Patents

Literature

1298 results about "Steel box girder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A box girder bridge is a bridge in which the main beams comprise girders in the shape of a hollow box. The box girder normally comprises either prestressed concrete, structural steel, or a composite of steel and reinforced concrete. The box is typically rectangular or trapezoidal in cross-section.

A kind of steel truss bridge and its manufacturing method

ActiveCN102277825AImprove stabilityImprove securityTruss-type bridgeBridge structural detailsBridge deckEngineering

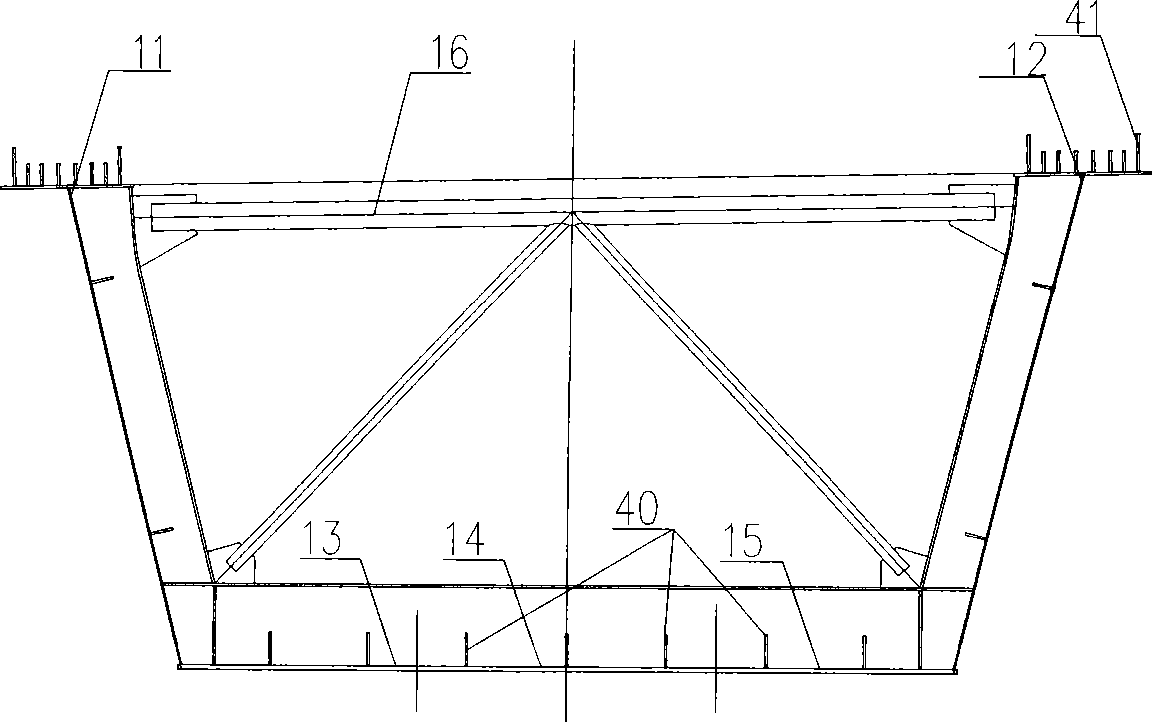

The invention discloses a steel truss bridge and a method for fabricating the same. The steel truss bridge comprises a steel box girder bridge deck, a main truss composed of two steel trusses, and a steel portal frame. The steel truss comprises an upper chord member, a lower chord member, and a web member which is connected with the upper chord member and the lower chord member through bolts. A sidewalk bracket is arranged outside each steel truss. The lower chord member is connected to the steel box girder bridge deck and the sidewalk bracket, respectively. Besides, the two steel trusses are connected through the steel portal frame. During fabrication, all the sections of the steel trusses, the steel portal frame and the bridge deck are independently fabricated, respectively; all the sections of the upper and lower chord members of the steel truss are pre-assembled circularly with the corresponding web members, and all the sections of the steel box girder bridge deck are pre-assembled with the corresponding lower chord members by an orthotectonic method, respectively; and the steel portal frame is pre-assembled with the steel trusses. The steel truss bridge disclosed by the invention completely meets the design requirements so that the stability and safety factor of the bridge can be enhanced; and by employing the fabricating method, positioning is accurate so that the risks during the field assembling can be reduced; and the construction period can be shortened.

Owner:JIANGSU JINGHU HEAVY IND

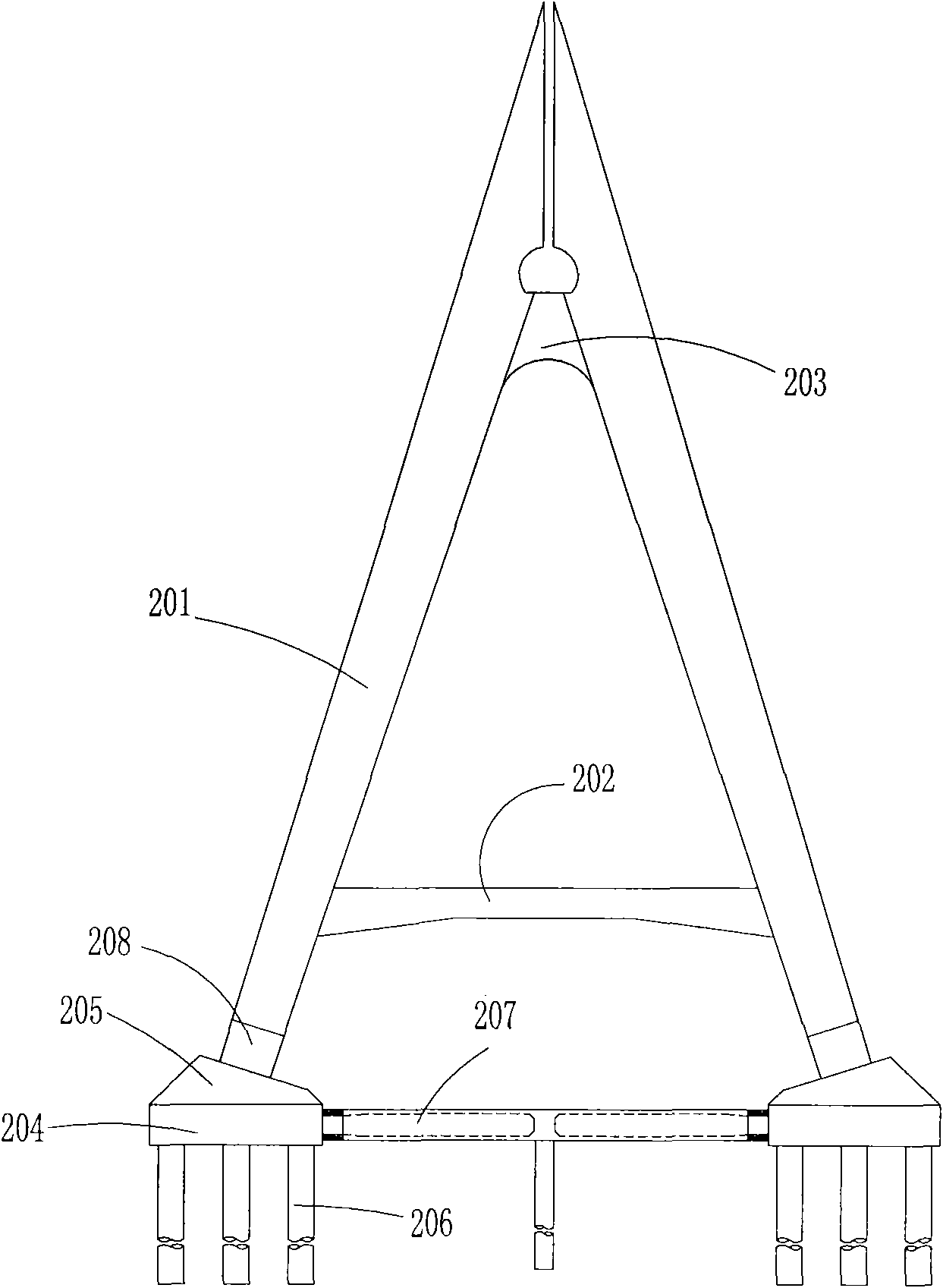

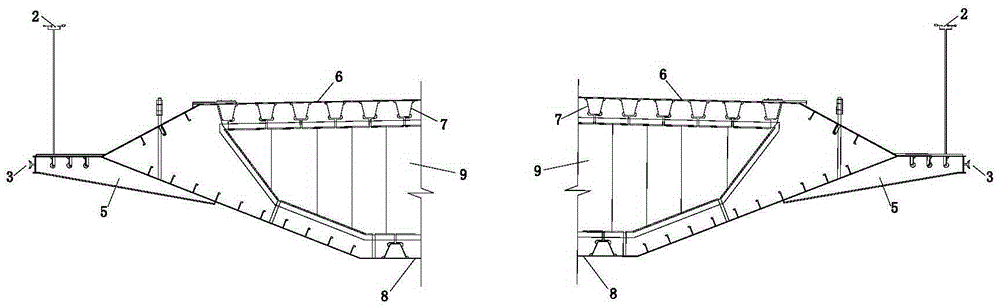

Construction method of single main cable inclined-suspender earth anchored suspension bridge

InactiveCN101914897AConstruction safetyGuarantee the quality of the projectSuspension bridgeFoundation engineeringTowerSteel box girder

The invention discloses a construction method of a single main cable inclined-suspender earth anchored suspension bridge, which is characterized by comprising the following steps of: respectively completing anchoring construction, main tower construction, steel box girder construction, main cable construction and suspender construction, then drawing a front anchor head of a suspender by adopting a jack, and fixing on a steel box girder; regulating the tensile force of the suspender till the tensile force of the suspender and the line shape of a main cable meet the requirements; disassembling all temporary supporting seats, and lowering the steel box girder to a main tower beam as a permanent supporting seat so as to complete the construction. The whole construction process has safety and reliability so as to provide a necessary precondition for ensuring project quality. The construction method has reasonability, high efficiency and concision, can not only ensure the project progress, but also effectively reduce the construction cost.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

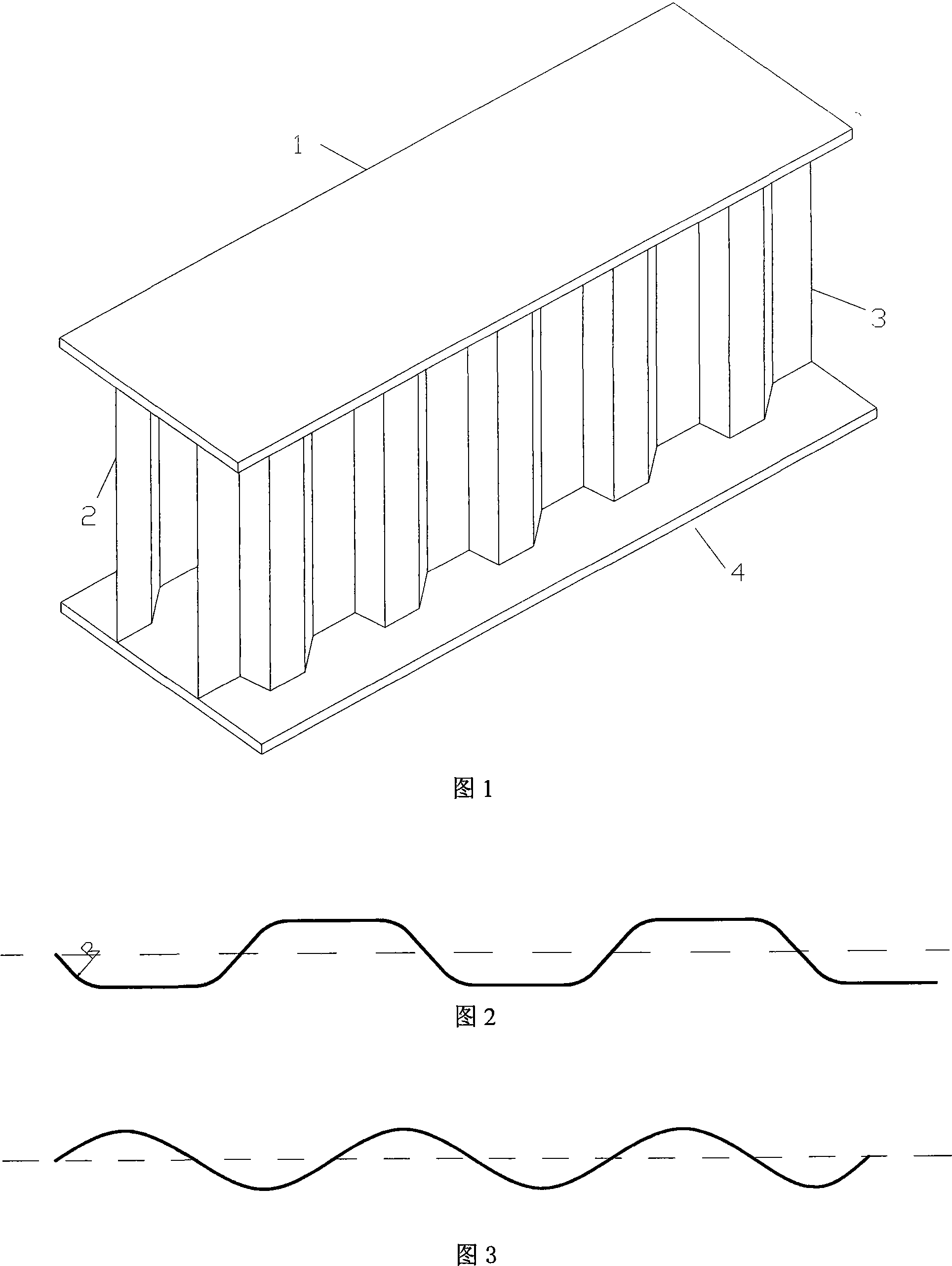

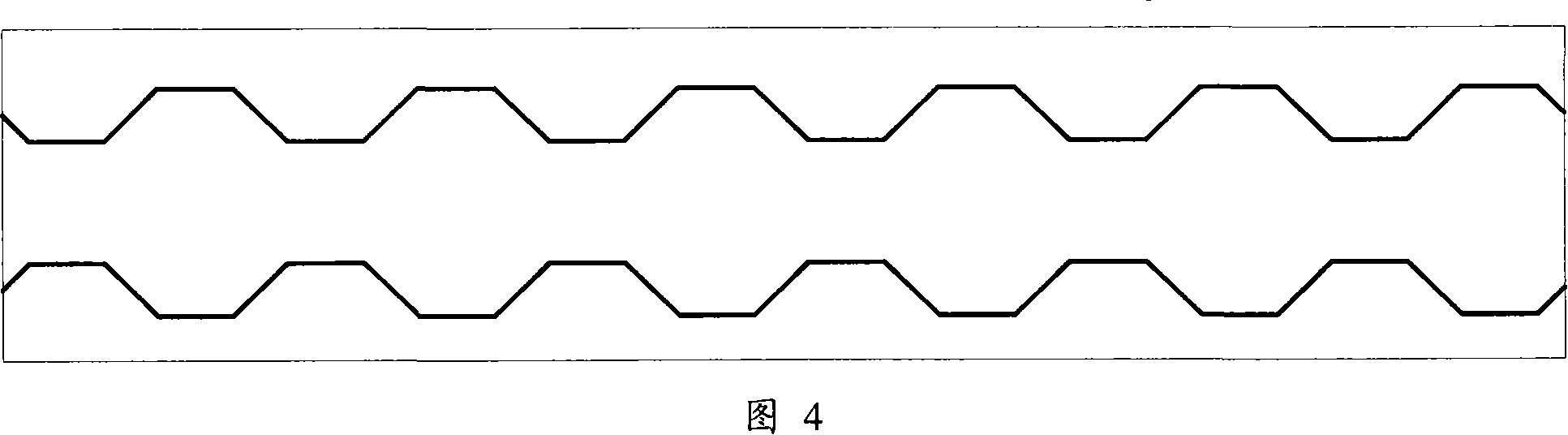

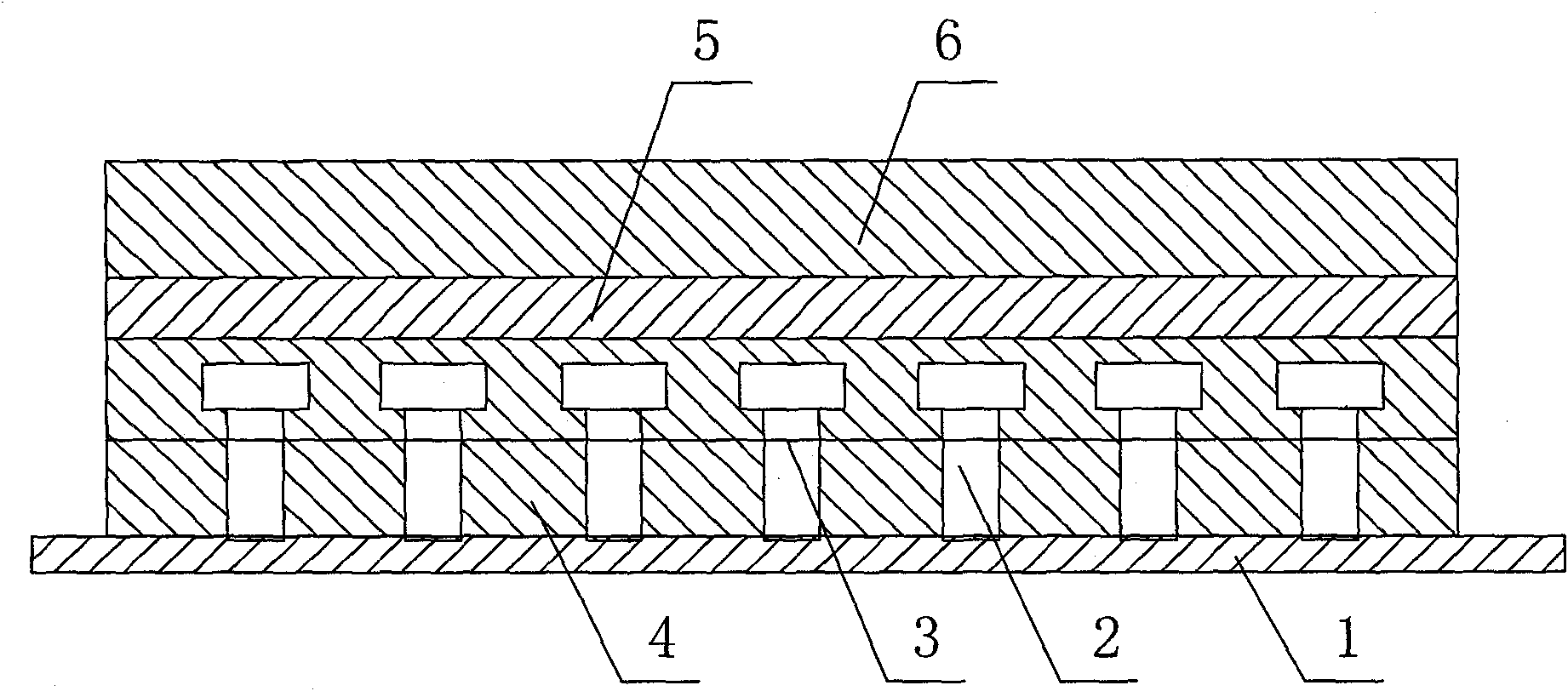

Double corrugated web plate steel box girder

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

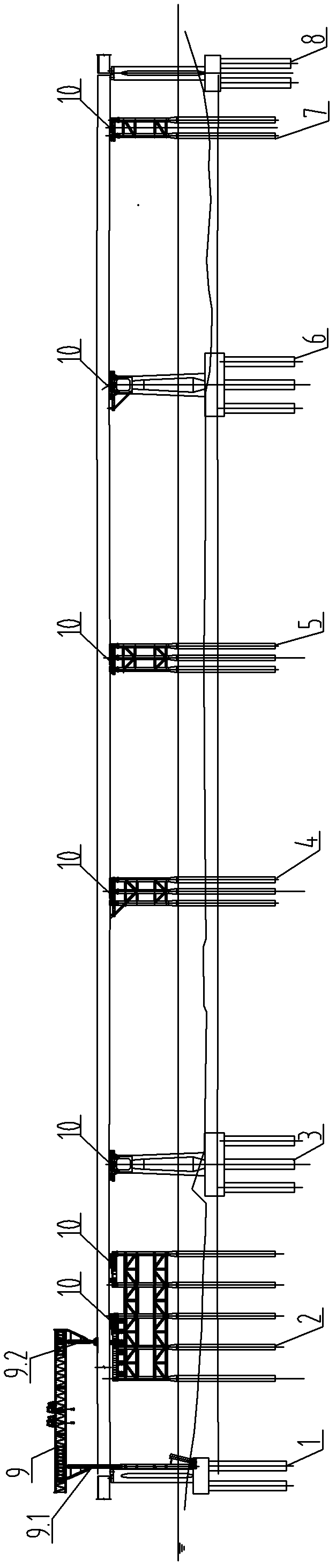

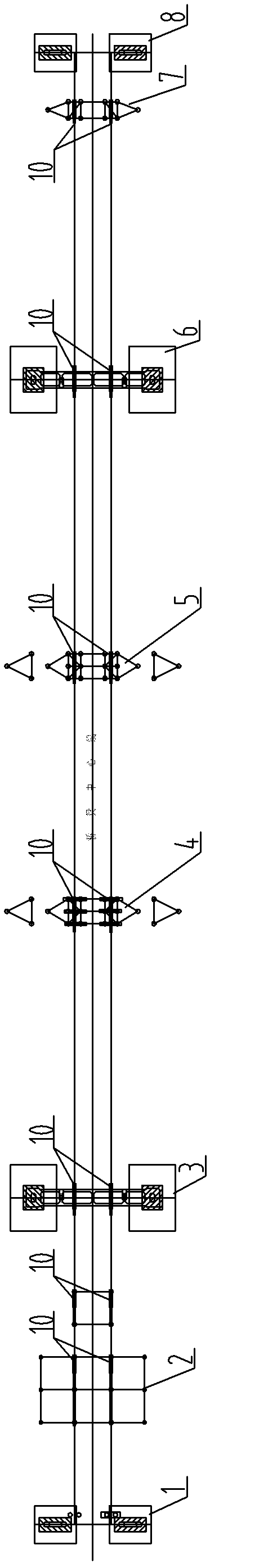

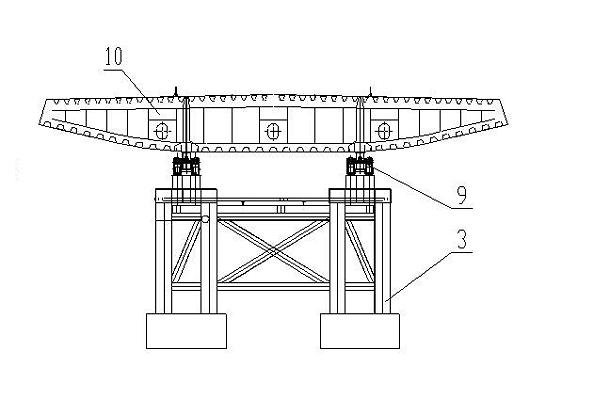

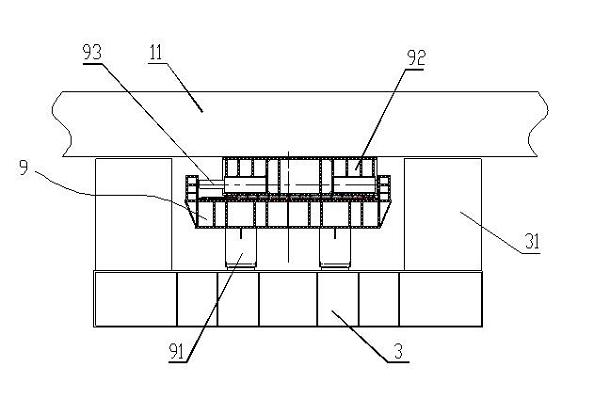

Walking type multipoint pushing construction method and walking type multipoint pushing construction system for steel box girder

ActiveCN102587291ASolve the shortcomings of conventional processesReduce stress valueBridge erection/assemblyHorizontal forceSteel box girder

The invention discloses a walking type multipoint pushing construction method for a steel box girder, which is an improved optimized scheme for improving the disadvantages of a pulling type pushing method. The optimized scheme comprises the steps of installing pushing devices at assembly platforms, temporary mounds, main mounds and other points, firstly jacking the steel box girder with a vertical jack to separate the steel box girder from a girder laying frame, then pushing the steel box girder for a stroke in the longitudinal direction by a pushing jack, lowering the steel box girder to the girder laying frame, retracting the pushing jack for a next stroke of pushing, and keeping the circulation of the work until the installation of the steel box girder is finished. The pushing construction method for the steel box girder provided by the invention adopts a multipoint walking type pushing system, which not only can avoid disadvantages in the process in prior arts, but also has the advantages that the horizontal force at the mound top is greatly reduced; the structure of the temporary mound is simplified; the damage to the steel box girder is small; the construction cost is low and the like.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

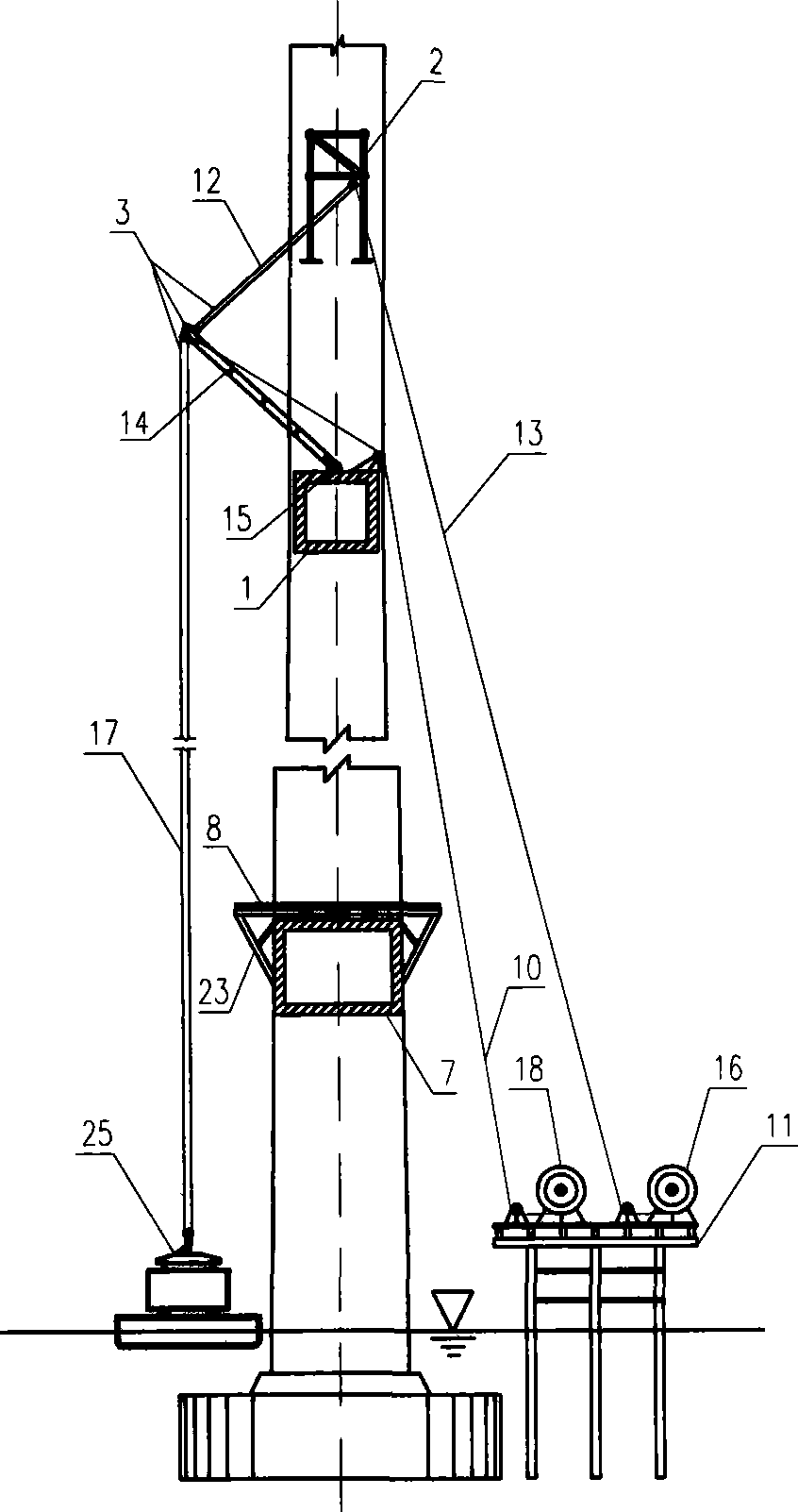

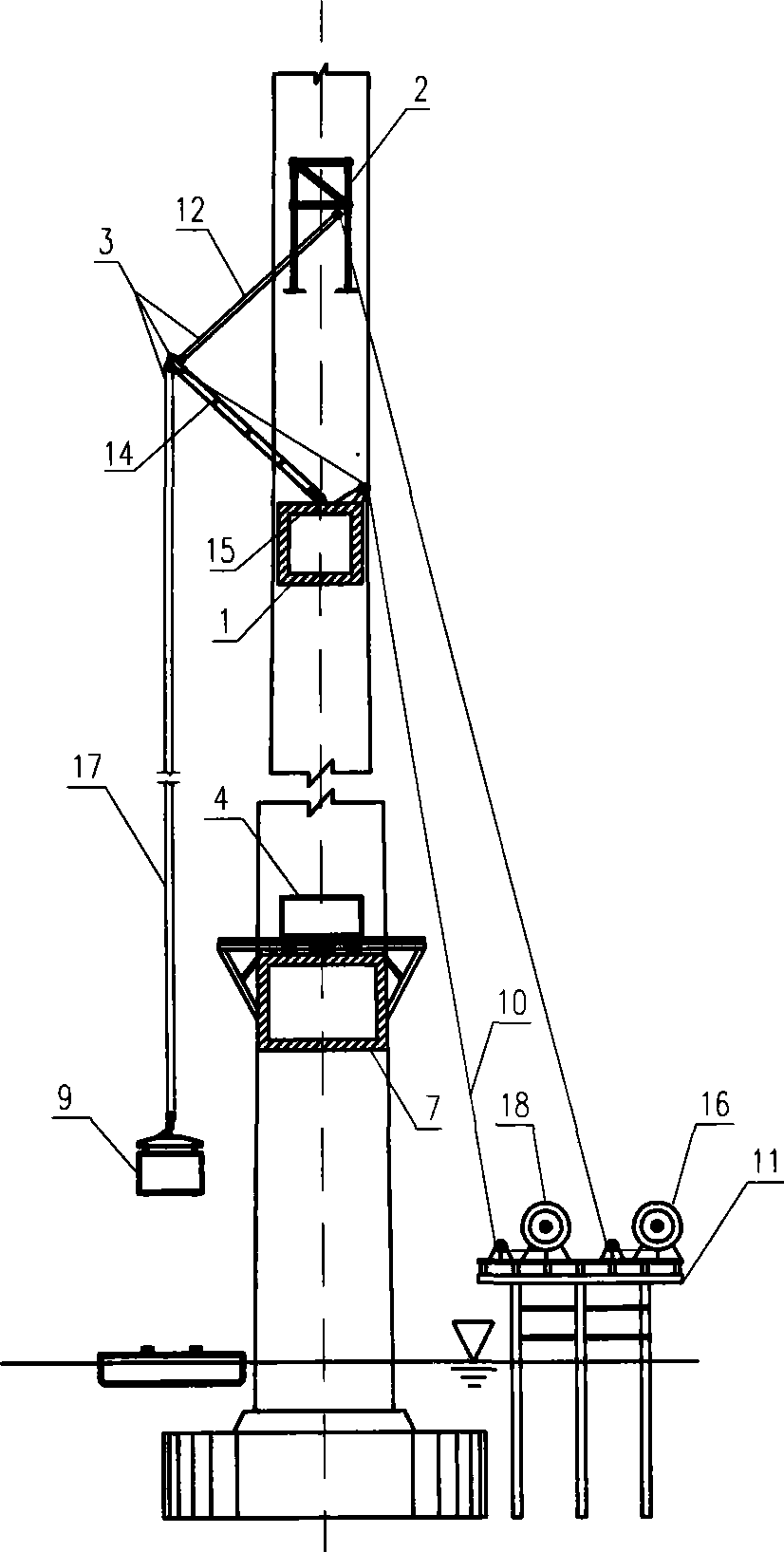

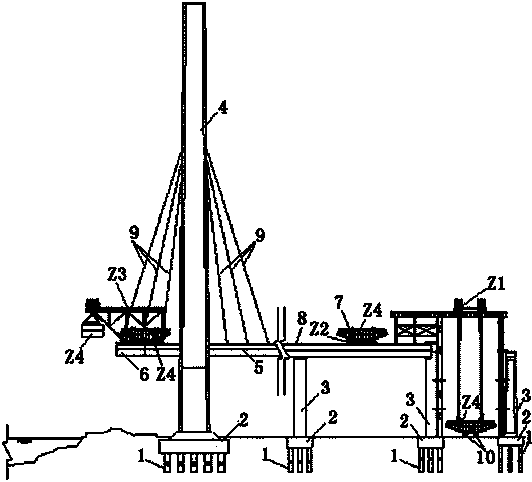

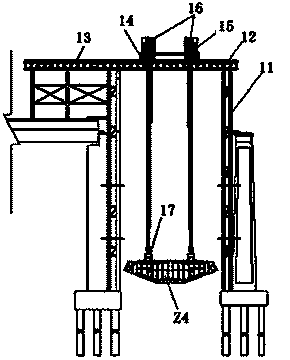

Mounting method for underbeam segment of large-stride steel box girder stayed-cable bridge

ActiveCN101476294AEasy to installThe installation method is safe and reliableBridge erection/assemblyCable stayedBridge deck

The invention relates to a large span steel box girder cable-stayed bridge tower lower beam segment mounting method, belonging to the bridge construction steel box girder construction technology field. The construction method comprises the steps: (1) setting up a masts type crane lifting tower area steel box girder by means of the upper crossbeam of the cable tower and the construction wind; (2) mounting the bridge deck crane in on the tower area steel box girder and lifting the first standard beam segment immediately adjacent to the tower area steel box girder; (3) mounting the bridge deck crane symmetrically on the mounted first standard beam segment, and starting the standard beam segment symmetrical hanging on both the river side and the bank side. The method in the invention achieves the advantages of simple, practical, safe, reliable, economic, convenient less limited by the construction condition, solves the problems in present large span steel box girder cable-stayed bridge construction process.

Owner:SICHUAN ROAD & BRIDGE GRP

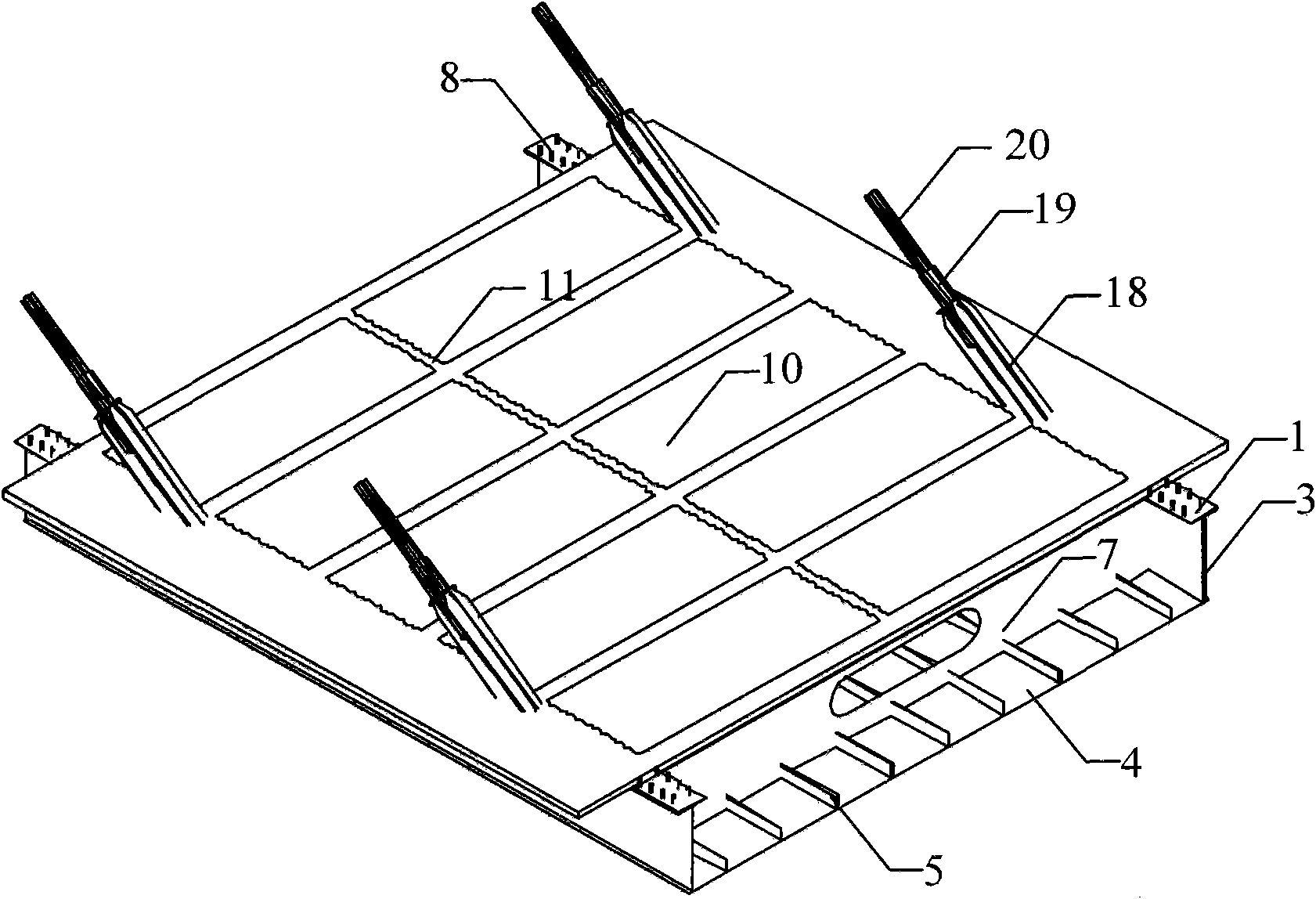

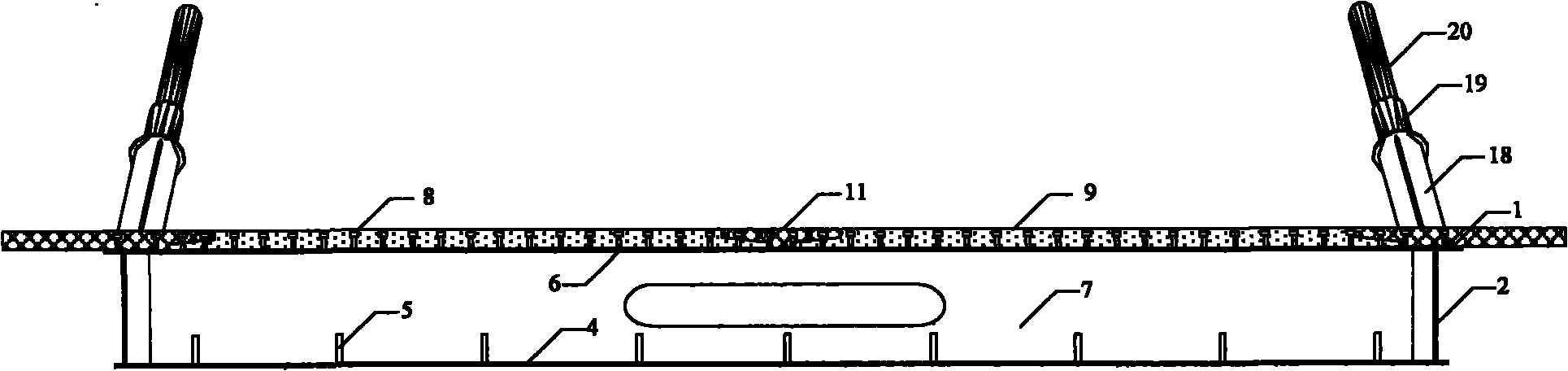

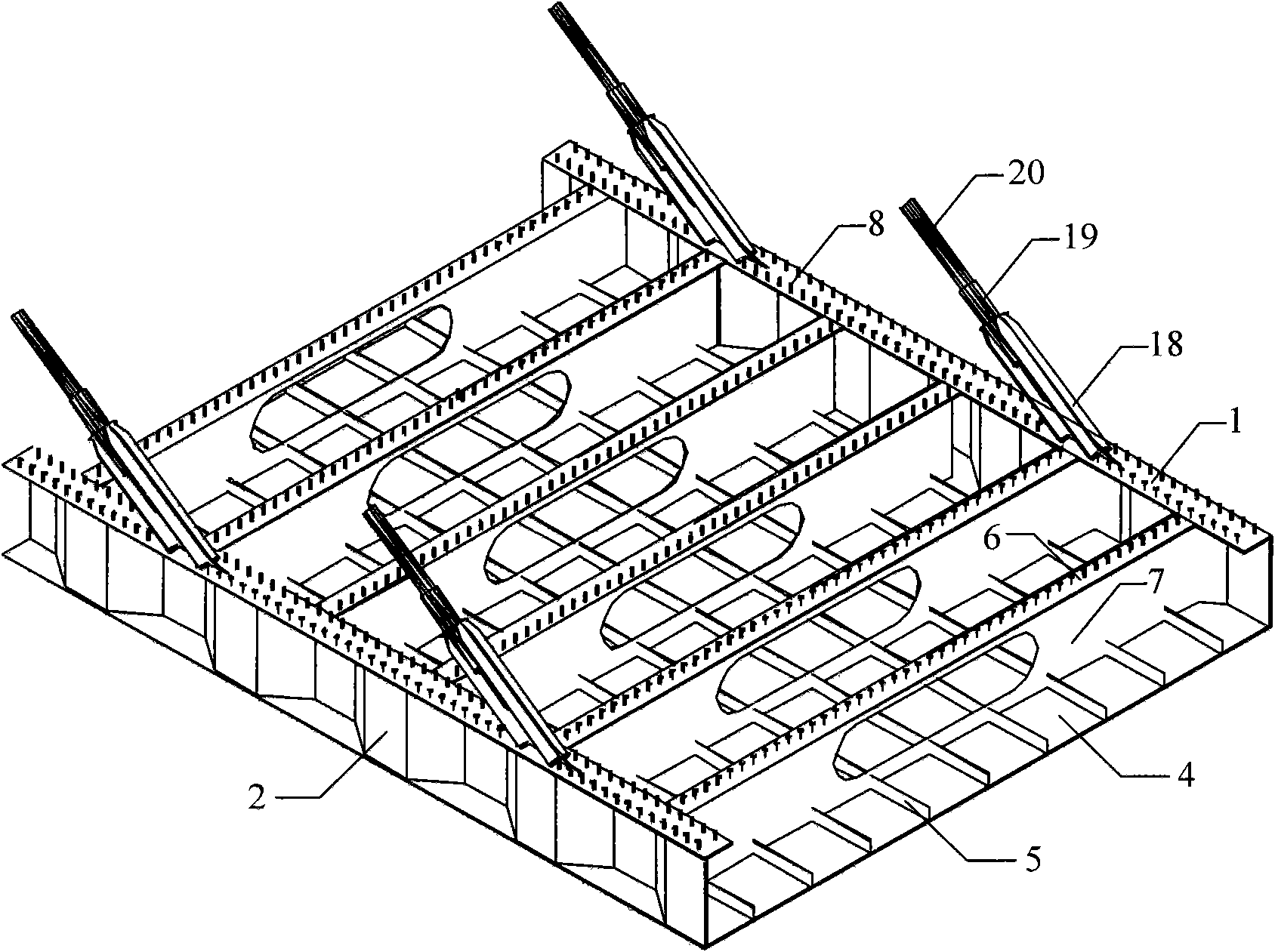

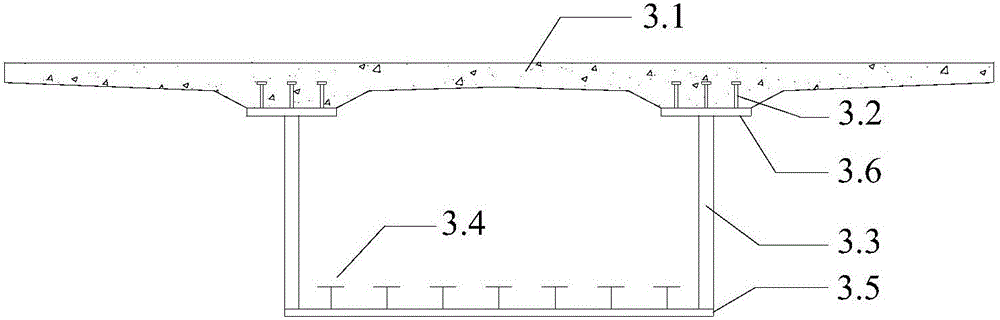

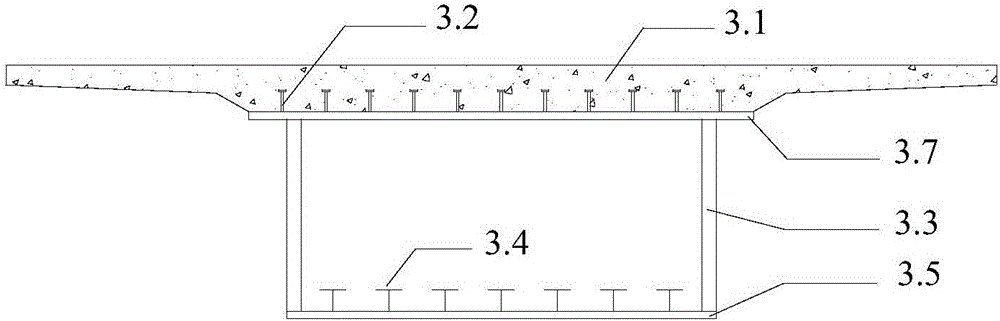

Corrugated steel webplate combined box girder floor system for cable-stayed bridge and construction method thereof

InactiveCN101864729AAvoid on-site molding processReduce wet work workloadCable-stayed bridgeBridge structural detailsCrack resistanceEngineering

The invention relates to a corrugated steel webplate combined box girder floor system for a cable-stayed bridge and a construction method thereof, and belongs to the technical field of bridge structures. The corrugated steel webplate combined box girder floor system comprises a precast concrete plank and a cast-in-place concrete seam, wherein the precast concrete plank is positioned on a steel box girder and is integrated with the steel box girder into a whole; the steel box girder is formed by welding a top flange steel plate, a corrugated steel webplate and a steel plate at the bottom of the box girder; a box girder baseplate stiffening rib and a diaphragm plate are welded in the steel box girder; the diaphragm plate comprises a top flange steel plate of the diaphragm plate and a steel webplate of the diaphragm plate; a toggle pin connecting piece is welded on the top flange steel plate and the top flange steel plate of the diaphragm plate; and a steel anchor pulling plate and a steel sleeve are welded on the top flange steel plate. The corrugated steel webplate combined box girder floor system simplifies the manufacturing process for the precast concrete plank, gives full play to the superior mechanical property of the corrugated steel webplate and the release action of the corrugated steel webplate on the creep effect of concrete shrinkage, improves the bearing capacity, stiffness and crack resistance of the structure, and improves the durability of the structure.

Owner:TSINGHUA UNIV

Method for construction of multi-point integral top pulling steel case beam

ActiveCN101250855AReduce width sizeImprove work efficiencyBridge erection/assemblyBridge materialsBridge engineeringPiston rod

The invention discloses a construction method of a multi-point whole incremental launching steel box girder, which belongs to the field of bridge engineering. The construction method uses a dental plate with a tooth socket, which is arranged on a steel box girder and a guiding beam web plate, a jacking force is supplied by an incremental launching jack, wherein a piston rod of the incremental launching jack is equipped with a slider, on which a spinous block with an inclined plane and a control spring are arranged, the inclined plane is arranged on the side of the incremental launching jack, the steel box girder and the guiding beam are applied with the jacking force through the push travel of the incremental launching jack, and the spinous block withdraws from the tooth socket during the return to enter into a next push travel. The construction method also supplies the support and adjusts the elevation of corresponding points through lifting-up the jack, simultaneously the incremental launching jack and the upper portion of the incremental launching jack are all equipped with a displacement sensor and a pressure sensor to collect information, thereby controlling an incremental launching process. The construction method has less consumption of steel material, a support reaction and a thrust force are capable of being controlled, and the problem of the rotation angle of the steel box girder is capable of being excellently solved.

Owner:SHANDONG LUQIAO GROUP

Method for paving resin filling type asphalt concrete steel box-beam bridge deck combined structure

ActiveCN101200873AHigh strengthChemically stableBridge structural detailsBuilding insulationsSheet steelSurface layer

The present invention relates to a paving method of the paving layer of the bridge deck of a steel box girder bridge. A resin infusion type paving method of the composite structure of the asphalt concrete steel box girder bridge deck includes three steps: (1) the sand blasting and the derusting of the steel plates of the steel box girder bridge deck; (2) the preparation of materials: (a) the preparation of high-viscosity modified asphalt; (b) mineral aggregate gradation; (c) the preparation of large pored asphalt concrete; (d) the preparation of thermoset resin grouting material; (3) The pavement of the paving layer of the bridge deck: (a) The large pored asphalt concrete is paved on the steel plates of the steel box girder bridge deck, the pavement thickness is 2cm to 4cm, and after final pressure, a large pored asphalt concrete skeleton layer is formed; (b) While the large pored asphalt concrete skeleton layer is still in a hot state, the thermoset resin grouting material is grouted into the large pored asphalt concrete skeleton layer; (c) After the maintenance of three days, a layer of bonding oil is sprinkled, and an asphalt abrasion surface layer with the thickness of 4cm is paved. The paving method is characterized in good interface cohesive property and simple and convenient construction process.

Owner:WUHAN MUNICIPAL CONSTR GROUP

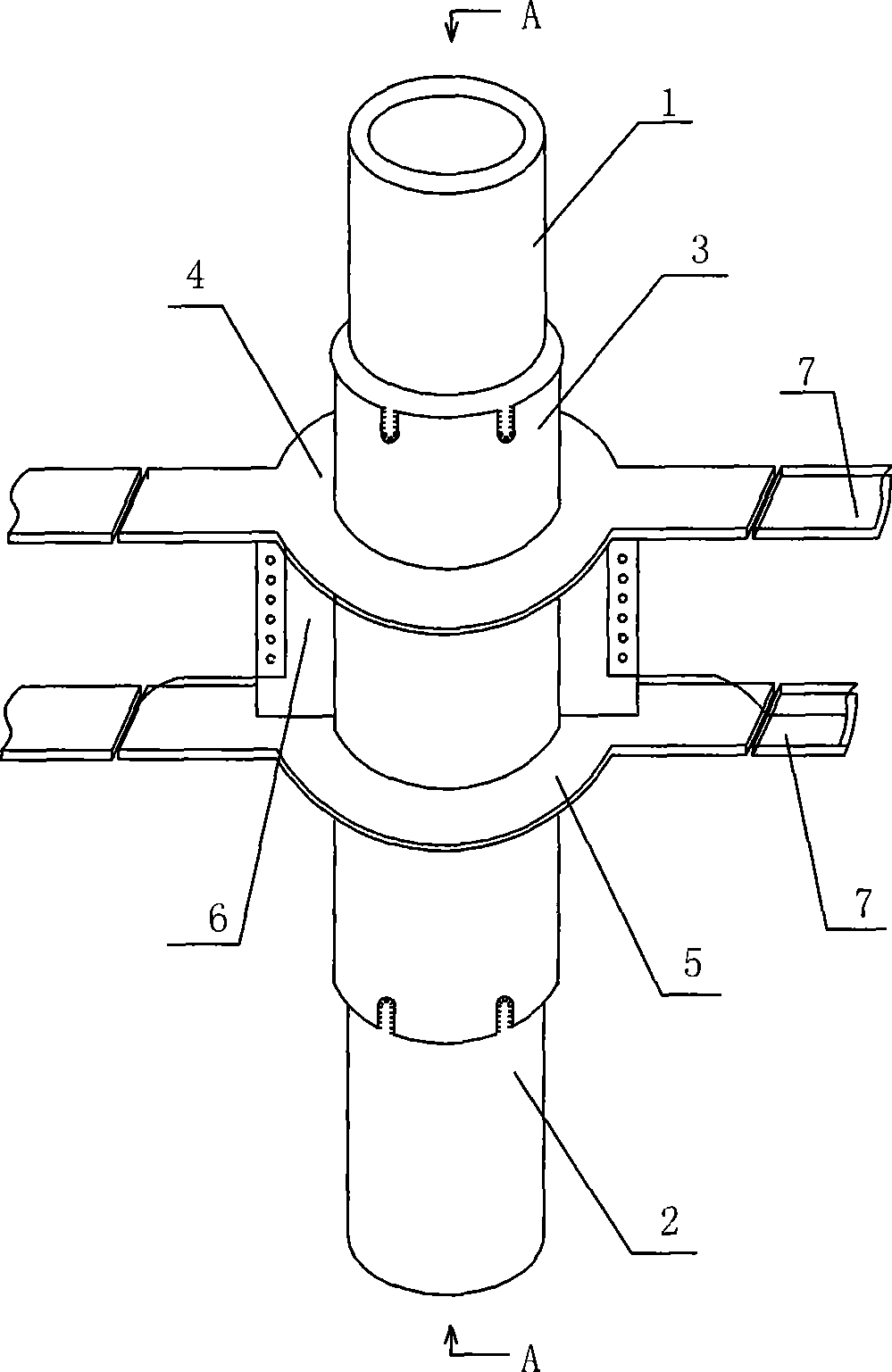

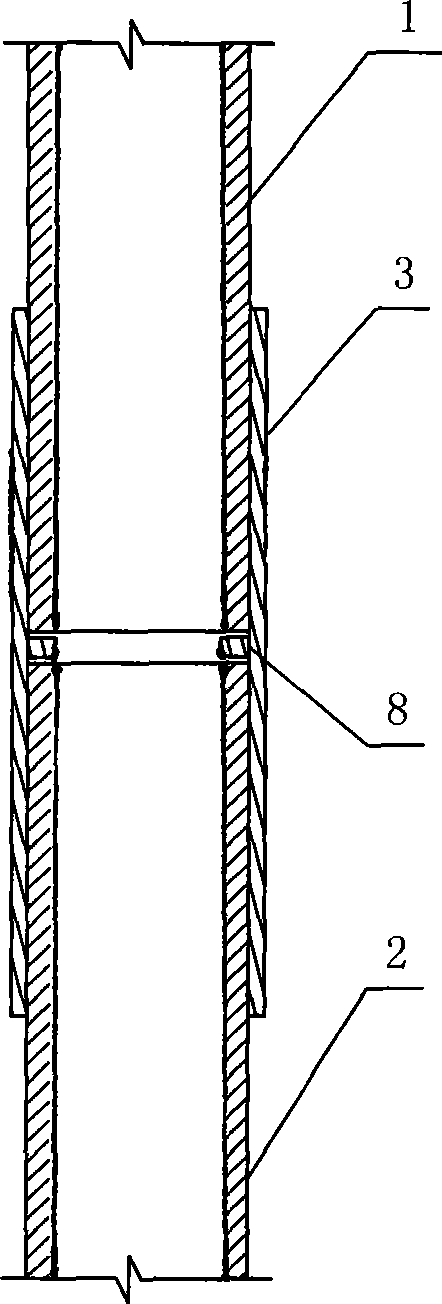

Steel pipe concrete segment type coat node and its construction method

InactiveCN101476348AMeet the needs of strong nodes and weak membersIncrease stiffnessBuilding constructionsUltimate tensile strengthMechanical property

The invention relates to a concrete-filled steel tube sectional type sleeve gusset and a construction method thereof, which relate to a connecting gusset for connecting a concrete-filled steel tube column and a girder in civil engineering and a construction method thereof. The concrete-filled steel tube sectional type sleeve gusset comprises the concrete-filled steel tube column and the steel girder which is connected with the column, wherein the concrete-filled steel tube column is formed by filling concrete into a steel tube; the steel tube is formed by connecting an upper column steel tube and a lower column steel tube through a connecting sleeve; the connecting sleeve and the lower column steel tube are in split type; an upper reinforcement ring plate and a lower reinforcement ring plate are arranged outside the connecting sleeve; and a vertical connecting plate is arranged between the upper reinforcement ring plate and the lower reinforcement ring plate. The connecting sleeve and the lower column steel tube in the concrete-filled steel tube sectional type sleeve gusset are in split type, so that the concrete casting strength of the lower column steel tube and the upper column steel tube can be different under the condition of construction, thereby the requirement of strong gussets and weak members can be met. Moreover, the concrete-filled steel tube sectional type sleeve gusset has the advantages of concise and definite force transferring path, large gusset rigidity, high bearing capacity, superior mechanical property, good anti-seismic performance and simple and convenient processing and manufacture.

Owner:DAQING GASOLINEEUM INST

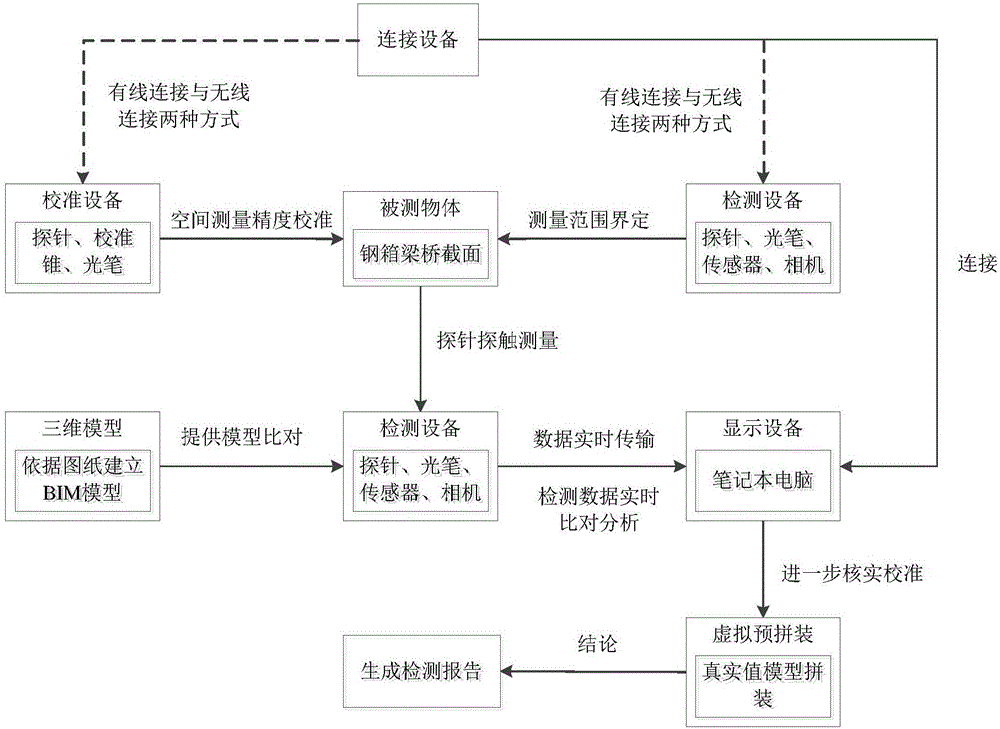

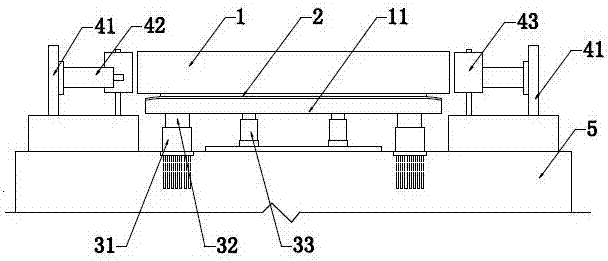

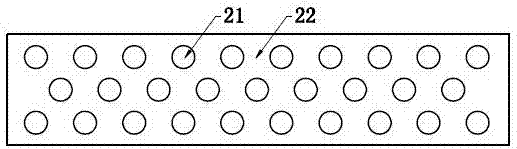

Steel structure pre-splicing method and system

ActiveCN106354950ARealize virtual assembly inspectionSave spaceGeometric CADImage data processingThree dimensional measurementDesign values

The invention discloses a steel structure pre-splicing method and system. When steel structures are pre-spliced, workpiece actual values are measured through a three-dimensional measurement technology and then compared with design models in real time, the design value models are modified to obtain actual value models, the actual value models are pre-spliced, and the factory on-site splicing process is omitted. Sensors are erected on the sections of the steel structures, calibration devices are arranged, probes are used for detecting and touching the sections of steel box girders, the actual value models are compared with the design models, and manufacturing error values are obtained. Virtual splicing can be achieved in software, the measured actual value models are spliced in the software in real time, and the result whether splicing can be conducted or not is visually obtained. By means of the technology, the steel structures are virtually spliced and detected, more reliable guarantees are provided for construction detection, and the site, labor cost and time are saved.

Owner:HUAZHONG UNIV OF SCI & TECH

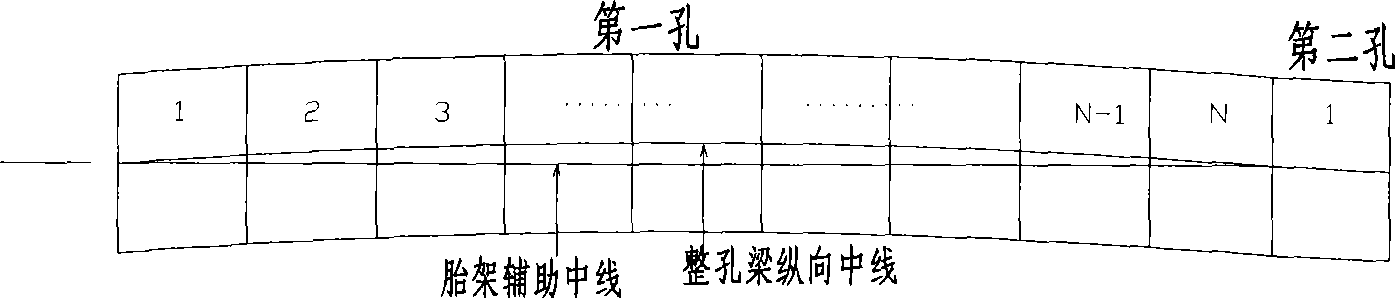

Long continuous structural steel box beam or combination box beam construction method

InactiveCN101368373AReduce welding workloadSatisfy \"Light Large Span\"Bridge erection/assemblyBridge materialsButt weldingEngineering

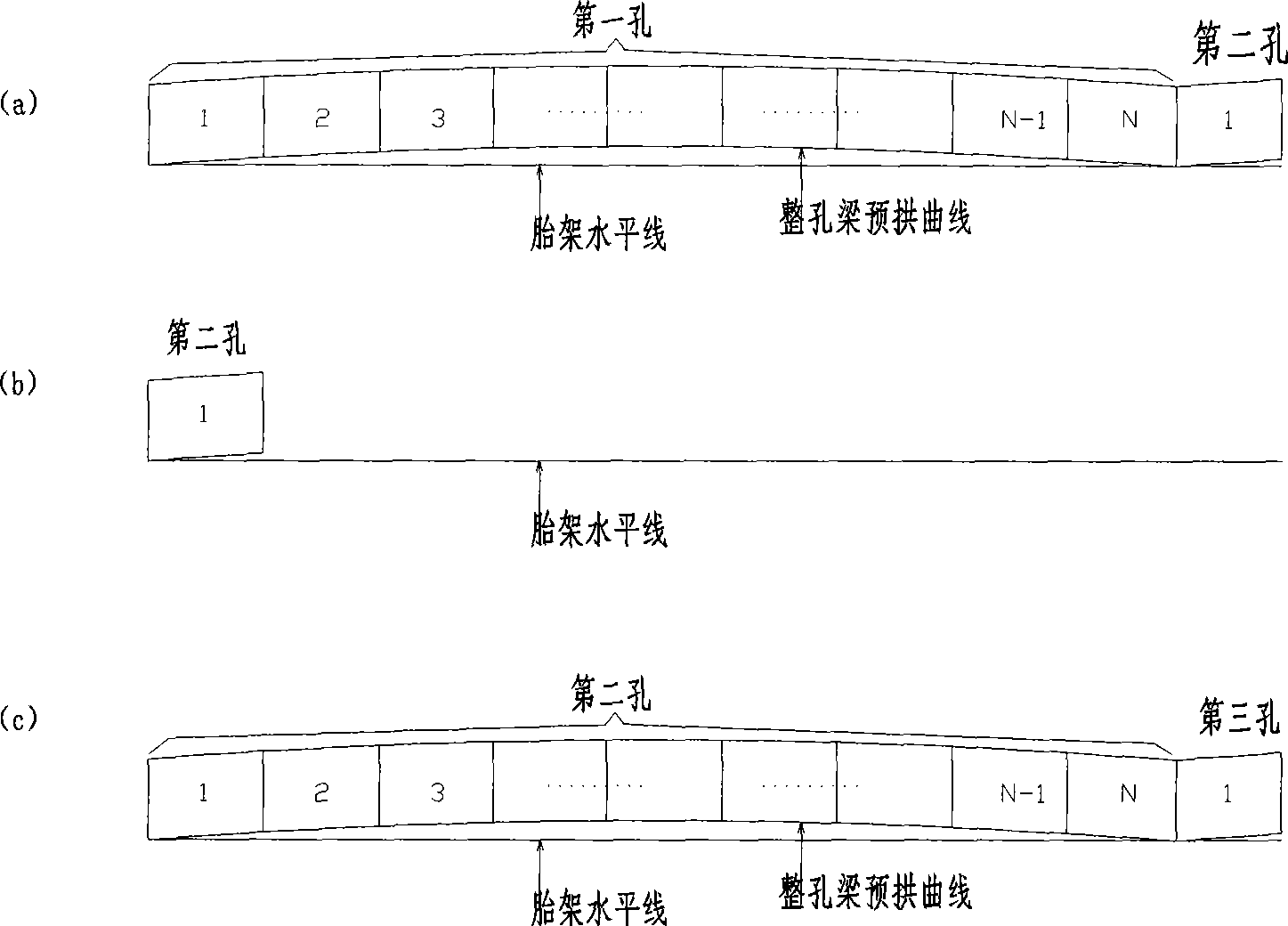

The invention discloses a long continuous steel box girder or combined box girder construction method, including the following steps: 1, segment division and plate unit division; 2, butt welding the fulcrum segmental box girders and standard segmental box girders at a prefabrication plant, namely, pre-splicing the segmental box girders of a full span box girder and the first box girder segment of the adjacent span box girder through long line method on a segmental box girder molding bed on which plane curves and pre-camber are arranged; marking the box girder segments, taking away the segmental box girders of the full span box girder, leaving the first box girder segment of the adjacent span box girder, and continuing to splice and weld the segmental box girders of the rest full span box girders; 3, generally assembling the full span box girders in the prefabrication plant. The invention adopts full span prefabrication and arrangement to construct a long continuous steel box girder or combined box girder, thus greatly reducing welding work load at the site. The invention ensures that the adjacent spans close smoothly after the steel girders are arranged and meets the requirements of light large span, precast assembly and quick construction.

Owner:CHINA MAJOR BRIDGE ENG

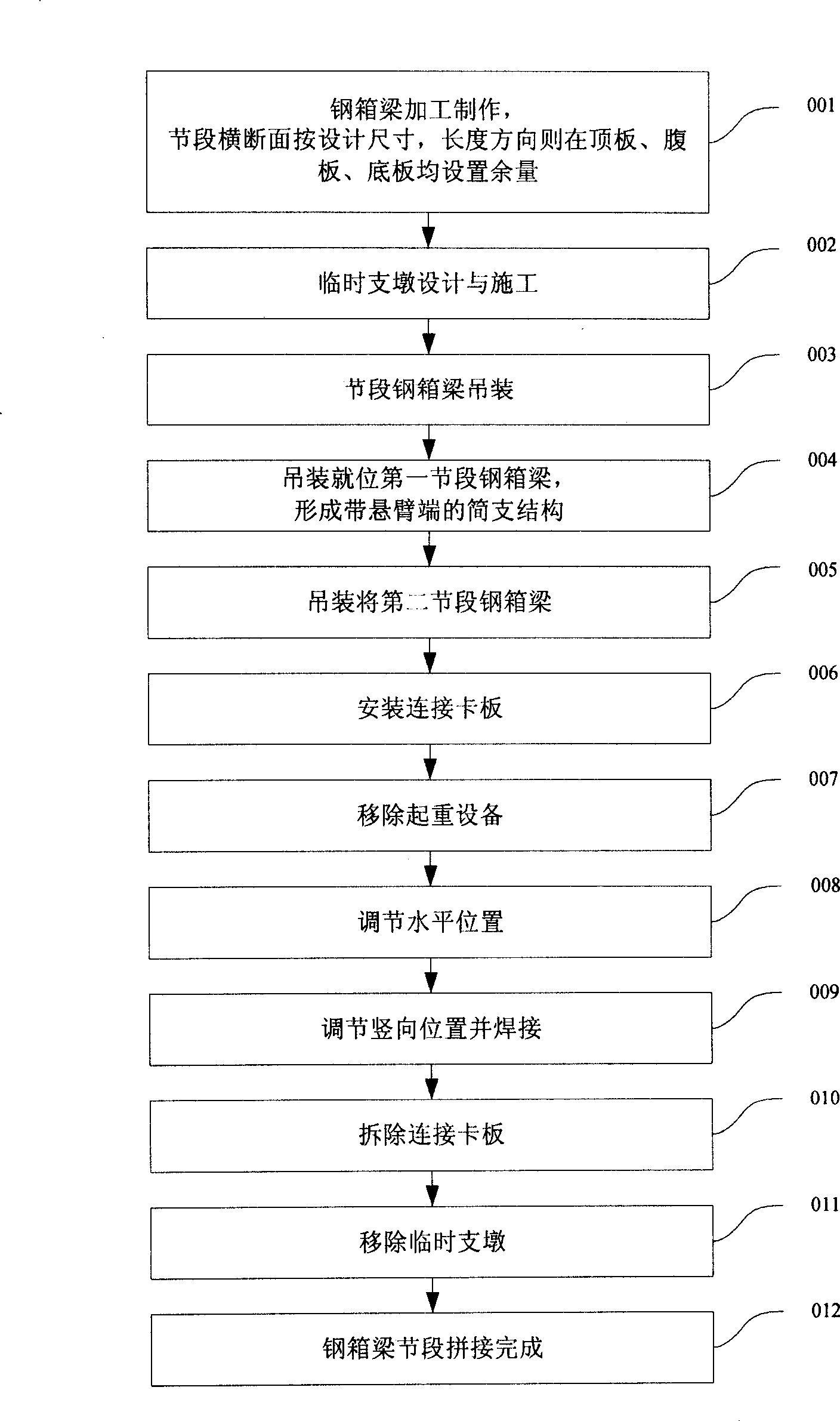

Steel box girder assembling construction method

InactiveCN101487232ASolve layout difficultiesReduce usageBridge erection/assemblySteel box girderMutual position

The invention provides a construction method for assembling steel box girders, which is used for the hoisting construction of the steel box girders during the road and bridge construction. The method comprises the steps as follows: a first steel box girder section is hoisted; a second steel box girder section is hoisted and suspended on the soleplate of the first steel box girder section; a connecting clamp plate is arranged at the top plate of the first steel box girder section and the second steel box girder section and is respectively suspended on top of the first steel box girder section and welded on the top of the second steel box girder section; hoisting equipment is removed; the mutual position of the steel box girder sections is adjusted and the steel box girder sections are welded to each other; the connecting clamp plate is removed; the temporary pier is removed; and the assembly is completed. As the residual assembly is adopted, the steel box girder construction under complex construction environment has large elasticity, thus ensuring the assembly precision and quality; the loading form is adopted to carry out the assembly of the steel box girder, thus solving the problem that the temporary pier is difficult to be arranged when the site is restricted; the construction time of hoisting equipment and the use of the temporary piers are reduced; and the whole assembly process is simple, feasible, safe, reliable, economical and reasonable.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

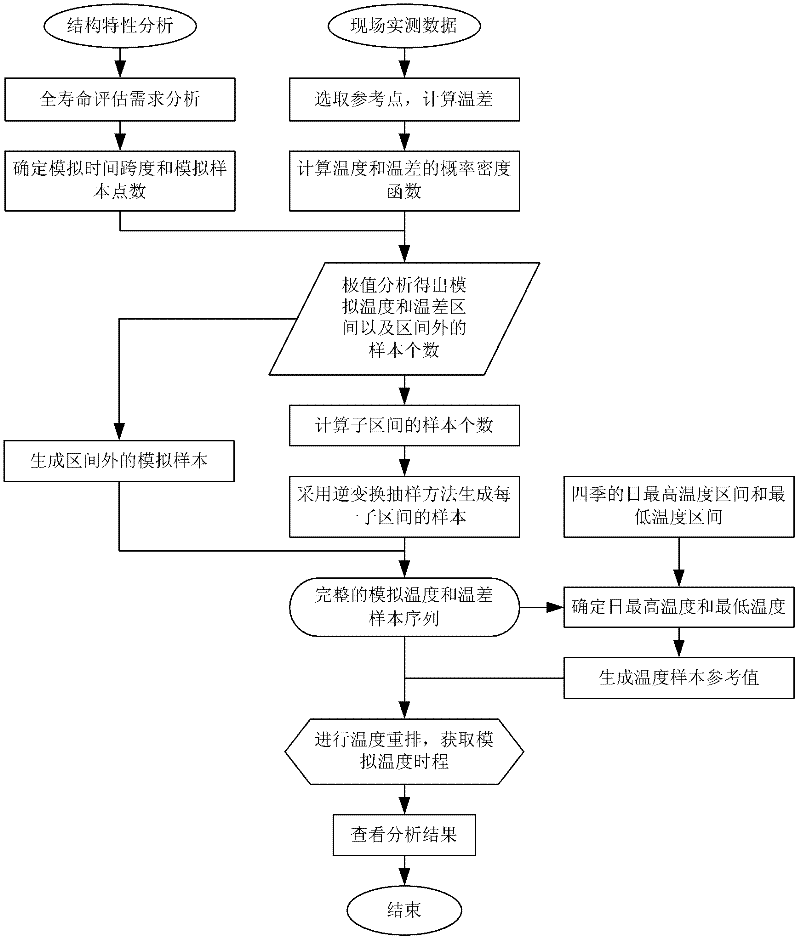

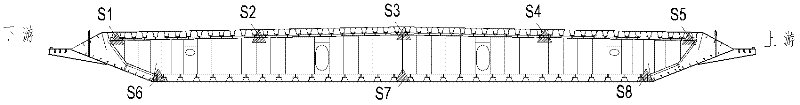

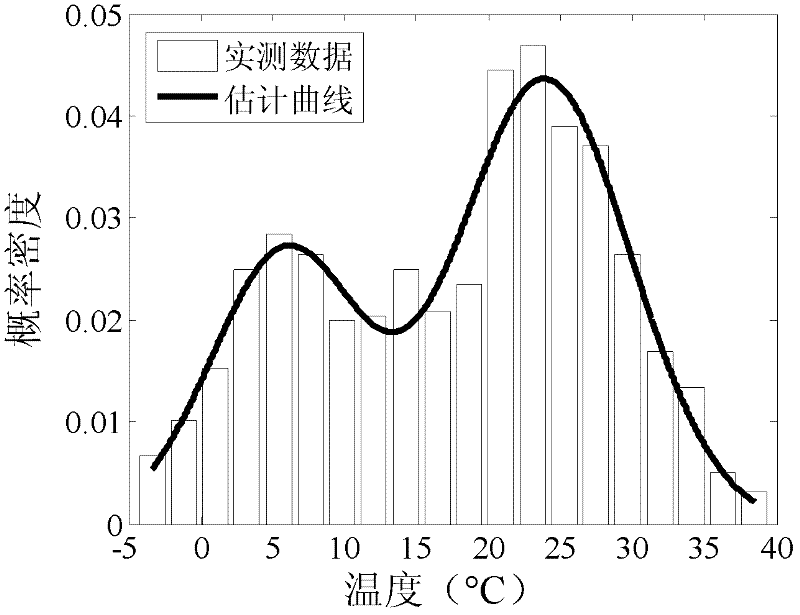

Method for simulating random temperature field of steel box beam of bridge construction

InactiveCN102393877AGood serviceSpecial data processing applicationsNormal densityStatistical analysis

The invention relates to a method for simulating a random temperature field of a steel box beam of a bridge construction. According to the method, a change characteristic of an actual temperature and a statistical characteristic of a temperature value of the steel box beam of the bridge construction are fully taken into account, and a numerical method is used for realizing the simulation for the random temperature field of the steel box beam of the bridge construction, thereby providing an effective method for acquiring the random temperature field of the steel box beam. The problem that a temperature load data is seriously insufficient during an analysis process for a temperature effect of the steel box beam is efficiently solved. The method comprises the following steps: firstly, performing statistic analysis and acquiring a probability density function of temperature and temperature difference according to a finite actual measured temperature data of the steel box beam; utilizing extreme value analysis to acquire a temperature range and a temperature difference range in a simulating time span; dividing the temperature range and the temperature difference range into a plurality of sub-ranges, utilizing an inverse transformation sampling method to generate a sample for each sub-range, and acquiring a random temperature sample in the simulating time span; and lastly, rearranging simulating samples on the basis of a daily variation law and a seasonal variation law of the temperature of the steel box beam, thereby acquiring a temperature schedule in the simulating time span.

Owner:SOUTHEAST UNIV

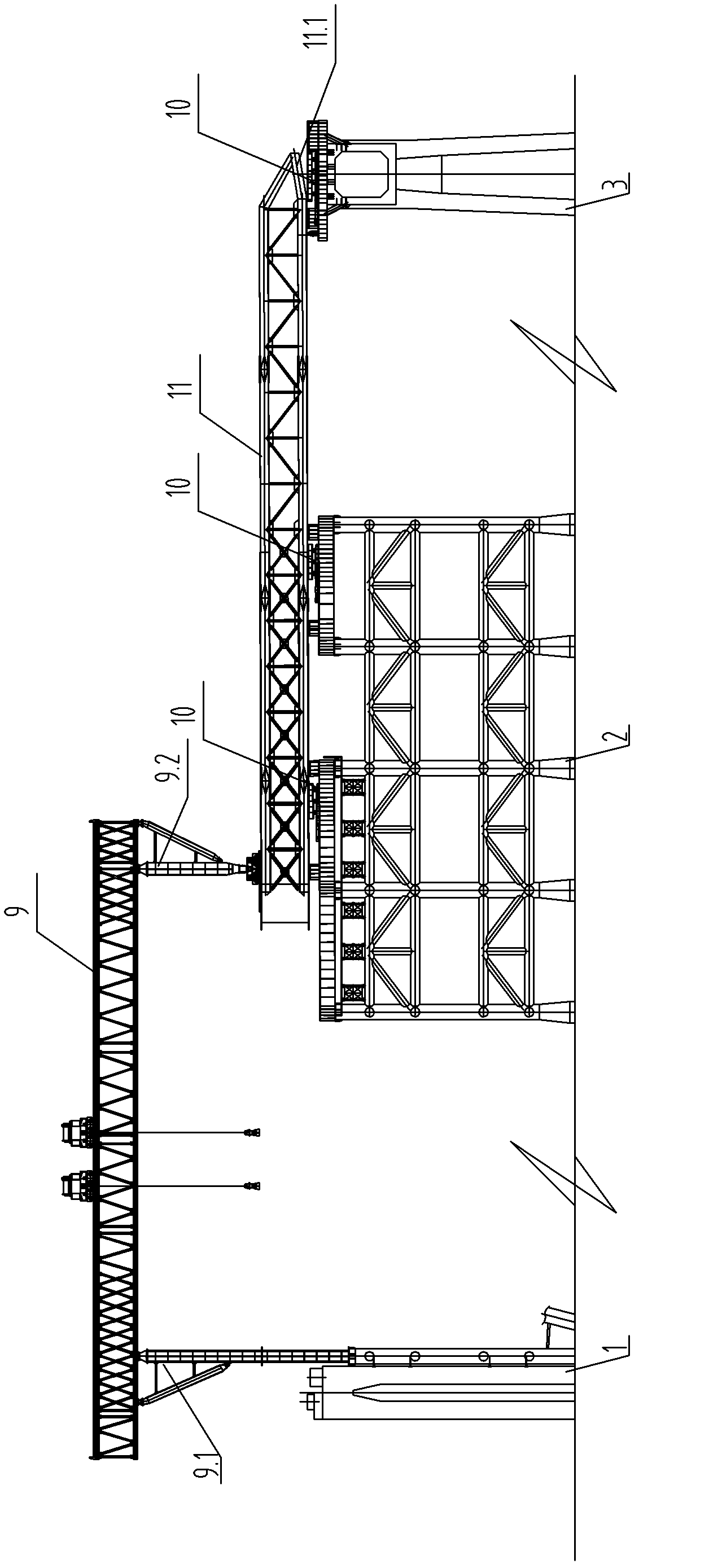

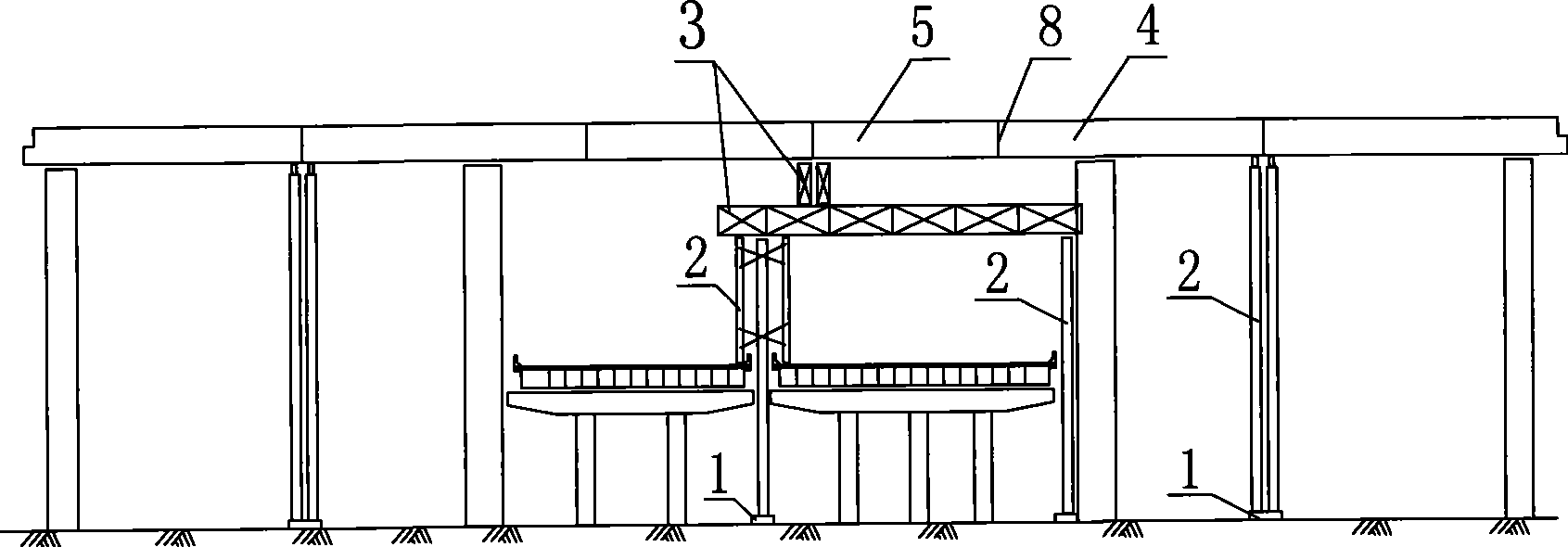

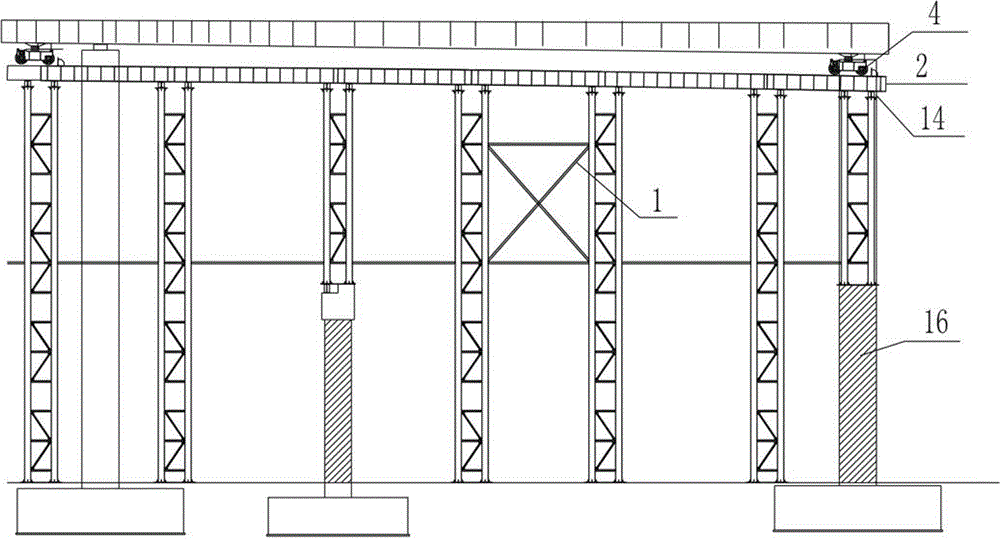

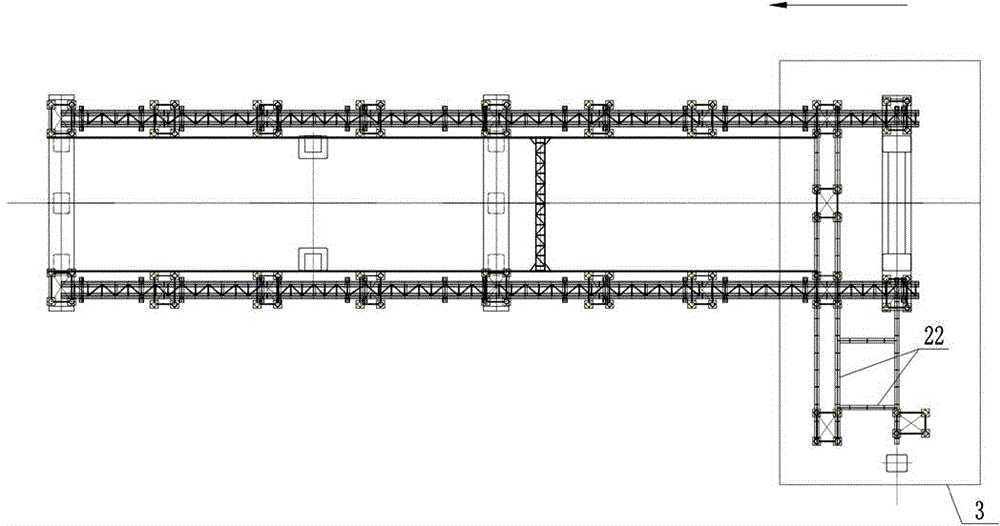

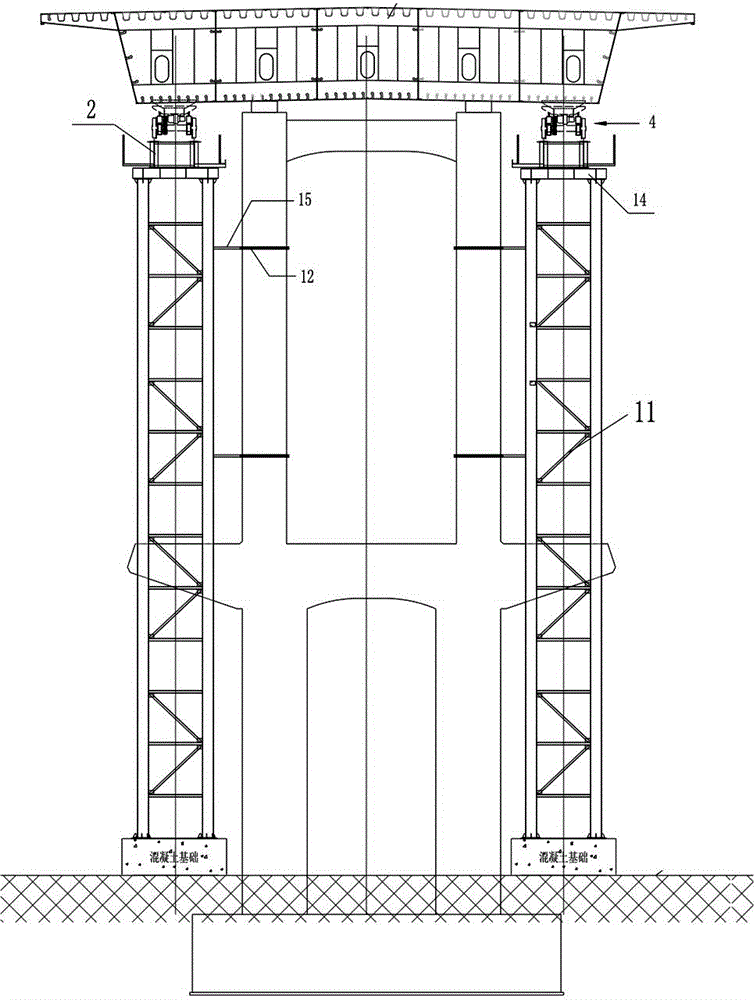

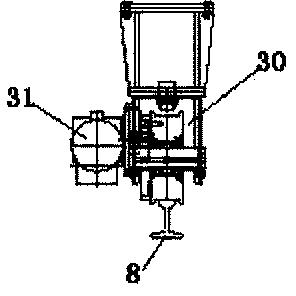

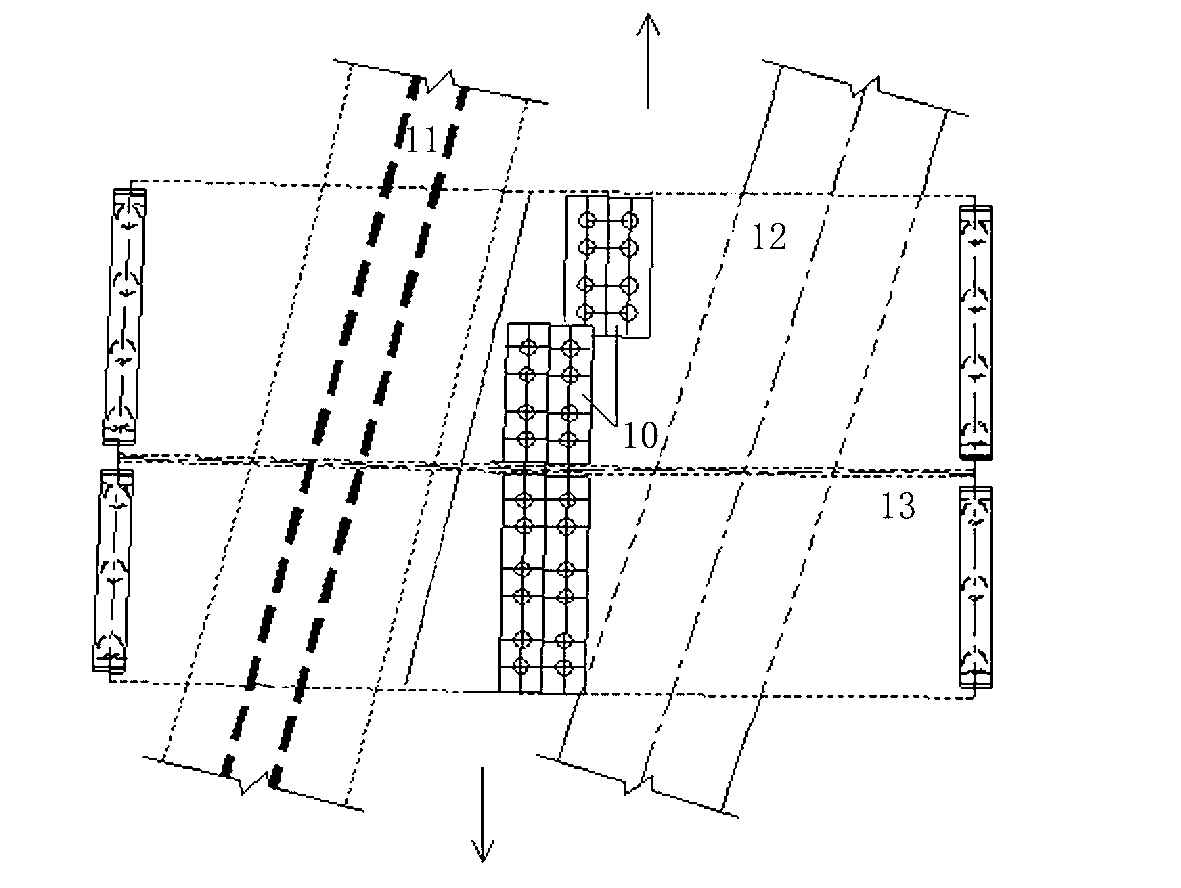

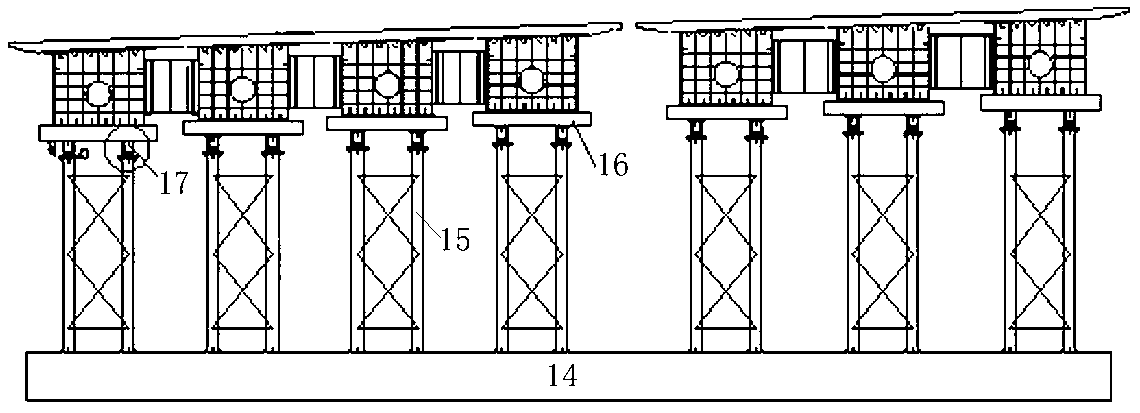

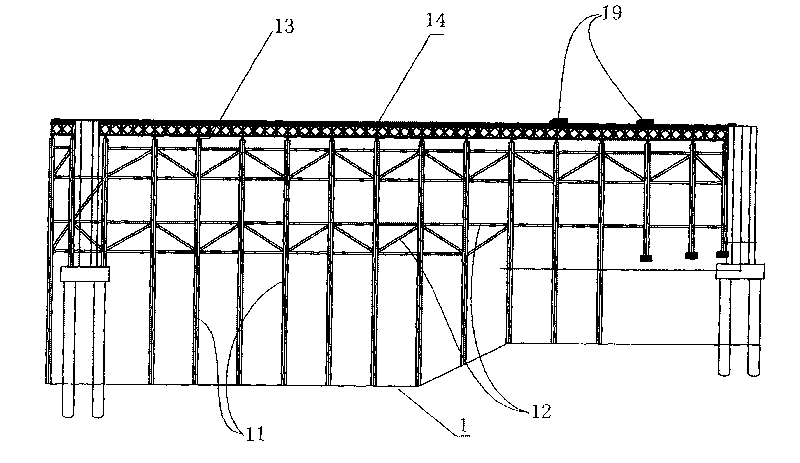

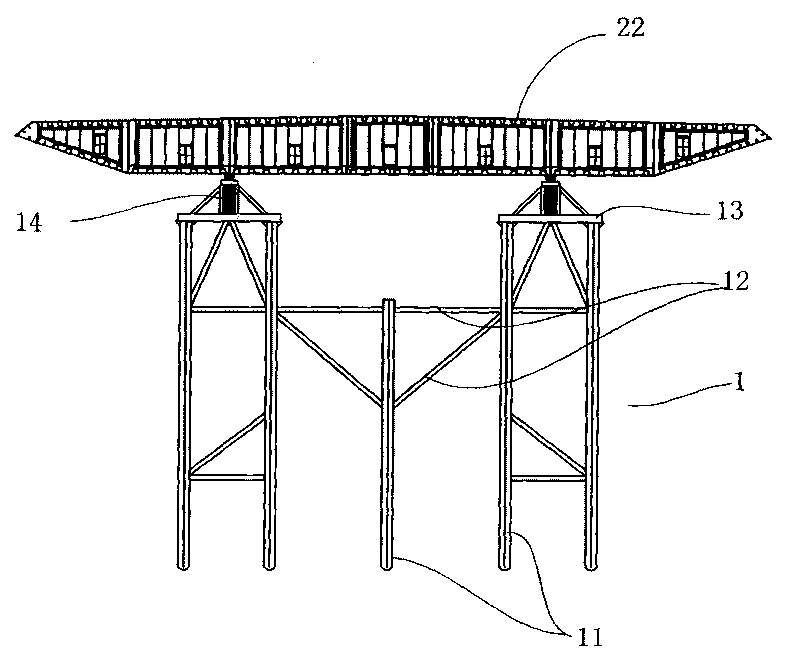

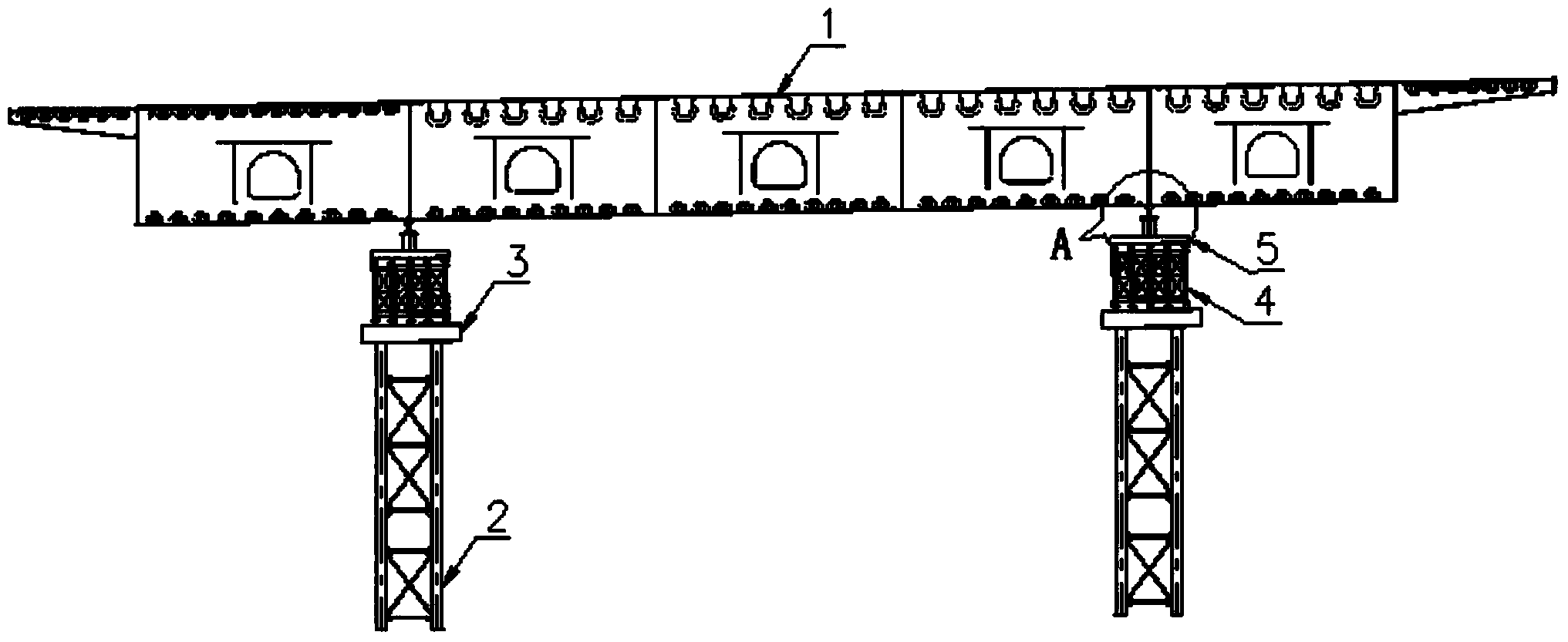

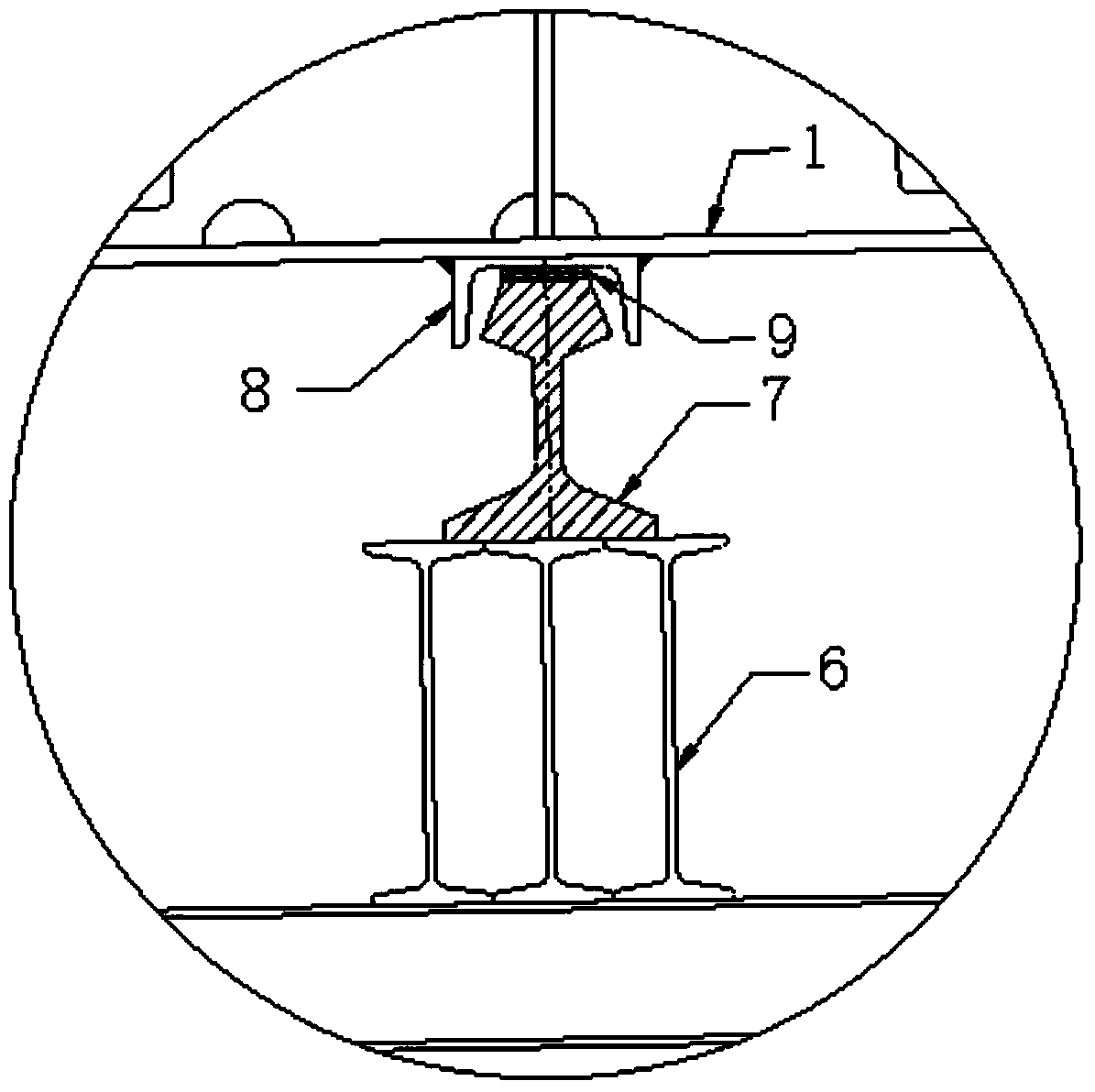

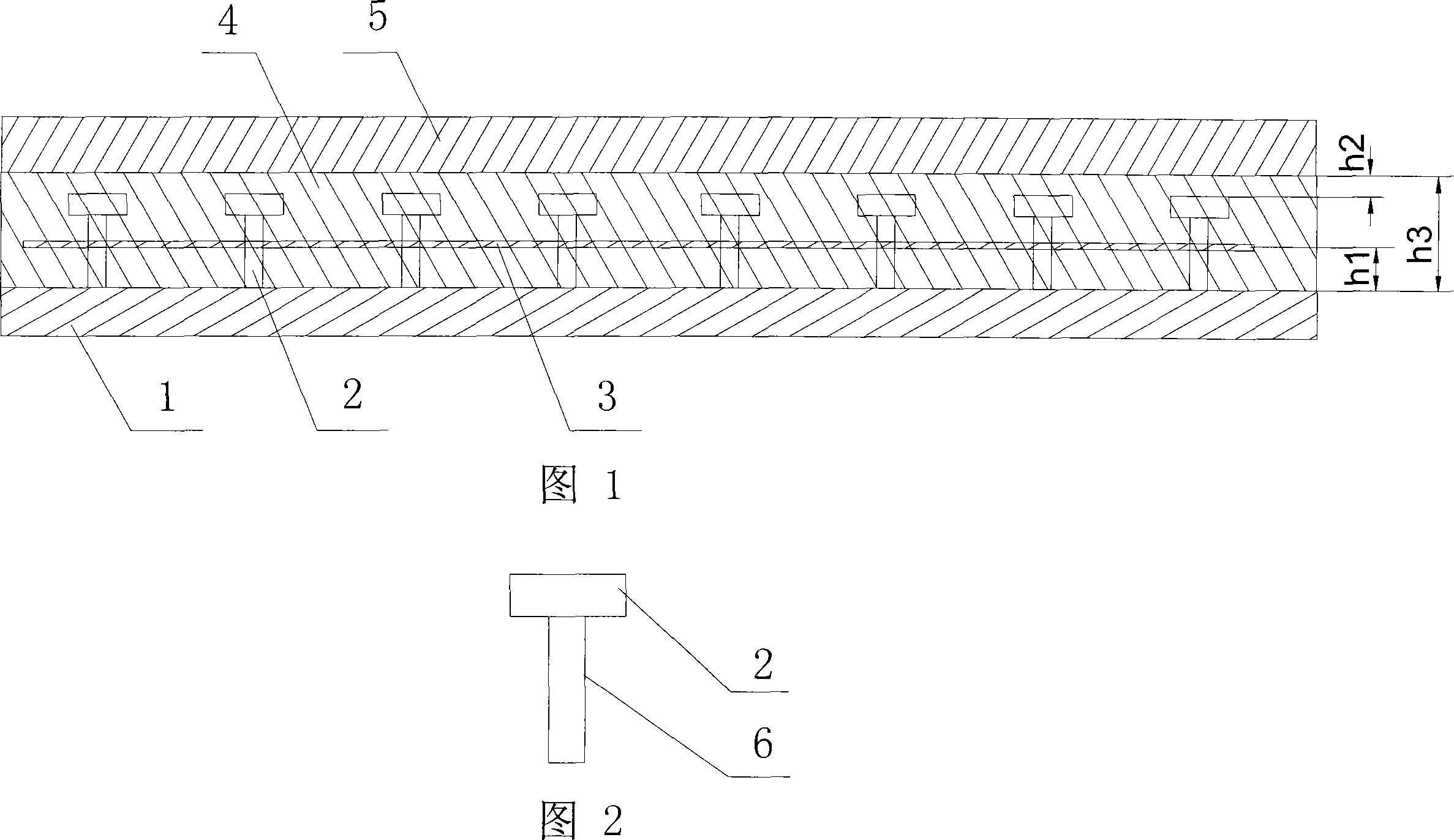

Full-bracket track-bogie bearing and moving device and construction method for installing steel box girders

The invention discloses a full-bracket track-bogie bearing and moving device and a construction method for installing steel box girders. The device consists of a bracket system, a slideway longitudinal beam system, a splicing platform and a traction system; steel pipe buttresses in the bracket system are fixed on a treated foundation, the slideway longitudinal beam system is arranged on the bracket system, and mainly comprises two-slideway longitudinal beams, each of the two-slideway longitudinal beams is formed by connecting I-shaped rod pieces in an upper-lower parallel connection method, each side of the slideway longitudinal beam system is provided with one two-slideway longitudinal beam, and two two-slideway longitudinal beams are arranged totally on two sides; and berth bogies on the slideway longitudinal beam system slide on berth bogie tracks on the two-slideway longitudinal beams, and the berth bogies adopt a parallel connection mode and share one electric control switch to realize synchronous starting and closing. The bearing and moving device and the construction method have the beneficial effects that advantages of a large machinery hoisting method and a full-bracket jacking and sliding method are synthesized, the influence on ground traffic is less, the construction speed is fast, the cost is low, and the safety is high.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

Steel box girder erection method applied to steel and concrete hybrid girder cable-stayed bridge

InactiveCN104195952AReduce distractionsReduce cost inputCable-stayed bridgeBridge erection/assemblyCable stayedCantilever

The invention discloses a steel box girder erection method which is applied to a steel and concrete hybrid girder cable-stayed bridge. Side-span concrete girders are constructed first, and middle-span steel box girders are installed in a segmented mode. The segments of the steel box girders are lifted to a girder transport cart on the constructed side-span girder face through a bridge tail girder lifting gantry, the steel box girders are transported into a cantilever bridge girder erection machine along rails on the girder face through the cart, and then the steel box girders are hoisted, transferred forward, turned, transferred backward and installed through the cantilever bridge girder erection machine. The constructed side-span concrete girders serve as the middle-span steel box girder transportation channel for transporting girders on girders, the steel box girder lifting, transporting and erecting process is not limited by ground construction, and navigation is not affected; the problems of construction environment constraints are solved, and multiple construction devices involved in steel box girder erection are innovatively designed, developed and successfully applied. According to on-site practice, all links are compact and controllable in terms of construction time, the steel box girder erection method is safe, reliable and high in applicability, the defects of a traditional construction method are compensated for, and development of the steel box girder erection construction technology is promoted.

Owner:THE SECOND CONSTR OF CTCE GROUP +2

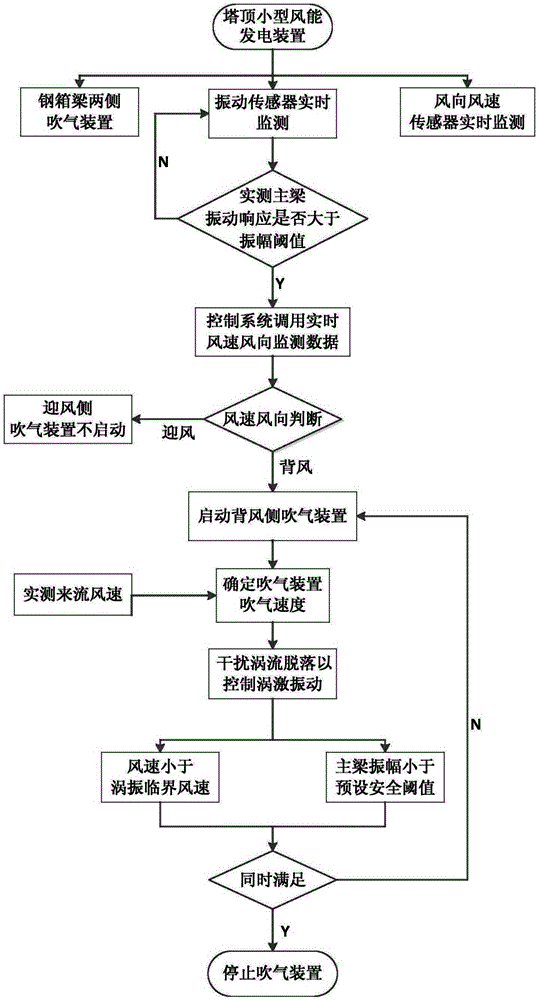

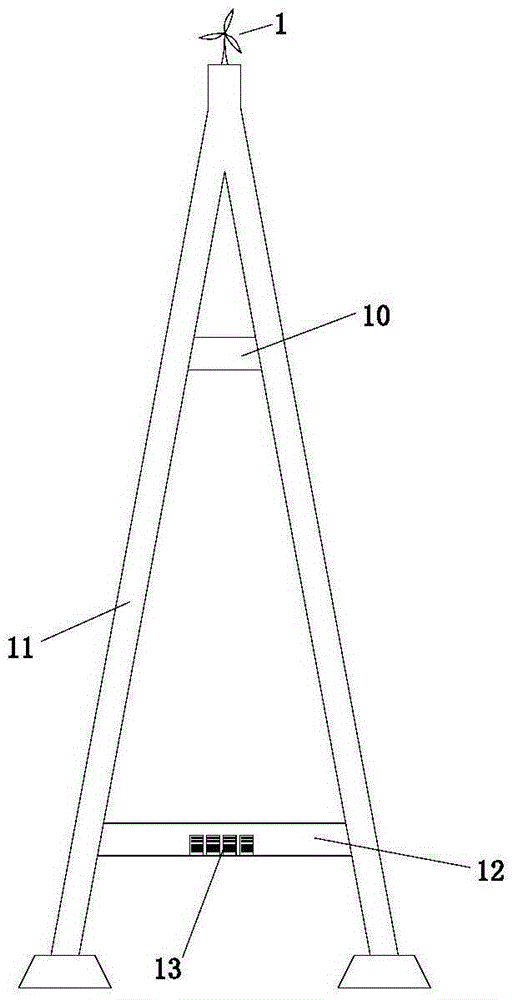

Air blowing method for controlling vortex-induced vibration of large-span bridge steel box girder

ActiveCN105388926AHigh degree of automationGood control effectMechanical oscillations controlBridgesStructural engineeringEngineering

The present invention discloses an air blowing method for controlling vortex-induced vibration of a large-span bridge steel box girder at a low wind speed. According to the air blowing method, when the steel box girder has a large vortex-induced vibration amplitude, air blowing devices arranged at two sides of the steel box girder are utilized to blow air at the leeward side of the steel box girder, so as to disturb the formation of a vortex shedding phenomenon at the leeward side of the steel box girder structure, thereby avoiding vortex-induced resonance of the steel box girder; wherein a vibration sensor arranged on the steel box girder is used to monitor vortex-induced vibration response of the steel box girder in real time, when the measured vortex-induced vibration amplitude of the steel box girder is greater than a preset amplitude threshold, a control system calls real-time monitoring data of a wind speed and wind direction sensor, starts the air blowing devices at the leeward side and automatically adjusts the air blowing speed. The air blowing method is mainly applied to control for vortex-induced vibration of the large-span bridge steel box girder, is high in automation degree and obvious in control effect, and provides a brand new effective means for the large-span bridge steel box girder in a strong wind / typhoon high frequency region to resist the vortex-induced vibration.

Owner:SOUTHEAST UNIV

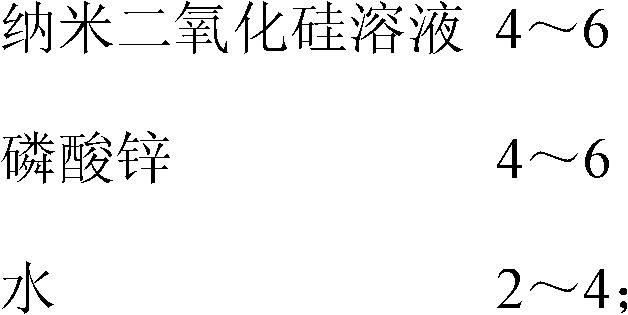

Paving method of steel box girder bridge deck payment layer

ActiveCN101660293AReduce tensile stressReduce shear stressSolid waste managementBridge structural detailsBridge deckEngineering

The invention belongs to the field of building materials, in particular to a paying method of a steel box girder bridge deck payment layer. The paying method of the steel box girder bridge deck payment layer is characterized by comprising the following steps: (1) bridge deck pre-cleaning; (2) welding of shearing rivets; (3) binding of reinforcing mats; (4) payment of a high-toughness high-strengthlight aggregation concrete layer: paying high-toughness high-strength light aggregation concrete on steel plates of a steel box girder bridge deck and forming the high-toughness high-strength light aggregation concrete layer, wherein the high-toughness high-strength light aggregation concrete is higher than the shearing rivets by 1-2 cm and the thickness of the high-toughness high-strength lightaggregation concrete is 5-8 cm; (5) payment of a waterproof bonding stress absorbing layer, wherein the thickness of the waterproof bonding stress absorbing layer is 1-2 cm; and (6) payment of a payment layer for resisting slipping, reducing noise and draining: preparing the payment layer for resisting slipping, reducing noise and draining, wherein the thickness of the pavement layer is 3-5 cm. The payment layer has the characteristics of stress absorption, lightness and excellent slipping resistance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

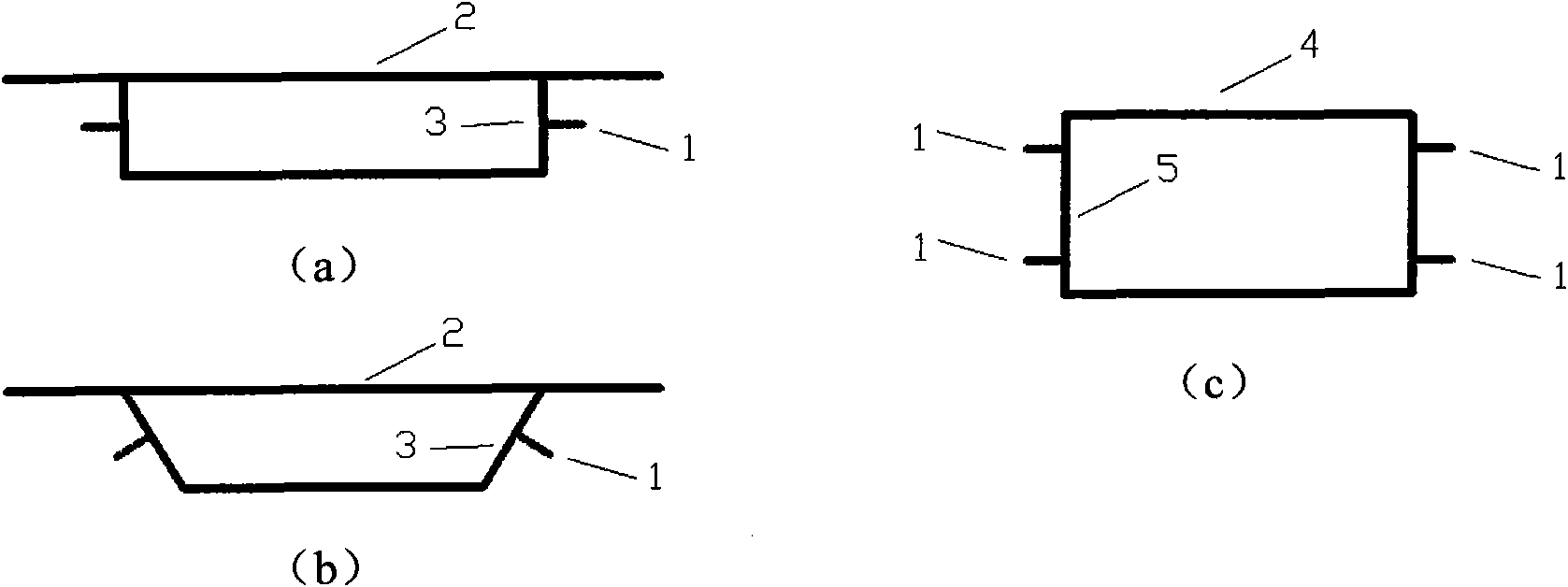

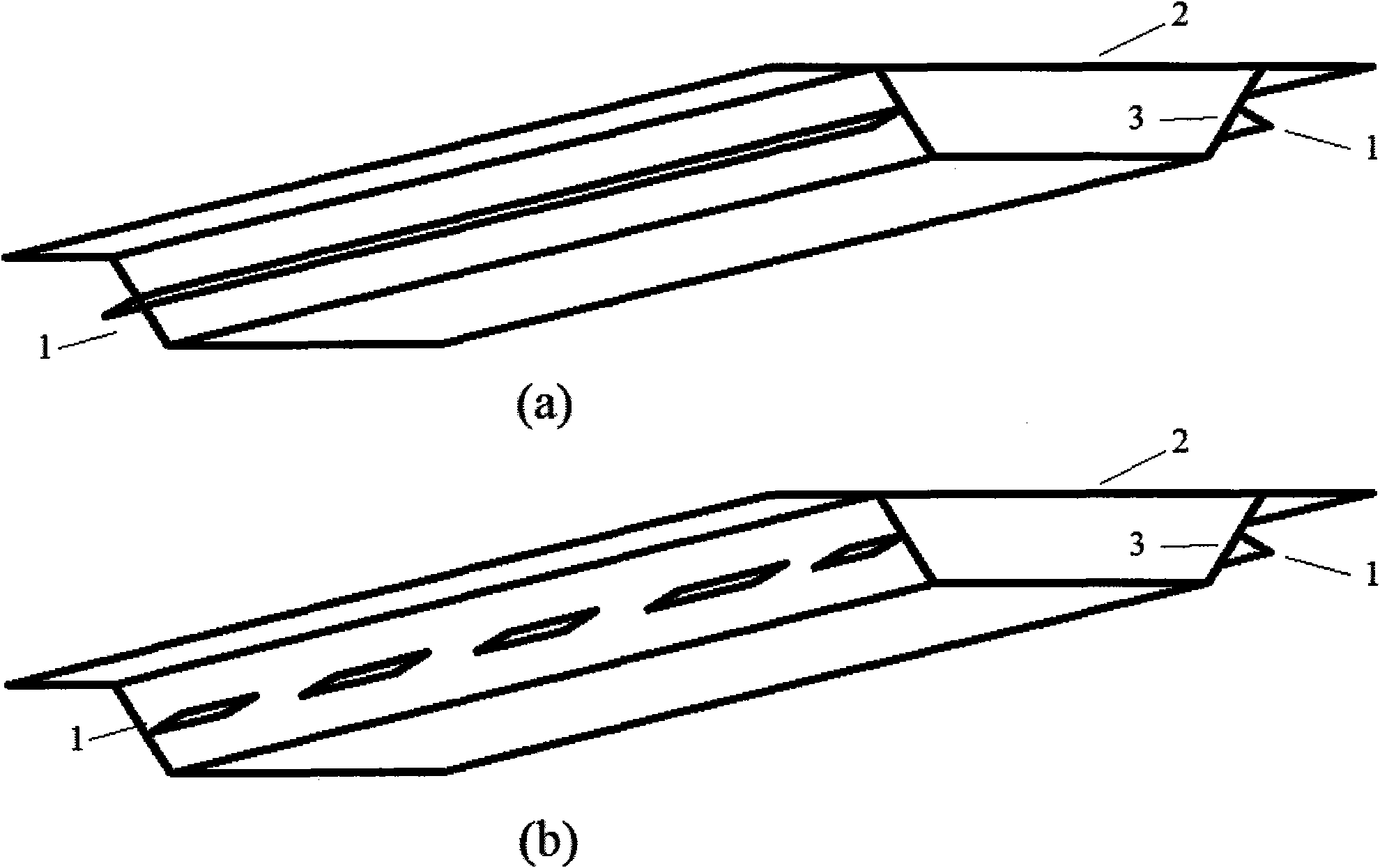

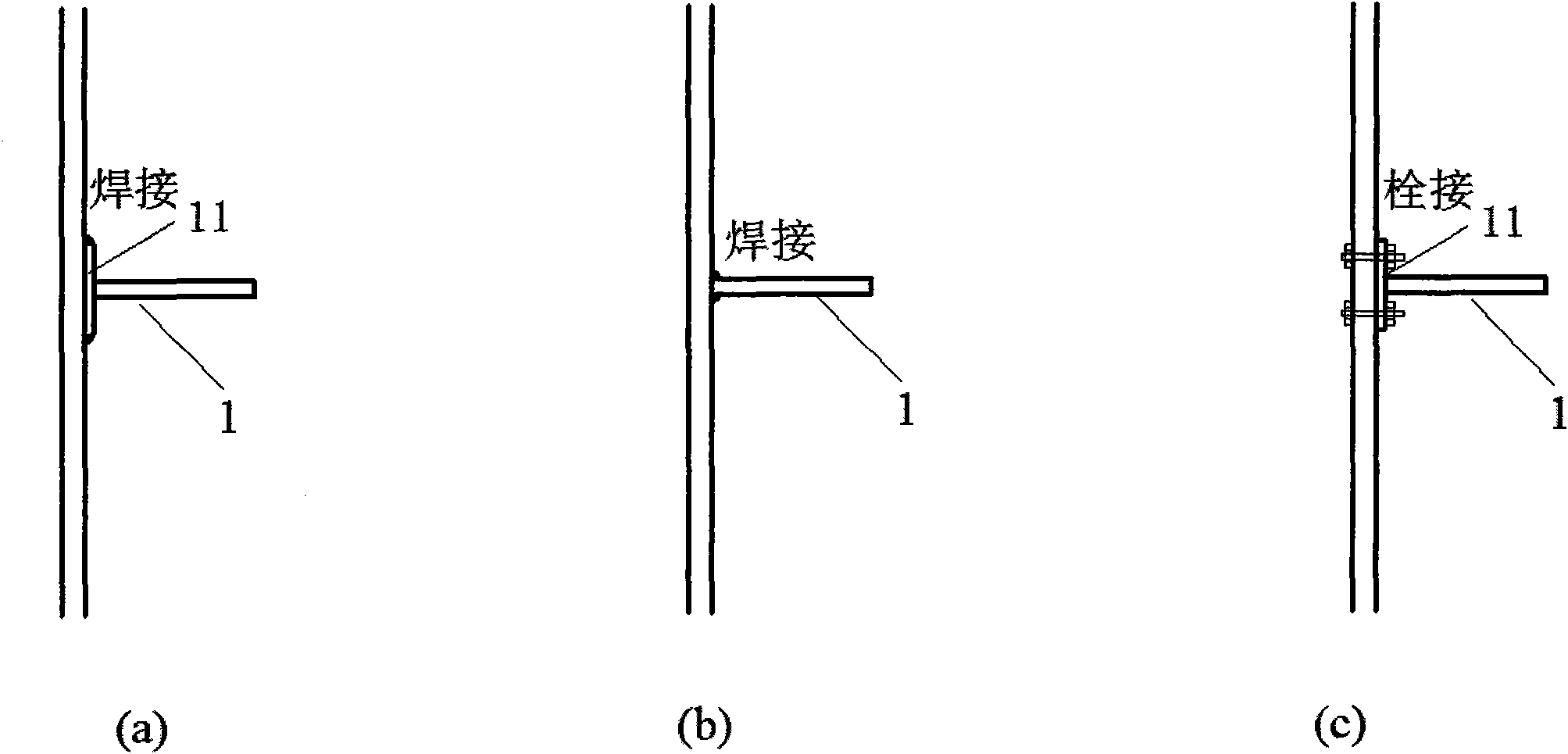

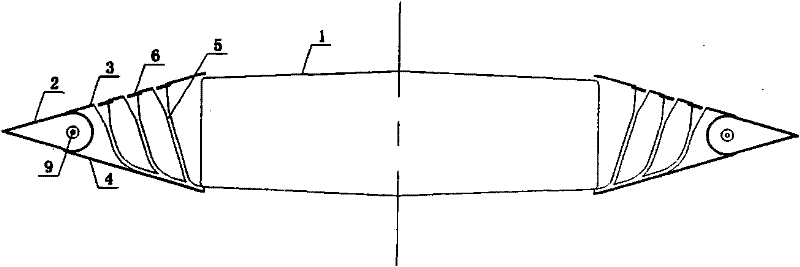

Wind fin plate for improving pneumatic performance of bridge

InactiveCN101892625AImprove flutter stabilityRaise flutter safety reservesBridge structural detailsShock proofingAccessory structureEngineering

The invention discloses a wind fin plate for improving the pneumatic performance of a bridge. The wind fin plate is arranged on an accessory structure of a main structure at a certain included angle; the wind fin plate can be designed in an equal section along the extending direction of the main structure or is divided into a plurality of sections to be arranged on the main structure at intervals; the main structure can be a girder of the bridge and the accessory structure can be a web plate of the bridge, wherein the girder of the bridge is a steel box girder or concrete box girder, and the web plate is a straight web plate or an inclined web plate; and the main structure also can be a bridge tower and the accessory structure also can be a tower column wall plate. The wind fin plate can greatly improve the pneumatic performance of the bridge, improve flutter stability and galloping stability, and effectively reduce or inhibit vortex-induced vibration so as to improve the wind resistance of the bridge; and the wind fin plate can be widely applied to members such as girders and bridge towers of bridges.

Owner:TONGJI UNIV

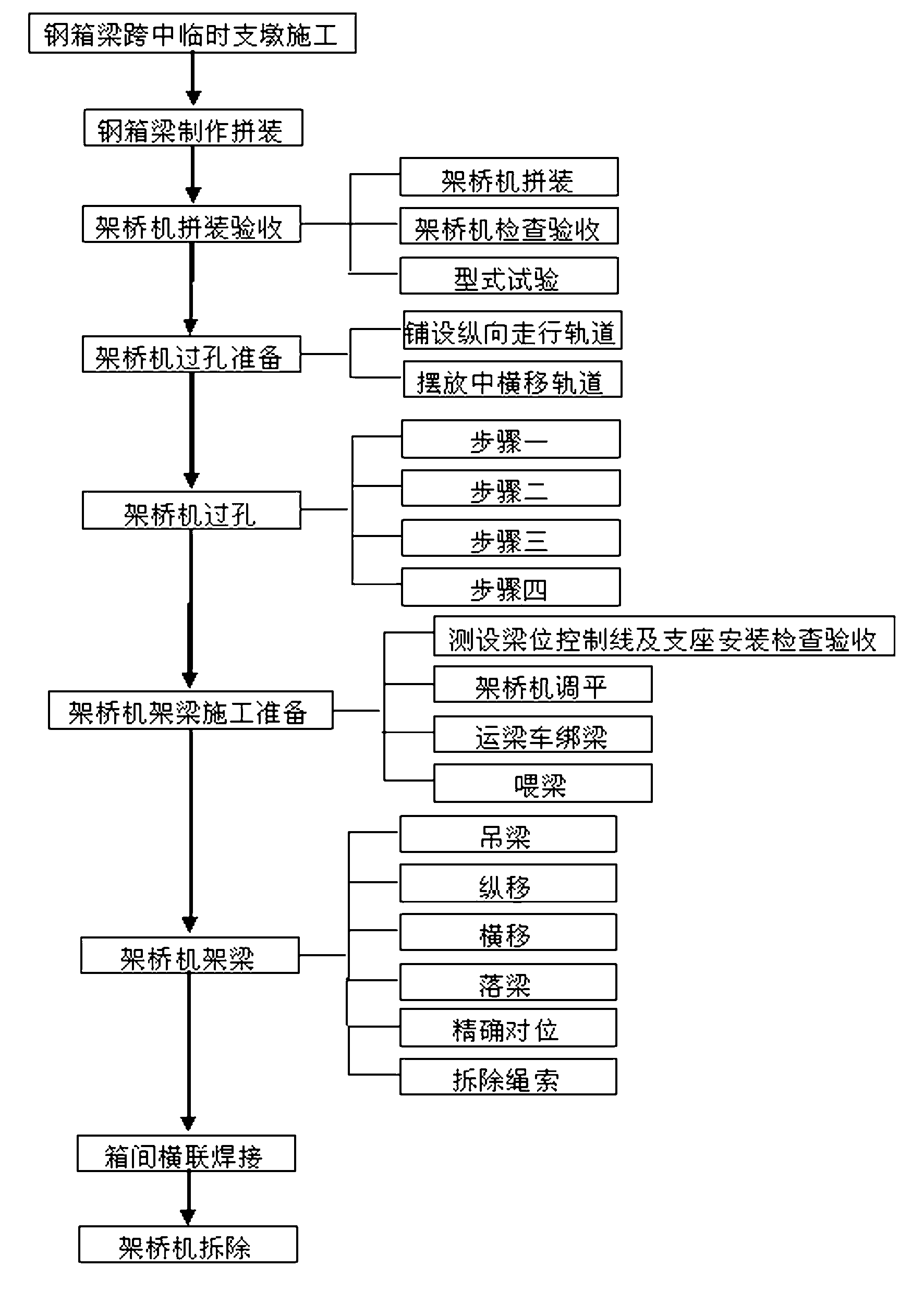

Integral erection construction method of 60m steel box girder

ActiveCN102797226AGuaranteed operational safetySolve the problems of installation and constructionBridge erection/assemblyOperation safetySteel box girder

The invention belongs to the technical field of the construction of large bridge bodies, and specifically relates to an integral erection construction method of a 60m steel box girder, which reduces the influence of the construction of long-span steel box girders to communications and transportation and surrounding structures. The method comprises the following steps of: midspan construction of temporary pillar of steel box girder, steel box girder assembling manufacturing, bridge girder erection machine assembling and checking, hole passing of the bridge girder erection machine, preparation for girder erection of the bridge girder erection machine girder and girder erection, transverse welding among boxes, and bridge girder erection machine dismantling. In the method, a hollow box-shaped double-beam bridge girder erection machine is used for carrying out the construction of the steel box girder so as to efficiently solve the construction problem that the 60m and 230t steel box girder simultaneously spans over railways and roads; and the method ensures the operation safety of the conventional railways and national roads and minimizes the influence of the construction to railways and national roads.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

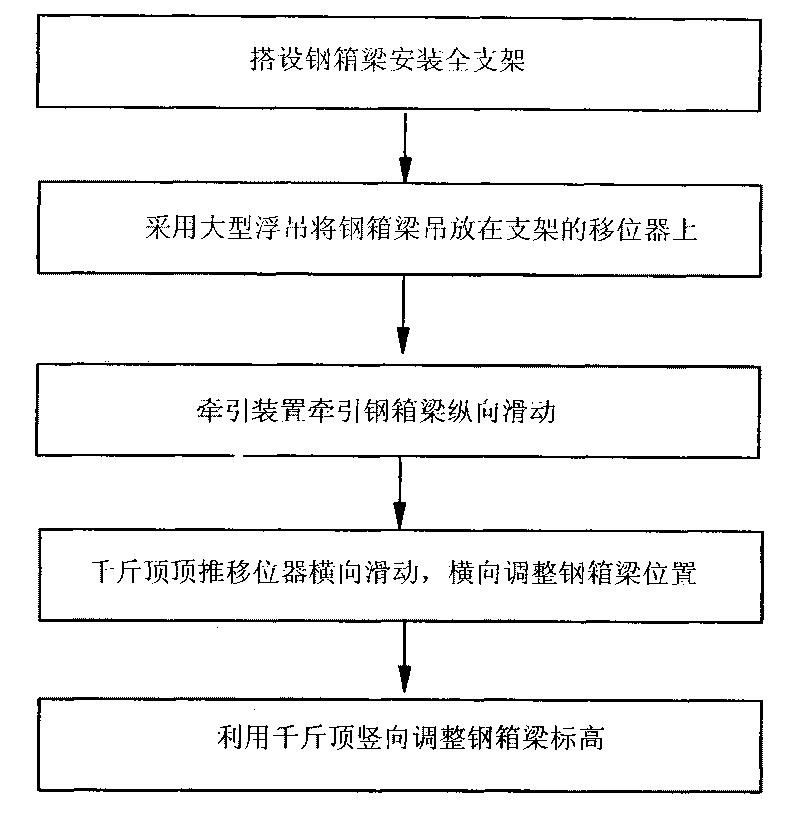

Accurate positioning method of sliding of full-support frame steel box girder

ActiveCN101736699APrecise positioningSimple processBridge erection/assemblyStructural engineeringSteel box girder

The invention relates to an accurate positioning method of the sliding of a full-support frame steel box girder, comprising the following steps of: firstly setting up a steel box girder installation full-support frame, wherein the upper part of the full-support frame is provided with a sliding chute, and a shifter is placed on the sliding chute; then placing the steel box girder on the shifter of the full-support frame by a large-sized floating crane, and towing the steel box girder to longitudinally move to a specified position along the sliding chute; horizontally pushing the shifter by a jack so that the steel box girder horizontally moves to a set position; and finally vertically regulating the steel box girder by the jack so that the accurate positioning and installation of the steel box girder is realized.

Owner:CHINA COMM ROAD & BRIDGE NORTH CHINA ENG +1

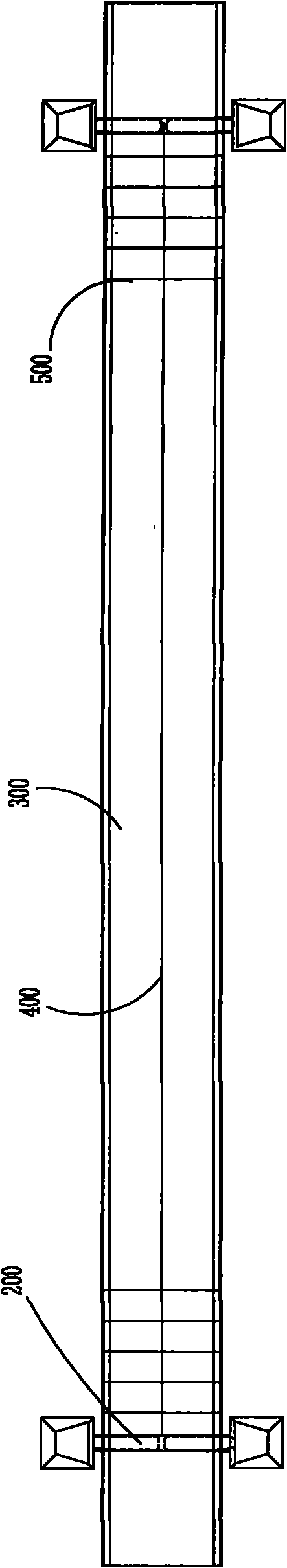

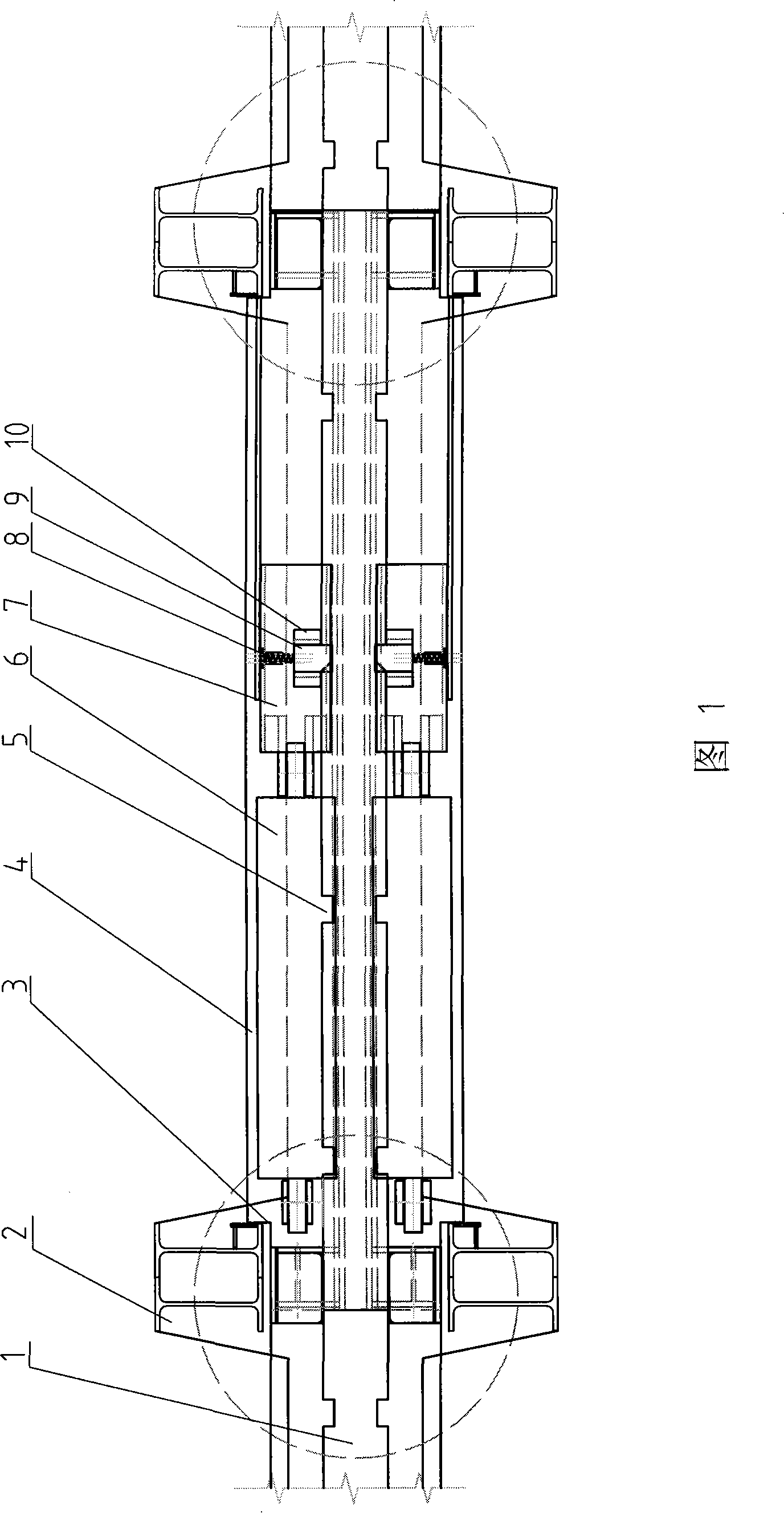

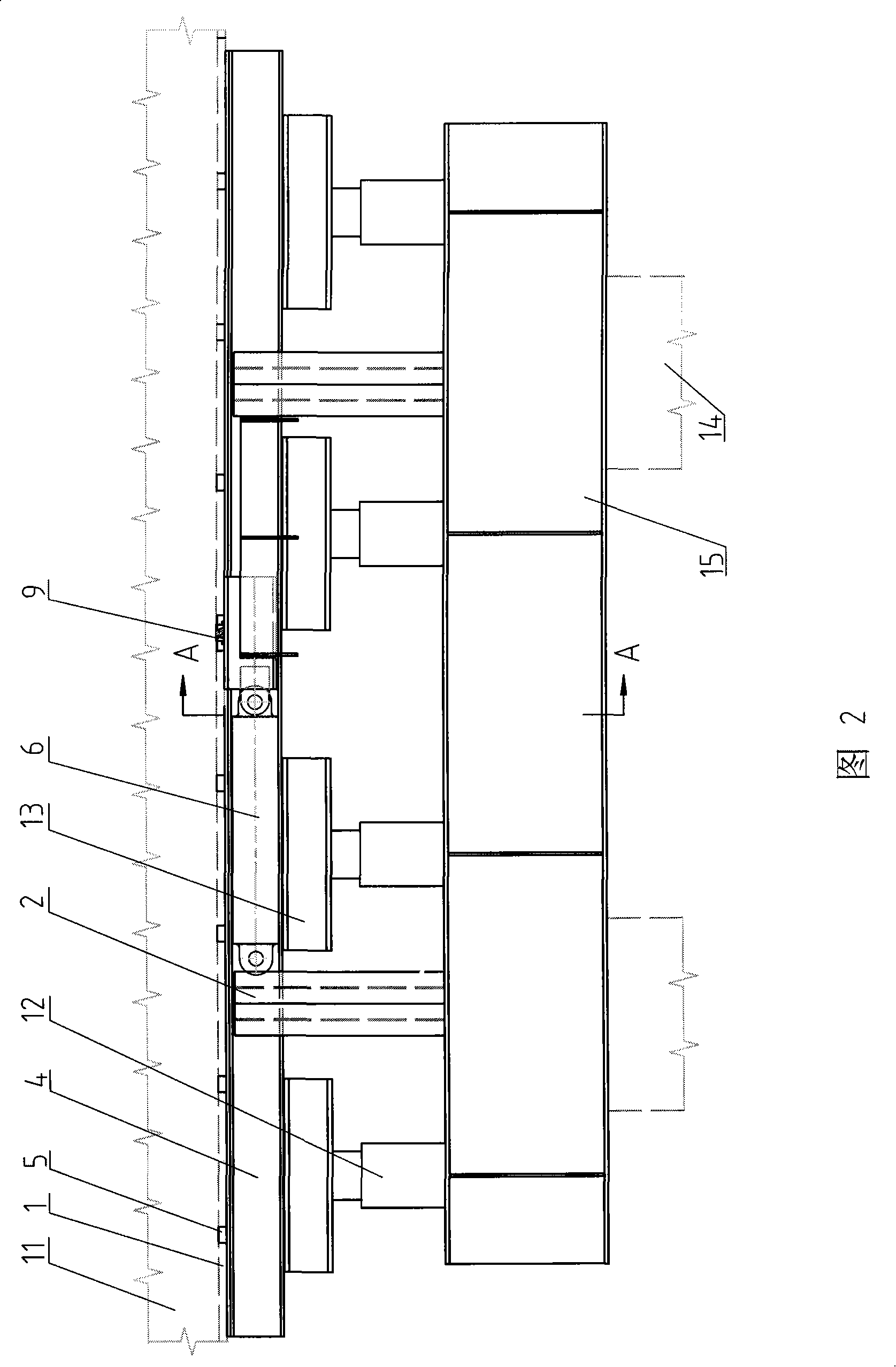

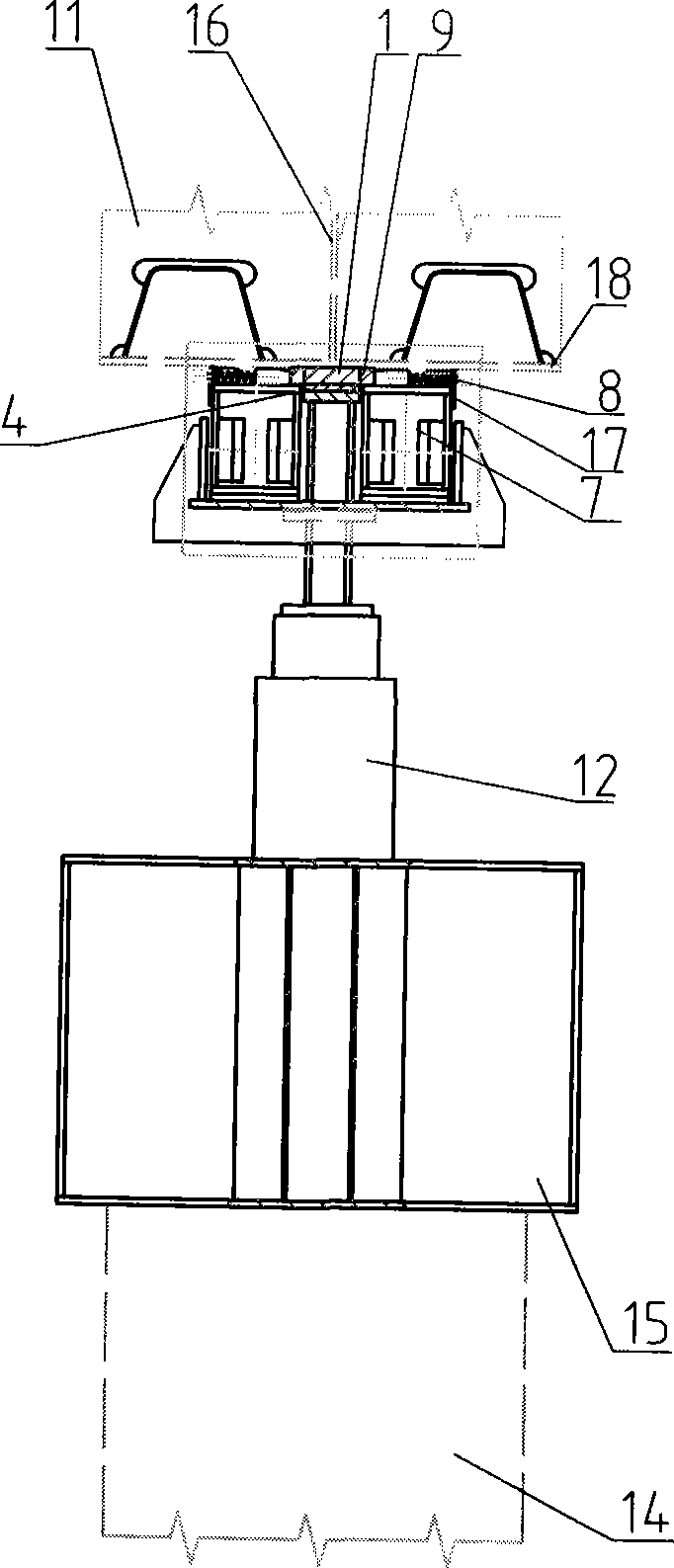

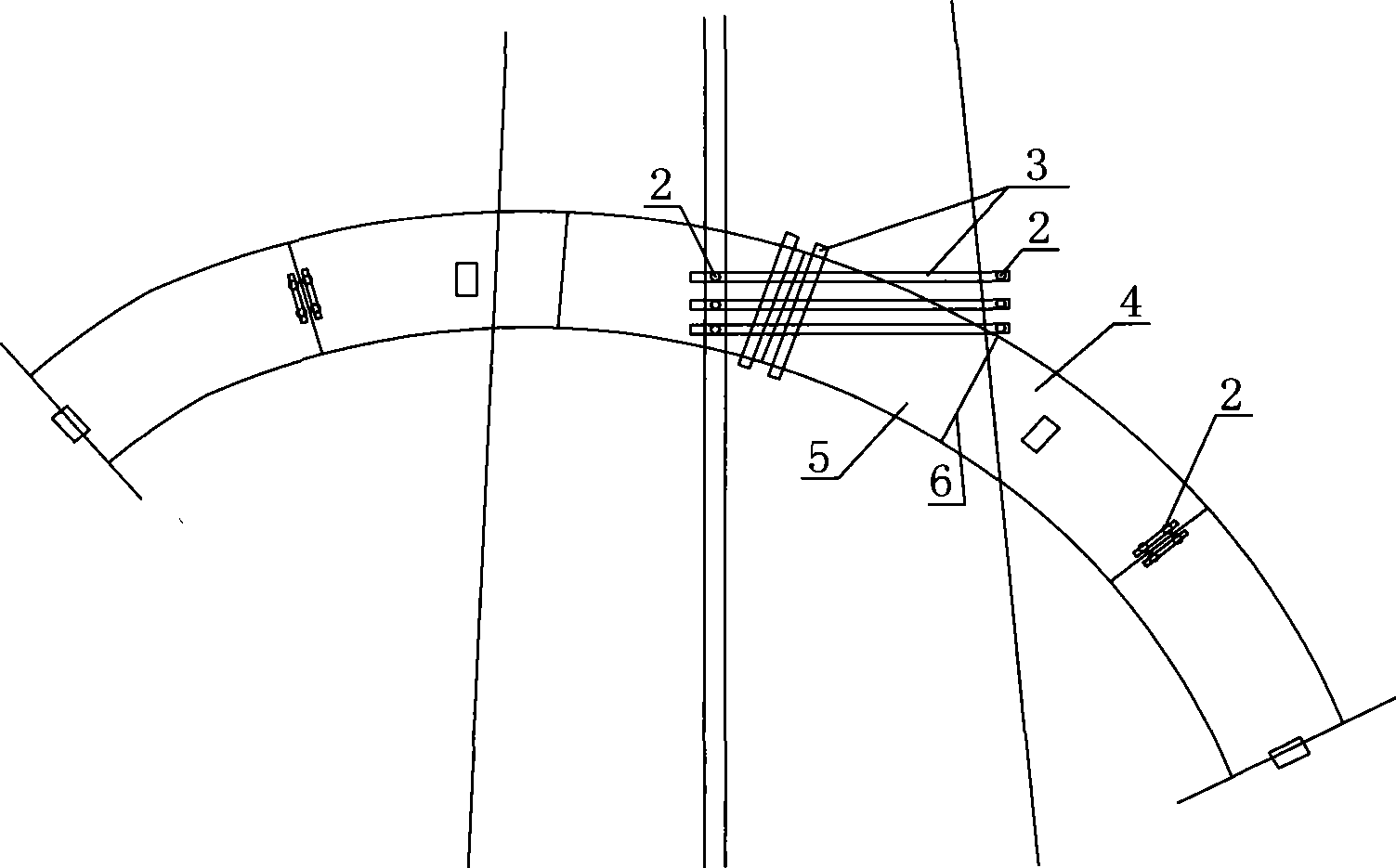

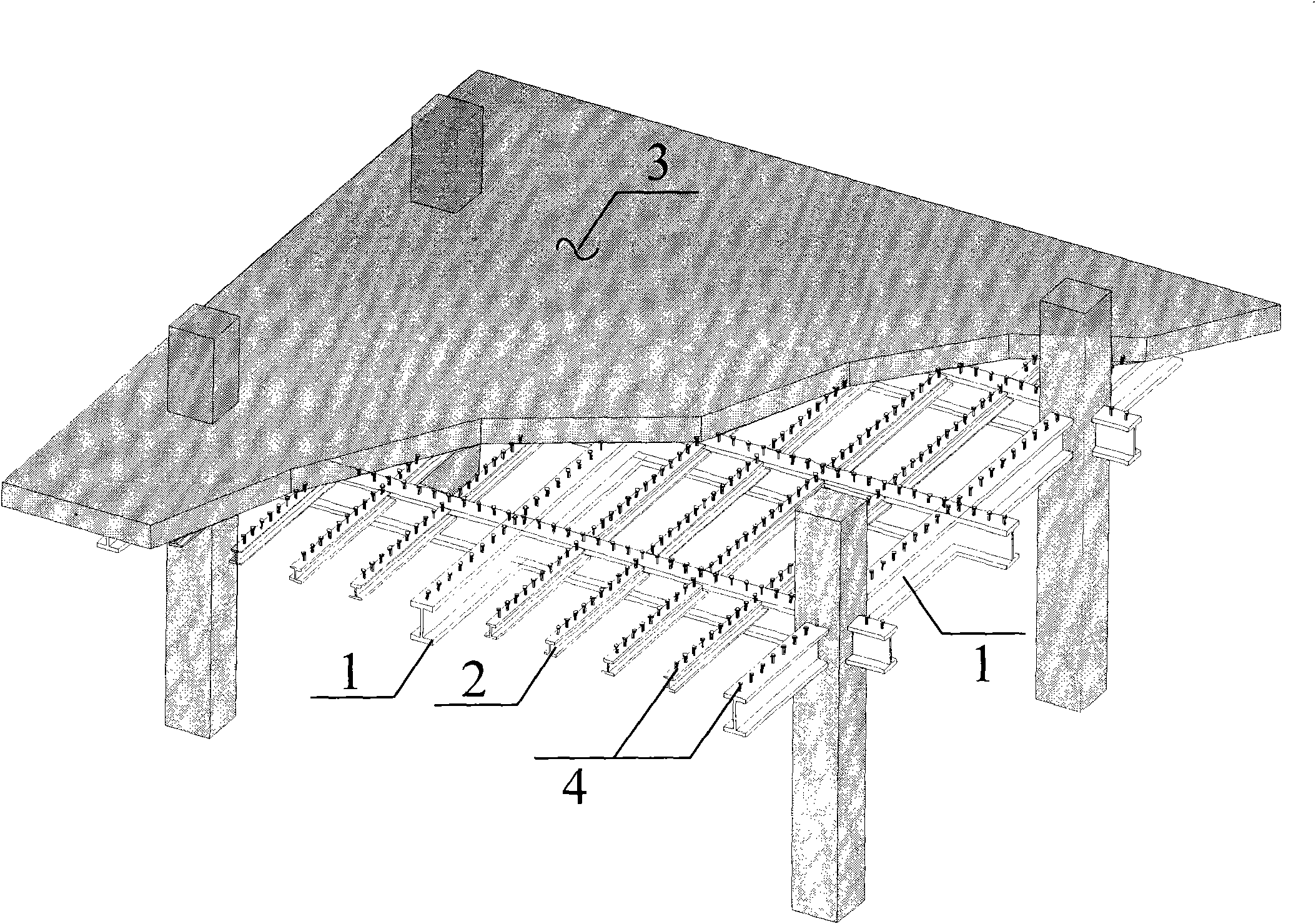

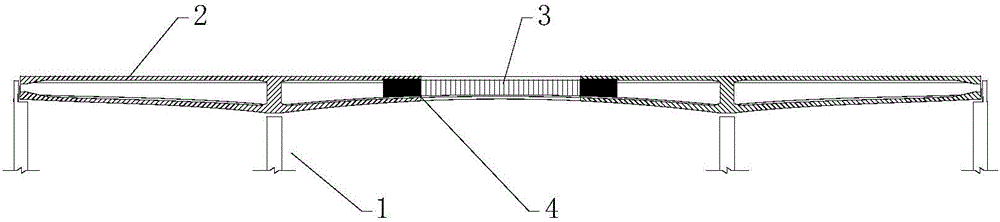

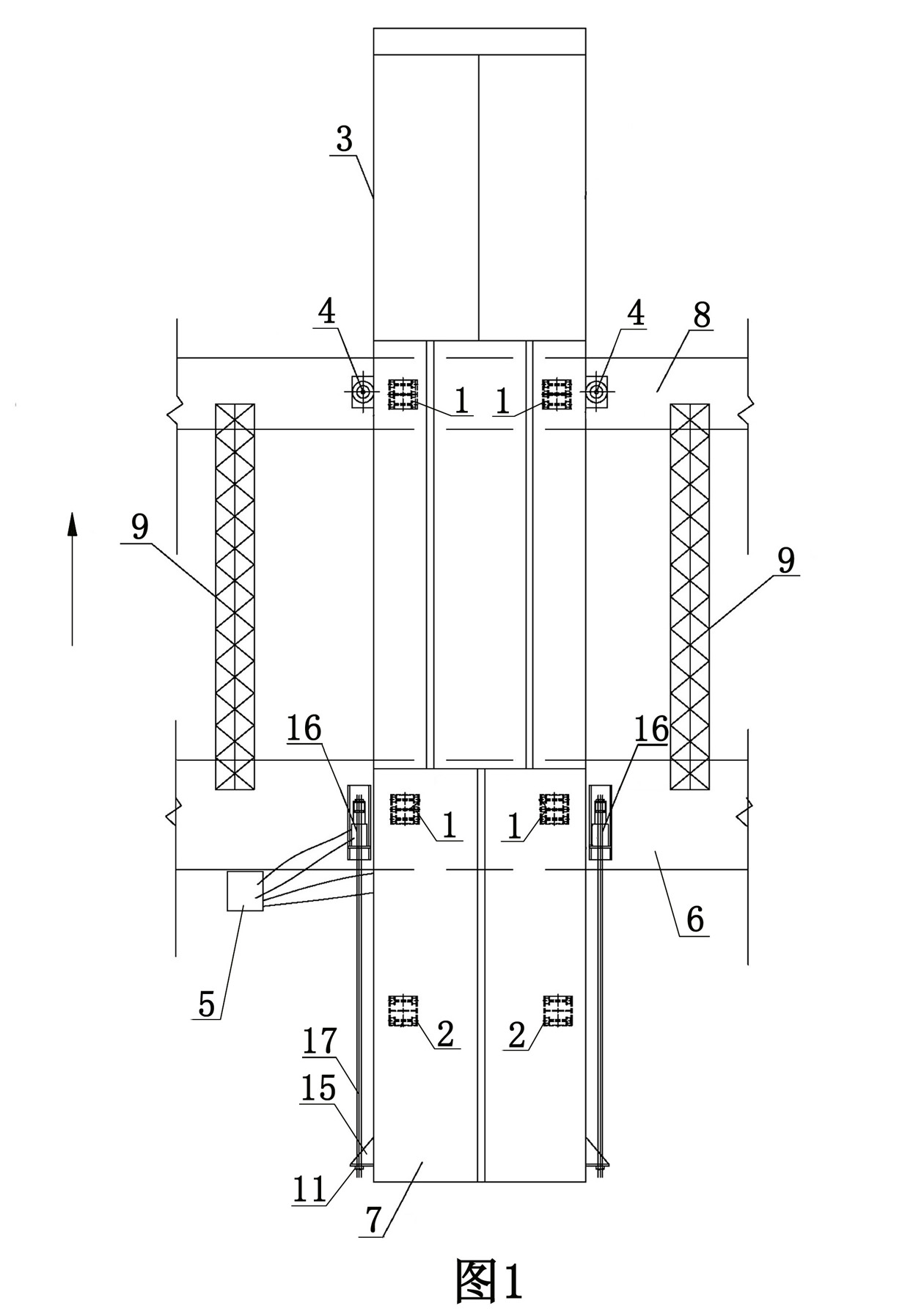

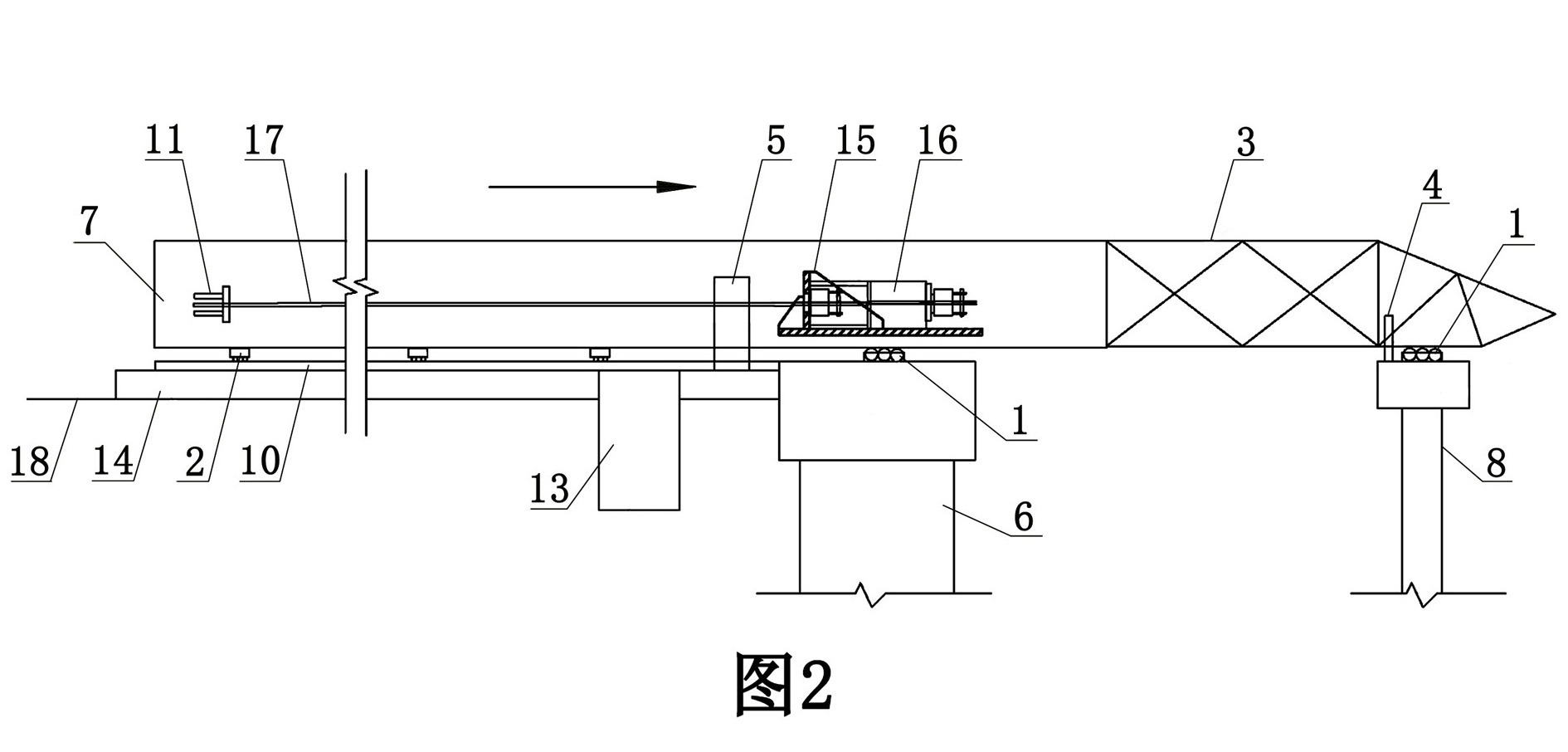

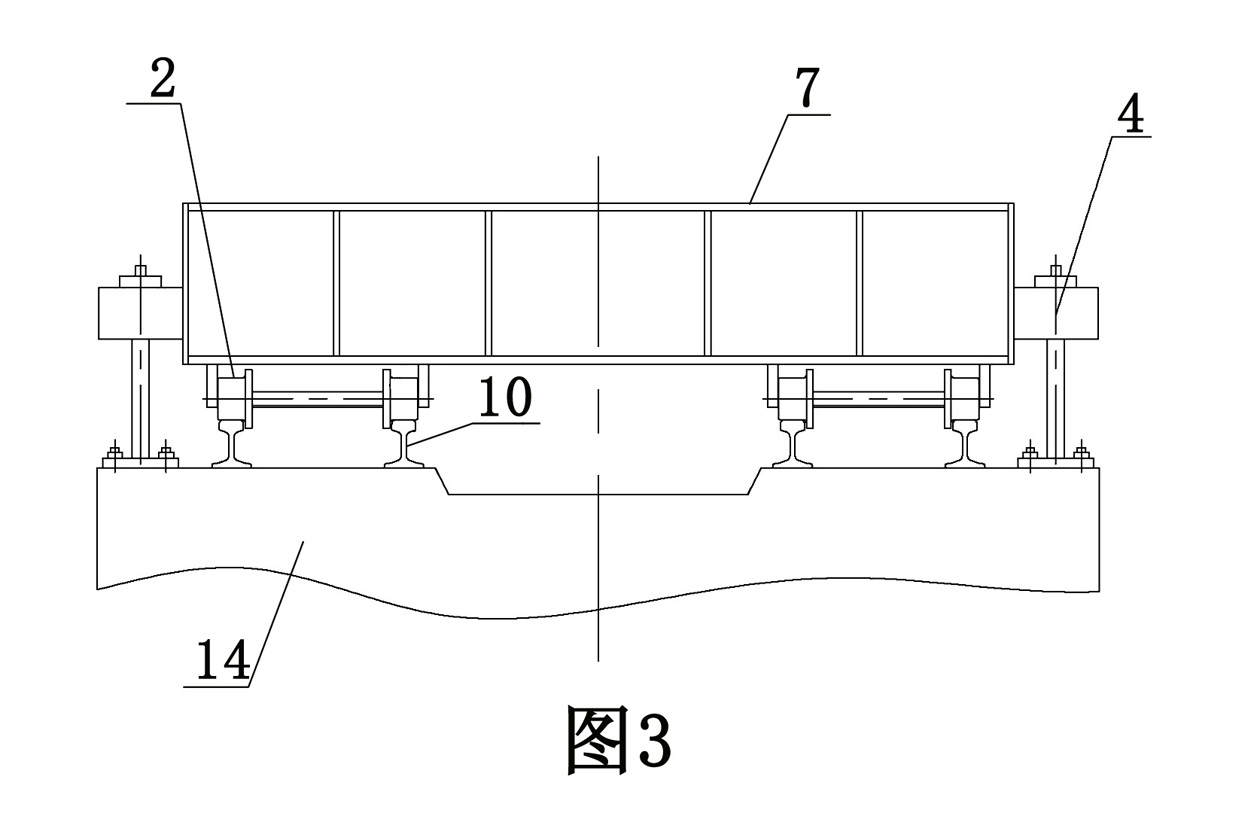

Steel box girder scattered-splicing sliding device and installation method

InactiveCN103669216AOvercoming many difficulties brought about by constructionAdaptableBridge erection/assemblyLarge sizeBox girder

The invention discloses a steel box girder scattered-splicing sliding device and an installation method and relates to the technical field of continuous steel box girder bridge construction. The steel box girder scattered-splicing sliding device and the installation method are high in adaptability, safe and reliable in construction and capable of saving large-size devices and improving the work efficiency. The device comprises a steel tube support (2), a bearing connecting beam (3) arranged at the top of the steel tube support and a sliding rail structure installed on the bearing connecting beam (3). The steel box girder scattered-splicing sliding installation method comprises the following steps that the support is erected, the sliding rail structure is installed, steel box girders are hoisted and welded in a spliced mode section by section in the hoisting position and slide to a designed position, the axes of the sectioned box girders are designed, elevation is adjusted, girth welding is conducted, and the girders are detached. The steel box girder scattered-splicing sliding device is high in adaptability, safe and reliable. The sparse sliding support is erected so that influence on the ground by construction can be reduced, foundation treatment and support usage can be reduced, the large-size devices can be omitted, the two sides of the hoisted position can be constructed at the same time, and the work efficiency of large-size hoisting devices can be improved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

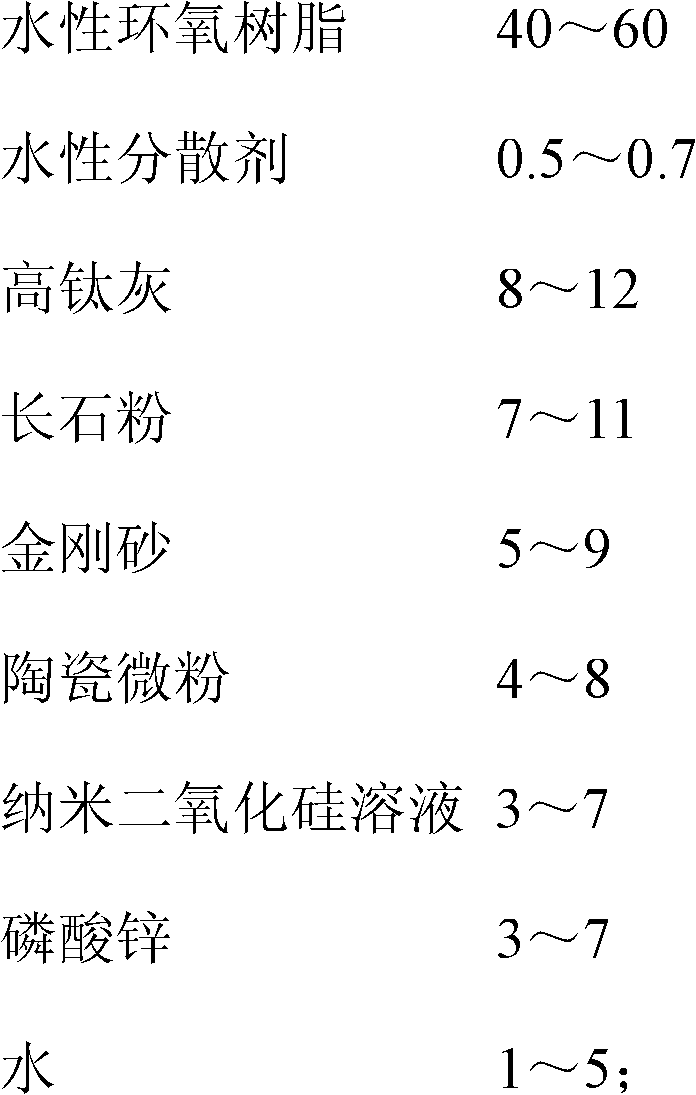

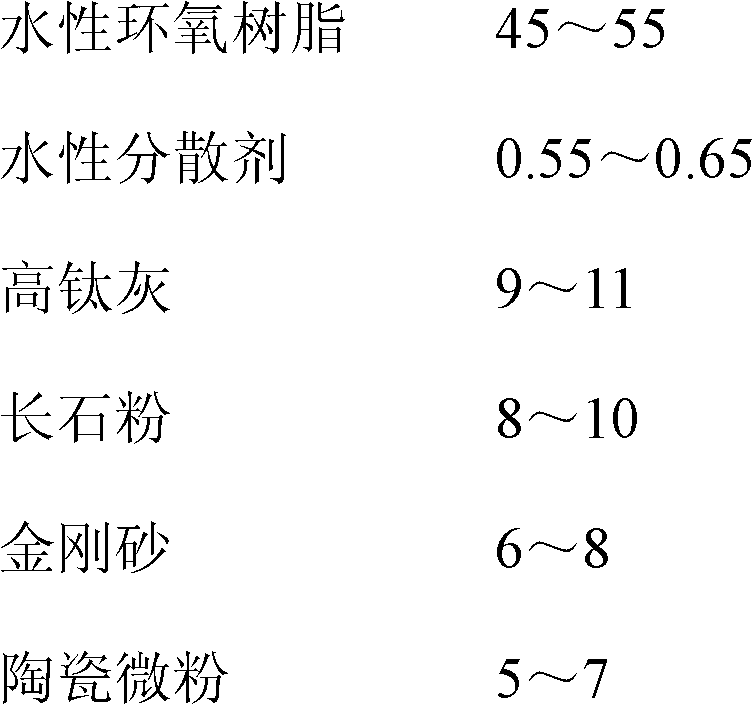

Waterborne epoxy anti-corrosive coating and preparation method thereof

InactiveCN102627905AImprove wear resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a waterborne epoxy anti-corrosive coating and a preparation method thereof. The coating comprises a component A and component B, wherein the component A comprises high titanium ash, feldspar powder, silicon carbide, ceramic fine powder, a nanometer silicon dioxide solution, zinc phosphate, water and the like; and the component B is a waterborne epoxy curing agent. The preparation method comprises the following steps of: adding a waterborne epoxy resin and a waterborne dispersing agent into a reaction kettle, starting a dispersing machine, adding the high titanium ash, feldspar powder, silicon carbide, ceramic powder, nanometer silicon dioxide solution, zinc phosphate and water in sequence, and dispersing; treating with a sand grinding machine; and adding auxiliary materials such as a waterborne antifoaming agent, a waterborne flatting agent and the like, and stirring to obtain a bottom and top-combined thick film waterborne epoxy anti-corrosive coating. The coating provided by the invention is corrosion resistant and wear resistant after one-time molding, the coating requirement of the inner wall of a steel structure bridge steel box girder is met, and the coating technical requirements of a plurality of severely-corrosive indoor steel structure platforms are met.

Owner:TIANCHANG JULONG TRAVEL PAINT

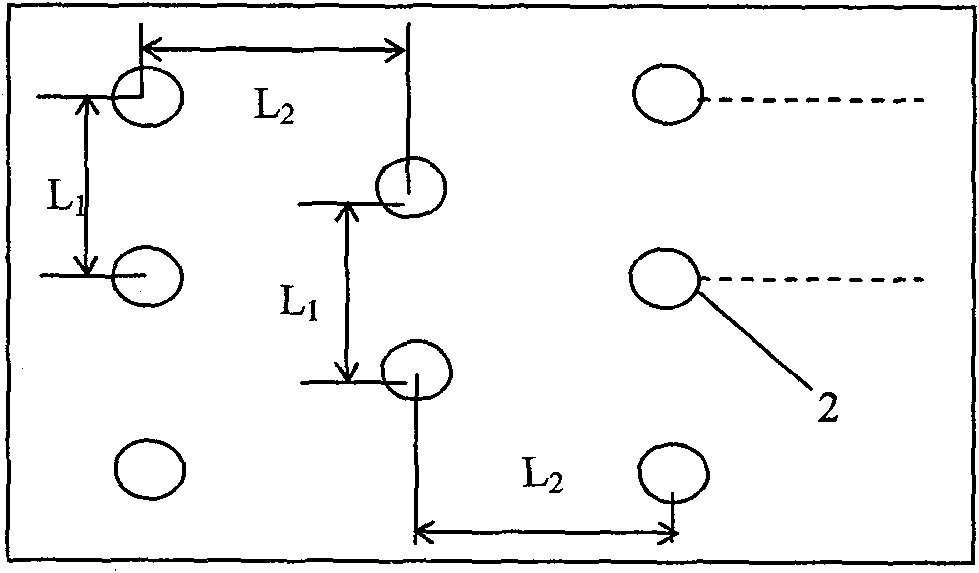

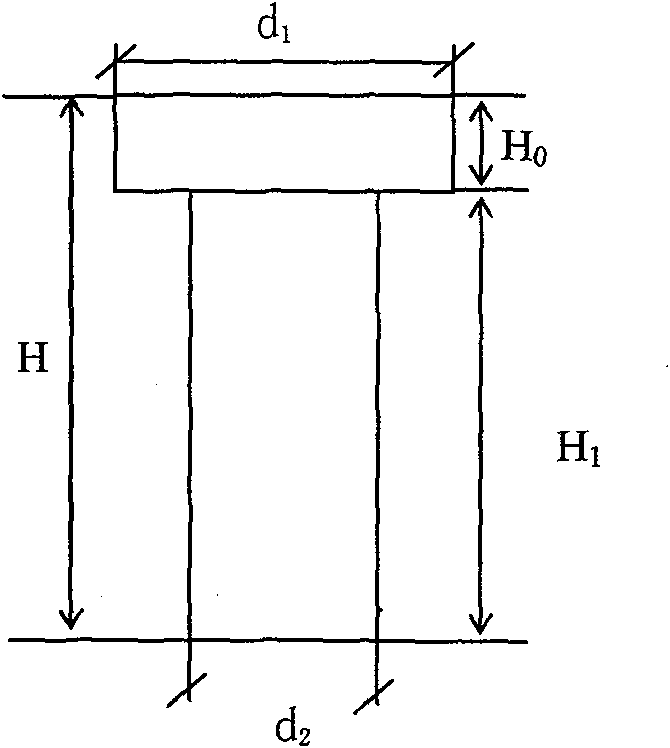

Method for preparing antiskid wearable lightweight steel box girder bridge floor paving layer

ActiveCN101234876AWear-resistantWith wear resistanceSolid waste managementWear resistantMesh reinforcement

The invention relates to an anti-sliding, wear-resistant and light steel box girder bridge deck pavement and a preparation method thereof, which is characterized in that the method includes the following steps: 1) preparation of high toughness and high strength lightweight aggregate concrete and cement paste on a basalt bare stone surface layer: a. the high toughness and high strength lightweight aggregate concrete is prepared; b. the cement paste on the basalt bare stone surface layer is prepared; 2) pretreatment of the steel box girder bridge deck; 3) welding of shear key: the shear key is welded on the steel box girder bridge deck one by one according to mutual spacing of the shear keys with (30-60)cm plus (30-60)cm; the shear key is stud; 4) lashing of mesh reinforcement; 5) paving of the high toughness and high strength lightweight aggregate concrete layer: thickness of the high toughness and high strength lightweight aggregate concrete layer is 50-80cm; 6) paving of the surface layer of the basalt bare stone; then maintenance is carried out. The bridge deck pavement prepared by the method can effectively prevent disease occurrence of the steel box girder, prolong service life of the bright deck and simultaneously has the functions of anti-sliding, wear-resistant and noise reduction and has good pavement performance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Walking type multi-point jacking-pushing construction method

InactiveCN102587281ASolve the problem of erectionLittle traffic impactBridge erection/assemblyBridge engineeringSteel box girder

The invention relates to the technical field of bridge engineering, in particular to a walking type multi-point jacking-pushing construction method which solves problems of safely moving and fast taking place for girders in engineering construction such as bridges, interchanges and the like. The walking type multi-point jacking-pushing construction method is characterized in that a jacking-pushing device integrated with jacking, translation and cross adjustment is arranged so as to realize movement or adjustment of a steel box girder in the longitudinal bridge direction, the transverse bridge direction and the vertical direction; two steps of jacking and pushing are performed alternately to jack the whole steel box girder and then deliver the steel box girder forward; then the steel box girder is put on a temporary mound structure to complete a jacking and pushing process, after that a jacking-pushing oil cylinder is shrunk to the bottom of the oil cylinder so as to perform the next jacking and pushing work; and the steps are circulated. The method provided by the invention has the steps of jacking, pushing, dropping and returning to place, is safe and stable, can be operated conveniently, has low comprehensive engineering cost and high efficiency and can realize the integral movement and adjustment of the steel box girder in the longitudinal bridge direction, the transverse bridge direction and the vertical direction.

Owner:CHINA RAILWAY 24TH BUREAU GRP +1

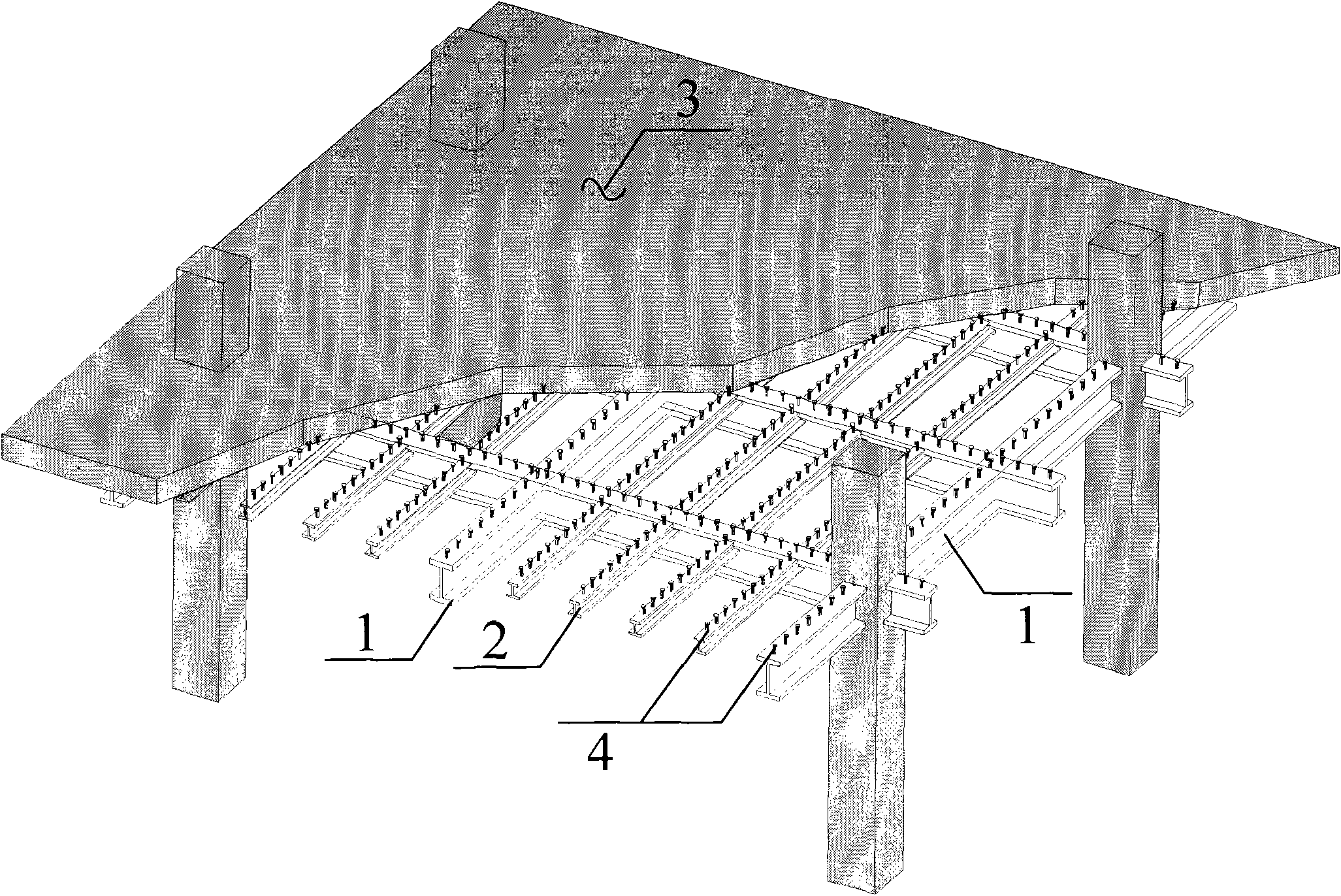

Integral two-way partial one-way steel-concrete slab composite floor and its construction method

The invention relates to an integral two-way partial one-way steel-concrete composite floor and a construction method thereof, belonging to the field of structural engineering. The invention consists of an integral two-way steel main girder, a local one-way steel secondary girder and a concrete slab. The two-way steel main girder is an I-shaped section or a box-shaped section; the local one-way steel secondary beam is an I-shaped section; The upper flanges of main beams and unidirectional steel secondary beams cover the grids between steel beams. The overall two-way partial one-way steel-concrete composite floor of the present invention can fully exert the material characteristics through the combination effect, and realize the force effect of the overall two-way support. On the basis of ensuring the mechanical performance of the structure, the number of nodes is reduced to further facilitate the construction of the steel structure.

Owner:TSINGHUA UNIV

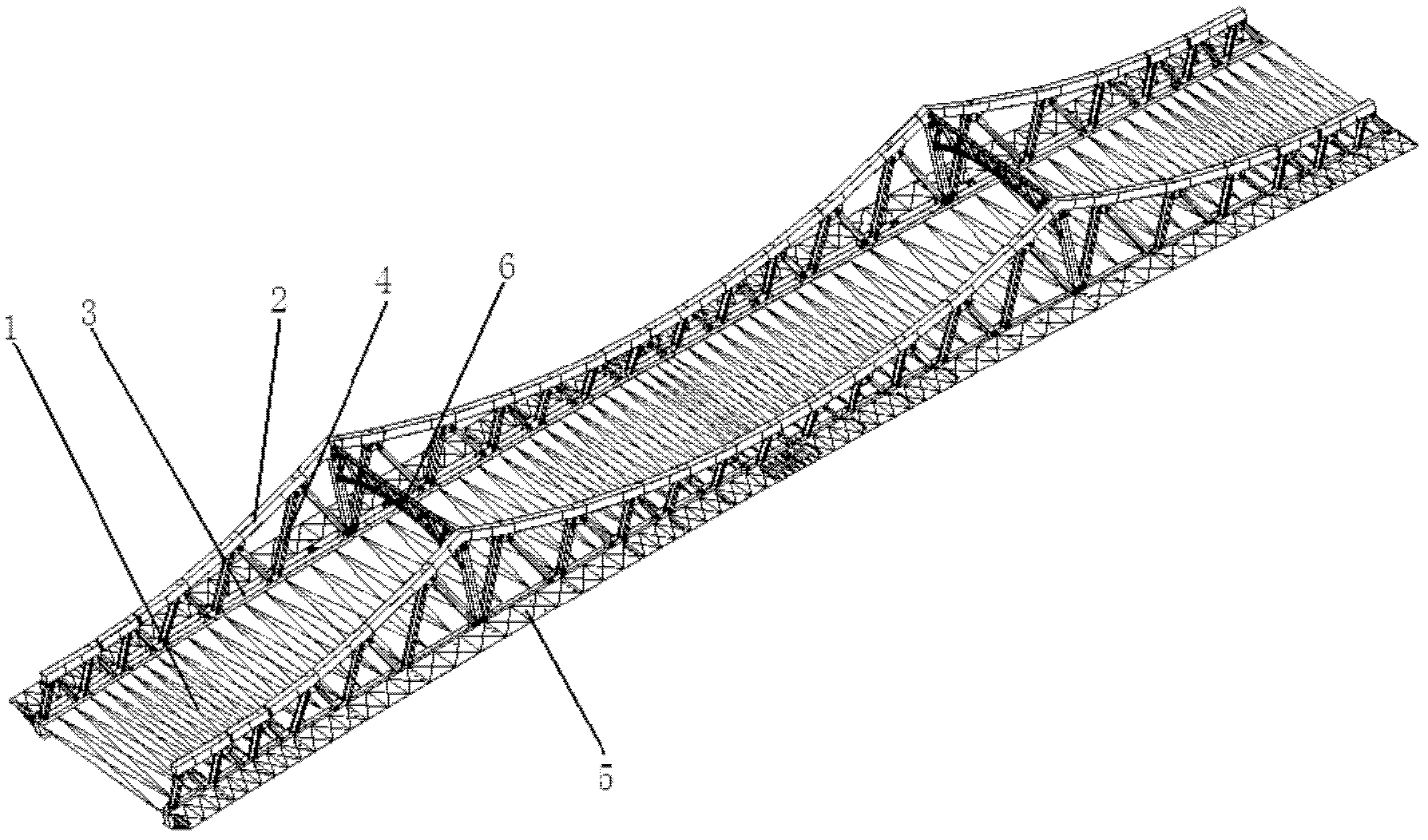

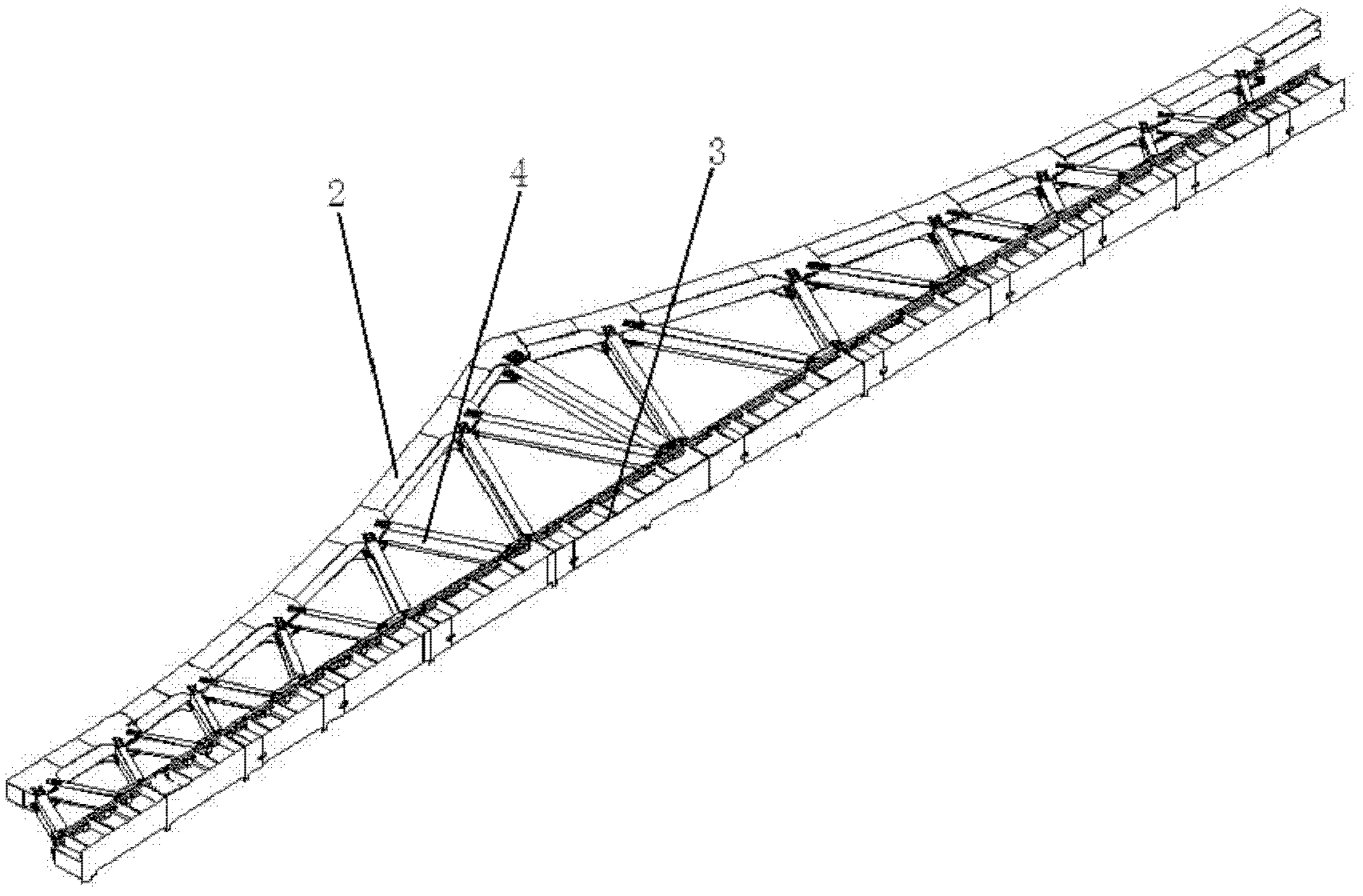

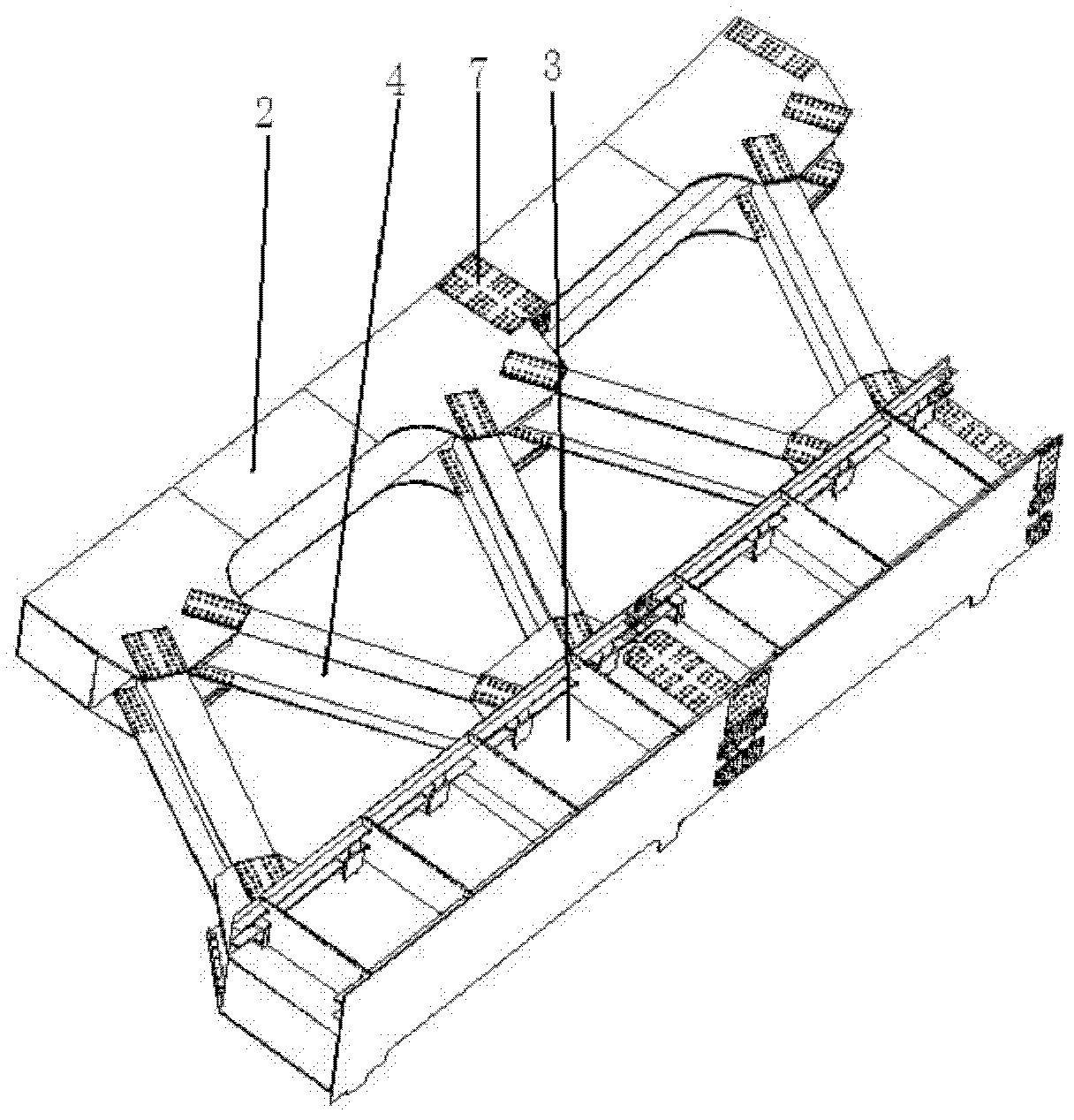

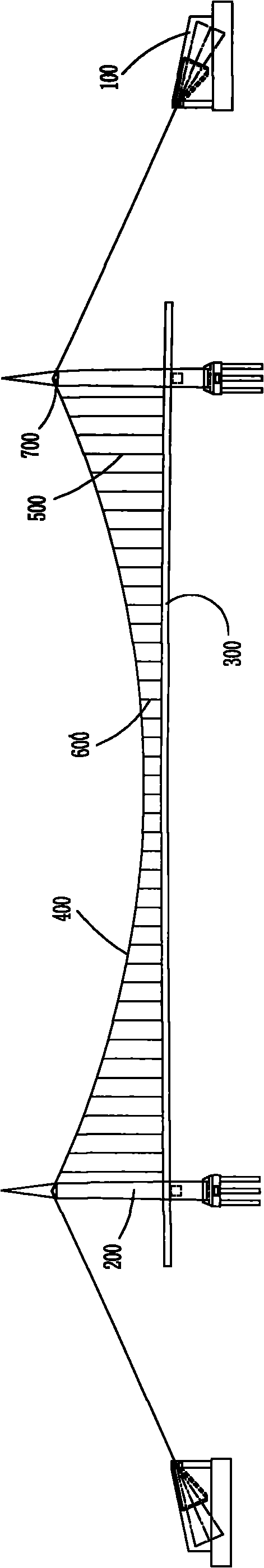

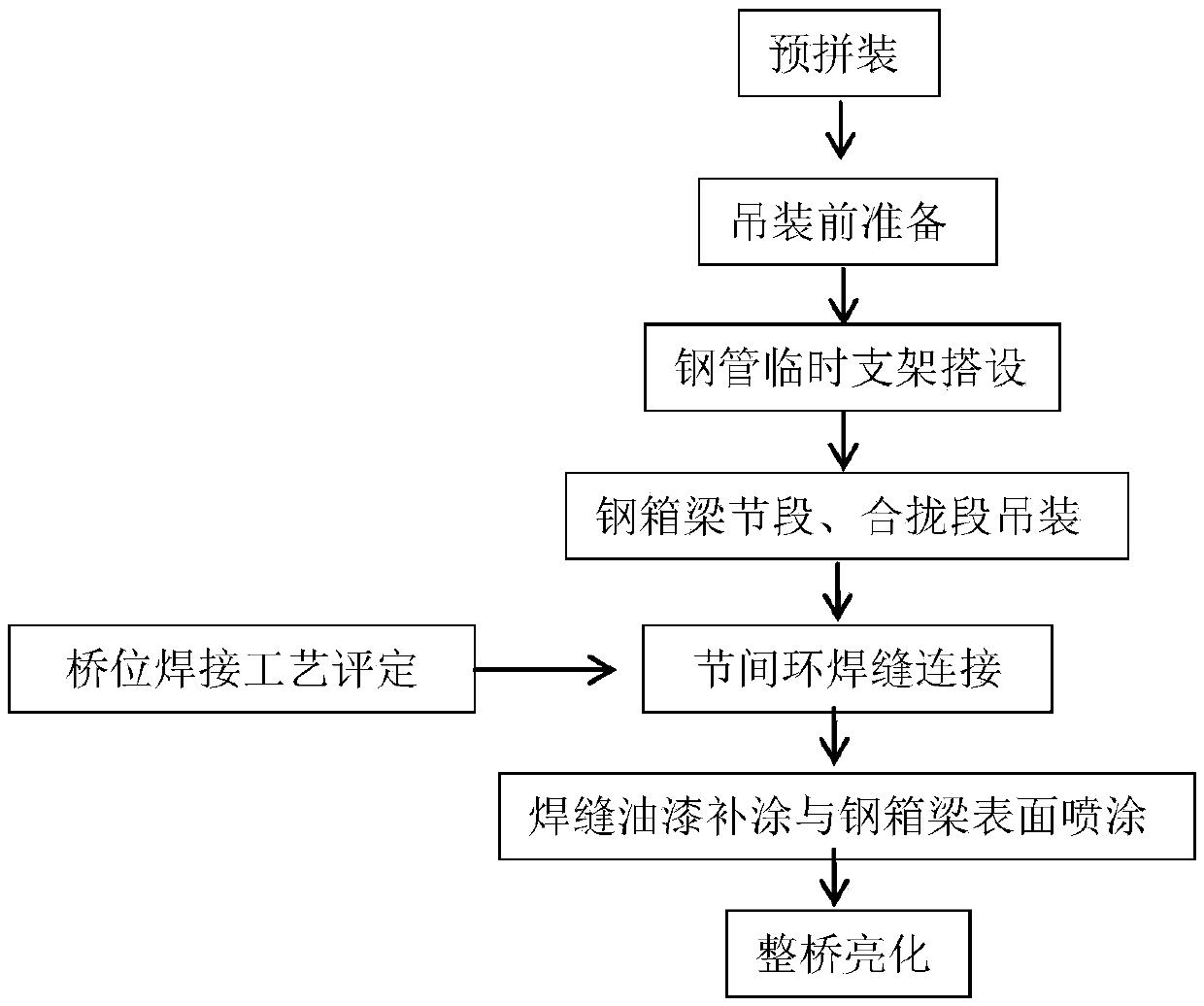

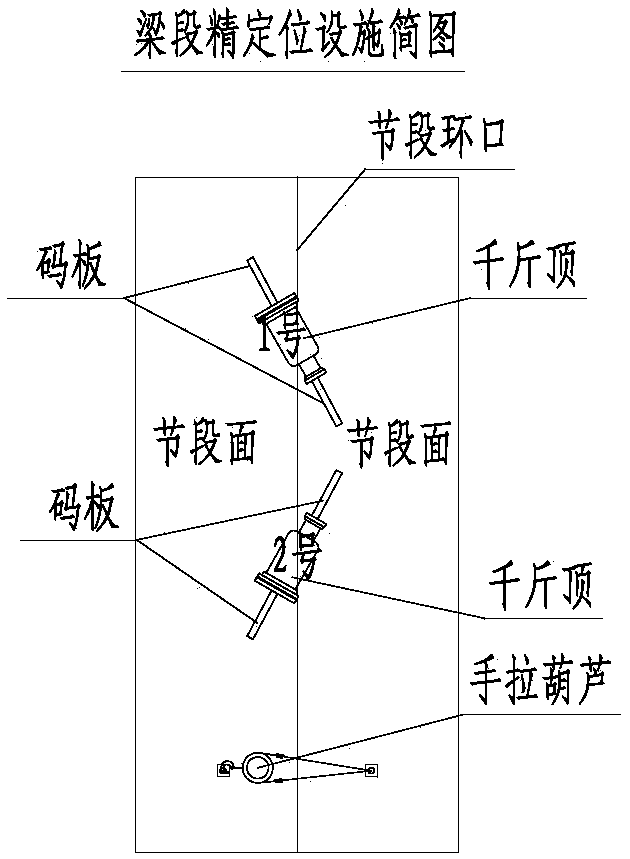

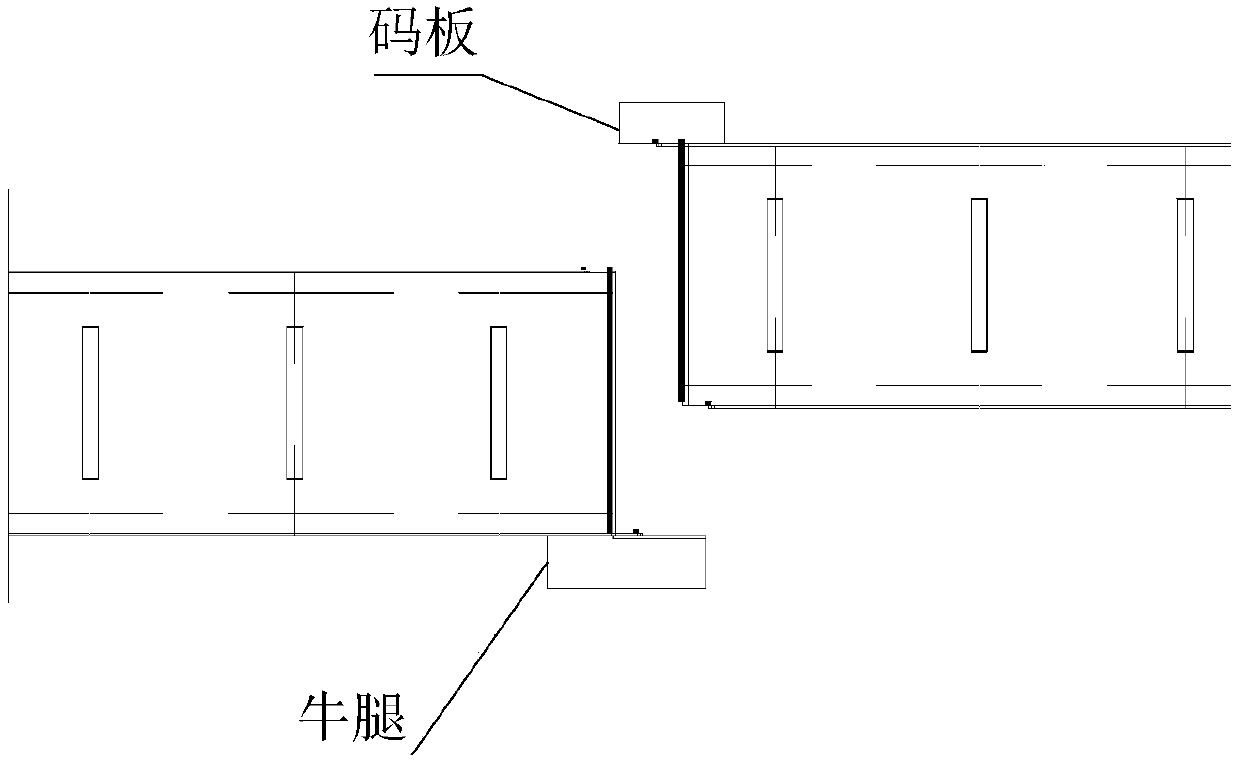

Limited bracket construction method of large-span S-shaped steel box girder

InactiveCN109594474ASmall footprintReduce the impactBridge erection/assemblyBridge materialsEngineeringSteel box girder

The invention discloses a limited bracket construction method of a large-span S-shaped steel box girder. The steel box girder comprises 14 small sections of prefabricated steel box girders; and the 14small sections of prefabricated steel box girders are assembled into seven large sections at a construction site, and then the seven large sections are hoisted and fixed. The construction method comprises the following specific steps of: prefabricating and assembling the steel box girders, constructing temporary brackets in water, hoisting and positioning steel box girder section blocks, connecting steel box girder interfaces, constructing closure sections and welding the collar extension of the steel box girders. According to the limited bracket construction method, a prefabricated assemblymode is used during construction; a floating crane is used for assembly, so that the occupation and pollution of a water area under a bridge are reduced; the parallel operation of multiple processes speeds up the construction progress and shortens the construction period; the temporary brackets are arranged only at circular seams of large-section girder joints; and the brackets occupy small space,thereby facilitating the navigation under the bridge in the construction state and reducing the influence on the navigation under the lake-across construction bridge and surrounding social environments.

Owner:合肥市公路桥梁工程有限责任公司

Prestressed concrete-corrugated web steel box connecting beam hybrid beam structural system

InactiveCN106400666ASolve crackingReduce the weight of the structureBridge structural detailsBridge materialsCrazingPre stress

The invention discloses a novel hybrid beam structural system. The novel hybrid beam structural system comprises a corrugated web steel box connecting beam segment and prestressed concrete box beam segments. The prestressed concrete box beam segments are located on the two sides of the corrugated web steel box connecting beam segment. The novel hybrid beam structural system is mainly used for a continuous beam bridge or a rigid frame bridge. The midspan part of a main span is the corrugated web steel box connecting beam, the rest part of the main span and sidespans are prestressed concrete box beams, and steel-concrete composite segments are used for connection transition between the prestressed concrete box beams and the corrugated web steel box connecting beam. The novel hybrid beam structural system overcomes the defects of a traditional prestressed concrete box beam unitary system and defects of a traditional steel box beam unitary system, and has the beneficial effects of being good in stress performance and economical efficiency, high in span capacity and the like. According to the structural system, the dead load is effectively reduced, the span capacity is improved, the midspan deflection can be reduced, and the defects that the continuous downwarping and crazing of the midspan of the prestressed concrete box beam, poor stability of an ordinary steel box beam web and poor durability of bridge deck pavement are avoided.

Owner:SOUTHEAST UNIV

Liftable self-propelled continuous pushing system for large-span steel box beam and construction method thereof

ActiveCN107151980AReduced midline deviationReduced quality damageHydro energy generationBridge erection/assemblyAuto regulationControl system

The invention discloses a liftable self-propelled continuous pushing system for a large-span steel box beam. The liftable self-propelled continuous pushing system for the large-span steel box beam comprises a automatically-positioning continuous pushing device, an automatic pier top slideway elevation adjusting device and a horizontal limiting and correcting device. By virtue of a highly automated control system, precise positioning and synchronous pushing are achieved, damage to the quality of a steel box structure is minimized, and a relatively good quality control effect is ensured. The invention further discloses a pushing construction method. Through arrangement of the automatically-positioning continuous pushing device and the automatic pier top slideway elevation adjusting device in a pushing construction technology, self-propelled advancement and precise positioning of the pushing device are achieved, lifting and mounting and dismounting operation procedures of mechanical equipment are saved, the operation of the construction technology is simplified, the technical difficulty is reduced, the on-site controllability is substantially improved, the construction time is shortened, the safety risks are reduced, and popularization and application are easy.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

Adaptive tuyere of steel box girder

ActiveCN102191747AIncrease flutter critical wind speedImprove wind resistanceBridge structural detailsShock proofingEngineeringPressure difference

The invention relates to an adaptive tuyere of a steel box girder. A bracket is arranged on the side surface of the steel box girder; a reinforcement plate is arranged in a panel of a movable air guide plate; the reinforcement plate is provided with a rotating shaft; the movable air guide plate is arranged at the end of the bracket through the rotating shaft; an upper fixed air guide plate and a lower fixed air guide plate are arranged on the upper part and the lower part of the bracket respectively; an air inlet and an air outlet are formed at both ends of a middle tube of an air guide tube with a constant section or a variable section; a plurality of middle tubes share one air outlet; air guide tube cover plates are arranged outside the air inlets; the air inlets and the air outlet are fixed on the upper fixed air guide plate and the lower fixed air guide plate respectively; the movable air guide plate and the air guide tube cover plates are connected with a servo system and a sensor system respectively; and the servo system and the sensor system are connected with a singlechip. A lifting coefficient and a pitching moment coefficient are changed by changing an air pressure difference between the top surface and the bottom surface of the steel box girder, so that the vortex falling frequency can be changed and the shimmy critical air speed of the box girder is increased; moreover, the pneumatic characteristic of the structure can be adjusted and the anti-wind capability of a bridge structure can be enhanced.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

Device for performing incremental launching construction on bridge by using multi-roller sliding ways and construction method thereof

ActiveCN101818481AMeet the needs of climbingReduced longitudinal stiffness requirementsBridge erection/assemblyEngineeringSteel box girder

The invention discloses a device for performing incremental launching construction on a bridge by using multi-roller sliding ways and a construction method thereof. The device comprises a drawing part and a sliding part, wherein the drawing part comprises jack reaction supports, centre hole jacks, steel stranded wires, fixed end clampers, steel box girder reaction seats and an oil pump; the jack reaction supports are fixed on two sides at a predetermined position of a steel box girder of a structural pier; the centre hole jacks are arranged on the jack reaction supports; one end of each steel stranded wire is fixed with corresponding centre hole jack, while the other end is fixed on the corresponding steel box girder reaction seat through the corresponding fixed end clamper; and the sliding part comprises the multi-roller sliding ways fixed on the structural pier and a temporary pier in pairs, and further comprises a railway foundation and a steel guide way which are paved on a platform foundation, and a girder-transporting track run on the steel guide way. The device utilizes the mechanical characteristics of a roller structure so as to reduce requirements on the longitudinal rigidity of the temporary pier, satisfying needs on the climbing of vertical curves in the incremental launching process and greatly accelerating the incremental launching construction process.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com