Patents

Literature

92 results about "Strip packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

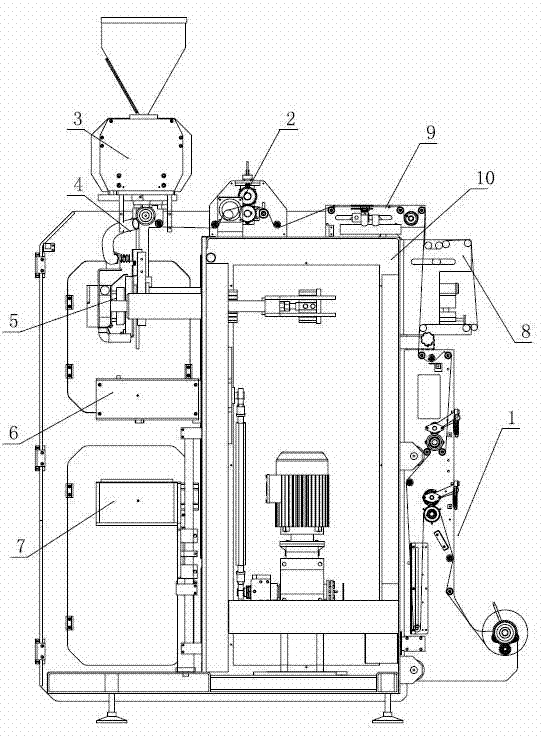

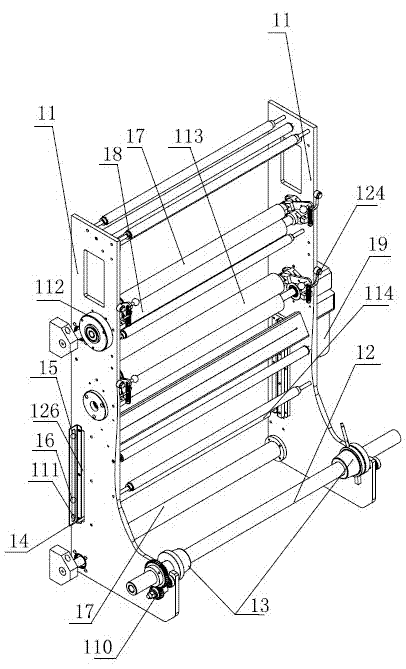

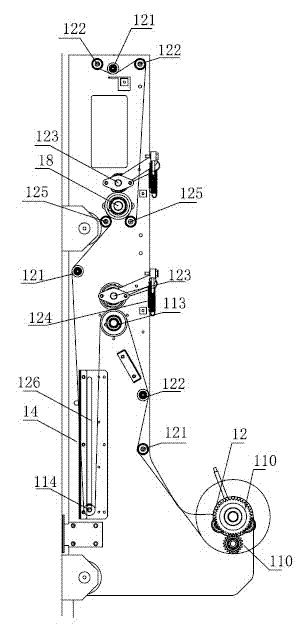

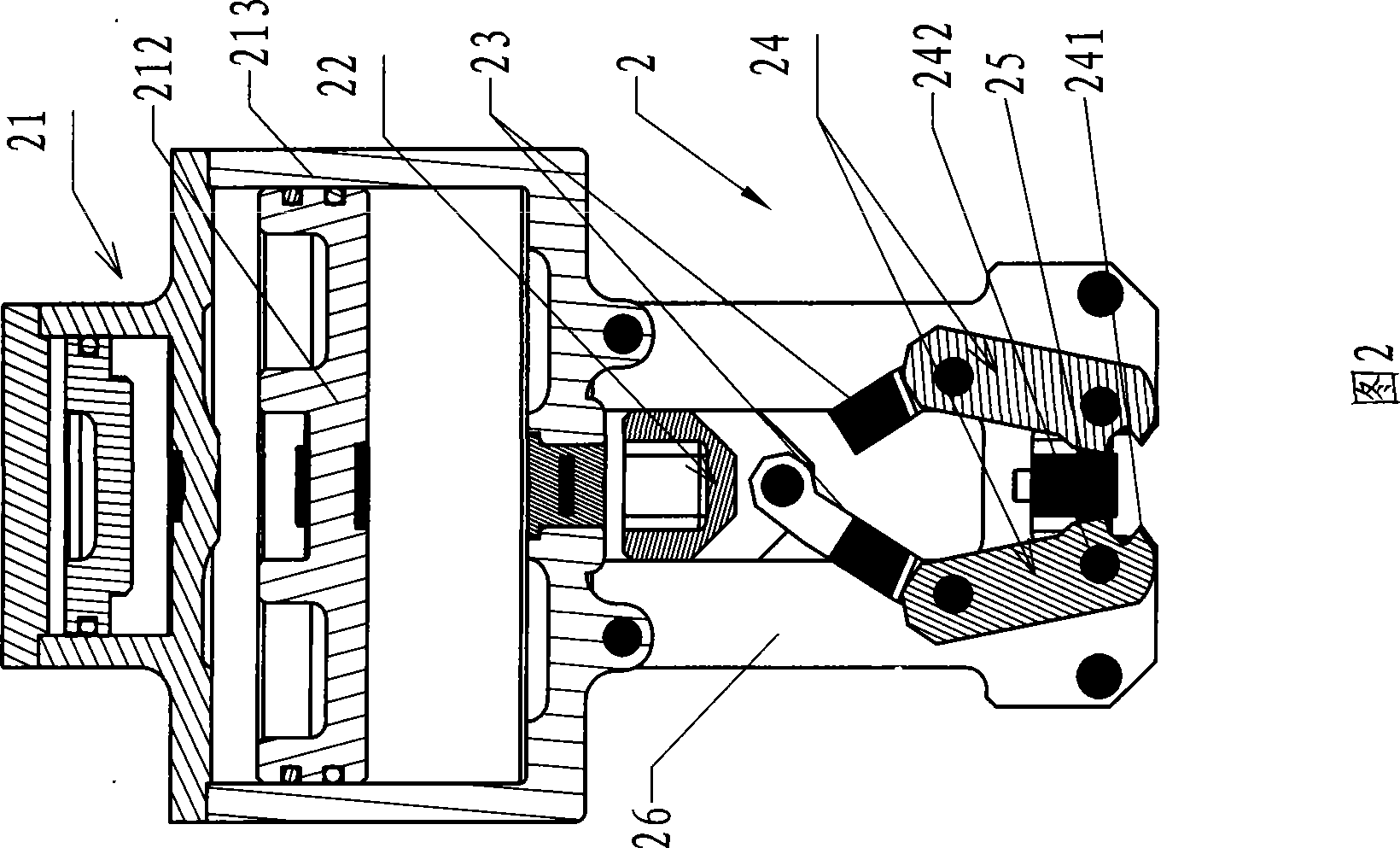

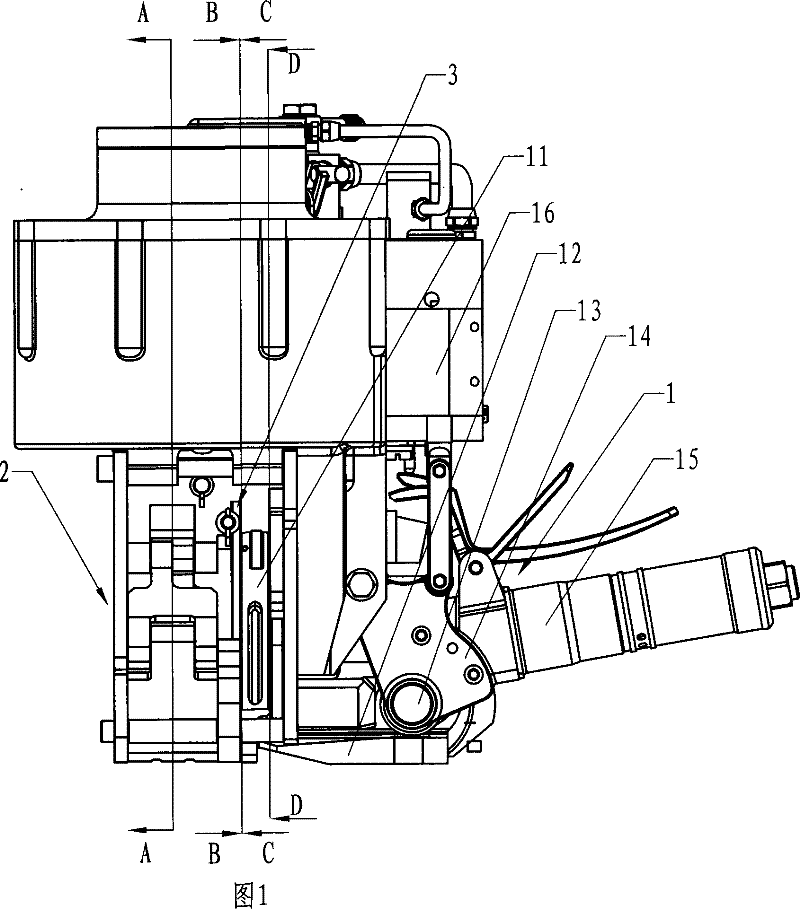

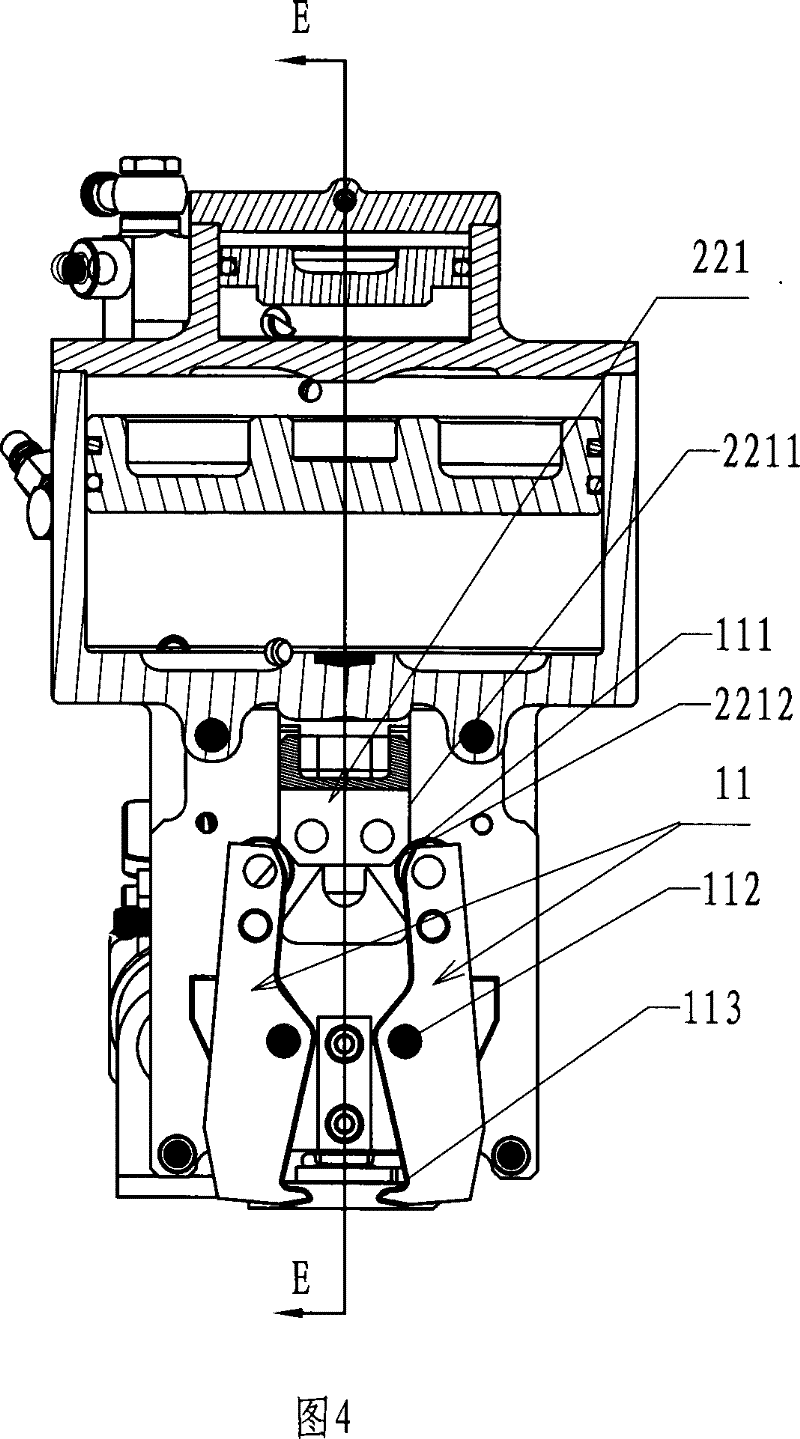

Multicolumn strip packing machine

ActiveCN102730214AIncrease productivitySimple structureWrapping material feeding apparatusWrapper twisting/gatheringReciprocating motionEngineering

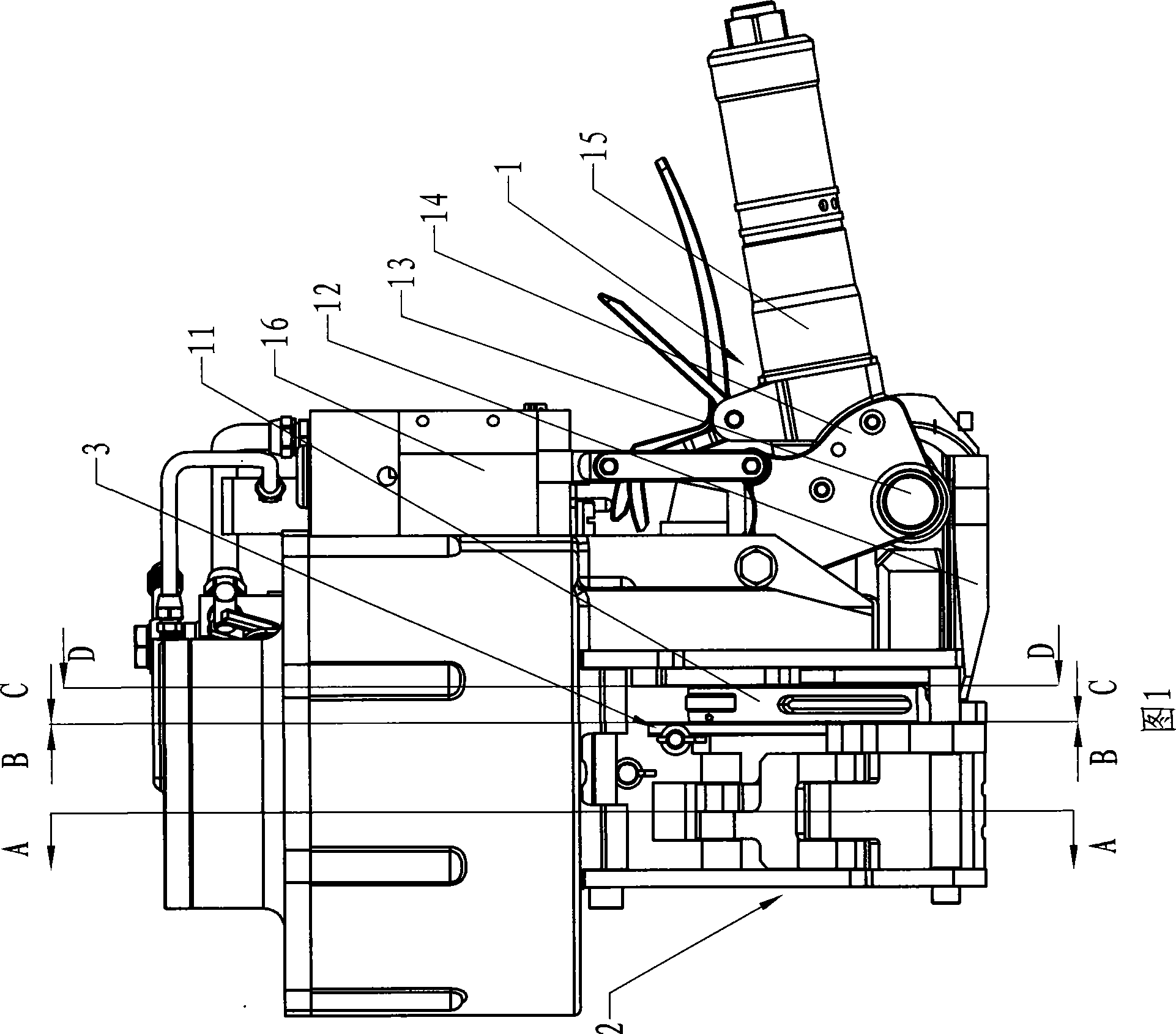

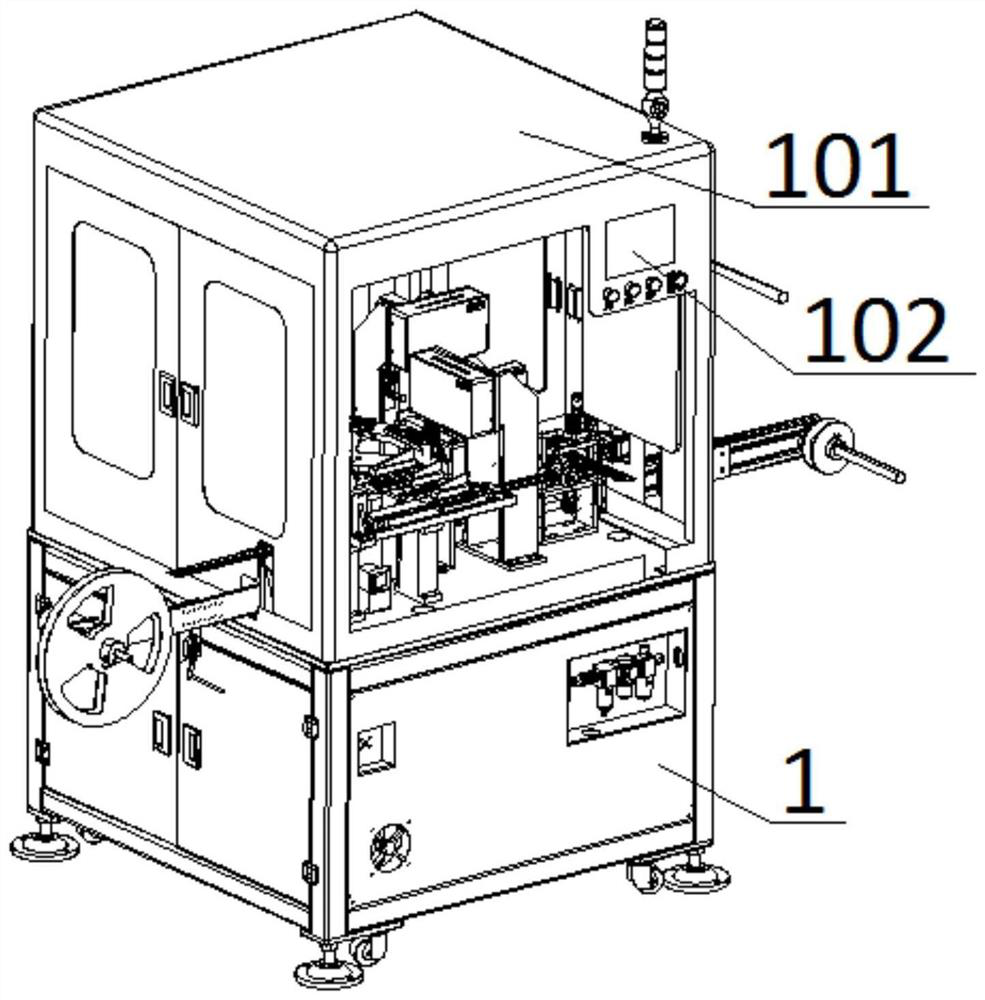

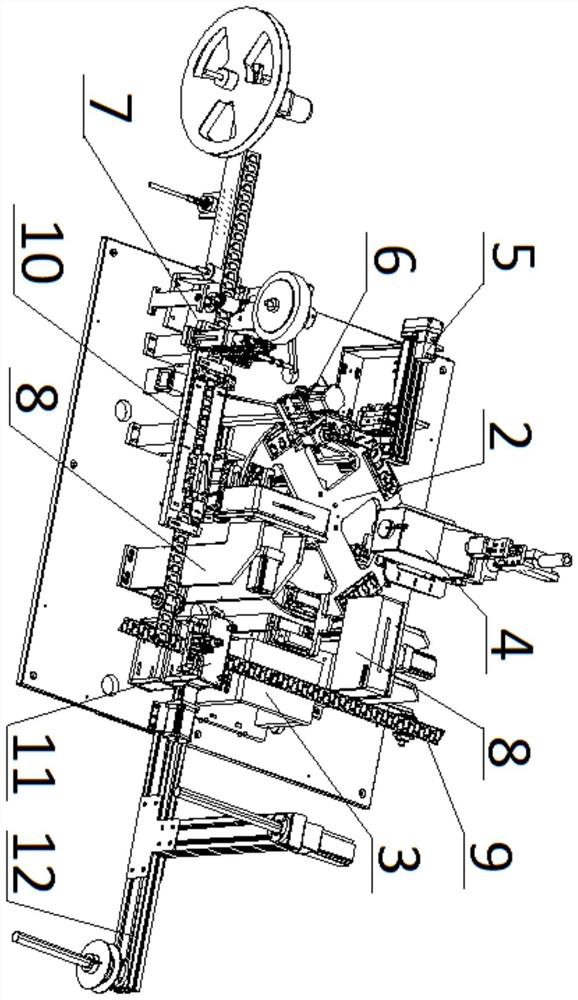

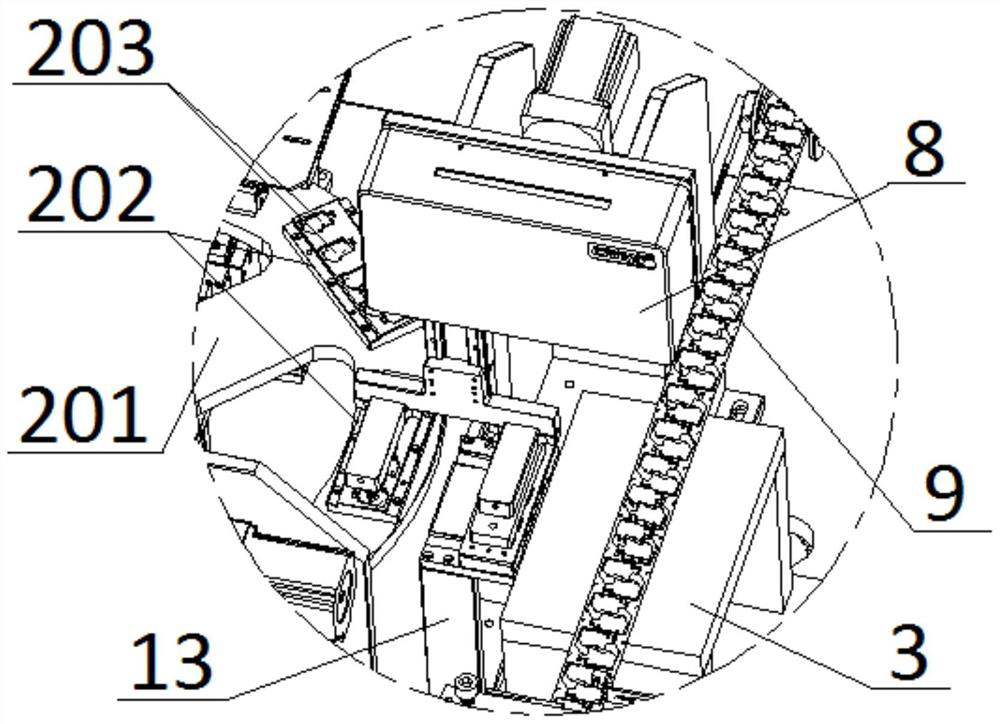

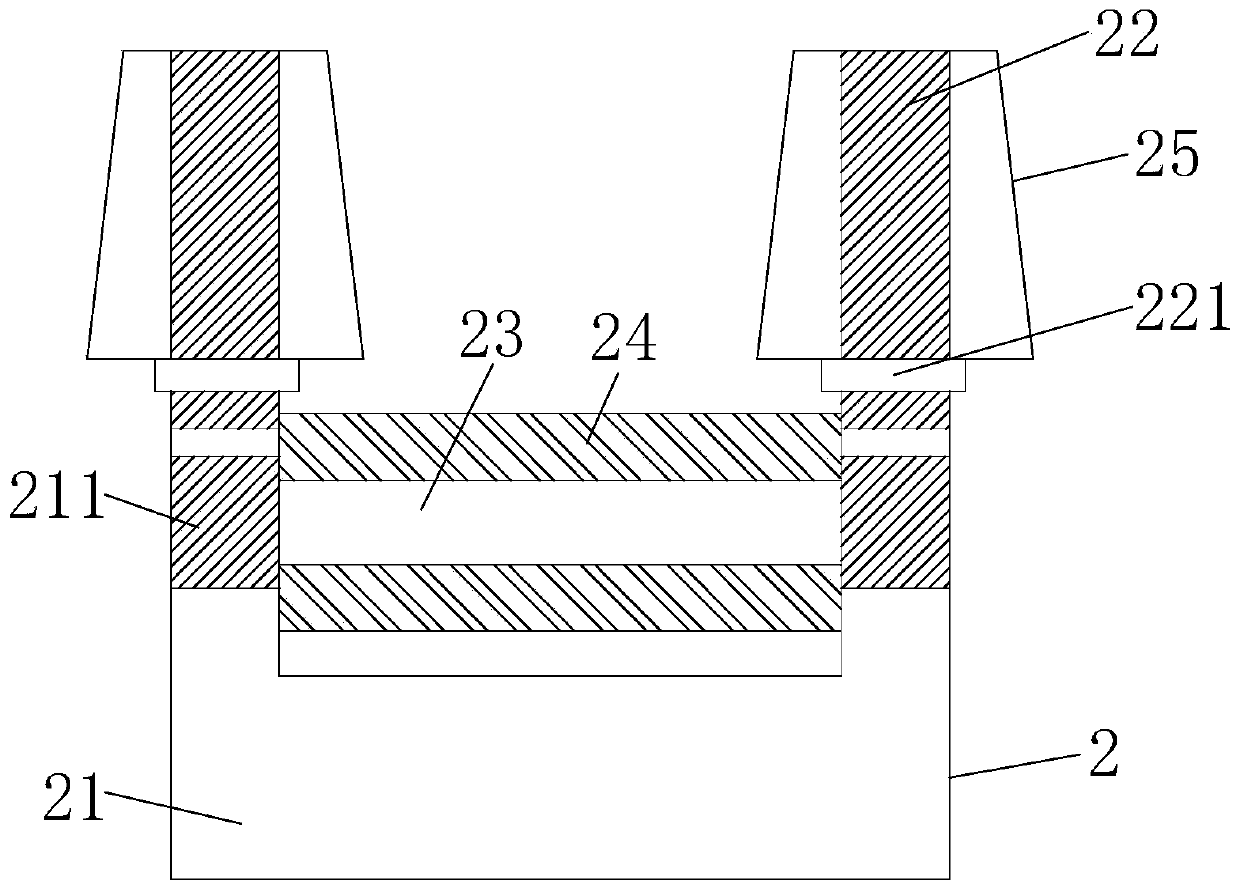

The invention relates to a multicolumn strip packing machine, in particular to a multicolumn strip packing machine capable of carrying out continuous bag-making and packing through automatic operation, comprising a frame, and a film feeding mechanism, a slitting cutter mechanism, a feeding mechanism, a bag molding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism and a cut-off mechanism arranged on the frame respectively, wherein the transverse sealing mechanism comprises a transverse sealing device which comprises a transverse sealing floating device, two transverse sealing holders, and transverse sealing seats arranged on the two transverse sealing holders respectively; a plurality of transverse sealing guide shafts are together sleeved to transverse beam sliders on the same side; at least one transverse sealing seat is connected to a transverse sealing cylinder for driving the transverse sealing seat to do reciprocating motion; and the axial direction of the transverse sealing guide shaft is consistent with the motion direction of the transverse sealing seat. The transverse sealing mechanism of the multicolumn strip packing machine is capable of providing a buffering force for an object to be packed so that the impact on the object to be packed can be reduced and the object to be packed can be protected against damage; and a plurality of combined components are arranged in a multi-row parallel manner, so that the production of a plurality of packing bags can be completed at the same time; as a result, the production efficiency is greatly improved.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

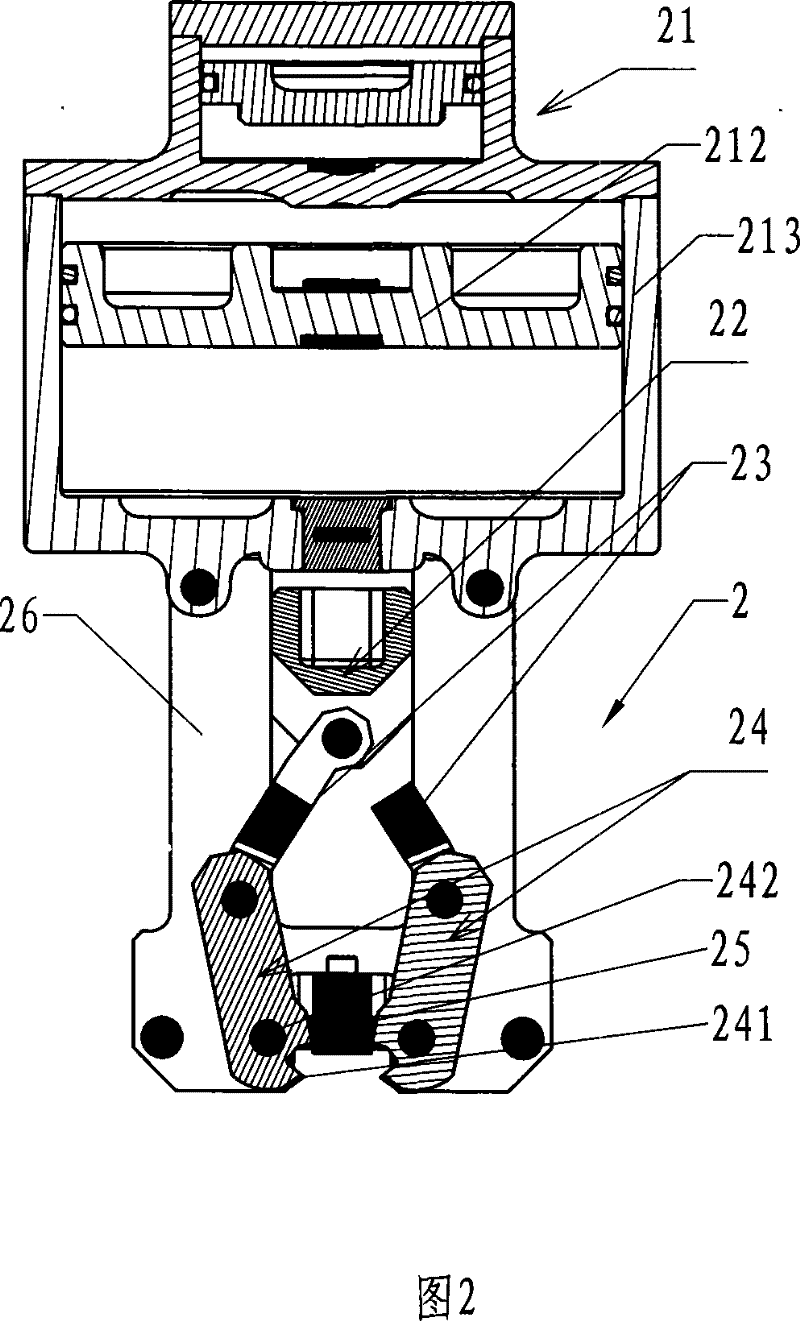

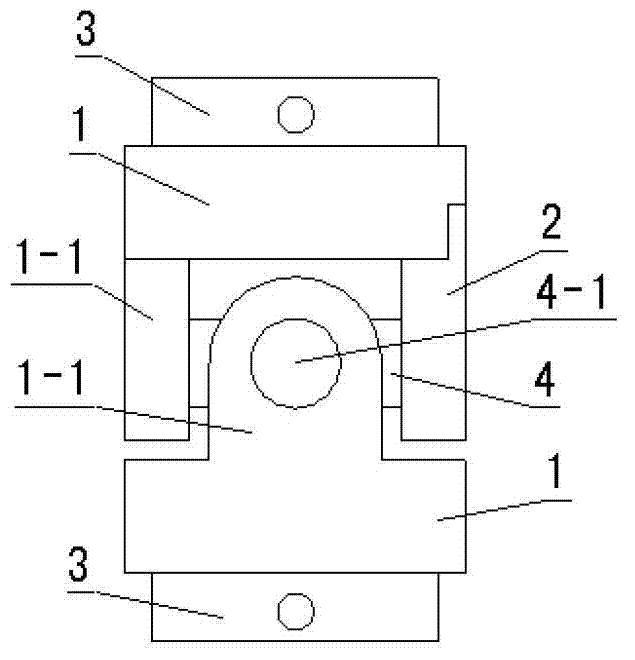

Binding machine with buckling-free steel belt

InactiveCN101391661AImprove bindingSave lockBinding material applicationBundling machine detailsLocking mechanismEngineering

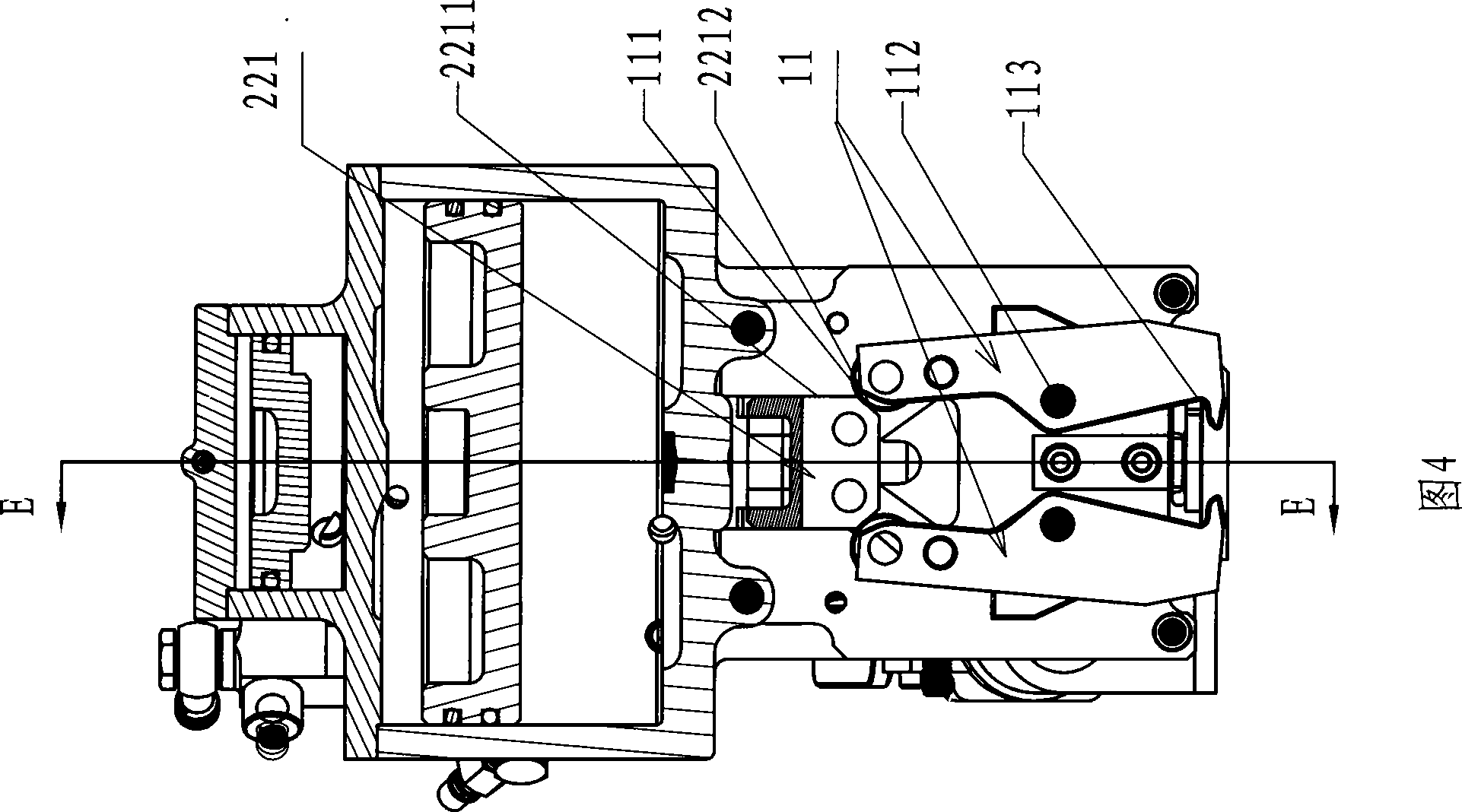

The invention relates to a non-fastening steel strip packing machine which comprises a steel strip tensing mechanism, a steel strip pressing and locking mechanism and a steel strip cutting mechanism. The steel strip pressing and locking mechanism comprises left and right static indentation blocks, a left dynamic indentation block and a right dynamic indentation block, a front back fixing side board and a back fixing side board that are used for fixedly connecting a second air cylinder and a second air cylinder body, and a slide block that is fixed on a telescopic rod of the second air cylinder, the lower end of the slide block is respectively hinged with left and right connecting boards, the lower ends of a left connecting board and a right connecting board are hinged with the left dynamic indentation block and the right dynamic indentation block, the lower ends of the left dynamic indentation block and the right dynamic indentation block respectively take a shape of an arc indented claw, the static indentation blocks are fixedly arranged between the left and right dynamic indentation blocks and simultaneously above the arc indented claws, the second air cylinder is a double-level air cylinder, the slide block has an extension end, side walls at two sides of the extension end take a shape of being vertical at the upper end and inwardly-tilted at the lower end, a left pressure board and a right pressure board are hinged with a back fixing board, the lower ends of the left pressure board and the right pressure board are provided with inward dummy clubs that are arranged below a tensing seat, and the upper ends of the left pressure board and the right pressure board respectively press against the side walls of the extension end of the slide block.

Owner:张温堤

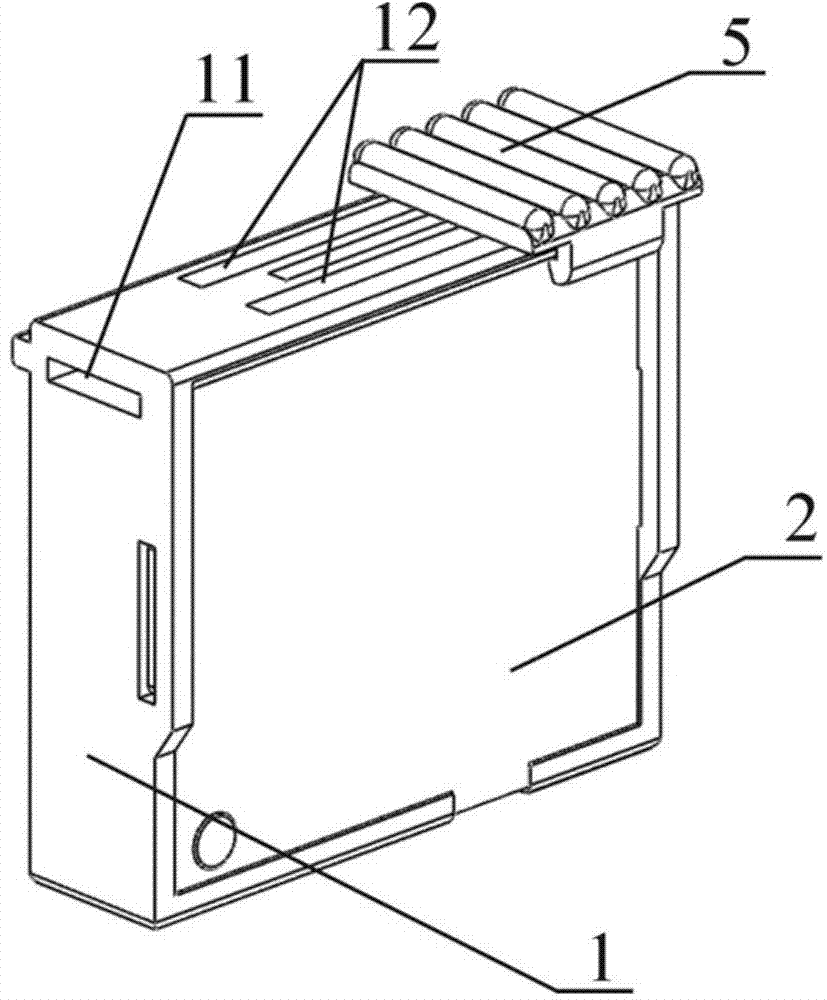

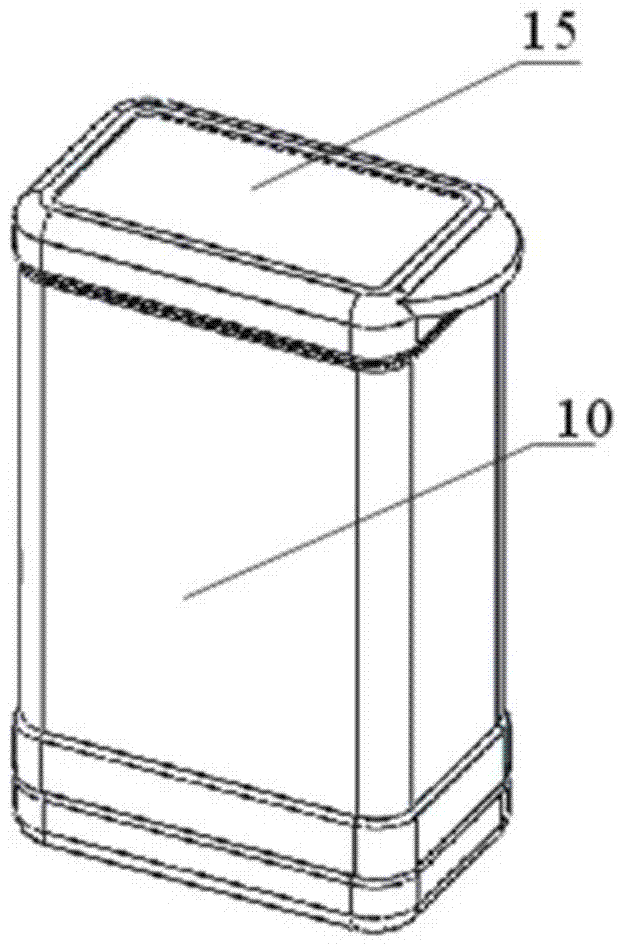

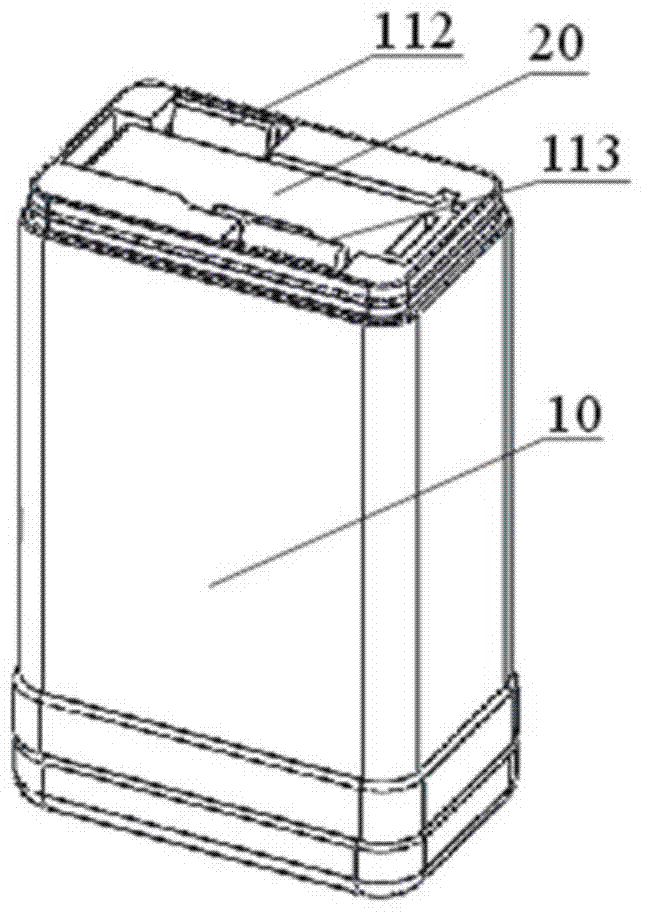

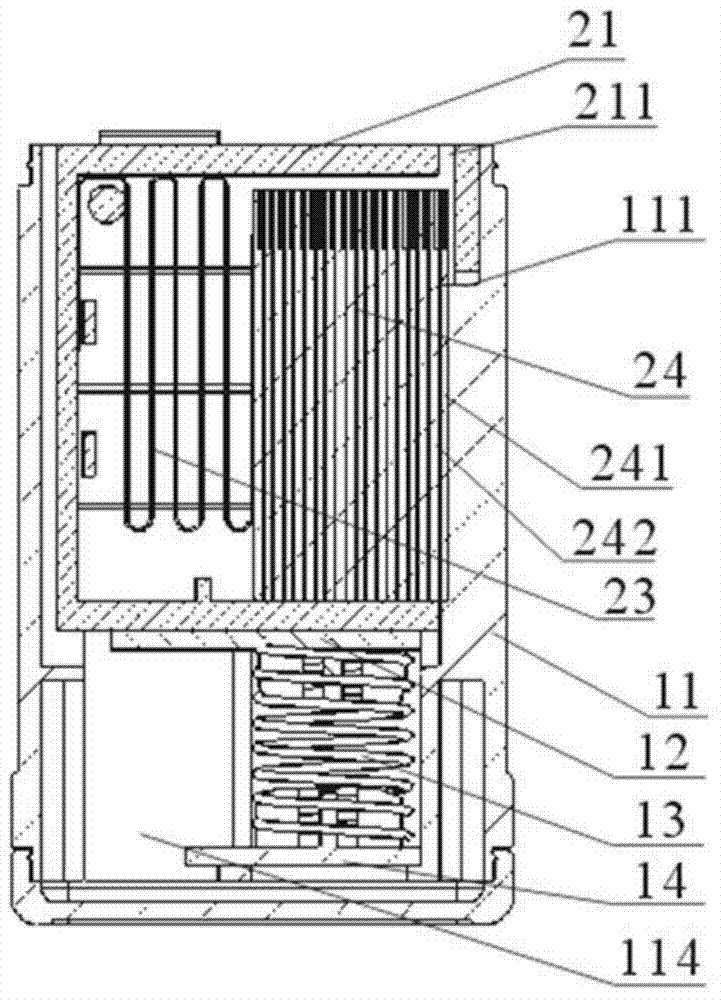

Testing strip packing box

InactiveCN103496515AAvoid pollutionGood effectFlat article dispensingEngineeringStructural engineering

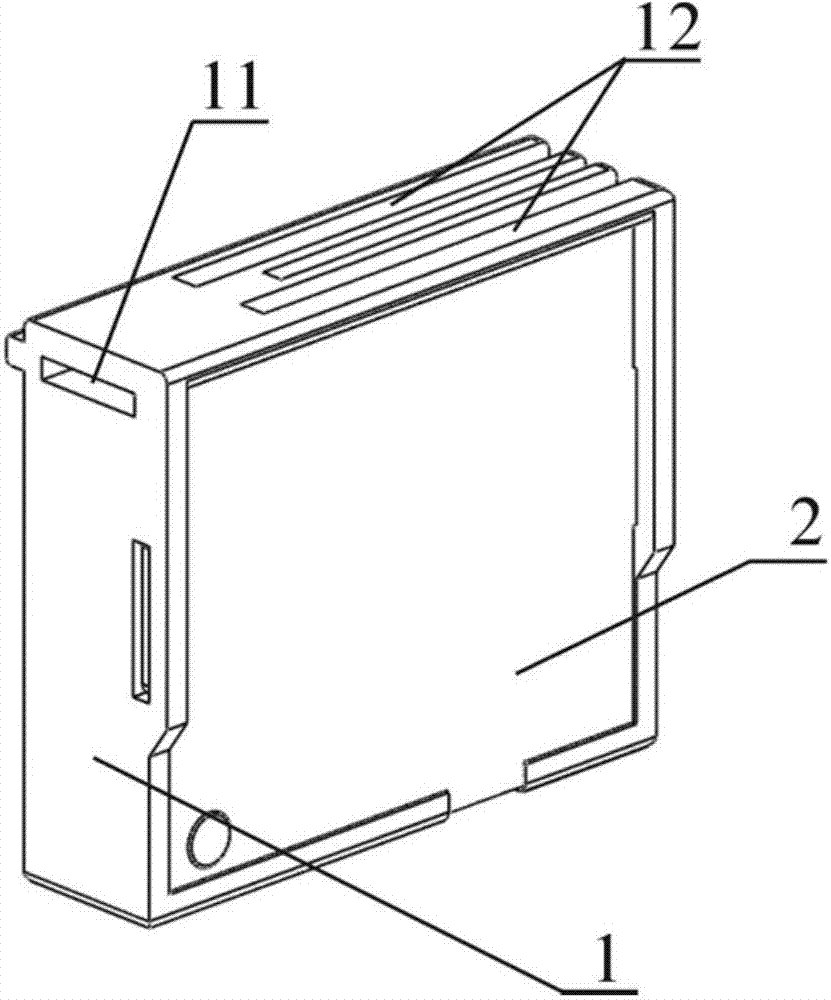

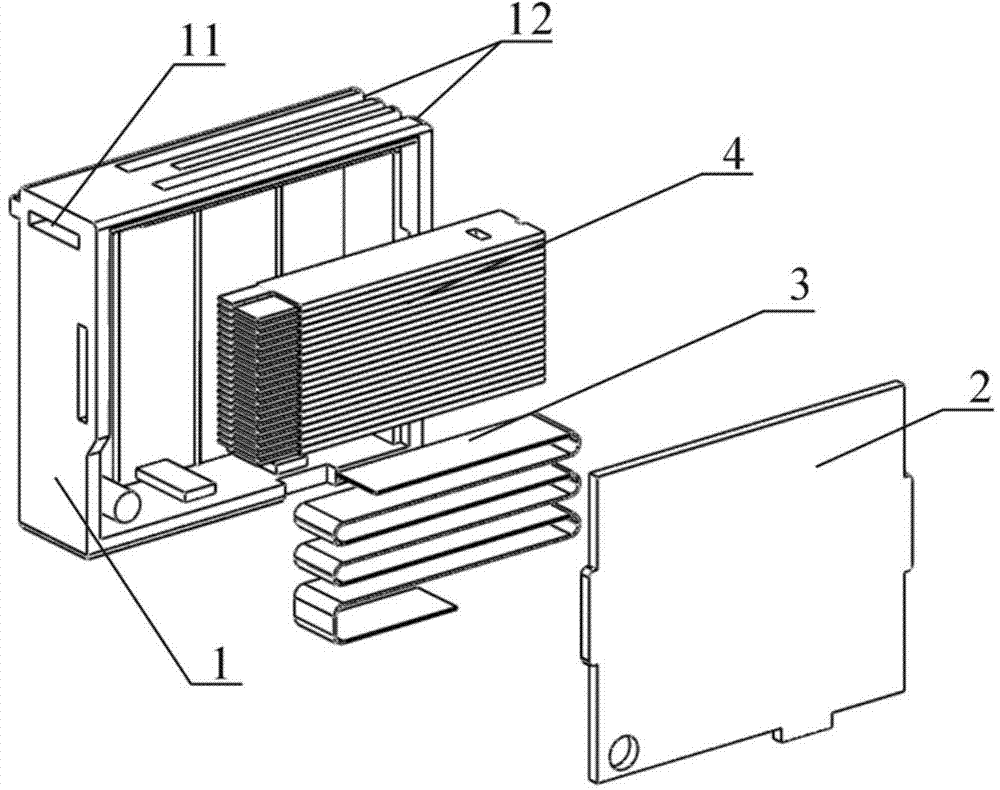

The invention discloses a testing strip packing box. The testing strip packing box comprises a box body and a box cover, wherein an outlet and at least one notch are formed in the box body, the notches allow testing strips to be pushed out, an elastic pressing device used for pressing the testing strips is arranged in the box body, and the two ends of the elastic pressing device make contact with the inner wall of the box body and the contact face of each testing strip respectively so that each testing strip can be sent to the waiting position of the outlet. A transfer plate is arranged between the elastic pressing device and the testing strips, and the elastic pressing device presses the testing strips through the transfer plate. The packing box further comprises a testing strip pushing part which can slide along a side wall of the box body, and the testing strip pushing part is detachably connected with the side wall, provided with the notches, of box body. Protruding blocks and buckles are arranged on the testing strip pushing part, the testing strip pushing part is connected with the side wall, provided with the notches, of the box body in a clamped mode through the buckles, and the protruding blocks extend into the box body through the notches to push the testing strips out of the outlet. According to the testing strip packing box with the structure, a user can take out the testing strips without making contact with the testing strips by hand when using the testing strip packing box, and therefore the testing strips are prevented from being stained.

Owner:NANJING YUYUE SOFTWARE TECH +3

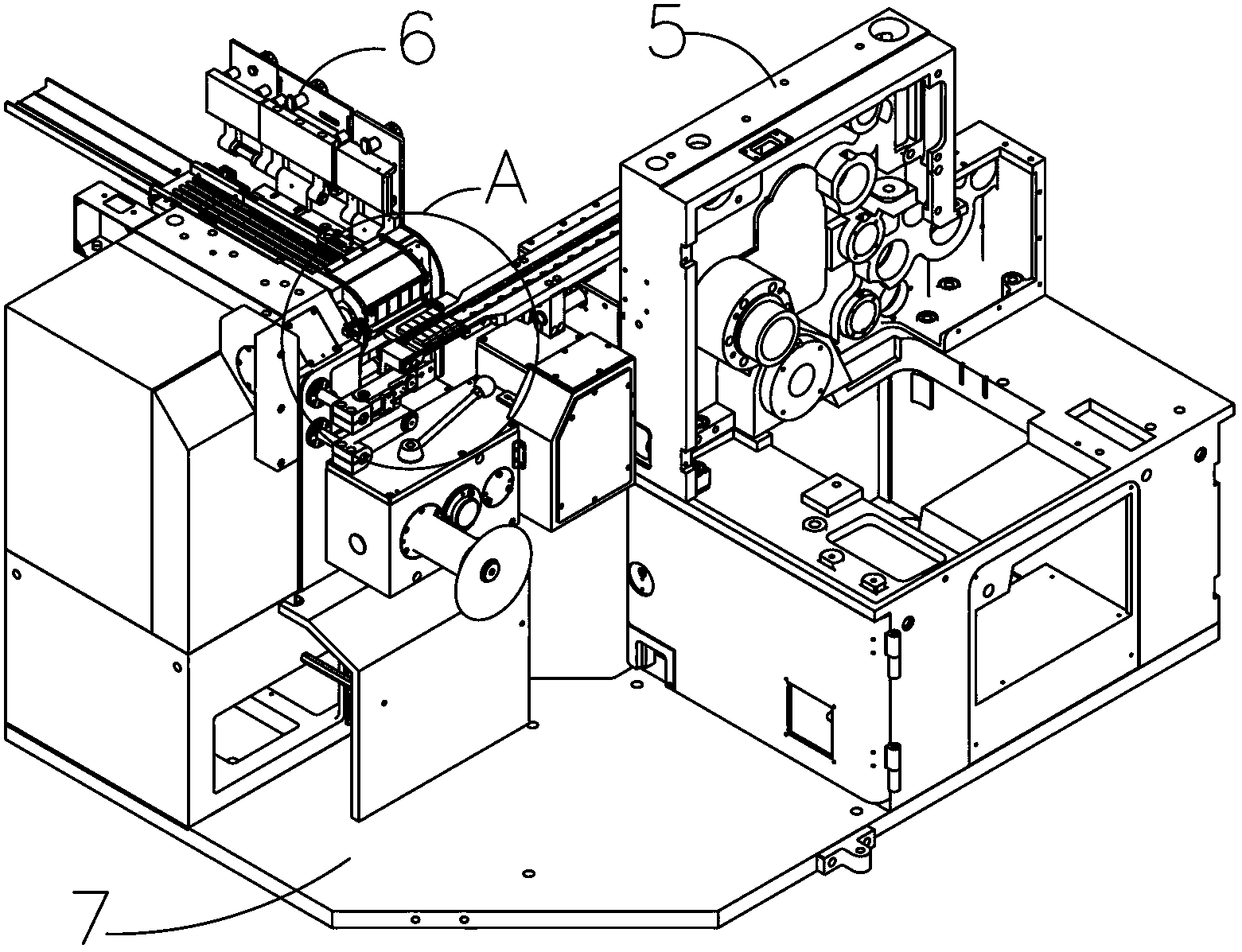

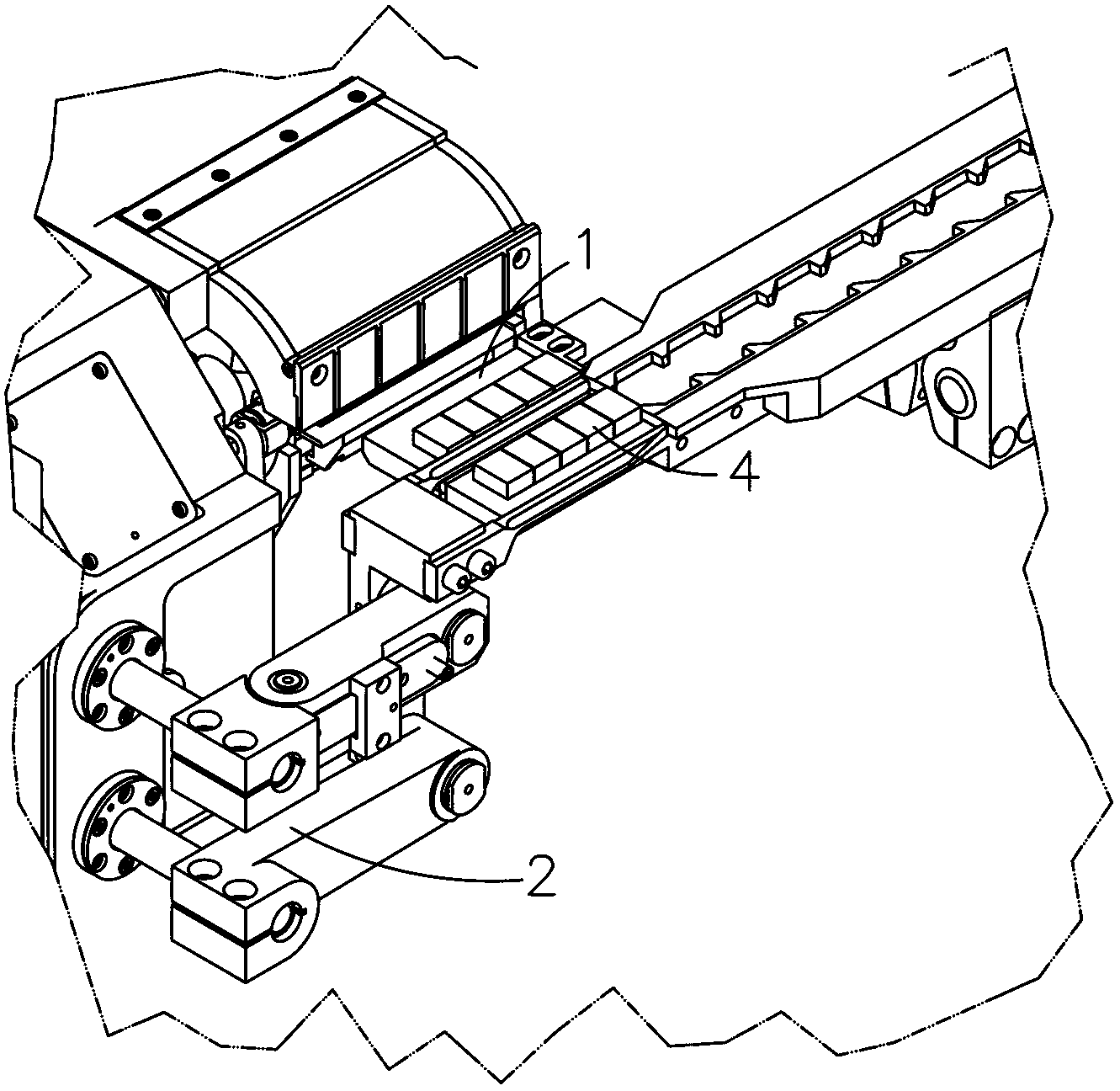

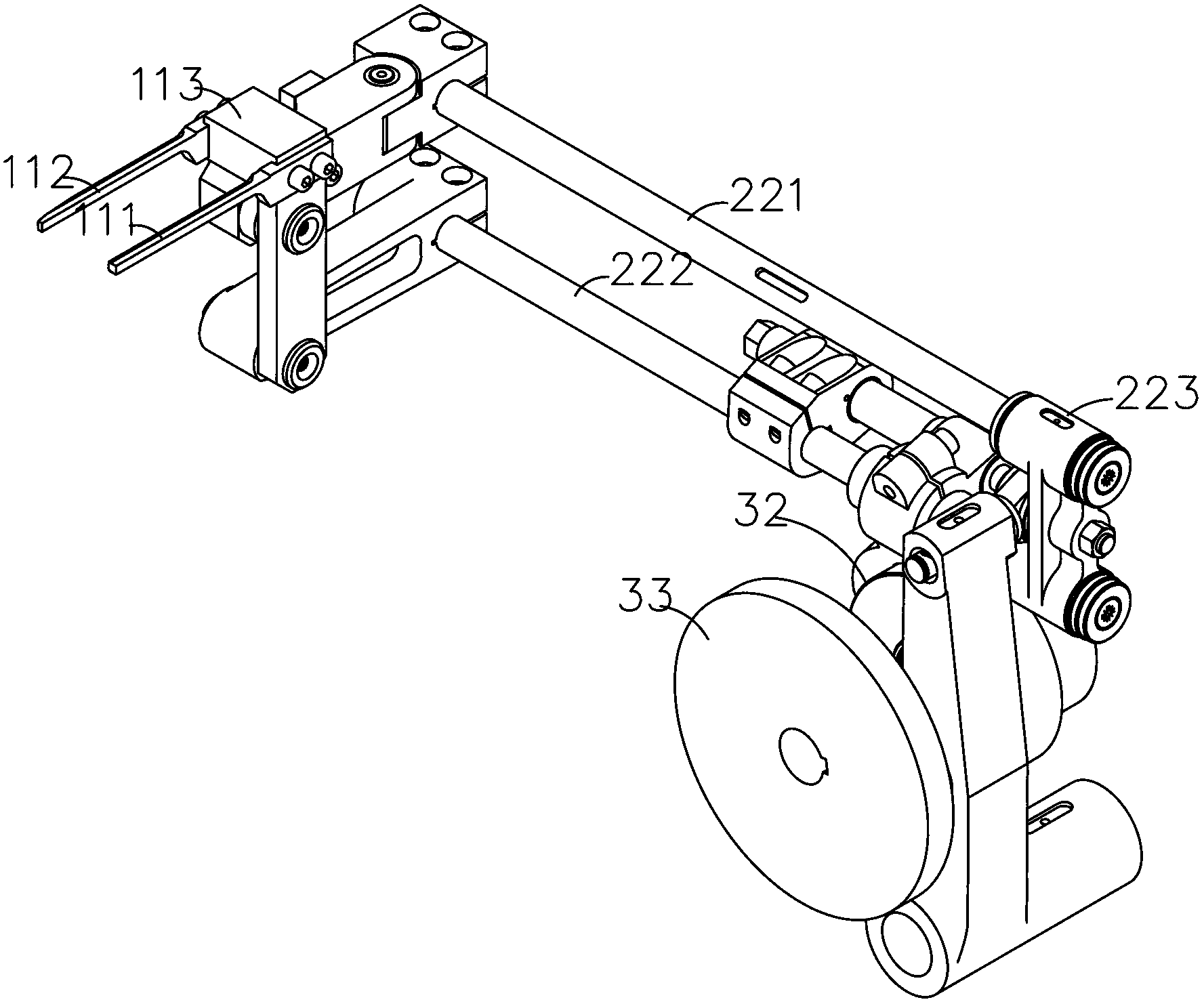

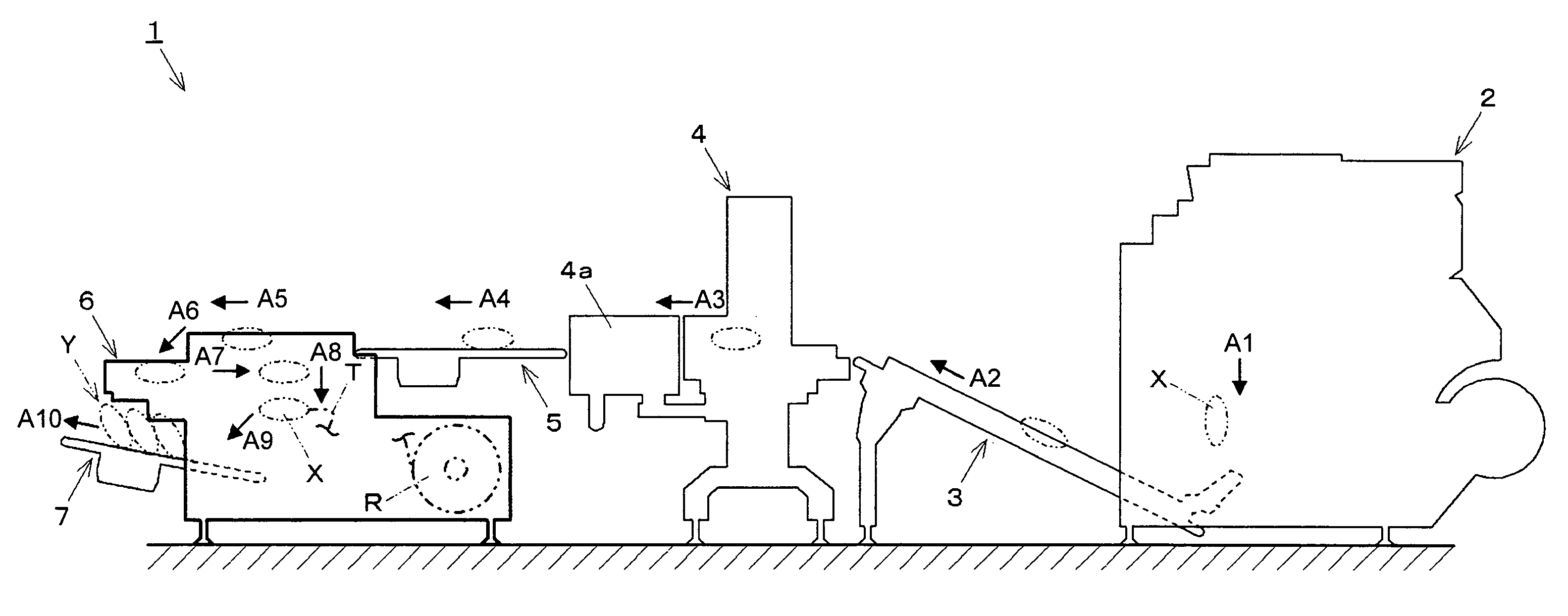

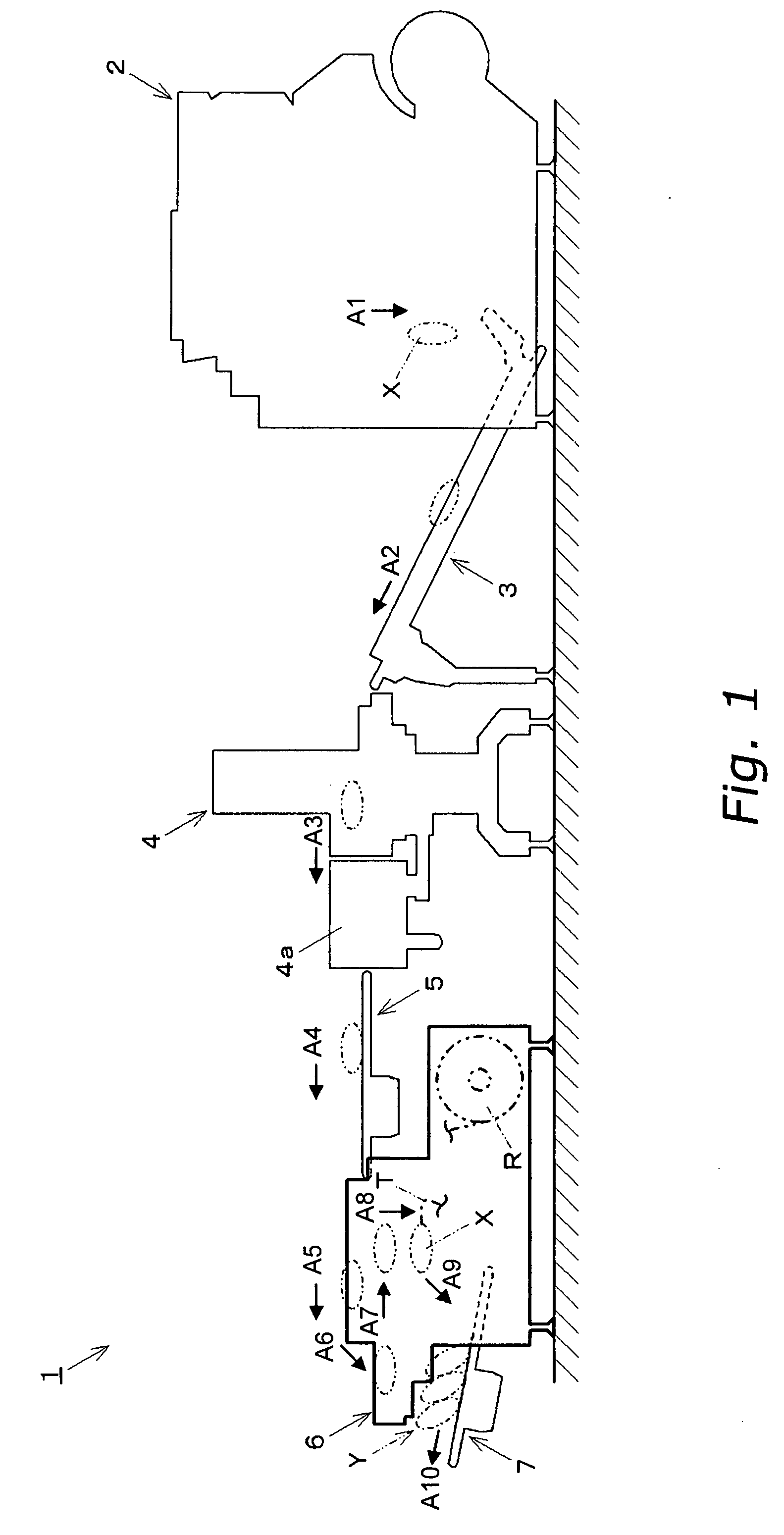

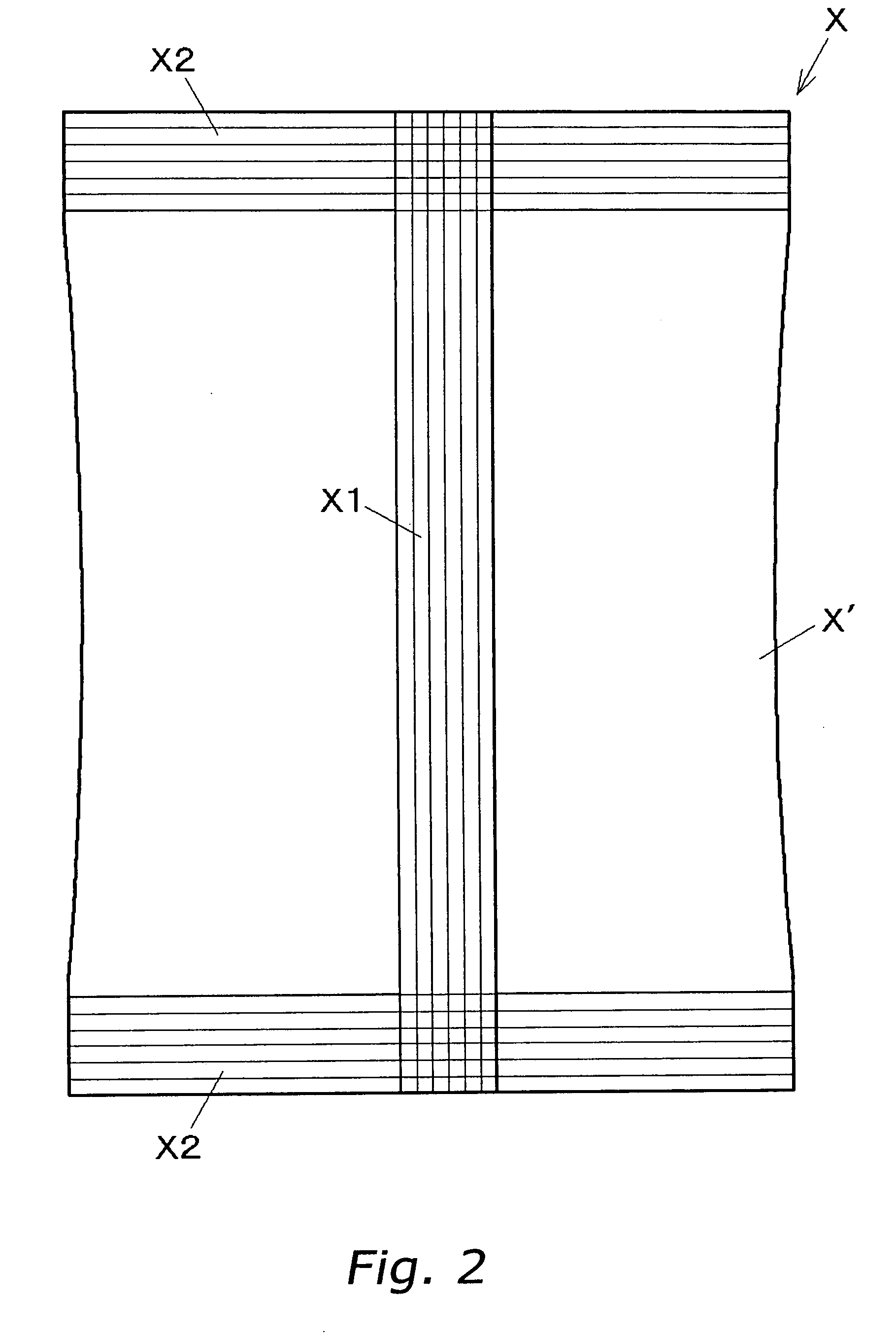

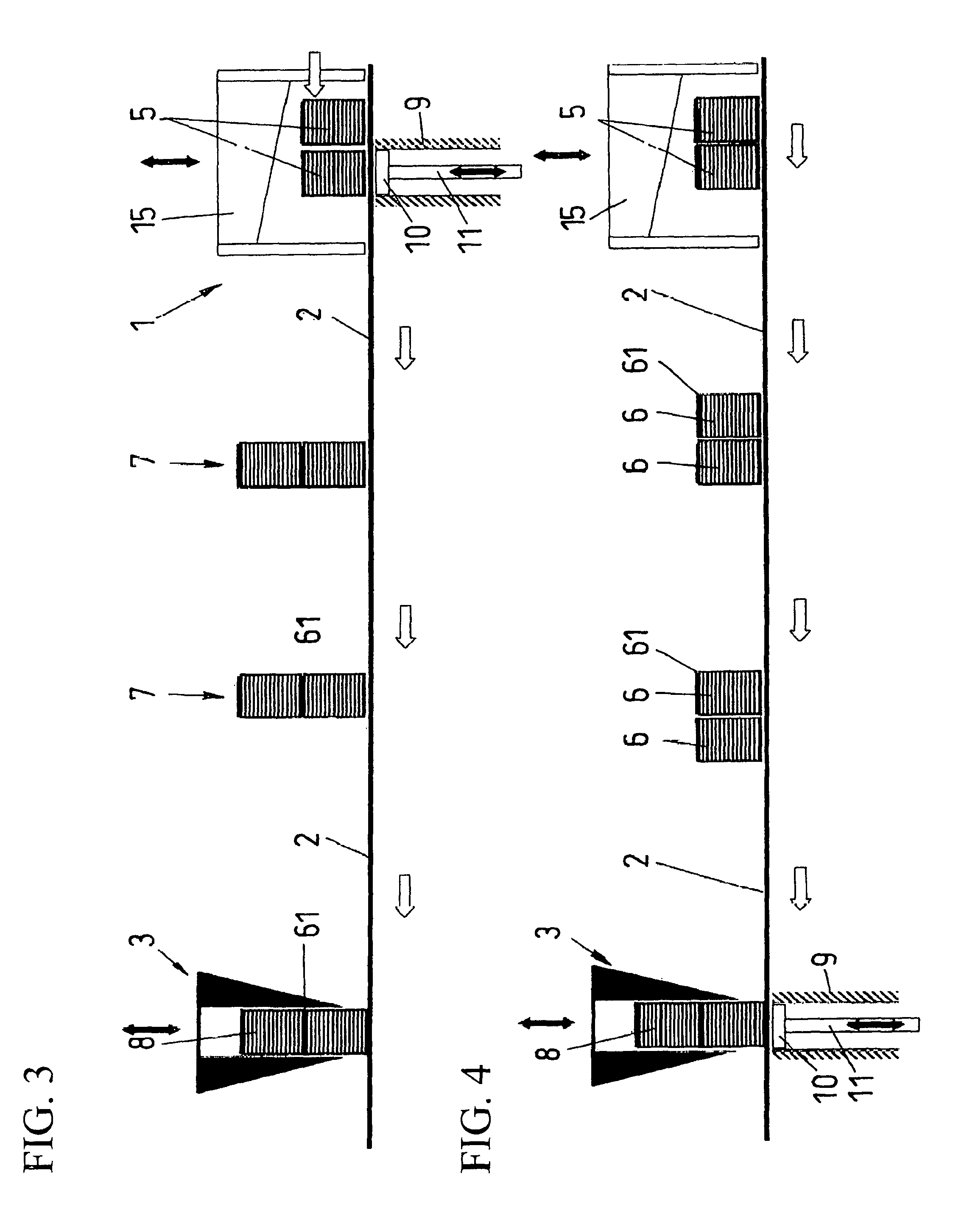

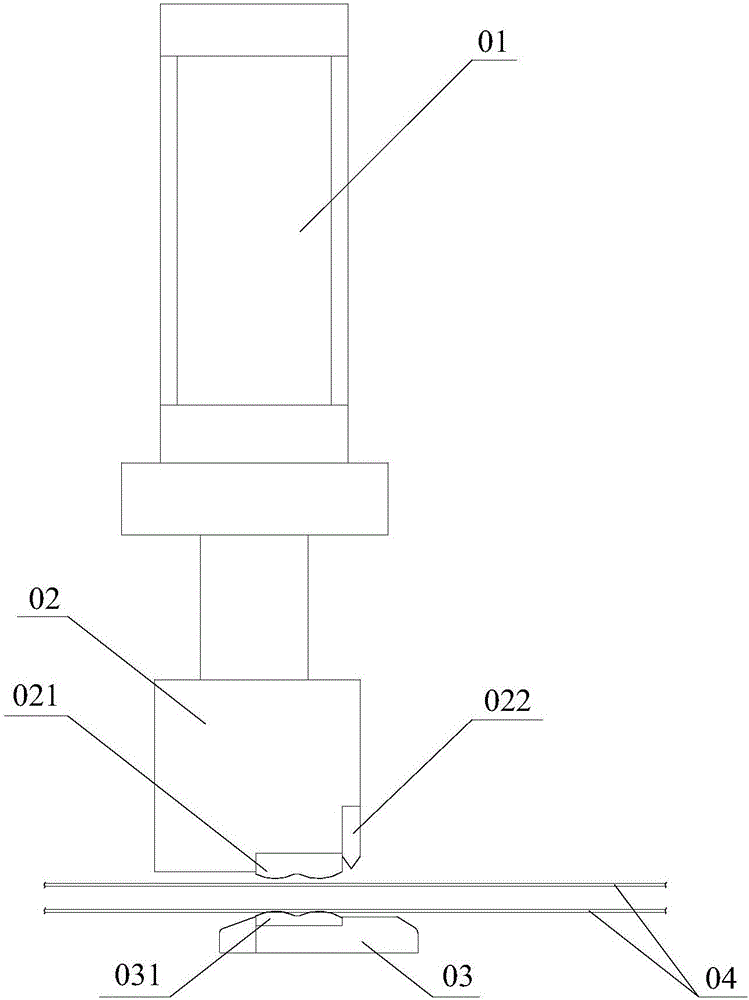

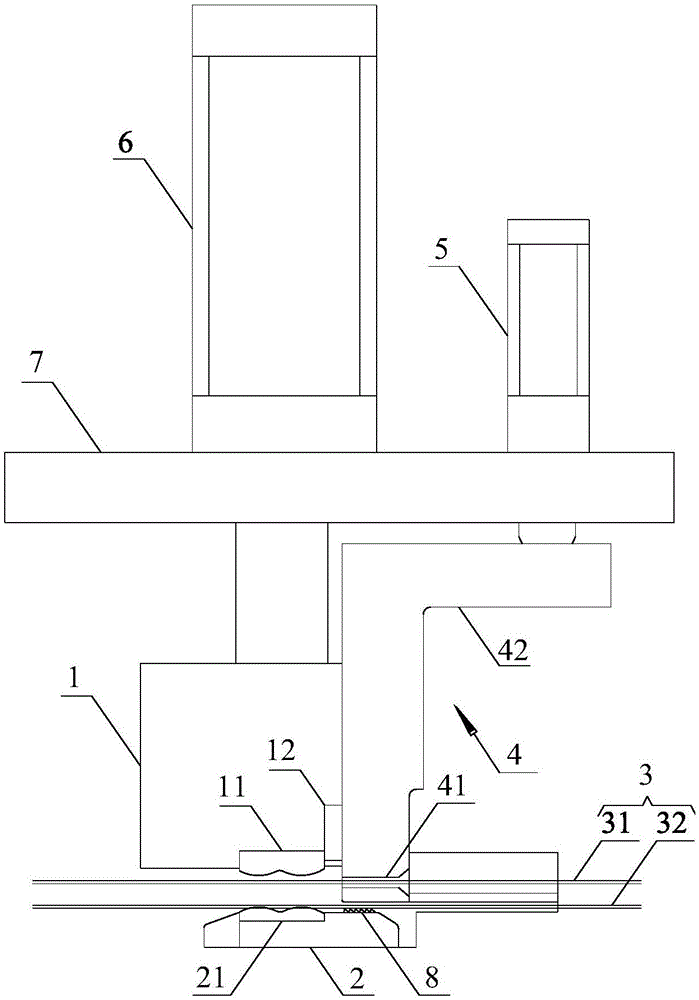

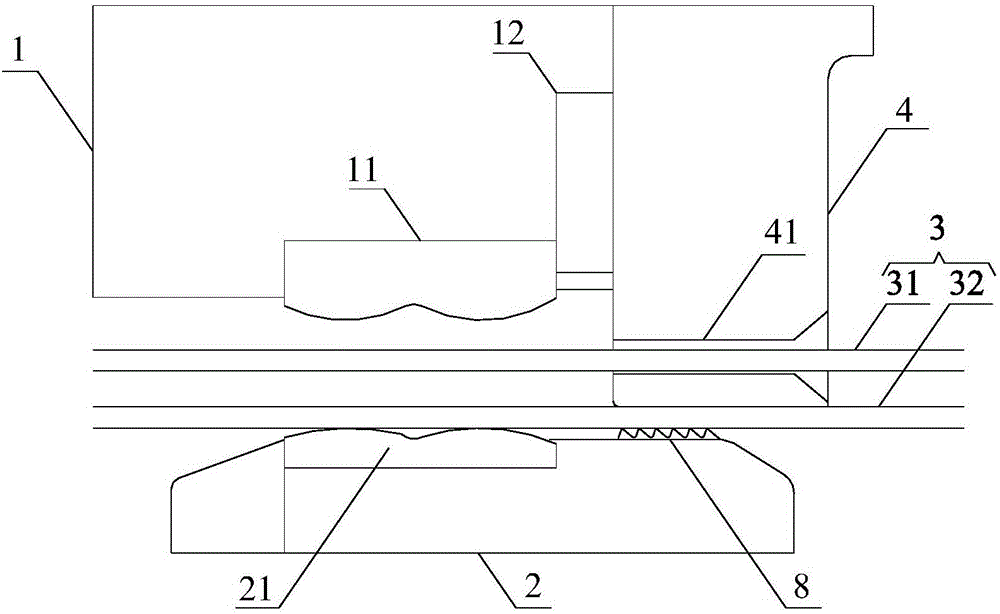

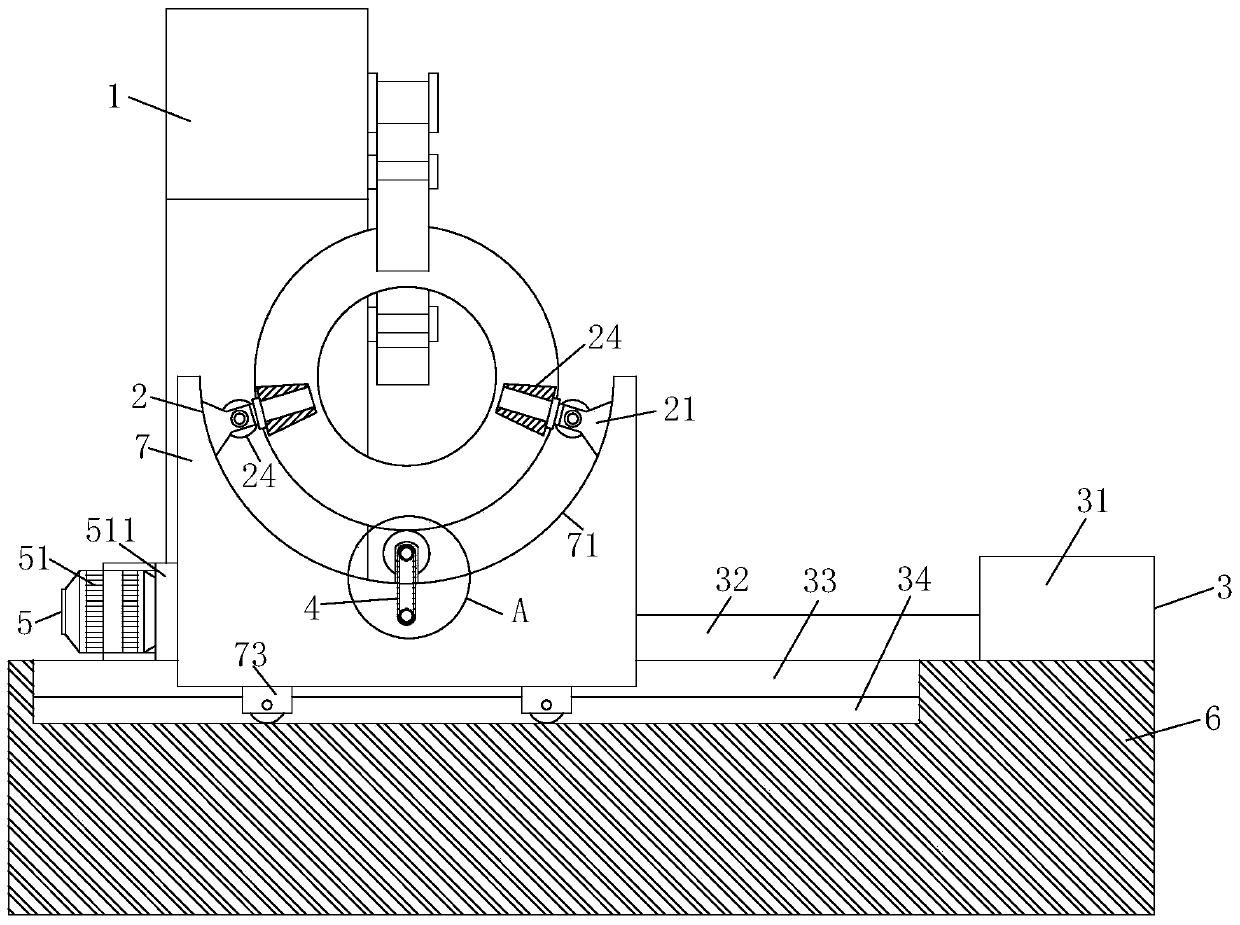

Block pack to strip pack switching device and automatic packaging machine using same

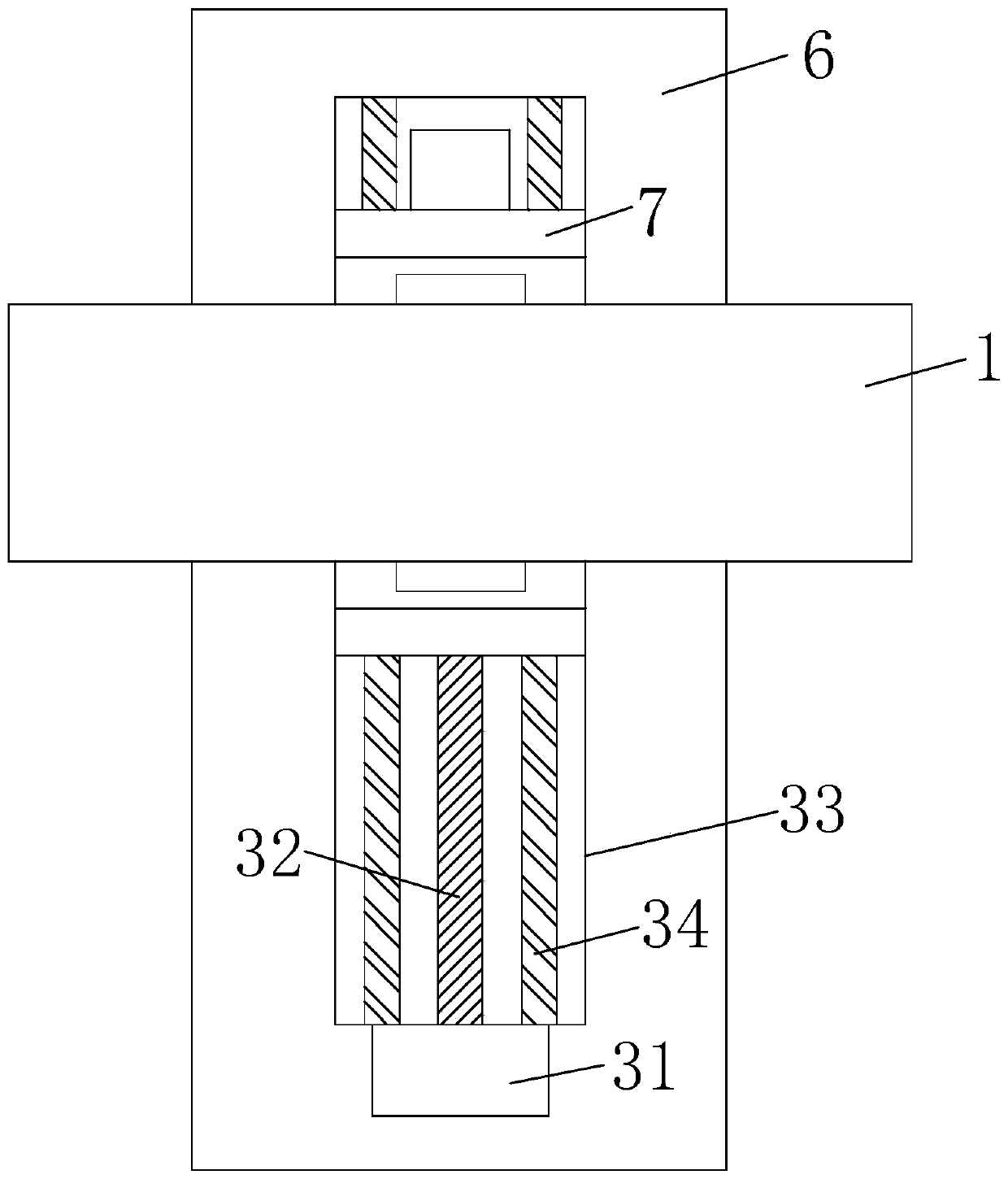

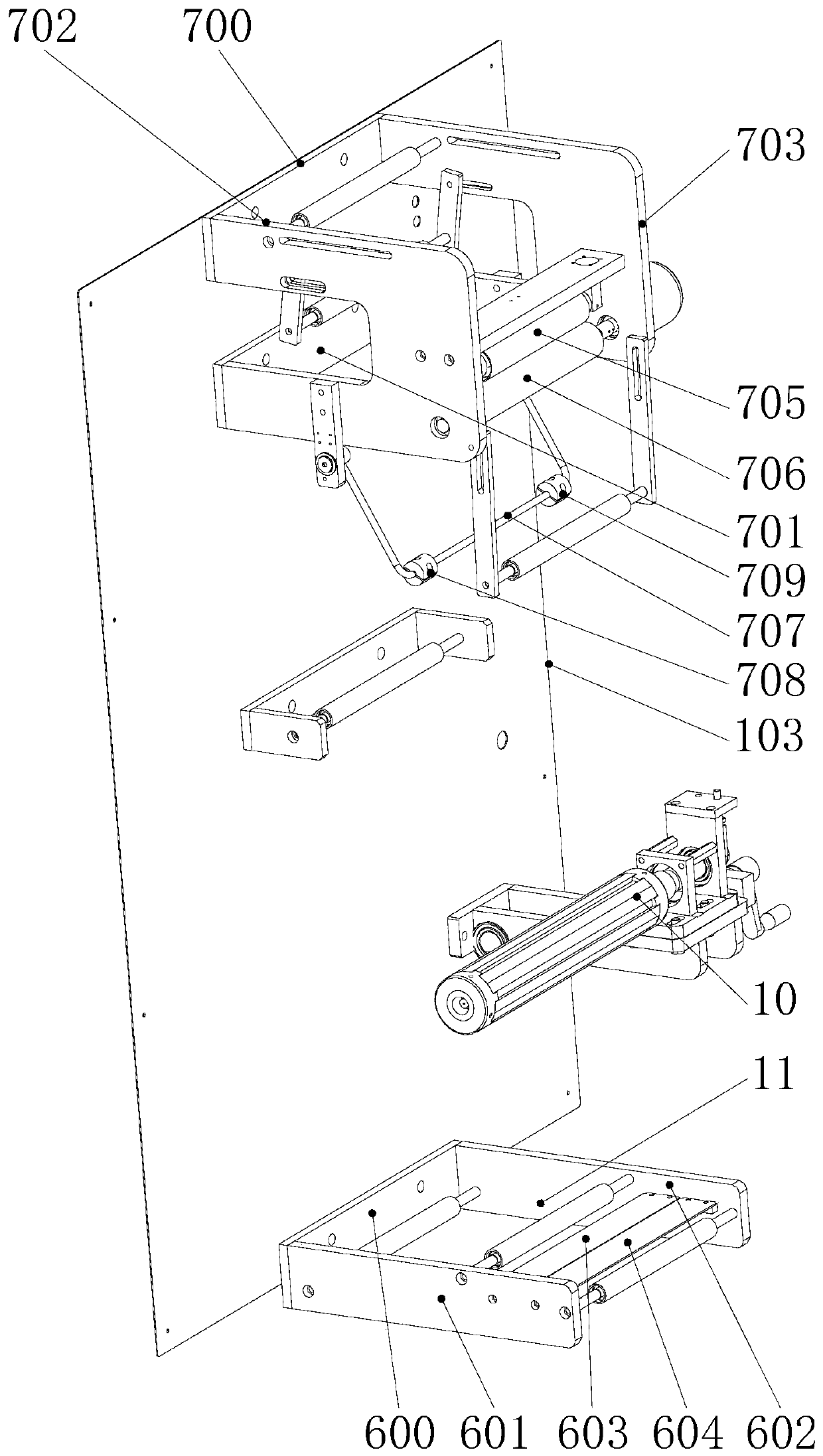

The invention relates to a block pack to strip pack switching device and an automatic packaging machine using the same. The block pack to strip pack switching device comprises a push rod system, a transmission system and a power system, wherein the push rod system comprises a push rod component and a bearing plate component; the bearing plate component is connected with a block pack machine; and the push rod component is connected with the power system through the transmission system. The automatic packaging machine using the block pack to strip pack switching device comprises the block pack machine, a strip pack machine, a baseplate and the block pack to strip pack switching device. According to the invention, power is obtained from the strip pack machine by adopting mechanical structures such as a cam, a transmission shaft and a parallelogram component, so that the block pack to strip pack switching device and the strip pack machine can operate with higher synchronicity, the operation processes are more stable, and the power system is more simplified. The automatic packaging machine can fulfill the whole process of a packed material from block packing to strip packing, can push a block-shaped material at the outlet of the block pack machine to the inlet of the strip pack machine for strip packing more smoothly, and is lower in error rate.

Owner:成都三可实业有限公司

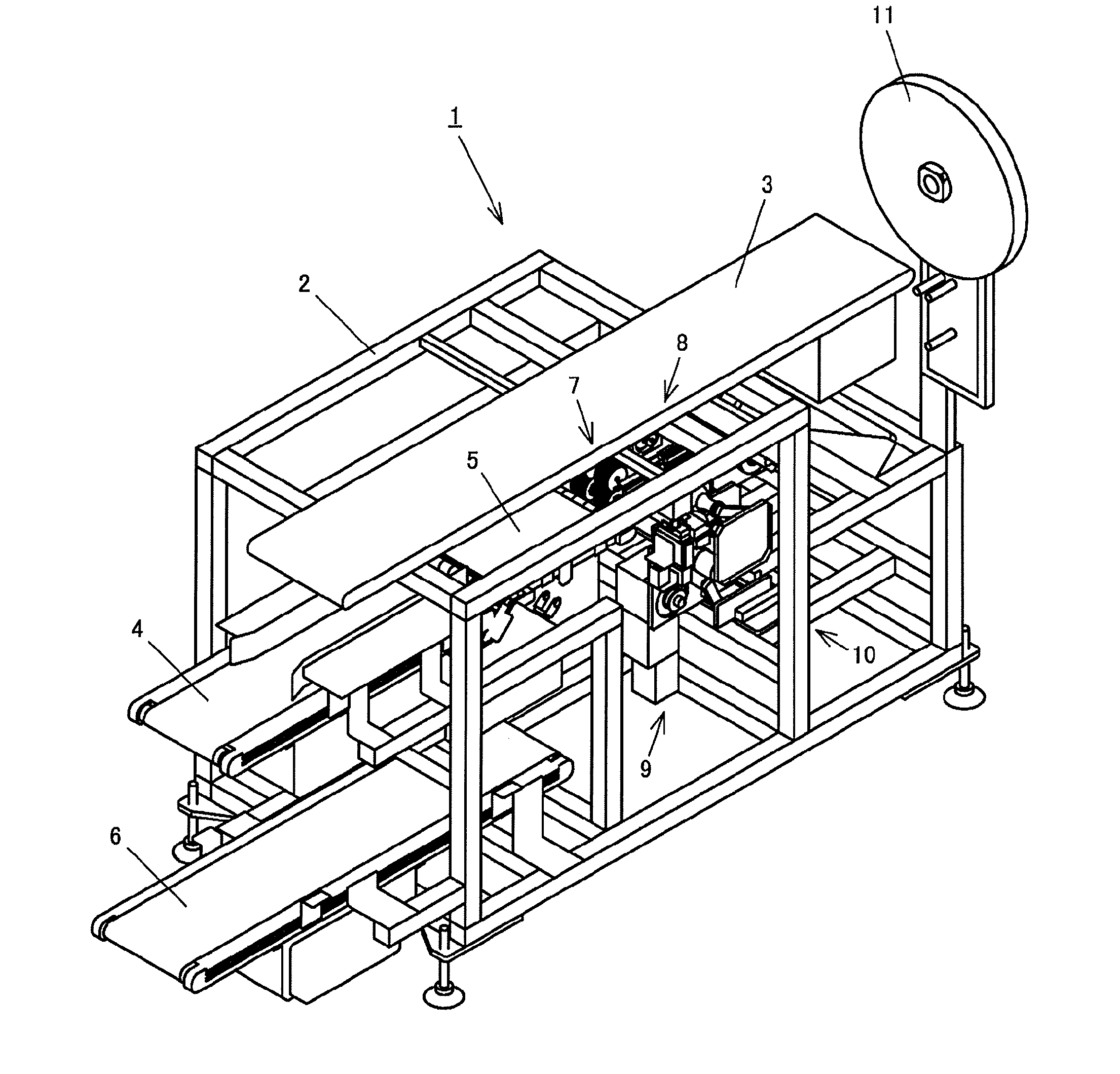

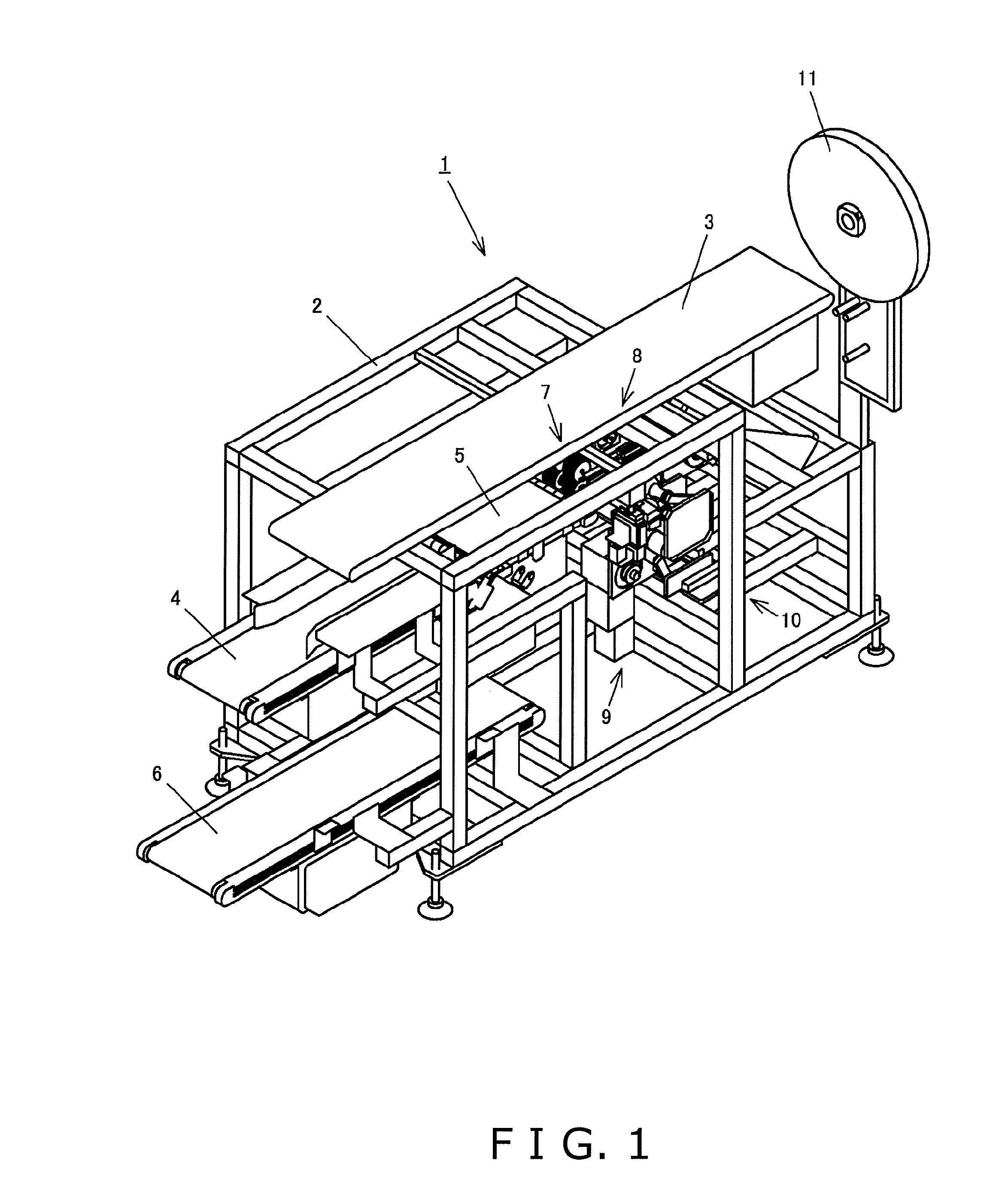

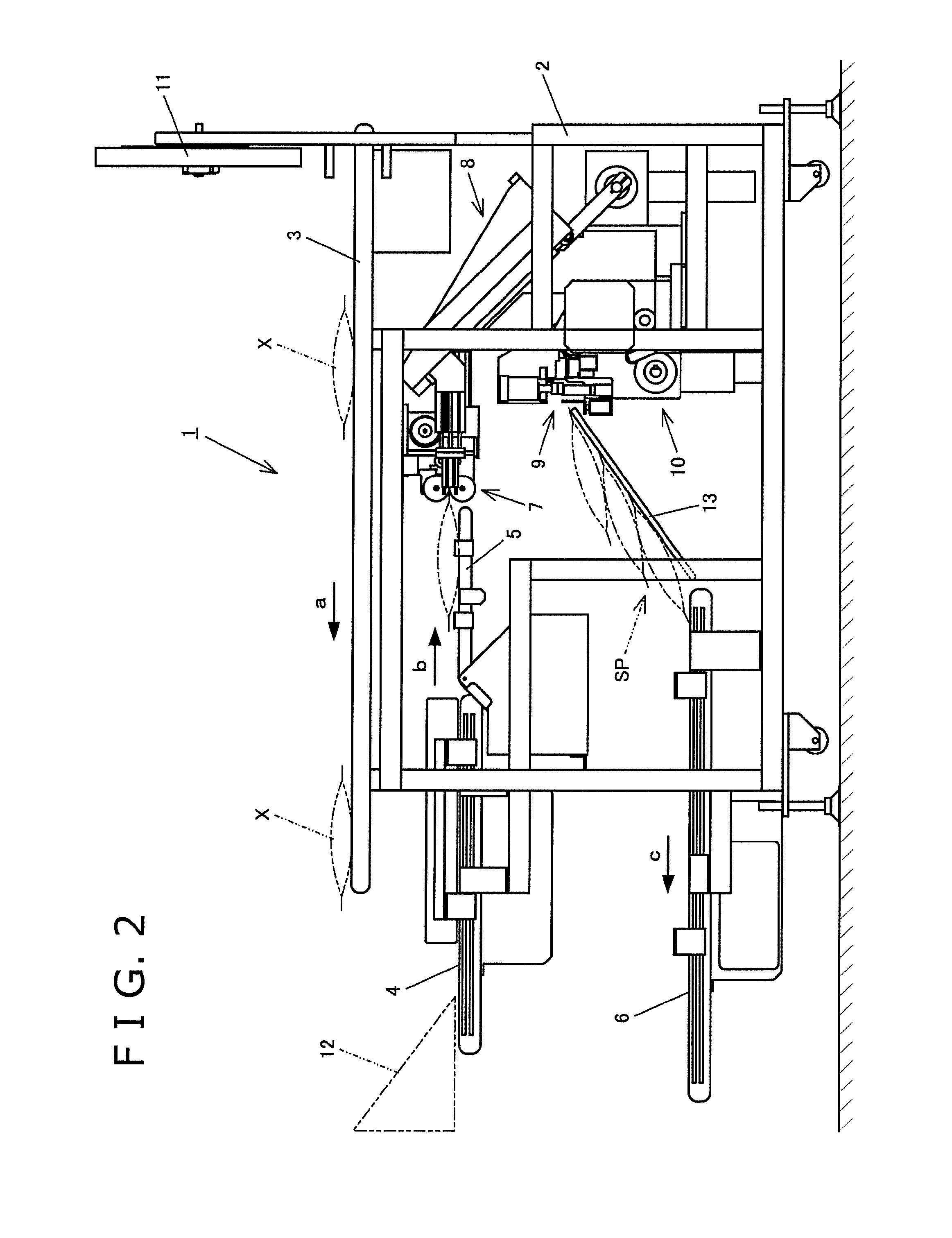

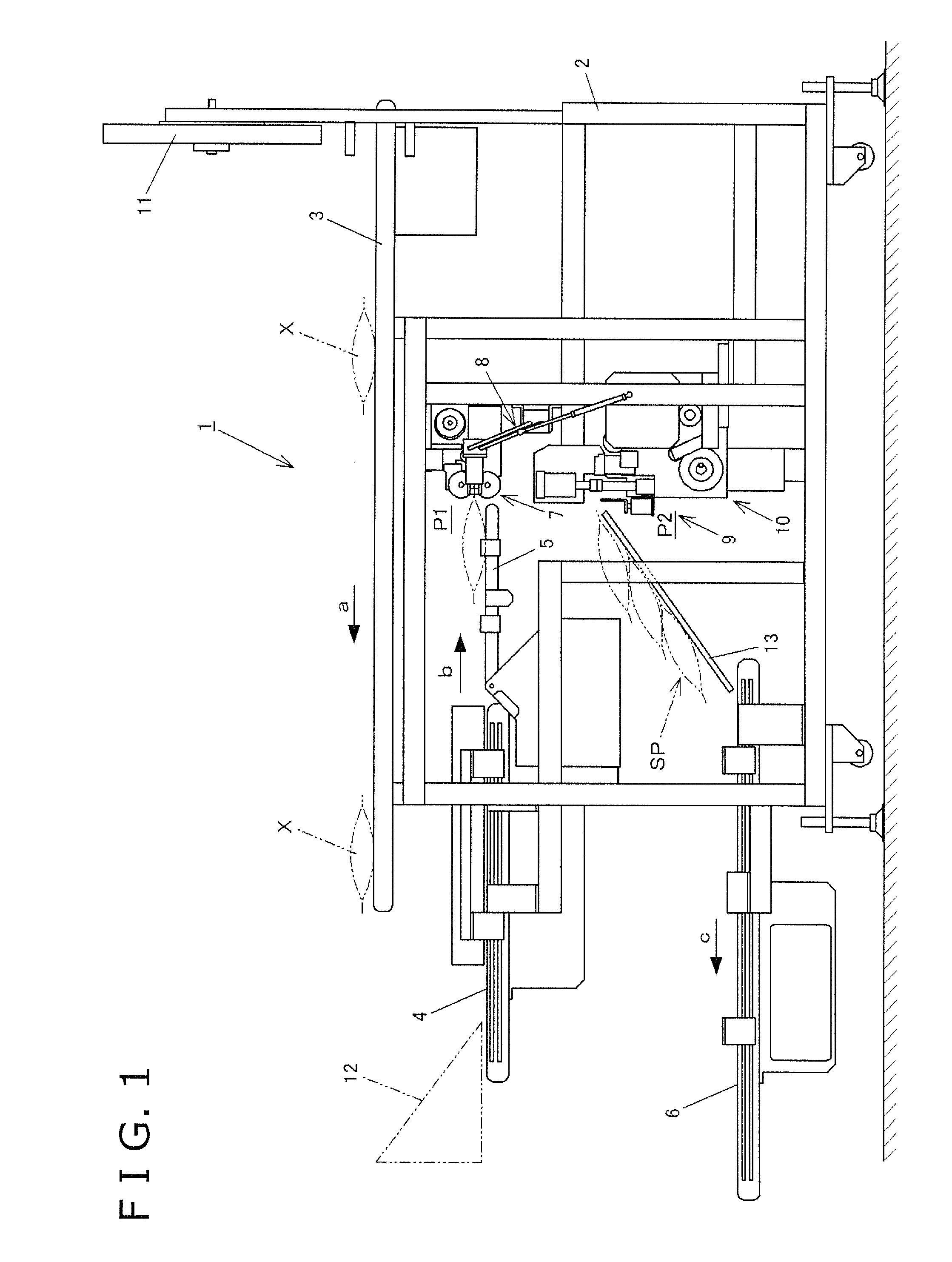

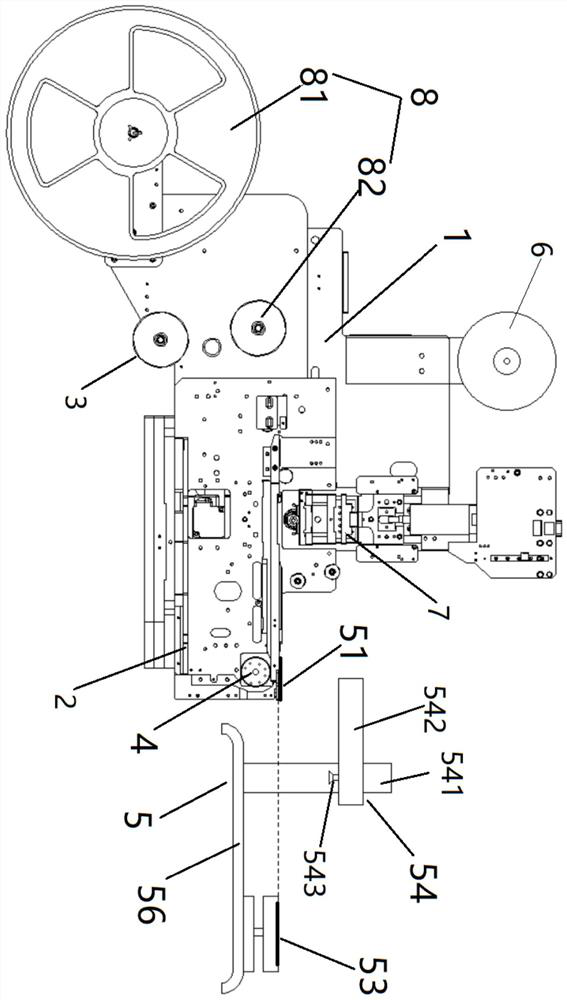

Strip-pack manufacturing apparatus

A strip-pack manufacturing apparatus is arranged to receive an article having a projecting portion at a prescribed receiving position and to affix the article to a tape at a prescribed affixing position, and includes a transporting mechanism, a grasping section, a transfer mechanism, an affixing mechanism, and a wrinkle smoothing mechanism. The transporting mechanism is arranged to transport the article to the receiving position with the projecting portion of the article being oriented in front. The transfer mechanism is arranged to transfer the article from the receiving position to the affixing position in a state wherein the article is grasped at the project portion by the grasping section. The affixing mechanism is arranged to affix the article to the tape at the affixing position. The wrinkle smoothing mechanism is disposed at the receiving position and arranged to smooth wrinkles of the projecting portion.

Owner:ISHIDA CO LTD

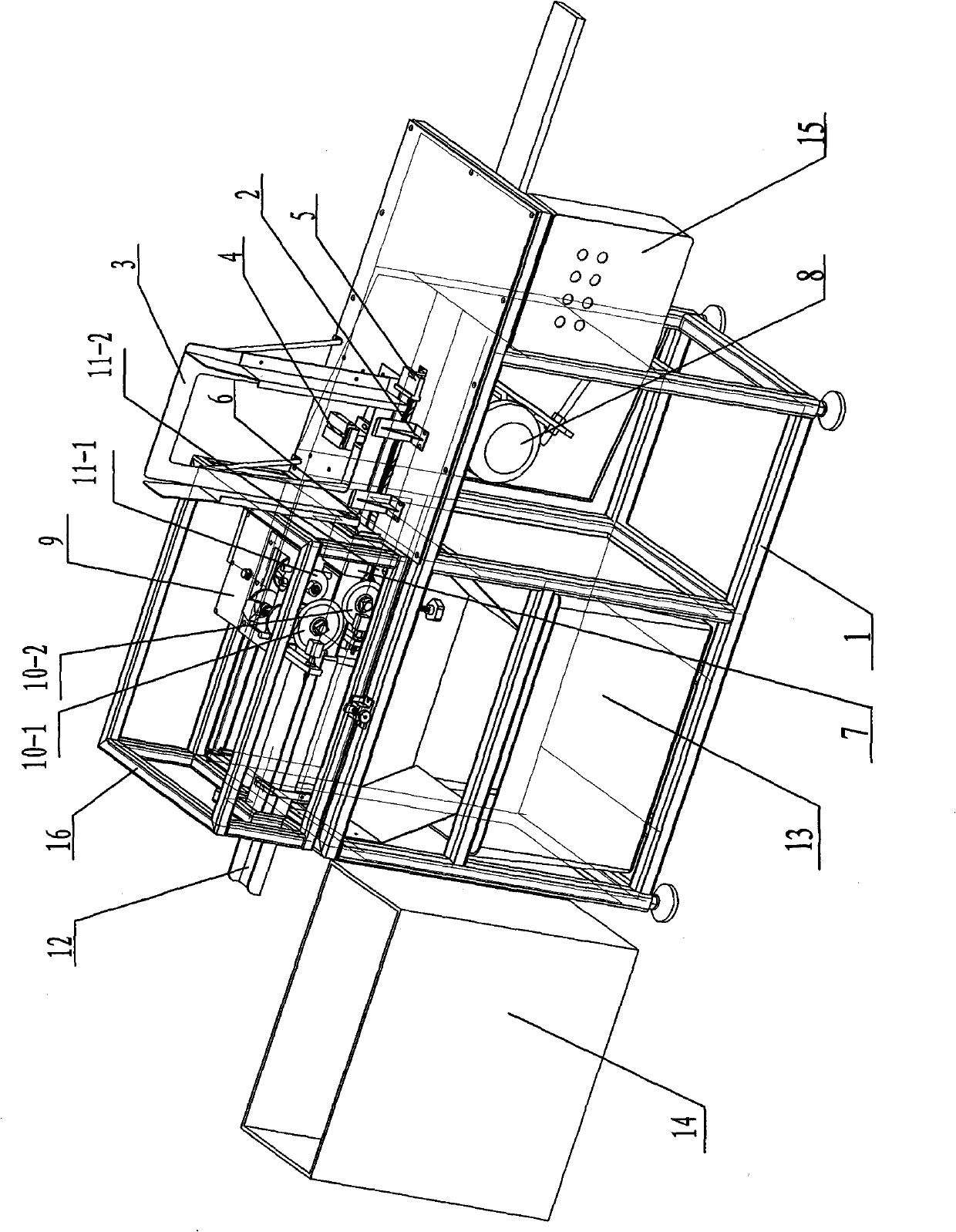

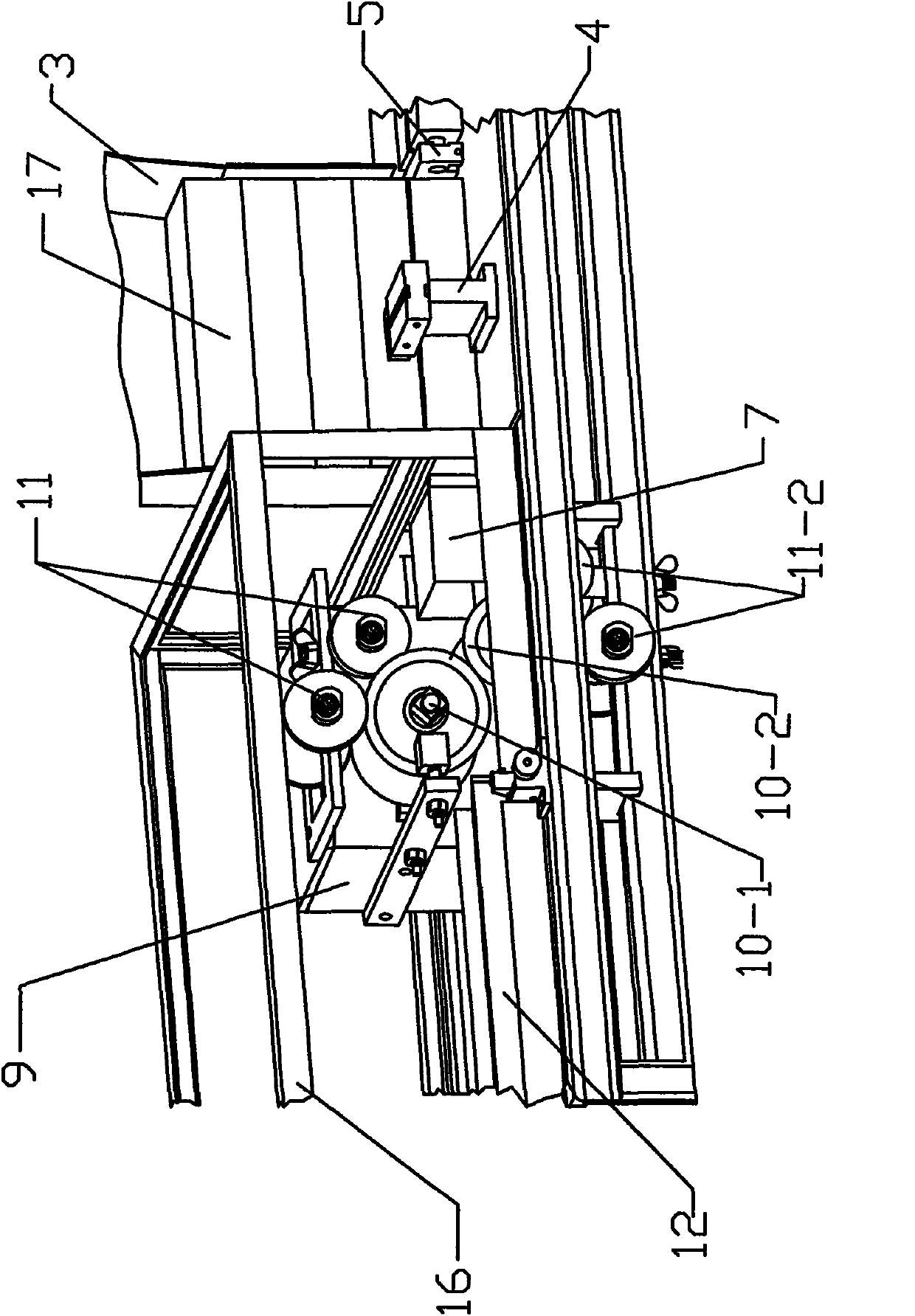

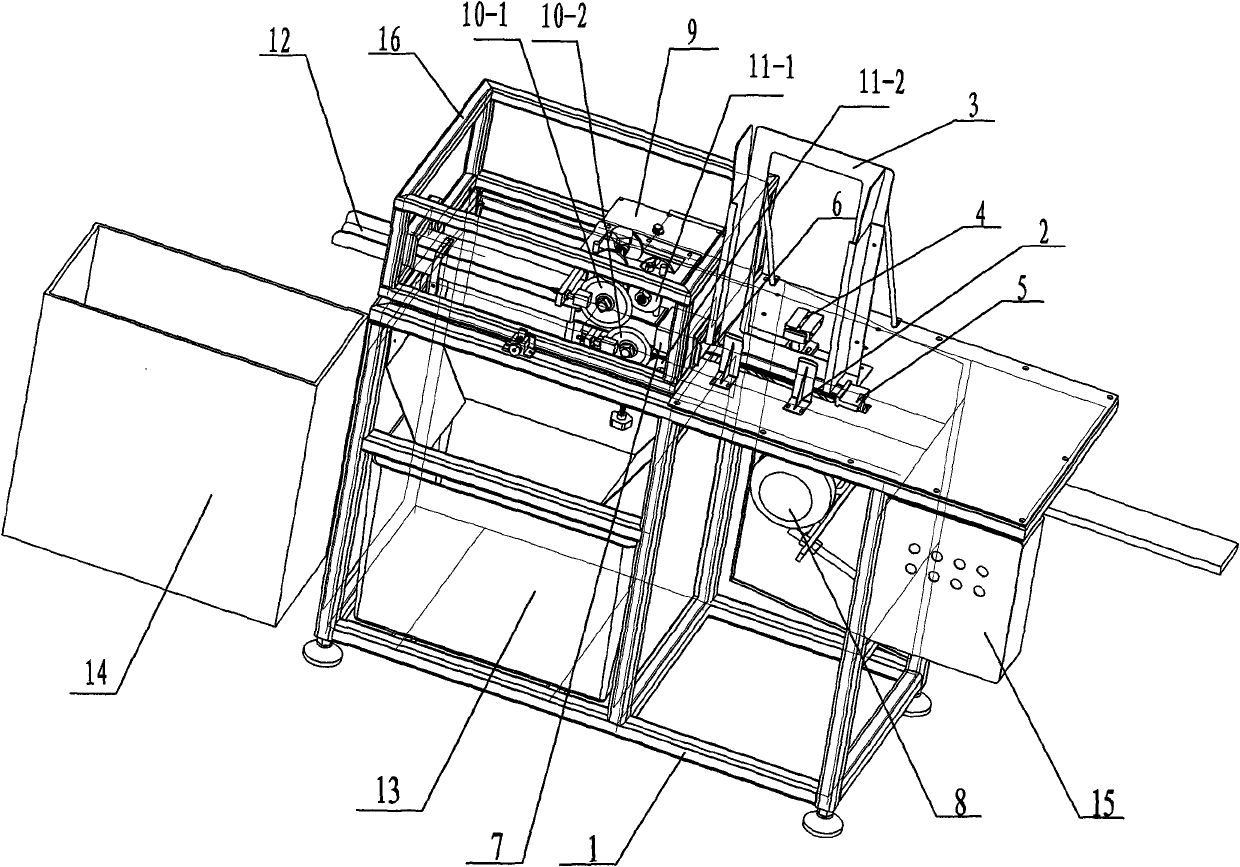

Waste strip-packed cigarette processor

InactiveCN102018282ASimple structureEasy to operateCigarette manufactureArticle unpackingEntrywayWaste product

The invention relates to a waste strip-packed cigarette processor. A drive gear box (9) is arranged at the middle part of the end surface of a rack (1), an upper cutter (10-1), a lower cutter (10-2), an upper knife grinder (11-1) and a lower knife grinder (11-2) are respectively arranged on the output shaft of the drive gear box (9) and respectively formed by connecting two coaxially connected sheets, an output channel guide rail (12) used for passing the strip-paced cigarette is arranged between two cutters, the rack worktop at the front end and the back end of the strip-packed cigarette blocking frame (3) is respectively provided with a cigarette clamping cylinder (4) and a pneumatic accessory (2), the rack worktop at the left end and the right end thereof is respectively provided with a strip cigarette entryway (7) and a cigarette pushing cylinder (5), and a detection sensor (6) is arranged at the bottom of the strip-packed cigarette blocking frame (3); the input end of an electriccontrol box (15) is connected with the output end of the detection sensor (6), and the output end of the electric control box (15) is respectively connected with the cigarette clamping cylinder (4), the cigarette pushing cylinder (5) and the operating switch of a motor (8). The invention can rapidly and effectively cut the waste strip-packed cigarette, and has the advantages of simple structure, simple and convenient operation method, wide application range and safety in use.

Owner:HUBEI CHINA TOBACCO IND

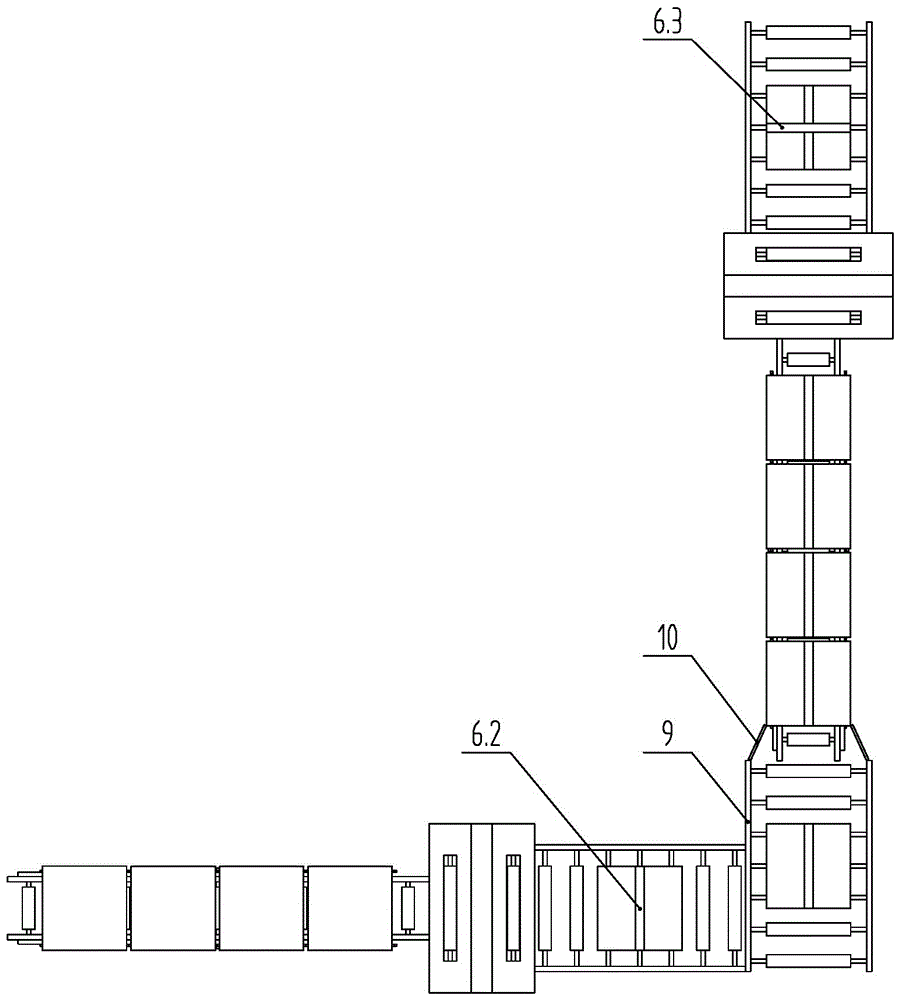

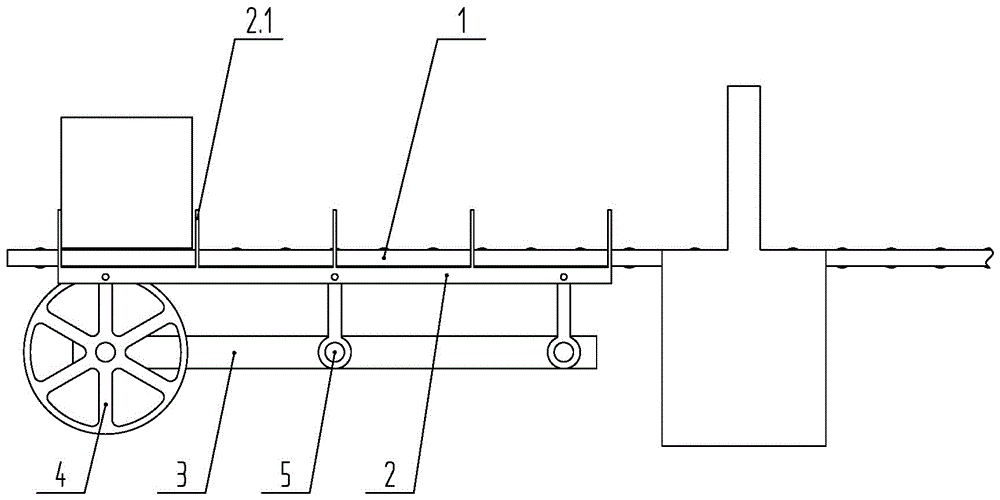

Automatic continuous double-strip packing and conveying system

InactiveCN106043784ABinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention discloses an automatic continuous double-strip packing and conveying system. The automatic continuous double-strip packing and conveying system comprises a first packing and conveying mechanism, a second packing and conveying mechanism and a connecting conveying belt with a steering function. The first packing and conveying mechanism and the second packing and conveying mechanism have the same structure and each comprise a conveying mechanism capable of conveying packing boxes intermittently, a packer and an outlet conveying belt, wherein the packer is provided with a detection device used for judging whether the packing boxes are located in the packing position or not and used for packing the packing boxes conveyed from the conveying mechanism, the outlet conveying belt is capable of continuously conveying the packing boxes and used for conveying the packed packing boxes to the next step, and an inlet and an outlet of the packer are further provided with transmission rollers. The automatic continuous double-strip packing and conveying system has the beneficial effects that the conveying mechanisms capable of intermittently conveying the packing boxes are used for conveying the packing boxes into the packers to be packed according to a certain period, conveying and packing are effectively linked, and the purpose of man-free continuous packing is realized.

Owner:SUZHOU GAOTONG MACHINERY TECH CO LTD

Binding machine with buckling-free steel belt

InactiveCN101391661BImprove bindingSave lockBinding material applicationBundling machine detailsLocking mechanismEngineering

The invention relates to a non-fastening steel strip packing machine which comprises a steel strip tensing mechanism, a steel strip pressing and locking mechanism and a steel strip cutting mechanism. The steel strip pressing and locking mechanism comprises left and right static indentation blocks, a left dynamic indentation block and a right dynamic indentation block, a front back fixing side board and a back fixing side board that are used for fixedly connecting a second air cylinder and a second air cylinder body, and a slide block that is fixed on a telescopic rod of the second air cylinder, the lower end of the slide block is respectively hinged with left and right connecting boards, the lower ends of a left connecting board and a right connecting board are hinged with the left dynamic indentation block and the right dynamic indentation block, the lower ends of the left dynamic indentation block and the right dynamic indentation block respectively take a shape of an arc indented claw, the static indentation blocks are fixedly arranged between the left and right dynamic indentation blocks and simultaneously above the arc indented claws, the second air cylinder is a double-levelair cylinder, the slide block has an extension end, side walls at two sides of the extension end take a shape of being vertical at the upper end and inwardly-tilted at the lower end, a left pressure board and a right pressure board are hinged with a back fixing board, the lower ends of the left pressure board and the right pressure board are provided with inward dummy clubs that are arranged below a tensing seat, and the upper ends of the left pressure board and the right pressure board respectively press against the side walls of the extension end of the slide block.

Owner:张温堤

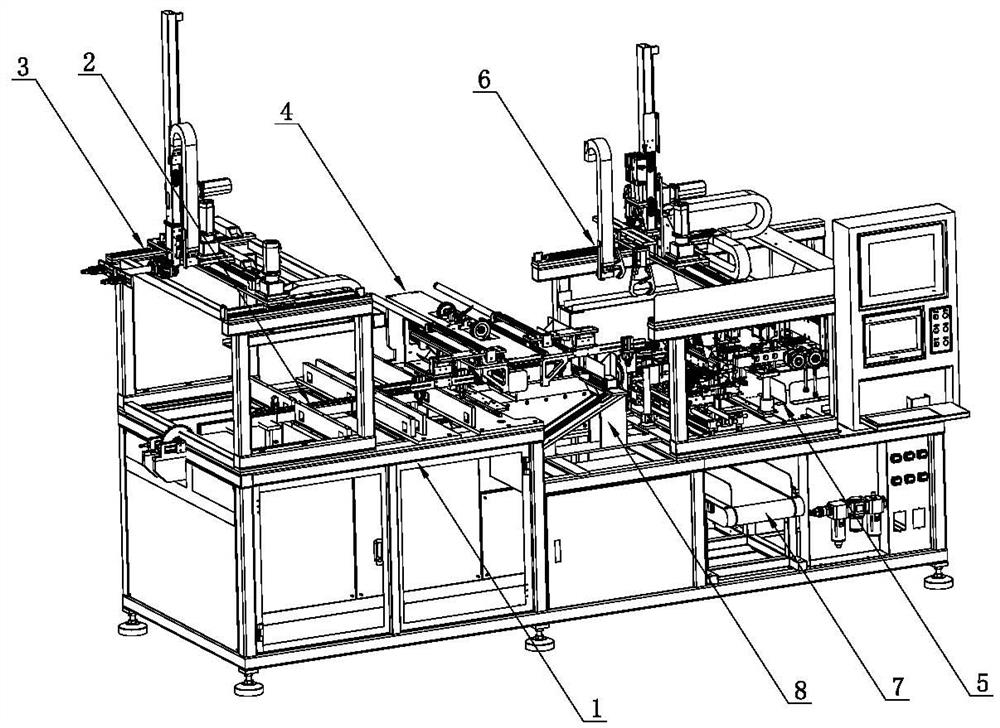

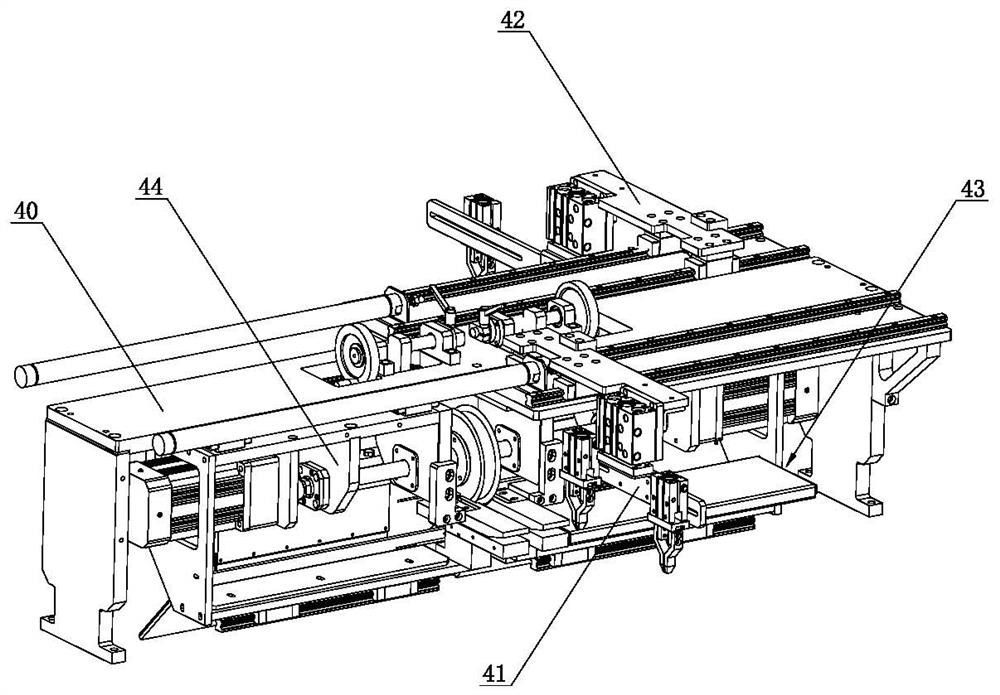

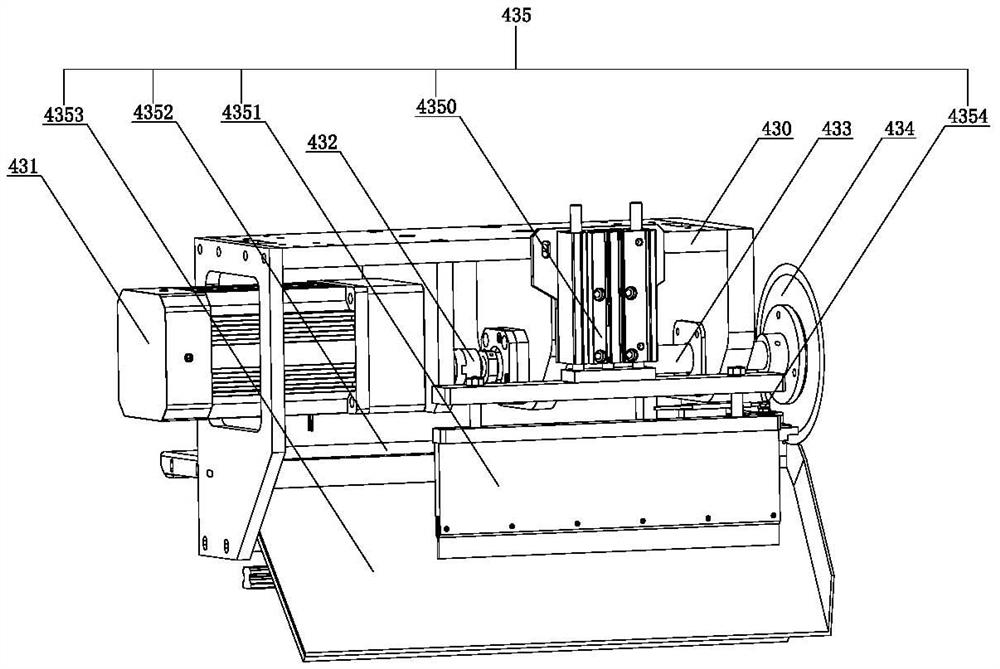

Full-automatic nylon binding tape cutting and packaging all-in-one machine

PendingCN112319922AMeet the needs of mass productionReduce labor costsWrapper twisting/gatheringPackaging automatic controlConveyor beltFully automated

The invention relates to the technical field of binding tape packaging, in particular to a full-automatic nylon binding tape cutting and packaging all-in-one machine which comprises a rack, wherein the rack is transversely provided with a feeding conveyor belt used for conveying water gap pieces connected to a plurality of nylon binding tapes; the front end of the feeding conveyor belt is providedwith a feeding mechanical arm used for clamping injection-molded water gap pieces and conveying the water gap pieces to the feeding conveyor belt, and the rear end of the feeding conveyor belt is provided with a cutting-off mechanism used for cutting off the connecting positions of the water gap pieces and the multiple nylon binding tapes; a packaging mechanism used for packaging a plurality of nylon binding tapes is arranged at the rear end of the cutting-off mechanism, a transferring mechanical arm is arranged between the cutting-off mechanism and the packaging mechanism, and a dischargingconveyor belt used for transferring the packaged nylon binding tapes is arranged below the packaging mechanism. Full-automatic cutting and packaging operation on the nylon binding tapes is achieved, so that labor cost is effectively reduced, production quality and work efficiency are improved, and requirements for large-batch production of the nylon binding tapes are met.

Owner:DONGGUAN TONGYI MACHINE

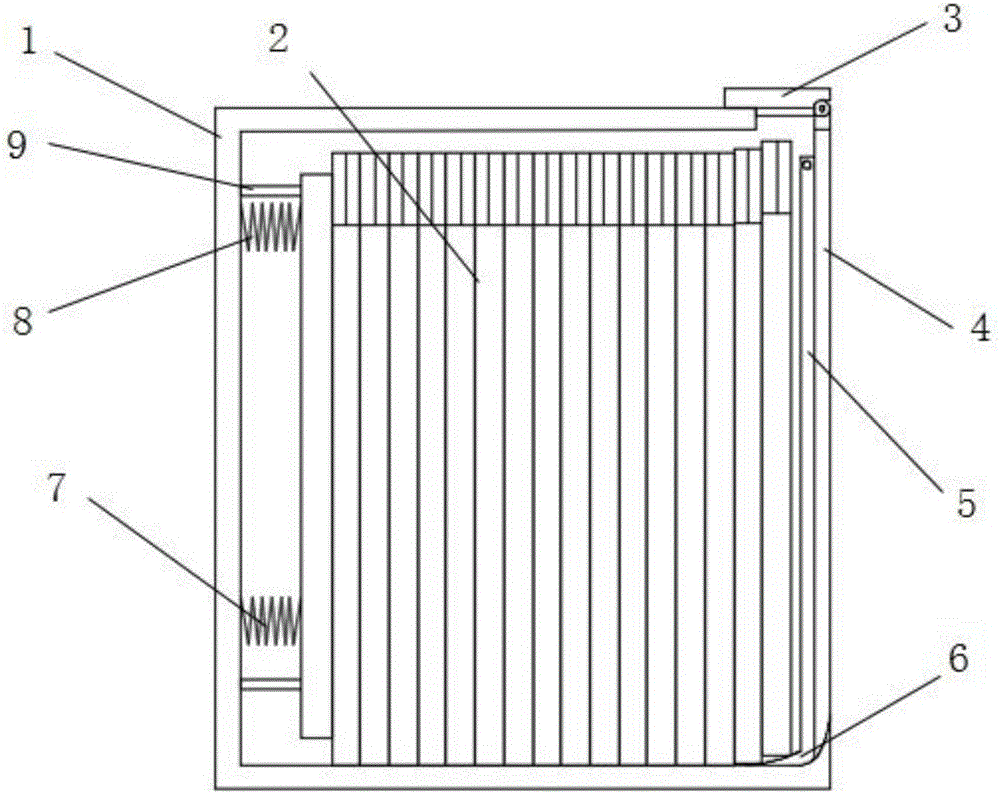

Pressing type test strip packing box

The invention discloses a pressing type test strip packing box. The pressing type test strip packing box comprises a box body, wherein a test strip outlet is formed in the upper end of the right side of the box body; a pressing block is arranged on the right side surface of the test strip outlet; the pressing block is arranged on the box body through a rotating shaft; the rotating shaft is positioned at the part one tenth to a quarter of the upper part of the pressing block; an upper side spring and a lower side spring are arranged on the left side surface, relative to the pressing block, inside the box body; an extrusion block is arranged inside the box body; the upper side spring is connected with the upper end of the inner side of the left side surface of the box body and the upper end of the extrusion block; the lower side spring is connected with the lower end of the inner side of the left side surface of the box body and the lower end of the extrusion block; test strips are stored between the extrusion block and the pressing block; and an arc-shaped scraping corner is arranged at the bottom of the inner side of the pressing block.

Owner:江苏艾拓生物技术有限公司

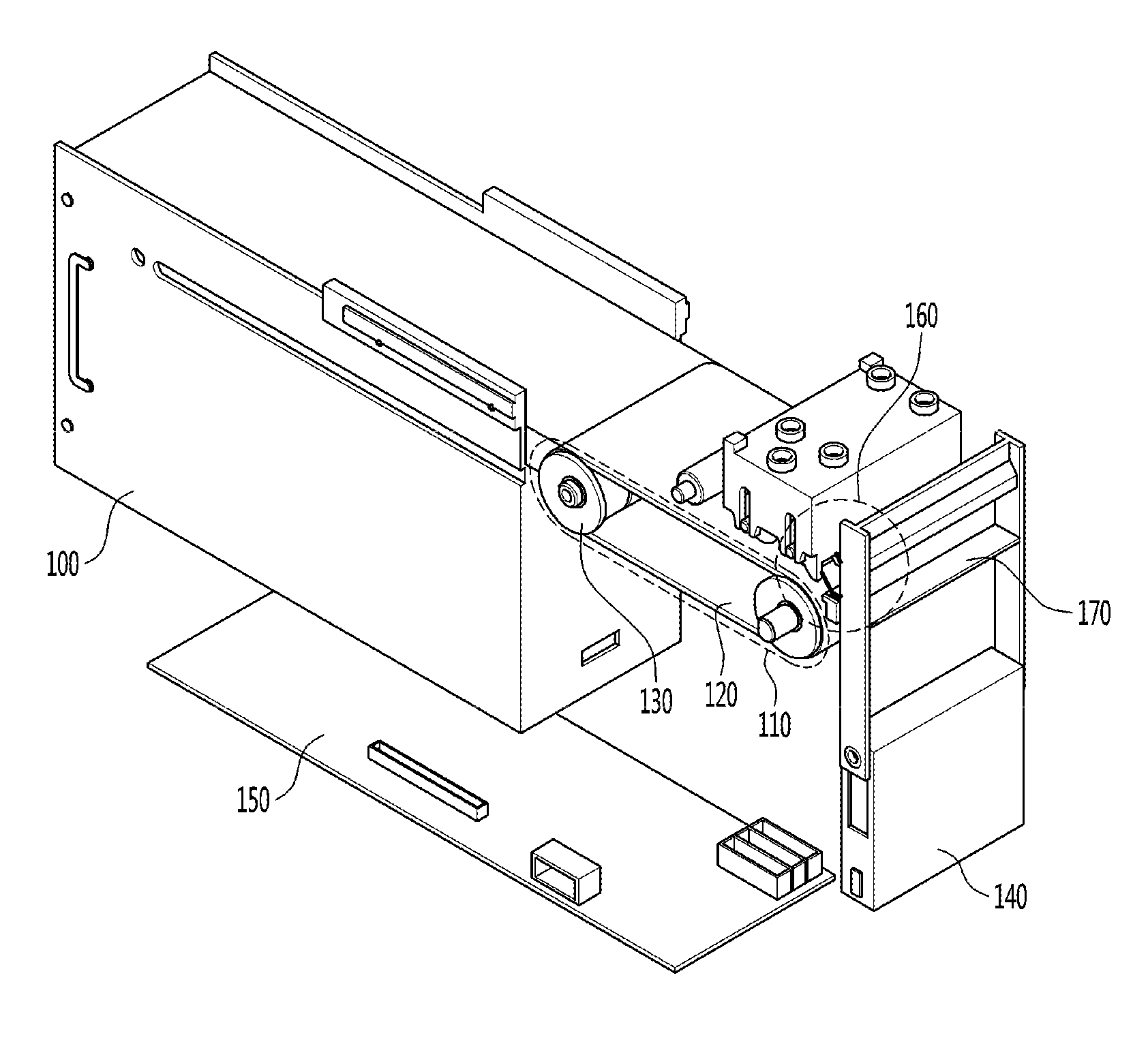

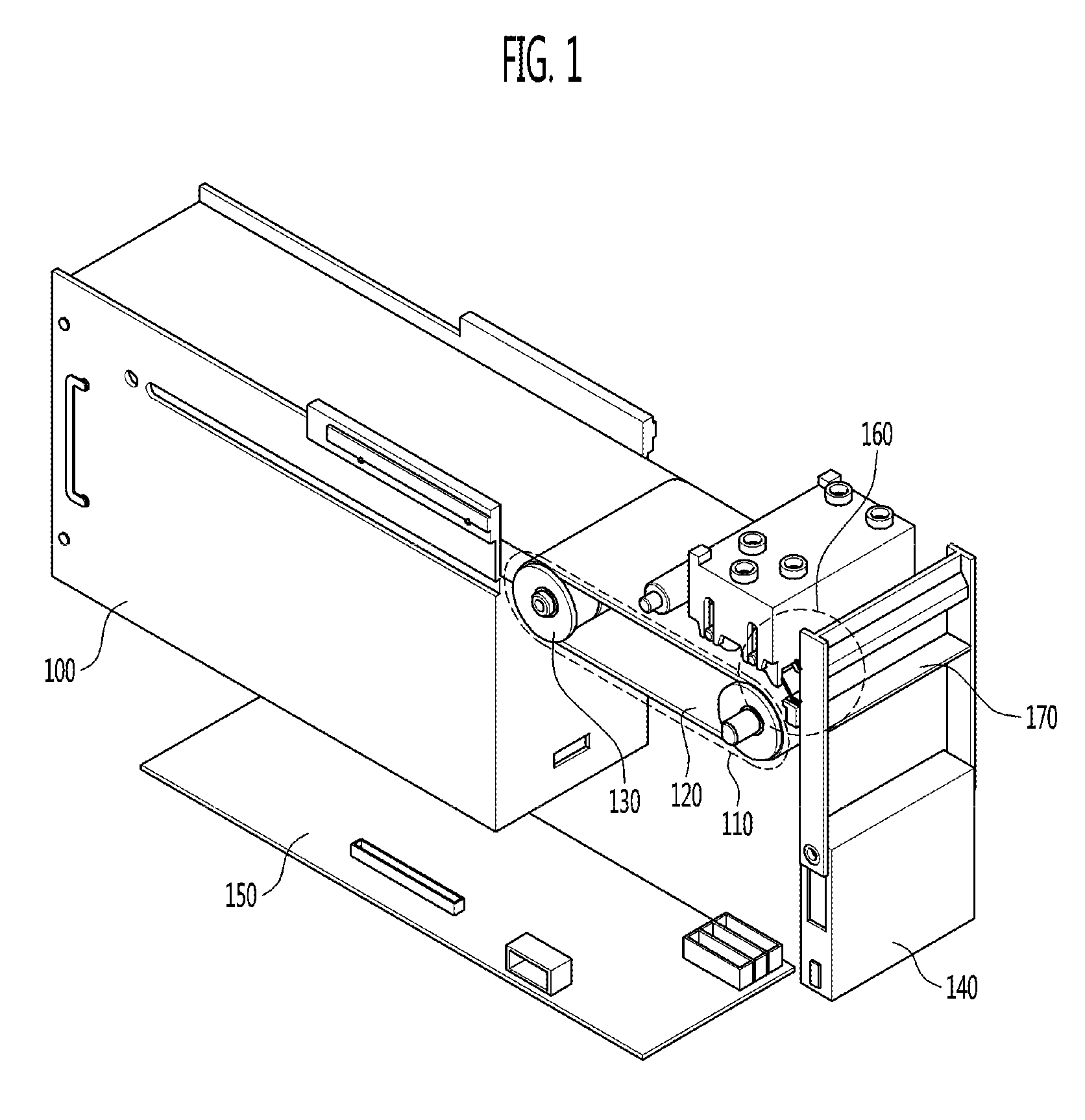

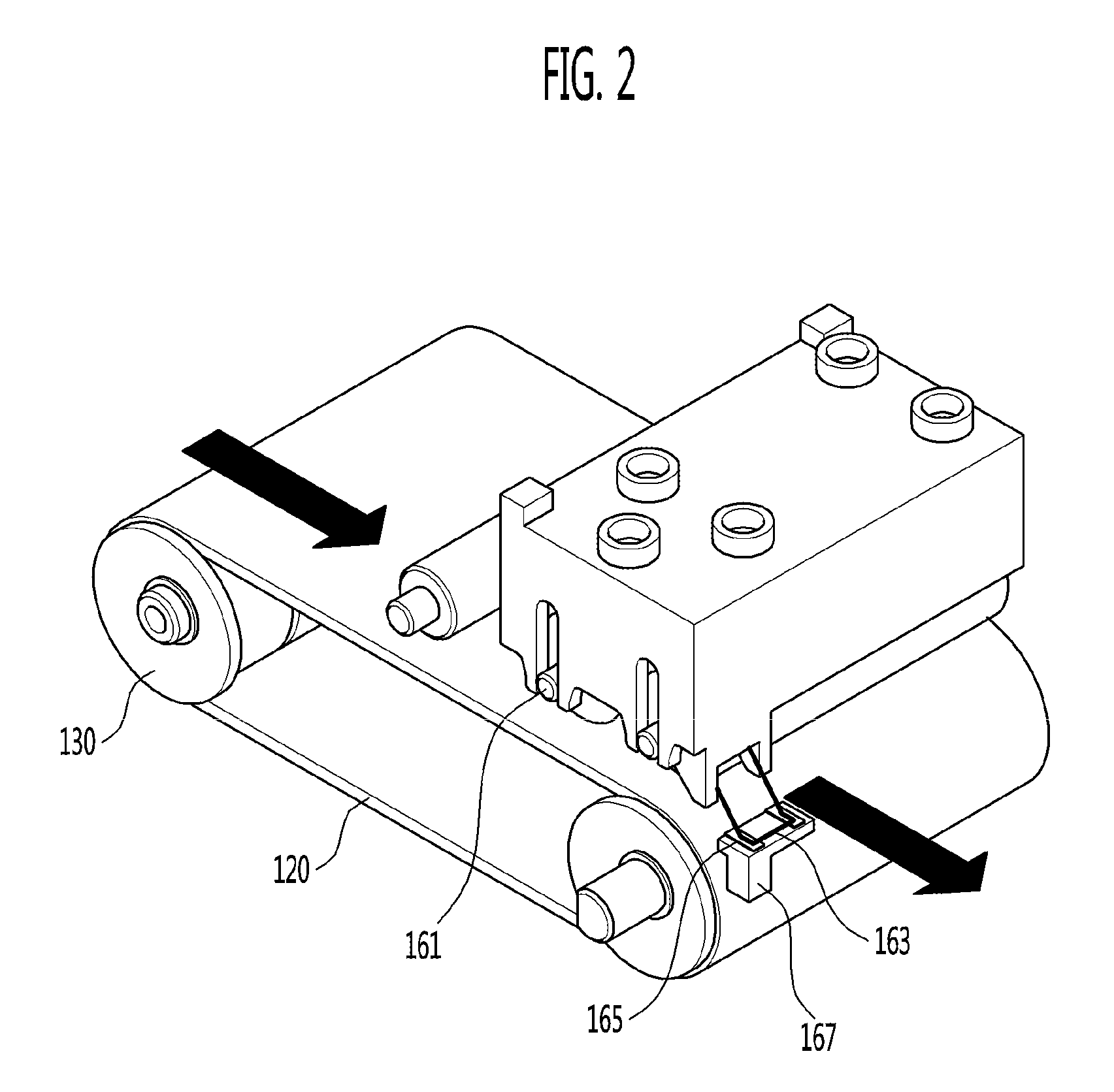

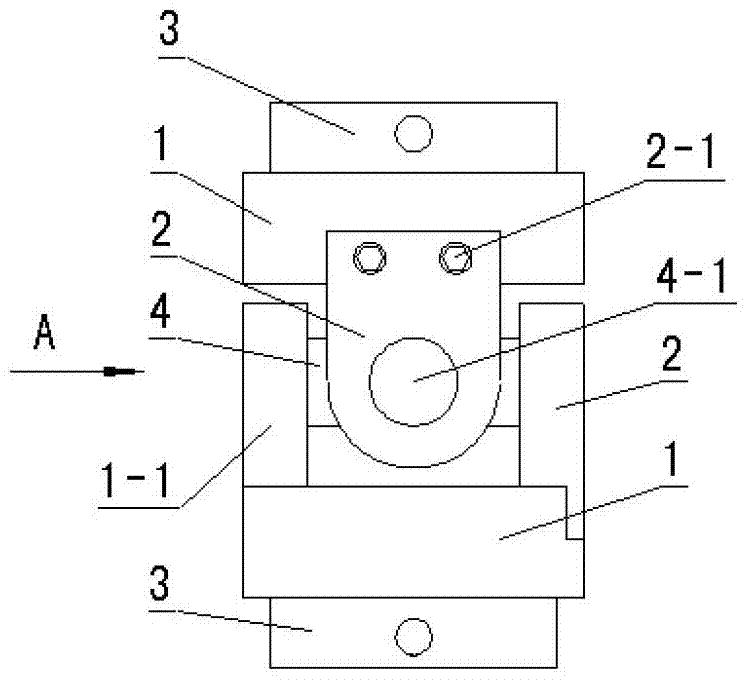

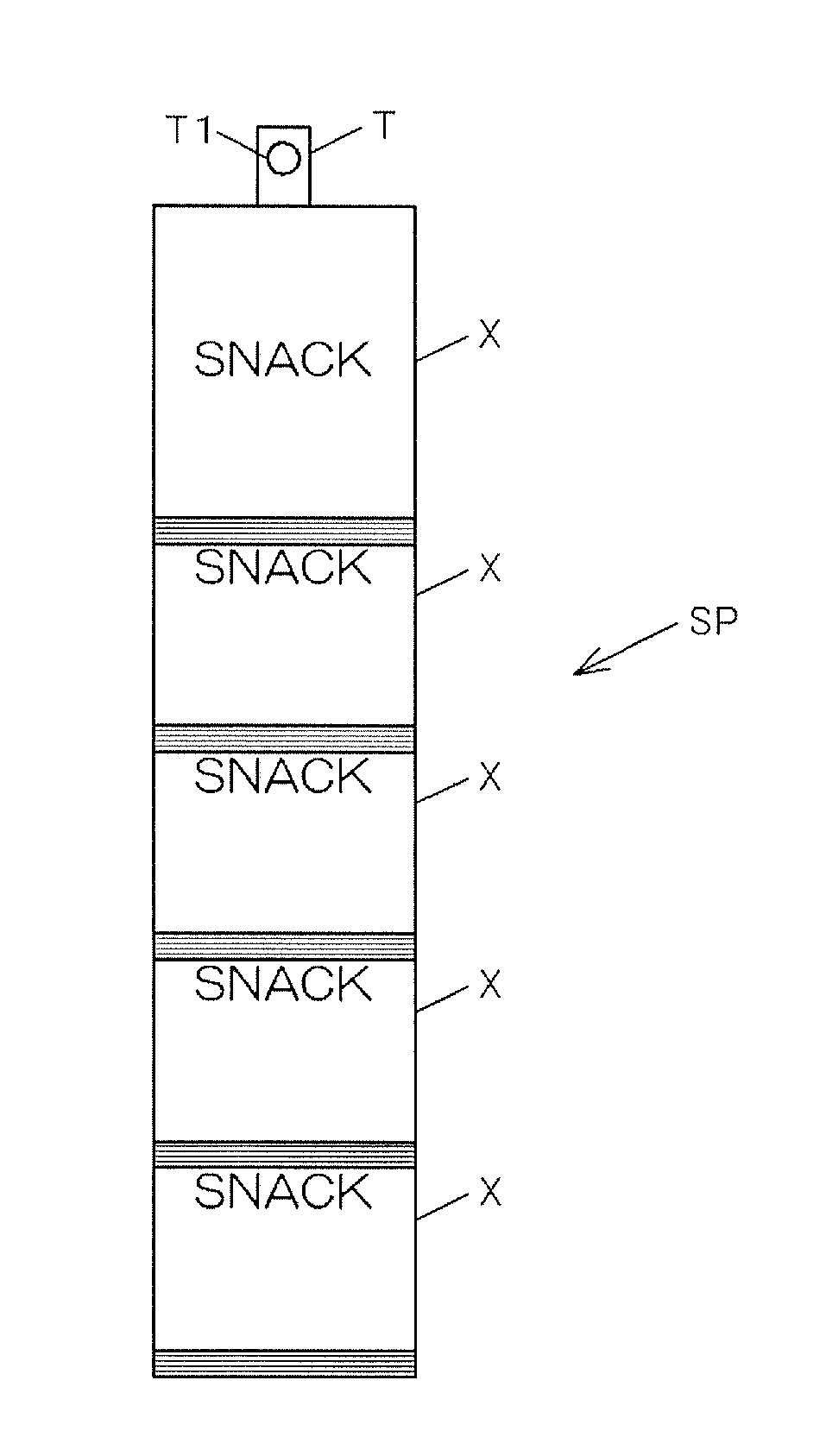

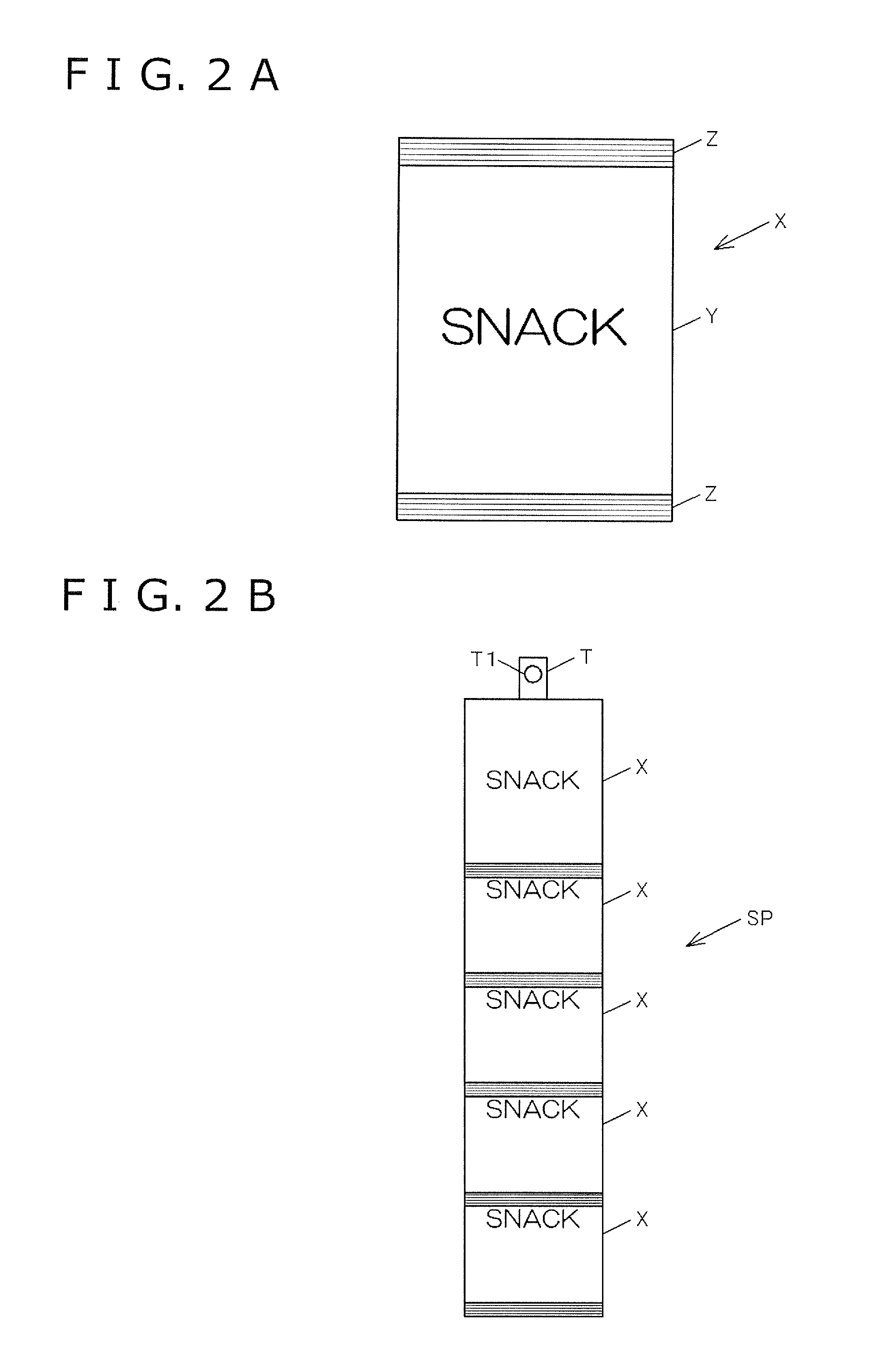

Medication supporting apparatus and method

InactiveUS20110068115A1Accurate identificationCoin-freed apparatus detailsOral administration deviceBiomedical engineeringStrip packing

Provided are a medication supporting apparatus and method. In the medication supporting apparatus, a storage section stores a strip of dosage bags that are continuously connected. A carrier section carries the dosage bag strip in the storage section. A sensor section generates a detection signal detecting a position of the dosage bag strip on the carrier section. A circuit section determines the position of the dosage bag strip according to the detection signal of the sensor section, and controls the carrier section. The dosage bag strip packed in continuous dosage bags is recognized in a unit of one dosage bag, is adjusted to a start position thereof, and is dispensed by a size of one dosage bag, so that the dosage bag strip can be accurately dispensed.

Owner:ELECTRONICS & TELECOMM RES INST

Reinforced crossed shaft universal coupling

InactiveCN102817927AHigh strengthFacilitates trouble-free operationYielding couplingEngine lubricationDrive shaftCoupling

The invention relates to a reinforced crossed shaft universal coupling. One side of a forked joint base is provided with a shaft rack integrated with the base, the other side of the base symmetrical with the shaft rack is provided with a shaft rack plate inlaid in a base groove, the shaft rack plate is concentric with a shaft hole of the shaft rack and provided with a bolt for fixing the shaft rack plate in the base, symmetrical end shafts of an integral intermediate connector provided with vertical and crossed shafts are respectively connected with the shaft rack of each fork joint and the shaft hole of the shaft rack plate, and the base is provided with shaft sleeves connected with relevant shafts. The shaft rack and the shaft rack plate are provided with bearings for supporting the end shafts of the integral intermediate connector, the joint faces of the base and flange plates of the shaft sleeves are respectively provided with mutually meshed tooth grooves so that tooth embedded connection is formed, and a bolt installing hole of the flange plate provided with the tooth groove in the end surface is an arc-shaped slot hole. The reinforced crossed shaft universal coupling has the extruded advantage of long-term trouble-free stable running and is especially suitable for connecting transmission shafts of transparent paper packaging machines and hard strip packing machines for cigarette packing machine sets.

Owner:天驰天新机电技术配套(天津)有限公司

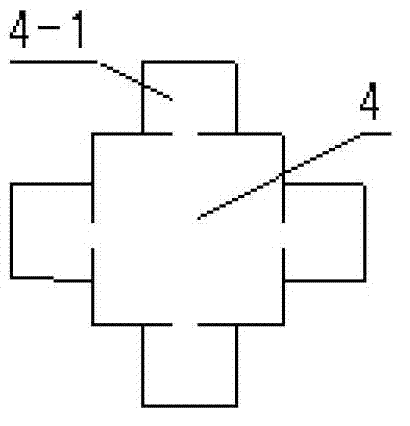

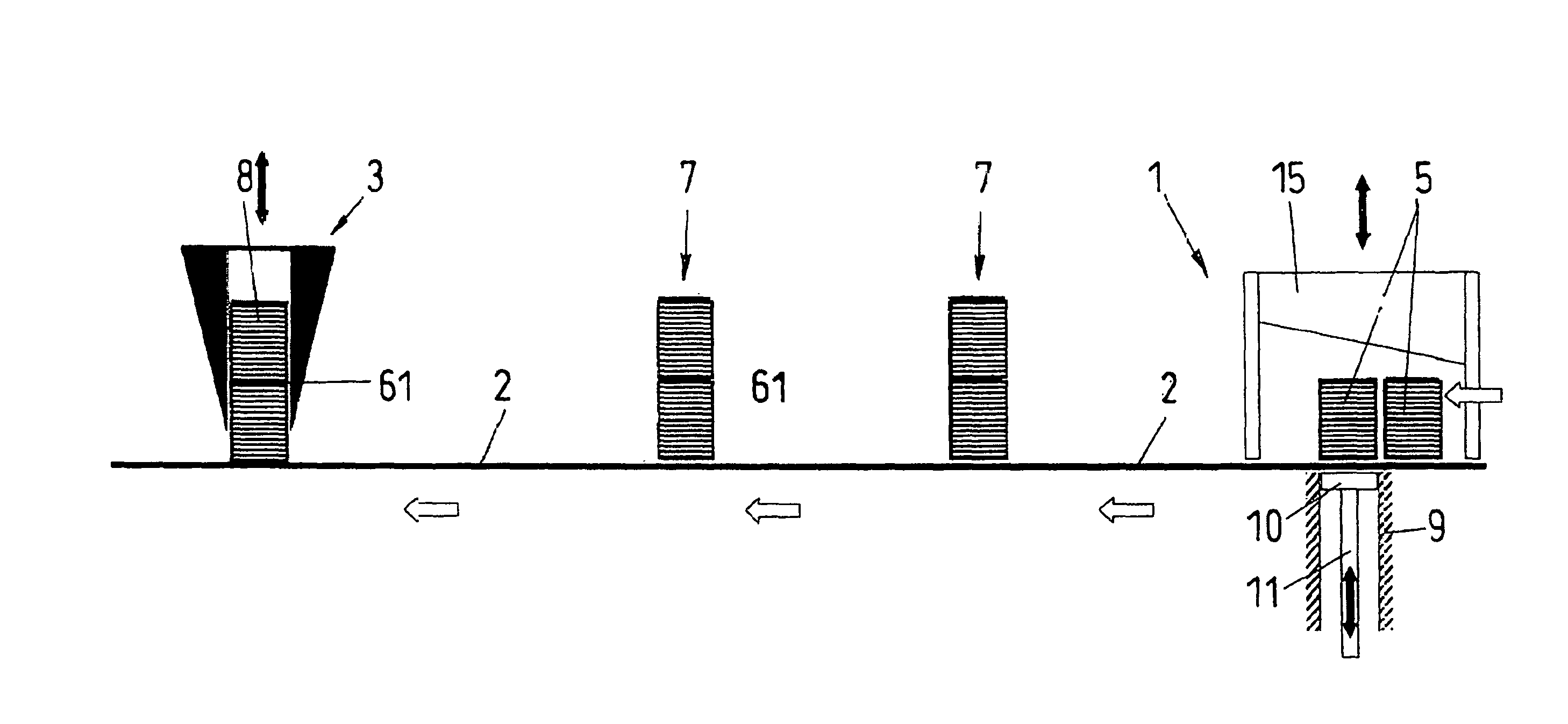

Method for forming shaped label stacks

A method for shortening the processing time on creating shaped label stacks. Between a strip pack cross-cutter and a die-cutting device in the region of a conveying section, the strip packs cut by way of the strip pack cross-cutter into stack packs are transferred and then die-cut in the die-cutting device into shaped label stacks. Two or more stack packs are layered on one another in the region of the conveying section and the layered stack packs are die-cut into shaped label stacks, for increasing the die-cutting output. The layered, die-cut stacks can then be divided again into shaped label stacks that can be managed and banded.

Owner:BLUMER MASCHENBAU

Strip pack apparatus, and grasper device and dewrinkler device used therein

InactiveUS20100083475A1Moved to the attaching position efficiently and sufficientlyOperation is necessaryLarge fixed membersPackagingMechanical engineeringStrip packing

Owner:ISHIDA CO LTD

Steel strip packer with steel belt stagger cutting function and steel belt packing method

The invention discloses a steel strip packer with a steel belt stagger cutting function and a steel strip packing method. The steel strip packer comprises a first knife holder and a second knife holder. The first knife holder can axially move and is provided with a first knife mold and a shear edge. The second knife holder is provided with a second knife mold capable of being matched with the first knife mold. The steel belt packer further comprises a strip guide part which is attached to the shear edge. A steel belt can penetrate through the strip guide part and winds to-be-bundled cargos. A gap allowing the steel strip winding the to-be-bundled cargos to rewind and pass though is arranged between the belt guide part and the second knife holder. The steel strip packer with the steel belt stagger cutting function can shear off the steel strip with small stamping force.

Owner:DALIAN FIELD HEAVY MACHINERY MFG CO LTD

Strip pack device

Owner:ISHIDA CO LTD

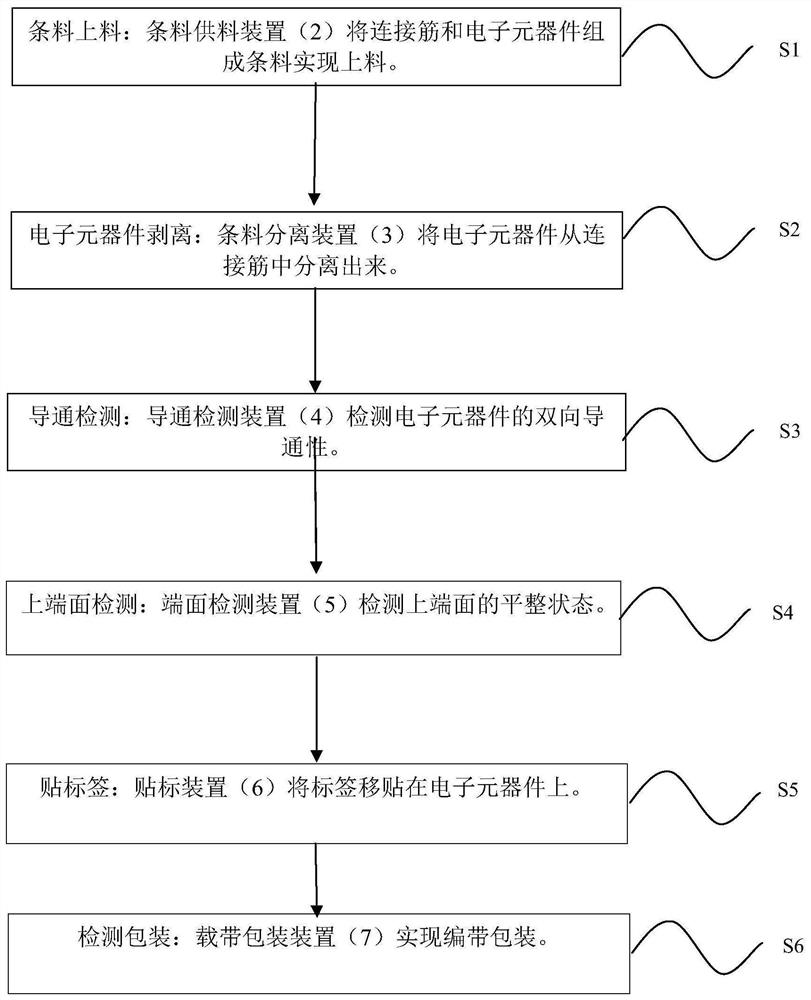

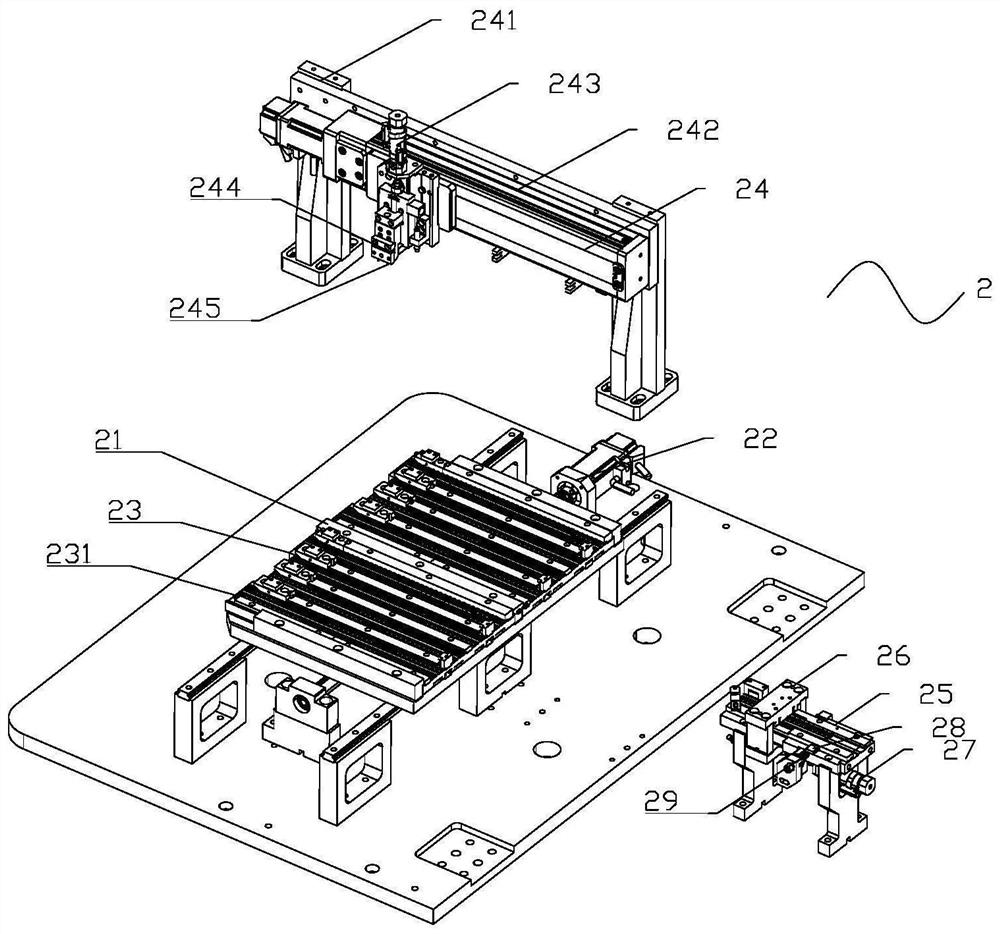

Electronic component carrier tape packaging equipment and carrier tape packaging method

InactiveCN112319895AIncrease storage capacityEasy to replaceArticle unpackingSortingEngineeringElectronic component

The invention discloses electronic component detecting and packaging equipment. The equipment comprises a rack, and further comprises a strip feeding device, a strip stripping device, a conduction detecting device, an end face detecting device, a labeling device and a carrier tape packaging device which are mounted on the rack. In the machining direction, the strip feeding device, the strip stripping device, the conduction detection device, the end face detection device, the labeling device and the carrier tape packaging device are sequentially connected and linearly arranged. The equipment has the advantages of multi-task detection, automatic production, automatic inferior-quality product reject and high transfer efficiency.

Owner:倪旭鑫

Packaging machine capable of realizing carrier tape detection

PendingCN112093168ASave human effortShorten the timePackaging automatic controlPackaging machinesCamera moduleDISC assembly

The invention discloses a packaging machine capable of realizing carrier tape detection. The packaging machine comprises a bottom platform; a rotary disc assembly is installed in the center of the topof the bottom platform; a cutting-off module, a camera module, a removing module, a position changing module and a packaging module are sequentially installed around the rotary disc assembly on the bottom platform in the anticlockwise direction; a carrying module is installed between the cutting-off module and the rotary disc assembly; a carrying module is also installed between the packaging module and the rotary disc assembly; a carrier tape passes through the cutting-off module; and a braid passes through the packaging module. According to the packaging machine capable of realizing carriertape detection, the positions of various functional assemblies are arranged reasonably, connection production work of automatic cutting-off, detecting and packaging can be performed on 3C part products, manpower and time are saved, the product machining and production efficiency and yield are increased, the situations that the products are contaminated, scratched, crushed and the like are avoided, and the product quality is guaranteed.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

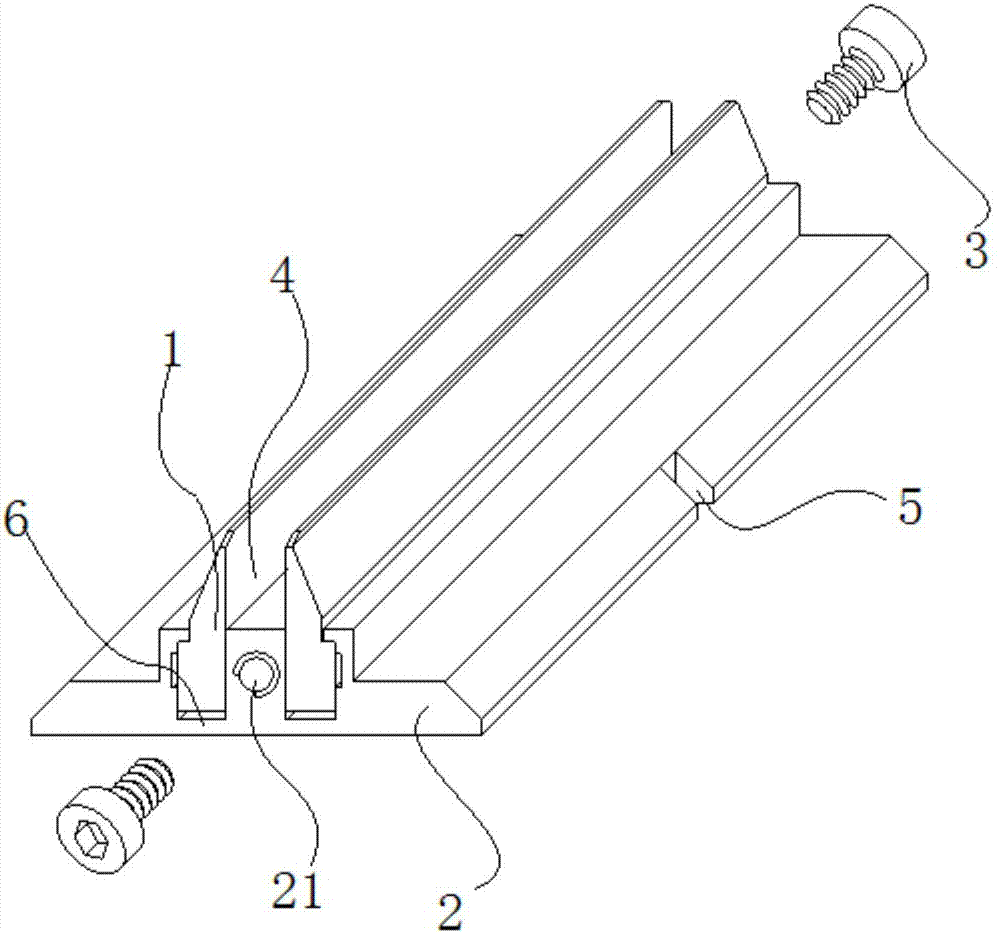

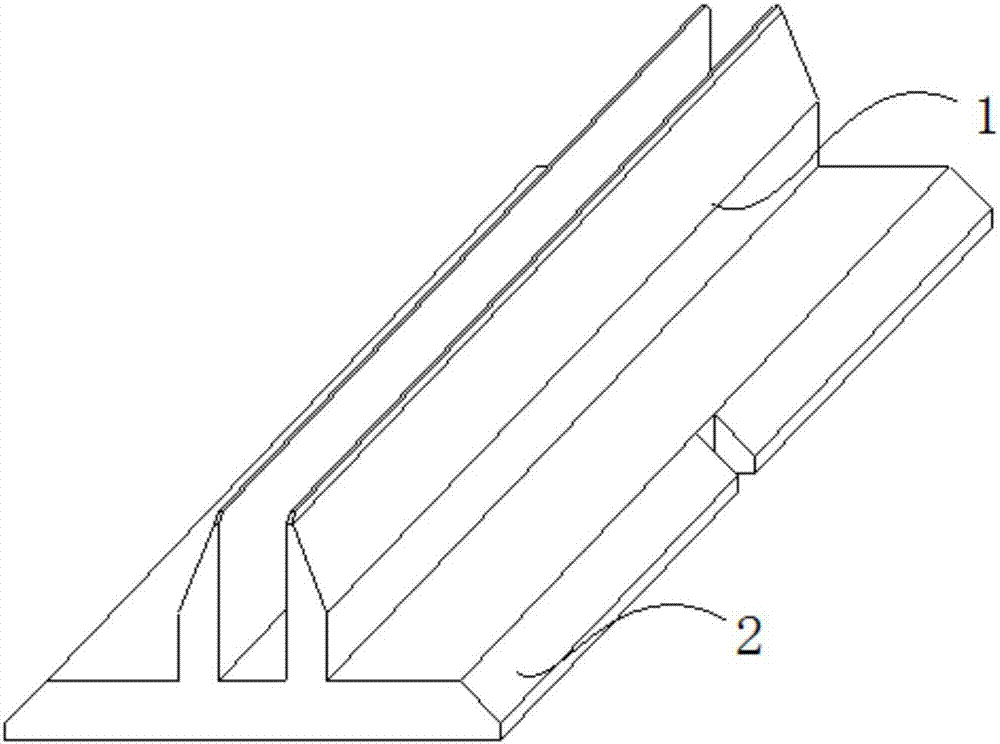

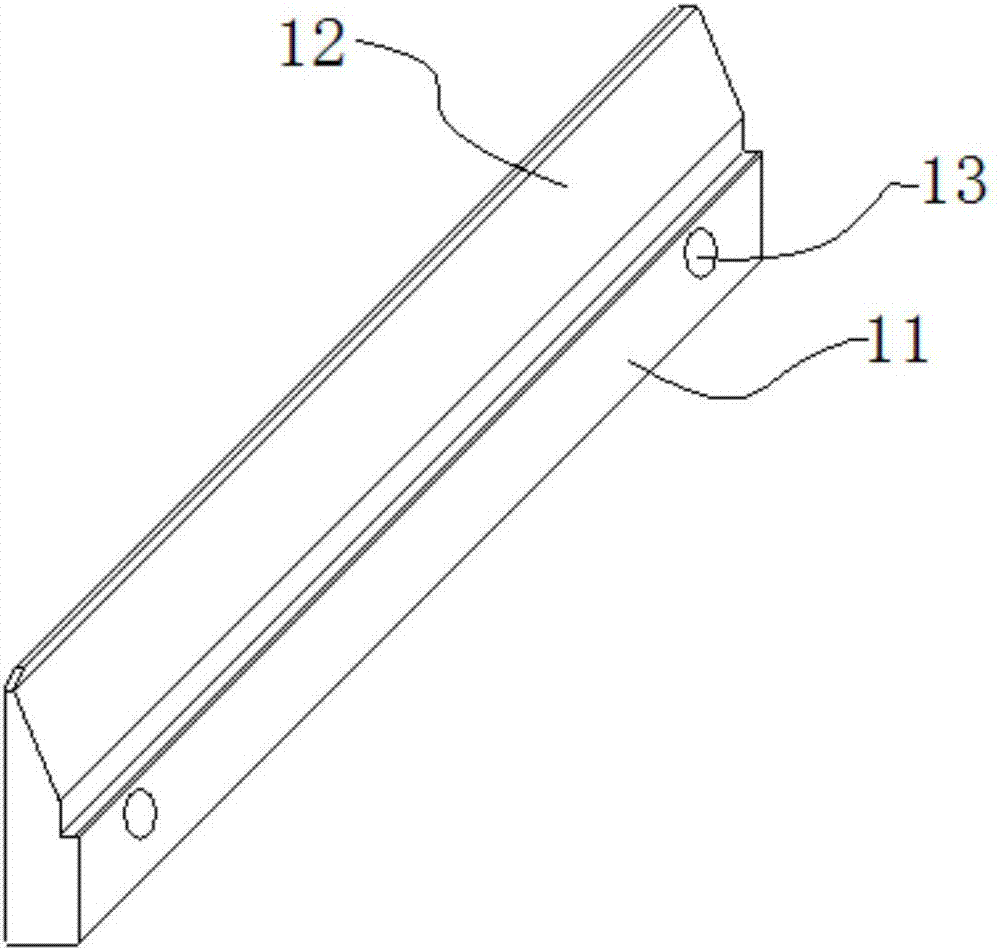

Automatic separate-preventing independent movable sealing cutter and assembling and sealing method

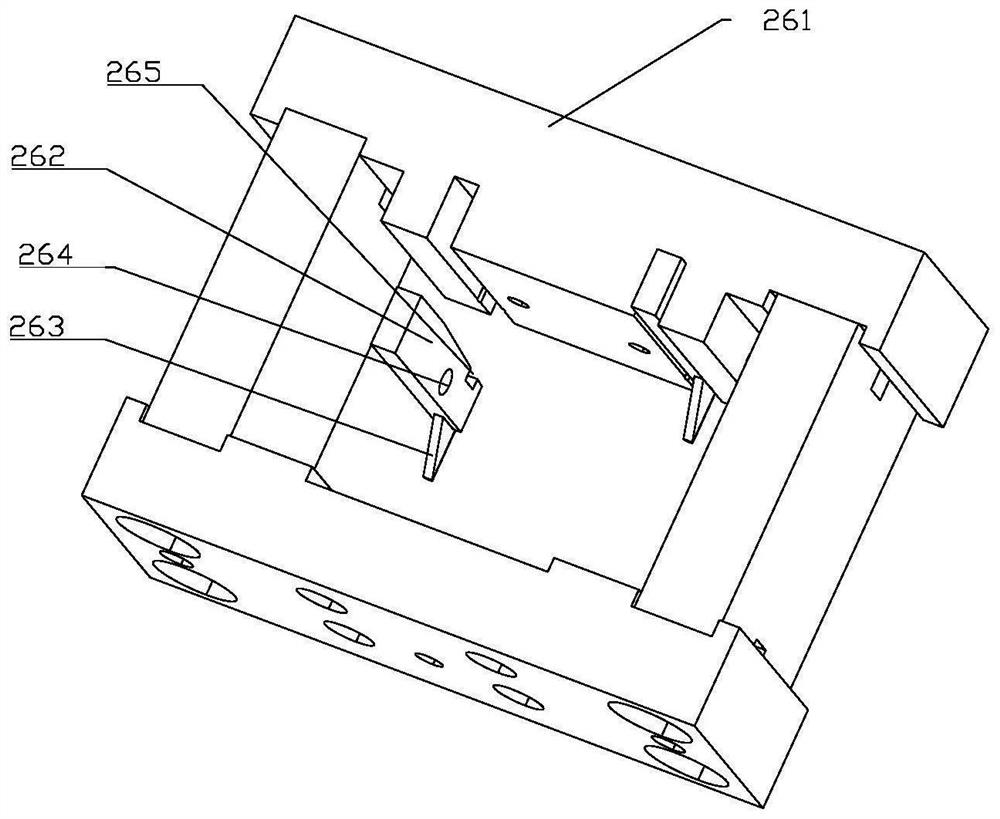

ActiveCN107499607AAvoid hard contactEvenly sealedWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses an automatic separate-preventing independent movable sealing cutter and an assembling and sealing method, and belongs to the technical field of carrier tape packaging. The automatic separate-preventing independent movable sealing cutter comprises a sealing cutter body. When a cutter edge of the sealing cutter body is pressed downwards, soft pressure is applied to a cover tape and the carrier tape, and the sealing cutter is prevented from being in superhard contact with the cover tape and the carrier tape, therefore the technical effects of even sealing and compact sealing are achieved. According to the assembling method, through the steps of sealing cutter assembling, transverse inserting, sealing cutter fixing, resonance and positioning, the purpose of assembling of the automatic separate-preventing independent movable sealing cutter is achieved. The sealing method solves the technical problem that the cover tape is separated and blushed due to the fact that sealing is poor in the sealing process of the cover tape and the carrier tape.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

Copper strip packaging tool

ActiveCN110654594APrevent affecting the packaging effectWrapped tightlyWrapping material feeding apparatusDrive wheelEngineering

The invention relates to the field of copper strip packaging, in particular to a copper strip packaging tool which comprises a shell, a clamping structure, a first driving mechanism, a transmission mechanism and a second driving mechanism. An operating platform is fixedly connected to the bottom of the shell, the first driving mechanism is arranged on the upper surface of the operating platform, an objective table is arranged in the shell, and an arc-shaped groove is formed in the upper surface of the objective table. Since a clamping structure and a driving wheel are arranged, a copper stripcan be prevented from being inclined and affecting the packaging effect when packaged, a second sleeve can continuously clamp the two sides of the copper strip, folds of packaging strips on the two sides of the copper strip can be flattened, a first sleeve can flatten the folds of a packaging strip on the outer side of the copper strip to enable the packaging strips to wind and pack the copper coil more tightly and firmly, the objective table can be extracted from the shell through the arrangement of the first driving mechanism, the copper strip can be conveniently taken and placed by workers,and workers can conveniently carry out feeding and discharging on the copper strip packaging tool.

Owner:浙江金桥铜业科技有限公司

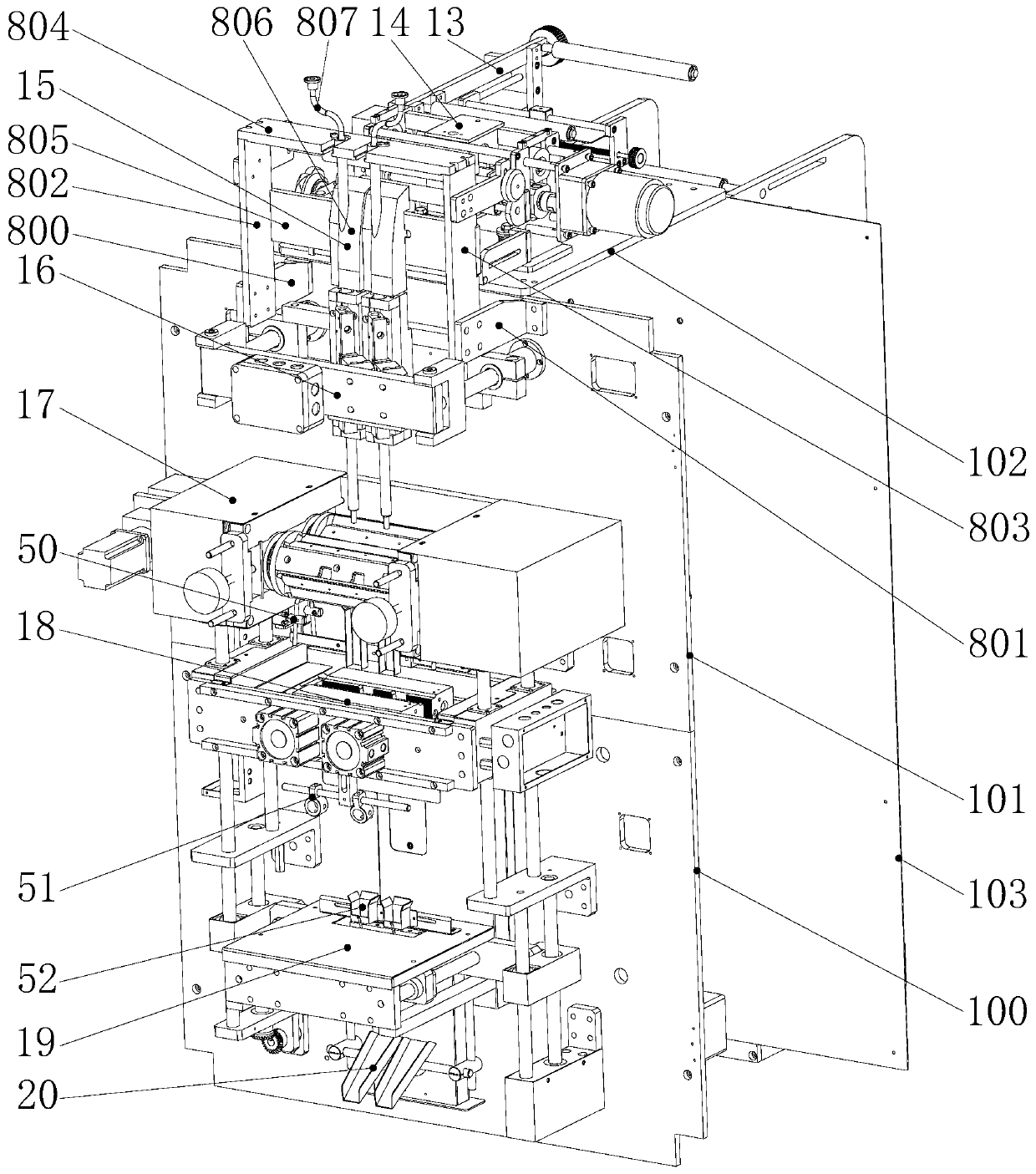

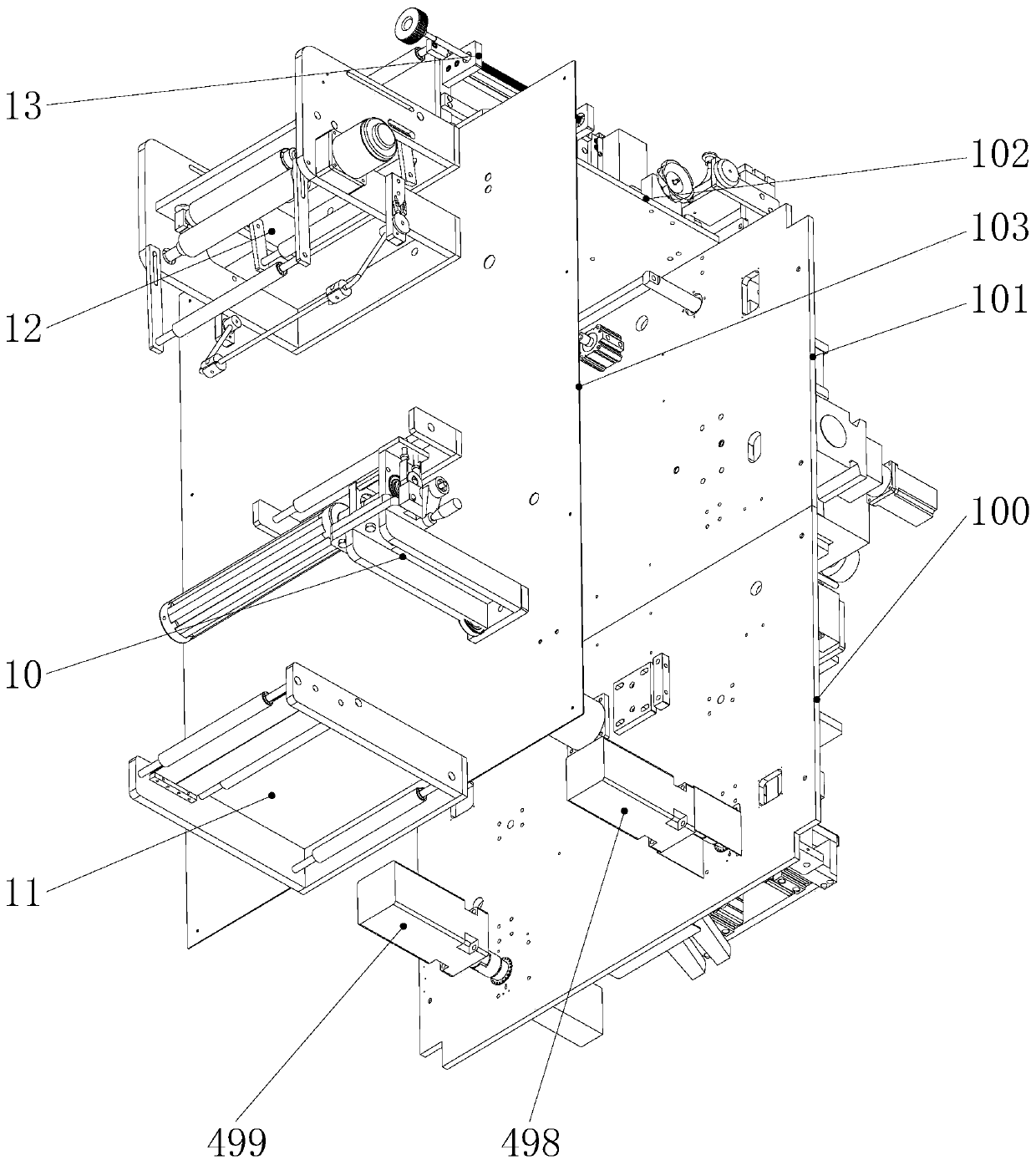

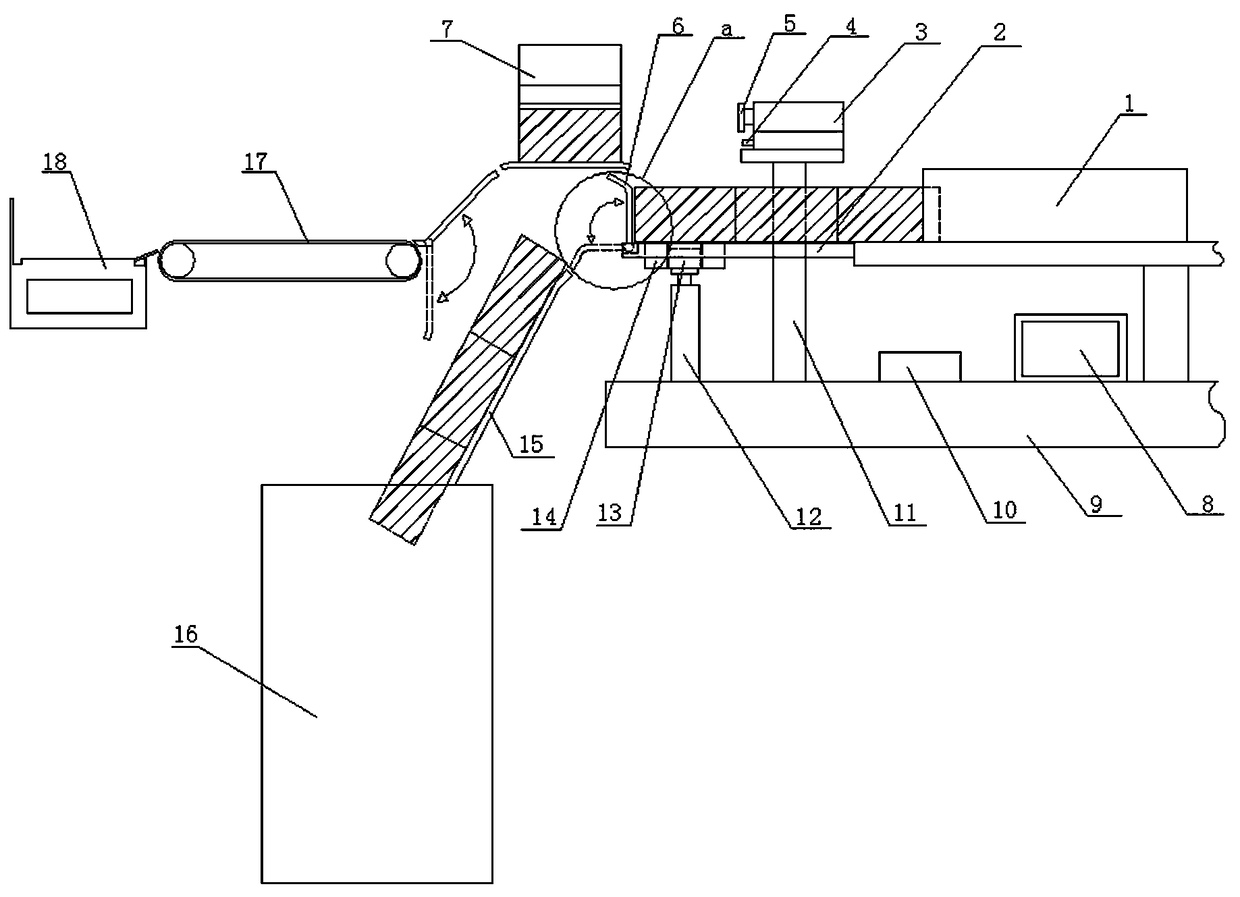

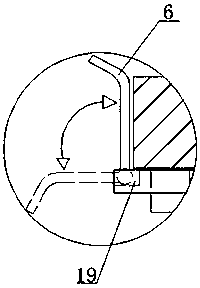

Roller enhancing type strip packing machine

PendingCN110342004AImprove leakageGuaranteed seal strengthWrapping material feeding apparatusWrapper twisting/gatheringColor ScaleThin membrane

The invention relates to a roller enhancing type strip packing machine. According to the moving direction of a film, the strip packing machine comprises a film coiling device, a film connecting device, a film feeding device, a color scale adjusting device, a middle cutting device, a former device, a longitudinal sealing device, a roller device, a transverse sealing device and a cutting device, wherein the film coiling device, the film connecting device and the film feeding device are arranged on the rear side of a rear plate. The front portion of the rear plate is provided with a front base plate, wherein the top ends of the rear plate and the front base plate are provided with top plates, and the front base plate is formed by an upper base plate and a lower base plate in a splicing mode.The color scale adjusting device and the middle cutting device are installed on the top plates, the former device, the longitudinal sealing device, the roller device and the transverse sealing deviceare sequentially arranged from top to bottom on the upper base plate, and the cutting device is installed on the lower base plate. According to the roller enhancing type strip packing machine, compared with the prior art, the roller device is arranged between the longitudinal sealing device and the transverse sealing device, so that the advantages of a roller and a sealing plate can be combined, opening sealing strength and sealing performance of a transverse sealing opening of a package bag is ensured, thus preventing leakage phenomena as well as improving the product yield.

Owner:SHANGHAI KOMATSU PACKAGING MACHINERY

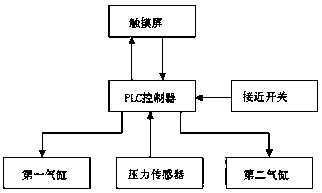

GD packing machine cigarette separation device

ActiveCN108082601AReduce stuck cigarettesAvoid the problem of inaccurate detection of missing packets and false rejectionPackaging automatic controlEngineeringStrip packing

The invention discloses a GD packing machine cigarette separation device. The GD packing machine cigarette separation device comprises a PLC, a vertical cigarette lifting mechanism and a horizontal cigarette pushing mechanism. The vertical cigarette lifting mechanism comprises a vertically arranged first air cylinder and a supporting plate arranged at the output end of the first air cylinder; thehorizontal cigarette pushing mechanism comprises a horizontally arranged second air cylinder and a push plate arranged at the output end of the second air cylinder; and the first air cylinder and thesecond air cylinder are in control connection with the PLC. According to the GD packing machine cigarette separation device, a pack missing detection device is arranged to be higher than the horizontal plane of a cigarette conveying plate, a through hole is formed in the free end of the cigarette conveying plate of a CV strip packing transparent machine, the first air cylinder arranged below the through hole vertically pushes cigarettes, and therefore cigarettes being not seriously adhered are automatically separated due to self gravity; the second air cylinder is horizontally arranged above the middle of the cigarette conveying plate, and pushes the cigarettes pushed upwards by the first air cylinder into the pack missing detection device to be subjected to pack missing detection, and thephenomenon of mal-removing generated by inaccurate pack missing detection caused by adhesion of the cigarettes is effectively avoided.

Owner:CHINA TOBACCO HENAN IND

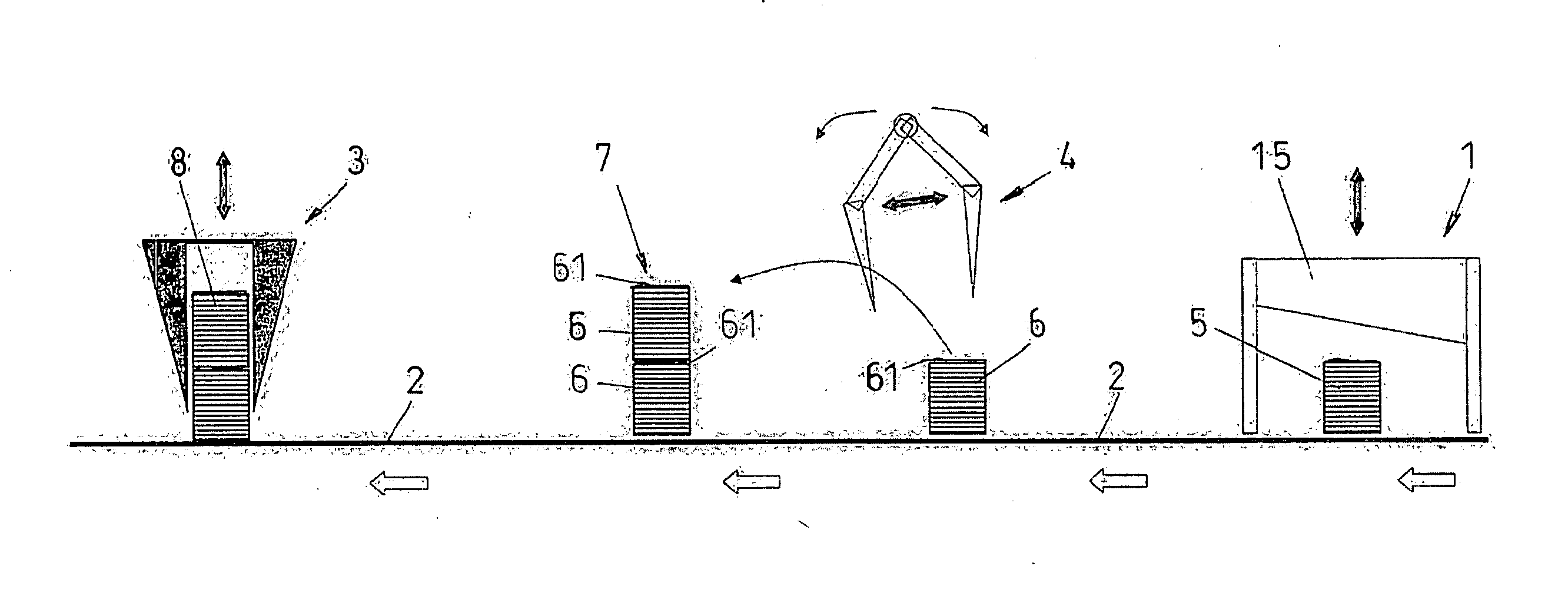

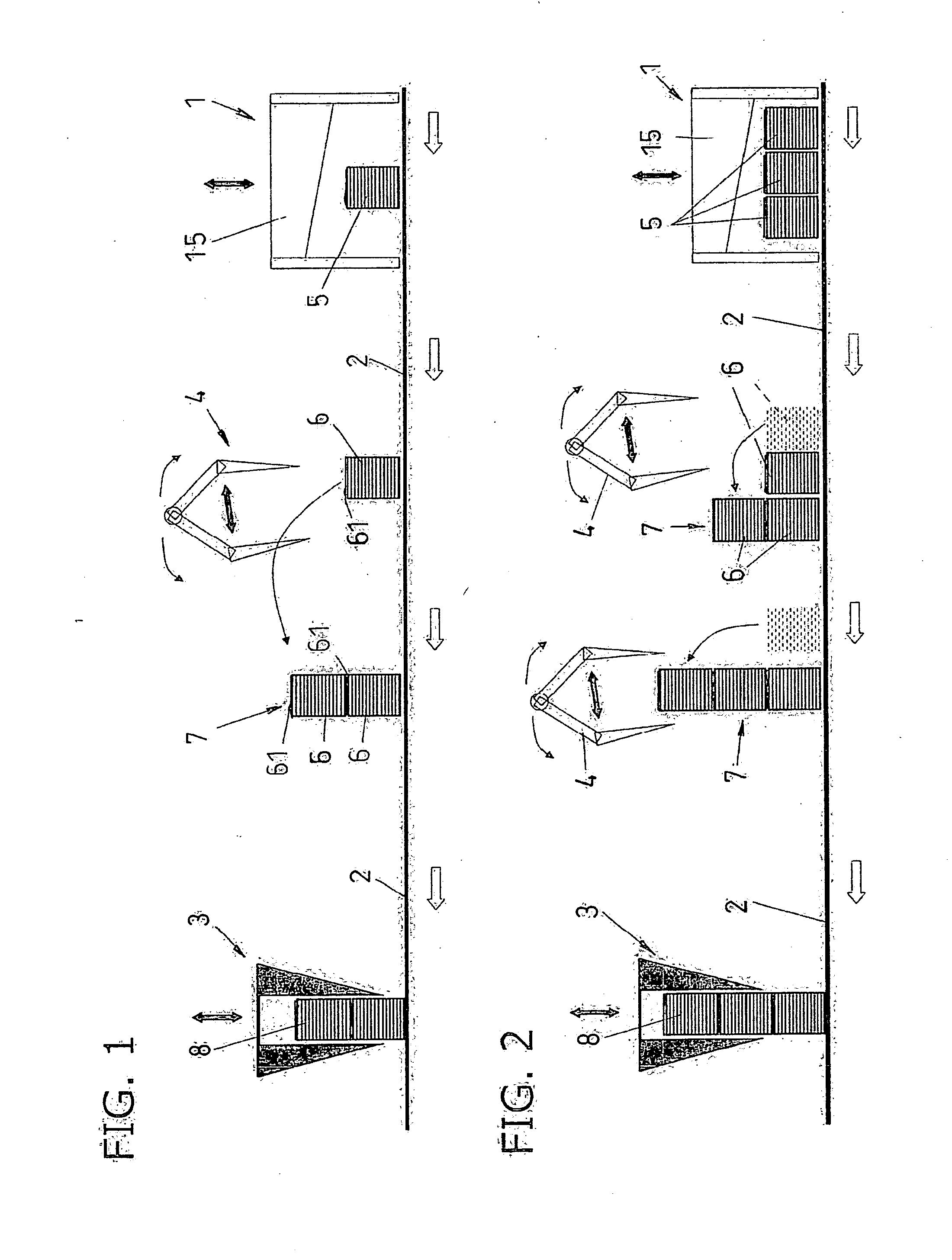

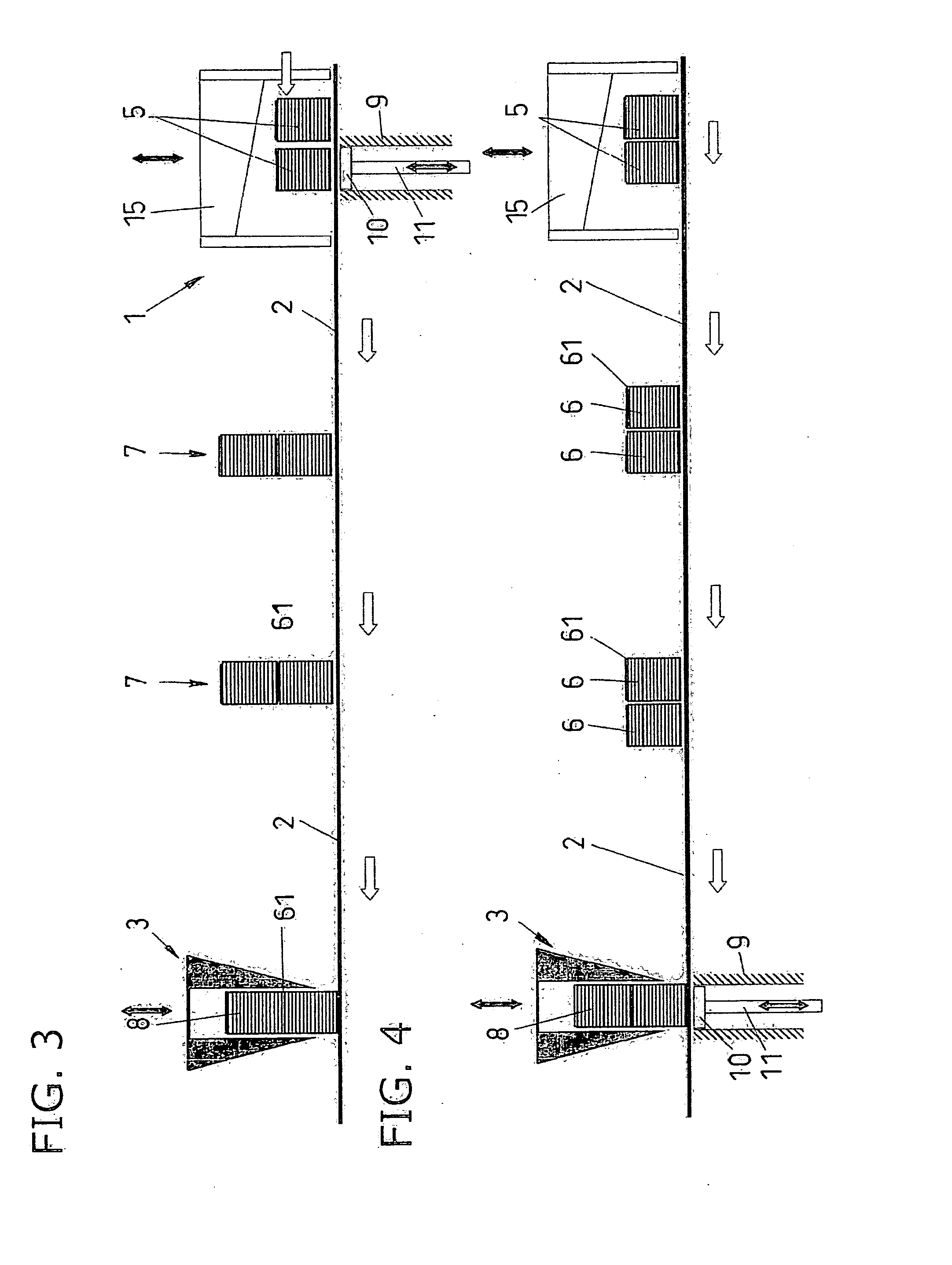

Method for forming shaped label stacks

ActiveUS20140165805A1Increase productionMetal working apparatusStructural engineeringMechanical engineering

A method for shortening the processing time on creating shaped label stacks. Between a strip pack cross-cutter and a die-cutting device in the region of a conveying section, the strip packs cut by way of the strip pack cross-cutter into stack packs are transferred and then die-cut in the die-cutting device into shaped label stacks. Two or more stack packs are layered on one another in the region of the conveying section and the layered stack packs are die-cut into shaped label stacks, for increasing the die-cutting output. The layered, die-cut stacks can then be divided again into shaped label stacks that can be managed and banded.

Owner:BLUMER MASCHENBAU

Braid packaging system for DFN miniature device

ActiveCN113320732AEnsure uniform orientationGuaranteed yieldWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a braid packaging system for a DFN miniature device. The braid packaging system is characterized by comprising a frame body and a carrier tape track assembly arranged on the frame body, wherein a carrier tape discharging mechanism, a carrier tape driving mechanism, a feeding conveying mechanism, a cover tape discharging mechanism, a hot-pressing packaging mechanism and a discharging mechanism are sequentially arranged on the frame body in the carrier tape conveying direction of the carrier tape track assembly; the feeding conveying mechanism comprises a conveying platform, and the conveying platform comprises a first platform and a second platform rotationally connected to the first platform; and the top surface of the second platform is provided with an accommodating groove and a detection mechanism, the accommodating groove is used for accommodating the DFN miniature device, and the detection mechanism is used for detecting the orientation of the DFN miniature device in the accommodating groove. The device can detect the orientation of the DFN miniature device and adjust the angle of the DFN miniature device according to the orientation, so that the DFN miniature device is aligned with a material carrying position on a carrier tape, the orientation unification of the DFN miniature device during packaging is ensured, and the packaging quality is ensured.

Owner:东莞市华越半导体技术股份有限公司

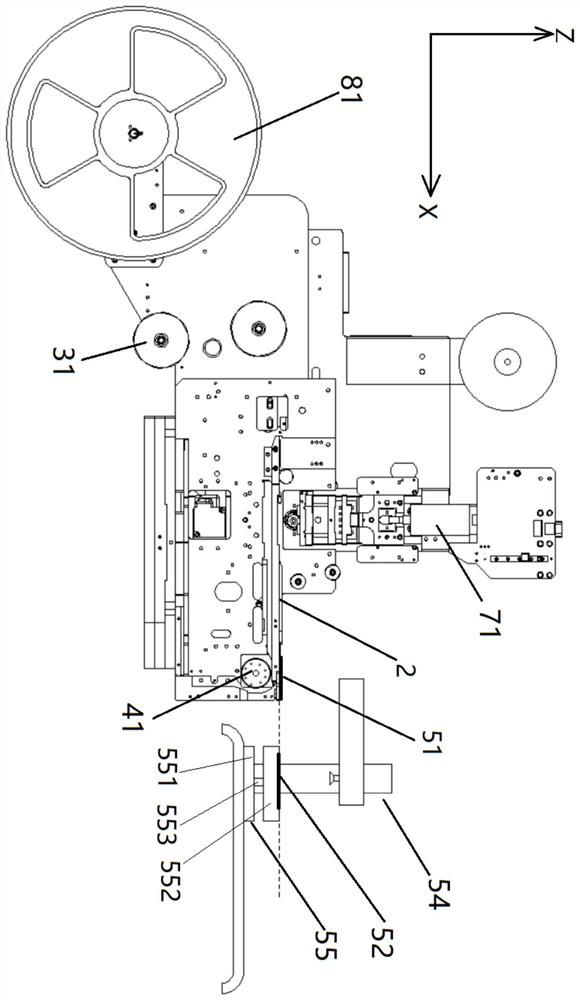

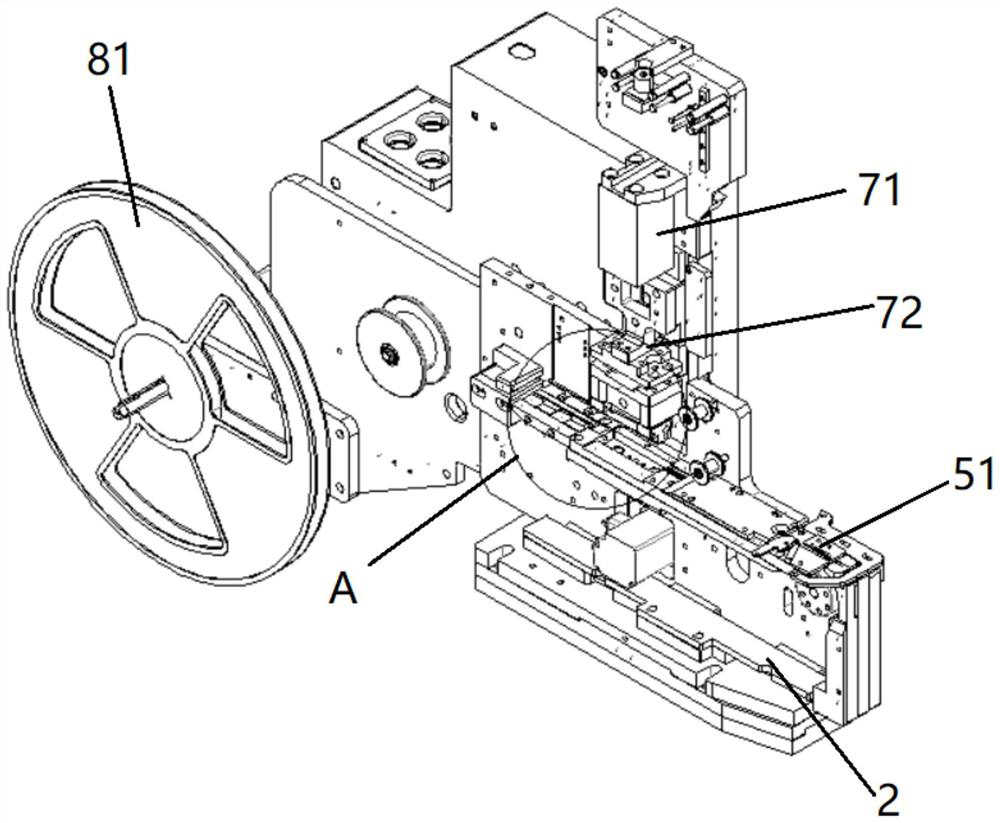

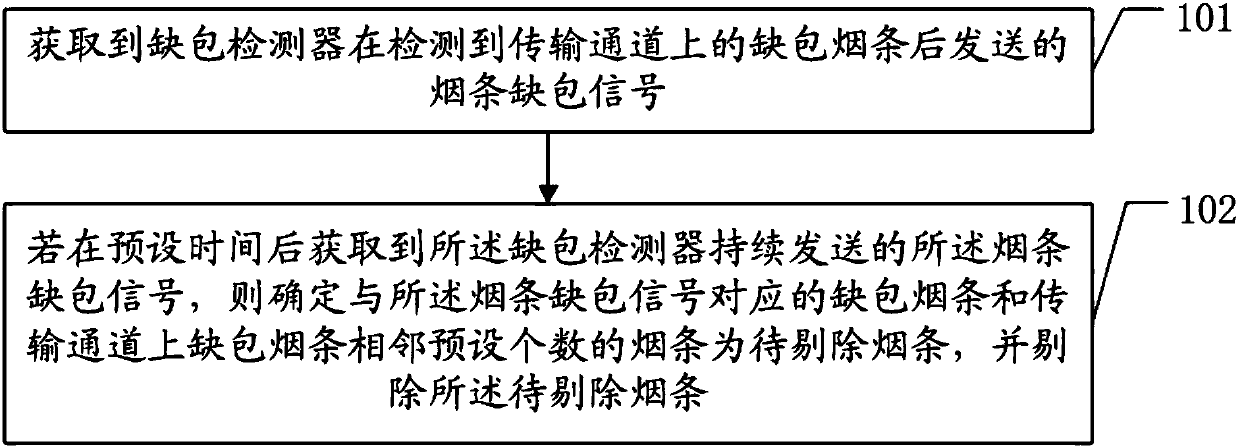

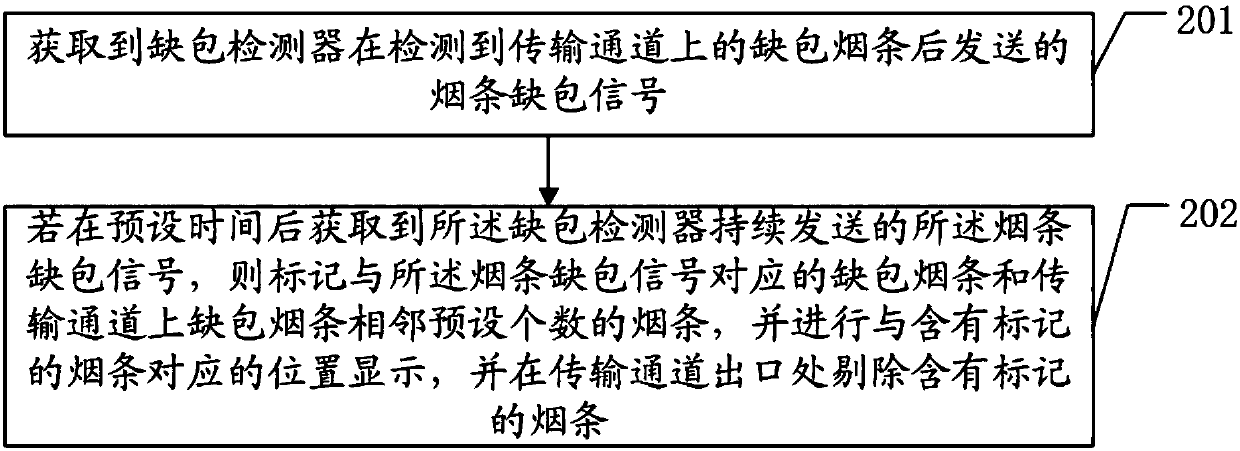

Pack-missing cigarette strip removing method and device

ActiveCN109987293ASolve the problem of false detectionSolve the situationPackaging automatic controlSortingTransmission channelEngineering

The invention discloses a pack-missing cigarette strip removing method and device. When the cigarette strip pack missing signal sent by a packing missing detector lasts for a certain period of time isdetected, the fact that the cigarette strip corresponding to the cigarette strip packing missing signal is mis-detected or missed to be detected is determined, the fact that the packing missing cigarette strip corresponding to the cigarette strip packing missing signal and the cigarette strips with the preset number adjacent to the packing missing cigarette strip on a transmission channel are theto-be removed cigarette strips is determined, then the removing of the to-be removed cigarette strips is conducted, and the problem that the pack missing cigarette strip enters the next process and the market due to the fact that an existing cigarette strip packing missing detector adopted by each cigarette factory mainly comprises a photon pack missing detector, a weight packing missing detector, a negative pressure pack missing detector, an imaging pack missing detector and the like, the devices can better solve the pack missing quality defects in the operation process of the equipment, butthe actual detecting process of cigarette strip packing missing is affected by the various external factors, and sometimes the mis-detecting and missing detection happen is solved.

Owner:CHINA TOBACCO GUIZHOU IND

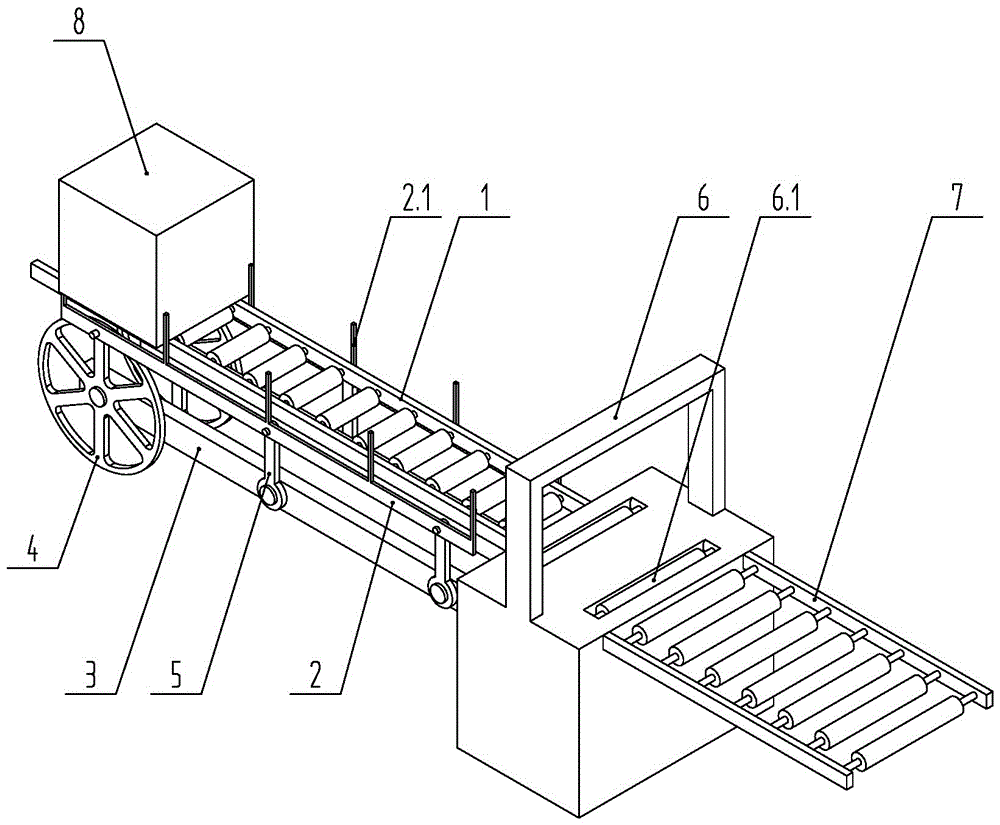

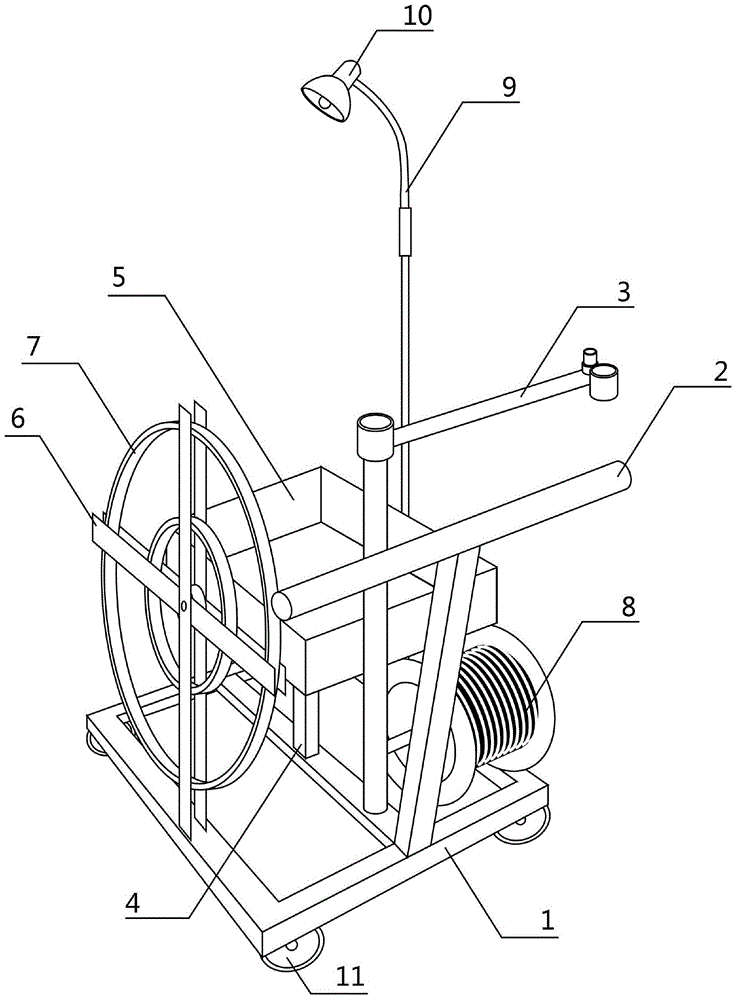

Steel strip packing car

InactiveCN104648708AEasy to operateIngenious designBinding material applicationEngineeringSteel belt

The invention aims to provide a steep strip packing car. The steel strip packing car consists of a base, a push handle, an auxiliary tool rod, a bottom support frame, a packing wheel bracket, a cable shaft and a wire groove, wherein the push handle is positioned at the upper part of one side of the base, and is in fixed connection; the auxiliary tool rod is positioned at the upper part of the base, and is in fixed connection; the bottom support frame is positioned at the upper part of the base, and is in fixed connection; the packing wheel bracket is positioned at the upper part of one side of the base, and is in fixed connection; the cable shaft is positioned at the upper part of the base, and is in fixed connection; the wire groove is positioned at the upper part of the other side of the base, and is in fixed connection; a tool box is additionally arranged on the bottom support frame; a packing belt wheel disc is additionally arranged on the packing wheel bracket; an illuminating lamp is additionally arranged in the wire groove; and multiple rollers are arranged on the base, are positioned at the bottom of the base, and are in fixed connection. The packing car integrates steel strips, cable plugboards, the tool box and illuminating facilities for finished product packing as a whole, so that the operation of internal staff is convenient, and precious time is gained for customers.

Owner:TIANJIN ZHONGLAN PUMP

Moyeam instant tea powder and making method thereof

The invention discloses a moyeam instant tea powder, which is characterized in that the moyeam instant tea powder is made by smashing, extracting, filtering, concentrating, spraying, drying, pelletizing, packing and filling moyeam original leaves. A method for preparing the moyeam instant tea powder comprises steps: 1 smashing; 2 digesting; 3 filtering; 4 concentrating; 5 spraying and drying; 6 pelletizing; and 7 strip packing and filling. The moyeam instant tea powder which is prepared through the method is convenient to carry, does not have residues, is easy to adjust concentration, is easy to deploy with other foods, and is beneficial for users to adsorb substances such as amino acids, microelements and flavones and the like. The moyeam instant tea powder can be brewed through water, also can be directly eaten ( kept under tongue and the like), and is more convenient to eat.

Owner:ZHANGJIAJIE MAOYANMEI

Contact-free testing strip packing device

ActiveCN103496514AAvoid pollutionReduce mistakesFlat article dispensingClassical mechanicsStructural engineering

The invention discloses a contact-free testing strip packing device which is simple in structure and convenient to use. The contact-free testing strip packing device comprises a testing strip taking device and a testing strip packing box arranged in the testing strip taking device. The contact-free testing strip packing device is characterized in that (a) the testing strip packing box comprises a box body and a box cover, the box body is provided with a testing strip outlet and at least one groove opening, the inside of the box body is provided with an elastic pressing device used for pressing a testing strip, one end of the elastic pressing device abuts against the inner wall of the box body, the other end of the elastic pressing device abuts against the contact face of the testing strip, and the testing strip is sent to an outlet waiting position; (b) the testing strip taking device comprises a device shell, a spring device and a device cover, the inner wall of the device shell is provided with a boss capable of pushing out the testing strip, the boss corresponds to the position of the groove opening, and the spring device is located between the device shell and the testing strip packing box so as to eject the testing strip packing box. The contact-free testing strip packing device solves the pollution problem of the testing strip and improves the testing strip taking speed when the testing strips are frequently used clinically.

Owner:江苏鱼跃凯立特生物科技有限公司

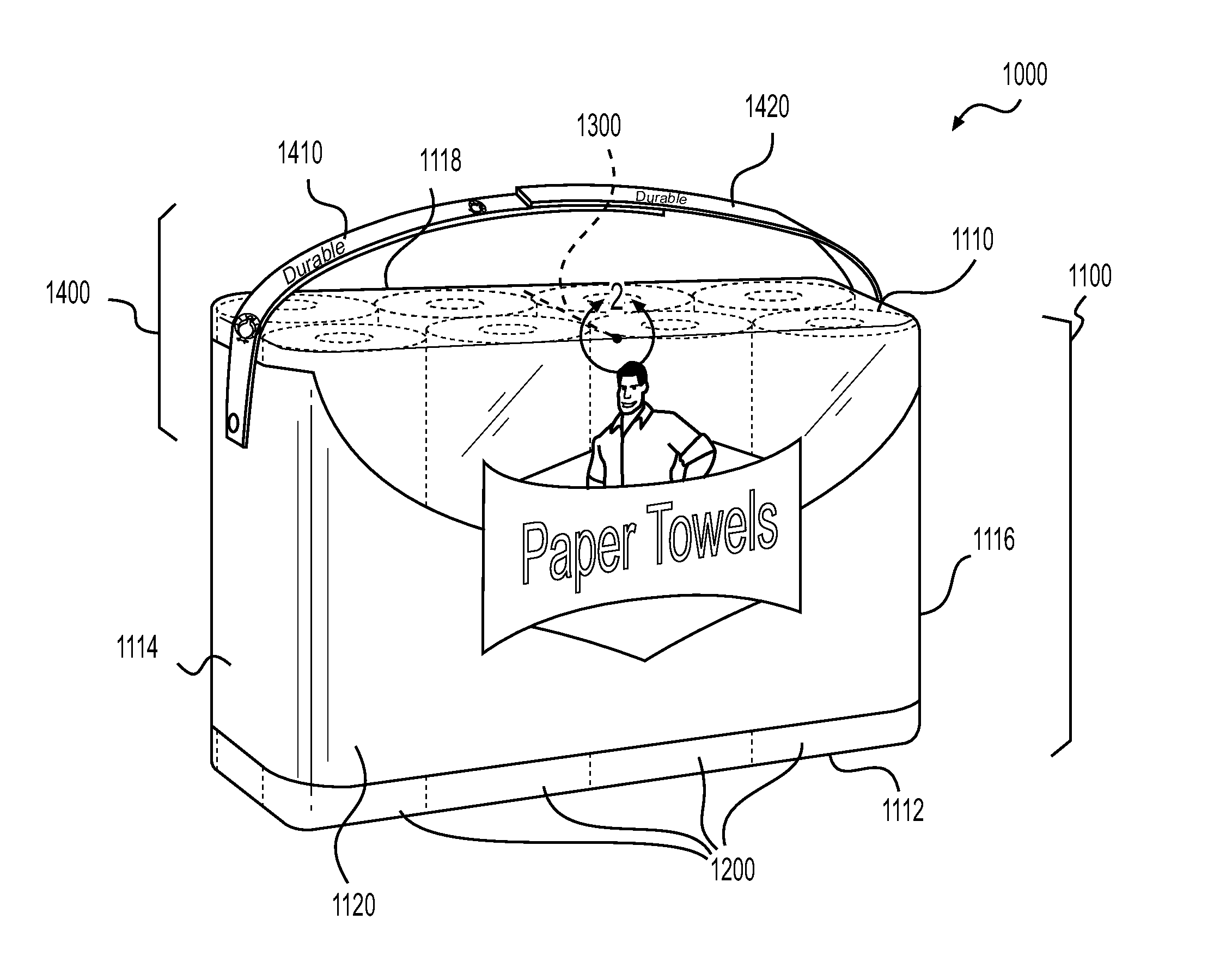

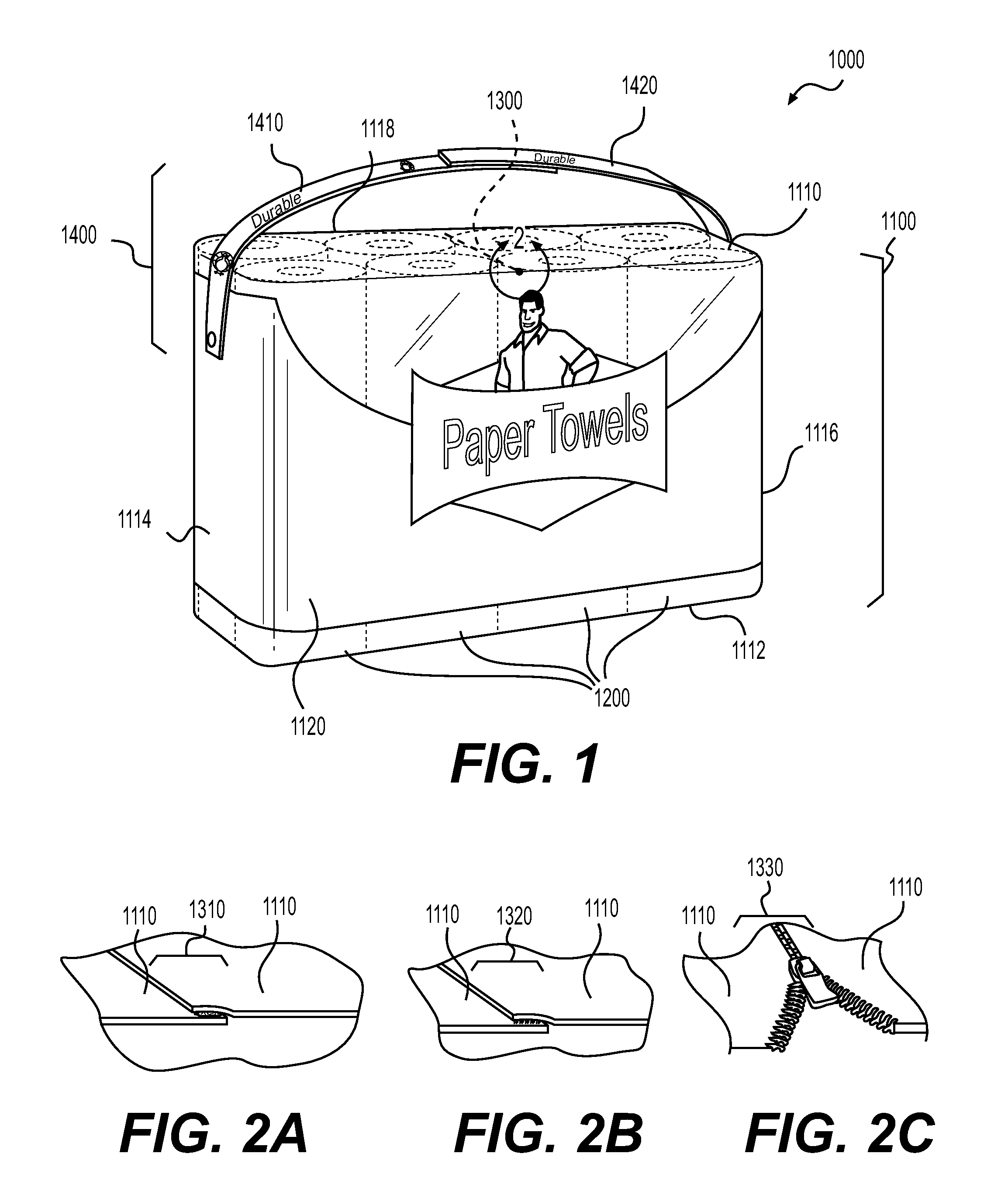

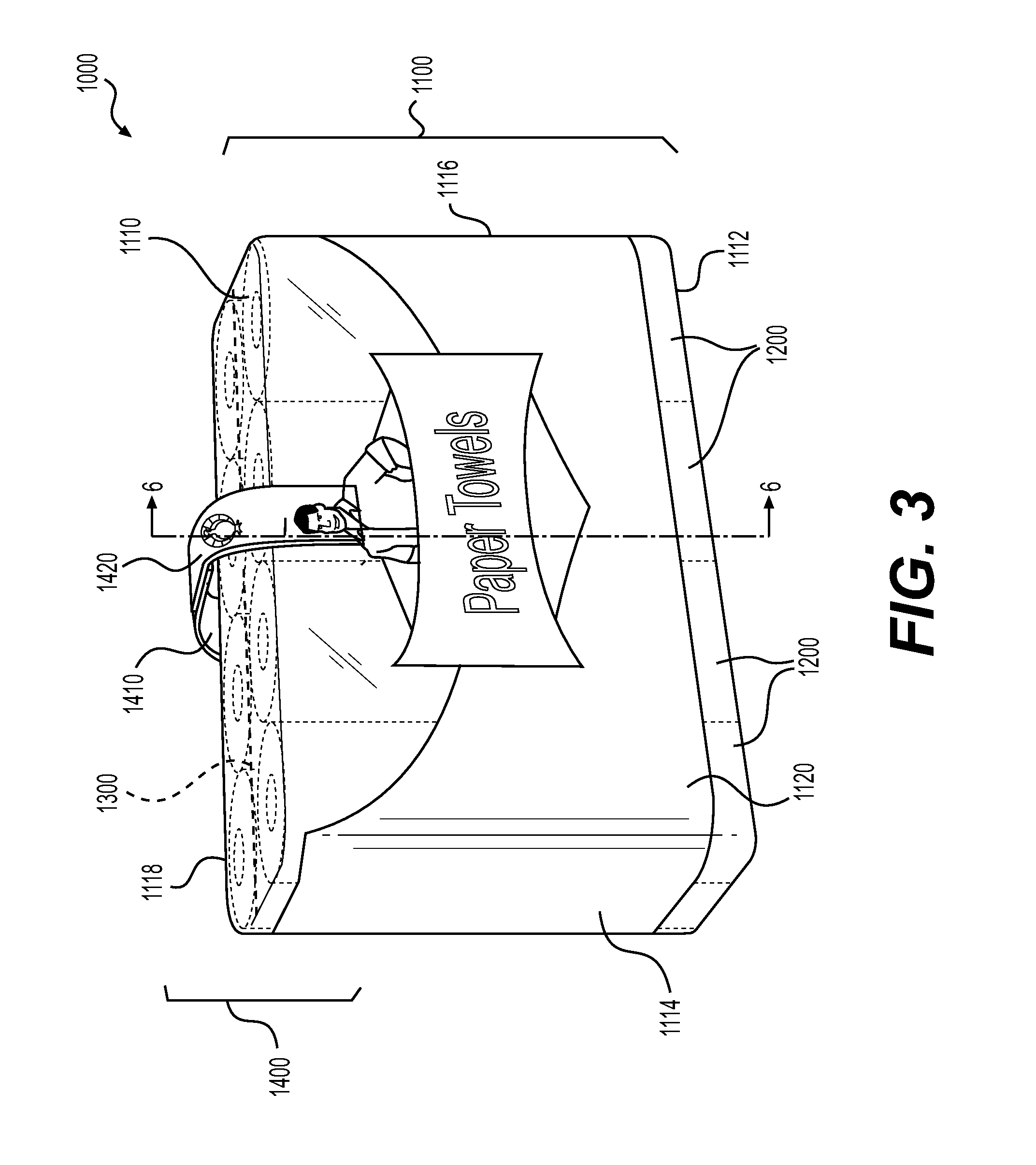

Package with a multi-piece handle

A package has a flexible package body and a handle for carrying the package. The flexible package body has at least six faces and a reclosable opening on a face of the flexible package body. The handle is positioned over the reclosable opening and has a first strap, a second strap, and a connection portion. The first strap includes a first end and a second end. The first end of the first strap is attached to one face of the package body. The second strap includes a first end and a second end. The first end of the second strap is attached to another face of the package body that is opposite to the face that is attached to the first strap. The connection portion is located on the second end of the second strap and is detachably engaged to the second end of the first strap.

Owner:GPCP IP HLDG LLC

Preparation method of anti-stripping packing material

ActiveCN104118643AOvercoming the problem of low peel strengthMeet the needs of actual useFlexible coversWrappersPolymer scienceMixed materials

The invention relates to a preparation method of an anti-stripping packing material. The preparation method of the anti-stripping packing material comprises the following steps of firstly, taking polyamide fiber, poly-p-benzamide fiber, succinimid and polyisobutene, putting the polyamide fiber, the poly-p-benzamide fiber, the succinimide and the polyisobutene into a reaction tank, and keeping the temperature constant for the reaction; secondly, taking a high polymer material mixture out of the reaction tank after the reaction, and performing double-screw extrusion to extrude out the high polymer material mixture through double screws; thirdly, performing thermal rolling on the extruded high polymer material mixture and enabling a mixed material to form a film through rolling; fourthly, performing thermal compression bonding on the mixed film material obtained in the third step and polypropylene; fifthly, performing natural cooling after the thermal compression bonding so as to obtain the anti-stripping packing material.

Owner:江西春光新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com