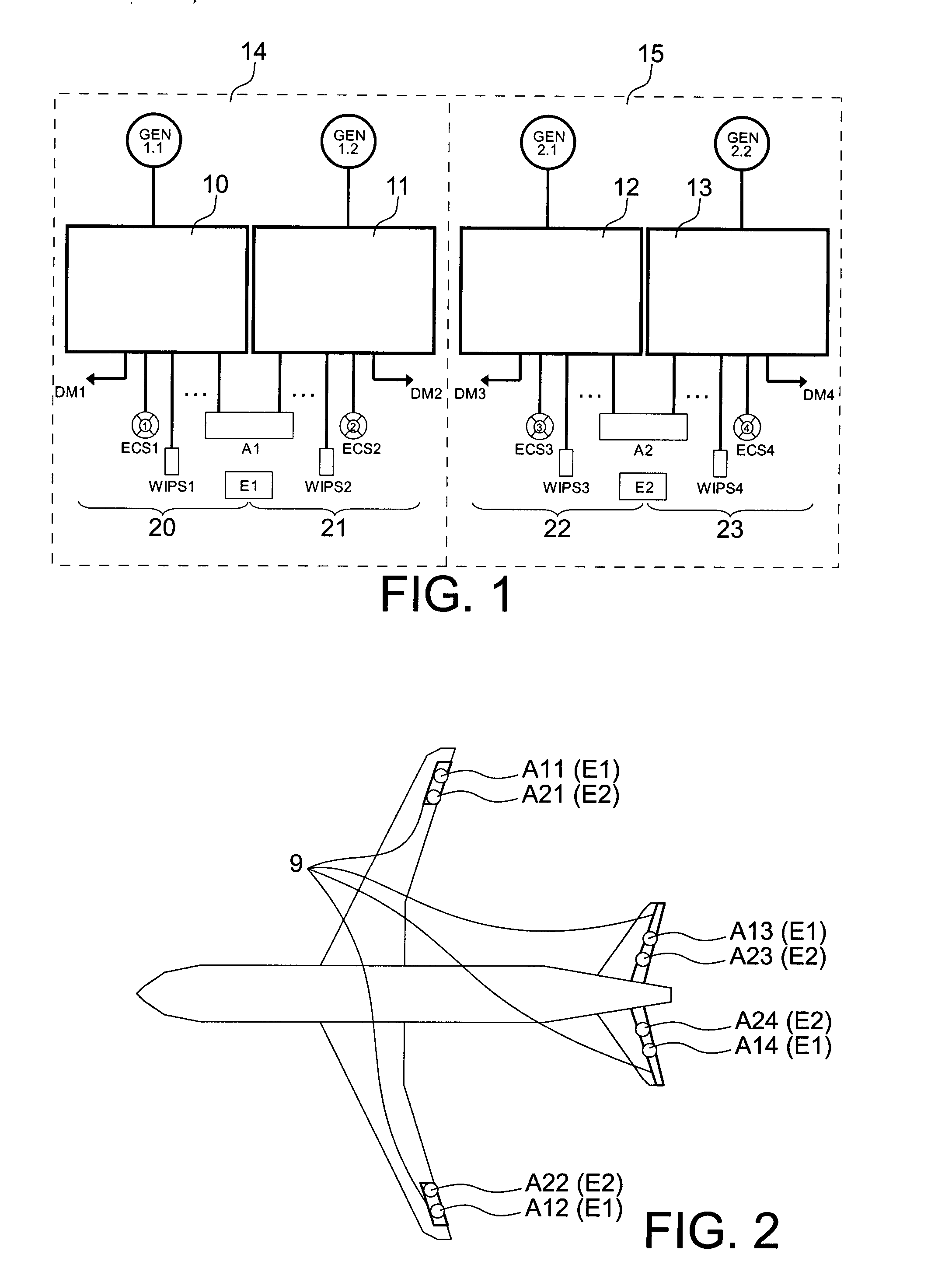

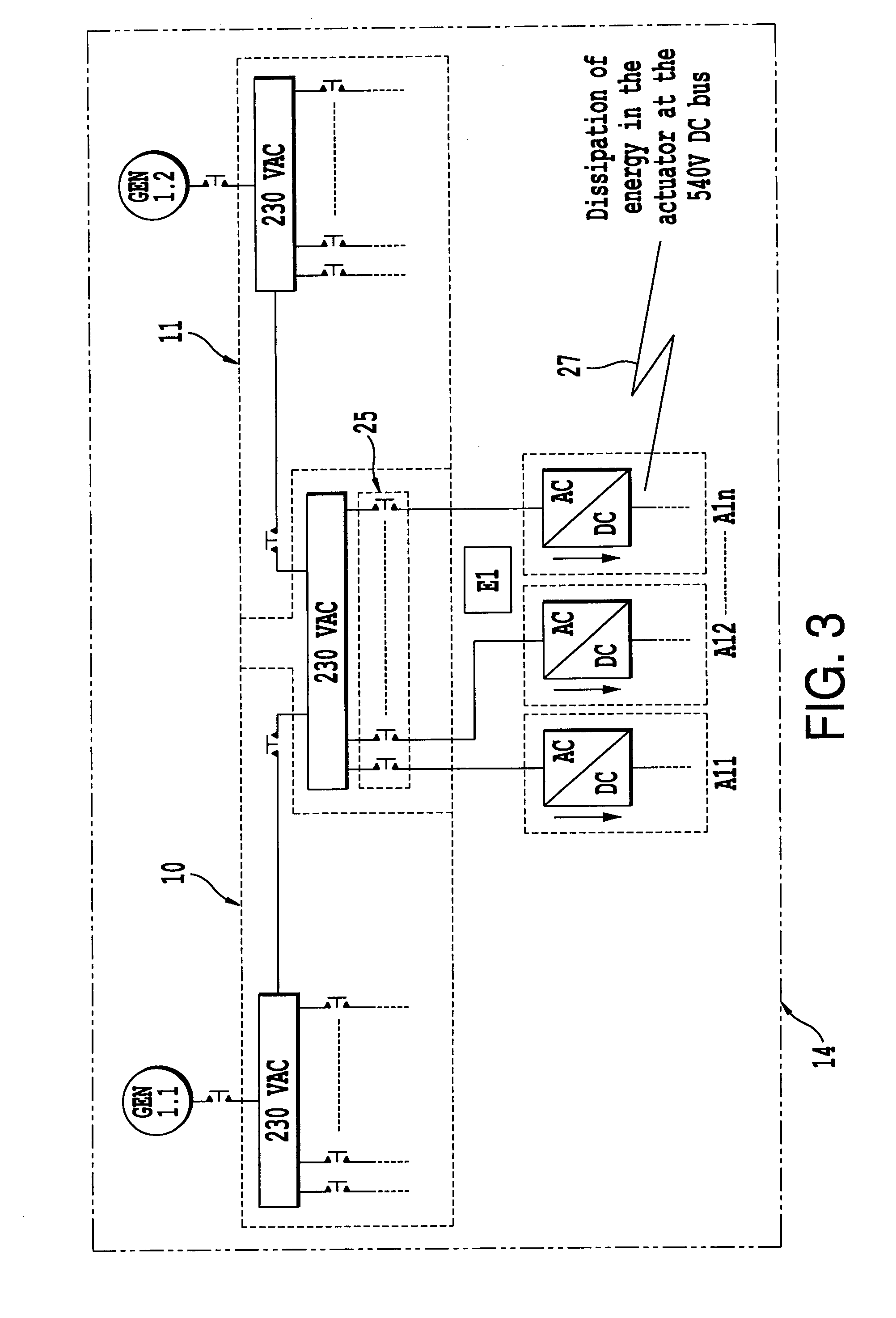

System and method for supplying power for actuators on board an aircraft

InactiveUS20080174177A1Consume energyReduce thermal stressBatteries circuit arrangementsElectric power distributionOn boardAlternating current

The invention relates to a system and a method for supplying power to an aircraft comprising several generators supplying alternating current to several different primary electrical master boxes (10, 11, 12 and 13), the various aircraft loads being connected to each of these master boxes. This system comprises conventional master boxes (10, 11, 12 and 13) which supply power loads and at least one master box (40, 41) devoted to actuator loads, this at least one devoted master box being connected to conventional master boxes.

Owner:AIRBUS OPERATIONS (SAS)

Reinforced structural body

InactiveUS6896320B2Consume energySimple structureVehicle seatsSuperstructure subunitsVehicle frameEngineering

Owner:DOW GLOBAL TECH LLC

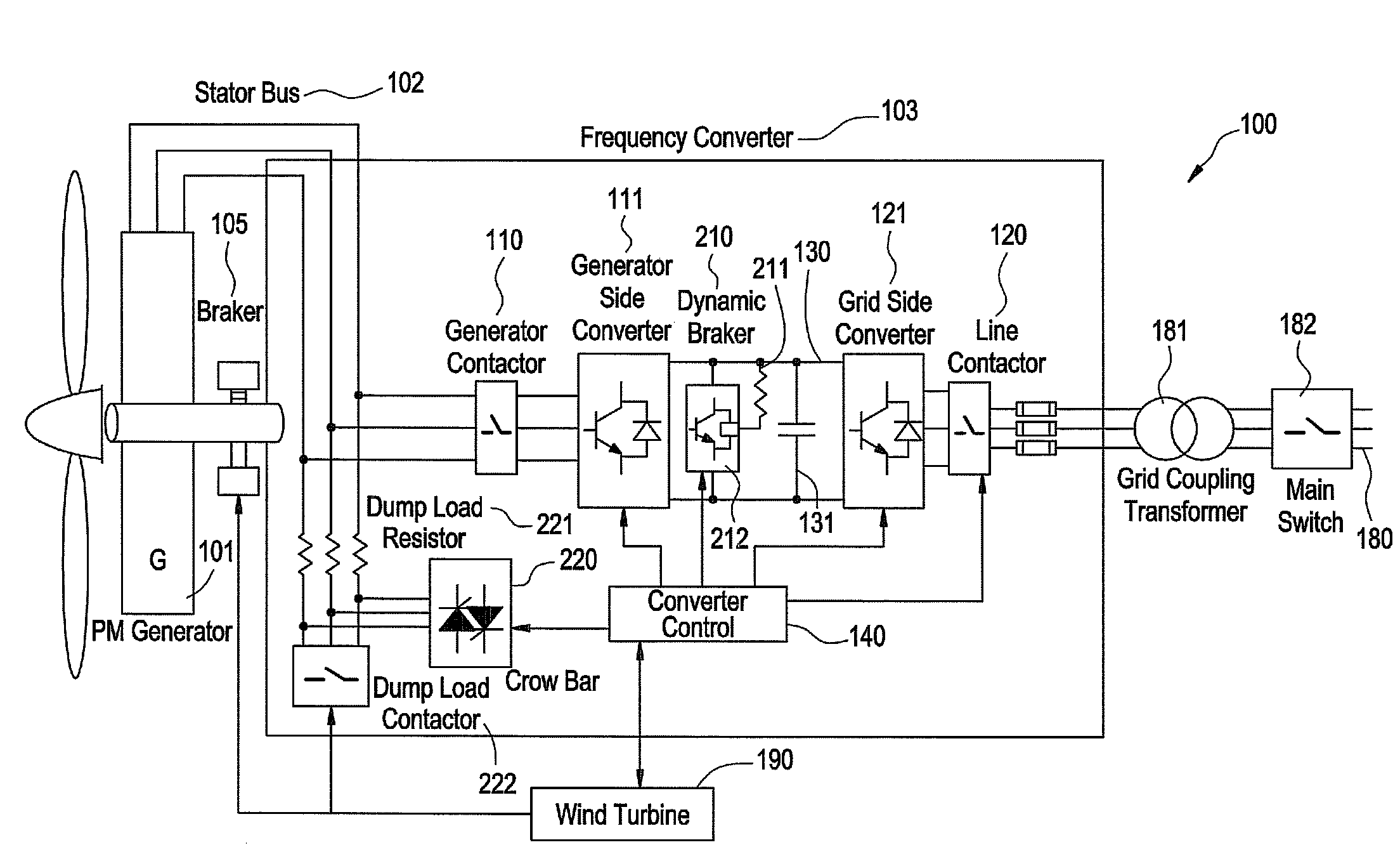

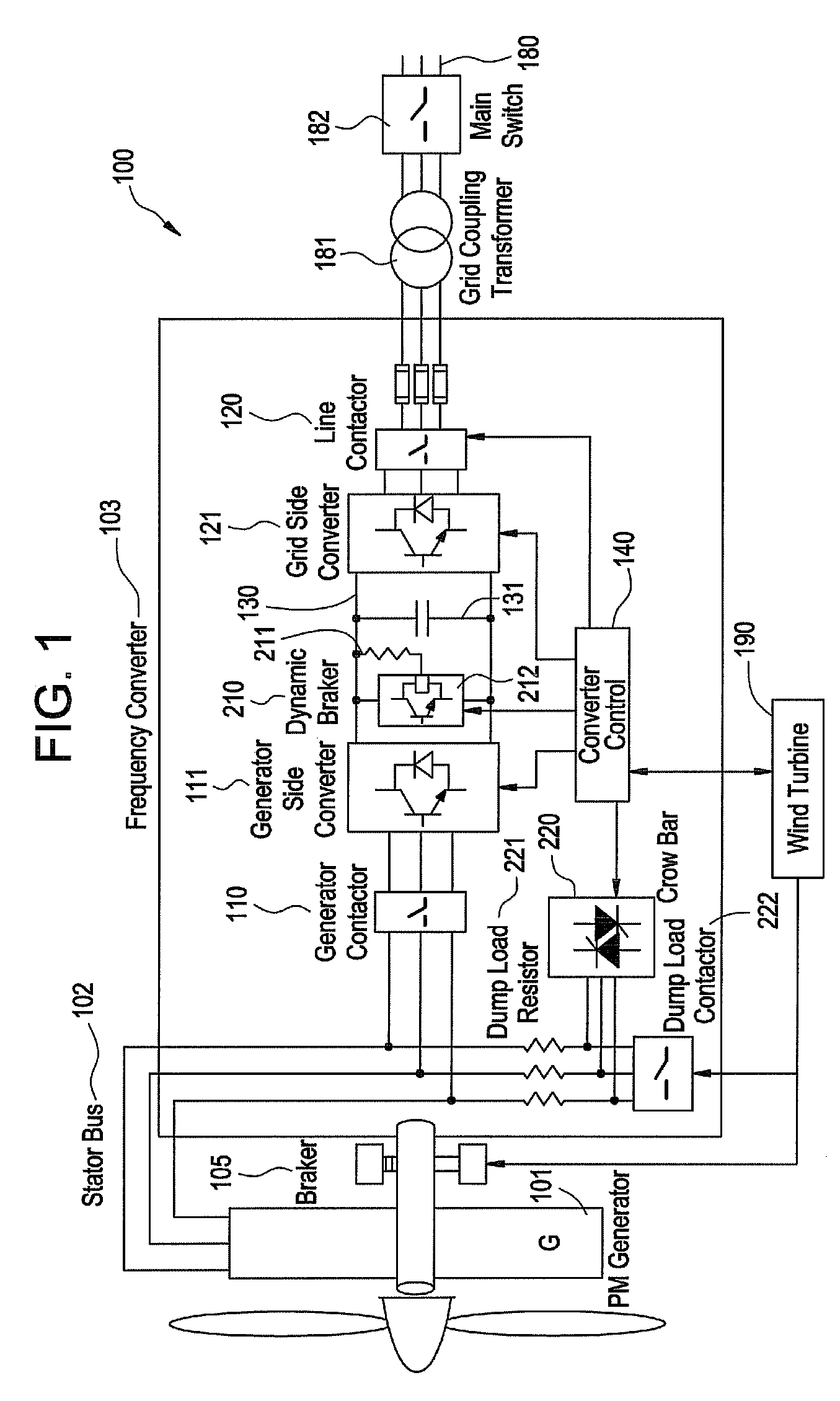

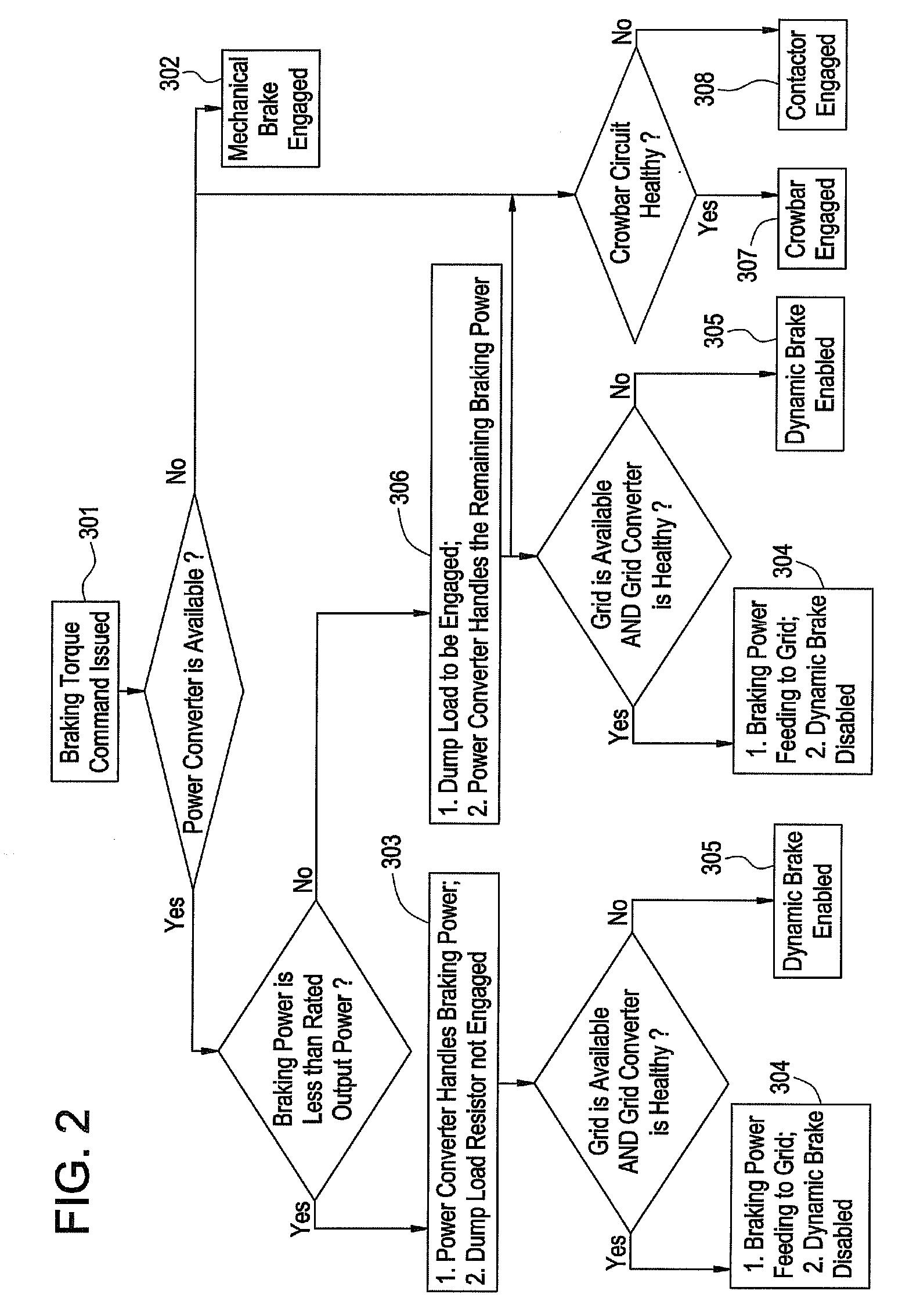

Redundant electrical brake and protection system for electric generators

ActiveUS20070279815A1Consume energySynchronous motors startersWind motor controlElectricityEngineering

An apparatus for electric braking and system protection for an electric generator includes a dynamic brake and a crowbar circuit designed for cooperation with power converters to dump power upon command. The dynamic brake includes at least one resistor and the crowbar circuit includes another at least one resistor for dissipating power from the electric generator. Methods for use of the electric braking and system protection calls for shunting the power to at least one of the dynamic brake, the crowbar circuit and the generator side power converter.

Owner:GENERAL ELECTRIC CO

Agitators for wave-making or mixing as for tanks, and pumps and filters

A tank agitator connects to a low head feed and causes agitation by discharging through a port that might rotate, oscillate, or otherwise issue a pulsing stream. This agitator has a housing with a turbine plenum and an exhaust plenum. A turbine in the turbine plenum spins by the flowthrough of the feedwater and exhausts to the exhaust plenum. A hollow drive shaft is spun by the turbine and extends through the exhaust plenum and to terminate outside the housing. It has an aperture that allows water in the exhaust plenum to flow into its lumen. A nozzle caps the shaft and is bent such that the discharge issuing therefrom sweeps in circles with the spinning of the drive shaft. A variant form of the agitator includes a drive train that incorporates a drag link to convert the spinning input of the turbine into an oscillating output in the drive shaft. In another variant form, the discharge is pulsed. To do this, the exhaust plenum lies between an opening to the turbine plenum and a port in the housing wall to the outside. A blocker door is coupled to and driven by the spinning turbine to cycle between uncovering and covering one of the exhaust opening and the discharge port. Given the foregoing, the discharge stream issuing from the discharge port will pulse between alternating phases of flow and quiescence.

Owner:SEAMAN ANTHONY E

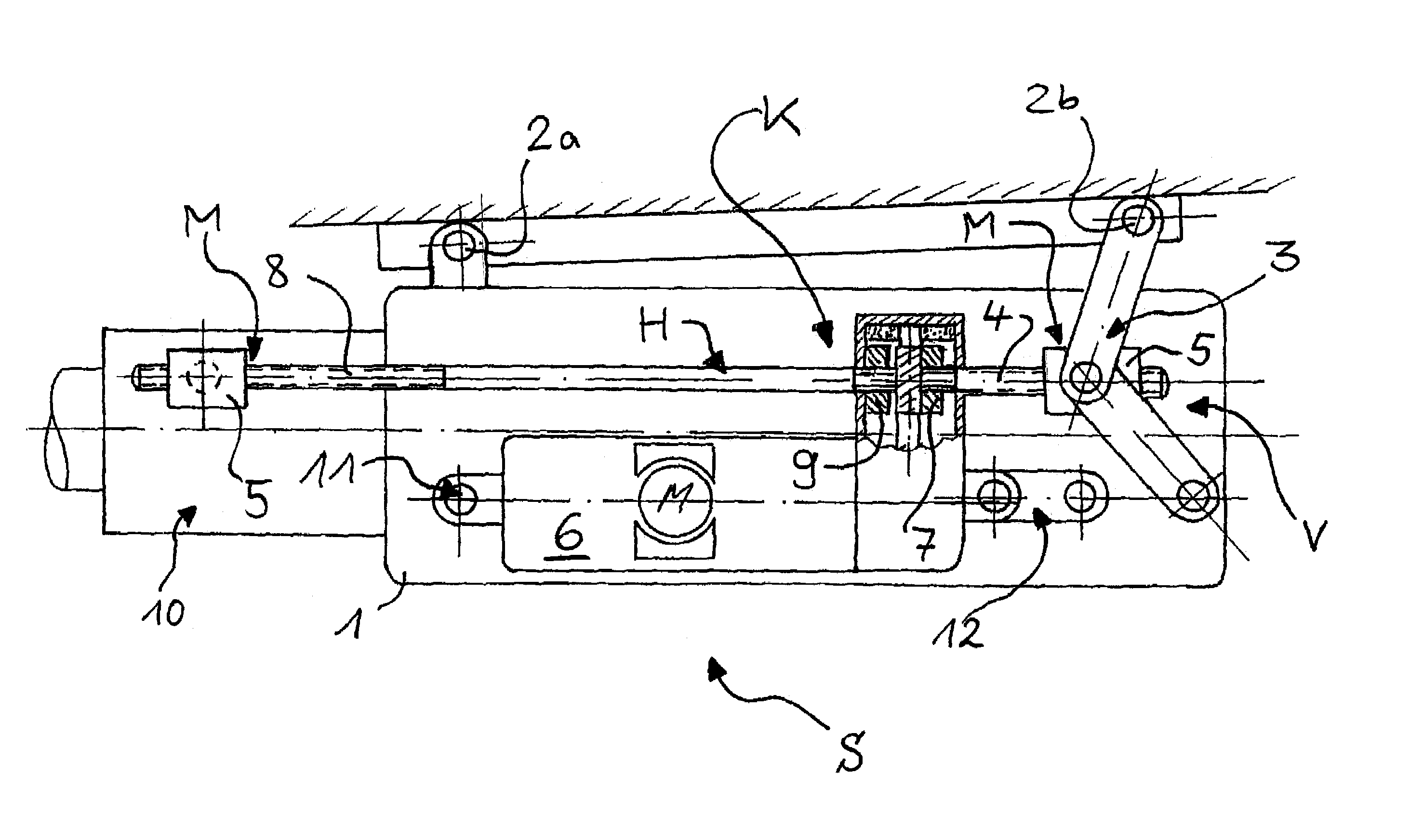

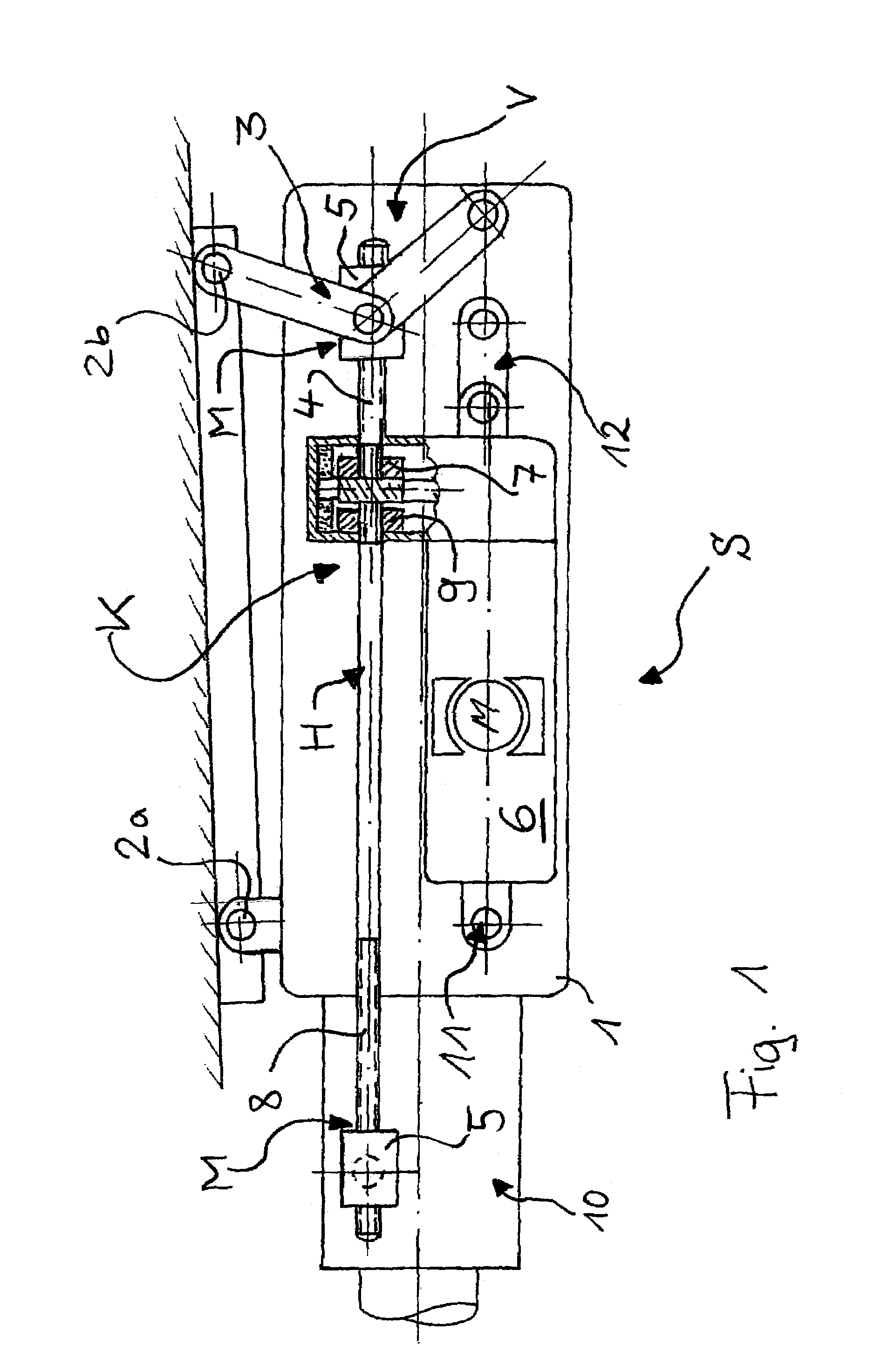

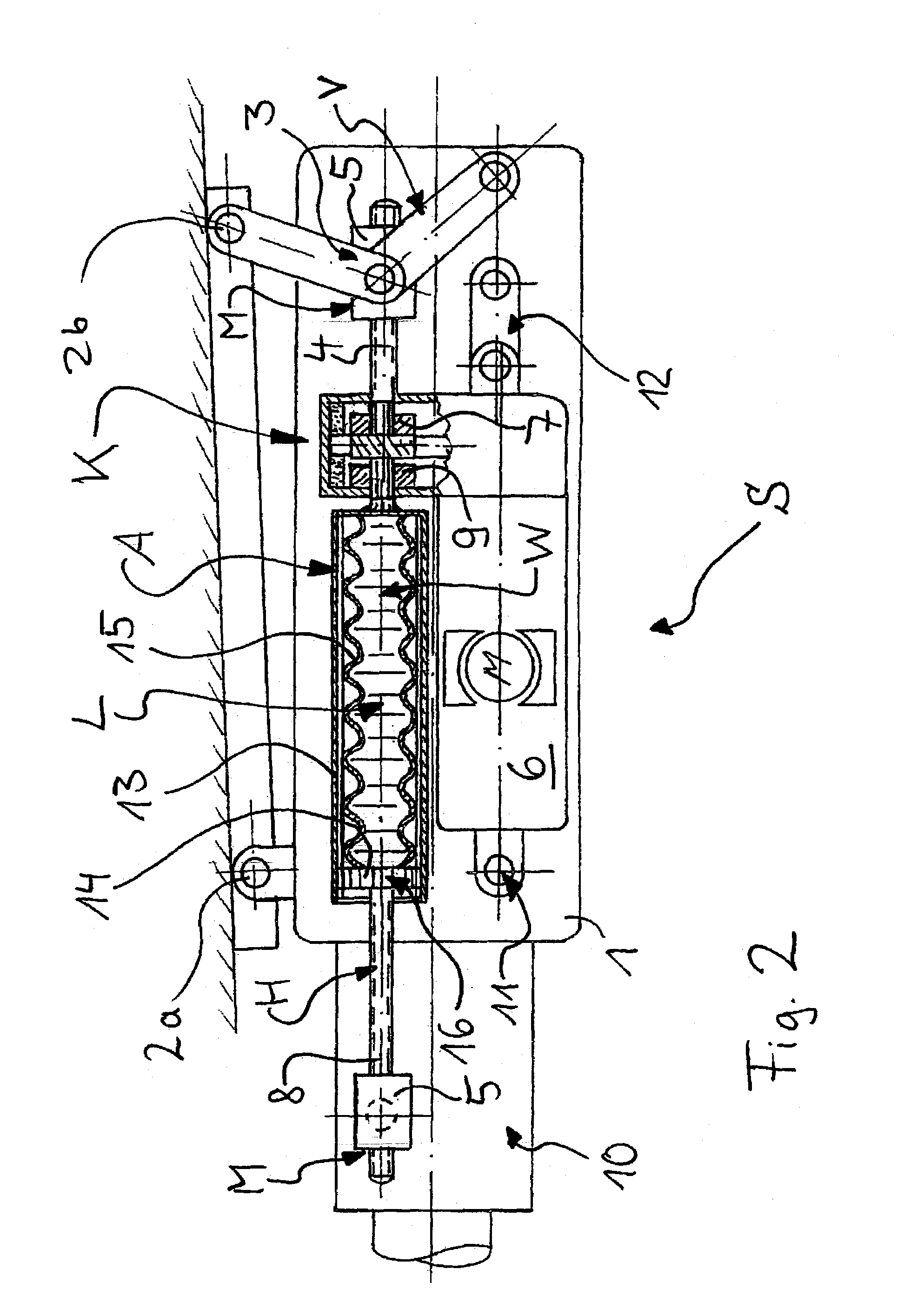

Safety steering and mechanism and a method of operating

A safety steering mechanism for a steering column, with a steering-column comfort adjustment having linear positioning devices, and provided with safety devices designed such that, in an accident situation, at least an end area of the steering column can be moved away from a driver's position. The linear positioning devices include load absorption devices and / or withdrawal devices regarding the movement of at least the end area of the steering column away from a driver's position. An operating method for a safety steering mechanism for a steering column that can be adjusted by a comfort adjustment in accordance with the requirements and / or wishes of a driver by means of linear positioning devices and of which at least an end area of the steering column can be moved away from a driver's position in an accident situation. The movement of at least the end or the steering column away from a driver's position is braked in an accident situation in a load-receiving manner by load absorption devices contained in the linear positioning devices.

Owner:THYSSENKRUPP PRESTA AG

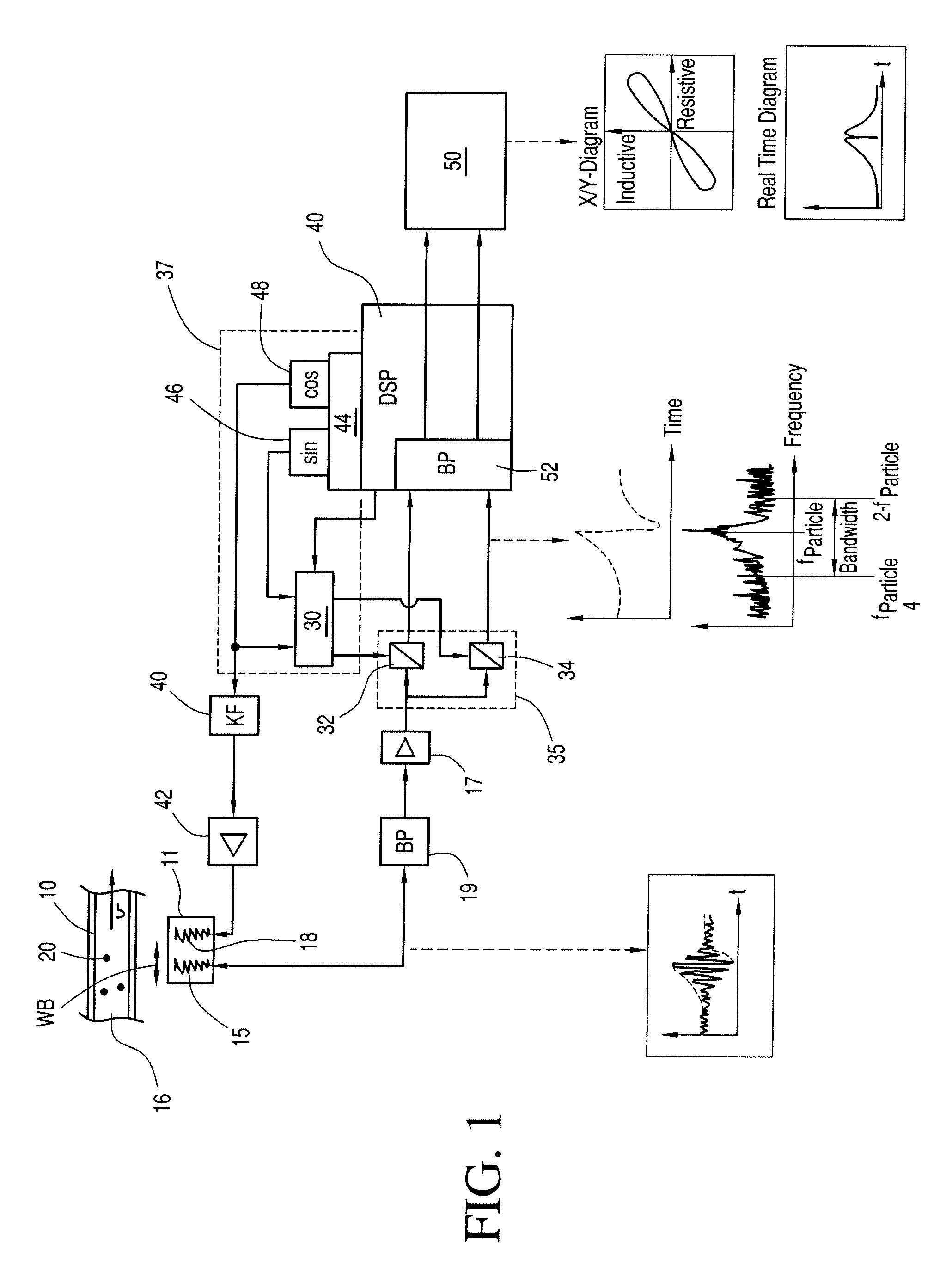

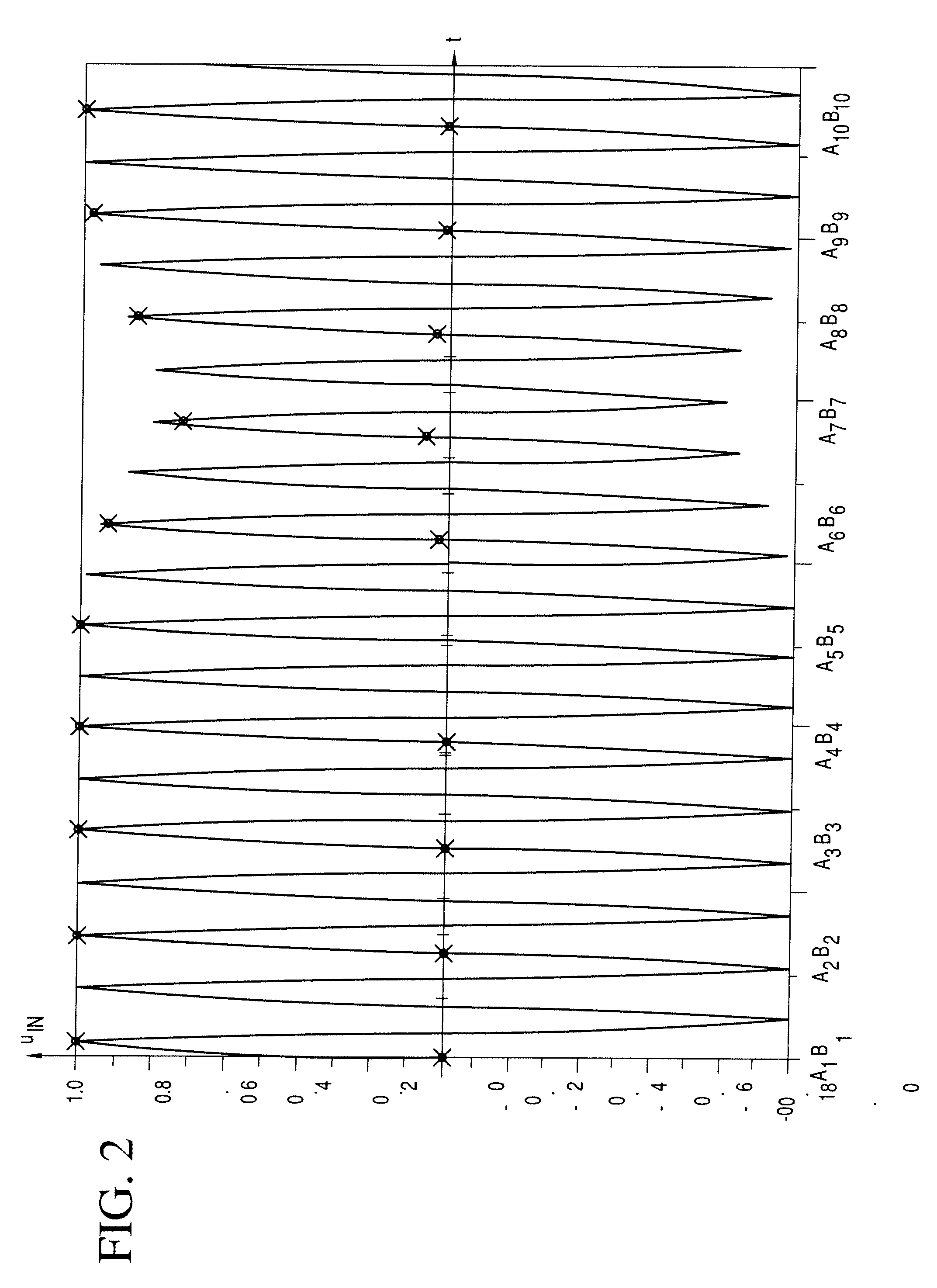

Device and process for detecting particles in a flowing liquid

InactiveUS20090051350A1Easy to identifyEasy to set upAverage speed measurementDigital computer detailsPeriodic alternatingElectricity

A process and device for detecting electrically conductive particles in a liquid flowing in a pipe section, the liquid being exposed to periodic alternating electromagnetic fields by a transmitter coil which induces eddy currents in the particles, a probe made as a coil arrangement and which has an effective width producing a periodic electrical signal based on the eddy currents. The signal ha a carrier oscillation with an amplitude and / or phase which is modulated by particles passing across the effective width of the coil arrangement, the probe signal being filtered by a frequency-selective first filter unit, the filtered signal being sampled by a triggerable A / D converter stage to obtain a demodulated digital measurement signal, the digital measurement signal being filtered by a digital, frequency-selective adjustable second filter unit to obtain a useful signal, and the useful signal being evaluated to detect passage of electrically conductive particles in the pipe section.

Owner:PRUTECHNIK DIETER BUSCH AG

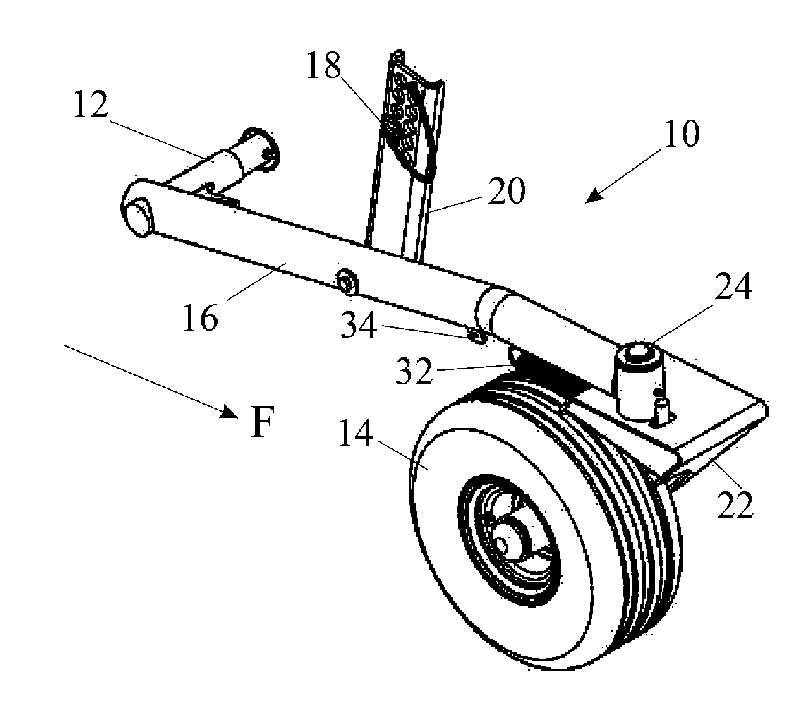

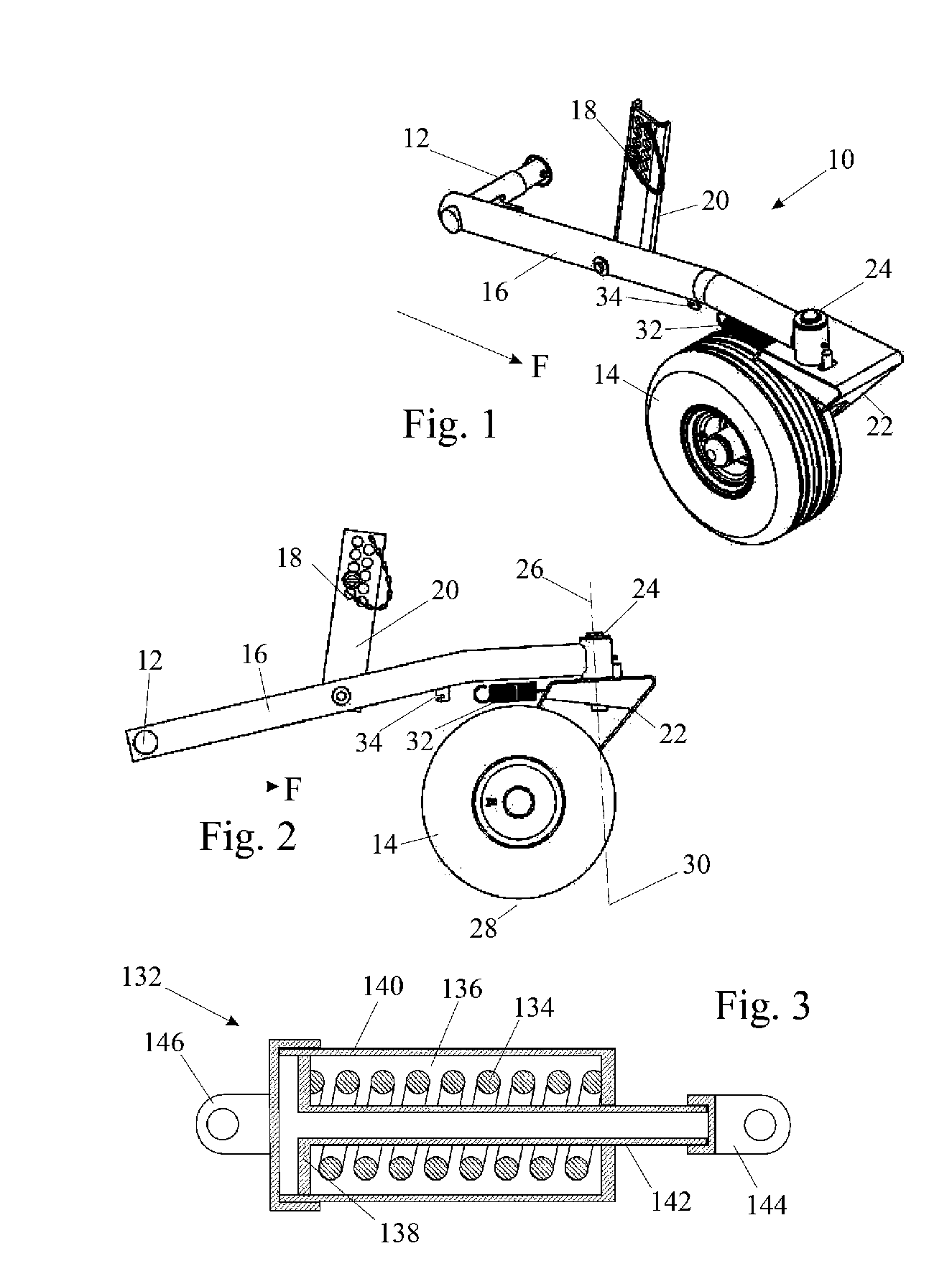

Pickup for an Agricultural Machine

ActiveUS20130305683A1Prevent uncontrolled oscillationConsume energyLoadersMowersAgricultural engineeringAgricultural machinery

An agricultural machine having a frame carrying a crop pickup mechanism and supported on the ground by means of two support wheels. Each support wheel is rotatably mounted on a carrier that is connected to the frame of the pickup for rotation about a caster axis. Each wheel carrier is connected by a respective spring to a point fixed relative to the frame of the pickup. The spring biases the carrier to cause the support wheel to park in a predetermined direction relative to the frame of the pickup.

Owner:BLUE LEAF I P INC

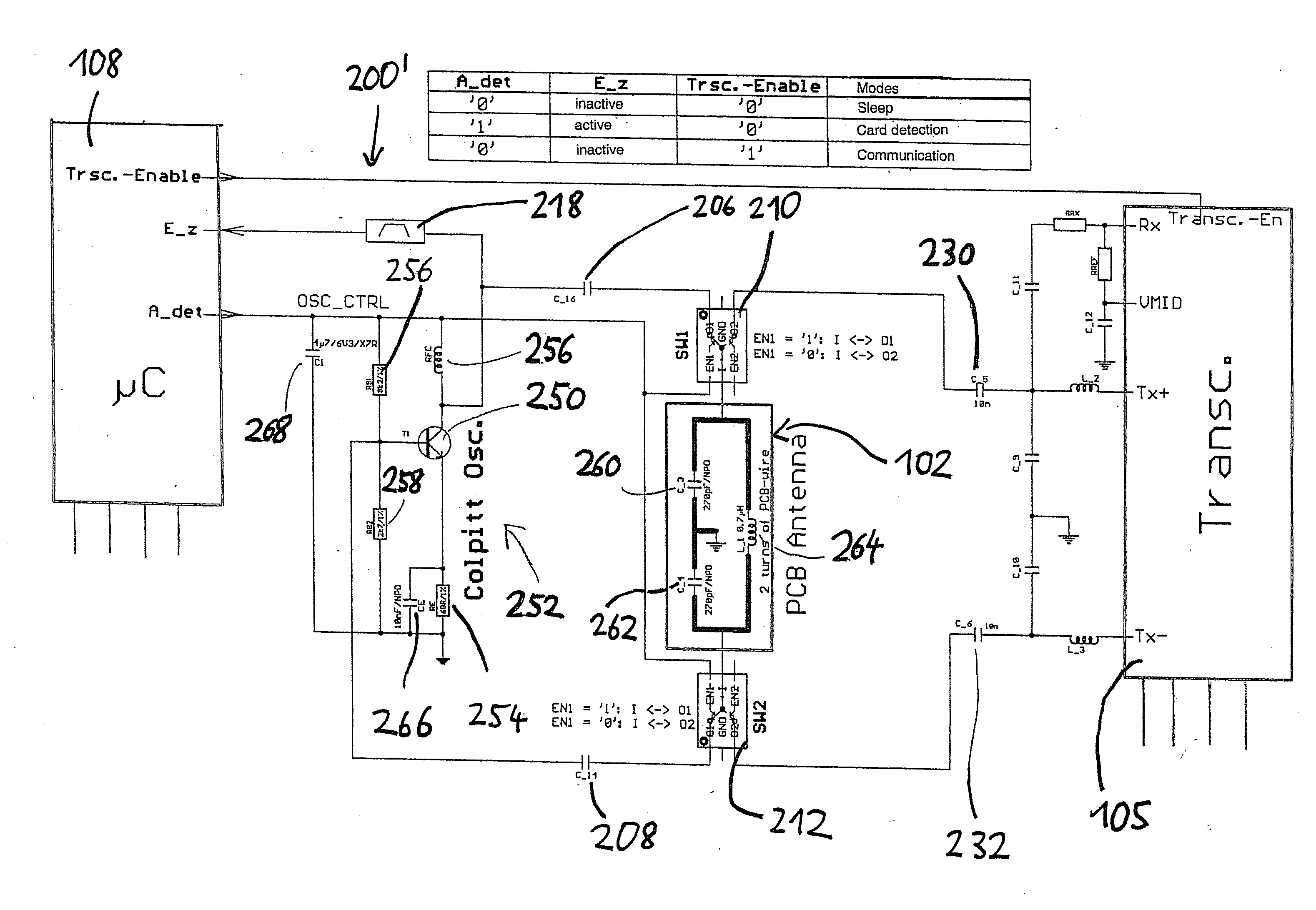

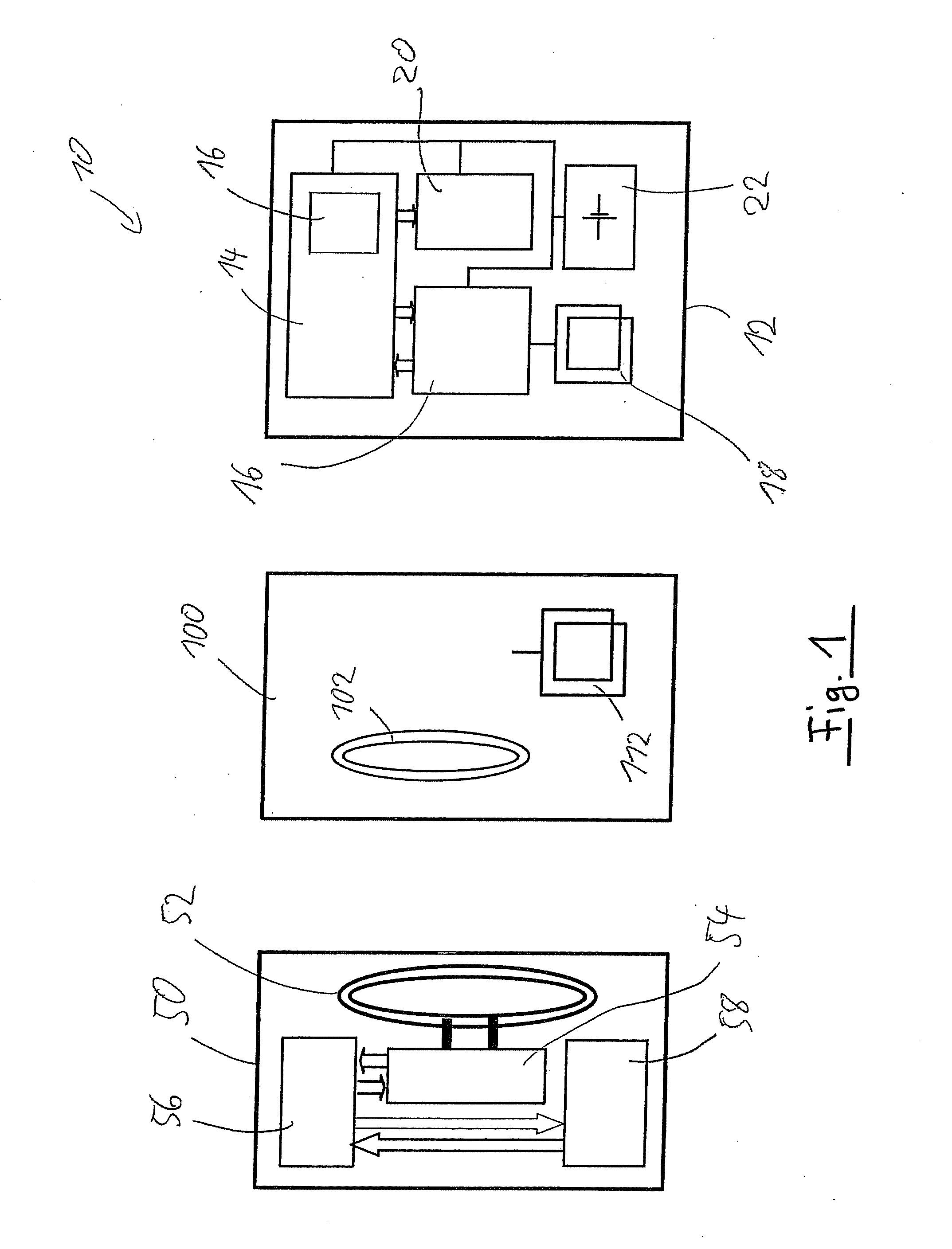

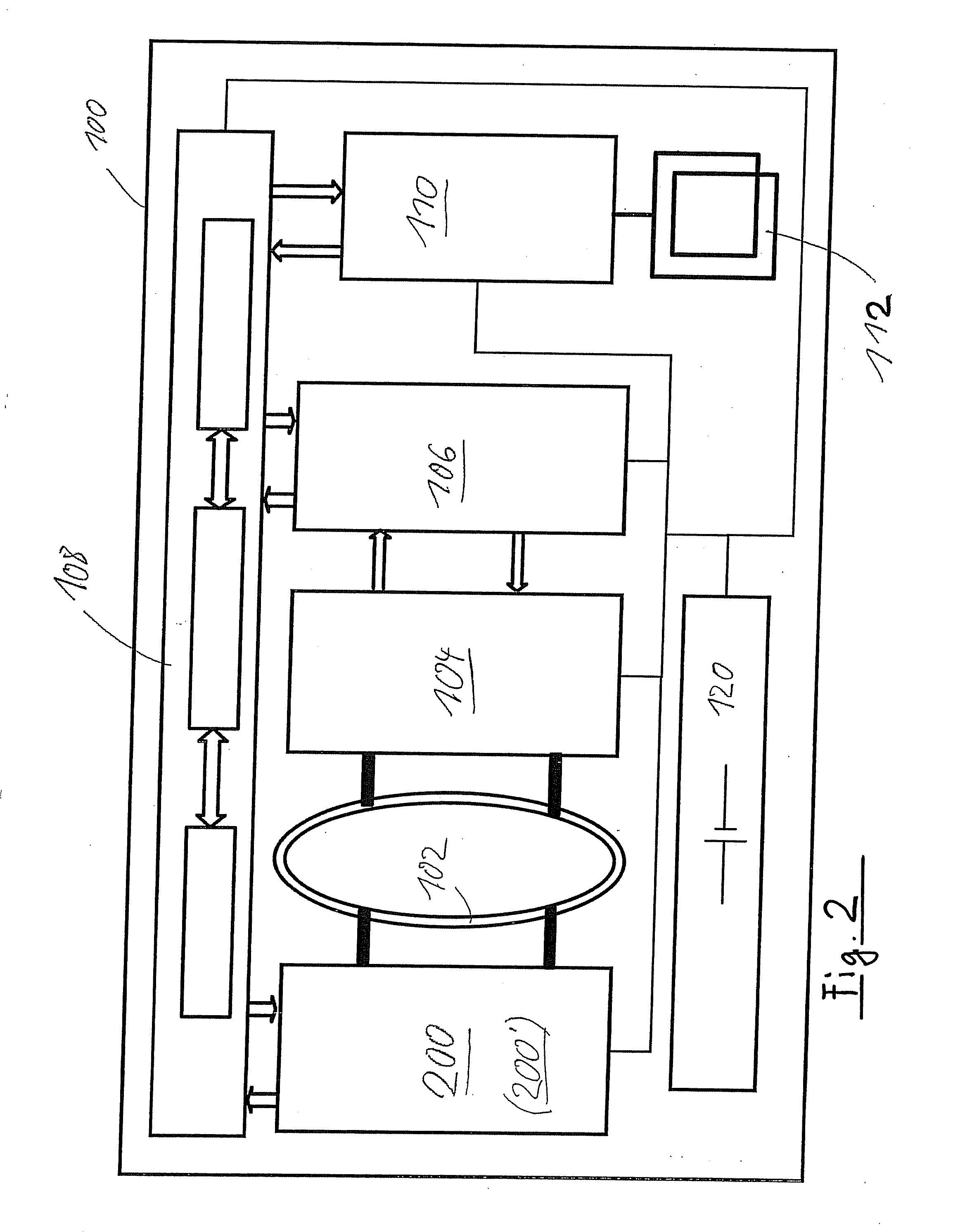

Low-energy detection of a transponder by means of read unit and a system for identity determination and/or authorization determination, optionally in the form of a locking system

InactiveUS20100144269A1Reduce energy consumptionLong battery lifeNear-field transmissionMemory record carrier reading problemsSupply energyAuthorization

Among others, the invention relates to a method and a system for controlling a system for receiving a wireless data transmission between at least two components (12, 100, 50), wherein at least one wireless interface (102, 112) can be activated, or is activated, for wireless data transmission. According to the invention, a first component (100) monitors an environment for the occurrence of at least one predefined change and / or for the occurrence of at least one predefined feedback from the environment. Once such a change, or feedback, has occurred, a wireless interface (102) is activated for the wireless data transmission, and optionally for the energy supply of a second component (50) via the wireless interface. The predefined change or feedback is caused particularly in that the second component (50) is returned to the environment. The system may be a system (10) for determining the identity and / or authorization, such as a locking system. The first component (100) may arrange an interaction between the second component (50) and a further component (12), which, for example, is associated with a target mechanism.

Owner:SIMONSVOSS TECH

Blast curtain

InactiveUS6886299B2Consume energySafely dissipatedHuman health protectionArmourVisibilityEngineering

A flexible blast curtain will reduce casualties and property damage in the event of a terrorist bombing by intercepting flying debris and dissipating over pressure through deflection of the curtain. The blast curtain may be attached directly to buildings or mounted on frames anchored in close proximity to buildings. The curtain provides complete visibility and easy pedestrian ingress and egress for the buildings.

Owner:TARGUS INT

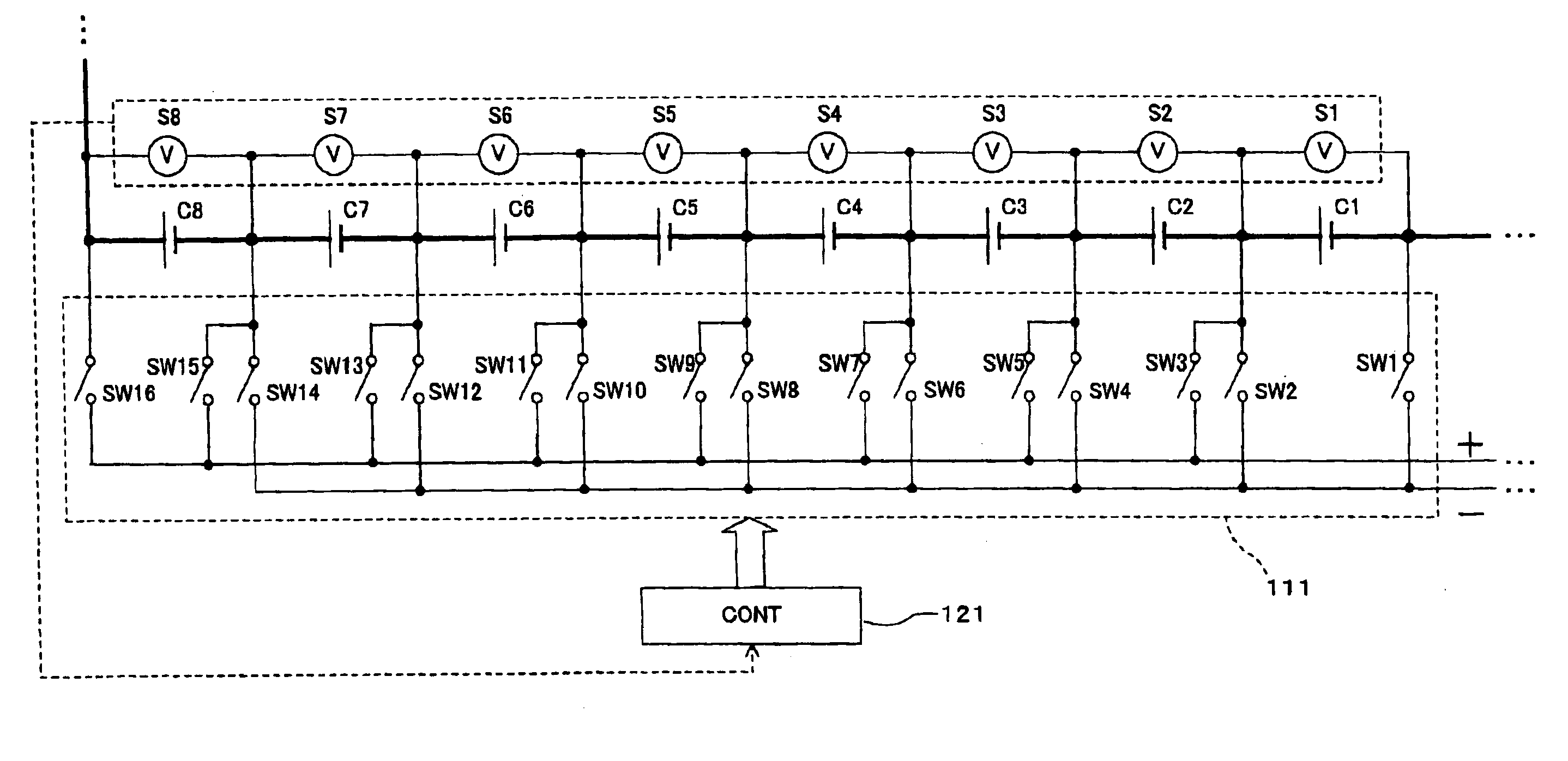

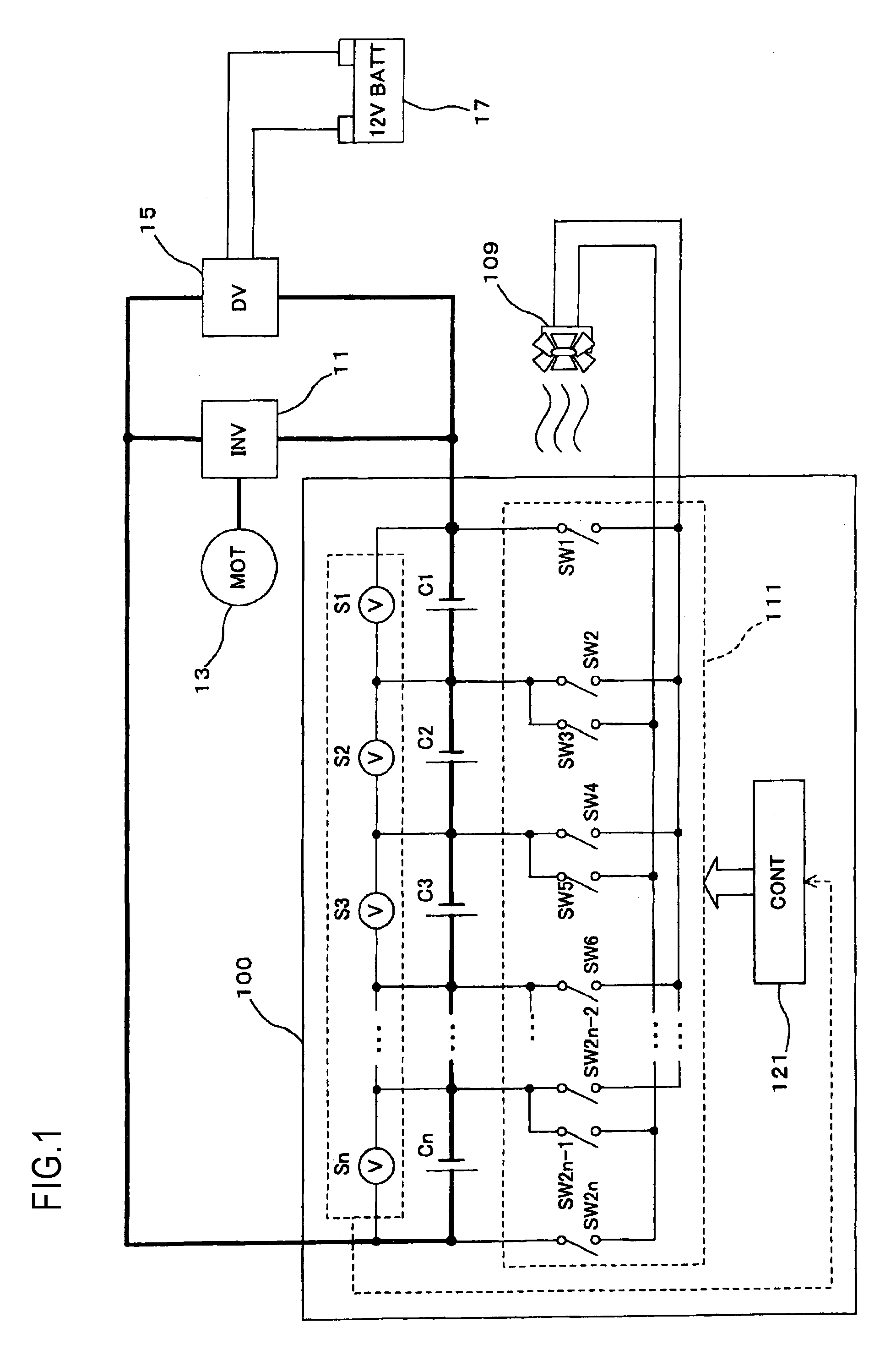

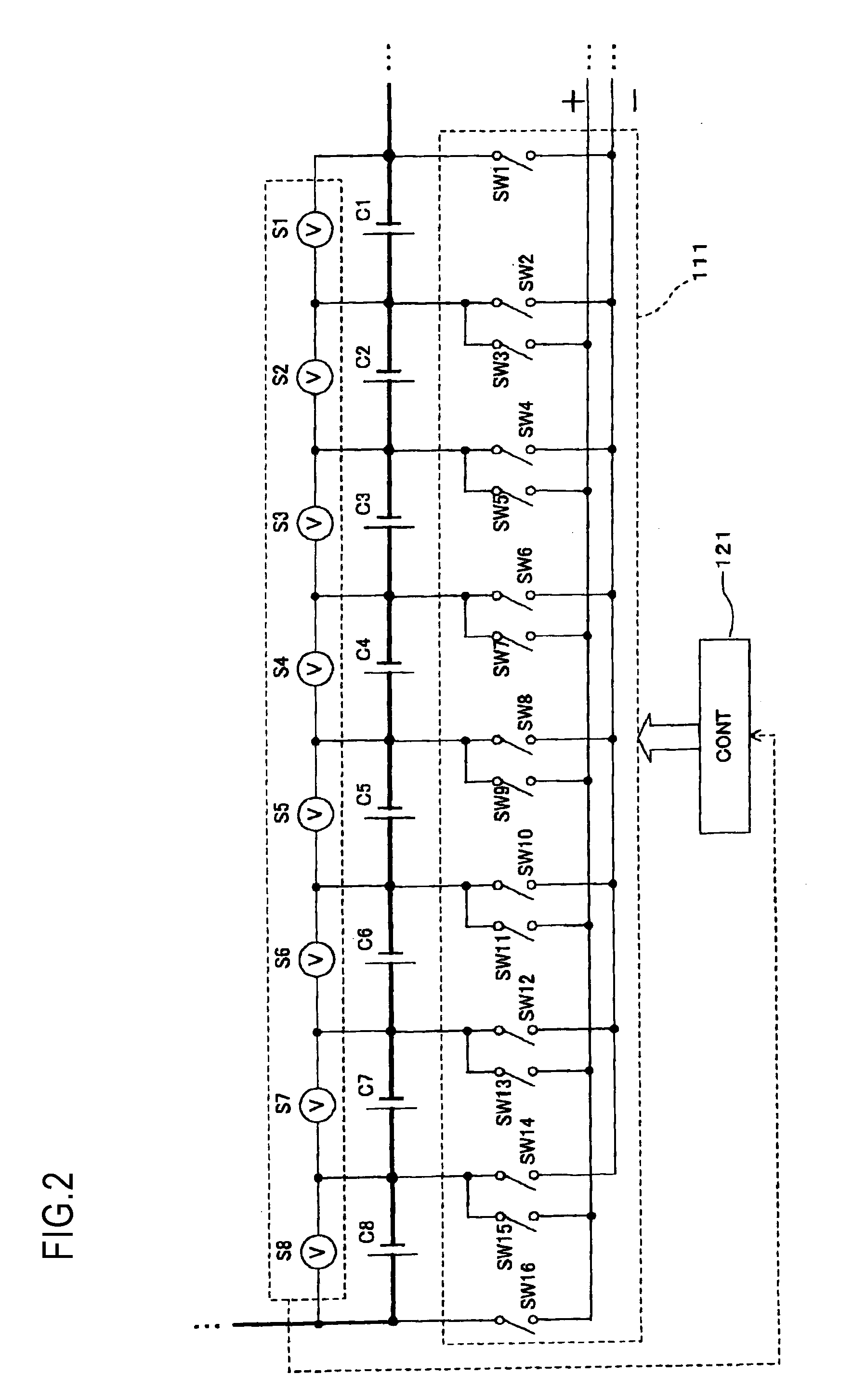

Discharge controller

ActiveUS20090102422A1Not affectEfficient consumptionCharge equalisation circuitElectrical testingCell voltageStorage cell

There is provided a discharge controller for a multiple cell battery that has a plurality of storage cells connected in series with each other. A discharge path from the storage cell is connected a load. The discharge controller includes: cell voltage detection units for detecting respective cell voltages of the storage cells; a switch group comprising a plurality of switches each connected between the storage cells; and a control unit for performing ON / OFF control on the respective switches individually in response to detection results detected by the cell voltage detection units so as to form the discharge path from the storage cell to the load.

Owner:HONDA MOTOR CO LTD

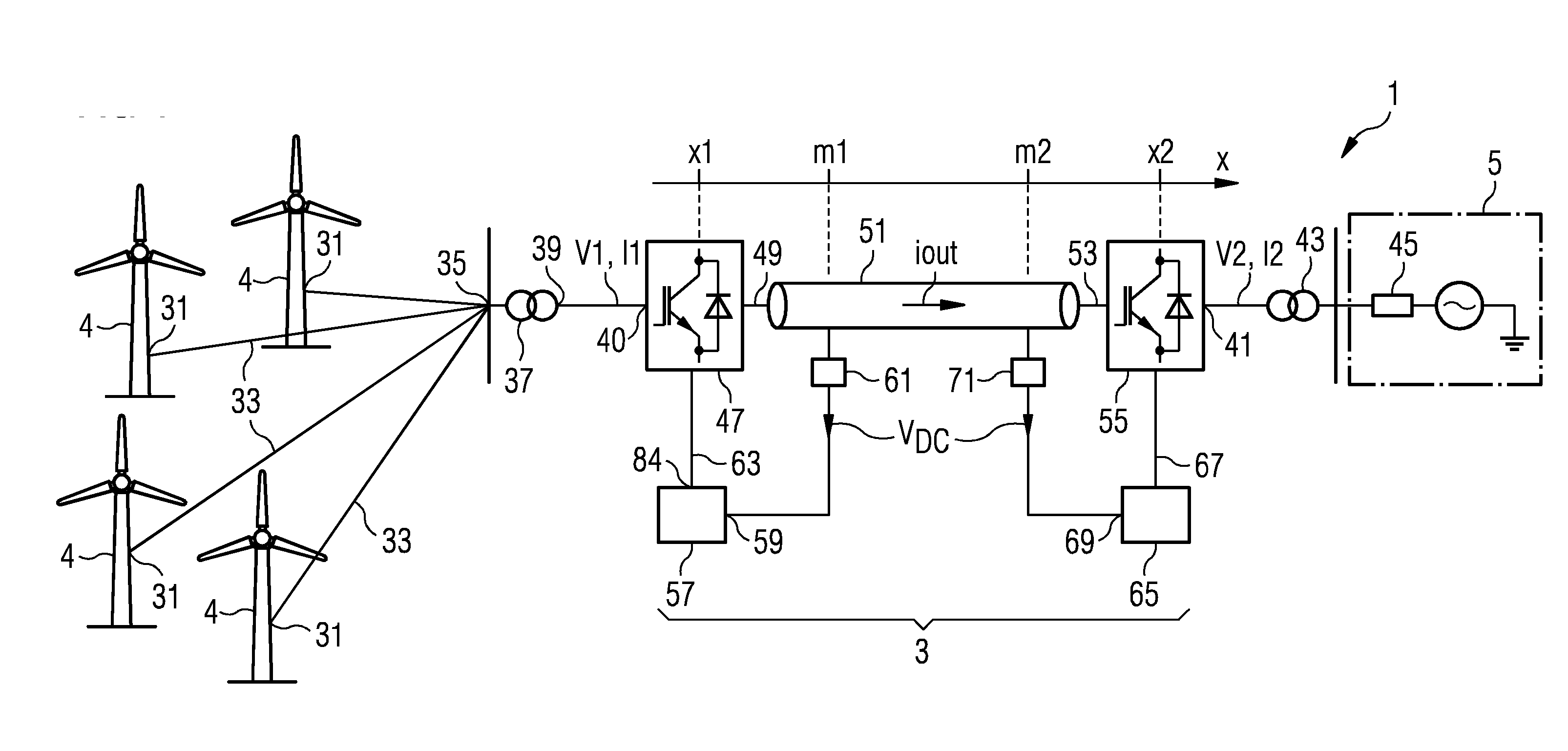

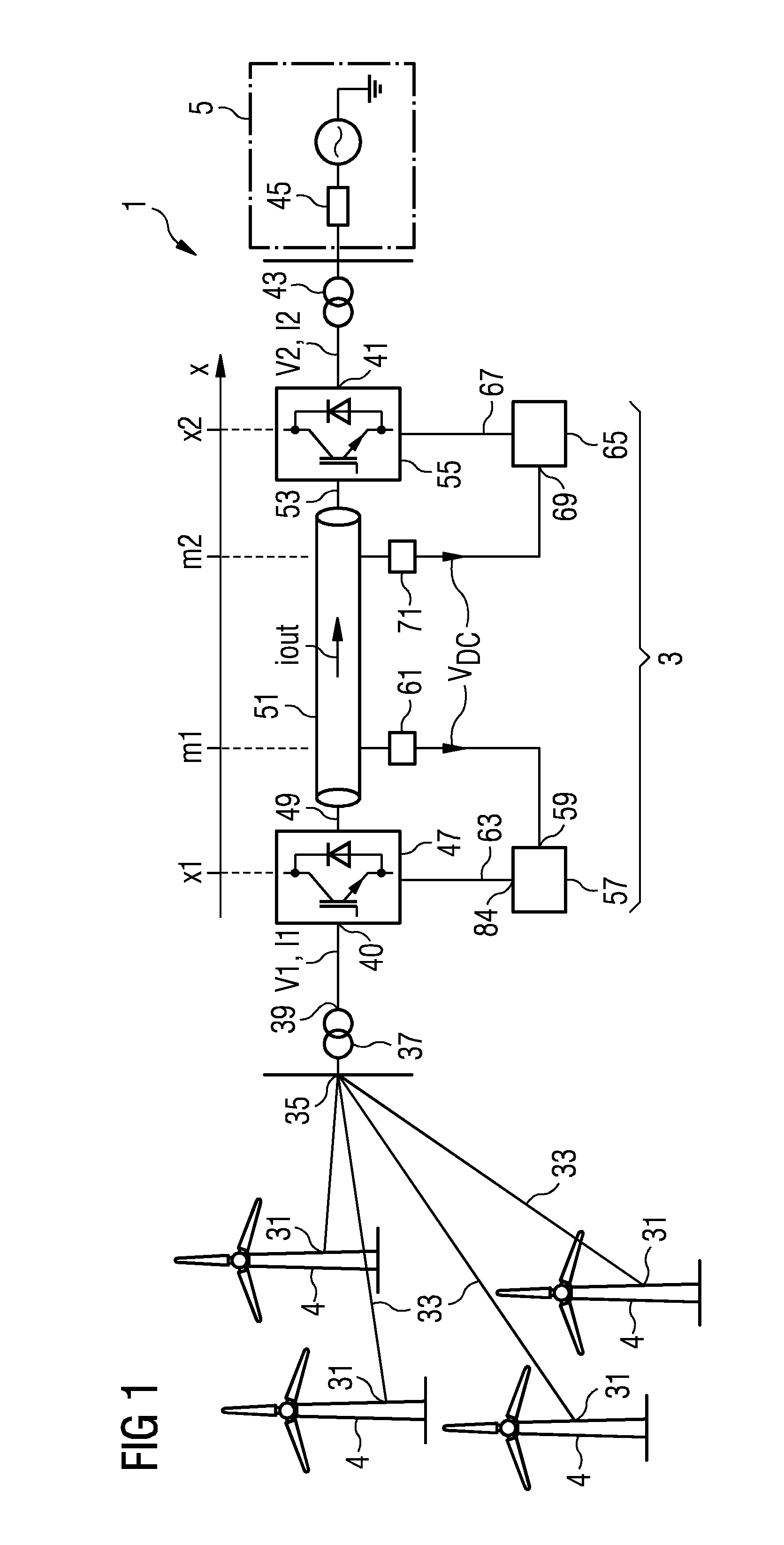

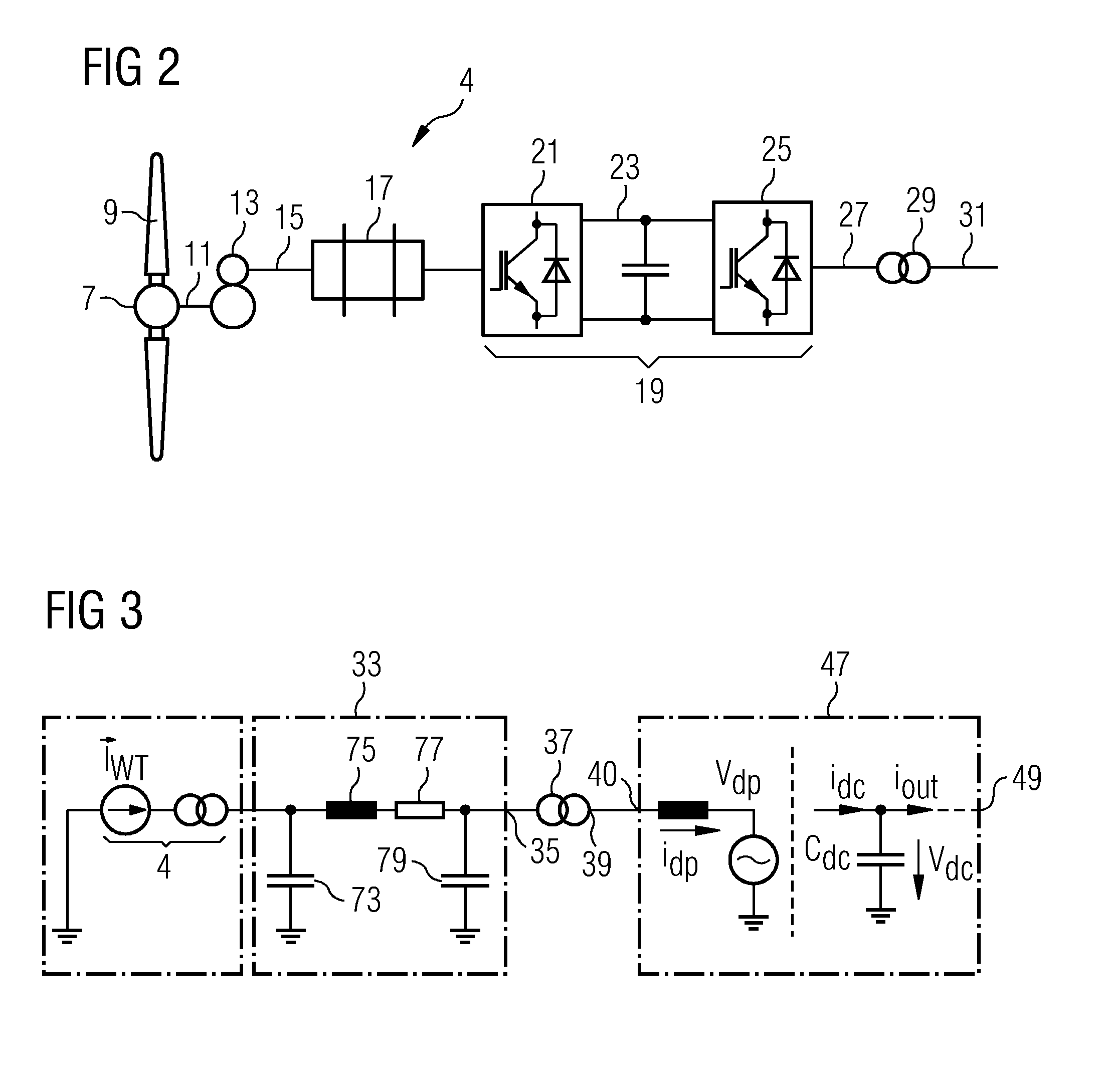

Method and apparatus for controlling a dc-transmission link

InactiveUS20120300510A1Easy constructionIncrease rotation speedElectric power transfer ac networkEnergy industryEngineeringDc ac converter

A method for controlling a DC-transmission link for transmitting electric power from a power production unit connected to an AC-DC converter at a first side of the DC-transmission link to a utility grid connected to a DC-AC converter at a second side of the DC-transmission link is provided. The method includes: obtaining a DC voltage signal indicative of a DC voltage at the DC transmission link; controlling the AC-DC converter such that an AC voltage at an AC side of the AC-DC converter is adjusted based on the DC voltage signal. Further, an apparatus for controlling a DC-transmission link is provided.

Owner:SIEMENS AG

Fastener Driving Apparatus

ActiveUS20100213235A1Avoid consumptionPrecludes of drive in drive speedStapling toolsFluid couplingsLinear motionControl circuit

A fastener driving apparatus includes a power source, a control circuit, a motor, a first cylinder, a first piston, a linear motion converter, a second cylinder, a second piston, an anvil, a valve arrangement and at least one sensor. During a compression stroke, the first piston is configured to compress gas in a first cylinder to a predetermined pressure. At the predetermined pressure, the valve arrangement assumes an open position for communicating the compressed gas to the second cylinder, thereby causing the second piston to move linearly and enabling the anvil to drive the fastener into the workpiece. During a return stroke, at a predetermined position of the first piston in the first cylinder, the valve arrangement assumes the open position for communicating a vacuum created in the first cylinder to the second cylinder and thereby causing the second piston and the anvil to retract to their initial positions.

Owner:TRICORD SOLUTIONS

Fastener driving apparatus

ActiveUS7793811B1Overcomes drawbackShorten speedStapling toolsFluid couplingsLinear motionEngineering

Owner:TRICORD SOLUTIONS INC

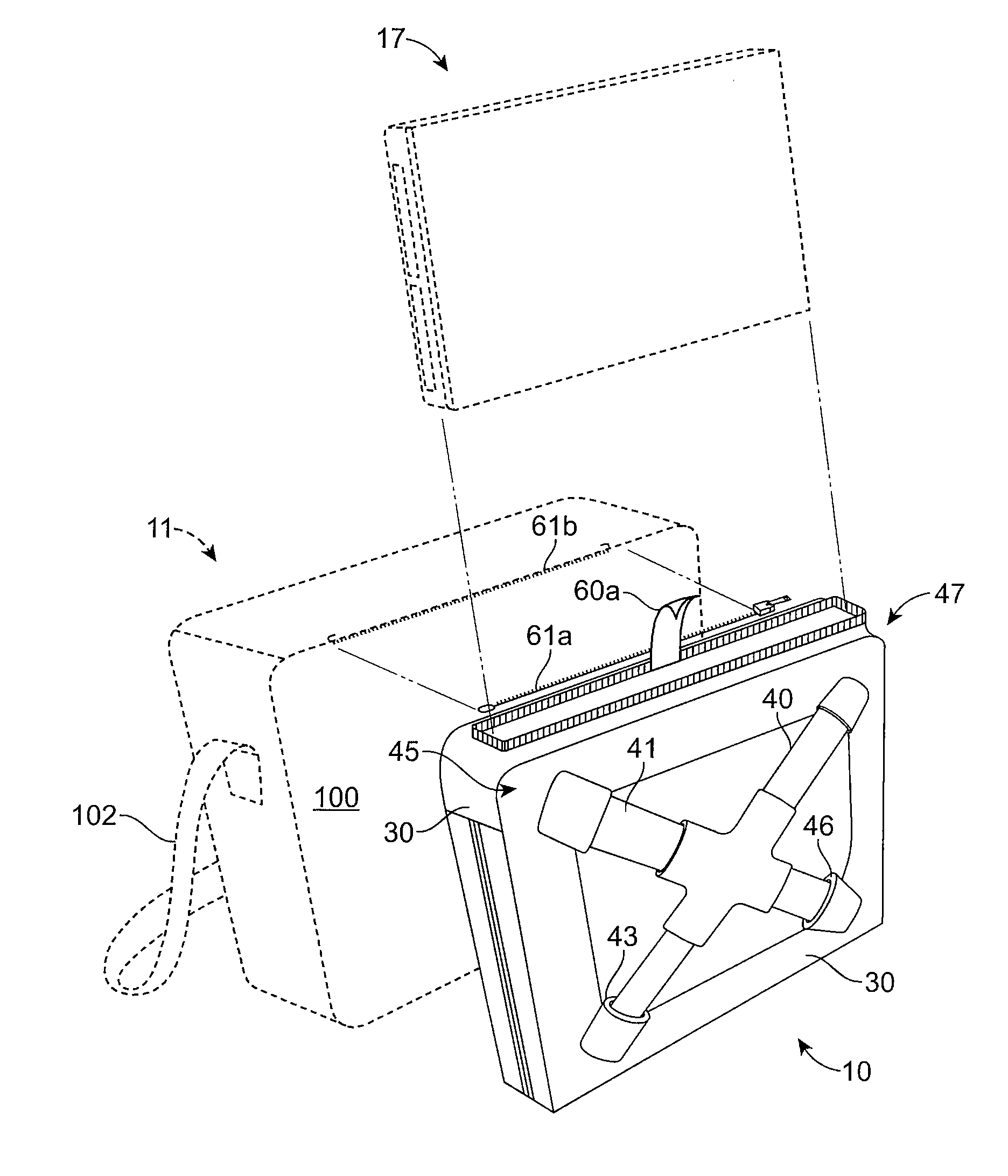

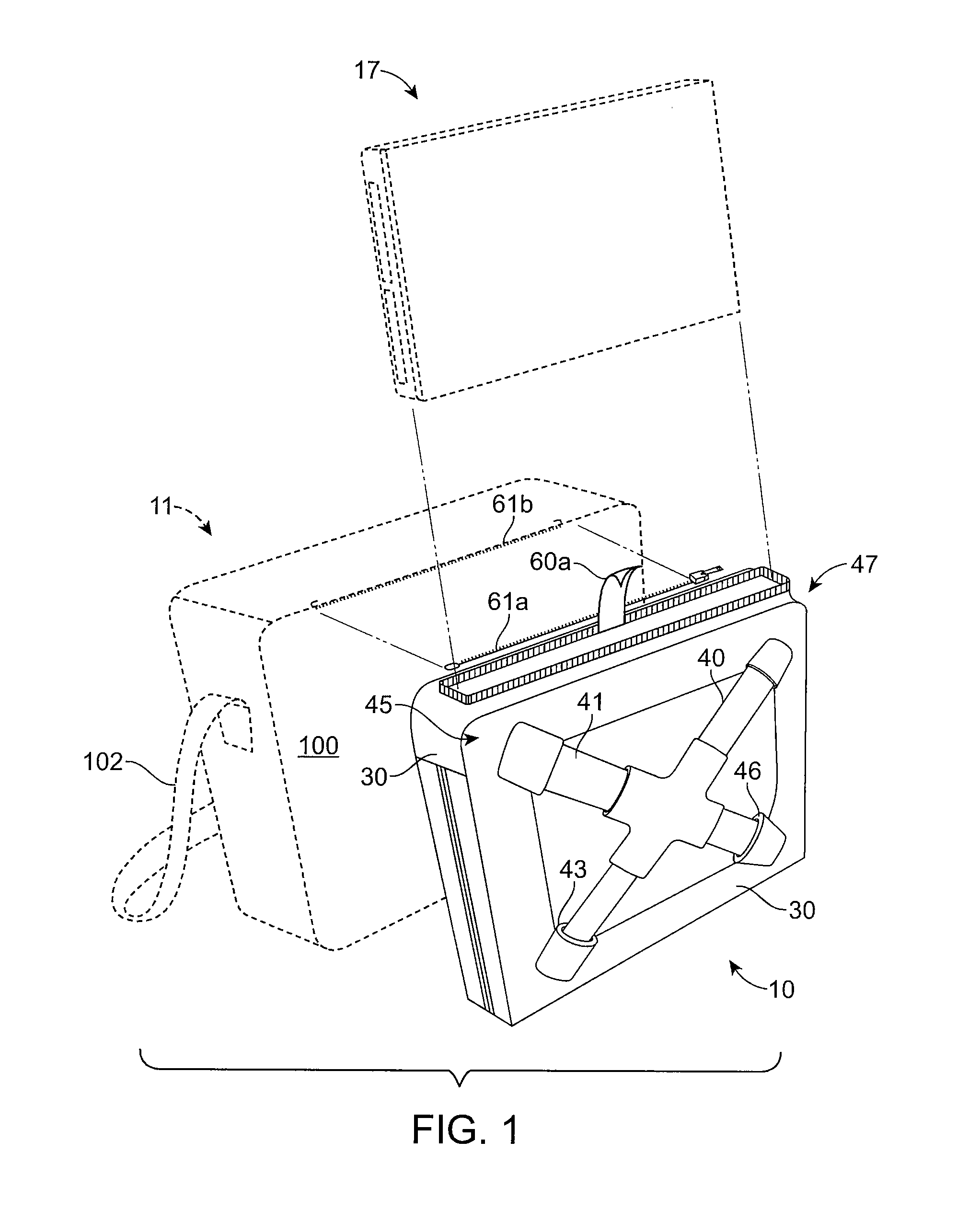

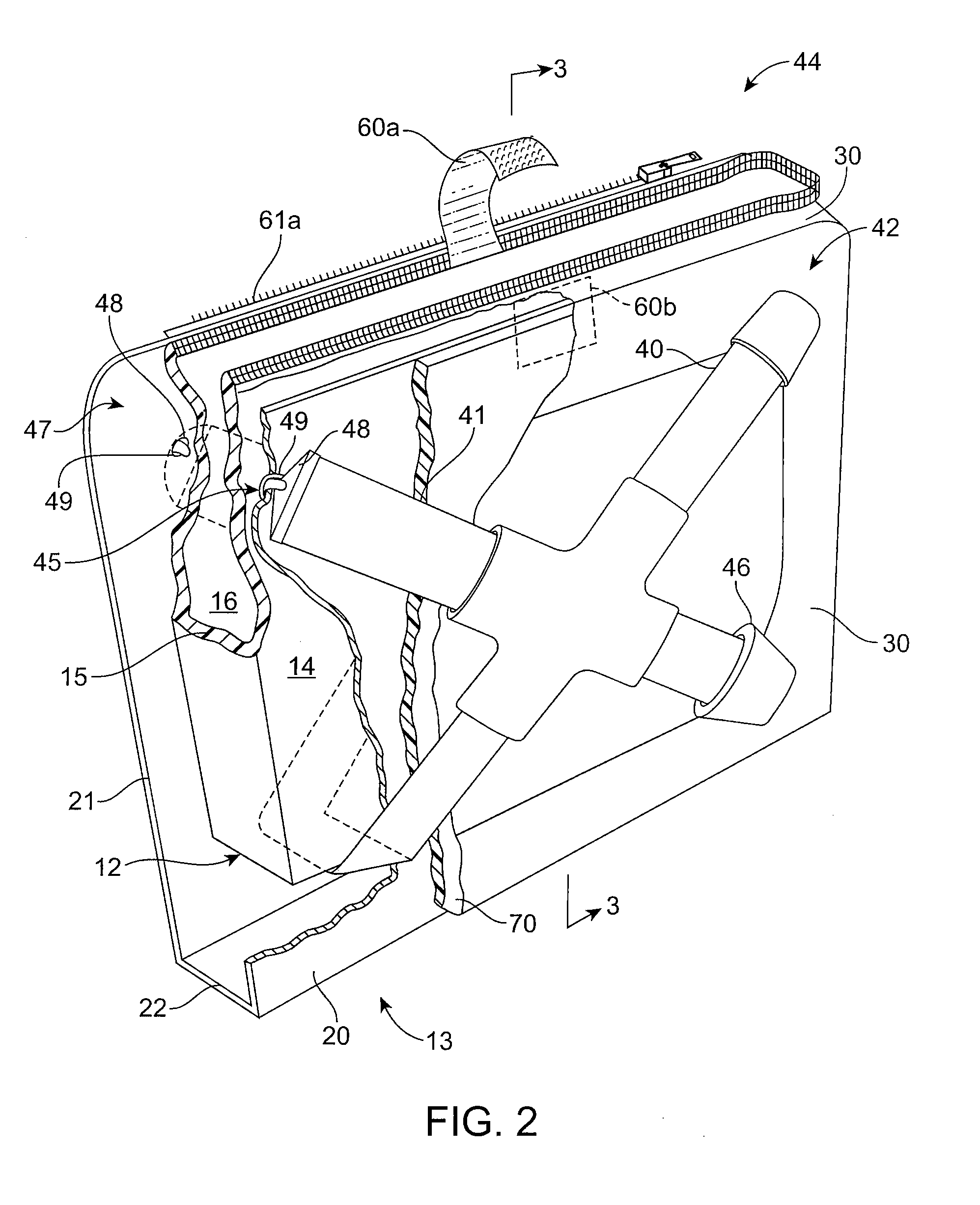

Computer bag with cross-brace support

InactiveUS7293649B2Restrict movementConsume energyOther accessoriesContainer/bottle contructionSupporting systemEngineering

A carrying case or bag that includes a soft pouch portion that is supported with a more rigid support structure. The soft pouch portion is supported by a cross-brace support system that allows limited movement relative to the support structure.

Owner:ACCO BRANDS USA LLC

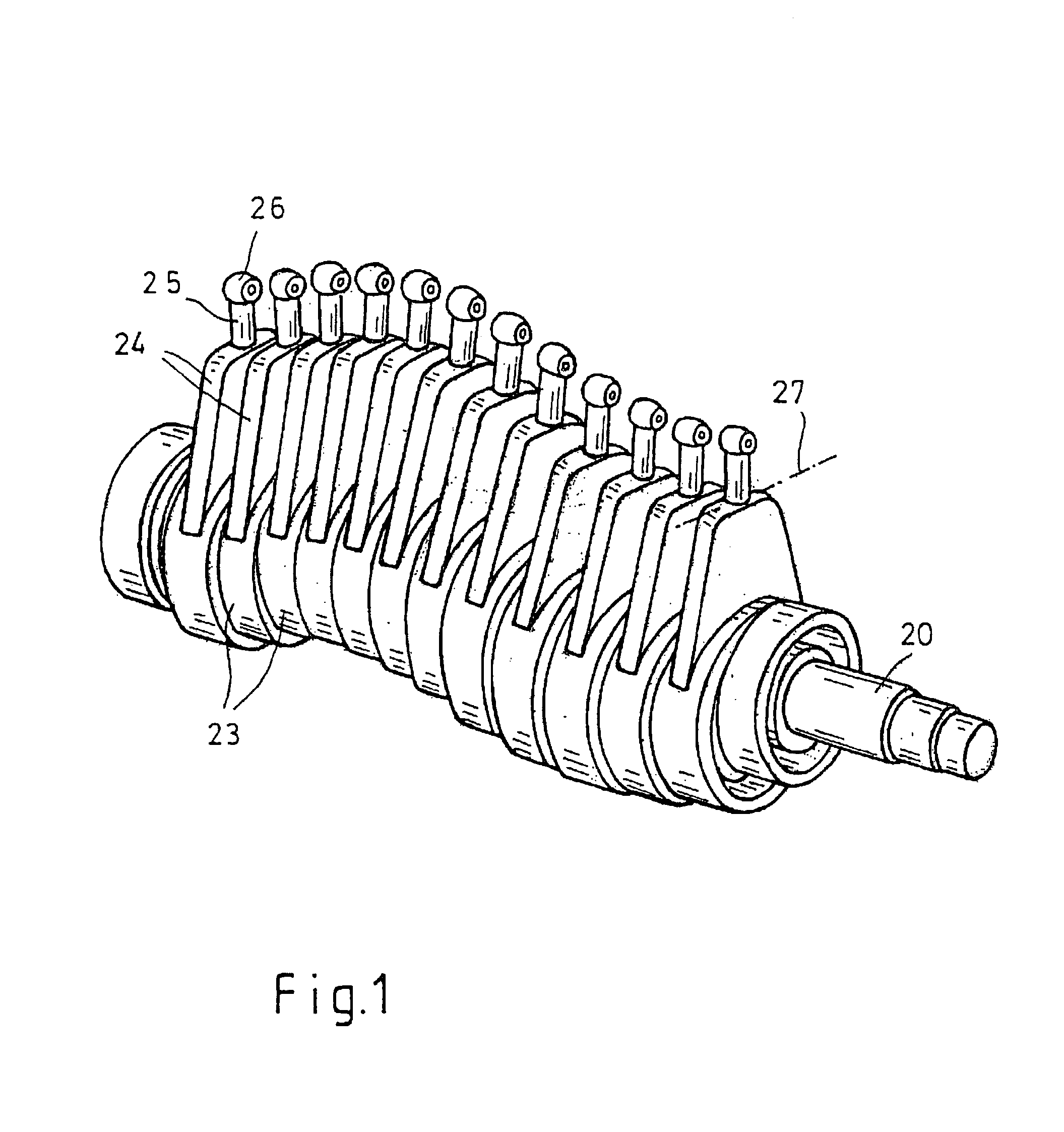

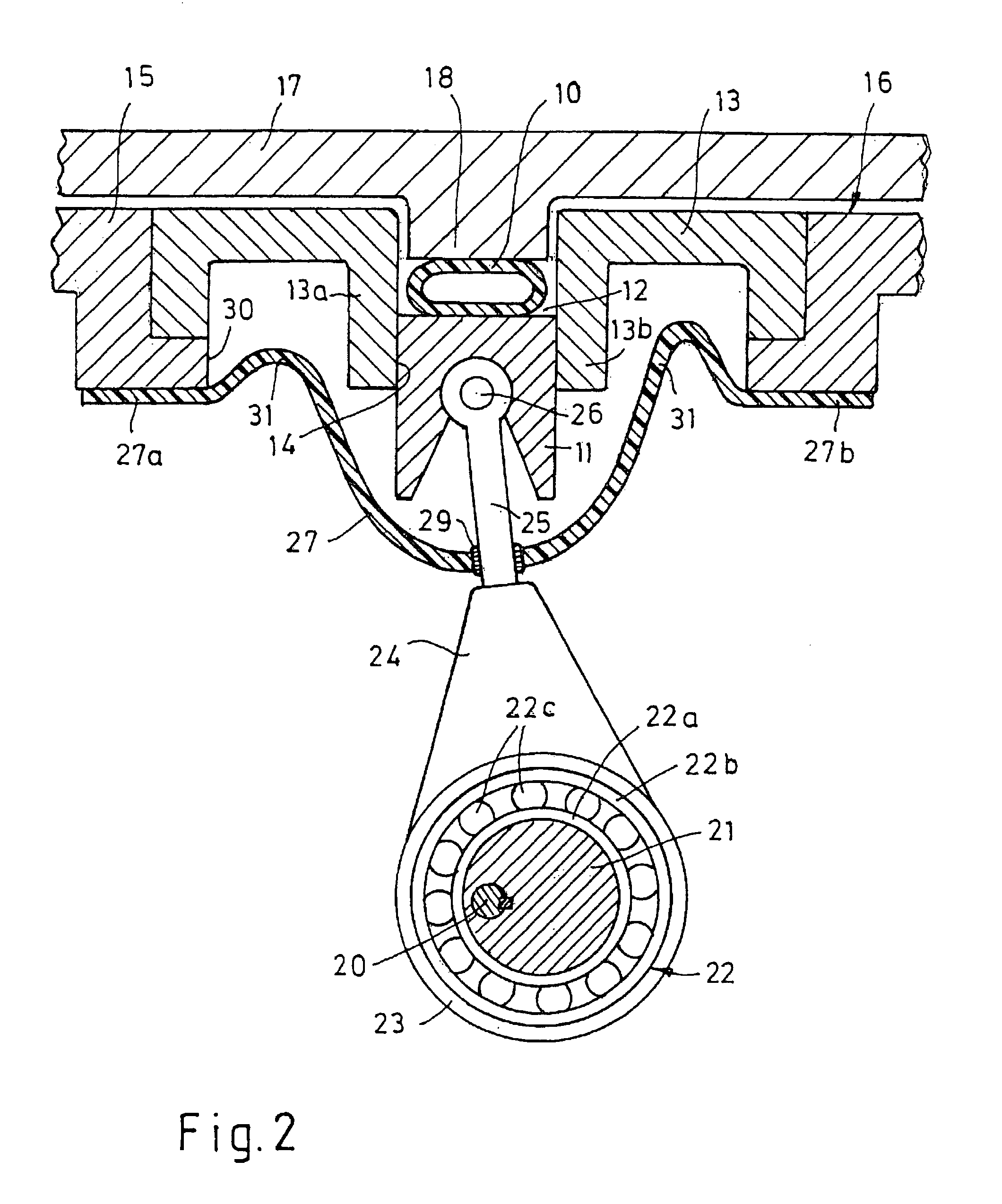

Peristaltic hose pump

InactiveUS7217108B2Lower energy requirementsAvoid contaminationFlexible member pumpsPositive-displacement liquid enginesCompression PumpEngineering

The hose pump comprises an eccentric drive with numerous eccentric discs (21) fastened to a shaft (20). Each eccentric disc (21) drives a crank drive (24) having a connecting rod (25). At the end of the connecting rod (25), a pump finger (11) is borne for compressing a pump hose (10). A sealing diaphragm (27) is disposed between the eccentric drive and the pump hose (10) for preventing liquid from intruding into the interior of the housing (16). The connecting rod (25) sealingly passes through the sealing diaphragm (27). The sealing diaphragm (27) comprises lateral folds (31) so that it does not exert any substantial forces upon the crank drive (24). The hose pump has a low power consumption and permits a small structure.

Owner:B BRAUN MELSUNGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com