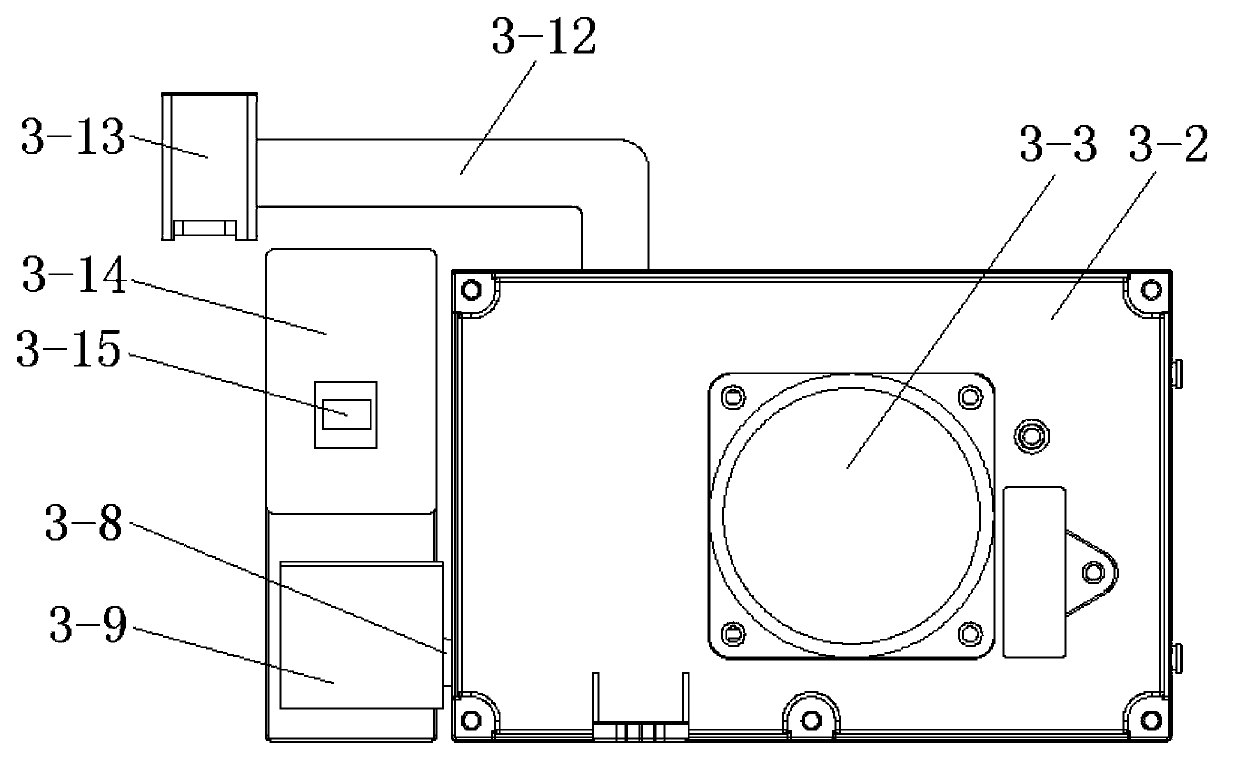

Patents

Literature

12563results about How to "Flat surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vapor deposition of silicon dioxide nanolaminates

ActiveUS20050112282A1Easy to produceUniform thicknessMaterial nanotechnologySemiconductor/solid-state device manufacturingPorosityElectrical conductor

This invention relates to materials and processes for thin film deposition on solid substrates. Silica / alumina nanolaminates were deposited on heated substrates by the reaction of an aluminum-containing compound with a silanol. The nanolaminates have very uniform thickness and excellent step coverage in holes with aspect ratios over 40:1. The films are transparent and good electrical insulators. This invention also relates to materials and processes for producing improved porous dielectric materials used in the insulation of electrical conductors in microelectronic devices, particularly through materials and processes for producing semi-porous dielectric materials wherein surface porosity is significantly reduced or removed while internal porosity is preserved to maintain a desired low-k value for the overall dielectric material. The invention can also be used to selectively fill narrow trenches with low-k dielectric material while at the same time avoiding deposition of any dielectric on the surface area outside of the trenches.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

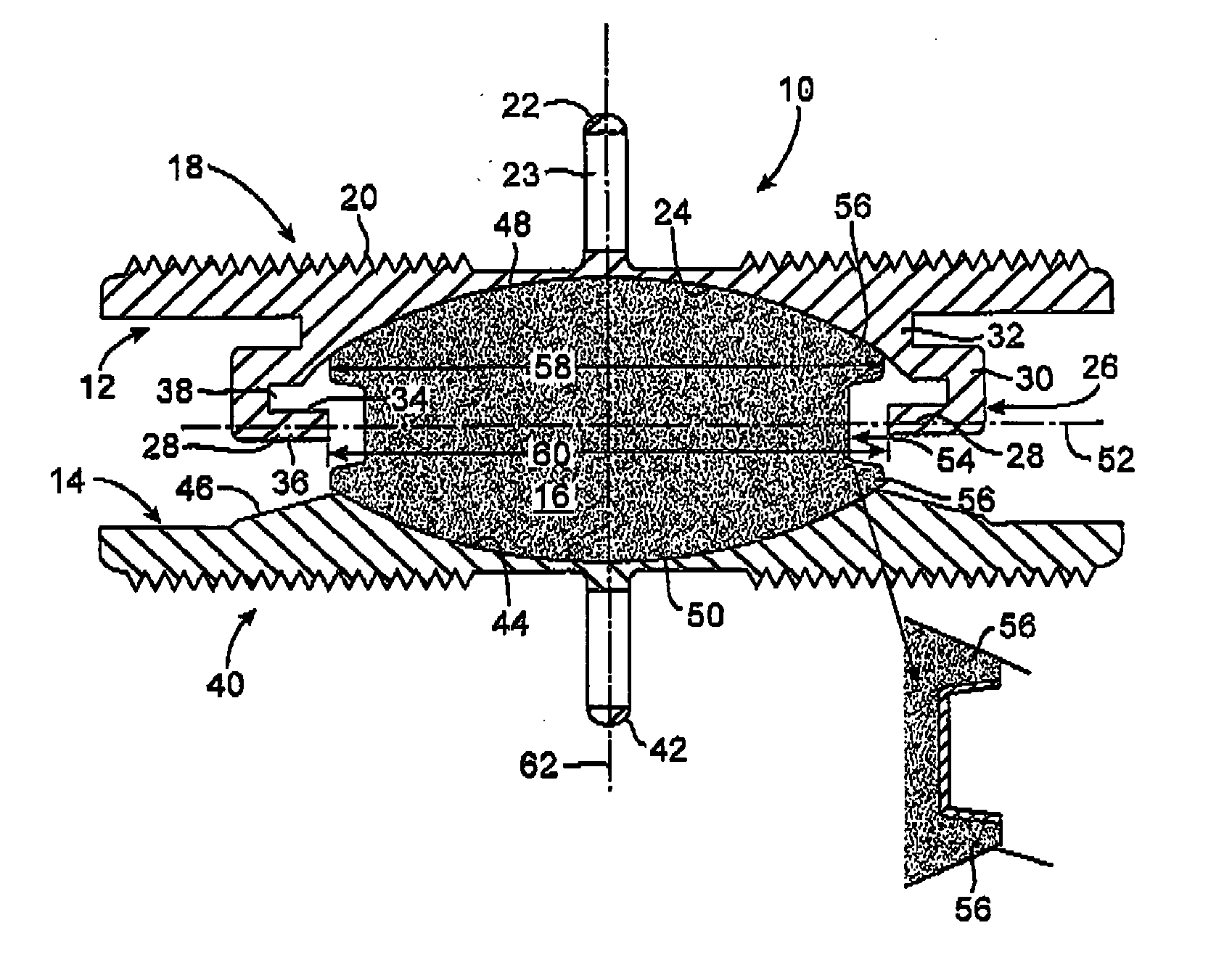

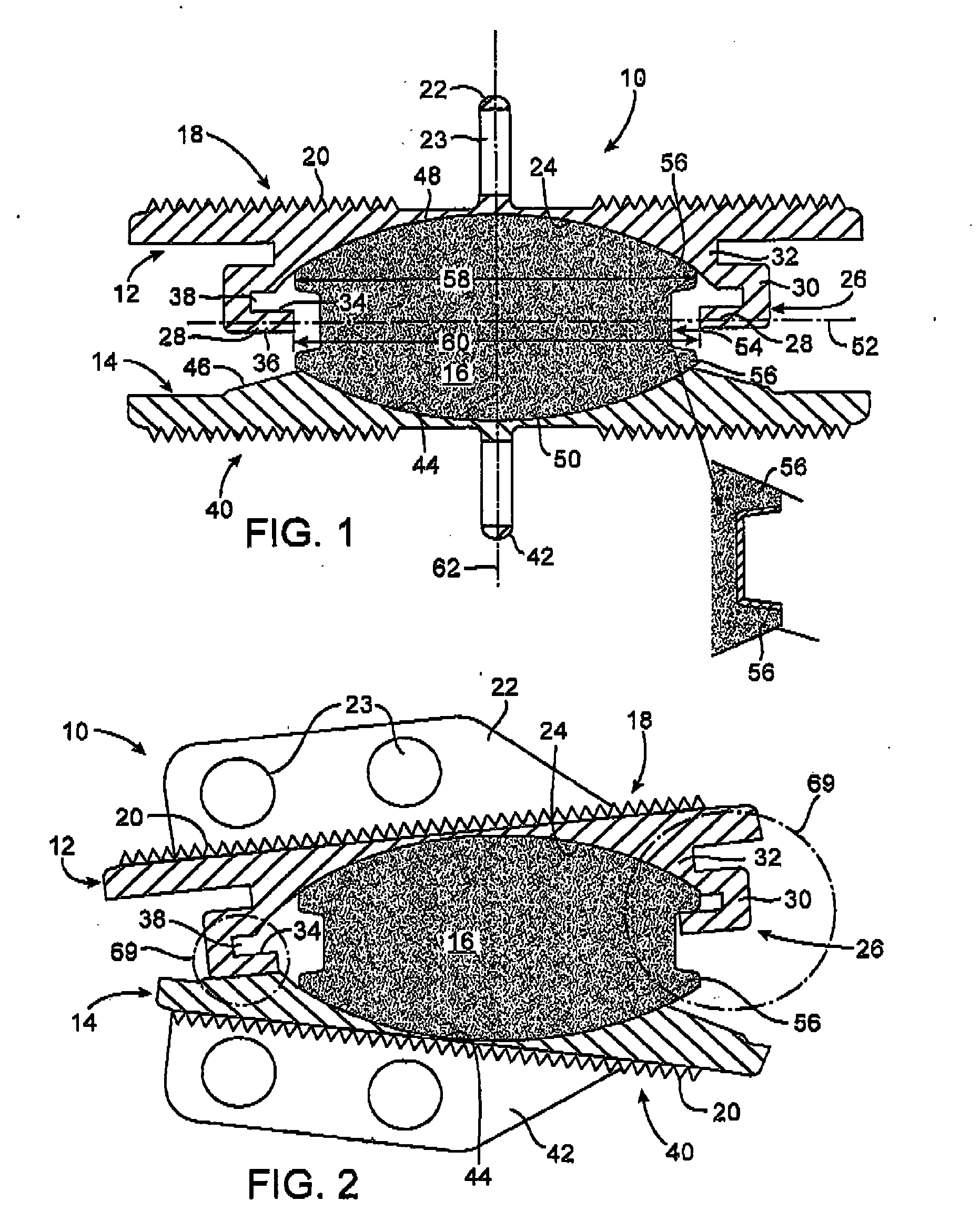

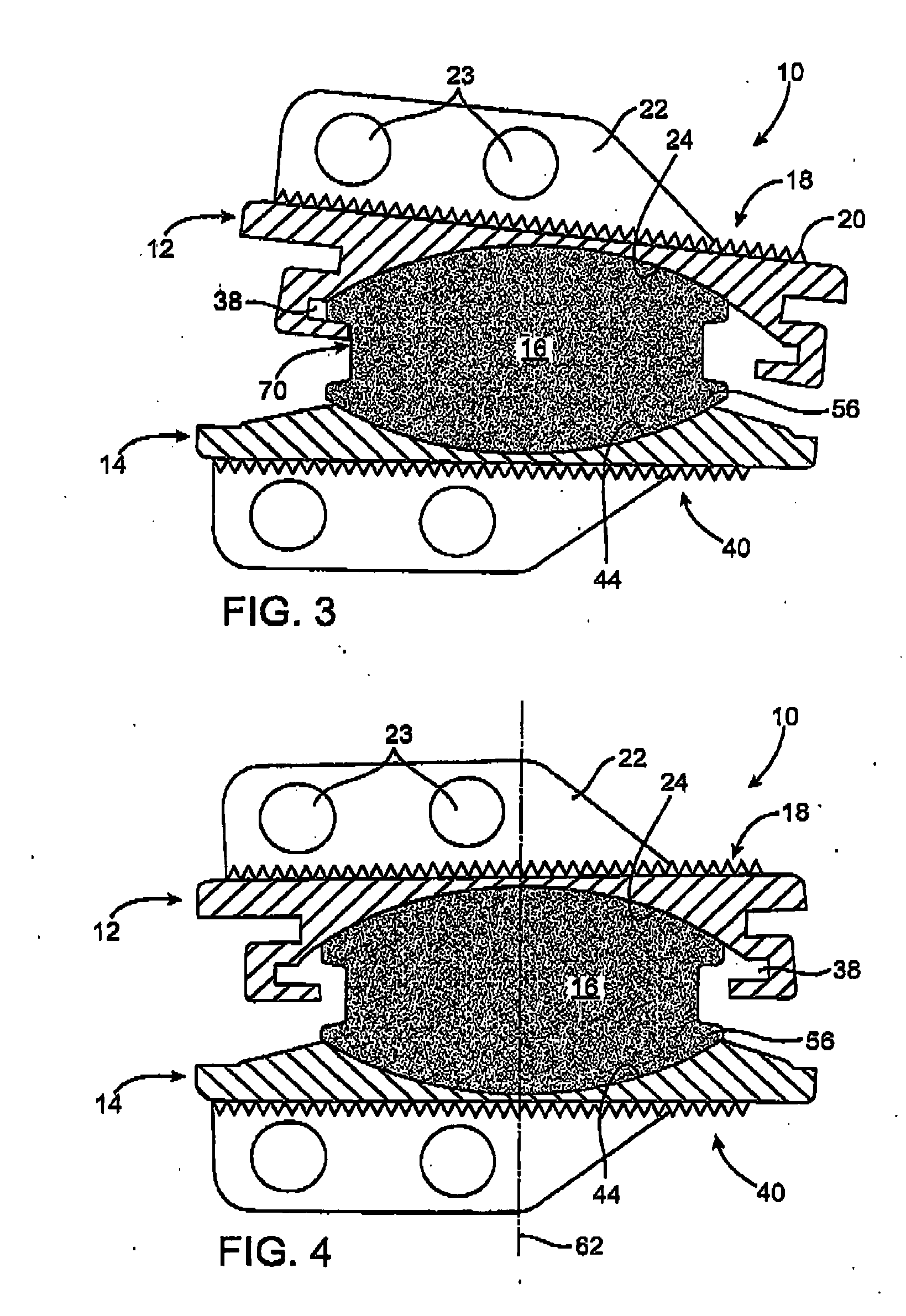

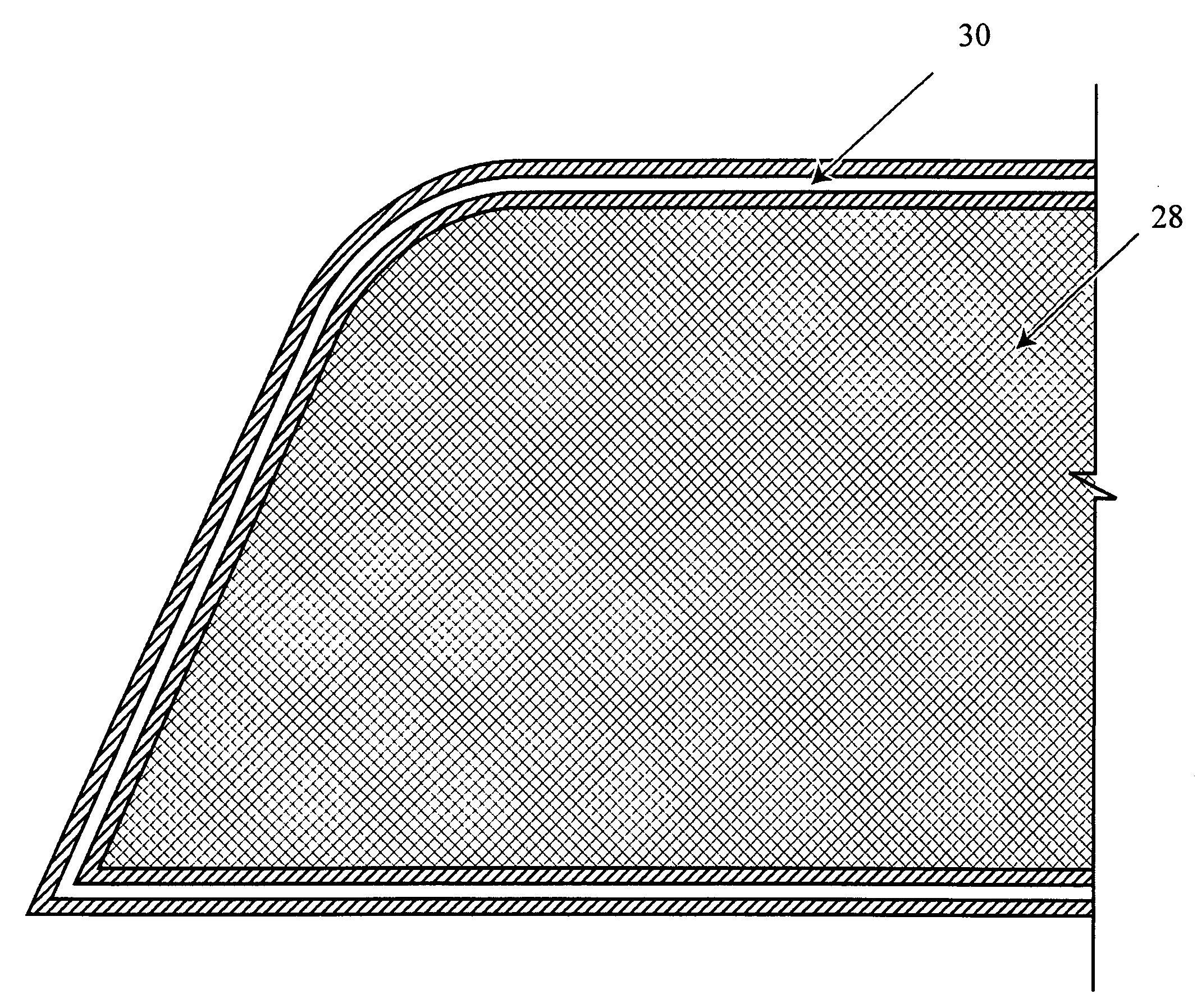

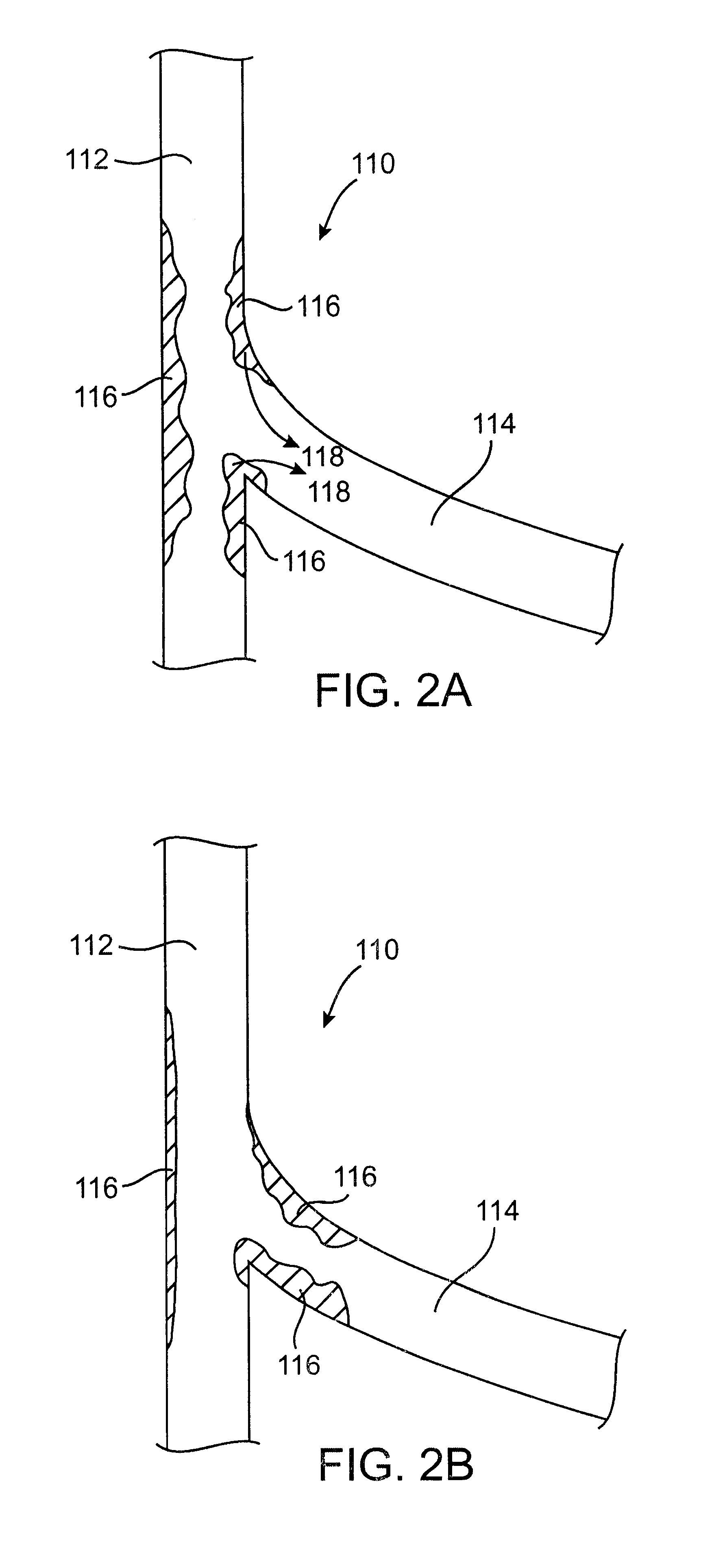

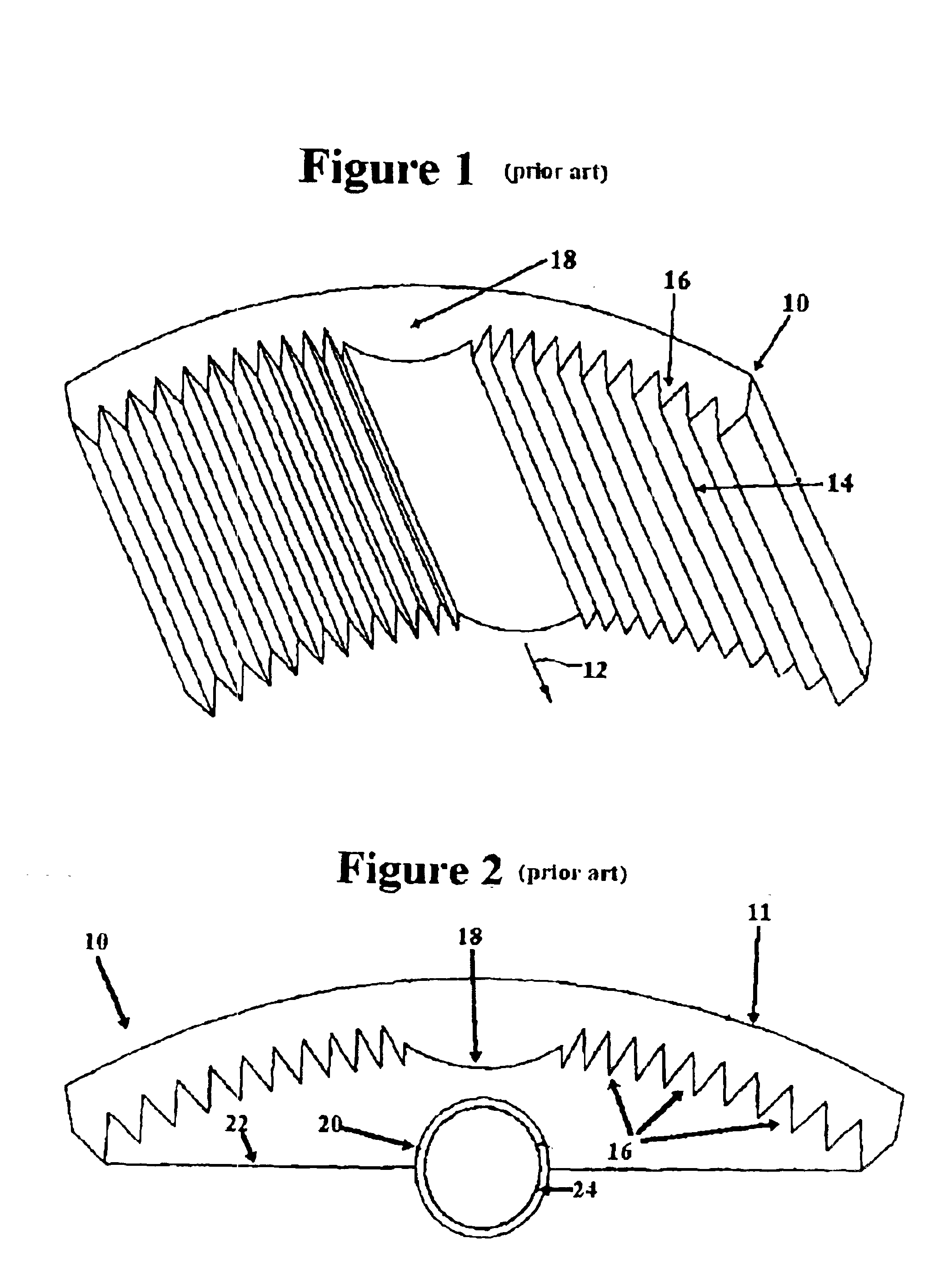

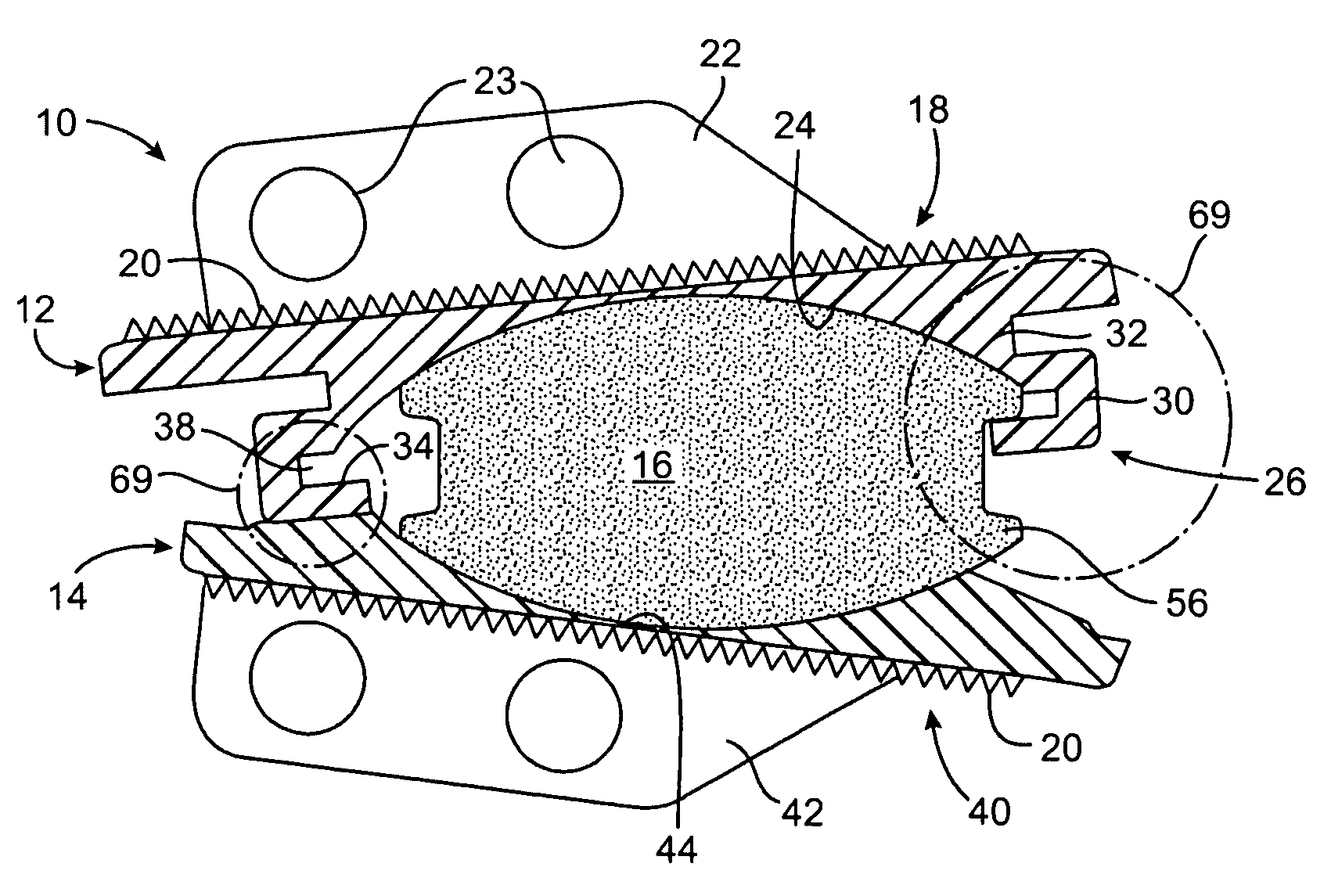

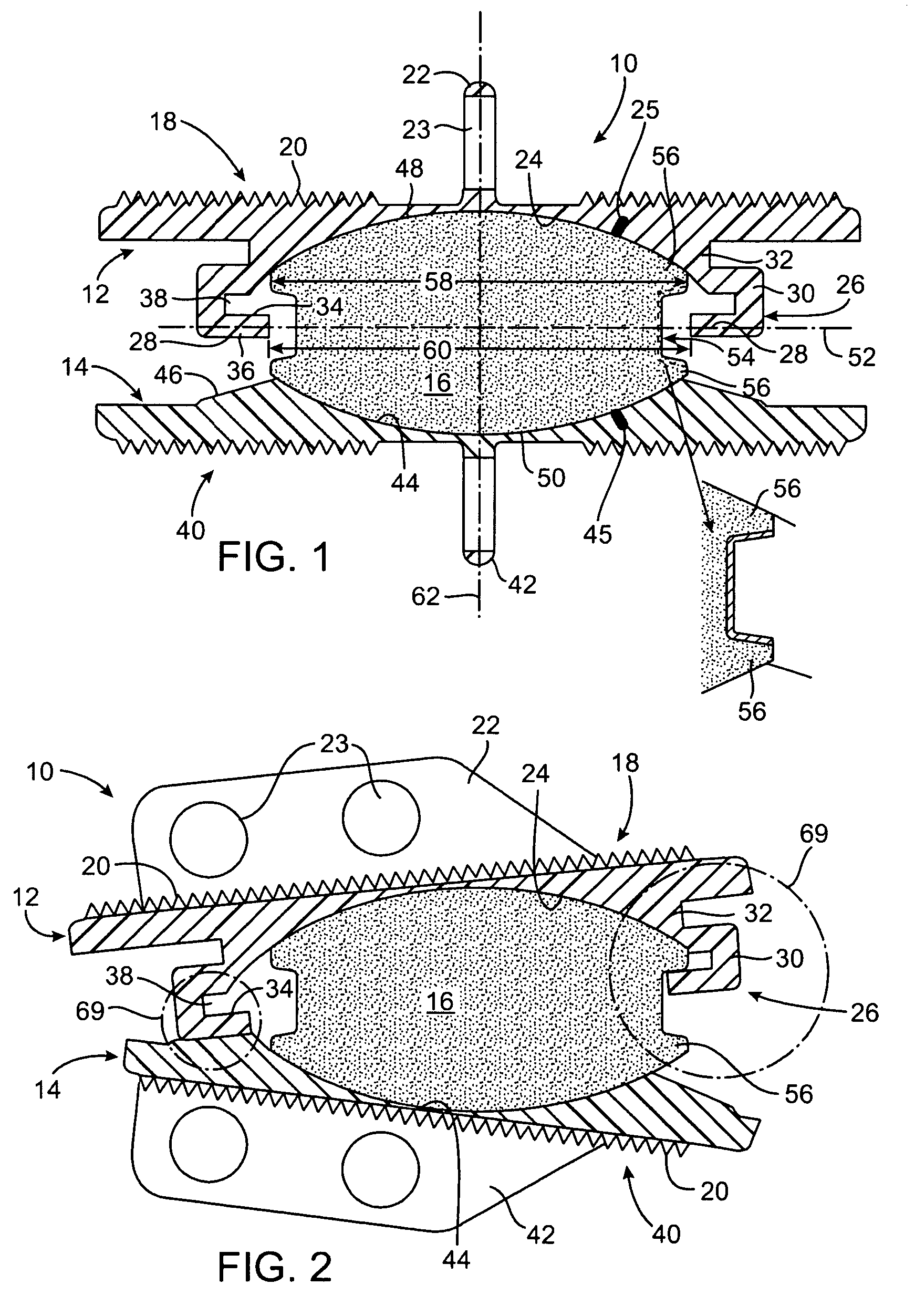

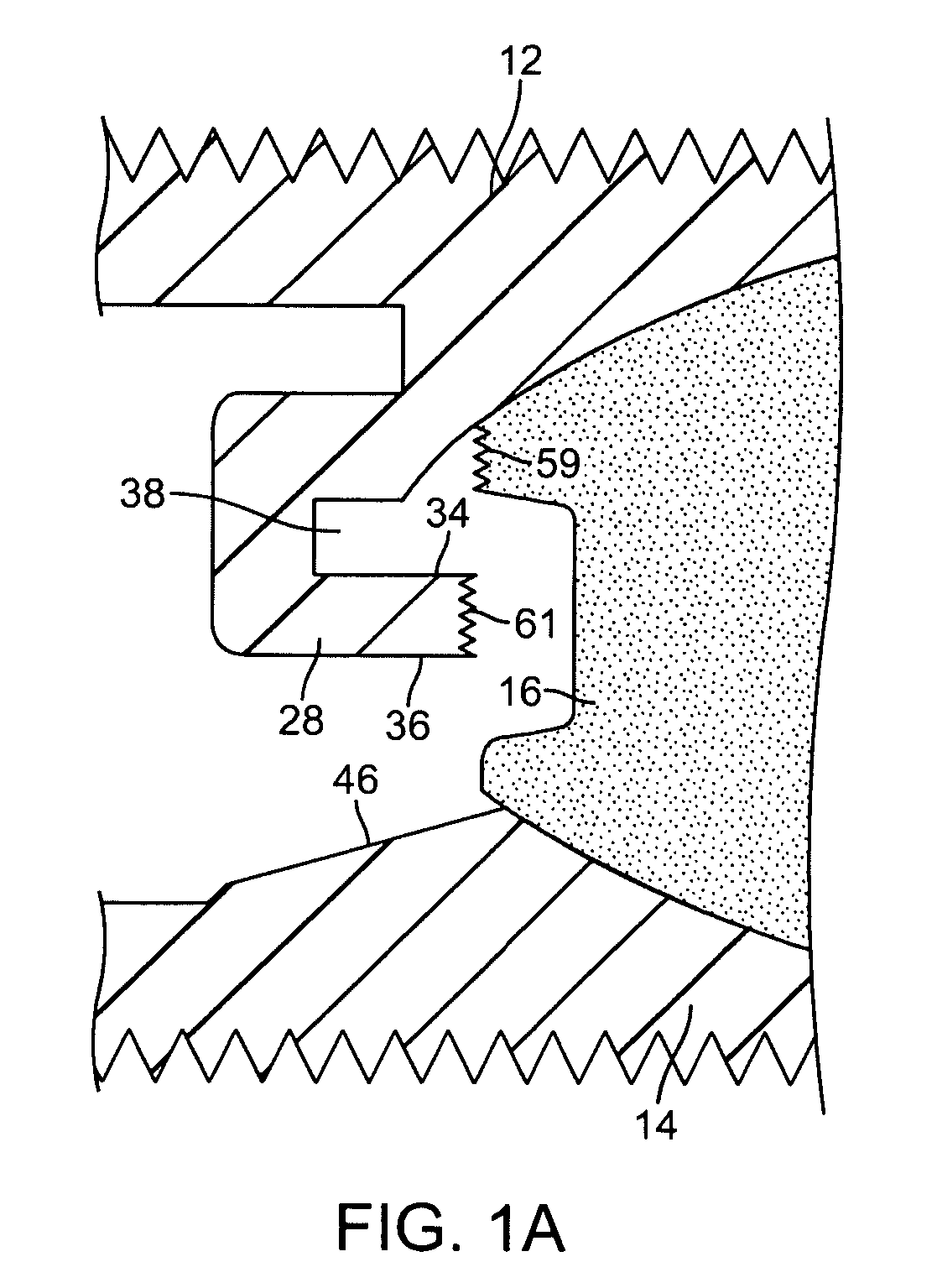

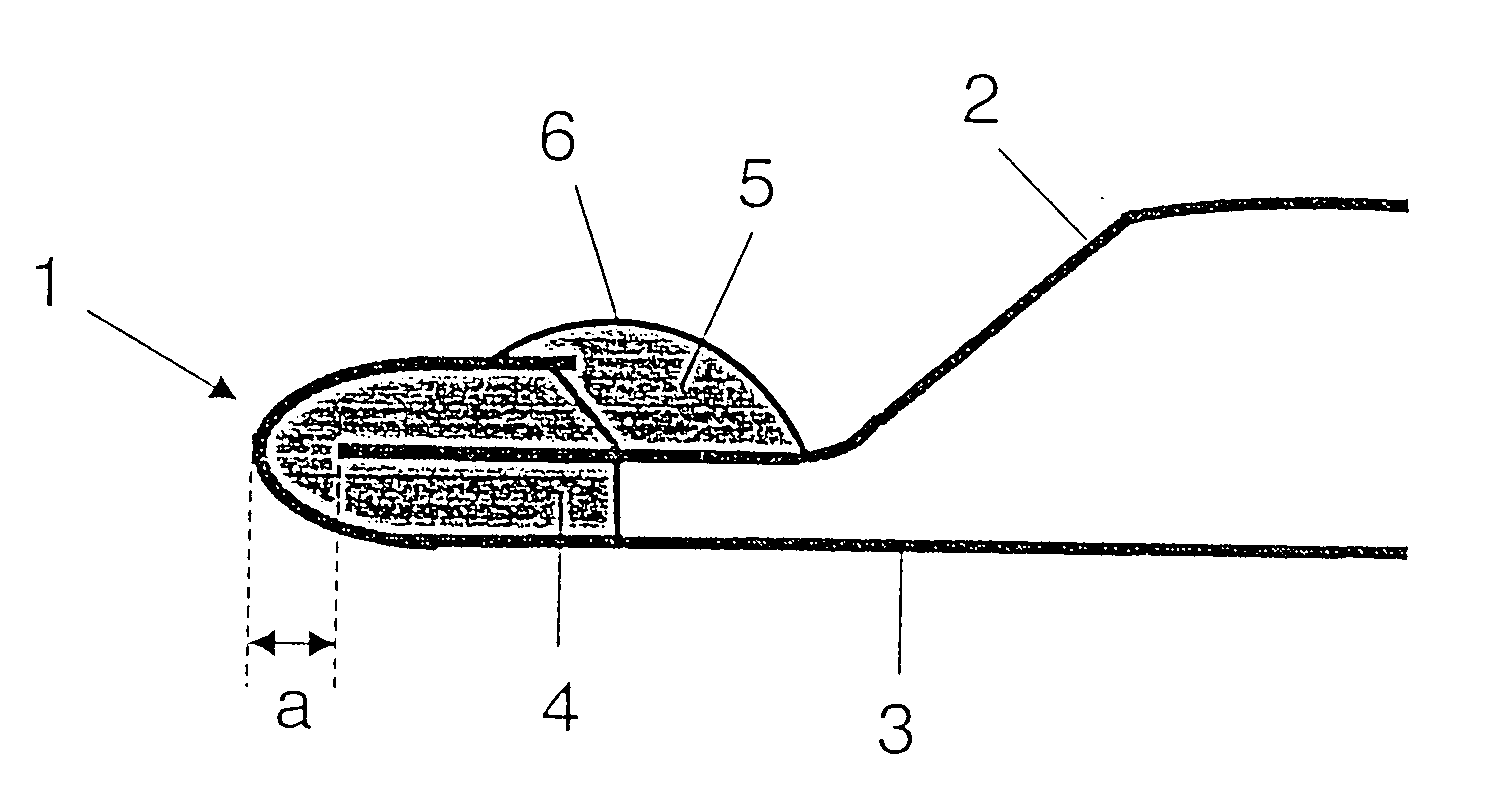

Prosthetic disc for intervertebral insertion

ActiveUS20050021145A1Reduce frictionDiameter can be maximizedJoint implantsSpinal implantsProsthesisIntervertebral disk

A prosthetic disc for insertion between adjacent vertebrae includes a core having upper and lower curved surfaces, upper and lower plates, and peripheral restraining structure on at least one of the upper plate, the lower plate and the core. Each plate has an outer surface which engages a vertebra and an inner curved surface which slides over the curved surface of the core. The peripheral restraining structure serves to hold the core against a curved surface of at least one of the plates during sliding movement of the plates over the core.

Owner:SIMPLIFY MEDICAL PTY LTD

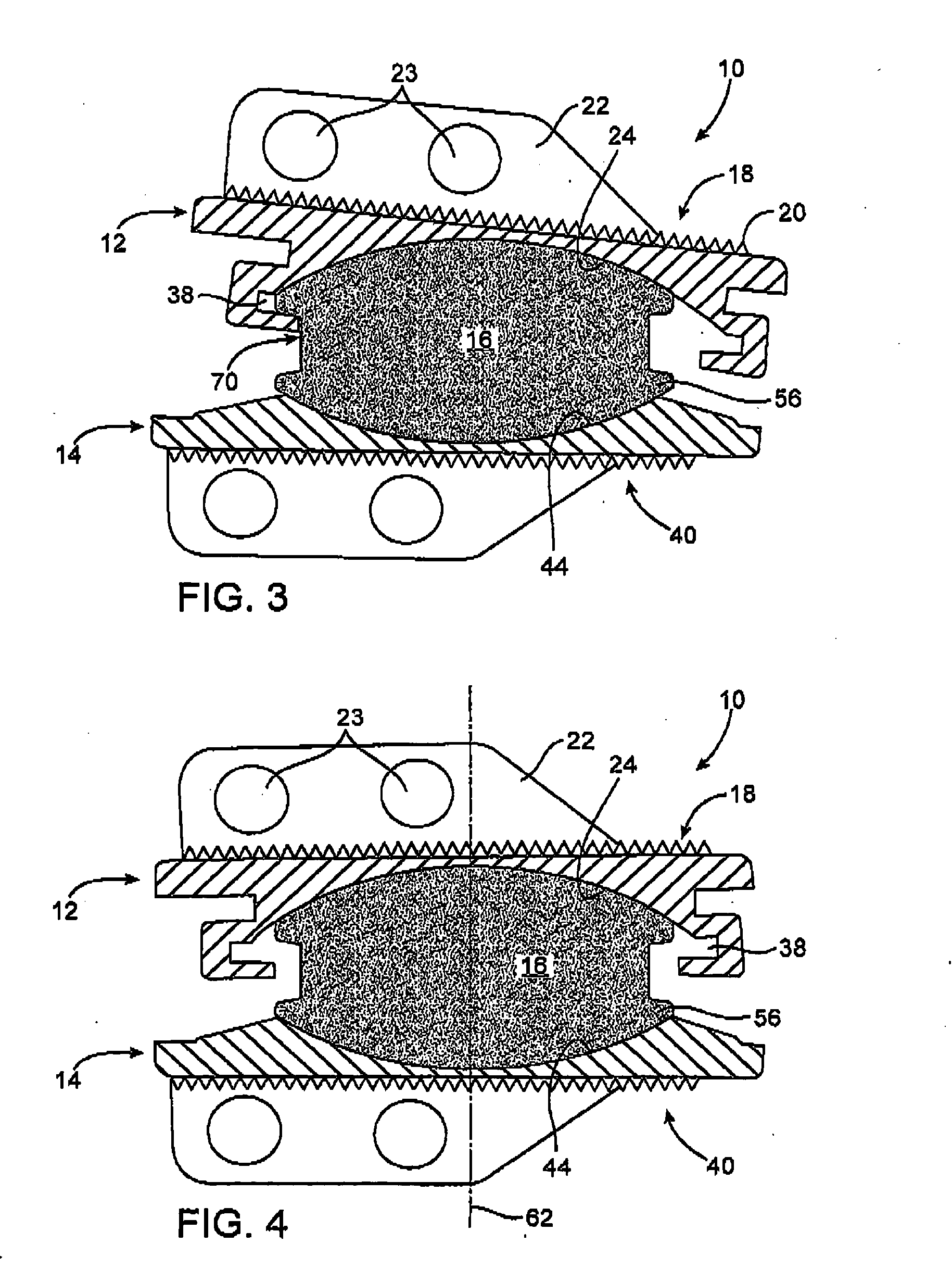

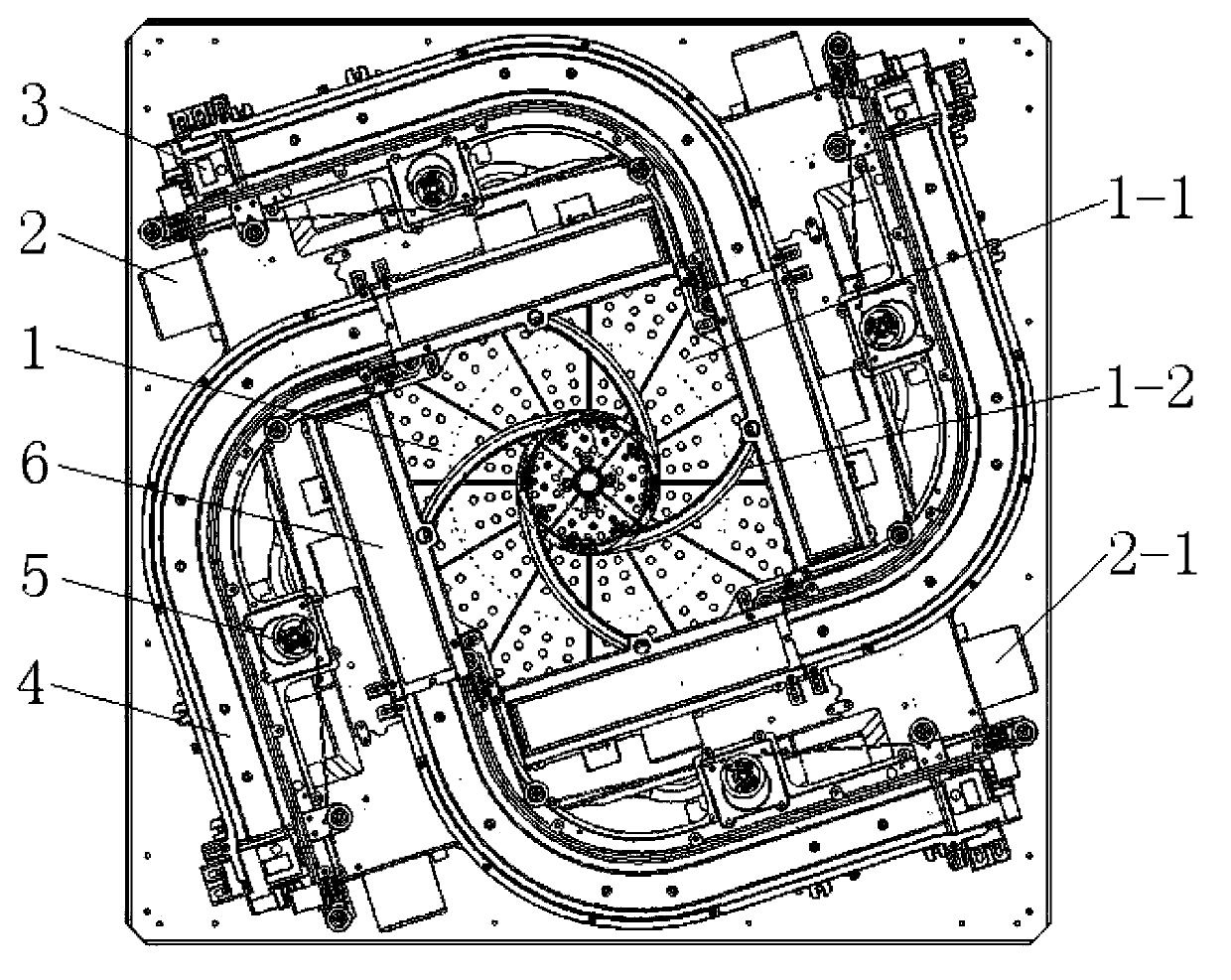

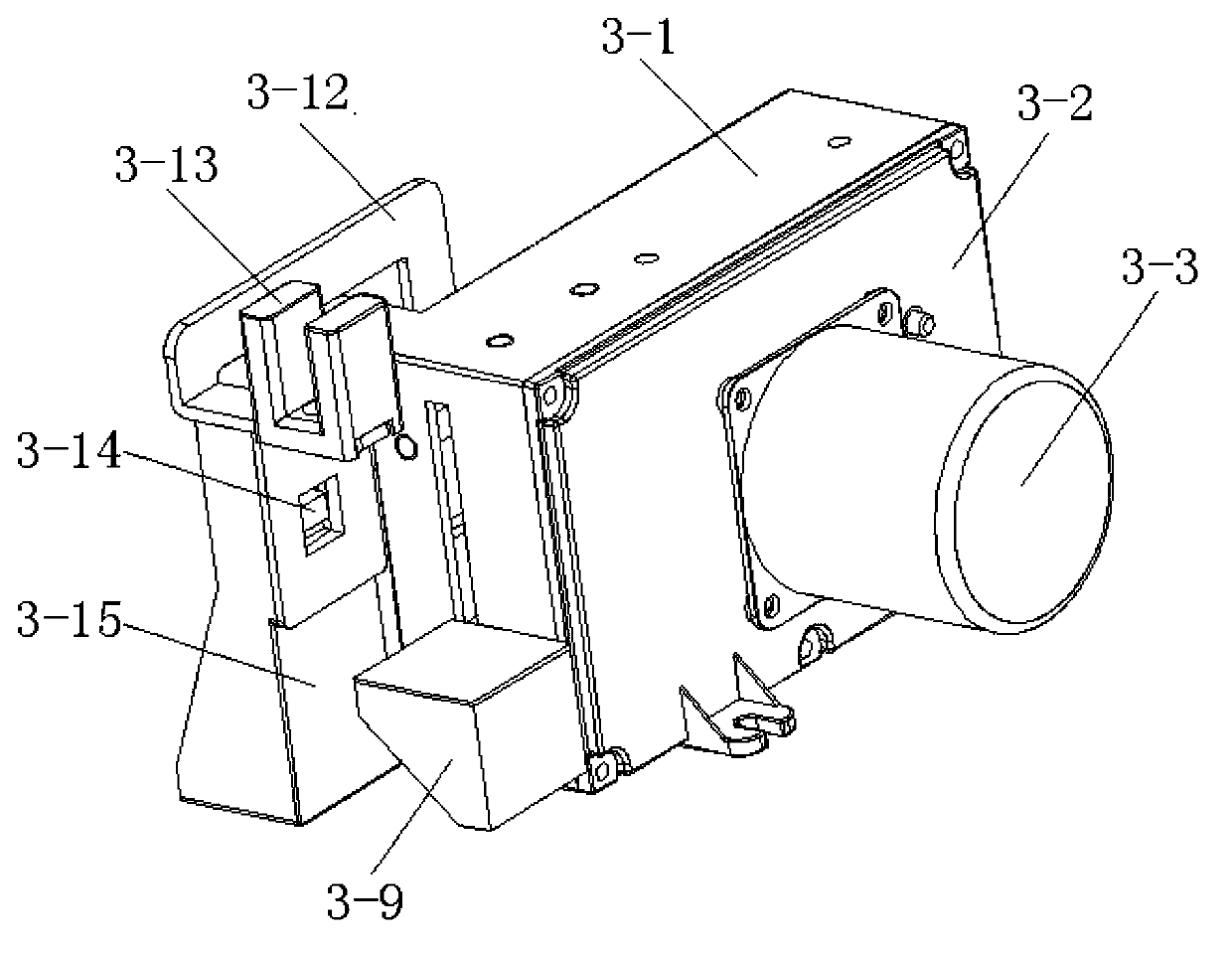

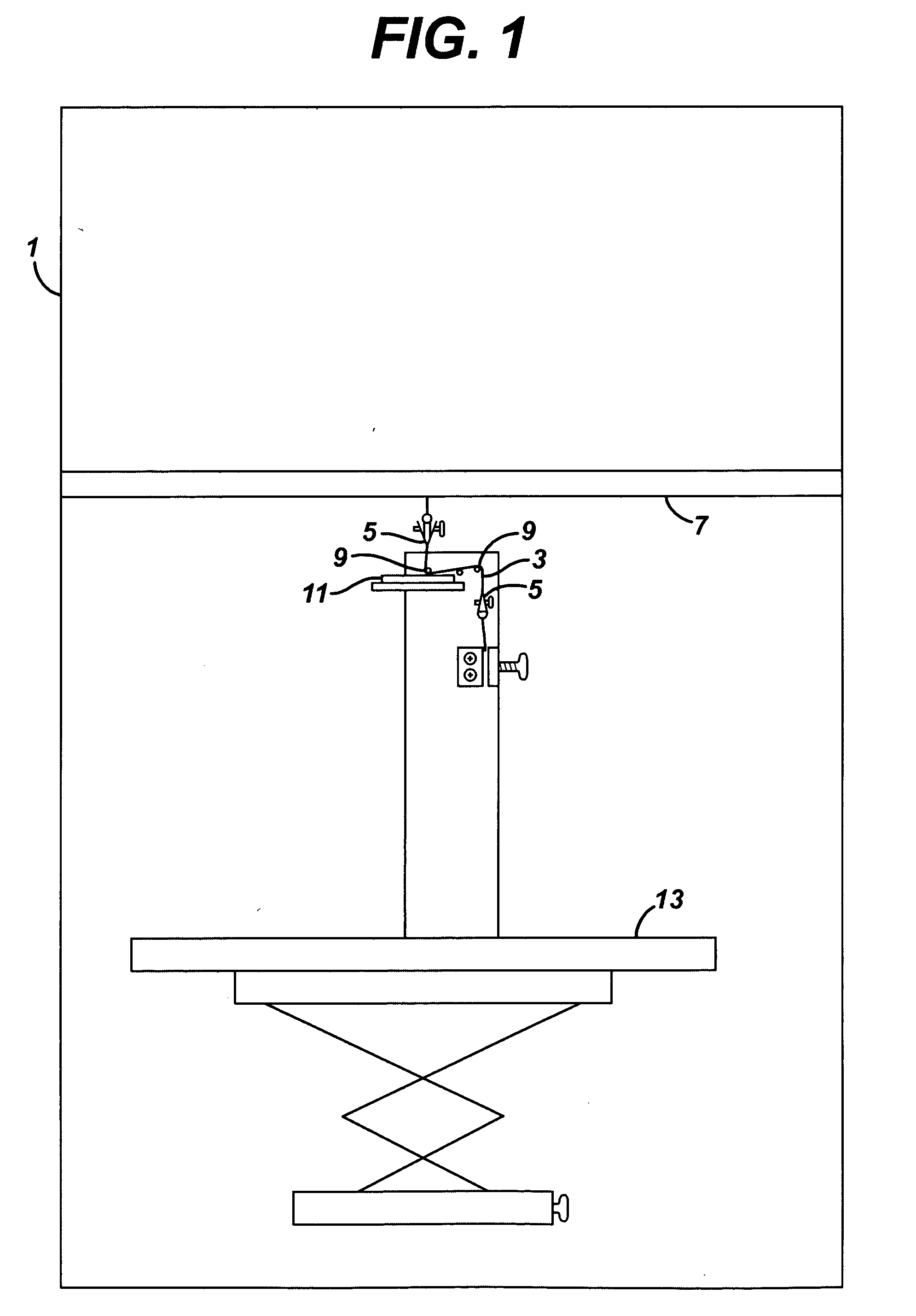

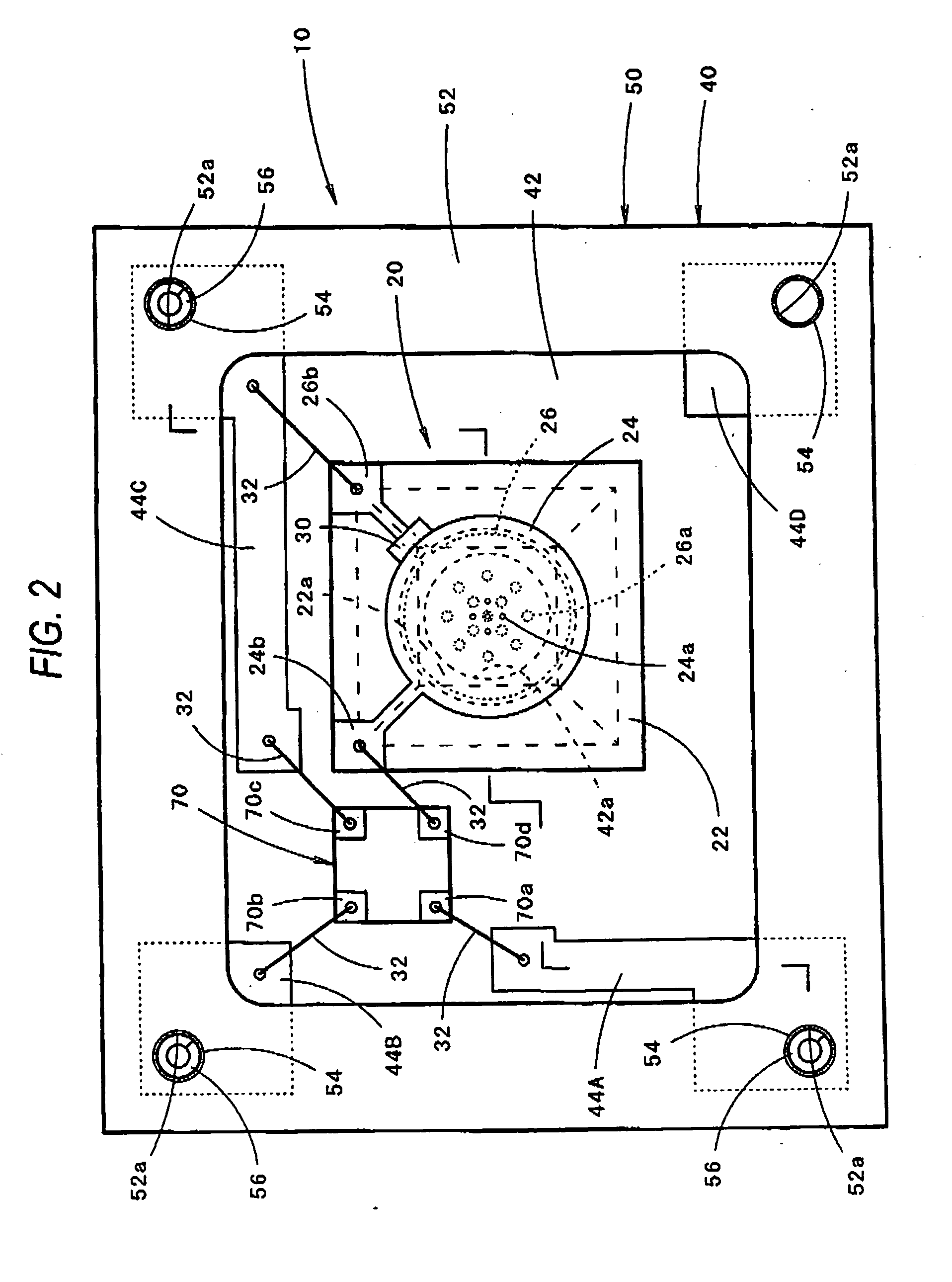

Automatic mahjong machine

ActiveCN103861280ACompact and ingenious structureGuaranteed uptimeIndoor gamesEngineeringMechanical engineering

The invention discloses an automatic mahjong machine. The automatic mahjong machine comprises a shuffling mechanism, a conveying mechanism, a tile stacking, lifting and pushing mechanism, a rail mechanism, a tile sending driving mechanism and a tile sending mechanism; the conveying mechanism, the tile stacking, lifting and pushing mechanism, the rail mechanism, the tile sending driving mechanism and the tile sending mechanism are arranged at the periphery of the mahjong machine; an input end of the conveying mechanism is arranged at the edge of the shuffling mechanism; an output end of the conveying mechanism is connected with an input end of the tile stacking, lifting and pushing mechanism; the rail mechanism is arranged above the stacking mahjong pushing mechanism; an input end of the rail mechanism is connected with an output end of the tile stacking, lifting and pushing mechanism; an output end of the rail mechanism is connected with an input end of the tile sending mechanism. The automatic mahjong machine has the advantages of being compact and skillful in structure, stable in operation, reasonable in cost control and long in service life.

Owner:德兴市永达娱乐设备有限公司

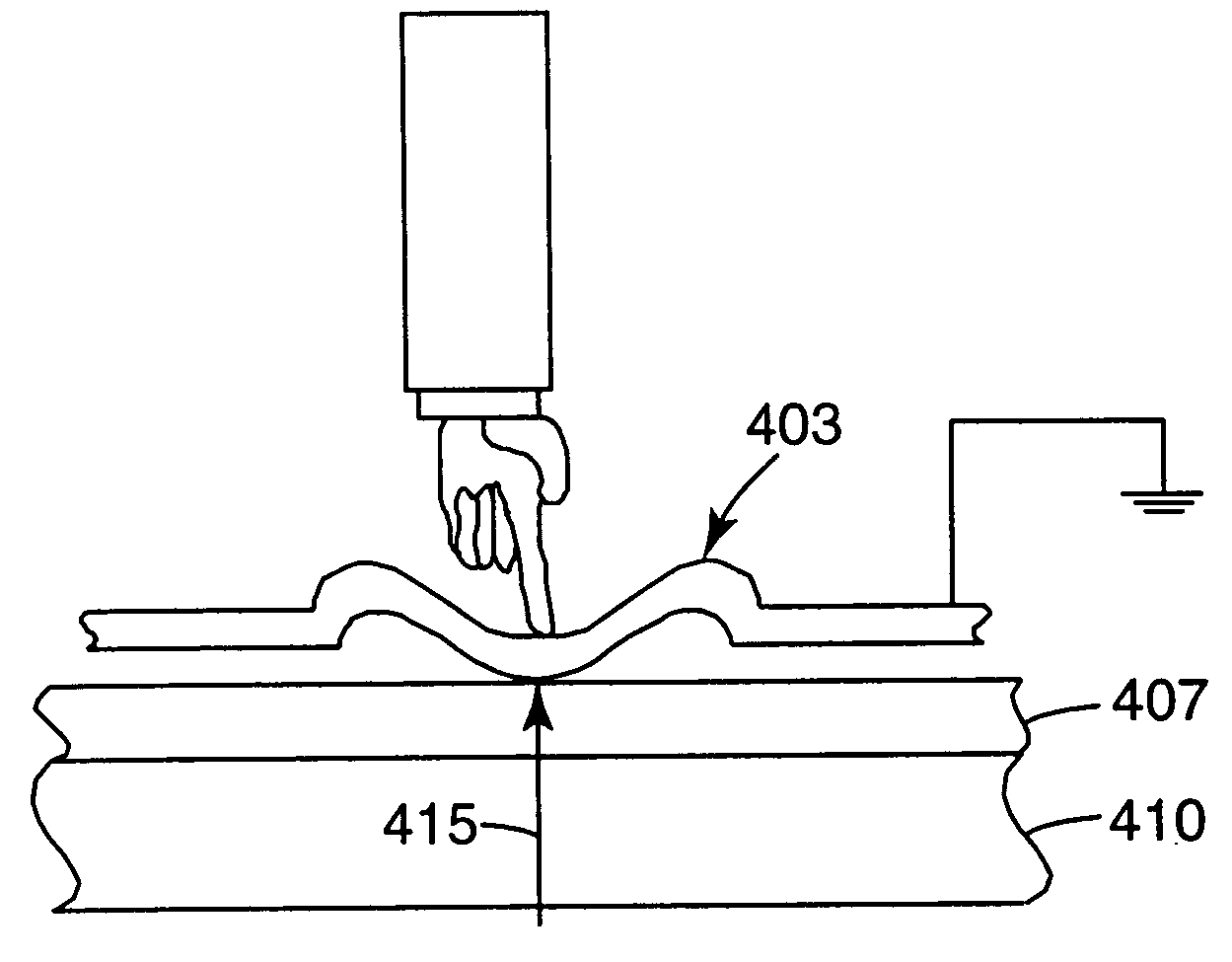

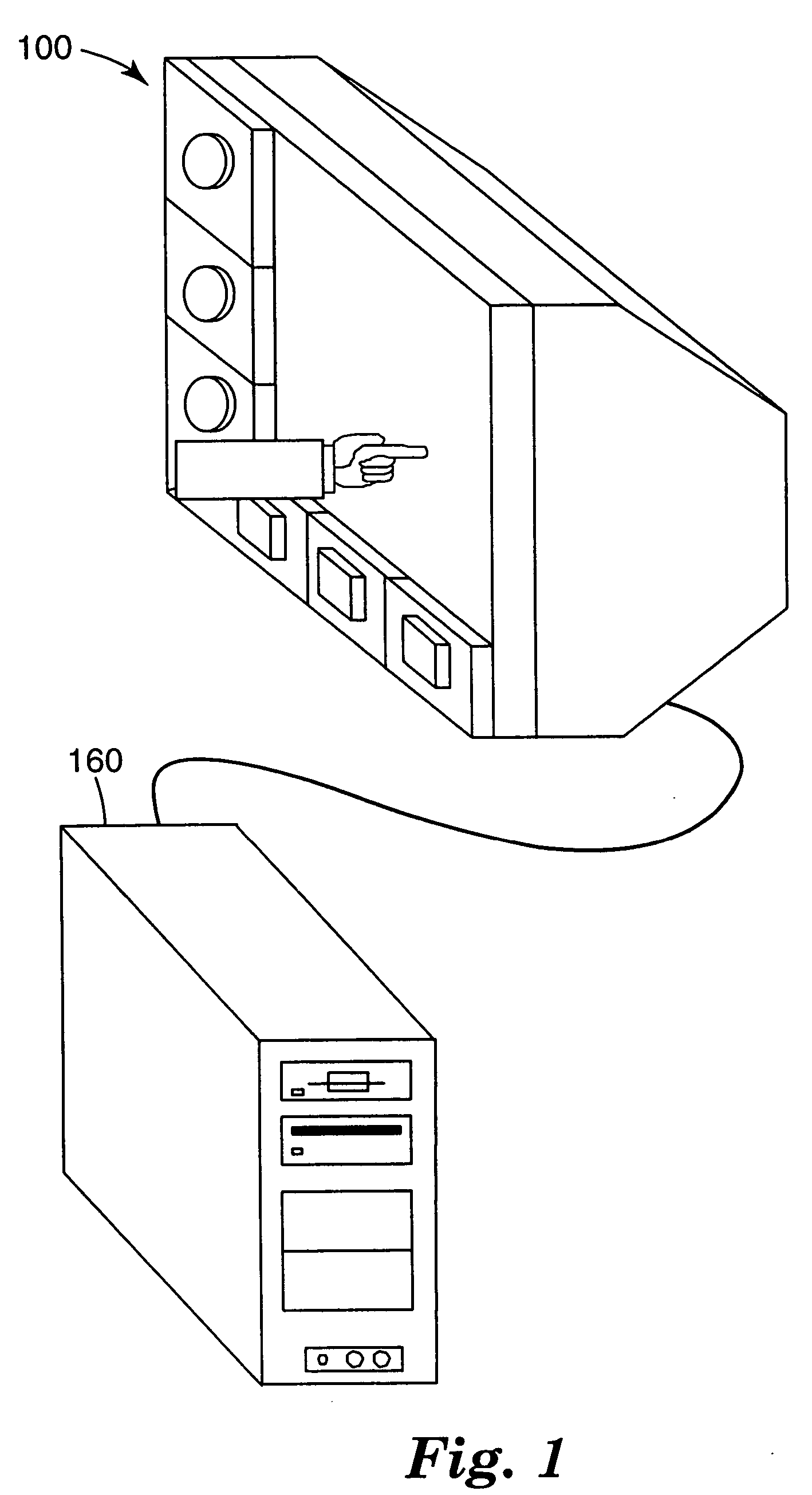

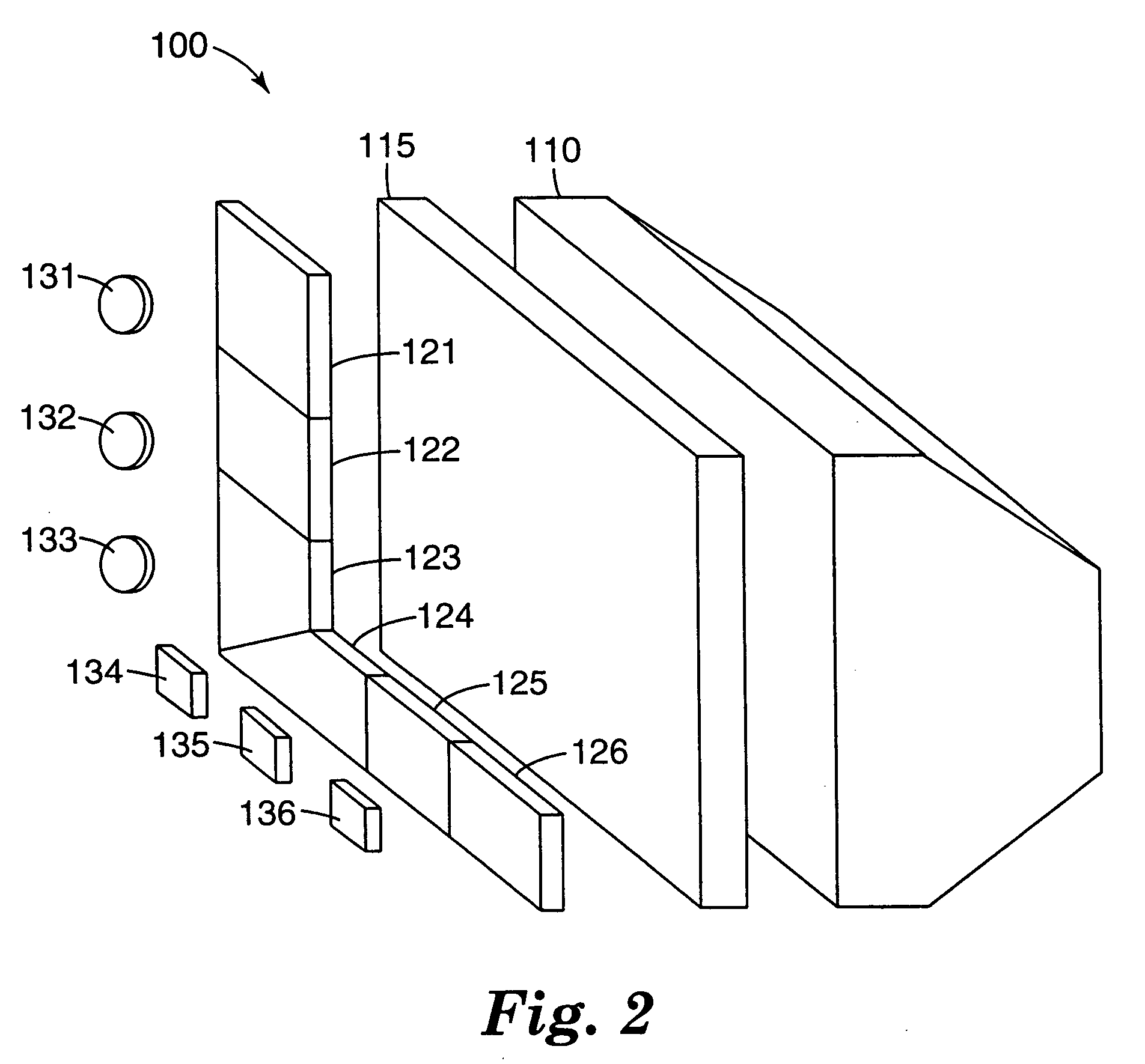

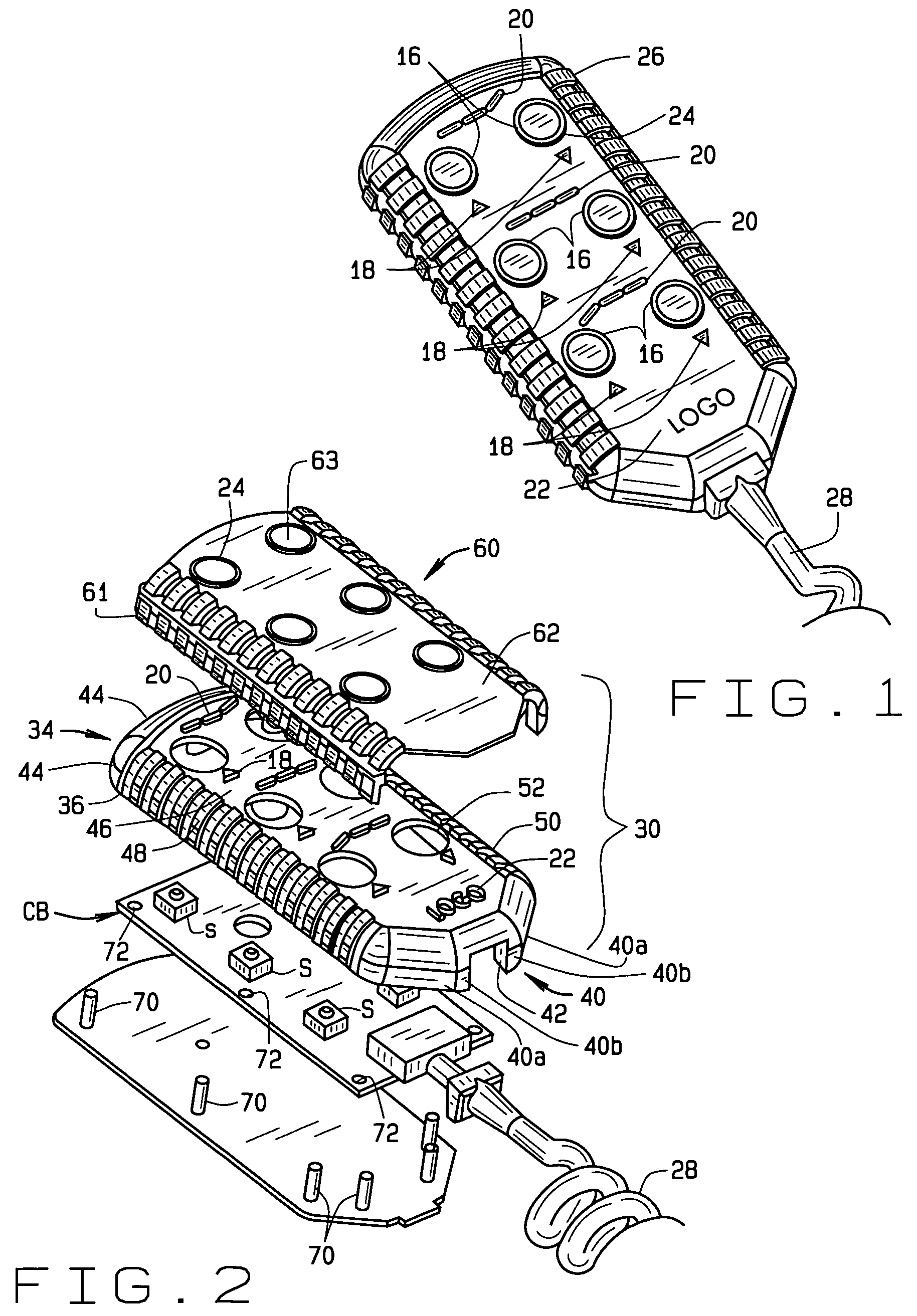

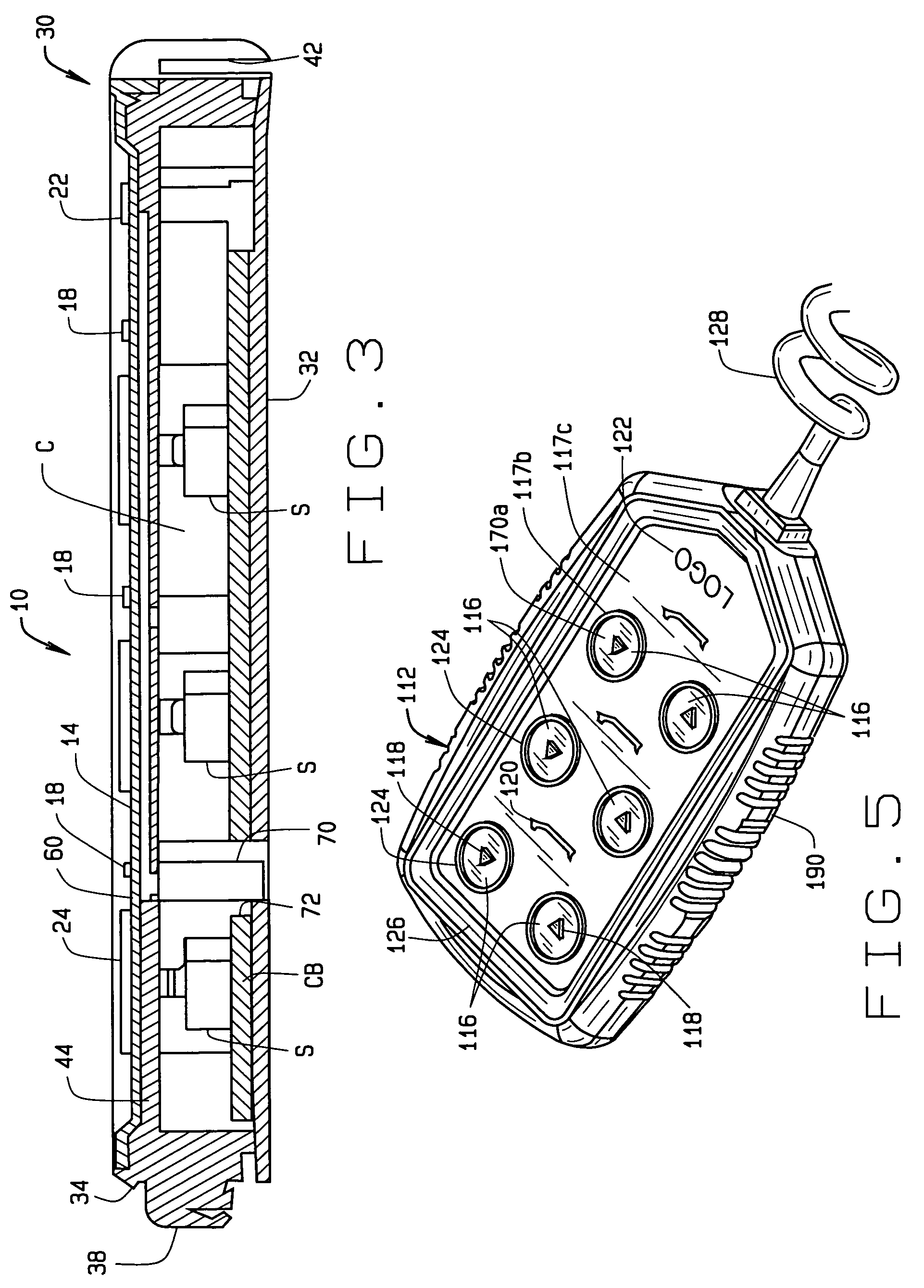

Tactile touch-sensing system

InactiveUS20050088417A1No tactile feedbackWithout complicationInput/output for user-computer interactionCathode-ray tube indicatorsTouch SensesEngineering

A tactile touch-sensing system that includes a touch sensor, touch-generating pads, and tactile buttons. The touch sensor is configured to produce an electrical signal in response to a touch. The touch-generating pads cover at least a part of the touch sensor and are configured not to cause a touch on the touch sensor before they are activated. A user can activate a touch-generating pad by pressing a tactile button associated with the touch-generating pad. In response to being pressed, the tactile button is configured to provide tactile feedback to the user. The touch-generating pad, when activated by the tactile button, causes a touch on the touch sensor.

Owner:3M INNOVATIVE PROPERTIES CO

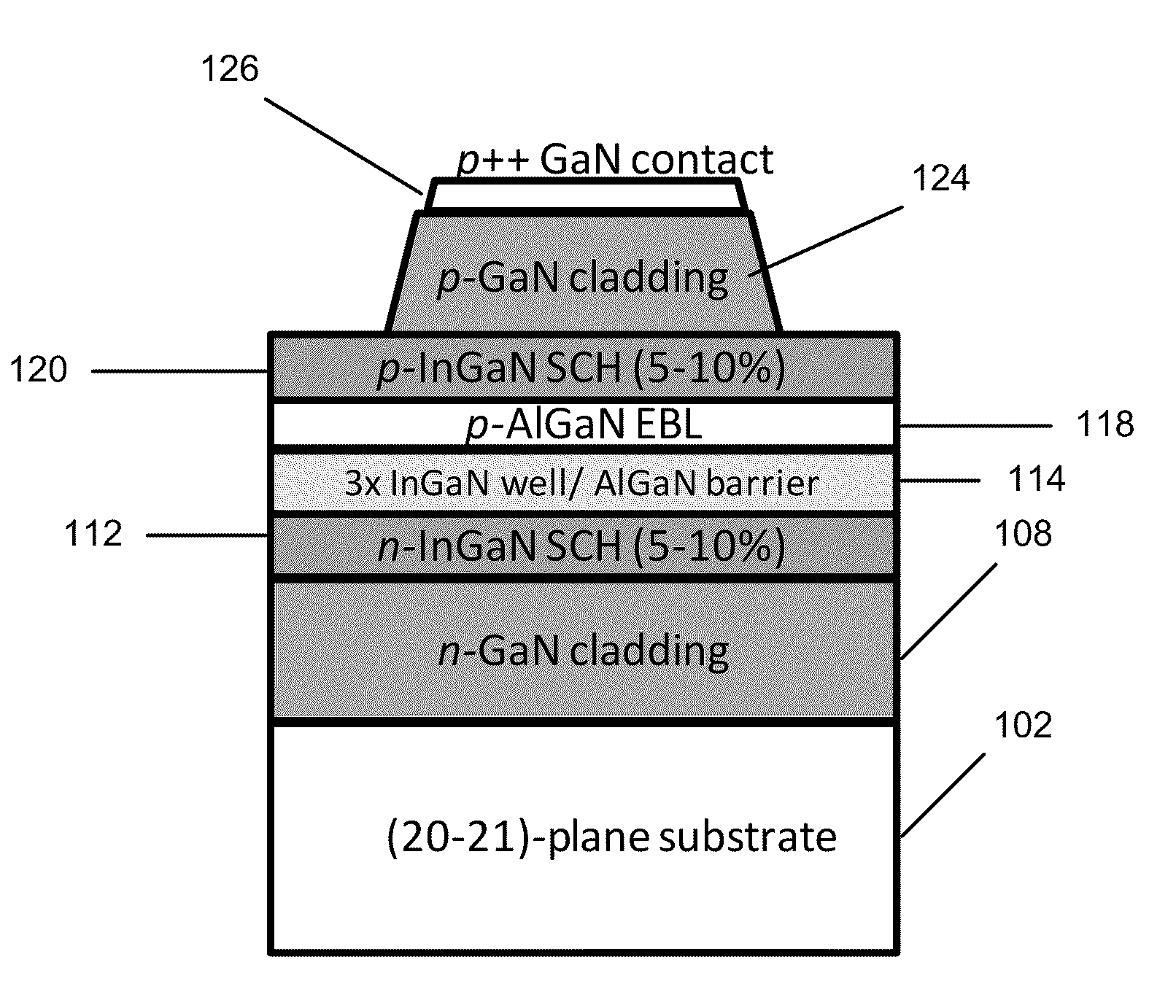

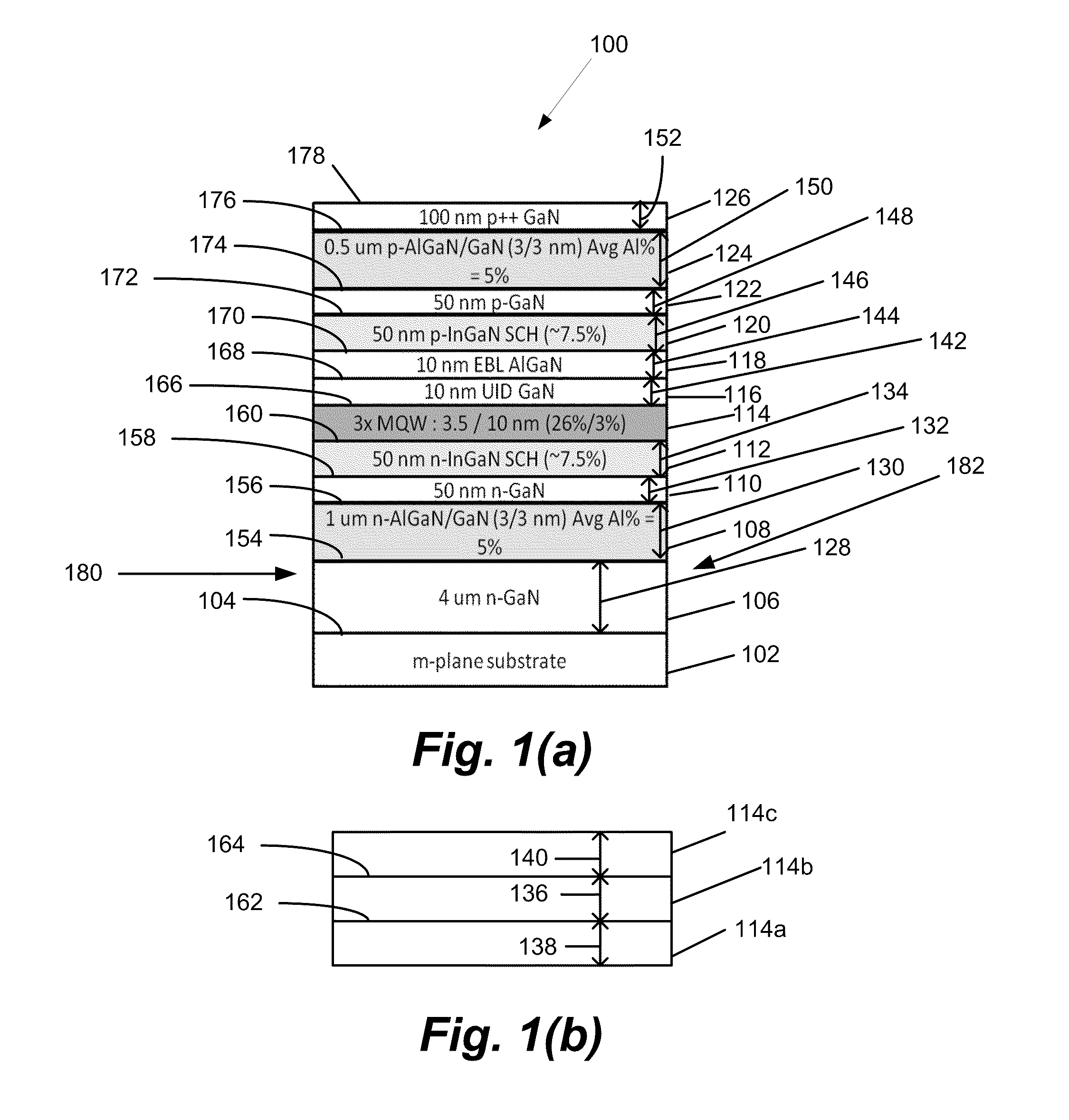

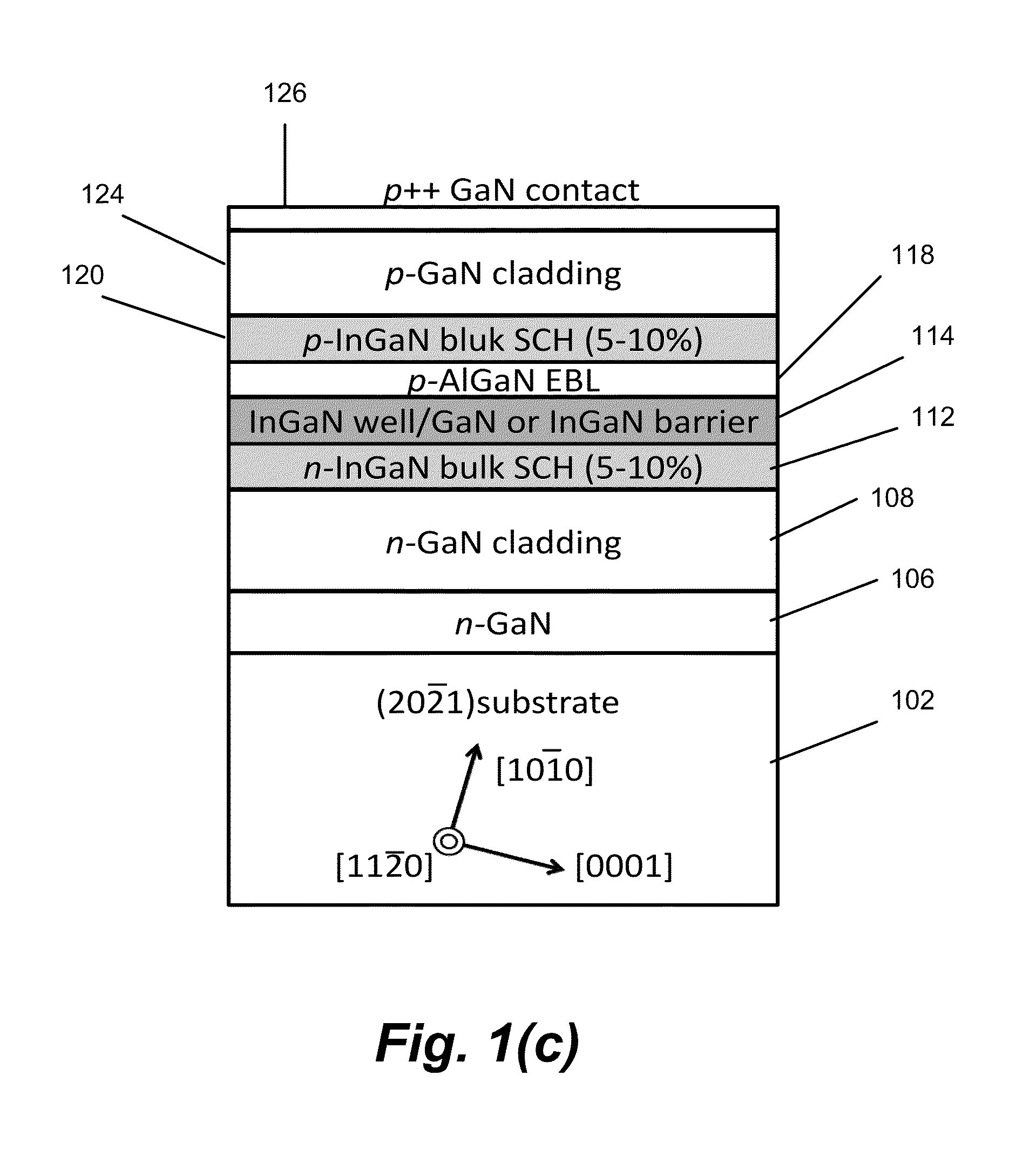

LONG WAVELENGTH NONPOLAR AND SEMIPOLAR (Al,Ga,In)N BASED LASER DIODES

InactiveUS20100309943A1Simple structureImprove electricityOptical wave guidanceLaser detailsContact layerStimulated emission

A laser diode, grown on a miscut nonpolar or semipolar substrate, with lower threshold current density and longer stimulated emission wavelength, compared to conventional laser diode structures, wherein the laser diode's (1) n-type layers are grown in a nitrogen carrier gas, (2) quantum well layers and barrier layers are grown at a slower growth rate as compared to other device layers (enabling growth of the p-type layers at higher temperature), (3) high Al content electron blocking layer enables growth of layers above the active region at a higher temperature, and (4) asymmetric AlGaN SPSLS allowed growth of high Al containing p-AlGaN layers. Various other techniques were used to improve the conductivity of the p-type layers and minimize the contact resistance of the contact layer.

Owner:RGT UNIV OF CALIFORNIA

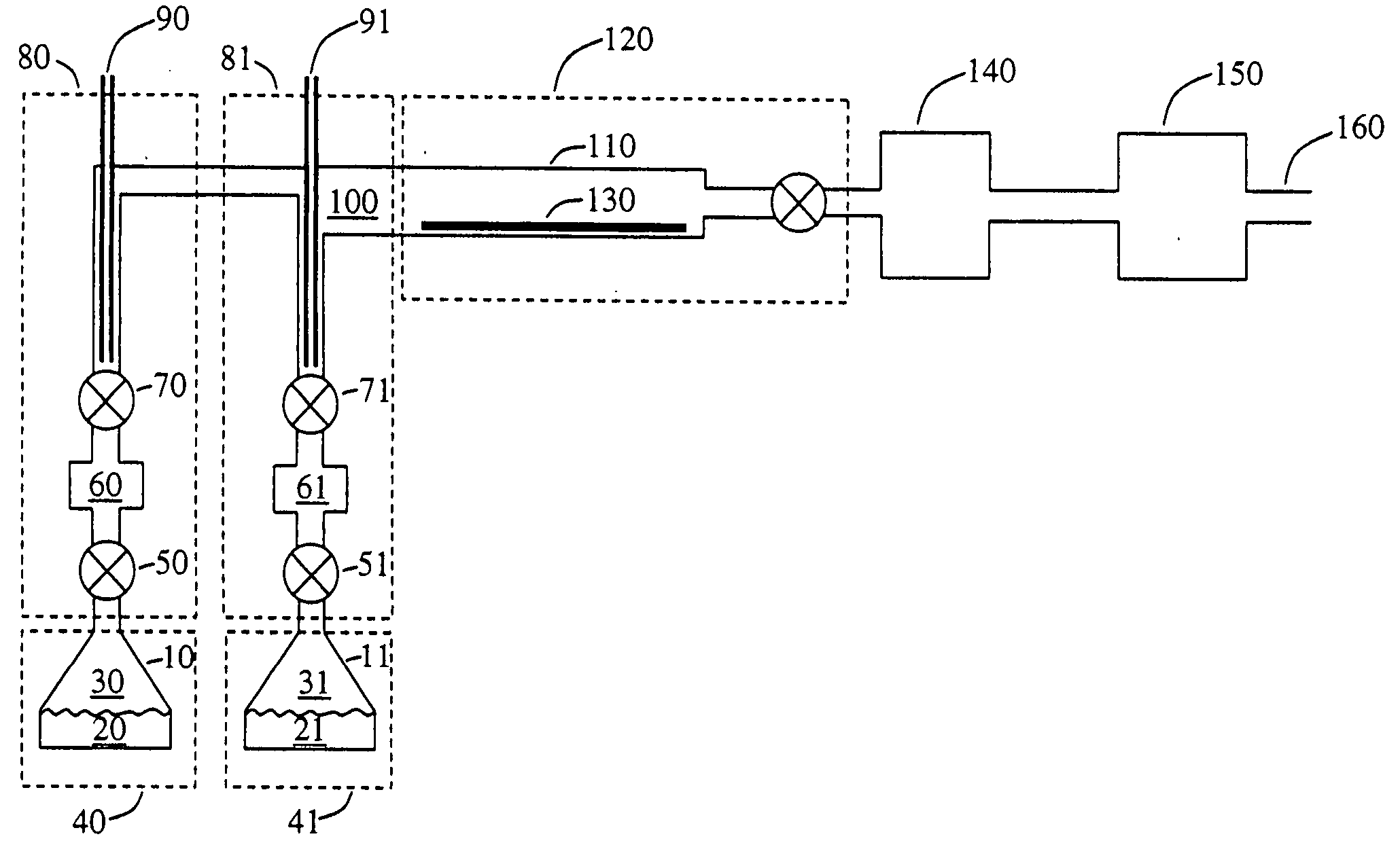

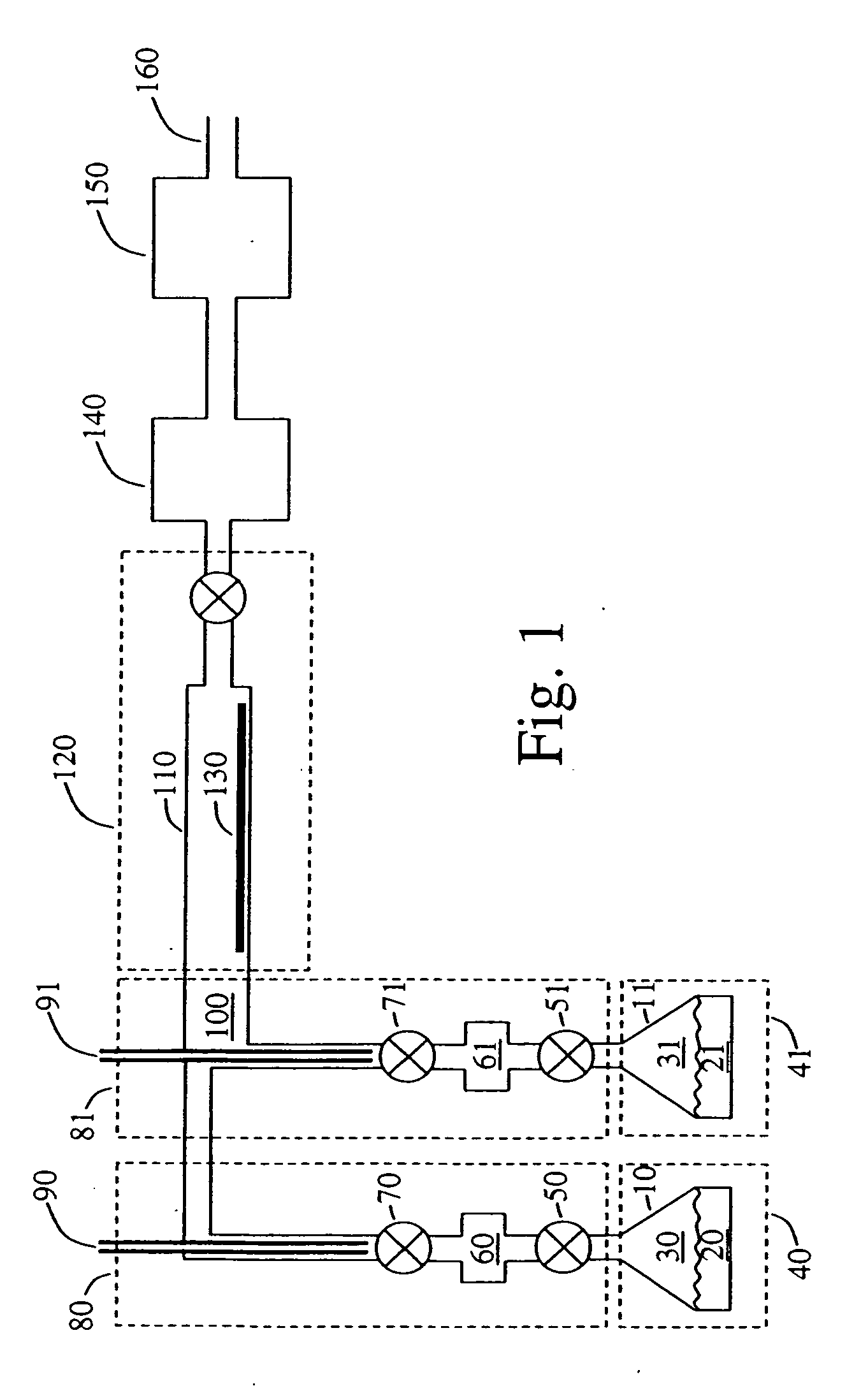

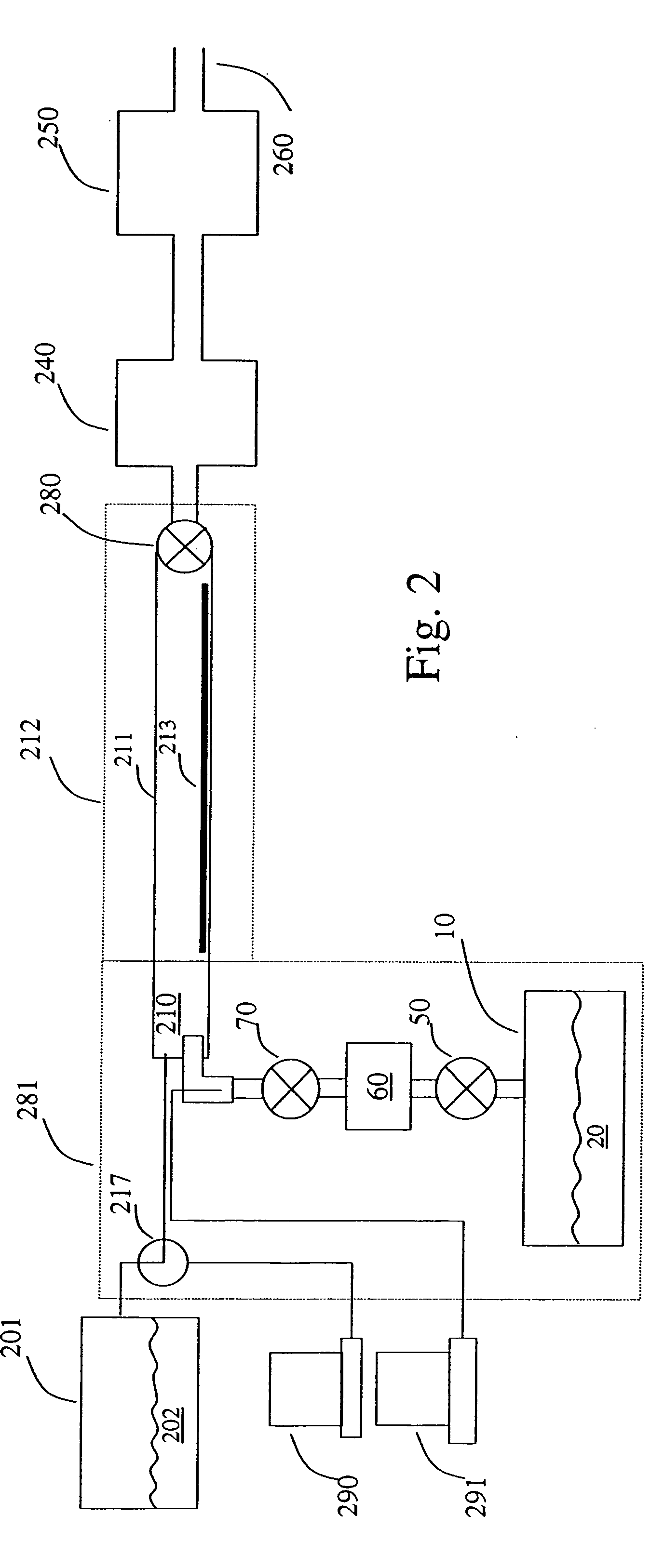

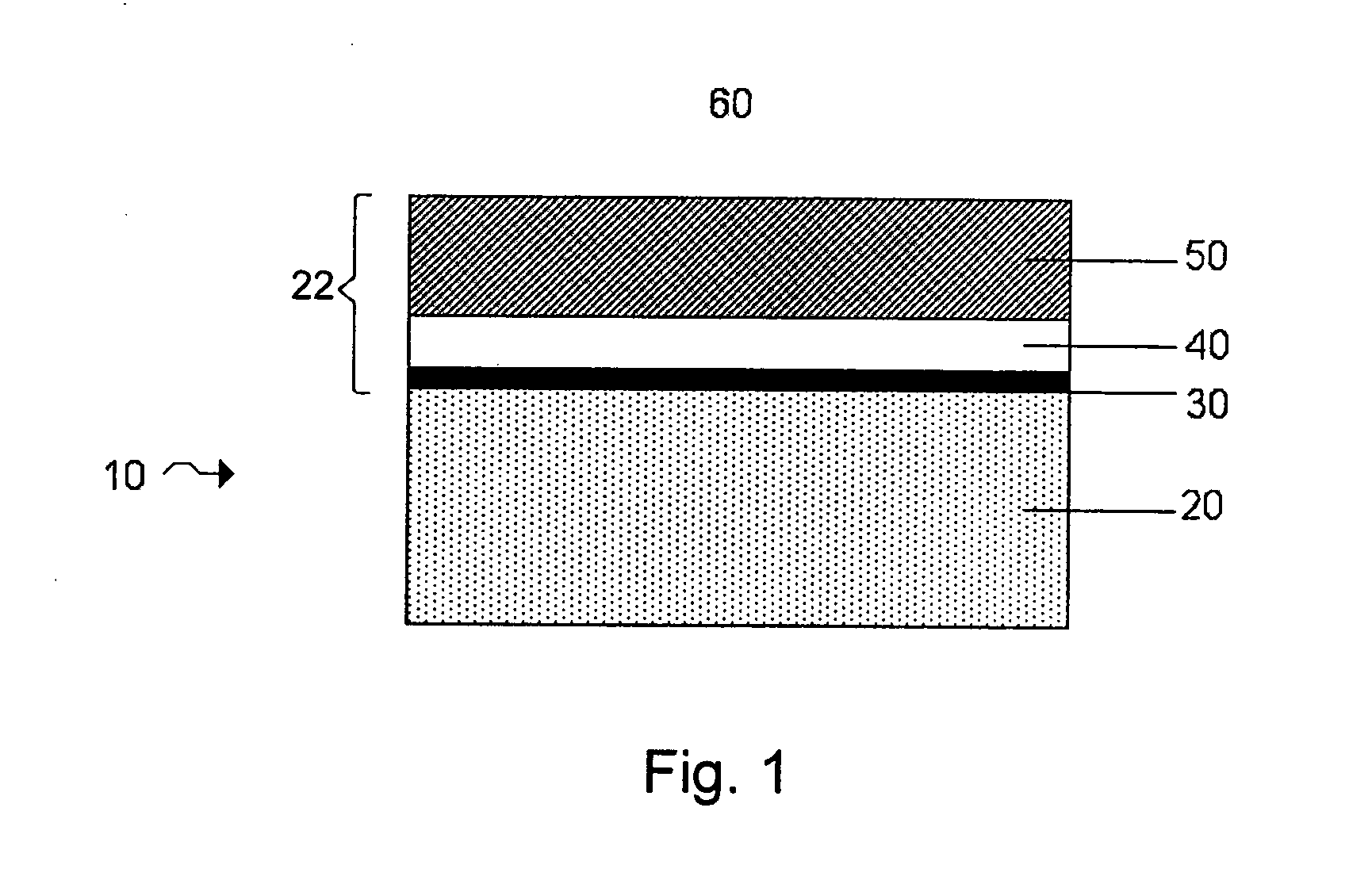

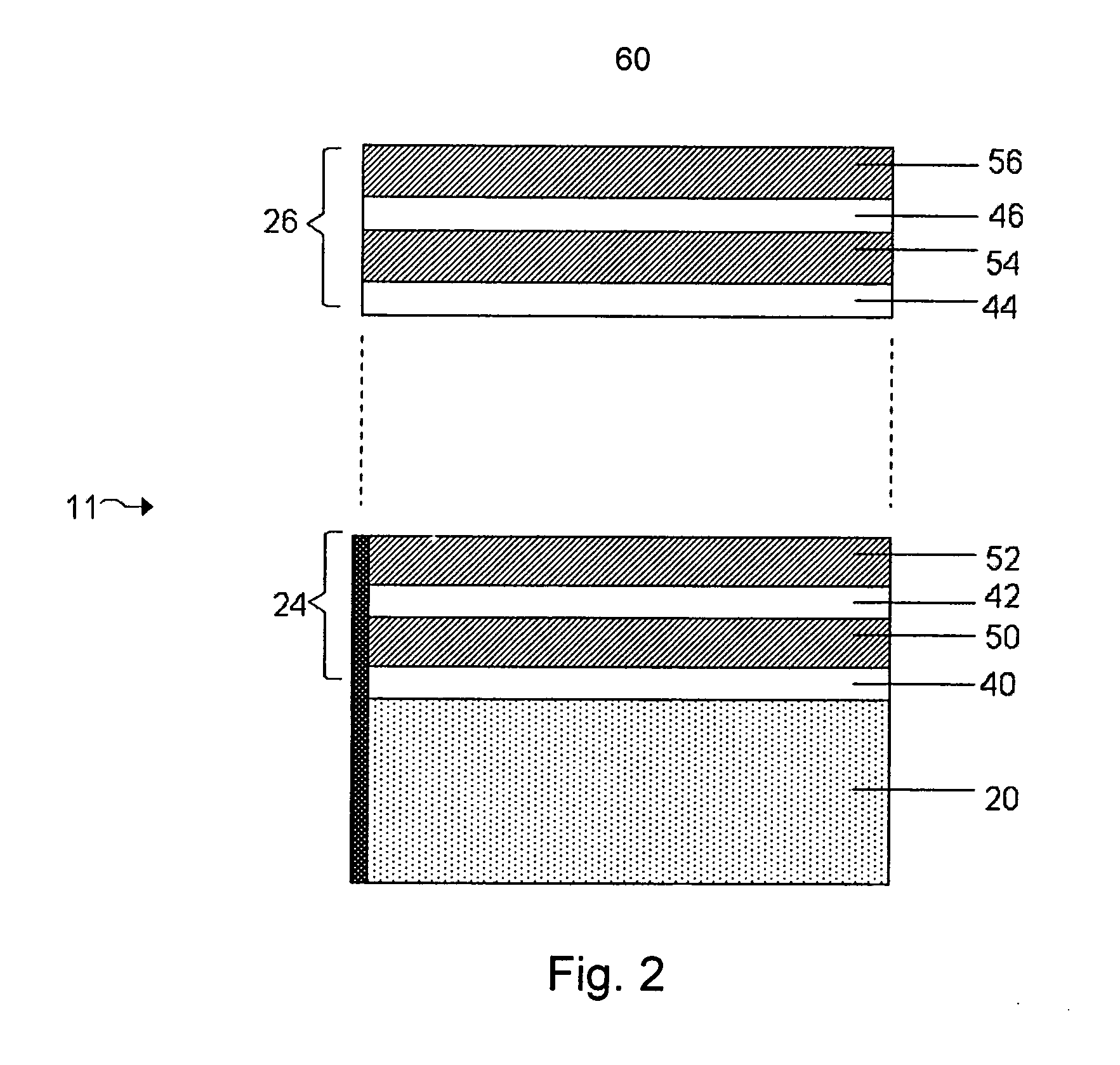

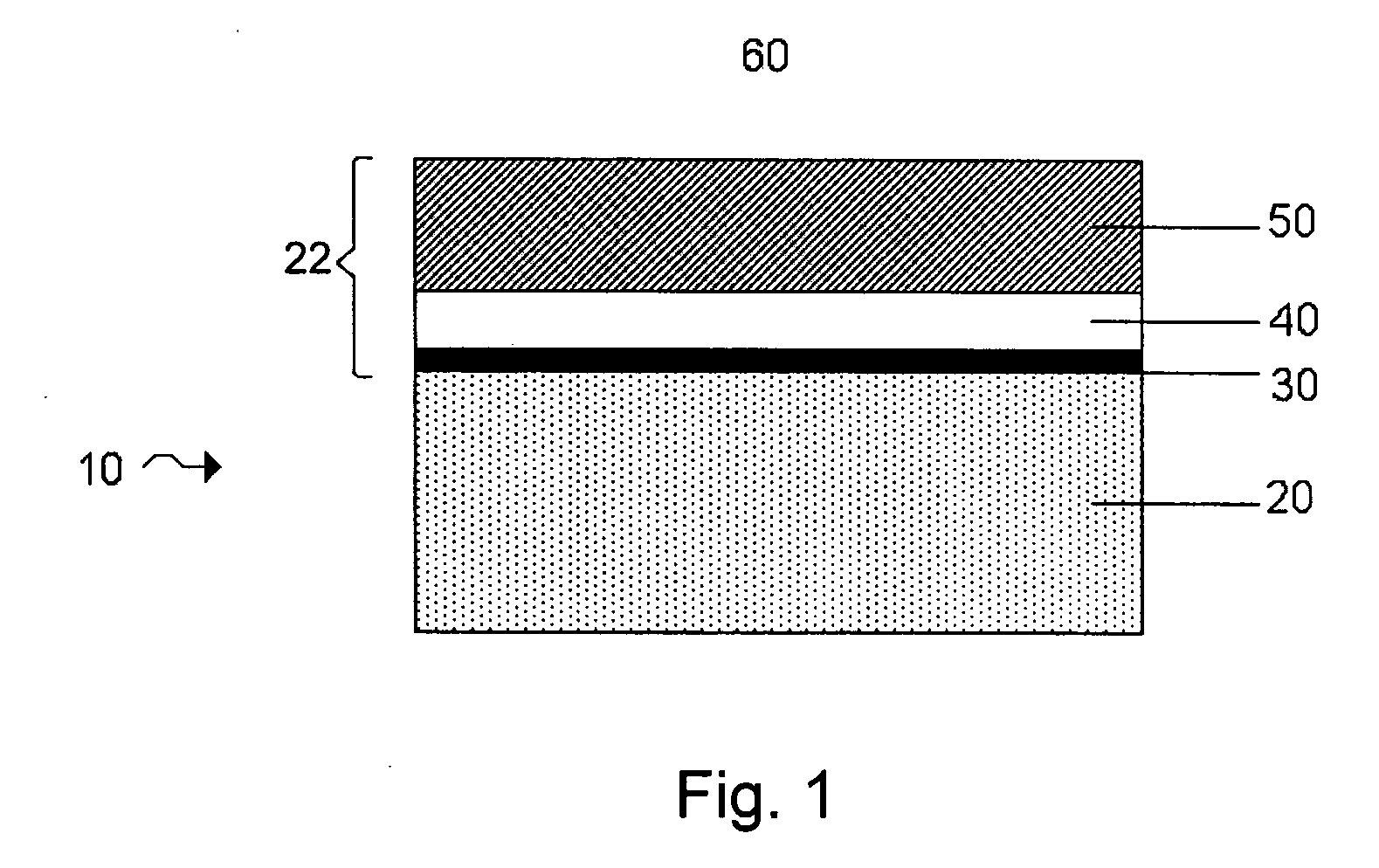

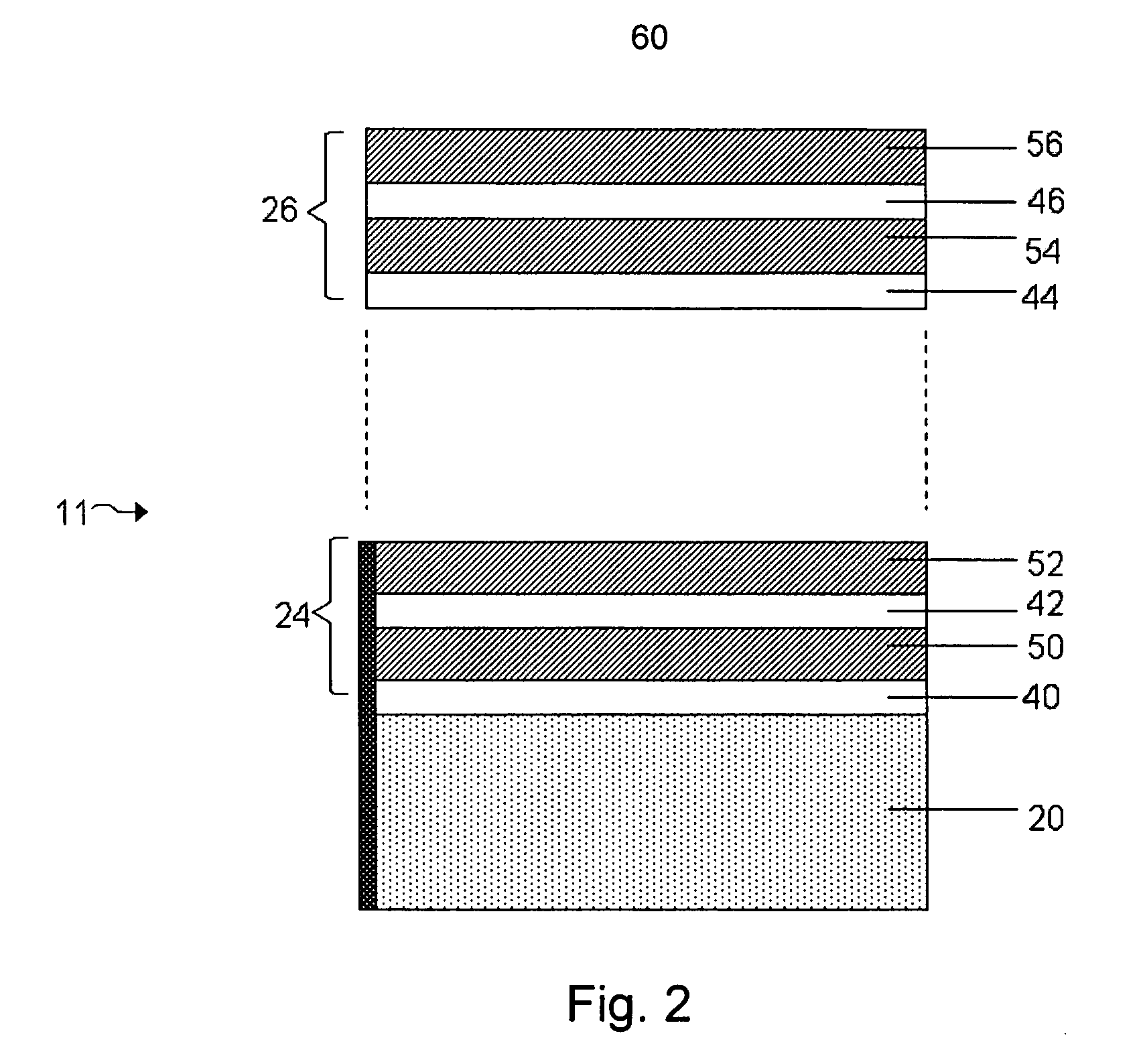

Rechargeable lithium/water, lithium/air batteries

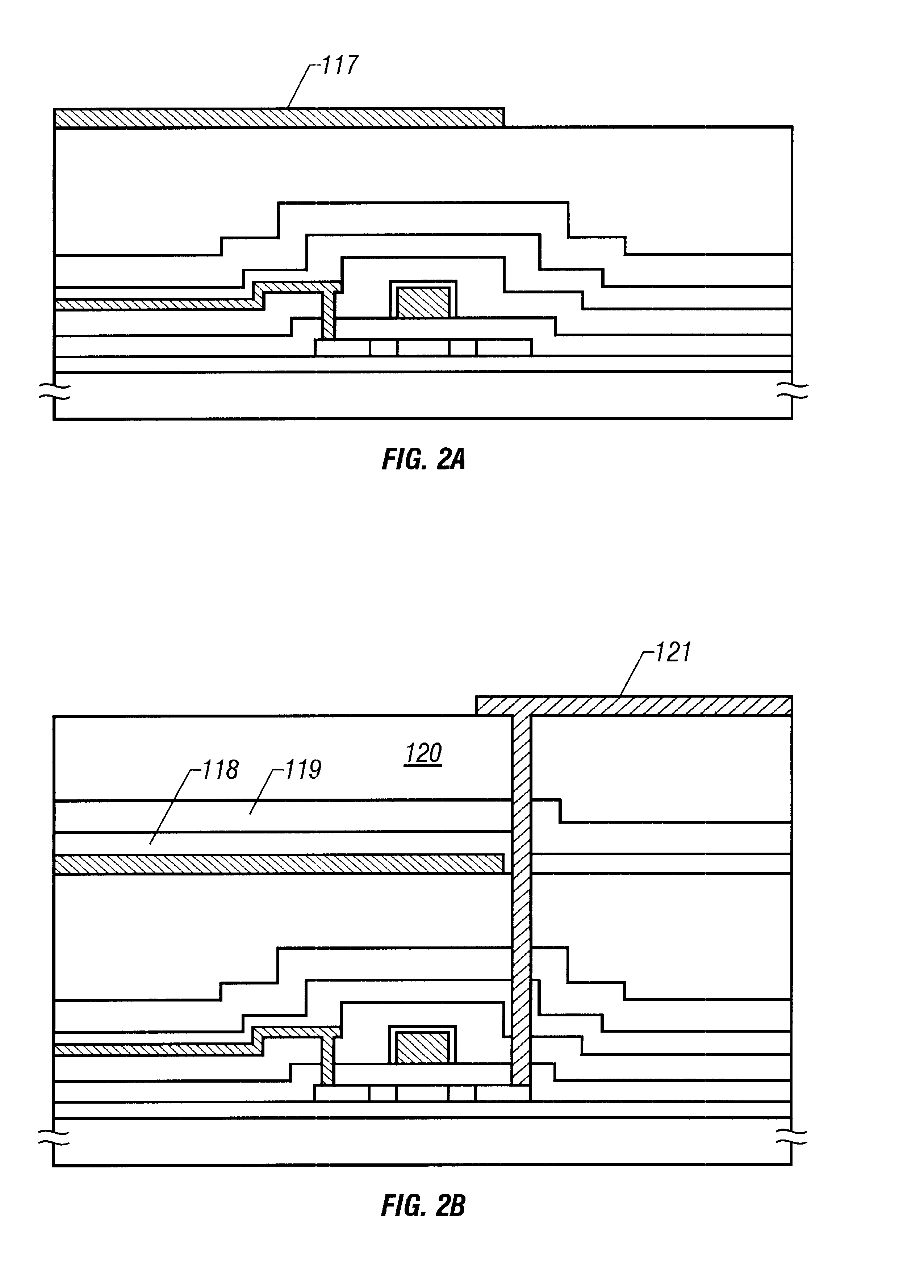

InactiveUS20070221265A1Improve protectionEasy to controlFinal product manufacturePV power plantsHigh energyOptoelectronics

Electrochemical cells, and more specifically, rechargeable batteries comprising lithium anodes for use in water and / or air environments, as well as non-aqueous and non-air environments, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

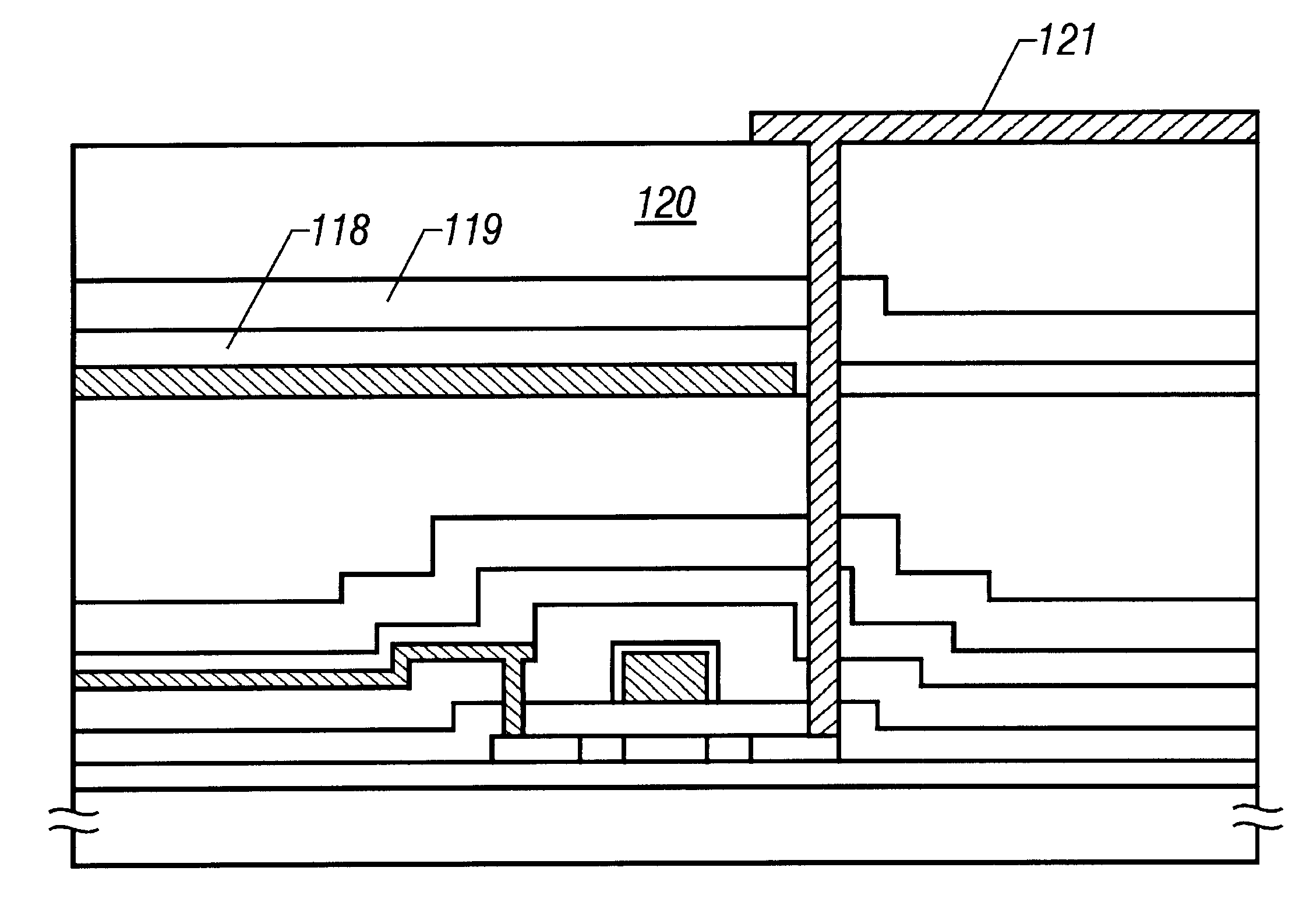

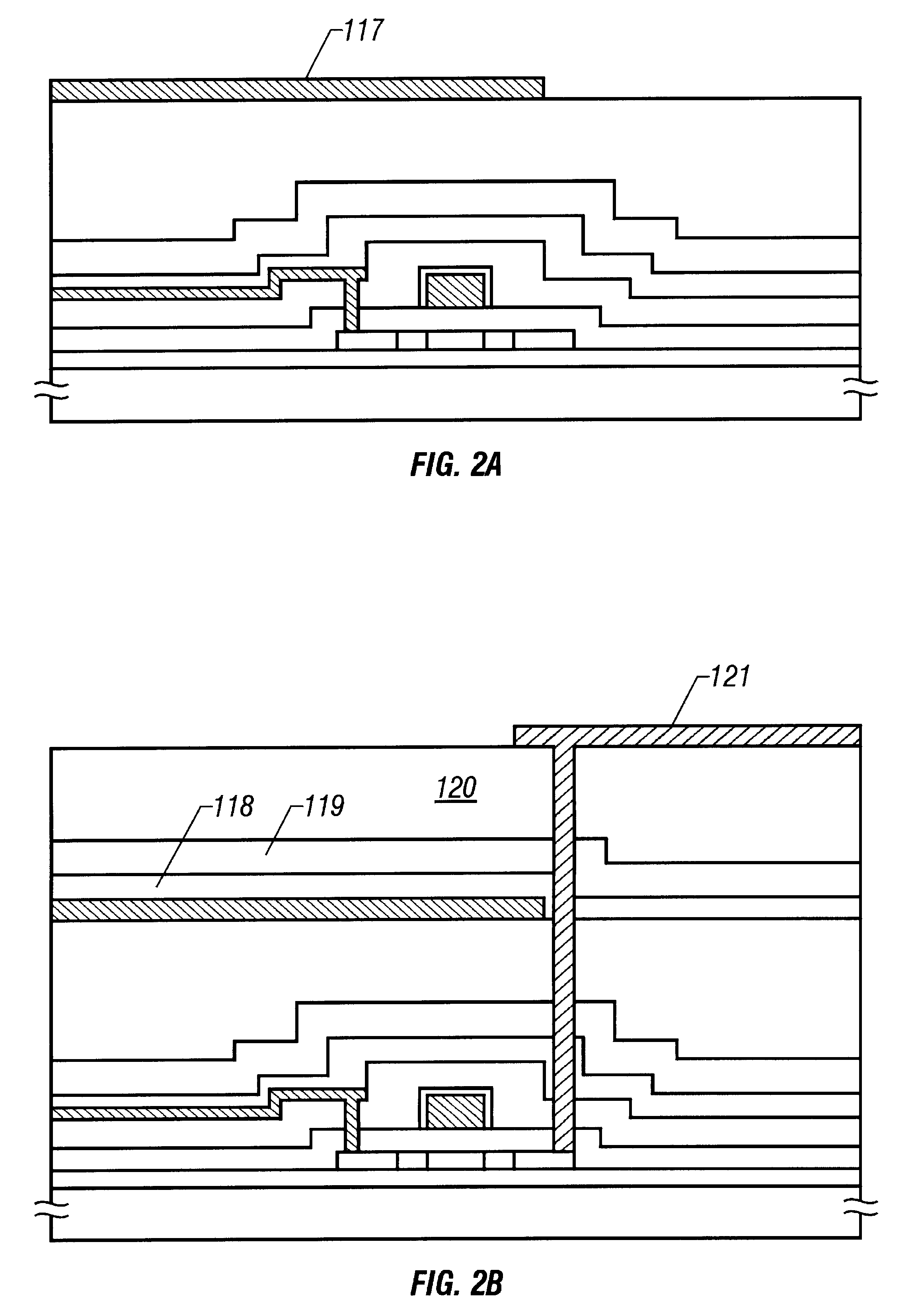

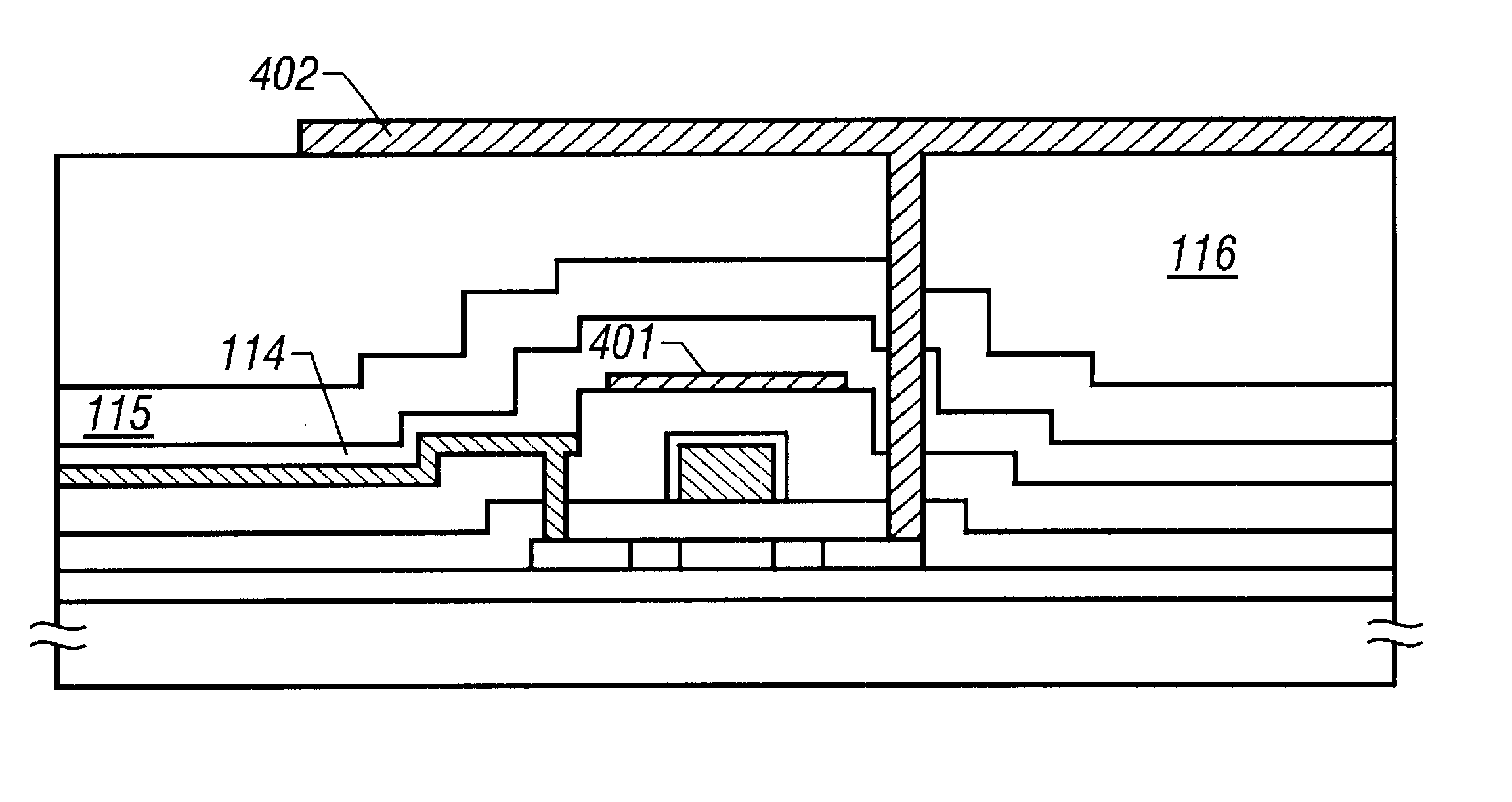

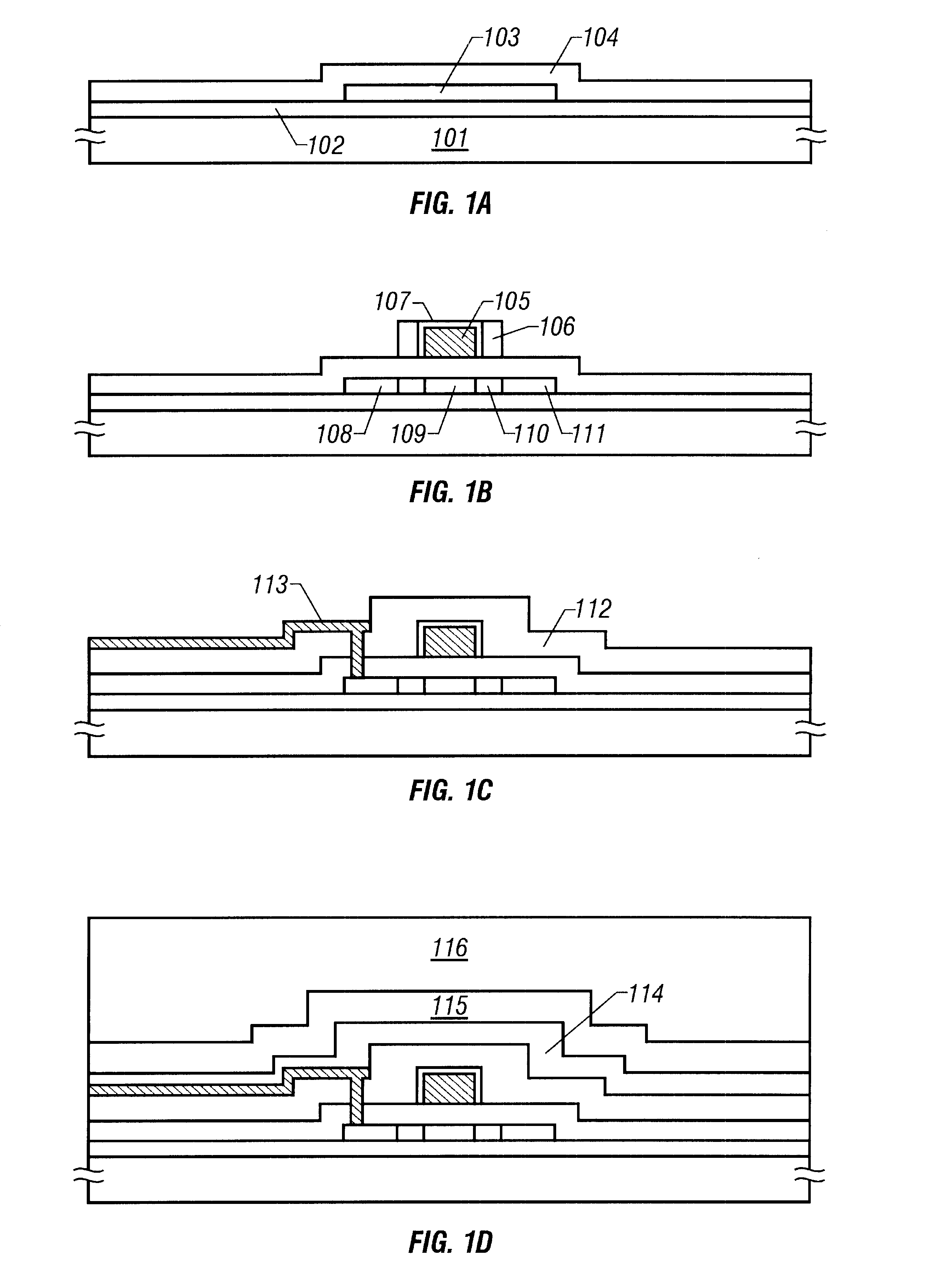

Semiconductor device

InactiveUS6441468B1Capacity producedReduce capacityTransistorSemiconductor/solid-state device detailsPhysicsLow-k dielectric

A resin material having low dielectric constant is used as an inter-layer insulating film and its bottom surface is contacted with a silicon oxide film across the whole surface thereof. Thereby, the surface may be flattened and capacity produced between a thin film transistor and an pixel electrode may be reduced. Further, it allows to avoid a problem that impurity ions and moisture infiltrate into the lower surface of the resin material, thus degrading the reliability of whole semiconductor device.

Owner:SEMICON ENERGY LAB CO LTD

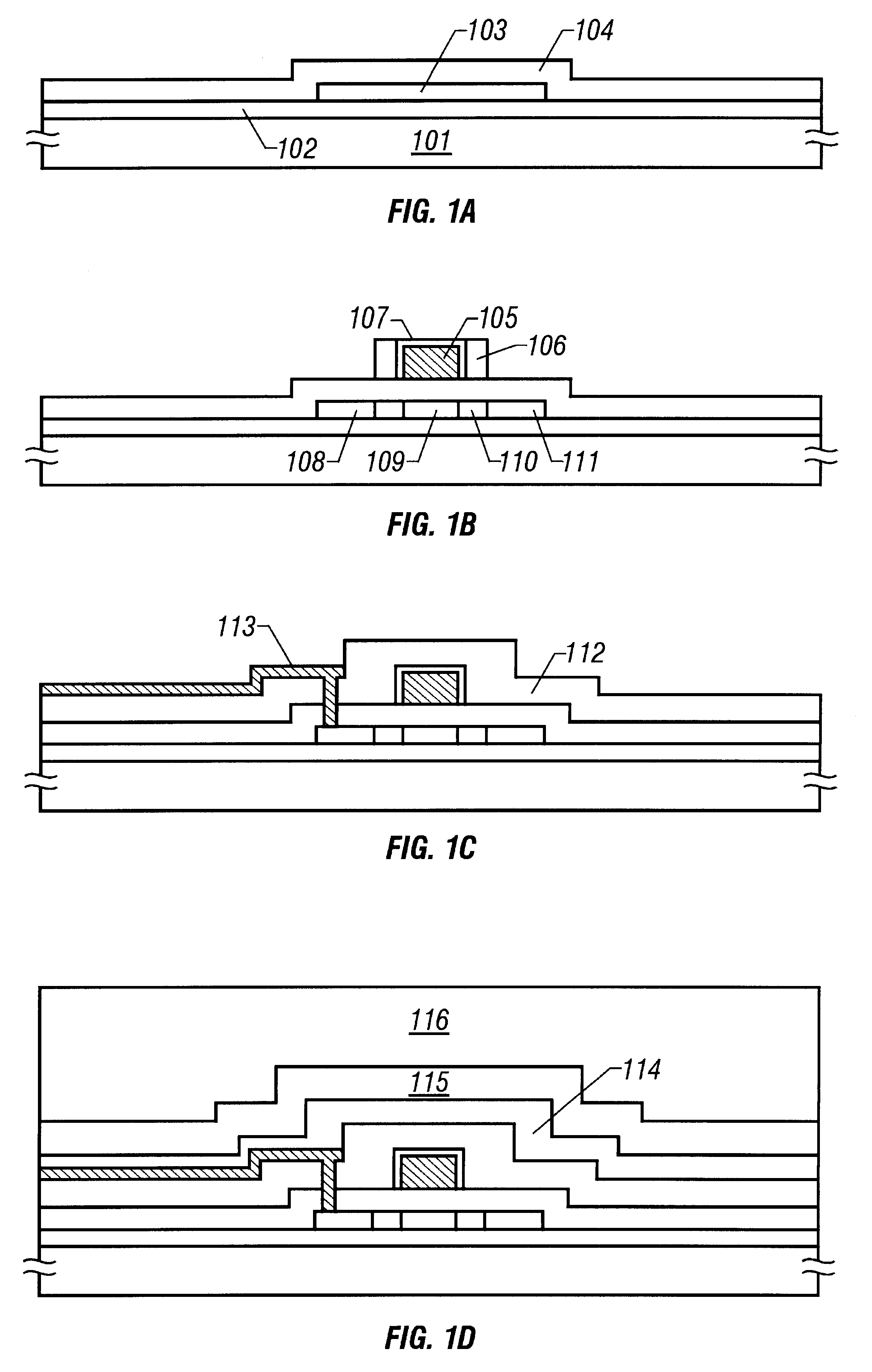

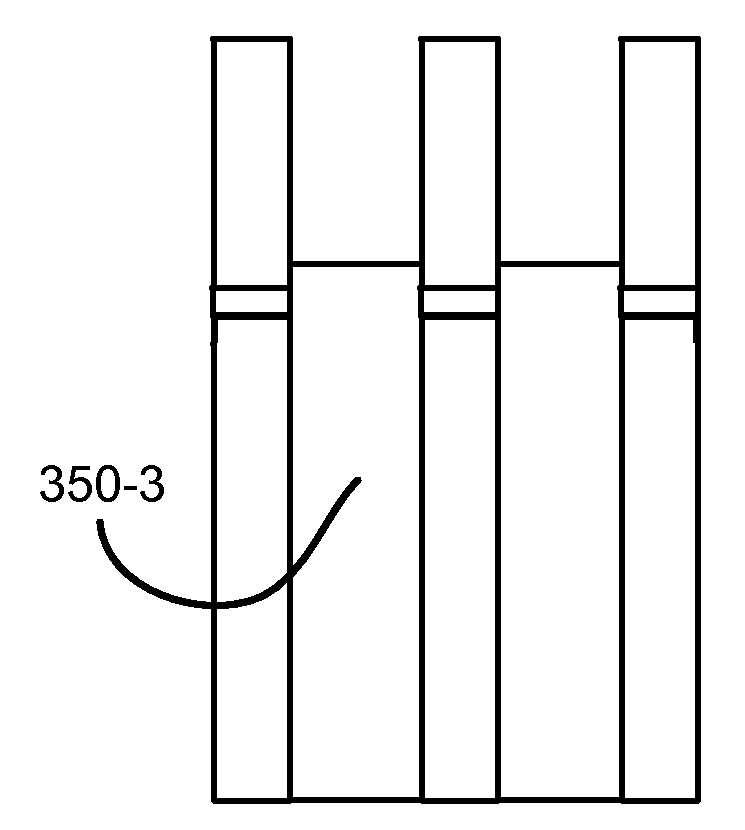

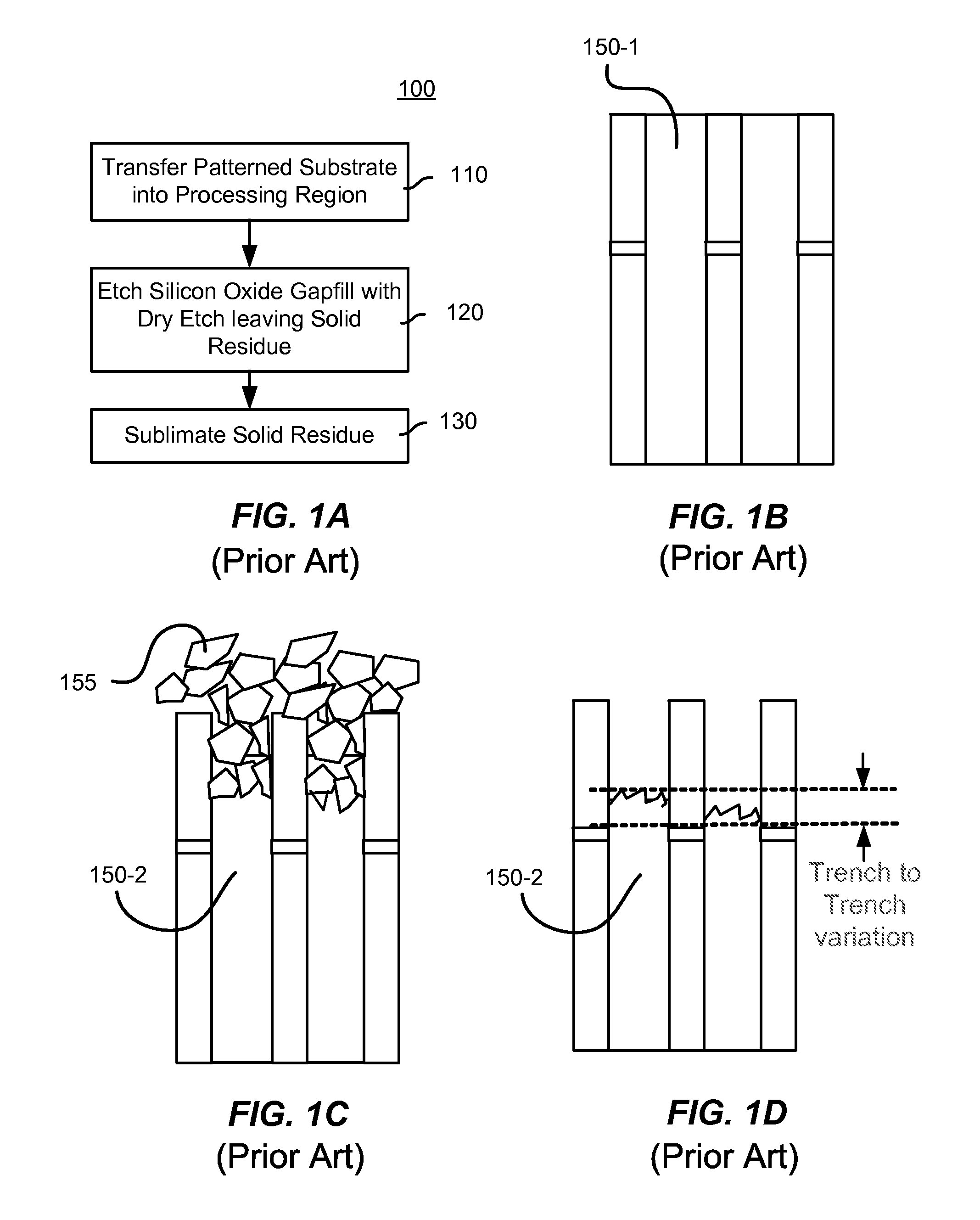

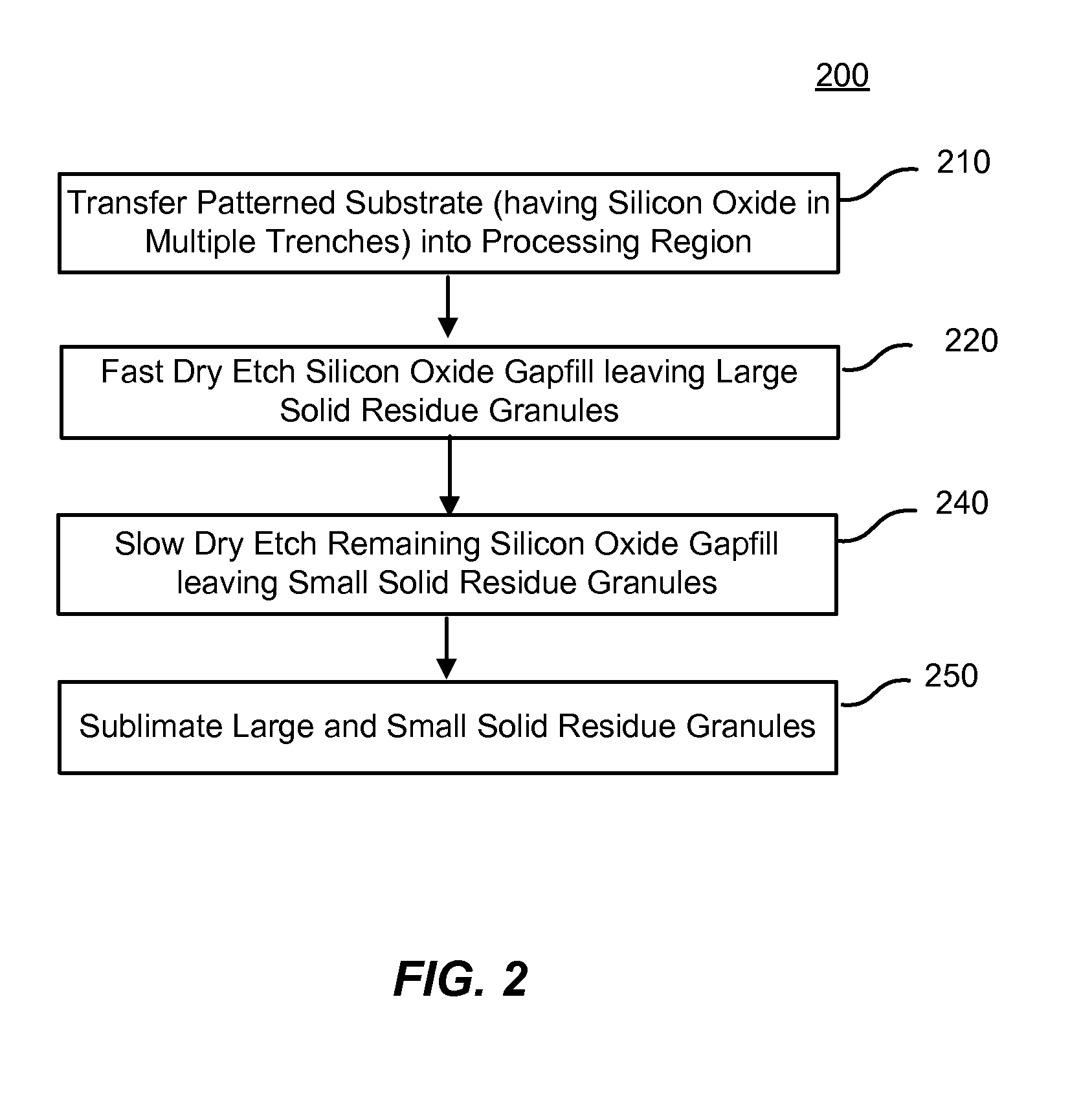

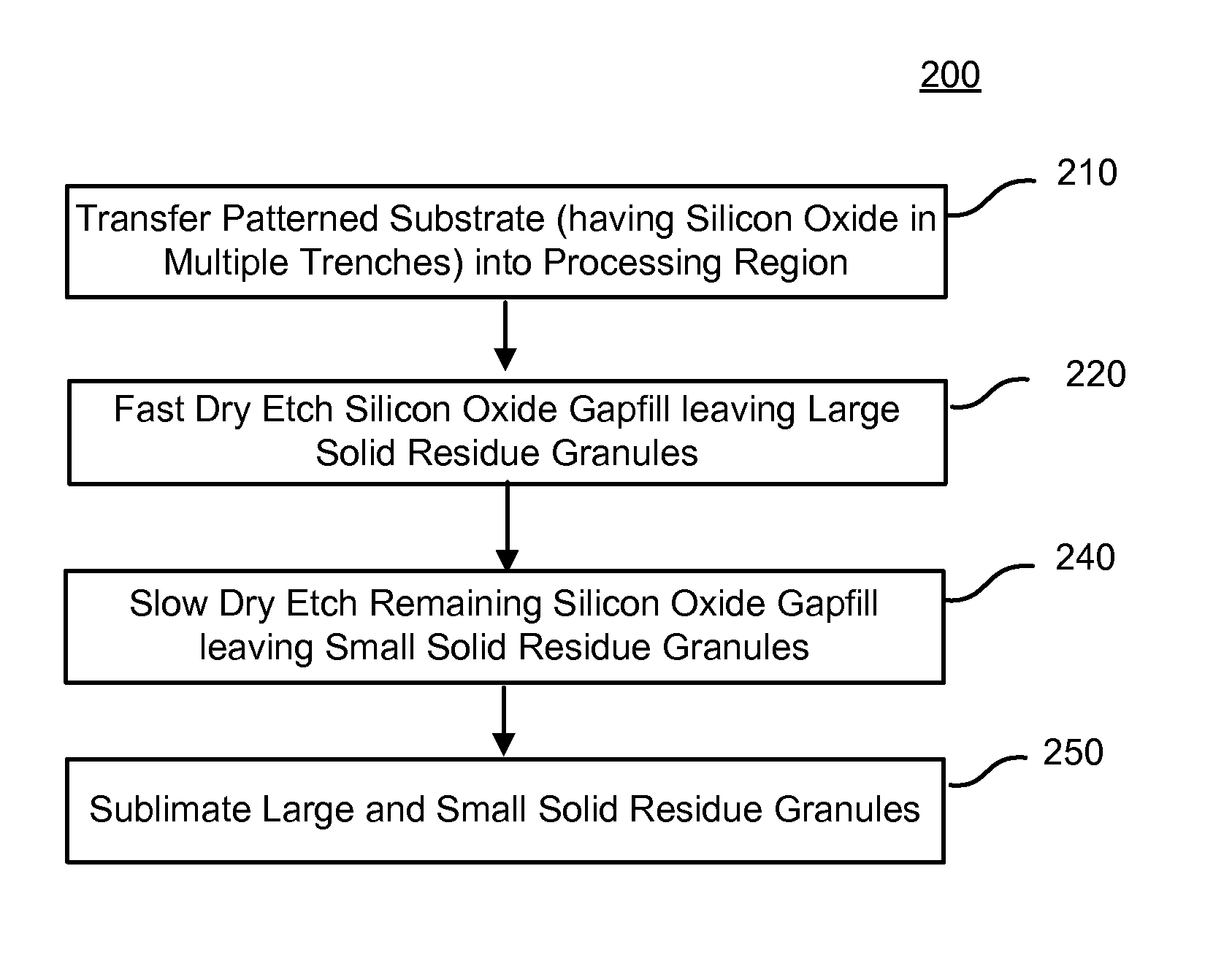

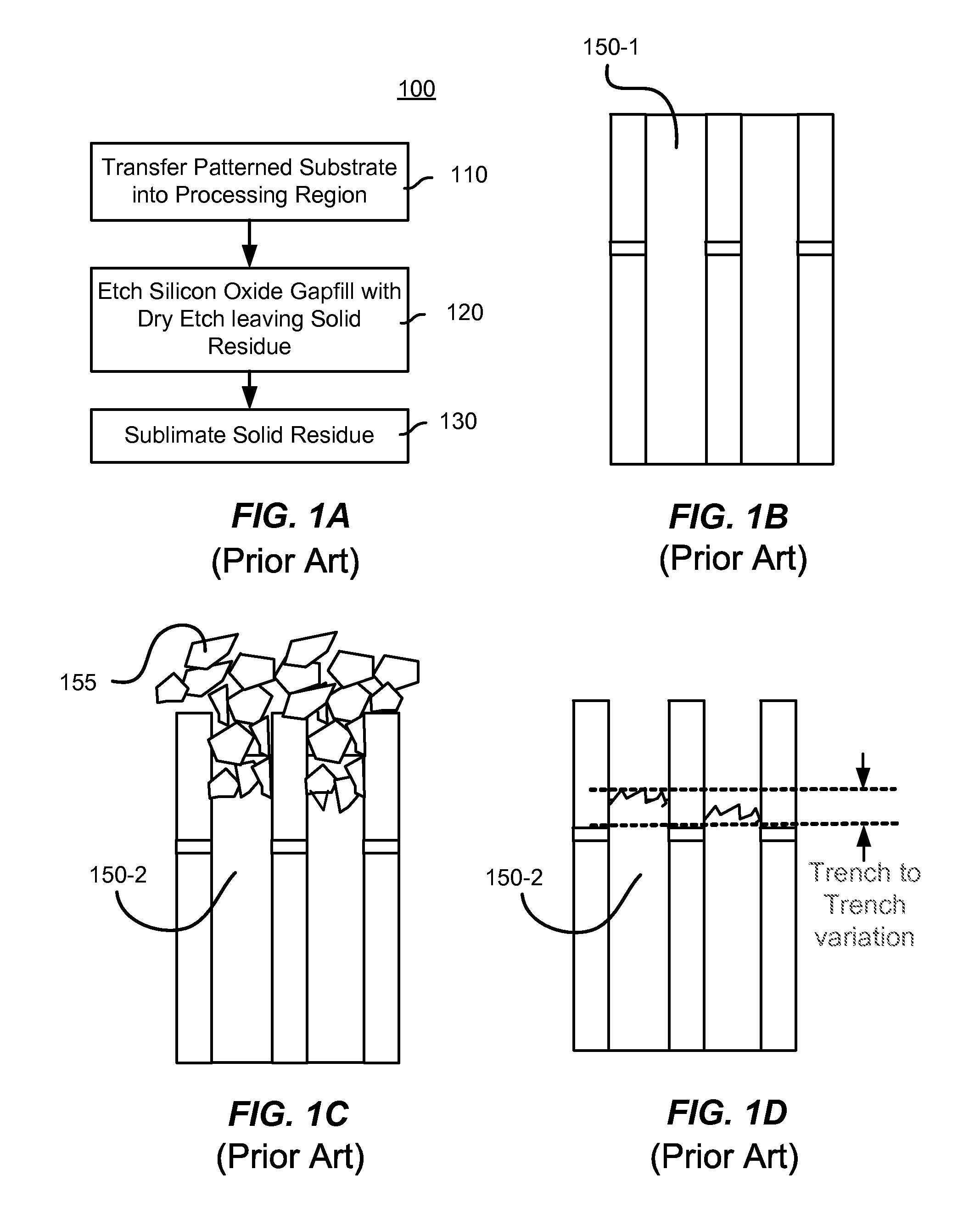

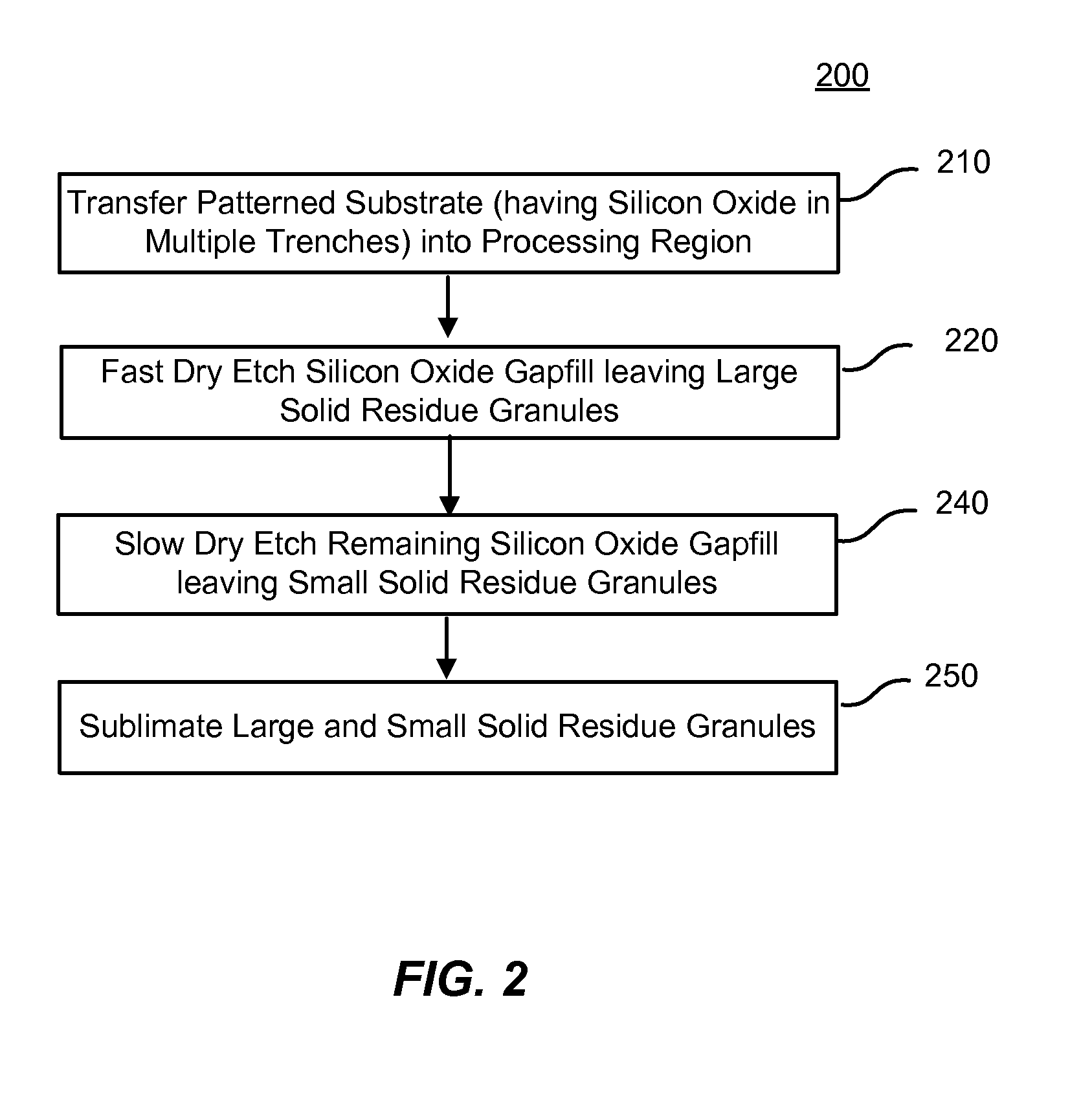

Uniform dry etch in two stages

ActiveUS20120196447A1Flat surfaceEasy to removeSemiconductor/solid-state device manufacturingSilicon oxideDry etching

A method of etching silicon oxide from a multiple trenches is described which allows more homogeneous etch rates among trenches. The surfaces of the etched silicon oxide within the trench following the etch may also be smoother. The method includes two dry etch stages followed by a sublimation step. The first dry etch stage removes silicon oxide quickly and produces large solid residue granules. The second dry etch stage remove silicon oxide slowly and produces small solid residue granules in amongst the large solid residue granules. Both the small and large solid residue are removed in the ensuing sublimation step. There is no sublimation step between the two dry etch stages.

Owner:APPLIED MATERIALS INC

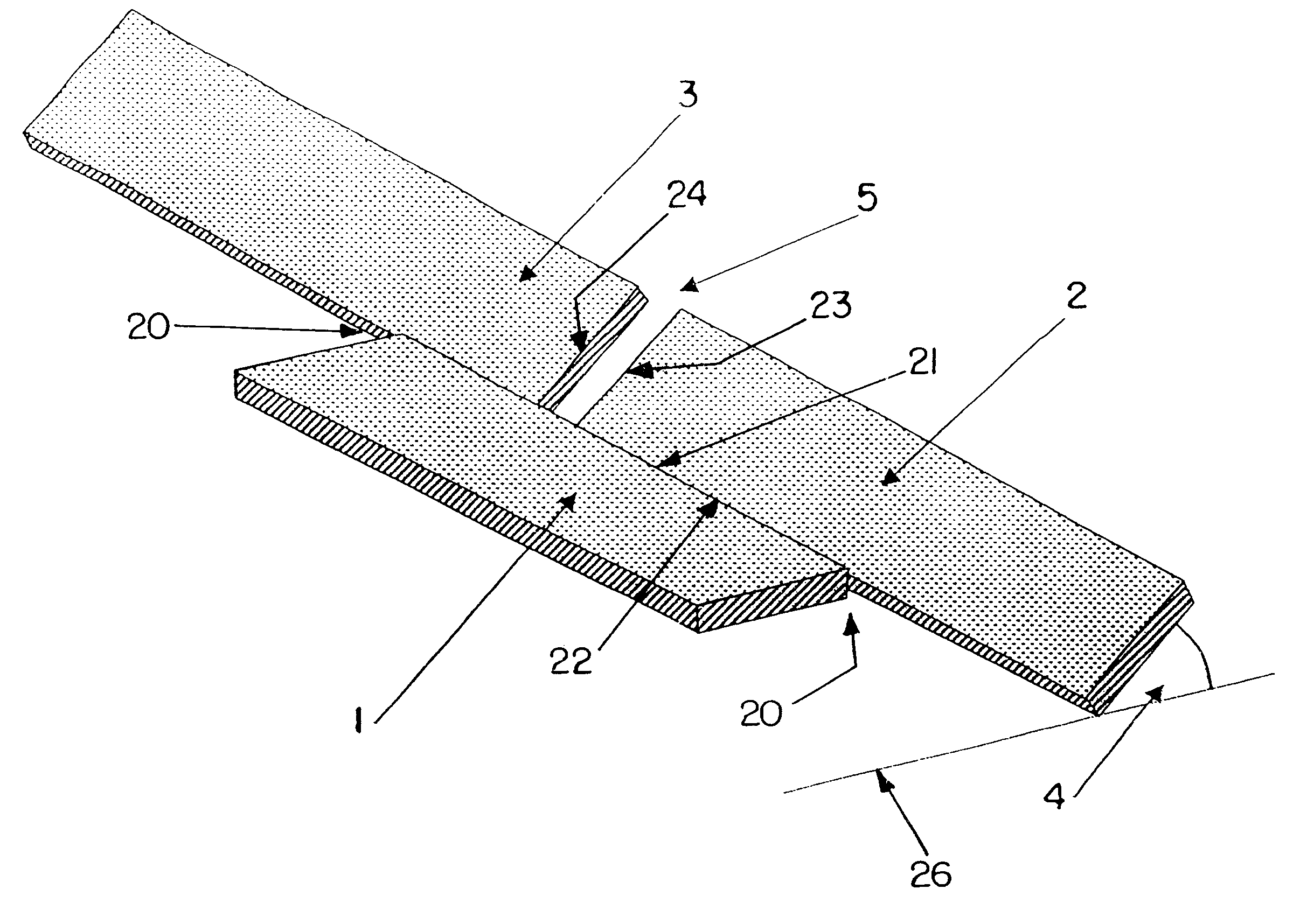

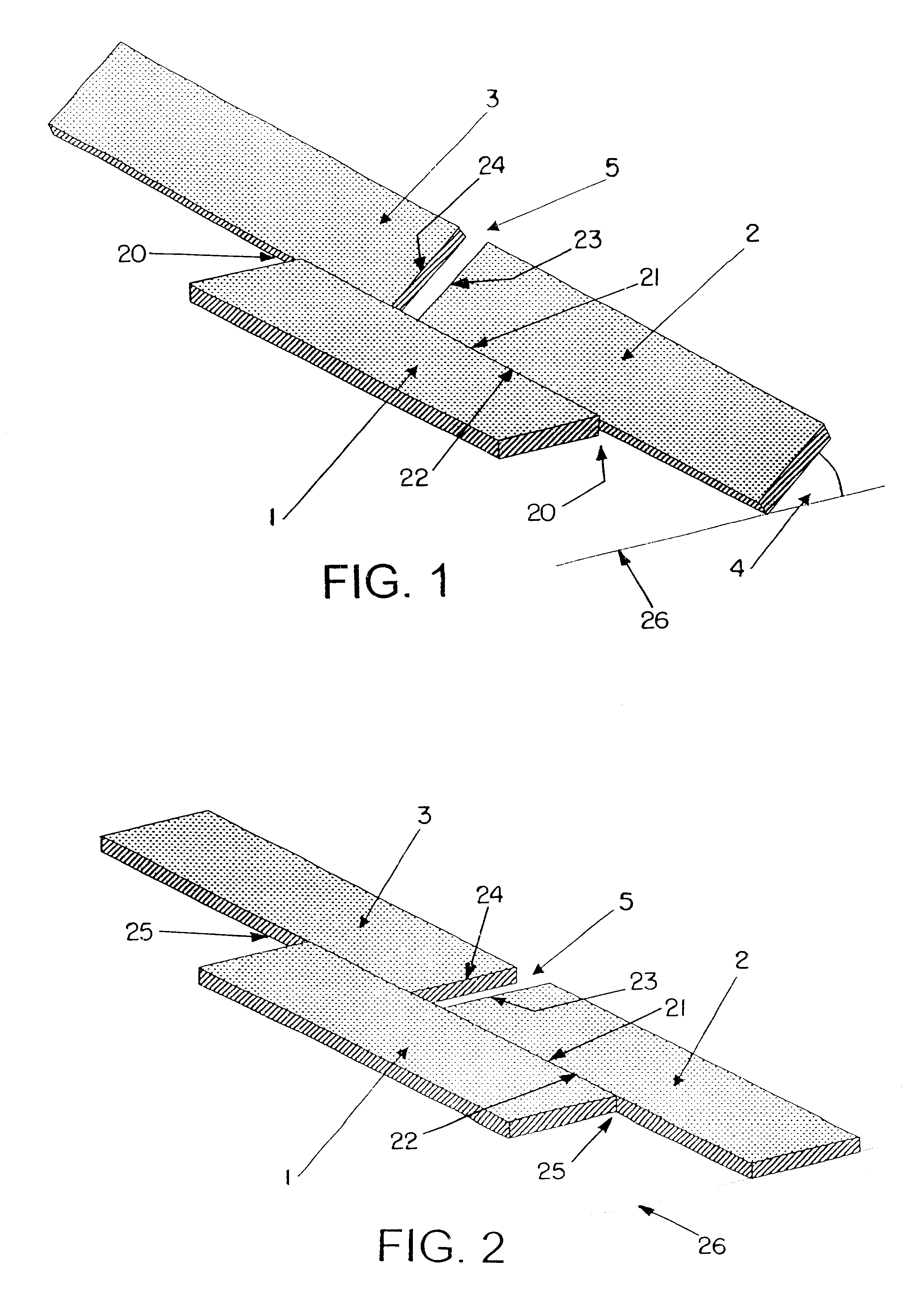

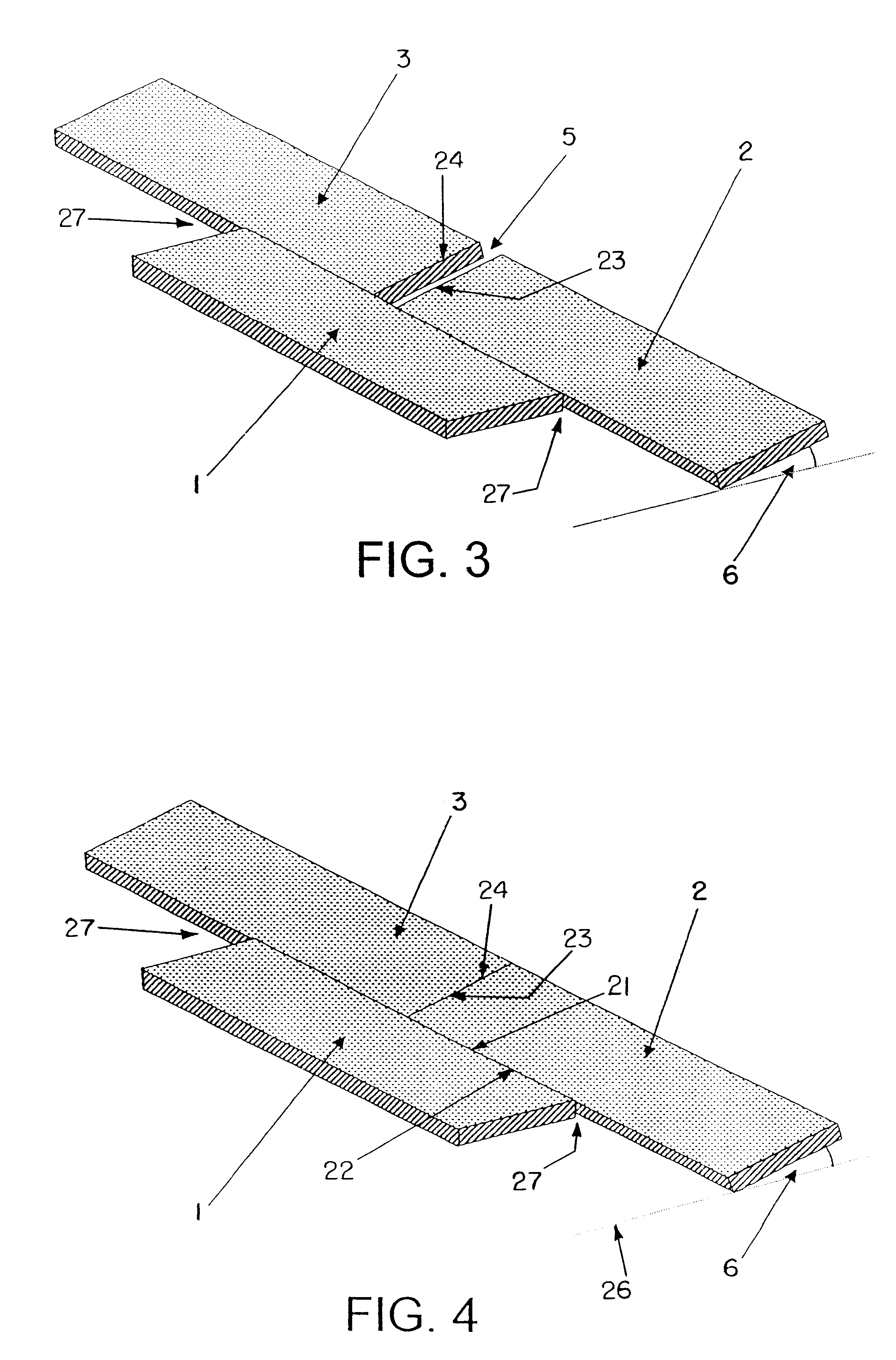

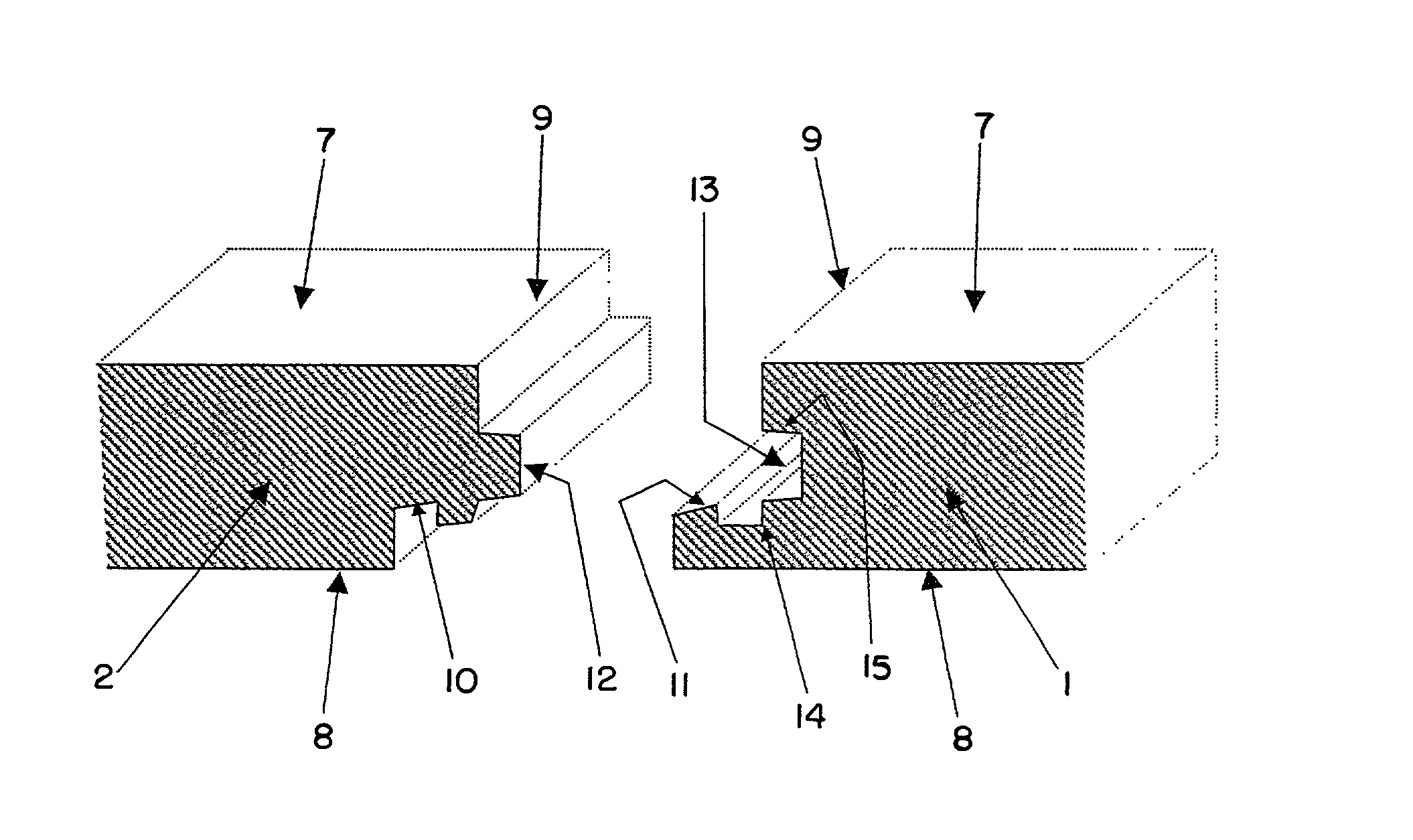

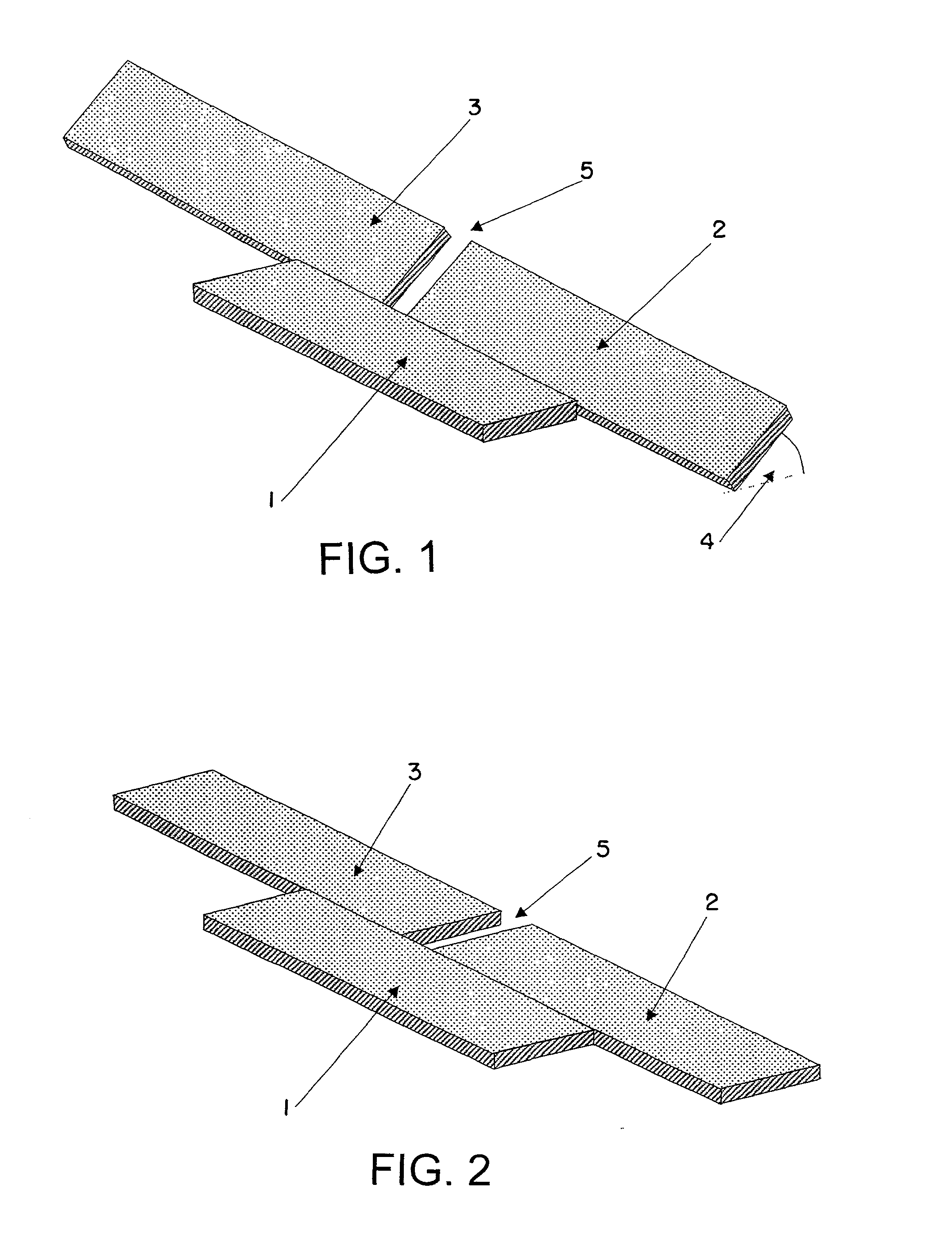

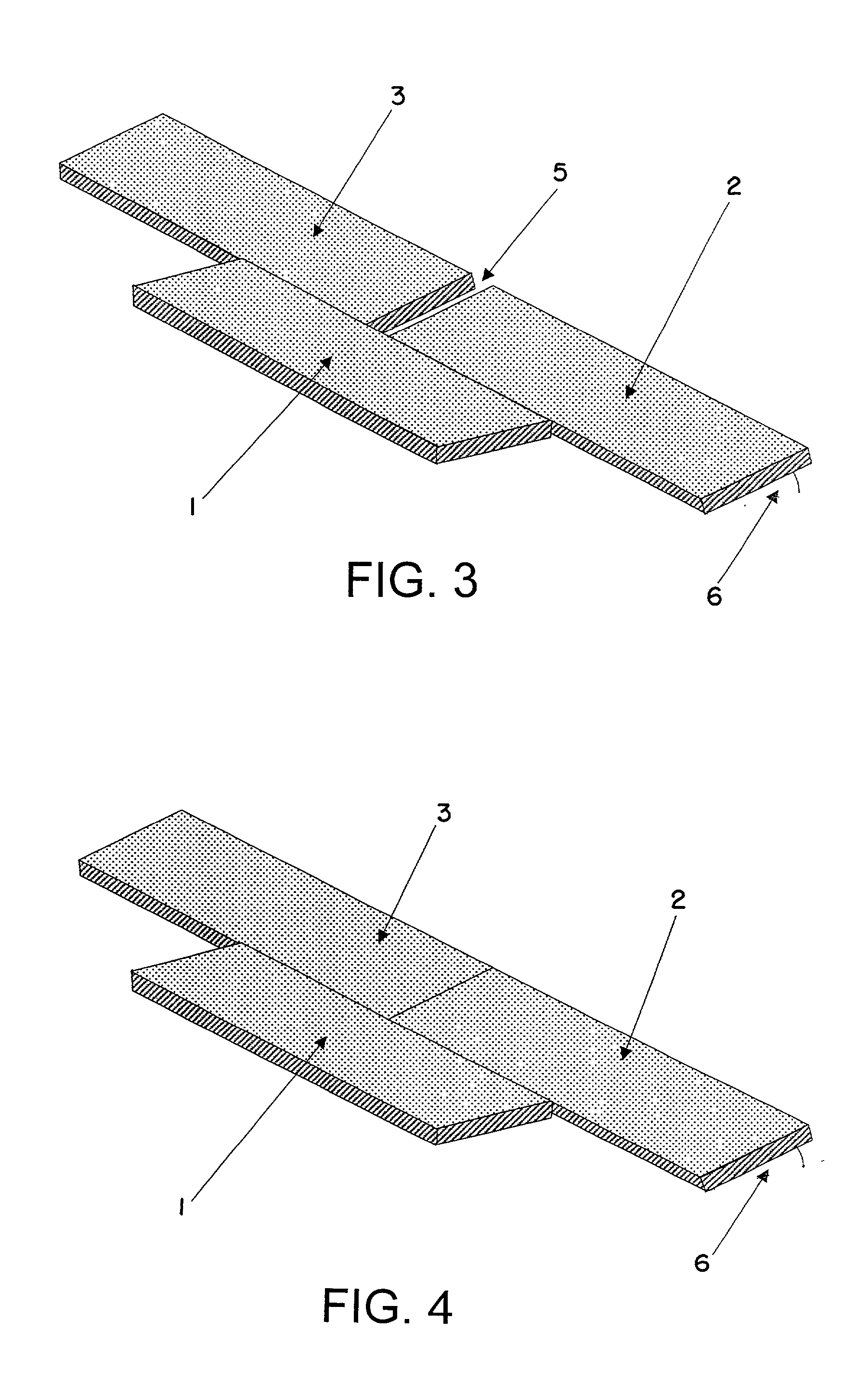

Method of laying panels

InactiveUS6546691B2Increase displacementAvoid the needRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

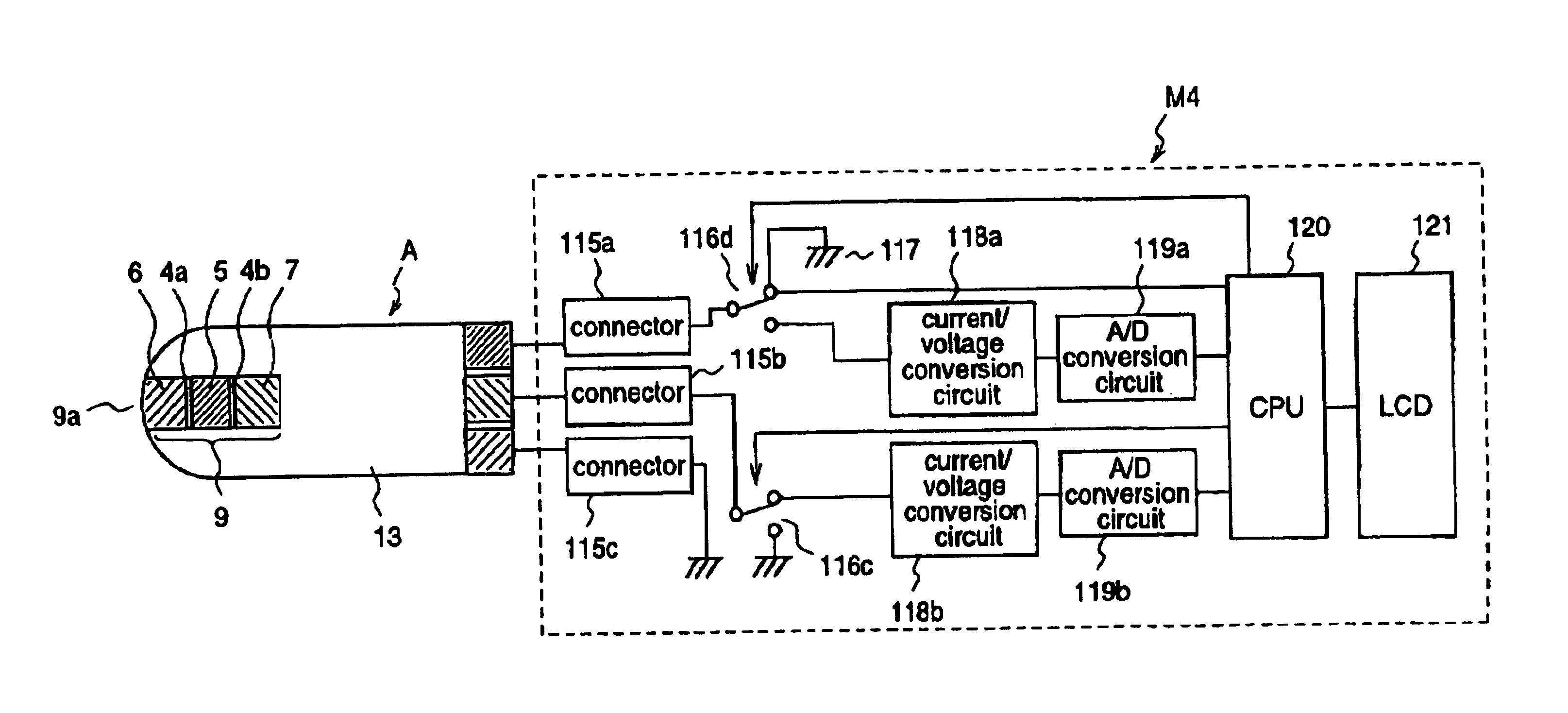

Biosensor, method of forming thin-film electrode, and method and apparatus for quantitative determination

InactiveUS6875327B1Improve convenienceImprove securityImmobilised enzymesBioreactor/fermenter combinationsThin film electrodeQuantitative determination

The invention provides a biosensor comprising a support; a conductive layer composed of a electrical conductive material such as a noble metal, for example gold or palladium, and carbon; slits parallel to and perpendicular to the side of the support; working, counter, and detecting electrodes; a spacer which covers the working, counter, and detecting electrodes on the support; a rectangular cutout in the spacer forming a specimen supply path; an inlet to the specimen supply path; a reagent layer formed by applying a reagent containing an enzyme to the working, counter, and detecting electrodes, which are exposed through the cutout in the spacer; and a cover over the spacer. The biosensor can be formed by a simple method, and provides a uniform reagent layer on the electrodes regardless of the reagent composition.

Owner:PHC HLDG CORP

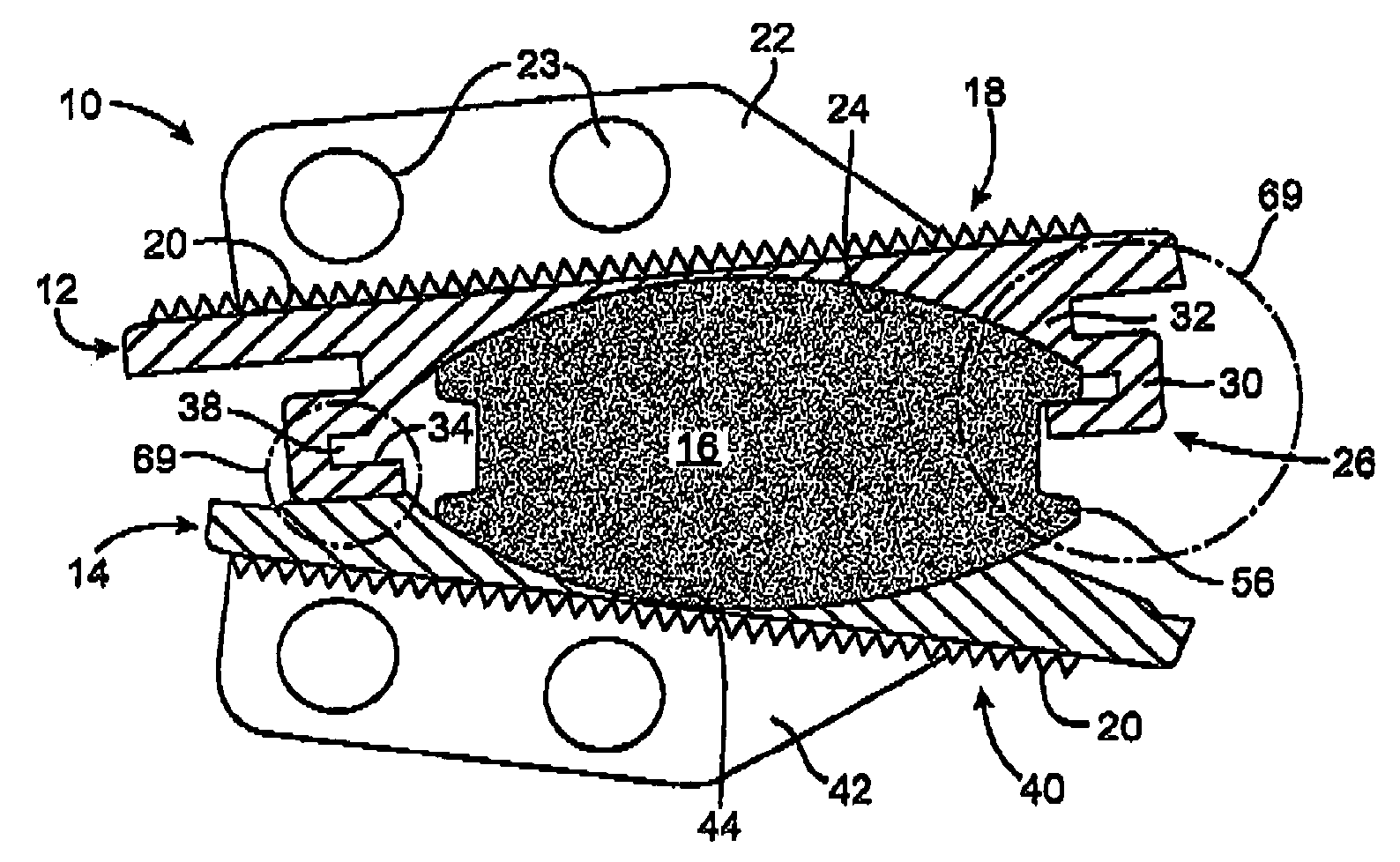

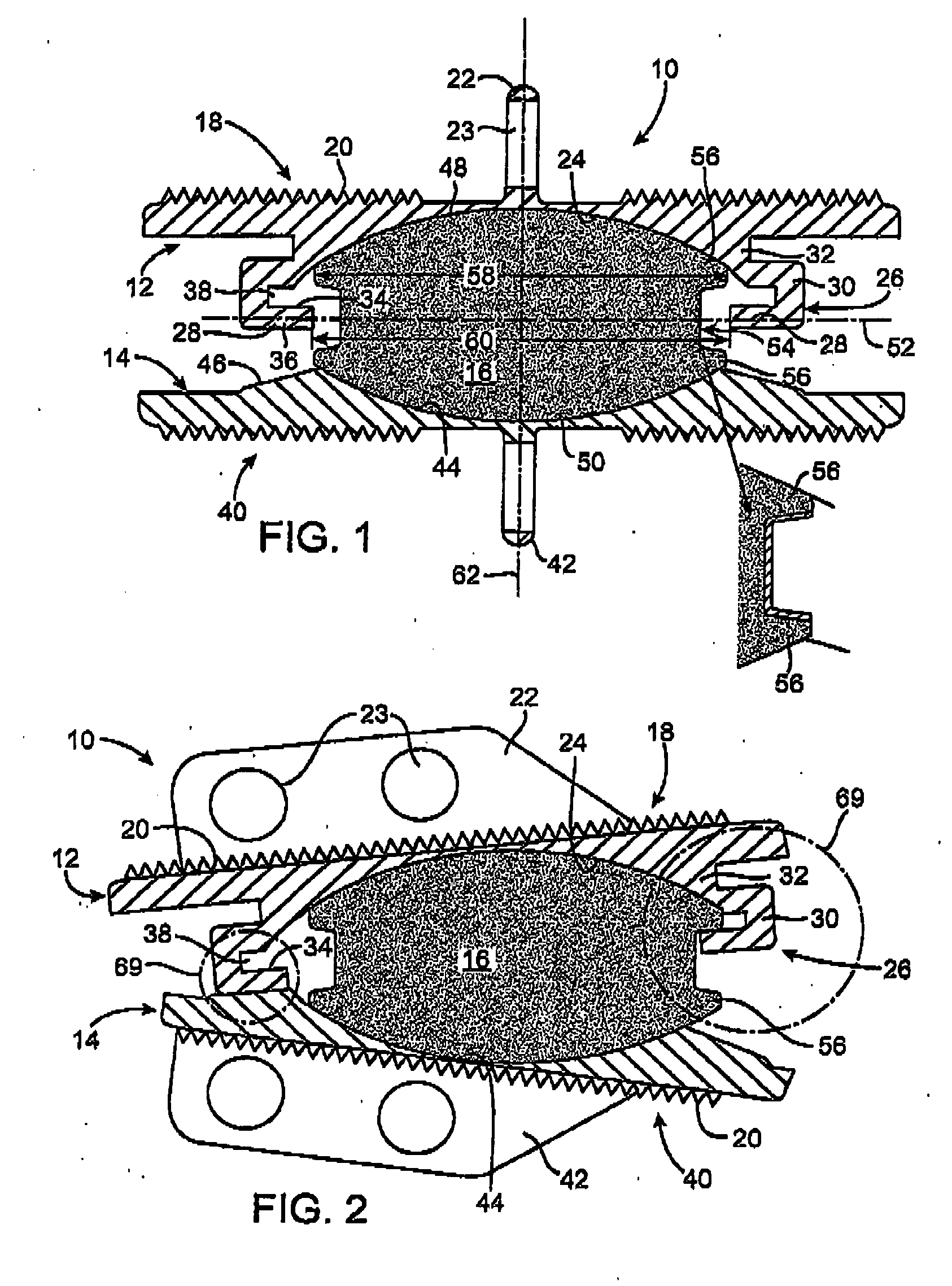

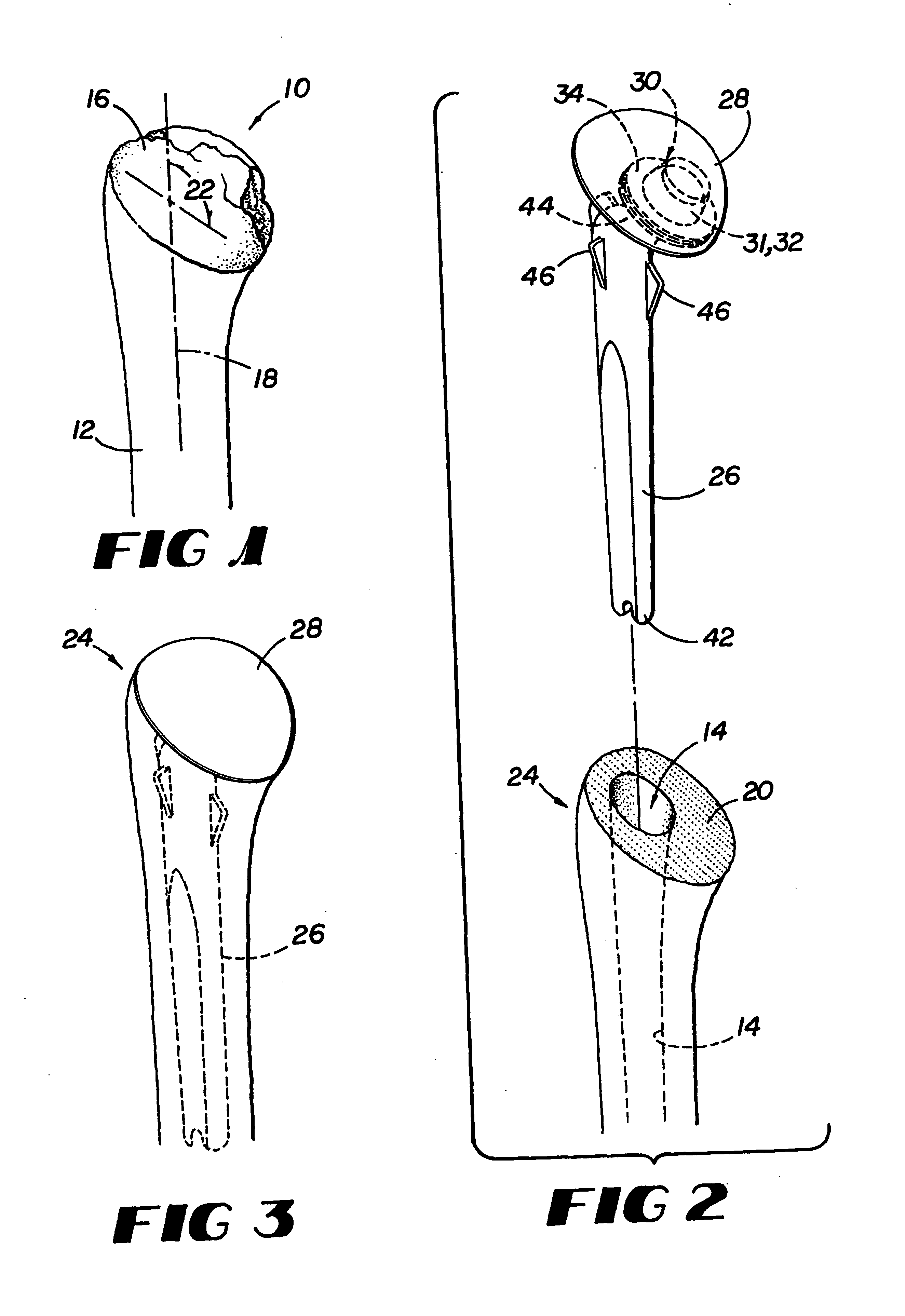

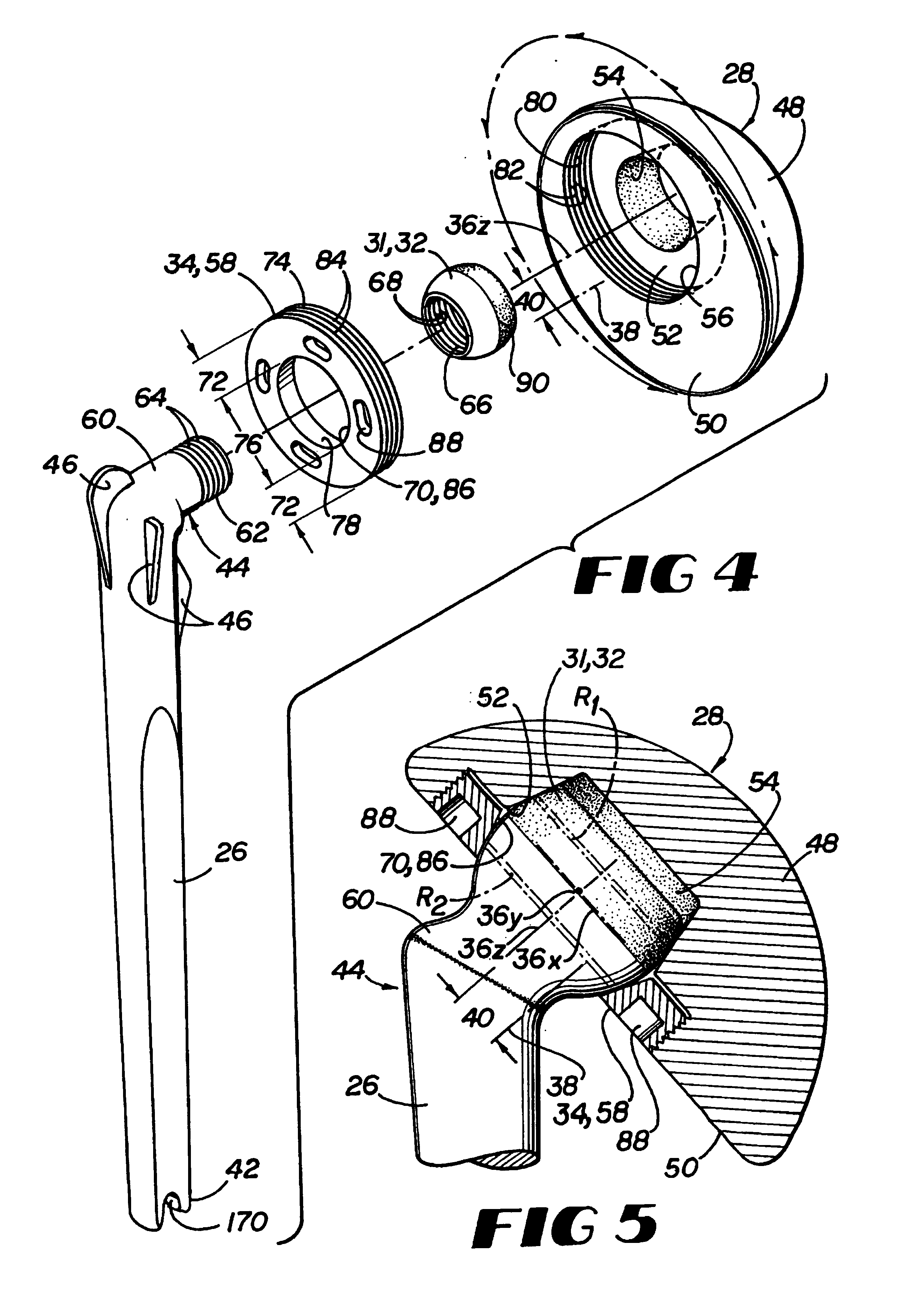

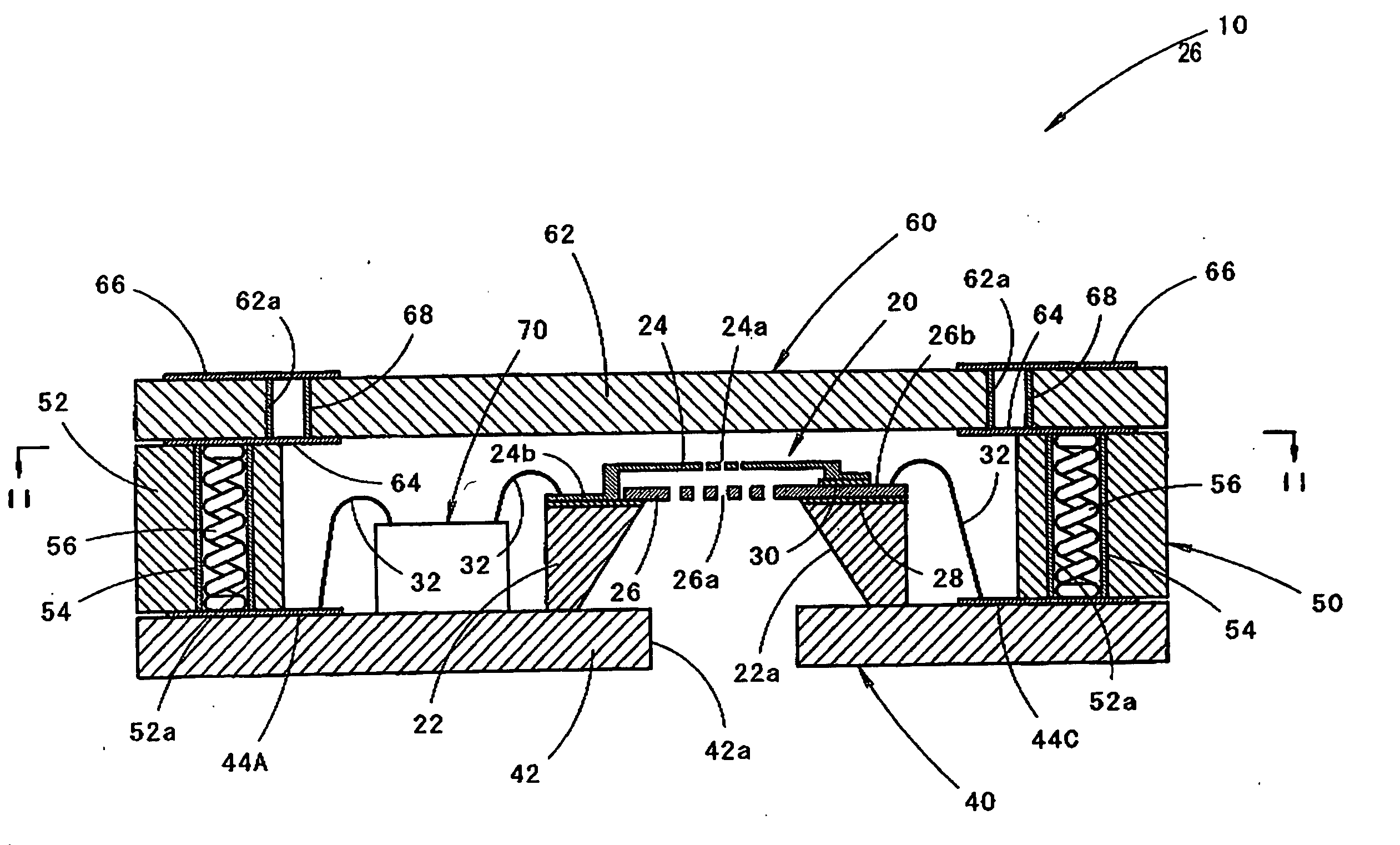

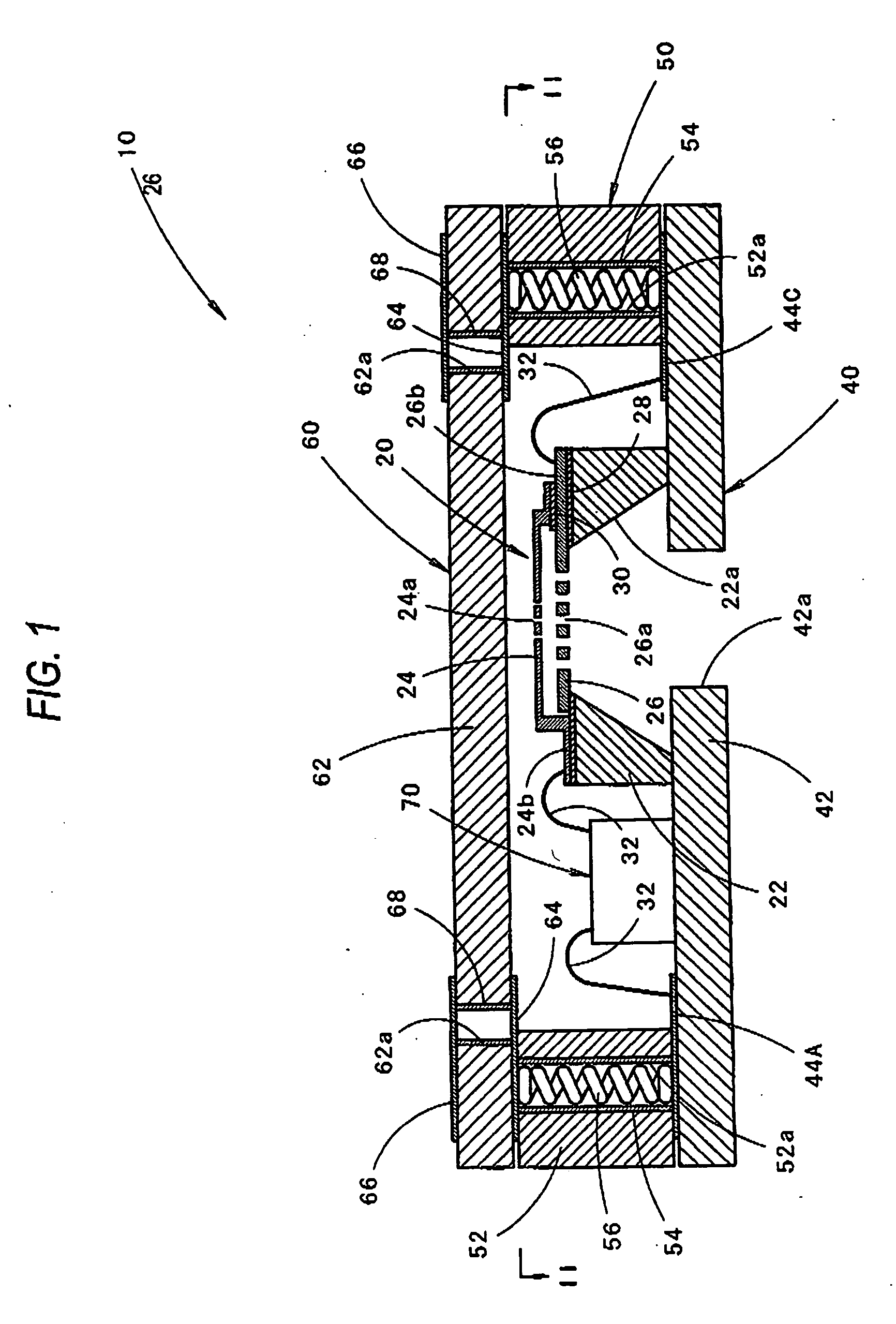

Intervertebral prosthetic disc with metallic core

ActiveUS20060025862A1Inhibit wearAvoid tearingSpinal implantsCoatingsIntervertebral discCentre of rotation

A prosthetic disc for insertion between adjacent vertebrae includes a core having upper and lower curved surfaces and upper and lower plates. At least one of the curved surfaces of the core is metallic, and in some embodiments the entire core is metallic. Each plate has an outer surface which engages a vertebra and a metallic inner curved surface which is shaped to slide over one of the curved surfaces of the core. In some embodiments, the center of rotation of the core is free to move relative to the upper and lower metallic plates. In some embodiments, one or more channels extend across one or both of the curved surfaces of the core for allowing passage of bodily fluid to promote lubrication between the core and at least one of the plates.

Owner:SIMPLIFY MEDICAL PTY LTD

Method of laying panels

InactiveUS20020069611A1Easy to provideIncrease displacementRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

Uniform dry etch in two stages

ActiveUS8741778B2Flat surfaceEasy to removeDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxideDry etching

Owner:APPLIED MATERIALS INC

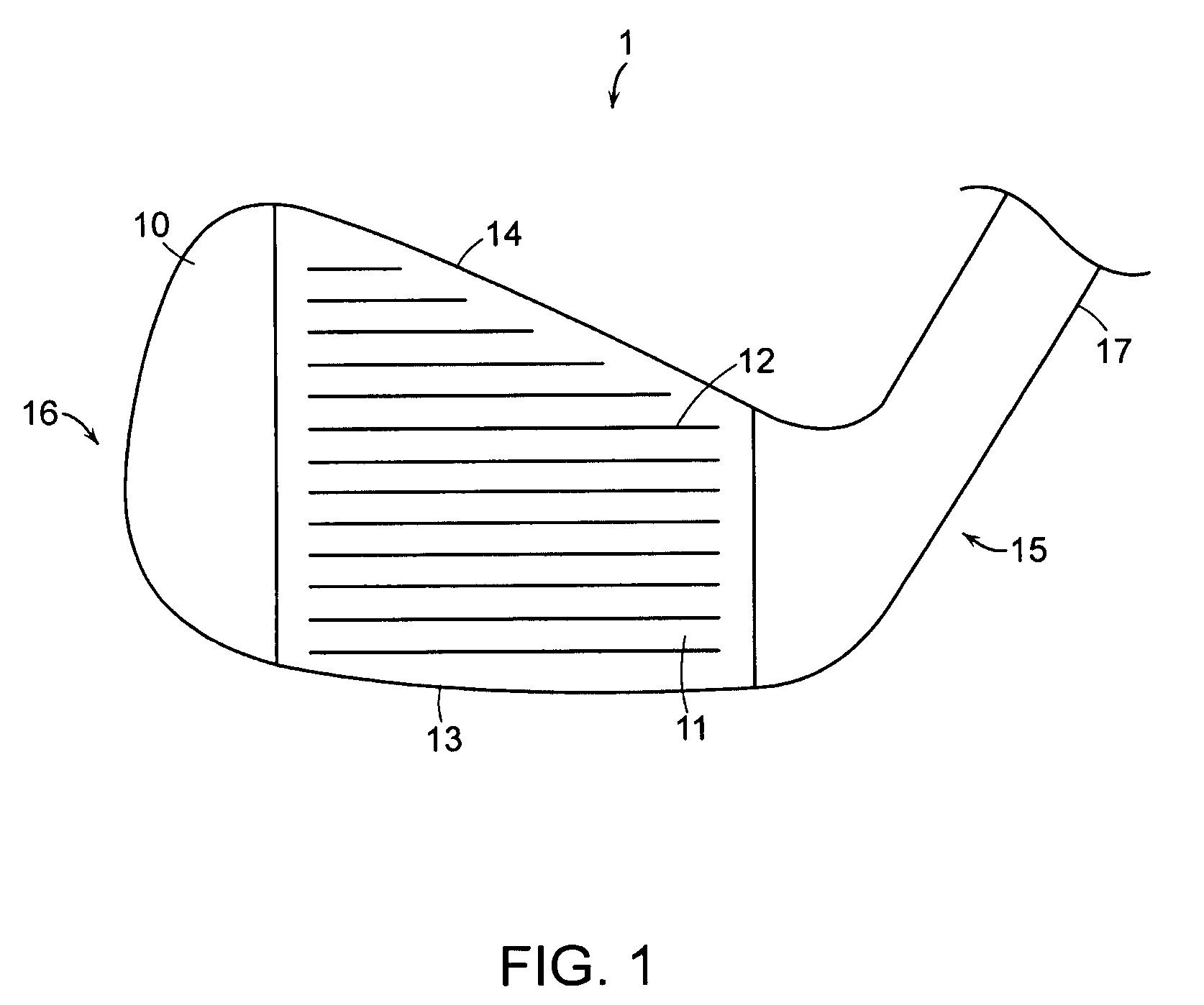

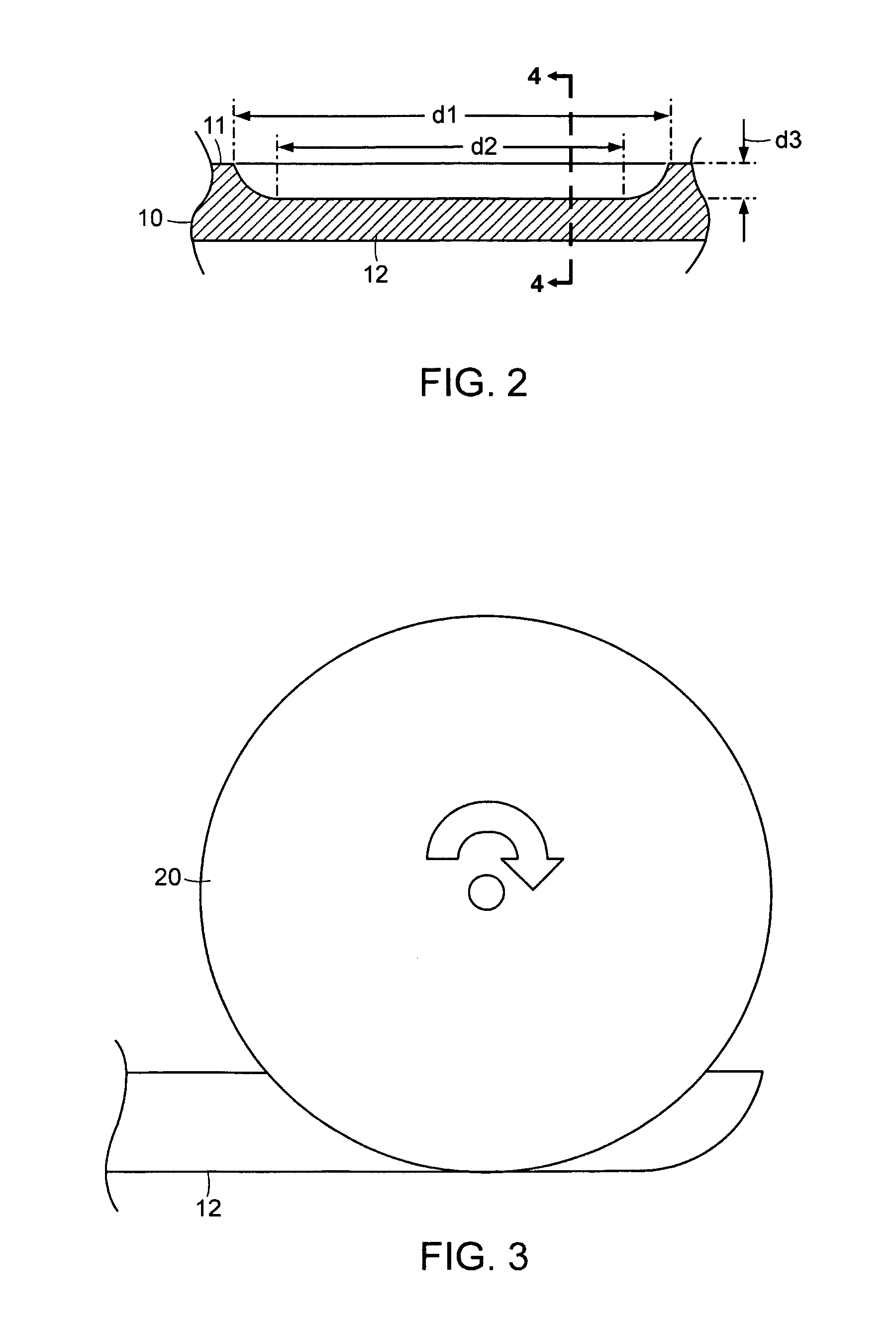

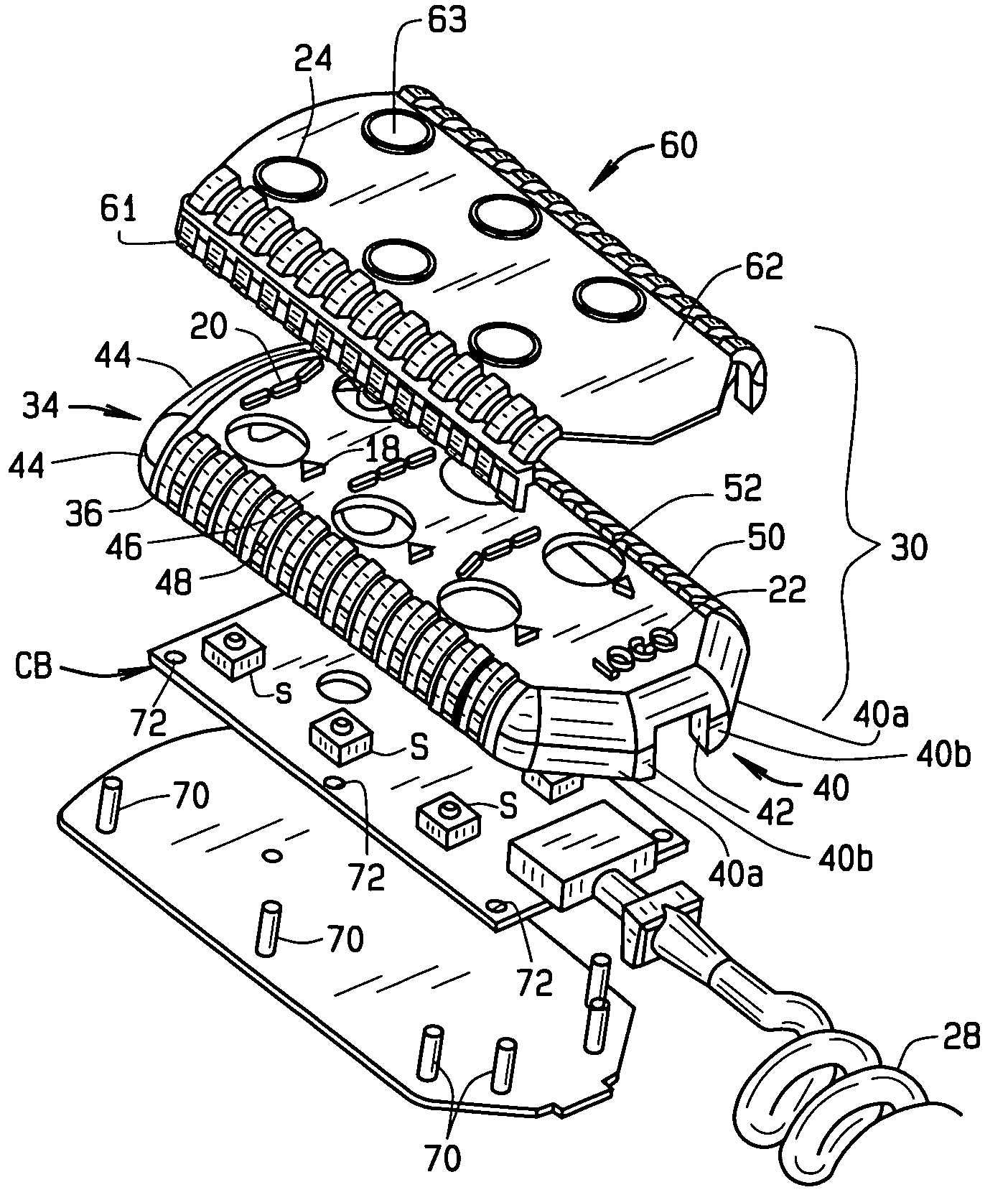

Golf club head

InactiveUS7594862B2Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face. The golf club head has a hard, wear resistant material as the ball-impacting face surface coupled to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

Semiconductor device

InactiveUS6445059B1Capacity producedReduce capacityTransistorSemiconductor/solid-state device detailsInter layerSilicon oxide

A resin material having low dielectric constant is used as an inter-layer insulating film and its bottom surface is contacted with a silicon oxide film across the whole surface thereof. Thereby, the surface may be flattened and capacity produced between a thin film transistor and an pixel electrode may be reduced. Further, it allows to avoid a problem that impurity ions and moisture infiltrate into the lower surface of the resin material, thus degrading the reliability of whole semiconductor device.

Owner:SEMICON ENERGY LAB CO LTD

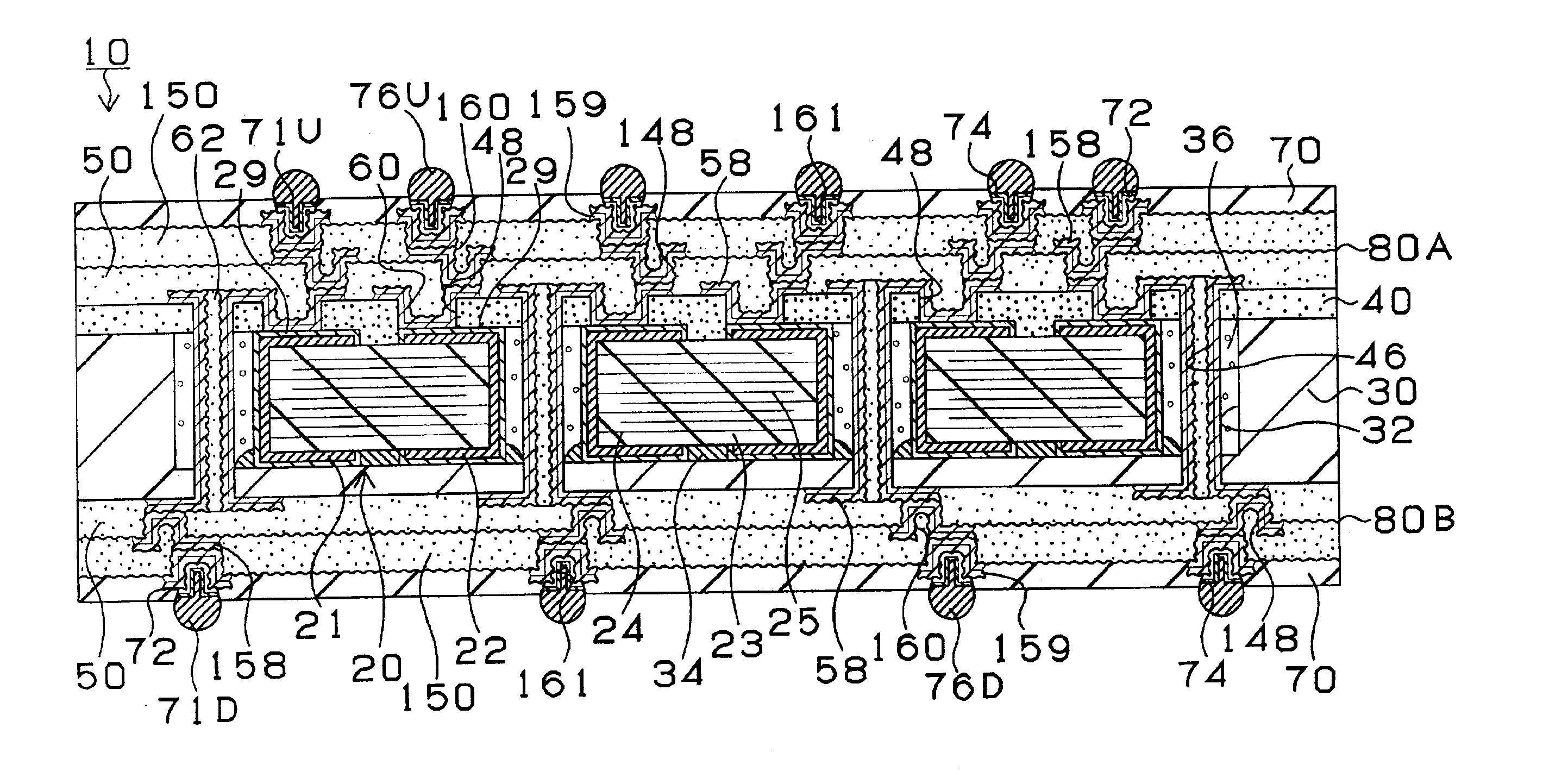

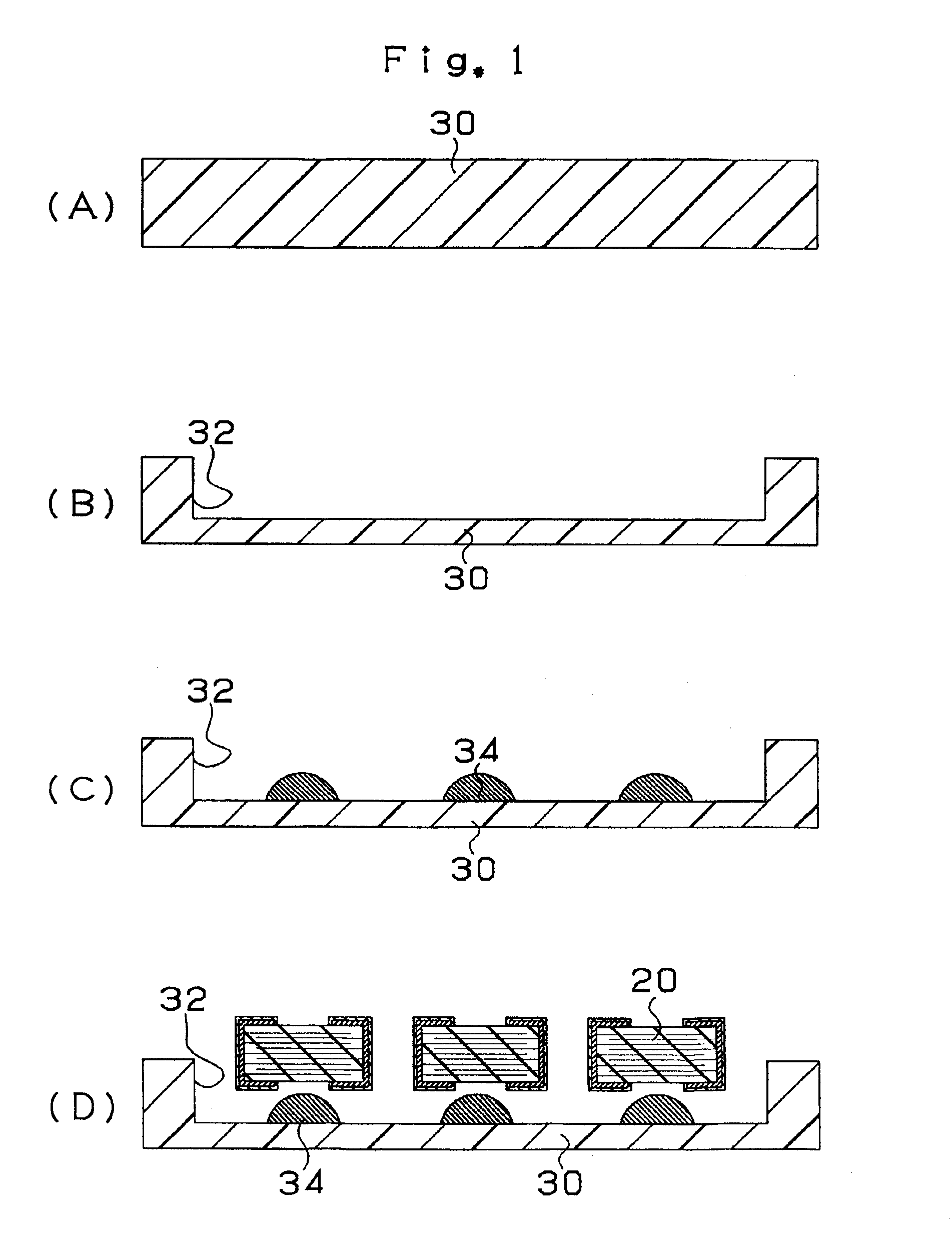

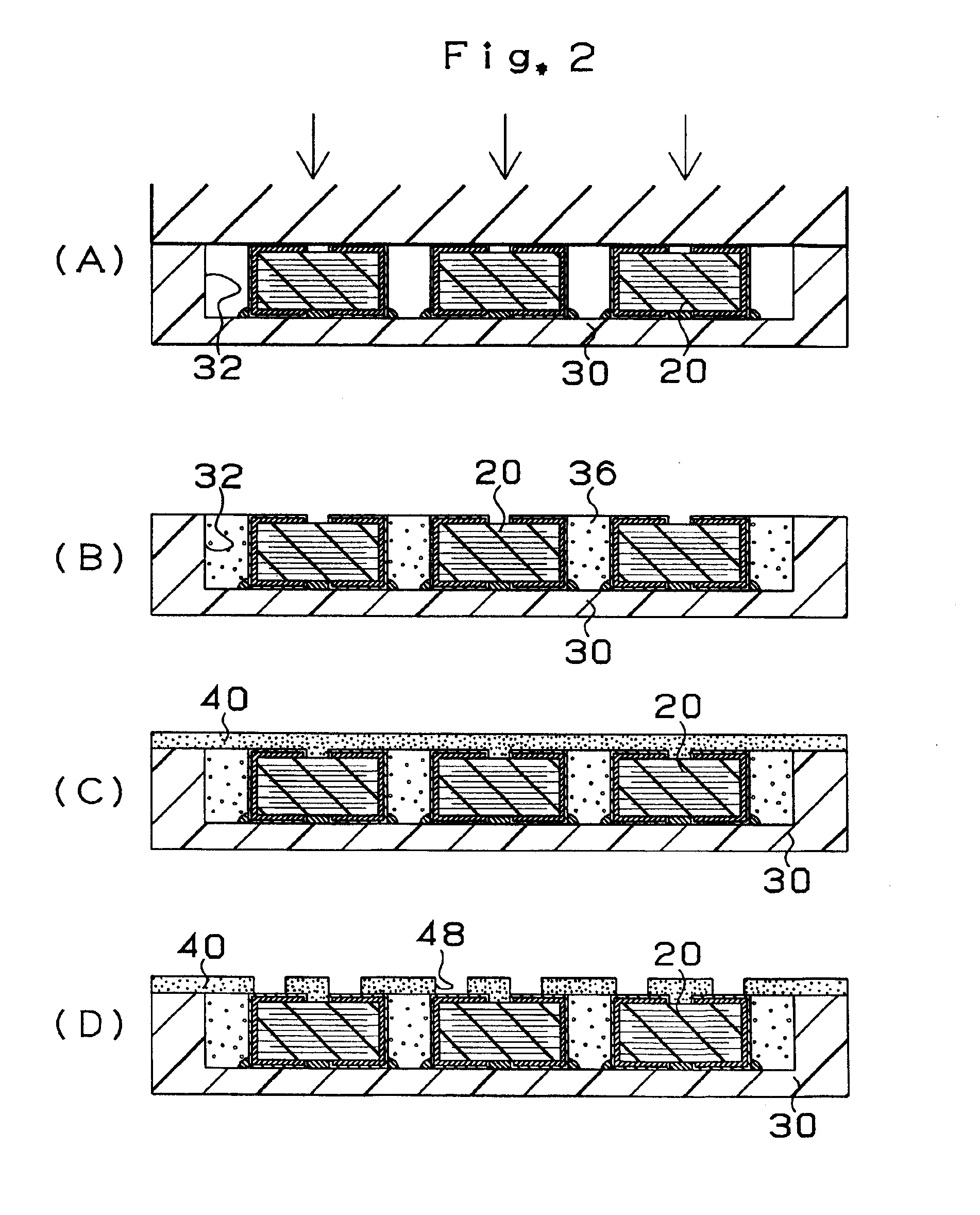

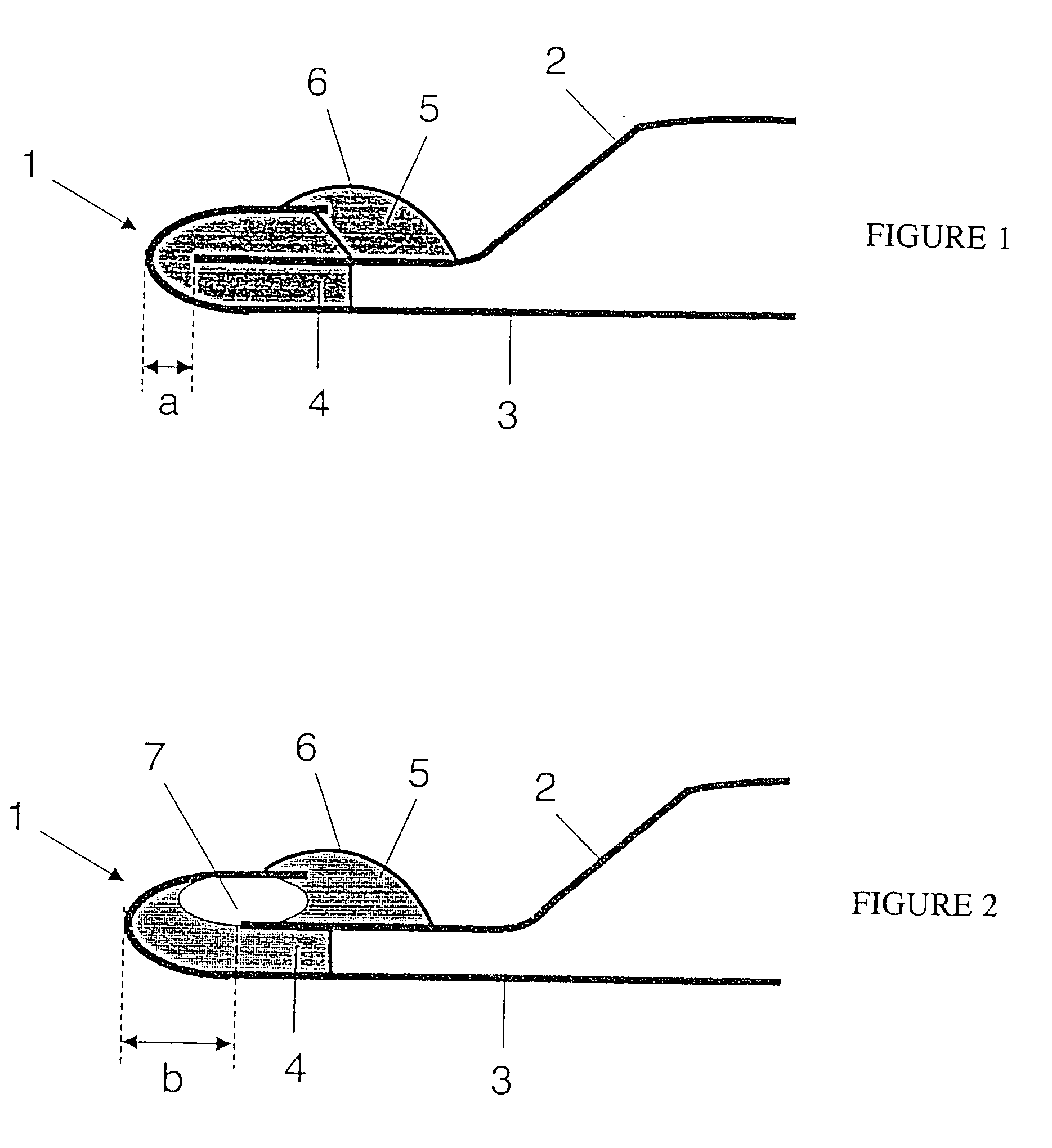

Printing wiring board and method of producing the same and capacitor to be contained in printed wiring board

InactiveUS6876554B1Improve reliabilityFlat surfaceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPrinted circuit board

Chip capacitors 20 are provided in a printed circuit board 10. In this manner, the distance between an IC chip 90 and each chip capacitor 20 is shortened, and the loop inductance is reduced. In addition, the chip capacitors 20 are accommodated in a core substrate 30 having a large thickness. Therefore, the thickness of the printed circuit board does not become large.

Owner:IBIDEN CO LTD

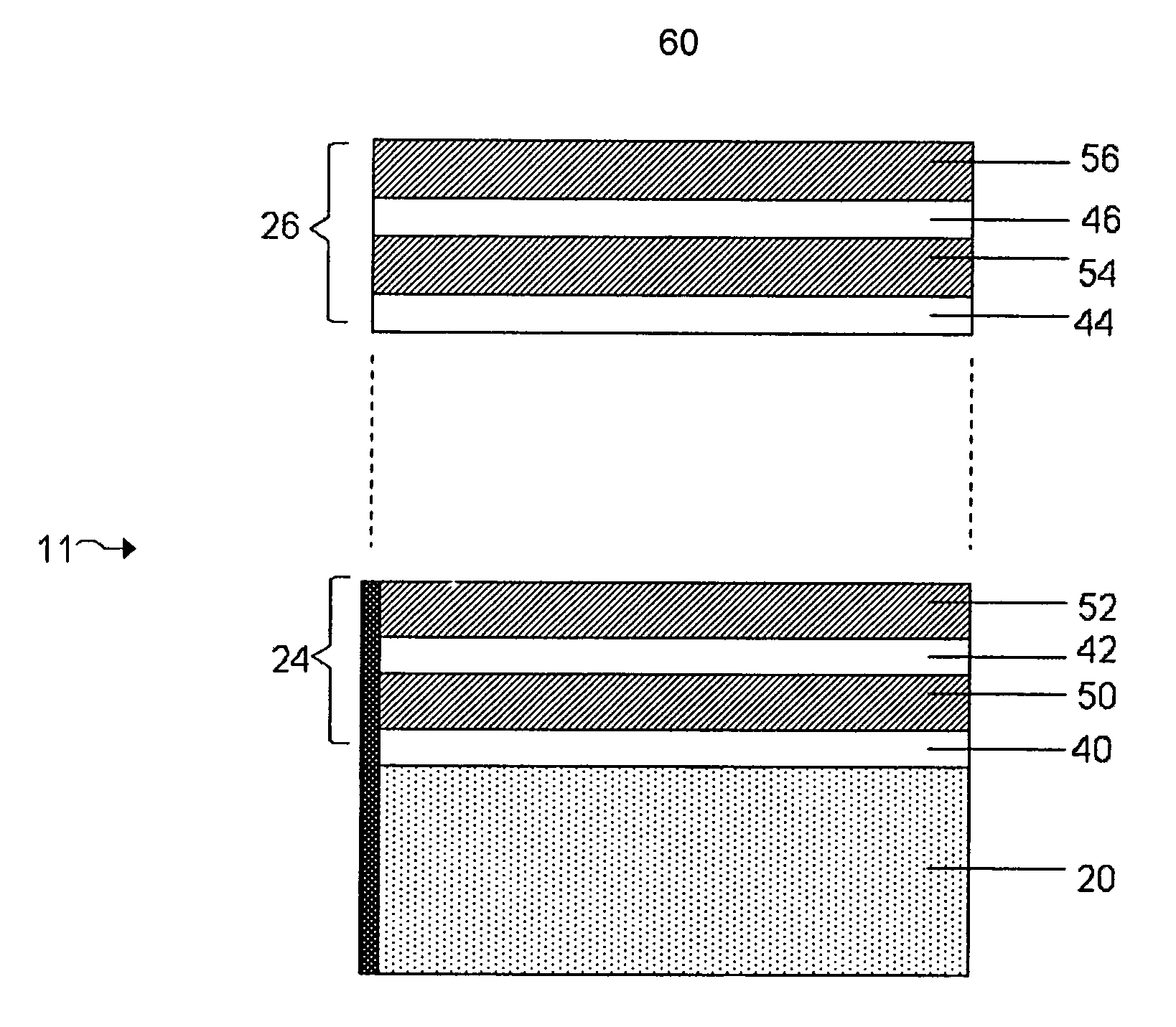

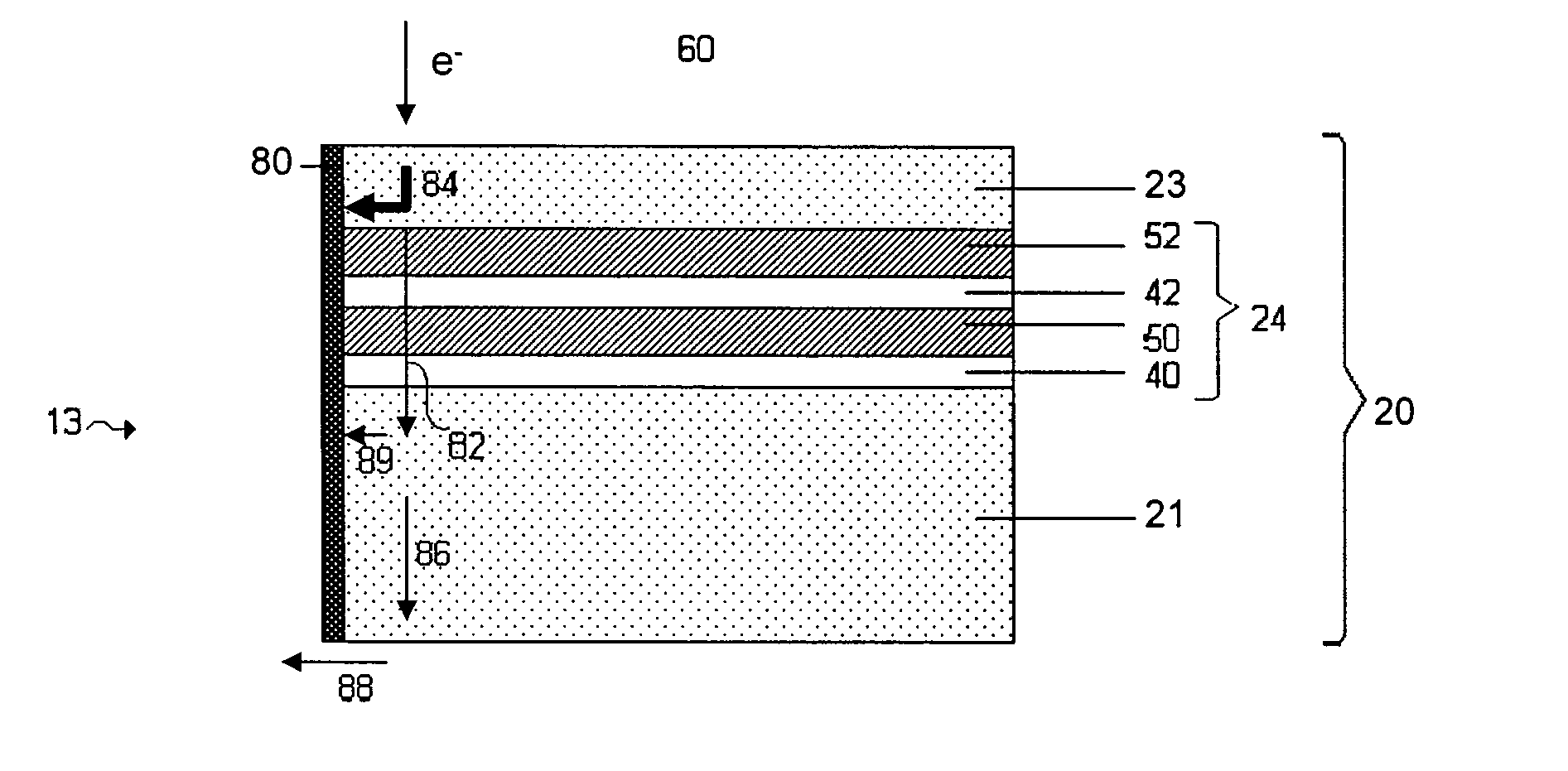

Electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries

ActiveUS20070224502A1Preventing electronic communicationAvoid communicationFinal product manufactureElectrode carriers/collectorsHigh energyConductive materials

Electrode protection in electrochemical cells, and more specifically, electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

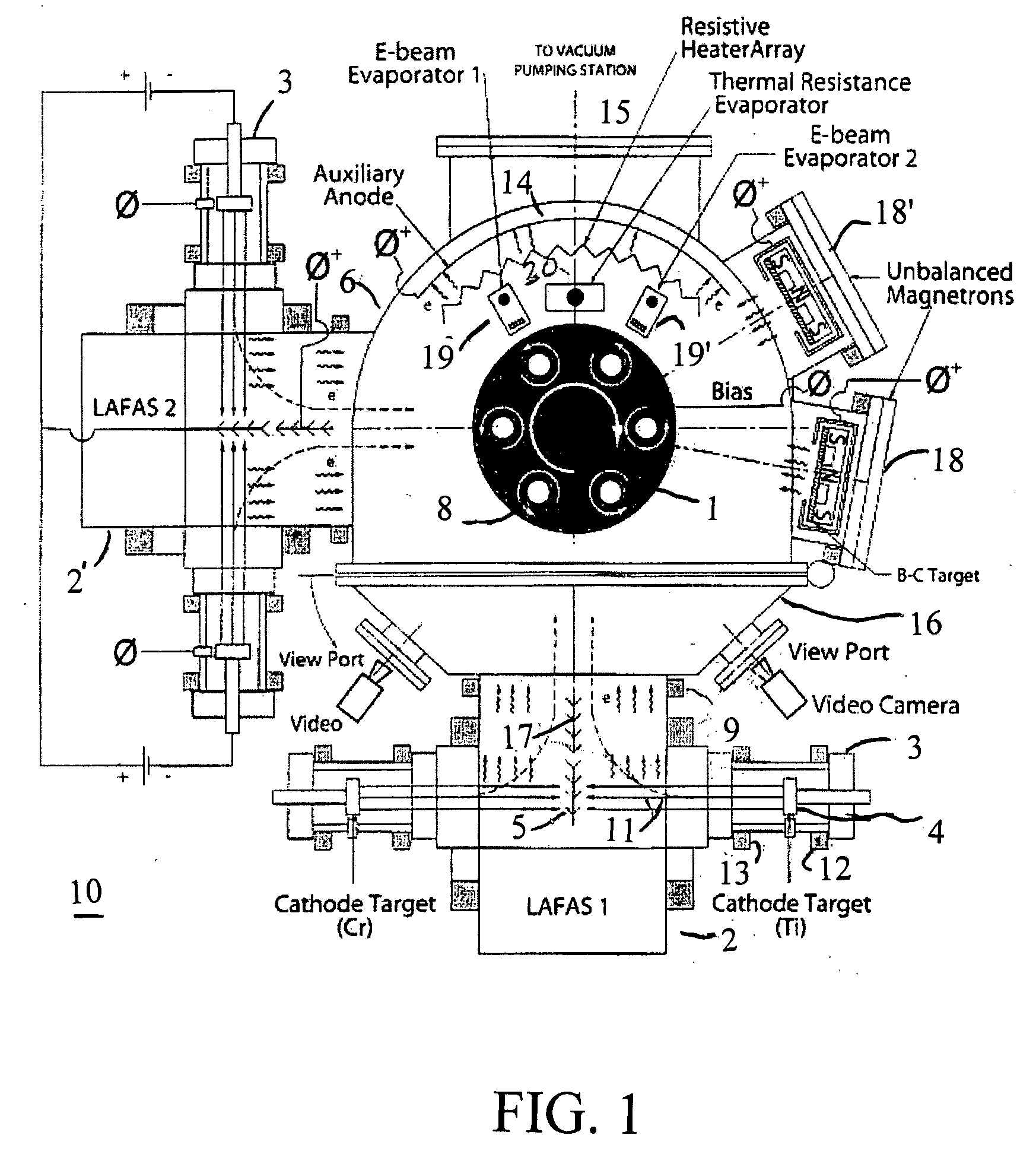

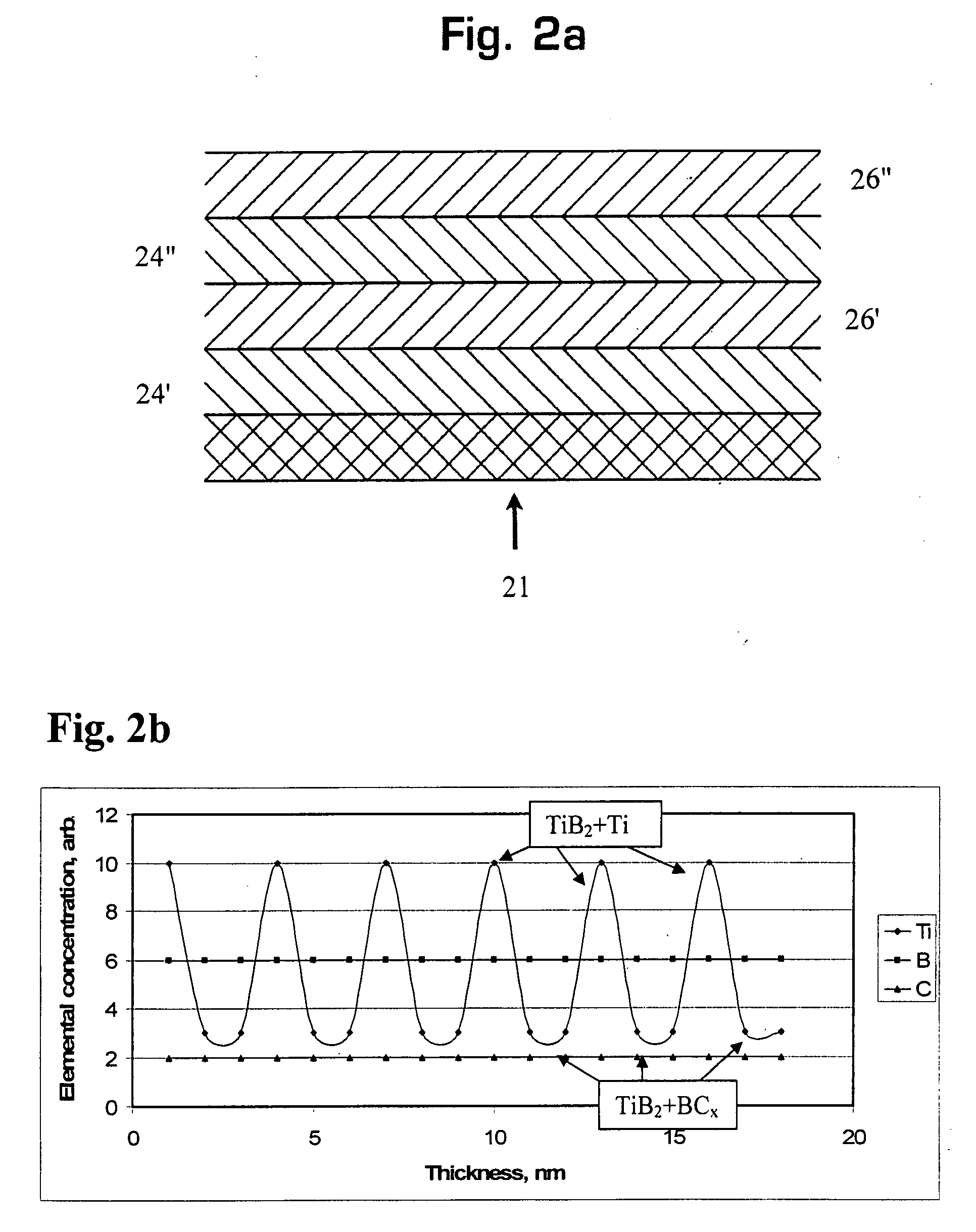

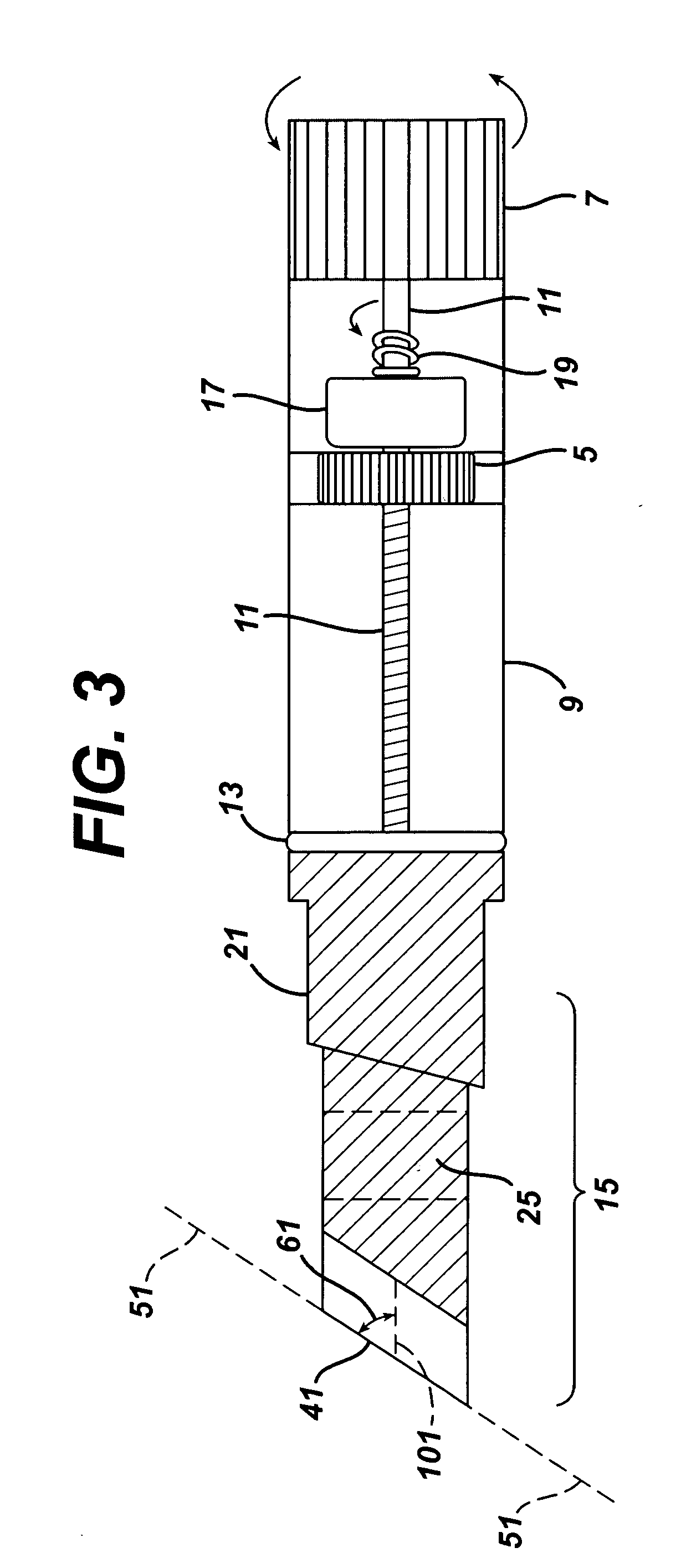

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

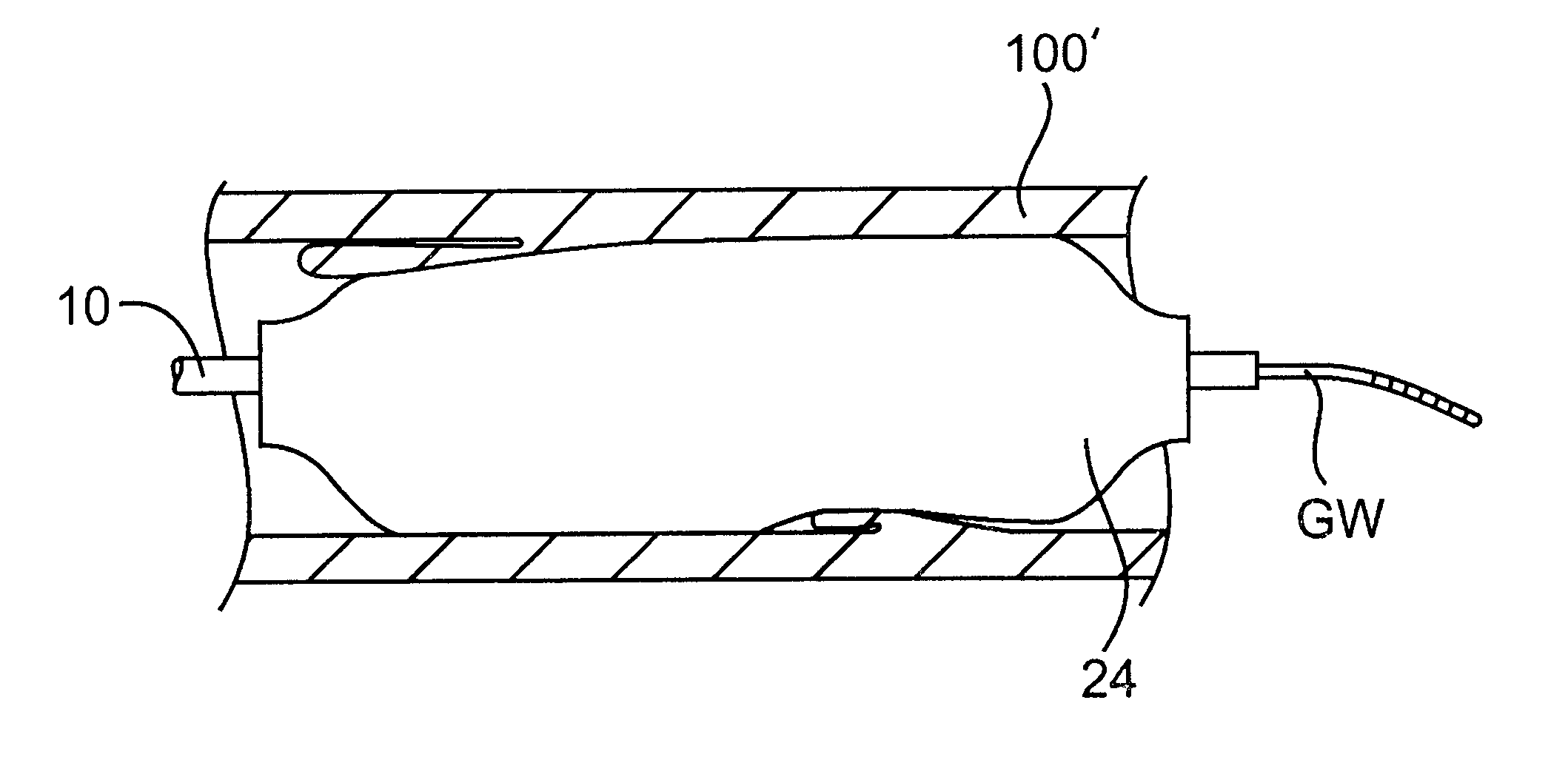

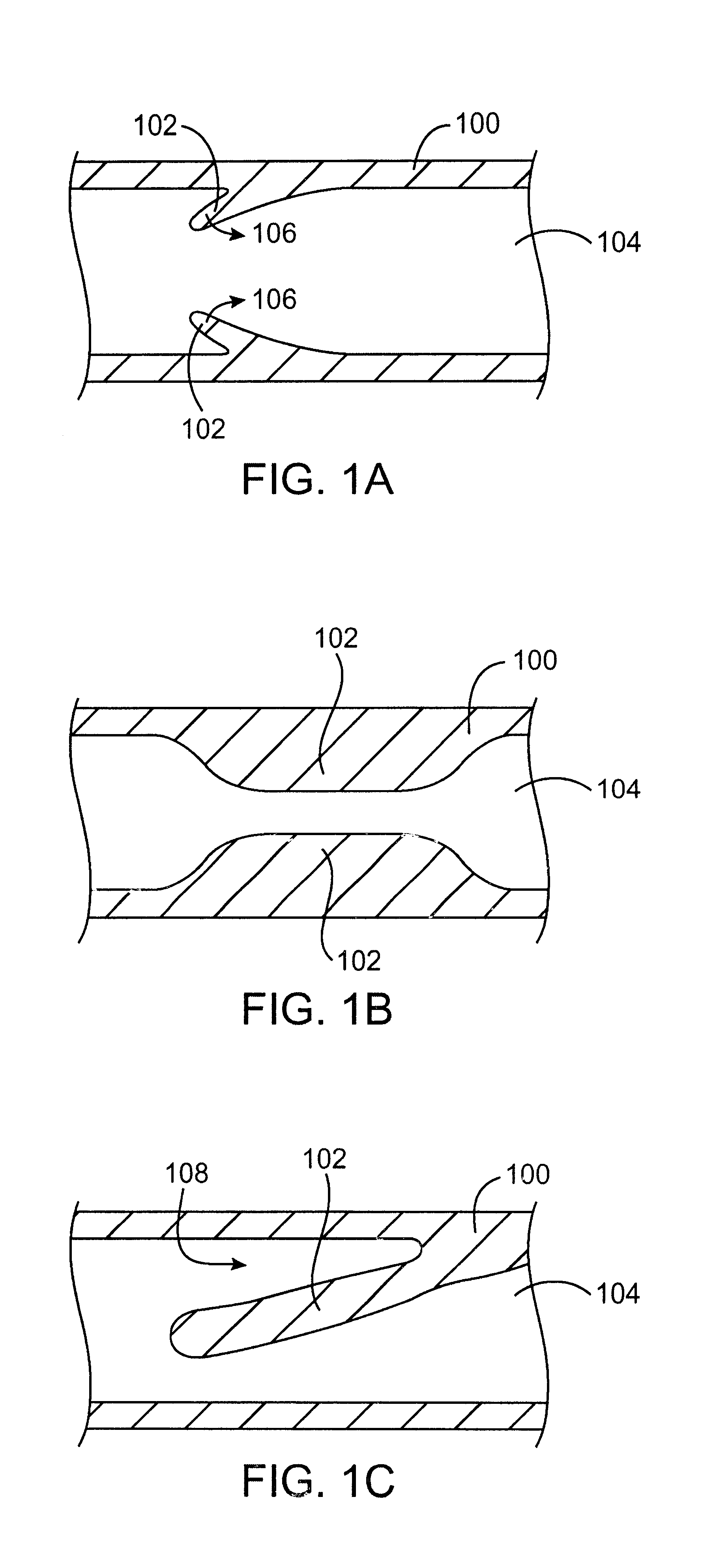

Cryotherapy methods for treating vessel dissections and side branch occlusion

The present invention provides cryotherapy treatment of dissections in a blood vessel of a patient. The present invention further provides cryotherapy treatment of side branch occlusion in a bifurcated blood vessel. One method for treating potential or existing dissections in a blood vessel comprises cooling the blood vessel to a temperature and for a time sufficient to remodel the blood vessel such that dissections of the blood vessel are reduced. Another method for treating side branch occlusion in a bifurcated blood vessel, the bifurcated blood vessel having a side branch and a main branch, the main branch having plaque disposed thereon, comprises cooling an inner surface of the main branch to a temperature and for a time sufficient to inhibit plaque shift from the main branch into the side branch.

Owner:BOSTON SCI SCIMED INC

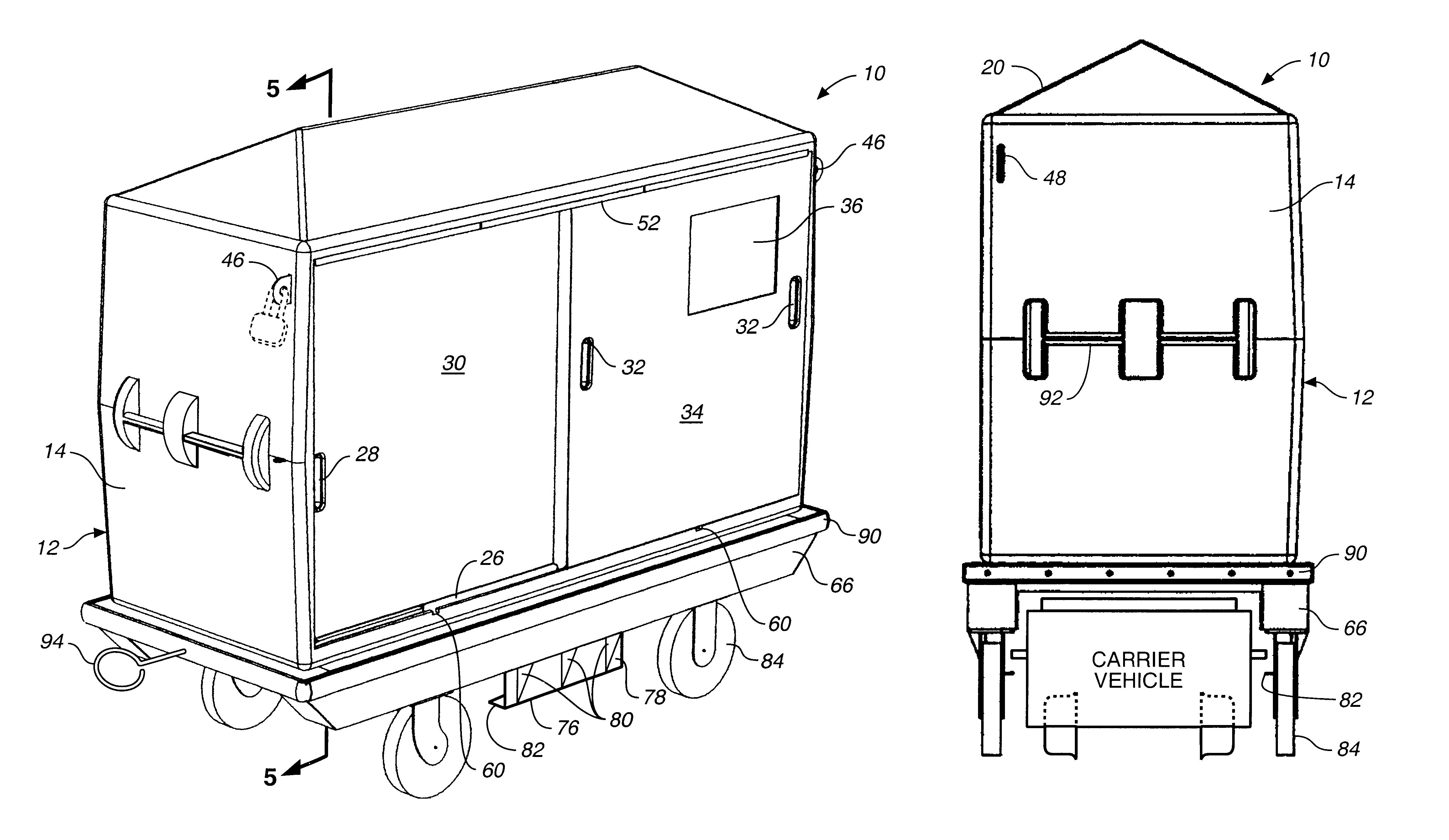

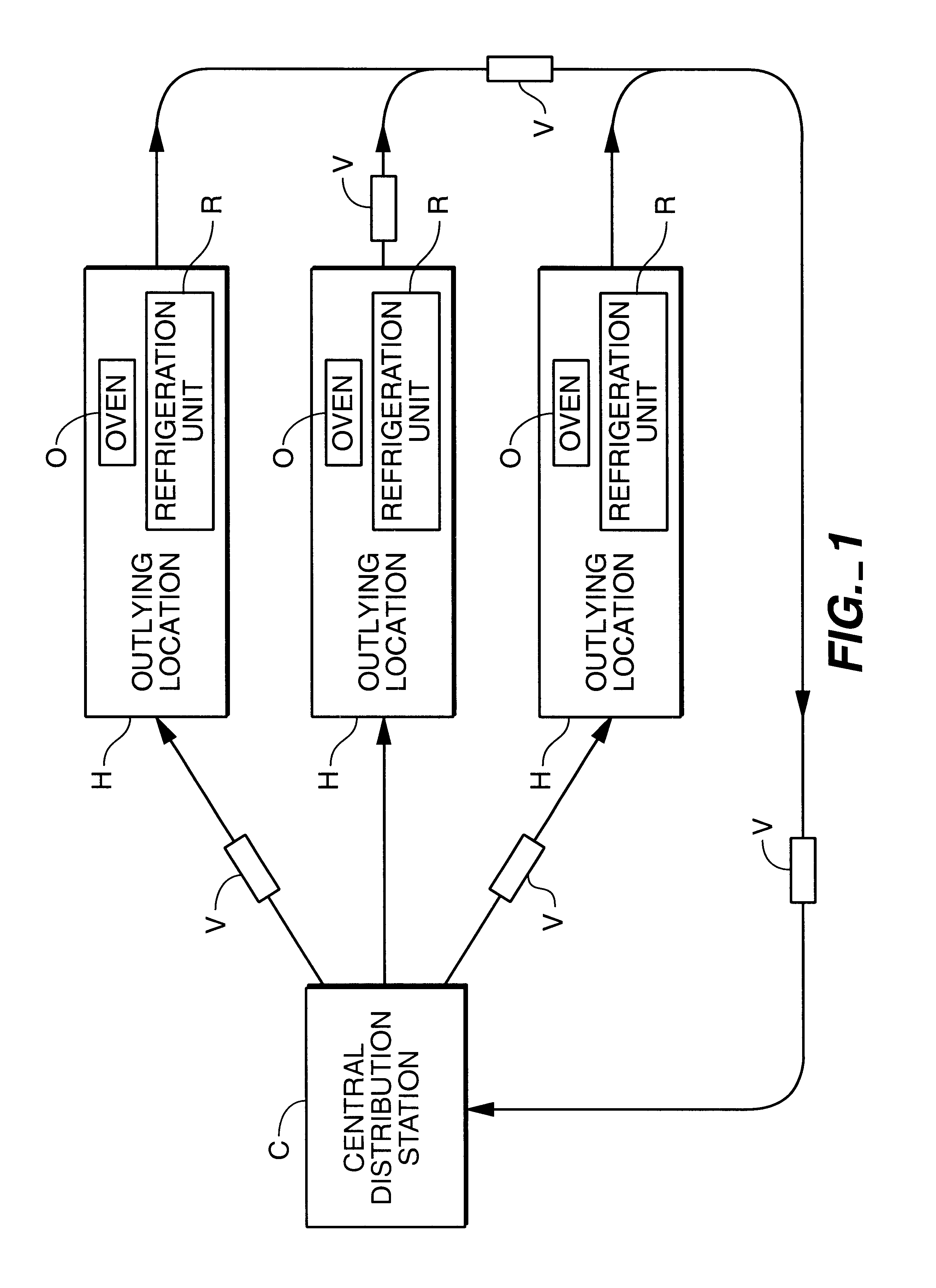

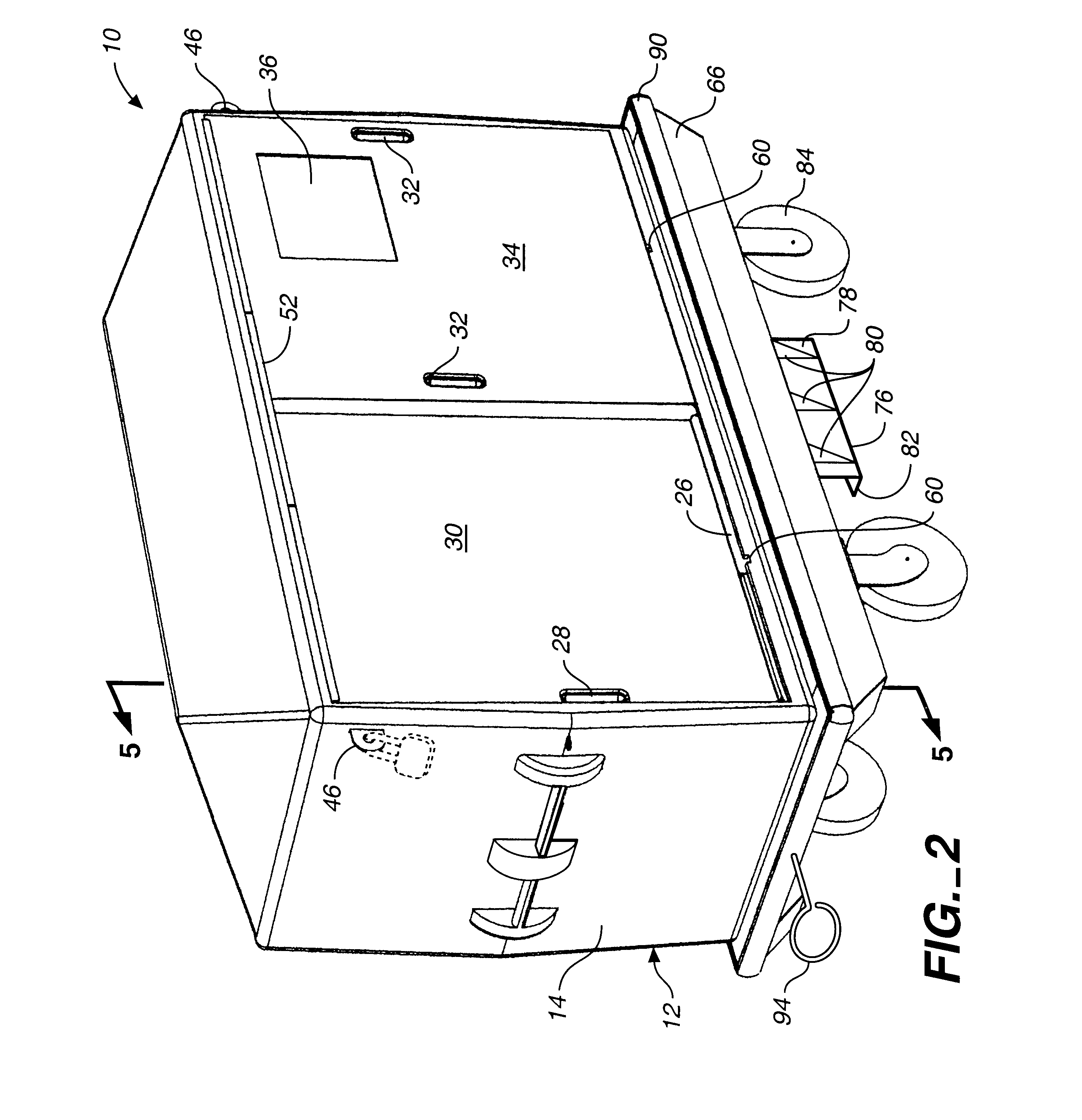

Meal delivery cart

InactiveUS6672601B1Durable and impervious to waterAvoid excessive absorptionVentilationService system furnitureDelivery vehicleAutomated guided vehicle

An improved meal delivery system and a method for delivery of pre-cooked, chilled meals from a central distribution station to a plurality of remote locations in cooperation with an Automatic Guided Vehicle system, and in particular a one-piece, molded, insulated meal-delivery cart for transportation of chilled meals.

Owner:COUNTY OF ALAMEDA THE A POLITICAL SUBDIV OF THE STATE OF CALIFORNIA

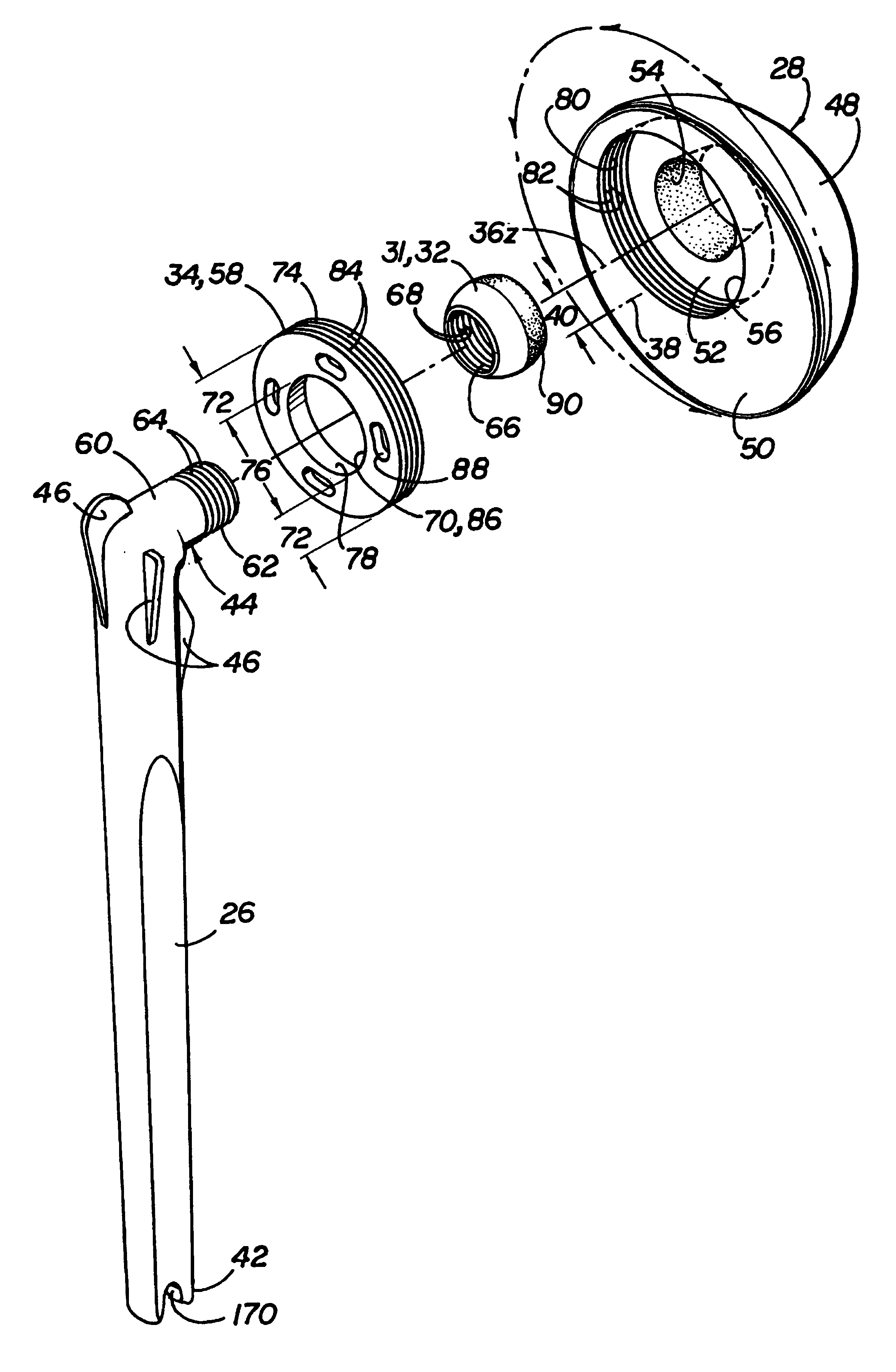

Modular prosthesis system with novel locking mechanism

InactiveUS7097663B1Reliable lockingReduce the risk of infectionJoint implantsShoulder jointsLocking mechanismSurgical repair

A modular prosthesis for replacement of a joint articulating surface of a bone, where the modular prosthesis generally comprises a head with a recessed socket, an elongate stem, and a connecting member including a patrix member having a generally spherical surface and adapted to be attached to an end of the stem and to be received in the head, and a locking member adapted to lock the head to the stem in a desired orientation; a system for use in surgical repair of a joint including a selection of components for assembling the modular implant prosthesis, a selection of components for assembling a trial prosthesis, and a transfer device for arranging the components of the implant prosthesis in the same orientation as the components of the trial prosthesis; and methods of using the modular prosthesis and system of the invention.

Owner:SMITH & NEPHEW INC

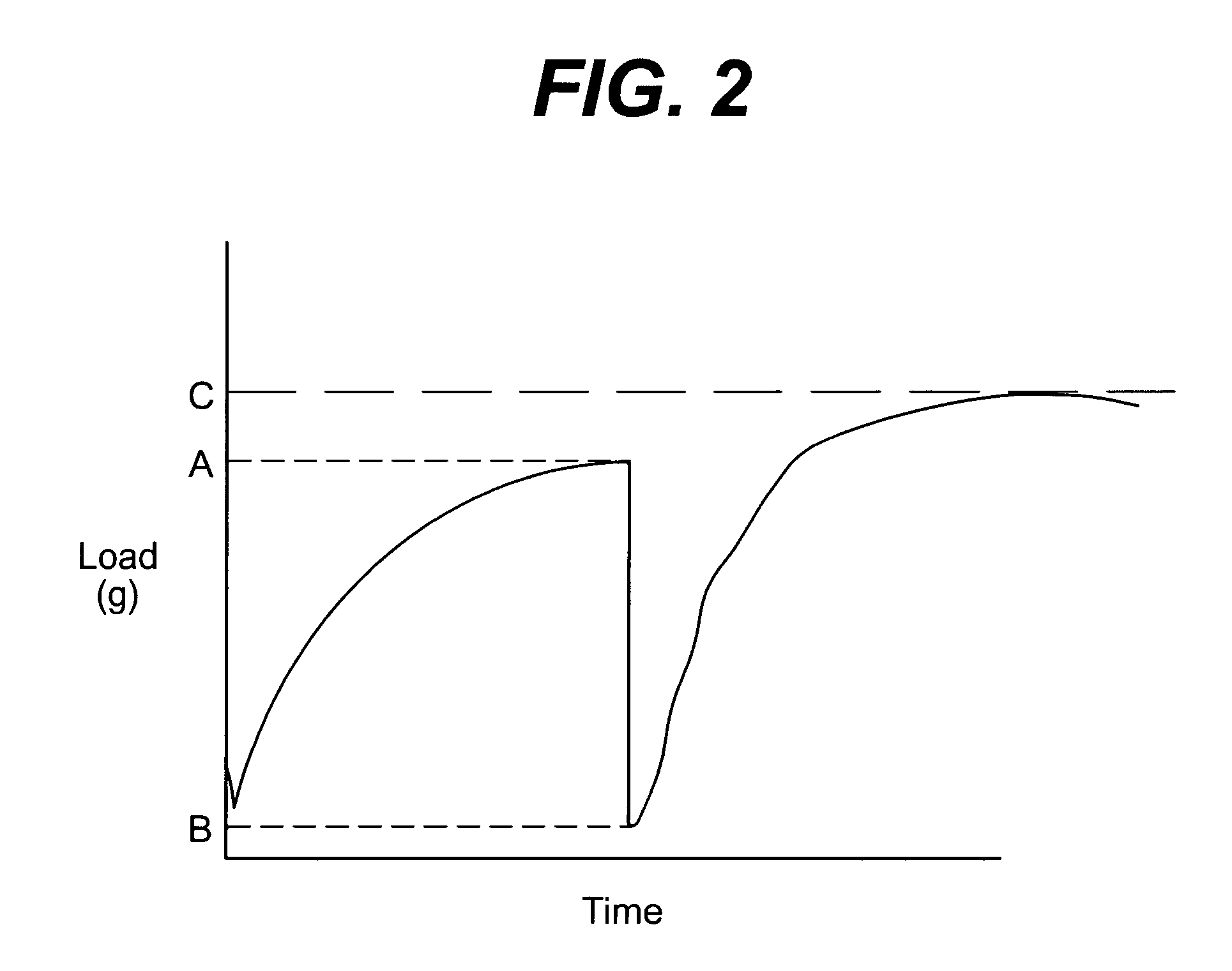

Method of using skin compositions including tensioning polymers

InactiveUS20060210513A1Improving skin functionReduce appearance problemsCosmetic preparationsToilet preparationsWrinkle skinThird generation

The invention features a method of treating at least one sign of aging on the skin selected from the group consisting of (i) thickening the skin, (ii) enhancing the barrier function of skin, and / or (iii) treating at least one sign of aging on the skin selected from the group consisting of enhancing the elasticity of said skin, enhancing the firmness of said skin, smoothing the surface of the skin, and reducing the appearance of wrinkles on the skin, wherein the method includes applying to skin in need of such treatment a skin care composition including a tensioning polymer, wherein the tensioning polymer has a contractile force greater than about 3 g / mg and a water resistance index from about 0.9 to about 1.9.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

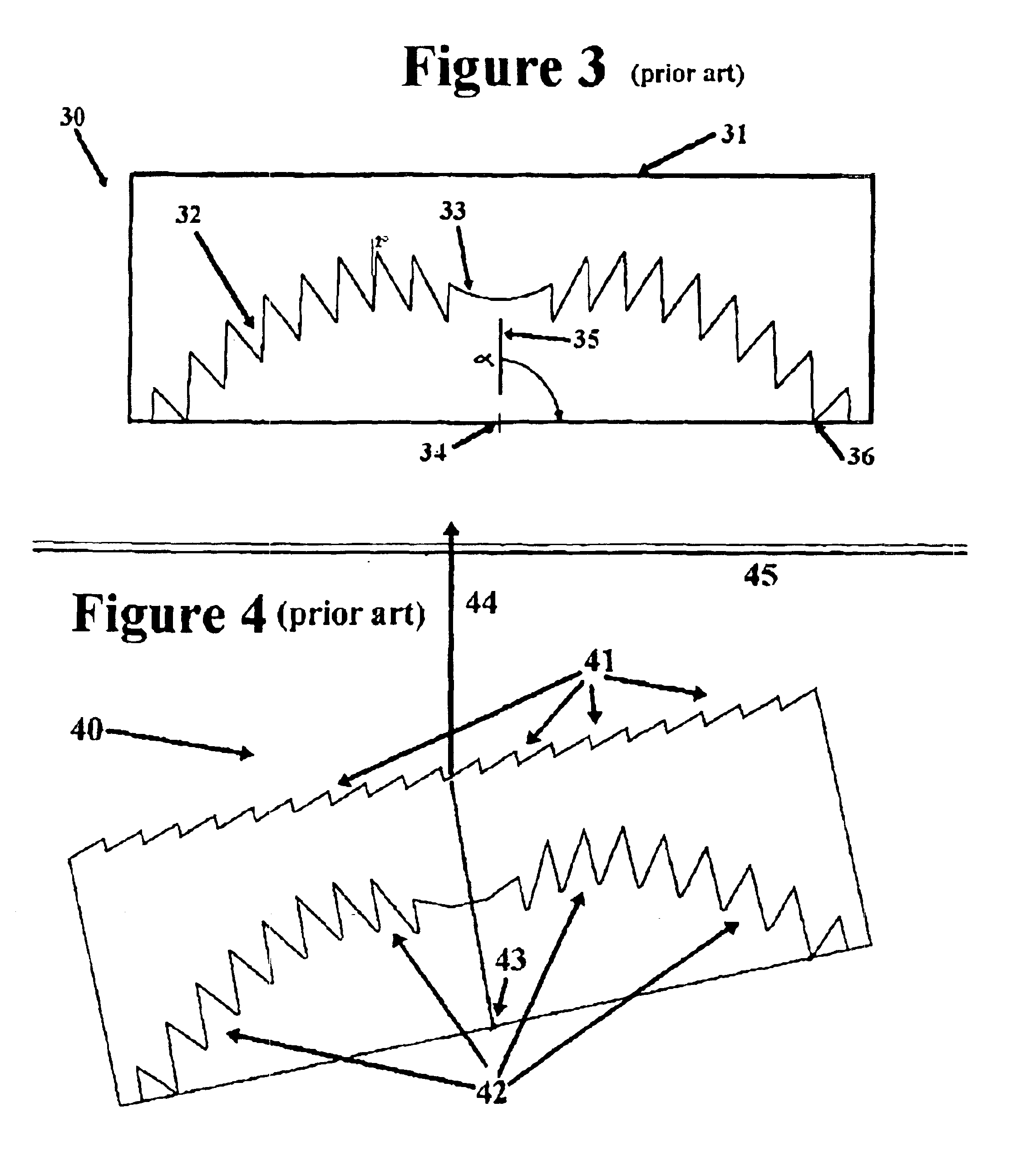

Asymmetric TIR lenses producing off-axis beams

The present invention relates to an improvement of a total internal reflection lens whereby a tilted symmetry axis leads to a net deflection of the output beam away from the surface normal of the exit surface. Linear TIR lenses have a net deflection transverse to their focal strip. Circular TIR lens profiles going beyond 90° are tilted to bring the rim level with the source, the deflected rays exiting the lens to form an off-axis beam.

Owner:LIGHT ENGINE

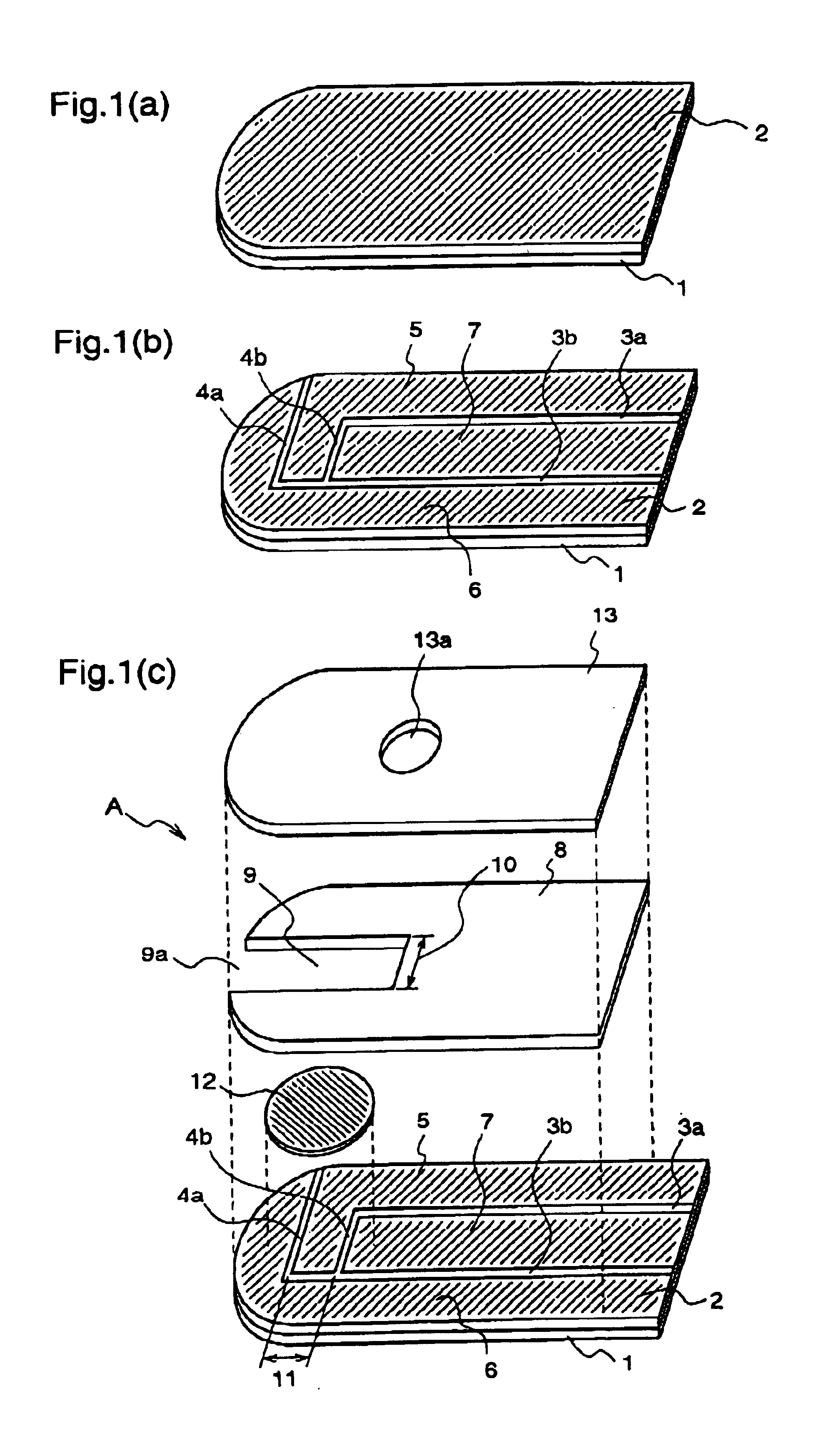

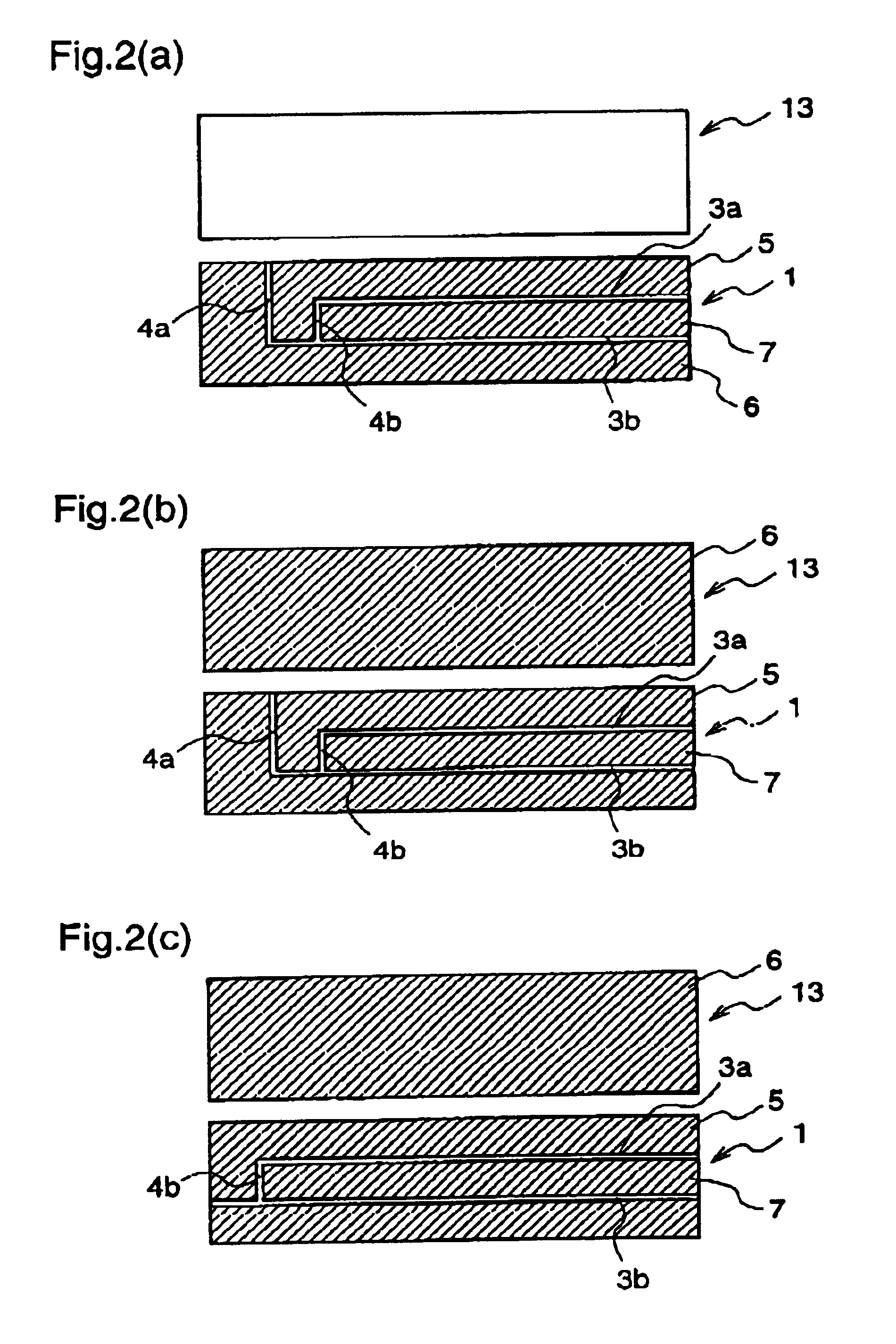

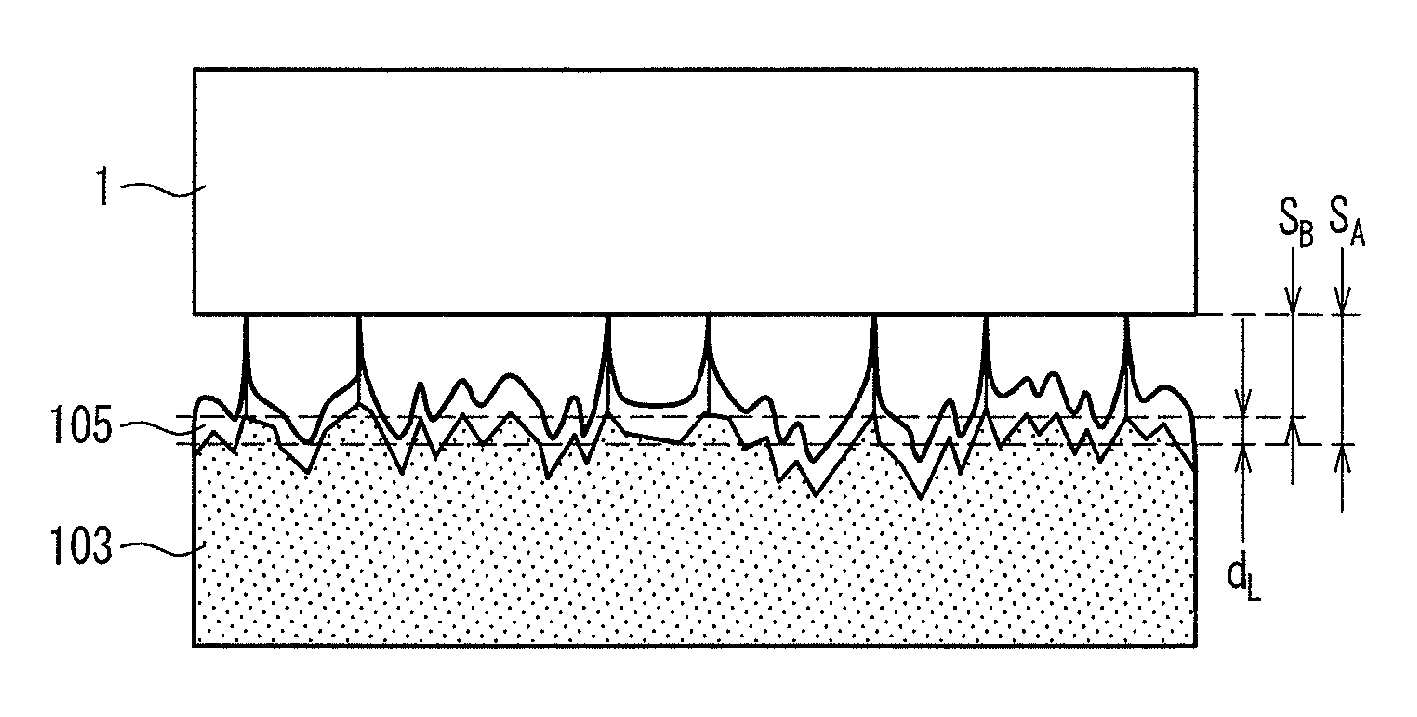

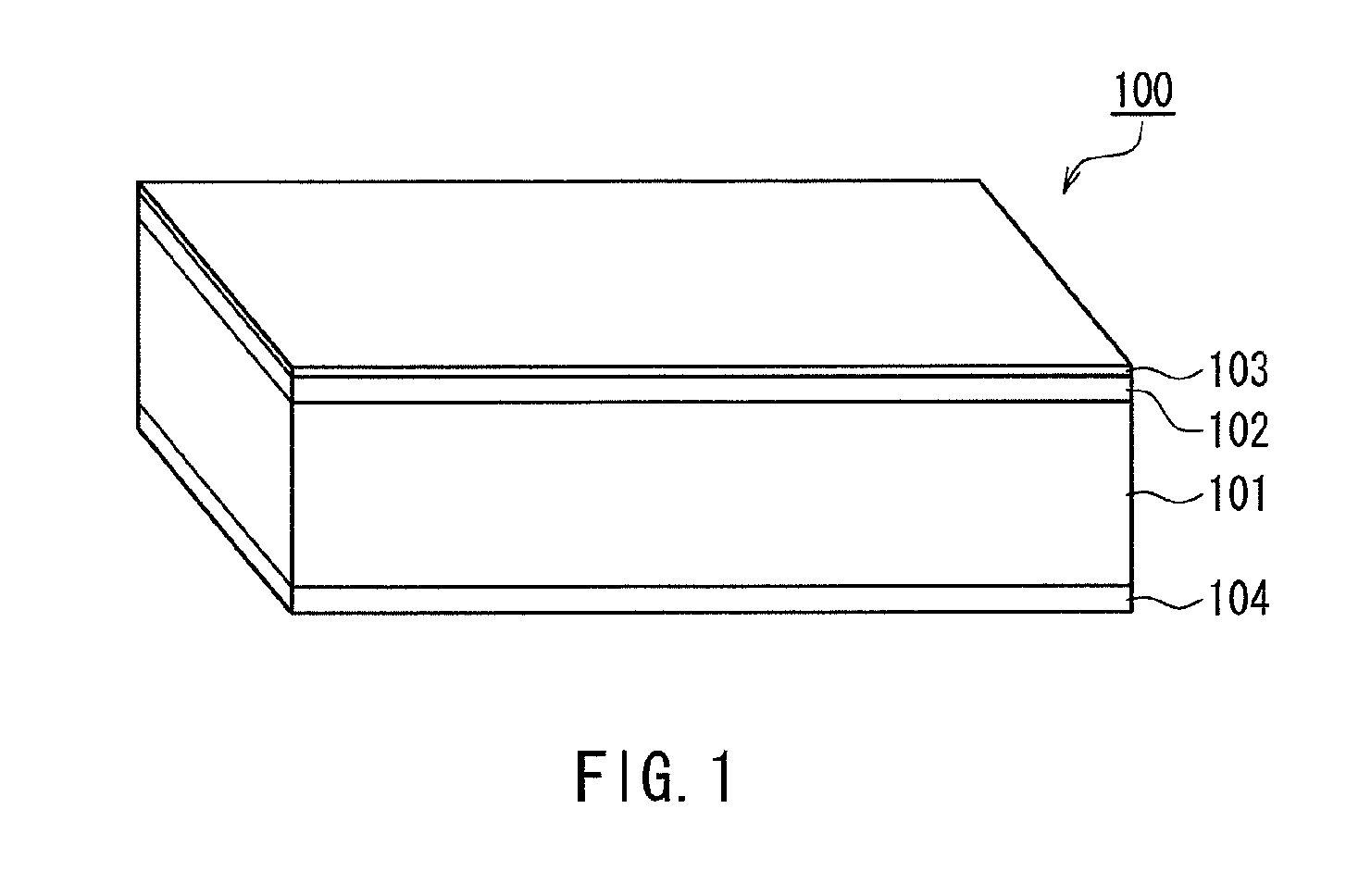

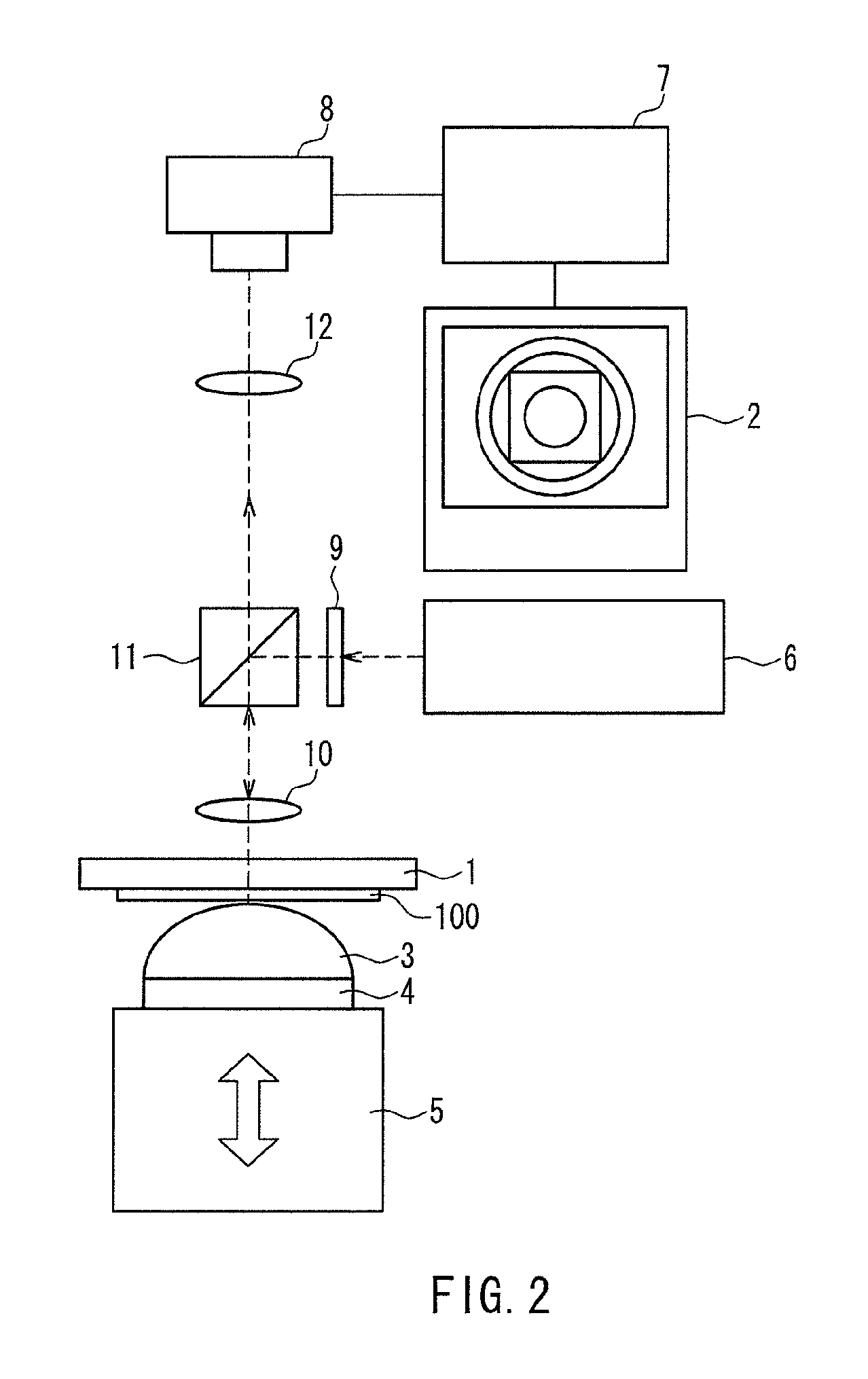

Magnetic recording medium

ActiveUS9311946B2Superior recording/reproducing characteristic and transport characteristicFlat surfaceMaterials with ironRecord information storageNon magneticHexane

A magnetic recording medium of the present invention is a magnetic recording medium including a non-magnetic substrate; a non-magnetic layer that is formed on one of principal surfaces of the non-magnetic substrate and contains a non-magnetic powder, a binder, and a lubricant; and a magnetic layer that is formed on a principal surface of the non-magnetic layer opposite to the non-magnetic substrate and contains a magnetic powder and a binder. The magnetic powder has an average particle size between 10 nm and 35 nm inclusive. The lubricant is migratable to the magnetic layer and forms a lubricant layer on a surface of the magnetic layer when a pressure is applied to the magnetic layer. When spacing of the surface of the magnetic layer before and after washing the lubricant with n-hexane is measured with a TSA (Tape Spacing Analyzer), the value of the spacing after washing is 3 to 10 nm, and the value of the spacing before washing is 1 to 5 nm smaller than the value of the spacing after washing.

Owner:FUJIFILM CORP

Intervertebral prosthetic disc with metallic core

Owner:SIMPLIFY MEDICAL PTY LTD

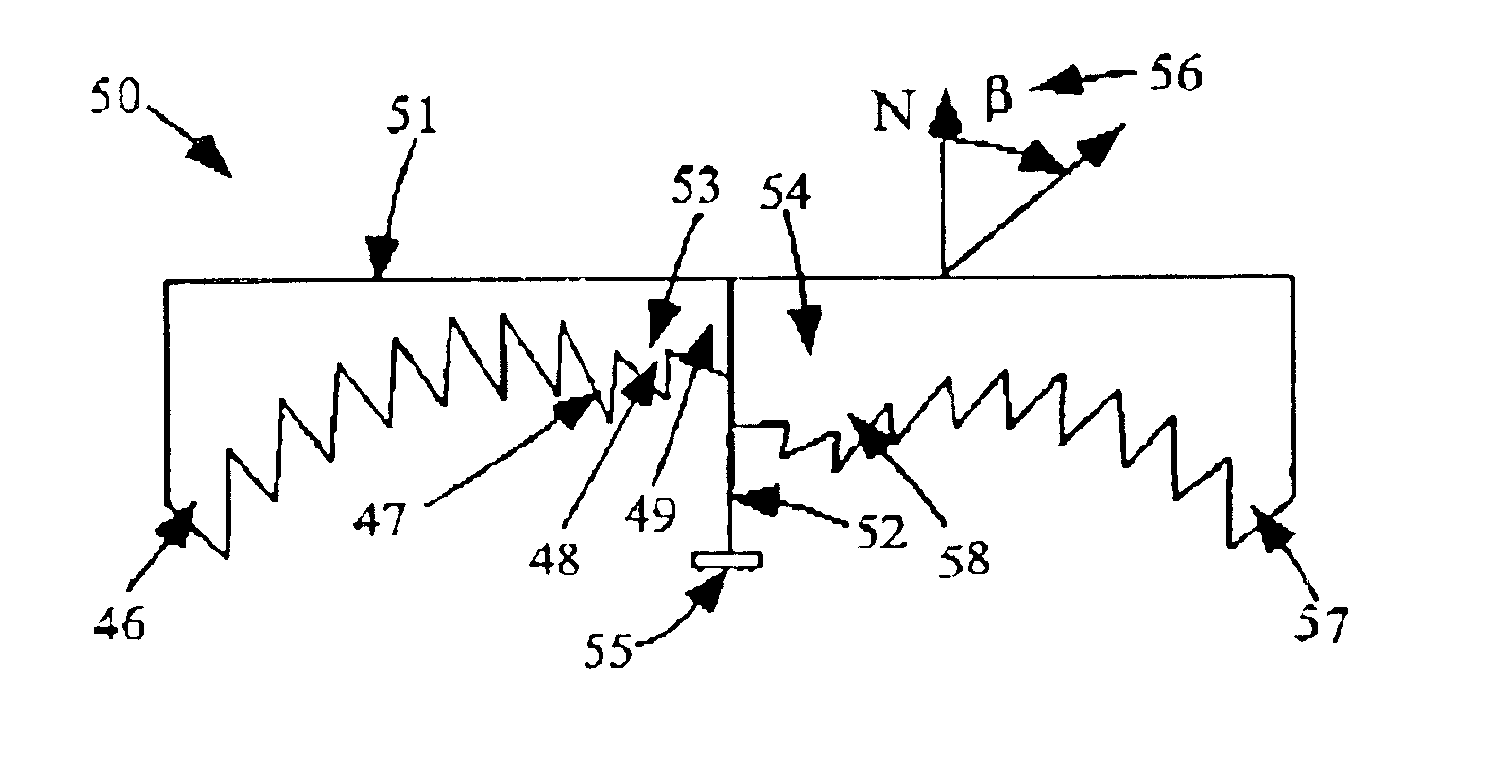

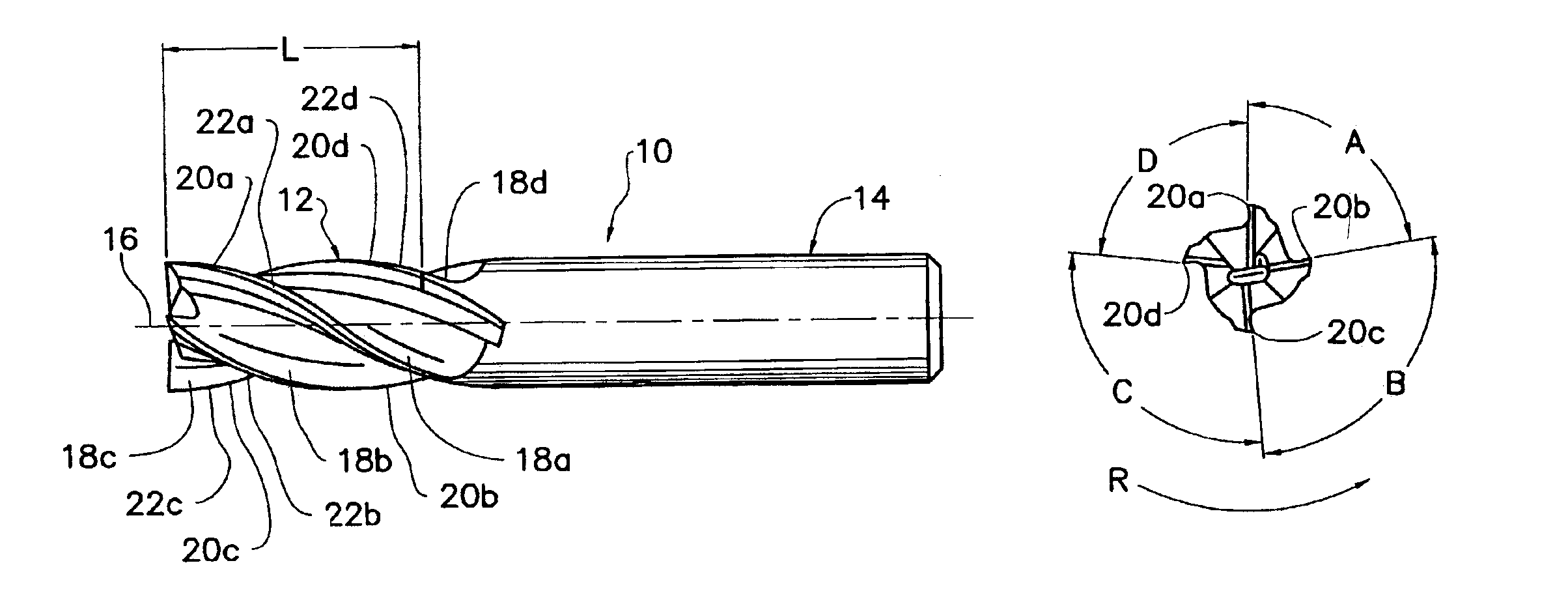

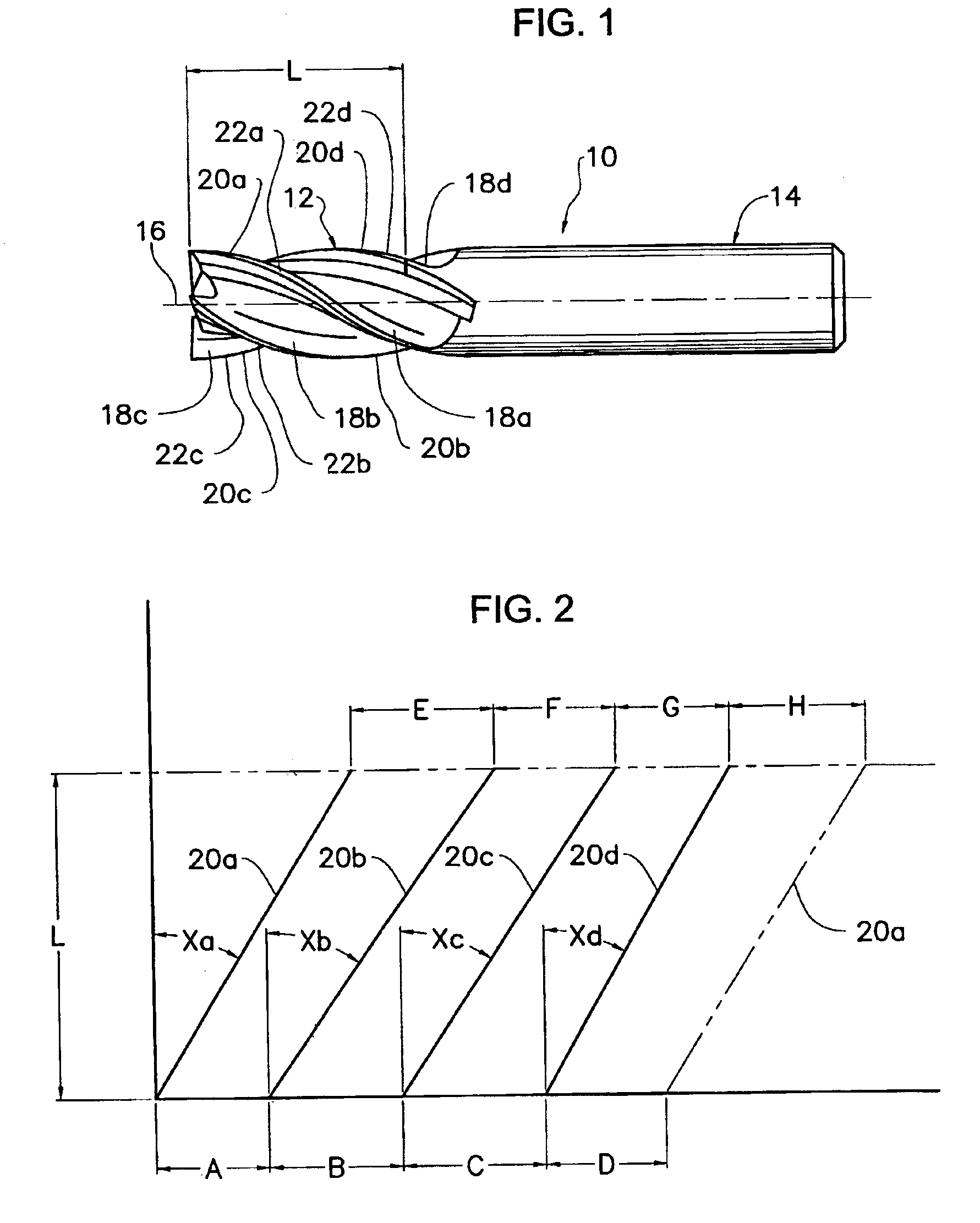

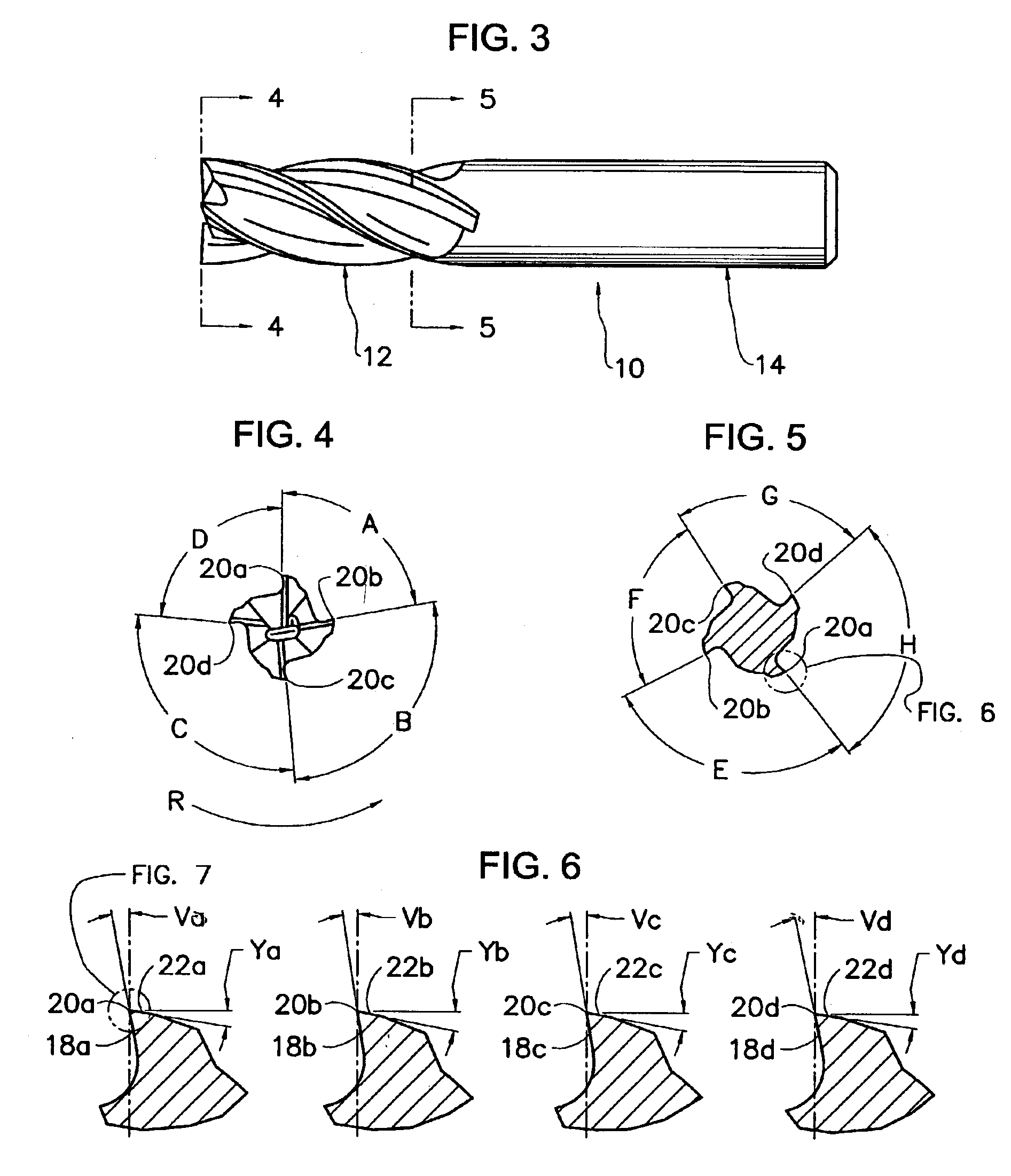

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

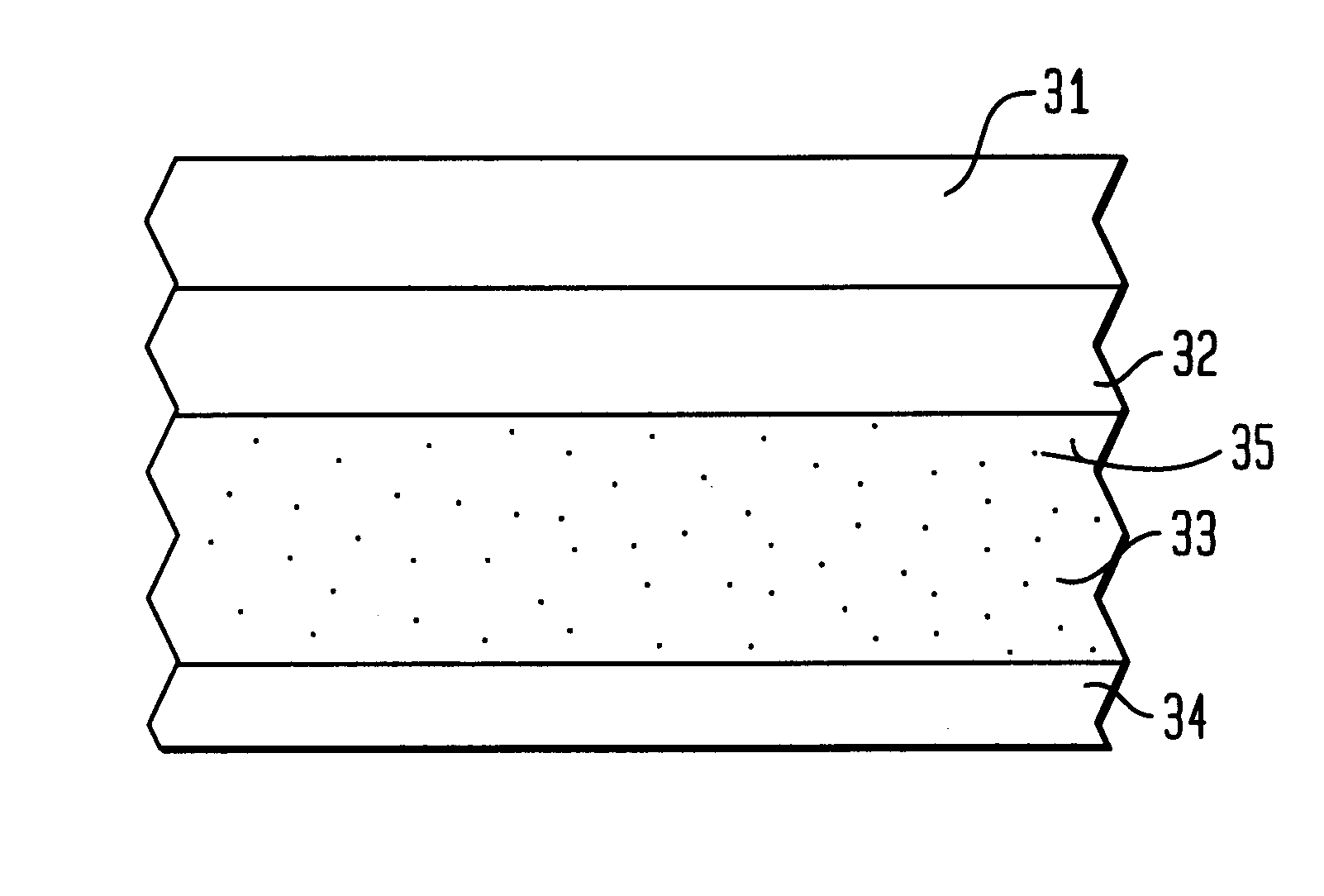

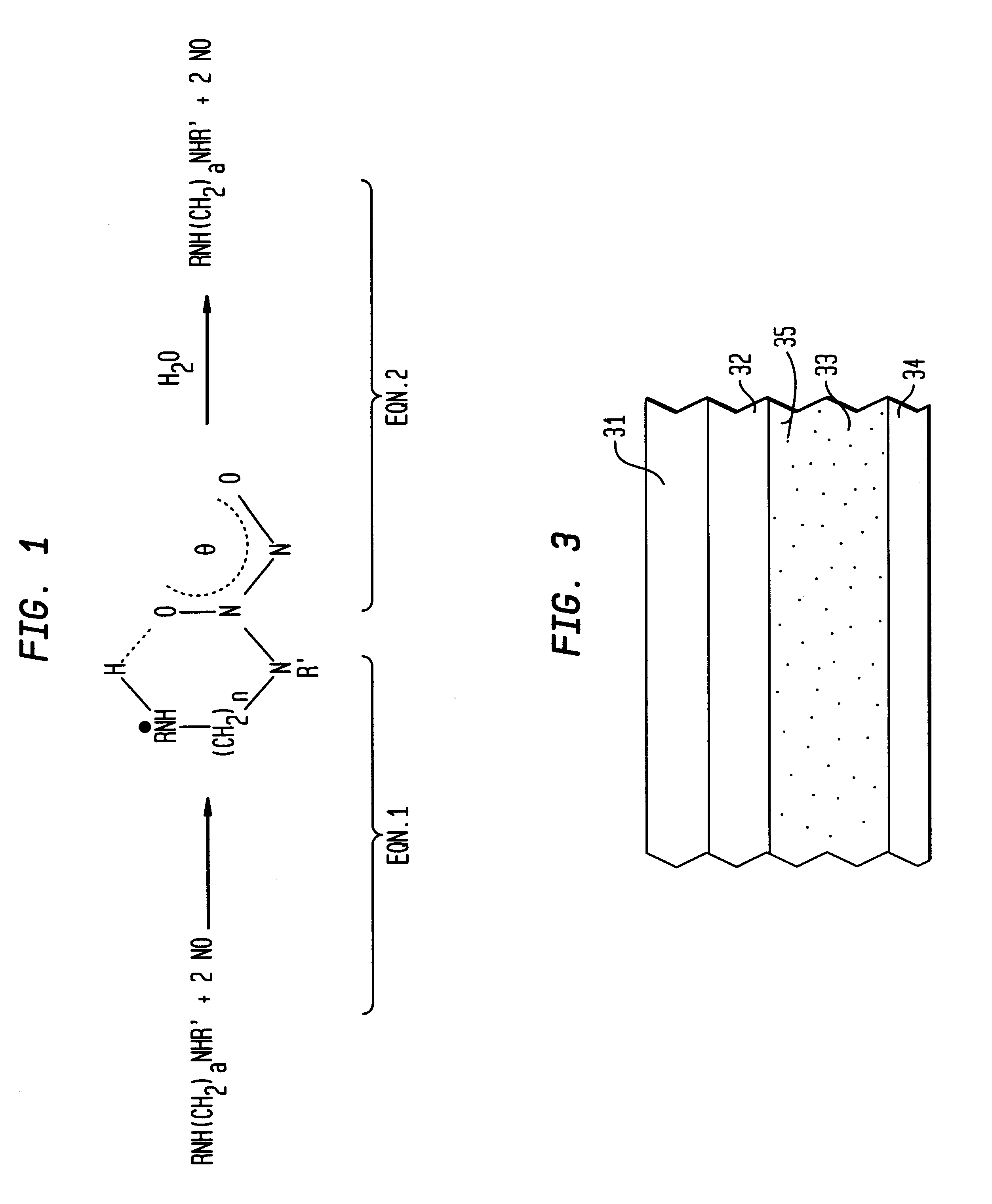

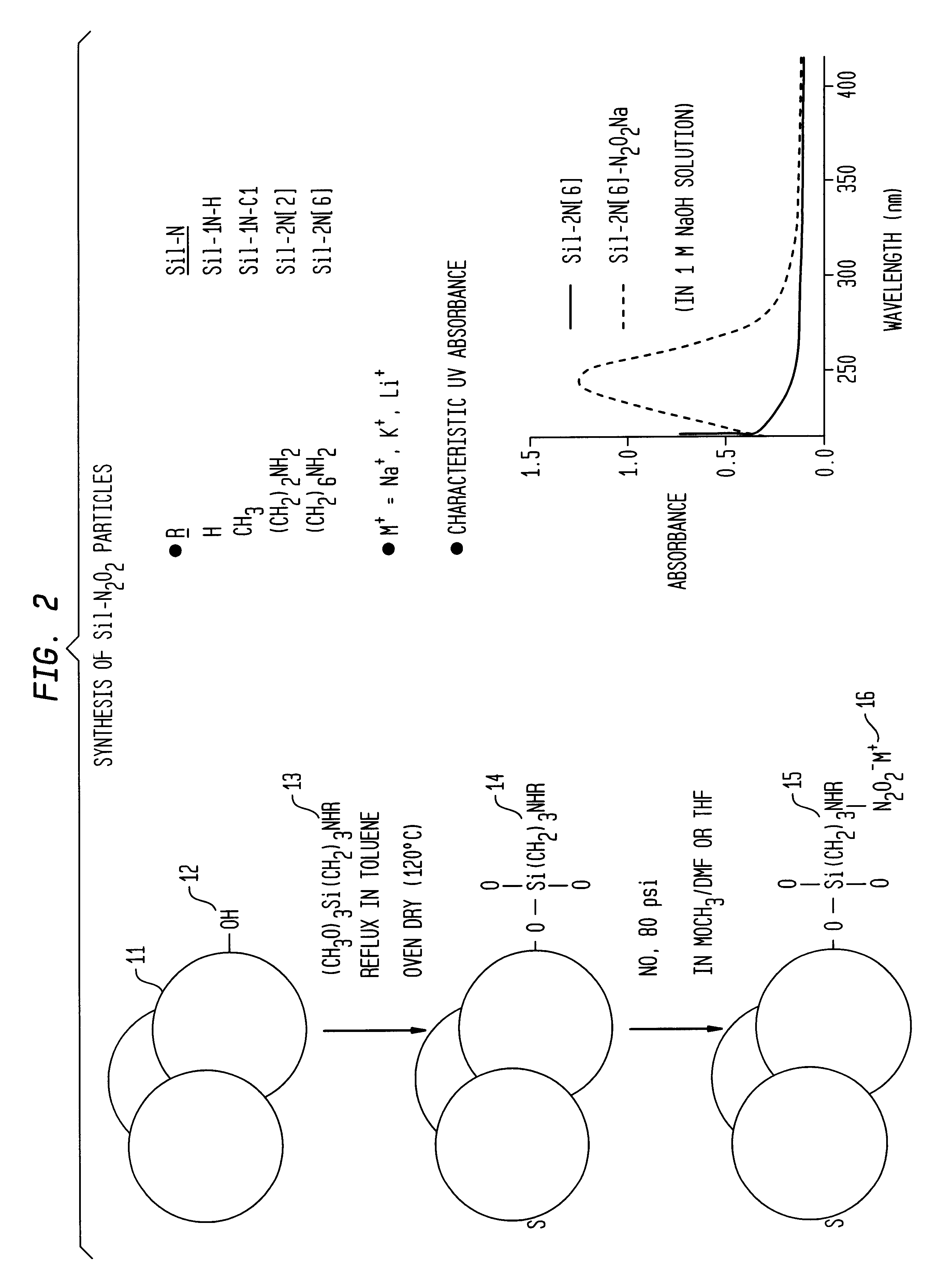

Nitric oxide-releasing polymers incorporating diazeniumdiolated silane derivatives

InactiveUS6841166B1Reduce activationReduce aggregationBiocideInorganic active ingredientsPolymeric surfaceSilanes

Biocompatible polymeric materials capable of providing in situ release of nitric oxide (NO) included diazeniumdiolated fumed silica as a filler in a multilayer polymer structure to release NO upon contact with water (blood). The blood-contacting polymer surface is preferably multi-layered so that the NO-releasing layer, containing the diazeniumdiolated fumed silica, is shielded from blood contact by one or more top (or base) coats. When in contact with blood, the NO released at the surface of the polymer prevents platelet activation and adhesion to the surface, thereby reducing platelet consumption, risk of thrombus formation and other clinical complications associated with interactions between blood and foreign materials.

Owner:RGT UNIV OF MICHIGAN

Adhesives for vehicle body manufacturing

InactiveUS20040079478A1Significant production advantageHigh strengthLamination ancillary operationsAdhesive processes with adhesive heatingCross-linkEngineering

Two-component systems are described which are suitable for underlining, adhesive bonding of the crimped fold and sealing of auto body sections, particularly for crimped fold sealing of add-on vehicle parts. The two-component systems attain the requisite grip strength for mounting the add-on parts on the body as well as the requisite strength and dimensional stability for the production process up to and with the CIP passage, within the predetermined cycle time, on the basis of cross-linking of the sealant composition twice. In one embodiment, the surface of the two-component system is pre-cross-linked by a UV-induced reaction and by the cross-linking of the two-component system to the extent of portability. In addition, two-component systems are described which cross-link intentionally only partially up to a consistency that permits a rugged course of the process through cleaning baths and which harden completely only by means of a further hardening process, for instance in the CIP forced circulation oven.

Owner:SIKA AG VORMALS KASPAR WINKLER

Control housing and method of manufacturing same

InactiveUS7146701B2Easy to cleanFlat surfaceContact surface shape/structureEmergency casingsEngineering

Owner:NEECO TRON

Condenser microphone

InactiveUS20070058826A1Simple structureFlat surfaceSolid-state devicesElectrostatic transducer microphonesCapacitanceCoil spring

A microphone element having a diaphragm and a fixed electrode disposed opposite to each other on a silicon board having a central opening portion is mounted and fixed onto a base board having a sound hole. A perimeter-shaped side board and a cover board are mounted and fixed onto the board, thereby forming a back cavity on an upper side of the microphone element. The diaphragm and the fixed electrode are conducted to conductive layers of the cover board through conductive layers of the base board, and a conductive layer and a coiled spring in the side board respectively, and mounting on a surface of a printed board of an external apparatus can be carried out in a conductive layer on an upper surface thereof.

Owner:STAR MICRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com