Patents

Literature

945 results about "Weathering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weathering is the breaking down of rocks, soil, and minerals as well as wood and artificial materials through contact with the Earth's atmosphere, water, and biological organisms. Weathering occurs in situ (on site), that is, in the same place, with little or no movement, and thus should not be confused with erosion, which involves the movement of rocks and minerals by agents such as water, ice, snow, wind, waves and gravity and then being transported and deposited in other locations.

UV resistant naphthalate polyester articles

ActiveUS7153588B2Extend life of and protectReduce solubilitySynthetic resin layered productsPretreated surfacesPolyesterBenzene

Naphthalate polyester articles can be coated with polymerizable compositions containing a vinyl-functional crosslinkable film former, a large amount of benzotriazole and a copolymerizable monomer that solubilizes the benzotriazole. The cured compositions help protect the naphthalate polyester from UV exposure and other weathering effects.

Owner:3M INNOVATIVE PROPERTIES CO

Stabilized aliphatic polyester compositions

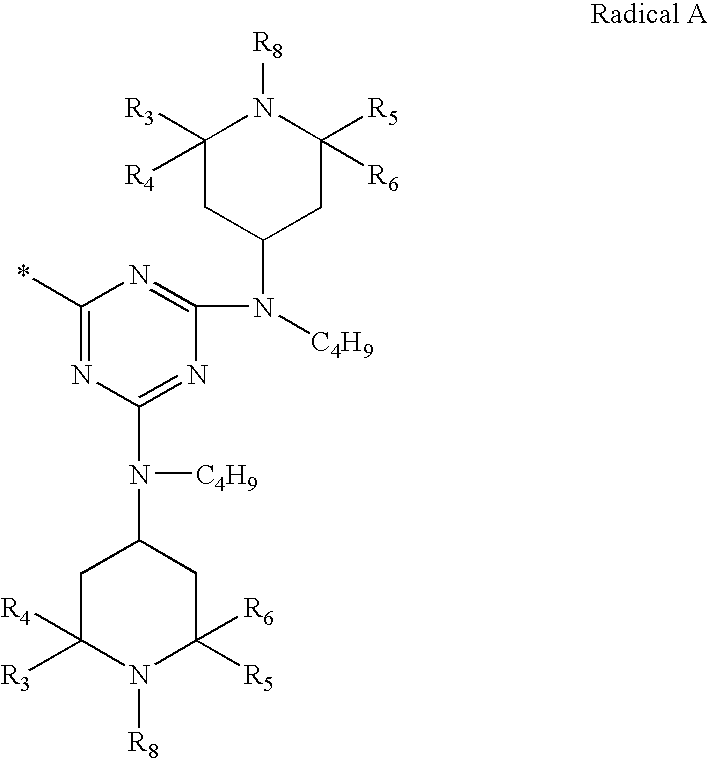

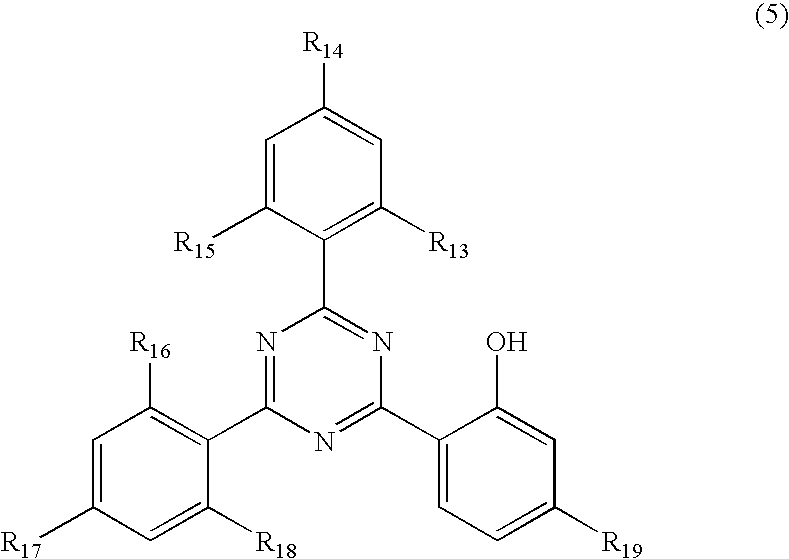

Disclosed are stabilized aliphatic polyester compositions comprising an aliphatic polyester, a HALS, and a tris-aryl-S-triazine UV absorber that show low embrittlement, haze formation, and discoloration during weathering. Also disclosed are aliphatic polyester compositions comprising aliphatic polyester, a hindered amine light stabilizer, a triazine UV absorber, and a phosphite that exhibit low color prior to weathering but retain good clarity, color, and excellent impact strength after exposure to weathering conditions. The aliphatic polyester compositions may be used prepare shaped articles such as, for example, films, sheets, bottles, tubes, profiles, fibers, and molded articles.

Owner:EASTMAN CHEM CO

Electrochromic polymeric solid films, manufacturing electrochromic devices using such solid films, and processes for making such solid films and devices

InactiveUS6855431B2Minimal shrinkageImprove adhesionOptical signallingGlass/slag layered productsMonomer compositionInherent safety

The present invention relates to electrochromic polymeric solid films, manufacturing electrochromic devices using such solid films and processes for making such solid films and devices. The electrochromic polymeric solid films of the present invention exhibit beneficial properties and characteristics, especially when compared to known electrochromic media. The electrochromic polymeric solid films are transformed in situ from a low viscosity electrochromic monomer composition by exposure to electromagnetic radiation, and in so doing minimum shrinkage occurs. The electrochromic polymeric solid films of the present invention also perform well under prolonged coloration, outdoor weathering and all-climate exposure, and provide an inherent safety aspect not known to electrochromic media heretofore.

Owner:DONNELLY CORP

Coating composition, process for preparing coating composition and process for preparing dispersing component of inorganic oxide sol

InactiveUS6022919AGood weather resistanceLow appearance requirementsSpecial tyresMixingMeth-Acrylonitrile

A coating composition which comprises (A) a resin having a glass transition temperature of 50 to 120 DEG C., a number average molecular weight of 2,000 to 100,000, a hydroxyl value of 50 to 150 mgKOH / g and an acid value of 1 to 25 mgKOH / g, which is produced by copolymerizing 10 to 90 percent by weight of (a) a (meth)acrylic acid ester of a C1 to C12 alkyl alcohol, 10 to 50 weight % of (b) a first polymerizable double bond-containing and hydroxyl group-containing monomer, 0.1 to 10 weight % of (c) a polymerizable double bond-containing and carboxyl group-containing monomer, 0 to 20 weight % of (d) styrene, 0 to 20 weight % of (e) acrylonitrile and 0 to 10 weight of (f) a second polymerizable double bond-containing monomer, (B) at least one compound selected from the group consisting of a polyisocyanate compound having two or more unblocked isocyanate groups and / or blocked isocyanate groups in the molecule and an aminoplast resin, (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of an aluminum oxide sol, a silica sol, a zirconium oxide sol and an antimony oxide sol, wherein an amount of a nonvolatile matter of component (C) is 5 to 60 percent by weight based on a total amount of nonvolatile matter of resin (A), compound (B) and component (C). The coating composition provides cured films having excellent weathering resistance, light resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and appearance and is environmentally friendly and safe.

Owner:BASF NOF COATINGS CO LTD

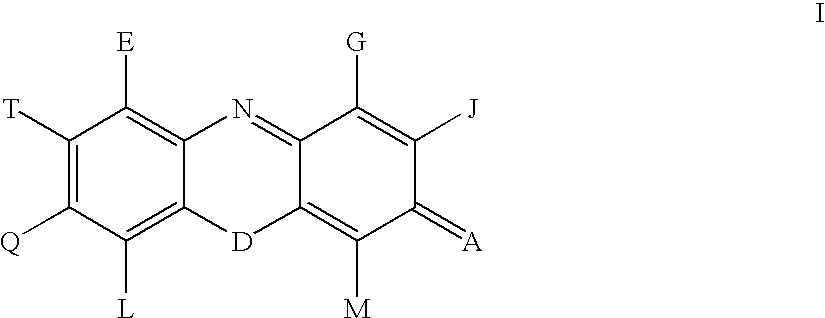

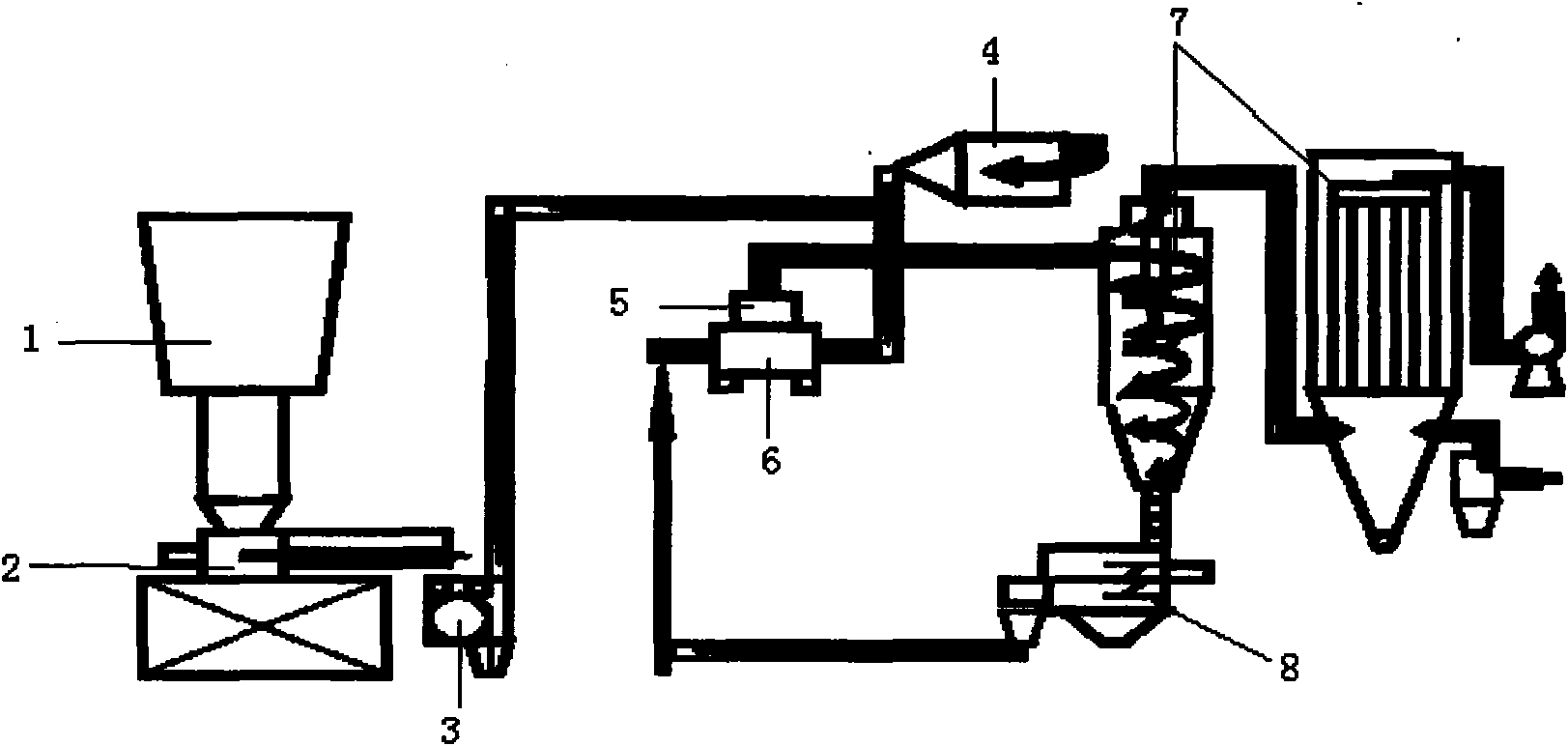

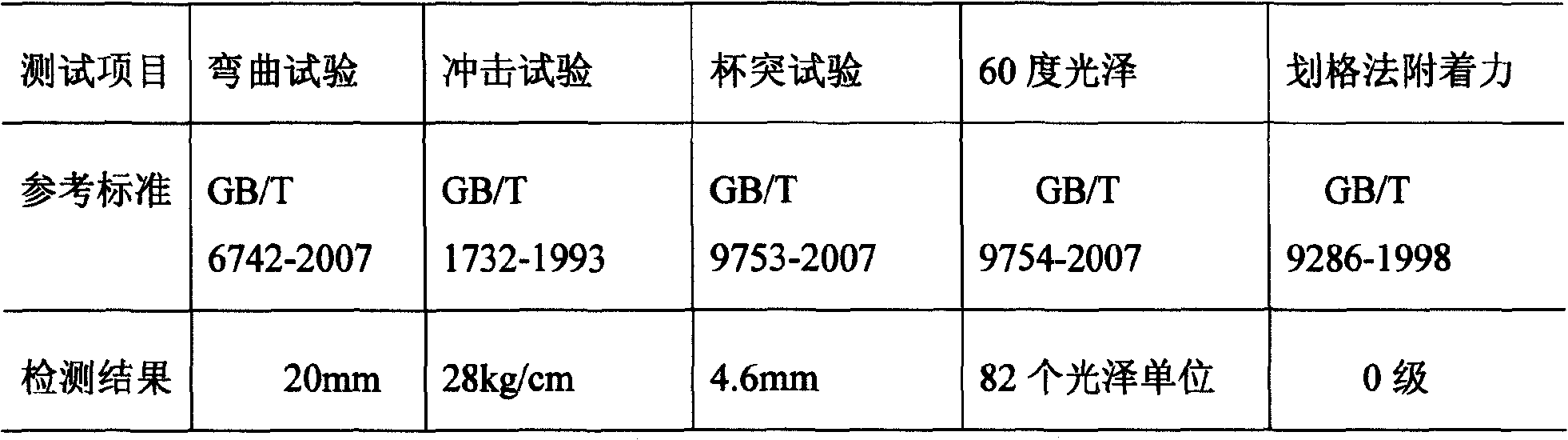

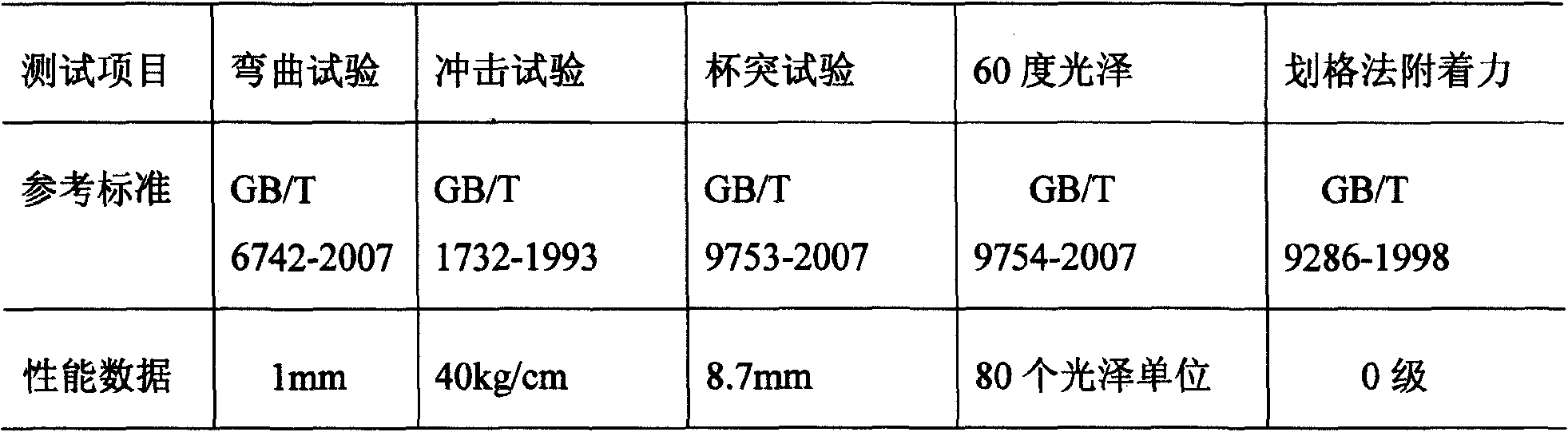

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

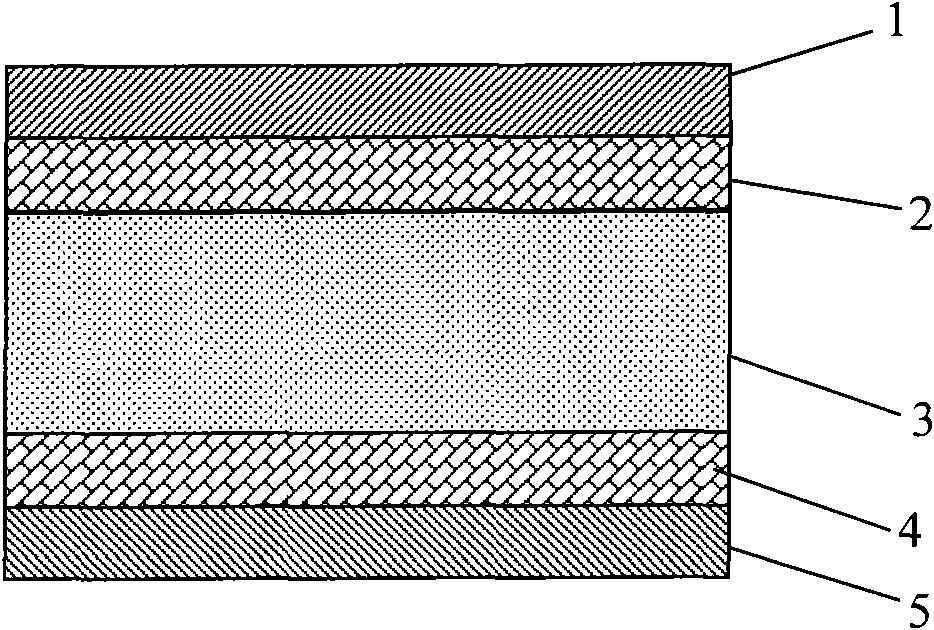

Solar battery backboard taking modified polyvinylidene fluoride alloy layer as weathering protective layer

ActiveCN101582459ANovel structureMaterials are readily availableSynthetic resin layered productsElectrical equipmentPolyurethane adhesiveAlloy

The invention relates to a solar battery backboard which takes a modified polyvinylidene fluoride alloy layer as a weathering protective layer. The backboard comprises the following components according to the adhesion in turn: a weathering layer, an adhesive layer, a structure-enhancing layer, a second adhesive layer and a second weathering layer; wherein, the first weathering layer and the second weathering layer are the polyvinylidene fluoride alloy layers modified by inorganic materials; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and fine performance, conforms to the requirement of backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

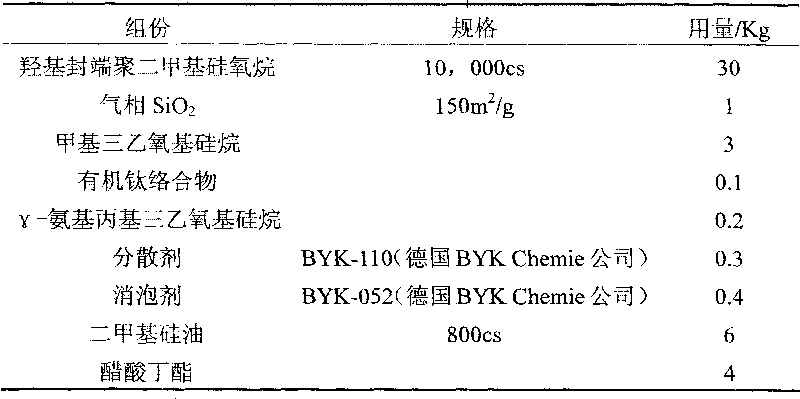

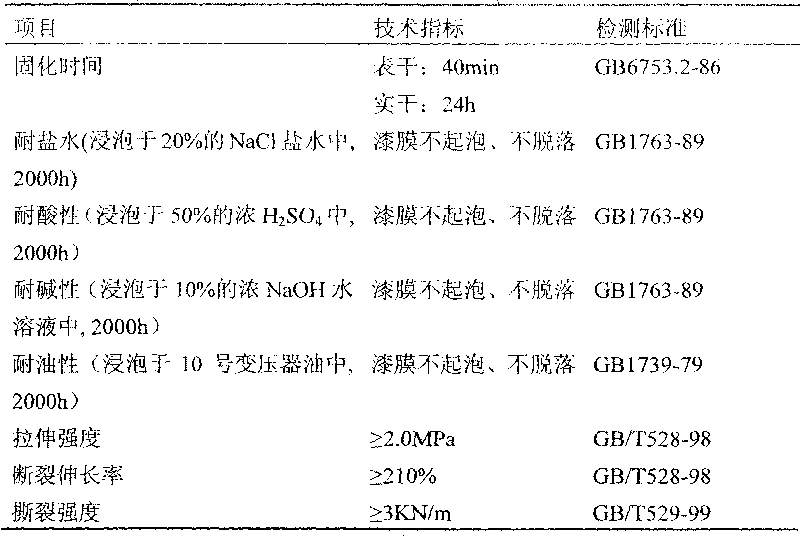

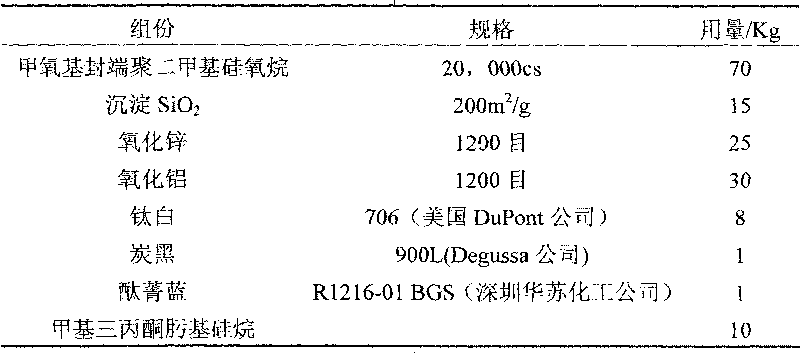

Elastic anti-corrosion coating

InactiveCN101747835AGood weather resistanceImprove water resistanceAnti-corrosive paintsRoom temperatureSolvent

The invention relates to an elastic anti-corrosion coating, which is a room-temperature silicon sulfide-based functional compound with high property. The formula of the coating comprises(in part by weight): 30 to 70 parts of polyorganosiloxane, 1 to 80 parts of pigments and fillers, 30 to 10 parts of crosslinking agent, 1 to 10 parts of auxiliary agent and 10 to 80 parts of thinning agent. The elastic anti-corrosion coating has high weathering resistance, water resistance, acid resistance, solvent resistance and oil resistance and alkali resistance; the paint film can be desirably adhered onto glass, ceramics, steel structural members, concrete, various resin primers and the like, and the paint film is good in elasticity and hydrophobicity and high in tensile strength and breaking elongation, can be widely used for the corrosion prevention of bridges, tanks and various steel structural members and the corrosion and leakage protection of ground, drainage channels and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Outdoor weatherable photopolymerizable coatings

InactiveUS6974850B2Prolong lifeLimited solubilityOrganic chemistryLayered productsBenzeneBenzotriazole

Plastic articles can be coated with polymerizable compositions containing a vinyl-functional crosslinkable film former, a large amount of benzotriazole and a copolymerizable monomer that solubilizes the benzotriazole. The cured compositions help protect the article from UV exposure and other weathering effects.

Owner:3M INNOVATIVE PROPERTIES CO

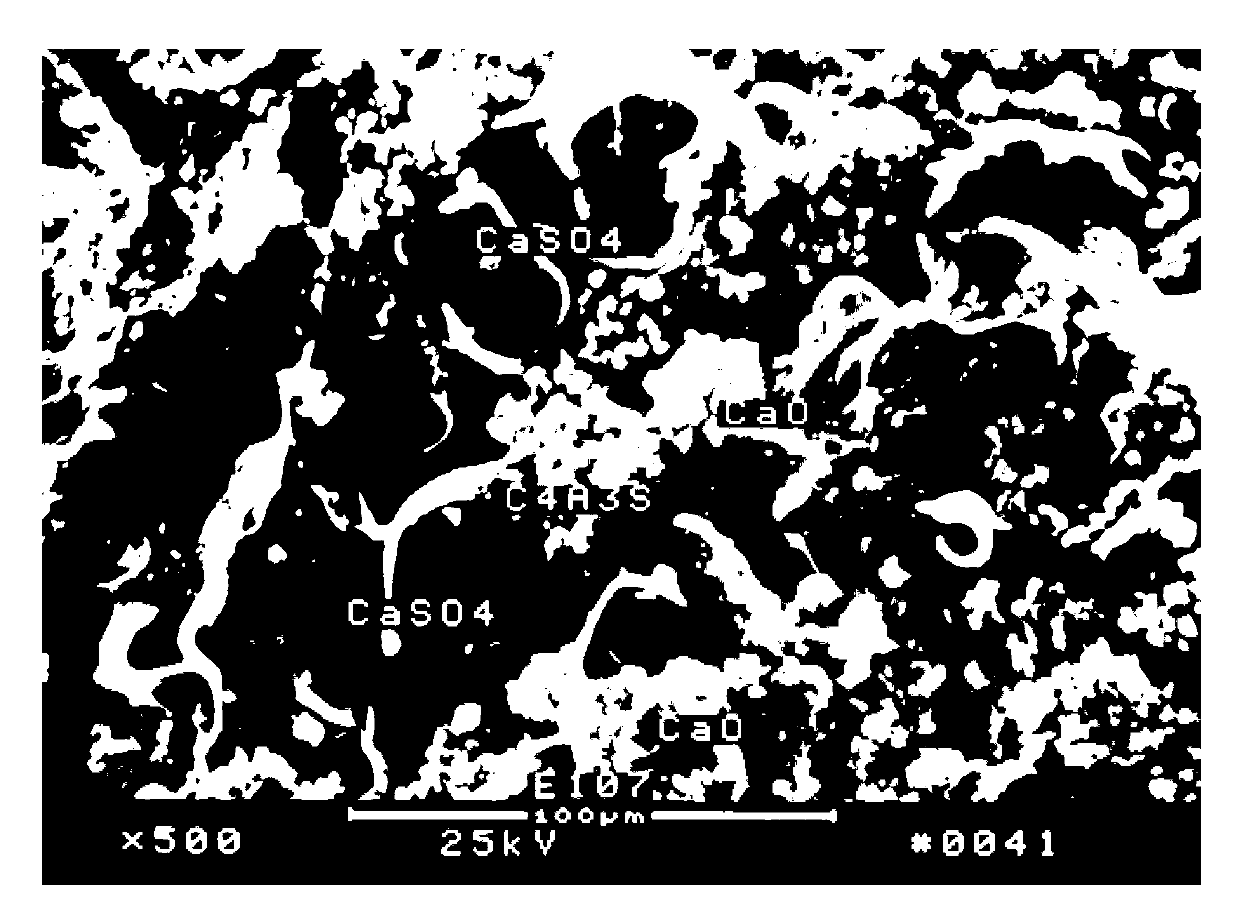

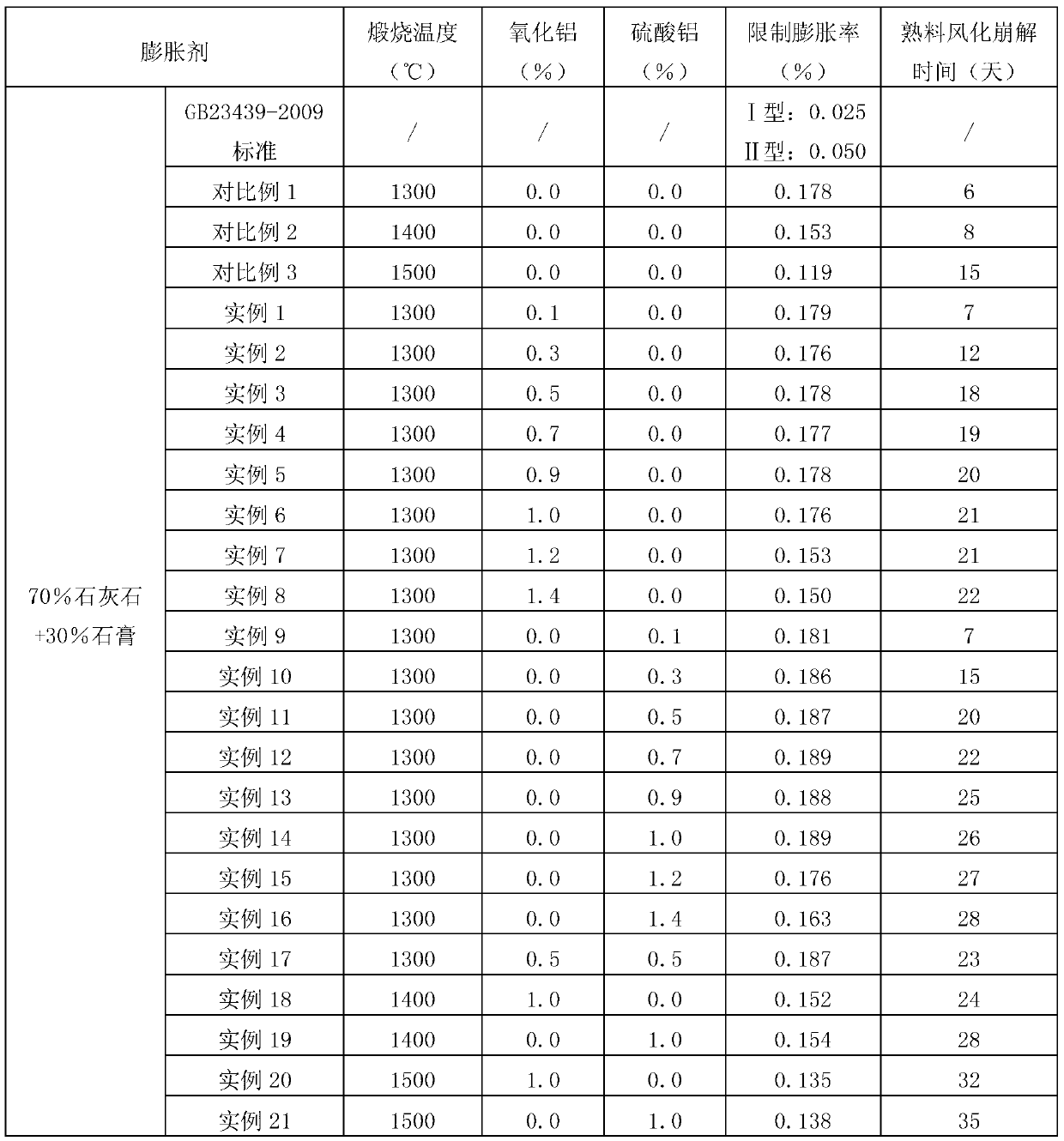

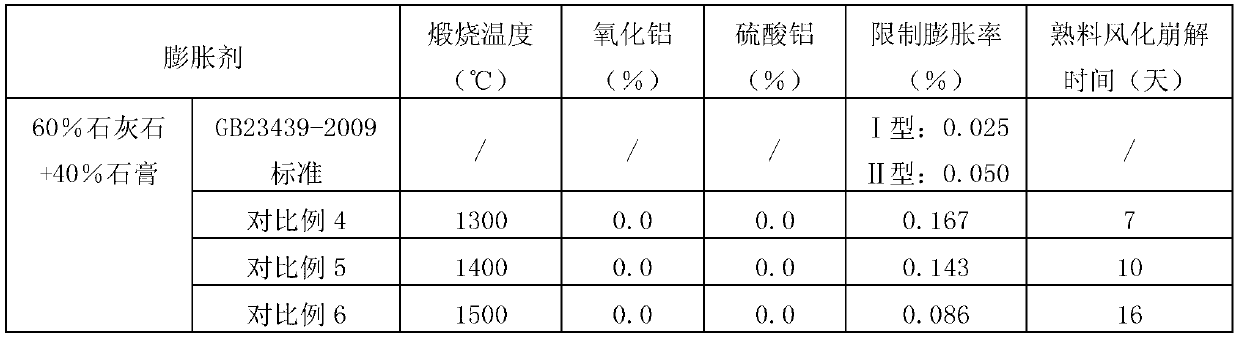

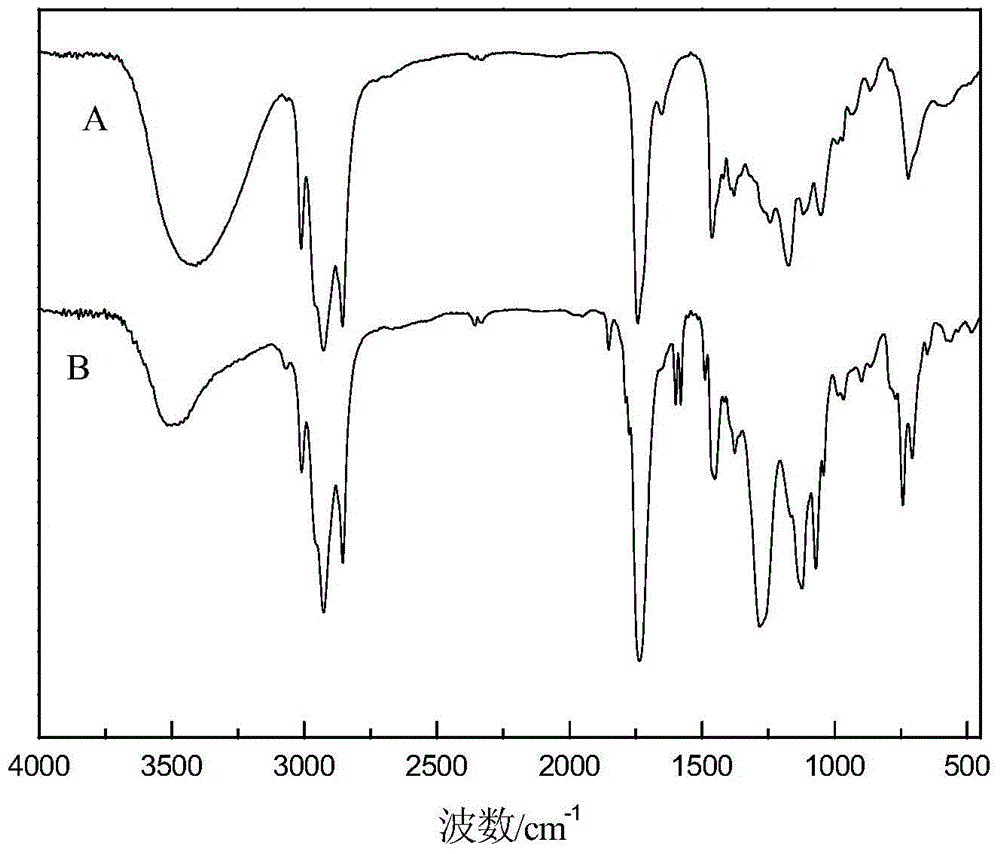

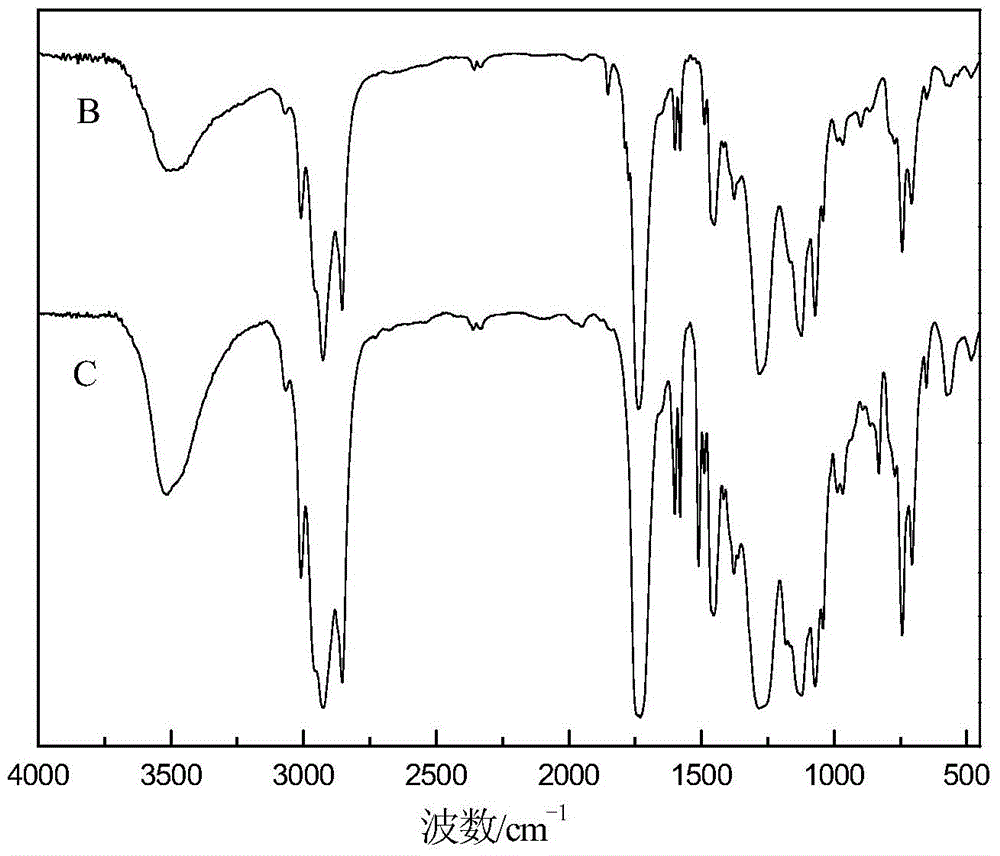

Gypsum and calcium oxide melt inclusion expansion clinker, concrete expansion agent, and preparation method and application thereof

The invention relates to a gypsum and calcium oxide melt inclusion expansion clinker, a concrete expansion agent, and a preparation method and application thereof, belonging to the field of construction materials. The expansion clinker provided by the invention is prepared by mixed grinding and high-temperature burning of limestone, gypsum and aluminum oxide and / or aluminum sulfate. The concrete expansion agent is prepared by grinding the expansion clinker together with a calcium sulphoaluminate cement clinker, calcium stearate or / and triethanolamine until the specific surface area is 140-400 m<2> / kg. According to the invention, the expansion clinker has high restrained expansion rate and high clinker weathering resistance; the concrete expansion agent has the functions of cracking resistance, seepage resistance, shrinkage compensation and the like, and has the advantage of long product shelf life (up to 6 months). The concrete expansion agent can be used for cracking resistance and seepage resistance of a common concrete structure, and can greatly enhance the durability of the concrete.

Owner:CHINA BUILDING MATERIALS ACAD

High performance pavement material of epoxy asphalt, preparation method and application

InactiveCN101003688AGood weather resistanceImprove fatigue resistanceIn situ pavingsBuilding insulationsHigh resistanceEpoxy

This invention discloses a method for preparing high-performance epoxy asphalt road surface material and its application. The road surface material comprises components A and B. Component A is composed of: asphalt 50-100 parts, curing agent 20-50 parts, promoter 0.4-1 part, and antifoaming agent 0.5-1 part. Component B is epoxy resin. The weight ratio of A to B is (2.5-7):1. The method comprises: (1) heating asphalt to 100-130 deg.C, adding curing agent, mixing by high-speed shearing for 10-60 min, adding promoter and antifoamer, and mixing by high-speed shearing for 5-50 min to obtain component A; (2) heating component A to 100-160 deg.C, mixing components A and B according to the weight ratio of (2.5-7):1, stirring uniformly at 120-140 deg.C, and curing for 4-8 h. The product is a main material for producing epoxy asphalt concrete. The product has high resistance to corrosion, water, weathering, fatigue, creep at high temperatures, and cracking at low temperatures.

Owner:NANJING UNIV

Acrylic photovoltaic module backsheet

ActiveUS20110315189A1Easy to mergeEasy to stickPV power plantsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an acrylic layer (in the form of a coating, film or sheet) useful as part of a photovoltaic module backsheet. The acrylic layer contains at least 40 percent of one or more acrylic polymers, including an acrylic polymer matrix and optionally acrylic impact modifiers. The acrylic polymer is preferably a polymer, copolymer, or terpolymer containing at least 50 weight percent of methylmethacrylate monomer units. The acrylic layer is flexible and optionally contains high levels of white pigment. It may also contain fluoropolymers such as polyvinylidene fluoride to improve weathering, processibility and film formation. The acrylic layer adheres to a polymer support layer such as polyethylene terephthalate (PET). A preferred substrate is PET that is pre-treated to improve adhesion, but unprimed PET can also be used. The backsheet provides excellent weatherability, environmental stability and reflectivity as part of a photovoltaic module.

Owner:TRINSEO EURO GMBH

Epoxy acrylate modified waterborne alkyd resin and preparation method and application thereof

The invention discloses an epoxy acrylate modified waterborne alkyd resin and a preparation method and an application thereof. The method comprises the steps: firstly, synthesizing a waterborne alkyd resin from a polyol, a polybasic acid and an oil monomer by adopting a dehydration condensation reaction; then carrying out an epoxy resin ring opening reaction to graft onto the waterborne alkyd resin so as to modify the waterborne alkyd resin; followed by carrying out free radical solution polymerization of acrylic soft and hard monomers with the modified alkyd resin, and modifying the alkyd resin by using acrylic ester; and finally pumping out a part of a polymerization solvent to neutralize the obtained waterborne alkyd resin, adding a cosolvent, and dispersing the alkyd resin to prepare an aqueous dispersion by adopting a high-speed disk dispersion machine and with water as a dispersion medium. In the addition to retaining own excellent characteristics, the modified alkyd resin also has good dryness, adhesive power and corrosion resistance of epoxy resin and the acrylic resin advantages of excellent drying, water resistance, chemical medicine resistance, high hardness, good weathering resistance and the like, and effectively improves the alkyd resin performance of water resistance, weather resistance and the like.

Owner:SOUTH CHINA UNIV OF TECH

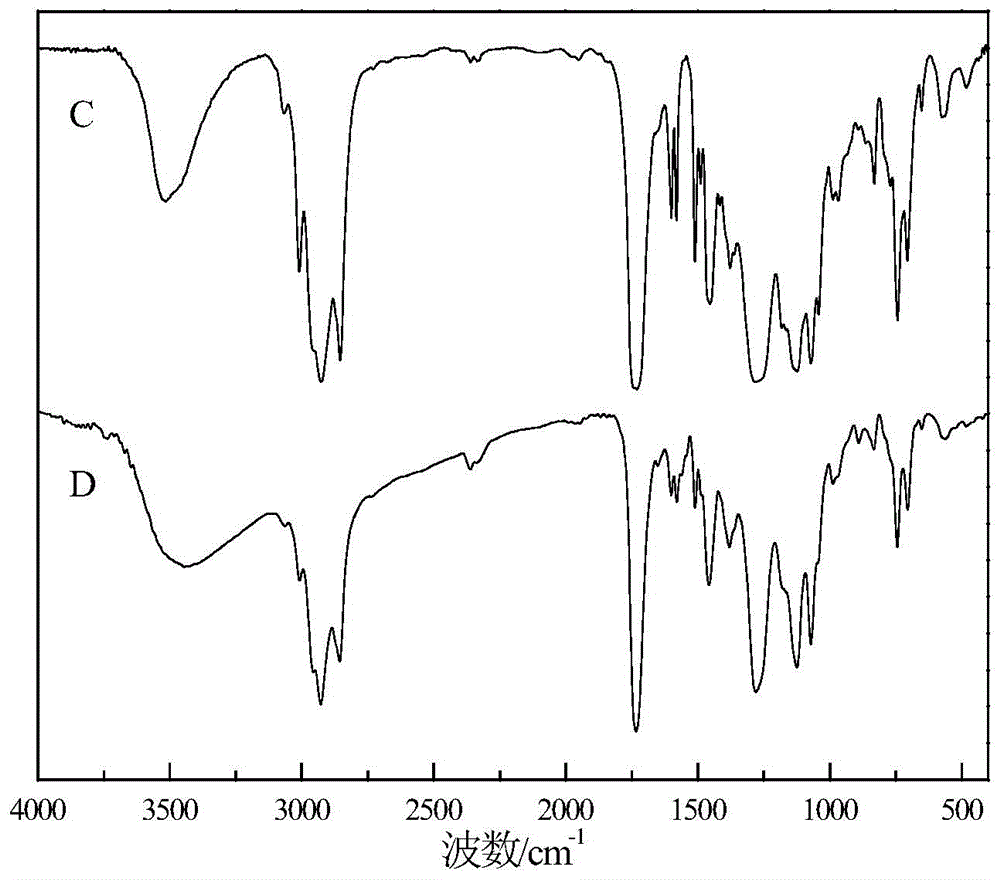

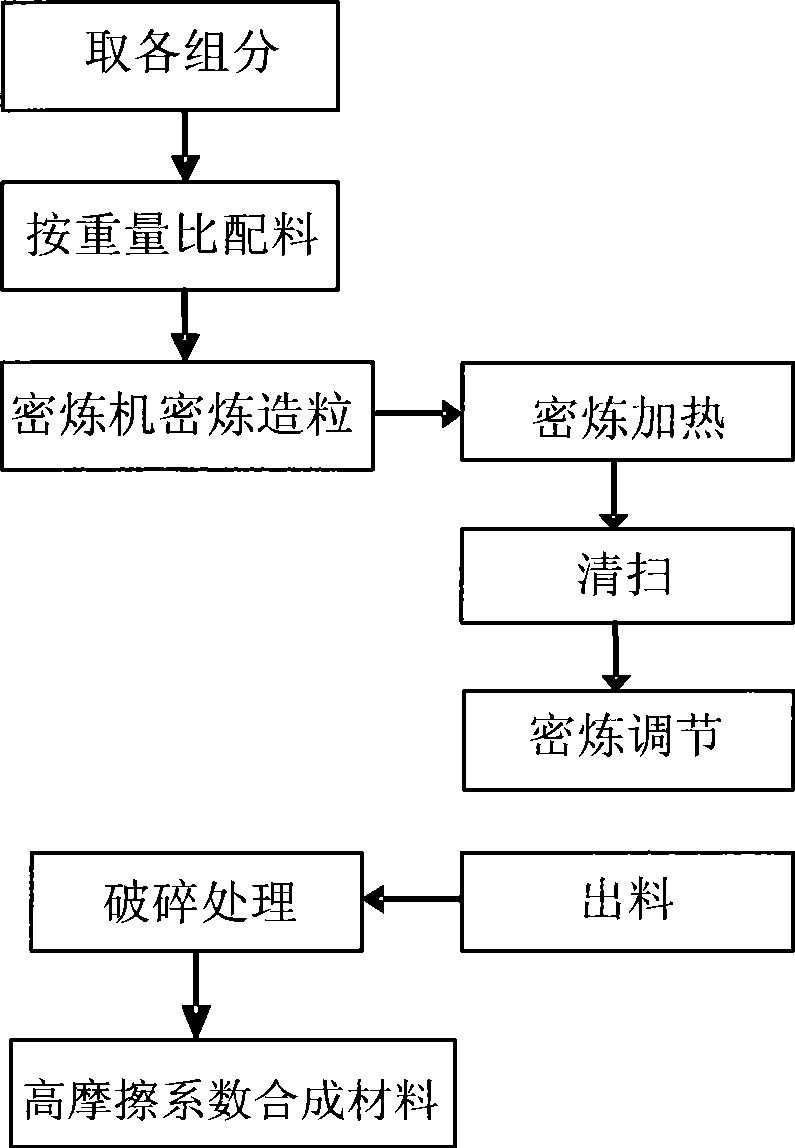

High friction coefficient synthetic materials and preparation method thereof

The invention discloses a high friction coefficient composite material and a manufacturing method thereof, wherein the material is prepared through material sealing and grain-making processing by the following compositions in weight percentage: 8 to 13 percent of butadiene-acrylonitrile rubber, 2 to 10 percent of styrene-butadiene rubber, 5 to 10 percent of cresol methyl-stage phenol-formaldehyde resin modified, 15 to 30 percent of steel fiber, 10 to 15 percent of magnesia, 5 to 10 percent of calcined petroleum coke, 2 to 5 percent of silicon carbide, 10 to 25 percent of mineral fiber, 5 to 10 percent of calcium hydroxide, 10 to 20 percent of barium sulfate, 5 to 10 percent of graphite, 1 to 5 percent of supramoly, 1 to 5 percent of carbon black, 1 to 3 percent of sulfur and 1 to 3 percent of accelerant. The material can be applied in a plurality of situations to prepare friction components, has stable friction performance and good abrasion resistance, effectively inhibits the phenomena of metal inlay, cracking, chip off-falling and so on, reduces the damage on vehicle wheels, has good impact resistance and good weathering resistance, can be used in the environment with large temperature variation for a long time, and has the application characteristics of wide application region and large difference of the regional environment.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

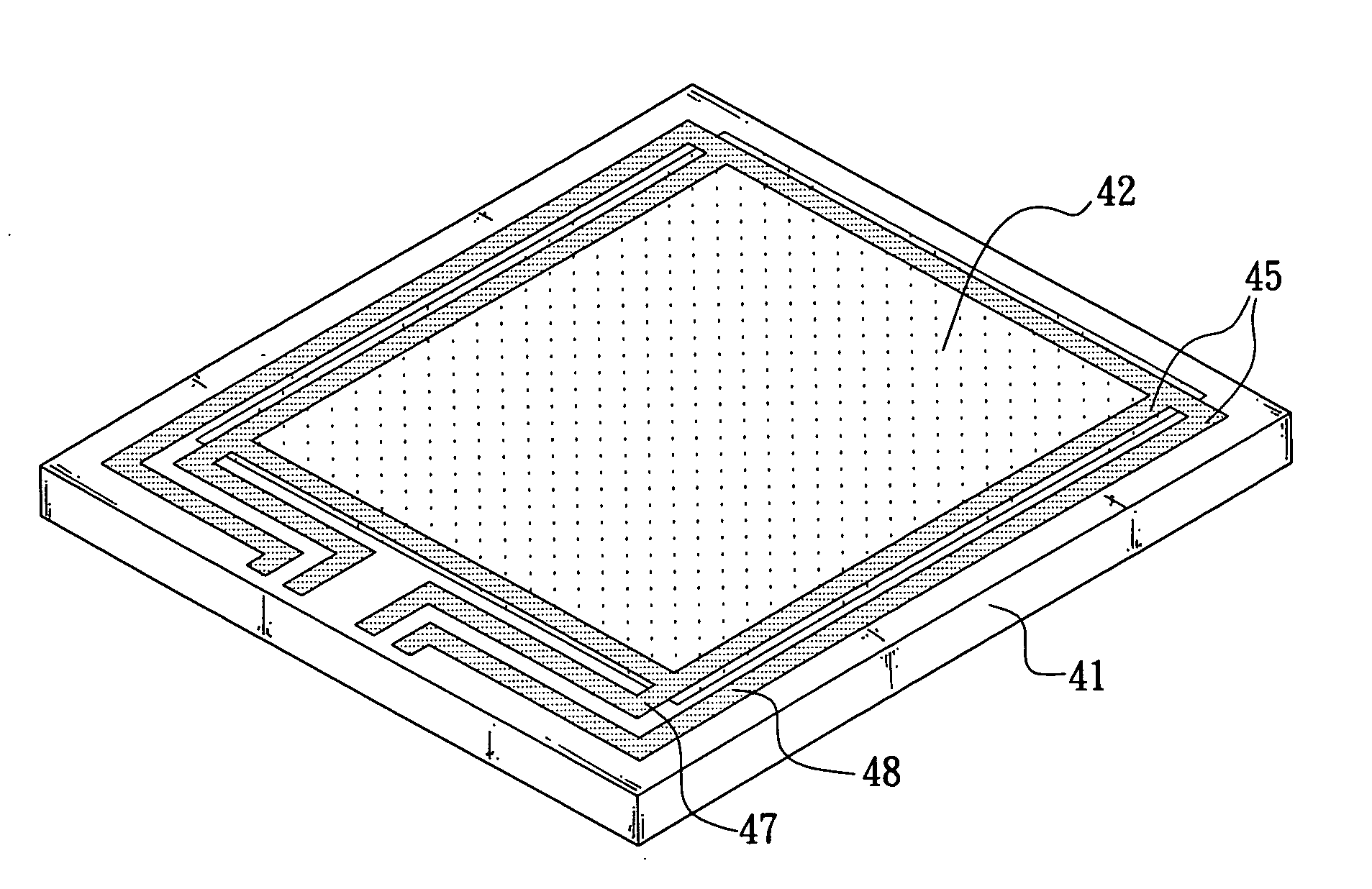

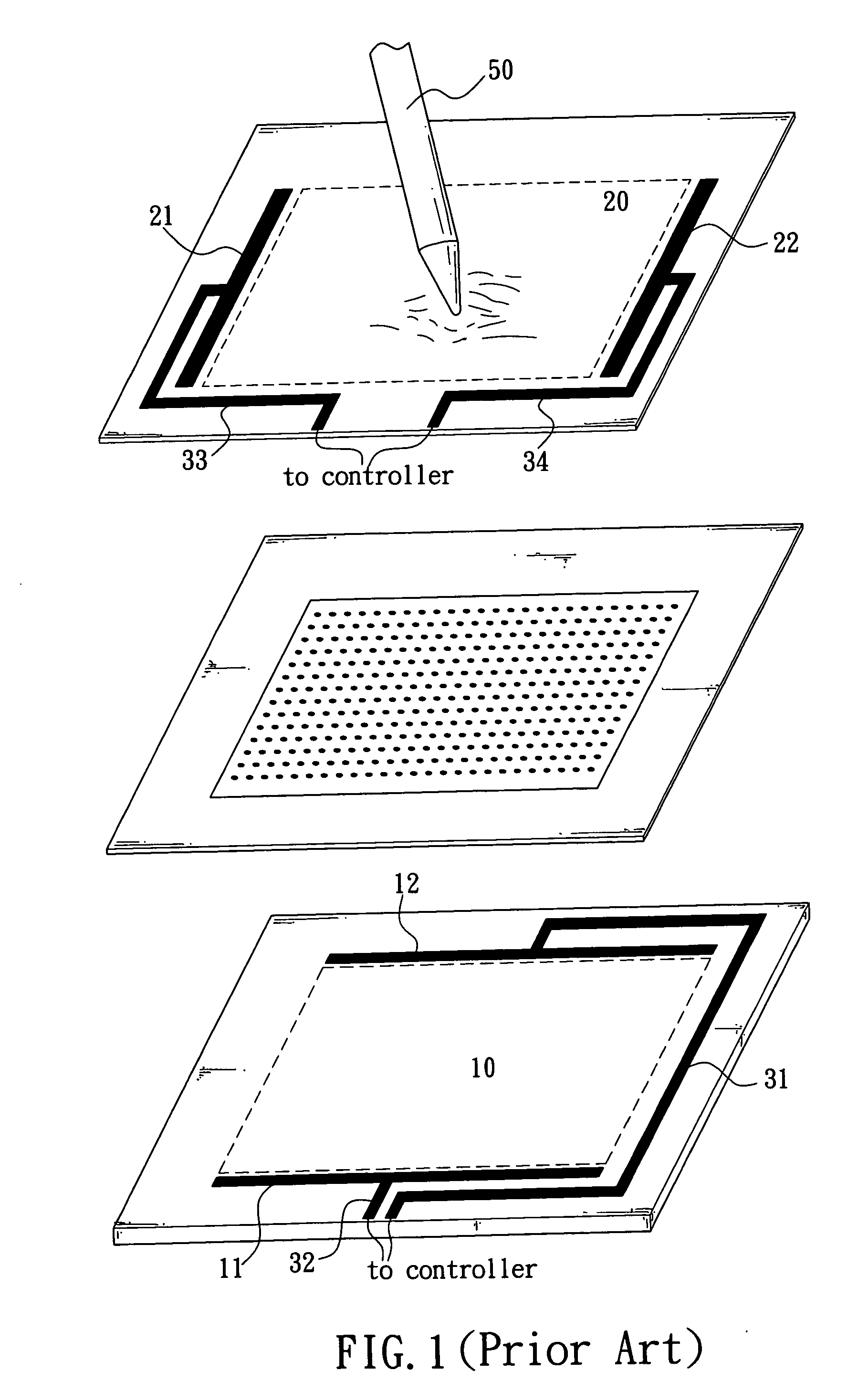

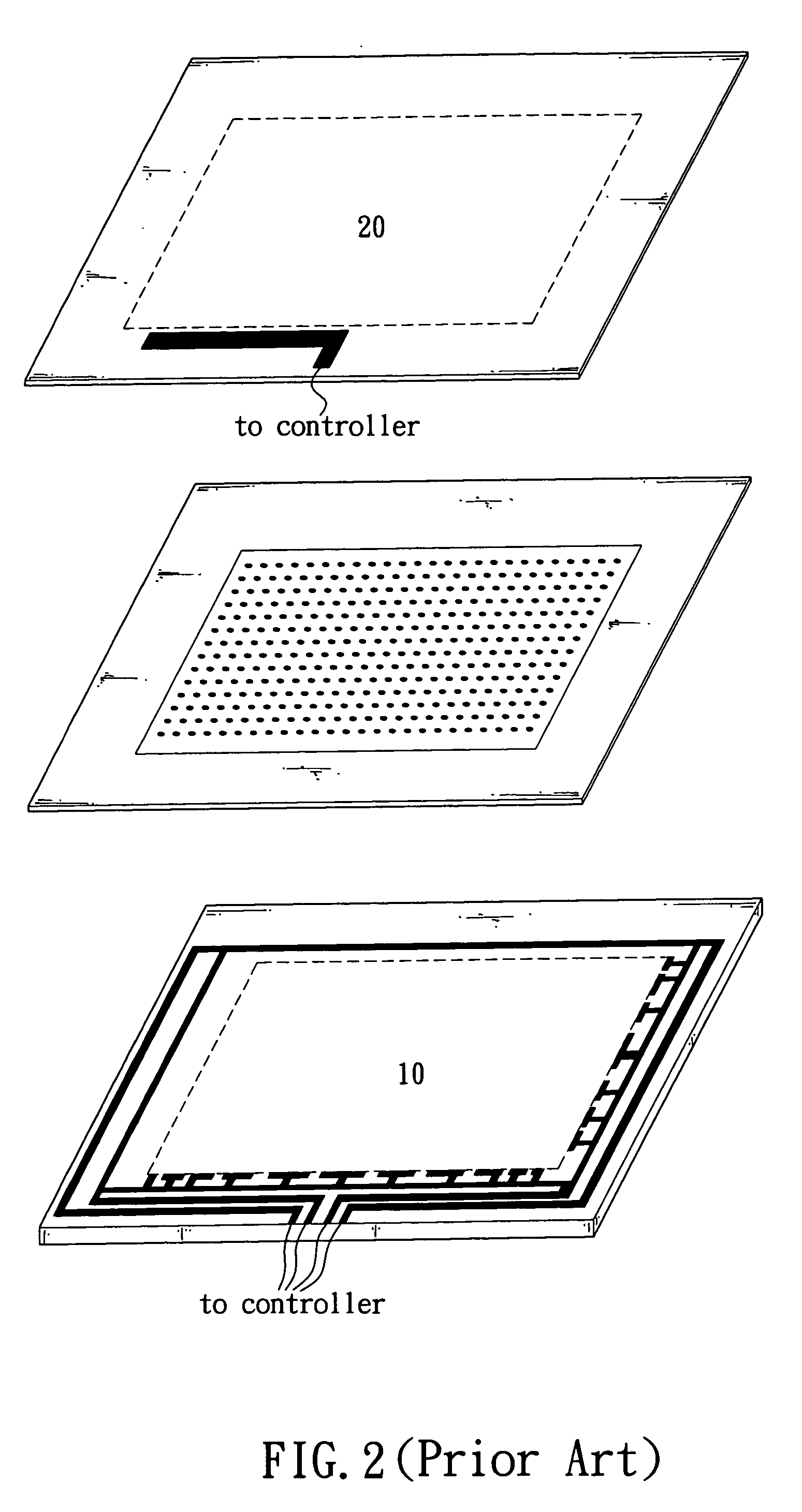

Method of manufacturing circuit layout on touch panel by utilizing metal plating technology

InactiveUS20050260338A1Uniform thicknessImprove adhesionPrinted circuit aspectsLiquid/solution decomposition chemical coatingSolderabilityEngineering

The present invention is to provide a method of manufacturing a circuit layout on a touch panel by utilizing metal plating technology, comprising uniformly coating a conductive metal or conductive oxidized metal on predetermined areas proximate edges of a transparent conductive layer on a transparent glass substrate for forming a circuit by utilizing metal plating technology, which has the advantages of uniform thickness of circuit, higher hardness, better adhesion of the plated material to the underlying substrate, whether it is a resistive film or bare glass, improved weathering and chemical properties, and solderability.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Color master batch for polyolefin grass fiber and its preparation method

InactiveCN101187076AReduce dosageGood weather resistanceGround pavingsMonocomponent polyolefin artificial filamentYarnParaffin wax

The invention relates to a technology of color master batches for a polyolefin yarn fiber, which comprises pigments, plastic additives and carrier resin, wherein the plastic additives comprise dispersed lubricant, an antioxidant, a light stabilizer, a coupling agent and liquid paraffin. The process for preparation is that the pigments, a part of plastic additives and the carrier resin are added into a high-speed mixer to be mixed, and then the coupling agent and the liquid paraffin are added to be stirred in a high speed, and at last the above stirred mixture is sent to a twin-screw extruder to be extruded, cooled, dried and granulated. The invention has the characteristics of less dosage, excellent weathering resistance, easy dispersing and excellent processability, and is suitable for the yarn fiber which takes polyethylene, polypropylene and other copolymer as base materials.

Owner:EAST CHINA UNIV OF SCI & TECH

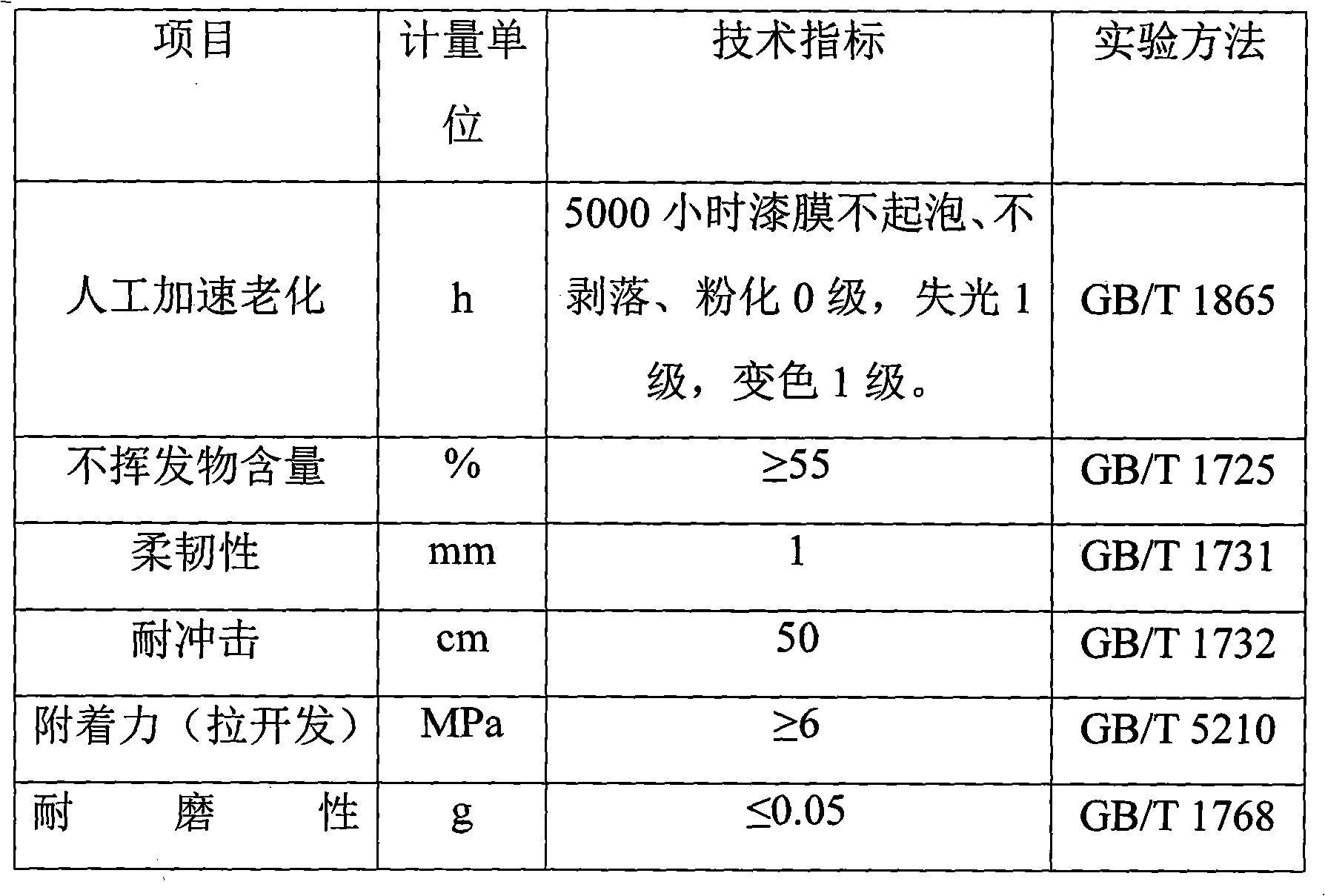

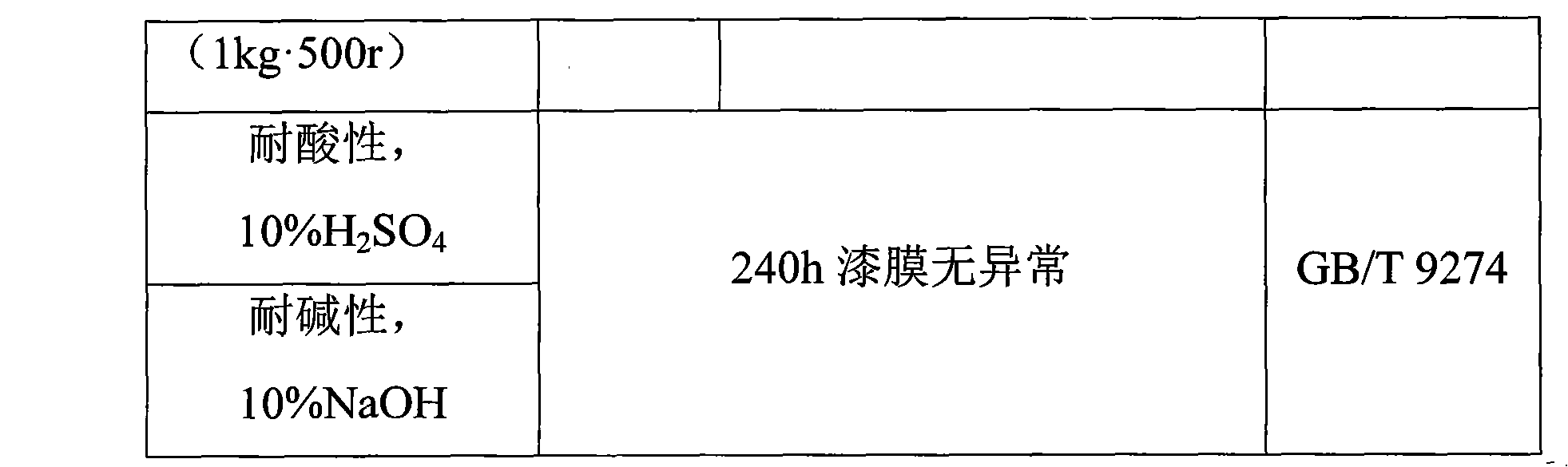

Transparent anti-graffiti dirt-resistant anti-weathering coating

ActiveCN101781519AAvoid damageGood weather resistanceAntifouling/underwater paintsPaints with biocidesBrickLacquer

The invention discloses a solvent type double-component transparent anti-graffiti dirt-resistant anti-weathering coating and a preparation method thereof. The coating can be used for surfaces of decorative bricks, ceramic surfaces, mosaic layers, metals and color paint coatings of structures such as bus stops, sidewalks and public facilities for protecting long-life surfaces, prevents graffiti and dirt, and is easy to remove painted ink of marking pens, sprayed paints, crayon marks, pasted adlets, chewing gum, dust and scale, and the like.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

Method for producing high weathering resistance titanium dioxide pigment

The invention supplies a manufacture method for high weathering resistance titanium dioxide pigment that includes the following steps: making slurry; adjusting the pH value of the slurry; adding dispersing agent and filtering; heating; adding sodium silicate solution; adding mixture of sodium silicate and sulphuric acid solution; adding sulphuric acid; adding sodium aluminate solution and sulphuric acid solution; adjusting the pH value; filtering, washing, drying, taking gas smashing and organic process. The invention has strong covering power, good dispersibility and high weathering resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

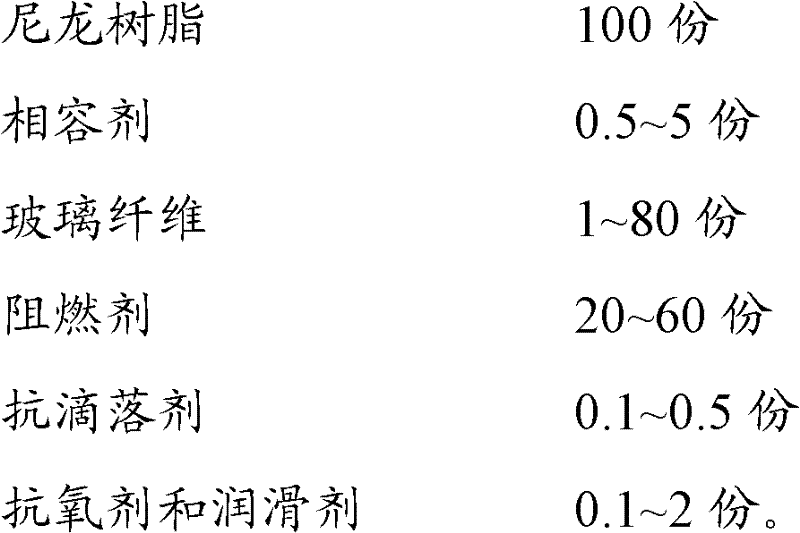

Flame-retardant nylon resin composition and preparation method thereof

The invention relates to a flame-retardant nylon resin composition which comprises the following components in parts by weight: 100 parts of nylon resin, 0.5-5 parts of compatibilizer, 1-80 parts of glass fiber, 20-60 parts of flame retardant, 0.1-0.5 part of anti-dripping agent and 0.1-2 parts of antioxidant and lubricant. Due to the addition of the flame retardant, the flame-retardant nylon resin composition has excellent flame-retardant performance; at the same time, the components in the formula have better compatibility, and the synergy of the lubricant and antioxidant can improve the processing flow properties of the nylon resin and improve the dispersion of the flame retardant in the composition; and the prepared flame-retardant nylon resin composition has the advantages of good outdoor weathering resistance, high impact strength, bending strength and tensile strength, good flame retardancy and high mobility. In addition, the invention also relates to a preparation method of the flame-retardant nylon resin composition.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

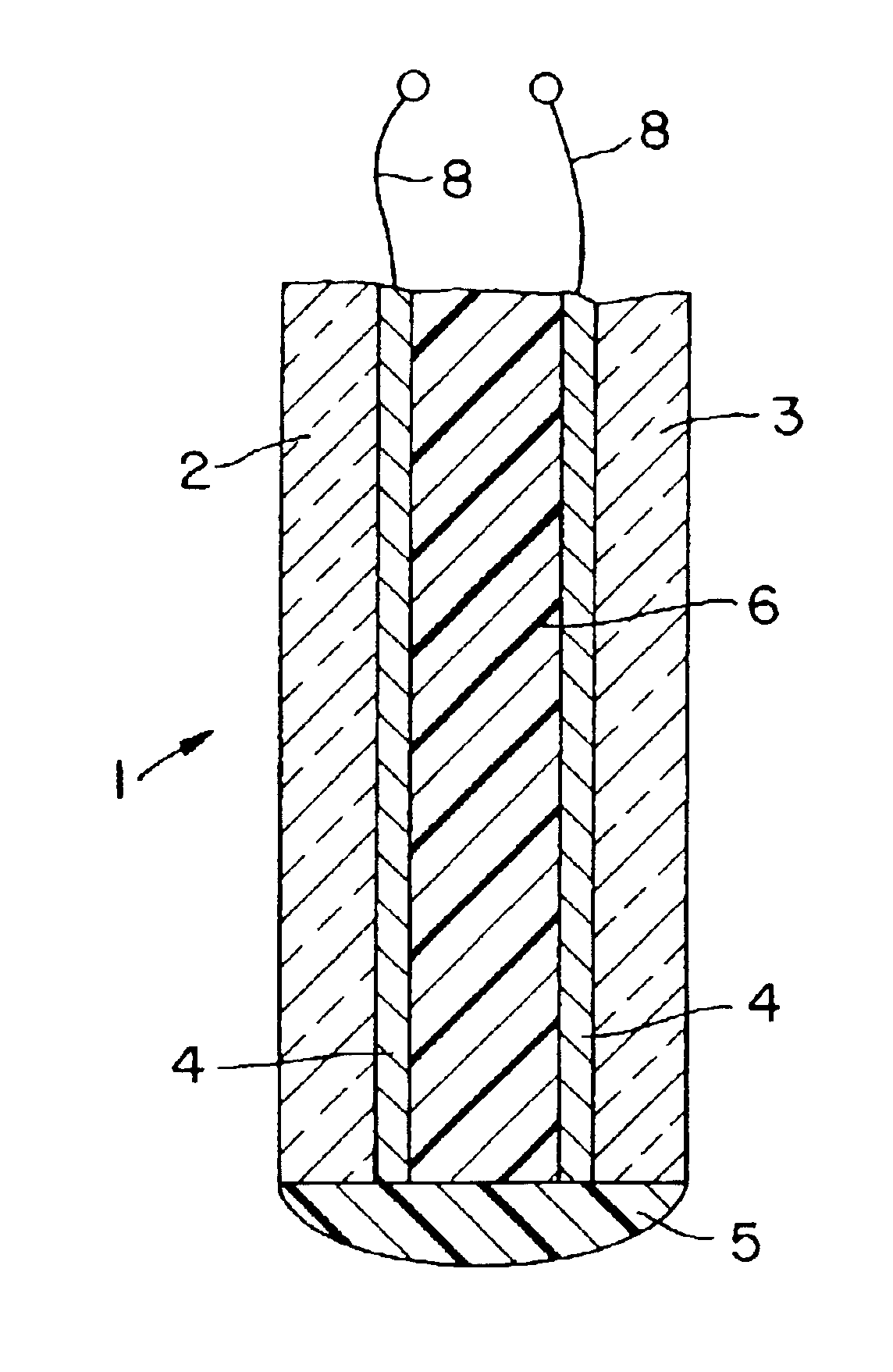

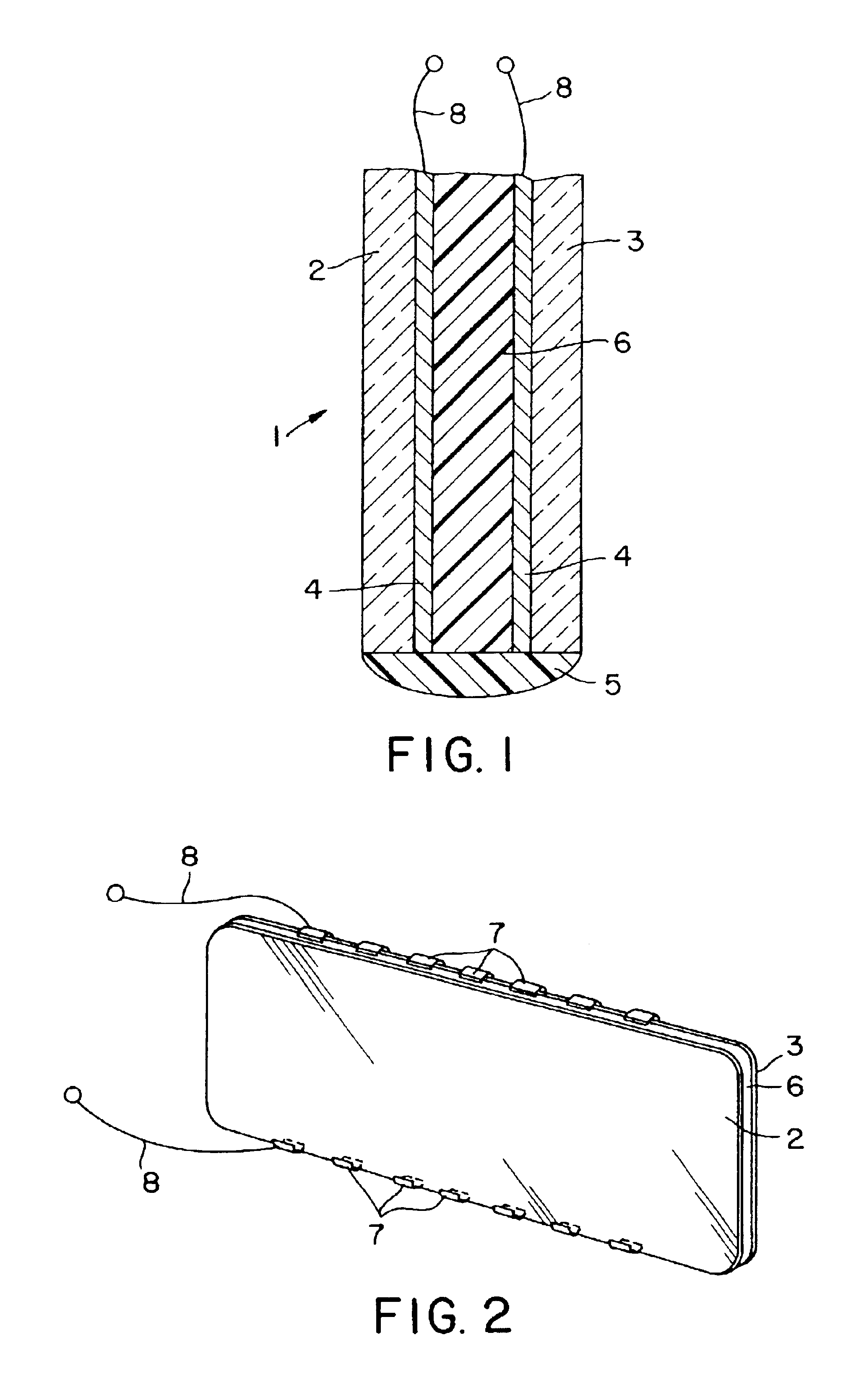

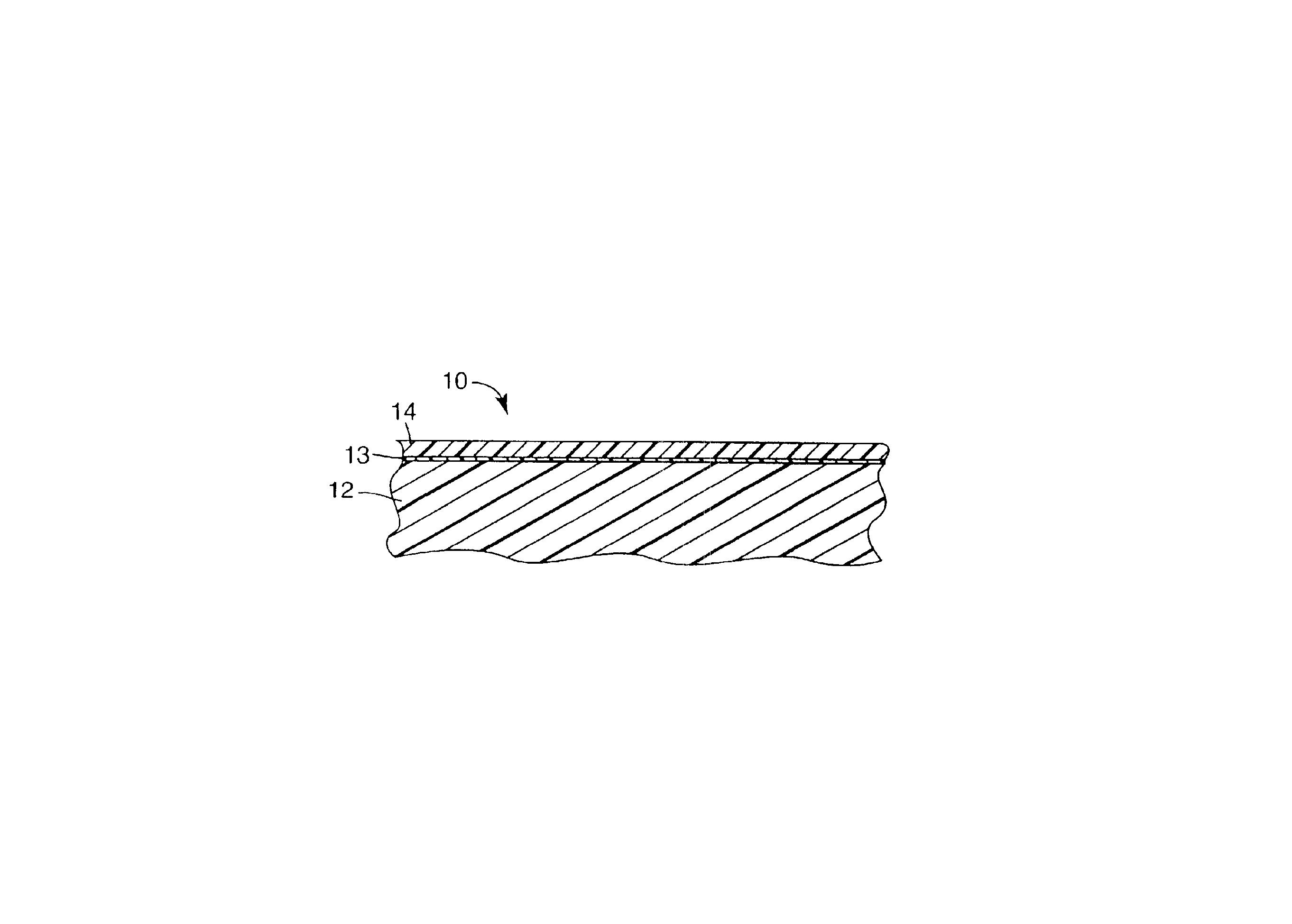

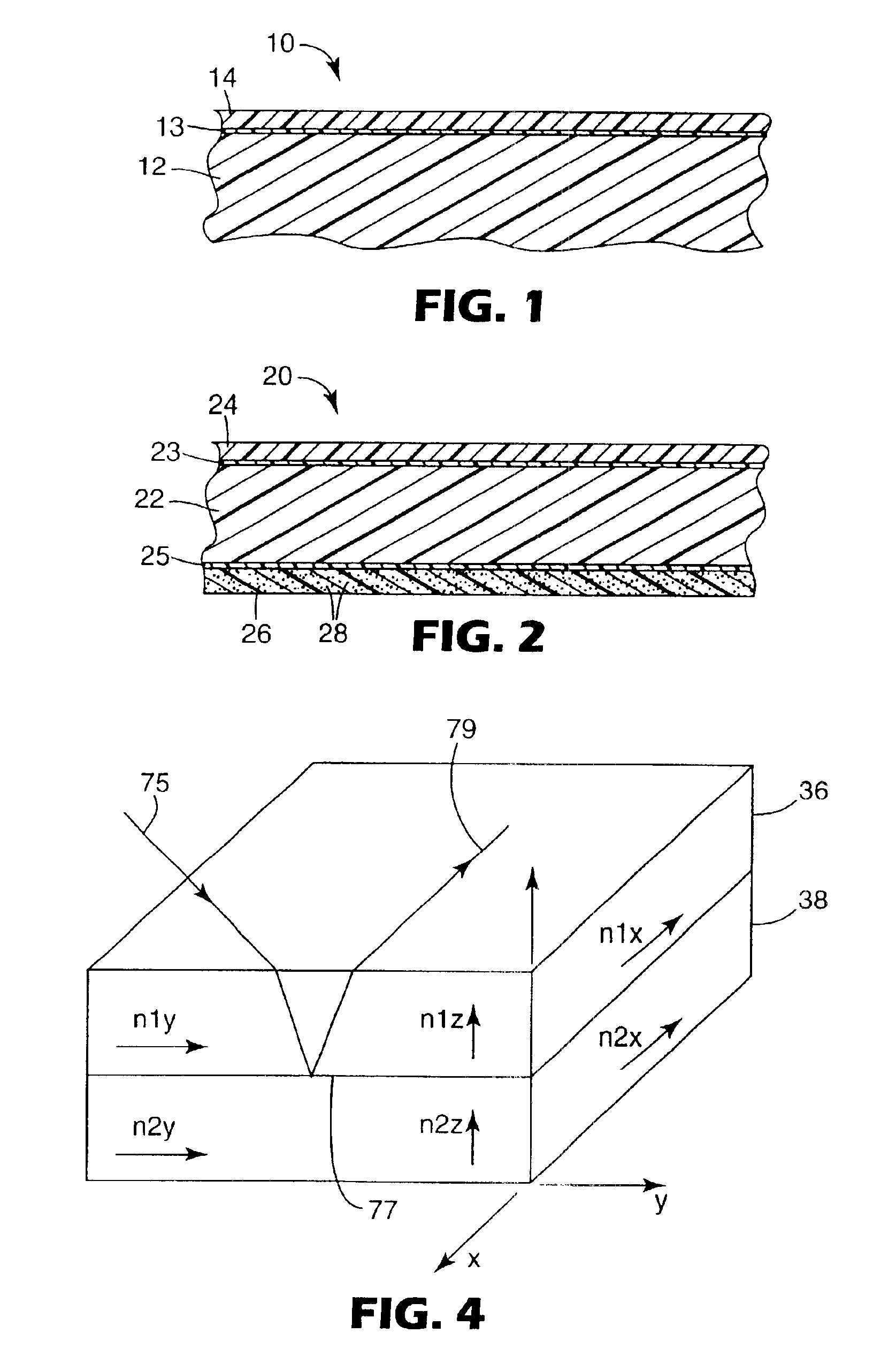

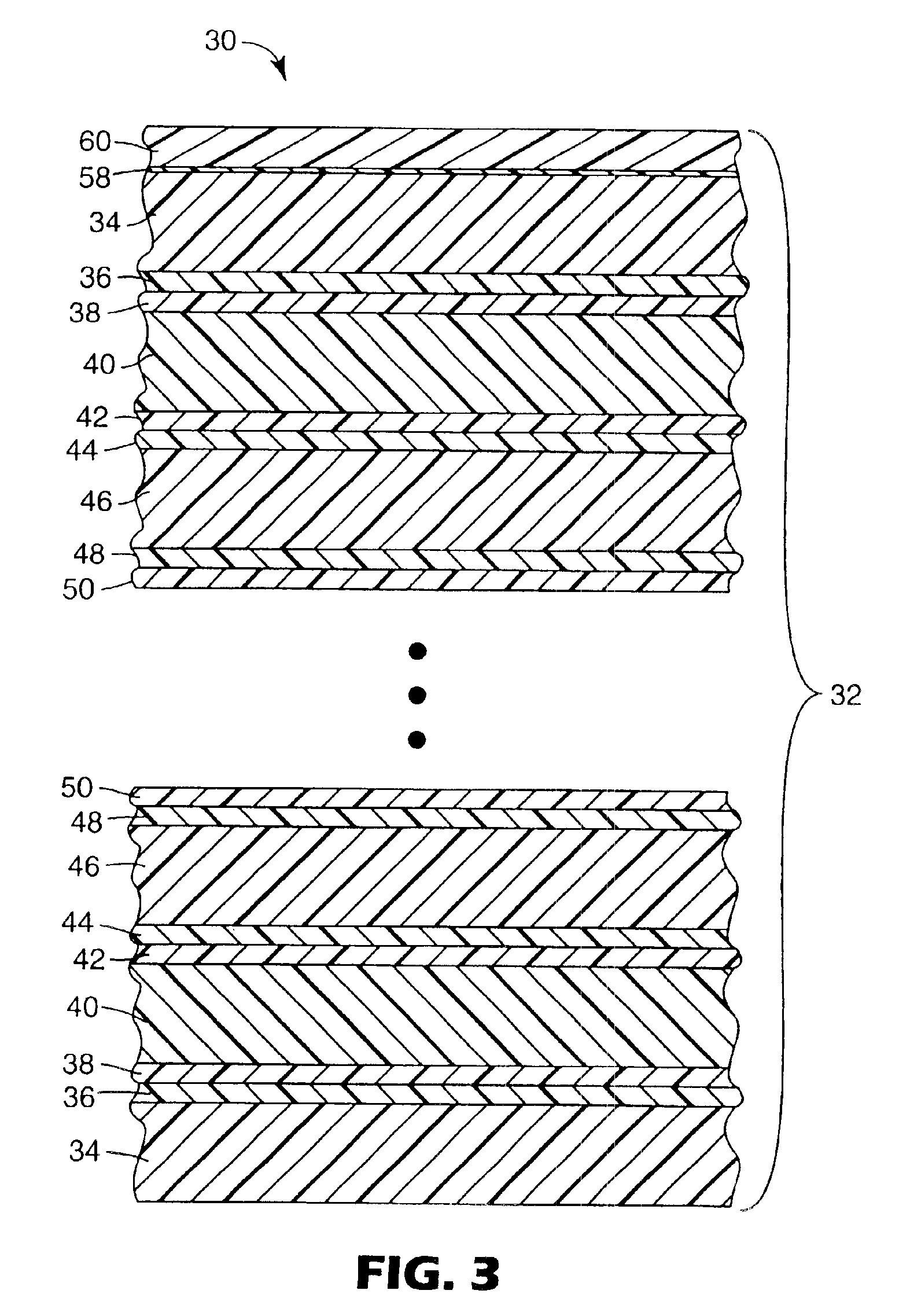

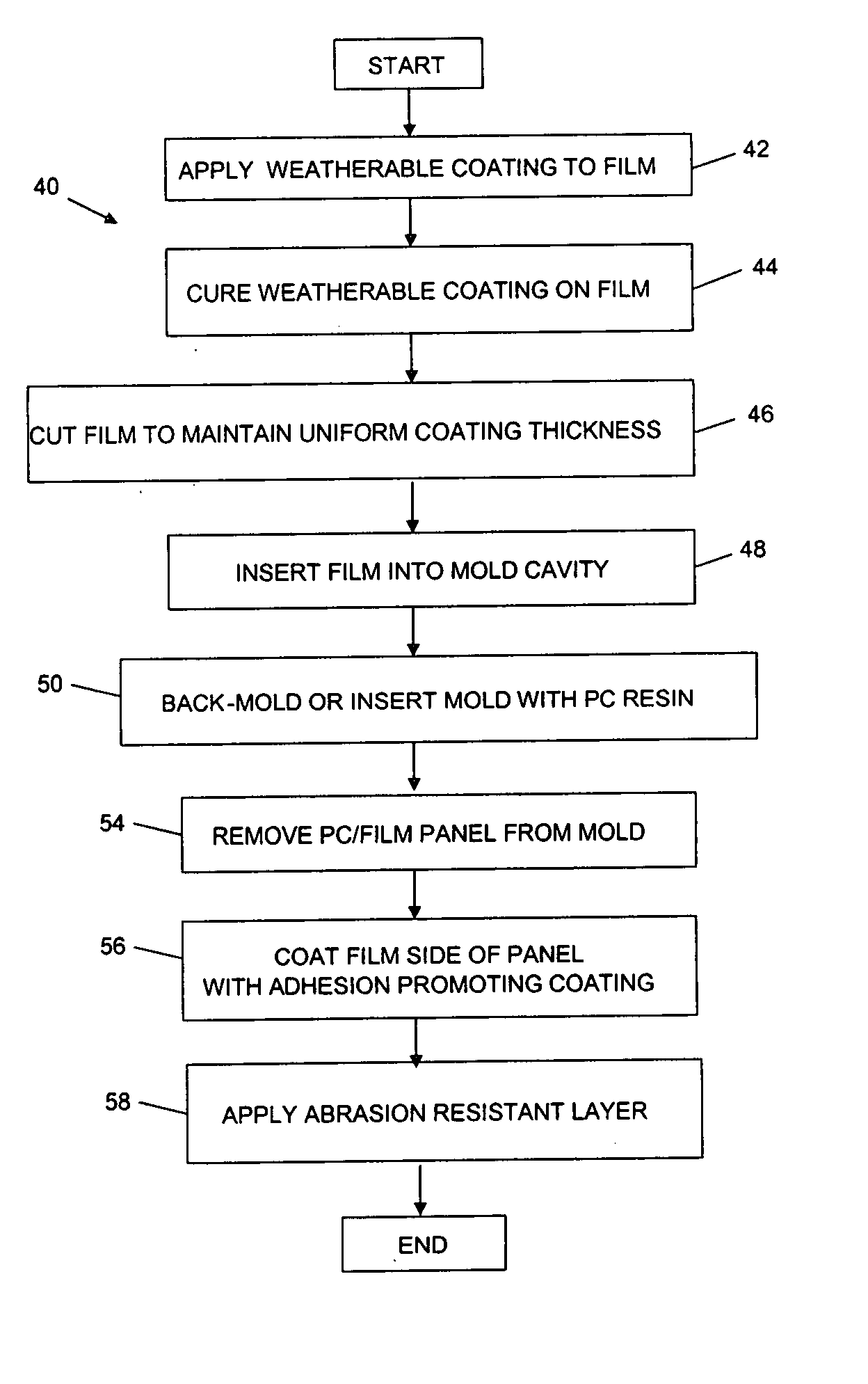

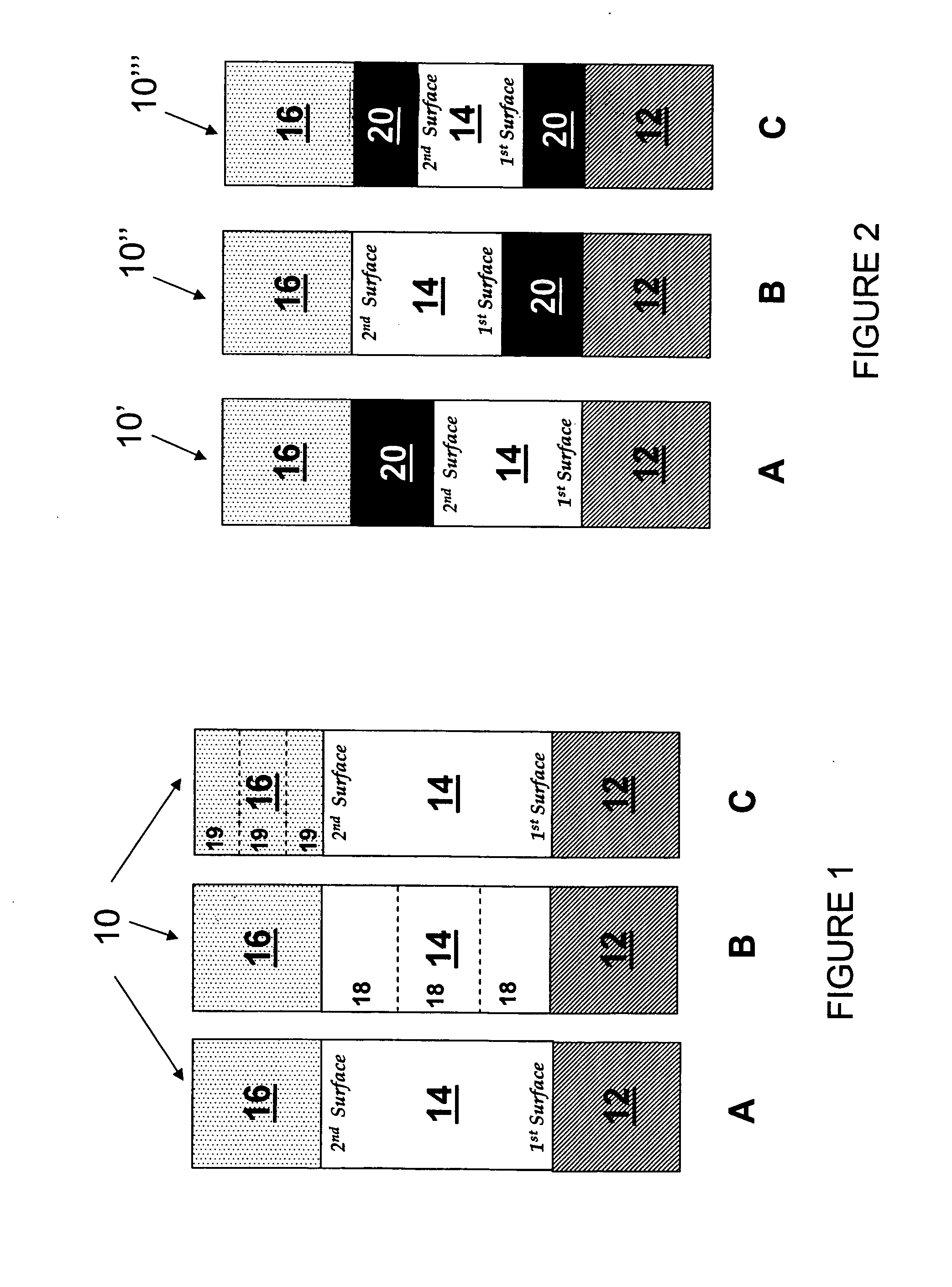

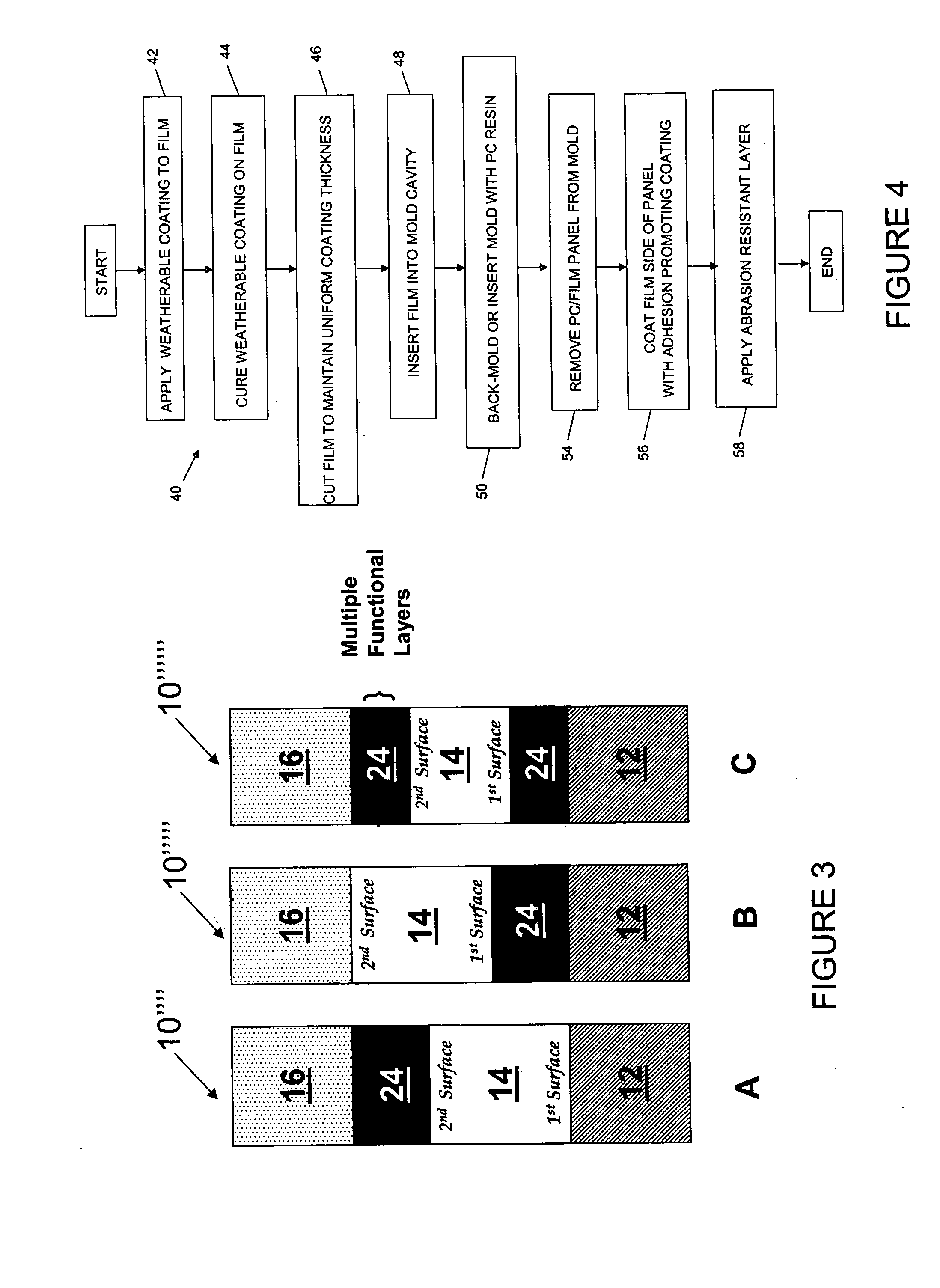

Plastic panels with uniform weathering characteristics

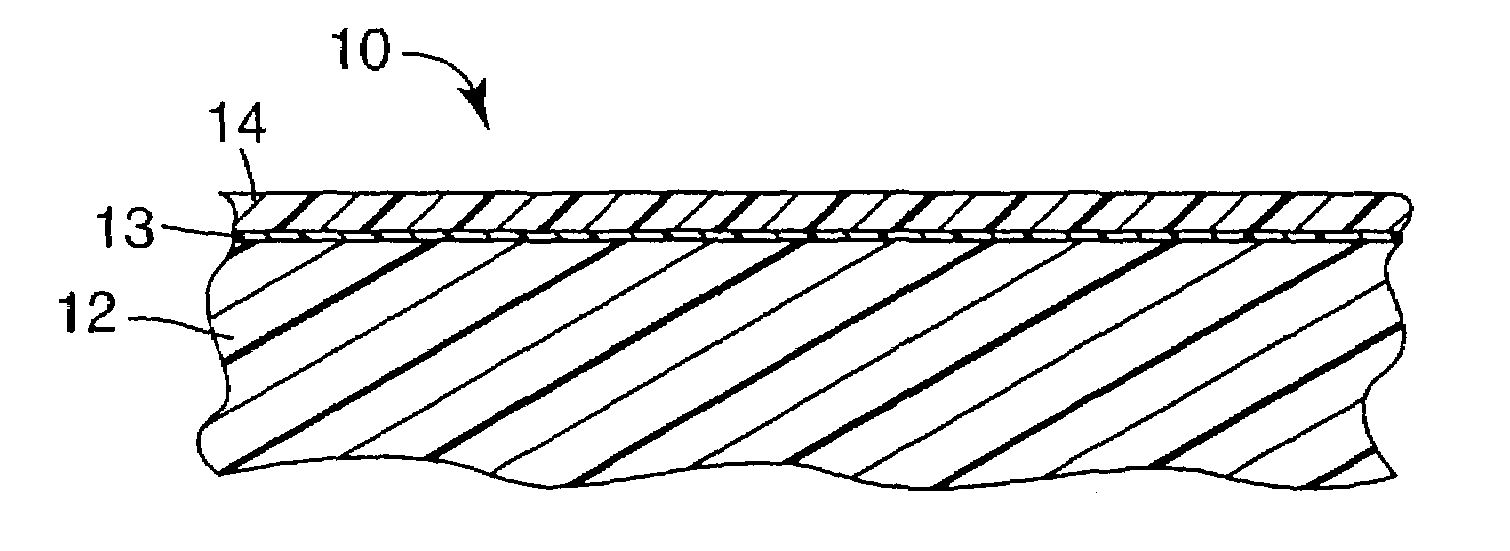

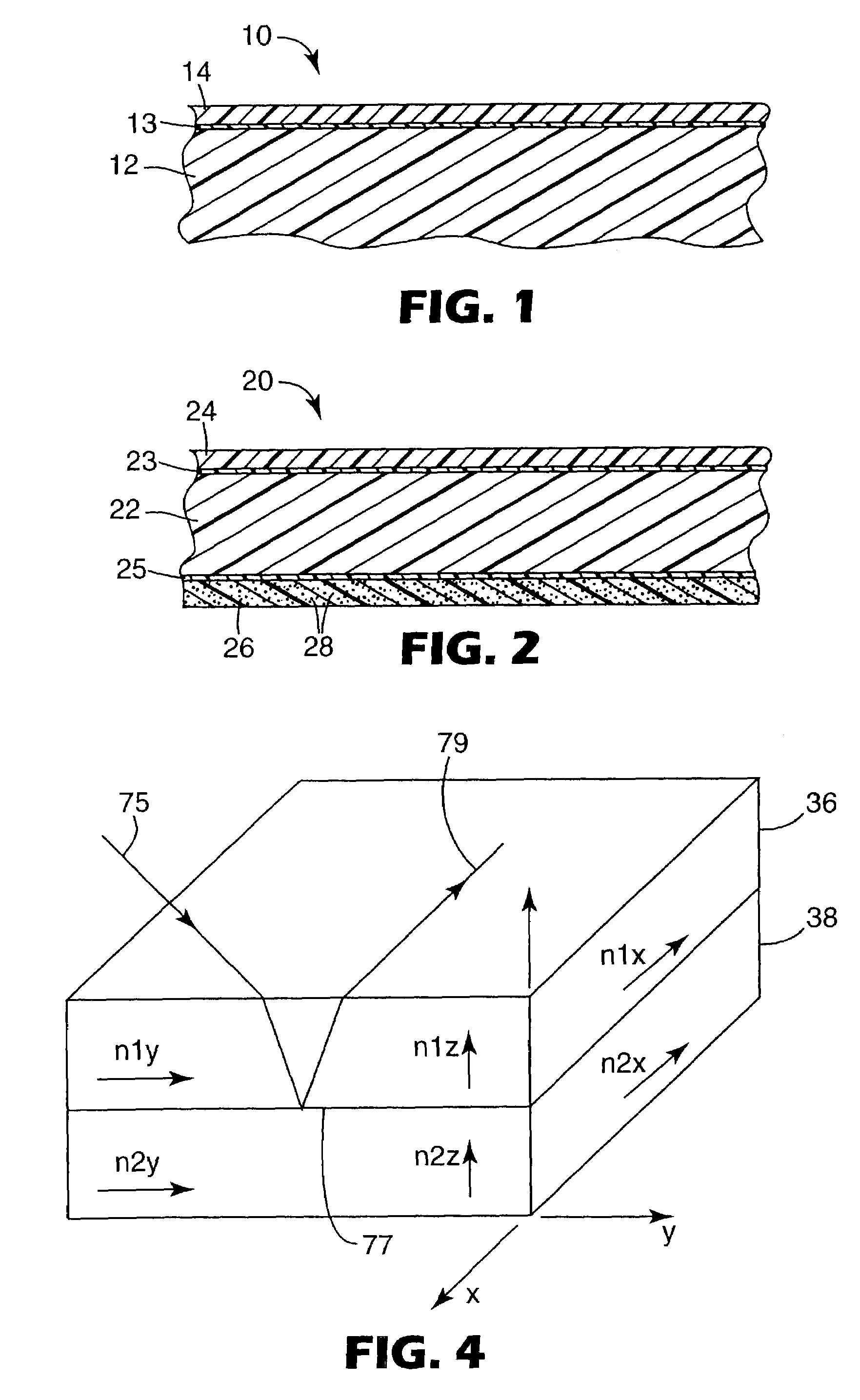

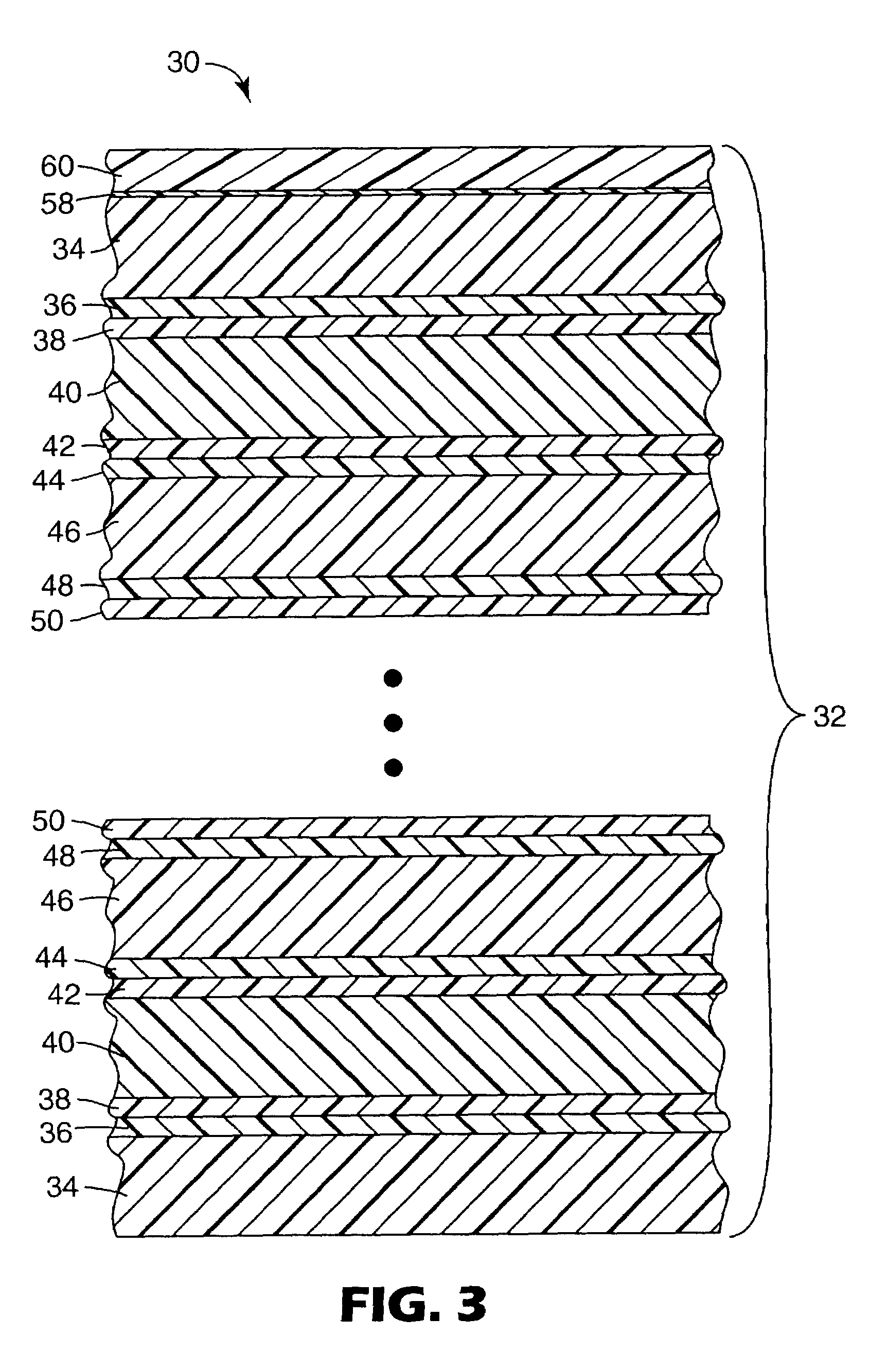

InactiveUS20060204746A1Damage is causedImprove adhesionMouldsSynthetic resin layered productsEngineeringWeathering

A plastic panel and method of application for vehicle windows is disclosed. The plastic panel includes: a base layer; a weatherable film layer having a first and second surface, wherein the first surface of the film layer is adhered to the base layer; and an abrasion resistant layer adhered to the second surface of the weatherable film layer. The abrasion resistant layer is useful for protecting the weatherable film and base layers from damage caused by abrasion.

Owner:EXATEC LLC

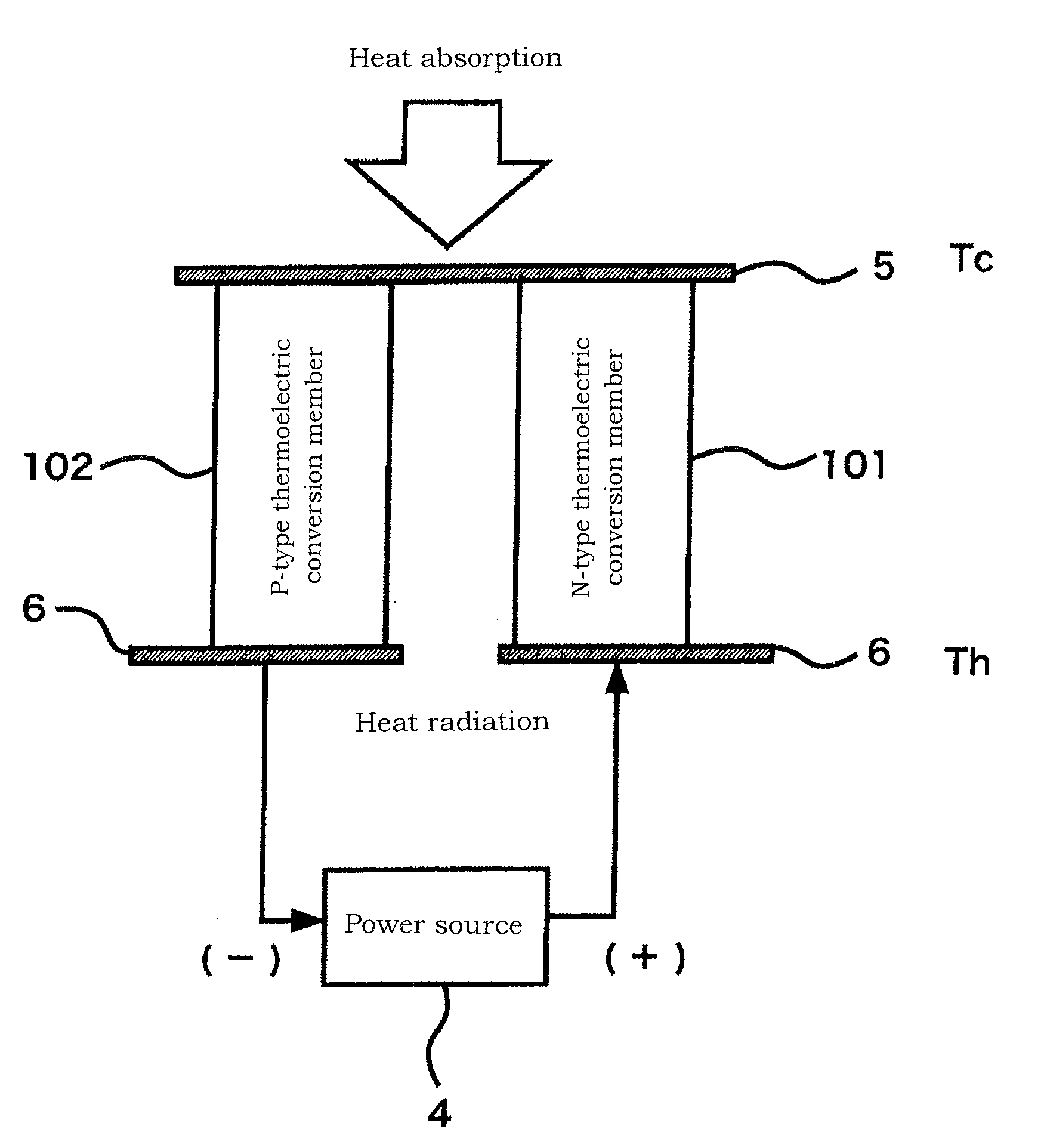

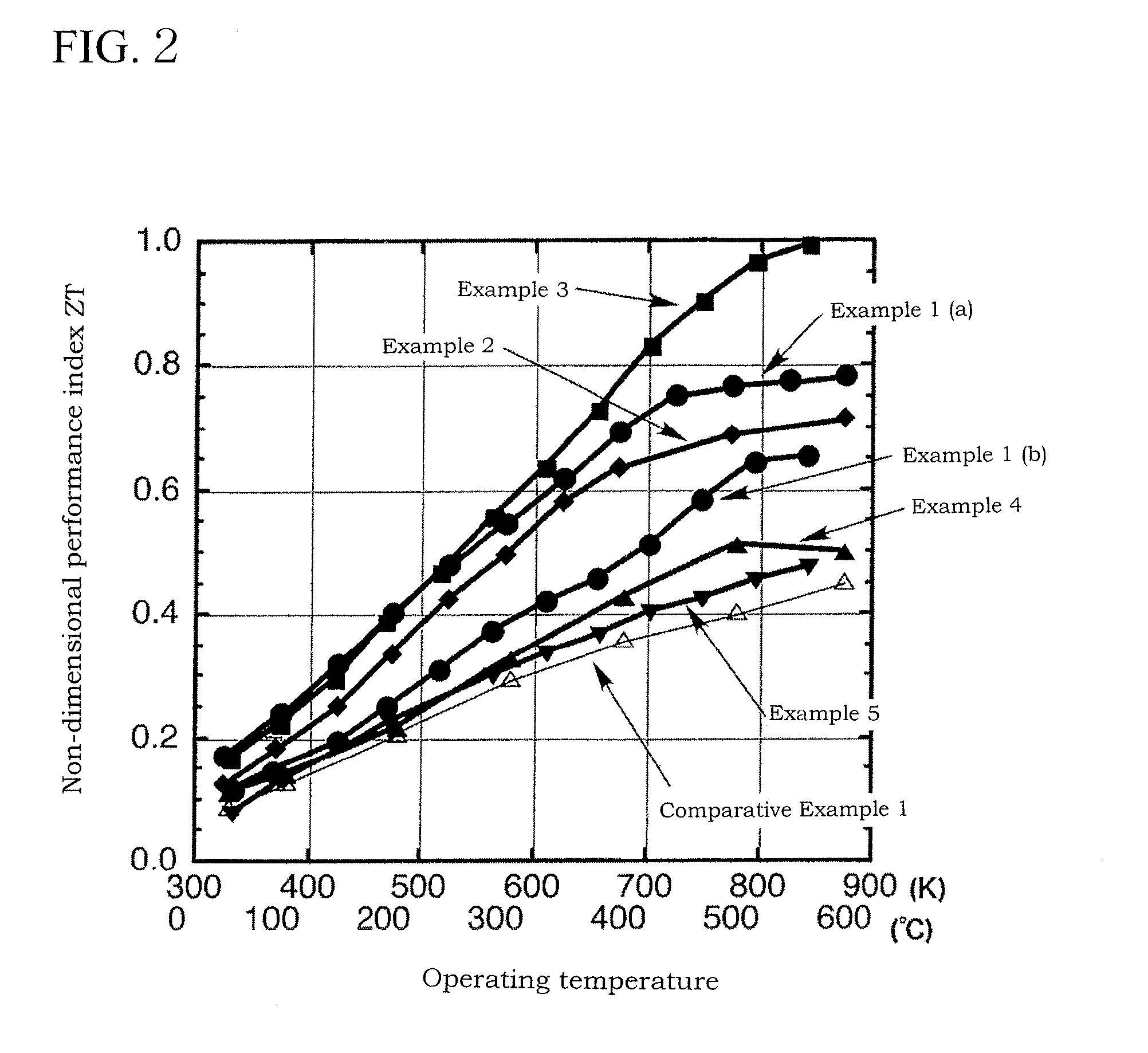

Thermoelectric conversion material, method for manufacturing the same, and thermoelectric conversion element

InactiveUS20100051081A1Increased durabilityHigh physical strengthSludge treatmentSiliconSludgeMagnesium silicide

A thermoelectric conversion material is provided which stably exhibits high thermoelectric conversion performance at about 300 to 600° C. and has high physical strength, resistance to weathering, durability, stability, and reliability. A method for manufacturing the same, and a thermoelectric conversion element are also provided. Also provided is a thermoelectric conversion material produced using, as a raw material, silicon sludge which has had to be disposed of in landfill. The thermoelectric conversion material of the invention is characterized by containing, as a main component, a sintered body composed of polycrystalline magnesium silicide containing at least one element selected from As, Sb, P, Al, and B. The manufacturing method uses purified and refined silicon sludge.

Owner:SHOWA KDE +2

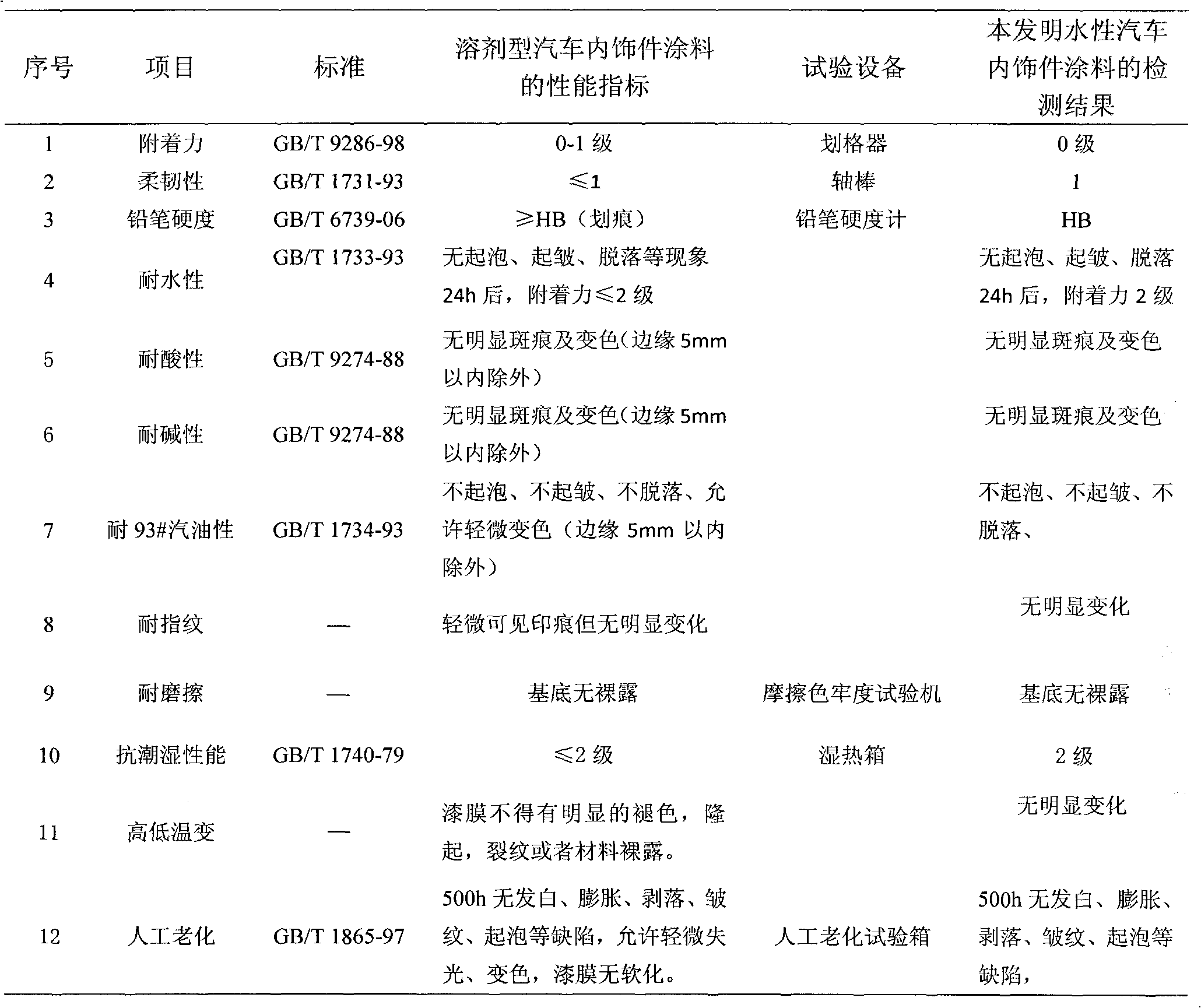

Waterborne acrylic ester-polyurethane resin emulsion and application thereof

InactiveCN101775106AImprove performanceImprove wear resistanceCoatingsMechanical propertyAcrylic monomers

The invention provides waterborne acrylic ester-polyurethane resin emulsion, which is prepared by the emulsion polymerization of waterborne polyurethane emulsion and an acrylic monomer. The conventional coating contains waterborne dispersion having a single polyurethane(PU) structure or single emulsion of acrylic ester(PA), so the performance of the conventional coating cannot meet the application requirements, but the waterborne acrylic ester-polyurethane resin emulsion of the invention changes the situation. The waterborne acrylic acid-polyurethane resin is good in abrasion resistant and fingerprint resistant properties; the waterborne automobile interior part coating obtained by the resin prepared by the core-shell emulsion polymerization organically combines high abrasion resistance and mechanical properties of the polyurethane and high weathering resistance and water resistance of the acrylic acid, so that the performance of the waterborne automobile interior part coating is improved.

Owner:常州市弘可利办公用品有限公司 +1

Preparation method of epoxidized castor oil modified water-borne polyurethane

InactiveCN101967222ASolve the shortcomings of low reaction efficiency and poor stability of modified productsAvoid dependencyPolyesterDistillation

The invention discloses a preparation method of epoxidized castor oil modified water-borne polyurethane, which relieves the degree of dependence on petroleum resources of the water-borne polyurethane, and simultaneously overcomes the defects poor product water resistance, poor chemical resistance, poor weathering resistance and the like of the existence of water-borne polyurethane. The technical scheme is that the preparation method comprises the following steps of: (1) preparing polyurethane prepolymer from isocyanate, polyether or polyester polyol, a catalyst and a hydrophilic chain extender; (2) performing a secondary chain extension reaction on the prepolymer and an organic solvent mixture of a polyhydroxy compound and the epoxidized castor oil to prepare epoxidized castor oil modified prepolymer; (3) reacting the modified prepolymer with a salifying agent, and then performing neutralization and salifying; (4) adding the prepolymer after the salifying into deionized water for high-speed emulsification, and simultaneously adding a chain extender into the mixture for chain extension; and (5) performing distillation to remove the organic solvent to prepare an epoxidized castor oil modified water-borne polyurethane emulsion.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

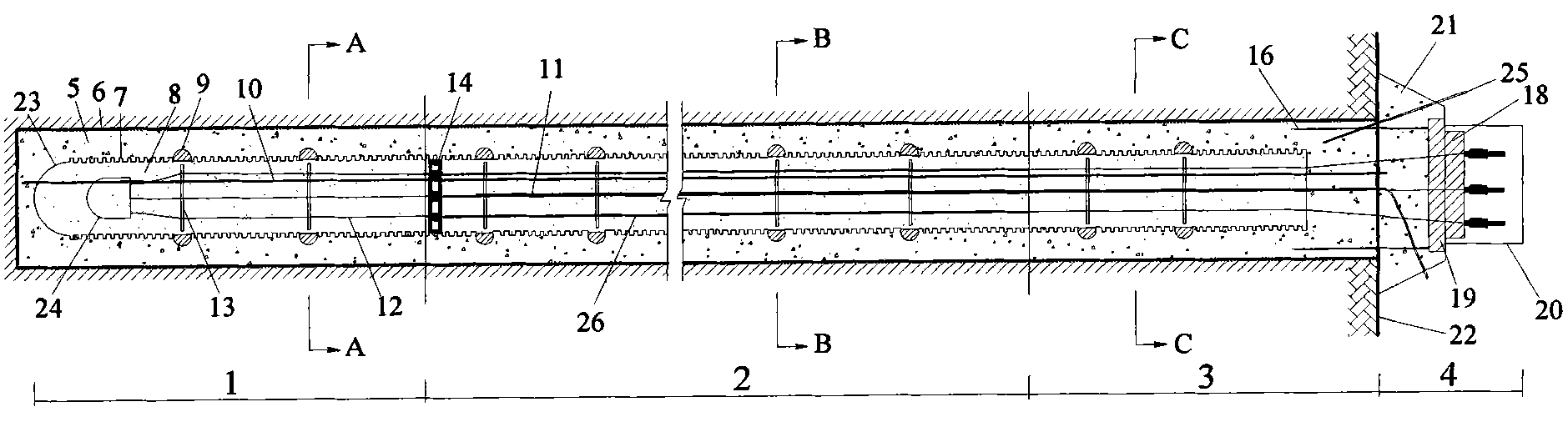

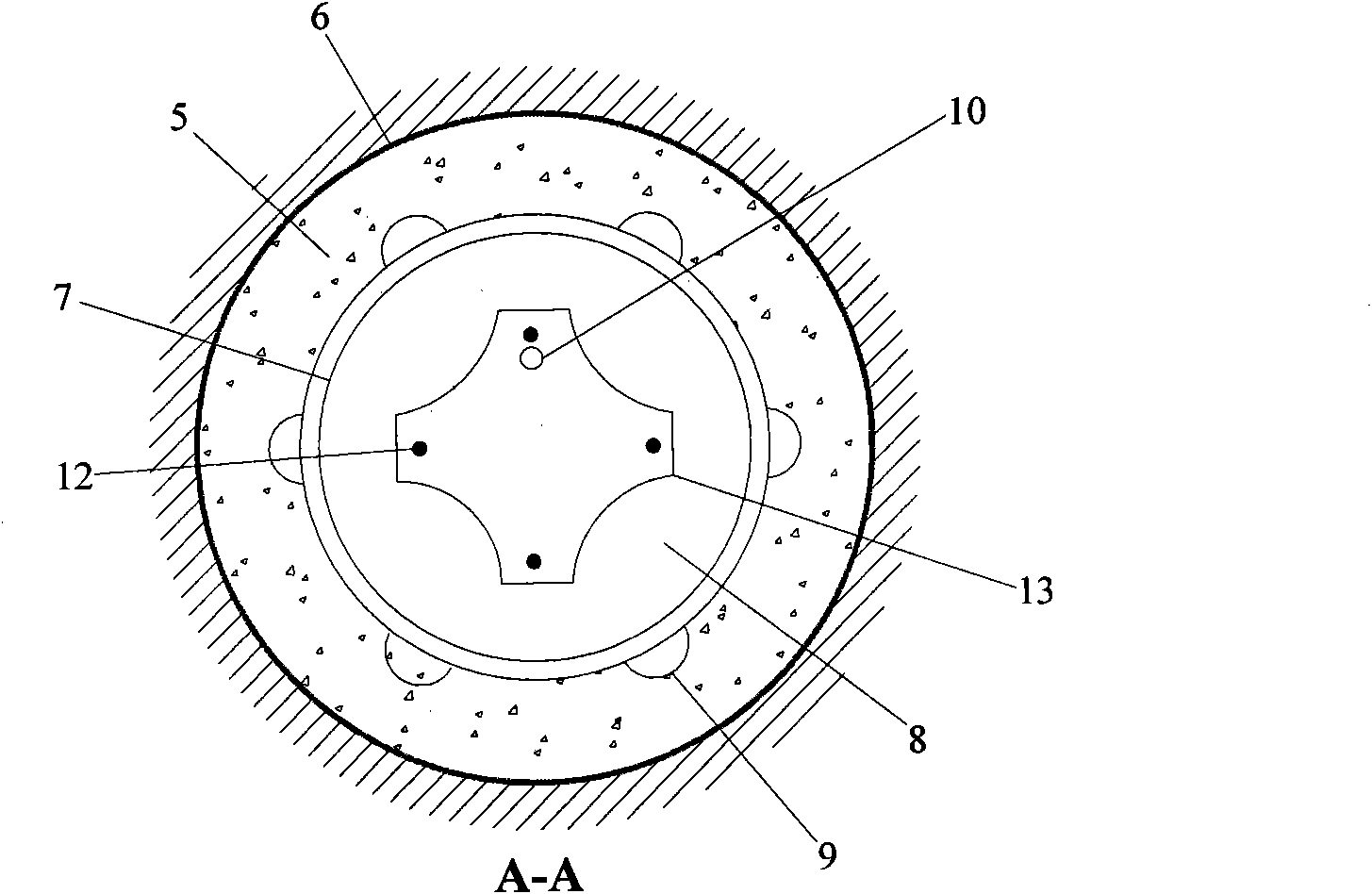

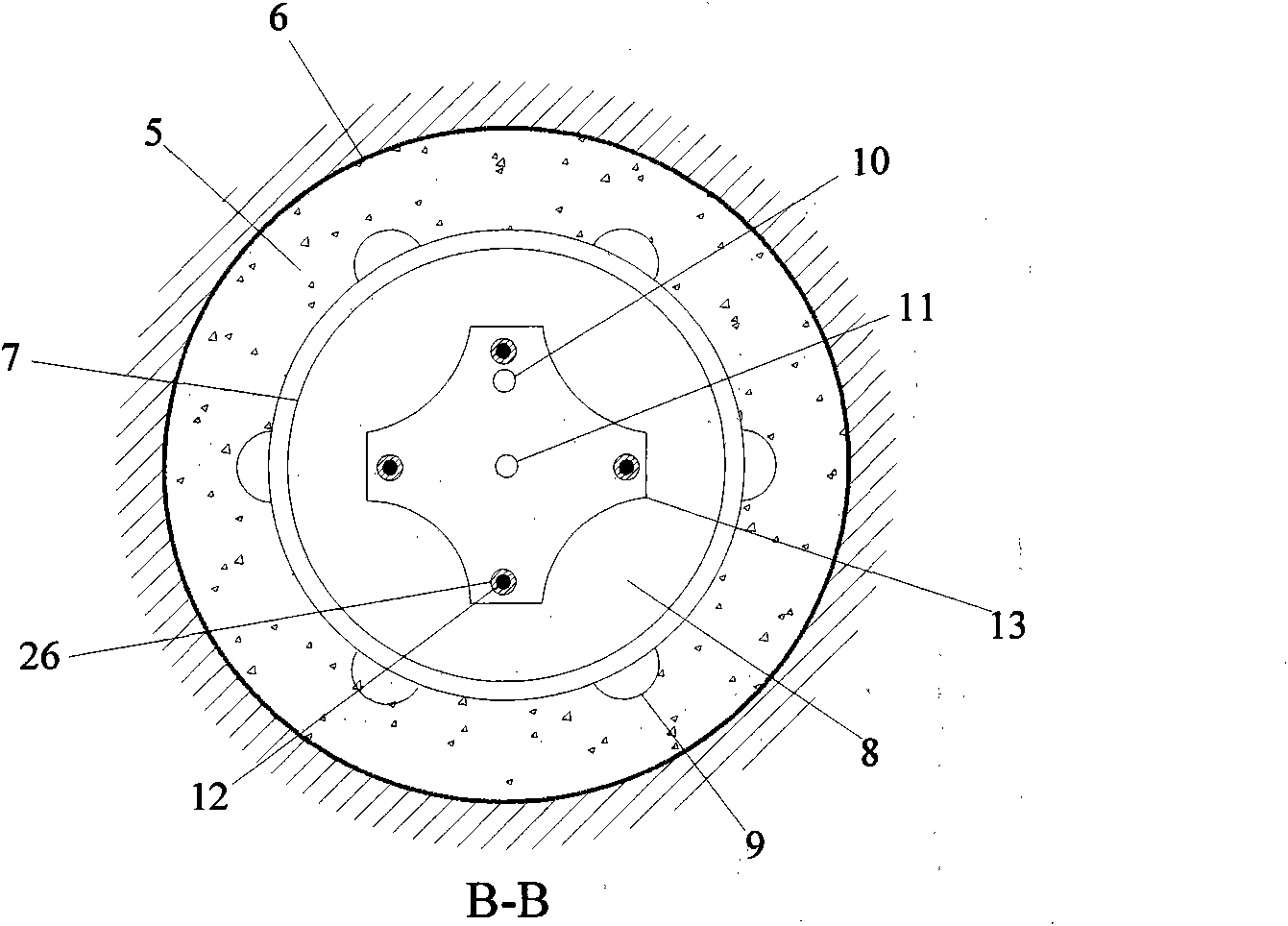

Double anchoring section prestressed anchoring system with three-layer protection and anchoring method thereof

ActiveCN101798812AImprove stabilityImprove durabilityClimate change adaptationExcavationsPre stressOperability

The invention relates to a double anchoring section prestressed anchoring system with three-layer protection and anchoring method thereof. The anchoring system is composed of an inner anchoring section, a free section, an outer anchoring section and an anchor section. Outer layer binder, corrugated pipe and inner layer binder form three-layer protection for the inner and outer anchoring sections of the anchoring system, the outer layer binder, the corrugated pipe, a sleeve and the inner binder form four-layer protection for the free section, thus greatly improving resistance to corrosion of anchoring structure. Double anchoring sections form an anchoring force holding end and a prestress holding end. Compared with common single anchoring section anchoring method, the invention has the advantages that the outer anchoring section in specific design can effectively inhibit influence of creep, weathering, corrosion, blasting and earthquake of mantle rock soil body on anchoring system and the aim of avoiding or reducing prestress loss can be achieved. The invention has simple implementation and strong operability, procedure change is less compared with the existing anchoring method, and the invention has obvious advantage compared with the permanent anchoring system and can be applicable to reinforcement of geotechnical engineering such as side slope and foundation pit.

Owner:UNIV OF SCI & TECH BEIJING

Method for relieving and cutterhead repairing of shield machine in weathering groove

ActiveCN102305082AAvoid enteringNo damageUnderground chambersTunnel liningSocial benefitsAccessory structure

The invention relates to the technical field of tunnel shield construction, in particular to a method for relieving and cutterhead repairing of a shield machine in a weathering groove. By means of the method, the problems of complex process, long construction period, high cost and the like during shield body relieving and cutterhead repairing in conventional construction are solved. The method comprises the steps of: carrying out grouting reinforcement on collapse body in front of a cutterhead, collapse body above the cutterhead, collapse body above shield tail and collapse body of an anchor cable; building water pressure of cut, eliminating counter-force of tunneling, retreating the shield body and relieving the cutterhead; drilling, exploding and repairing caverns, cleaning the excavated bin and repairing internal structure, body structure and accessory structure of the cutterhead to ensure that the shield body recovers tunneling. The method has the advantages of simple process, short construction period, low construction cost, strong applicability and the like. By means of the method, the relieving and the repairing of the cutterhead of the tunnel are successfully completed; the risk that river water backward pouring into the tunnel is avoided; the shield machine can rapidly recovering the normal tunneling; and the favorable economic benefit and social benefit are obtained.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY +1

Curable resin composition for use in water-based coating materials

InactiveUS6103788ALowering of curabilityExcellent solventPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsWater basedSilylene

PCT No. PCT / JP96 / 03476 Sec. 371 Date Jul. 22, 1997 Sec. 102(e) Date Jul. 22, 1997 PCT Filed Nov. 28, 1996 PCT Pub. No. WO97 / 20004 PCT Pub. Date May 6, 1997The present invention relates to a curable resin composition for use in water-based coating materials which includes as essential components an emulsion polymer (A) containing tertiary amino groups obtained by carrying out emulsion polymerization of a vinyl monomer containing a tertiary amino group with another copolymerizable vinyl monomer in a water-based medium, and a compound (B) containing, at least, an epoxy group and a hydrolyzable silyl group, with this composition preferably also including a water-based compound (C) obtained by adding a neutralizing agent to a vinyl polymer (I) containing acidic groups and / or tertiary amino groups so as to neutralize at least 10% of the acidic groups and / or the tertiary amino groups, and then dispersing or dissolving in water, and / or a compound (D), which is not included in compound (B), and contains hydrolyzable silyl group and / or a silanol group. The coating material provided by the composition of the present invention is curable at ambient temperatures and demonstrates excellent coating properties. Moreover, the cured coating obtained from the composition of the present invention offers superior resistance to weathering, solvents, chemicals and water, and is not problematic with respect to conservation of the environment.

Owner:DAINIPPON INK & CHEM INC

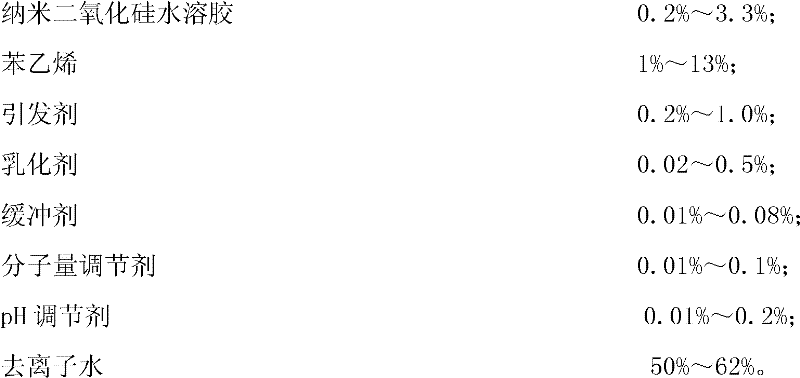

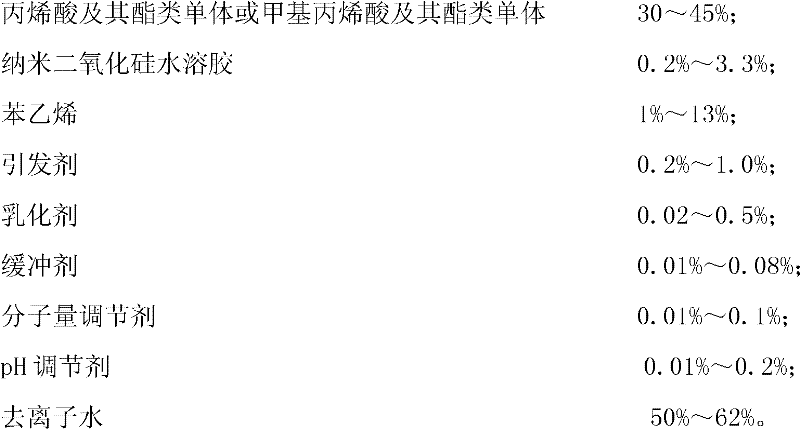

Adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and preparation method thereof

InactiveCN102533186AImprove sticking powerExcellent dry resistanceGraft polymer adhesivesPolymer adhesivePolymer science

The invention discloses an adhesive for alkali resistant acrylate glass fiber mesh cloth shaping, and a preparation method thereof, and belongs to the field of polymer adhesive preparation. The adhesive is prepared through the reaction of the following components, wherein the components comprise: a material selected from acrylic acid and an ester monomer thereof, or methacrylic acid and an ester monomer thereof; nano-silicon dioxide; a styrene monomer; an initiator; an emulsifier; a buffering agent; a molecular weight regulator; a pH value modulator; and deionized water. According to the adhesive, the nano-silicon dioxide is adopted as the core, a copolymer of the styrene monomer and the acrylic acid monomer is adopted as the shell layer, and the shell layer hard monomer is the acrylate copolymer emulsion with the significant core-shell structure, wherein the concentration of the shell layer hard monomer shows the gradient change. The glass fiber mesh cloth treated by the adhesive of the present invention has advantages of excellent positioning effect, strong adhesive force, bright mesh cloth, good elasticity, high alkali resistance, good water resistance, strong weathering resistance, no yellowing, and no after tack. The adhesive of the present invention is the single mass component glue, is easy to use, does not contain any organic solvents, and has advantages of aquosity and environmental protection.

Owner:BEIJING COMENS NEW MATERIALS

Construction heat-insulating mortar

InactiveCN101279833AImprove adhesionImprove toughnessSolid waste managementCalcium formateMaterials science

The invention belongs to the building material technique field, in particular relates to a building thermal insulating mortar. The building thermal insulating mortar is characterized in that the mortar is composed of dry powder and water, the dry powder and water are present in a weight ratio of 1:1.3, when in use, the dry powder is added to the water and agitated evenly; and the dry powder is mixed by materials of modified cement, modified fly ashes, a re-dispersible latex powder, wood fibers, polypropylene fibers, calcium formate, hydroxypropyl methylcellulose, hydrophobic agent, multi-functional auxiliary agent and modified expanded perlite, materials of the dry powder include: 500 parts of modified cement, 160 parts of modified fly ashes, 25 parts of re-dispersible latex powder, 3 parts of wood fibers, 1 part of polypropylene fiber, 5 parts of calcium formate, 6 parts of hydroxypropyl methylcellulose, 1 part of hydrophobic agent, 3 parts of multi-functional auxiliary agent and 300 parts of modified expanded perlite by weight. The building thermal insulating mortar has advantages of strong heat preservation, firm bonding with wall bodies, compression resistance, superior tensile performance, good weathering resistance, environmental protection, and excellent waterproofing, anti-cracking and shedding prevention properties.

Owner:QIUSHI HUBEI PAINT

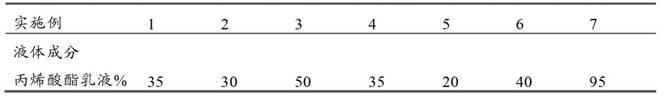

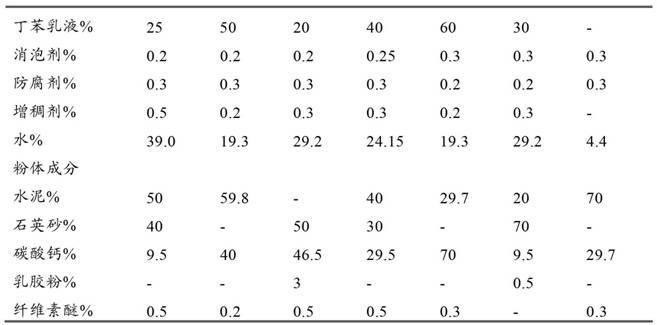

Waterproof gum for stone

InactiveCN102674769AImprove adhesionDoes not affect the decorative effectCoatingsMaterials scienceLiquid composition

The invention discloses a waterproof gum for stone. The waterproof gum is composed of liquid components and powdery components in a weight ratio of 1:(1-3), wherein the liquid components comprise 20-95% of acrylate emulsion, not more than 5% of antifoaming agent, not more than 4% of preservative and 4-75% of water; the powdery components comprise 0-70% of cement, 0-70% of quartz sand and 0-70% of calcium carbonate; and the powdery components comprise at least two of cement, quartz sand and calcium carbonate. By the adoption of the waterproof gum for the stone, disclosed by the invention, immersion of water and other harmful substances on the stone is reduced, so that the weathering of the stone is slowed down; and meanwhile, a good bonding performance is existent between the waterproof gum and base courses in the wet-sticking construction process, so that the phenomena, such as efflorescence, waterlogging, peeling, hollowing, dropping and cracking, on the stone are prevented.

Owner:余春冠

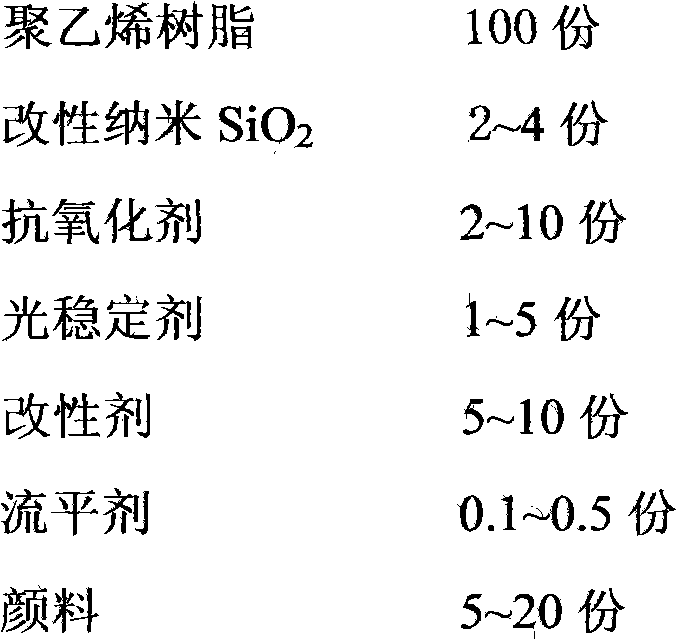

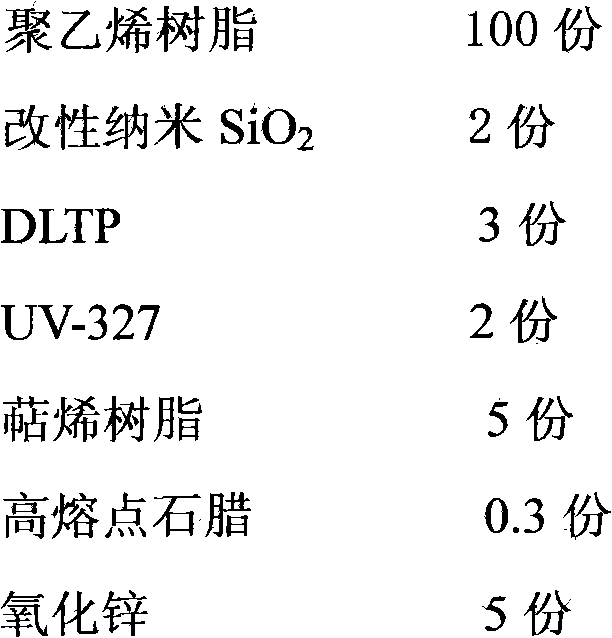

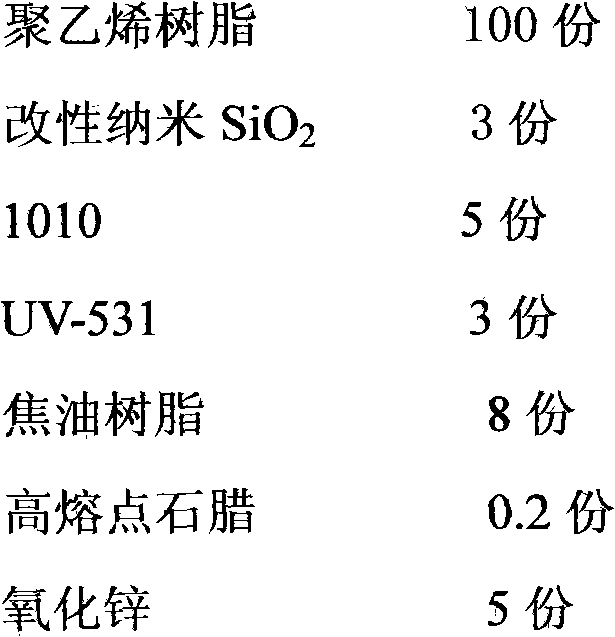

A kind of polyethylene powder coating for anti-corrosion steel pipe and preparation method thereof

The invention belongs to the field of coatings and particularly relates to a polyethylene powder coating used for an anti-corrosion steel pipe and a preparation method thereof. The polyethylene powder coating is characterized by comprising the following components in parts by weight: 100 parts of polyethylene resin, 2-4 parts of modified nanometer SiO2, 2-10 parts of antioxidant, 1-5 parts of light stabilizer, 5-10 parts of modifying agent, 0.1-0.5 part of flatting agent and 5-20 parts of pigment. In the polyethylene powder coating, the nanometer SiO2 is used for modifying the coating, and the adhesive force of the polyethylene powder coating and a metal matrix is improved. In order to realize the purpose that the nanometer SiO2 is stable and even in the matrix material, a silane couplingagent KH-550 adopted in the polyethylene powder coating is adopted for modifying the nanometer material. The powder coating disclosed by the invention has the advantages of good adhesiveness with metal steel, small possibility of cracking, good anticorrosive weathering resistance, long service life, smooth and flat coating film surface, good decoration effect, good mobility and wide market space,and is simple to construct.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

Multifunctional green environment-friendly interior wall emulsion paint

InactiveCN102391733AAnti-agingSkinnyEmulsion paintsMulticolor effect coatingsPolyvinyl alcoholElectromagnetic radiation

The invention relates to multifunctional green environment-friendly interior wall emulsion paint comprising a styrene-acrylate copolymerized microemulsion, pure water, hydroxyethyl cellulose, an antifoaming agent, propylene glycol, titanium dioxide, heavy calcium carbonate powder, kaolin, saponite, a film-forming auxiliary agent, a plant scent agent, nano-grade titanium dioxide powder, nano-grade silica powder, zinc oxide powder, negative ion powder, ferromanganese powder, pyrethrin, polyvinyl alcohol, an elastic acrylic emulsion, and the like. The multifunctional green environment-friendly interior wall emulsion paint is characterized by aging resistance, peeling resistance, discoloration resistance, good weathering resistance, no toxicity, no odor, good leveling property, and easy construction. The paint can be prepared into a plurality of colors. With the paint, a decorated wall surface can be provided with elegant and splendid effects, and beautiful and dignified appearances as natural marbles. The production cost of the paint is low. With the paint, a produced paint film has a strong antifouling function, and has mould proofing and algae inhibiting functions. Also, the paint has good functions of sterilizing, disinfecting, and electromagnetic radiation resisting.

Owner:袁文君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com