Directional water pressure blasting method for improving coal bed gas permeability

A technology of hydraulic blasting and air permeability, which is applied in earth-moving drilling, wellbore/well components, mining equipment, etc., can solve problems such as failure to meet actual production needs, failure to meet coal seam permeability, coal and gas outburst disasters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

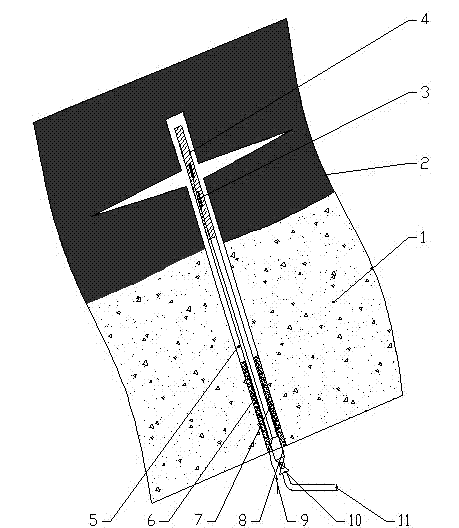

[0016] Example 1: The average thickness of coal seam 2 in a mine is 5m, the hardness of coal seam 2 is f=3, it is a gently inclined coal seam 2, and the overlying rock layer is hard sandstone 1, and its average thickness is 20m. , using a drilling rig to drill a hole 5 into the pre-mined coal and rock mass, the hole diameter is 75mm, and the depth of the hole 5 is 24m. Then, hydraulic slitting is performed in the coal seam, and a deep flat slit is formed around the drilled hole 5 in the coal seam after cutting. A steel casing 8 with a diameter of 36 mm is placed at the orifice, and cement mortar 6 is used to fill the gap between the steel casing 8 and the borehole 5. When the cement mortar 6 is cured for more than 48 hours and has sufficient strength, The emulsion explosive 4 is filled in the PVC pipe 7 with a diameter of 32mm, and the charge amount is 100g. A detonator 3 is set every 1 m in the emulsion explosive 4, and the PVC pipe 7 is sent to the coal seam 2, and the lead ...

Embodiment 2

[0017] Example 2: The average thickness of coal seam 2 in a mine is 9m, the hardness of coal seam 2 is f=4, it is a gently inclined coal seam 2, and the overlying rock layer is hard sandstone 1, and its average thickness is 28m. , using a drilling rig to drill a hole 5 into the pre-mined coal and rock mass, the hole diameter is 94mm, and the depth of the hole 5 is 35m. Then, hydraulic slitting is performed in the coal seam, and a deep flat slit is formed around the drilled hole 5 in the coal seam after cutting. A steel casing 8 with a diameter of 45mm is placed at the orifice, and cement mortar 6 is used to fill the gap between the steel casing 8 and the borehole 5. When the cement mortar 6 is cured for more than 48 hours and has sufficient strength, The emulsion explosive 4 is filled in the PVC pipe 7 with a diameter of 40mm, and the charge is 200g. A detonating detonator 3 is set every 1 m in the emulsion explosive 4, and the PVC pipe 7 is sent to the coal seam 2, and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com