Patents

Literature

522 results about "Mutual position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

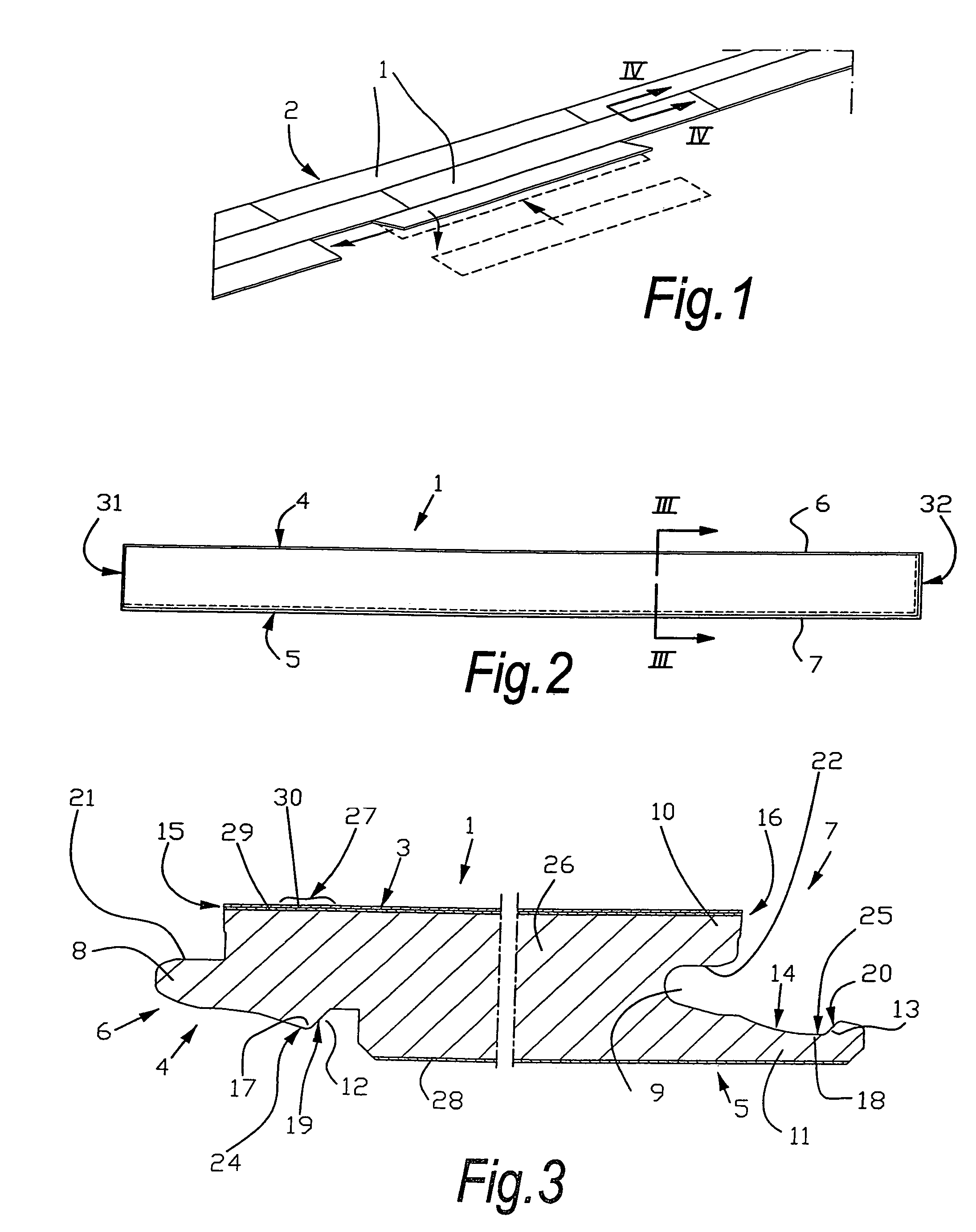

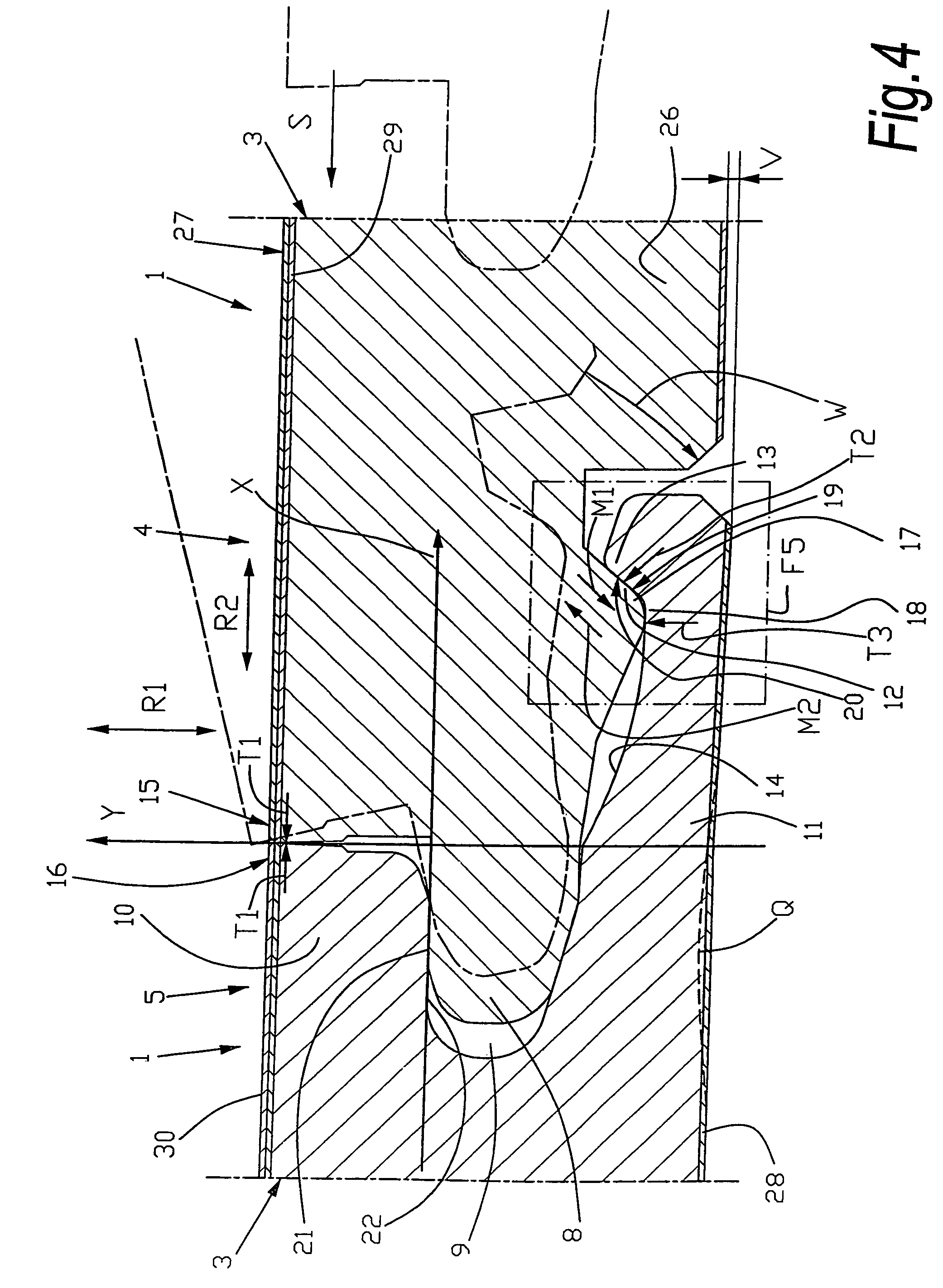

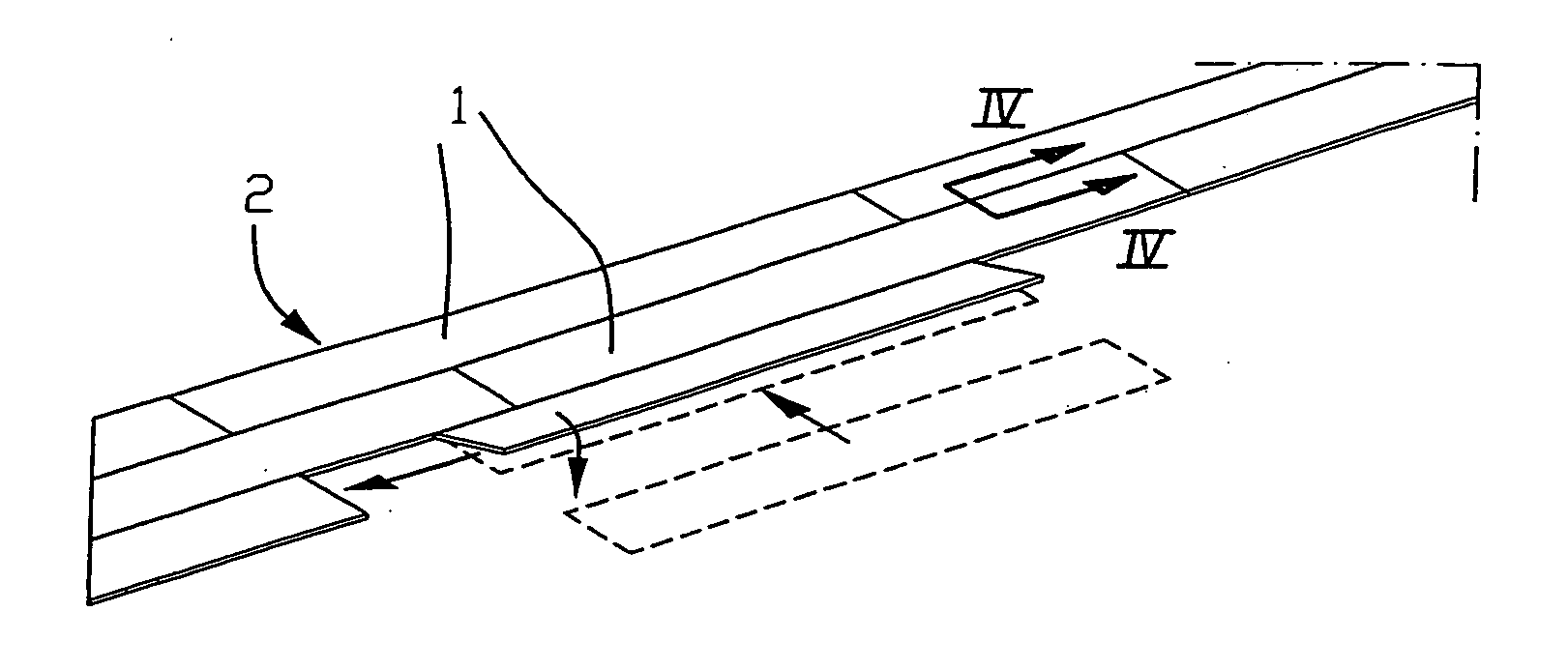

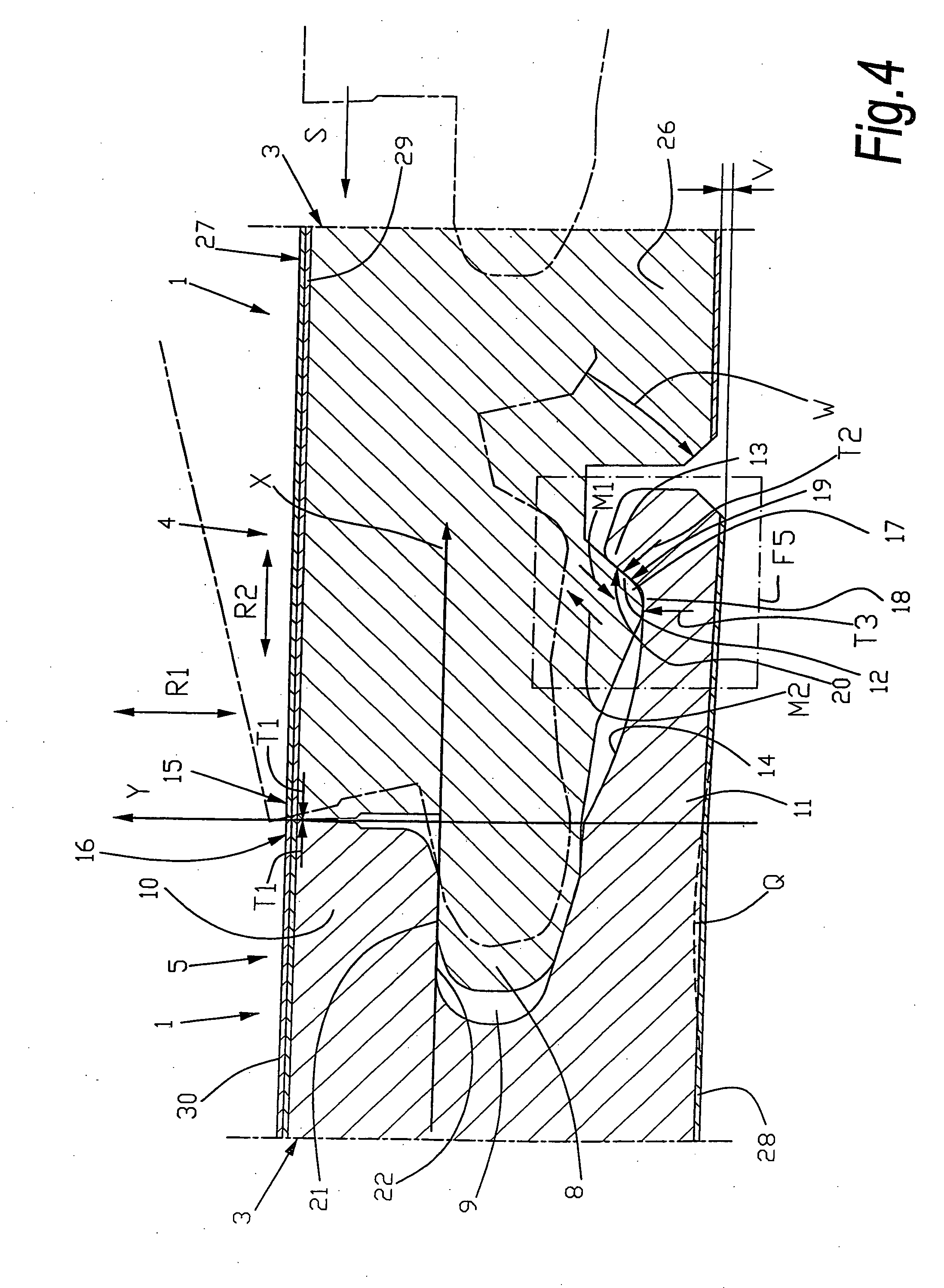

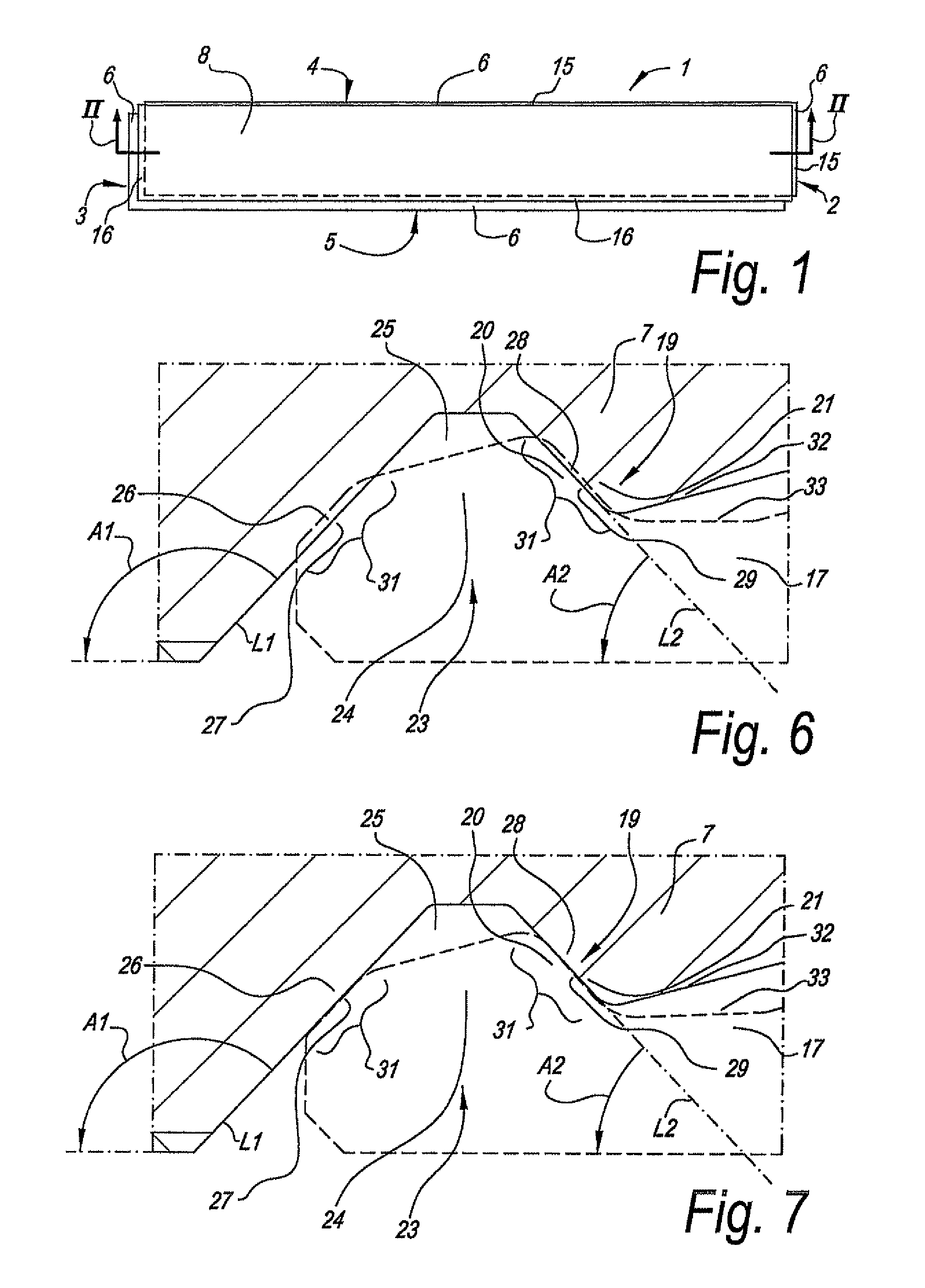

Method of laying panels

InactiveUS6546691B2Increase displacementAvoid the needRoof covering using tiles/slatesWallsEngineeringMutual position

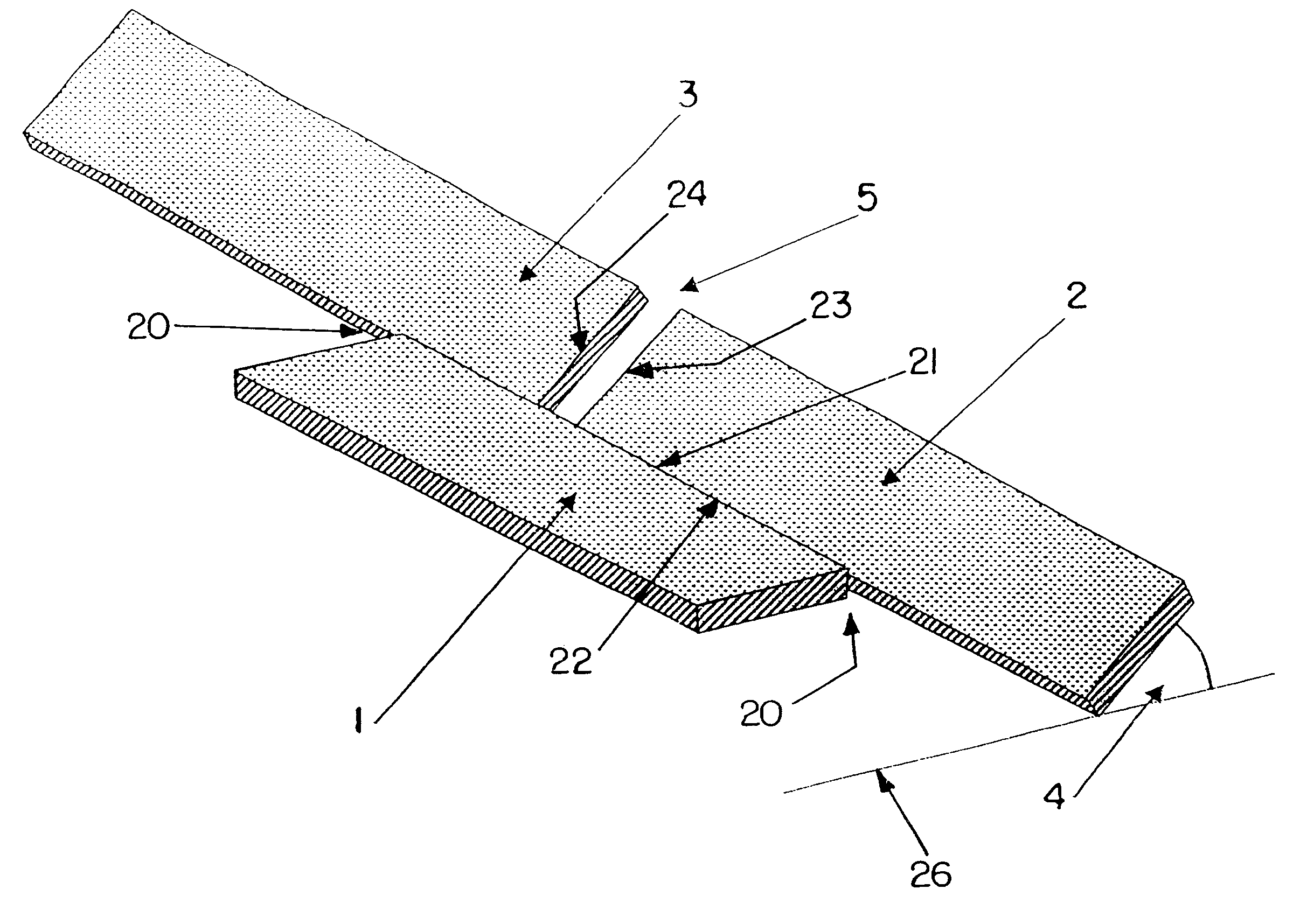

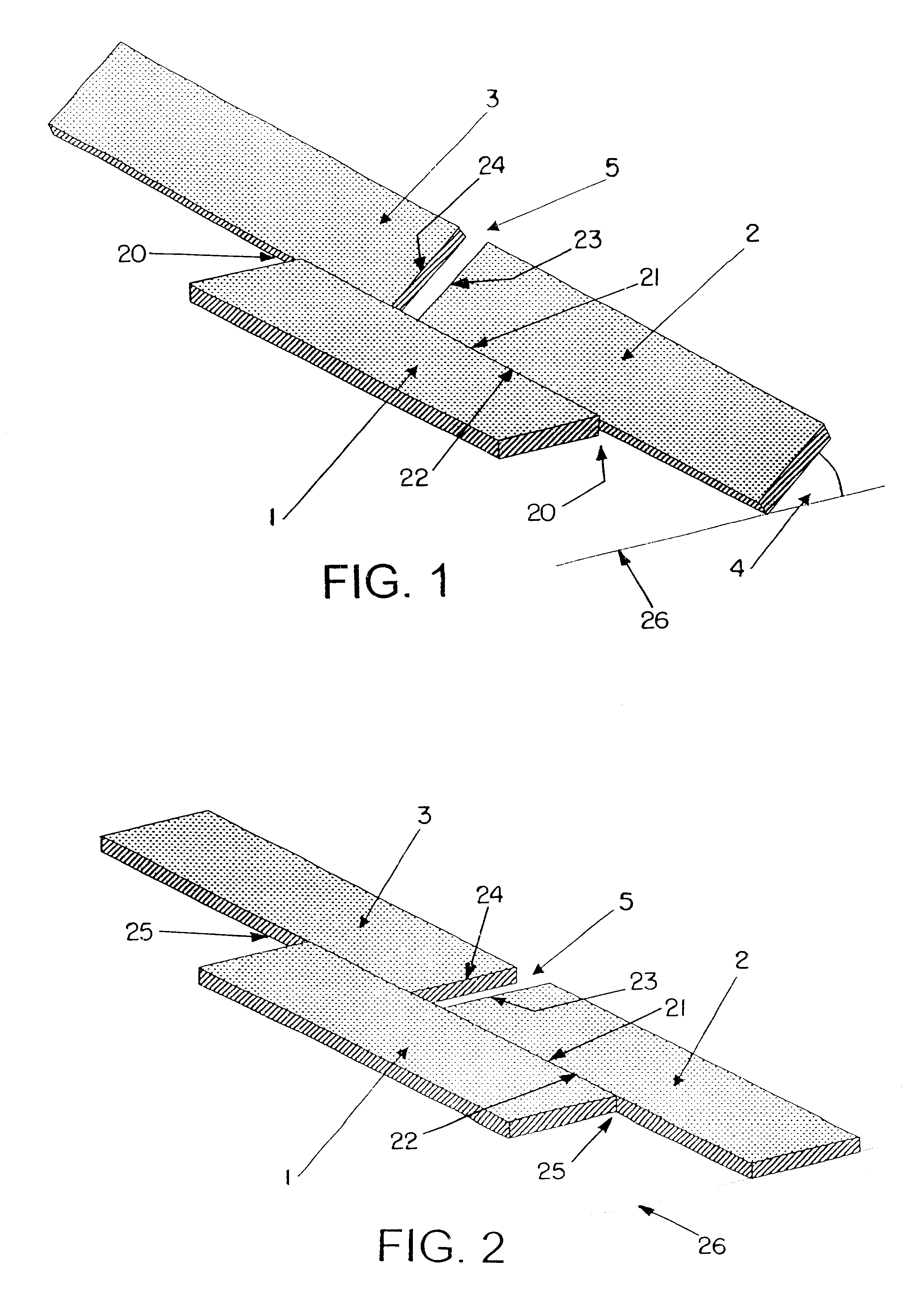

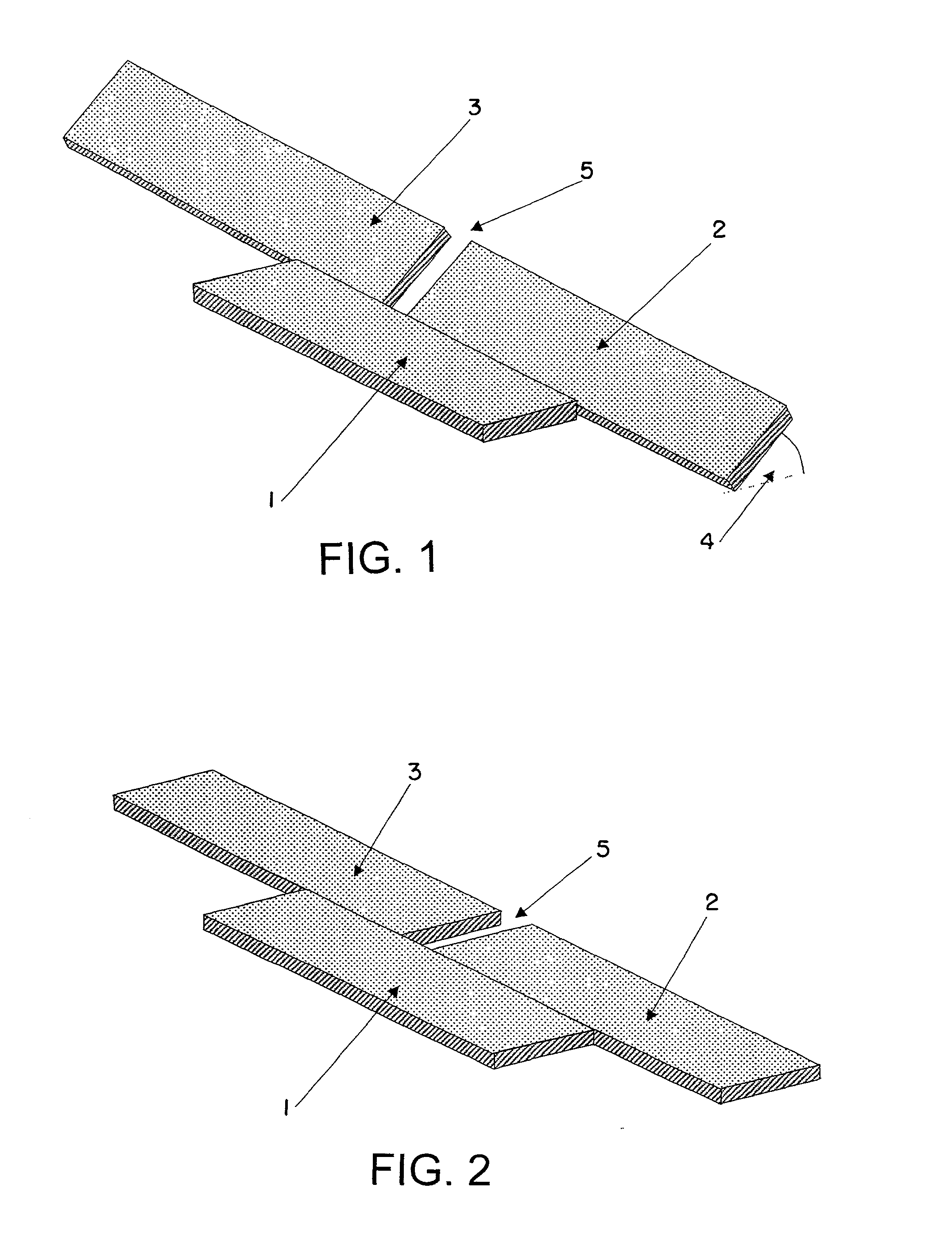

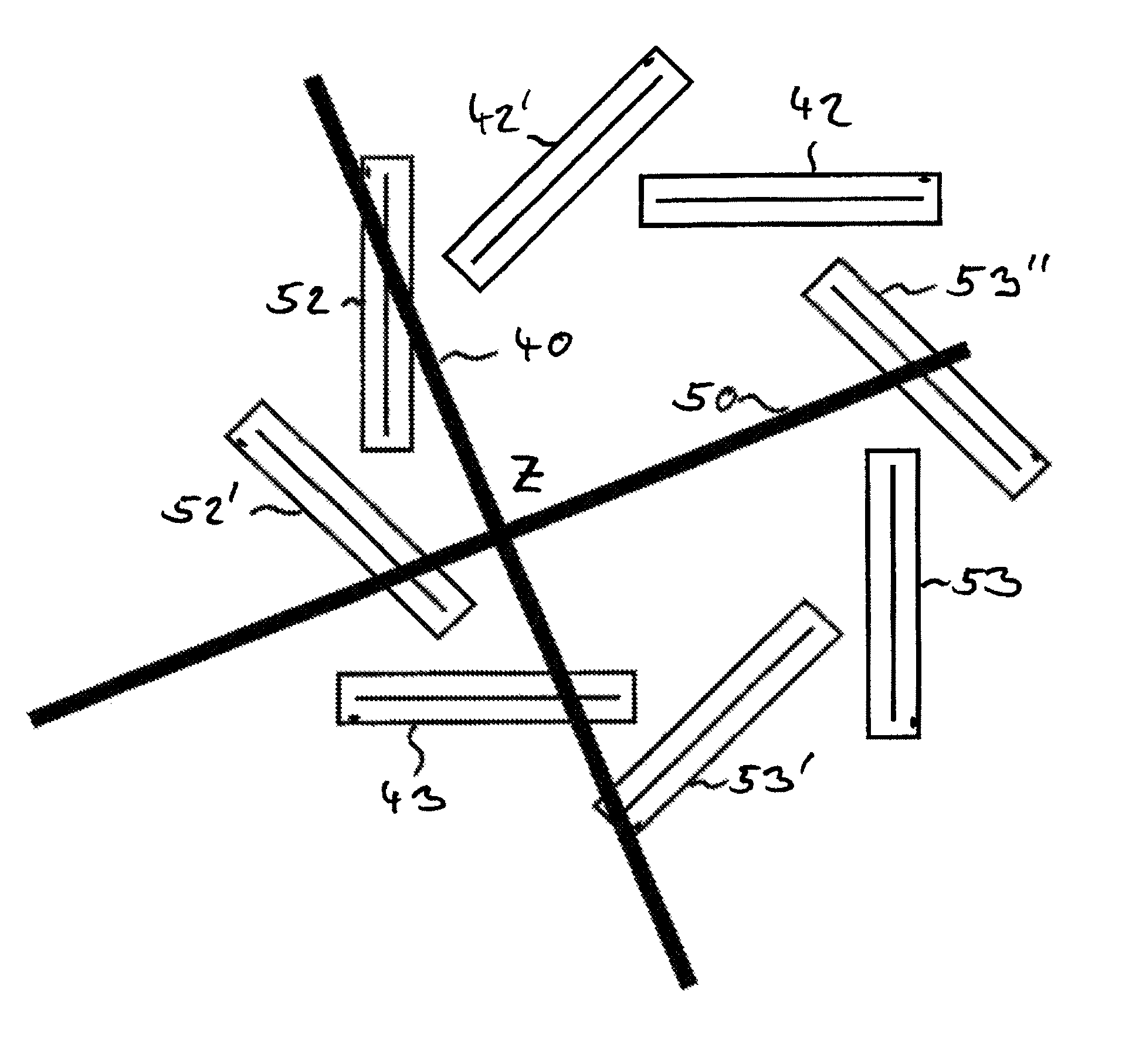

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

Method of laying panels

InactiveUS20020069611A1Easy to provideIncrease displacementRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

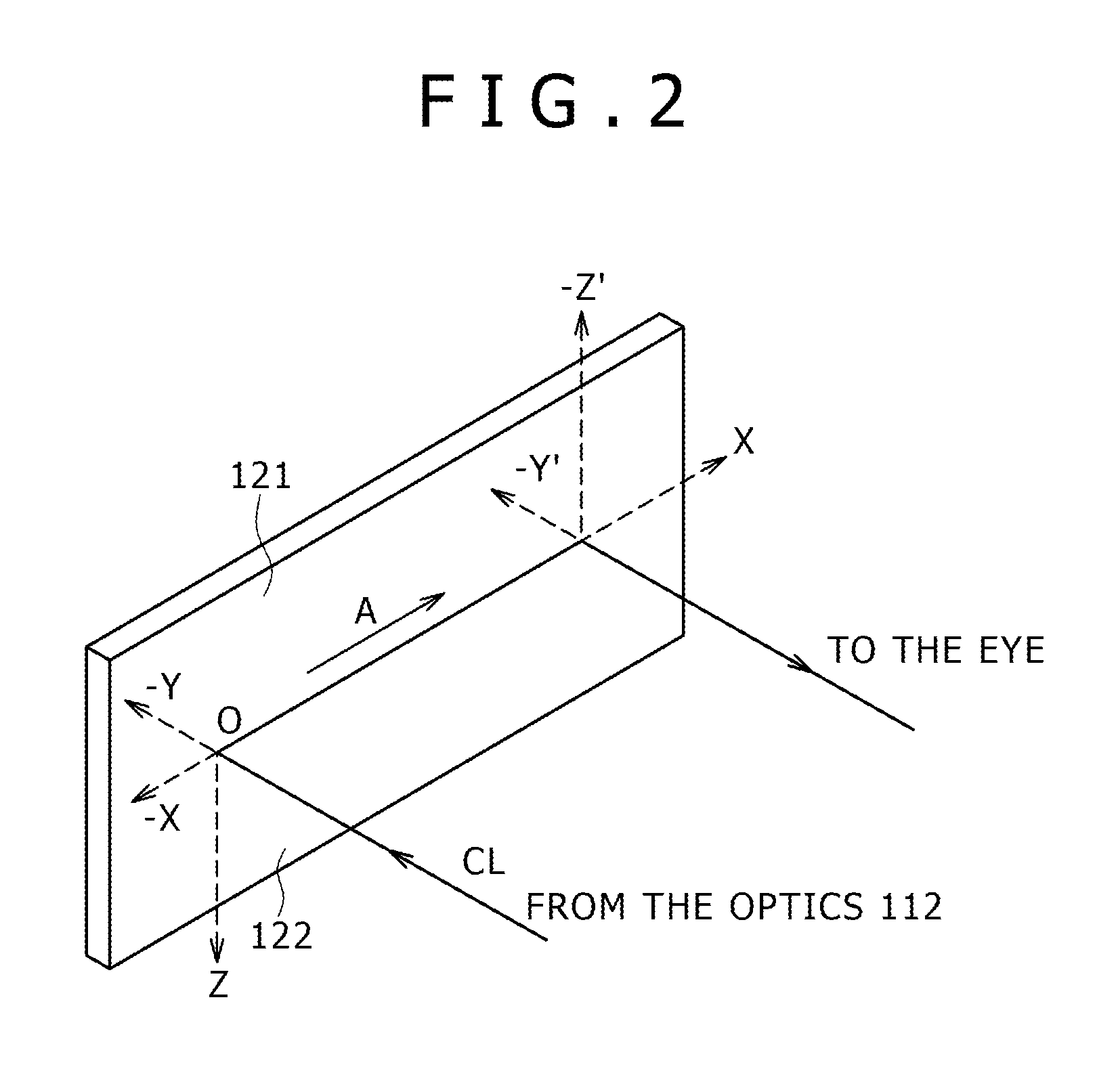

Head mounted display and optical position adjustment method of the same

ActiveUS20110248904A1Improve responseSmall sizeCathode-ray tube indicatorsImage data processingDisplay deviceImage signal

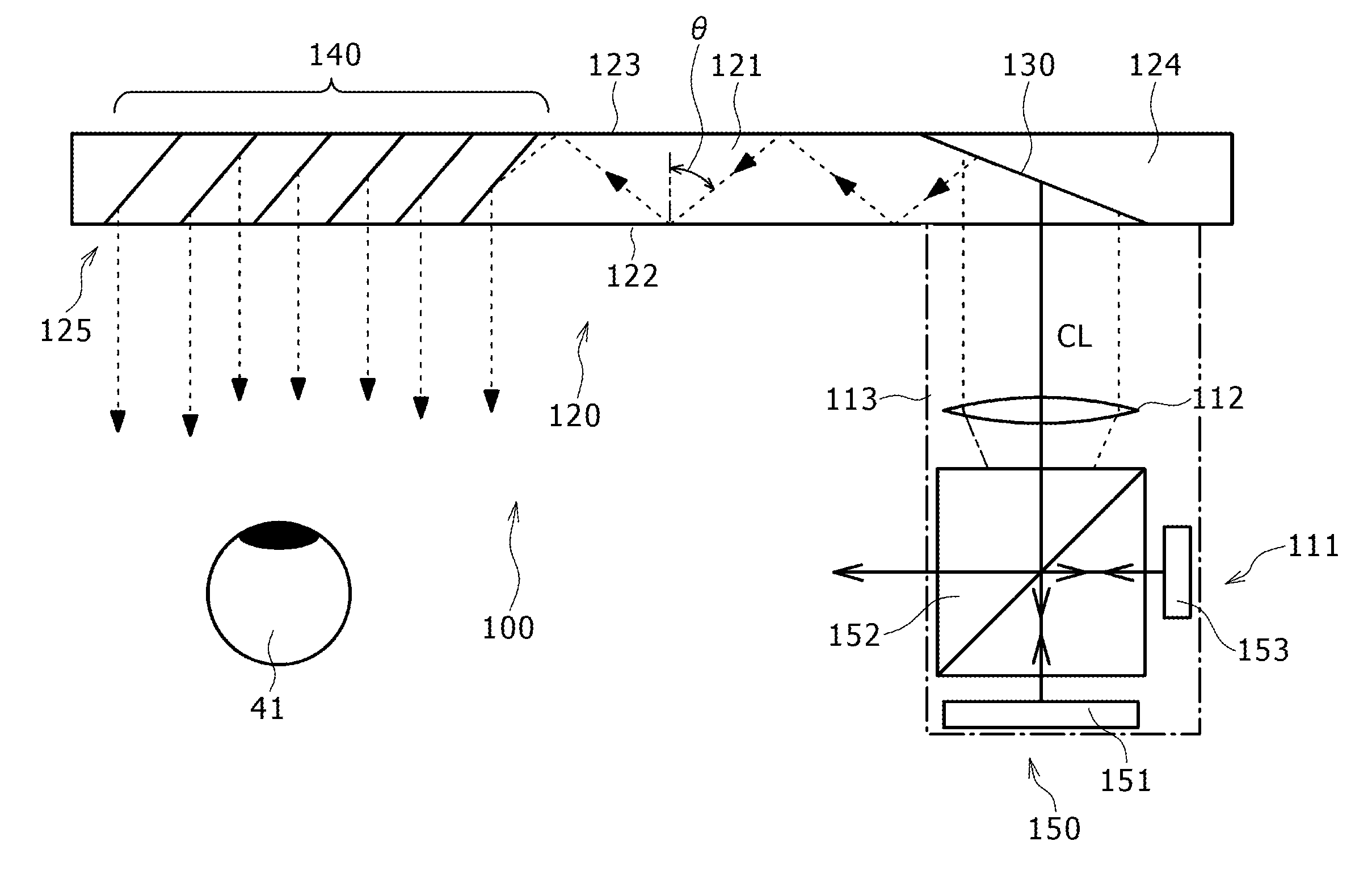

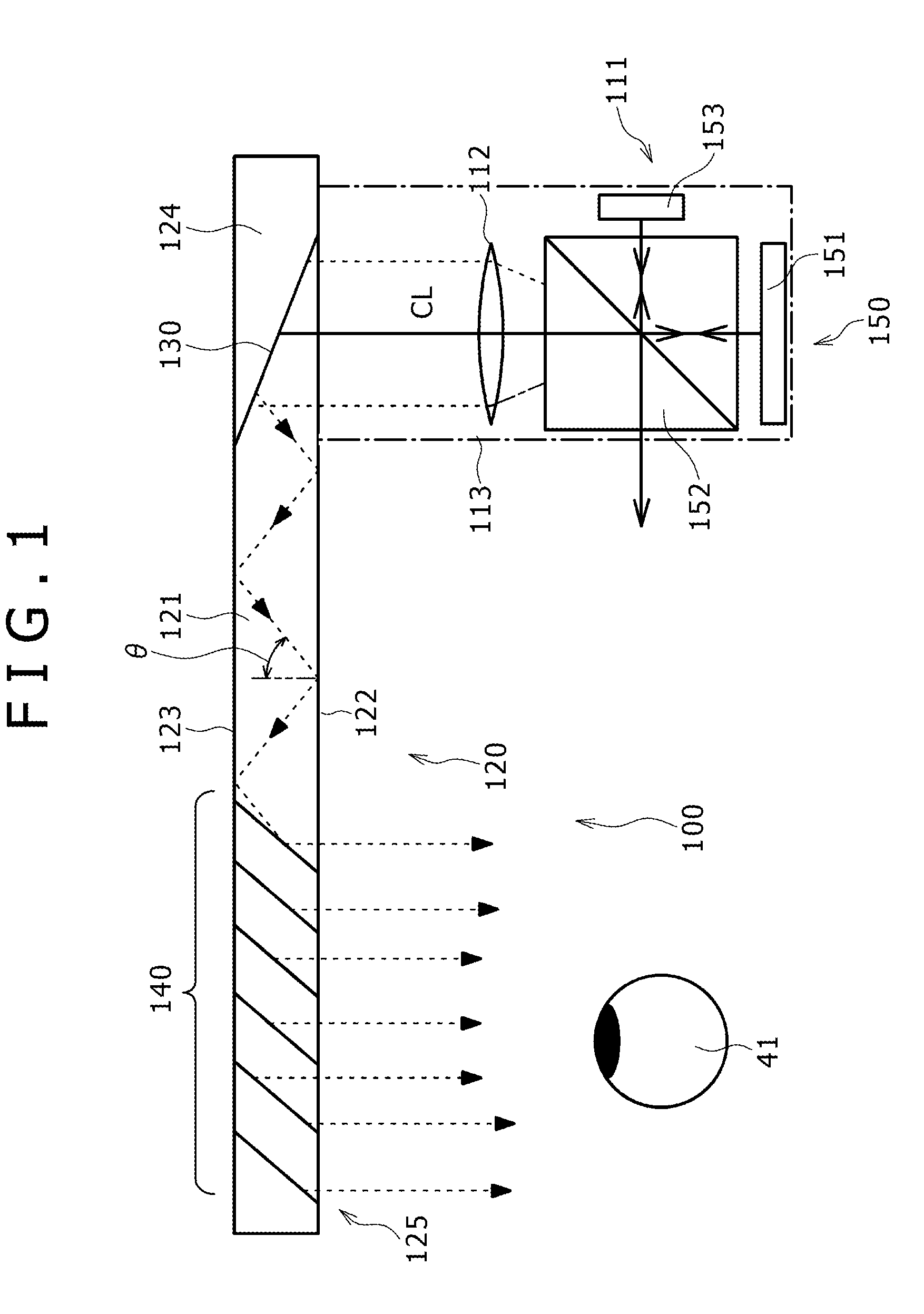

Disclosed herein is an optical position adjustment method of a head mounted display, the head mounted display including (a) an eyeglass type frame worn on the head of a viewer, and (b) two image display devices for the right and left eyes attached to the frame, and each of the image display devices including (A) an image forming device, and (B) an optical device adapted to receive, guide and emit light emitted from the image forming device, wherein the optical position adjustment method includes the step of: controlling an image signal that is supplied to the image forming device making up at least one of the image display devices so as to control the position of the image displayed on the optical device making up at least one of the image display devices and adjust the mutual positions of the two images.

Owner:SONY CORP

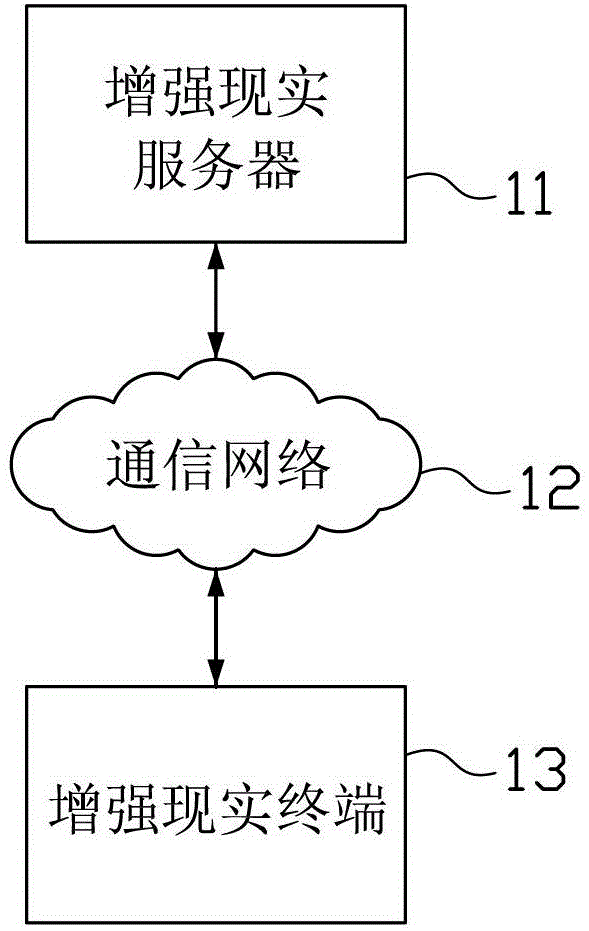

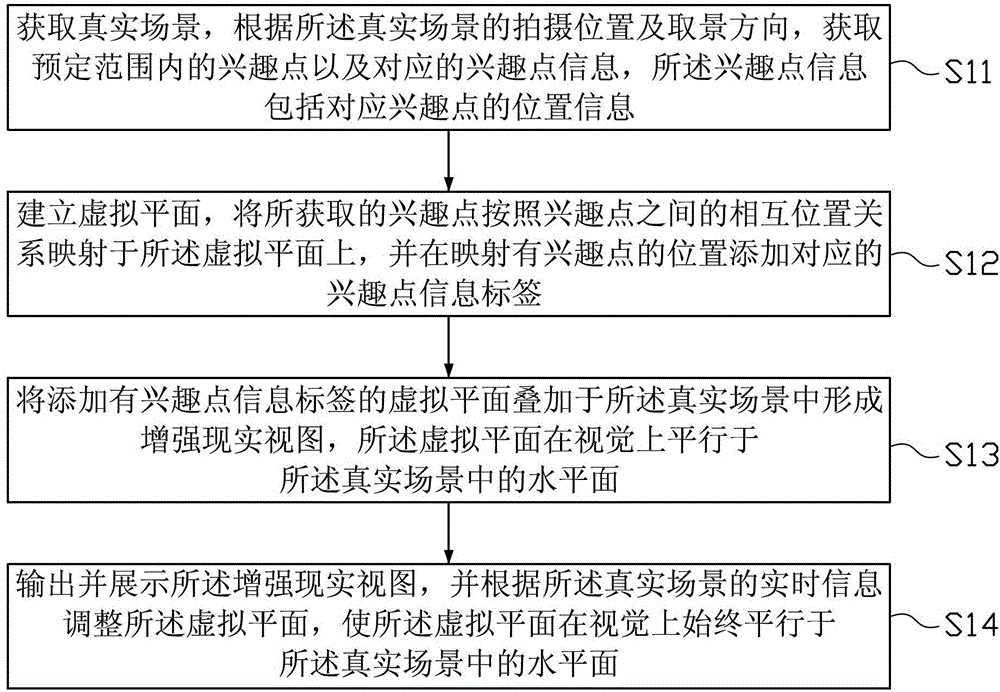

Method and device for realizing augmented reality

ActiveCN104102678AThree-dimensionalLayeredImage data processing detailsSpecial data processing applicationsTime informationComputer graphics (images)

The invention provides a method and a device for realizing augmented reality. The method comprises the following steps of obtaining a real scene, and obtaining interest points in a preset range and corresponding interest point information according to a camera site and a viewing direction of the real scene; establishing a virtual plane, mapping the obtained interest points on the virtual plane according to a mutual position relation among the interest points, and adding corresponding interest point information labels at positions, at which the interest points are mapped; forming an augmented reality view by overlaying the virtual plane, to which the interest point information labels are added, in the real scene, wherein the virtual plane is in parallel to a horizontal plane in the real scene based on visual sense; outputting and showing the augmented reality view, and adjusting the virtual plane according to real-time information of the real scene to enable that the virtual plane always is in parallel to the horizontal plane in the real scene based on the visual sense. According to the method and the device for realizing the augmented reality, the distance relation among the interest points and the mutual position relation between the interest points and the users can be more intuitively shown for the users.

Owner:TENCENT TECH (SHENZHEN) CO LTD

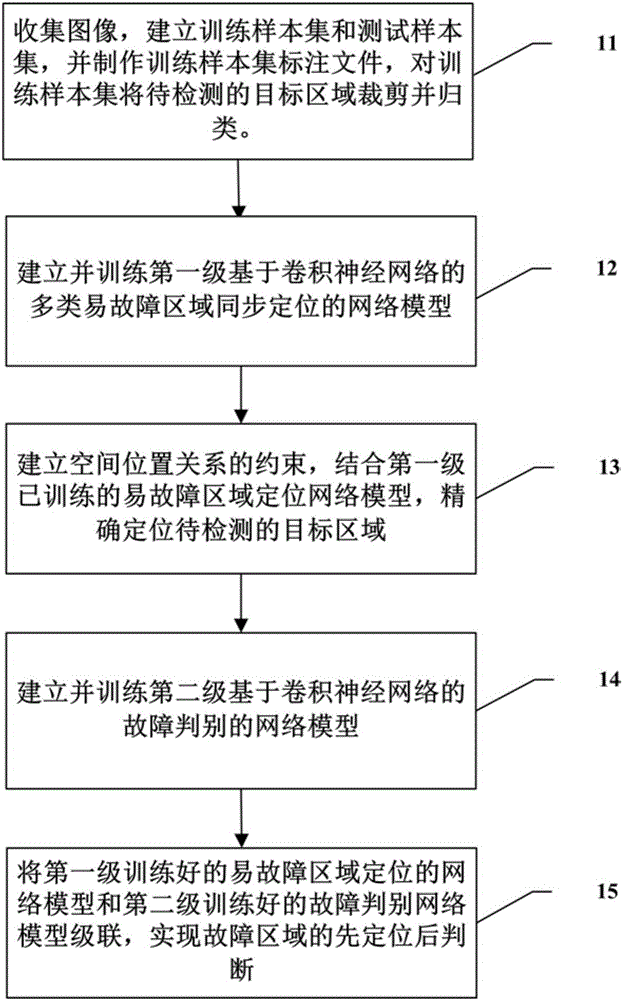

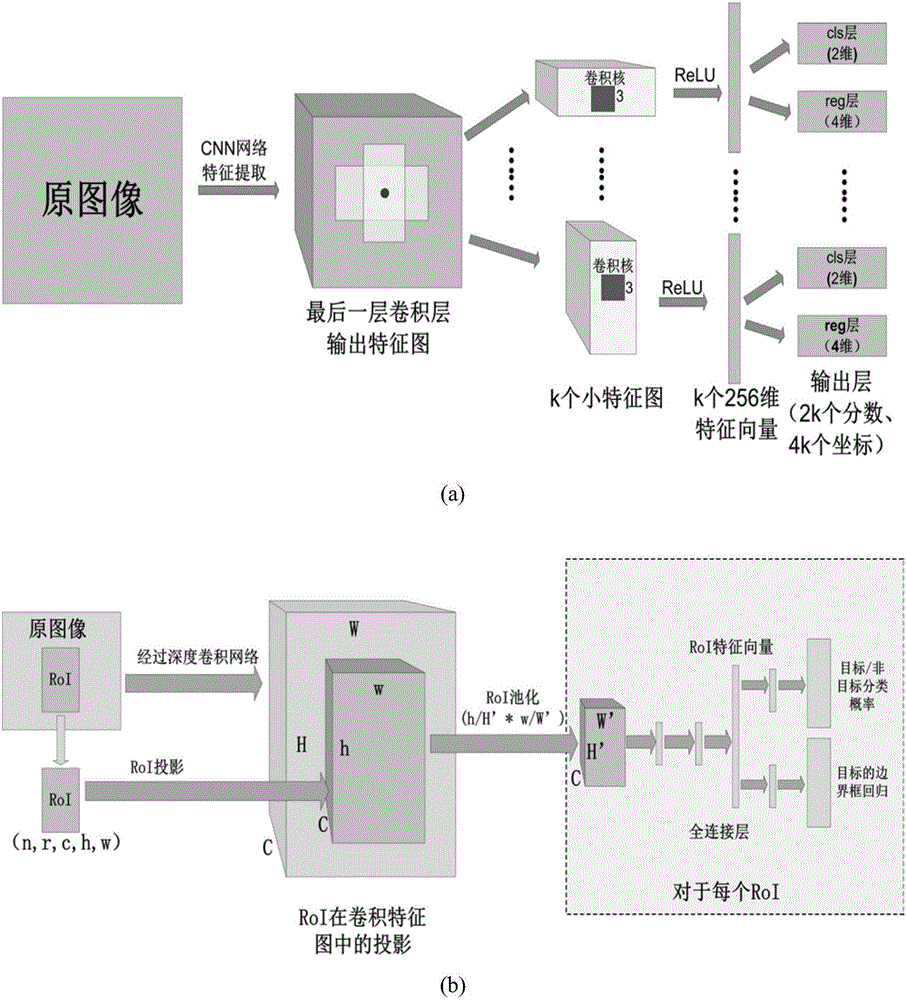

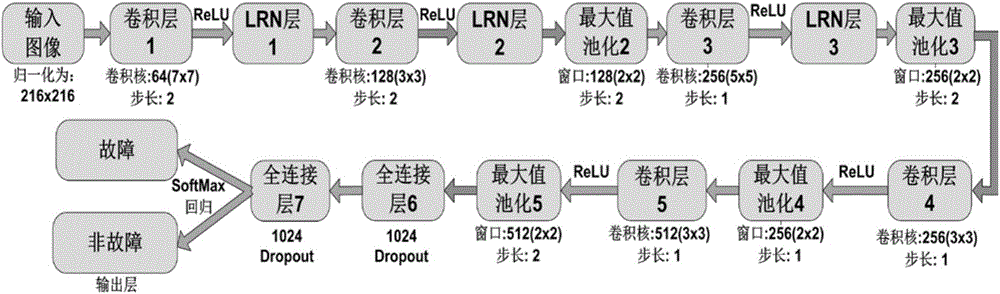

TFDS fault automatic recognition method

ActiveCN106226050AMachine part testingCharacter and pattern recognitionNetwork modelHigh effectiveness

The invention discloses a TFDS fault automatic recognition method. The method is formed by a two-stage cascaded convolution neural network model based on a deep learning theory: the first stage is a network model with multi-class fault region synchronous positioning, and with the combination of space mutual position relation constraint of multi-fault regions, synchronous and accurate positioning of the multi-fault target regions is realized; and the second stage is a fault determination network model, and determination of faults and non-faults for the regions located by the first stage is realized. According to the TFDS multi-class fault synchronous and automatic recognition method, the design of recognition methods for different faults is not needed, features are adaptively extracted through a learning training mode by the convolution neural network theory in deep learning, synchronous positioning and fault determination of multiple faults can be performed, and high effectiveness and high robustness are achieved.

Owner:BEIHANG UNIV

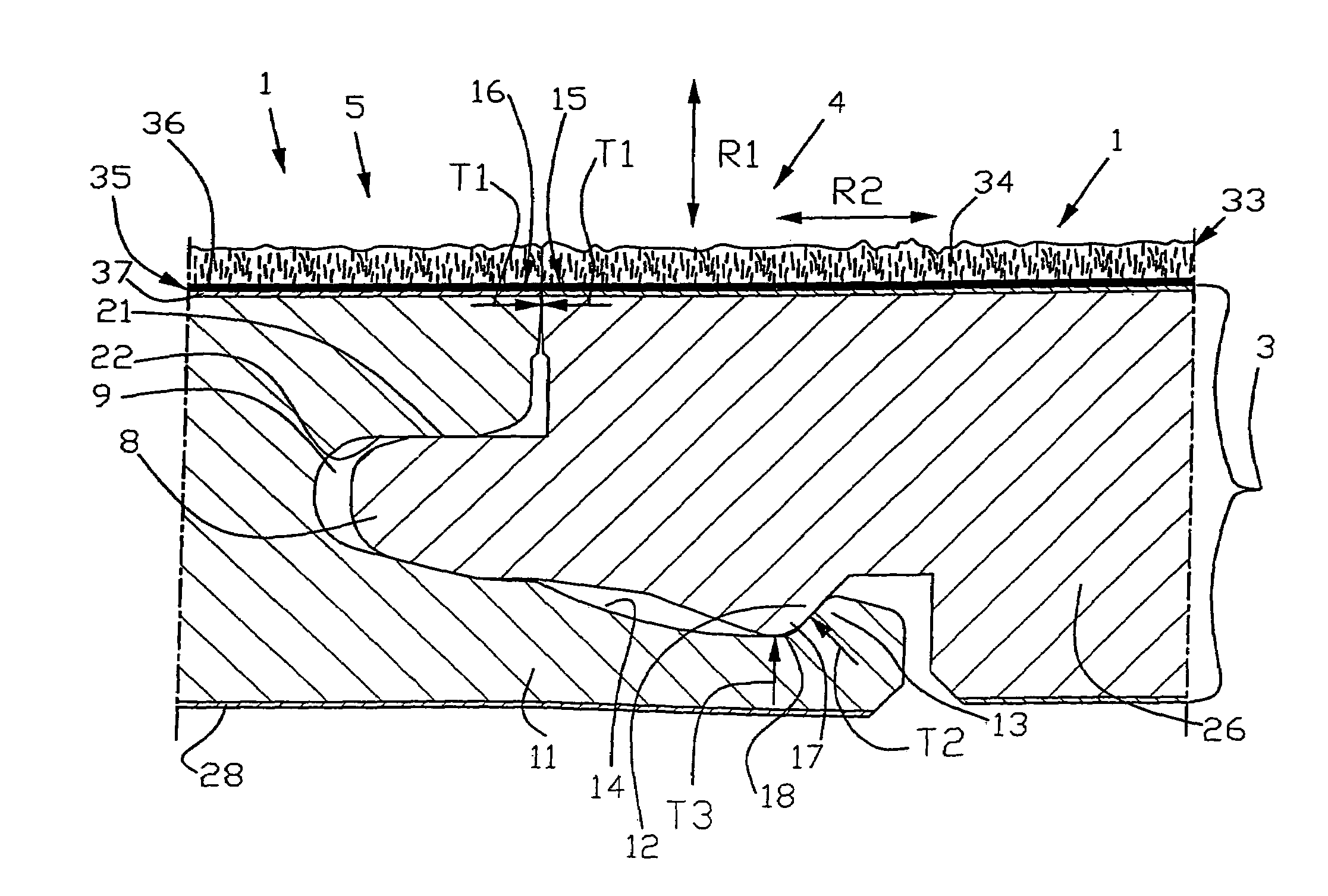

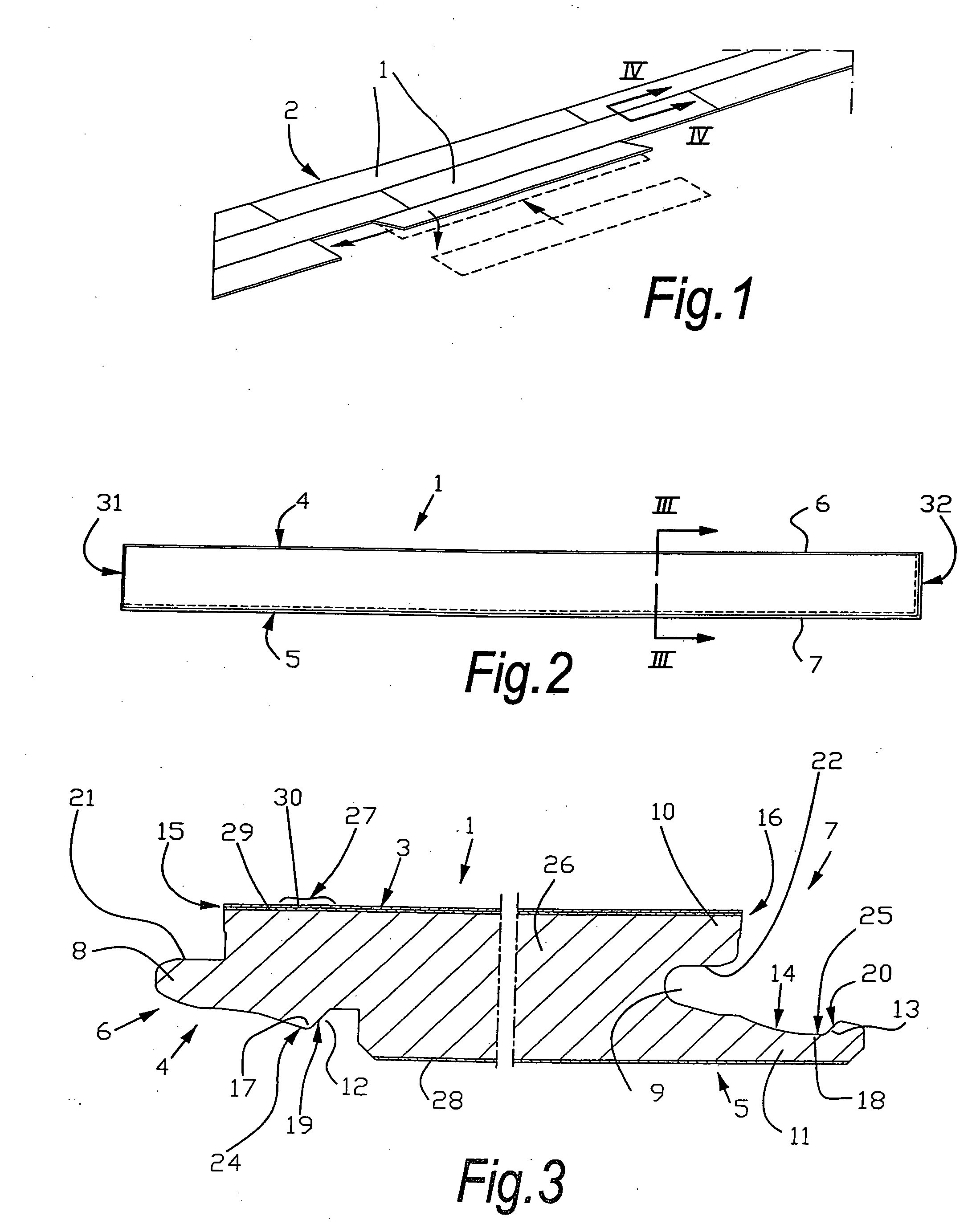

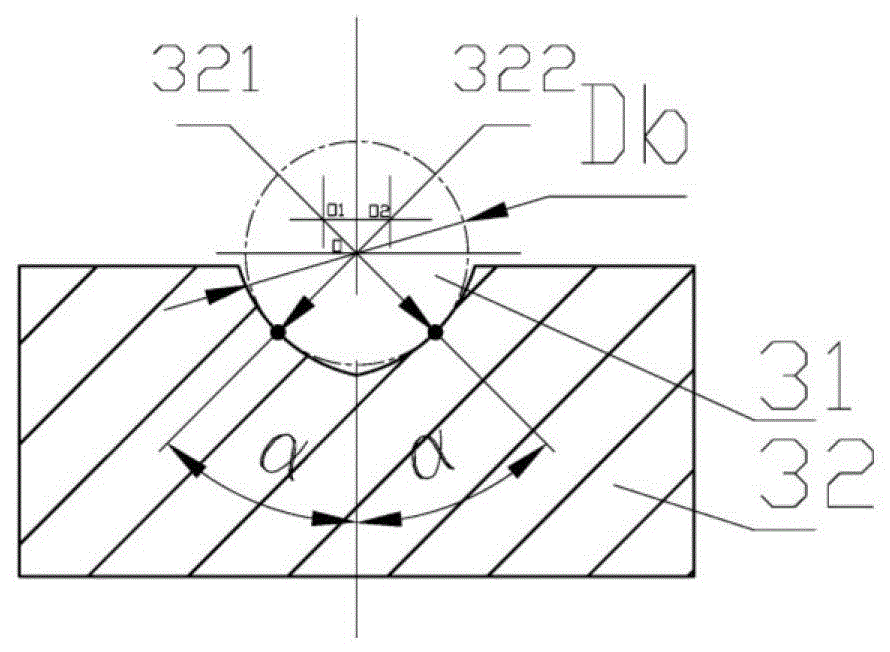

Floor panel and floor covering composed of such floor panels

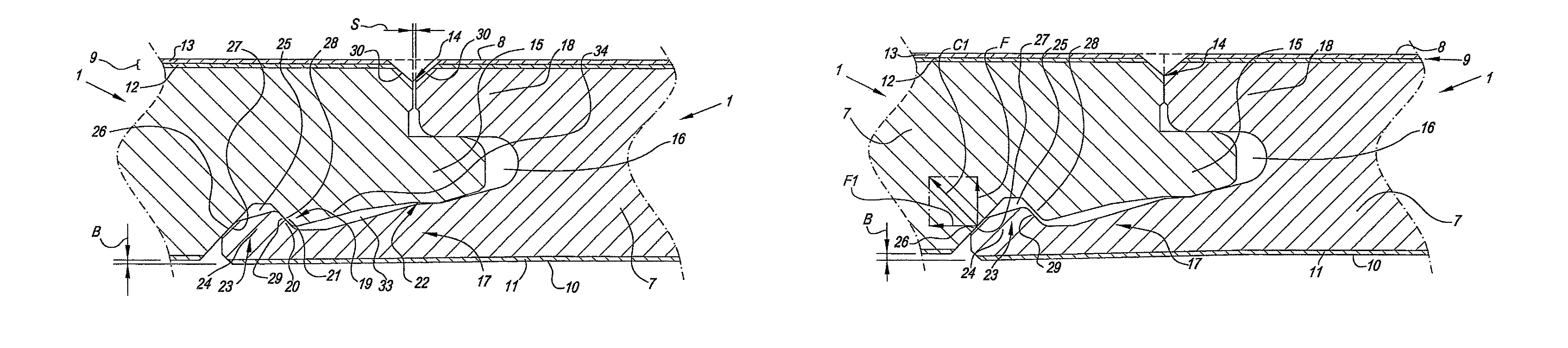

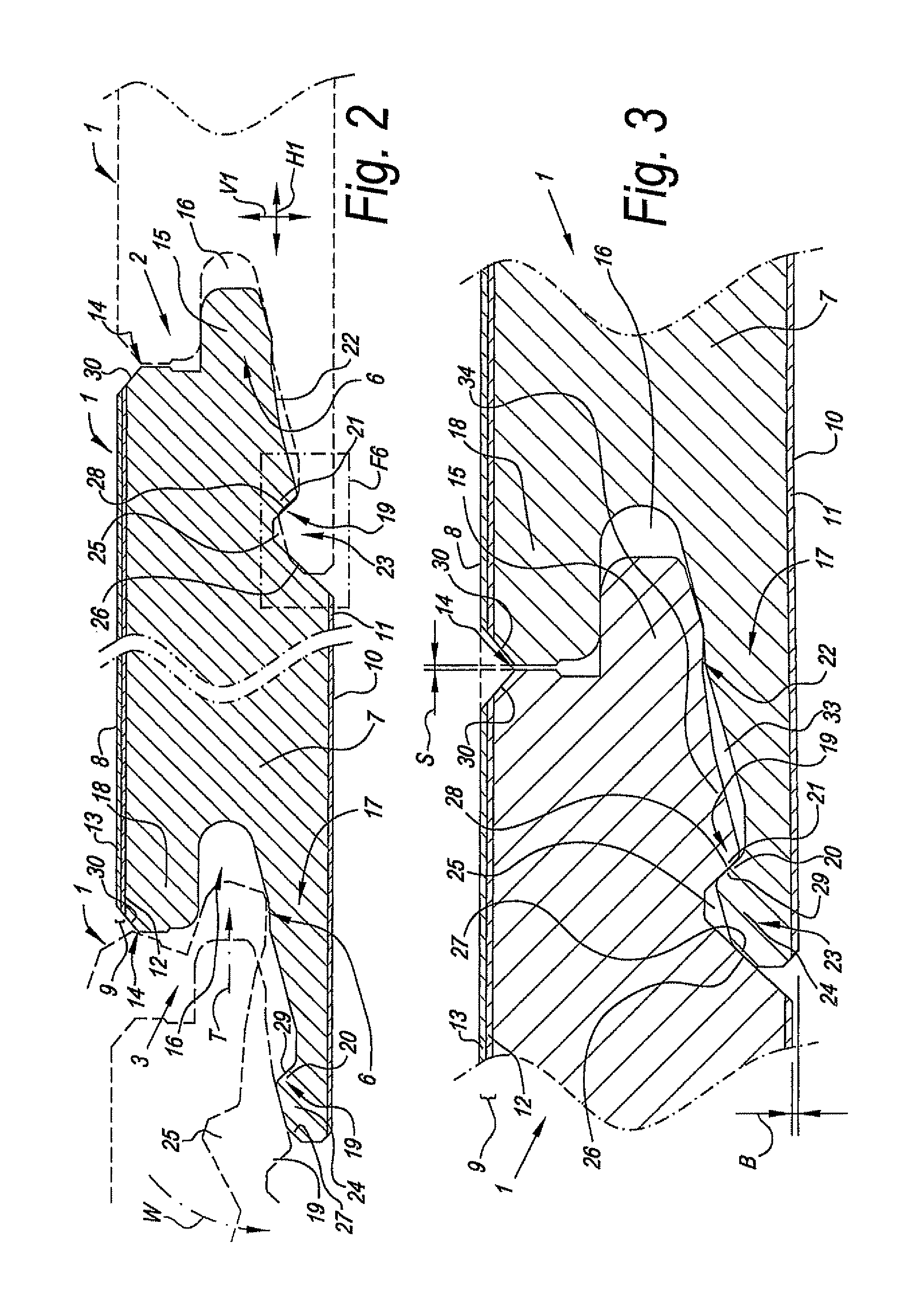

ActiveUS7762035B2Counteract riskReduce riskRoof covering using tiles/slatesCovering/liningsPanellingMechanical engineering

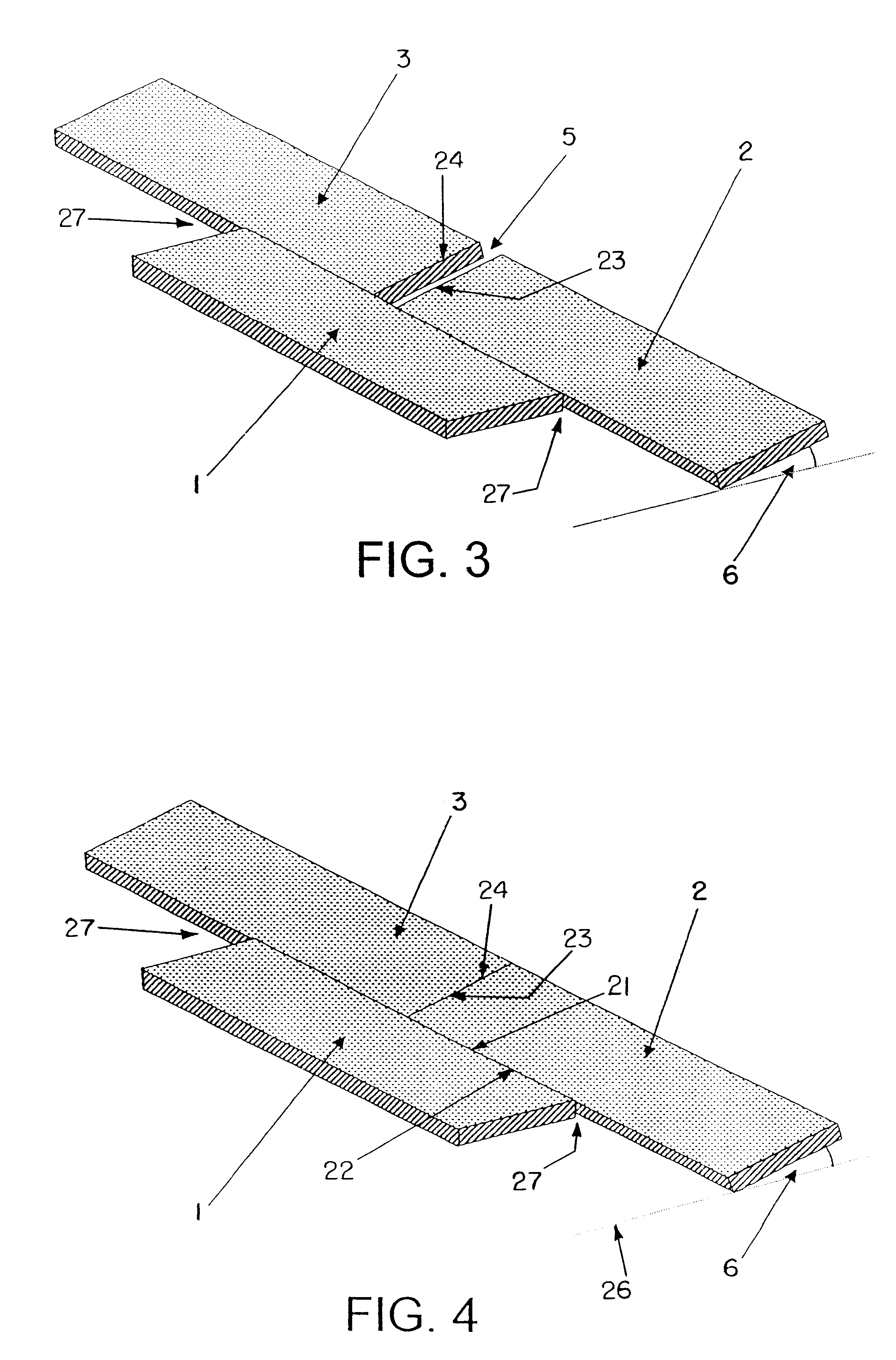

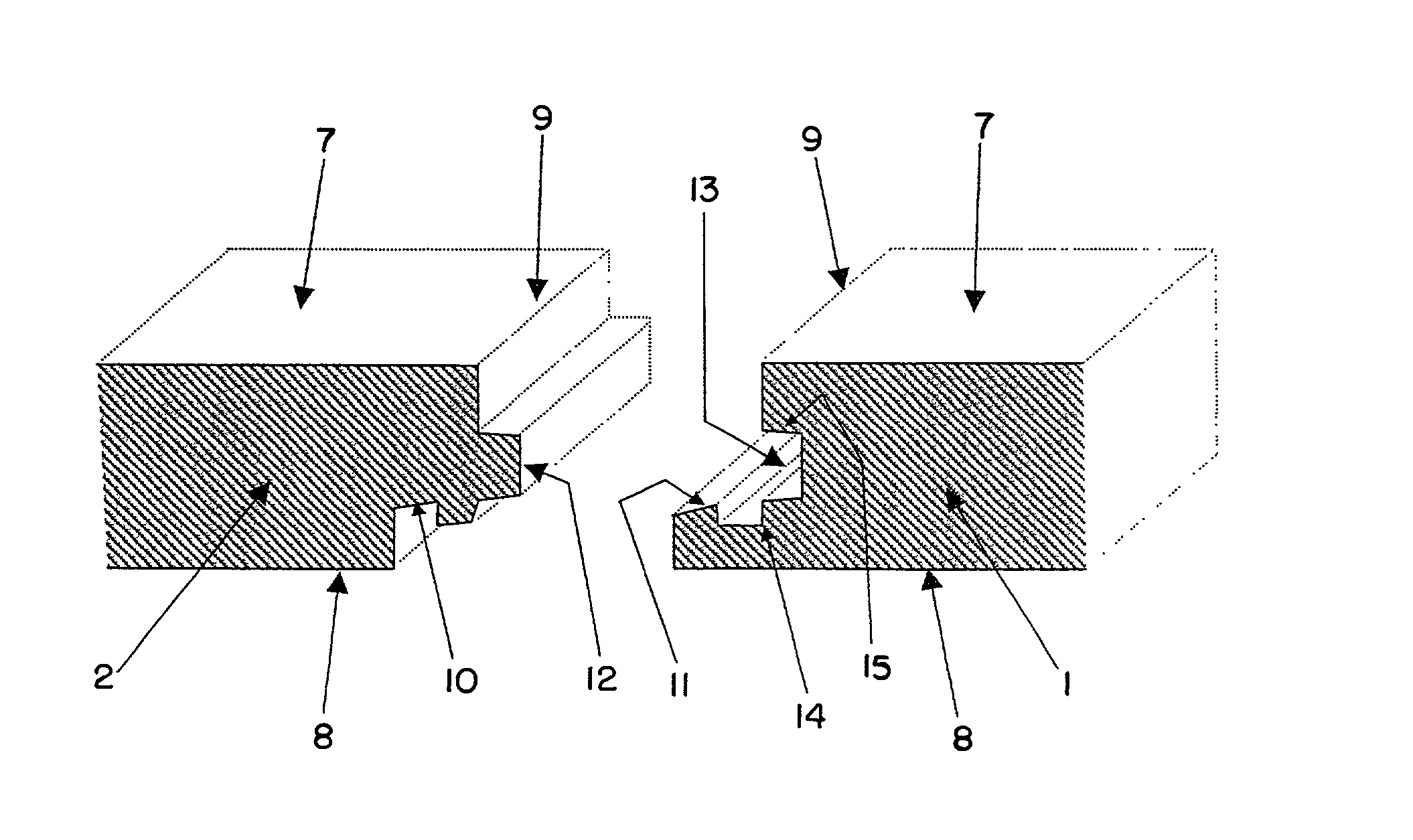

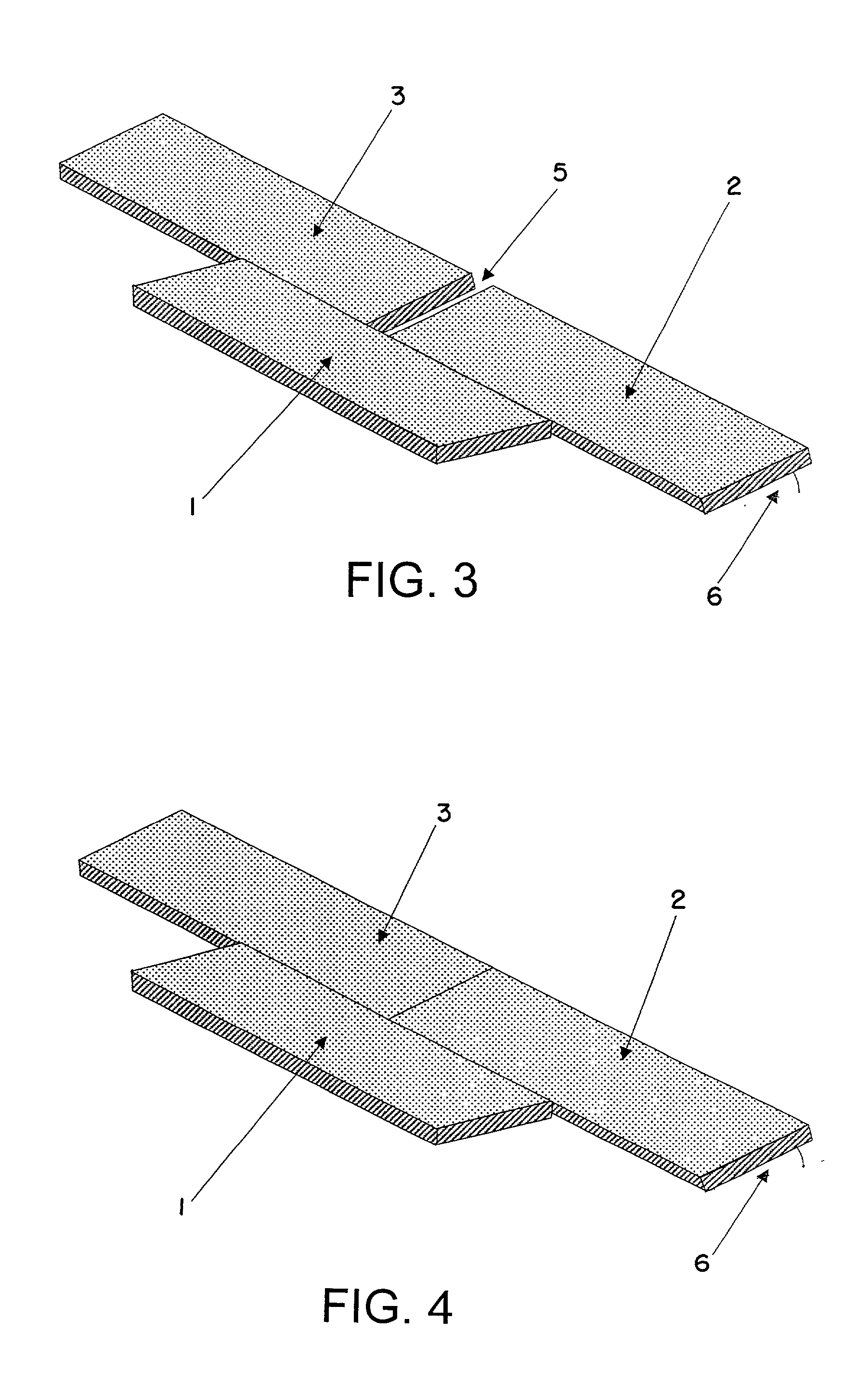

Floor panel in a board shape having at least at two opposite edges coupling parts enabling several of the panels to be coupled to each other, wherein the coupling parts have contact portions forcing the floor panels in the coupled condition with a tension force at least laterally towards each other. The coupling parts also include support portions, which, in the coupled condition of floor panels, create a fixation in the mutual position of the contact portions cooperating under tension.

Owner:FLOORING IND LTD

Floor panel and floor covering composed of such floor panels

ActiveUS20060064940A1Counteract riskReduce riskRoof covering using tiles/slatesCovering/liningsMutual positionEngineering

Floor panel in a board shape having at least at two opposite edges coupling parts enabling several of the panels to be coupled to each other, wherein the coupling parts have contact portions forcing the floor panels in the coupled condition with a tension force at least laterally towards each other. The coupling parts also include support portions, which, in the coupled condition of floor panels, create a fixation in the mutual position of the contact portions cooperating under tension.

Owner:FLOORING IND LTD

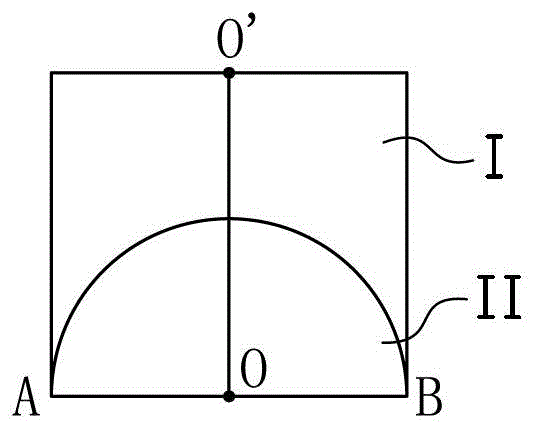

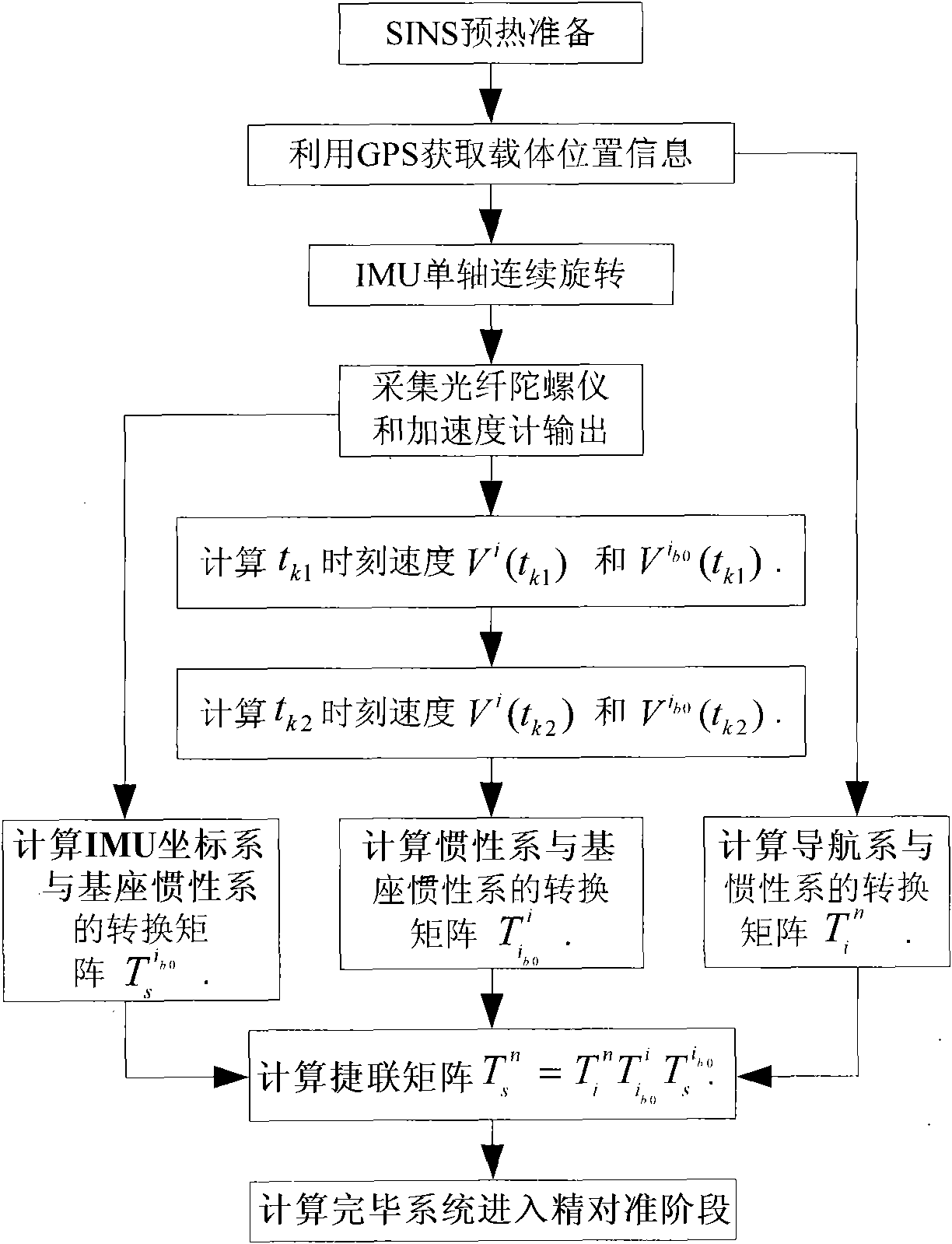

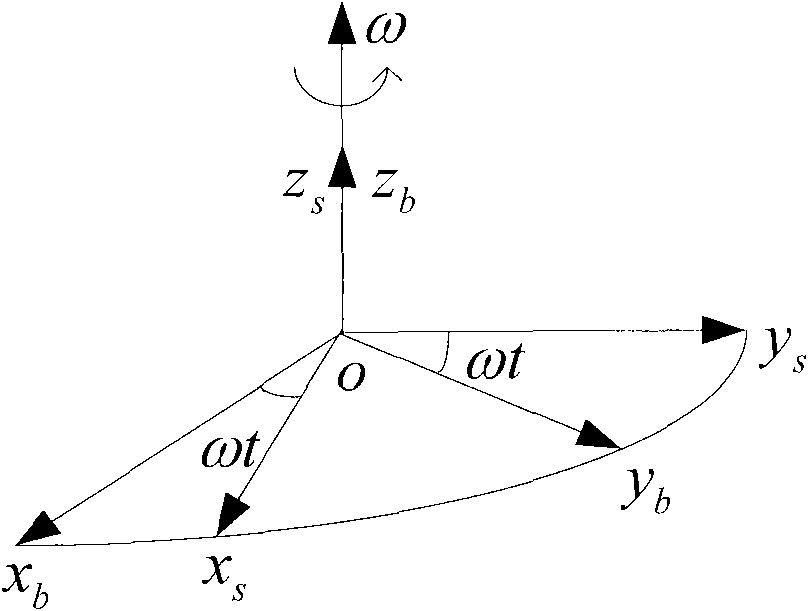

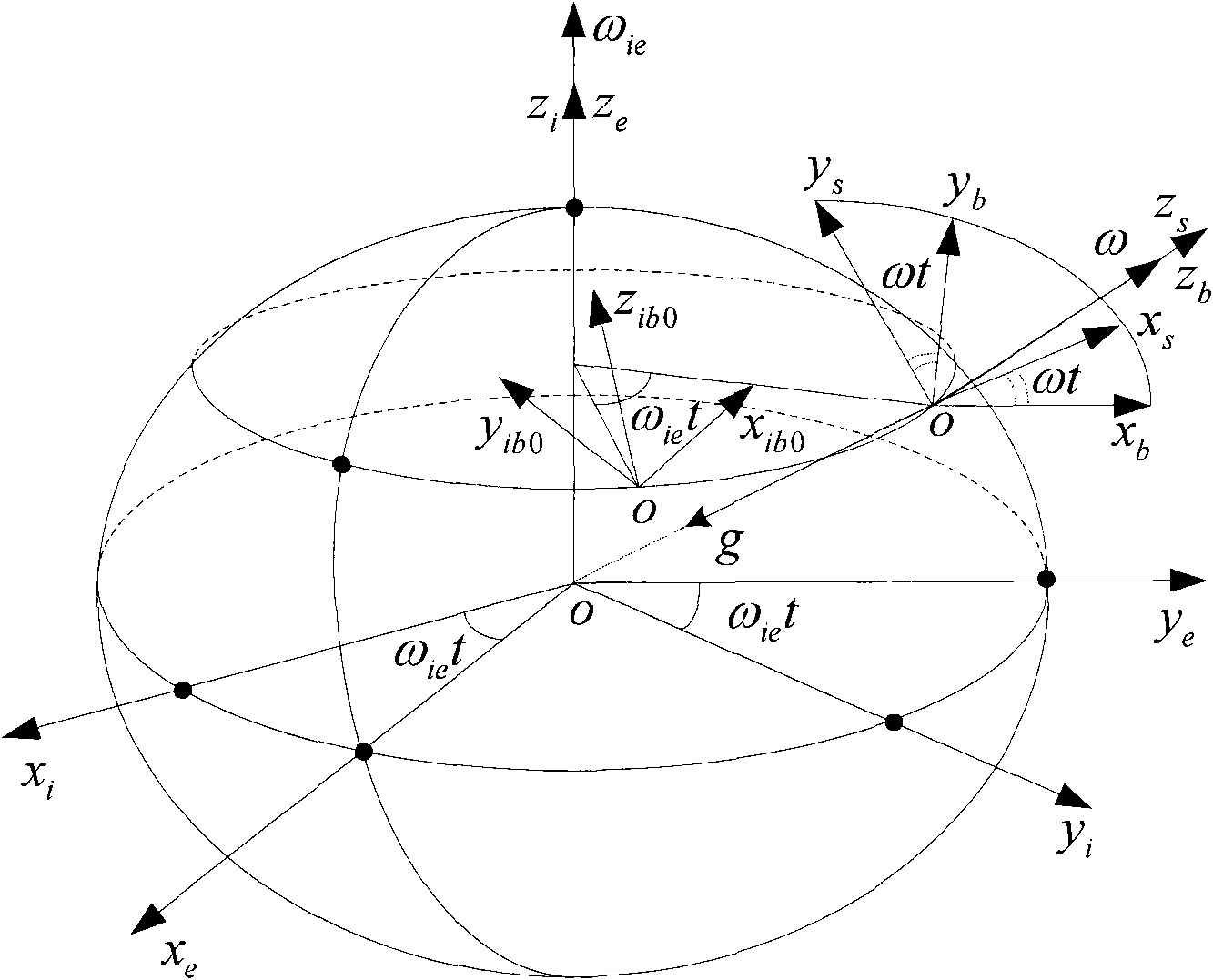

Coarse alignment method for fiber optic gyro strapdown inertial navigation system based on single axis rotation

InactiveCN101629826AImproved Coarse Alignment AccuracyNavigation by speed/acceleration measurementsFiberAccelerometer

The invention provides a coarse alignment method for a fiber optic gyro strapdown inertial navigation system based on single axis rotation. The coarse alignment method comprises the following steps: (1) determining initial position parameters of a carrier by a GPS; (2) collecting the data output by a fiber optic gyroscope and a quartz accelerometer and processing the data; (3) determining a transfer matrix Ti<n> of a navigation coordinate system and an inertial coordinate system according to the mutual position relation of the coordinate systems; (4) allowing a single axis of an inertial measurement unit to continuously rotate, setting superposition of an initial time IMU coordinate system s and a carrier coordinates b, then allowing the inertial measurement unit to continuously rotate around a positive direction of an azimuth axis ozb of the carrier coordinate system with an angular velocity Omega=6 degrees / s; (5) determining the relative position relation of the inertial coordinate system and a base inertial coordinate system; and (6) determining an expression of a strapdown matrix after coarse alignment is over according to the calculated relative conversion relation of the coordinate systems calculated in step (3), (4) and (5). The coarse alignment method can help obtain higher coarse alignment precision under a swinging interference condition.

Owner:HARBIN ENG UNIV

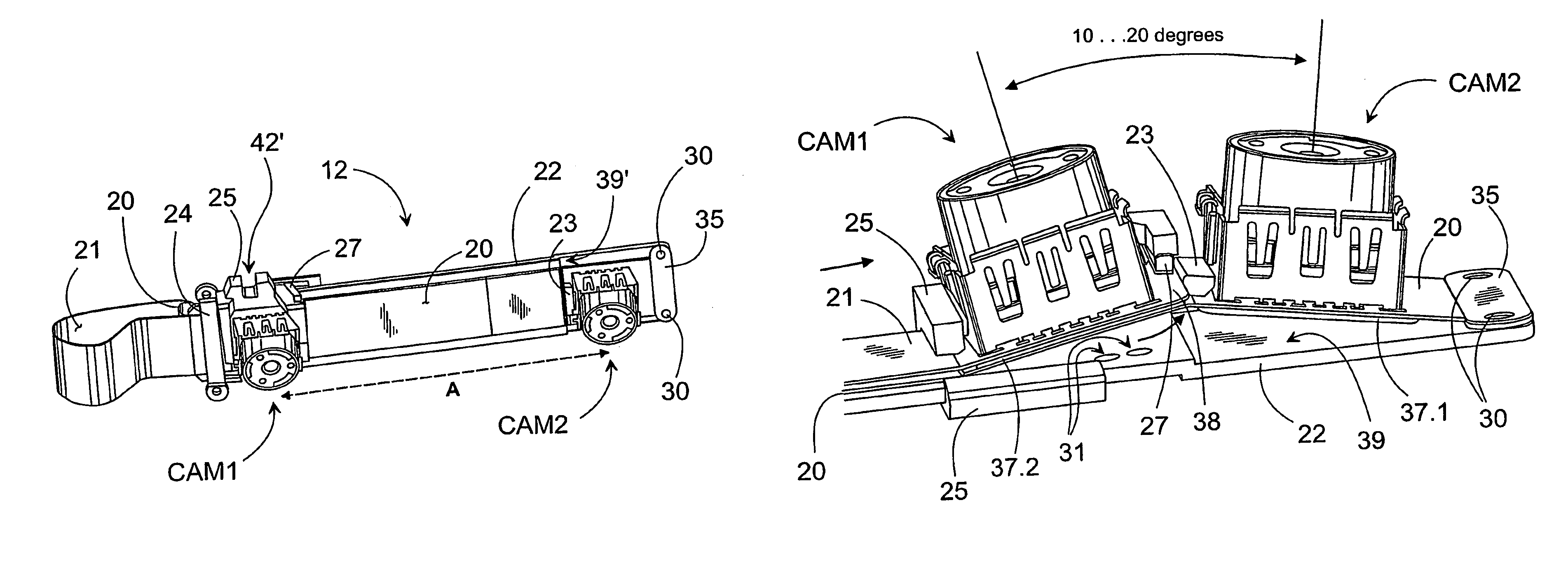

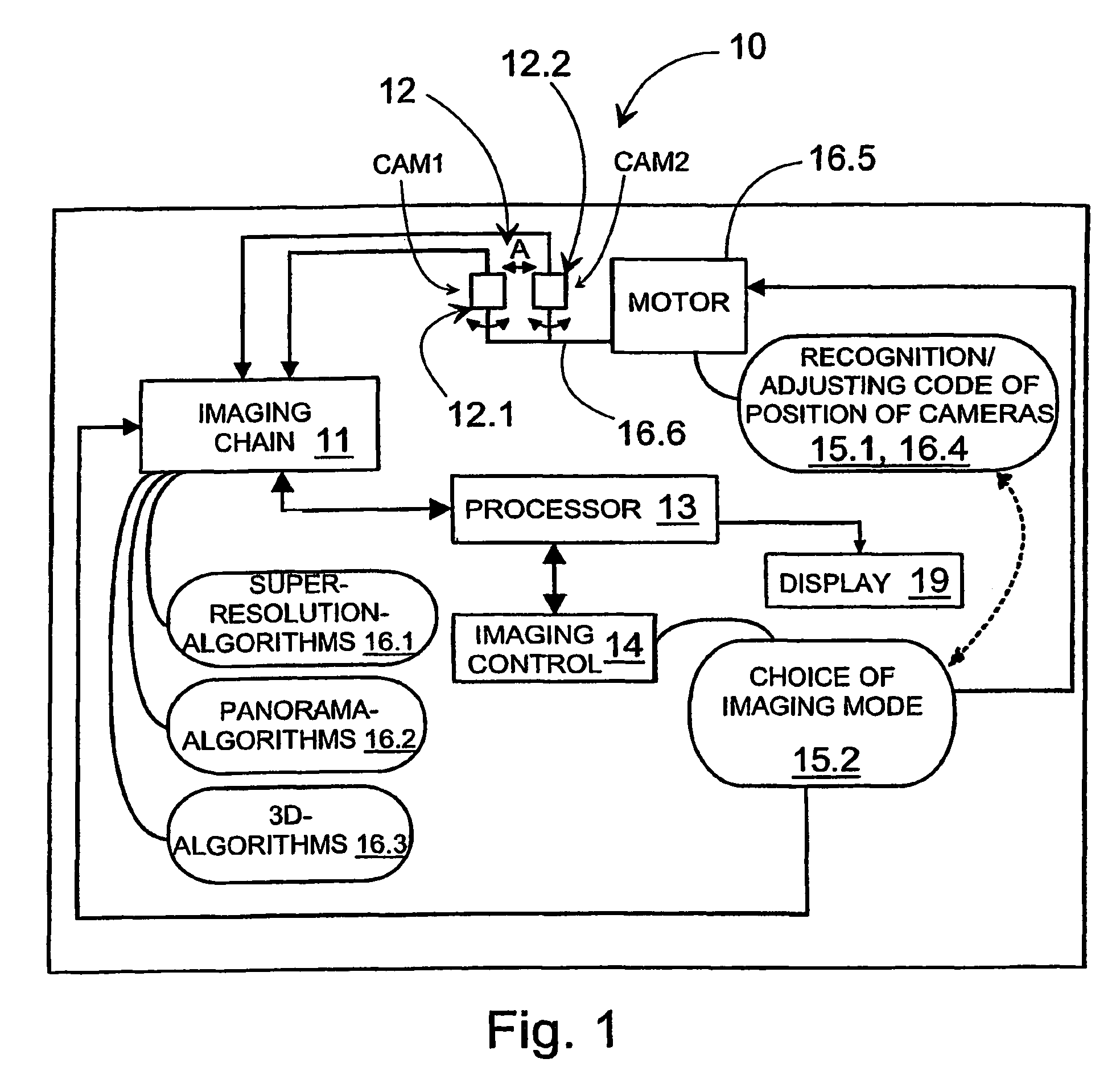

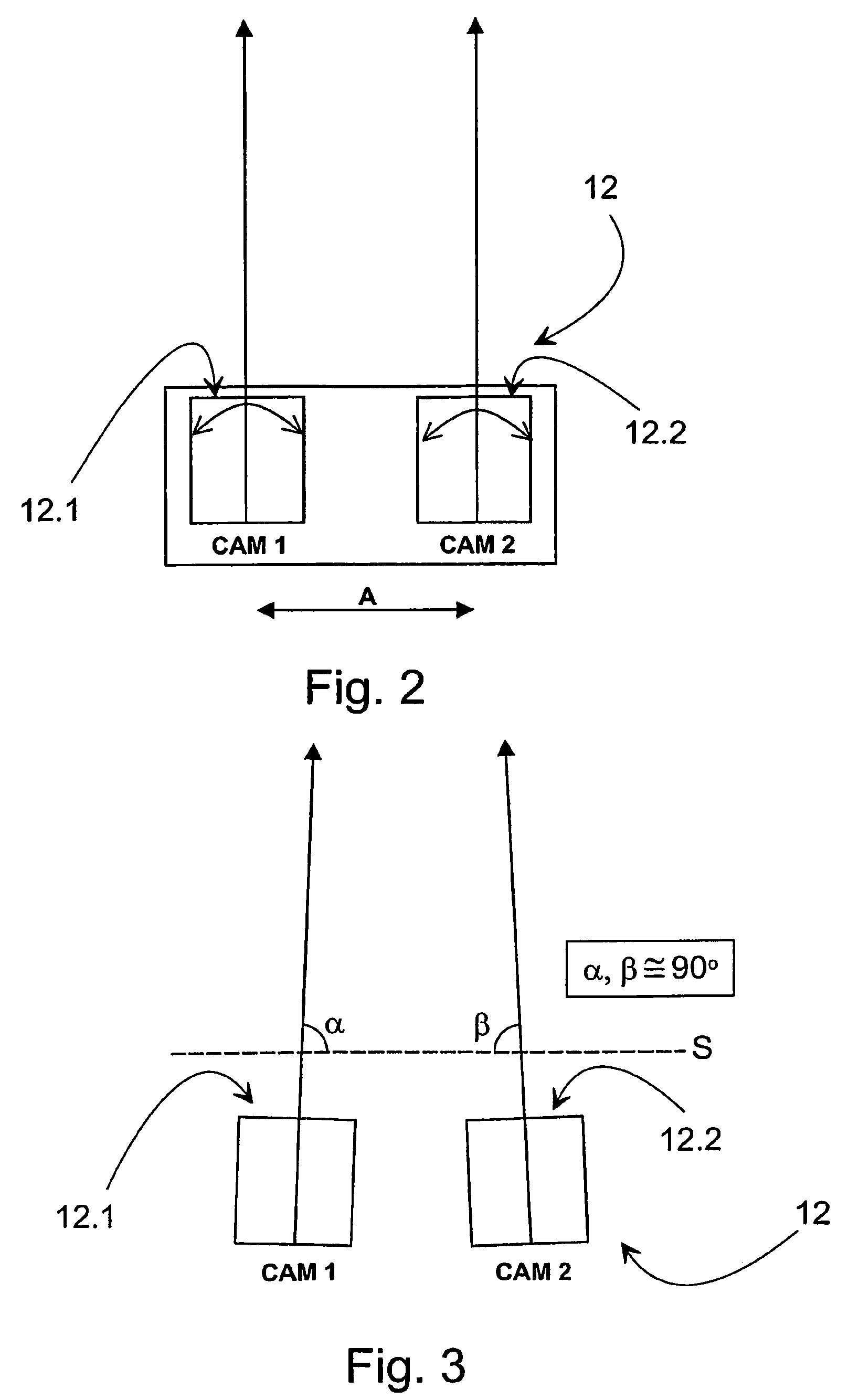

Electronic equipment and method in electronic equipment for forming image information and a program product or implementation of the method

ActiveUS7961234B2Simply performedImage is differentTelevision system detailsCharacter and pattern recognitionCamComputer vision

The invention relates to electronic equipment. The equipment includes camera means for forming data from an object located in the imaging direction, in which case the said camera means include at least two camera units (CAM1, CAM2) and data-processing means, which are arranged to process the data formed using the camera means, in a manner corresponding to the currently selected imaging mode, to form image information. In the equipment, the mutual position of the camera units (CAM1, CAM2) relative to each other is arranged to be altered to correspond to the current imaging mode.

Owner:NOKIA TECHNOLOGLES OY

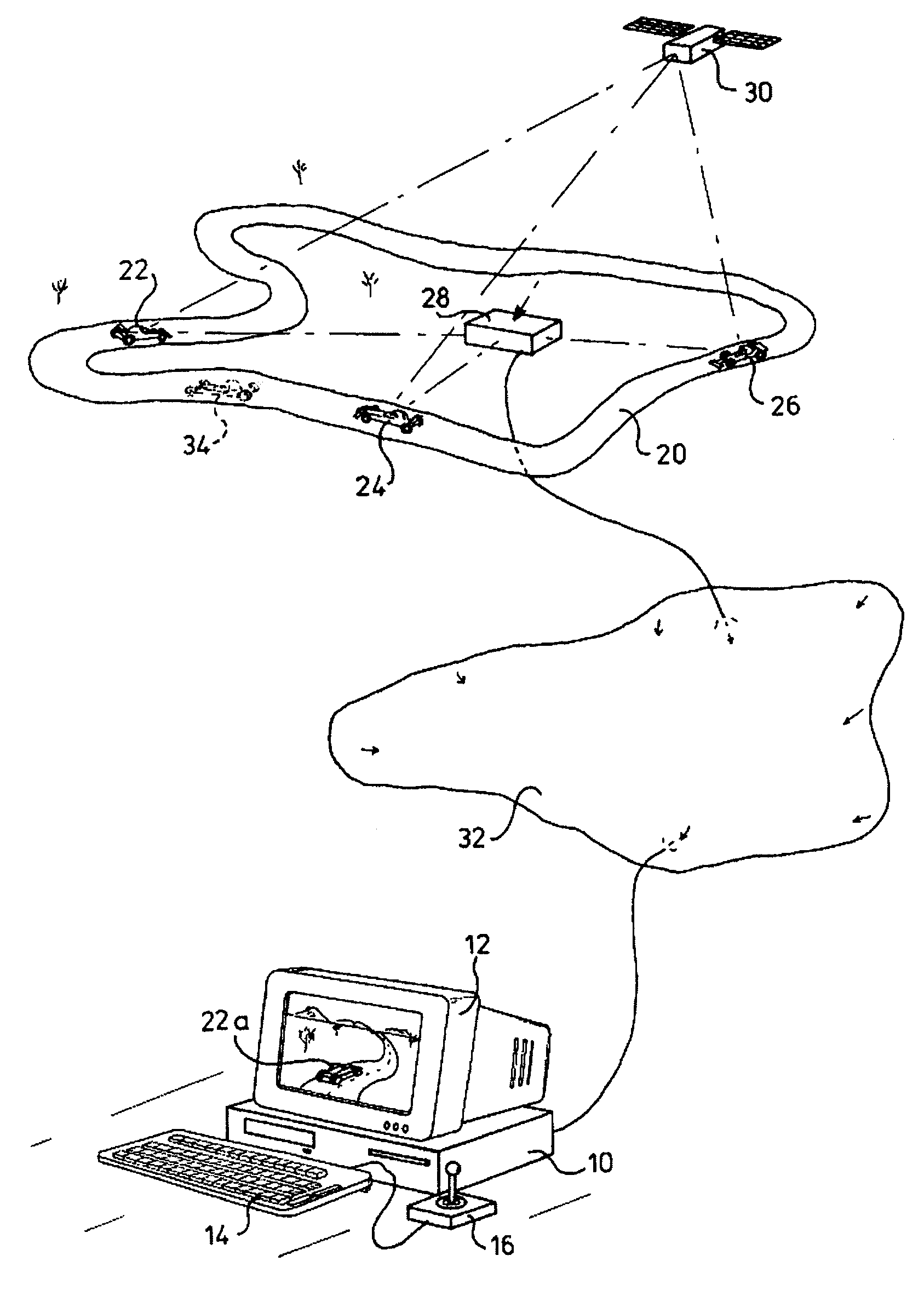

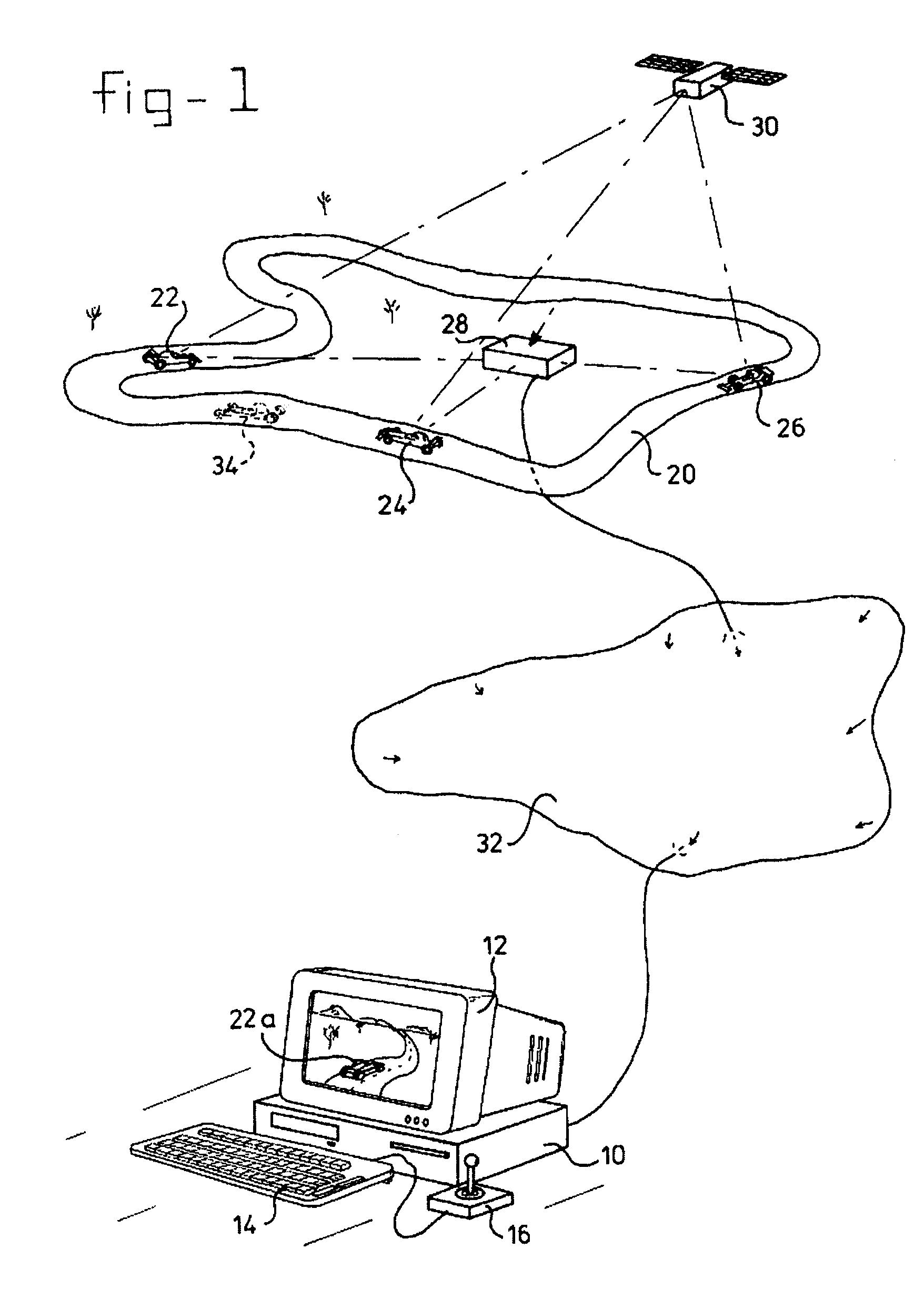

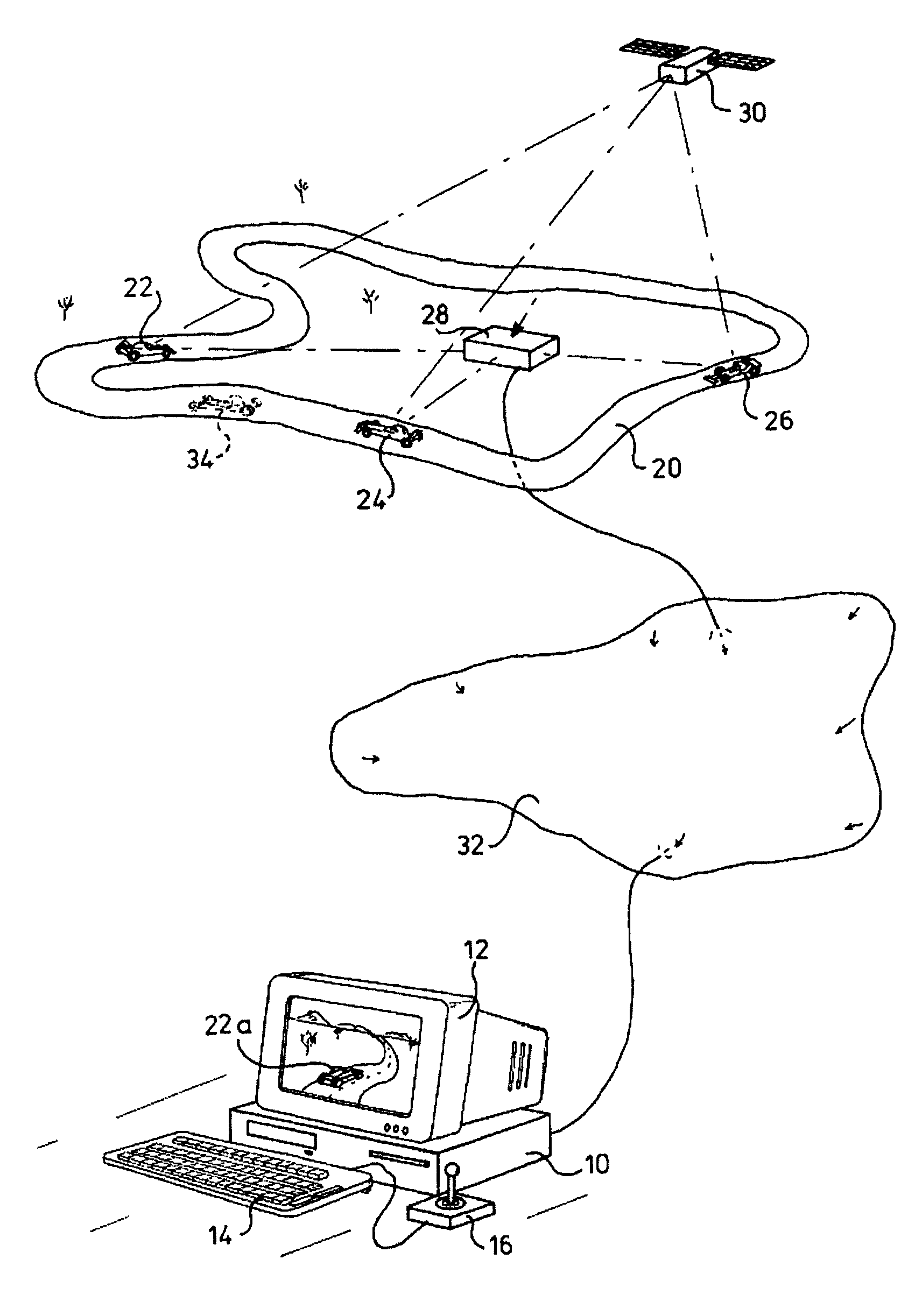

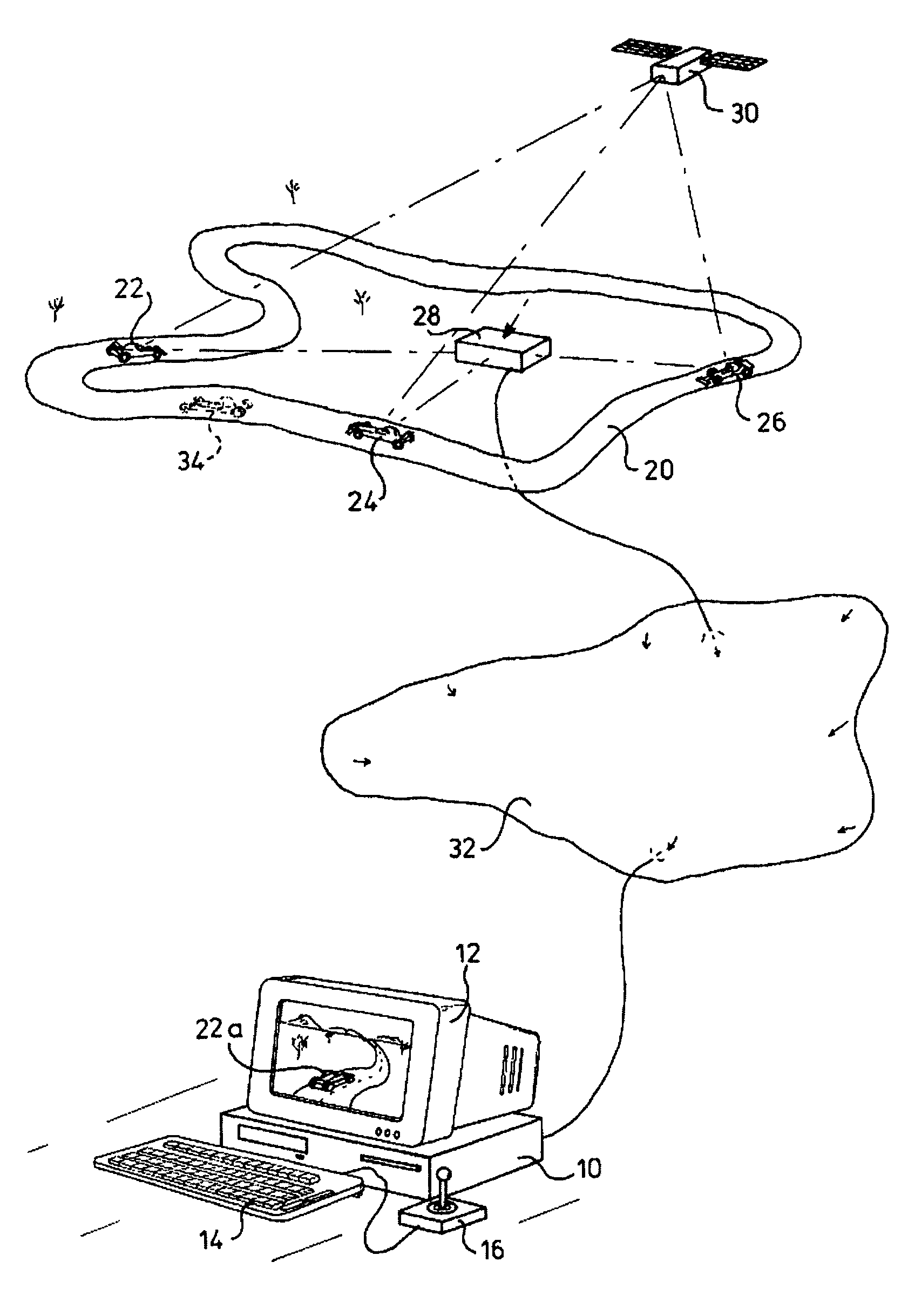

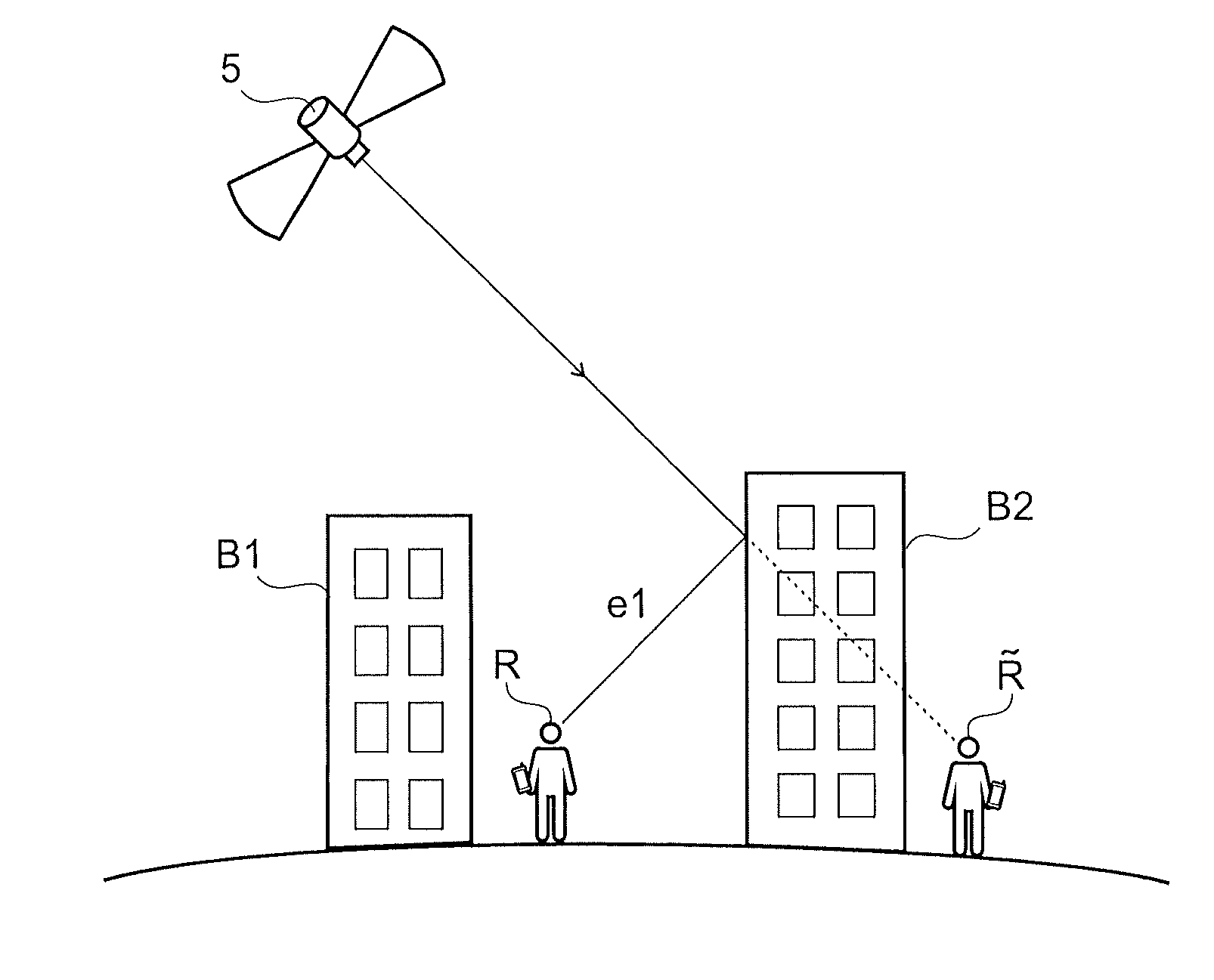

System for simulating events in a real environment

ActiveUS20090076784A1Eliminate disadvantagesDigital computer detailsArtificial lifeSimulationTime moment

System for simulating events in a real environment containing static objects and dynamic objects: a) position locating unit for continuously determining the real environment the position of the dynamic objects in relation to the static objects within a time period in which the even takes place; b) storage elements for storing data describing the dynamic and static objects of the environment; c) processing elements for processing (b1) data from the storage elements describing the static and dynamic objects (b2) data from the position locating unit indicating at a certain moment the mutual positions of the static and dynamic objects of the environment, the processing elements being loaded with simulation software; d) display elements for displaying a simulated view from a selected viewpoint on the simulated environment as a result of the processing by the processing elements; e) control elements to repeat the functioning of the processing and display elements for a range of consecutive time moments which together determine the above-mentioned time period wherein the position locating unit includes a satellite navigation system, or a thereto-related system.

Owner:IOPENER MEDIA

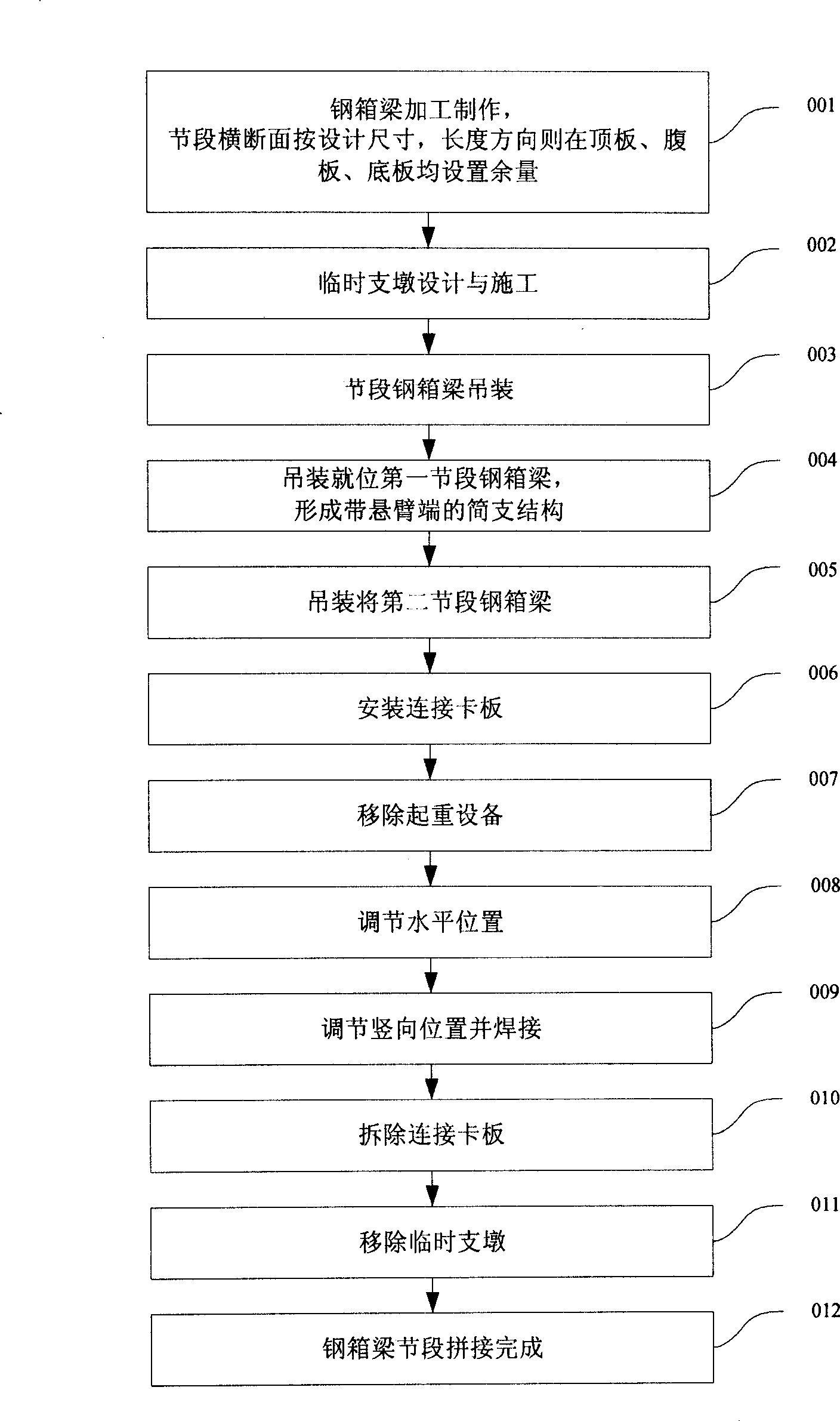

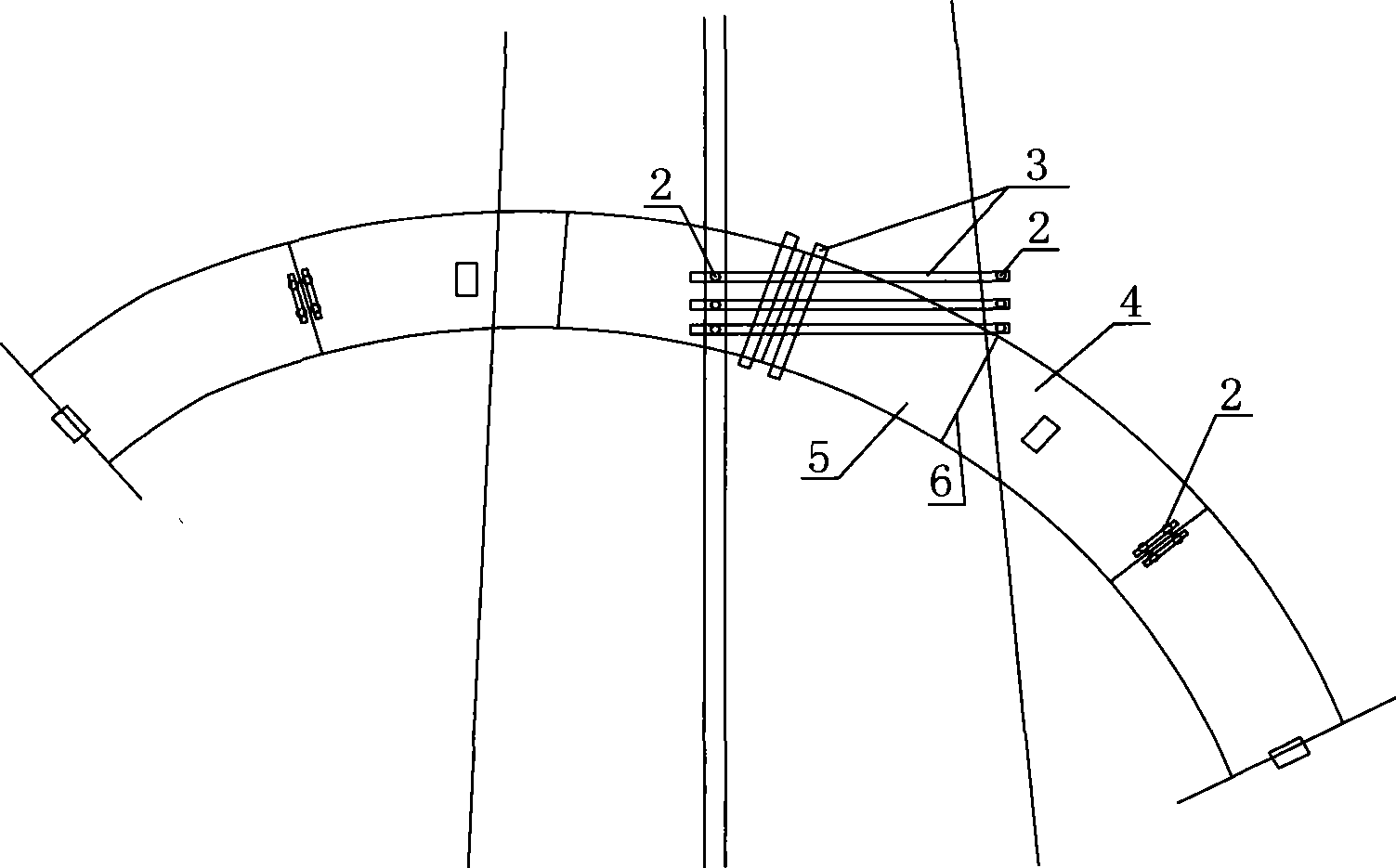

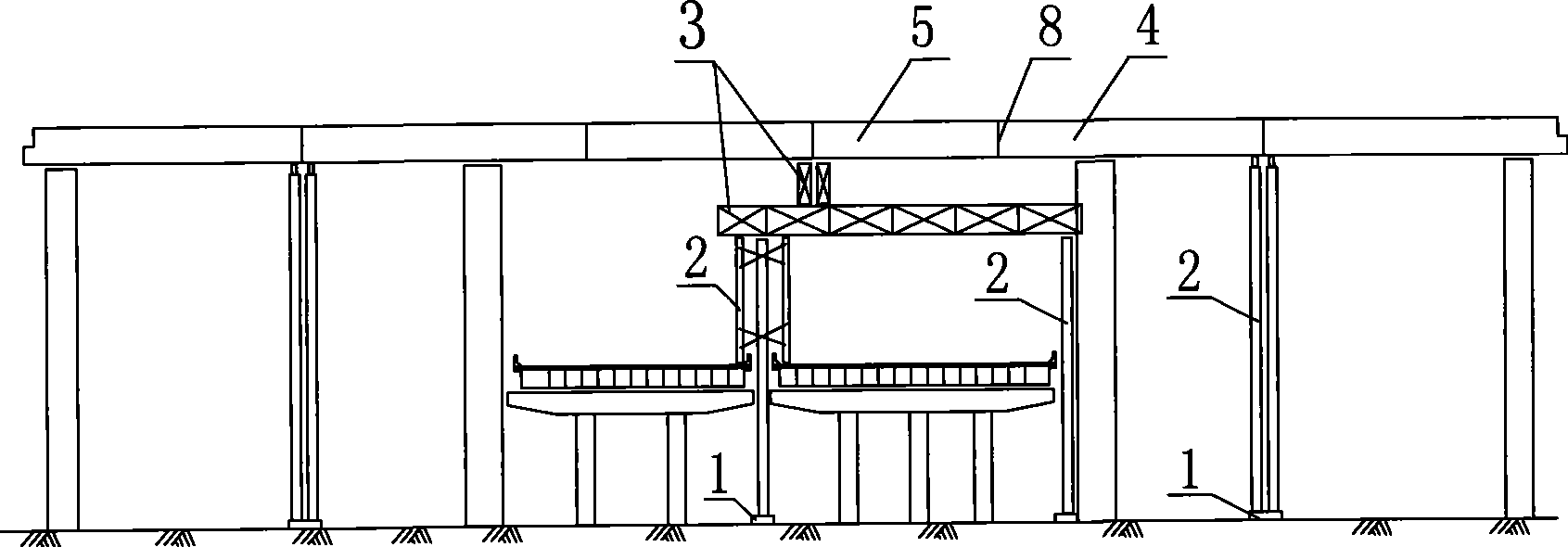

Steel box girder assembling construction method

InactiveCN101487232ASolve layout difficultiesReduce usageBridge erection/assemblySteel box girderMutual position

The invention provides a construction method for assembling steel box girders, which is used for the hoisting construction of the steel box girders during the road and bridge construction. The method comprises the steps as follows: a first steel box girder section is hoisted; a second steel box girder section is hoisted and suspended on the soleplate of the first steel box girder section; a connecting clamp plate is arranged at the top plate of the first steel box girder section and the second steel box girder section and is respectively suspended on top of the first steel box girder section and welded on the top of the second steel box girder section; hoisting equipment is removed; the mutual position of the steel box girder sections is adjusted and the steel box girder sections are welded to each other; the connecting clamp plate is removed; the temporary pier is removed; and the assembly is completed. As the residual assembly is adopted, the steel box girder construction under complex construction environment has large elasticity, thus ensuring the assembly precision and quality; the loading form is adopted to carry out the assembly of the steel box girder, thus solving the problem that the temporary pier is difficult to be arranged when the site is restricted; the construction time of hoisting equipment and the use of the temporary piers are reduced; and the whole assembly process is simple, feasible, safe, reliable, economical and reasonable.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

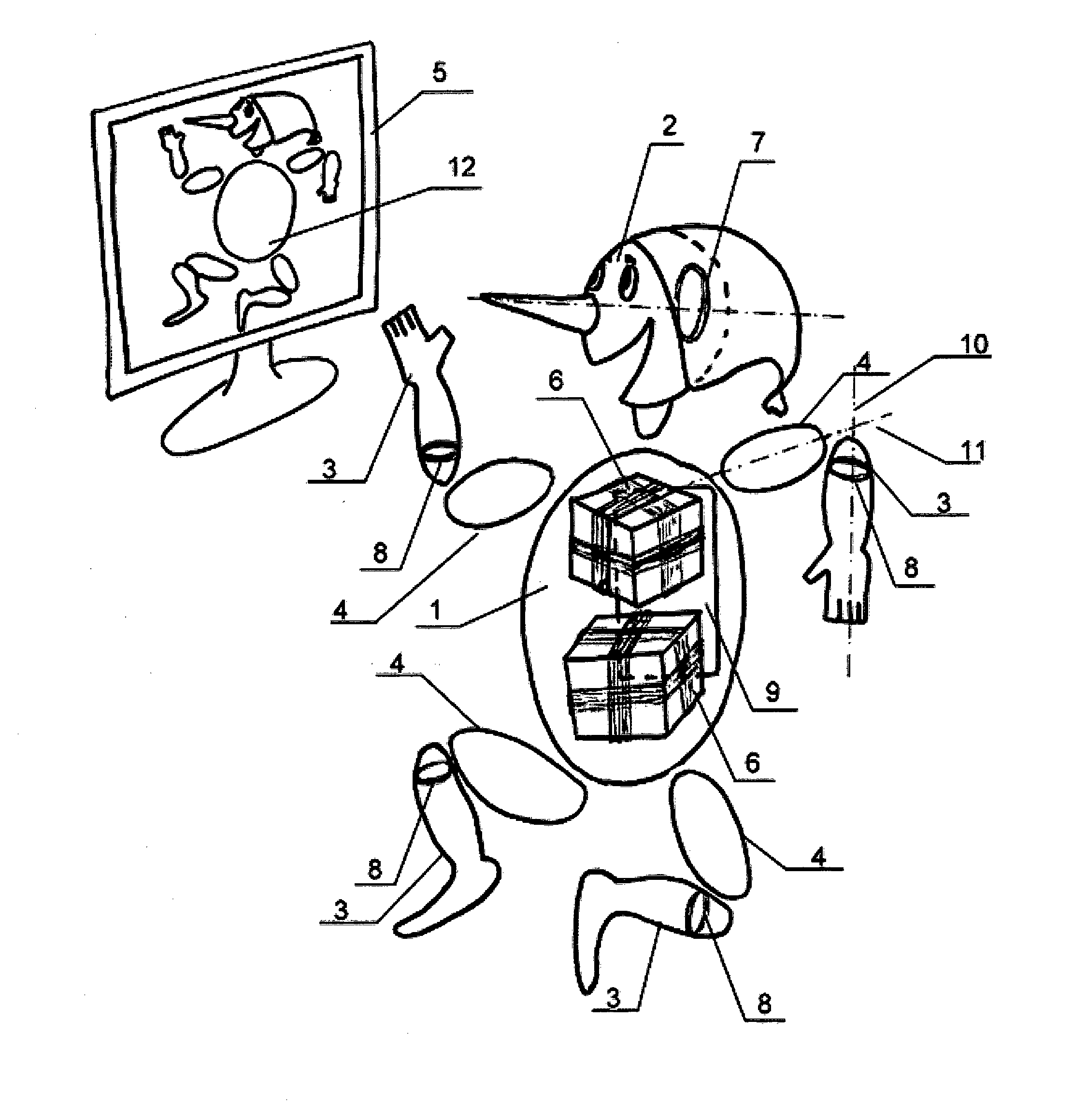

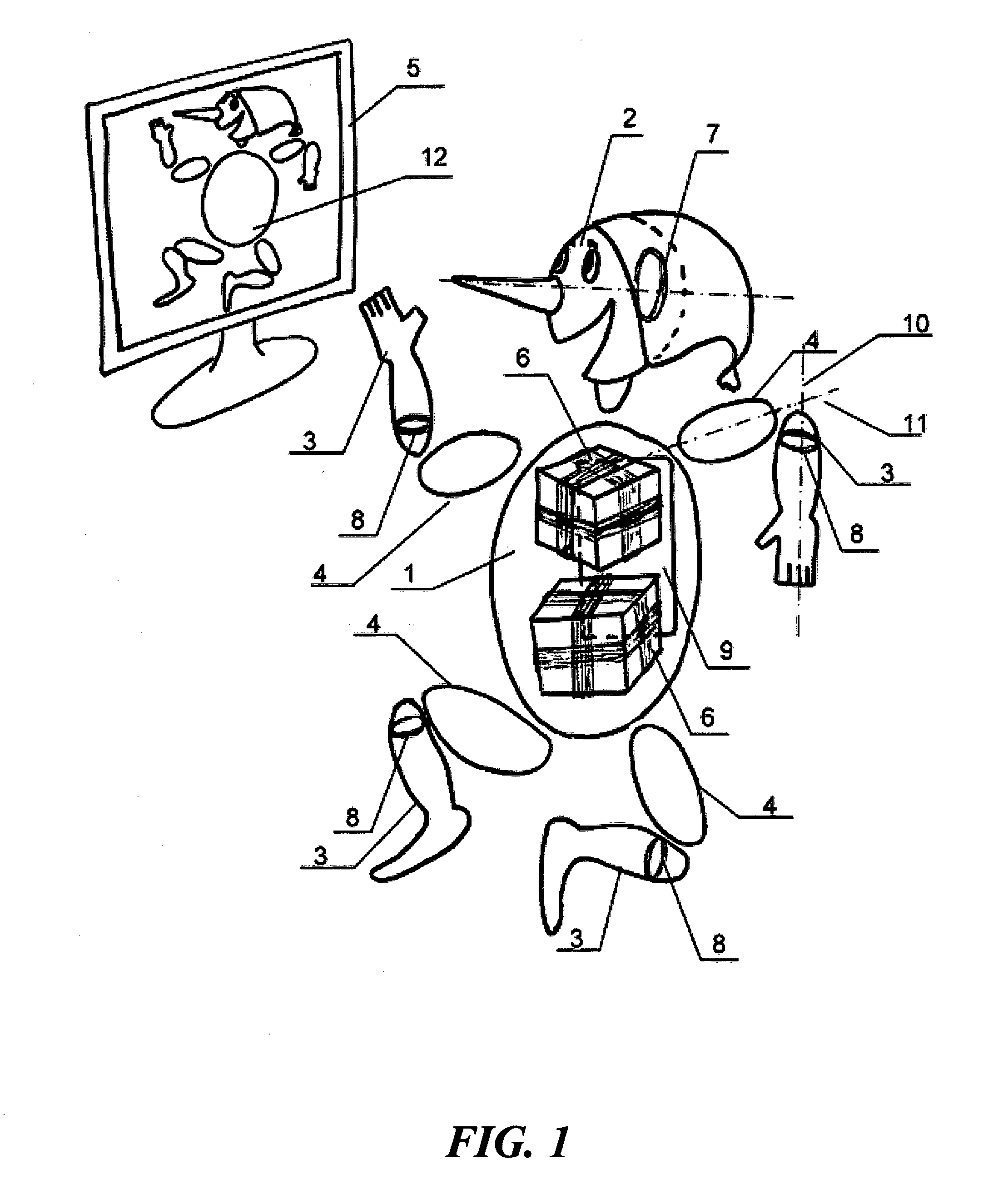

Method and system for determination of one or more limbs of one or more toy devices

InactiveUS20140030955A1Accurate acceleration measurementLow costDollsComputerized toysEngineeringInductance

The invention relates to gaming devices, in particular to toysThe device contains a body which moving parts are coupled with. Inductance coils are attached to the inside of the body and the moving parts. The device is equipped with a means of measurement of mutual induction between the coils connected with a computing means designed for determination of mutual position of the specified inductance coils based on mutual induction values, and the computing means is connected to a means designed for creating effects perceivable by the user based on information on mutual position of inductance coils. The gaming device in another variant is physically divided into a controlling part which includes the said body and moving parts in which coils and a means of measurement of mutual induction between coils are located, and a controlled part which includes a means designed for creation of effects perceivable by the user.

Owner:SMETANIN EVGENY NIKOLAYEVICH +3

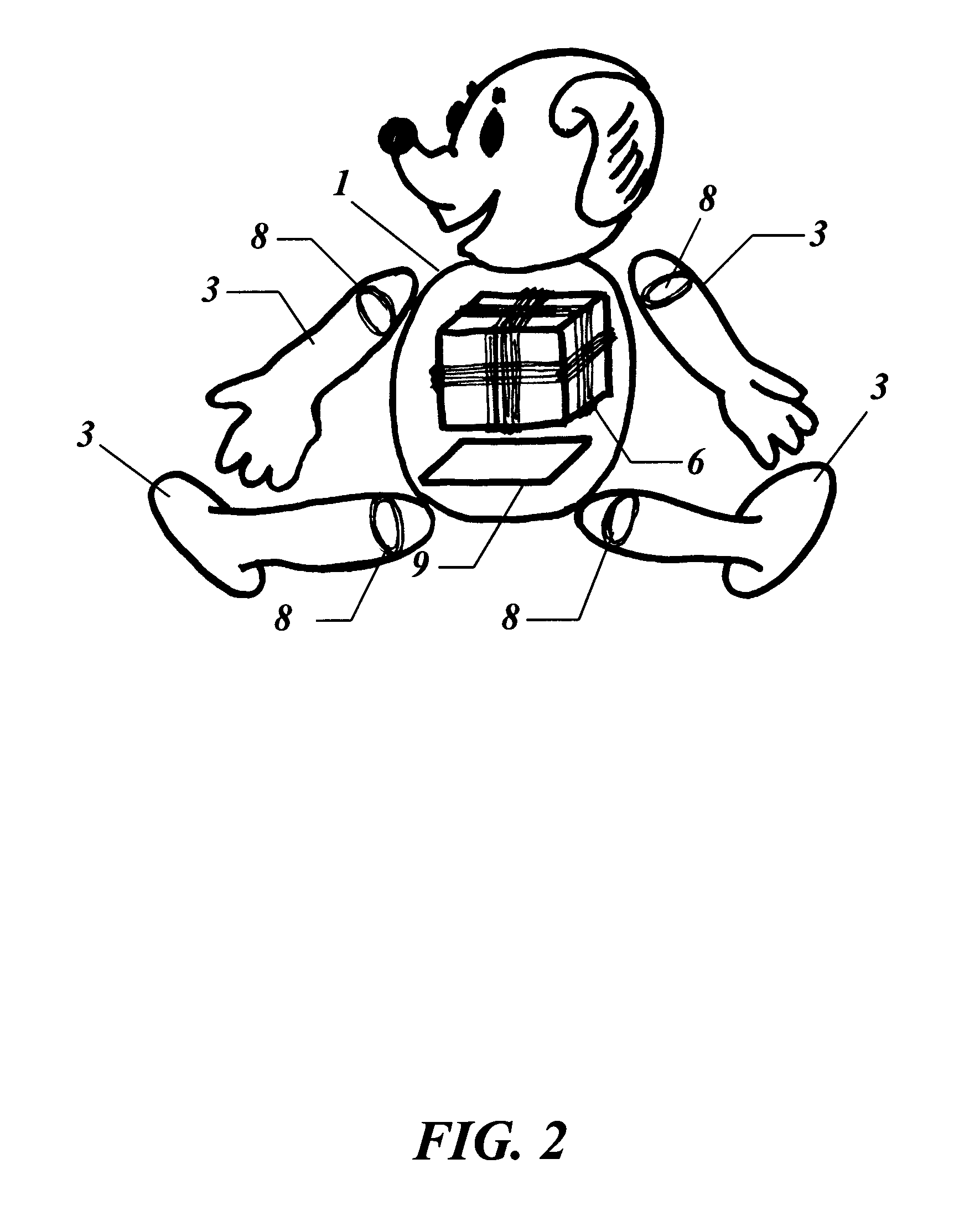

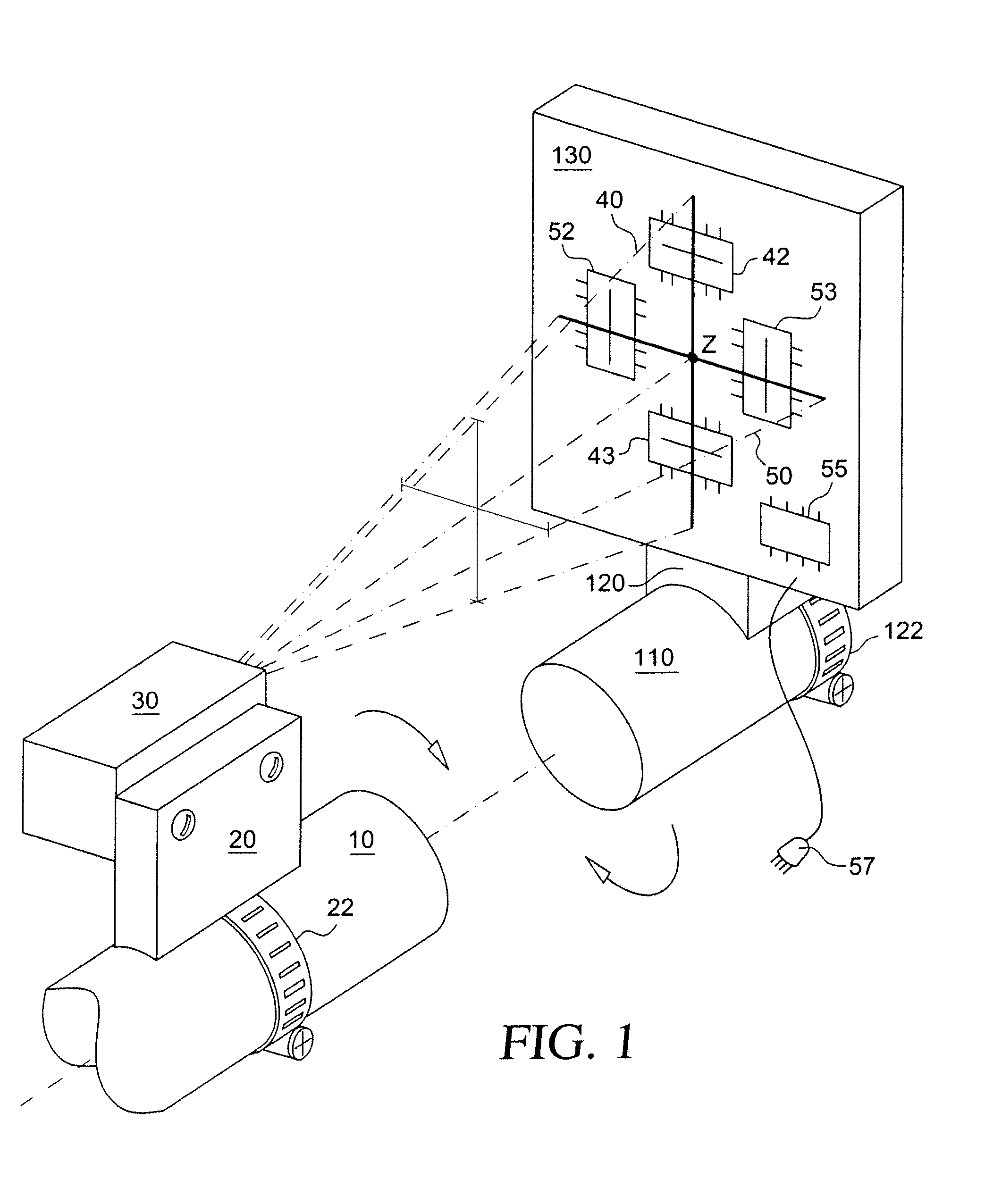

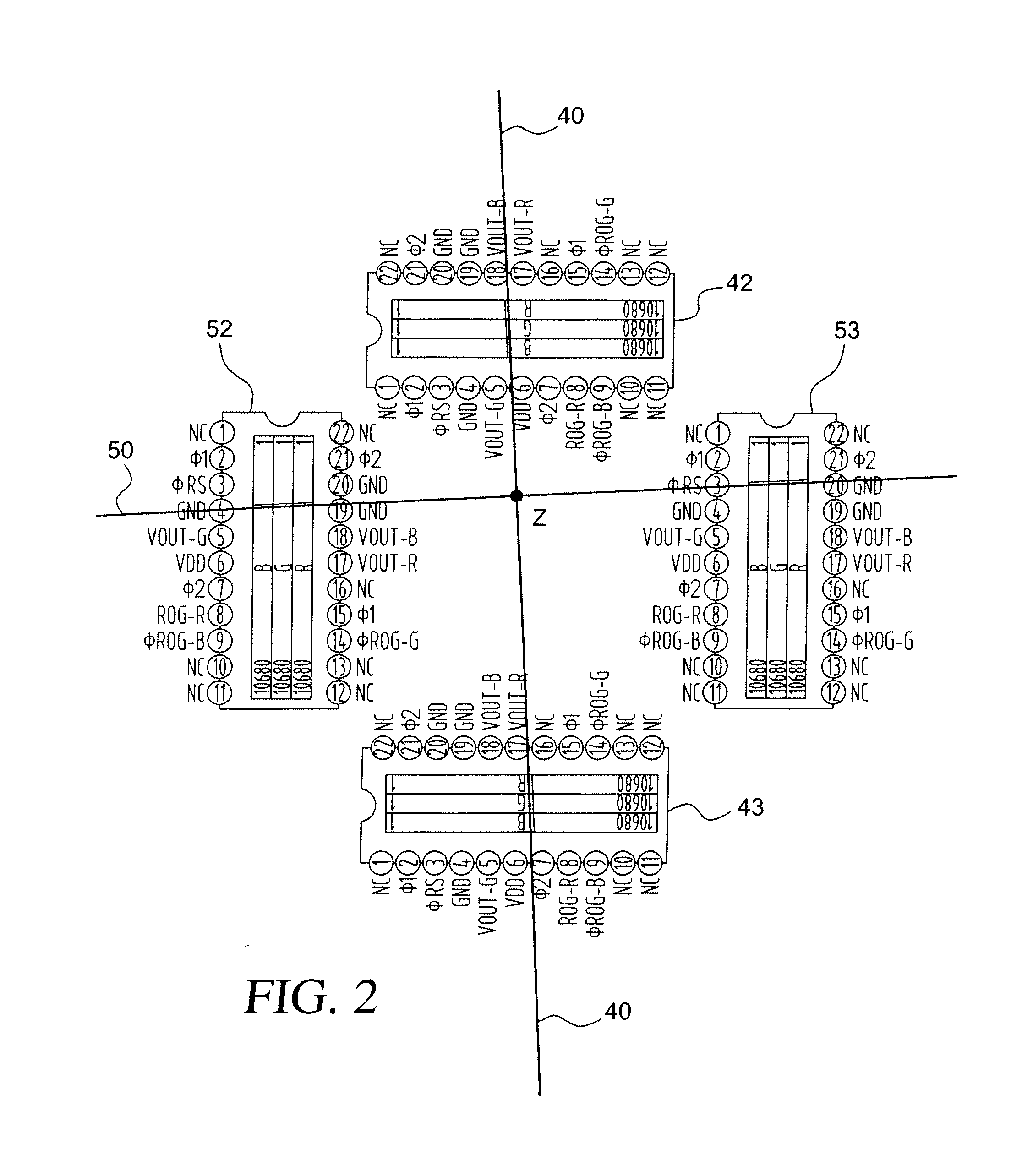

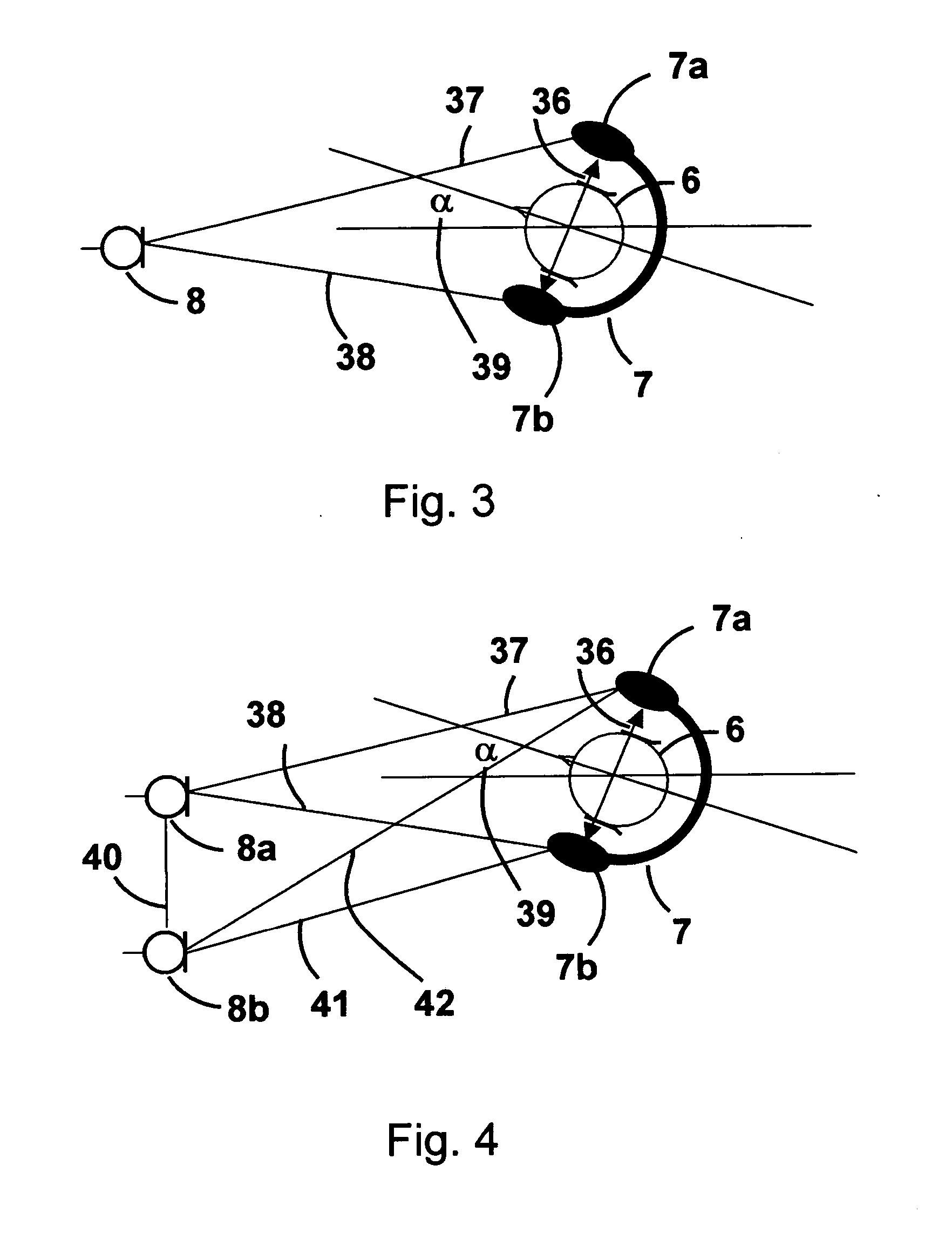

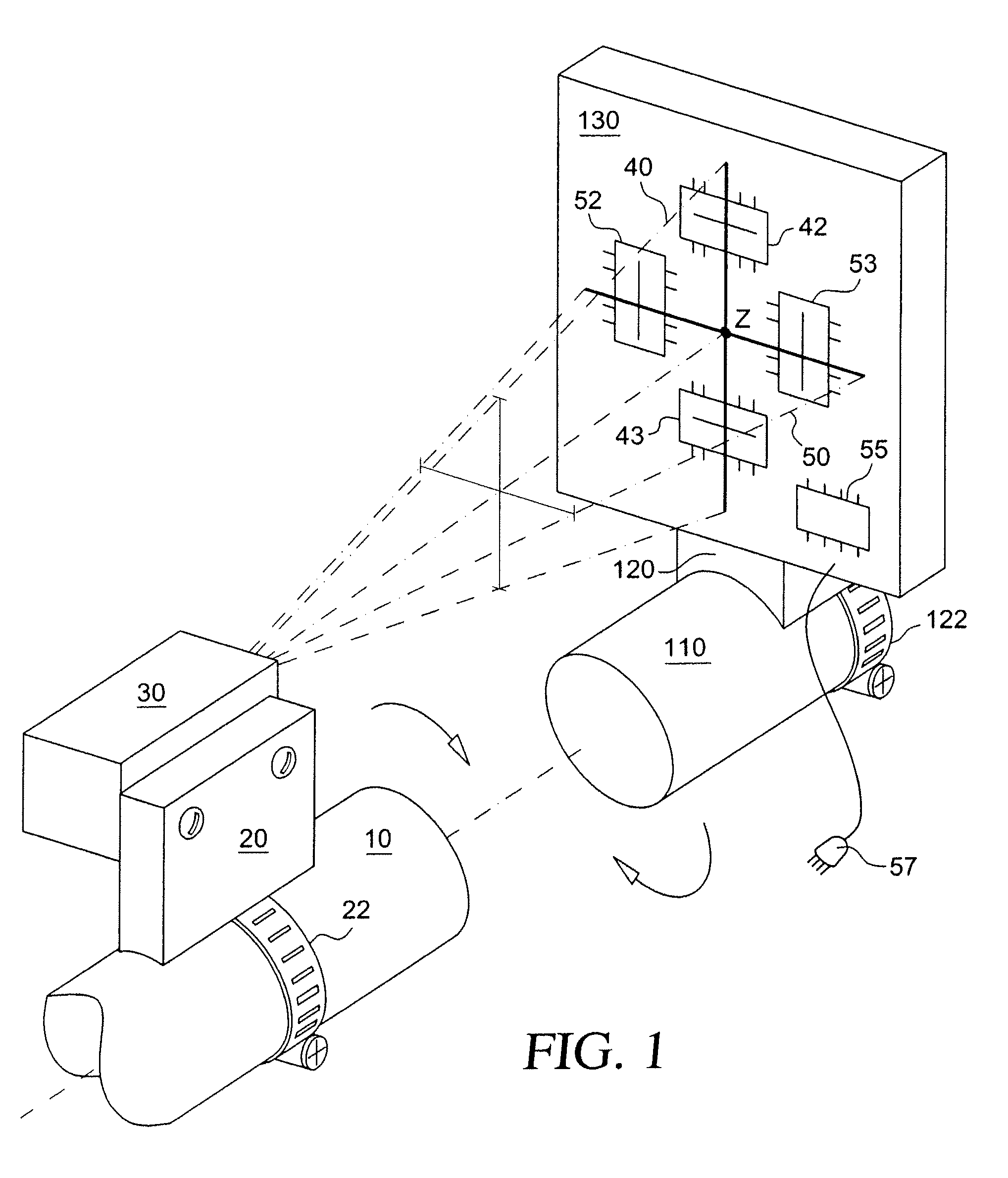

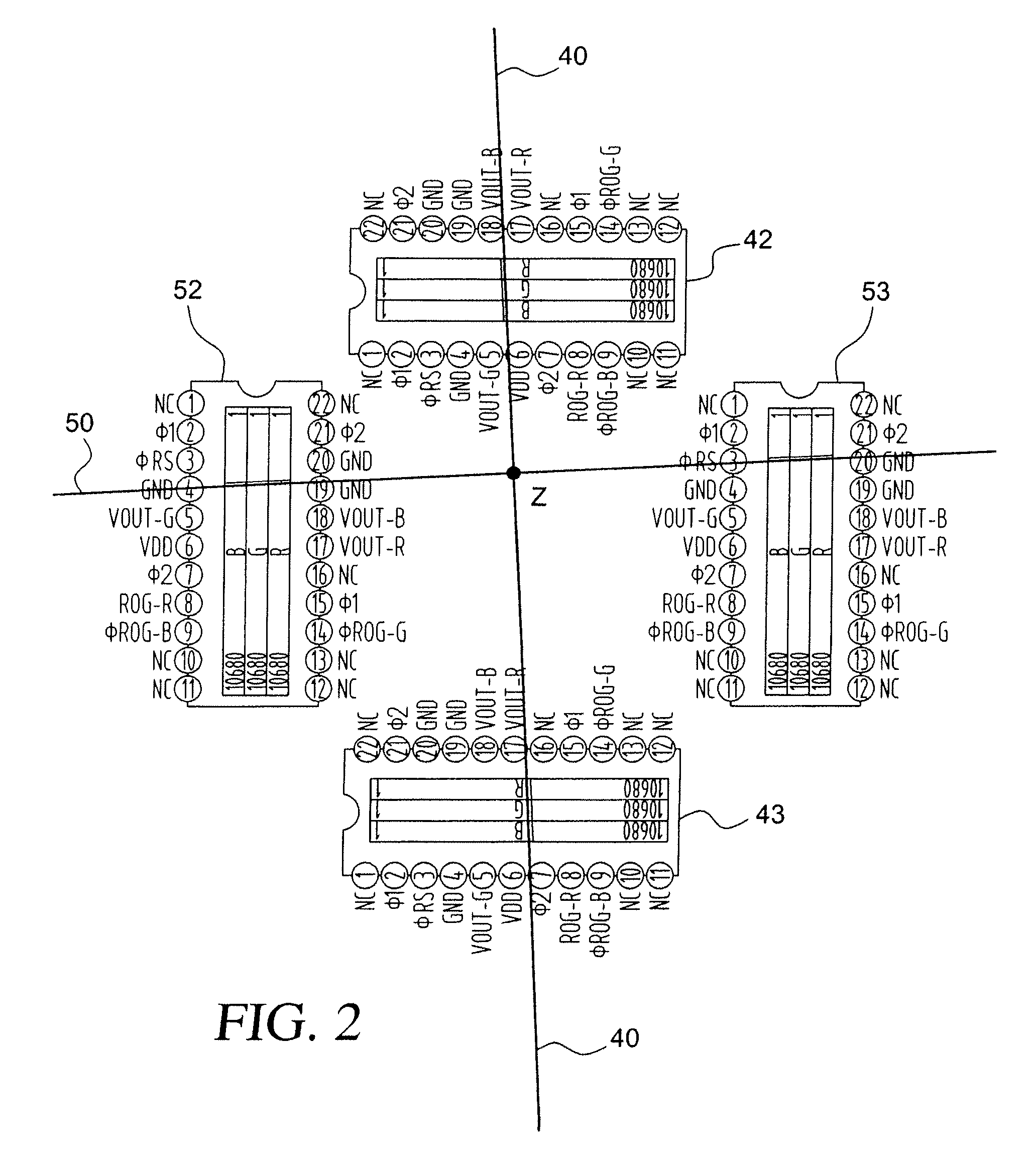

Device and process for quantitative assessment of the three-dimensional position of two machine parts, shafts, spindles, workpieces or other articles relative to one another

ActiveUS20070253002A1Expand the measurement rangeSpeed up the processUsing optical meansTarget surfaceLine sensor

An apparatus and a method that can be used for qualitative or quantitative determination of the three-dimensional location of two bodies relative to one another which can be used, for example, to determine the mutual position of two bodies according to angular or translational coordinates. Furthermore, the apparatus and method can be used in a measurement robot or in a coordinate measurement device. The device composed of a device for emitting a light beam which is fanned in several planes and at least three, preferably four or more, optoelectronic line sensors or linear sensors for determination of the incidence points of the light beam which has been flared in several planes on the line sensors or an upstream target surface.

Owner:PRUTECHNIK DIETER BUSCH AG

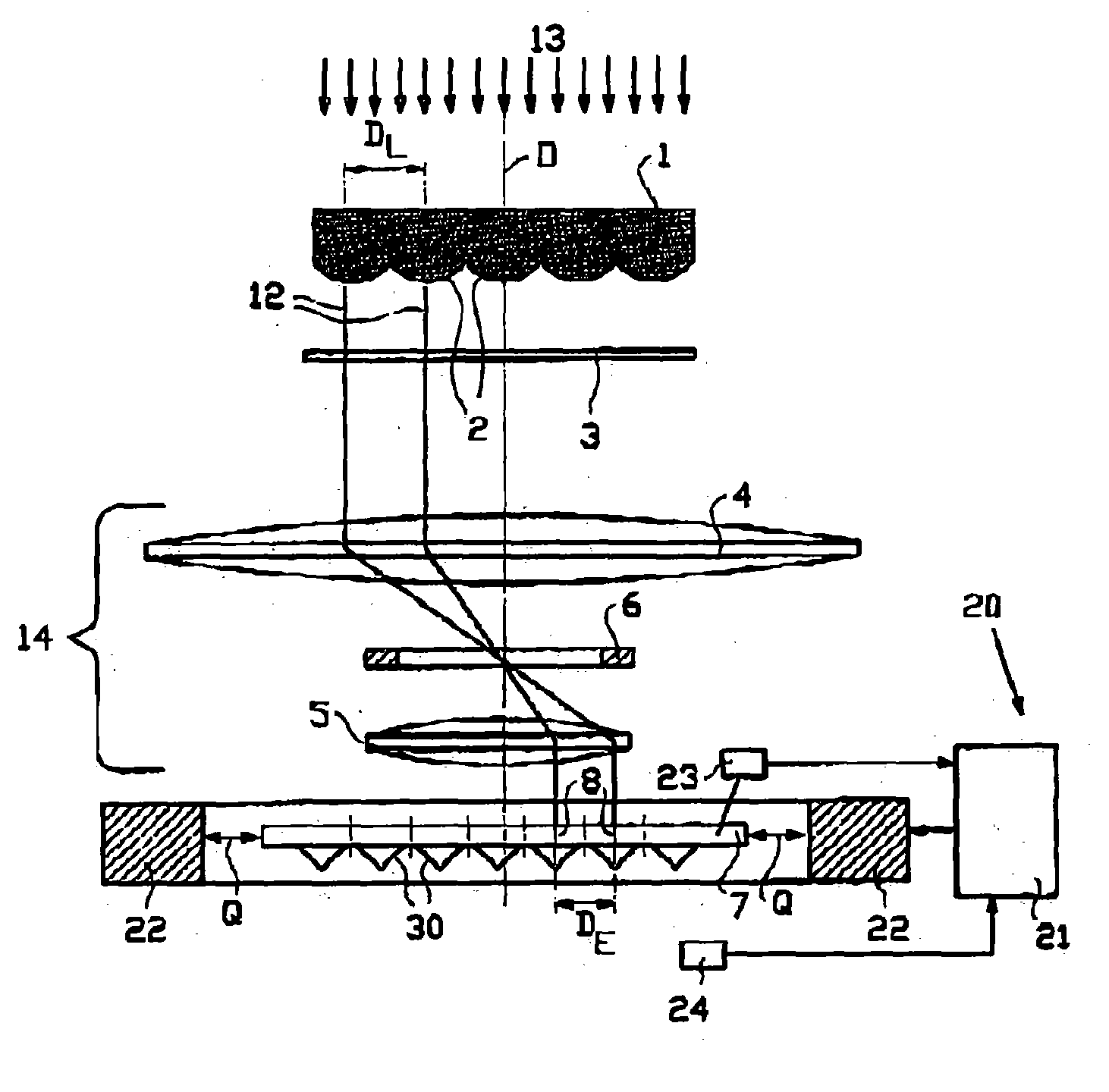

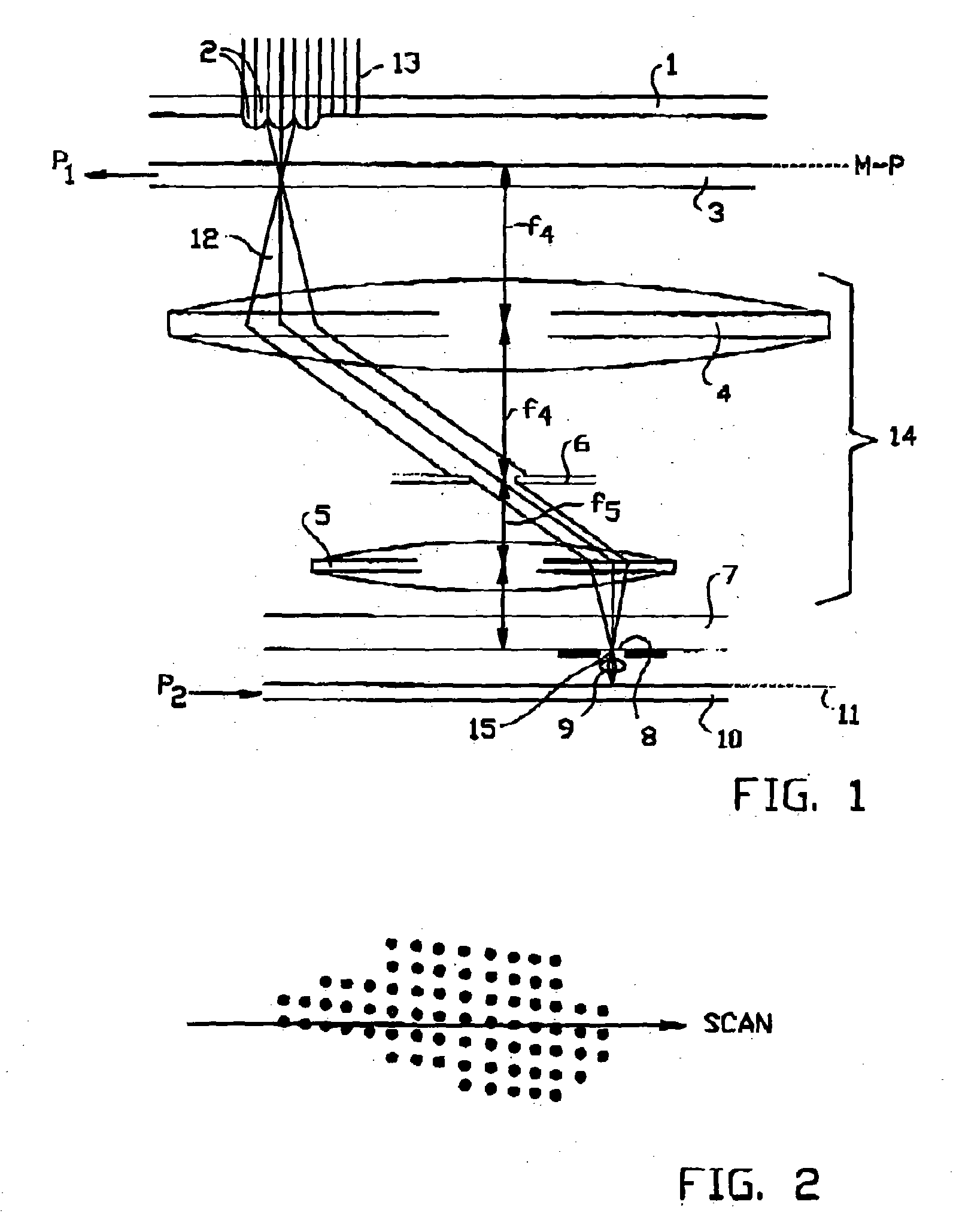

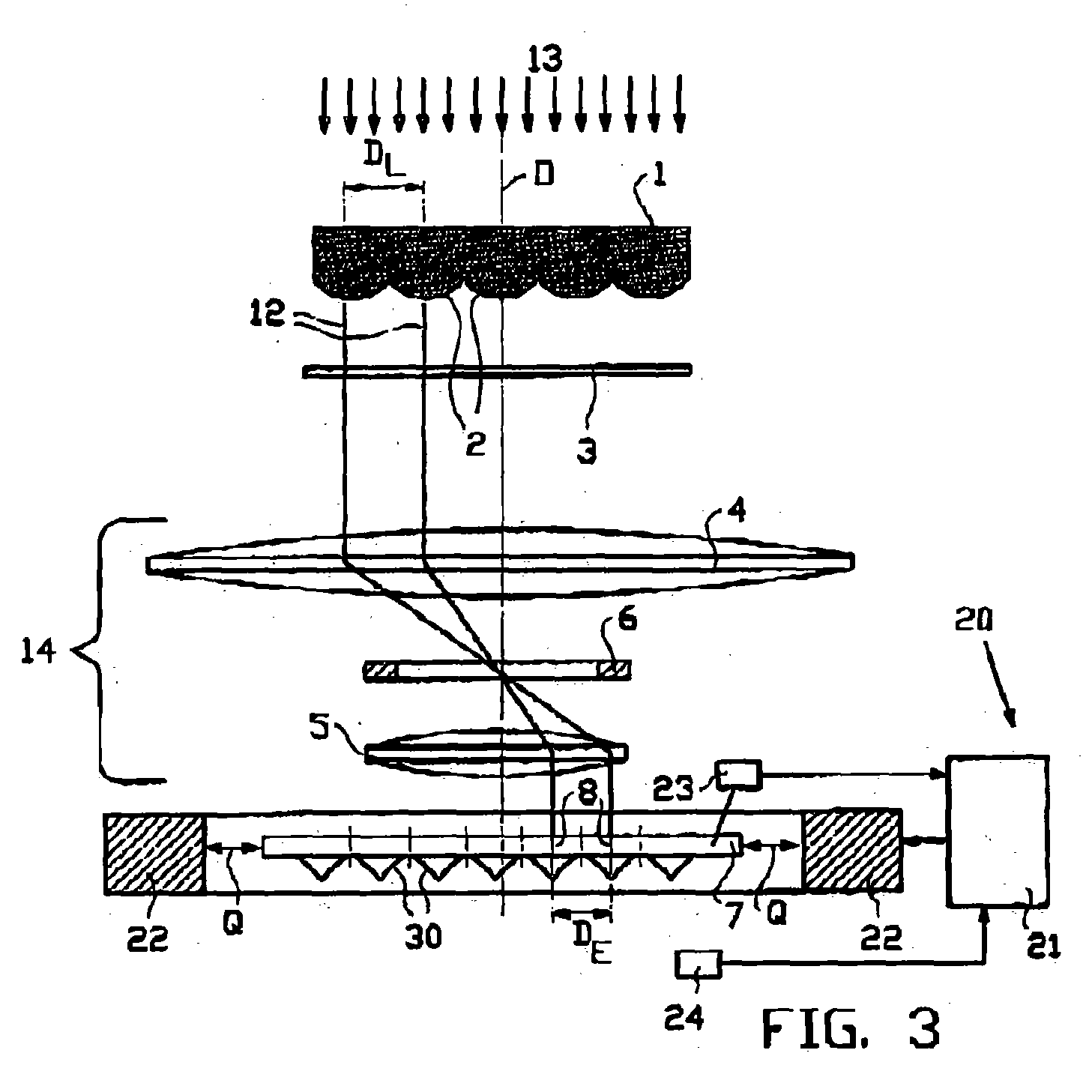

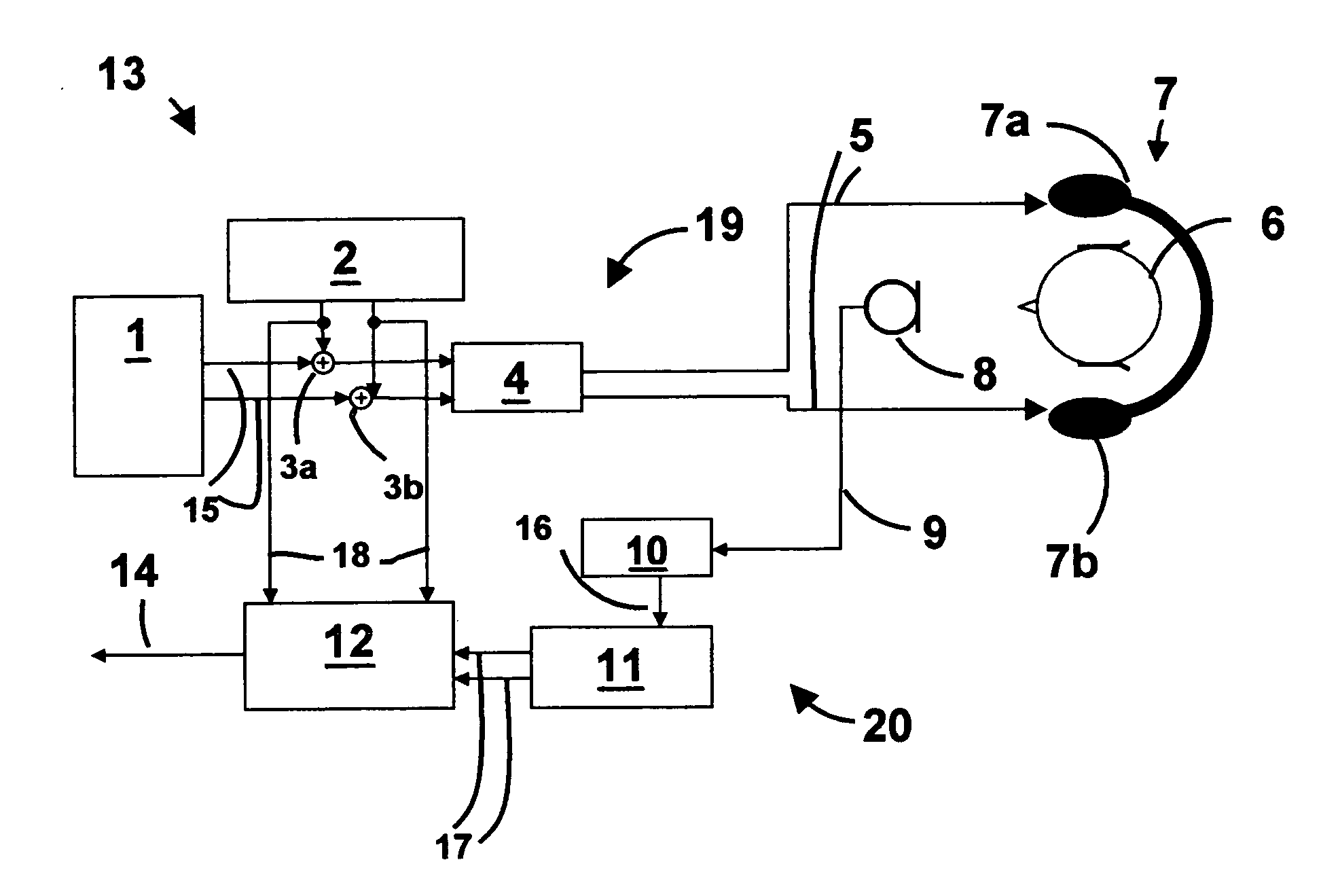

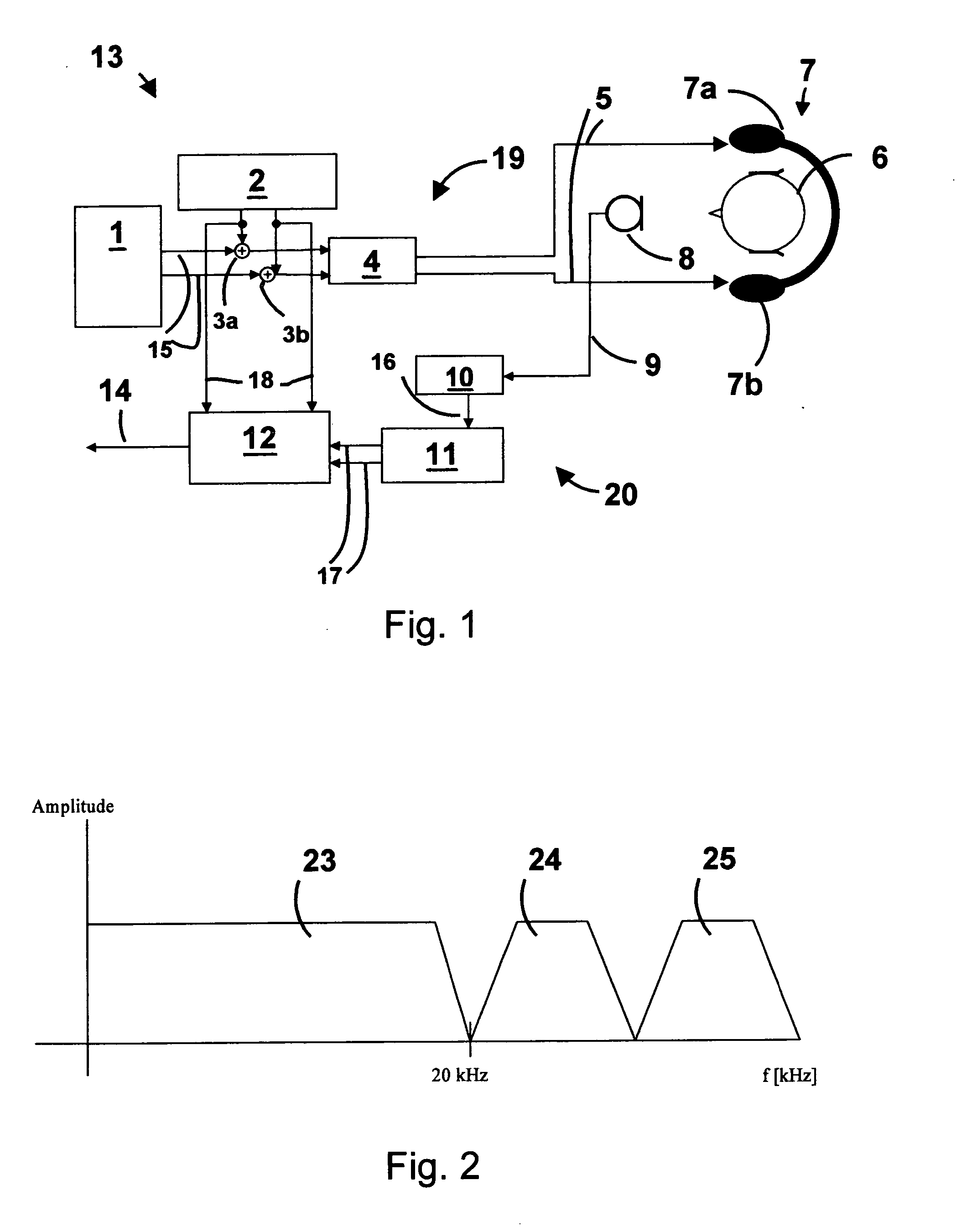

Adjustment in a MAPPER system

The present invention relates to a lithography system comprising: means for generating a plurality of light beamlets, and an electron source, arranged to be illuminated by said light beamlets, said electron source comprising a plurality of converter elements at an element distance from each other for converting a light beamlet impinging onto it into an electron beamlet directed towards and focussed on an object plane, said lithography system further comprising control means for manipulating the mutual positions of the light beamlets with respect to the converter elements. These control means can be of optical, thermal, mechanical or magnetical nature, and work on for instance the micro lens array, the converter plate, and the mask.

Owner:ASML NETHERLANDS BV

System for simulating events in a real environment

ActiveUS8160994B2Analogue computers for electric apparatusDigital computer detailsSimulationTime moment

System for simulating events in a real environment containing static objects and dynamic objects: a) position locating unit for continuously determining the real environment the position of the dynamic objects in relation to the static objects within a time period in which the even takes place; b) storage elements for storing data describing the dynamic and static objects of the environment; c) processing elements for processing (b1) data from the storage elements describing the static and dynamic objects (b2) data from the position locating unit indicating at a certain moment the mutual positions of the static and dynamic objects of the environment, the processing elements being loaded with simulation software; d) display elements for displaying a simulated view from a selected viewpoint on the simulated environment as a result of the processing by the processing elements; e) control elements to repeat the functioning of the processing and display elements for a range of consecutive time moments which together determine the above-mentioned time period wherein the position locating unit includes a satellite navigation system, or a thereto-related system.

Owner:IOPENER MEDIA

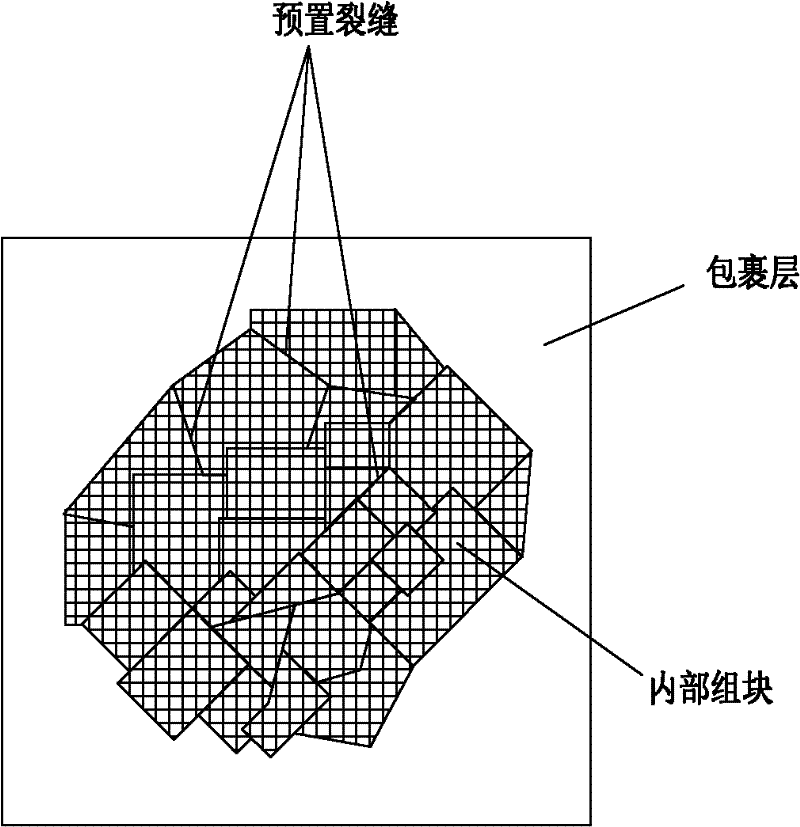

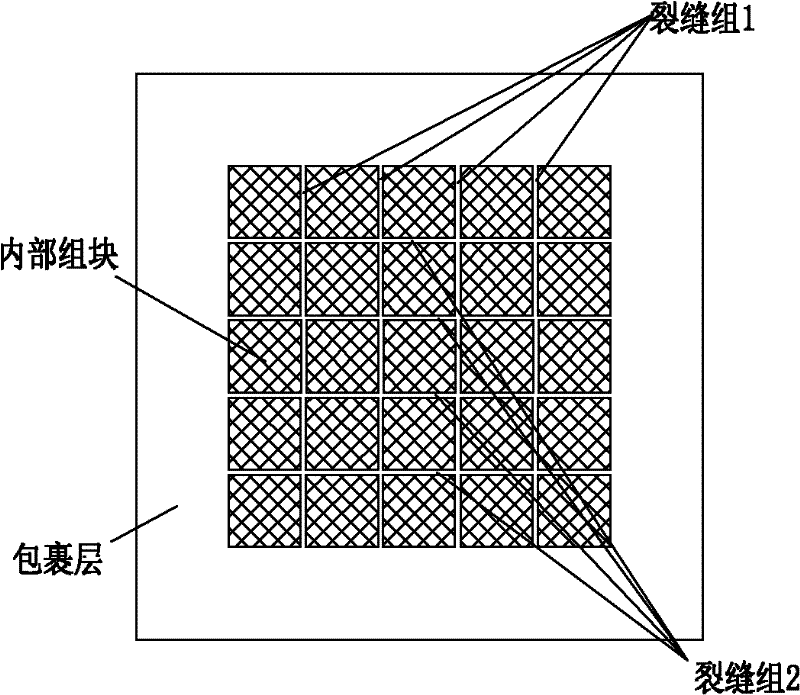

Method for Preparing Prefabricated Fractures in Hydraulic Fracturing Simulation Test Specimen

InactiveCN102289980AHigh similarityImprove controllabilityEducational modelsHydraulic fracturingMaterials science

The invention provides a method for preparing preset cracks in a hydrofracture simulation specimen. The simulation specimen is formed by splicing a plurality of internal chunks. The method comprises the following steps: firstly determining sizes, shapes and mutual positions of internal chunks for forming the simulation specimen according to crack morphology of a to-be-simulated stratum; manufacturing an internal chunk module according to the size and shape of each internal chunk; selecting a casting material to cast the internal chunks; then splicing and combining the internal chunks according to the mutual positions, wherein preset cracks are formed by contact surfaces among the intern chunks; casting a cladding layer on the periphery of the spliced combined component, thus forming a simulation specimen containing a plurality of preset cracks. The method can set the preset cracks in any quantity and any shapes in the simulation specimen so that the simulation specimen is more similarto the actual stratum so as to improve the accuracy of the simulation test.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

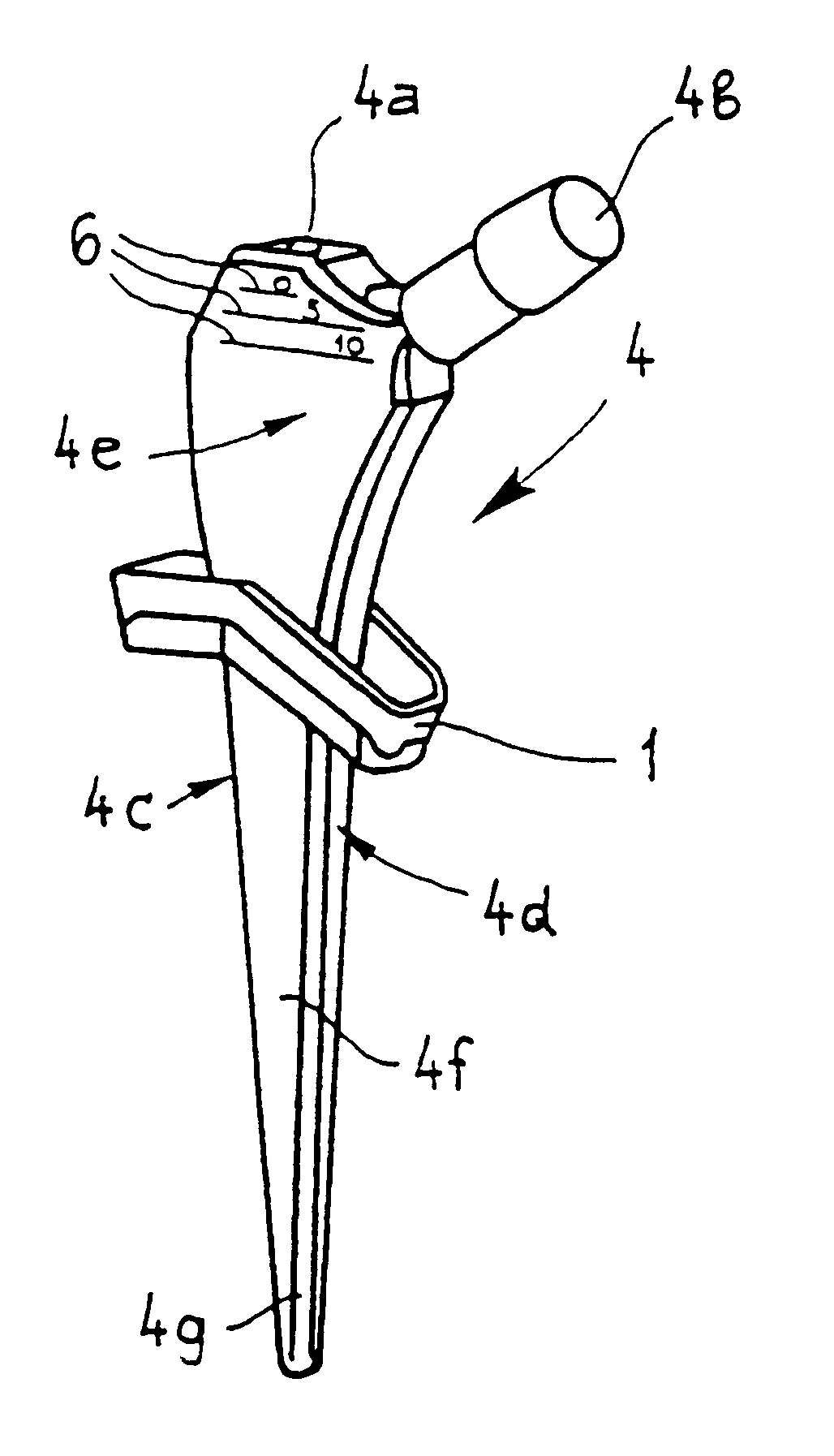

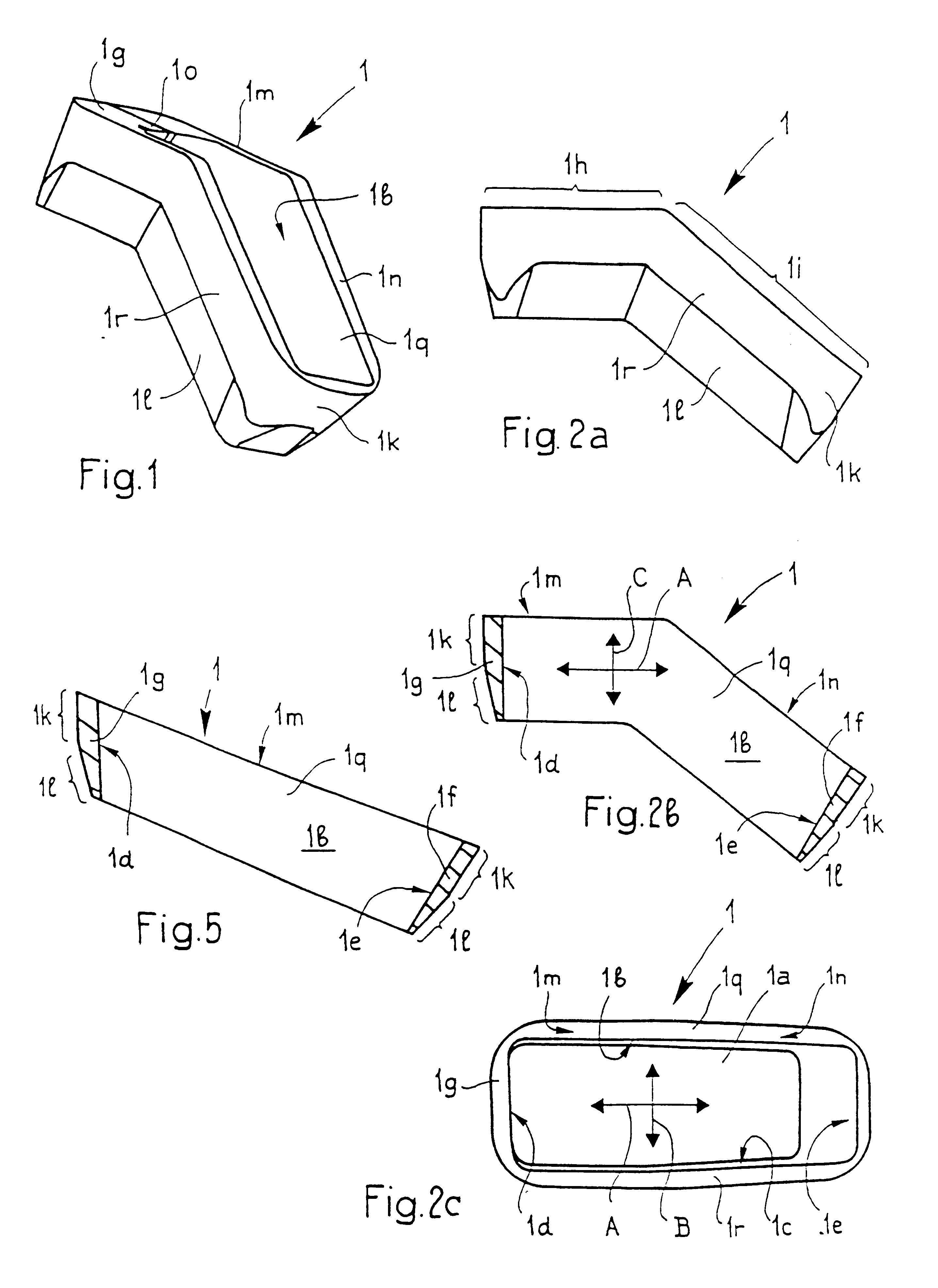

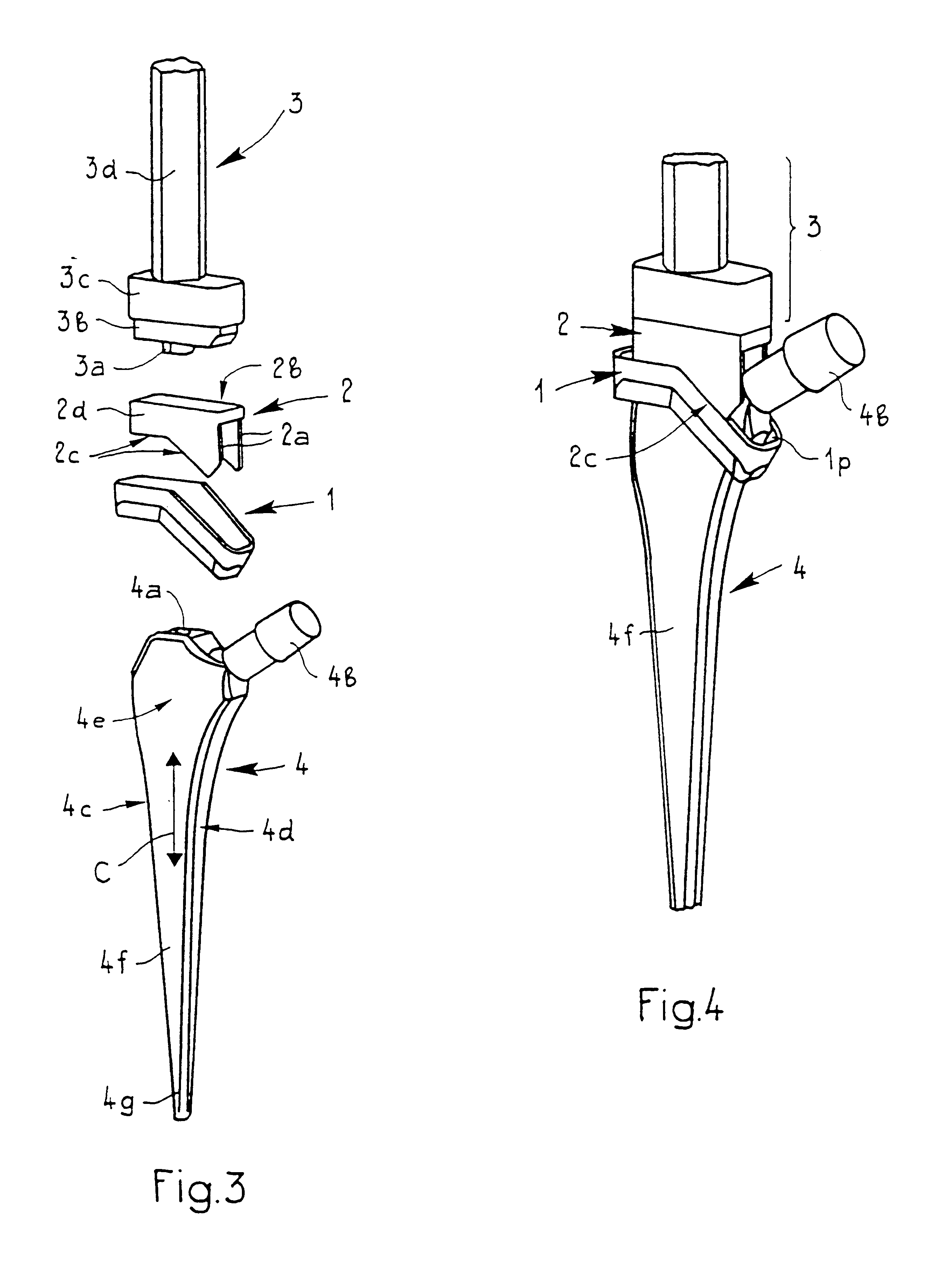

Kit for implanting a cementable endoprosthesis

Owner:PLUS ENDOPROTHETIK AG

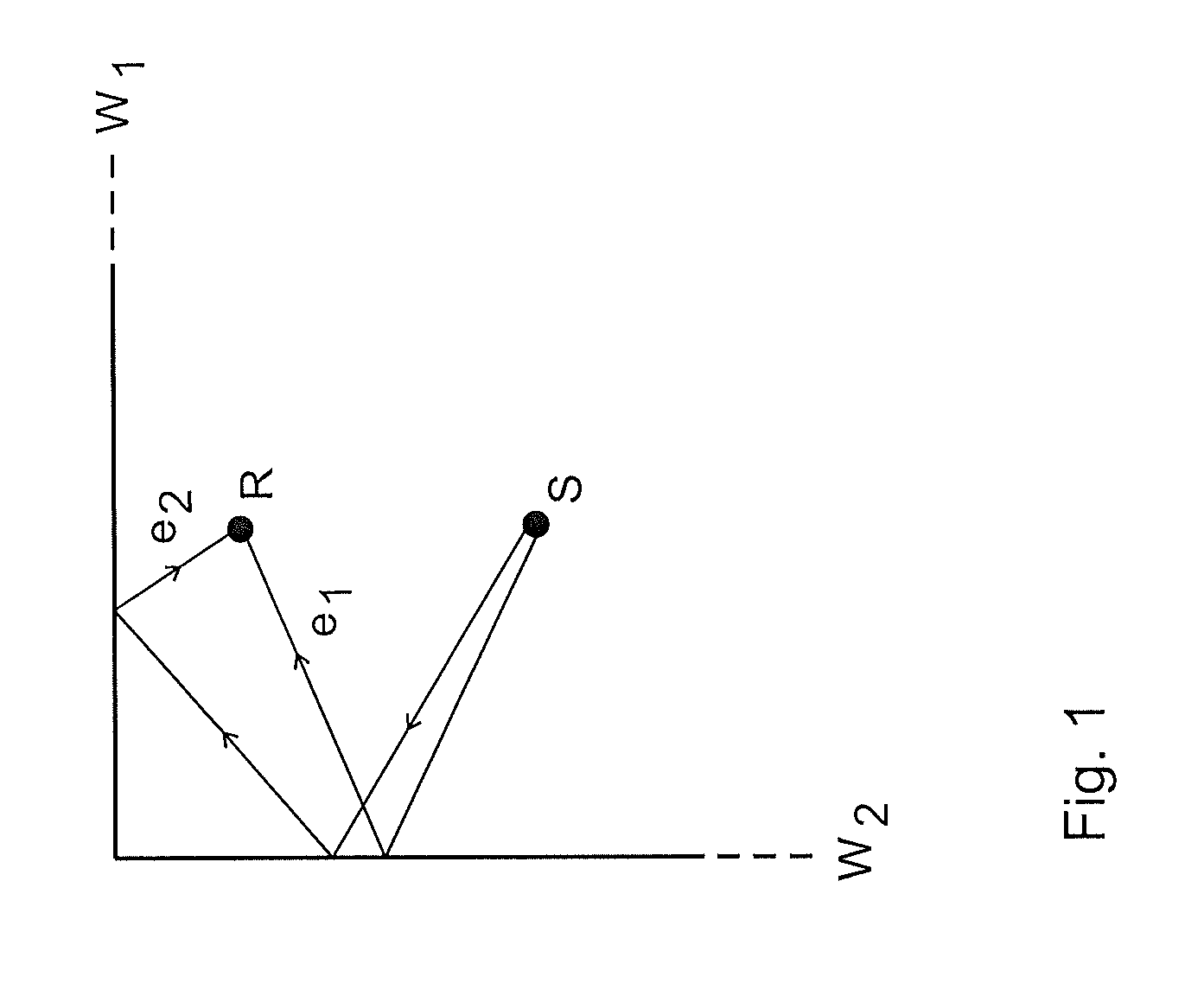

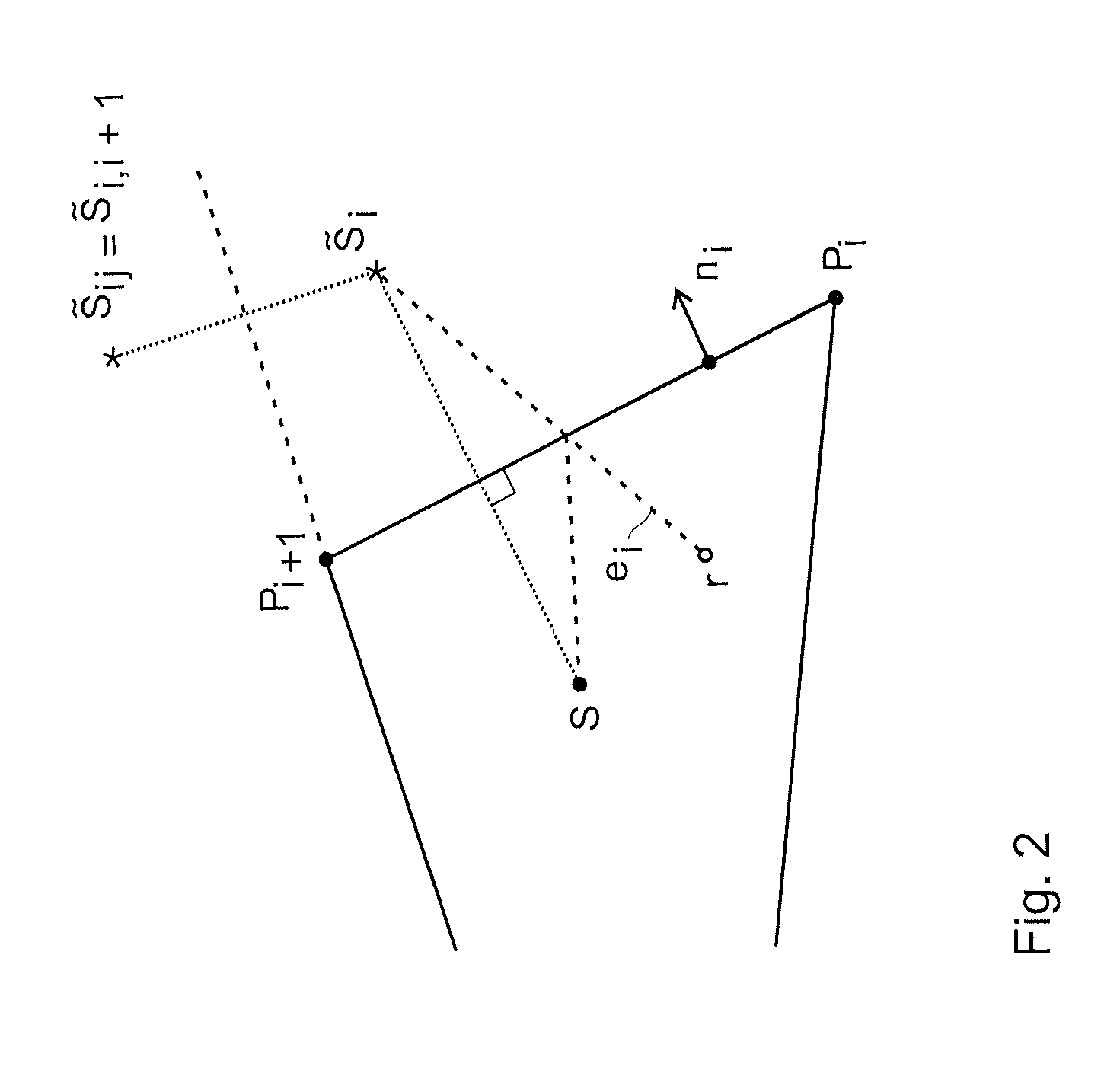

Method and a system for determining the geometry and/or the localization of an object

InactiveUS20140180629A1Multiple microphoneReduce in quantitySurveying instrumentsReverberation timeObject basedDistance matrix

A method for determining the geometry and / or the localisation of an object comprising the steps of:sending one or more signals by using one transmitter;receiving by one or more receivers the transmitted signals and the echoes of the transmitted signals as reflected by one or more reflective surfacesbuilding by a computing module a first Euclidean Distance Matrix (EDM) comprising the mutual positions of the receivers;adding to the EDM matrix a new row and a new column, the new row and a new column comprising time of arrivals of said echoes and computing its rank or distance to an EDM matrixdetermining the geometry and / or the position of the object based on said rank or distance.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

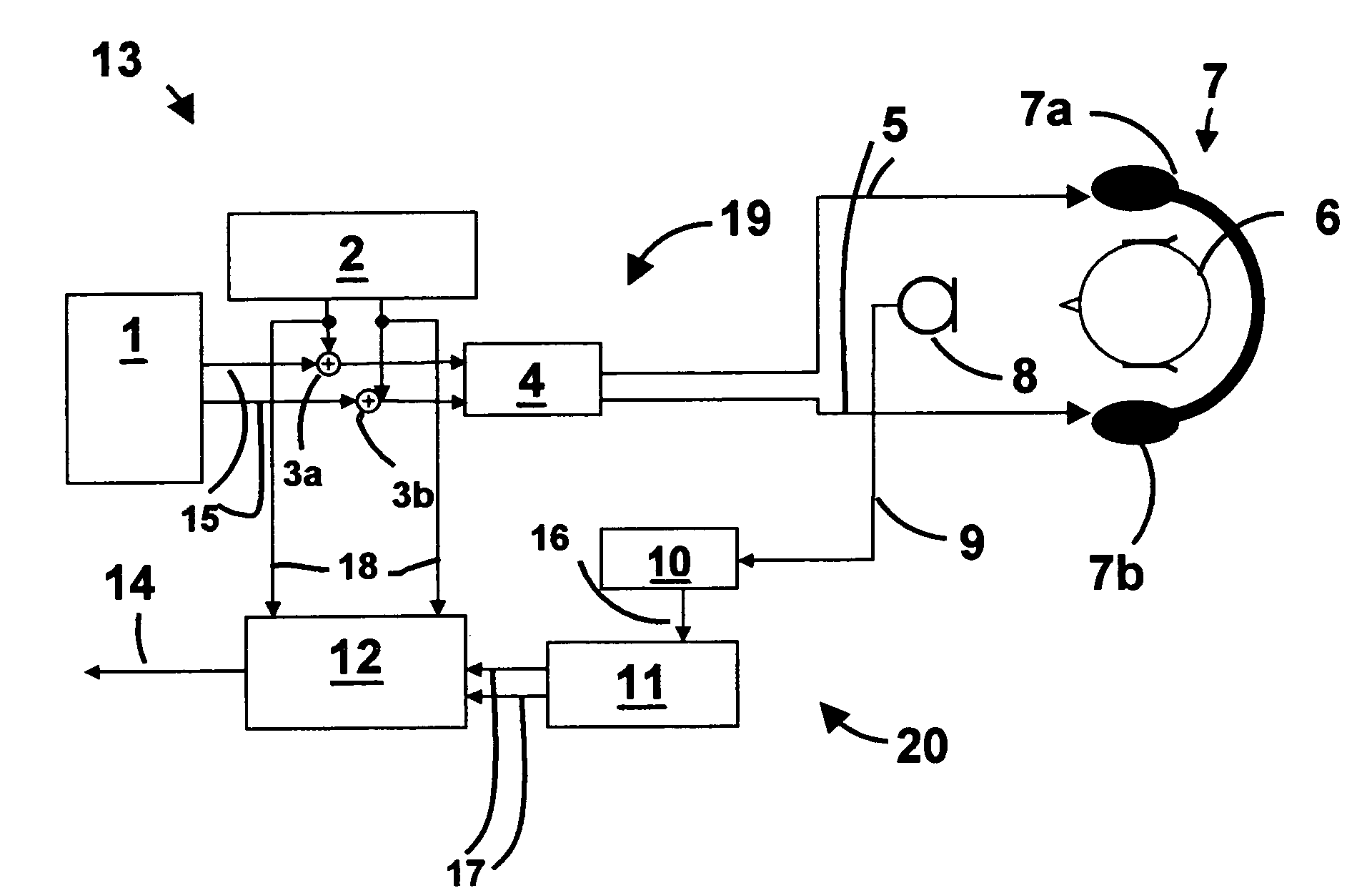

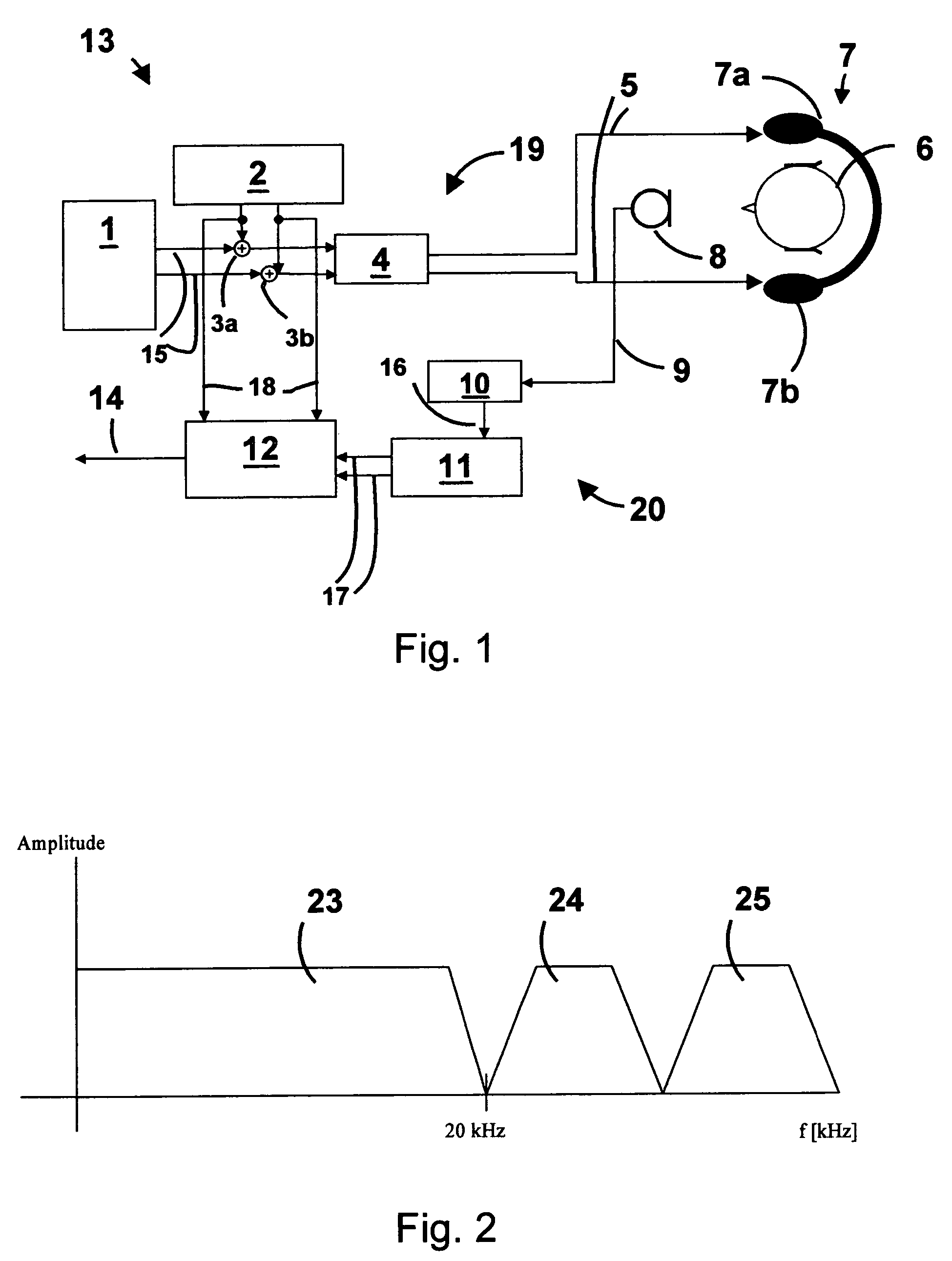

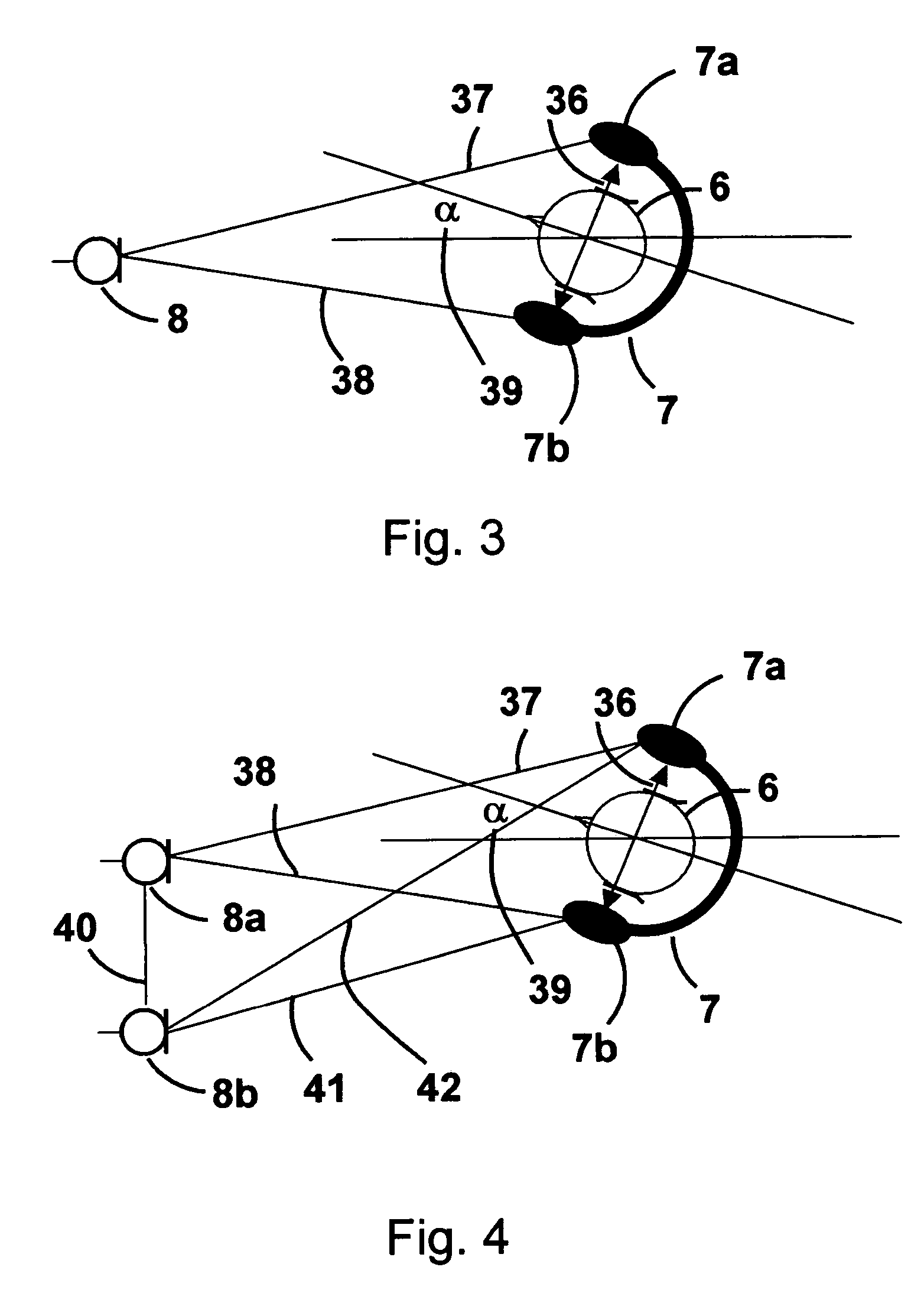

Method and device for generating information relating to relative position of a set of at least three acoustic transducers (as amended)

ActiveUS20050226437A1Direction finders using ultrasonic/sonic/infrasonic wavesEarpiece/earphone attachmentsSonificationTransducer

The invention relates to a method and device for generating data about the mutual position of at least three acoustic transducers. The aim of the invention is to make it possible to continuously measure and calculate the mutual position of at least three acoustic transducers, particularly the rotation and the position of a human head wearing headphones within a room without using any additional transmitter element on the head, headphone, or body of the listener, during audio playback. This aim is achieved by connecting the acoustic transducers to a digitally operated system which comprises an output path emitting audio signals to first and second acoustic transducers, an input path receiving audio signals from the third acoustic transducer, an audio signal source that is connected to the output path, an ultrasound generator that is connected to the output path, and an information generator which indicates a position and is connected to the input path.

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

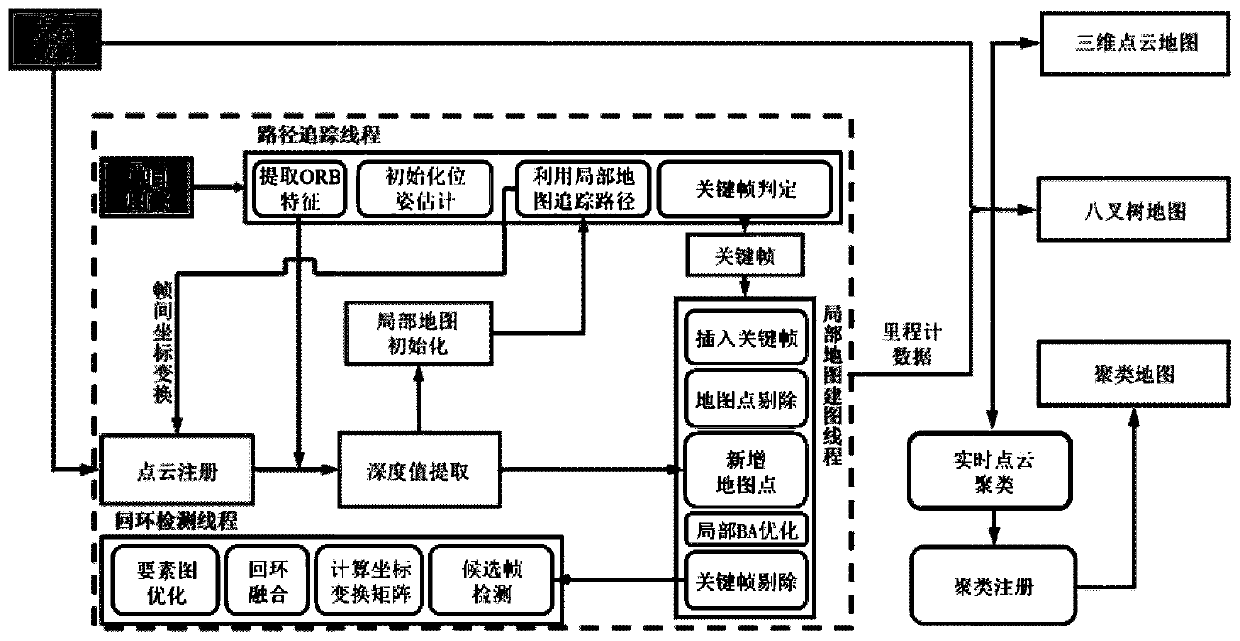

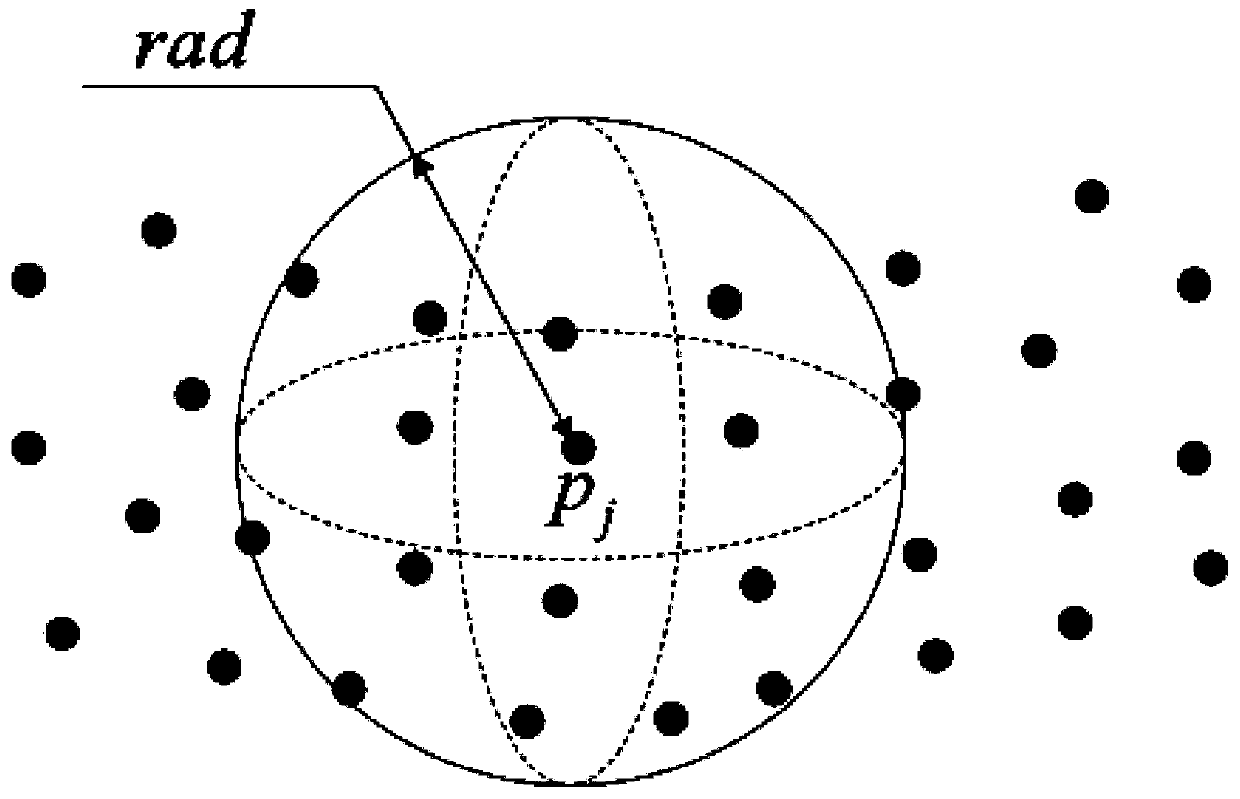

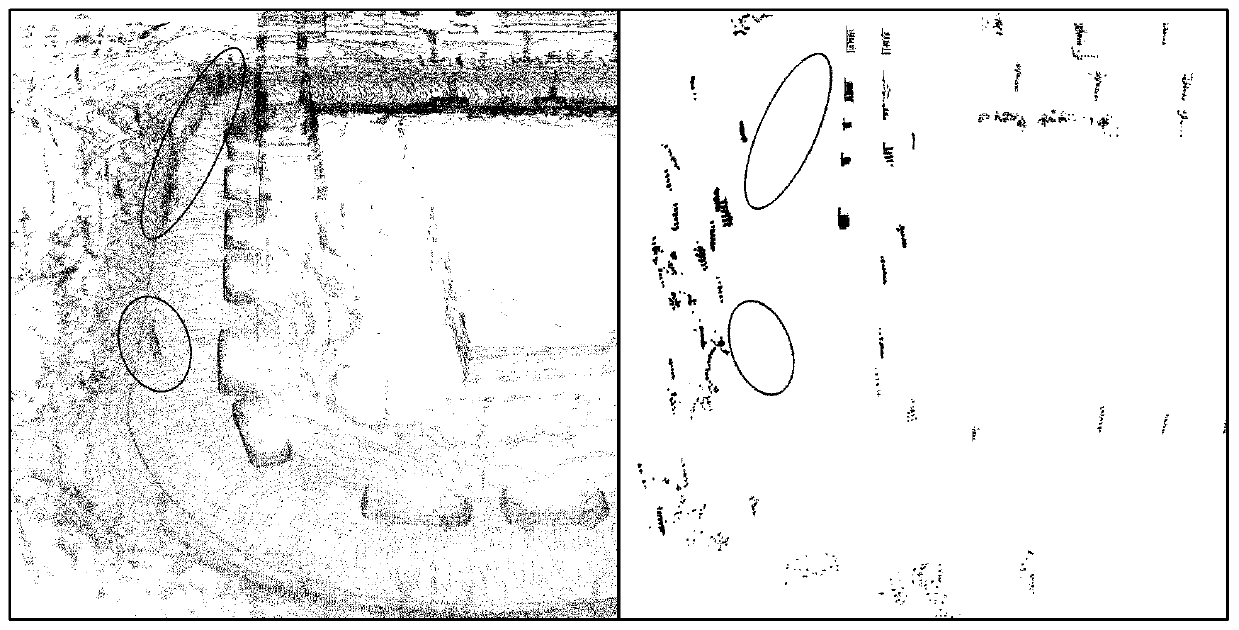

Clustering map creating method and repositioning method based on matching of clustering map and position descriptor

ActiveCN110084272ARespond effectively to adverse changesHigh retargeting success rateCharacter and pattern recognitionPoint cloudSystem structure

The invention discloses a clustering map creating method and a repositioning method based on matching of a clustering map and a position descriptor. The invention provides a three-dimensional visual laser SLAM system with a complete system structure and a cluster map creating method. The repositioning method of the unmanned vehicle is designed based on the clustering map and the position descriptor. A clustering map consistent with the scale of a real scene is created for an urban dynamic environment. A position descriptor used for describing point cloud clustering position characteristics isdesigned, and reliable repositioning of the unmanned vehicle in the urban environment is achieved through matching and screening of the position descriptor. By ignoring the change of the shape of a single object and focusing on the mutual position relation between different objects, the repositioning method provided by the invention can effectively cope with the adverse change of various scene conditions, realizes higher repositioning success rate, and has wider application prospect and higher research value.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

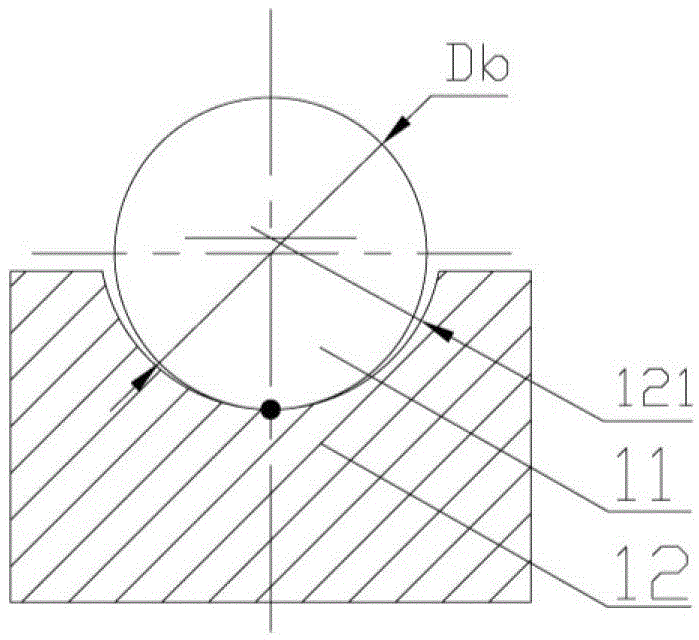

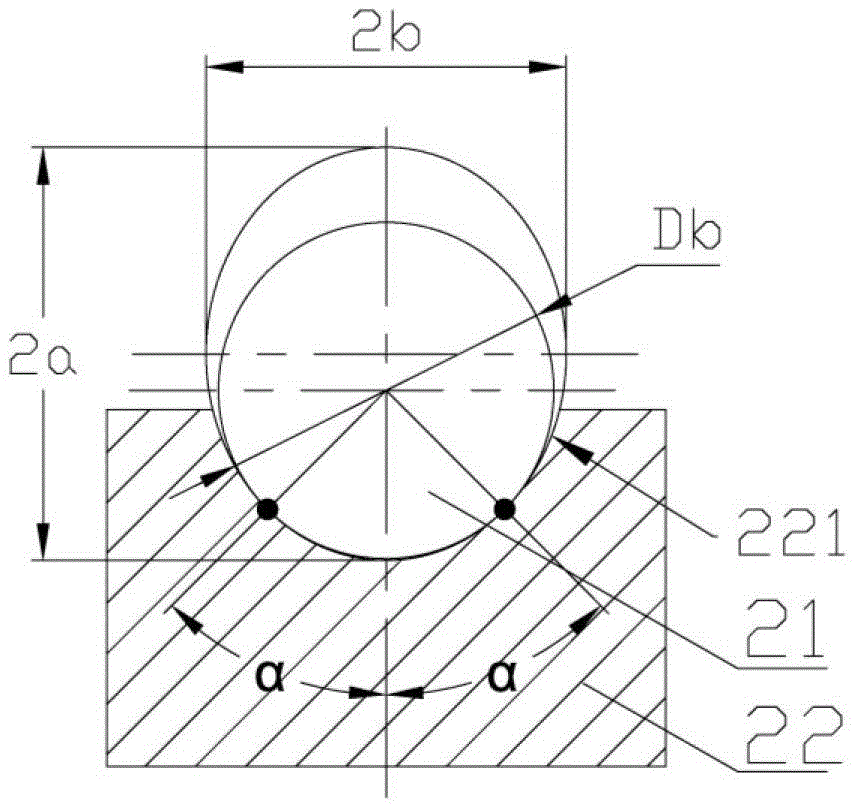

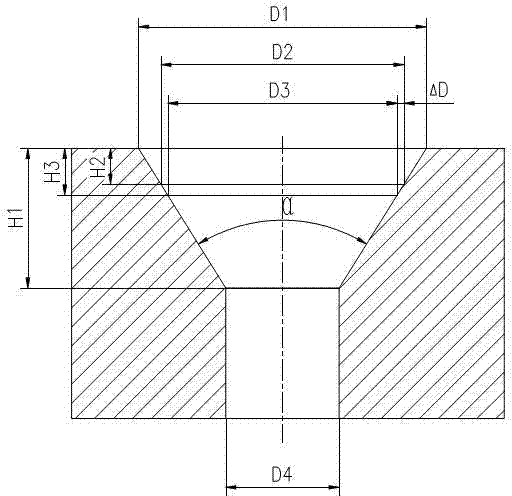

Machining method of rolling bearing formed by whole and precise hard turning and molding of sleeve ring

InactiveCN103331456AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesParticle adhesionEnvironmental resistance

The invention provides a machining method of a rolling bearing formed by whole and precise hard turning and molding of a sleeve ring. The machining method is characterized by comprising the following steps: after quenching and annealing heat treatment of the sleeve ring, carrying out the whole and precise hard turning and molding; and then combining and assembling a rolling body, wherein a sleeve ring rolling path comprises a fixed-curvature-groove-shape rolling path, a non-groove-shaped rolling path, a variable-curvature-shaped rolling path and a non-groove-shaped rolling path according to section shapes. The machining method disclosed by the invention overcomes the defects in the prior art that (1) performance defects on a machining surface, including grinding burn, a grinding metamorphic layer, grinding tensile stress, abrasive particle adhesion, scratches and the like, are caused by grinding and molding the sleeve ring; (2) shape defects on the machining surface that mutual position precision of all parts is not high, the shape of the rolling path cannot be accurately guaranteed and the like, are caused by carrying out a plurality of times of machining on different surfaces, even the same surface; (3) the defects that large investment of equipment, a tool clamp and personnel, and high machining cost are caused; and (4) the defects that a cutting solution needs to be used and the machining method is not environment-friendly enough are caused. The invention provides an anti-fatigue and green machining method which has the very great engineering actual meanings.

Owner:SHANGHAI F&S BEARING TECH

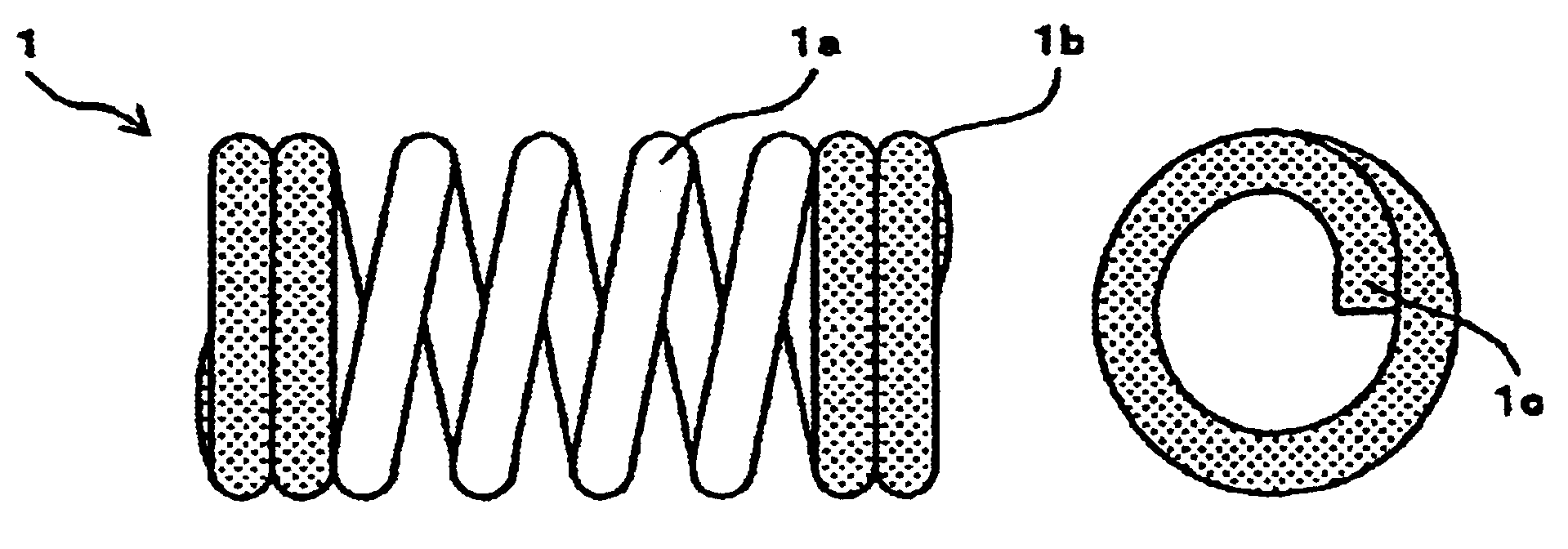

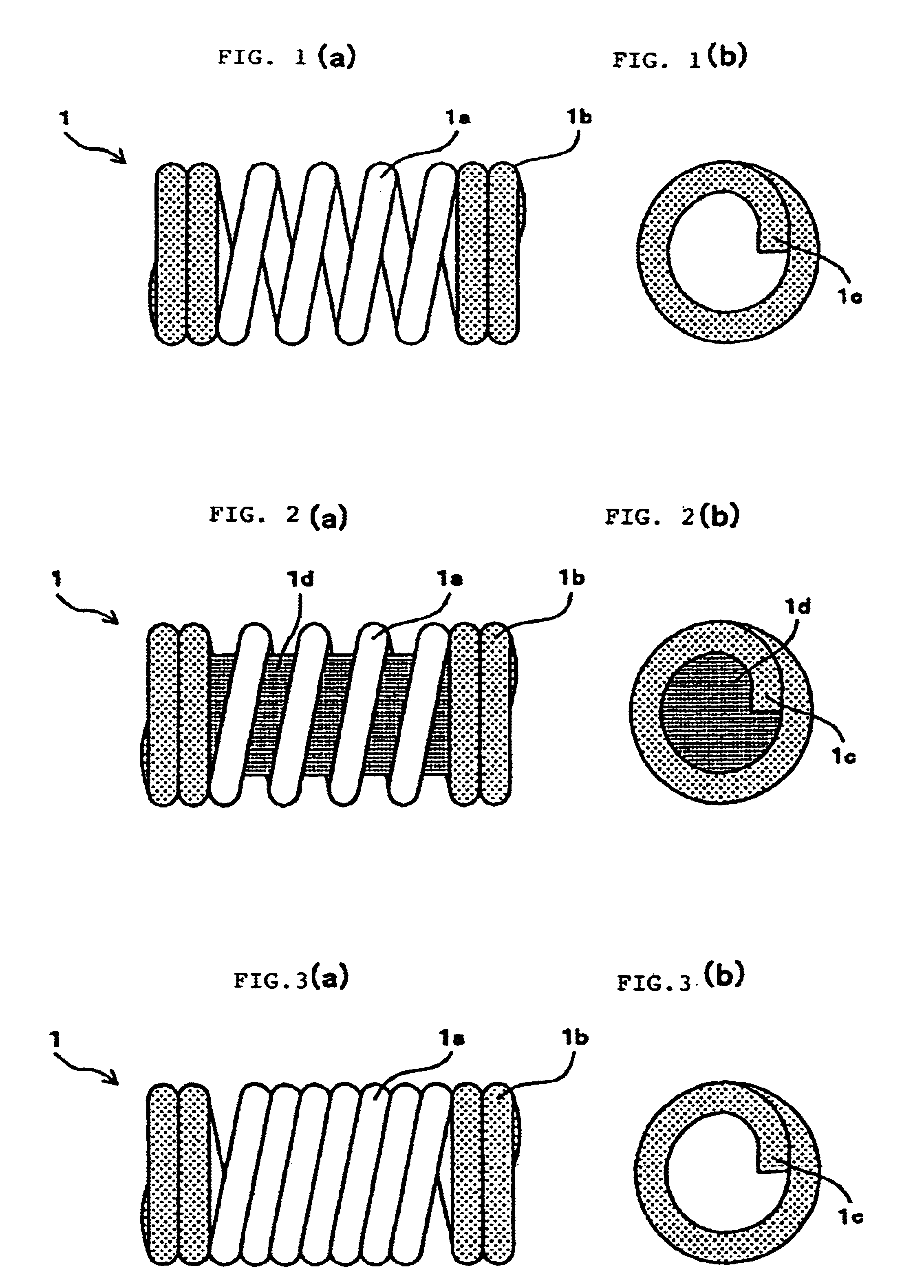

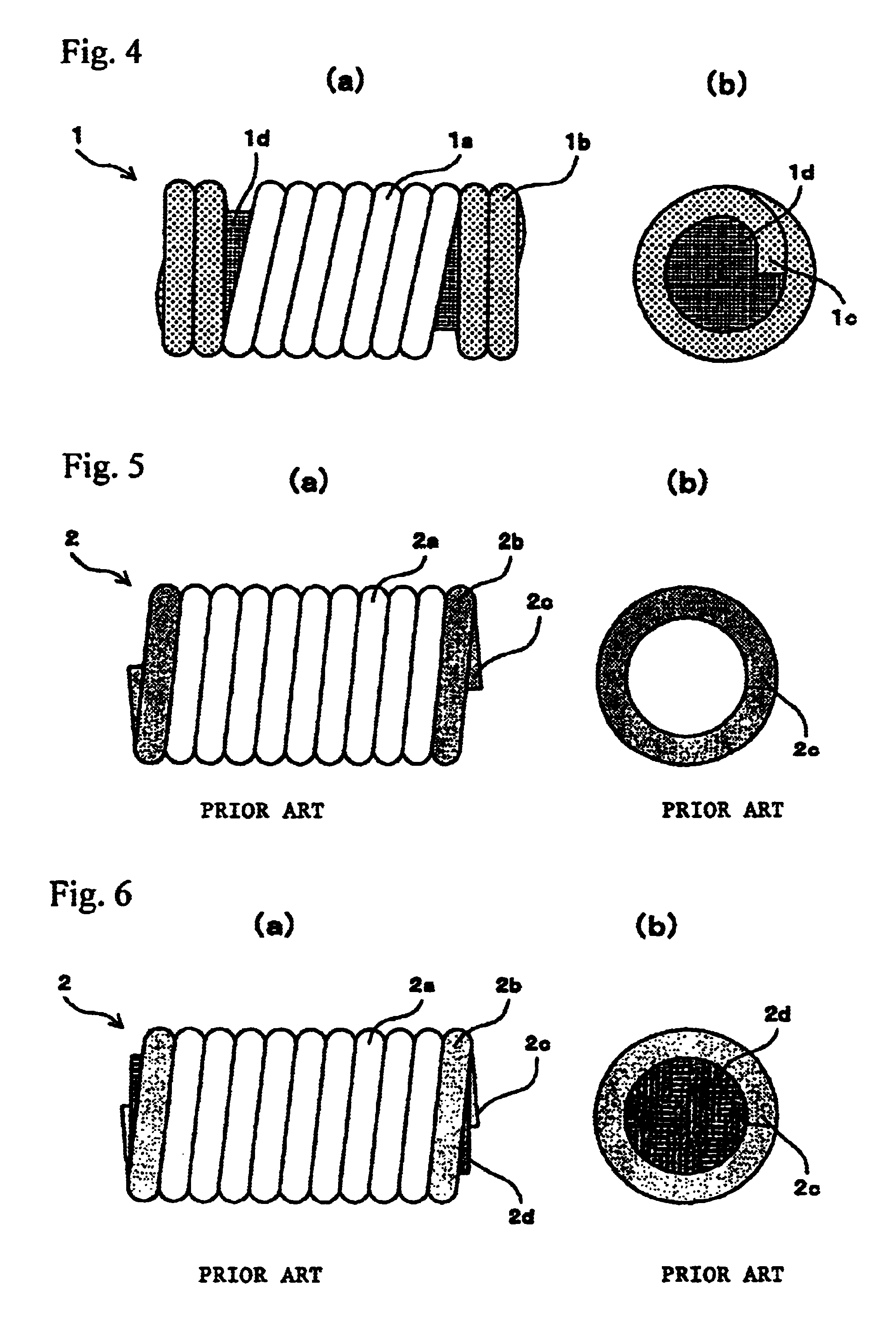

Coil filter and method for manufacturing the same

InactiveUS6940366B2Multiple-port networksTransformers/inductances coils/windings/connectionsSurface mountingWide band

The present invention provides a coil filter suitable for surface mounting on an electronic circuit board by automatic mounting and capable of realizing wide band isolation excellent in high-frequency characteristics without requiring consideration for the mutual position of parts. The coil filter functions to block electromagnetic waves or high-frequency signals propagating while being superimposed on a DC power supply, signal, or the like of an electronic apparatus such as an electronic circuit board. Conducting wires are bonded electrically at coil end parts such that a conducting wire part wound by one turn or more constitutes a short ring conducting in a ring shape on both sides of an intermediate part in which electrically insulated conducting wires are wound. End parts of the conducting wire are positioned on the inner side of the outermost circumferential part of the coil-shaped end faces.

Owner:KOMIYA KUNIFUMI

Method and device for generating information relating to the relative position of a set of at least three acoustic transducers

ActiveUS7272073B2Near-field transmissionDirection finders using ultrasonic/sonic/infrasonic wavesTransducerEngineering

The invention relates to a method and device for generating data about the mutual position of at least three acoustic transducers. The aim of the invention is to make it possible to continuously measure and calculate the mutual position of at least three acoustic transducers, particularly the rotation and the position of a human head wearing headphones within a room without using any additional transmitter element on the head, headphone, or body of the listener, during audio playback. This aim is achieved by connecting the acoustic transducers to a digitally operated system which comprises an output path emitting audio signals to first and second acoustic transducers, an input path receiving audio signals from the third acoustic transducer, an audio signal source that is connected to the output path, an ultrasound generator that is connected to the output path, and an information generator which indicates a position and is connected to the input path.

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

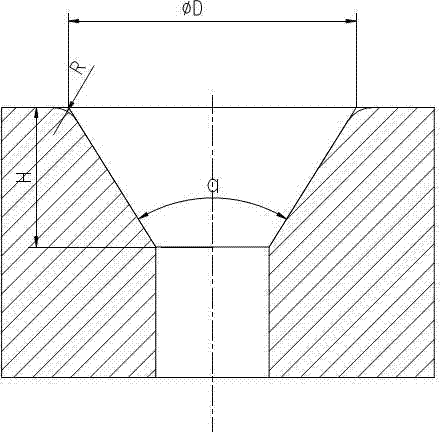

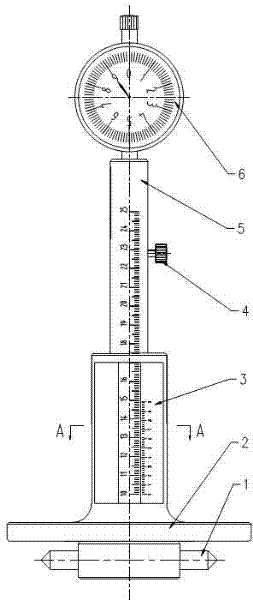

Device for measuring taper hole

InactiveCN102506632AMeet the requirements of measurement accuracyLow technical requirementsAngles/taper measurementsMechanical diameter measurementsEngineeringMachining process

The invention relates to a device for measuring a taper hole, which is composed of a base (2), a slide rod (5), a slide core (8), a contact (1) and a dial indicator (6), wherein the contact (1) is installed in a hole at the lower end of the slide rod (5) and the slide core (8) is installed in the slide rod (5); the dial indicator (6) is installed at the upper end of the slide rod (5) through an expansion ring (10); a locking screw (4) on the slide rod (5) is used for limiting a mutual position of the slide core (8) and the slide rod (5); the contact (1) is reliably contacted with the slide core (8) by springs (7 and 9) in the slide rod (5); the slide rod (5) is installed in the middle of the base (2) and the slide rod (5) can be observed from a window (3) on the side surface of the base (2); scales are arranged on the window (3) of the base and the slide rod, and a vernier depth gauge is formed by the base (2) and the slide rod (5). According to the device, the requirements on the measurement precision of the taper hole can be met and the requirements on an operator are not high; and the device provided by the invention can be used in a process after machining and a machining process, and has the characteristics of wide adaptability, convenience for manufacturing and the like.

Owner:CITIC DICASTAL

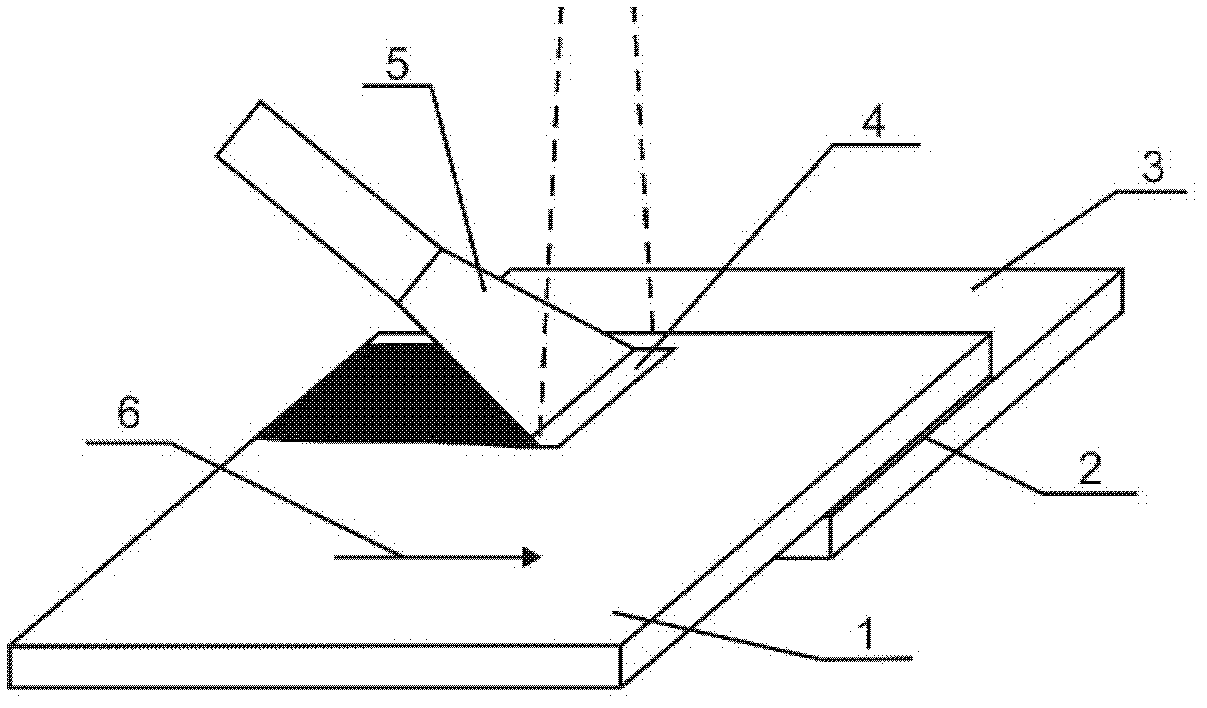

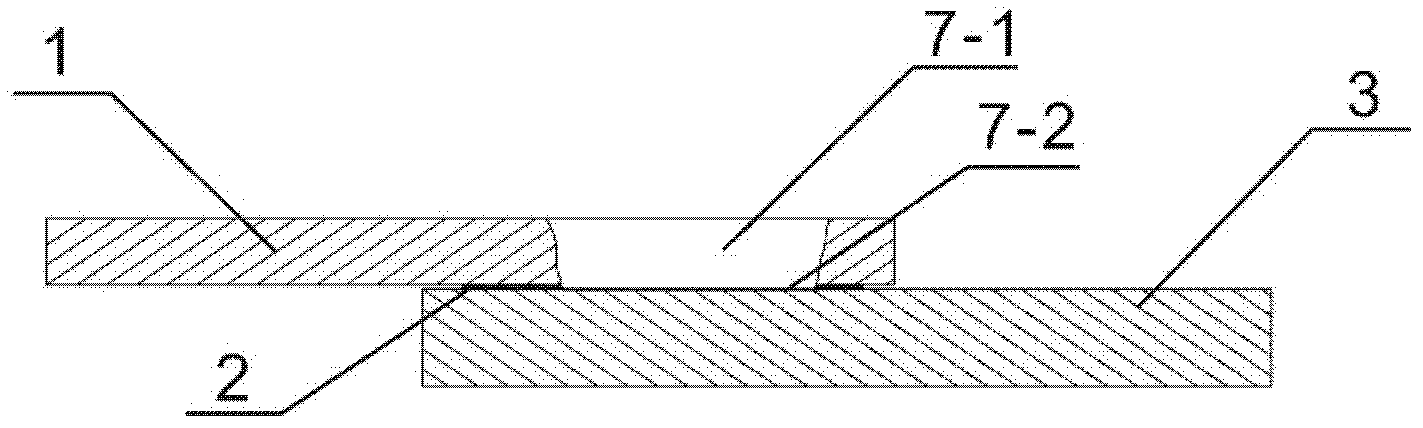

Method for laser powder-filled welding of aluminum/steel dissimilar metal joint without brazing flux

InactiveCN102407404AAchieve weldingImprove absorption rateLaser beam welding apparatusHigh power lasersMetal powder

Owner:BEIJING UNIV OF TECH

Floor panel and floor covering consisting of such floor panels

InactiveUS8261508B2Efficient and effective absorbanceAvoid makingWallsCellulosic plastic layered productsCouplingPanelling

Floor panel of the type having, at least at two opposite sides, coupling means enabling two of such floor panels to be locked in a mutual position at which the upper edges of the respective floor panels are located substantially in the same horizontal plane, with a space being present at the level of the upper edges between the respective sides and where the respective coupled floor panels in said mutual position are mutually locked free from play at least in the horizontal direction. The space between the sides defines a mutual distance of one to three millimeters between the upper edges.

Owner:FLOORING IND LTD

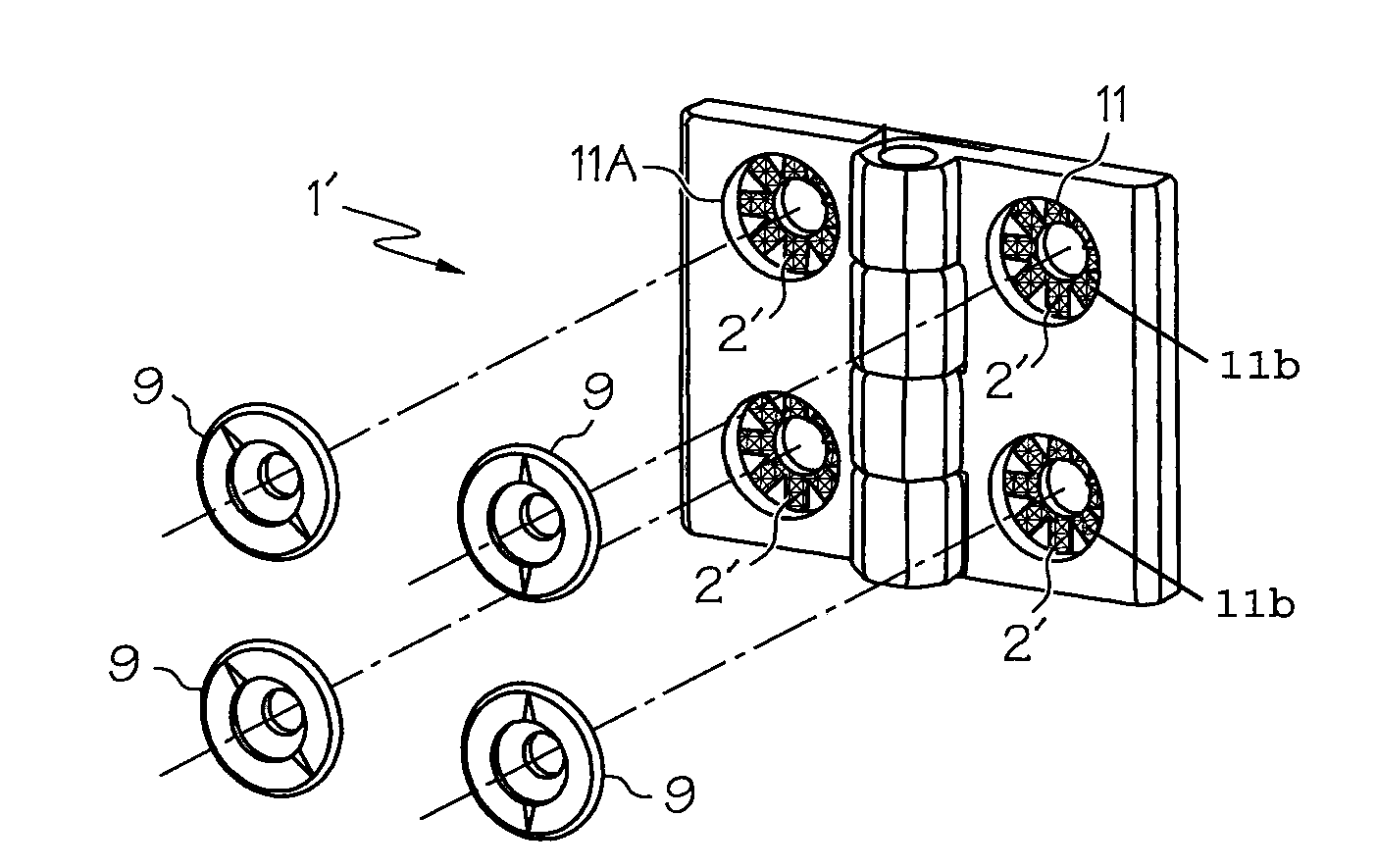

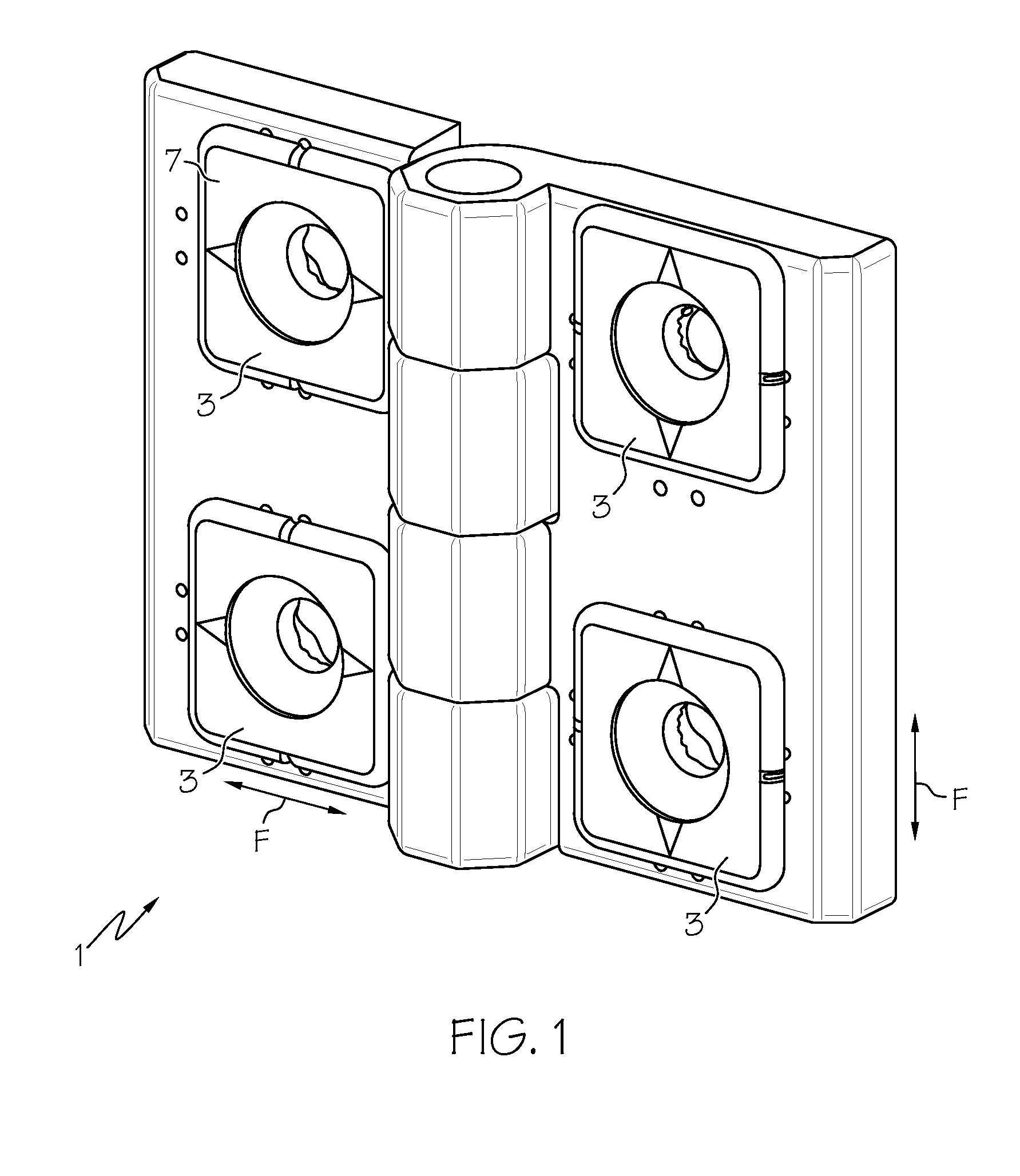

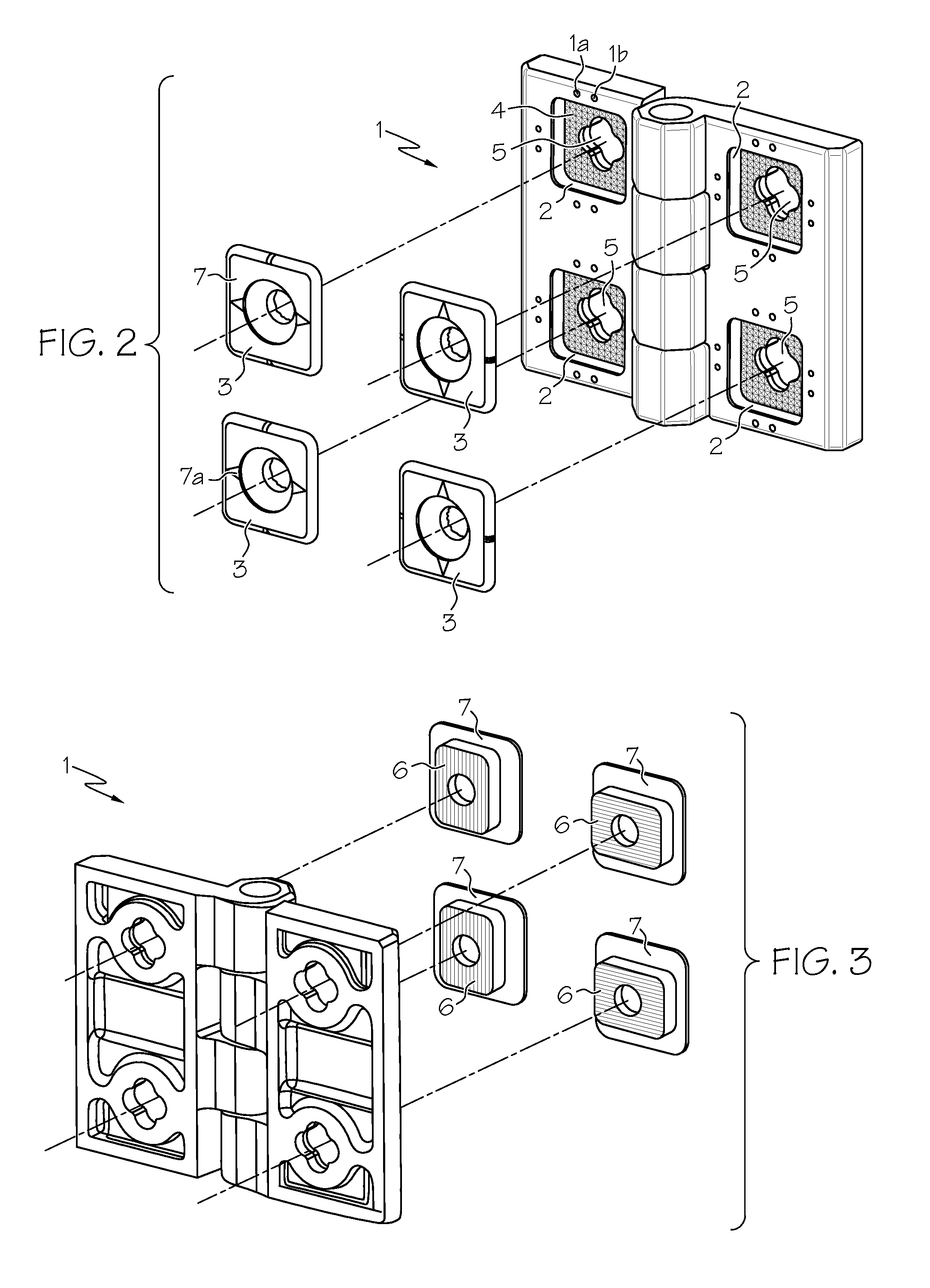

Adjustable hinge

The invention concerns a hinge of the type including of a pair of members of a hinge (1), each having a pair of screw-anchoring holes (5). The holes are obtained within housing seats (2) prearranged for the introduction of adjusters (3, 9). Each adjuster includes a body (6) and a flange (7). The edge of the flange rests on the surface of each member of the hinge (1) in various mutual positions of the adjuster in its respective seat. According to the invention, said housing seats (2) have a centered-symmetry base layout, and guiding means (6, 11, 11a) are provided for guiding said adjuster body (6) into its respective housing seat (2) so as to allow the free movement of the adjuster (3, 9) in a single direction, among multiple possible directions, depending on the orientation of each adjuster (2) in its respective seat.

Owner:ELESA

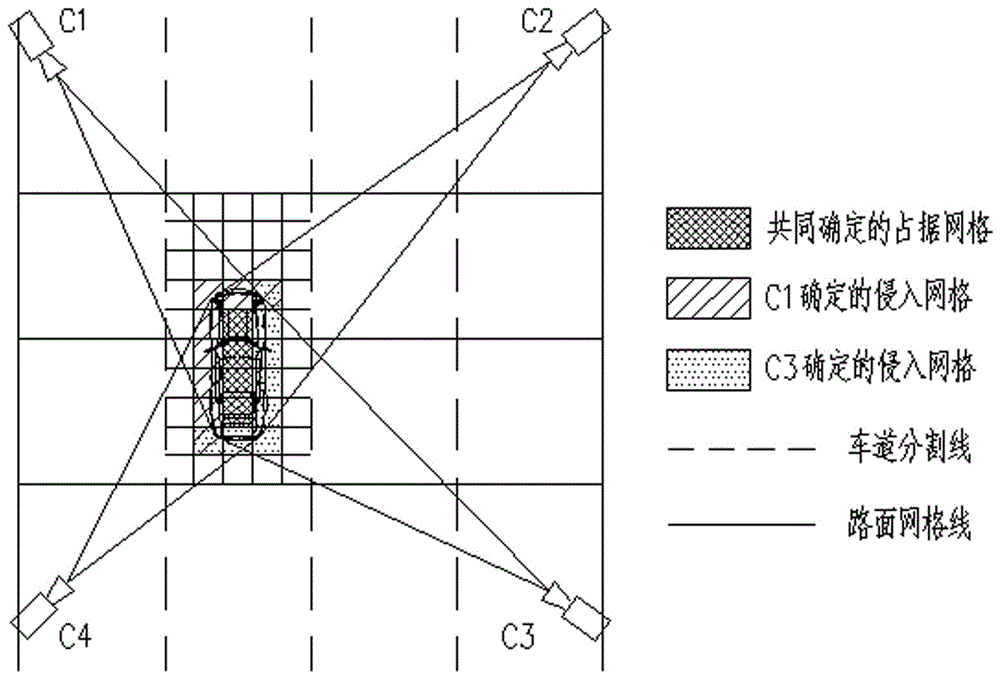

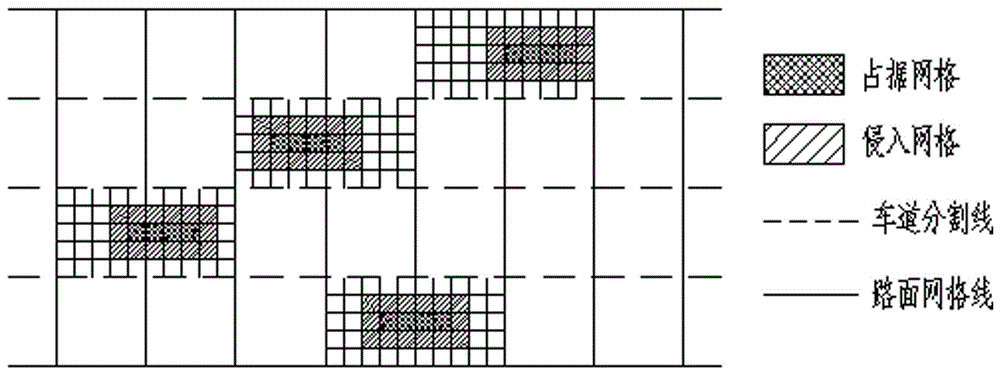

Vehicle-road cooperation auxiliary driving method based on road surface grid system

ActiveCN106571046AAchieve field of view coverageReal-timeArrangements for variable traffic instructionsDetection of traffic movementVideo monitoringVisual field loss

The invention relates to a vehicle-road cooperation auxiliary driving method based on a road surface grid system; the method is characterized by comprising the following steps: A, dividing a road into grids in forwarding and lateral directions; B, arranging a plurality of groups of video monitoring devices on roadsides, wherein each group of monitoring devices are formed by a plurality of cameras, thus realizing visual field coverage in certain road section scope; C, monitoring vehicles in a visual field domination area in real time, determining vehicle occupied road grids, transmitting vehicle positions and grid occupation information between the plurality of monitoring devices in real time, and determining the vehicle positions and sizes according to the vehicle occupied road grids; D, transmitting the road surface grid information to a plurality of vehicles in real time, and combining with the vehicle auxiliary driving system so as to cooperatively determine mutual position relations and relative speed vectors of surrounding vehicles. The method can grid the existing road so as to provide a fixed coordinate system for vehicle real time positioning determination, and the grid occupied distribution conditions can serve as simplified indexes, thus providing high efficiency support for vehicle-road cooperation works.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Device and process for quantitative assessment of the three-dimensional position of two machine parts, shafts, spindles, workpieces or other articles relative to one another

ActiveUS7672001B2High precisionExpand the measurement rangeUsing optical meansTarget surfaceLine sensor

An apparatus and a method that can be used for qualitative or quantitative determination of the three-dimensional location of two bodies relative to one another which can be used, for example, to determine the mutual position of two bodies according to angular or translational coordinates. Furthermore, the apparatus and method can be used in a measurement robot or in a coordinate measurement device. The device composed of a device for emitting a light beam which is fanned in several planes and at least three, preferably four or more, optoelectronic line sensors or linear sensors for determination of the incidence points of the light beam which has been flared in several planes on the line sensors or an upstream target surface.

Owner:PRUTECHNIK DIETER BUSCH AG

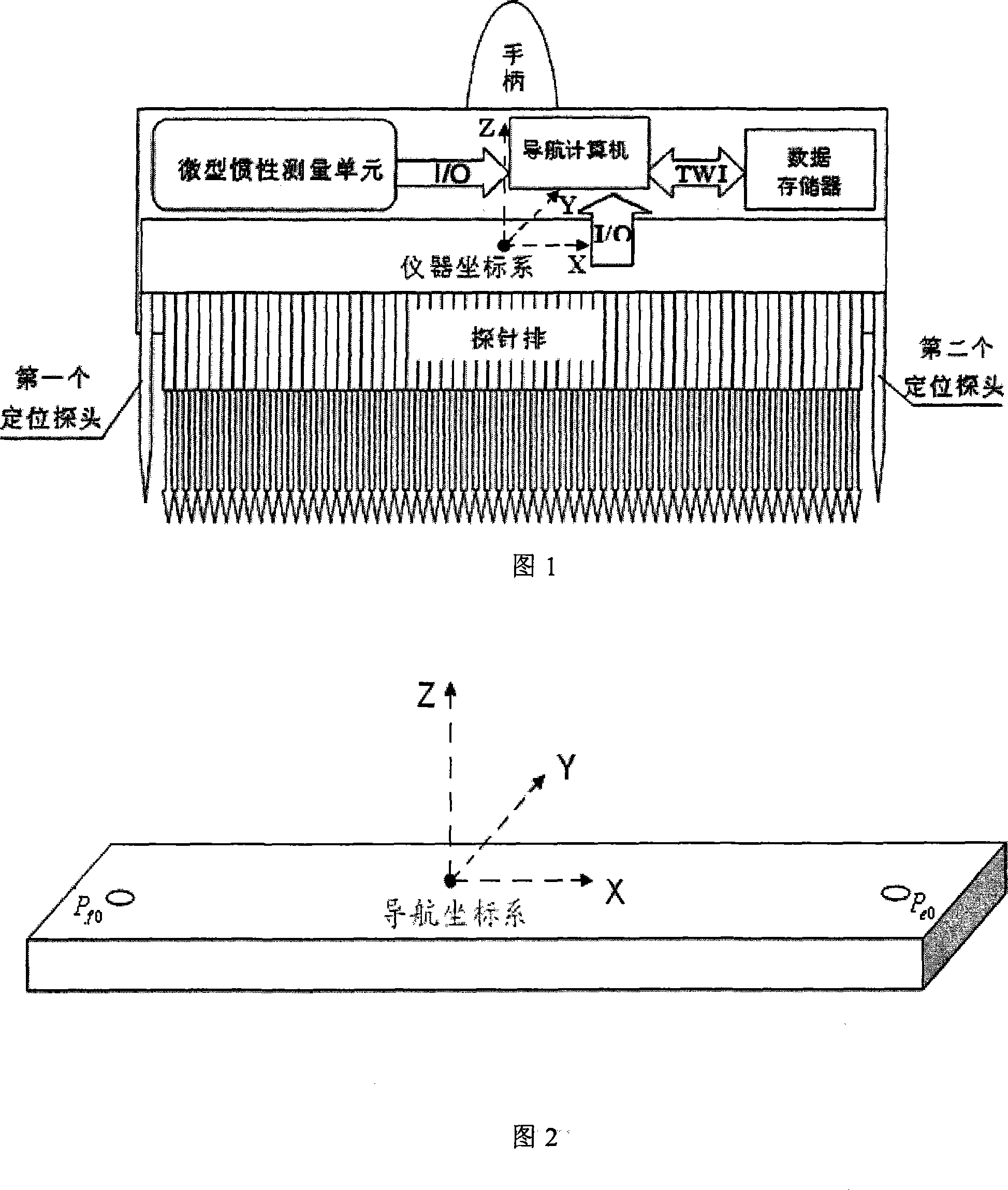

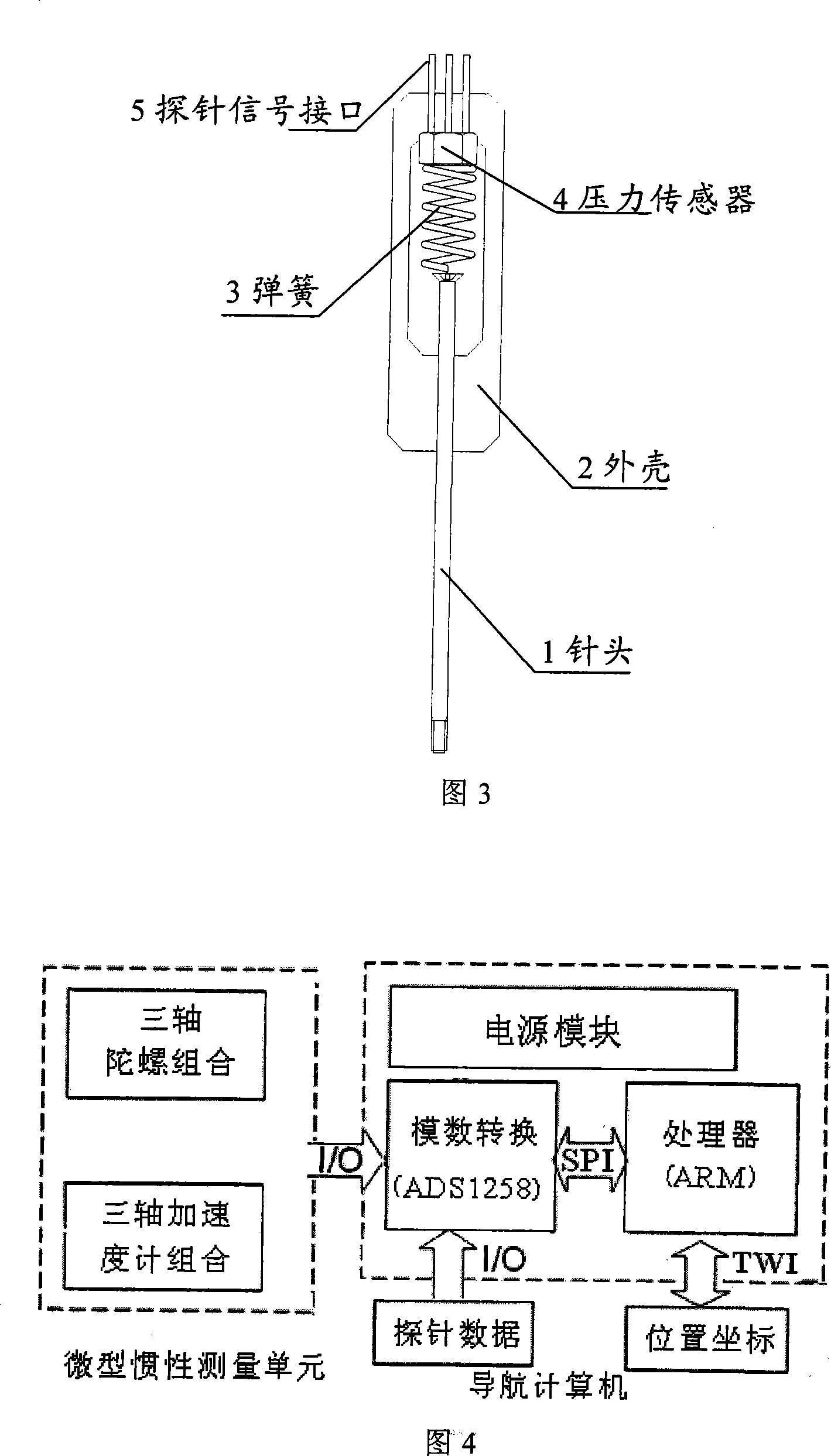

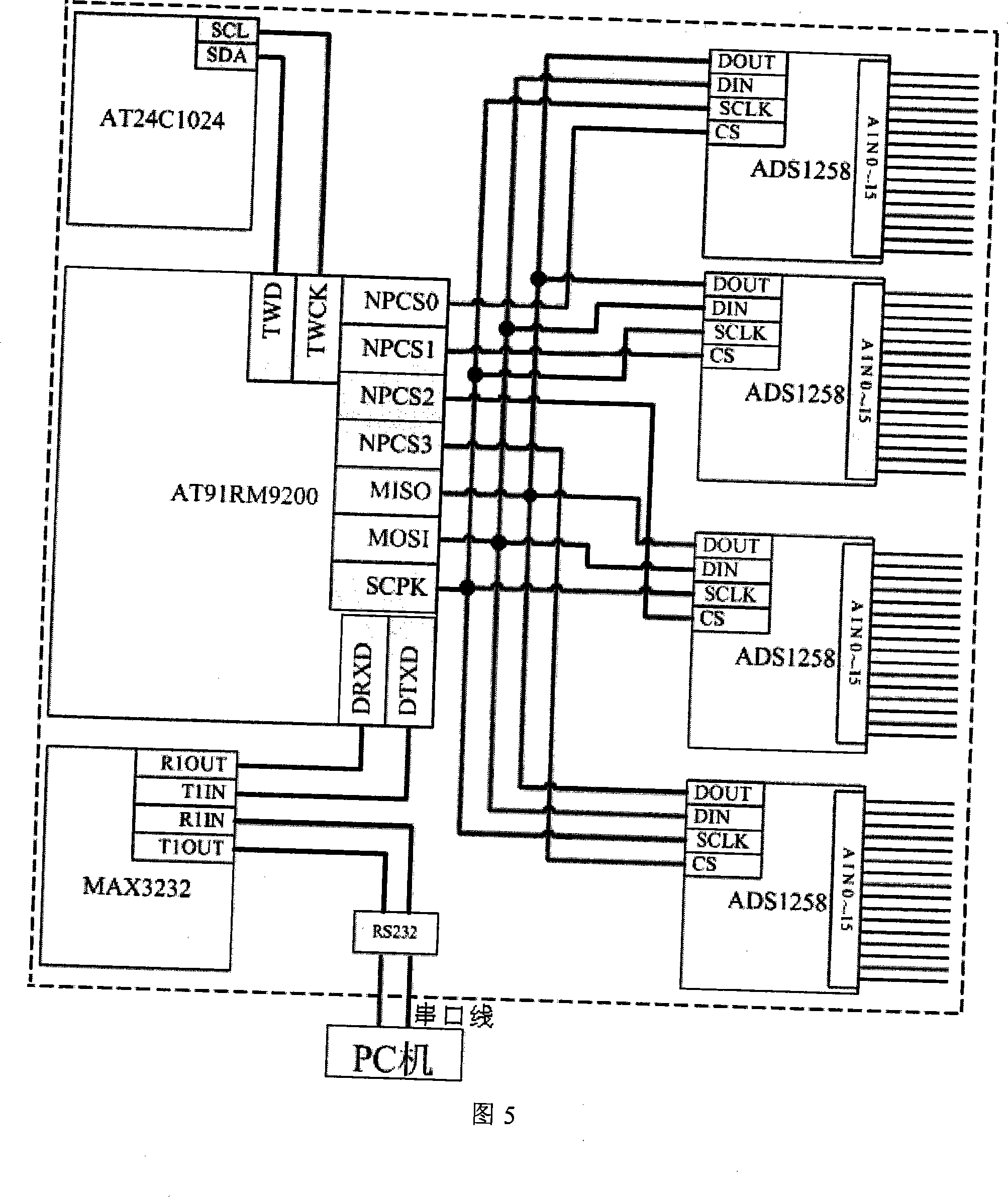

Device for measuring entity appearance by micro-inertial navigation

InactiveCN101246005ASimple structureEase of mass productionNavigation by speed/acceleration measurementsAviationData memory

The invention discloses a substance shape measuring device with micro inertial navigation, which comprises a probe group for shape data collecting, a strapdown inertial navigation system and a data storage; the probe group for shape data collecting consists of a row of stretchable probes with pressure sensors, the strapdown inertial navigation system consists of a micro inertia measuring unit and a navigation computer, implements alignment and then measures one surface of a substance, and further implements the alignment and the measurement till the end, and the substance shape is computed by processing software. The substance shape measuring device with micro inertial navigation has free movement, can measure the internal and external shape of the substance with a convenient posture, and has small volume, convenient operation, low cost and easy application generalization. The substance shape measuring device with micro inertial navigation is applicable for the accurate measurement of the size, shape and mutual position of three-dimensional complicated substances in the field of machinery, construction, aviation, spaceflight, war industry, automobiles and commercial manufacture, etc., particularly for the reverse engineering of various substances.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com