A method of directional hydraulic blasting to improve the air permeability of coal seam

A technology of hydraulic blasting and air permeability, which is applied in earth-moving drilling, wellbore/well components, mining equipment, etc., can solve the problems such as the inability to meet the coal seam permeability, coal and gas outburst disasters, and the inability to meet the actual needs of production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

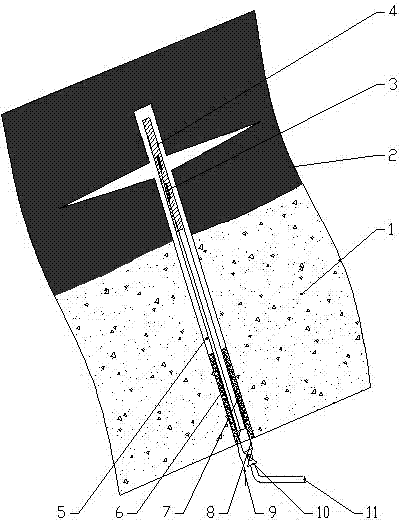

[0016] Example 1: The average thickness of the coal seam 2 of a certain mine is 5m, the hardness of the coal seam 2 is f=3, it is a gently inclined coal seam 2, the overlying rock layer is hard sandstone 1, and its average thickness is 20m, in the coal mine underground transport stone gate , using a drilling rig to drill a hole 5 into the pre-mined coal and rock mass, the hole diameter is 75mm, and the depth of the hole 5 is 24m. Then carry out hydraulic cutting in the coal seam, and form a deep flat slot around the coal seam borehole 5 after cutting. Place a steel casing 8 with a diameter of 36 mm at the orifice, and use cement mortar 6 to fill the gap between the steel casing 8 and the drilled hole 5. When the cement mortar 6 is maintained for more than 48 hours and has sufficient strength, Fill the emulsion explosive 4 in a PVC pipe 7 with a diameter of 32mm, the charge amount is 100g, set a detonator 3 every 1 m in the emulsion explosive 4, send the PVC pipe 7 to the coal ...

Embodiment 2

[0017] Example 2: The average thickness of a coal seam 2 in a certain mine is 9m, and the hardness of the coal seam 2 is f=4, which is a gently inclined coal seam 2, and the overlying rock layer is hard sandstone 1, and its average thickness is 28m. , using a drilling rig to drill a hole 5 into the pre-mined coal and rock mass, the hole diameter is 94mm, and the depth of the hole 5 is 35m. Then carry out hydraulic cutting in the coal seam, and form a deep flat slot around the coal seam borehole 5 after cutting. Place a steel casing 8 with a diameter of 45 mm at the orifice, and use cement mortar 6 to fill the gap between the steel casing 8 and the drilled hole 5. When the cement mortar 6 is maintained for more than 48 hours and has sufficient strength, Fill the emulsion explosive 4 in a PVC pipe 7 with a diameter of 40 mm, the charge amount is 200 g, set a detonator 3 every 1 m in the emulsion explosive 4, send the PVC pipe 7 to the coal seam 2, and connect the lead wire 9 Le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com