Patents

Literature

5656 results about "Transverse beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

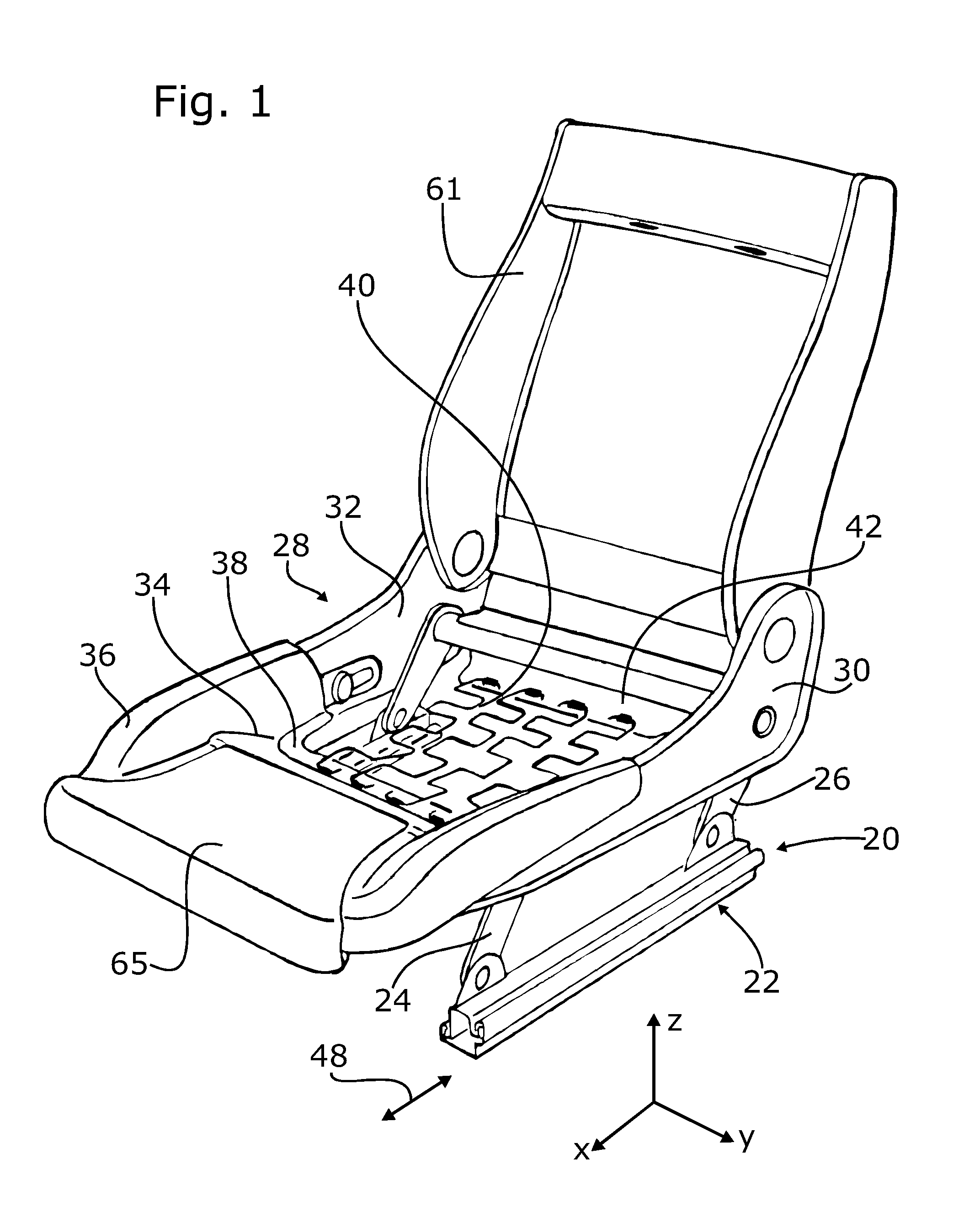

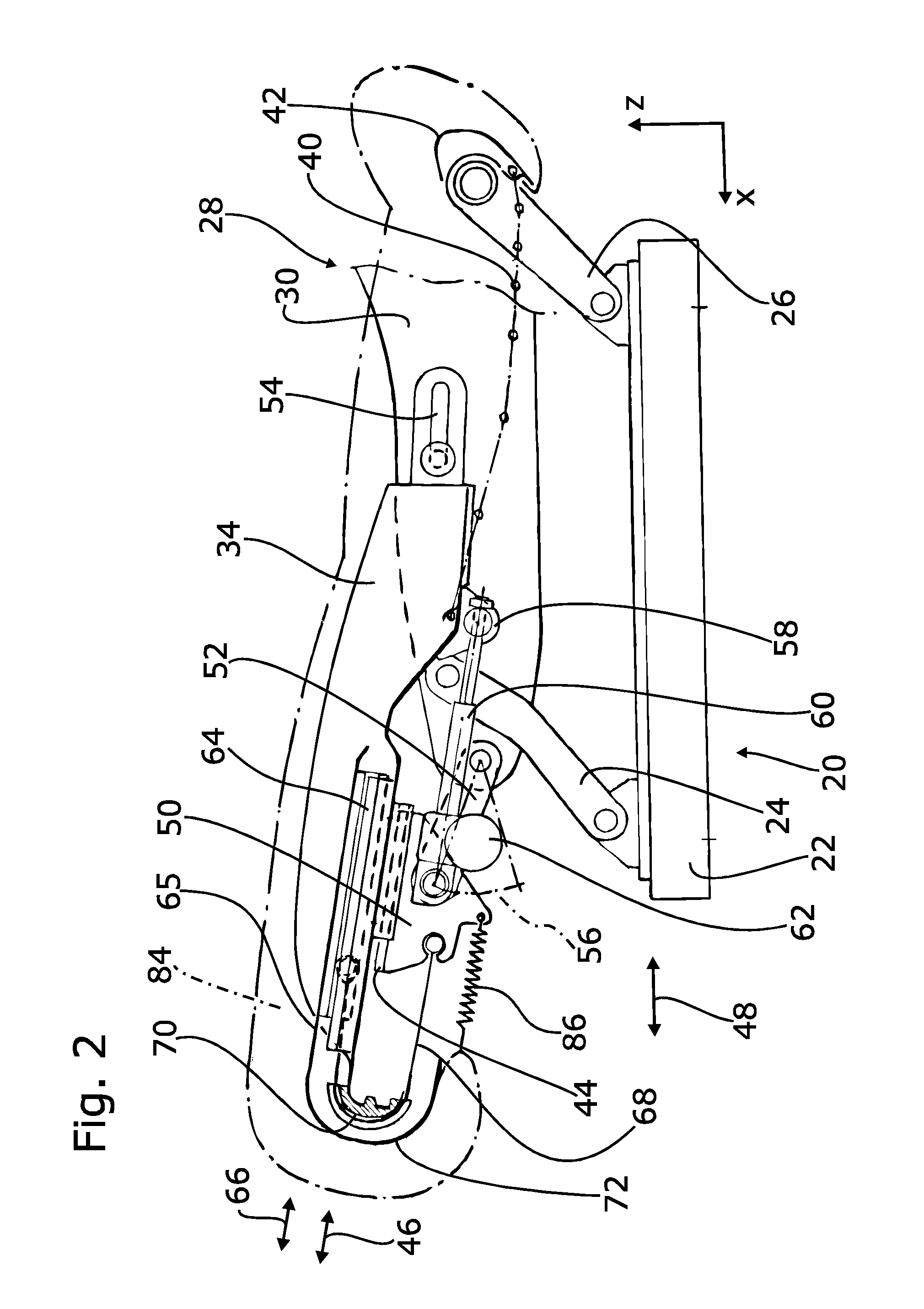

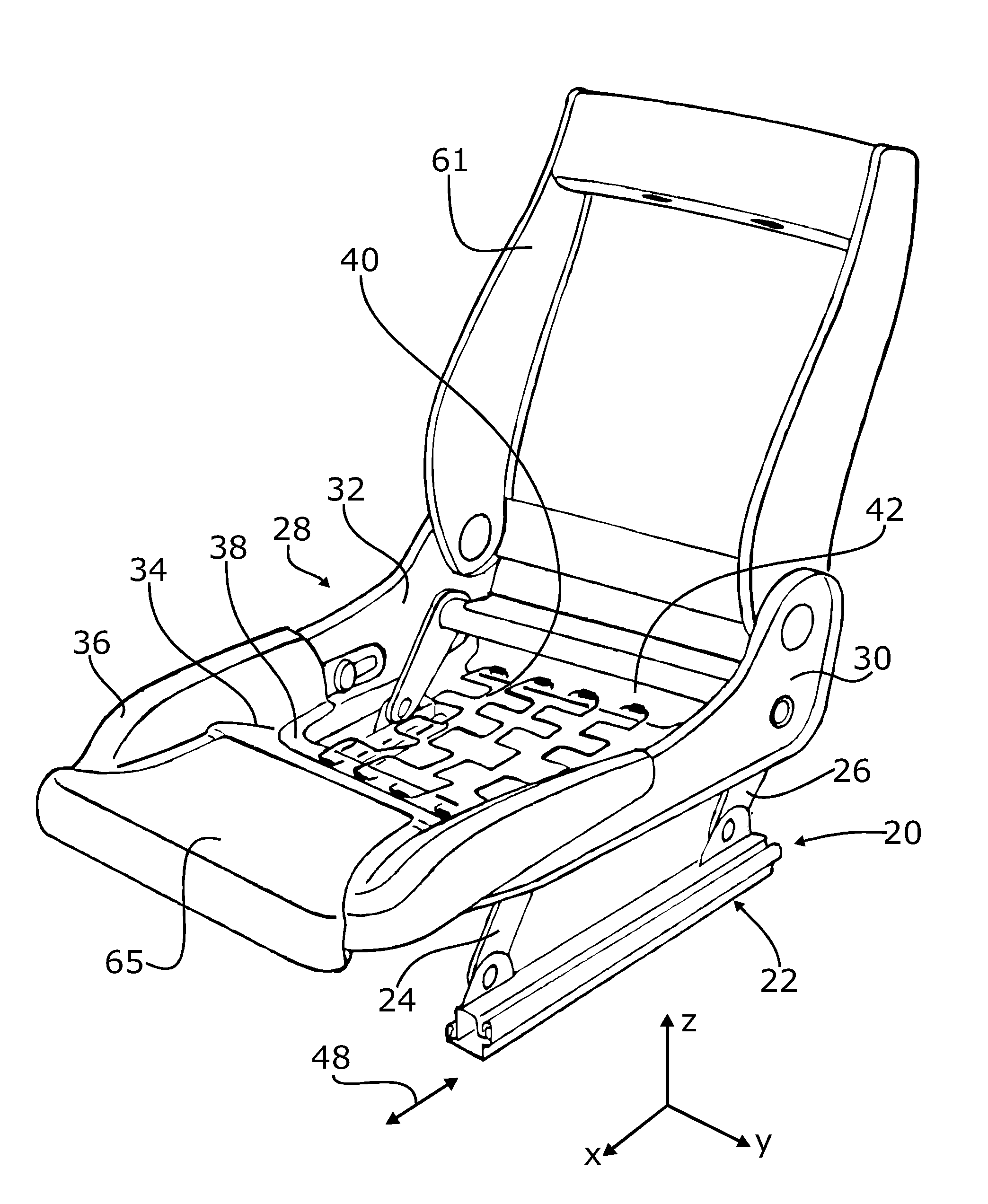

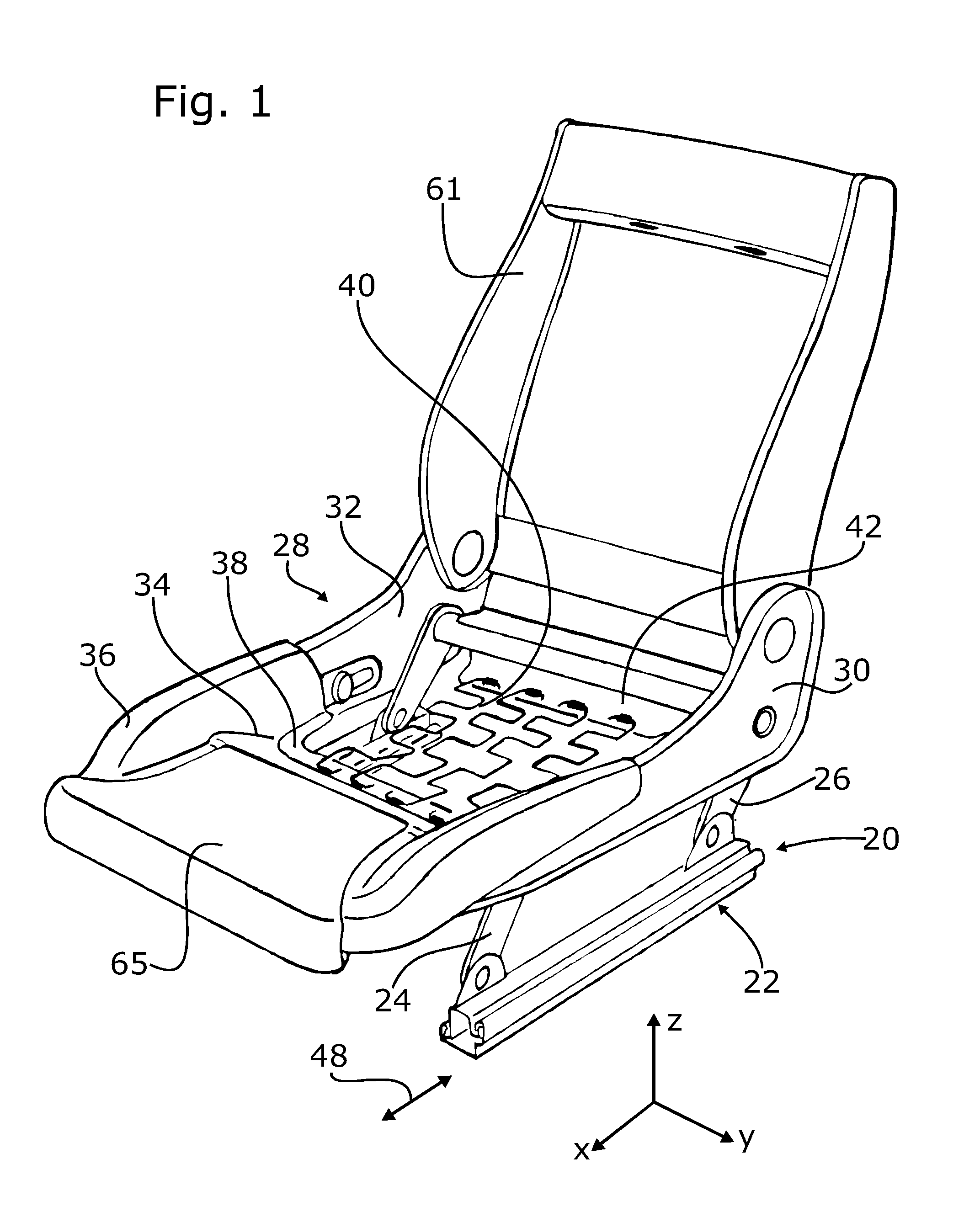

Motor vehicle seat with seat depth adjustment

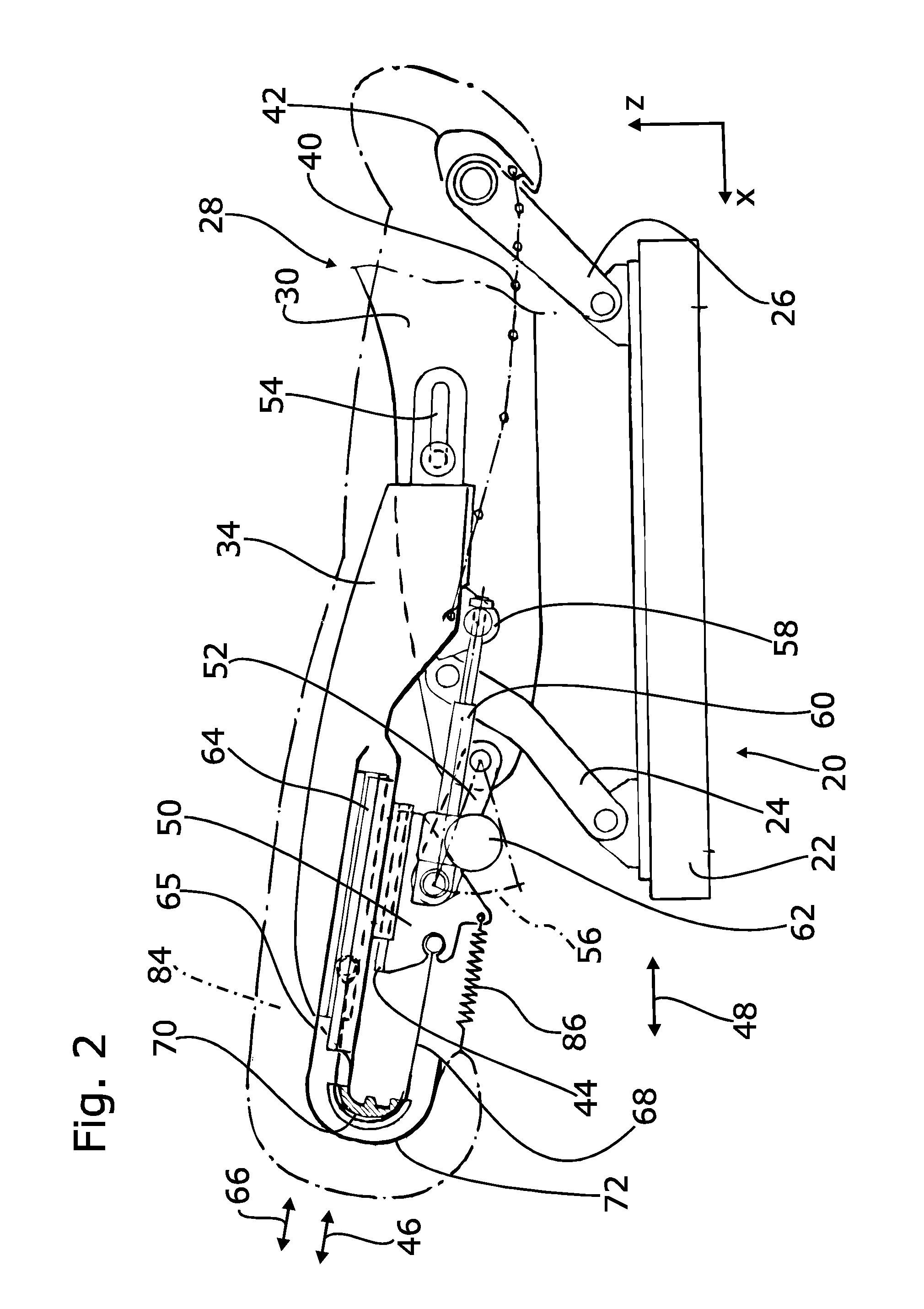

An adjustable motor vehicle seat with an underframe (20), a seat carrier (28) carried by the underframe (20), a cushion shell (34), a first longitudinal guide (44) being disposed between the seat carrier (28) and the cushion shell (34), and a first drive being provided for adjusting the cushion shell (34) relative to said seat carrier (28). The seat includes a front transverse beam (65) associated with a front edge (72) of the seat. A second longitudinal guide (64) is interposed between the cushion shell (34) and the transverse beam (65). A second drive is responsible for adjusting the seat carrier (28) relative to the cushion shell (34).

Owner:KEIPER SEATING MECHANISMS CO LTD

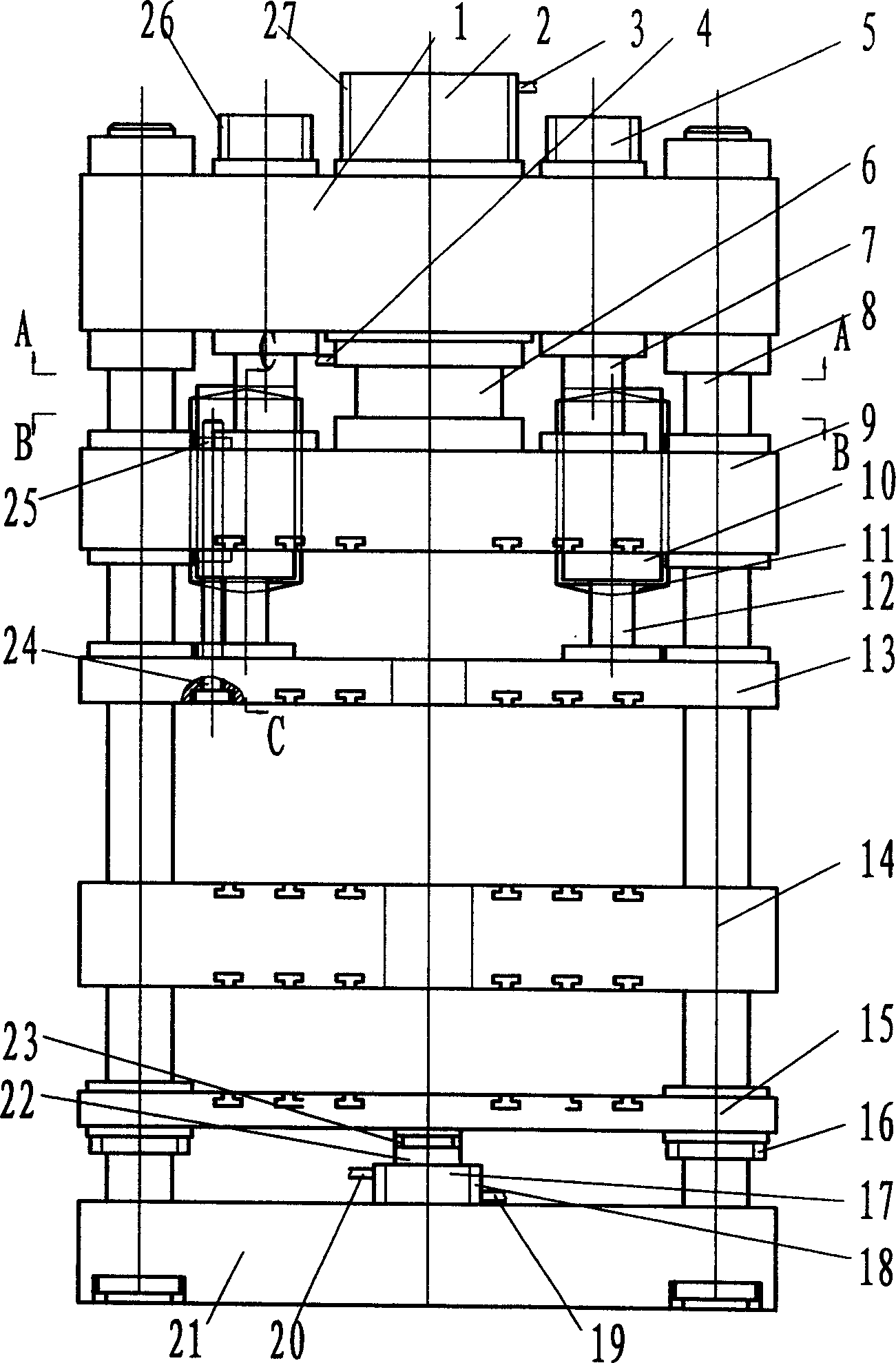

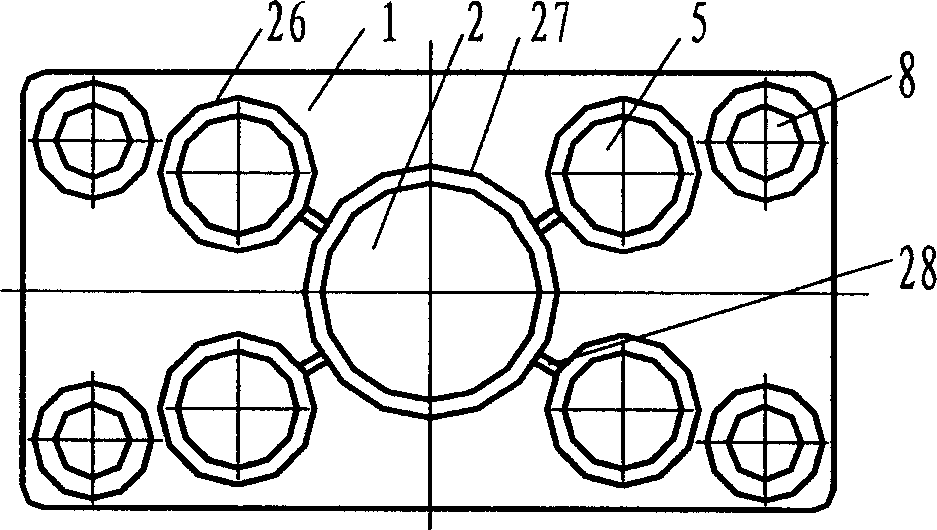

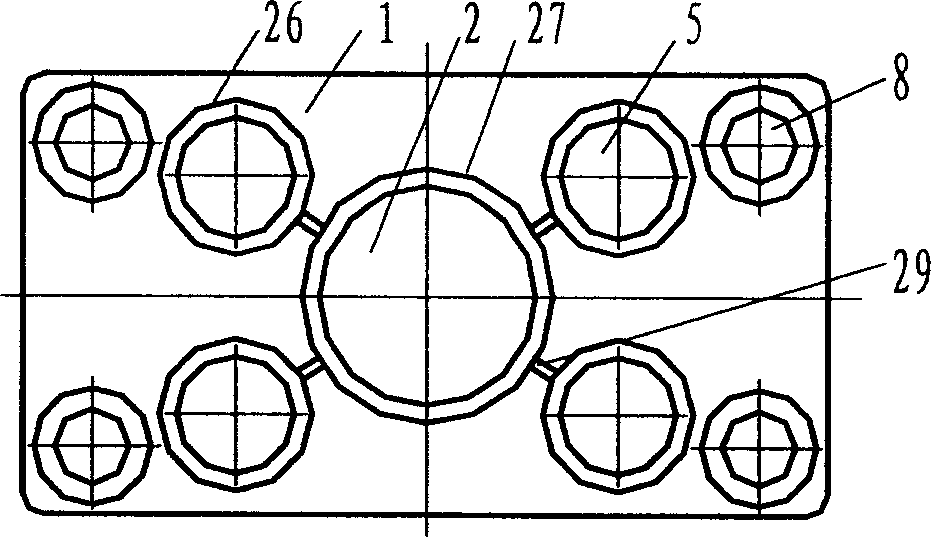

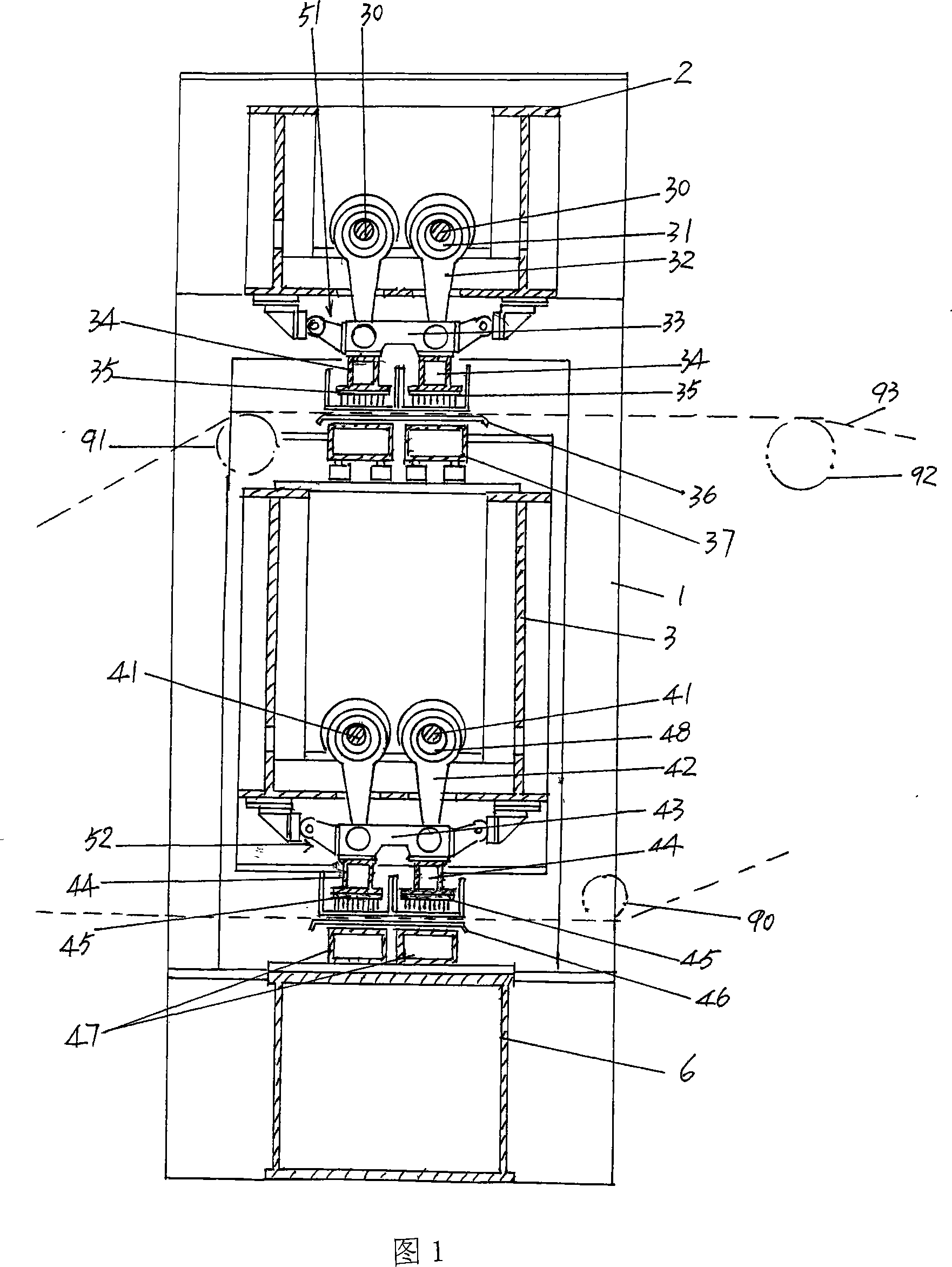

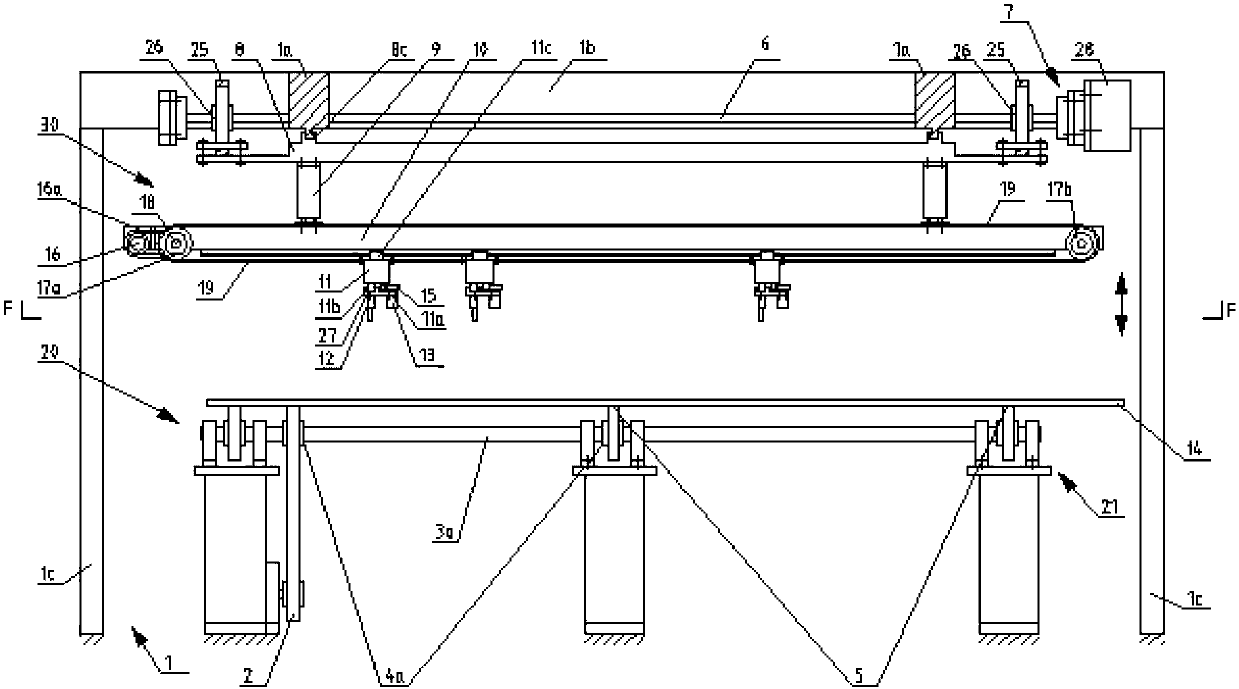

Regulatable hydraulic machine with up and down both double moving

InactiveCN1559792AInnovative designSimple structureForging press drivesPress ramMarine engineeringMaster cylinder

An adjustable hydraulic press with movable upper and lower units is composed of vertical columns, upper transverse beam, primary slide block, the slide block for pressing edge, bench, floating bench, lower transverse beam, the primary and secondary cylinders fixed to upper transverse beam, and a push-up cylinder fixed to lower transverse beam for driving said floating bench.

Owner:JILIN UNIV

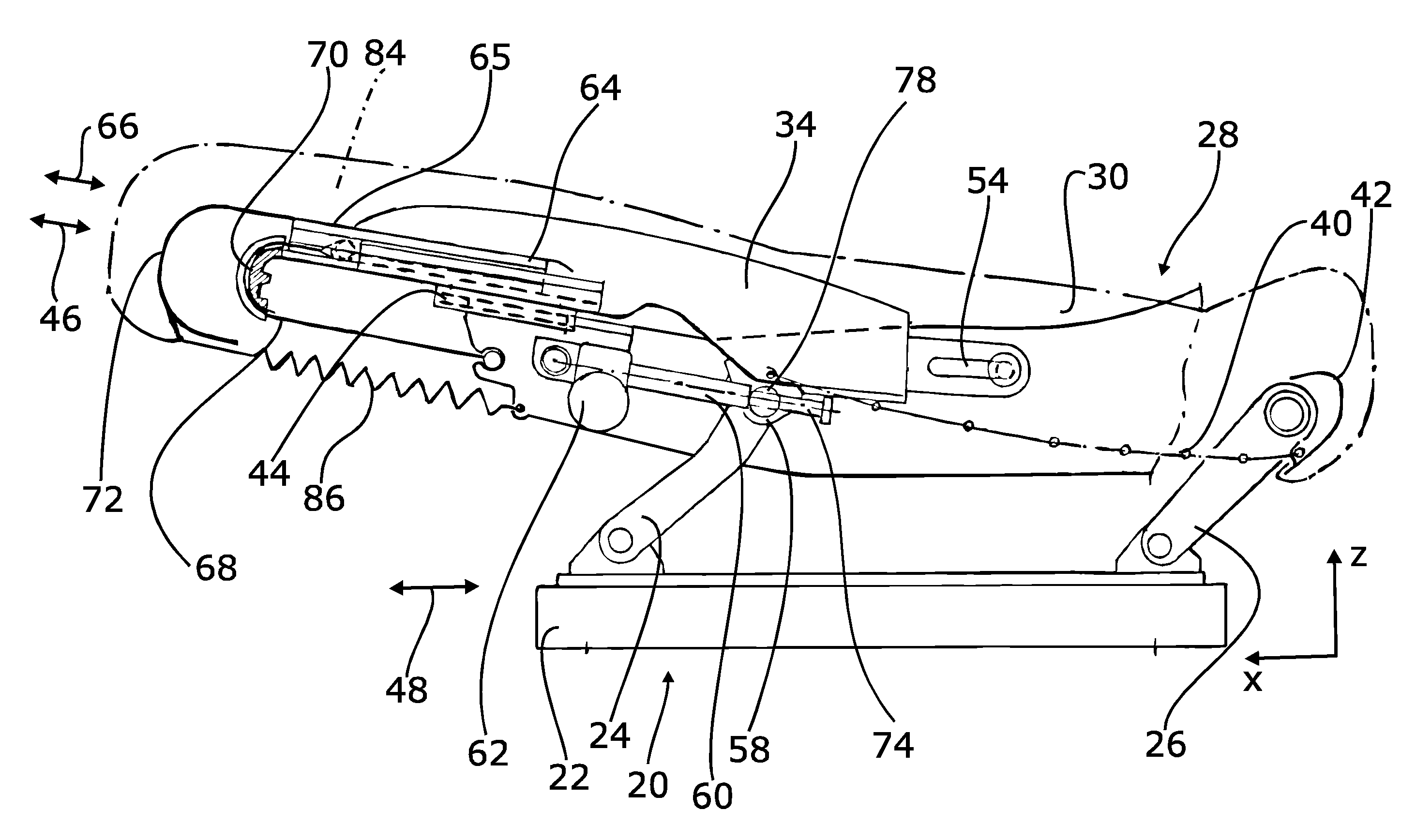

Motor Vehicle Seat with Seat Depth Adjustment

An adjustable motor vehicle seat with an underframe (20), a seat carrier (28) carried by the underframe (20), a cushion shell (34), a first longitudinal guide (44) being disposed between the seat carrier (28) and the cushion shell (34), and a first drive being provided for adjusting the cushion shell (34) relative to said seat carrier (28). The seat includes a front transverse beam (65) associated with a front edge (72) of the seat. A second longitudinal guide (64) is interposed between the cushion shell (34) and the transverse beam (65). A second drive is responsible for adjusting the seat carrier (28) relative to the cushion shell (34).

Owner:KEIPER SEATING MECHANISMS CO LTD

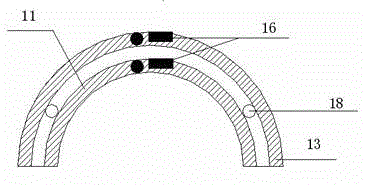

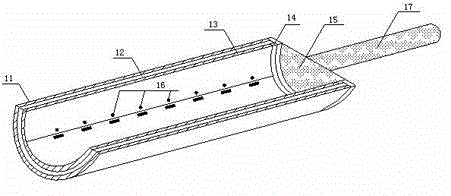

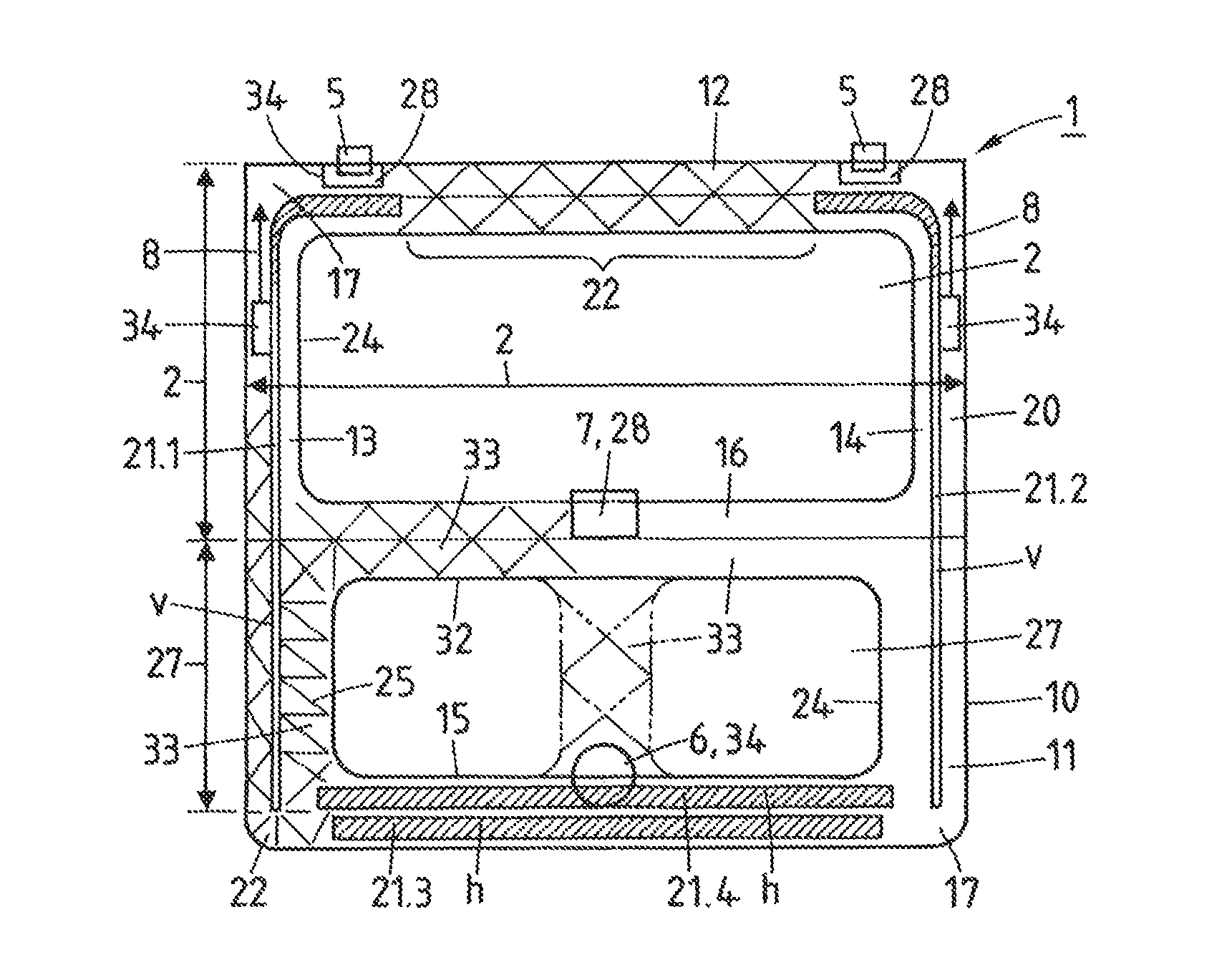

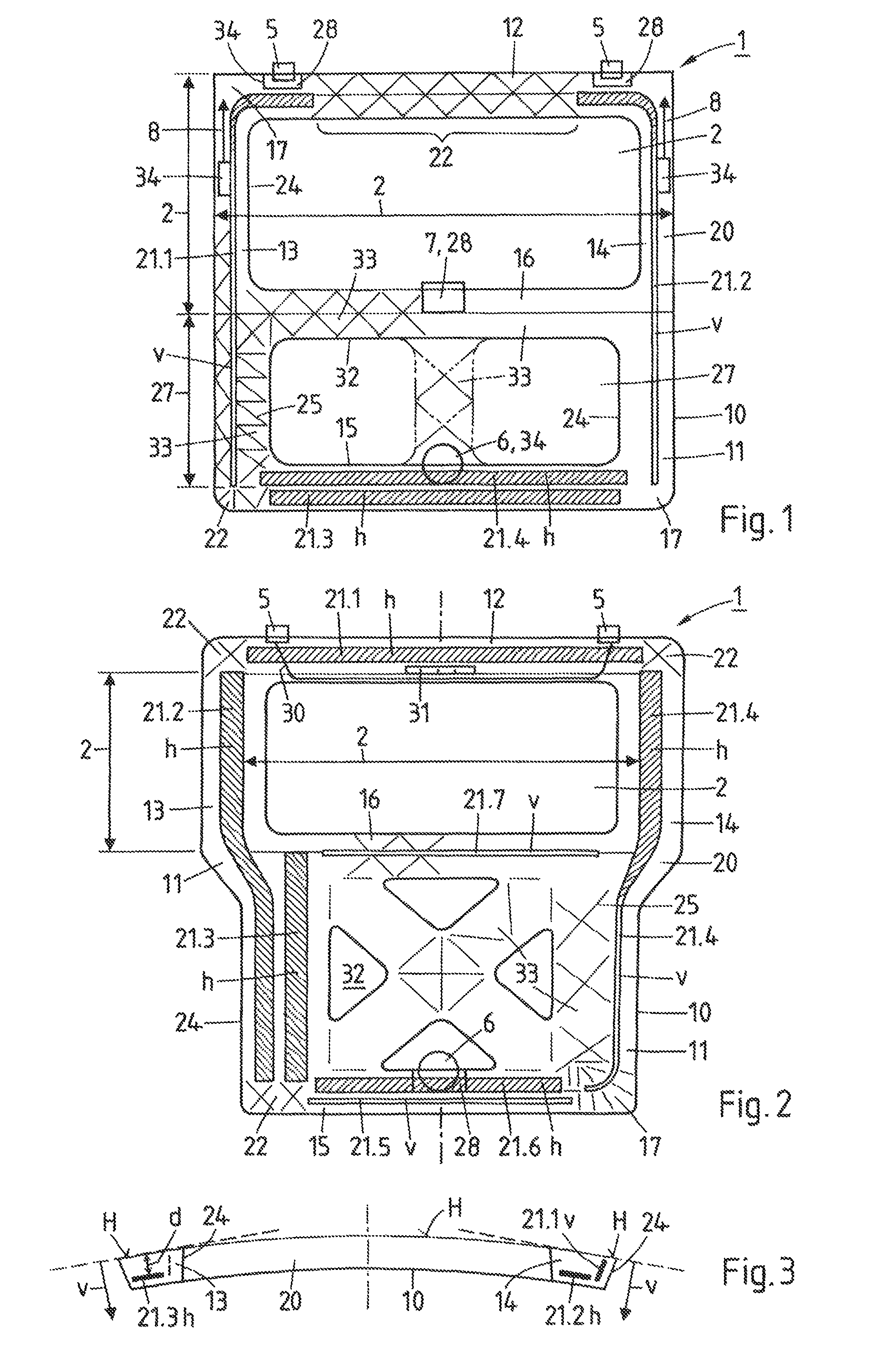

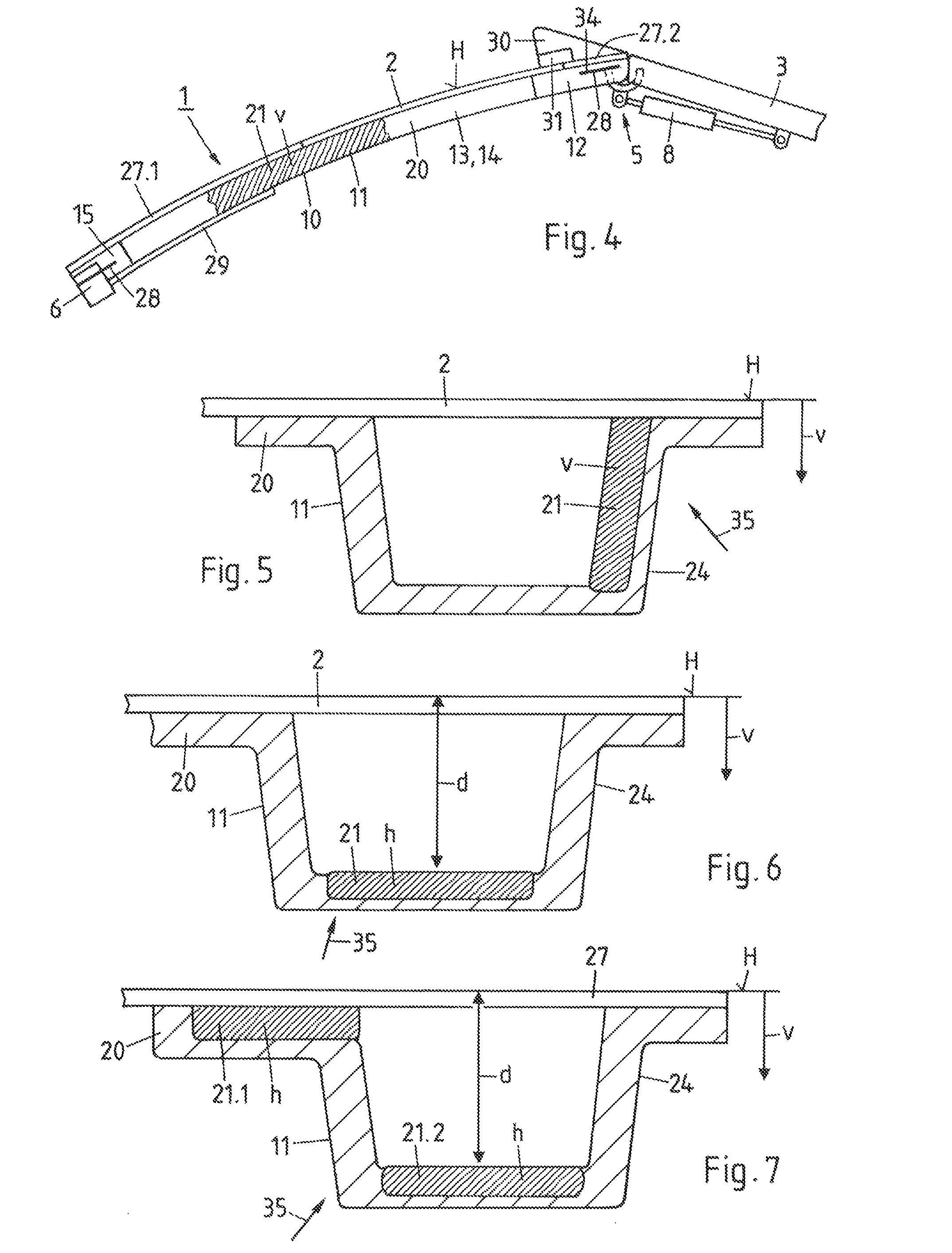

Tailgate from fibre-reinforced thermoplastic plastic

ActiveUS20120280533A1Stiffer and simply and inexpensively manufacturableImprove featuresSuperstructure subunitsMonocoque constructionsThermoplasticEngineering

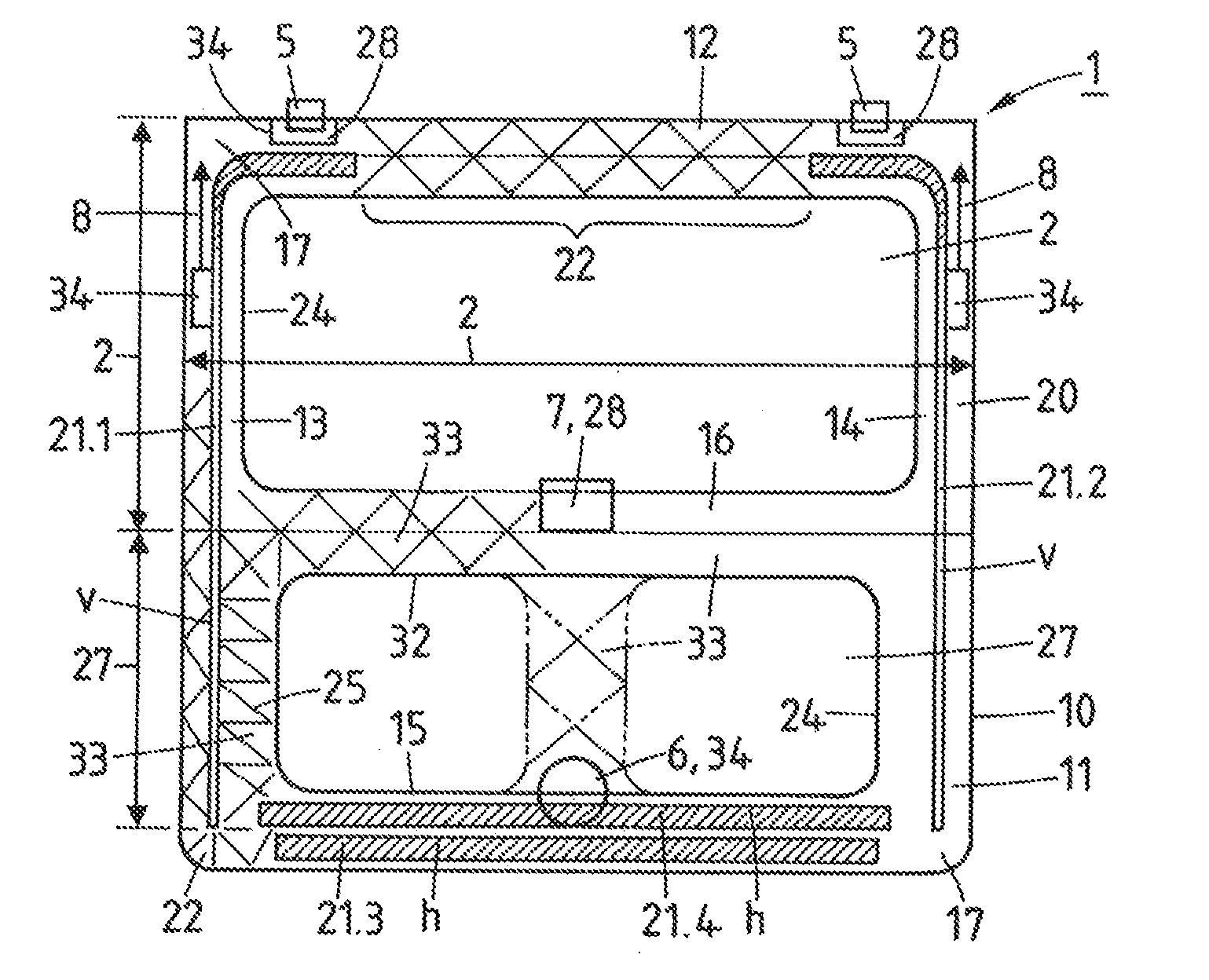

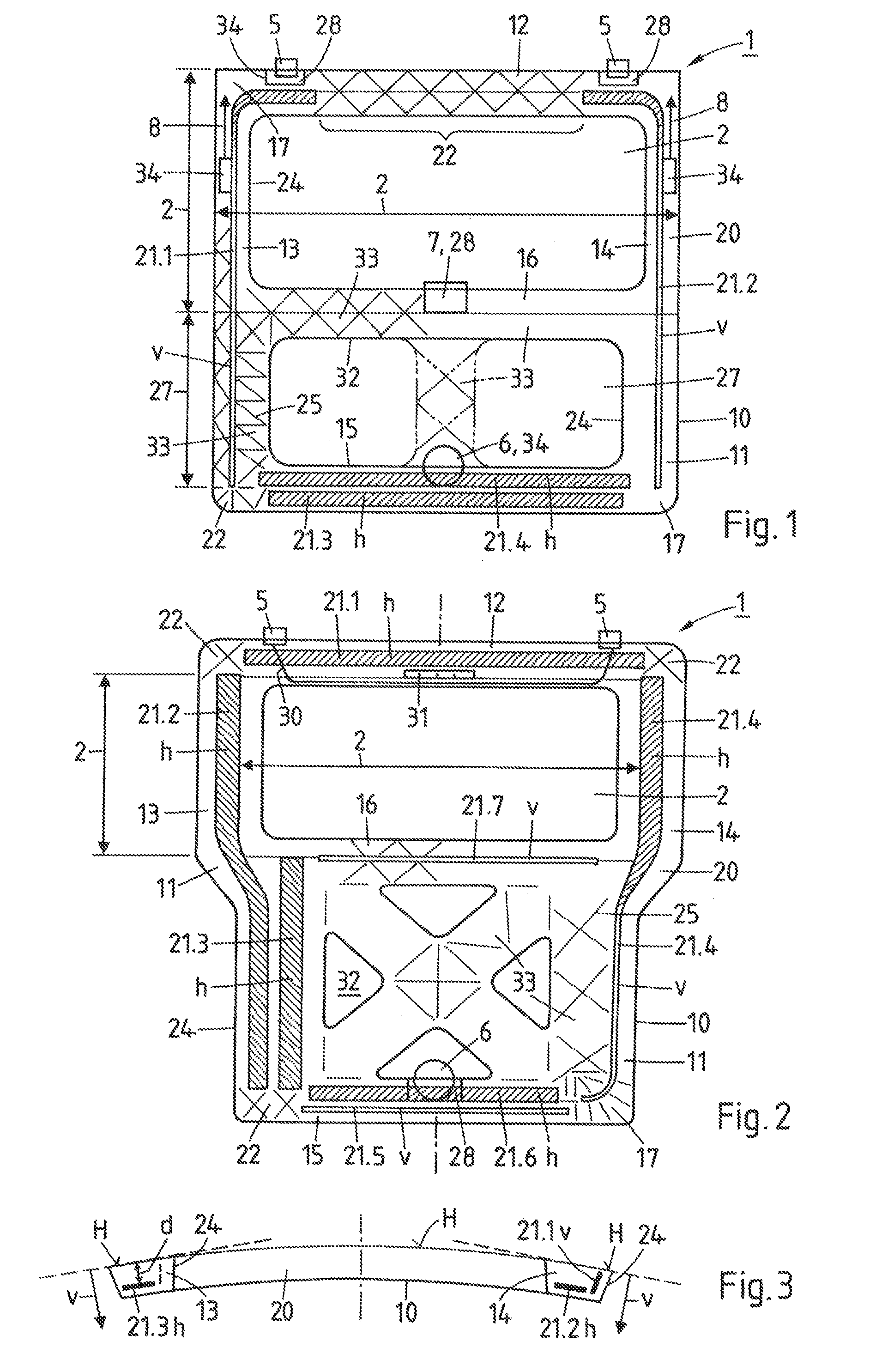

The tailgate (1) or rear door for a motor vehicle with a rear window includes a single-piece main carrying structure (10) with a peripheral, flexurally resistant frame (11), with an upper transverse beam (12), two lateral longitudinal beams (13, 14) and at least one lower transverse beam (15). The main carrying structure consists of a fibre-reinforced moulding compound (20) with at least two impregnated, integrated continuous-fibre bands (21) and this moulding compound is non-positively connected to the rear window (2) and together with this forms a flexurally resistant structure. Thereby, the continuous-fibre bands (21) in sections are integrated into the frame (11) in an arrangement vertical (v) to the surface (H) of the tailgate, by way of the continuous-fibre bands (21) being arranged vertically to the surface (H) and / or at a vertical distance (d) to the surface (H).

Owner:WEBER AUTOMOTIVE HLDG

Exercise apparatus

InactiveUS6042516AMovement coordination devicesCardiovascular exercising devicesClosed loopEngineering

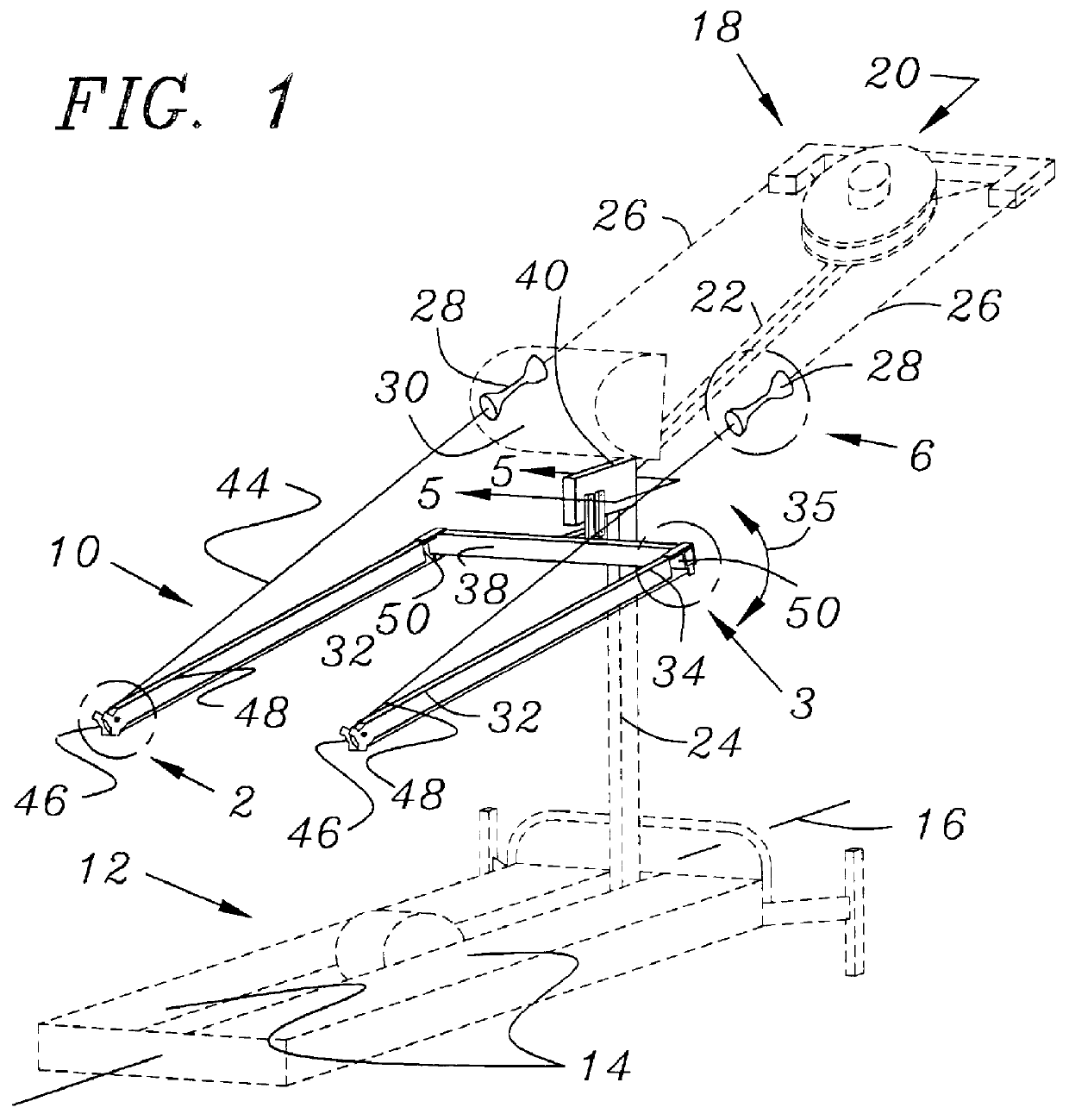

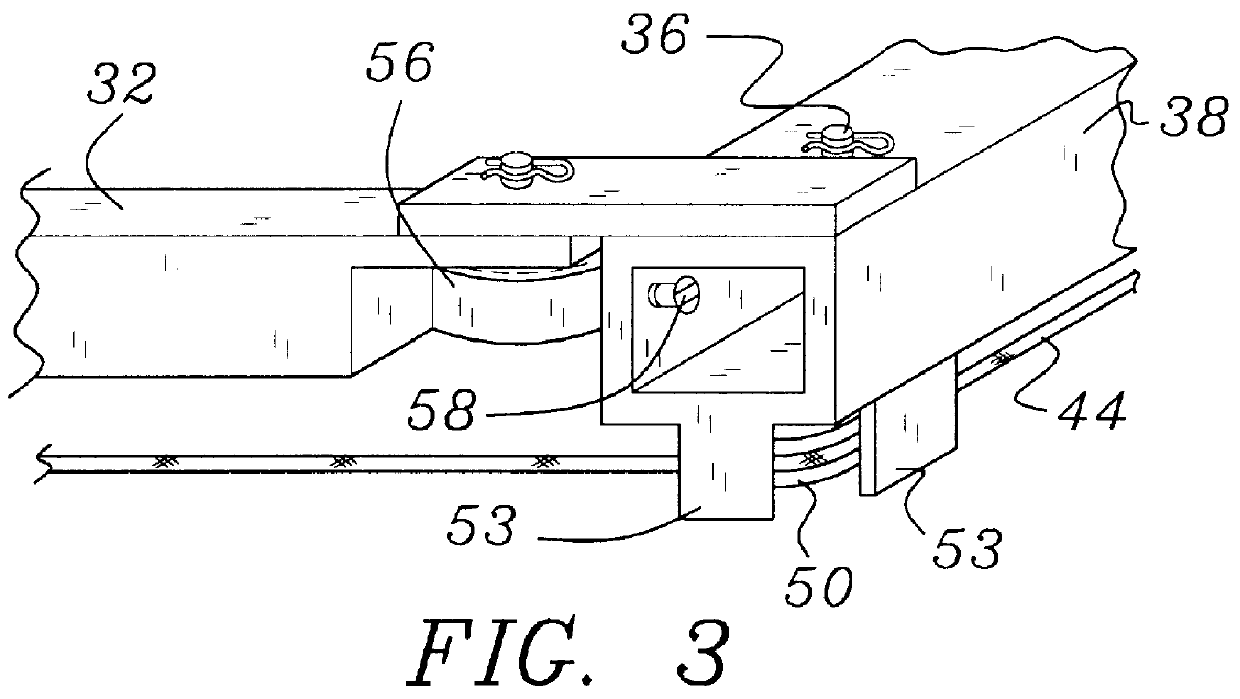

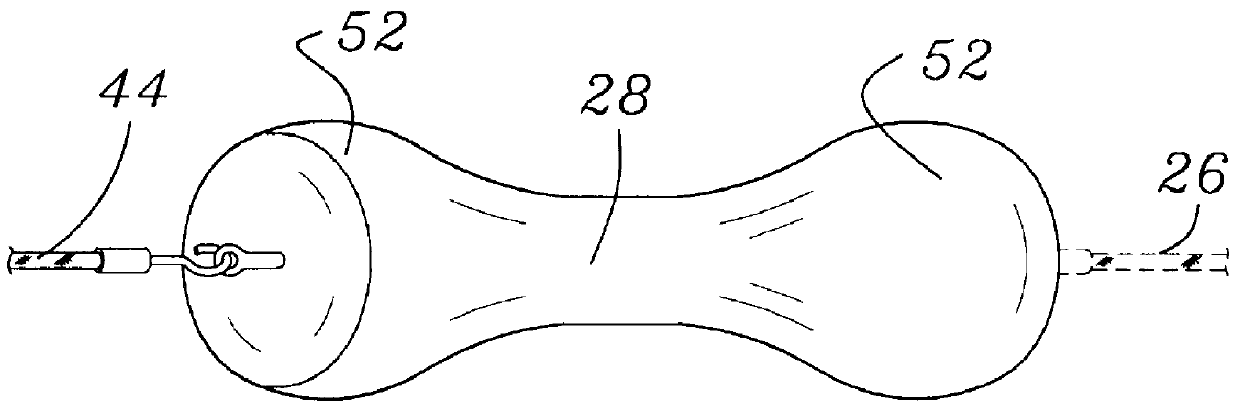

Apparatus that can be added to an existing ski treadmill provides resistance to a forward, as well as a rearward motion of an exerciser's arm. The apparatus includes a transverse beam attached to a body supporting post that is part of the treadmill. Longitudinal arms are hinged to the ends of this beam and swing away from their normal operating positions to allow an exerciser to mount or dismount from the apparatus. A closed rope loop having an indented portion is formed by connecting the two handgrips of a conventional ski treadmill with another piece of rope that engages, in sequence, a first pulley at the rear end of a first of the longitudinal arms, a second pulley near a hinge connecting that arm to the transverse beam, a third pulley at the other end of the beam, and a fourth pulley at the rear end of the second longitudinal arm.

Owner:NORTON DAVID A

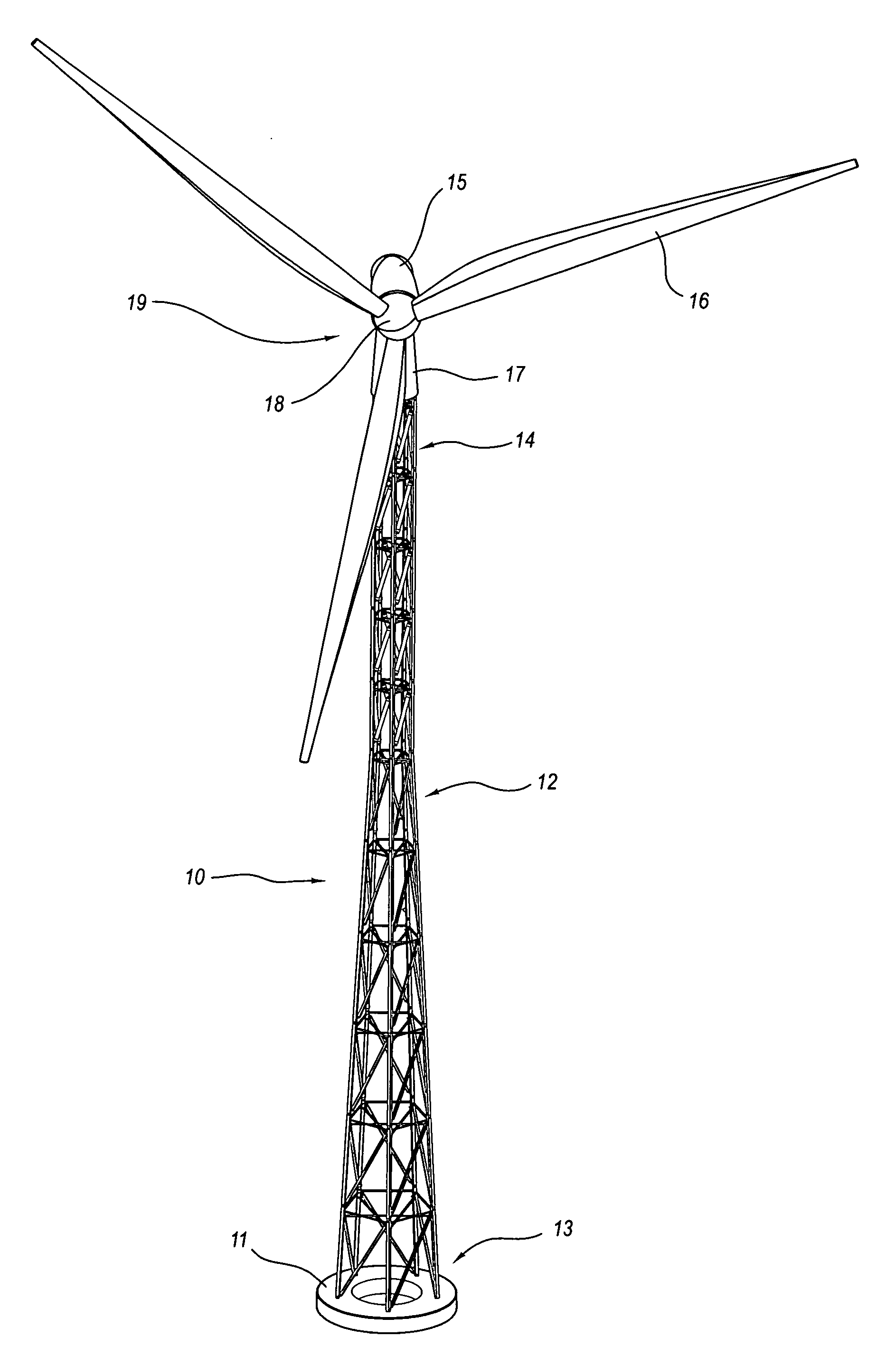

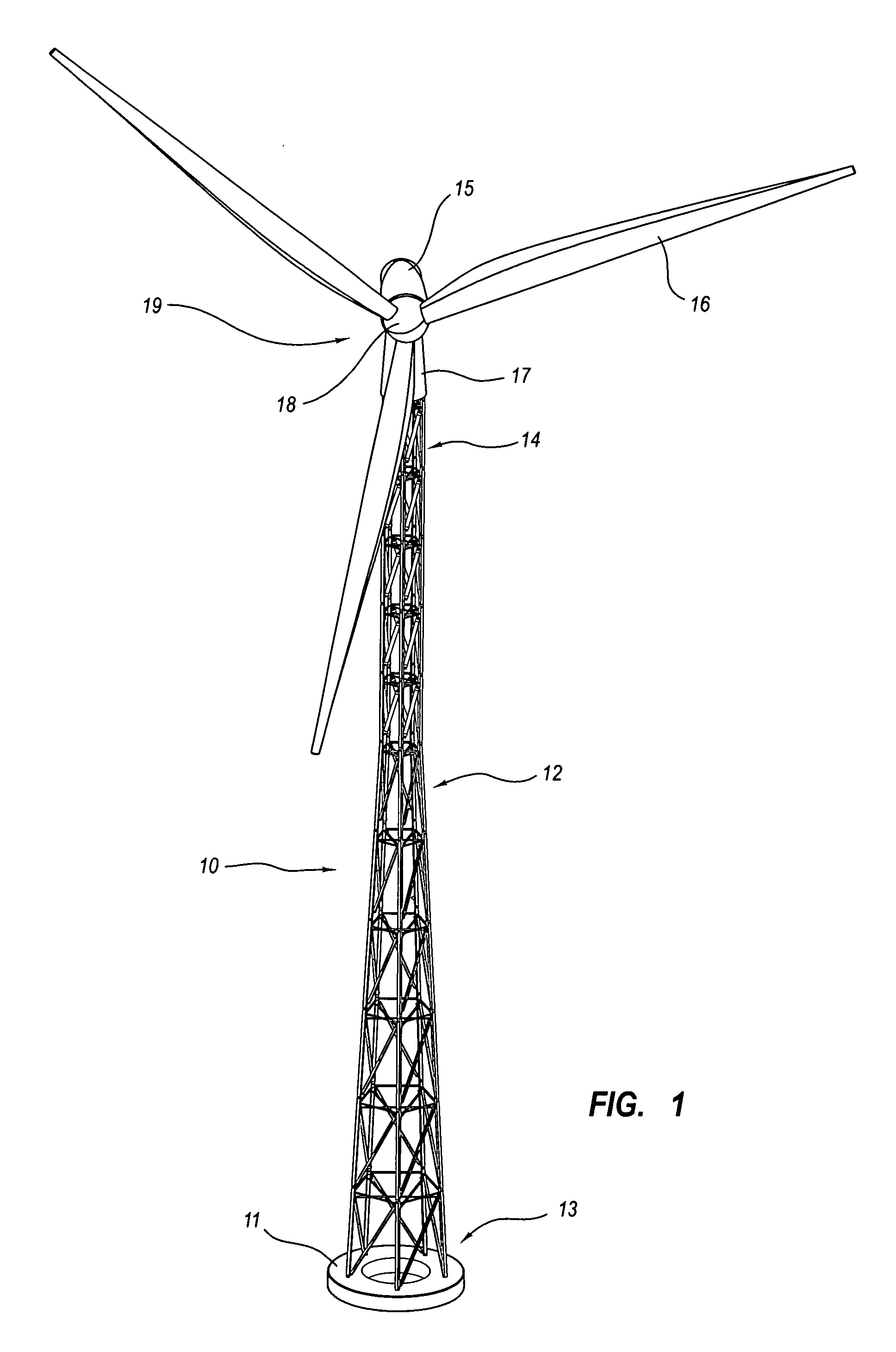

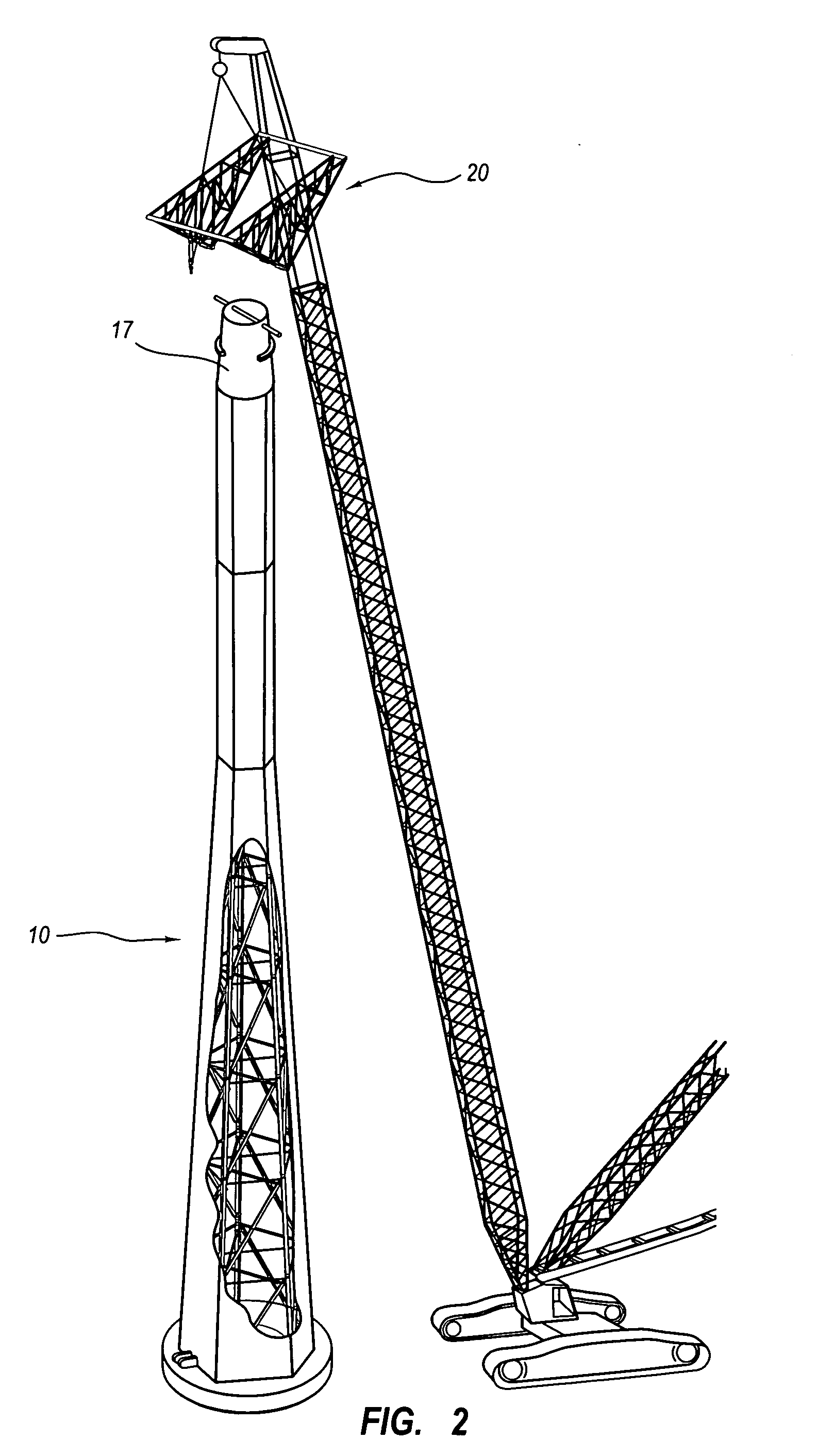

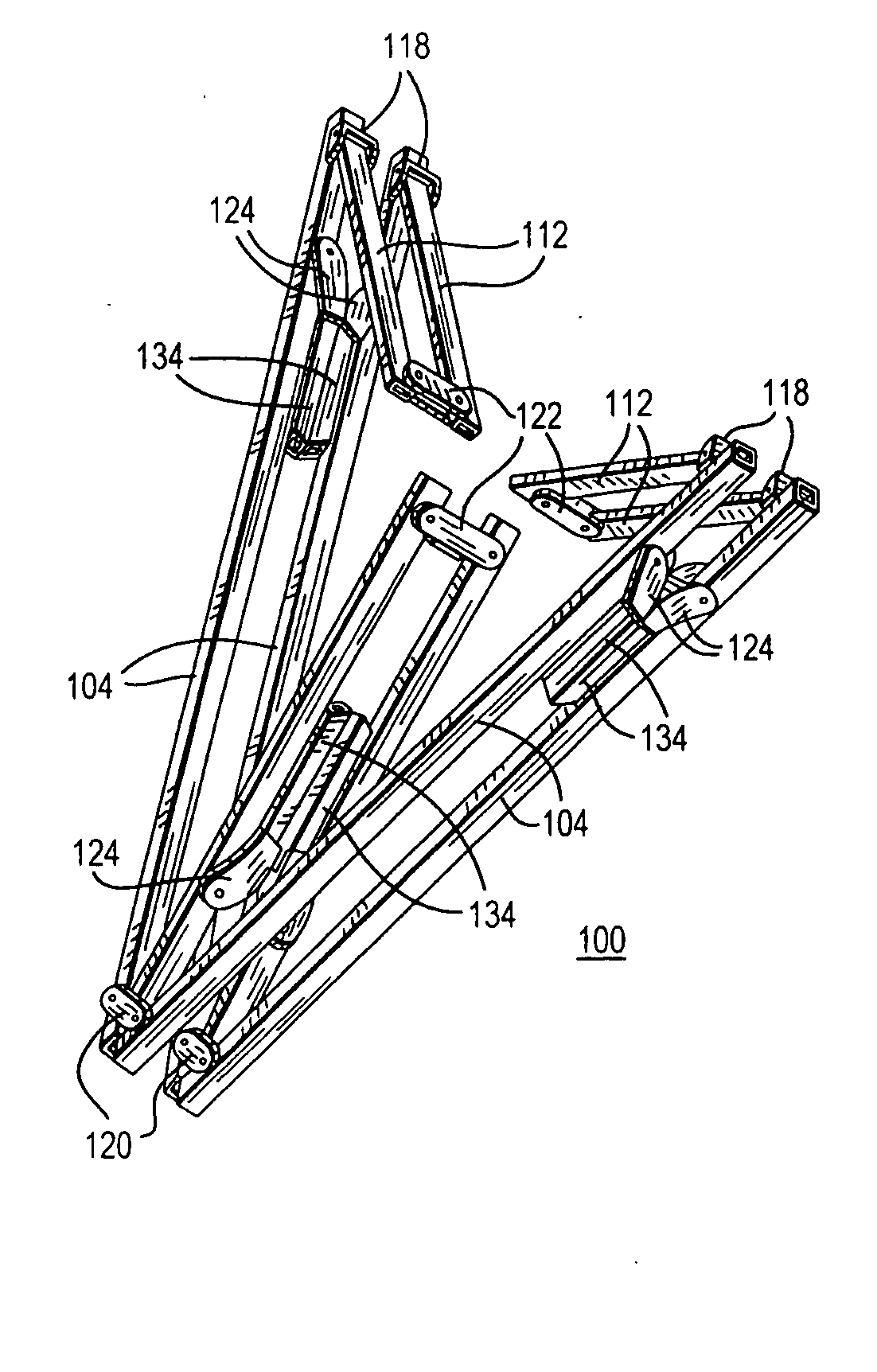

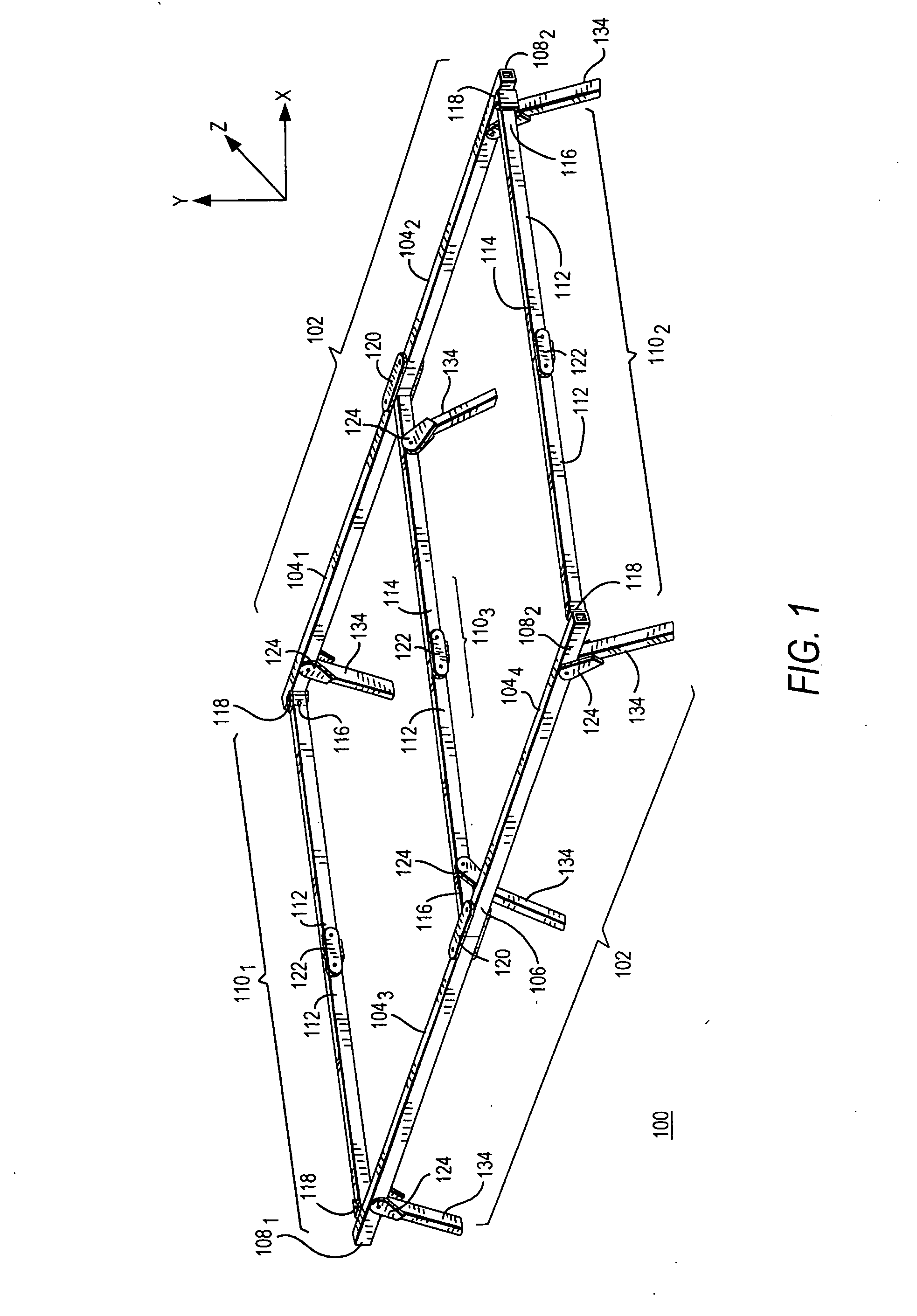

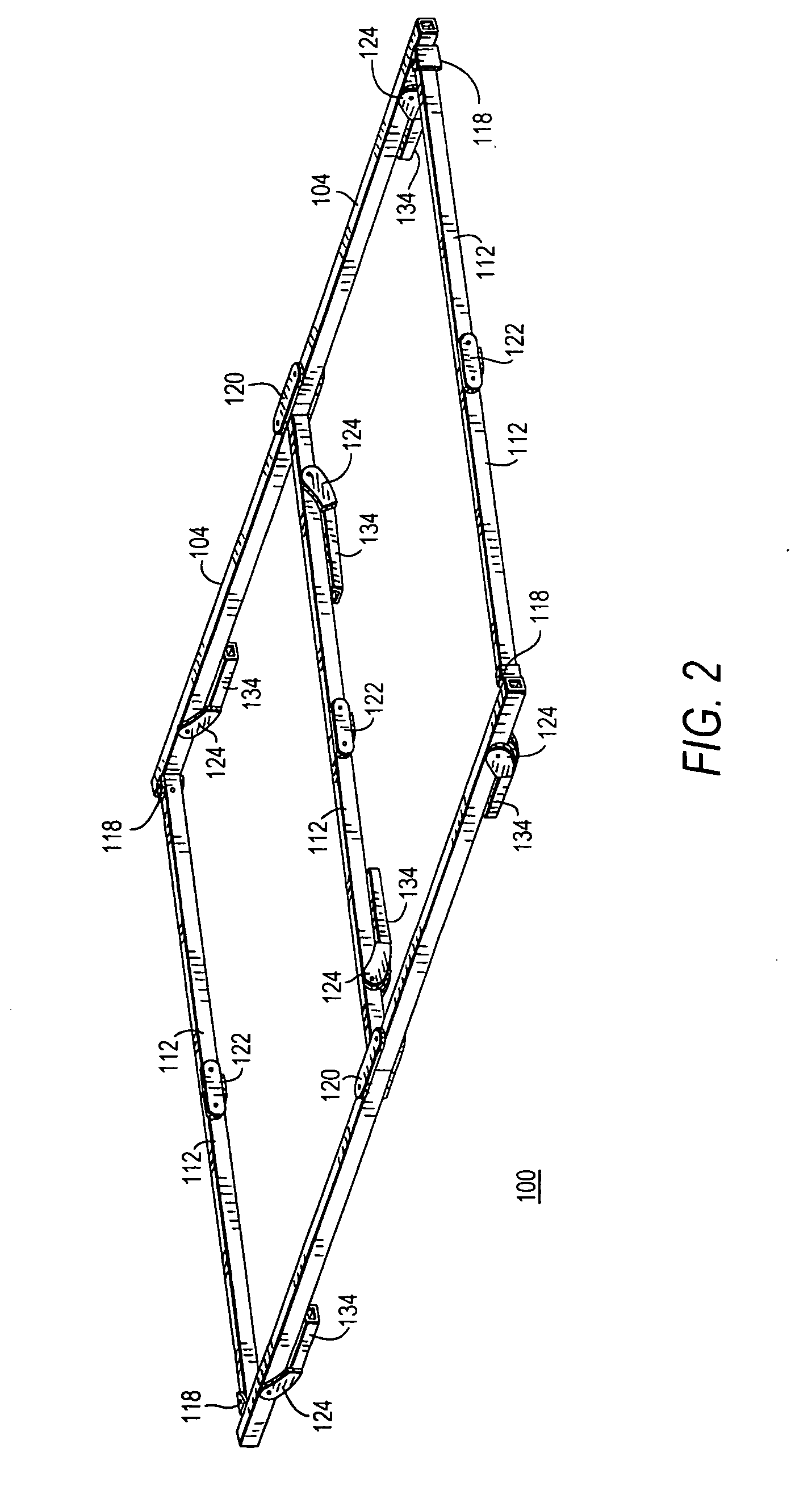

Lifting system and apparatus for constructing wind turbine towers

The disclosed invention is utilized for mounting a wind turbine and blade upper end of a wind turbine tower. The invention generally includes a frame or tally secured to the top bay assembly of the tower. A transverse beam is e frame or truss and extends fore of the tower when the frame or truss is in a first erally above the tower when in a second position. When in the first position, a blade assembly can be hoisted to the top of the tower. The wind turbine or blade n moved into position for mounting to the tower as the frame or truss is pivoted to n. When the turbine and blade assembly are secured to the tower, the frame or ected from the tower and lowered to the ground.

Owner:GE WIND ENERGY

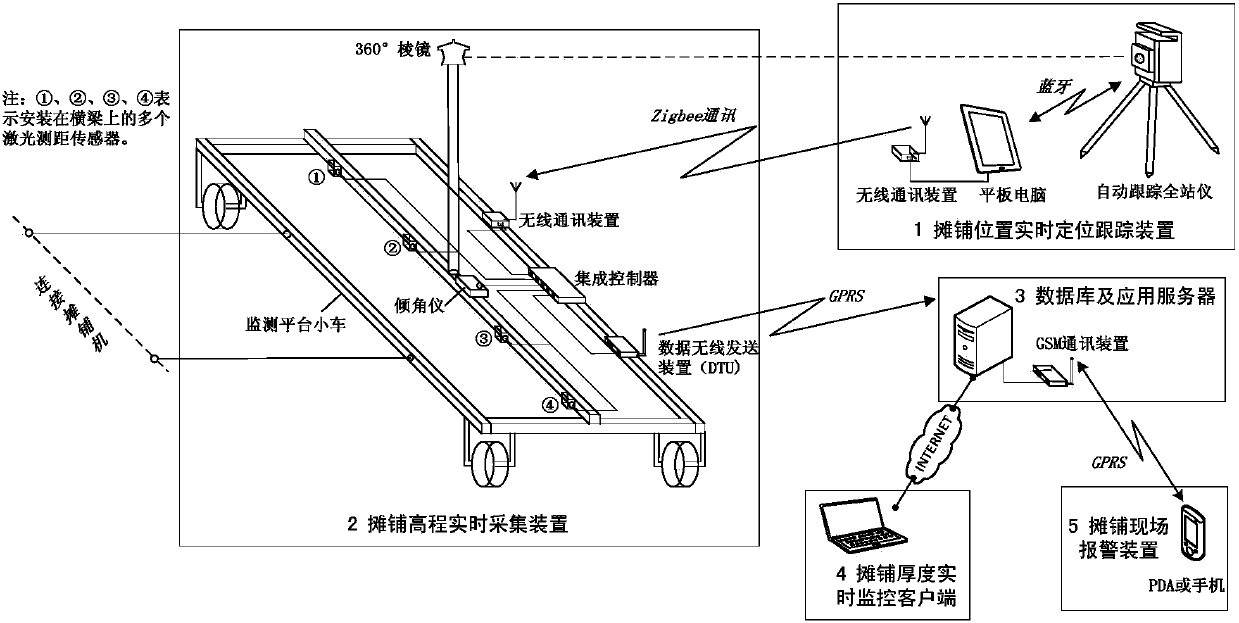

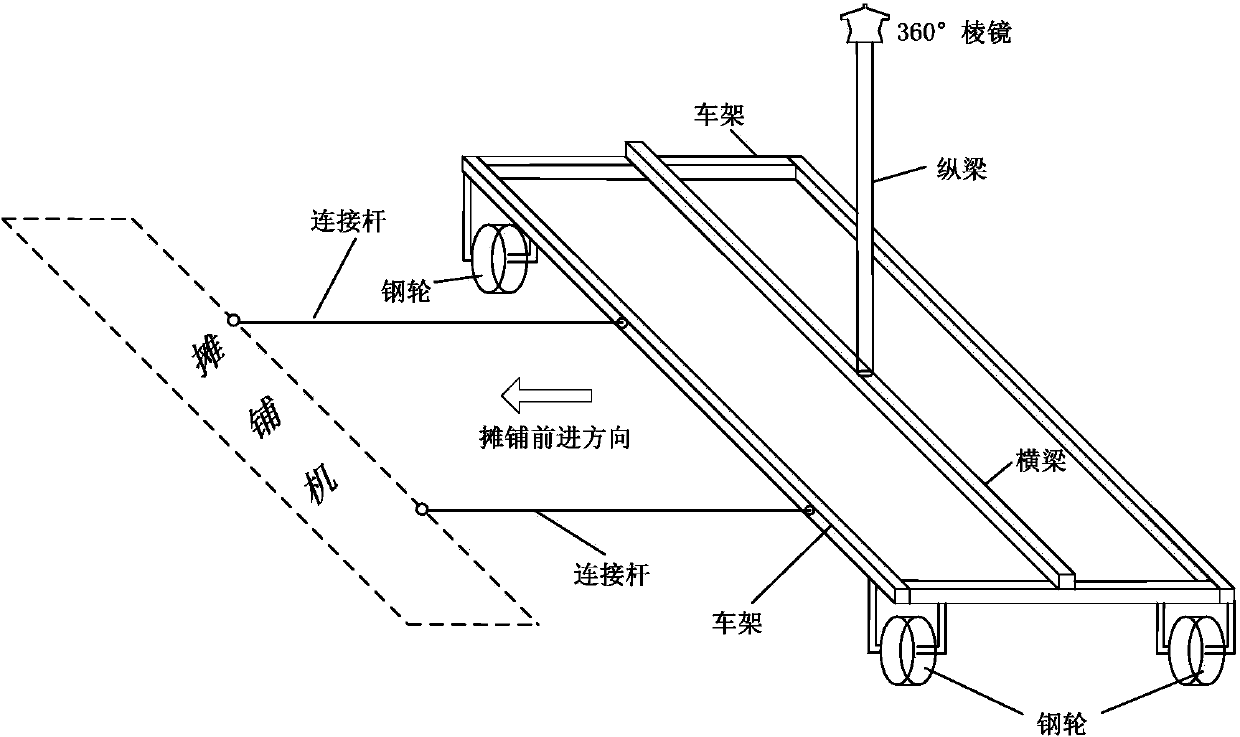

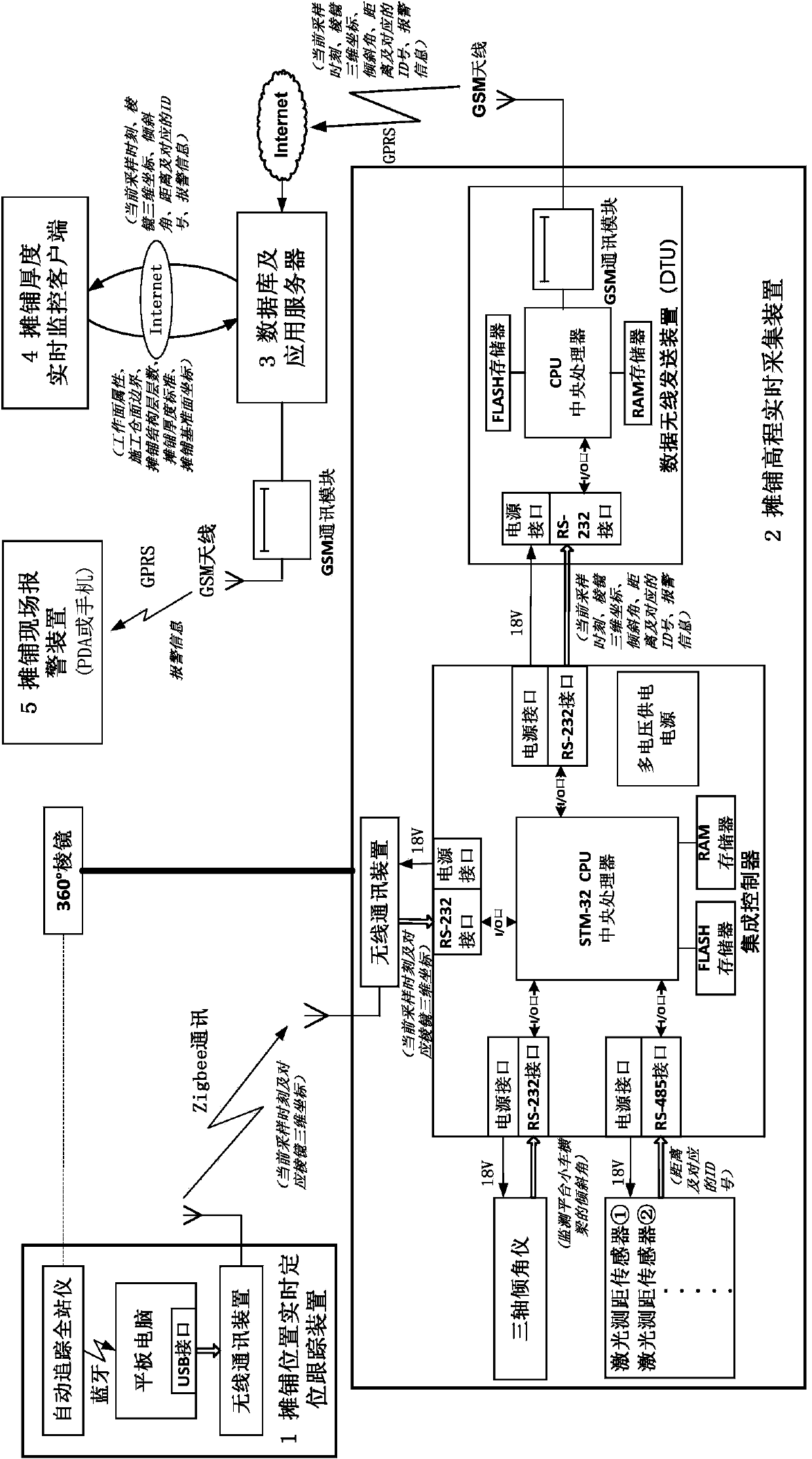

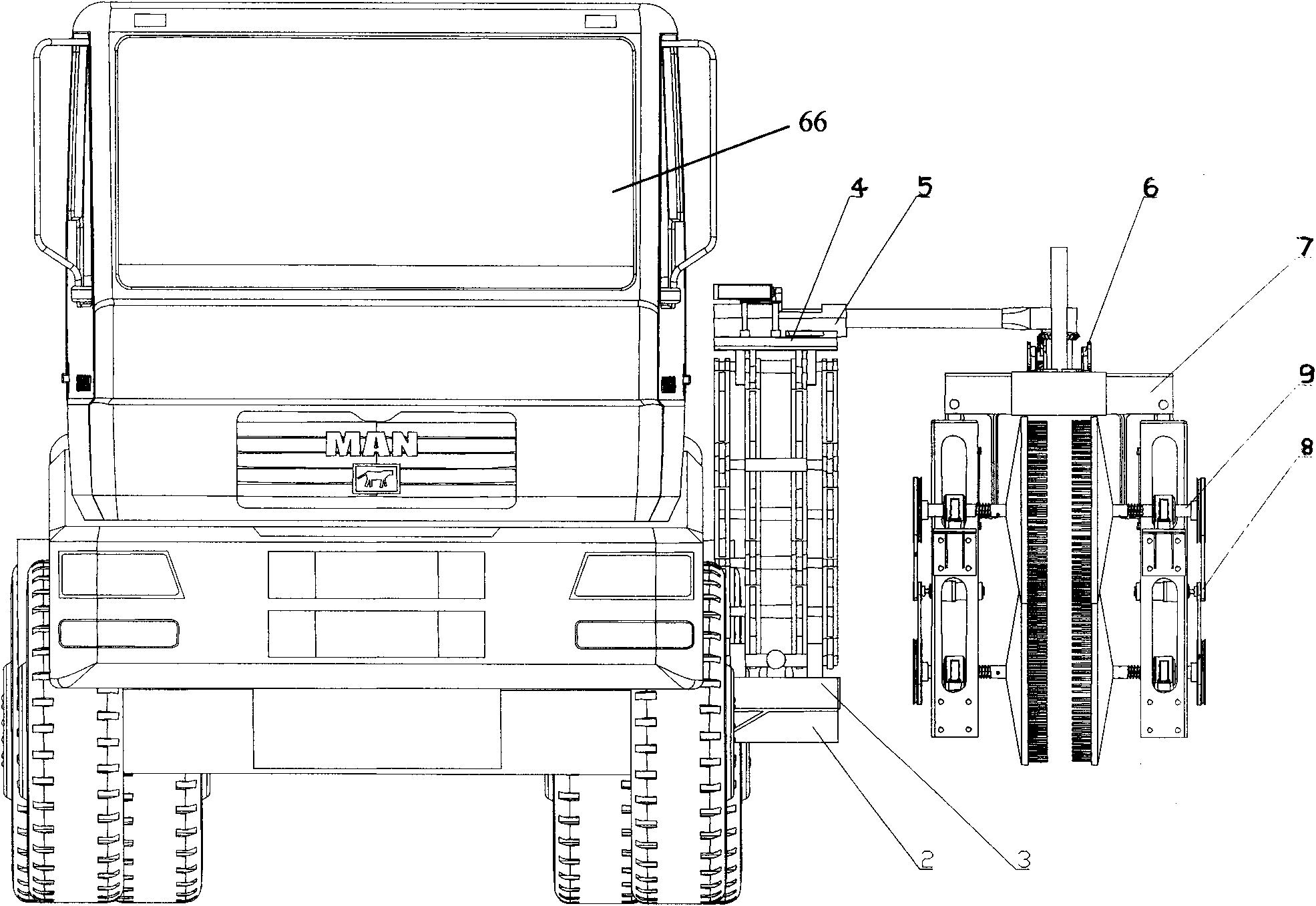

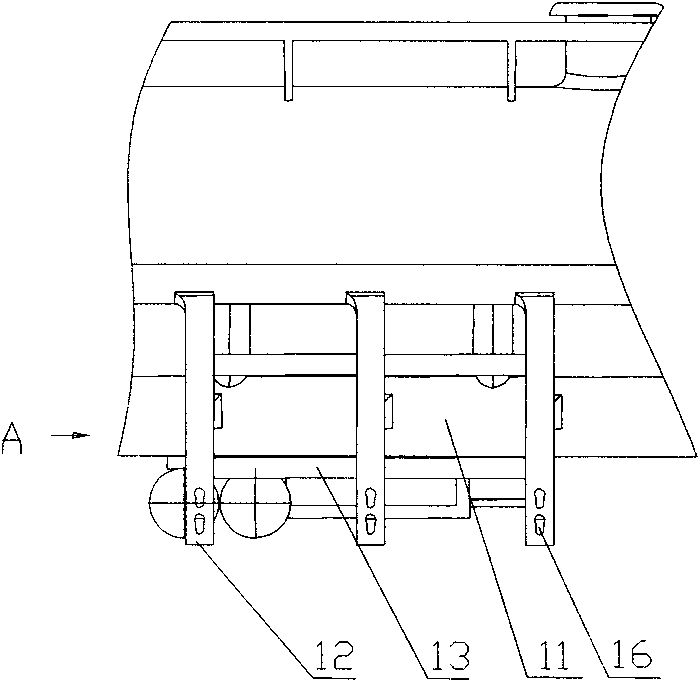

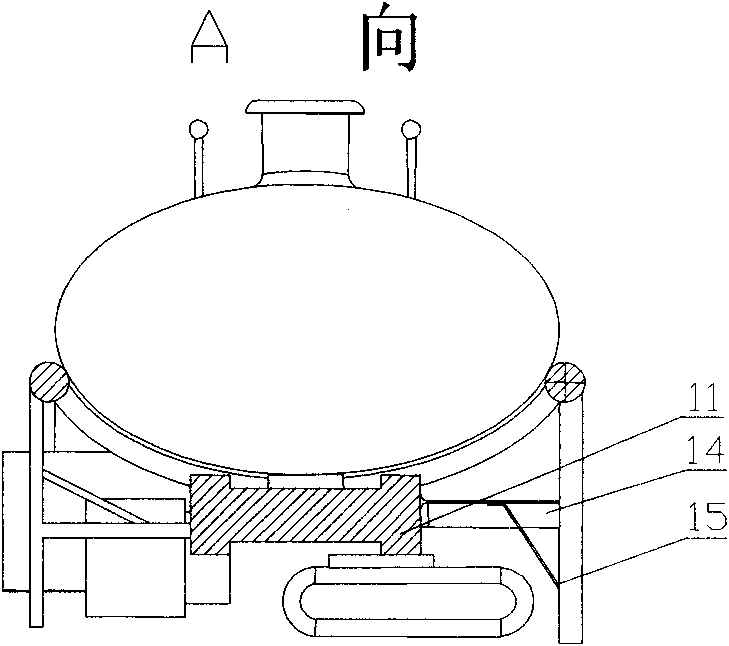

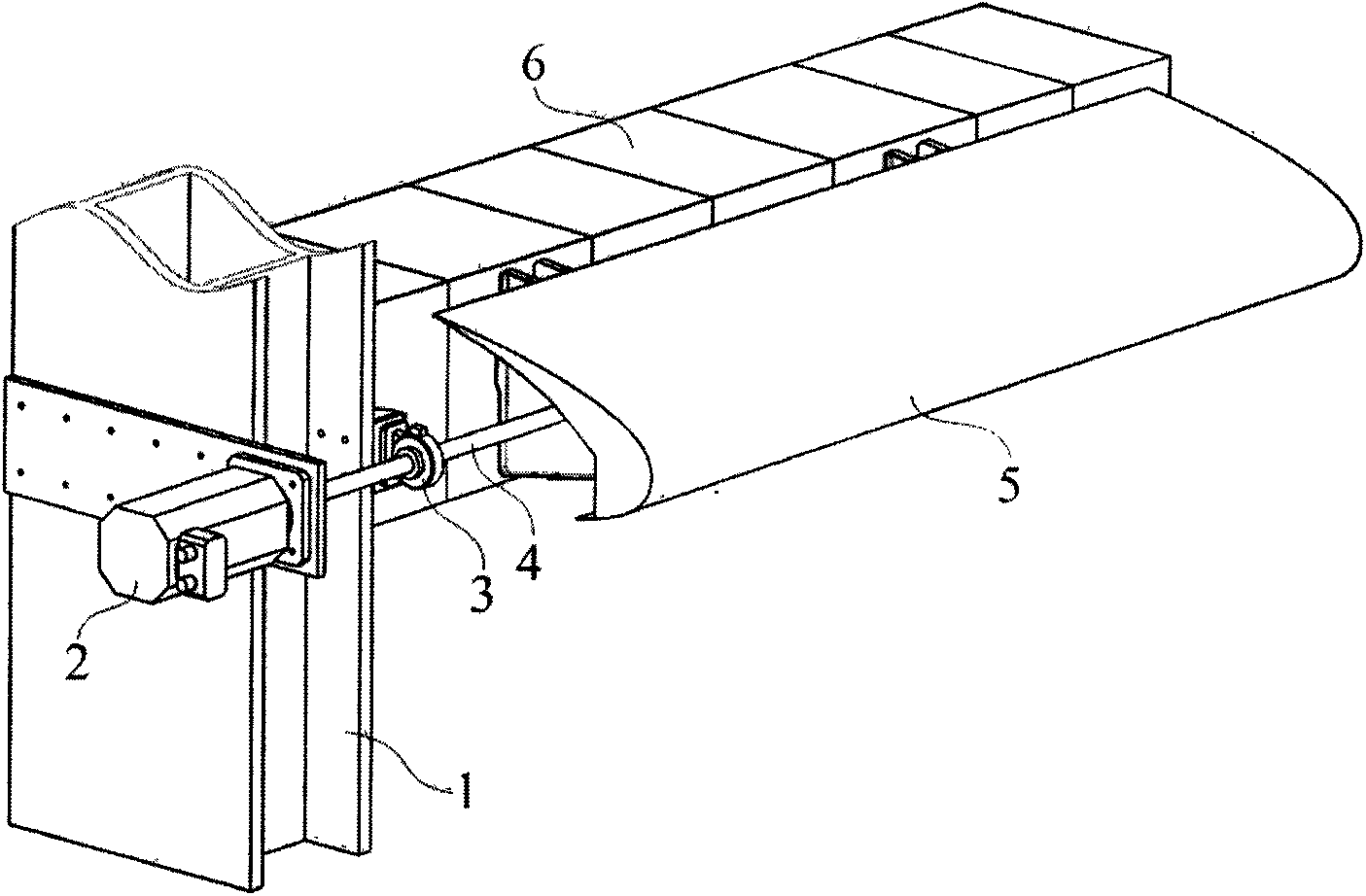

Method and system for monitoring paving thickness of high-level highway pavement in real time

ActiveCN103866673ARealize full-section acquisitionReduce one-sidednessUsing optical meansRoads maintainenceLaser rangingGeomorphology

The invention discloses a method and a system for monitoring paving thickness of a high-level highway pavement in real time, belonging to the field of road construction quality control. The method comprises the following steps: erecting an automatic tracking total station nearby a paving site, determining the position of an erection point through a resection survey method according to the known point coordinate, positioning and tracking a 360-degree prism according to enough short time interval by utilizing the automatic tracking total station, measuring the inclination angles of a transverse beam and a longitudinal beam of a platform trolley in the device by adopting an inclinometer, and measuring the distance from the transverse beam to the paved pavement by adopting a laser distance measuring sensor arranged on the transverse beam; calculating three-dimensional coordinates (x, y, z) of the position points of the paved pavement measured by each laser distance measuring sensor according to a spatial geometrical relation between each laser distance measuring sensor and the prism; projecting to obtain elevation z0 of the position point on a datum plane before paving; solving the difference between elevations z and elevation z0 to obtain the paving thickness; and judging whether the paving thickness at the position point accords with the control standard, otherwise, transmitting alarm information. The method is mainly applied to road construction quality control.

Owner:TIANJIN UNIV

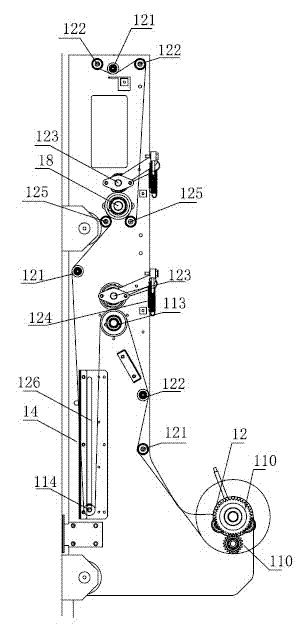

Road guardrail cleaning machine

InactiveCN101831884AEliminate the cumbersome labor of manual cleaningRelieve complicated laborRoad cleaningRoad surfaceEngineering

The invention provides a road guardrail cleaning machine, comprising a locomotive and a cleaning device installed at the side of the locomotive. The locomotive is provided with a power source; and the cleaning device at least comprises a lifting mechanism, a rotating mechanism, a telescopic mechanism, a turnover mechanism, a gantry clamping mechanism, a self-adapting mechanism and a cleaning mechanism. The power source is connected with the lifting mechanism by a transmission mechanism; the rotating mechanism is fixedly installed on the lifting mechanism; a sleeve seat is installed on a rotating platform of the rotating mechanism; one end of the front arm of the telescopic mechanism is sleeved in the sleeve seat while the other end is fixedly connected with the turnover mechanism; the turnover mechanism is connected with a transverse beam of the gantry clamping mechanism; two ends of the transverse beam of the gantry clamping mechanism are respectively connected with side arms which are respectively provided with the self-adapting mechanisms; and the self-adapting mechanisms are connected with a cleaning brush of the cleaning mechanism. In the cleaning course, the height of the cleaning brush can be adjusted to improve the cleaning efficiency and ensure the cleaning quality. After the cleaning is finished, the cleaning mechanism is folded and fixed at the top of the water tank of the locomotive, and the cleaning vehicle can run on the road safely.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

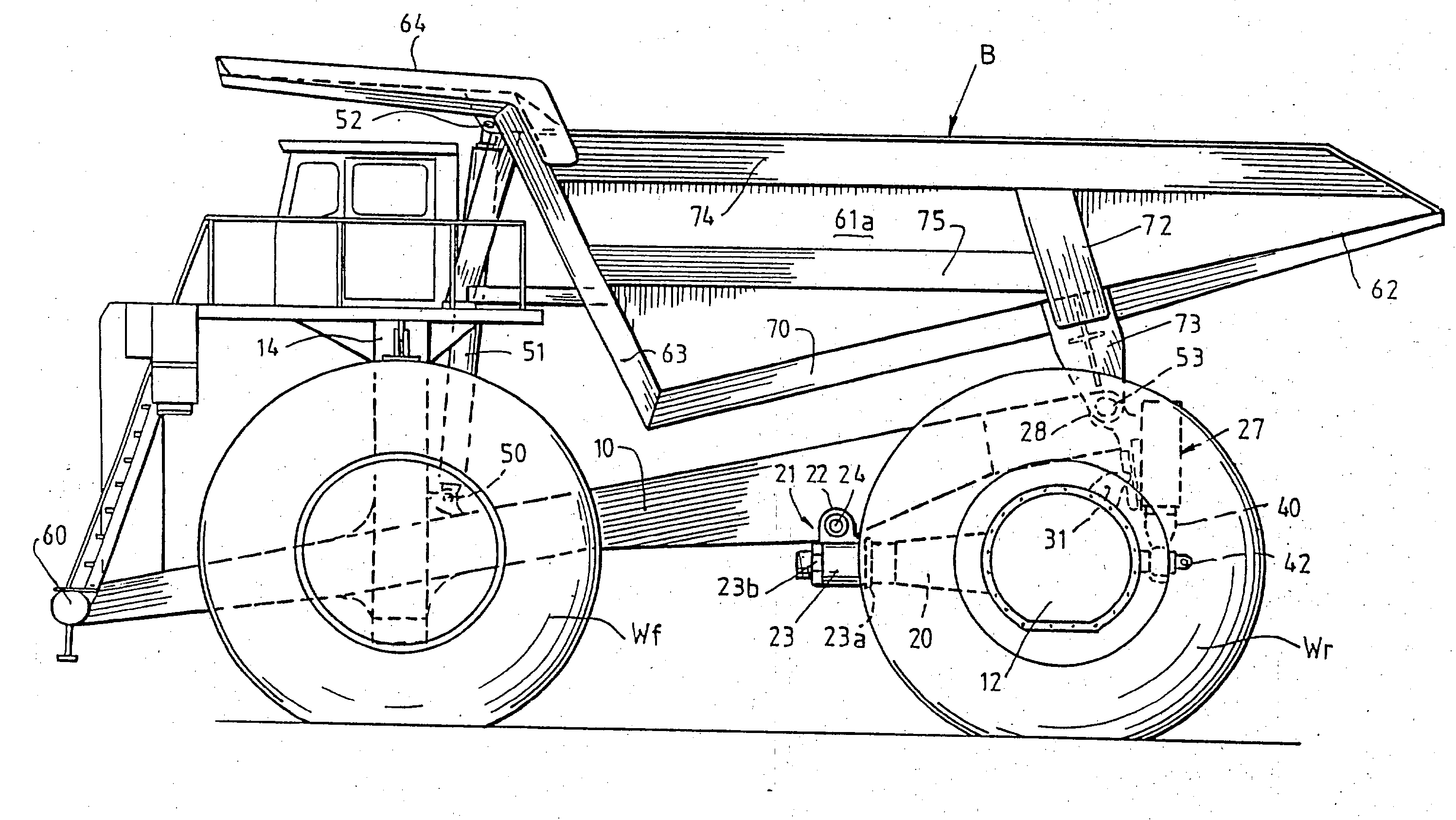

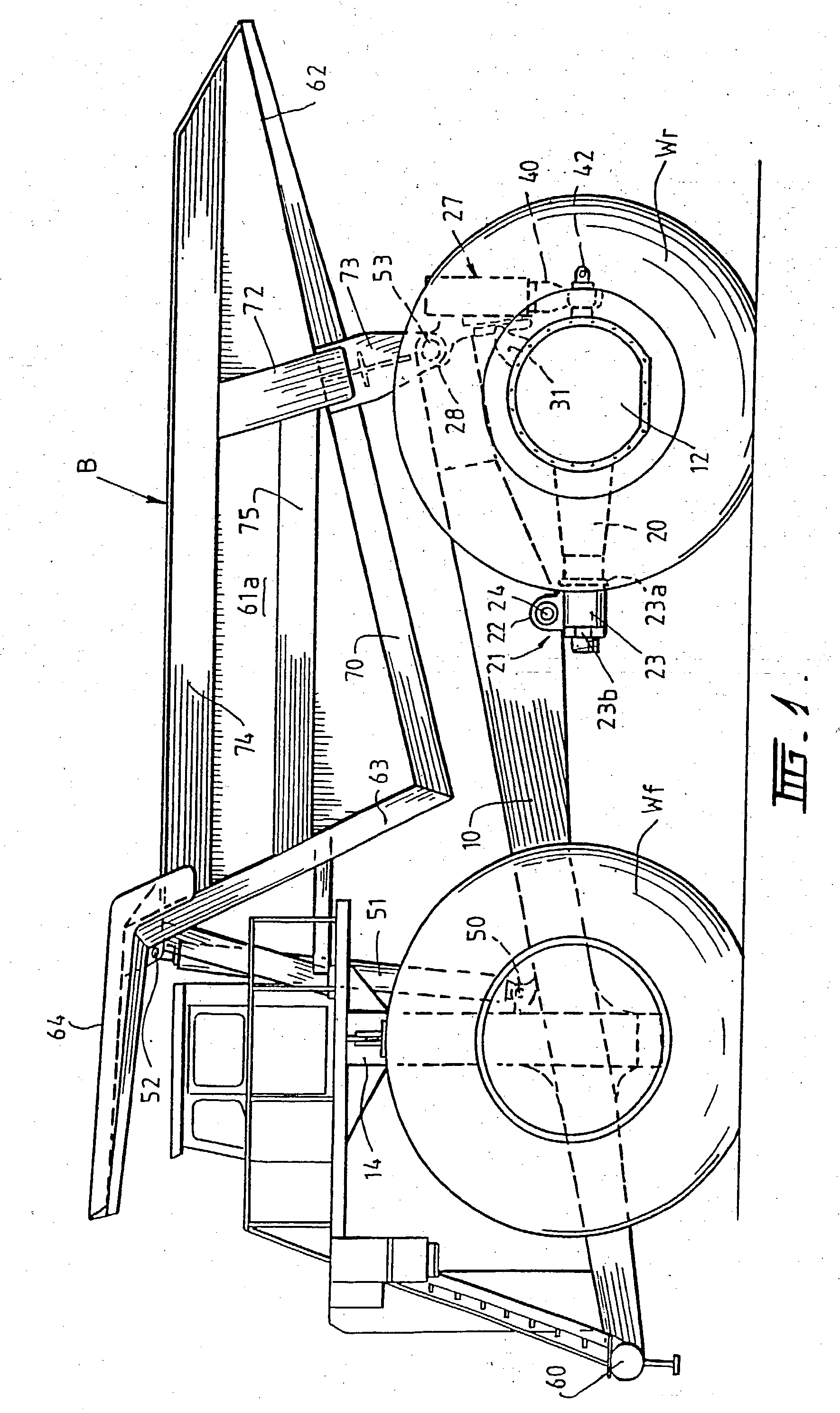

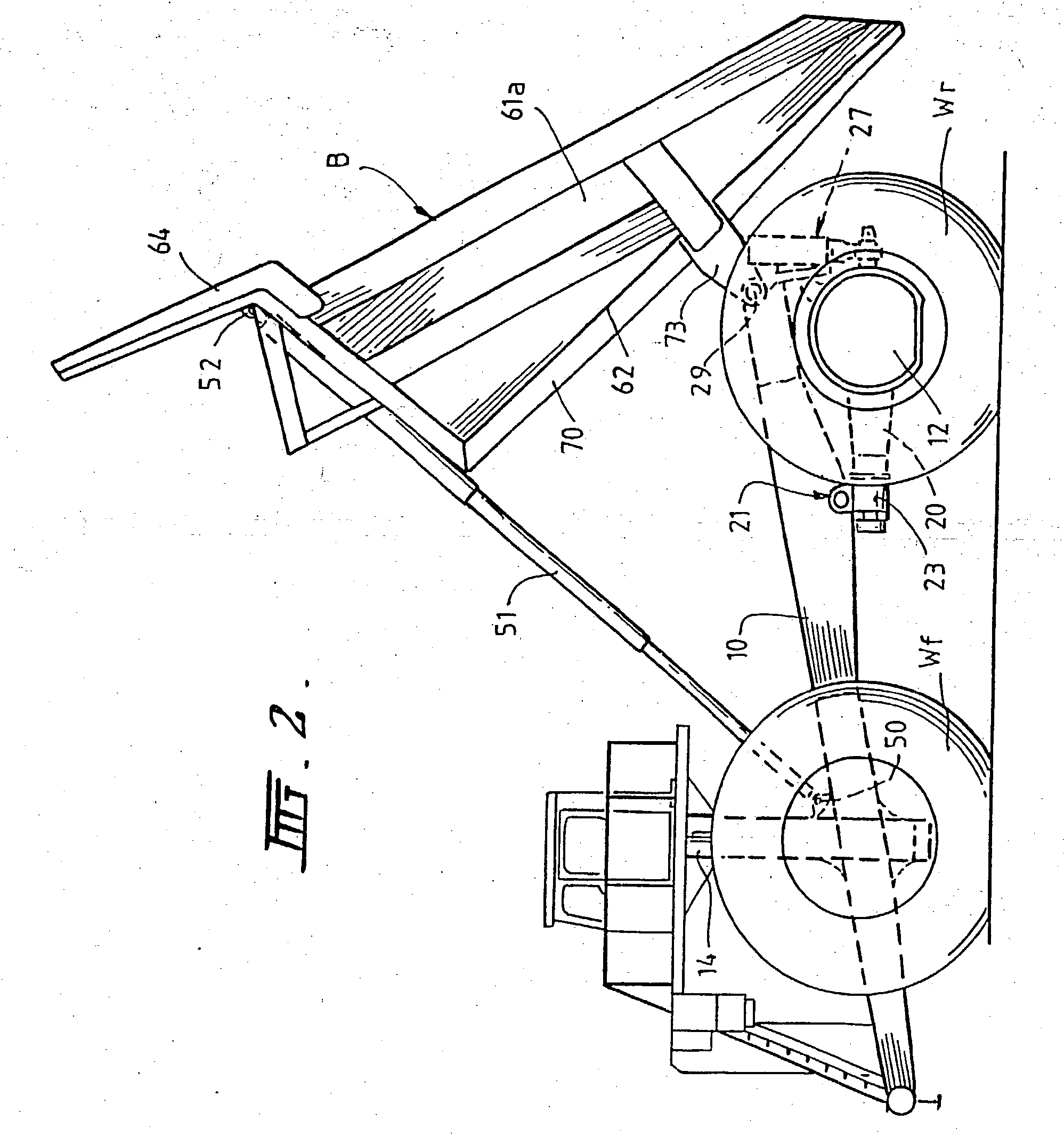

Suspension system and body for large dump trucks

InactiveUS20040036245A1Easy dischargeWear minimizationElectric propulsion mountingInterconnection systemsTransverse axisVehicle frame

A suspension system for the main frame of a large dump truck having laterally spaced frame members (10) each associated with a wheel mounting hub (12) the system comprising, for each hub (12), a hollow forward attachment arm (20) supported by a bearing block (21) having a longitudinal journal (23) and a transverse journal (22), the longitudinal journal (23) receiving the attachment arm (20) and the transverse journal (22) receiving the ends of a shaft rigidly secured to the frame members (10) and extending therebetween to define a cross member and a vertically compliant suspension strut comprising a cylinder (41) rigidly attached to a support (28) secured to the frame member (10) and receiving a piston (40) attached to a rear extension (42) from the hub (12) via a bearing which allows each hub (12) to rotate about longitudinal and transverse axes relative to the respective frame member (10). Also disclosed is dump truck body (B) having side walls (61), a floor (62) and an end wall (63), the floor (62) being reinforced by longitudinal reinforcing beams and by only one transverse beam (72). The side walls (61) slope inwardly, the floor (62) slopes downwardly and forwardly and the width of the floor (62) increases towards the rear of the body (B).

Owner:LIEBHERR WERK BIBERACH

Welding tool for front collision transverse beam of automobile

InactiveCN103008953AEasy to weld productionEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTransverse beam

The invention discloses a welding tool for a front collision transverse beam of an automobile. The welding tool comprises a base, wherein the base is provided with two clamping devices I which correspond to front collision box welding assemblies one by one, clamping devices II which correspond to side locking plates one by one, and clamping devices III for clamping and positioning lug plates. Through the clamping devices I which are arranged corresponding to the front collision box welding assemblies one by one, the front collision box welding assemblies can be compressed and fixed at the two ends of an outer plate, and the front collision box welding assemblies are convenient to weld and fix on the outer plate; through the clamping devices II which are arranged corresponding to the side locking plates one by one, the side locking plates can be compressed and fixed on the outer plate, and are convenient to weld and fix on the outer plate; due to the arrangement of positioning rods I, the clamping position accuracy of the outer plate and an inner plate can be ensured; and through the clamping devices III which are arranged corresponding to the lug plates, the lug plates can be clamped and positioned at design positions, and are convenient to weld and fix on the inner plate.

Owner:CHONGQING DADONG AUTO PARTS

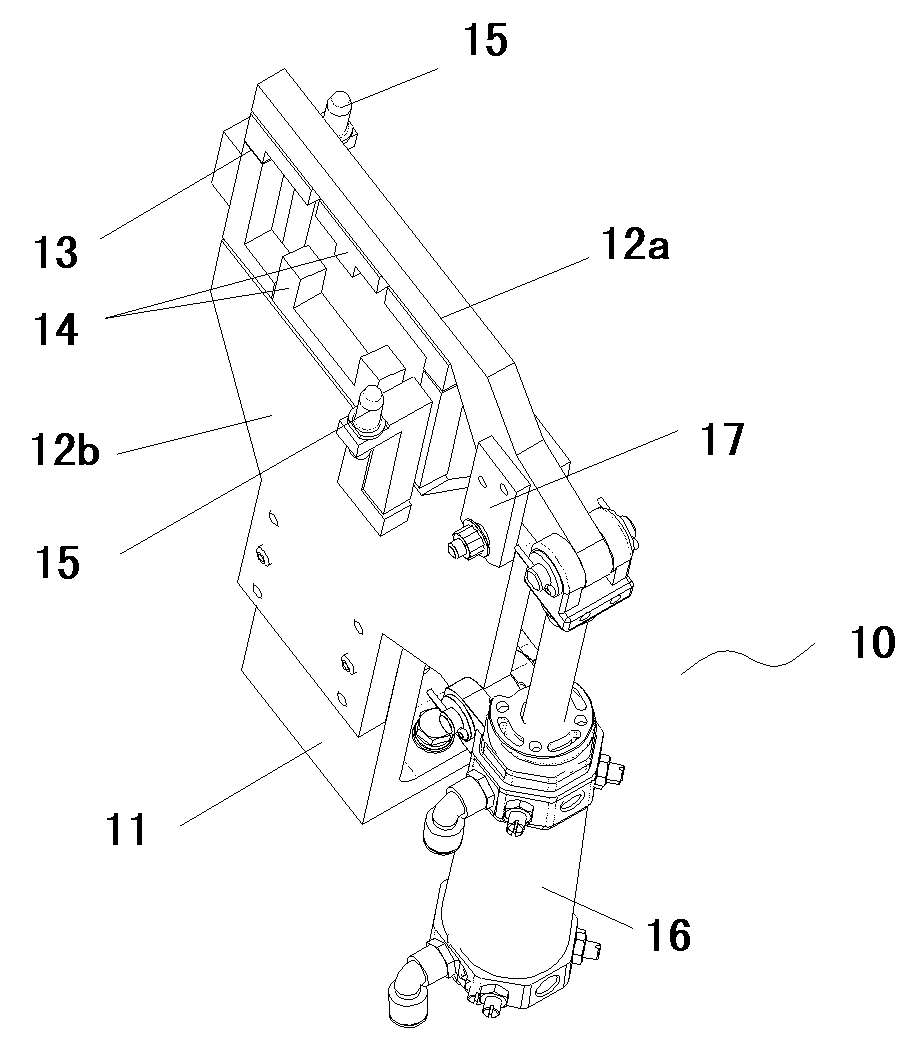

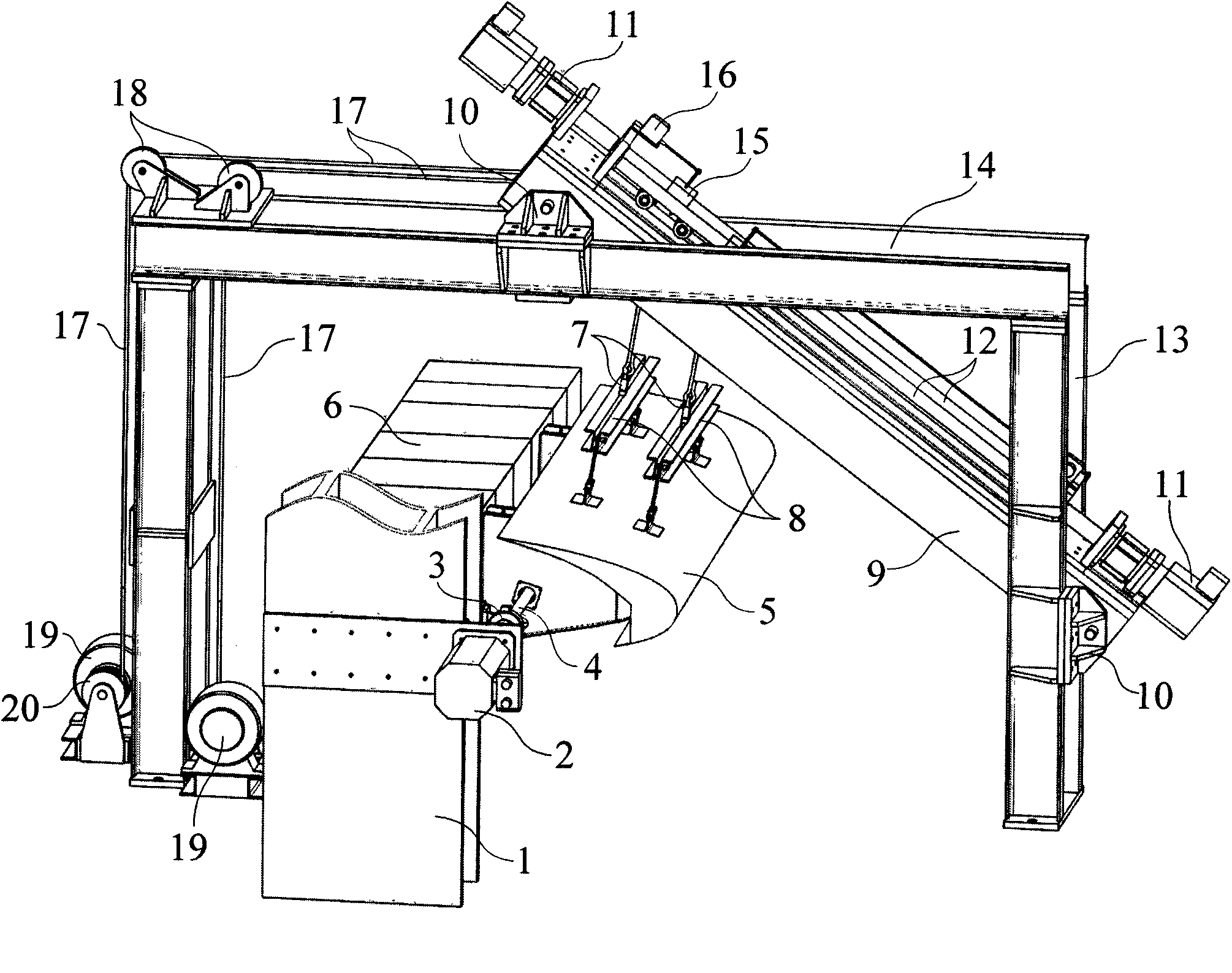

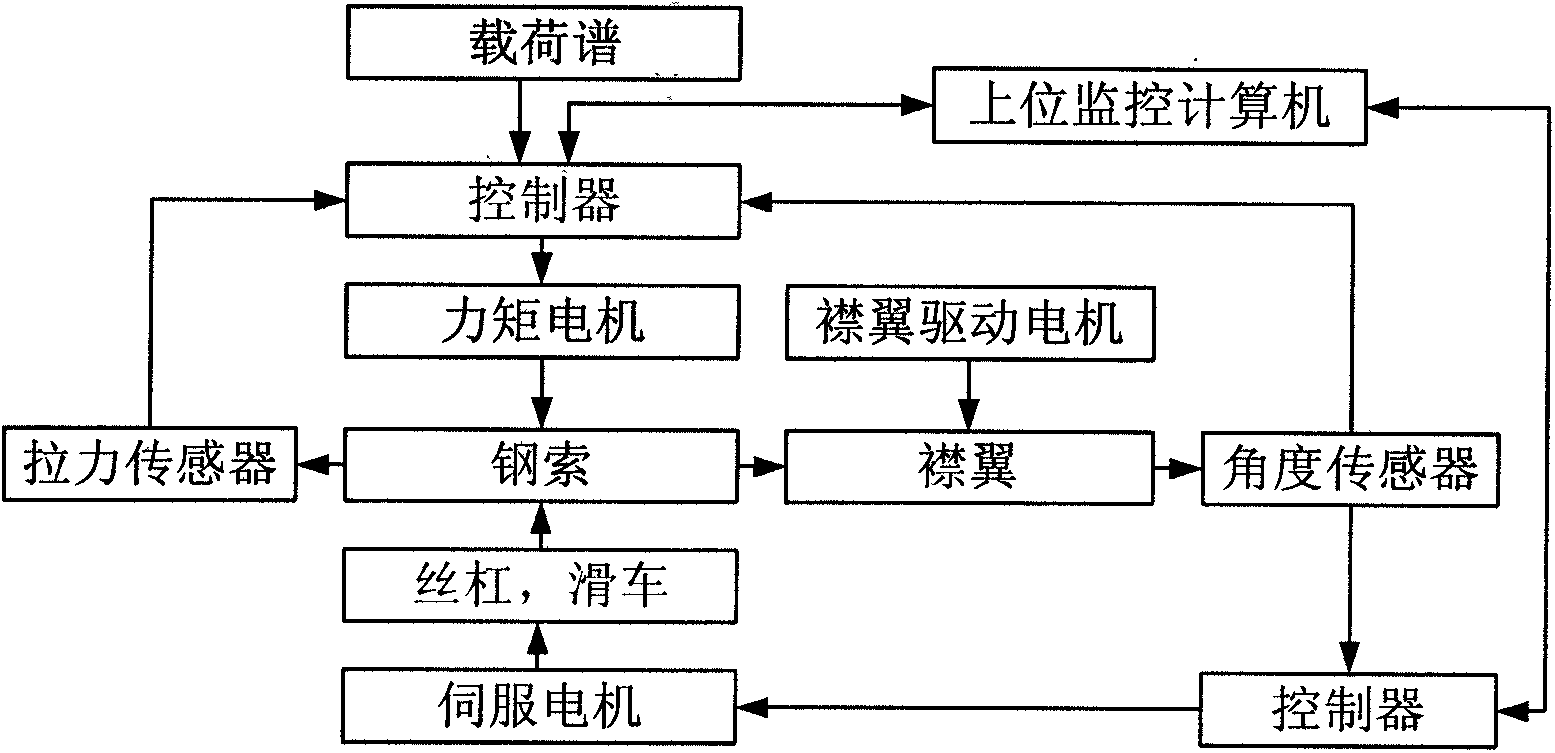

Load follow-up loading system for plane flap reliability test

ActiveCN104048874ARealize closed-loop controlReduce distanceMachine part testingStrength propertiesEngineeringAirplane

The invention relates to a load follow-up loading system for plane flap reliability tests. The system comprises a bearing wall. The system is characterized by further comprising a support component, a load loading adjusting unit and a load detection and adjusting unit, wherein a flap is mounted on a wing; the root of the wing is mounted on the bearing wall; the support component comprises two vertical columns and a transverse beam for supporting the load loading adjusting unit and the load detection and adjusting unit; the load loading unit comprises a moment motor and a steel rope; the moment motor is arranged on the support component and is used for exerting an action force on the flap; the steel rope is connected with the moment motor; the load detection and adjusting unit comprises an angle sensor, a sliding track component and a pulley component. A plurality of loading points are arranged on the surface of the flap, one loading point corresponds to one set of loading system, the size, the direction and an equivalent action point of real-time flap surface aerodynamic force can be simulated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

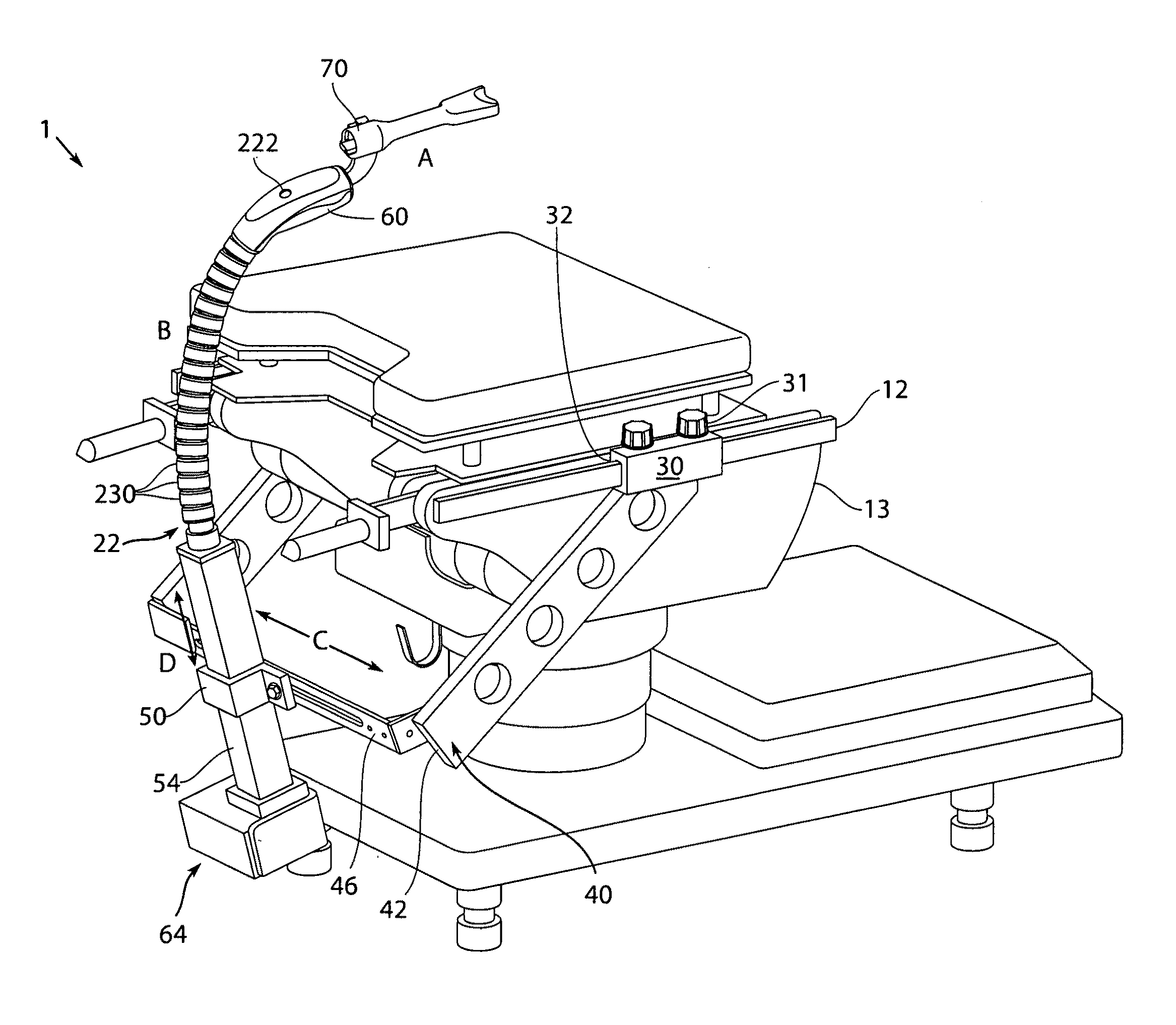

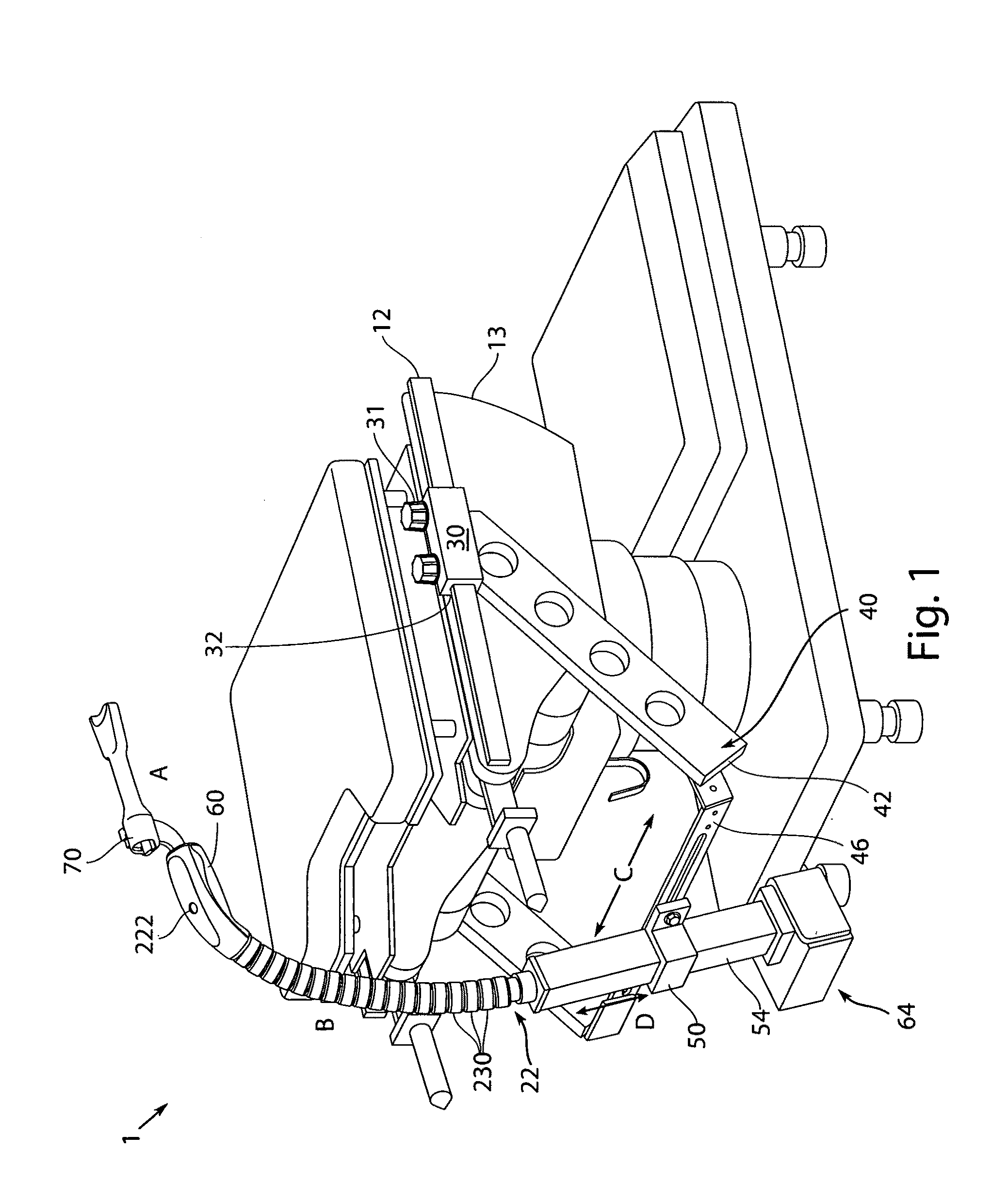

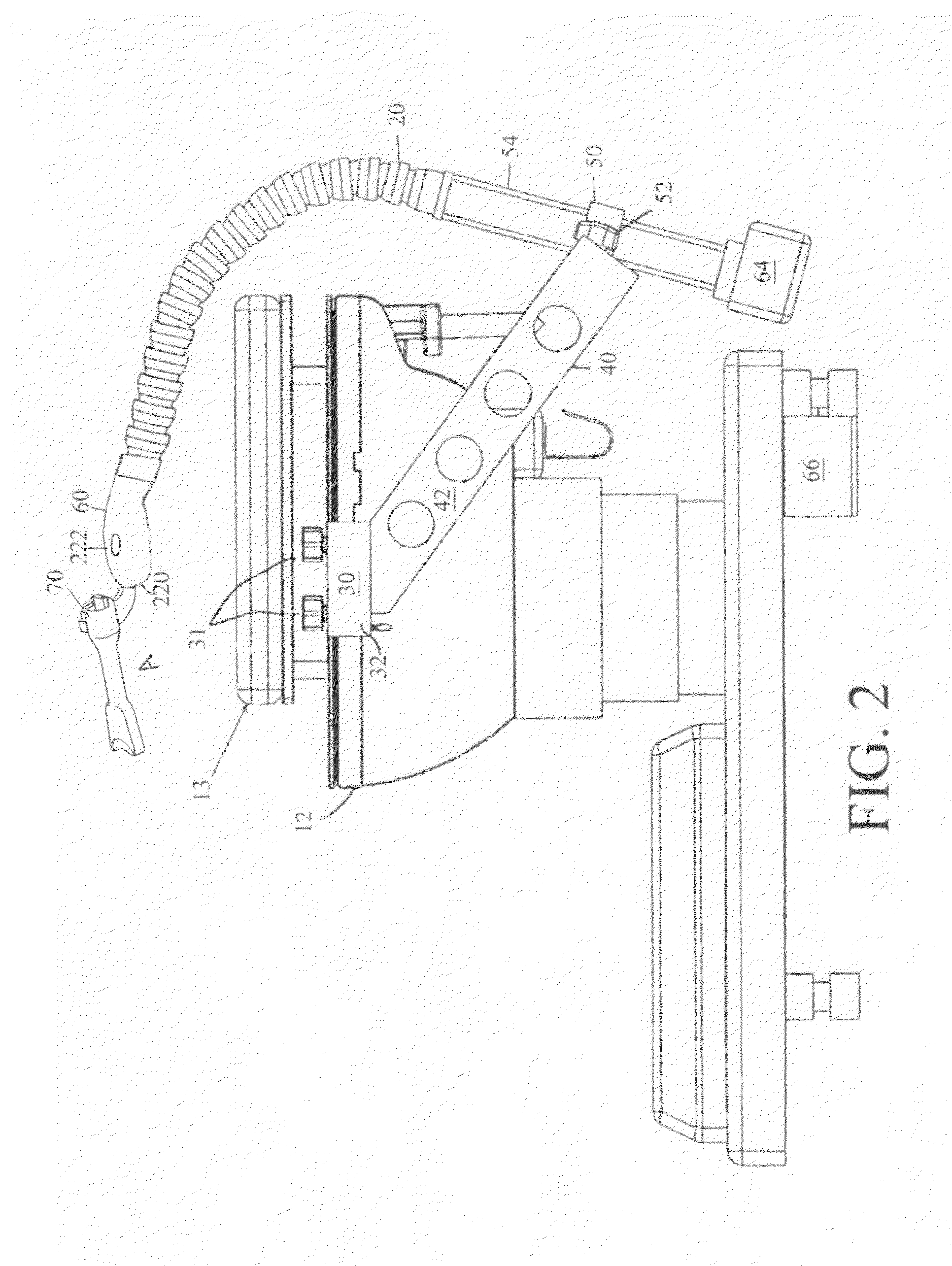

Table-mounted surgical instrument stabilizers with single-handed or voice activated maneuverability

InactiveUS20100152749A1Maintain tissue positioningThe process is convenient and fastDiagnosticsSurgical instrument supportSurgical operationEngineering

A surgical instrument stabilizer system for securely holding virtually any instrument during any procedure, delivering vacuum when applicable, and yet allowing easy single-handed or voice activated repositioning by a user. The system utilizes opposing horizontal side-rails mounted to opposing sides of a surgical table, and opposing arms each slidably mounted on a side rail for global lengthwise positioning along the side rails. The arms carry a transverse beam at the foot of the operating table, and a flexible arm is movably mounted on the beam for global lengthwise positioning along the beam. Alternately, the flexible arm may be affixed directly to one of the existing horizontal side rails. The flexible arm leads to an instrument-supporting hand piece pivotally mounted for angular orientation of an instrument supported thereby. The flexible arm can be freely articulated to any position and locked in place. Thus, a supported instrument can be repositioned quickly and easily by single-handed or voice activated manipulation by a surgeon or surgical assistant, and locked in any position up and down along a vertical axis, forward and back, i.e, toward or away from the patient, and rotationally.

Owner:COOPERSURGICAL INC

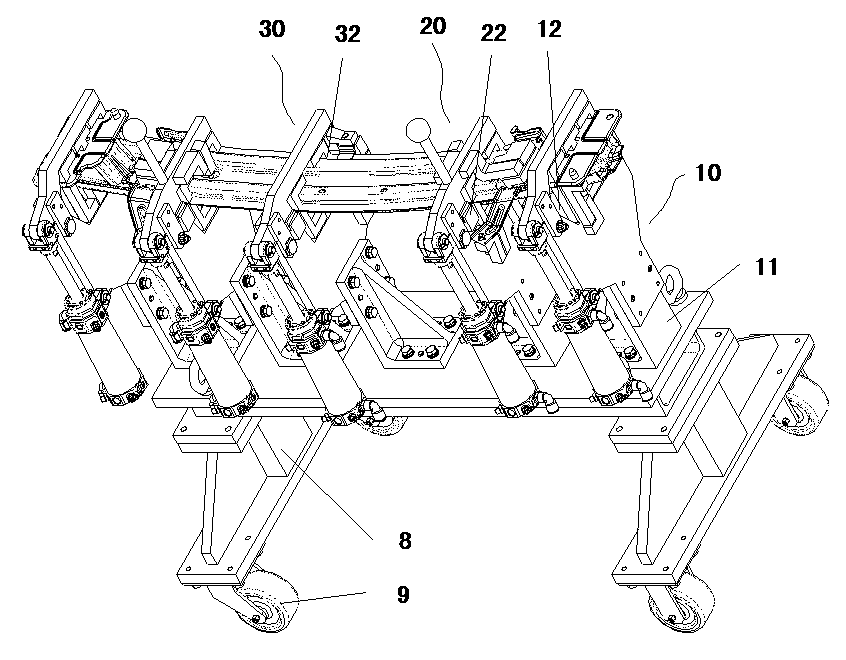

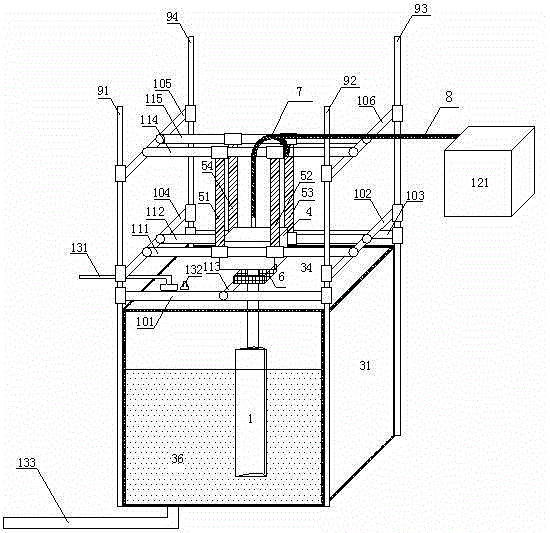

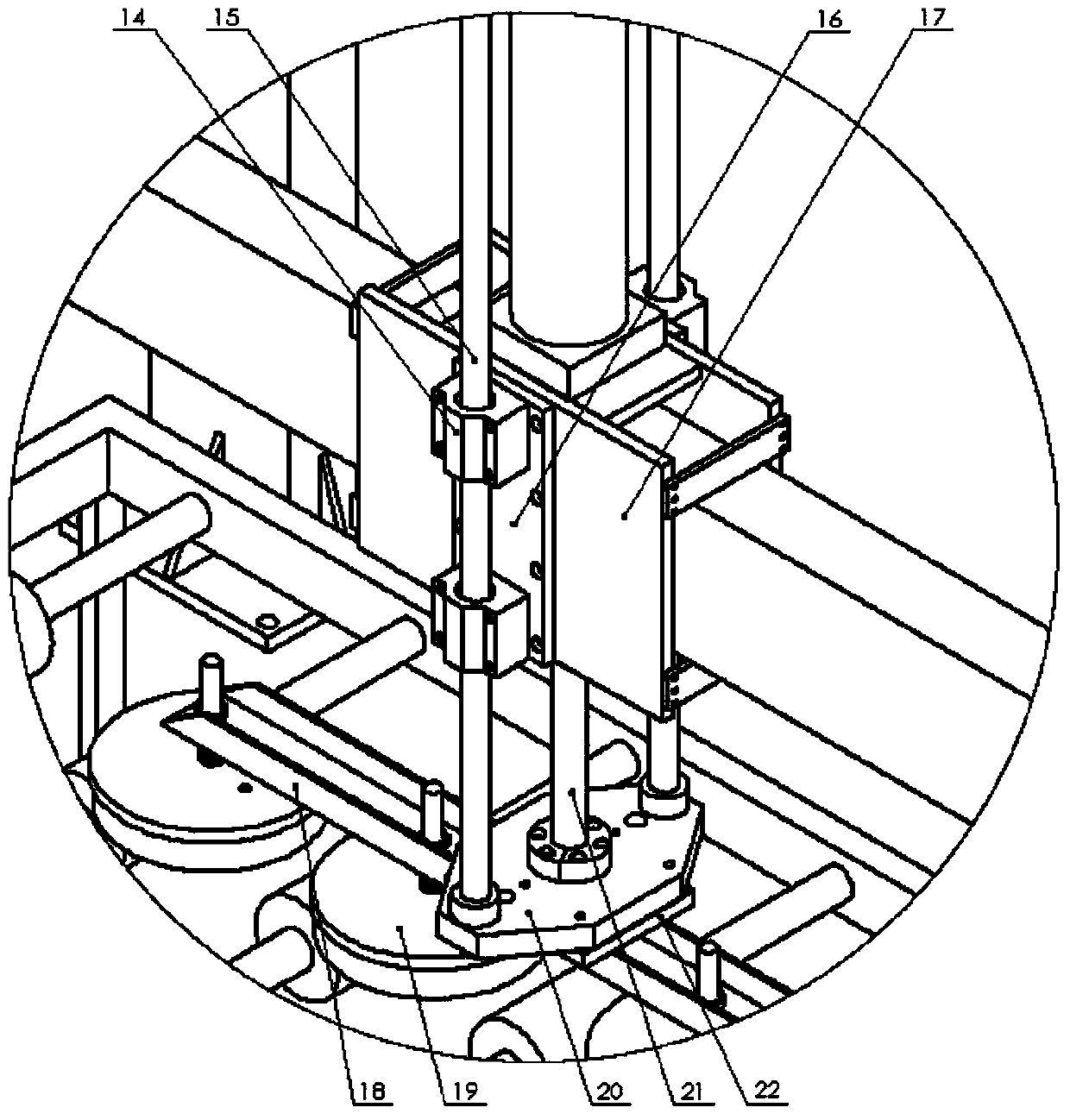

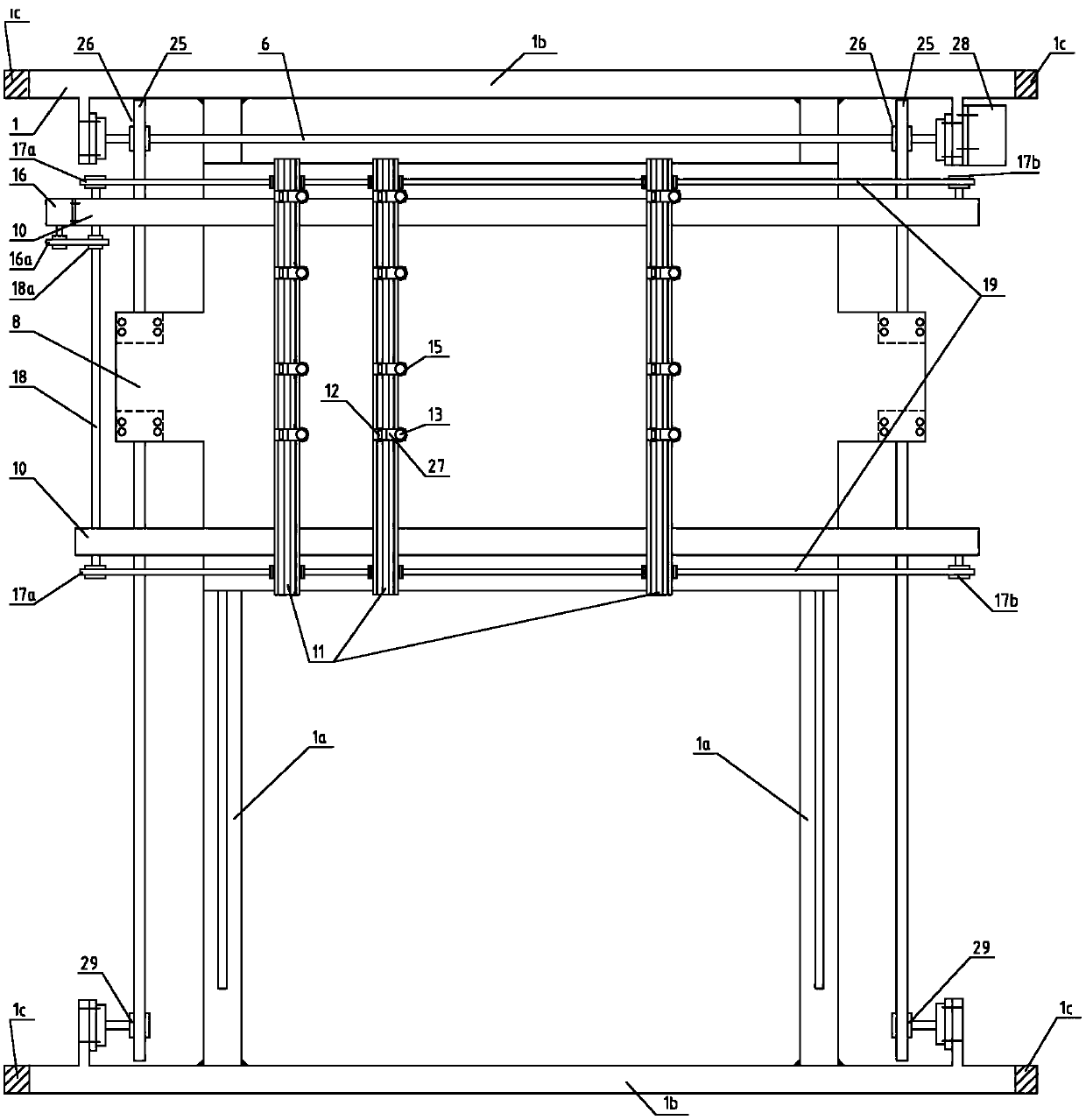

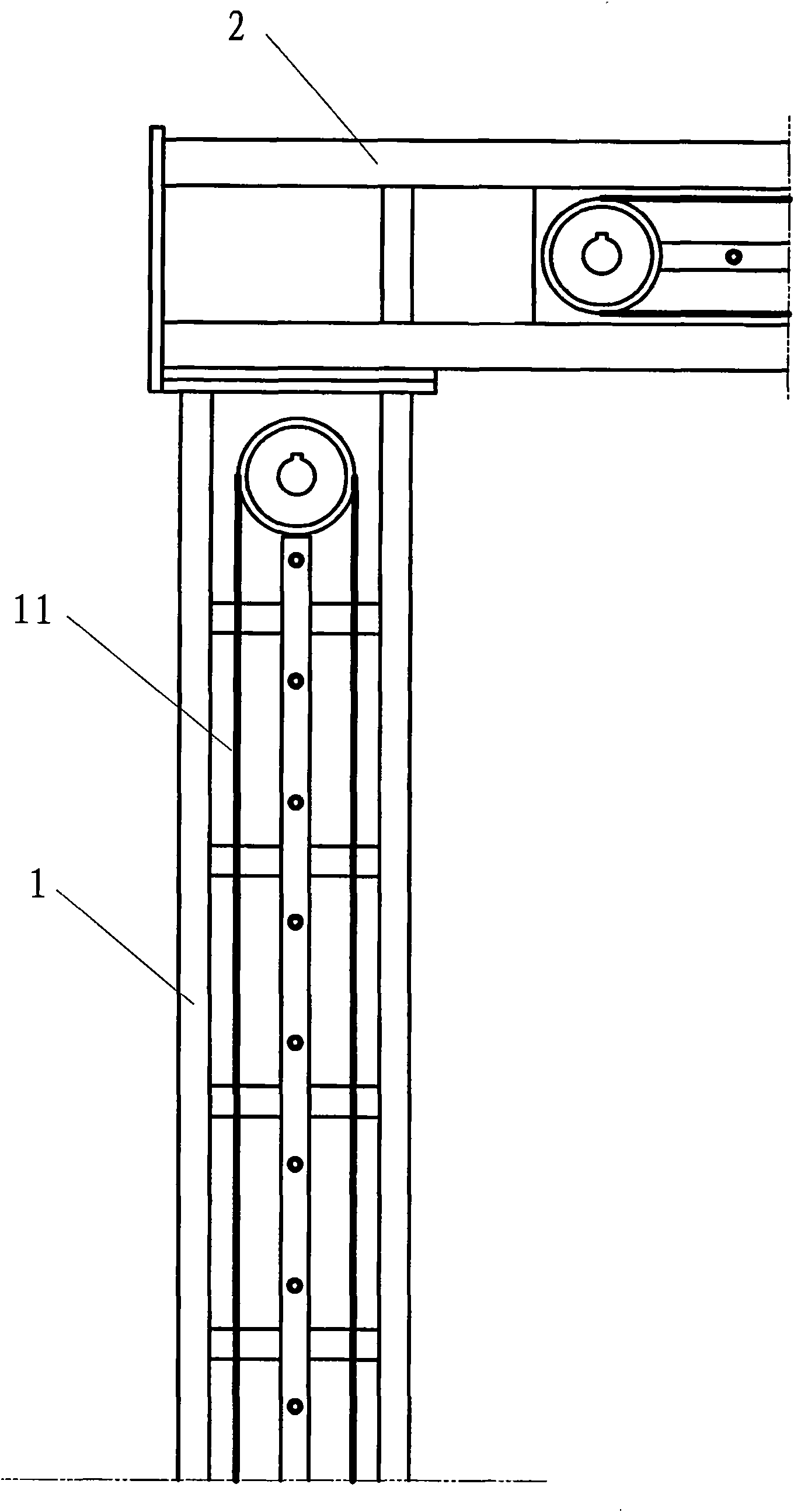

Opened tubular pile hammering injection and static load simulation experiment device and method

The invention provides an opened tubular pile hammering injection and static load simulation experiment device and method. The simulation experiment device comprises a model box, a model pile, a vertical column assembly, transverse beam assemblies as well as a piling assembly and a static load assembly, wherein the model pile comprises an outer cylinder, an inner cylinder, a semicircular steel plate and a guide rod column; axial and radial sensors are arranged on the walls of the inner cylinder and outer cylinder; the vertical column assembly comprises four vertical columns which are in rigid connection with the periphery of the model box; the transverse beam assemblies comprise lower transverse beam assemblies and upper transverse beam assemblies; the pulley assembly is connected between the upper transverse assemblies. Compared with the prior art, the simulation experiment device has the advantages that a real stress filed of a soil mass can be simulated, and the friction on the inner and outer sides of the wall of an opened tubular pile can be respectively measured; the defect that in the prior art, the real load transfer process of the opened concrete tubular pile cannot be measured is overcome. Moreover, the simulation experiment device is simple to operate, and the simulation experiment method is convenient.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

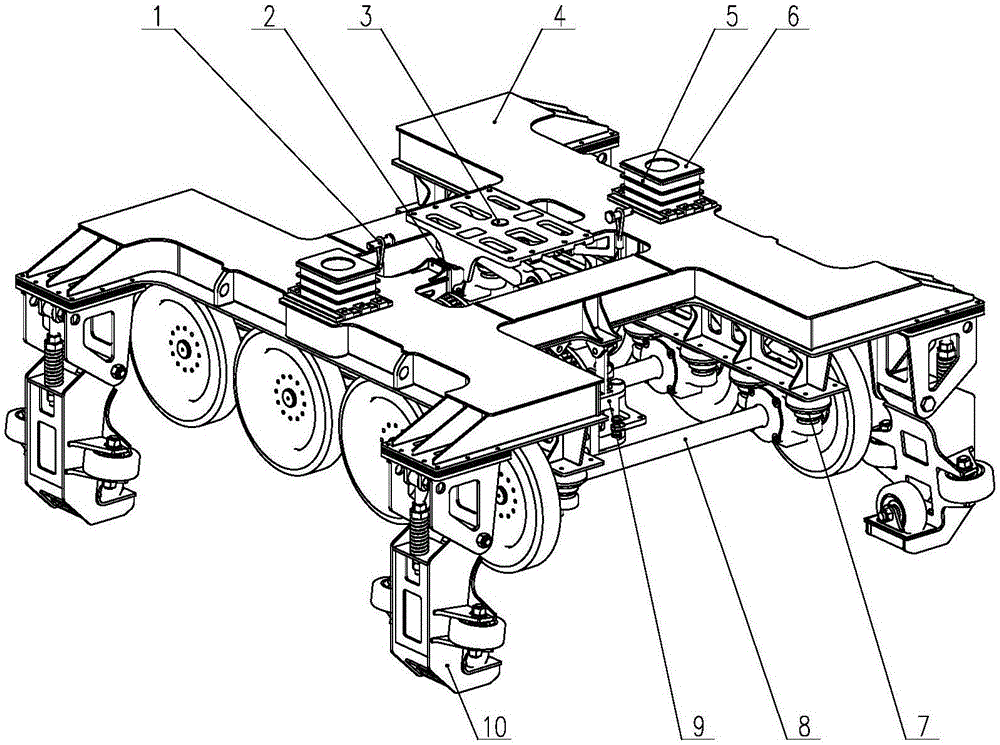

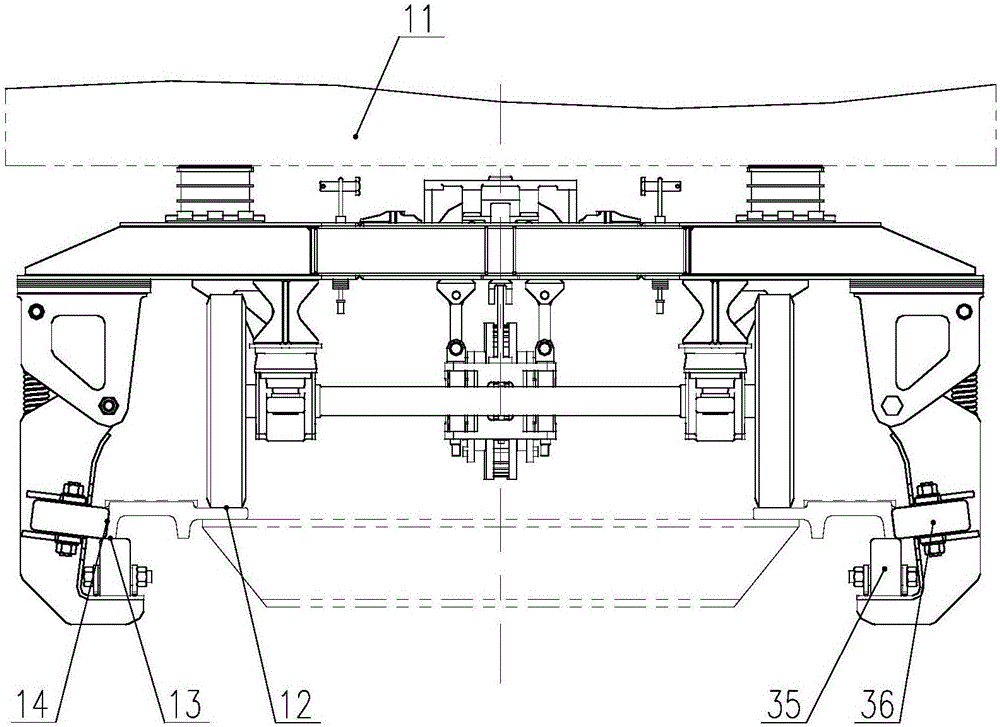

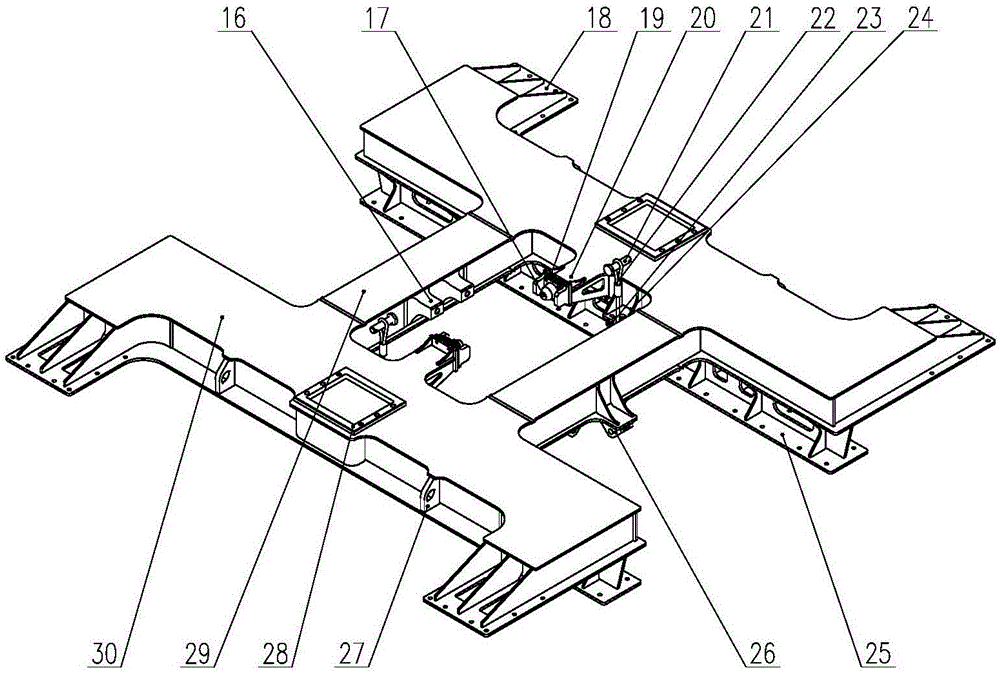

Magnetic levitation railway vehicle and bogie thereof

The invention discloses a magnetic levitation railway vehicle and a bogie thereof. The bogie comprises a frame composed of a lateral beam and a transverse beam, a plurality wheelset shaft box device below the frame, a plurality of guide devices installed on the outer side of the lateral beam of the frame, a first-stage suspension device, a second-stage suspension device, a traction device used for being installed between the inner side of the transverse beam of the frame and a vehicle body, and a transverse stop dog. An anti-disengaging and hoisting device is installed between the inner side of the lateral beam of the frame and the vehicle body. A foundation braking device is installed between the bottom of the transverse beam of the frame and an axle of the wheelset shaft box device. The bogie can adapt to running of medium-speed and low-speed magnetic levitation railway vehicles, and the moving problem of the medium-speed and low-speed magnetic levitation railway vehicles on tracks is solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

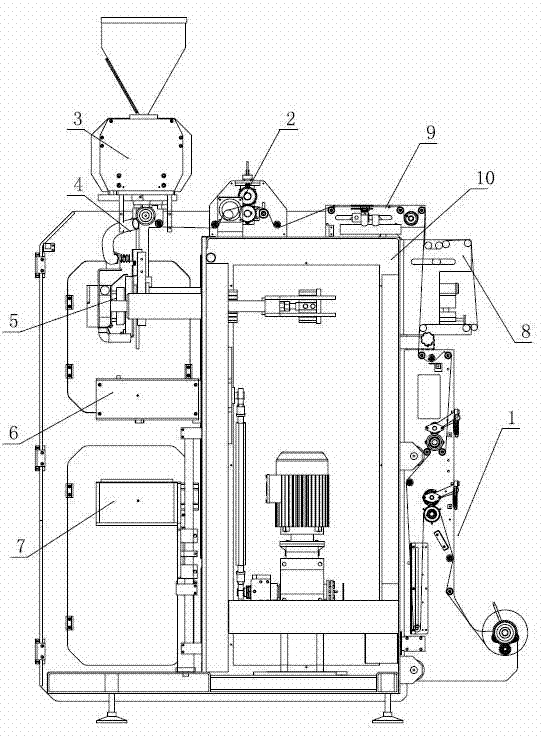

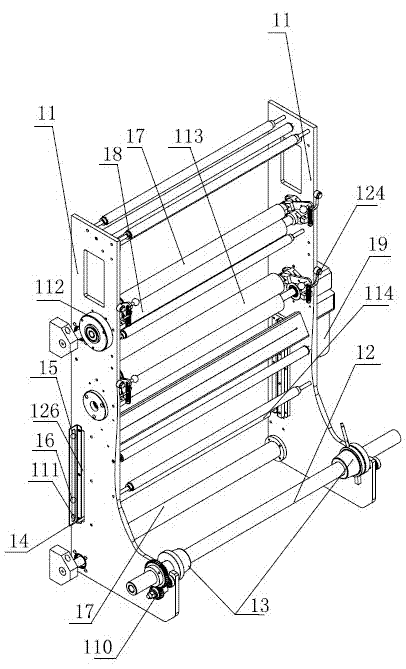

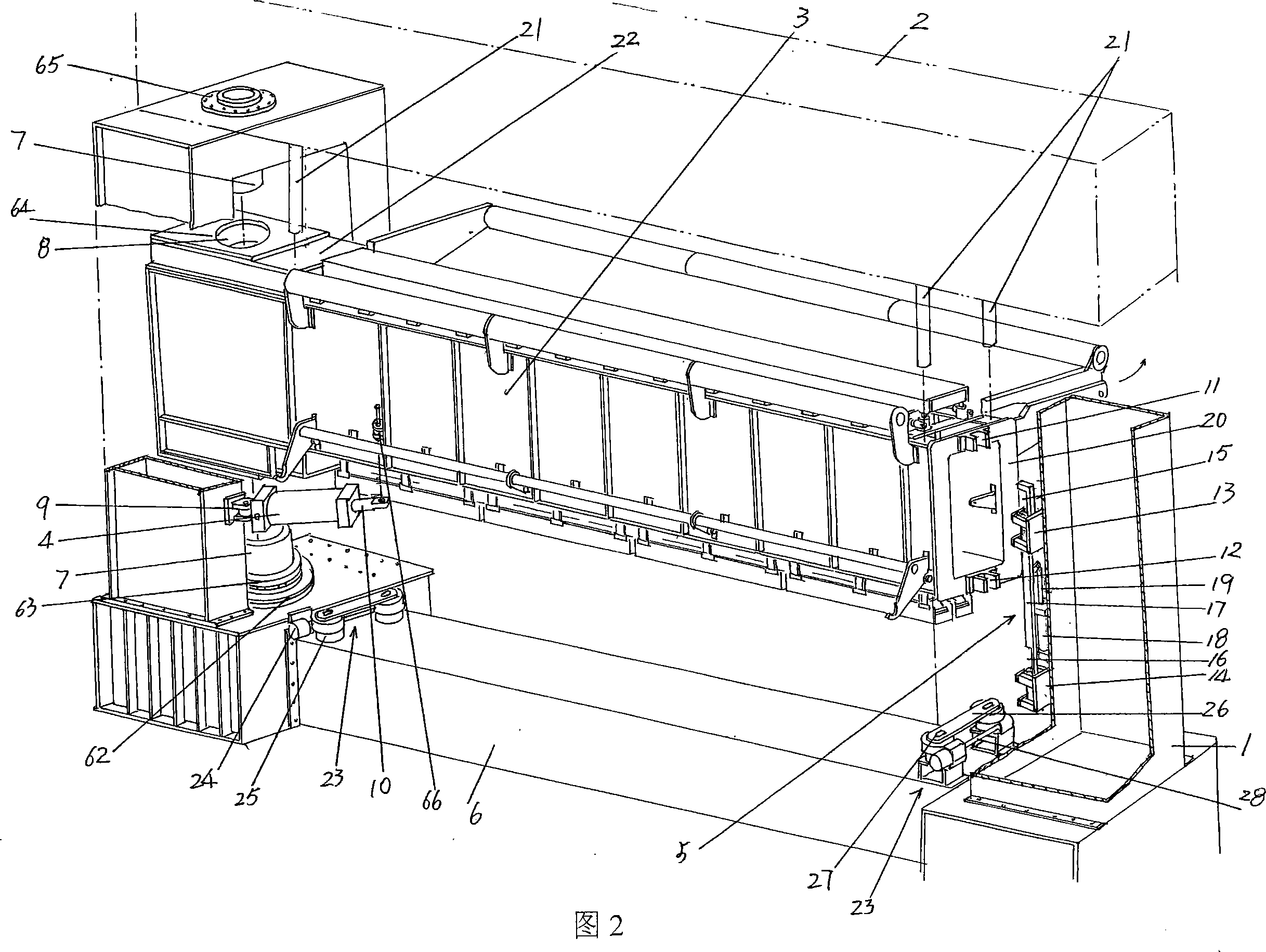

Multicolumn strip packing machine

ActiveCN102730214AIncrease productivitySimple structureWrapping material feeding apparatusWrapper twisting/gatheringReciprocating motionEngineering

The invention relates to a multicolumn strip packing machine, in particular to a multicolumn strip packing machine capable of carrying out continuous bag-making and packing through automatic operation, comprising a frame, and a film feeding mechanism, a slitting cutter mechanism, a feeding mechanism, a bag molding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism and a cut-off mechanism arranged on the frame respectively, wherein the transverse sealing mechanism comprises a transverse sealing device which comprises a transverse sealing floating device, two transverse sealing holders, and transverse sealing seats arranged on the two transverse sealing holders respectively; a plurality of transverse sealing guide shafts are together sleeved to transverse beam sliders on the same side; at least one transverse sealing seat is connected to a transverse sealing cylinder for driving the transverse sealing seat to do reciprocating motion; and the axial direction of the transverse sealing guide shaft is consistent with the motion direction of the transverse sealing seat. The transverse sealing mechanism of the multicolumn strip packing machine is capable of providing a buffering force for an object to be packed so that the impact on the object to be packed can be reduced and the object to be packed can be protected against damage; and a plurality of combined components are arranged in a multi-row parallel manner, so that the production of a plurality of packing bags can be completed at the same time; as a result, the production efficiency is greatly improved.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

Foldable bed frame

A foldable bed frame including first coupling members each having an opening facing outwardly with respect to the frame being in an open state; two sets of longitudinal beams, each formed by two longitudinal bars having two free ends, and two inner ends pivotally connected within one of the openings of the first coupling members. At least two transverse beams, each being formed by two transverse bars having first and second ends, the first ends respectively being pivotally connected together by a second coupling member. A plurality of third coupling members provided proximate to each free end of the longitudinal bars, each third coupling member having an opening facing inwardly with respect to the frame being in the open state, the opening being configured to pivotally connect one of the free ends of the longitudinal bars. A leg pivotally connected respectively proximate the free end of each longitudinal bar.

Owner:JIN KI HO

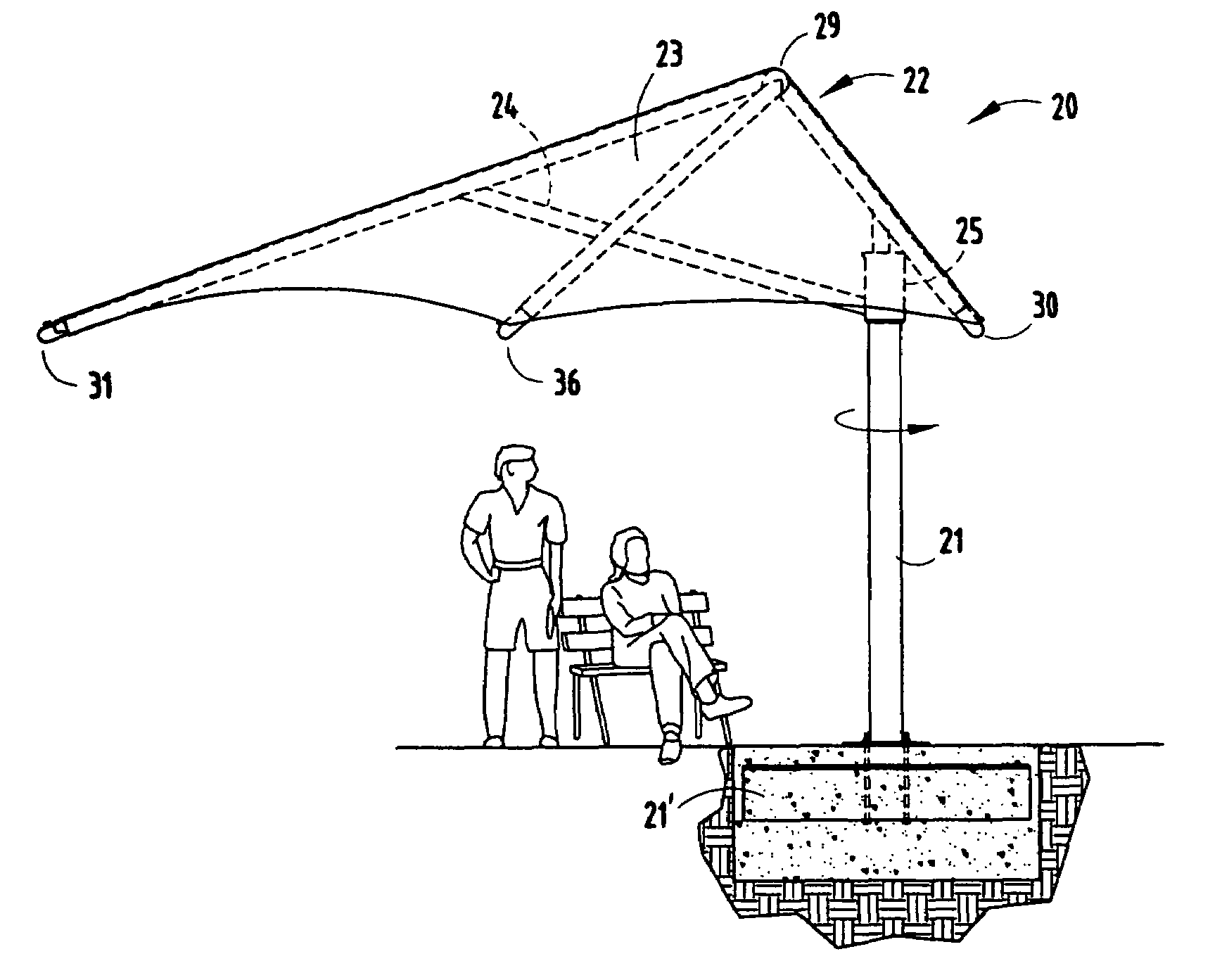

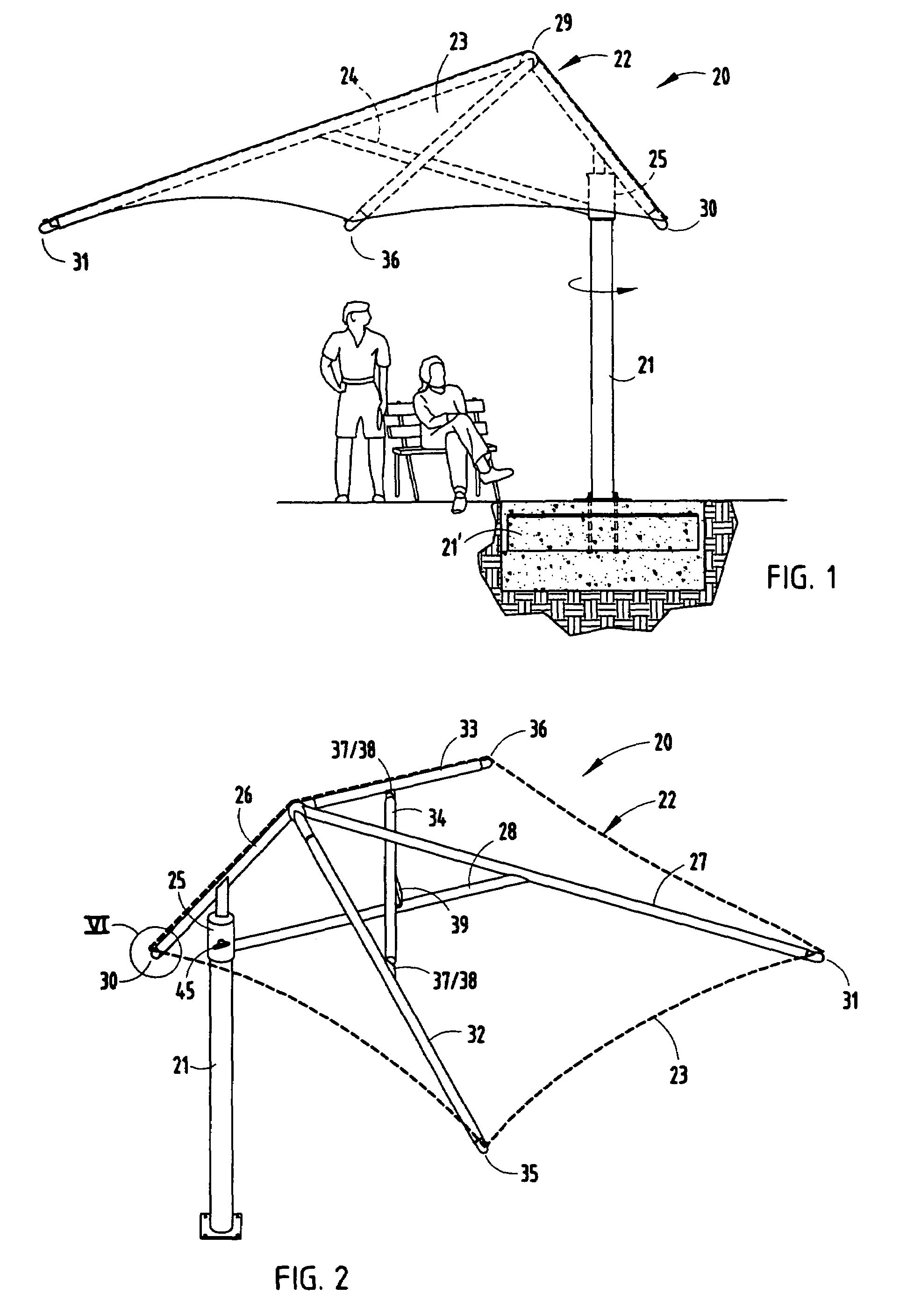

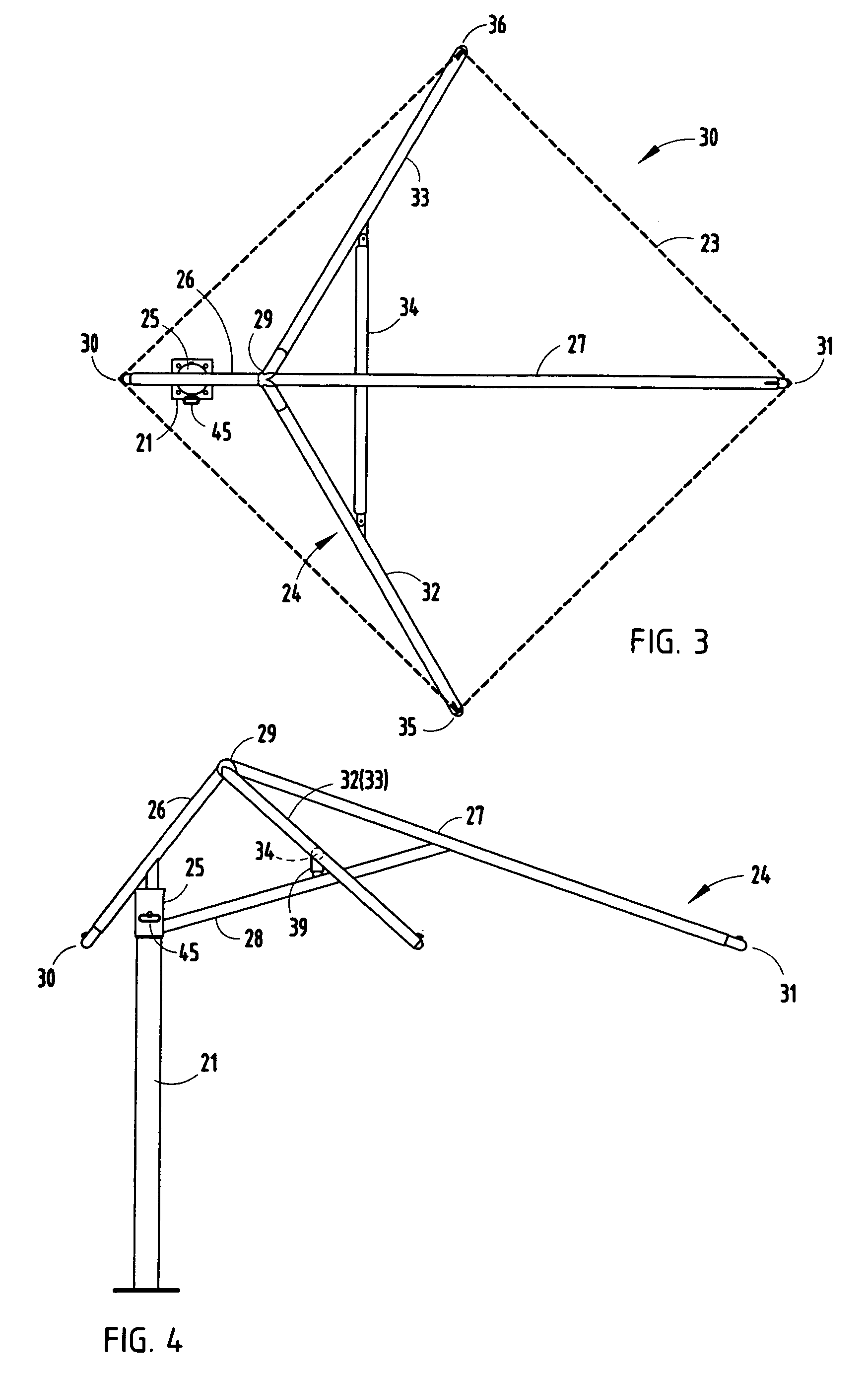

Adjustable shade-providing building structure

A shade structure includes a vertical column and a roof having a cover, a framework supporting the cover, and a mount attached for rotational adjustment to a top of the column and supporting the roof on the column. The framework includes a triangularly-shaped main beam arrangement comprising a plurality of beams secured together to form a triangle that lies in a vertical plane and that defines a peak and opposing first corners, with the mount being located between the peak and one of the opposing corners. The framework further includes a pair of transverse beams and a bracing beam secured to the triangular main beam arrangement that define opposing second corners. By this arrangement, an adjustable shade structure is provided that is able to withstand over 40 mph wind loads.

Owner:P L PORTER

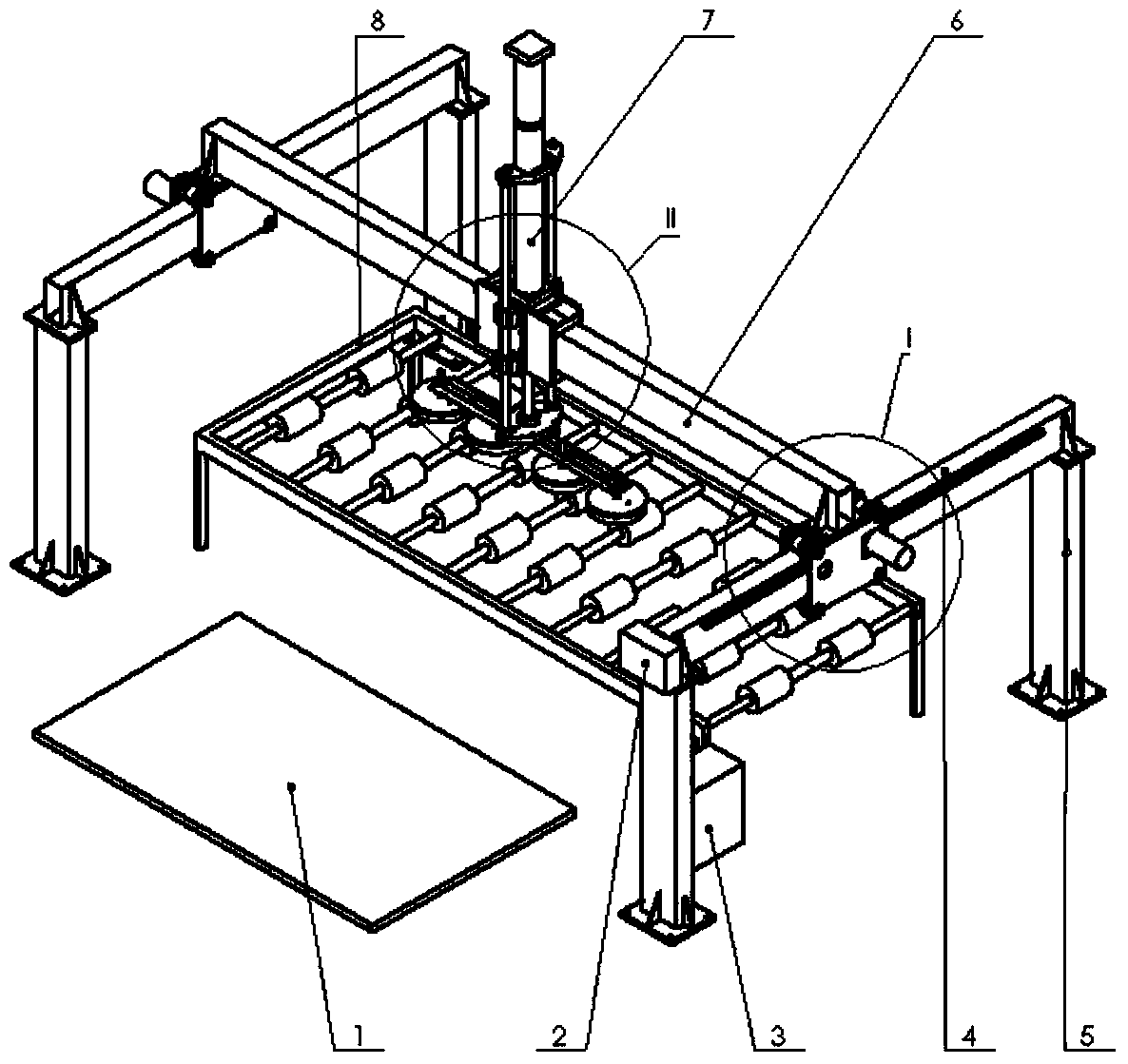

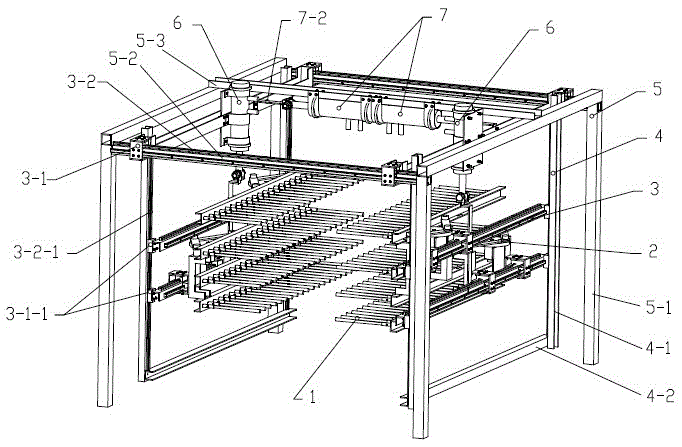

Device and method for automatic feeding and discharging of stone slabs

ActiveCN104176498ARealize automatic crawlingAchieve horizontal movementGrinding machine componentsConveyor partsMechanical engineeringTransverse beam

Owner:RIZHAO HEIN SAW

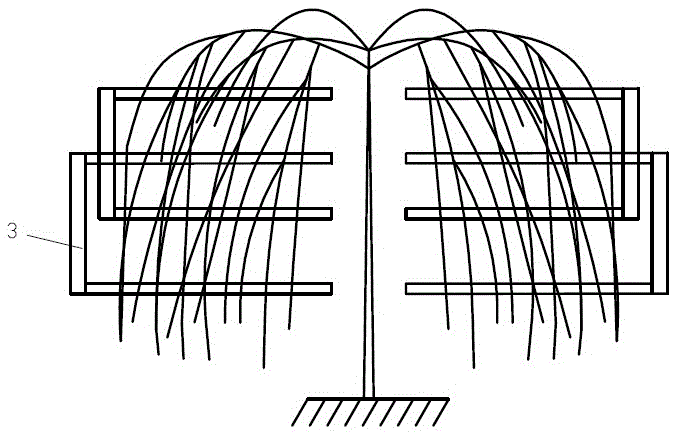

Vibration-type wolfberry fruit picking mechanism

ActiveCN105594374AEliminate avoidance of vibrating rodsReduce harmPicking devicesHydraulic motorFixed frame

The invention relates to a vibration-type wolfberry fruit picking mechanism and belongs to the technical field of agricultural machinery. A fixed frame of the mechanism is formed by fixedly connecting door-shaped brackets on the left and right sides, front and rear slide ways and a middle connecting beam; the two sides of the front and rear slide ways, and left and right hoisting opening / closing frames from left and right horizontal movement pair respectively; two opening / closing air cylinders are mounted in the middle of the middle connecting beam; stretching-out piston rod ends of the opening / closing air cylinders are fixedly connected with the left and right hoisting opening / closing frames respectively; each hoisting opening / closing frame is a rectangular framework; front and rear vertical beams, and upper and lower vibration rod mechanisms with opposite vibration directions form vertical movable pairs respectively; a hoisting air cylinder is mounted in the middle of an upper transverse beam; a piston rod end of the hoisting air cylinder is fixedly connected with the vibration rod mechanisms; each vibration rod mechanism comprises horizontal slide rails, and the horizontal slide rails, and upper and lower rows of vibration rod rows form front and rear horizontal movement pairs; the vibration rod rows are in transmission connection with an output shaft mounted on a hydraulic motor. By virtue of the vibration-type wolfberry fruit picking mechanism, the picking efficiency and the picking rate are effectively improved; a needed excitation force is relatively small, and injuries to branches, caused by the picking excitation force, is remarkably reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

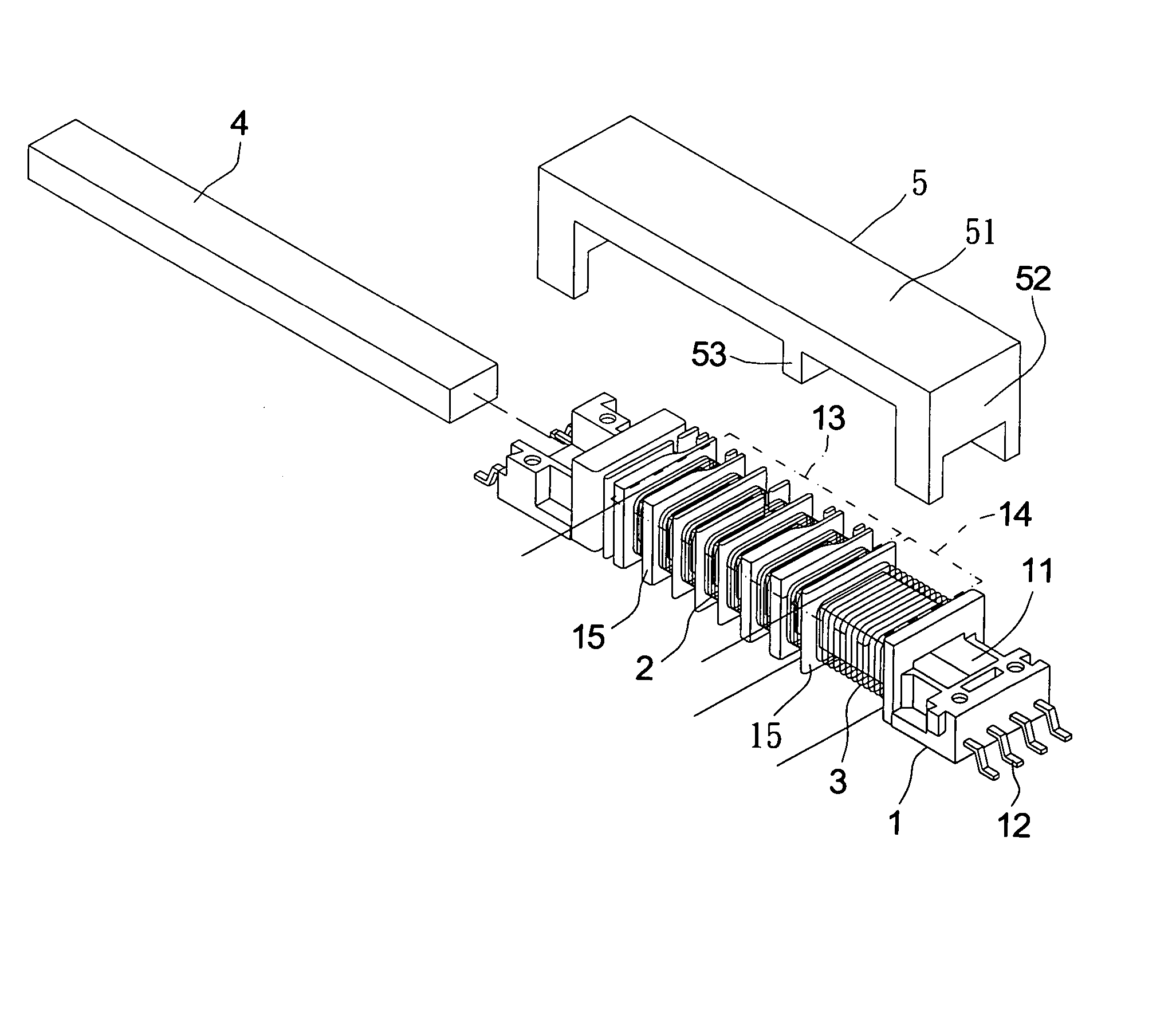

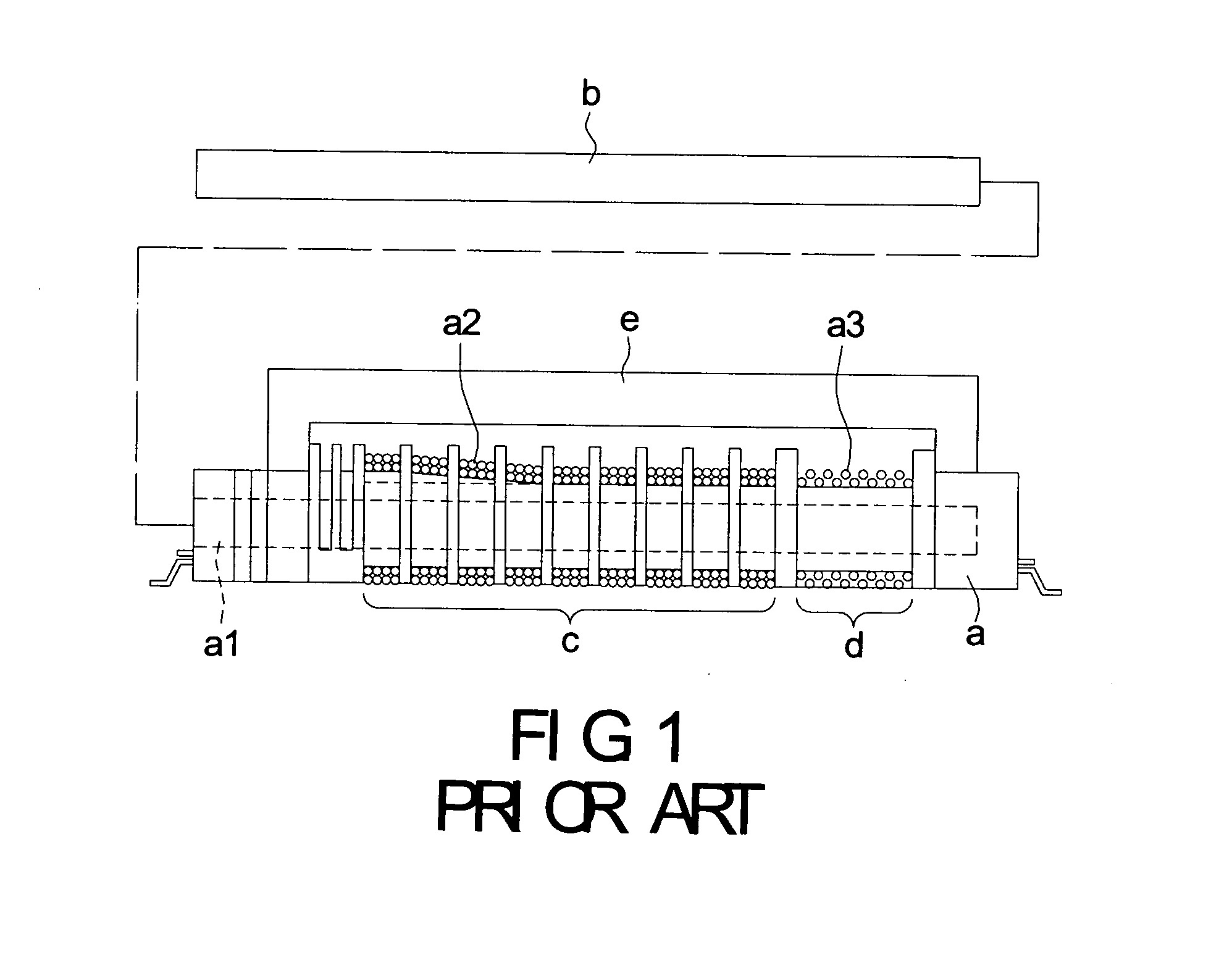

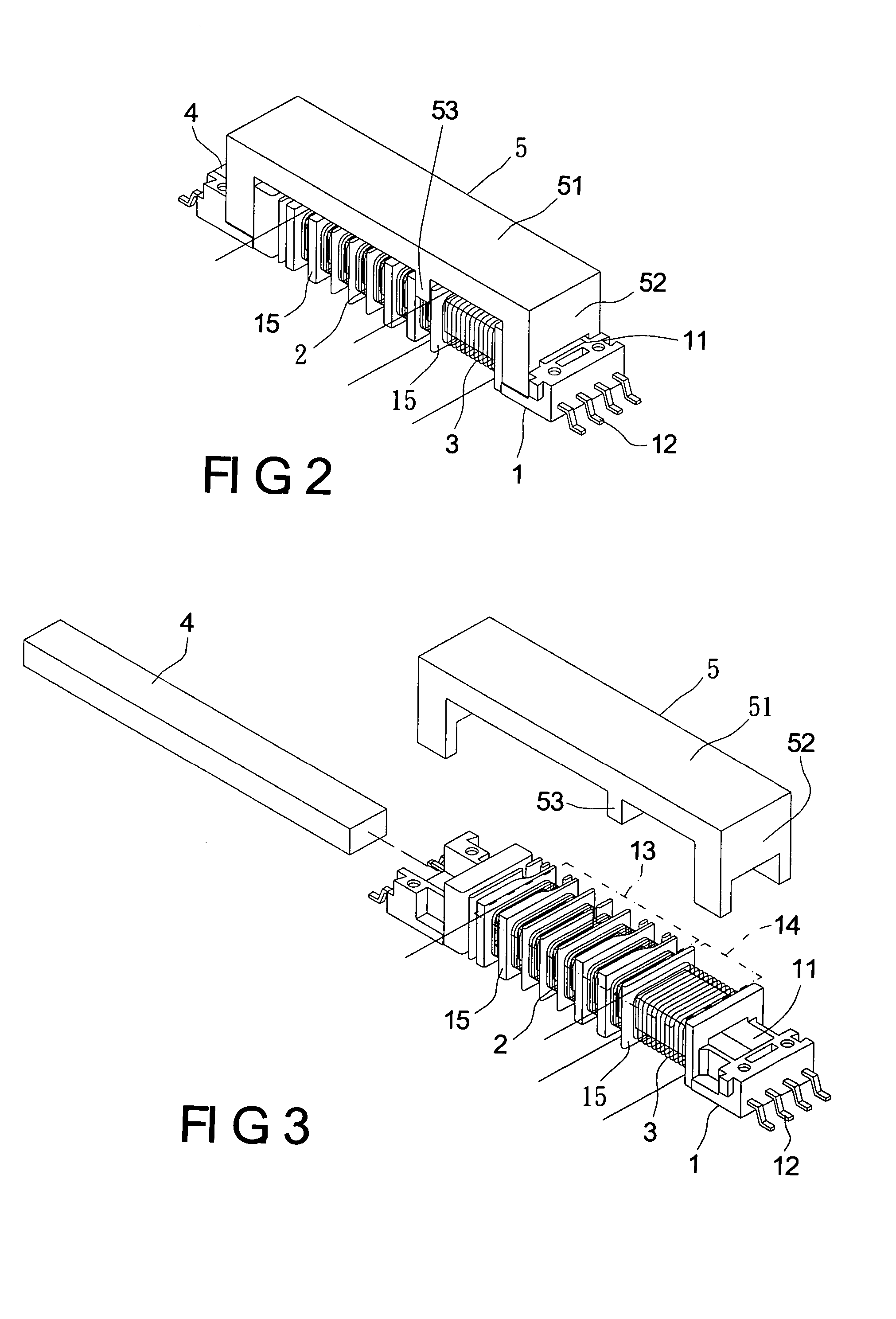

High voltage transformer for controlling inductance leakage

InactiveUS20070268104A1Inductance leakage is enhancedSwitching loss can be suppressedTransformersTransformers/inductances magnetic coresLow voltageEngineering

A high voltage transformer for controlling inductance leakage used for a multiple lamp driving system includes at least one wire frame, a first winding, a second winding, a first magnetic unit, and a second magnetic unit. There is a receiving space in the wire frame for receiving the first magnetic unit, and a first region and a second region is formed on its surface. The first winding and the second winding are individually wound at the first region and the second region. The second magnetic unit is covered on the side of the wire frame. On an appropriate location of the bottom of the second magnetic unit, a transverse beam extends. Thereby, the transverse beam fully separates the low voltage magnetic flux path produced on the first magnetic unit by the first winding and the second winding and the high voltage magnetic flux path produced by the AC.

Owner:LIEN CHANG ELECTRONICS ENTERPRISE

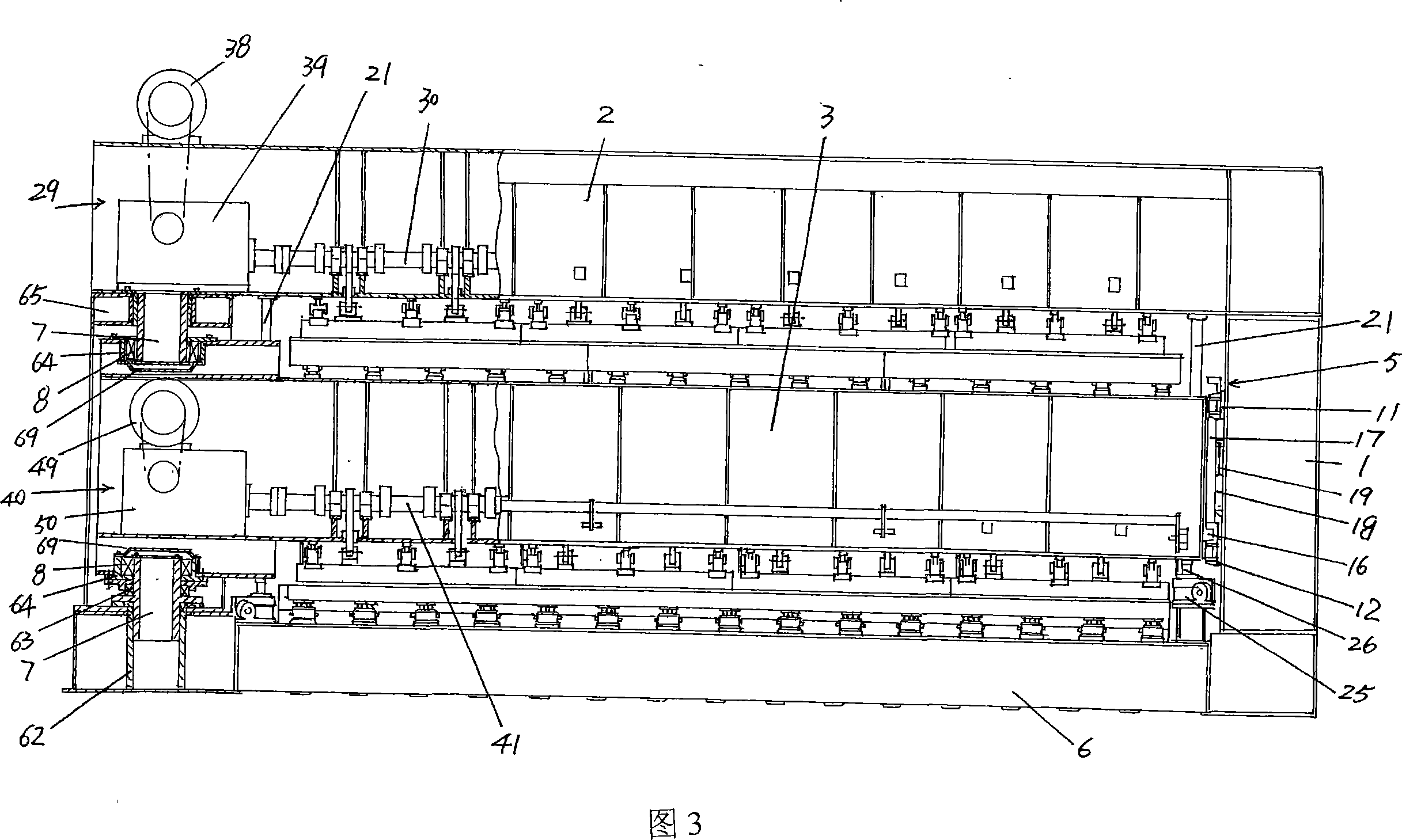

Joint-free industrial felt needle machine

InactiveCN101122069AReduce labor intensityImprove processing efficiencyNeedling machinesFiberConveyor belt

An industrial woolen textile needle machine without adapter belongs to the technical field of non-woven machinery and includes a machine frame provided with bottom beam, an outer needle mechanism arranged on a first transverse beam of the machine frame for needling one side of the non-woven fiber base cloth and an inner needle mechanism arranged on a second transverse beam correspondingly below the outer needle mechanism for needling the other side of the non-woven fiber base cloth; one end of the second transverse beam is articulated with one side of the machine frame, and the other end becomes a free end; one end of the machine frame which is correspondingly articulated with the second transverse beam is provided with a transverse beam driving device which is connected with the second transverse beam for driving the second transverse beam to move; the other side of the machine frame is provided with a locking device for locking or opening the free end of the second transverse beam. The invention can process paper making felts and conveyor belts with broad width and without adapter; during processing, the locking device is controlling without need of turning over the felts and belts manually, which can reduce the labor intensity of workers and improve the processing efficiency.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

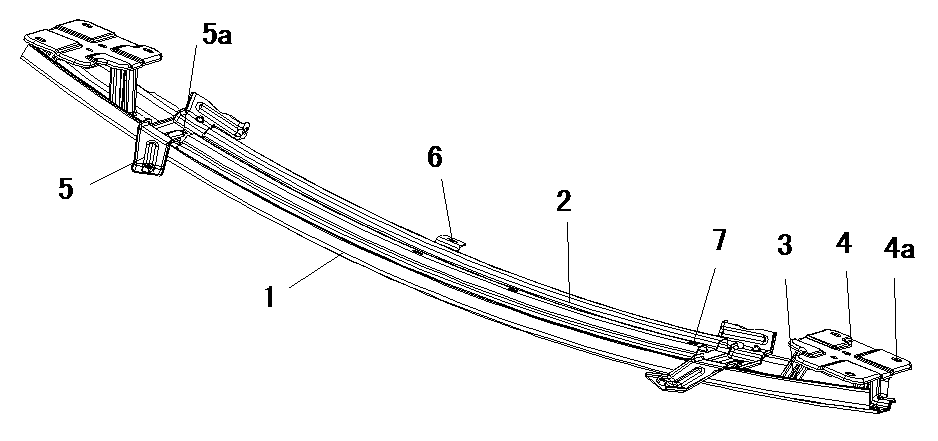

Tailgate from fibre-reinforced thermoplastic plastic

ActiveUS8550536B2Stiffer and simply and inexpensively manufacturableImprove featuresSuperstructure subunitsMonocoque constructionsBack doorFibre reinforcement

The tailgate (1) or rear door for a motor vehicle with a rear window includes a single-piece main carrying structure (10) with a peripheral, flexurally resistant frame (11), with an upper transverse beam (12), two lateral longitudinal beams (13, 14) and at least one lower transverse beam (15). The main carrying structure consists of a fibre-reinforced moulding compound (20) with at least two impregnated, integrated continuous-fibre bands (21) and this moulding compound is non-positively connected to the rear window (2) and together with this forms a flexurally resistant structure. Thereby, the continuous-fibre bands (21) in sections are integrated into the frame (11) in an arrangement vertical (v) to the surface (H) of the tailgate, by way of the continuous-fibre bands (21) being arranged vertically to the surface (H) and / or at a vertical distance (d) to the surface (H).

Owner:WEBER AUTOMOTIVE HLDG

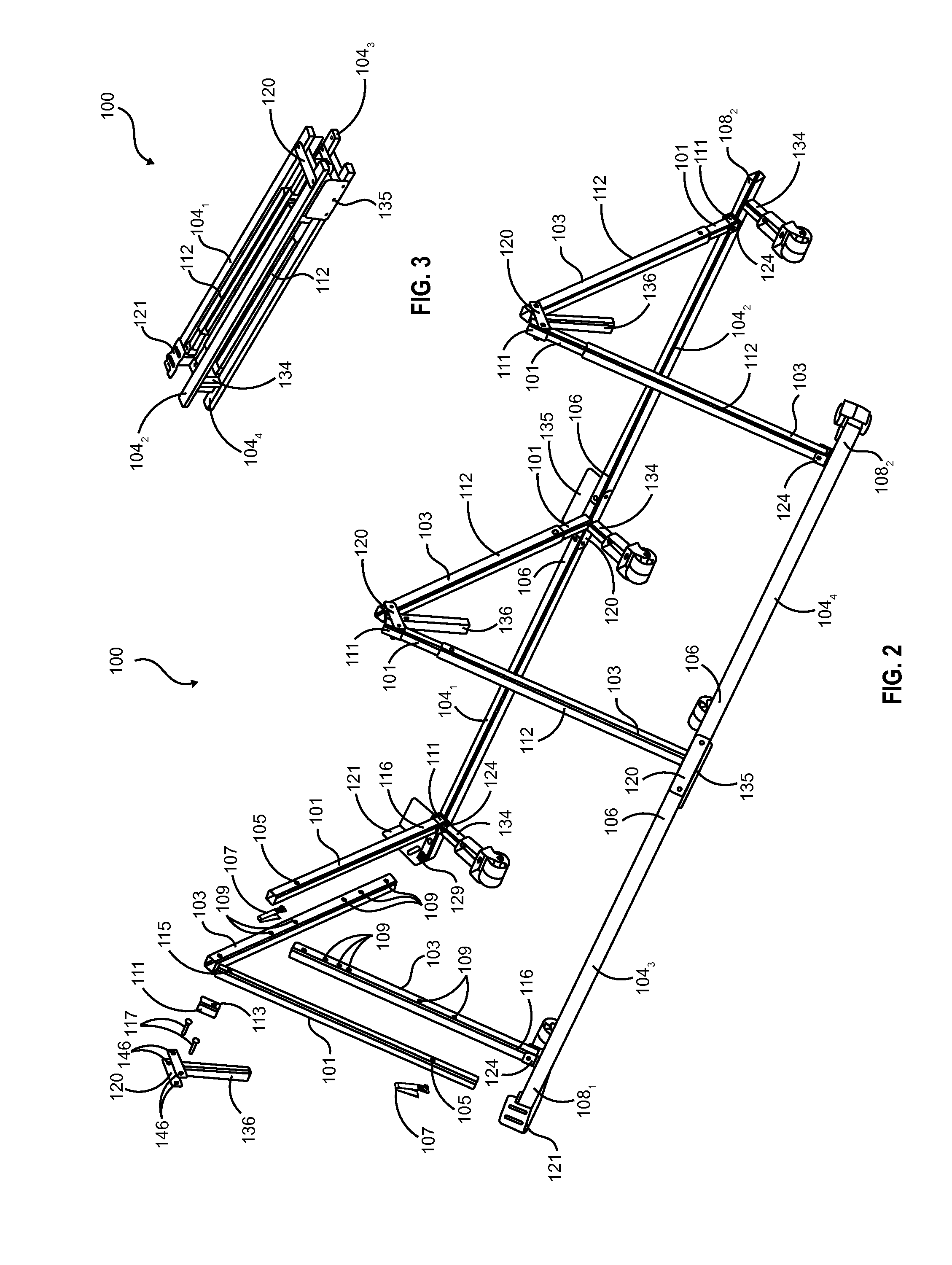

Adjustable folding bed frame

An adjustable folding bed frame including a plurality of longitudinal beams spaced apart and parallel to each other. Each longitudinal beam is formed by a pair of longitudinal bars that are pivotally connected together. The bed frame also includes a plurality of transverse beams spaced apart and parallel to each other. Each transverse beam is formed by a pair of transverse bars that are pivotally connected together. Each transverse bar has a first sliding member slidingly coupled with a second sliding member for adjusting the bed frame to predetermined widths. The bed frame also includes legs connected to a corresponding lower side of each longitudinal bar free end. The longitudinal and transverse bars are coupled together to form a generally rectangular frame when the bed frame is in an open configuration, and are folded adjacent and parallel to each other when the bed frame is in a folded configuration.

Owner:JIN KI HO

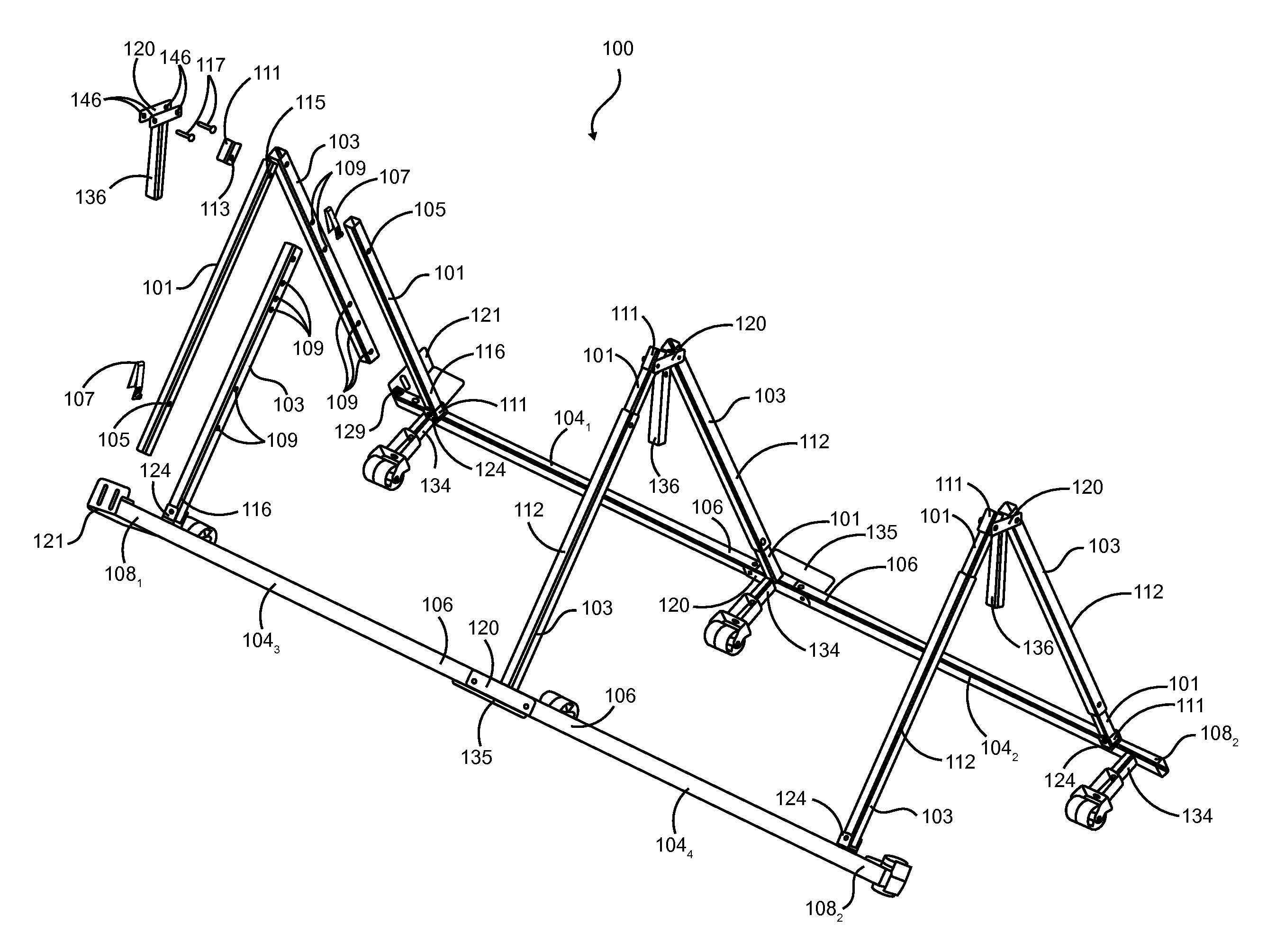

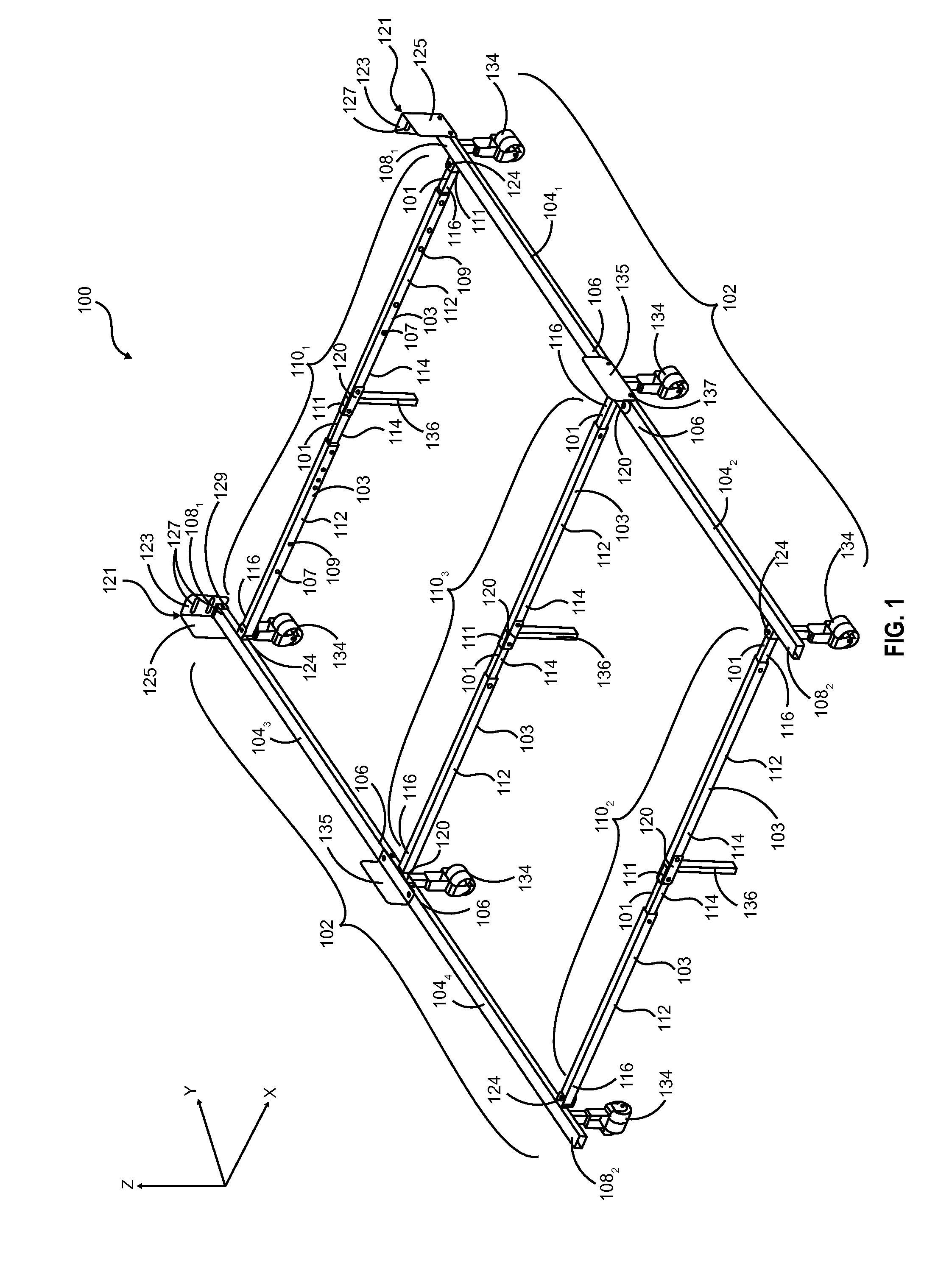

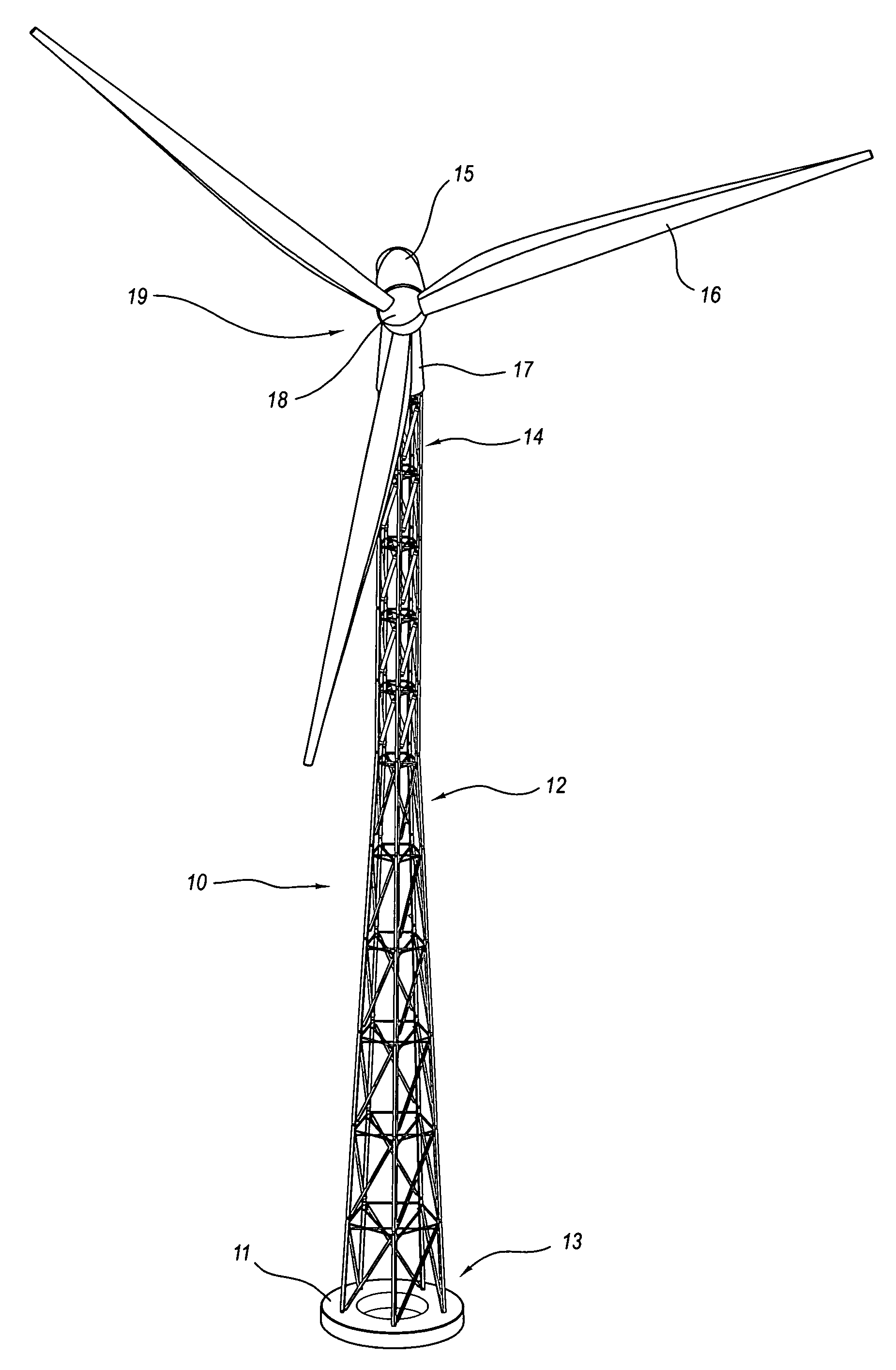

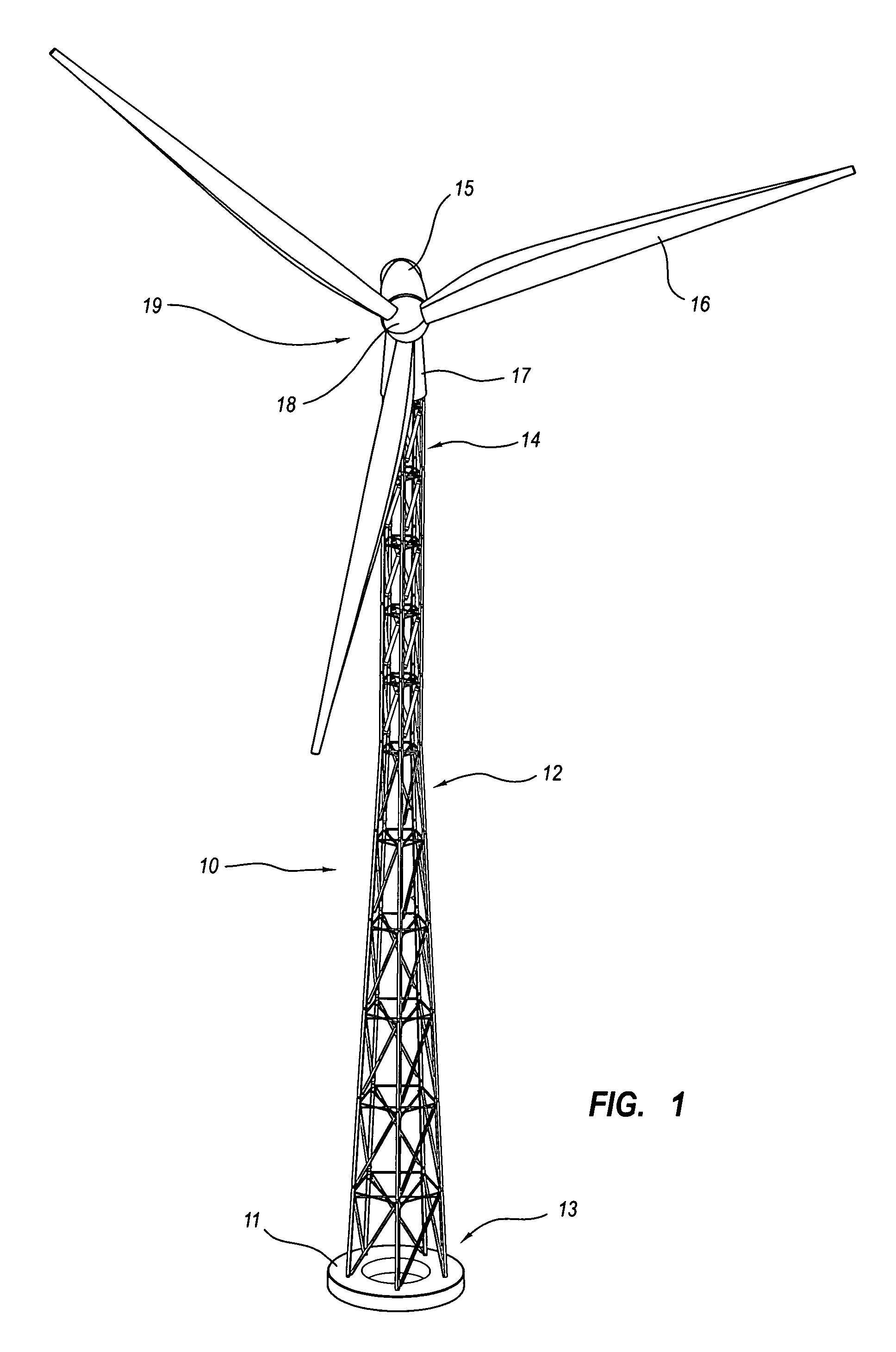

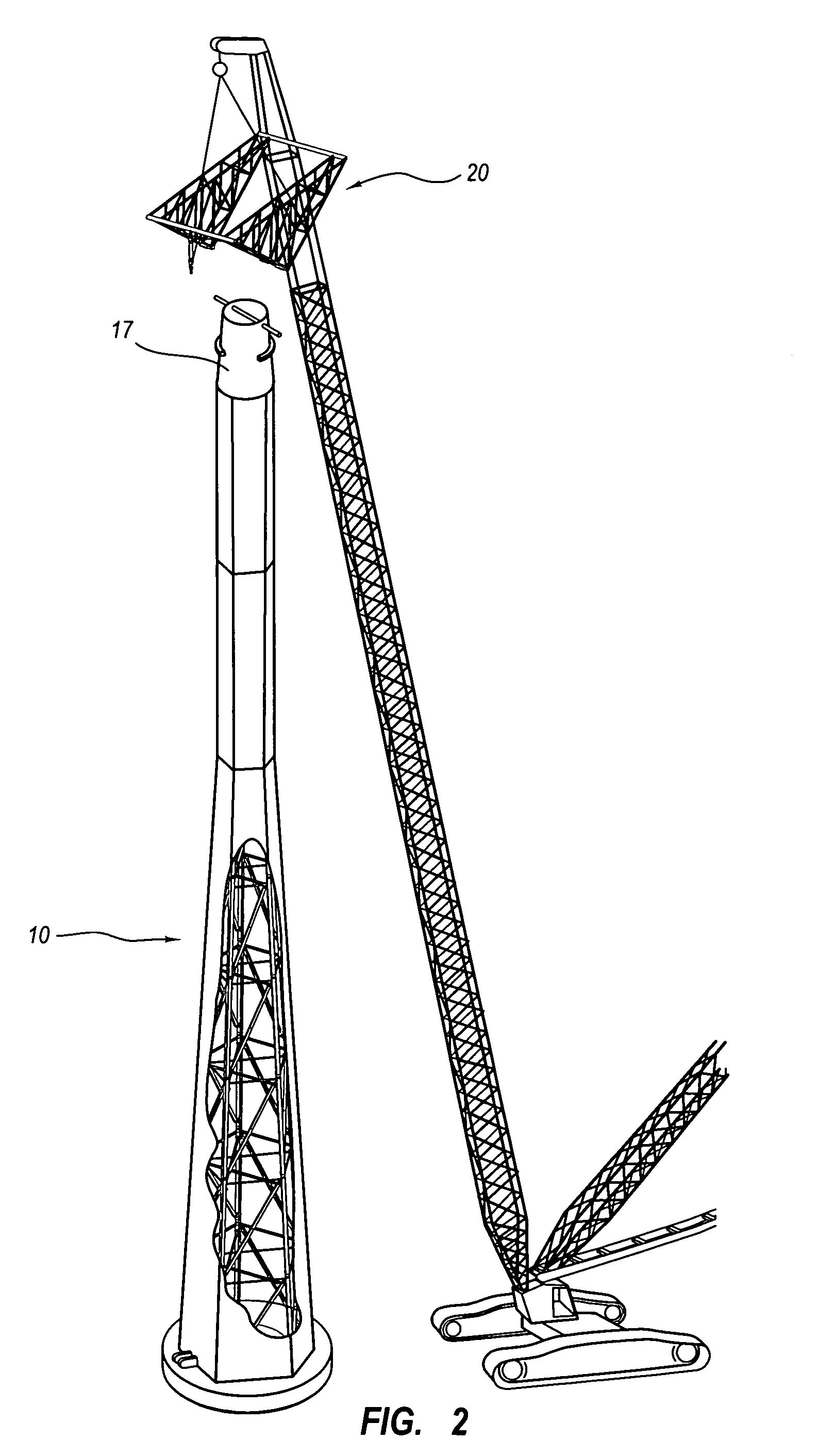

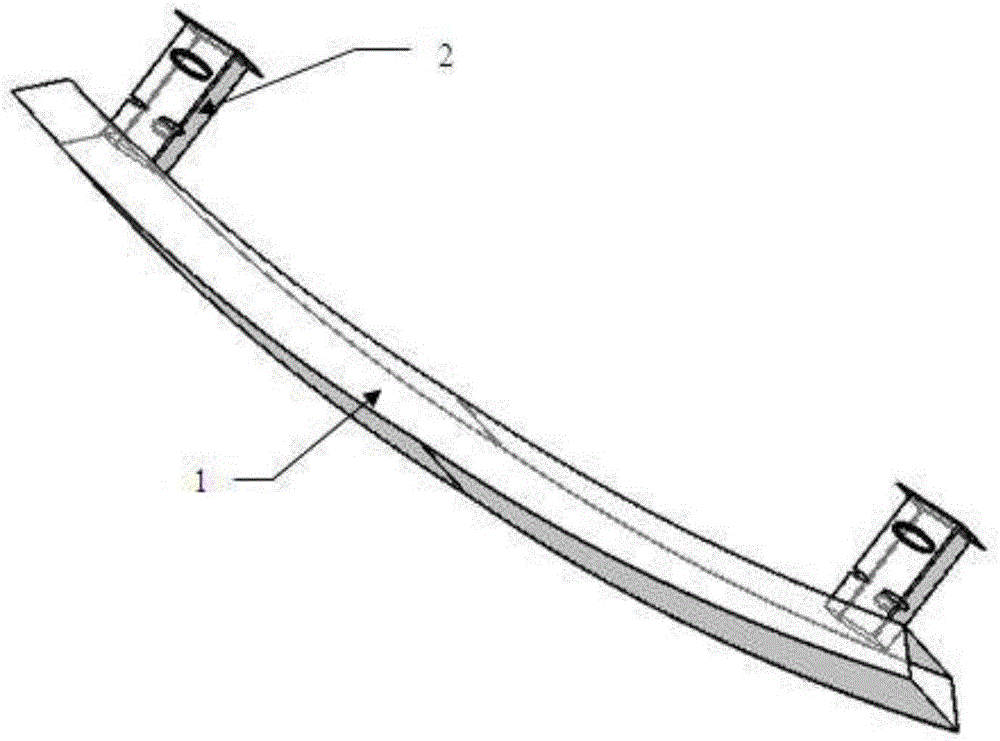

Lifting system and apparatus for constructing wind turbine towers

The disclosed invention is utilized for mounting a wind turbine and blade assembly on the upper end of a wind turbine tower. The invention generally includes a frame or truss that is pivotally secured to the top bay assembly of the tower. A transverse beam is connected to the frame or truss and extends fore of the tower when the frame or truss is in a first position and generally above the tower when in a second position. When in the first position, a wind turbine or blade assembly can be hoisted to the top of the tower. The wind turbine or blade assembly is then moved into position for mounting to the tower as the frame or truss is pivoted to a second position. When the turbine and blade assembly are secured to the tower, the frame or truss is disconnected from the tower and lowered to the ground.

Owner:GE WIND ENERGY

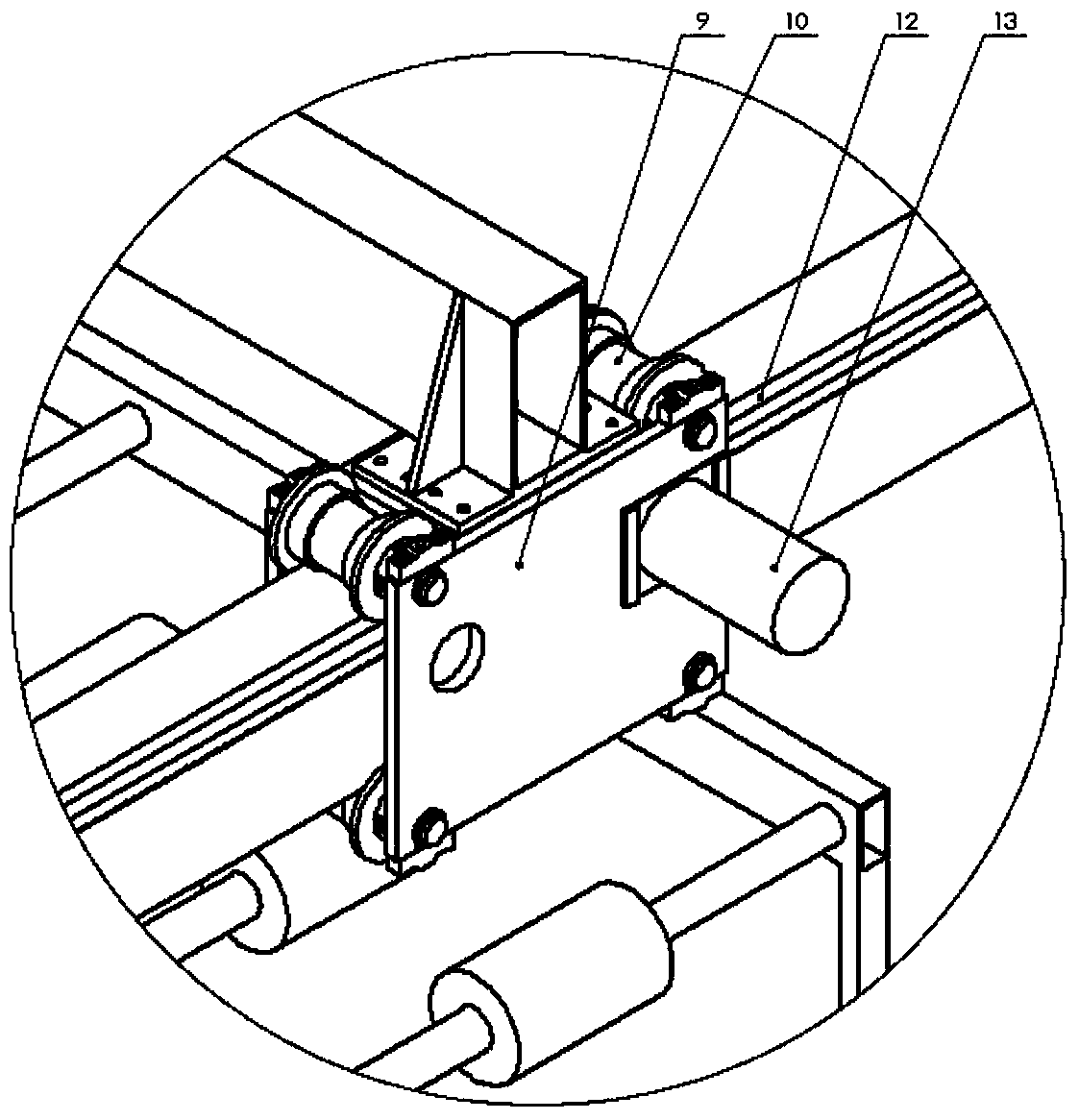

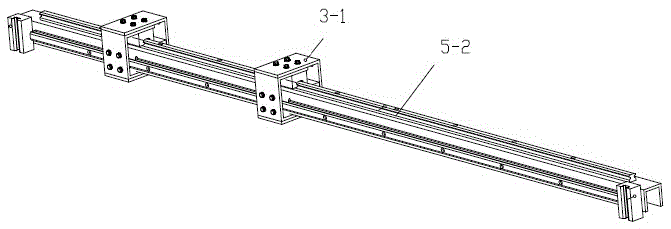

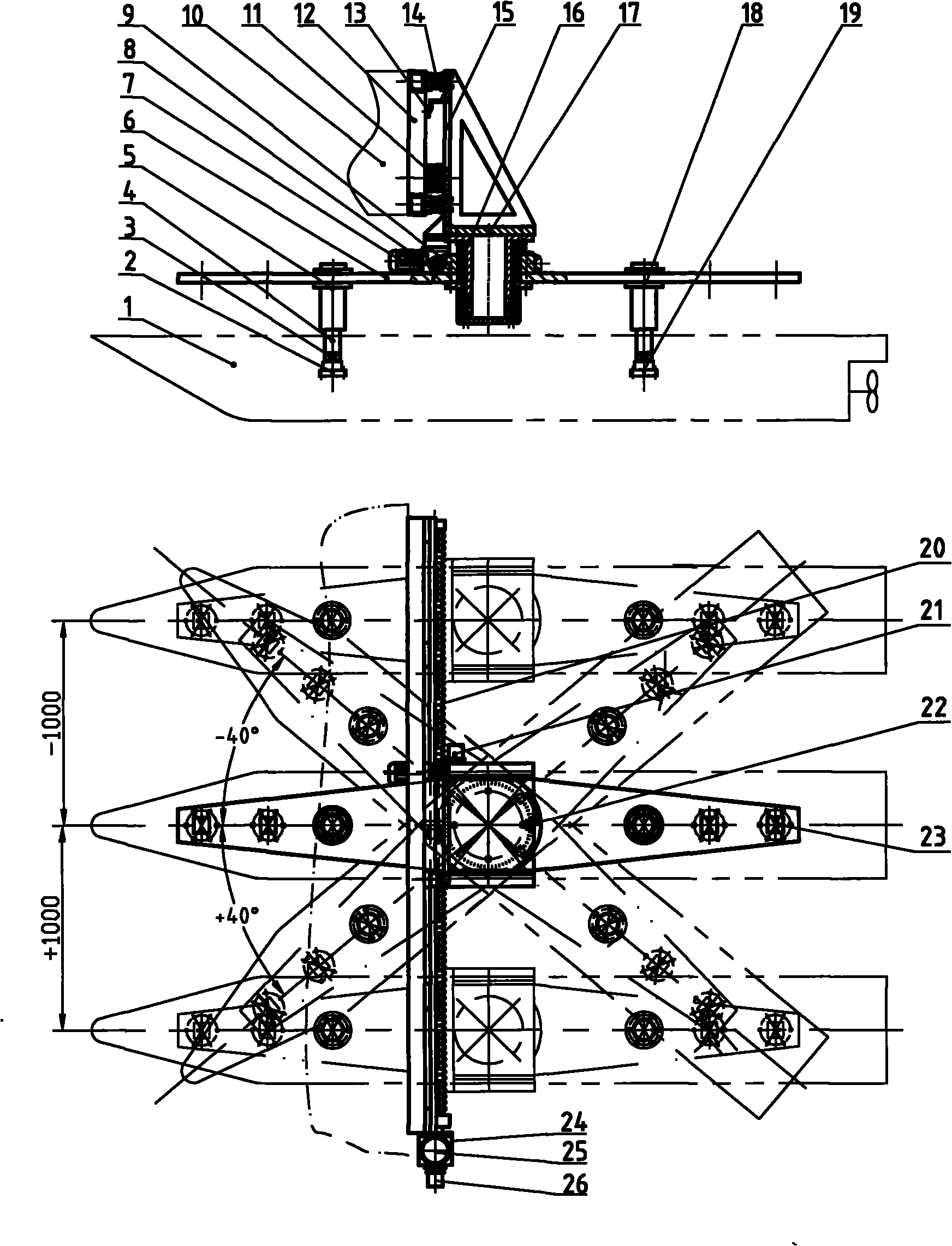

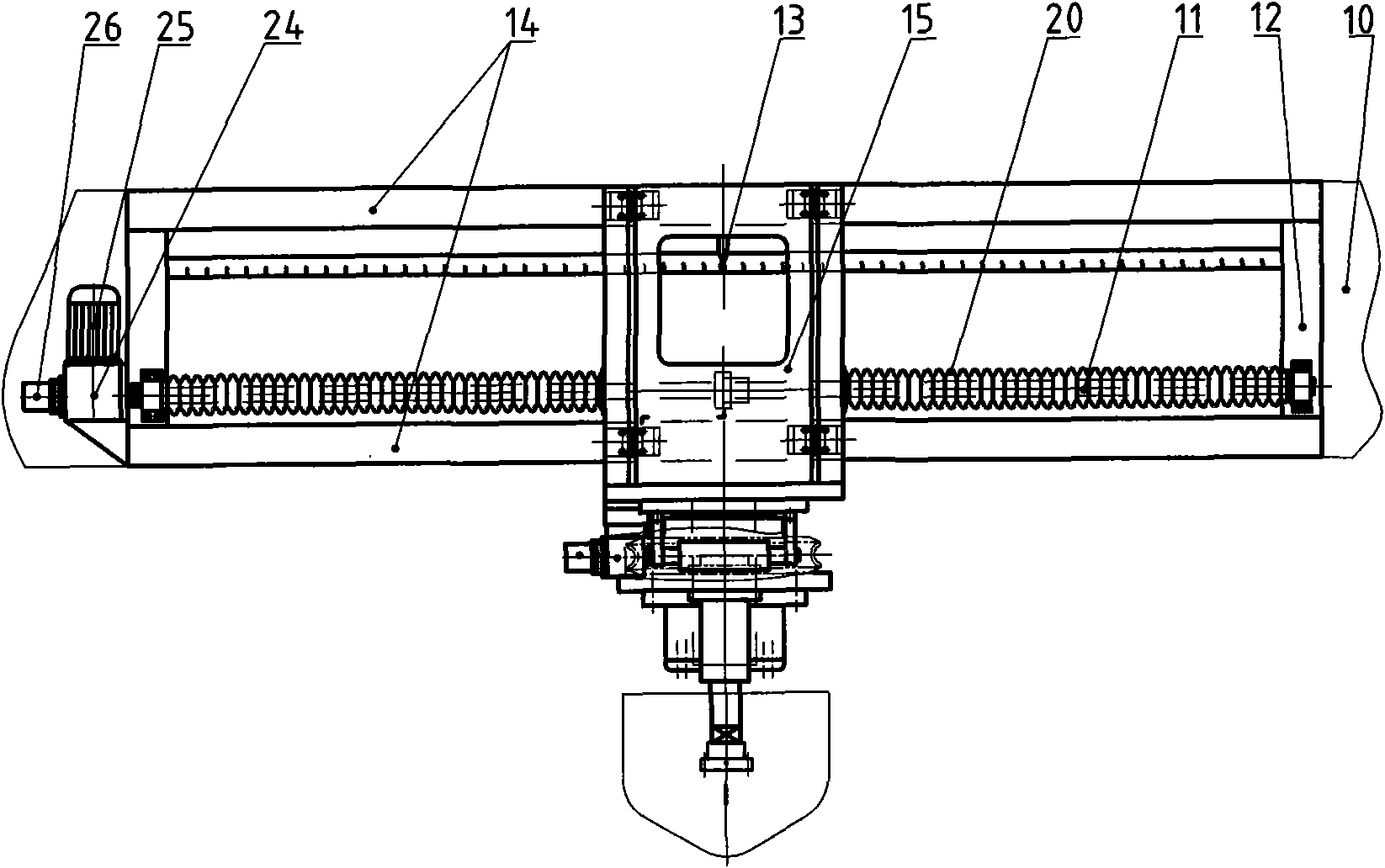

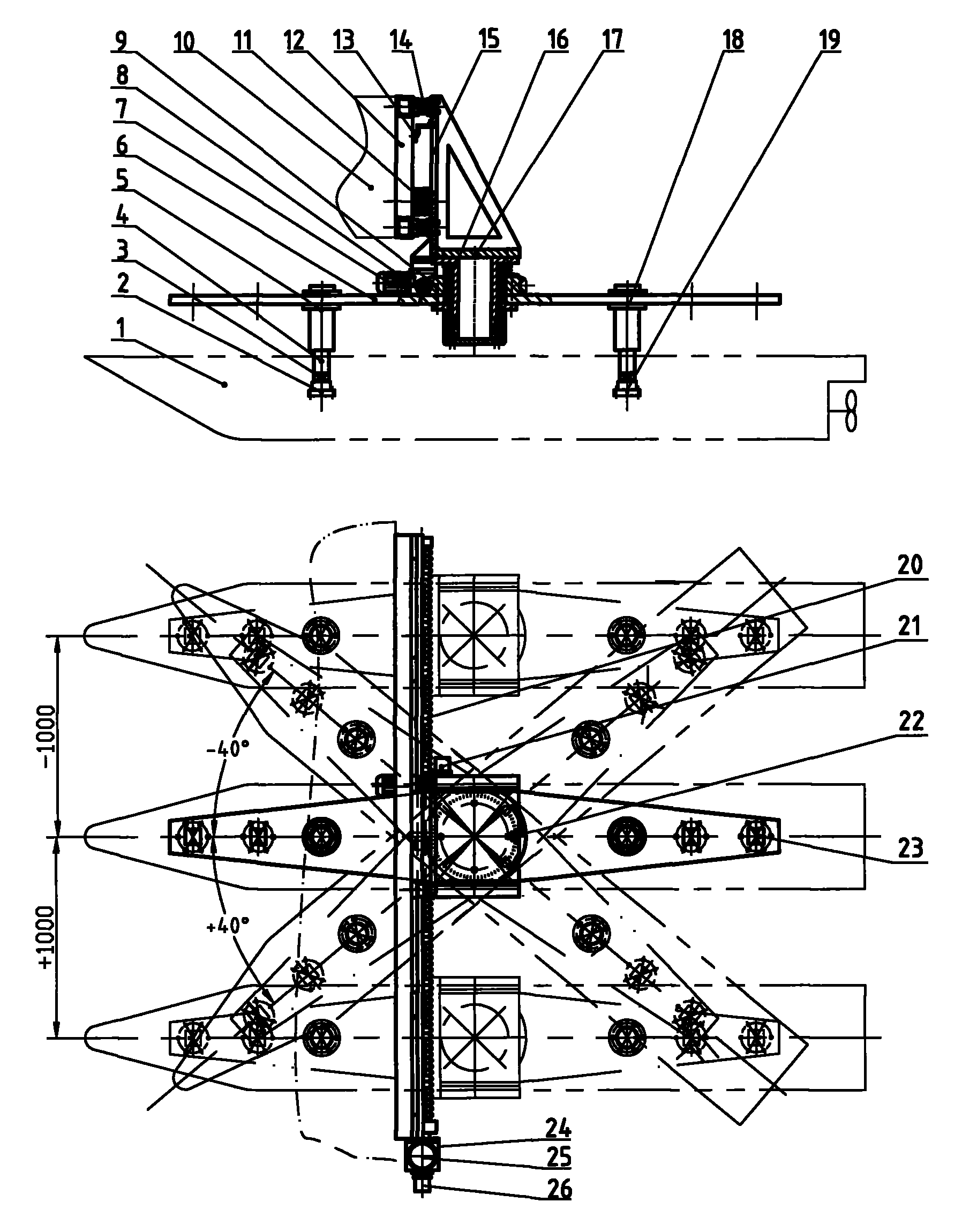

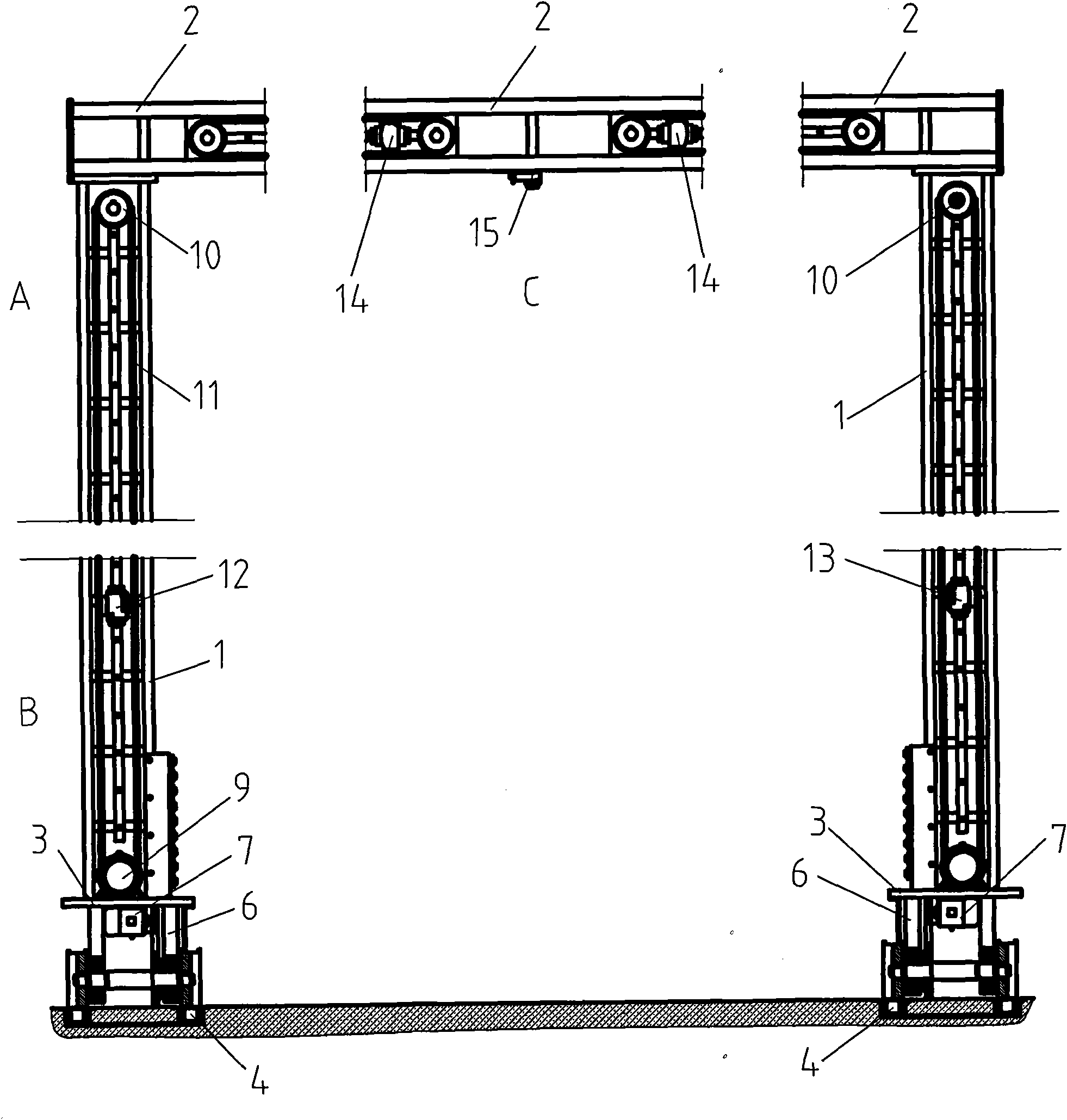

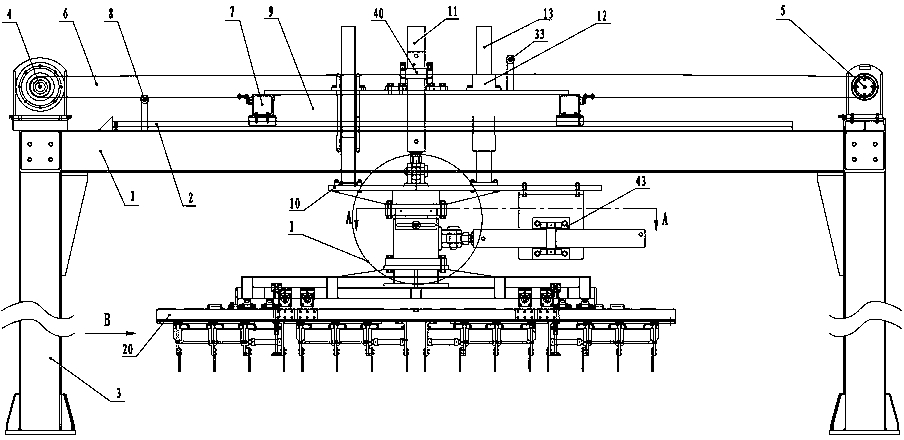

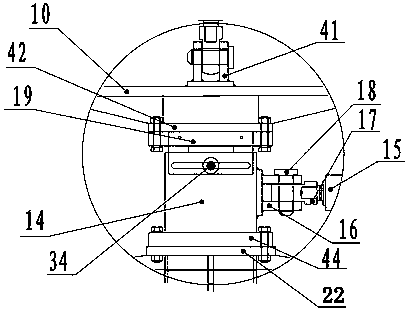

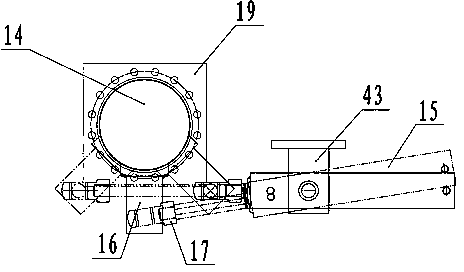

Horizontal plane motion mechanism for towing tank test

The invention discloses a horizontal plane motion mechanism for a towing tank test, which comprises a plane motion mechanism comprising a transverse oscillation frame 8, a transverse oscillation motion component 9, a yawing oscillation motion component 10, a transverse beam 6, a front connecting rod 5, a front connecting rod 11, adjusting rods 4 and 12, joints 3 and 13, force balances 2 and 14, and the like. The upper part of the horizontal plane motion mechanism is connected with a tank trailer 7 through the transverse oscillation frame 8, while the lower part is connected with a ship model 1 through the connecting rods 5 and 11 and force balances 2 and 14. By adopting a rolling guide rail, the transverse oscillation motion component has the characteristics of long service life, free maintenance for long-term work, high speed, low noise, high capacity of absorbing a mounting dimension error, and the like; and the transverse oscillation amplitude is over + / -1m, the ball screw precision is high and a transverse oscillation amplitude error is less than 0.2mm. Due to the adoption of a self-lubricating bearing and worm gear transmission, the yawing oscillation motion component has the advantages of wide rotation angle range, high torque, high self-locking property and high precision. A plurality of groups of connecting rod mounting holes are formed on the transverse beam and are suitable for different ship models. The connecting rod is provided with a linear bearing, and when the ship model is influenced by an external force to oscillate up and down, the connecting rod automatically adjusts the length, can remove a force in the vertical direction, and improves the accuracy of the maneuvering performance test. The control system is driven by a servo motor, a photoelectric encoder is used for sampling and feeding back, and a PLC programmable logic controller is used for controlling. The horizontal plane motion mechanism has the advantages of convenient control.

Owner:SHANGHAI ZHUGUANG MACHINERY +1

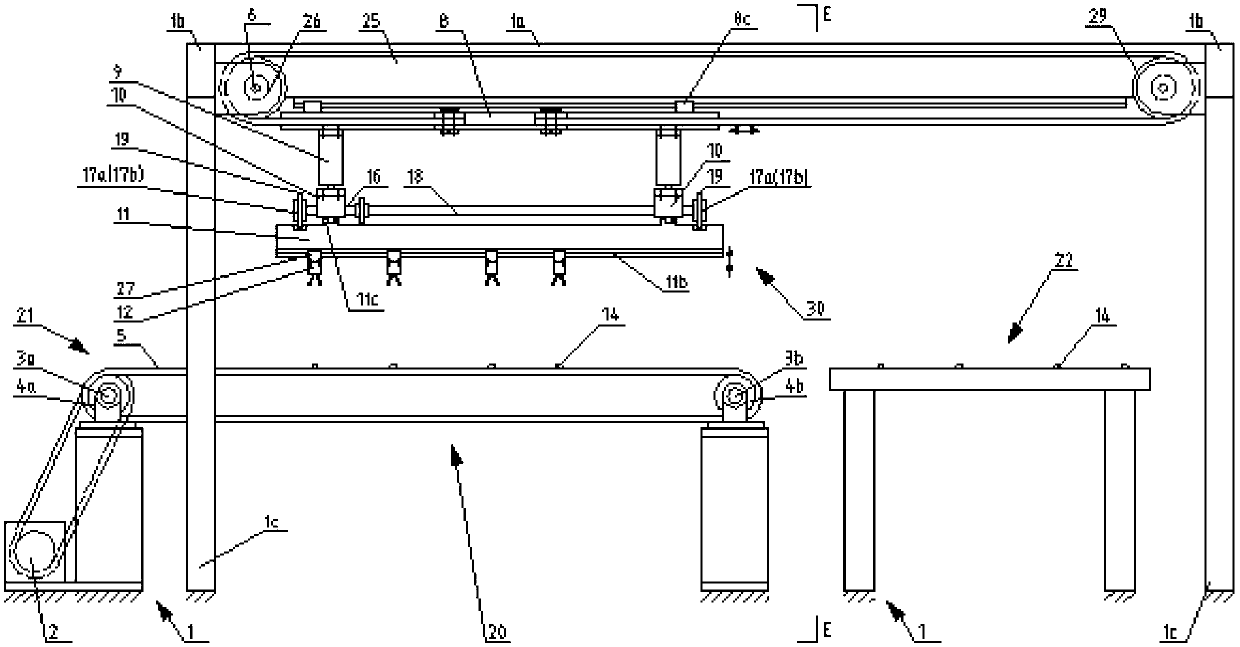

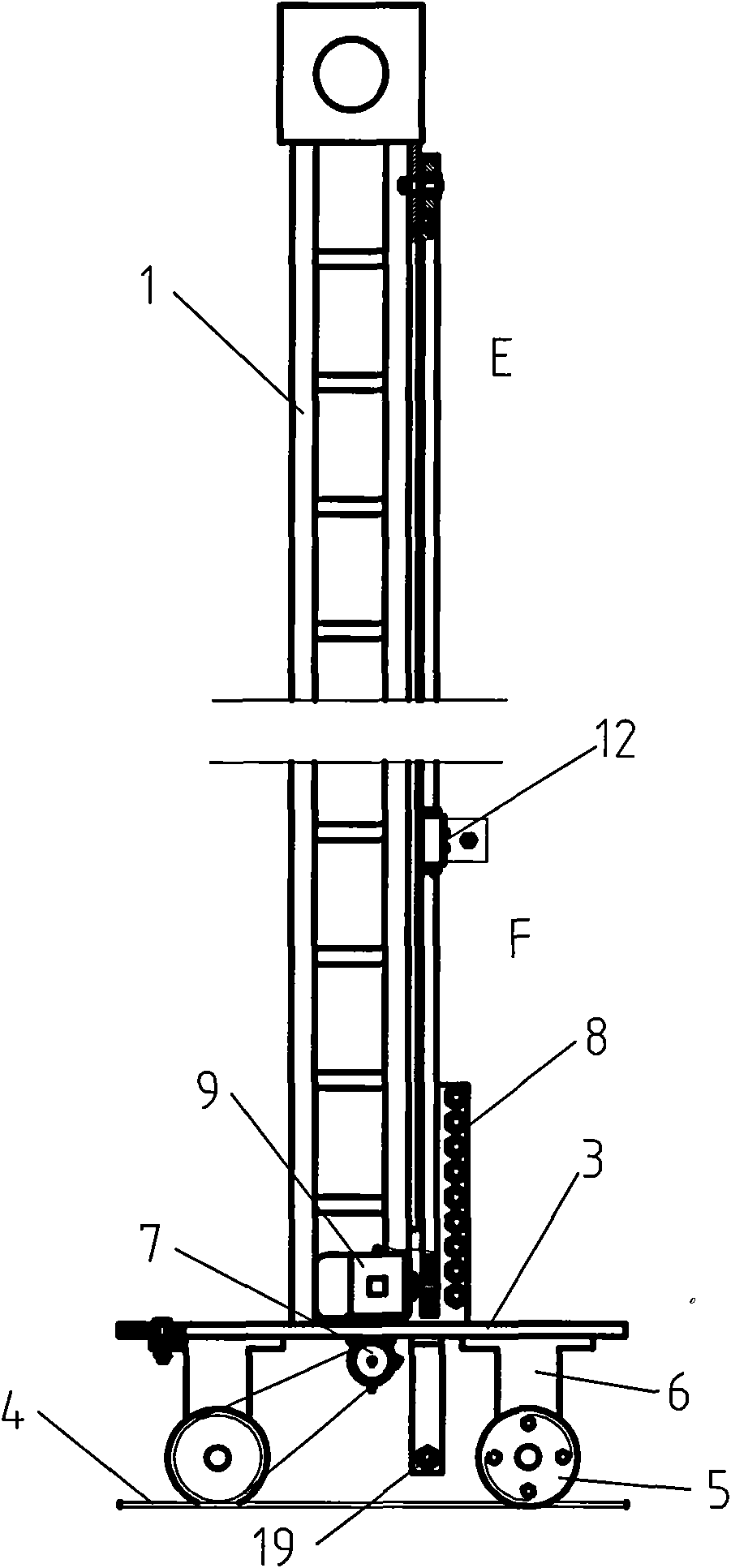

Reinforcing steel bar movement conveying mechanism of welding machine of mesh

The invention discloses a reinforcing steel bar movement conveying mechanism of a welding machine of mesh. The reinforcing steel bar conveying mechanism comprises a machine frame, a reinforcing steel bar movement input mechanism, a reinforcing steel bar movement output mechanism and a mesh welding work table. The reinforcing steel bar movement input mechanism comprises a plurality of horizontal conveying devices, and the reinforcing steel bar movement output mechanism comprises a plurality of longitudinal regulating beams, wherein a plurality of clamping mechanical arms are arranged at the bottom of each longitudinal regulating beam. The upper portion of each longitudinal regulating beam is provided with a transverse sliding block which is matched with the bottom of each transverse regulating beam in a sliding mode and is connected with the bottom of each transverse regulating beam in a hung mode, each transverse regulating beam is connected with a lifting mechanism connected with the lower portion of one conveying movement beam, and the upper portion of each conveying movement beam is hung on an upper longitudinal beam in a sliding match mode and is connected with a conveying driving mechanism which is arranged on an upper transverse beam of the machine frame. The reinforcing steel bar movement conveying mechanism has the advantages that the diameter and the length of each reinforcing steer bar on each horizontal conveying device can be regulated freely, reinforcing steer bar grids having different diameters and different intervals can be welded on the same mesh, market requirements are met, and production efficiency is high.

Owner:TJK MACHINERY TIANJIN

Machine for measuring outline dimension of vehicle

InactiveCN101685005AHigh measurement accuracyStrengthen supervisionUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansVehicle frameGobio gobio obtusirostris

The invention discloses a device for detecting three-dimensional dimensions of a vehicle, which has the advantages of accurate measurement and high measurement efficiency. The device comprises symmetric portal frames, a control circuit and an operation panel, wherein an vehicle frame (3) which can drive the frames to move and a track (4) which is matched with a wheel (5) are arranged at the lowerend of each of the frames; especially, a length measuring device for measuring the length of the vehicle and a height measuring device for measuring the height of the vehicle are arranged on an upright post (1) of each of the frames, and a width measuring device for measuring the width of the vehicle is arranged on a transverse beam (2) of each of the frames; and the control circuit and the operation panel are connected with each measuring device. The invention has high measurement accuracy and high measurement speed, and can quickly complete the measurement of the three-dimensional dimensionsof the vehicle.

Owner:廊坊市威达科技发展有限公司 +1

Baked brick setting machine

The invention discloses a baked brick setting machine, which comprises a walking system, an elevating system, a rotating system and a picking and placing system, wherein the elevating system, the rotating system and the picking and placing system are positioned on upper, middle and lower layers respectively; two parallel transverse beams of the walking system are provided with guide rails; the elevating system which can move along the transverse direction of the guide rails stretch across the guide rails; the lower part of the elevating system is fixedly connected with the rotating system; and a gripper system is fixedly connected to the lower part of the rotating system. The baked brick setting machine has the advantages of simple structure, flexibility and convenience in moving, running stability, high travel positioning accuracy, low power consumption, high efficiency and great increase in the automatic degree and working efficiency.

Owner:郑州德亿重工机器制造有限公司

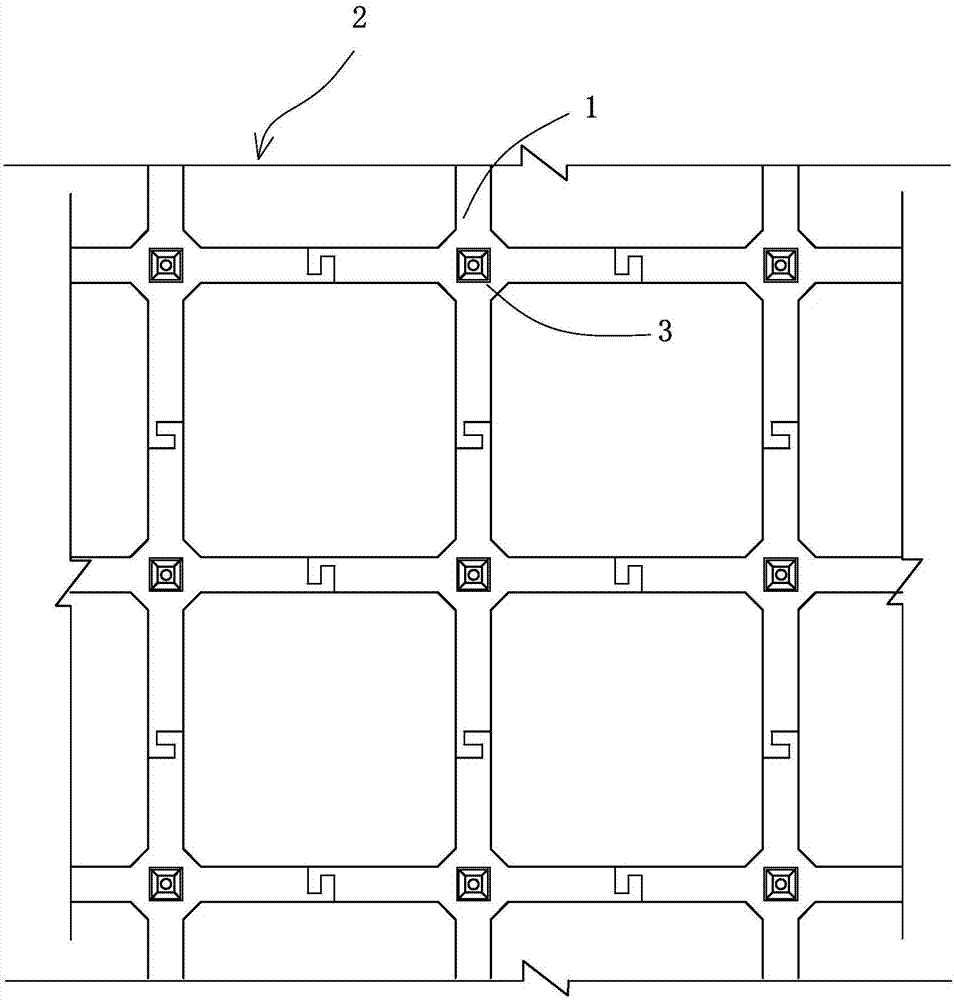

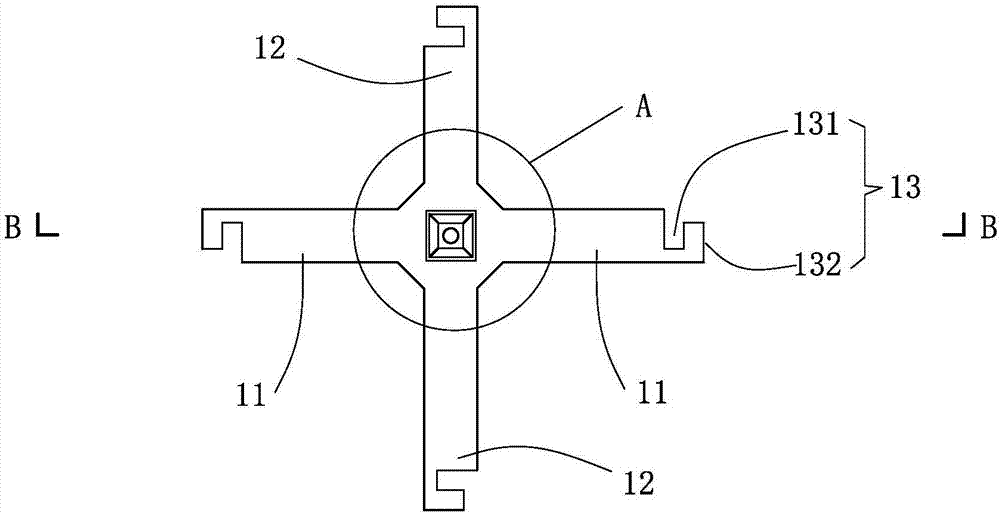

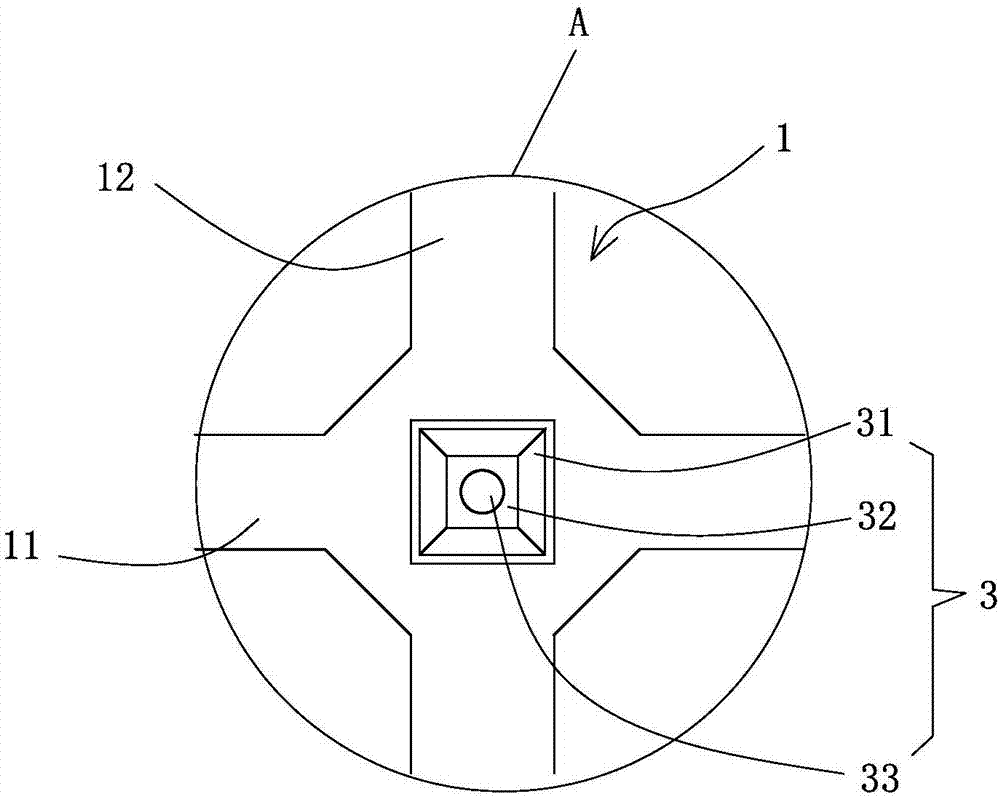

Precast lattice beam used for slope reinforcement, manufacturing method thereof and construction method for slope reinforcement adopting precast lattice beam

PendingCN107030874AEasy to manufactureEasy to installCeramic shaping apparatusExcavationsShaped beamChinese characters

The invention provides a precast lattice beam used for slope reinforcement and a construction method for slope reinforcement adopting the precast lattice beam, as well as a slope structure reinforced by the precast lattice beam and a construction method thereof. The precast lattice beam comprises a plurality of precast cross-shaped beam units which are arranged and connected in a matrix manner; each of the cross-shaped beam units comprises a transverse beam and a longitudinal beam in intersection; an anchor head part is formed in the central interacting part of each of the cross-shaped beam units; each of the anchor head parts comprises a concrete groove and a backing plate placed on the concrete groove; an anchor hole is formed in each of the concrete grooves and the backing plates; the two end parts of the transverse beam and the two end parts of the longitudinal beam of each of the cross-shaped beam units extend respectively to form L-shaped hook parts reversed in directions; the transverse beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; the longitudinal beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; therefore the precast lattice beam is formed by splicing a plurality of structures taking the shapes of the Chinese character jing. According to the precast lattice beam used for slope reinforcement, the manufacturing method thereof and the construction method for slope reinforcement adopting the precast lattice beam, the following characteristics are achieved: on-the-spot construction steps are reduced, the construction period is shortened, the standardized management production is realized, the quality is ensured, and high efficiency and environment protection are realized.

Owner:SHENZHEN ROAD & BRIDGE CONSTR GRP

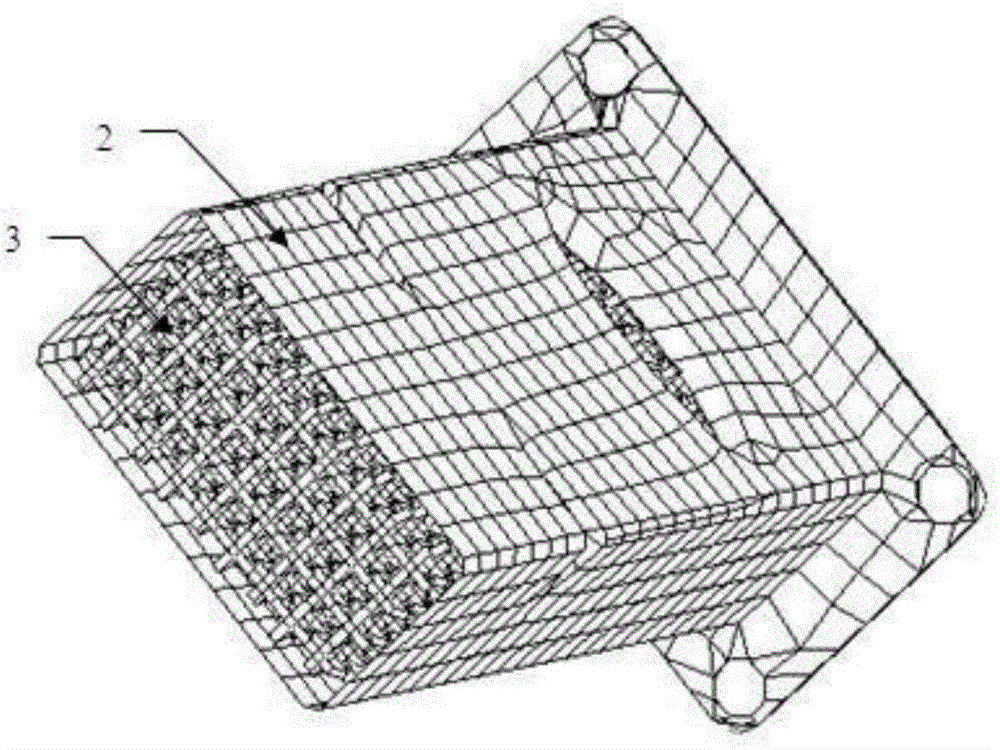

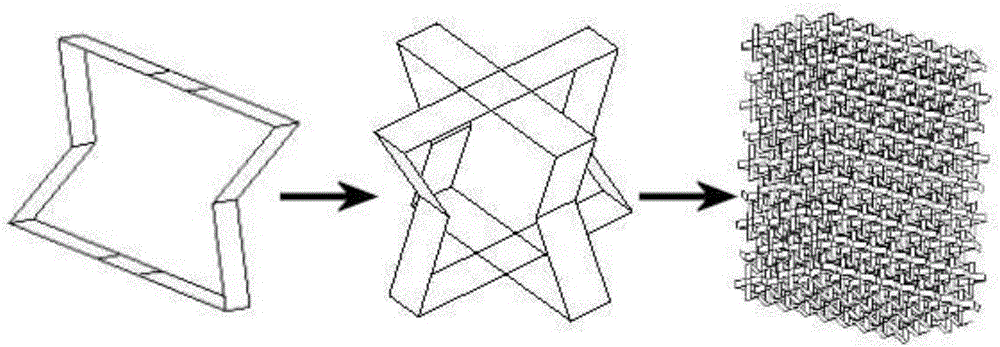

Automobile energy absorption box based on negative poisson ratio structure filling and multi-object optimization method thereof

ActiveCN106740620AImprove energy absorptionGood mechanical propertiesGeometric CADInternal combustion piston enginesEnergy absorptionEngineering

The invention discloses an automobile energy absorption box based on negative poisson ratio structure filling and a multi-object optimization method thereof. An energy absorption box body (2) is filled with negative poisson ratio filling inner cores (3) with an inner sunken hexagonal negative poisson ratio structure, wherein deformation induction grooves are designed on the energy absorption box body (2). The energy absorption box body is connected between front protection transverse beams and front longitudinal beams. Through mechanical properties uniquely owned by the negative poisson ratio structure, a stress deformation state during automobile collision is improved, and the energy absorption effect is reinforced, so that safety of passengers is improved, and maintenance cost is reduced. Meanwhile, the invention provides a multi-object optimization scheme aiming at the novel structure; through parametric modeling of the energy absorption inner cores, an energy absorption outer shell and a surrounding structure, on the basis of the Hamersley experimental design, the structure is subjected to crash simulation, a model approximating a response surface is obtained, and finally optimal design parameter combination is obtained on the basis of multi-object optimization of imperial competition algorithm; and the process can be applied to the development process of actual industrial production, reliability is improved, and the development time is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com