Patents

Literature

987 results about "Mechanical failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

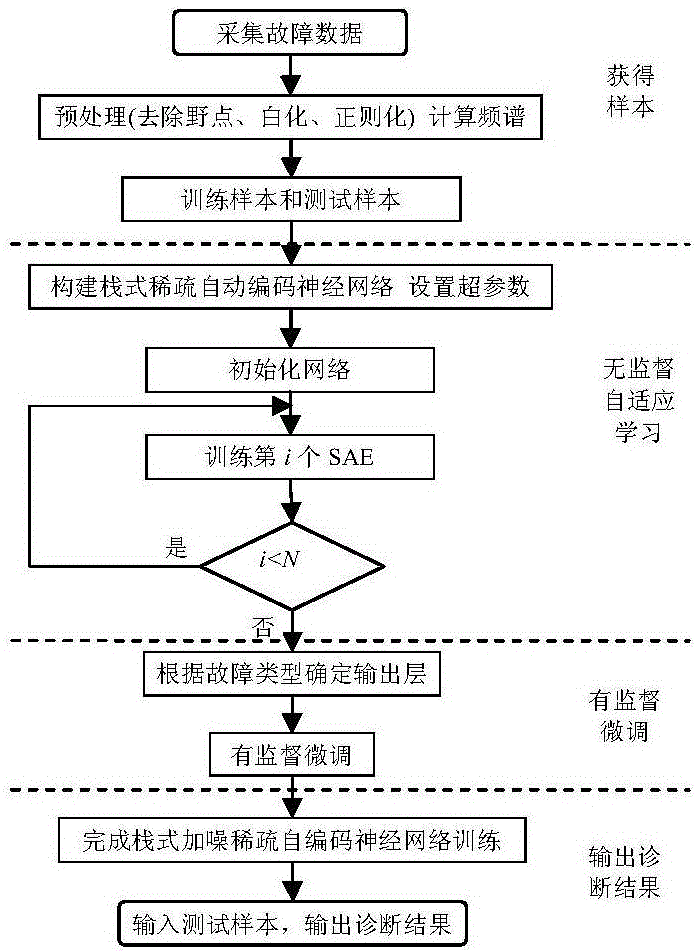

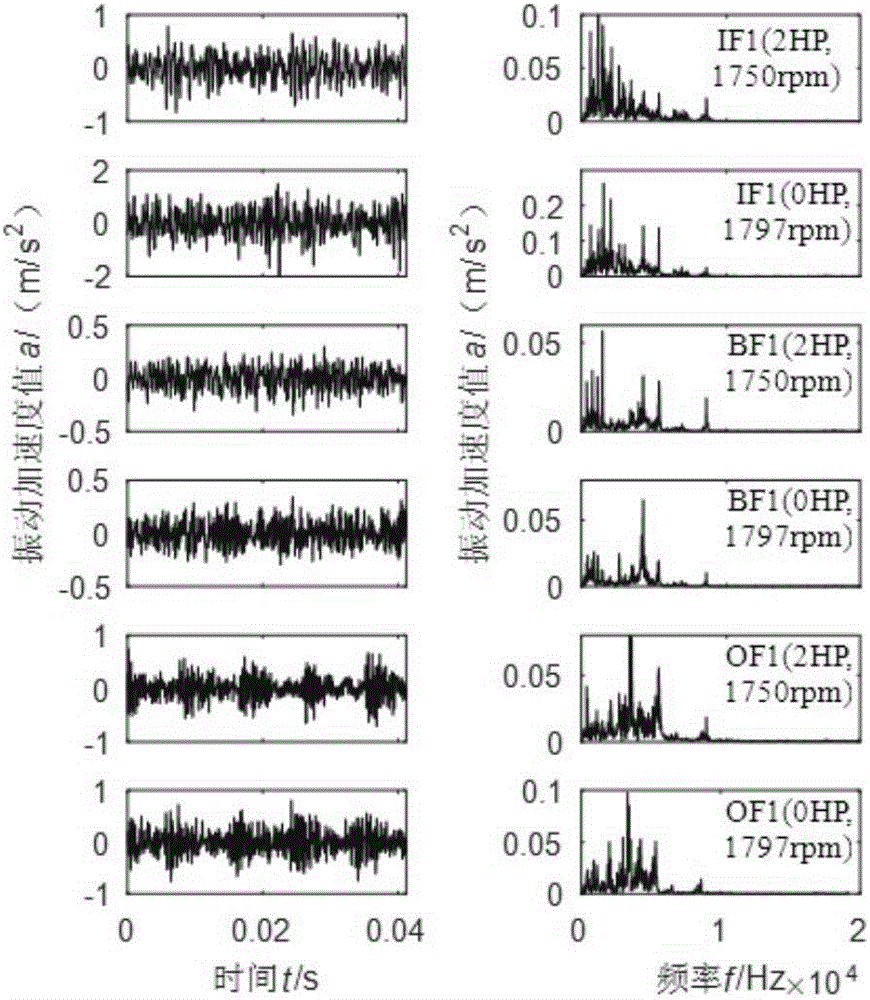

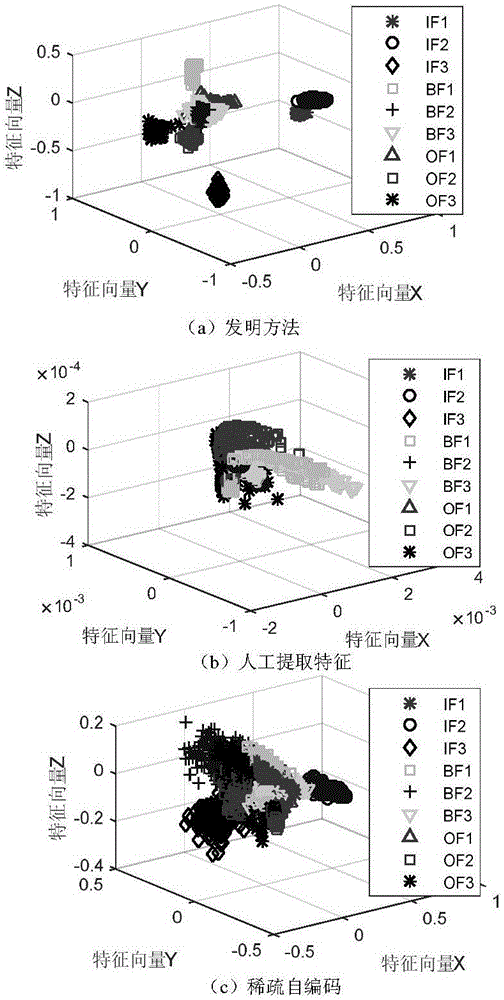

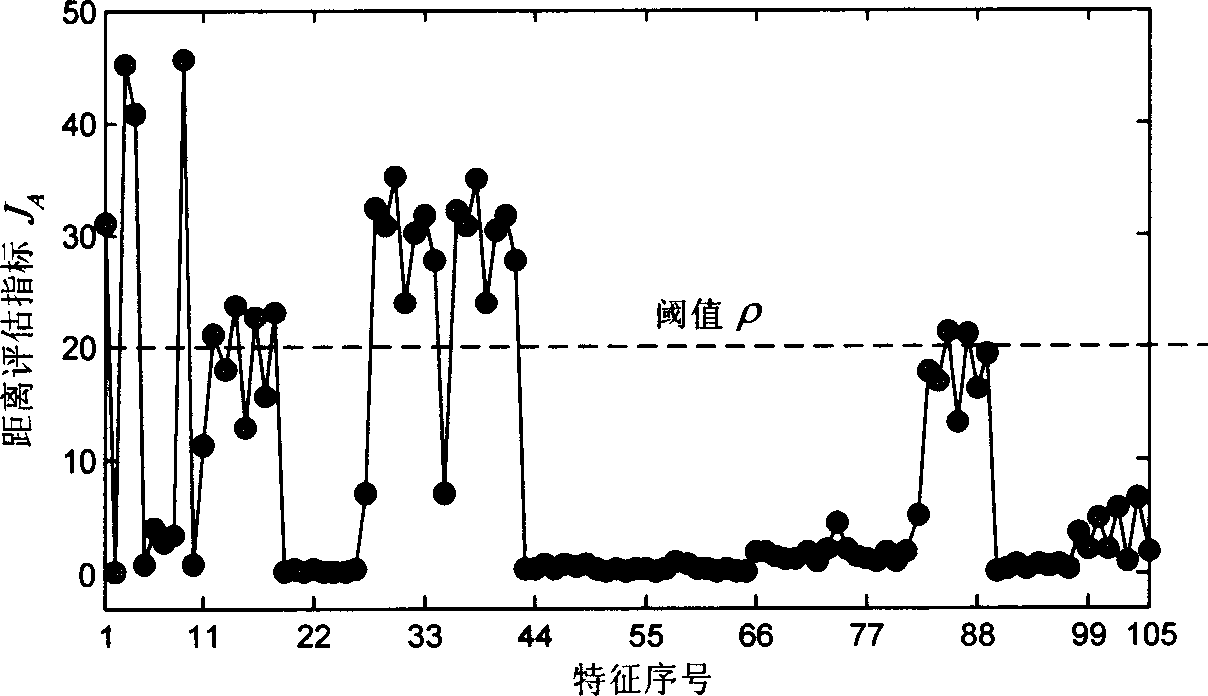

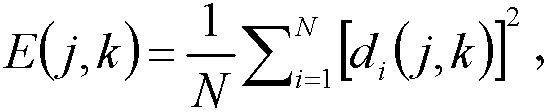

Adaptive extraction and diagnosis method for degree features of mechanical fault through stack-type sparse automatic coding depth neural network

InactiveCN106323636AImprove robustnessRealize intelligent diagnosis of fault levelMachine bearings testingNeural learning methodsAdaptive learningFeature extraction

The invention relates to an adaptive extraction and diagnosis method for degree features of a mechanical fault through a stack-type sparse automatic coding depth neural network, and belongs to the technical field of mechanical equipment state monitoring and reliability evaluation. The method aims at a problem of intelligent diagnosis of the degree of the mechanical fault, and comprises the steps: carrying out the stacking of sparse automatic coding, adding a classification layer, and constructing the stack-type sparse automatic coding depth neural network which integrates the adaptive learning and extraction of the degree features of the fault and fault recognition; employing the advantage that the sparse automatic coding can automatically learn the internal features of data, and adding noise coding to be integrated in the sparse automatic coding for improving the robustness of feature learning; carrying out the layer-by-layer no-supervision adaptive learning and supervision fine tuning of the original input complex data through multilayer sparse automatic coding, completing the automatic extraction and expression of the degree features of the mechanical fault and achieving the intelligent diagnosis of the degree of the fault. The method is used for the diagnosis of the degree of faults of rolling bearings under different work conditions, and obtains a good effect of feature extraction and diagnosis.

Owner:CHONGQING JIAOTONG UNIVERSITY

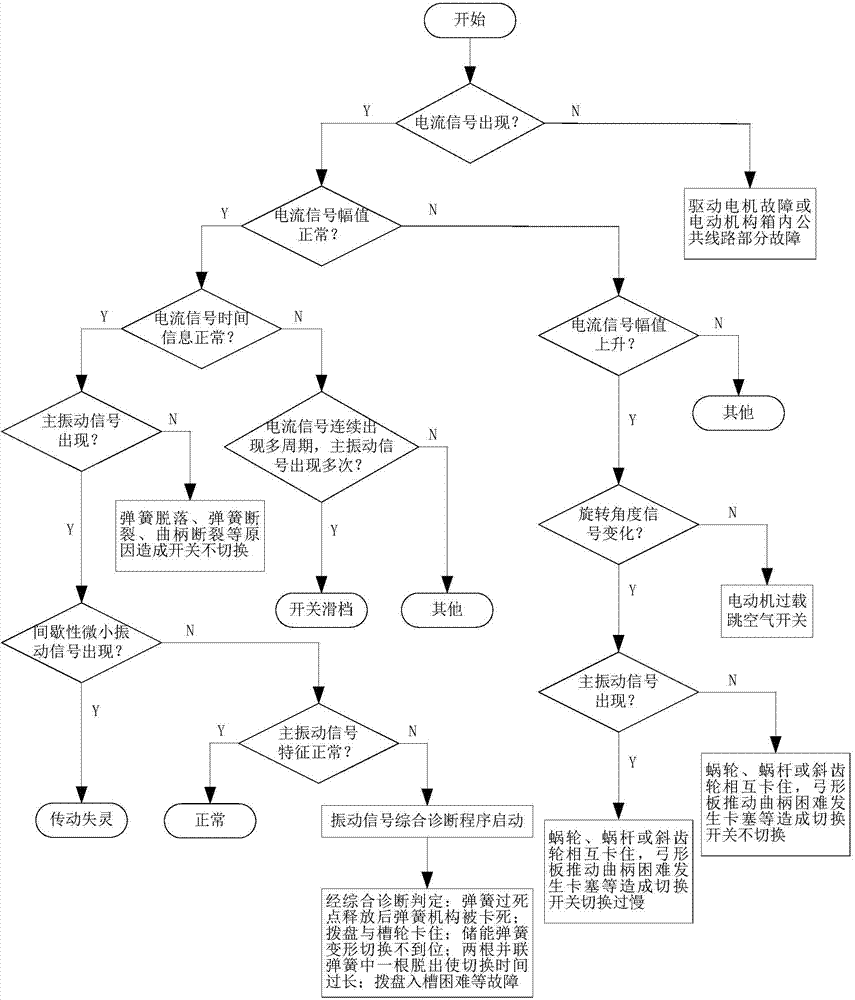

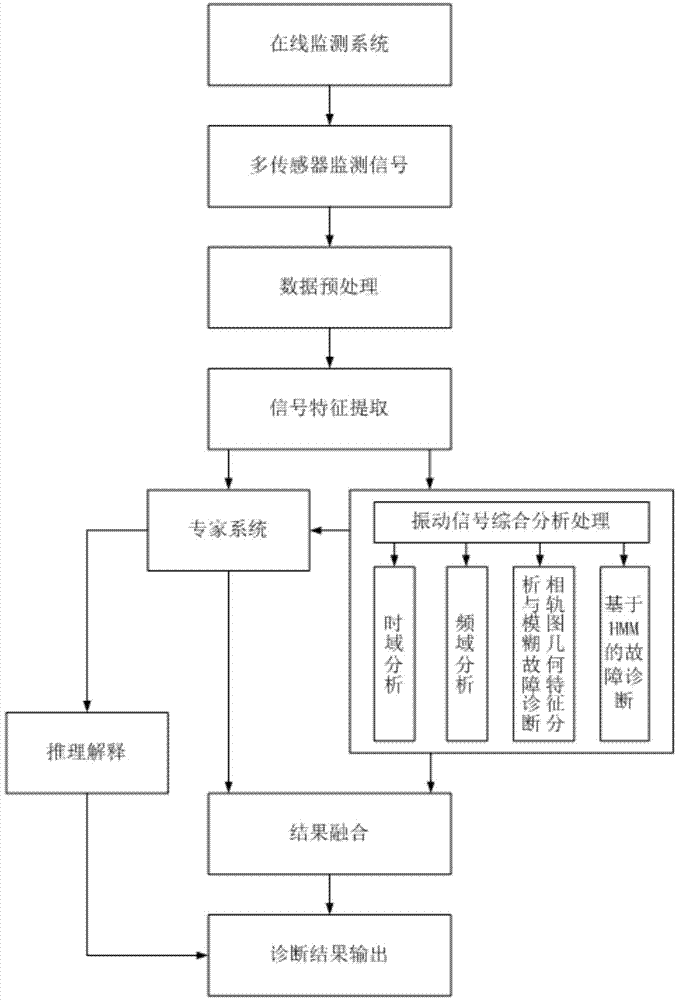

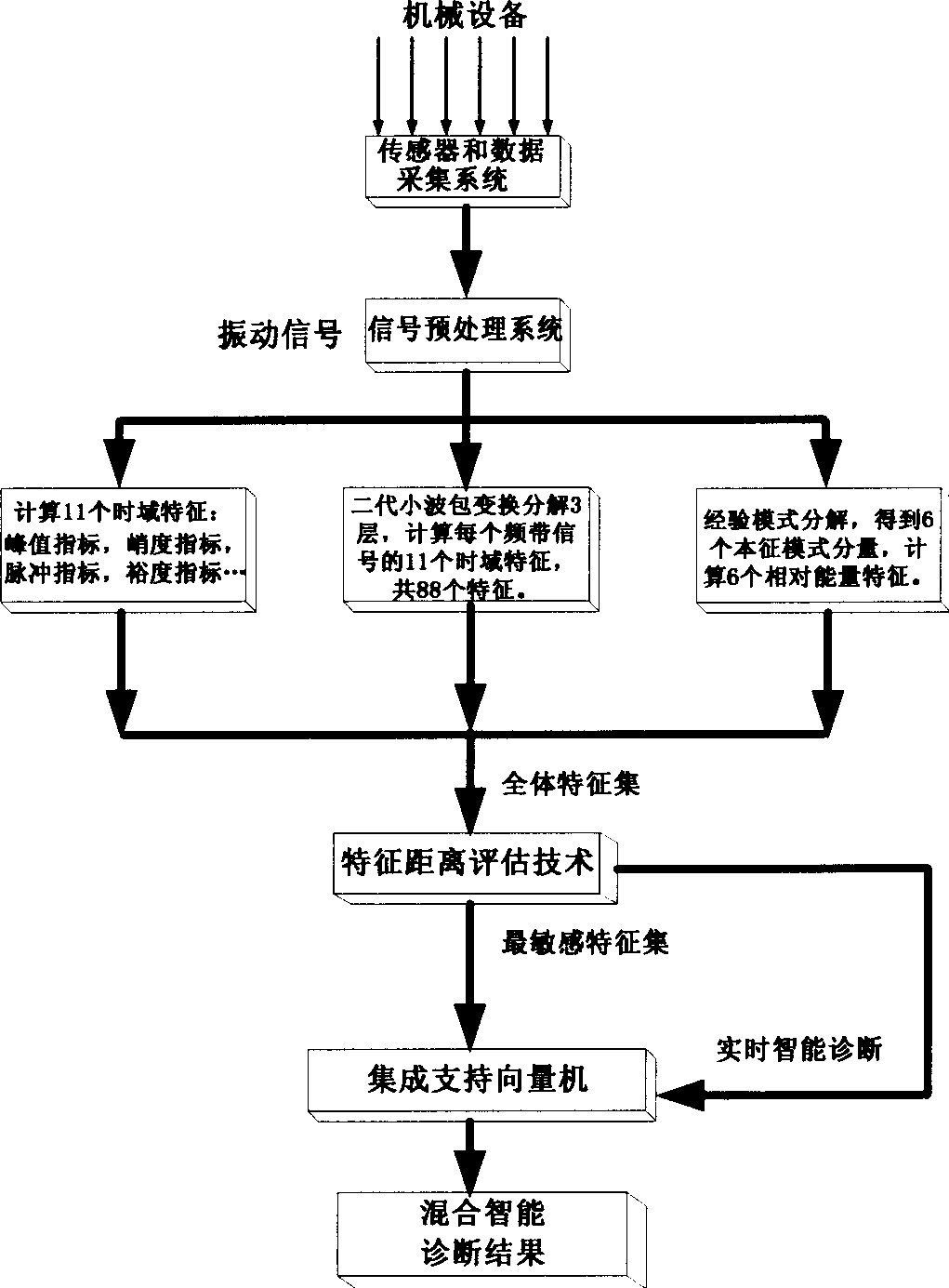

On-line monitoring and diagnosing system and method for mechanical state of high-voltage circuit breaker

ActiveCN103487749ASatisfy sample training needsEffective Diagnosis of Mechanical FaultsMachine part testingCircuit interrupters testingData retrievalSignal conditioning

The invention discloses an on-line monitoring and diagnosing system for the mechanical state of a high-voltage circuit breaker. The system comprises a multi-path sensor which is arranged on a high-voltage circuit breaker body and located in a switch operation mechanism box and can reflect the operation state of a device. The multi-path sensor is connected with a signal conditioning device through a circuit, and the signal conditioning device is connected with an on-line monitoring server through a circuit. The on-line monitoring server comprises a data acquisition module which is in communication with a network transmission module, a data storage module, a data analysis module and a report printing module. The data storage module is in communication with the report printing module, the data analysis module and a data retrieval module, and the data analysis module is connected with the data storage module and the report printing module. The invention further discloses a monitoring and analyzing method utilizing the system. Therefore, mechanical failures of the high-voltage circuit breaker can be effectively diagnosed and a superior failure classification function is achieved.

Owner:STATE GRID CORP OF CHINA +1

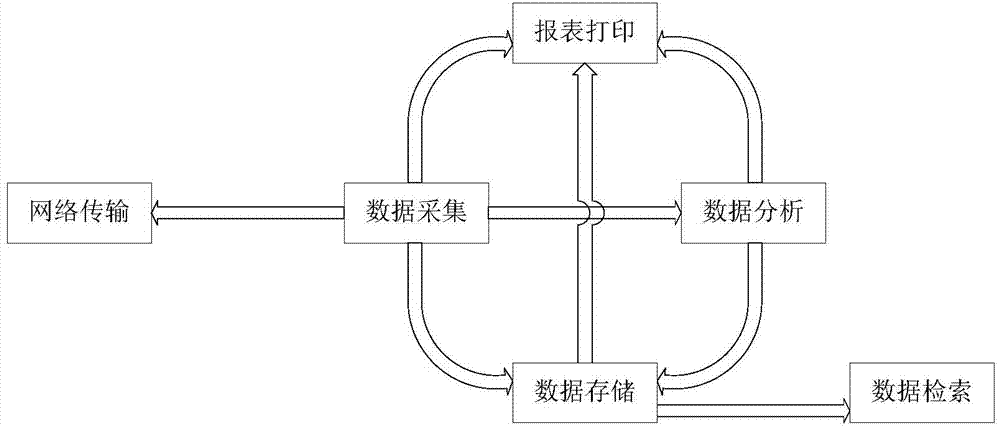

Integrated supporting vector machine mixed intelligent diagnosing method for mechanical fault

InactiveCN1811367ARealize intelligent diagnosisEfficient removalMachine part testingTime domainSupport vector machine

The present invention discloses an integrated support vector machine mixed intelligent diagnosis method of machine failure. Said method includes the following steps: respectively adopting and lifting small wave packet, utilizing frequency band and empirical mode decomposition process to decompose vibration signal according to the eigen mode component and extract time domain statistical character of decomposed signal to form total characteristic set; providing characteristic distance evaluation technique and characteristic evaluation index; utilizing said characteristic evaluation index to select most sensitive characteristic set from the total characteristic set; using said most sensitive characteristic set as diagnosis characteristics and creating integrated support vector machine mixed intelligent diagnosis model so as to implement intelligent diagnosis of machine failure state.

Owner:SHENJI GRP KUNMING MACHINE TOOL

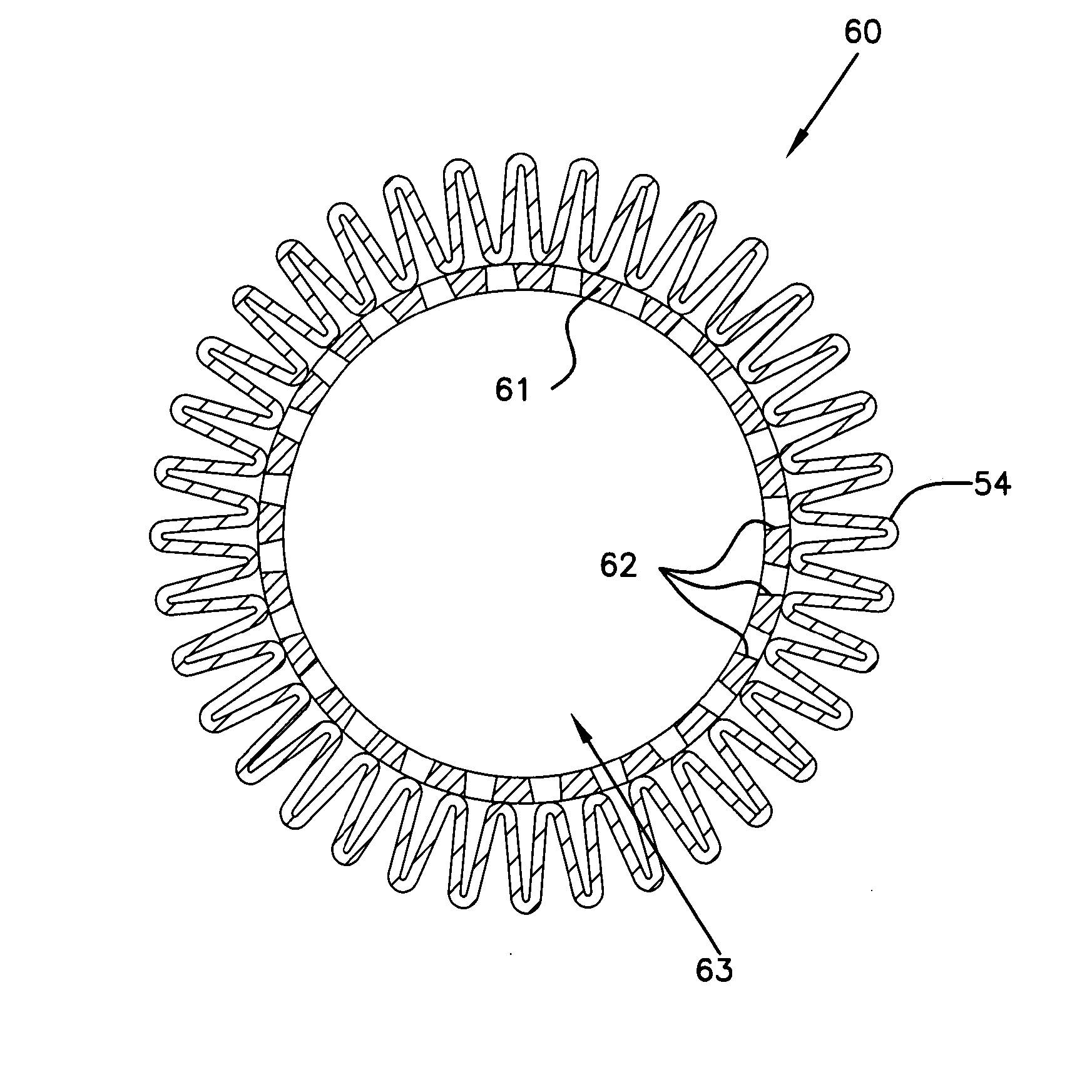

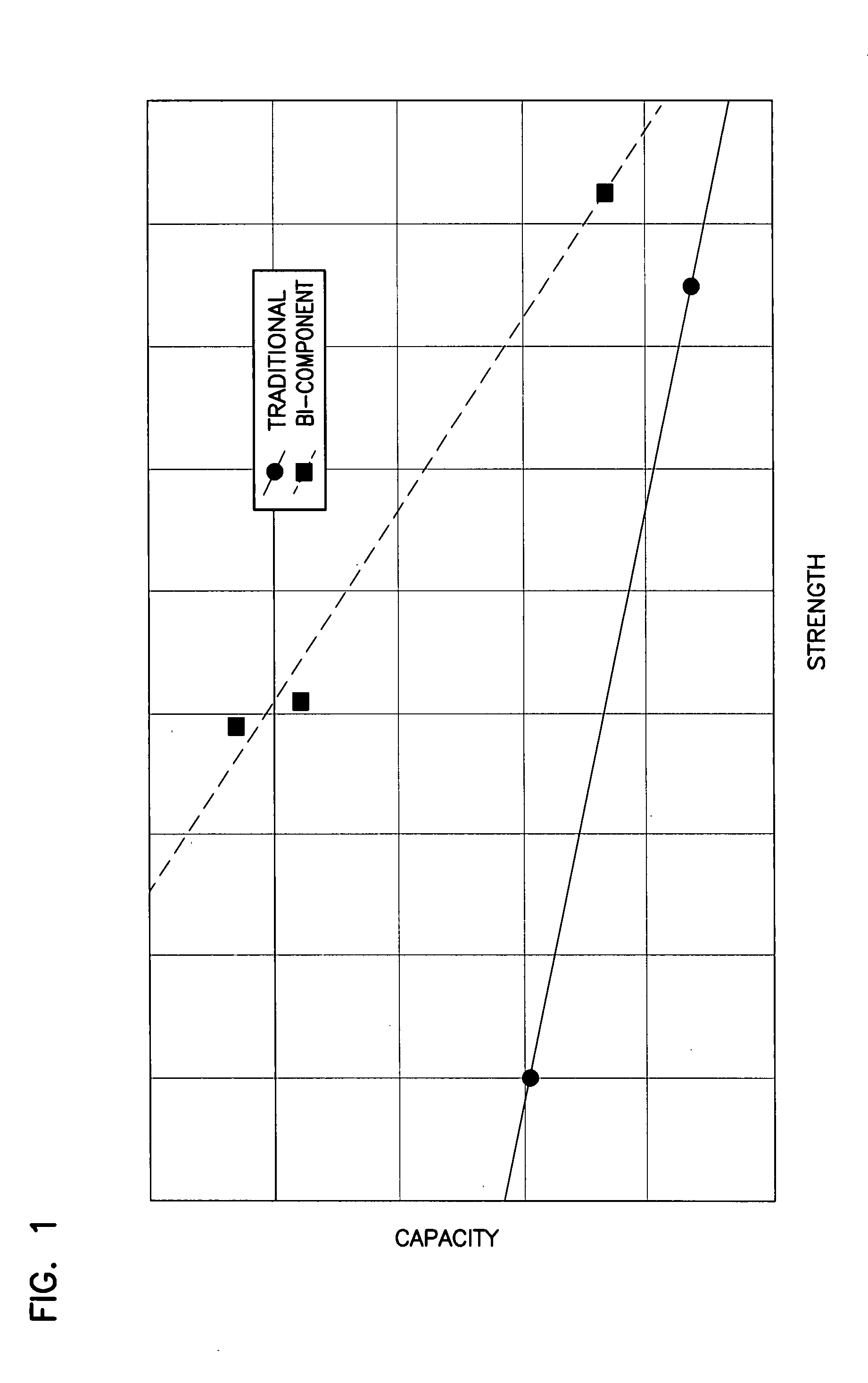

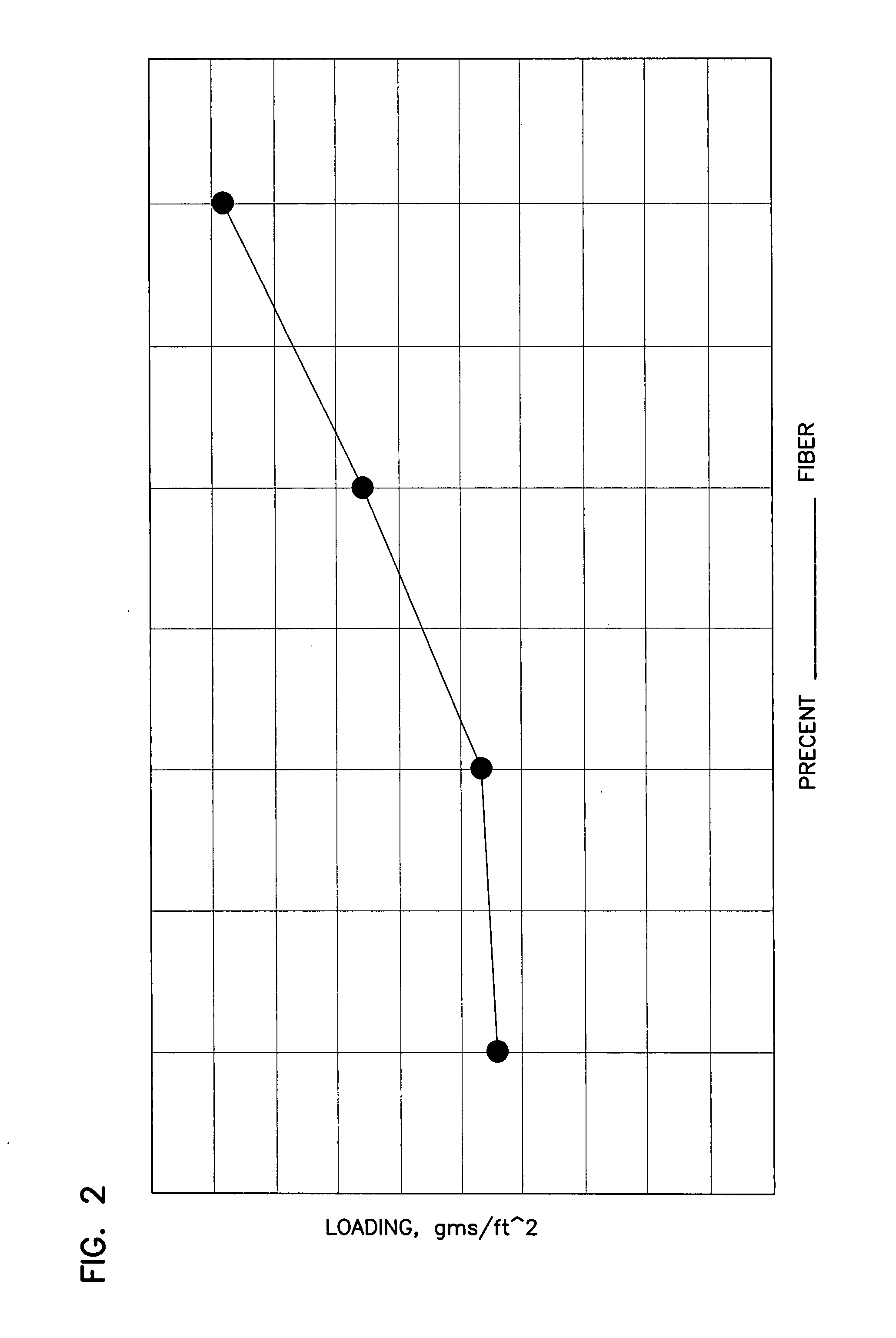

High strength, high capacity filter media and structure

ActiveUS20080073296A1Large capacitySubstantial permeabilitySemi-permeable membranesWater/sewage treatmentParticulatesFilter media

In the filtration of fluid materials, the removal of particulate from the moving stream requires substantial pressure to maintain flow and substantial capacity for removing particulate. The filters of the invention are rugged, high wet strength materials having a basis weight, permeability and efficiency suitable to obtain substantial reduction in particulate loading from liquid streams without plugging or mechanical failure. In particular, the filters of the invention permit the removal of substantial proportions of particulate from non-aqueous streams including lubricant oils, hydraulic fluids and other contaminated streams.

Owner:DONALDSON CO INC

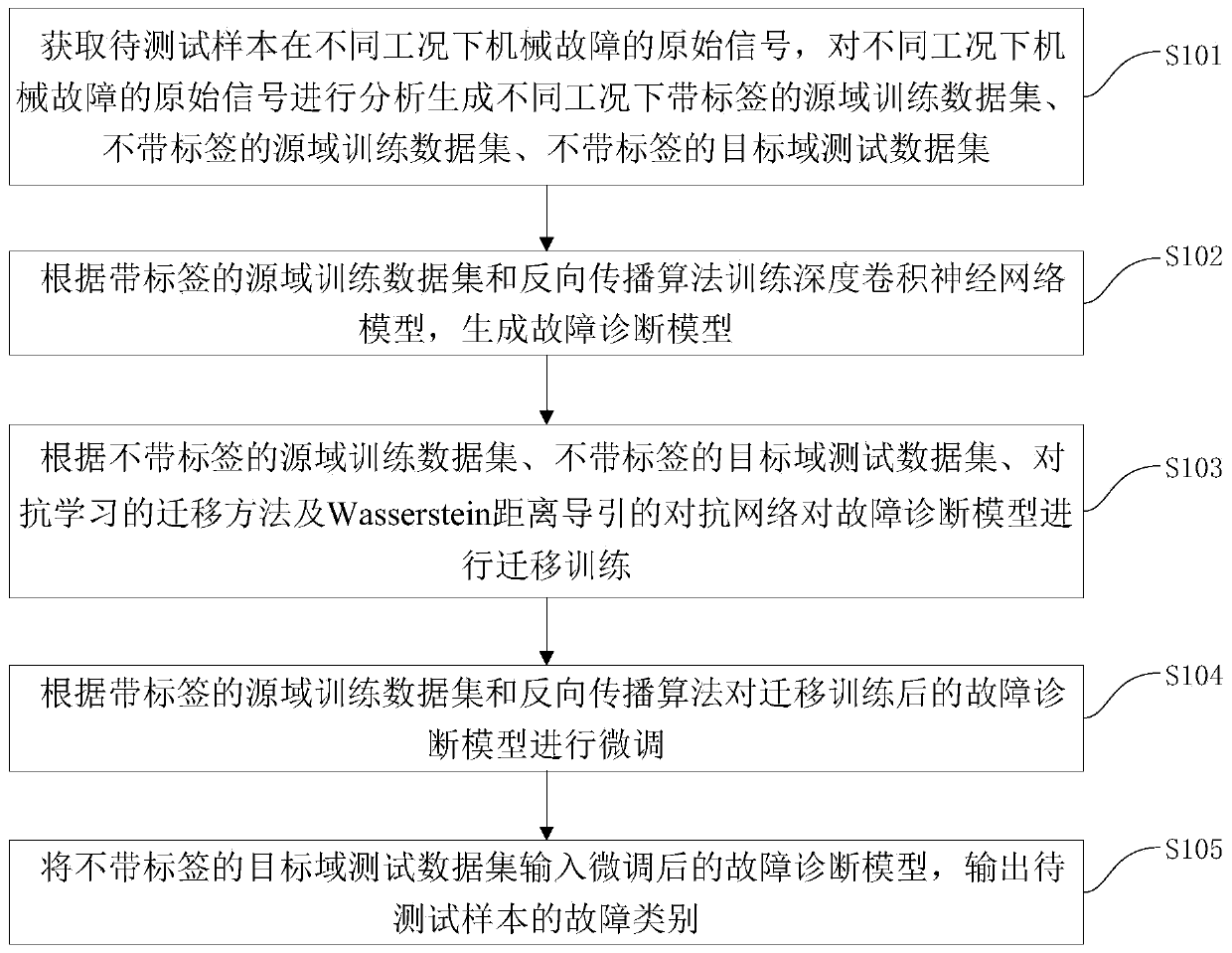

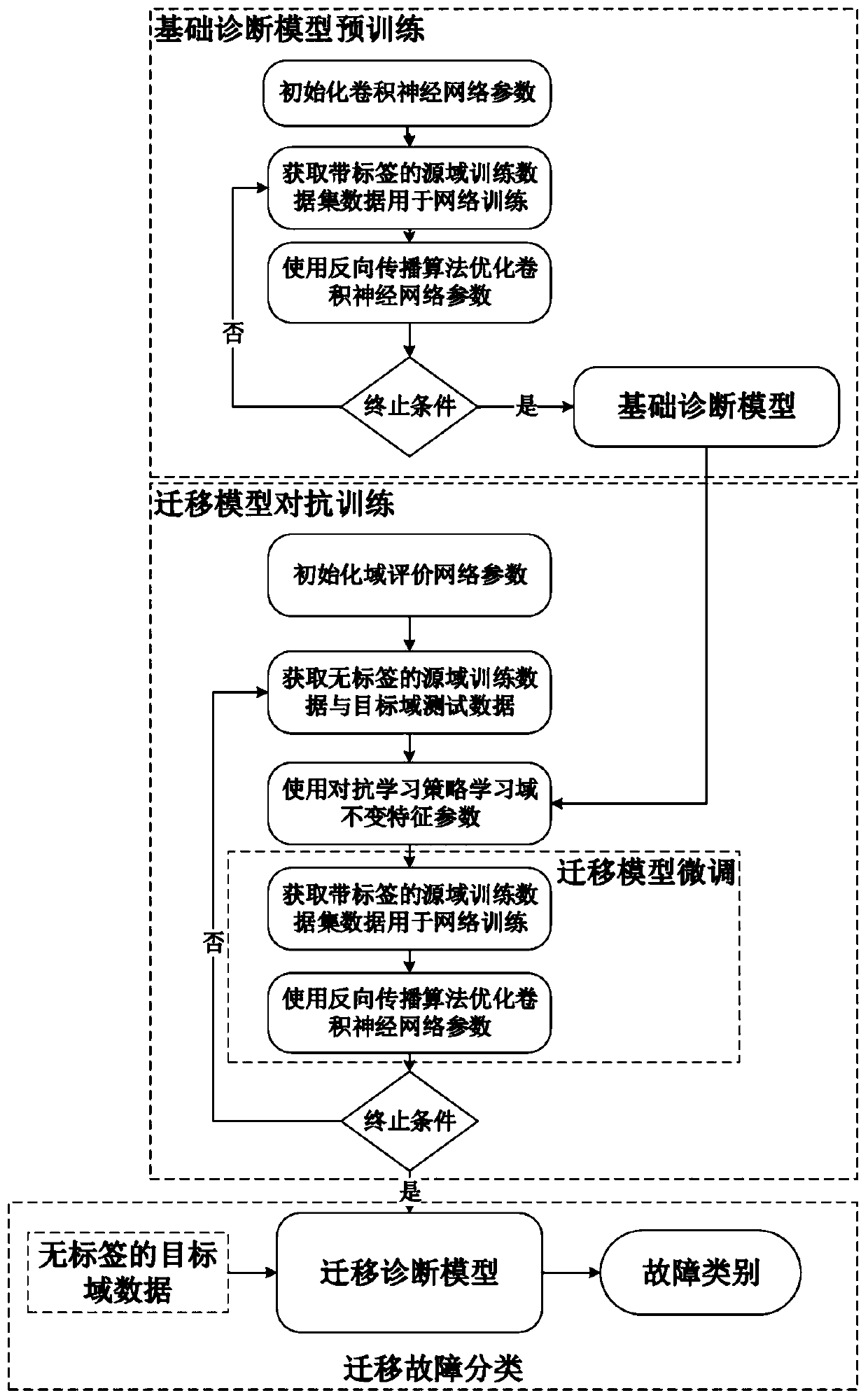

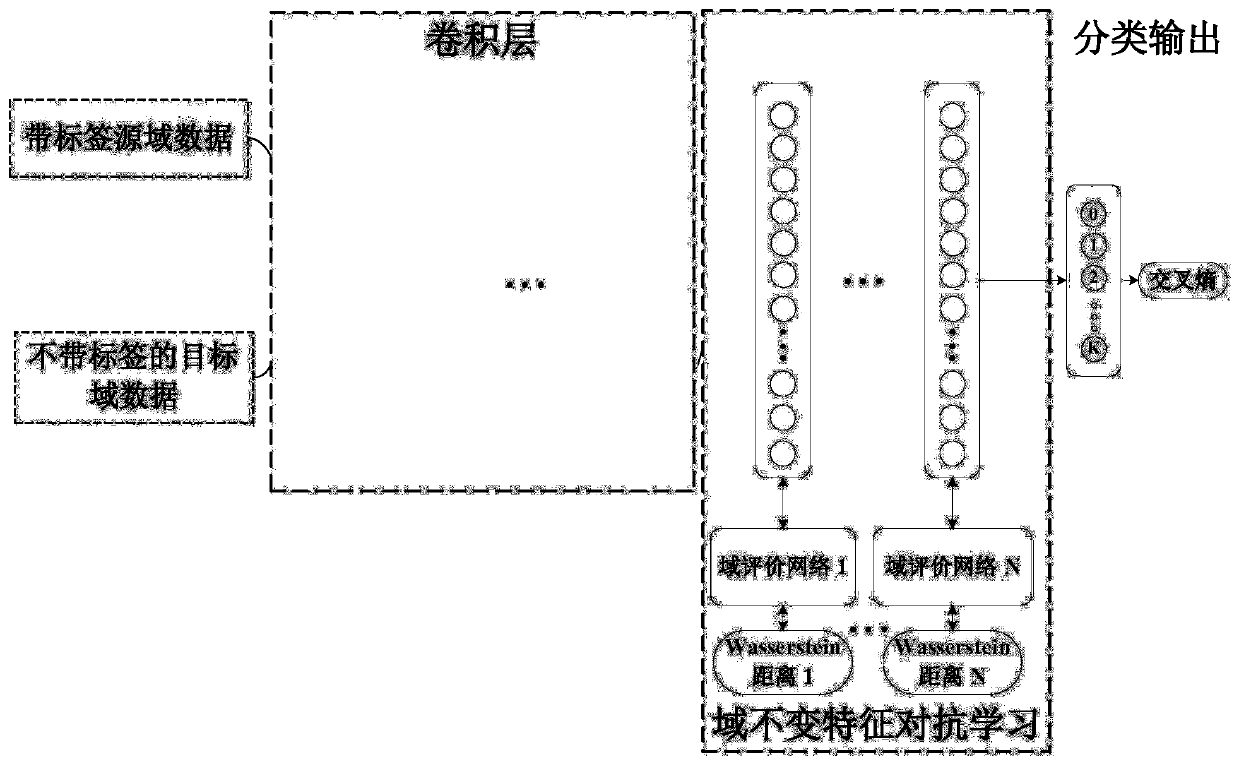

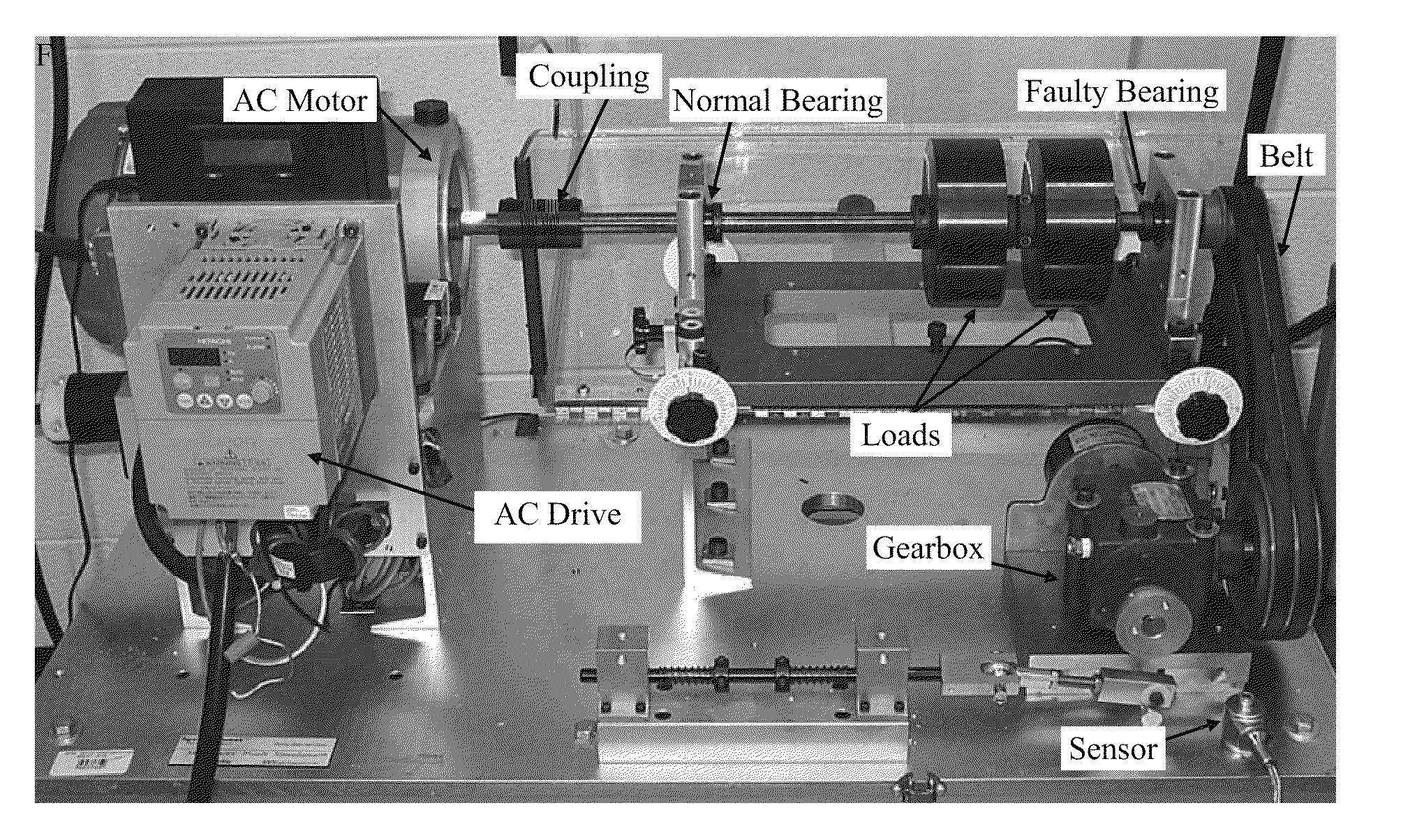

Mechanical failure migration diagnosis method and system based on adversarial learning

ActiveCN109947086AAchieve migrationAvoid Migration ProblemsElectric testing/monitoringNerve networkData set

The invention discloses a mechanical failure migration diagnosis method and system based on adversarial learning. The method comprises the following steps: acquiring and analyzing original signals ofmechanical failure under different working conditions to generate a labeled source domain training dataset, an unlabelled source domain training dataset and a target domain test dataset under different working conditions; training a deep convolutional neutral network model according to the labeled source domain training dataset and a back propagation algorithm to generate a failure diagnosis model; training the failure diagnosis model according to the unlabelled source domain training dataset and the target domain test dataset; fine adjusting the trained failure diagnosis model according to the labeled source domain training dataset and the back propagation algorithm; inputting the unlabelled target domain test dataset into the fine adjusted failure diagnosis model, and outputting the failure category of a to-be-tested sample. By means of the method, the domain invariant feature is obtained with the adversarial learning method, migration among different domains is realized, and intelligent diagnosis of mechanical failure under variable working conditions is realized.

Owner:TSINGHUA UNIV

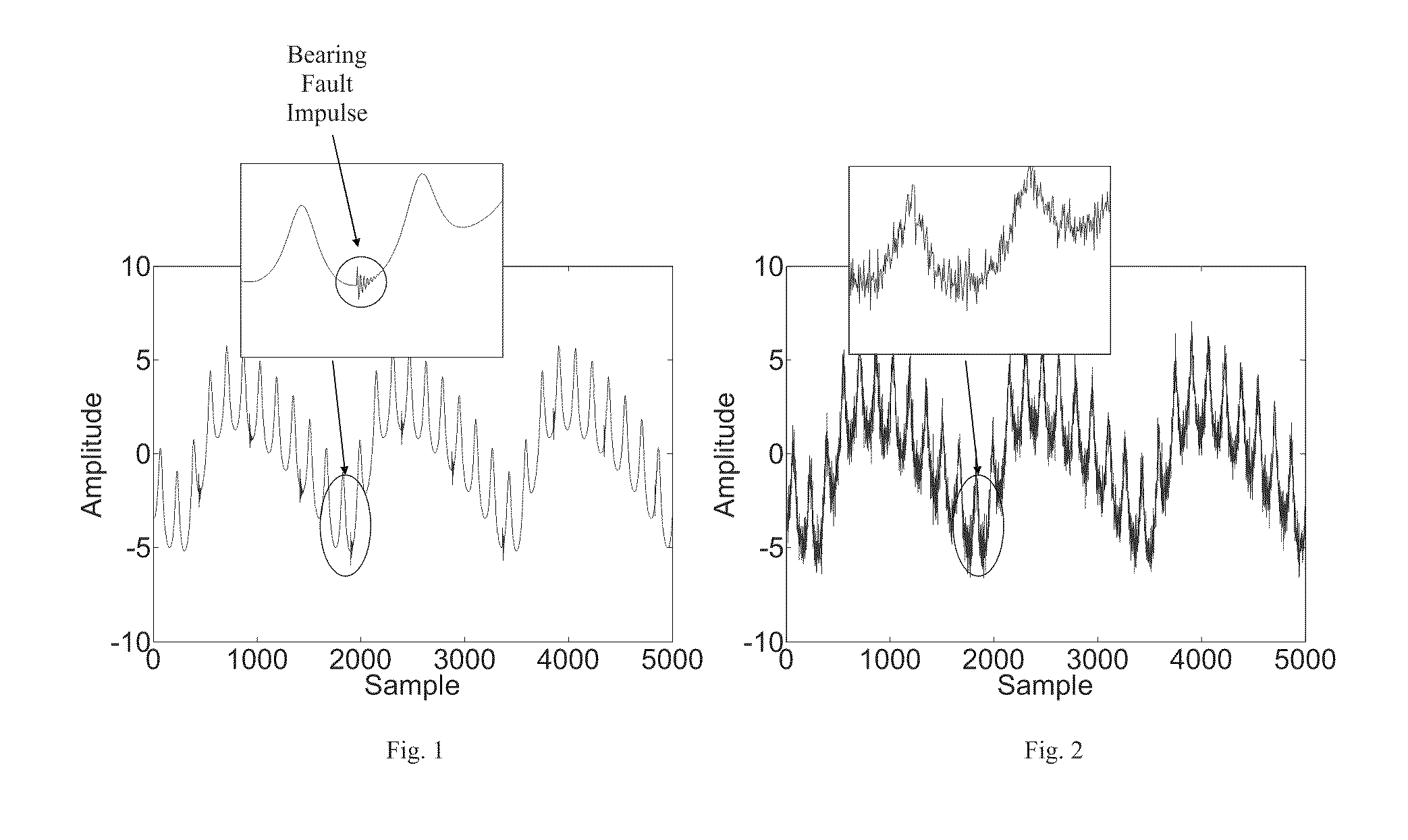

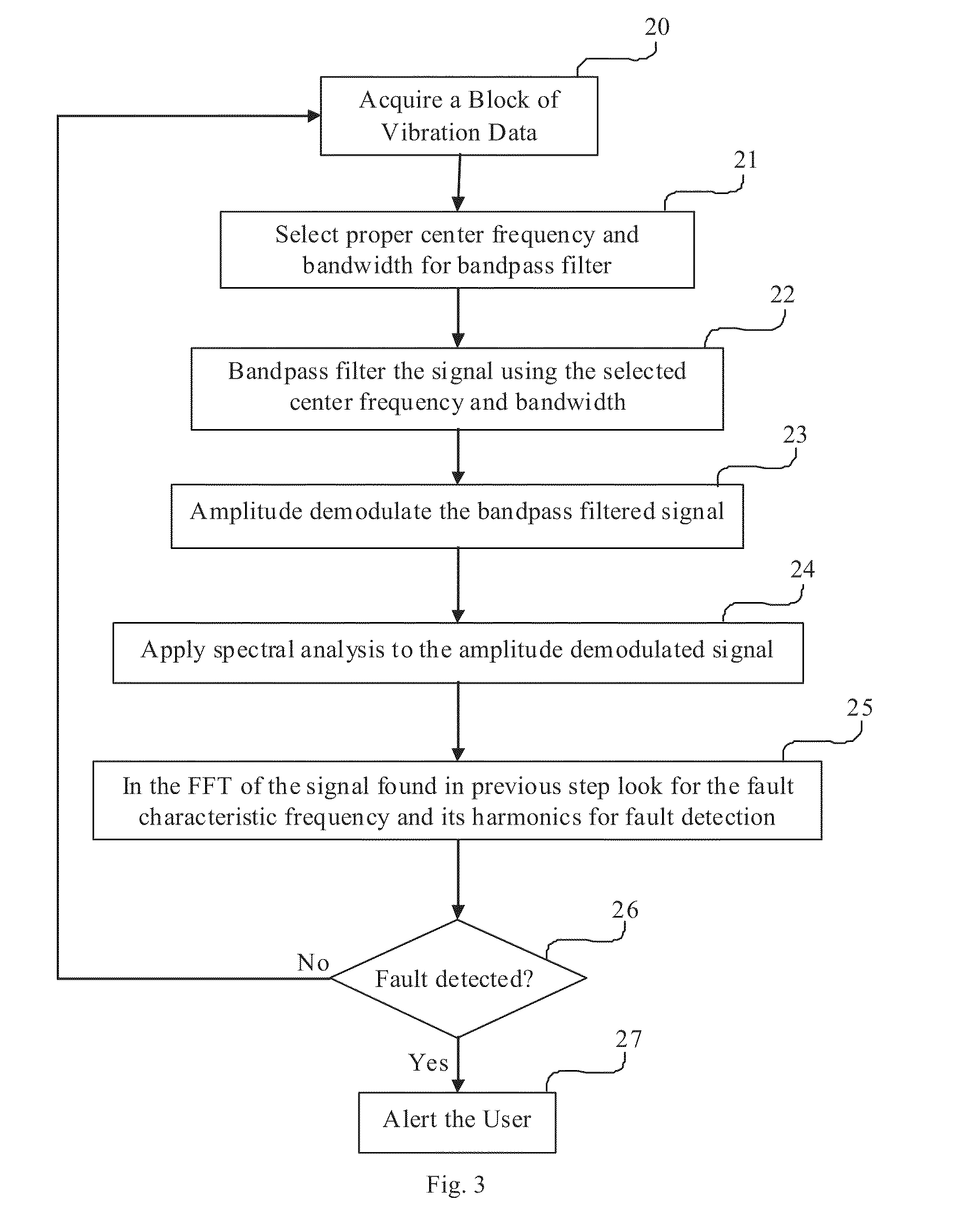

Parameter independent detection of rotating machinery faults

InactiveUS20100139403A1Efficient implementationVibration measurement in solidsMachine part testingMechanical componentsAmplitude demodulation

A parameter-free method to analyze sensor signals incorporates two or more of frequency demodulation, amplitude demodulation and phase demodulation of the raw signal data. The resulting signal is transformed to a frequency domain, and target fault characteristics from the demodulated signal are identified. The method is used to detect faults in bearings, gears and other mechanical components.

Owner:UNIVERSITY OF OTTAWA

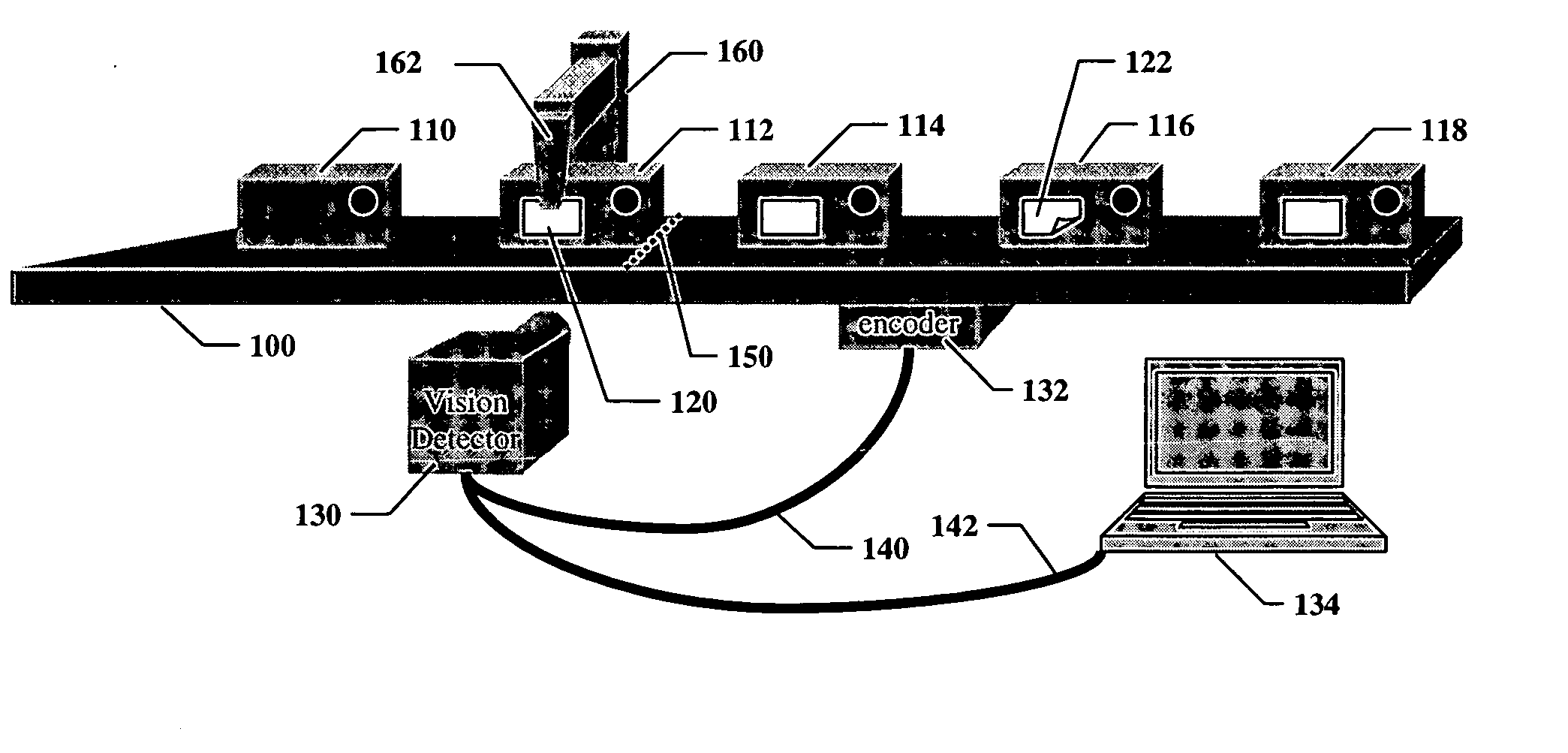

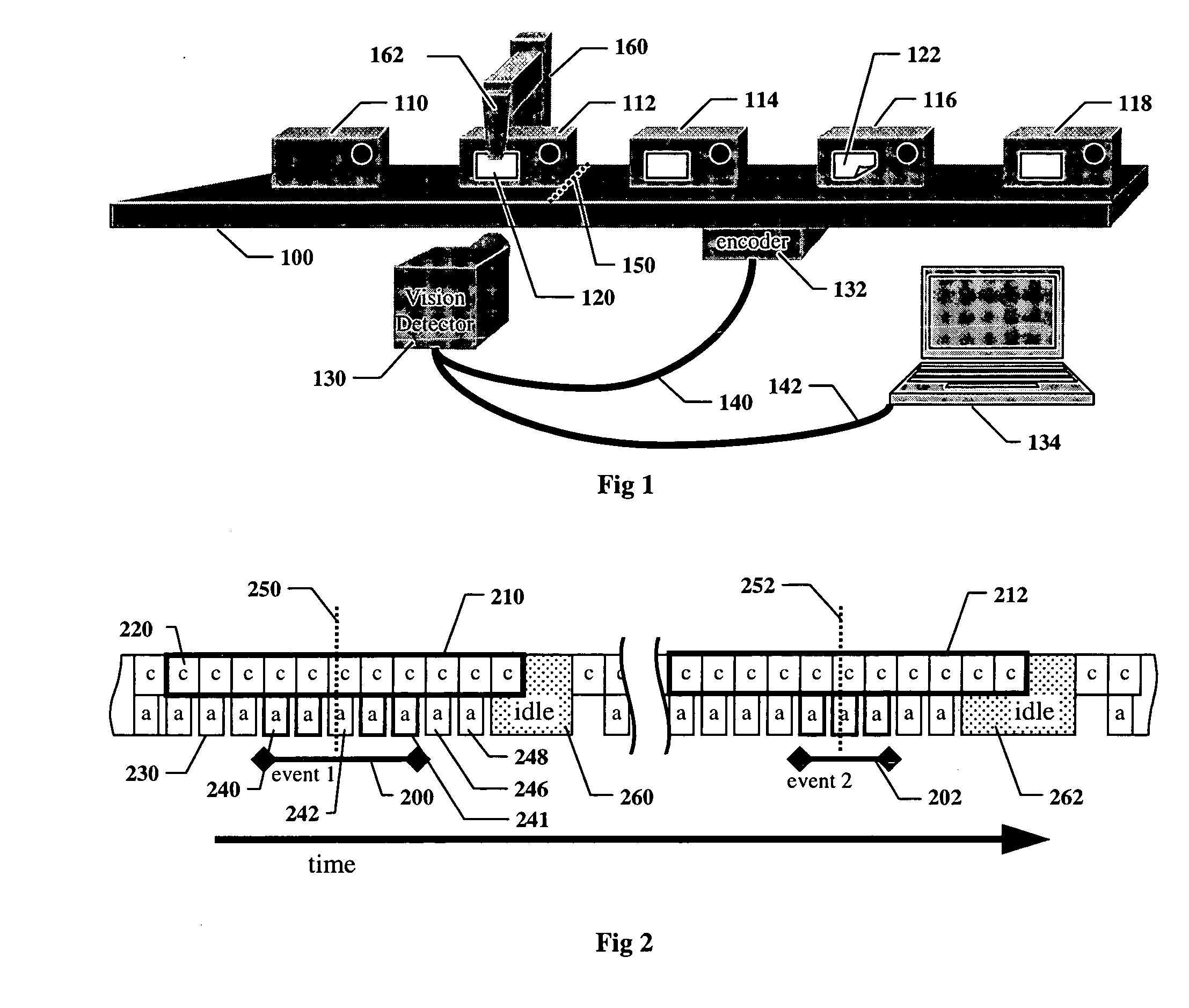

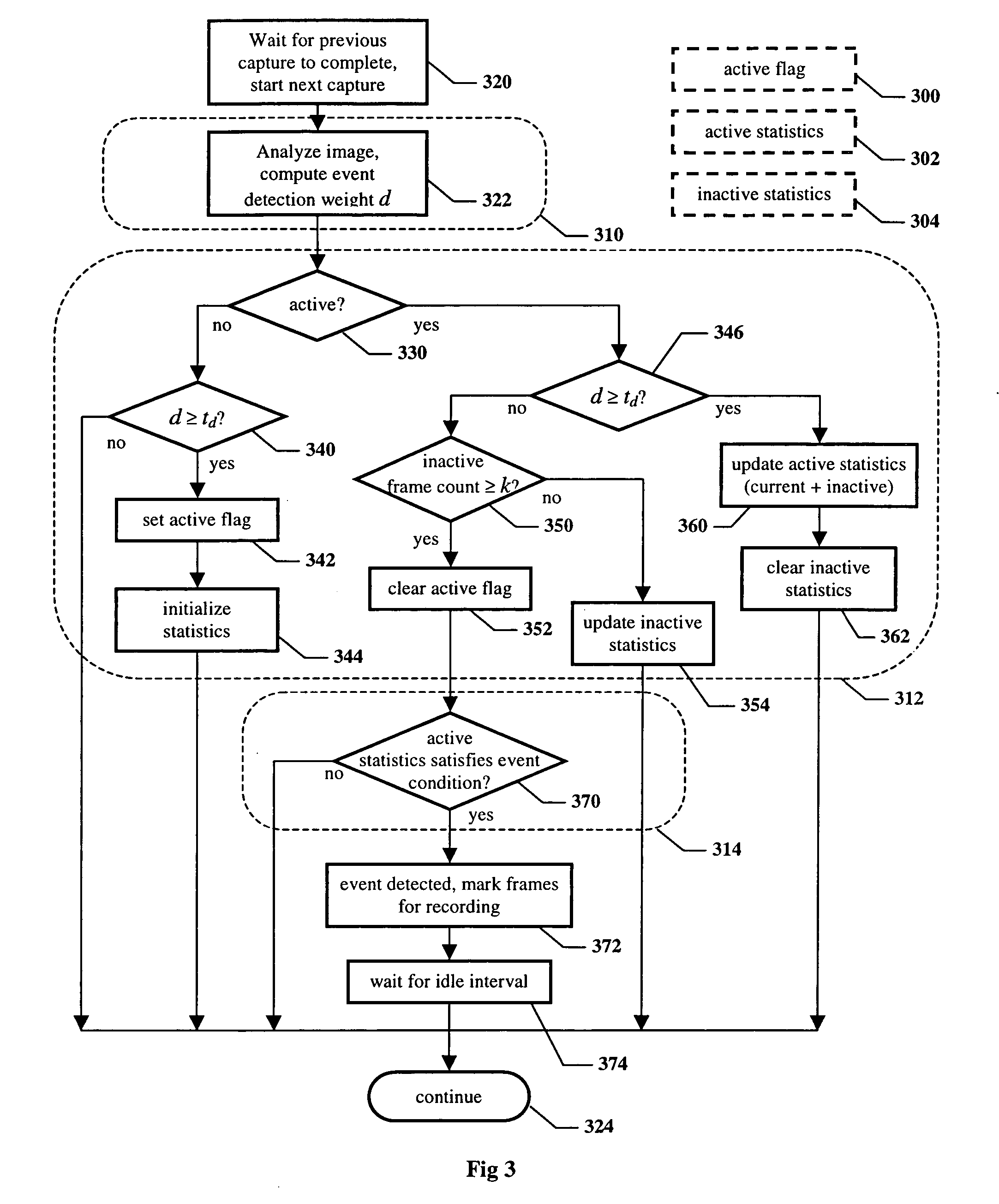

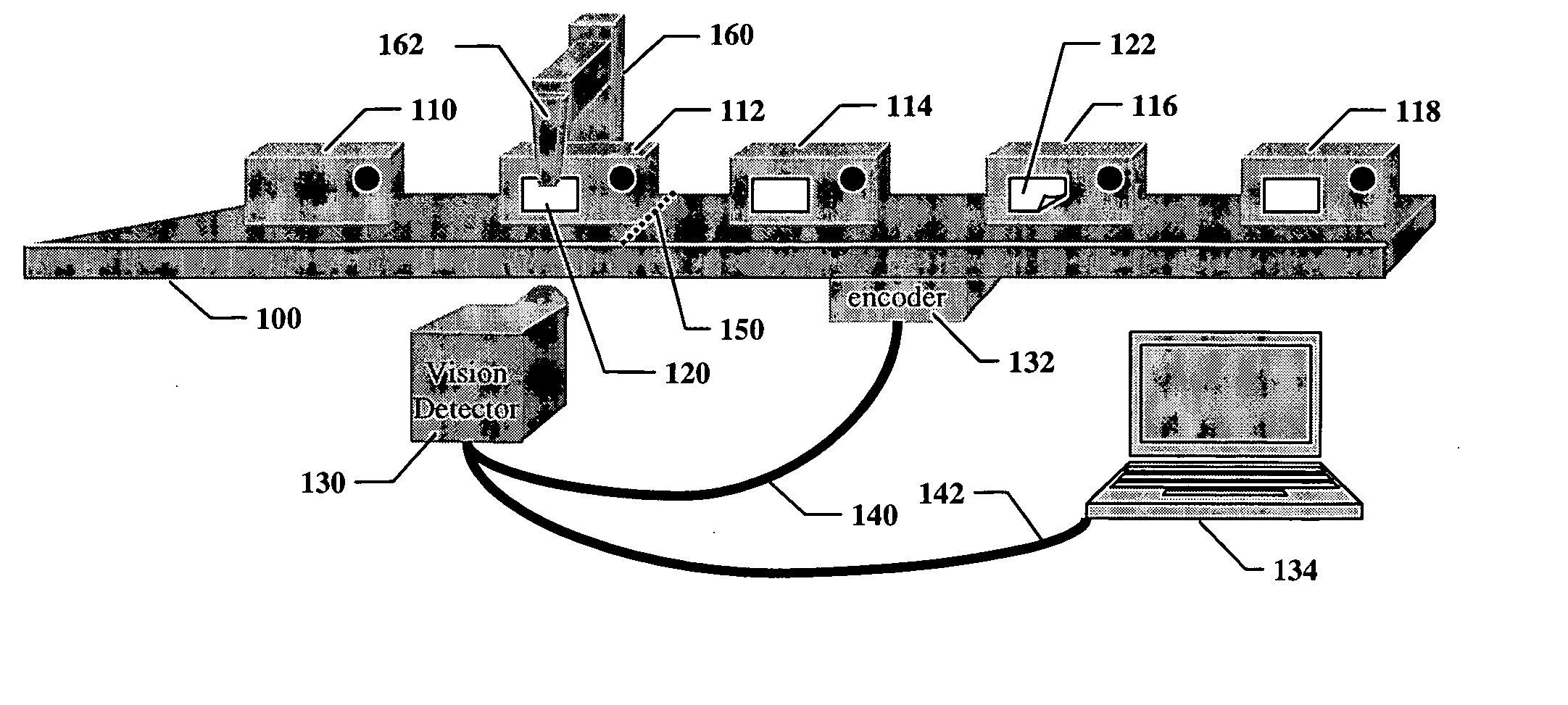

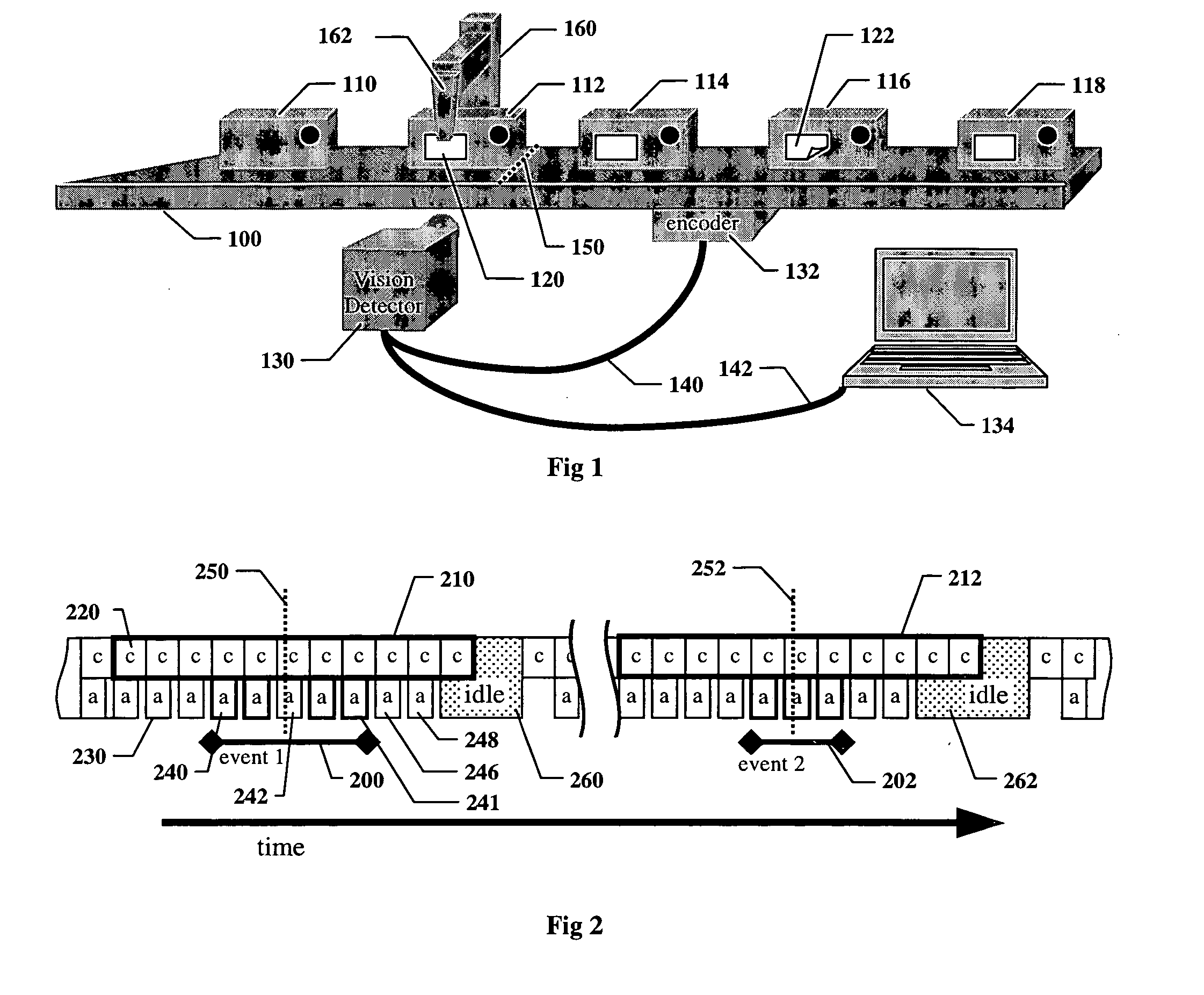

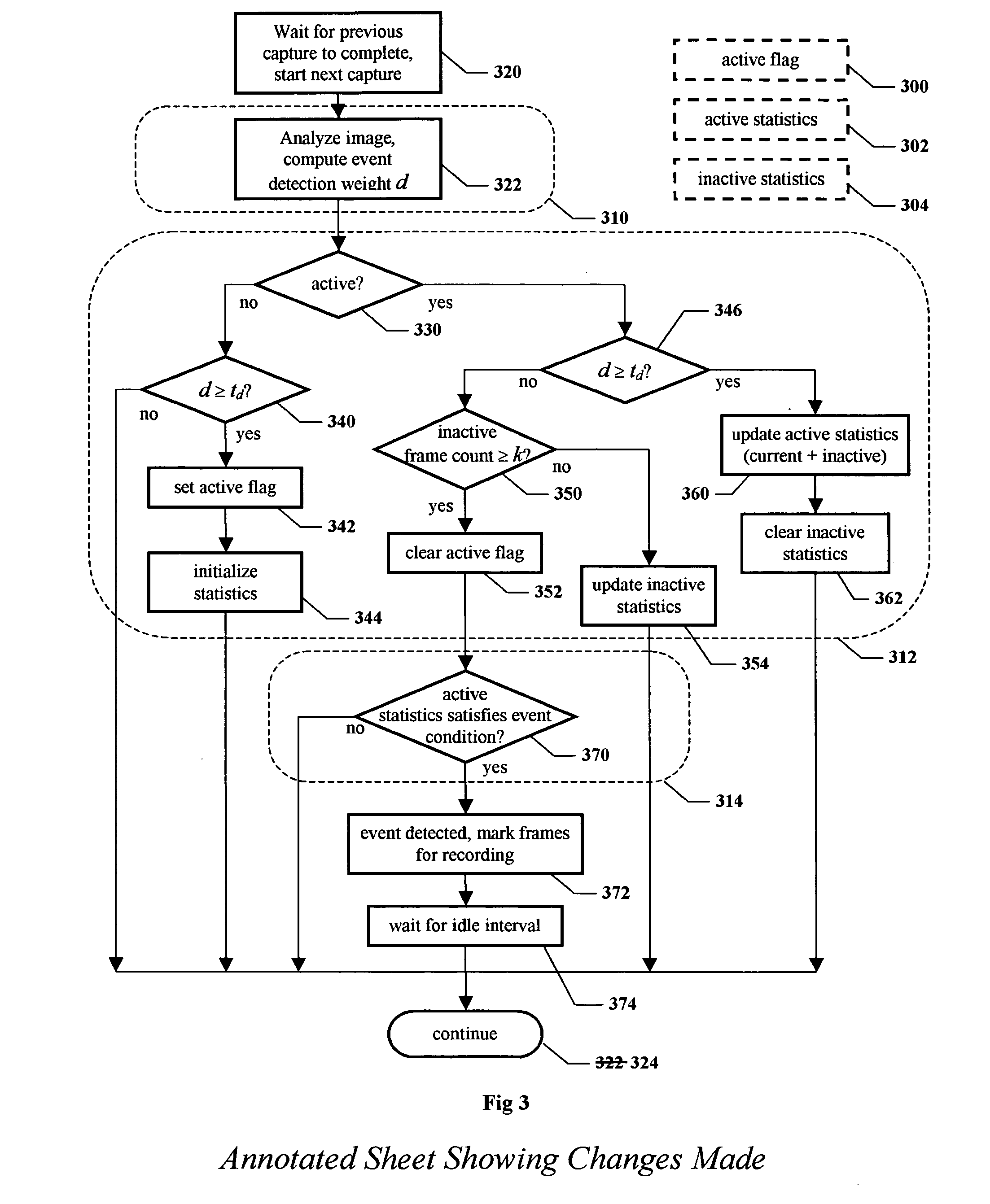

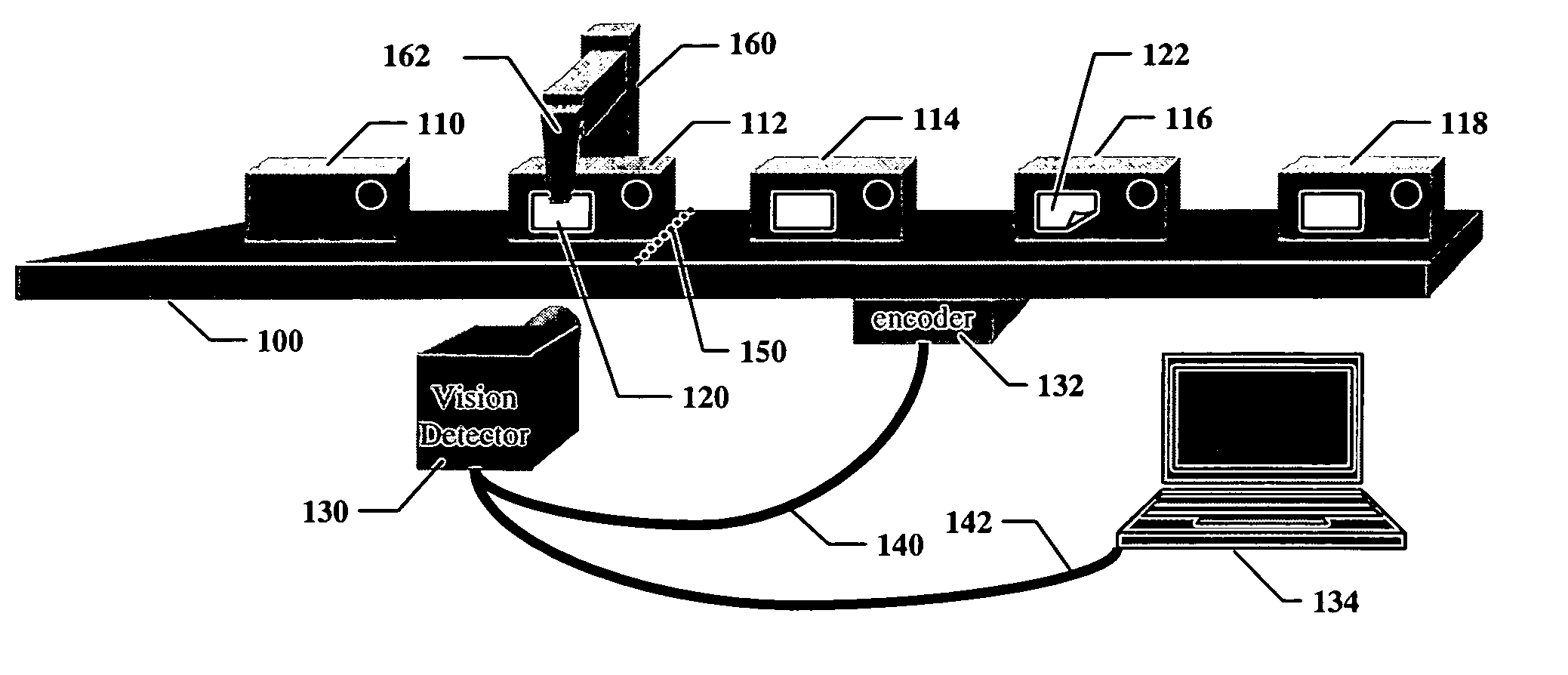

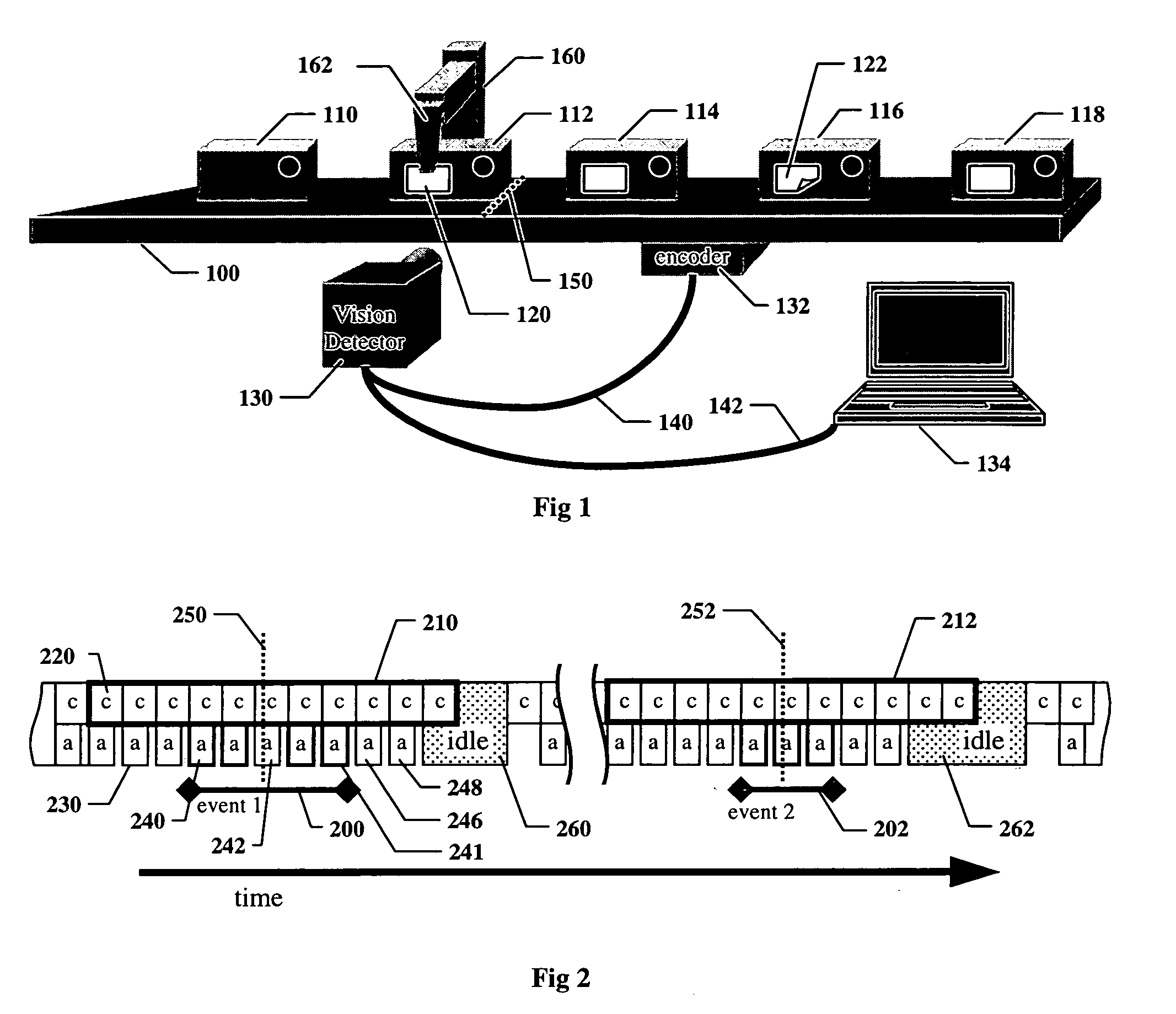

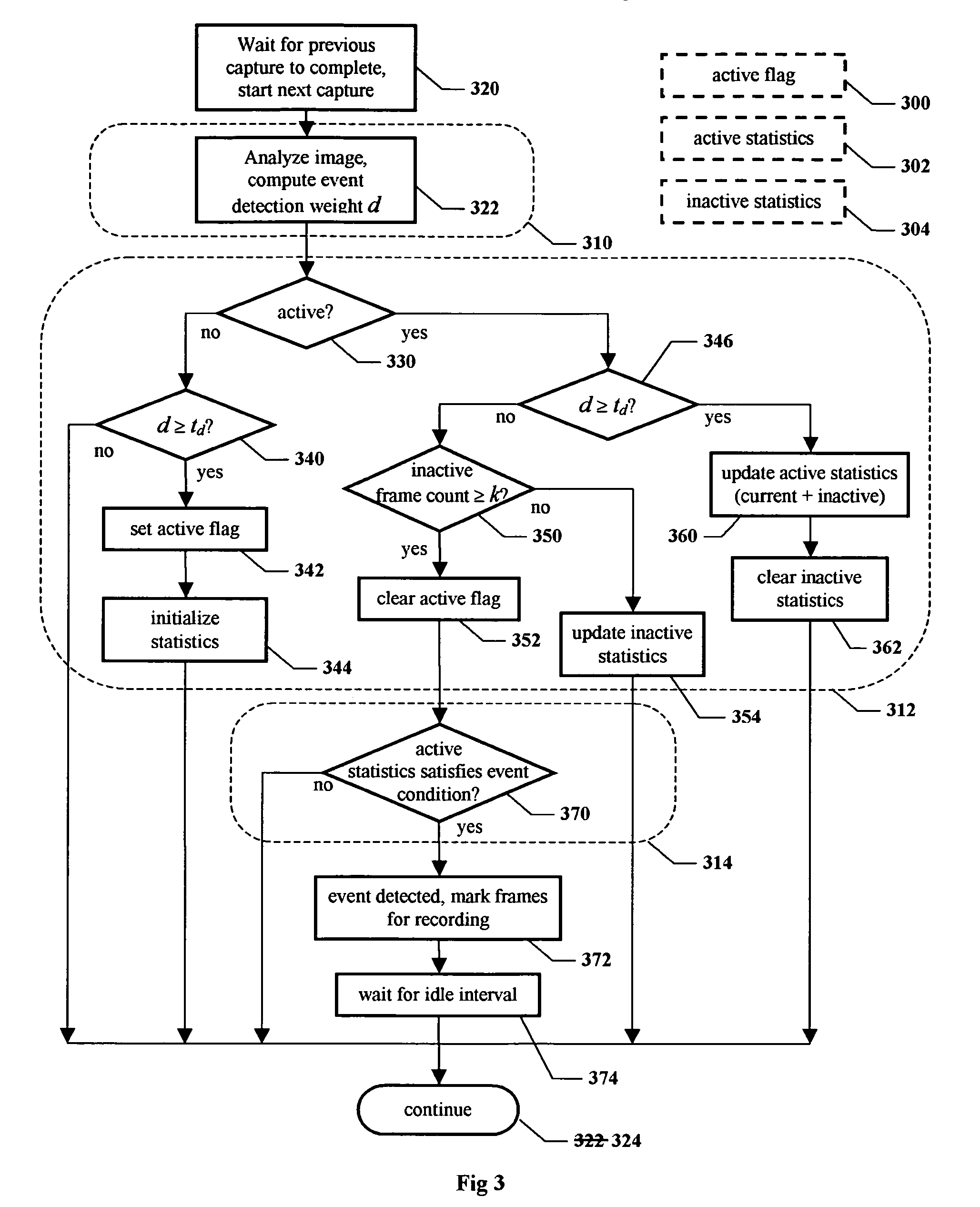

Method and apparatus for automatic visual detection, recording, and retrieval of events

InactiveUS20050276445A1Accurate calculationSpecificTelevision system detailsImage analysisMechanical componentsShort duration

Disclosed are methods and apparatus for automatic visual detection of events, for recording images of those events and retrieving them for display and human or automated analysis, and for sending synchronized signals to external equipment when events are detected. An event corresponds to a specific condition, among some time-varying conditions within the field of view of an imaging device, that can be detected by visual means based on capturing and analyzing digital images of a two-dimensional field of view in which the event may occur. Events may correspond to rare, short duration mechanical failures for which obtaining images for analysis is desirable. Events are detected by considering evidence obtained from an analysis of multiple images of the field of view, during which time moving mechanical components can be seen from multiple viewing perspectives.

Owner:COGNEX TECH & INVESTMENT

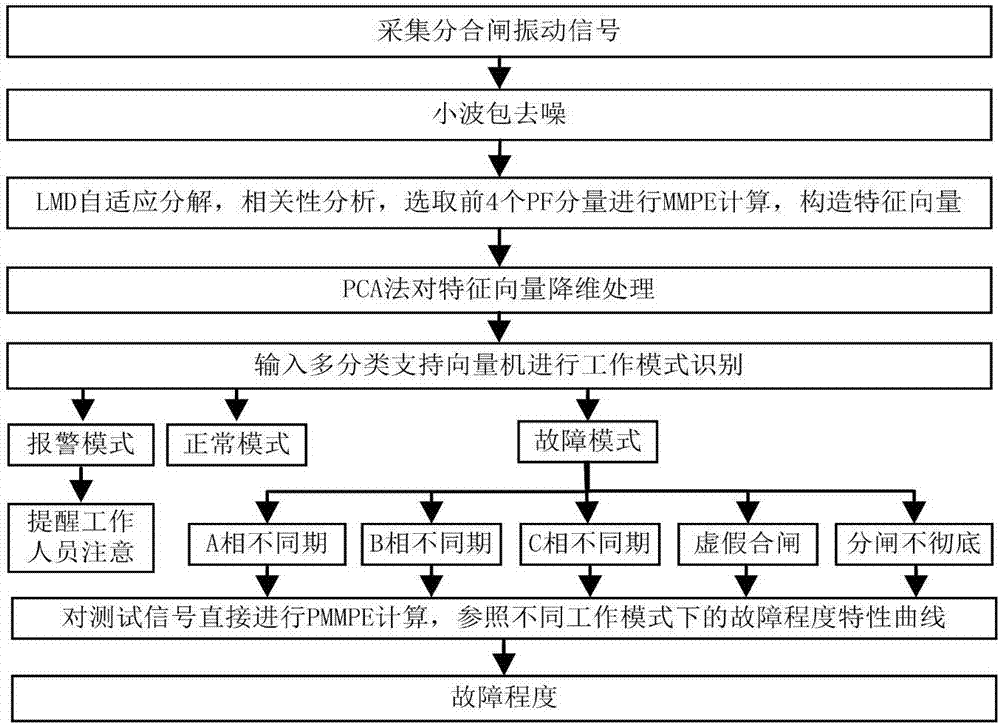

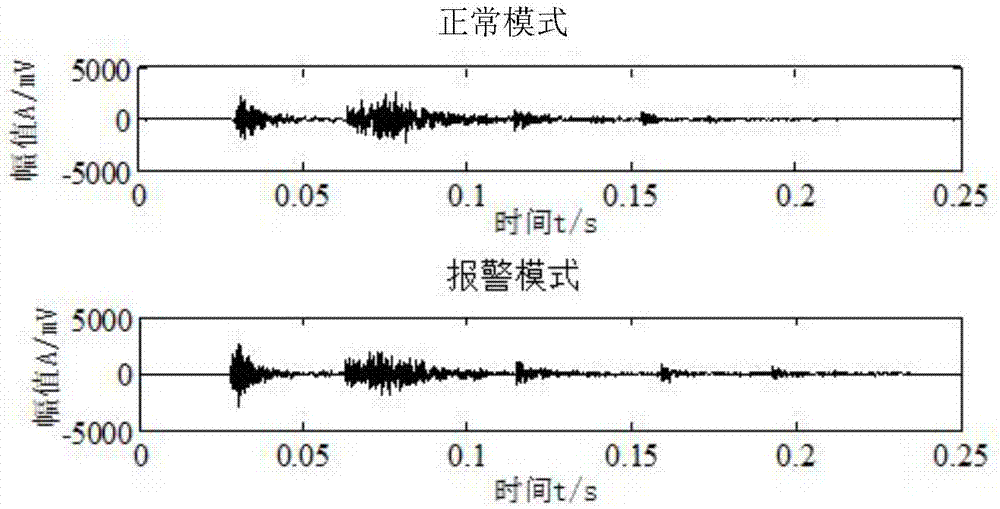

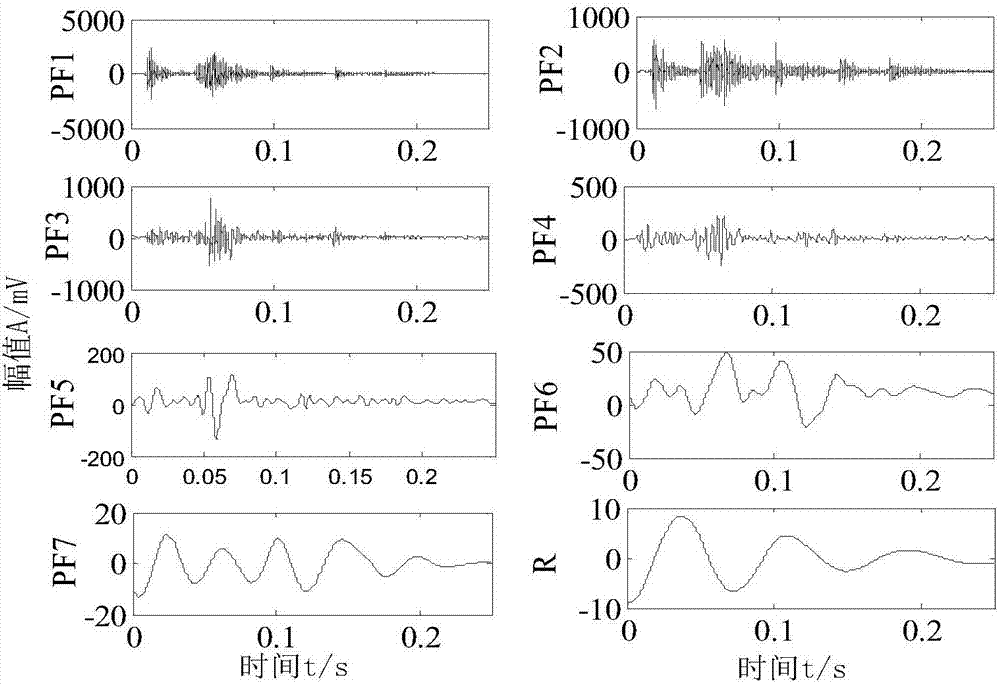

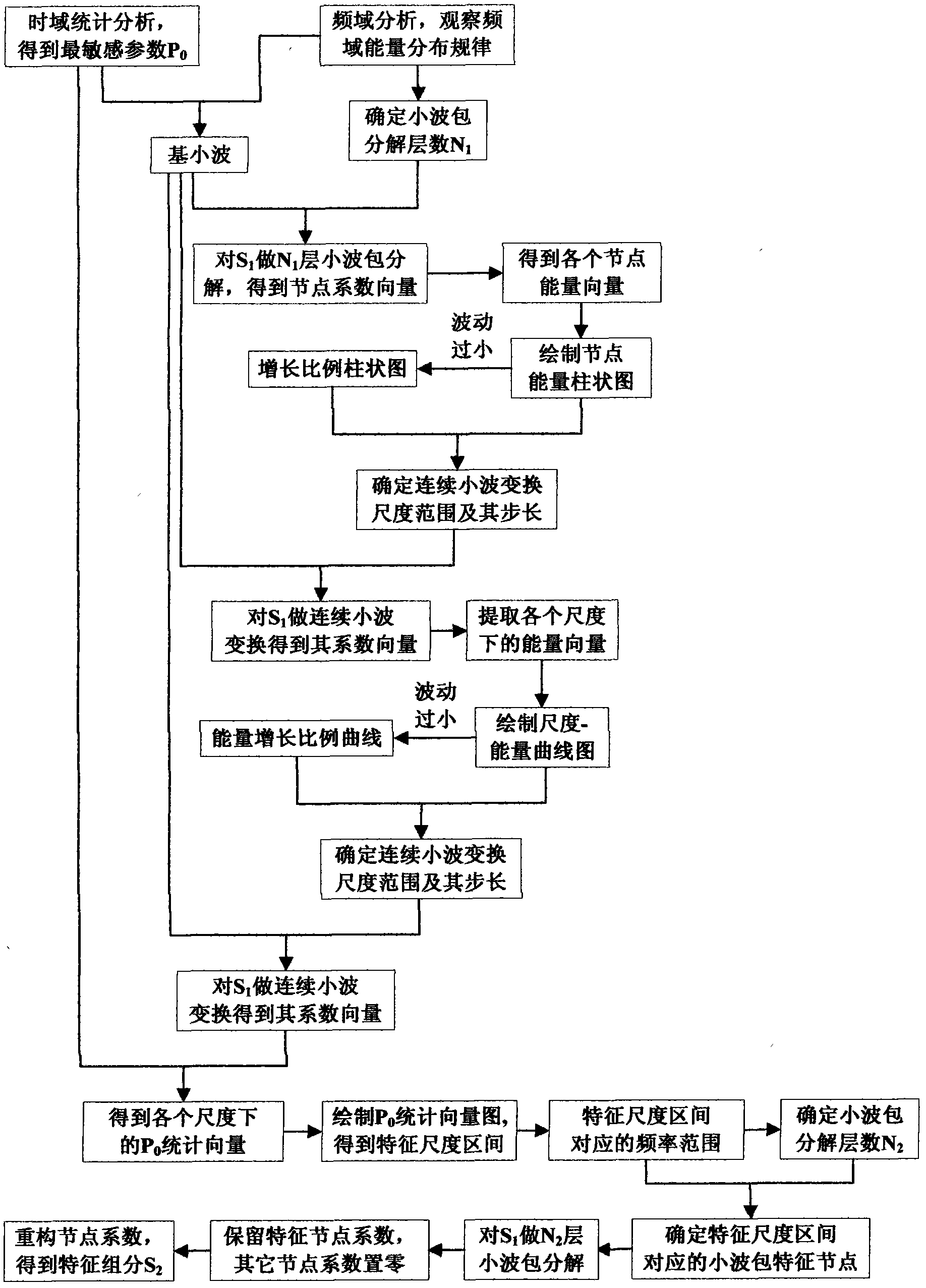

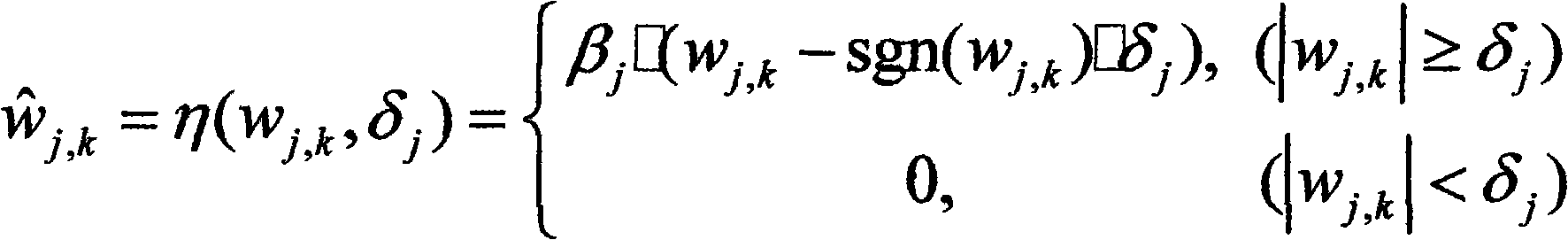

Method for evaluating degree of mechanical fault of frame-type circuit breaker based on vibration signal

InactiveCN107101813AEffective guidance and maintenanceImplement state detectionMachine part testingCircuit interrupters testingSupport vector machineFeature vector

The invention discloses a method for evaluating the degree of a mechanical fault of a frame-type circuit breaker based on a vibration signal. The vibration signal in the method is a mechanical vibration signal collected by a frame-type circuit breaker mechanical fault detection system in the switching process of the frame-type circuit breaker. The method comprises the steps: employing a wavelet packet to carry out the denoising preprocessing of the vibration signal; carrying out the adaptive decomposition of a denoised vibration signal through employing a local mean decomposition algorithm; screening out the former d PF components with the maximum correlation with an original vibration signal; carrying out the improved multiscale arrangement entropy analysis of al PF components, and carrying out the dimension reduction of a feature vector formed by the above improved multiscale arrangement entropy values through the PCA method; building a fault feature vector; constructing a multi-class supporting vector machine, and carrying out the pattern recognition; carrying out the quantitative evaluation of the severity of the mechanical fault happening in the switching process of the circuit breaker through referring to the fault degree characteristic curves in different fault modes. The method is stable, is reliable and is effective.

Owner:HEBEI UNIV OF TECH

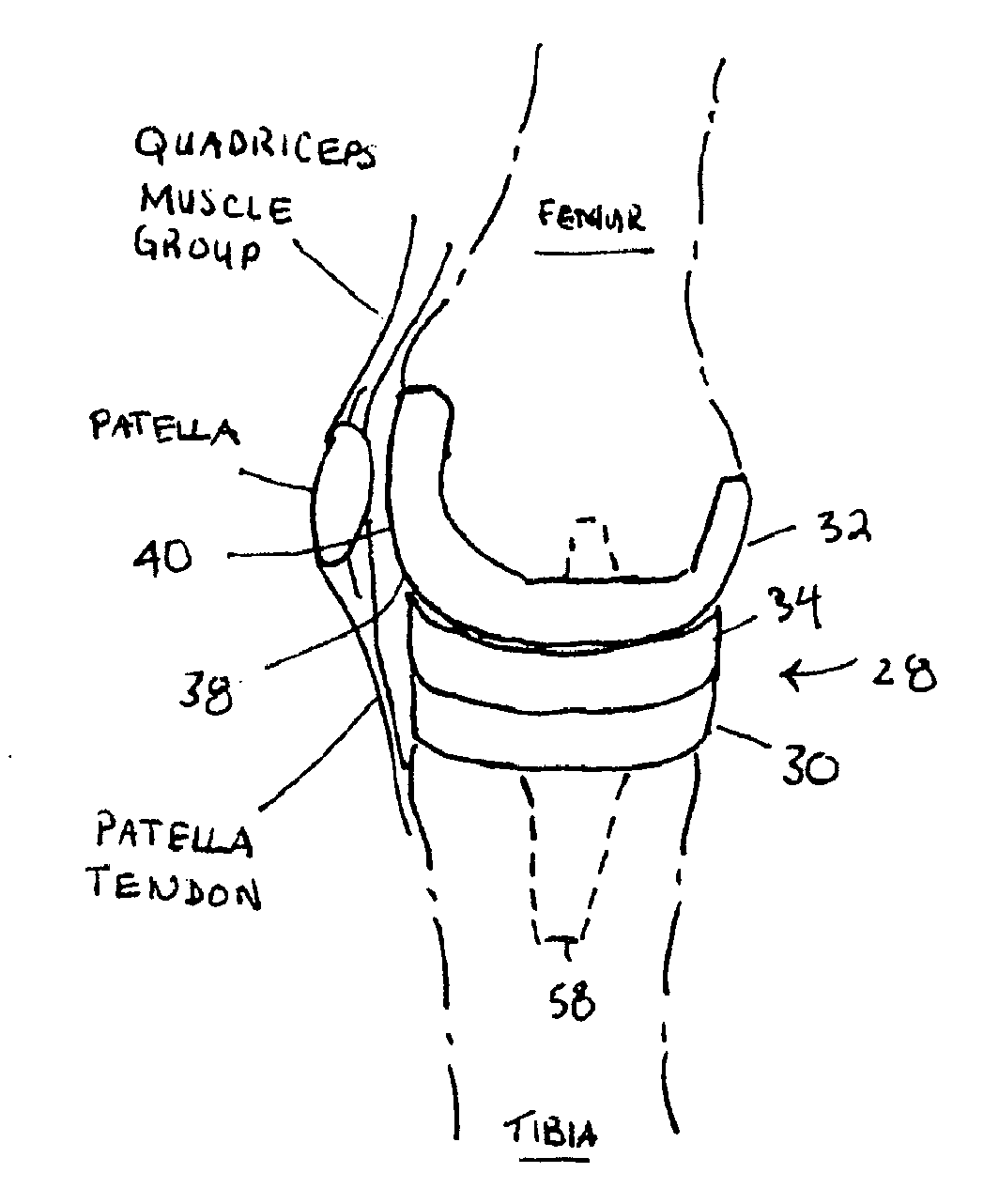

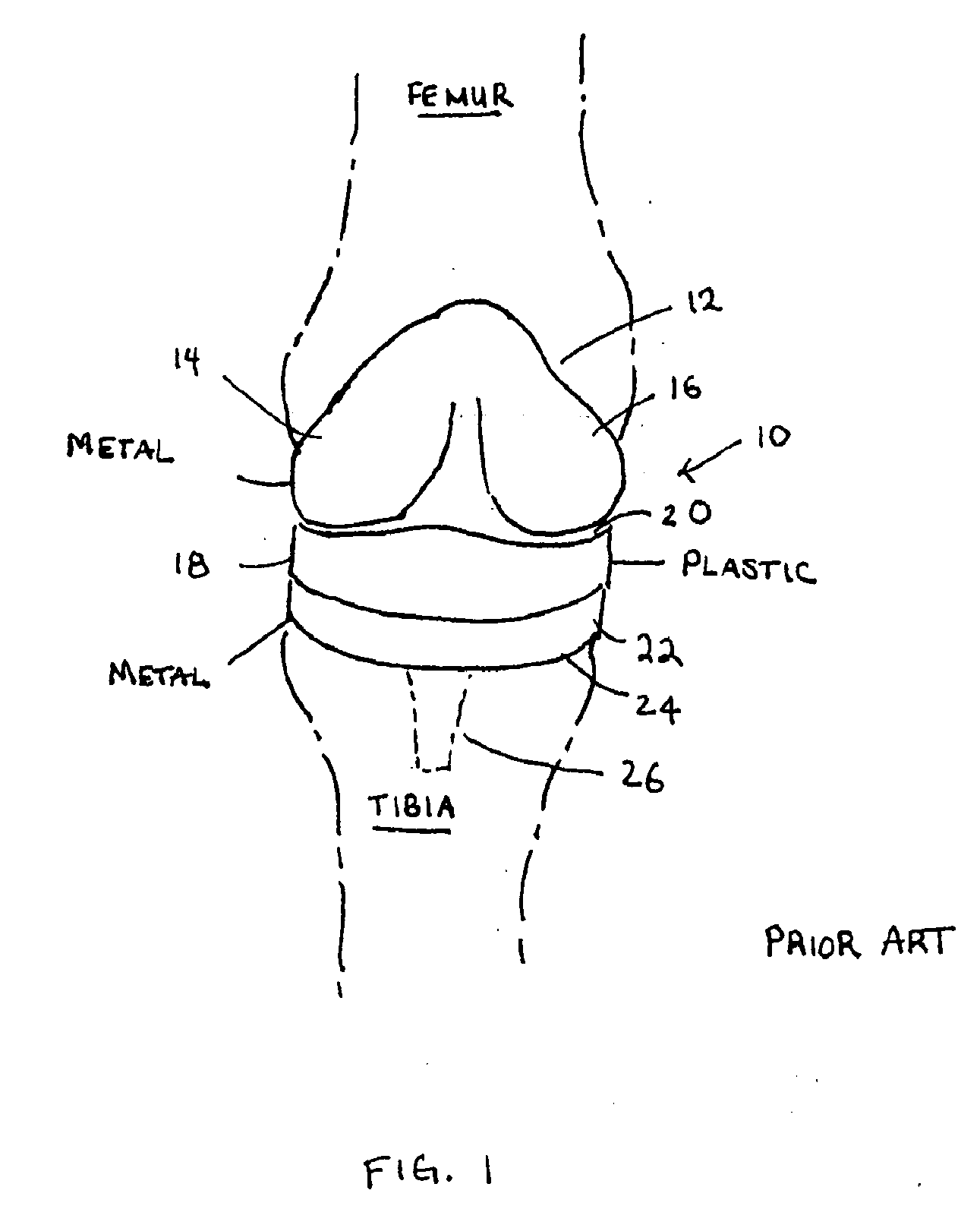

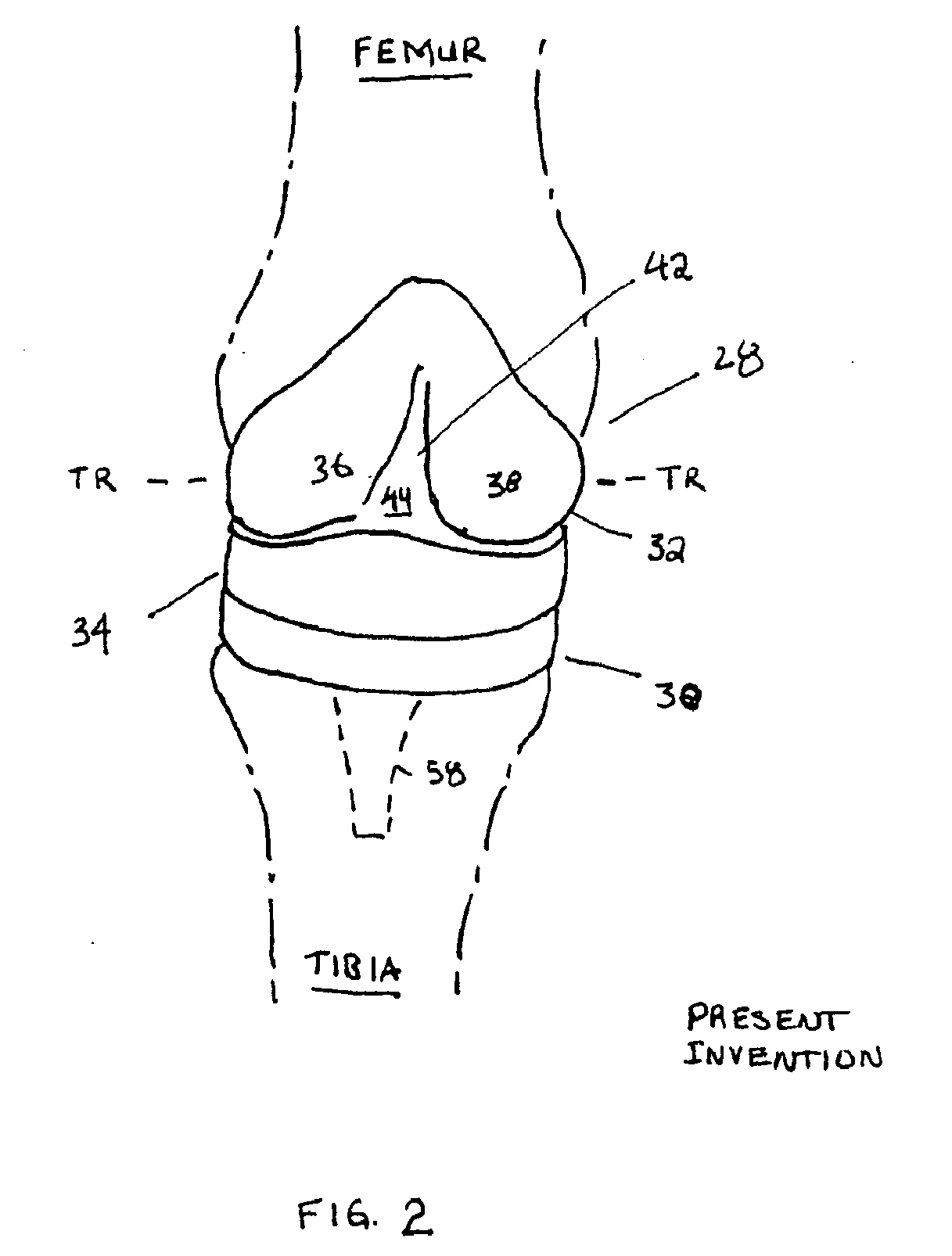

Knee prosthesis

A femoral component for a knee prosthesis comprises a reduced wear polyethylene (RWPE). Preferably all of the femoral component is the RWPE and / or at least one condylar surface of the femoral component is the RWPE. The use of RWPE instead of conventional metal components reduces or eliminates complications associated with the use of metal such as fracture (mostly at the area of the bone-metal interface), mechanical failure, and metallosis. Use of the RWPE gives a prosthesis with long life, especially with respect to wear of the femoral component.

Owner:SHUR VLADIMIR

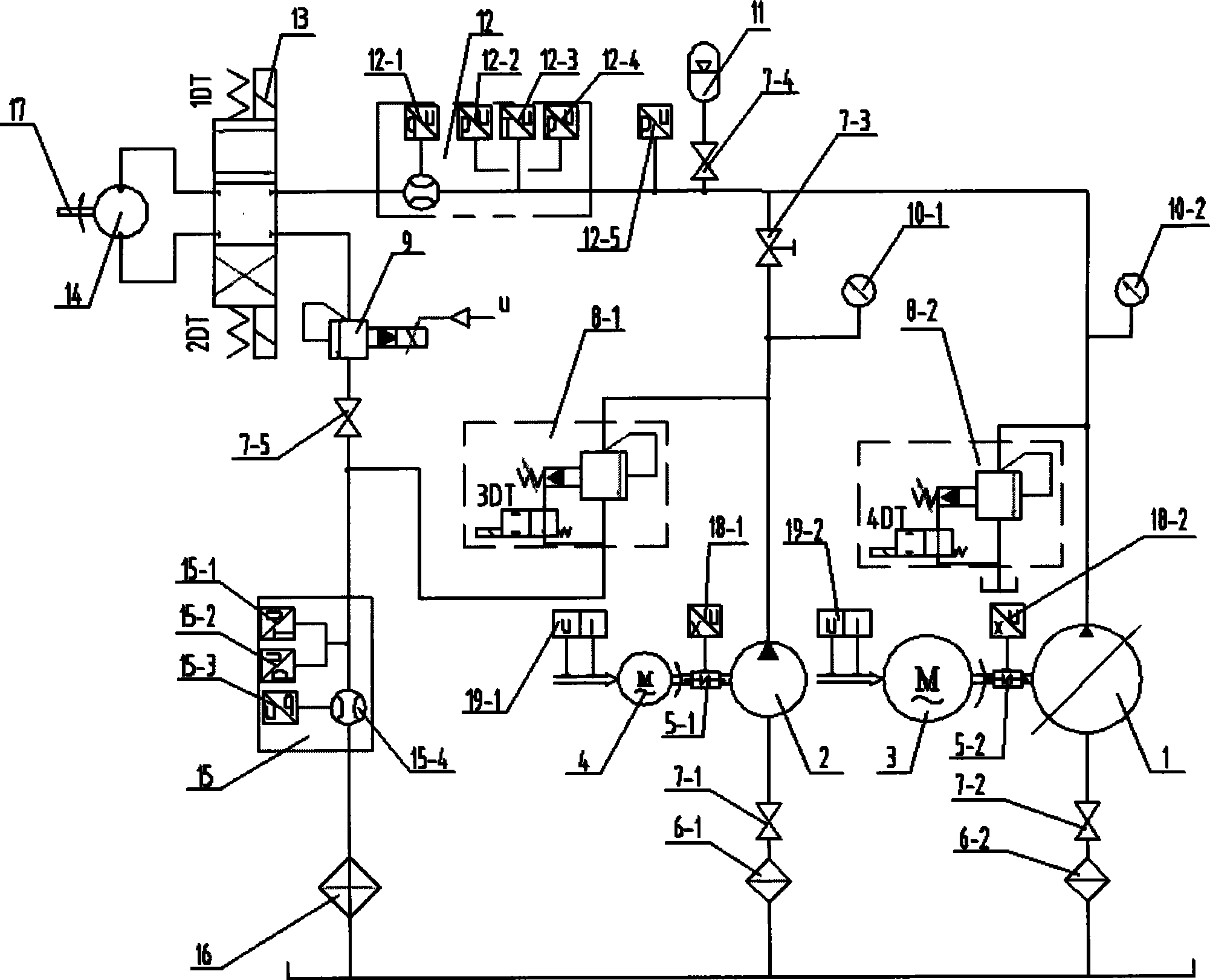

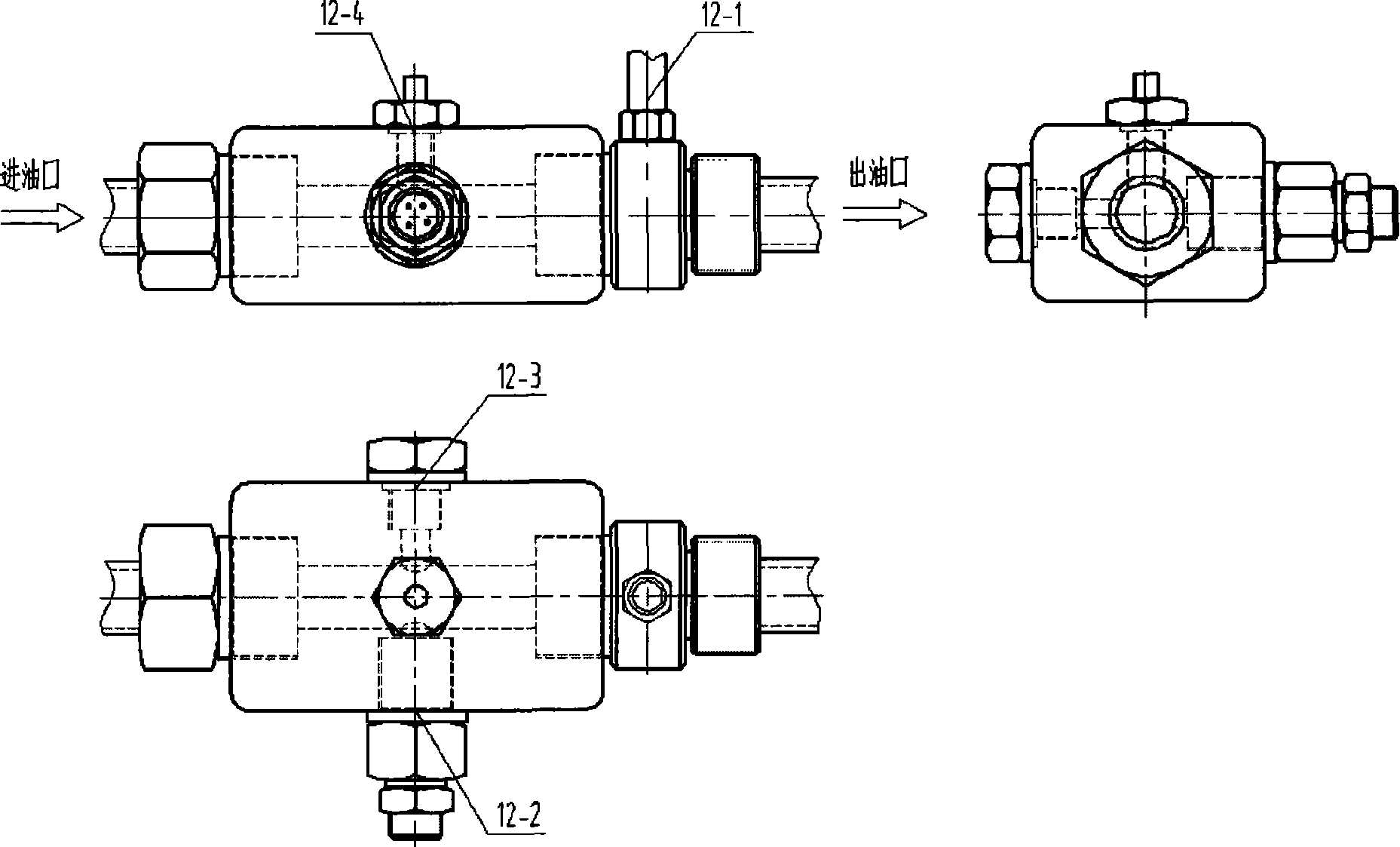

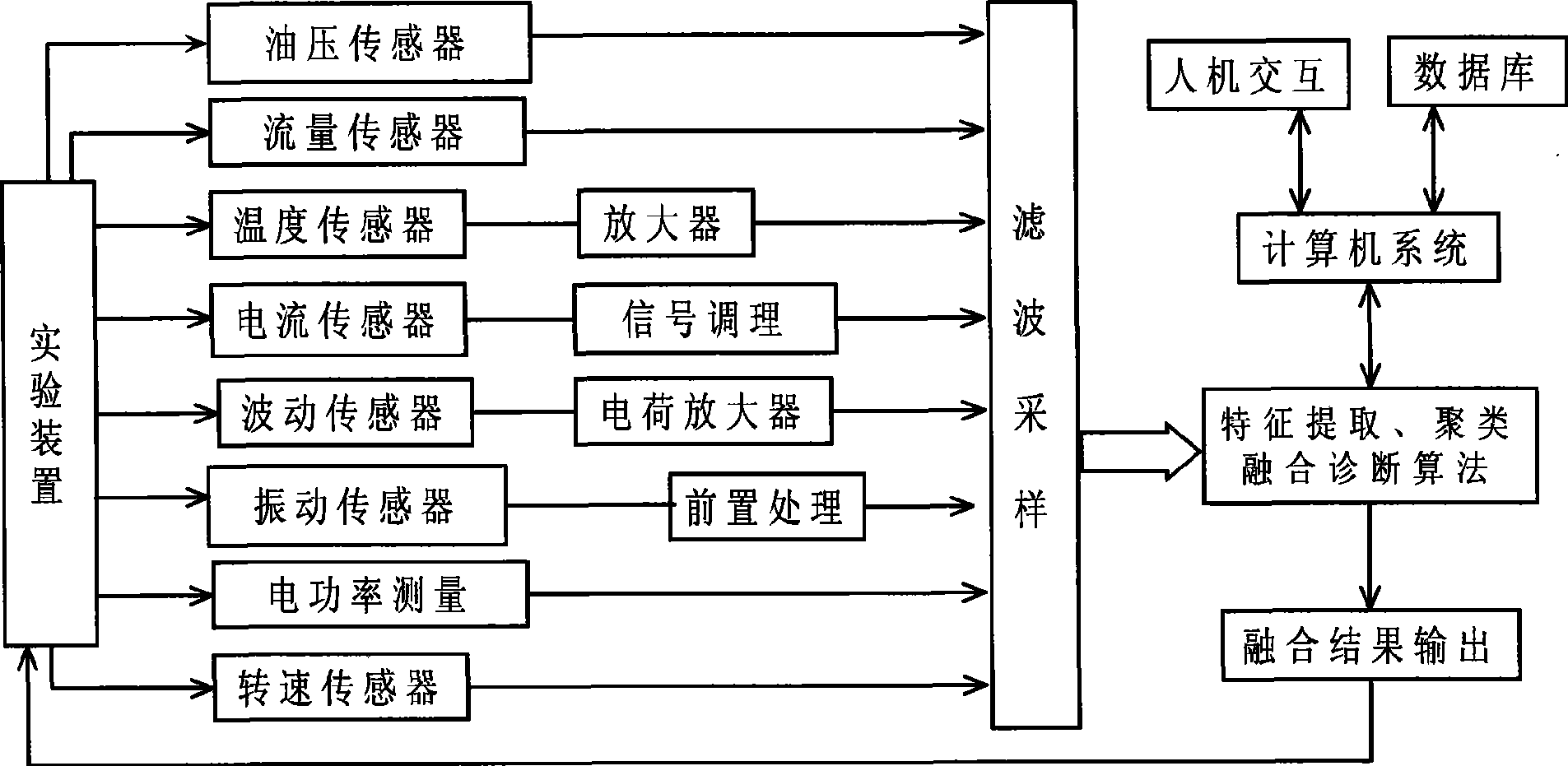

Experimental apparatus and method for obtaining multi-source diagnostic information of hydraulic equipment

InactiveCN101413521ALow efficiencySimple and fast operationFluid-pressure actuator testingSelf organizing map neural networkGear pump

The invention relates to an experimental device and an experimental method for multi-source information fusion for fault diagnosis of a hydraulic device. The device comprises the following elements: a variable plunger pump, a gear pump, two motors, two suction filters, five throttle and stop valves, two electromagnetic relief valves, an electromagnetic proportional relief valve, two pressure meters, an energy accumulator, two sets of combined sensors, a three-position four-way electromagnet directional valve, a hydraulic motor and a cooler. The experimental device can simulate eight typical running states (faults) of the hydraulic device, including low efficiency, oil and liquid pollution, air suction, leakage, oil pump fault, relief valve failure, motor failure and mechanical failure and can perform cluster analysis and fusion diagnosis to characteristics of the eight faults through a self organizing maps neural network.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

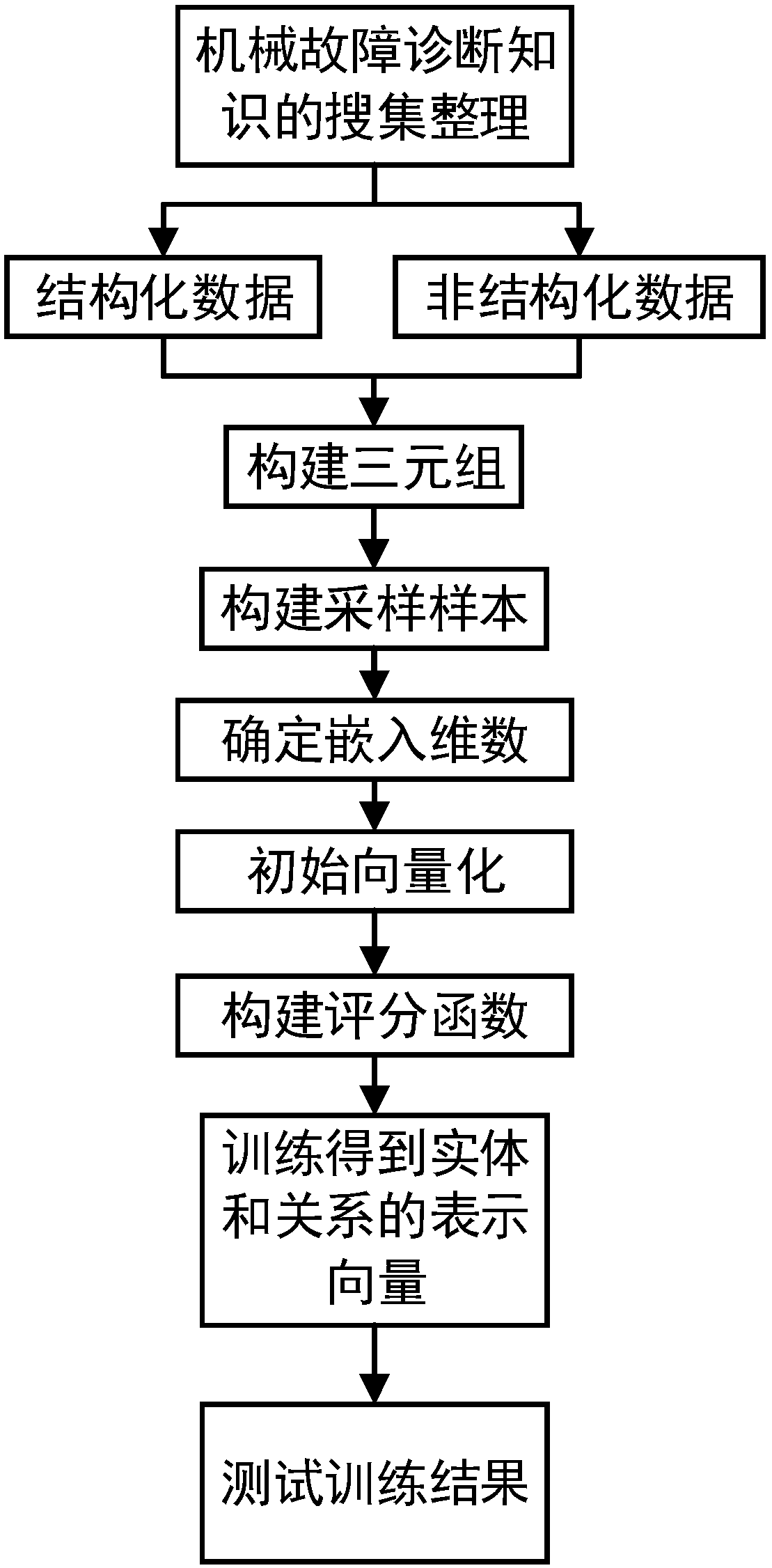

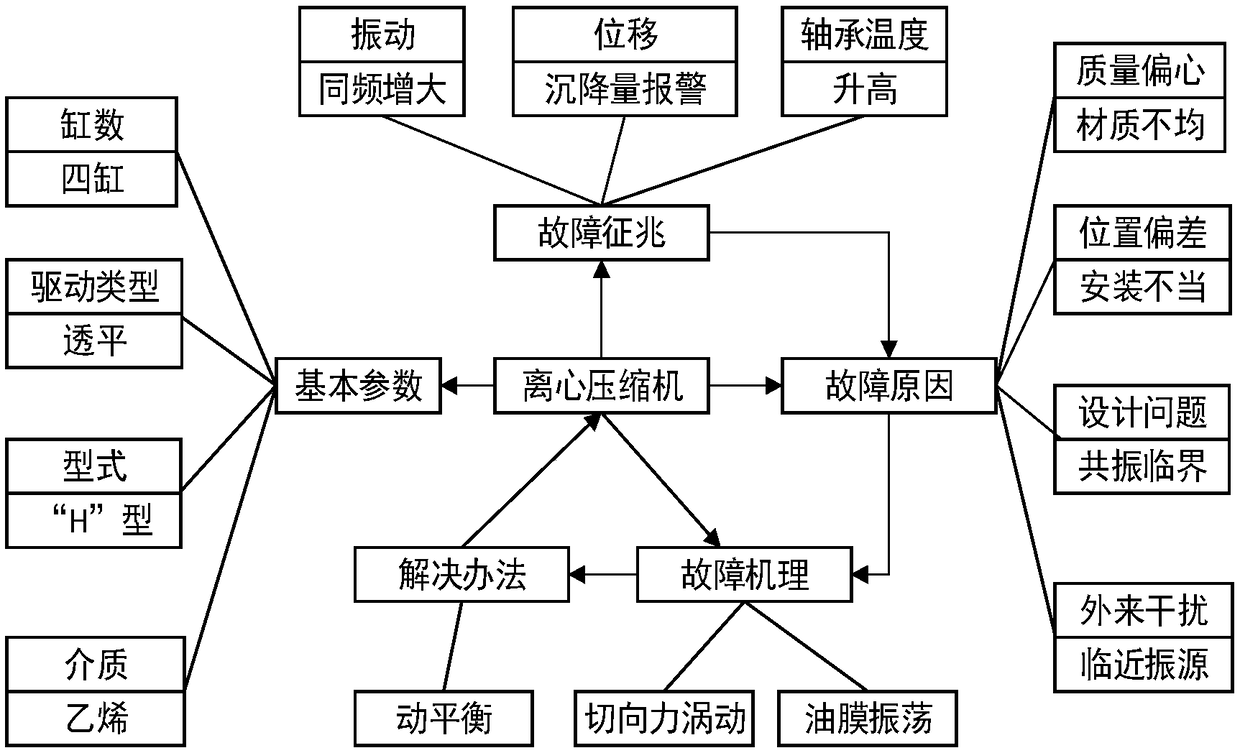

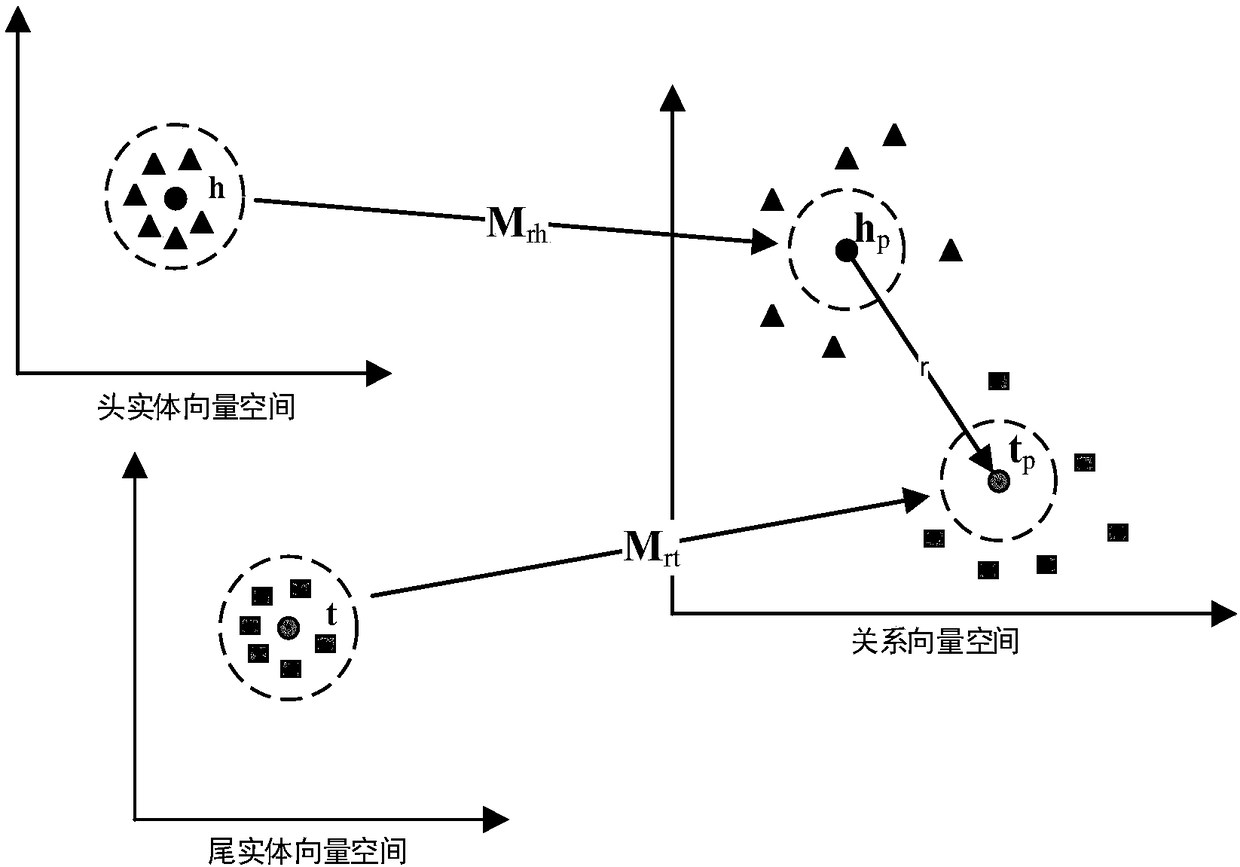

Knowledge graph-based mechanical fault diagnosis knowledge base construction method

InactiveCN108509483ASpeed up searchEnhance reasoning abilityKnowledge representationInference methodsNODALKnowledge graph

The invention discloses a knowledge graph-based mechanical fault diagnosis knowledge base construction method, and belongs to the field of mechanical fault diagnosis. A mechanical fault diagnosis knowledge base reflects fault generation essences and domain expert experiences; and through a knowledge processing module, the fault generation essences and the domain expert experiences are stored in the knowledge base, thereby providing support for mechanical fault diagnosis. A conventional knowledge graph is represented in a network form; nodes represent entities; connection lines represent relationships; and for the representation form, a special graph algorithm needs to be designed for storing and utilizing a database, so that the disadvantage of time and labor waste exists. According to a representation learning technology represented by deep learning, a triple object is mapped to a vector space and represented as a dense low-dimensional vector, and efficient calculation and reasoning are realized through vector conversion. The knowledge graph-based mechanical fault diagnosis knowledge base construction method is established; mechanical fault diagnosis knowledge is represented as atriple, and the tripe is represented as the vector by utilizing a TransD model, so that the problems of inaccurate case representation, difficult maintenance and modification, low reasoning and calculation efficiency and the like of a conventional knowledge base can be optimized; and the method has important significance for the field of fault diagnosis.

Owner:BEIJING UNIV OF CHEM TECH

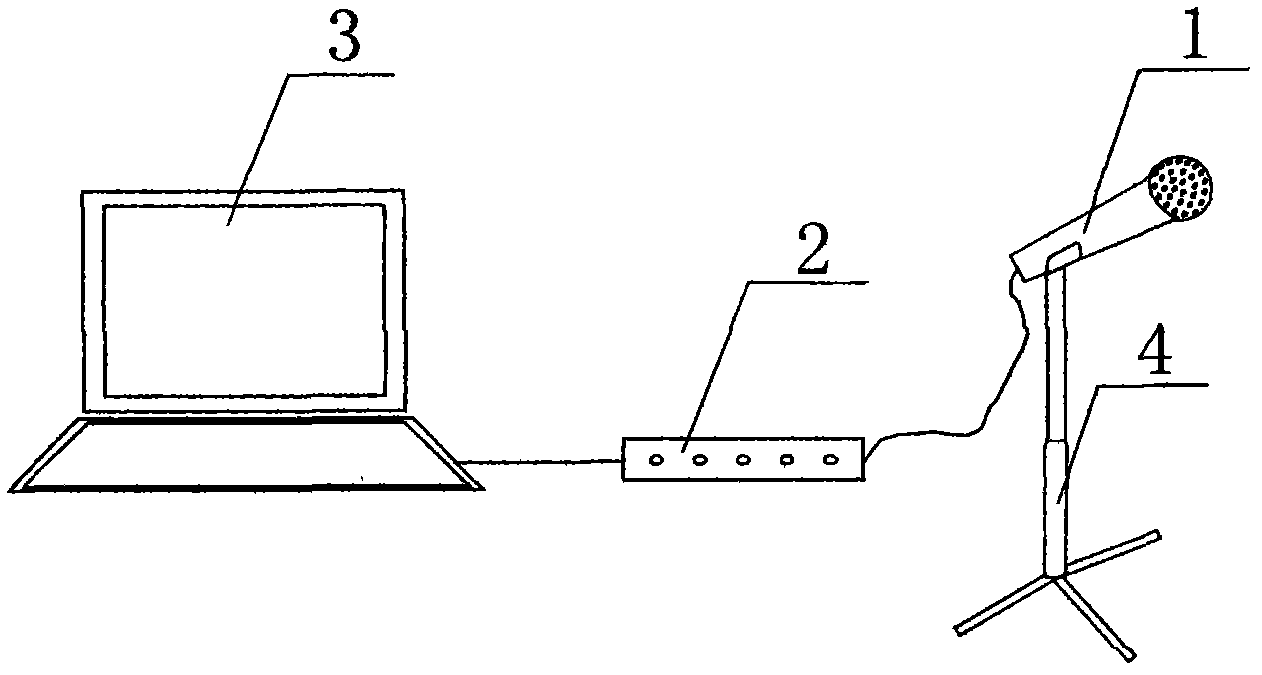

Mechanical fault judgment system and method based on noise test

InactiveCN102095560AEasy to set upReduce economic costsMachine part testingVibration testingEngineeringPersonal computer

The invention belongs to the fields of the state monitoring and the fault diagnosis of vehicles, ships, engineering machinery, locomotive cars, engines, and the like by applying noise signals, in particular to a mechanical fault judgment system and method based on noise test, particularly suitable for complicated mechanical machinery which can not be provided with various sensors. The system comprises a high-frequency microphone, a sound card, a PC (Personal Computer) and a telescopic bracket, wherein the high-frequency microphone is fixed on the telescopic bracket and connected with the sound card, the sampling frequency of the high-frequency microphone can meet the requirement of the Nyquist theorem, and the sound card is connected with the PC. On the basis of combing the extraction andfractal algorithm of an energy band, noise signals in machinery operation are acquired and calculated to test mechanical faults by using the method; the system is simple to set, the economic cost is decreased, and the operation safety and the fault diagnosis accuracy are improved.

Owner:CHONGQING TELECOMMUNICATION INSTITUTE

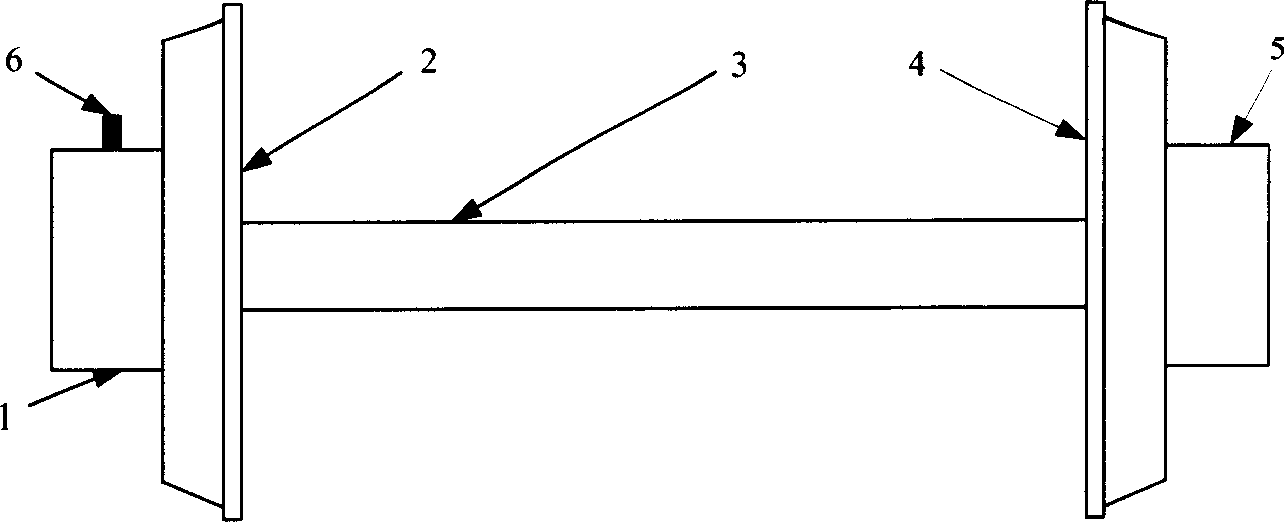

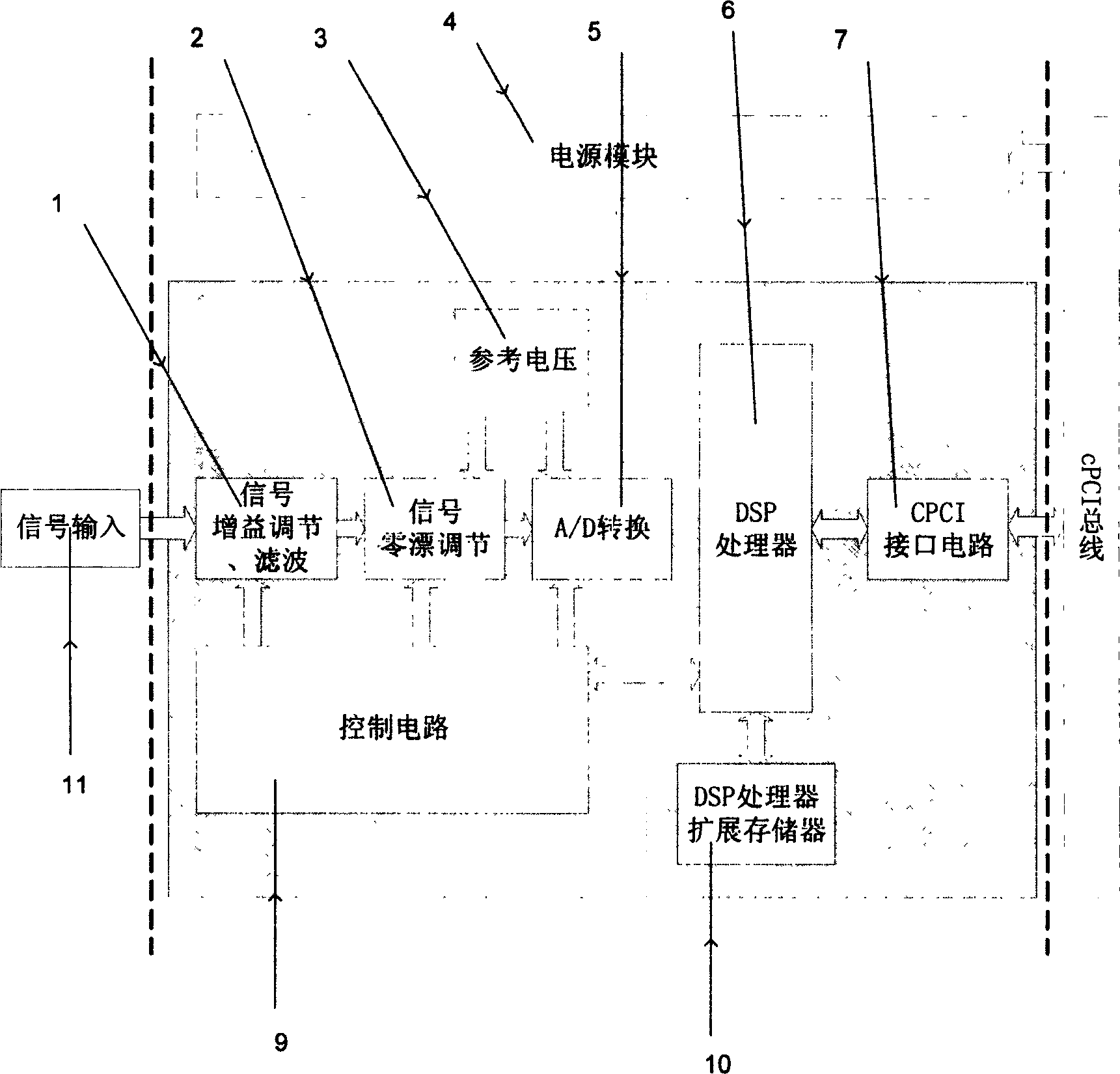

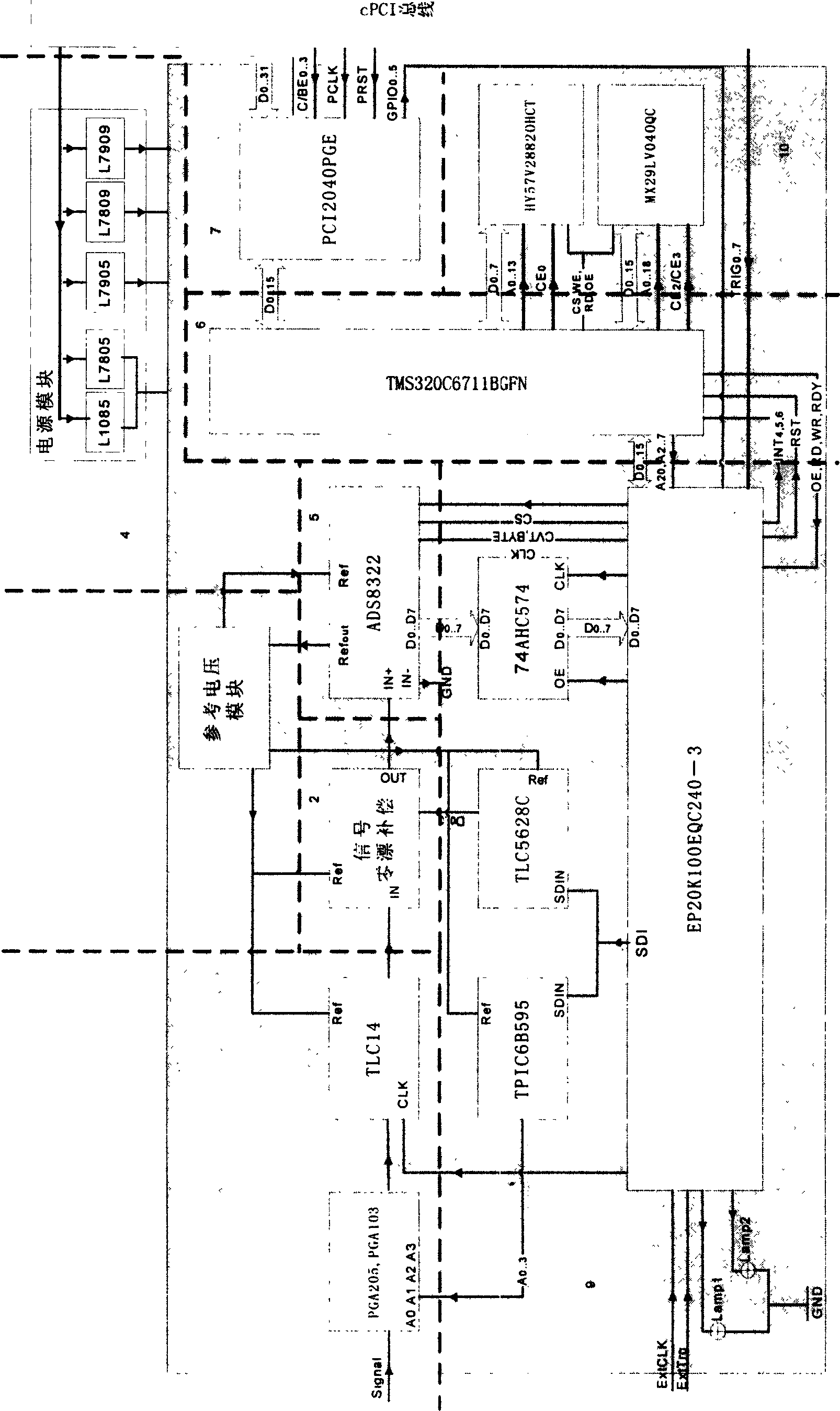

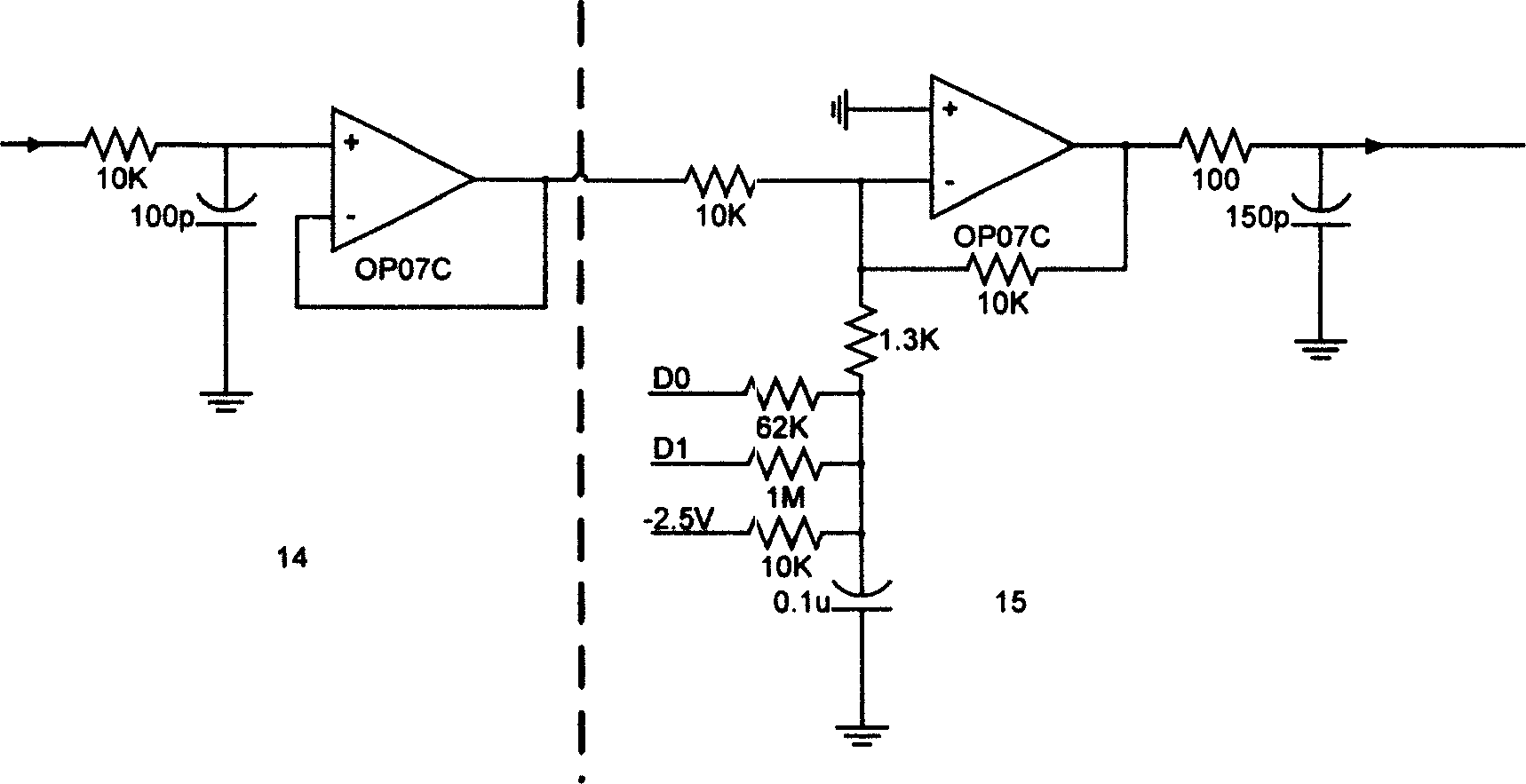

Intelligent collectingm monitor and collecting monitoring method for large rotary machinery apparatus

InactiveCN1584511AGuaranteed accuracyMeasurement devicesSpecial data processing applicationsModularityData acquisition

A monitoring device comprises CPCI bus, DSP processor and hardware of eight channel synchronous high-speed data collection. The method includes realizing dynamic adaptive setting and adjusting of monitoring paramter according to equipment running state, carrying out monitoring data intelligent storage for providing real time monitoring in total running period of large scale rotating equipment.

Owner:XI AN JIAOTONG UNIV +1

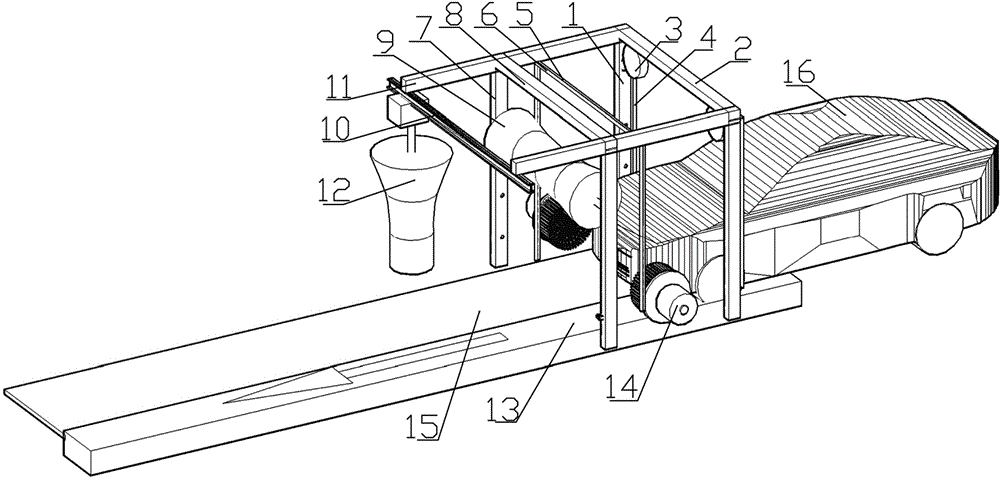

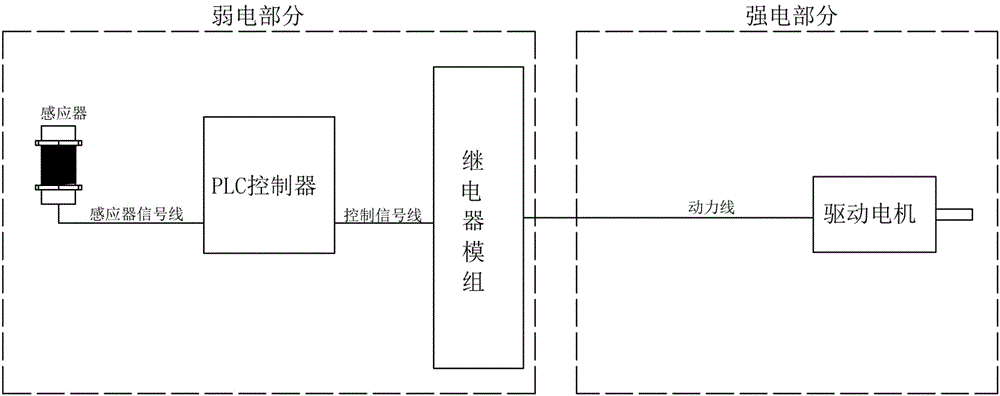

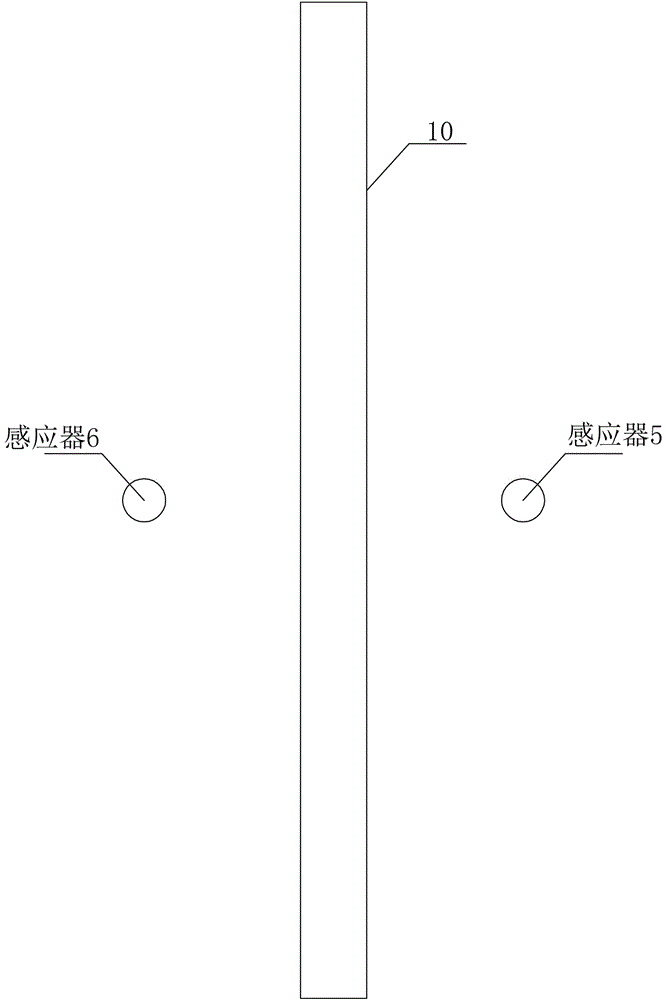

Equipment and method for intelligently automatically cleaning vehicle

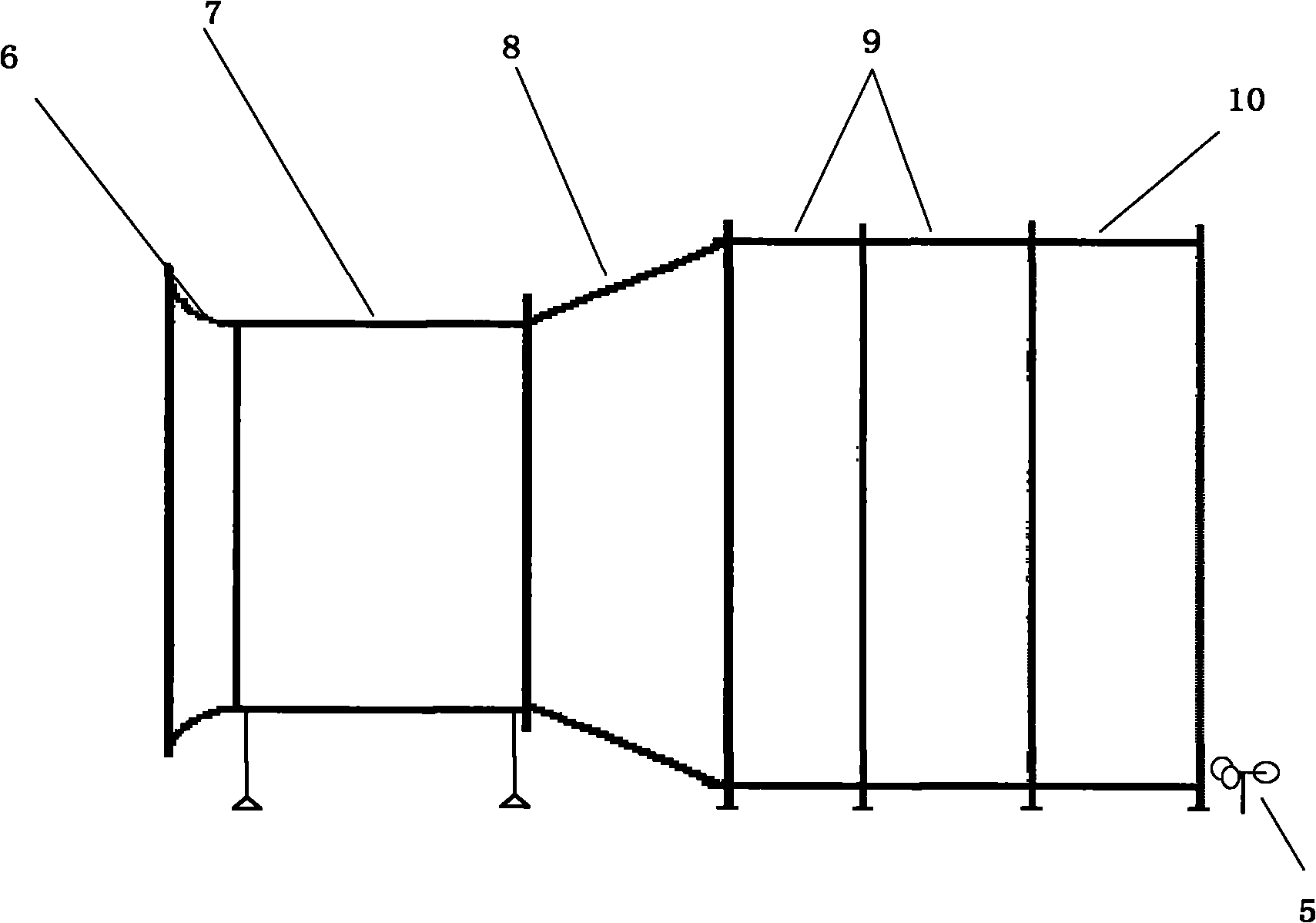

ActiveCN105857264AAvoid damageSimple mechanical structureCleaning apparatus for vehicle exteriorsFailure rateGrounding grid

The invention relates to equipment and a method for intelligently automatically cleaning vehicles. The equipment comprises a pull guide rail. The pull guide rail is arranged on a side of a ground grid, a first upright column is vertically mounted at the right end of the ground grid, a first transverse beam is fixedly connected with the top of the first upright column, a second upright column is mounted at the rear of the first upright column, a second transverse beam is fixedly connected with the top of the second upright column, longitudinal beams are mounted between the first transverse beam and the second transverse beam, and a third transverse beam is mounted at the tail ends of the longitudinal beams. A second water spray pipe and a water wax spray pipe are arranged between the first transverse beam and the second transverse beam, and a top brush device is mounted on the second upright column. A vertical brush device is mounted on the third transverse beam. Wheel brush devices are symmetrically mounted on the side surfaces of the pull guide rail and are positioned between the first upright column and the second upright column. The equipment and the method have the advantages that mechanical structures can be simplified, power consumption and water consumption can be reduced, failure rates of machinery can be decreased, and the later-stage maintenance cost can be saved; the equipment is additionally provided with an automatic control system, accordingly, the vehicles can be fully automatically cleaned, and the work efficiency can be improved.

Owner:李勇

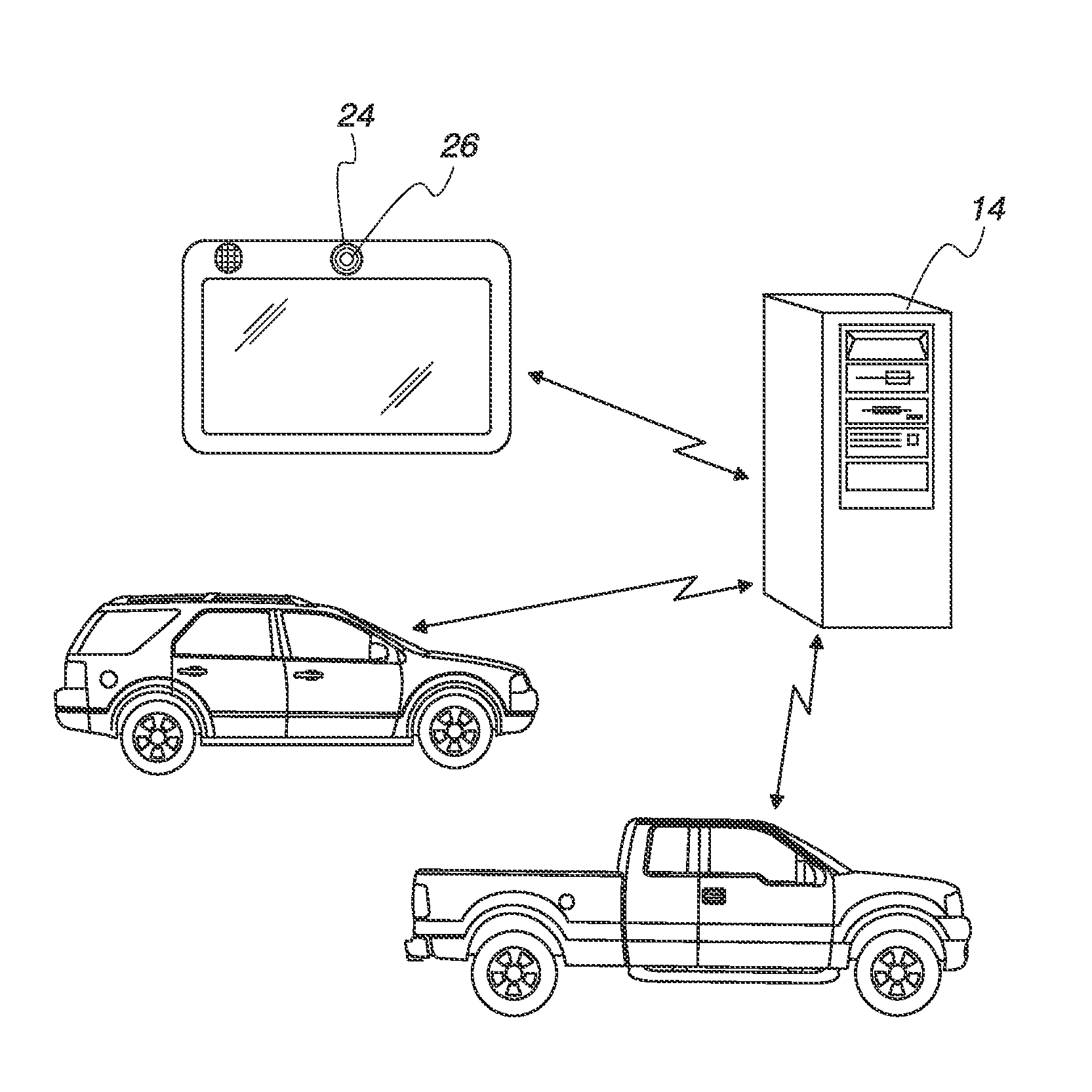

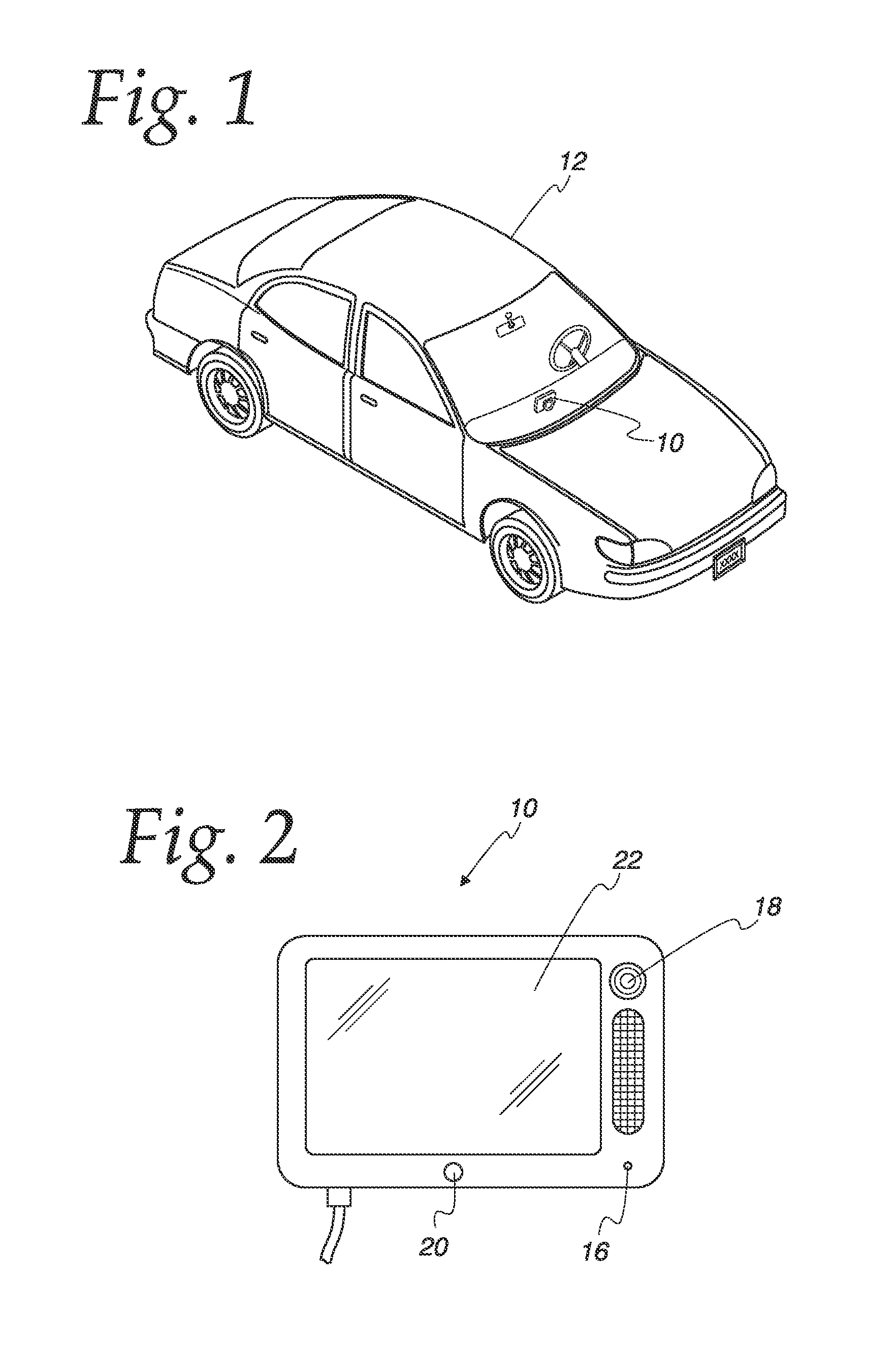

System and Method for Detecting and Remotely Assessing Vehicle Incidents and Dispatching Assistance

InactiveUS20150371456A1Registering/indicating working of vehiclesDigital data processing detailsEngineeringCellular telephone

A system and method for detecting and remotely assessing a vehicle incident and dispatching assistance to a motorist. The system includes an in-car device for detecting vehicular incidents such as mechanical failures and collisions. The system transmits an incident notification to a remote monitoring station. A camera associated with the device transmits images to the station, where an operator can view and assess the nature of the incident, communicate by voice and / or video with the occupant of the vehicle via a cellular telephone connection, and dispatch assistance. Assistance may include sending a replacement vehicle.

Owner:HERTZ SYST

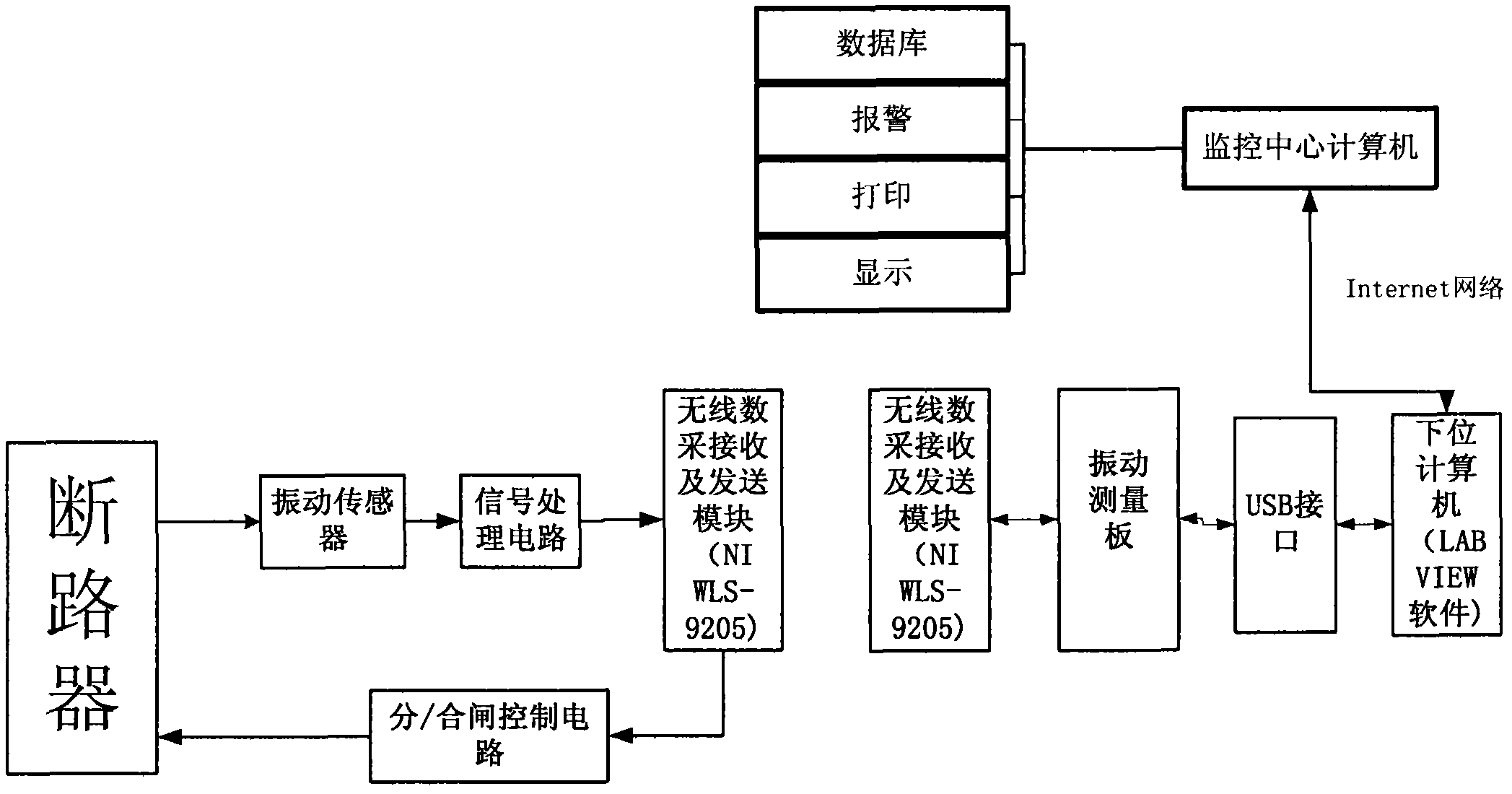

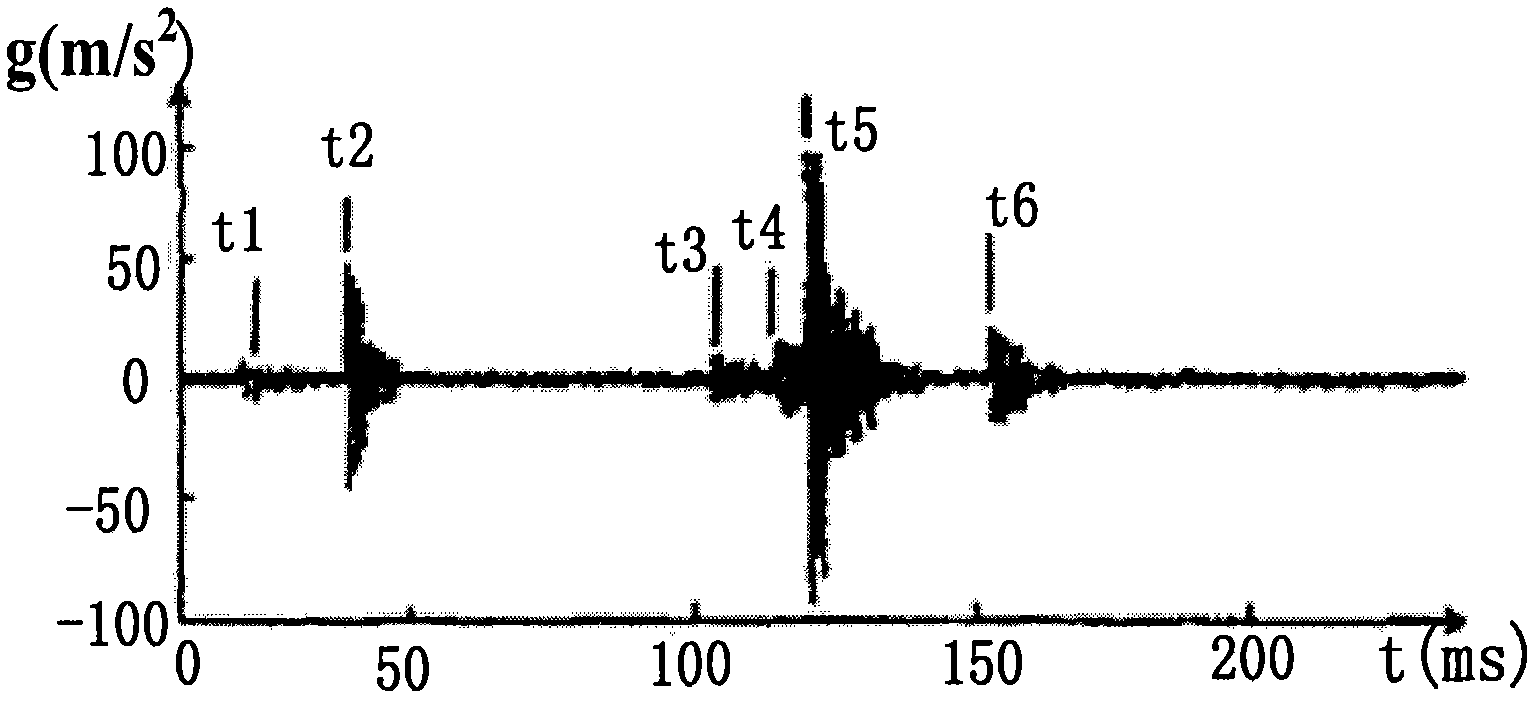

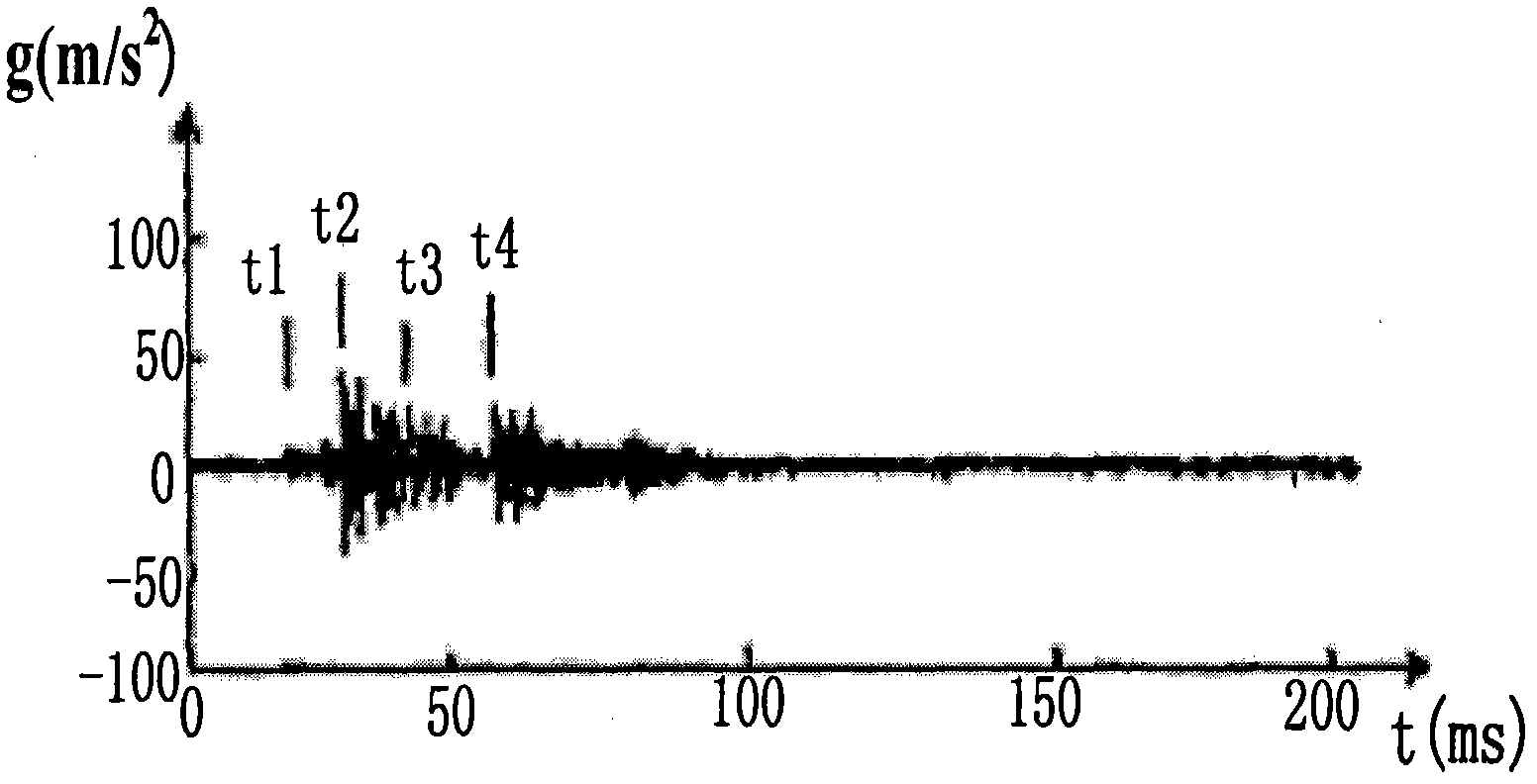

On-line monitoring system for high-voltage breaker based on vibration characteristics

InactiveCN102435424AEasy to installEasy to implement safe measurementVibration measurement in solidsMachine part testingSignal processing circuitsWireless data

The invention discloses an on-line monitoring system for a high-voltage breaker based on vibration characteristics. The on-line monitoring system comprises a vibration sensor arranged on a mechanical shell of a breaker, a signal processing circuit, a wireless data receiving and sending module, a vibration measuring plate and a lower computer, wherein the vibration sensor is used for collecting mechanical vibration response signals of a breaker switch; after the mechanical vibration response signals are subjected to signal pre-treatment by the signal processing circuit, short-range wireless receiving and sending can be performed by the wireless data receiving and sending module; the vibration measuring plate is used for collecting the wirelessly transmitted vibration signals and sending the signals to the lower computer; and the vibration signals are sequentially compared with a characteristic waveform 'fingerprint' at a moveably switching moment of the normal breaker stored in the lower computer, so as to judge whether the breaker is in mechanical fault. The on-line monitoring system has the advantages that the method is simple, the mounting and maintenance are convenient, and the sensor need not be placed in the breaker, and the like, so that the danger of mounting personnel is greatly reduced.

Owner:XIAN UNIV OF POSTS & TELECOMM

Method and apparatus for automatic visual event detection

ActiveUS20050276462A1SpecificTelevision system detailsImage analysisMechanical componentsShort duration

Disclosed are methods and apparatus for automatic visual detection of events, for recording images of those events and retrieving them for display and human or automated analysis, and for sending synchronized signals to external equipment when events are detected. An event corresponds to a specific condition, among some time-varying conditions within the field of view of an imaging device, that can be detected by visual means based on capturing and analyzing digital images of a two-dimensional field of view in which the event may occur. Events may correspond to rare, short duration mechanical failures for which obtaining images for analysis is desirable. Events are detected by considering evidence obtained from an analysis of multiple images of the field of view, during which time moving mechanical components can be seen from multiple viewing perspectives.

Owner:COGNEX TECH & INVESTMENT

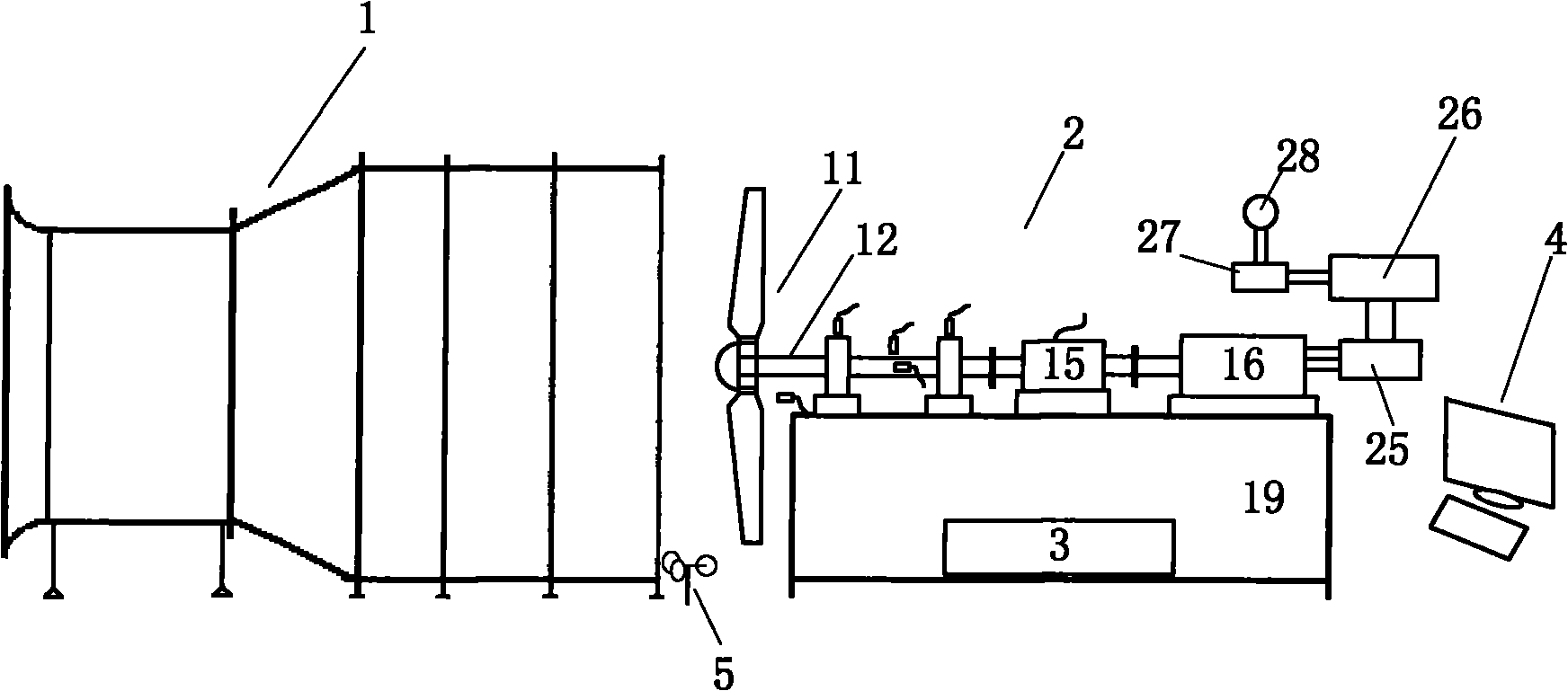

Performance analysis and fault simulation experiment system of wind machine

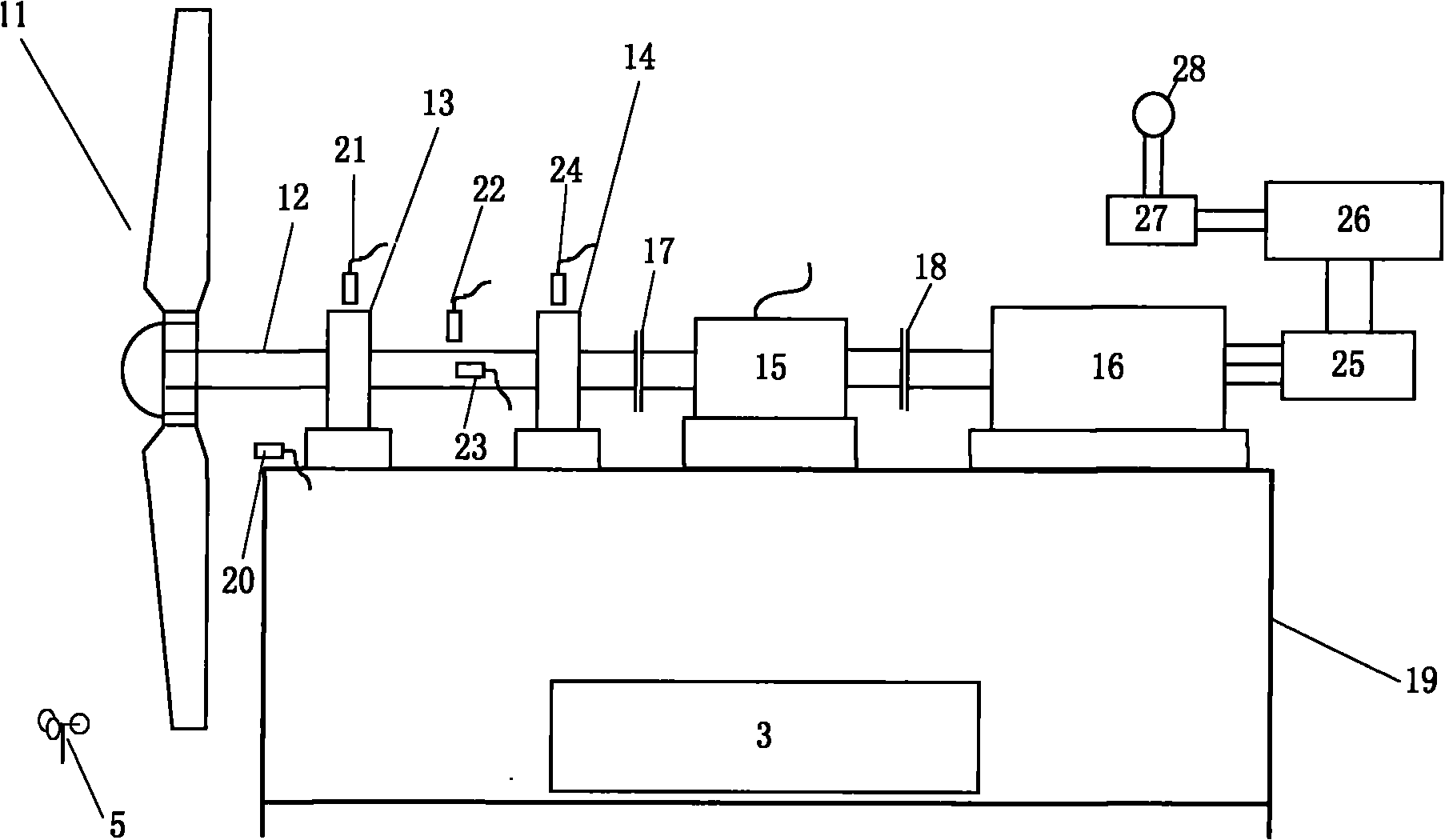

ActiveCN101871844ASimulation is accurateIncrease opennessAerodynamic testingEngine testingWinding machineReal time analysis

The invention relates to a performance analysis and fault simulation experiment system of a wind machine, belonging to the technical field of wind machine experiment devices. The system comprises a wind tunnel, a wind machine experiment device and a data analysis and processing system, wherein the wind machine experiment device comprises a rack, a wind wheel, a spindle, a generator, a controller and a sensor of torques, wind speed, speed and displacement. The system can be used for researching the influences of different airfoil profiles, wind speeds, wind wheel faults and mechanical faults on the aerodynamic performance of the wind machine, the vibration characteristics and the output force of a shaft system, and the like, and various faults such as unbalanced wind wheel mass, unbalanced pneumatic power, yawing, no shaft system centering, supporting seat loosening, bearing damages, and the like of the wind machine are simulated and analyzed in real time. Through selecting and assembling different types of bearings such as a self-aligning roller bearing, a cylinder roller bearing, a tapered roller bearing, and the like, the performances of the wind machine in different supporting forms can be compared. The system has good openness, dismantlability and expansibility and is mainly suitable for the fields of scientific researches and teaching of the wind machine.

Owner:TSINGHUA UNIV

Rotating speed tracking and sampling and spectrum number curing and analyzing method of variable speed mechanical fault diagnosis

ActiveCN101846692ASimplify the tedious processFacilitate automatic diagnosisLinear/angular speed measurementFast Fourier transformFrequency spectrum

The invention relates to a rotating speed tracking and sampling spectrum number solidifying method of variable speed mechanical fault diagnosis, which is characterized by comprising the steps of: sampling mechanical related fault signals by replacing rotating speed pulse signals with frequency of Xfn in a moving machine with astronomical clock recurrent pulse signals; and then carrying out numerical analysis on the signals by applying an FFT (Fast Fourier Transform) technology, reconstructing a classical frequency coordinate system of FFT analysis output information into a spectrum number coordinate system of rotating speed tracking FFT analysis, and establishing a recognition function of spectrum numbers corresponding to information characteristics. The invention can change the classical rotating speed variable state which can not be monitored and diagnosed in a process of sampling a astronomical clock period into a state which can be monitored and diagnosed by rotating speed tracking and sampling, thereby greatly improving the time coverage rate of safety monitoring, preventing a dead zone of a classical technology, and being especially suitable for fault diagnosis in fields of city light rail traffic, subway, city buses, wind power generation and the like. The recognition of the classical technology to spectrogram and frequency spectrum is greatly simplified by applying a curing characteristic spectrum number formula, which is beneficial to manual spectrum recognition and more computer automatic diagnosis.

Owner:北京唐智科技发展有限公司

Resonance demodulation detection method of mechanical failure impact

ActiveCN101620024AReliable impactTimely detection meansMachine part testingShock testingLow-pass filterTransducer

The invention relates to a resonance demodulation detection method of mechanical failure impact, comprising the following steps: an acceleration transducer installed on a machine to be detected and can flat detect limited frequency band acceleration is used, signals output by the acceleration transducer are transmitted to an electronic resonator processing generalized resonance signals triggered by the acceleration transducer subjected to impact excitation, signals outputted by the electronic resonator are transmitted to a detector, signals outputted by the detector are transmitted to a low-pass filter enable of carrying out smooth filtering to detected unidirectional pulse signals so as to realize the envelope demodulation of the generalized resonance signals of the electronic resonator, and finally resonance demodulation detection results are outputted by the low-pass filter. The resonance demodulation detection method of mechanical failure impact is characterized in that the acceleration transducer is a high-frequency generalized resonance peak acceleration sensor with the frequency characteristic containing frequency F1, the resonance frequency F2 of the matched electronic resonator is equal to or smaller than the frequency F1 of the acceleration transducer, and the electronic resonator selects the signals generated by the acceleration transducer subjected to the impact excitation and equal to the generalized resonance frequency F1 of the acceleration transducer or converts the signals of the generalized resonance frequency F1 of the acceleration transducer into generalized resonance signals of the frequency equal to F2 and outputs resonance demodulation signals through the detection of the detector and the smooth filtering of the low-pass filter.

Owner:北京唐智科技发展有限公司

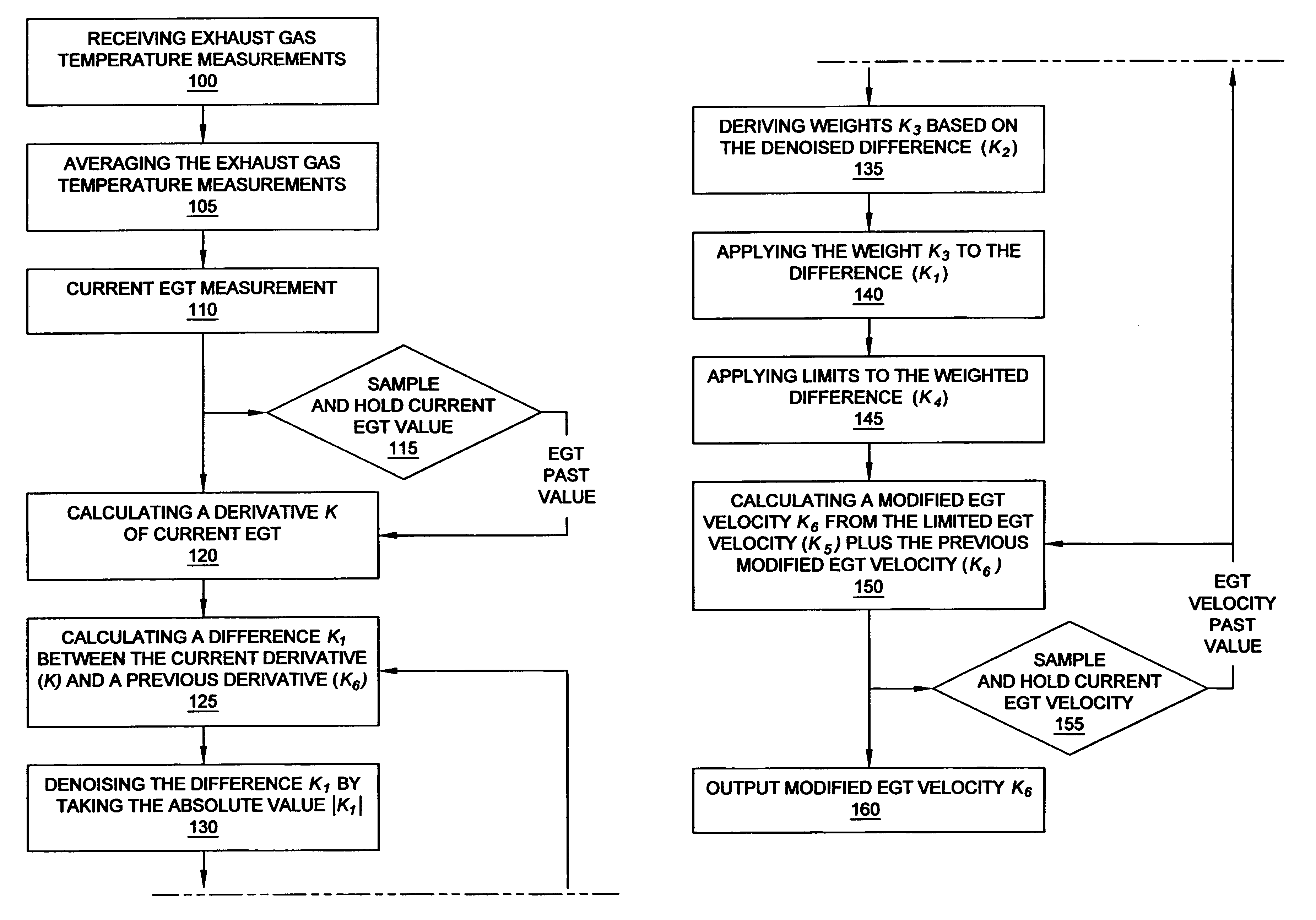

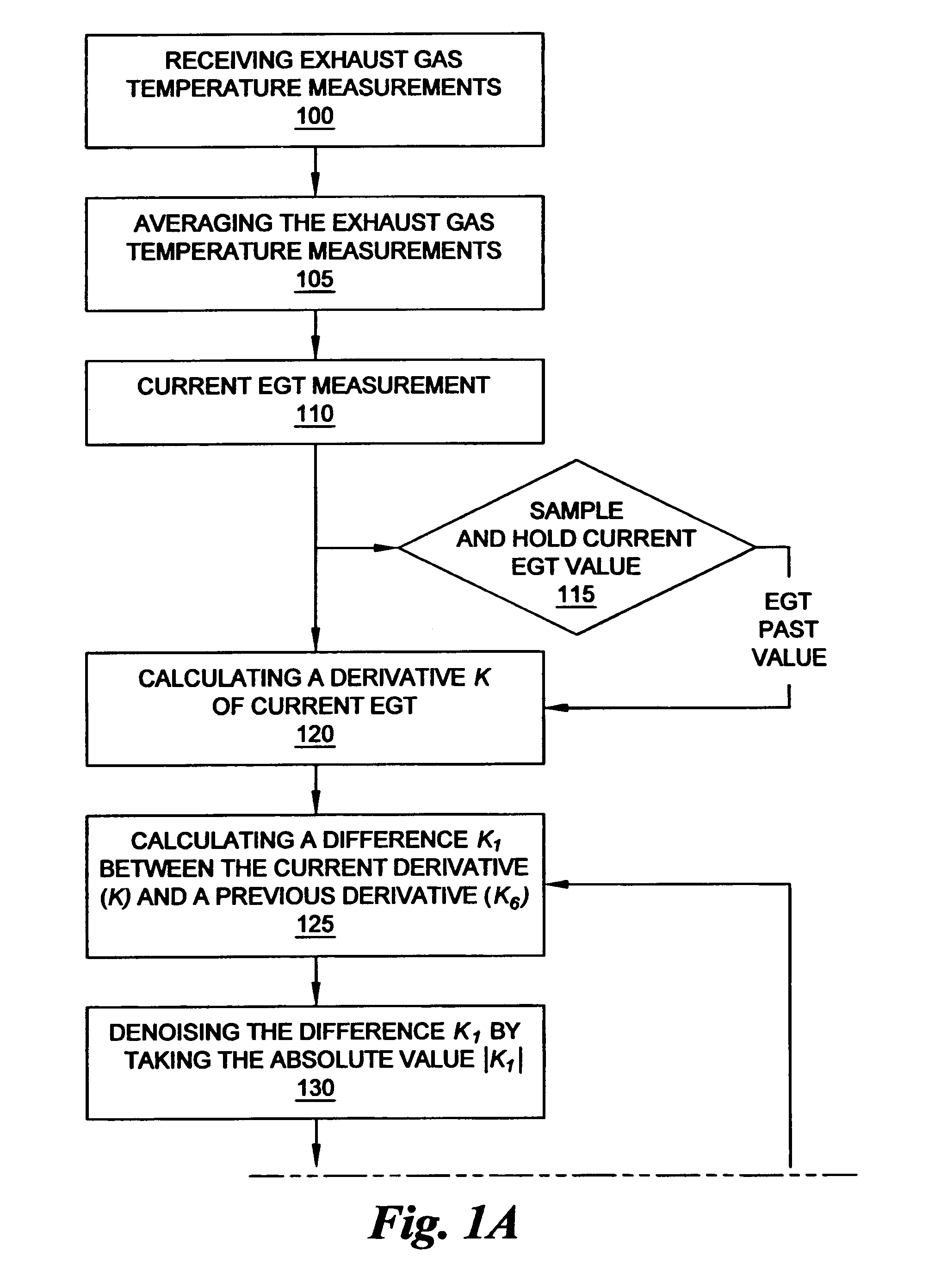

Determining bleed valve failures in gas turbine engines

The invention detects gas turbine bleed valve position discordances. The invention derives a modified exhaust gas temperature derivative as the predictive criteria in conjunction with a control logic to determine bleed valve position discordances that may indicate a mechanical failure in a valve, or in the control means for a valve.

Owner:RAYTHEON TECH CORP

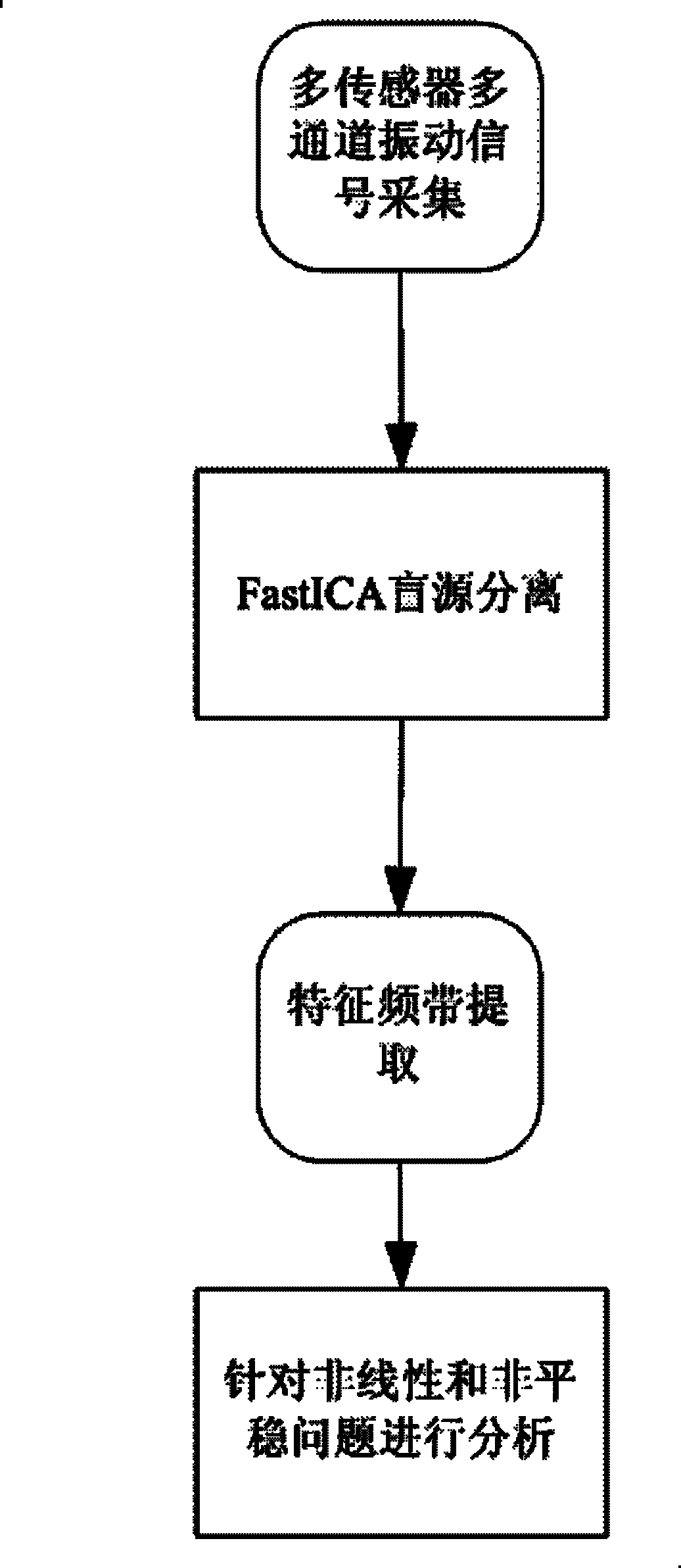

Characteristic extracting method for prediction of rotating mechanical failure trend

ActiveCN102661783AEasy to identifyTo achieve the purpose of preventing failures in advanceSubsonic/sonic/ultrasonic wave measurementStructural/machines measurementDecompositionIndependent component analysis

The invention relates to a characteristic extracting method for prediction of rotating mechanical failure trend. The method includes the steps: (1) utilizing the remote online monitoring diagnostic center to conduct industrial onsite data collection and collecting vibration signals xj (t) of a plurality of channels through a plurality of sensors arranged on a rotating mechanical device; (2) conducting blind source separation on the vibration signals xj (t) according to FastICA algorithm and obtaining similar signal source yj (t) of the original independent vibration source sj (t); and (3) conducting characteristic frequency band decomposition of time frequency domain based on small wavelet packet on vector signals Y of the similar signal source yj (t) and extracting fault sensitive characteristic band. The characteristic extracting method is capable of recognizing the original independent signal source which shows as collecting signals in aliasing mode by adopting independent component analysis (ICA) processing, conducts characteristic frequency band acquisition based on the small wavelet packet on the independent signal source to judge whether one source signal has the development trend to fault and achieve the aim of preventing the fault in advance. The characteristic extracting method can be widely applied to prediction of the rotating mechanical failure trend.

Owner:BEIJING INFORMATION SCI & TECH UNIV

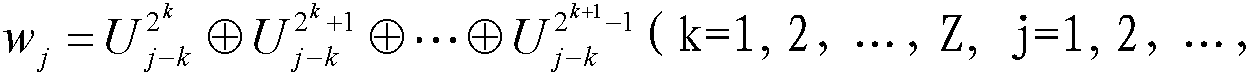

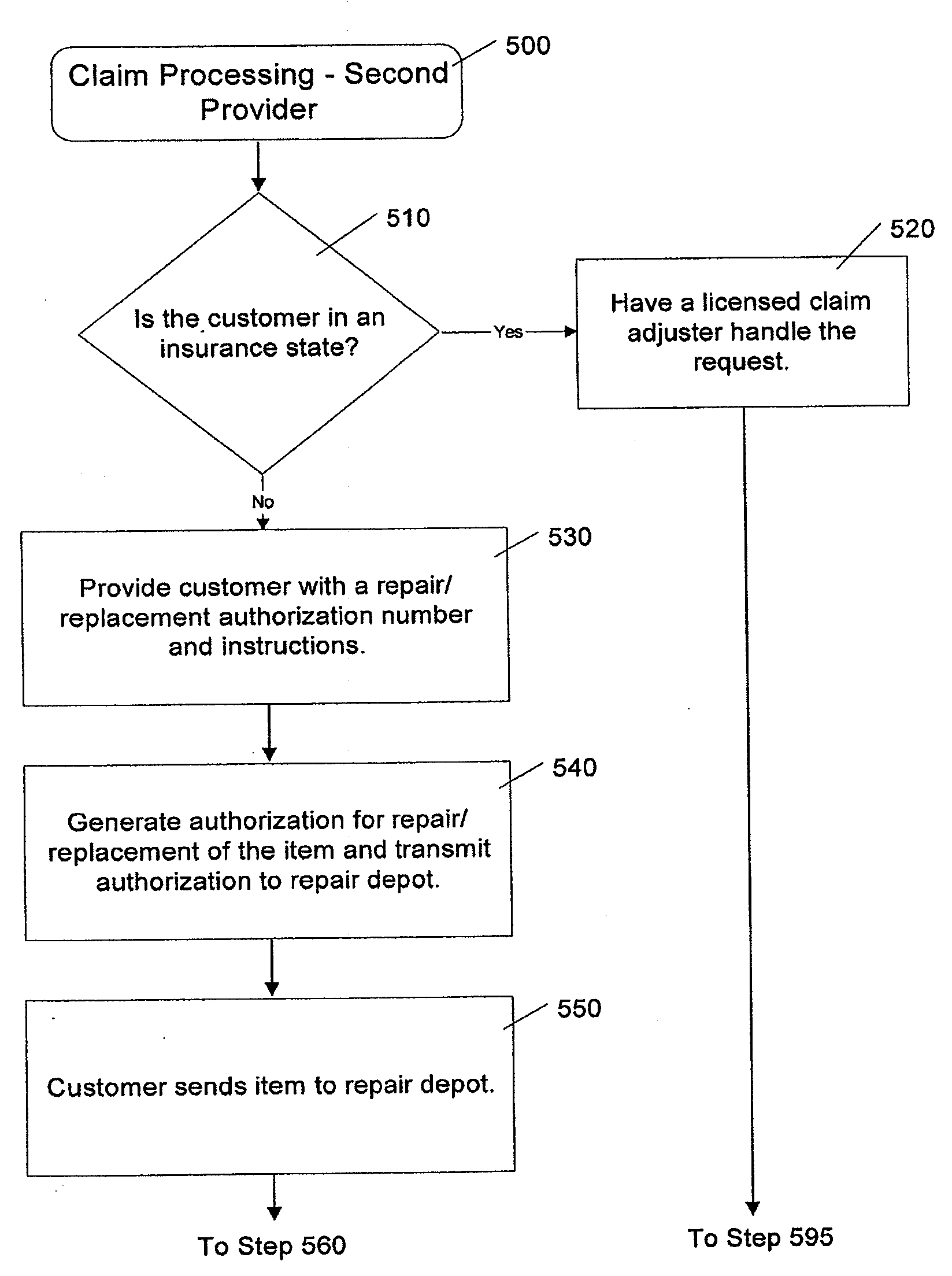

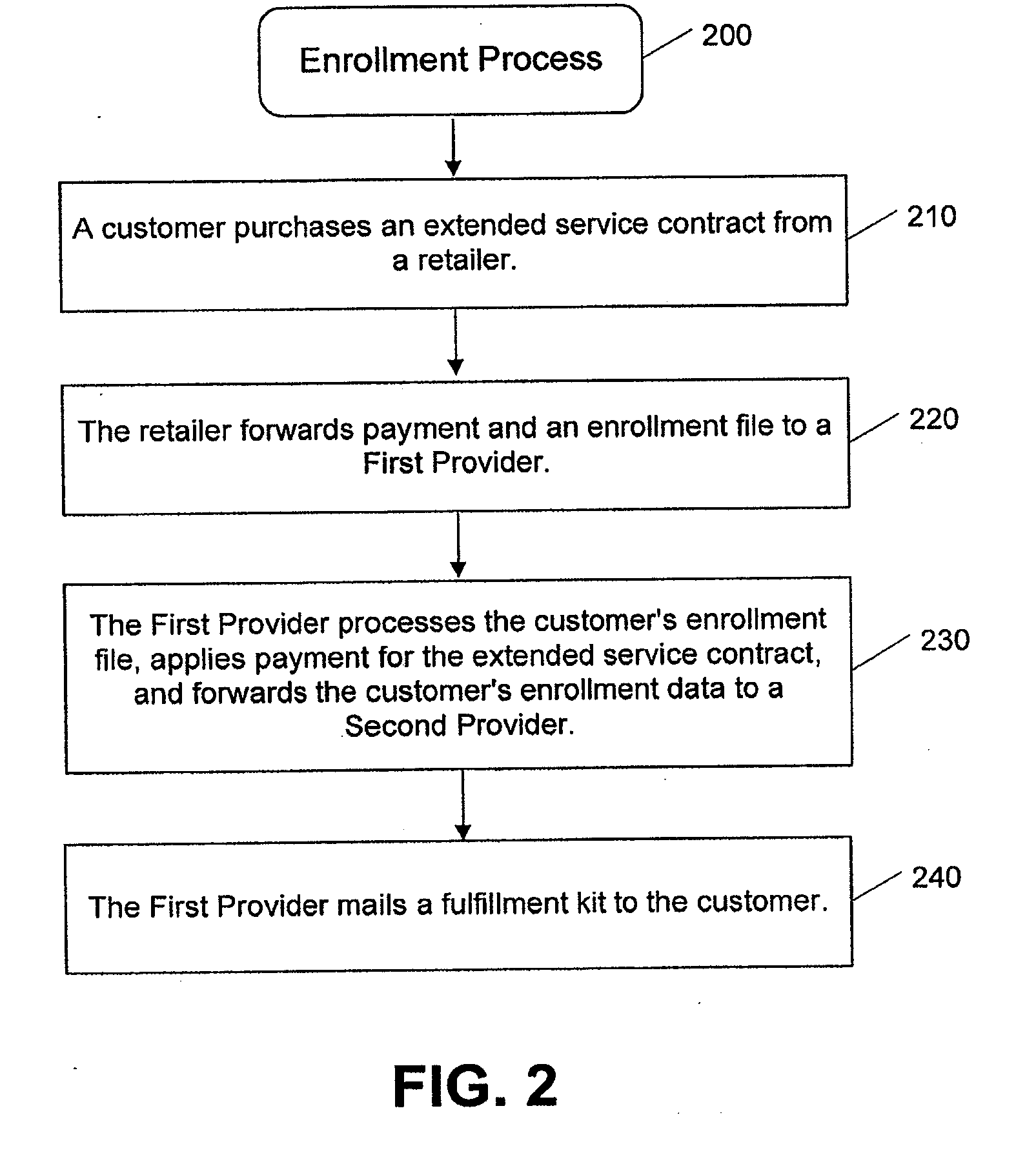

Systems and methods for providing insurance and non-insurance products

A method of providing insurance to a customer that comprises the steps of: (1) selling a service contract to the customer that provides protection against the mechanical breakdown or other failure of an item (and in some cases, accidental damage); and (2) in response to the customer purchasing the service contract, providing, at no cost to the customer, third-party-paid insurance coverage that protects the customer against damage to the item, which, in some cases, includes accidental damage. In one embodiment of the invention, the step of providing the third-party-paid insurance coverage is done in order to permit the provision of insurance without the use of a licensed insurance agent.

Owner:ASSURANT INC

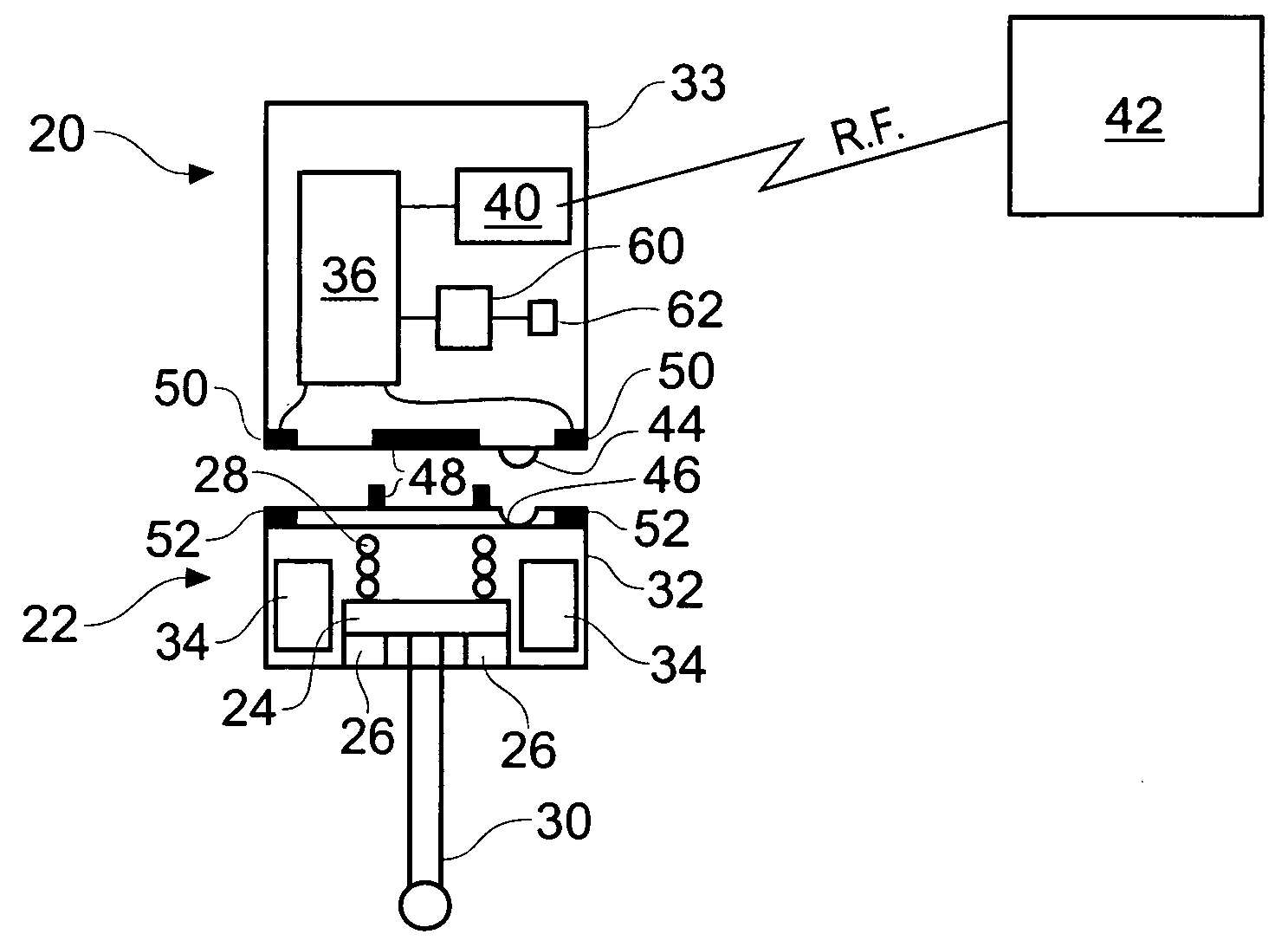

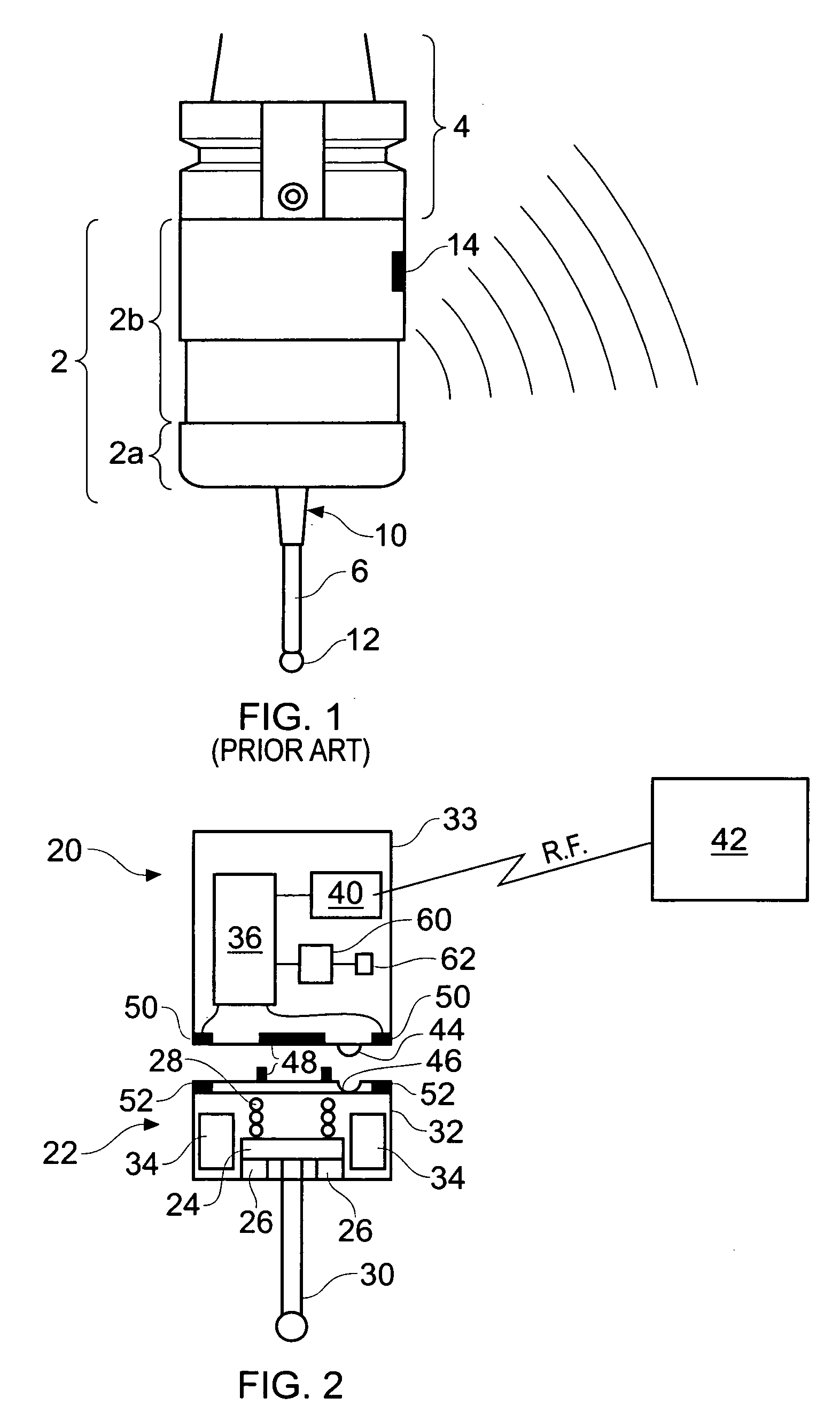

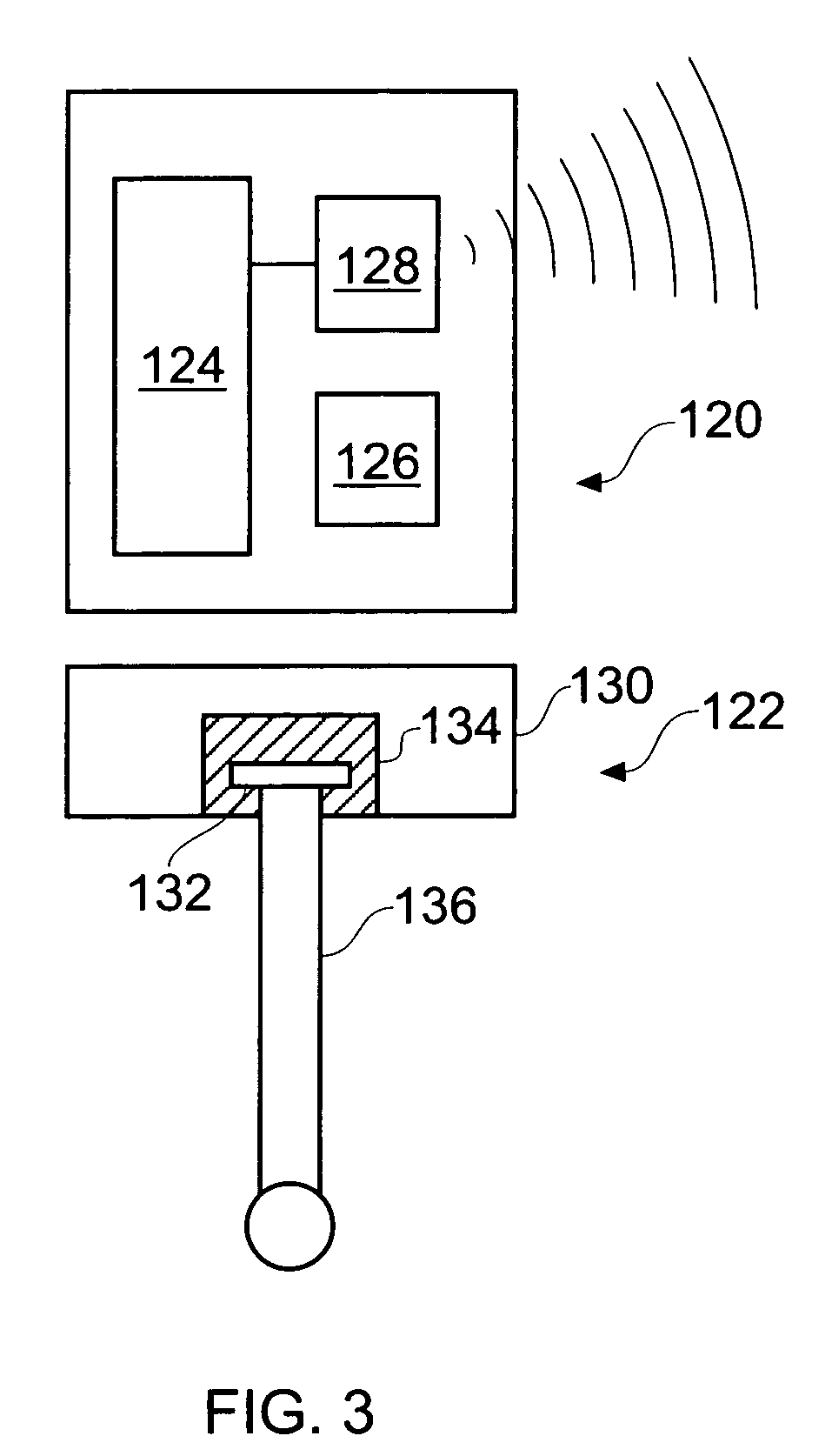

Modular Measurement probe

InactiveUS20090025243A1Reduce usageNeed long operating lifetimesMechanical measuring arrangementsEngineeringCatastrophic failure

A measurement probe, such as a touch trigger probe, is described that comprises a stylus module attachable to a base module. The stylus module comprising a housing and a stylus holder moveably attached to the housing. The base module comprises a measurement portion for generating measurement data indicative of movement of the stylus holder relative to the housing. The stylus module has an inbuilt failure mode and thereby a substantially predetermined operational lifetime. In one embodiment, the inbuilt failure mode is provided by integrating a battery into the stylus module. Providing a mechanical failure mode in which a component of the stylus module catastrophically fails after a certain amount of usage is also described.

Owner:RENISHAW PLC

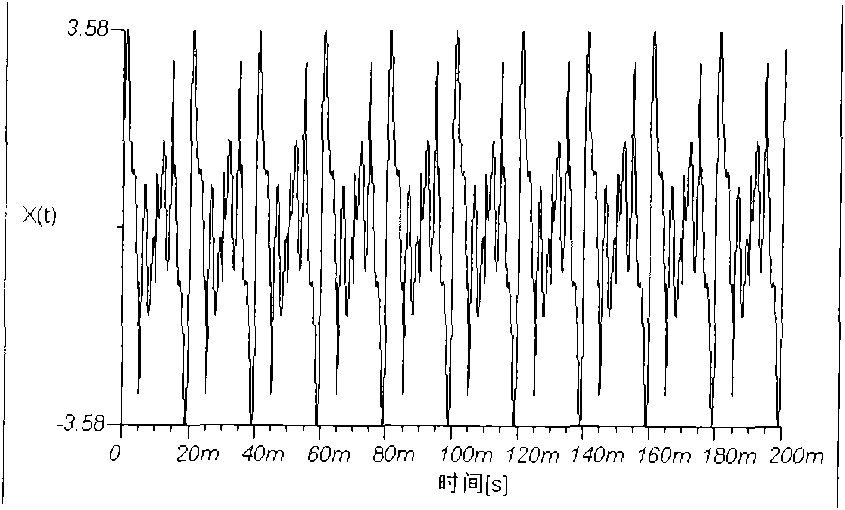

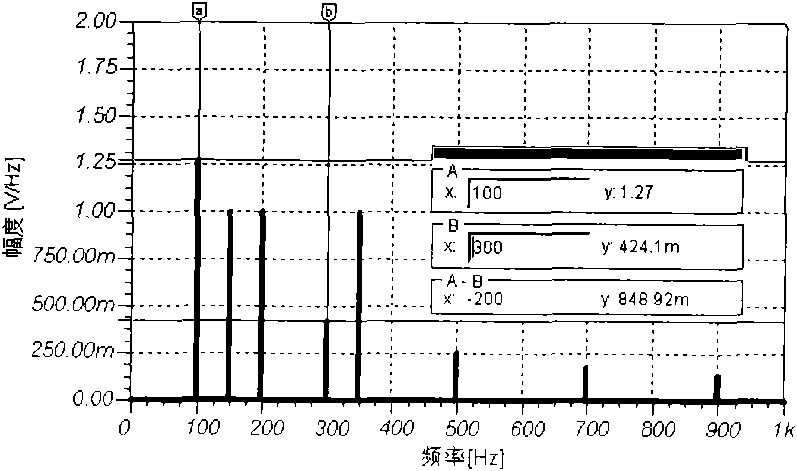

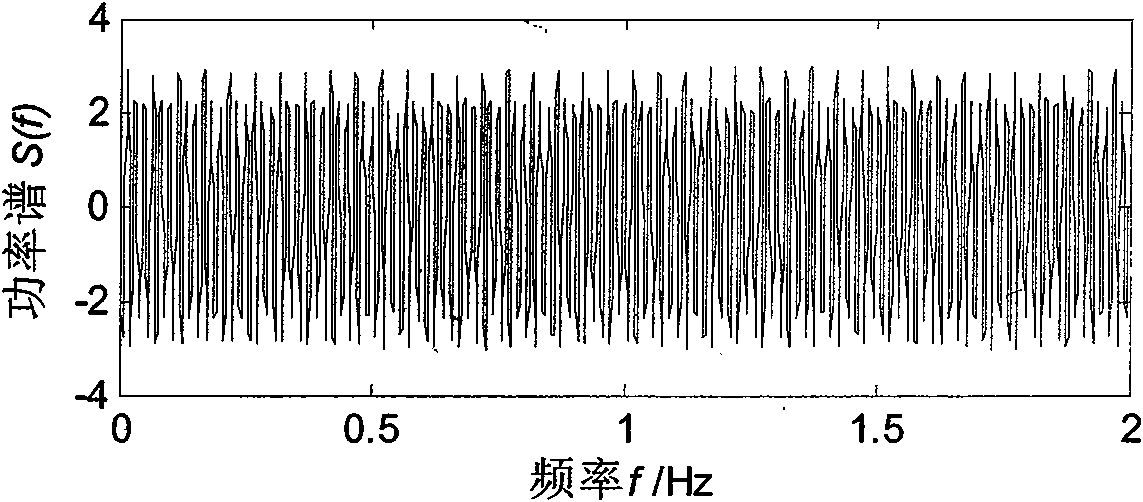

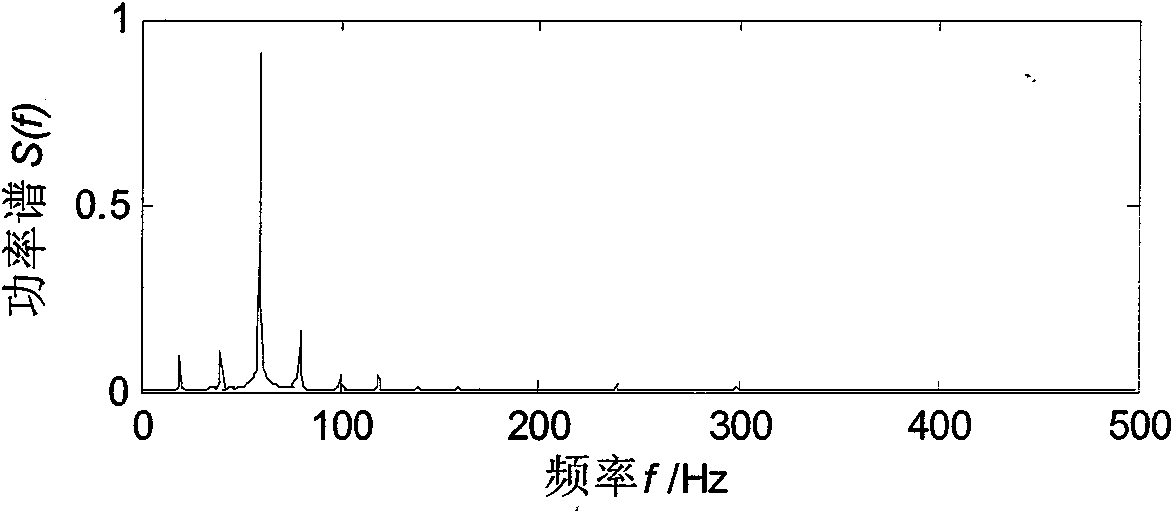

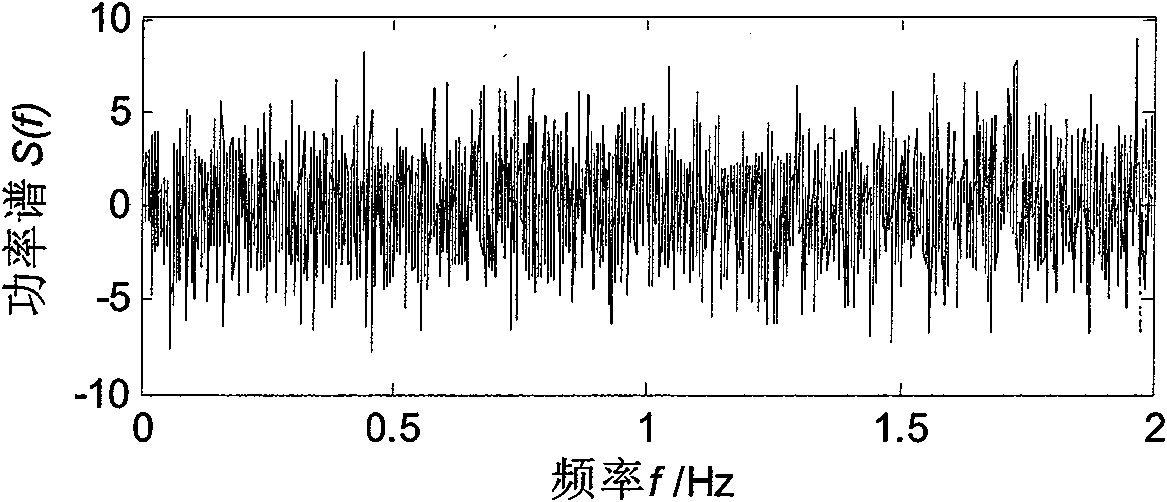

Method for testing stochastic resonance-chaotic weak signal

InactiveCN101561314AAvoid healthy runAvoid rubbingMachine part testingSubsonic/sonic/ultrasonic wave measurementSignal-to-noise ratio (imaging)Signal-to-quantization-noise ratio

The invention discloses a method for testing stochastic resonance-chaotic weak signal, comprising the following steps: firstly, testing whether a frequency signal with weak feature exists by means of self-adapting parameter adjusting stochastic resonance to obtain the magnitude of the most probable signal-to-noise ratio of the signal which is practically to be tested; on the basis, designing a corresponding duffing chaotic vibrator and computing conversion relationship between the input period encouragement of the chaotic vibrator and the output large magnitude periodic motion magnitude under the condition of different signal-to-noise ratio; and finally estimating to obtain the magnitude of the frequency signal with weak feature according to the magnitude of the signal which is practically to be tested by means of stochastic resonance. The method is applicable to test the frequency signal with weak feature in the early detection fields such as physics, chemistry, biology, mechanical failure, and the like, under the condition of low signal-to-noise ratio.

Owner:NAT UNIV OF DEFENSE TECH

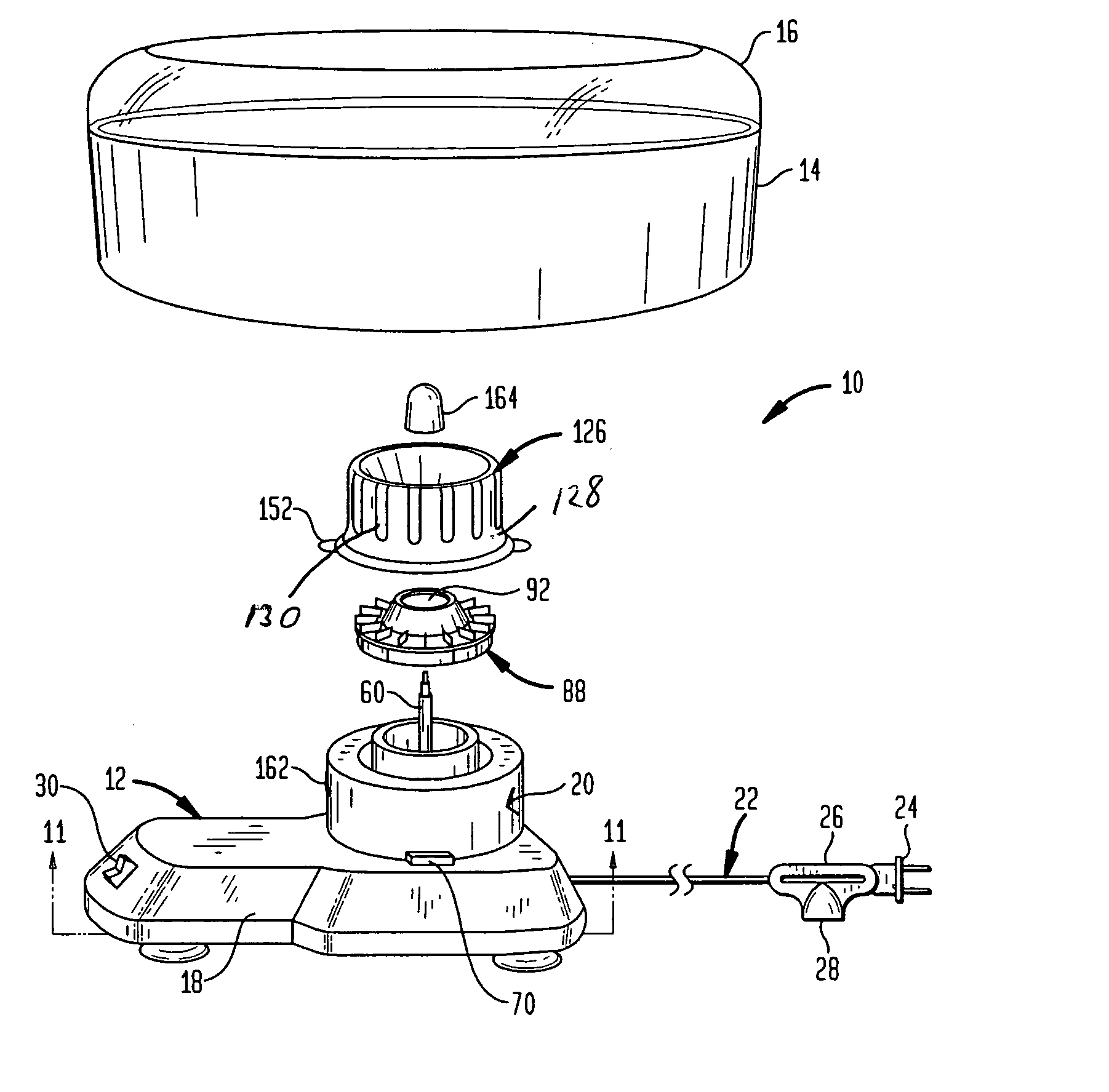

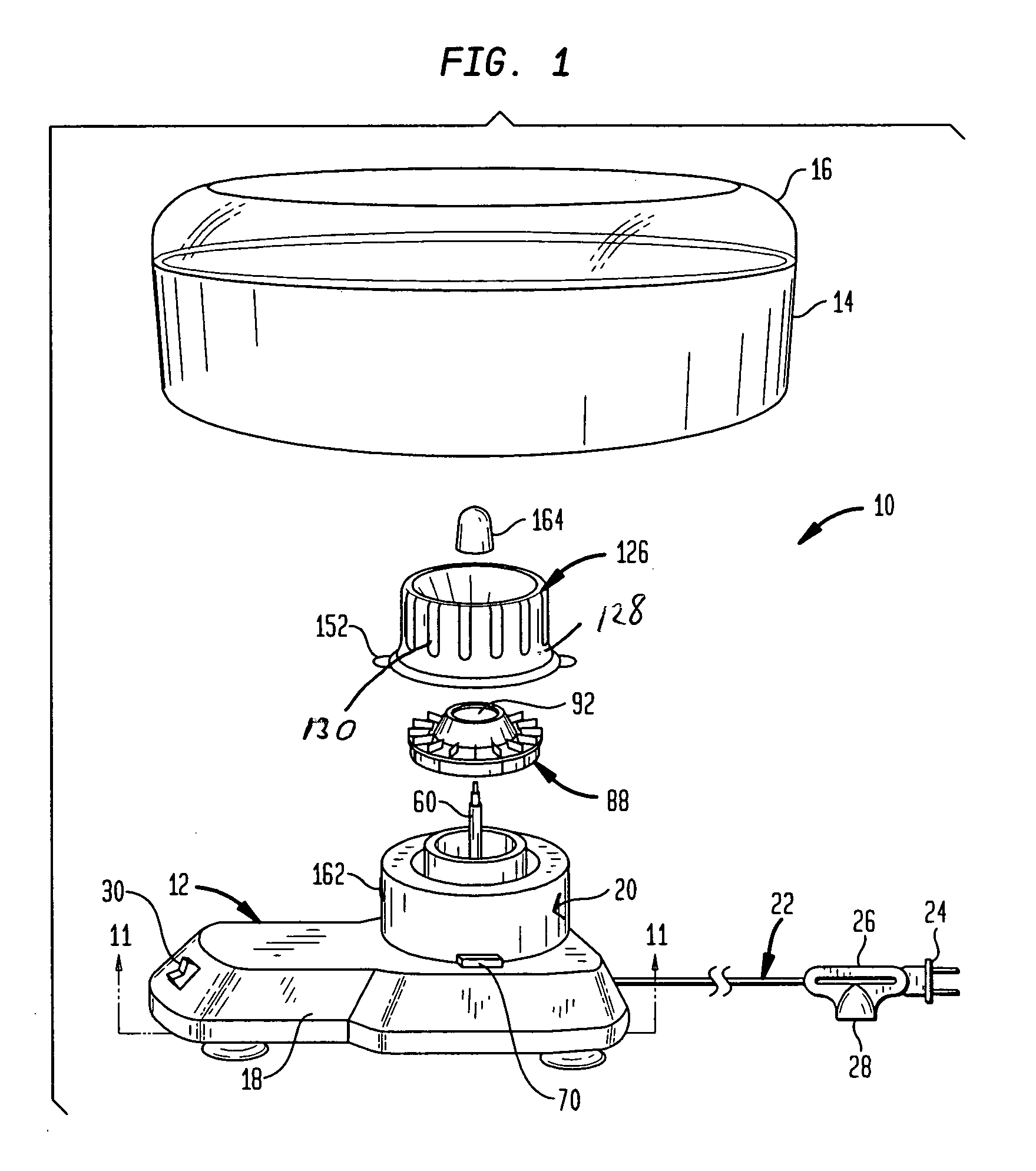

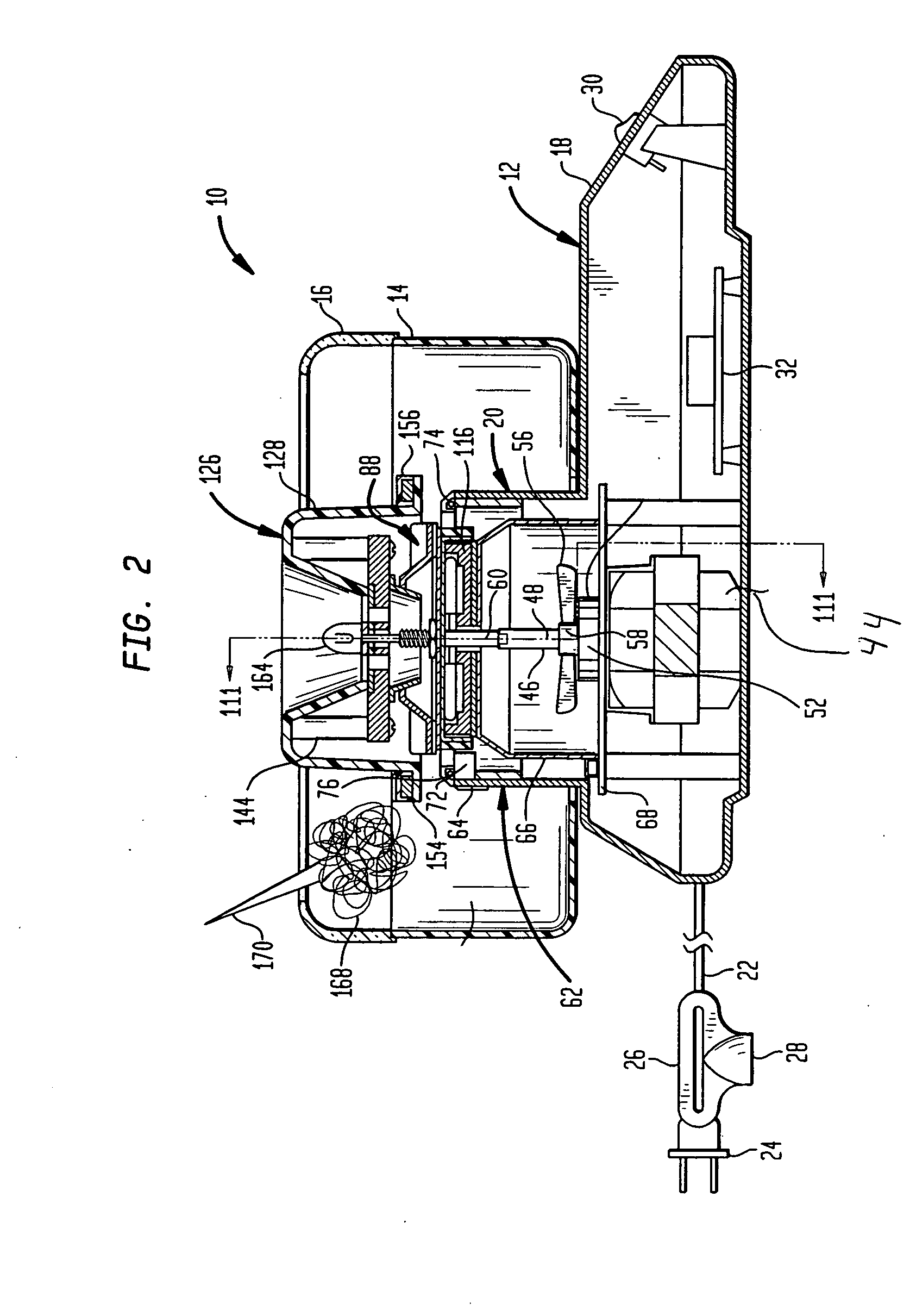

Cotton candy machine toy

The cotton candy machine includes a base and a bowl attached thereto. A spinner is included for rotating sugar as well as a heating assembly for heating sugar which falls on a plate of the spinner. A cap is also provided and is attached to the spinner. The cotton candy machine is also equipped with various safety devices. For example, an interlock safety switch is used to indicate whether the bowl has been removed from the cotton candy machine while the cotton candy machine is in operation. A reed switch / magnet arrangement is utilized to detect whether the cap has been removed from the cotton candy machine. Sensors are provided to detect mechanical malfunctions. Thermostats are also employed to monitor and to sense an overheat condition in the cotton candy machine.

Owner:MEGA BRANDS INT R L LUXEMBOURG ZUG BRANCH

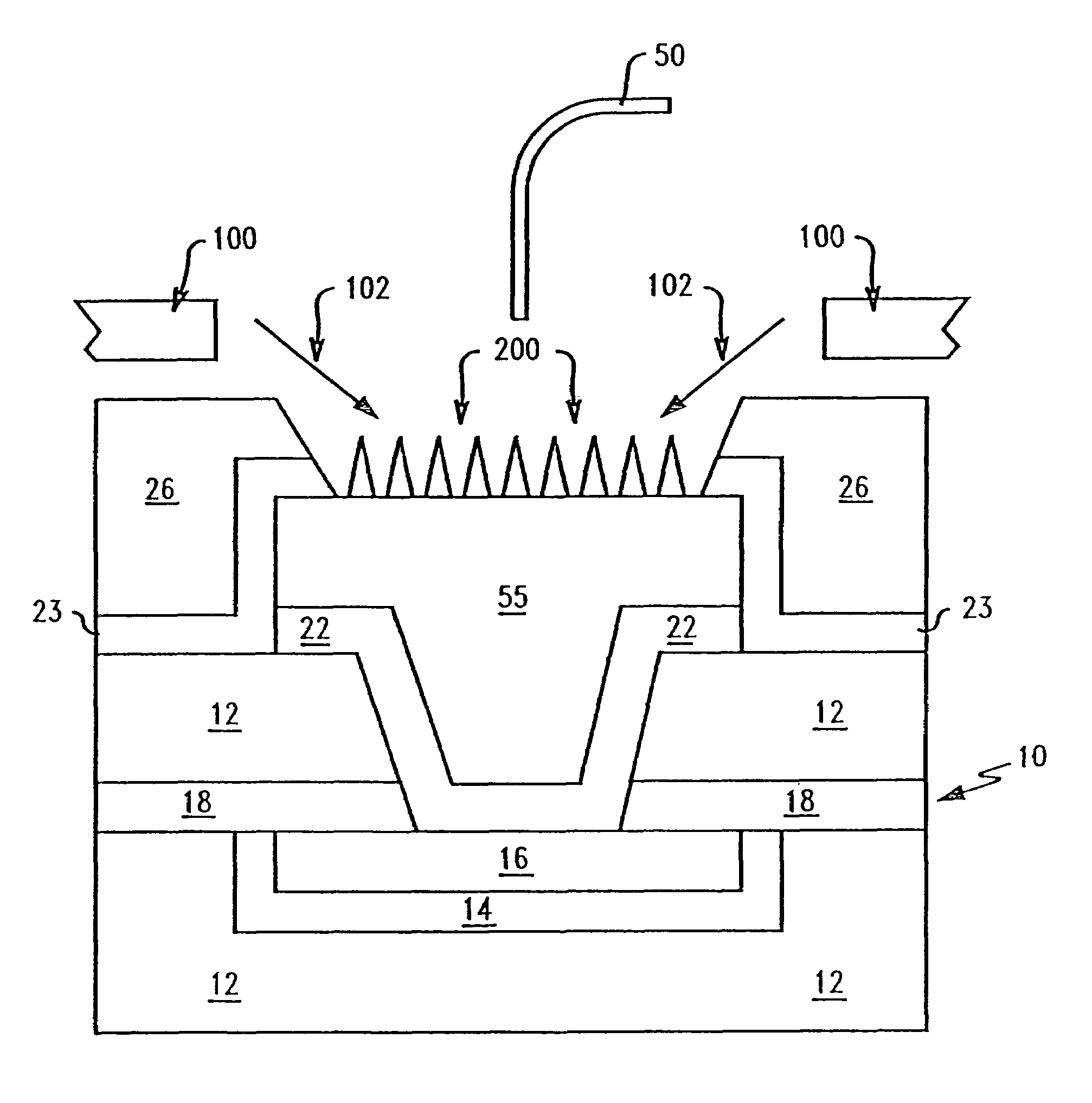

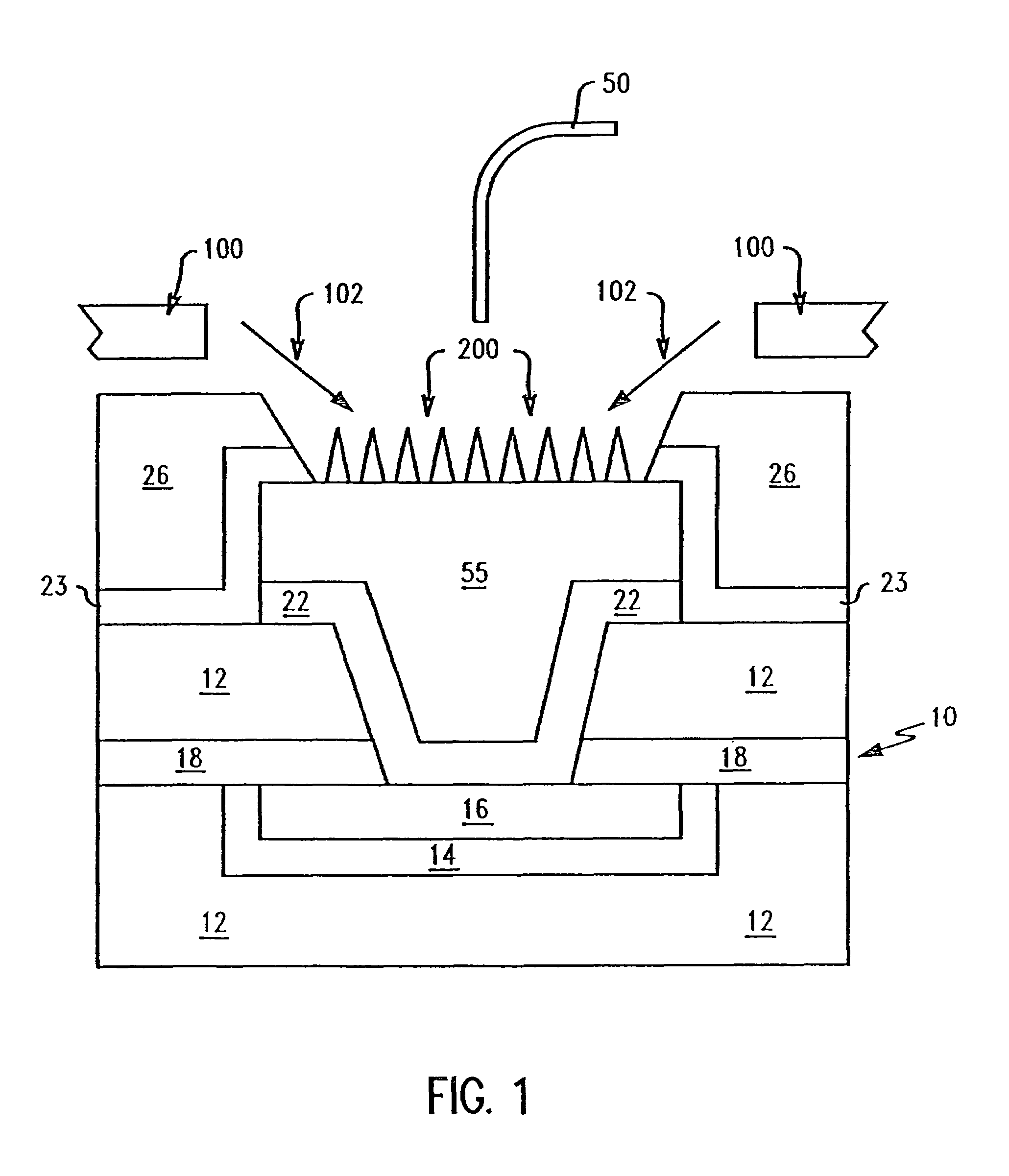

Roughened bonding pad and bonding wire surfaces for low pressure wire bonding

InactiveUS7015580B2Avoids creating any excessive force and powerStrong and reliable wire bondSemiconductor/solid-state device detailsSolid-state devicesPressure wireLead bonding

Owner:GLOBALFOUNDRIES U S INC

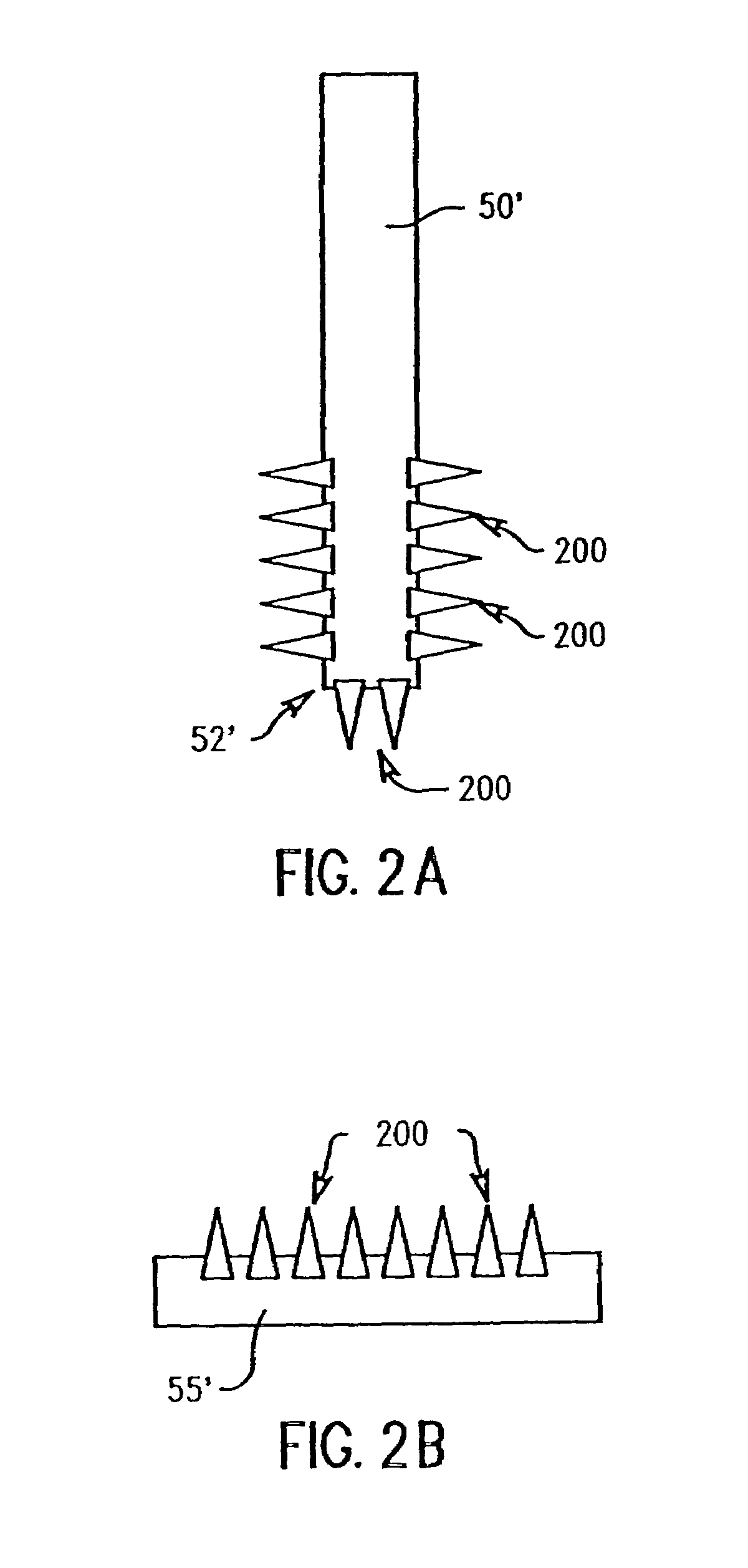

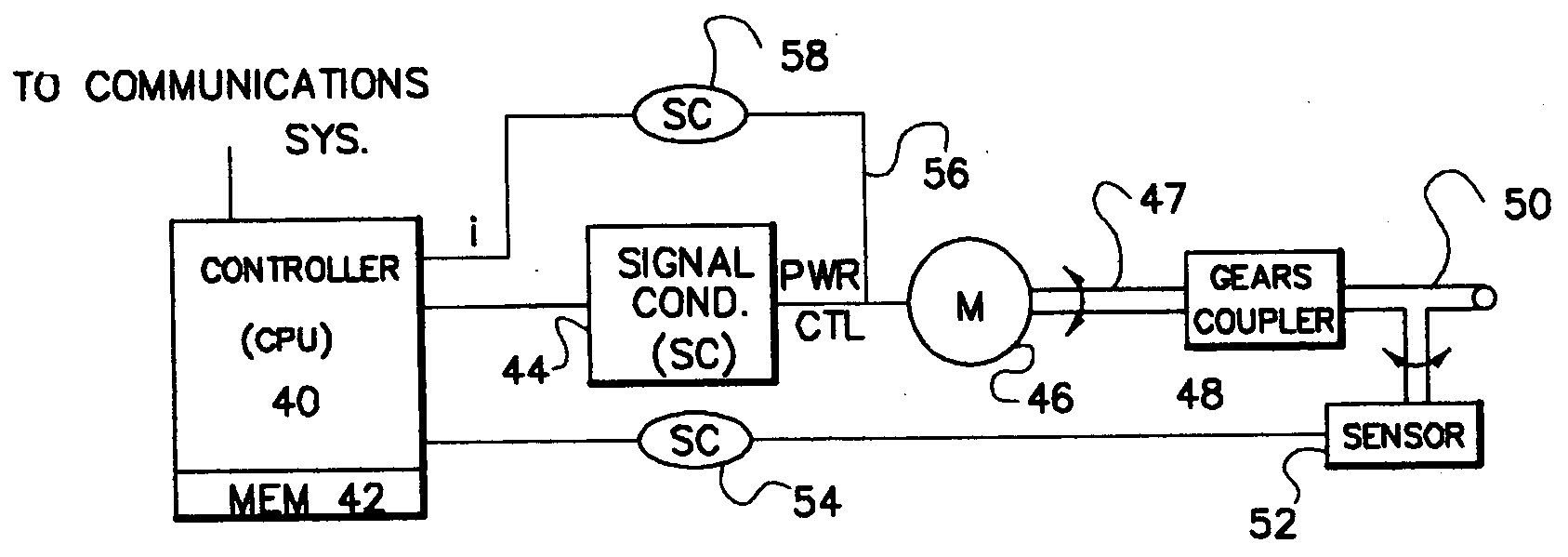

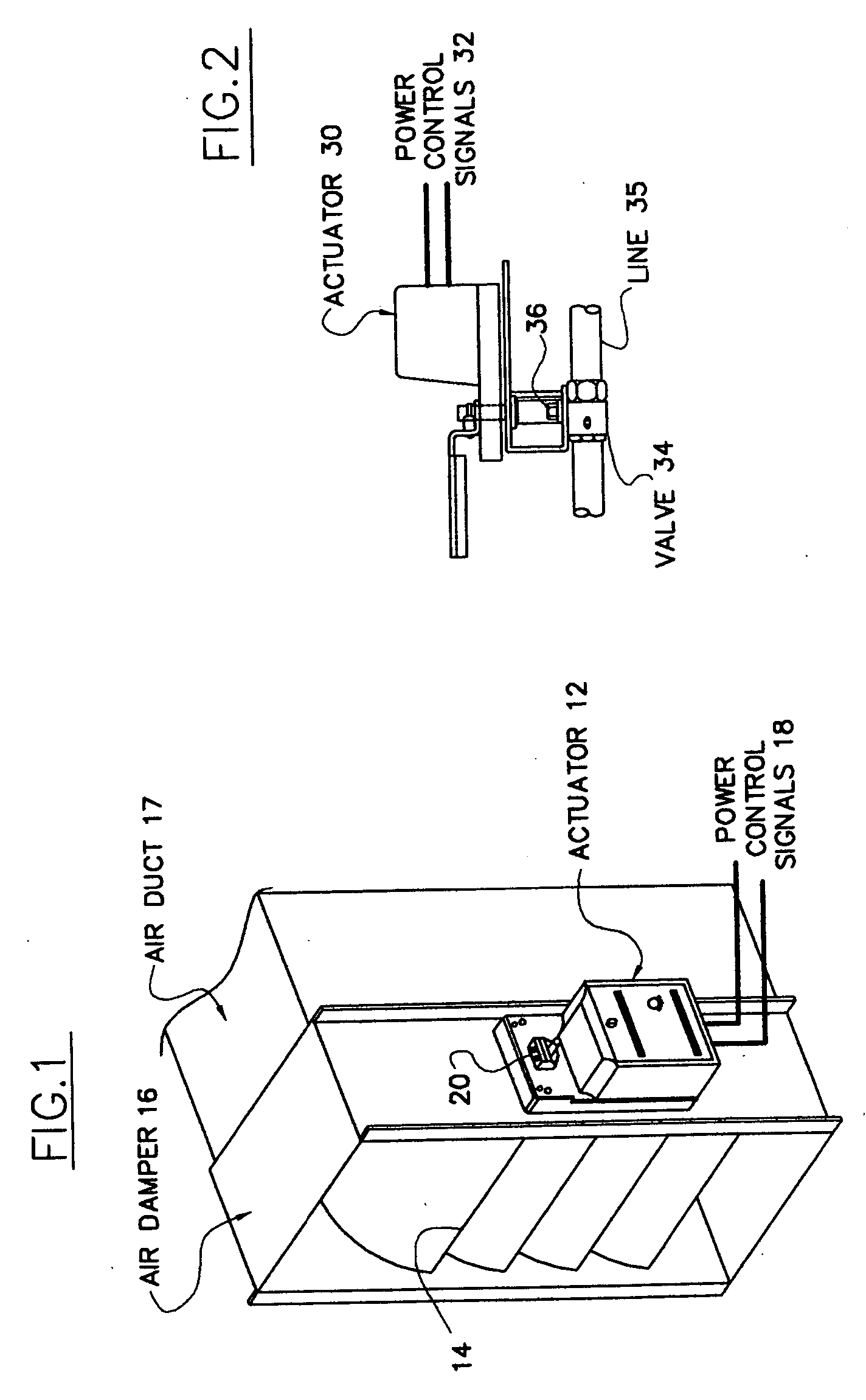

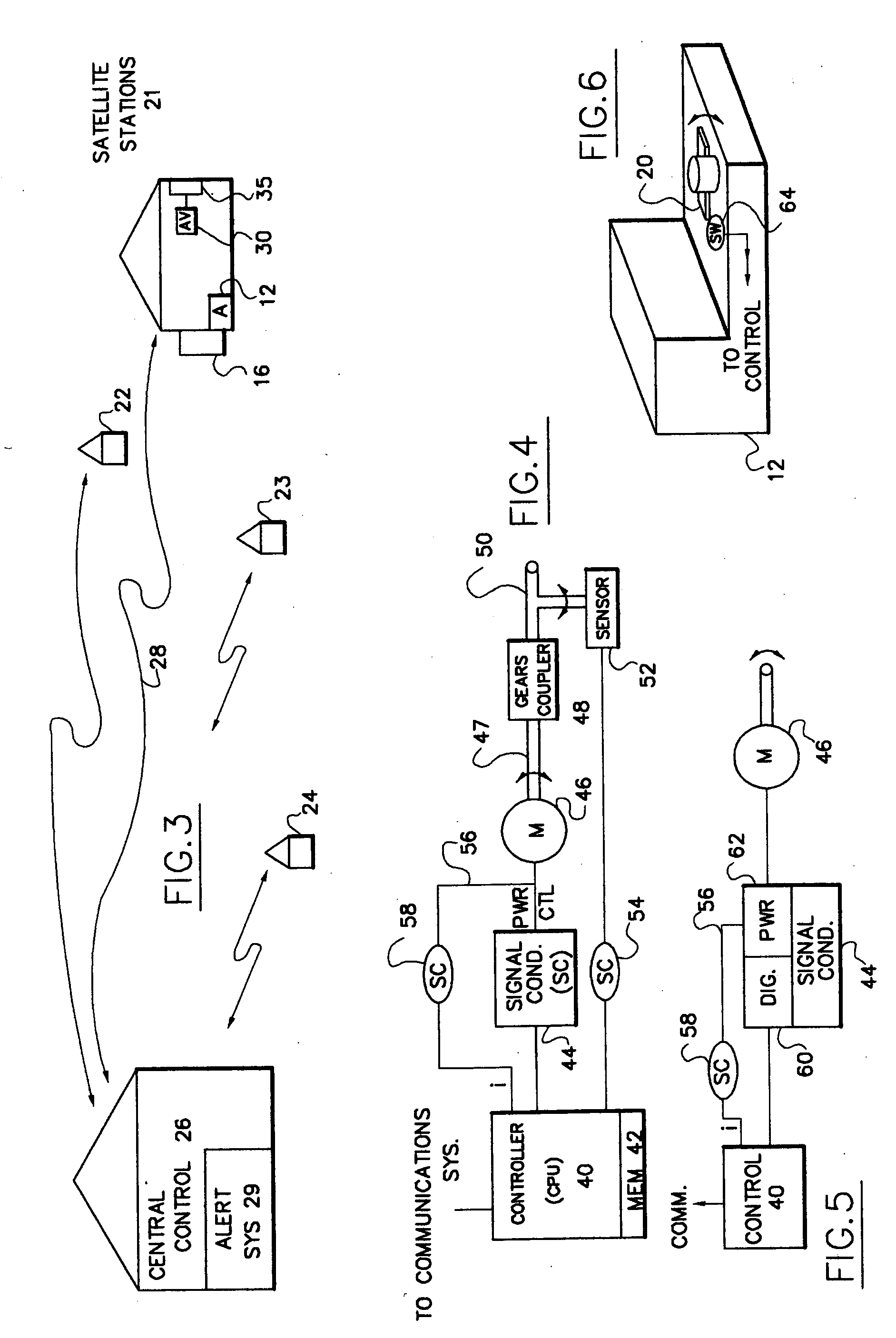

Actuator alarm for critical environments or applications

The air damper or valve actuator system with an alarm includes a motor coupled to the air damper or valve, an electrical power sensor for sensing an electrical power characteristic of the motor during the motor's motive operation of the air damper or valve and a threshold sensor. The threshold sensor determines and generates an alarm signal when the power characteristic exceeds a predetermined value during the motor's motive operation. An end point sensor is utilized to detect when the motor and coupled air damper or valve reaches a mechanical operational end point thereby disabling the alarm. The method for detecting and issuing an alarm indicative of potential impending mechanical failure includes sensing the product characteristic and determining and generating an alarm when the power characteristic exceeds a predetermined value before the motor driven actuator reaches a pre-set mechanical end position. The distributed system which monitors a plurality of actuator systems via a central control station.

Owner:NAT ENVIRONMENTAL PRODS

Method and apparatus for automatic visual event detection

ActiveUS20050276460A1Accurate calculationSpecificTelevision system detailsImage analysisMechanical componentsShort duration

Disclosed are methods and apparatus for automatic visual detection of events, for recording images of those events and retrieving them for display and human or automated analysis, and for sending synchronized signals to external equipment when events are detected. An event corresponds to a specific condition, among some time-varying conditions within the field of view of an imaging device, that can be detected by visual means based on capturing and analyzing digital images of a two-dimensional field of view in which the event may occur. Events may correspond to rare, short duration mechanical failures for which obtaining images for analysis is desirable. Events are detected by considering evidence obtained from an analysis of multiple images of the field of view, during which time moving mechanical components can be seen from multiple viewing perspectives.

Owner:COGNEX TECH & INVESTMENT

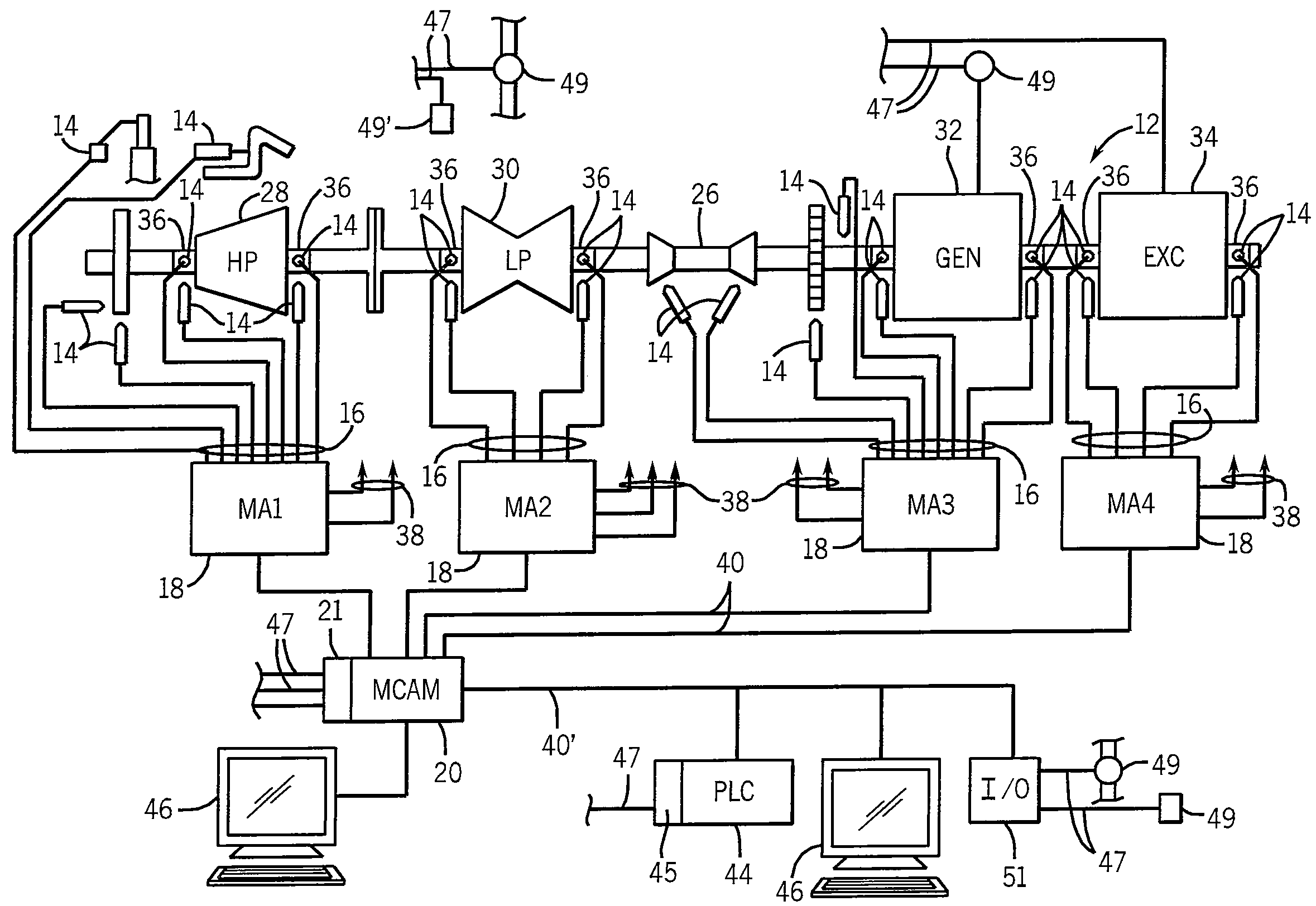

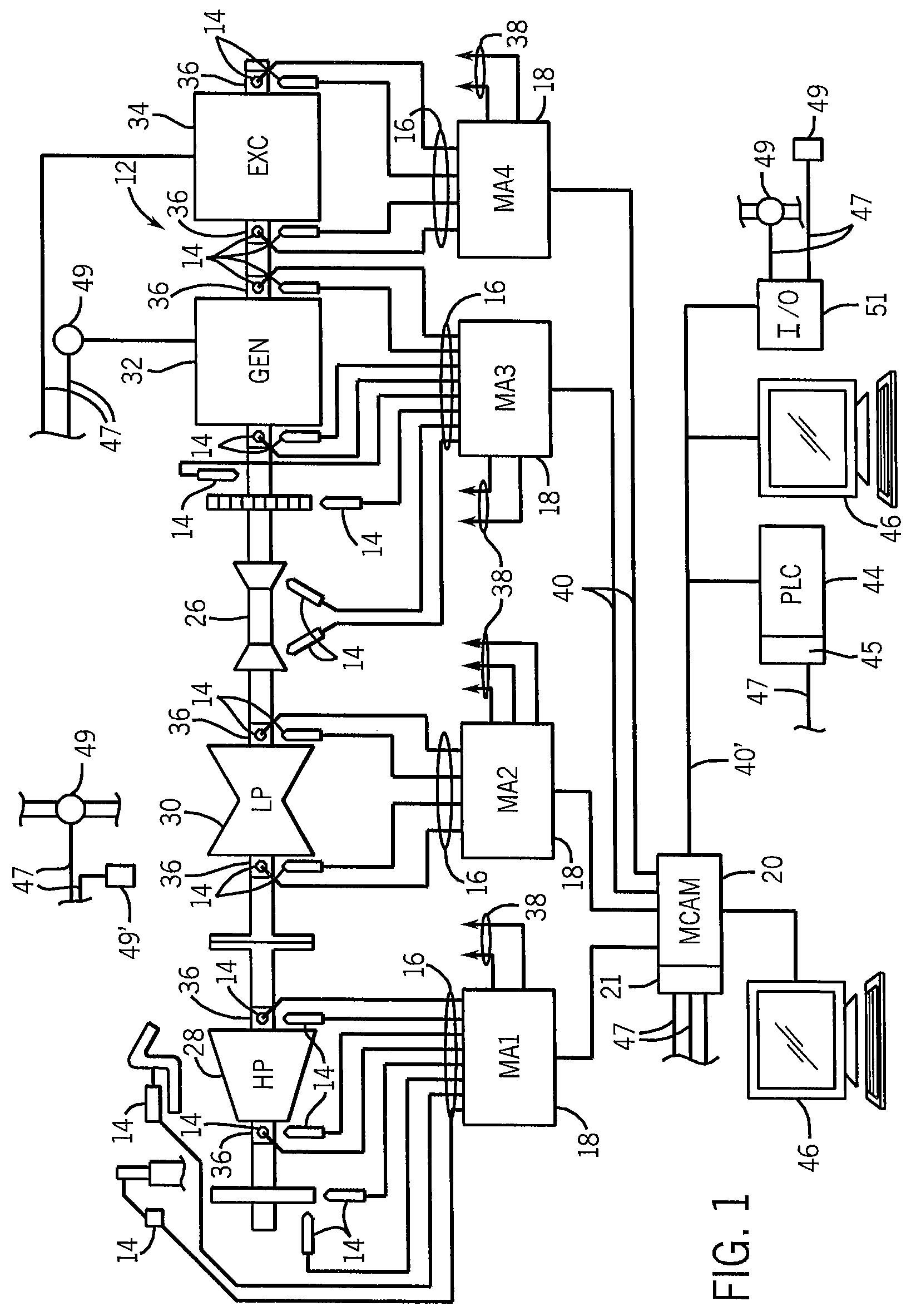

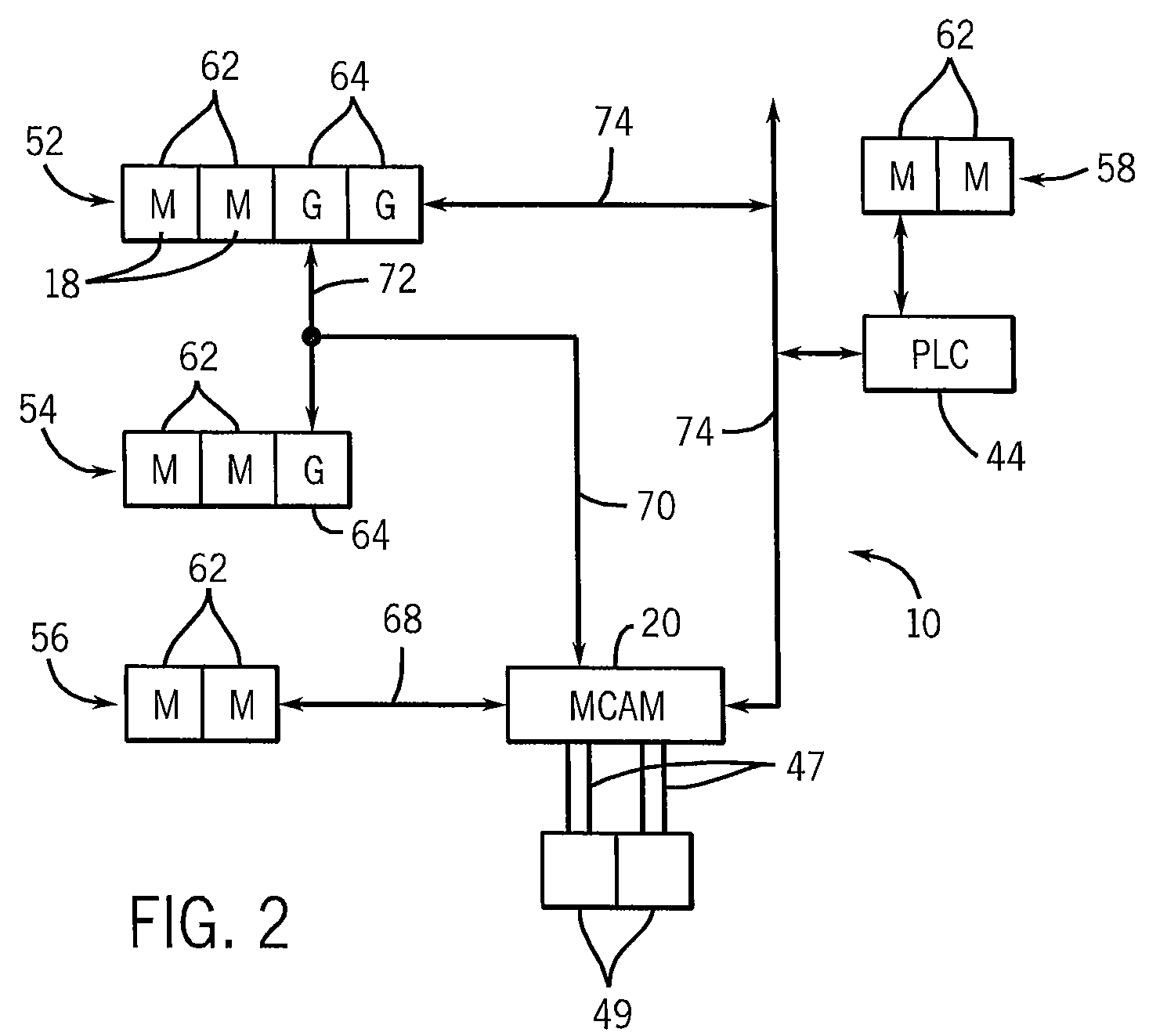

Machinery condition assessment module

ActiveUS7593784B2Safely stop machineryEasy to implementProgramme controlSafety arrangmentsNetwork integrationComputer science

Owner:ROCKWELL AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com