Variable-ball-diameter automatic screening and ball grinding machine

An automatic screening and ball grinding machine technology, which is applied to spherical grinders, grinding machine tools, and parts of grinding machine tools, can solve problems affecting production efficiency, product quality, and automatic detection of ball size, so as to reduce the splash of abrasive materials, The effect of reducing labor intensity and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

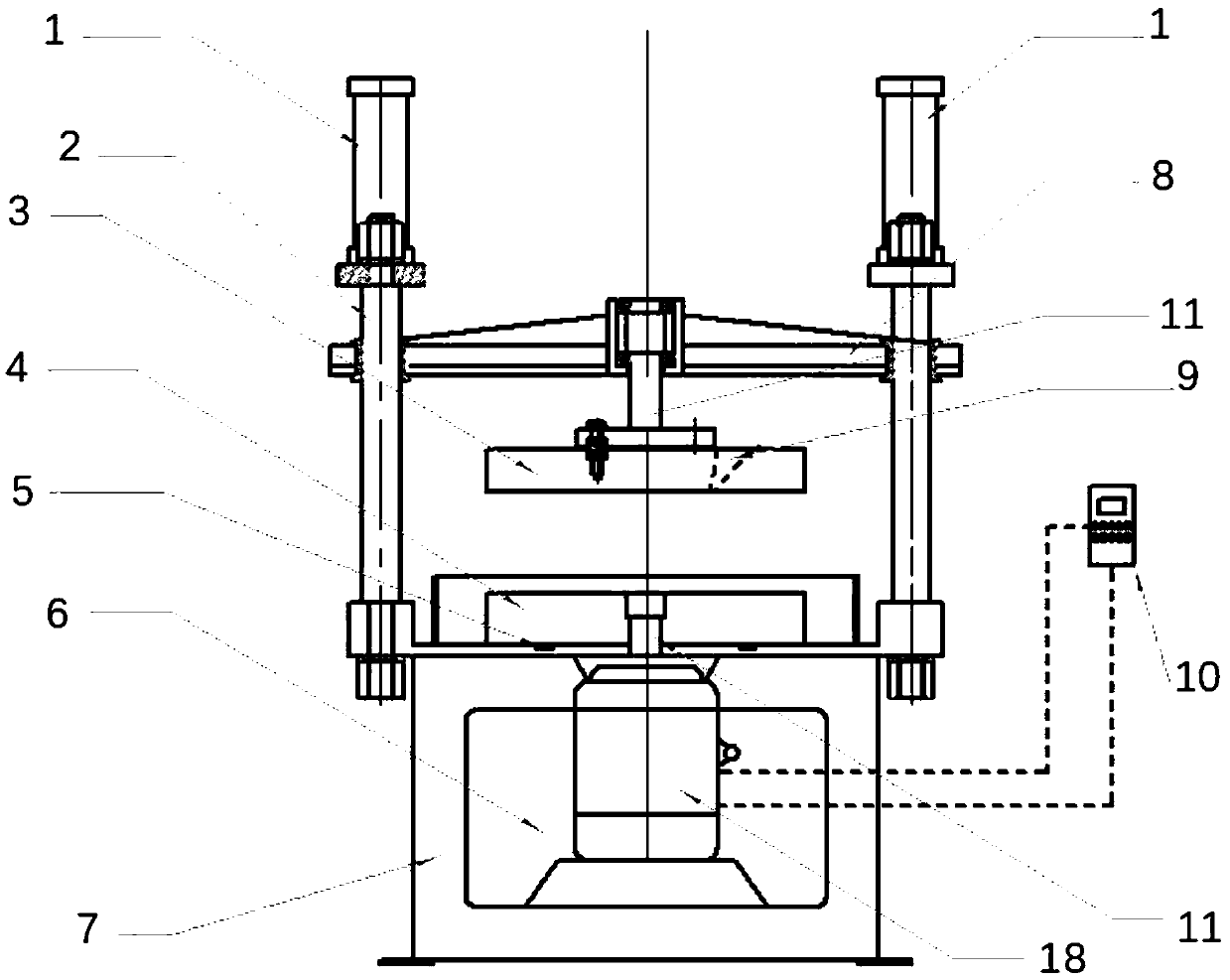

[0028] An automatic screening ball grinding machine with variable ball diameter, characterized in that: the ball grinding machine is composed of a hydraulic cylinder 1, a guide column 2, an upper plate 3, a lower plate 4, a machine base 7, a movable beam 8, a main shaft 11 and a motor 18 constitute;

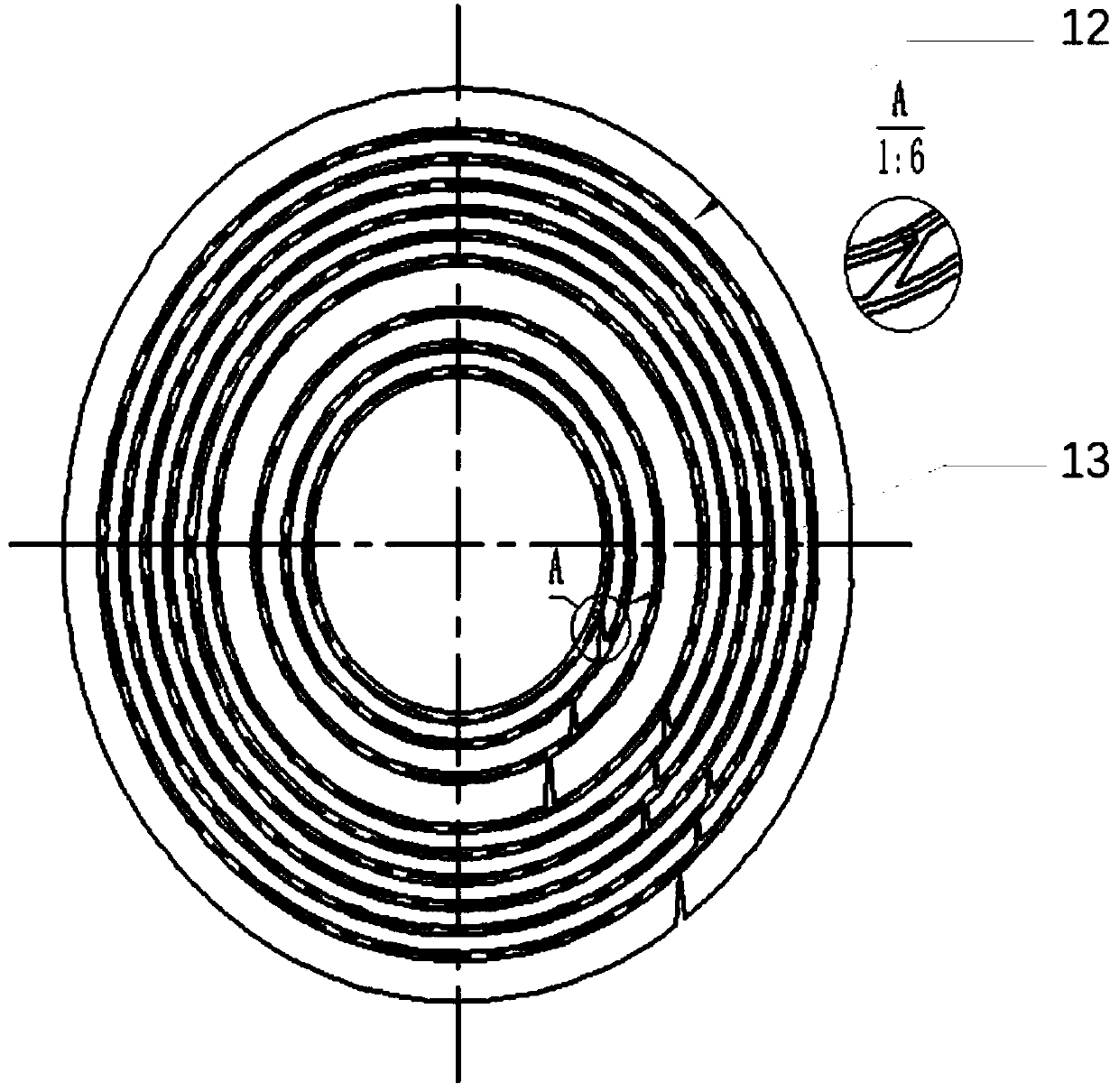

[0029] The machine base 7 is provided with weight reducing holes 6, the lower plate 4 is set on the upper surface of the machine base 7, four guide posts 2 are evenly distributed on the machine base 7, and the movable beam 8 is slidingly connected with each guide post 2; the hydraulic cylinder 1 is connected with the movable beam 8, and drives the movable beam 8 to move up and down along the guide column 2, while the upper plate 3 is fixed under the movable beam 8, and the movable beam 8 can drive the upper plate 3 to move up and down; the motor 18 communicates with the main shaft 11 The upper plate 3 or the lower plate 4 are connected, and the main shaft 11 is driven to rotate t...

Embodiment 2

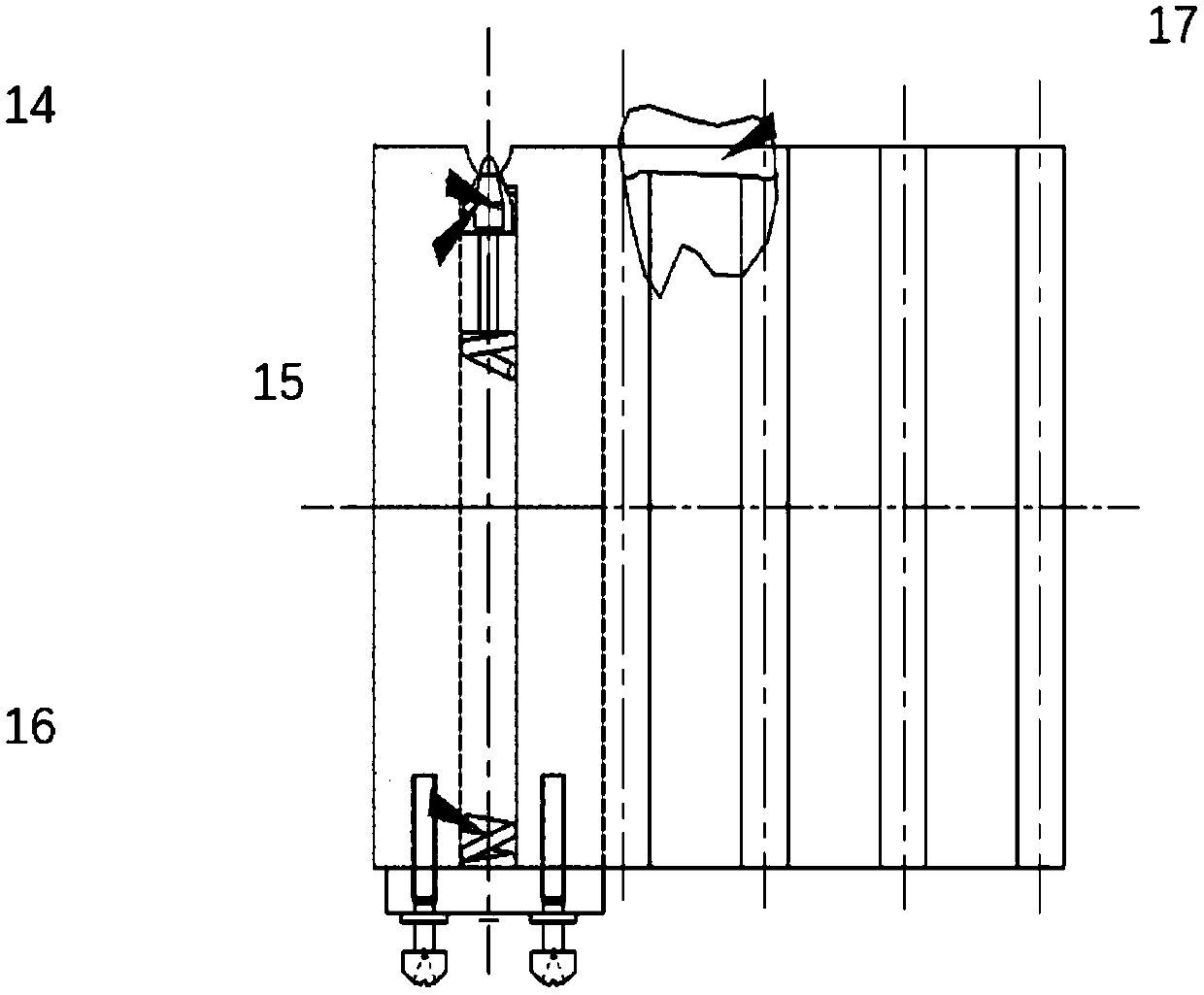

[0035]The difference from Embodiment 1 is that the upper plate 3 is fixed below the movable beam 8 through the main shaft 11, and the upper plate 3 and the main shaft 11 are connected by a composite flange, and the contact between the composite flange and the upper plate 3 is provided with a compression spring and a Fix the bolt assembly, wherein the upper surface of the upper plate 3 in contact with the composite flange is provided with variable-diameter blind holes, and the composite flange is provided with corresponding variable-diameter through holes, and the variable-diameter blind holes and the variable-diameter through holes are close to each other. The hole diameter of the side where the upper plate 3 is in contact with the composite flange is larger than the other side, and the fixing bolt is inserted into the blind hole of the upper plate 3 through the through hole of the composite flange, and the spring in the compressed state is stuck in the variable diameter blind h...

Embodiment 3

[0037] The difference from Embodiment 1 is that the outer surface of the main shaft 11 connected to the upper plate 3 is provided with threads, and the threaded sleeve matched with the thread is set on the main shaft 11, and when the upper plate 3 moves to the corresponding position, the threaded sleeve Unscrew, top the upper surface of the upper plate 3 to form a mechanical pressure maintaining device. The device can prevent the hydraulic system from being under pressure all the time when grinding the sphere, and make the pressure on the upper plate uniform, greatly reducing the splash of the grinding material, and improving the yield rate and grinding efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com