Patents

Literature

765results about "Spherical surface grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

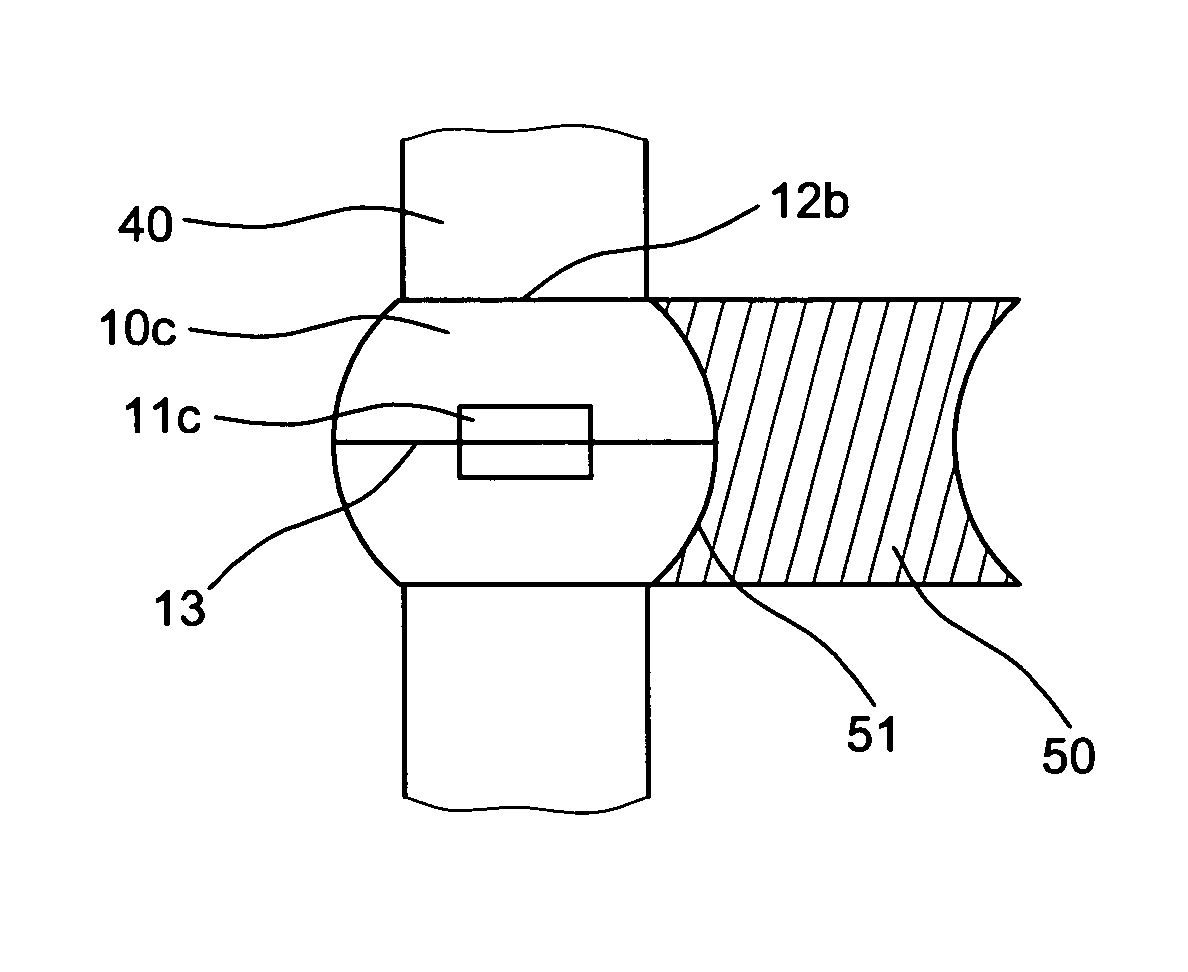

Method of grinding an axially asymmetric aspherical mirror

InactiveUS6537138B2Improve accuracyReliably madeEdge grinding machinesOptical surface grinding machinesNumerical controlSurface roughness

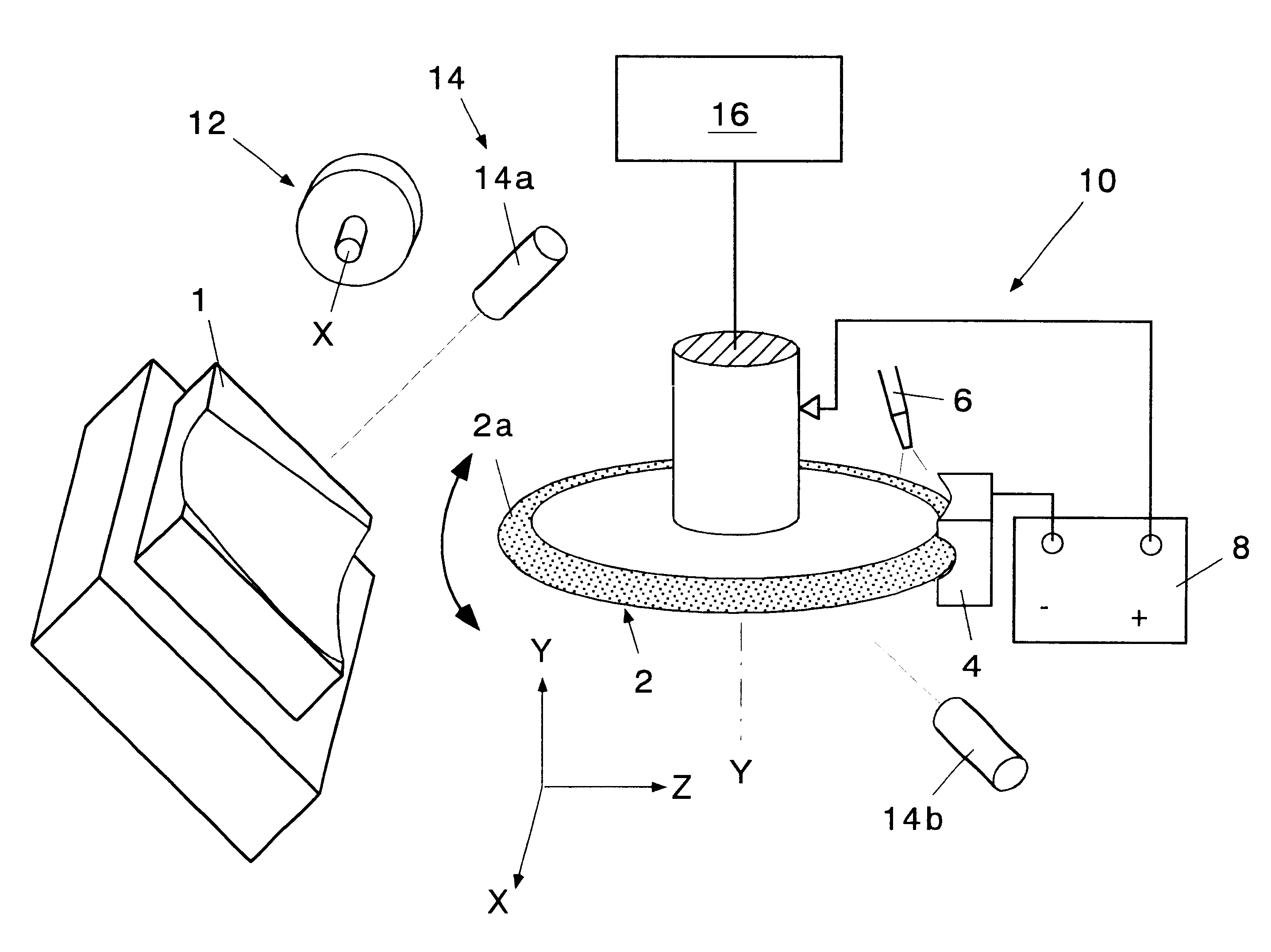

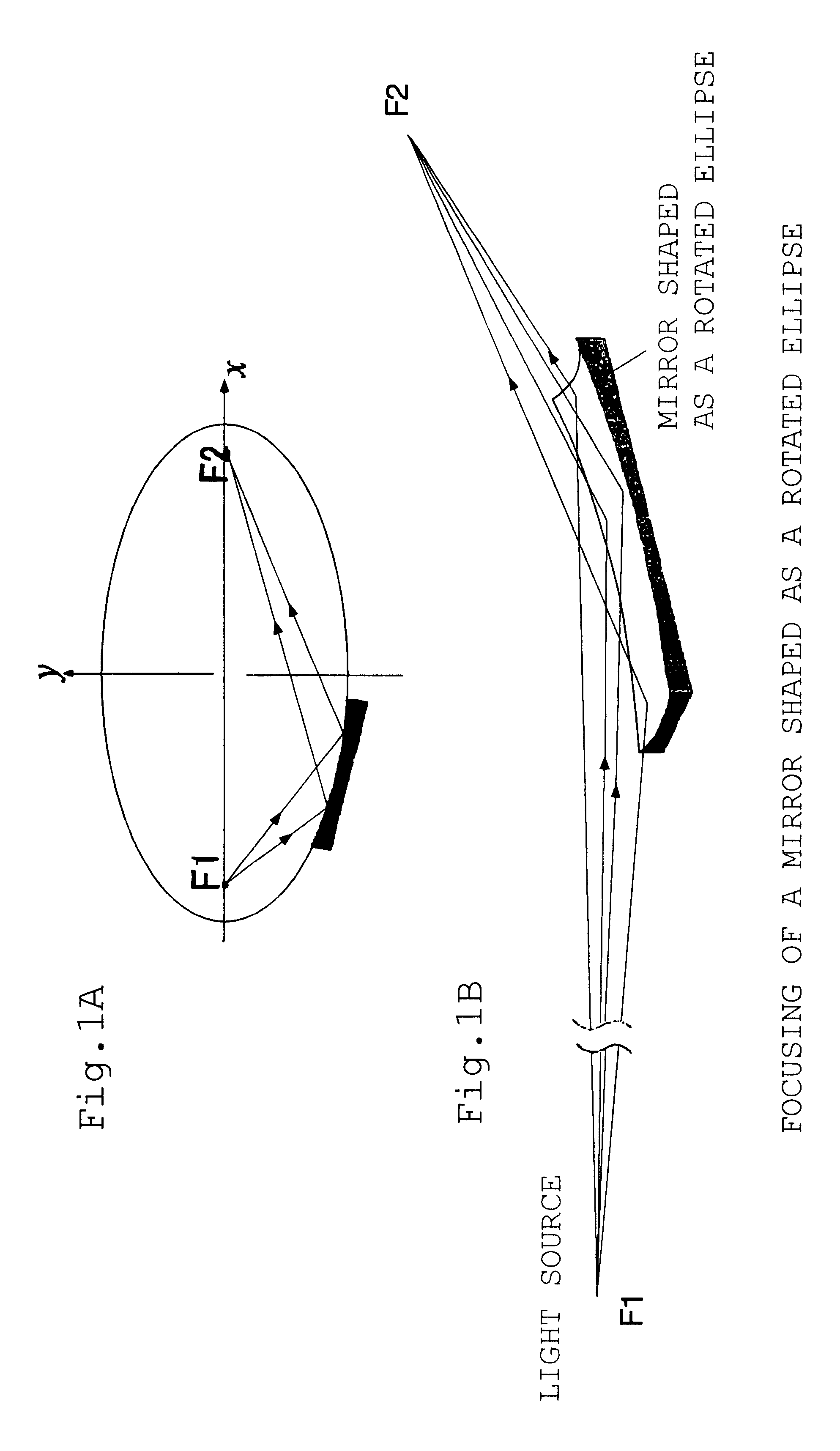

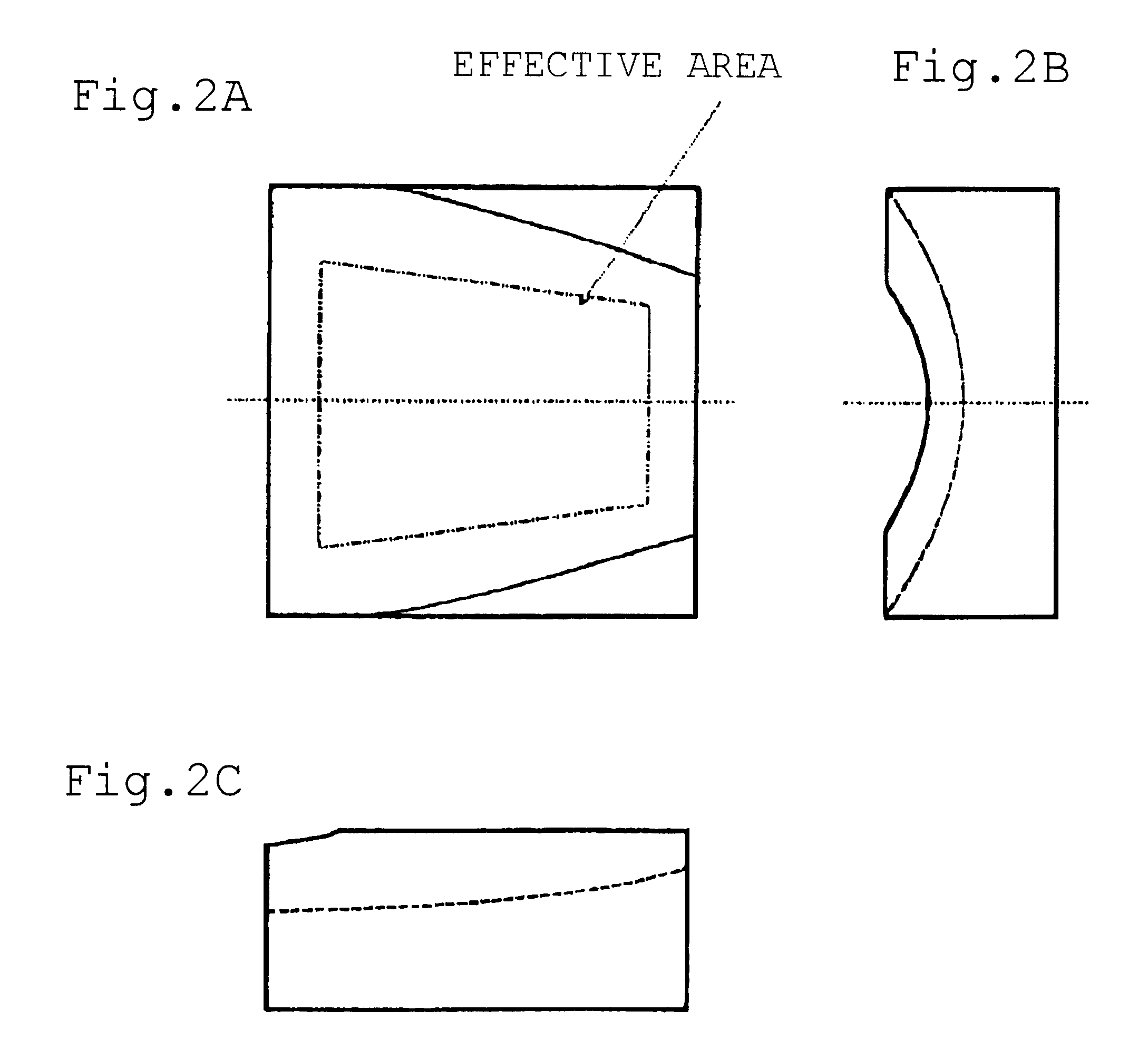

An electrolytic in-process dressing device 10 is provided with a disk-shaped metal-bonded grindstone 2 with a surface 2a with a circular arc shape with a radius R at its outer periphery and a numerical control device 16. The disk-shaped metal-bonded grindstone 2 rotates around an axis Y, and the grindstone is dressed electrolytically while the device 10 grinds the workpiece 1. The numerical control device 16 is provided with a rotary truing device 12 that rotates around the X axis that orthogonally crosses the axis of rotation Y and trues the circular arc surface 2a, a shape measuring device 14 for measuring the shape of the circular arc surface of the grindstone and the shape of the processed surface of workpiece 1 on the machine, and controls the grindstone numerically in the three directions along the axes X, Y and Z. The numerical control device 16 moves the grindstone in three axial directions and repeats the operations of truing, grinding and measurements on-line. Thus, an axially asymmetrical aspheric mirror with a highly accurate shape and extremely low surface roughness, that can precisely reflect or converge light can be manufactured within a short time with a high accuracy.

Owner:RIKEN +1

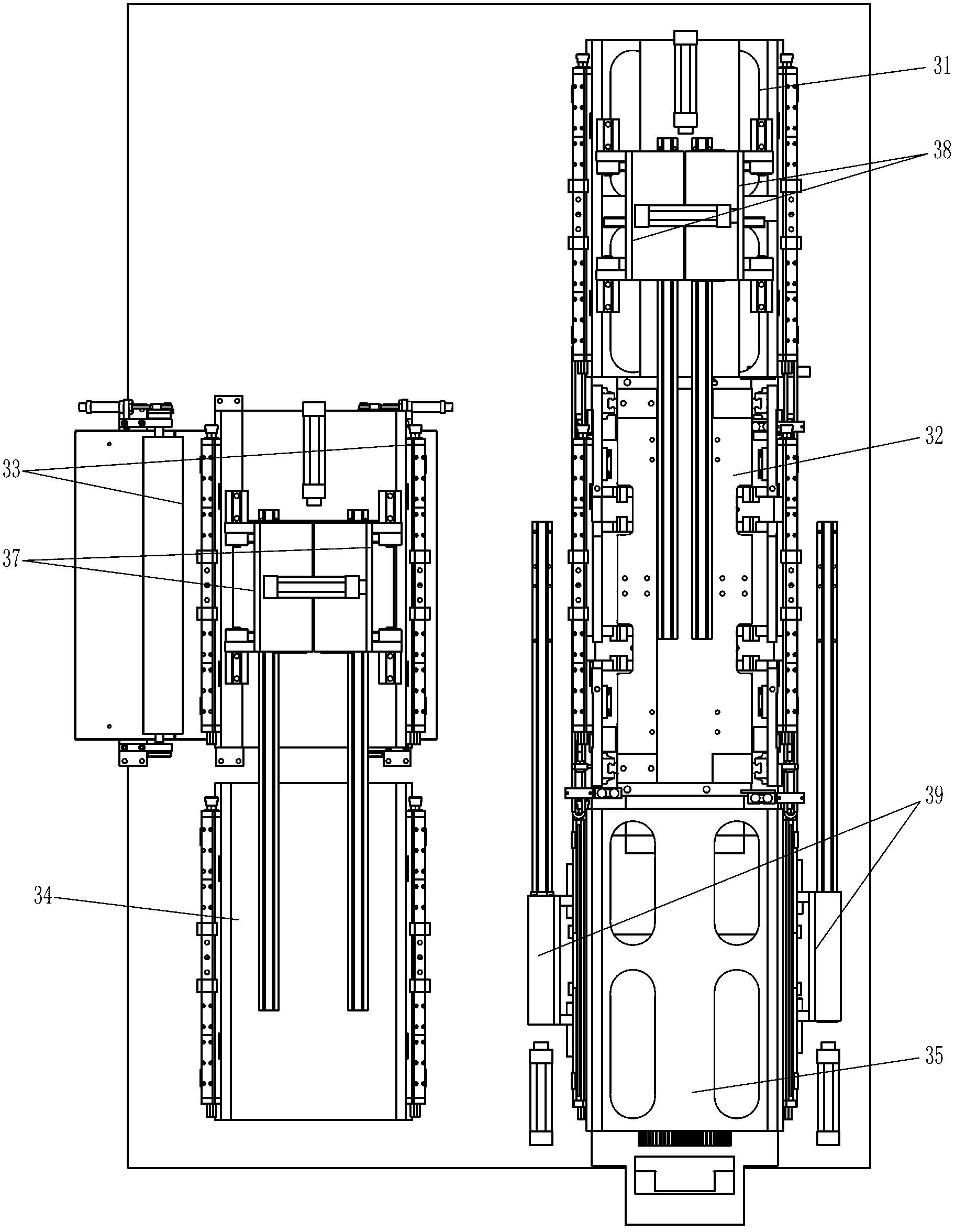

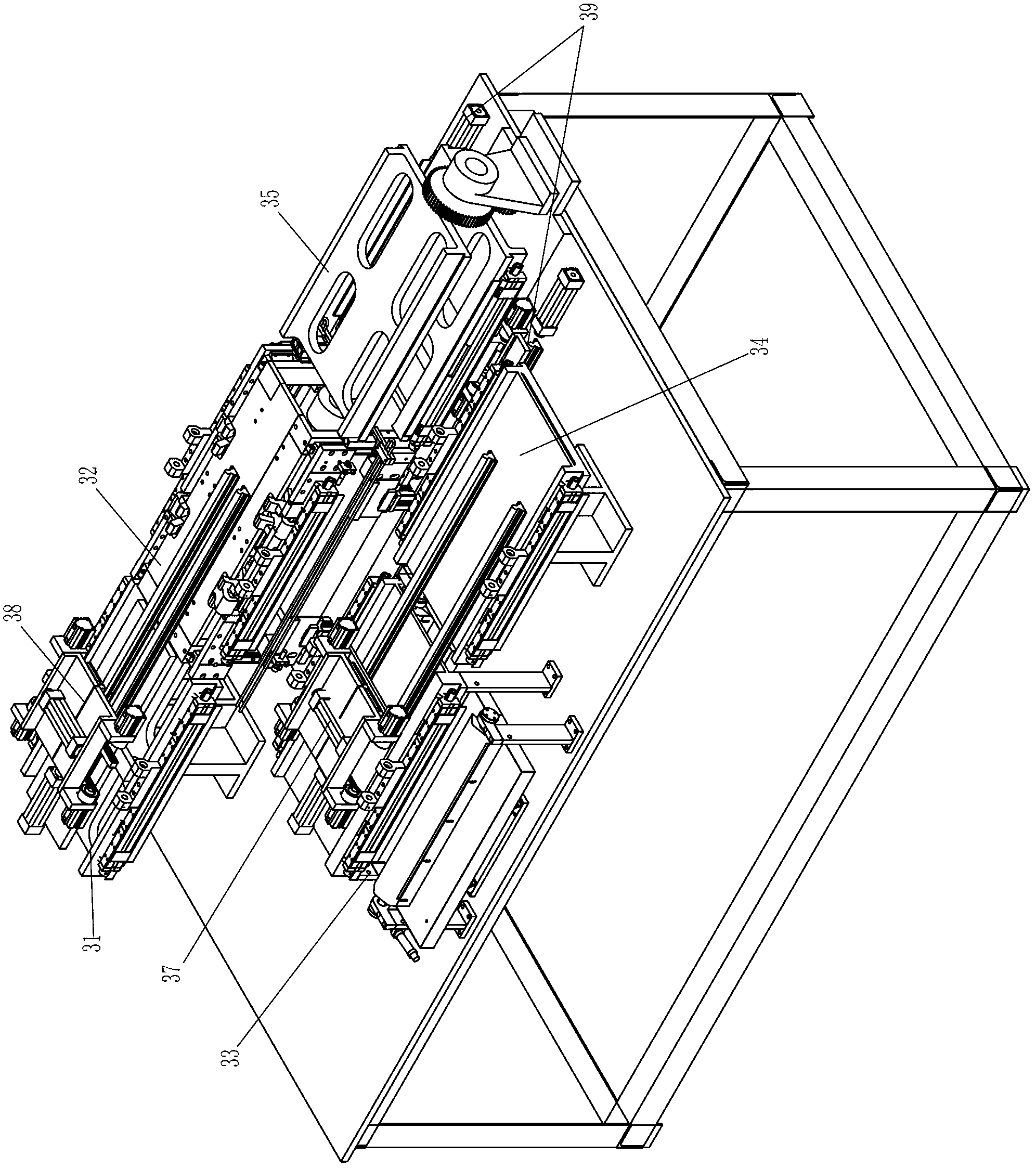

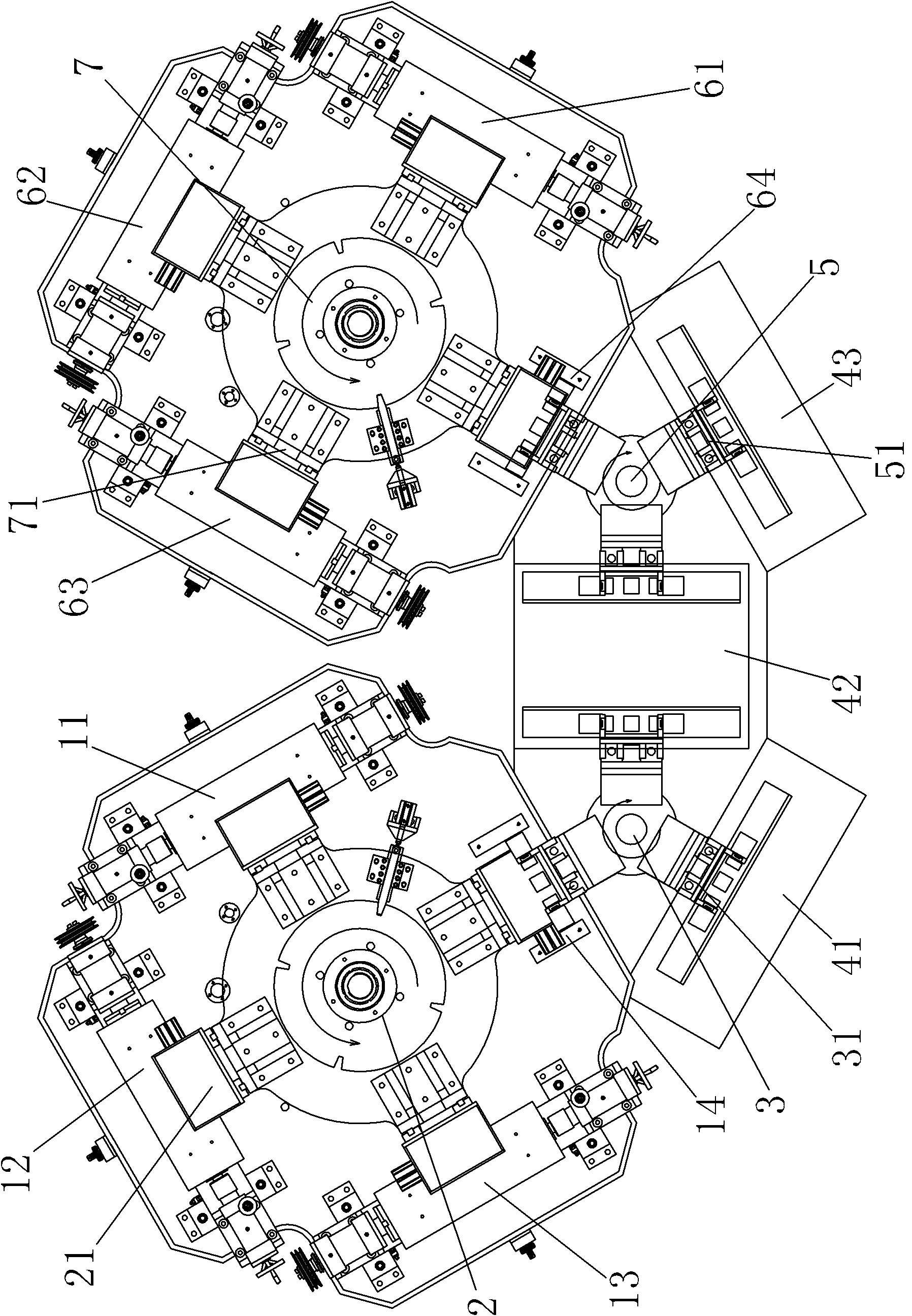

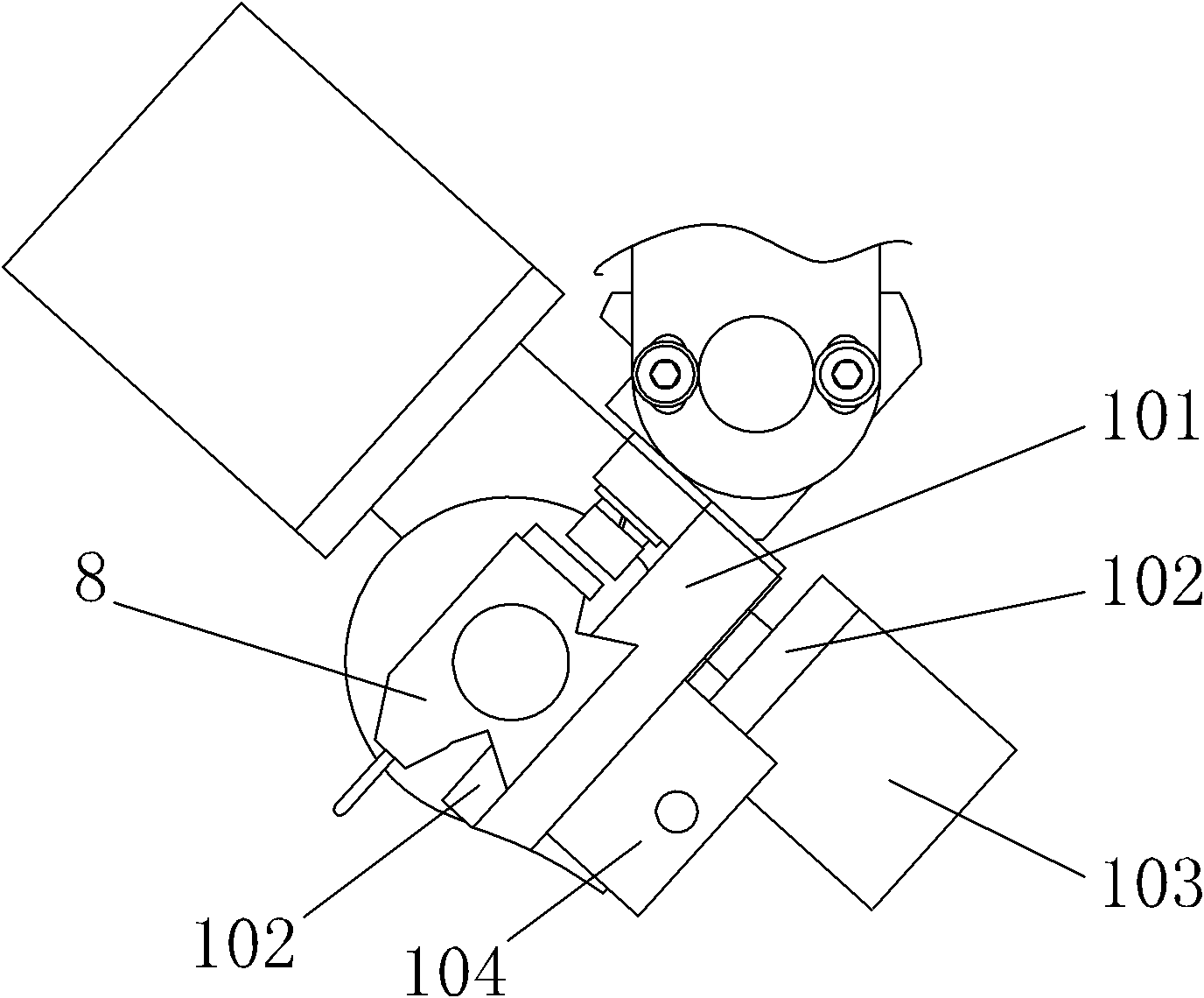

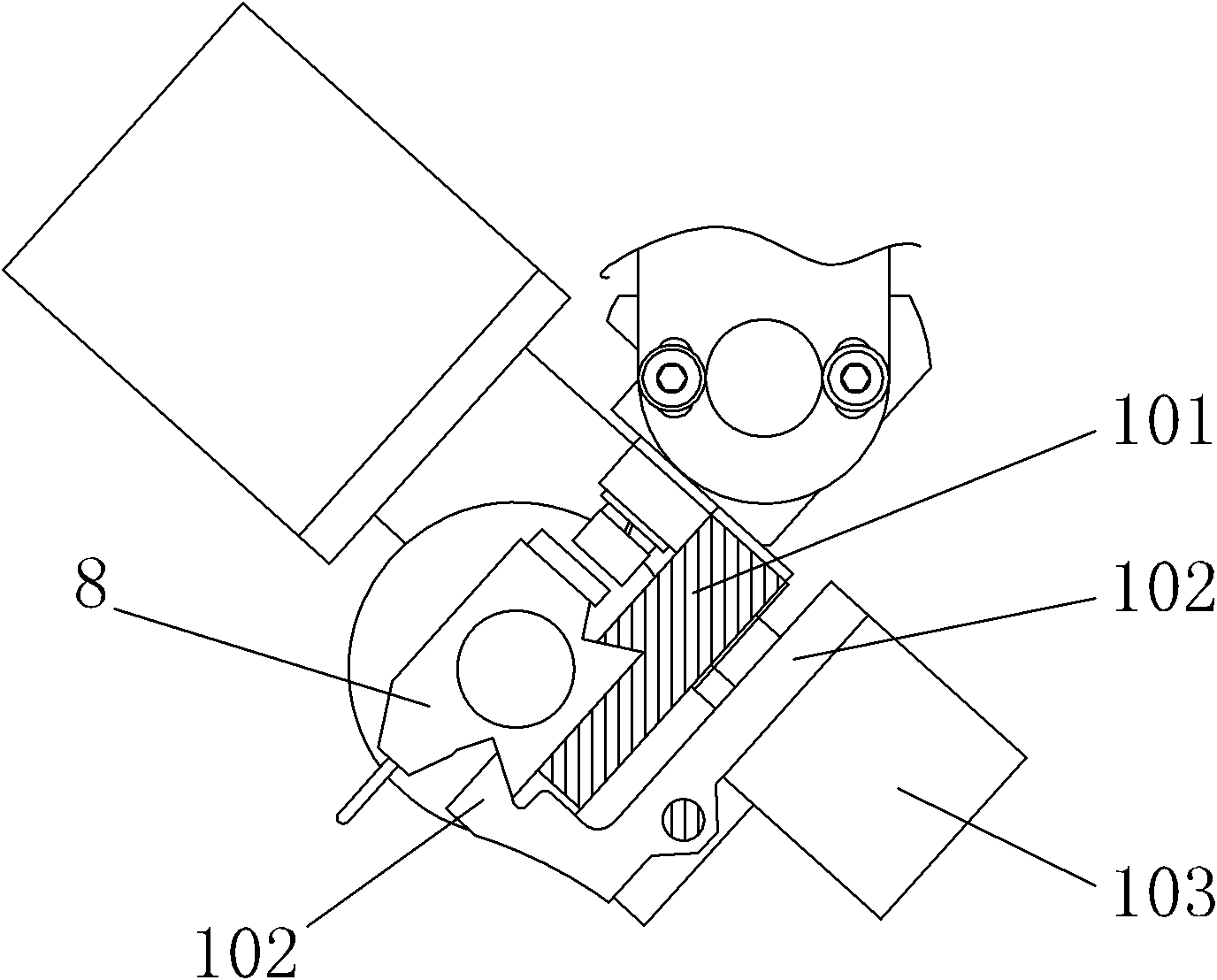

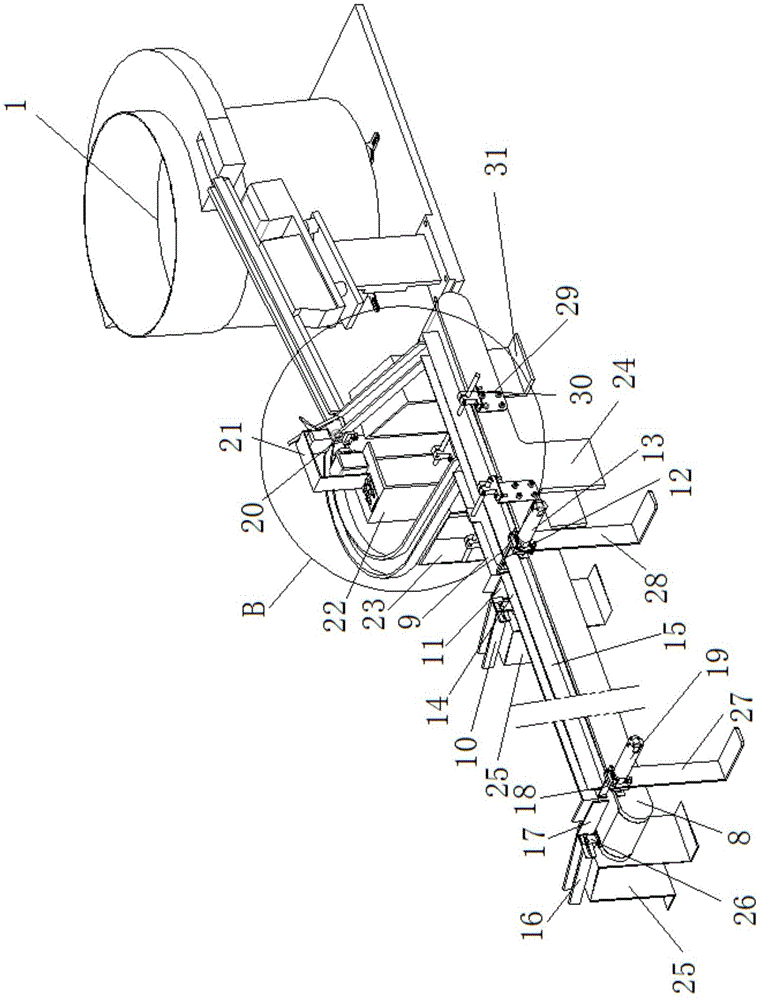

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

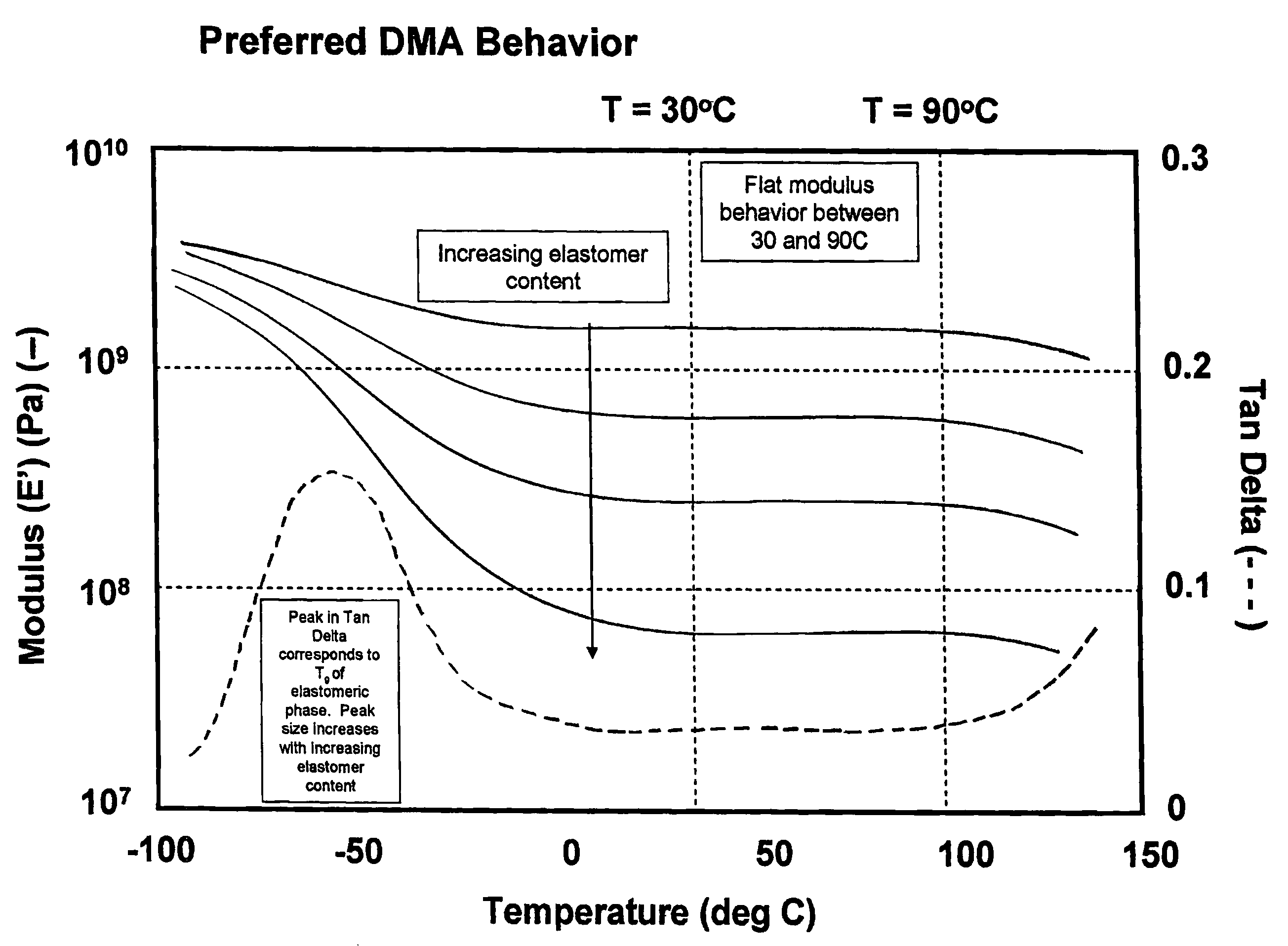

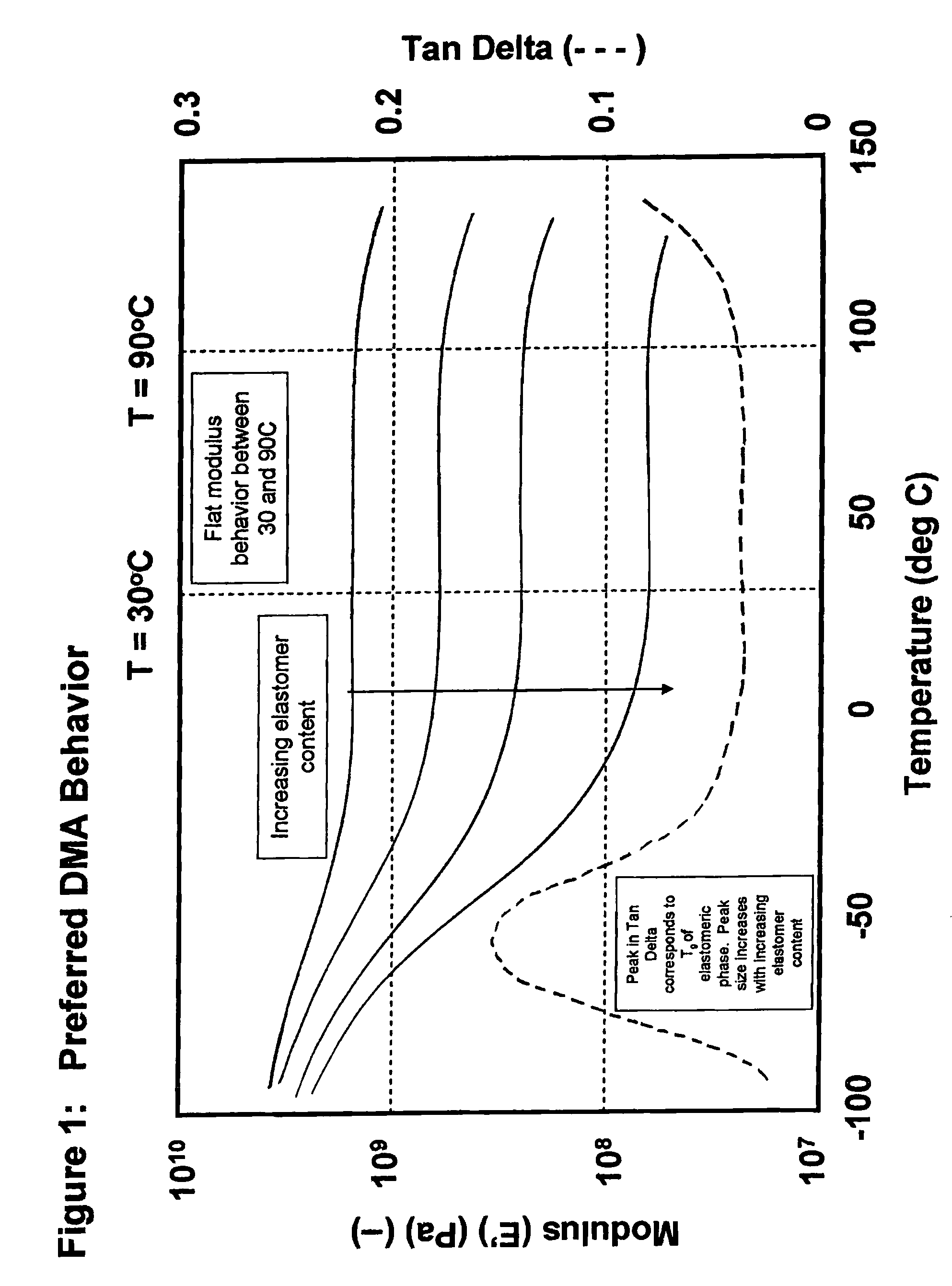

Elastomer-modified chemical mechanical polishing pad

ActiveUS7371160B1Fast cutting speedPigmenting treatmentOther chemical processesVitrificationElastomer

The chemical mechanical polishing pad is suitable for polishing at least one of semiconductor, optical and magnetic substrates. The polishing pad includes a polymeric matrix with an elastomeric polymer distributed within the polymeric matrix. The polymeric matrix has a glass transition above room temperature; and the elastomeric polymer has an average length of at least 0.1 μm in at least one direction, represents 1 to 45 volume percent of polishing pad and has a glass transition temperature below room temperature. The polishing pad has an increased diamond conditioner cut rate in comparison to a polishing pad formed from the polymeric matrix without the elastomeric polymer.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

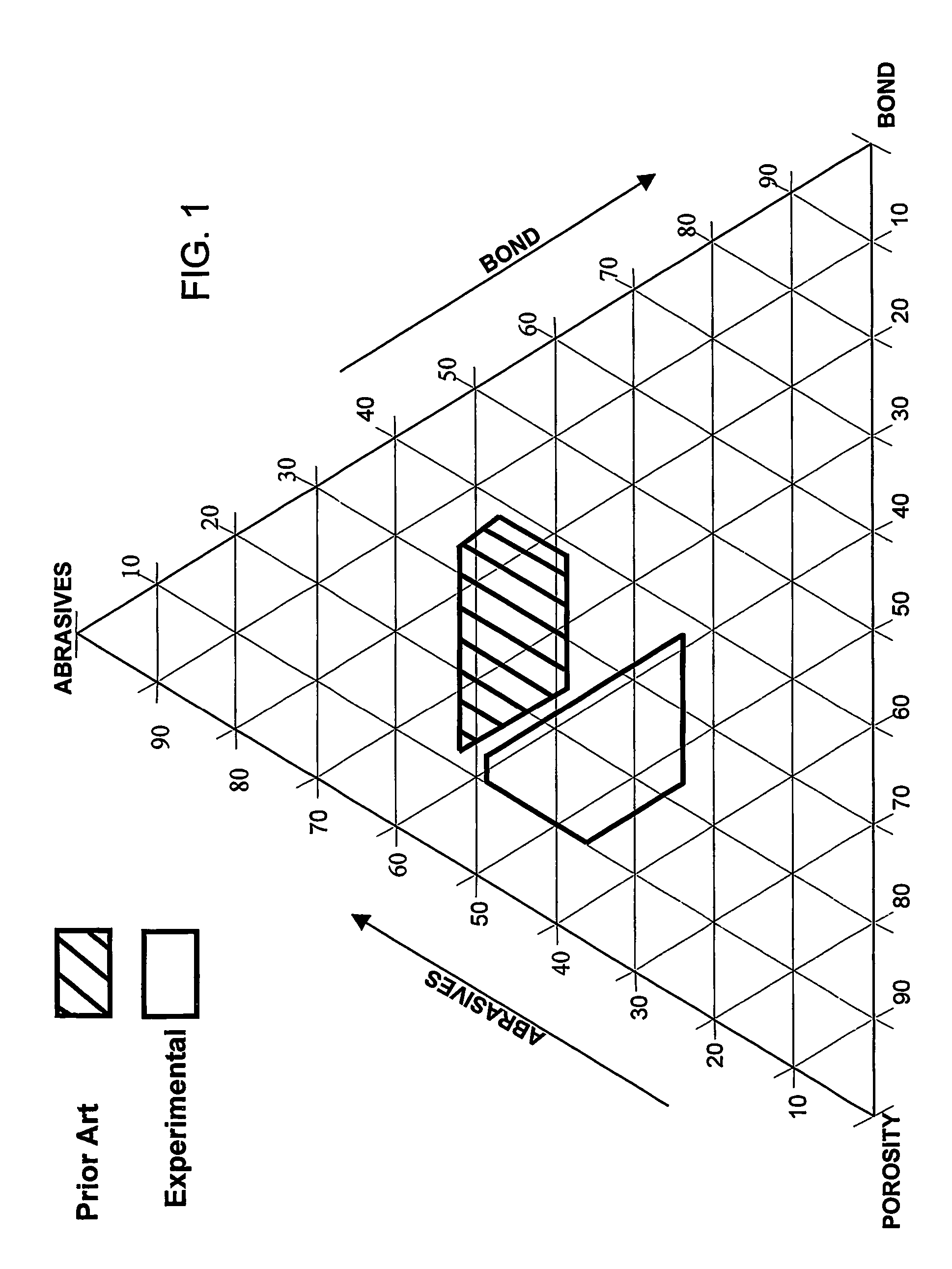

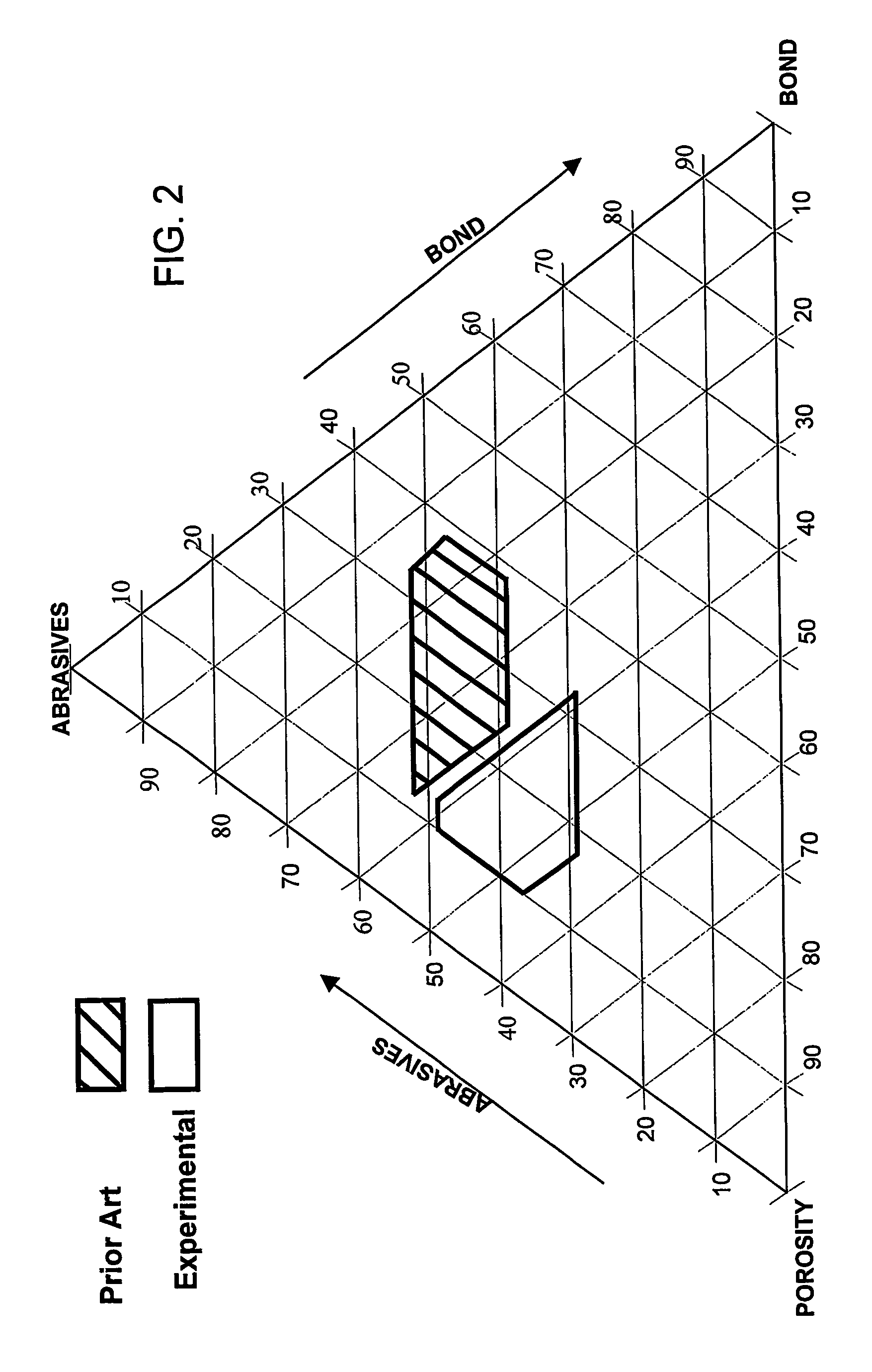

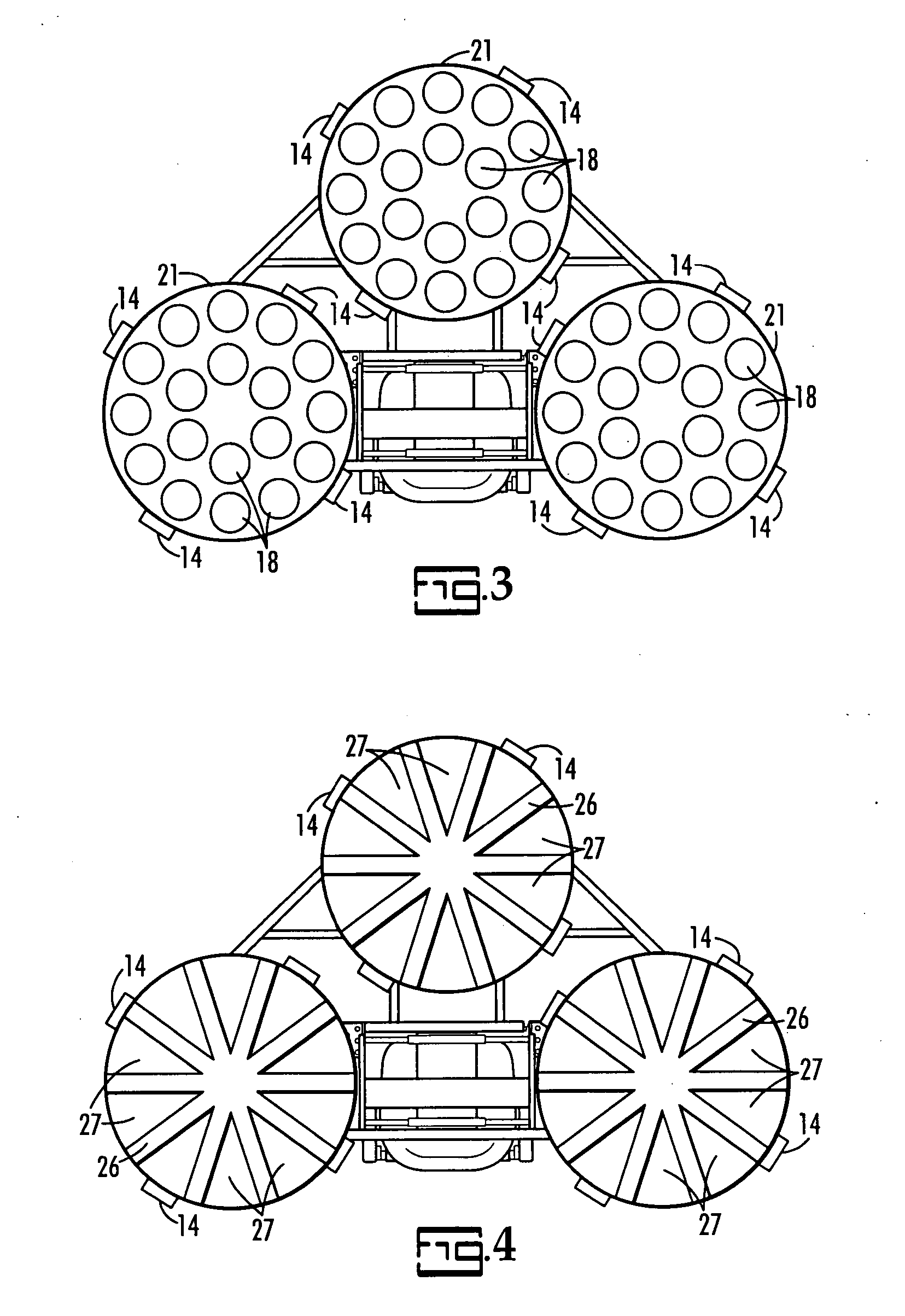

Abrasive articles with novel structures and methods for grinding

InactiveUS7275980B2Revolution surface grinding machinesOther chemical processesHardnessUltimate tensile strength

Bonded abrasive tools, having novel porous structures that are permeable to fluid flow, comprise a relatively low volume percentage of abrasive grain and bond, and a relatively low hardness grade, but are characterized by excellent mechanical strength and grinding performance. Methods for making the abrasive tools utilizing agglomerated abrasive grain are described.

Owner:SAINT GOBAIN ABRASIVES INC

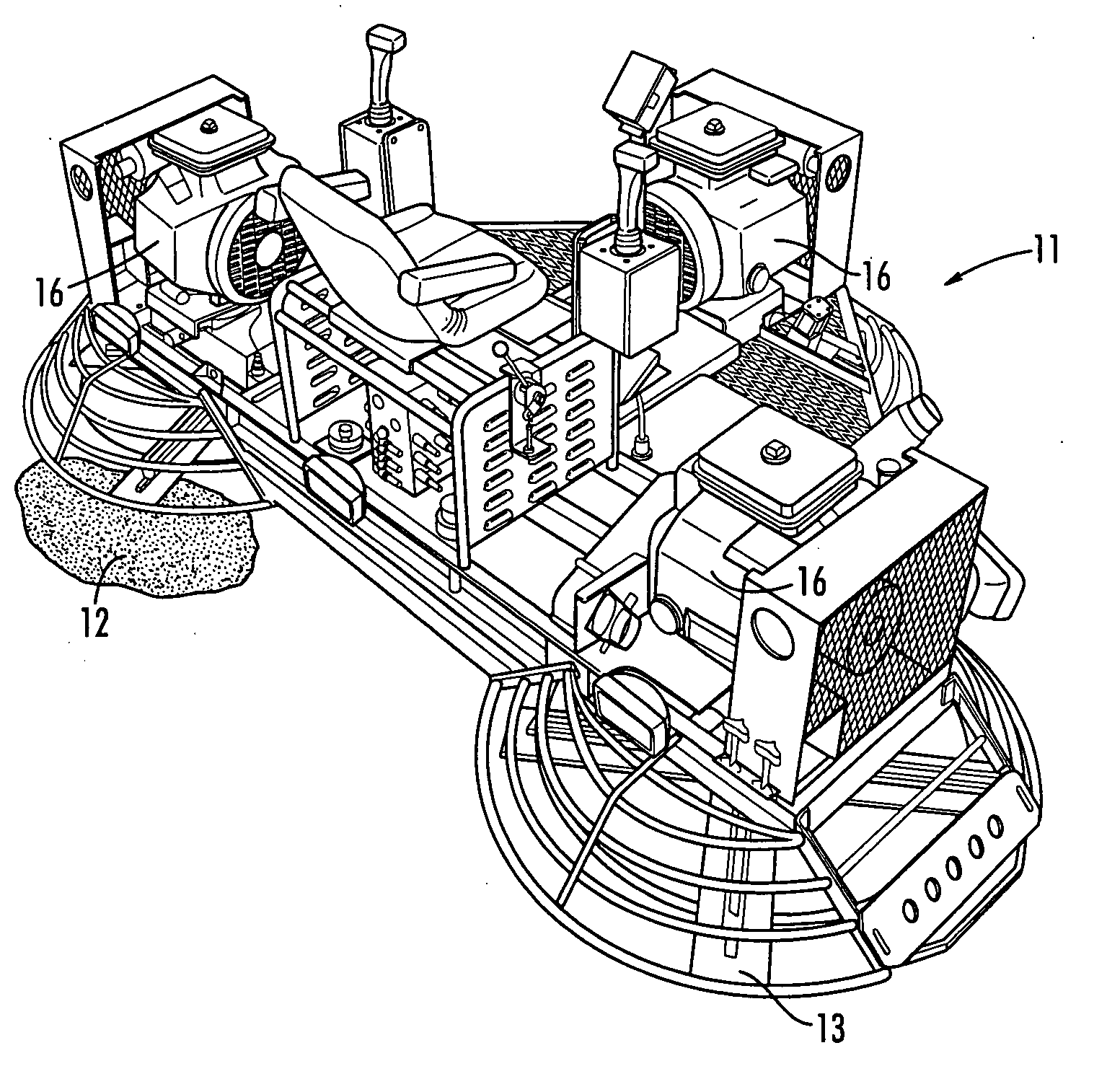

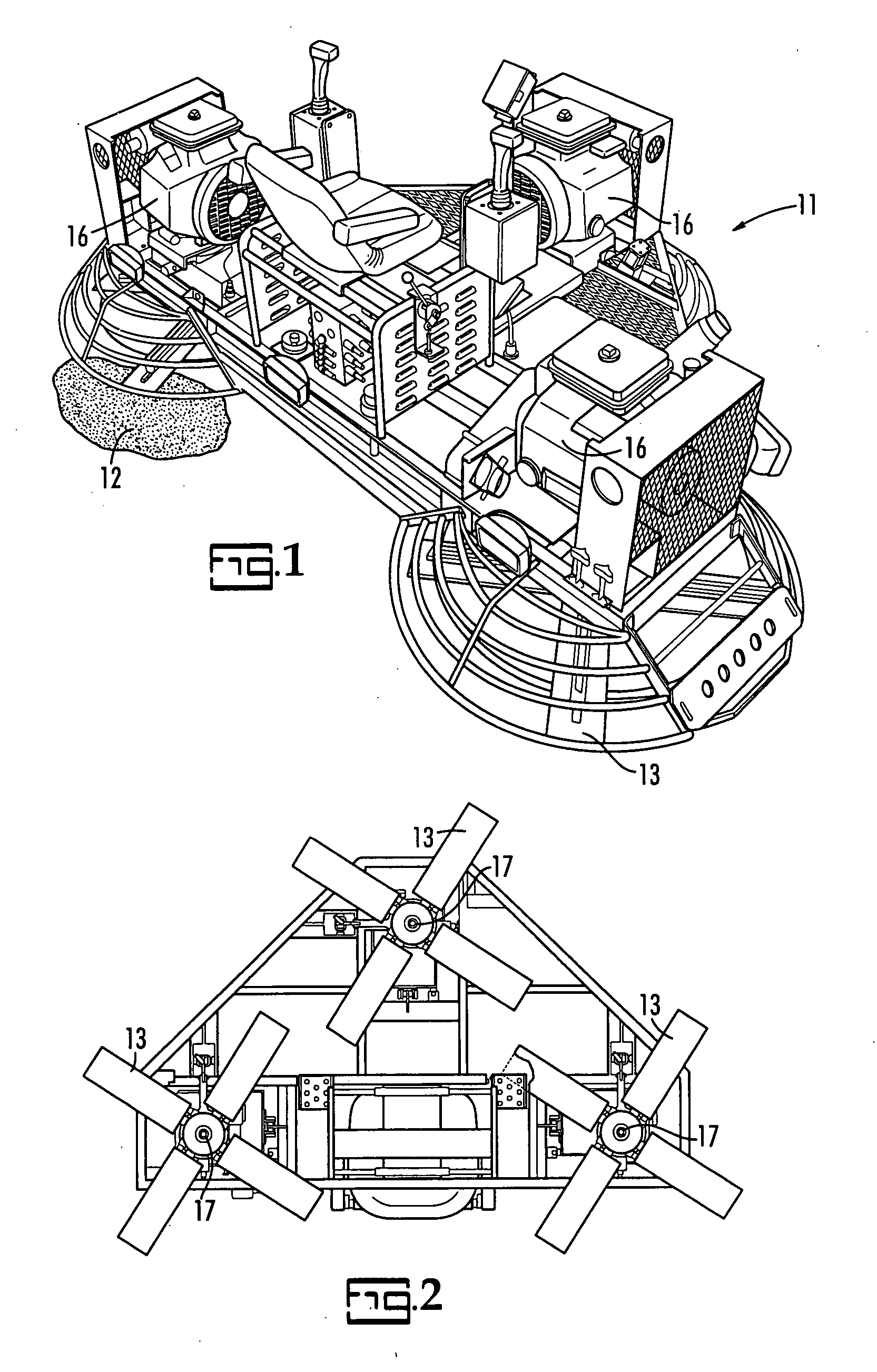

Methods and apparatuses for surface finishing cured concrete

InactiveUS20070292207A1Edge grinding machinesSpherical surface grinding machinesSurface finishCivil engineering

A method and apparatus for finishing cured concrete floors using a riding trowel to which large diameter pans are attached having a balanced distribution of abraders releasably secured to the undersides of the pans. The individual abraders are preferably individually spring biased so as to maintain full contact with the floor when traversing undulations of the floor.

Owner:NEXSEN PRUET

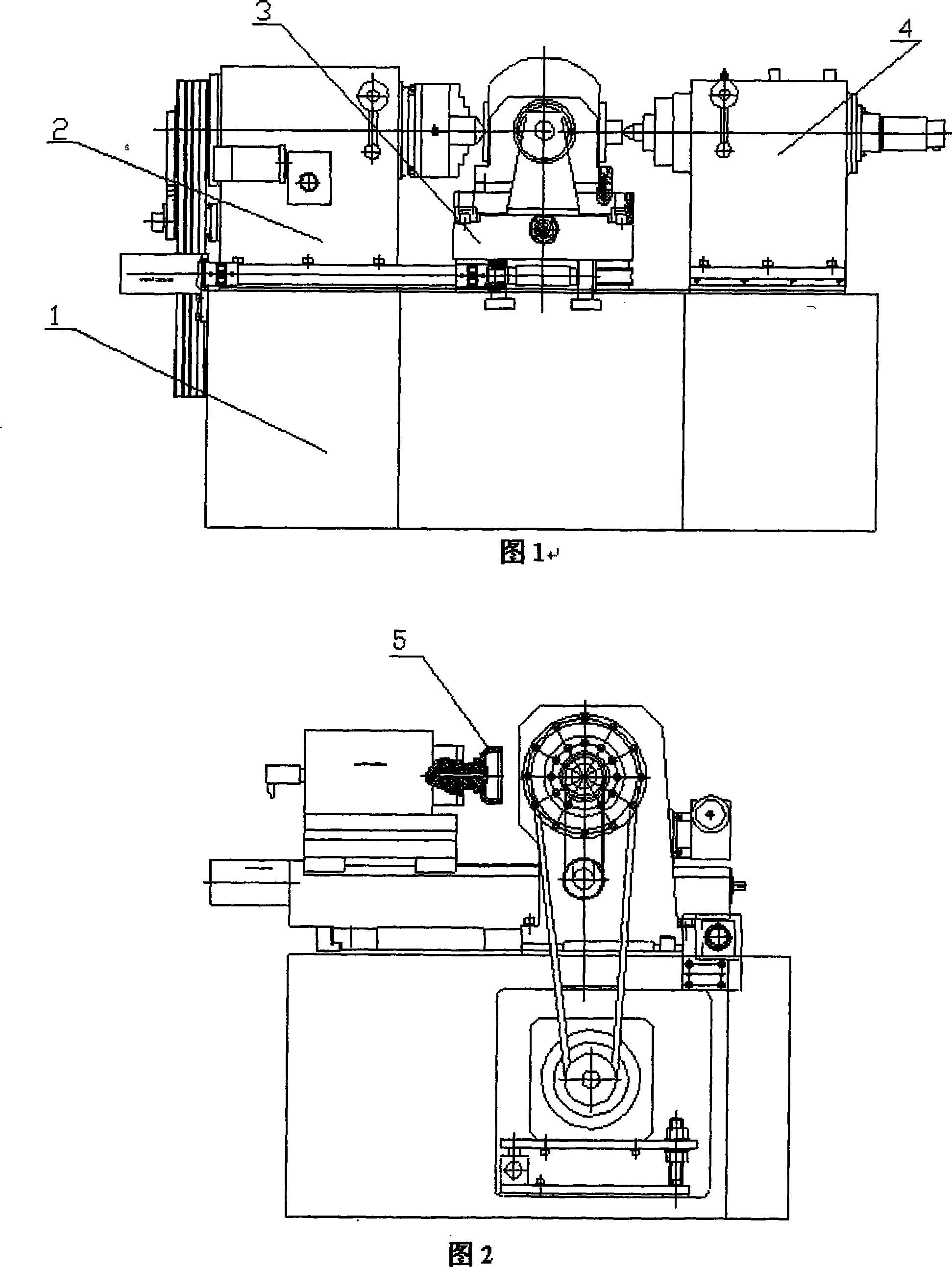

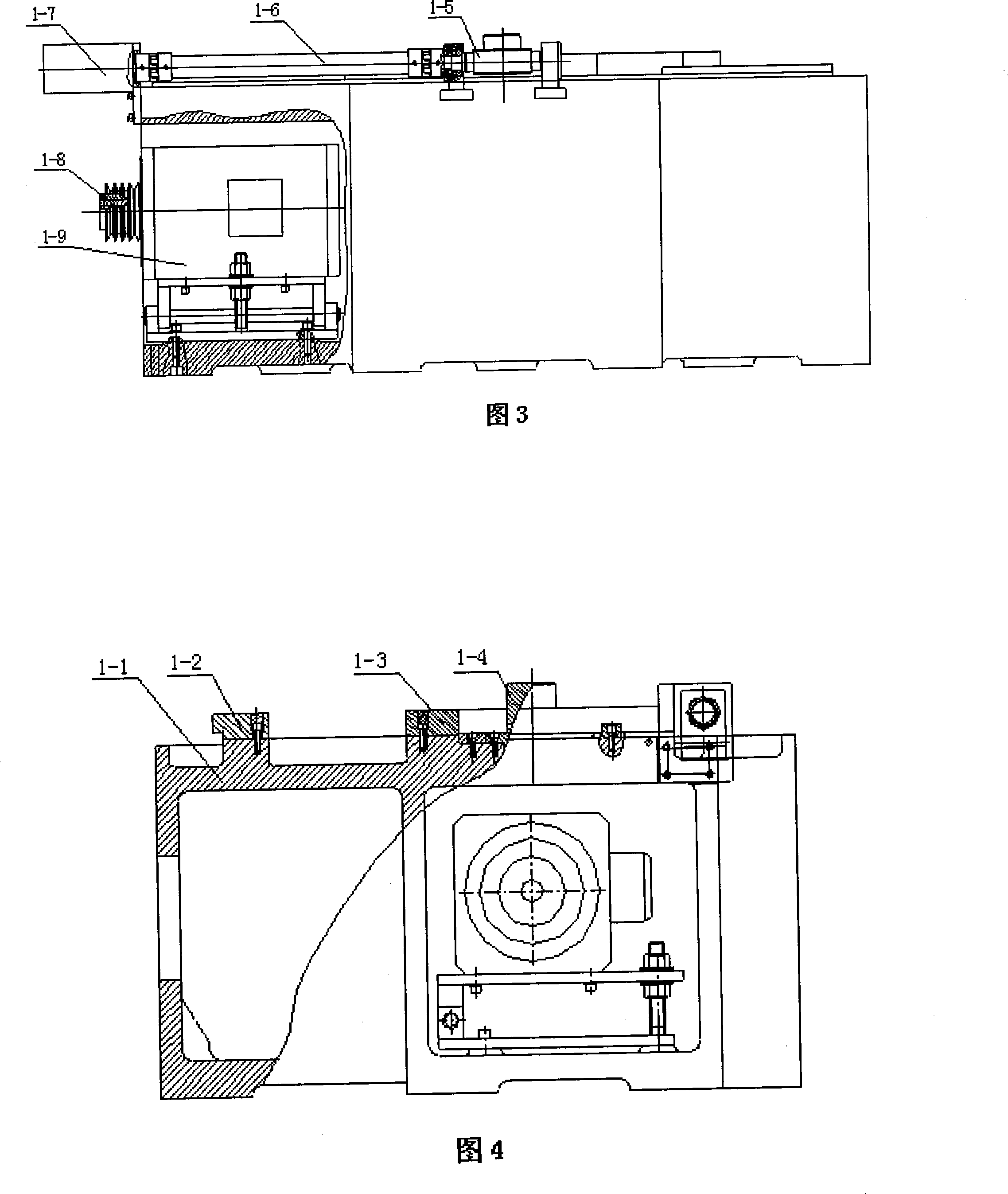

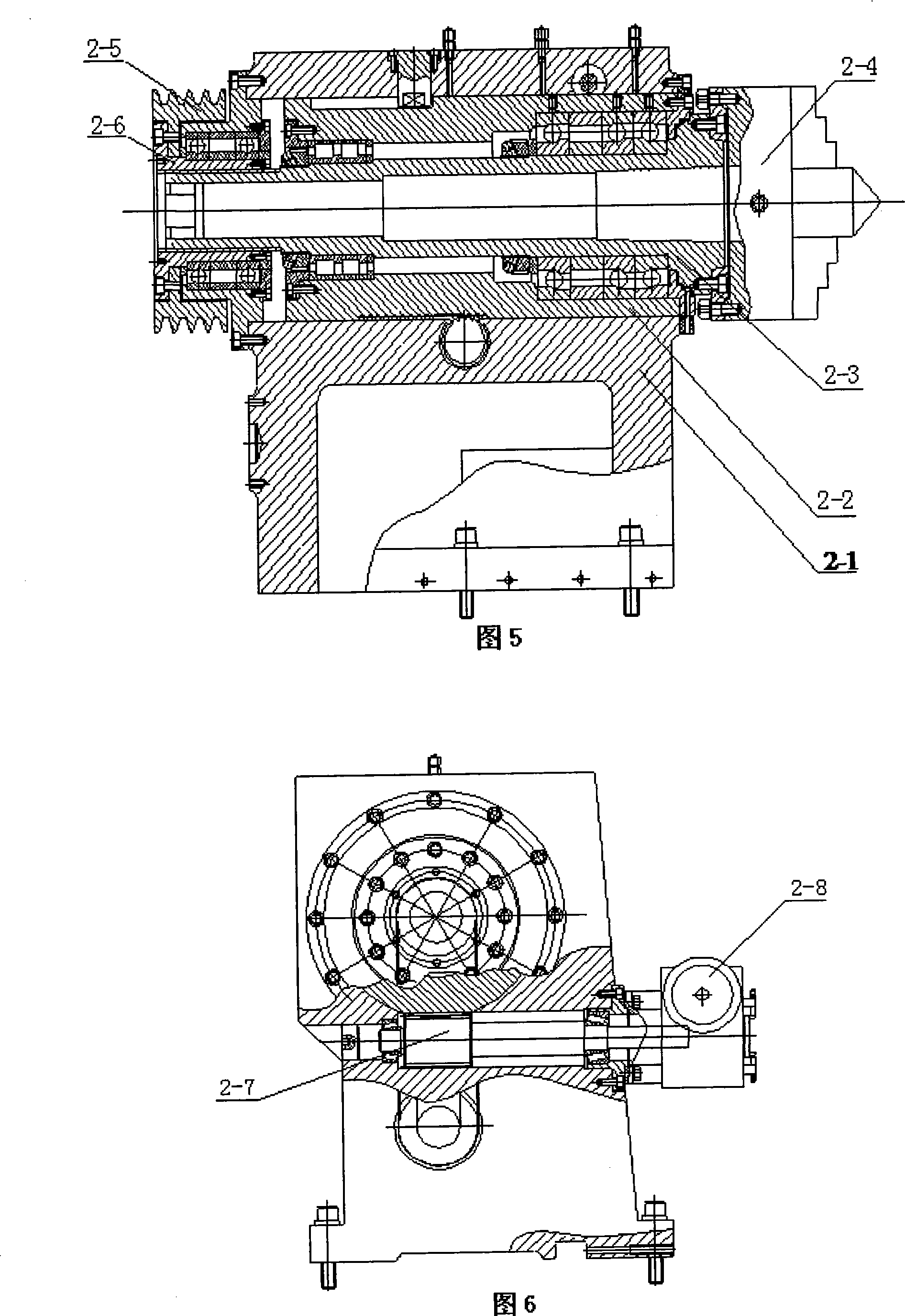

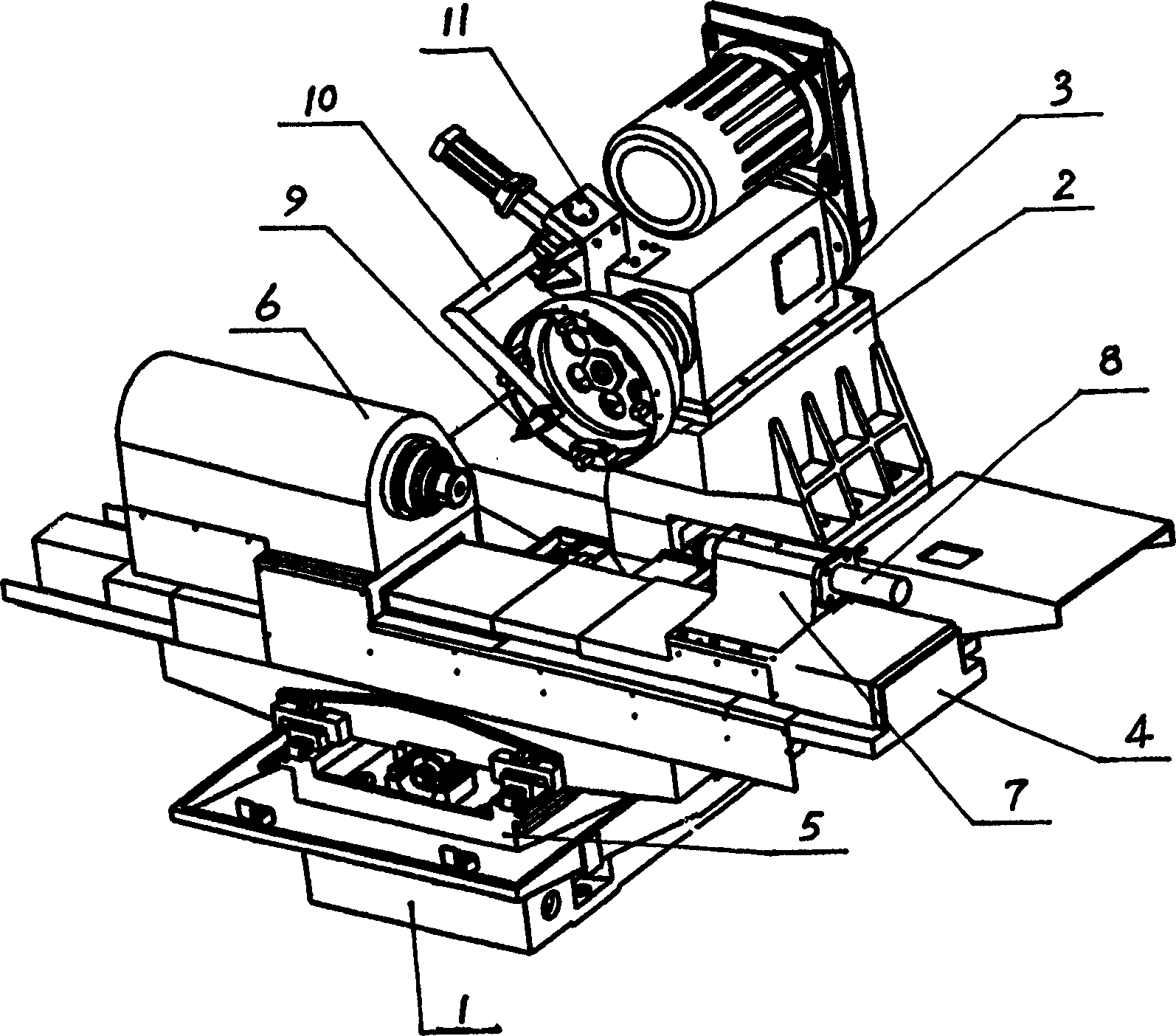

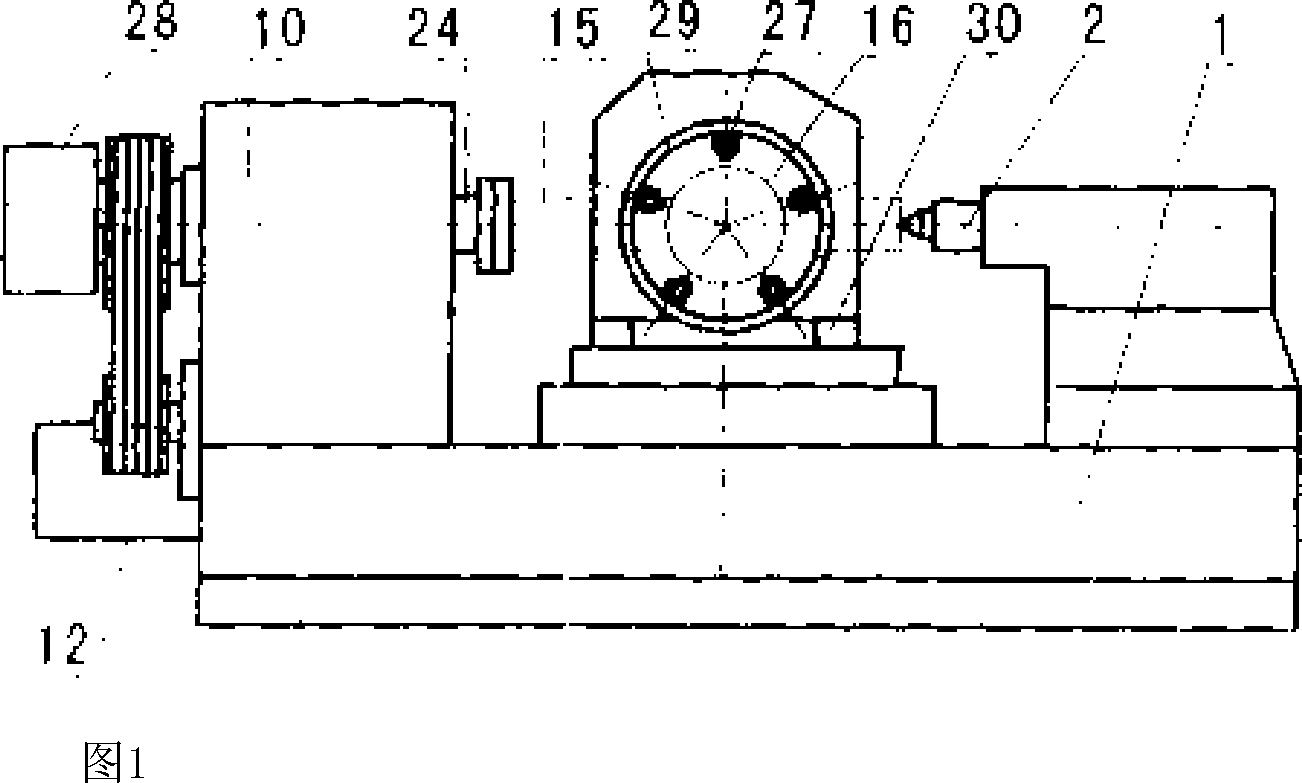

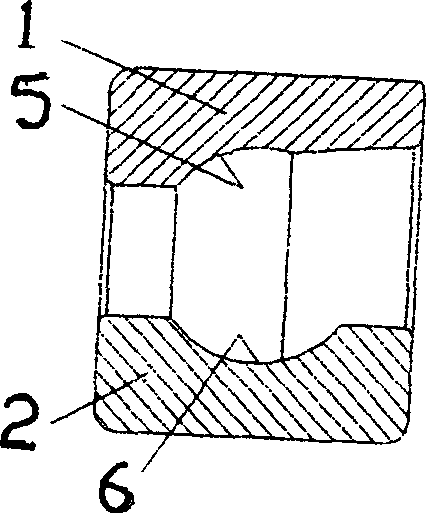

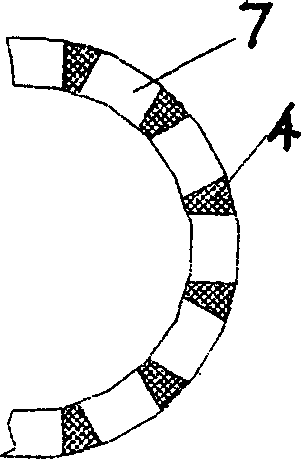

High-rigidity turning spherical surface numerical control accurate grinding equipment

InactiveCN101172330AFast precision grindingRapid grindingGrinding carriagesSpherical surface grinding machinesNumerical controlMotor drive

The invention relates to a rotating spherical surface numerically controlled accurate grinding equipment with high hardness. The equipment comprises a bed body part, a main spindle box part, a wheel stand rotating table part, a tail seat part and a grinding wheel. The main spindle box part and the tail seat part are fixed on the bed body through a bolt; the wheel stand rotating table part is supported on a circular arc guide rail and a circular ring guide rail, a winding and fixed axle moves to and fro through a worm rod and a sector worm wheel under the driving of an actuating motor; the actuating motor drives a wheel stand slide seat to do direct feed motion on the guide rail on the wheel stand rotating table through a feed screw nut pair; the grinding wheel composed of a grinding wheel disc and a grinding wheel block is directly connected with an electric principal axis through a connecting shaft, thereby the propose that the grinding wheel with diameter is used for grinding a rotating spherical surface work piece with high hardness and different diameters though the high speed rotation movement of the grinding wheel, the rotation movement of the rotating spherical surface work piece, the feed movement of the grinding wheel stand and the reciprocating motion of the grinding wheel stand.

Owner:SHANGHAI JIAO TONG UNIV

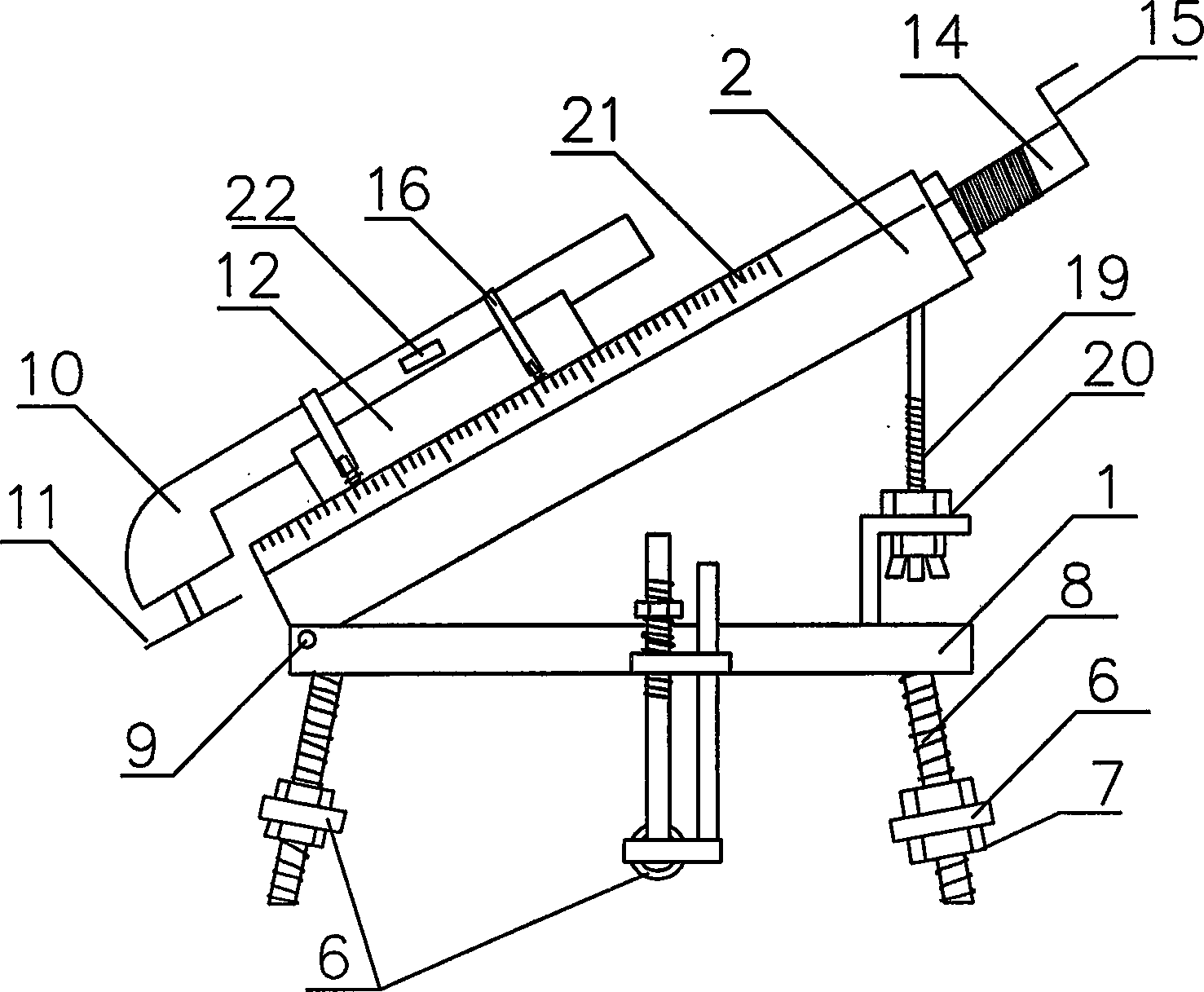

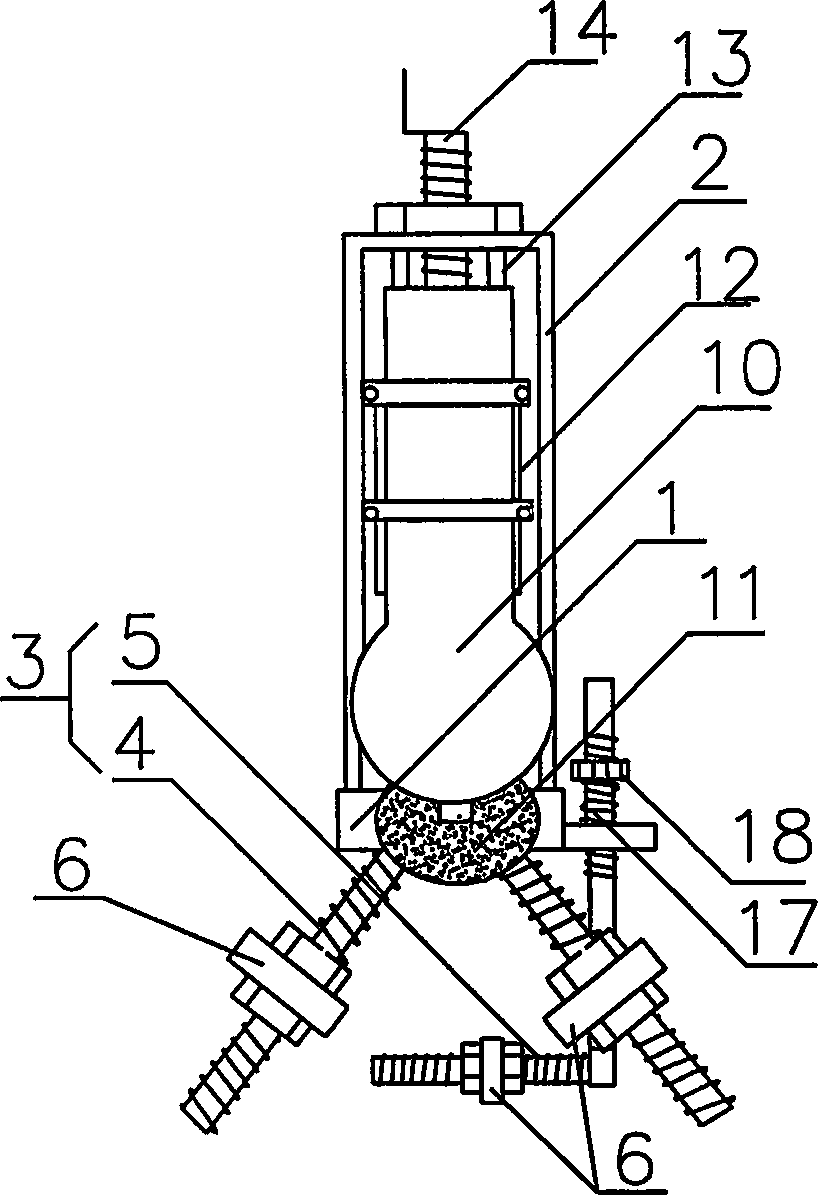

Technique for repairing surface damage on piston rod of hydraulic ram, and dedicated repairing tools

InactiveCN1872488AQuick fixQuick repairSpherical surface grinding machinesArc welding apparatusHydraulic cylinderHydraulic ram

A technology for repairing the surface damage of piston rod for hydraulic cylinder includes such steps as treating the surface at damaged position, build-up welding for filling the damaged recess, grinding and polishing. Its repair tool is composed of the hinged slide frame and grinding frame, an electric grinder with grinding wheel and fixed to the said grinding frame and a clamping arm with roller and arranged on said slide frame.

Owner:崔学斌

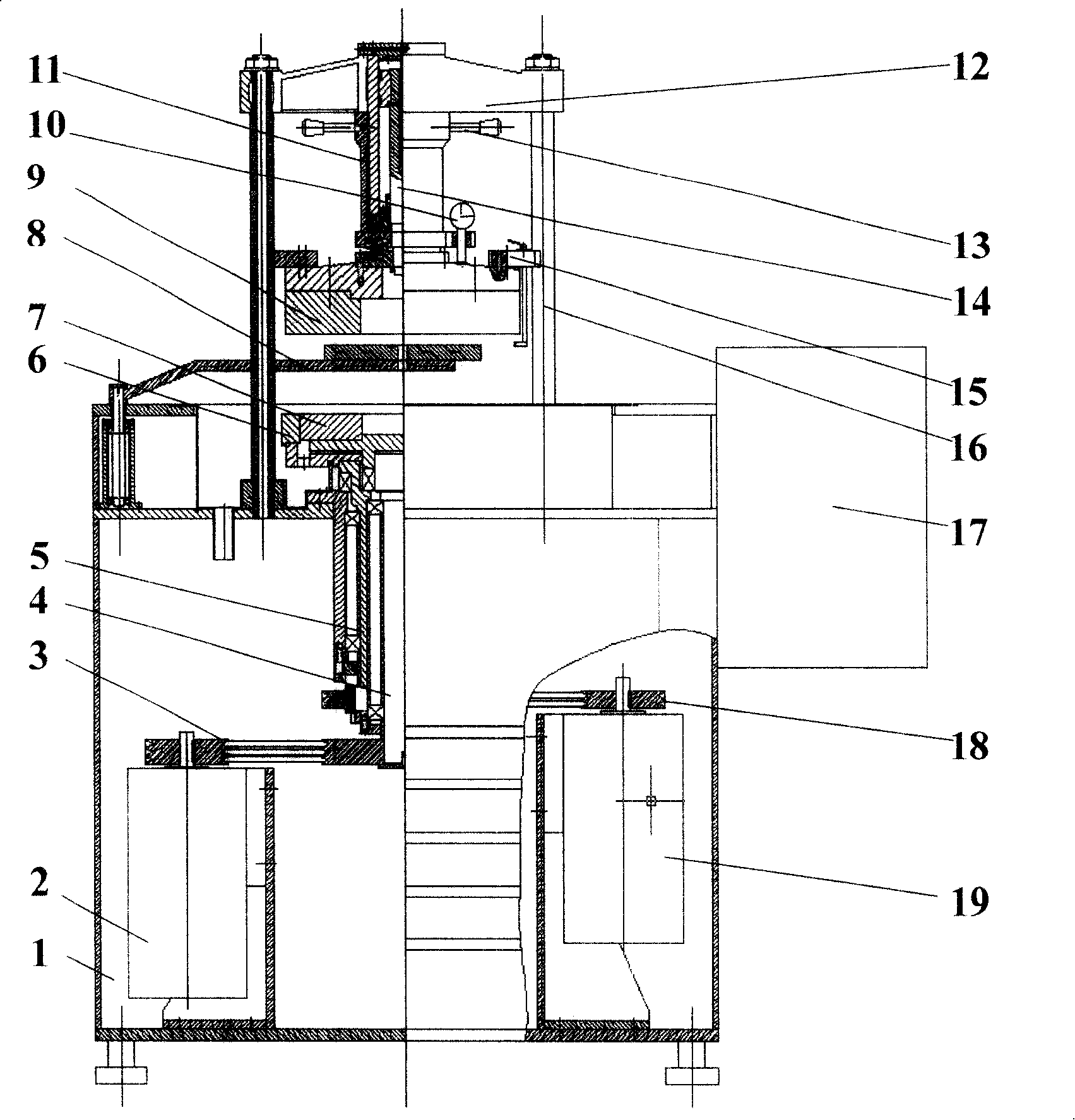

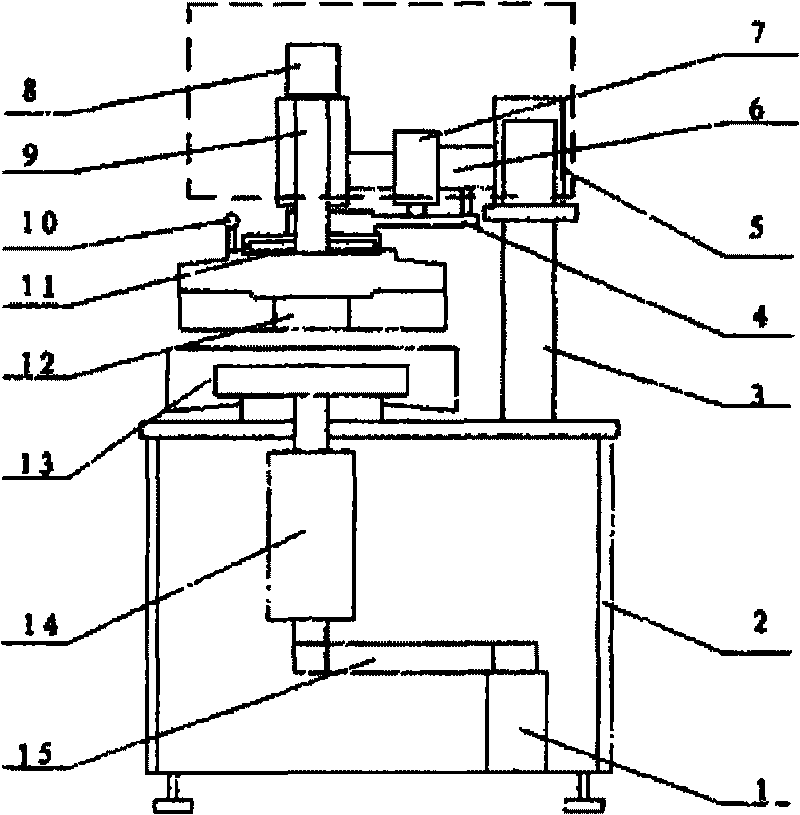

Digital controlled sperical grinding machine having auto detection

InactiveCN1833817ARealize online automatic detectionReduce measurement errorSpherical surface grinding machinesGrinding feed controlControl systemEngineering

A numerally controlled spherical grinding machine with automatic measuring function is composed of base, main body, feeding unit, workpiece holding unit, grinding head unit, hydraulic system, and numeral control system. It features that its automatic measuring unit consisting of detecting element, detecting arm, drive cylinder and signal transmission unit is used for measuring the sizes of workpiece and controlling the feeding unit.

Owner:CHAORAN DIGITAL CONTROL MACHIENRY ZHEJIANG

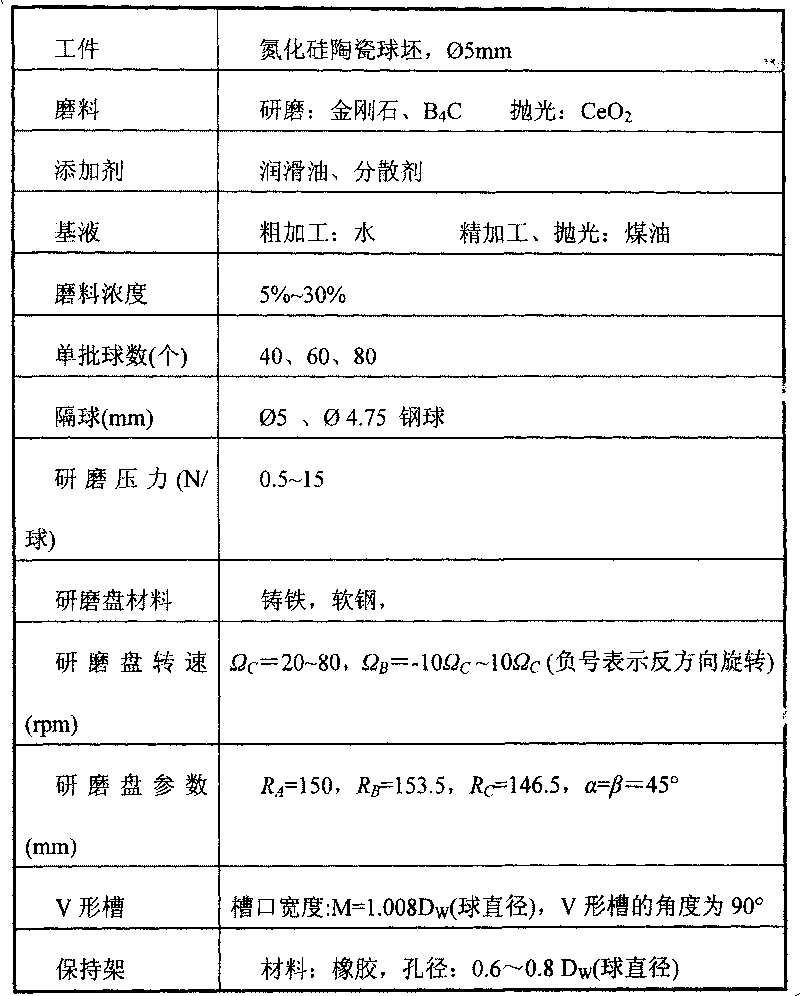

Processing technique of 9Cr18 stainless steel capable of being improved to G3 level

InactiveCN101186005AOptimize processing parametersSpherical surface grinding machinesMetal working apparatusCold treatmentProcess quality

The invention relates to a 9Cr18 stainless steel ball processing technique which can be raised to G3 grade. The processing technique sequentially includes raw material inspection, ball-forging, stress-relief and anneal, hot-acid pickling, polishing, quenching plus cold treatment plus backfire, hard milling, a first-time stabilizing treatment, fine milling, a second-time stabilizing treatment, fine grinding, washing, fine appearance-forming and lubricating and packing. On a basis of making a full use of the existing steel ball processing technology, machine-tool equipments and testing equipments, the technique of the invention adopts a reinforced steel ball manufacturing equipment, industrial preparations, and a novel abrasive to optimize various machining process parameters in the steel ball processing technique and to strengthen a process quality testing and has a proper washing, packing and conserving proposals, etc. process technology. The invention can raise the precision grade of the stainless steel ball to G3 grade and solves the processing technology, testing control and finished-product washing of the 9Cr18 stainless steel ball, and then a batch manufacture is realized finally.

Owner:LUOYANG BEARING SCI & TECH CO LTD

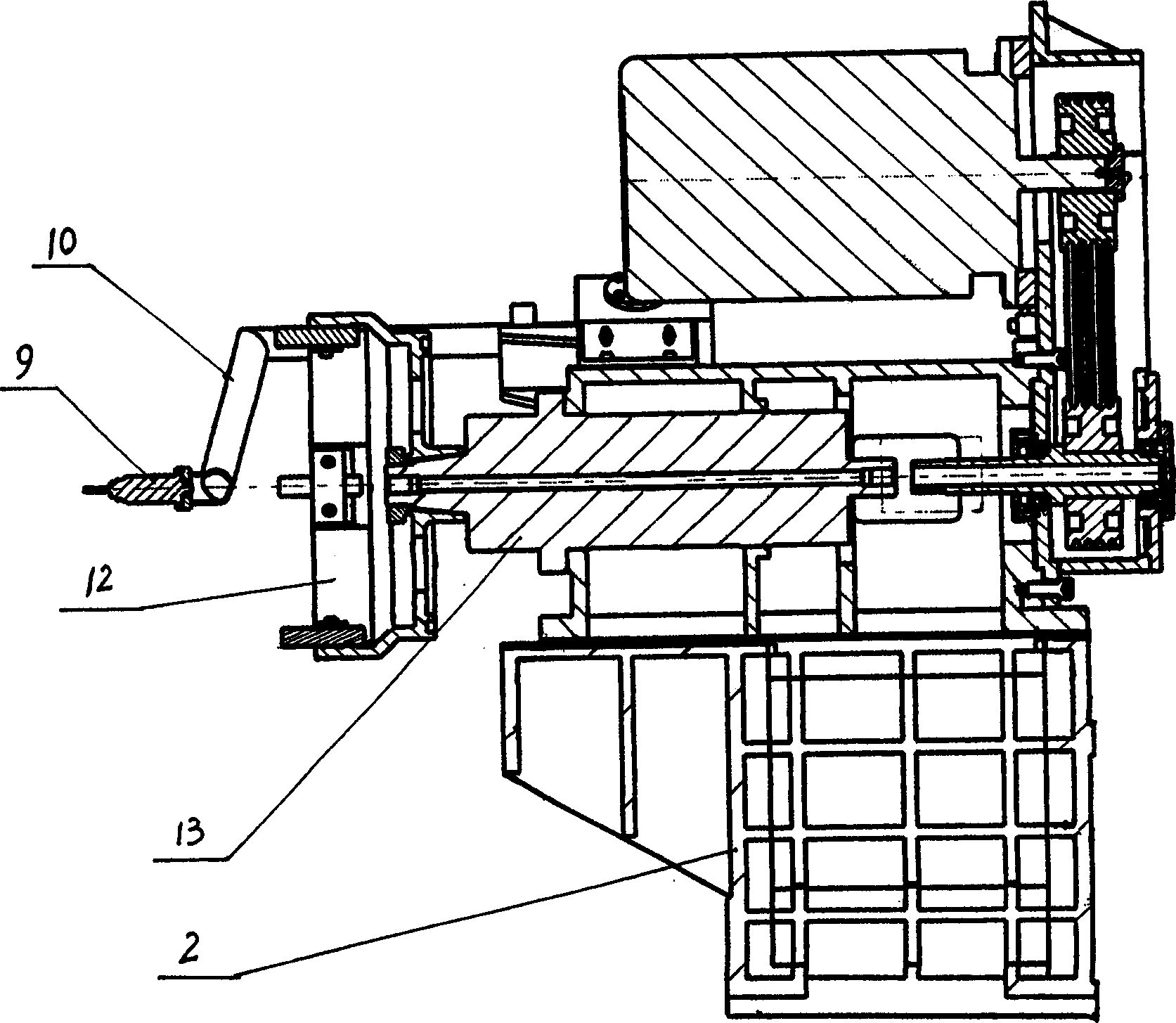

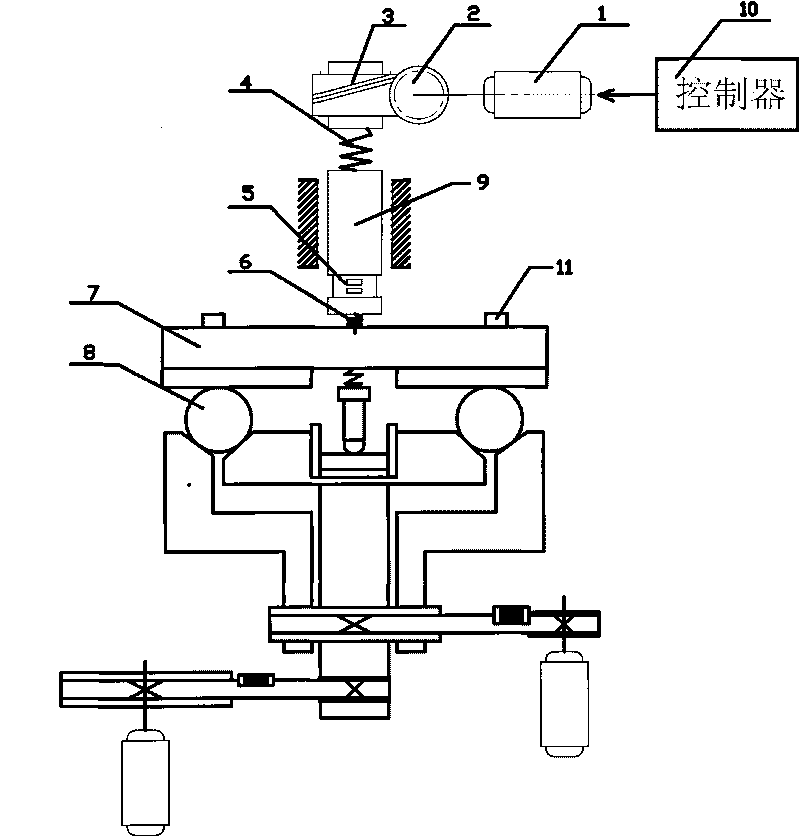

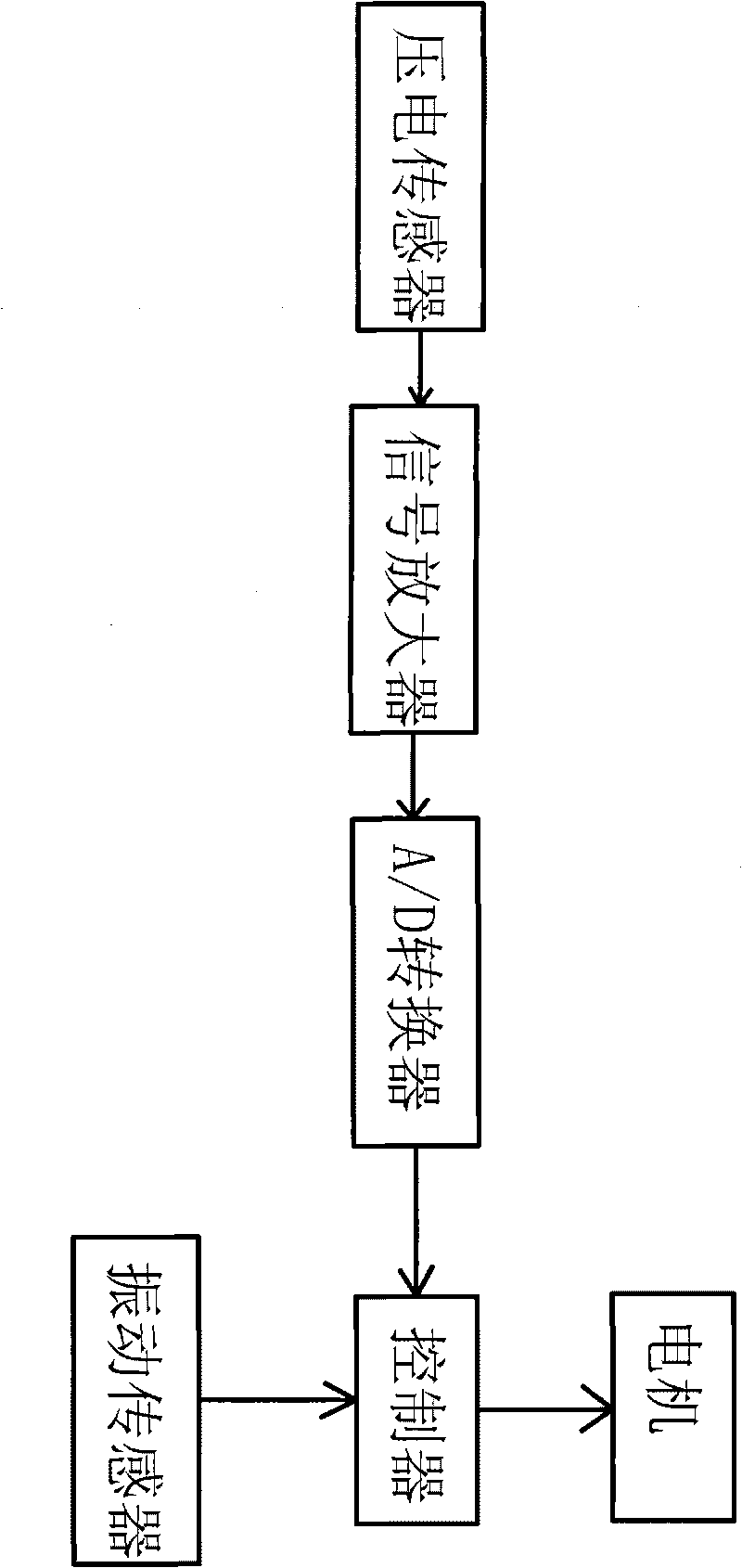

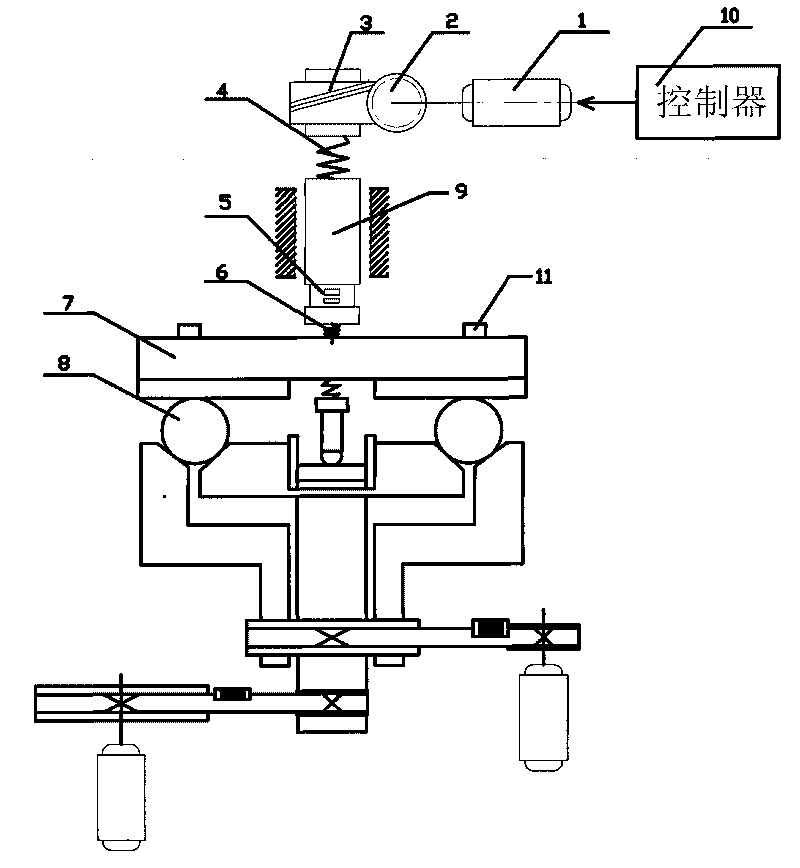

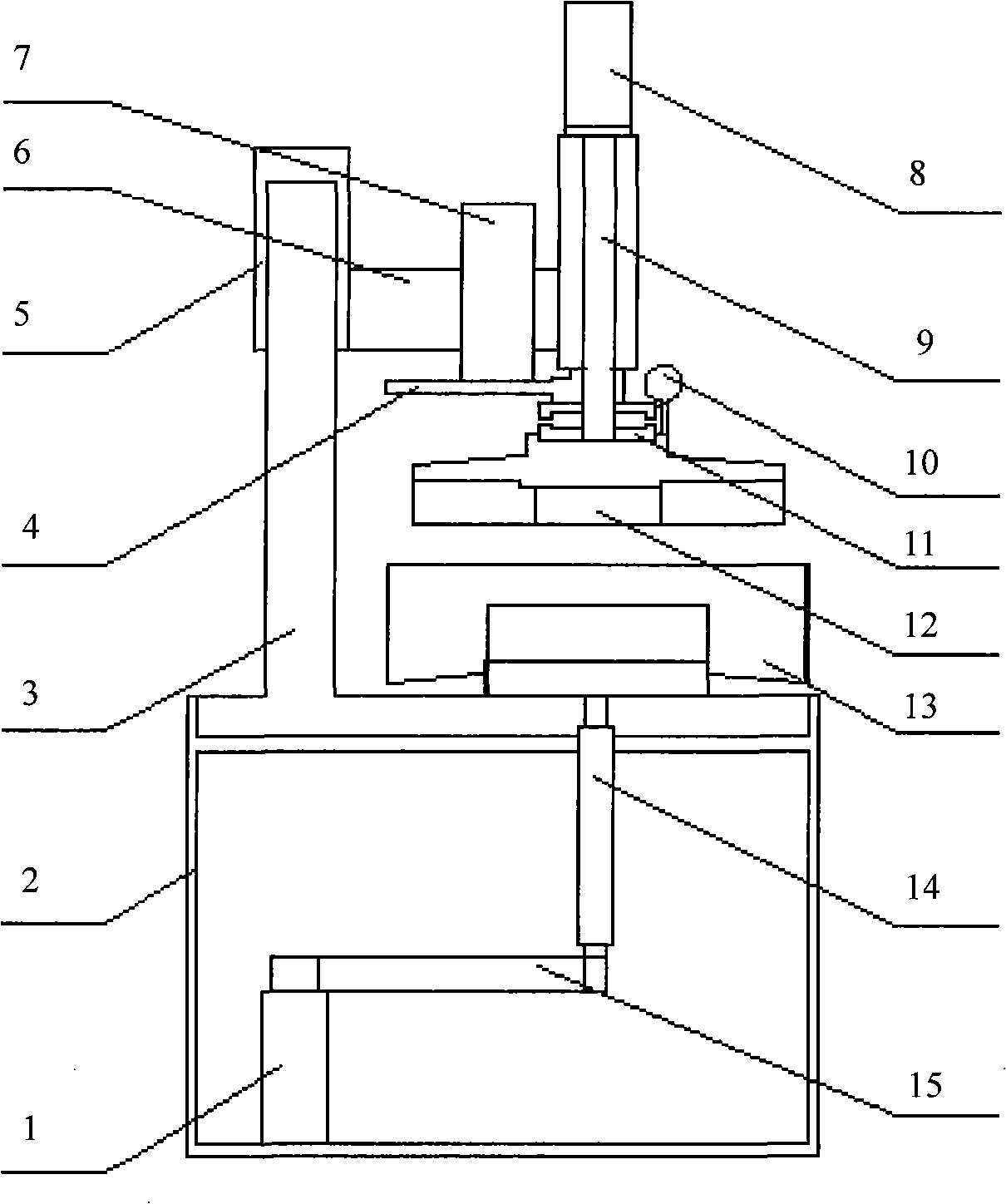

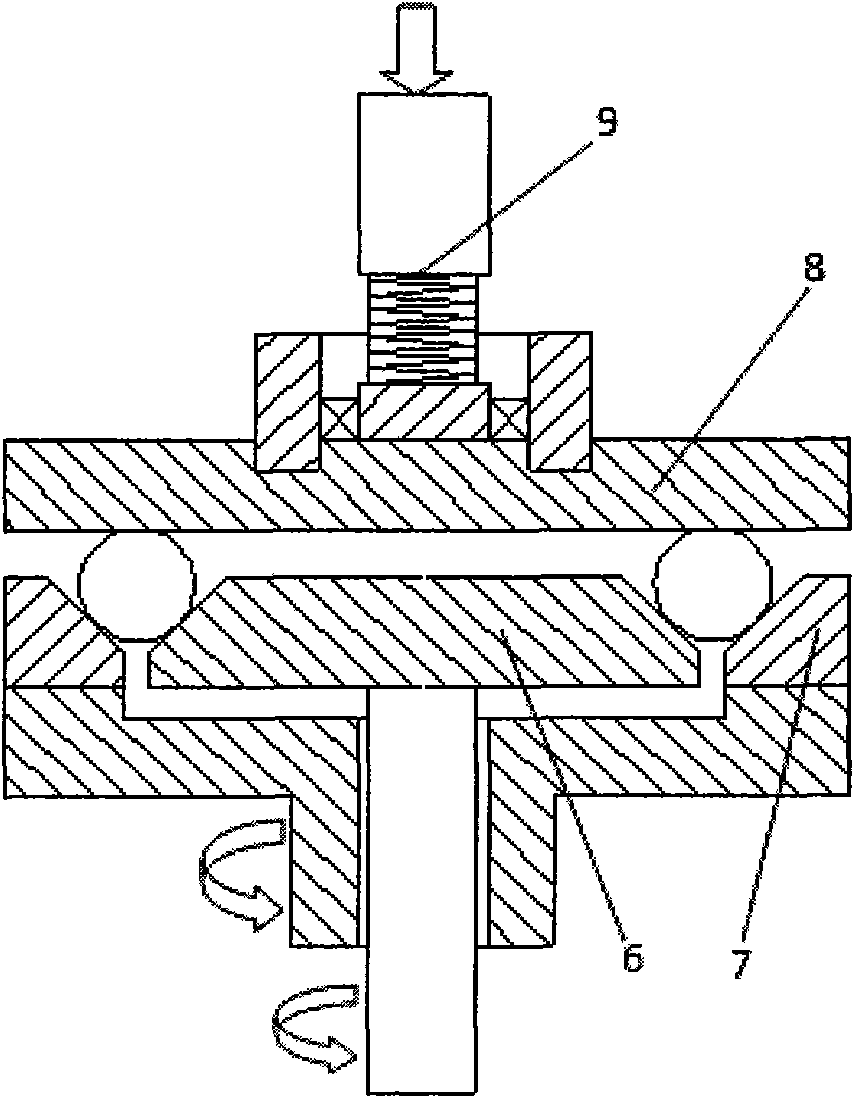

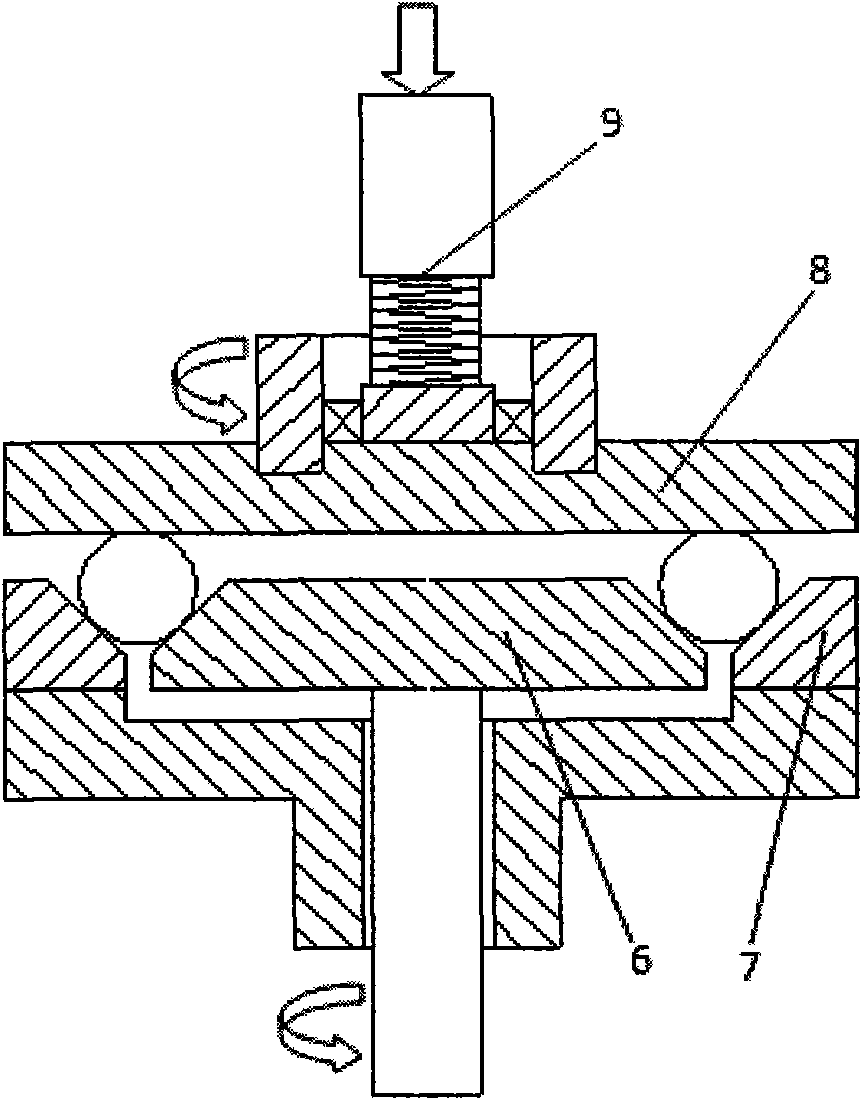

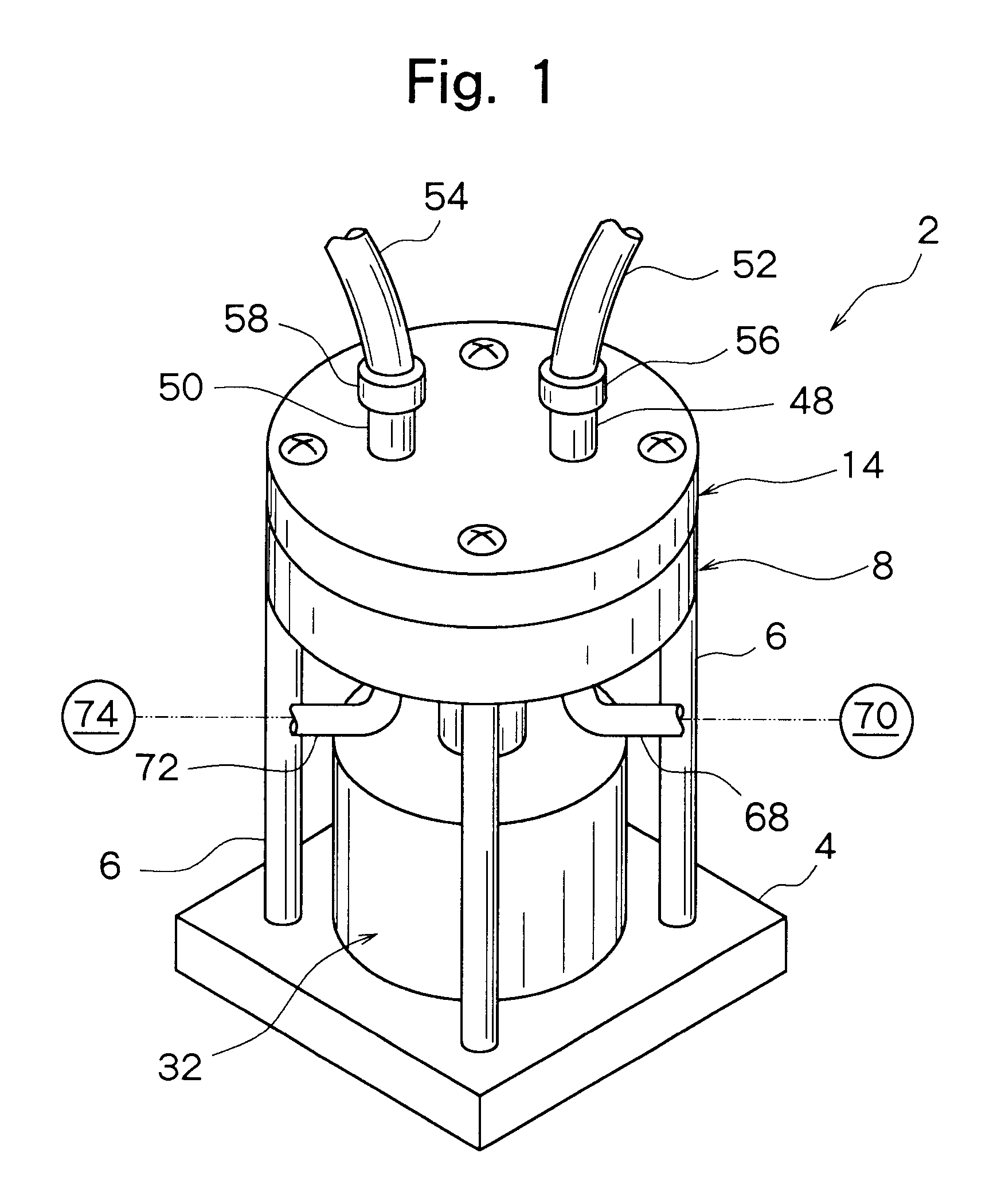

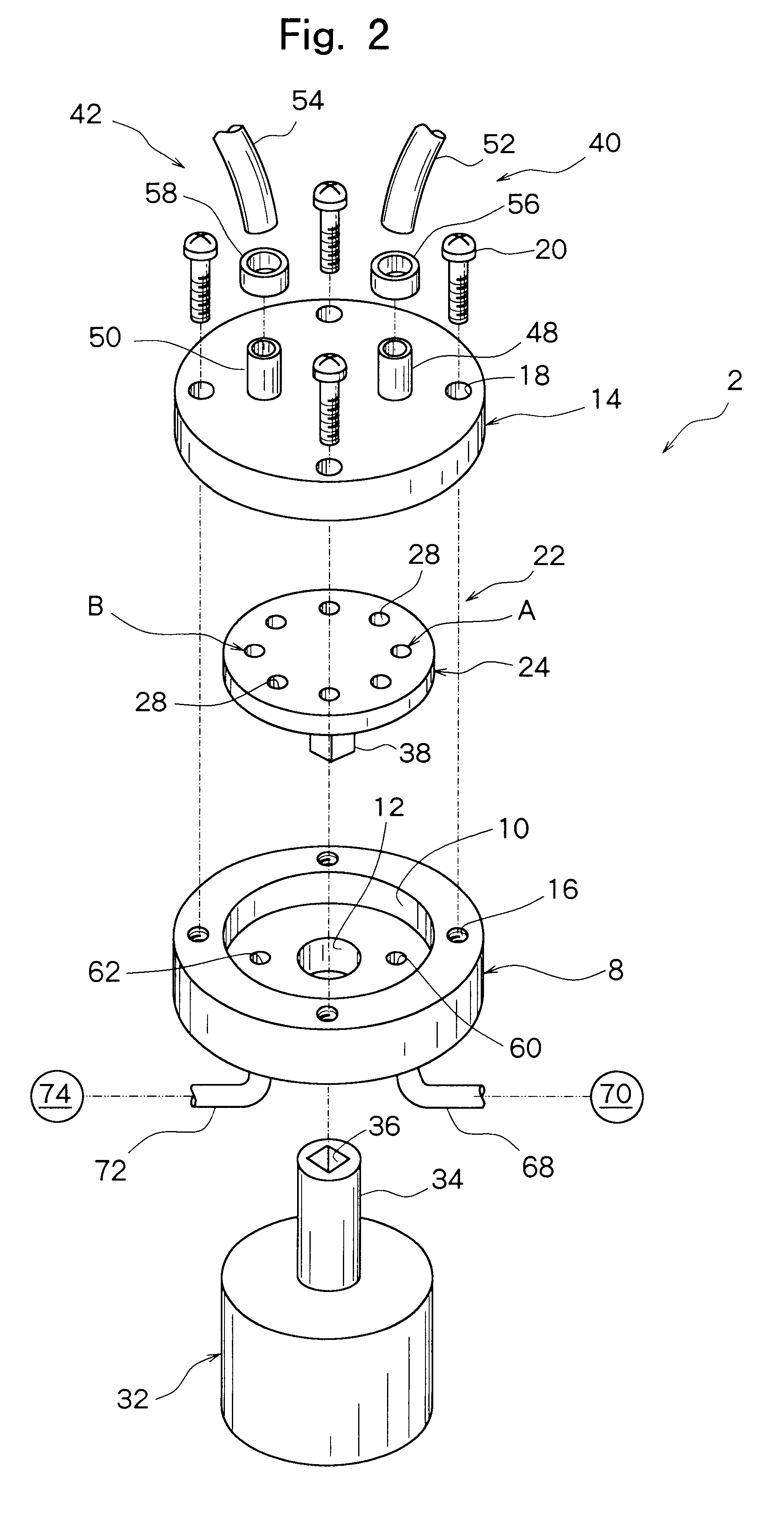

Loading device for sphere precise grinding

InactiveCN101758434AWith self-locking functionConstant pressureSpherical surface grinding machinesGrinding feed controlElectric machineryPiezoelectric sensor

The invention relates to a loading device for sphere precise grinding. The loading device comprises a motor, a worm and a gear, wherein the worm is connected with an output shaft of the motor; the gear is engaged with the worm. The gear is connected with an upper grinding disc through a press block. A first spring is arranged between the press block and the upper grinding disc. A second spring is arranged between the worm and the press block. The press block is provided with a piezoelectric sensor for detecting the suffered pressure of the second spring. The piezoelectric sensor is connected with a controller. A pressure threshold value is preset in the controller. The motor is controlled by the controller. The invention has the advantages of high grinding precision, simple structure, accurate control in the grinding process, and low cost.

Owner:ZHEJIANG UNIV OF TECH

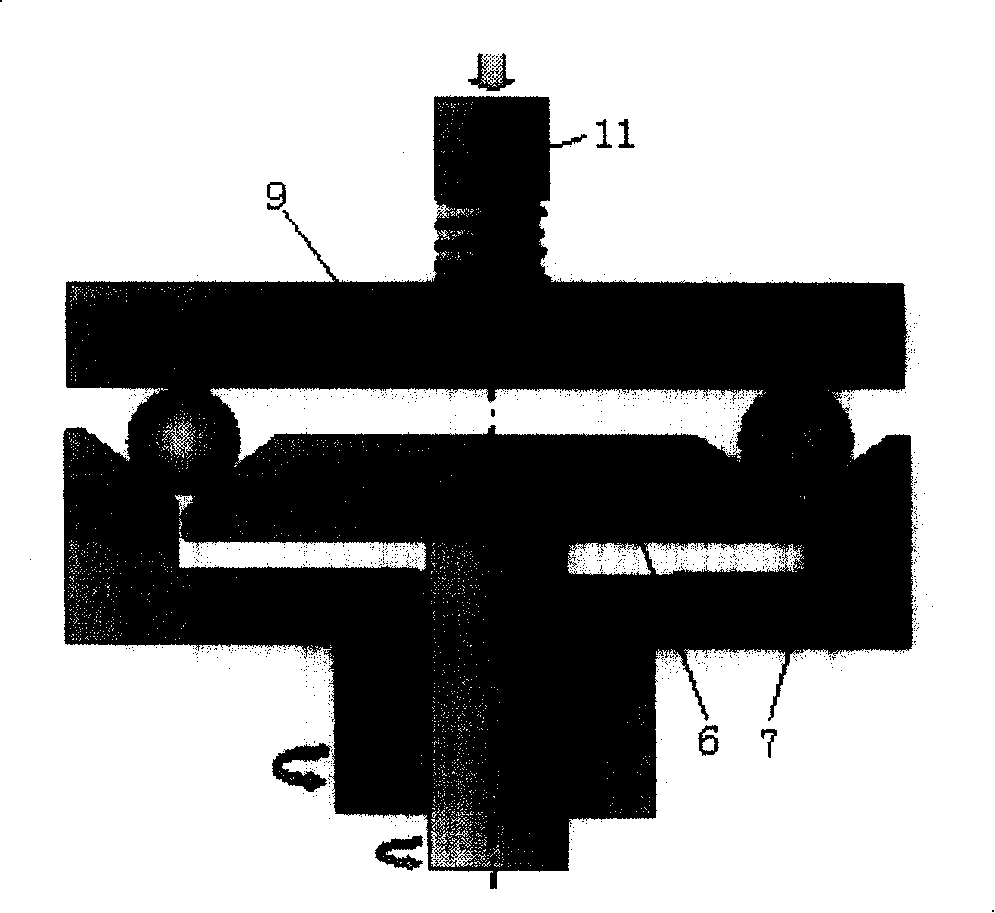

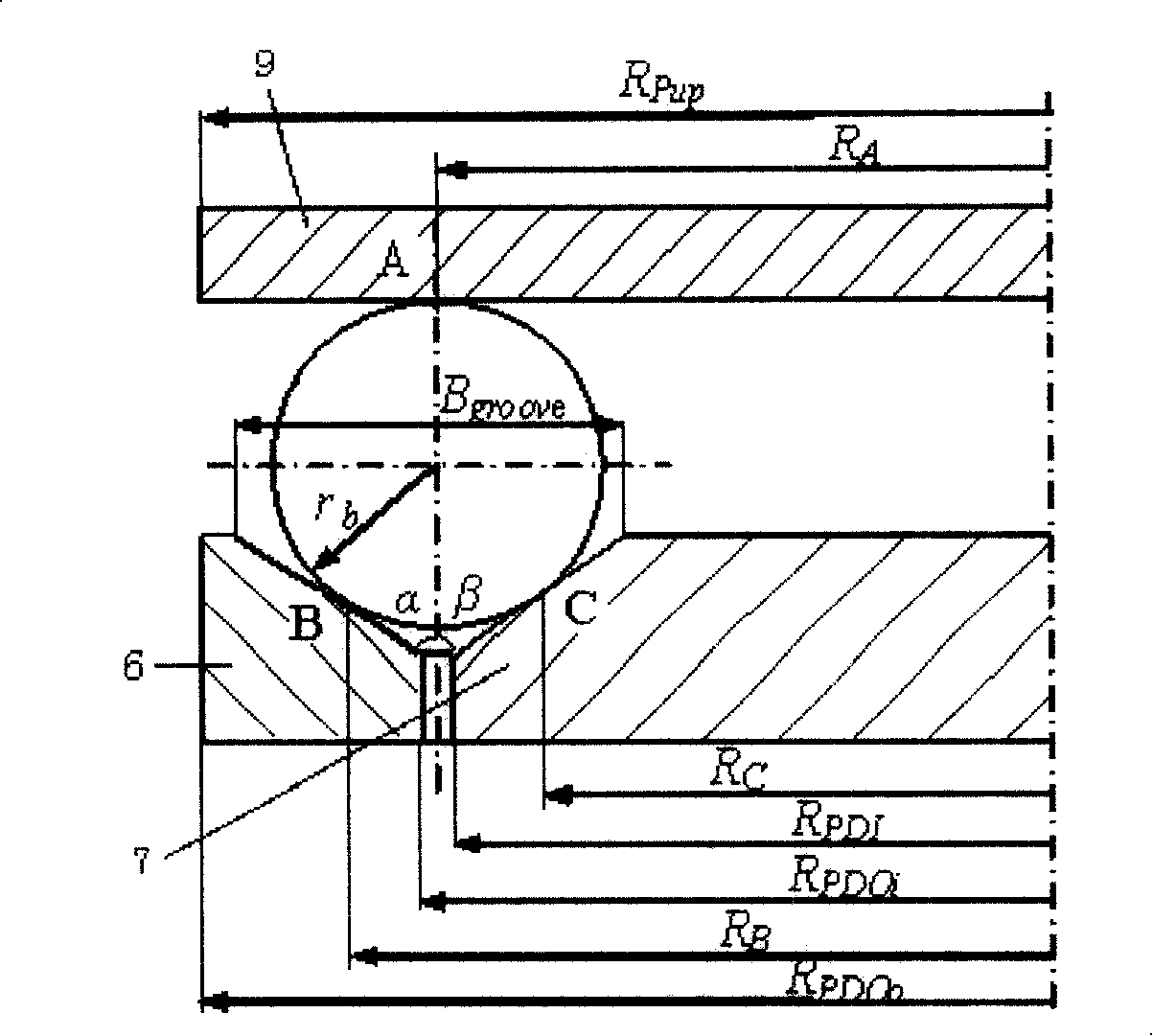

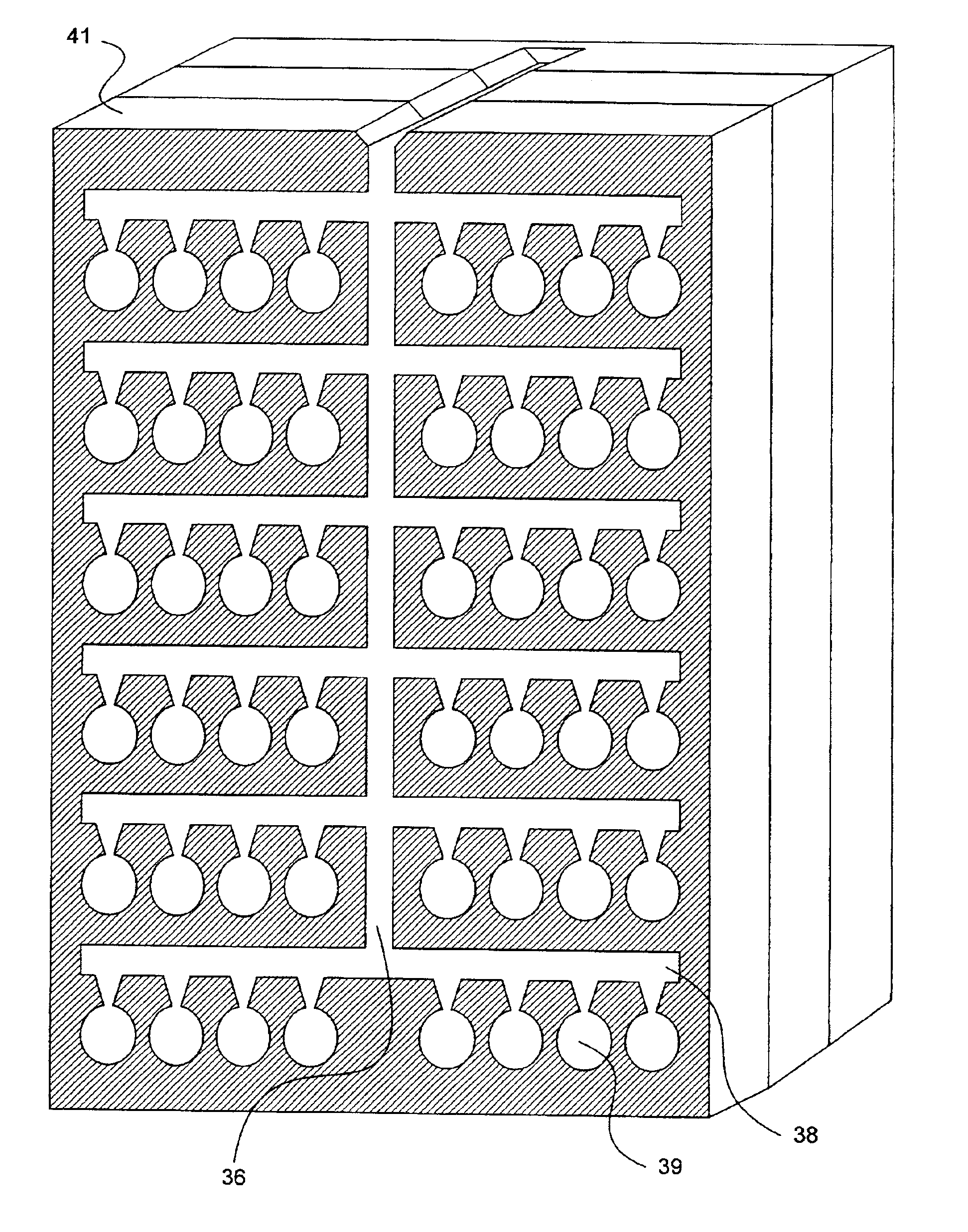

High accuracy ball double autorotation grinding tray high-efficiency grinding device

InactiveCN101204786AImprove grinding precisionImprove grinding efficiencySpherical surface grinding machinesRough surfaceDrive motor

A high precision ball double rotation abrasive disk high efficiency grinding unit includes an upper abrasive disk, a lower abrasive disk and an inner disk of the lower abrasive disk arranged on a frame. The cone abrasive surface at the outer side of the inner disk of the lower abrasive disk and the cone abrasive surface at the inner side of an outer disk of the lower abrasive disk form a V-shaped slot structure which together with the upper abrasive disk forms three machining contact points of a grinding ceramics ball. The drive axes of any two parts in the upper abrasive disk, the outer disk of the lower abrasive disk and the inner disk of the lower abrasive disk are selected to be connected with an electric motor. The parts not connected with a drive motor machine a loading device. The invention can realize the relative orientation adjustment of a rotating axis and a revolution axis for a ball rough and realizes uniform grinding / polishing of the ball rough surface. The invention has the advantages of high machining precision, machining efficiency and machining consistency, and simultaneously the drive and transmission devices have been reduced from 3 to 2. The invention has a simple structure and is a grinding unit with less requirements for machining and assembling precisions.

Owner:ZHEJIANG UNIV OF TECH

Production method for dedicated steel ball for bearing of high-speed high-precision numerical control machine tool

InactiveCN103008994AImprove manufacturing precisionExtend your lifeSpherical surface grinding machinesFurnace typesNumerical controlCarbon potential

The invention discloses a production method for a dedicated steel ball for a bearing of a high-speed high-precision numerical control machine tool. The method comprises the following steps of steel ball cold heading, namely machining blank by sleeve cutting, shaping, cold heading multi-station and high-speed cold heading ways; rough machining by adopting a macrocyclic light bulb technology; performing controllable atmosphere quenching, cold treatment and tapering treatment by adopting a continuous drum furnace, automatically controlling carbon potential; surface strengthening by adopting a frequency conversion speed adjusting multi-beating-plate structure; hard grinding by adopting a ceramic sand wheel to perform macrocyclic process to machine; after primary grinding, adopting double-roller sorting; after fine grinding, performing photoelectric eddy current test; performing ultra-fine grinding machining after aging treatment; and performing photoelectric detection after ultra-fine grinding. The diameter variation of the steel ball which is machined and produced by the method provided by the invention is less than 0.07 micron, the roundness is less than 0.05 micron, the spherical error is less than 0.05 micron, the surface roughness Ra is less than 0.07 micron, the variation of the diameter of the ball lot is less than 0.09 micron, and the bearing dmn value of the steel ball after being sleeved is more than 2.5*10<6> mm*r / min.

Owner:SHANDONG DONGE STEEL BALL GRP

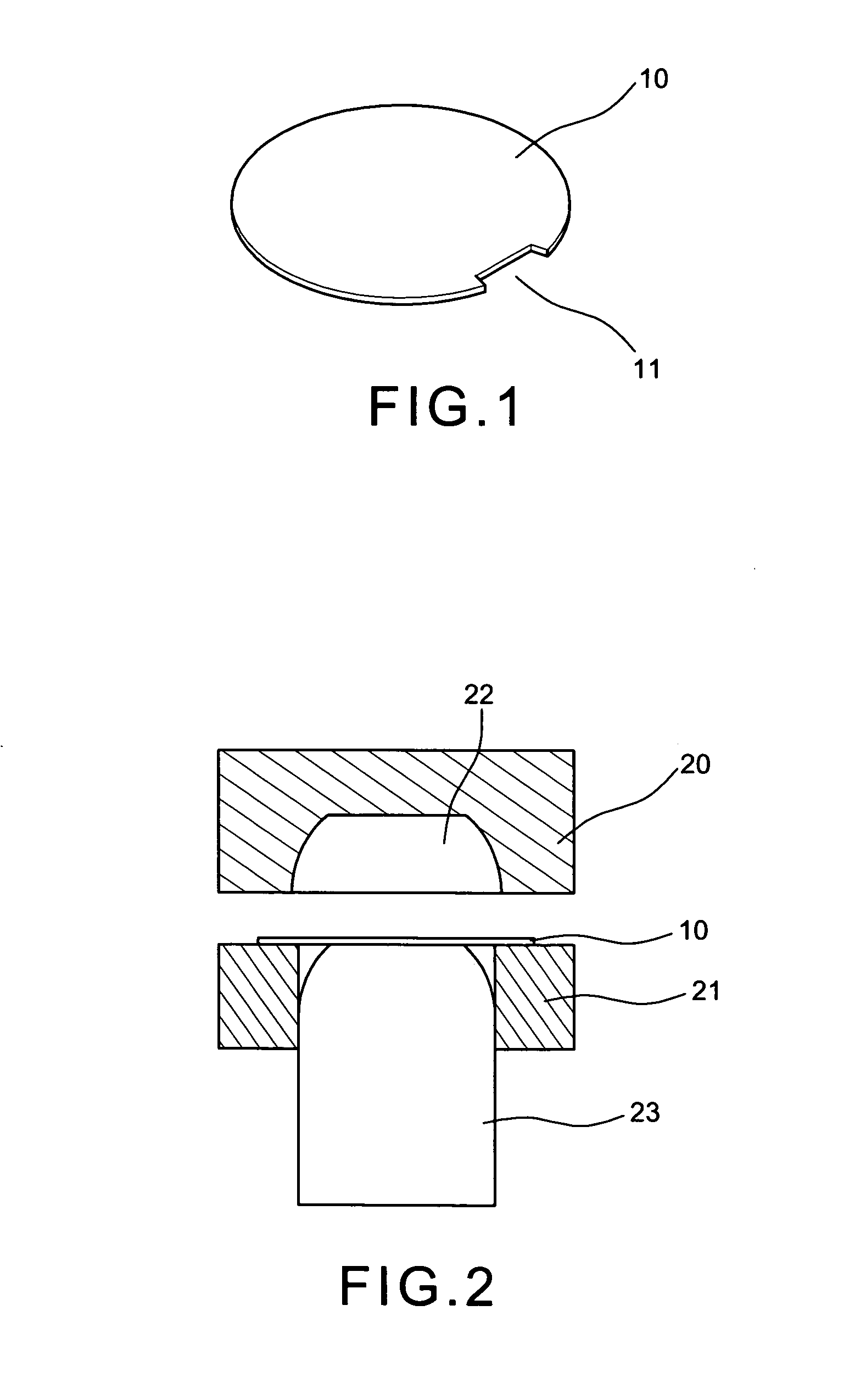

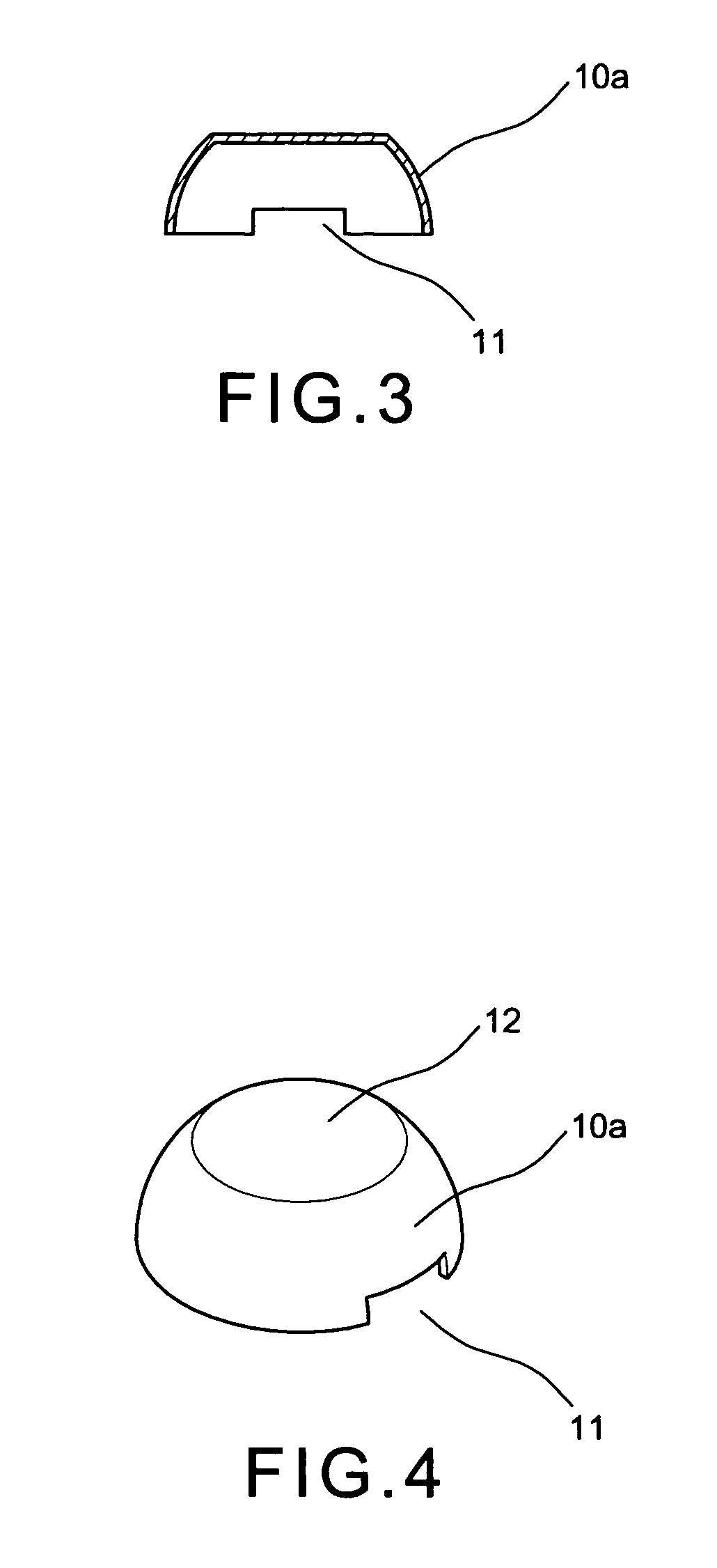

Manufacturing process to make a valve ball

InactiveUS6899599B1High qualified proportionProcess is rapid and precisePlug valvesSpherical surface grinding machinesEngineeringSpherical shaped

A manufacturing process to make a ball valve of the present invention includes the following steps: a) prepare flat circular metallic plates each of which has a rectangular indentation in a circumference; b) mold those plates into bowl shape; c) remove the circular bottom of the bowl shapes to reform a hemi-spherical shape by another mold; d) weld each pair of the hemi-spherical shapes into a spherical shape each of which has a pair of aligned openings and a lateral rectangular through hole; e) trim and grind the uneven connection seam; and f) polish and smooth the outer surface to finished a qualified ball valve which has uniform arc and thickness.

Owner:HSIANG HUI CHIANG

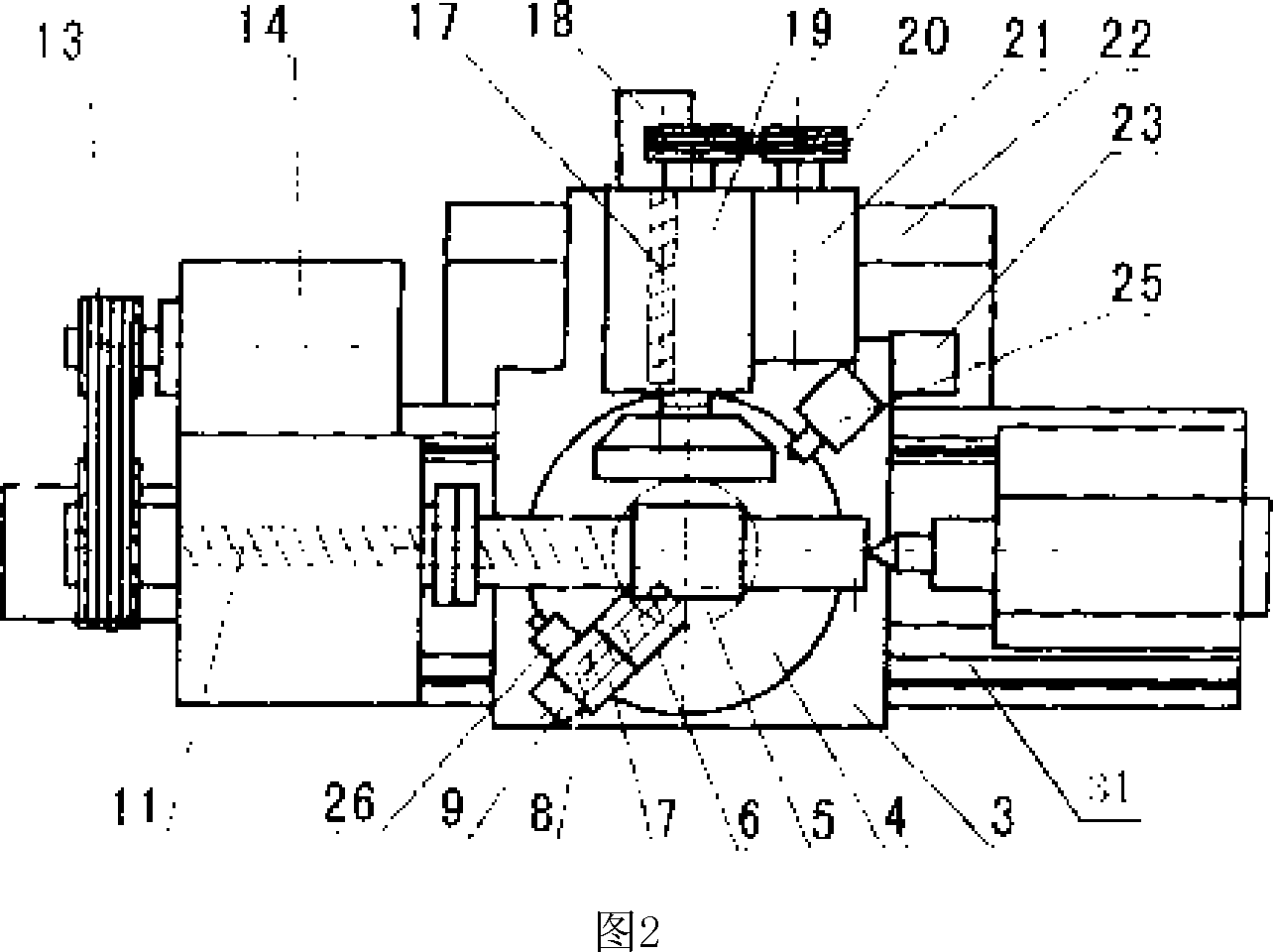

Numerically controlled ball grinding vehicle

InactiveCN101053935ASimple structure and principleImprove scalabilitySpherical surface grinding machinesMeasurement/indication equipmentsNumerical controlElectric machinery

The present invention relates to a numerical control ball milling machine tool, which comprises a lathe bed (1) provided with a main shaft servo drive motor (14), a clamp arranged above the lathe bed (1), a lathe bed saddle (3) provided with a rotating table (4) which is connected with a B-shaft servo drive motor (23) and is provided with a tool rest slide (6), a tool rest (7) fixedly arranged above the tool rest slide (6), and a wheel-head device (29) arranged behind the lathe bed saddle (3). In the present invention, the sphericity workpiece is processed by the tool and the wheel-head device arranged on one machine tool; the workpiece is clamped once in the whole course of processing, thereby, not only the processed precision can be ensured, but also the automaticity can be greatly improved, so that the labour force is saved, and the production efficiency and the production quality are improved. The machine tool of the present invention has a simple structure and principle, easy operation, and excellent expansibility.

Owner:ZHEJIANG HUZHOU BEIDAO CNC PRECISE MACHINERY

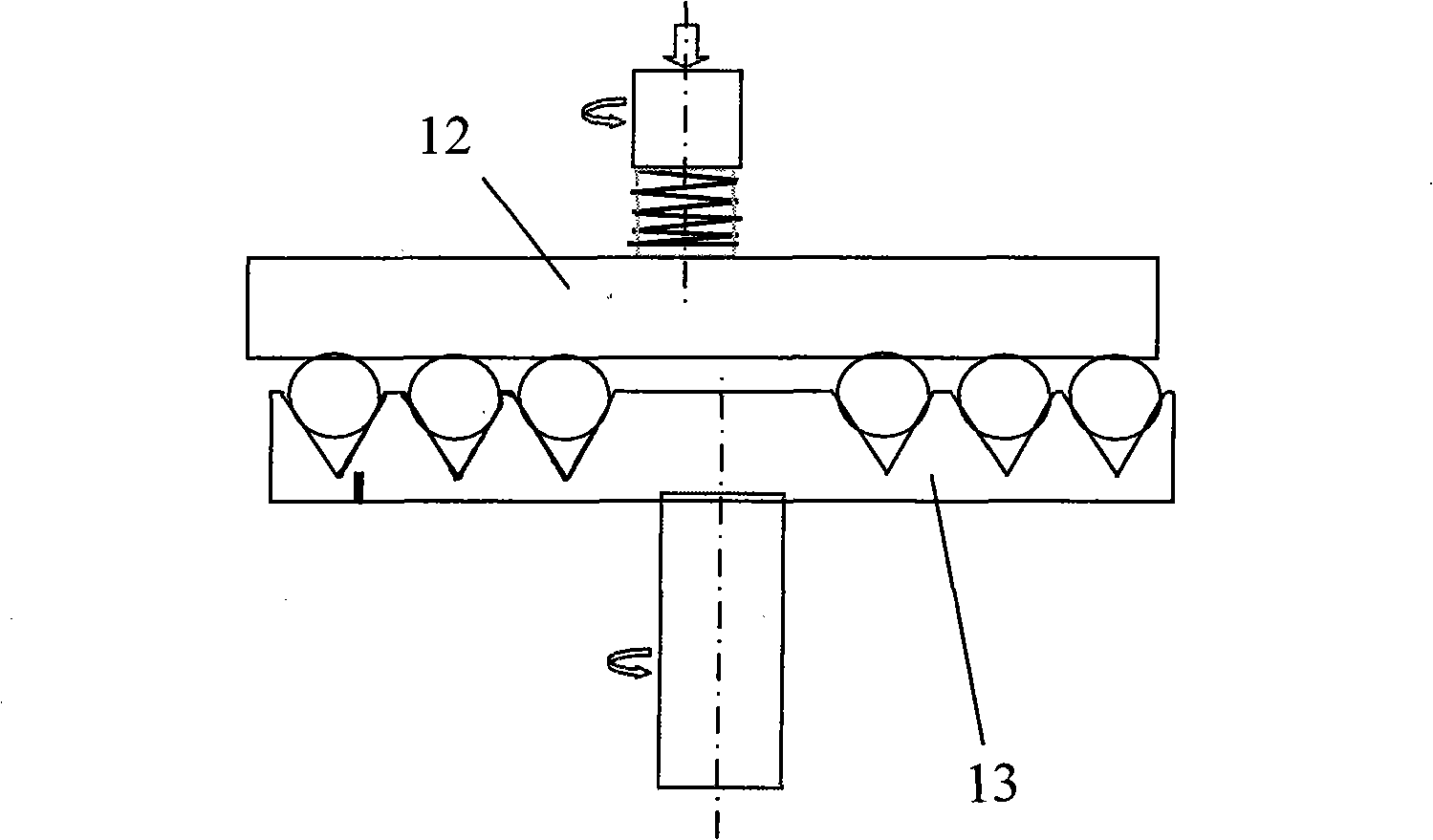

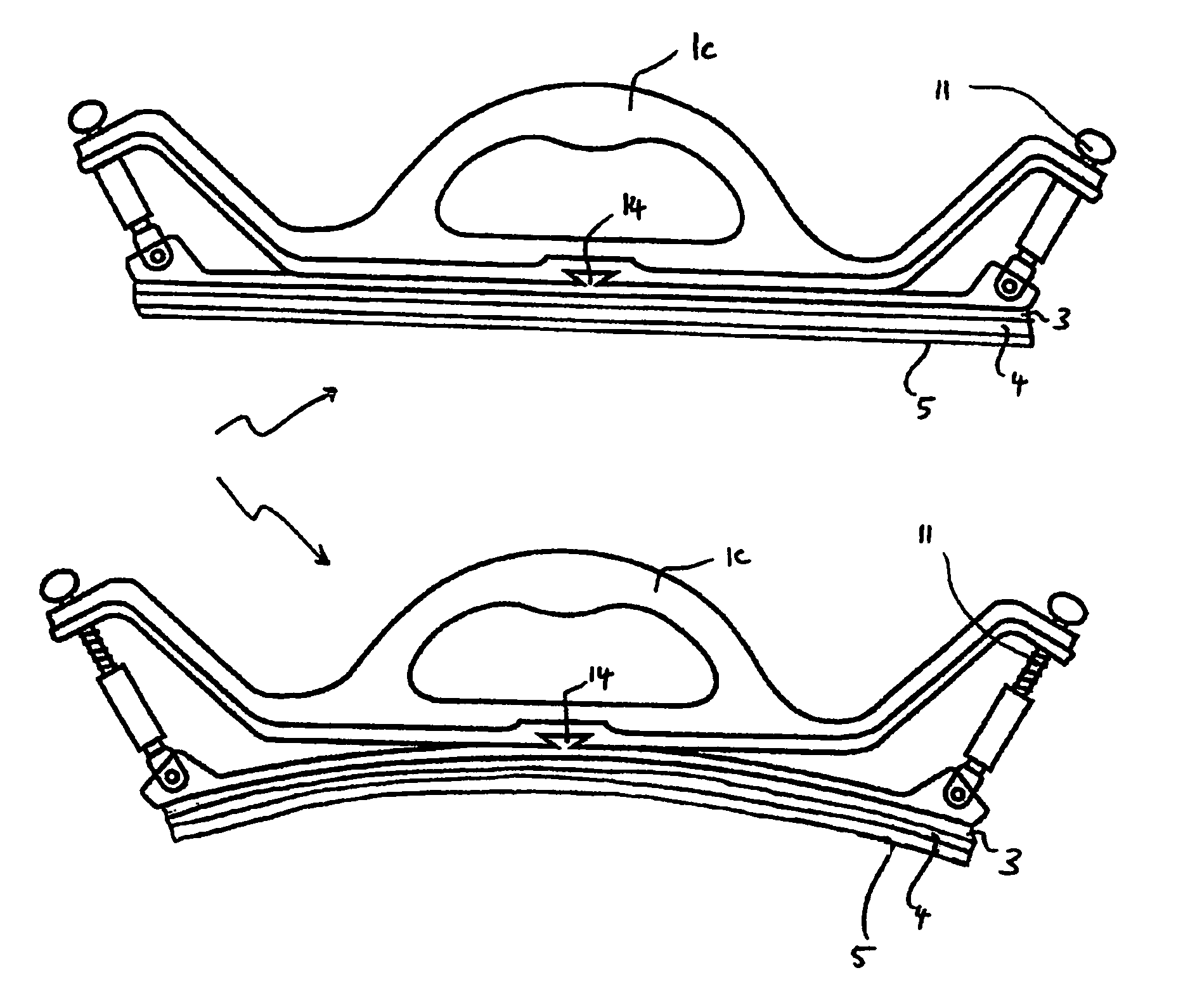

Double-disk rotation eccentric V shaped groove grinding miller

InactiveCN101279434AAdjustable speedSuitable for mass productionSpherical surface grinding machinesInsertion stentDrive motor

The invention discloses a double-disk autorotation eccentric V-shaped groove grinder, which comprises a frame, and an upper abrasive disk and a lower abrasive disk arranged on the frame; wherein, the upper abrasive disk is arranged on the spindle of the upper abrasive disk and the spindle of the upper abrasive disk is connected with the driving motor of the upper abrasive disk; the lower abrasive disk is connected with the driving motor of the lower abrasive disk, and the upper abrasive disk and the lower abrasive disk are arranged at the top and bottom. The frame comprises a frame body and an upper stent; wherein, the upper stent can be rotatablely arranged on the upper end of the frame body, and the upper abrasive disk is arranged on the upper stent while the lower abrasive disk is arranged on the frame body; at least three V-shaped grooves used for placing ball-billets are cut on the upper surface of the lower abrasive disk; each V-shaped groove is a concentric circle, the circle center of the concentric circle coincides with that of the lower abrasive disk, and the upper abrasive disk and the lower abrasive disk are eccentric with each other. The double-disk autorotation eccentric V-shaped groove grinder provided by the invention has simple structure and low manufacturing cost, and simultaneously has higher machining accuracy and machining efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

Crystal ball face milling machine

InactiveCN101708585AIncrease the grinding angle rangeImprove work efficiencySpherical surface grinding machinesMovable typeEngineering

The invention discloses a crystal ball face milling machine, which has a unique structure, is skillfully designed, can automatically position and clamp aluminum bar in aluminum assembly, allows a bracket towing mechanism to independently and accurately position and move along a horizontal or vertical direction relative to a milling disc mechanism, effectively improves production efficiency and accuracy. The invention solves a technical problems existing in the prior art that the positioning-clamping process of the aluminum bars is time consuming and labor consuming and the bracket towing mechanism cannot change the positions relative to the milling disc according to processing requirements, so that the face-milling range of the crystal ball becomes smaller and the production efficiency is low. The crystal ball face milling machine comprises a machine frame, a milling disc mechanism arranged on the machine frame and a pair of bracket towing mechanisms which horizontally slide along slide rails on the machine frame and are arranged on the machine frame and matched with the milling disc mechanism, wherein the bracket towing mechanisms are fixedly provided with the aluminum bars; the machine frame is provided with a mechanism which can make each bracket towing mechanism independently move on the machine frame along the horizontal or vertical direction; and the aluminum bars are fixed on the bracket towing mechanisms by movable type dovetail groove clamps.

Owner:浙江博联智能科技有限公司

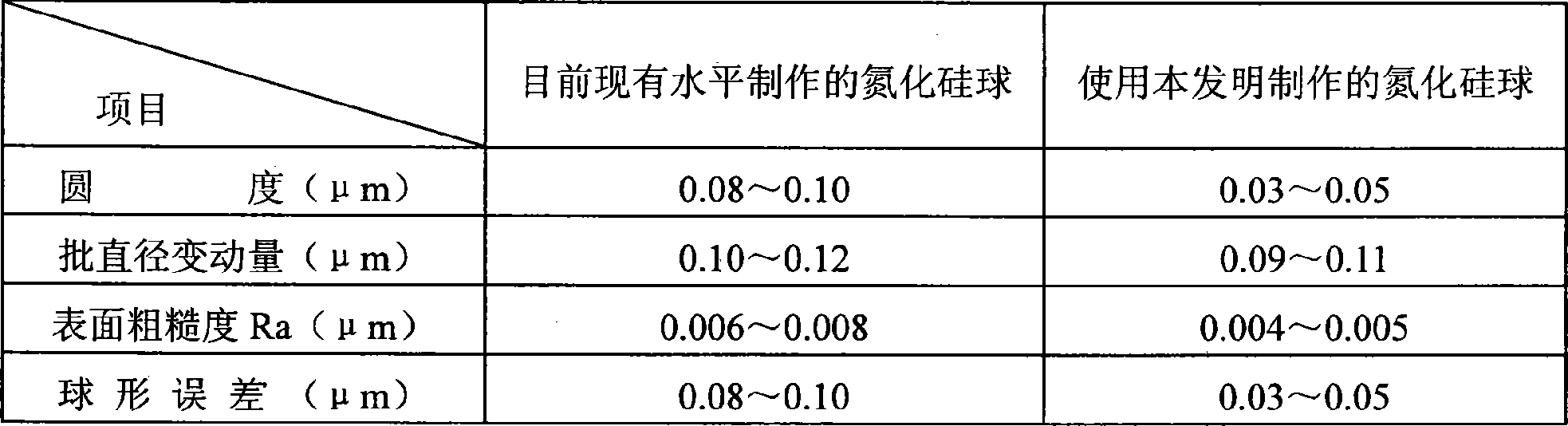

Technique for processing silicon fluoride ball in G3 grade

InactiveCN101049676ASimple processEasy to manufactureOther chemical processesSpherical surface grinding machinesInternal stressSuperfine grinding

A process for preparing the G3-class silicon nitride balls includes such steps as eliminating internal stress by heating at 130-160 deg.C for 6-8 hr and cooling in air, primary grinding, fine grinding, superfine grinding, and brightening by chromium oxide.

Owner:SHANDONG DONGE STEEL BALL GRP

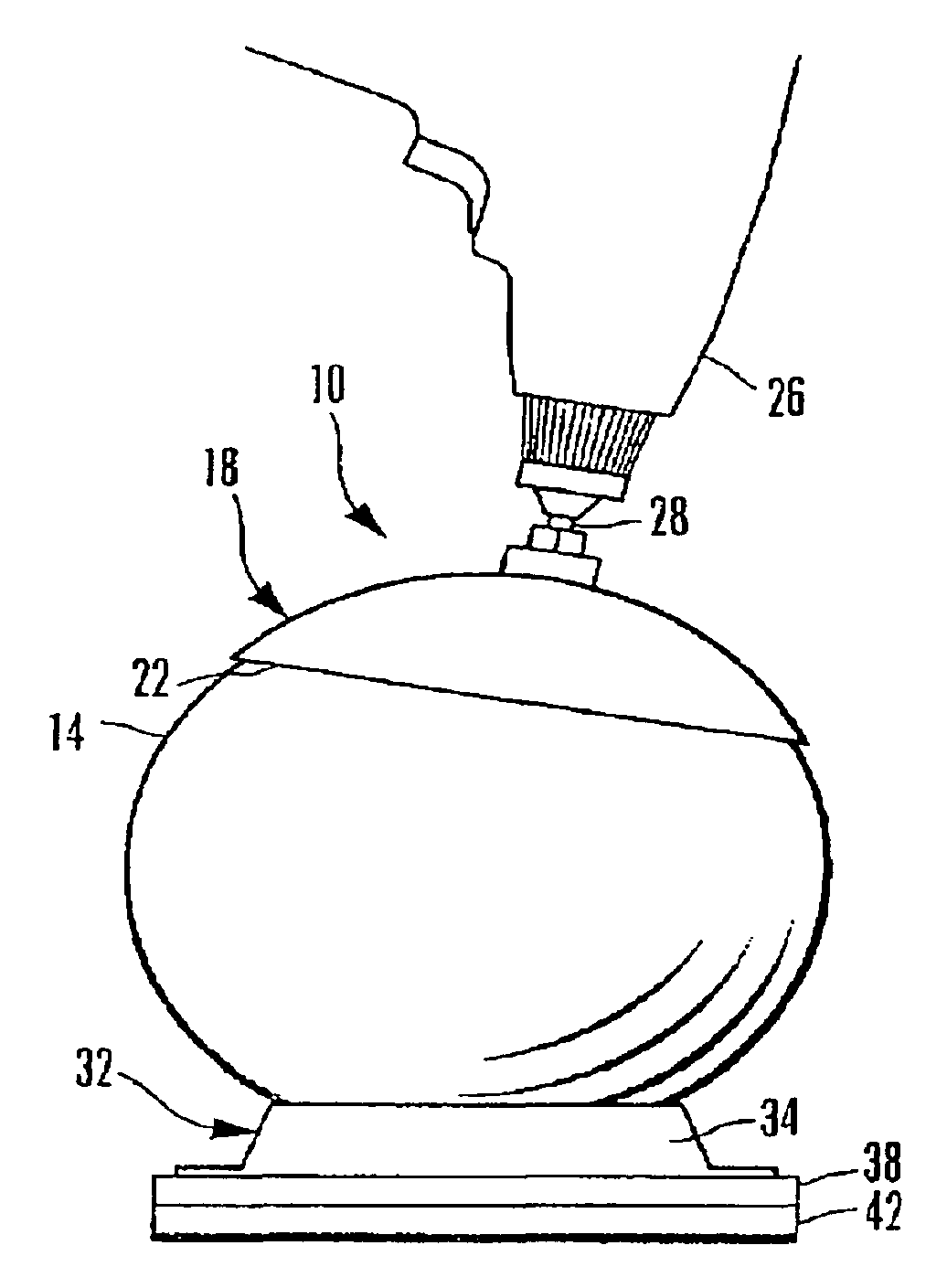

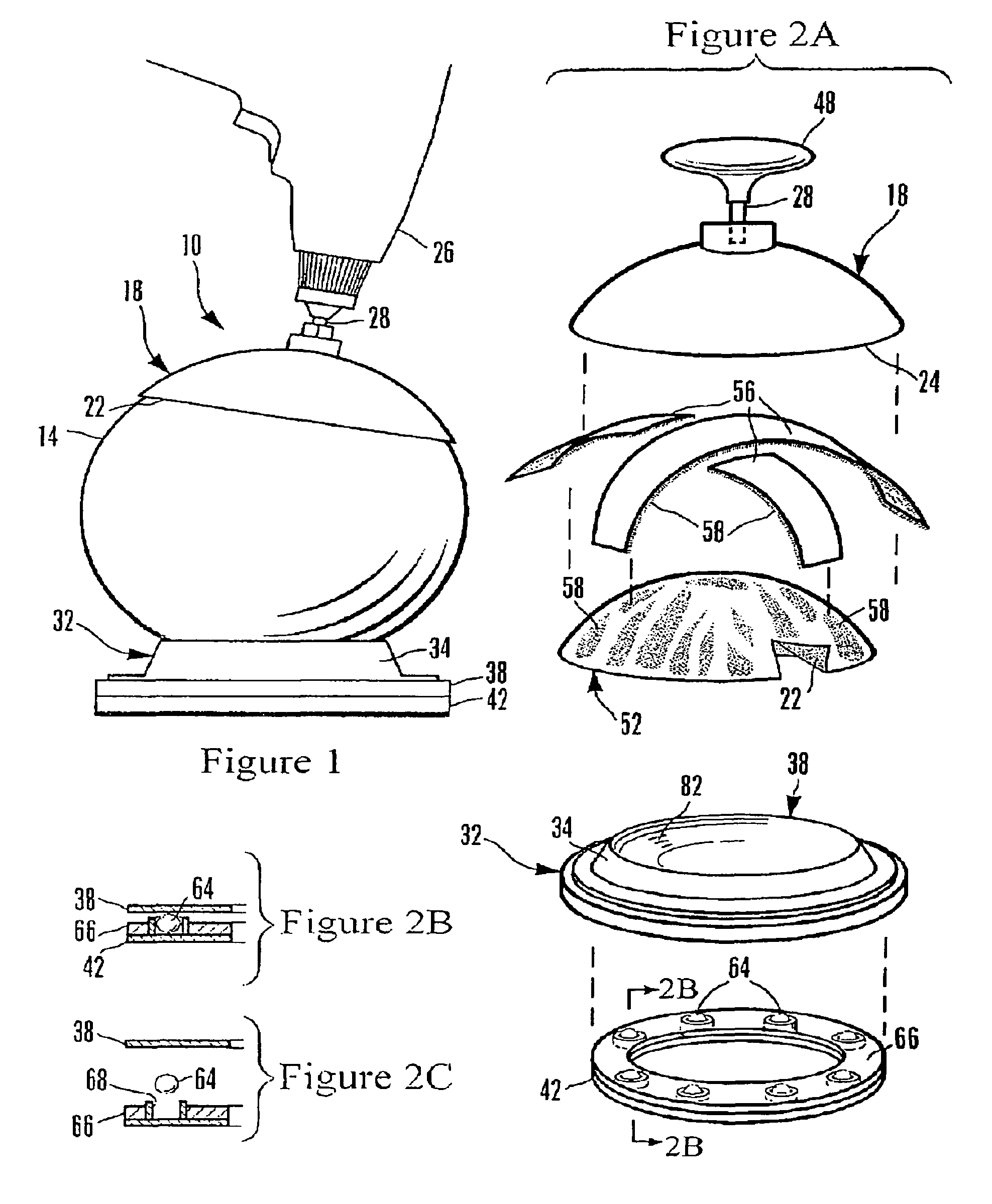

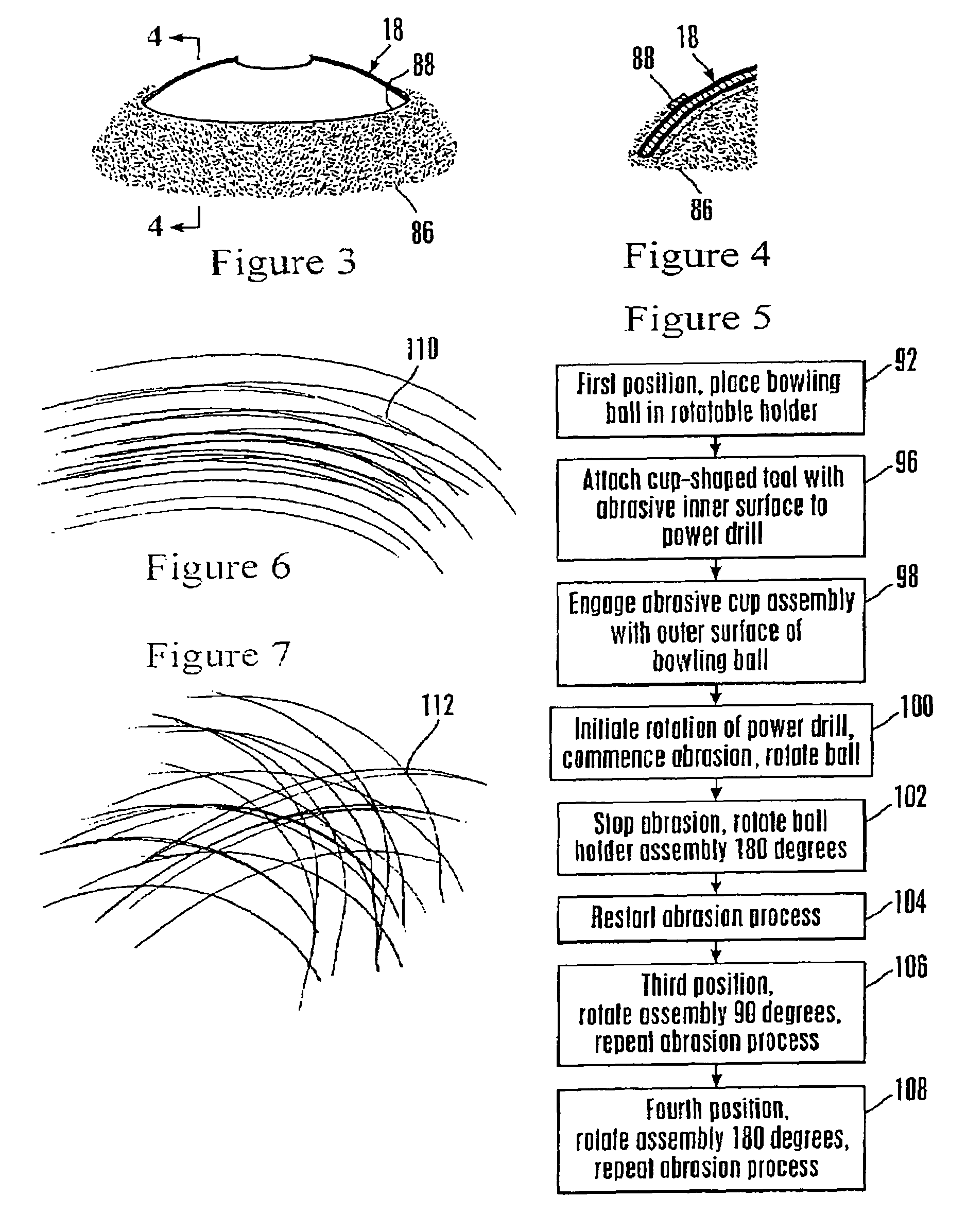

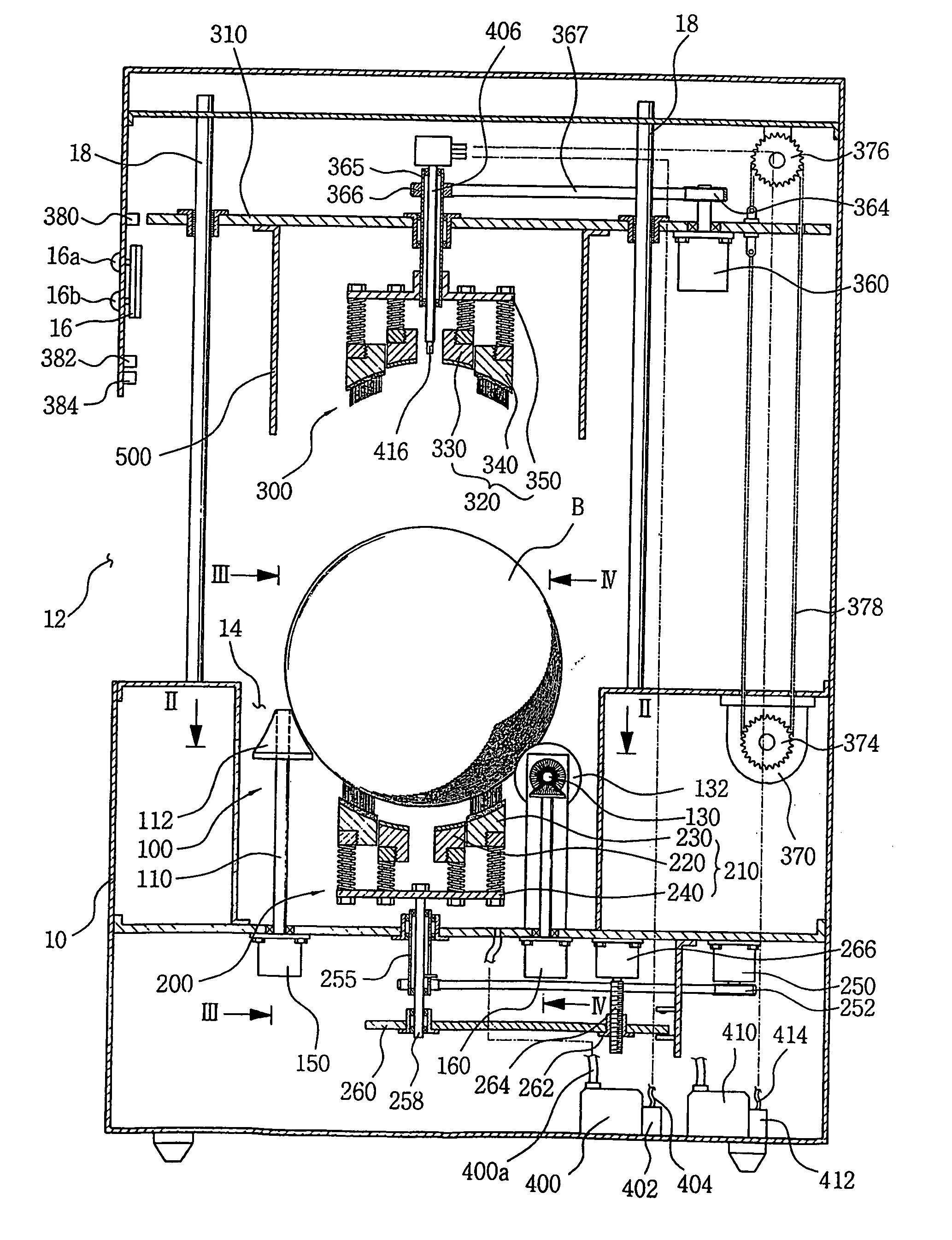

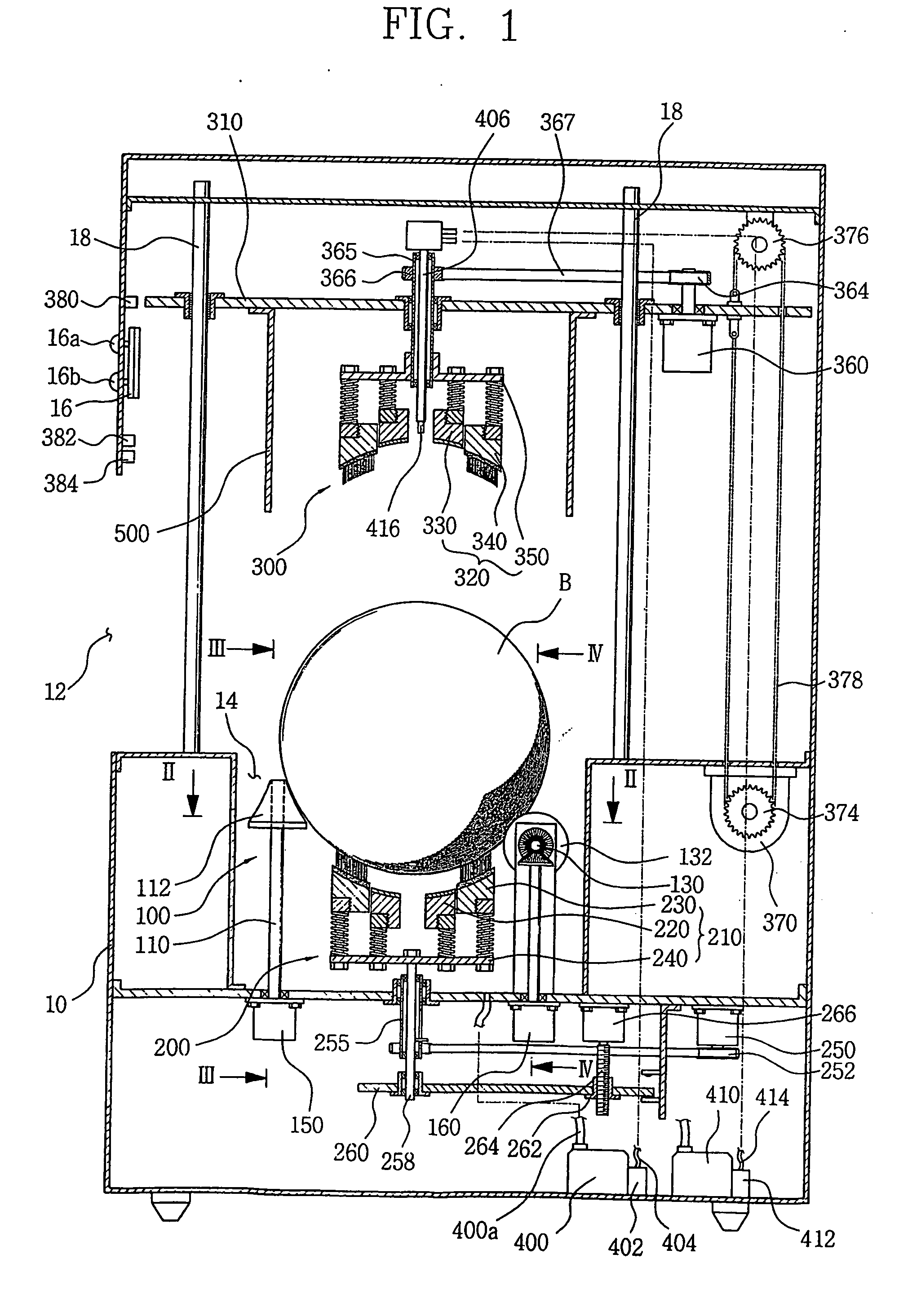

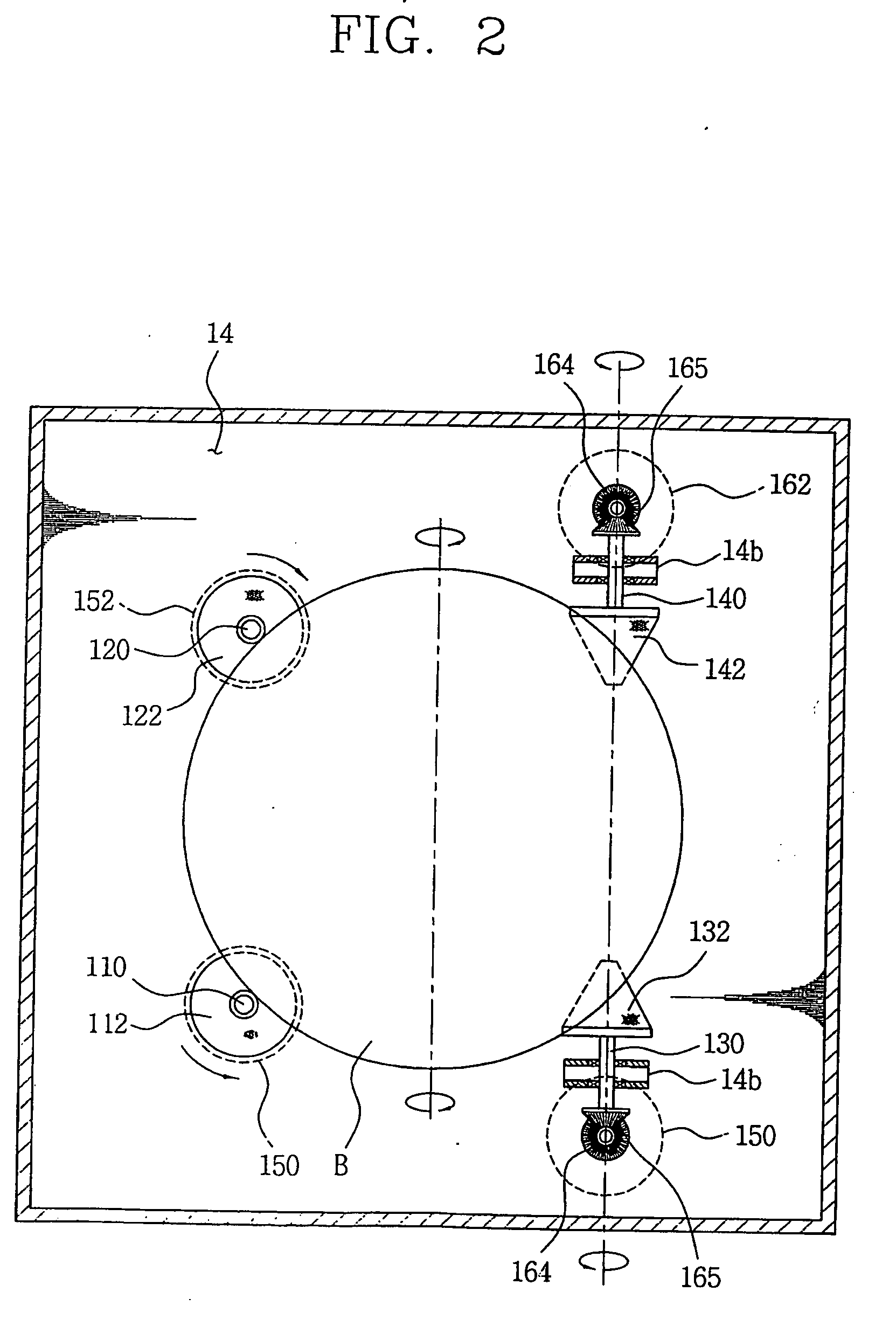

Bowling ball abrader and polisher system and method

InactiveUS7892073B1Consistent and reliable gripBowling gamesCarpet cleanersEngineeringMechanical engineering

A bowling ball abrader and polisher utilizes cooperative rotational inter-engagement between a cup-shaped abrading an polishing tool and a non-motorized rotating ball holder assembly to obtain even, concentric abrasion patterns on a bowling ball surface. Upon placement of a bowling ball in a ball cradling surface formed in the rotating ball holder, application of the rotating abrading and polishing tool on the surface of the bowling ball causes a corresponding rotation of the bowling ball using the non-motorized rotating ball holder, which enables the outer surface of the bowling ball to be more uniformly abraded and polished.

Owner:SMANIA GARY L

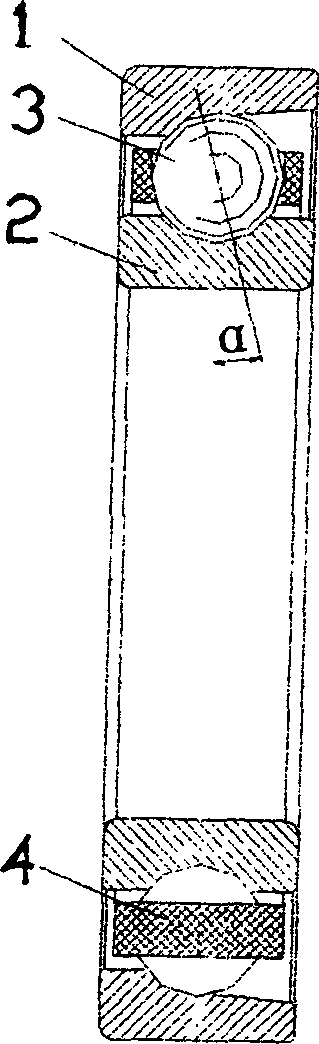

High precision hot press silicon nitride ceramic ball bearing and its manufacturing method

ActiveCN1619171AHigh limit speedImprove running accuracySpherical surface grinding machinesBall bearingsNumerical controlManufacturing technology

A high-precision hot-pressed silicon nitride ceramic ball bearing and its manufacturing method belong to bearing manufacturing technology and are suitable for installation on high-precision, high-speed, high-end CNC machine tools and machining center spindles. The high-precision hot-pressed ball bearing provided by the invention Silicon nitride ceramic ball bearings include: an inner ring and an outer ring made of steel. The inner ring and the outer ring respectively have ball bearing arc raceways; they are arranged between and in contact with the inner and outer ring ball bearing raceways. Ceramic ball rolling elements; a rolling element isolation ring, that is, a cage, arranged between the inner and outer rings to hold the ceramic balls; its characteristic is that the ceramic ball rolling elements are obtained by conical grinding processing technology and technical equipment, and its accuracy is Reached G5 and G3 levels. The characteristics of the invention are: high limit operating speed; high operating accuracy; high temperature resistance and can operate without lubrication; light weight; long-term stable operation in some highly corrosive media; high degree of standardization, easy maintenance and interchange.

Owner:SHENYANG JIANZHU UNIVERSITY

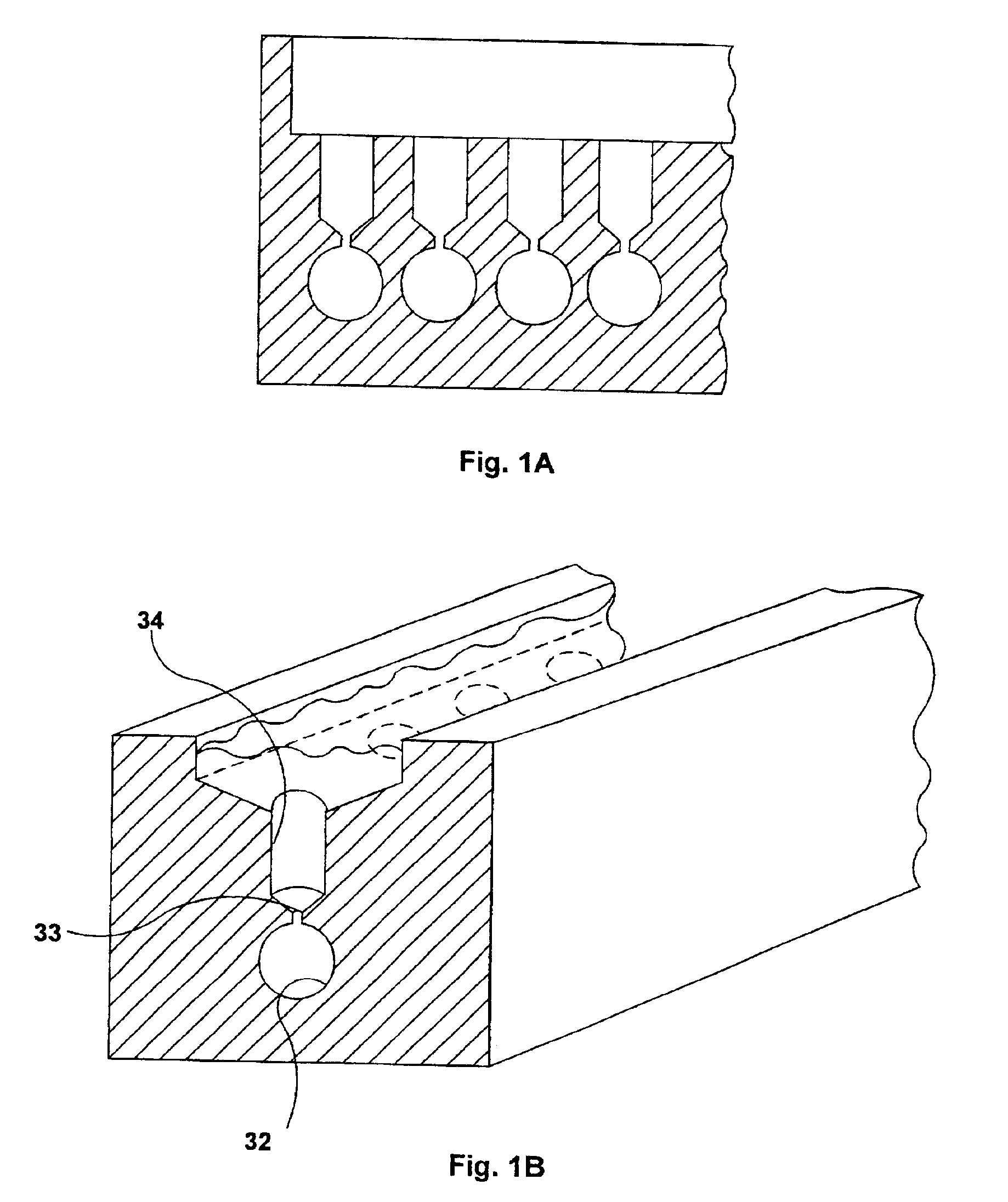

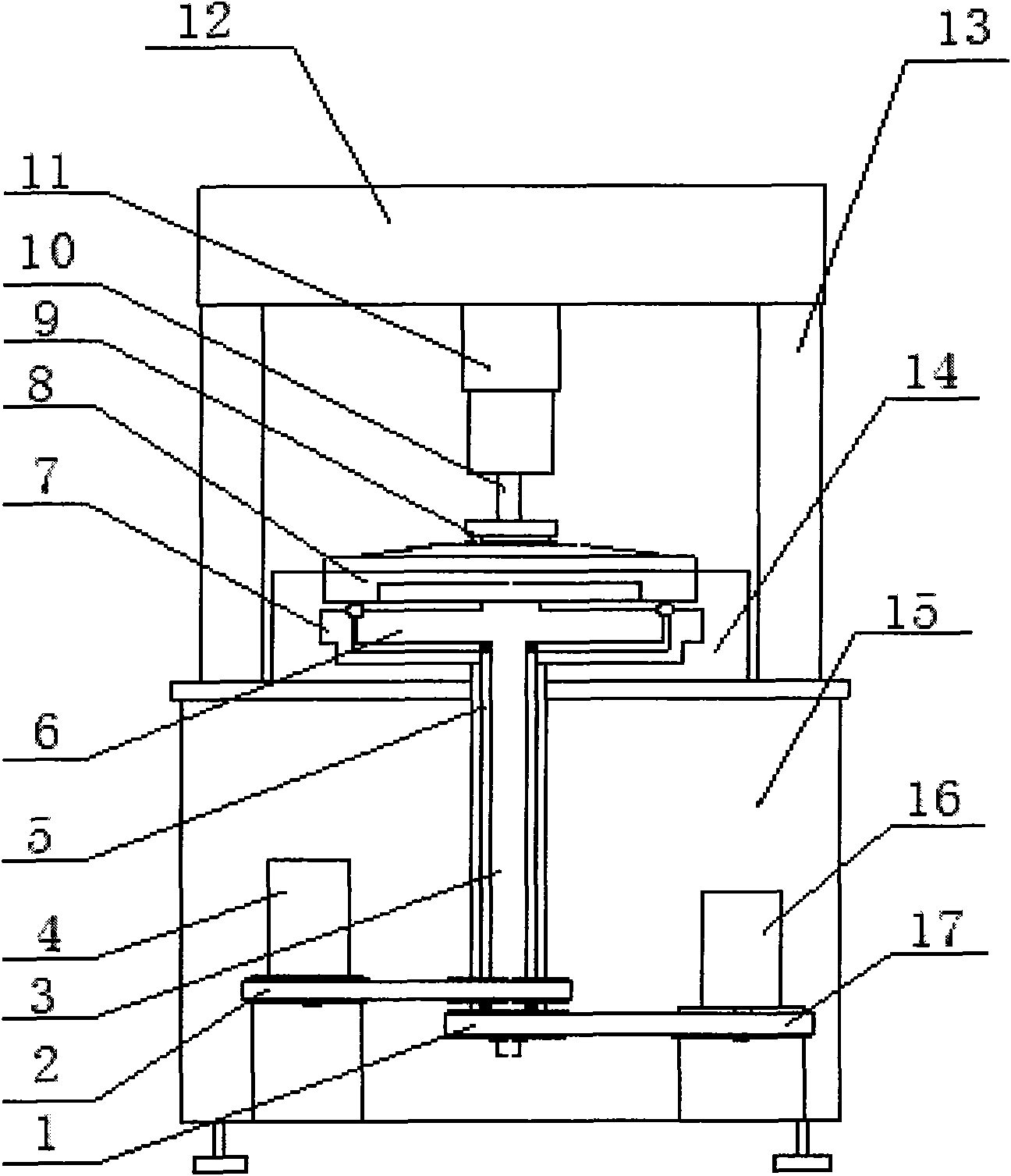

Nitinol ball bearing element and process for making

InactiveUS6886986B1High strengthImprove damping performanceRevolution surface grinding machinesSpherical surface grinding machinesBall bearingConventional casting

A bearing having bearing elements made of Type 60 Nitinol made by an investment casting process for producing near net shape parts of Nitinol includes making a ceramic mold having a series of spherical cavities, pouring molten Nitinol into the mold cavities, cooling the mold and the Nitinol in the cavities to produce solidified Nitinol balls, and breaking the mold away from the Nitinol balls. Nitinol rods for roller bearings can be made by conventional casting directly from the crucible in a draw-down oven. The bars are hot machined or hot rotary swaged and then centerless ground and laser cut to length, or are first cut to length and then centerless ground individually for crowned roller elements. The balls are broken or cut from the risers, leaving the gates attached, and are consolidated by healing under pressure in a hot isostatic press, then ground to the desired size. The balls or rollers are polished, then treated to create an integral ceramic finish. They are then repolished to produce an extremely smooth finish. The balls can also be cut from a sheet or plate of the ball material as cubes or cylinders and processed in an abrasive tumbler to round off the corners and edges, and the rounded cubes or cylinders can hen be ground to spherical form in conventional ball grinder.

Owner:NITINOL TECH

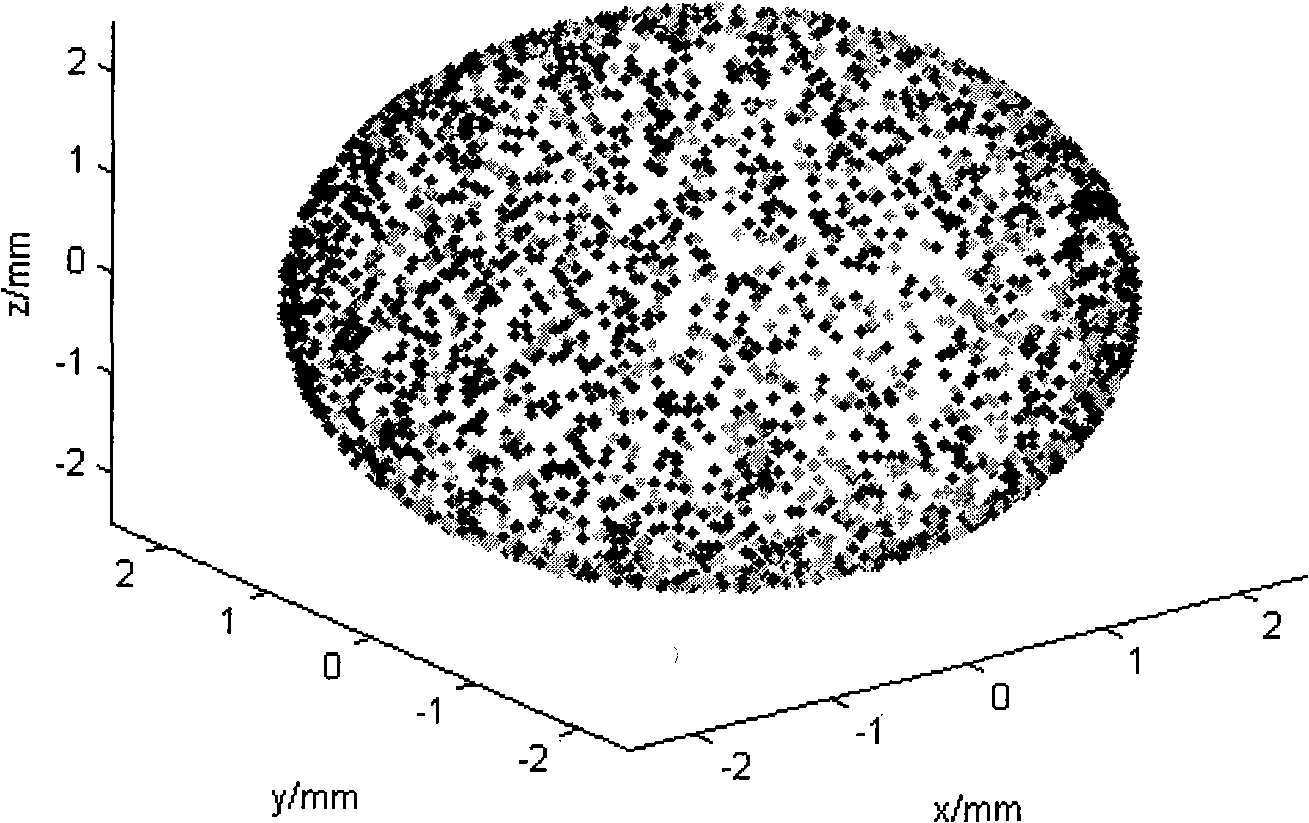

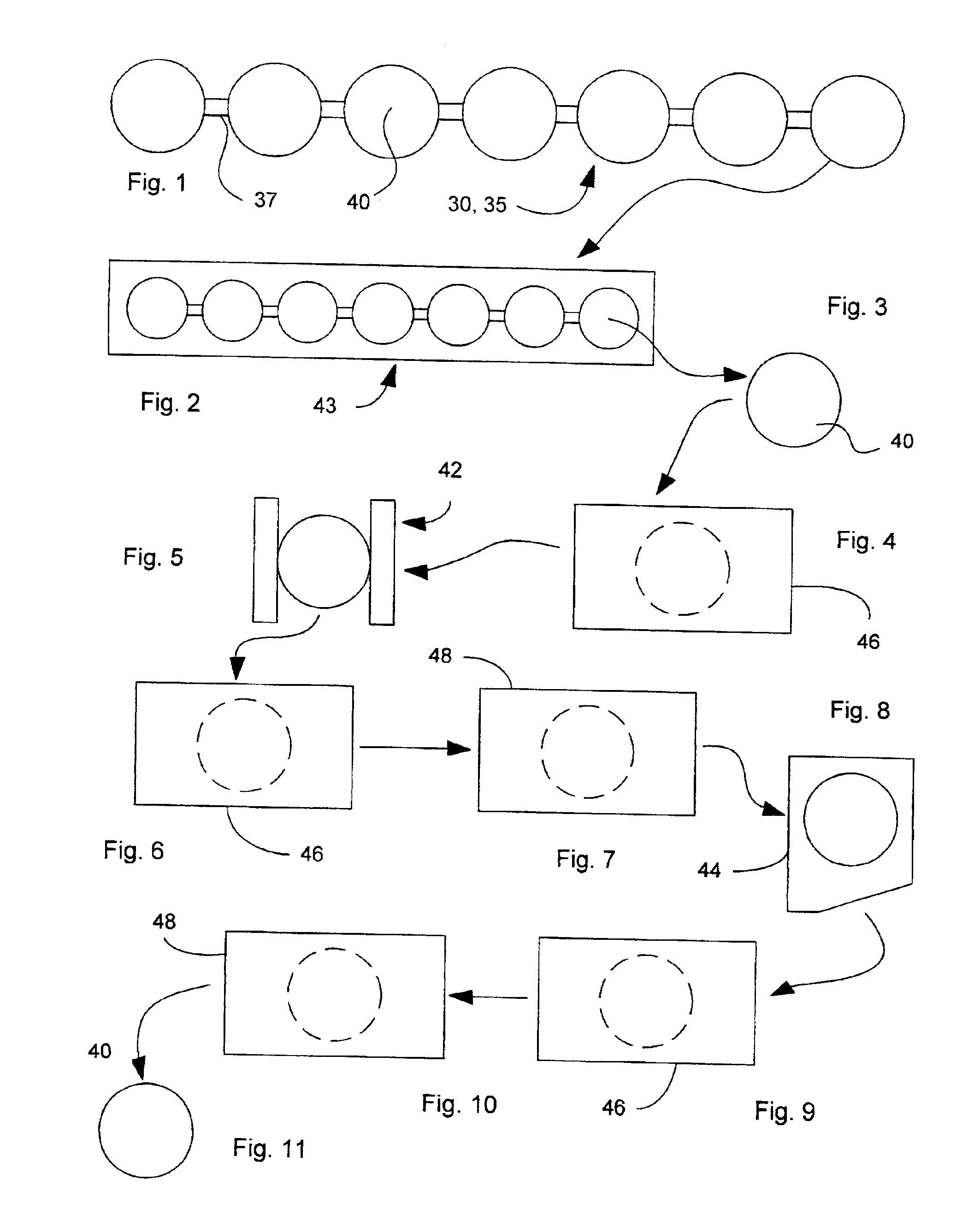

High-precise ball highly-efficient grinding and polishing processing method

InactiveCN101579840AImprove efficiencyImprove machining accuracyPolishing machinesSpherical surface grinding machinesEngineeringElectric motor

The invention discloses a high-precise ball highly-efficient grinding and polishing processing method, in the processing devices for realizing the processing method, a V-shaped groove is formed by a pyramidal face abrasive surface of the outer of an inner plate of a lower grinding plate and a pyramidal face abrasive surface of the inside of an outer plate of the lower grinding plate, a loading pressure device acts on a ball billet through an upper grinding plate, three processing contact points of the grinding ball are formed by the V-shaped groove and the upper grinding plate, the upper grinding plate, the outer plate of the lower grinding plate and the inner plate of the lower grinding plate share a same rotary shaft; a rotating shafts of two plates among the upper grinding plate, the outer plate of the lower grinding plate and the inner plate of the lower grinding plate are driven by an electric motor; relative orientation changing is carried out on a ceramic ball through adjusting the velocity combination of the omega[B] and omega[C], so that the grinding trails are distributed on the face of the ball uniformly, thus grinding the surface of the ceramic ball uniformly. In the invention, the higher processing precision and processing efficiency can be realized, and the processing device has simple structure and low manufacturing cost.

Owner:ZHEJIANG UNIV OF TECH +1

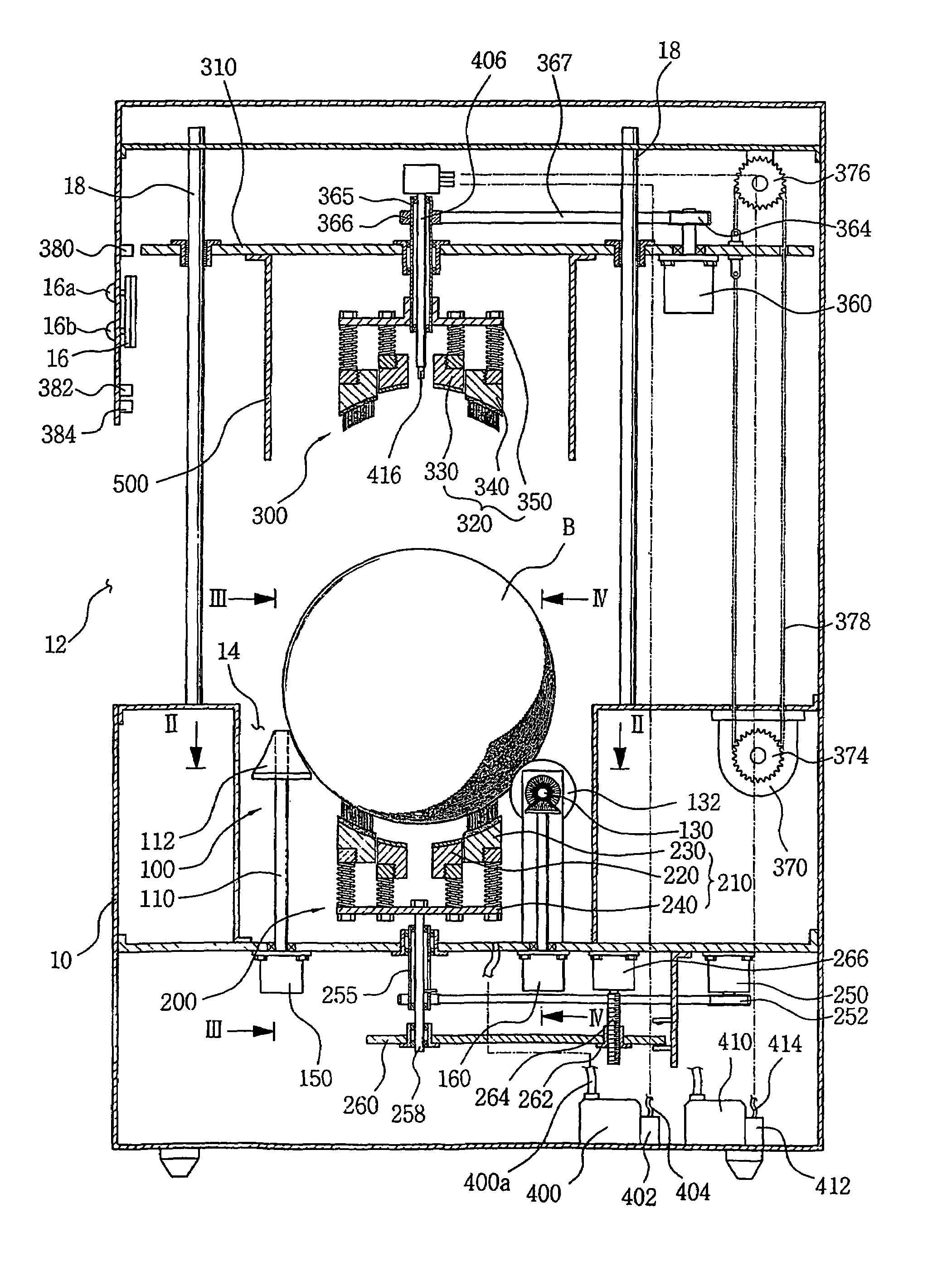

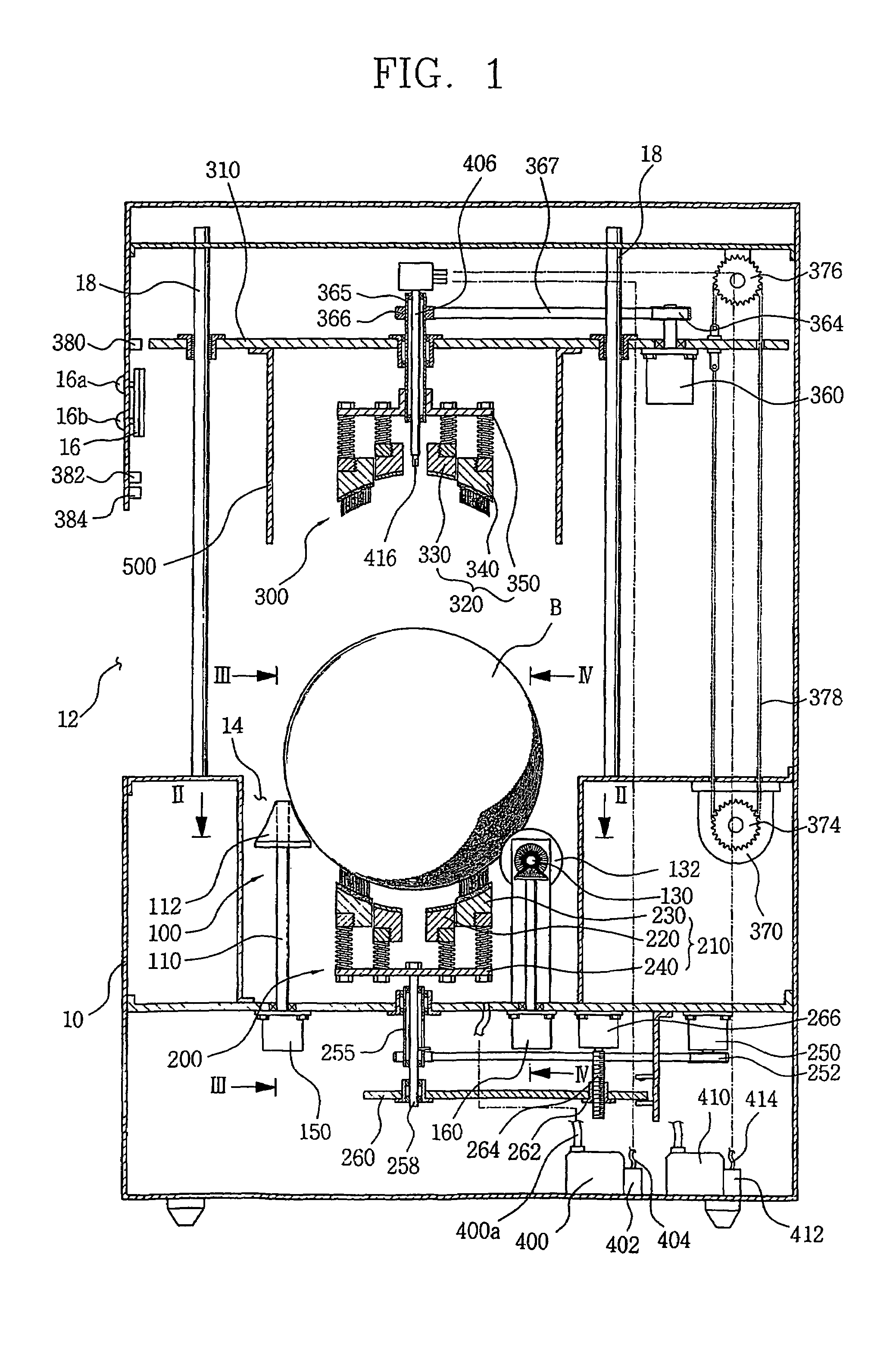

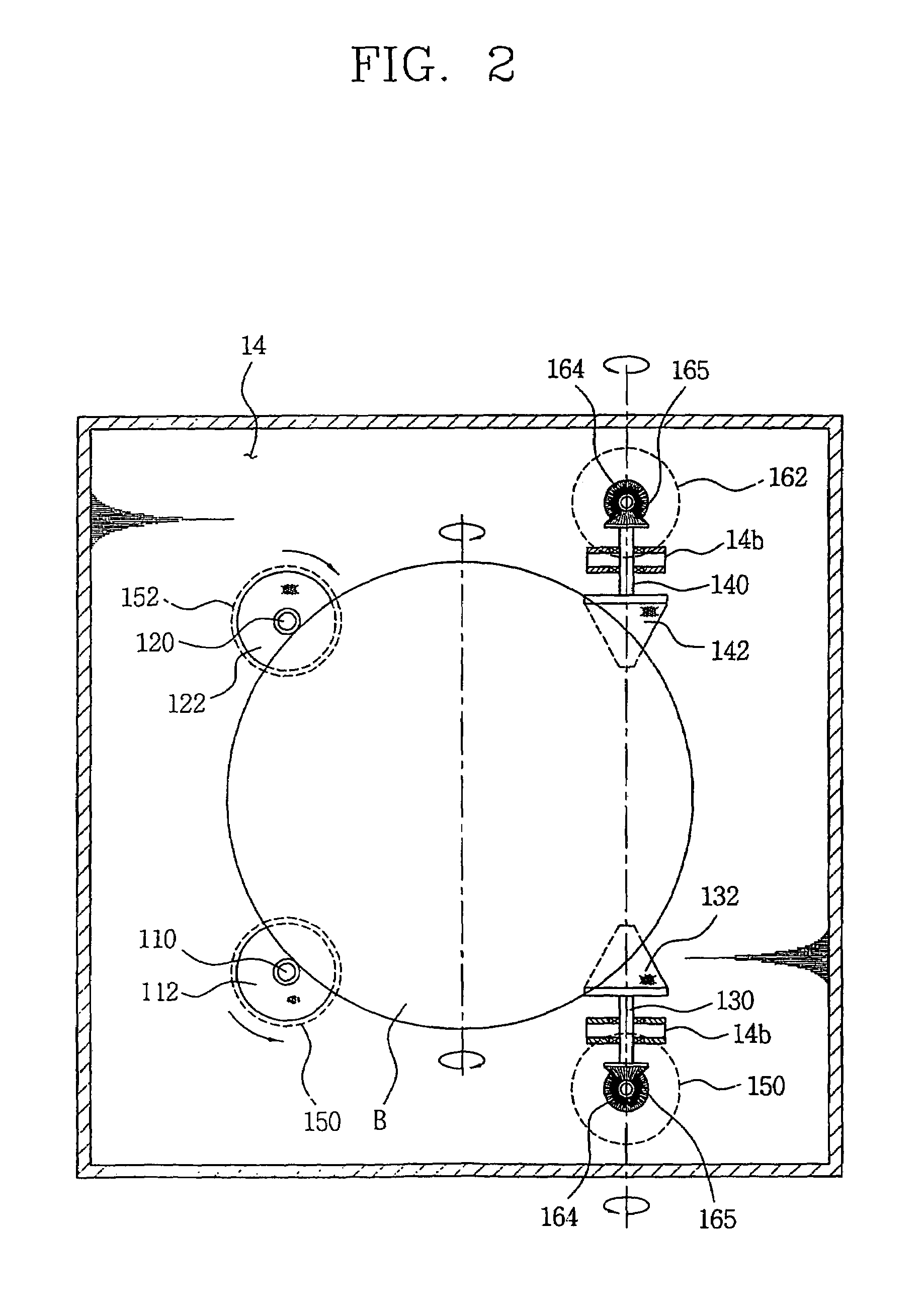

Bowling ball resurfacing apparatus

A bowling ball resurfacing apparatus comprises a housing, first and second vertical support rollers mounted to the housing for rotation about parallel vertical axes, each of the vertical support rollers adapted to make contact with the surface of the bowling ball at one lateral bottom side of the bowling ball, first and second horizontal support rollers mounted to the housing for supporting the bowling ball in cooperation with the vertical support rollers, each of the horizontal support rollers rotatable about horizontal axes and adapted to make contact with the surface of the bowling ball at the other lateral bottom side of the bowling ball, drive motors for causing the support rollers to rotate, and a grinding-and-polishing wheel assembly for making frictional contact with the surface of the bowling ball to grind or polish the bowling ball.

Owner:SIM SANG BAE

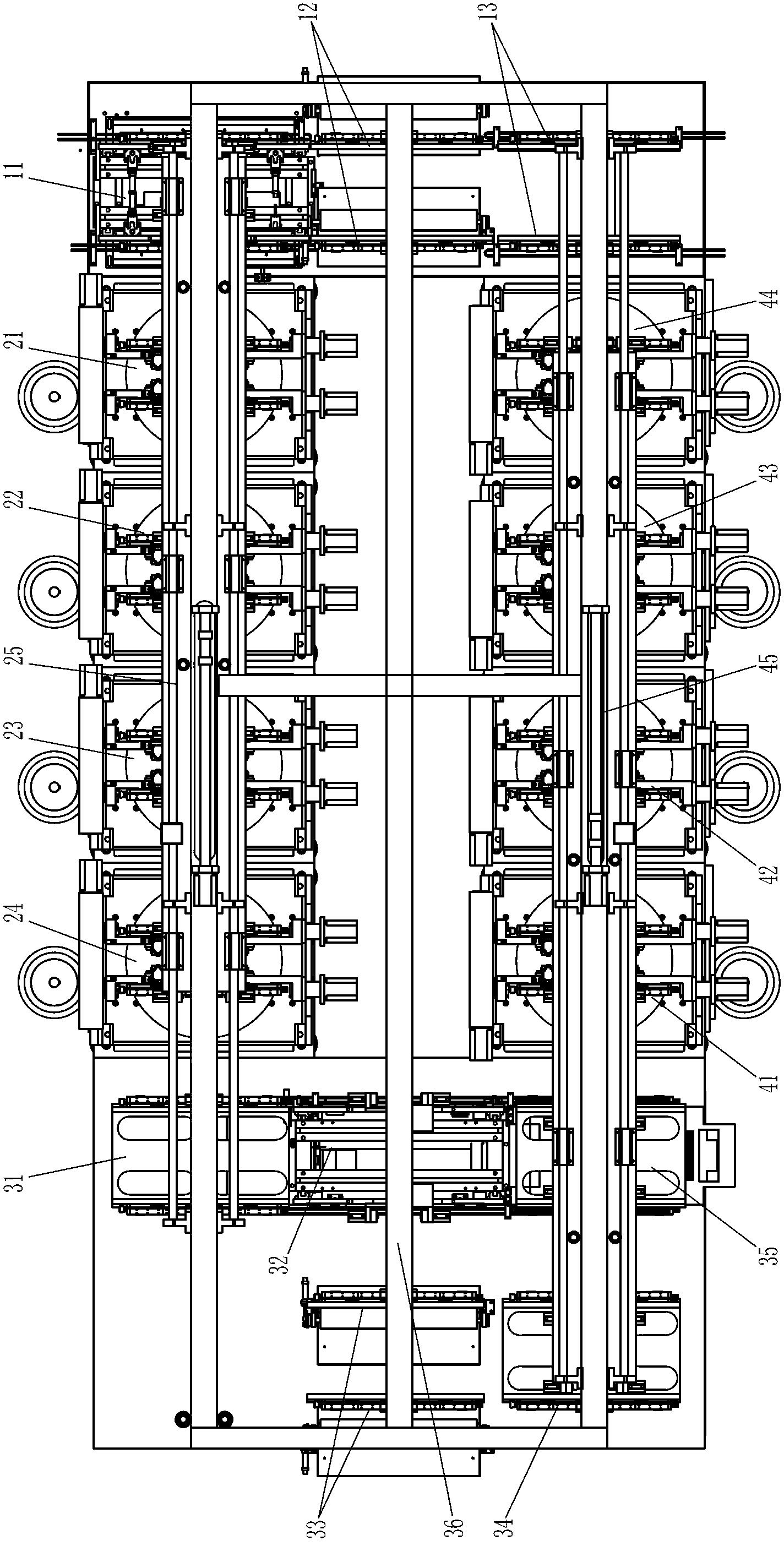

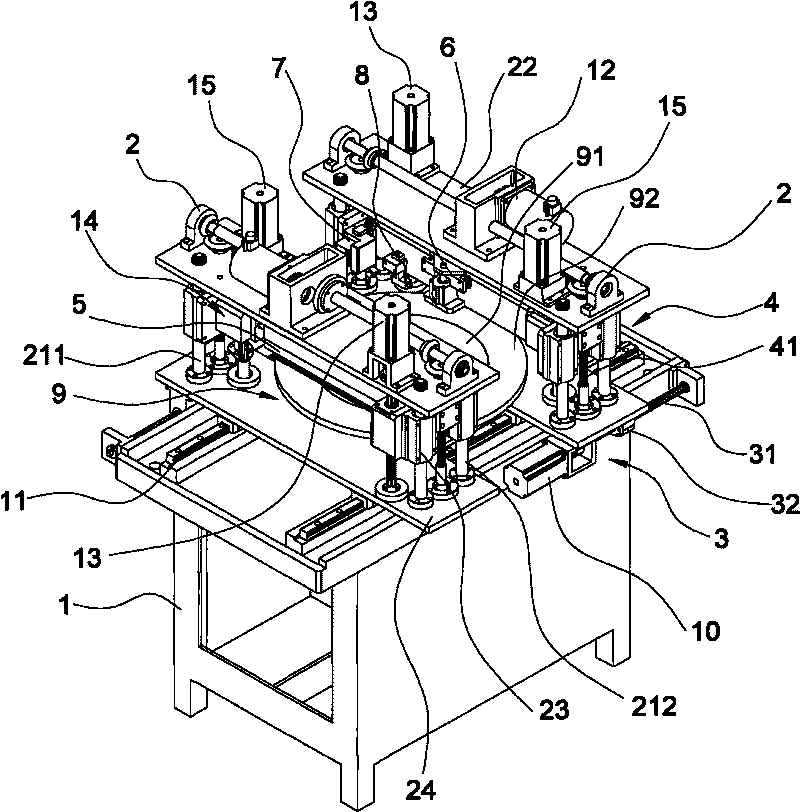

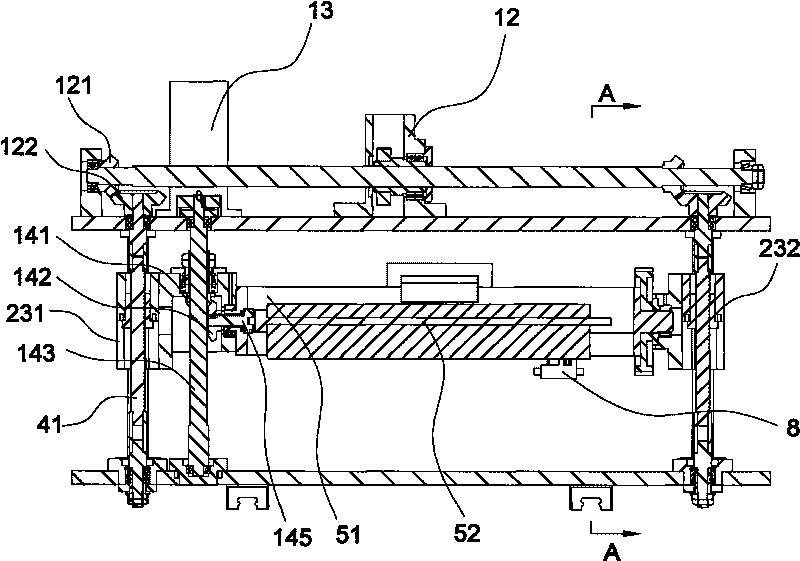

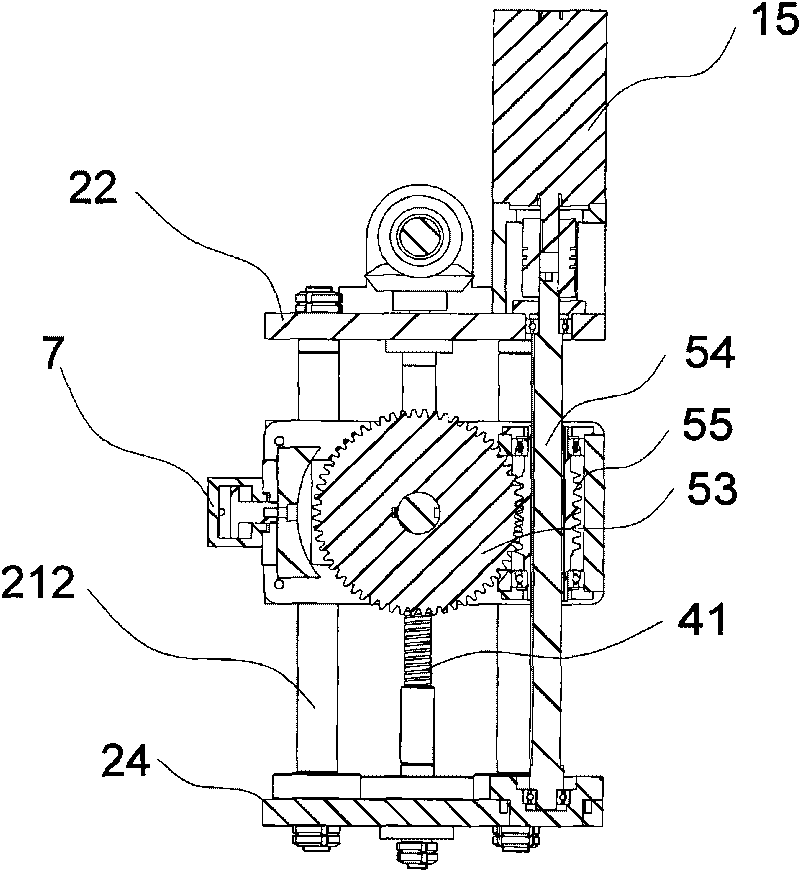

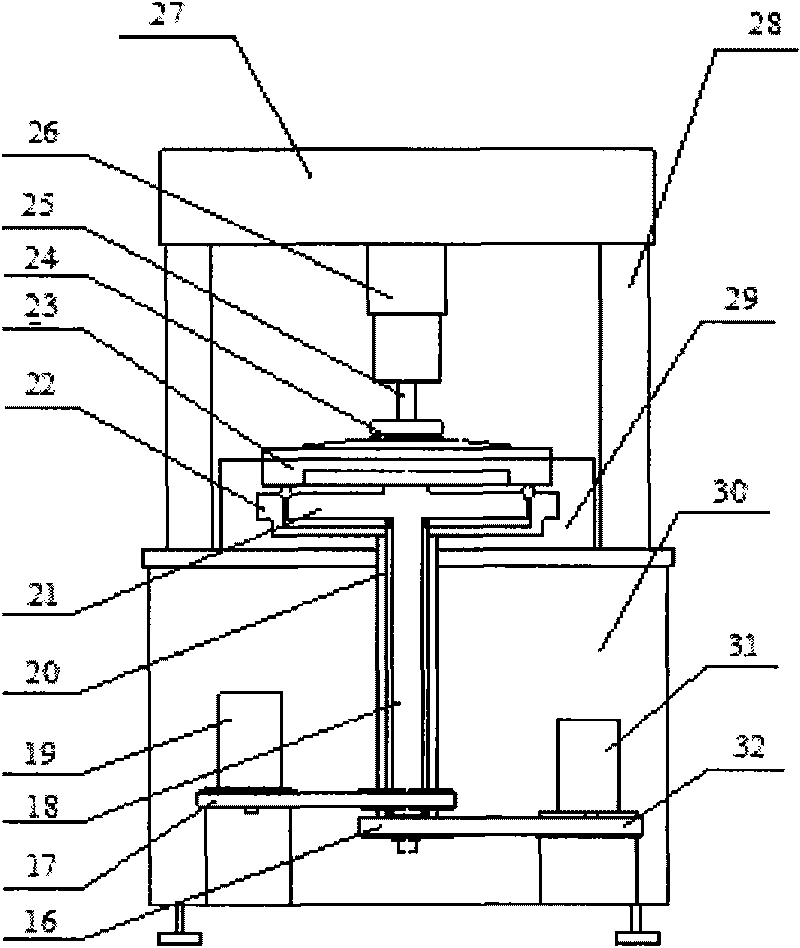

Crystal blank automatic grinding and polishing system, grinding and polishing machine and auxiliary machine thereof

InactiveCN102248460ASimplify the complexity of the actionGuarantee the quality of grinding and polishingEdge grinding machinesPolishing machinesEngineeringTransfer mechanism

The invention relates to a crystal blank automatic grinding and polishing system. The system comprises a first rotating stand, a second rotating stand, a loading station, a butting station, an unloading station, at least one first transfer mechanism and at least one second transfer mechanism, wherein the first rotating stand is provided with an upper semi-sphere grinding station and a polishing station, and a nose is arranged on the first rotating stand; the second rotating stand is provided with a lower semi-sphere grinding station and a polishing station, and a nose is arranged on the second rotating stand; the first transfer mechanism can pick up and release a clamp, and can transfer the clamp among the feeding station, the butting station and the nose on the first rotating stand; and the second transfer mechanism can pick up and release the clamp, and can transfer the clamp among the butting station, the discharge station and the nose on the second rotating stand. The invention also discloses a grinding and polishing machine and an auxiliary machine used by the system. By utilizing the technical scheme, the upper and the lower semi-sphere inclined planes of a crystal blank canbe automatically ground and polished to ensure the quality of grinding and polishing processing, and the advantages of the machine models can be sufficiently utilized to simplify the complex degree of the mechanism action. The crystal blank automatic grinding and polishing system, the polishing machine and the auxiliary machine are easy to manufacture and maintain.

Owner:虞雅仙

Efficient grinding/polishing process of high-precision ceramic balls

InactiveCN101704208AImprove grinding precisionImprove grinding efficiencyPolishing machinesOther chemical processesProcess equipmentMaterials science

The invention relates to an efficient grinding / polishing process of high-precision ceramic balls, which comprises the following steps: (1) rough grinding; (2) semi-finish grinding; (3) finish grinding; (4) super-finish grinding; and (5) polishing, wherein a double-disc self-rotating eccentric V-shaped slot grinding machine is adopted in the steps (1)-(2), and a grinding machine with double self-rotating grinding discs is adopted in the steps (3)-(5). In the invention, not only can higher processing accuracy and processing efficiency be realized, but also processing equipment has simple structure, and the manufacturing cost is lower.

Owner:ZHEJIANG UNIV OF TECH +1

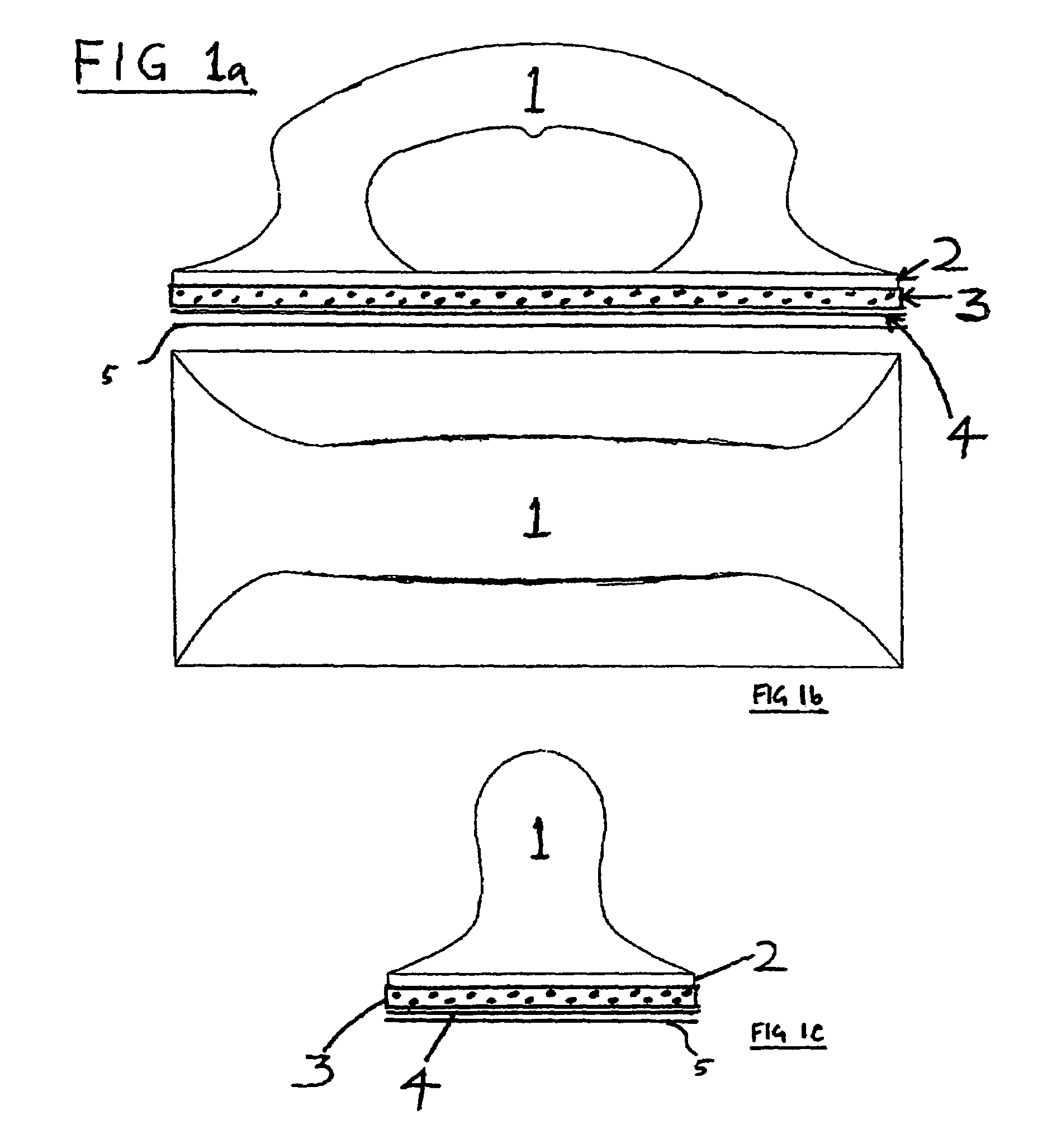

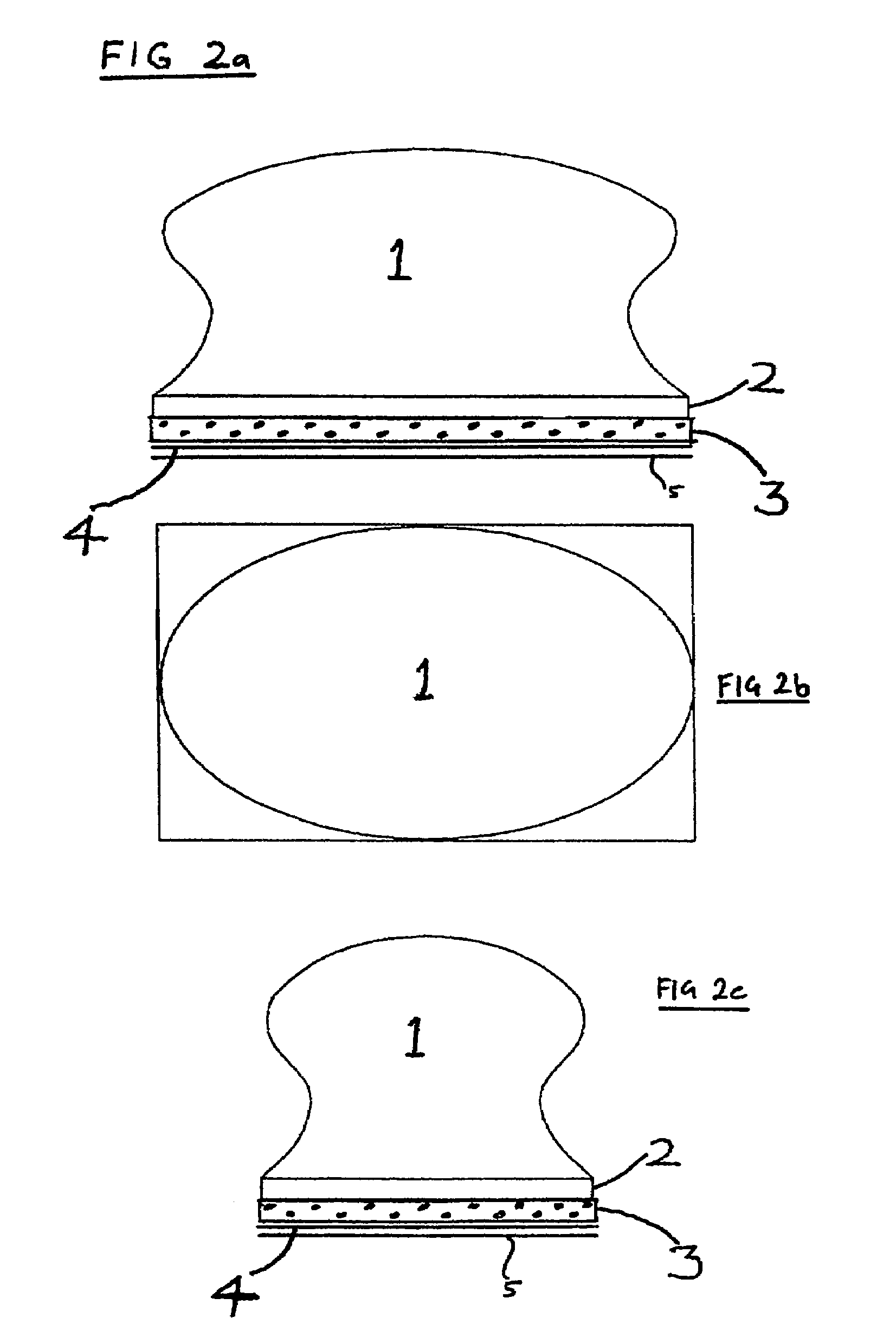

Abrasive holder

An abrasive tool comprising of a base portion (2), having a foam layer (3) affixed to the abrasive tool base portion, and a plastic film layer (4) affixed, bonded or glued to the foam layer. This tool is adapted to receive an abrasive material layer (5) or sand paper or other abrasive material having a pressure sensitive adhesive applied to one side of the abrasive material, to allow said abrasive material to be stuck and affixed to the abrasive tool. The abrasive tool may be hand operated, or operated by electric power, air power, or other motive power.

Owner:RED DEVIL SANDFAST

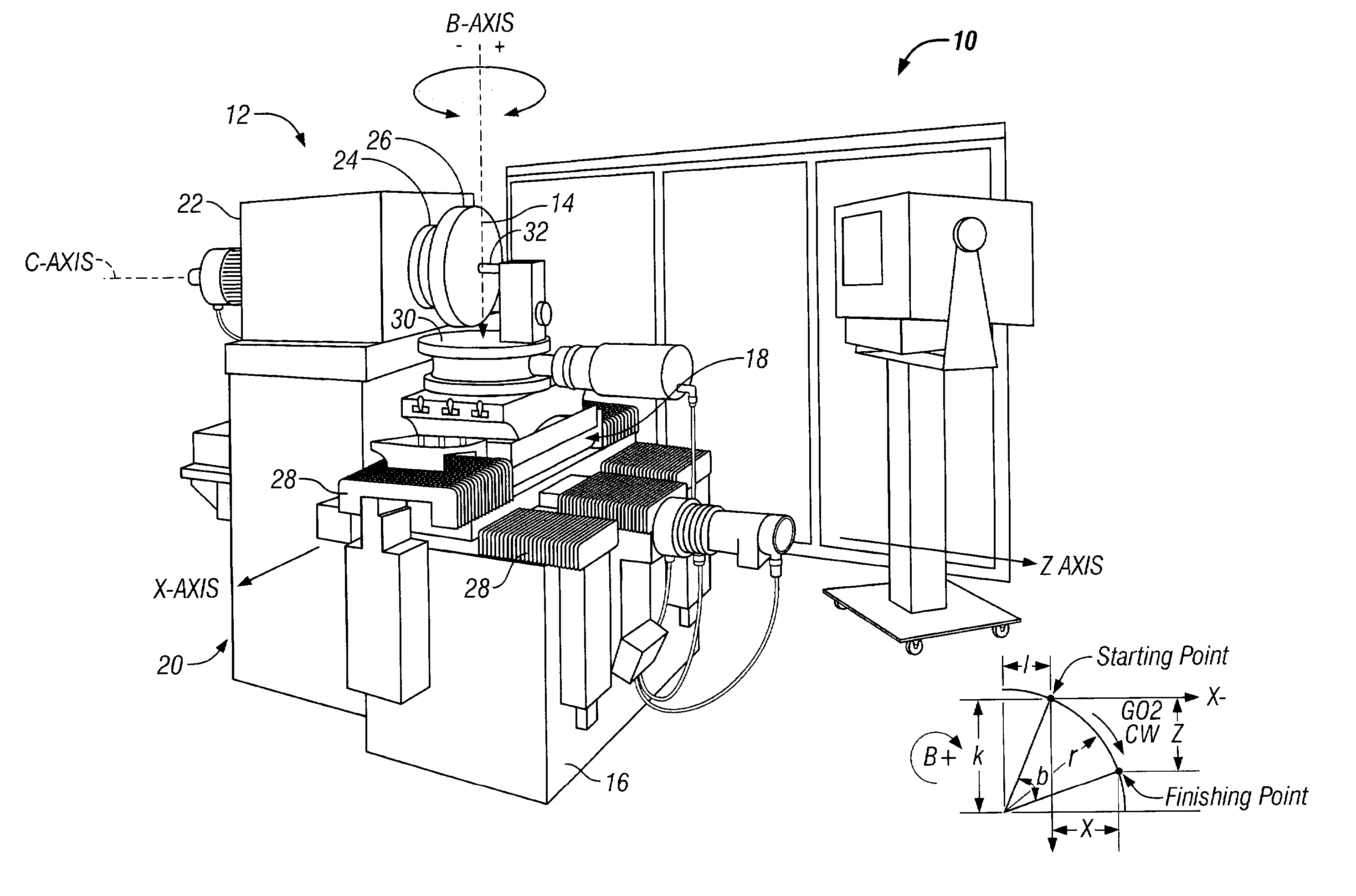

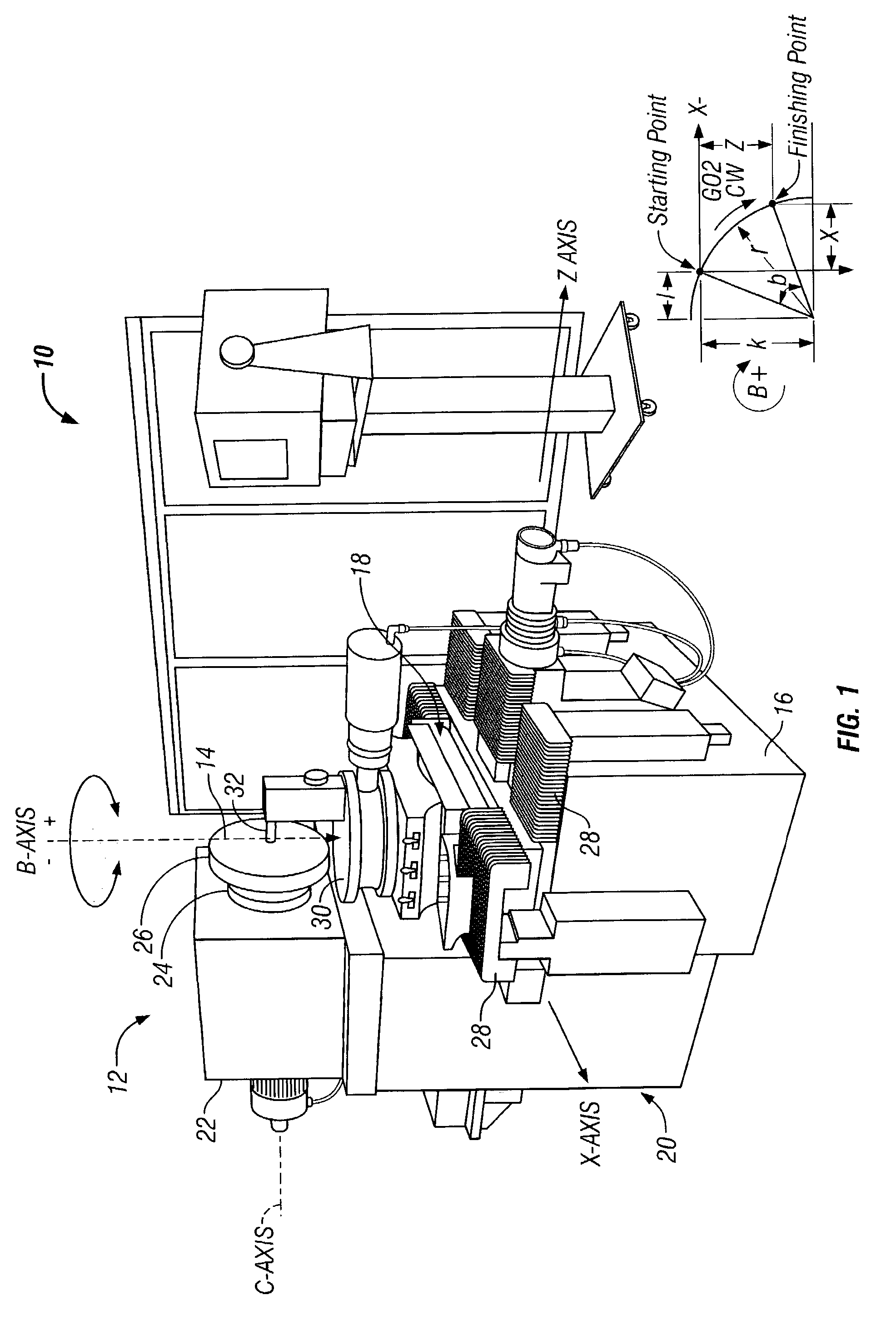

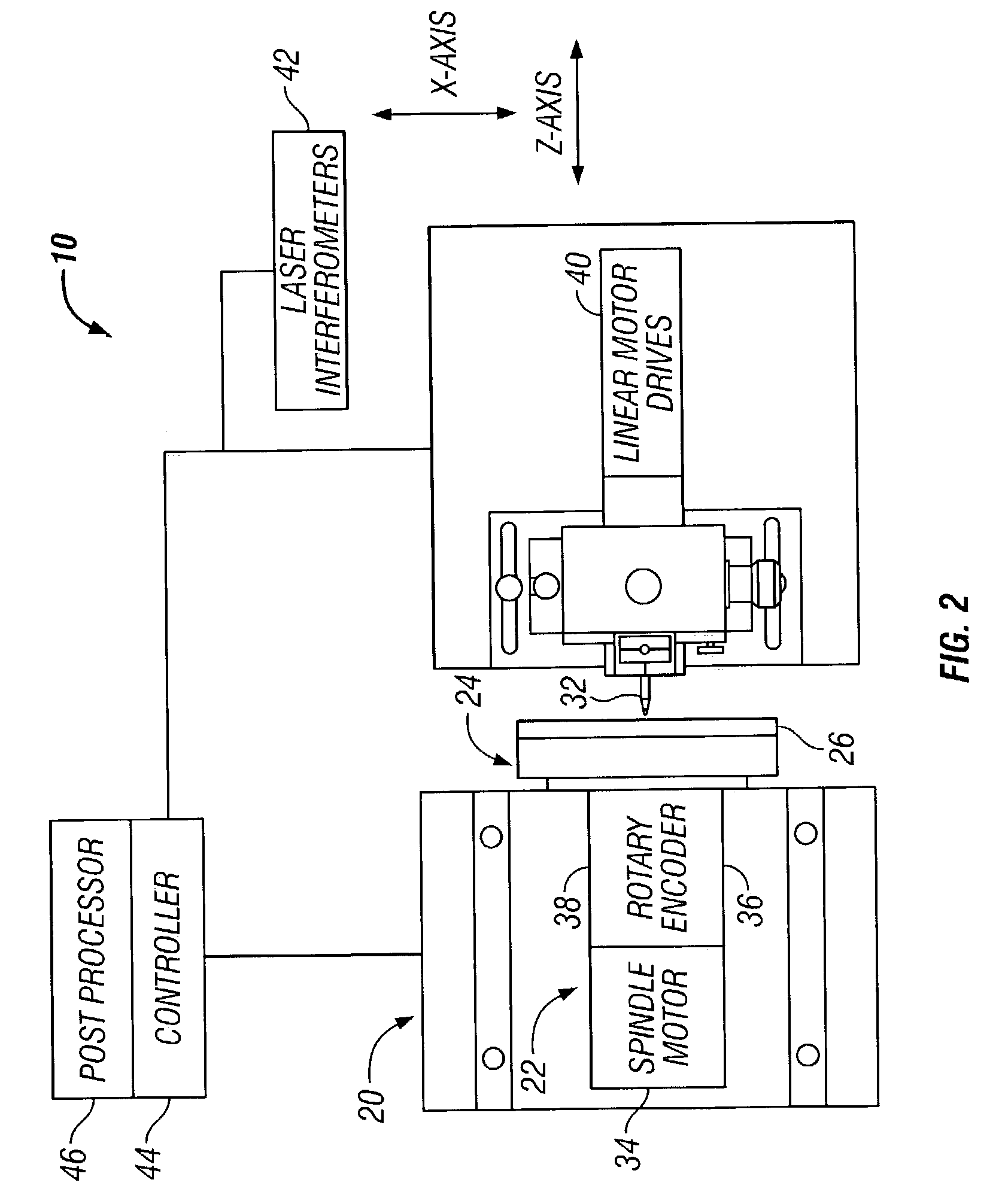

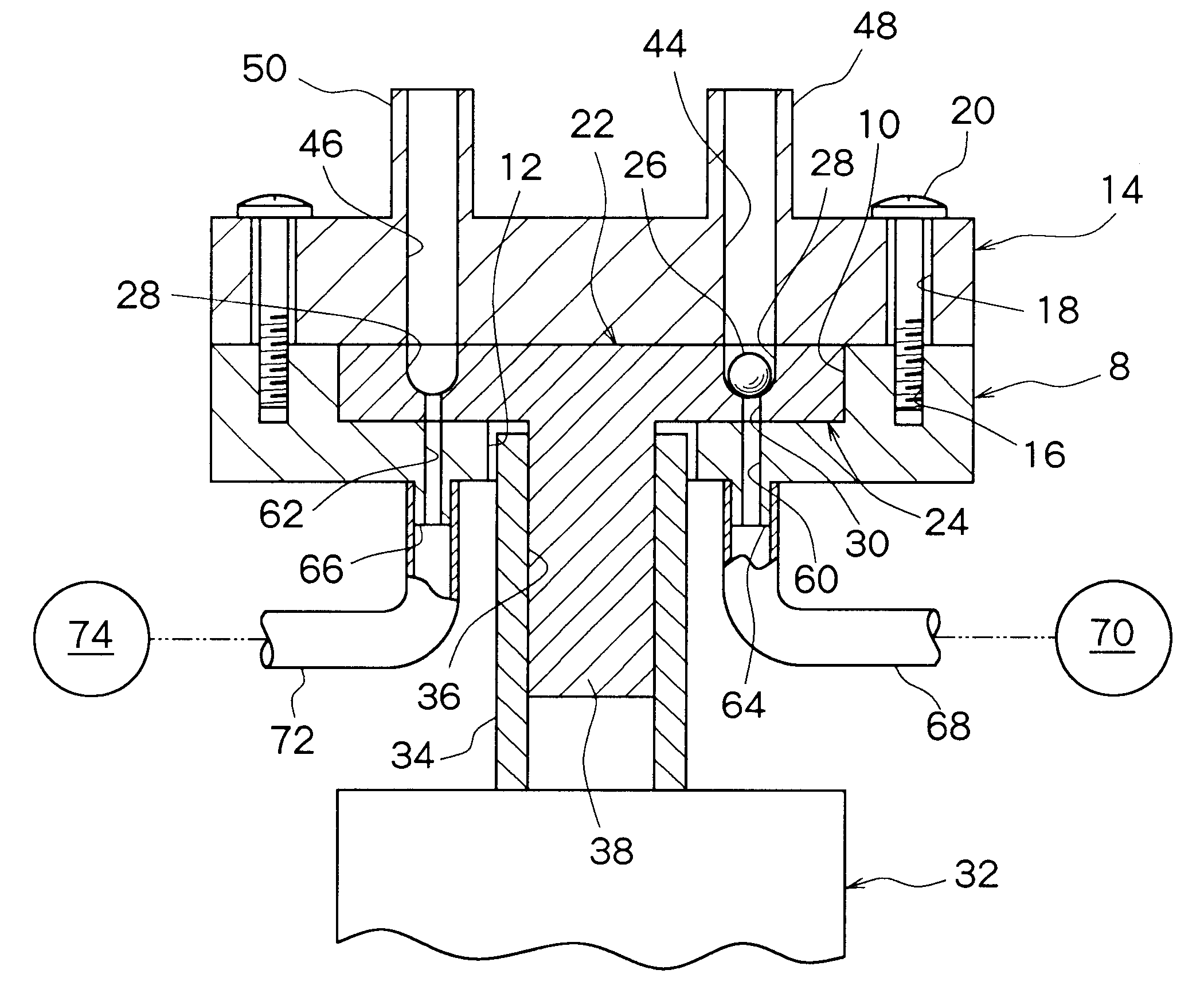

System and method for forming a non-rotationally symmetric portion of a workpiece

A method and control system for forming workpiece surfaces with at least a portion being non-rotationally symmetric (i.e., axis asymmetric) is provided. In one aspect, a slow tool servo system is provided to fabricate a surface having at least an axis asymmetric portion, and optionally, a superimposed axis symmetric asphere or spherical portion. A workpiece is mounted on a spindle and a tool is mounted to a translatable tabletop surface. The z position of the contact point of the workpiece and working tool is determined as a function of the x position of the same contact point and as a function of the angle of rotation of the spindle about the spindle axis. By making the z position of the contact point a function of both the angle of spindle rotation and the x position, the lateral and longitudinal position of the working tool can be moved at designated spindle rotation angles to form a surface having both axis asymmetric and axis symmetric asphere or spherical portions.

Owner:OMNIVISION TECH INC

Spherical body transport apparatus

A spherical body transport apparatus applicable in accepting a small spherical body, such as a spherical semiconductor, from a first spherical body treating device and feeding it to a second spherical body treating device. Such a spherical body transport apparatus includes a spherical body holding component having at least one spherical body accommodating component and designed to hold a spherical body temporarily, a spherical body carry-in component for carrying the spherical body into the spherical body accommodating component of the spherical body holding component, and a spherical body carry-out component for carrying the spherical body out of the spherical body accommodating component of the spherical body holding component.

Owner:DISCO CORP

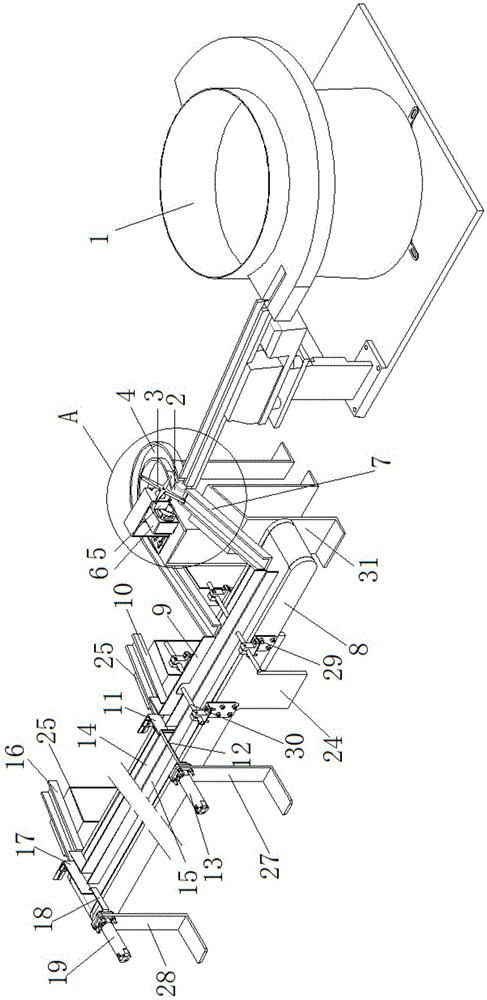

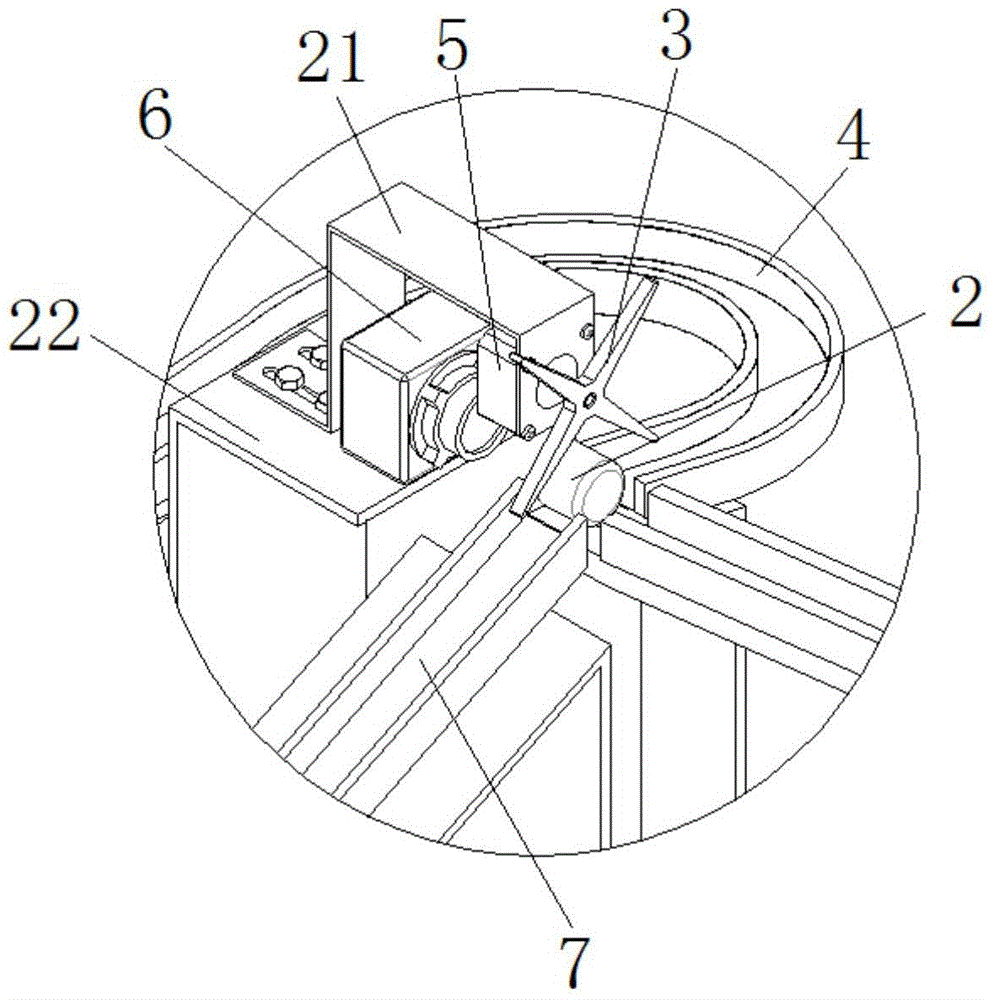

Automatic feeding device of spherical rollers

ActiveCN105523366AAvoid scatterSimple structureConveyorsSpherical surface grinding machinesMotor driveEngineering

The invention discloses an automatic feeding device of spherical rollers. The automatic feeding device comprises a vibration disc mechanism and a conveying mechanism, and further comprises a material distributing mechanism and a pushing mechanism; in the material distributing mechanism, an industrial camera is used for detecting and identifying the orientations of the end faces of the spherical rollers, and a stepping motor drives a material pulling blade to pull the spherical rollers with different orientations into different sliding ways; a material distributing spiral sliding way and a material distributing straight sliding way are used for conveying the spherical rollers to corresponding material ways of a belt conveyor, and the belt conveyor is divided by a baffle into two conveying material ways which correspond to two roller grinding machines; and in the pushing mechanism, telescoping mechanisms are installed in front of feeding openings of the grinding machines and used for pushing the spherical rollers into the feeding openings of the grinding machines. By means of the automatic feeding device, the end faces of the rollers can be automatically identified, the rollers can be sequentially conveyed to the grinding machines, the requirement for machining the spherical rollers in different specifications is met, materials can be supplied by one automatic feeding device to the two grinding machines to work, scattering of the rollers can be prevented through the arrangement of the different material ways, and the production efficiency is improved.

Owner:南通大学技术转移中心有限公司

Bowling ball resurfacing apparatus

A bowling ball resurfacing apparatus comprises a housing, first and second vertical support rollers mounted to the housing for rotation about parallel vertical axes, each of the vertical support rollers adapted to make contact with the surface of the bowling ball at one lateral bottom side of the bowling ball, first and second horizontal support rollers mounted to the housing for supporting the bowling ball in cooperation with the vertical support rollers, each of the horizontal support rollers rotatable about horizontal axes and adapted to make contact with the surface of the bowling ball at the other lateral bottom side of the bowling ball, drive motors for causing the support rollers to rotate, and a grinding-and-polishing wheel assembly for making frictional contact with the surface of the bowling ball to grind or polish the bowling ball.

Owner:SIM SANG BAE

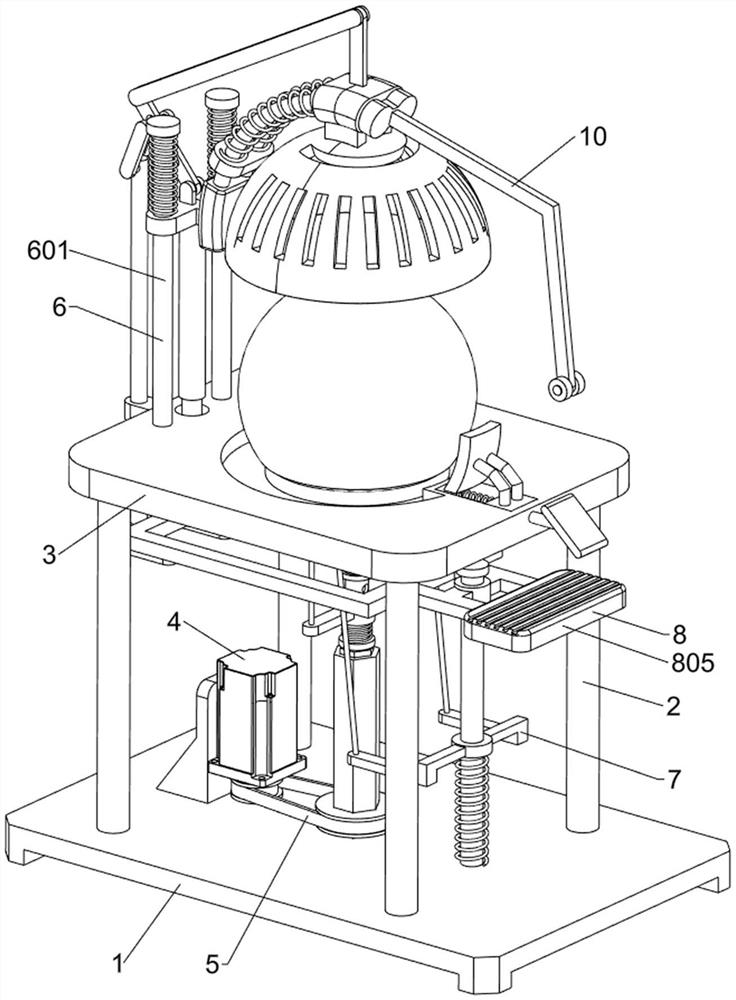

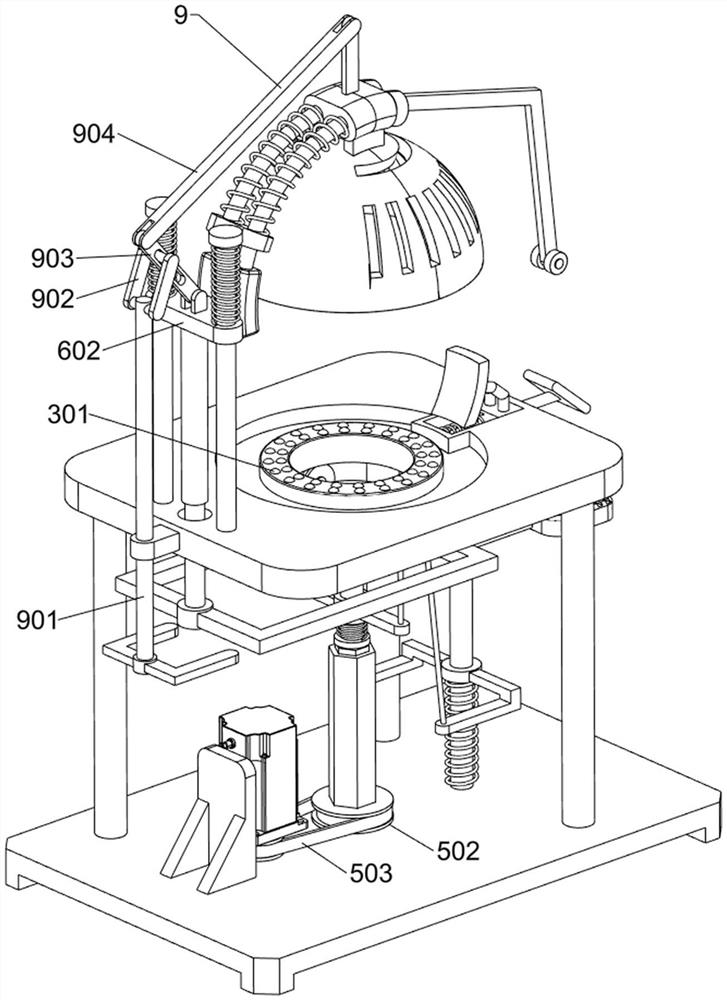

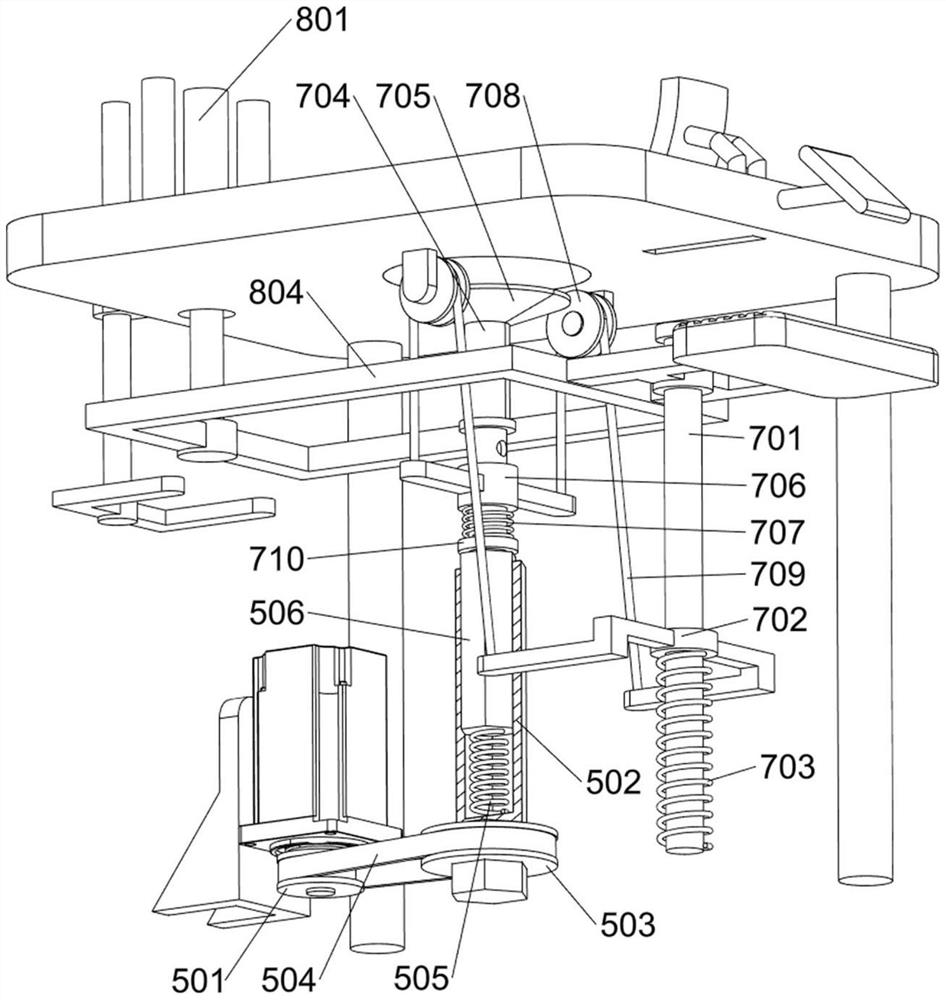

High-gravity-center and super-hemisphere multi-attachment polishing device

The invention relates to a polishing device, in particular to a high-gravity-center and super-hemisphere multi-attachment polishing device. The technical problem of the invention is to provide the high-gravity-center and super-hemisphere multi-attachment polishing device which is capable of rotating a high-gravity-center super-hemisphere and polishing the high-gravity-center super-hemisphere onlyby attaching a polishing tool to the high-gravity-center super-hemisphere. According to the technical scheme, the high-gravity-center super-hemisphere multi-attachment polishing device comprises a bottom plate, a workbench and balls, wherein supporting rods are arranged at the front side and the rear side of the top of the bottom plate in a bilateral symmetry mode; the workbench is connected between the tops of the supporting rods; and the balls are rotatably arranged in the middle of the top of the workbench. Through cooperation of a driving component and a rotating component, the high-gravity-center super-hemisphere can be continuously rotated, and therefore the high-gravity-center super-hemisphere can be polished; and through cooperation of a polishing component and a second polishing block, all the surfaces, except the bottom, of the high-gravity-center super-hemisphere can be polished to be smooth.

Owner:山东沂南园区开发建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com