Transparent armor system and method of manufacture

一种装甲、透明的技术,应用在装甲、装甲板的结构、化学仪器和方法等方向,能够解决剥离、透明装甲变色等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

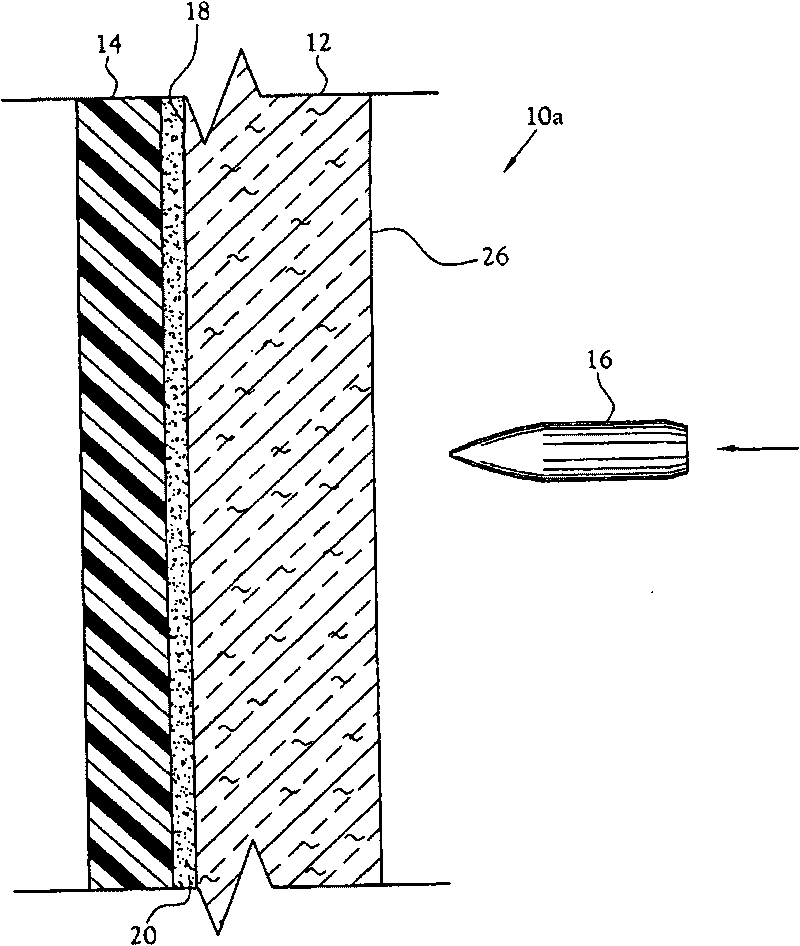

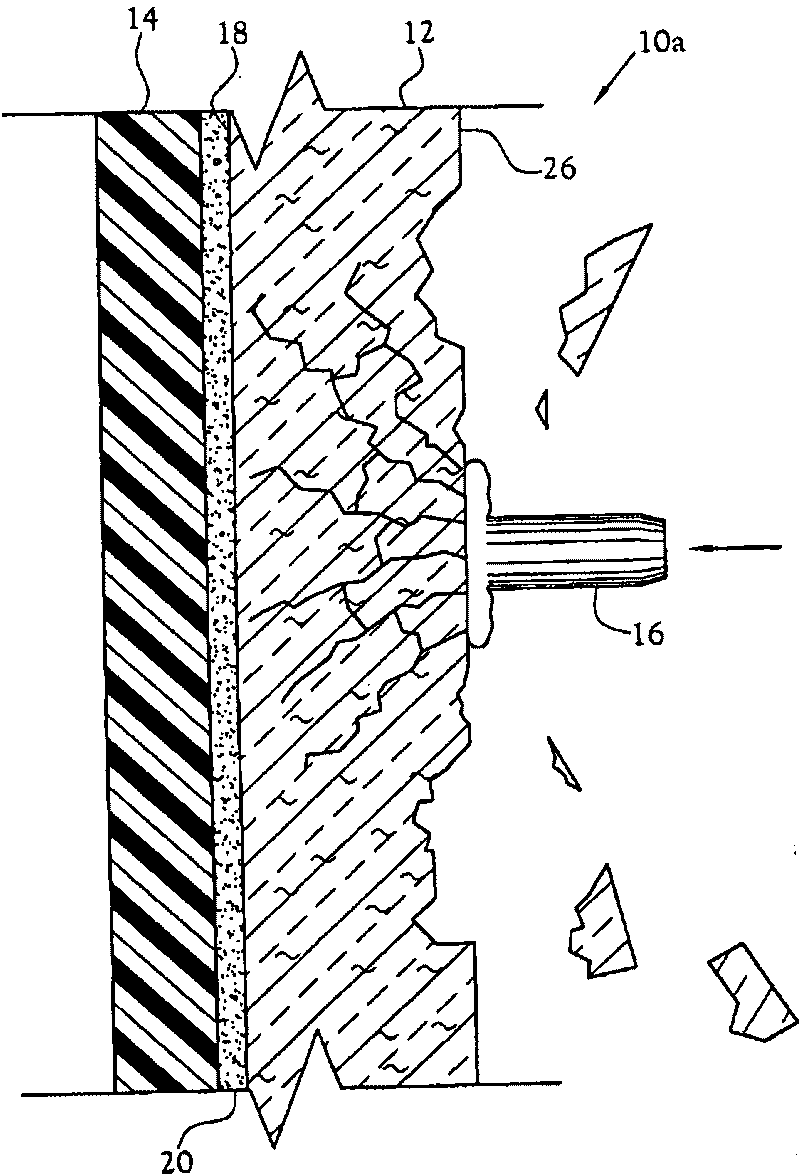

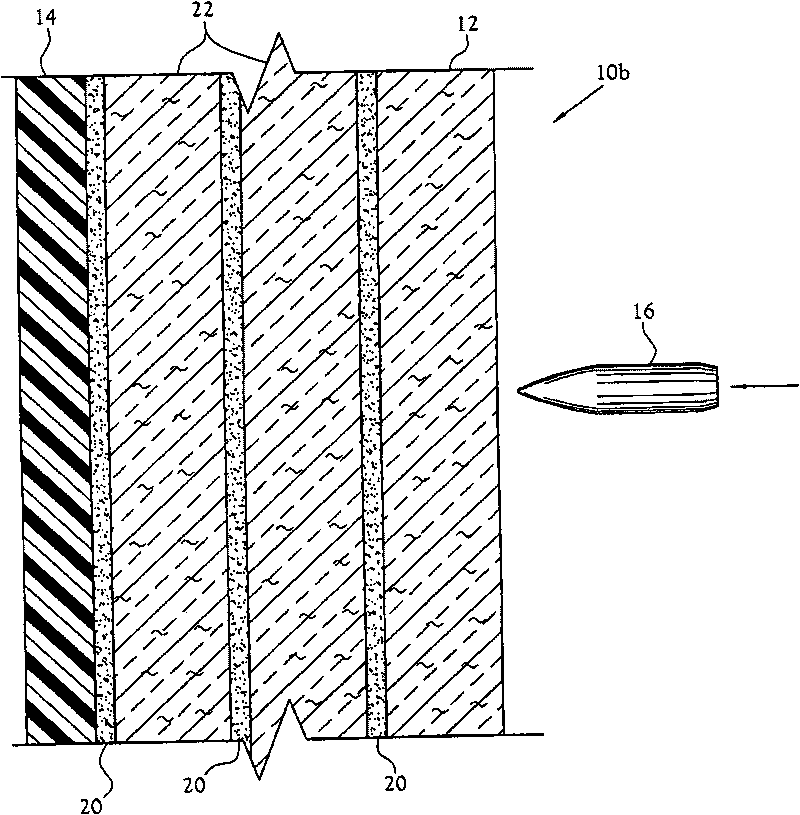

[0021] Disclosed herein is a transparent armor system for limiting the transmission of projectile impact forces and a corresponding method of manufacture. The transparent armor system is indicated generally at 10 in the Figures. refer to figure 1 , one embodiment of a transparent armor system 10a includes a hard layer 12 and a back layer 14 covering a rear surface 18 of the hard layer 12 that faces away from an incoming projectile 16 in anticipation.

[0022] The hard layer 12 is formed by a layer of glass-ceramic material having a hardness and compressive strength sufficient to substantially absorb at least a portion of the impact of an incoming projectile 16 . The hard layer 12 is formed with a front surface 26 configured to face the incoming projectile 16 and a rear surface 18 configured to face away from the incoming projectile 16 . It should be understood that the particular type of glass-ceramic material suitable for use in hard layer 12 depends on the mass, velocity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com