Automatic separate-preventing independent movable sealing cutter and assembling and sealing method

An anti-detachment and automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of whitening of cover tapes and detachment of cover tapes, and achieve the effect of uniform sealing, stable tension and elimination of gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

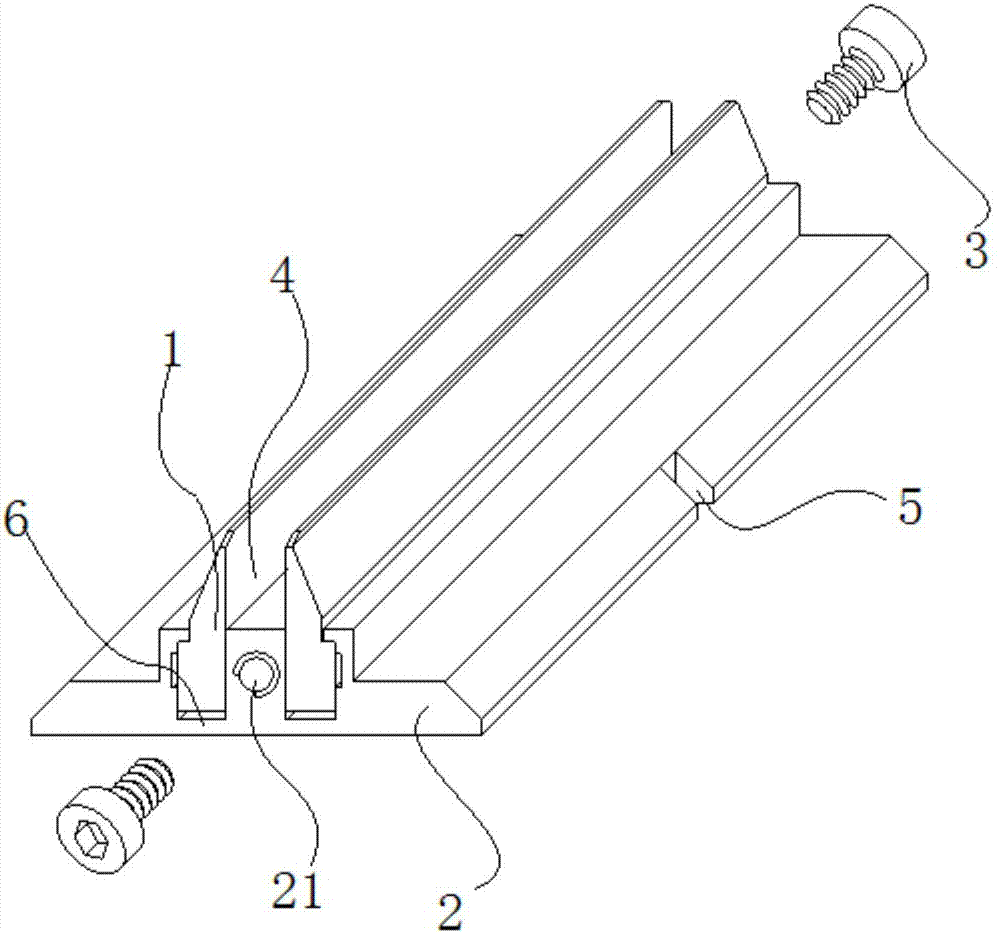

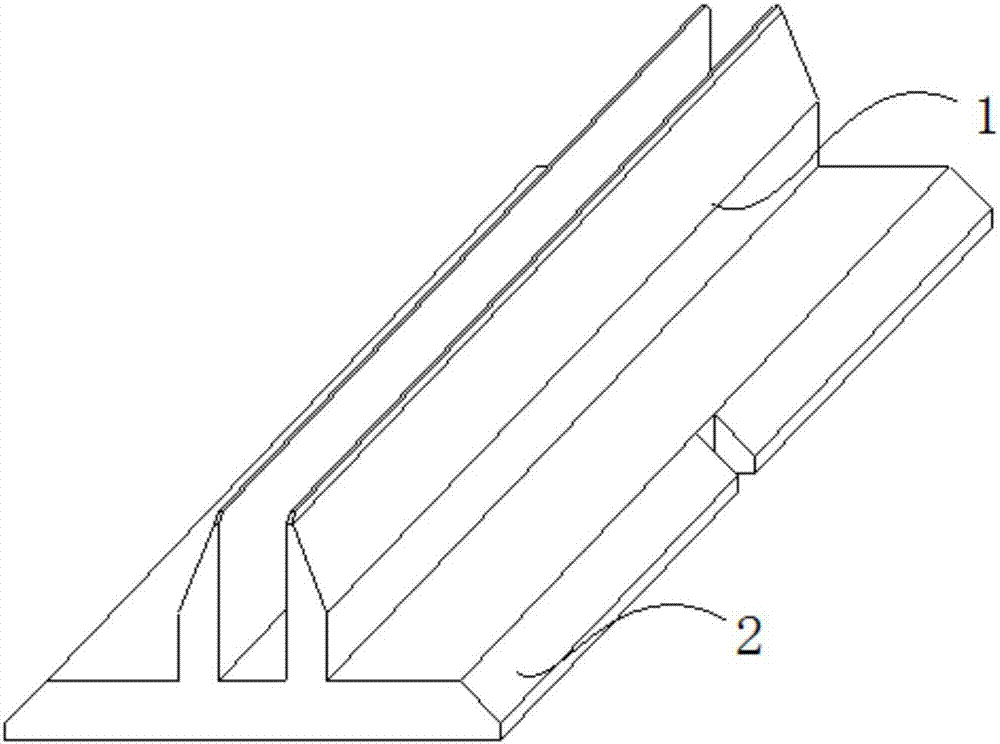

[0052] The automatic anti-disengagement independent movable sealing knife of this embodiment includes a sealing knife 1. When the knife edge 12 of the sealing knife 1 is pressed down, soft pressure is applied to the cover tape and the carrier tape, so as to avoid sealing knife 1 and the cover tape and the carrier tape. Excellent hard contact, so as to achieve the technical effect of uniform sealing and tight sealing. The soft pressure can be realized by a buffer or an elastic device, and the elastic device can realize the technical effect of buffer adjustment and balance sealing knife 1, cover tape and carrier tape pressure. Such as figure 1 , 8 , 9, the automatic anti-disengagement independent movable sealing knife of this embodiment also includes a base 2, the sealing knife 1 and the base 2 are split, and the soft pressure passes through the sealing knife 1 and the base 2 The joint is provided with an elastic device. The elastic device can be a longitudinal spring or a sh...

Embodiment 2

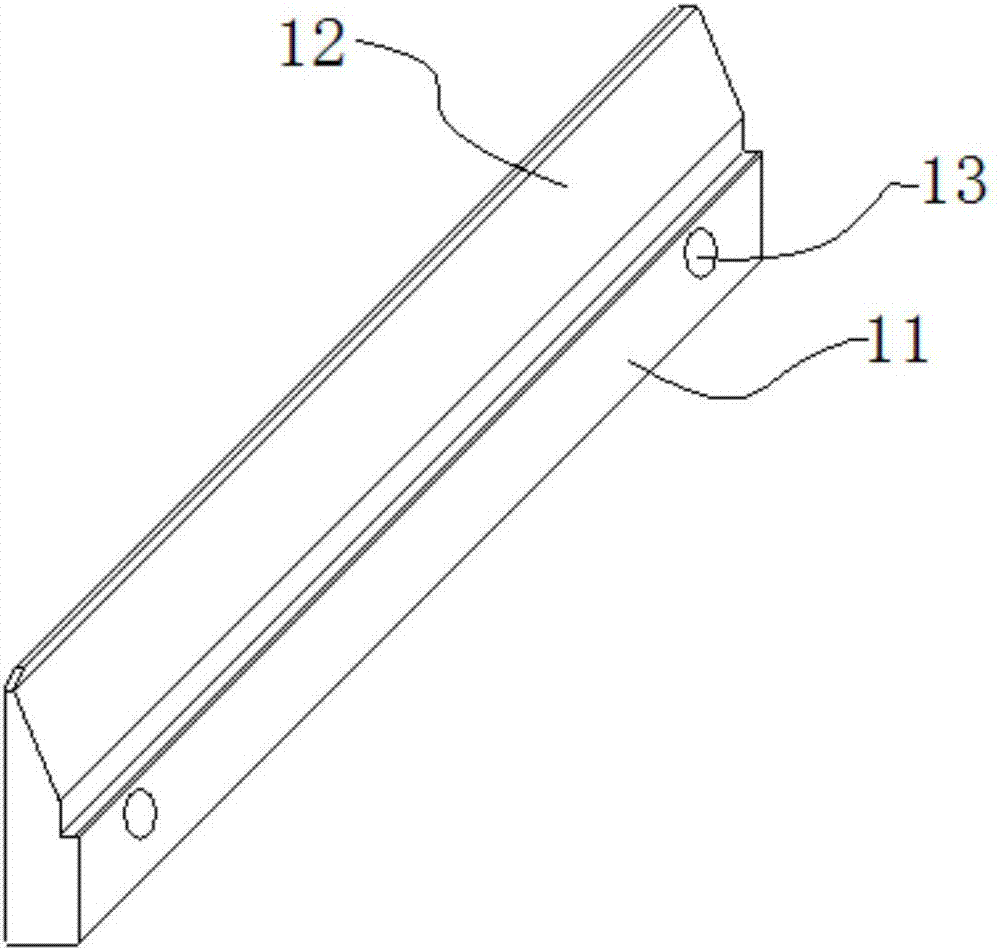

[0054] The basic structure of the automatic anti-disengagement independent movable sealing knife of this embodiment is the same as that of Embodiment 1, the differences and improvements are as follows: image 3 As shown, the bottom of the sealing knife 1 is a knife seat 11, and the upper part is a knife edge 12. The bottom of the knife seat 11 is symmetrically and evenly distributed with longitudinal spring holes 14, and the longitudinal springs are embedded in the longitudinal spring holes 14 to ensure the elastic force. Close to the cylinder pressure, even if the front and rear of the substrate are unbalanced, that is to say, the front and rear sealing knives are one high and one low relative to the substrate at this time, or the left and right are one high and one low, etc. At this time, the front and rear two independently movable sealing knives 1 can be compensated with the help of appropriate elastic force; Figure 7 As shown, the cross section of the base 2 is "convex" ...

Embodiment 3

[0056] The basic structure of the automatic anti-disengagement independent movable sealing knife of this embodiment is the same as that of embodiment 2, the difference and improvement are that the length of the sealing knife 1 is slightly smaller than the length of the base 2, so as to form the left and right small angle rotation of the sealing knife 1 gap 6, to avoid that when the lengths are the same, there is no way to rotate and cause the pressure on the length direction of the sealing knife 1 to be unable to be adjusted and balanced. There are also two transverse spring holes 13 on the side of the knife seat 11, which are symmetrically arranged near the two ends of the knife seat 11. The transverse spring holes 13 have built-in transverse springs to eliminate gaps and ensure the same overall width of the seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com