Multicolumn strip packing machine

A packaging machine and strip-shaped technology, which is applied to multiple packages, packaging, transportation packaging, etc., can solve the problems of gap heat sealing effect, unevenness, and badness, so as to improve the quality and efficiency of horizontal sealing, improve Productivity, the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

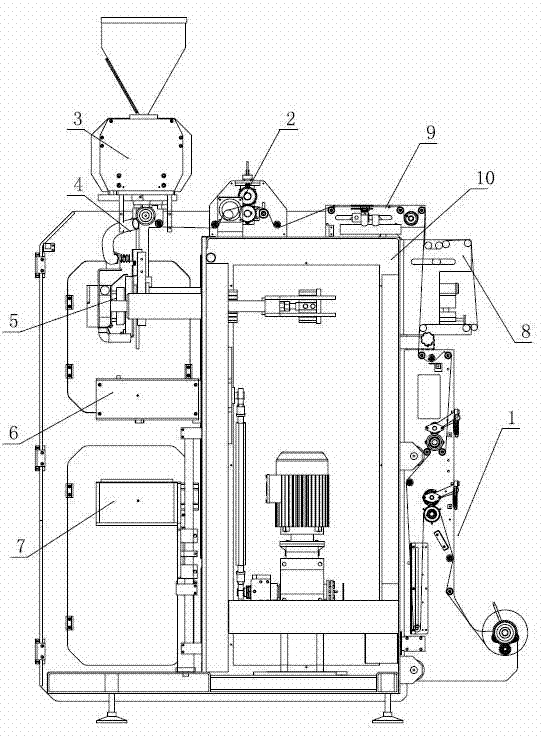

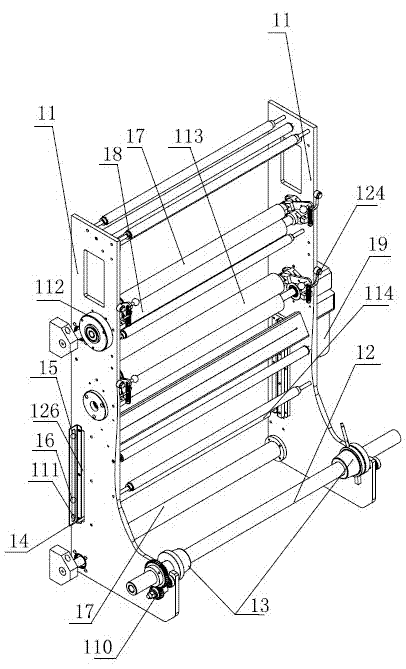

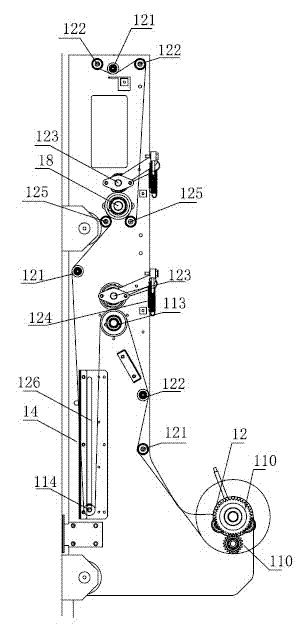

[0061] The multi-row strip packaging machine includes a frame 10, and a film-moving mechanism 1, a cutting knife mechanism 2, a feeding mechanism 3, a bag forming mechanism 4, a vertical sealing mechanism 5, and a horizontal sealing mechanism 6 respectively arranged on the frame 10. And cutting mechanism 7, described moving film mechanism 1 top is provided with dividing cutter mechanism 2, and adjacent dividing cutter mechanism 2 is provided with feeding mechanism 3 and bag forming mechanism 4, and feeding mechanism 3 is connected with bag forming mechanism 4 A vertical sealing mechanism 5 is arranged below the bag forming mechanism 4, a horizontal sealing mechanism 6 is arranged below the vertical sealing mechanism 5, and a cutting mechanism 7 is arranged below the horizontal sealing mechanism 6.

[0062]After the packaging film passes through the film moving mechanism 1, the cutting knife mechanism 2 and the bag forming mechanism 4, the packaging material input from the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com