Cantilever beam structure of antique plank road along cliff and construction technology thereof

A construction technology and cantilever beam technology, applied in the field of basic construction of antique plank roads, can solve the problems of low bearing capacity and inability to adapt to construction, etc., and achieve the effects of high speed, good antique effect, and safe and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

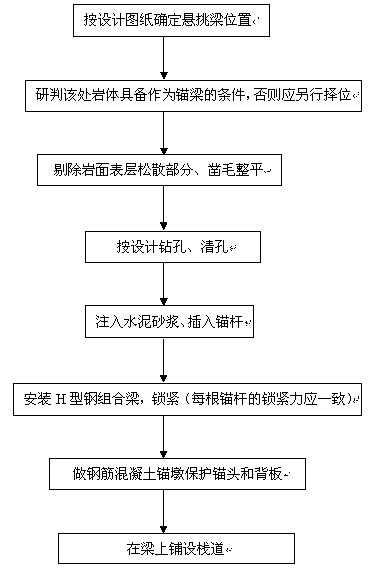

Method used

Image

Examples

Embodiment Construction

[0039] In order to further describe the present invention, the cantilever beam structure and construction technology of the antique plank road of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

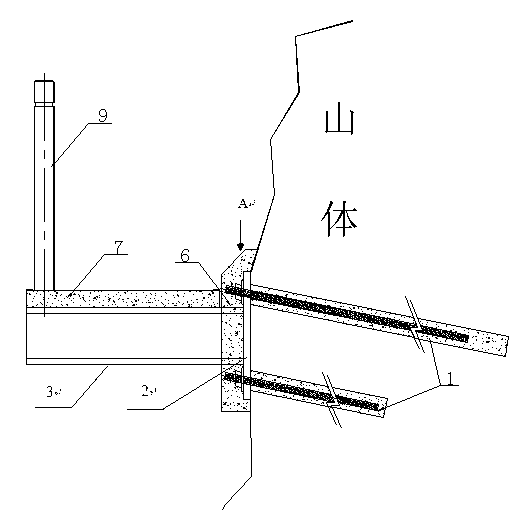

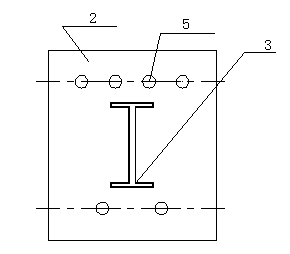

[0040] Depend on figure 2 The sectional view of the cantilever beam structure of the shown antique plank road of the present invention and in combination image 3 , Figure 7It can be seen that the cantilever beam structure of the antique plank road in the present invention is composed of H-shaped steel components and anchor rod components anchored on the rock wall of the mountain. The H-shaped steel assembly is composed of a steel back plate 2 and an H-shaped steel 3, and the H-shaped steel 3 is vertically welded on the steel back plate 2 as a supporting beam for the road panel 7 of the antique plank road. Two rows of bolt holes are drilled, the number of bolt holes in the upper row is 4, and the number of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com