Patents

Literature

1023 results about "Spherical body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intervertebral nucleus prosthesis and surgical procedure for implanting the same

InactiveUS7037340B2Restores balanced positionControl developmentJoint implantsSpinal implantsFree rotationProsthesis

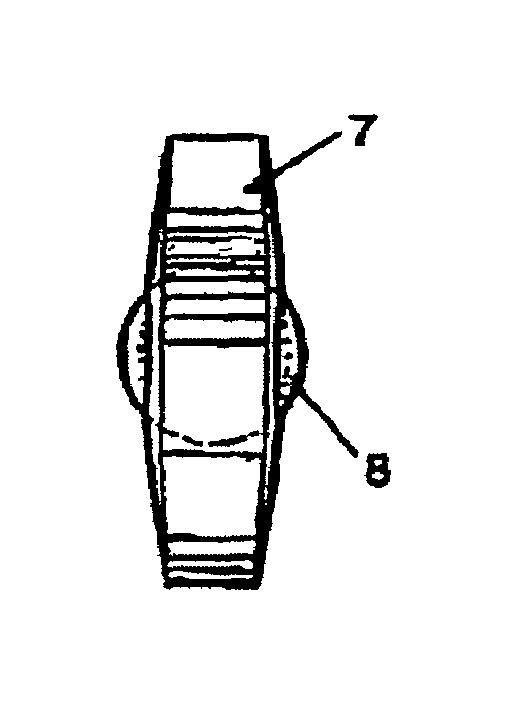

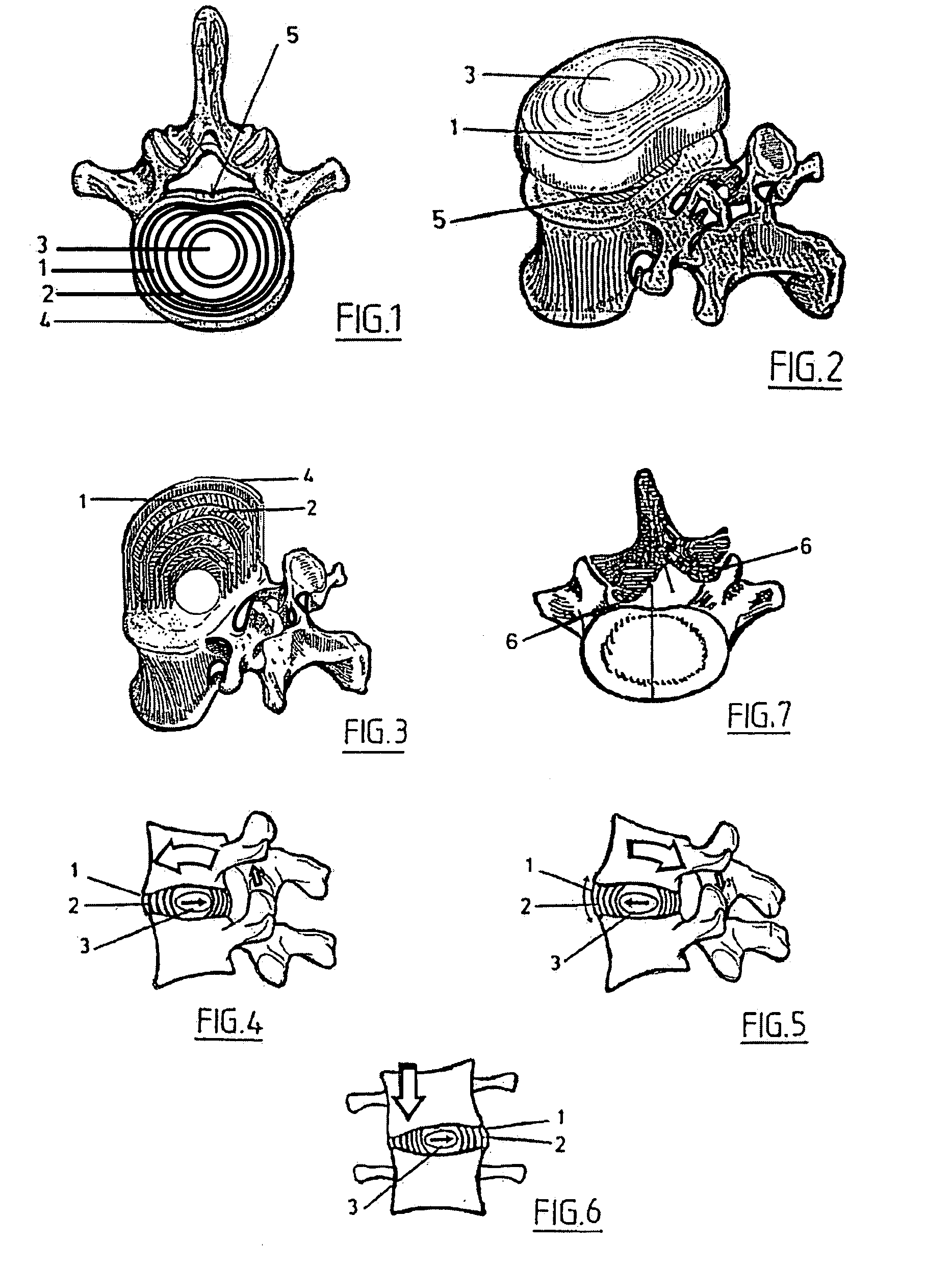

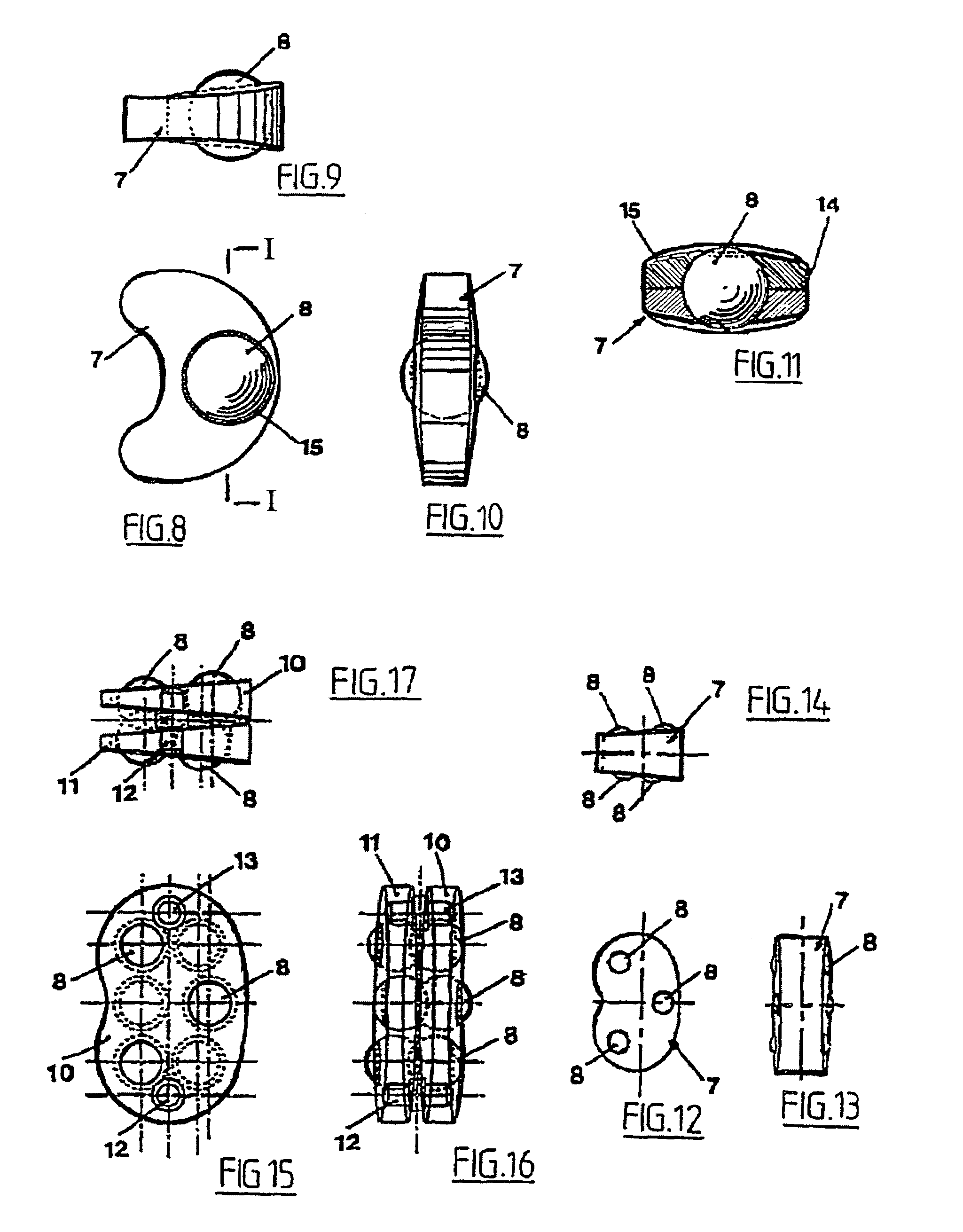

An intervertebral nucleus prosthesis characterized in that it consists of at least one, in particular, spherical body movable in two directions of a plane and made of a rigid, non-oxidizing, biocompatible material with a diameter adapted to the biological nucleus, the spherical body being mounted non-displaceably but freely rotatably about its center in a cage and protruding at both opposite sides of said cage in the form of a spherical caps. Also proposed is a method for implanting such a prosthesis.

Owner:LDR MEDICAL

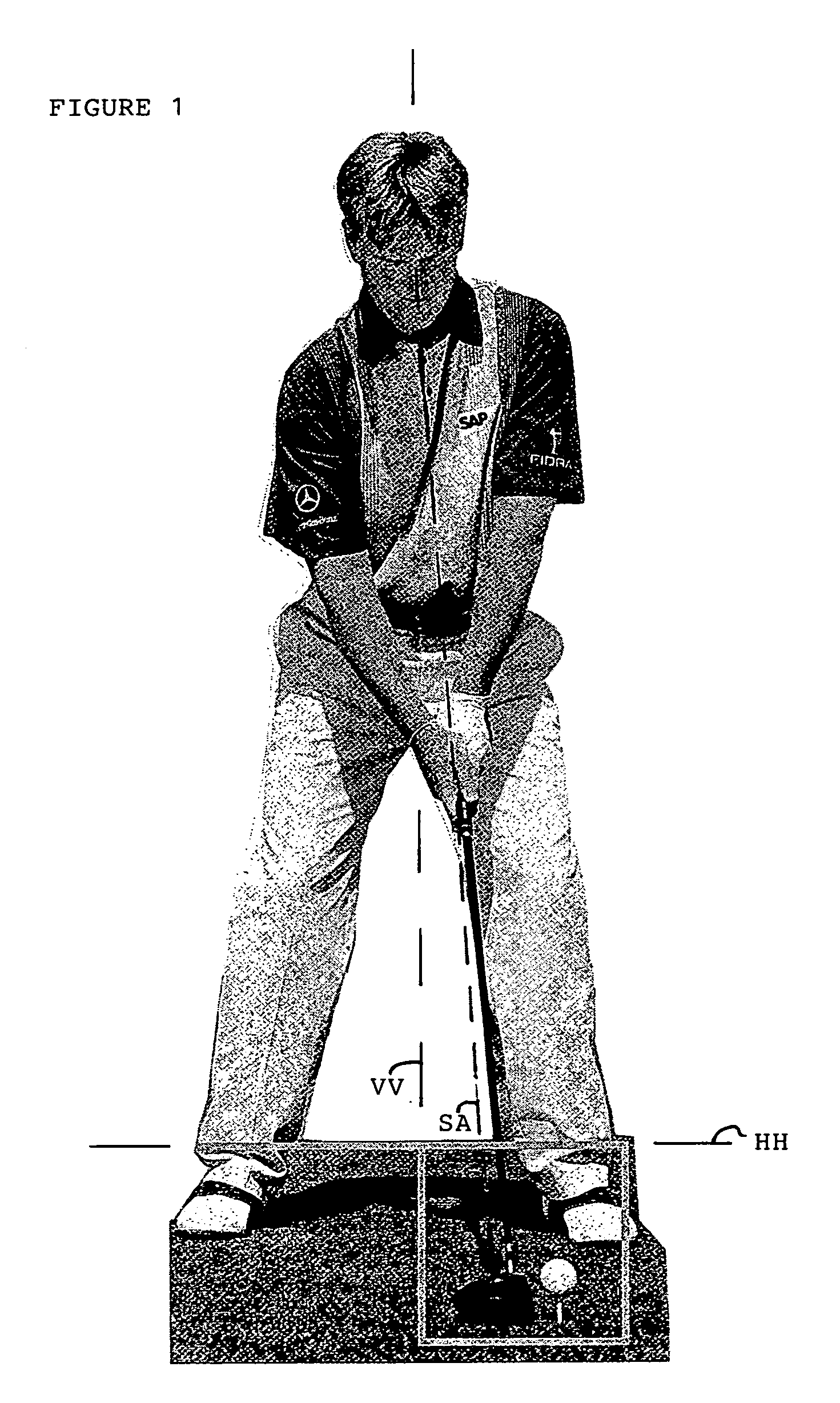

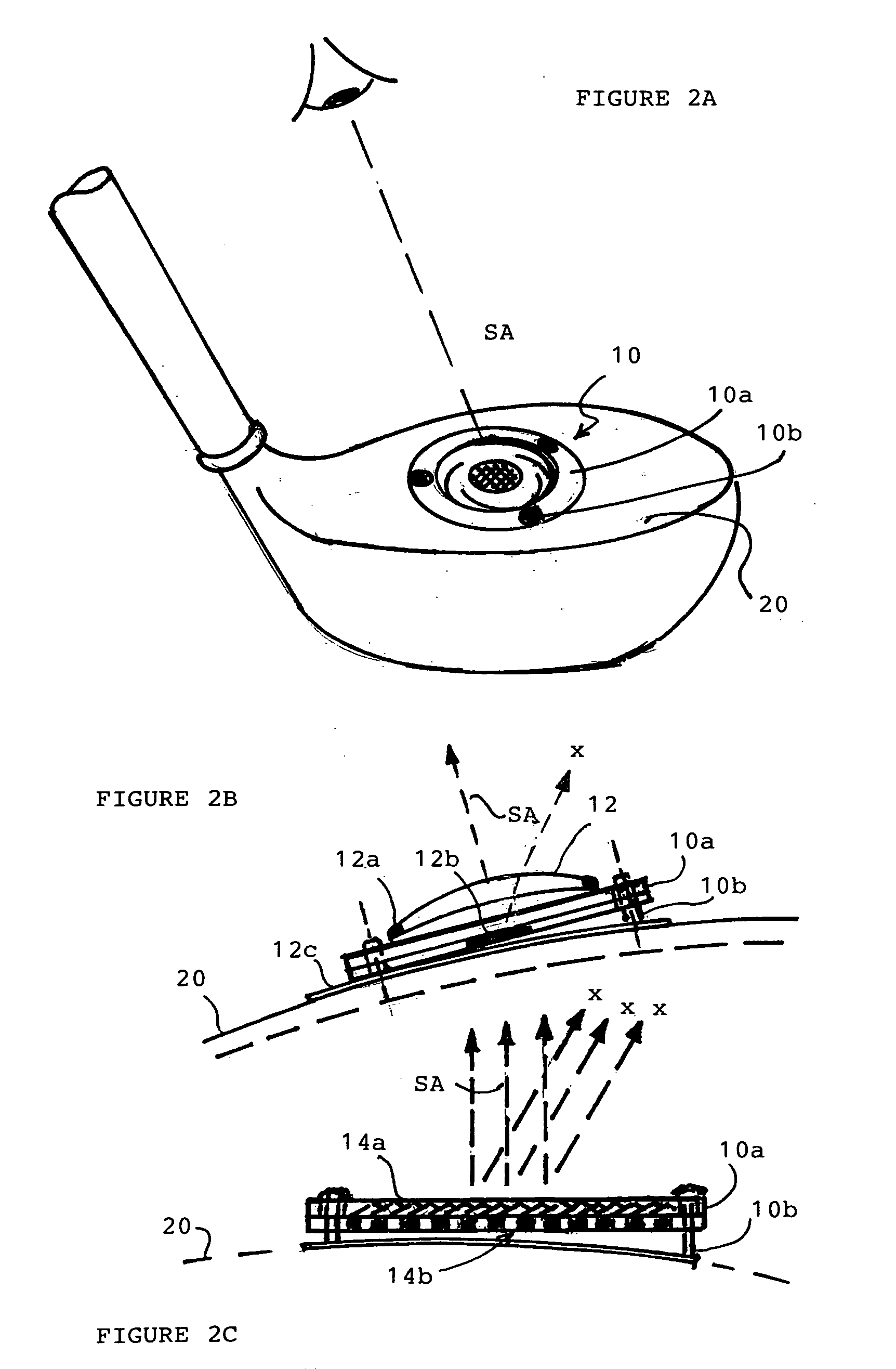

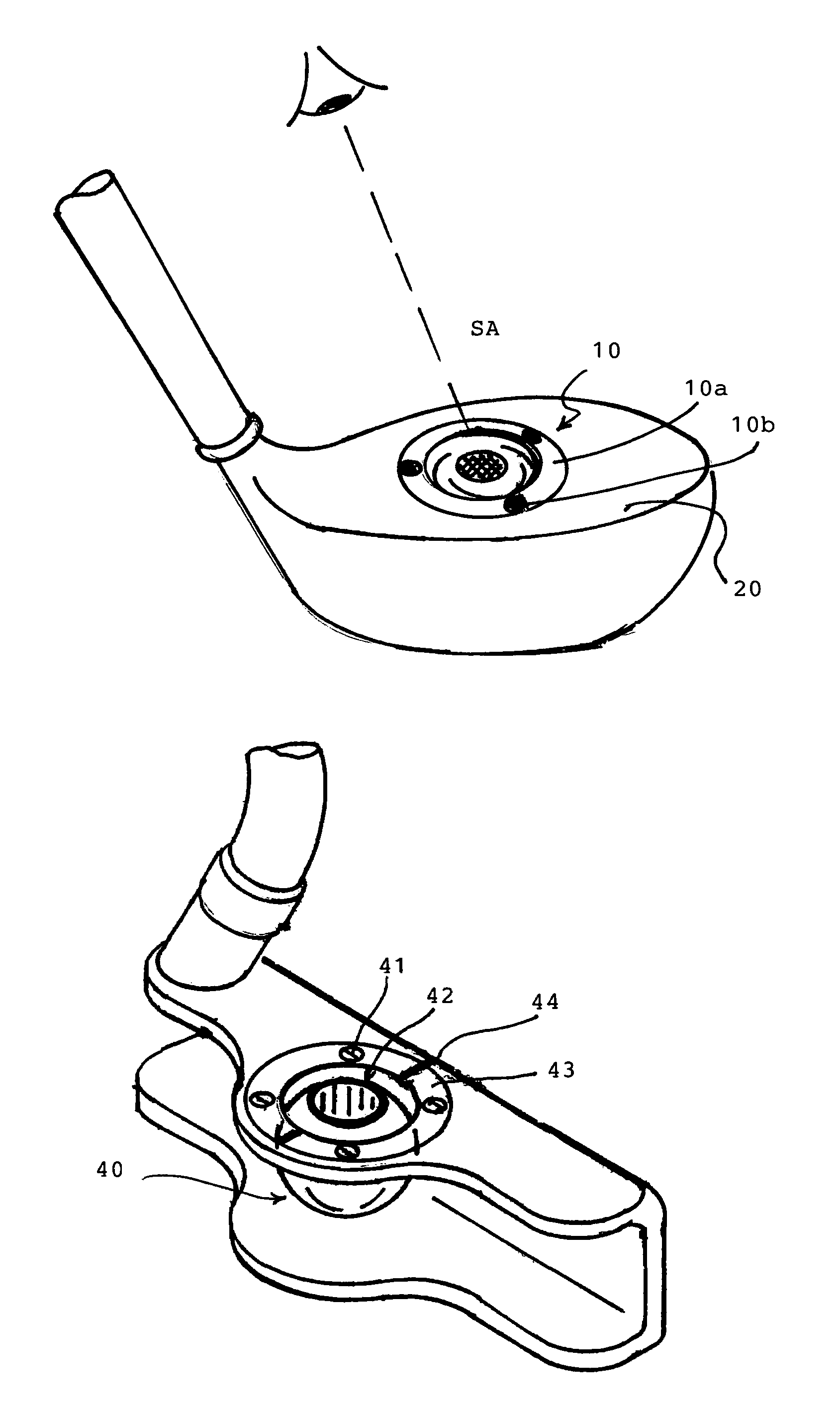

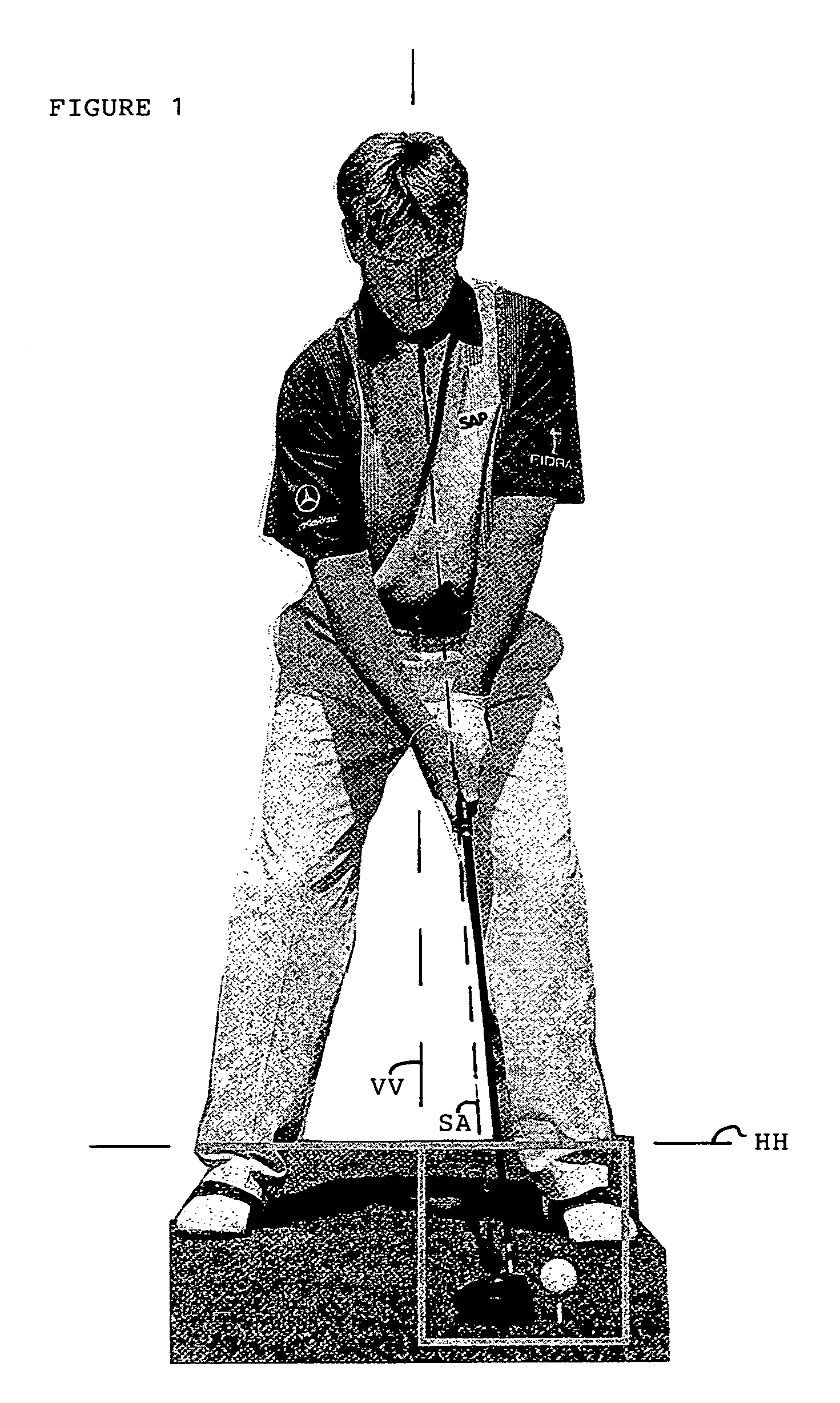

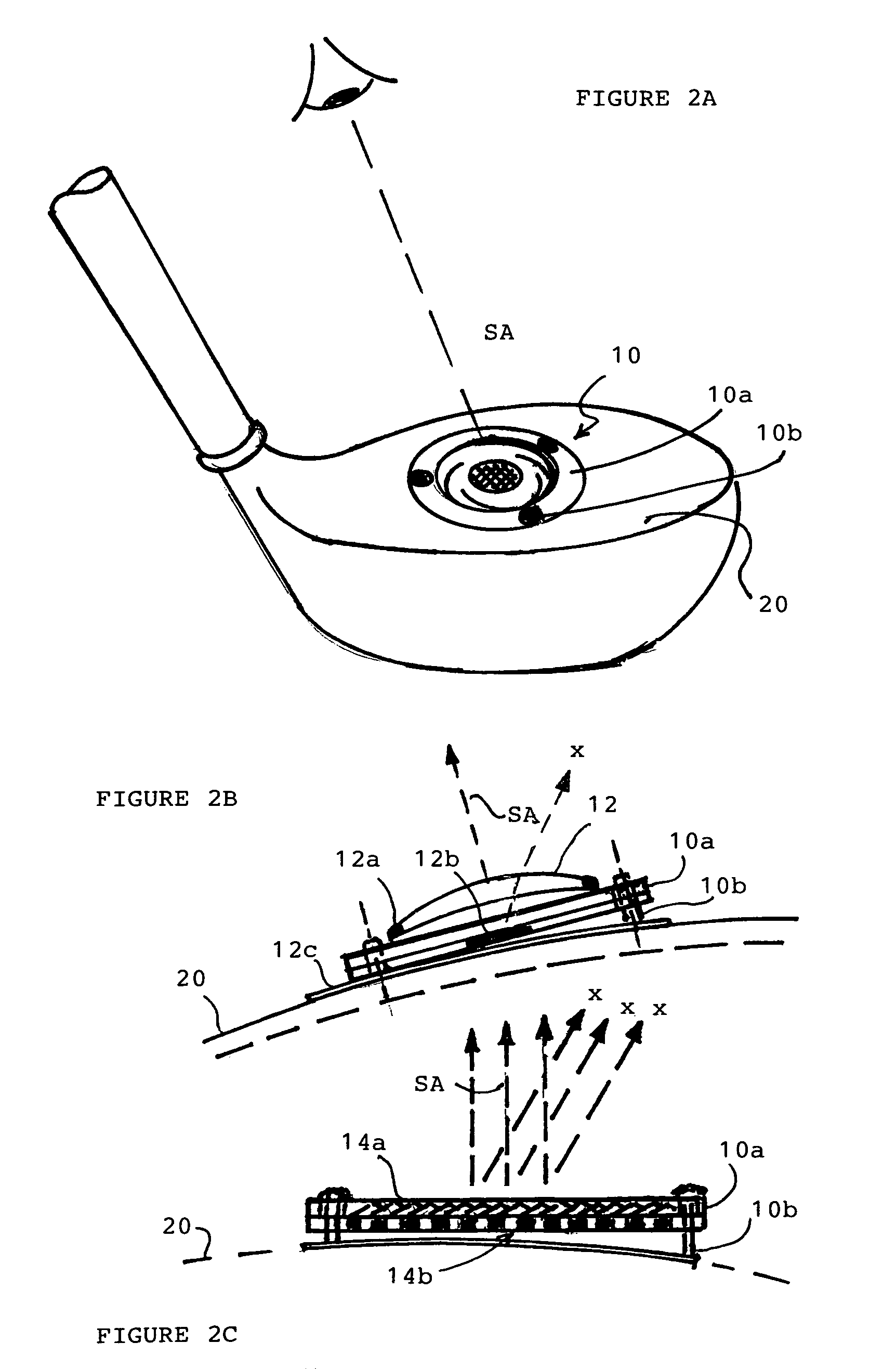

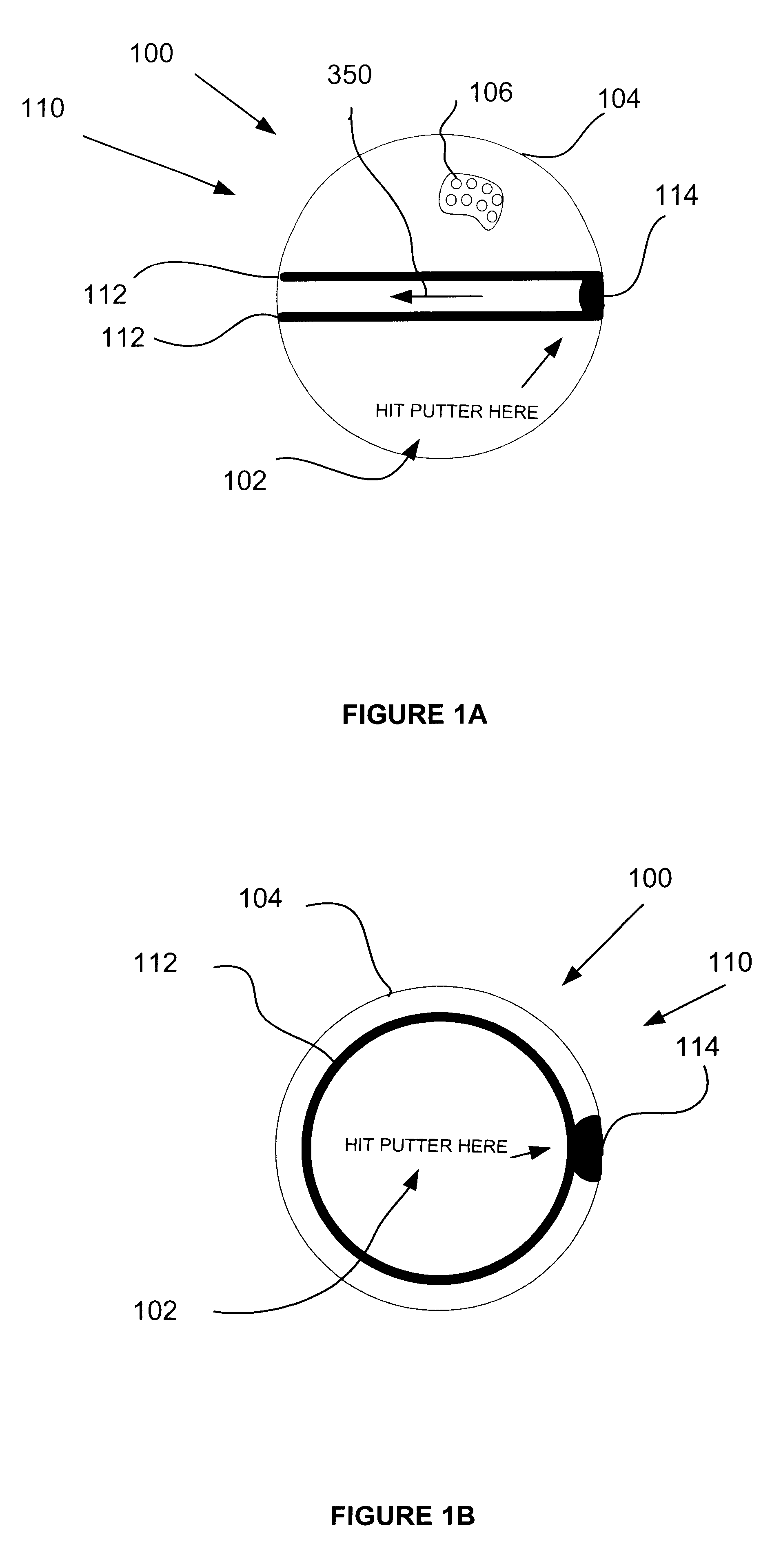

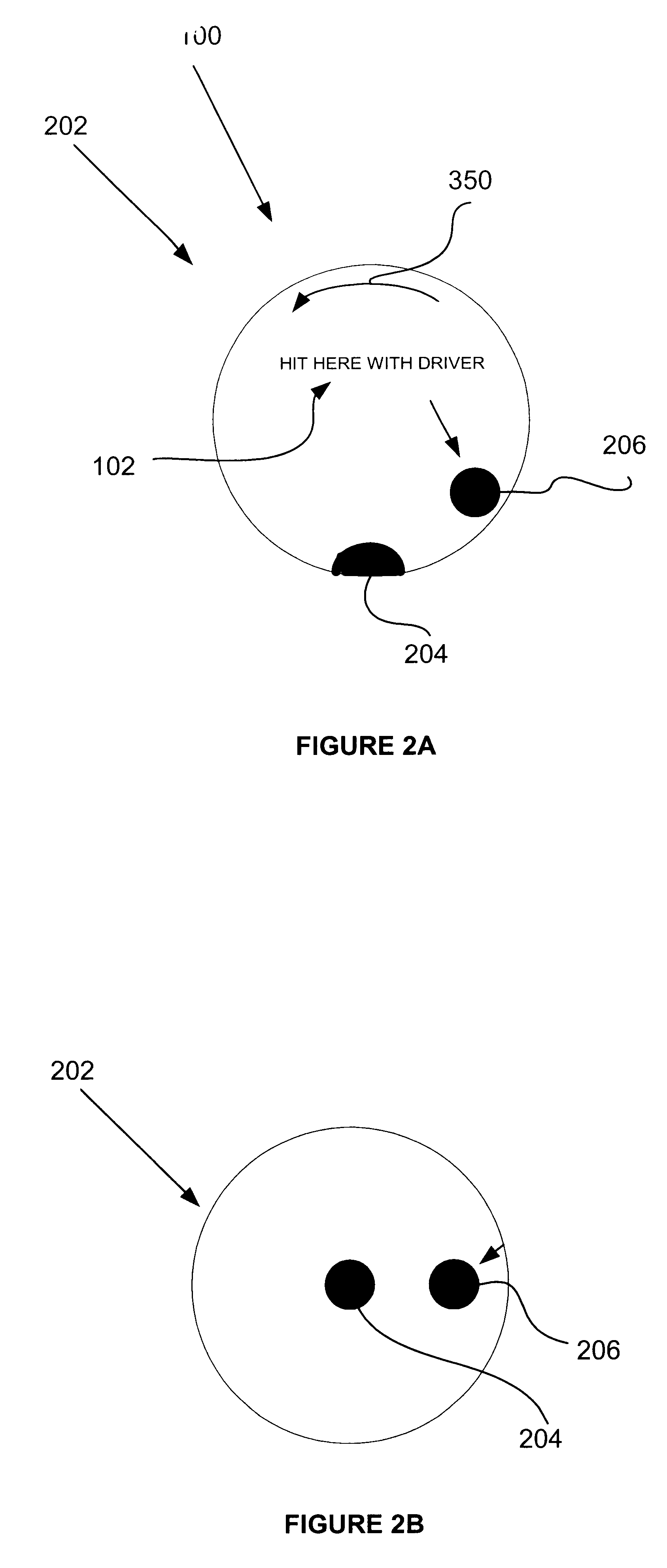

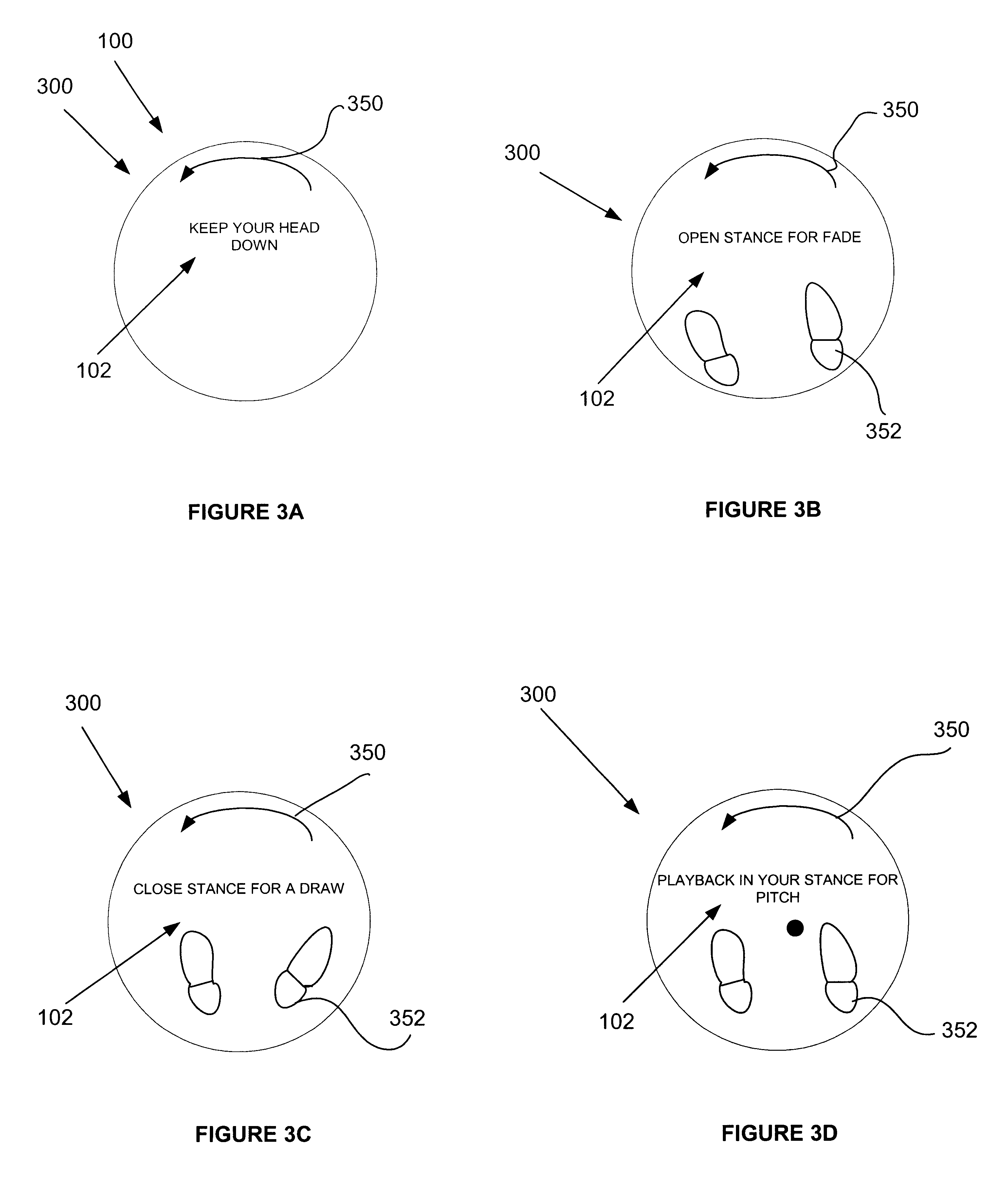

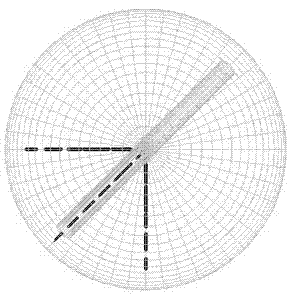

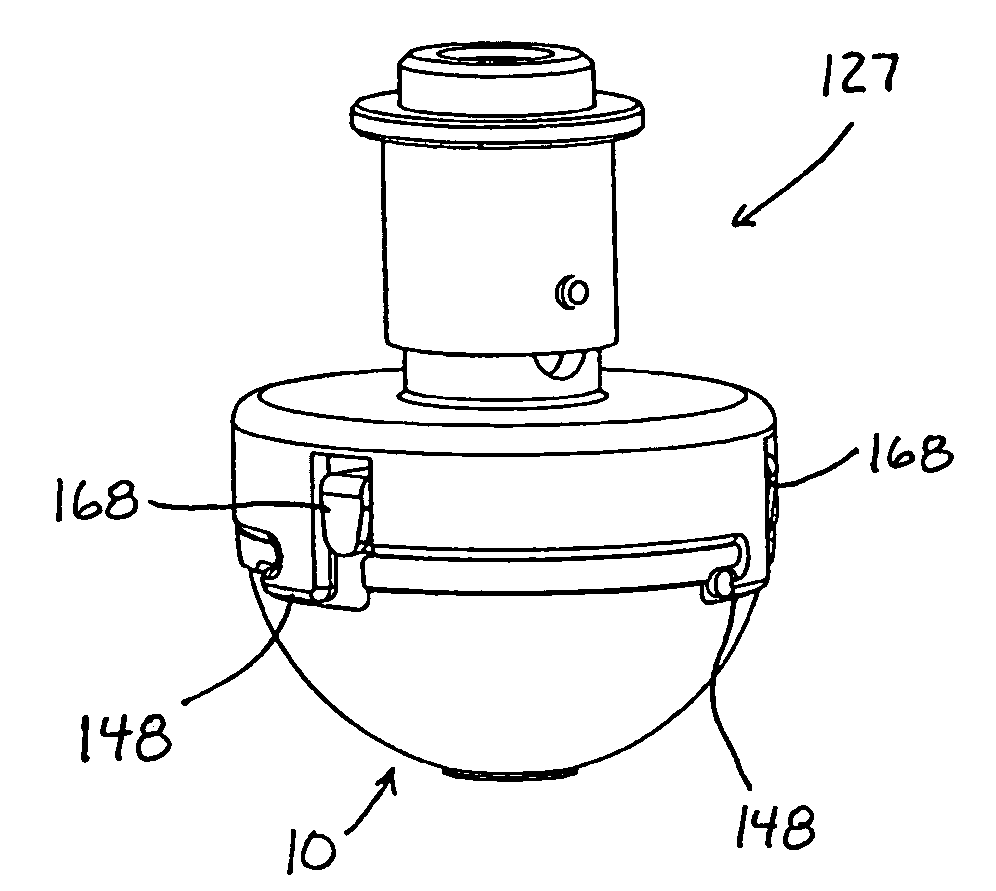

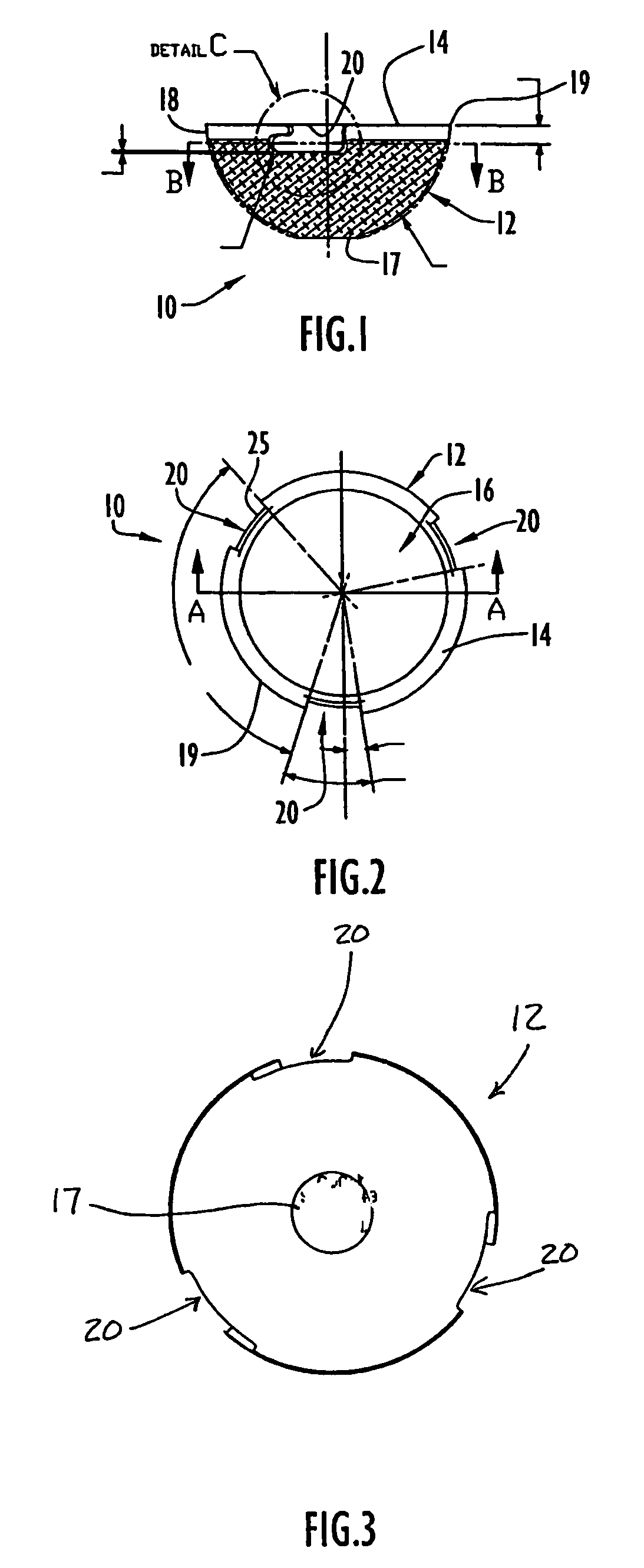

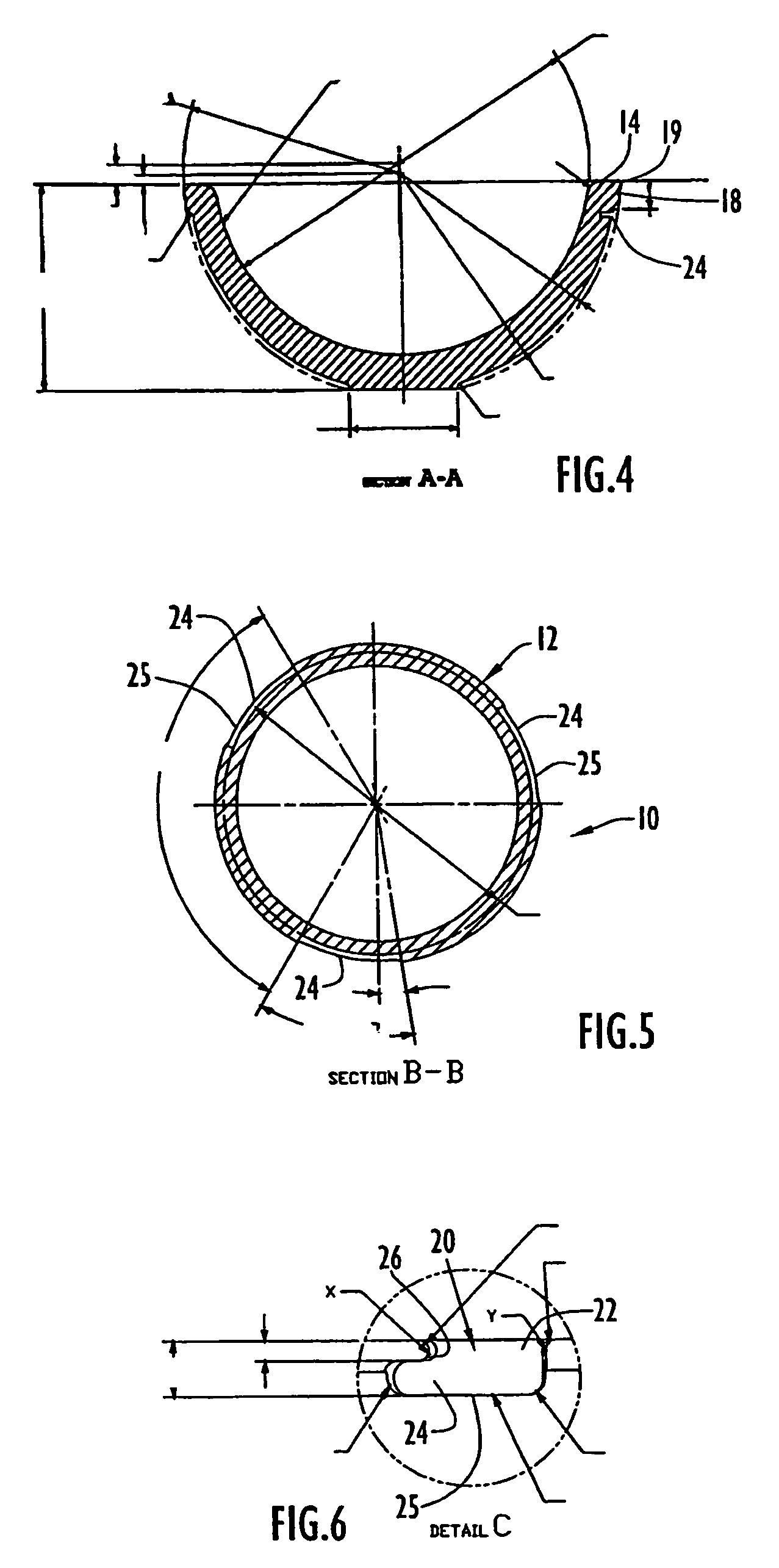

Golf club with customizable alignment sighting & weighting device

InactiveUS20060068928A1Precise aimingEasy to adjustGolf clubsRacket sportsInterference fitCircular disc

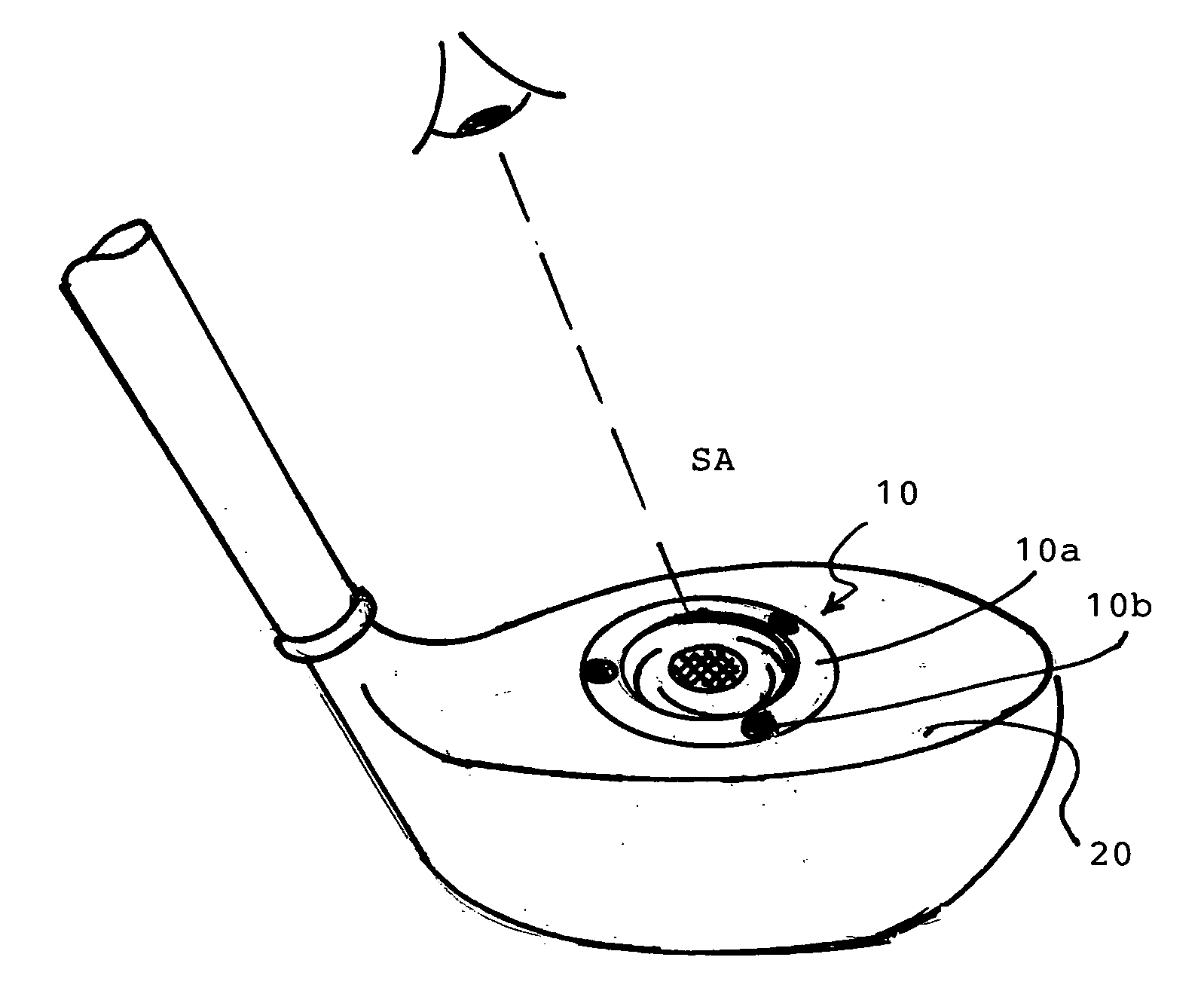

A customizable alignment sighting device for a golf club is mounted to an upper surface of the head of the golf club with a sighting element providing the user a visual target indicator for desired alignment of the club head with the user's line of sight. The sighting element can be readily adjusted for the user's preferences. When not aligned, the sighting element provides an indication of the magnitude and direction of misalignment. In one embodiment, the device is shaped as a planar disc mounted on the upper surface of the club head by leveling posts spaced around its periphery. The sighting element is a concave lens or lenticulated grid or grill superimposed on a target image. In another embodiment, the device has a 3D device body mounted in a mounting cup or socket fastened to or formed in the head of the golf club. The device body has a larger-diameter circle marked around an annular opening, and a smaller-diameter circle marked depthwise inside the opening in the device body to provide a target of concentric circles by parallax effect. The device body can be formed as a sphere with axially split sides that are expanded outward when an expansion plug is threaded in the bottom, providing an interference fit holding it in position in the mounting cup. The spherical body can be formed with 4 alignment sighting holes at 90° intervals around a vertical plane and provided with a weighting element fixed at an offset position, such that it can be rotated to use any of the different alignment holes for adjusting the weight distribution in the club head.

Owner:NAGY LAJOS I

Gold club with customizable alignment sighting and weighting device

A customizable alignment sighting device for a golf club is mounted to an upper surface of the head of the golf club with a sighting element providing the user a visual target indicator for desired alignment of the club head with the user's line of sight. The sighting element can be readily adjusted for the user's preferences. When not aligned, the sighting element provides an indication of the magnitude and direction of misalignment. In one embodiment, the device is shaped as a planar disc mounted on the upper surface of the club head by leveling posts spaced around its periphery. The sighting element is a concave lens or lenticulated grid or grill superimposed on a target image. In another embodiment, the device has a 3D device body mounted in a mounting cup or socket fastened to or formed in the head of the golf club. The device body has a larger-diameter circle marked around an annular opening, and a smaller-diameter circle marked depthwise inside the opening in the device body to provide a target of concentric circles by parallax effect. The device body can be formed as a sphere with axially split sides that are expanded outward when an expansion plug is threaded in the bottom, providing an interference fit holding it in position in the mounting cup. The spherical body can be formed with 4 alignment sighting holes at 90° intervals around a vertical plane and provided with a weighting element fixed at an offset position, such that it can be rotated to use any of the different alignment holes for adjusting the weight distribution in the club head.

Owner:NAGY LAJOS I

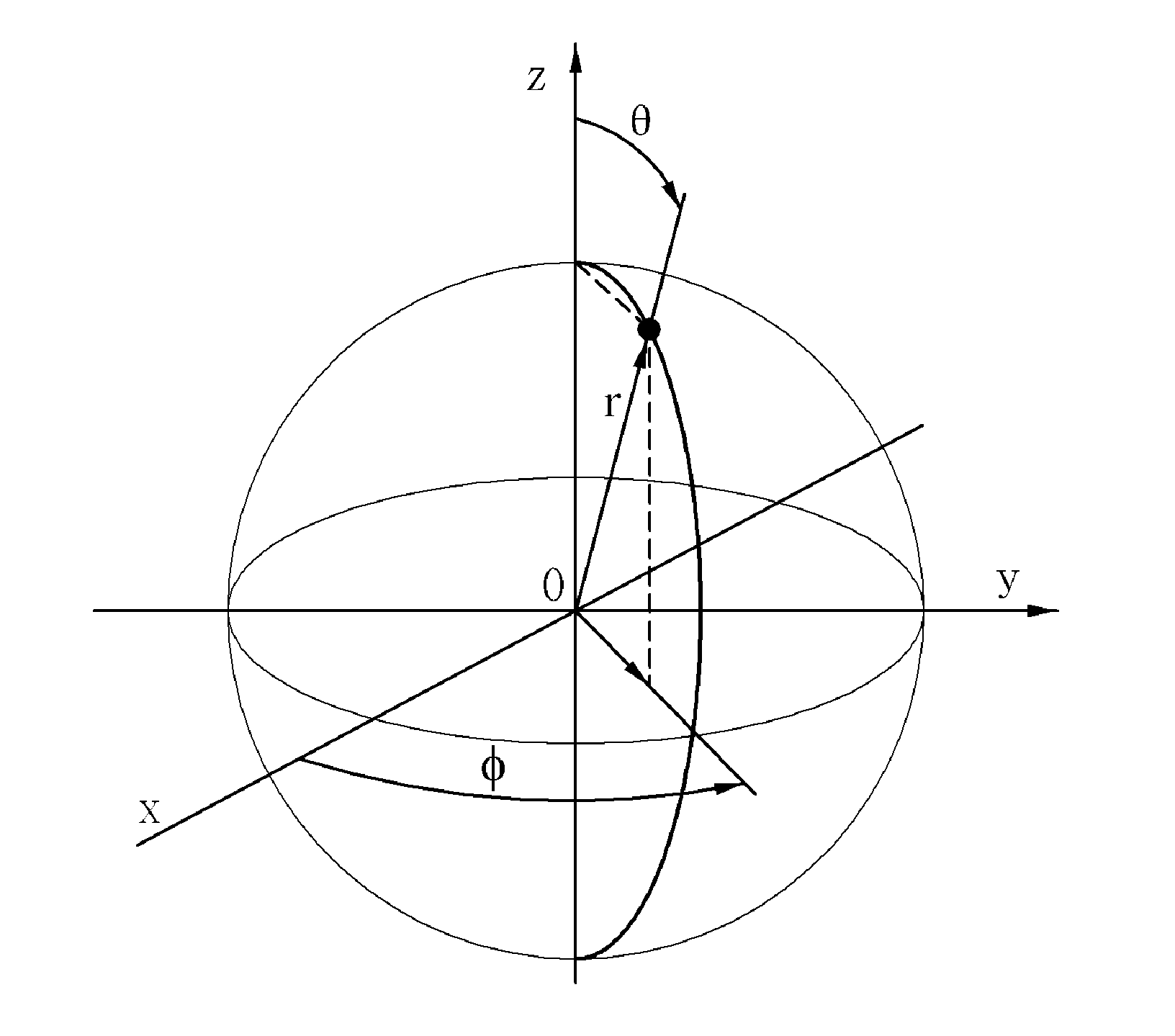

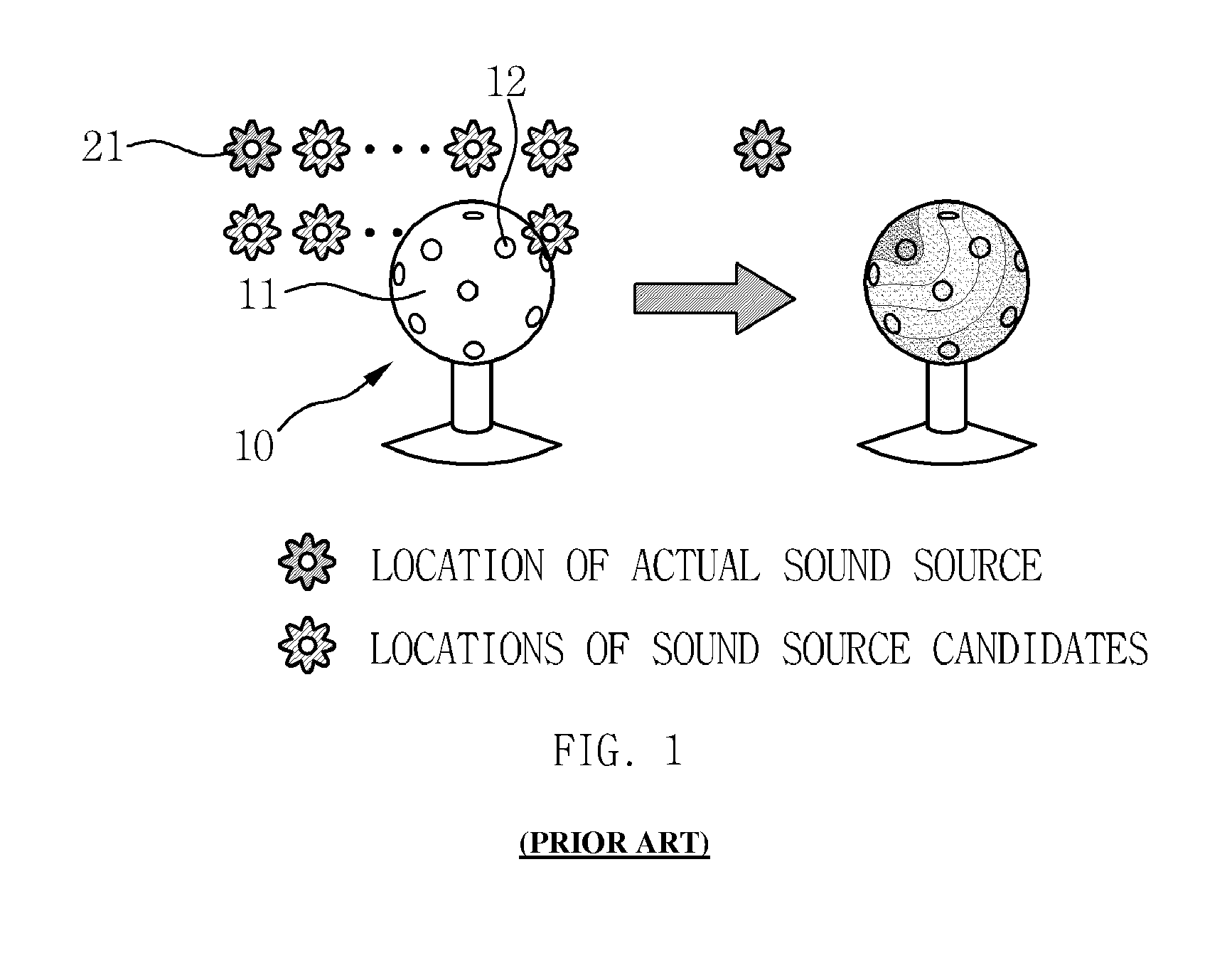

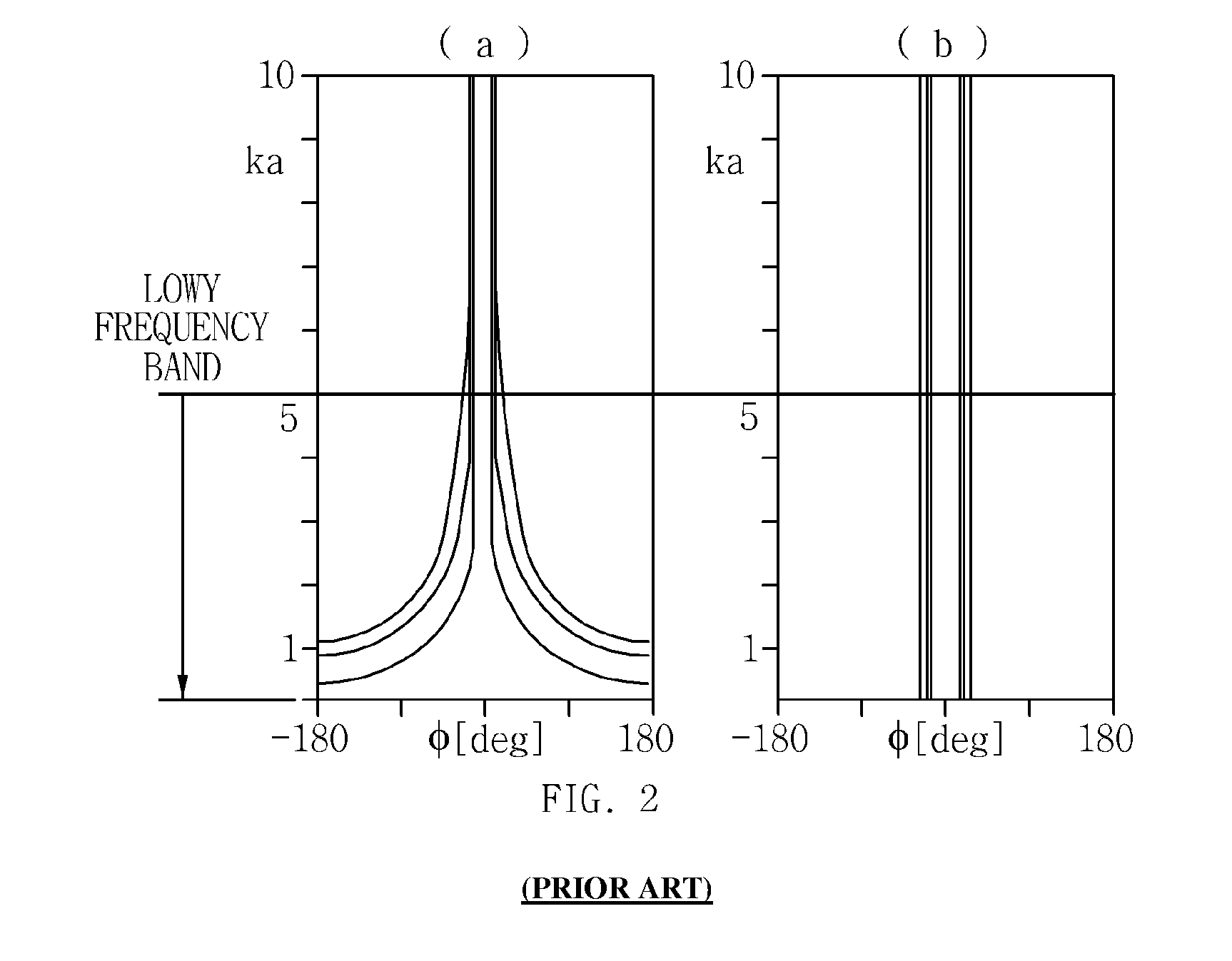

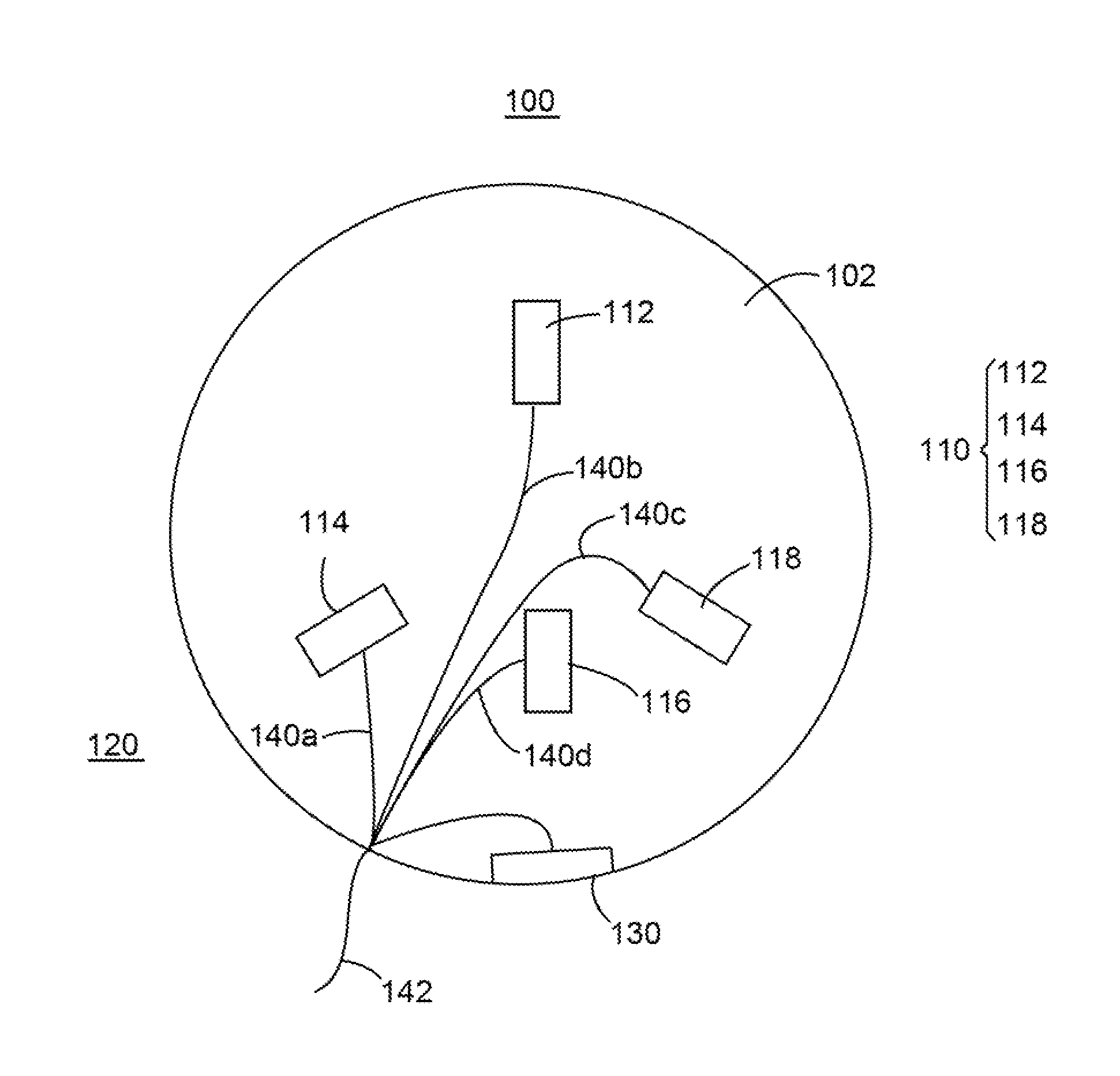

Technique for localizing sound source

ActiveUS20130147835A1High resolutionReduce measurement frequencyMicrophonesSignal processingSound sourcesSound pressure

Disclosed is a technique for localizing a sound source. In the technique, a sound pressure signal measured by microphones is acquired using a spherical microphone array sensor where the microphones are fixedly arranged on a surface of a spherical body. A sound pressure distribution on the surface of the spherical body is obtained by a controller from a sound pressure calculation formula for calculating a sound pressure at a certain location of a spherical surface using the sound pressure signal measured by the microphones as an input value. A location of the sound source is estimated from the obtained sound pressure distribution.

Owner:HYUNDAI MOTOR CO LTD

Image stabilizing actuator and camera furnished therewith

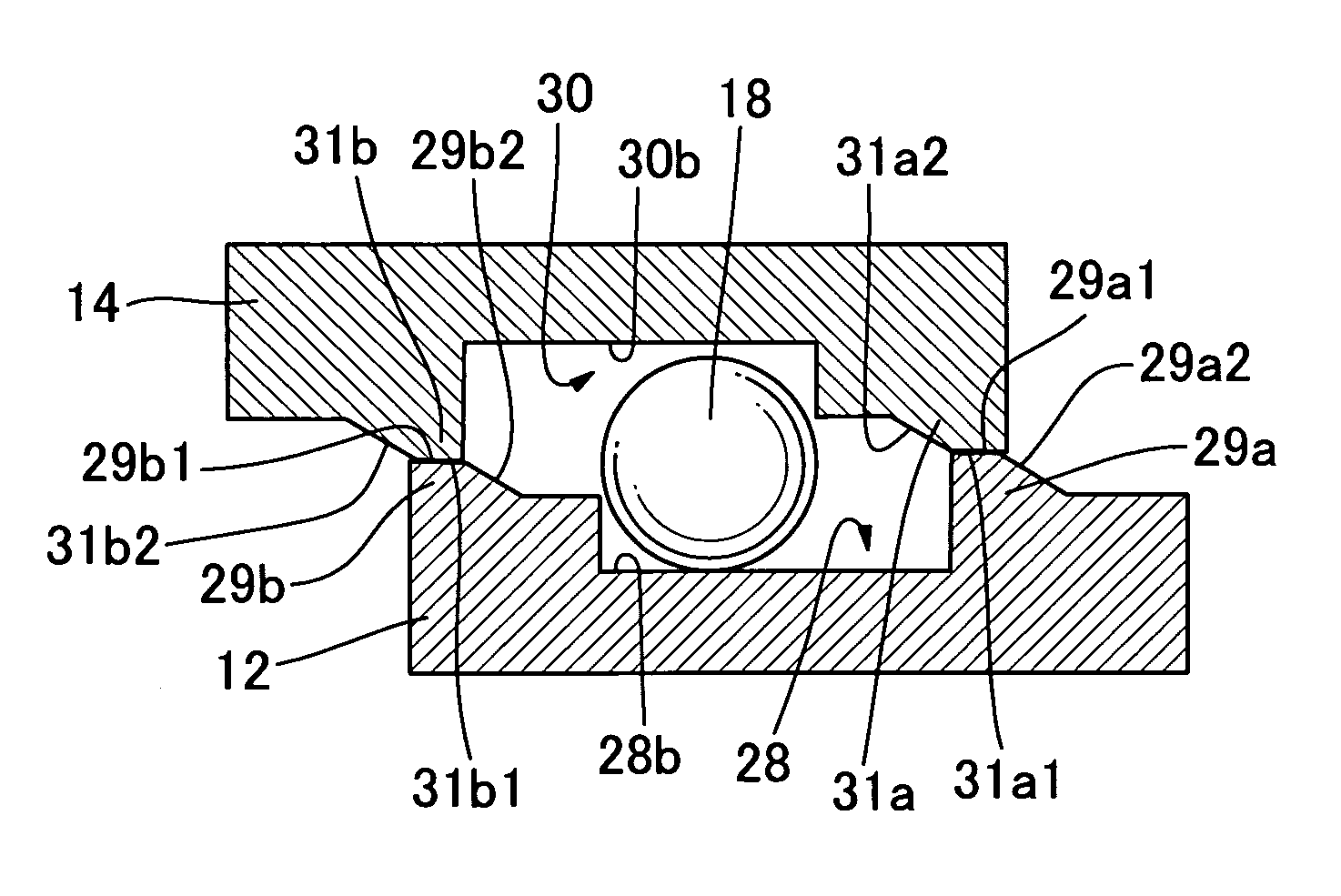

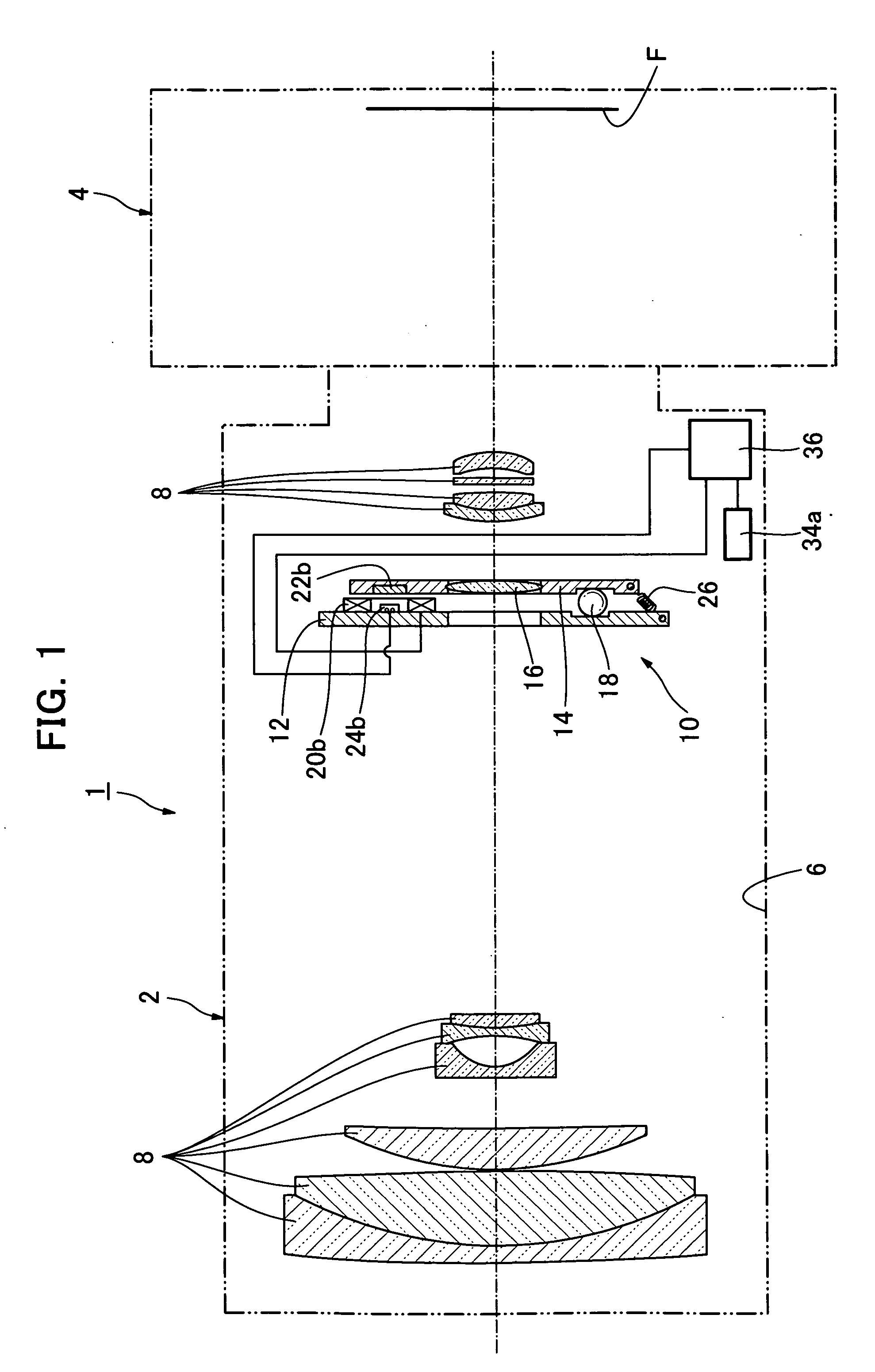

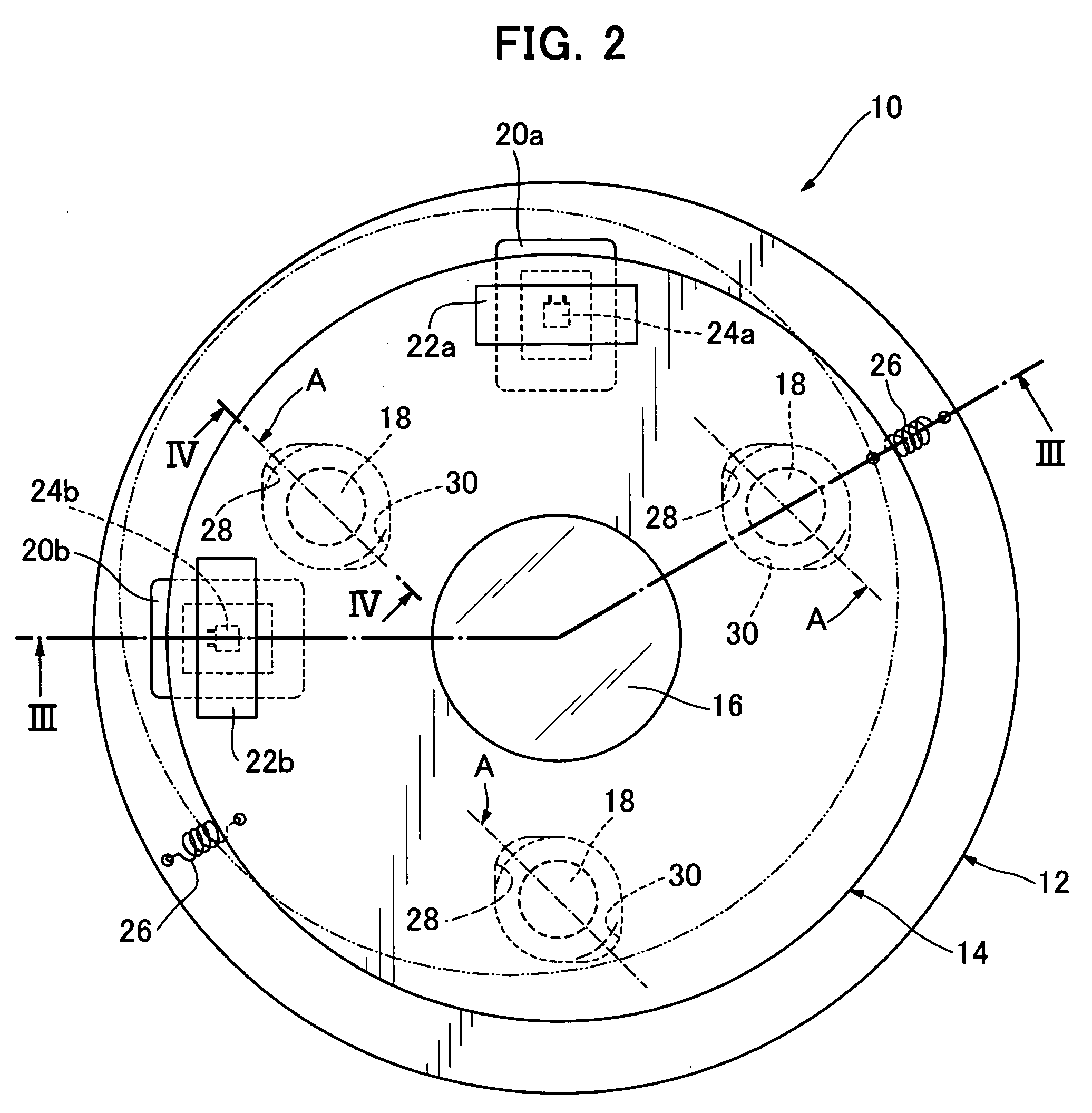

Problem: To provide an actuator capable of preventing damage to spherical bodies and their receiving surfaces when subjected to a shock force.Solution Means: The present invention is an actuator (10) for stabilizing images by moving an imaging lens, comprising a fixed portion (12), a movable portion (14) to which an imaging lens is attached, a plurality of spherical bodies (18) for supporting the movable portion, a fixed portion spherical body receiving surface (28b) disposed on the fixed portion and contacting the spherical bodies, a movable portion spherical body receiving surface (30b) disposed on the movable portion and contacting the spherical bodies, a biasing means (26) for sandwiching the spherical bodies between the fixed portion spherical body receiving surface and the movable portion spherical body receiving surface, and spherical body receiving surface protection means (29, 30) which, when image stabilization control is not in effect, reduce the contact pressure acting on the spherical bodies so as to sandwich the spherical bodies when the movable portion is moved to a predetermined protected position.

Owner:TAMRON

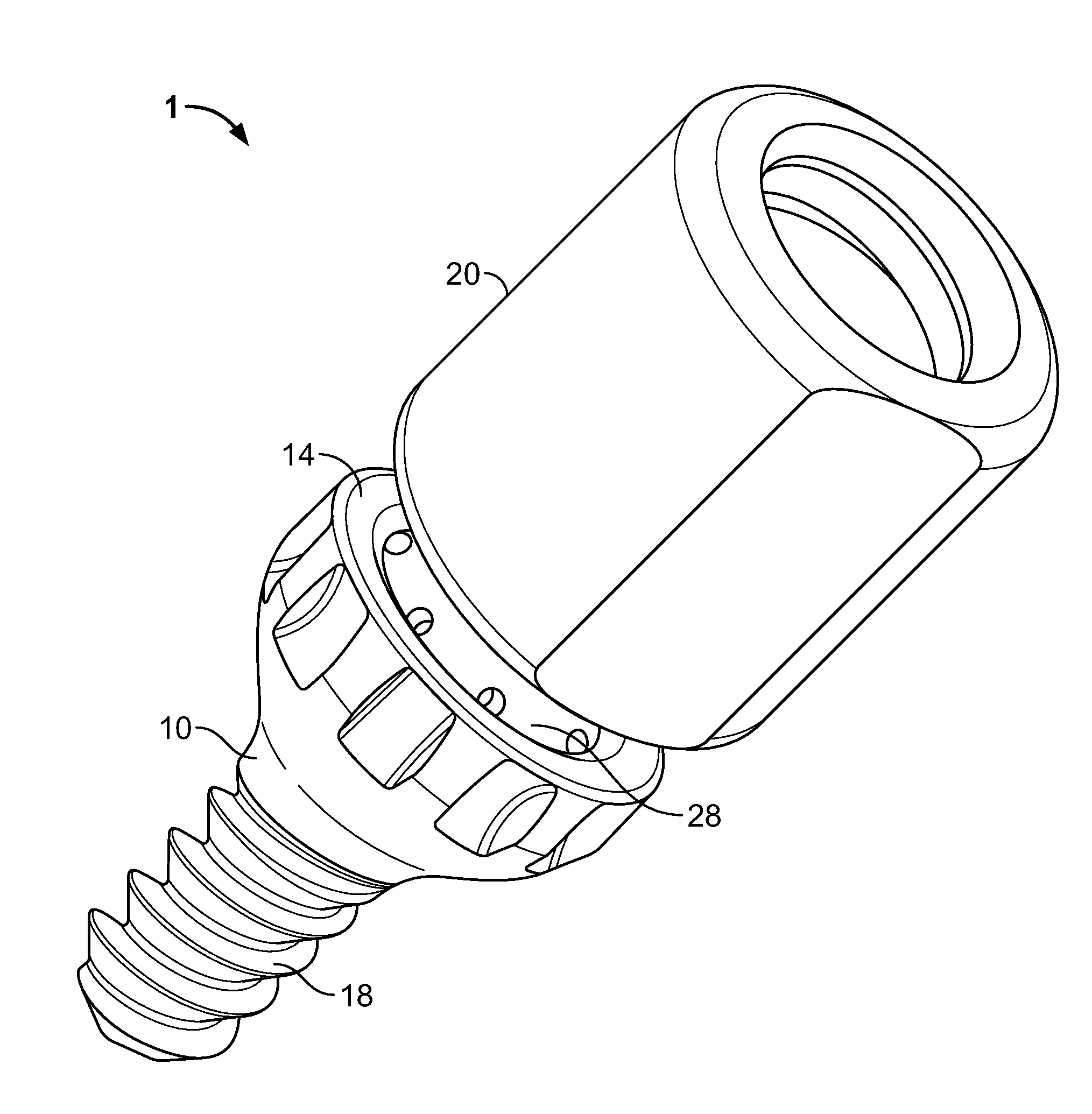

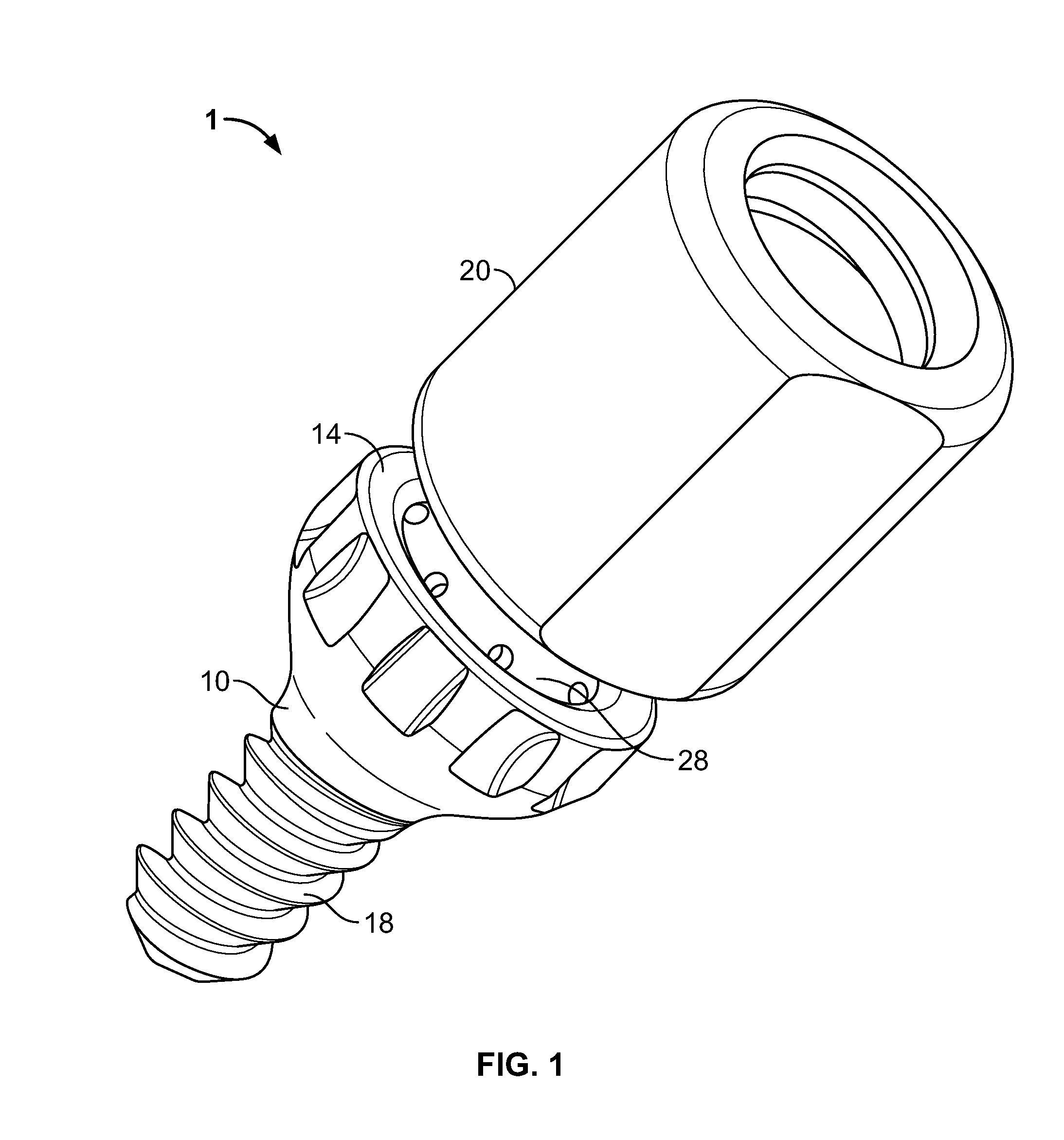

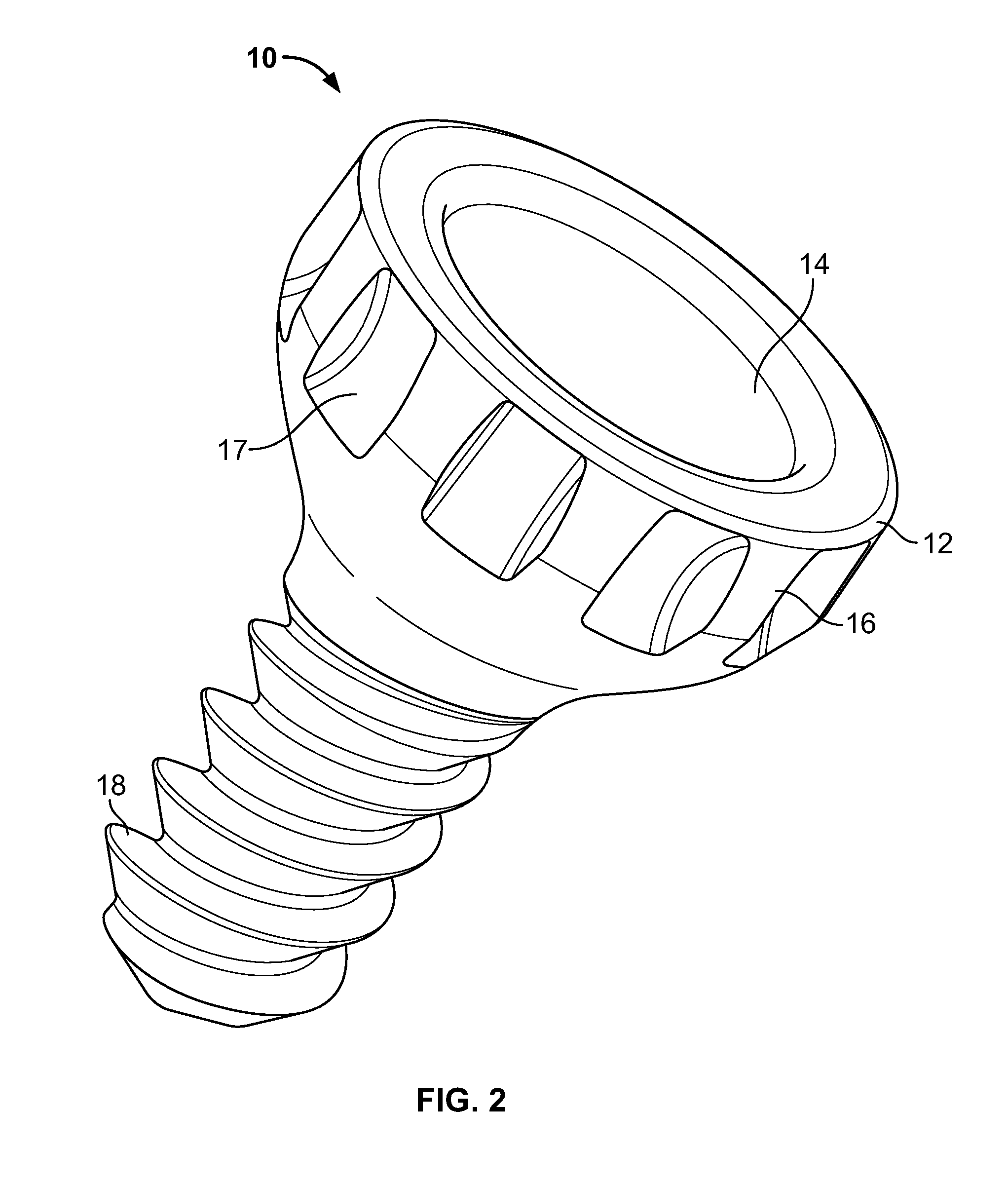

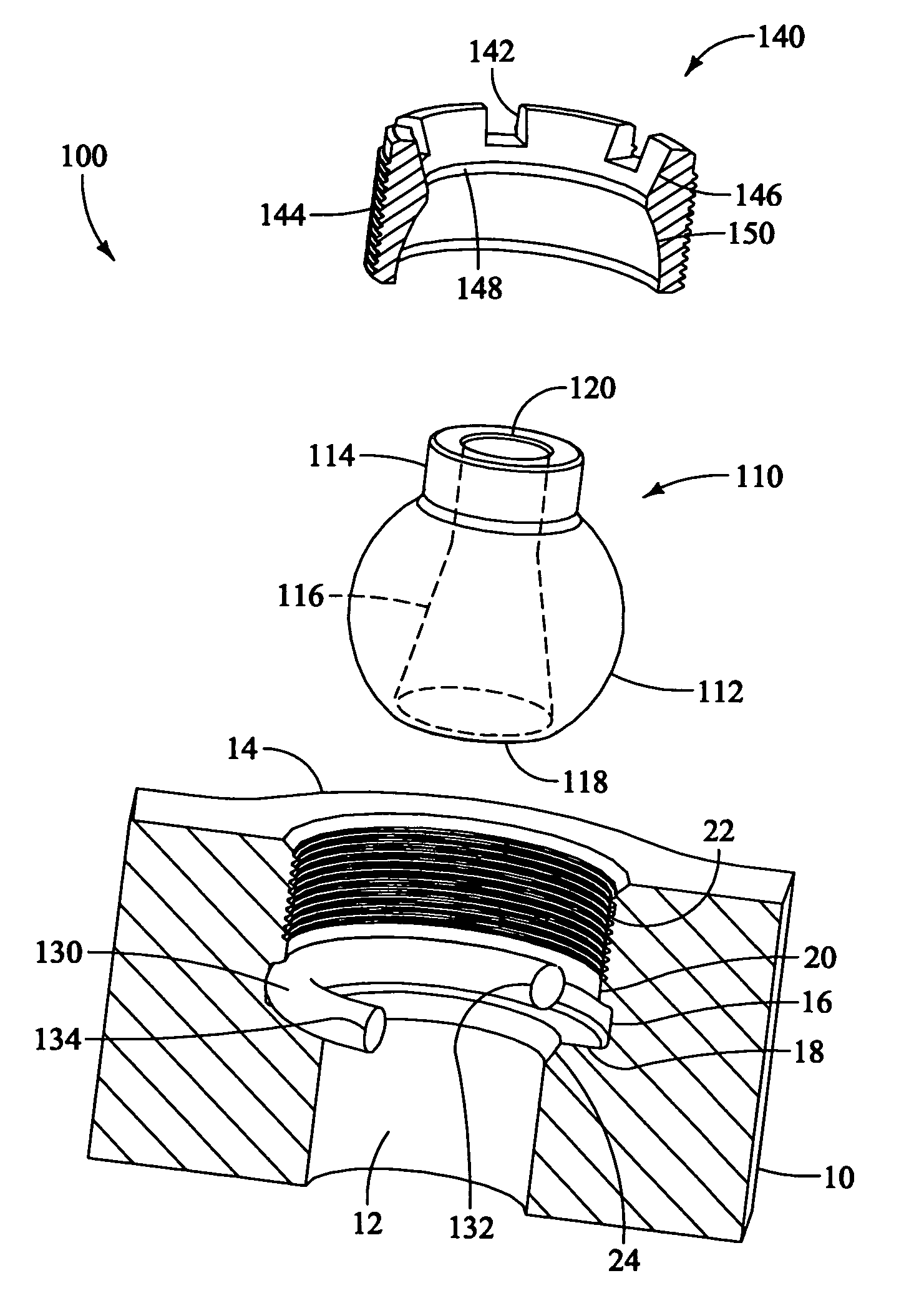

Polyaxial Dental Implant

A polyaxial dental implant includes an abutment member that includes a channel bored through a longitudinal axis of the abutment member, and an outwardly protruding and expandable round bulbous body coupled to an end of the abutment member. The implant includes a fixture member coupled to the bulbous body, where the fixture member receives the bulbous body; and a pin engaged within the abutment member via the channel and contacting the bulbous body causing the bulbous body to outwardly expand into the fixture member.

Owner:CUSTOM SPINE INC

High temperature insulating mould coating

The invention relates to a high temperature insulating coating, comprising thermal- resistant resin, solvent, and nano-porous packing material and hollow microsphere inorganic packing material. The thermal- resistant resin comprises more than one thermal- resistant polymer, nano-porous packing material possesses nano- micropore structure, and the hollow microsphere inorganic packing material is hollow sphere.

Owner:IND TECH RES INST

Golf ball with textual instructions positioned thereon

The present invention includes an instructional golf ball including a spherical body having an outer surface with a plurality of dimples formed therein. Situated on the outer surface of the body is instructional indicia. Such instructional indicia include text for providing guidance as to the manner in which a user should play the golf ball. During use, a user might read the instructional indicia while addressing the golf ball, and address and / or strike the golf ball in the manner indicated by the instructional indicia.

Owner:PETTIGREW STEPHEN H +1

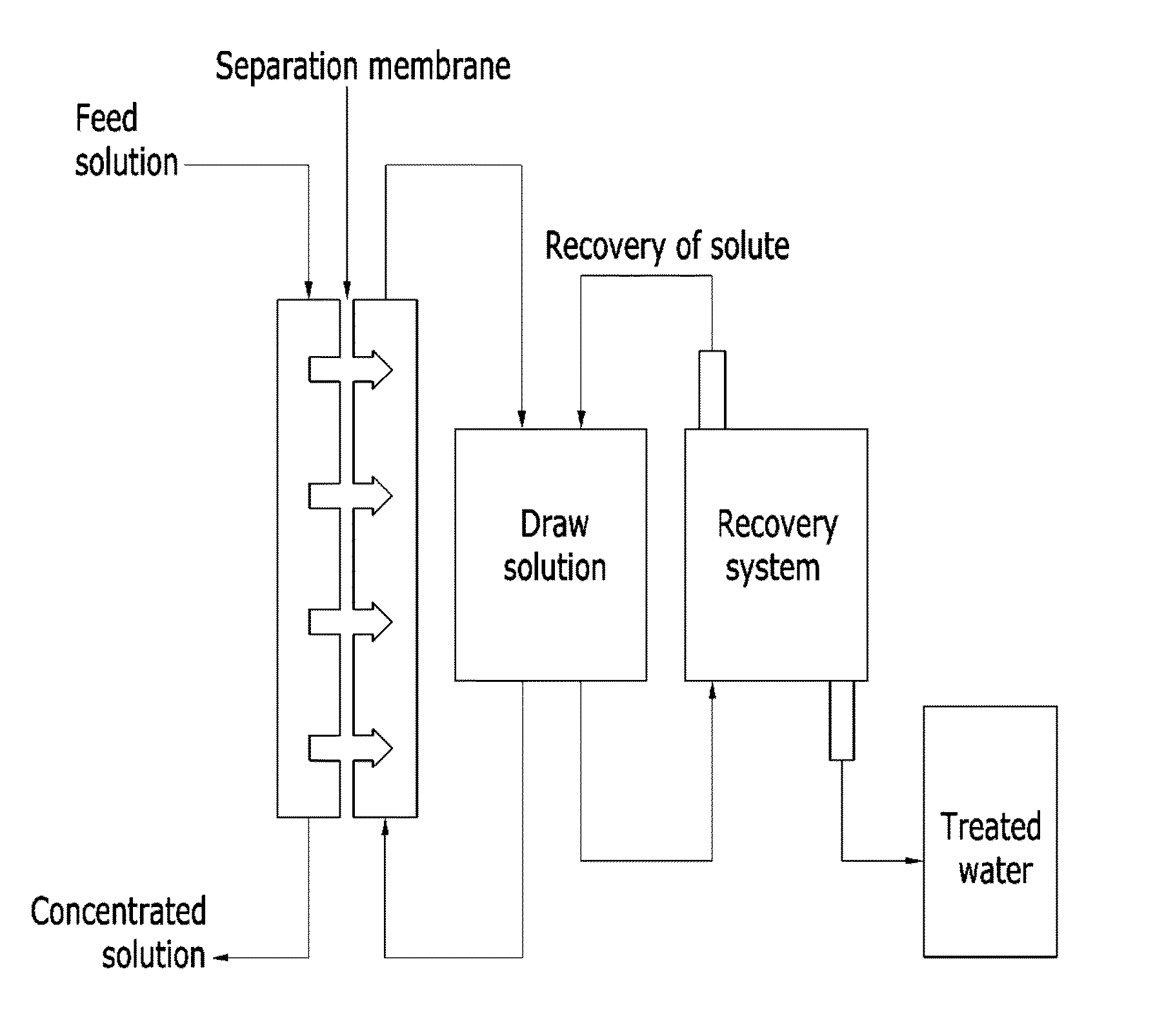

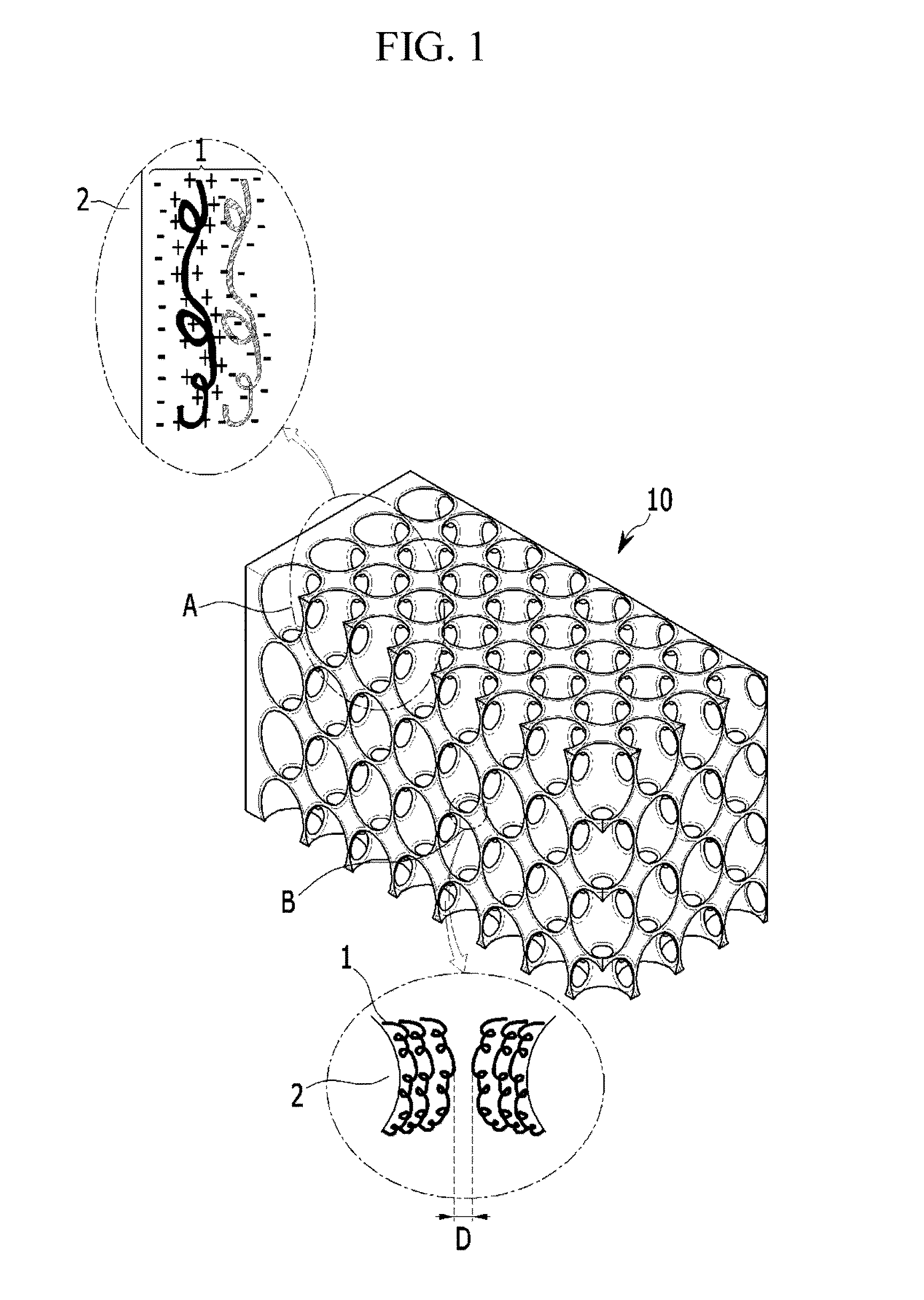

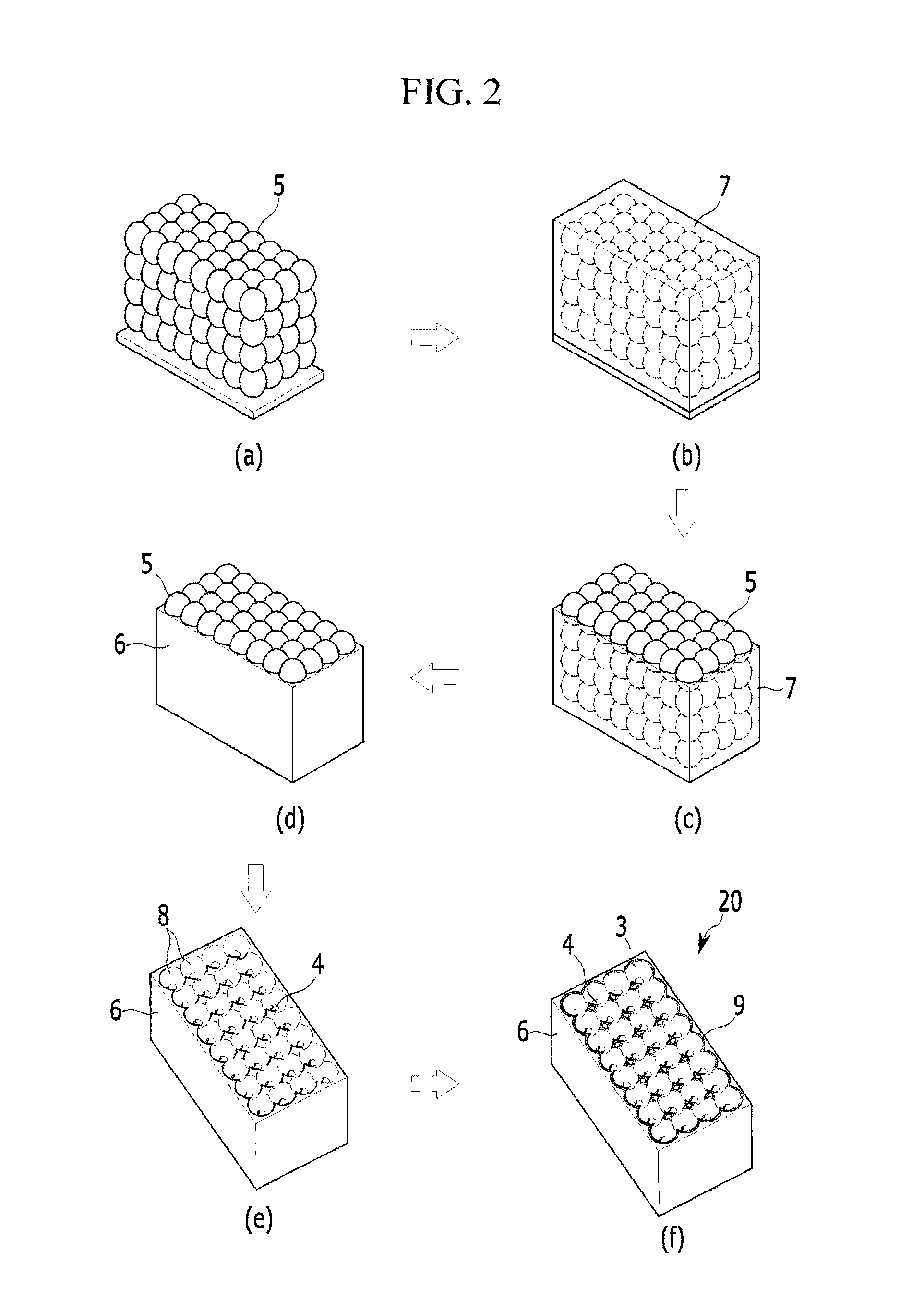

Hybrid porous structure, method of preparing hybrid porous structure, separation membrane including hybrid porous structure, and water treatment device including membrane

ActiveUS20130134081A1High pHReduced pHPretreated surfacesLoose filtering material filtersPolymer coatingsMembrane configuration

A hybrid porous structure may include a base template and an ionic polymer coating layer within the base template. The structural framework of the base template itself is non-porous. The base template fills the gaps among a plurality of imaginary spherical bodies stacked in three-dimensions as an imaginary stack. The ionic polymer coating layer is laminated on an inner surface of the base template inside the imaginary spherical bodies. The imaginary spherical bodies may have a pore in the center which is not occupied by the ionic polymer coating layer. The hybrid porous structure may include a plurality of necks, which are openings formed in a contact part where adjacent imaginary spherical bodies contact each other. The necks may be interconnected to the pores located in the center part of the imaginary spherical bodies.

Owner:SAMSUNG ELECTRONICS CO LTD

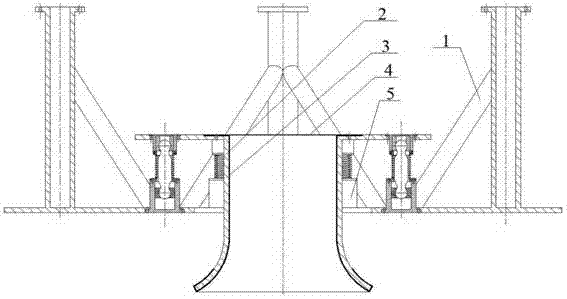

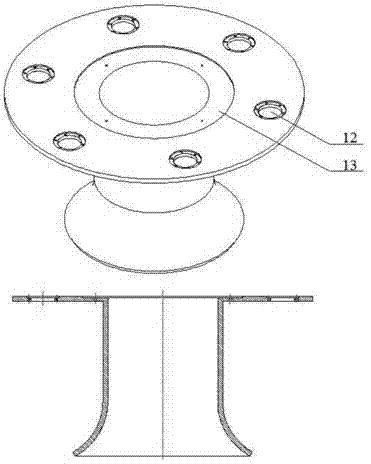

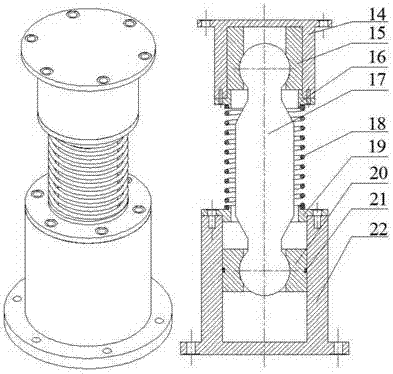

Anti-blocking-and-hanging drilling well water-secluding pipe recovery guiding device

ActiveCN105443058AAvoid hanging problemsInhibit sheddingBorehole/well accessoriesWell drillingMouth shape

The invention relates to an anti-blocking-and-hanging drilling well water-secluding pipe recovery guiding device. The device is characterized by comprising a support, a guiding chamber, a rubber sleeve, a rubber sleeve pressing ring and a supporting device; the support is provided with multiple connecting legs, multiple supporting device lower portion mounting holes are formed in the outer side of the support, and a guiding chamber mounting hole is formed in the middle of the support; the guiding chamber is in a horn-mouth shape, the rubber sleeve is arranged inside the guiding chamber, and the rubber sleeve pressing ring is arranged at the top of the guiding chamber; the supporting device comprises an upper supporting barrel, a wearproof bushing, an upper supporting barrel cover, a connecting rod, a spring, a lower supporting barrel cover, a piston, a piston embracing clamp and a lower supporting barrel; the wearproof bushing is arranged inside the upper supporting barrel, and the piston is arranged inside the lower supporting barrel; a groove is formed at the outer side of the piston, and the groove is matched with the piston embracing clamp; the upper end and the lower end of the connecting rod are both spherical bodies, and the spring is arranged at the outer side of the connecting rod; the spring is provided with an installing ring. The device is simple in structure, convenient to operate, high in reliability and easy and convenient to assemble and can be widely applied to all types of maritime water-secluding pipe anti-blocking-and-hanging recycling operation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Glass steel radar cover single element and forming method thereof

InactiveCN101630774AAdjust and control thicknessFlat surfaceRadiating element housingsRadarSingle element

The invention relates to a glass steel radar cover single element and a forming method thereof. The radar cover single element is a spherical body, the periphery of which is provided with a sewing structure, wherein the spherical body is formed by assembling the inner skin and the outer skin of the glass steel with a foam core layer and the foam core layer is formed by solidifying injected polyurenthane foam glue material. The forming method comprises the following steps of: presetting a fundamental mould, and copying the female mould and the male mould of the glass steel with the same curvature based on the fundamental mould; respectively manufacturing the inner skin and the outer skin of the radar cover single element on the inner surfaces of the female mould and the male mould of the glass steel; and merging the moulds, and forming an inner cavity between the inner skin and the outer skin. The invention is characterized in that the inner skin is provided with a plurality of through holes which enter into the inner cavity; and the inner cavity is filled with polyurenthane foam glue material from the outside to the inside by the through holes and is solidified to be a foam core layer. The method has simple operation, effectively reduces the use waste of polyurenthane foam, has low cost, guarantees the consilient thickness of the inner skin and the outer skin, and can assemble the radar cover with good safety, reliability and wave permeability.

Owner:北京玻钢院复合材料有限公司

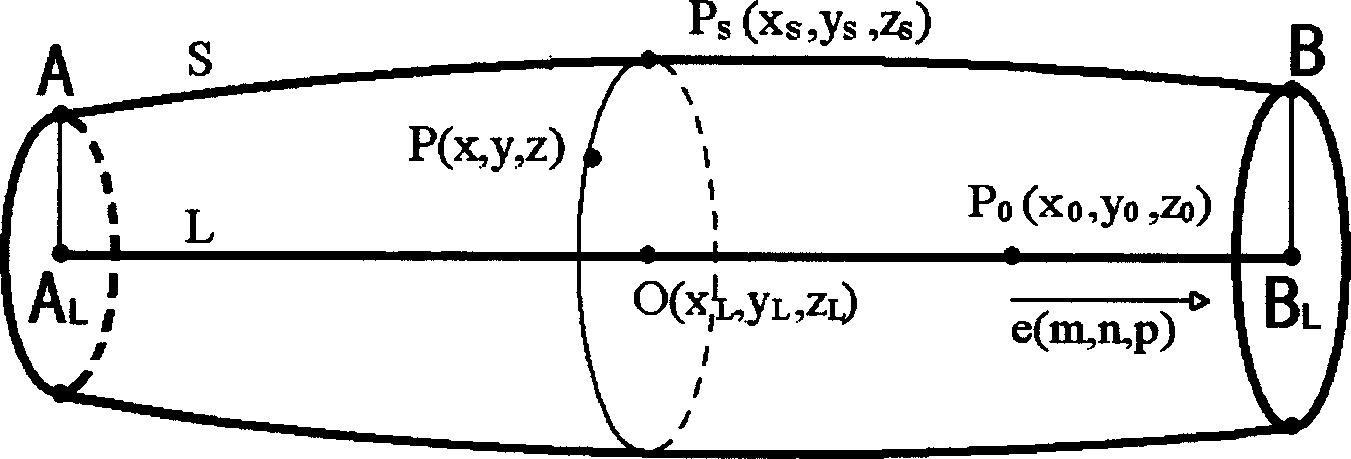

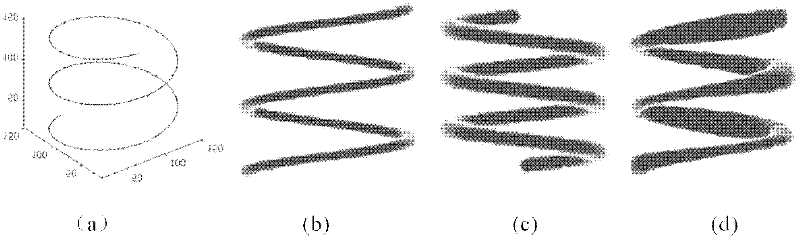

Human limb three-dimensional model building method based on image cutline

InactiveCN1617174AReduce computational complexitySimple method3D modellingCircular coneCurve fitting

The 3D human limb model building method based on image outline adopts rotating conic curved surface, and has joint points and line segments connecting the joint points to constitute skeleton layer to represent the human limb skeleton structure and rotating conic curved surface to represent the skin layer, with human limb skin deformation being reflected in two deforming parameters. Human limb edge contour information is first extracted from human limb image sequence obtained with binocular stereo vision system, the limb contours of the right and left images in different times are fitted with 2D conic curve, the deformation parameters of 2D conic curve equation are found out, corresponding 3D conic curve equation is found out and made to rotate around the skeleton line to find out the 3D rotating conic curved surface equation, and three spherical bodies and two rotating conic curved surfaces are adopted to draw human limb model. The method is simple and easy to realize.

Owner:SHANGHAI JIAO TONG UNIV

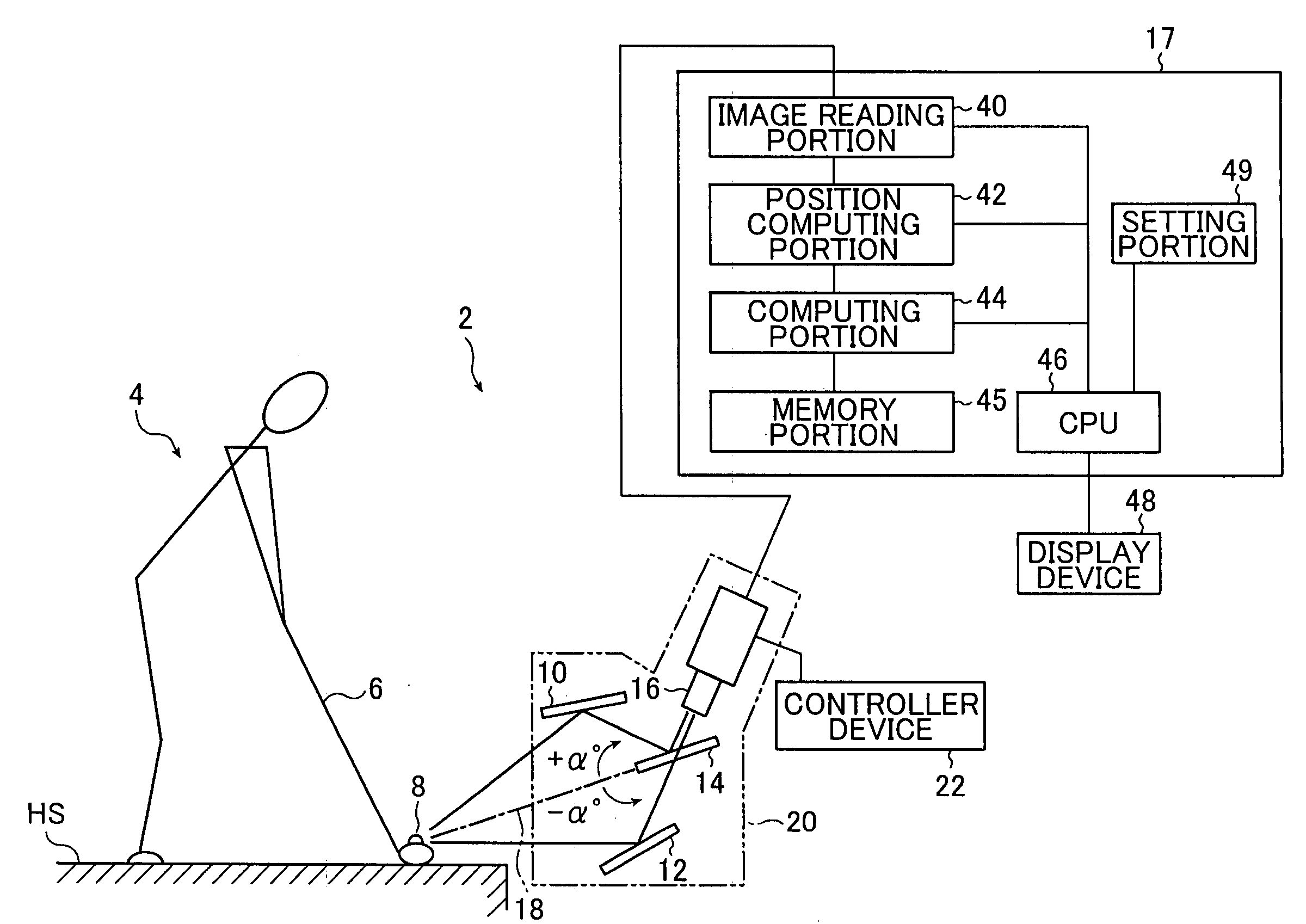

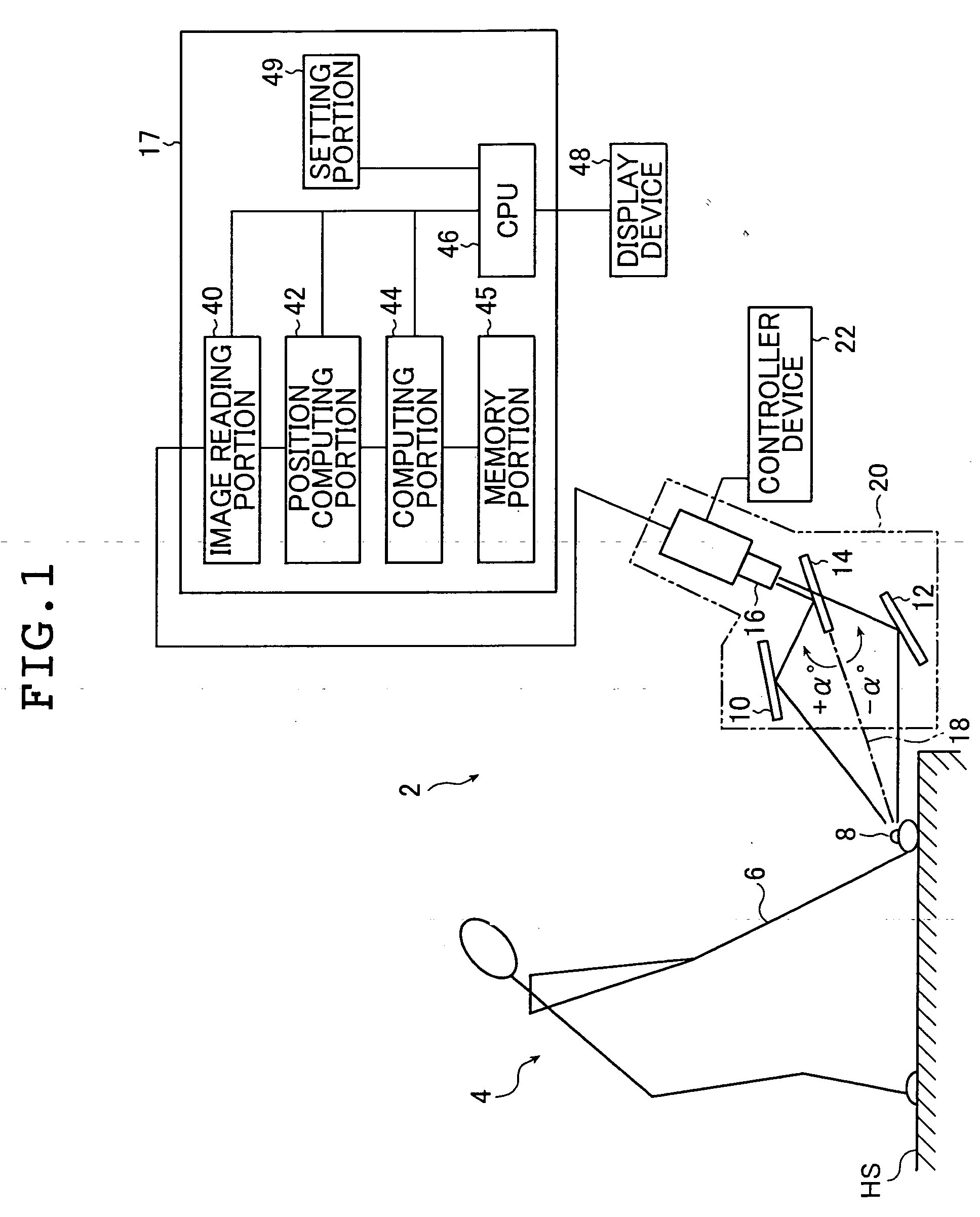

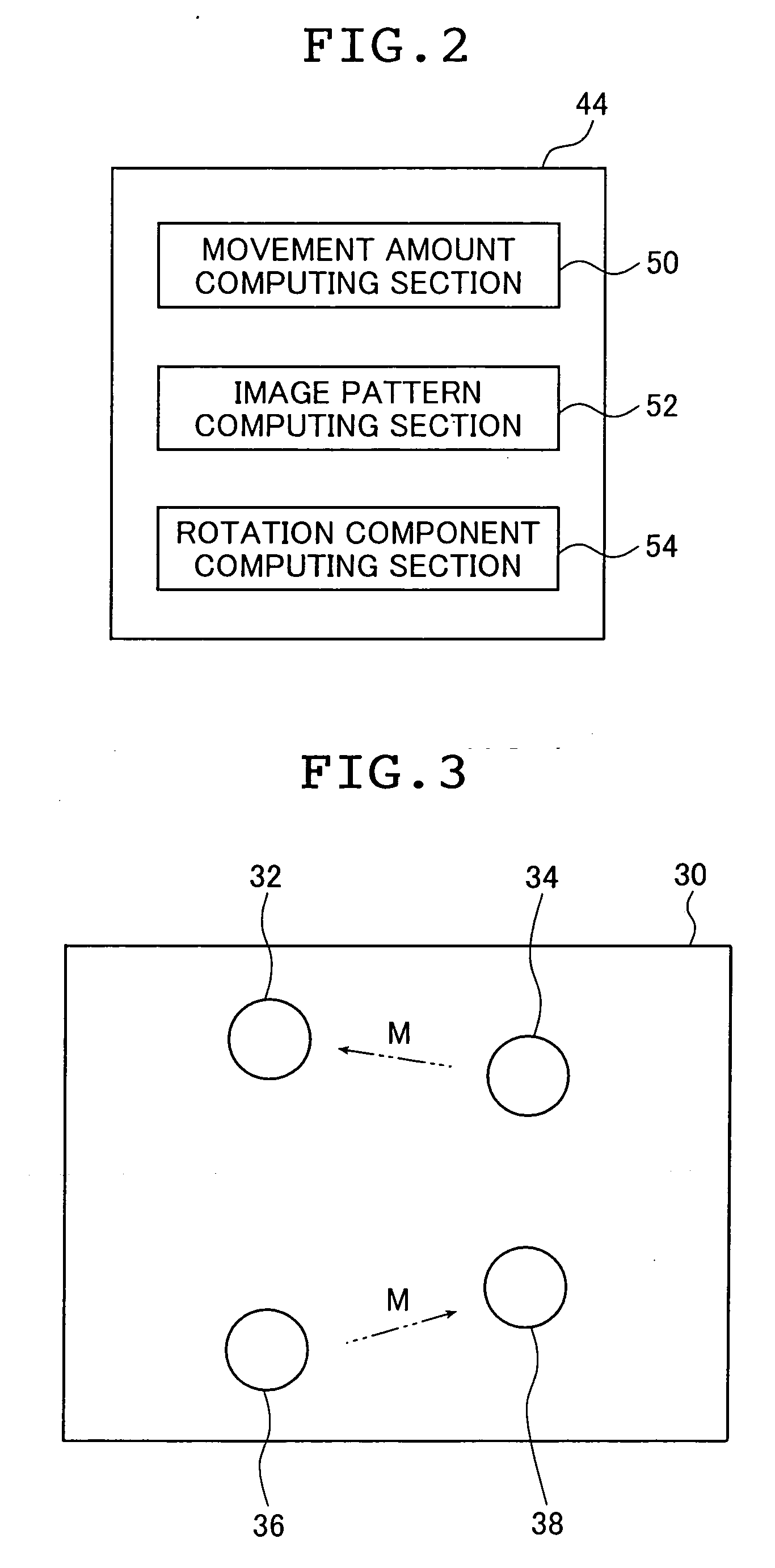

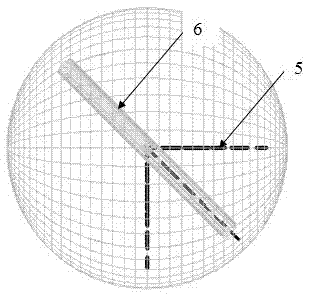

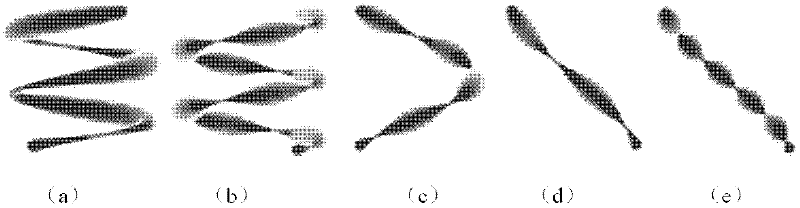

Apparatus and method of measuring the flying behavior of a flying body

InactiveUS20050233816A1Improve accuracyReduce measurementImage enhancementImage analysisComputer graphics (images)Flight behaviour

A measuring apparatus of a flying behavior of a spherical flying body has: a recording portion that optically records the flying body during flight with a predetermined interval of time, to obtain a first image and a second image of the fling body; image information computing portion that detects a first outline region of the flying body in the first image of the flying body and a second outline region of the flying body from the second image of the flying body, and finds first image information from the first image of the flying body in at least a portion of the first outline region and second image information from the second image of the flying body in the second outline region; and rotation amount computing portion that maps the first image information to a surface of a first virtual spherical body, the second image information to a surface of a second virtual spherical body, and computes a rotation amount that is used for rotation processing when the rotation processing is performed on the first virtual spherical body to obtain a highest correlation between the first image information and the second image information.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV +1

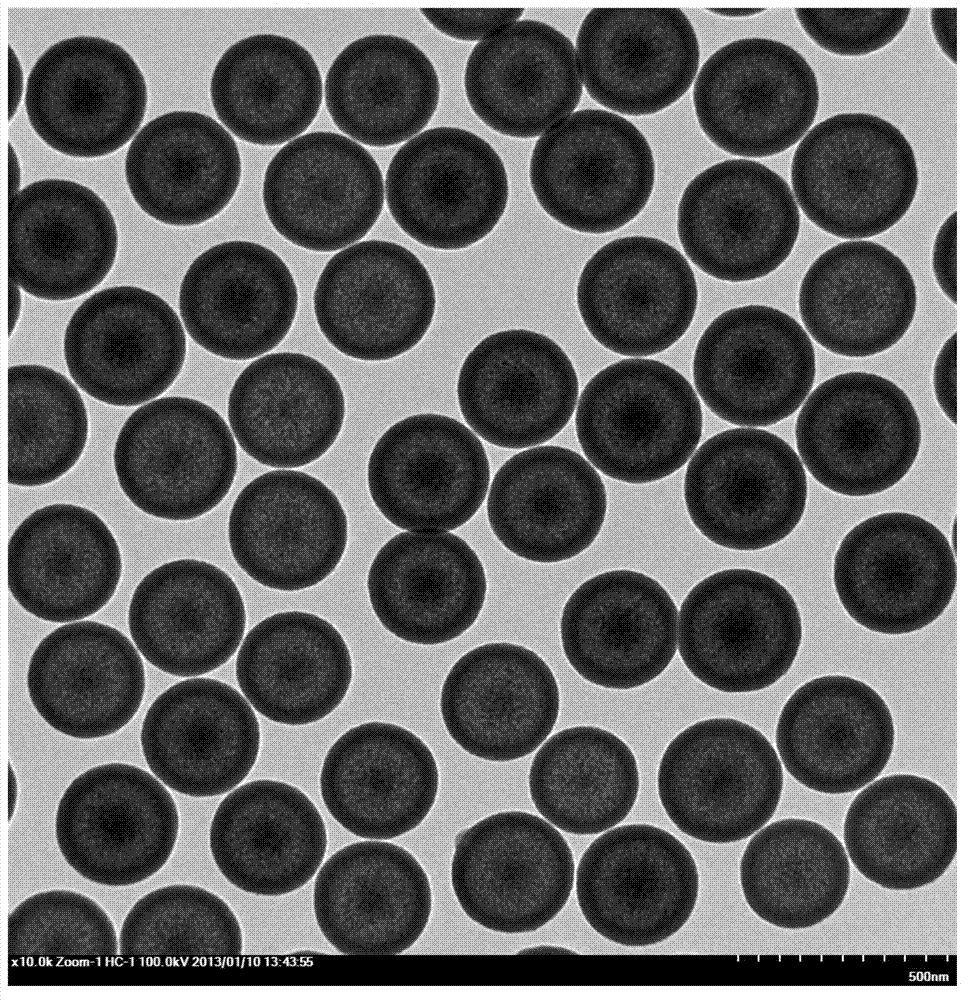

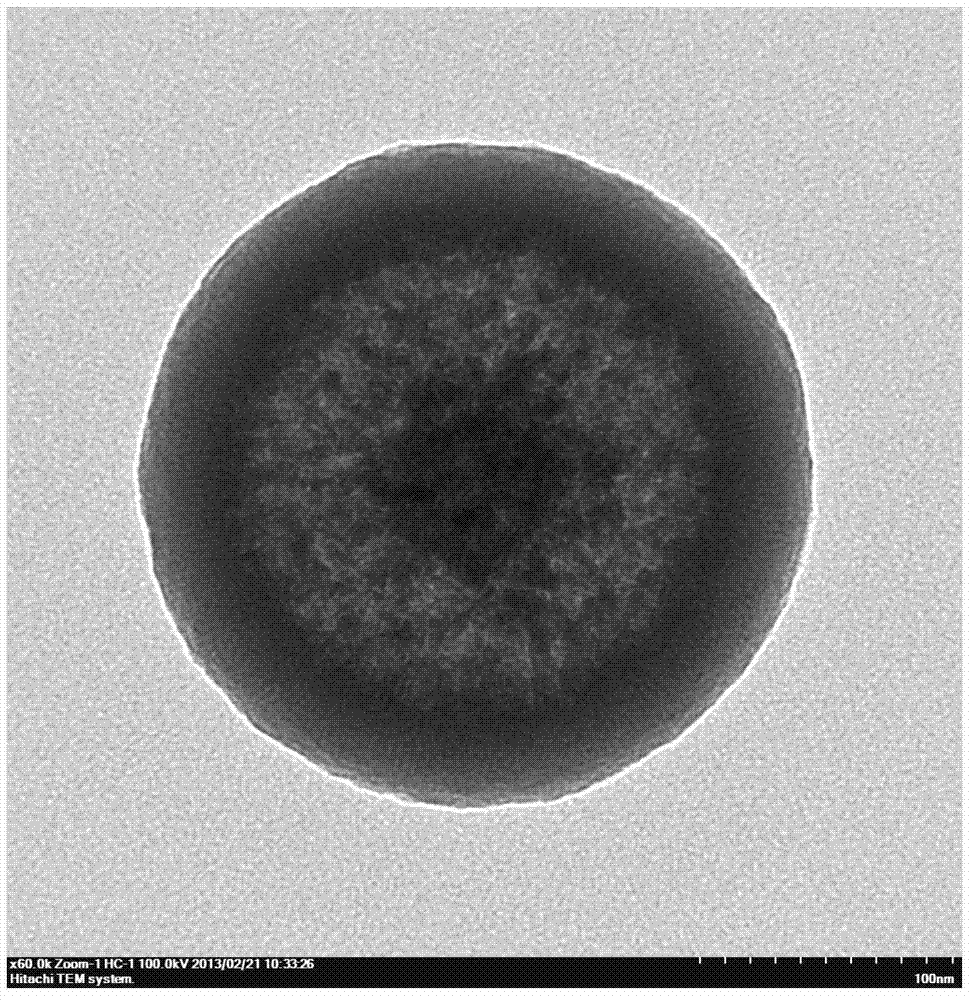

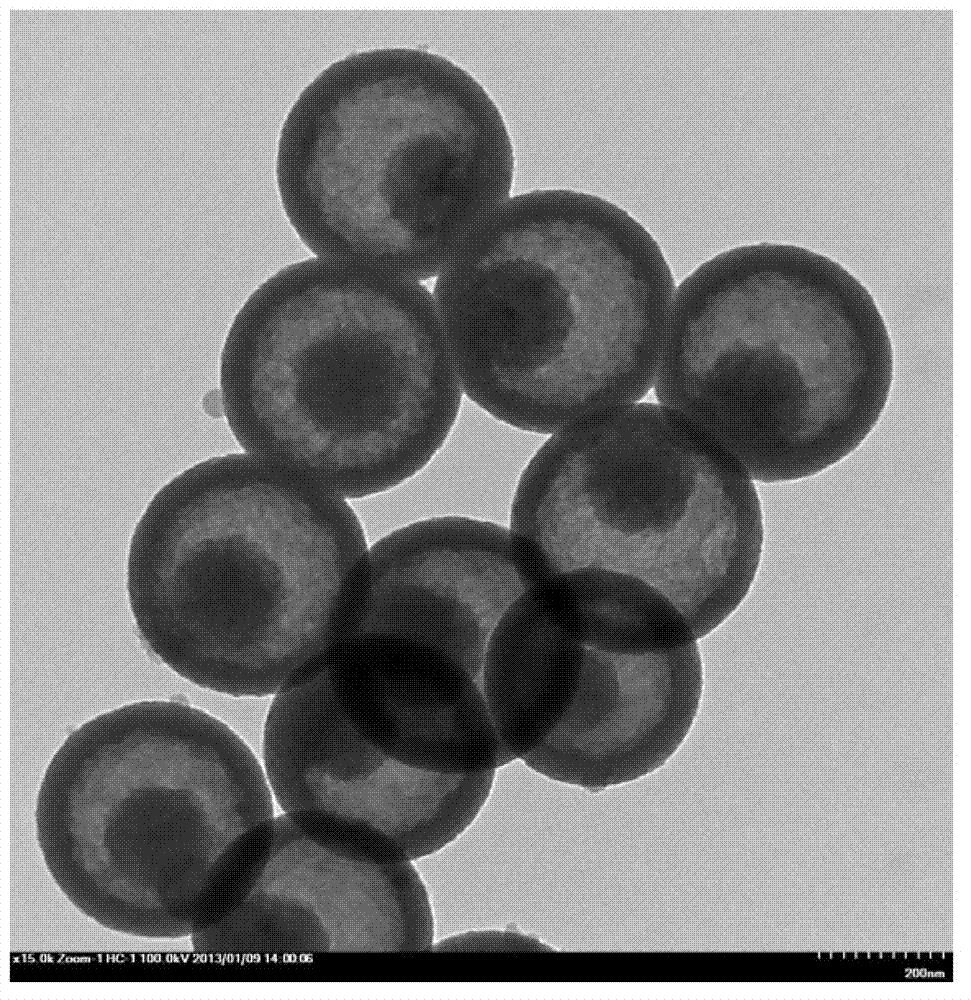

Mesoporous silica with yolk-shell structure and preparation method thereof

The invention discloses mesoporous silica with a yolk-shell structure and a preparation method thereof. The morphology of the mesoporous silica is of spherical bodies. The spherical body has a mesoporous core and a mesoporous shell. A cavity structure is between the mesoporous core and the mesoporous shell. Mesoporous silica balls have high specific surface area, uniform and adjustable particle size and uniform pore size. The preparation method of the mesoporous silica includes: dissolving a surface active agent in a mixed solution of ethanol, ammonia and water, adding two silica precursors into the mixed solution under heating and stirring conditions, transferring the obtained spherical silica into water after reacting for a period, etching to remove intermediate loose layers of silica balls, finally removing the surface active agent to obtain mesoporous silica products having the yolk-shell structure. The preparation method of the present invention has the characteristics of simple process, low cost, and environmental protection. The prepared mesoporous silica has great application potential in medical imaging, drug delivery and other fields.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

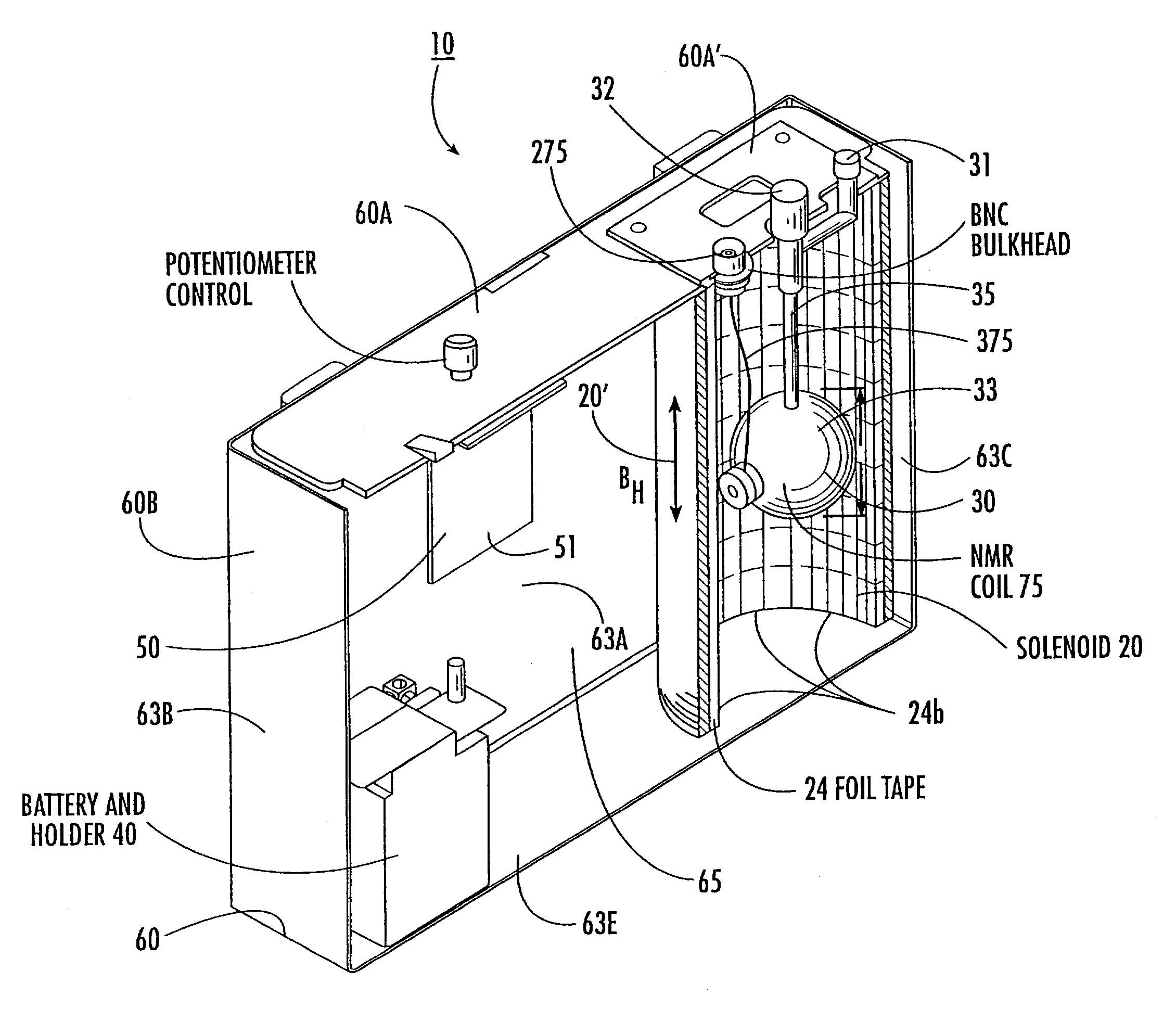

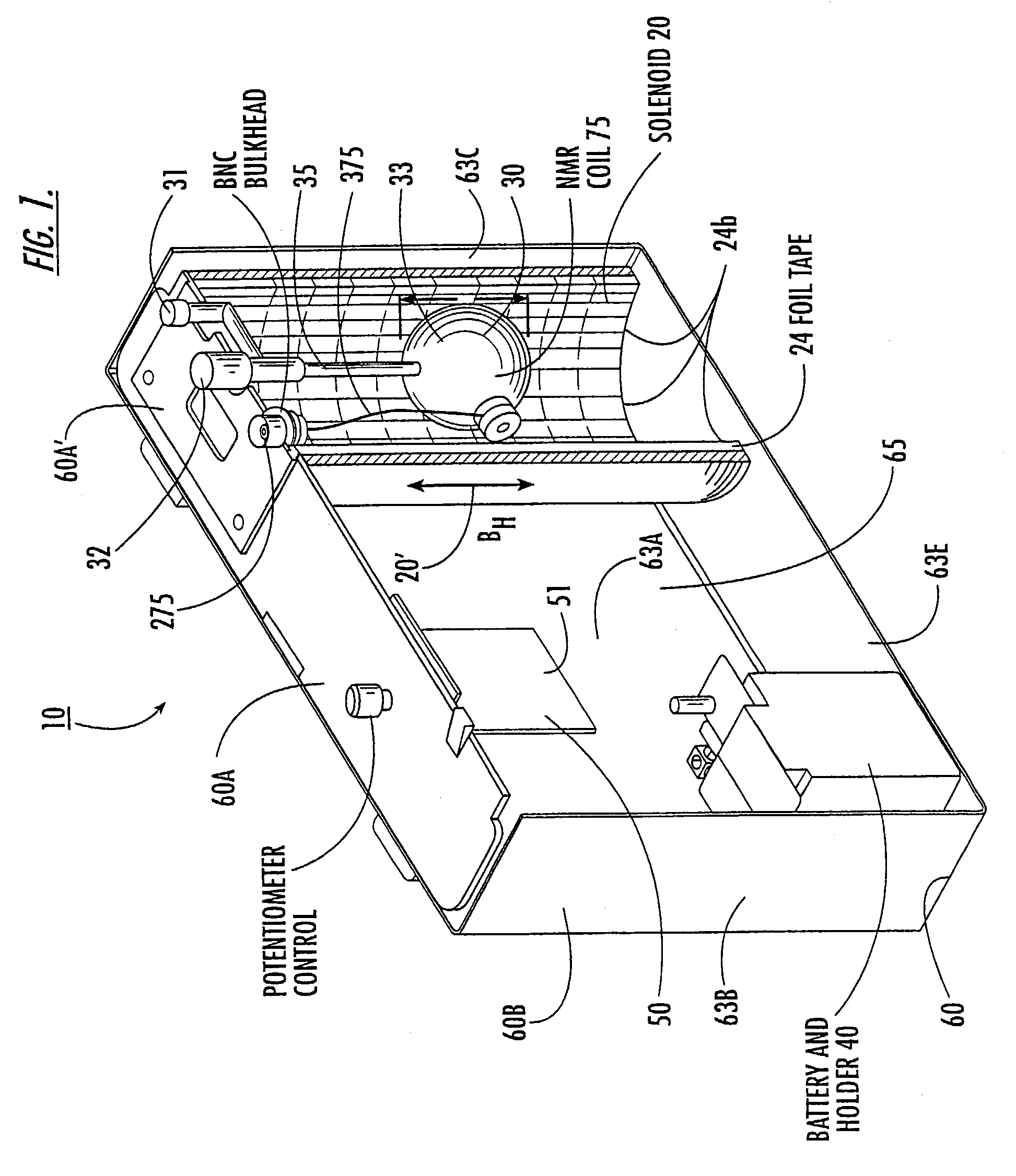

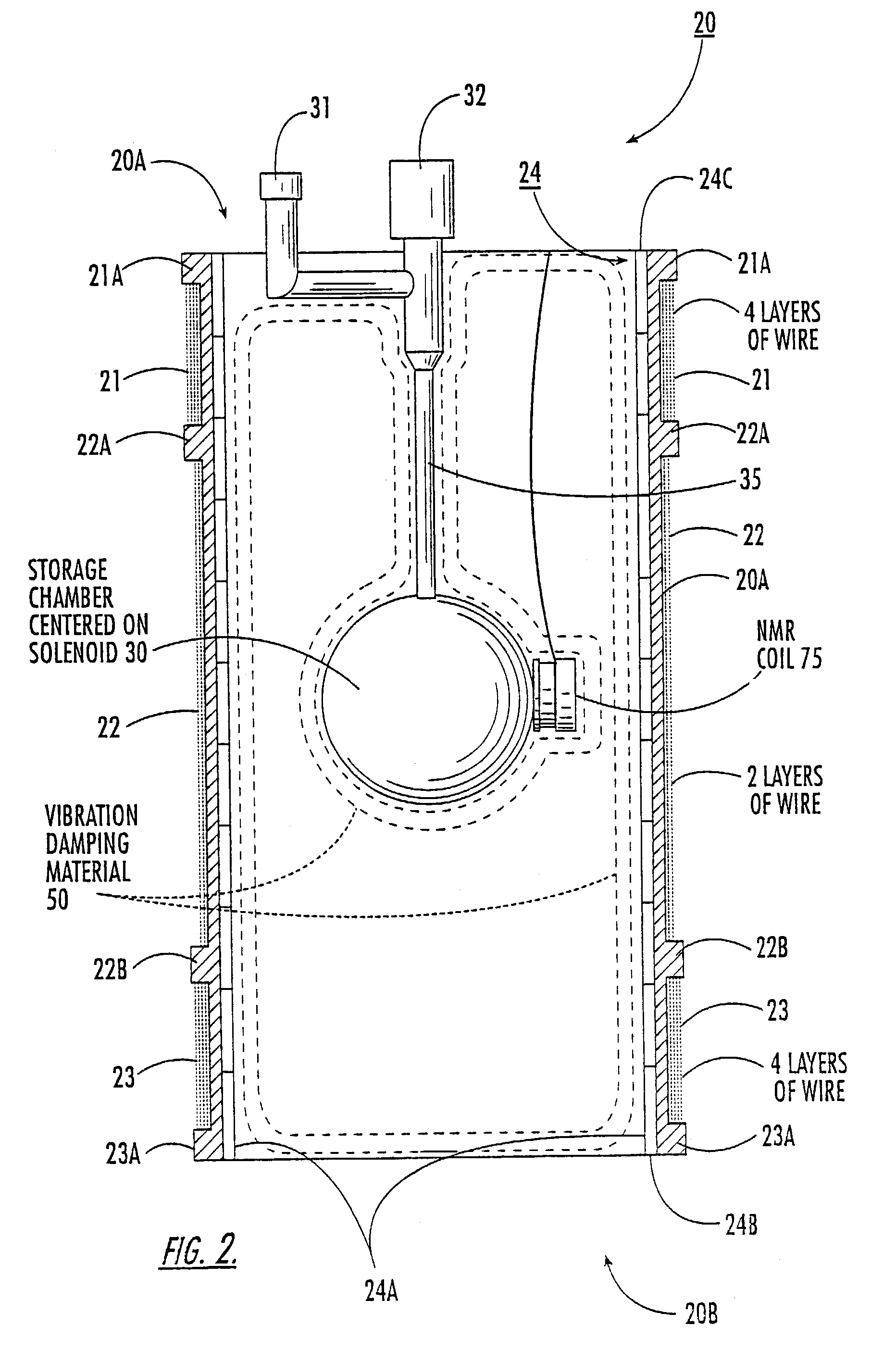

Hyperpolarized gas containers, solenoids, transport and storage devices and associated transport and storage methods

InactiveUS6995641B2Minimize impactEasy to transportLiquefactionDispersion deliveryNoble gasDistribution method

A compact portable transport unit for shipping hyperpolarized noble gases and shielding same from electromagnetic interference and / or external magnetic fields includes a means for shifting the resonance frequency of the hyperpolarized gas outside the bandwidth of typical frequencies associated with prevalent time-dependent fields produced by electrical sources. Preferably the transport unit includes a magnetic holding field which is generated from a solenoid in the transport unit. The solenoid includes a plurality of coil segments and is sized and configured to receive the gas chamber of a container. The gas container is configured with a valve, a spherical body, and an extending capillary stem between the valve and the body. The gas container or hyperpolarized product container can also be formed as a resilient bag. The distribution method includes positioning a multi-bolus container within the transport unit to shield it and transporting same to a second site remote from the first site and subsequently dispensing into smaller patient sized formulations which can be transported (shielded) in another transport unit to yet another site.

Owner:POLAREAN

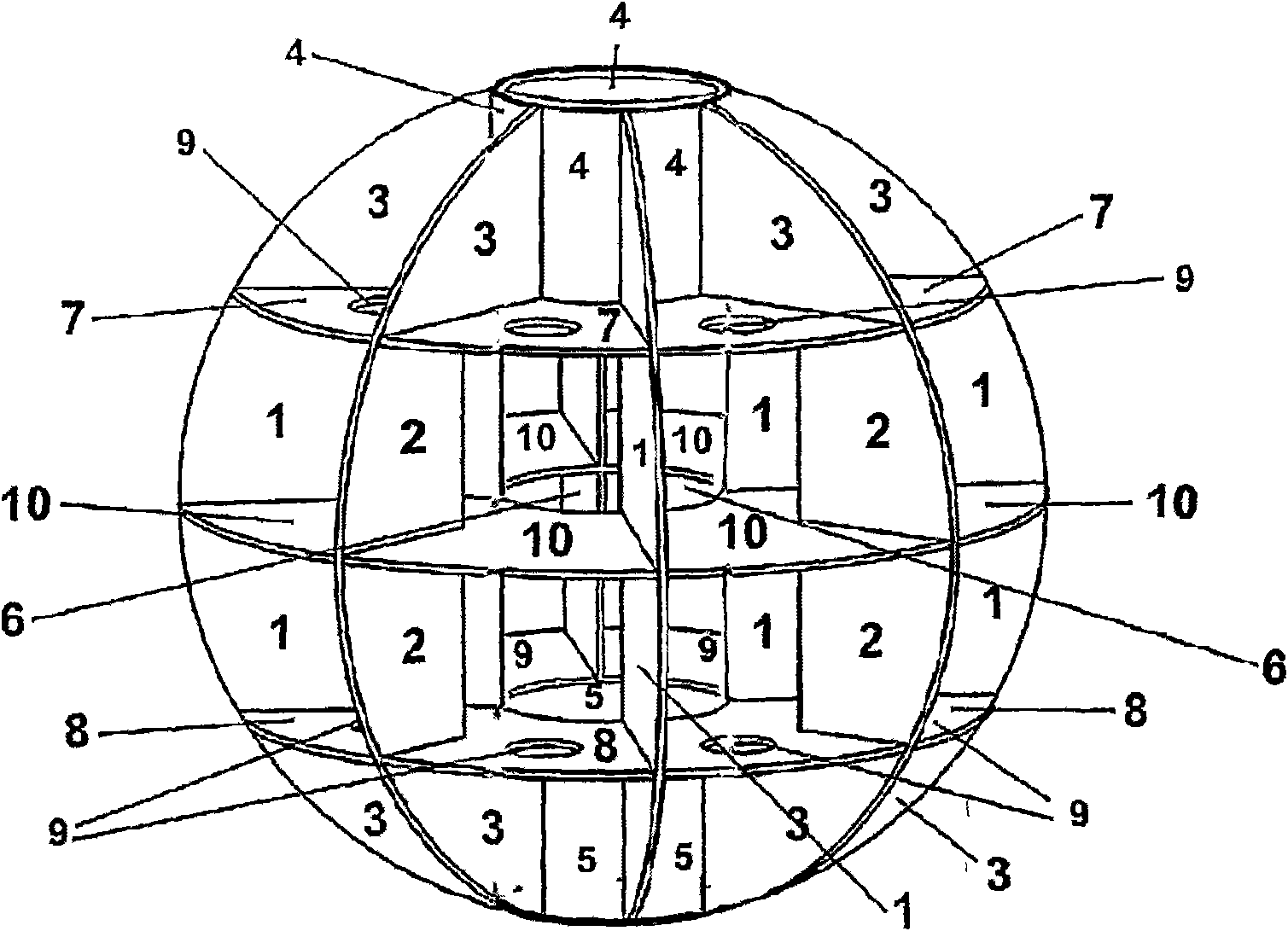

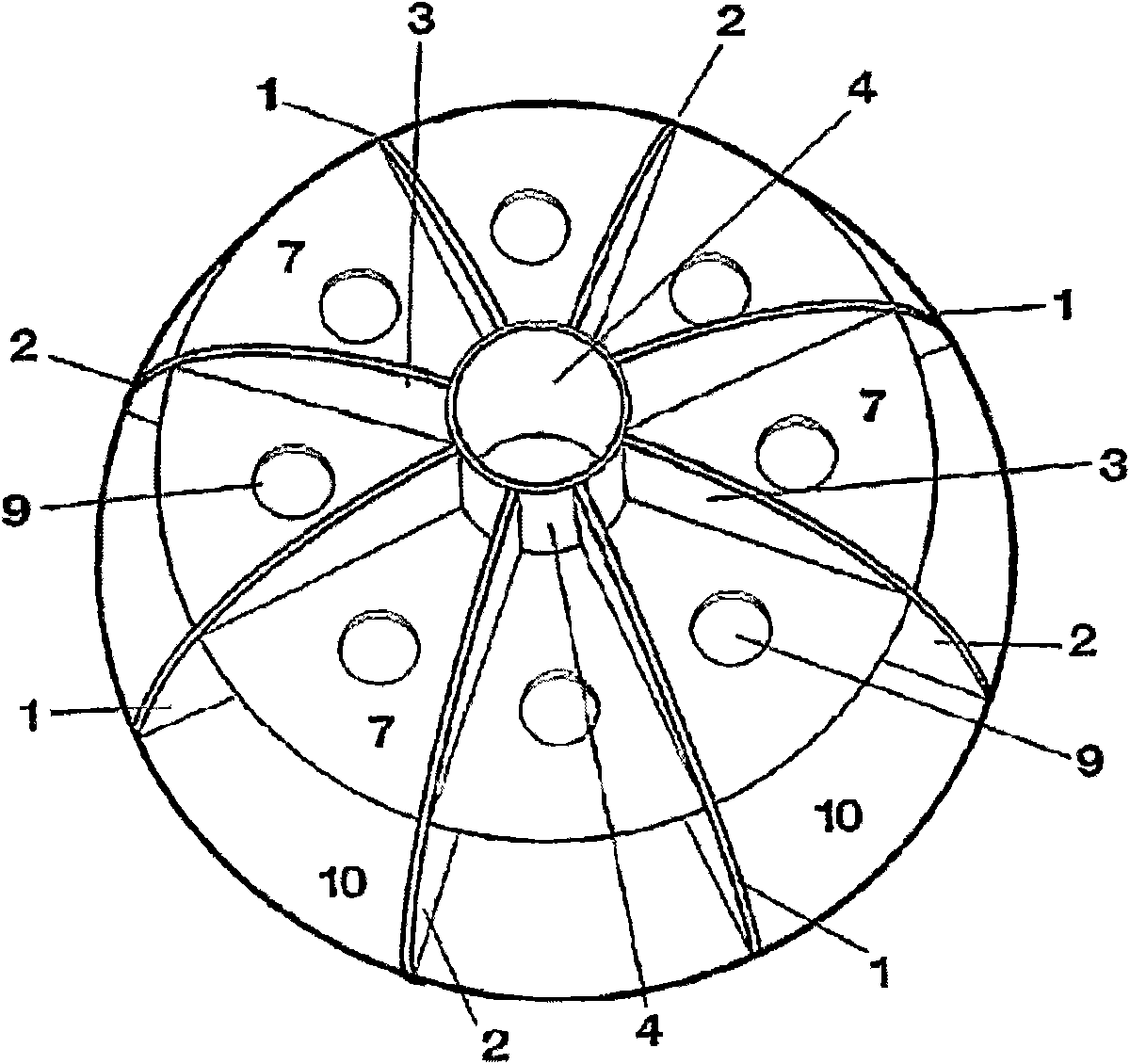

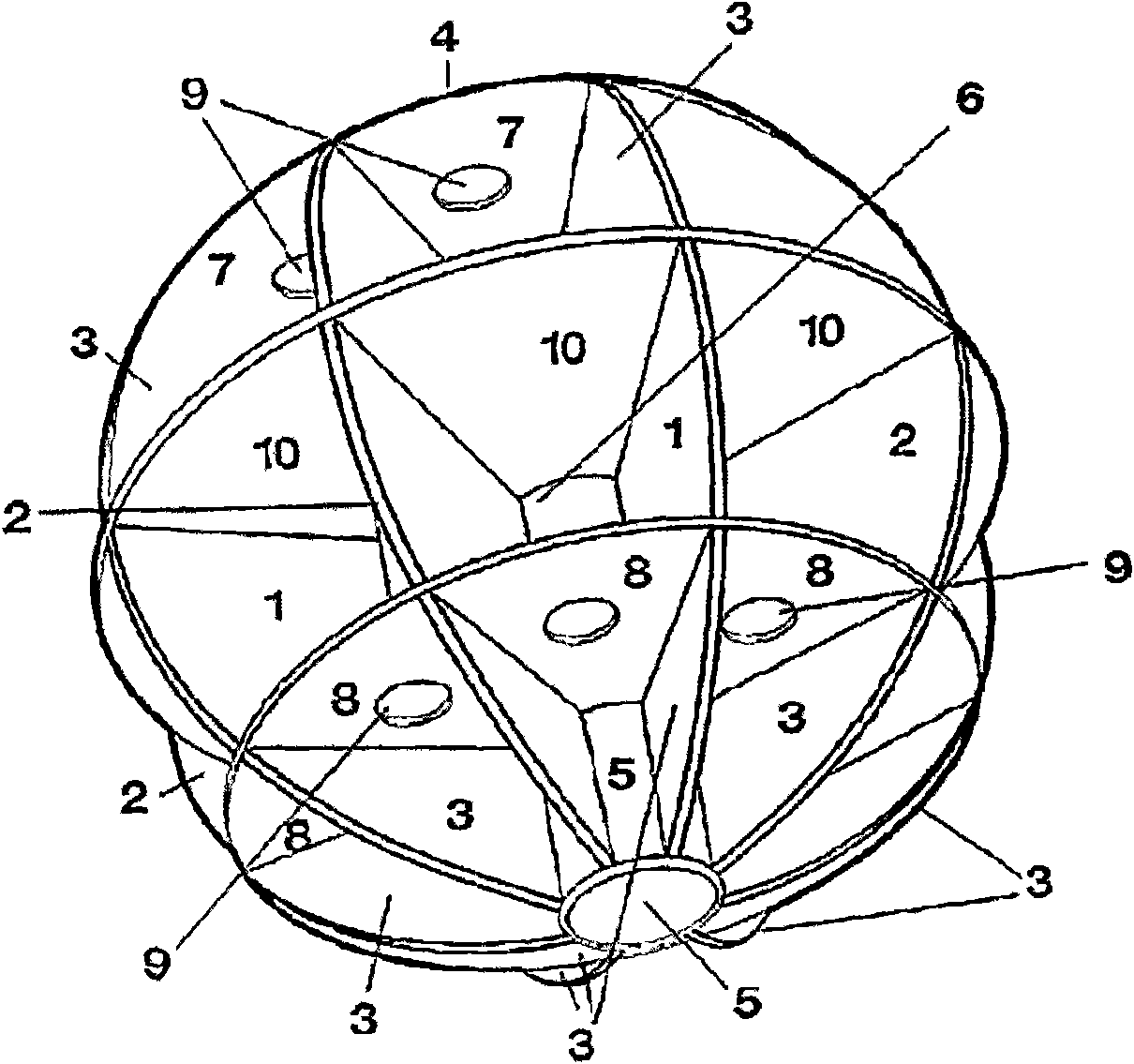

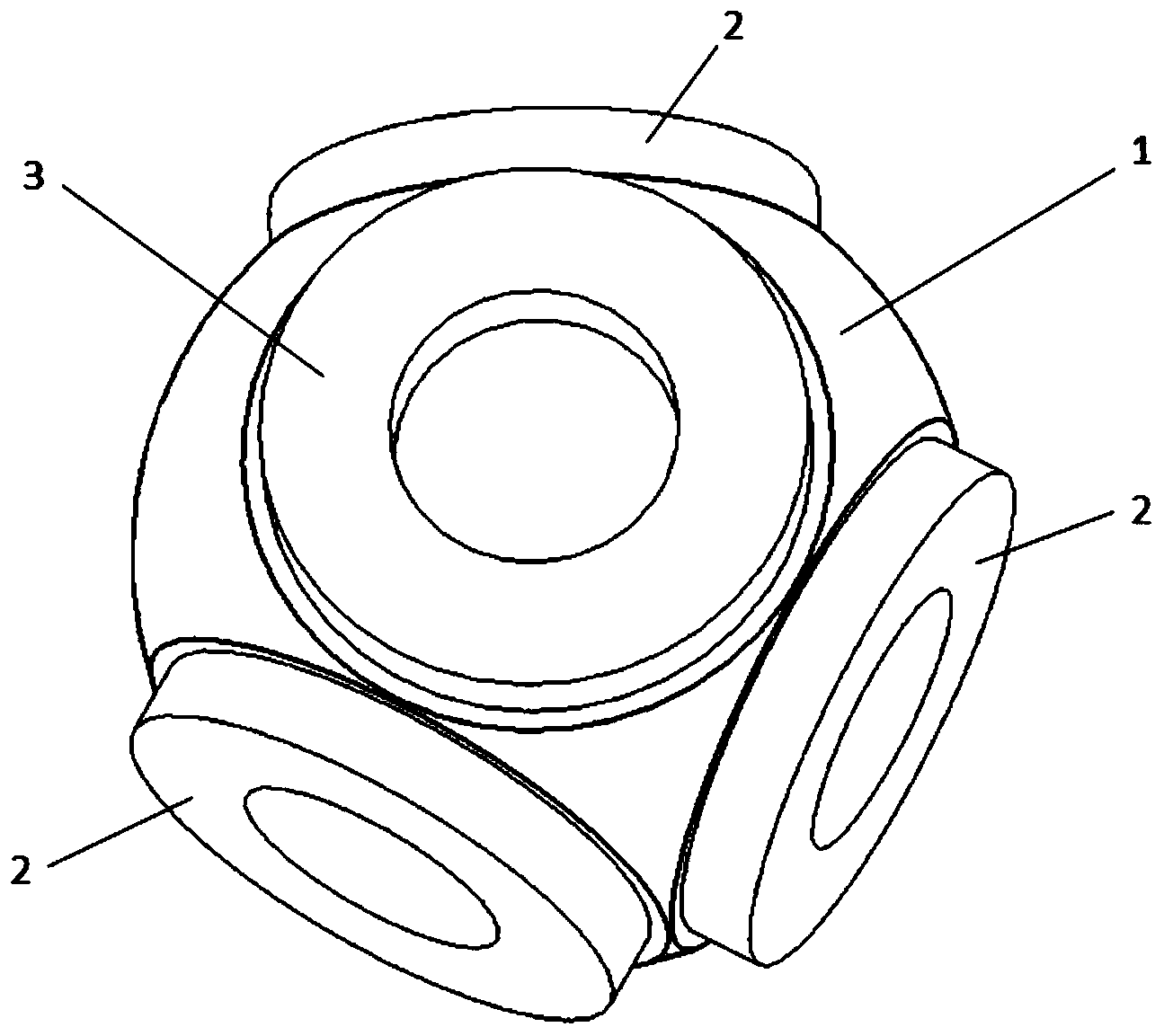

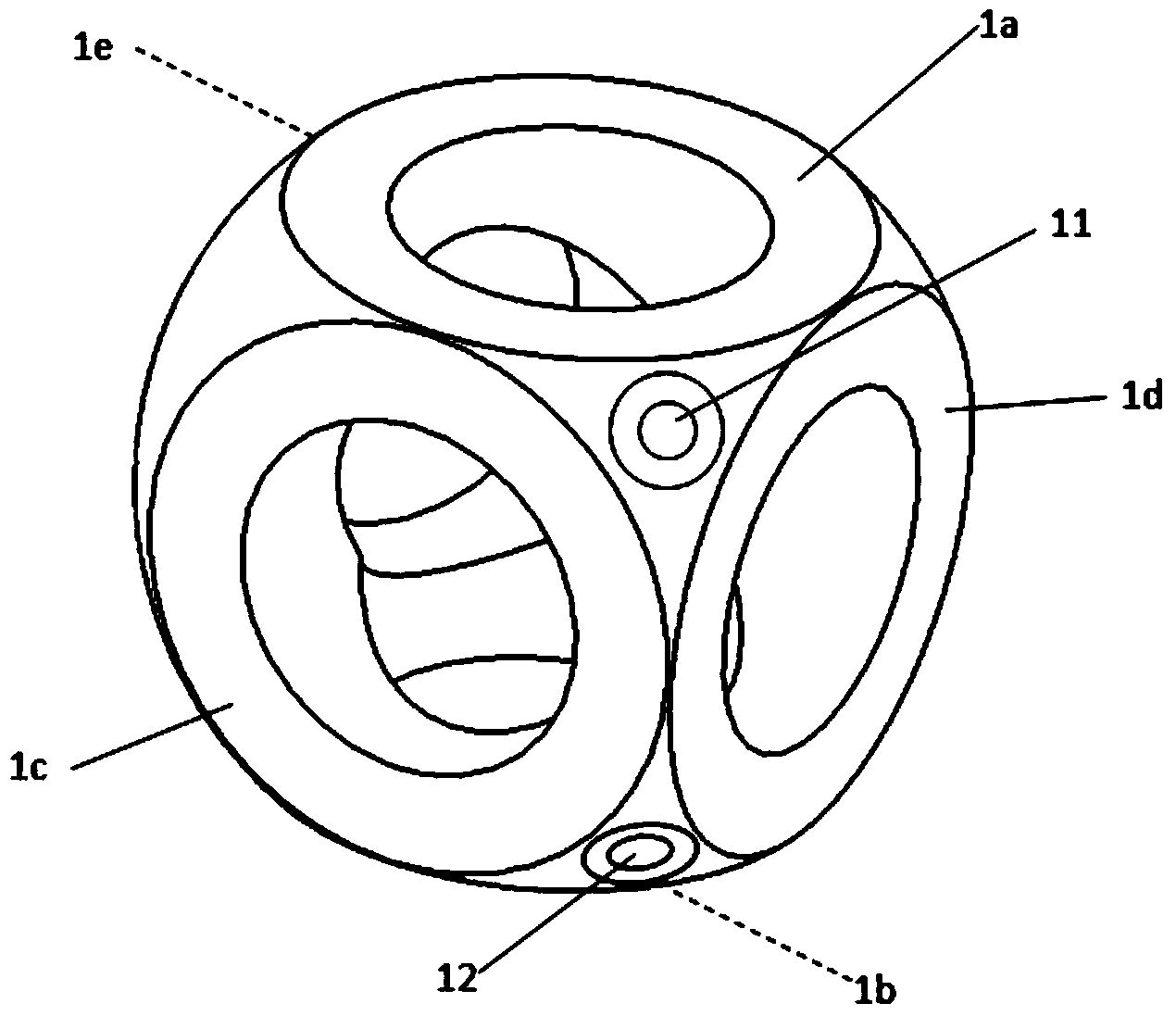

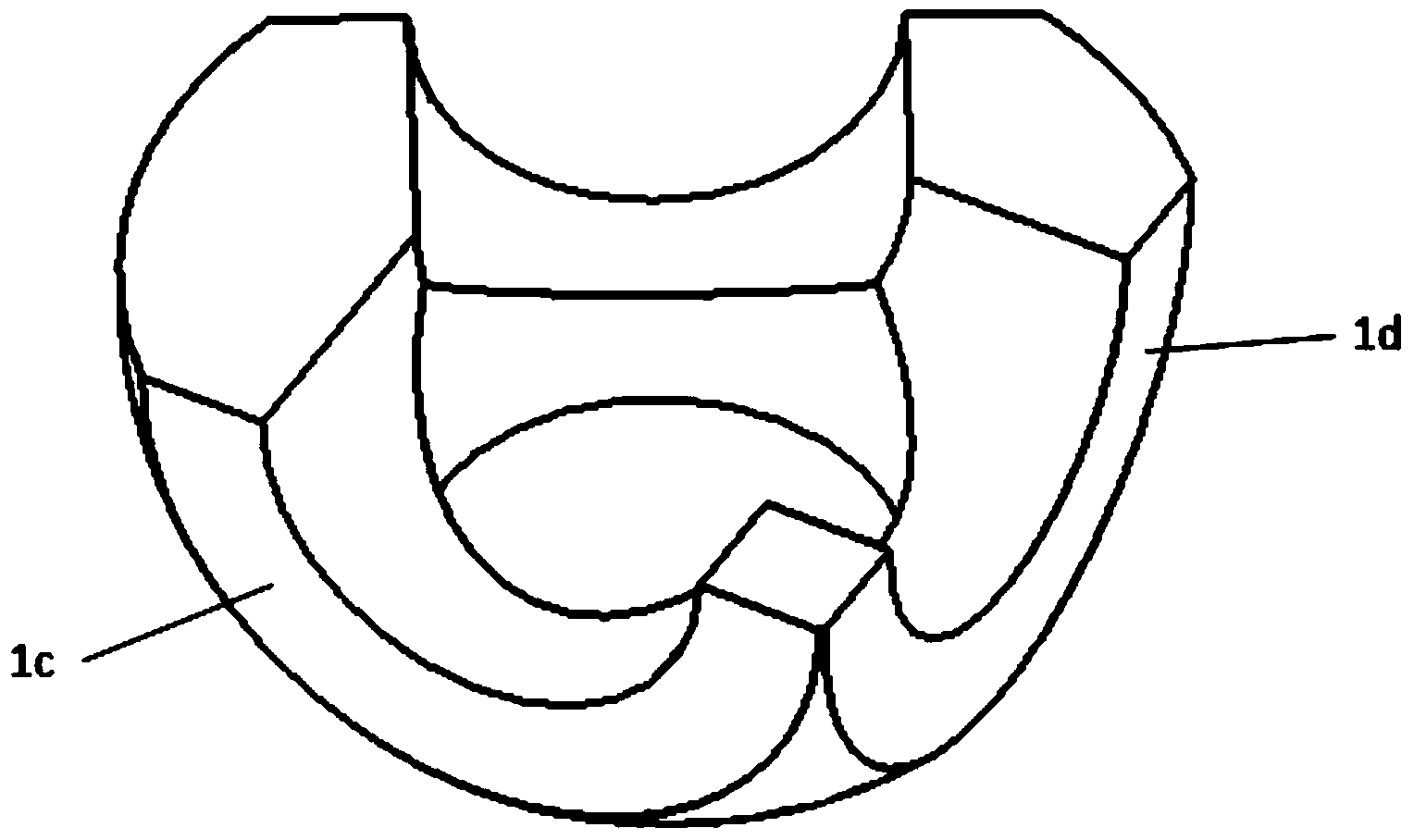

Spherical filling body

The invention relates to the production of a spherical hollow filling body for filling containers for combustible and inflammable liquids or gases, and to a method for the especially advantageous usesthereof, for example, for preventing explosive combustion processes and explosions, for extinguishing fires, as protection against corrosion in tanks, for separating fuels and water, as protection ag ainst bacteria and fungi in fuel tanks, as protection against theft, for reducing hydrocarbon emissions, for increasing the stability and safety of tanks in the event of a crash, for reducing the boil-off effect of hydrogen, for applications in the chemical industry, for deriving static electricity from fuel containers, for protection against electromagnetic interferences, for reducing and slowingdown the B.L.E.V.E. effect, for increasing the filling quantity of gas containers, for heating and cooling liquids and gases, and for reducing evaporation loss. The invention also relates to methodsfor producing the filling body. Figure 1 shows a spherical filling body according to the invention, consisting of a plurality of disk-type circular vertical surfaces (1, 2 and 3) and a plurality of disk-type circular horizontal surfaces (7, 8 and 10) which are parallel to each other. A circular opening (6) is located in the centre of the horizontal surface (10), said opening forming an axial continuous tube in the centre, from the top (4) to the bottom (5), together with the upper, inwardly open, circular sleeve-type body (4) and the lower, inwardly open, circular sleeve-type body (5), the inner diameters of the sleeve-type, inwardly open circular bodies (4 and 5) and the circular opening (6) being identical. The vertical surfaces (1) extend from the outer edge of the spherical body to theedge of each circular opening (4, 5 and 6) of the parallel horizontal surfaces (7, 10 and 8) respectively surrounding the openings.

Owner:托马斯·K·斯特尔泽尔

Device and method for integrated collection of stress and displacement of surrounding rocks

InactiveCN102818665ACan measure three-dimensional stressThree-dimensional stress can be calculatedForce measurement by measuring optical property variationUsing optical meansFiberStress measurement

The invention discloses a device for integrated collection of stress and displacement of surrounding rocks, which comprises a spherical body, a casing pipe, a steel wire and an optical cable, wherein a threaded hole is formed by drilling along one diameter of the spherical body; a fiber bragg grating is adhered along six different directions in the spherical body respectively; one end of the steel wire is fixed on the spherical body; and one end of the optical cable is connected with the fiber bragg gratings in the spherical body. According to the device and the method for integrated collection of stress and displacement of surrounding rocks disclosed by the invention, three-dimensional stress of a point can be calculated by measuring stresses in six directions of the point, and stress and displacement can be simultaneously measured in one drill hole, therefore, not only comparison and analysis are convenient, but also accuracy of a test result is ensured as mutual interference among a plurality of near-distance drill holes is avoided, and meanwhile, workloads of the drill holes are decreased; the fiber gratings are not influenced by electromagnetic, humid and corrosive environments, and the spherical body is sufficiently contacted with the surrounding rocks as well as with slurry poured in the holes, so that accuracy and reliability of stress measurement result are guaranteed; furthermore, the spherical body is fixed in surrounding rock holes in a way that slurry is poured into the surrounding rock holes, looseness of the spherical body is avoided, as a result, a wrong displacement test result is prevented.

Owner:CHINA UNIV OF MINING & TECH

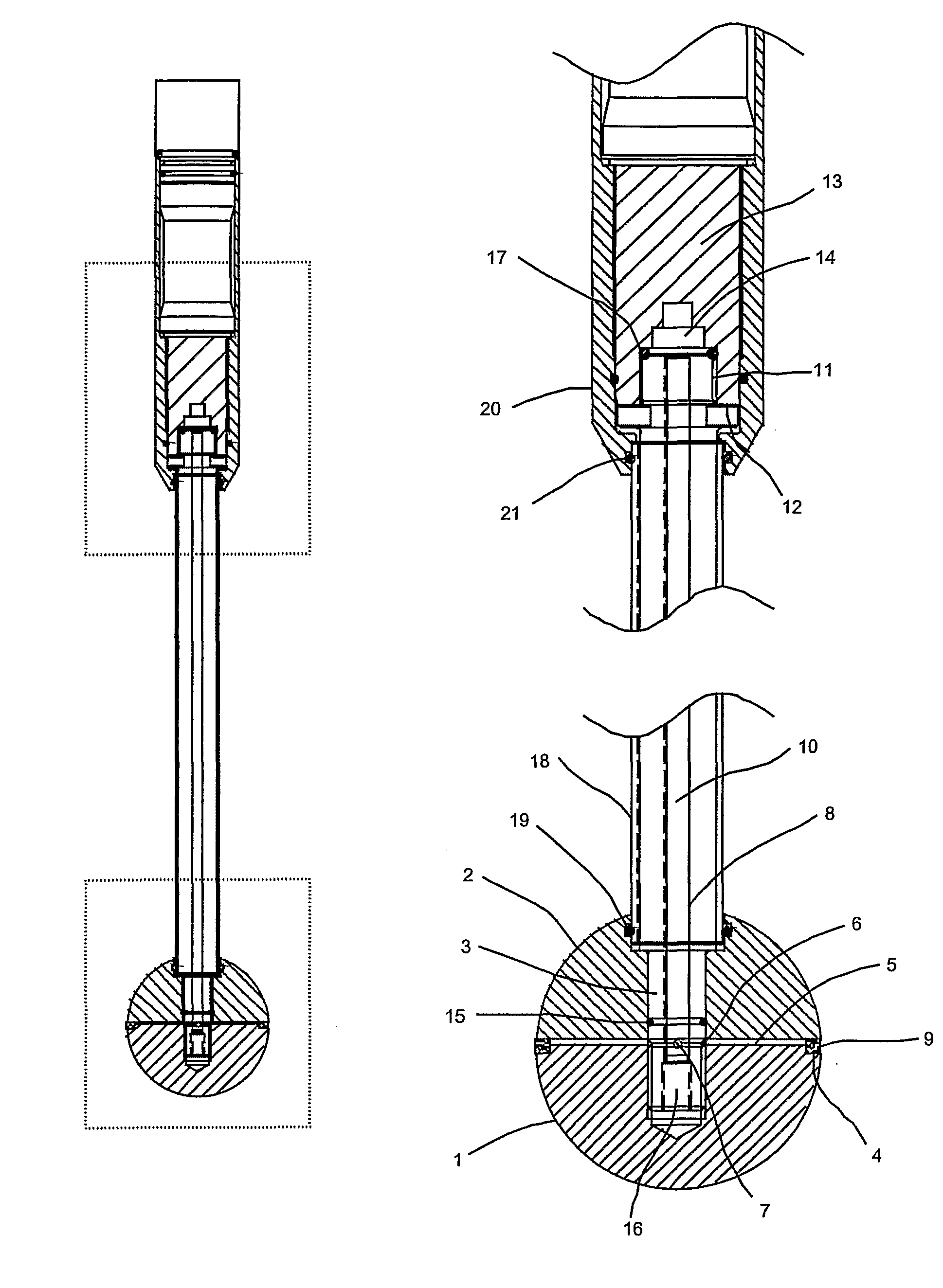

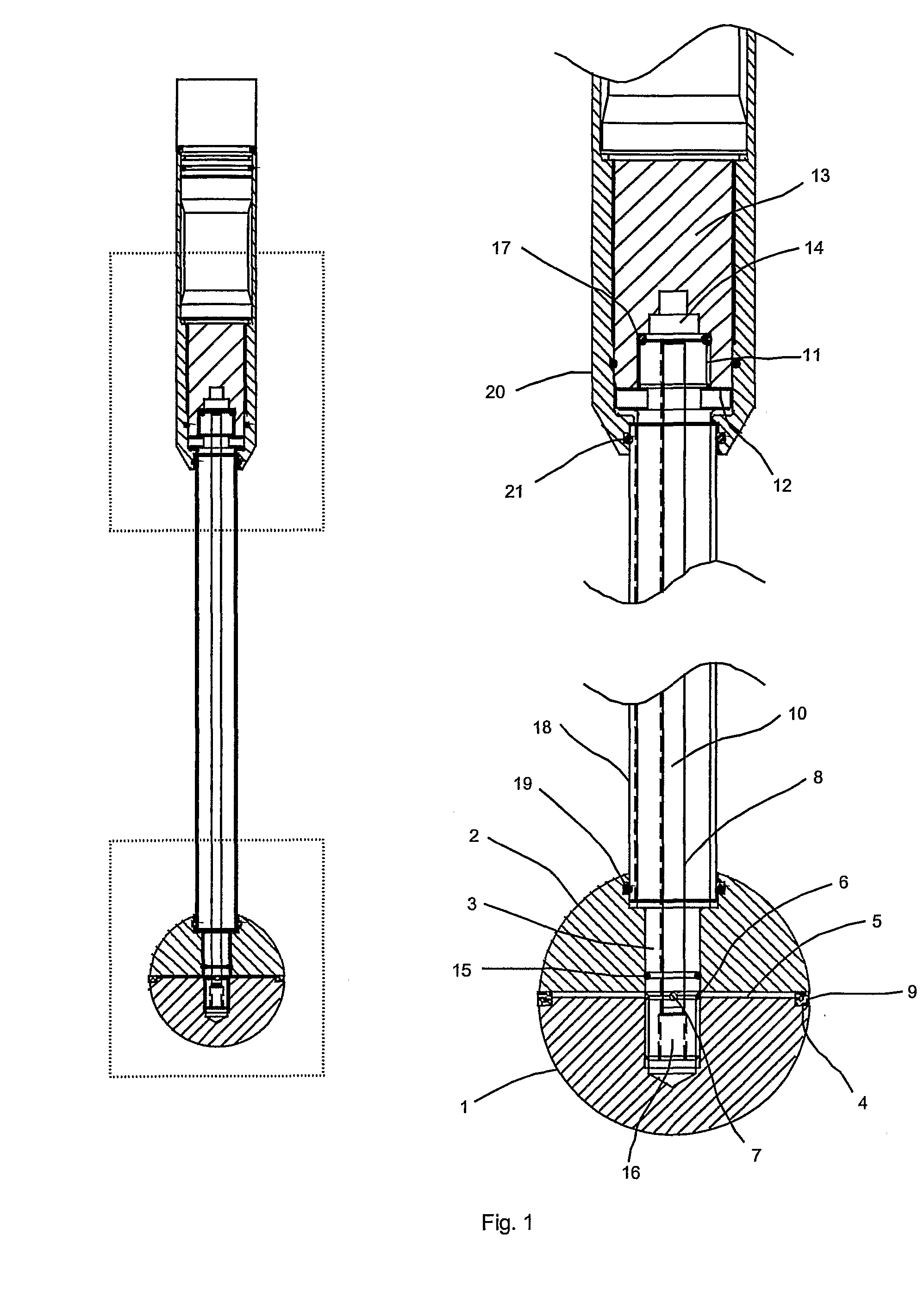

Ball penetrometer for soft soils testing

A ball penetrometer probe for in situ measurement of soft soil properties, particularly in the seabed, comprises a spherical body and slender shaft assembly, and either individually or in combination, an anti-friction sleeve enclosing the shaft and / or a peripheral porous ring on the spherical body with connecting internal passages through the shaft assembly, the shaft being adapted to attach to an electronic transducer module. The ball penetrometer is deployed to penetrate the soil bed, to continuously measure the soil bearing forces resisting penetration and withdrawal of the ball, to optionally measure the pore water pressure of the soil in contact with the ball and to transmit the measurement data from the probe to a remote operating station, either by wireless means such as an acoustic transducer or via a wired electrical connection.

Owner:BENTHIC GEOTECH PTY LTD

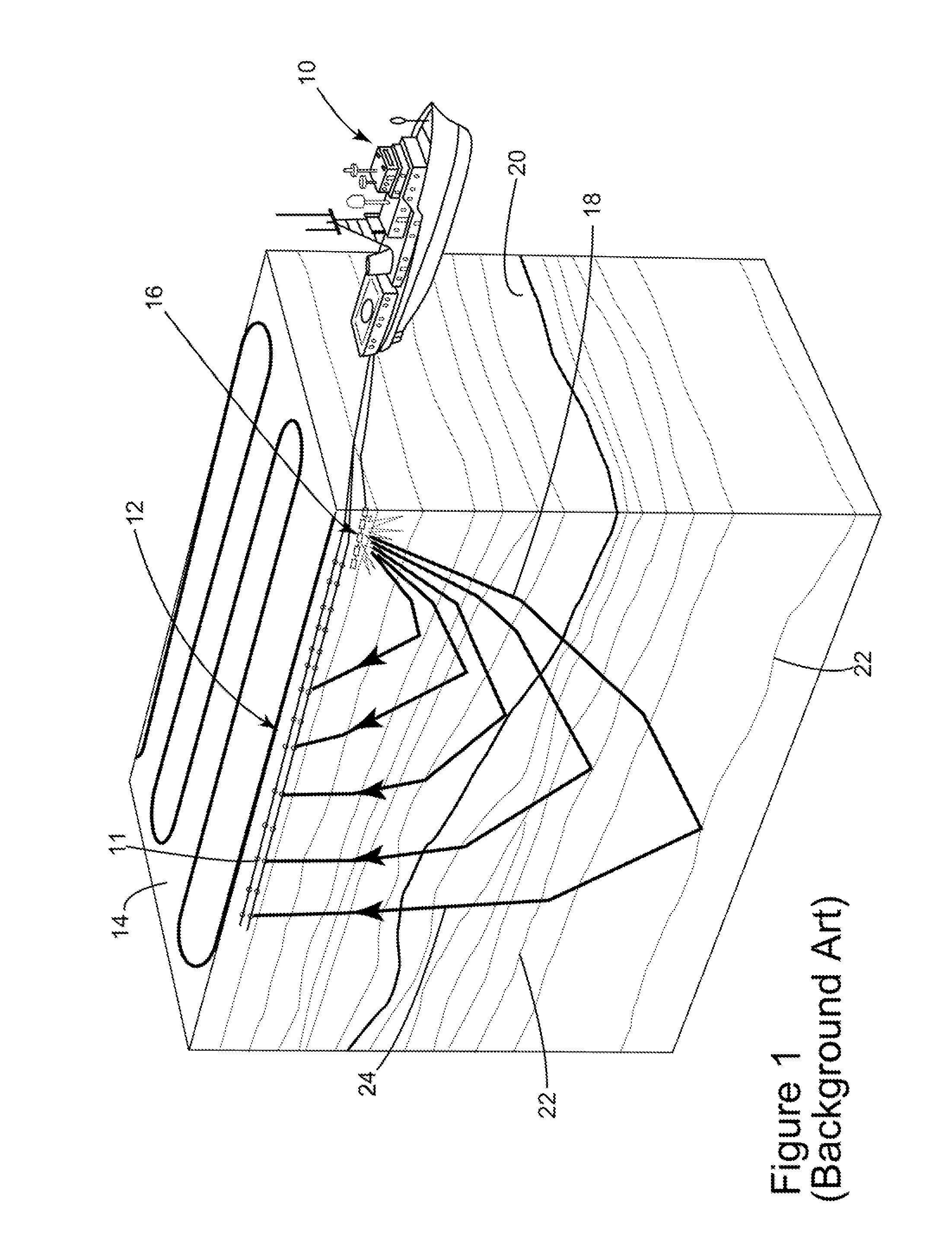

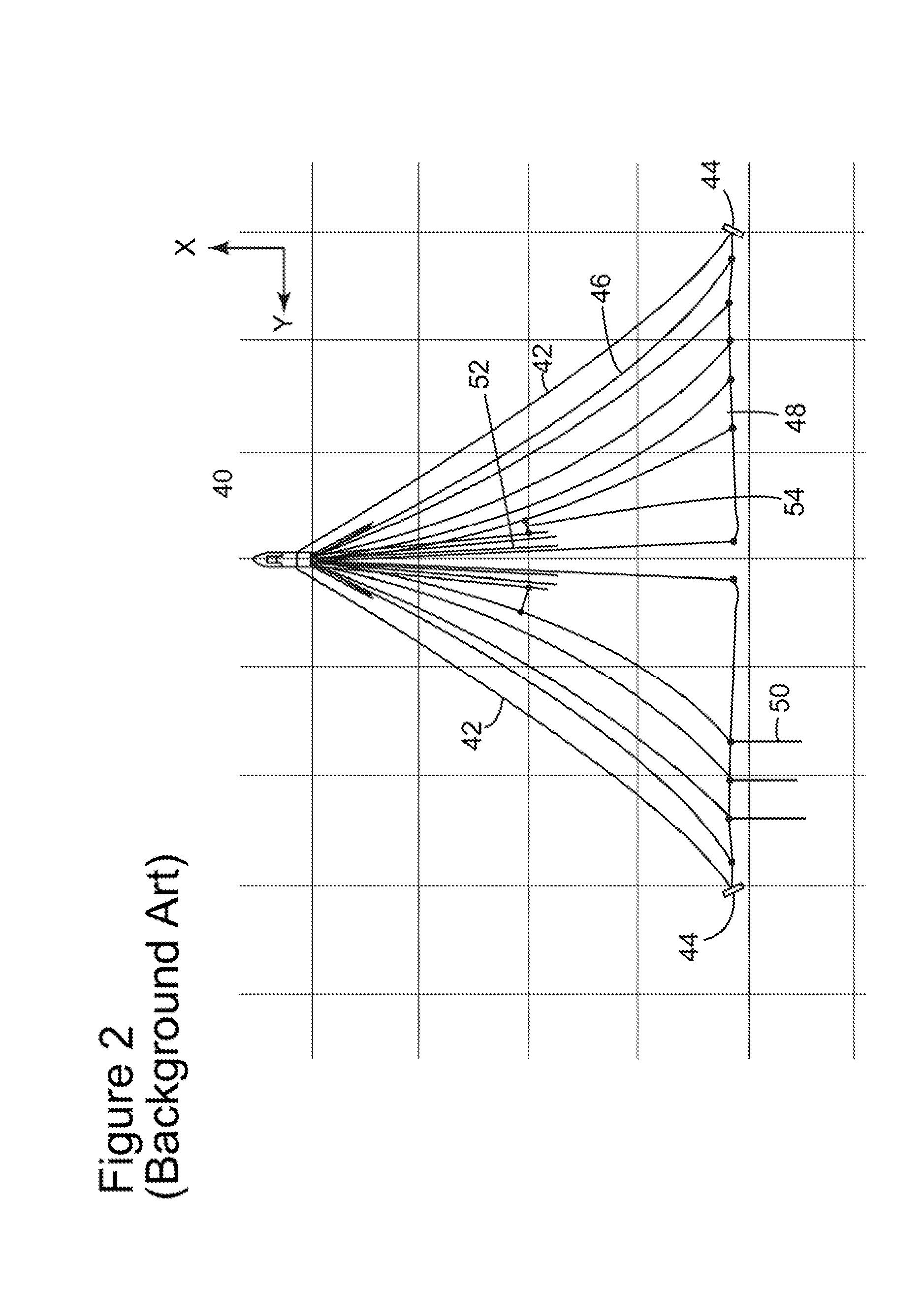

Water-coupled underwater node for seismic surveys

A marine node for recording seismic waves underwater. The node includes a spherical body made of a material that has a density similar to a density of the water so that the body is buoyant neutral; a first sensor located in the body and configured to record three dimensional movements of the node; a second sensor located in the body and configured to record pressure waves propagating through the water; and one or more cables connected to the first and second sensors and configured to exit the body to be connected to an external device. The body is coupled to the water.

Owner:SEABED GEOSOLUTIONS

Blood vessel modeling method

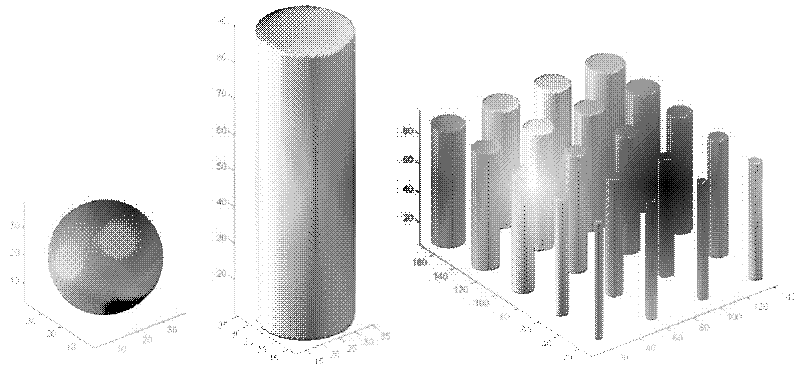

ActiveCN102521873AMeet clinicalFulfil requirements2D-image generation3D-image renderingProportional controlModel method

The invention relates to a blood vessel modeling method, which comprises the following steps of: constructing density distribution of spherical bodies, cylindrical bodies and target bodies; using the constructed spherical bodies to generate a tubular target; using Gaussian noise to simulate a target background; using a Markov statistical model to generate textures of the background; and using a proportional control method to fuse the background with the target to form a simulated image. The blood vessel modeling method can provide a systematic simulation training dataset for mathematic split models of various medical images such as computerized tomography (CT) or magnetic resonance (MR) angiograms.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Acetabular component insertion and extraction tool for use therewith, and method of locking an acetabular component to an insertion and extraction tool

An acetabular component comprises a thin-walled, partial spherical body having an inner surface defining an articular surface and having angled recesses along an outer surface of the body for releasable engagement with an insertion and extraction tool. An insertion and extraction tool comprises a spring-loaded locking member movable from an extended position to a retracted position in response to relative sliding movement of an outer sleeve and inner shaft of the tool effected via an actuating force at a proximal end of the tool. The tool comprises engagement members insertable in the recesses when the locking member is retracted and, upon release of the actuating force, the locking member automatically returns to the extended position causing fingers of the locking members to enter the recesses and lock the acetabular cup to the tool.

Owner:MICROPORT ORTHOPEDICS HLDG INC

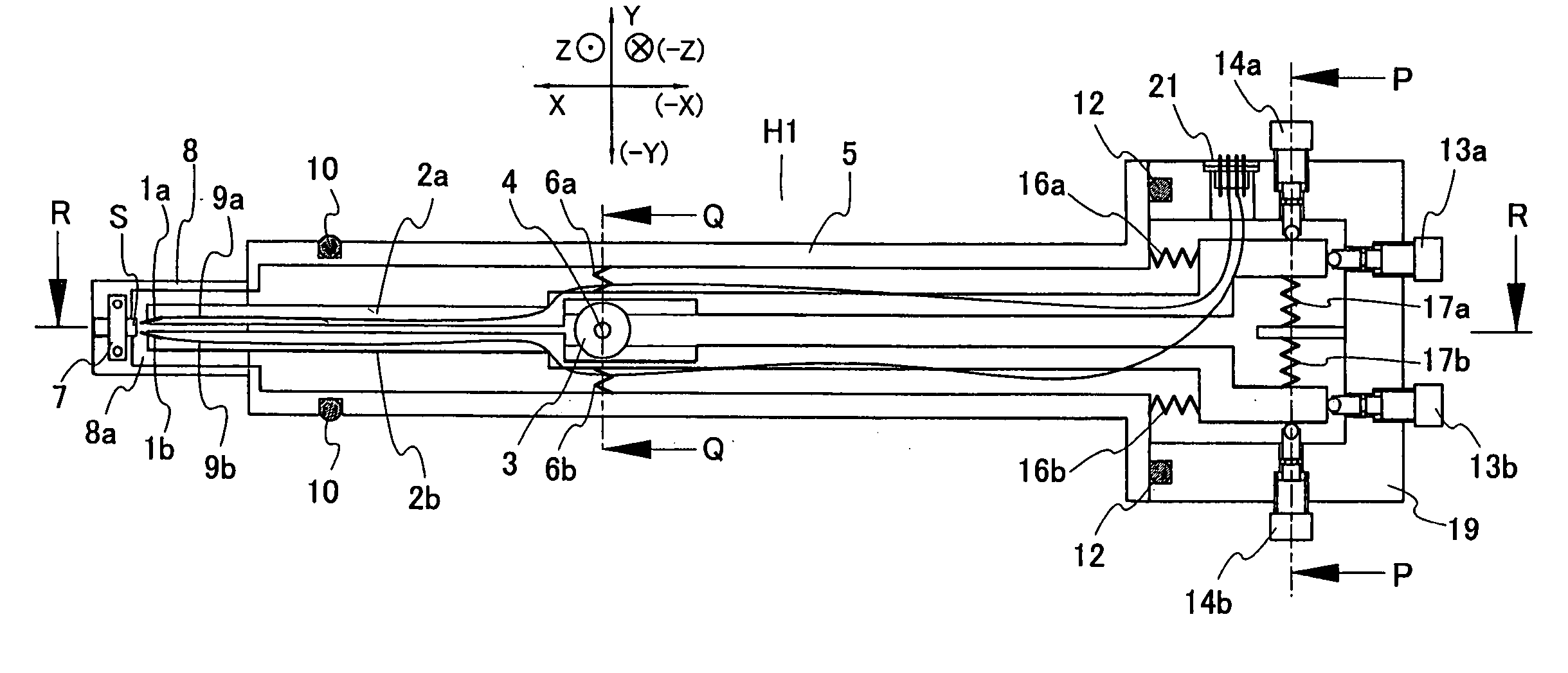

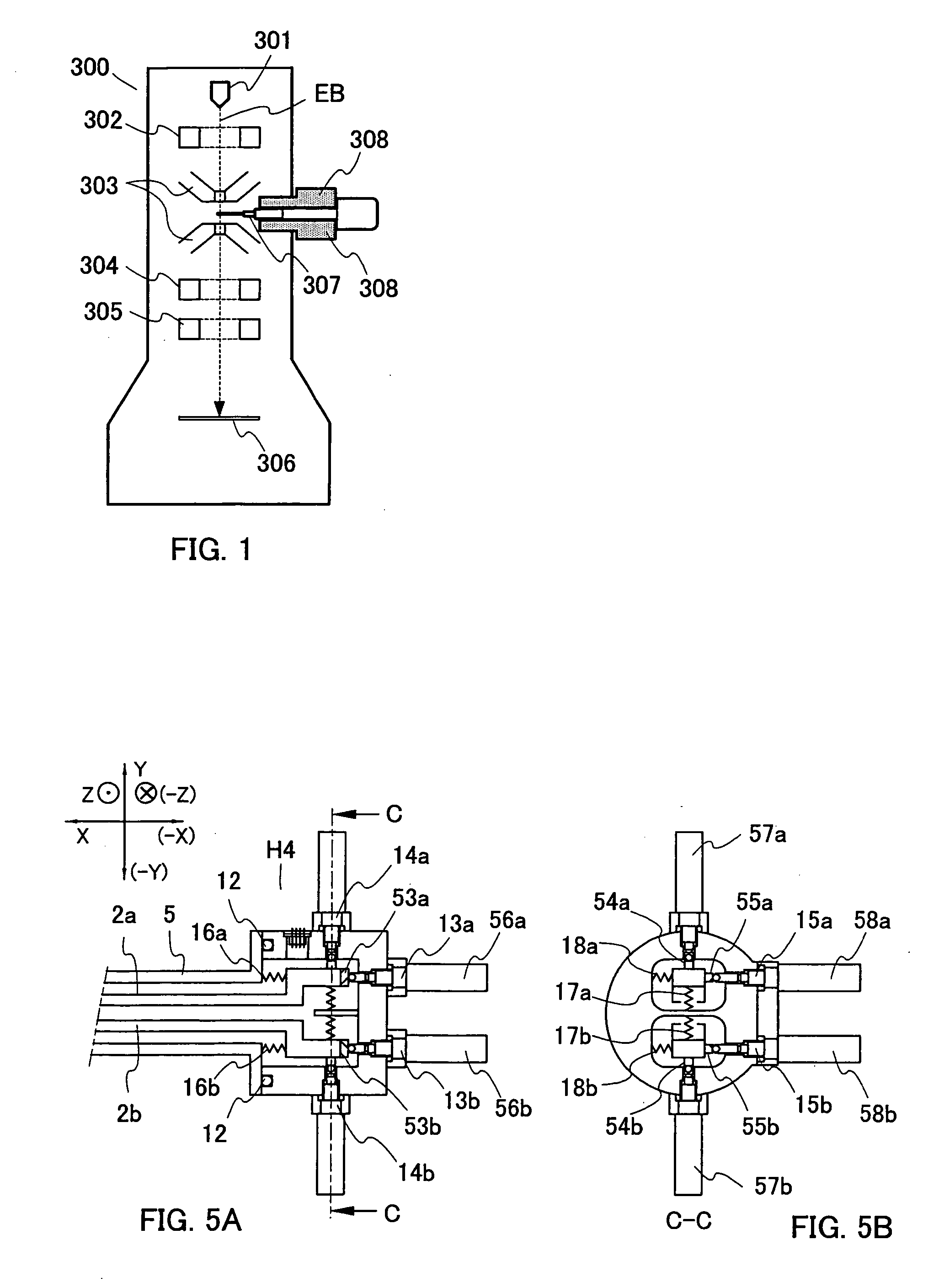

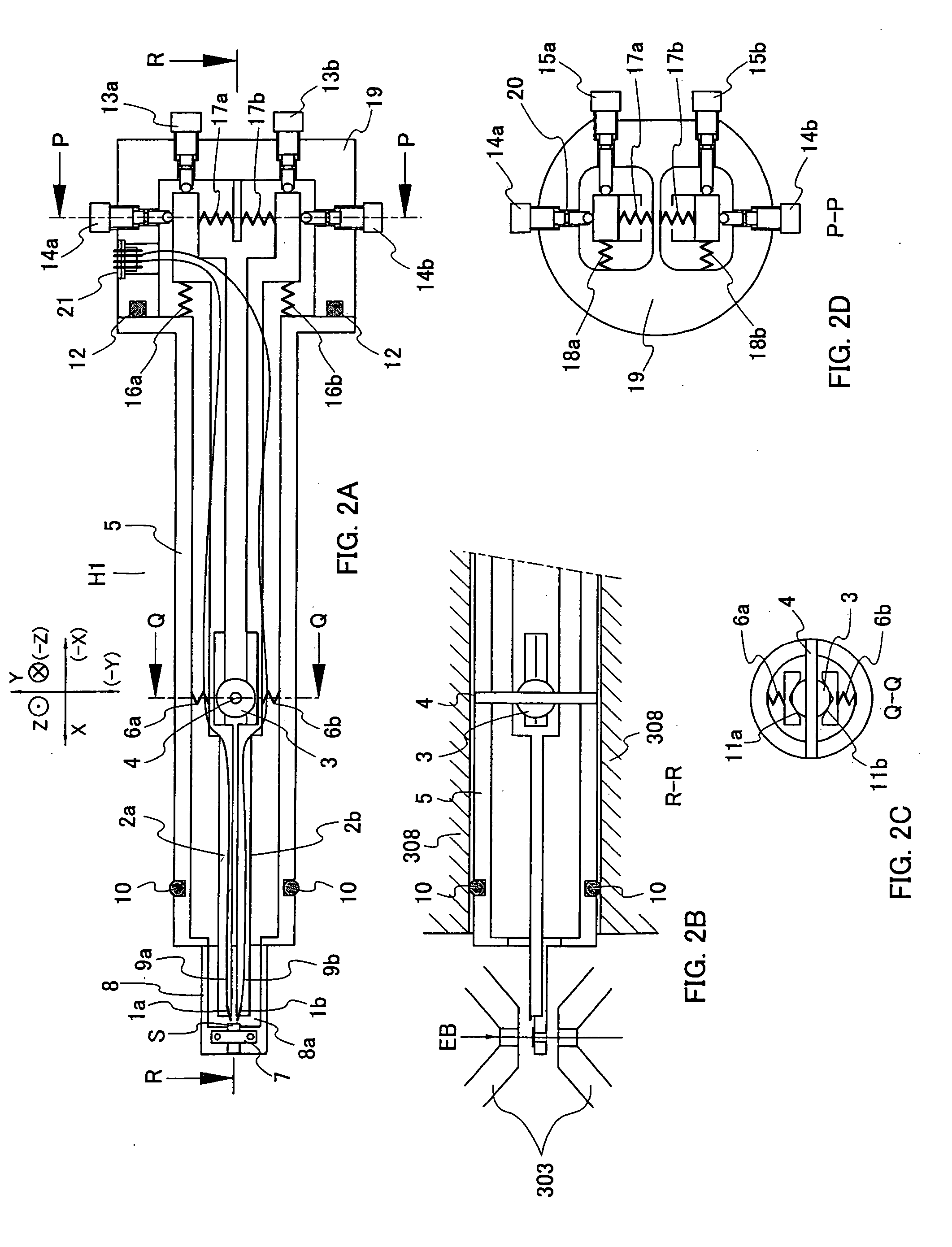

Specimen holder for electron microscope

ActiveUS20060289784A1Easy to operateElectric discharge tubesThermometers using material expansion/contactionMicrometerElectron microscope

A specimen holder has two levers on which probes for current measurement are carried. The levers are in contact with a spherical body, the spherical body acting as a pivotal point. When the levers are pushed by micrometer heads, the probes move in the X-direction. When the levers are pulled, the probes are pushed back by springs and move in the −X-direction. When the first lever is pushed by a further micrometer head, the first probe rotates about the spherical body and thus moves in the Y-direction. When the first lever is pulled, the first probe is pushed back by the first spring and moves in the −Y-direction. The second probe is moved along the Y-axis by similarly manipulating a further micrometer head. The two probes can be moved along the Z-axis by similarly manipulating other micrometer heads.

Owner:JEOL LTD

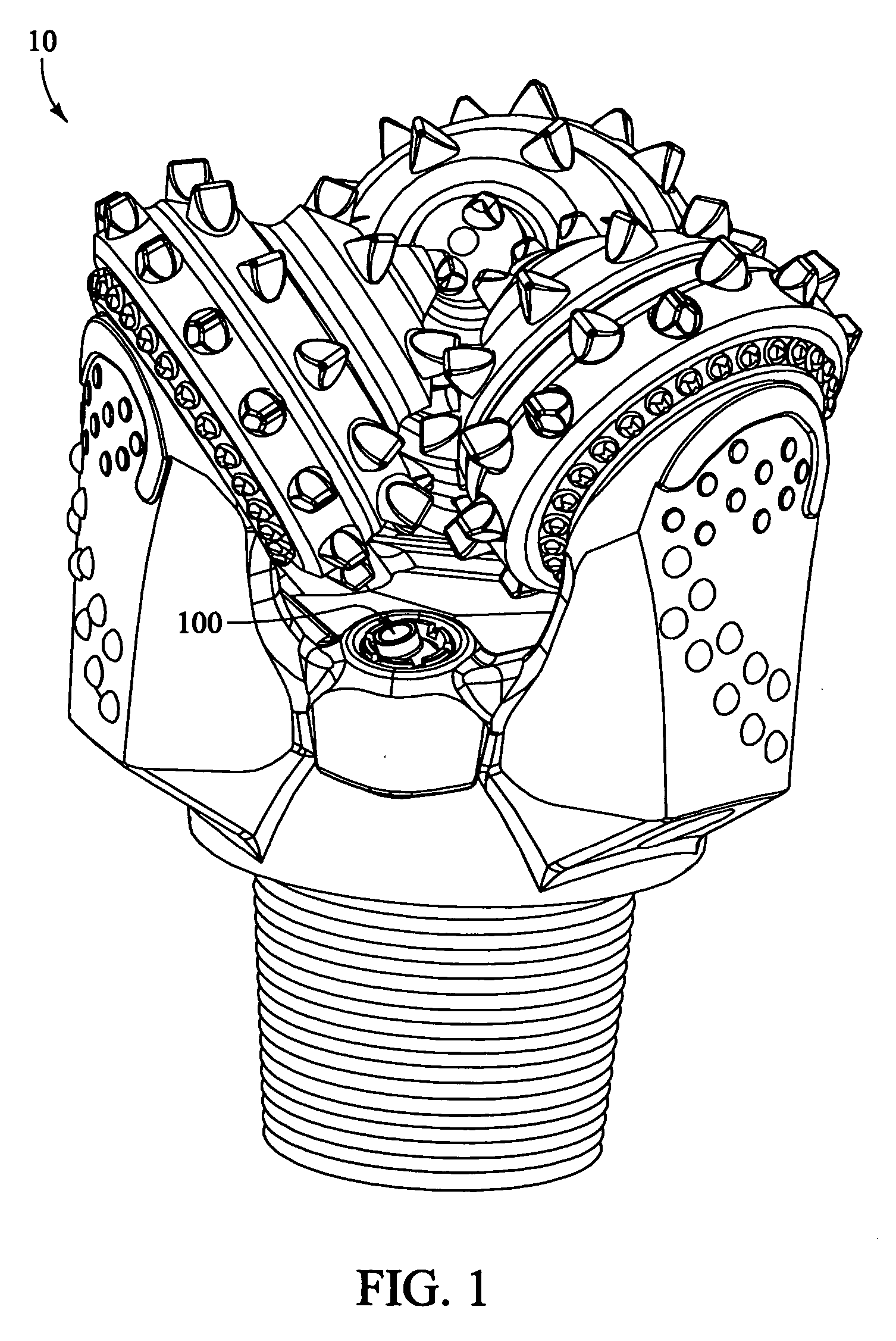

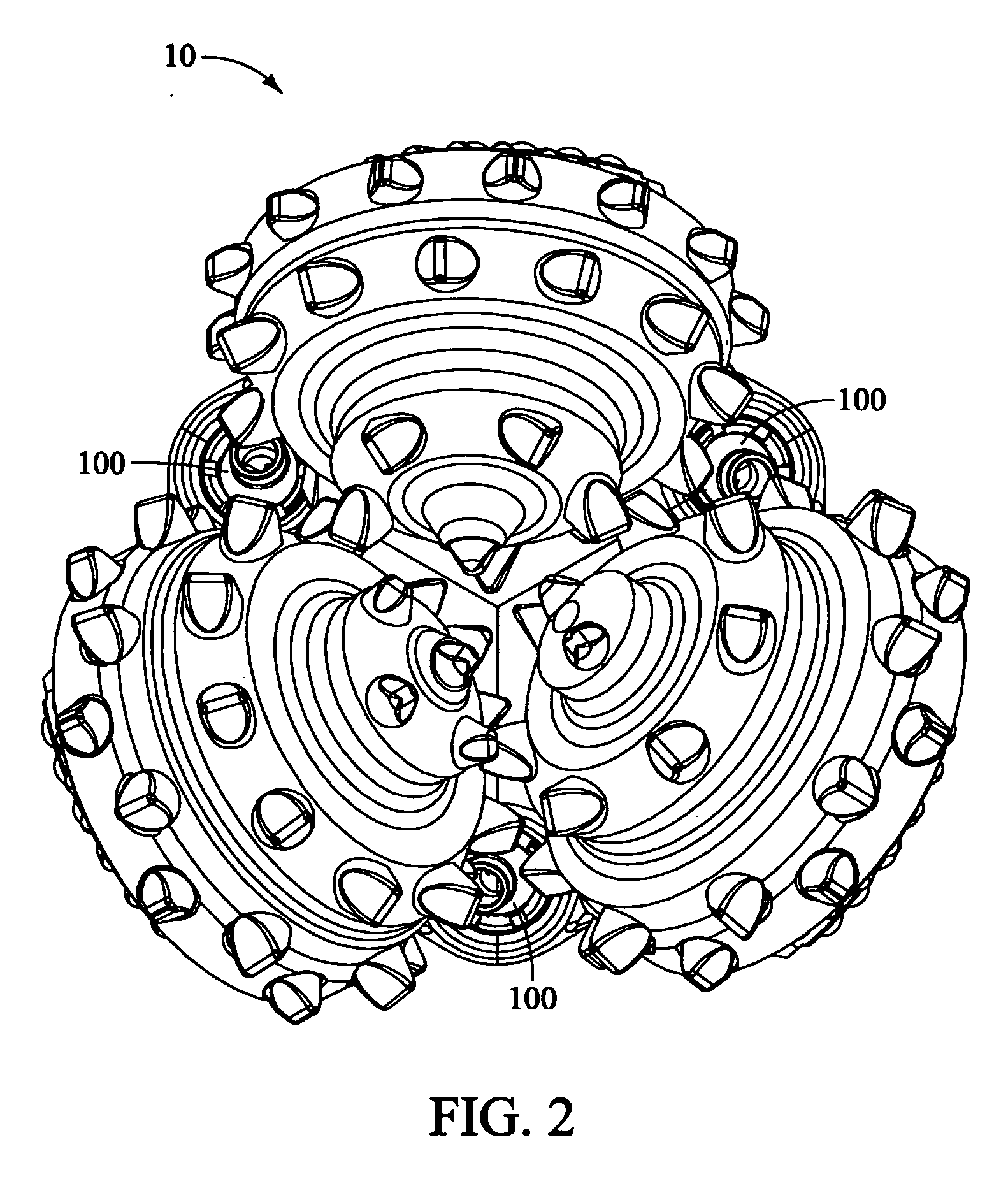

Directable nozzle for rock drilling bits

InactiveUS20060266557A1Prevents excessive nozzle angularityPrevents excessive angularityDrill bitsDrilling rodsEngineeringDrill bit

Owner:GEN ELECTRIC CAPITAL +2

Spherical multifunctional constant volume bomb

ActiveCN103926196AEasy to processEasy to installMaterial analysis by optical meansPlanar laser-induced fluorescencePresent method

The invention discloses a spherical multifunctional constant volume bomb. The spherical multifunctional constant volume bomb comprises a body with a spherical shape and more than two window holes in the spherical body, wherein the axes of the window holes are intersected at the sphere center of the body; the area close to the sphere center is a hollow test area; a through hole pointing to the test area is reserved between the window holes. The spherical multifunctional constant volume bomb is simple in structure, convenient to machine, compact in structure and light in bomb body weight, and can bear high strength; the temperature field of the test area is uniform; all sealing pieces of a volume bomb adopt non-cooling sealing; the internal temperature and the pressure are easily controlled; continuous test at a high temperature and a high temperature can be realized; an optical system and an injector are arranged flexibly; the test range is wide; a plurality of test methods, such as planar laser-induced fluorescence, a laser absorption and scattering method, a Phase Doppler method, a schlieren method and Mie scattering, combination of various test methods and simultaneous measurement can be realized for spraying, evaporating, mixing, combusting, soot forming and the like; a testing optical circuit can be arranged at any angle; the spherical multifunctional constant volume bomb has universality.

Owner:平湖瓦爱乐发动机测试技术有限公司

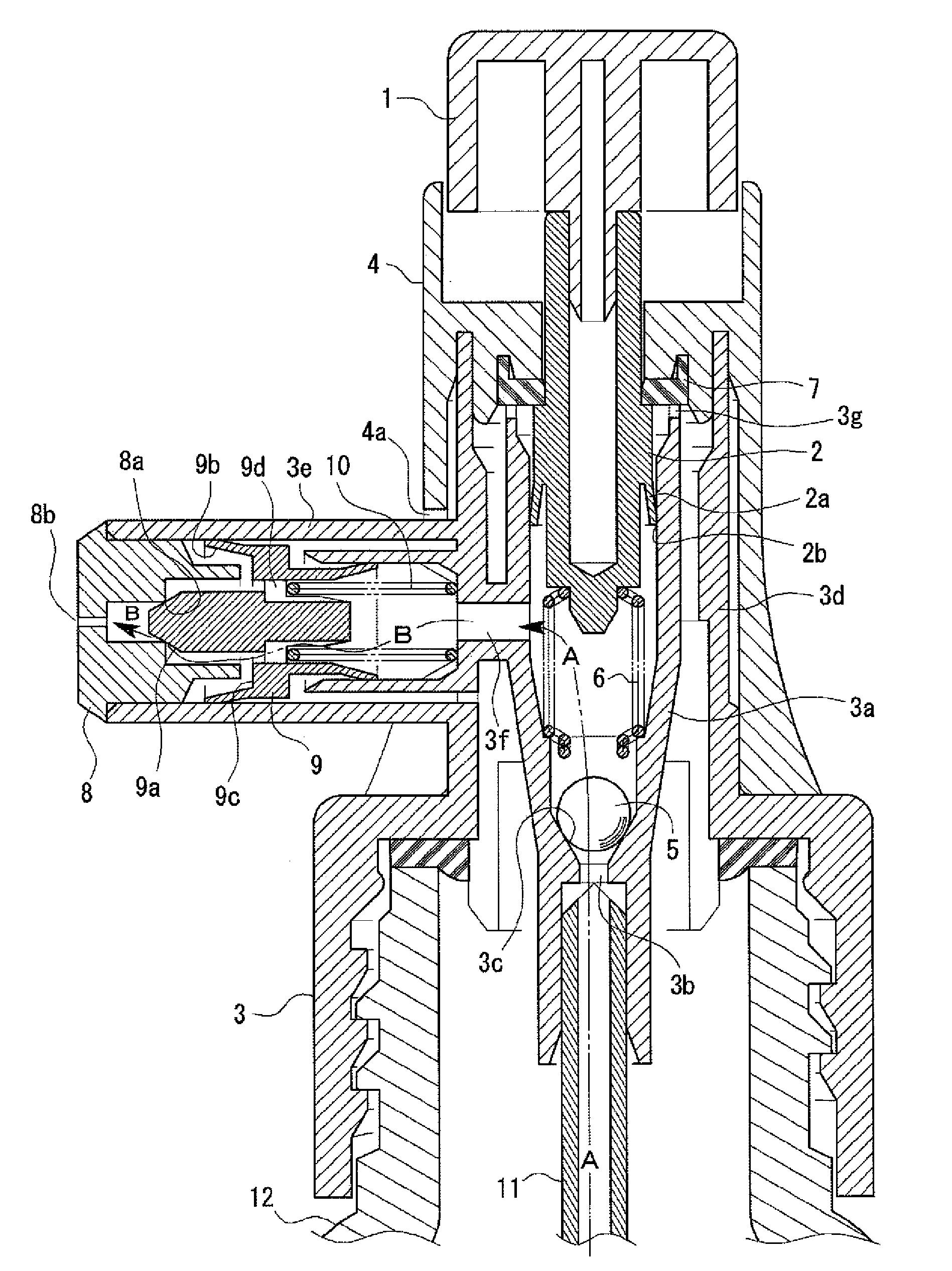

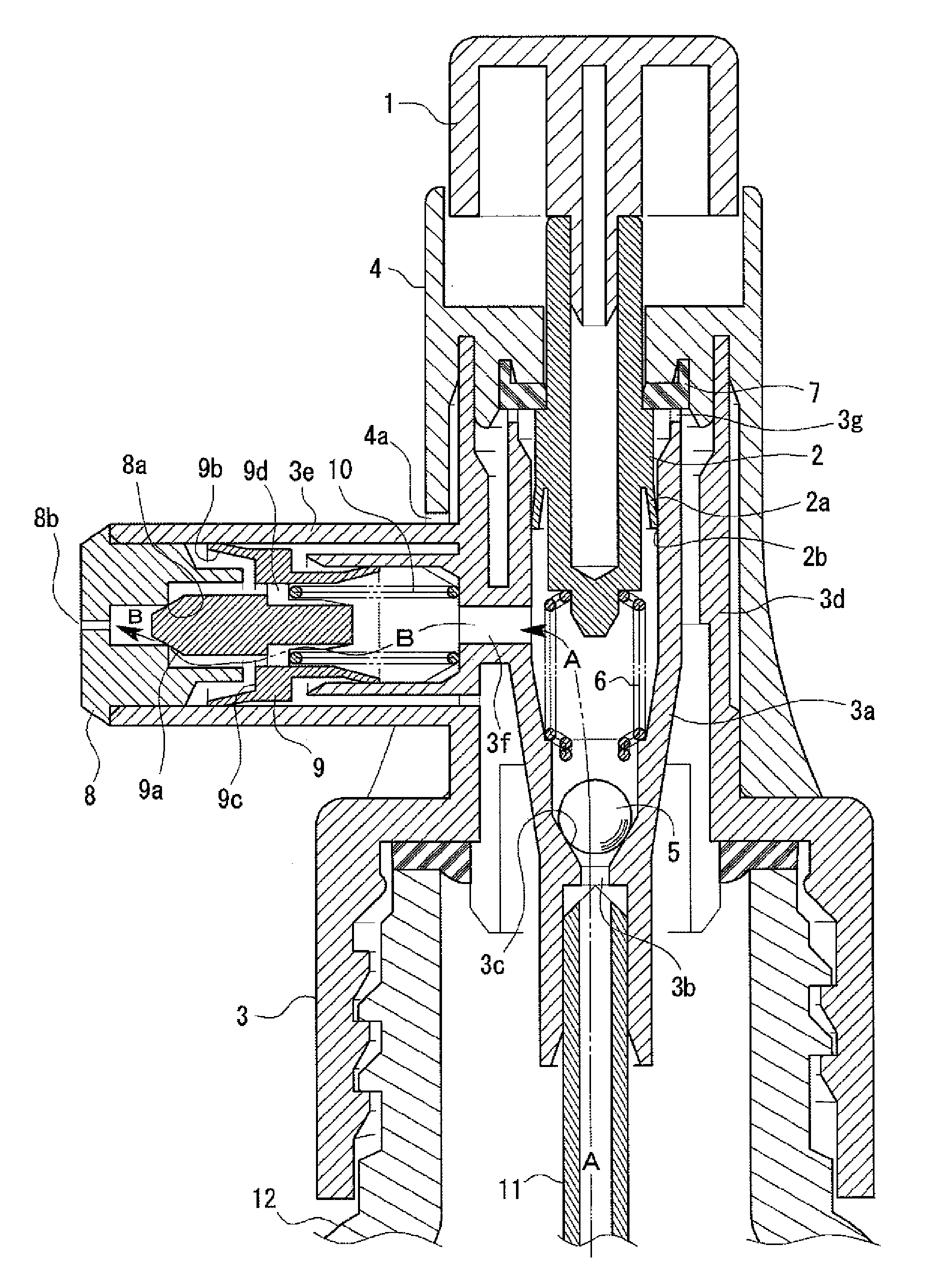

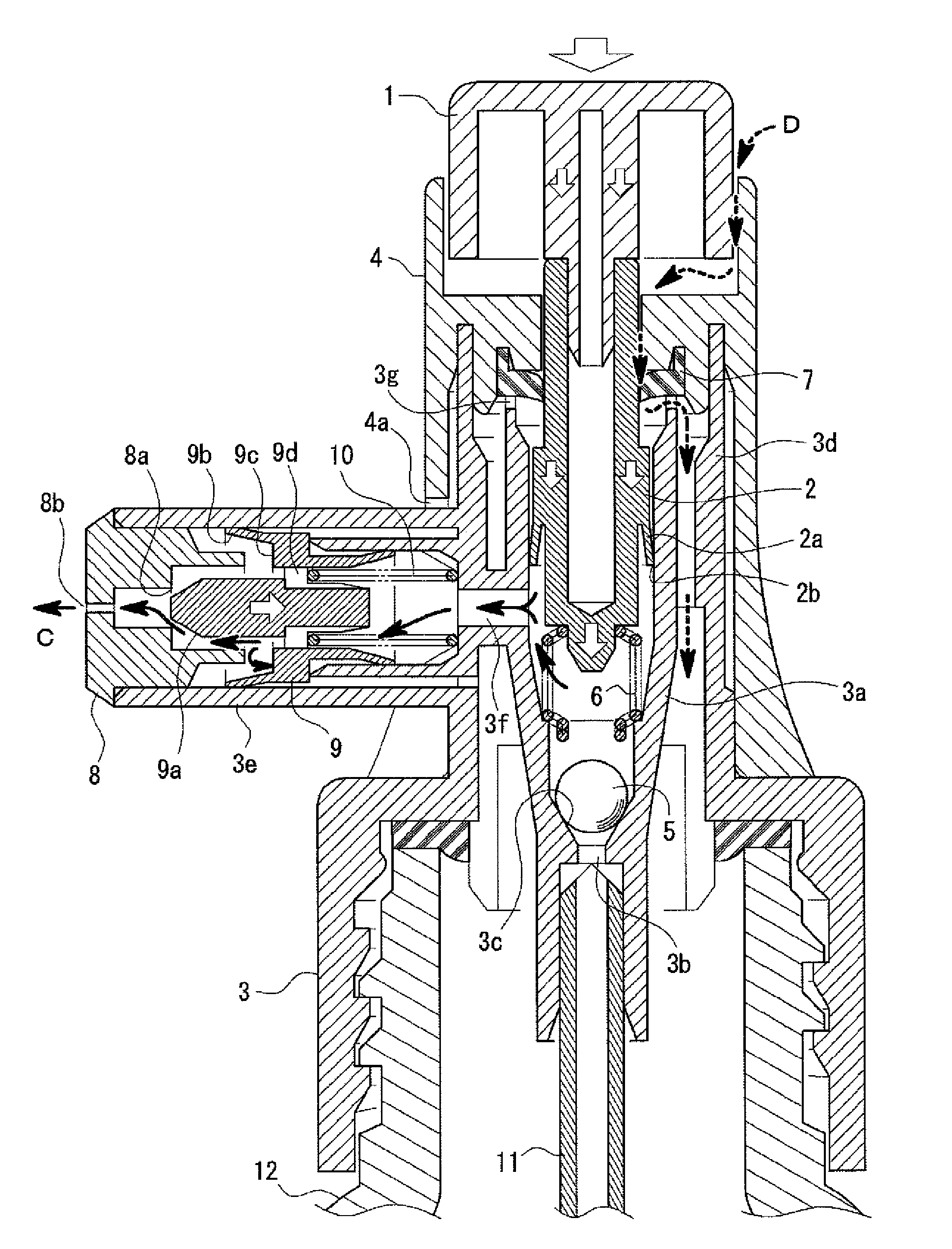

Content discharge mechanism for pump-type container and pump-type product with content discharge mechanism

ActiveUS20090008415A1Reduce pressureEasy to operateFire rescueLiquid transferring devicesEngineeringStorage type

A content discharge mechanism of a pump type container, which prevents the position of a content discharge outlet from moving following discharge operation is disclosed. The mechanism includes an operation button 1; a sheath-shaped piston 2 interlocking with the operation button 1; a suction valve including annular reception surface 3c and spherical body 5 actuated in response to the movement of the sheath-shaped piston 2; an upstream passage A formed between the sheath-shaped piston 2 and the suction valve; a downstream passage B communicated with the upstream passage A and formed between it and a discharge outlet 8b; and a pressure storage type discharge valve including annular edge part 8a and annular tapered surface 9a. In a discharge finishing mode, the pressure in the contents is lowered by permitting the downstream side passage B to be communicated with a passage outside space region E via a hole 3f, to close the discharge valve.

Owner:MITANI VALVE CORP

Physical Therapy Ball

A physical therapy ball comprises inner and outer hallow spherical bodies. A web positions the inner spherical body with respect to the outer spherical body to form a gap there between. The gap is filled with a high heat capacity gel. An array of conical sections extends from the outer surface of the outer spherical body to facilitate foot massage.

Owner:BALDUCCI JENNIFER

Cylinder head assembly and spherical valve for internal combustion engines

InactiveUS7328680B1Easy to movePlug valvesMachines/enginesReciprocating motionExternal combustion engine

A cylinder head assembly includes a spherical valve for an internal combustion engine having at least one cylinder defining a combustion chamber and housing a piston reciprocally movable therein throughout successive intake, compression, power, and exhaust strokes for facilitating the flow of engine gasses between a manifold and the combustion chamber. The cylinder head assembly comprises a cylinder head defining therein a spherical valve race in gaseous communication with the combustion chamber. A spherical valve is disposed in the spherical valve race and has a spherical body defining a central axis of rotation and further defining a passageway therethrough. The passageway has a first opening substantially coaxial with the central axis for gaseous communication with a manifold and has a second opening substantially transverse from the central axis. The spherical valve is rotatable in the spherical valve race about the central axis of rotation to selectively place the second opening in gaseous communication with the combustion chamber.

Owner:DIAMOND GARY

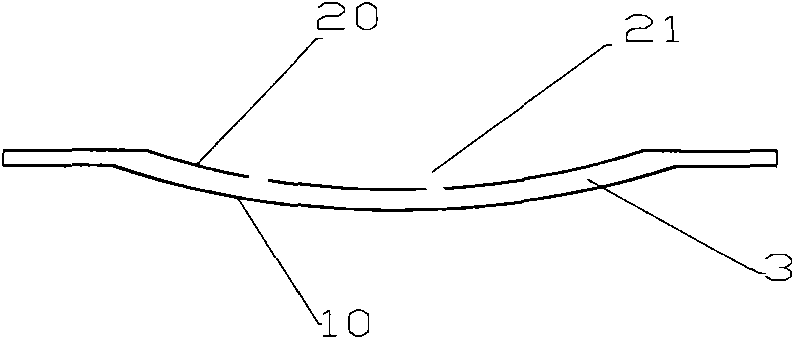

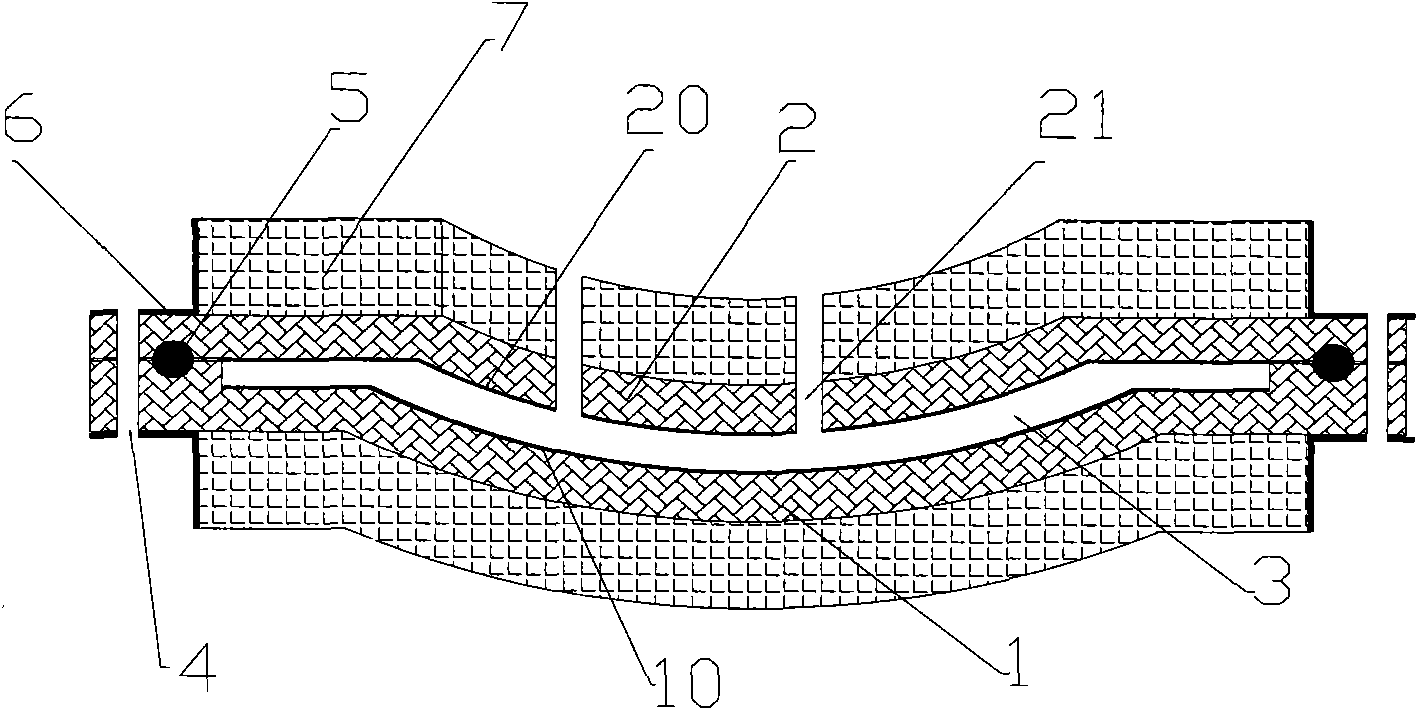

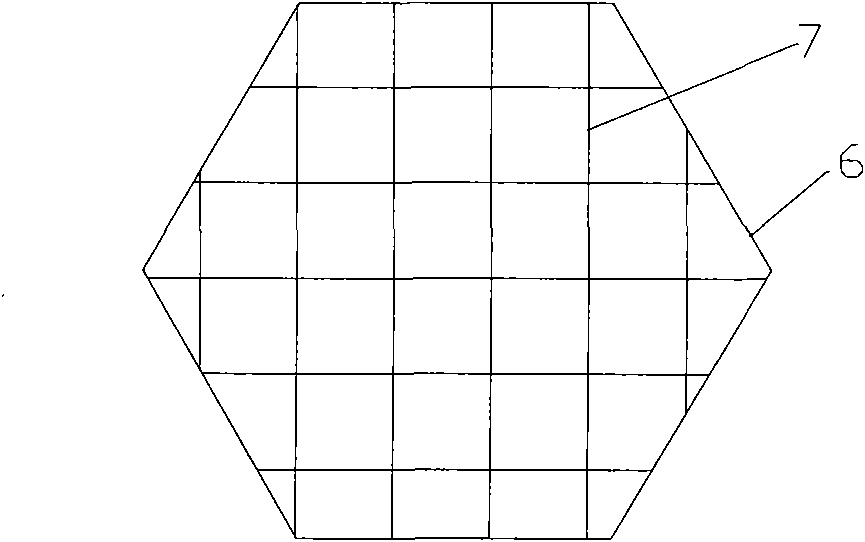

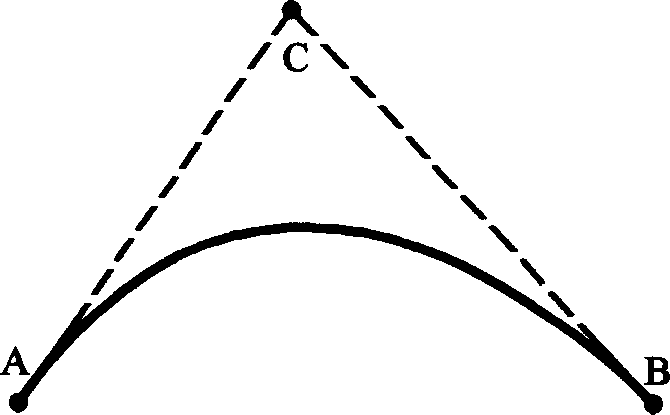

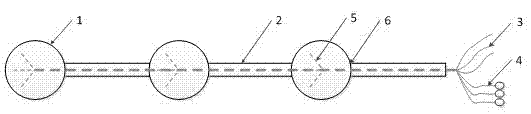

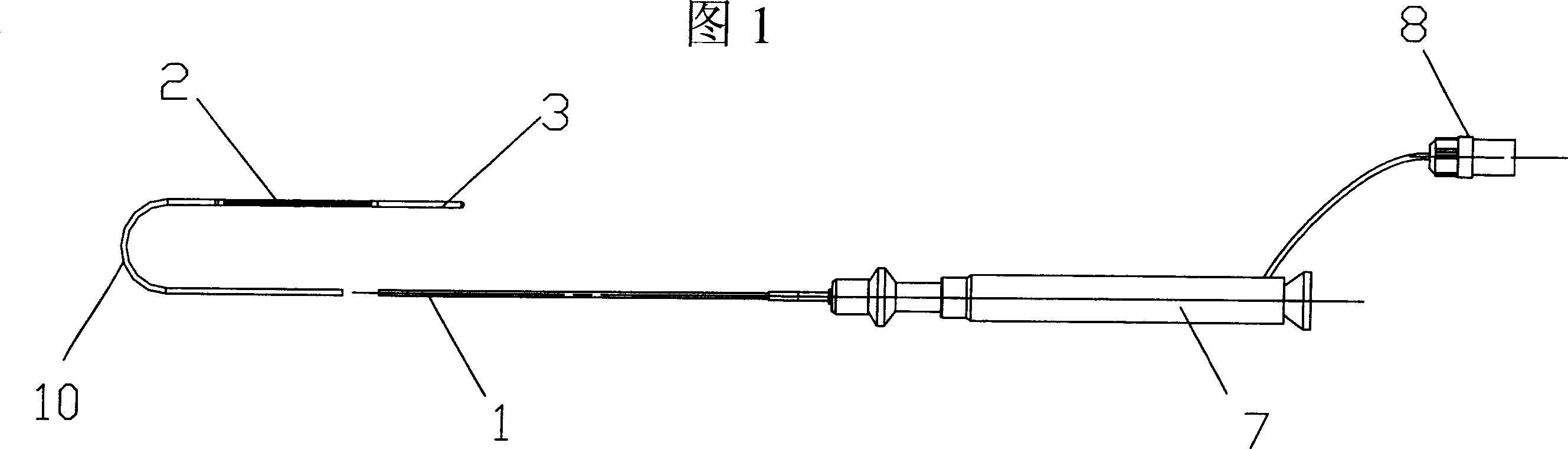

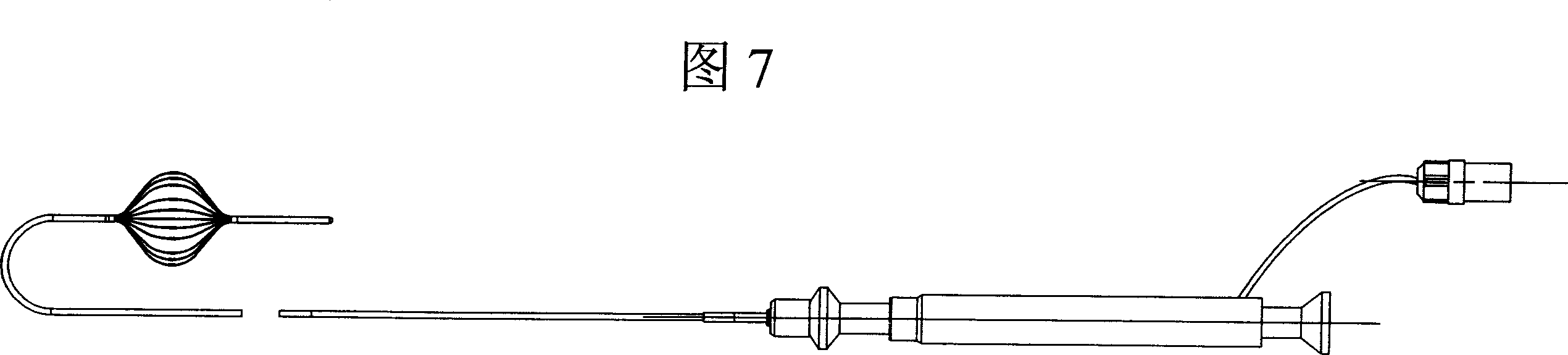

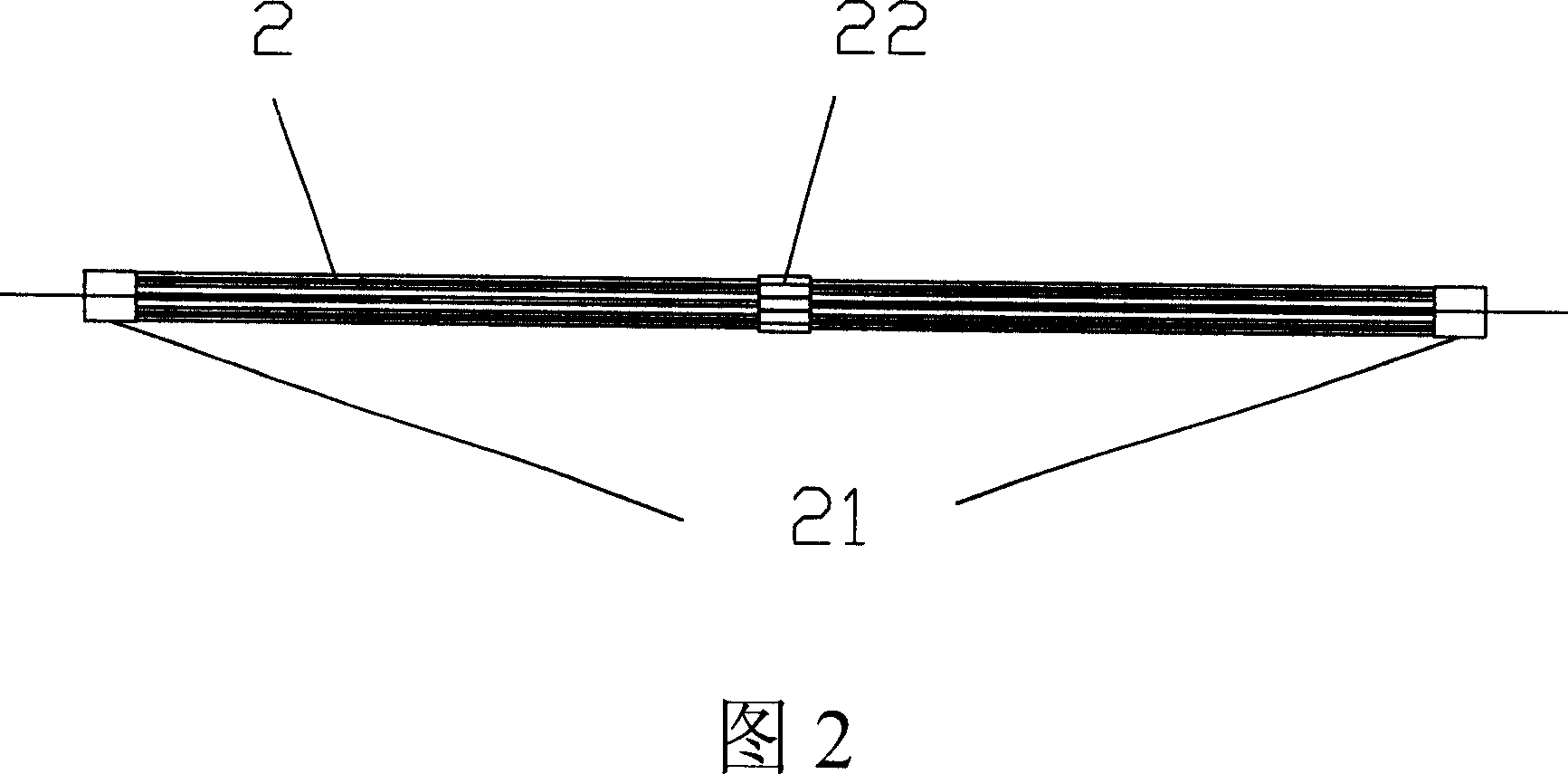

Net-cage electrode catheter

ActiveCN1947810AContact stabilityFully contactedCatheterDiagnostic recording/measuringMetallic electrodeEngineering

A net basket type electrode catheter for the stable contact between electrode and endocardium has a handle unit and a net basket unit consisting of a near-end annular coupler, a far-end annular coupler with soft head, and multiple metallic wires between said both coupler and with coated insulating layer. Said metallic wires are electrically connected to the electrode interface on handle unit. The metallic electrodes are at the middle of said metallic wires. When a push rod is moving forward, said metallic wires are curved to form a spherical body.

Owner:APT MEDICAL INC

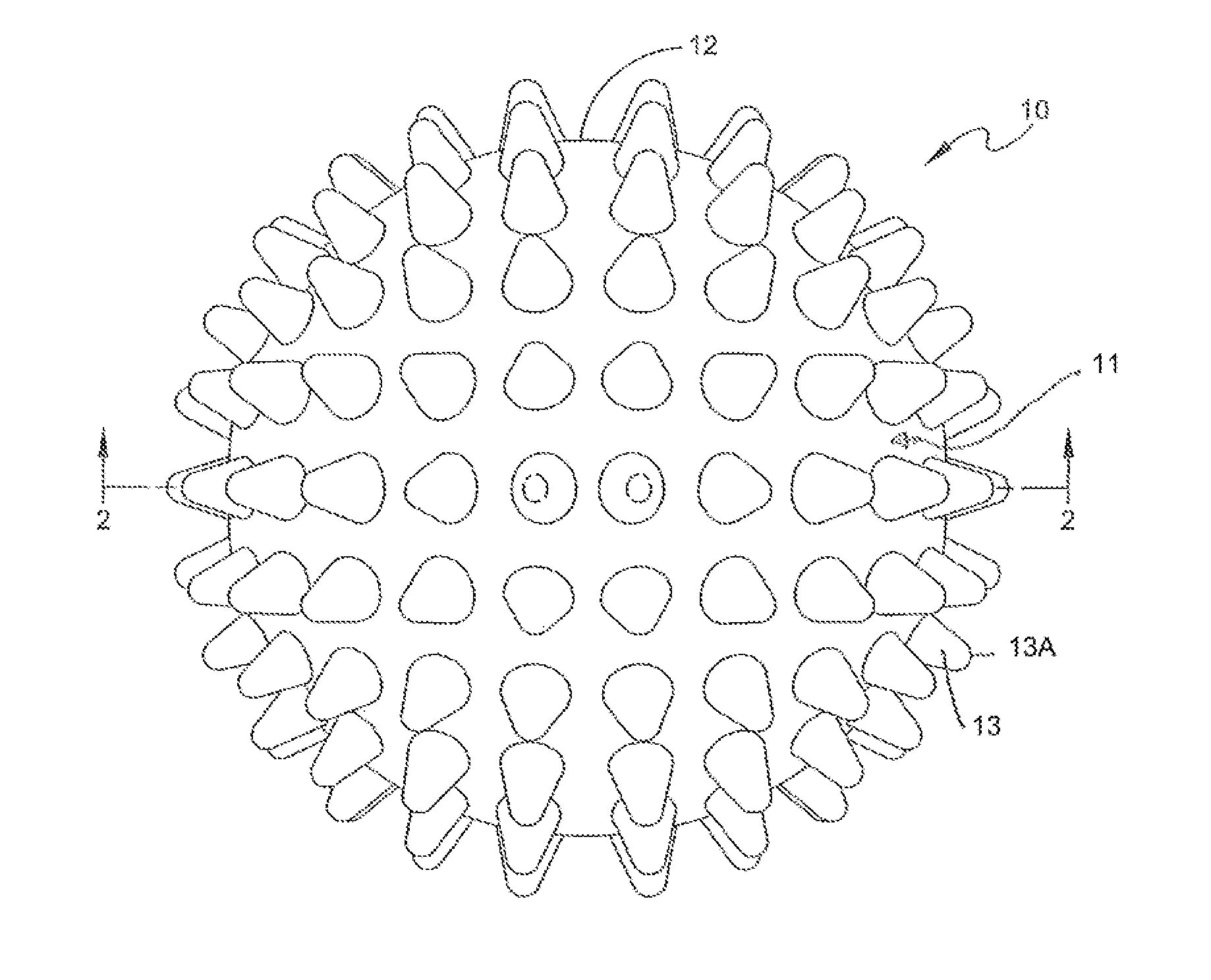

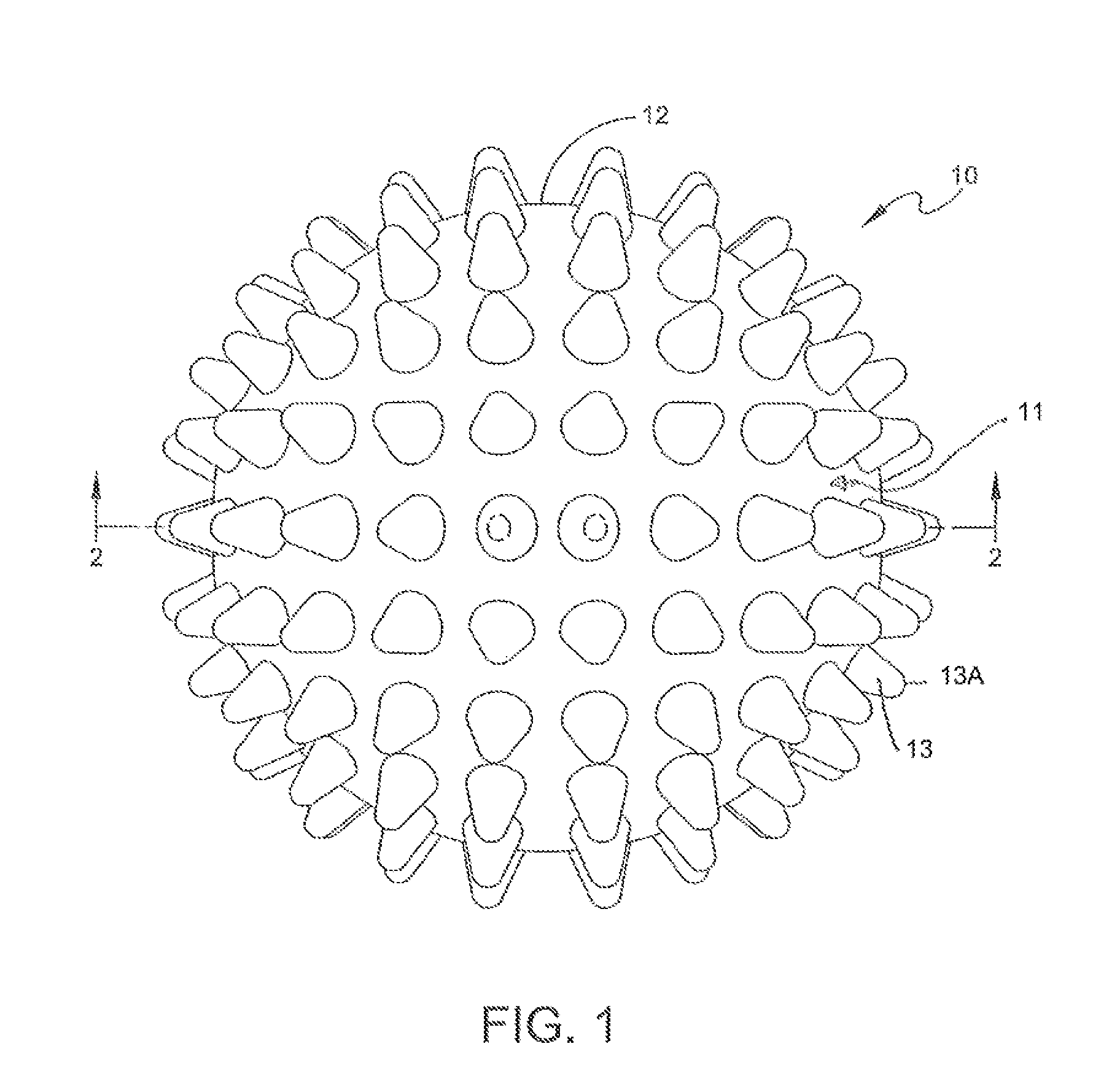

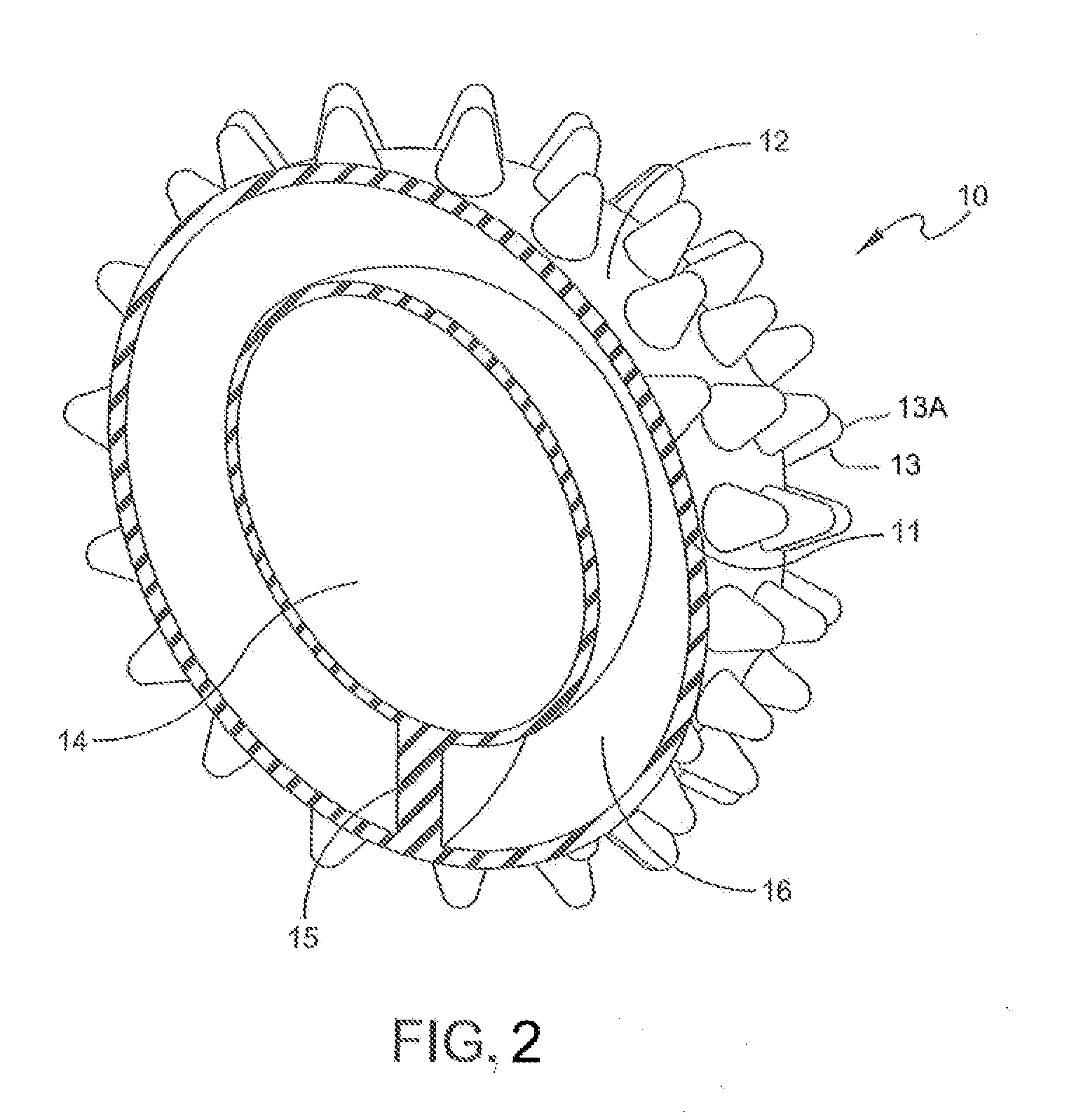

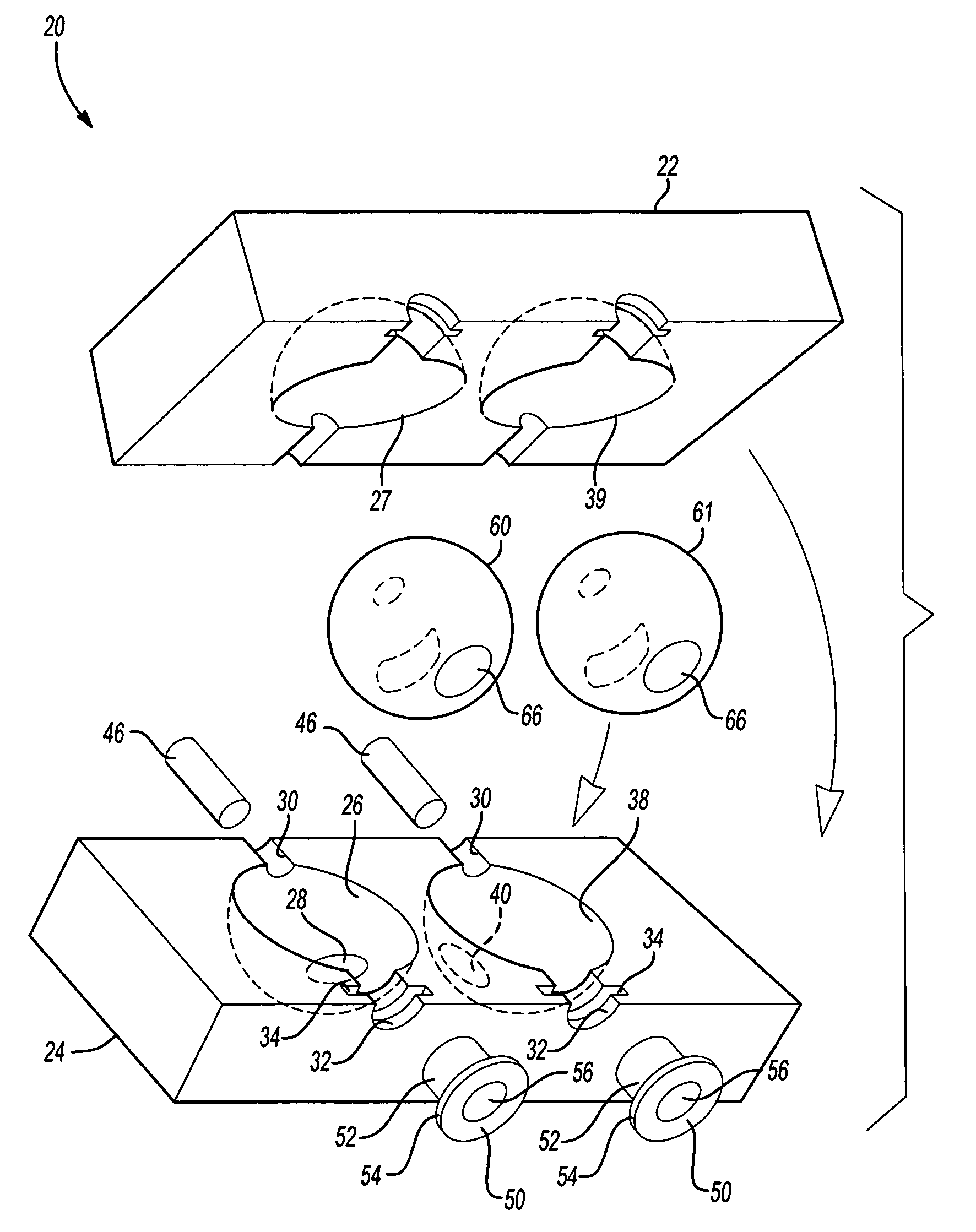

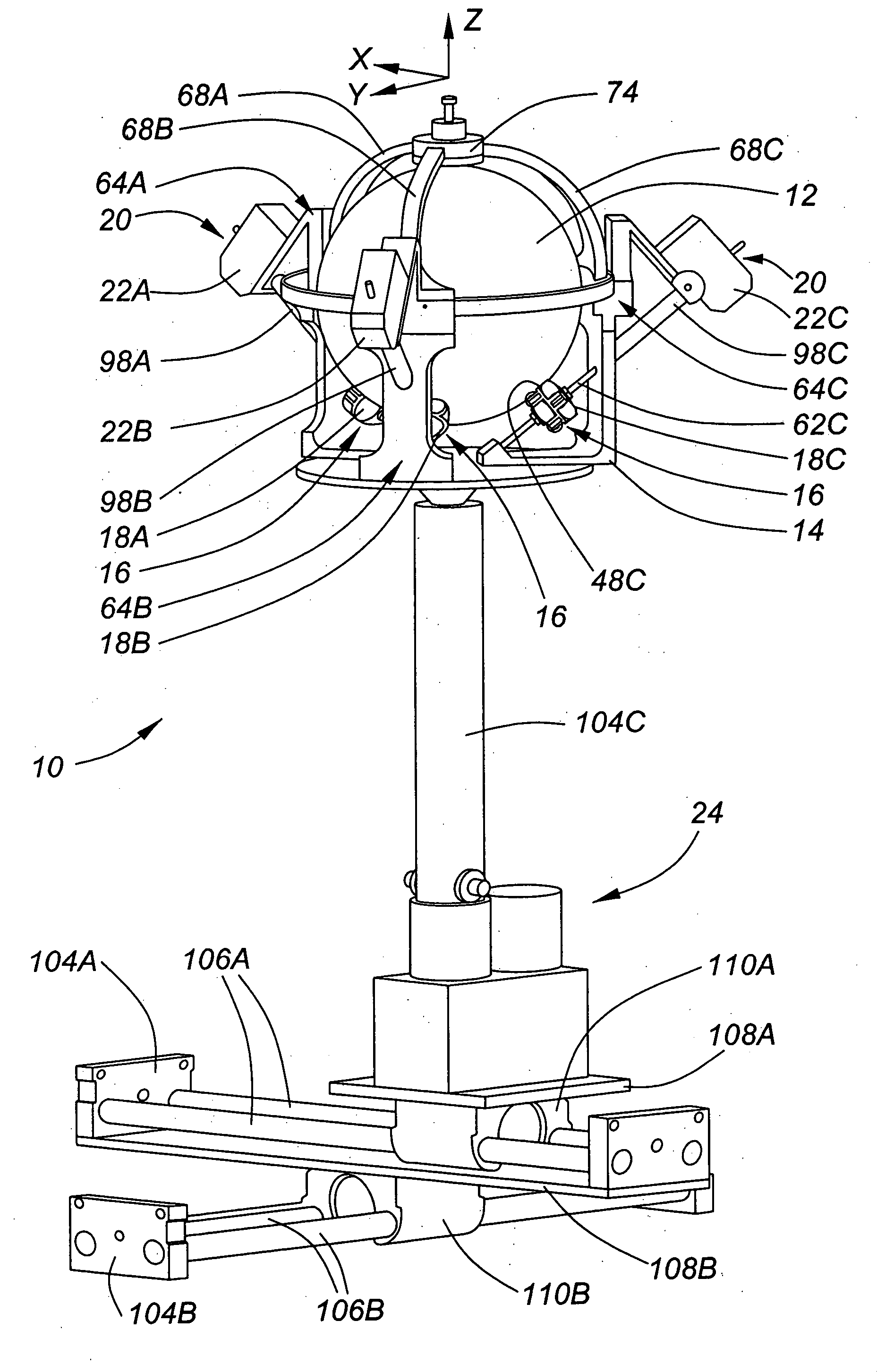

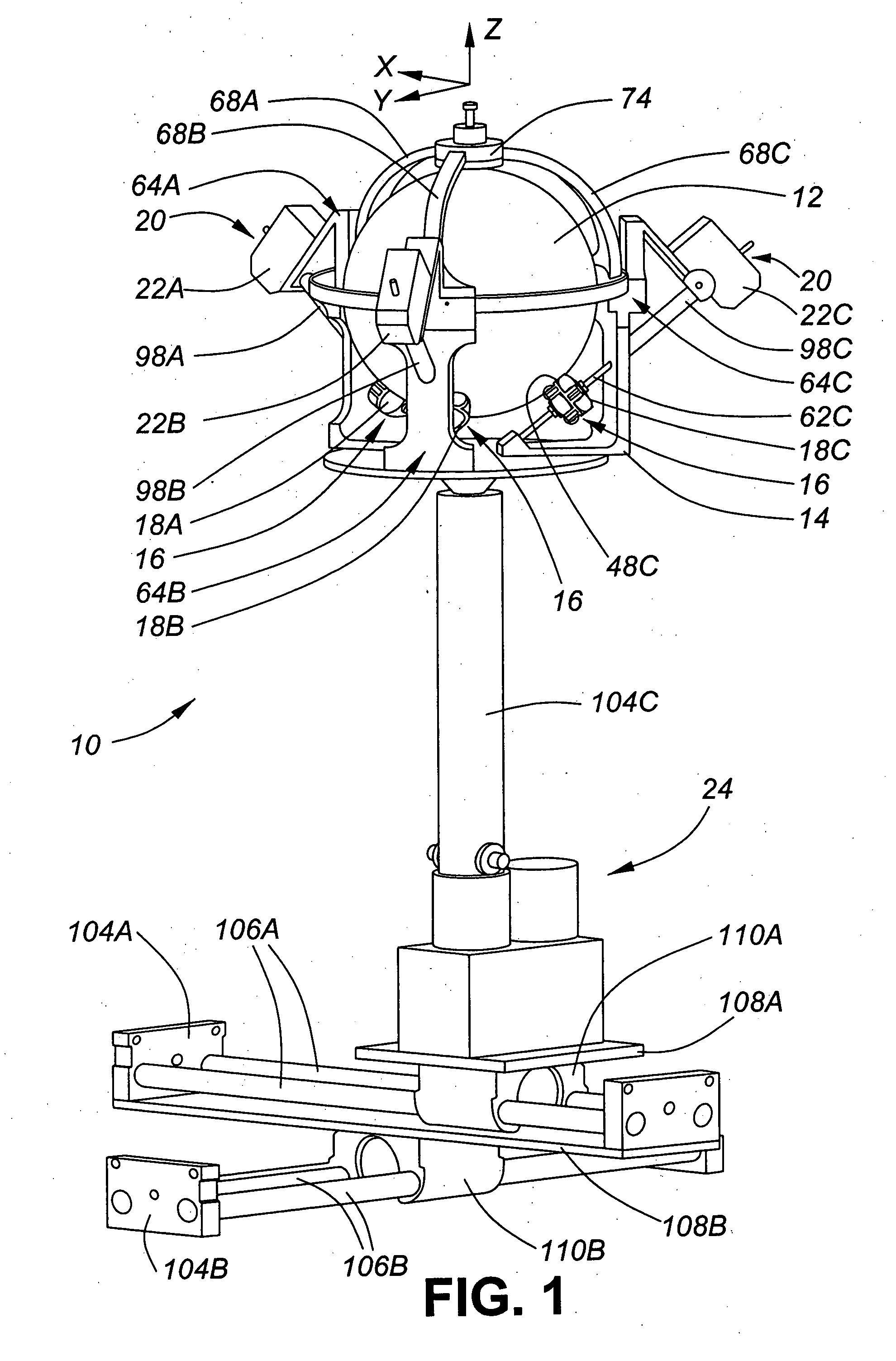

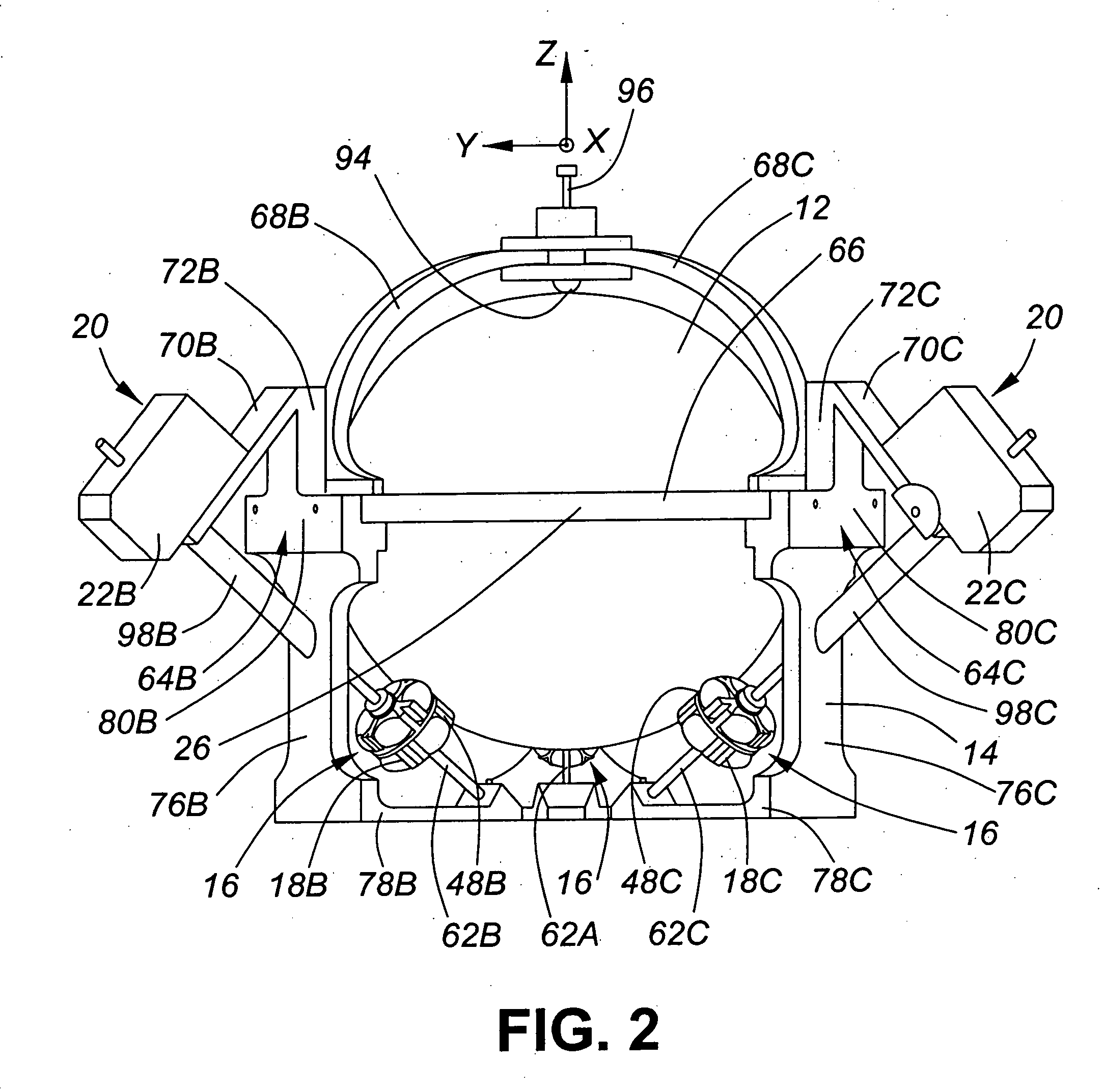

Apparatus for multi-axis rotation and translation

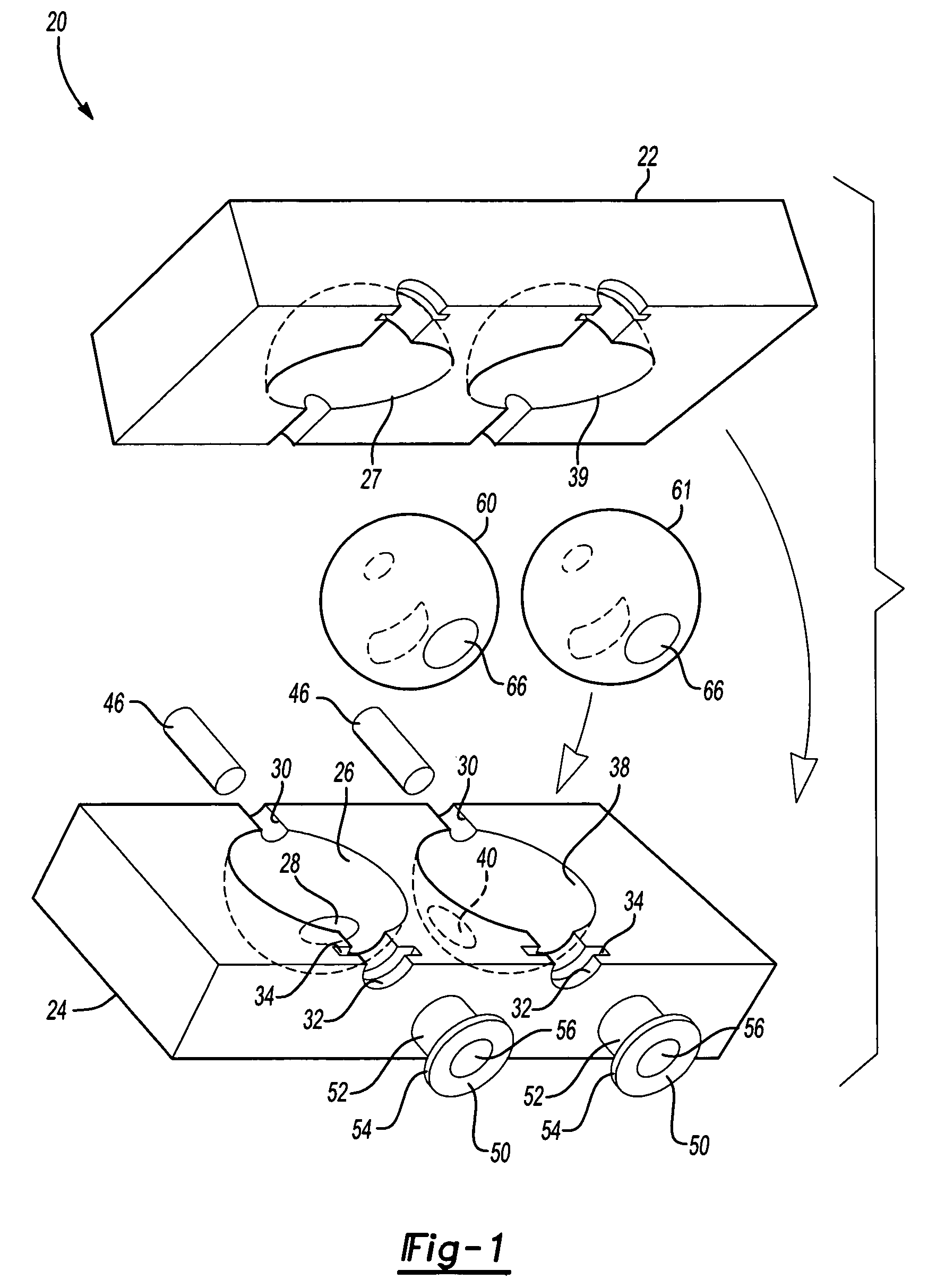

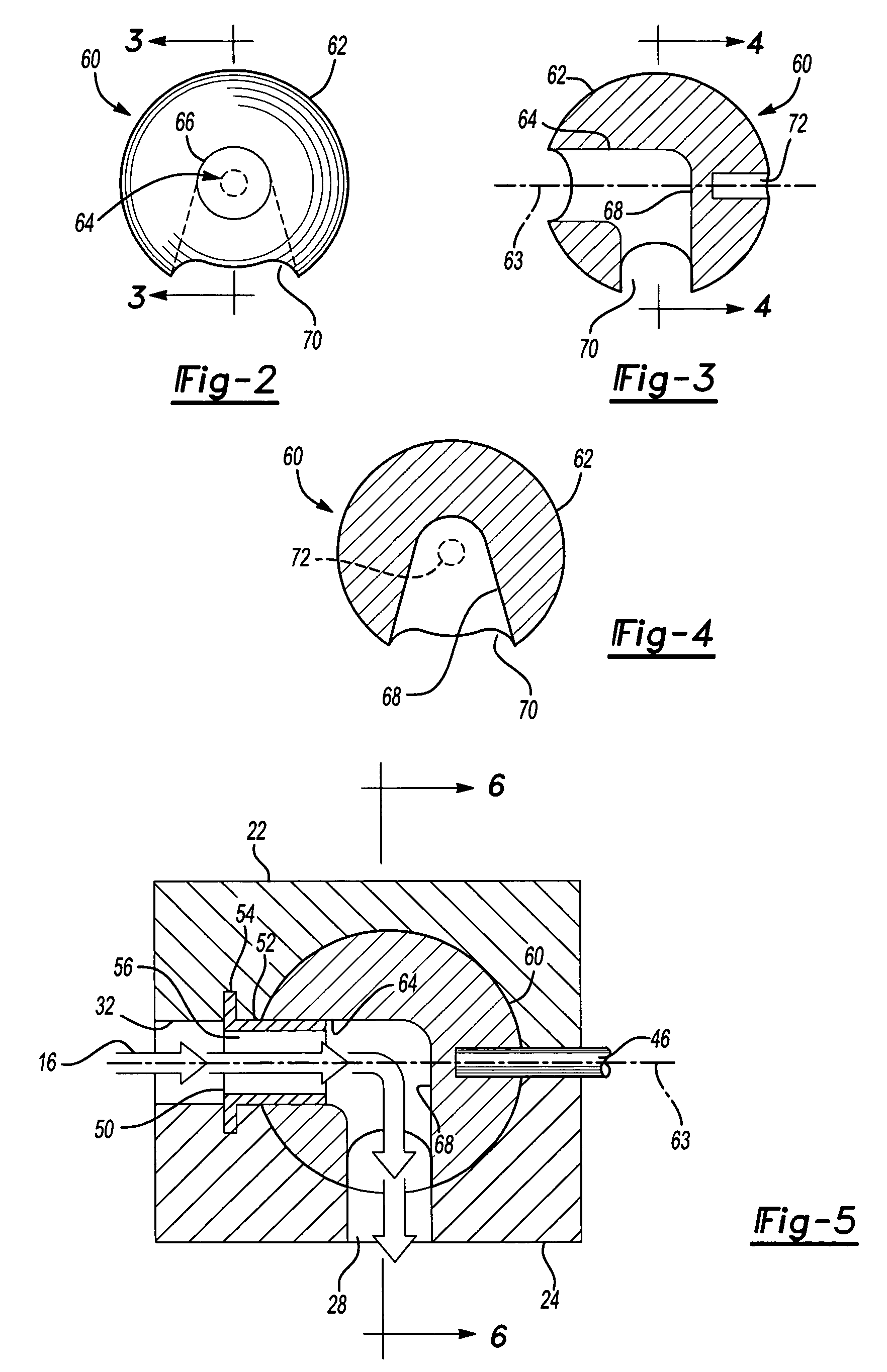

An apparatus for multi-axis rotation and translation comprises a spherical body, a plurality of roller assemblies each engaging the outer surface of the spherical body, a plurality of actuators for driving said roller assemblies, a frame for supporting the plurality of roller assemblies and the plurality of actuators and translation means for translating the frame along each of three orthogonal axes. The actuators are selectively operated to drive the roller assemblies thereby imparting unlimited angular displacement to the spherical body and rotating the spherical body about any axis passing through its geometric center. The translation means may be operated to translate said spherical body along at least one of said three orthogonal axes. The apparatus is particularly applicable to use as a manipulator with six degrees of freedom (unlimited rotational displacement and translational displacement limited only by the boundaries of the workspace).

Owner:HAYES MATTHEW JOHN D +2

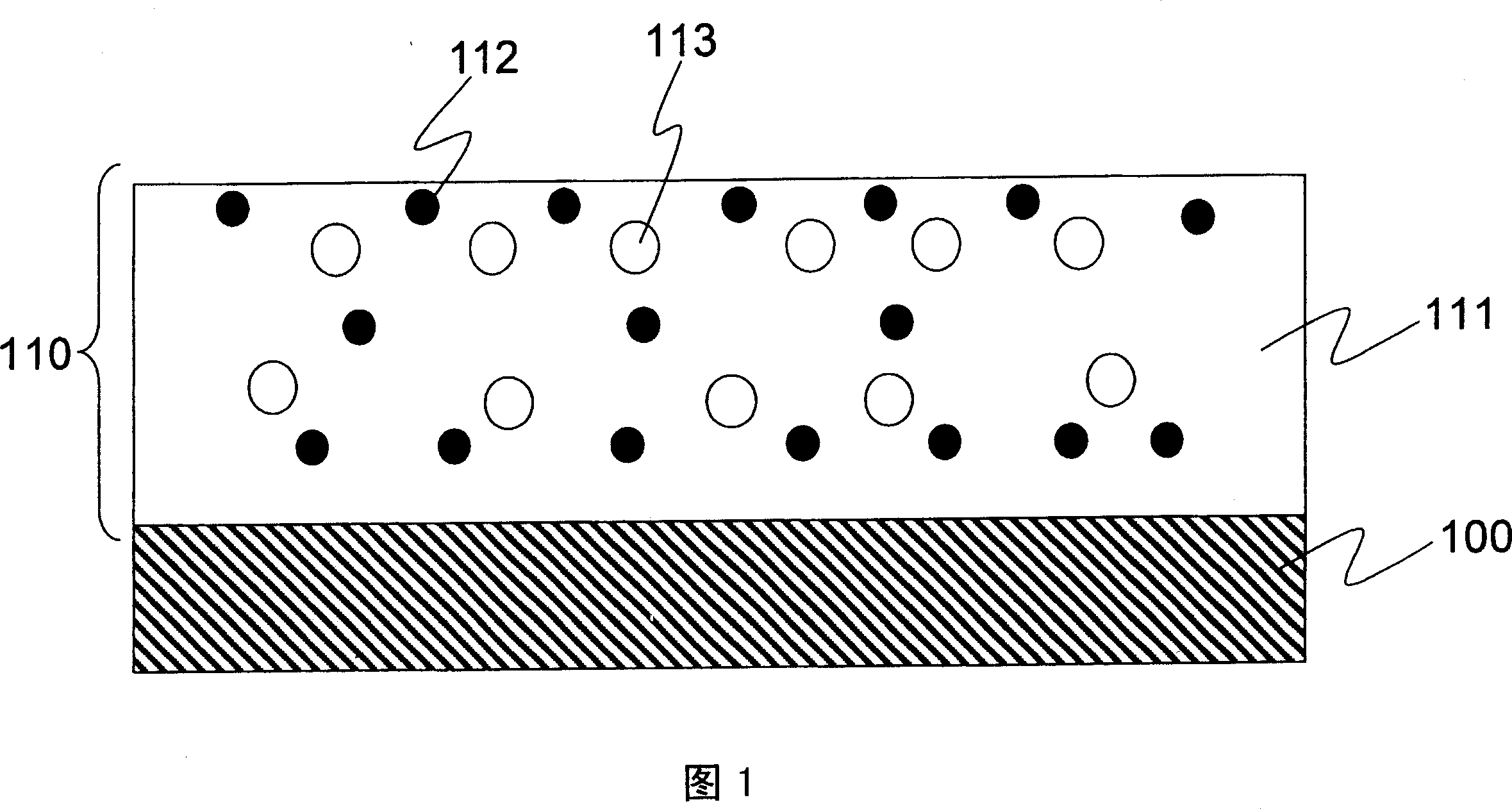

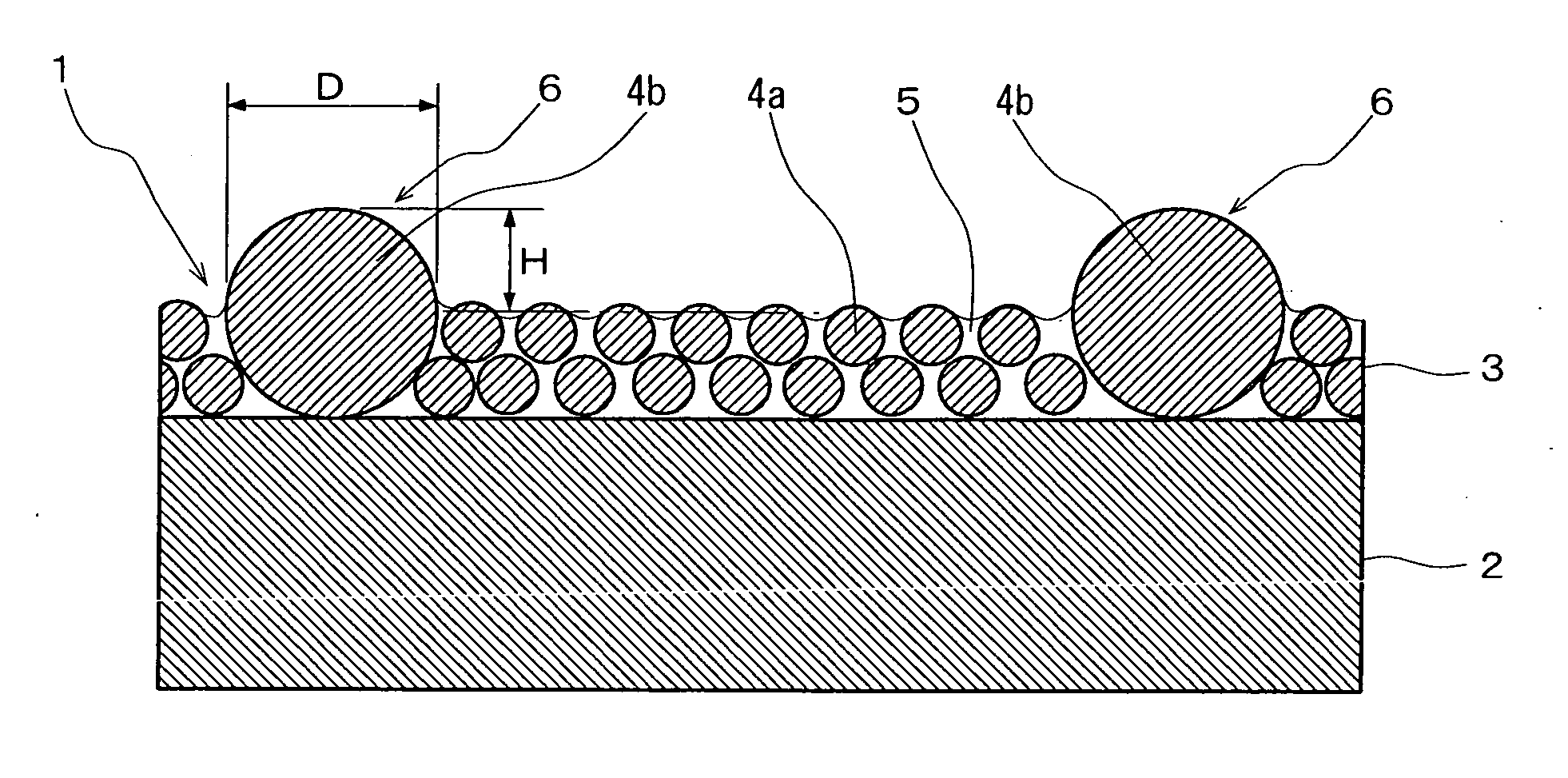

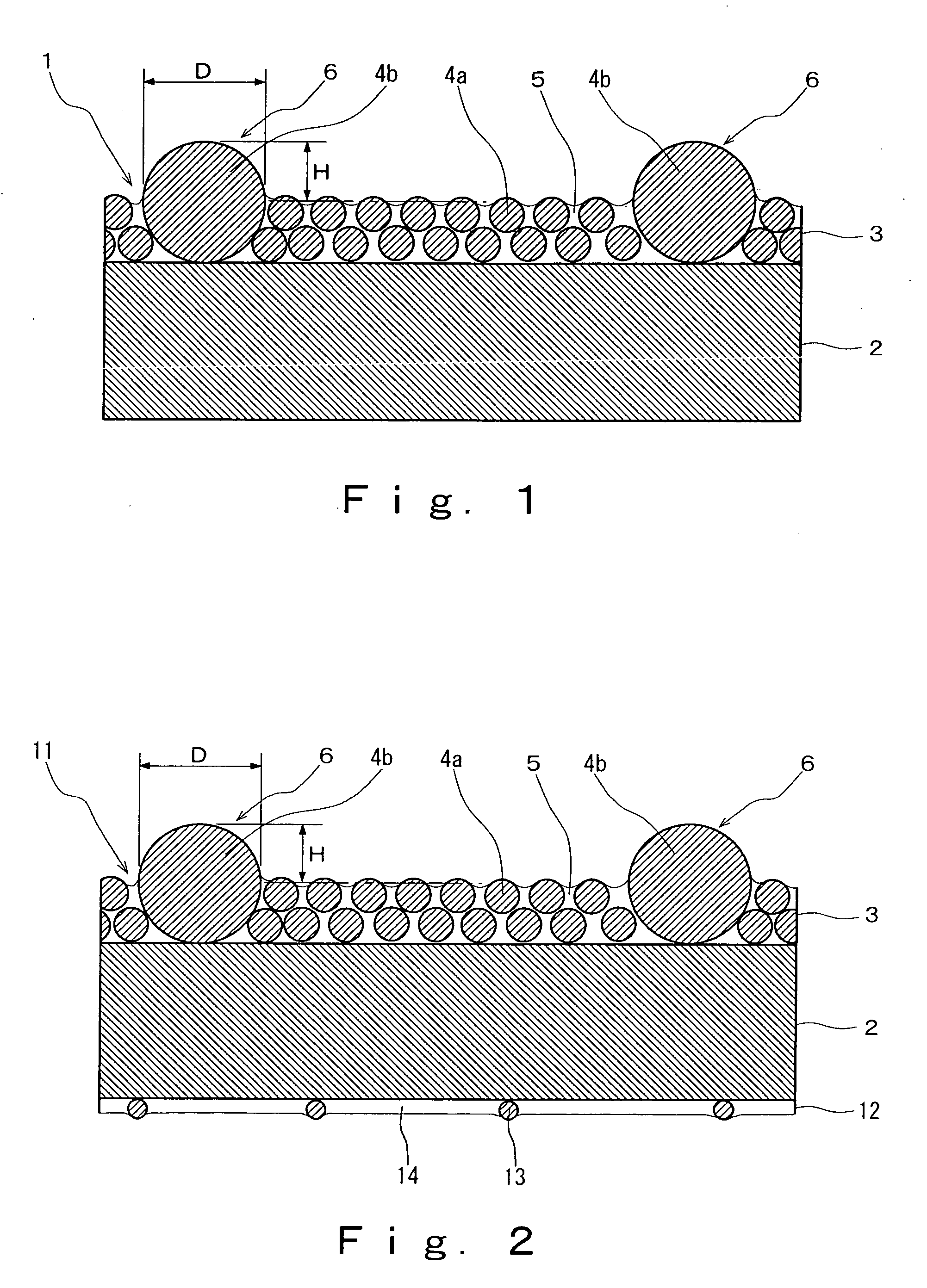

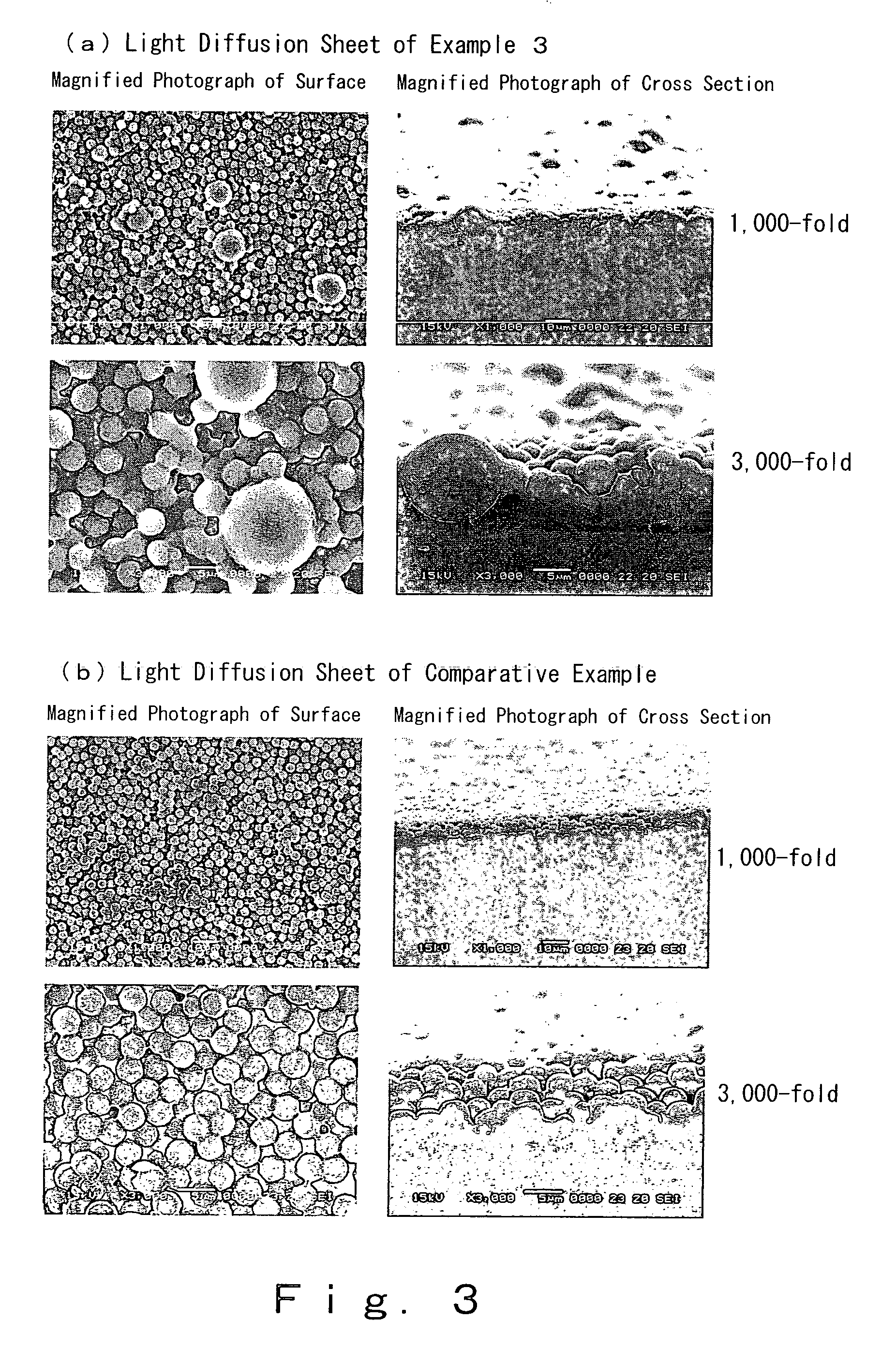

Light diffusion sheet and backlight unit using the same

ActiveUS20070087167A1Lower capability requirementsImprove scratch resistanceLayered productsRecord information storageOccupancy rateDiffusion

An object of the present invention is to provide a light diffusion sheet having a favorable cost reduction capability due to excellent scratching preventive property of the front face, and having in addition thereto, a favorable directional light diffusion function, transmittivity of rays of light, and a thin film character; and a backlight unit capable of promoting performances such as luminance as well as price reduction, and thin and light modeling capability. The light diffusion sheet of the present invention has a light diffusion sheet including a transparent substrate layer, and a light diffusion layer overlaid on the front face side of the substrate layer, wherein the light diffusion layer has resin beads and a resin binder, characterized in that the light diffusion layer has protruding parts having a shape of a partial spherical body on the front face in a scattering manner. It is preferred that mean height of the protruding parts be 1 μm or greater and 10 μm or less, mean diameter of the protruding parts be 4 μm or greater and 18 μm or less, mean occupancy rate of the protruding parts be 2% or greater and 20% or less, and surface roughness (Ra) of the light diffusion layer be 1.5 μm or greater and 10 μm or less. As the beads, small monodisperse beads as a principal component, and large beads as a sub component may be included.

Owner:KEIWA INCORPORATED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com