Patents

Literature

254 results about "Explosive force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Explosive force is released in a direction perpendicular to the surface of the explosive. If a grenade is in mid air during the explosion, the direction of the blast will be 360°. In contrast, in a shaped charge the explosive forces are focused to produce a greater local effect.

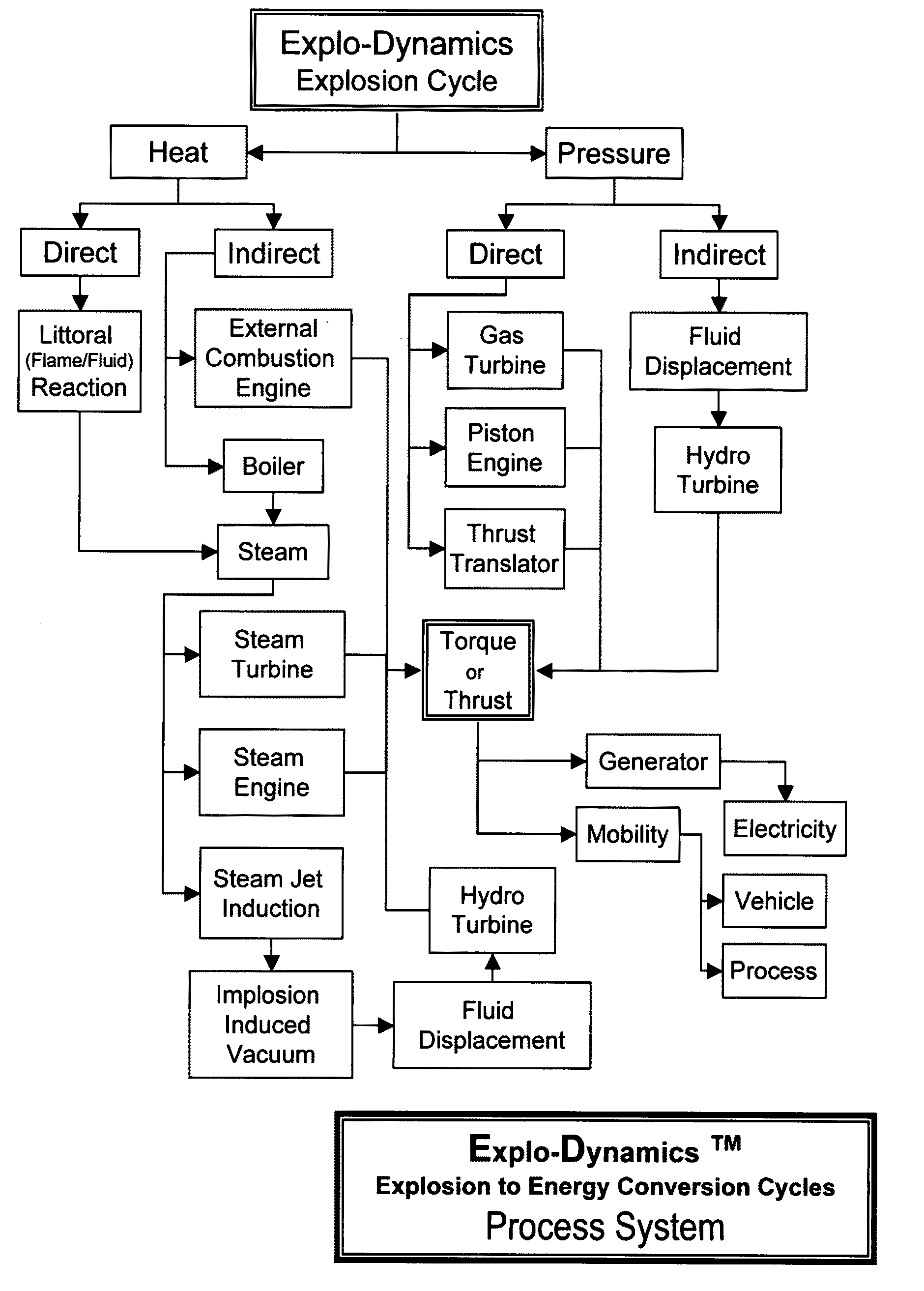

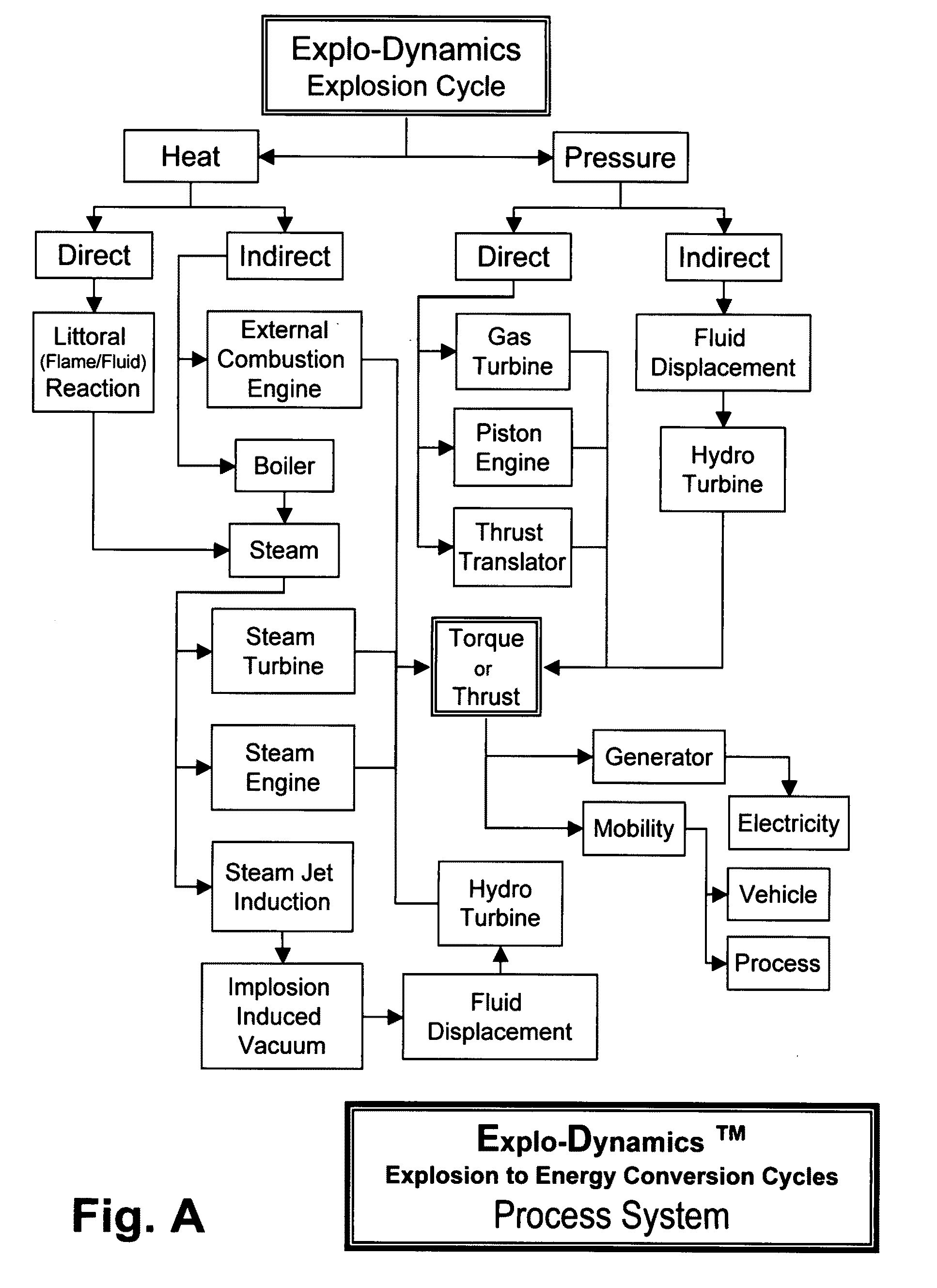

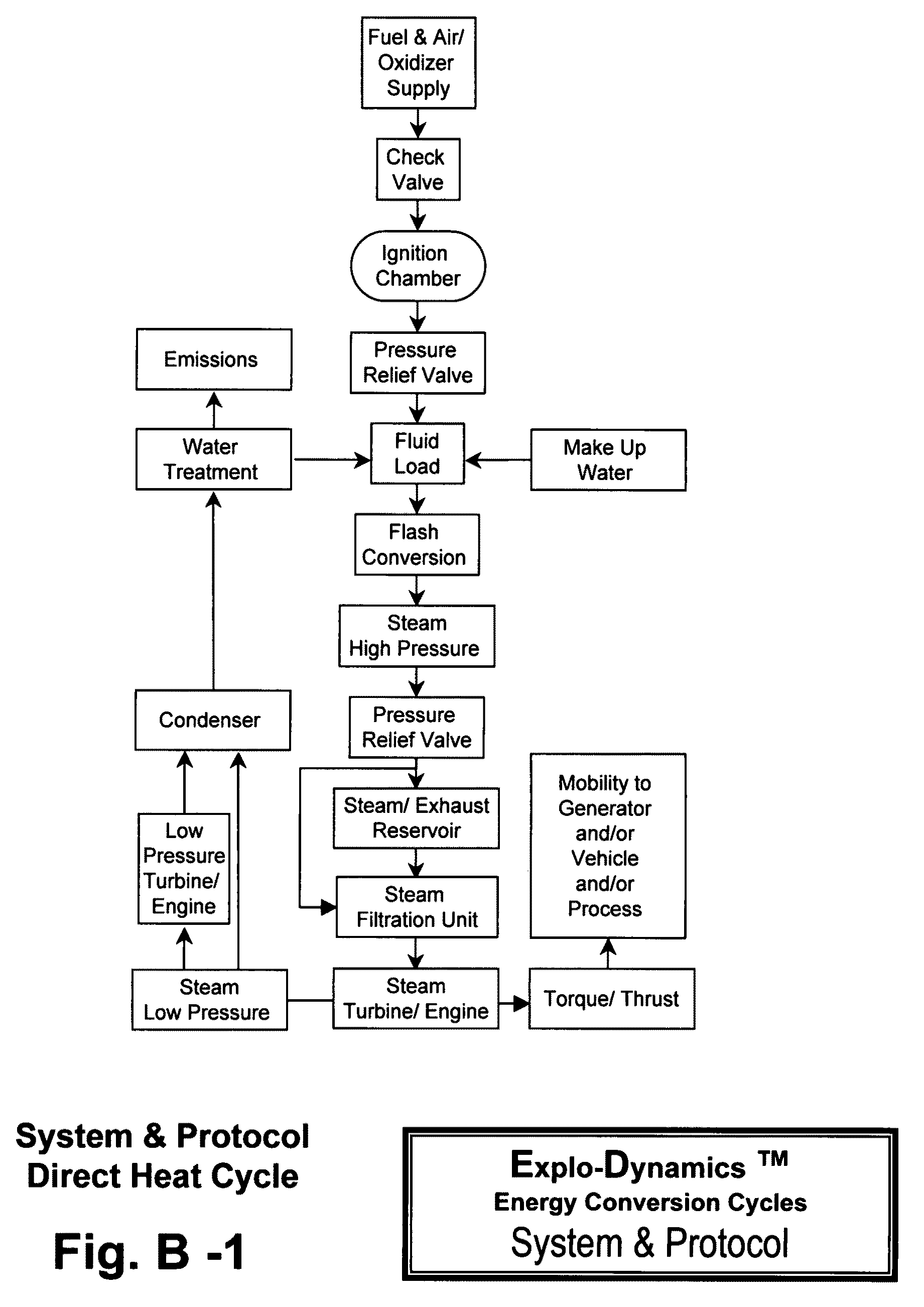

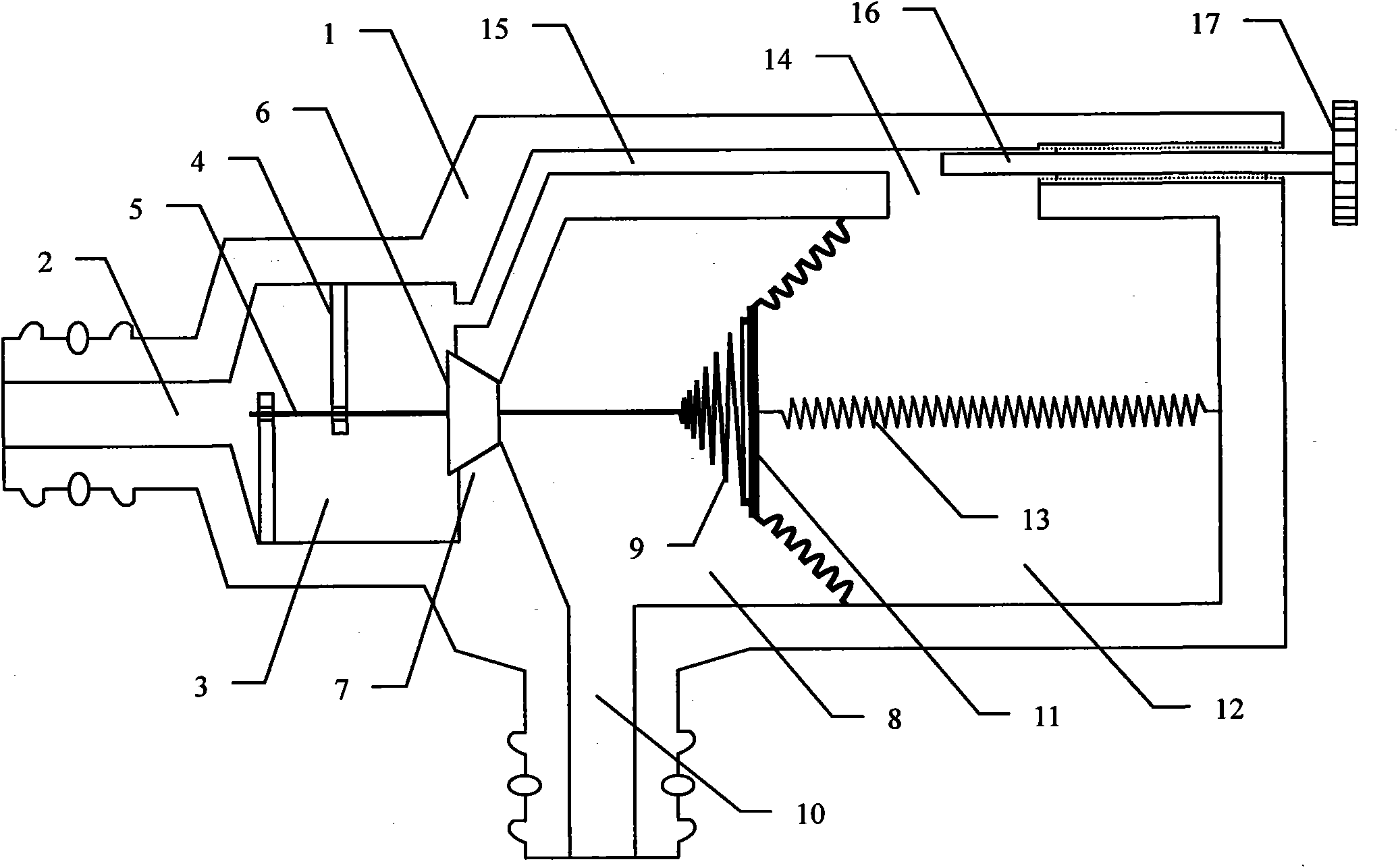

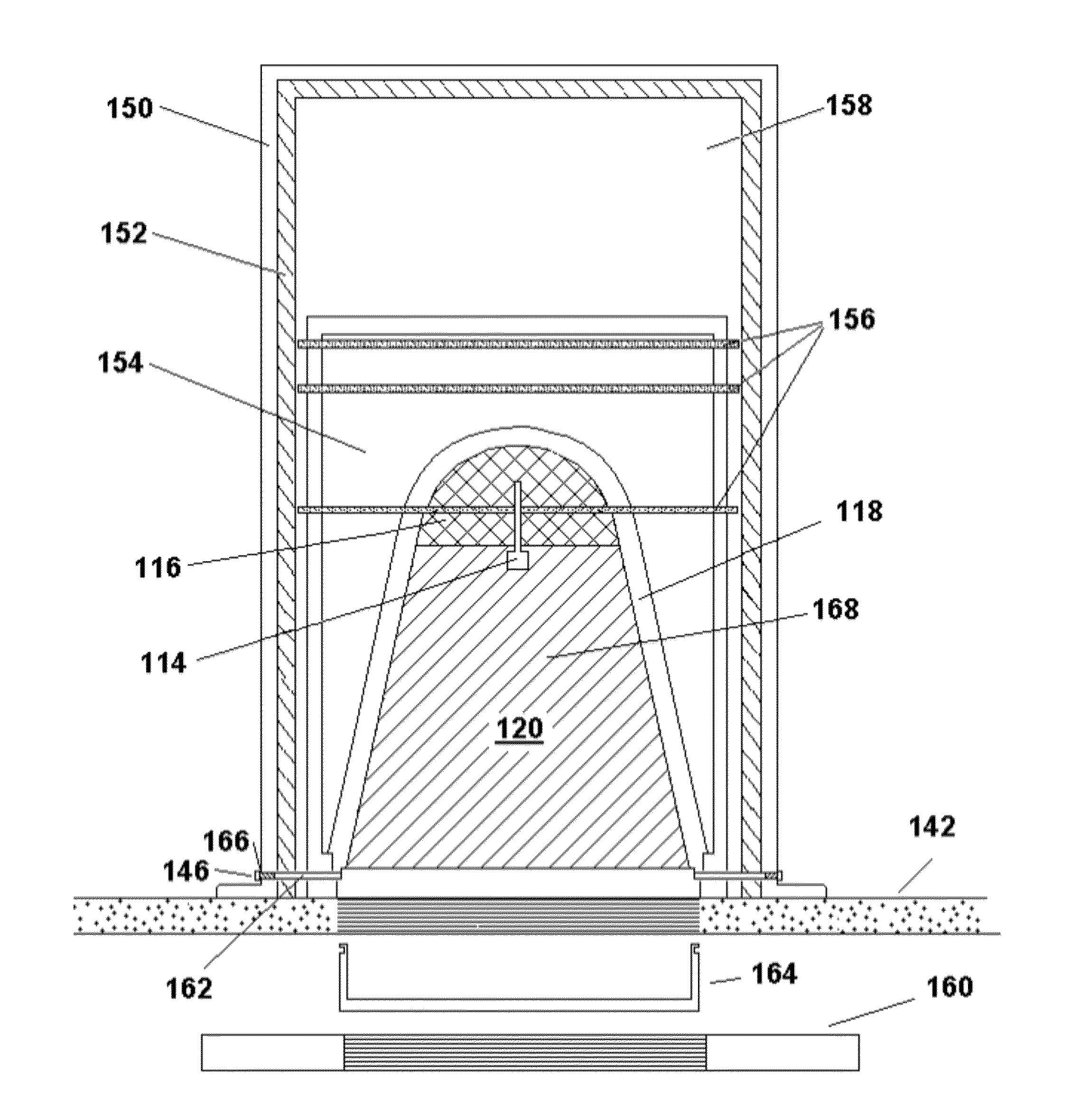

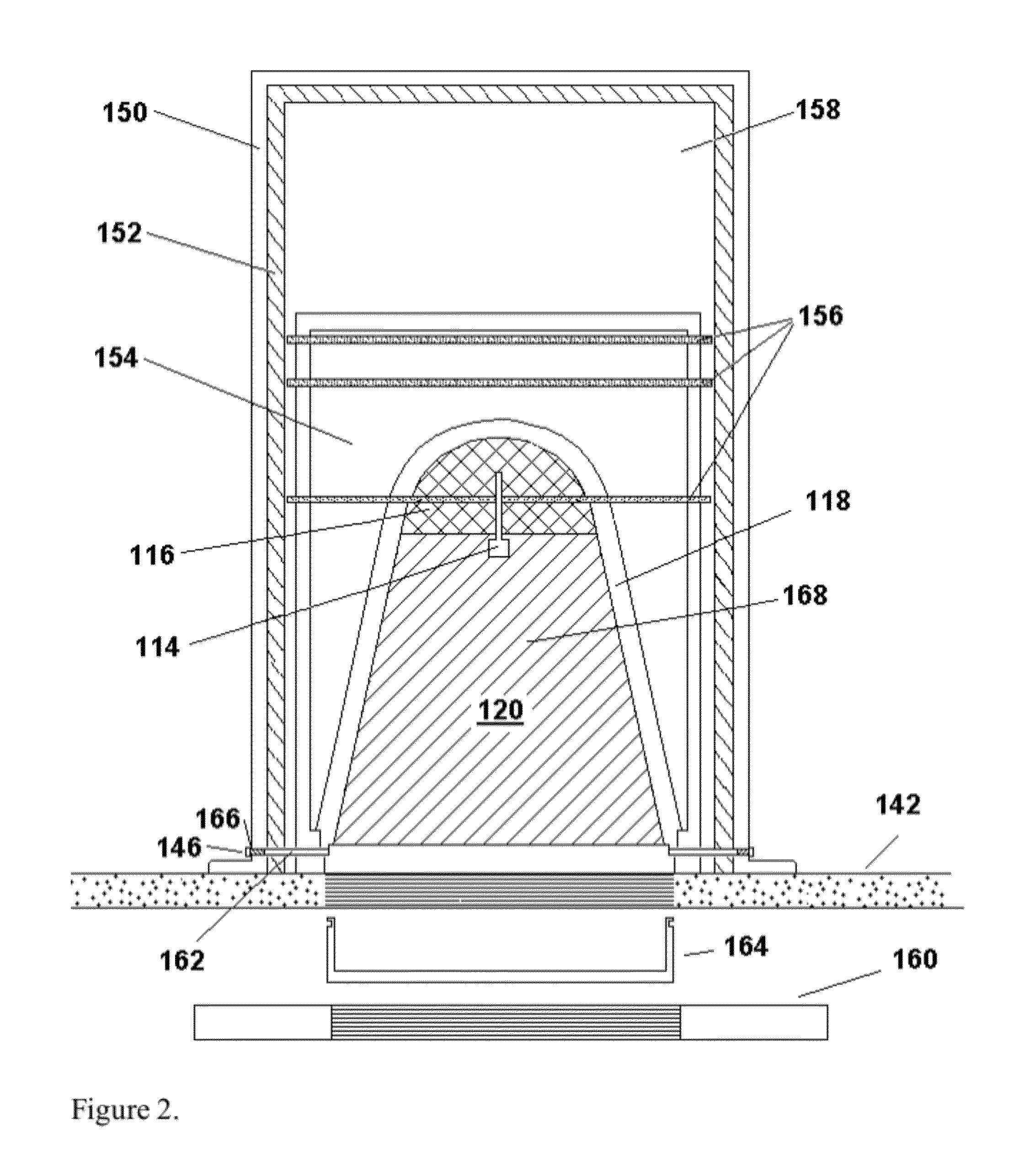

EXPLO-DYNAMICS™: a method, system, and apparatus for the containment and conversion of explosive force into a usable energy resource

InactiveUS20110283705A1Rapidly and more efficiently translated into conversion of steamMore impulse heat per unit of fuel consumedReciprocating combination enginesCombination enginesProcess configurationProcess engineering

Methods, systems, and apparatus for generating energy from a process contained series of explosion cycles is provided. The Explo-Dynamics™ energy generating system includes several embodiments for stimulating the heat and pressure release episodes of the process configurations and translating the released forces into torque, thrust, motive force, and / or super-heat impulses. The methods and systems of the present invention include a comprehensive arrangement of process configurations and components as well as a means of operation.

Owner:OLIVER TROY

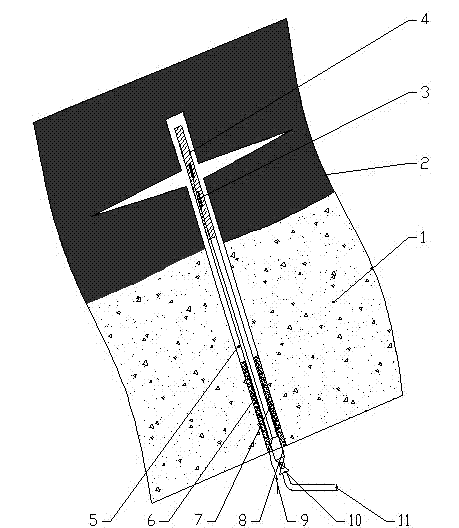

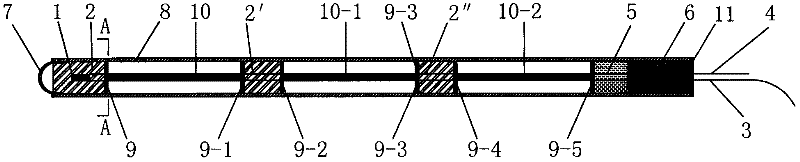

Directional water pressure blasting method for improving coal bed gas permeability

ActiveCN103195466ASolving difficult extraction problemsImprove breathabilityFluid removalGas removalDetonationPore water pressure

A directional water pressure blasting method for improving coal bed gas permeability includes utilizing water pressure blasting splitting to change the structure of the coal and rock mass, firstly drilling holes inside a coal bed, performing high-pressure hydraulic cutting seam, and forming a deep flat slot around the drilling holes of the coal bed after cutting; and filling explosive into the drilling holes of the coal bed, then injecting water and sealing the hole, detonating the explosive to perform water pressure blasting, and enabling the periphery of the drilling holes of the coal bed to generate directional expanding fractures under the function of detonation pressures. Performing water pressure blasting in a high-gas low gas permeability coal bed can organically combine the waterpower and the explosive force of the explosive fully and reasonably, the water pressure blasting enables the cracks generated by hydraulic cutting seam to further expand and a directional expanding cross fracture net is formed on the periphery of the drilling holes of the coal bed, so that the gas permeability of the coal bed is greatly improved, the problem that the gas of the coal bed is hard to extract due to the small number of the cracks can be effectively solved, the concentrated stress of the coal bed is transferred to the deep of the coal mass, and the capacity of gas emission is improved. The directional water pressure blasting method for improving the coal bed gas permeability is simple in process, convenient to operate, safe, reliable, and good in controllability and effects.

Owner:CHONGQING UNIV

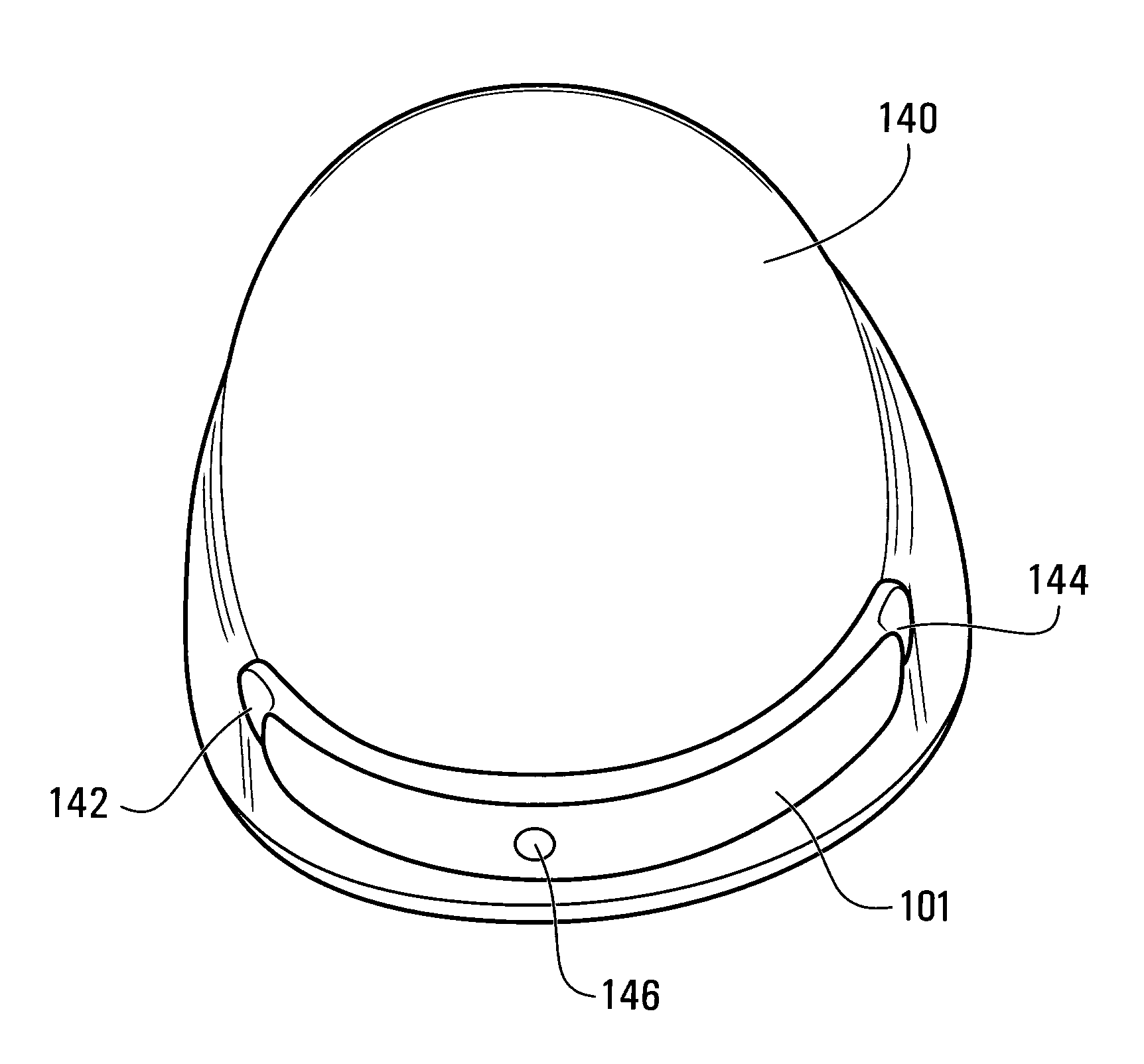

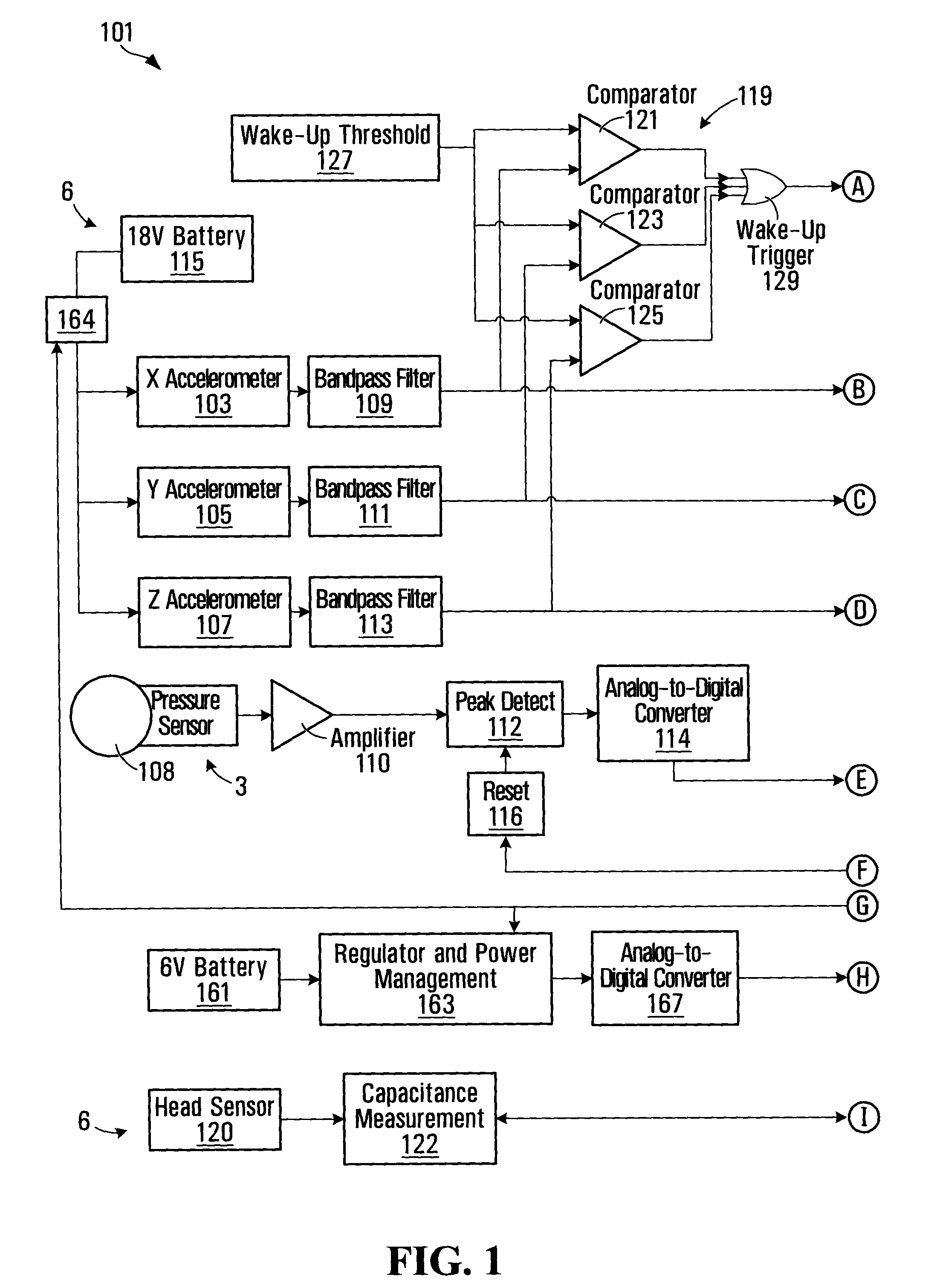

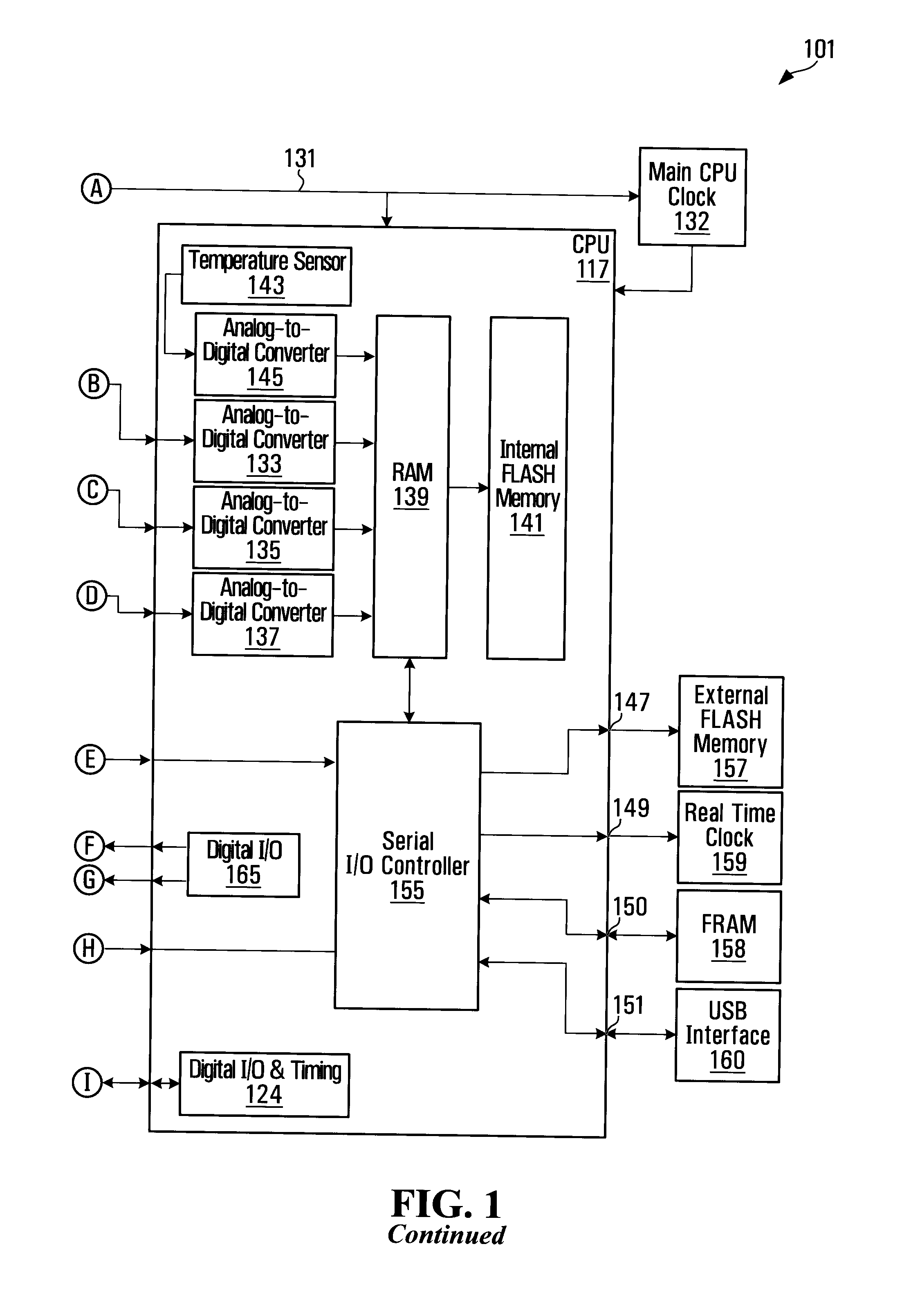

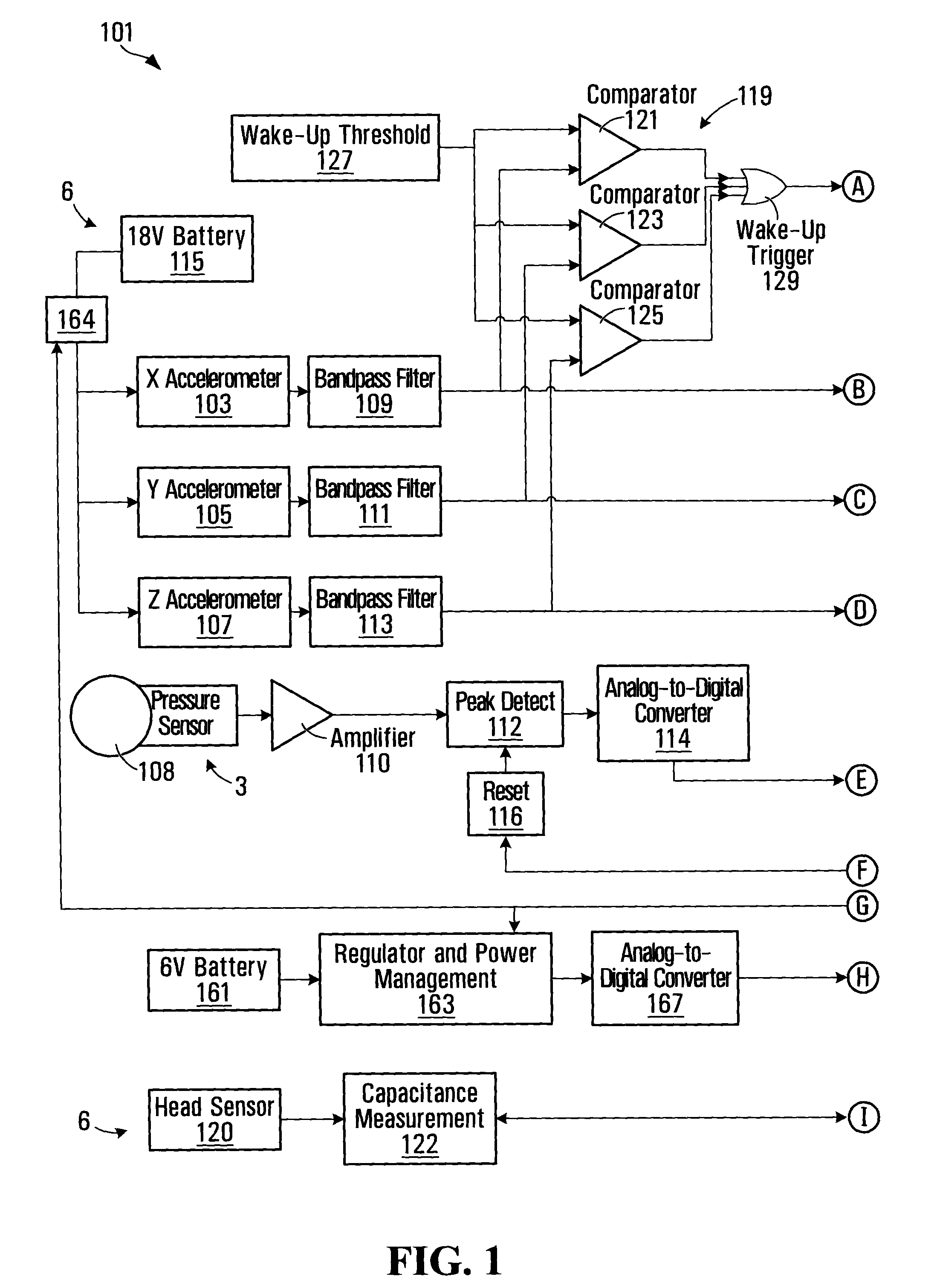

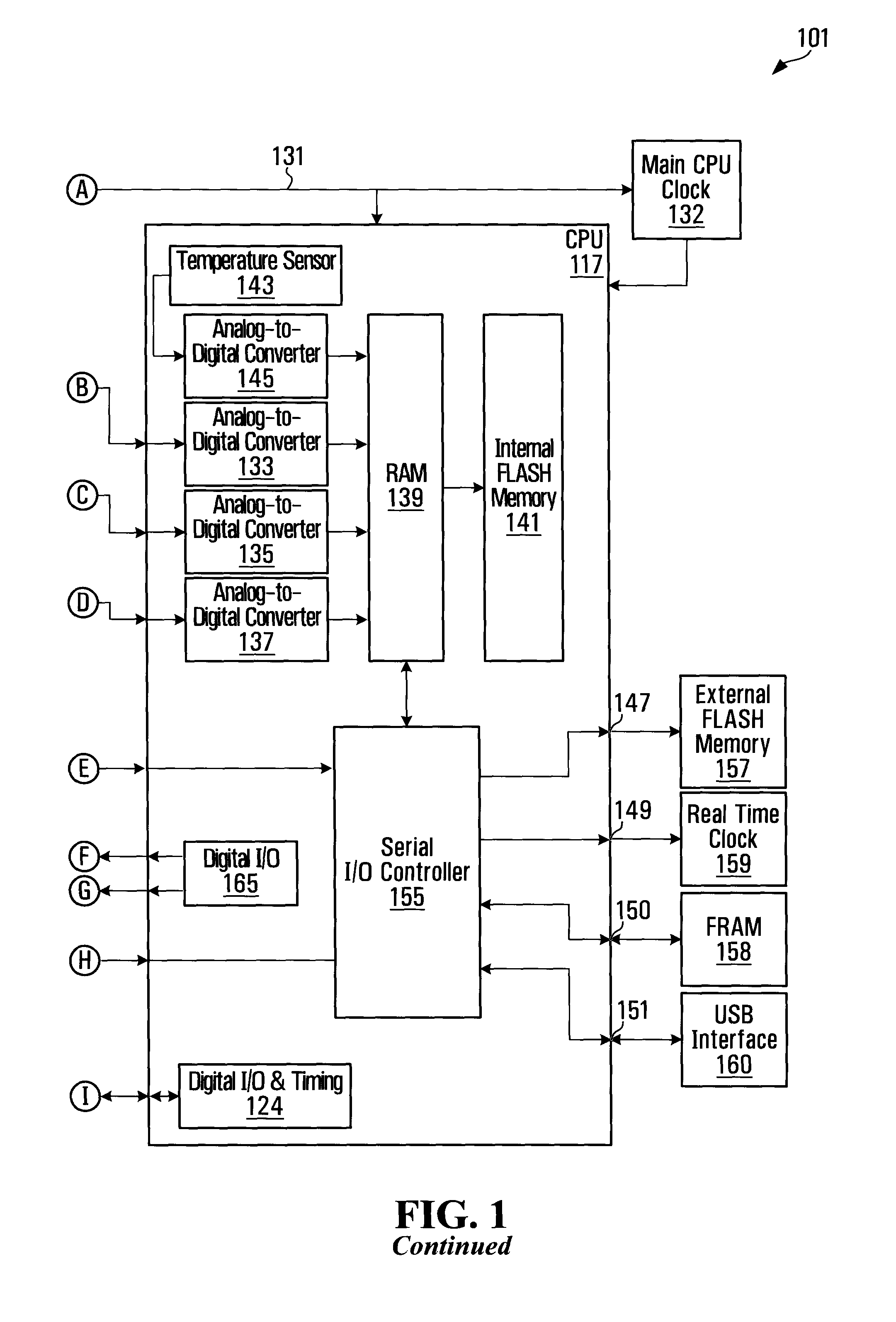

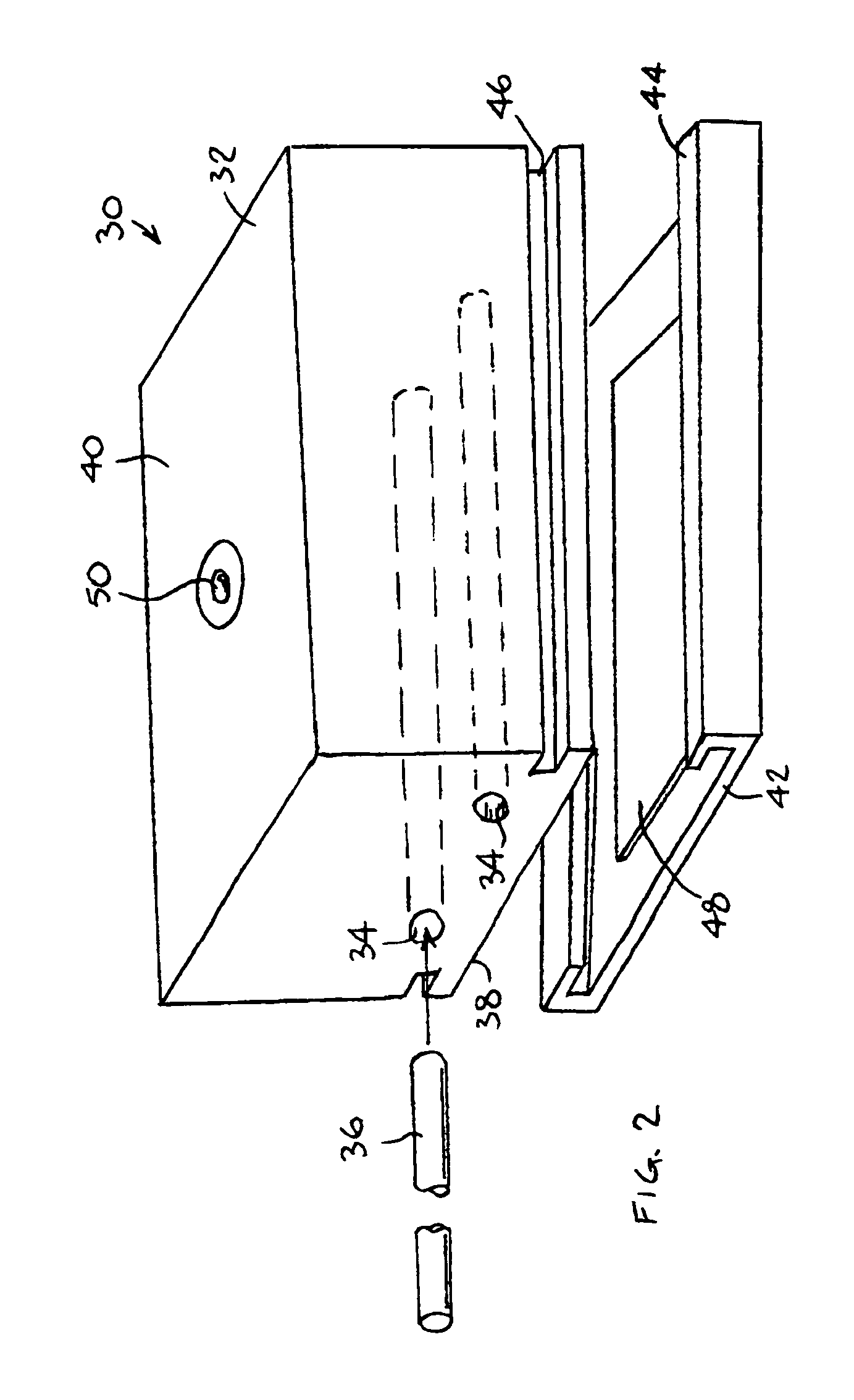

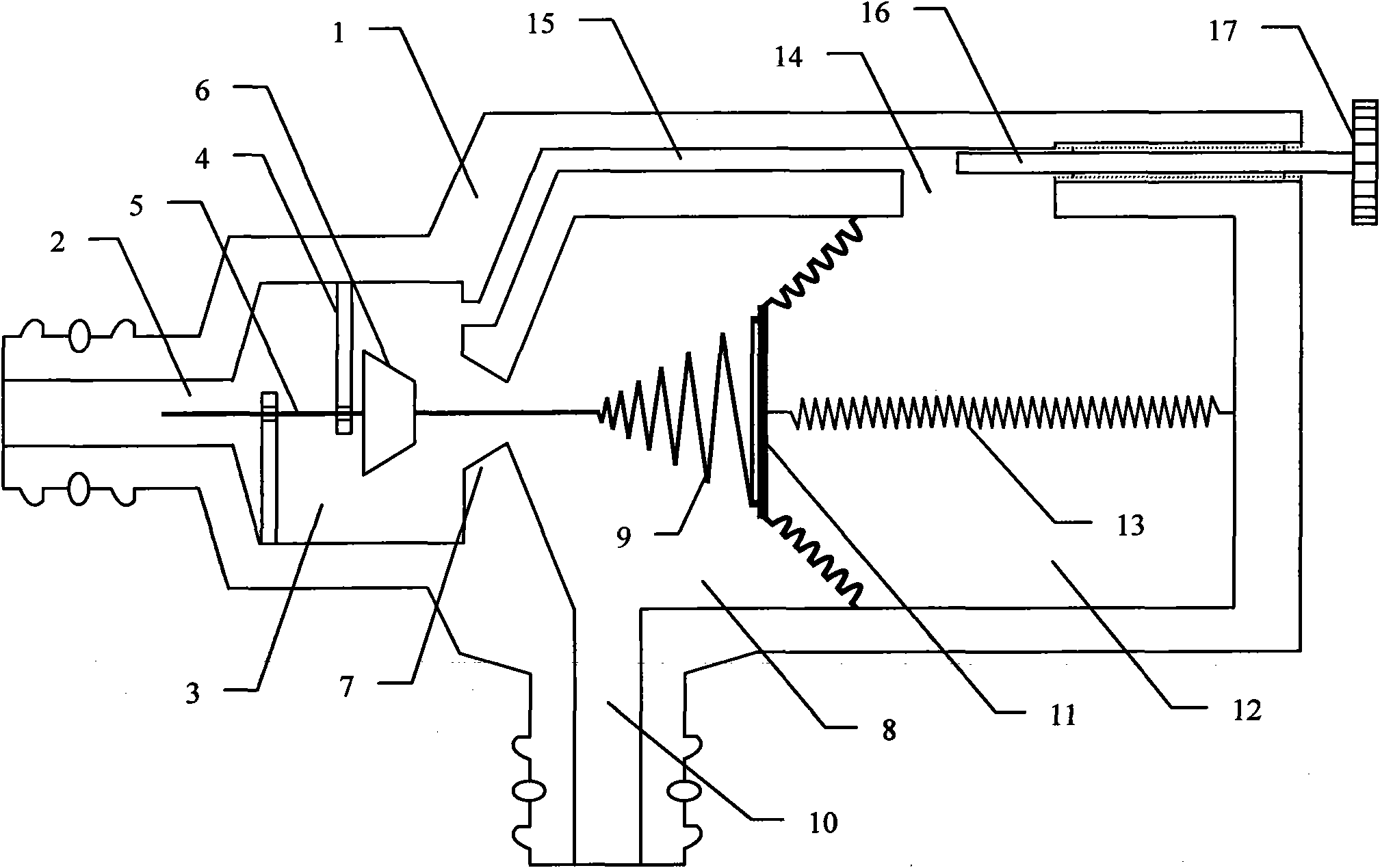

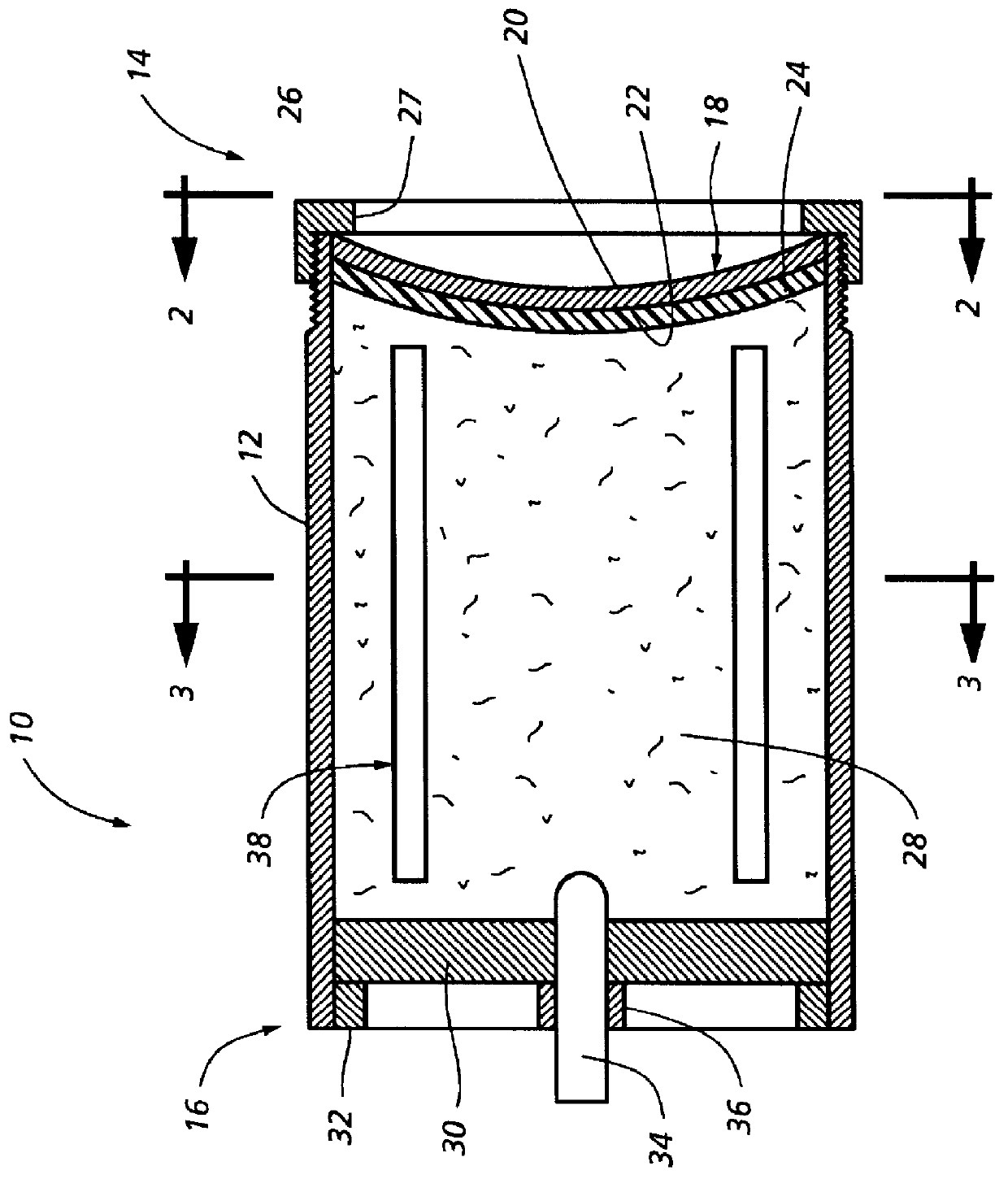

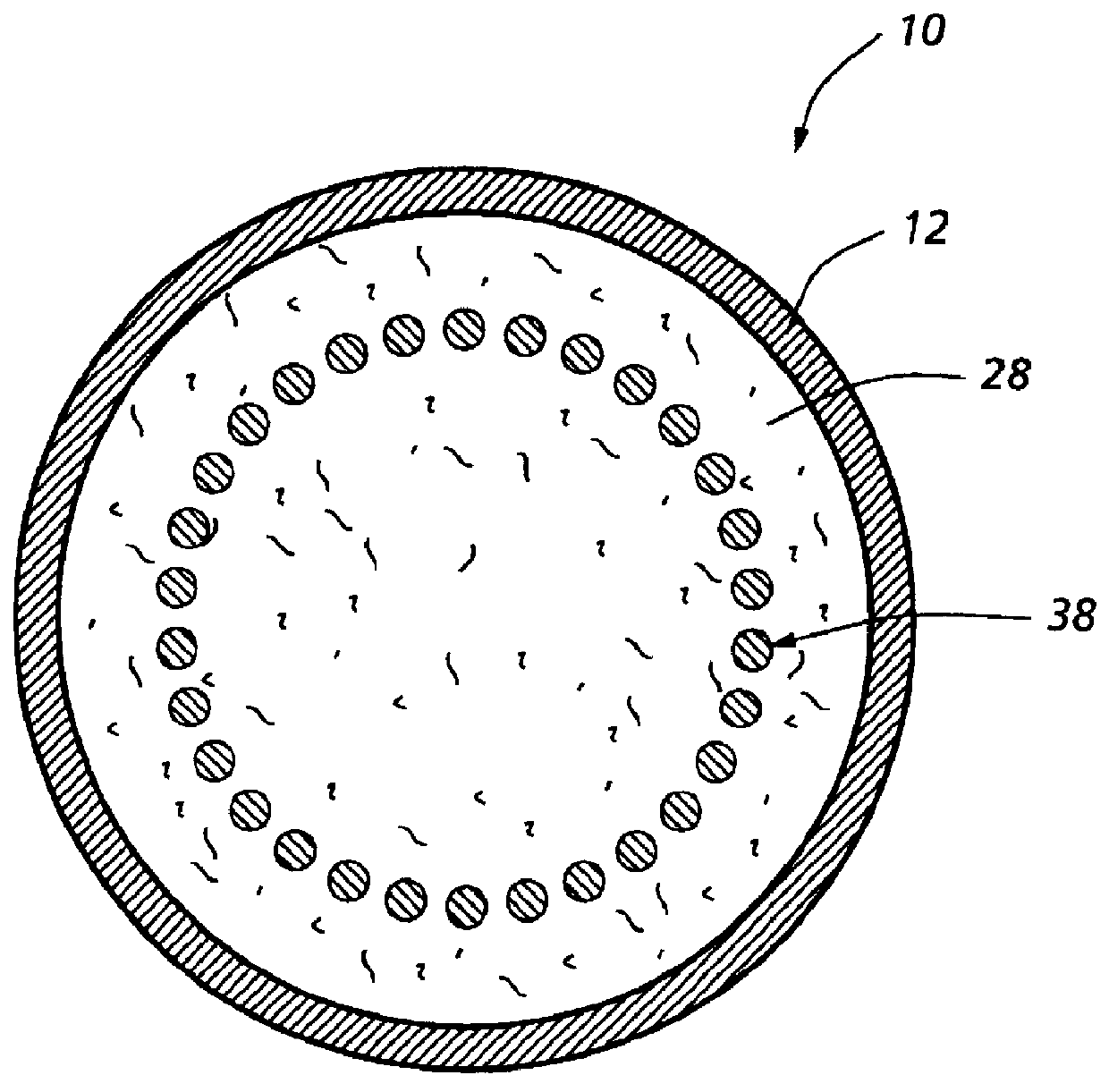

Apparatus and Method for Measuring and Recording Data from Violent Events

ActiveUS20100307223A1High occurrenceEvaluate effectivenessFluid pressure measurementSpeed/acceleration/shock instrument detailsControl dataEvent data

An apparatus is provided for recording information about an event resulting in application of a force to a body. The apparatus comprises data recording means for recording the information, sensor means for sensing a parameter which enables a predetermined source of force to be distinguished from another, different source of force, and control means responsive to the sensed parameter for controlling the data recording means. The sensor means may comprise a pressure sensor for sensing shockwaves resulting from an explosive force and the resulting signal used to distinguish from other events, such as blunt impacts. The pressure signal may be used to control the storage of acceleration data for injury analysis.

Owner:MED ENG

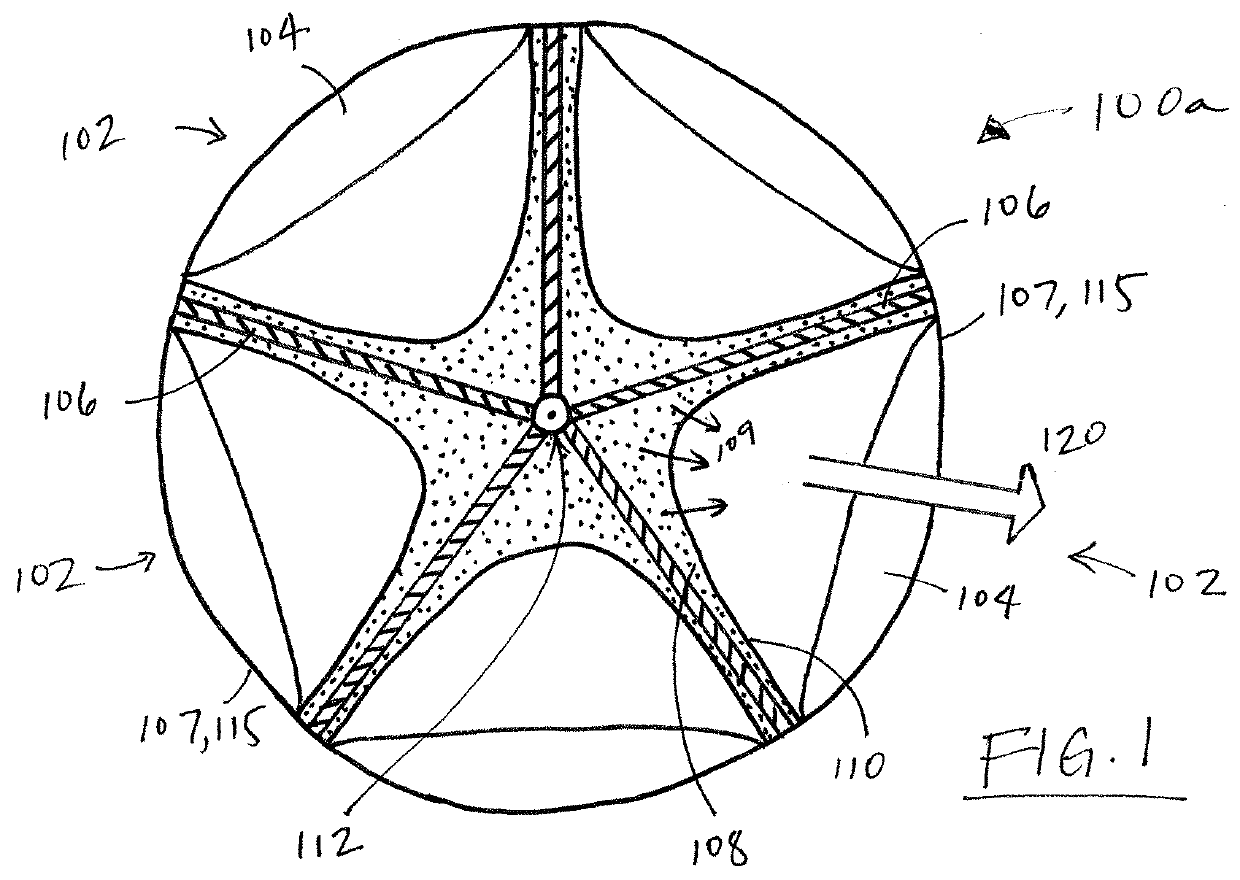

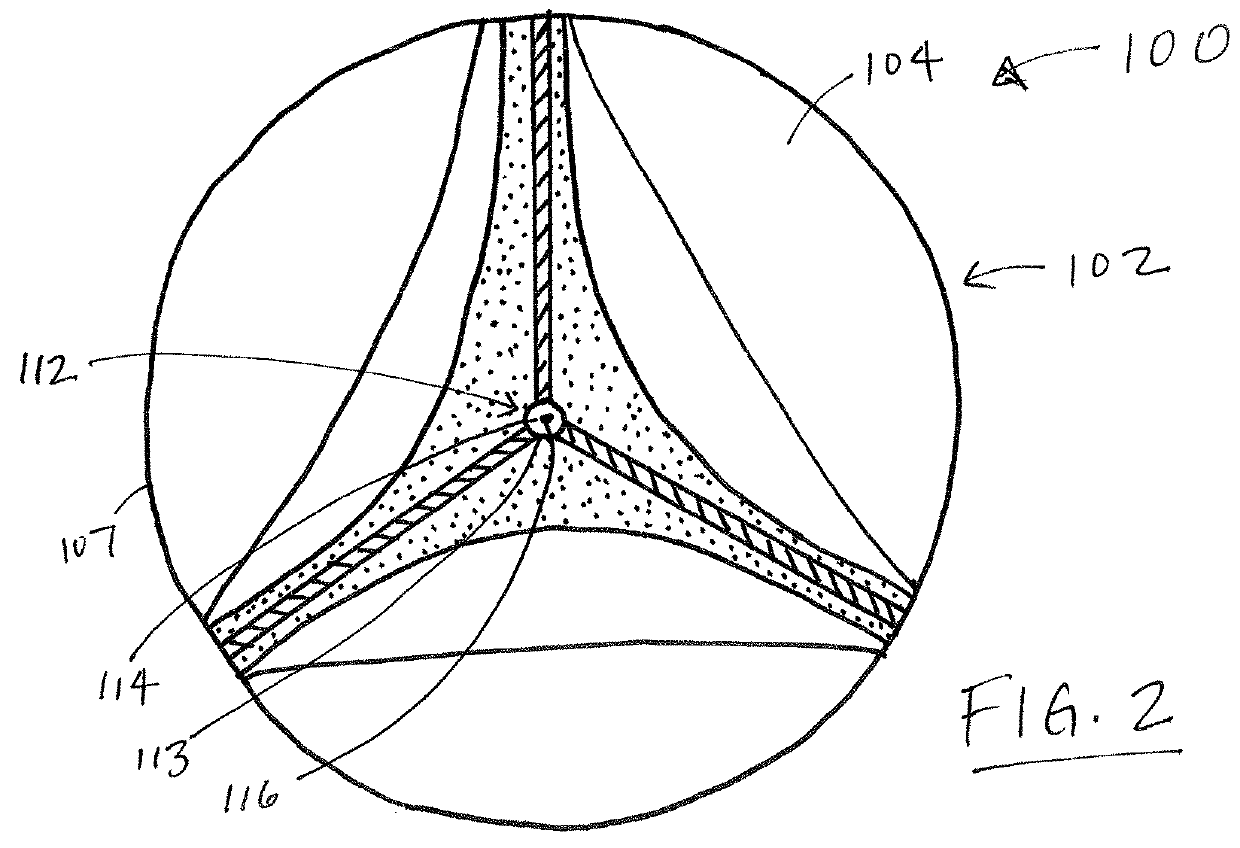

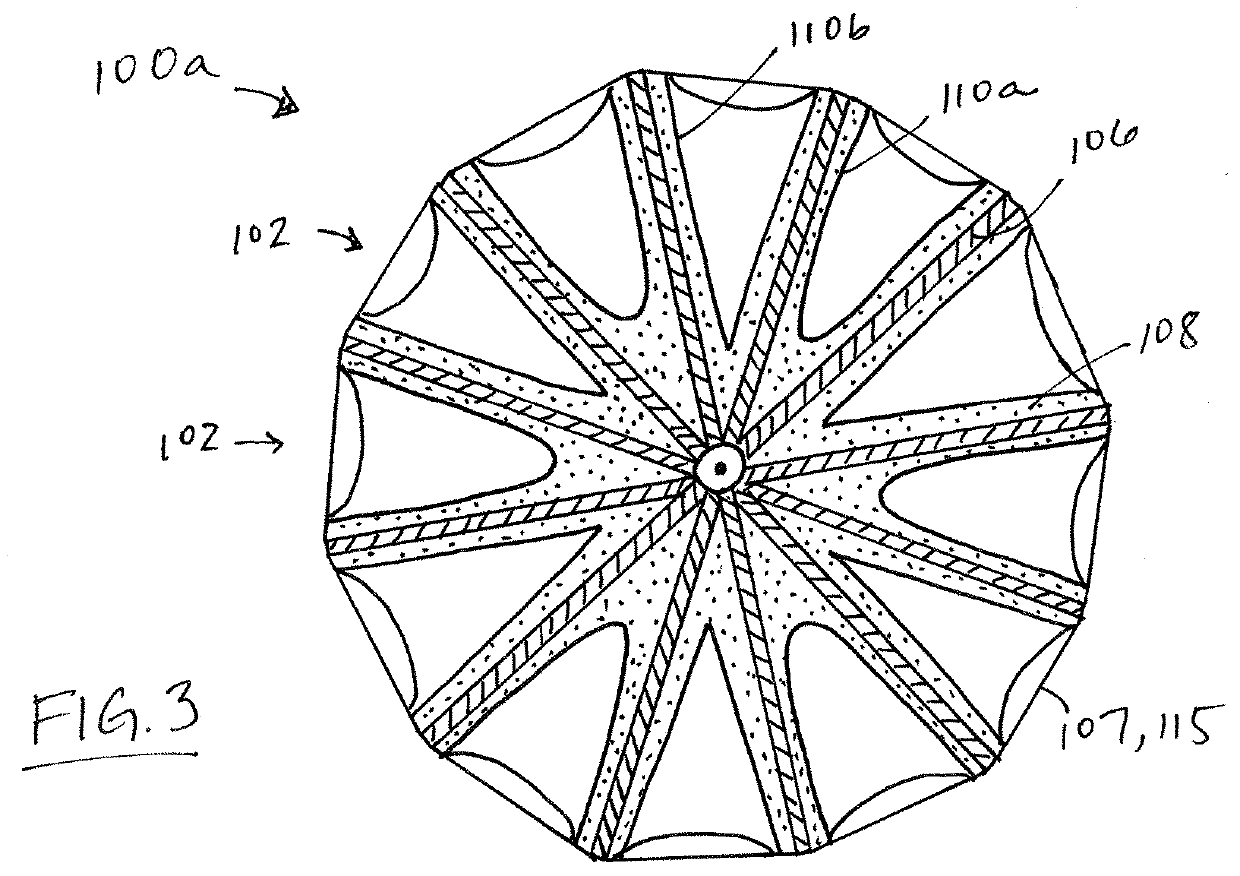

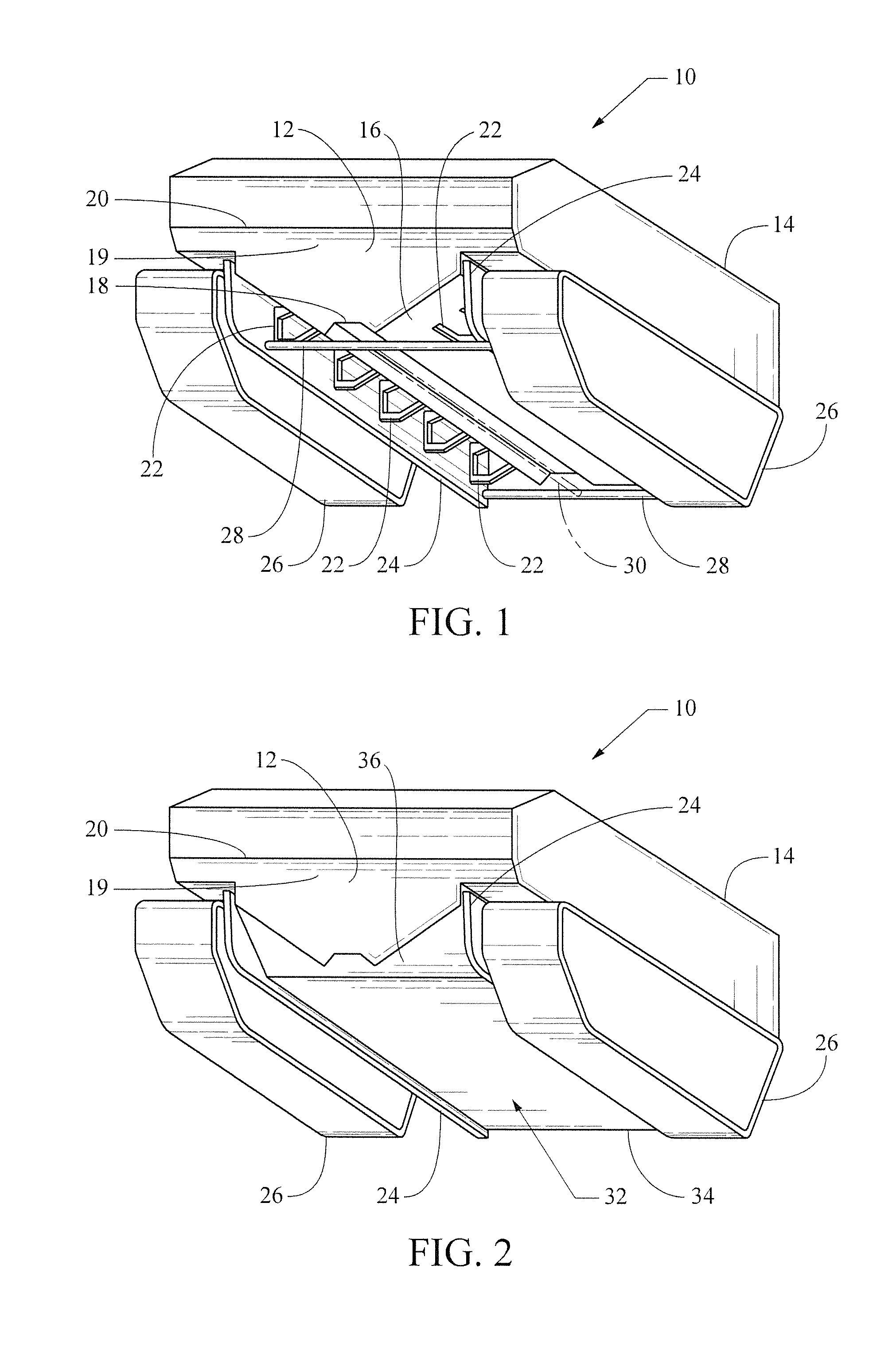

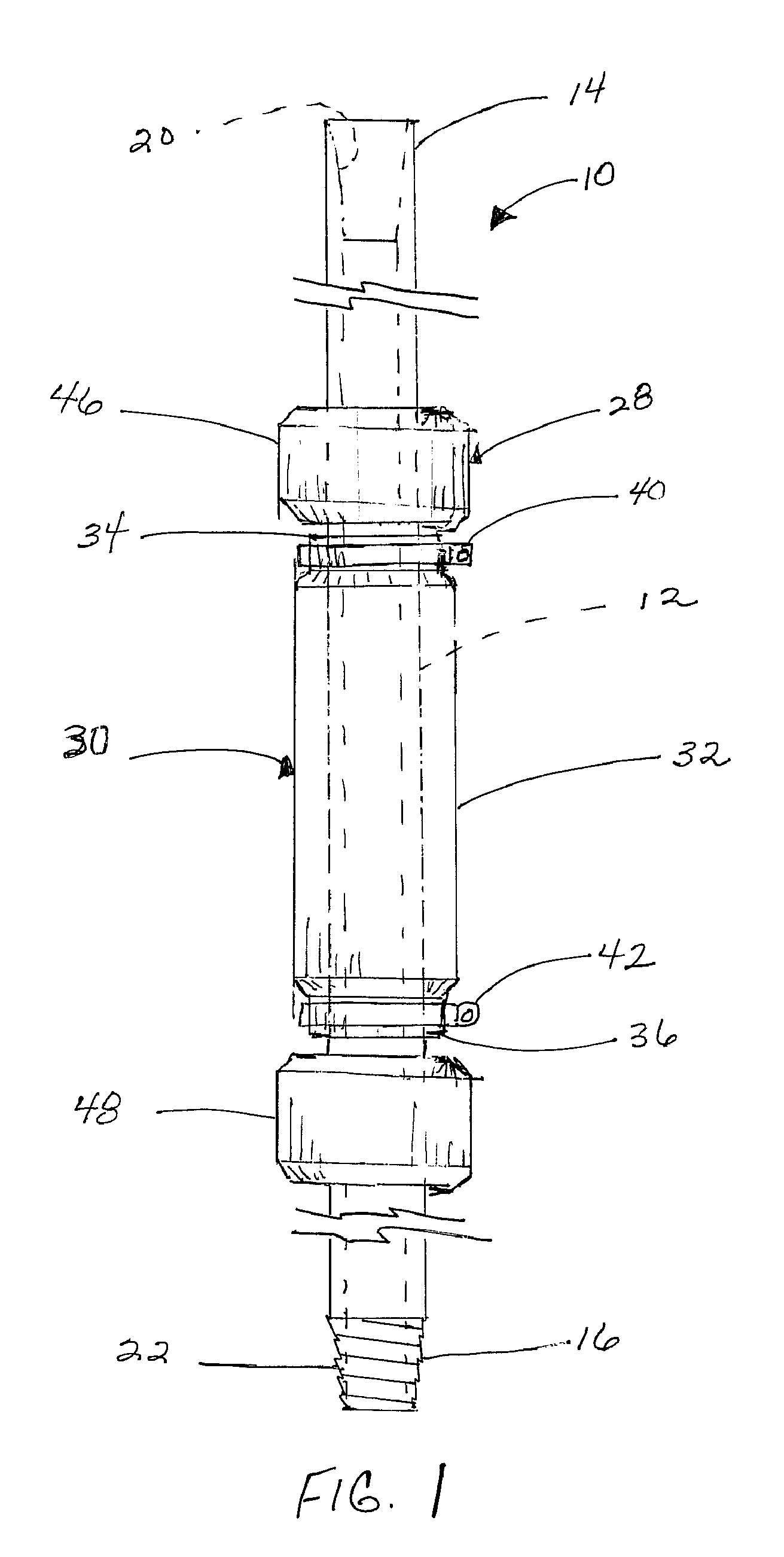

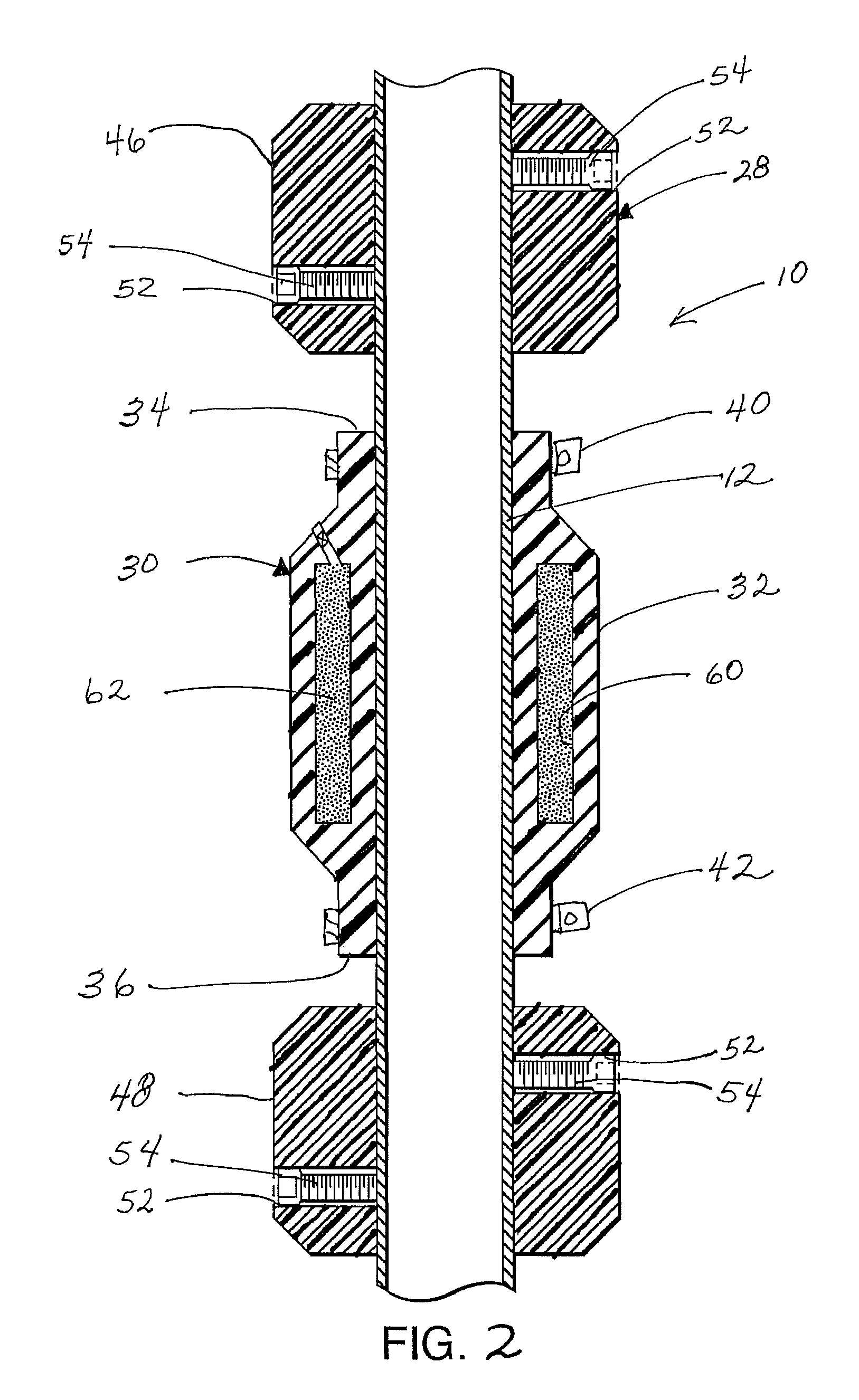

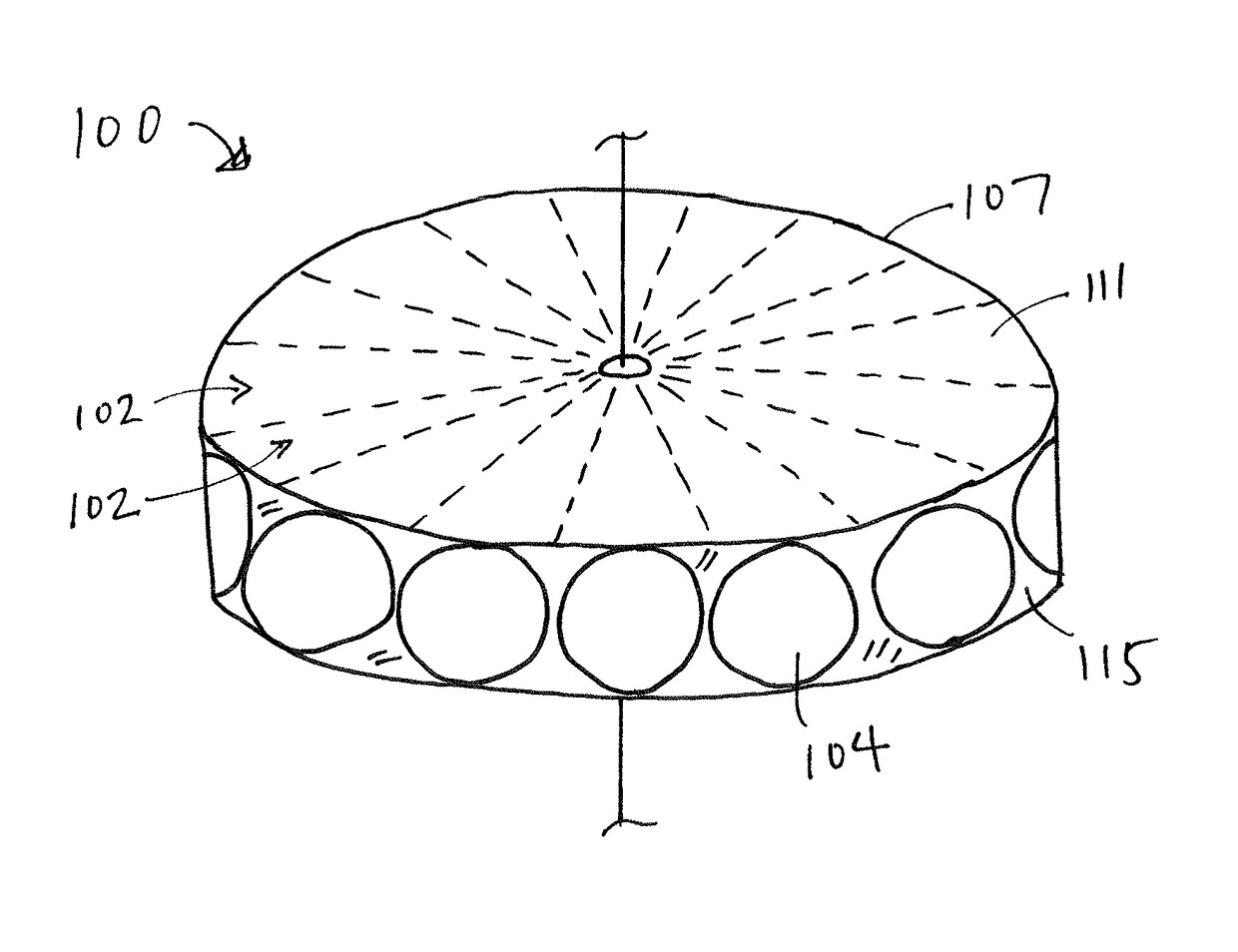

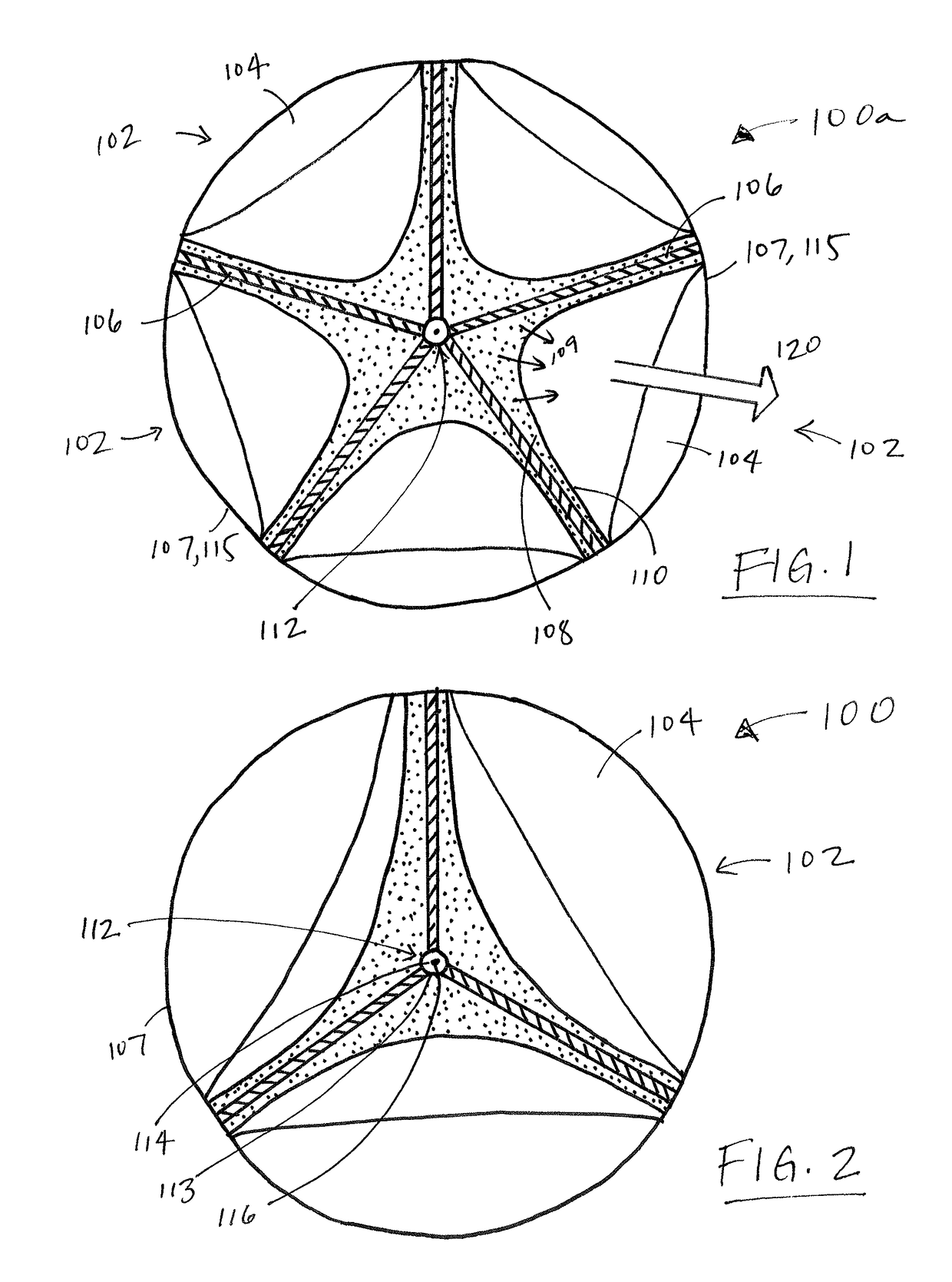

Multi-Shot Charge for Perforating Gun

ActiveUS20180274342A1Increase the number ofSmall sizeExplosive chargesBlasting cartridgesDetonationEngineering

A multi-shot explosive charge includes a plurality of chambers divided by shared walls between adjacent chambers. Explosive material within at least one of the chambers creates an explosive force in an outward direction upon detonation and a perforating jet through the open end of the chamber. A perforating charge includes at least one explosive material producing explosive forces, upon detonation that collide within the chamber to create a perforating jet. Such perforating charge may be a chamber(s) within a multi-shot explosive charge, or an individual charge. First and second explosive materials can have the same or different compositions and detonation rates that together with the arrangement of materials within the chamber create the collision of forces. A plurality of multi-shot explosive charge or stand-alone perforating charges with colliding forces can be interconnected in an array, and can be included in a perforating gun(s).

Owner:IDEASCO LLC

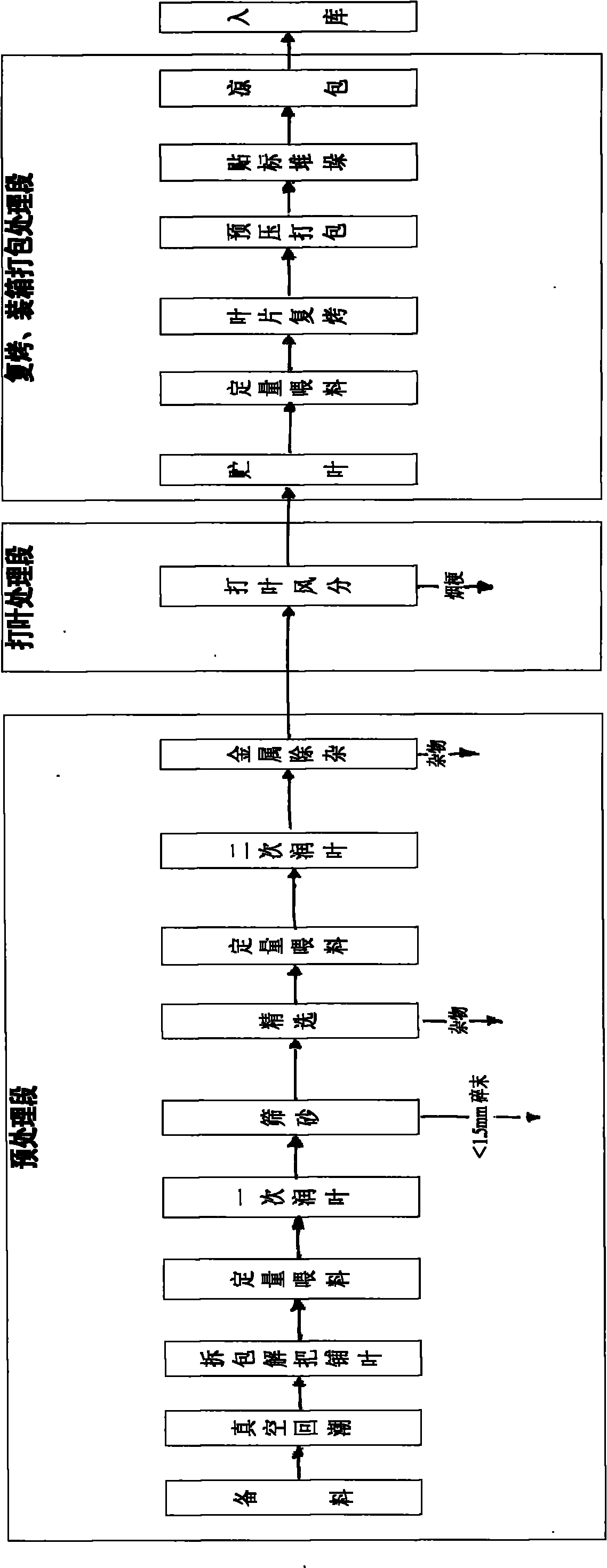

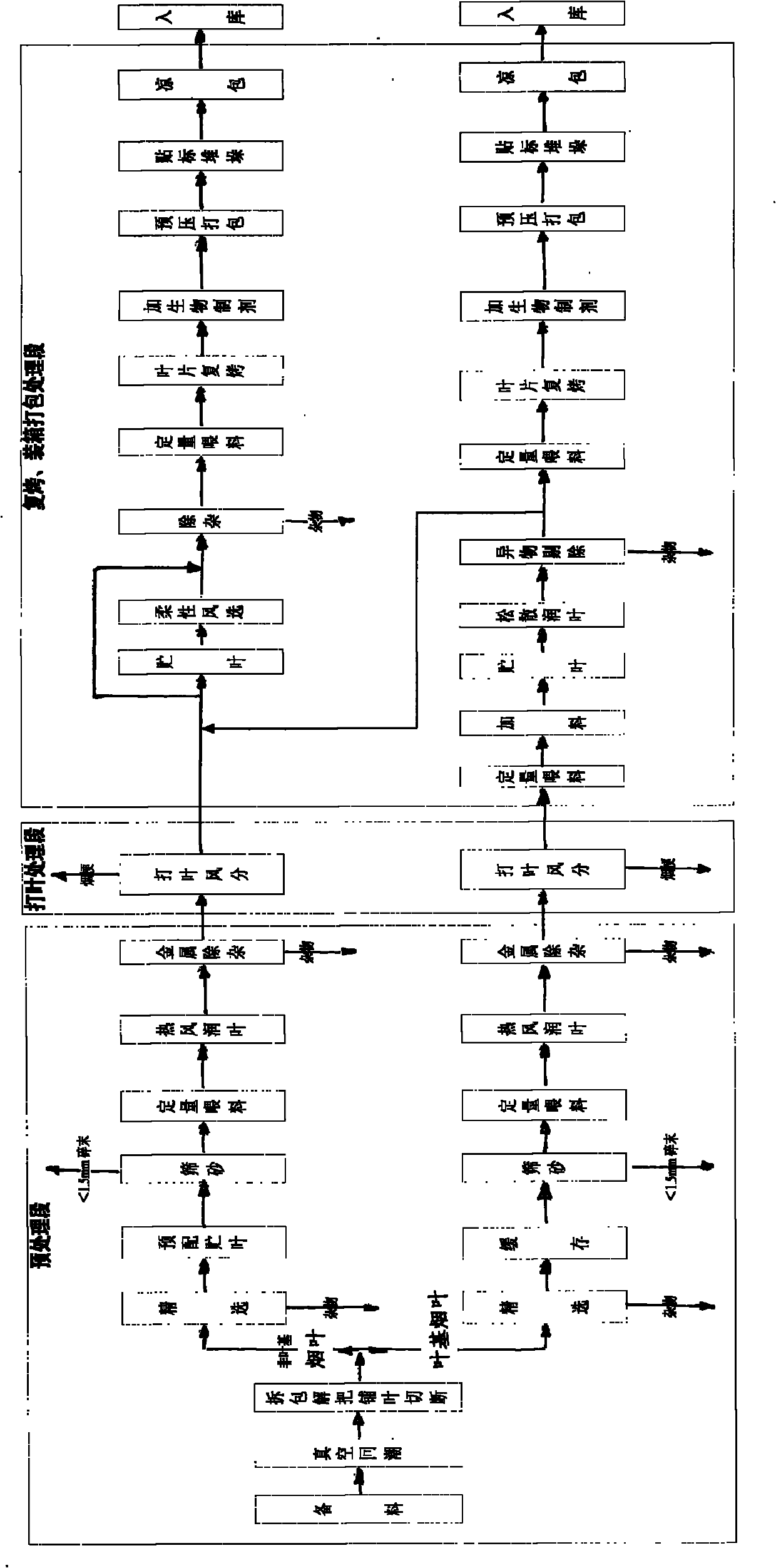

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

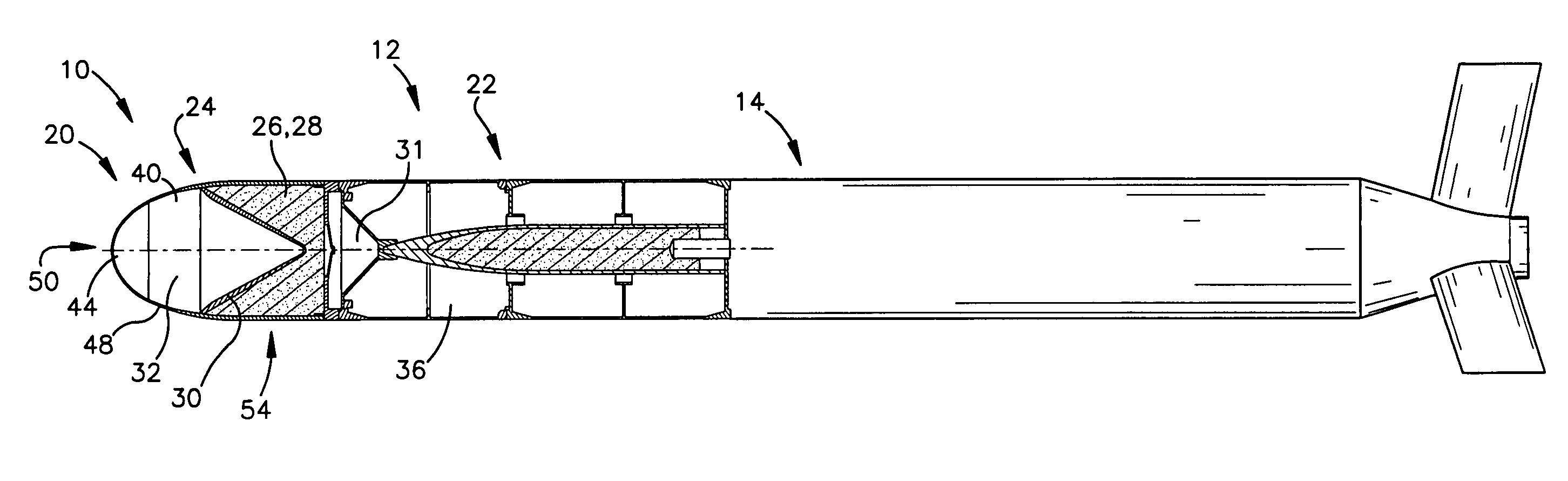

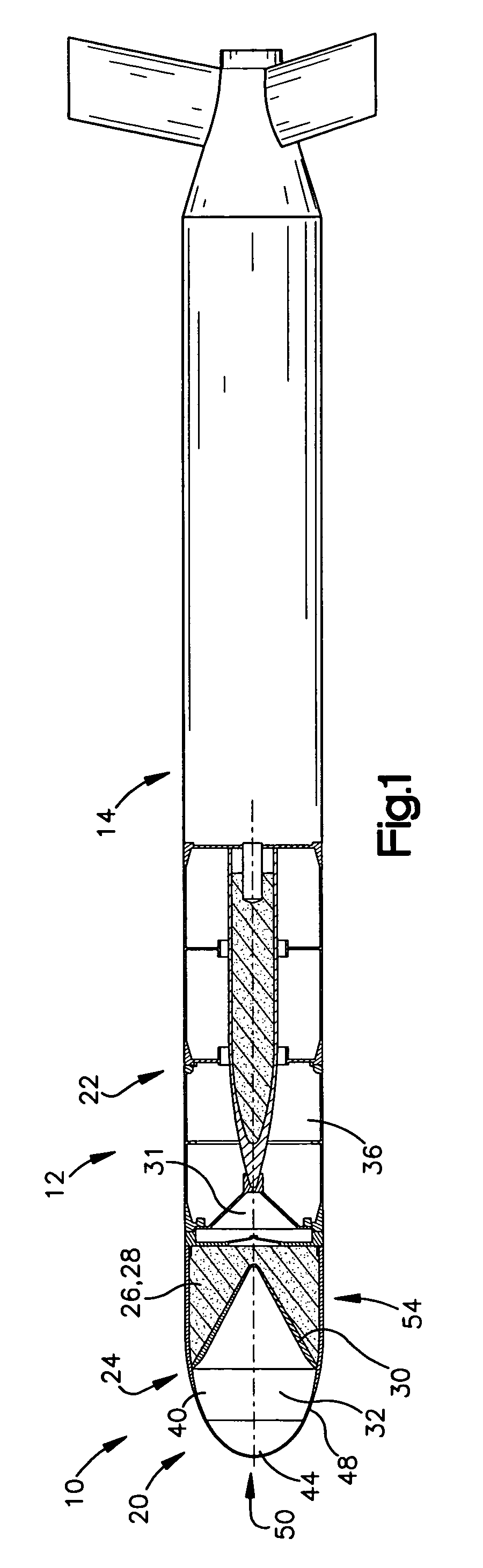

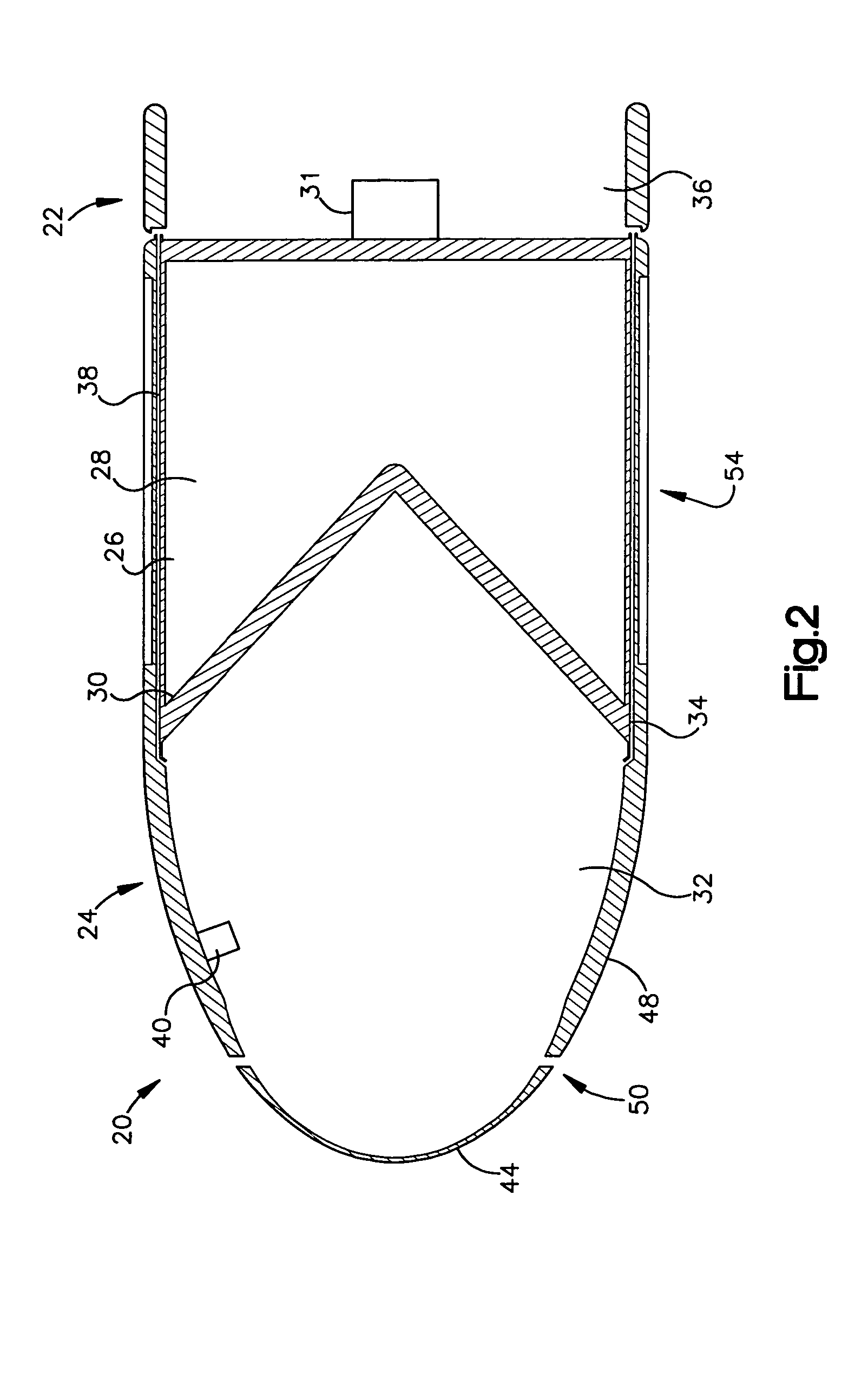

Multi-mission payload system

A missile, such as a cruise missile, has a nose payload portion having a frangible nose cover and a relatively hard target penetration nose cone. The nose cone may have a liquid fuel tank within, and a chemical energy explosive charge, such as a shaped charge, aft of the liquid fuel tank. The target penetration nose cone enables perforation of certain types of targets prior to detonation of the chemical energy explosive and the liquid fuel. The frangible nose cover is configured to be easily perforated or otherwise removed by the explosive force of the chemical energy explosive charge when the missile system is utilized for the attack of hard targets. The nose payload portion may have a fragmentation case, with one or more features designed to enhance fragmentation during detonation of the explosive and / or the liquid fuel.

Owner:RAYTHEON CO

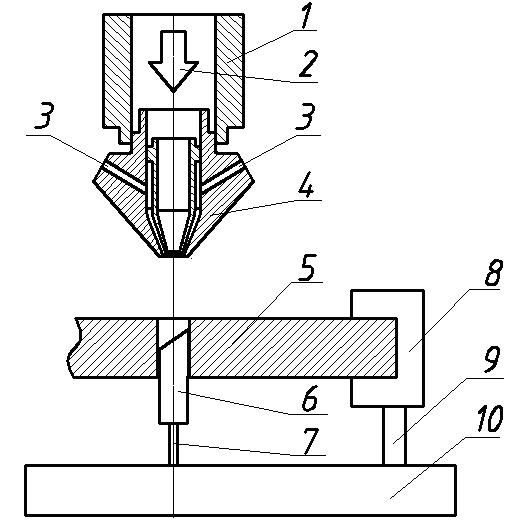

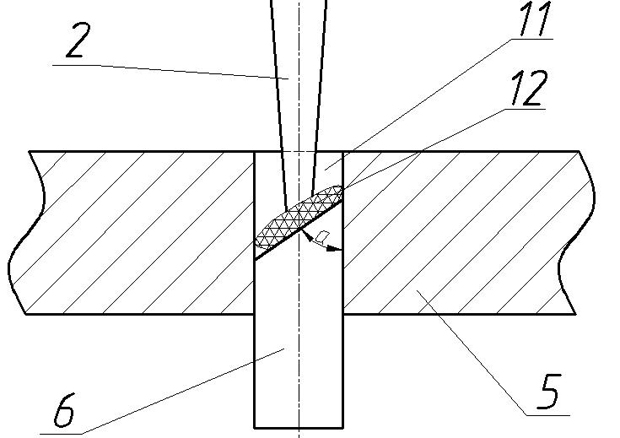

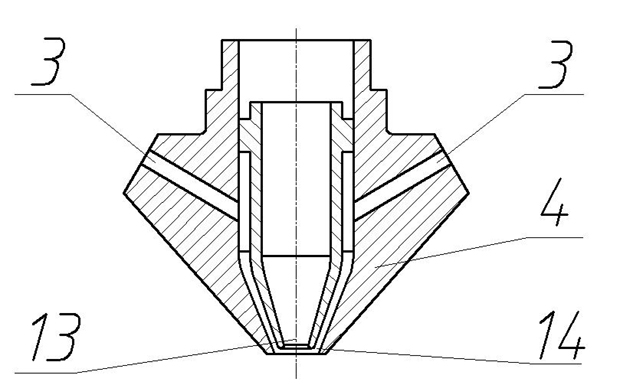

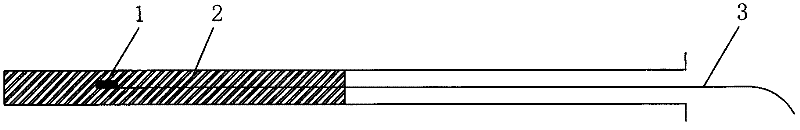

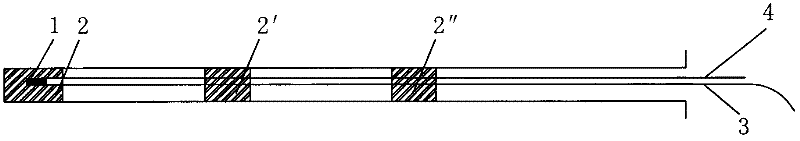

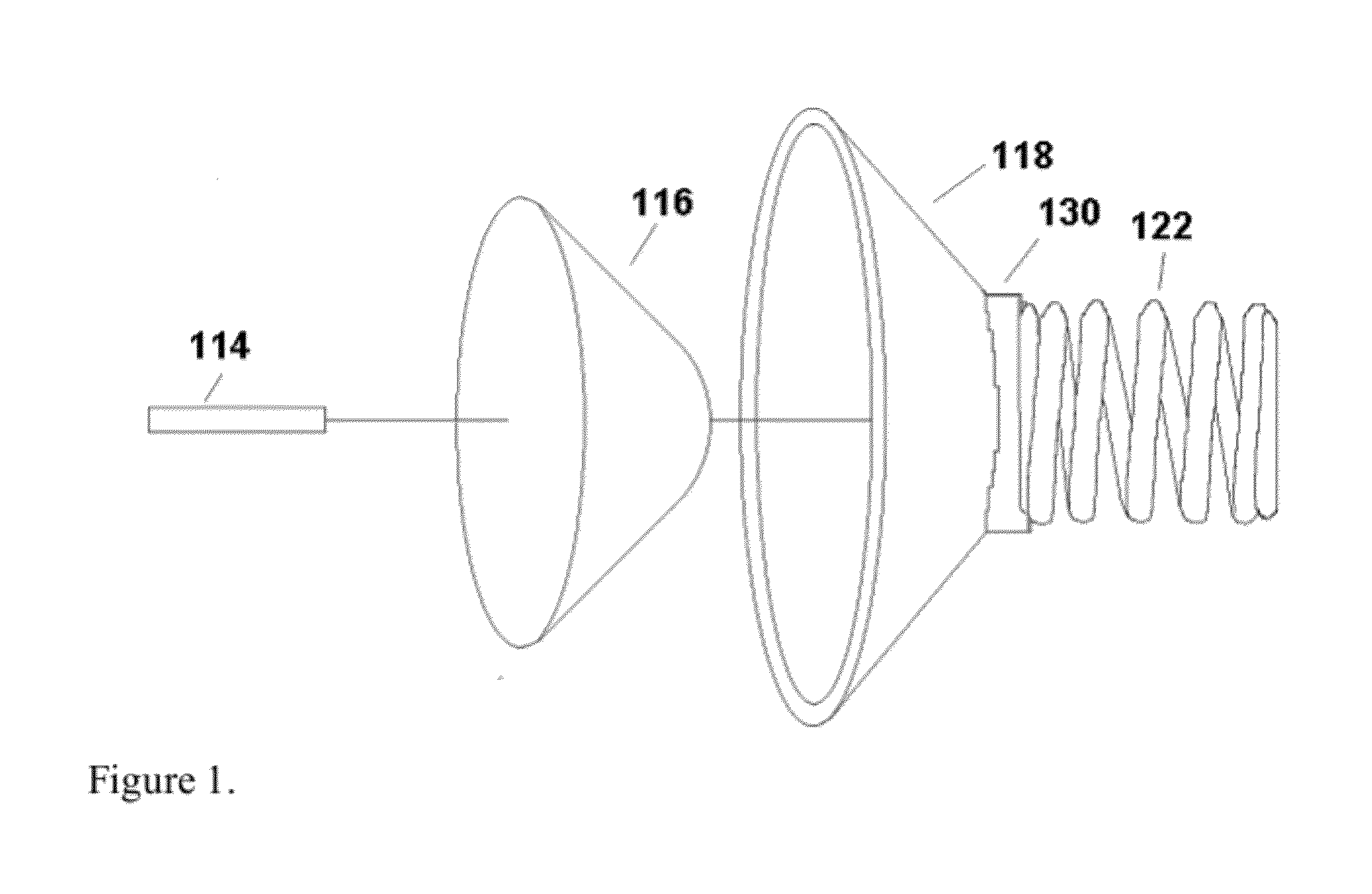

Method and device for laser shock processing of fastening holes

InactiveCN101942546AImprove fatigue lifeNo damageProcess efficiency improvementShock waveEngineering

The invention discloses a method and a device for laser shock processing of fastening holes, and relates to the field of processing and manufacturing of the fastening holes. An energy absorbing rod (6) is placed at a proper position in a fastening hole, laser pulse (2) acts on a bevel of a head of the energy absorbing rod (6) to induce the explosion of a plasma (6) to generate a shock wave to act on an inner wall of the fastening hole, so that the fastening hole is processed; and the device comprises a laser, a concentrating system (1), a laser head (4), the energy absorbing rod (6), a feed mechanism A (7), a feed mechanism B (9), a fixture (8) and a workbench (10). The explosive force of the plasma (12) induced by the laser in the fastening hole acts on the inner wall of the hole to make the inner wall of the hole generate certain plastic deformation, so that the residual stress larger than that generated by the common processing is introduced, and the fatigue life of the fastening hole is effectively improved.

Owner:JIANGSU UNIV

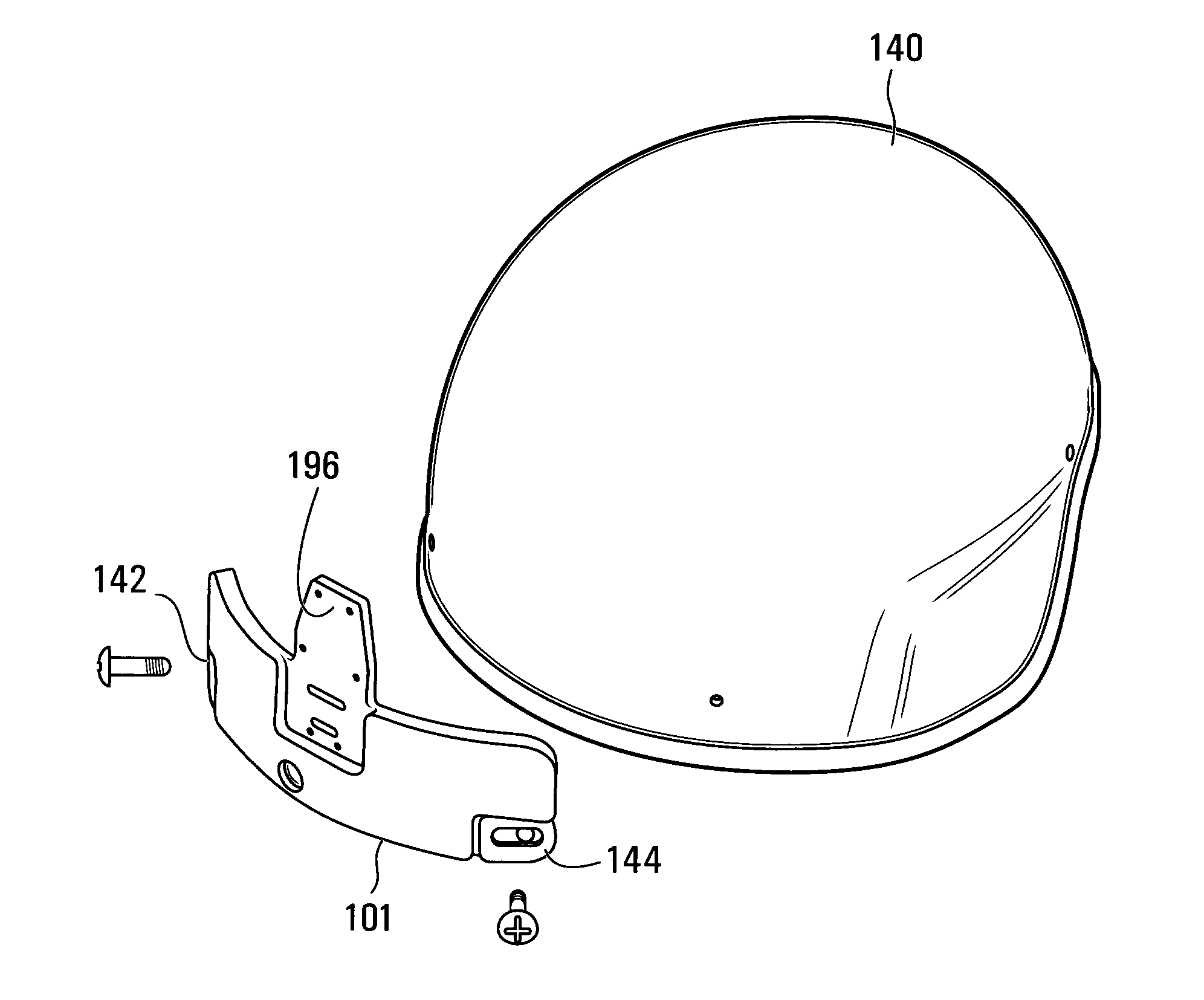

Apparatus and method for measuring and recording data from violent events

ActiveUS7992421B2High occurrenceEvaluate effectivenessFluid pressure measurementAcceleration measurementControl dataEvent data

An apparatus is provided for recording information about an event resulting in application of a force to a body. The apparatus comprises data recording means for recording the information, sensor means for sensing a parameter which enables a predetermined source of force to be distinguished from another, different source of force, and control means responsive to the sensed parameter for controlling the data recording means. The sensor means may comprise a pressure sensor for sensing shockwaves resulting from an explosive force and the resulting signal used to distinguish from other events, such as blunt impacts. The pressure signal may be used to control the storage of acceleration data for injury analysis.

Owner:MED ENG

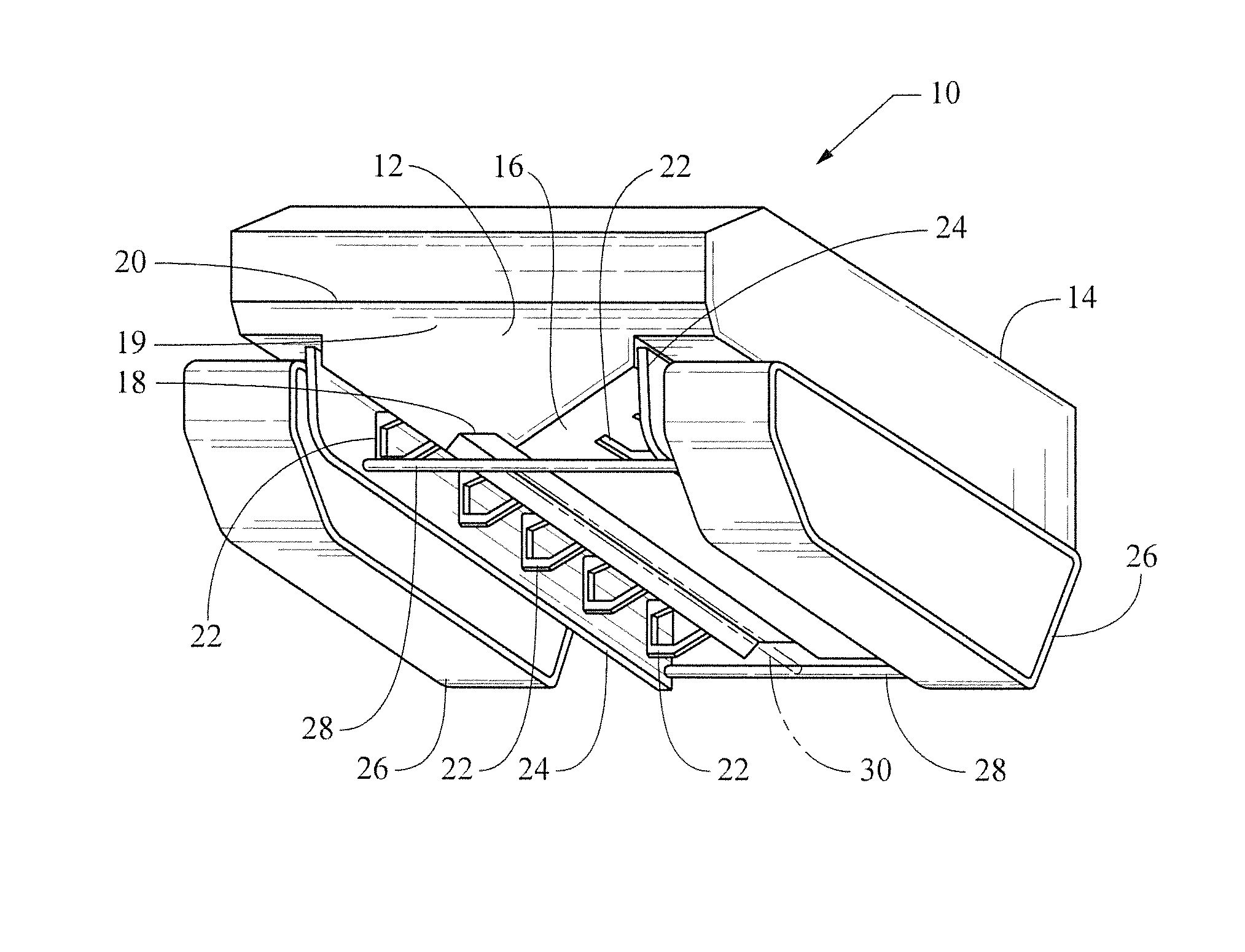

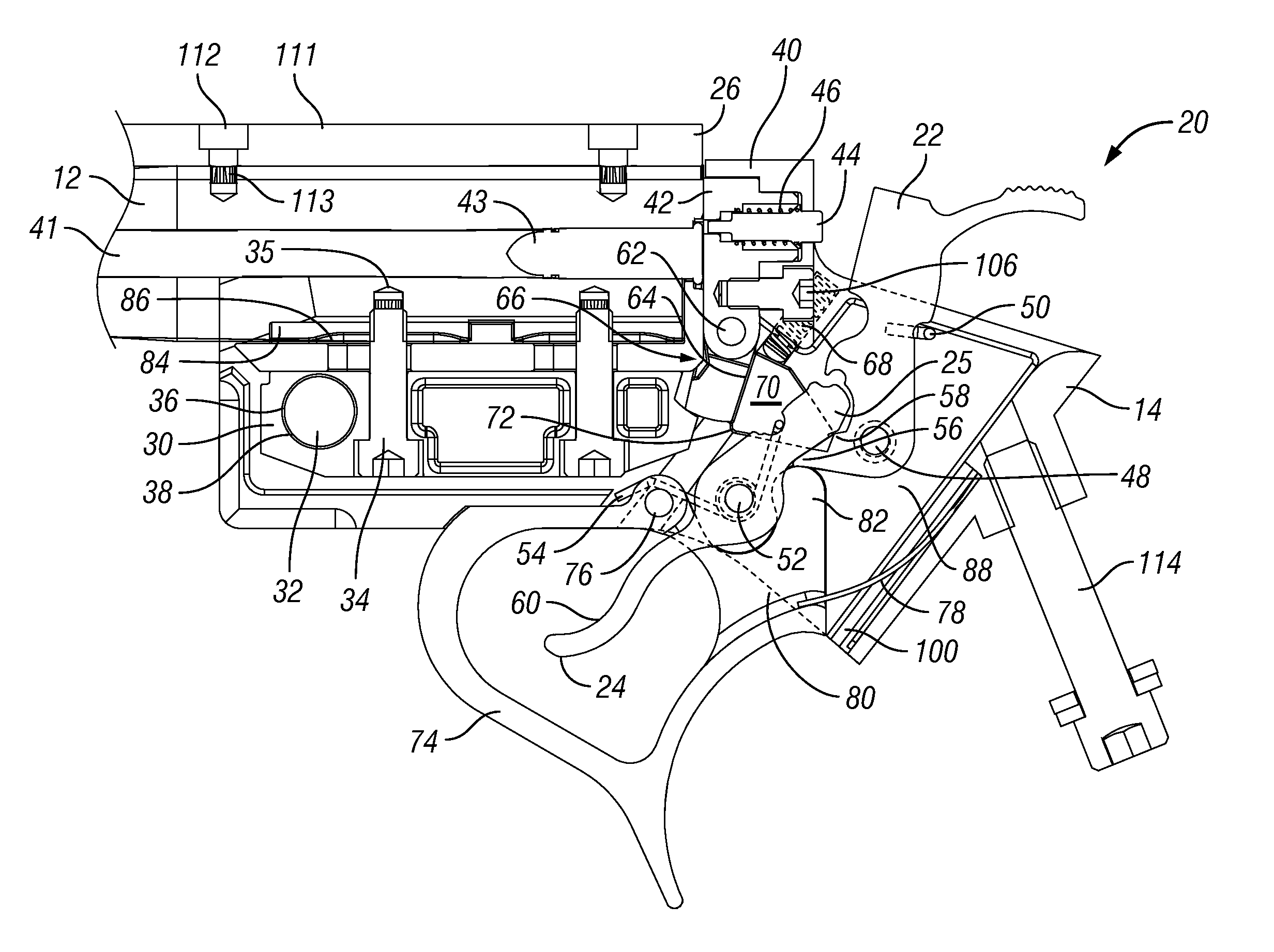

Multifunctional breaching apparatus

InactiveUS7000545B2Improve explosive powerEfficient detonationExplosive chargesBlasting cartridgesEngineeringExplosive force

Breaching apparatus including a housing constructed of a material that disintegrates upon explosion without significant amounts of fragments being given off, and an explosive element disposed in the housing capable of producing an explosive force sufficient for breaching a structure.

Owner:SANSOLO ARIE

Vehicle with sacrificial underbody structure

A vehicle has a sacrificial buoyancy structure for attenuating damage to the vehicle body due to an under-vehicle explosion. The vehicle has a primary hull, connector plates disposed along the primary hull, track assemblies mounted to the connector plates, and gussets attaching the connector plates to the primary hull. The connection of the gussets to the primary hull is sacrificial in that a sufficient amount of explosive force detaches the gussets, connector plates and track assemblies from the primary hull, whereby the gussets, connector plates and track assemblies absorb a portion of the explosive force. The vehicle further has cross rods disposed between the connector plates and affixed thereto. The vehicle also has a sacrificial buoyancy hull beneath the primary hull attached to the cross members wherein the buoyancy hull, connector plates and primary hull form an enclosed buoyancy compartment enabling the vehicle to float on water.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Security bench

A security bench for use as a seat and as a defensive barricade against vehicles and explosive force comprises a support base, a framed screen securely attached to and overlapping the top of the base, and a seating surface attached to the top of the framed screen. The base, made of granite, concrete, or the like, is relatively massive, providing resistance to vehicular and explosive force. The frame portion of the framed screen, made from structural steel, reinforces the structural integrity of the base, and, along with the screen (and potentially the seating surface) acts to repel or absorb explosive force or debris.

Owner:WALTON DOROTHY GOODRICH

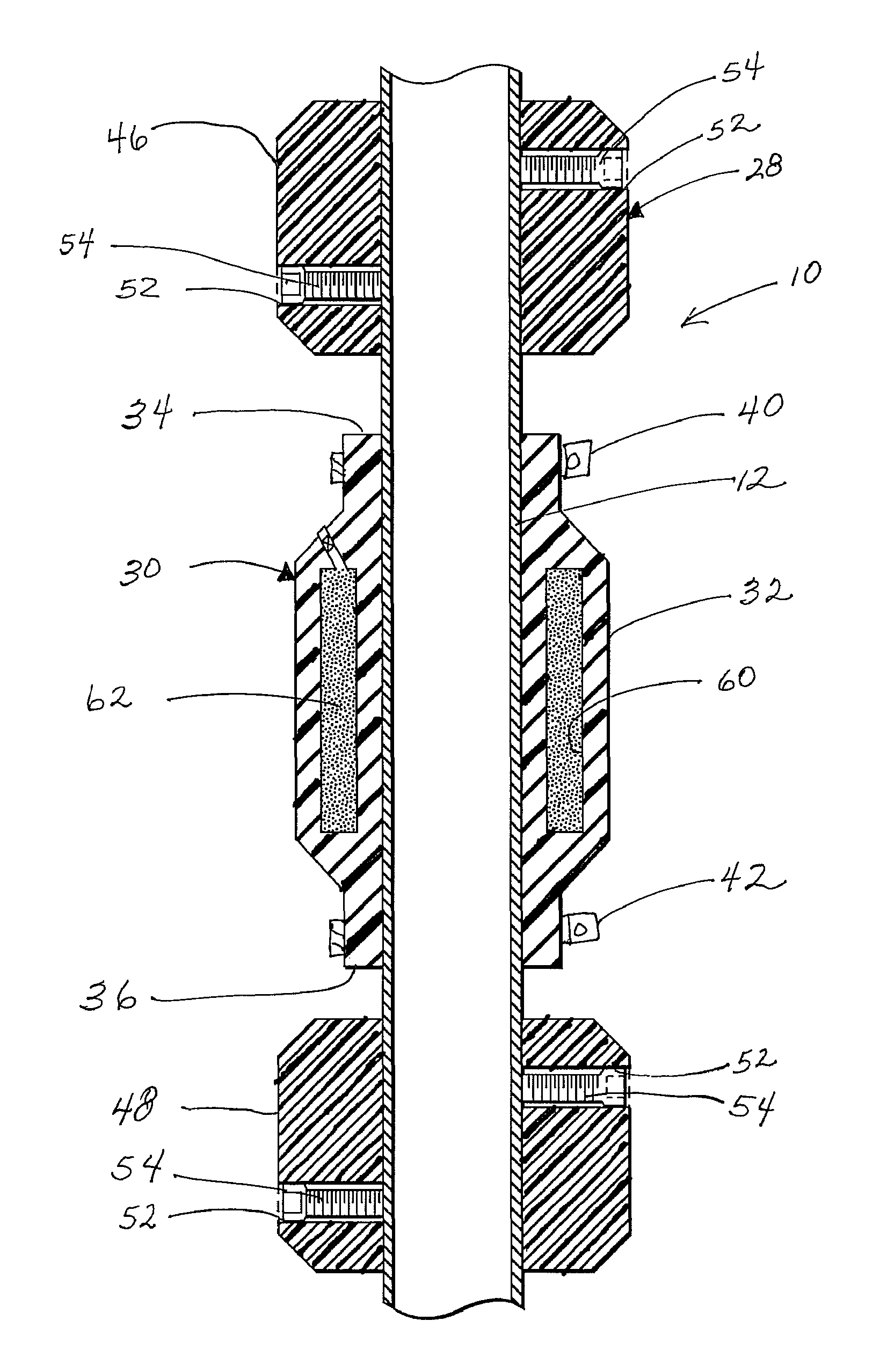

Well stimulation using reaction agents outside the casing

Methods and apparatus for stimulating oil or gas wells using material cemented outside the casing. Reaction agents, usually comprising oxygen-rich material and a coil of high order explosive, are positioned around the outside of the well casing at a desired level in a carrier and reacted later. The stimulation operation is initiated by firing a shaped charge into the high order explosive material. The combination of the explosive force of the high order explosive and burning of the oxygen-rich material fractures and cleans the formation adjacent to the well casing. The reaction agents may be provided in a sleeve supported on the casing joint at the time it is inserted into the well. In another embodiment, all components would be cemented externally to the casing and reacted remotely by a coded signal.

Owner:SUPERIOR ENERGY SERVICES LLC

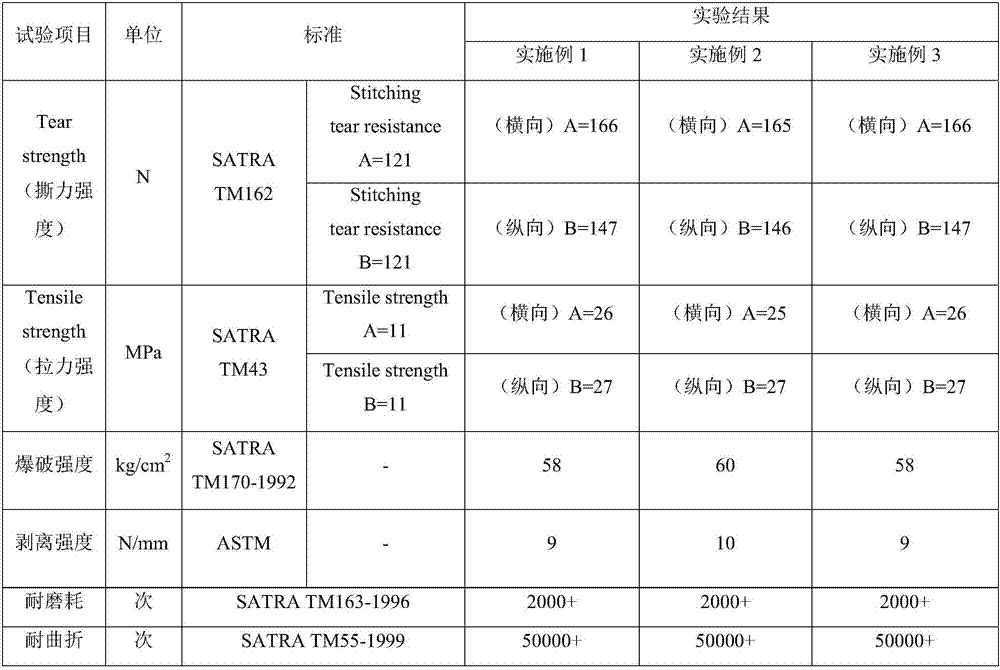

Preparation technology of two-layered leather with high explosive force

InactiveCN107287365AEasy to cleanGood flexibilityTanning treatmentPre-tanning chemical treatmentFiberPull force

The invention discloses a preparation technology of two-layered leather with high explosive force, and belongs to the technical field of leather. The preparation technology of the two-layered leather with the high explosive force comprises the following steps of primary water returning, secondary water returning, retanning and leather basifying, neutralizing, dyeing and greasing, color fixing, water washing, drum removing, drying, softening, leather fluffing and light beating. An independently researched and developed green and environment-friendly agent is added in all the steps, and the two-layered leather with the high explosive force is obtained through a safe and controllable preparation technological process; and the two-layered leather is stable in performance, high in tearing and pulling force resistant performance and high in explosive force, leather face fibers are thin, a leather body is full, and a velvet feeling is achieved.

Owner:漳州香洲皮革有限公司

Pulse water flow forming system driven by hydraulic power of fountain and surf

InactiveCN102139254AStrong water flowStrong ornamentalLiquid spraying apparatusPressure riseWater source

The invention relates to a pulse water flow forming system driven by the hydraulic power of fountain and surf. Water enters a branch pipe through a main pipe and an air pressure storage tank after being pressurized by a water pump, enters respective capillary pipes in a manner of the pulse water flow with the pressure rising quickly and dropping slowly after passing though pulse valves in the front of the respective capillary pipes, and is jet in pulse manner through sprayers (nozzles) installed on the respective capillary pipes for people to appreciate and play. Jet water flows back to a water source to recycle after confluence, sterilization and filtering. As the pressure rises quickly while drops slowly, based on the design of the air pressure storage tank, jet water flow has the characteristics of strong explosive force, slow drop, good visual effect and strong appreciation. The pulse frequency can be regulated in a large range; the sprayers (nozzles) of different groups and different types can be driven through setting pulse valves at different frequencies, so that the jet water flow has changeable patterns, rises one after another, and is interesting. Compared with an electronically controlled system driven by electrical power, the system adopts simple structure, has good safety, needs low investment cost, and is easy to maintain and repair.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

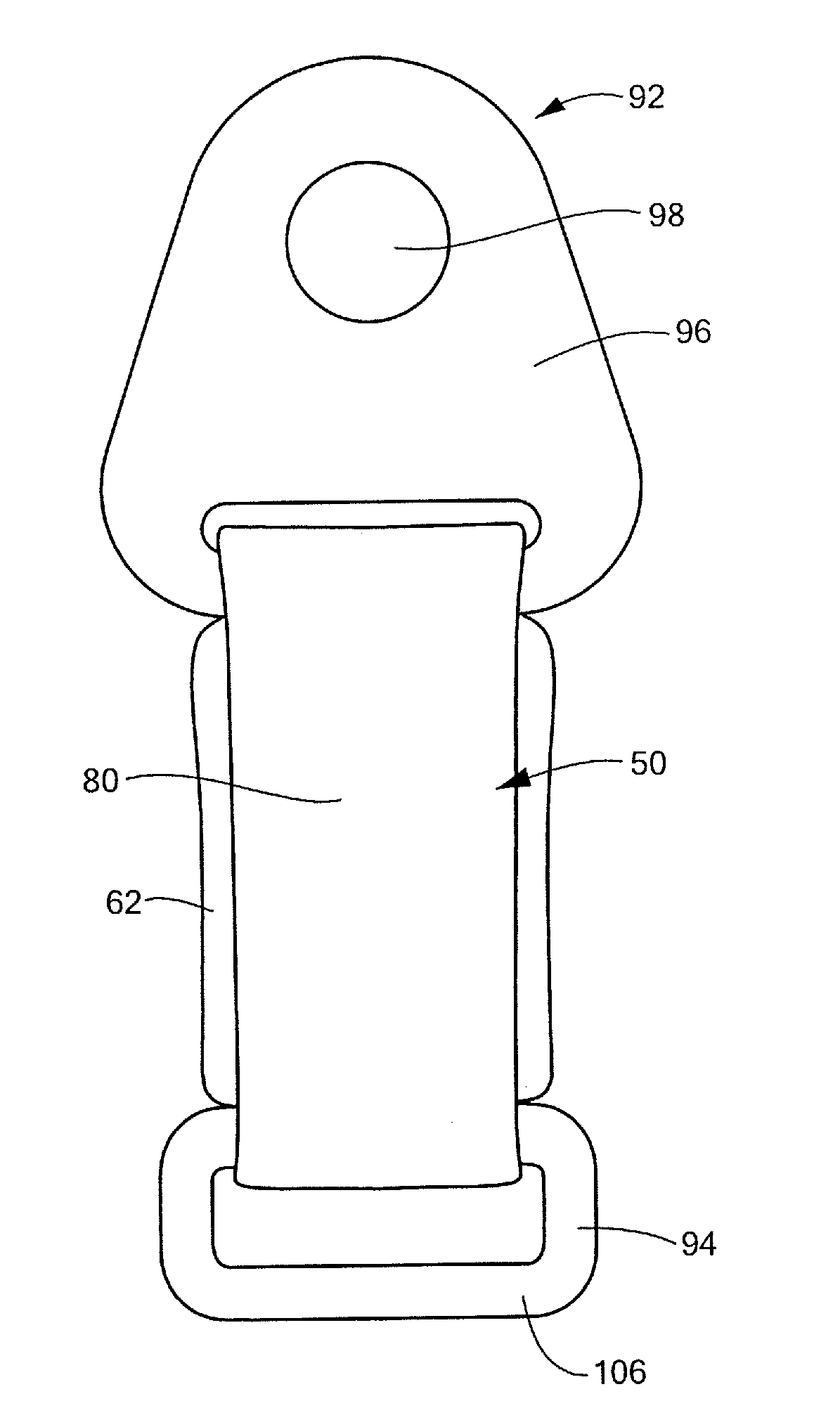

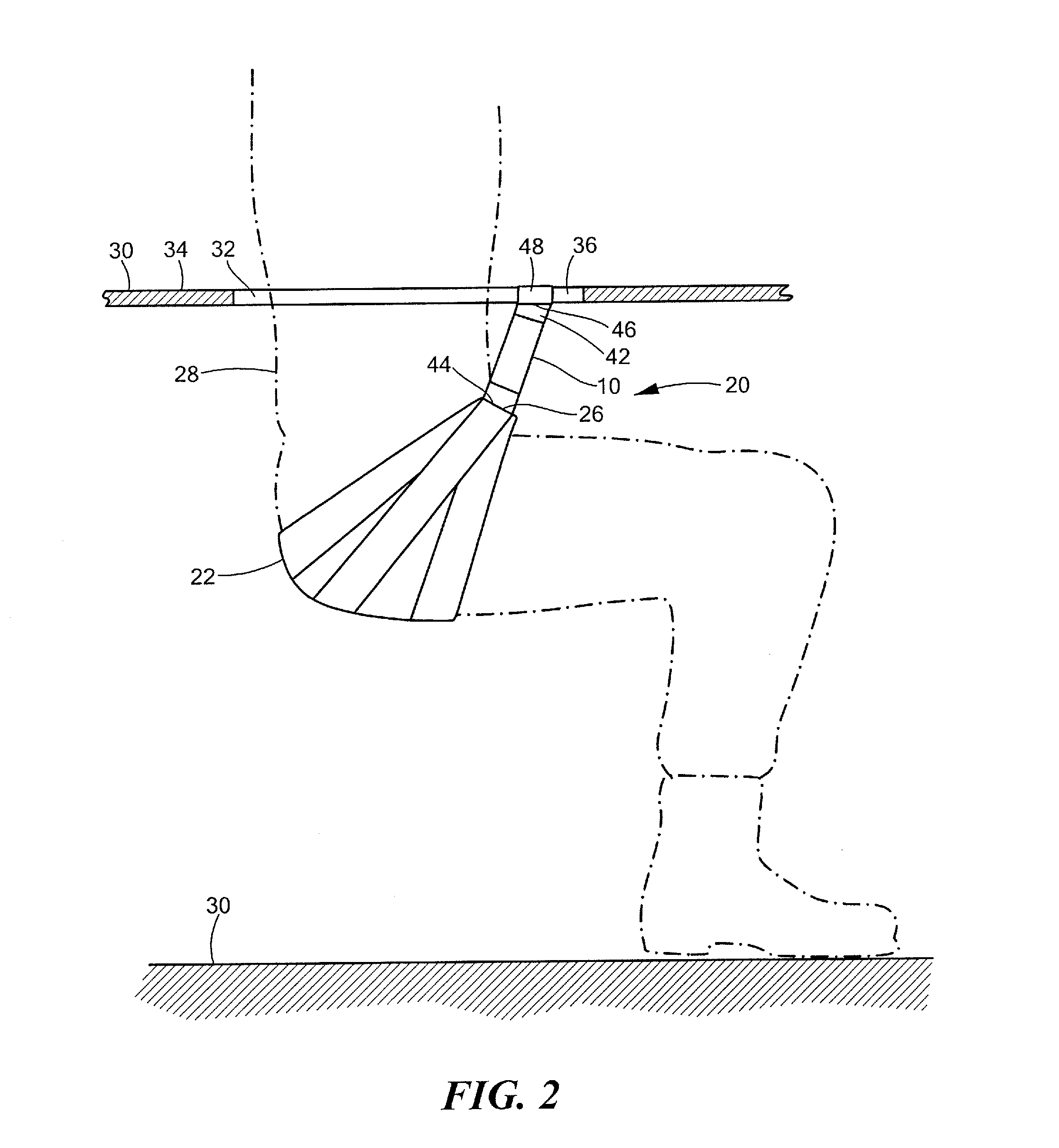

Energy absorbing system for blast mitigation of support elements such as suspended seats or stretchers in military vehicles

InactiveUS20130033056A1Reduce harmProtection from damageVehicle seatsPedestrian/occupant safety arrangementFiberAbsorbed energy

An energy absorbing system for blast mitigation is provided for a suspended support element, such as a gunner seat or medical stretcher, in a vehicle. An energy absorbing element is located in series within at least one suspension element of the seat or stretcher. The energy absorbing element includes an extensible section having a contracted, folded configuration and an extended configuration. A retention element, such as stitching or entangled interlocking fibers, retains the energy absorbing element in the contracted configuration. The retention element remains intact when the energy absorbing element supports a load from the person on the seat or stretcher and fails over a period of time when an explosive force is applied to the vehicle from underneath, causing the vehicle to move upwardly, the extensible section thereby extending in length and absorbing energy. Injury to the person can thereby be reduced.

Owner:HARDWIRE

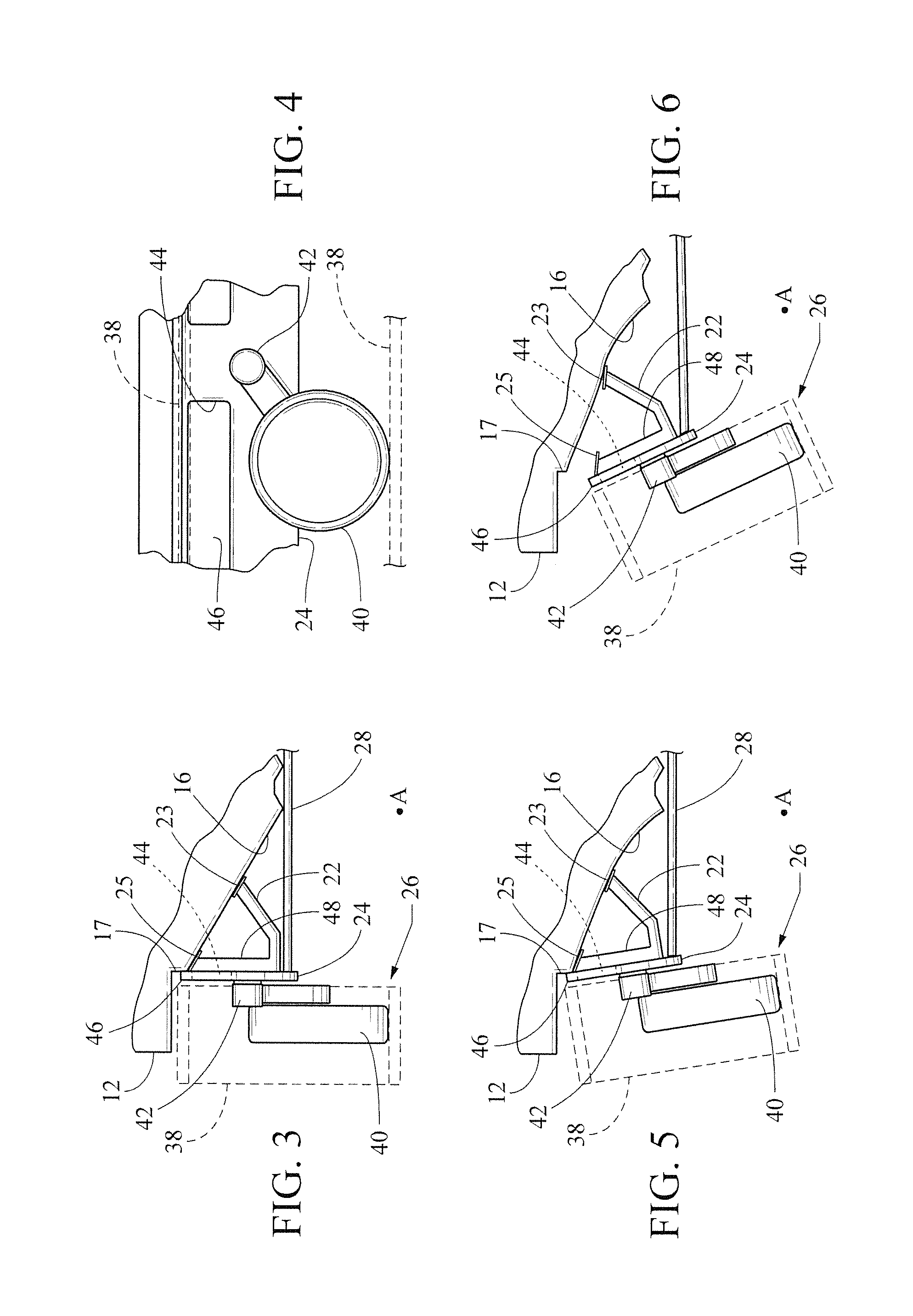

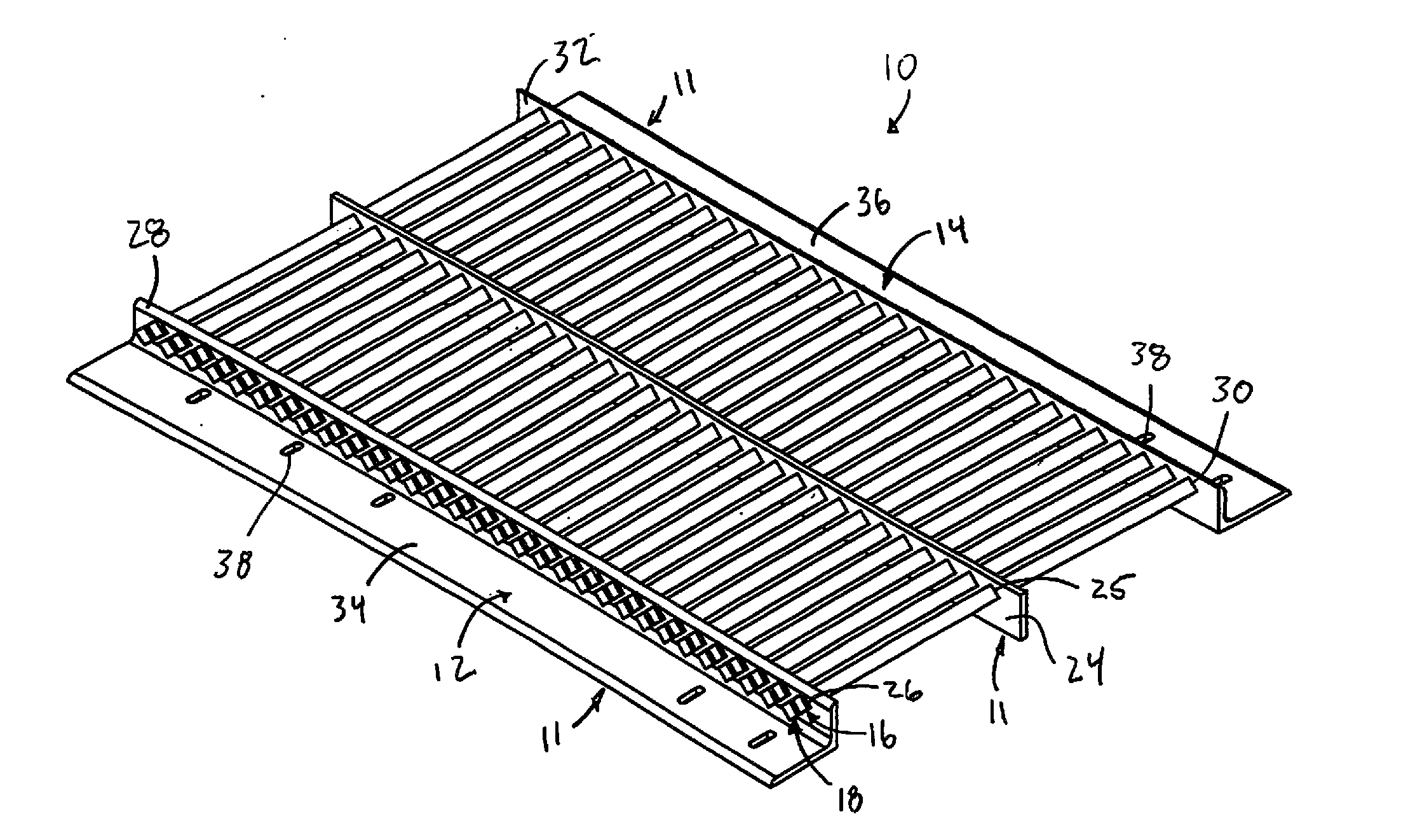

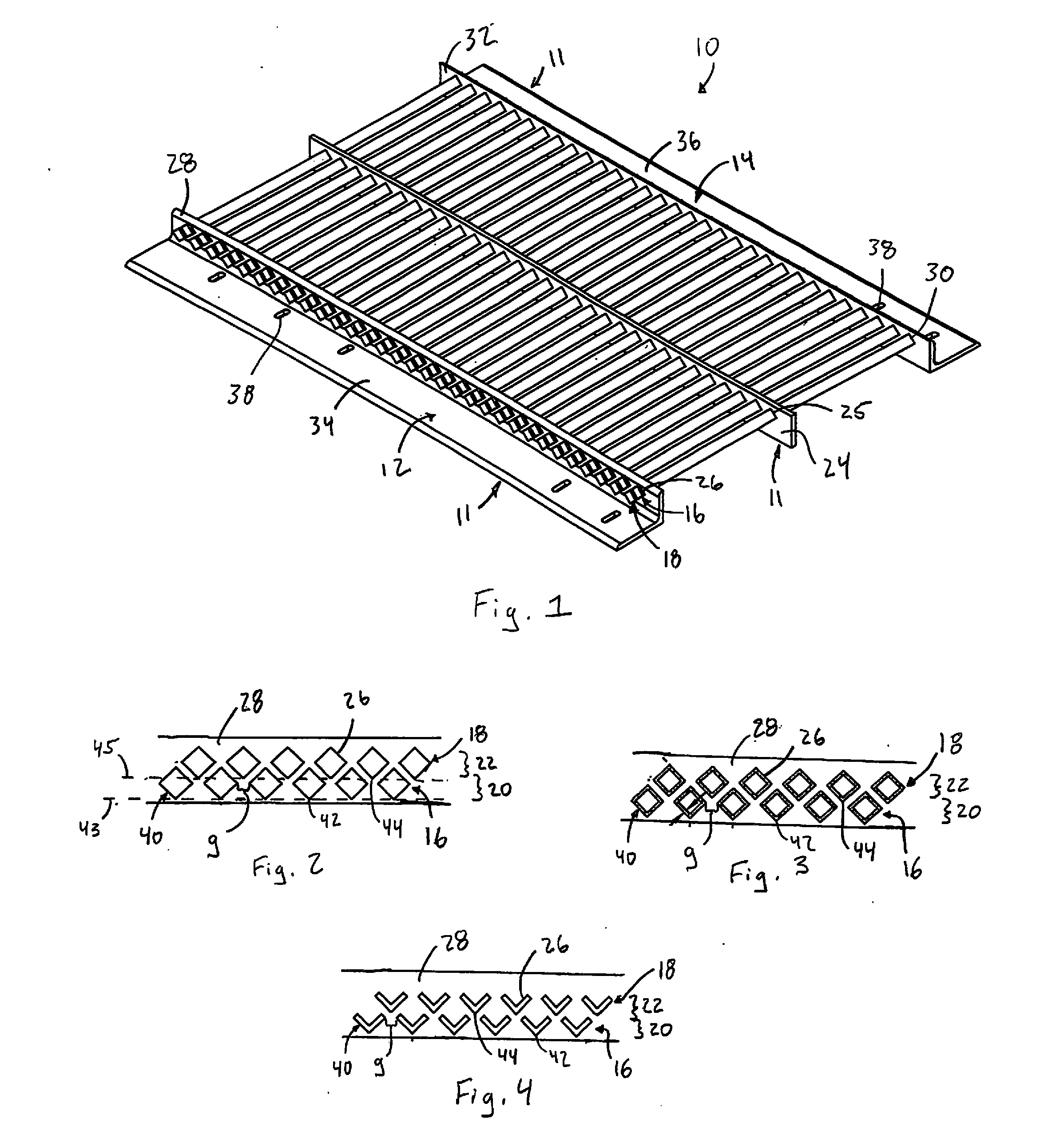

Blast shield

InactiveUS20140123842A1Dissipating momentumProtection from forceArmour platesShieldsMomentumEngineering

A blast shield placed over a structure to be protected from the force of a blast includes a support assembly and a plurality of first deflection members secured to said support assembly. Each of said plurality of first deflection members present opposed surfaces angling away from the direction of an incoming explosive force, such that an incoming explosive force is split and deflected by the opposed surfaces thus dissipating the momentum of the explosive force. A plurality of second deflection members presenting opposed surfaces angling away from the direction of an incoming explosive force may also be employed, whereby an incoming explosive force is further split and deflected by the opposed surfaces thus dissipating the momentum of the explosive force.

Owner:MEGGITT ROCKMART

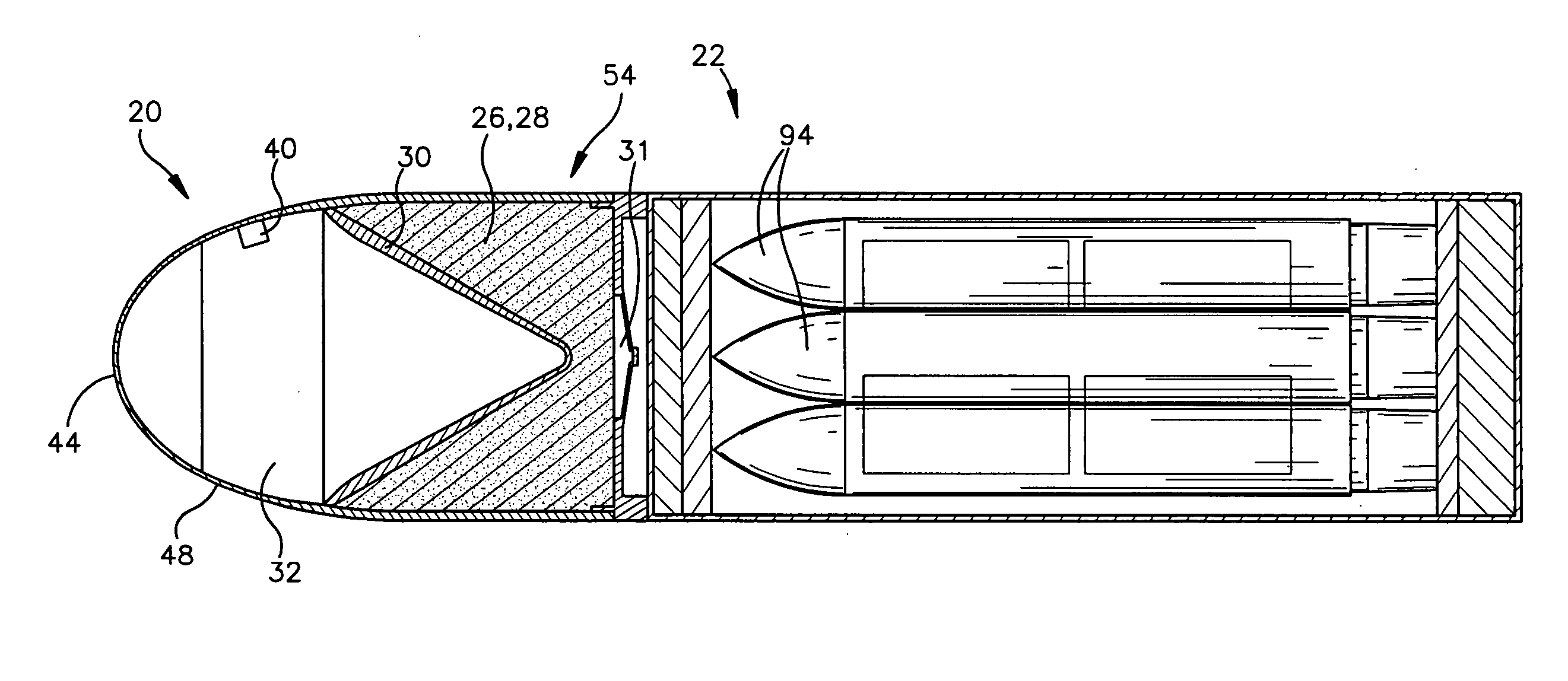

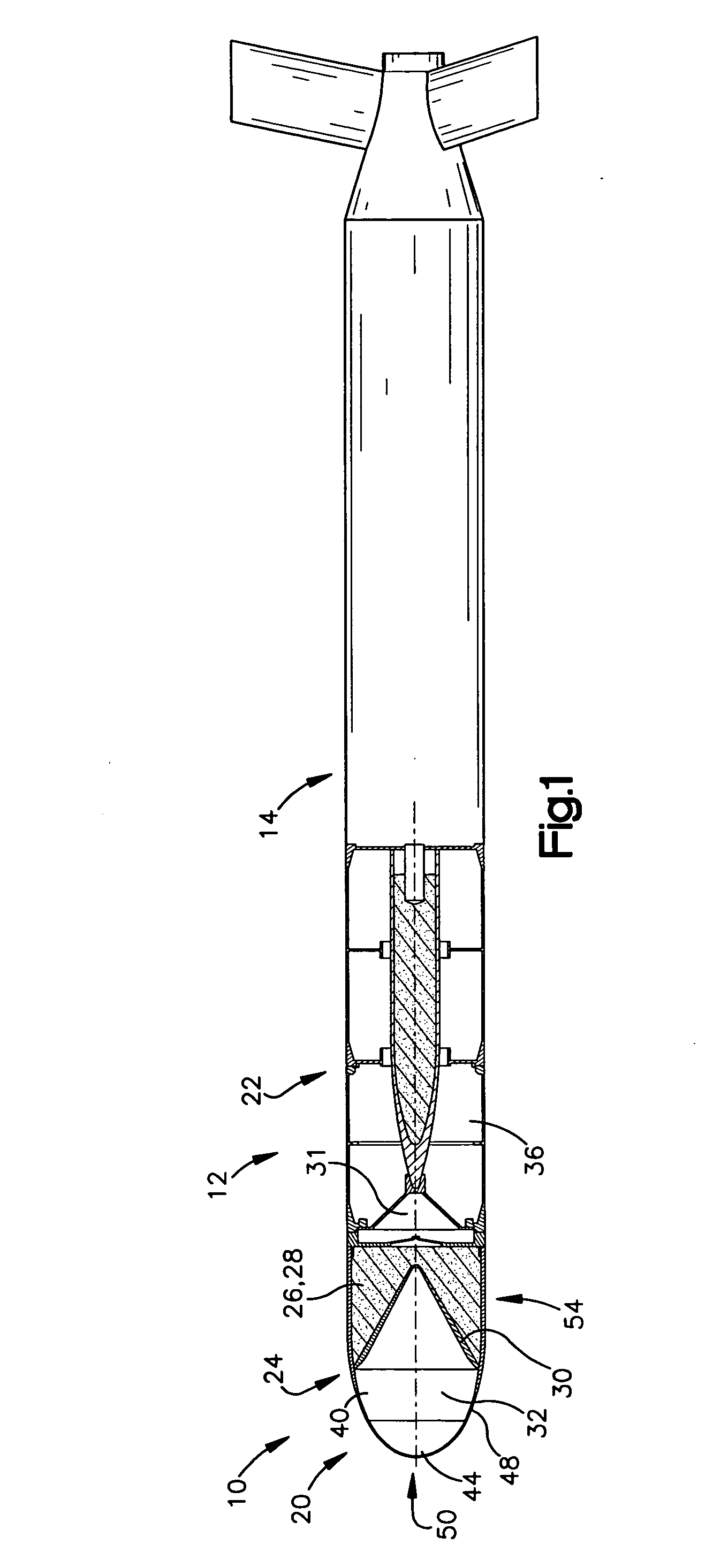

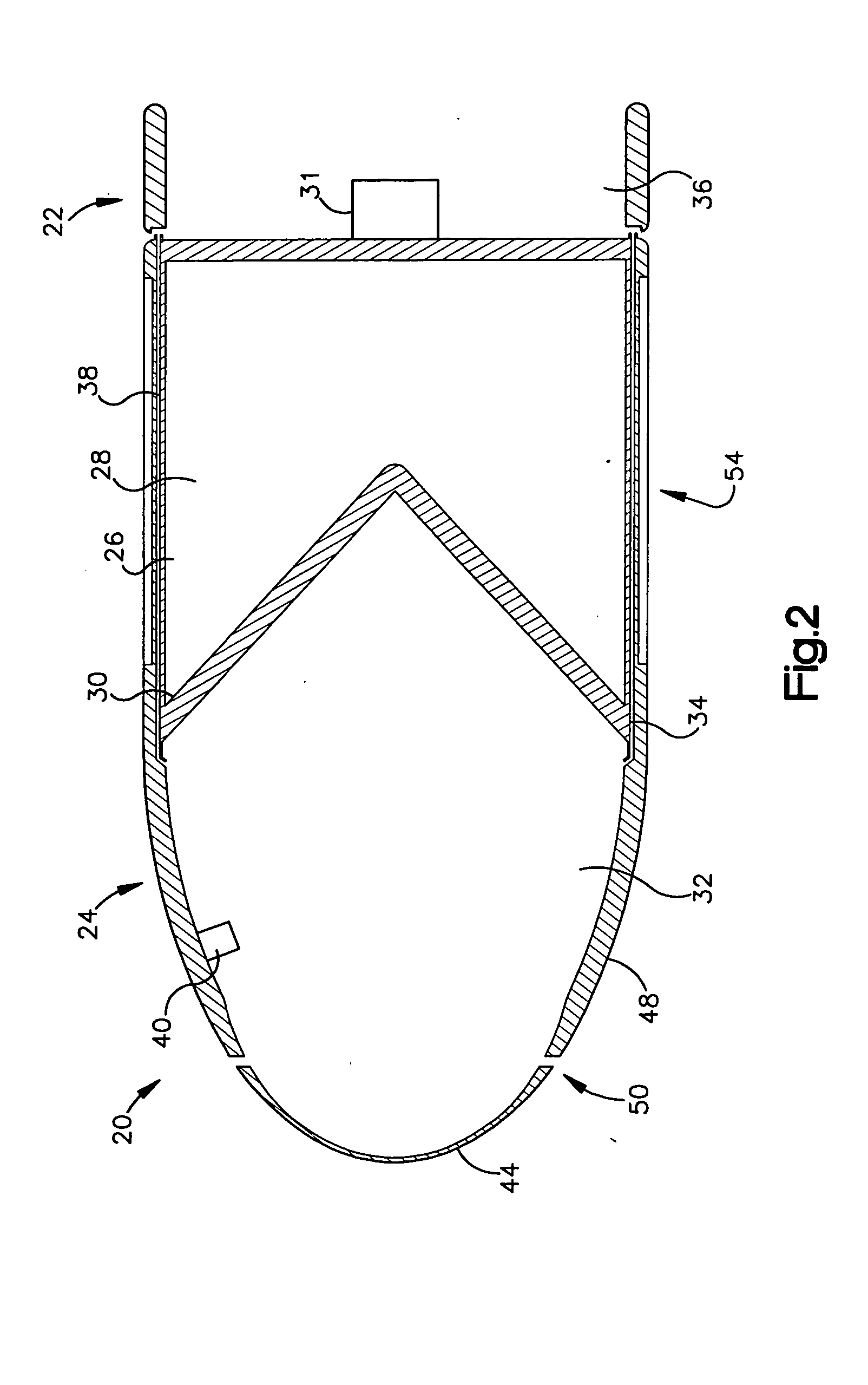

Multi-mission payload system

A missile, such as a cruise missile, has a nose payload portion having a frangible nose cover and a relatively hard target penetration nose cone. The nose cone may have a liquid fuel tank within, and a chemical energy explosive charge, such as a shaped charge, aft of the liquid fuel tank. The target penetration nose cone enables perforation of certain types of targets prior to detonation of the chemical energy explosive and the liquid fuel. The frangible nose cover is configured to be easily perforated or otherwise removed by the explosive force of the chemical energy explosive charge when the missile system is utilized for the attack of hard targets. The nose payload portion may have a fragmentation case, with one or more features designed to enhance fragmentation during detonation of the explosive and / or the liquid fuel.

Owner:RAYTHEON CO

Multi-shot charge for perforating gun

ActiveUS10000994B1Increase the number ofSmall sizeExplosive chargesAircraft componentsDetonationEngineering

A multi-shot explosive charge includes a plurality of chambers divided by shared walls between adjacent chambers. Explosive material within at least one of the chambers creates an explosive force in an outward direction upon detonation and a perforating jet through the open end of the chamber. A perforating charge includes at least one explosive material producing explosive forces, upon detonation that collide within the chamber to create a perforating jet. Such perforating charge may be a chamber(s) within a multi-shot explosive charge, or an individual charge. First and second explosive materials can have the same or different compositions and detonation rates that together with the arrangement of materials within the chamber create the collision of forces. A plurality of multi-shot explosive charge or stand-alone perforating charges with colliding forces can be interconnected in an array, and can be included in a perforating gun(s).

Owner:IDEASCO LLC

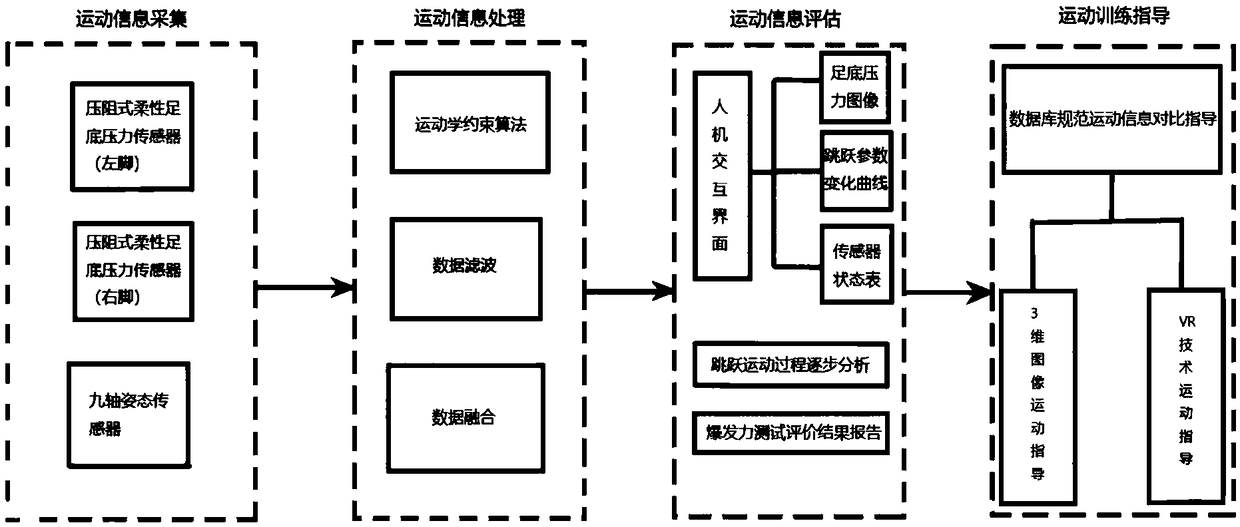

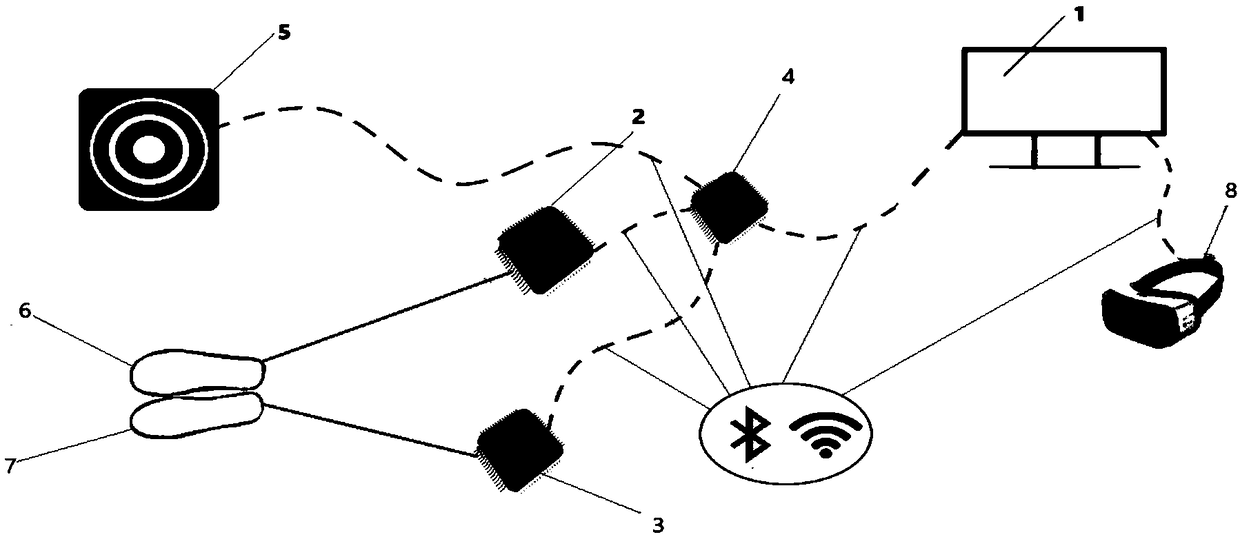

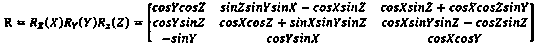

Comprehensive evaluation and training system for human jump indexes based on multi-modal signal

InactiveCN109260647AWatch clearlySave training timeJumping apparatusInformation processingEvaluation result

A comprehensive evaluation and training system for human jump index based on multi-modal signal is composed of a motion information collection module, a motion information processing module, a motioninformation evaluation module and a motion training guidance module, which can analyze and train a human lower limb explosive force, speed and other motion indexes. The device is designed based on nine-axis sensor, which overcomes the shortcomings of single data dimension, big error of evaluation result and single evaluation of traditional evaluation device. In the human-computer interaction interface of the information evaluation module, subjects can clearly see the multi-dimensional motion data and analysis results, and store and share them to the evaluation center. In the human-computer interaction interface of the training instruction module, the instructor can also set the movement parameters by himself, display the movement effect through VR technology, and make the best human jump training scheme. The device has the advantages of small volume, low cost of use and maintenance, high reliability, and is suitable for the evaluation and training of human jumping movement indexes.

Owner:ZHENGZHOU UNIV

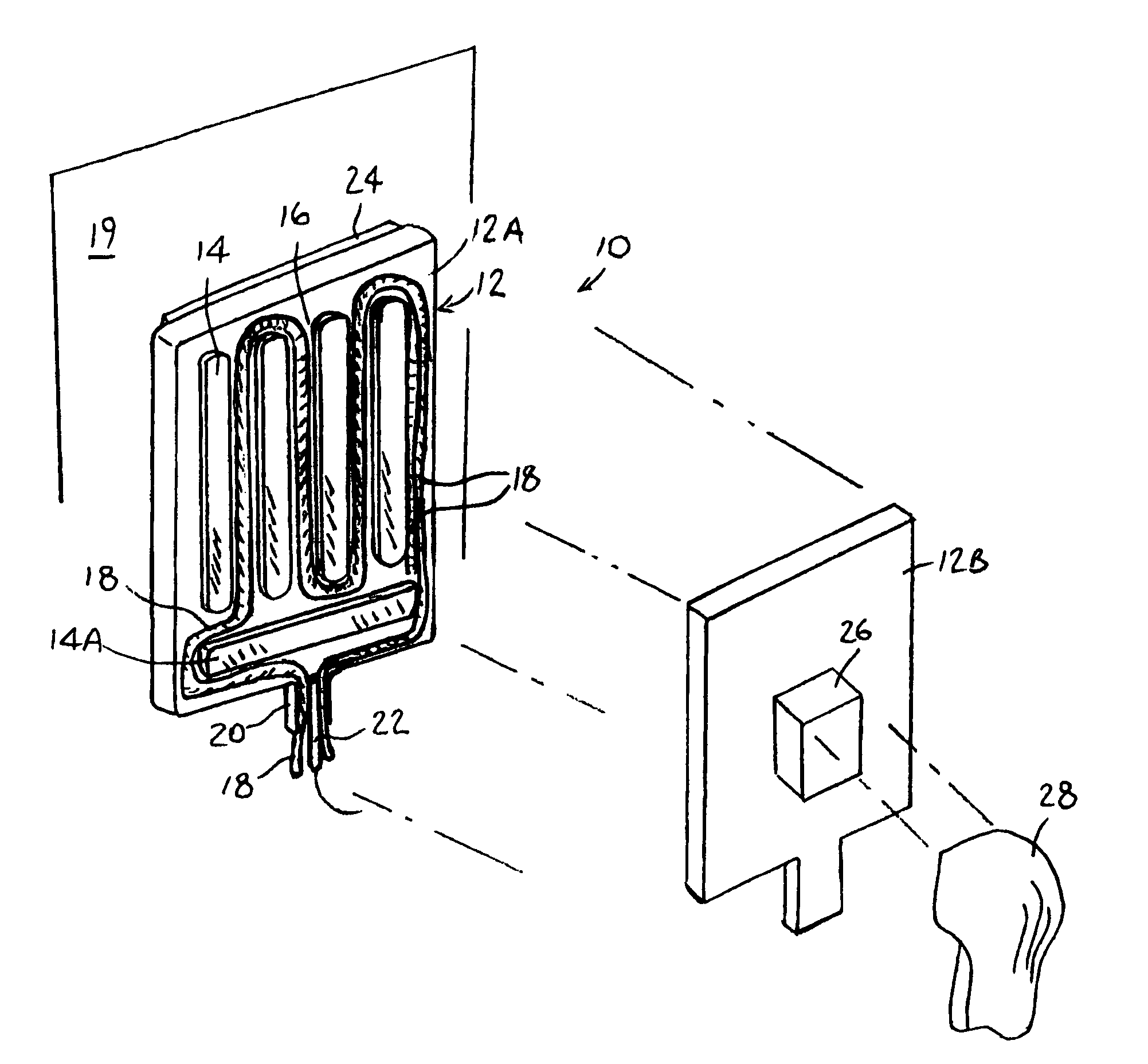

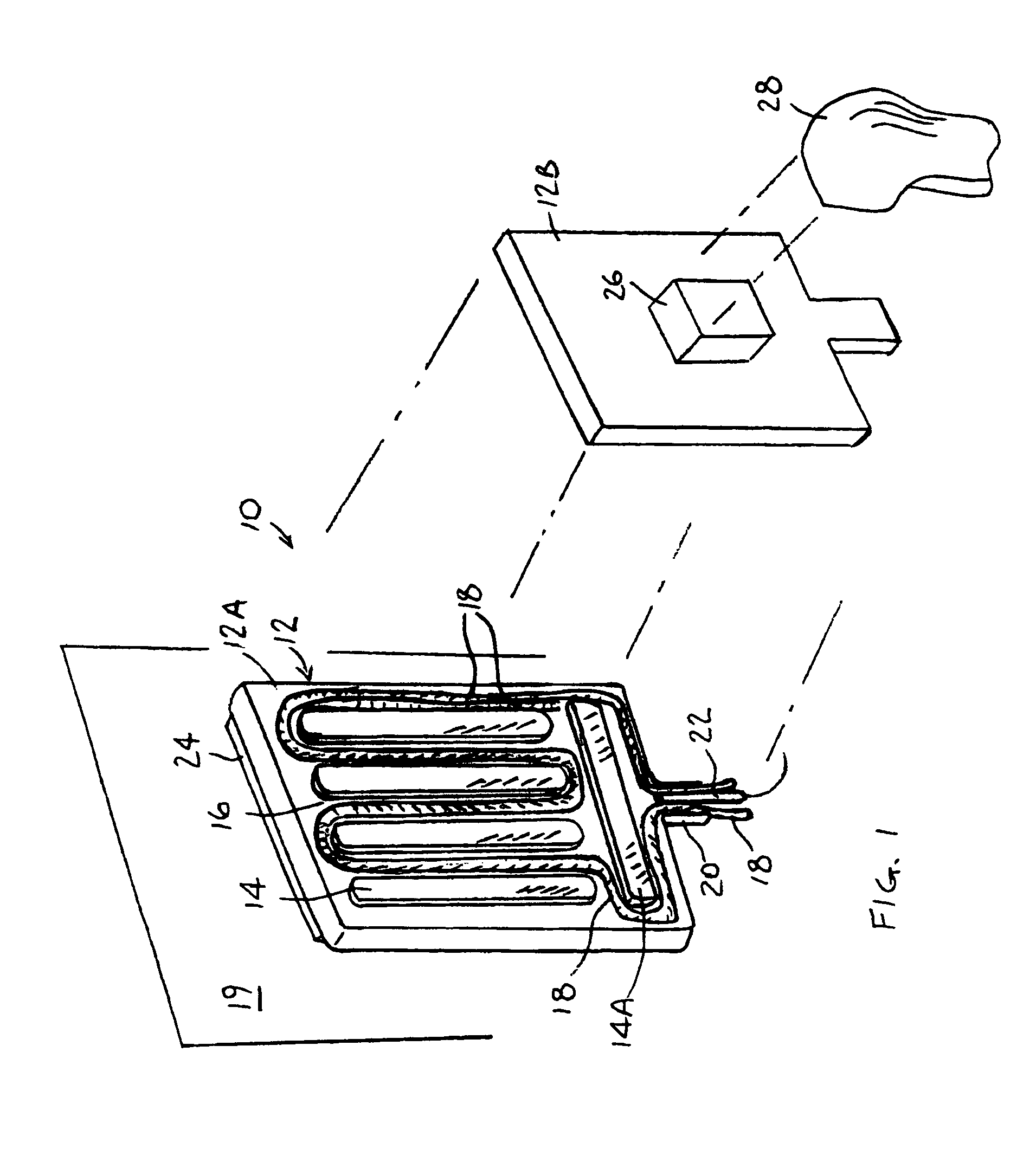

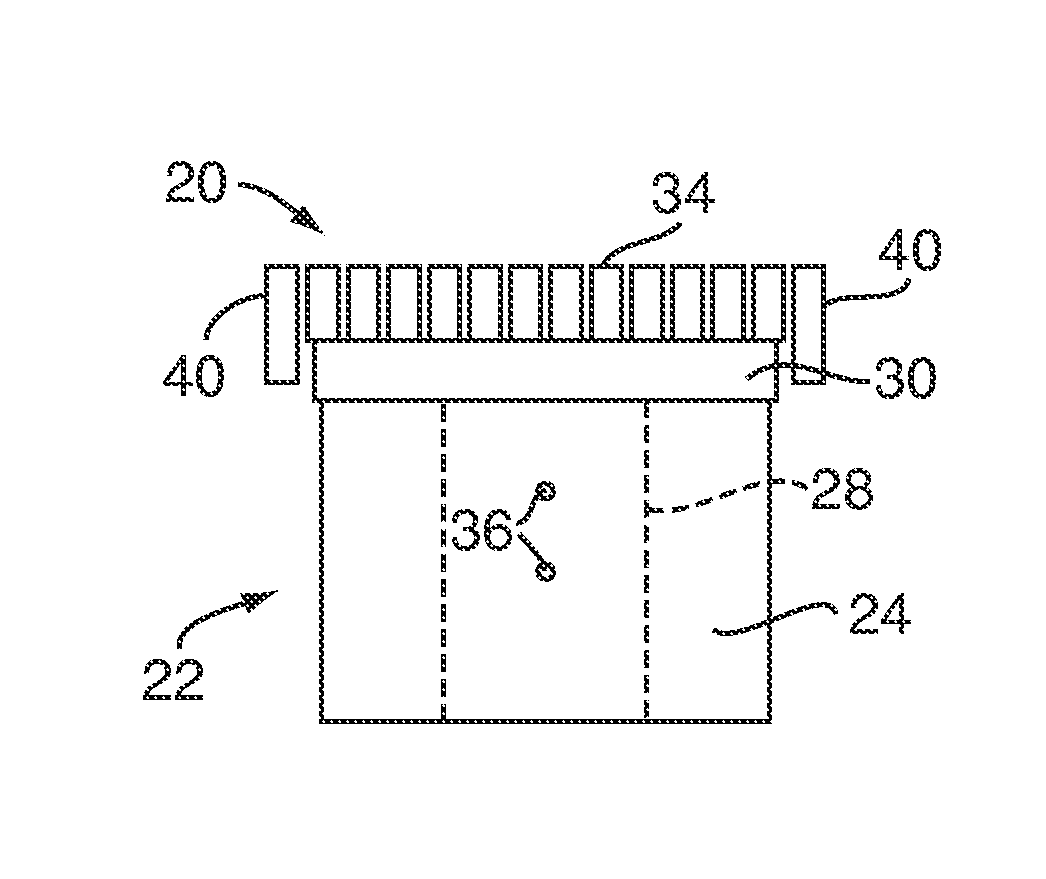

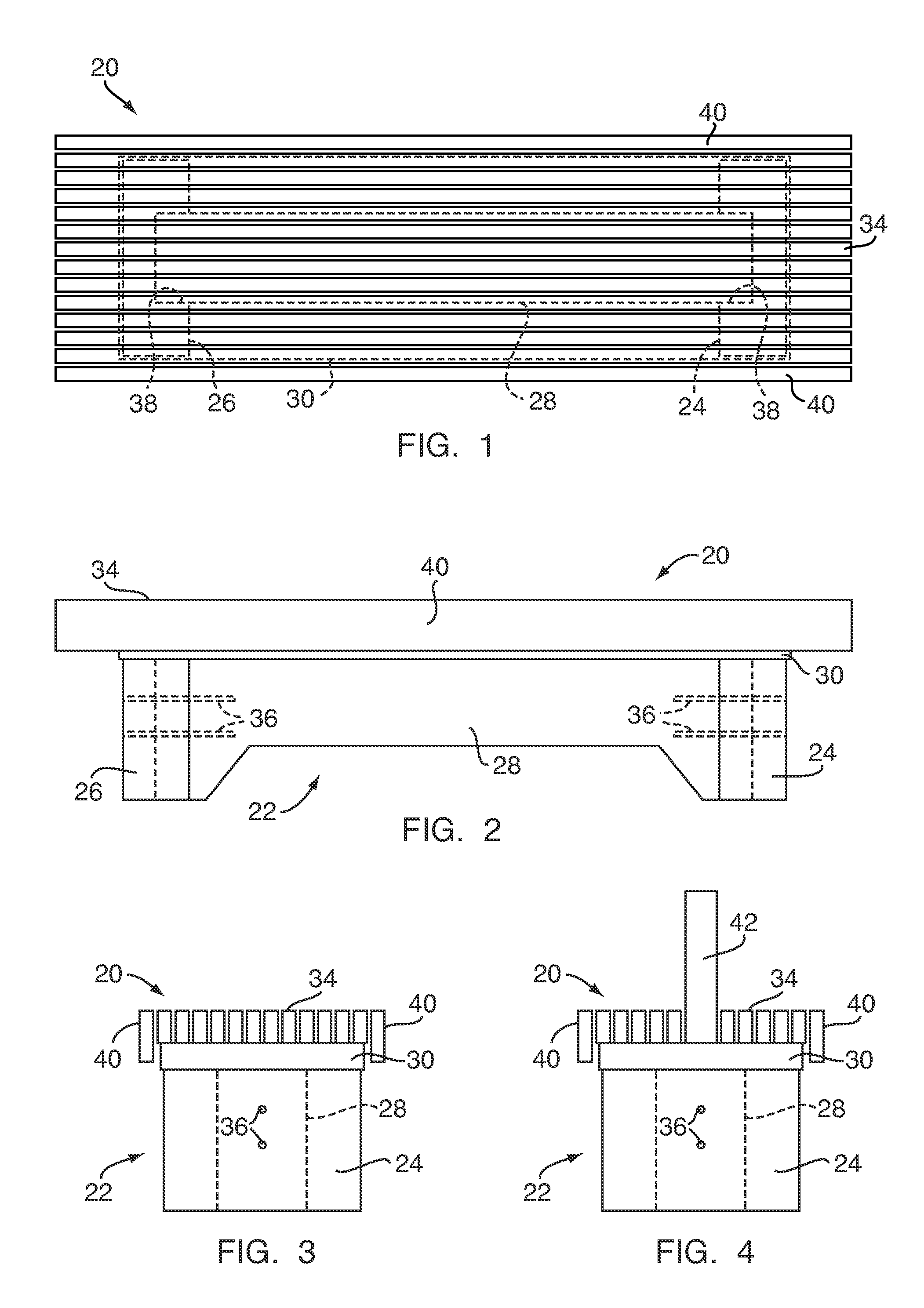

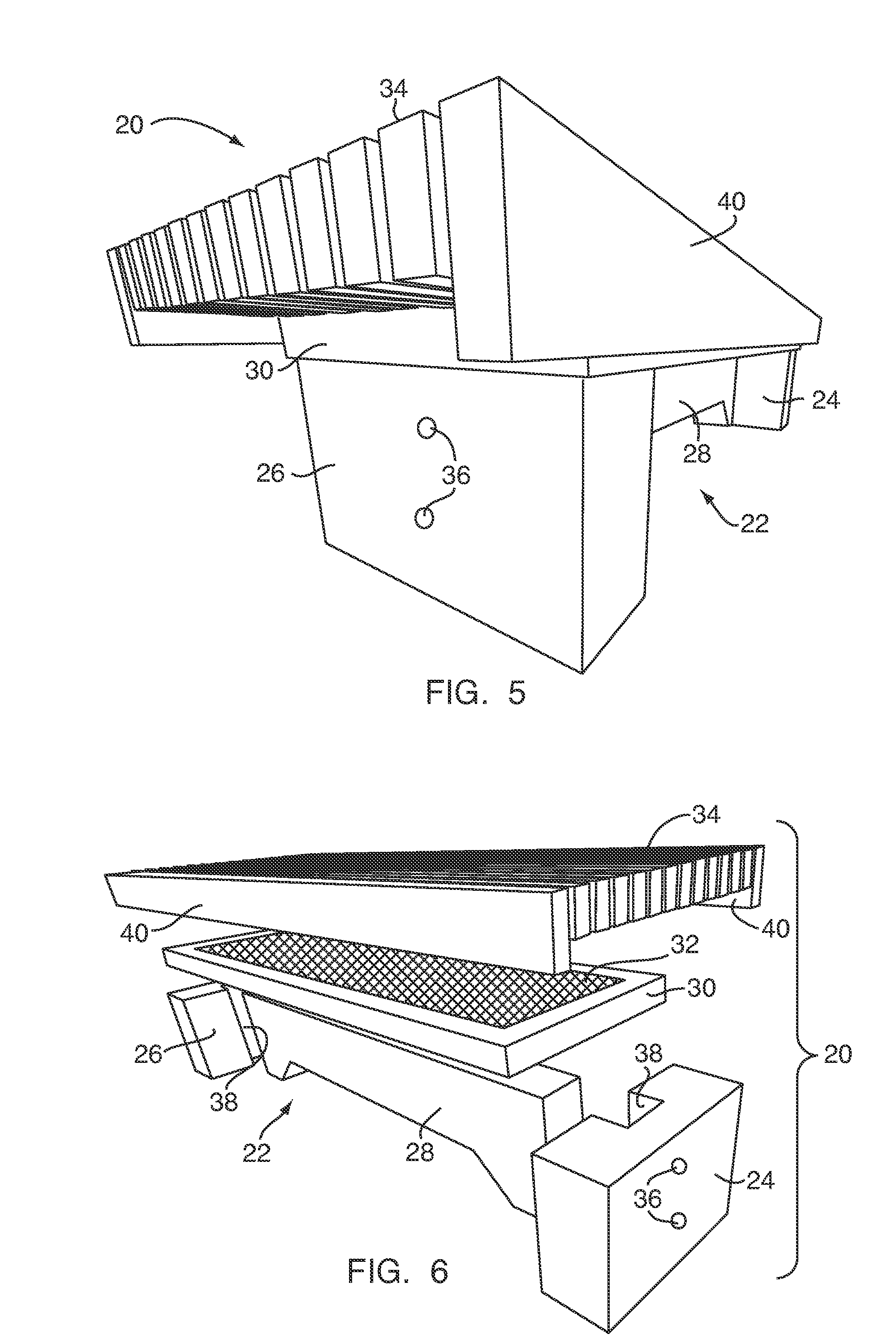

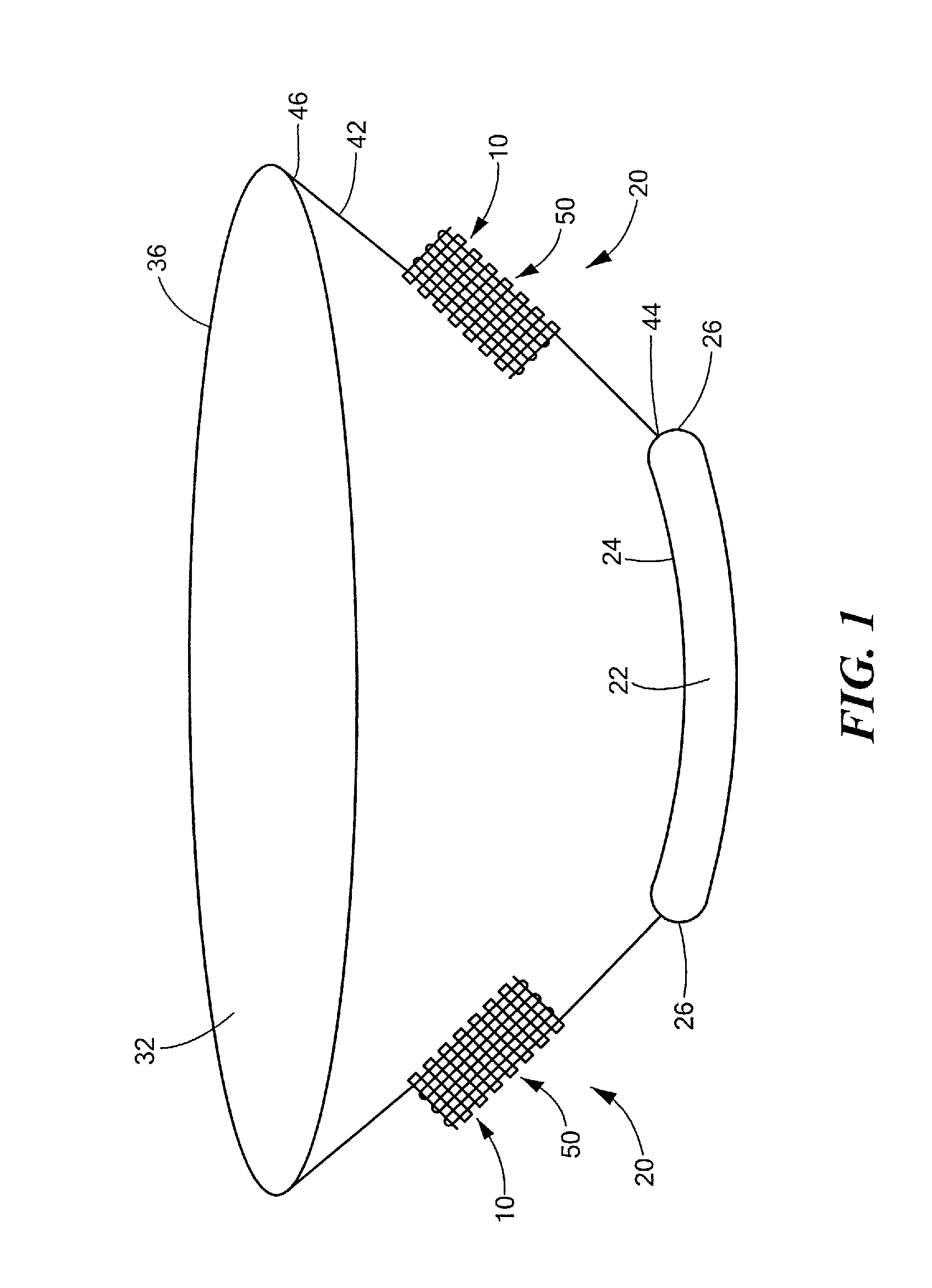

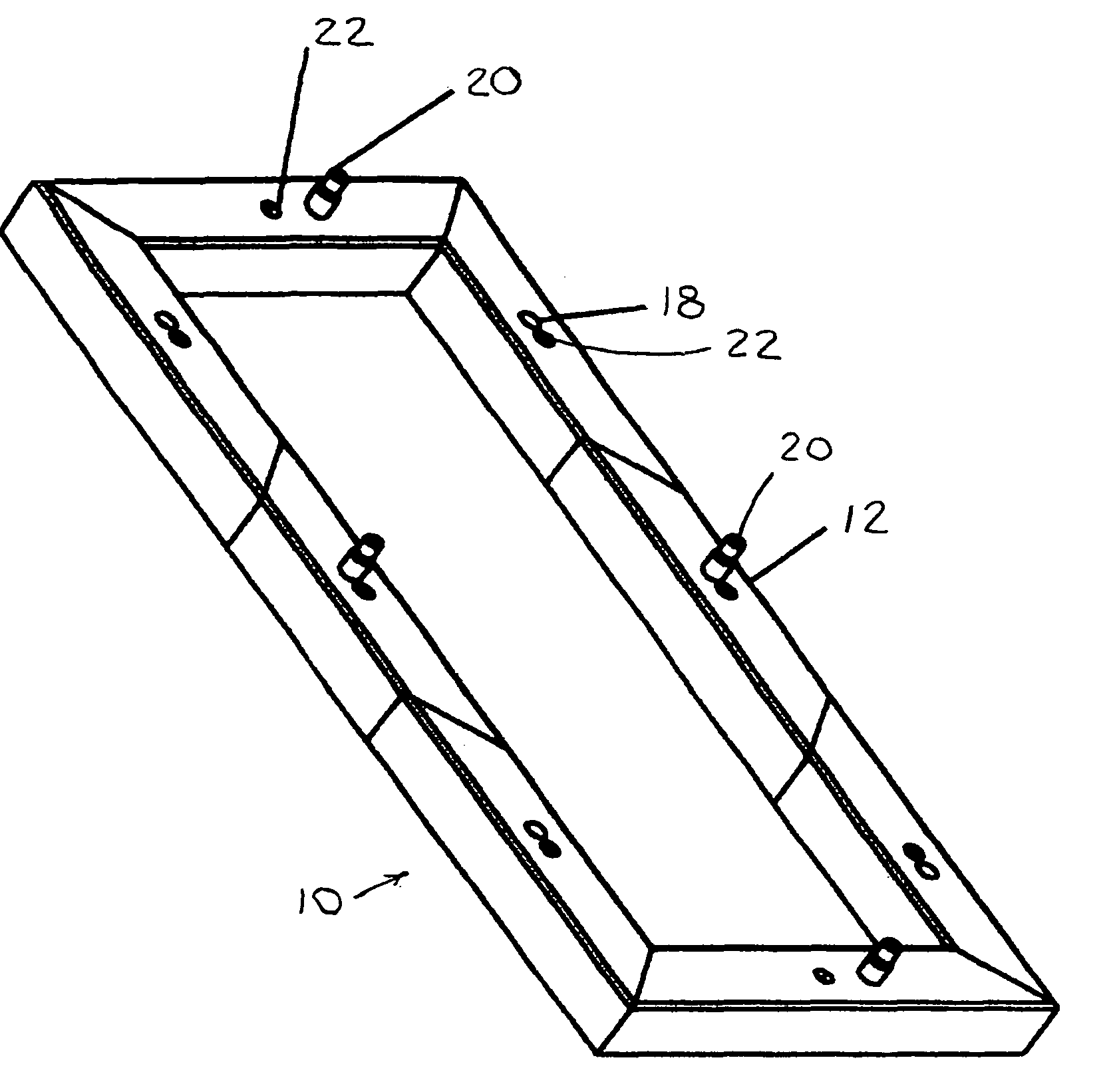

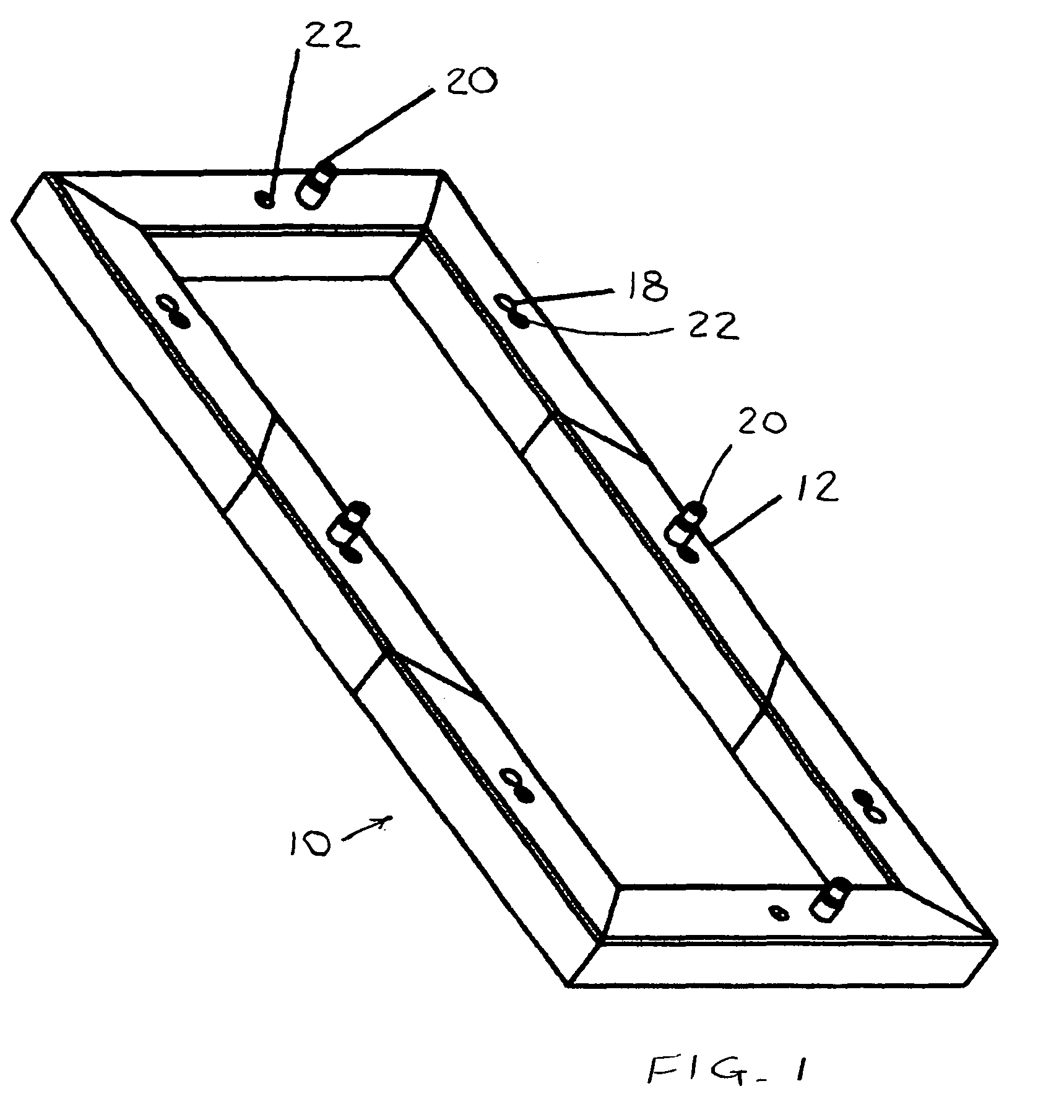

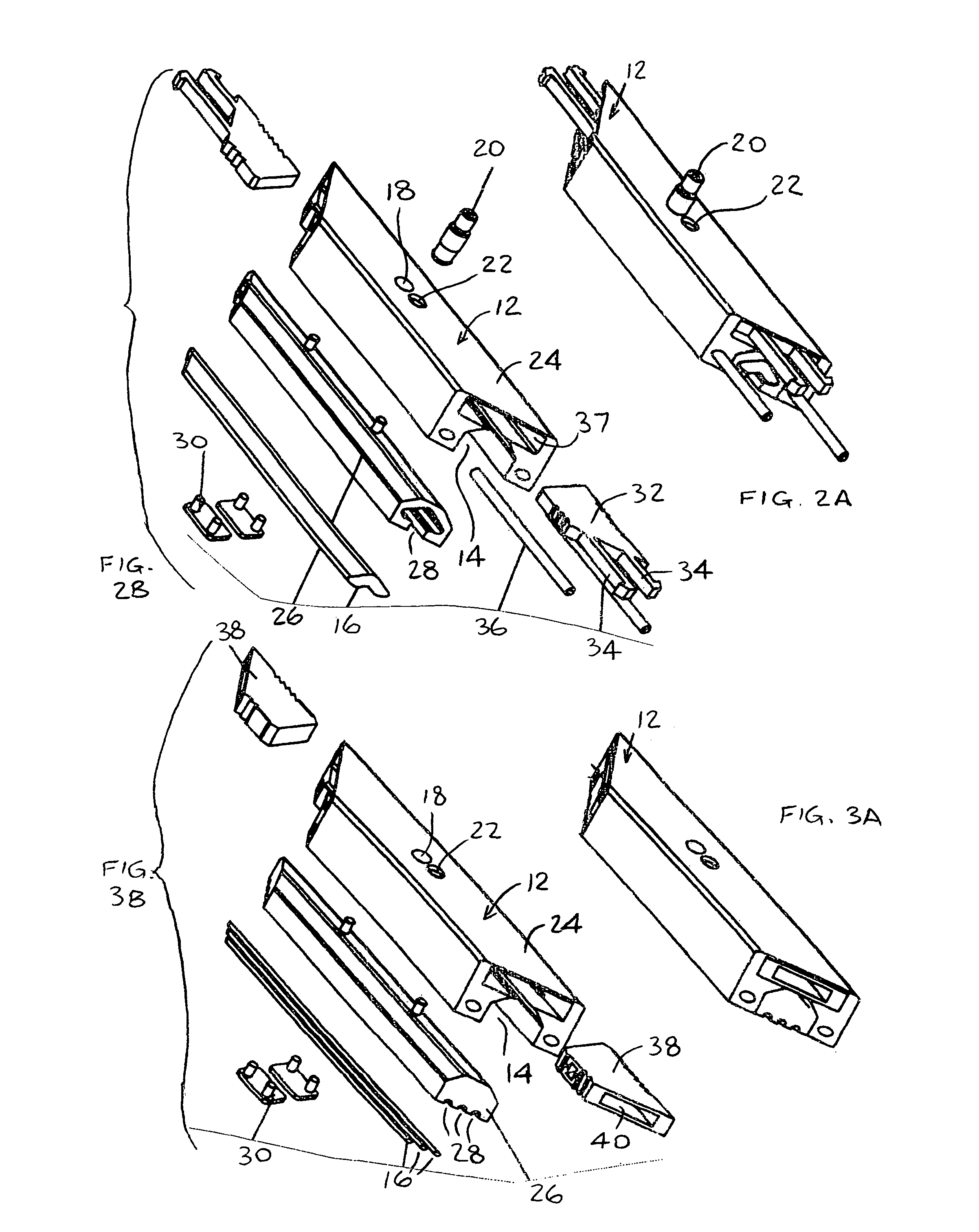

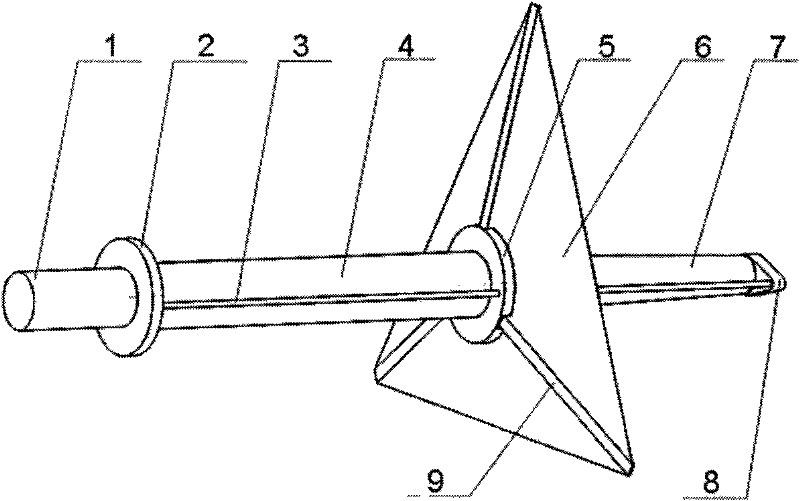

Modular breaching apparatus

Modular breaching apparatus including a plurality of breaching elements, each breaching element being formed with a groove for receiving therein a flexible explosive element capable of producing an explosive force sufficient for breaching a structure, wherein each breaching element includes a receptacle for placing therein a detonator, an attachment device for attaching to a structure.

Owner:SANSOLO ARIE

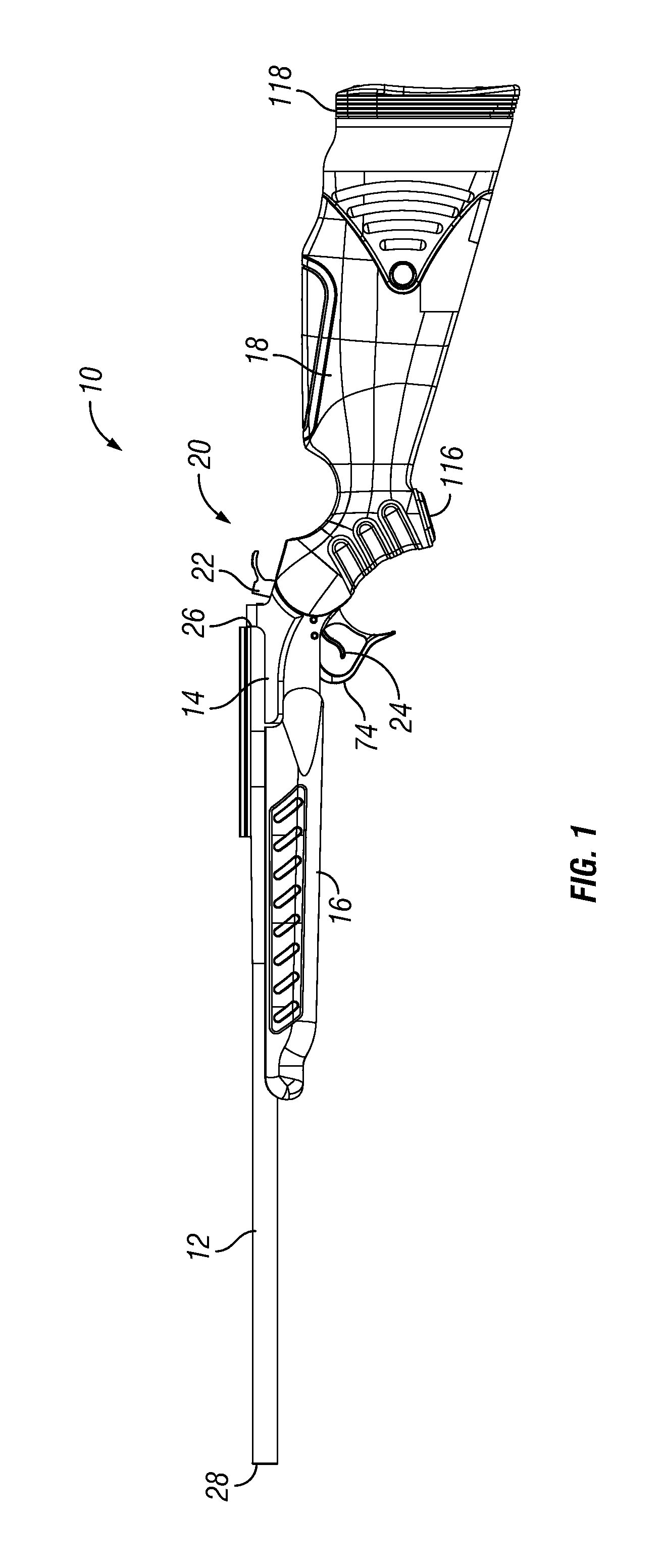

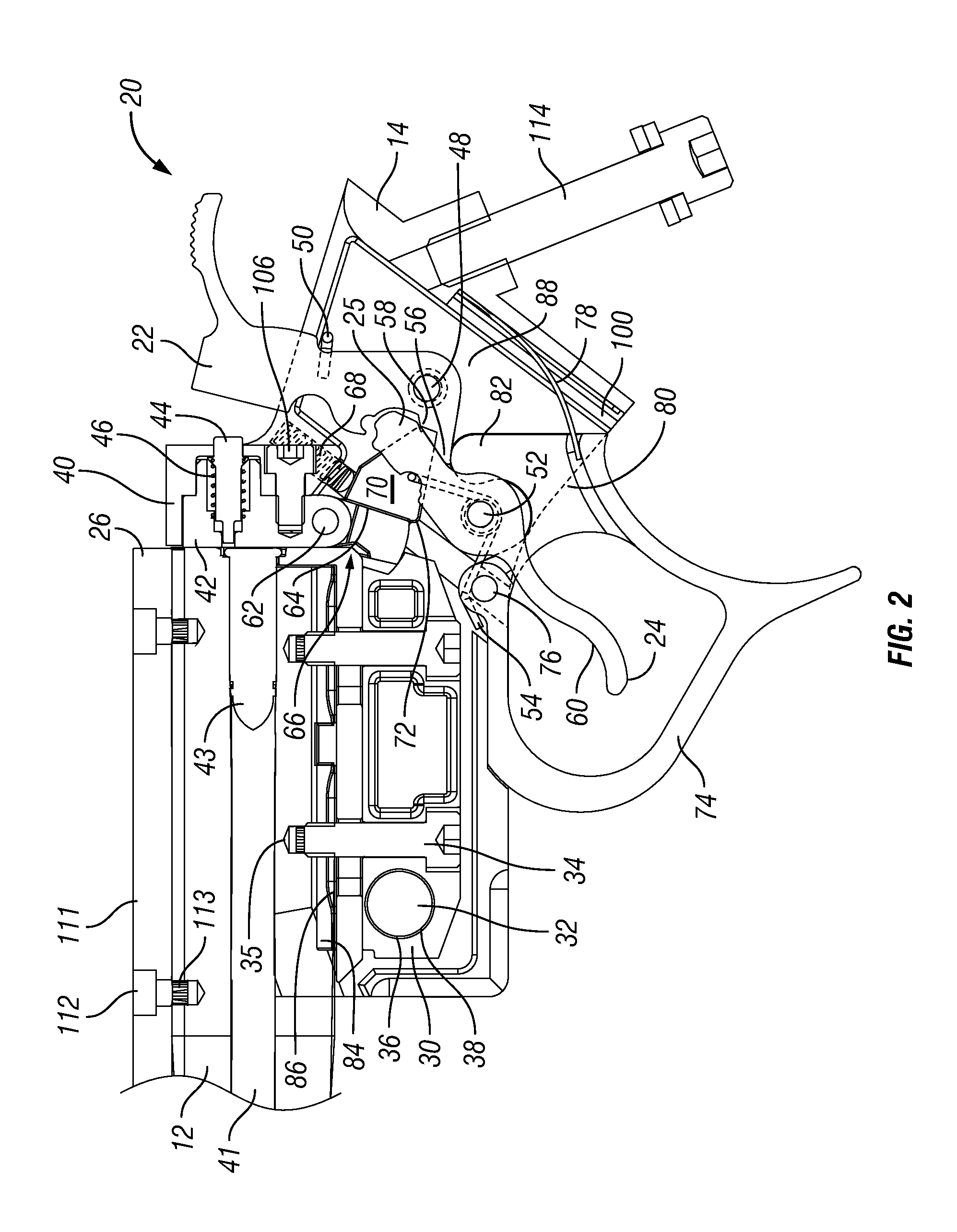

Unitary breechblock assembly

InactiveUS20120023800A1Low costSturdy wearBreech mechanismsShoulder-fired smallarmsEngineeringSingle shot

A single-shot break action firearm includes a receiver, a barrel, and a stock. The receiver has a breach portion that defines a cavity that is sized and shaped to house a breechblock therein. The breechblock is constructed from a powdered metal formed by metal-injection-molding. The breechblock is form from a higher strength material than the receiver to contain explosive forces produced during discharge of the firearm. The barrel is connected with the receiver and extends forward therefrom. The stock is connected with the receiver and extends rearward therefrom.

Owner:SMITH & WESSON

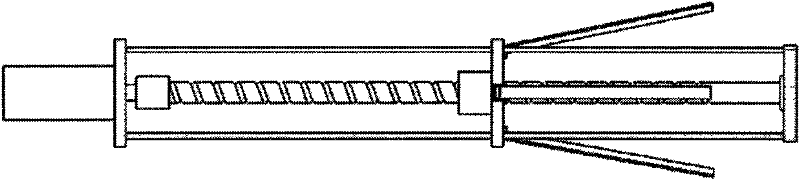

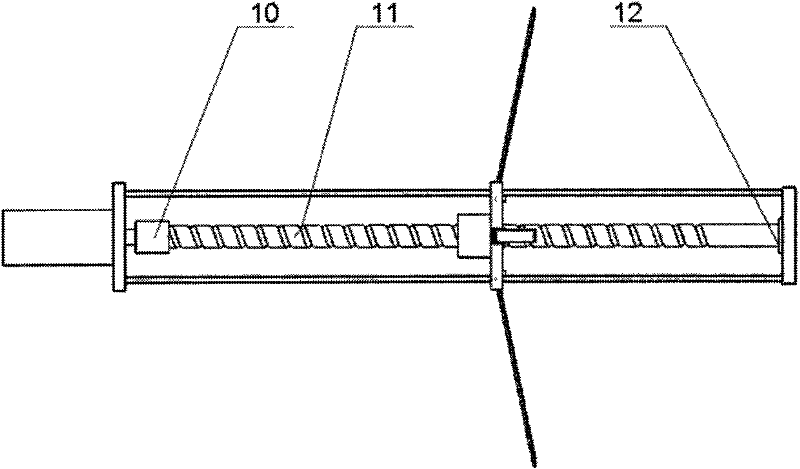

Blast tube of tunnel

The invention discloses a blast tube of a tunnel. The blast tube is characterized in that explosive, supporting rods, a detonator, a detonating tube, a detonating cord, a water bag and a tamping plug are fixedly formed and are assembled in a plastic tube according to a certain sequence so as to form the blast tube of the tunnel; the utilization rate of blast holes is high, so that explosive is saved, the explosive force is strong and the environmental pollution can not be caused; the diameter of the section of the plastic tube is slightly less than the diameter of the blast hole, and the inner diameter of the plastic tube body is more than the diameters of the explosive, the tamping plug and the water bag. The plastic tube is good in flexibility, higher in strength, convenient for transportation, less in dampness when in filling, and is convenient for an operator to put assembled explosive tubes into the blast holes, so that the blast tube is convenient and fast in filling and safe in detonation.

Owner:NO 1 ENG CO LTD OF CR11BG +1

Jellyfish-like underwater propulsion device

InactiveCN102225702ASimple structureLow costPropulsive elements of non-rotary typeLow speedExplosive force

The invention discloses a jellyfish-like underwater propulsion device. The propulsion device simulates the opening and closing movement process of a canopy of the jellyfish based on the bionics principle; a servo motor is controlled to rotate forward and rotate reversely so as to drive a nut to correspondingly move back and forth along a guide rod under the drive of a feed screw; when the nut moves forward, a supporting rod mounted on a nut groove drives a flexible web contract under the effect of the hydrodynamic force, and the device suffers small resistance; and when the nut moves backward, the supporting rod mounted in the nut groove drives the flexible web to unfold under the effect of the hydrodynamic force, and a great thrust is generated to propel the device to sail forward. The jellyfish-like underwater propulsion device is simple in structure, low in cost and good in explosive force. The propulsion device is mounted on the existing underwater vehicle to effectively improve the maneuvering performance of the underwater vehicle in low-speed sailing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

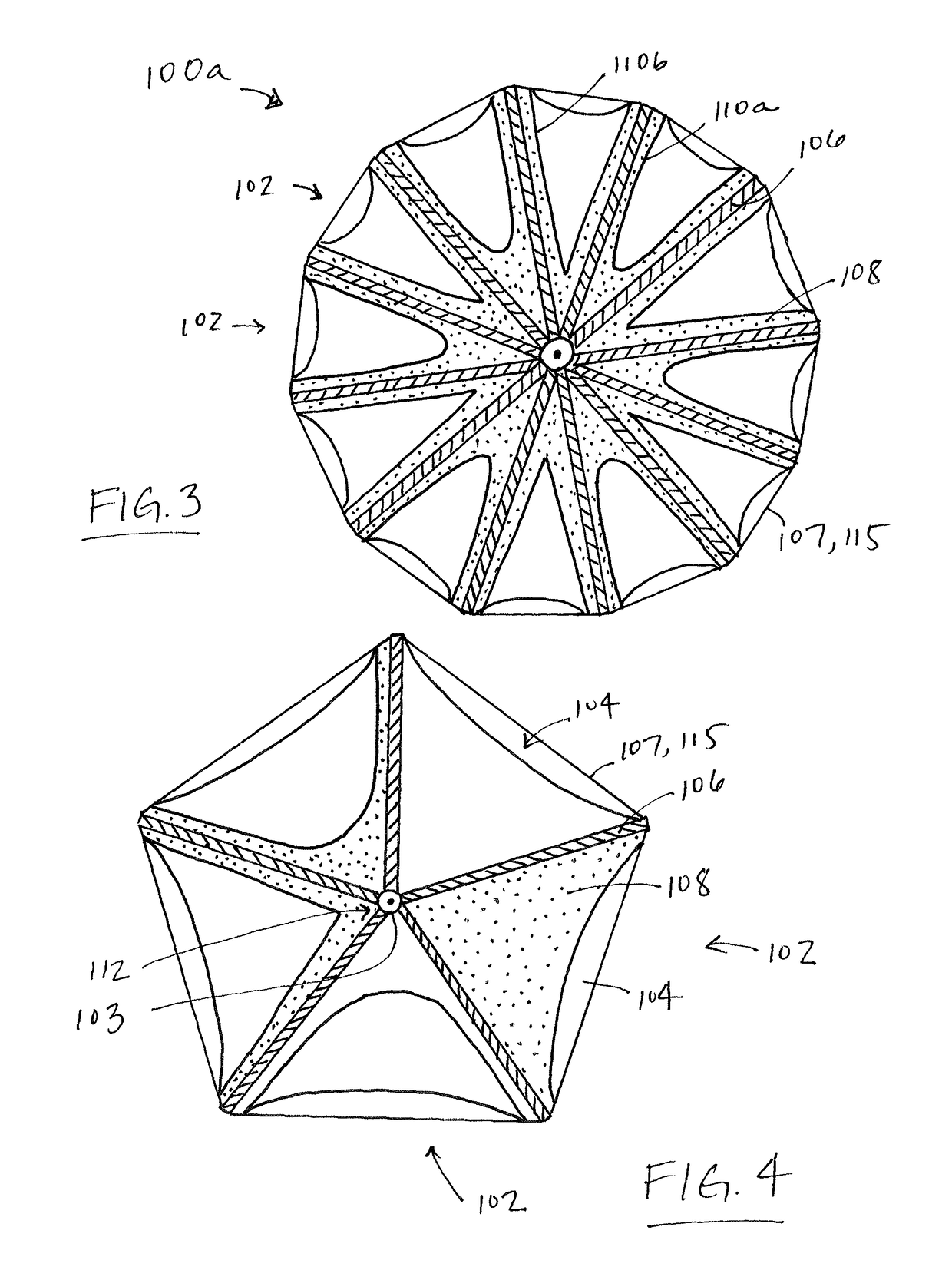

Clearing obstacles

System for clearing both light and heavy obstacles, in which one or more flying metal plates are propelled against heavy obstacles by explosive forces which also expand a folded continous rod member into a curvilinear, generally annular configuration that cuts through light obstacles such as concertina wire in the process of unfolding.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

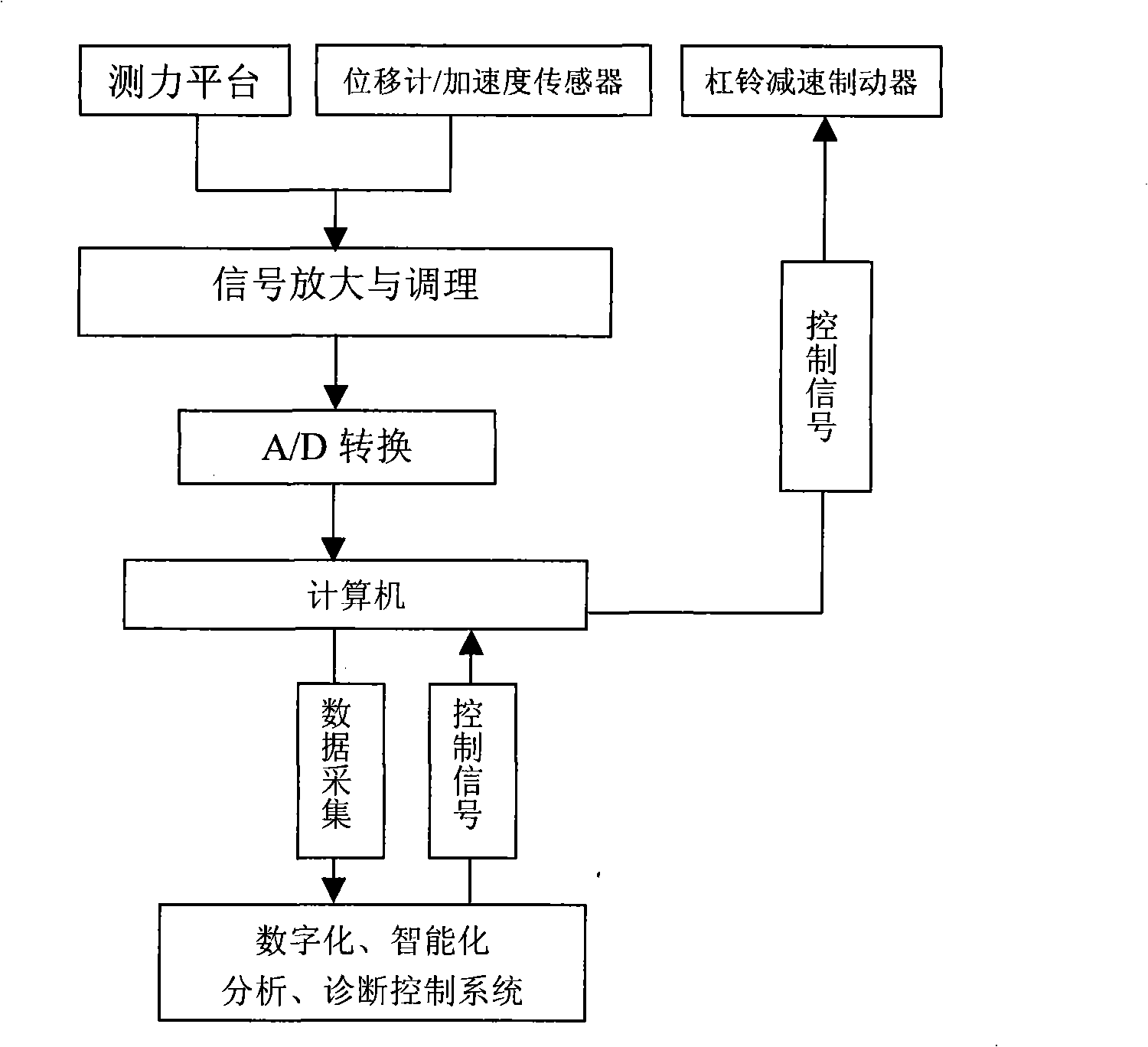

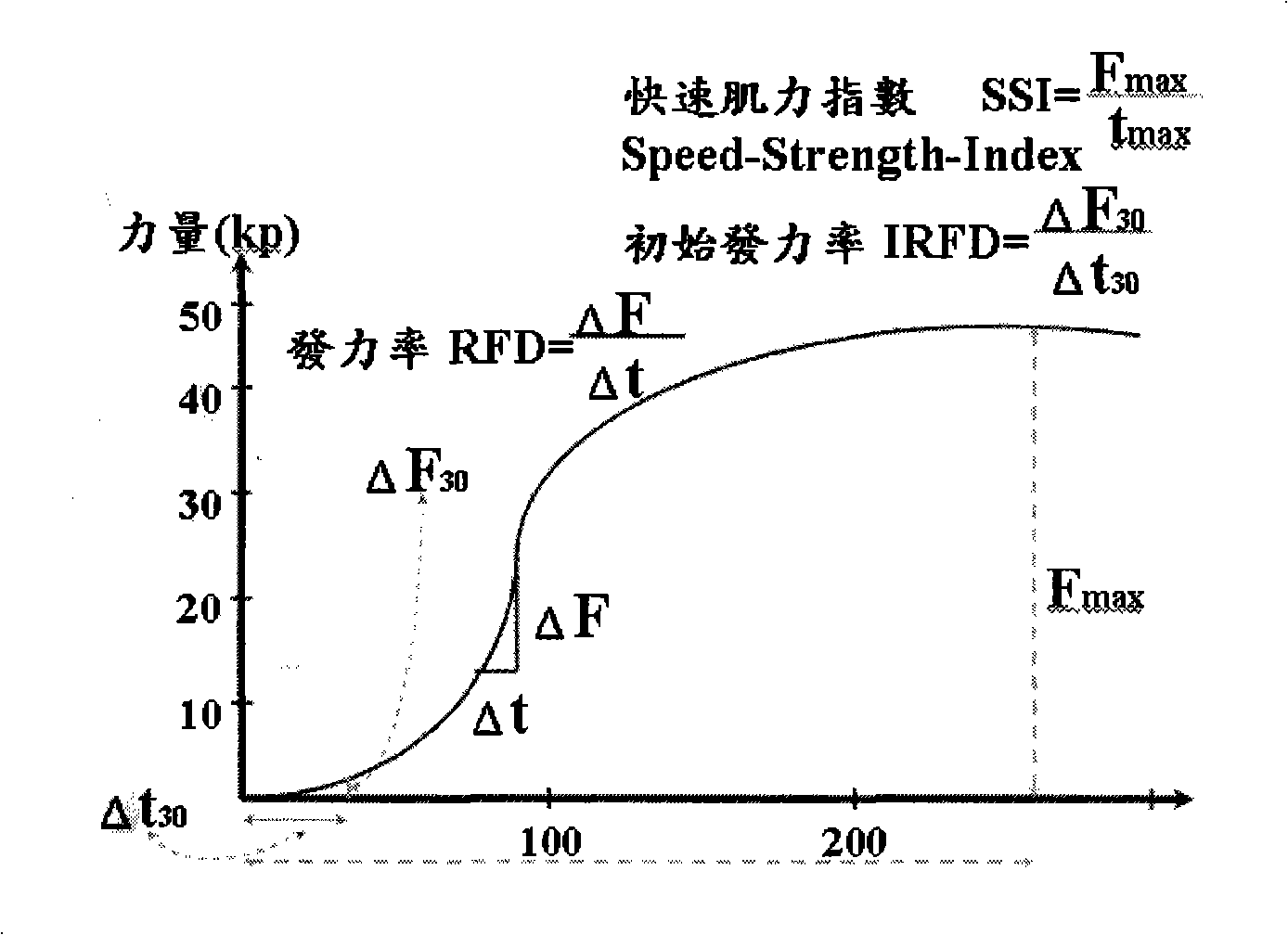

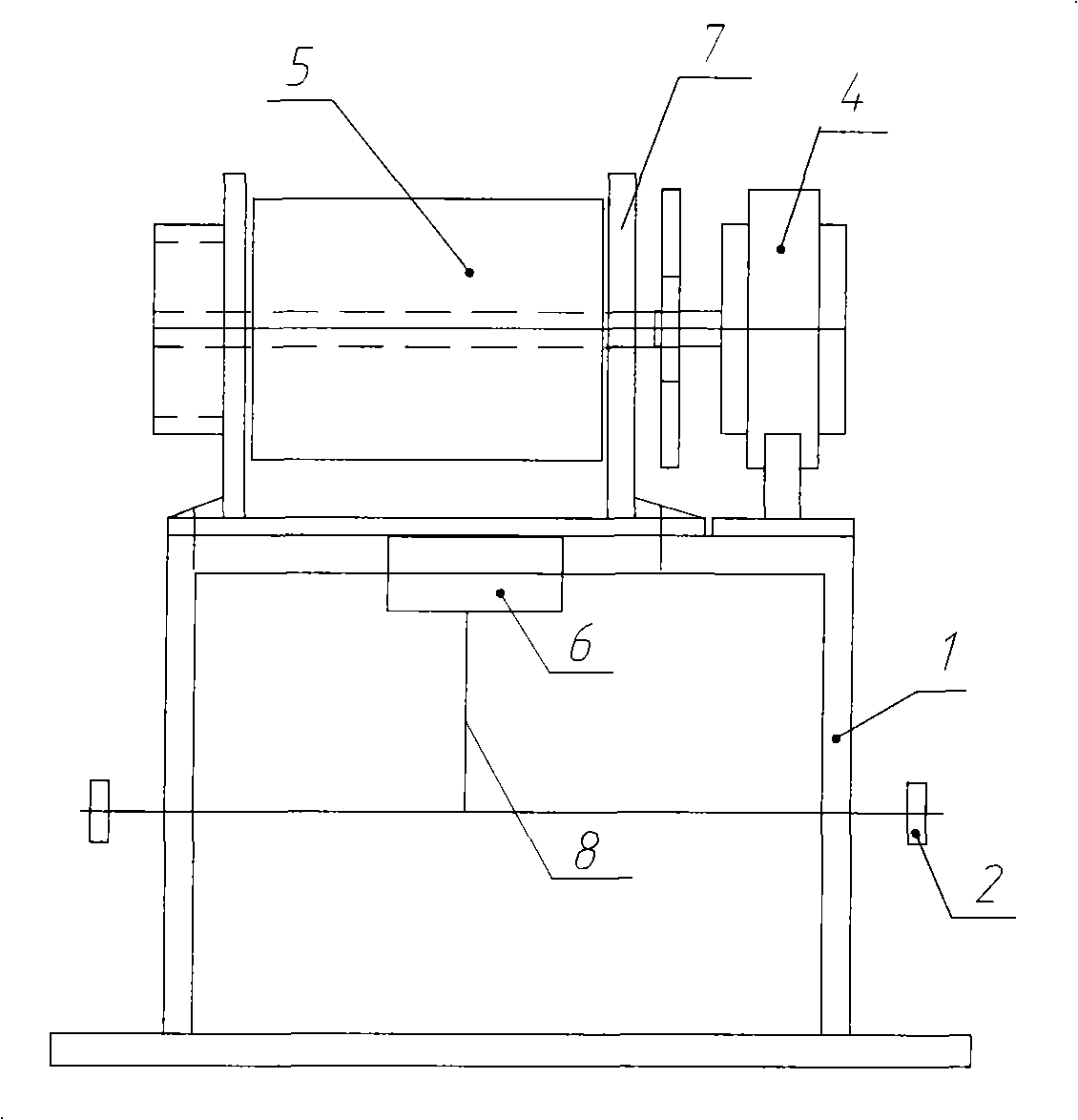

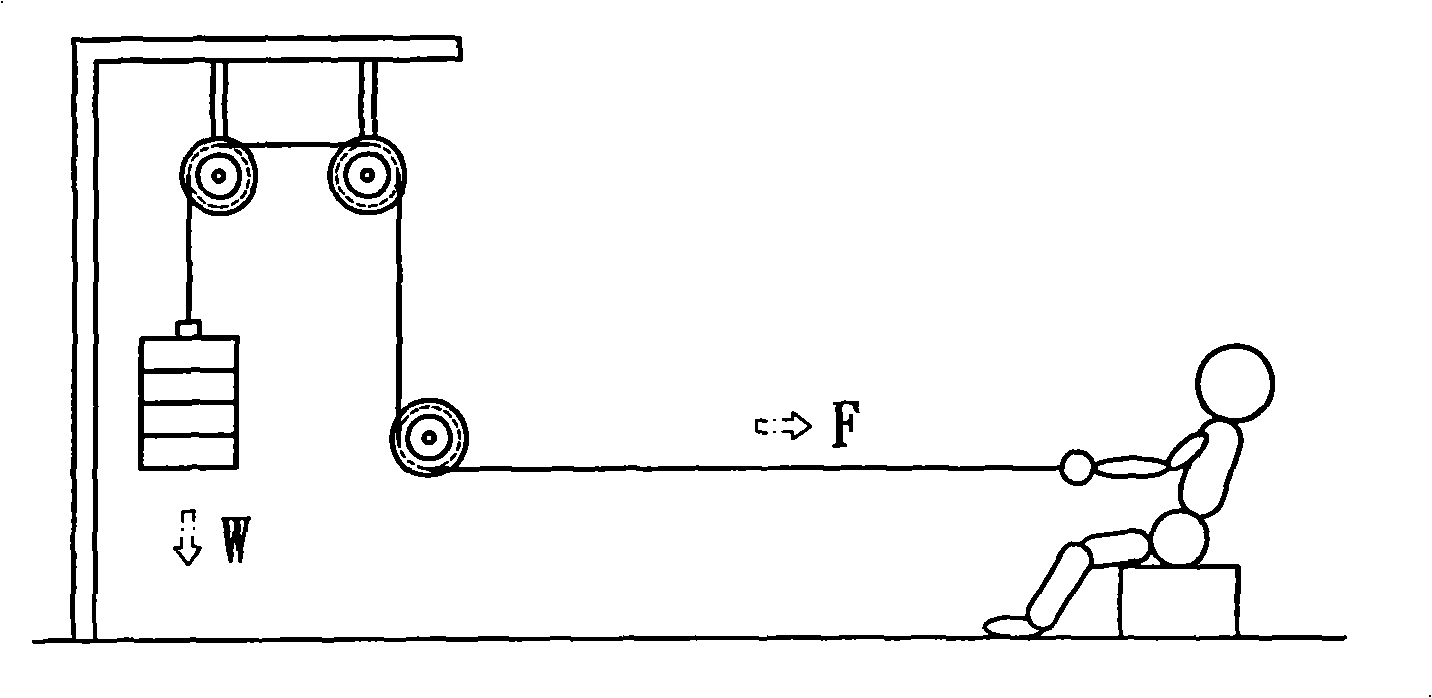

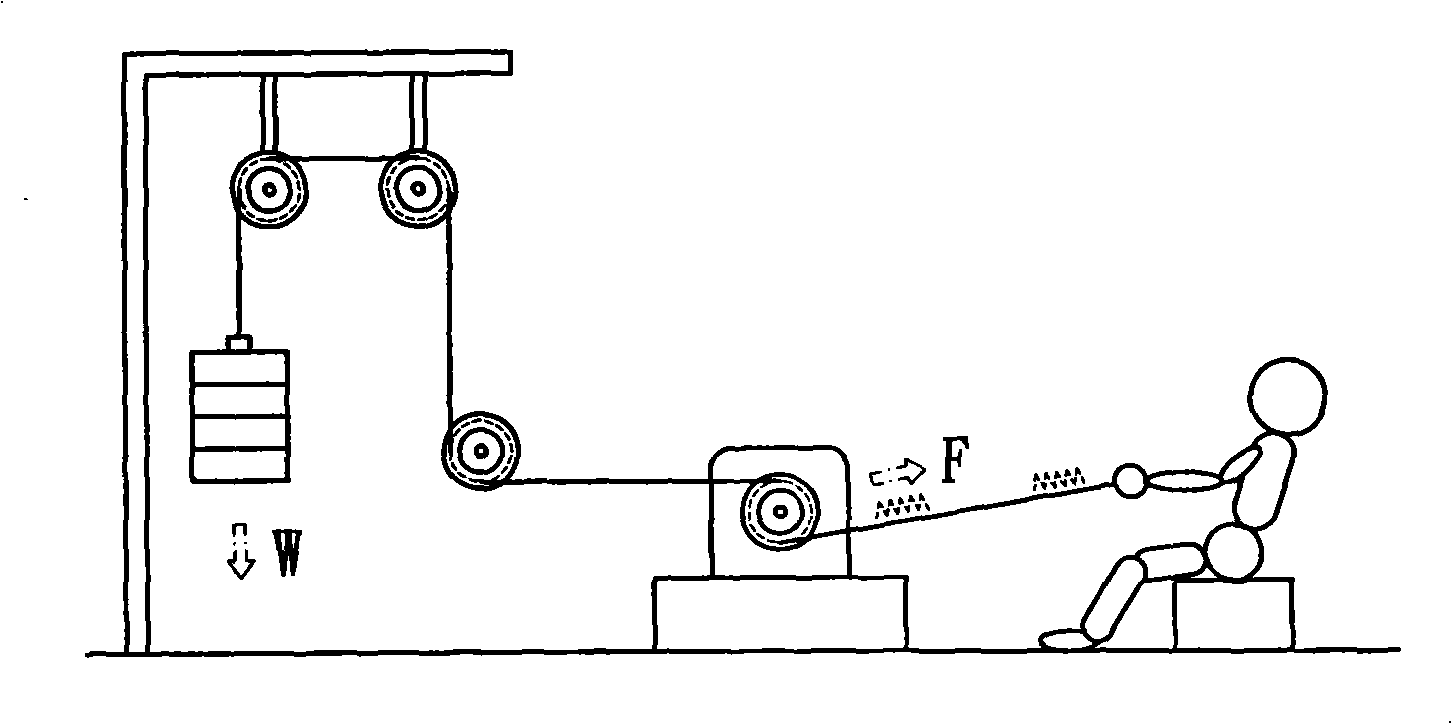

Intellectual plyometrics weight training and diagnosing system

InactiveCN101513567AReduce impactDumb-bellsDiagnostic recording/measuringMuscle strengthMeasurement device

The invention provides an intellectual plyometrics weight training and diagnosing system, which comprises a training frame, a load-bearing device arranged on the training frame, a safety device connected with the load-bearing device to control the deceleration of the load-bearing device and a signal measurement and analysis system for acquiring, converting and analyzing dynamic force, displacement and acceleration signals in a training process. The signal measurement and analysis system provides an open synchronous signal transmission platform and is correspondingly provided with an exercise biosignal synchronous acquisition and measurement device. The system contributes to the improvement of training safety, and can calculate the force applied to a barbell by a person receiving the test and explosive force output, monitor indexes such as training intensity and volume to realize training and muscle diagnosis; and the system also can study the properties and differences of the dynamic load and neural mechanics of loaded plyometric action by using a dynamometric system, an electromyography and a displacement meter or an acceleration transducer, and provides a scientific research parameters and basis for efficient development of explosive force training methods.

Owner:SHANGHAI UNIV OF SPORT

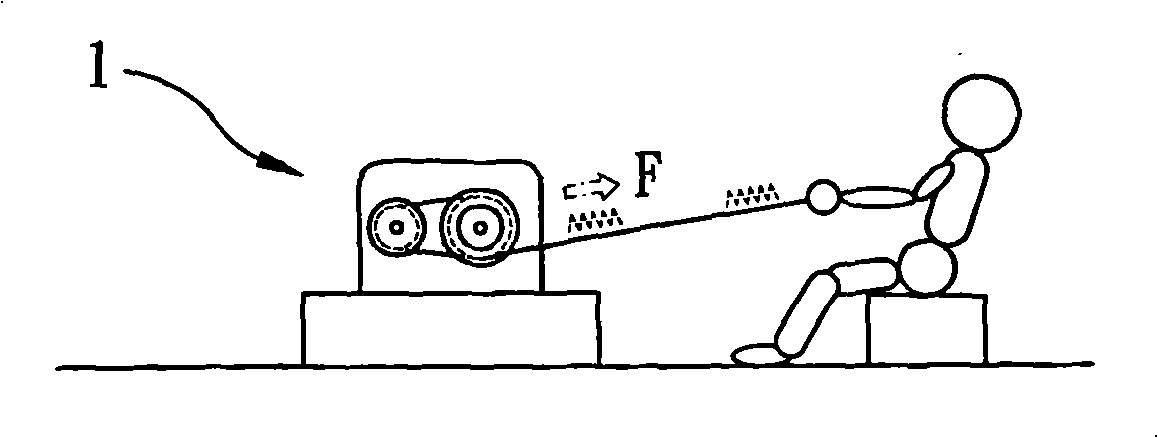

Break-out force training device capable of simultaneously training muscular strength and promoting nerve sensitivity

InactiveCN101406728AImproves nerve sensitivitySave spaceMuscle exercising devicesMuscle strengthElectrical connection

The invention relates to an explosive force training device capable of simultaneously training the muscular strength and increasing the sensitivity of the nerve, which mainly comprises a motor, a torque force output mechanism and a control unit, wherein the motor is provided with a sensor capable of sensing the rotation angle and the rotation speed of the motor; the sensor is connected with the control unit by means of electrical connection; the torque force output mechanism is arranged on the output end of the motor; the force exerted by a user can be transferred to the motor through the torque force output mechanism, and the torque force outputted by the motor is transferred to the user through the torque force output mechanism; and the control unit is connected with the sensor, can control the sensor to sense the state of the motor according to an input command, and further controls the motor to generate the torque force which is enough to contend with the force exerted by the user. Therefore, the explosive force training device is a device which is used for training the explosive force of sportsmen and capable of simultaneously training the muscular strength and increasing the sensitivity of the nerve.

Owner:欣麟科技股份有限公司

System for Protecting Surfaces against Explosions

A system for mitigating the effects of an unexpected explosion against a surface is described and claimed. This invention comprises at least one containment vessel containing explosive material fitted with a detonator; and at least one sensing device that can ignite the detonator; or, in another embodiment, a computer interposed between sensing devices and a plurality of detonators to optimize the response. Because transient voltages from a high-voltage firing system can accidentally ignite the detonators, a safety switch driven by an EBW detonator is interposed between the firing system and the counter-explosive devices. The explosive force generated by the current invention attenuates the shockwave and deflects the shrapnel from the unexpected explosion. In various embodiments, this counter-explosive device can be adapted to protect a multiplicity of surface types including exterior vehicle surfaces, building facades, bridges, embassies and military checkpoints and guard stations.

Owner:TAWIL JACK JOSEPH

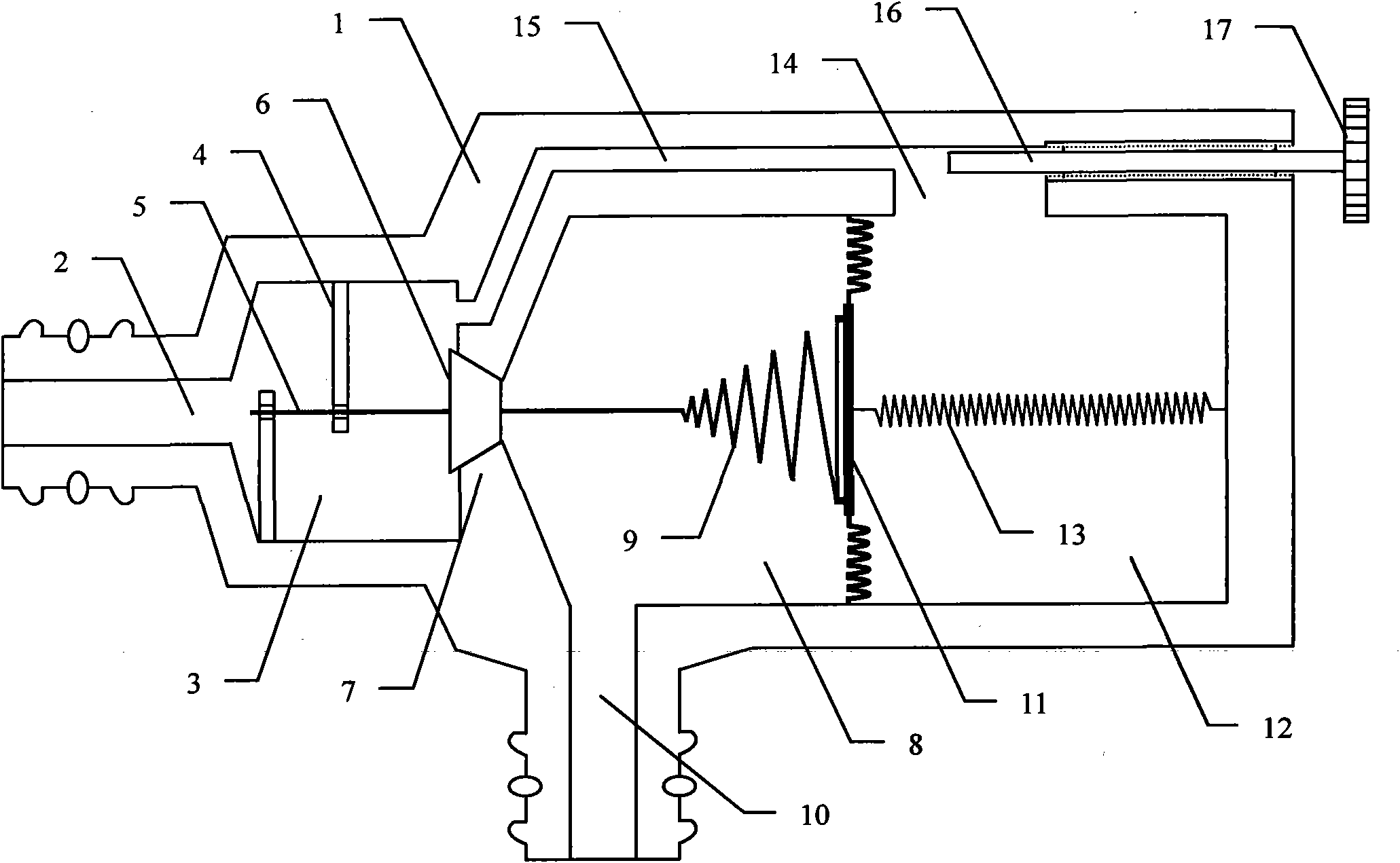

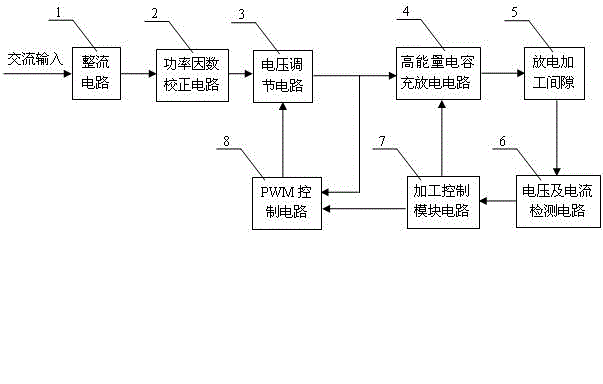

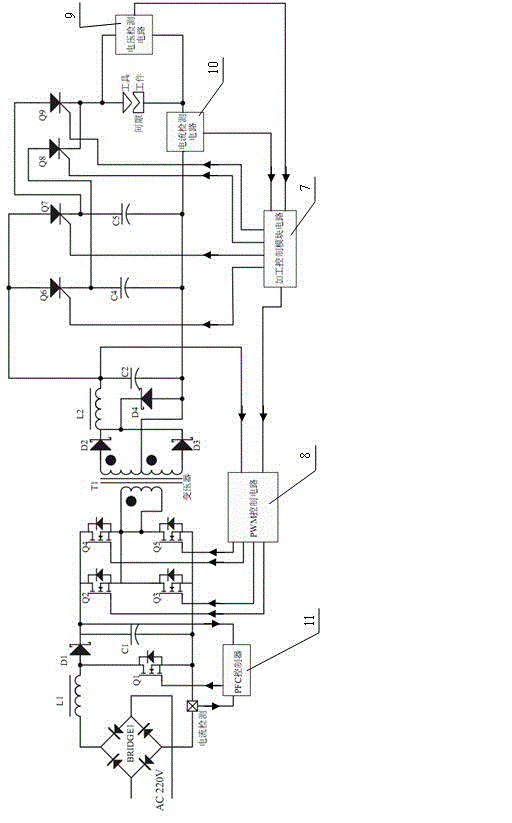

Pulsed power supply with parallel high-energy capacitors for electrosparking

ActiveCN102909444AHigh instantaneous discharge energyStrong discharge explosive powerElectric circuitsCapacitanceHigh energy

The invention relates to a pulsed power supply for electrosparking in the machining field, in particular to a pulsed power supply with parallel high-energy capacitors for the electrosparking. The power supply comprises a rectification circuit (1), a power factor correction circuit (2), a voltage regulator circuit (3), a high-energy capacitor charge and discharge circuit (4), a voltage and current detection circuit (6), a machining control module circuit (7) and a PWM (Pulse-Width Modulation) control circuit (8). The pulsed power supply can provide approximately 150 V no-load breakdown voltages and 100-500 J discharge energy for an electrical discharge machining gap (5) in a single discharge process. The power supply adopts an accumulator structure, the parallel large-capacity capacitors are charged and discharged independently; the high energy stored in the capacitors is directly released to a discharge gap without passing through a current-limiting resistor, so that high instantaneous discharge energy and a strong discharge explosive force can be achieved; the power supply is applicable to difficult-to-machine materials such as ceramics and polycrystalline diamonds in the machining engineering; the current-limiting resistor with serious energy consumption is removed thoroughly; and the utilization rate of electrical energy can be increased by 2-3 times.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

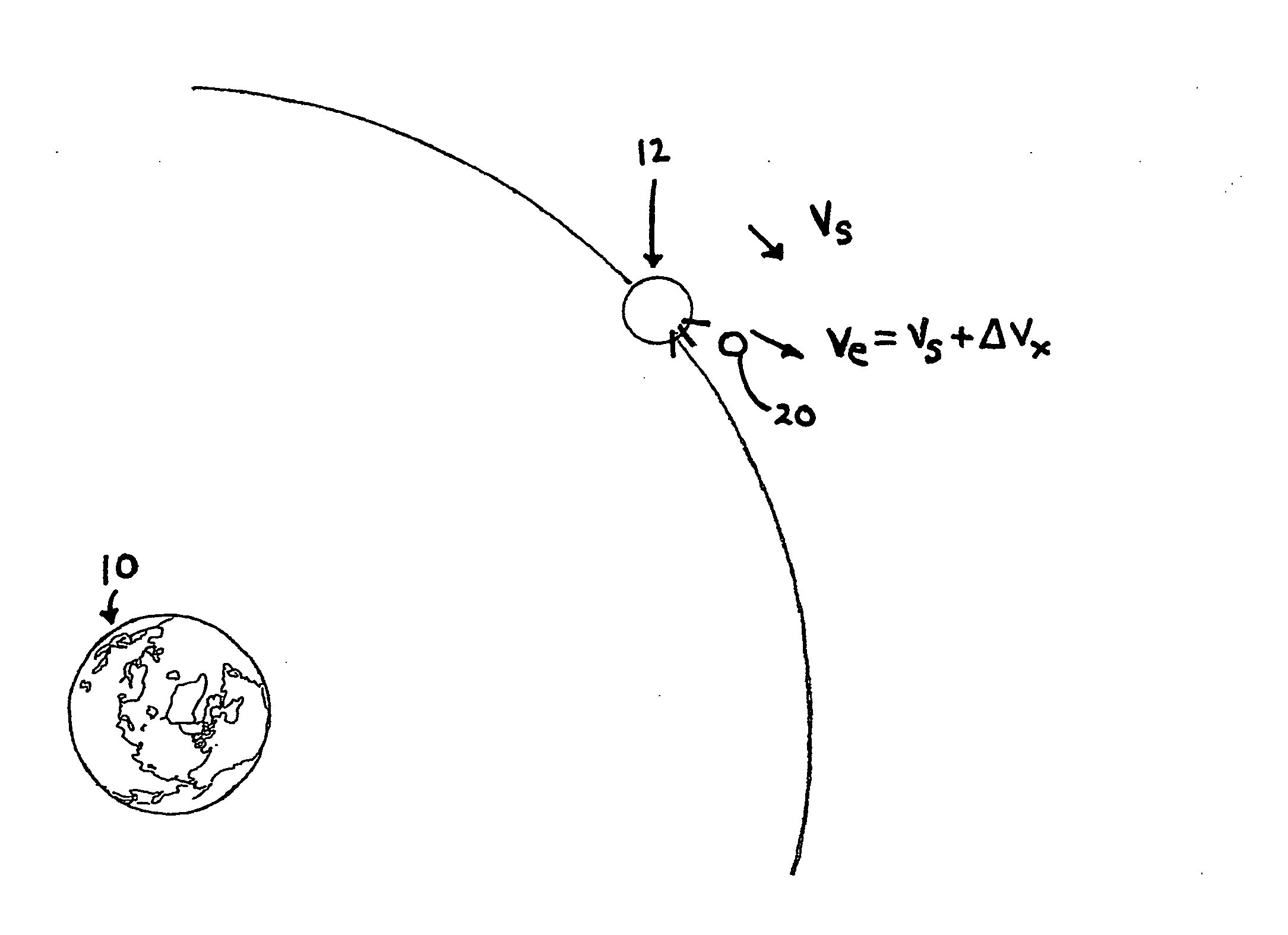

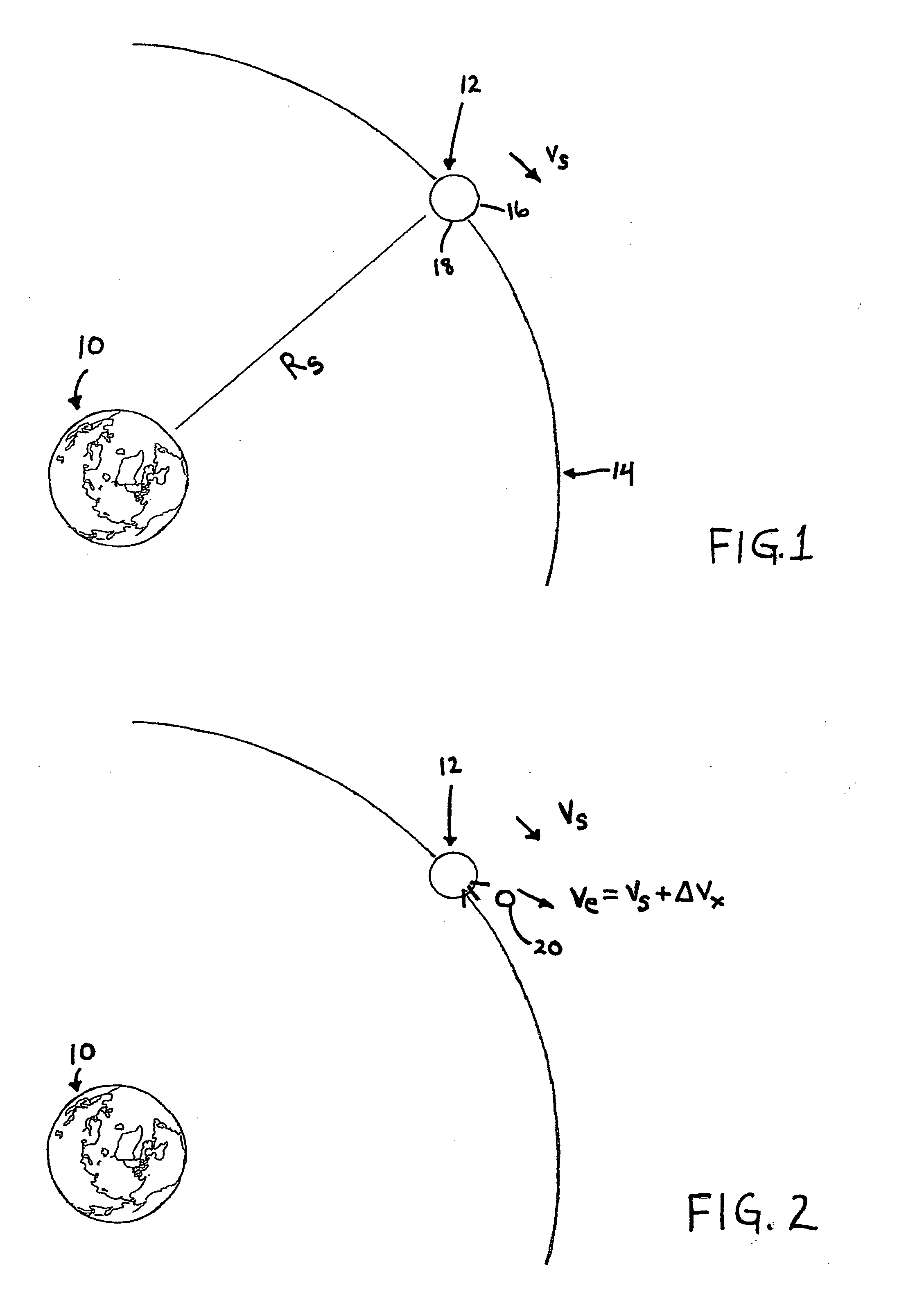

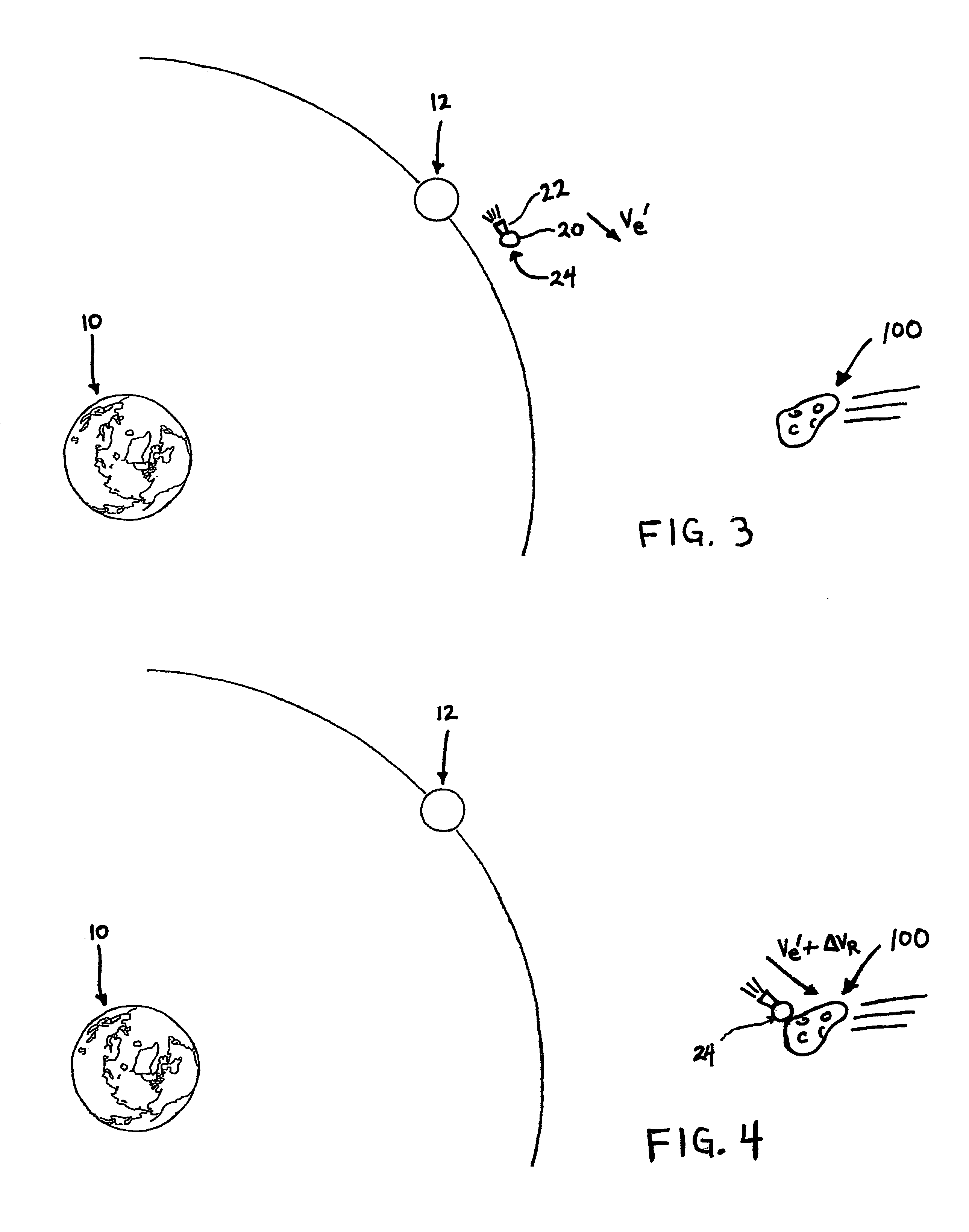

Planetary impact defense system

A system for defending a planet having a satellite against impact from an incoming body includes an explosive system and a propulsion system. The explosive system is adapted for deployment on the satellite and detonation thereon with sufficient explosive force to produce at least one ejectum to which is imparted a velocity increment sufficient for the ejectum to exceed the satellite's escape velocity and enter orbit about the planet. The propulsion system is adapted to be secured to at least one ejectum and impart a velocity increment to the ejectum sufficient to leave orbit about the planet and enter an orbit intercepting the incoming body.The system is used in a planetary defense method in which the explosive system is deployed at a deployment site on the satellite and detonated to produce at least one ejectum having a velocity that exceeds the escape velocity of the satellite. The ejectum enters into orbit around the planet, at which time the propulsion system is secured to the ejectum to produce a projectile. The propulsion system is then activated to increase the velocity of the projectile, causing the projectile to enter into an intercept orbit targeting the incoming body and subsequently intercept and impact the incoming body. The impact prevents the incoming body from impacting the planet.

Owner:PICCIONELLI GREGORY A

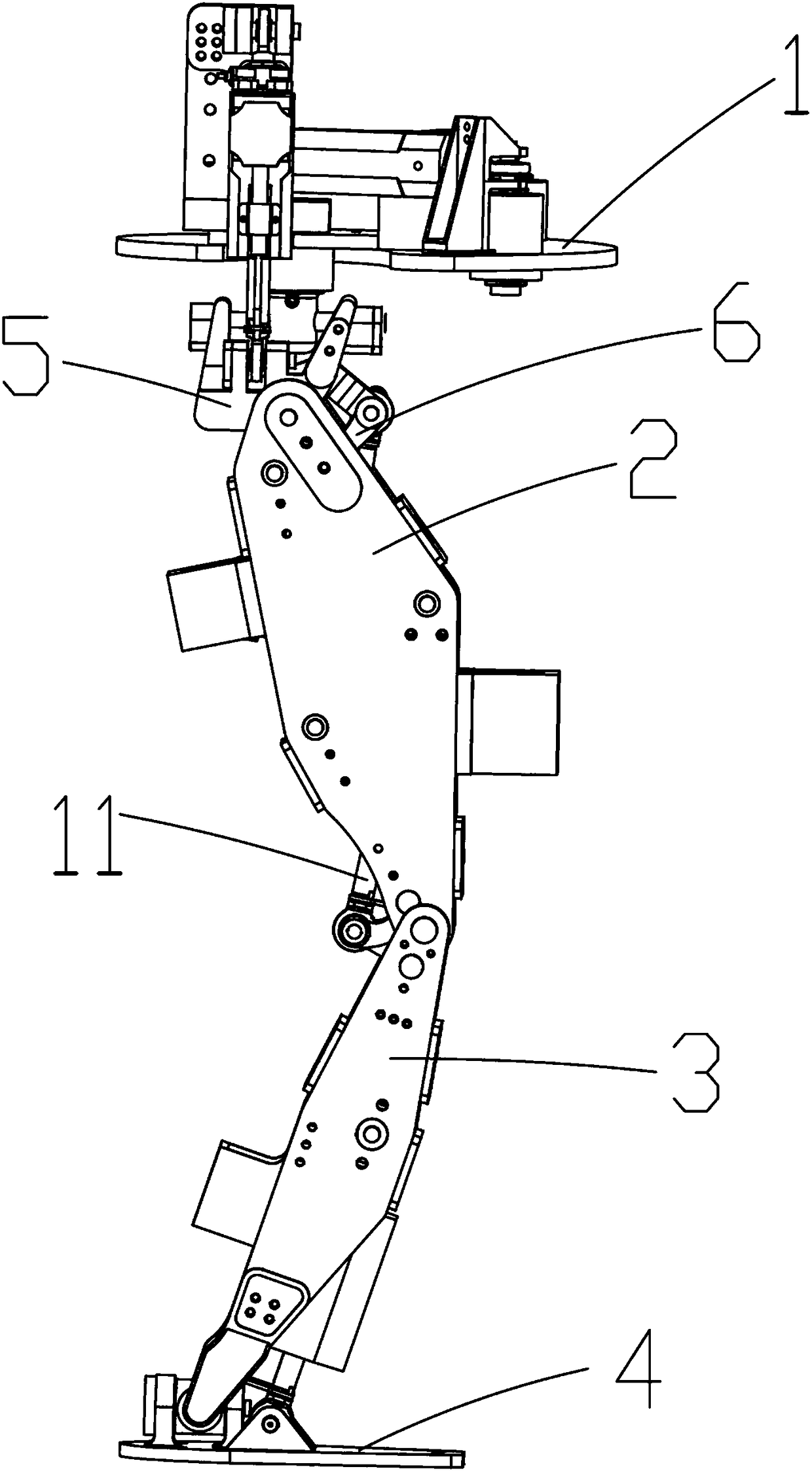

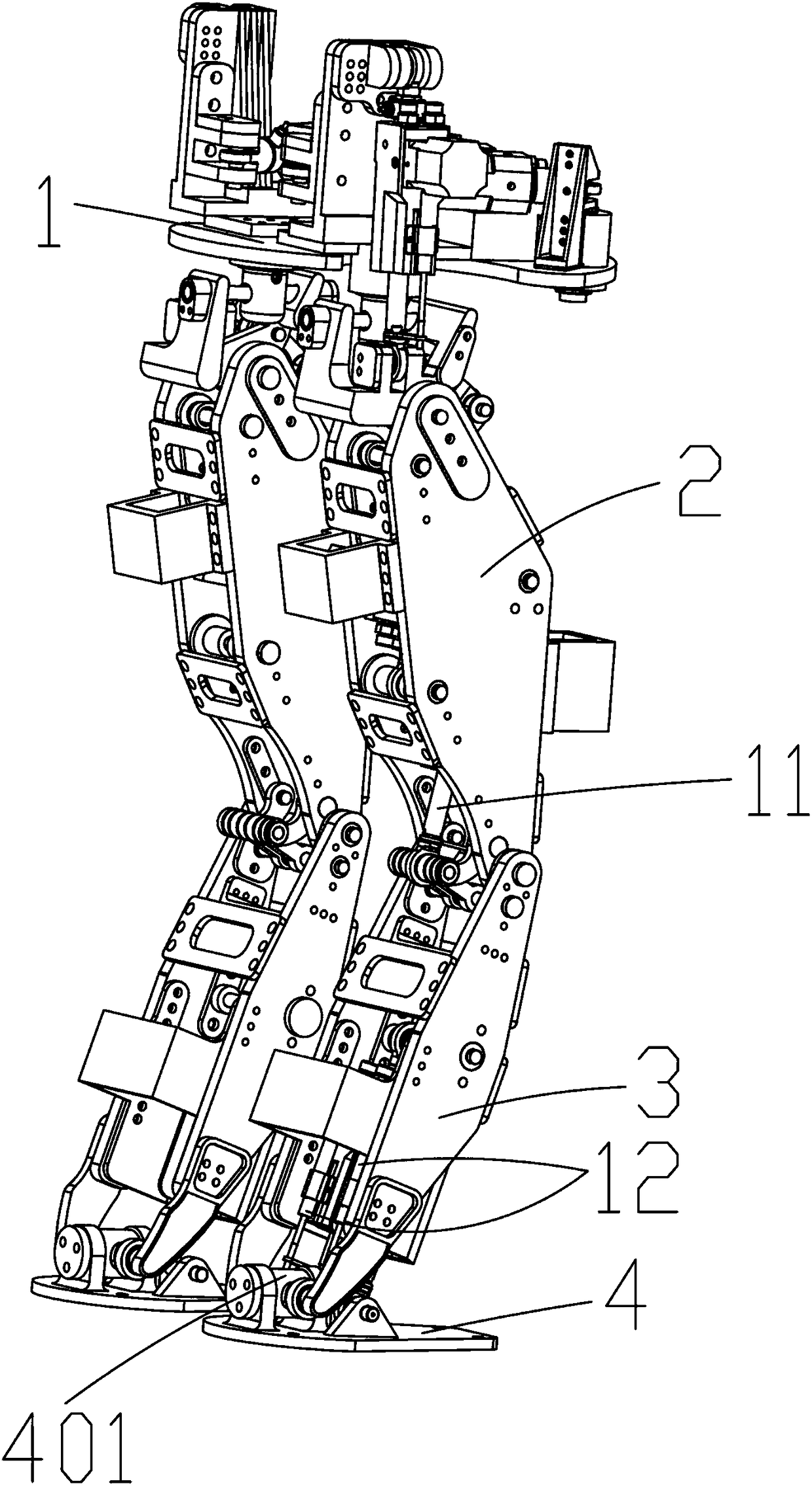

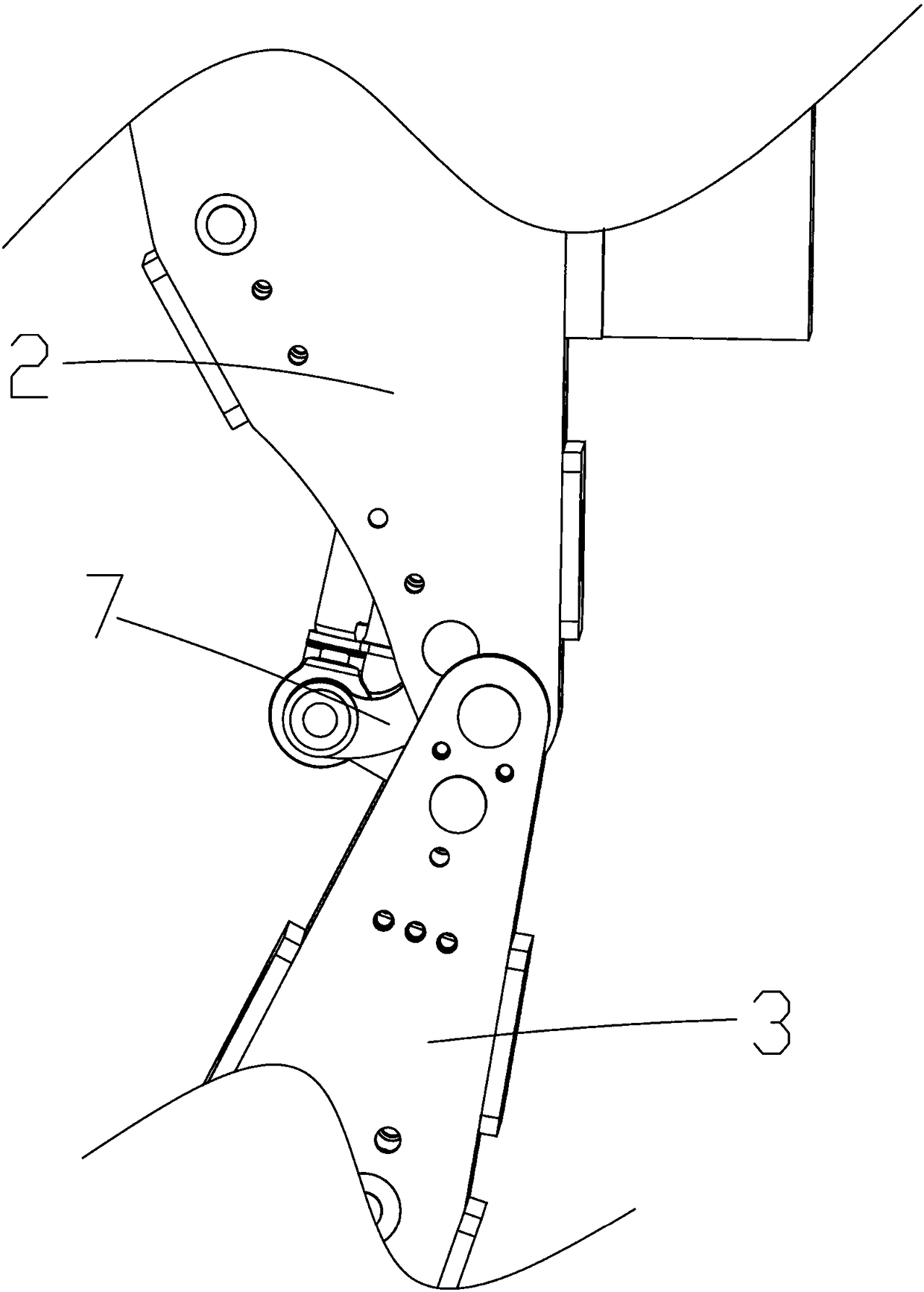

Hydraulic-driven biped robot lower limb mechanism

The invention belongs to the field of robots, and particularly relate to a hydraulic-driven biped robot lower limb mechanism. The hydraulic-driven biped robot lower limb mechanism comprises a trunk, aleft leg and a right leg, the left leg comprises a foot part, an ankle joint assembly, a shank, a knee joint assembly, a thigh and a hip joint assembly; the thigh is connected with the truck and theshank, the shank is hinged to the foot part, the hip joint assembly comprises a cantilever, a hip joint pitching hydraulic driving unit and a hip joint side hydraulic driving unit, the hip joint sidehydraulic driving unit is connected with the cantilever and the trunk, and the hip joint pitching hydraulic driving unit is connected with the cantilever and the thigh; and a knee joint hydraulic driving unit in the knee joint assembly is connected with the thigh and the shank; and the ankle joint assembly comprises two ankle joint hydraulic driving units which are arranged side by side, one endsof the ankle joint hydraulic driving units are hinged to a main body of the shank, and the other ends of the ankle joint hydraulic driving units are hinged to the foot part. The hydraulic-driven bipedrobot lower limb mechanism solves the problems that in the prior art, a motor-driven robot is small in moving speed, lacking of explosive force and difficult to adapt to complicated terrains.

Owner:INST OF INTELLIGENT MFG TECH JITRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com