Patents

Literature

76 results about "Ballistic impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ballistic impact is a high velocity impact by a small mass object, analogous to runway debris or small arms fire. The simulation of ballistic impacts can be achieved with a light-gas gun or other ballistic launcher. It is important to study the response of materials to ballistic impact loads. Applications of this research include body armor, armored vehicles and fortified buildings, as well as the protection of essential equipment, such as the jet engines of an airliner.

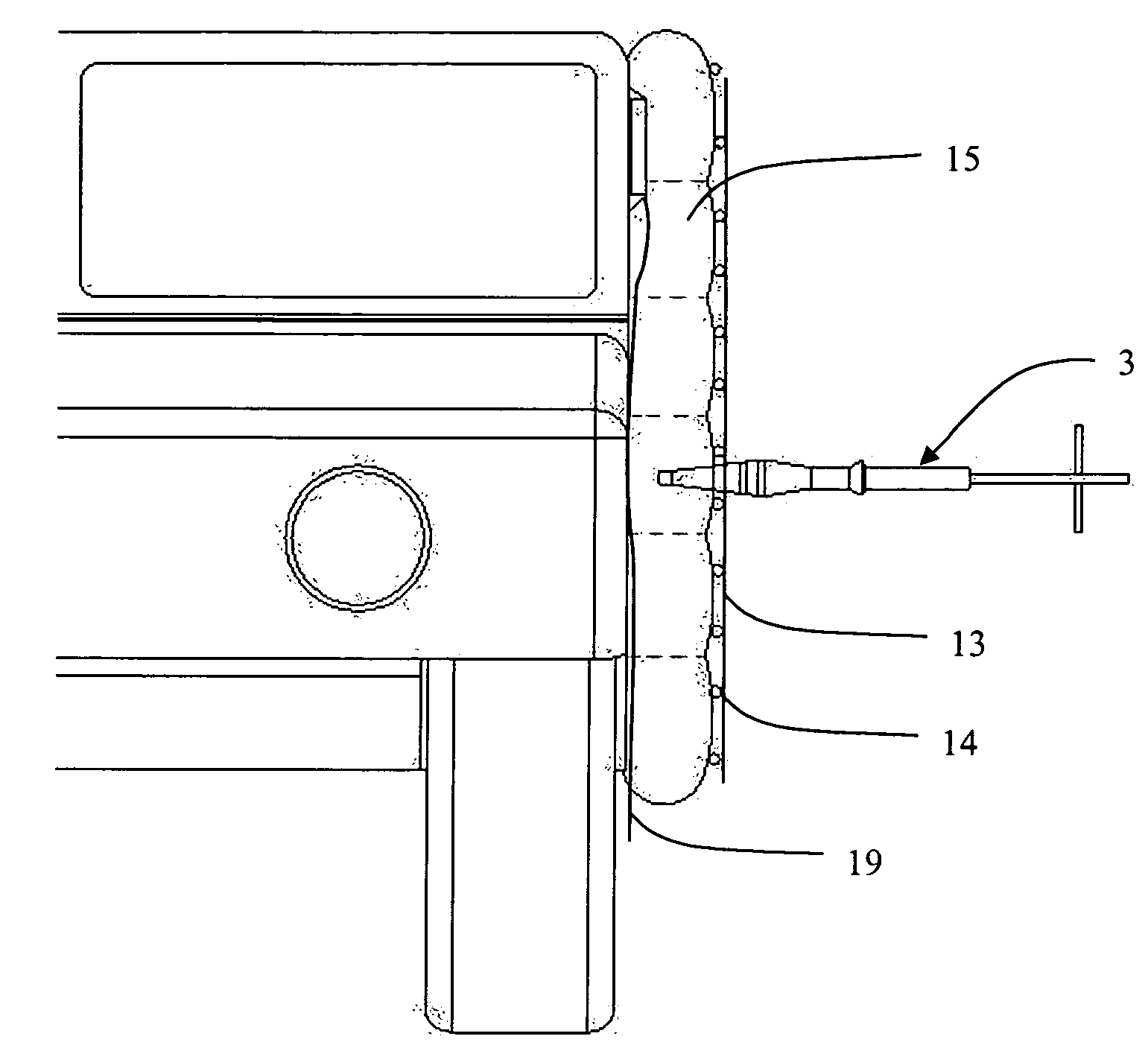

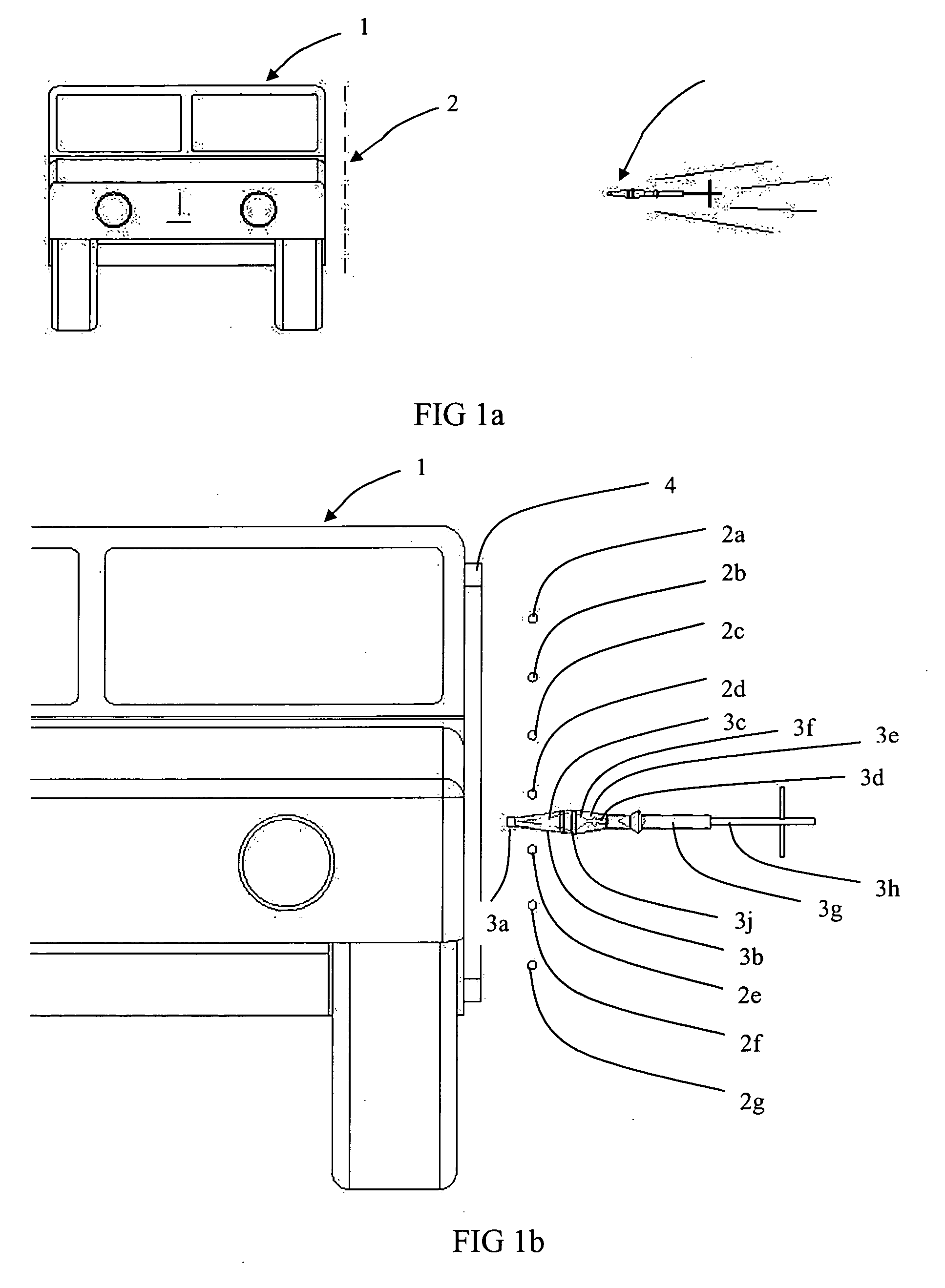

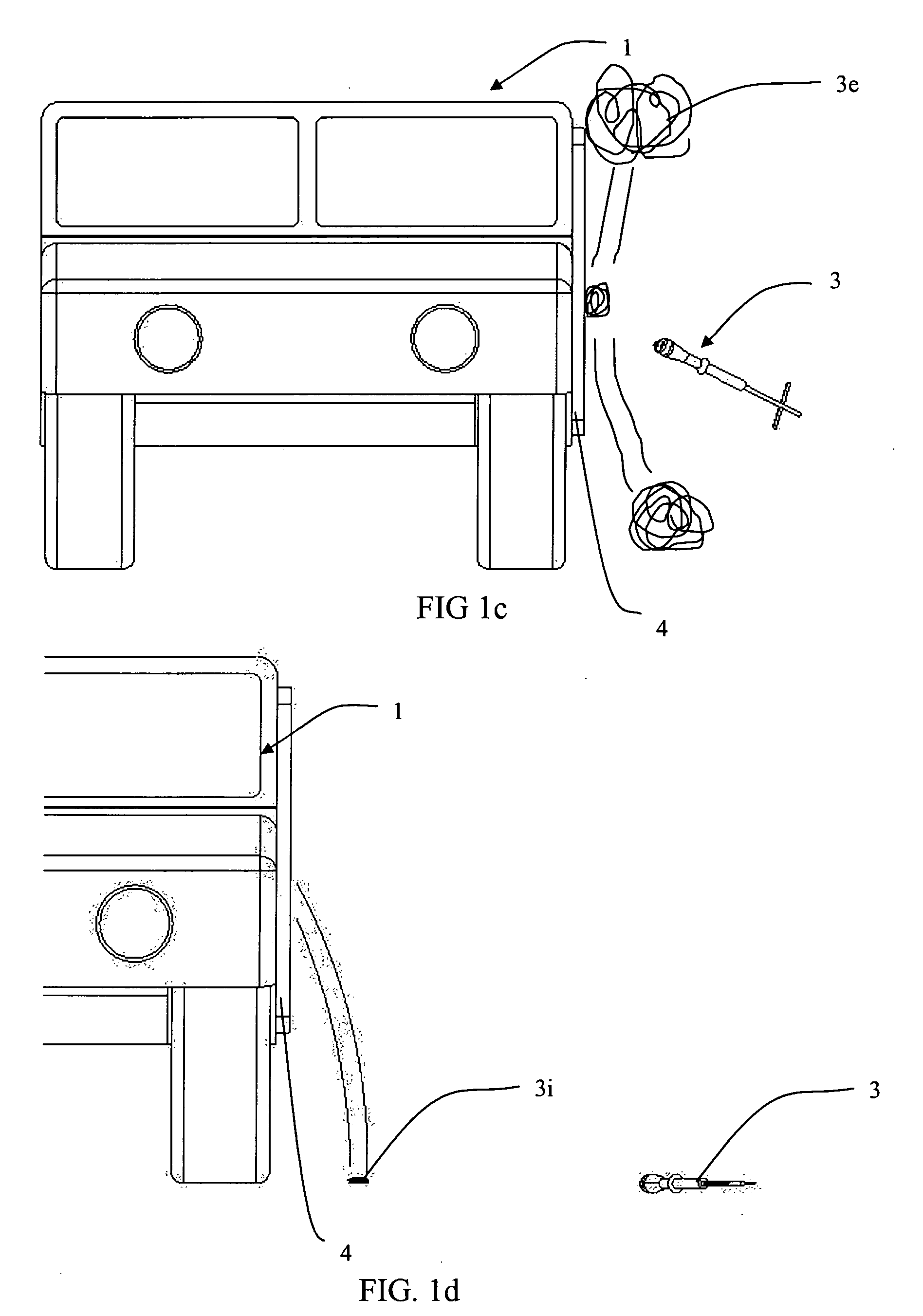

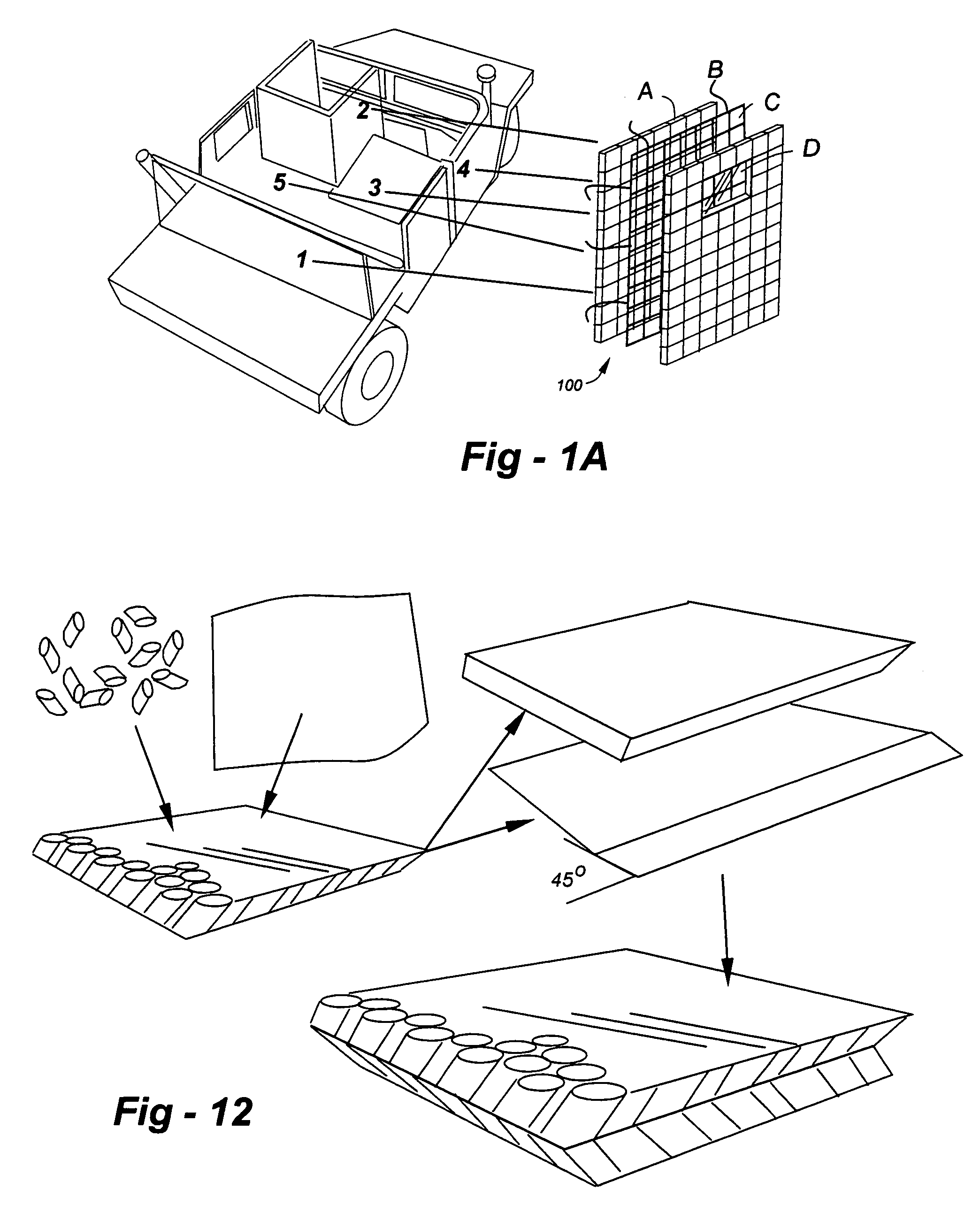

Explosive round countermeasure system

A countermeasure system which is capable of defusing rocket propelled grenades (RPG) is provided by spacing an array of explosive charges or primacord from the protected structure to allow and sense an ogive of the fused RPG to enter into a functional plane of the array initiating one or more of the charges to collapse to ogive. The array is supported flexibly or rigidly and further ballistic protection is incorporated behind the array in fixed or inflatable forms to provide protection of the structure from the explosive products from the array and the ballistic impact of the defused RPG.

Owner:TEXTRON SYST

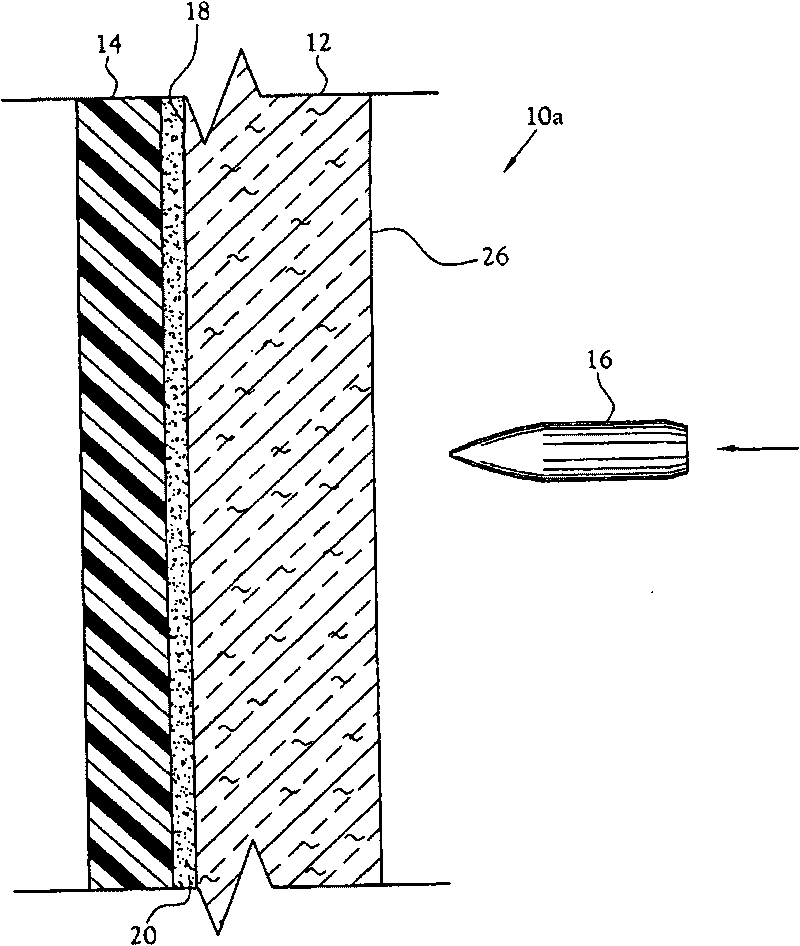

Polymeric ballistic material and method of making

PendingUS20060013977A1Dissipating projectile energySlow its forward motionLayered productsArmour platesBallistic impactPolymer

This invention relates to a polymeric ballistic material comprising a high molecular weight, high density polyethylene (HMW-HDPE) and / or composite, and to articles made from this ballistic material suitable for stopping projectiles. The articles may include backstops for firing ranges and home use, armor for vehicles, personnel, and aircraft, training targets, protection for temporary or mobile military and / or police installations, buildings, bunkers, pipelines or any “critical” need equipment that might require protection from ballistic impact, and the like.

Owner:BALLISTICS RES +1

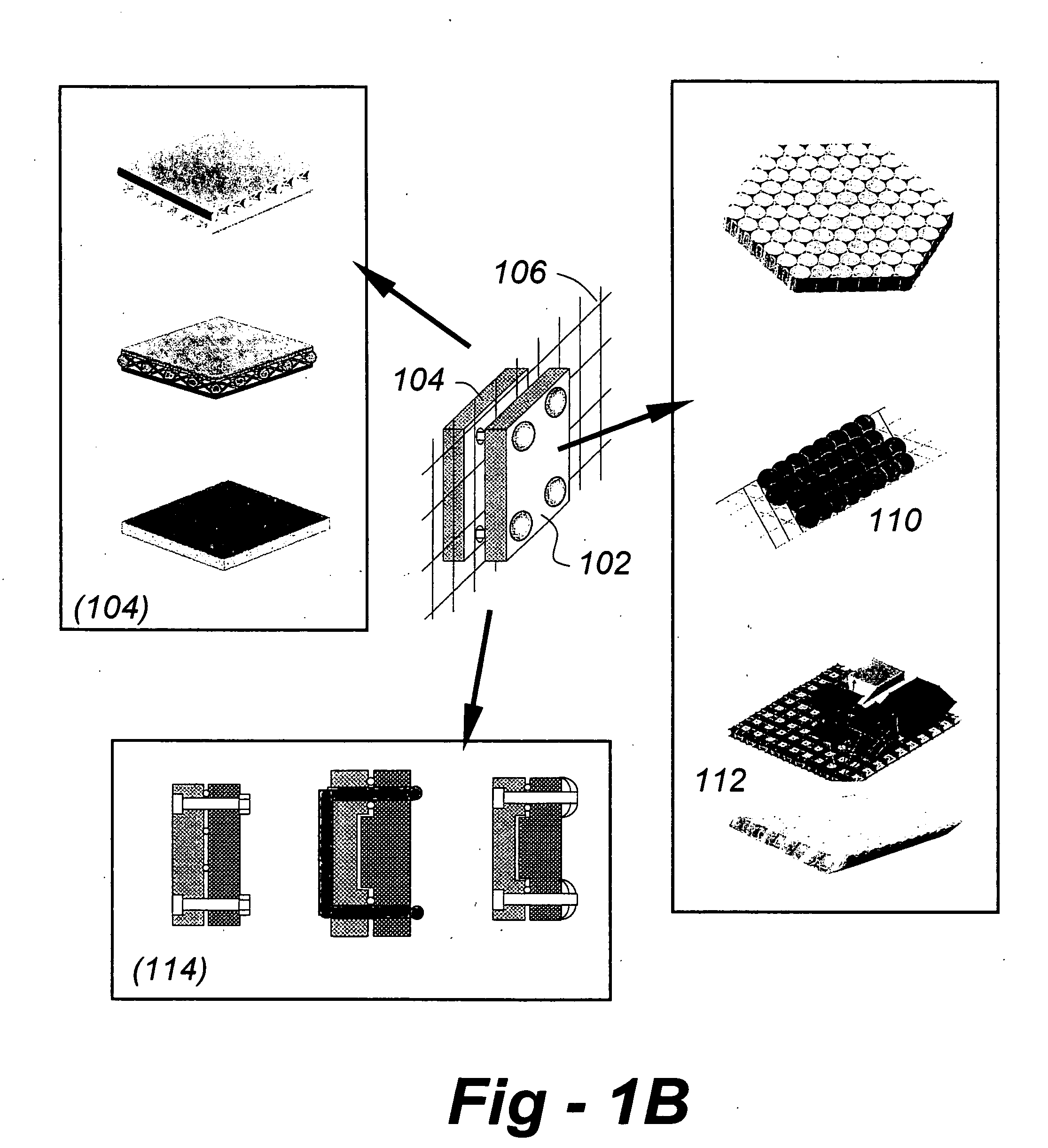

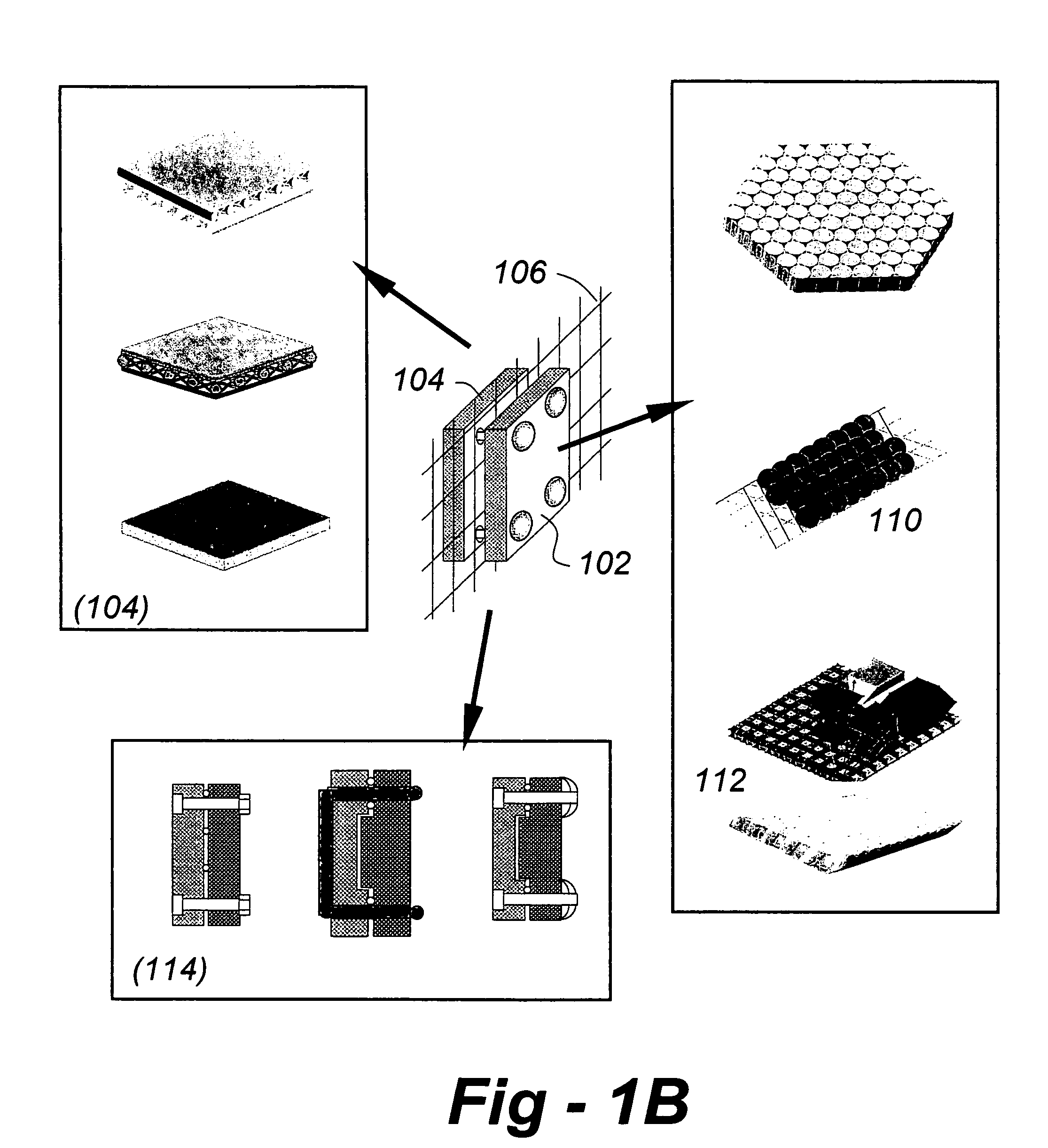

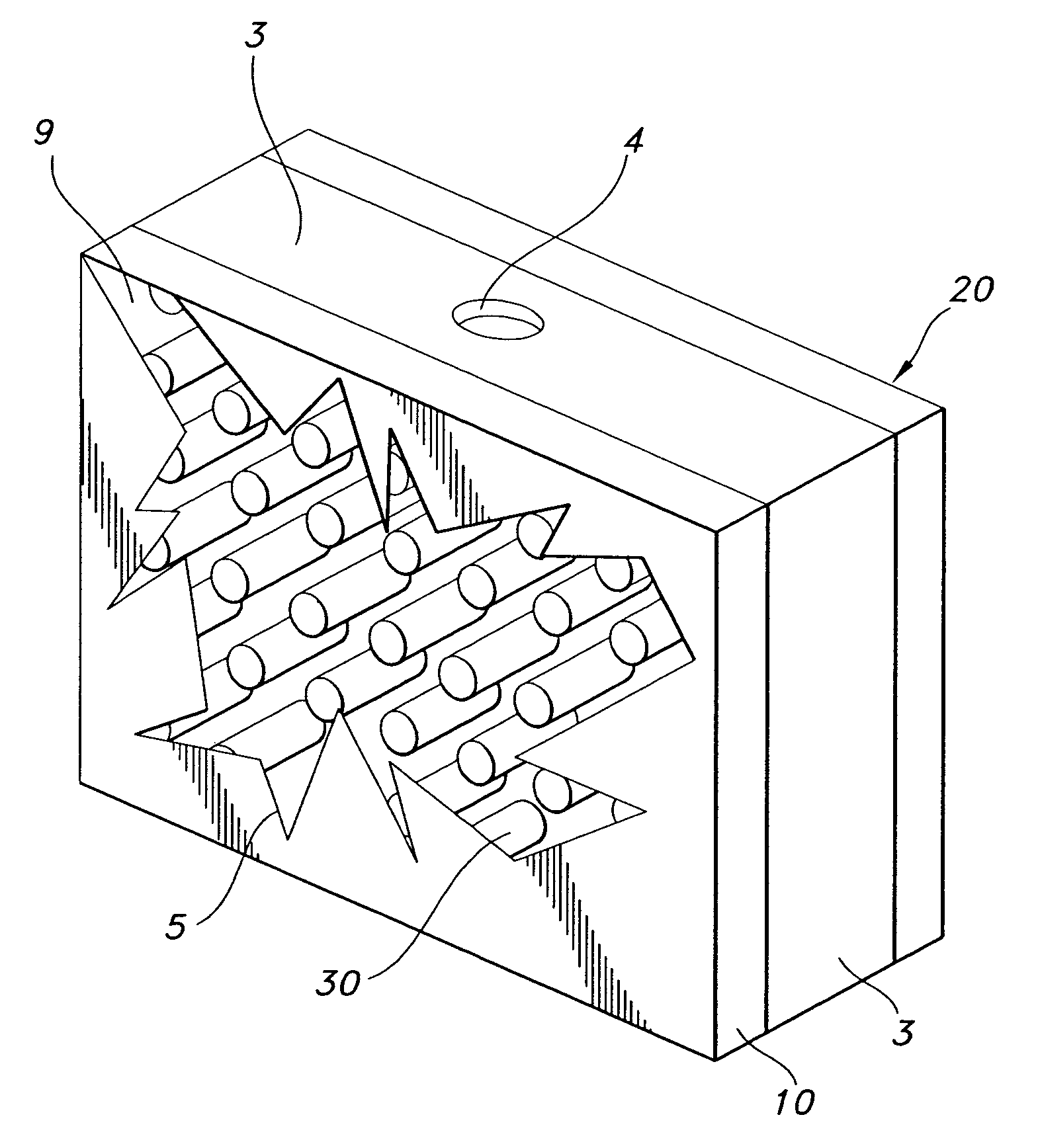

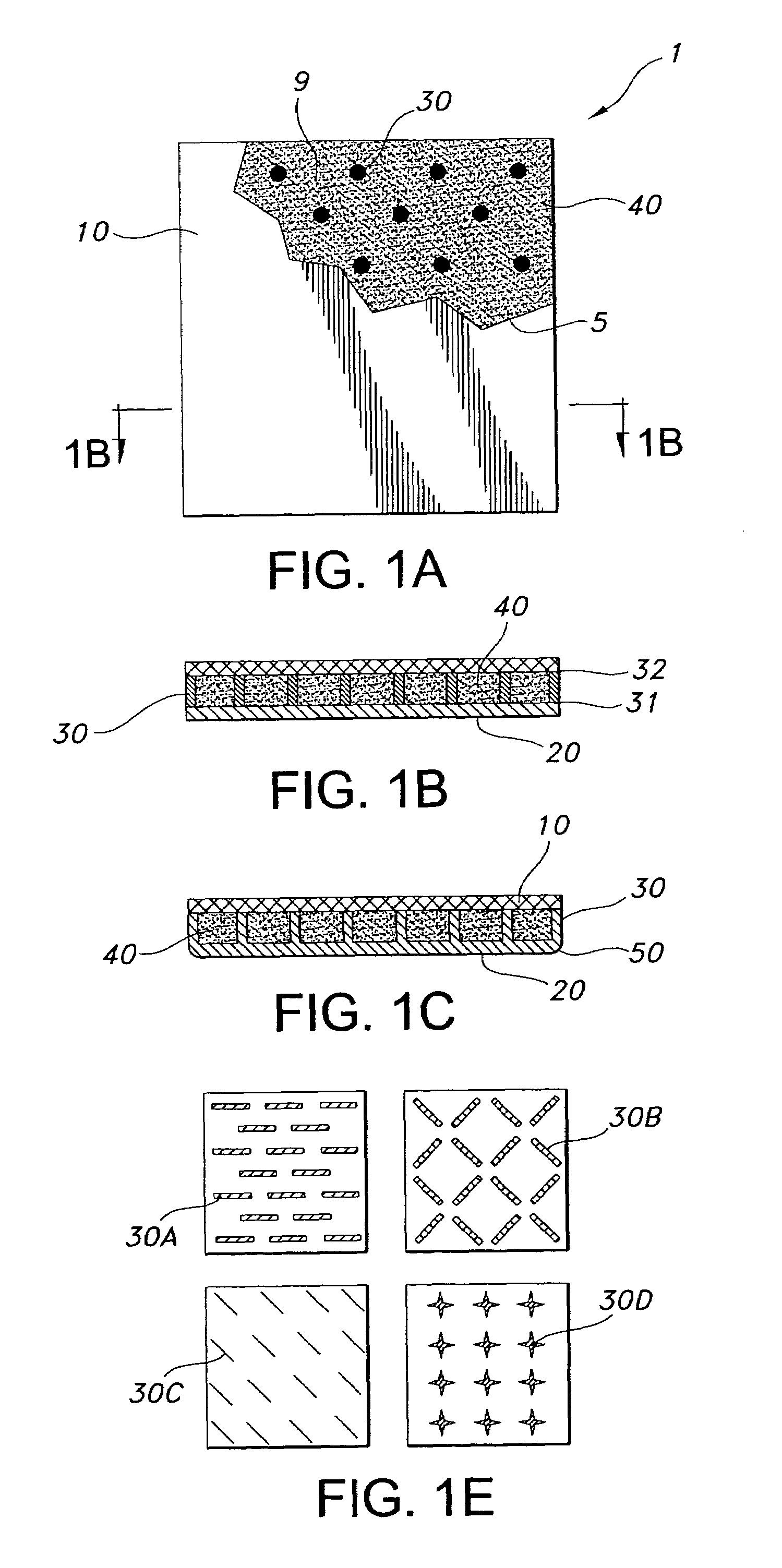

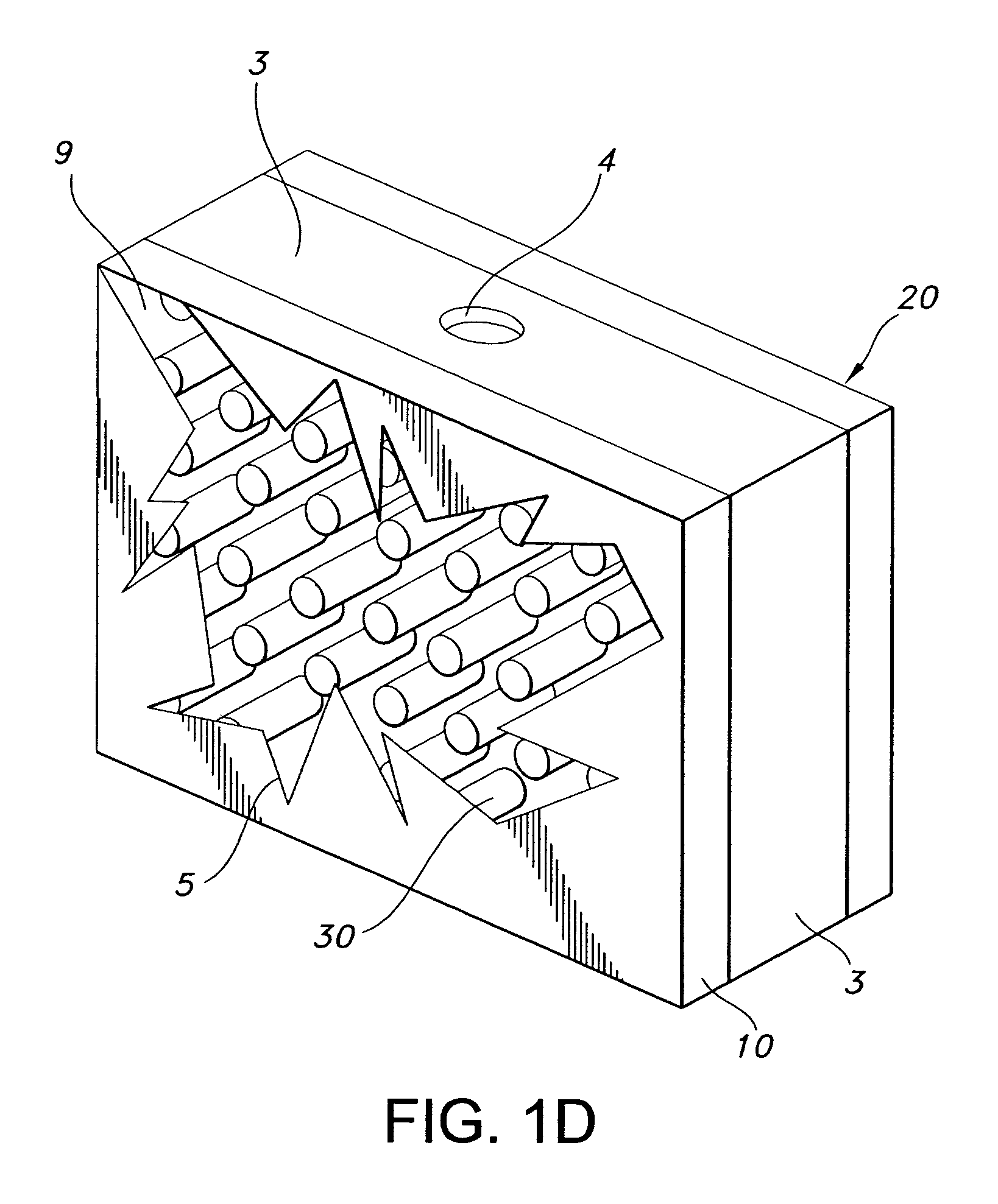

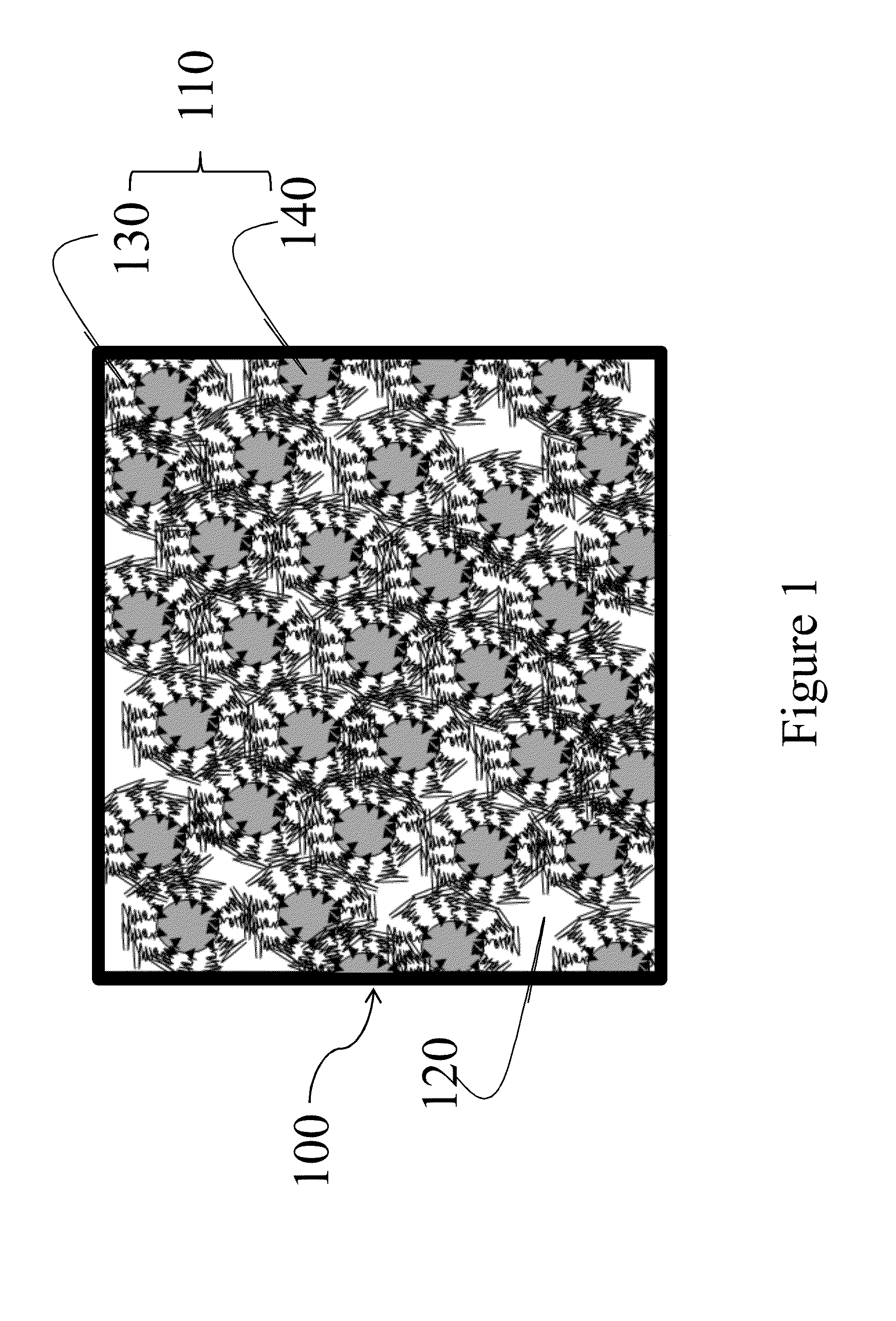

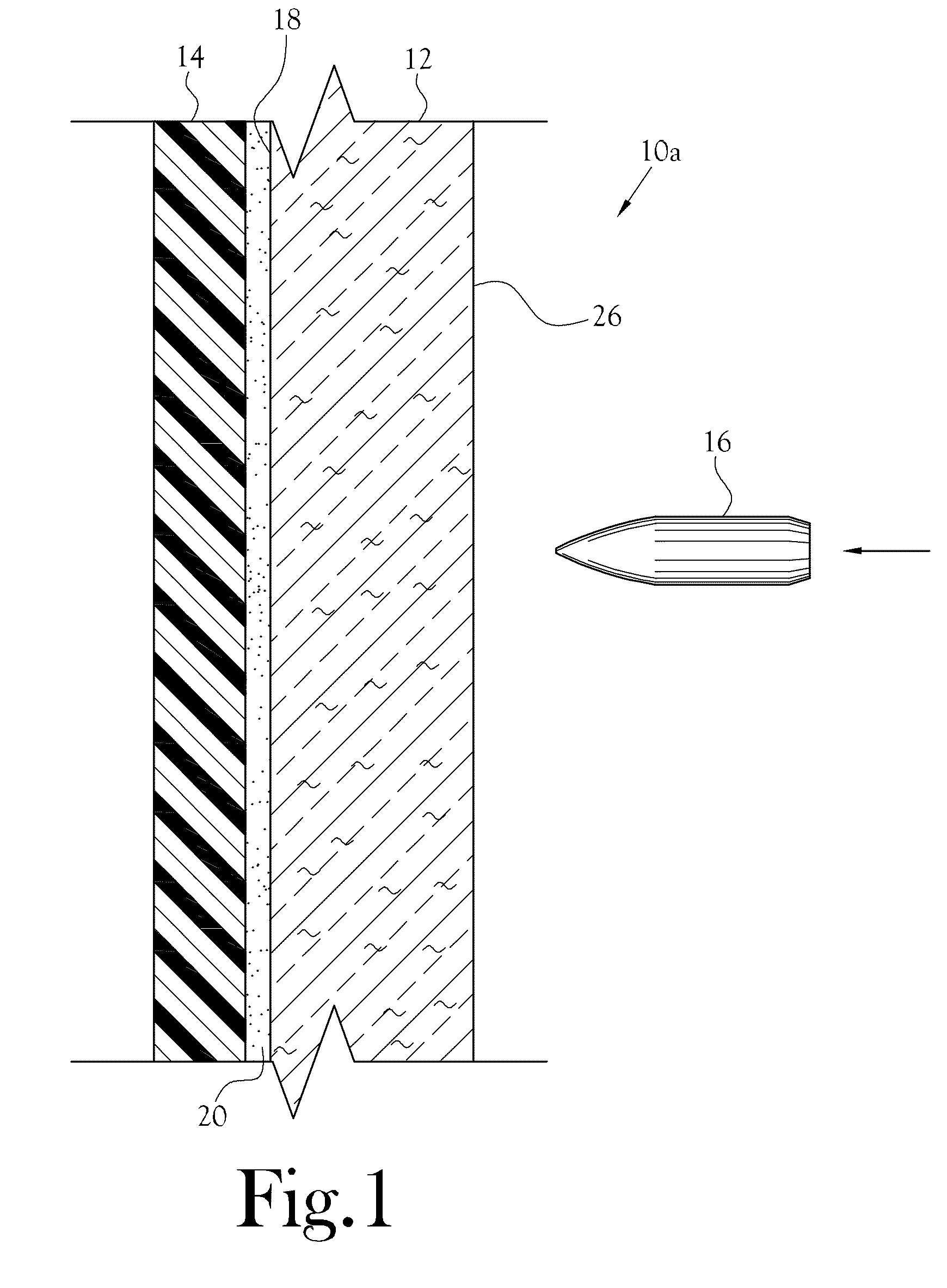

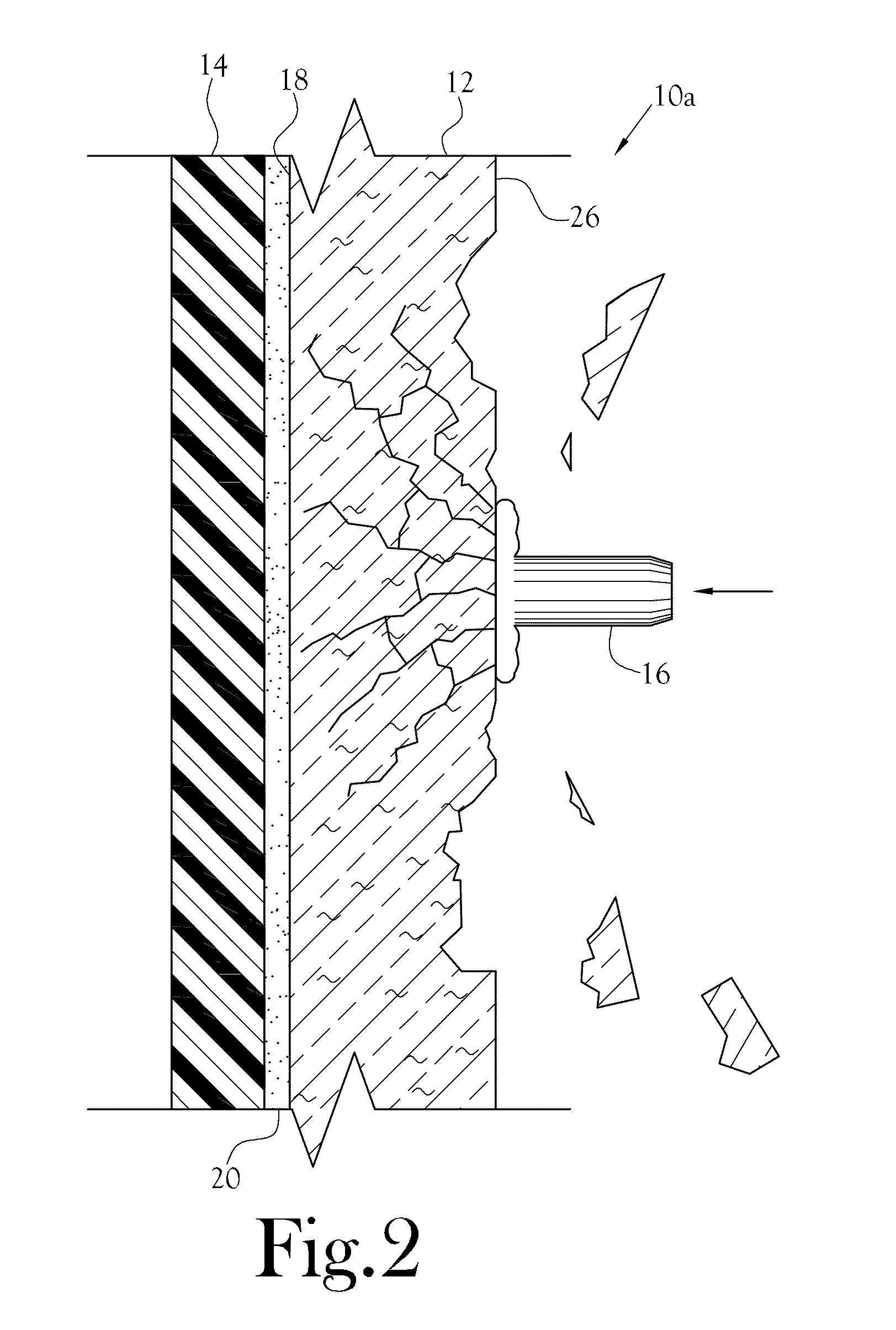

Lightweight composite armor

InactiveUS20070089597A1Improve manufacturabilitySimple structureArmour platesEnergy absorptionEngineering

Improved composite armor designs use optimally shaped ceramic pellets and a web system for patterning the pellets, improving manufacturability, and providing additional structural reinforcement. The result is lightweight, composite hybrid structures for ballistic protection particularly suited to tactical ground vehicles. The preferred embodiment is a combination of three major components: 1) an optimally designed web system that allows armor tiles to be attached to it and that can be easily integrated with existing vehicle structures; 2) an advanced composite armor unit using a patent-pending BTR (Bio-mimetic Tendon-Reinforced) material as the supporting structure; and 3) optimally placed “waiting materials” which can provide enhanced ballistic impact resistance, energy absorption capability and structural integrity. These “waiting materials” are structural members that are not active at the beginning of the ballistic impact, but become active when needed or the active members have failed.

Owner:MKP STRUCTURAL DESIGN ASSOCS

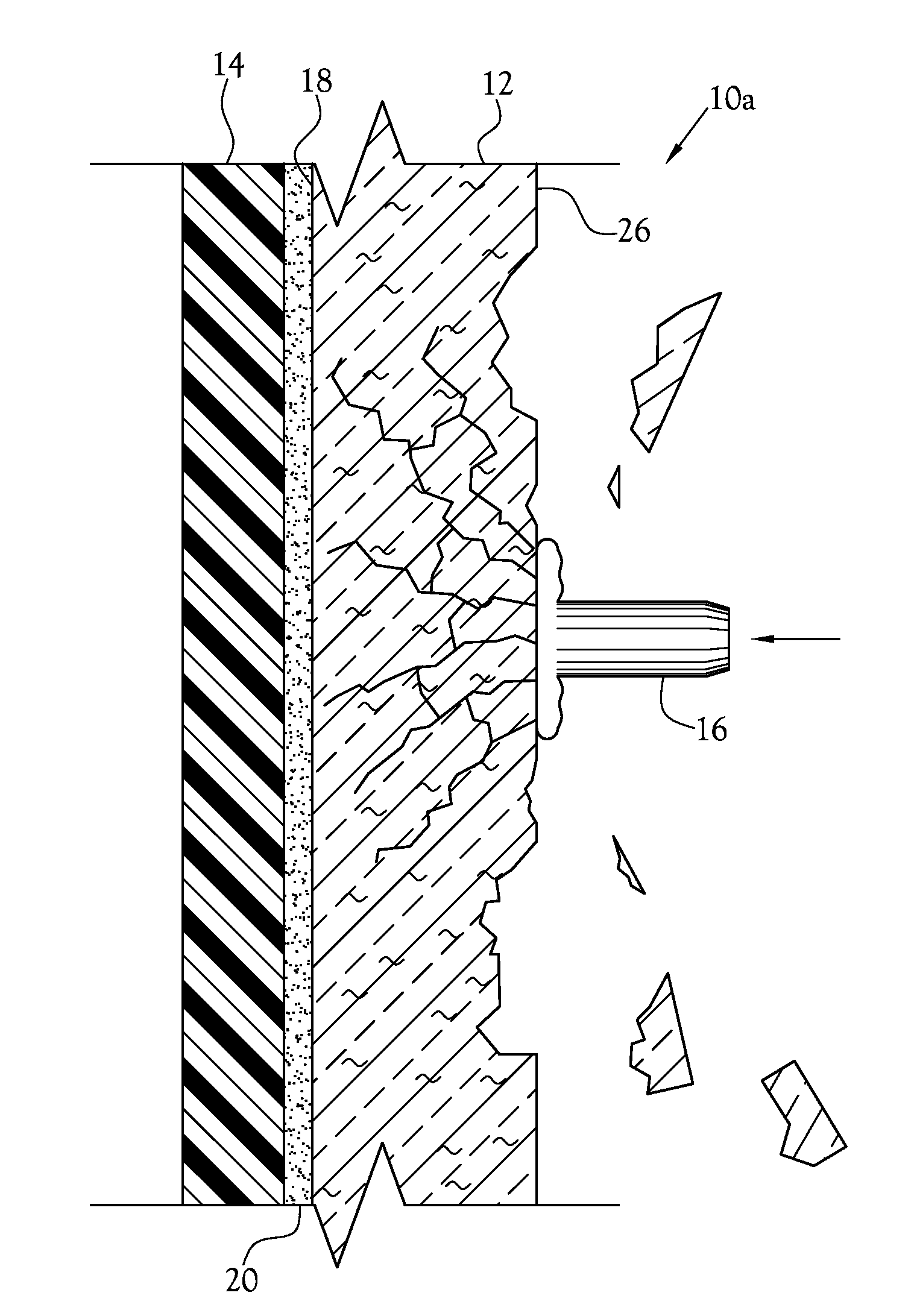

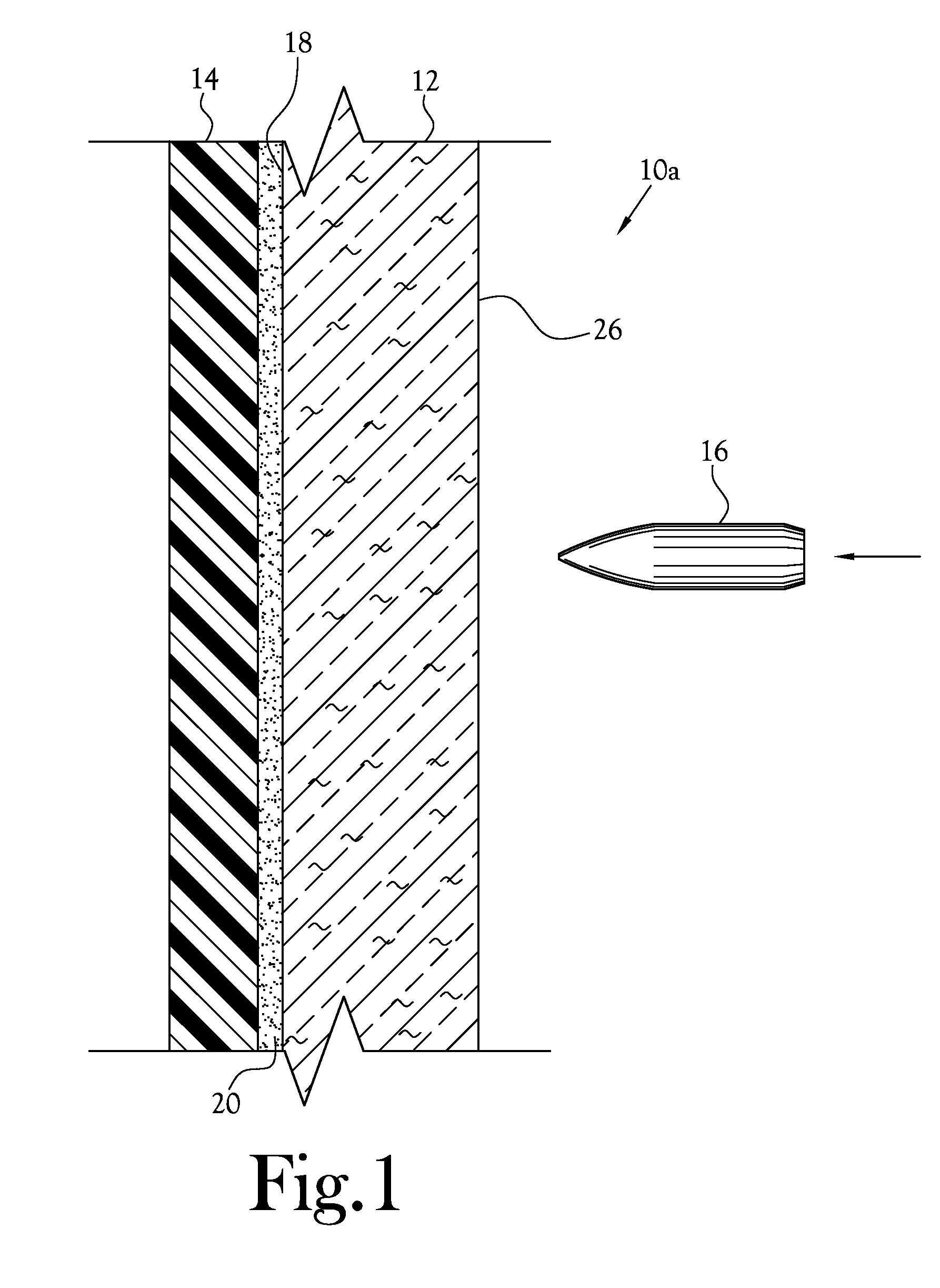

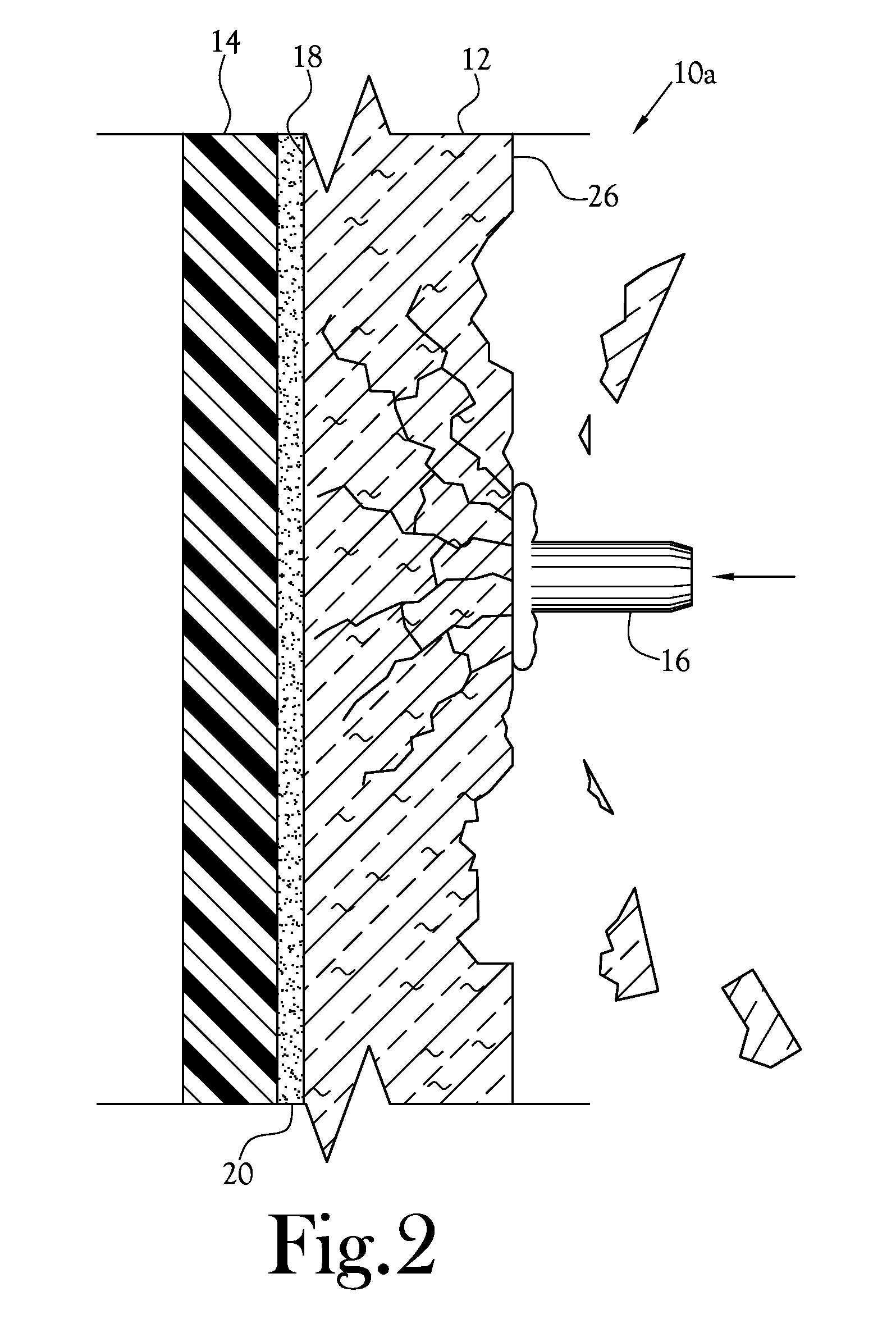

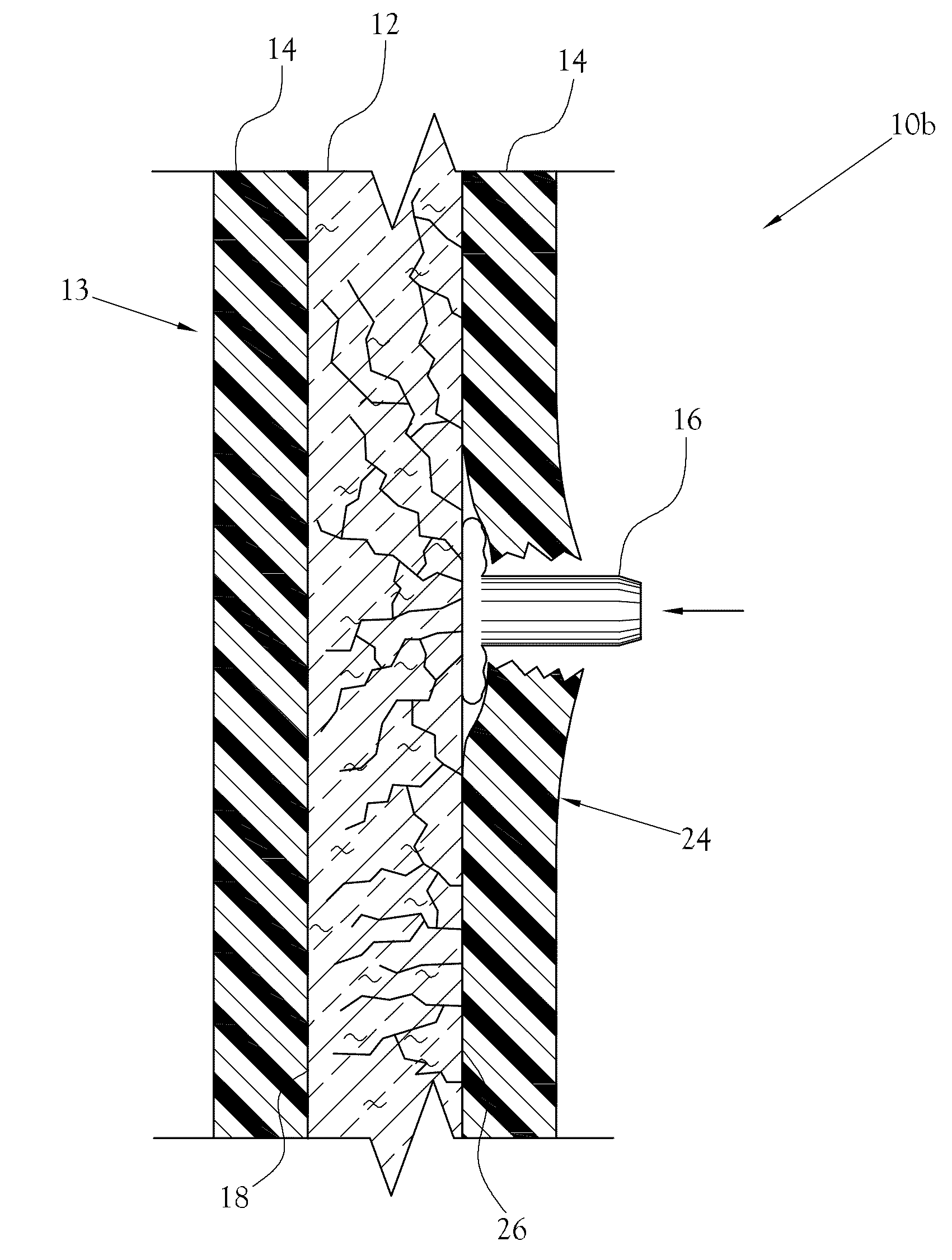

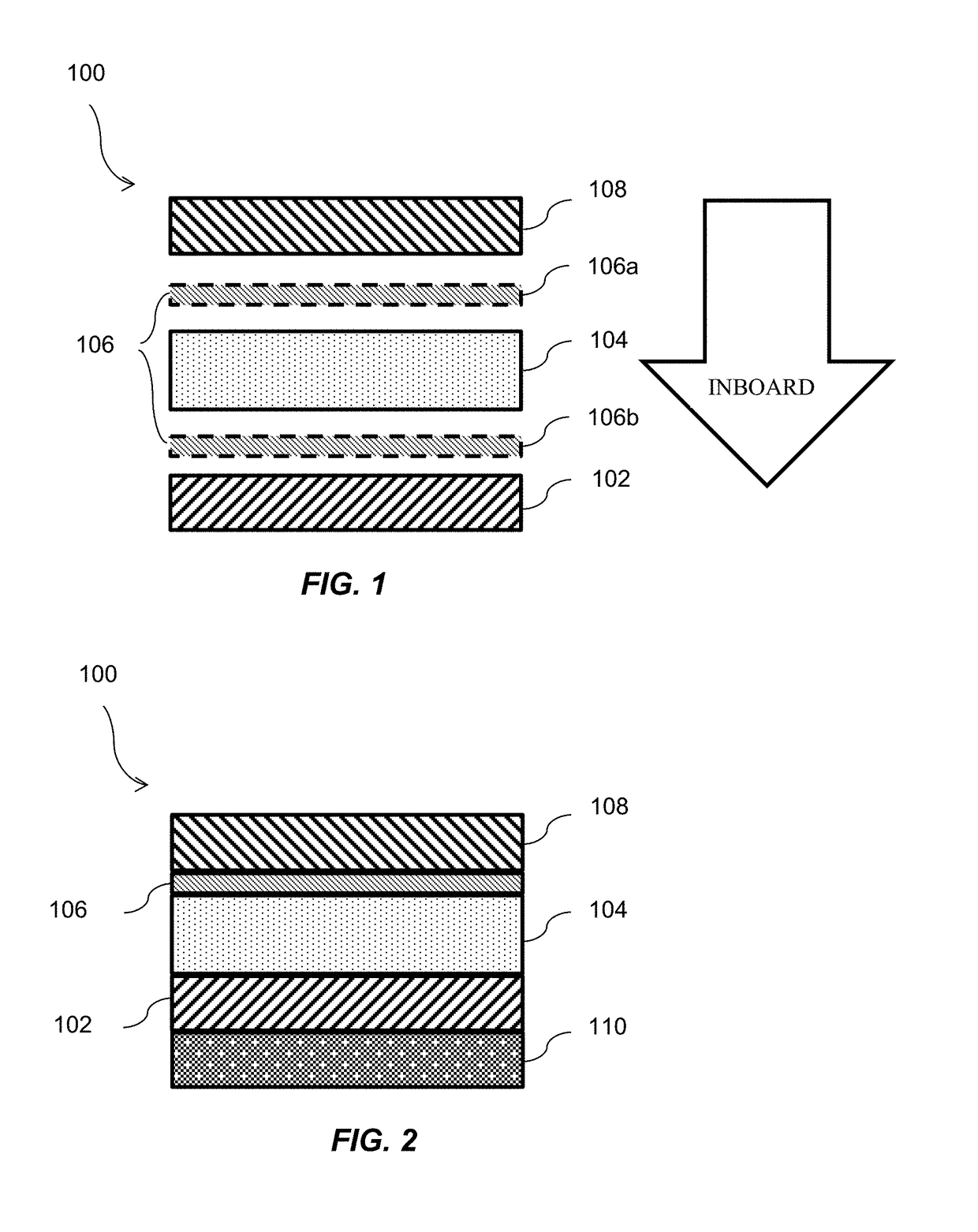

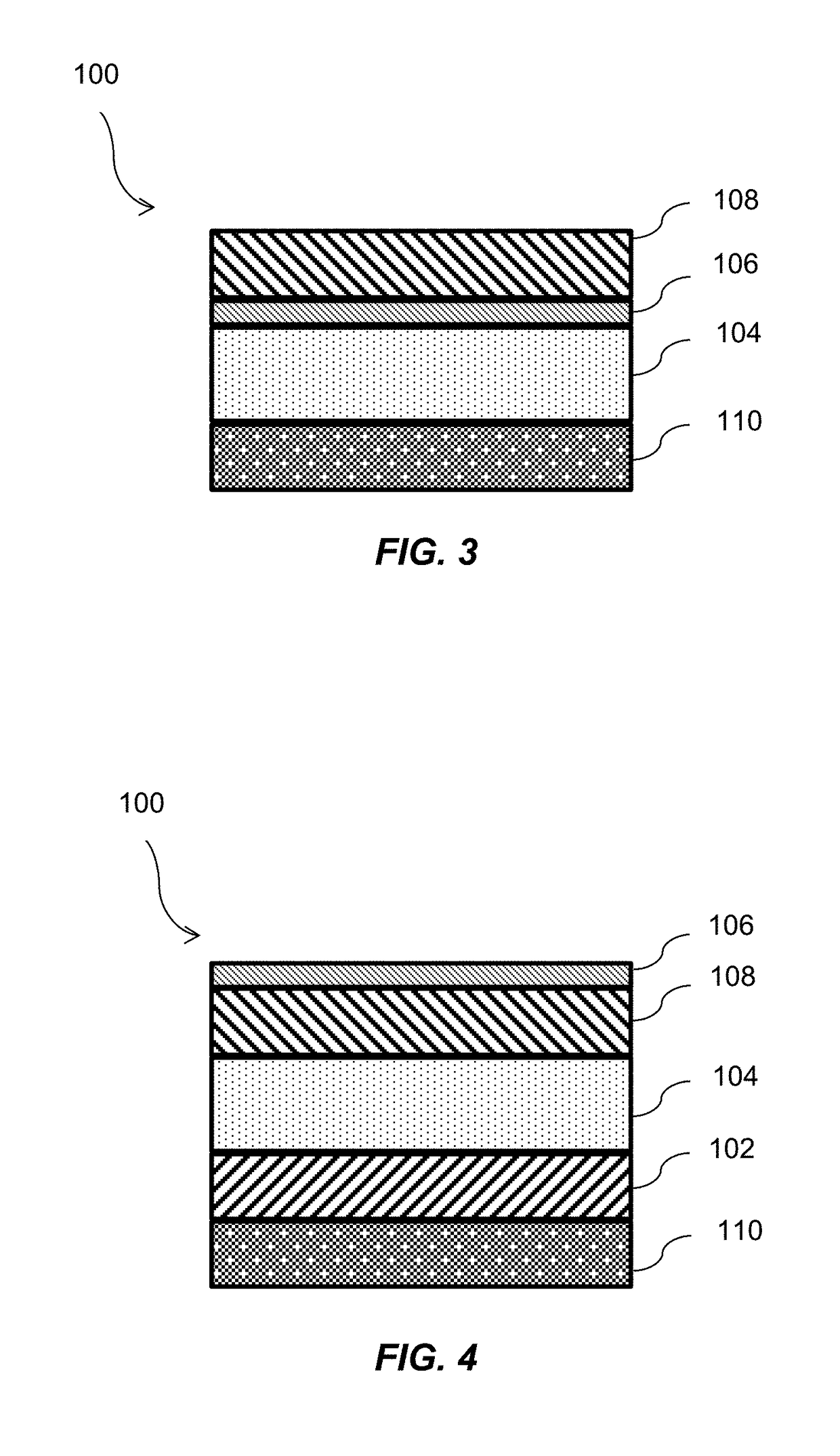

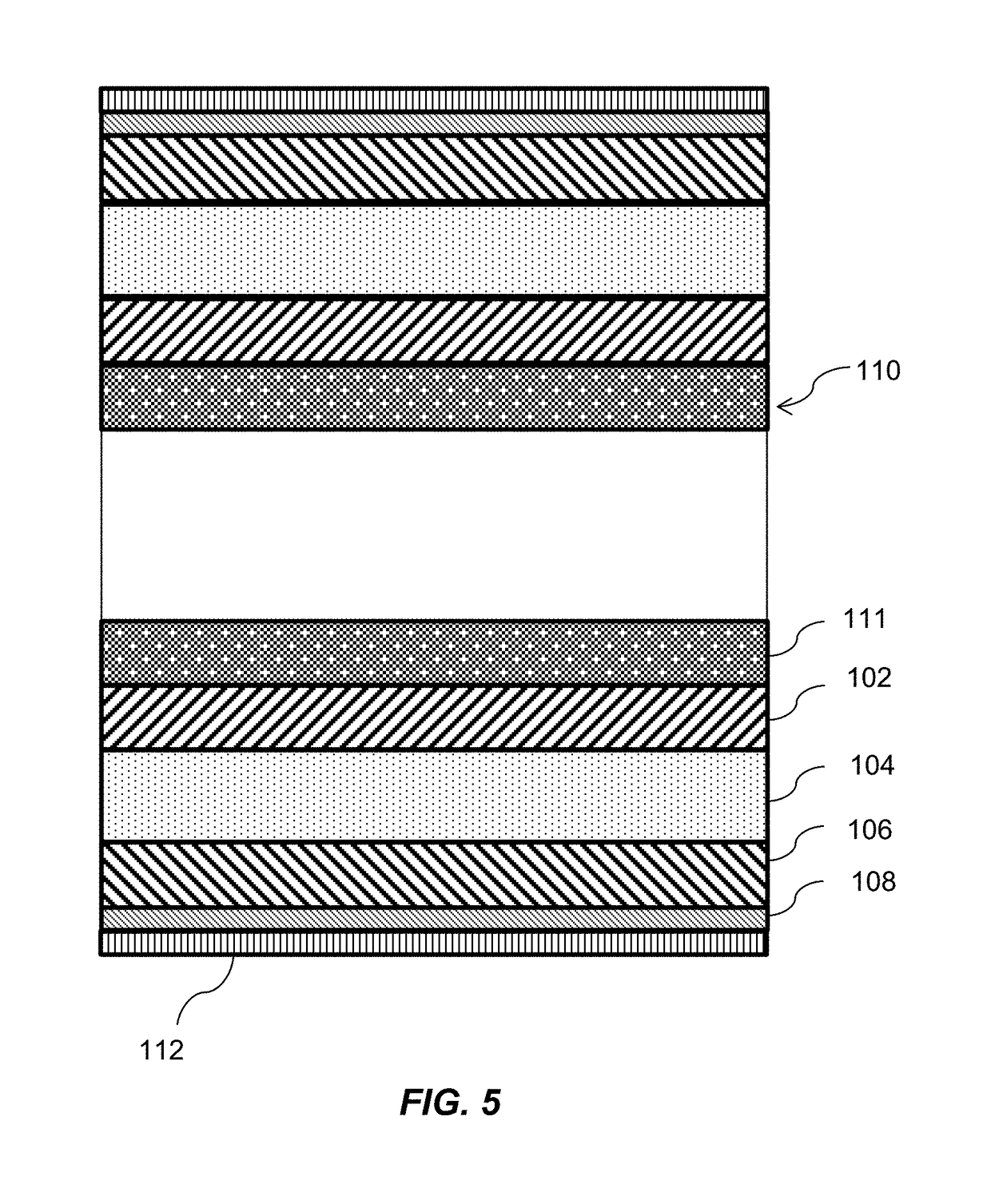

Glass-Ceramic with laminates

ActiveUS20090217813A1High strengthAvoid insufficient thicknessGlass/slag layered productsArmour platesRefractive indexBallistic impact

A transparent armor system includes a hard face fabricated from a substantially transparent glass-ceramic material exhibiting crystalline bodies throughout the mass of the glass-ceramic material and a backing covering a rear surface of the hard face opposite an anticipated incoming projectile. The backing has a refractive index substantially matching that of the hard face such as to allow substantial transparency of the transparent armor system. The hard face serves to disburse energy caused by the impact of an incoming projectile with the transparent armor system, while the backing serves to retain any pieces of the hard face fractured during ballistic impact. In certain embodiments, a plurality of hard faces are held in parallel and spaced apart arrangement.

Owner:ORAN SAFETY GLASS INC

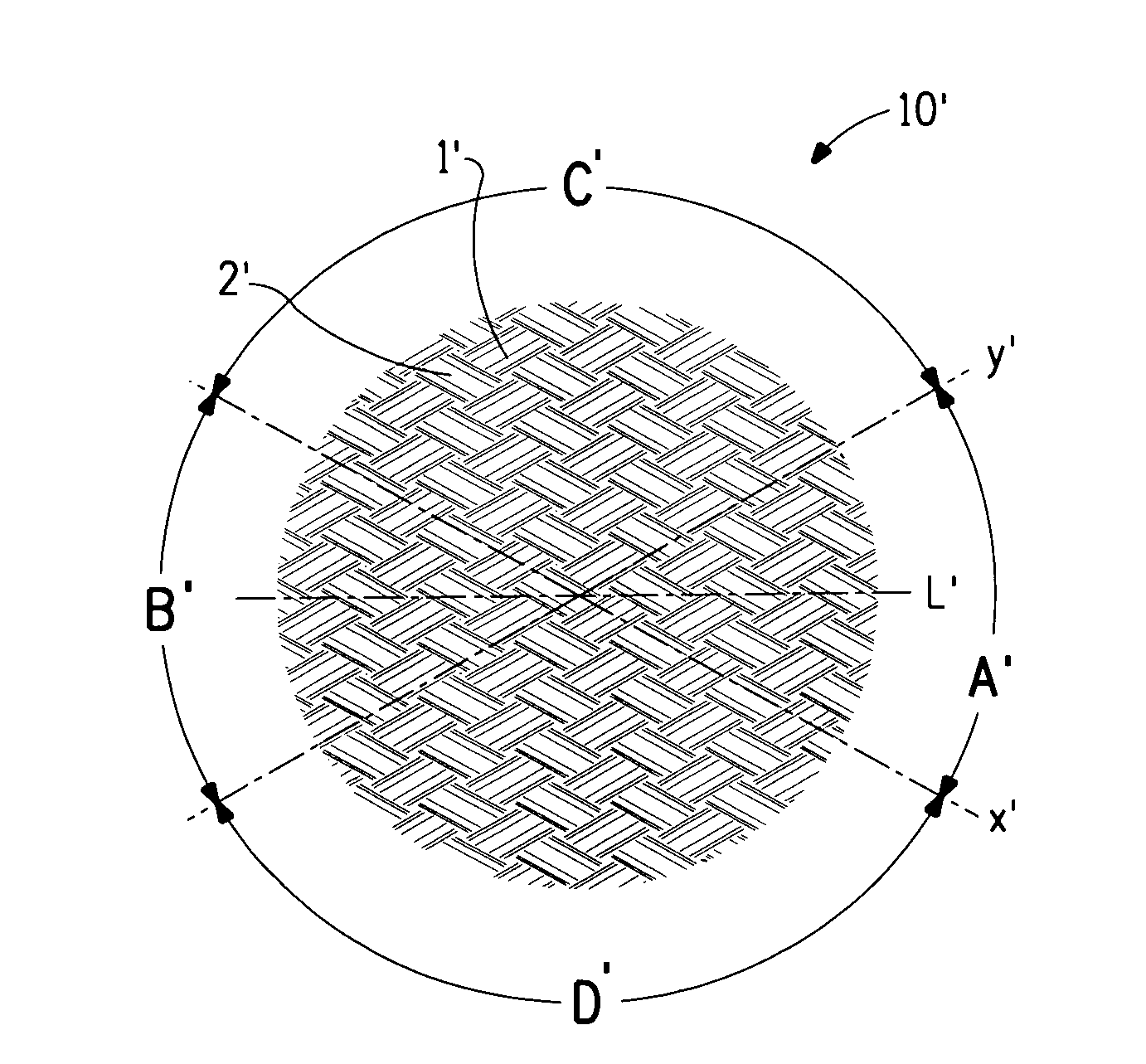

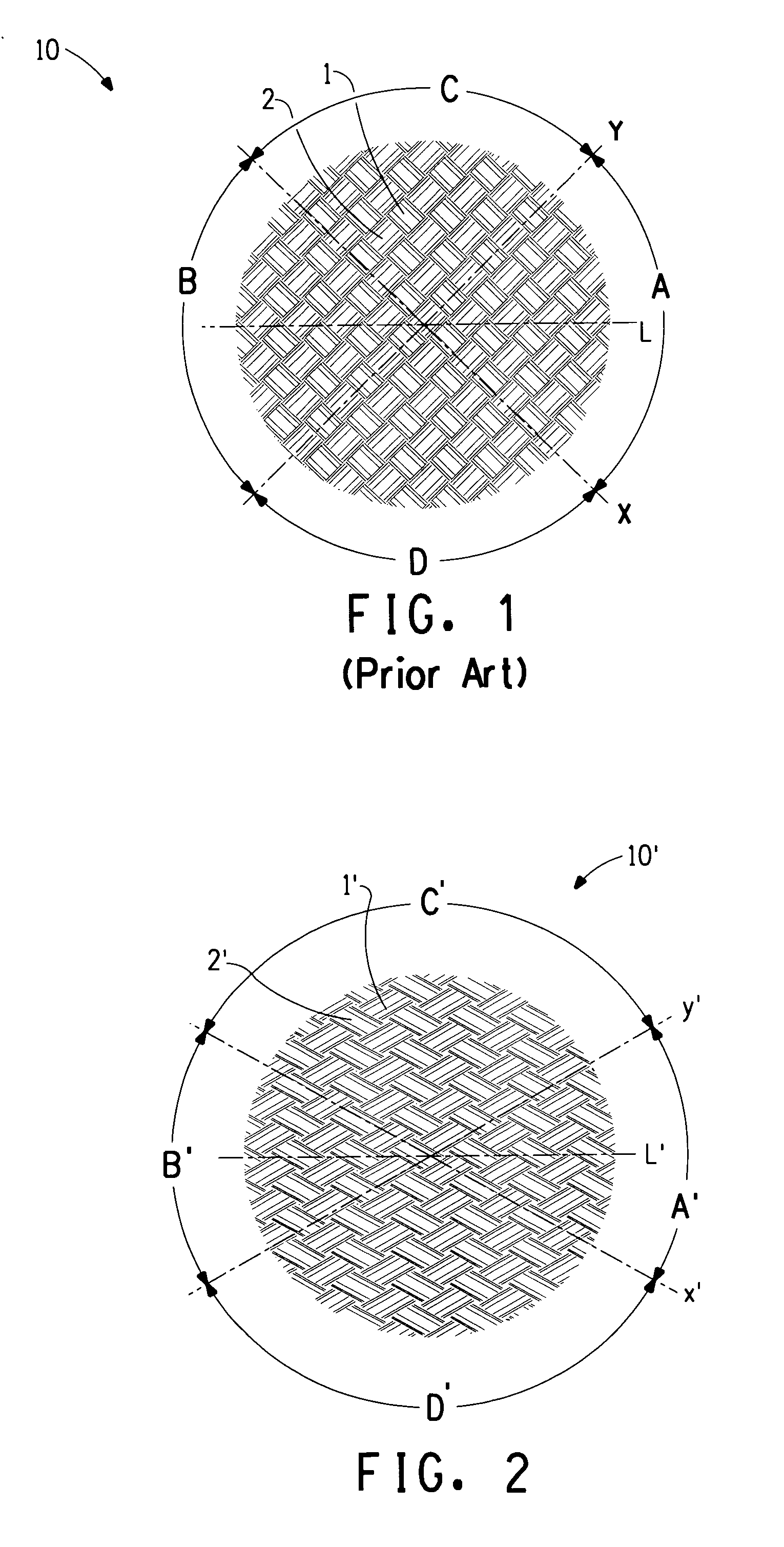

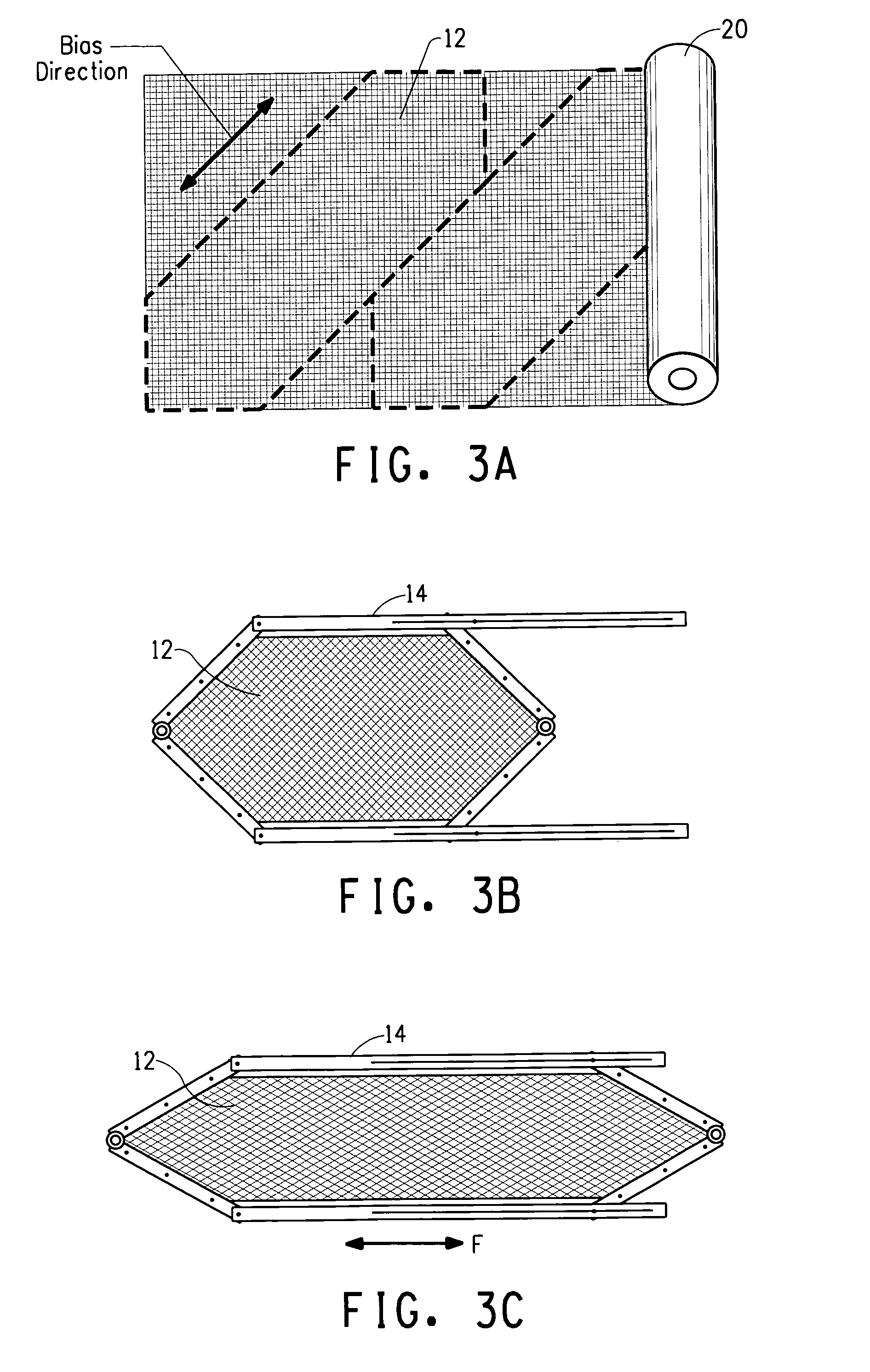

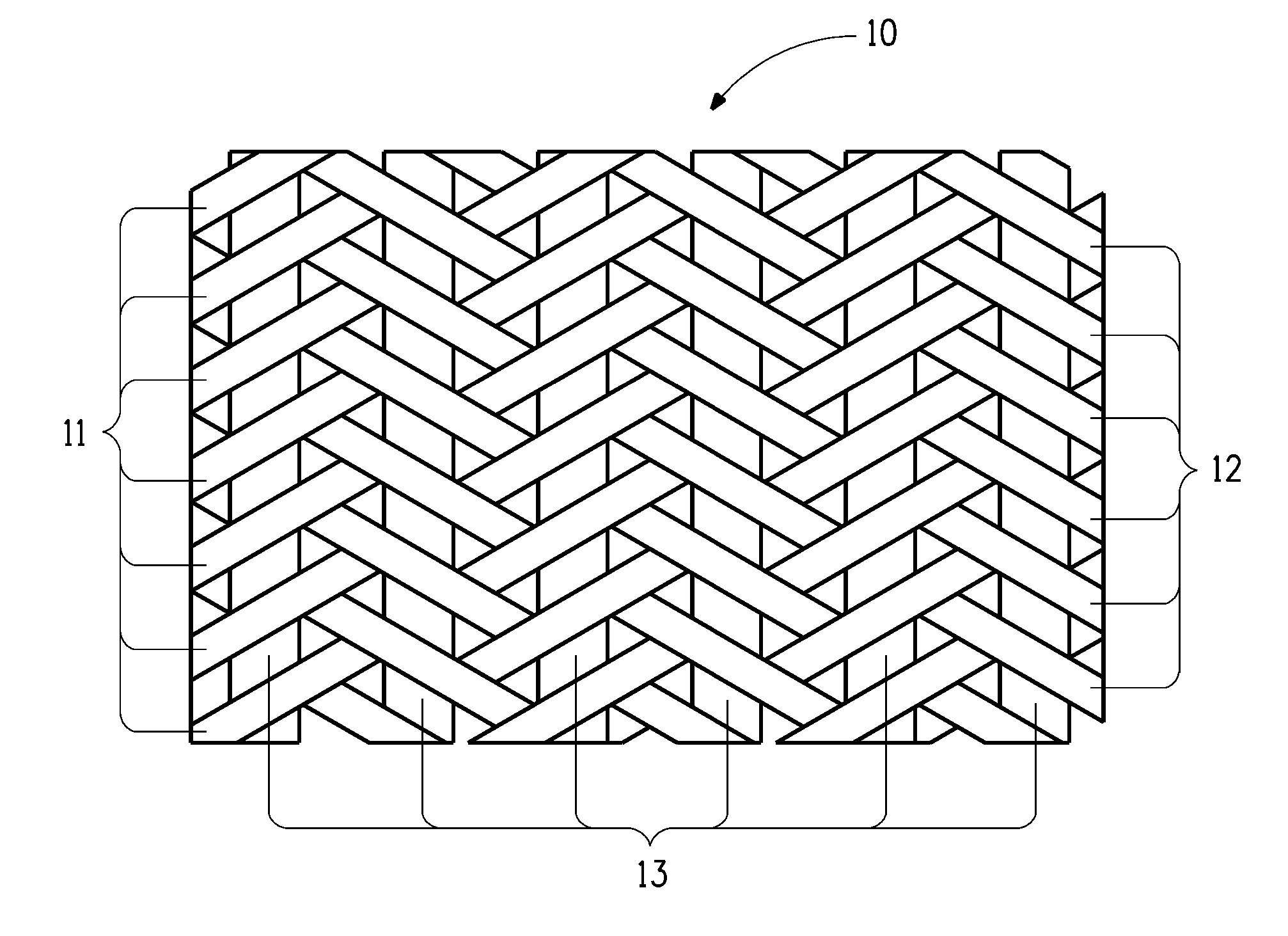

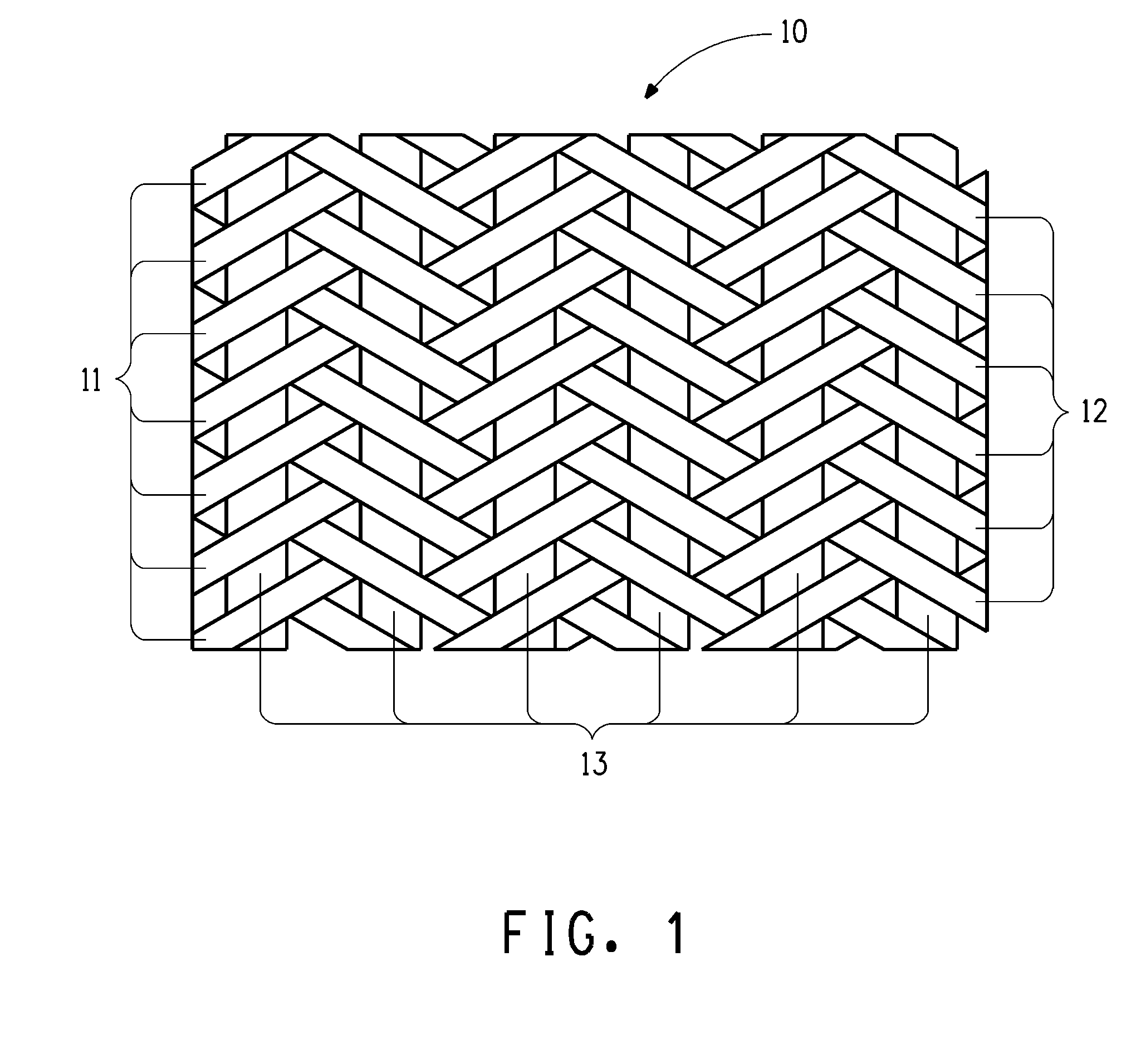

Fabric architectures for improved ballistic impact performance

A woven fabric from yarn for use in the manufacture of ballistic projectile or puncture resistant articles where the fabric has a first plurality of parallel oriented yarns within the plane of the fabric interwoven with a second plurality of parallel oriented yarns within the plane of the fabric having a direction / orientation within the plane of the fabric different from that of the first plurality and where the crossing of any fiber yarn from the first plurality with a fiber yarn from the second plurality forms a pair of acute vertical angles having an angular measurement less than 90 degrees.

Owner:EGRES JR RONALD G

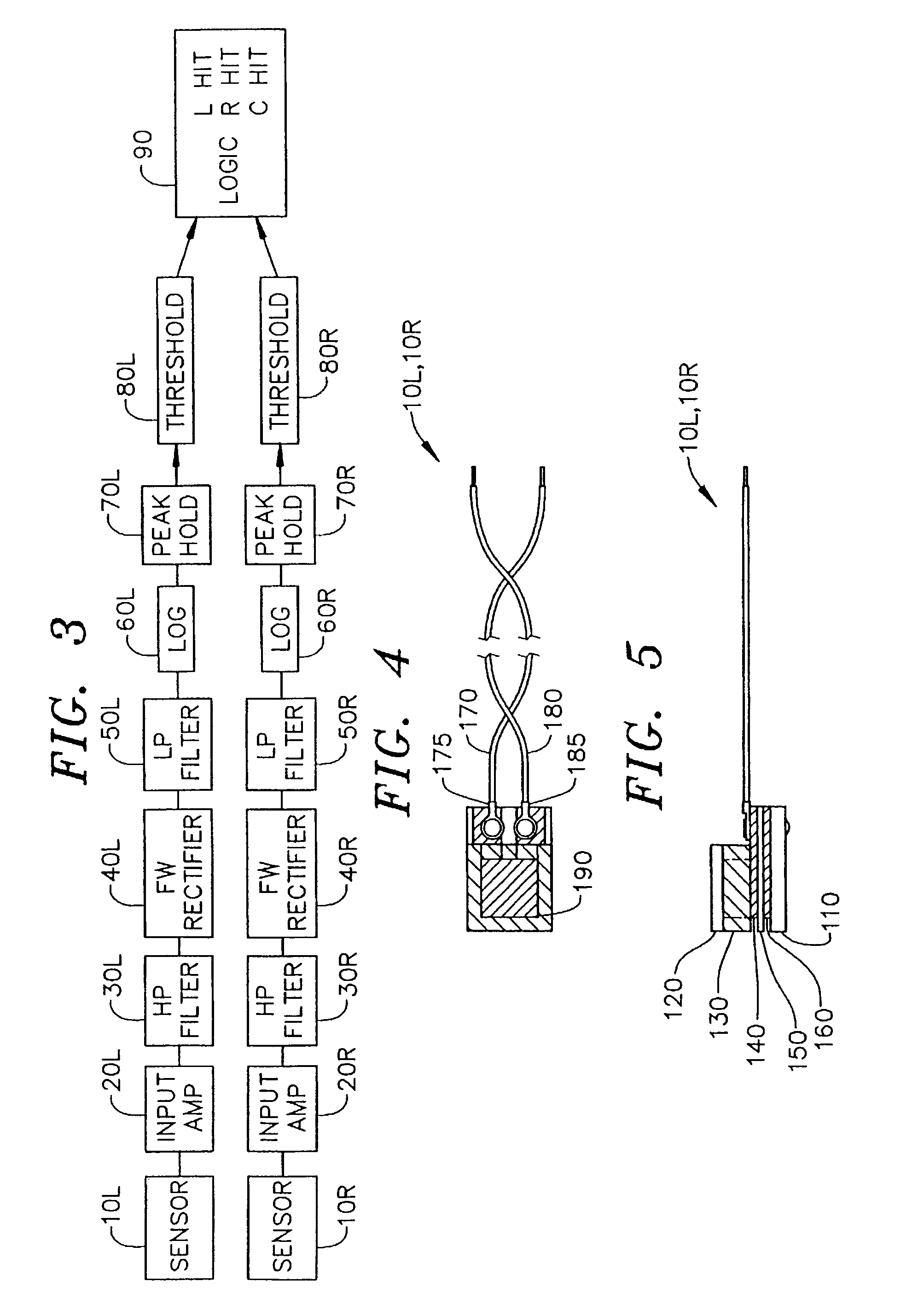

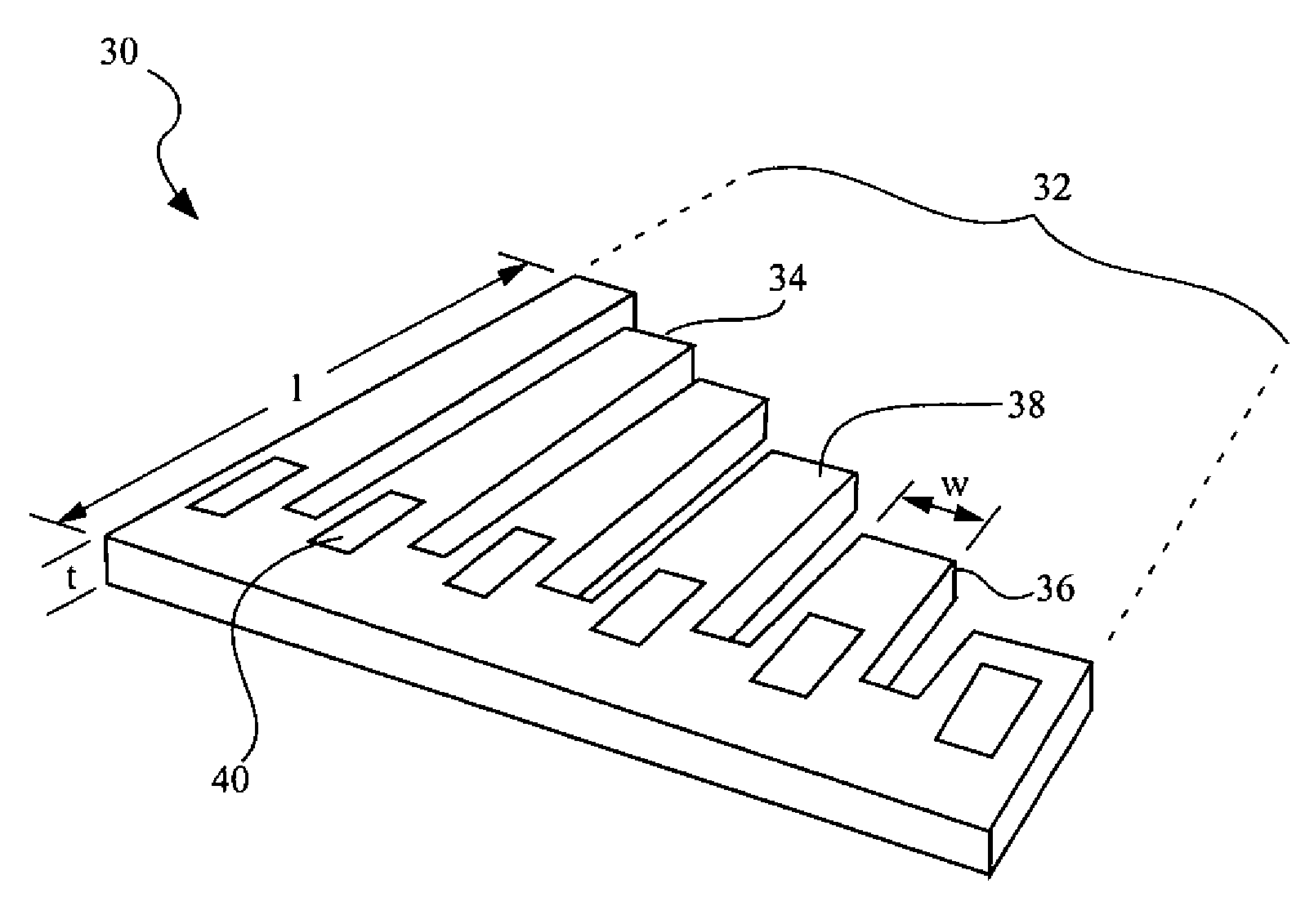

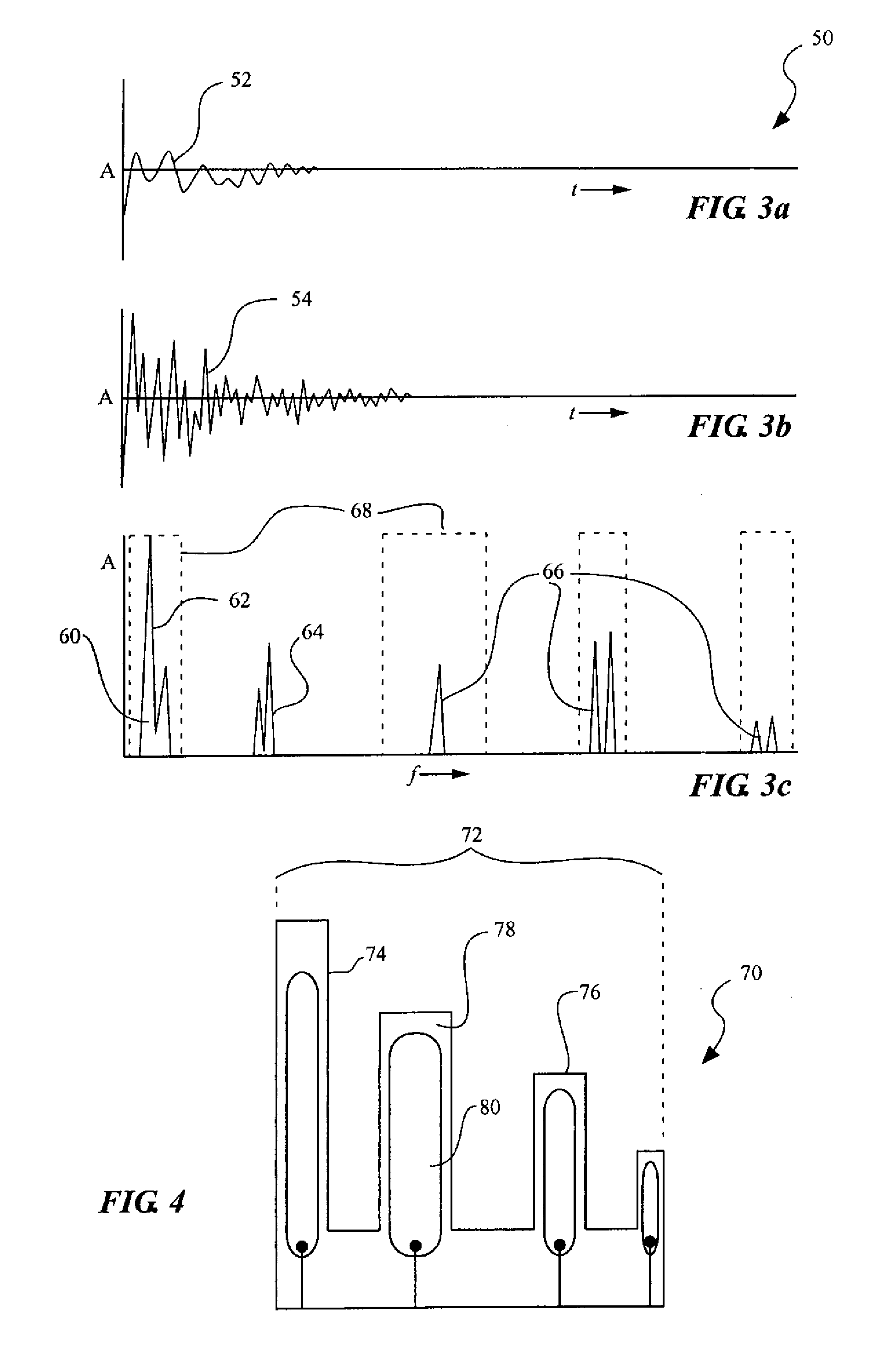

Digital ballistic impact detection system

InactiveUS20100326192A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringBallistic impact

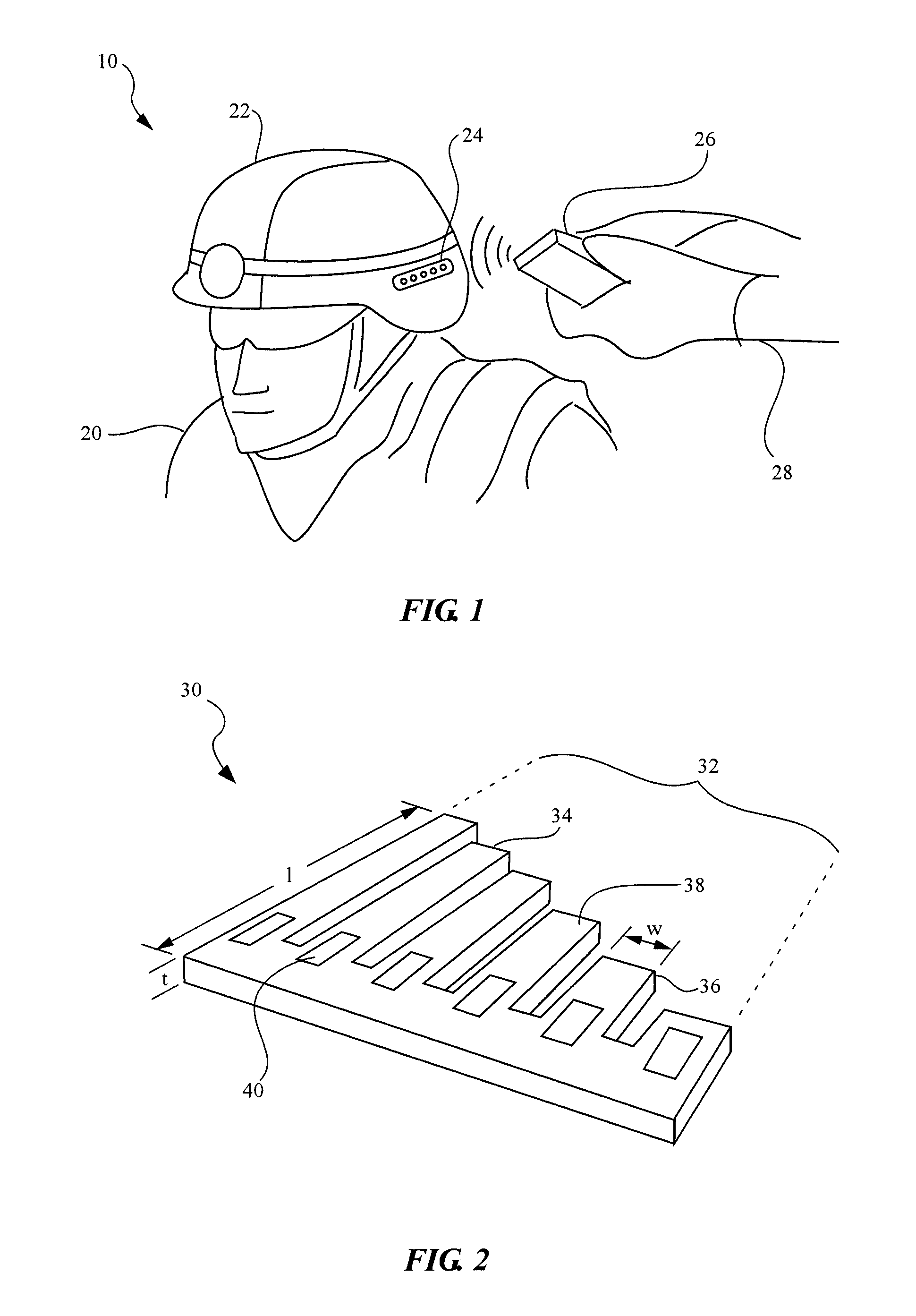

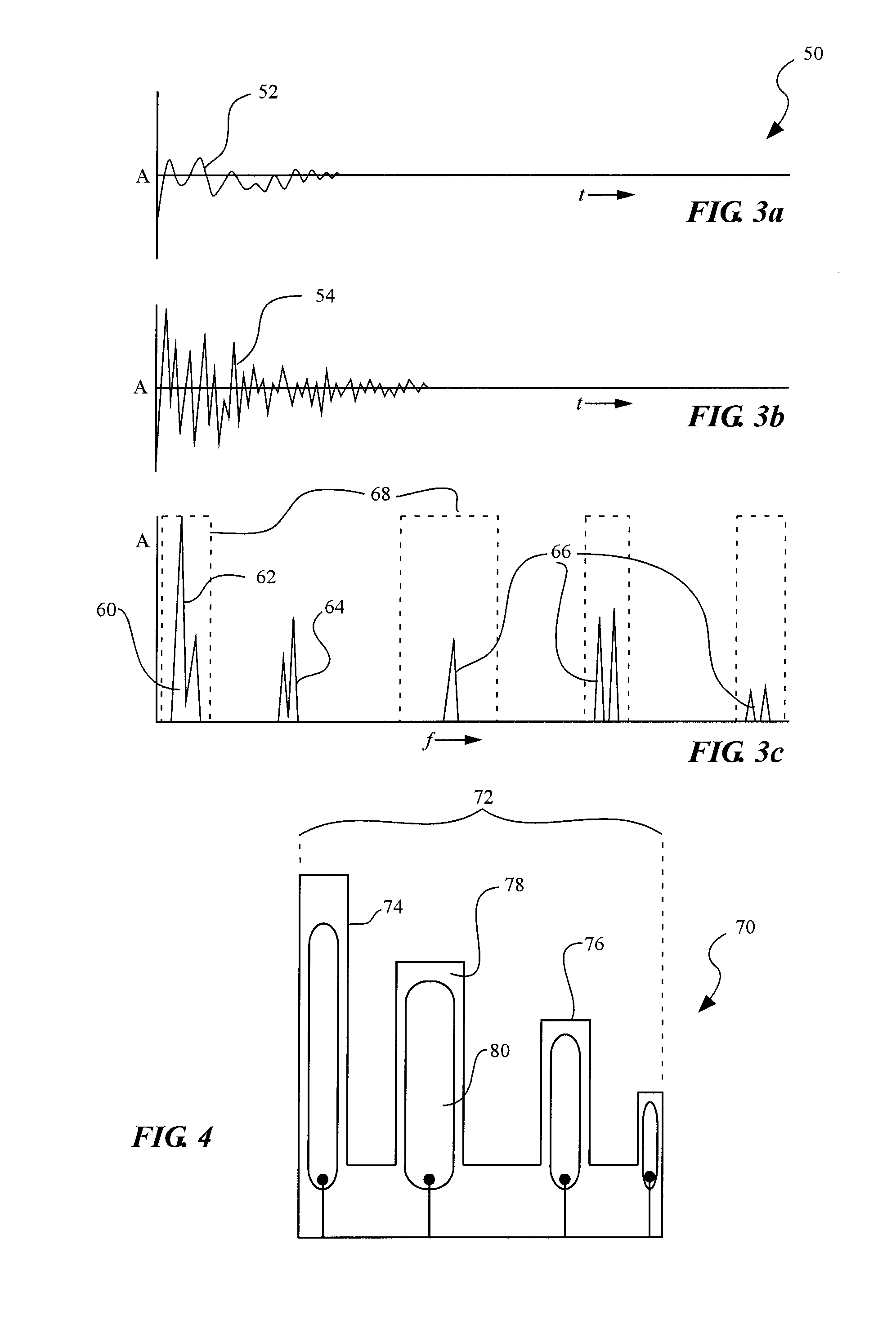

Methods and devices for a miniature, ultra-low power impact recorder for detecting, quantifying and recording the energy of an explosive blast or ballistic projectile impact. In one embodiment, the impact recorder can included a sensor comprised of an array of electromechanical resonators that is sensitive to the vibrations produced in selected, discrete frequency ranges that approximate the spectral signature characteristics of the shockwave resulting from the ballistic impact event, even after traveling through impacted material or body tissues.

Owner:EMPIRE IP LLC

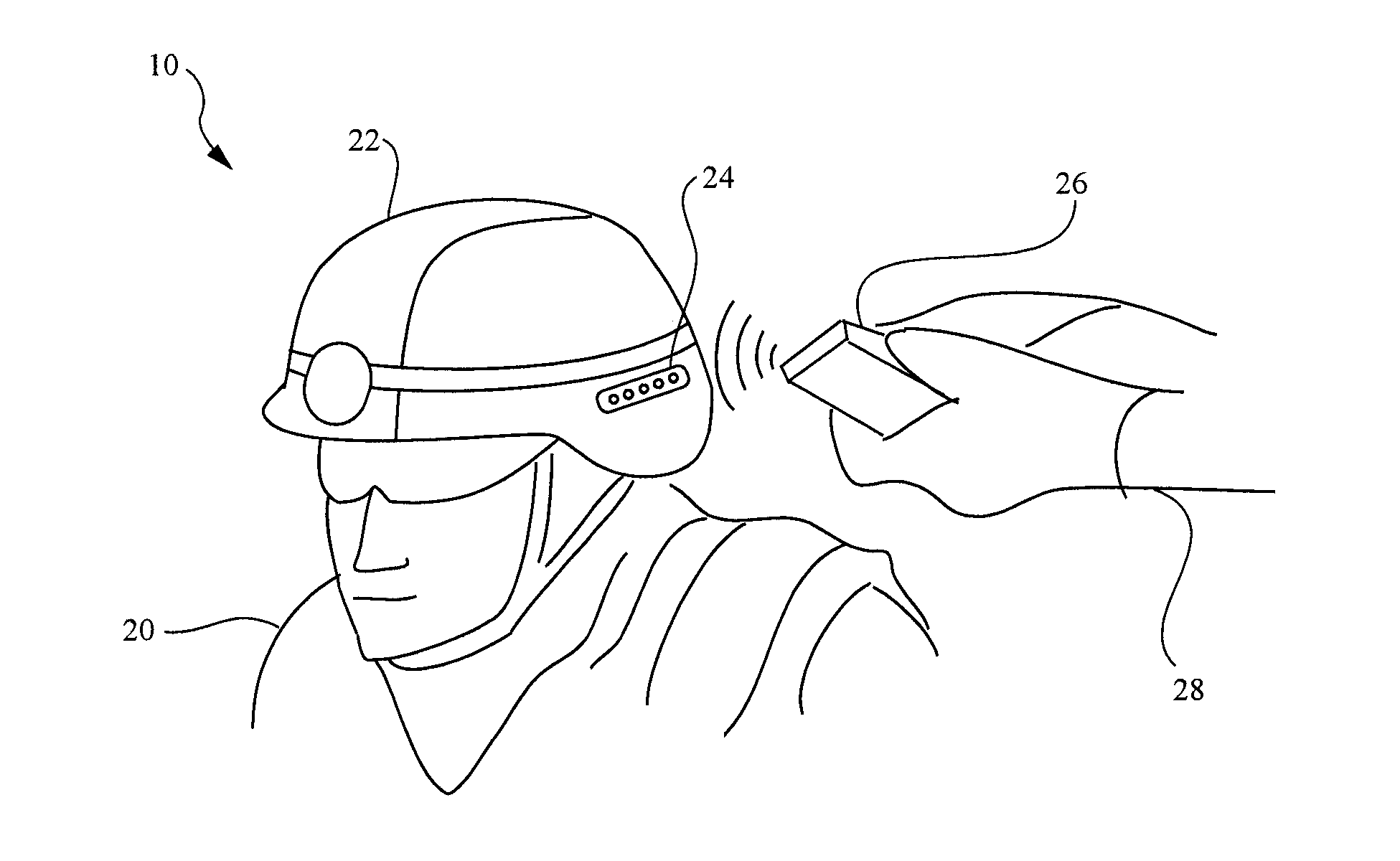

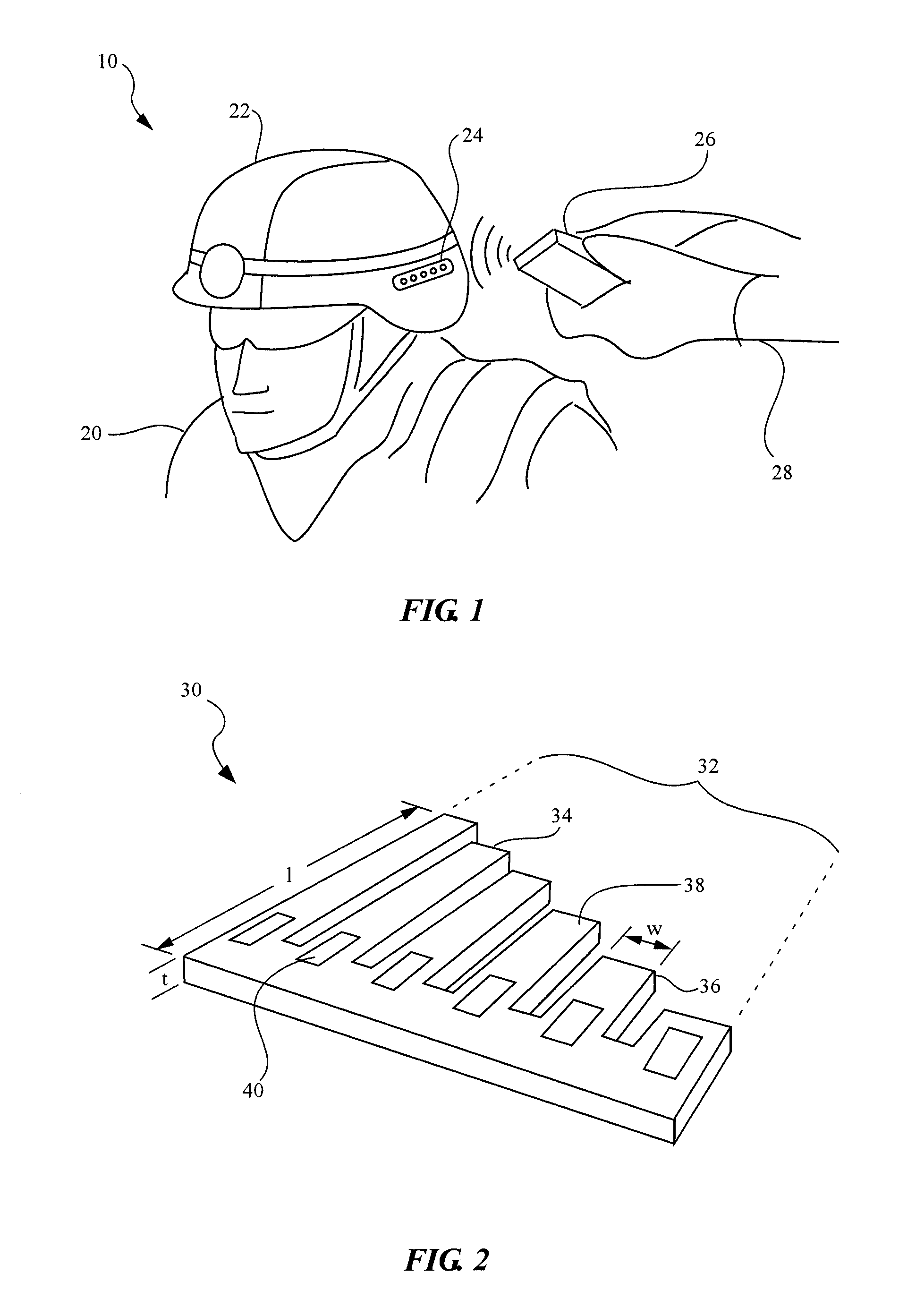

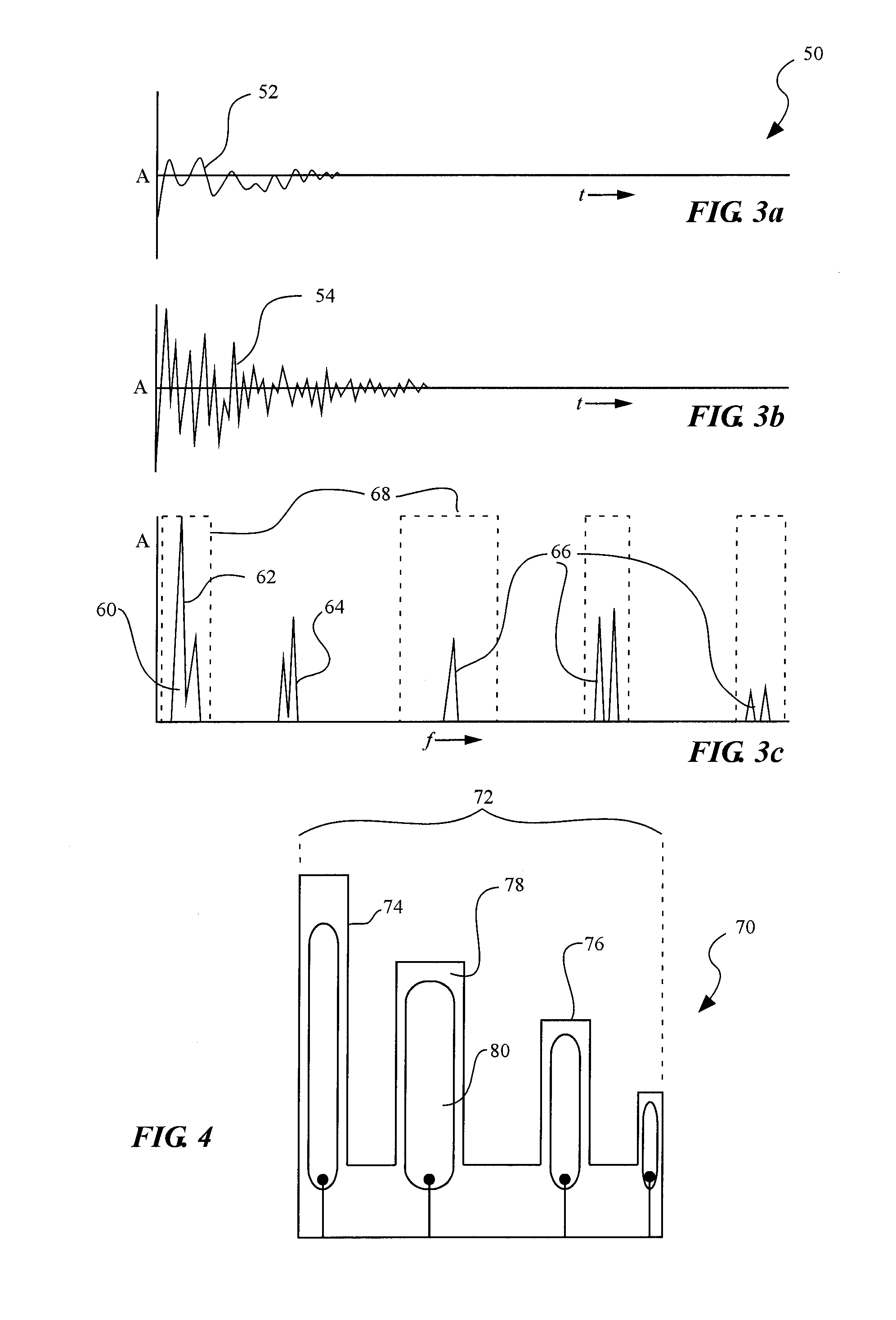

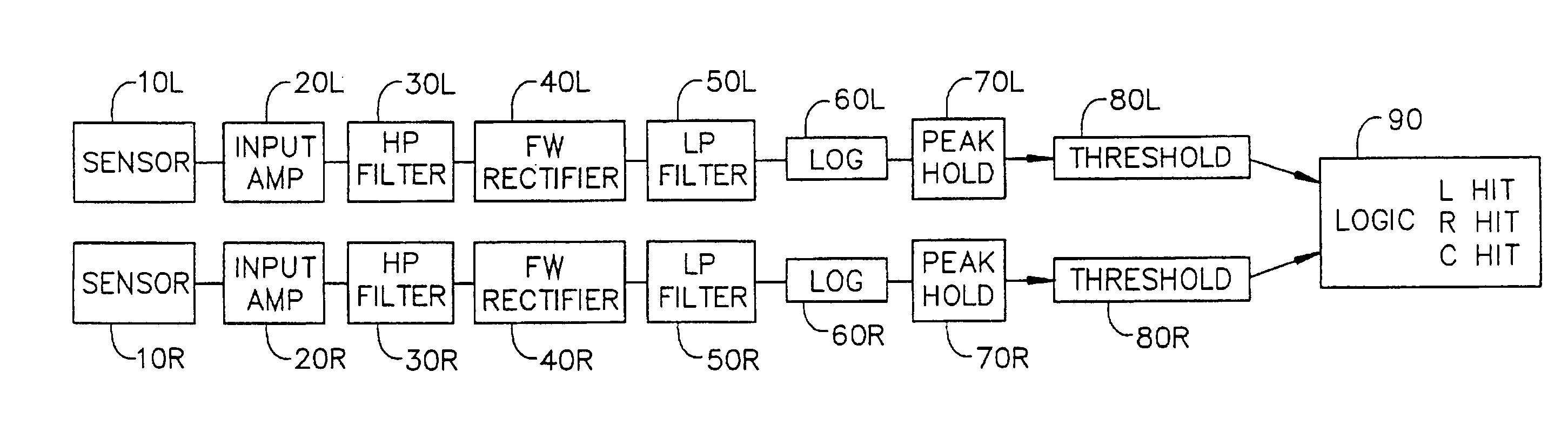

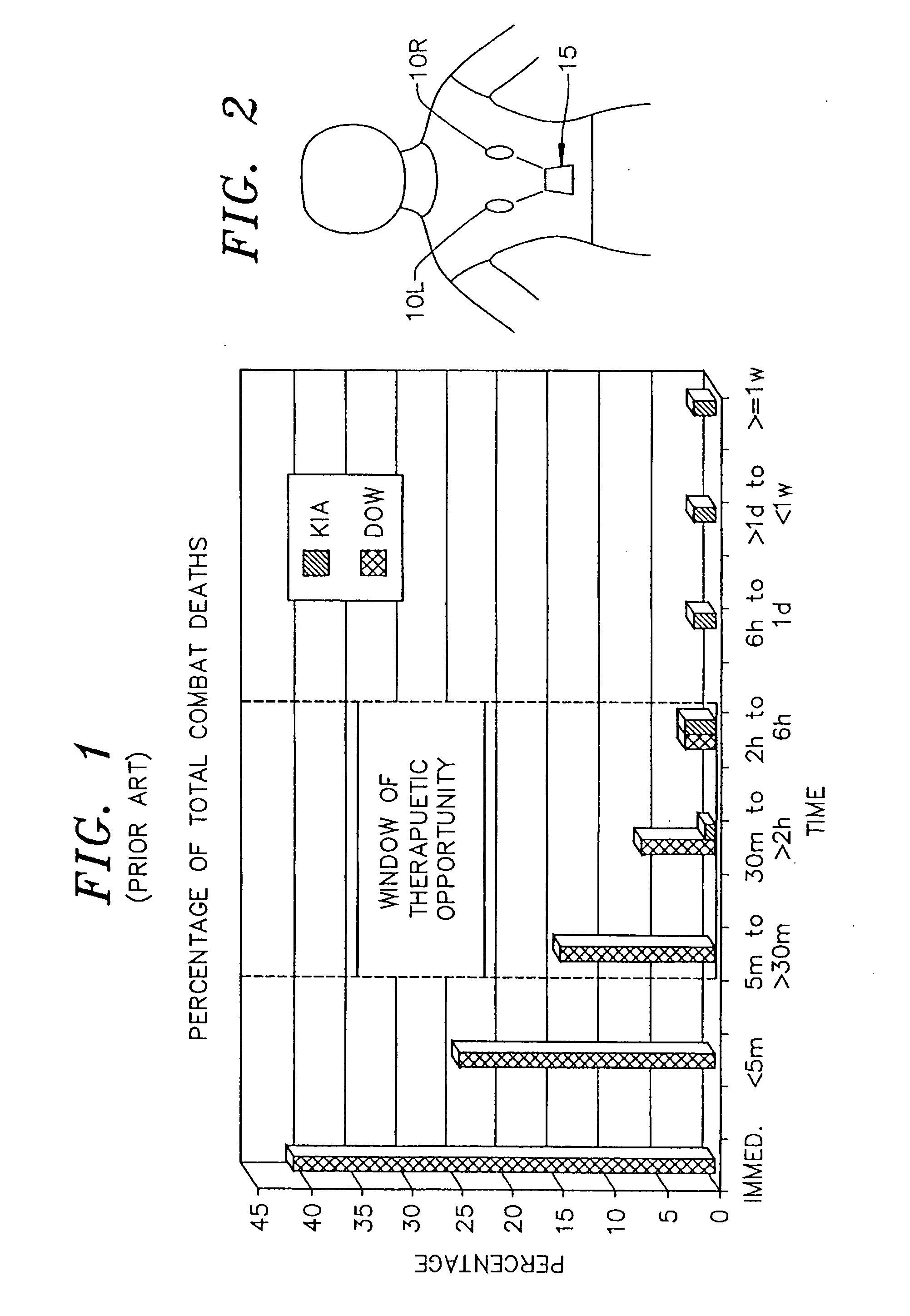

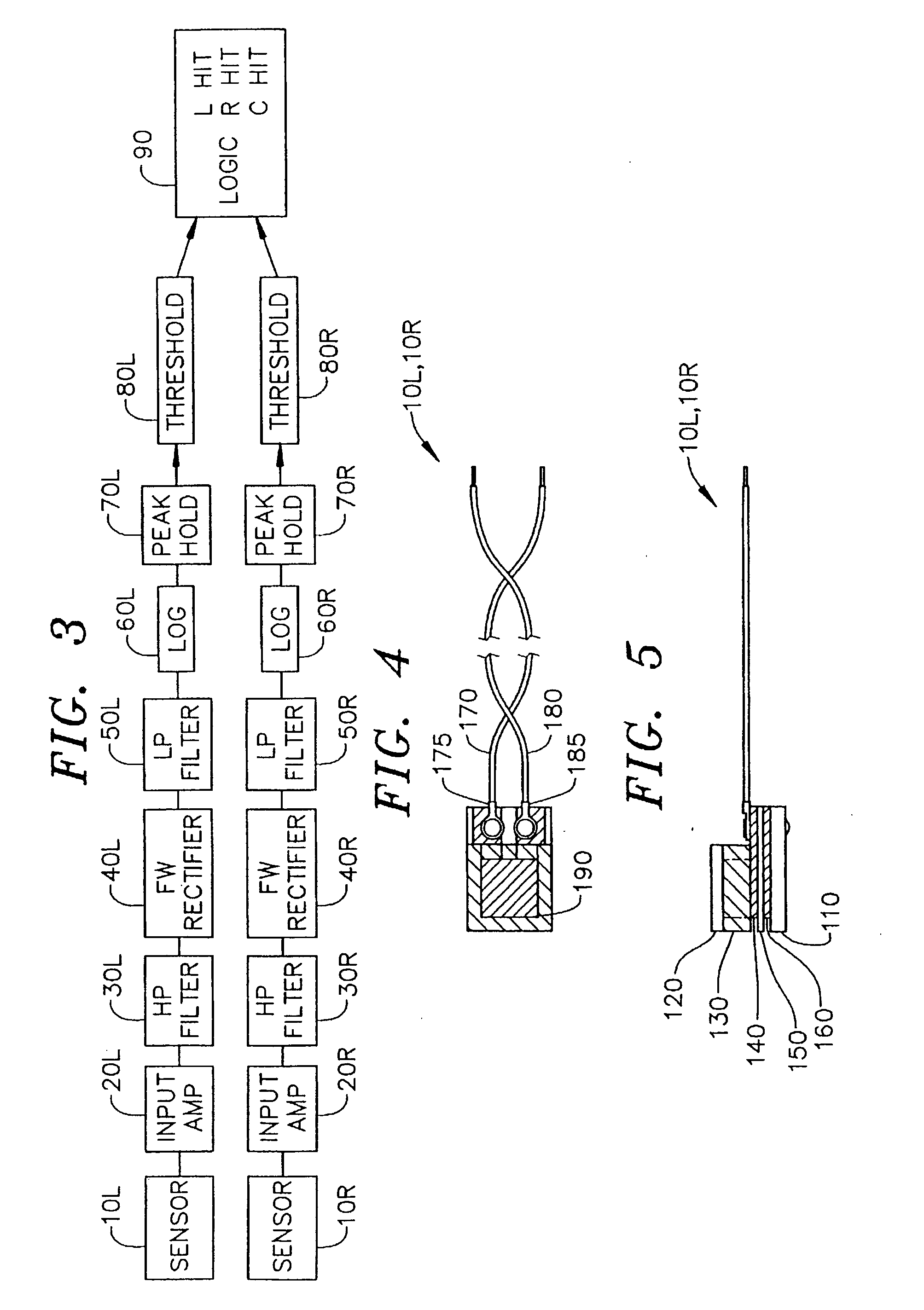

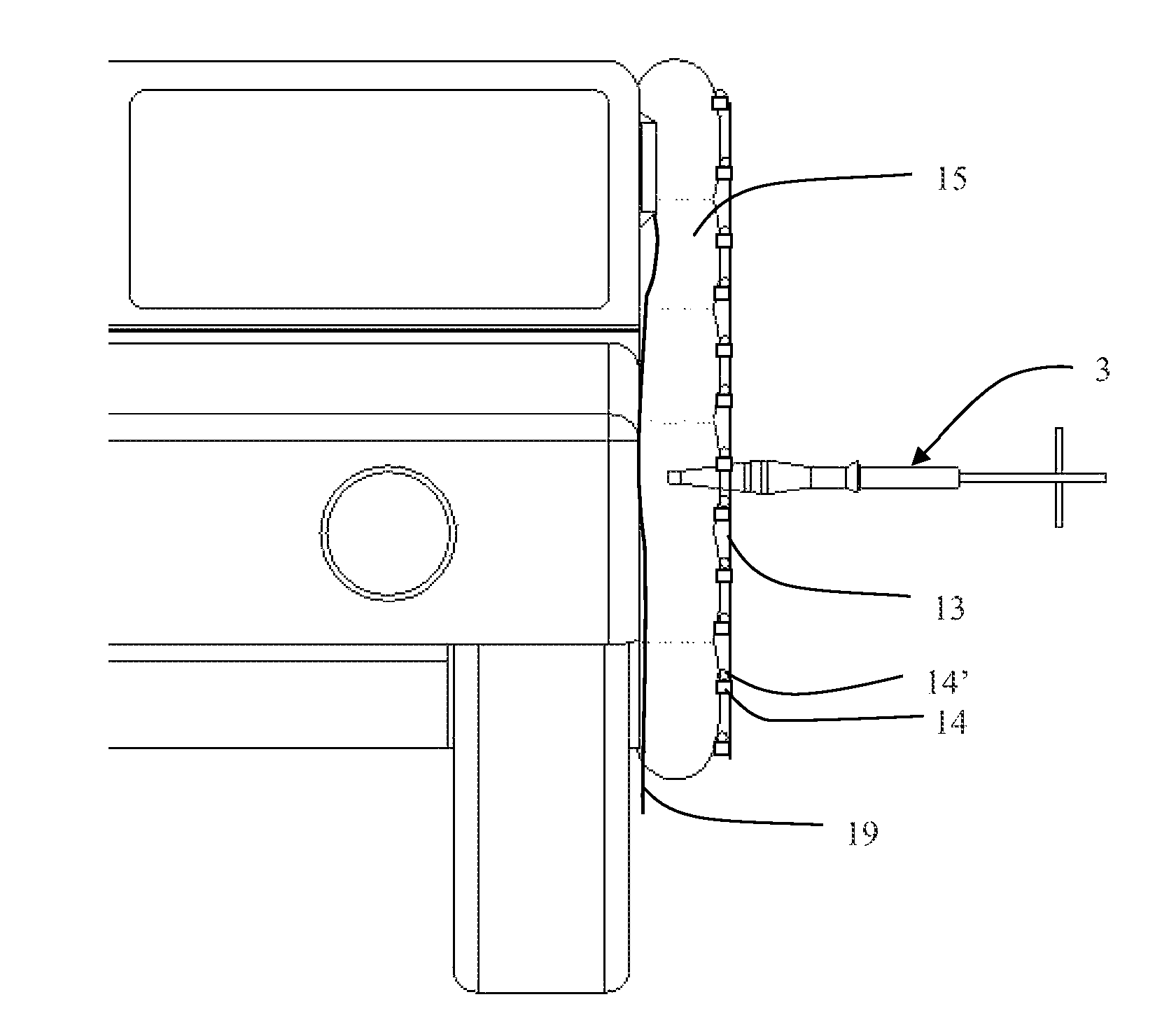

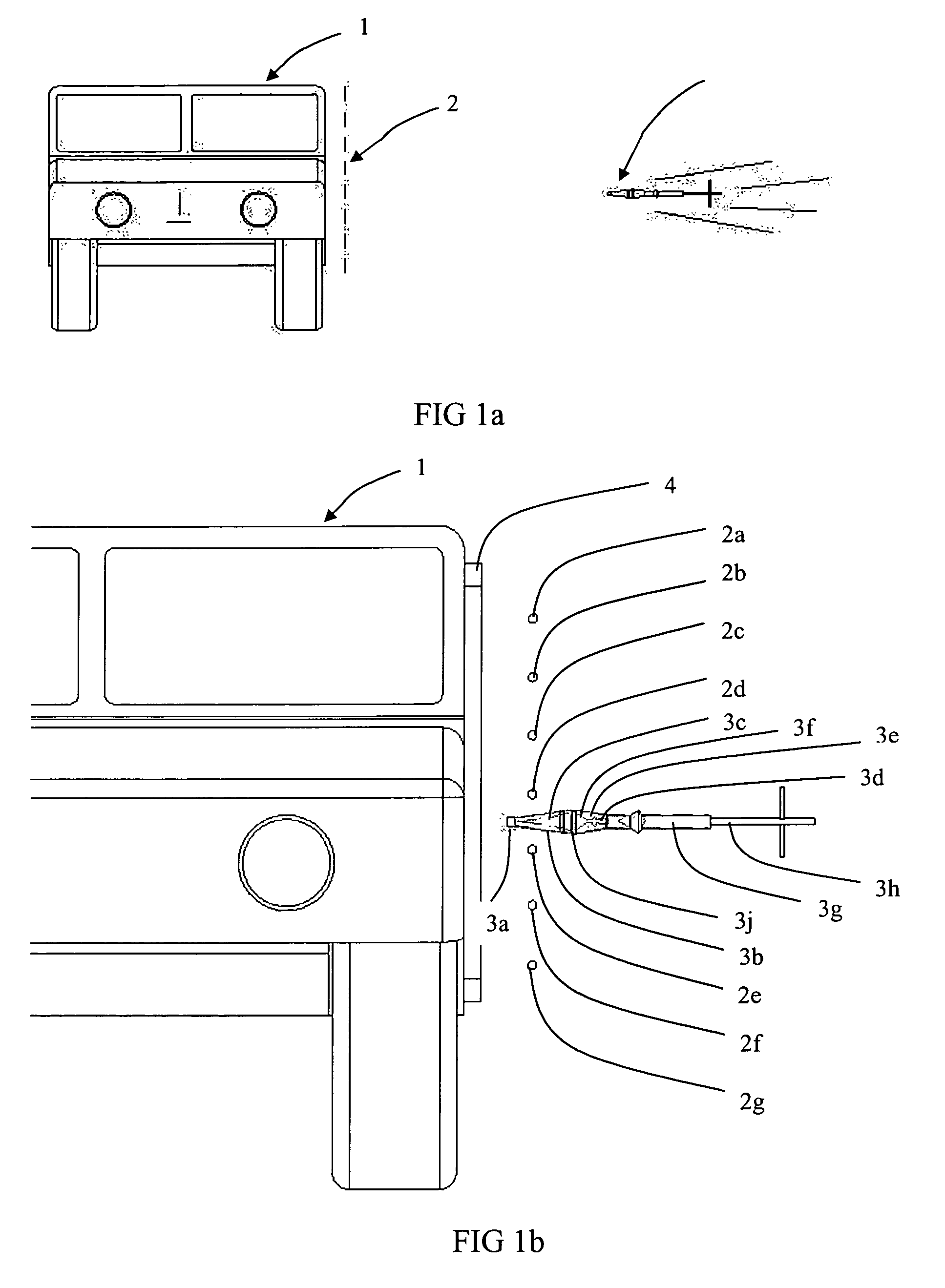

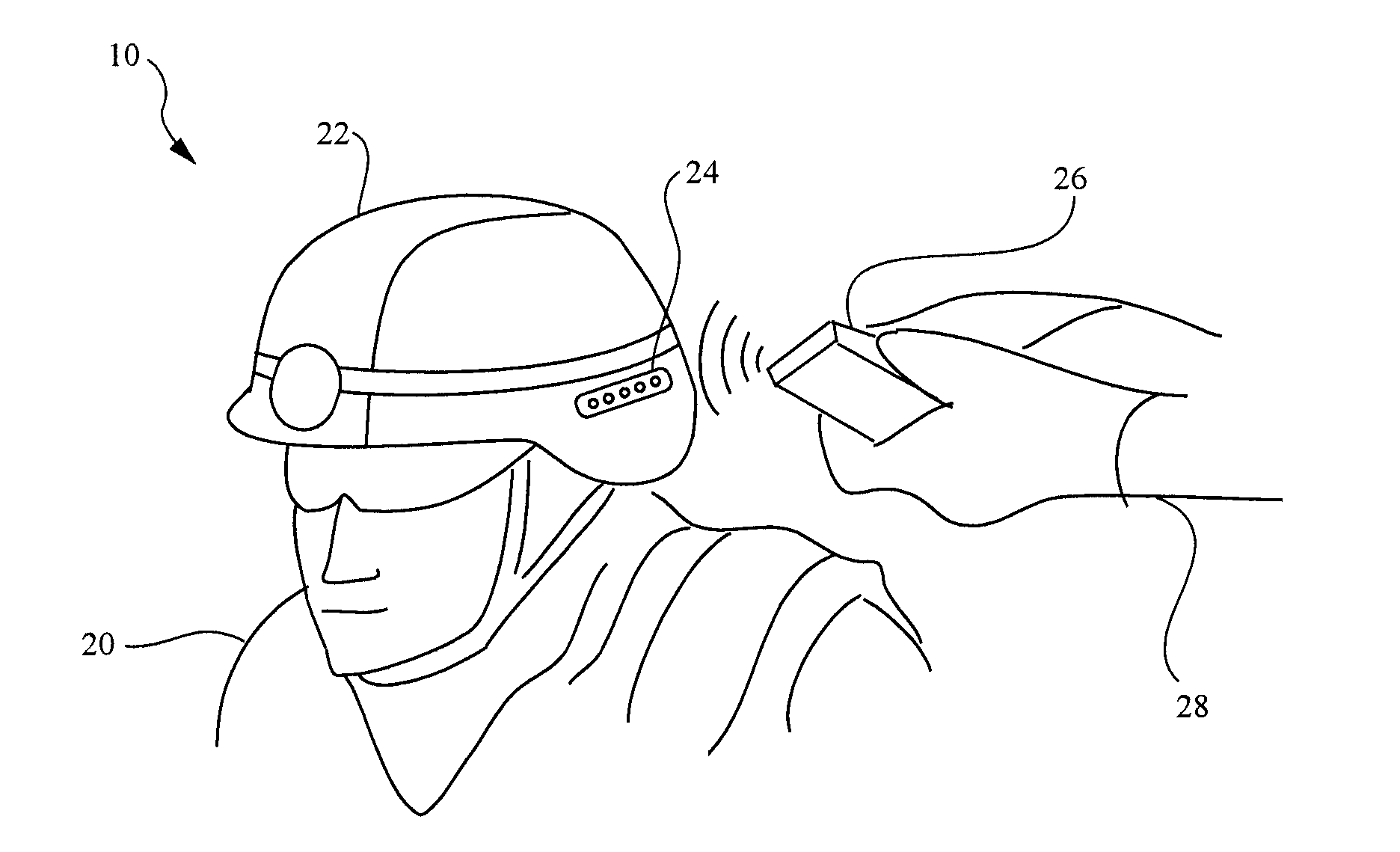

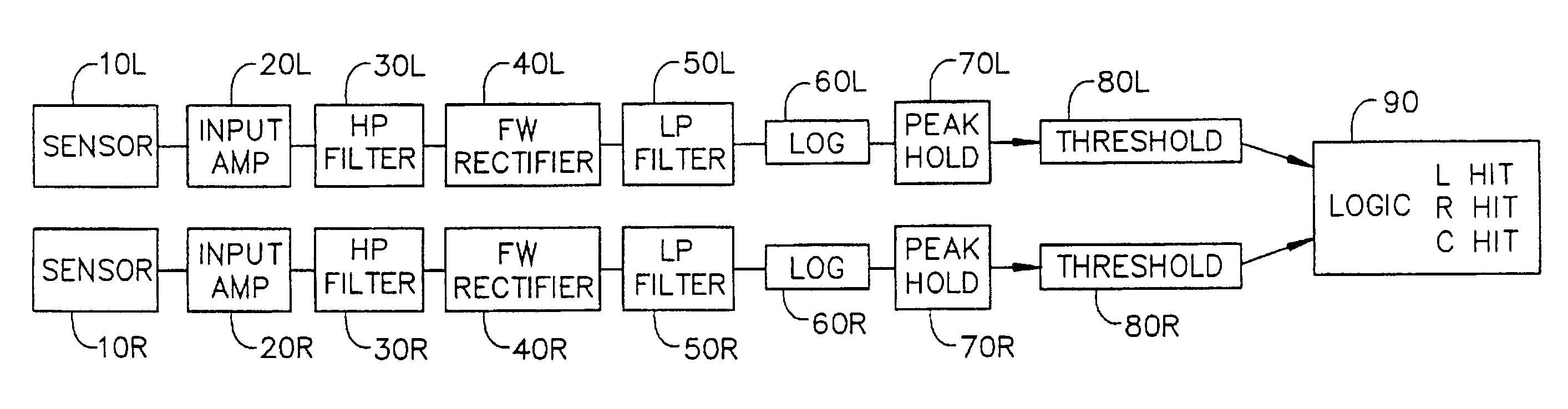

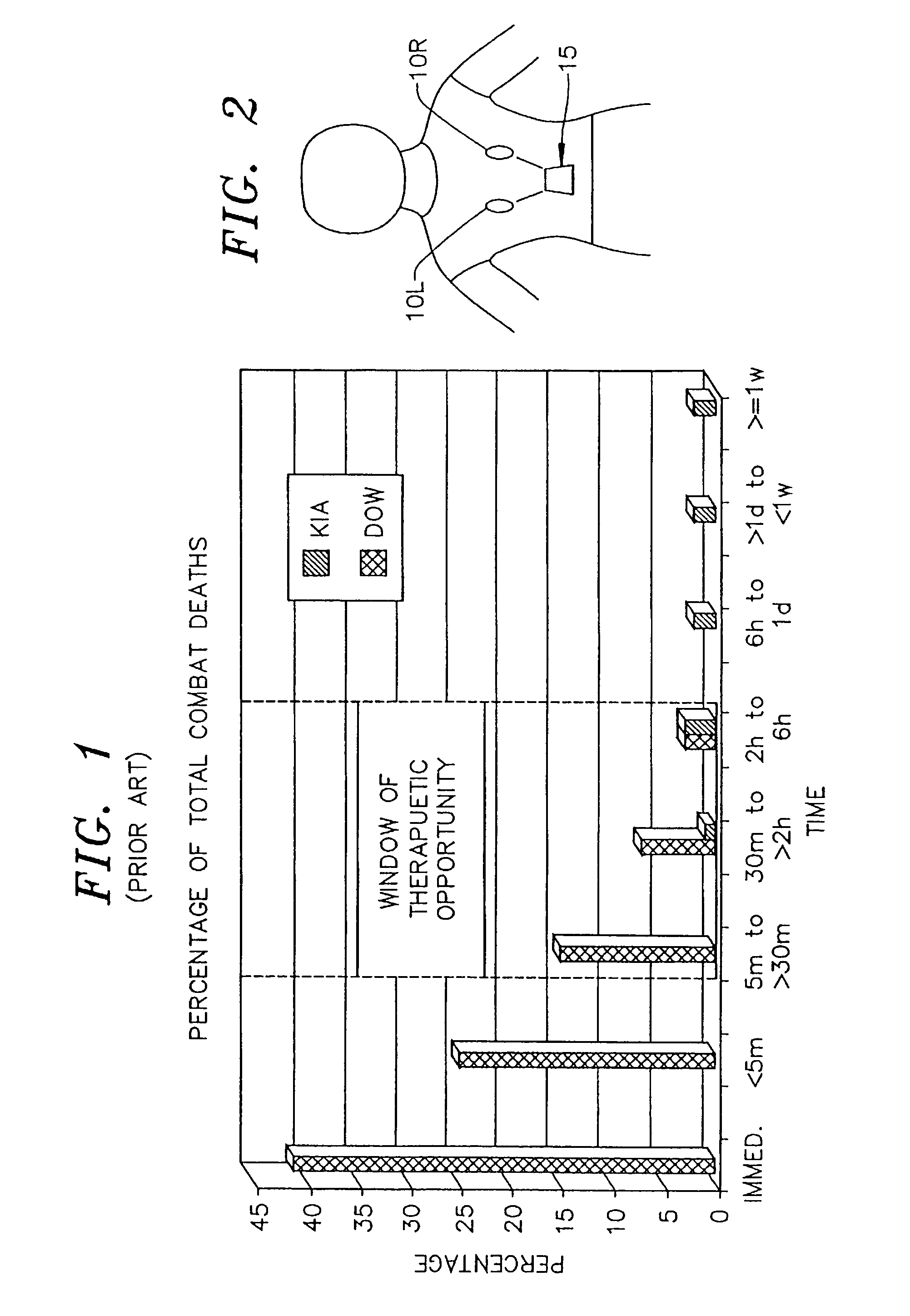

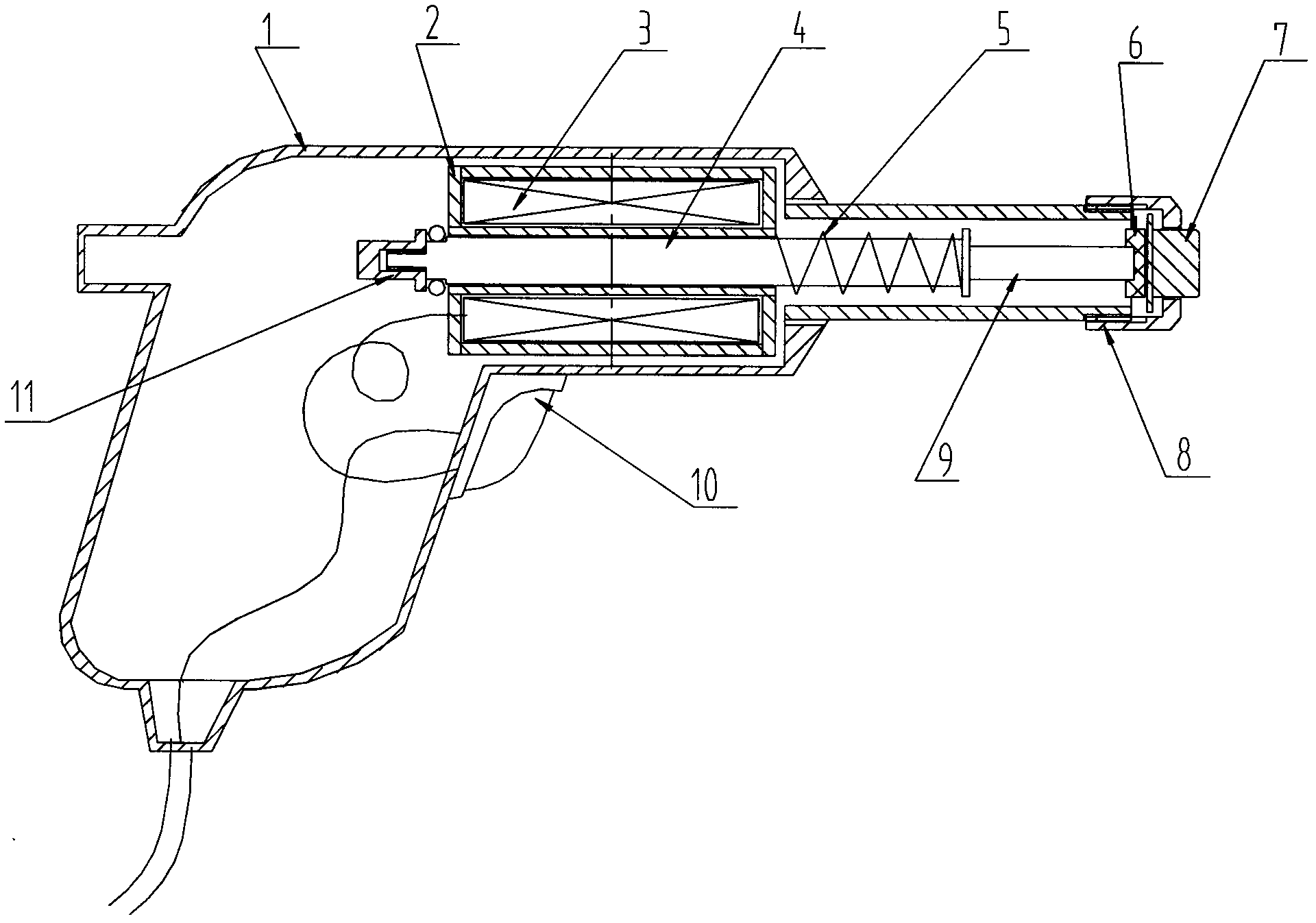

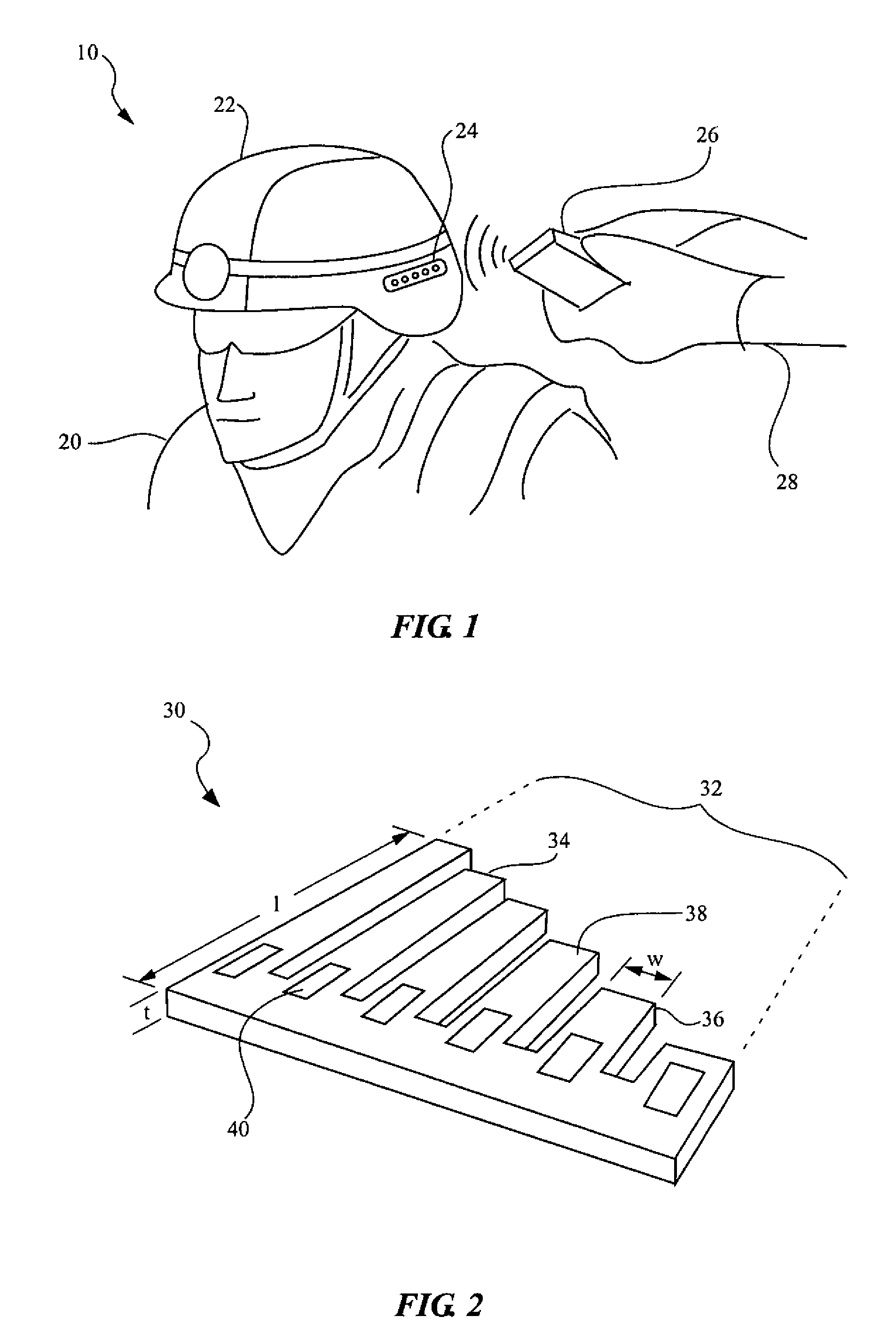

Ballistic Impact Detection System

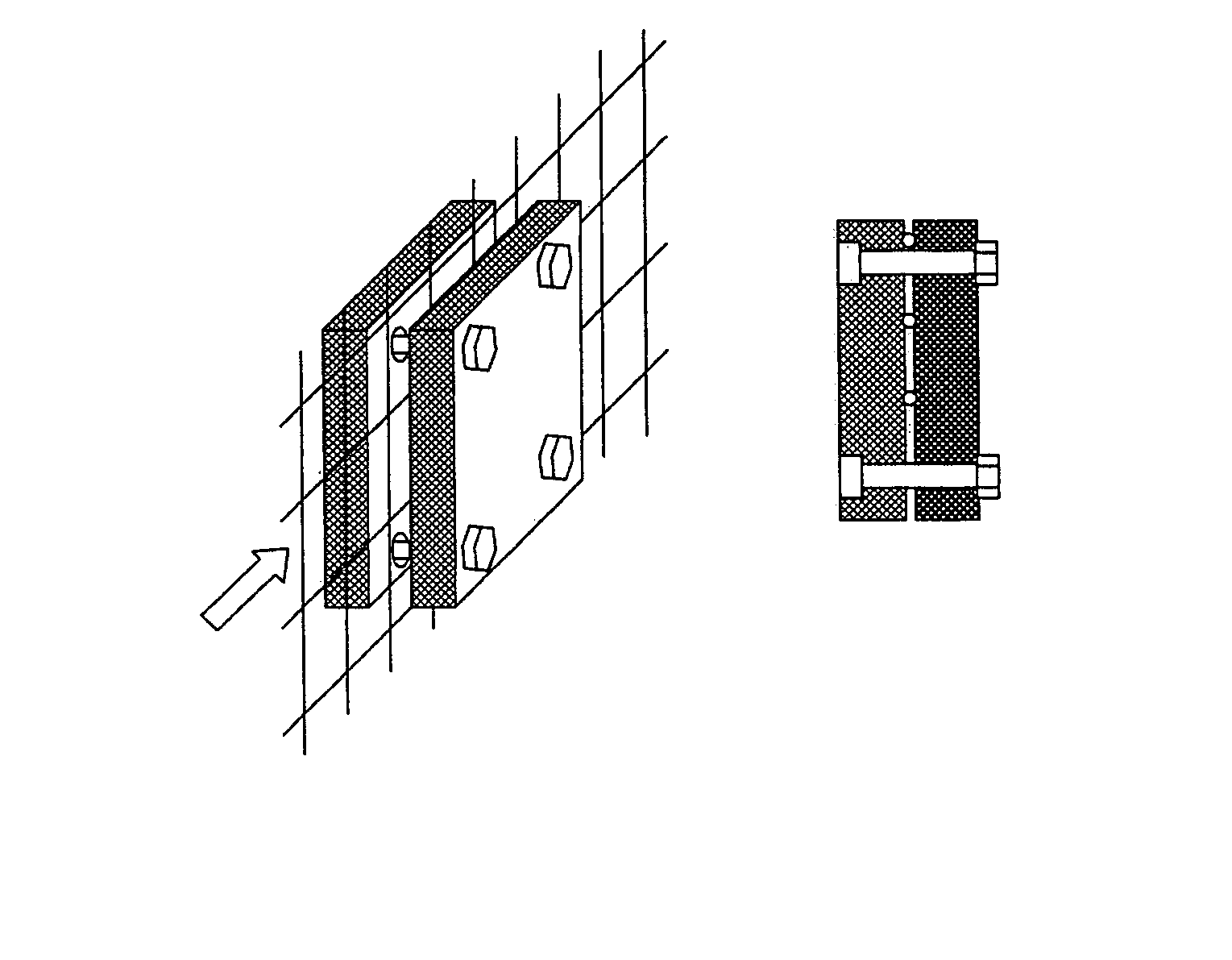

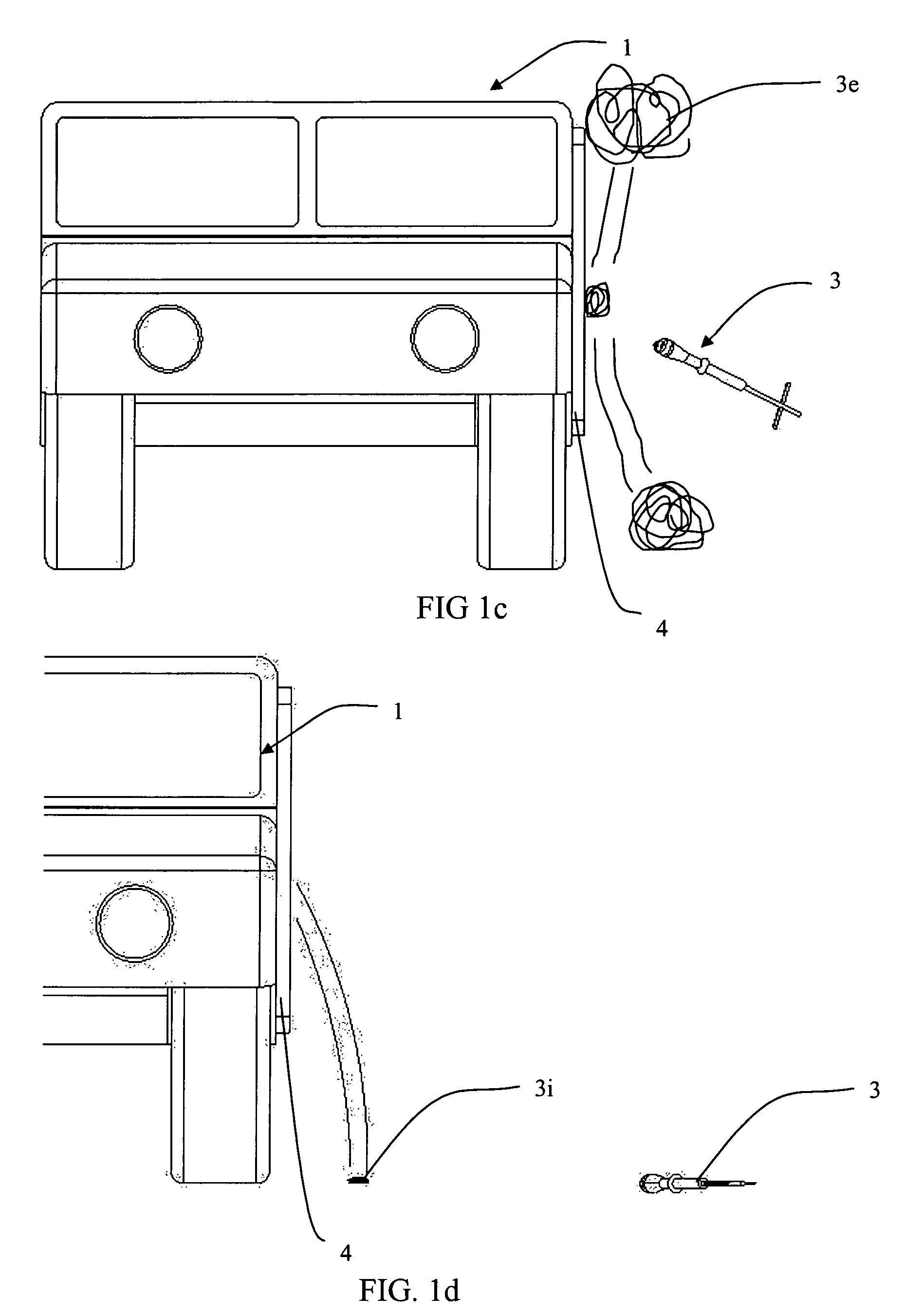

InactiveUS20070260407A1Readily apparentDigital computer detailsMeasurement arrangements for variableElectricityMultiple sensor

A wearable ballistic impact protection system detects impacts to a body. The system includes multiple sensors 10L, 10R for detecting vibration. The sensed vibrations are converted to electrical signals which are filtered. Electronic components 15 are provided to determine whether the filtered signal have frequency and amplitude characteristics of impact that cause injury to a body. Preferably, the sensors 10L, 10R are Piezo-electric film sensing elements. Information regarding the extent of the impact and injuries to the body may be transmitted to a remote location so that medics or other personnel may be informed to the extent of injuries to the body so that they may provide medical assistance.

Owner:QUANTUM APPLIED SCI & RES +2

Explosive round countermeasure system

A countermeasure system which is capable of defusing rocket propelled grenades (RPG) is provided by spacing an array of explosive charges or primacord from the protected structure to allow and sense an ogive of the fused RPG to enter into a functional plane of the array initiating one or more of the charges to collapse to ogive. The array is supported flexibly or rigidly and further ballistic protection is incorporated behind the array in fixed or inflatable forms to provide protection of the structure from the explosive products from the array and the ballistic impact of the defused RPG.

Owner:INNOVATIVE SURVIVABILITY TECH

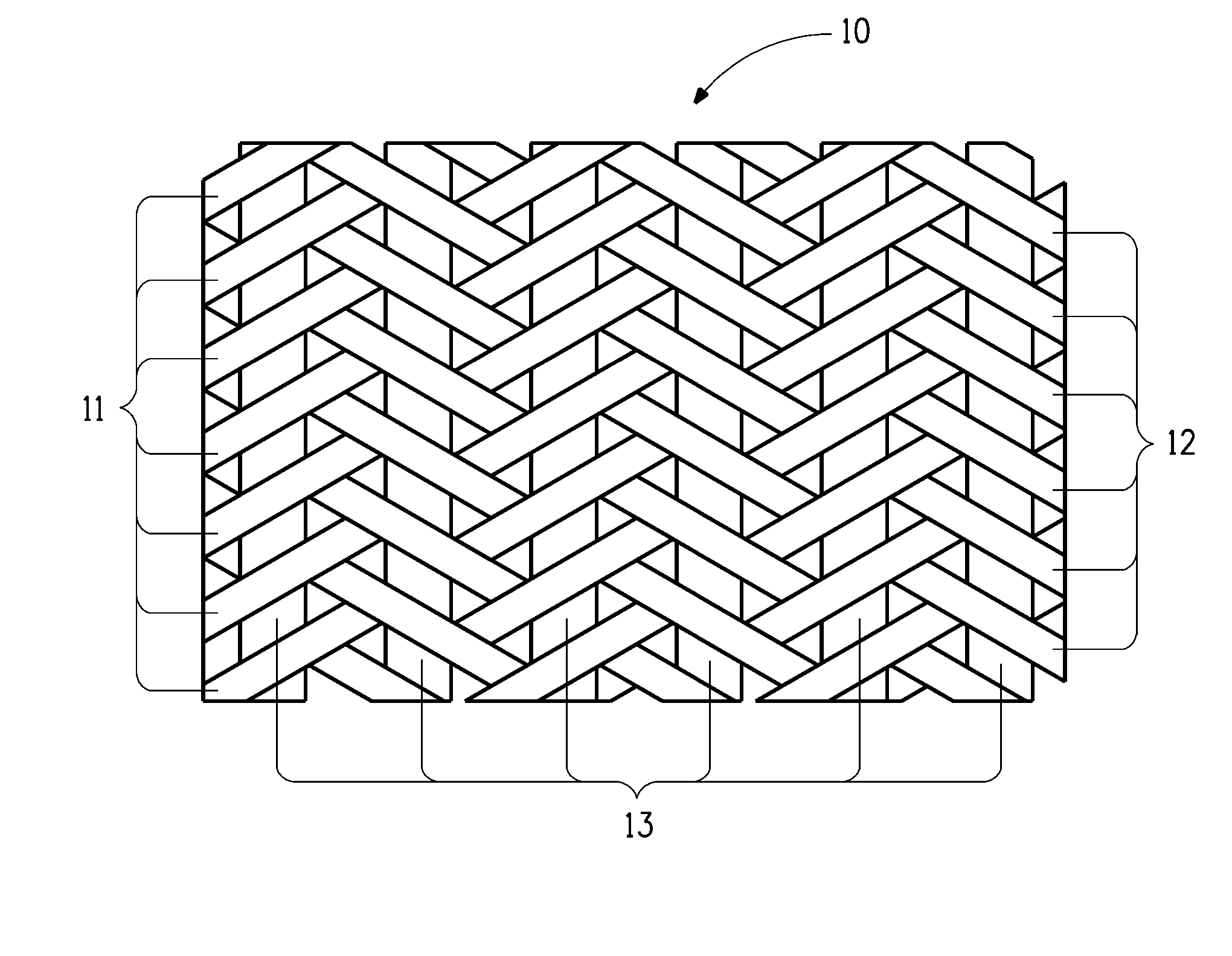

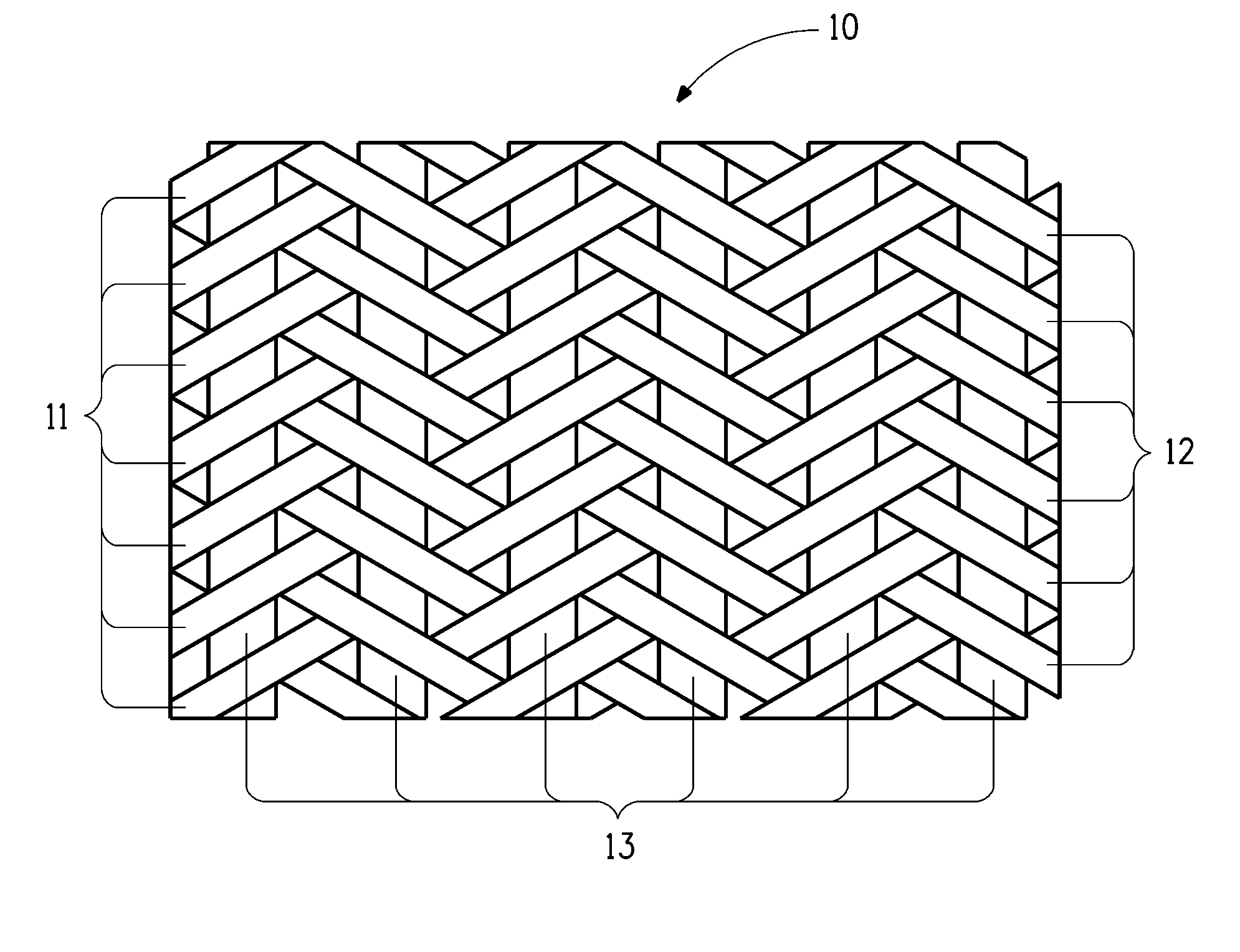

Triaxial braid fabric architectures for improved soft body armor ballistic impact performance

A fabric comprising a first plurality of yarns, a second plurality of yarns and a third plurality of yarns wherein the first, second and third pluralities of yarns have a yarn orientation that is different from each other. The third plurality of yarns is oriented in an axial direction. The second plurality of yarns is interwoven with the first plurality of yarns. The third plurality of yarns have no crimp. The yarns of the second plurality of yarns have an average linear density greater than or equal to the average linear density of the yarns of the first plurality of yarns and the yarns of the third plurality of yarns have an average linear density greater than the average linear density of the yarns of the second plurality of yarns and less than three times the average linear density of the yarns of the first plurality of yarns.

Owner:DUPONT SAFETY & CONSTR INC

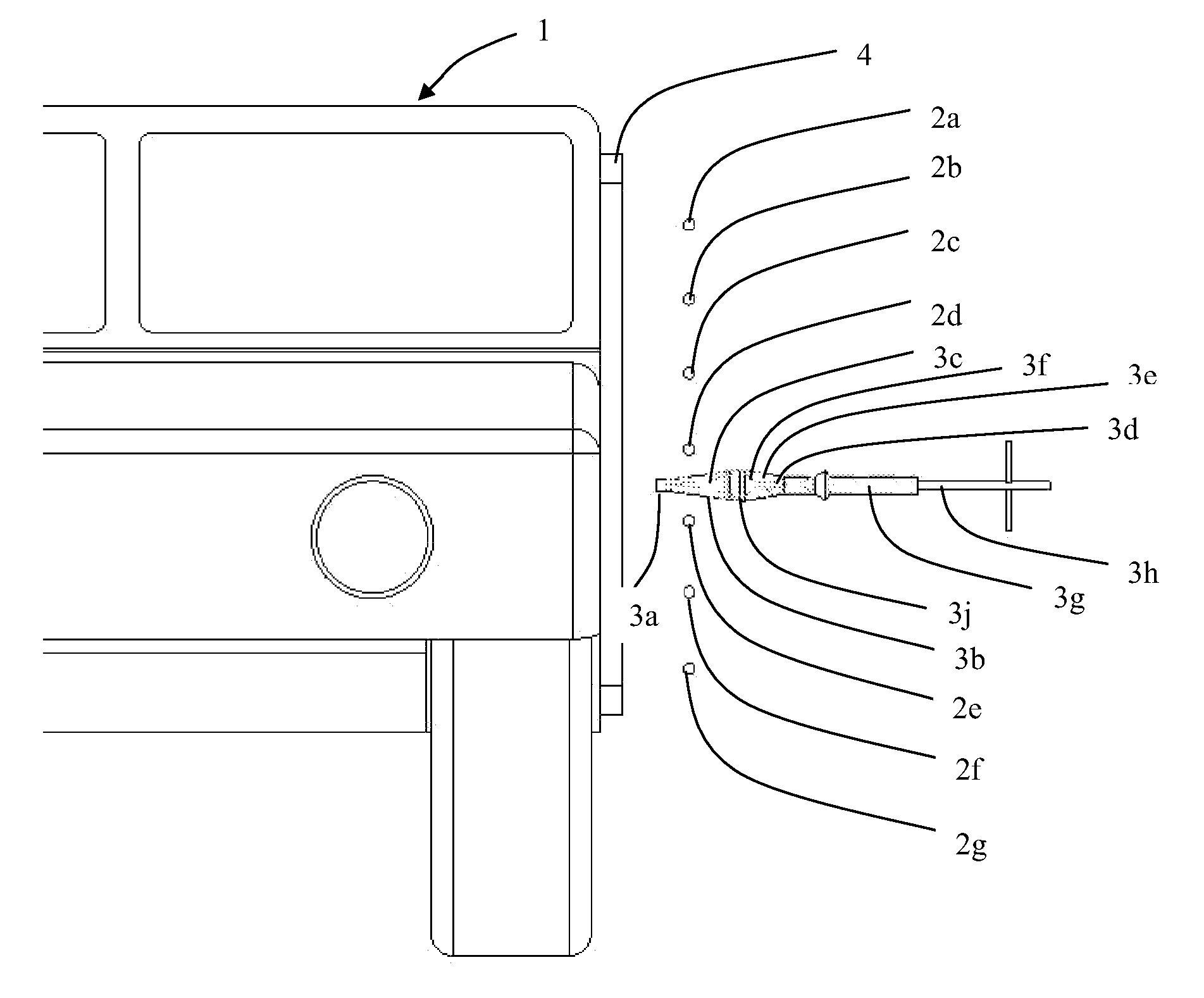

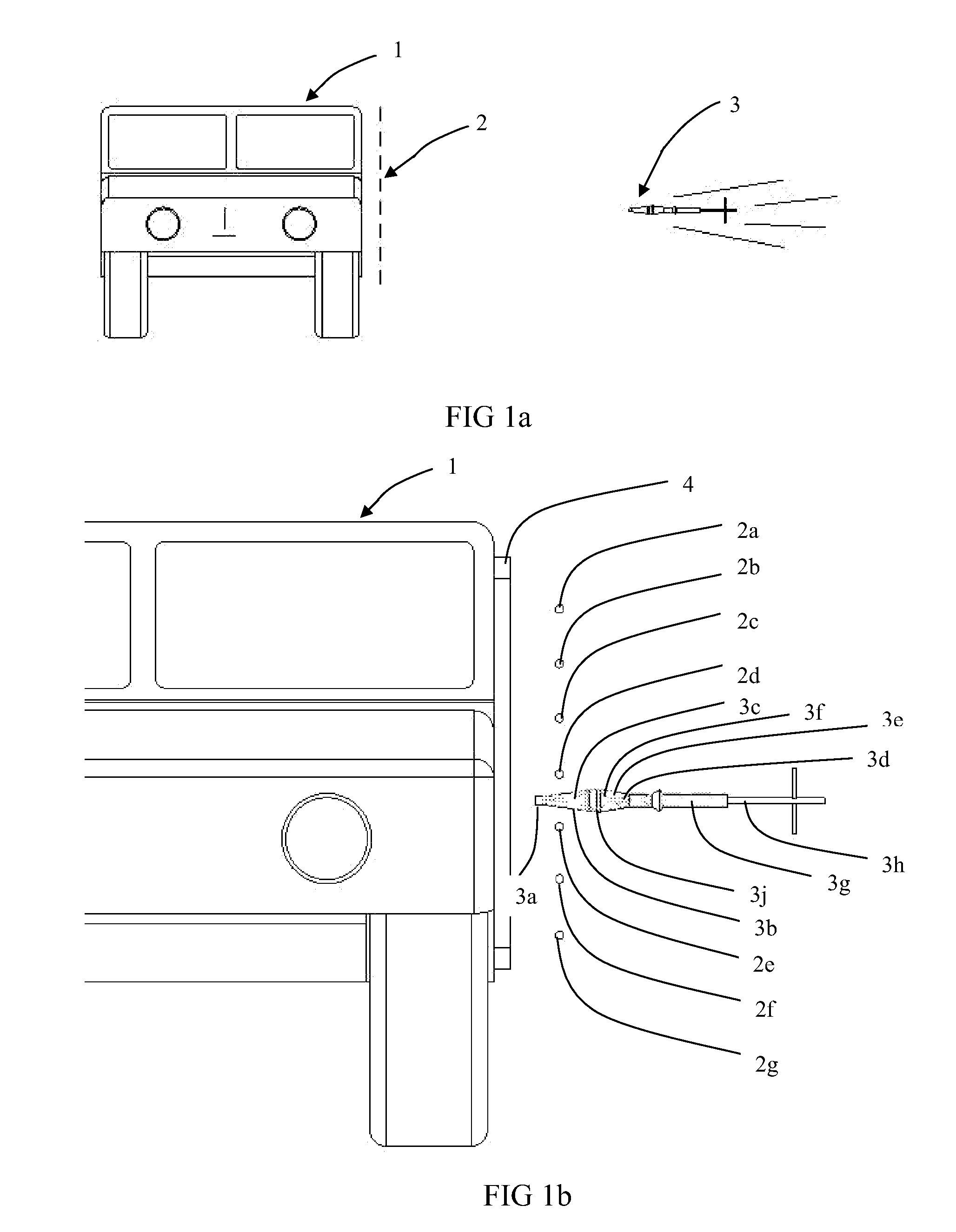

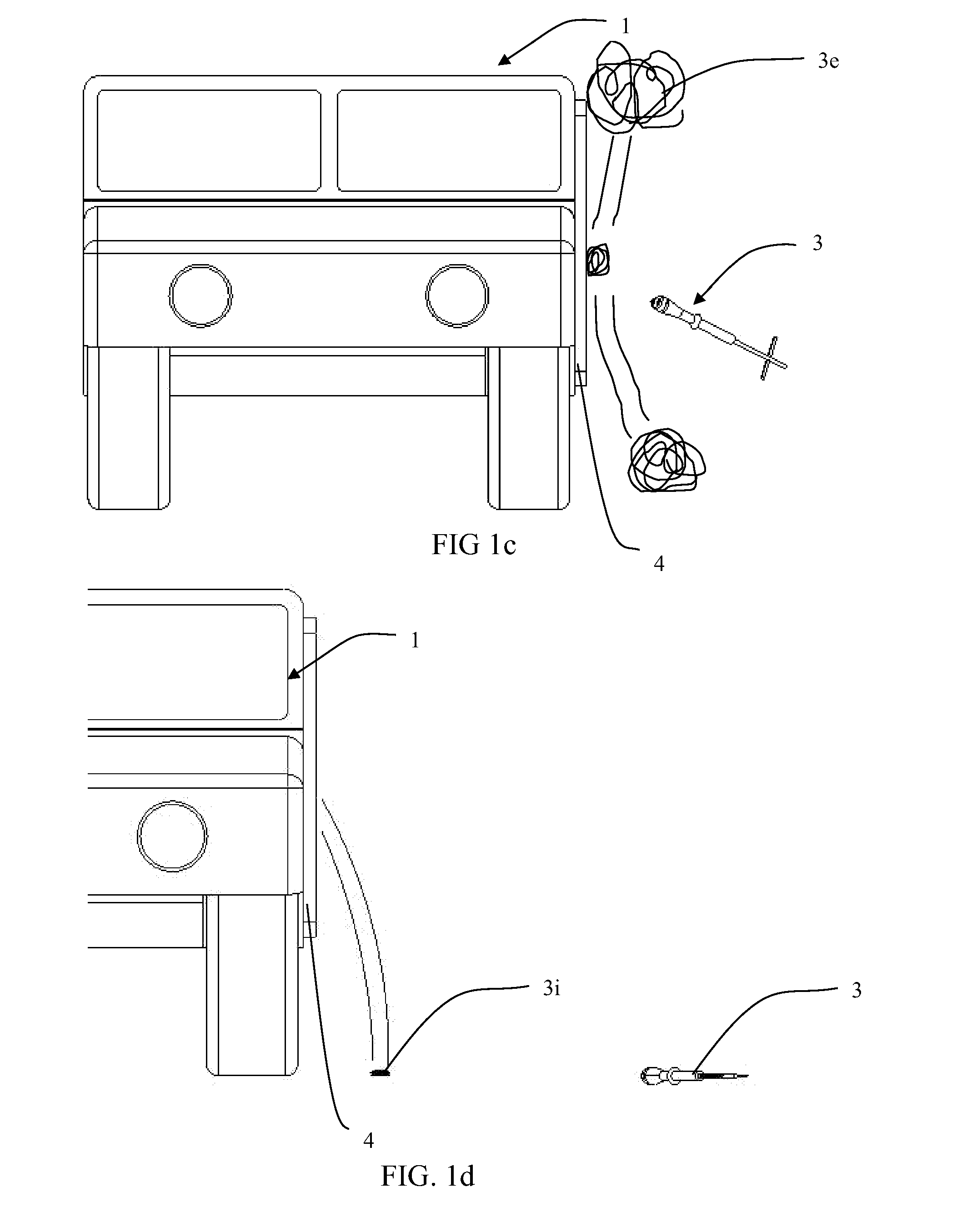

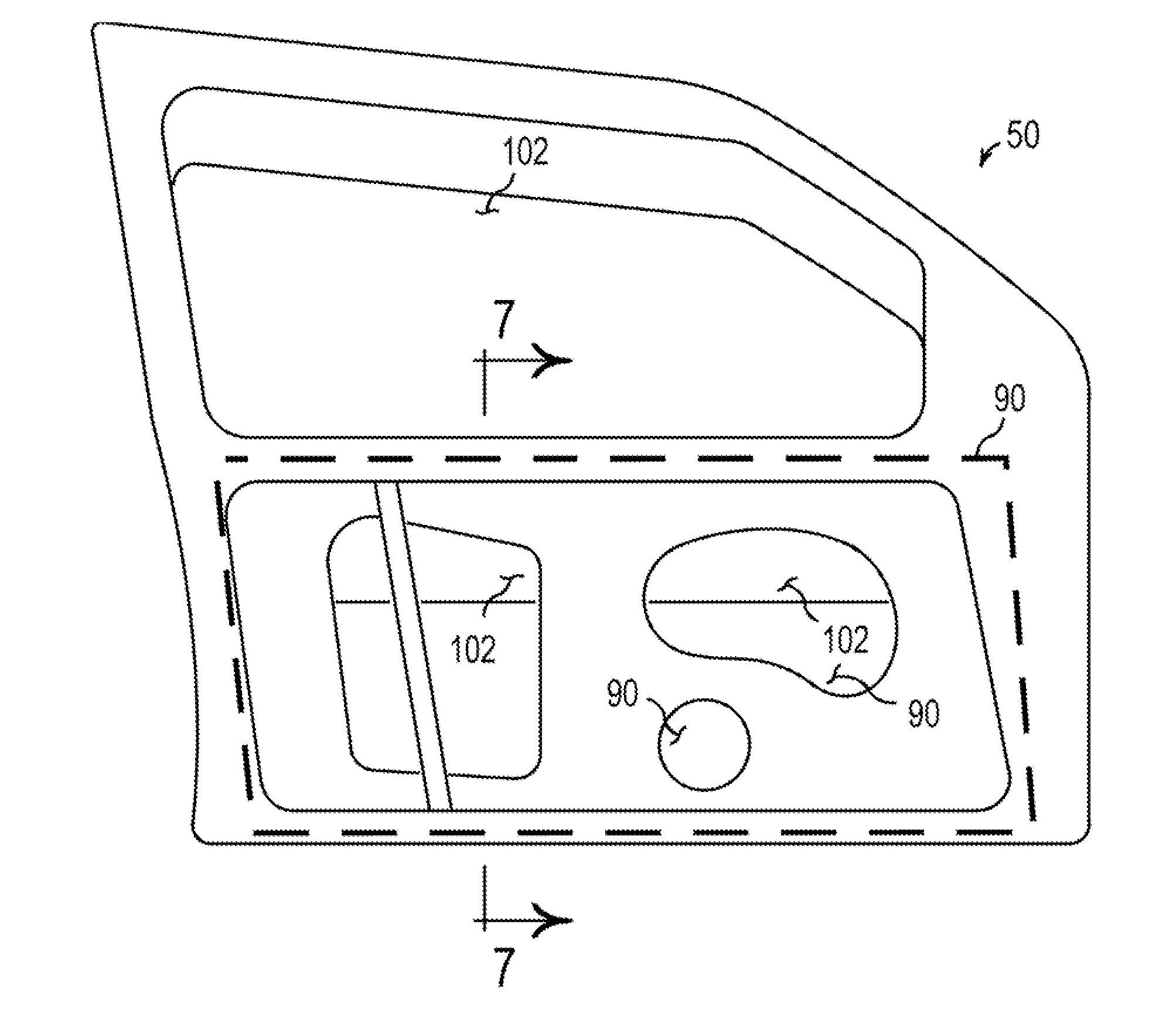

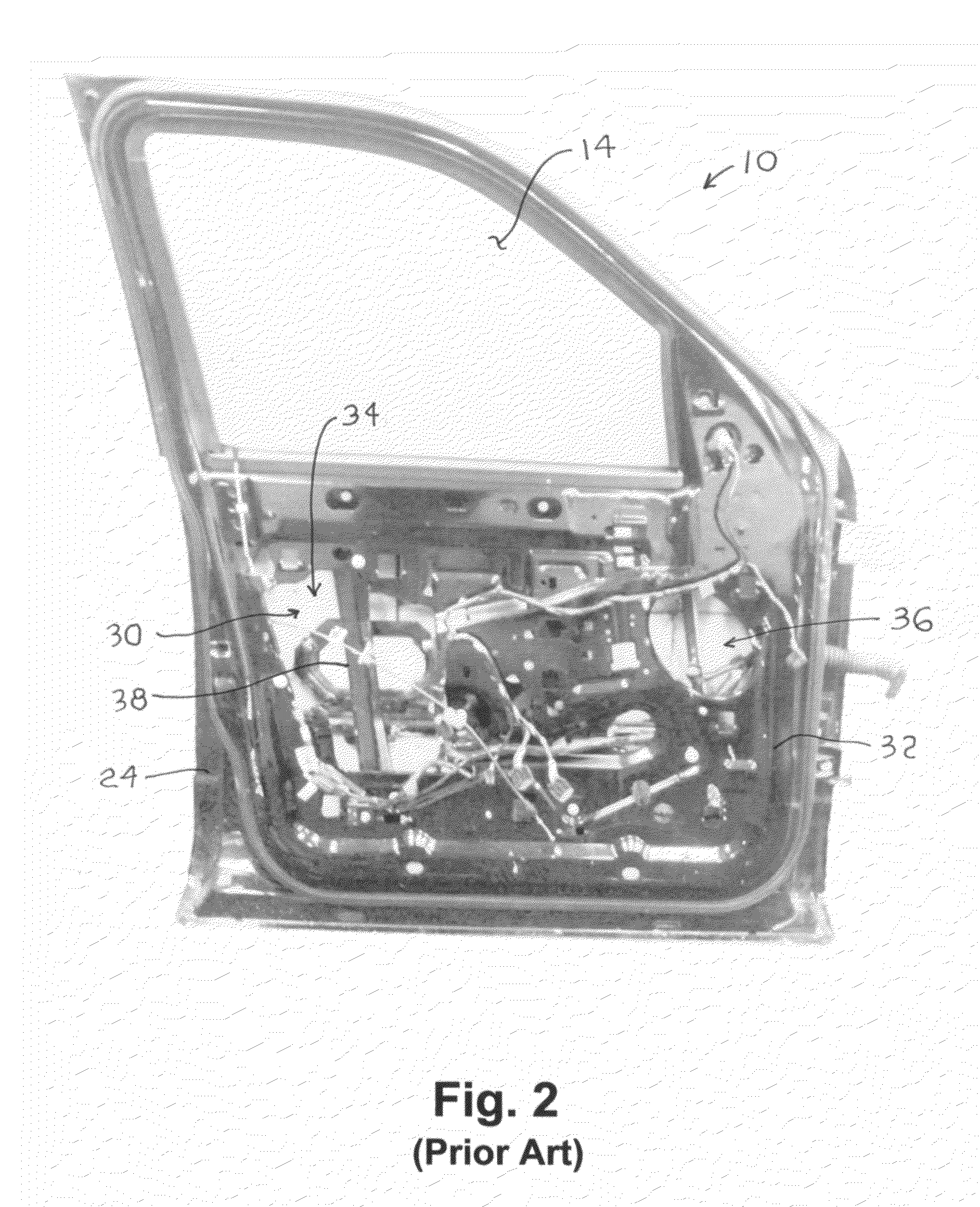

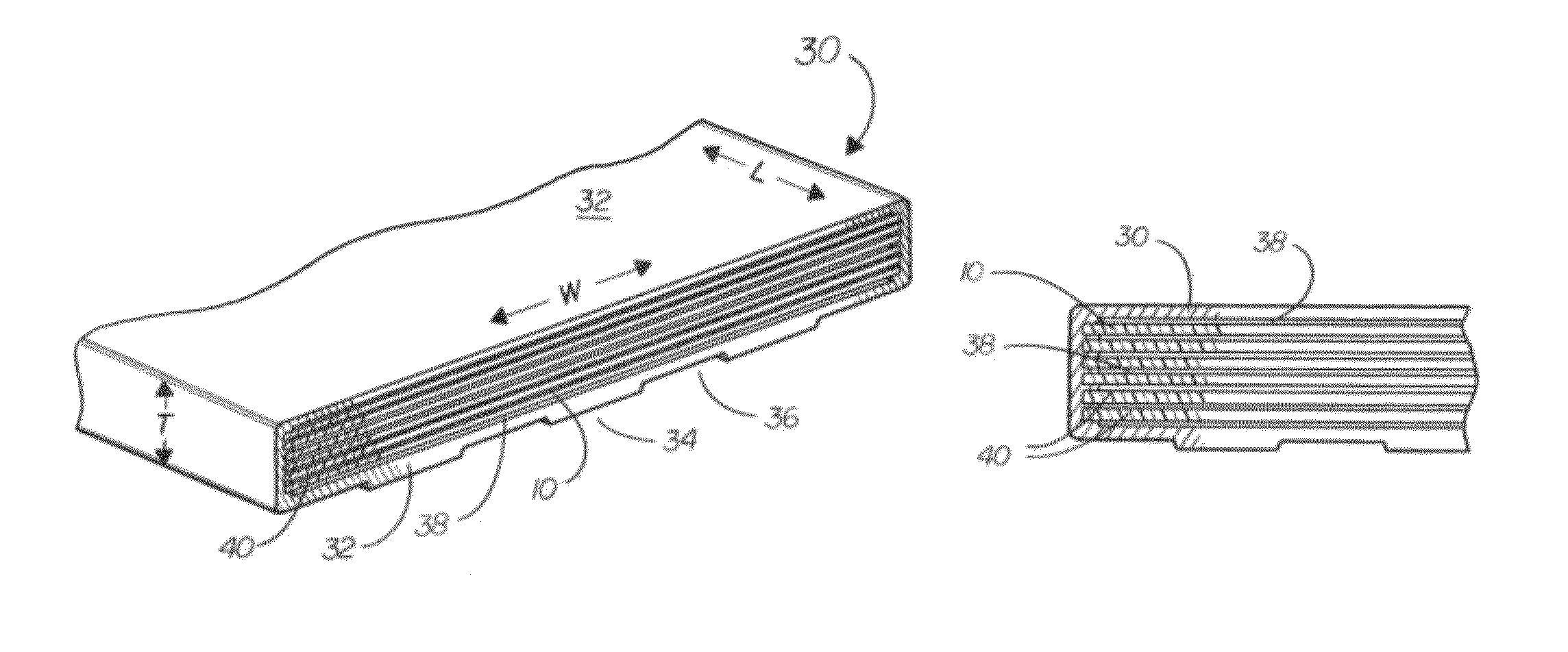

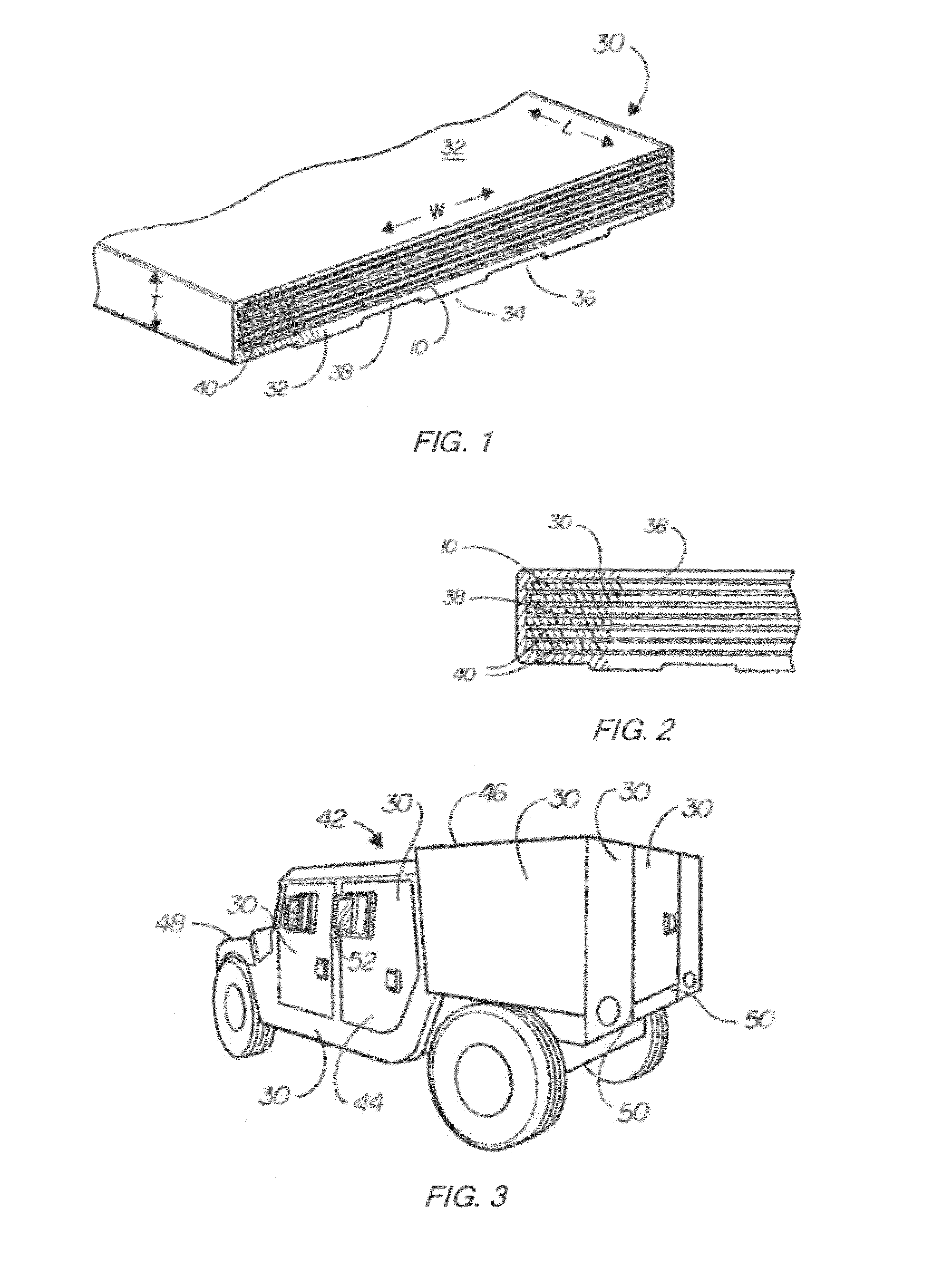

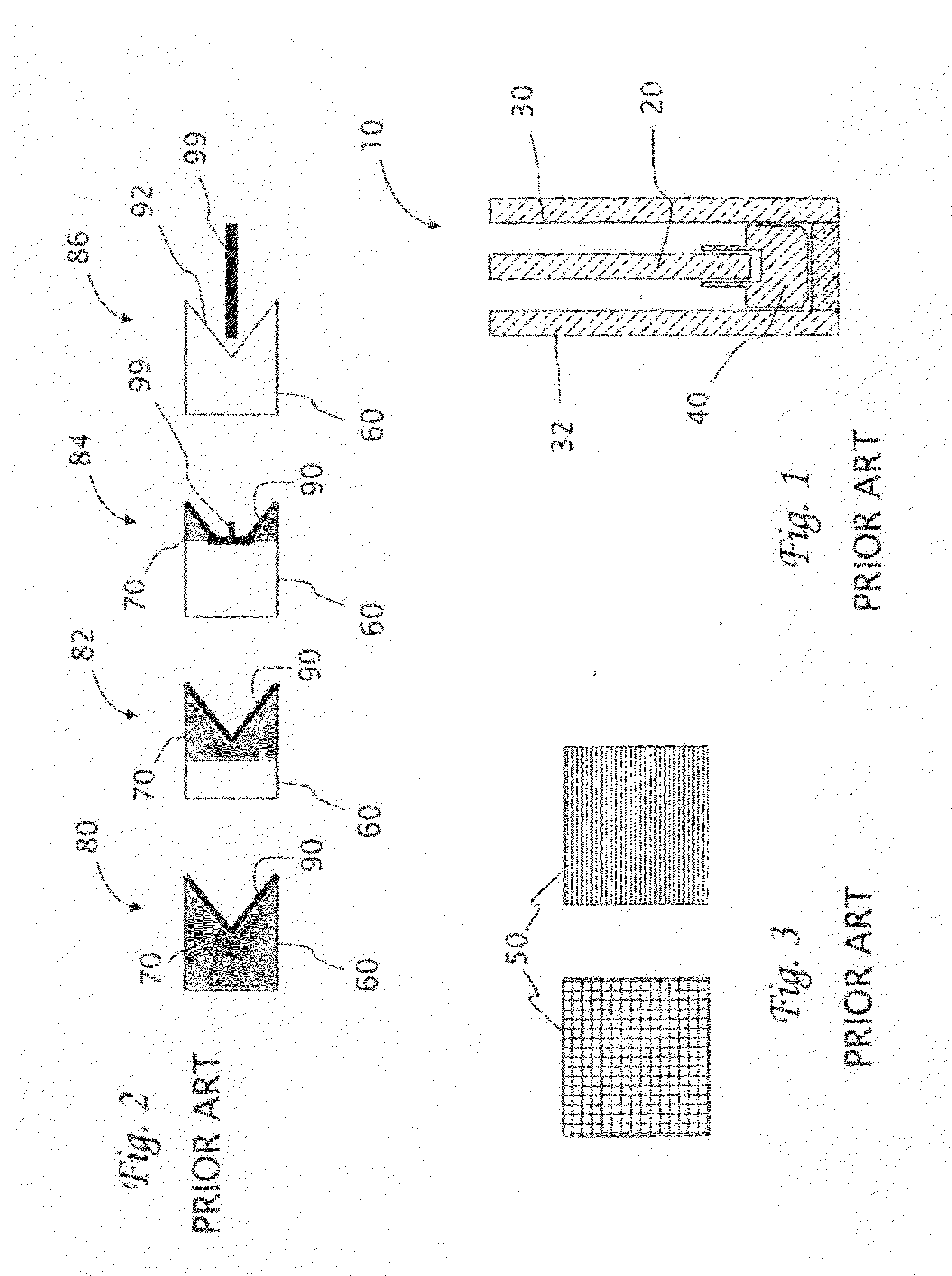

System and method for ballistic protection for a vehicle door

The invention is a method for applying ballistic protection to a vehicle door to protect against ballistic impact comprising: obtaining a plurality of ballistic-resistant panels, inserting each of said plurality of ballistic-resistant panels into an interior cavity of the vehicle door; and attaching each said plurality of ballistic-resistant panels to an interior surface of an exterior door panel of the vehicle door so as to form said contiguous ballistic-resistant panel assembly inside said interior cavity.

Owner:MILSPRAY

Non-metallic armor article and method of manufacture

A non-metallic armor article comprises a pultruded housing defining at least one cavity. A plurality of substantially dry ballistic impact resistant broad goods sheets are at least partially enclosed in the cavity and held in suspension independently within the cavity. The pultruded housing is engaged with the plurality of substantially dry ballistic impact resistant broad goods sheets by being secured to one or more of the plurality of substantially dry ballistic impact resistant broad goods sheets.

Owner:TECHDYNE

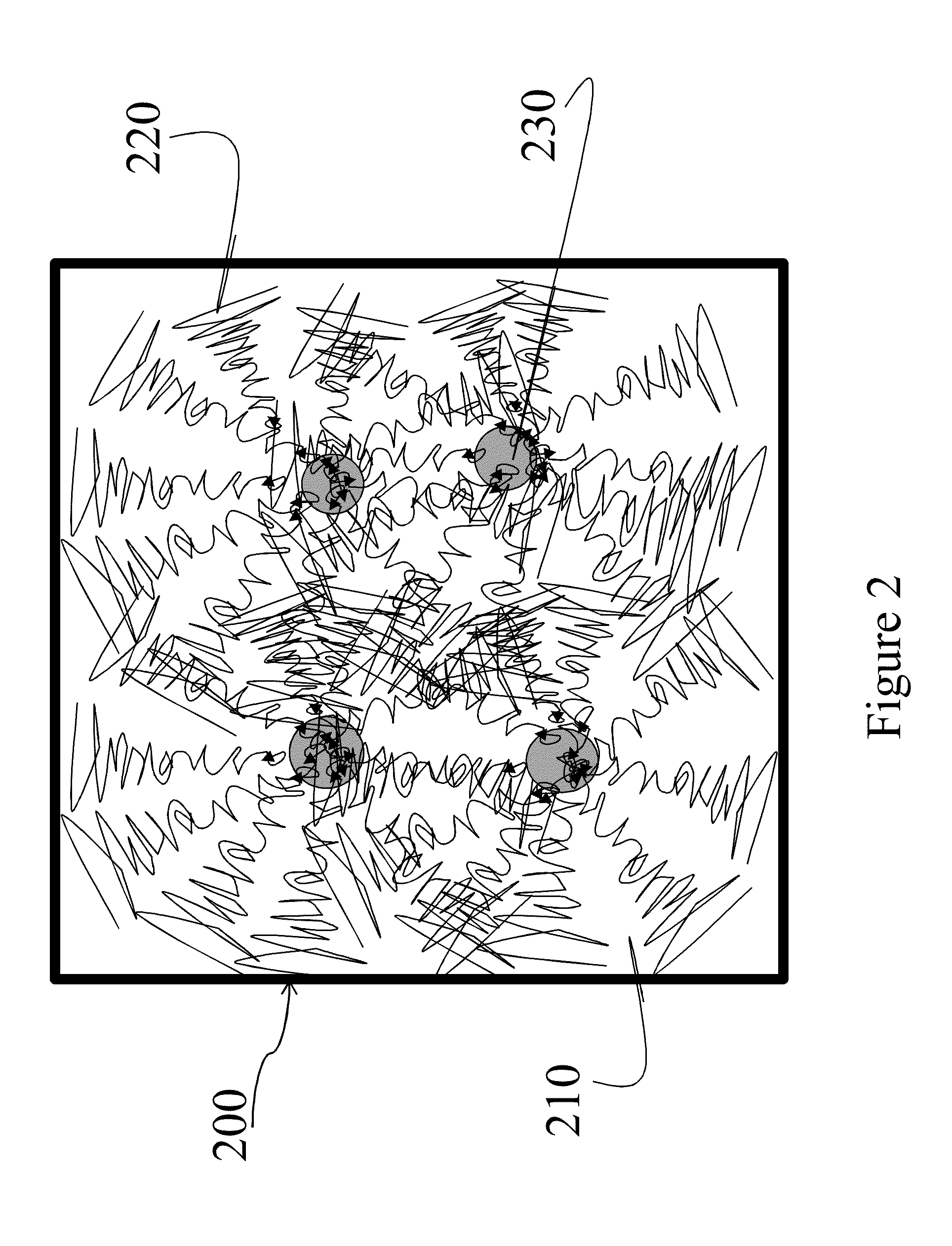

Armor arrangement

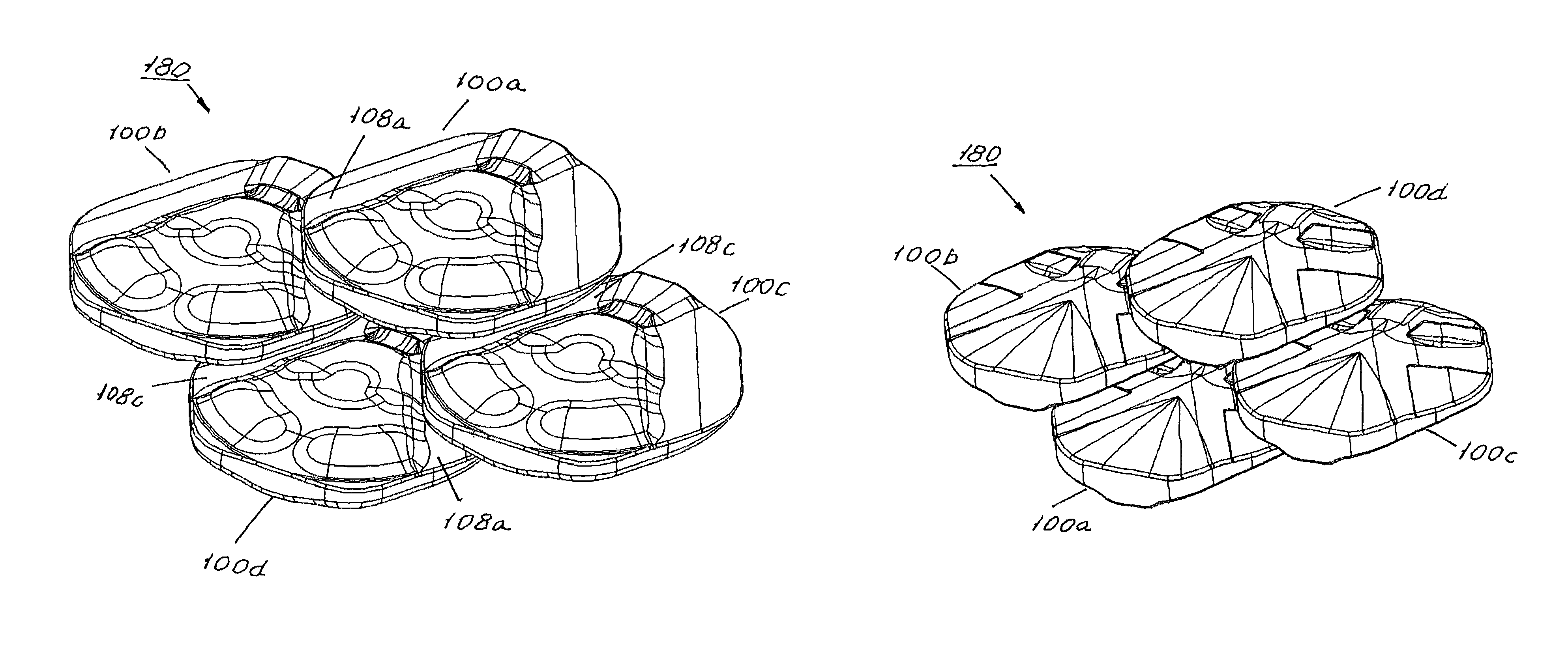

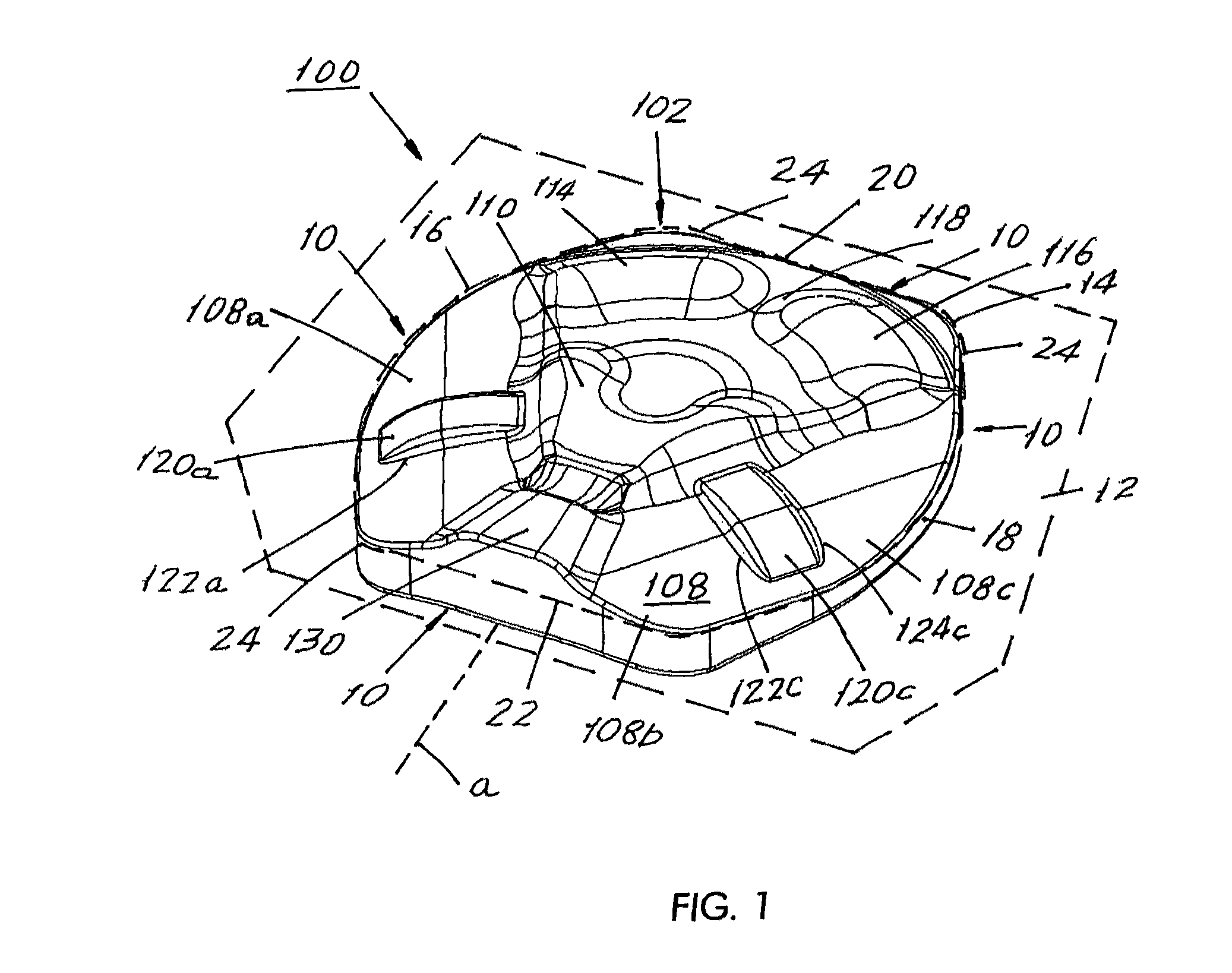

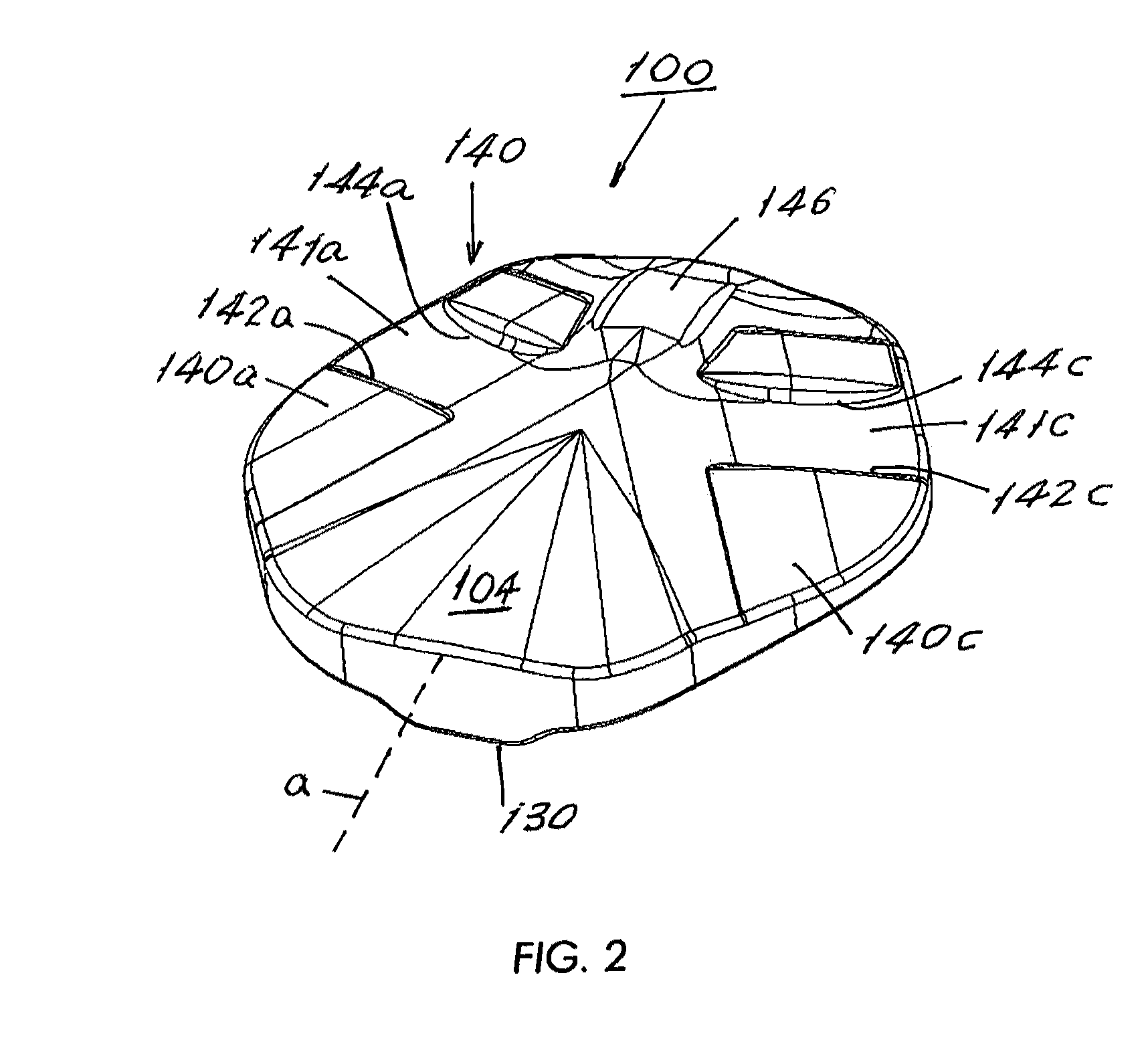

ActiveUS8434396B1Enhanced comfort and mobilityImprove rendering capabilitiesPersonal protection gearArmour platesEngineeringBallistic impact

A ballistic tile for use in an imbricated pattern of like ballistic tiles to achieve coverage of a protected area by the imbricated pattern, while having rounded corners to limit the potential for spalling on ballistic impact. The ballistic tile may include a strike face that is generally undulating to laterally deflect at least a portion of the impact force, and to induce turning of the ballistic projectile on impact to further distribute the impact force. The ballistic tile may also include one or more features on an obverse and reverse side thereof that, when arranged in an imbricated pattern, limit lateral motion of the tiles on ballistic impact, and / or laterally transmit the energy of the projectile for deflection and absorption thereof.

Owner:VERCO MATERIALS

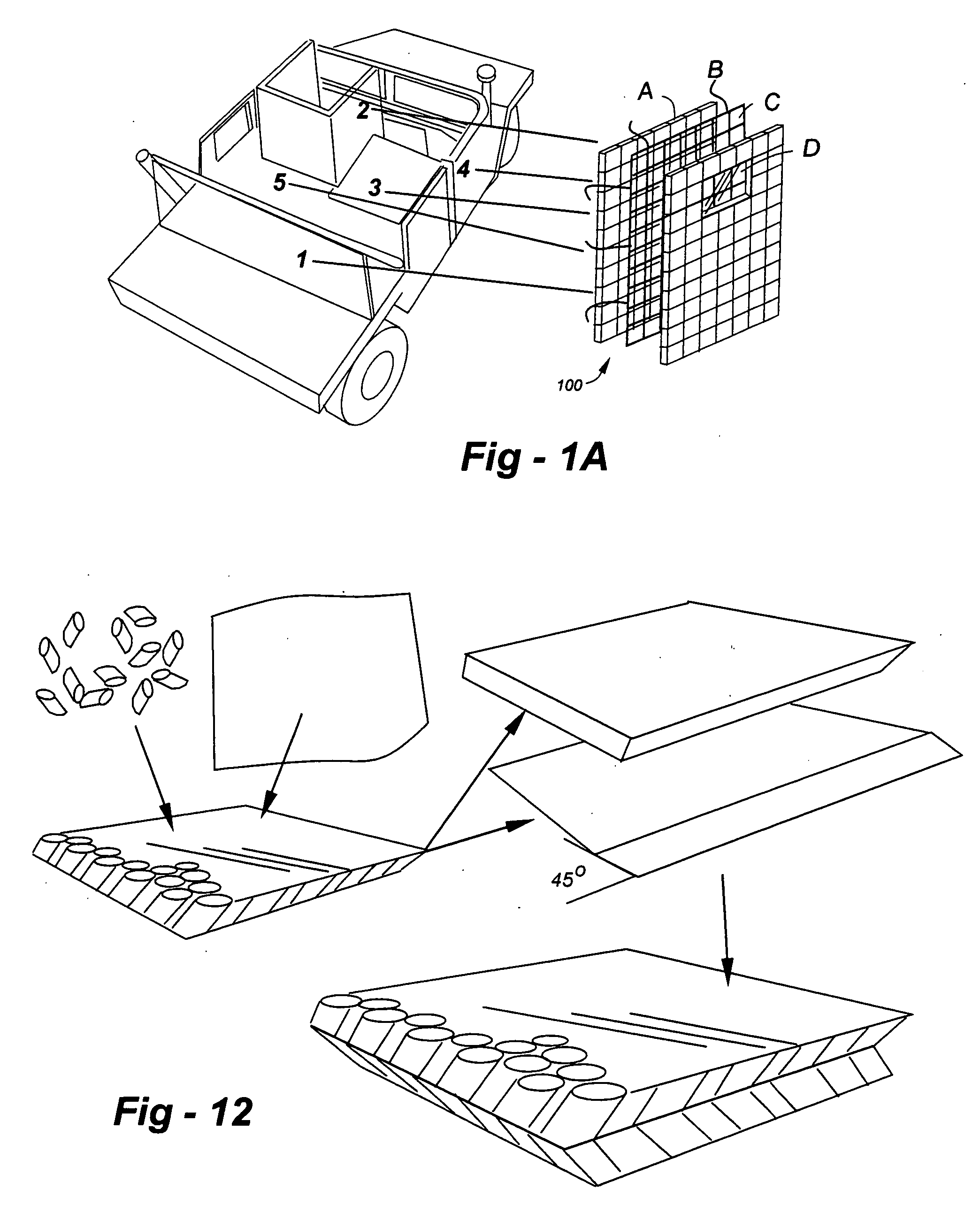

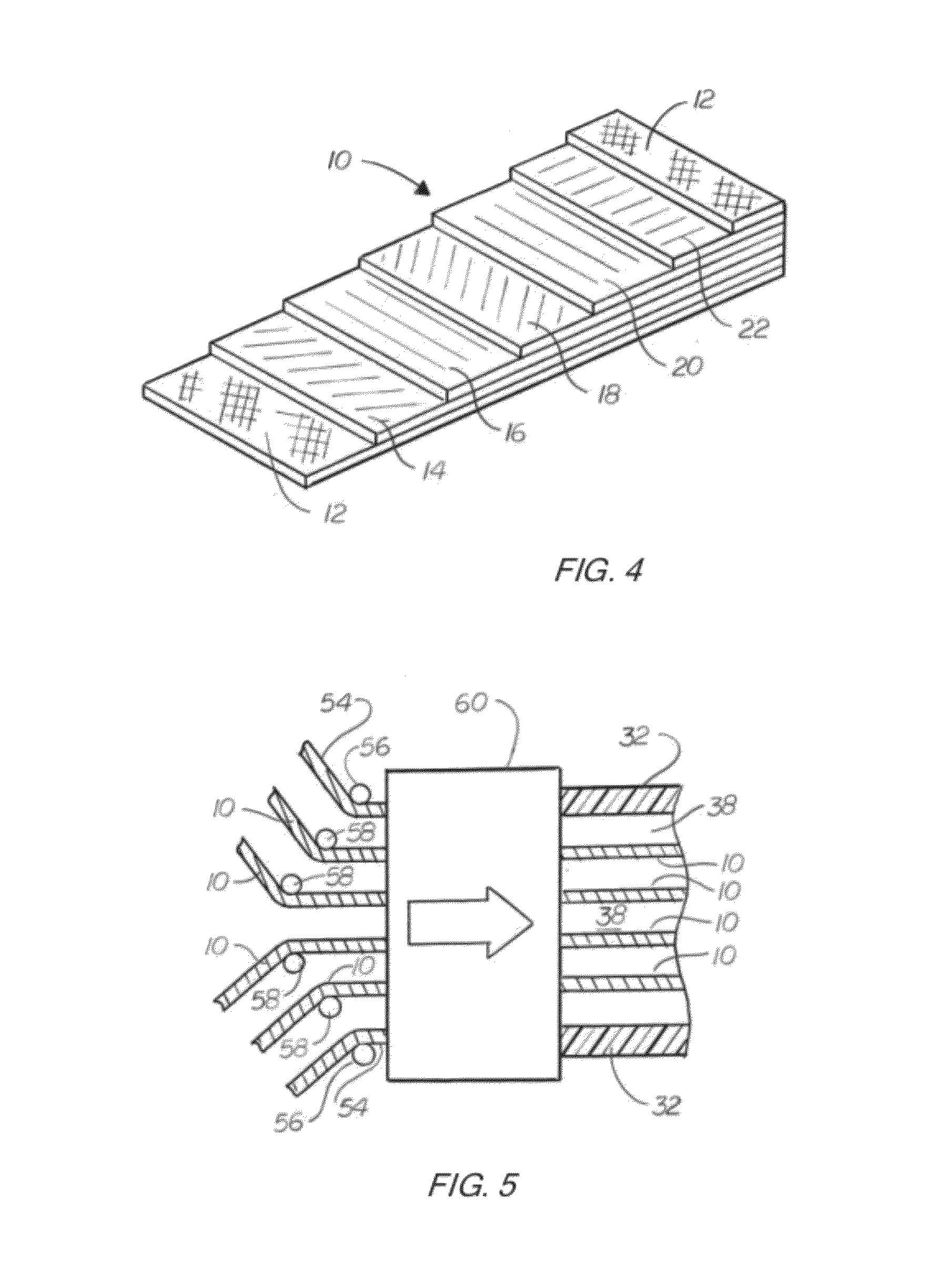

Lightweight composite armor

InactiveUS7490539B2Improve manufacturabilityEasy to integrateArmoured vehiclesArmour platesEnergy absorptionEngineering

Improved composite armor designs use optimally shaped ceramic pellets and a web system for patterning the pellets, improving manufacturability, and providing additional structural reinforcement. The result is lightweight, composite hybrid structures for ballistic protection particularly suited to tactical ground vehicles. The preferred embodiment is a combination of three major components: 1) an optimally designed web system that allows armor tiles to be attached to it and that can be easily integrated with existing vehicle structures; 2) an advanced composite armor unit using a patent-pending BTR (Bio-mimetic Tendon-Reinforced) material as the supporting structure; and 3) optimally placed “waiting materials” which can provide enhanced ballistic impact resistance, energy absorption capability and structural integrity. These “waiting materials” are structural members that are not active at the beginning of the ballistic impact, but become active when needed or the active members have failed.

Owner:MKP STRUCTURAL DESIGN ASSOCS

Explosive round countermeasure system

A countermeasure system which is capable of defusing rocket propelled grenades (RPG) is provided by spacing an array of explosive charges or primacord from the protected structure to allow and sense an ogive of the fused RPG to enter into a functional plane of the array initiating one or more of the charges to collapse to ogive. The array is supported flexibly or rigidly and further ballistic protection is incorporated behind the array in fixed or inflatable forms to provide protection of the structure from the explosive products from the array and the ballistic impact of the defused RPG.

Owner:TEXTRON SYST

Passive fire protection device

A fire protection device for holding a fire extinguishing agent. The device is made from a dual-face enclosure coupled to one another through internal ribs, and is configured such that a single chamber defined by the faces and ribs is configured to contain all of the agent. The coupling between the ribs and the two panel faces promotes transfer of an energy source, such as ballistic impact, explosion or excessive temperature, to the front face to promote cracking and subsequent shattering of the front face in a brittle manner. This opening up of the front face releases the fire extinguishing agent in a thorough and well-dispersed manner.

Owner:SKYWARD

Digital ballistic impact detection system

InactiveUS8191421B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringBallistic impact

Methods and devices for a miniature, ultra-low power impact recorder for detecting, quantifying and recording the energy of an explosive blast or ballistic projectile impact. In one embodiment, the impact recorder can included a sensor comprised of an array of electromechanical resonators that is sensitive to the vibrations produced in selected, discrete frequency ranges that approximate the spectral signature characteristics of the shockwave resulting from the ballistic impact event, even after traveling through impacted material or body tissues.

Owner:EMPIRE IP LLC

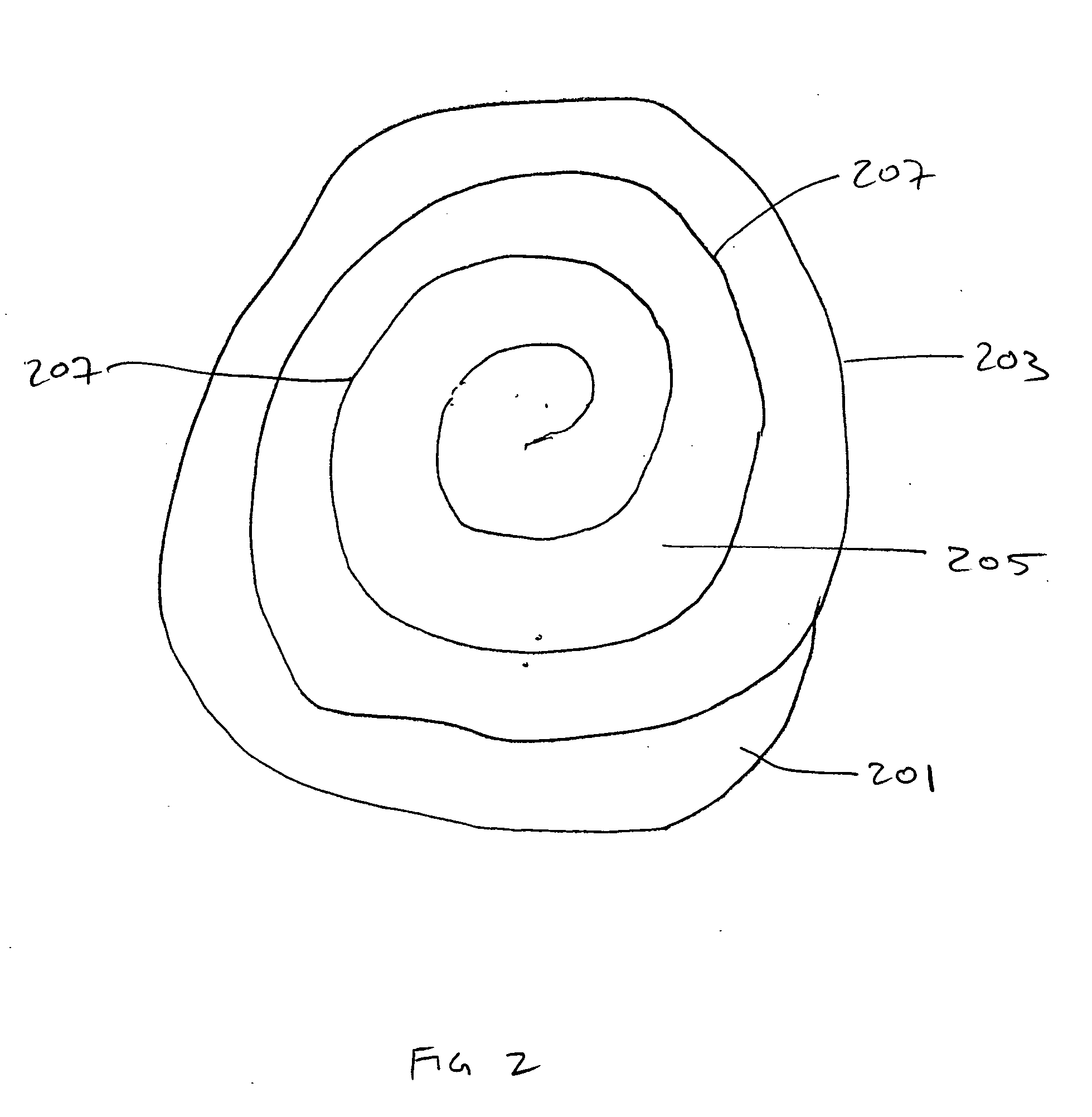

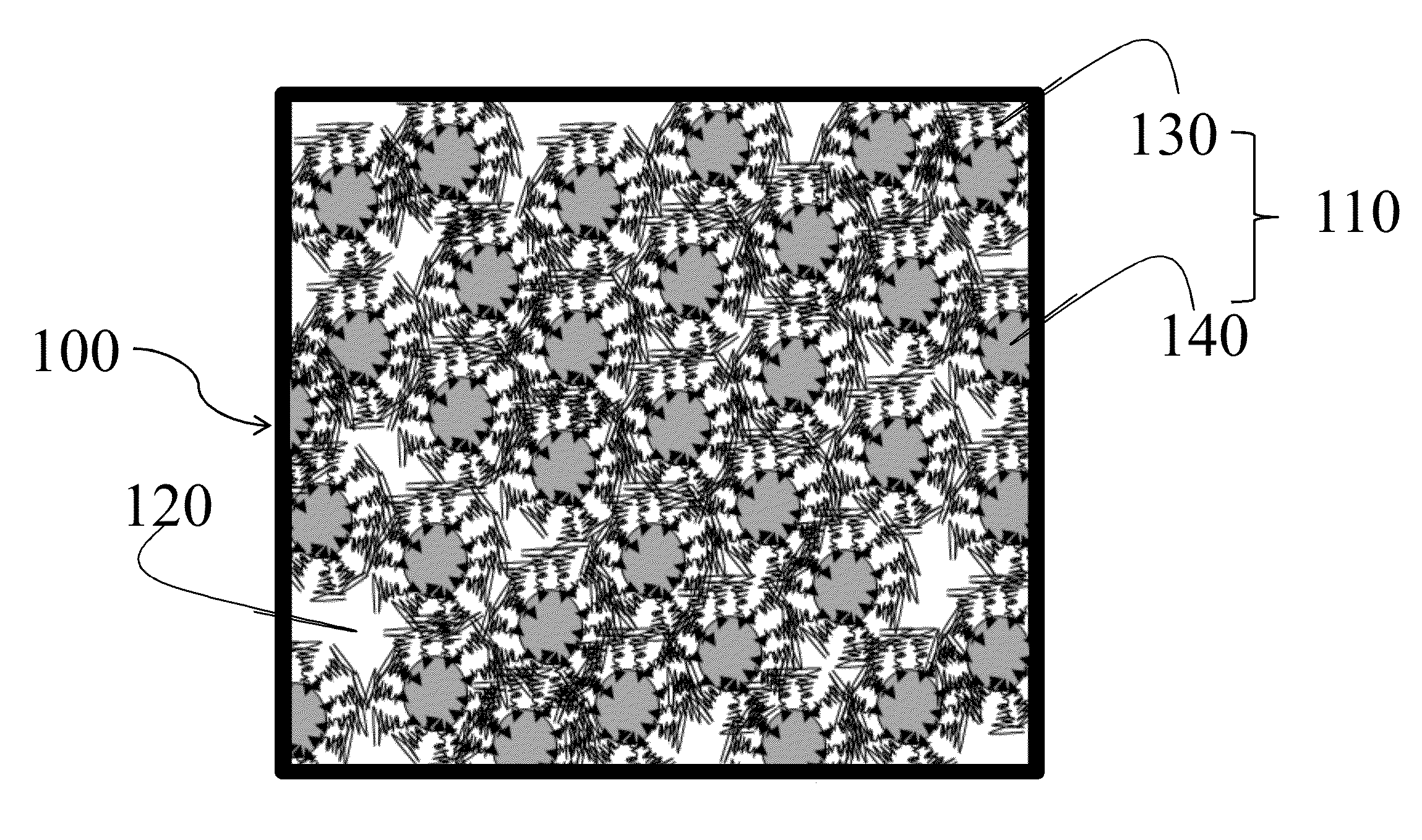

Self-healing composites

Lightweight self-healing composites comprise region-specific microstructures that dampen ballistic energy wherein the region-specific microstructures include at least one semi-crystalline thermoplastic and at least one nanoparticle nucleating agent. The distinctive region-specific microstructures allow the composites to dissipate high frequency and high amplitude shock wave into heat and reassemble itself into its original microstructure through reversible compression and decompression cycles. The region-specific microstructures comprise soft regions, comprised of highly polymeric entangled chains and hard regions, comprised of lamellae or spherullites anchored onto nanoparticle nucleating agents. The soft regions can trap the incoming energy shock wave while the hard regions provide the anchor sites, to allow the entangled chains to remain in place upon encountering ballistic impact. The anti-ballistic composites can be made in a monolithic form and do not significantly degrade under repeated fire.

Owner:TSAI FU JYA DANIEL +1

Ballistic impact detection system

InactiveUS7660692B2Measurement arrangements for variableDigital computer detailsElectricityMultiple sensor

A wearable ballistic impact protection system detects impacts to a body. The system includes multiple sensors for detecting vibration. The sensed vibrations are converted to electrical signals which are filtered. Electronic components are provided to determine whether the filtered signal have frequency and amplitude characteristics of impact that cause injury to a body. Preferably, the sensors are Piezo-electric film sensing elements. Information regarding the extent of the impact and injuries to the body may be transmitted to a remote location so that medics or other personnel may be informed to the extent of injuries to the body so that they may provide medical assistance.

Owner:QUANTUM APPLIED SCI & RES +2

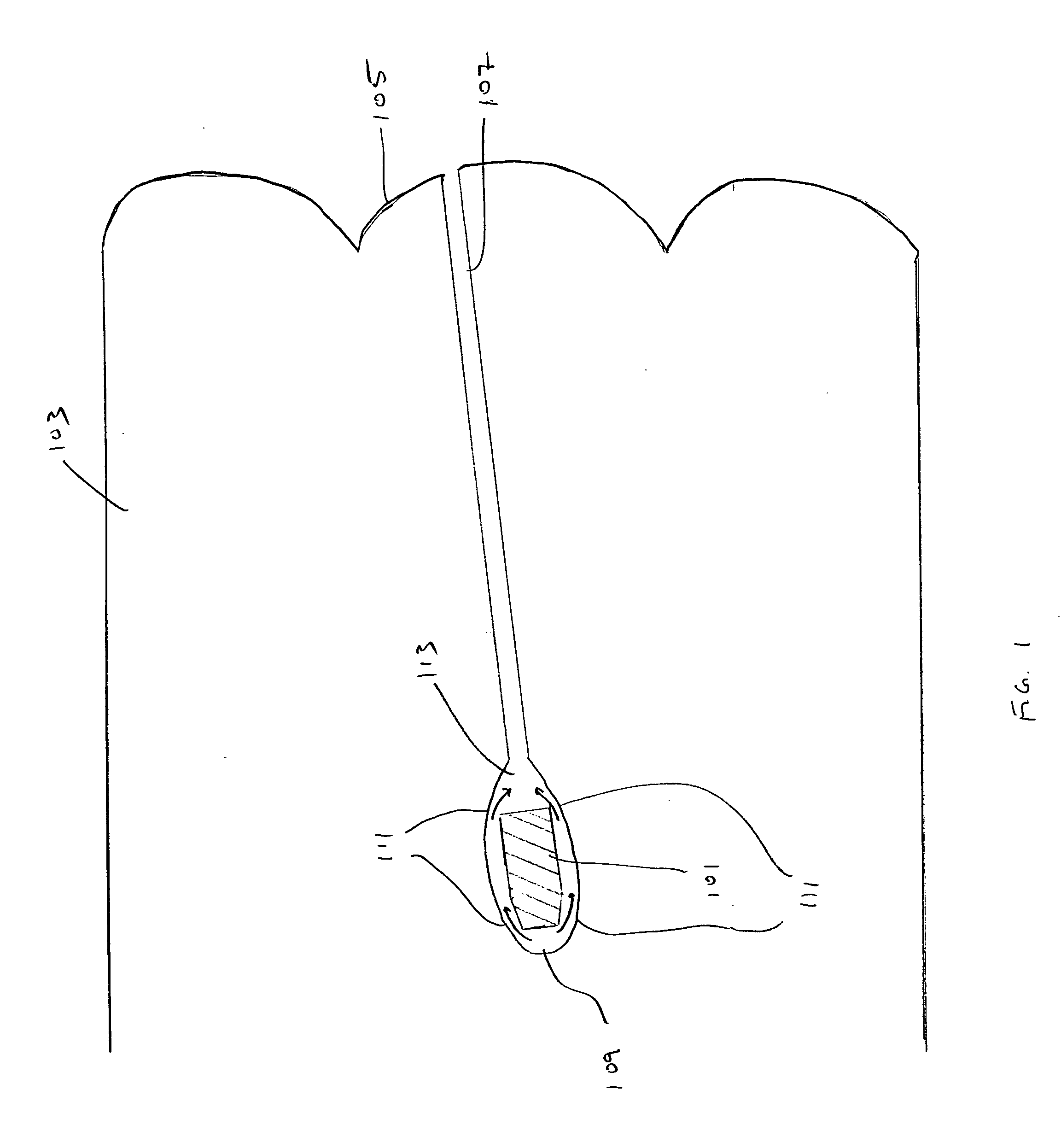

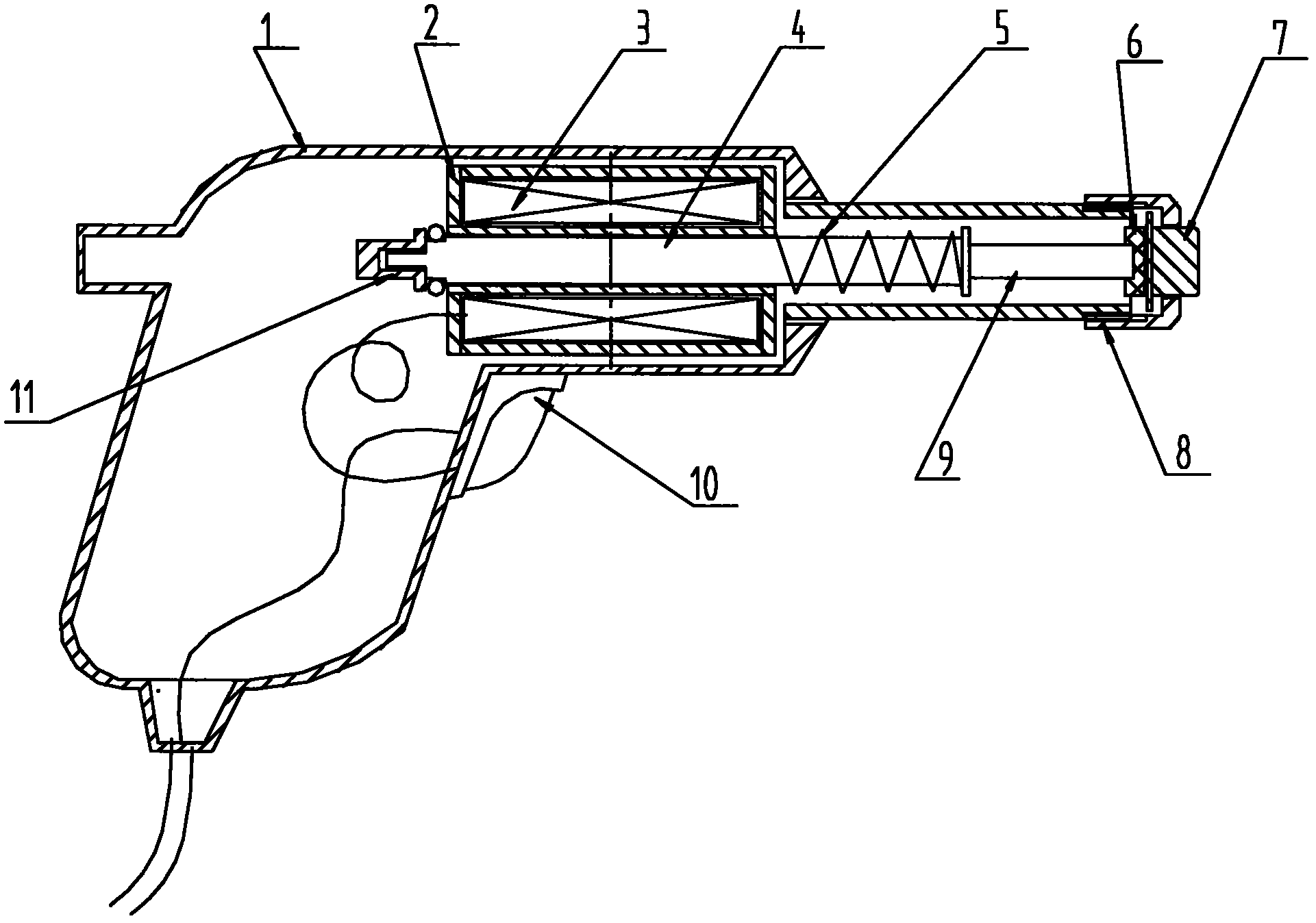

Impact wave therapy apparatus

InactiveCN102525789AIncrease oxygen uptakeImprove microcirculationVibration massageElectricityEngineering

The invention discloses an impact wave therapy apparatus which mainly comprises an impact head and an electromagnet, wherein the impact head is used for emitting impact waves under the action of impact; and the electromagnet is used for impacting the impact head. According to the ballistic impact wave therapy apparatus disclosed by the invention, the electromagnet is utilized to impact the impact head to generate the impact waves, but the compressed air is not used as power to generate the impact waves; and electricity is simpler and more convenient to control than the compressed air and parts such as a compressor, an air valve and the like are saved, and thus, the impact wave therapy apparatus can be made simpler and safer.

Owner:陈文韬

Triaxial braid fabric architectures for improved soft body armor ballistic impact performance

A fabric comprising a first plurality of yarns, a second plurality of yarns and a third plurality of yarns wherein the first, second and third pluralities of yarns have a yarn orientation that is different from each other. The third plurality of yarns is oriented in an axial direction. The second plurality of yarns is interwoven with the first plurality of yarns. The third plurality of yarns have no crimp. The yarns of the second plurality of yarns have an average linear density greater than or equal to the average linear density of the yarns of the first plurality of yarns and the yarns of the third plurality of yarns have an average linear density greater than the average linear density of the yarns of the second plurality of yarns and less than three times the average linear density of the yarns of the first plurality of yarns.

Owner:DUPONT SAFETY & CONSTR INC

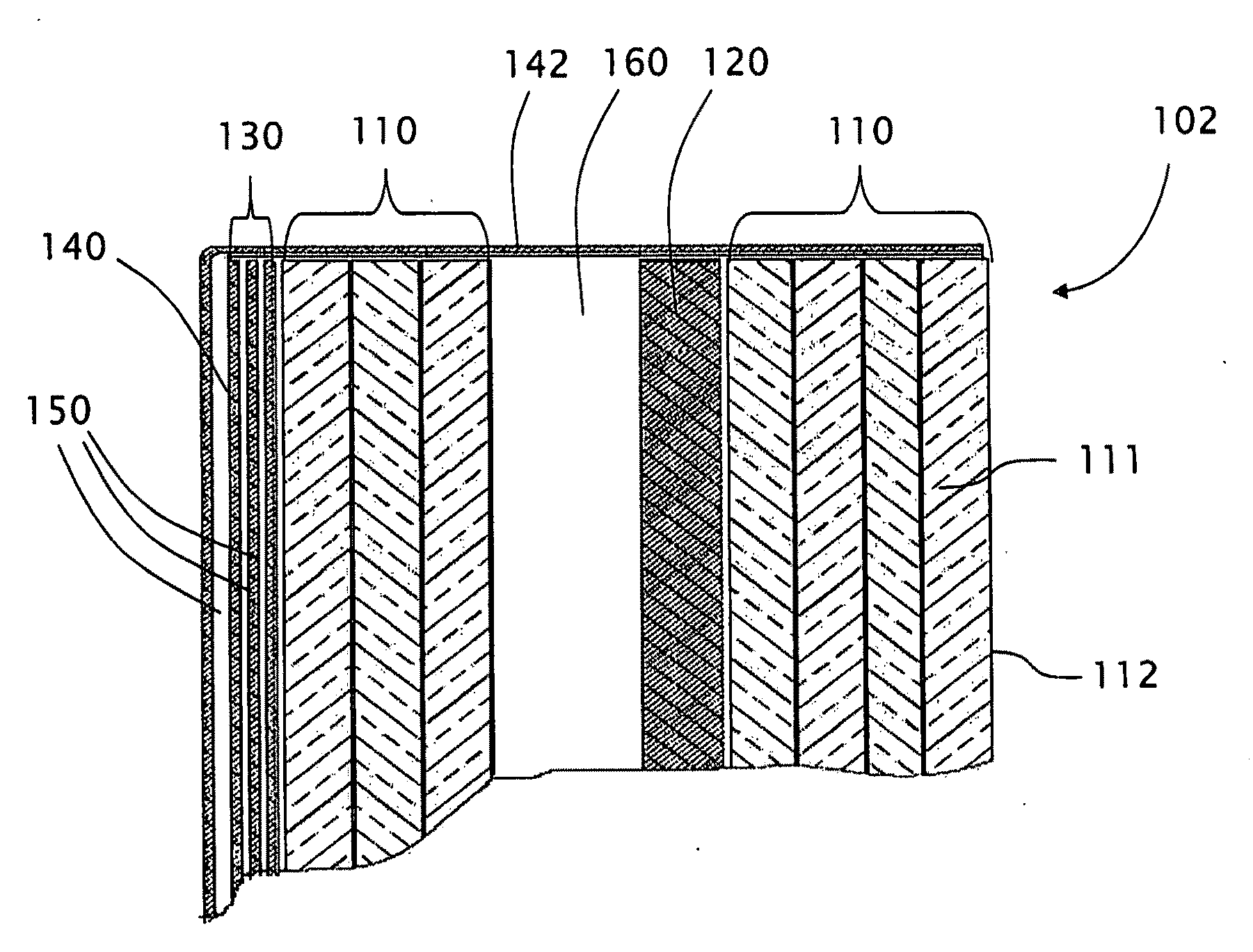

Blast and impact resistant window pane systems

InactiveUS20100024692A1Neutralize effectImprove protectionArmourConstruction materialShock waveThin layer

Window pane systems which offer improved protection against blast and impact hazards, including contact blast caused by a bomb or a shell, with or without hollow charge and bullets. A window pane system of the present invention includes multiple glass layers, to absorb the ballistic impact of the explosion; a thick polymer such as polycarbonate, to absorb the kinetic energy of the blast including contact blast; and multiple elastic thin layers of polymer such as polycarbonate, to absorb the blast impact such as the shock wave and shrapnel. Optionally, the last layer is extended such that the last layer is covering up to the full width of the window pane system, preferably in all four sides of the window pane system.

Owner:ORAN SAFETY GLASS

Digital wound detection system

InactiveUS8056391B2Vibration measurement in solidsAcceleration measurement using interia forcesBallistic impactUltra low power

Methods and devices for a miniature, ultra-low power impact recorder for detecting, quantifying and recording the energy of an explosive blast or ballistic projectile impact. In one embodiment, the impact recorder can included a sensor comprised of an array of electromechanical resonators that is sensitive to the vibrations produced in selected, discrete frequency ranges that approximate the spectral signature characteristics of the shockwave resulting from the ballistic impact event, even after traveling through impacted material or body tissues.

Owner:EMPIRE IP LLC

Transparent armor system and method of manufacture

A transparent armor system includes a hard face fabricated from a substantially transparent glass-ceramic material exhibiting crystalline bodies throughout the mass of the glass-ceramic material and a backing covering a rear surface of the hard face opposite an anticipated incoming projectile. The backing has a refractive index substantially matching that of the hard face such as to allow substantial transparency of the transparent armor system. In certain embodiments, a bonding layer is provided to bond the backing to the hard face. The hard face serves to disburse energy caused by the impact of an incoming projectile with the transparent armor system, while the backing serves to retain any pieces of the hard face fractured during ballistic impact.

Owner:SCHOTT DIAMOND OBSERVATION ARMOR PROD LLC

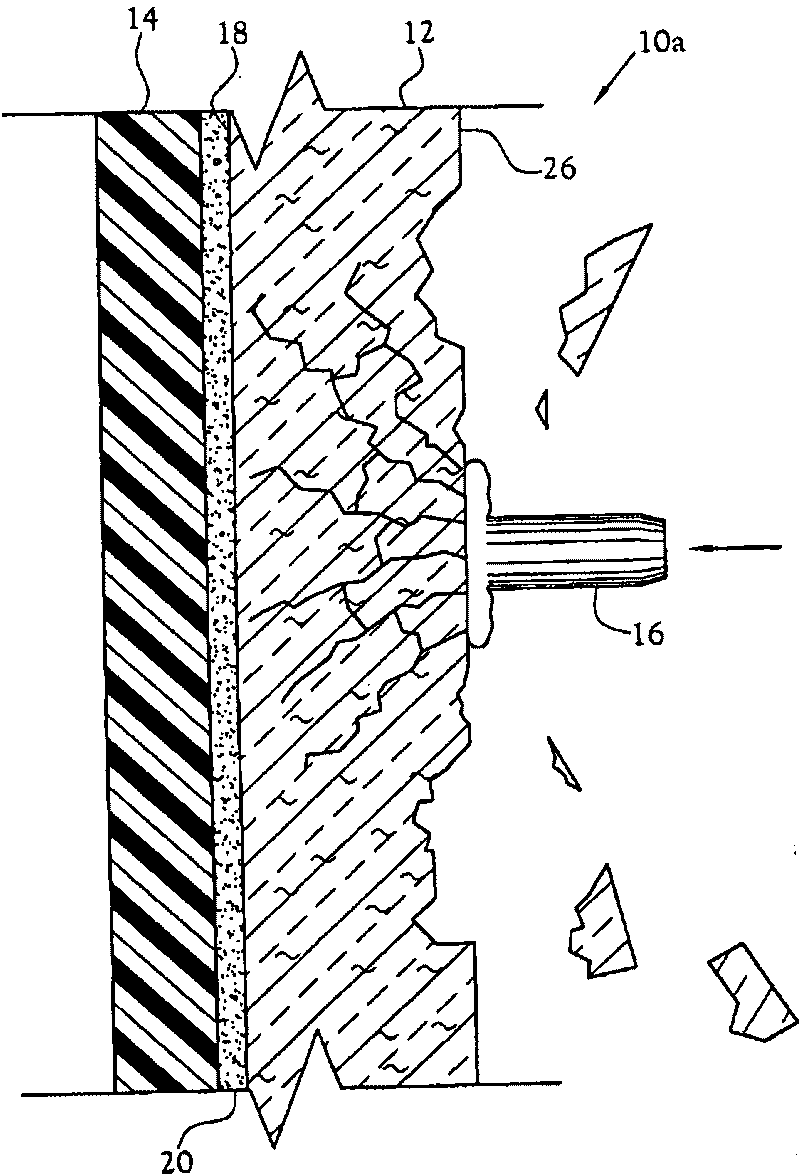

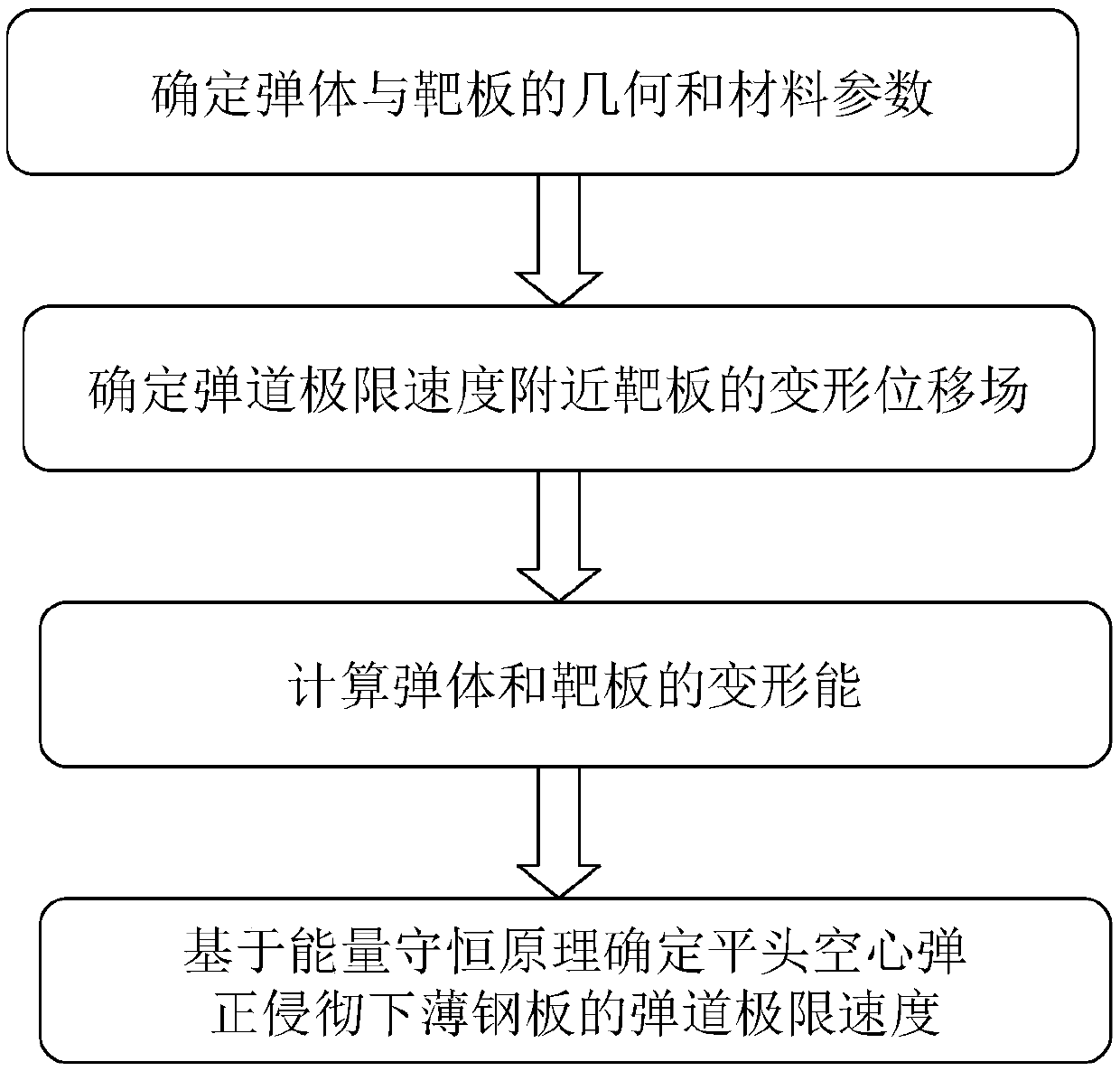

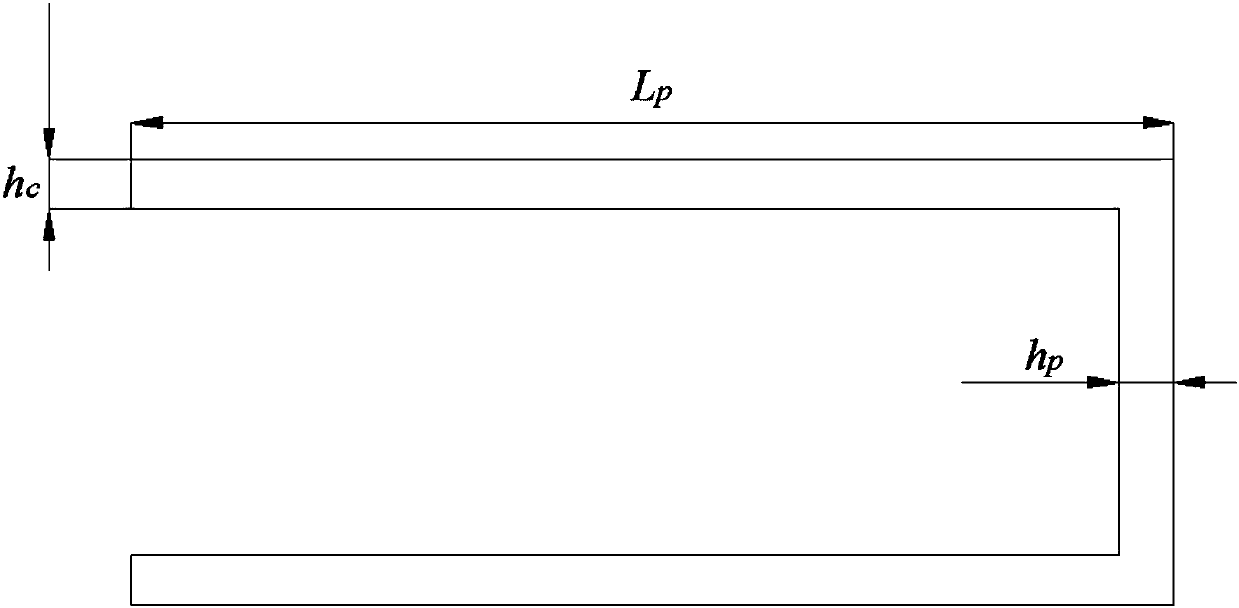

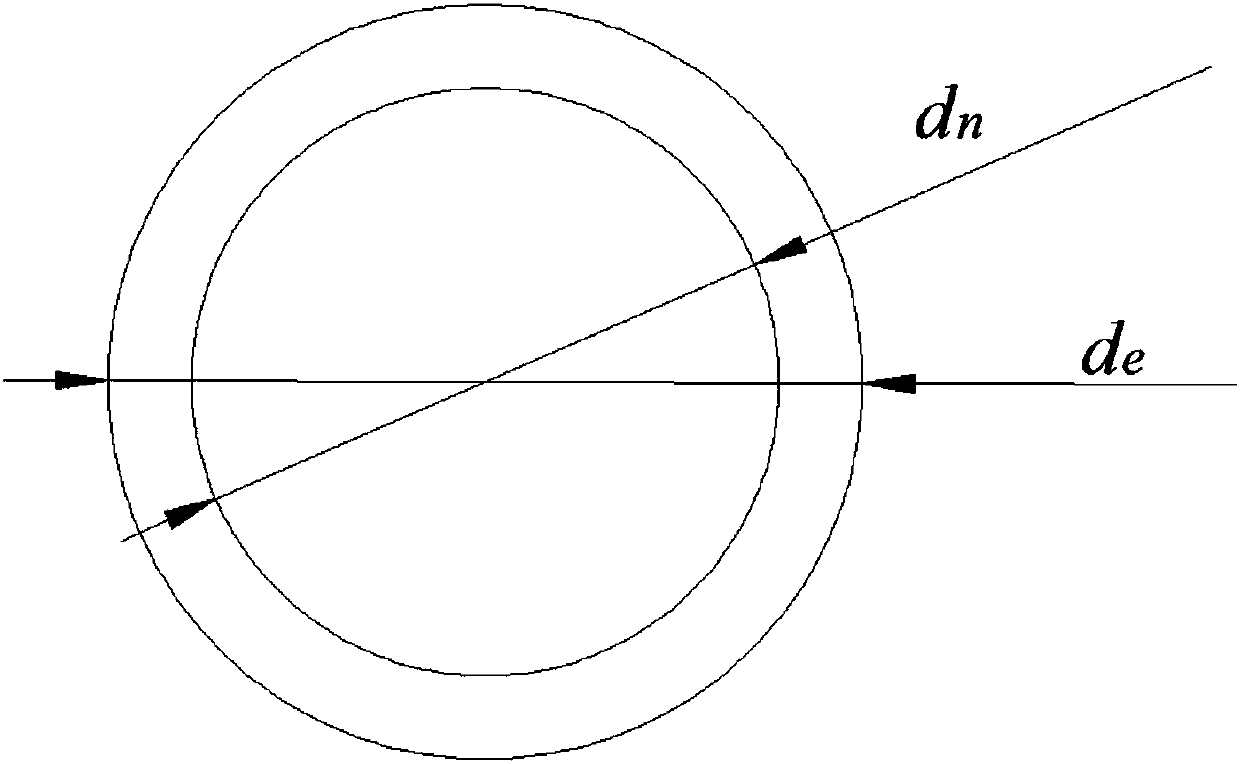

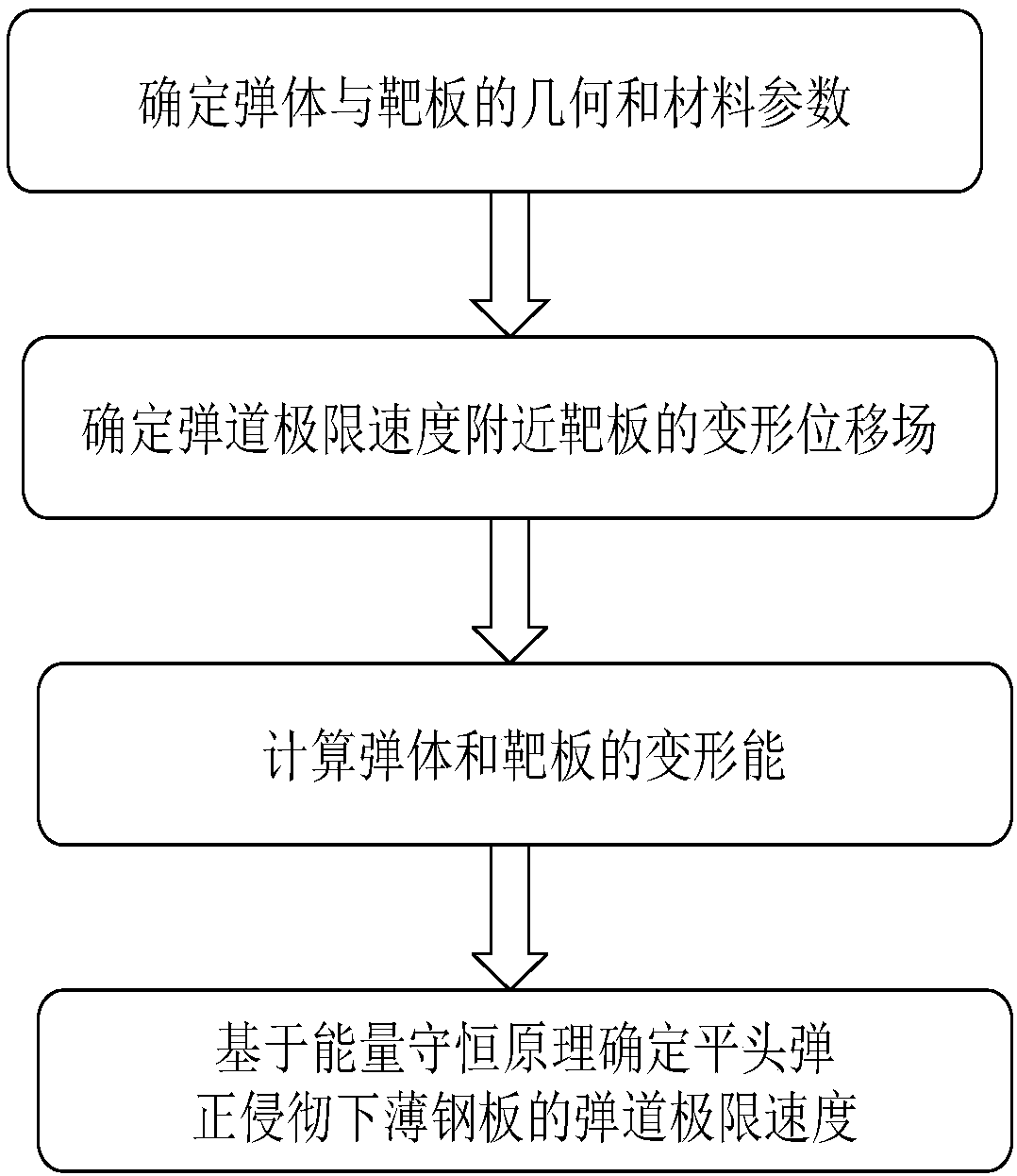

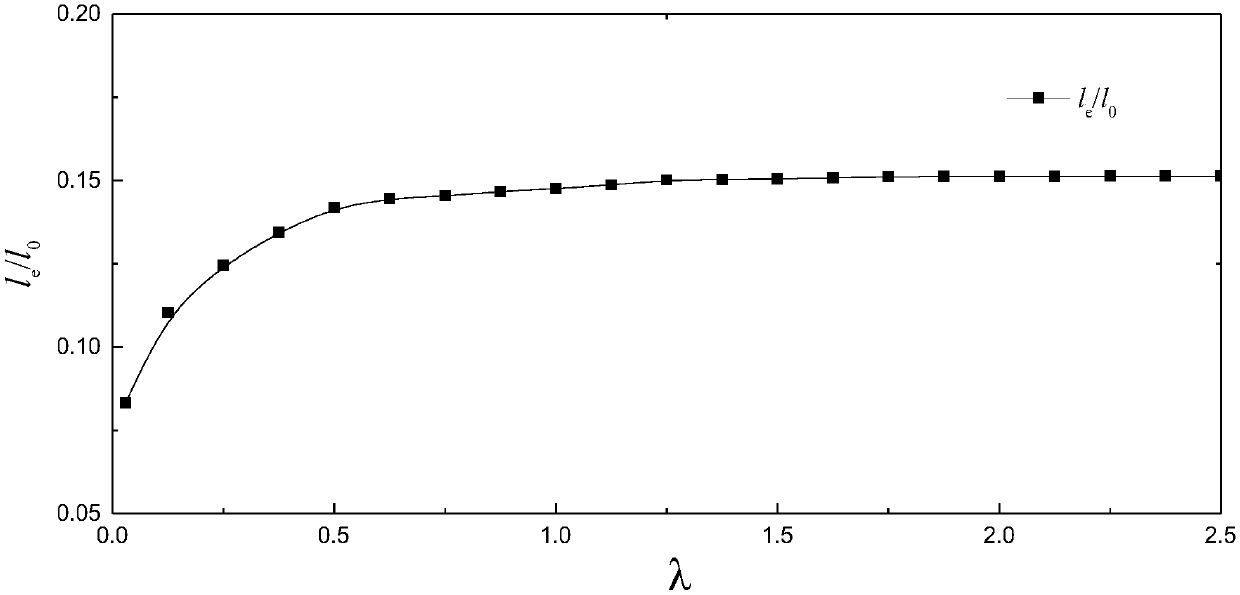

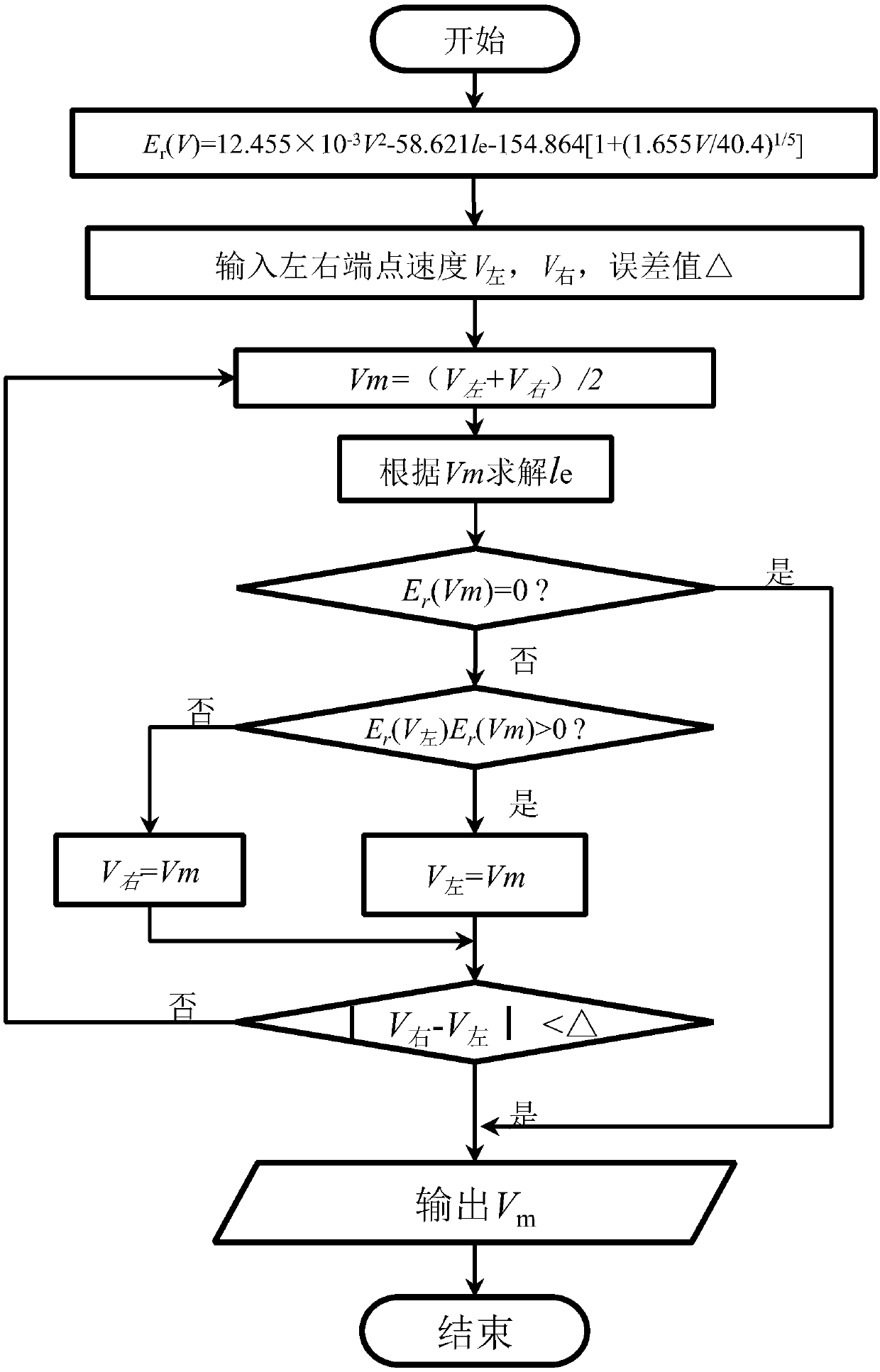

Calculation method for ballistic limit velocity of thin steel plate under vertical penetration of flat-nose hollow projectile at low velocity

ActiveCN107742006AEffective blockingConvenient and reliable referenceDesign optimisation/simulationSpecial data processing applicationsLow speedNose

The invention relates to a calculation method for ballistic limit velocity of a thin steel plate under vertical penetration of a flat-nose hollow projectile at low velocity. According to specific conditions of a warhead and a protection structure, geometric sizes and material parameters of a flat-nose hollow projectile body and a target plate are determined; a deformation displacement field of thetarget plate near the ballistic limit velocity is determined; deformation energies of the projectile body and the target plate are calculated based on deformation and destruction characteristics of the projectile body and the target plate wherein the deformation energies of the projectile body and target plate comprise plastic deformation energy and sheer plug energy of the projectile body and plastic deformation energy of the target plate, the plastic deformation energy of the projectile body comprises the energies consumed in upsetting deformation and inner concave deformation of the hollowpart; the ballistic limit velocity of a thin steel plate under vertical penetration of the flat-nose projectile at low velocity is determined based on the energy conservation principle. The ballisticlimit velocity of the target plate is effectively predicted by the method so as to determine that whether or not the target plate can be penetrated by the flat-nose hollow projectile body or the projectile body can be blocked by the target plate, and the method can also provide an effective reference for a ballistic impact test or a numerical simulation method so as to reduce the number of testsor simulation calculation time.

Owner:NAVAL UNIV OF ENG PLA

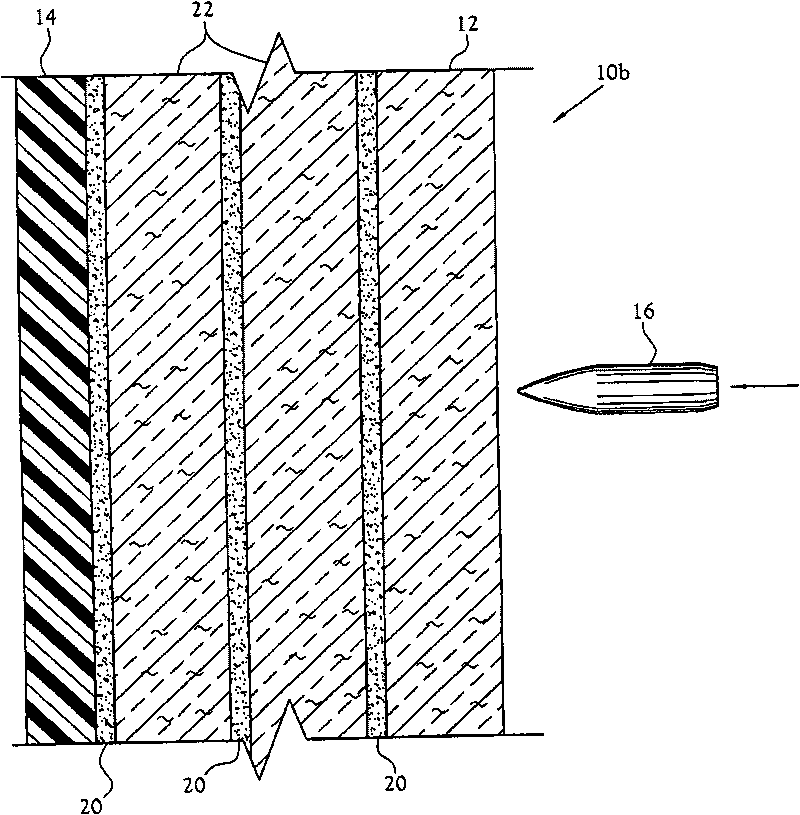

Calculation method for ballistic limit velocity of thin steel plate under vertical penetration of flat-nose projectile at low velocity

ActiveCN107742007AEffective blockingConvenient and reliable referenceDesign optimisation/simulationSpecial data processing applicationsLow speedNose

The invention relates to a calculation method for ballistic limit velocity of a thin steel plate under vertical penetration of a flat-nose projectile at low velocity. According to specific conditionsof a warhead and a protection structure, geometric sizes and material parameters of a projectile body and a target plate are determined; a deformation displacement field of the target plate near the ballistic limit velocity is determined; deformation energies of the projectile body and the target plate are calculated based on deformation and destruction characteristics of the projectile body and the target plate, wherein the deformation energies of the projectile body and target plate comprise plastic deformation energy and sheer plug energy of the projectile body and plastic deformation energy of the target plate, the plastic deformation energy of the projectile body is mainly the energy consumed in upsetting deformation of the projectile body; the ballistic limit velocity of a thin steelplate under vertical penetration of the flat-nose projectile at low velocity is determined based on the energy conservation principle. The ballistic limit velocity of the target plate is effectivelypredicted by the method so as to determine that whether or not the target plate can be penetrated by the projectile body or the projectile body can be blocked by the target plate, and the method can also provide an effective reference for a ballistic impact test or a numerical simulation method so as to reduce the number of tests or simulation calculation time.

Owner:NAVAL UNIV OF ENG PLA

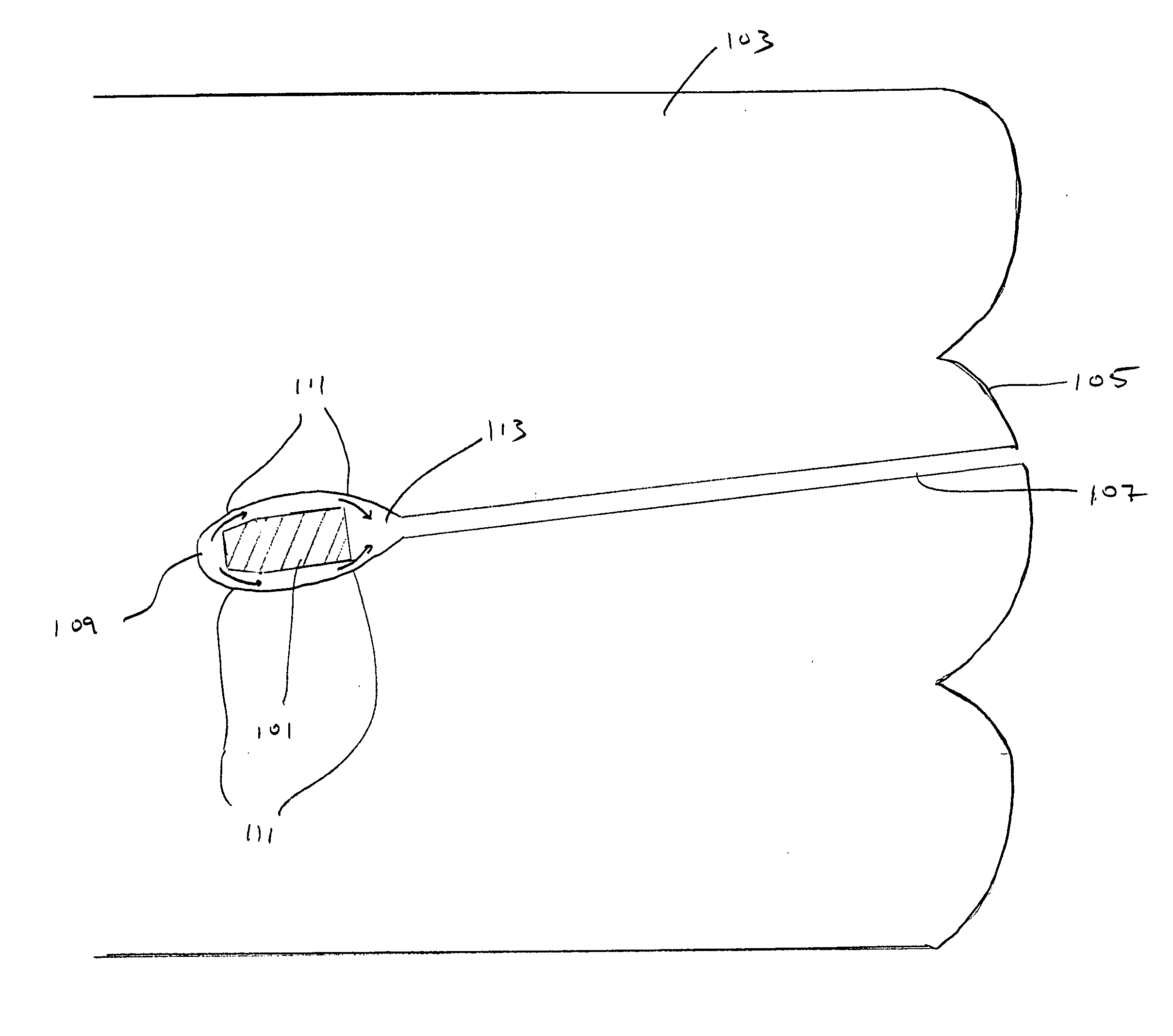

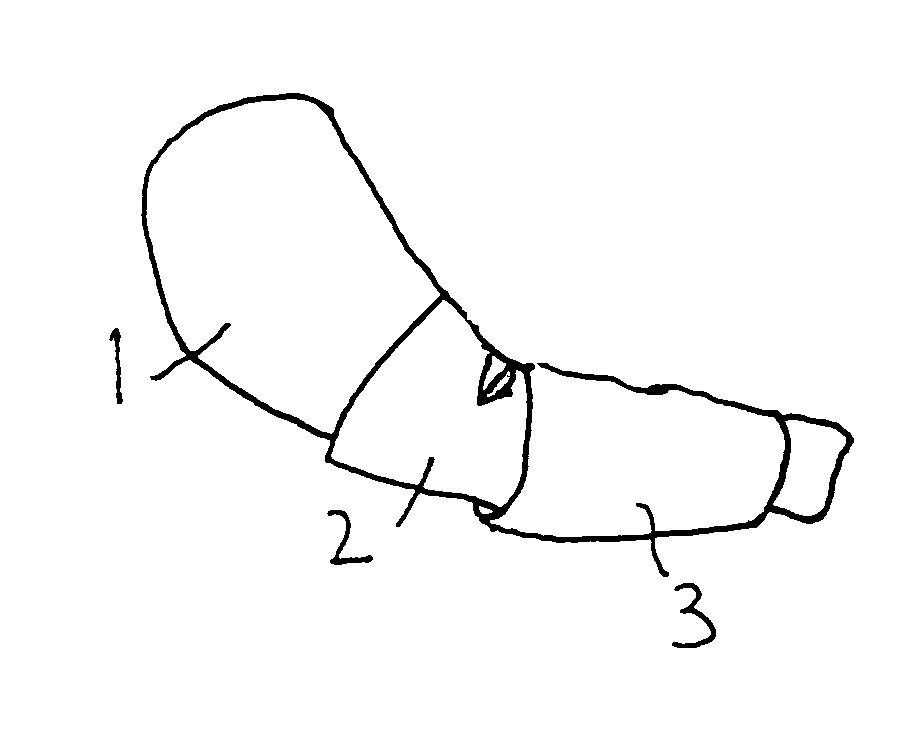

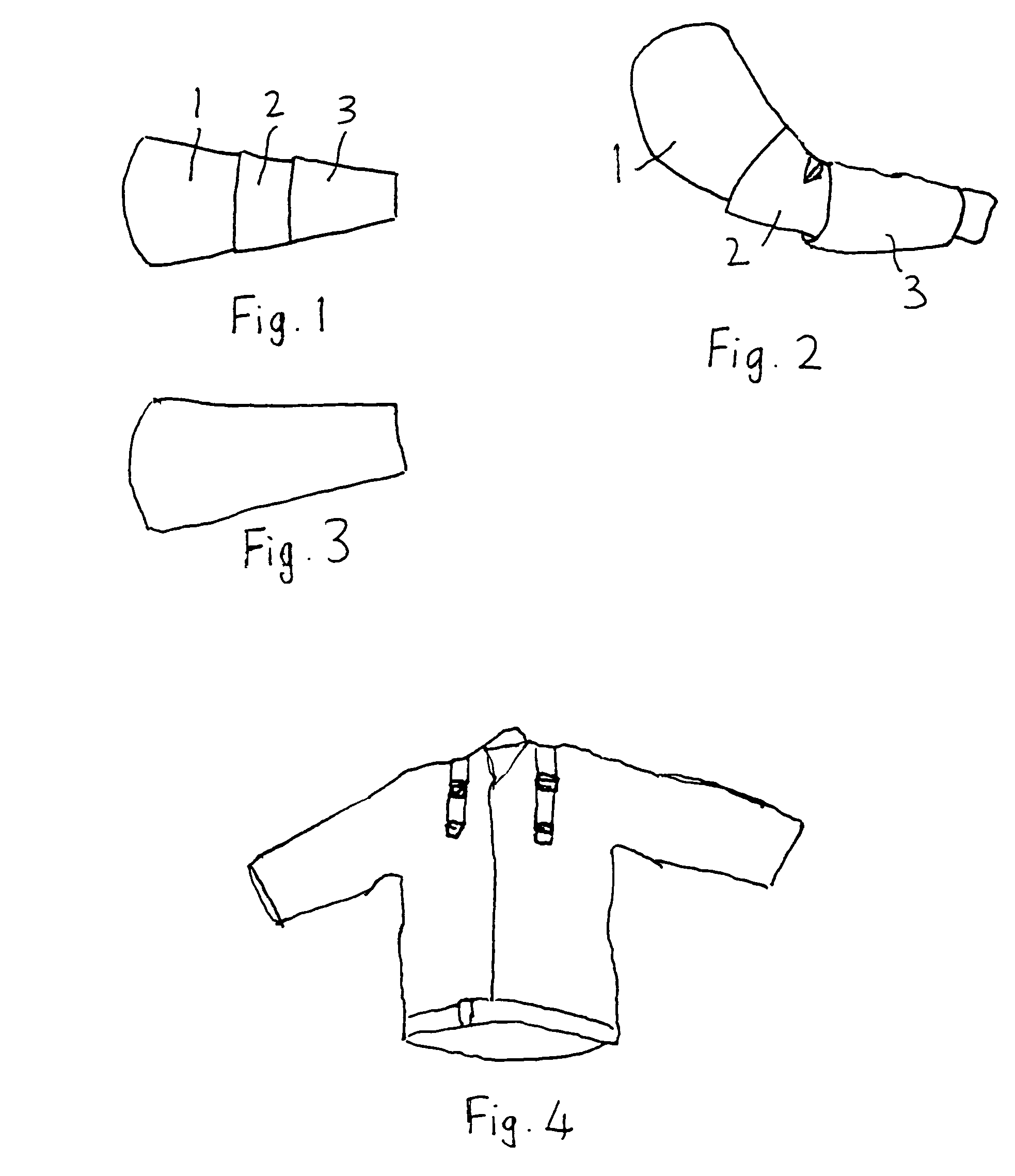

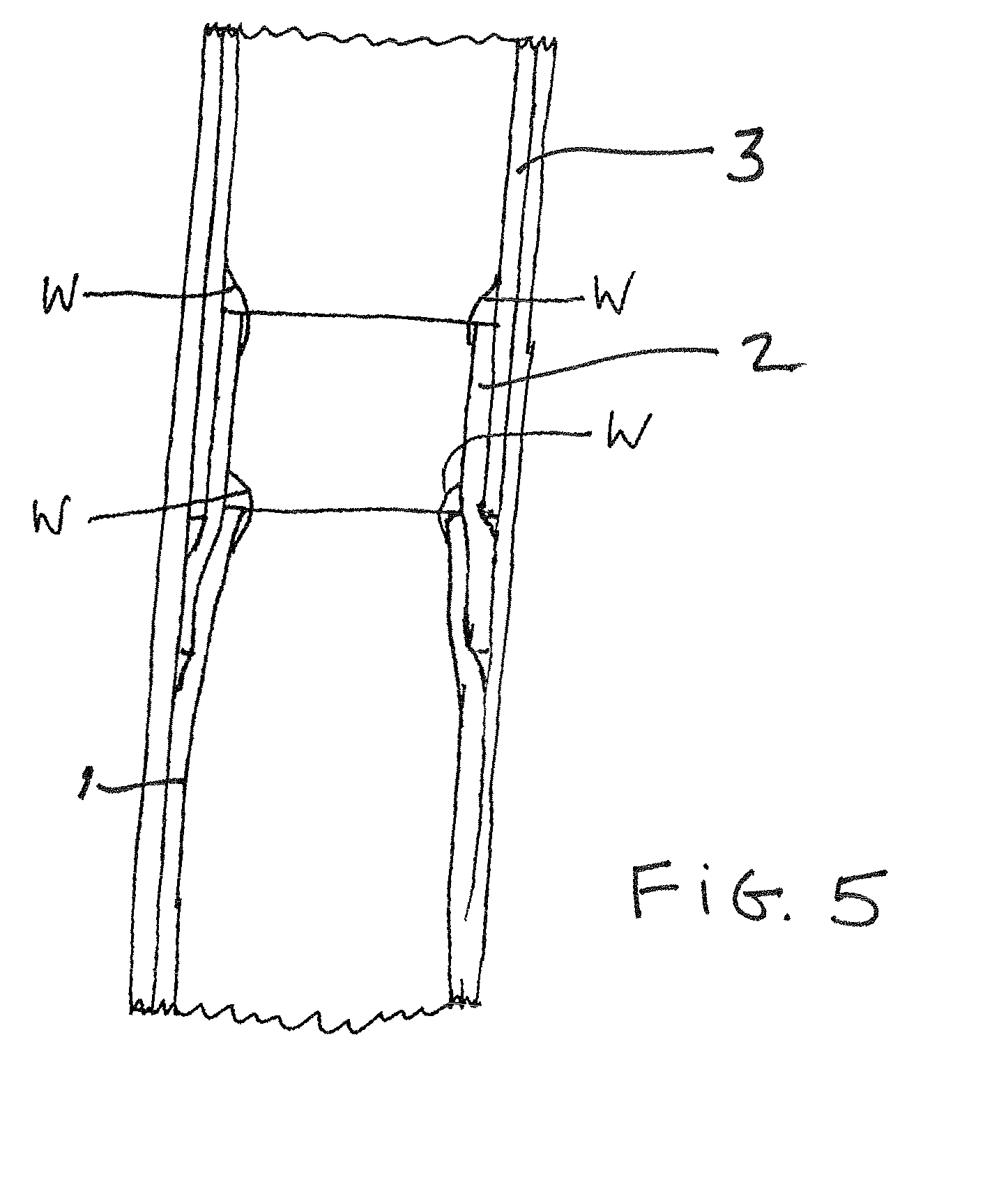

Protective garments

ActiveUS8479313B2Increase flexibilityEye treatmentPersonal protection gearBallistic impactBody armor

A garment, such a jacket or pair of pants, affords protection from ballistic impacts. The garment comprises at least two tubular sections of strong fabric, the sections overlapping such that said sections can telescope to allow flexing of a body part enclosed thereby without exposing any part of the body part. A set of protective clothing comprises the ballistic protective garment and an outer garment of heat and blast protective material.

Owner:NP AEROSPACE

Glass-ceramic with laminates

A transparent armor system includes a hard face fabricated from a substantially transparent glass-ceramic material exhibiting crystalline bodies throughout the mass of the glass-ceramic material and a backing covering a rear surface of the hard face opposite an anticipated incoming projectile. The backing has a refractive index substantially matching that of the hard face such as to allow substantial transparency of the transparent armor system. The hard face serves to disburse energy caused by the impact of an incoming projectile with the transparent armor system, while the backing serves to retain any pieces of the hard face fractured during ballistic impact. In certain embodiments, a plurality of hard faces are held in parallel and spaced apart arrangement.

Owner:ORAN SAFETY GLASS INC

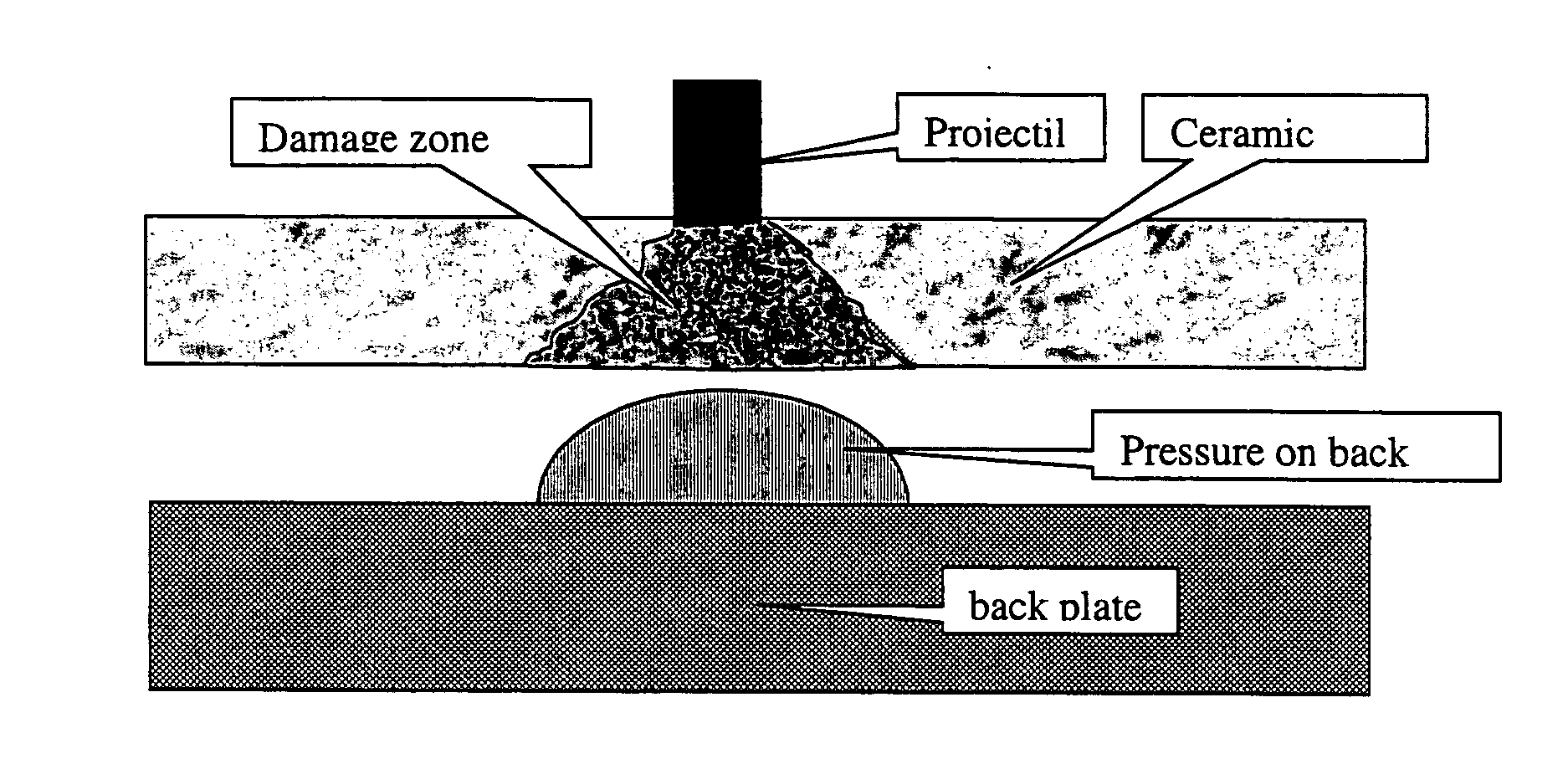

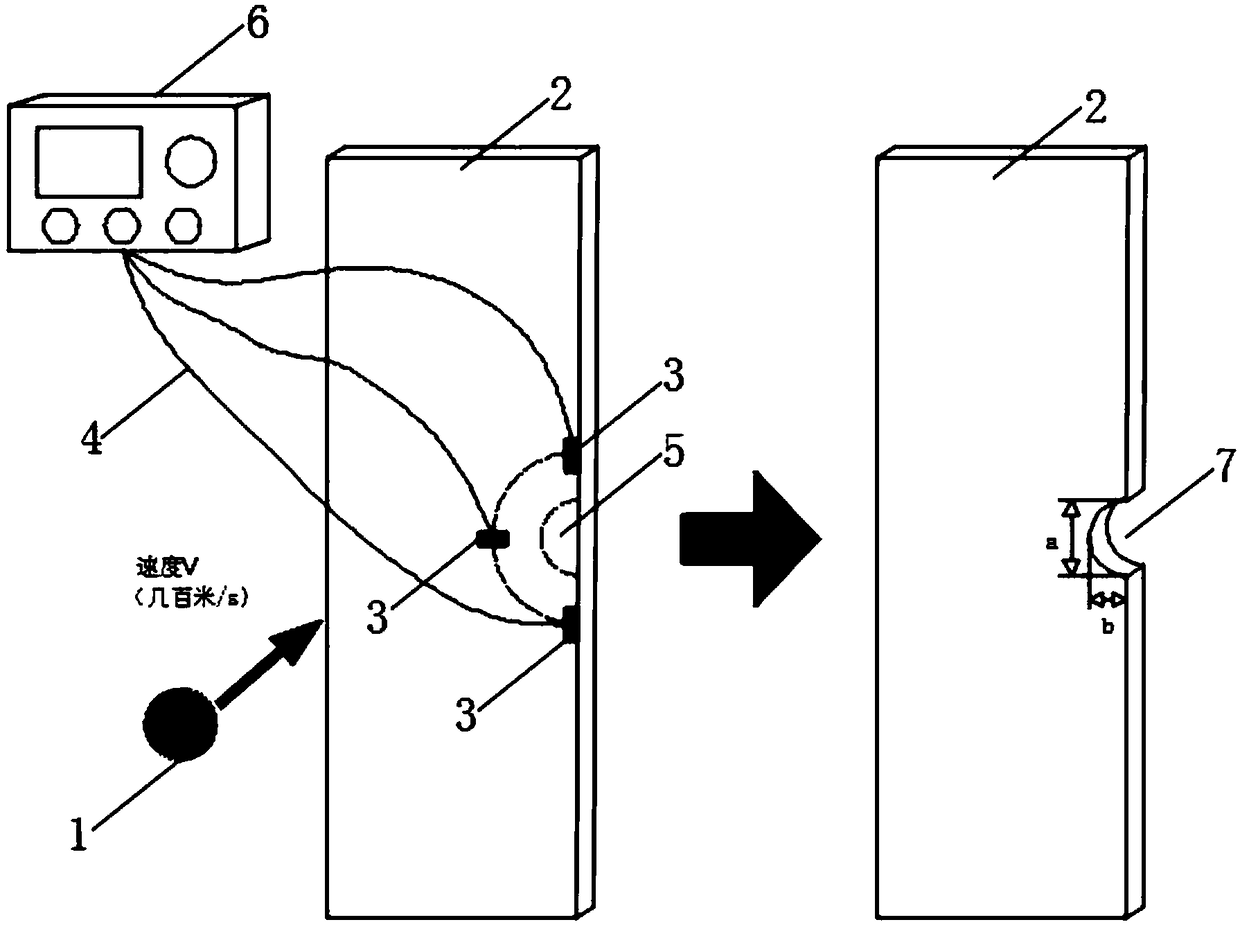

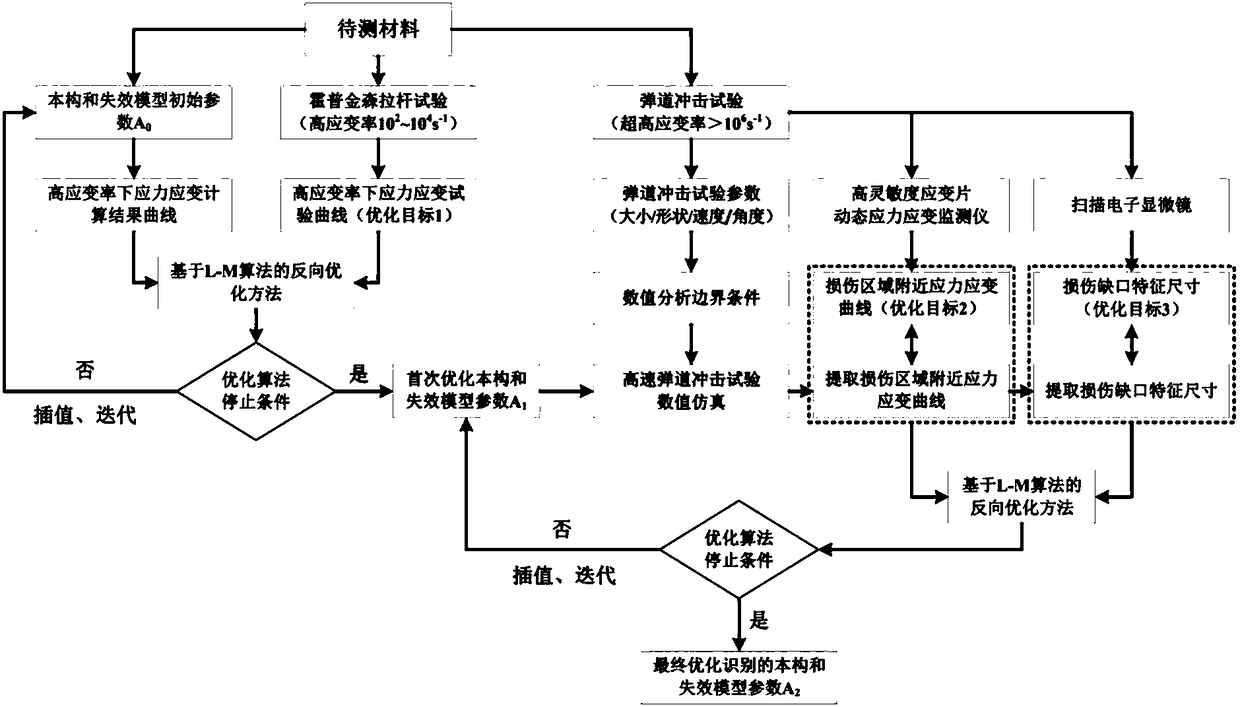

Parameter identification method for constitution and failure model of material under ultra-high strain rate

InactiveCN108169040AAddressing the lack of experimental dataAccurate Kinetic Response Behavior CharacterizationStrength propertiesEngineeringModel parameters

The invention discloses a parameter identification method for a constitution and failure model of a material under an ultra-high strain rate. A dynamic stress-strain curve of the deformation and failure process of the material under a high strain rate is obtained through Hopkinson pull rod test, and the dynamic stress-strain curve of the material under the high strain rate is used as a target forreverse optimization fitting to obtain parameters of the constitution and failure model after the first optimization are obtained; a light gas gun system is used to perform high-speed ballistic impacttests on the material, a high-sensitivity strain gauge is used to monitor the dynamic stress-strain curve of the material near a damage zone, and the feature size of a damage notch can be measured bya scanning electron microscopy; ballistic impact test parameters are used as boundary conditions for ballistic impact numerical simulation, and the dynamic stress-strain curve of the material corresponding to the position of the high-sensitivity strain gauge and the feature size of the damage notch can be extracted; the actually tested dynamic stress-strain curve of the material and the actuallytested feature size of the damage notch are used as targets for reverse optimization fitting to finally obtain the parameters of the constitution and failure model of the material under the ultra-highstrain rate.

Owner:AIR FORCE UNIV PLA

Multi-functional protective assemblies, systems including protective assemblies, and related methods

A protective assembly comprises a first region formulated and configured to provide protection from alpha, beta, and electromagnetic radiation and comprising a composite of particles and polymer; a second region formulated and configured to provide protection from ballistic impact and comprising a composite of fibers and polymer; and a third region formulated and configured to provide protection from thermal radiation and comprising a composite of particles, fiber, and polymer. The protective assembly may be provided on an aerospace structure. The protective assembly may be formed on the aerospace structure body using a co-curing process.

Owner:NORTHROP GRUMMAN SYST CORP

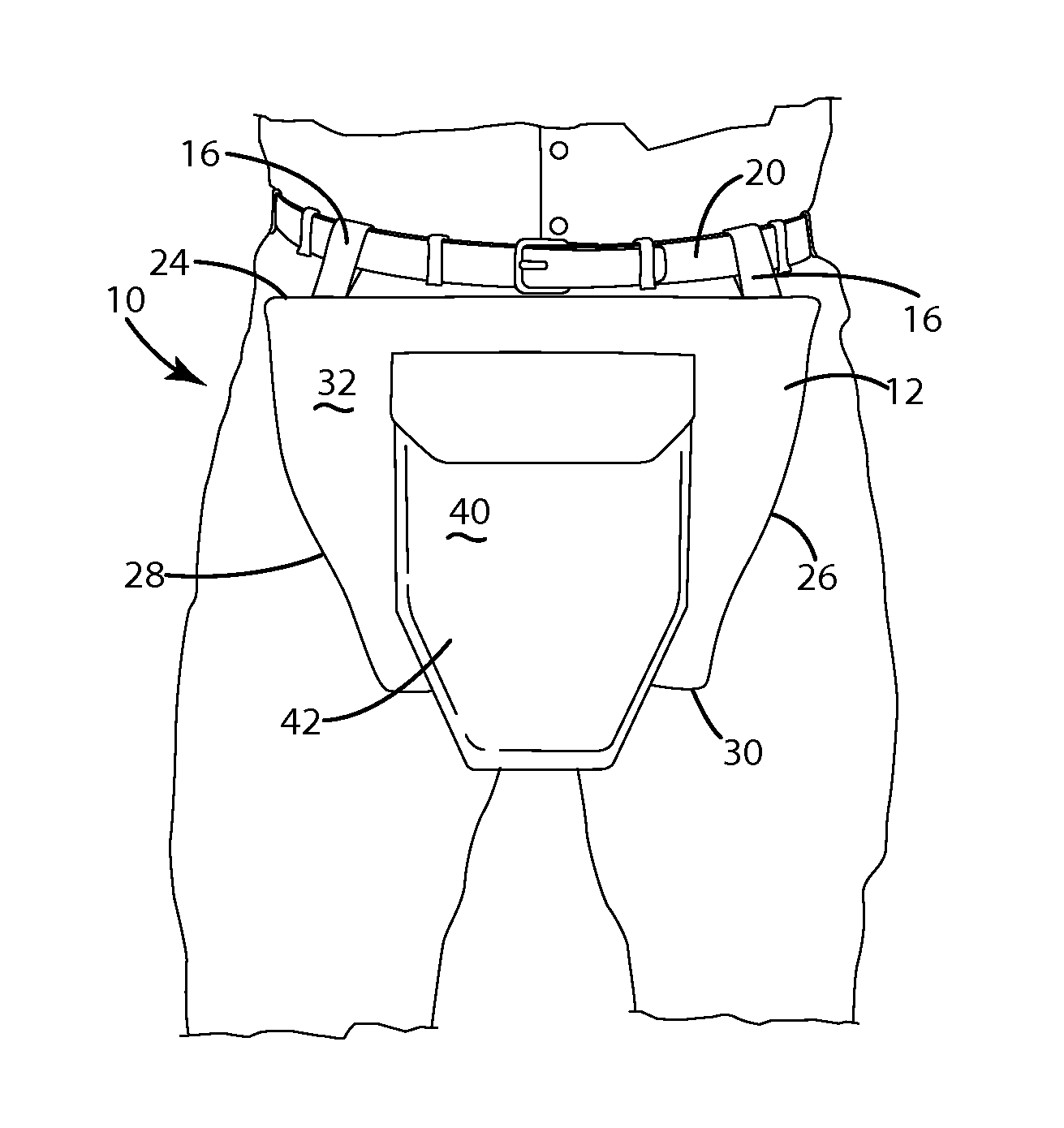

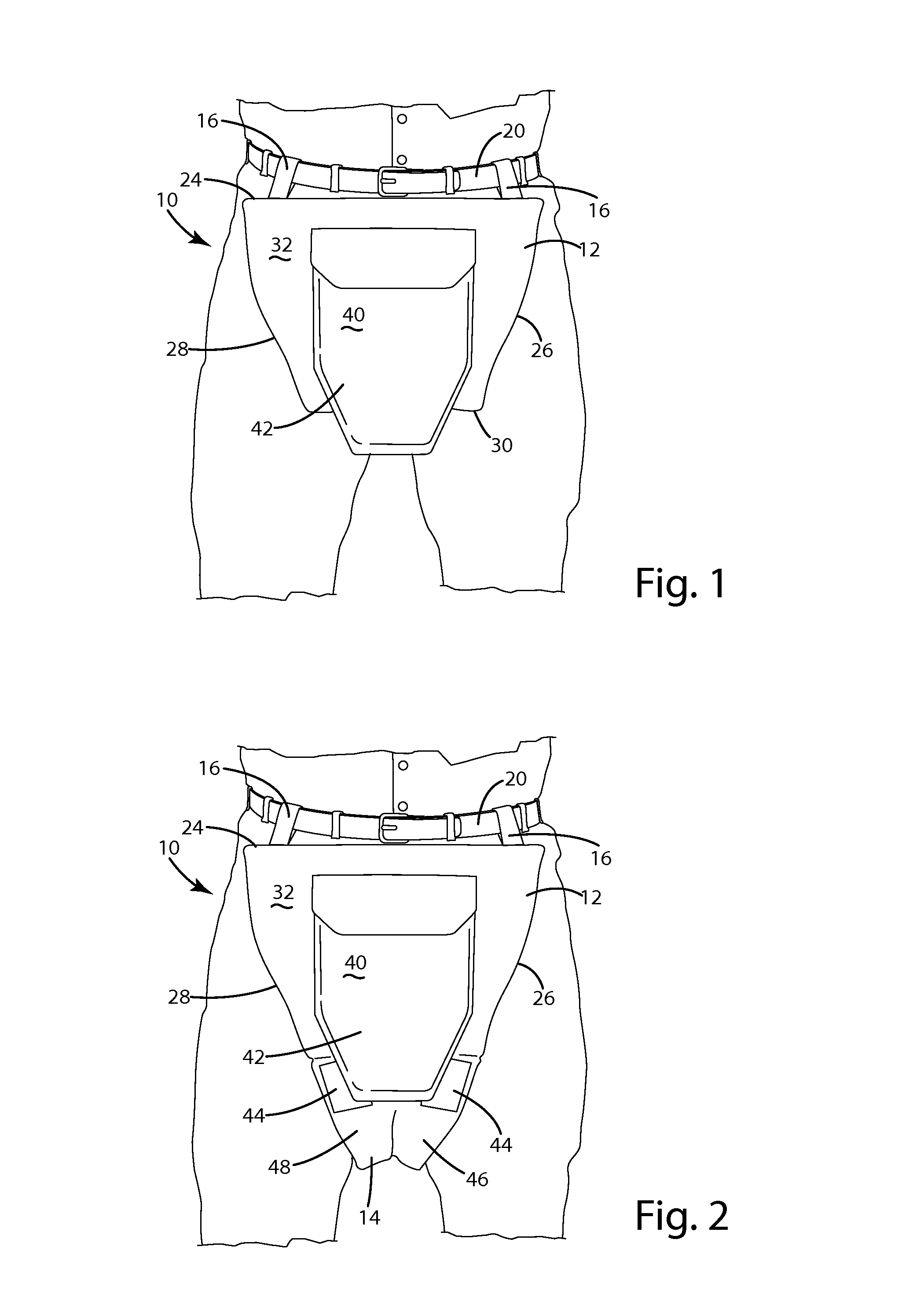

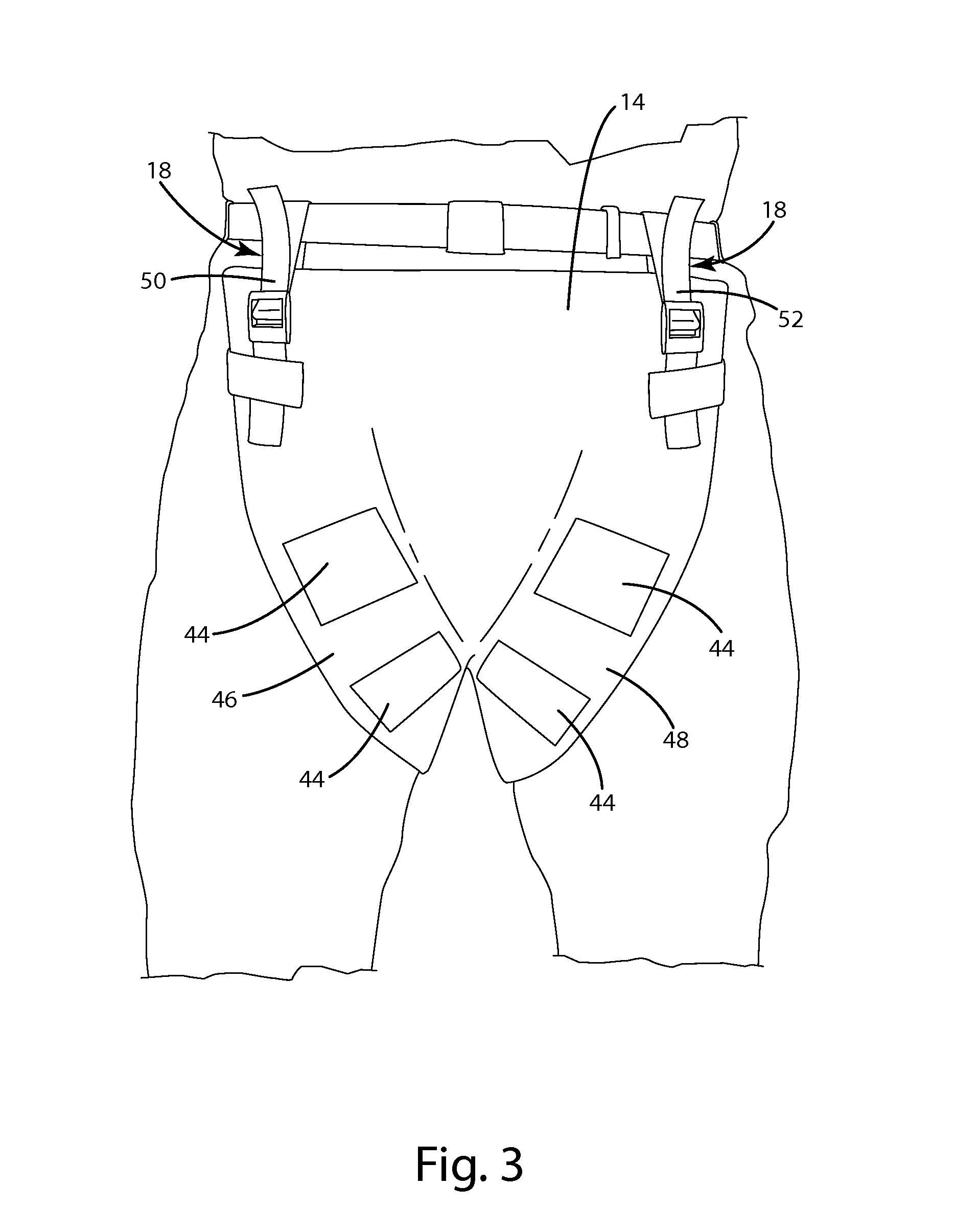

Ballistic resistant groin protector

ActiveUS20130074251A1Improve protectionProtect from harmPersonal protection gearProtective garmentThighPelvis

A ballistic resistant groin protector is provided. The groin protector includes a groin panel and a deployable groin wrap. The groin panel can be suspended from clothing or equipment to protect a wearer's anterior pelvic region from ballistic impact. The groin wrap is moveable from a stowed position adjacent the anterior pelvic region to a deployed position between the wearer's legs and adjacent a posterior pelvic region. One or more fasteners secure the groin wrap to the wearer's clothing or equipment to maintain the groin wrap in the deployed position. Optional left and right femoral protective portions extend downwardly from the groin wrap to protect the wearer's medial thigh regions against ballistic injury in the deployed position.

Owner:LINEWEIGHT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com