Patents

Literature

492results about How to "Reduce the weight of the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

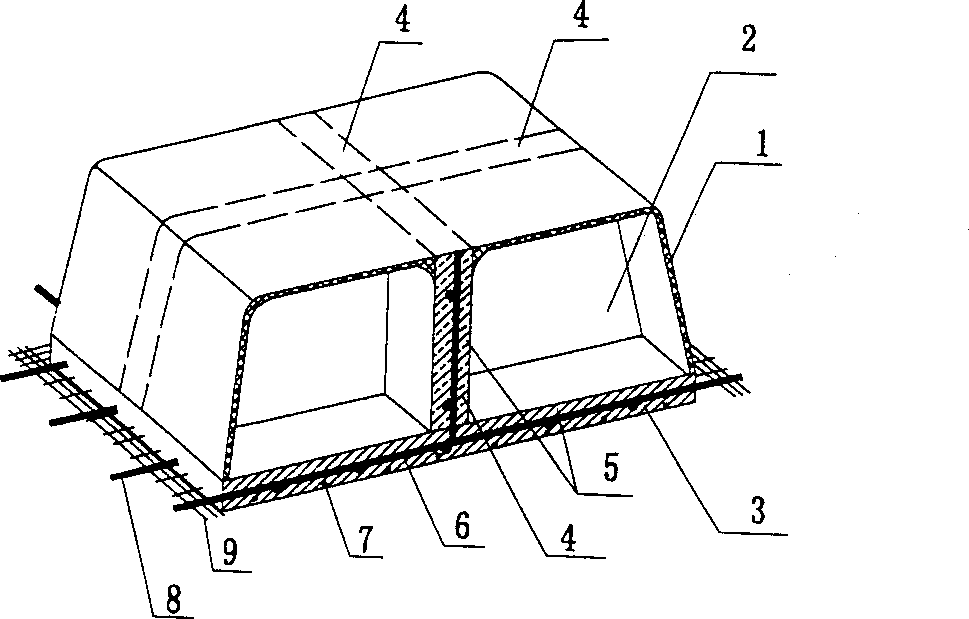

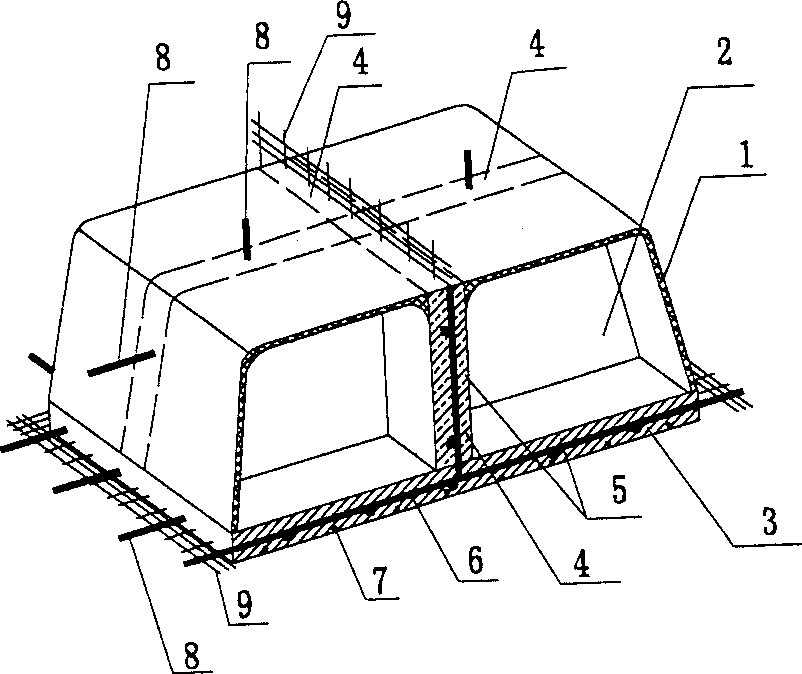

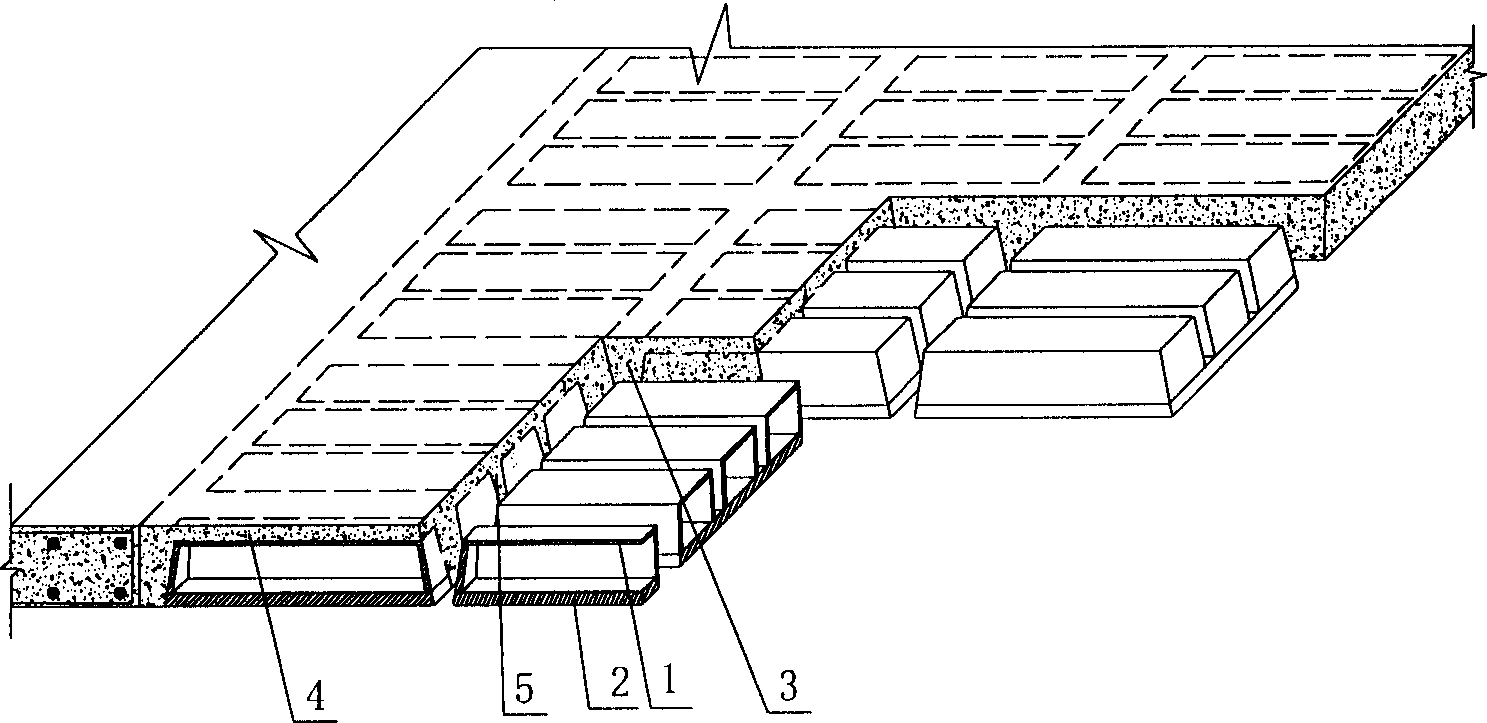

Prefabricated hollow member for roof with space structure and its application

InactiveCN1366118AImprove mechanical performanceImprove integrityFloorsSpatial structureShock resistance

The invention relates to a precast hollow floor board with spatial structure and its application. The floor board includes hollow form and cavity, and features including structural bottom slab and structural sub-rib. The structural bottom slab and structural sub ribs contain reinforcing bars or wire mesh to form an integrated load-bearing member with an inverted T-shape. There are exposed bars ormesh on the structural bottom slab. The thicknesses of structure bottom slab and structural sub-rib are larger than the thickness of hollow form whose upper part and side parts are connected to the structural sub-rib, and lower part is connected to the structural bottom slab so as to form a closed integral body. The invented precast hollow floor board possesses advantages of simple structure, high strength, easy for handlings, good shock resistance and reduced structural dead wt..

Owner:湖南邱则有专利战略策划有限公司

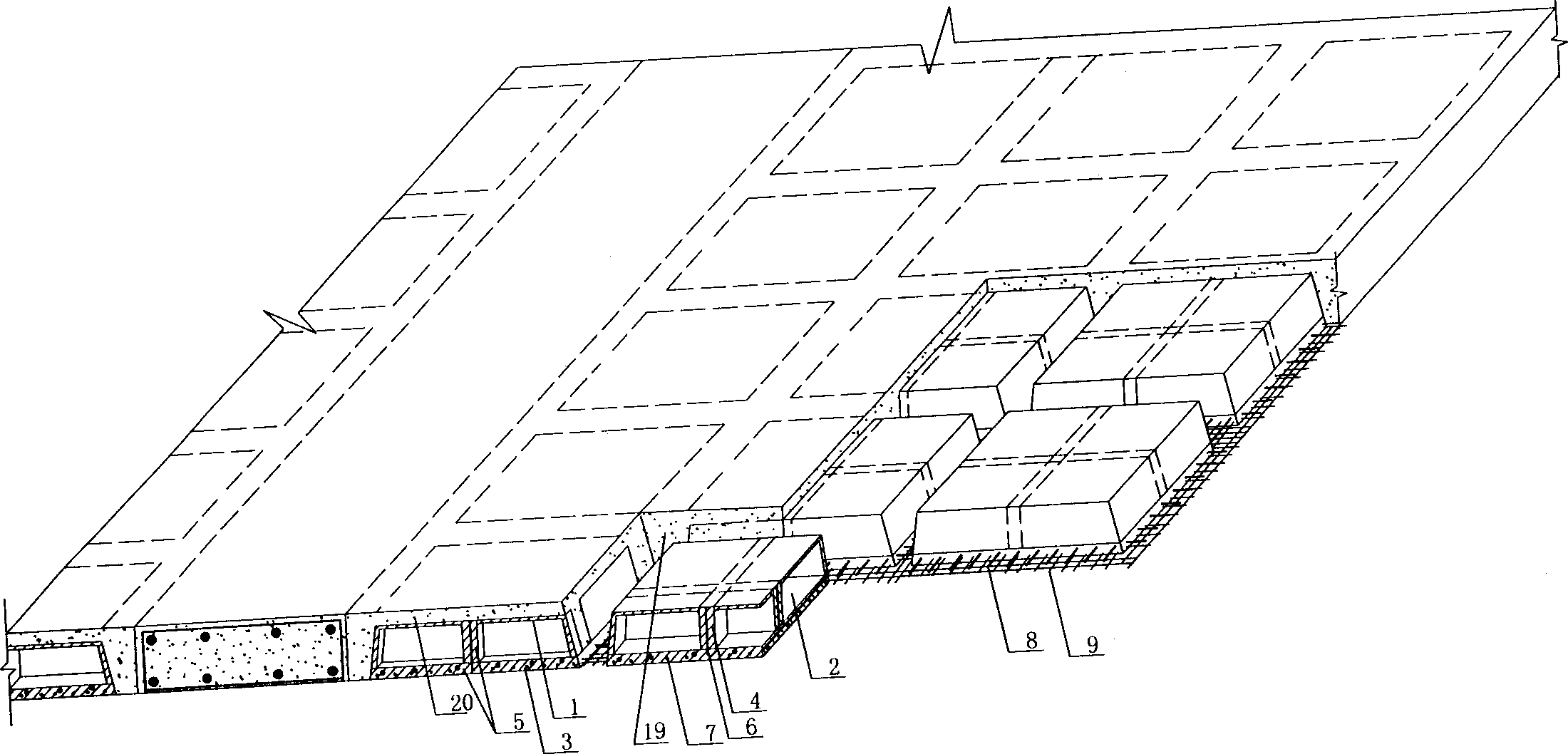

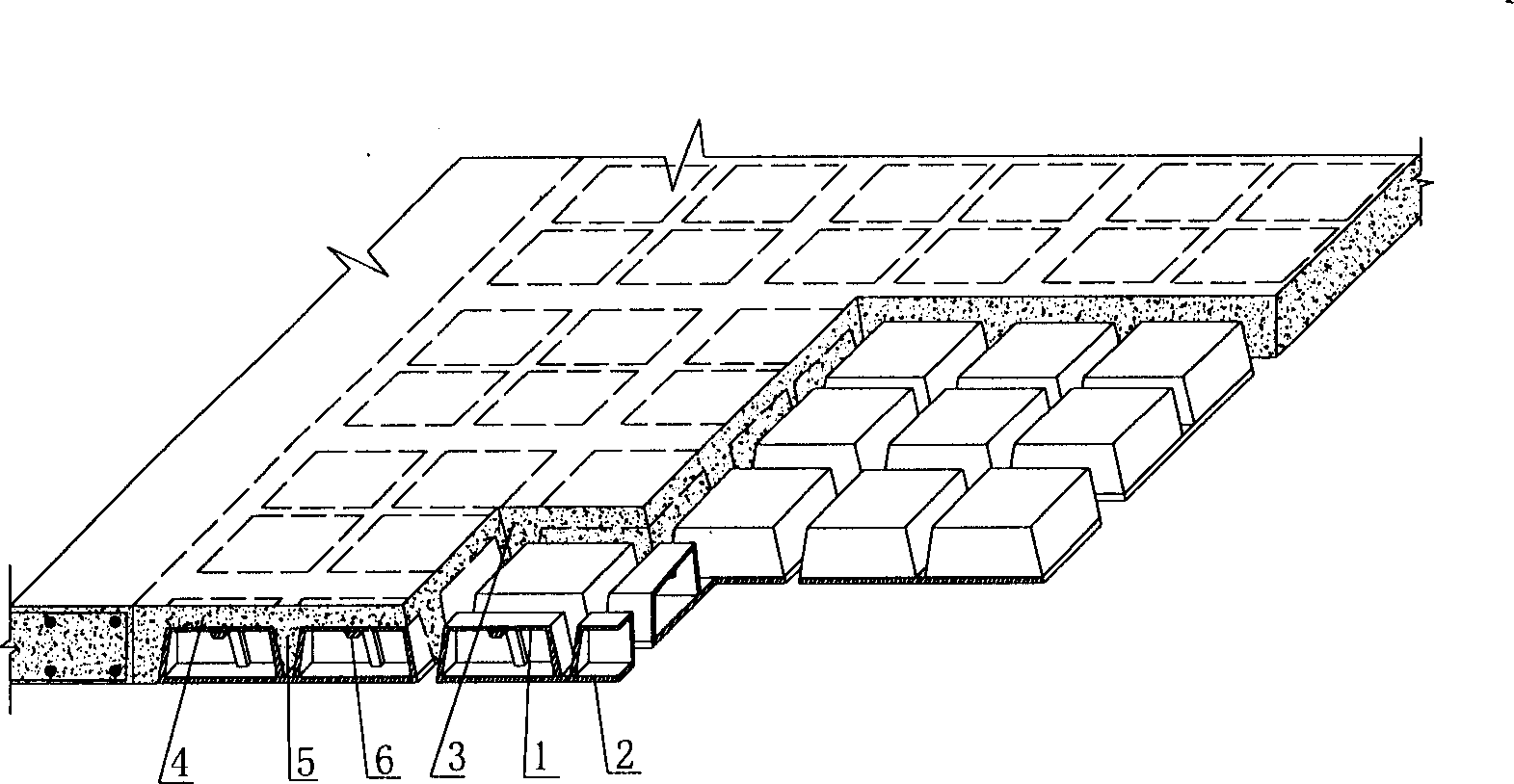

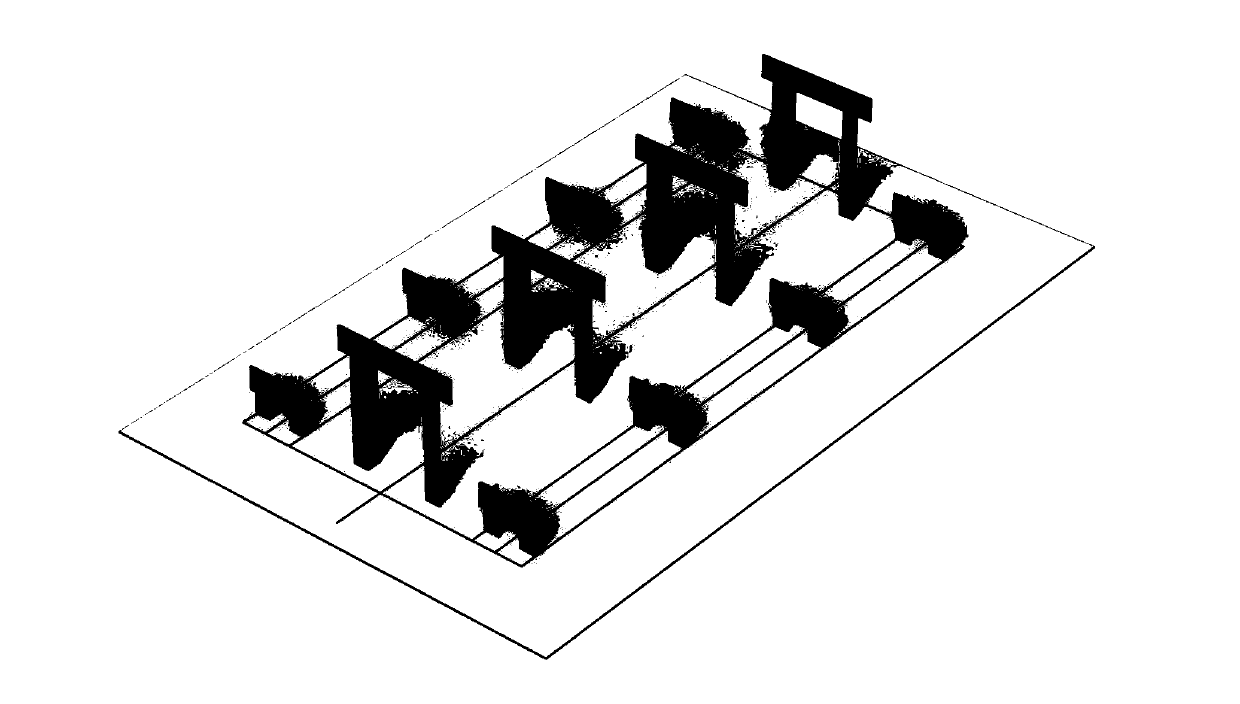

Floor with space structure

InactiveCN1356440AImprove mechanical performanceReduce thicknessFloorsReinforced concreteSpatial structure

A building roof with space structure is coposed of molded waffle members consisting of molded waffle and bottom plate, in-situ cast primary reinforced concrete rib, and in-situ cast reinforced concrete top plate. A prefabricated structured bottom plate has at least 2 molded waffle cavities and at least one in-situ cast secondary reinforced concrete rib. The said primary and secondary ribs constitute a hidden dense rib structure. Its advantages include high anti-earhquake performance and less thickenss, high strength.

Owner:湖南邱则有专利战略策划有限公司

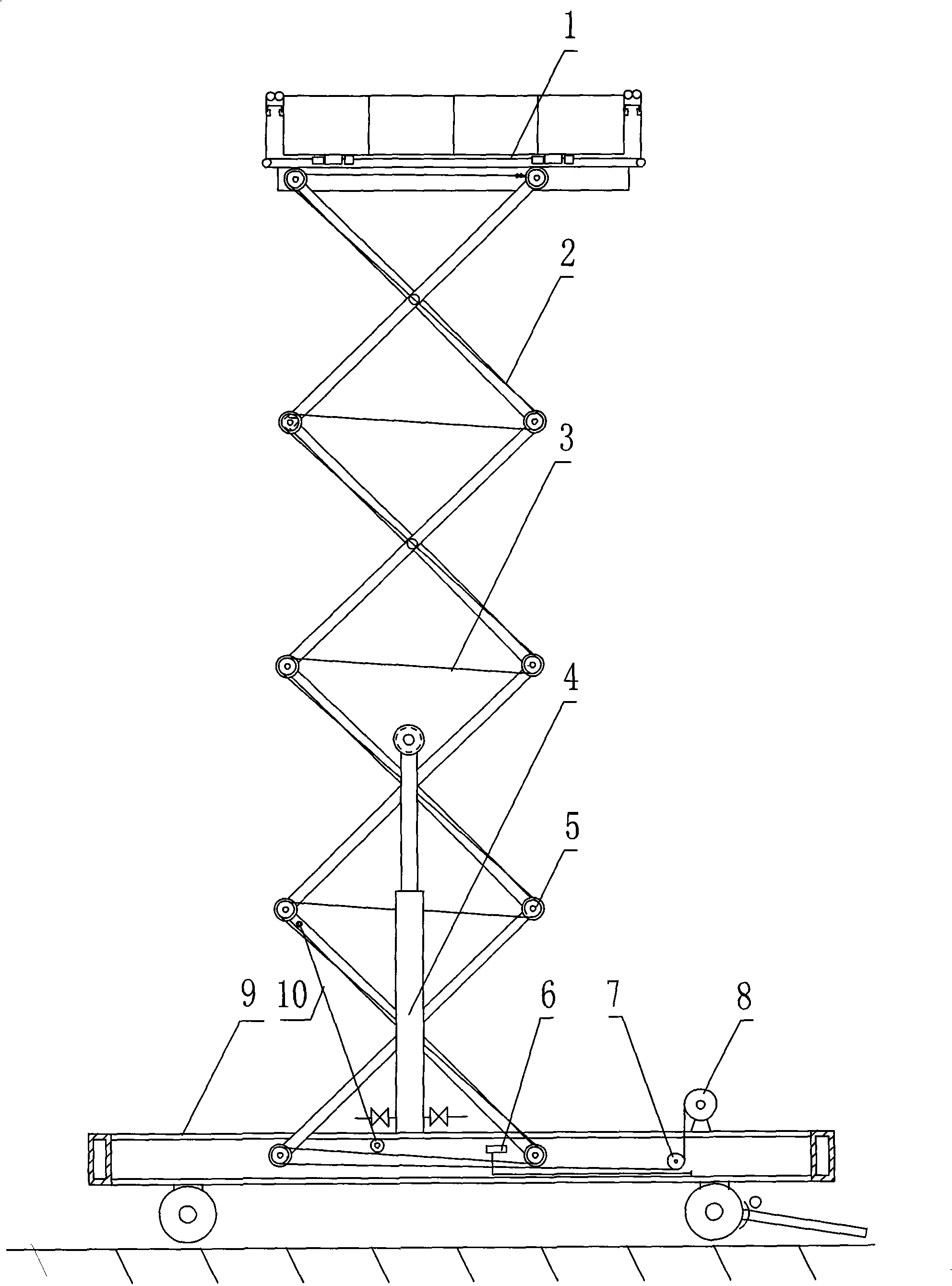

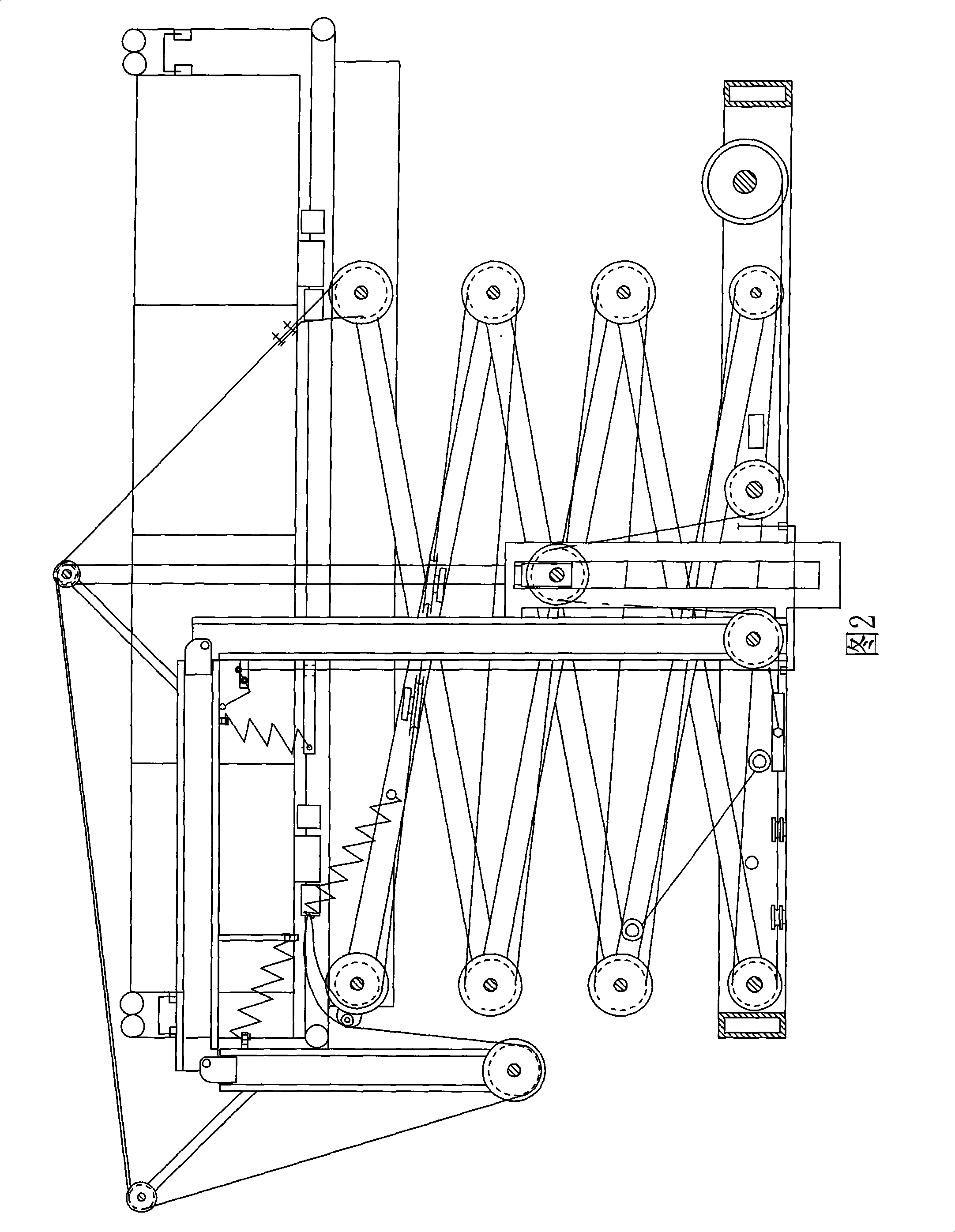

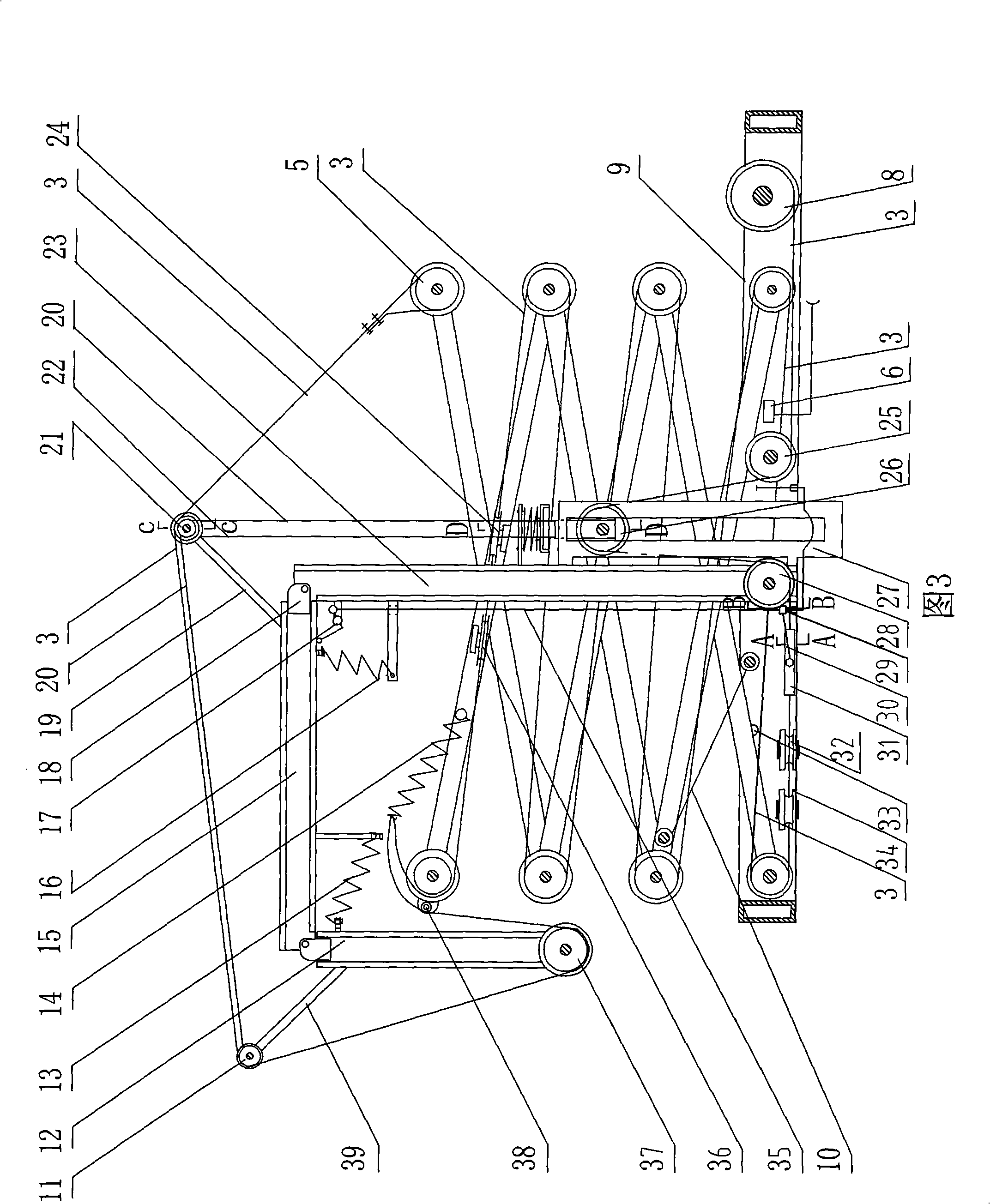

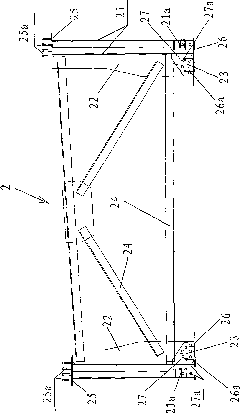

Mobile hoistable platform and labor-saving apparatus

InactiveCN101402440AImprove the unfavorable situationRelief of very unfavorable conditionsLifting devicesHydraulic cylinderEngineering

The invention discloses a mobile lifting platform labor-saving device, which consists of a chassis, a platform, a shearing fork rod, a pulley, a wire rope, and a wire rope loop cylinder, and is characterized in that the chassis of a vehicle is provided with the labor-saving device; when the mobile lifting platform is lifted initially, the labor-saving device is lifted firstly, and lifts the shearing fork rod through the wire rope with small force on an advantageous position, or pushes the shearing fork rod to lift through a hydraulic cylinder to increase the included angle on the ends of the shearing fork rod and reduce the stress of the shearing fork rod; and then the shearing fork rod gets rid of contacting the labor-saving device and is stressed in full load to lift. The various labor-saving devices improve the factor that the prior device is stressed adversely in initial lifting, and greatly reduce the stress of the shearing fork rod in the initial lifting. When the mobile lifting platform has the same load as the prior mobile lifting platform, the stress applied on the shearing fork rod in the initial lifting is about one fifteenth of that of the prior platform in the initial lifting, and the self weight of equipment can be reduced more then twice; and the labor-saving device has the advantages of simple operation and time conservation.

Owner:白天海

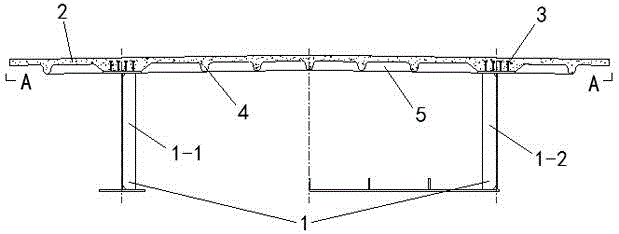

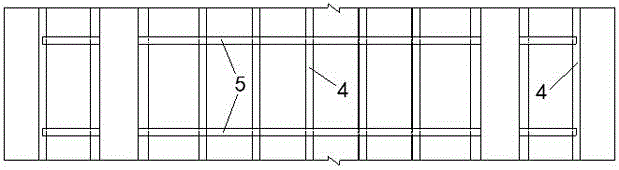

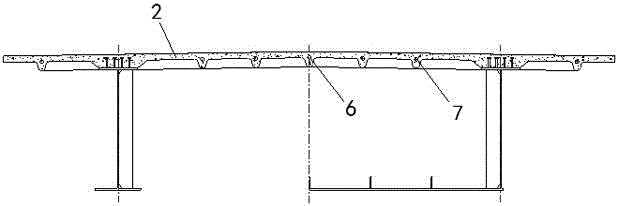

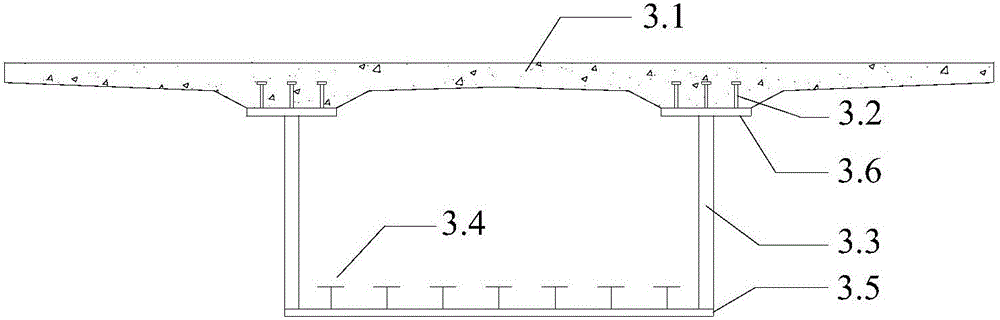

Steel-super high performance concrete composite beam based on ribbed plate type bridge deck and construction method

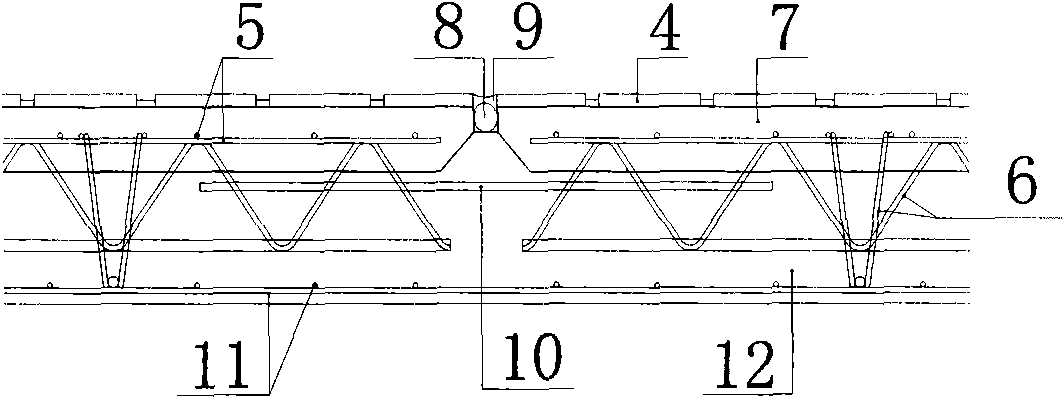

InactiveCN104831617AReasonable forceHigh strengthBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention discloses a steel-super high performance concrete composite beam based on a ribbed plate type bridge deck and a construction method. The construction method includes the following steps that step1, steel beams are machined, manufactured and installed; step2, shearing force connecting parts are welded; step3, the super high performance concrete bridge deck is constructed; step4, a guardrail or an anti-collision wall is constructed; step5, bridge deck pavement is constructed, wherein the super high performance concrete bridge deck and the steel beams are fixed through the shearing force connecting parts, the cross section or / and the longitudinal section of the super high performance concrete bridge deck is / are of a ribbed plate structure, and pre-stressed reinforcements can be arranged on a longitudinal rib region or / and a transverse rib region. The composite beam is reasonable in stress, high in strength and capable of substantially reducing the structure dead weight, effectively avoiding defects at a hogging moment region of a composite continuous beam and bringing tensile strength, compressive strength and high durability of super high performance concrete into full play; the composite beam has the advantages of being small in building height, high in rigidity, small in dead weight, good in durability, crack resistance and fatigue resistance and the like, and has great practical value and good economic benefits.

Owner:FUZHOU UNIV

Lower edge open truss style corrugated steel web combination beam

InactiveCN101139812AImprove crack resistanceIncreased durabilityLoad-supporting elementsBridge materialsFalseworkCrack resistance

A truss-type corrugated steel web composite beam with an open bottom chord belongs to a bridge support member. The bottom chord opened and truss-type corrugated steel web composite beam comprises an upper wing edge concrete slab, a corrugated steel web and a bottom chord opened truss-type rectanglar steel tube concrete member. Compared with steel truss-type web composite corss section, the invention adopts the corrugated steel web with rather high shear strength to replace a steel web member, so as to guarantee quite high shear bearing capacity. The opened truss-type bottom chord is composed of two parallel-arranged rectanglar steel tubes arranged in parallel and internally cast concrete, as well as horizontal braces and batter braces between the rectanglar steel tubes. Moreover, the bottom chord adopts the steel tube concrete member to overcome the problem of rather high work volume that, in traditional composite cross section of corrugated steel web box beams and steel truss-type webs, such execution measures as scaffolding, formwork-support, concrete casting and etc. should be taken for lower wing edge concrete slabs. Meanwhie, the invention can effectively improve structure crack resistance, avoid crackage exposure and etc, and considerably increase structure durability. The bottom chord is a brace-connected open-type structure with advantages of simple structure and fast, smooth and convenient execution.

Owner:TSINGHUA UNIV

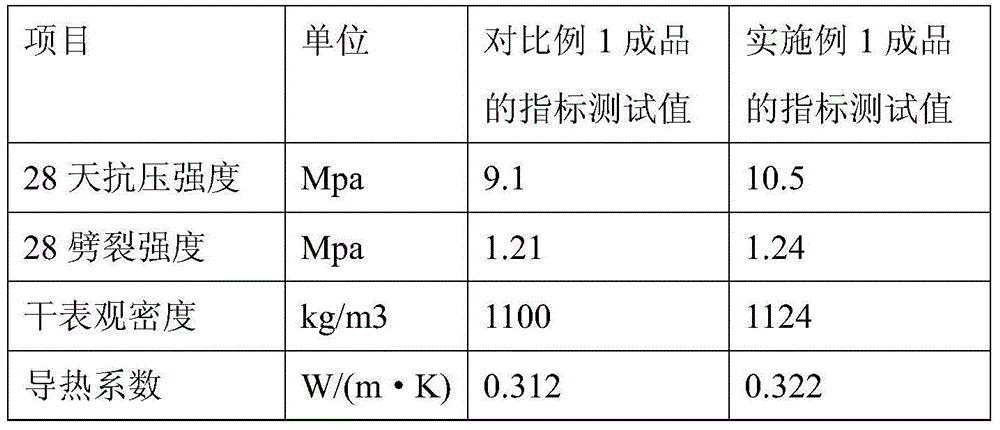

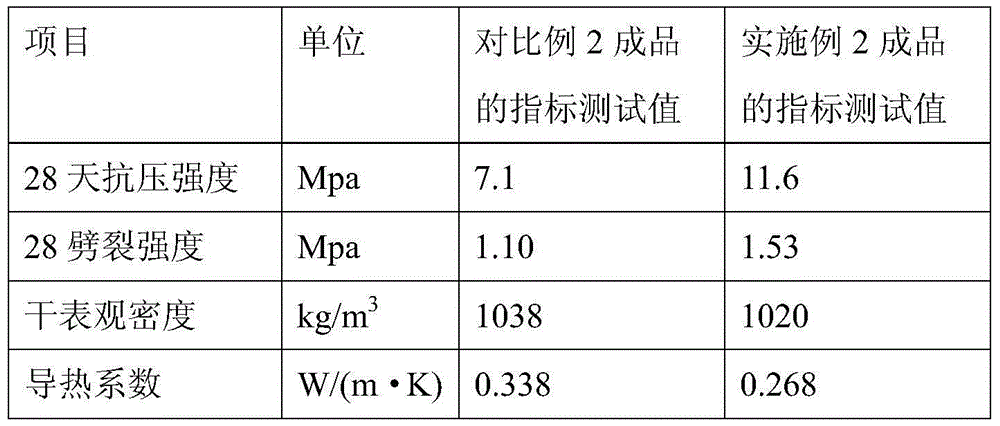

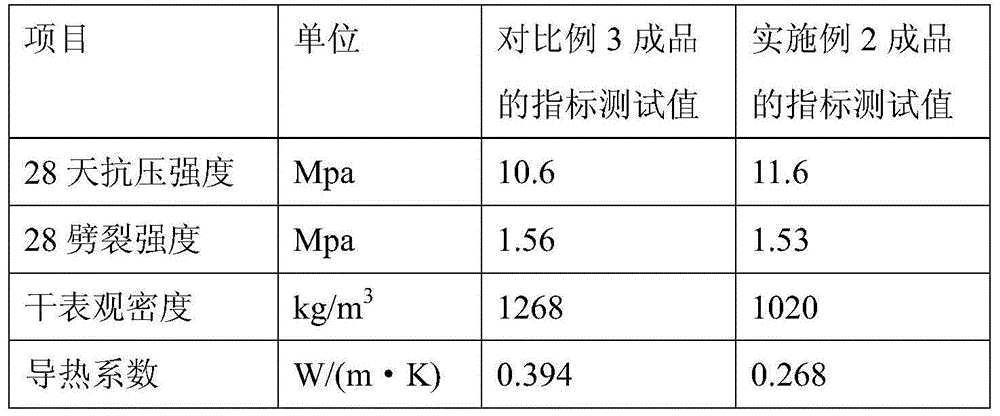

Lightweight aggregate concrete for heat preservation of structures

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

Integral type thermal insulation building

ActiveCN101684671AReduce indoor temperature fluctuationsReduce the weight of the structureConstruction materialSolid waste managementThermal insulationFly ash

The invention discloses an integral type thermal insulation building, which belongs to the technical field of building engineering. The problem to be solved is to provide the integral type thermal insulation building. The adopted scheme is that the integral type thermal insulation building at least uses one of an inorganic thermal insulation structure layer and an inorganic thermal insulation layer, wherein the inorganic thermal insulation structure layer is formed by combining one or two of inorganic thermal insulation load-bearing concrete and inorganic thermal insulation load-bearing building blocks; and the inorganic thermal insulation load-bearing concrete comprises the following components in a mixing weight ratio (kg / m<3>) of concrete composite light bone admixture to cement to sandto stone to porcelain granule to fly ash to water to concrete admixture of (6-225):(200-800):(300-700):(500-1,600):(150-650):(10-600):(80-400):(0.1-200). The integral type thermal insulation buildingcan be widely applied to the technical field of buildings.

Owner:李珠 +1

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

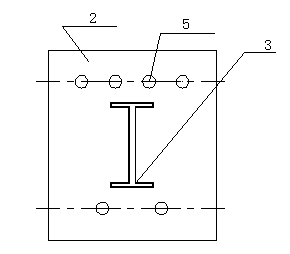

Ultra-large type combined H-section steel column and manufacturing method thereof

ActiveCN104196166AGuaranteed bearing capacityNovel structural designStrutsPillarsManufactured materialStructural engineering

The invention discloses an ultra-large type combined H-section steel column. The ultra-large type combined H-section steel column comprises two I-section steels and a connecting web; the two I-section steels are respectively arranged at two sides of the connecting web, and the section is of an H shape after installation; the upper end face of the connecting web and the I-section steels at two sides form a concave structure, a stiffening plate is arranged along the concave structure, and a reinforcing rod is arranged on the stiffening plate. Meanwhile, the invention further provides a manufacturing method of the steel column. According to the steel column and the manufacturing method thereof disclosed by the invention, when the bearing capacity of the post is ensured, the structure of the column is maximally simplified, raw materials are saved, the cost is saved, the manufacturing process is simple, the installation precision can be ensured, the effective usable area of a building is increased, the gravity of the structure is reduced, and the seismic response of the structure is decreased.

Owner:JIANGSU HUNING STEEL MECHANISM

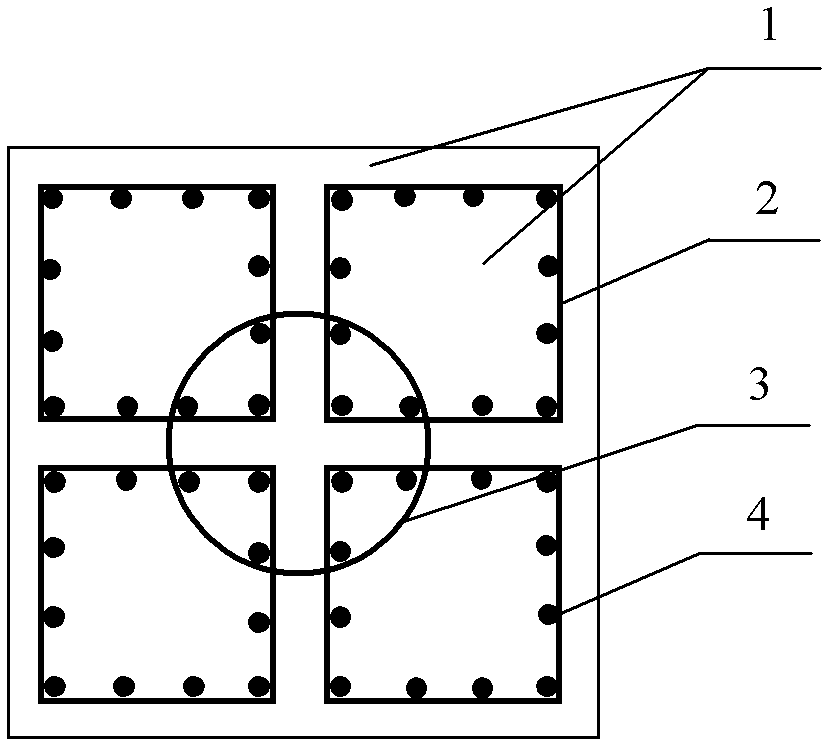

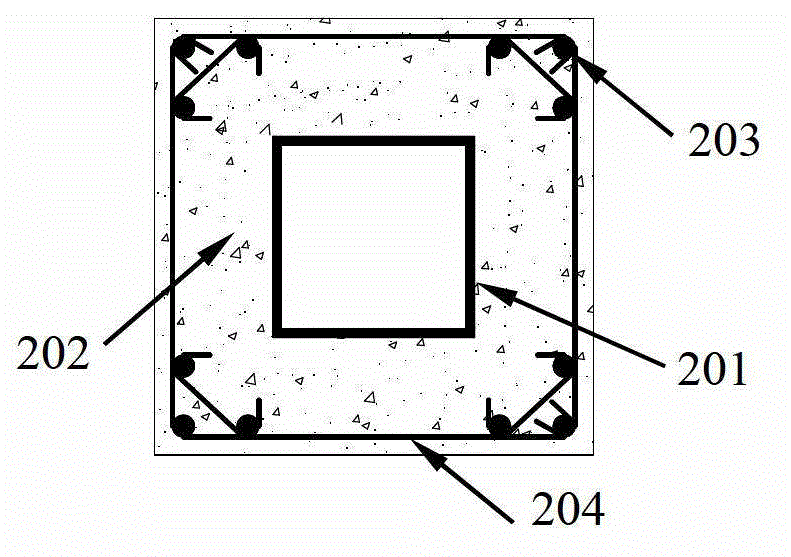

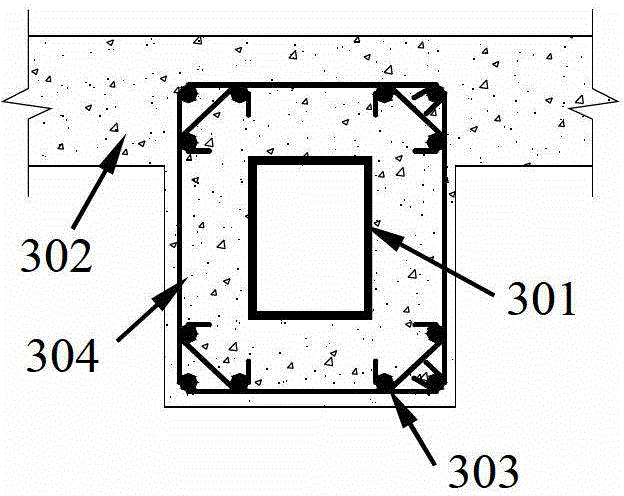

High-seismic-resistance light high-intensity reinforced column

InactiveCN102561595AImprove column deformabilityReduce the weight of the structureStrutsPillarsRebarEngineering

The invention relates to a high-seismic-resistance light high-intensity reinforced column and is characterized in that the high-seismic-resistance light high-intensity reinforced column is formed by depositing concrete after a reinforcement cage is assembled, wherein the reinforcement cage comprises four fission stirrups with equal sections, a center positioning stirrup, and longitudinal bards, the space between the external limbs of the two adjacent fission stirrups ranges from 25 mm to 200 mm; the center positioning stirrup is partially overlapped with the stirrup part of each limb of the four fission stirrups with equal sections, a plurality of longitudinal ribs are arranged on the inner sides of the fission stirrups and the positioning stirrup; at least one longitudinal rib is arranged in the overlapping part between the fission stirrup and the positioning stirrup, and the fission stirrup and the positioning stirrup are fixed into a whole; and the weights of the raw materials in the concrete are as follows: 130 kg / m3 to 180 kg / m of water, 160 kg / m3 to 500 kg / ms of cement, 50 kg / m3 to 250 kg / m of mineral admixtures, 100 kg / m3 to 400 kg / m of light aggregates, 300 kg / m3 to 900 kg / m of broken stones, 650 kg / m3 to 850 kg / m of sand, and 4 kg / m3 to 15 kg / m3 of water reducers. The high-seismic-resistance light high-intensity reinforced column has the advantages of high seismic performance, deformability, strong bearing capacity, and lightness.

Owner:WUHAN UNIV OF TECH

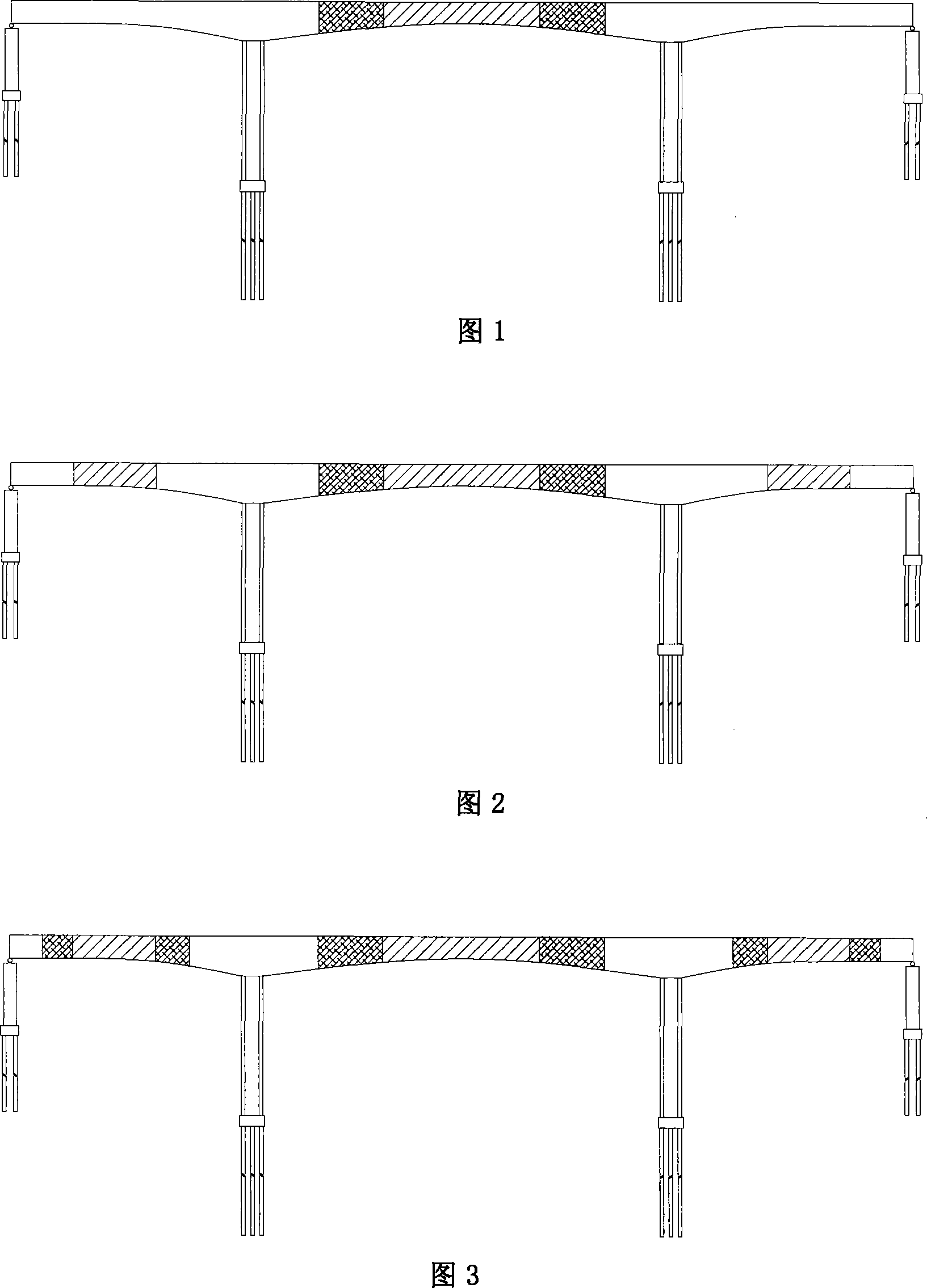

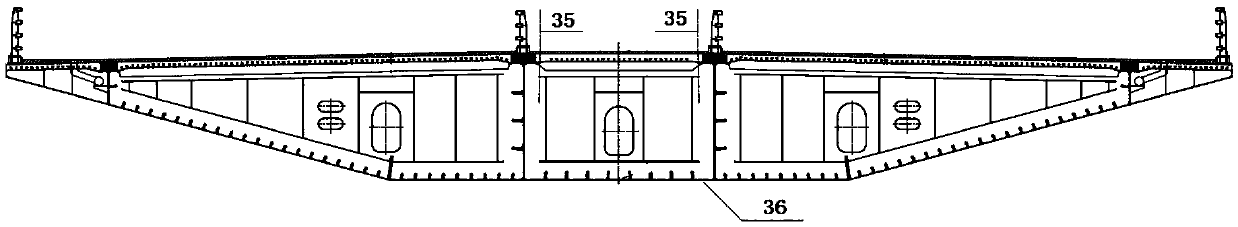

Prestressed concrete-corrugated web steel box connecting beam hybrid beam structural system

InactiveCN106400666ASolve crackingReduce the weight of the structureBridge structural detailsBridge materialsCrazingPre stress

The invention discloses a novel hybrid beam structural system. The novel hybrid beam structural system comprises a corrugated web steel box connecting beam segment and prestressed concrete box beam segments. The prestressed concrete box beam segments are located on the two sides of the corrugated web steel box connecting beam segment. The novel hybrid beam structural system is mainly used for a continuous beam bridge or a rigid frame bridge. The midspan part of a main span is the corrugated web steel box connecting beam, the rest part of the main span and sidespans are prestressed concrete box beams, and steel-concrete composite segments are used for connection transition between the prestressed concrete box beams and the corrugated web steel box connecting beam. The novel hybrid beam structural system overcomes the defects of a traditional prestressed concrete box beam unitary system and defects of a traditional steel box beam unitary system, and has the beneficial effects of being good in stress performance and economical efficiency, high in span capacity and the like. According to the structural system, the dead load is effectively reduced, the span capacity is improved, the midspan deflection can be reduced, and the defects that the continuous downwarping and crazing of the midspan of the prestressed concrete box beam, poor stability of an ordinary steel box beam web and poor durability of bridge deck pavement are avoided.

Owner:SOUTHEAST UNIV

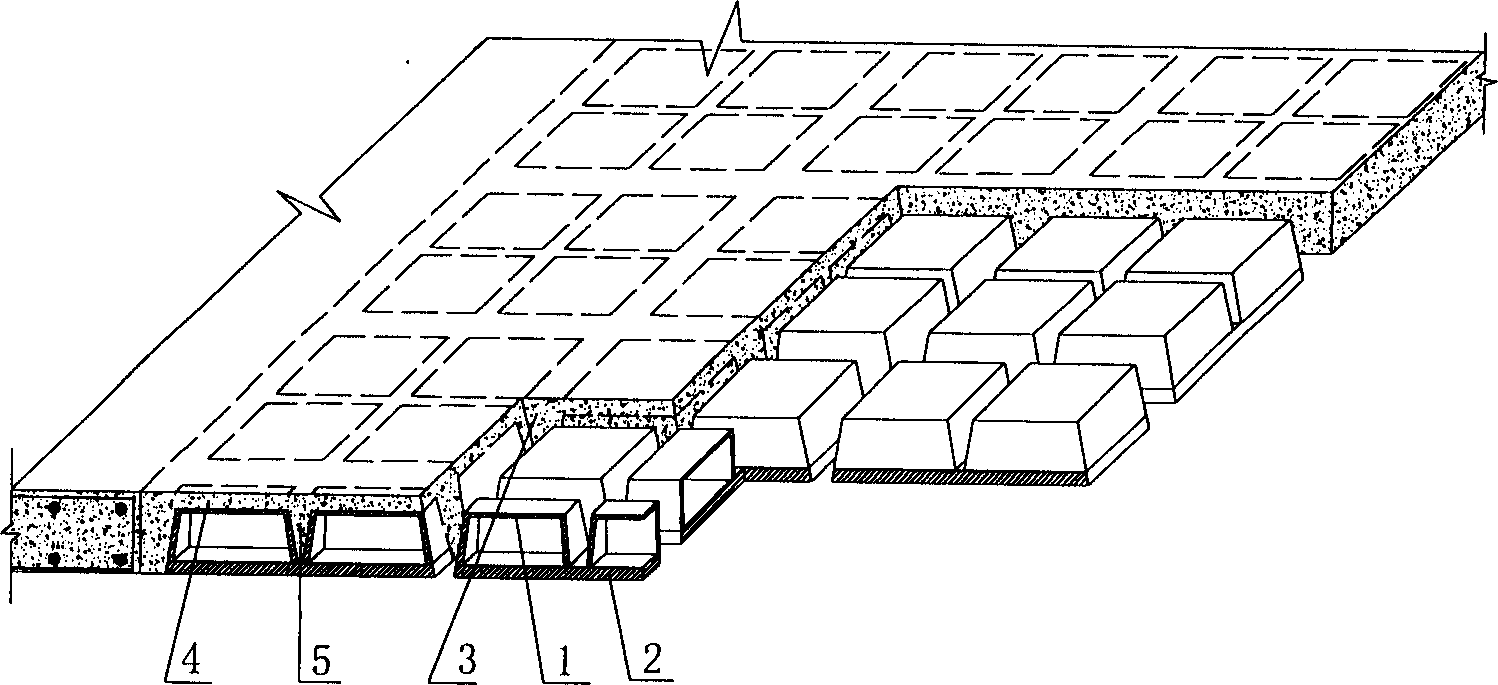

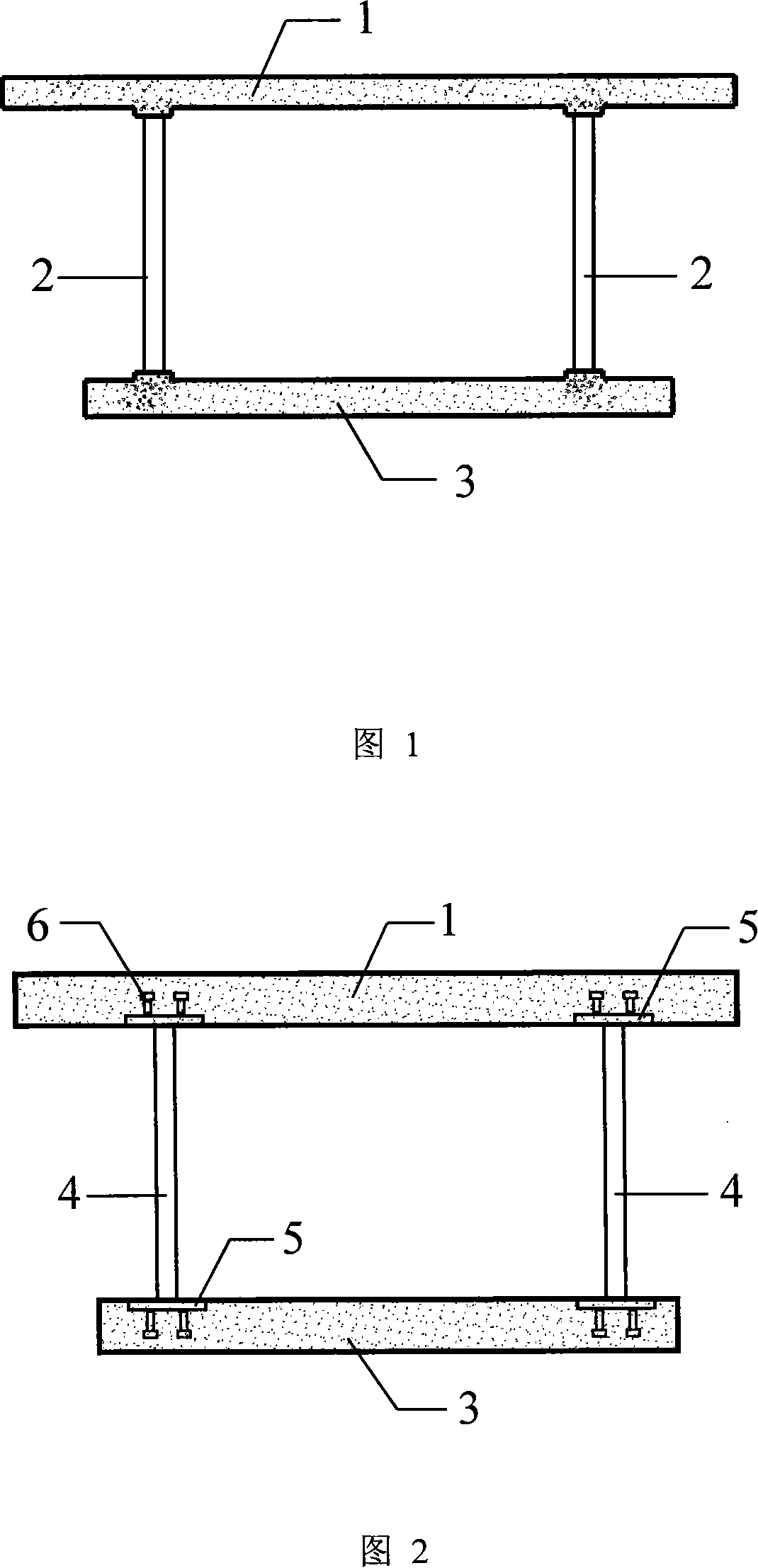

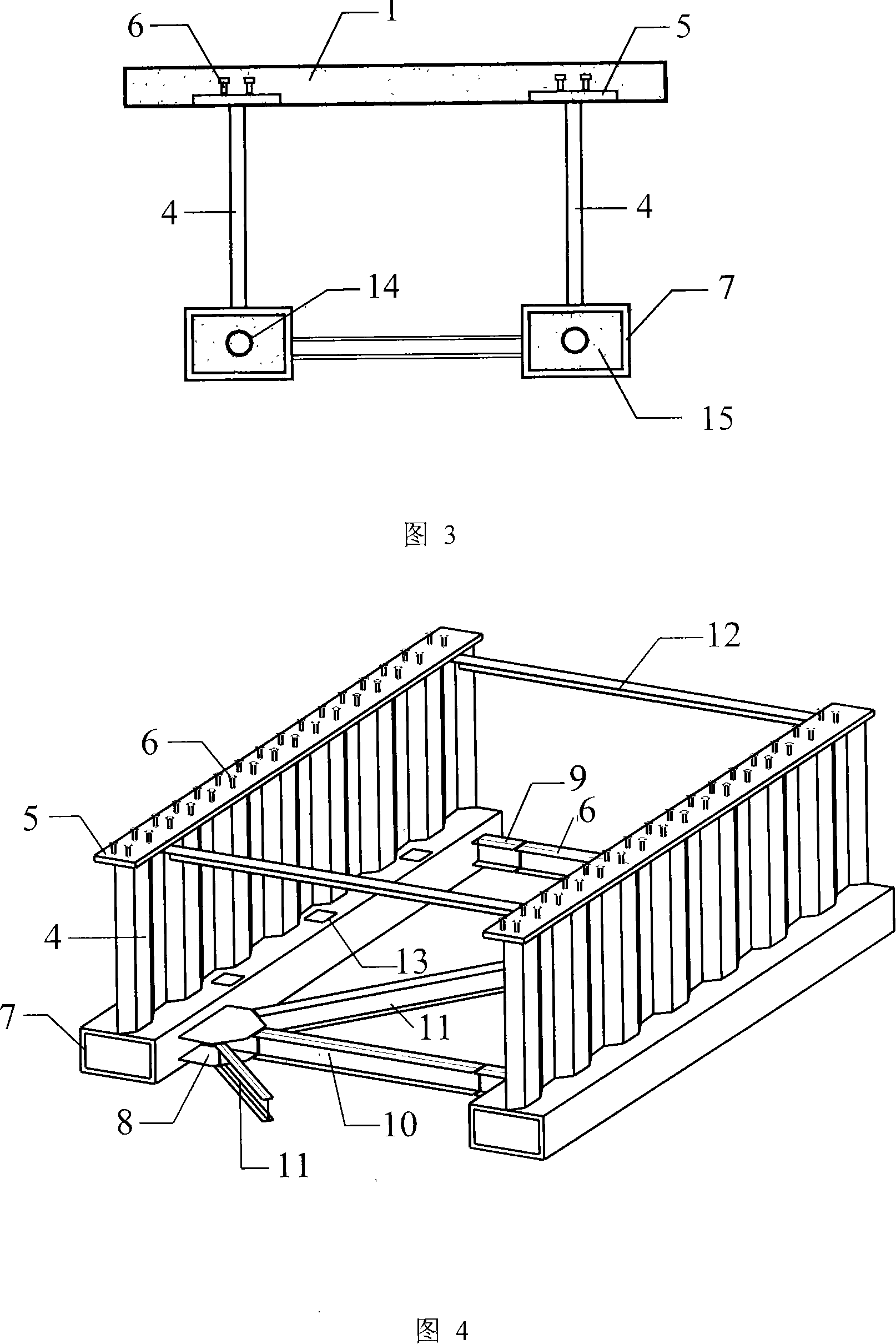

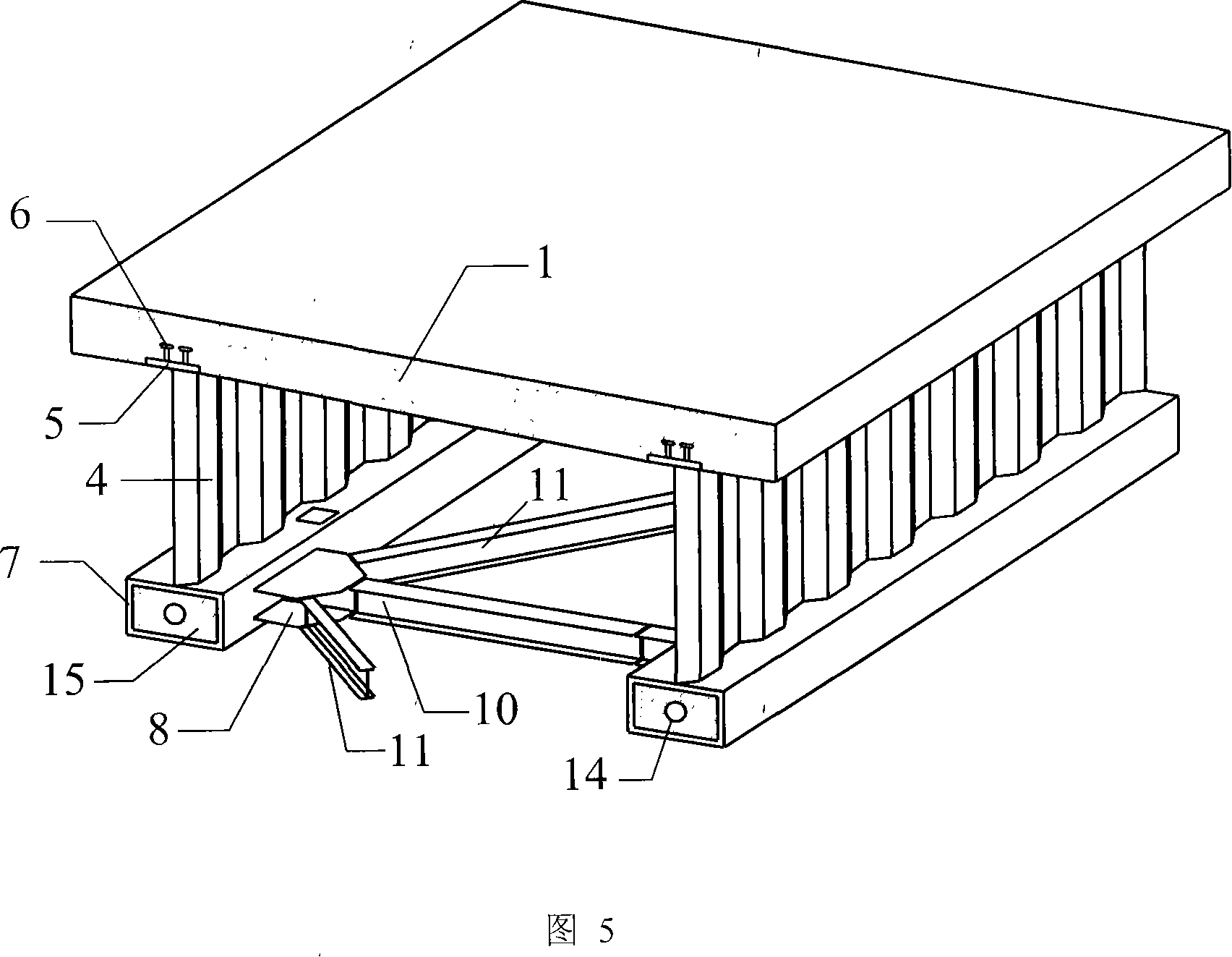

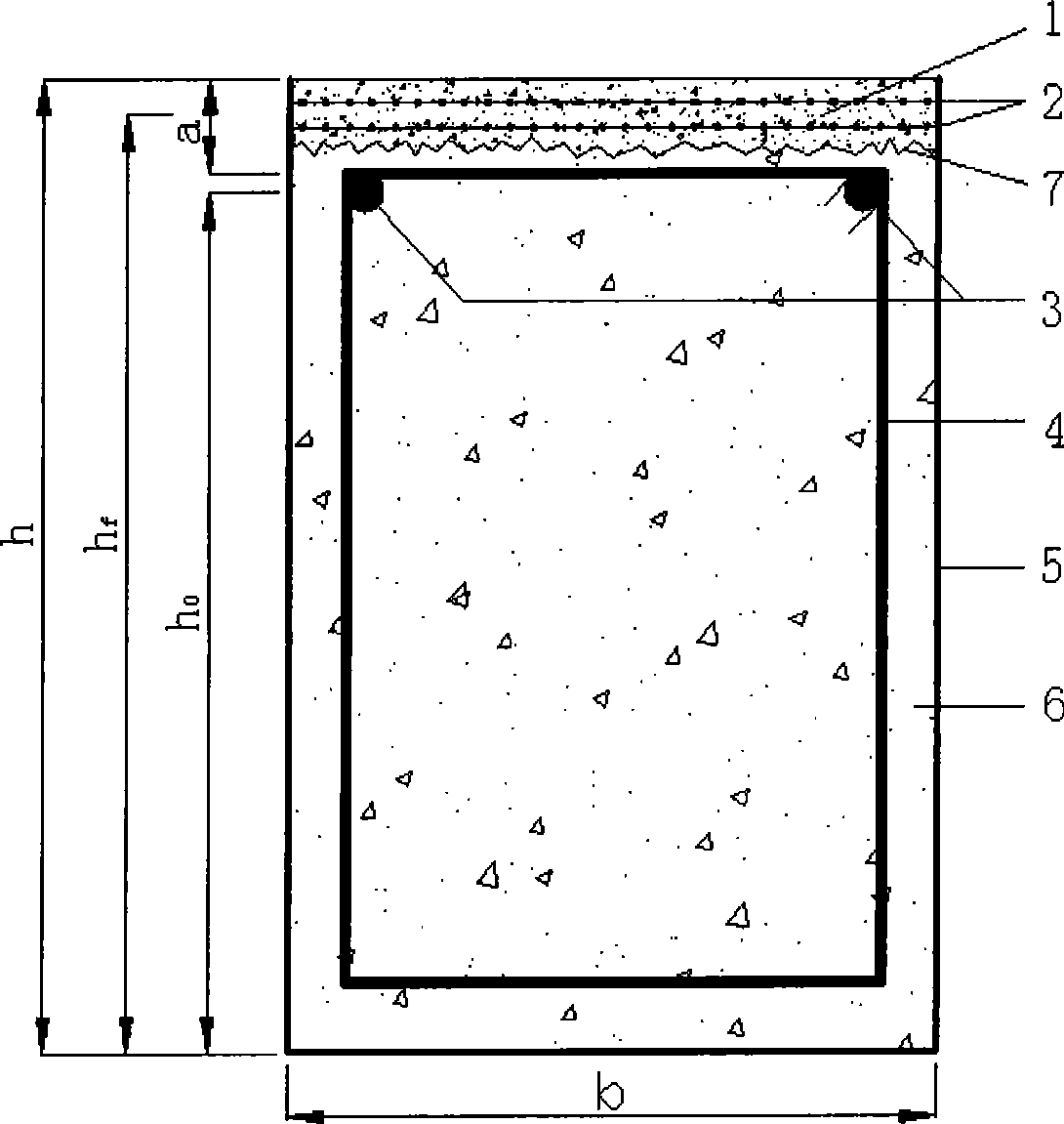

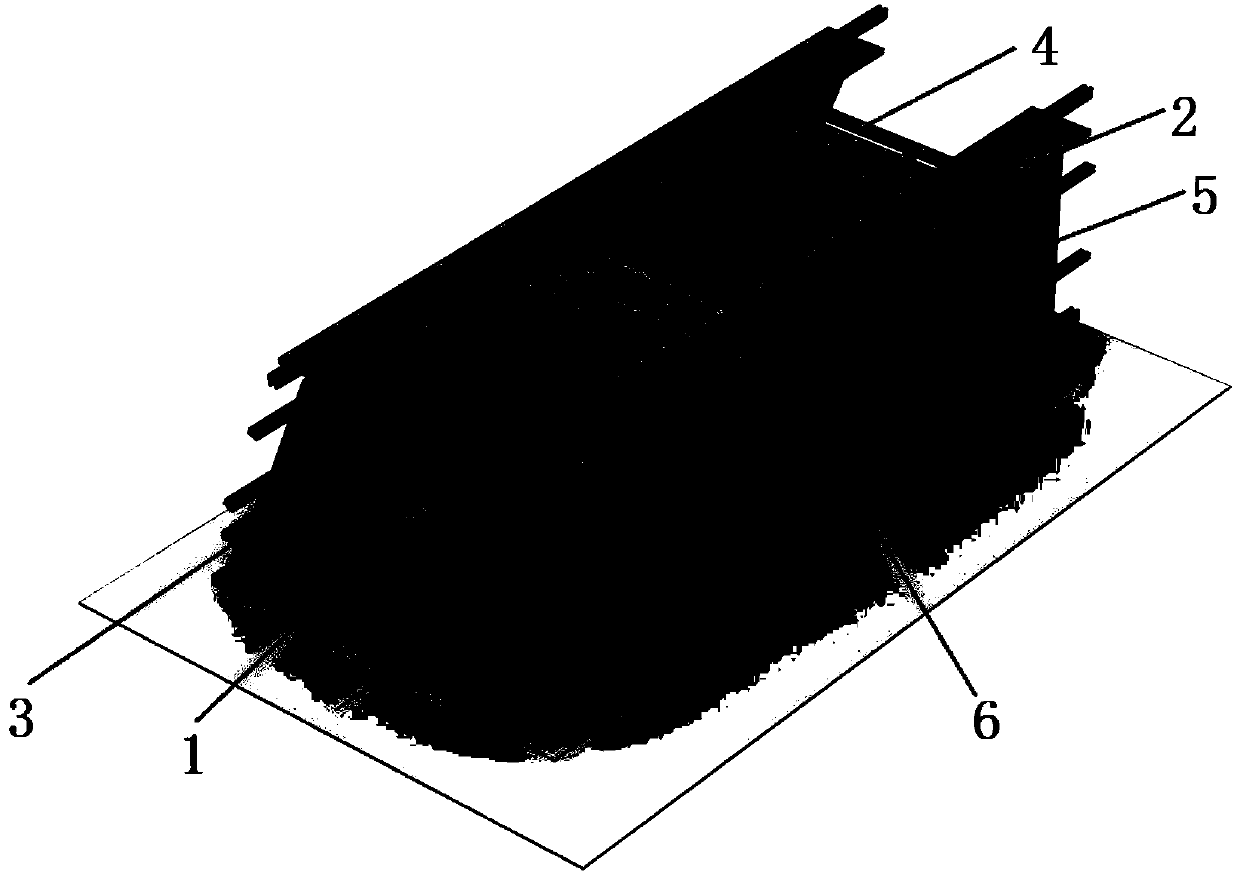

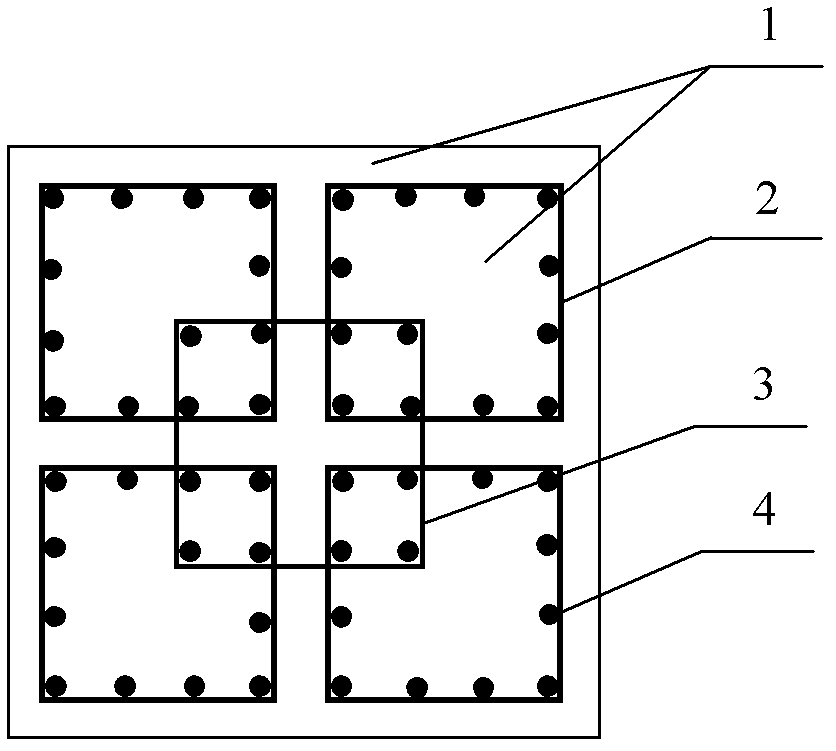

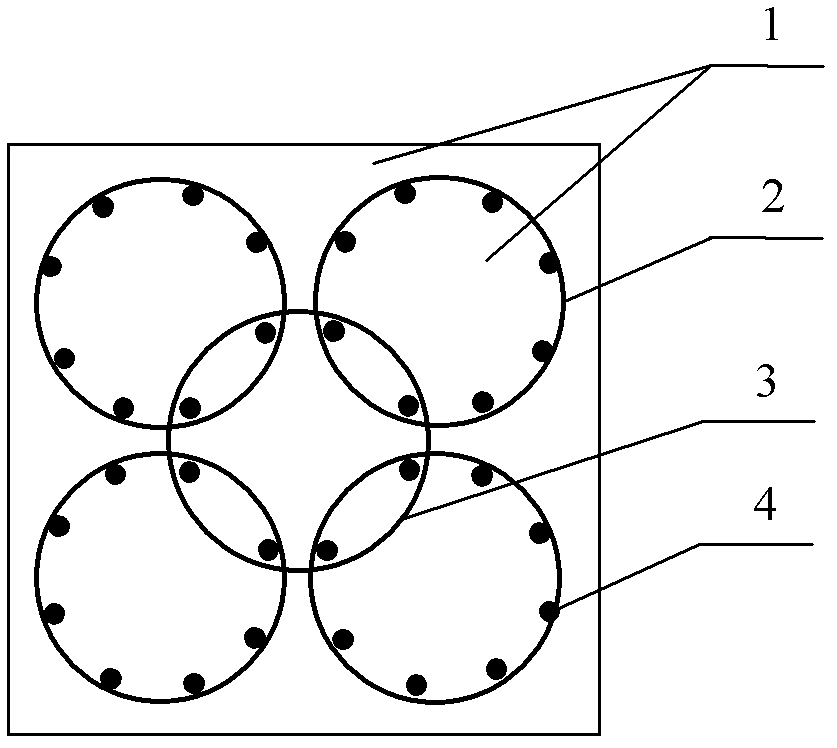

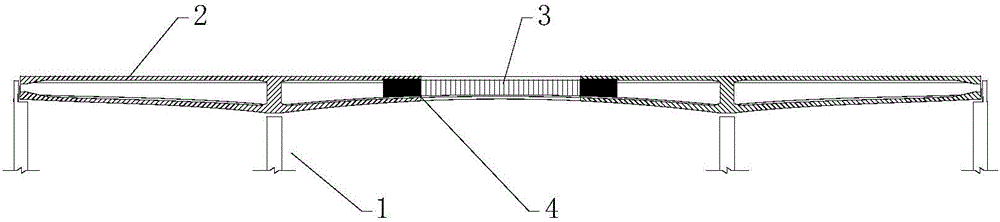

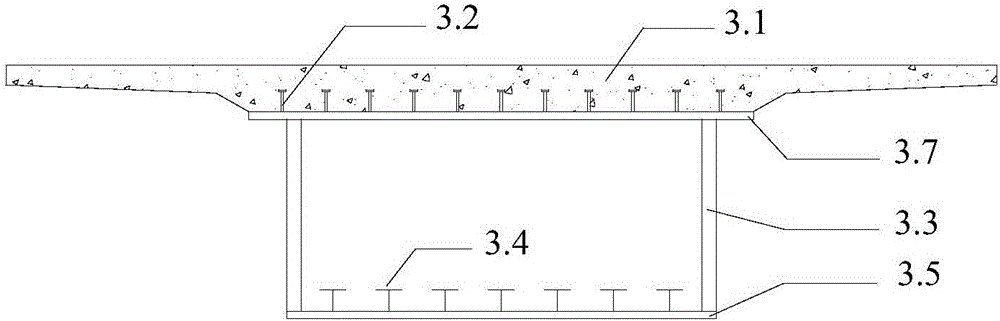

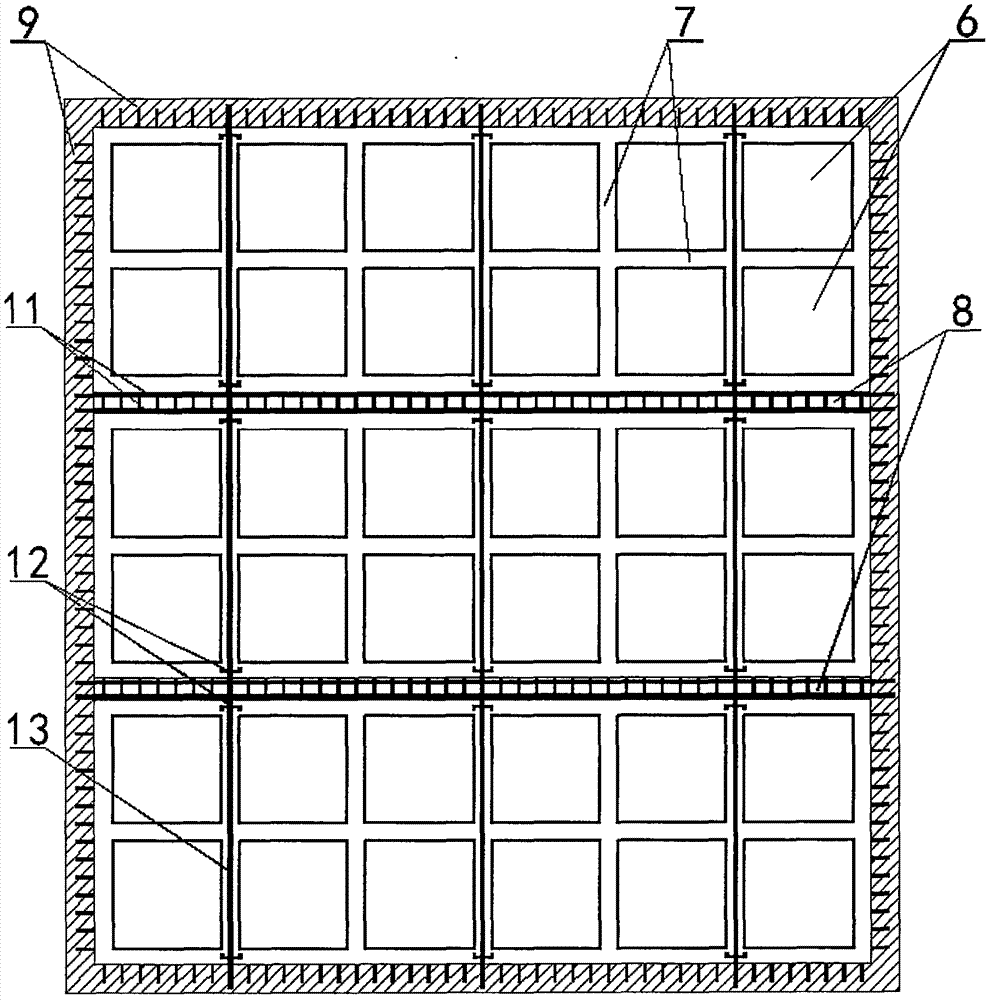

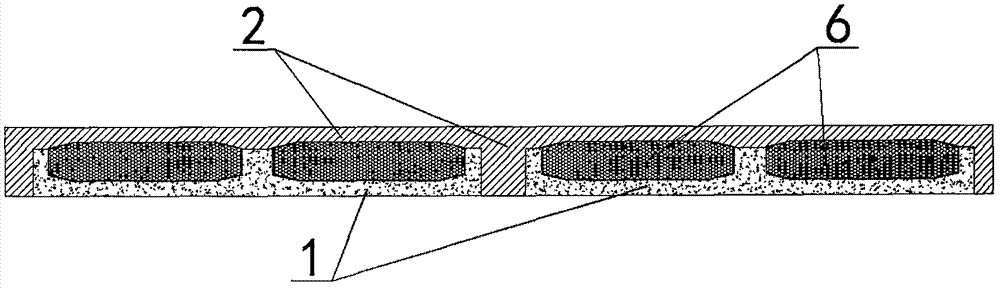

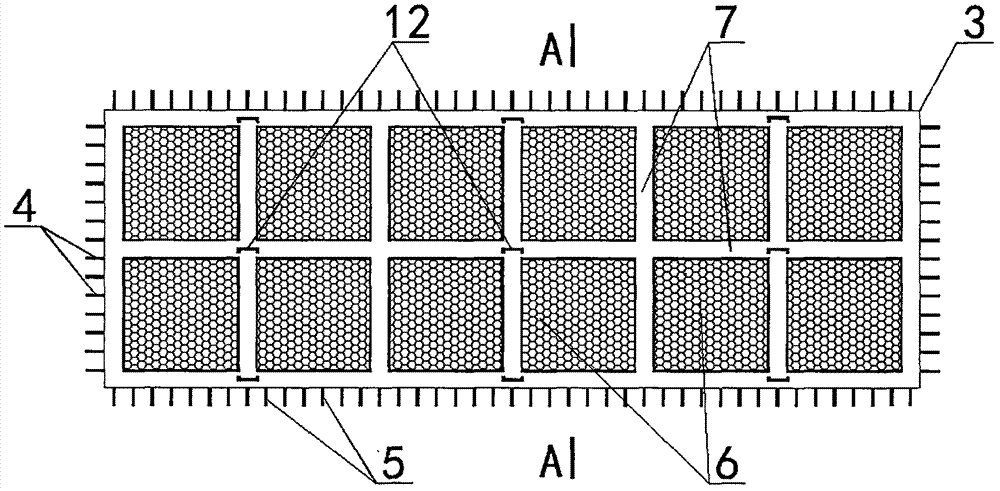

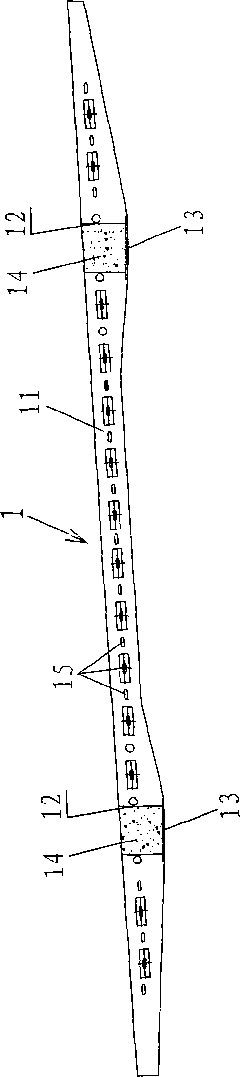

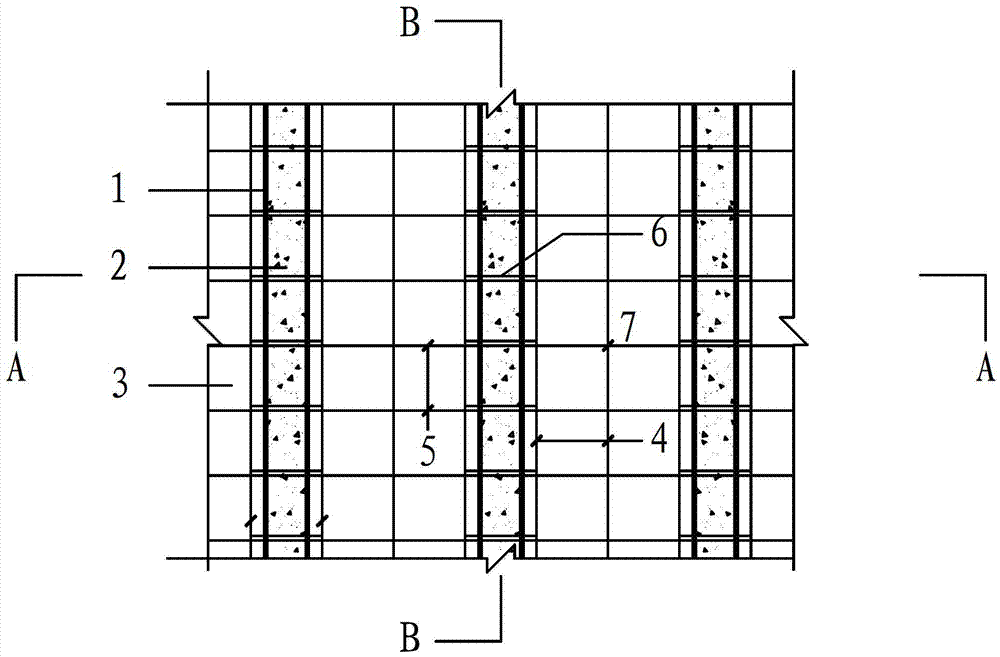

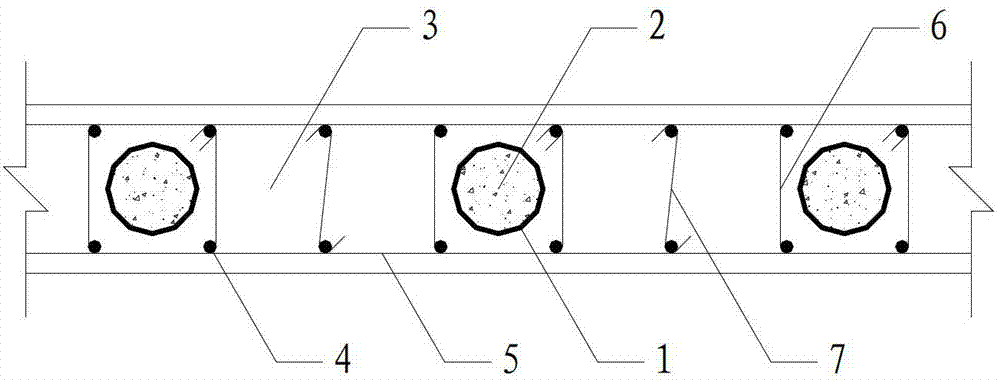

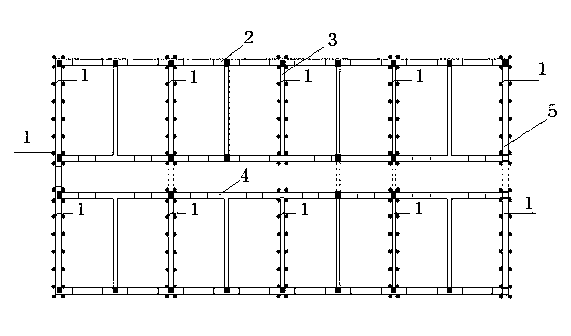

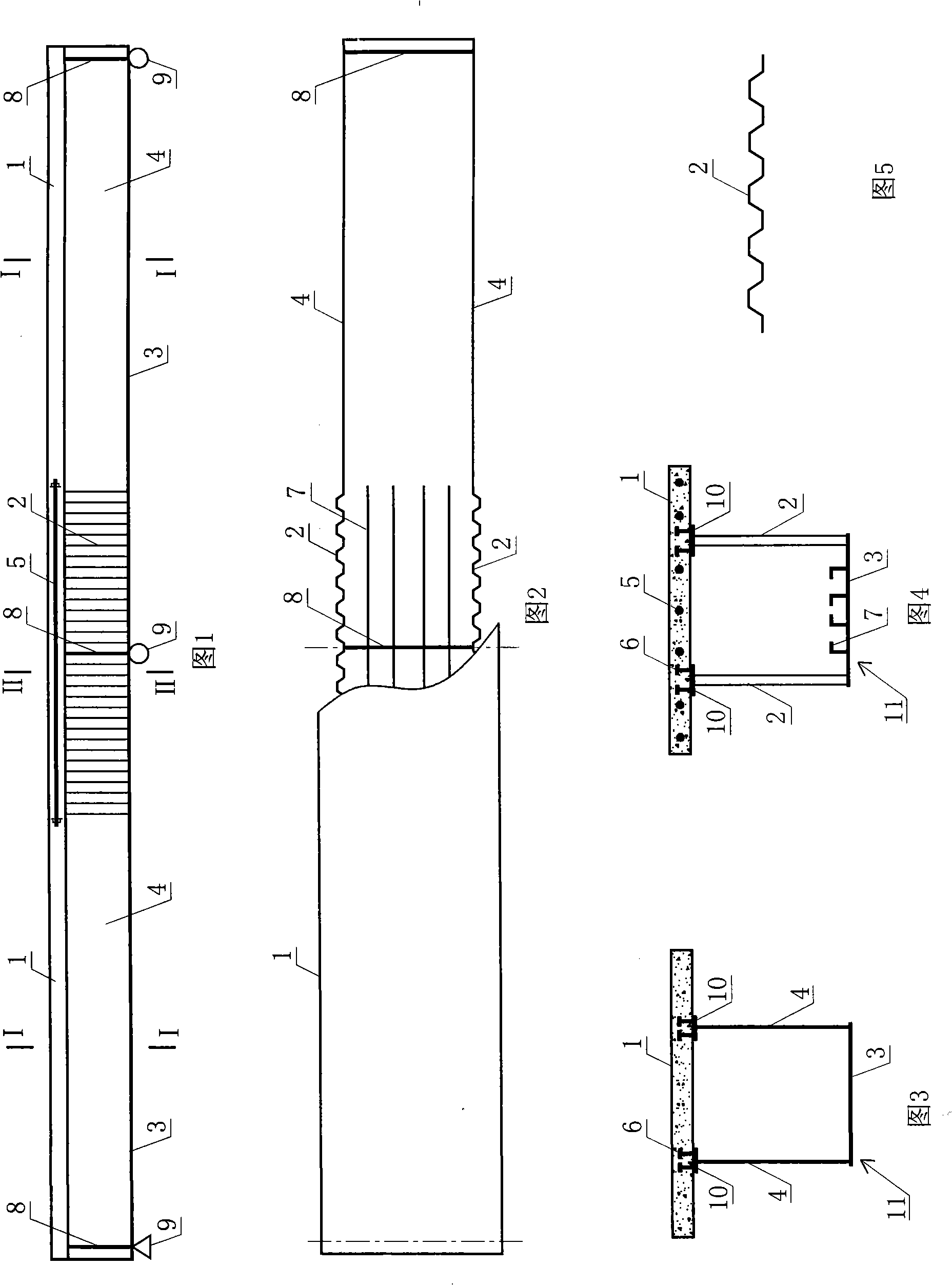

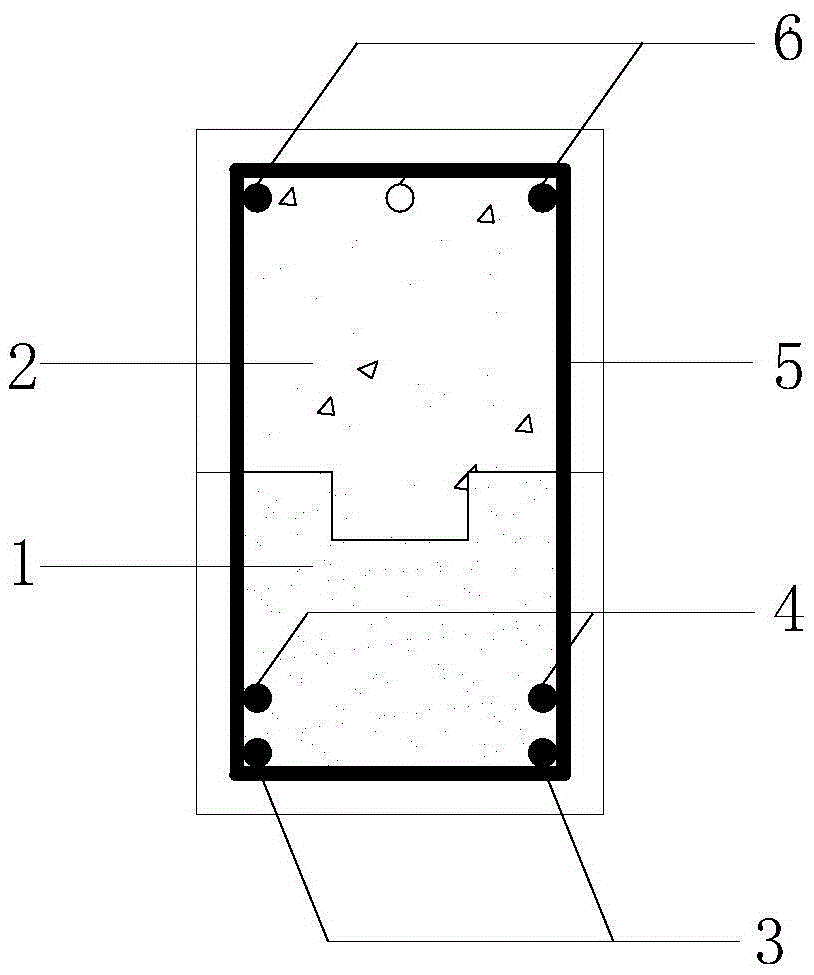

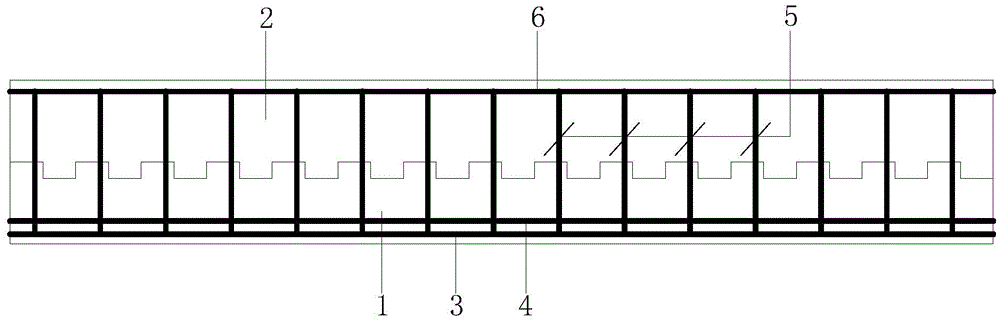

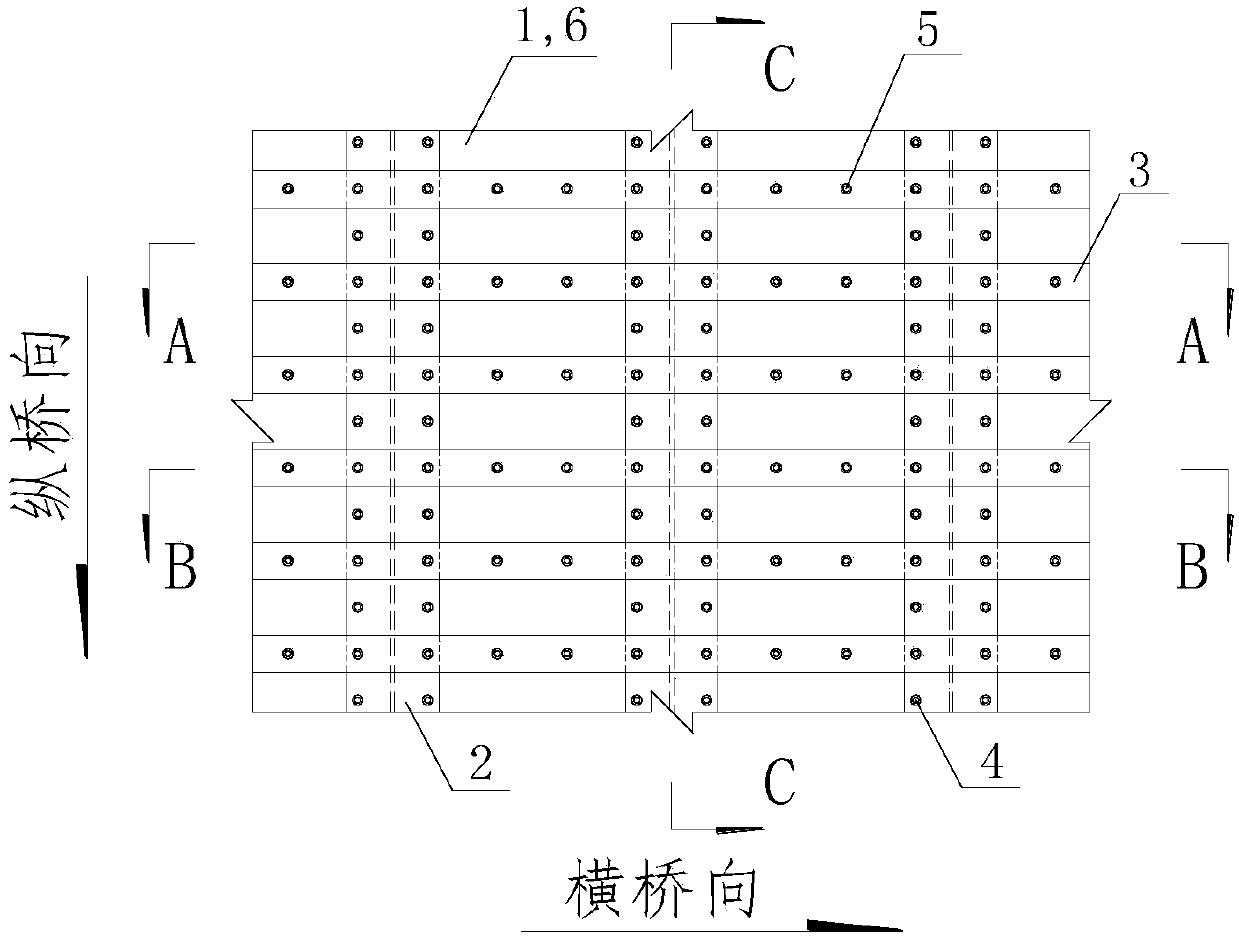

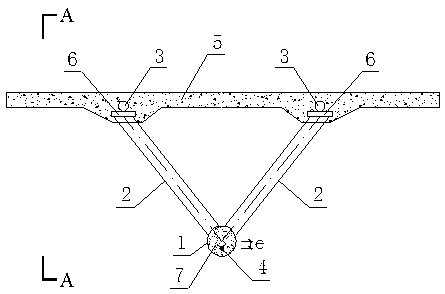

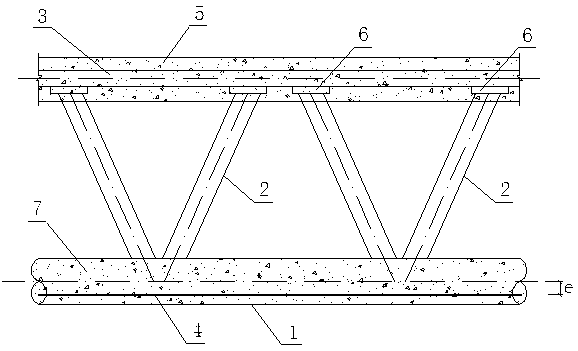

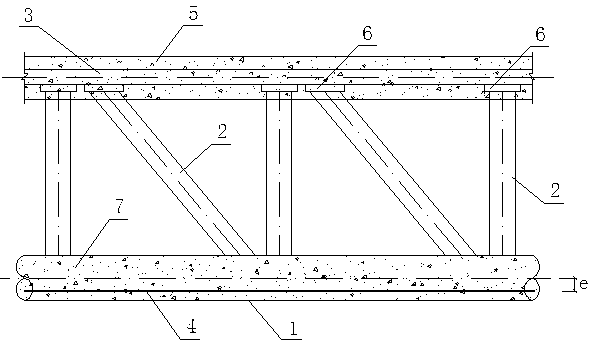

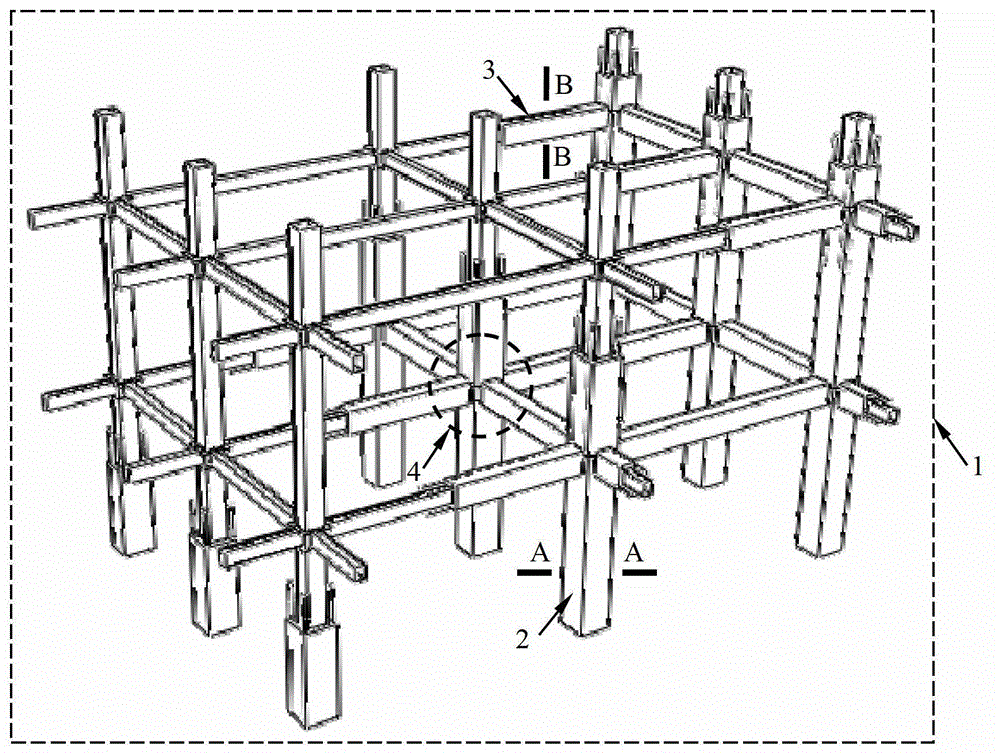

Prestressed hollow composite slab

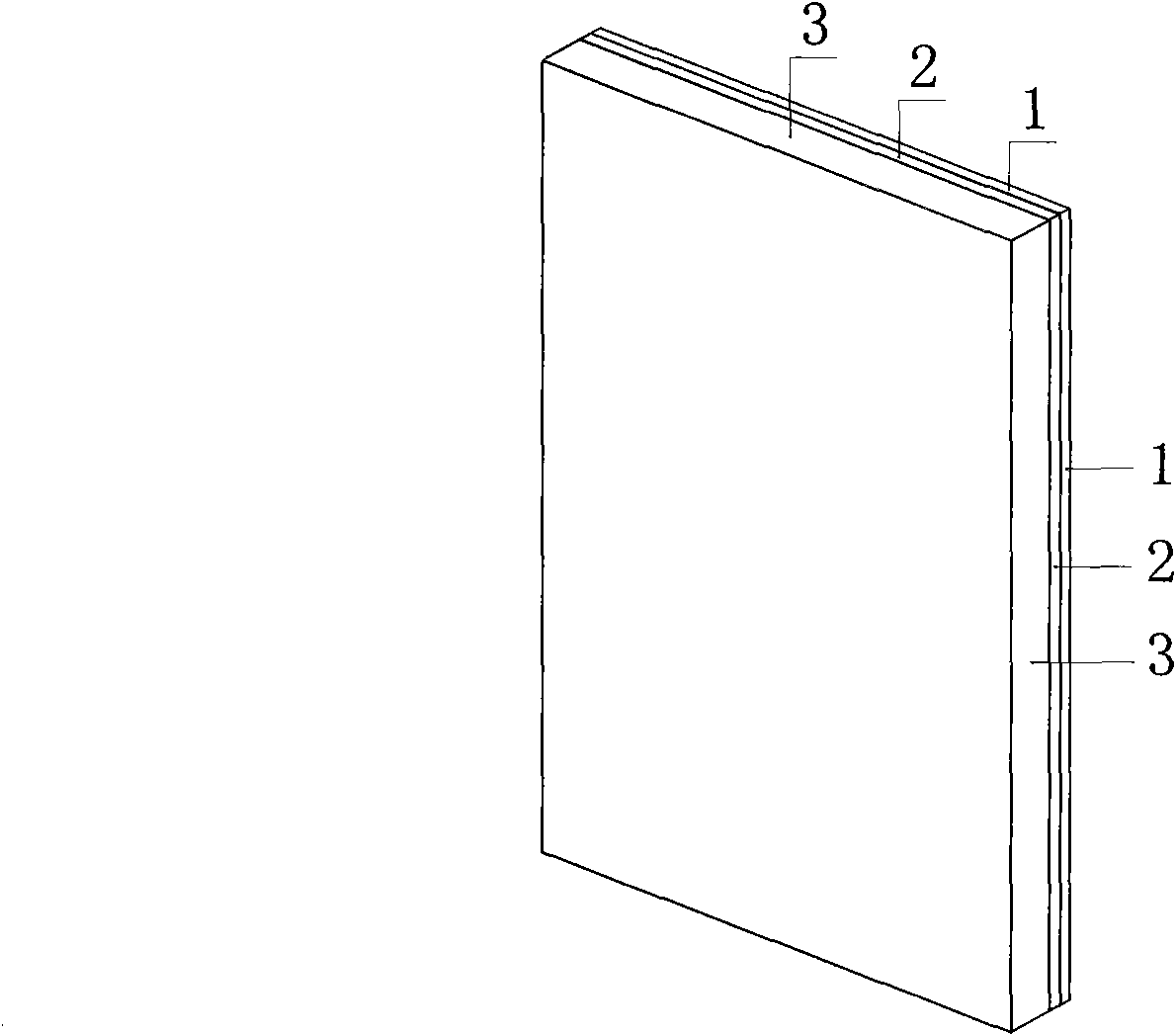

ActiveCN107313539ALight weightApplicable span is largeFloorsBuilding reinforcementsPre stressComposite slab

The invention relates to a prestressed hollow composite slab and a manufacturing method thereof, and belongs to the field of normal building construction. The composite slab comprises prefabricated pieces (1) and composite layers (2). Thickness of a bottom plate (3) of each prefabricated piece (1) is greater than or equal to 35 mm and less than or equal to 60 mm, prestressed steel wires (4) in the bottom plate are located at the upper parts of transversal steel bars (5), and the length of each prestressed steel wire (4) and each transversal steel bar (5) extending out of the corresponding bottom plate (3) is greater than or equal to 50 mm; the width of each prefabricated piece is greater than or equal to 1500 mm, light-weight material filling pieces (6) are arranged at the upper part of each prefabricated piece (1); the heights of concrete solid ribs (7) between adjacent filling pieces are greater than or equal to 50 mm; the transversal steel bars (5) between adjacent prefabricated pieces (1) are overlaid in a joint area (8), upper part steel bars (10) of the composite slab are bound, composite layer concrete is poured, and the composite slab is formed. According to the prestressed hollow composite slab and the manufacturing method thereof, the self-weight of the composite slab is light, the stiffness in the longitudinal direction and the transversal direction is high, the application range is large, and transportation and installation are convenient. The prestressed hollow composite slab and the manufacturing method thereof have good economic efficiency and applicability, and play a role on promoting the development of building technology.

Owner:徐焱

Low-density AAC (autoclaved aerated concrete) precise-masonry self-thermal insulation system and construction method

InactiveCN103074936ASimple structure designSolve thermal insulationWallsClimate change adaptationThermal insulationThin layer

The invention discloses a low-density AAC (autoclaved aerated concrete) precise-masonry self-thermal insulation system and a construction method, and belongs to the field of construction energy saving and structure integration. The system is characterized in that a wall body (1) is built by AAC building blocks (5) of which the density grade is B03-B05 grade; two adjacent AAC building blocks (5) are bonded by a building block binder layer (6); and one layer of stacked AAC building blocks (5) are built on the outer side surface of each column body (2). The construction method for the low-density AAC precise-masonry self-thermal insulation system mainly comprises the following steps of: stirring the building block binder layer (6); building the AAC building blocks (5); bonding an L-shaped bonding piece (8); and plastering thin-layer plaster mortar (11). According to the low-density AAC precise-masonry self-thermal insulation system and the construction method, the thermal insulation, fire prevention and energy saving requirements of a building can be satisfied without a composite thermal insulation layer, and construction working procedures are reduced, thereby being favorable for the engineering construction quality and shortening the days for construction.

Owner:山东高阳建材有限公司

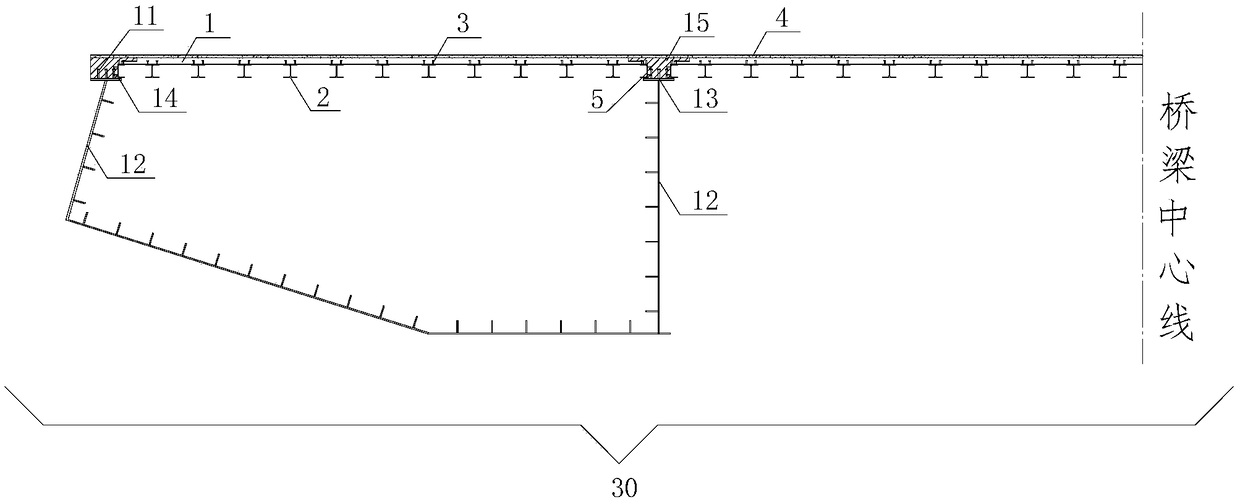

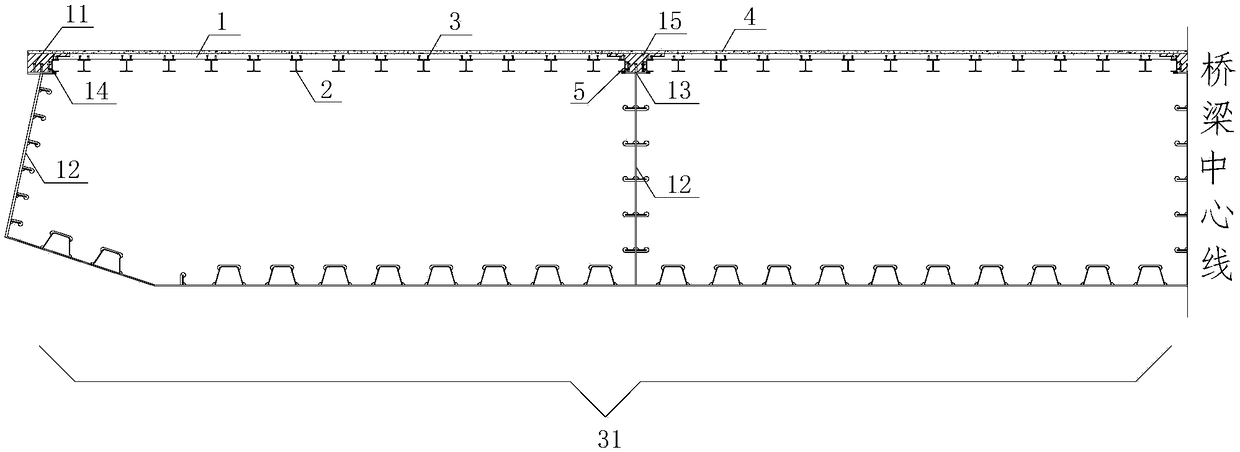

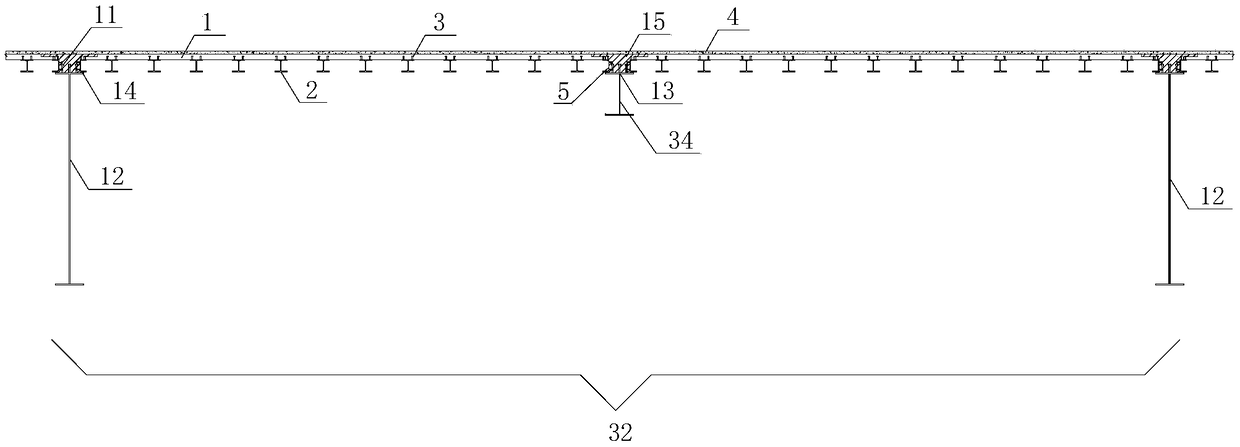

Composite box girder bridge erected in advance by using corrugated steel web steel girders and construction method thereof

ActiveCN101798794ASolve crackingEliminate the effects ofLoad-supporting elementsBridge erection/assemblySocial benefitsBox girder

The invention discloses a composite box girder bridge erected in advance by using corrugated steel web steel girders. The bridge comprises a concrete soleplate, a steel girder and a concrete upper top plate, wherein the steel girder is a corrugated steel web steel girder structure; the steel girder comprises a pair of corrugated steel webs which is arranged vertically and symmetrically and an open-web diaphragm unit erected between the pair of corrugated steel webs; and the upper end of each corrugated steel web is provided with an upper connecting mechanism to be firmly connected with the concrete top plate, and the lower end of the corrugated steel web is provided with a lower connecting mechanism to be firmly connected with the concrete soleplate. The invention also discloses a construction method for the composite box girder bridge erected in advance by using the corrugated steel web steel girders. The corrugated steel webs are used as composite box girder webs, so dead weight of a structure is reduced, live load efficiency is enhanced and a cracking problem of a conventional concrete box girder web is solved; and simultaneously, bracket-free construction can be realized in a high pier, construction quality is enhanced, construction process is fastened and remarkable economic and social benefits are achieved.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Concrete-filled steel tube combined shear wall and construction process thereof

InactiveCN102900169AHigh strengthImprove ductilityWallsBuilding material handlingReinforced concreteShear capacity

The invention relates to a concrete-filled steel tube combined shear wall and a construction process thereof. The shear wall comprises steel tubes which are distributed uniformly along the section of the shear wall, concrete filled into the steel tubes, concrete poured outside the steel tubes, square stirrups arranged outside the steel tubes, and vertically-distributed steel bars and horizontally-distributed steel bars which are arranged on front and rear sides of the steel tubes, tie steel bars which are tied between the steel tubes and the vertically-distributed steel bars and between the steel tubes and the horizontally-distributed steel bars, and longitudinal steel bars which are arranged at the positions of restraint members on edges of two sides of the steel bars. According to the concrete-filled steel tube combined shear wall, the steel tubes are embedded into the ordinary reinforced concrete shear wall, and the bearing capacity of the concrete is improved under the restraint action of the steel tubes, so that the sectional dimensions of the members are reduced, the dead weight of a structure is reduced, a seismic effect is reduced, and more usable areas are provided for buildings under the condition of the same design axial force; and anti-seismic properties of the flexural capacity, shear capacity, damage ductility and the like of the shear force are improved effectively by utilizing the high bearing capacity and high ductility of the concrete-filled steel tubes.

Owner:TSINGHUA UNIV

Continuously strong bridge structure with variable concrete density gradient

ActiveCN101113586AHigh compressive cracking strengthHigh tensile strengthBridge structural detailsBridge materialsApparent densityFiber

The invention relates to a successive rigid-frame bridge structure with gradient variation of concrete density. The upper structure of the bridge uses three concrete materials, wherein, mid-span base material uses strong light aggregate concrete with dried apparent density of no more than 1950kg / m3 so as to reduce structure weight; the base material at the concretion position of a frusta and a beam uses strong common concrete with dried apparent density of no less than 2300kg / m3 so as to satisfy higher compression resistance and splitting resistance strength the concretion position of frusta and beam; the base material of primary beam between mid-span and the concretion position of frusta and beam uses strong light concrete of fiber toughening and splitting resistance with dried apparent density of 1950kg / m3-2300kg / m3 so as to reduce structure weight, improve concrete splitting resistance performance and reduce adverse impacts caused by constrict creep. The invention can handle the technical problem of serious cracking between the mid-span downwarp of successive rigid-frame bridge and a box girder through the optimized combining matching of the material and the structure and the collocating way of the optimized prestress bundle.

Owner:WUHAN UNIV OF TECH

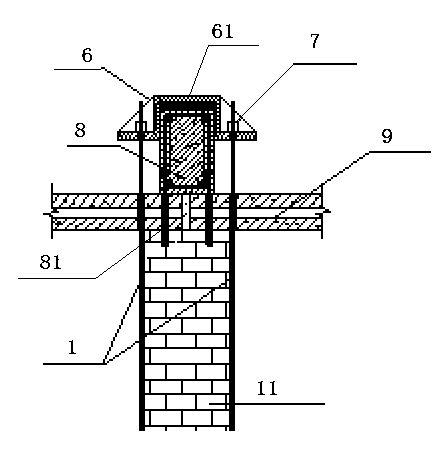

Vertical un-bonded prestressed anti-seismic strengthening structure of masonry building

InactiveCN102704704AImprove the seismic bearing capacityImprove integrityBuilding repairsShock proofingPre stressPre stressing

The invention relates to a vertical un-bonded prestressed anti-seismic strengthening structure of a masonry building. The structure is characterized in that un-bonded prestressed ribs are vertically arranged on each of two sides of a strengthened wall, a coping beam or a wall top force transfer shim block is arranged on the top of the strengthened wall, and the tension ends of the un-bonded prestressed ribs are anchored on the coping beam or the wall top force transfer shim block; a foundation force transfer shim block is arranged on the foundation part of the strengthened wall, and the fixed ends of the un-bonded prestressed ribs are anchored on the foundation force transfer shim block; and by applying a pre-stressing force, the anti-seismic capability of the strengthened wall is greatly improved. The vertical un-bonded prestressed anti-seismic strengthening structure of the masonry building can effectively improve the anti-seismic bearing capacity of the masonry wall and enhance the integrity and the energy dissipation capability of the masonry structure, is beneficial to deformation recovery after seism, is easy and convenient to construct, low in influence and low in manufacturing cost, and belongs to a novel anti-seismic strengthening technology of masonry structures which are worthy of vigorous promotion.

Owner:BEIJING ACAD OF BUILDING ENG

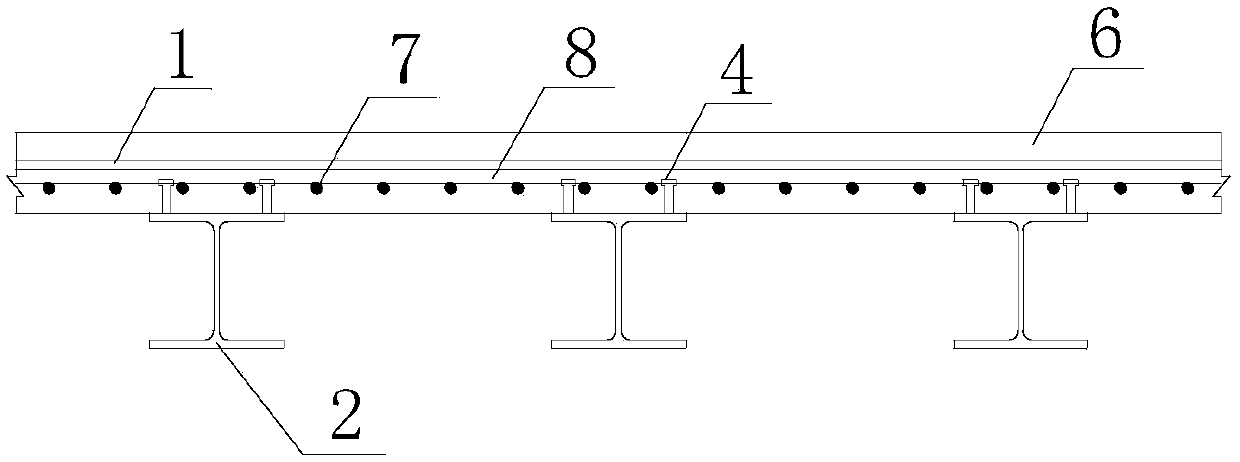

Ultra-light composite beam structure suitable for large-span bridge and construction method of ultra-light composite beam structure suitable

PendingCN109338866AReduced risk of crackingIncrease profitBridge structural detailsBridge erection/assemblyLifting capacityBridge deck

The invention discloses an ultra-light composite beam structure suitable for a large-span bridge and a construction method of the ultra-light composite beam structure. The ultra-light composite beam structure is mainly composed of steel beams and bridge deck slab units, wherein bridge deck slab unit comprise profile steel-UHPC light composite bridge deck slabs and peripheral seam constructions; the profile steel-UHPC light composite bridge deck slabs are composed of UHPC plates and profile steel, the profile steel used as longitudinal rib is arranged at the bottoms of the UHPC plates; and thelongitudinal and transverse seam constructions are T-shaped seams. The ultra-light composite beam structure suitable for the large-span bridge has the advantages that the cost is low, the welding amount is little, and risks of fatigue cracking are greatly reduced; meanwhile, the anti-bending inertia moment is higher, the cracking risk of the bridge deck slabs is reduced, fracture in a high tensilestress area is avoided, and the shrinkage fracture is further avoided; the longitudinal and transverse stiffness is convenient to match, self-weight of the bridge deck slabs is reduced, and the requirement of lifting capacity on site is not high; and the construction risk is reduced, the pouring amount on site is small, the workload of dabbing is small, a steel bar at a seam position does not need to be bound, the operation is simple, and the construction is easy.

Owner:邵旭东

Portion waveshape steel web plate pre-stress steel-concrete continuous combined case beam

InactiveCN101255677AGood three-dimensional flexibilityImprove tensile propertiesBridge materialsBridge engineeringSheet steel

The present invention relates to a partial corrugated steel web prestressed steel-concrete continuous composite box-girder. The concrete roof plate is permanently connected with the steel box-girder through a connecting plate and a shear connector. In the steel box girder the steel diaphragm plates are installed respectively corresponding to each fulcrum. The whole steel box-girder is composed of a structural negative monument area segment and the structural positive moment area segment arranged at two ends. The concrete roof plate of the structural negative moment area segment is stretched with a longitudinal prestressed rib. A longitudinal stiffening rib is arranged in the steel baseboard. The web plates at two sides of the steel box-girder in the structural negative moment area are corrugated steel webs. The web plates of the steel box-girder in the structural positive moment area steel box-girder are plane steel web plate. The invention can overcome the problems of low efficiency of longitudinal pre-stress of negative moment area in the continuous composite box-girder and corrugated steel web PC composite box-girder, easily destabilization of the plane steel web plate or more arrangement of the longitudinal prestressed rib inside or outside the box-girder and complex construction and the like. The invention has broad applying prospect in the bridge engineering and long-span structure.

Owner:HUNAN UNIV

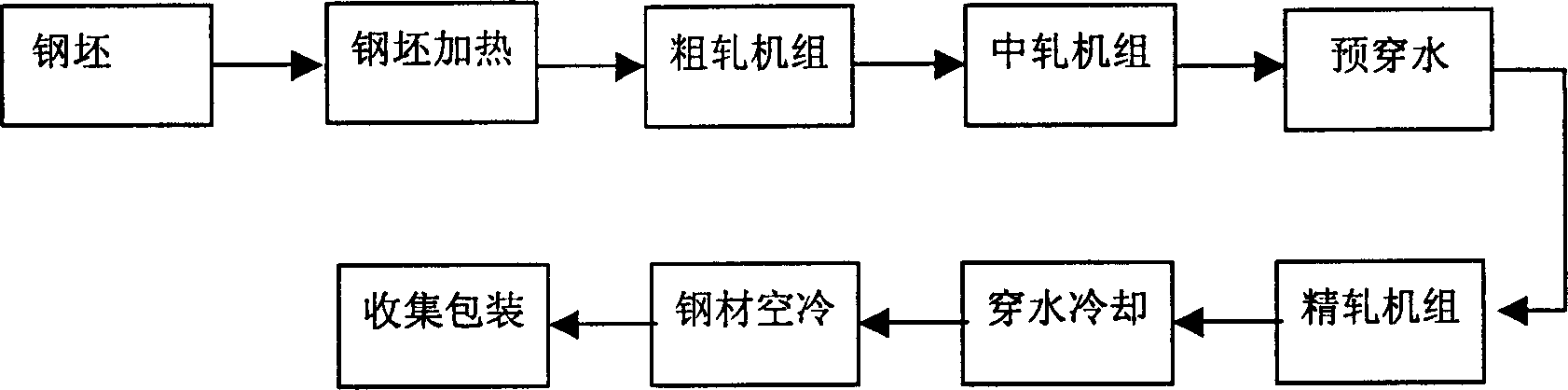

Method for producing 500 Mpa high strengh threaded reinforced bar

InactiveCN1792484AHigh strengthRaise Strength IndexTemperature control deviceWork treatment devicesHigh intensityWater cooling

A method for manufacturing the high-strength (500 MPa) threaded reinforcing bar includes such steps as providing 20MnSi steel bullet at 880-950 deg.C, cogging, middle rolling, pre-cooling by passing through water curtain, final rolling, cooling by passing through water curtain, and air cooling to release heat from its core for self tempering.

Owner:双菱钢铁集团控股有限公司

Prefabricated assembly FRP-reinforcing steel-bar-concrete combined bridge deck and construction method

InactiveCN104805767AReduce rustEasy to useBridge structural detailsBridge erection/assemblyPre stressBridge deck

The invention discloses a prefabricated assembly FRP-reinforcing steel-bar-concrete combined bridge deck and a construction method. The prefabricated assembly FRP-reinforcing steel-bar-concrete combined bridge deck comprises a semiclosed FRP groove and concrete inside the FRP groove, wherein the bottom surface and two side surfaces of the concrete are wrapped by the FRP groove to form the combined panel, a transverse through reinforcing steel bar reserved tunnel is formed in a transverse setting position of the combined panel, a transverse prestress reinforcing steel bar is arranged in the reinforcing steel bar reserved tunnel to connect a plurality of FRP-concrete combined panel prefabricated components to form an integral bridge panel structure in a needed size. The construction method comprises the steps: firstly producing the semiclosed FRP groove; arranging an FRP rib and an embedded corrugated pipe, and fixing the FRP rib and the embedded corrugated pipe; pouring concrete; splicing a plurality of prefabricated FRP-concrete combined deck components into a whole by utilizing the prestress after the strength of the concrete reaches the requirement. The factorization prefabrication and on-situ assembling of the FRP combined bridge deck are realized, the structure is simple, and the construction is convenient.

Owner:SHANDONG UNIV

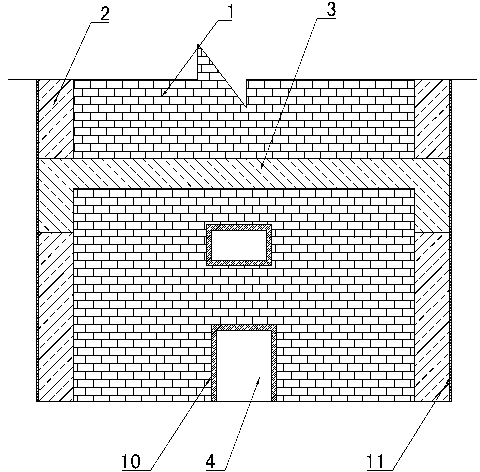

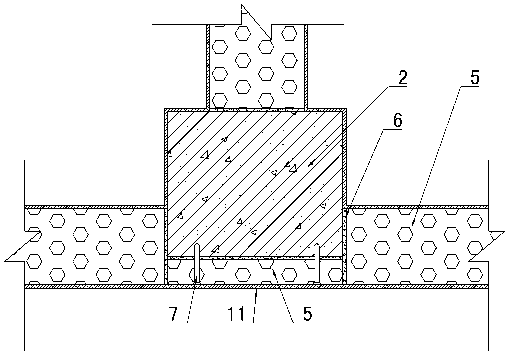

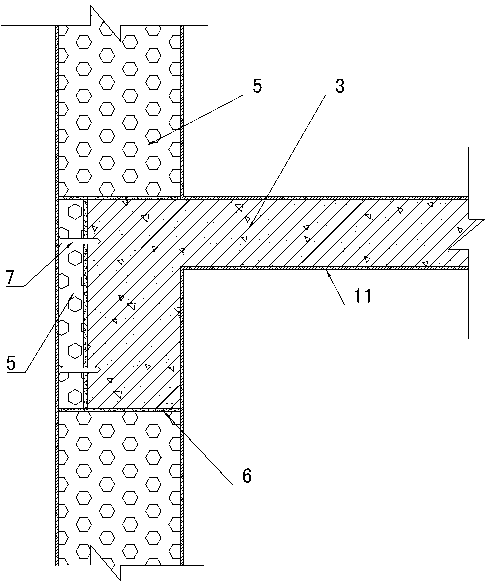

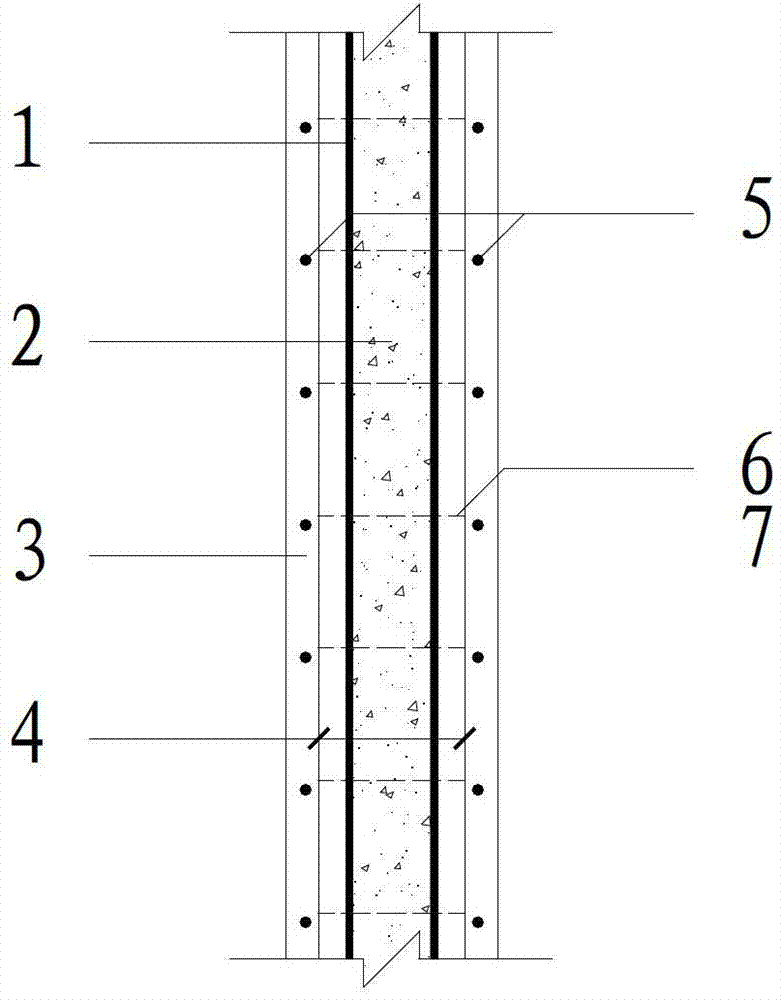

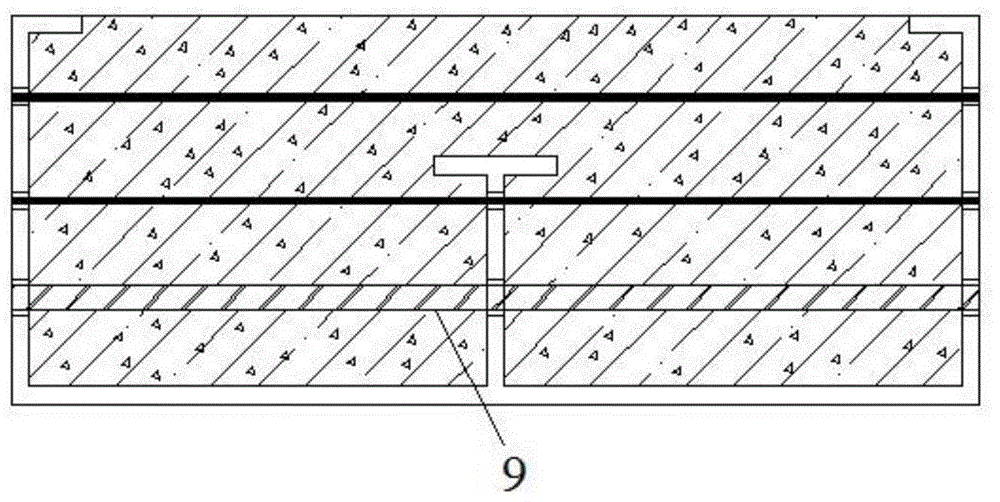

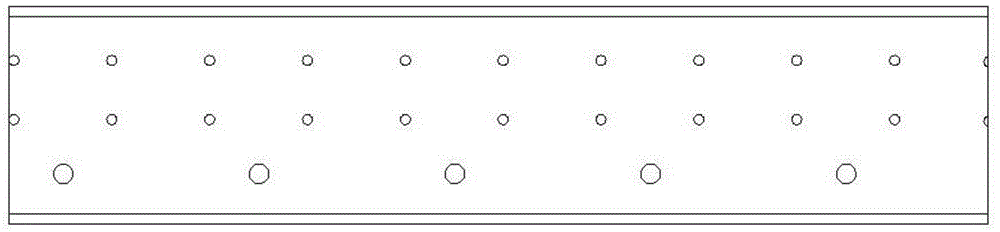

Overlapped shear wall with prefabricated part and cast-in-situ part and manufacturing method thereof

InactiveCN101649656AThe carrying capacity is not lowImprove the level of industrializationWallsCeramic shaping apparatusReinforced concreteSingle level

The invention belongs to the technical field of the civil engineering building structure, in particular to an overlapped shear wall with a prefabricated part and a cast-in-situ part and a manufacturing method thereof. The traditional reinforced concrete shear wall is divided into two parts, wherein one part is prefabricated (a PCF plate) in a factory; the other part is cast in situ in a construction site; and after block cast, the prefabricated part (the PCF plate) and the cast-in-situ part are formed the overlapped shear wall. The plate thickness of the prefabricated PCF plate is commonly controlled at 60-80mm. The plate width of the single PCF plate is not greater than 3.0m, the plate height is not greater than 6.0m, and the plate weight is not greater than 2 tons. A single-layer two-wayreinforced bar net piece is configured in the plate; simultaneously, longitudinal and transverse overlapped reinforced bars are embedded at the inner side according to a distance of 450-600mm in advance, and the exposed parts of the overlapped reinforced bars are anchored into the cast-in-situ part. Compared with a pure external-hanging wall plate of a shear wall structure used at present, the invention lessens the self weight, lowers the construction difficulty, enhances the production efficiency and the construction quality and has energy saving and environmental protection.

Owner:TONGJI UNIV

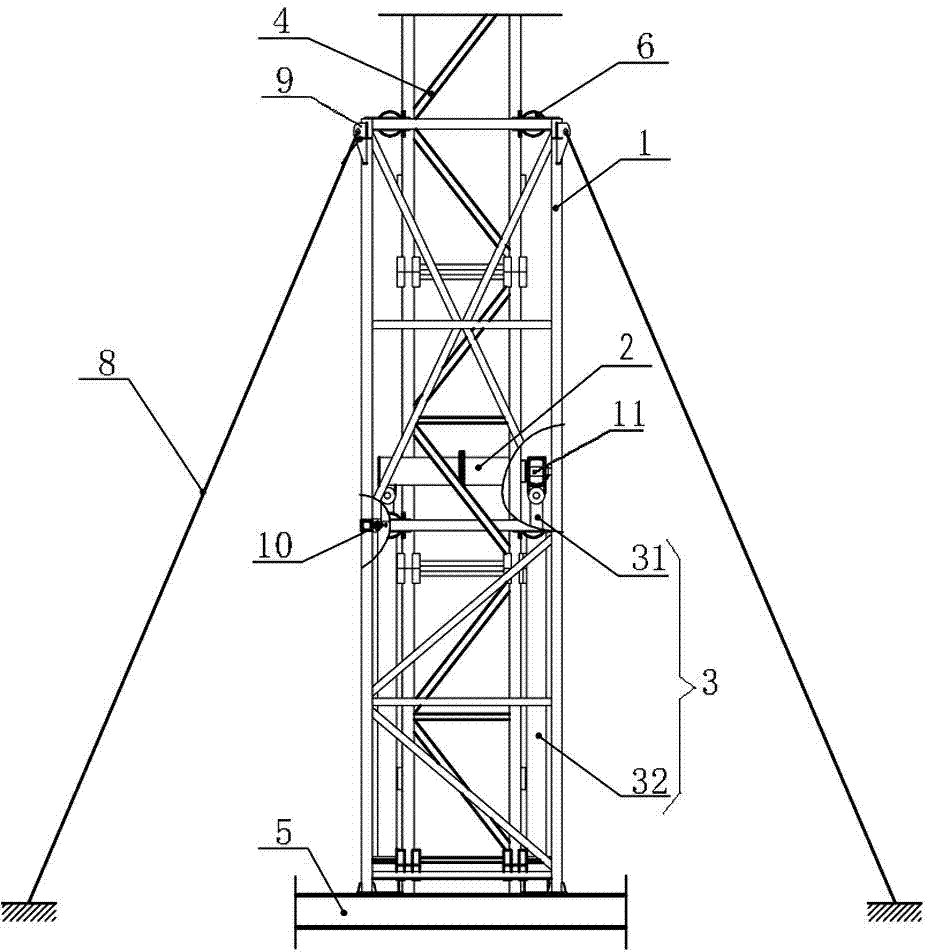

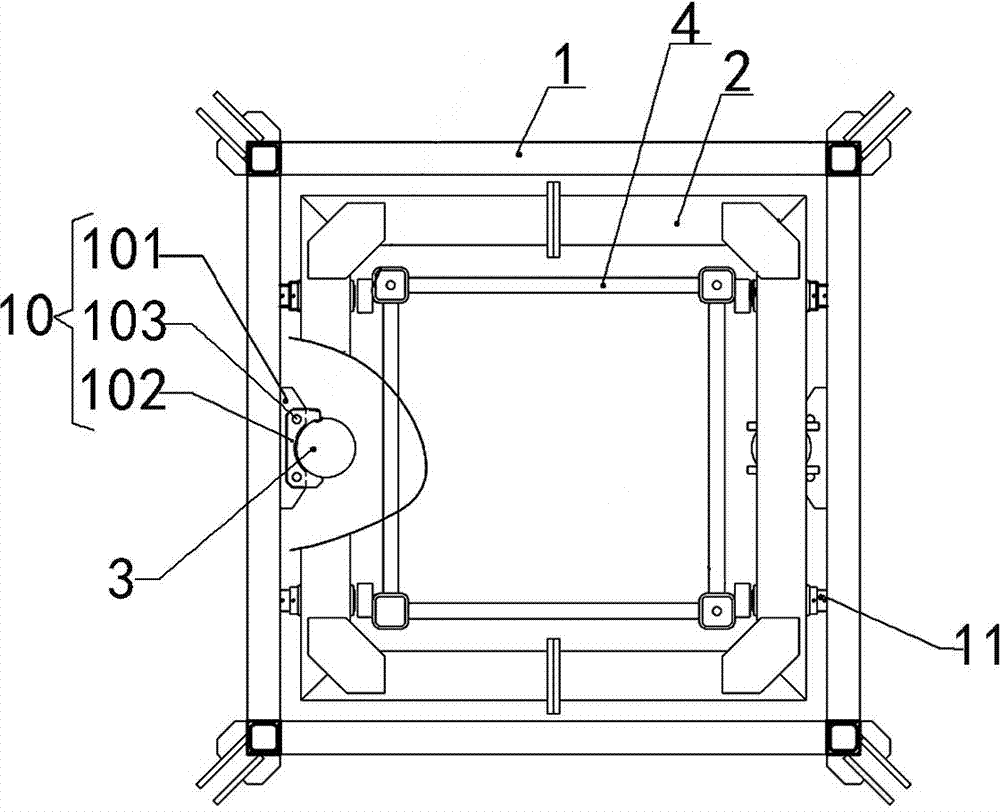

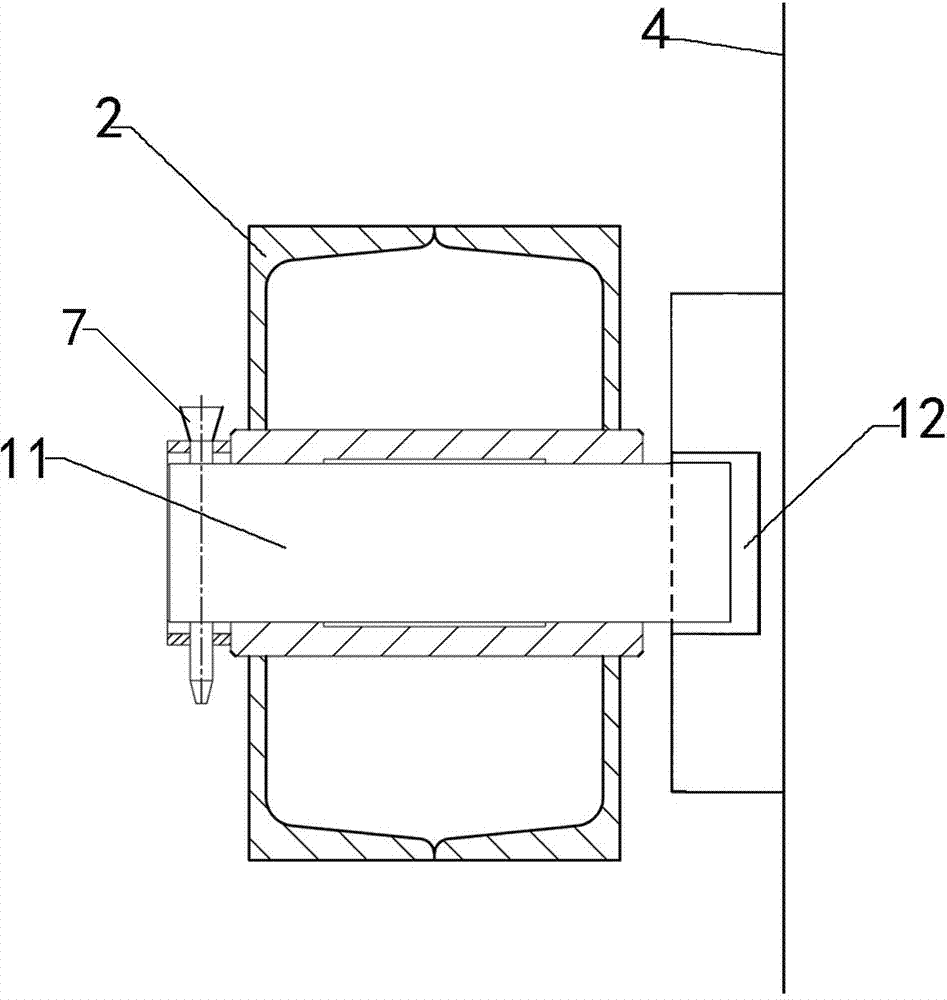

Double-oil-cylinder down jacking system and jacking construction method thereof

The invention provides a double-oil-cylinder down jacking system and a jacking construction method thereof. Double oil cylinders are adopted as jacking oil cylinders, the bottoms of oil cylinder barrels are fixed on a bottom frame, the heads of the oil cylinder barrels are connected with a jacking framework through additional supporting structures, and rod ends of piston rods are connected with a jacking frame. The jacking frame vertically ascends and descends between an upper guide wheel layer and a lower guide wheel layer of the jacking framework and is connected with or disconnected from a main chord of a tower body through axial movement of pin shafts. The bottom of the jacking framework is fixed on the bottom frame, and the top of the jacking framework is fixed on the ground through a cable rope. The double-oil-cylinder down jacking system is simple in structure, convenient to construct, high in safety and good in operating stability in a large stroke, one standard joint is jacked in each step, the number of step changing procedures is reduced, and efficiency is high. The step changing pin shafts are matched with step holes, and the danger that descending of the whole structure does not synchronize with descending of the jacking frame is avoided effectively. The jacking framework and the oil cylinders are all directly fixed on the bottom frame and matched with the cable rope to constitute the stable system, the structure of the system is simplified, and structure self-weight is reduced.

Owner:STATE GRID CORP OF CHINA +3

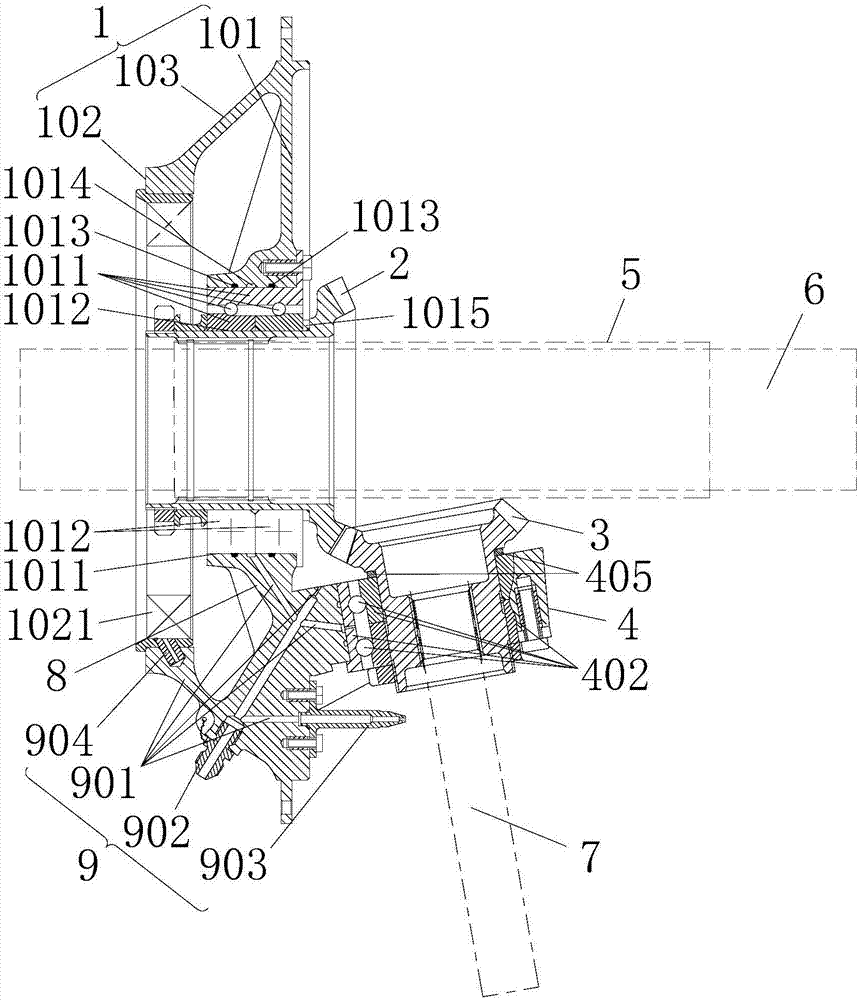

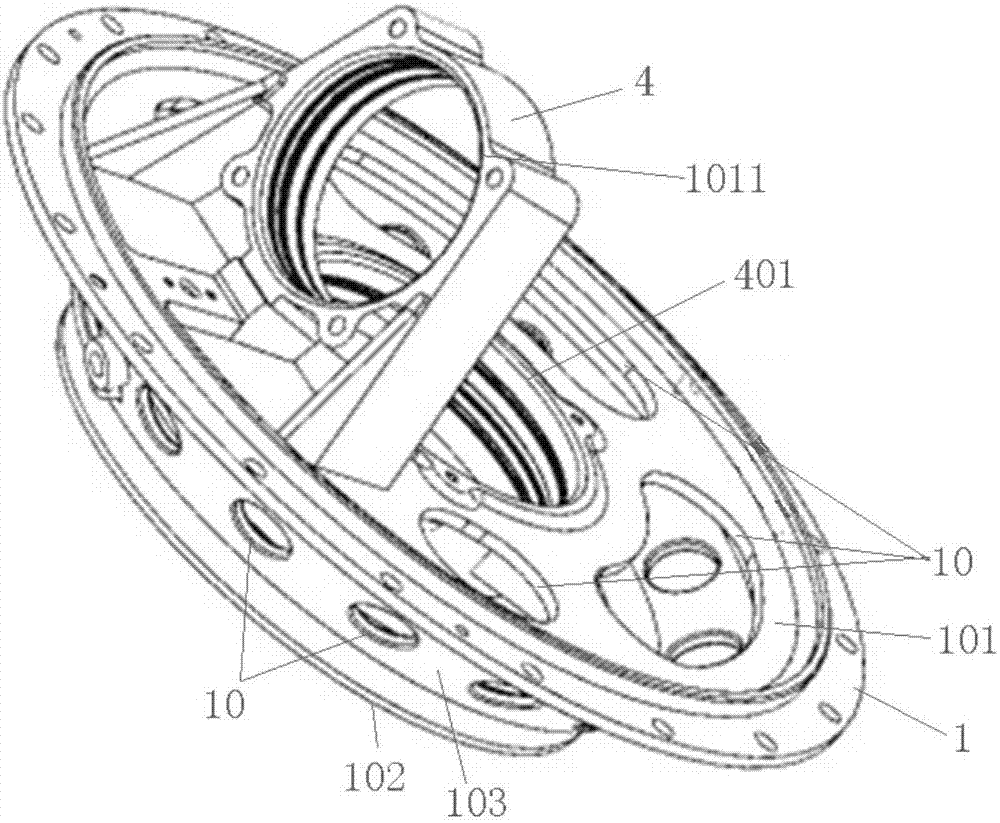

Oblique central transmission frame assembly used for aircraft engine and aircraft engine

ActiveCN107218355AStable deliveryIncrease independenceToothed gearingsGear lubrication/coolingAviationCantilever

The invention discloses an oblique central transmission frame assembly used for an aircraft engine and the aircraft engine. The oblique central transmission frame assembly used for the aircraft engine comprises a conical basin-shaped support. The conical basin-shaped support comprises a large end surface, a small end surface and an oblique side surface. A hollow inner cavity is formed in the conical basin-shaped support. A first bearing pedestal hole used for assembling a drive bevel gear along the conical basin-shaped support is formed in the axial center of the large end surface of the conical basin-shaped support. The large end surface of the conical basin-shaped support is provided with a cantilever bearing pedestal used for assembling a driven circular-arc bevel gear in conical tooth engagement with the drive bevel gear. The cantilever bearing pedestal inclines towards the central axis of the conical basin-shaped support and overhangs on the large end surface of the conical basin-shaped support. The cantilever bearing pedestal is provided with a second bearing pedestal hole used for assembling the driven circular-arc bevel gear. The bearing hole in the cantilever bearing pedestal is small in stress, and stress of all components of the oblique central transmission frame assembly should meet strength requirements. By adoption of the form of the oblique transmission assembly, the output power of the oblique central transmission frame assembly approximately triples that of up-down vertical transmission.

Owner:CHINA HANGFA SOUTH IND CO LTD

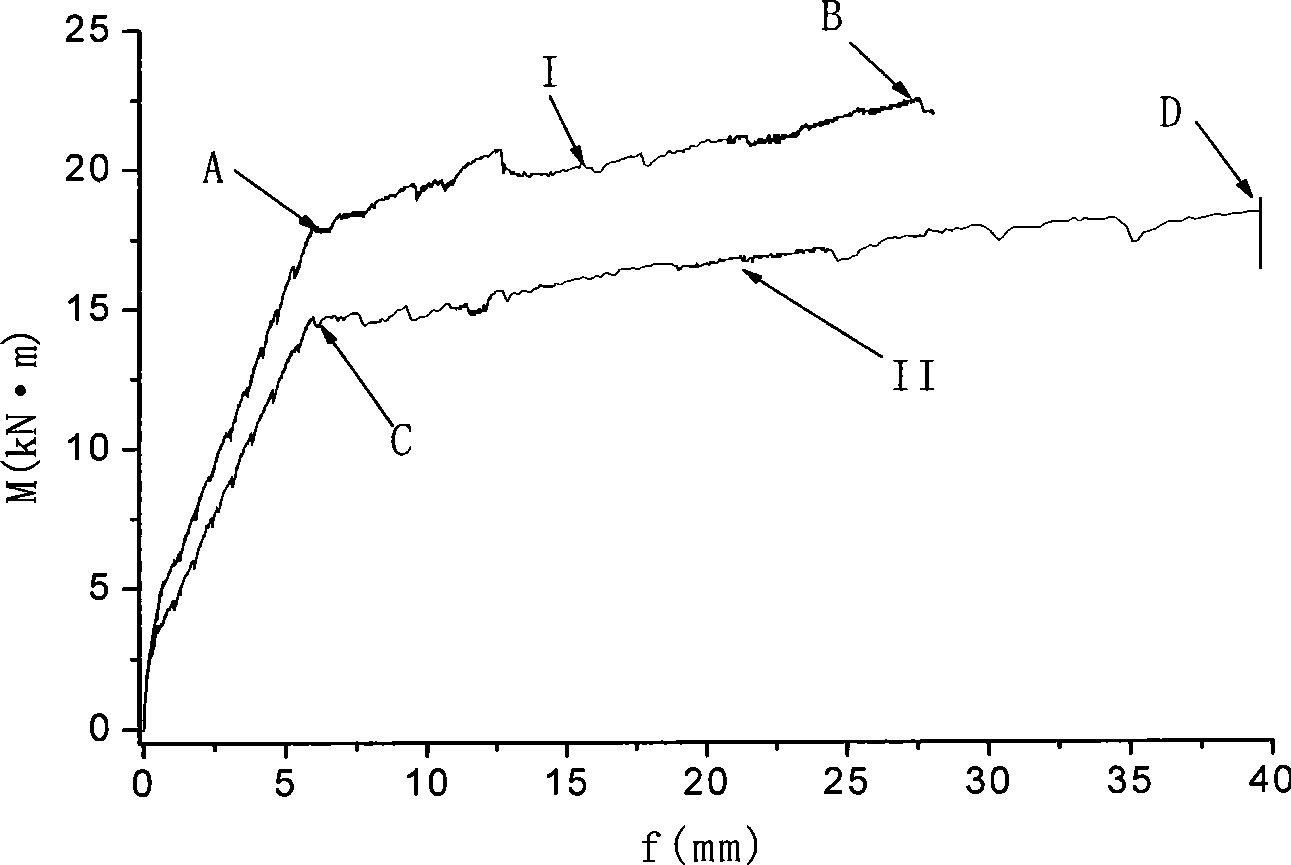

Composite bar-reinforced ECC and concrete composite beam and construction method thereof

InactiveCN105464288ASmall sizeReduce the weight of the structureClimate change adaptationGirdersSteel barMaterials science

The invention discloses a composite bar-reinforced ECC and concrete composite beam and a construction method thereof. The whole cross section of the composite beam is in a rectangular shape, and the composite beam comprises a fiber-reinforced cement-based composite material with concrete on the upper portion and interval grooves in the lower portion and an FRP bar-steel bar framework; in the FRP bar-steel bar framework, longitudinally-tensioned FRP bars are placed at the bottom of the beam, located on the inner sides of steel bar stirrups and bound together with the steel bar stirrups, longitudinally-tensioned steel bars are placed on the upper sides of the longitudinally-tensioned FRP bars, and a steel bar framework stud is placed on the top of the beam, located on the inner sides of the steel bar stirrups and bound together with the steel bar stirrups. According to the composite bar-reinforced ECC and concrete composite beam and the construction method thereof, on one hand, through the superior tensile property of the ECC material and the tiny crack mechanism, the dampproof and rustproof purposes are achieved while the bearing capacity and ductility of the composite beam are significantly improved; on the other hand, by mixing the FRP bars with the steel bar, the high strength and the corrosion resistance of the FRP bars and the ductility of the steel bar are fully utilized. The composite bar-reinforced ECC and concrete composite beam can be applied to beam components in building and bridge structures.

Owner:SOUTHEAST UNIV

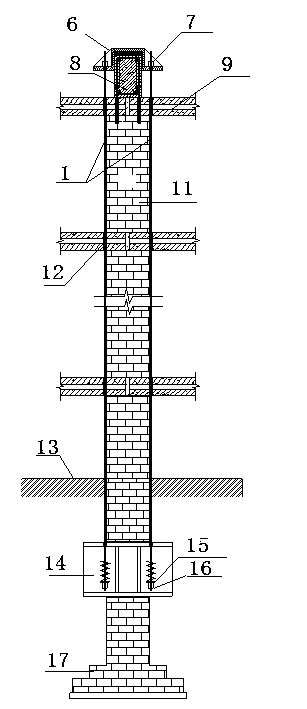

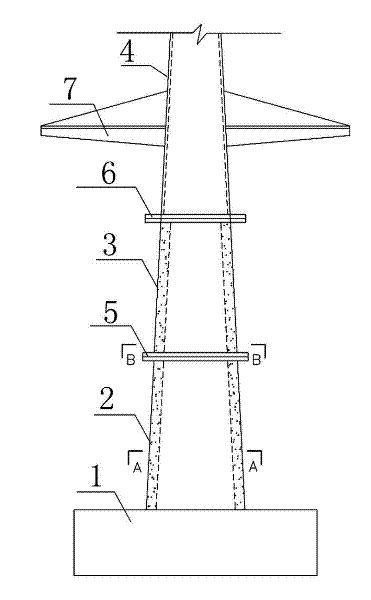

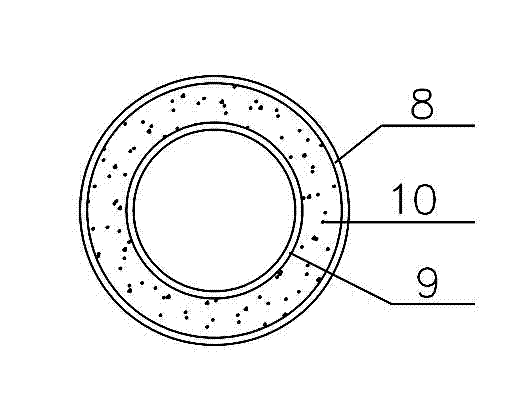

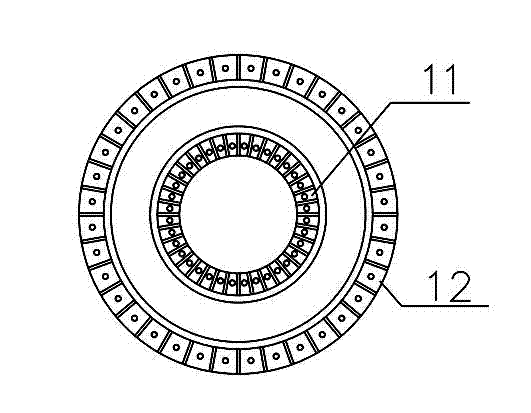

Hollow sandwich steel pipe concrete pole for power transmission line

InactiveCN102650175AImprove stress resistanceImprove bending resistanceTowersReinforced concreteEngineering

The invention provides a hollow sandwich steel pipe concrete pole for a power transmission line. The hollow sandwich steep pipe concrete pole comprises a hollow sandwich steel pipe concrete member, a hollow steel pipe member, inside and outside wall flanges, a common flange and a lead cross arm; the hollow sandwich steel pipe concrete member consists of an external steel pipe, an internal steel pipe and intermediate sandwich concrete; subsections of the hollow sandwich steel pipe concrete member are connected through the inside and outside wall flanges; the hollow sandwich steel pipe concrete member is connected with the hollow steel pipe member through the common flange; the hollow sandwich steel pipe concrete member is fixedly arranged in a rebar concrete foundation; the inside and outside wall flanges consist of an internal flange and an external flange; and the lead cross arm is arranged on the hollow steel pipe member. Compared with the conventional power transmission tower, the floor area is reduced, and the selection of tower position is more flexible; compared with the common steel pole, the compression resistance, the bending resistance and the local stability bearing capacity of the member are greatly improved; the application range of the power transmission pole is enlarged, and the use quantity of steel material is saved; and compared with the steel pipe concrete pole, the dead load of the structure is reduced, the action force of the foundation is reduced, and the use quantity of the foundation concrete is saved.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

Profile steel-UHPC (ultra-high performance concrete) combined bridge deck structure suitable for cantilever state as well as construction method thereof

ActiveCN109610310ALight weightReduced risk of crackingClimate change adaptationBridge structural detailsPre stressBridge deck

The invention discloses a profile steel-UHPC (ultra-high performance concrete) combined bridge deck structure suitable for a cantilever state as well as a construction method thereof. A profile steel-UHPC lightweight combined bridge deck slab is mainly formed by combining profile steel, steel plate strips welded with short studs as well as an UHPC slab; the profile steel serving as a longitudinalrib is arranged in a transverse bridge direction at intervals; the steel plate strips are arranged on an upper flangeslab of the profile steel in the bridge direction at intervals; and longitudinal and transverse seam structures are T-shaped seams. Finished product profile steel is adopted, so that the manufacturing cost is low, the welding quantity is small and the risk of fatigue cracking is greatly reduced; meanwhile, higher bending-resistant inertia moment is achieved, the cracking risk of the bridge deck slab is reduced and the transverse tension resistance of the bottom surface of the bridge deck slab is enhanced; UHPC in the longitudinal seam position is converted from a pulled state to a pressed state, so that the fact that the operation stage is not cracked can be guaranteed without configuring a prestressing force when the bridge deck slab is under the transverse cantilever state; moreover, breakage in a high tensile stress area can be avoided, shrinkage crack can be avoided,the self weight of the bridge deck slab is reduced, and the method is simple to operate and easy to construct.

Owner:HUNAN UNIV

Prestressed steel tube concrete combination trussed beam and construction method thereof

InactiveCN103061243AReduce distortionAvoid crackingTruss-type bridgeBridge structural detailsSteel tubeEngineering

The invention relates to a prestressed steel tube concrete combination trussed beam which comprises a steel tube trussed beam and a concrete bridge deck slab, wherein the top part of the steel tube trussed beam is connected with the bottom of the concrete bridge deck slab, the steel tube trussed beam consists of two parallel top chord steel tubes, a bottom chord steel tube and a plurality of steel web members which are abutted to the top chord steel tubes and the bottom chord steel tube, concrete is filled in the bottom chord steel tube, and a prestressed tendon used for adding prestress is paved in the bottom chord steel tube. The invention also relates to a construction method of the prestressed steel tube concrete combination trussed beam. With the adoption of the prestressed steel tube concrete combination trussed beam, by adding the prestress on the steel tube concrete bottom chord steel tube, the whole rigidity of the steel tube concrete combination trussed beam is strengthened in the premise of lightening the structure dead load, deformation of the steel tube concrete combination trussed beam under the structure dead load and the vehicle load is reduced, the welding part of the steel web members and the bottom chord steel tube cracks due to overlarge deformation can also be avoided, and the steel tube concrete combination trussed beam can be applied to a bridge structure with a larger span after the prestress is added on the bottom chord steel tube.

Owner:FUZHOU UNIVERSITY

Steel pipe-reinforced concrete laminated framework structural system

ActiveCN102979179ADelay or avoid corrosionIncreased durabilityStrutsFire proofingReinforced concreteEngineering

The invention discloses a steel pipe-reinforced concrete laminated framework structural system, which belongs to the field of structural engineering in civil engineering. The steel pipe-reinforced concrete laminated framework structural system is characterized in that laminated sections formed by wrapping reinforced concrete outside hollow steep pipes are adopted for beams and columns of the system. The hollow steel pipes are adopted inside, and the sections are unfolded, so that high rigidity is realized, the dead weight of the structure is reduced effectively while the using amount of concrete is reduced, and the acting force in earthquakes is reduced; and meanwhile, good fire-proof and corrosion-resistant protection is provided for the steel pipes by using the wrapped reinforced concrete. In node regions of the system, steel pipes in columns are connected with each other, and steel pipes in beams are welded on the steel pipes in columns through reinforced ring plates. Column longitudinal bars are arranged in a through way; a part of beam longitudinal bars go deep into nodes after bypassing the steel pipes in columns, and a part of beam longitudinal bars are welded on the steel pipes in columns; and beam and column stirrups are thickened appropriately in the node regions. The steel pipe-reinforced concrete laminated framework structural system is applied to the structural forms of frameworks, framework-shear force walls and the like, and is suitable to be taken as a main body structural system of large-sized high-rise, super-high-rise or huge structures.

Owner:TSINGHUA UNIV

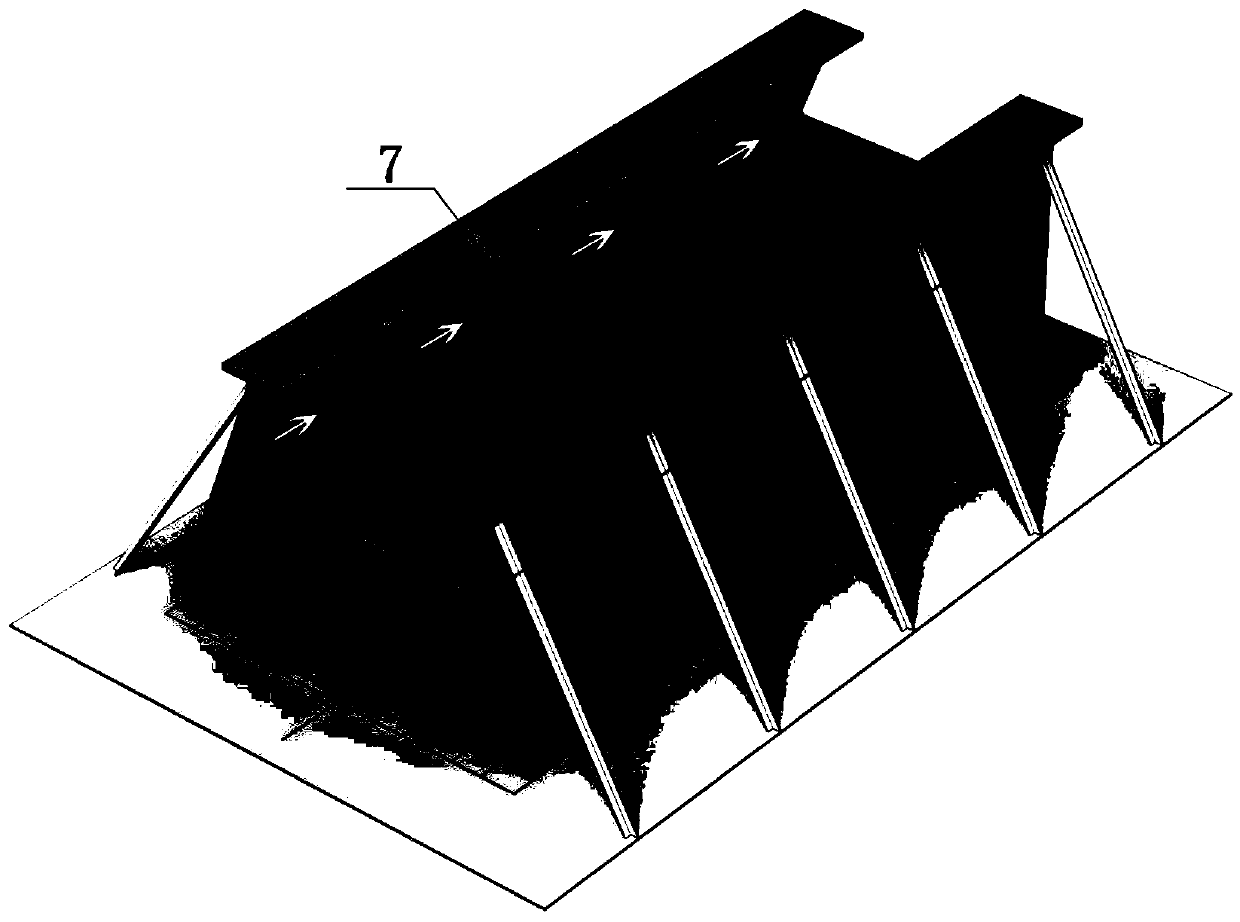

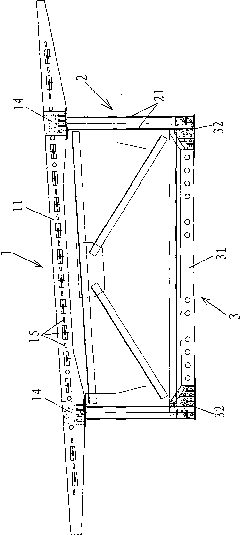

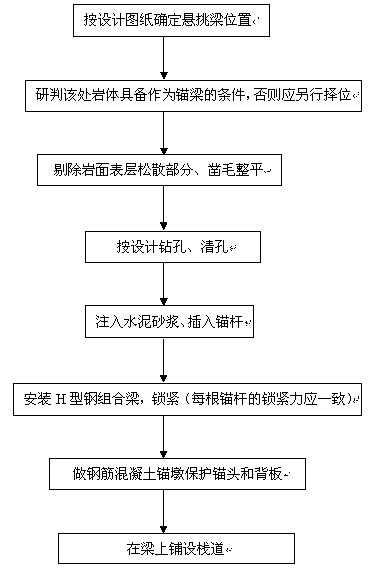

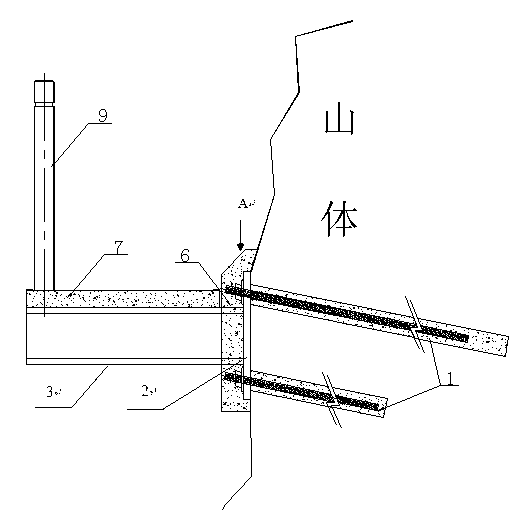

Cantilever beam structure of antique plank road along cliff and construction technology thereof

The invention discloses a cantilever beam structure of an antique plank road along a cliff and a construction technology thereof. The cantilever beam structure is formed by an H-type steel assembly, and a rock bolt assembly fixedly anchored on the rock wall of a mountain in a combining way, wherein the H-type steel assembly is formed by the combination of a steel backing plate (2) and H-type steel (3); the H-type steel (3) is welded on the steel backing plate (2) vertically and serves as the supporting beam of a road panel (7) of the antique plank road along the cliff; the rock bolt assembly is formed by the connection of rock bolts (1), bolts and nuts; and the rock bolts (1) are welded with the bolts in a surfacing manner. The construction technology of the cantilever beam structure is as follows: ensuring the position of the cantilever beam according to the design graph paper; eliminating the weathering surface and fractured rock mass of the locating-point rock surface, and scabbling and leveling; ensuring the length of the rock bolts (1) and drilling holes in the rock bolts; filling cement mortar into the rock bolt holes and inserting the rock bolts (1) welded with anchor heads; mounting the H-type steel assembly on the rock bolts after the cement mortar is solidified to a degree of the designed strength; and fastening with bolts. The cantilever beam structure is safe and reliable in structure, simple and convenient in construction technology, quick in speed, low in engineering cost, and good in simulating of the style of the antique, and is suitable for application along the cliff.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com