Patents

Literature

175 results about "Magnesium silicide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

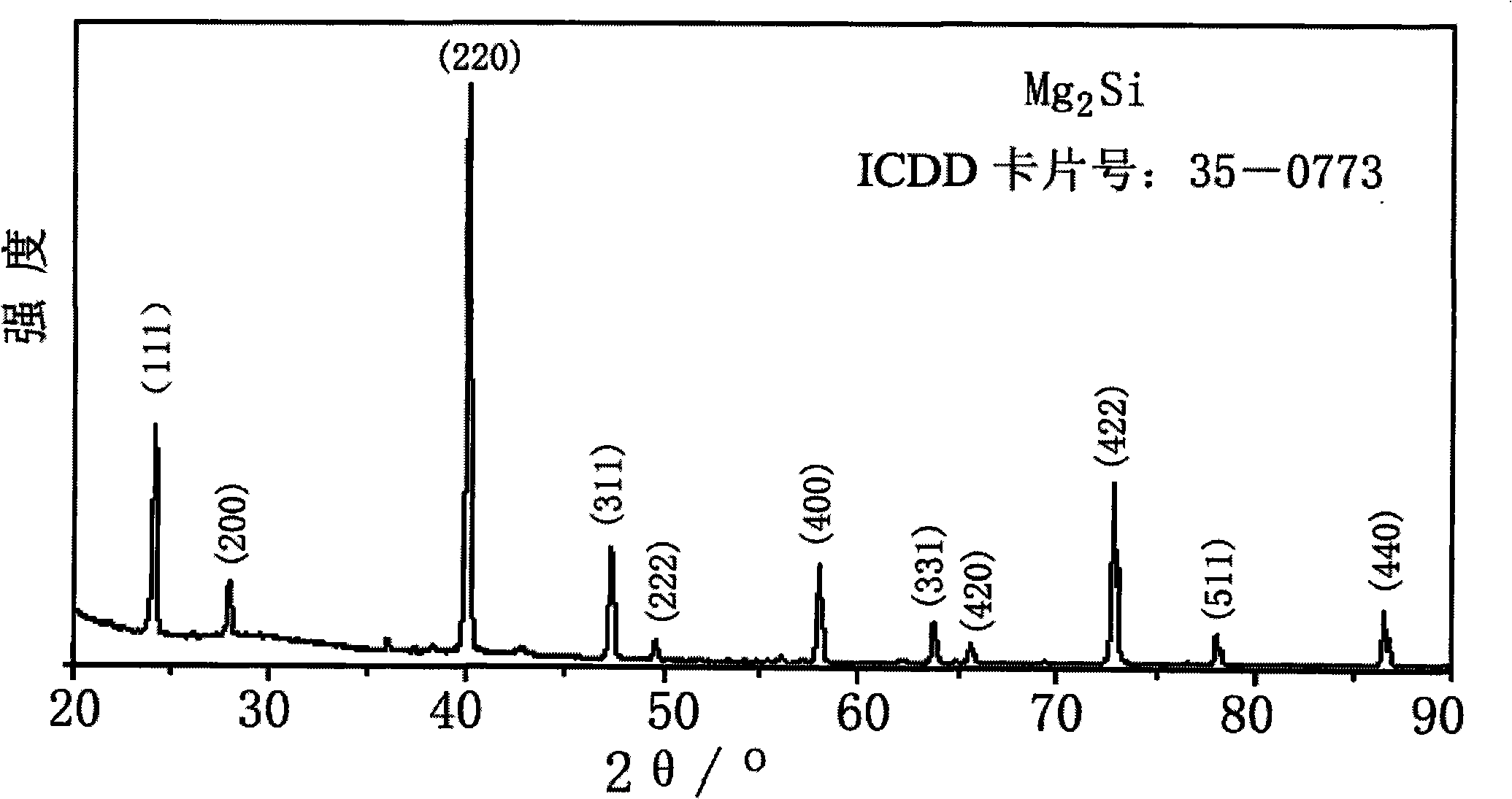

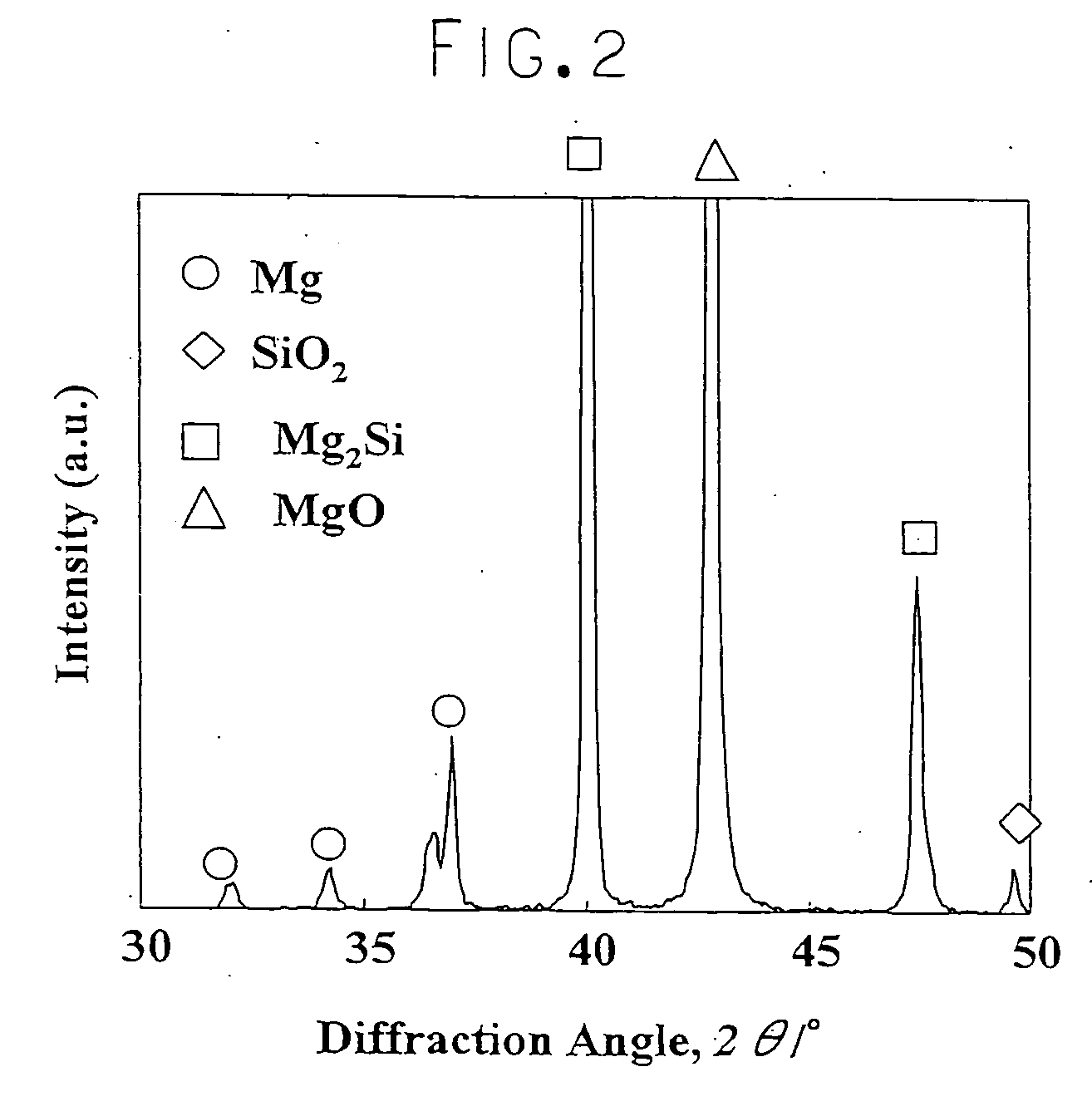

Magnesium silicide, Mg₂Si, is an inorganic compound consisting of magnesium and silicon. As-grown Mg₂Si usually forms black crystals; they are semiconductors with n-type conductivity and have potential applications in thermoelectric generators.

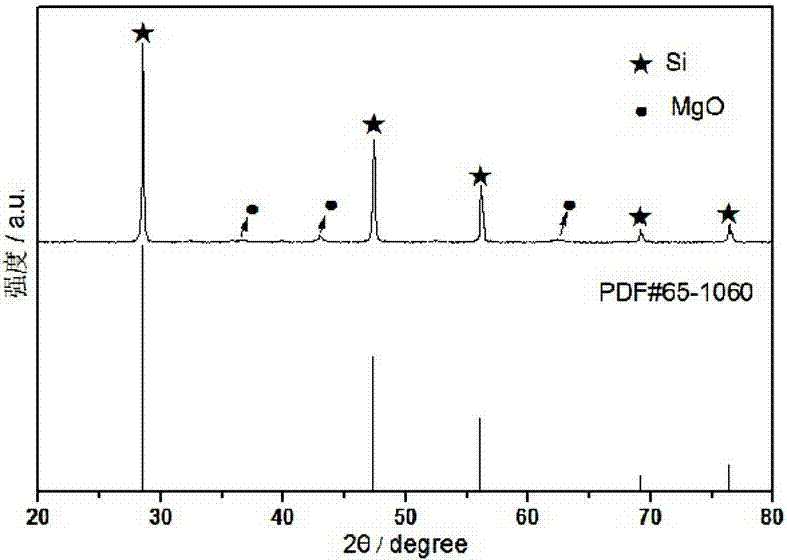

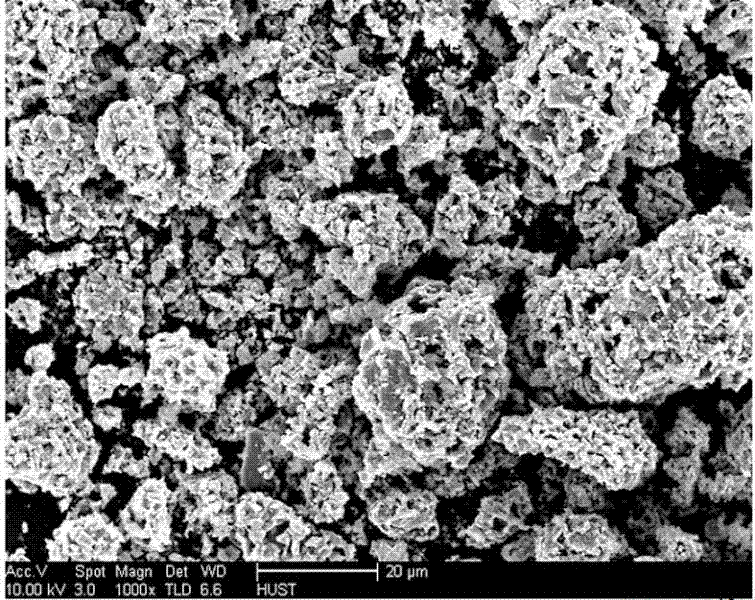

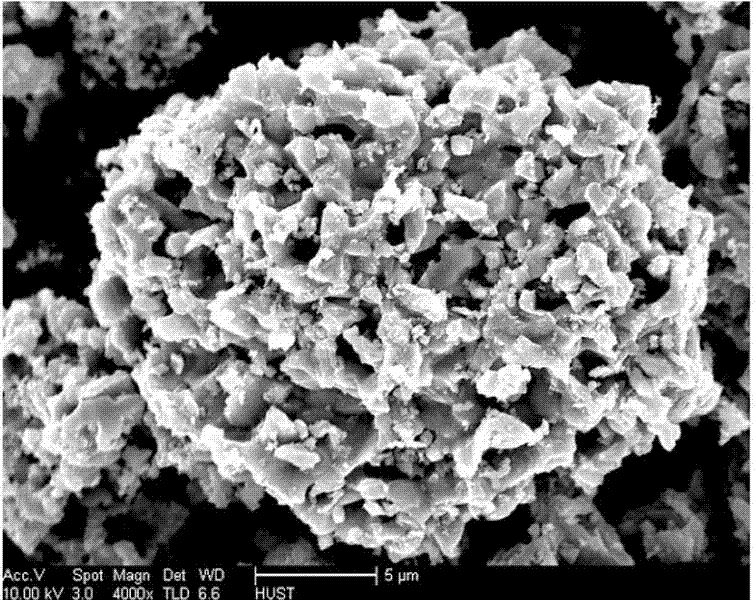

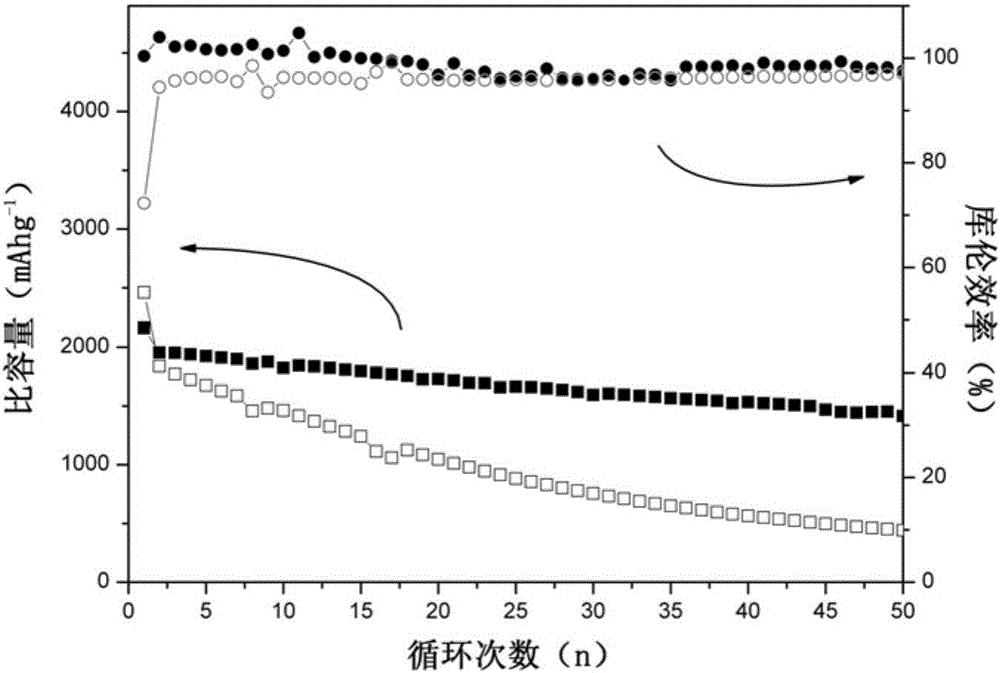

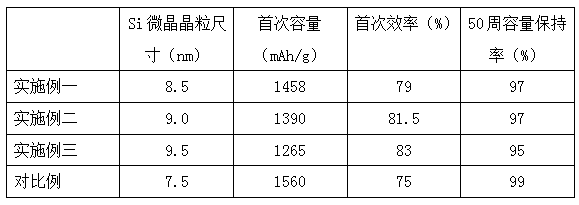

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

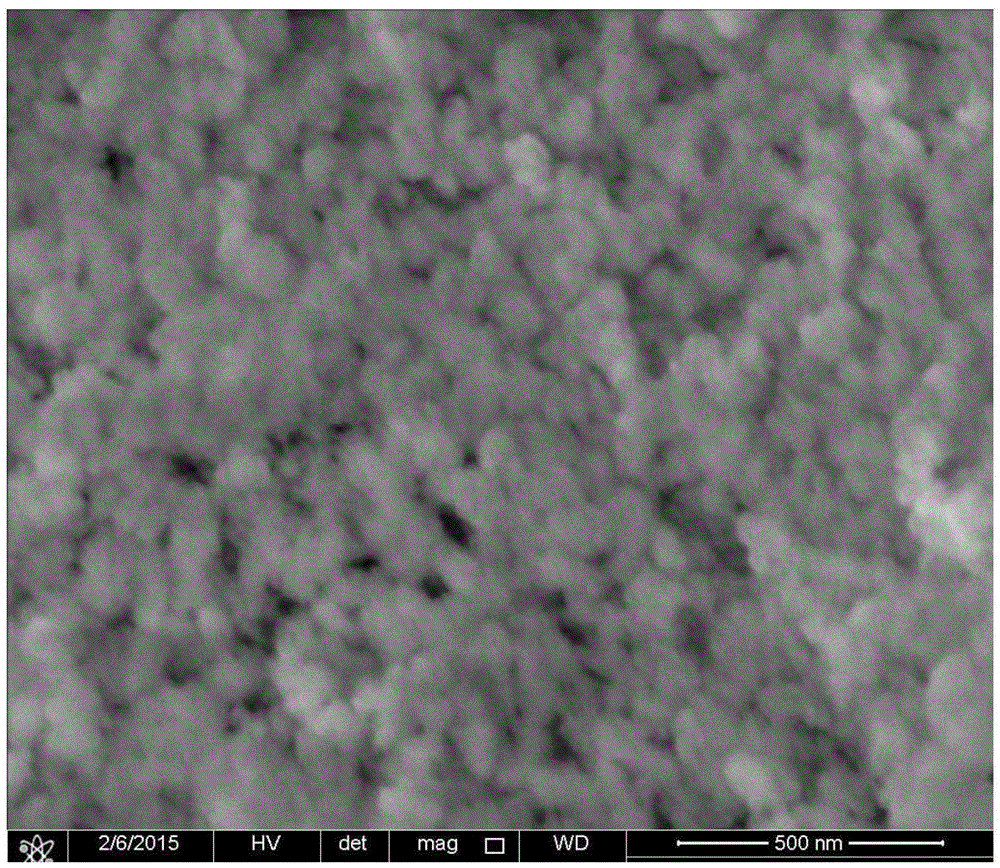

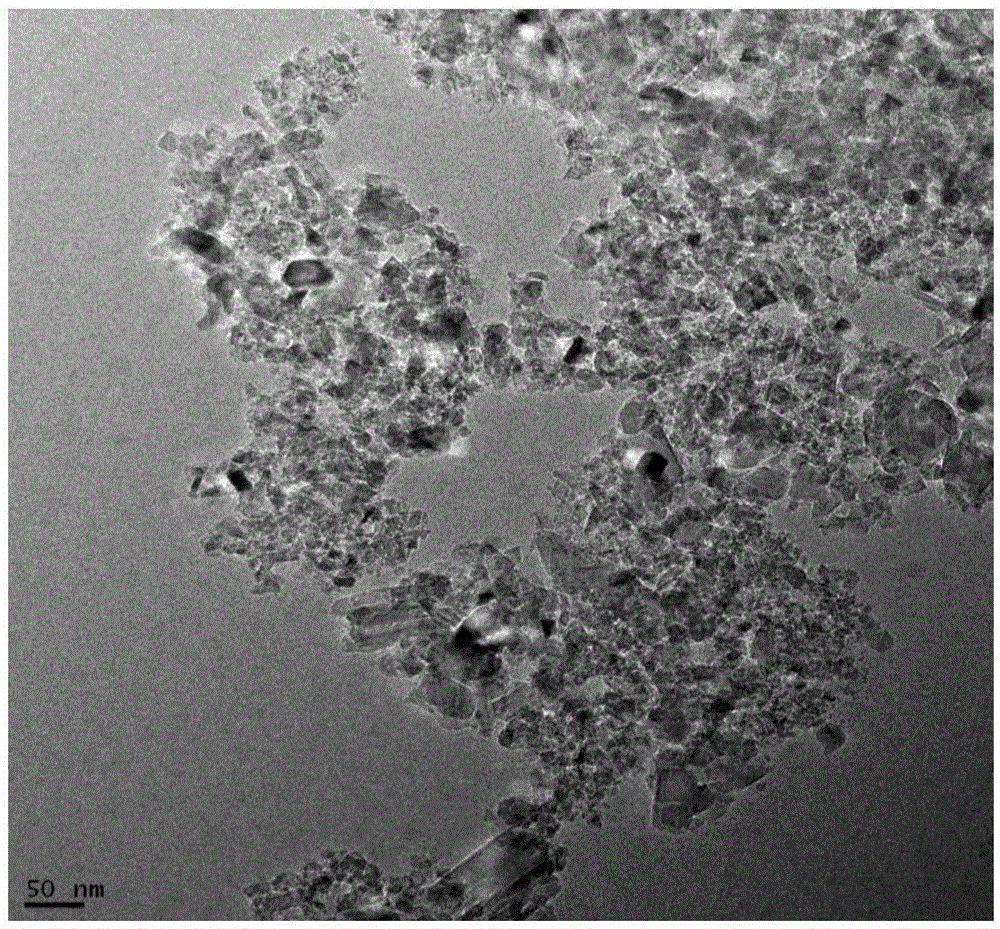

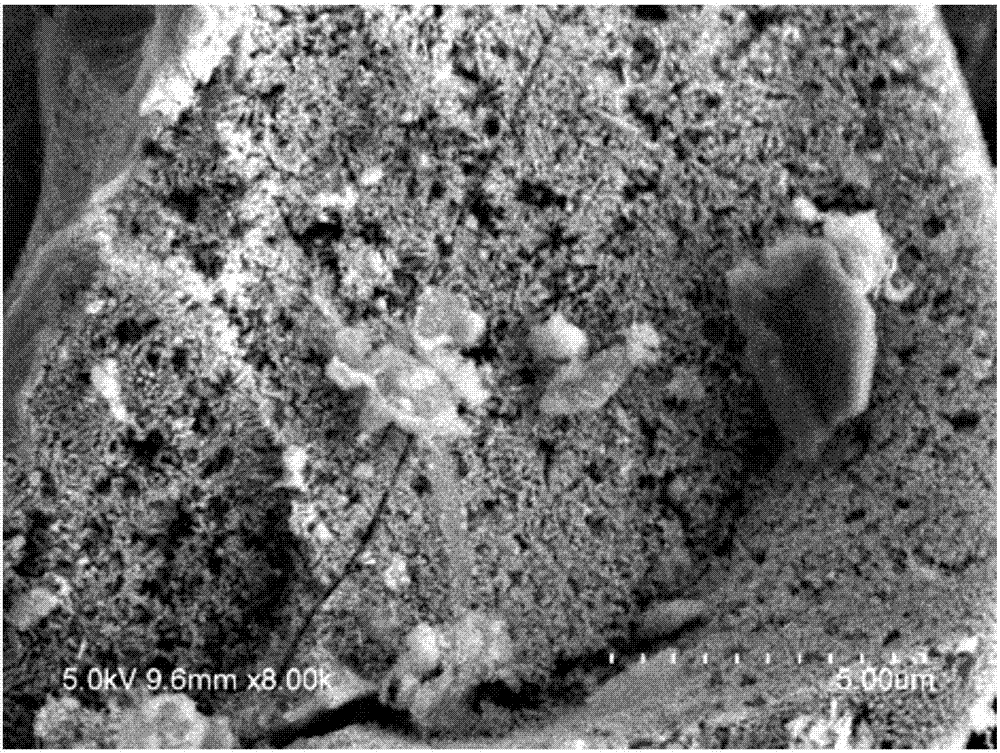

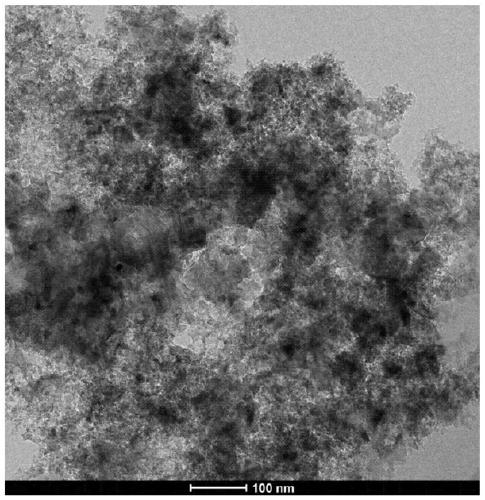

ActiveCN102237519AAvoid pollutionHigh specific capacityCell electrodesSodium-ion batterySilicon particle

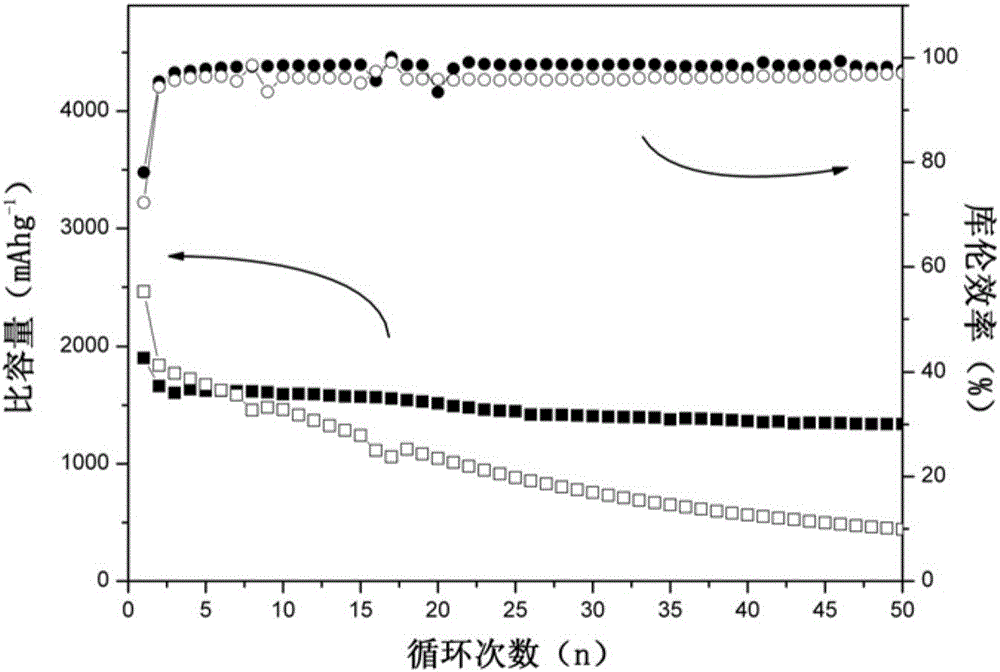

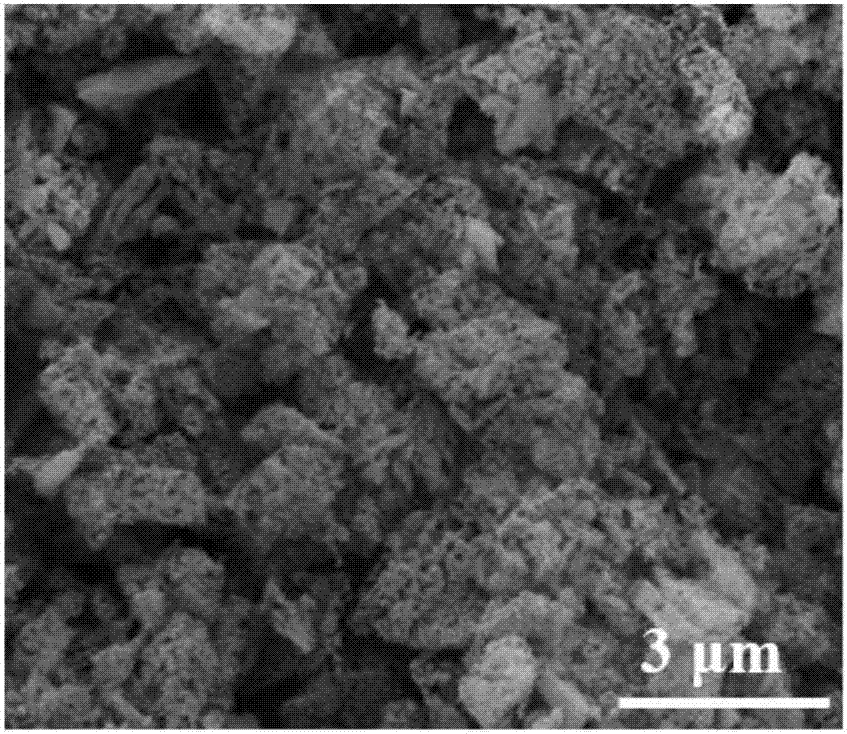

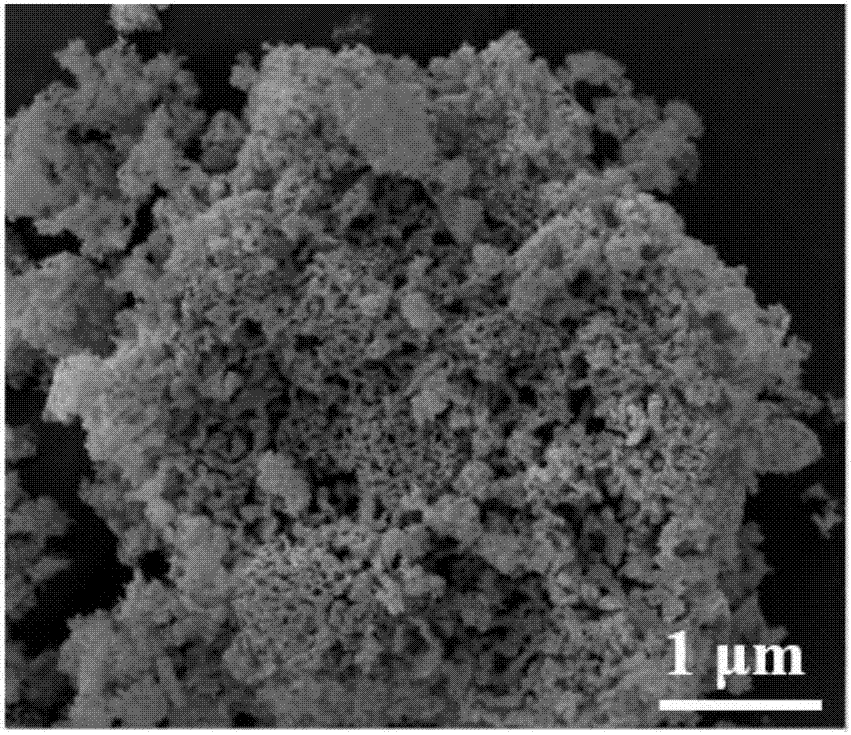

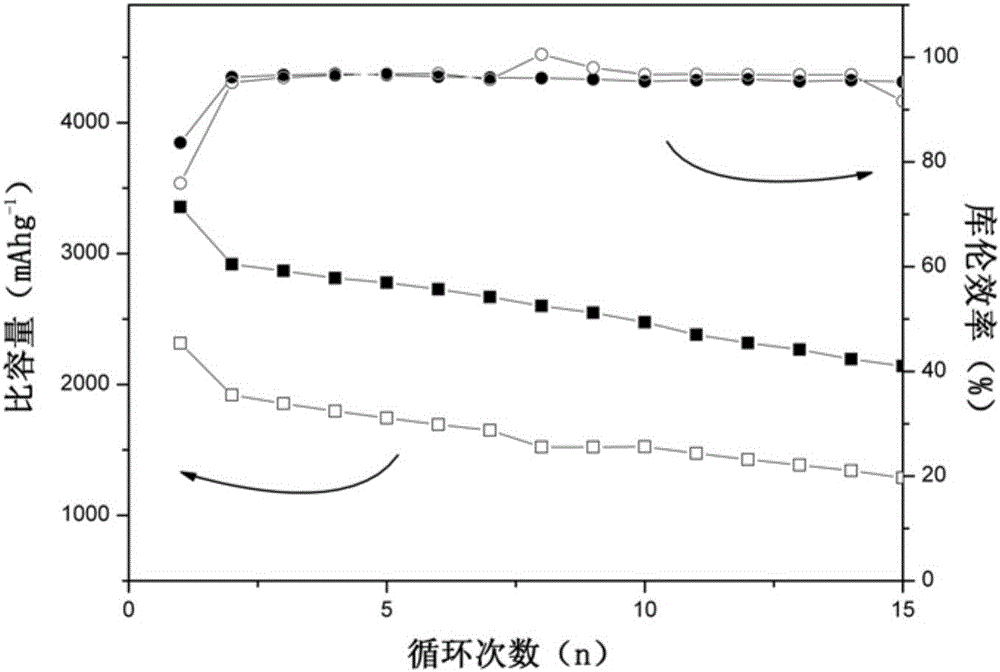

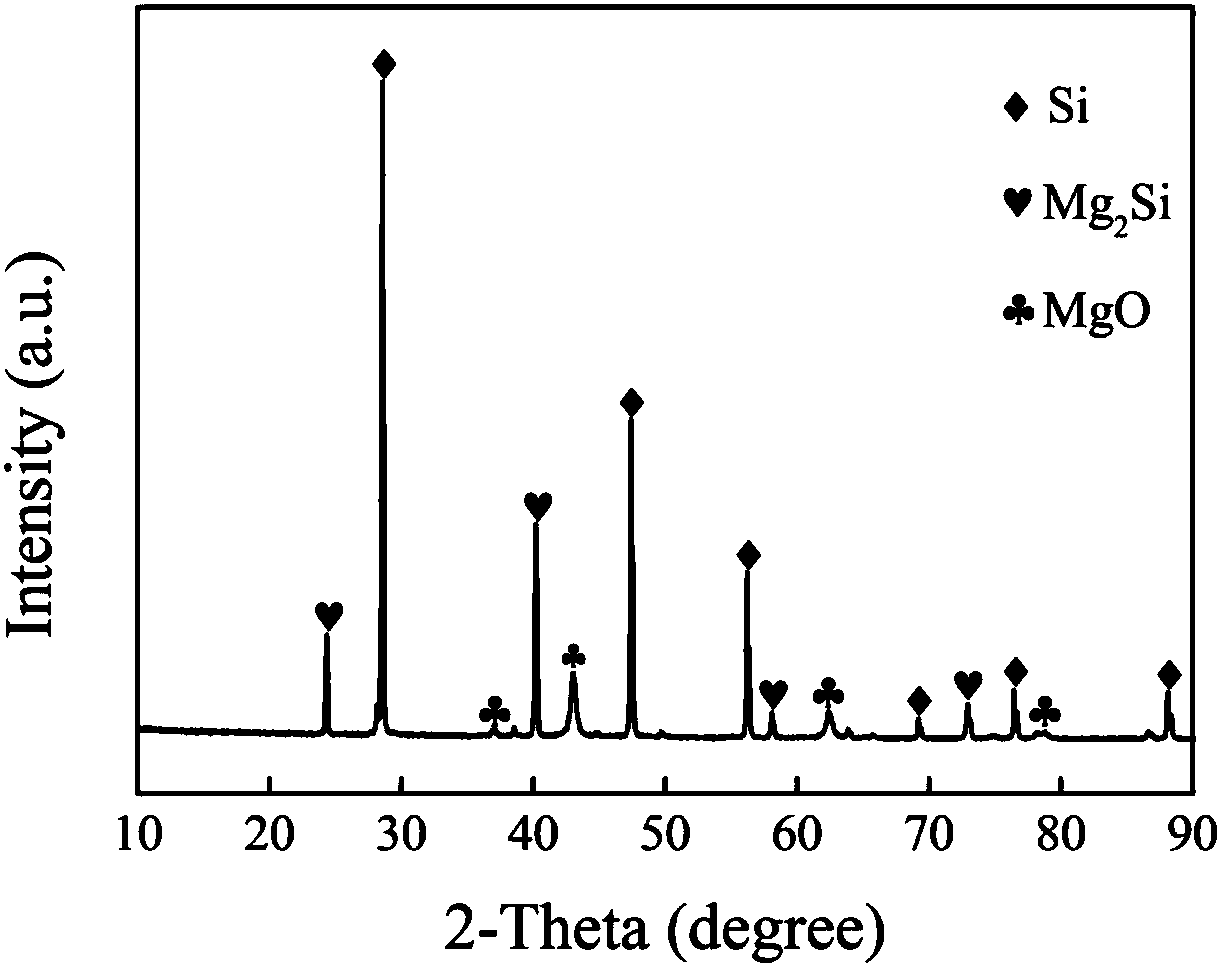

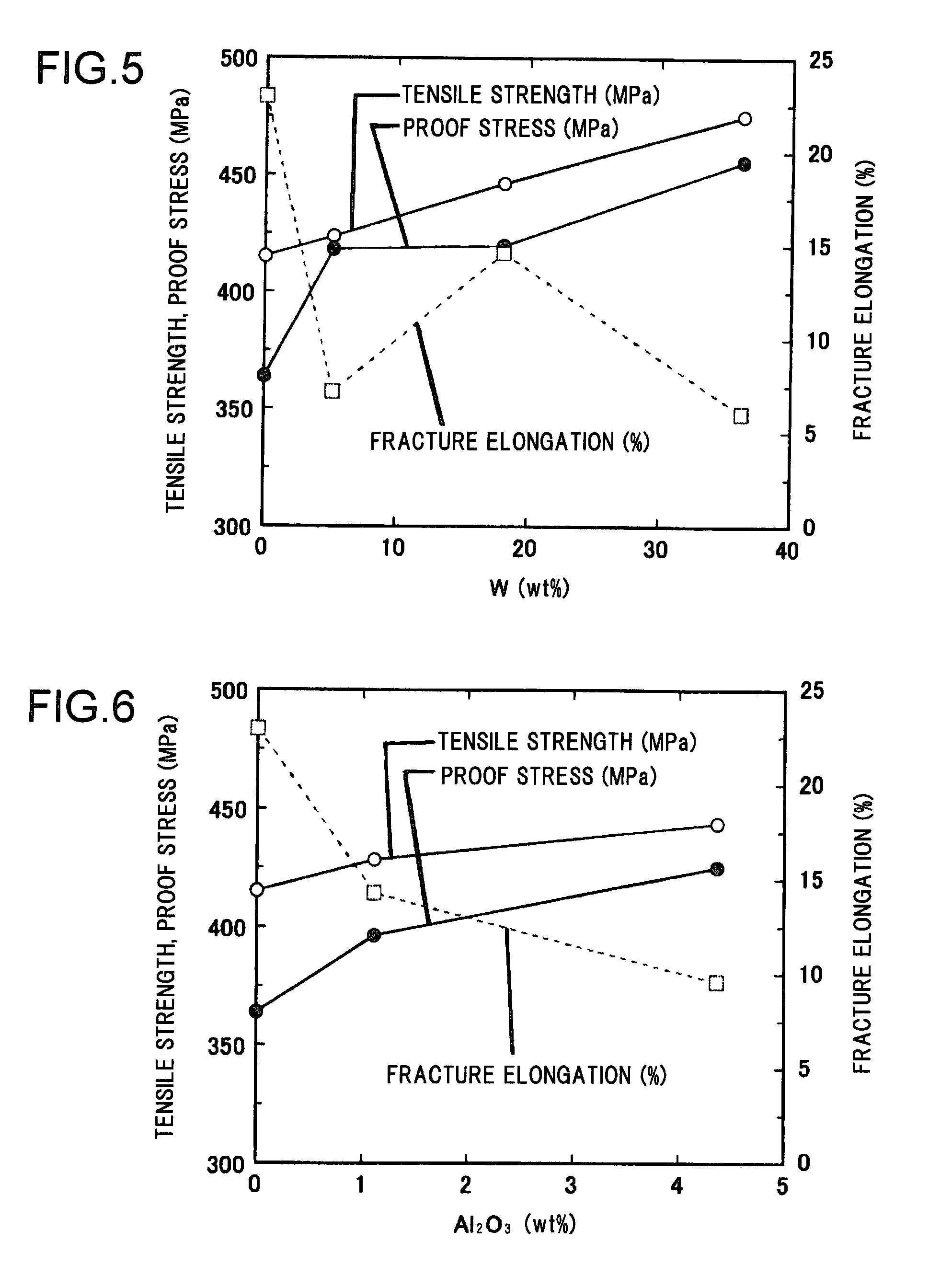

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

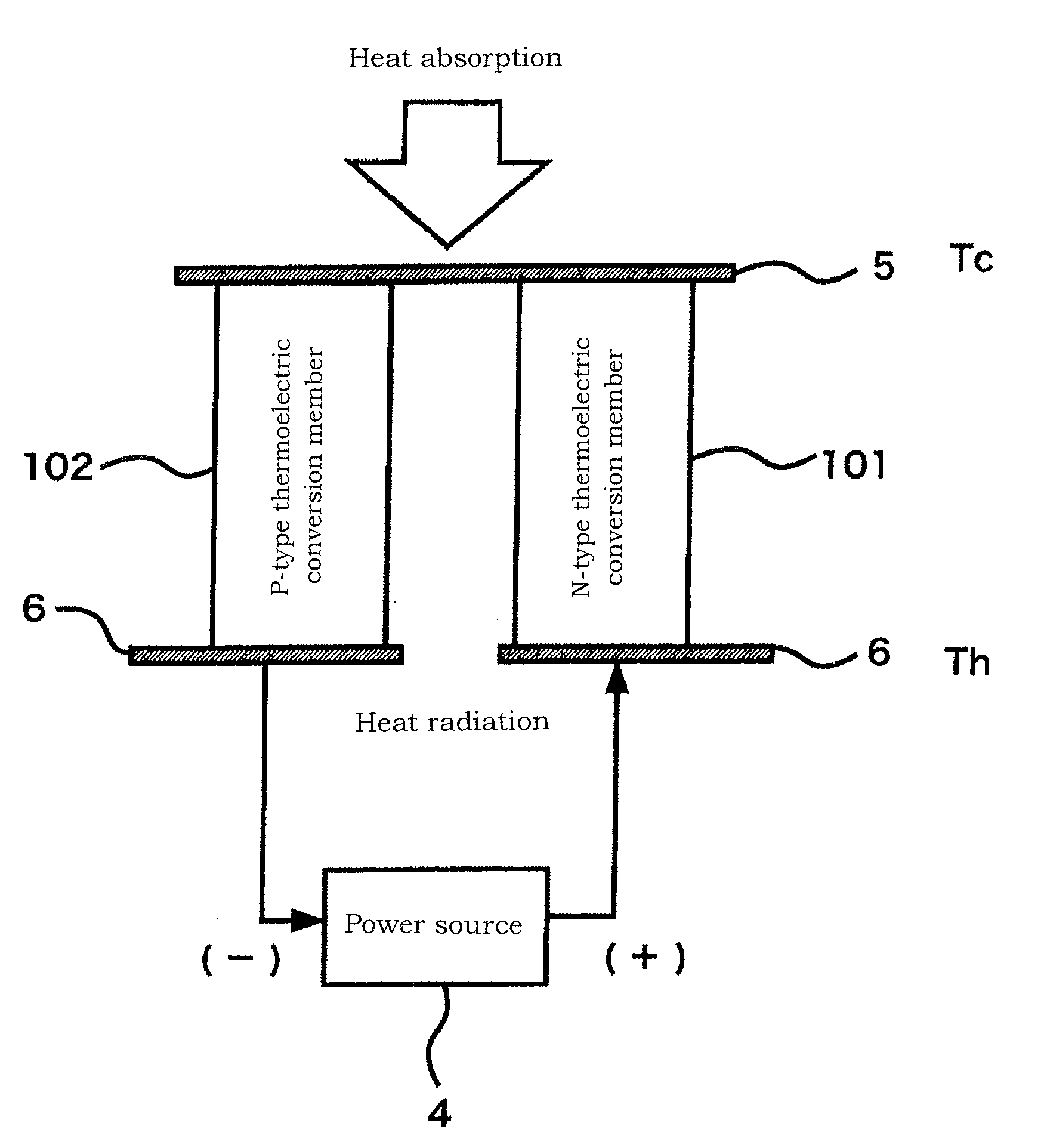

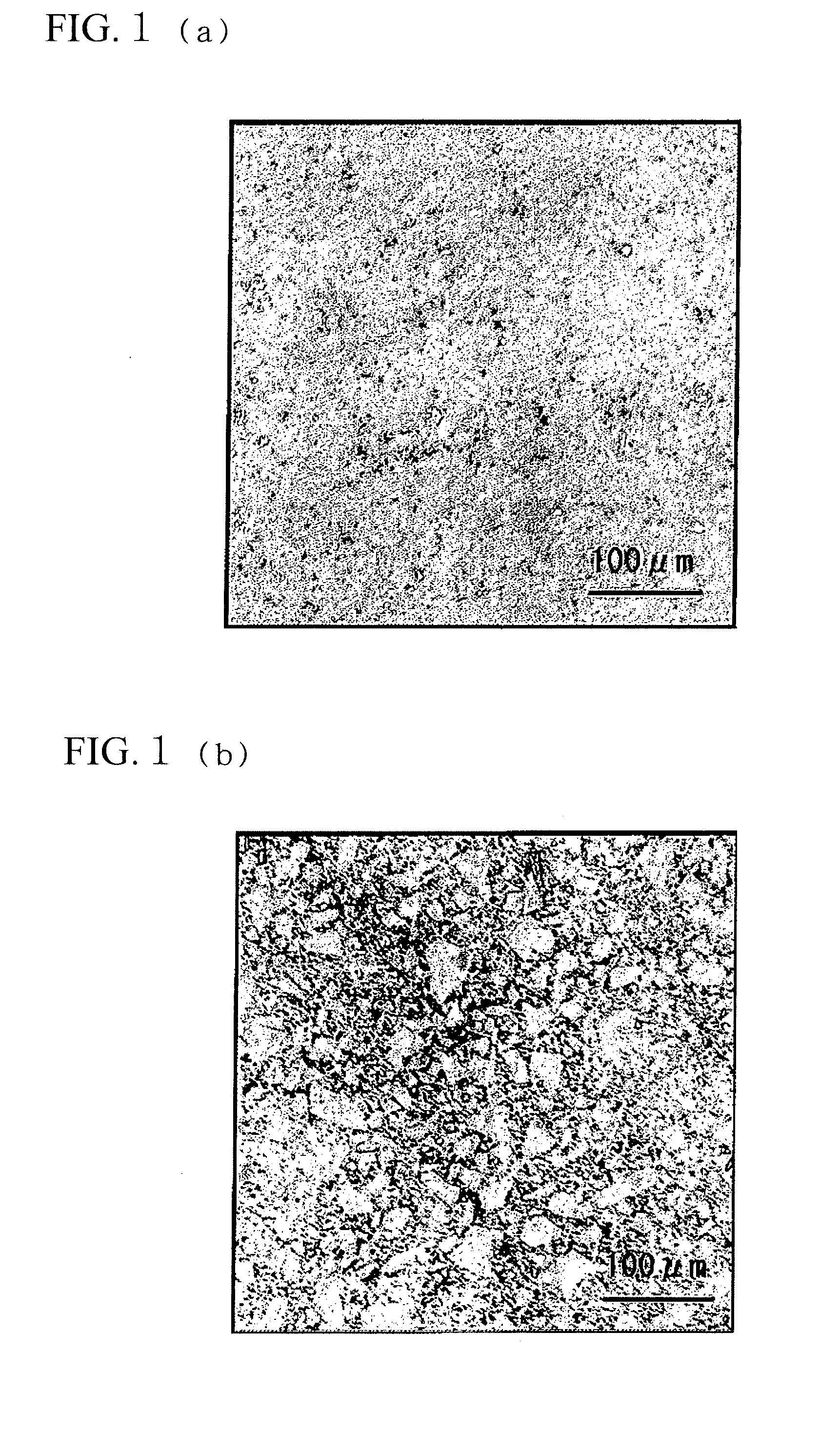

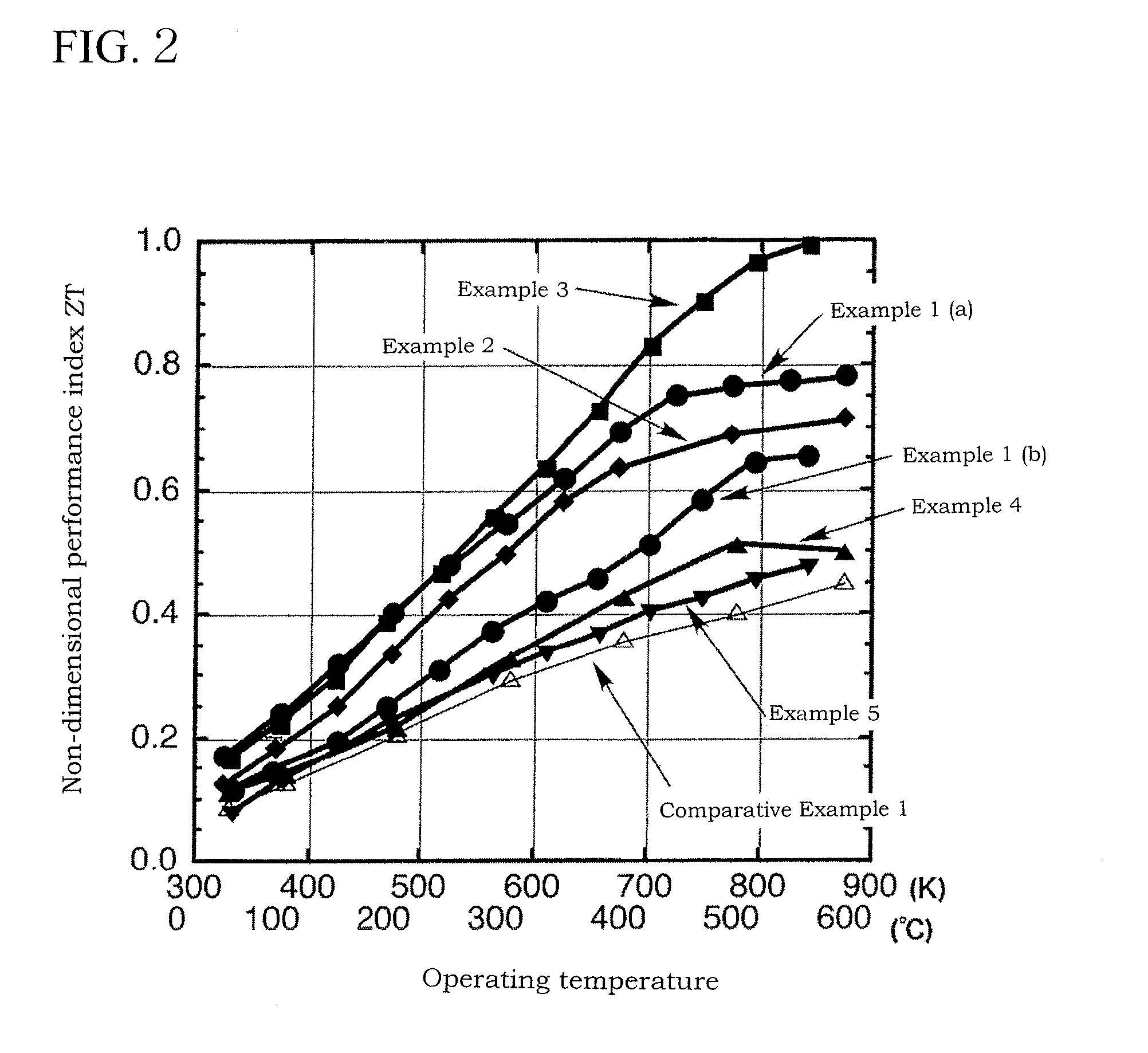

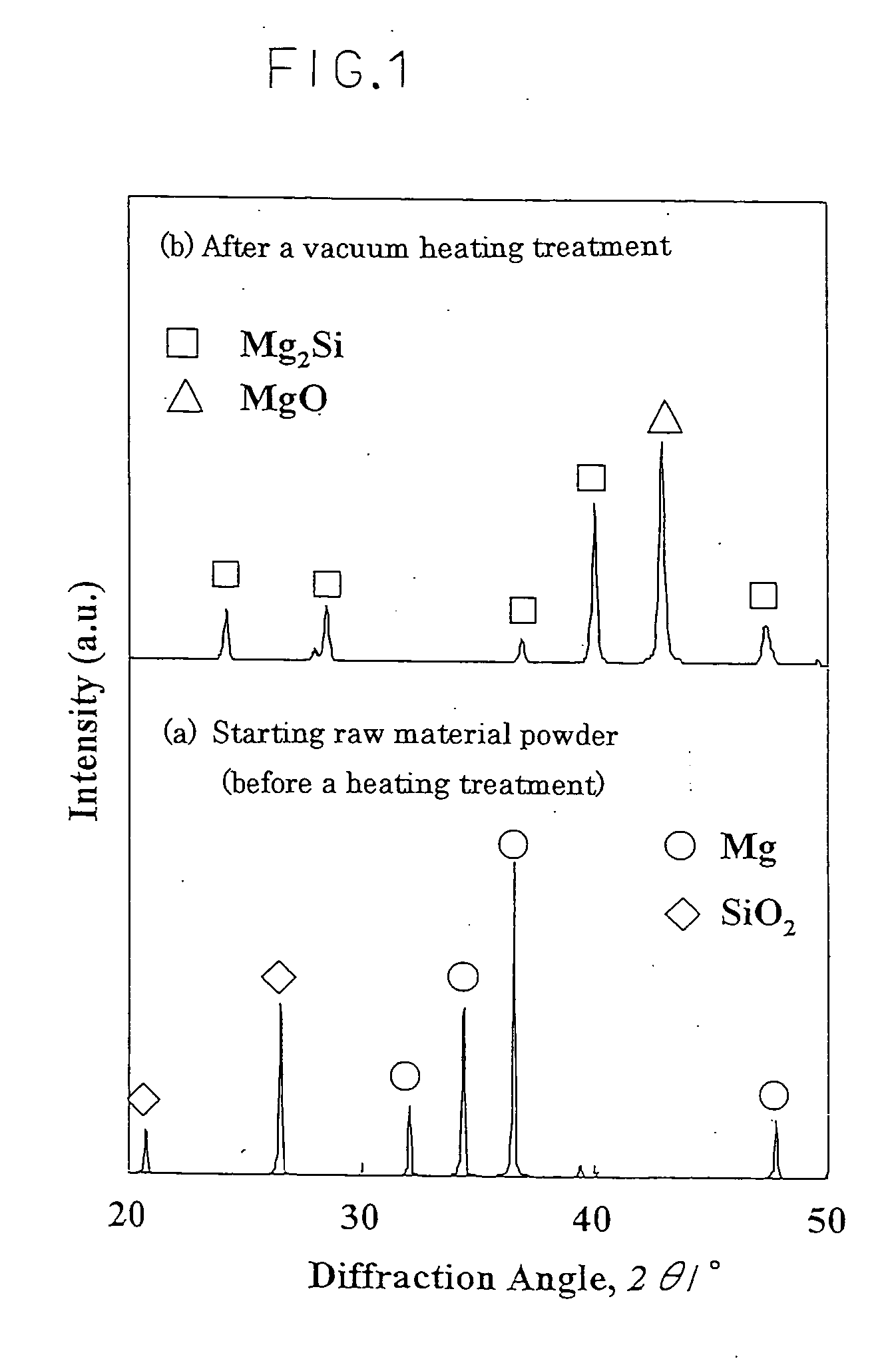

Thermoelectric conversion material, method for manufacturing the same, and thermoelectric conversion element

InactiveUS20100051081A1Increased durabilityHigh physical strengthSludge treatmentSiliconSludgeMagnesium silicide

A thermoelectric conversion material is provided which stably exhibits high thermoelectric conversion performance at about 300 to 600° C. and has high physical strength, resistance to weathering, durability, stability, and reliability. A method for manufacturing the same, and a thermoelectric conversion element are also provided. Also provided is a thermoelectric conversion material produced using, as a raw material, silicon sludge which has had to be disposed of in landfill. The thermoelectric conversion material of the invention is characterized by containing, as a main component, a sintered body composed of polycrystalline magnesium silicide containing at least one element selected from As, Sb, P, Al, and B. The manufacturing method uses purified and refined silicon sludge.

Owner:SHOWA KDE +2

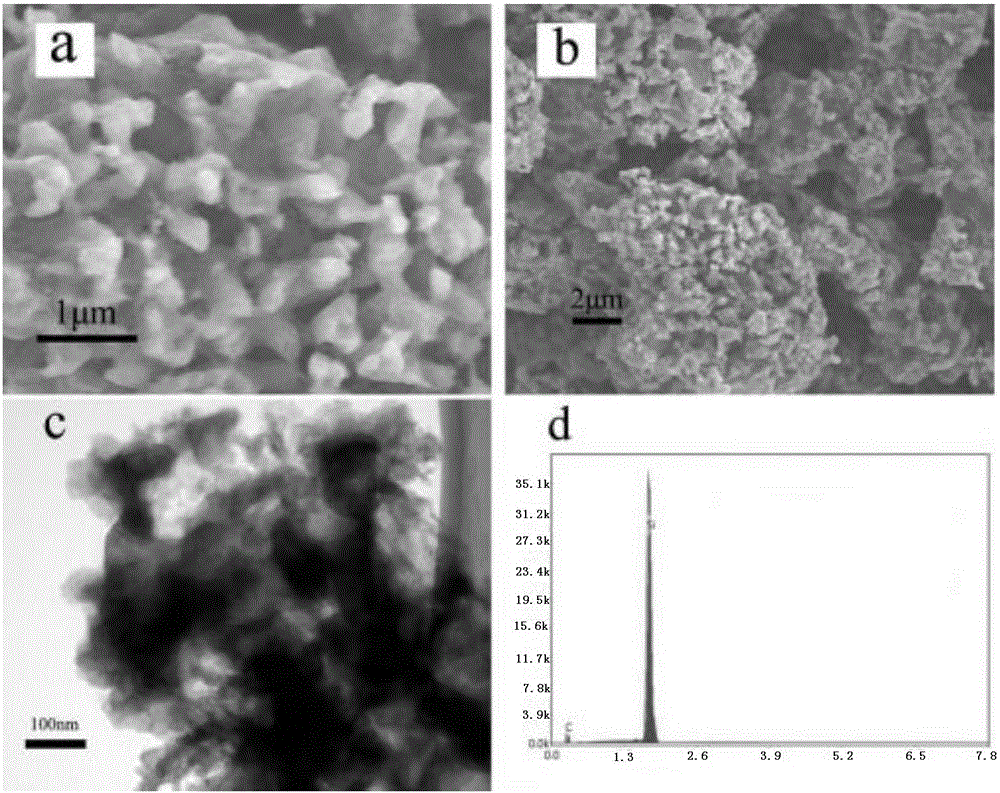

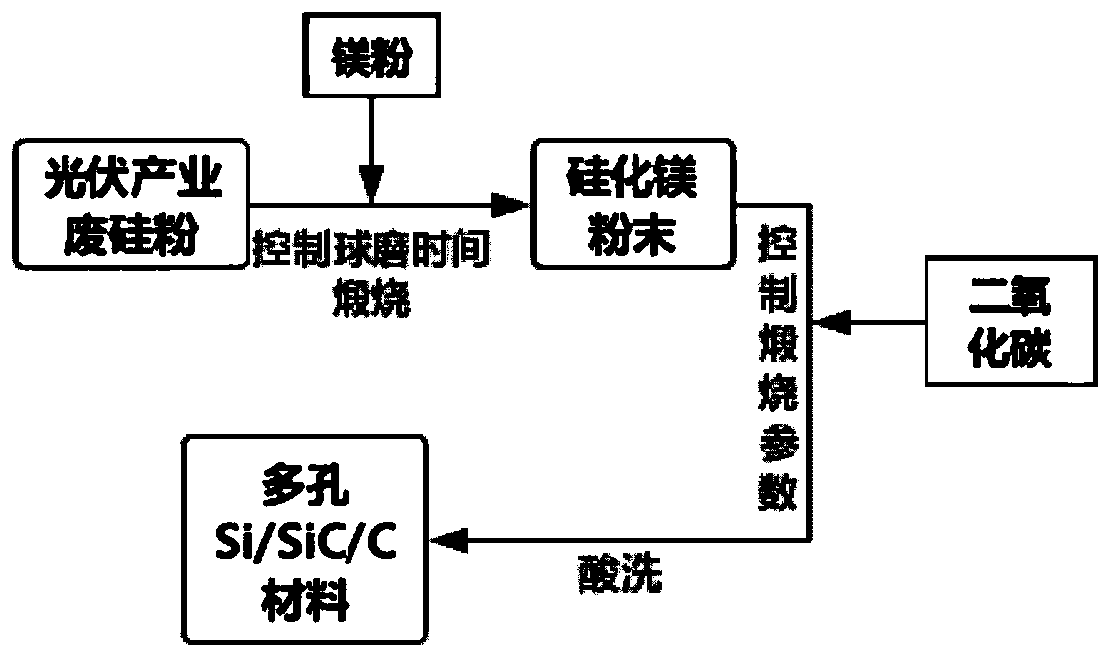

Porous silicon-carbon composite material and preparation method and application thereof

ActiveCN105826527AImprove cycle stabilitySimple processCell electrodesSecondary cellsCarbon compositesMagnesium silicide

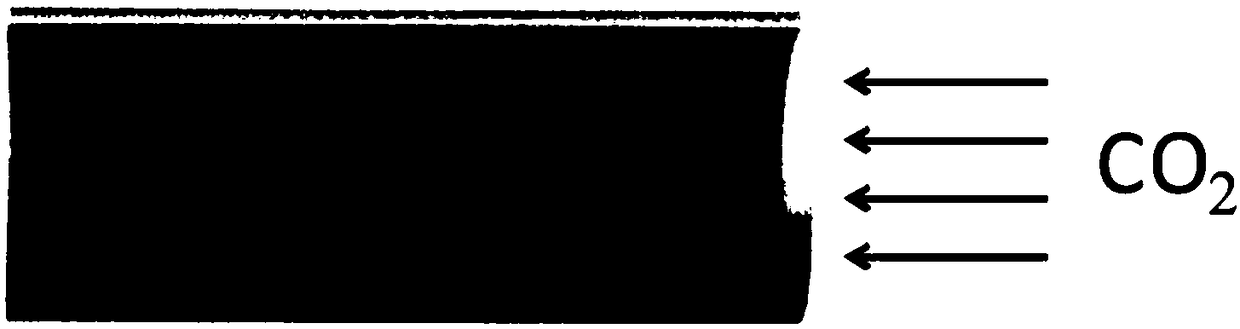

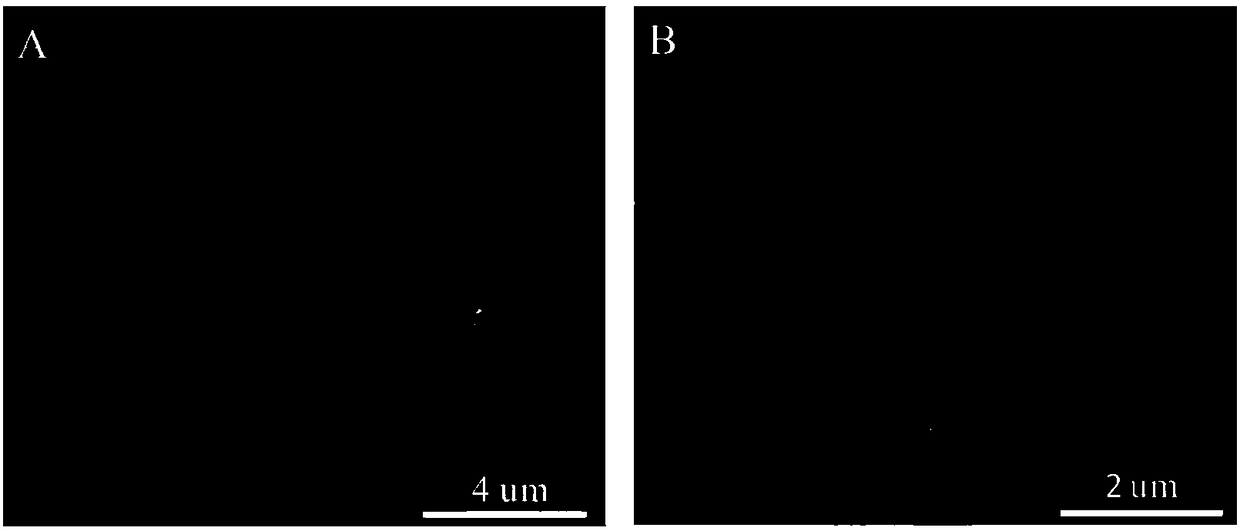

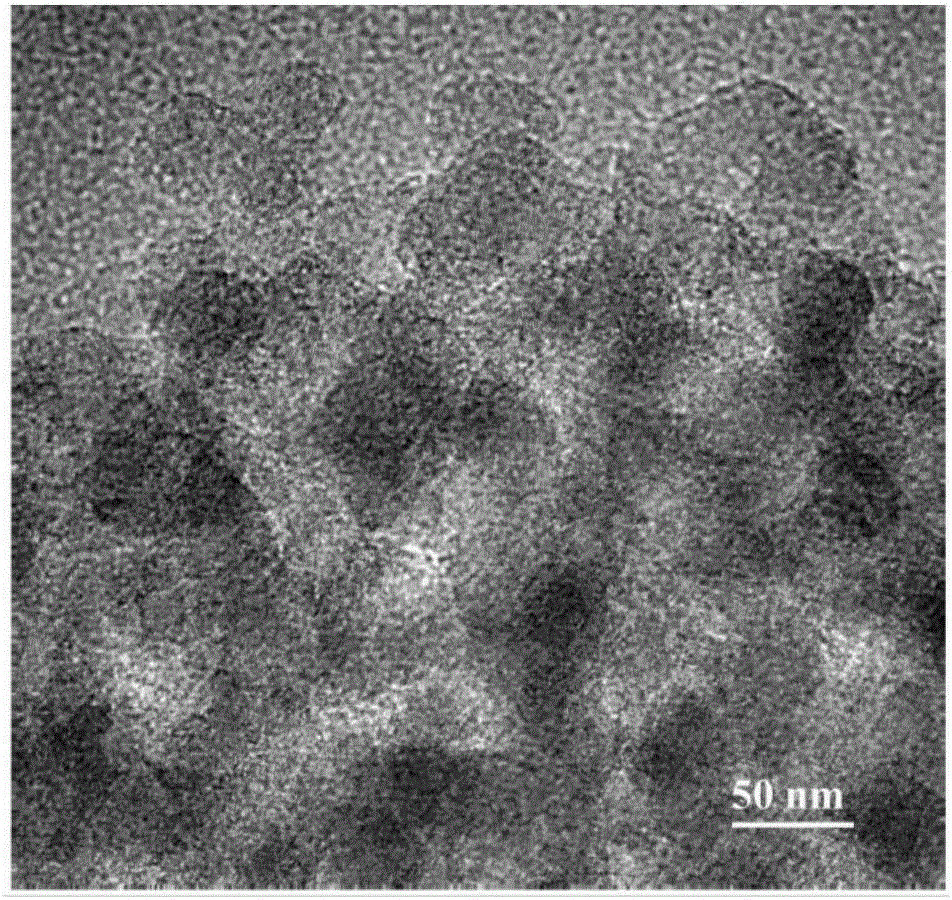

The invention discloses a preparation method of a porous silicon-carbon composite material.The preparation method specifically comprises the steps that magnesium silicide powder is placed in a CO2-Ar mixed atmosphere to be subjected to heat treatment at the temperature of 700 DEG C-900 DEG C and then subjected to acid pickling and aftertreatment to obtain the porous silicon-carbon composite material, wherein the volume fraction of CO2 in the CO2-Ar mixed atmosphere is 10%-90%.According to the preparation method, the technology is simple, repetition is easy to achieve, and large-scale industrialized production can be achieved.When the porous silicon-carbon composite material prepared through the method is applied to a lithium ion battery by serving as a negative electrode material, the circulating stability of the lithium ion battery can be significantly improved.

Owner:ZHEJIANG UNIV

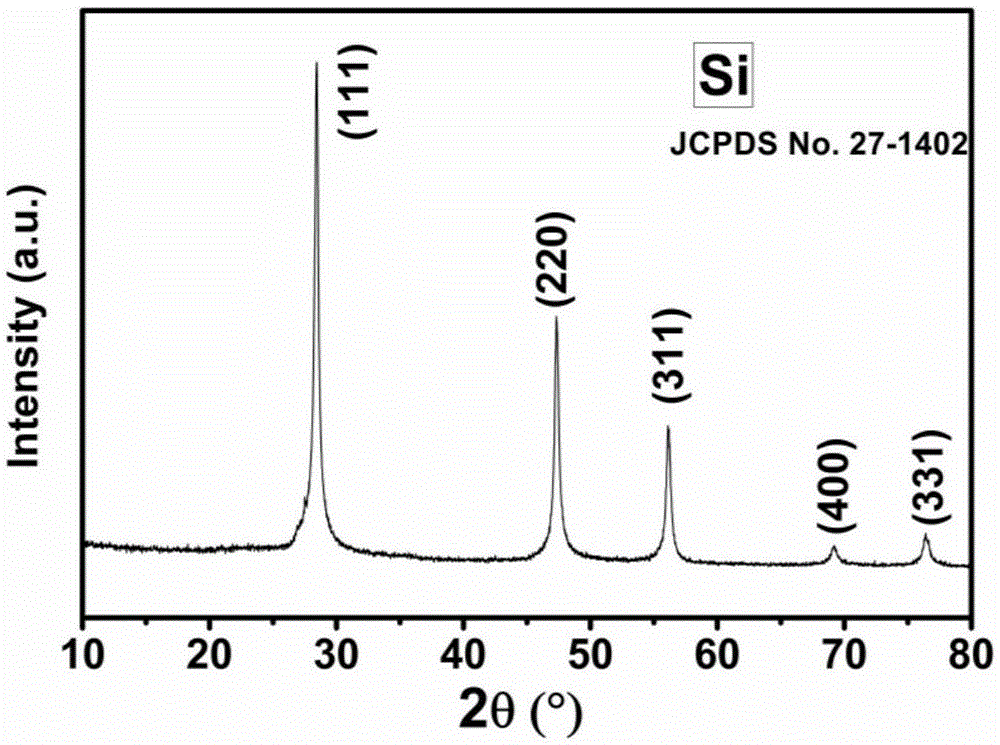

Method for producing nanometer silicon by adopting rice hull

ActiveCN104030290AReduce manufacturing costReduce pollutionMaterial nanotechnologySilicon compoundsSilicon dioxidePollution

The invention relates to a method for producing nanometer silicone by adopting rice hull. The method for producing the nanometer silicone by adopting the rice hull comprises the following steps: carrying out heat treatment on the rice hull, so that silicon dioxide is obtained; carrying out reduction reaction on the silicon dioxide and magnesium, so that an intermediate containing the nanometer silicone, magnesium silicide, silicon dioxide and magnesium oxide is obtained; treating the intermediate with hydrochloric acid, separating filtrate containing magnesium silicate and magnesium oxide, and treating with hydrofluoric acid, filtering to remove filtrate containing silicon dioxide; rinsing products of the previous step to be neutral, and drying, so that the nanometer silicone is obtained. By applying the method for producing the nanometer silicone by adopting the rice hull, the nanometer silicone can be produced by adopting the rice hull, the rice hull can be changed into things of value, pollution to the environment when the rice hull is incinerated is reduced, production cost of the nanometer silicone is reduced, and considerable social benefit and economic benefit can be obtained; the obtained nanometer silicon material has porous structures and strong physical properties and can be applied to the fields of medicines, electronics and environmental protection.

Owner:金之坚

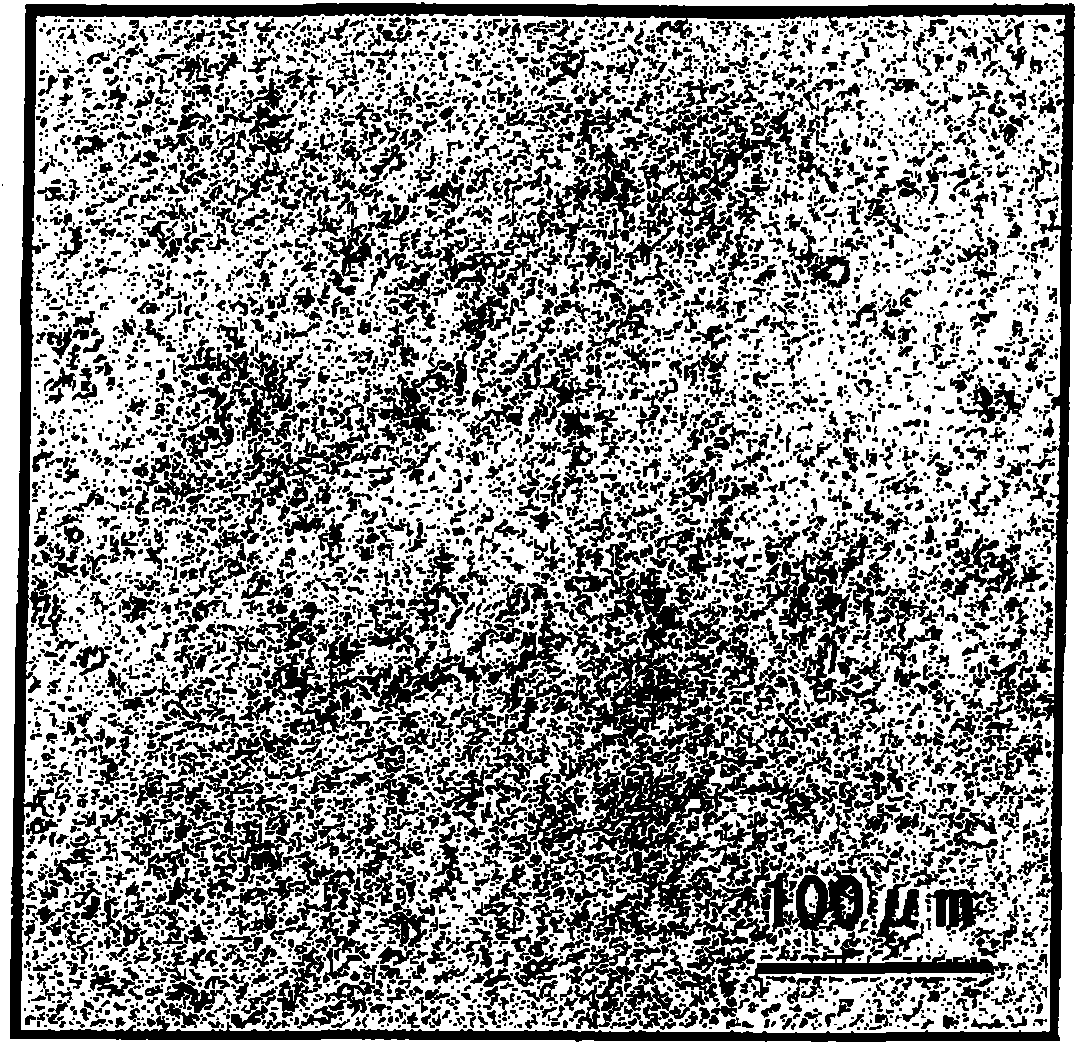

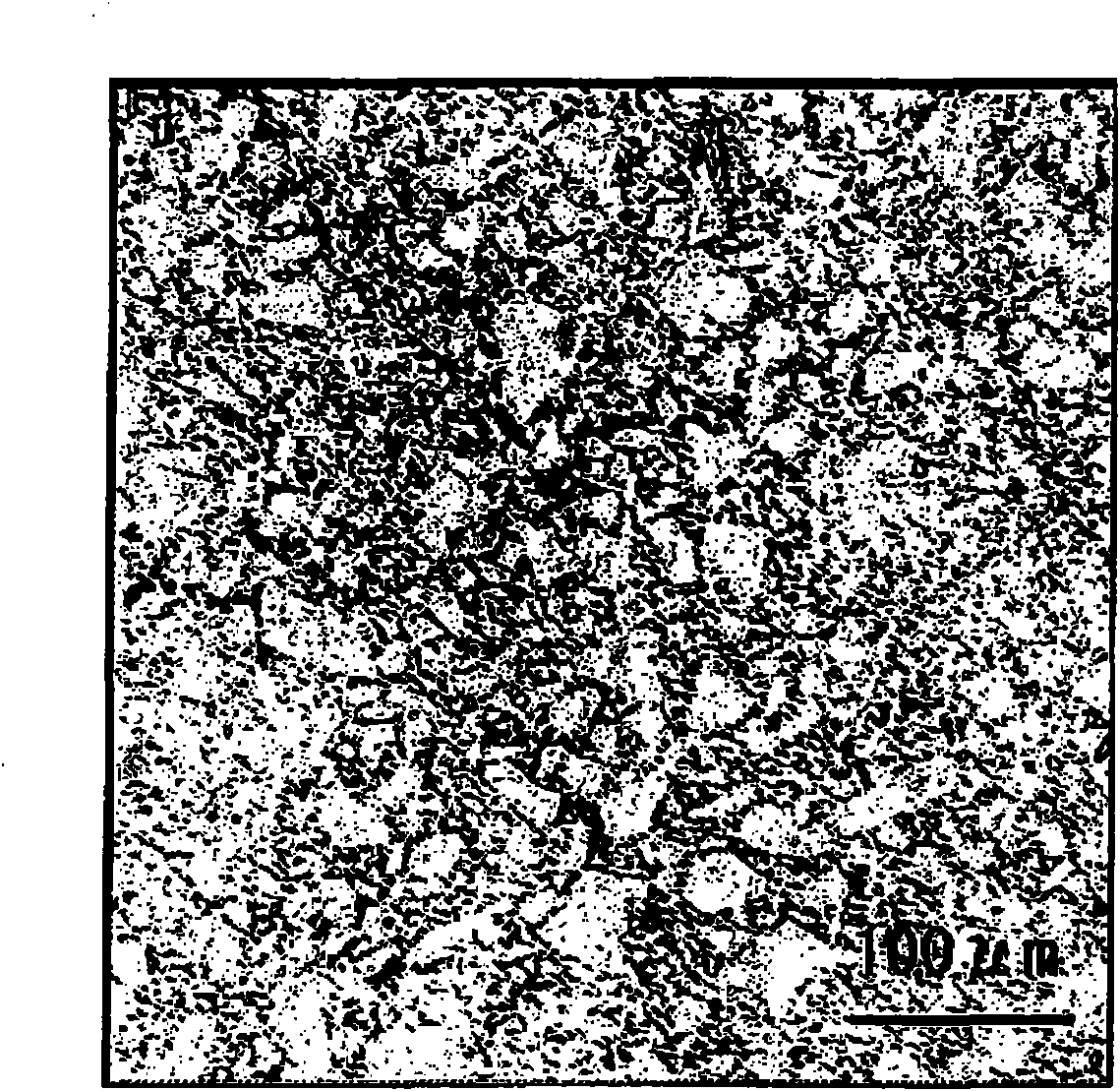

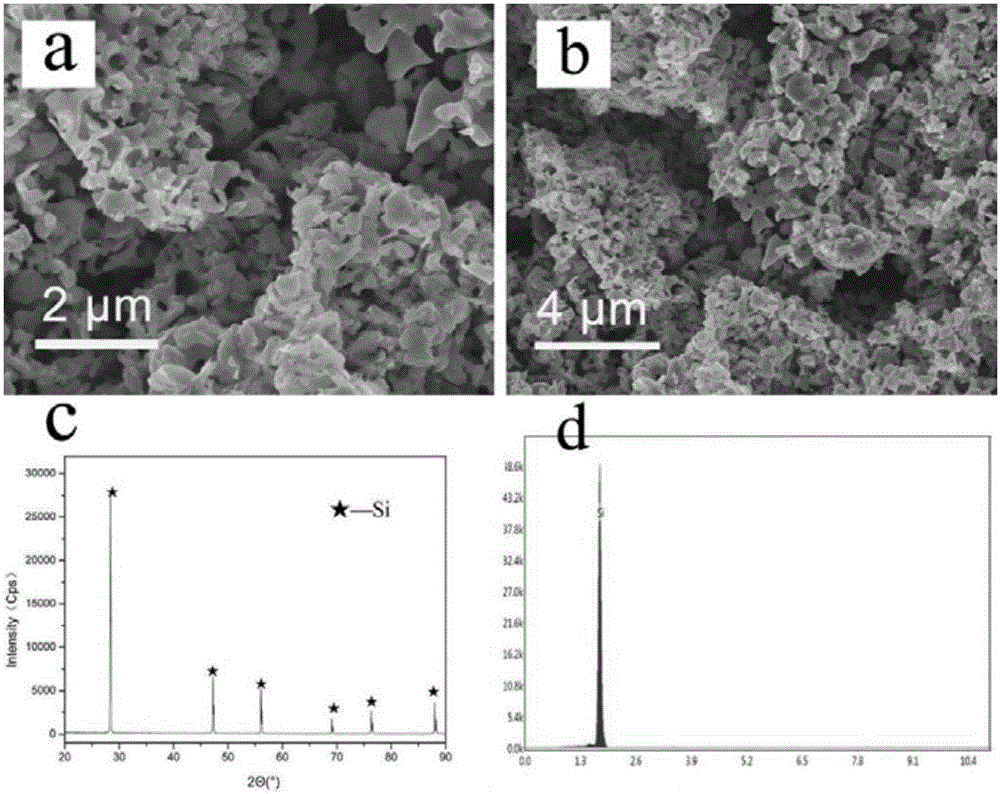

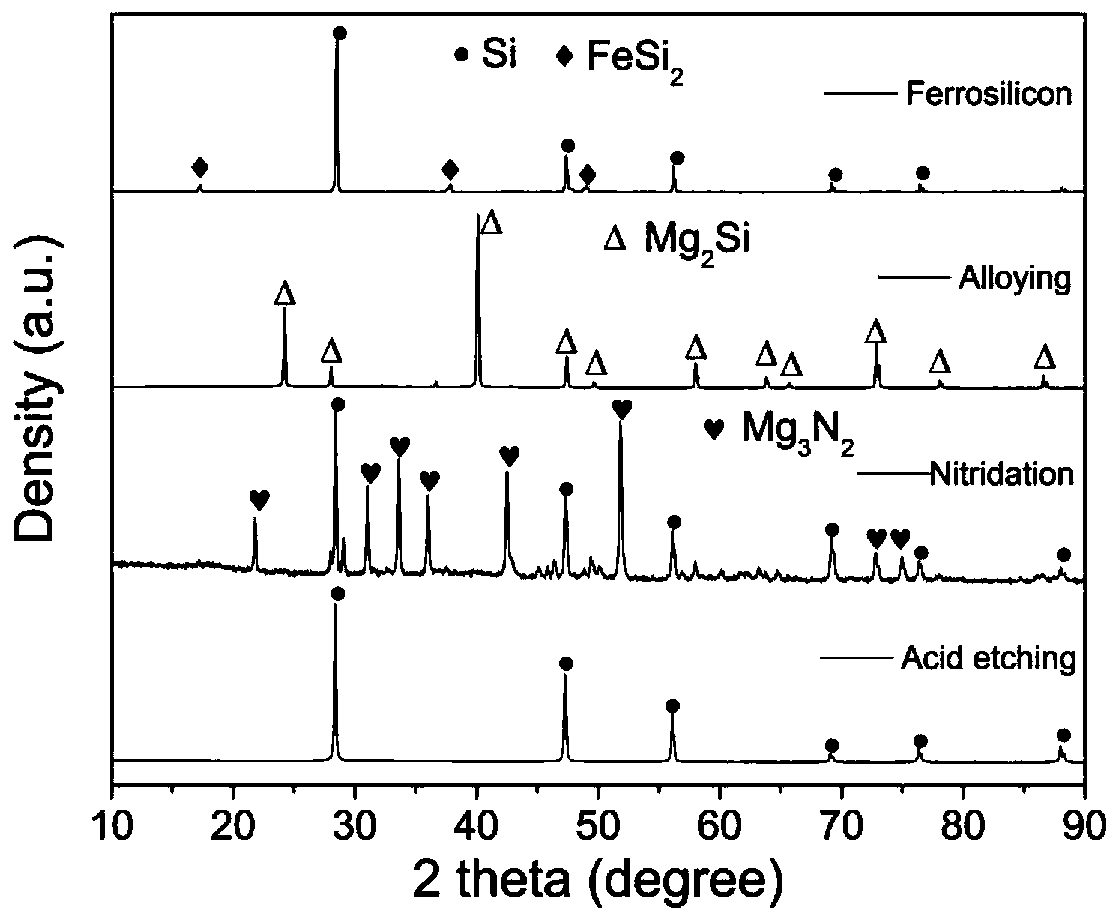

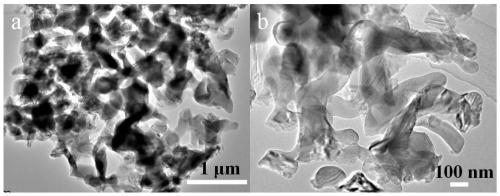

Preparation method of formicary-shaped porous silicon for lithium ion battery

ActiveCN107215874ASave raw materialsThe synthesis method is simpleCell electrodesSecondary cellsLithium-ion batteryReaction step

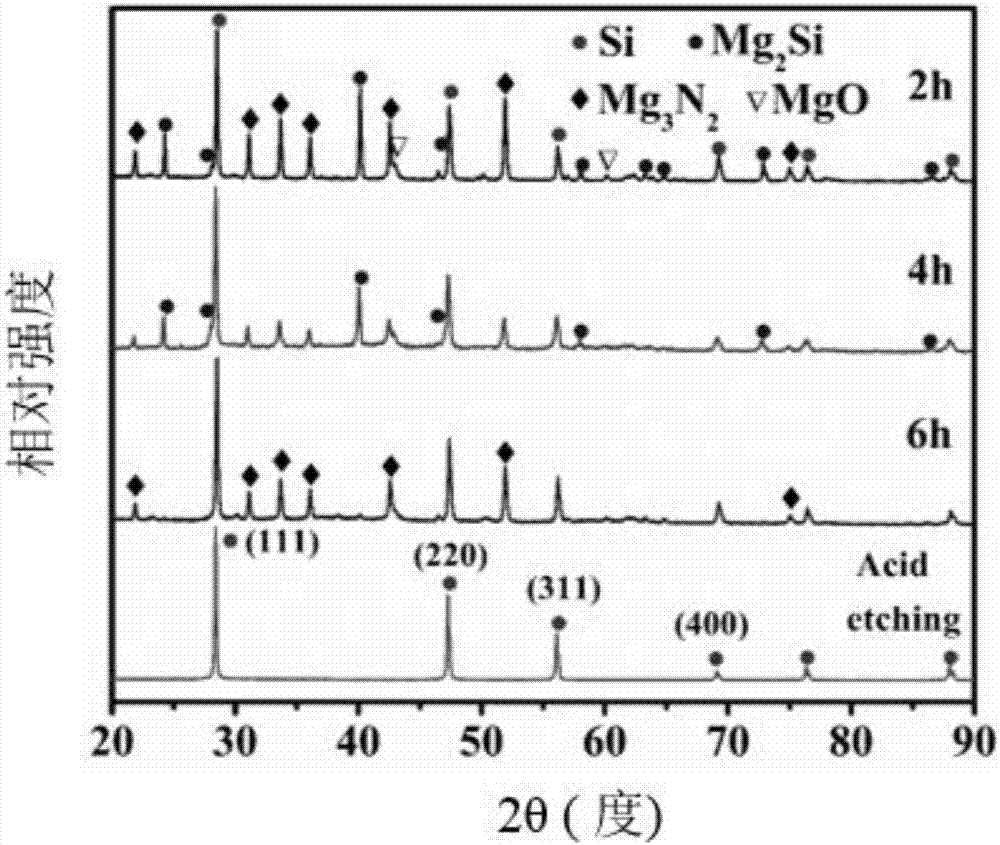

The invention discloses a preparation method of formicary-shaped porous silicon for a lithium ion battery. The preparation method comprises the following steps: (1) enabling a magnesium silicide raw material to react for 2 to 24h in an ammonia gas atmosphere at a temperature of 600 to 900 DEG C, and obtaining a crude product containing porous silicon (3Mg2Si+4NH3 to 3Si+2Mg3N2+6H2), wherein a particle size of the magnesium silicide raw material is 0.2 to 10 micrometers; and (2) acid pickling the crude product containing the porous silicon to obtain the formicary-shaped porous silicon for the lithium ion battery. By improving an overall process flow of the porous silicon key preparation method and parameters and conditions of various reaction steps, compared with the prior art, the preparation method has the advantage of simplicity and easiness, a great number of porous micrometer silicon can be obtained by directly heating the obtained magnesium silicide in ammonia gas (or mixed gas of the ammonia gas and inert gas), and the yield is high.

Owner:WUHAN UNIV OF SCI & TECH

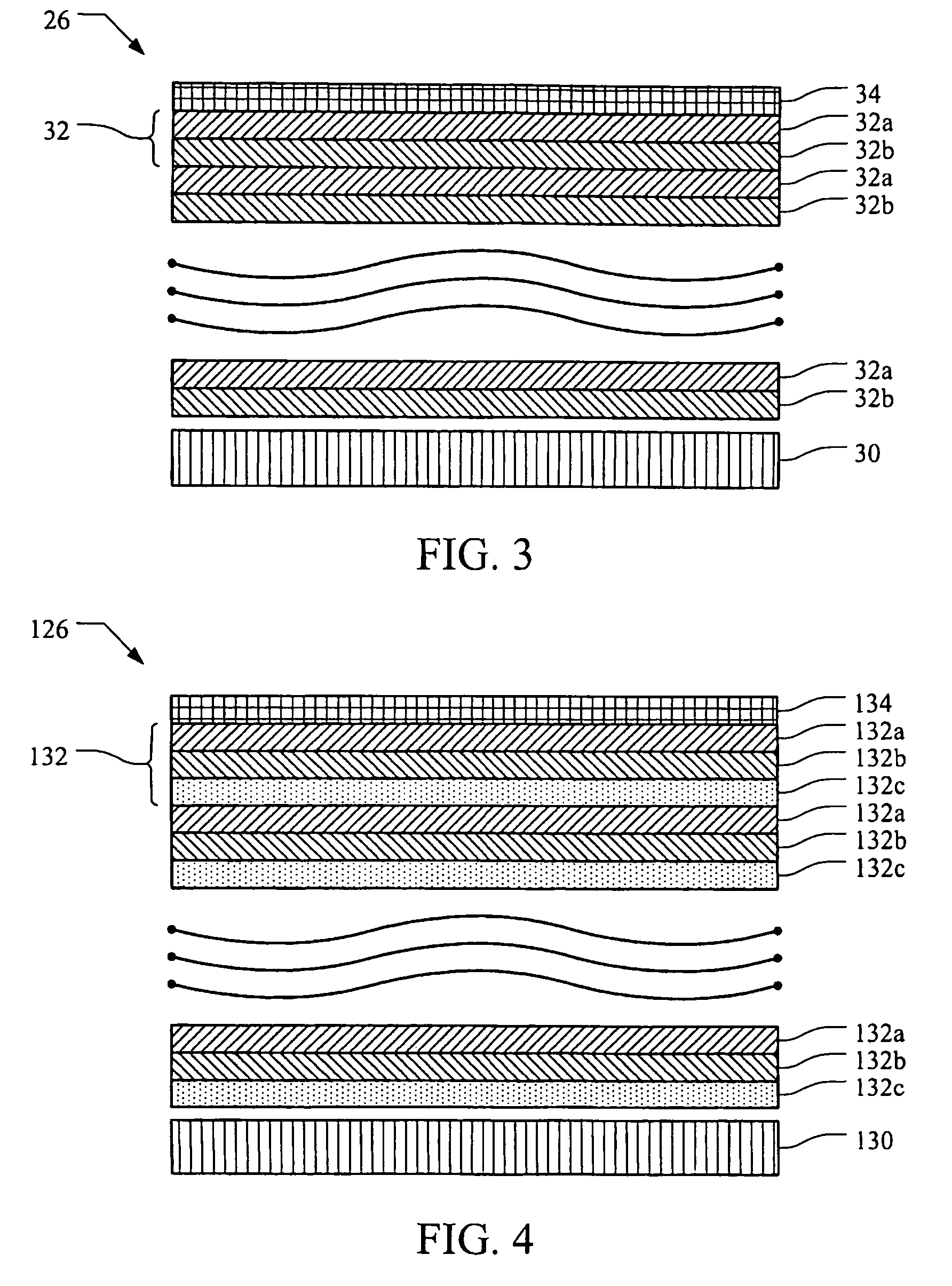

Magnesium silicide-based multilayer x-ray fluorescence analyzers

ActiveUS7848483B2Improve performanceSmoothnessX-ray/infra-red processesX-ray spectral distribution measurementBorideBoron carbide

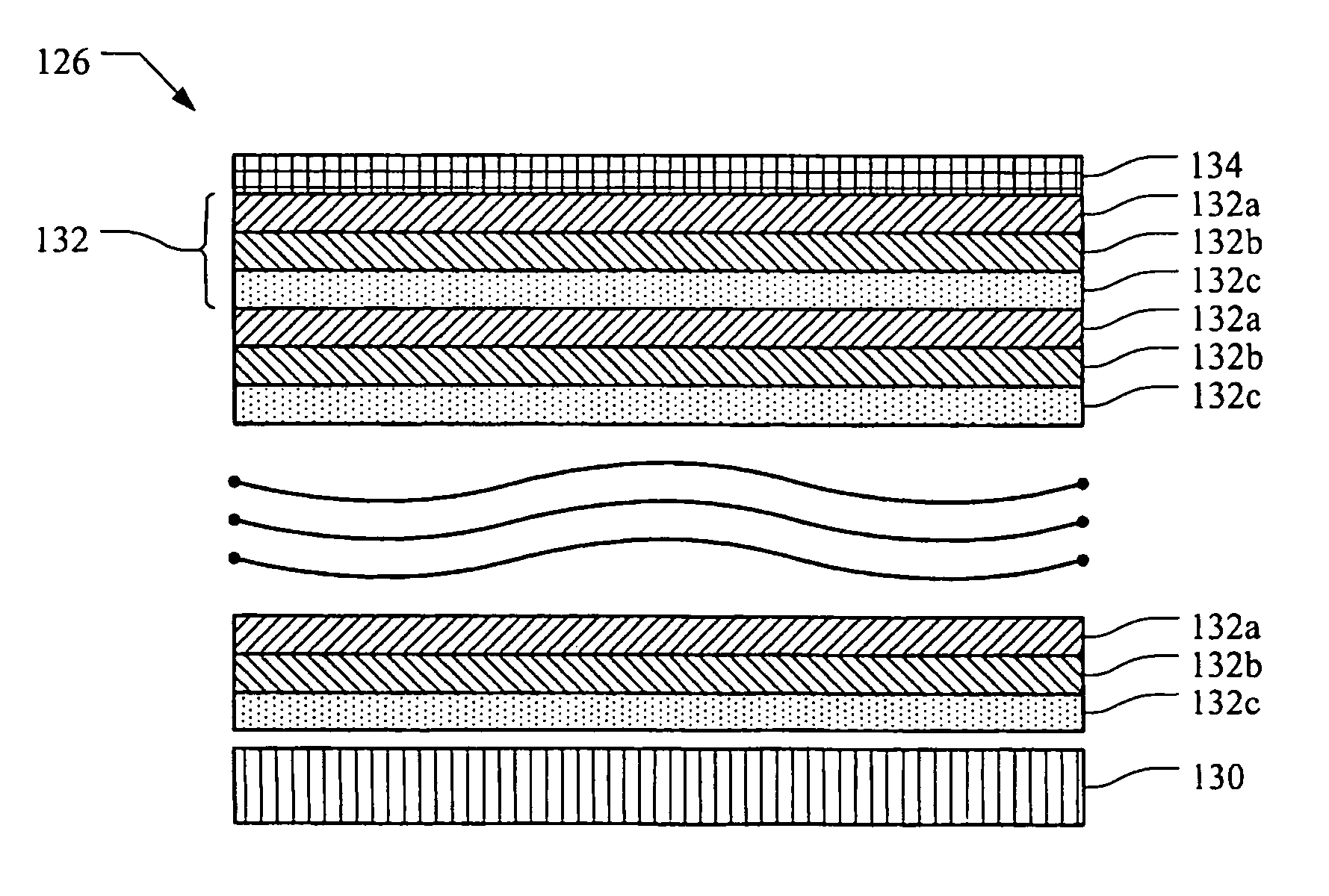

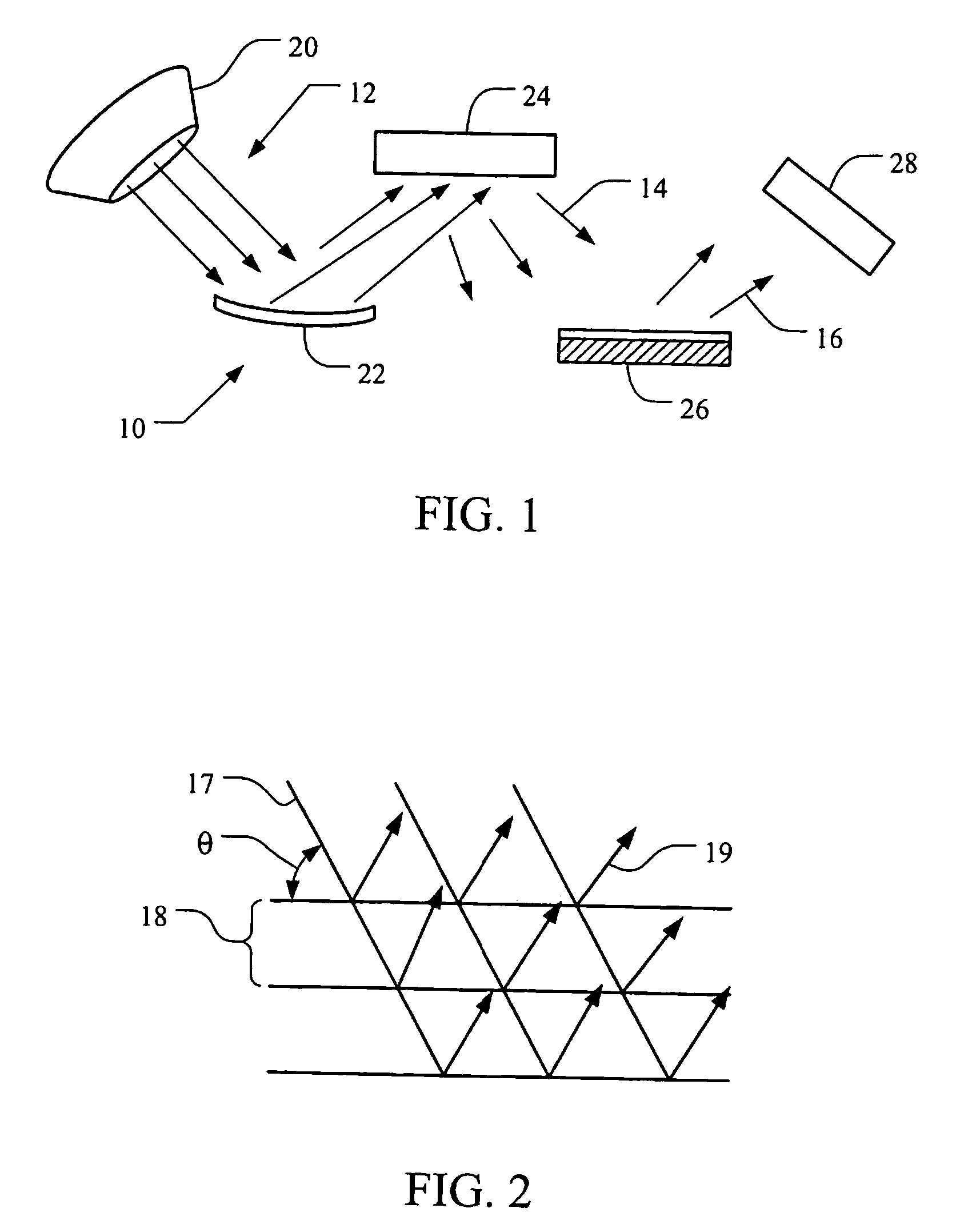

The present invention provides a multilayer structure including a substrate having formed on a surface thereof at least one period of individual layers, the period having at least two layers including a first layer which includes magnesium silicide and a second layer which includes at least one of tungsten, tantalum, cobalt, nickel, copper, iron, chromium, alloys, oxides, borides, silicides, and nitrides of these elements, silicon, carbon, silicon carbide, boron, and boron carbide. If the period includes three layers, the second layer includes one of silicon, carbon, silicon carbide, boron, and boron carbide and a third layer includes one of tungsten, tantalum, cobalt, nickel, copper, iron, chromium, and alloys, oxides, borides, silicides, and nitrides of these elements, the second layer being disposed between the first and the third layers. If the period includes four layers, a fourth layer includes one of silicon, carbon, silicon carbide, boron, and boron carbide, the third layer being disposed between the second and fourth layers, and the fourth layer being disposed between the third layer of multilayer period n and the first layer of multilayer period n−1.

Owner:RIGAKU CORP +1

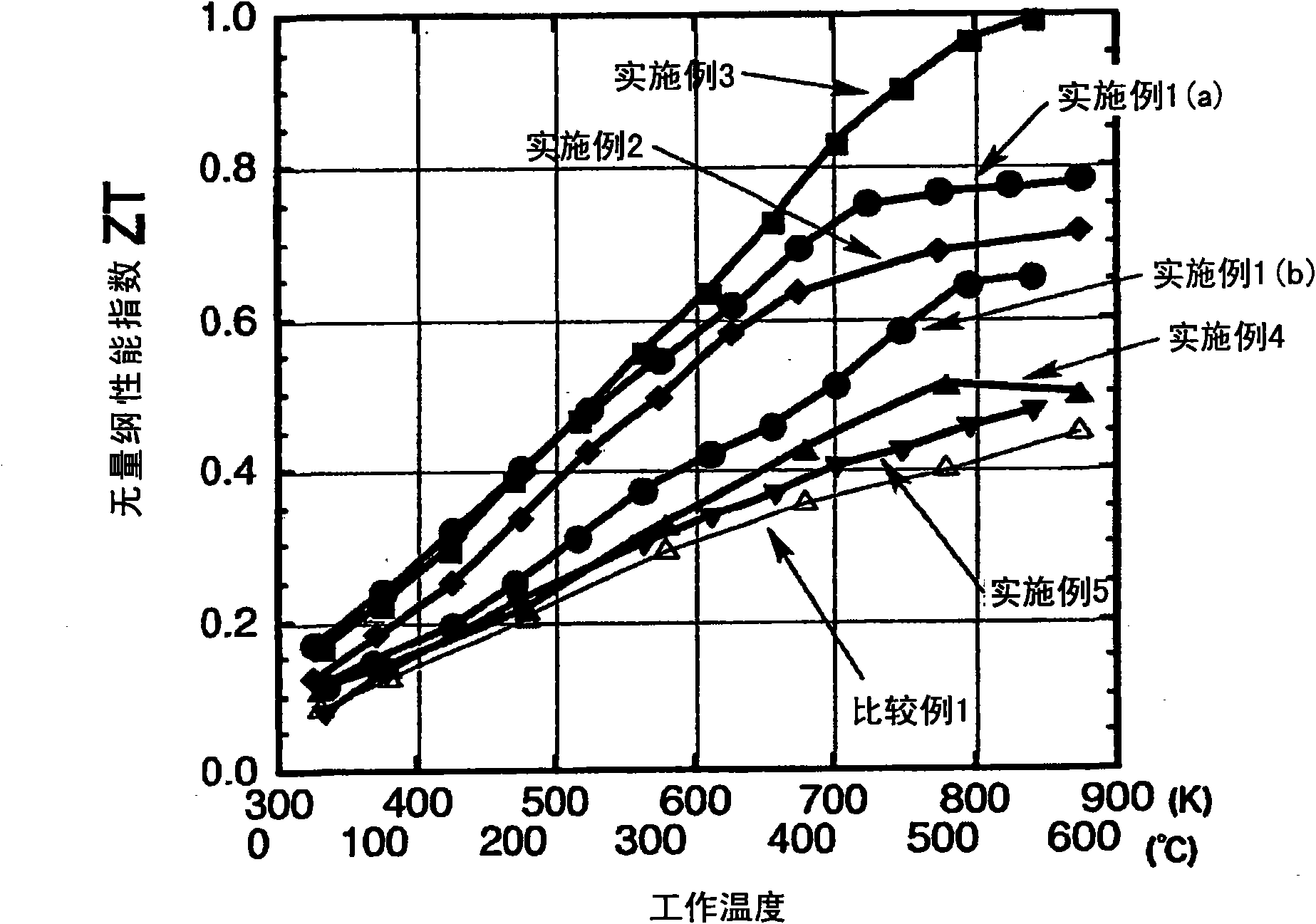

Thermo-electric converting materials, process for producing the same, and thermo-electric converting element

InactiveCN101589480AImprove thermoelectric conversion efficiencyImprove physical strengthSludge treatment by de-watering/drying/thickeningThermoelectric device manufacture/treatmentSludgeUltimate tensile strength

A thermo-electric converting material which can stably have high thermo-electric converting performances at about 300-600 DEG C, has high physical strength, does not weather, and has excellent durability. It has high stability and high reliability. Also provided are a process for producing the material and a thermo-electric converting element. Furthermore provided is a thermo-electric converting material obtained from raw materials including a silicon sludge, which has had no uses except for landfill disposal. thermo-electric converting materials are characterized by including, as a major component, a sinter made of magnesium silicide of a polycrystalline structure containing at least one element selected among arsenic, antimony, phosphorus, aluminum, and boron. In the production process, a silicon sludge which has undergone a purification treatment is used.

Owner:SHOWA KDE +1

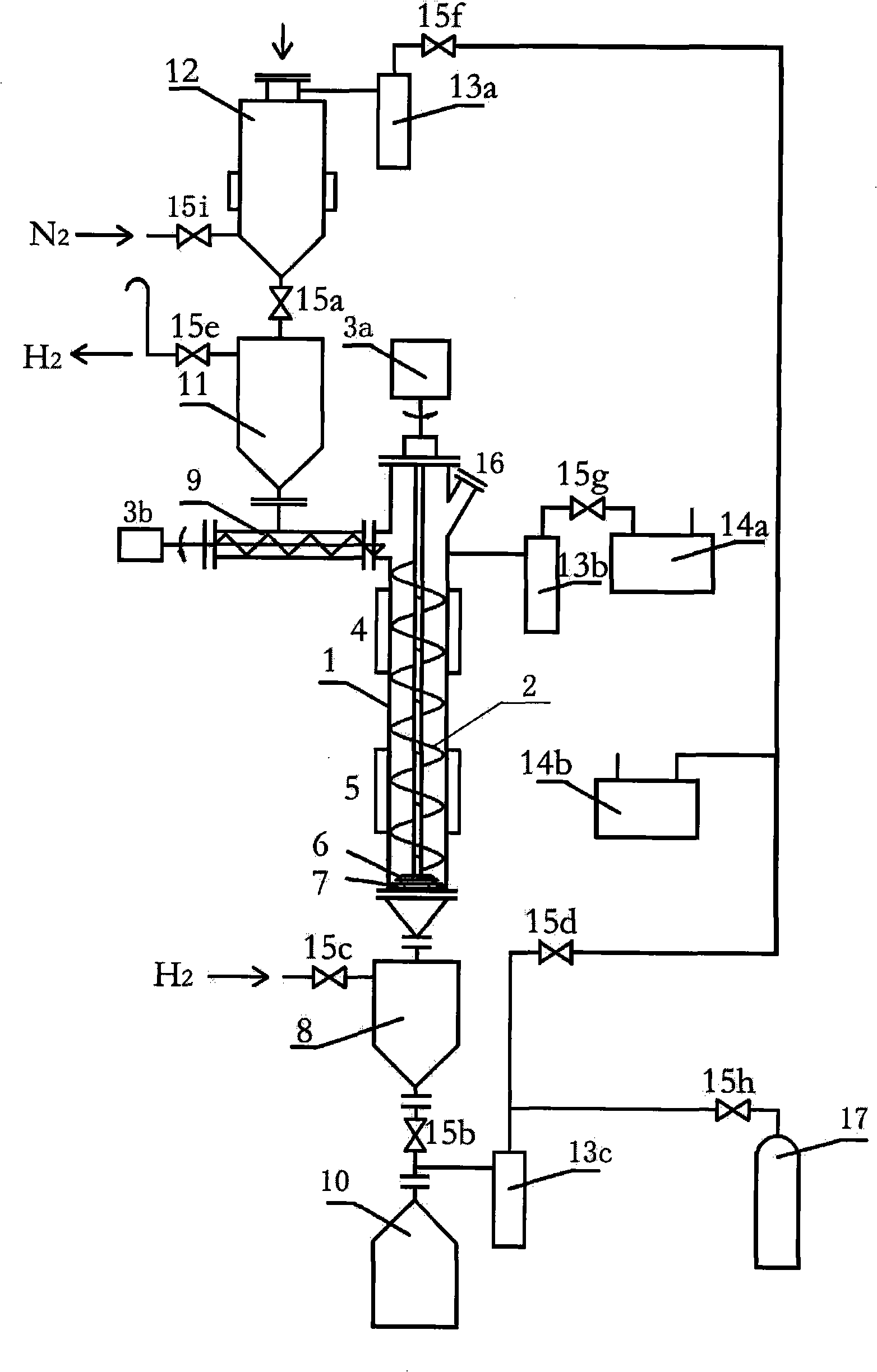

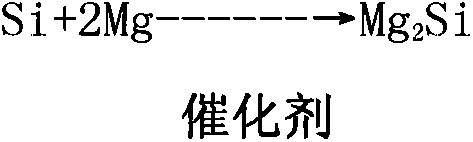

Method for preparing magnesium silicide and device

InactiveCN101306818AIncrease productivityReduce energy consumptionMetal silicidesProduct gasEquivalent weight

The invention discloses a preparation method of magnesium silicide and a device thereof. In the preparation method, equivalently mixed magnesium powder and silicon powder are used as raw materials, continuously fed into a vertical cylindrical reactor from the top under vacuum or gas protection, and continuously stirred, so as to allow uniform and complete reaction and prevent excessive heat generation from the reaction and magnesium vapor escape. The inventive device is mainly the vertical cylindrical reactor instead of a horizontal reactor, and a reducer at the top of the rector is used for driving a spiral stirrer to stir the raw materials; a heater is arranged on the upper part of the outer wall of the reactor for heating, a cooling water jacket is arranged on the lower part of the reactor for cooling, a scraper and a perforated plate are arranged at the bottom of the reactor for pulverizing the generated magnesium silicide from the reaction, the upper part of the reactor is connected with a feeding device, and the lower part of the reactor is connected with a discharge device. After the reaction is completed, the continuous product is made into magnesium silicide powder with fine particle size, uniform composition and equivalent weight through pulverization by the scraper and the perforated plate. The inventive preparation method can realize continuous production of magnesium silicide, improve conversion rate of raw materials, reduce magnesium consumption, and reduce energy consumption.

Owner:ZHEJIANG SCI-TECH UNIV

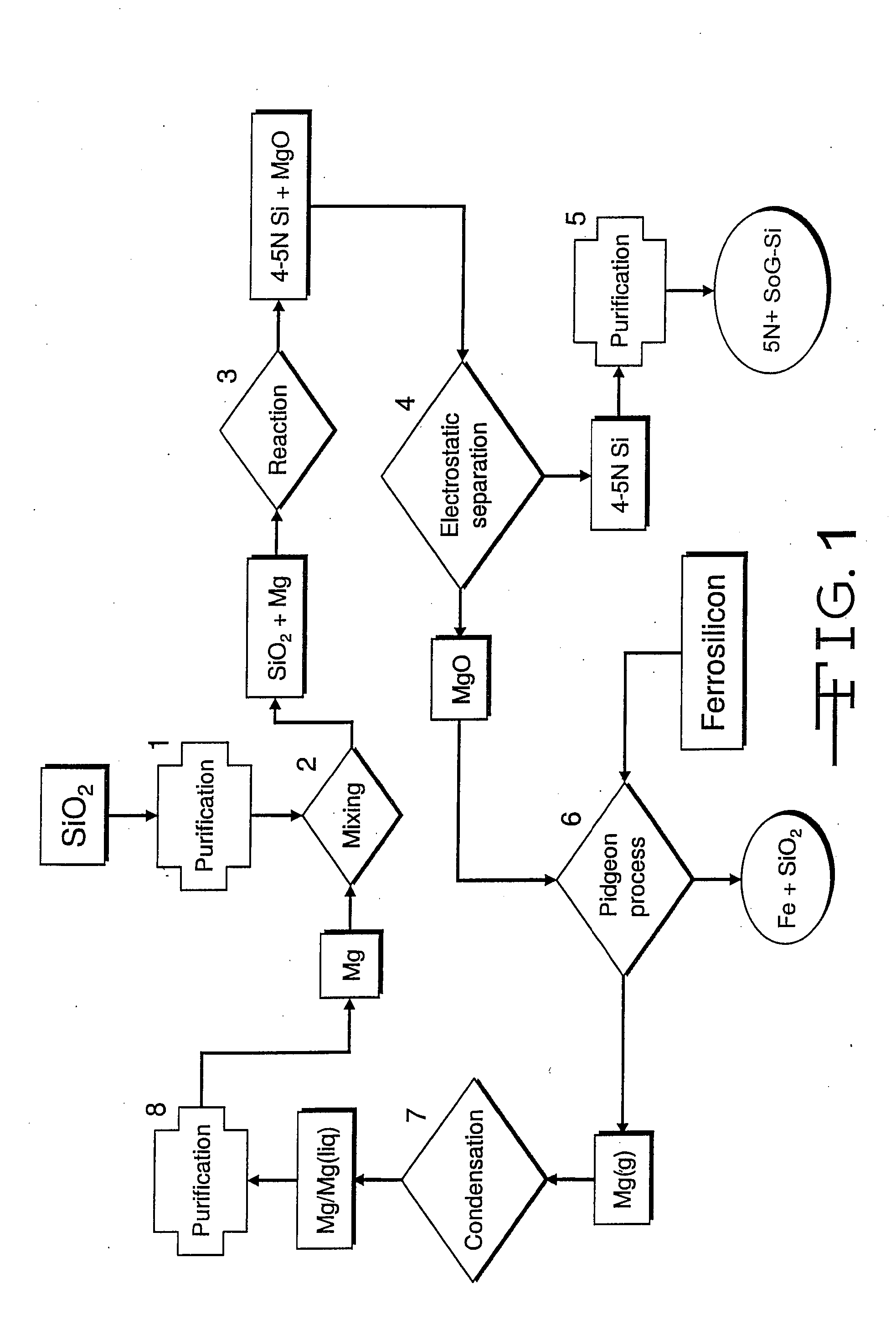

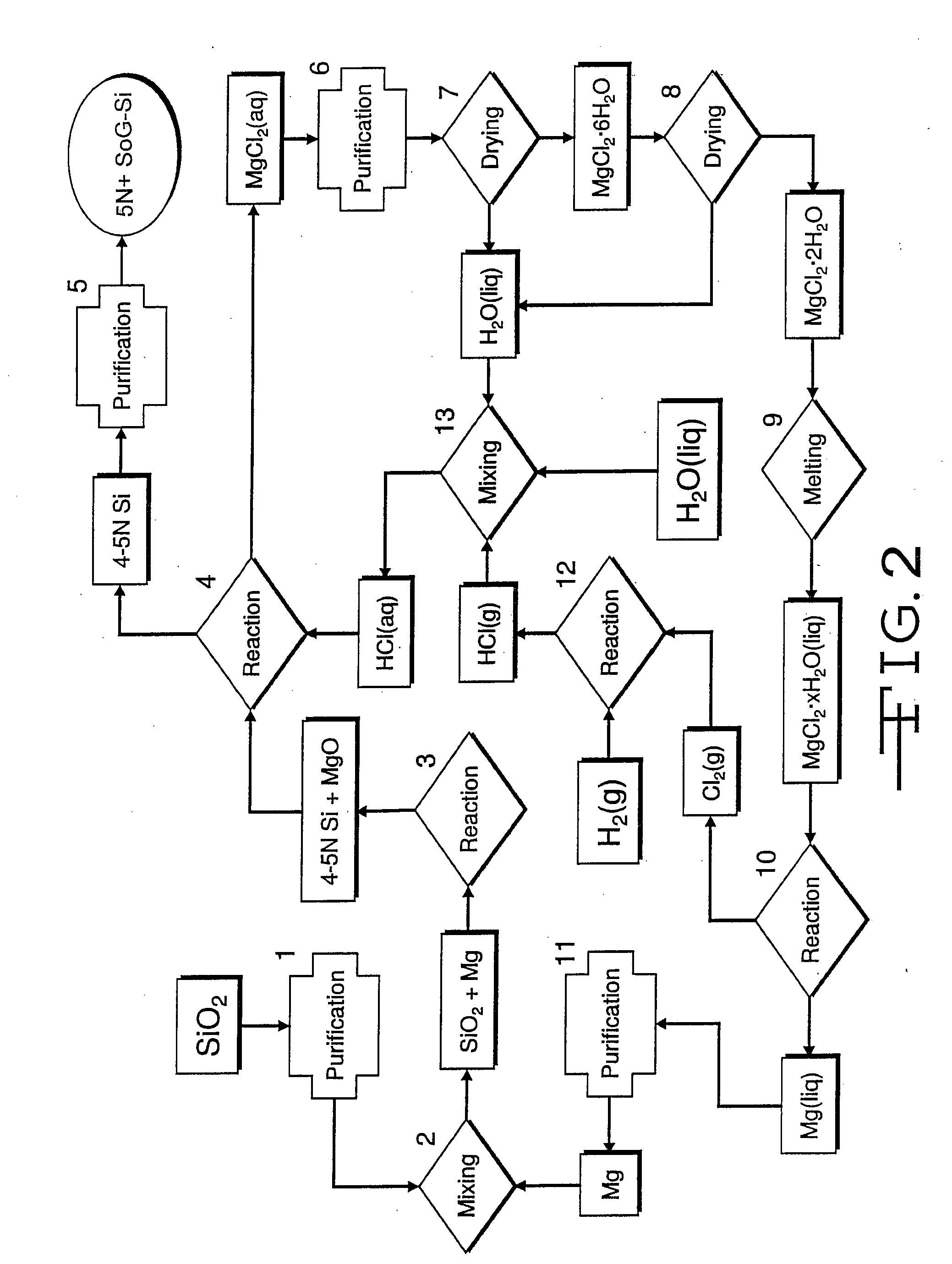

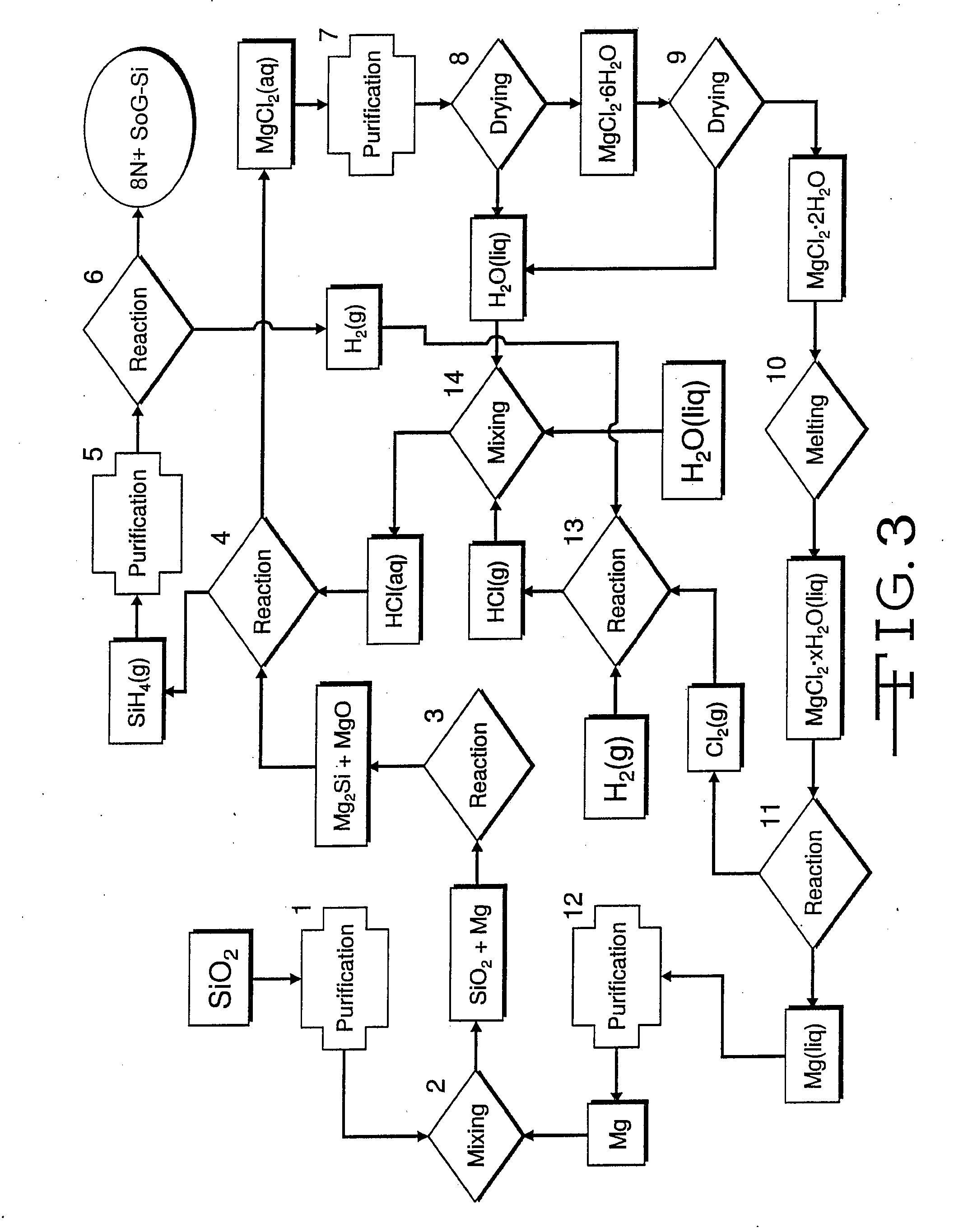

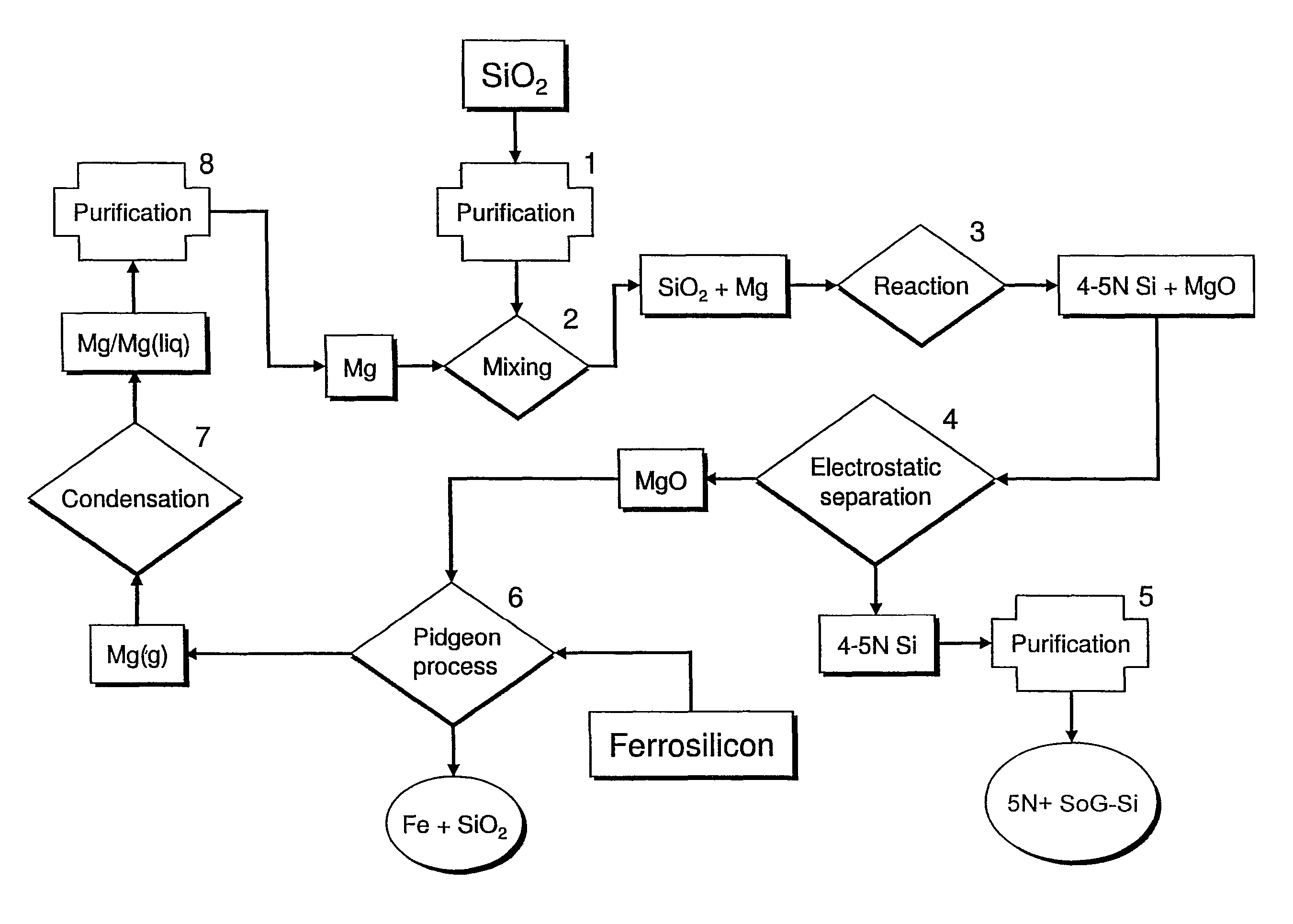

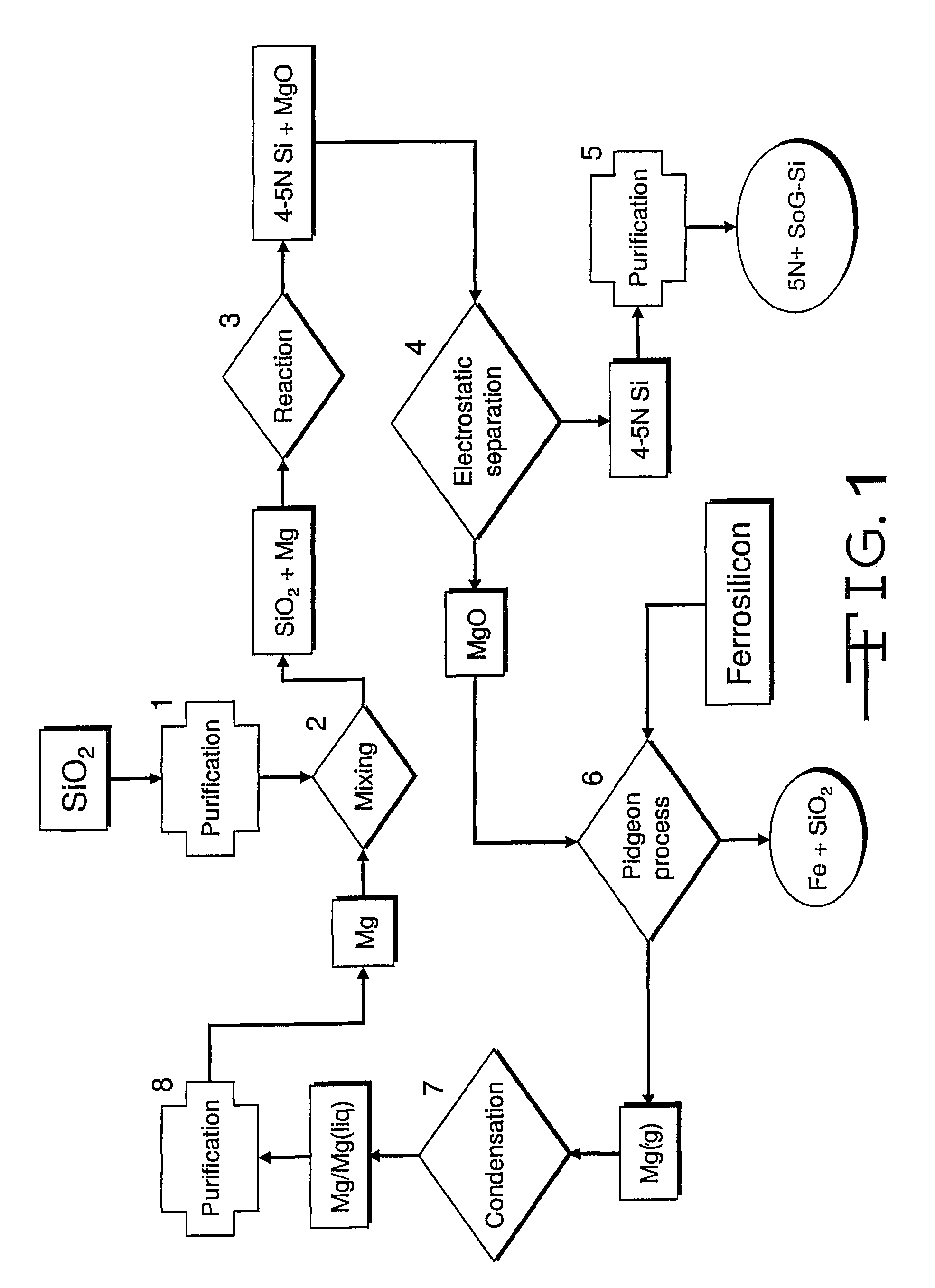

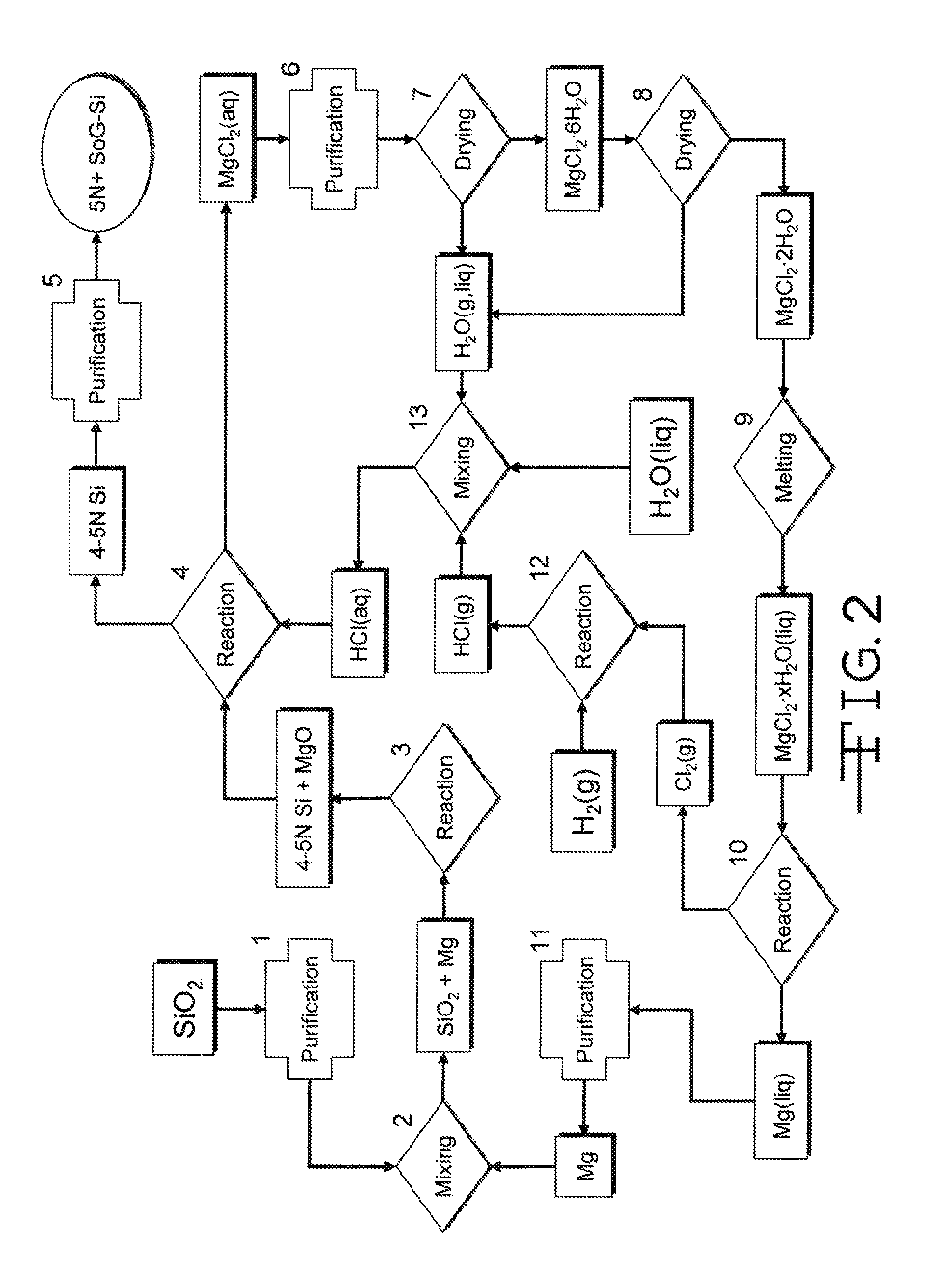

Magnesiothermic Methods Of Producing High-Purity Silicon

Magnesiothermic methods of producing solid silicon are provided. In a first embodiment, solid silica and magnesium gas are reacted at a temperature from 400° C. to 1000° C. to produce solid silicon and solid magnesium oxide, the silicon having a purity from 98.0 to 99.9999%. The silicon is separated from the magnesium oxide using an electrostatic technology. In a second embodiment, the solid silicon is reacted with magnesium gas to produce solid magnesium silicide. The magnesium silicide is contacted with hydrogen chloride gas or hydrochloric acid to produce silane gas. The silane gas is thermally decomposed to produce solid silicon and hydrogen gas, the silicon having a purity of at least 99.9999%. The solid silicon and hydrogen gas are separated into two processing streams. The hydrogen gas is recycled for reaction with chlorine gas to produce hydrogen chloride gas.

Owner:ORION LAB

Magnesium-containing silicon oxide negative electrode material for lithium ion batteries and preparation method thereof

ActiveCN110311120AThe production process is easy to controlAchieve mass productionNegative electrodesSecondary cellsSodium-ion batterySilicon oxide

The invention relates to the field of lithium battery materials, and specifically relates to a magnesium-containing silicon oxide negative electrode material for lithium ion batteries and a preparation method thereof. The preparation method mainly comprises the steps of raw material preparation, magnesium silicide preparation and magnesium-containing silicon oxide negative electrode material preparation. The preparation method in the invention can realize batch production and is easy for industrial application. The lithium ion battery prepared by adopting the negative electrode material obtained according to the preparation method provided by the invention has excellent electrochemical properties such as high specific capacity and good cycle performance.

Owner:洛阳联创锂能科技有限公司

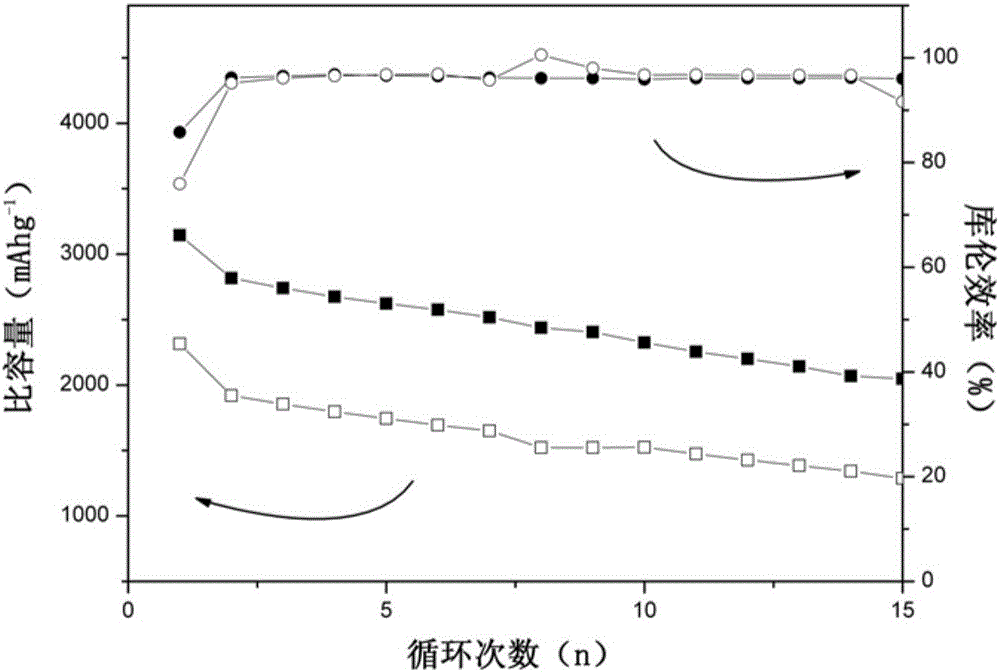

High capacity porous silicon material, preparation method and application thereof

ActiveCN105845918APrevent oxidationReduce oxygen contentCell electrodesSecondary cellsAir atmosphereHydrofluoric acid

The invention discloses a preparation method of a high capacity porous silicon material. The method is characterized by specifically including: placing magnesium silicide powder in nitrogen atmosphere, conducting 600-800DEG C heat treatment, then performing pickling and aftertreatment to obtain the porous silicon material with high capacity. The preparation method of the high capacity porous silicon material provided by the invention uses nitrogen atmosphere to replace air atmosphere, avoids oxidation of silicon at the same time of porous silicon preparation, and has no need of high volatility hydrofluoric acid to conduct treatment, and the process is simple, efficient and environment-friendly. The prepared porous silicon has very low oxygen content, can be applied as a negative electrode material in a lithium ion battery to remarkably improve the specific capacity and cycle stability of the lithium ion battery.

Owner:浙江锂宸新材料科技有限公司

Carbon coated micron silicon, preparation method and application thereof

ActiveCN108269989ASimple manufacturing methodExtended stayCell electrodesSecondary cellsMagnesium silicideInorganic materials

Belonging to the technical field of inorganic material preparation, the invention more specifically discloses a carbon coated micron silicon, a preparation method and application thereof. The method includes: reacting magnesium silicide with carbon dioxide in an atmosphere containing carbon dioxide, or decomposing magnesium silicide, then reacting the decomposed product with carbon dioxide, and conducting pickling to obtain the carbon coated micron silicon material. The preparation method is simple and practicable, can be used for large-scale production of carbon coated micron silicon, and cansolve the technical problems of complex technology, poor security, and no good for mass production application of carbon coated micron silicon materials in the prior art.

Owner:WUHAN UNIV OF SCI & TECH

High-flame-retardancy high-heat-resistance MPP pipe and preparation method thereof

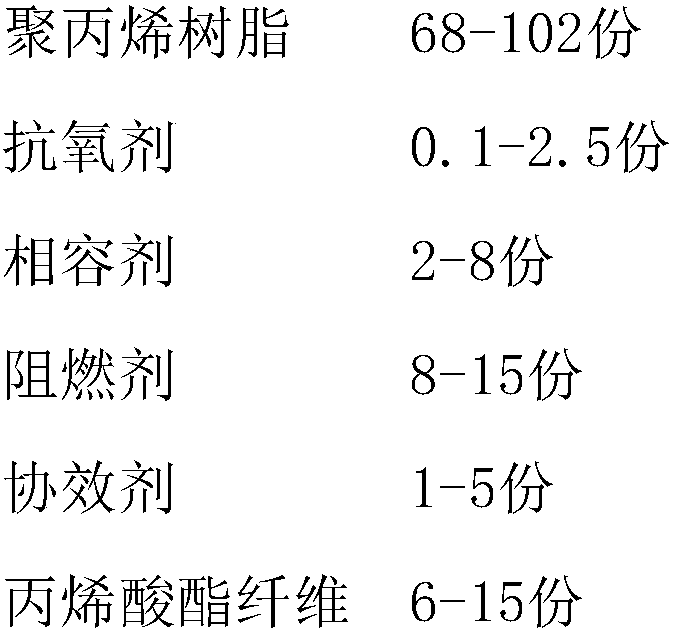

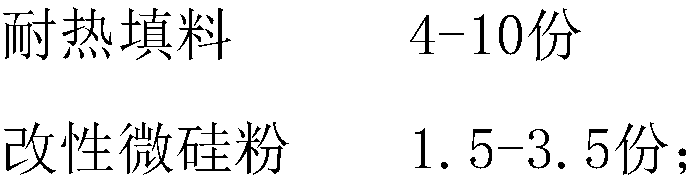

The invention relates to the technical field of high polymer materials, and in particular relates to a high-flame-retardancy high-heat-resistance MPP pipe and a preparation method thereof. The MPP pipe comprises the following raw materials in parts by weight: 68-102 parts of polypropylene resin, 0.1-2.5 parts of an antioxidant, 2-8 parts of a compatilizer, 8-15 parts of a flame retardant, 1-5 parts of a synergistic agent, 6-15 parts of an acrylate fiber, 4-10 parts of a heat-resistant filler and 1-5 parts of modified micro-silicon powder, wherein the heat-resistant filler is the mixture composed of calcium carbonate, lignocelluloses and magnesium silicide according to the weight ratio of 3-12:3-8:1-2. The MPP pipe disclosed by the invention has better flame retardancy, heat resistance, smoke inhibition performance, stability, oxidation aging resistance and the like, the strength is high, and the heat-resistant filler is adopted, the heat resistance and the processing flowing property of the MPP pipe can be effectively improved, the surface glossiness is reduced, the forming performance is good, the processing performance is good, and the use value is high.

Owner:SHENZHEN ANPOWER ELECTRIC

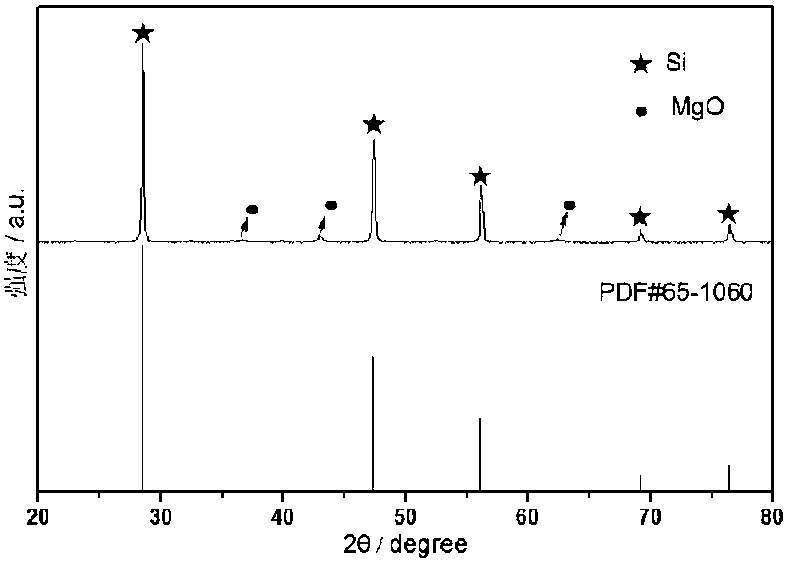

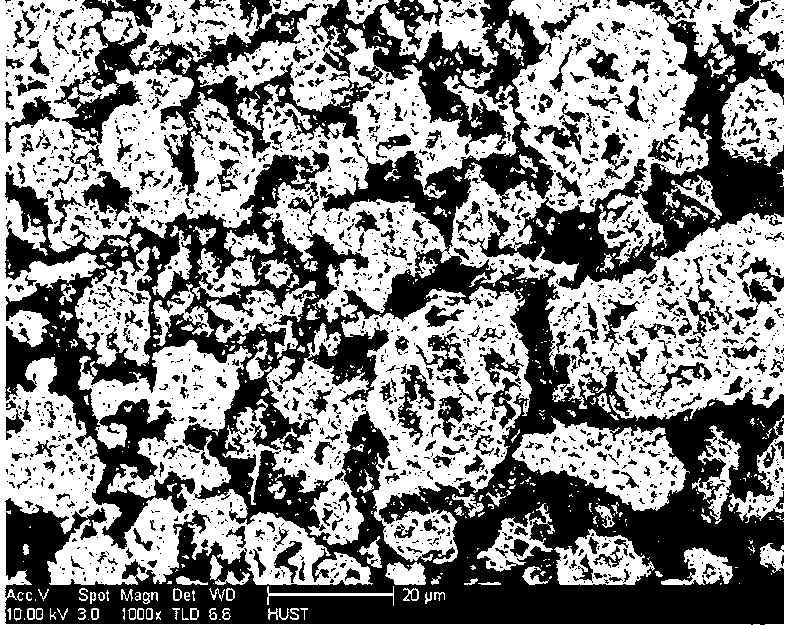

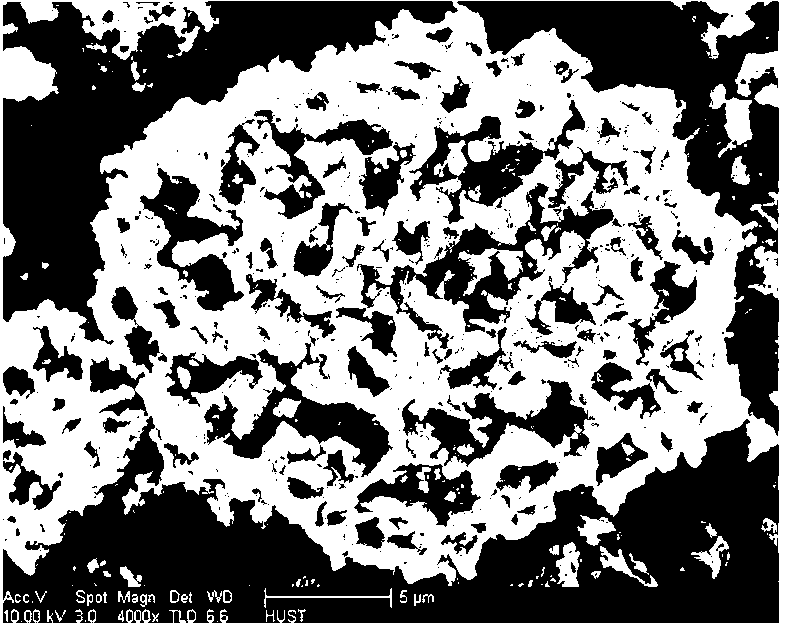

Method for preparing porous nanometer silicon through air auxiliary

The invention provides a method for preparing porous nanometer silicon through air auxiliary. The method comprises the following steps that silicon dioxide and an appropriate amount of magnesium powder which are obtained from different sources are evenly mixed and then put into a tube furnace to fully react in an inert atmosphere to obtain magnesium silicide (4Mg+SiO2=Mg2Si+2MgO); the reaction product is put in air or other mixed gas containing oxygen to react (Mg2Si+O2=Si+2MgO) under the appropriate temperature condition to obtain a product, and the product is processed through acid pickling to obtain the high-yield superfine porous nanometer silicon. According to the method, the steps are simple and easy to operate, and a large amount of the porous nanometer silicon can be obtained only by directly heating the obtained magnesium silicide in the air or the gas containing the oxygen; in addition, the source of the raw material silicon dioxide is wide, pollution is little, the yield is high, the obtained nanometer silicon has the advantages that particles are uniform and mesoporous exists, and the method can be widely applied to the field of lithium ion battery anode materials.

Owner:WUHAN UNIV OF SCI & TECH

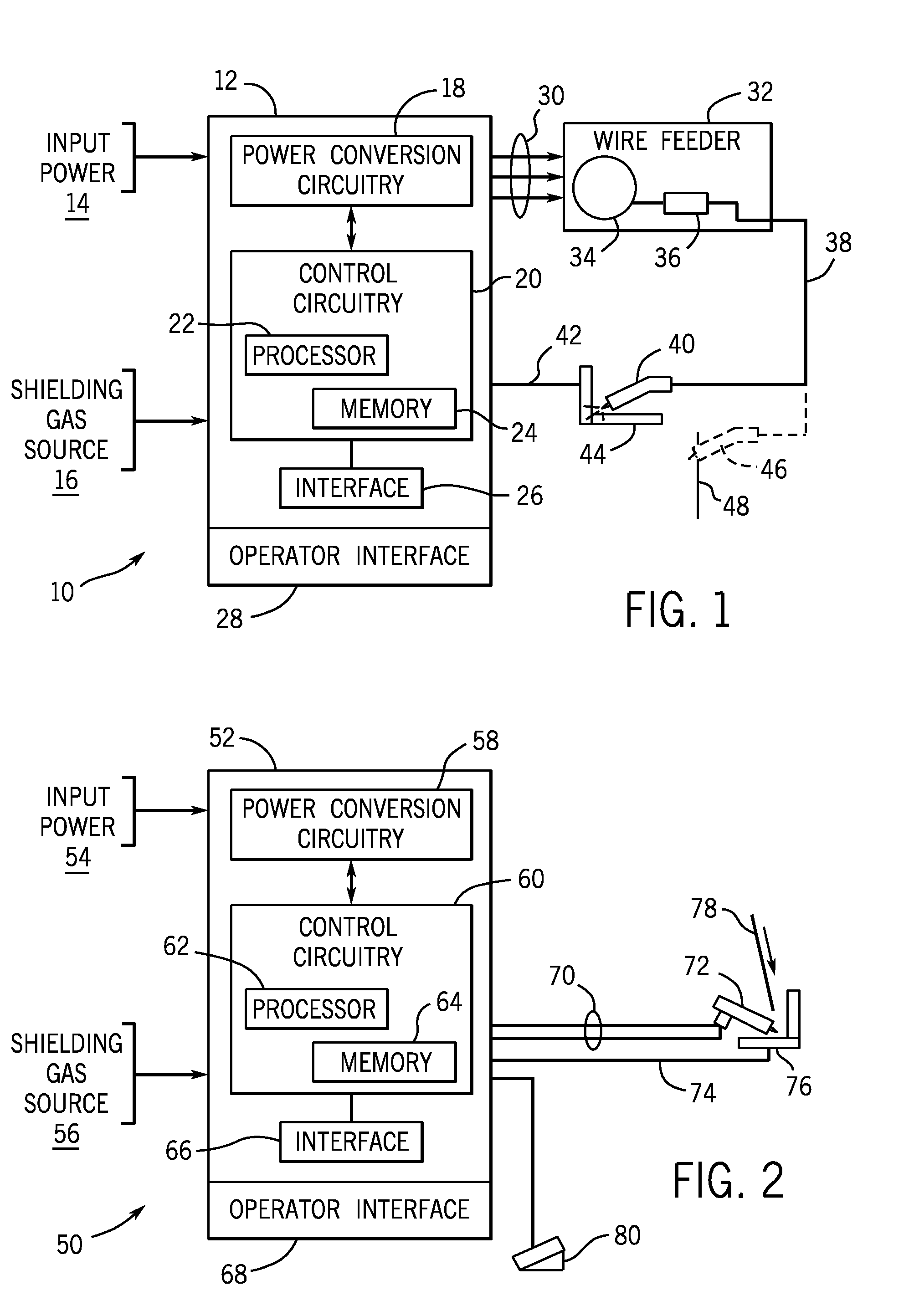

Aluminum alloy welding wire

The present disclosure relates generally to the field of welding filler metals, and more particularly to compositions suitable for welding or brazing aluminum alloys. In an embodiment, an aluminum-silicon-magnesium alloy, includes a magnesium content between approximately 0.1 wt % and approximately 0.5 wt %, wherein substantially all of the magnesium content is present as magnesium silicide. The alloy includes a silicon content between approximately 5.0 wt % and approximately 6.0 wt %, wherein at least 4.75 wt % of the silicon content is present as free silicon. The alloy includes one or more of iron, copper, manganese, zinc, and titanium. The alloy further includes a remainder of aluminum and trace components.

Owner:ILLINOIS TOOL WORKS INC

Method for preparing three-dimensional porous nanometer silicon at low temperature through molten-salt growth method

The invention provides a method for preparing three-dimensional porous nanometer silicon at low temperature through a molten-salt growth method. The method includes the following steps that silica particles obtained from different sources and magnesium powder are uniformly mixed and then are placed in a tube furnace to be fully reacted under an inert atmosphere, magnesium silicide is obtained, then the reaction product and anhydrous chloride metal salt are uniformly mixed and then are placed in a tube furnace filled with inert atmosphere to be fully reacted, reaction products are subjected to acid pickling, and the high-yield super-fine three-dimensional porous nanometer silicon is obtained. The method is simple and easy to implement, the raw materials are wide in source, most importantly, by adding the anhydrous chloride (MxCly), the nanometer silicon has the advantages of being small in pollution, high in yield and purity, large in specific area and uniform in particle and having mesopores, and the nanometer silicon can be applied to the fields of lithium ion battery cathode materials, semiconductor materials, medicine, high-quality alloy and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

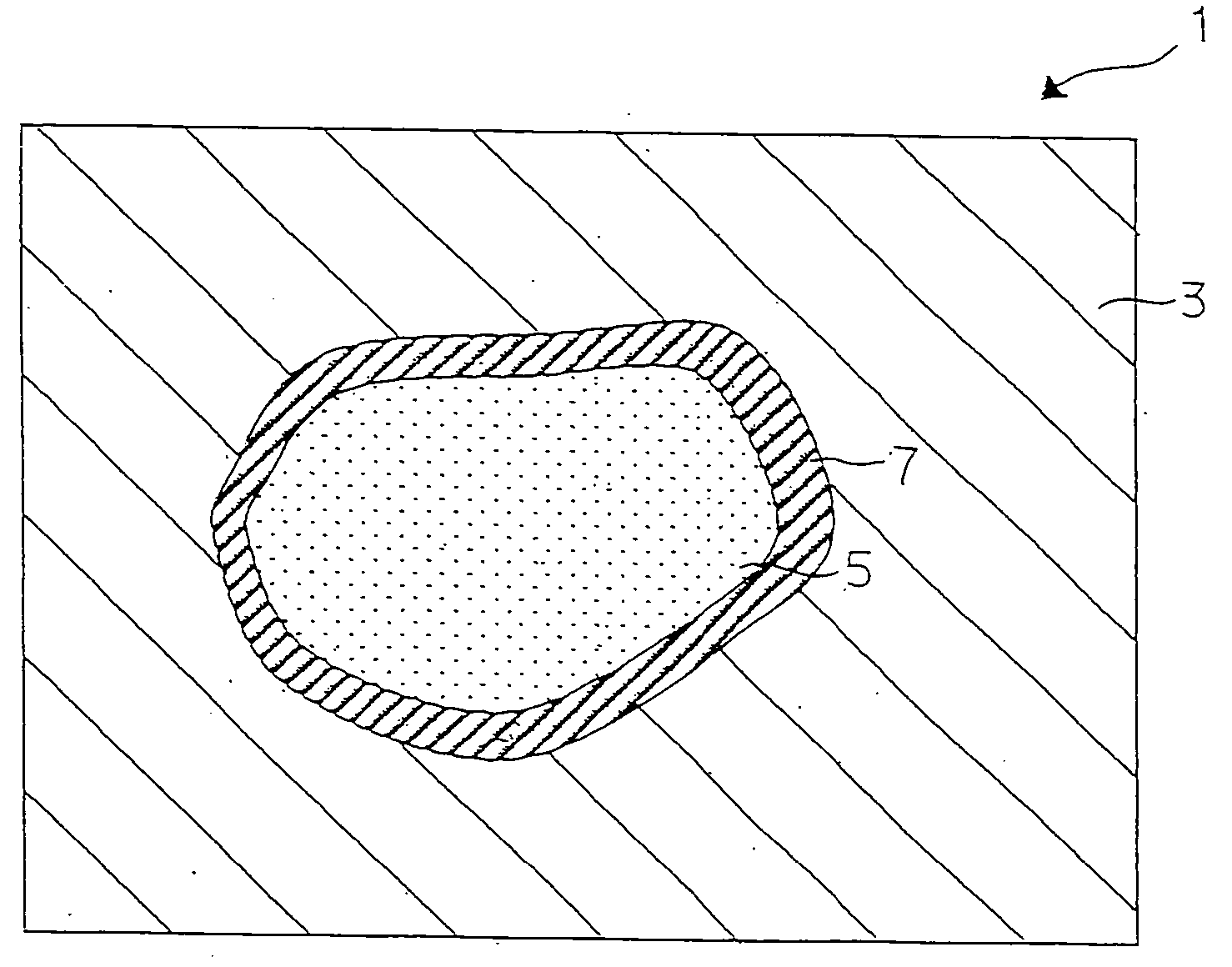

Magnesium base composite material and method for production thereof

InactiveUS20050089435A1Superior in strength and hardness and abrasion resistanceIncreased aggressionFriction liningActuatorsMagnesium matrix compositeHardness

A magnesium base composite material is provided such that compound particles generated by a solid-phase reaction with magnesium are uniformly dispersed in a magnesium alloy body. The compound particles dispersed in the body comprise magnesium silicide (Mg2Si) and magnesium oxide (MgO) so that the magnesium base composite material may have excellent strength, hardness and abrasion resistance and tempered opponent aggression.

Owner:TOUDAITLO LTD +1

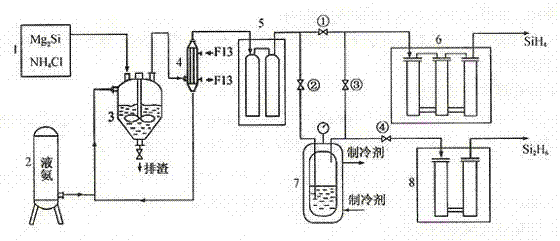

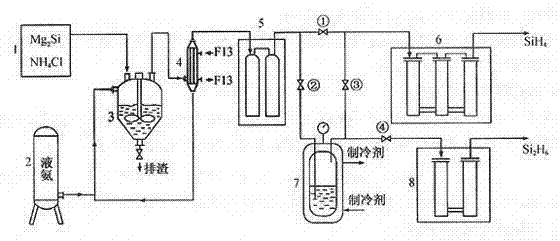

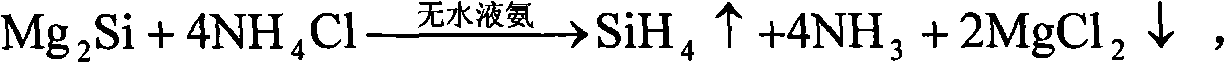

Method for producing disilane by reaction of magnesium silicide and ammonium chloride

InactiveCN102515169ALess investmentReduce energy consumptionSilicon hydridesChemical reactionSilanes

The invention discloses a method for producing disilane by the chemical reaction of magnesium silicide and ammonium chloride in a liquid ammonia medium. A silicide is synthesised at 600-900 DEG C and may be high-order magnesium chloride, i.e., Mg2Si2. The silicide is good for forming disilane. Once the mixed airflow of a crude silane purification device flows through a cold trap at minus 110 DEG C, the disilane is changed into liquid and condensed in a liquefaction bottle for disilane, and then the silane and hydrogen continue to enter in a working procedure of purification along a pipeline.

Owner:TIANJIN TAIHENG GASES

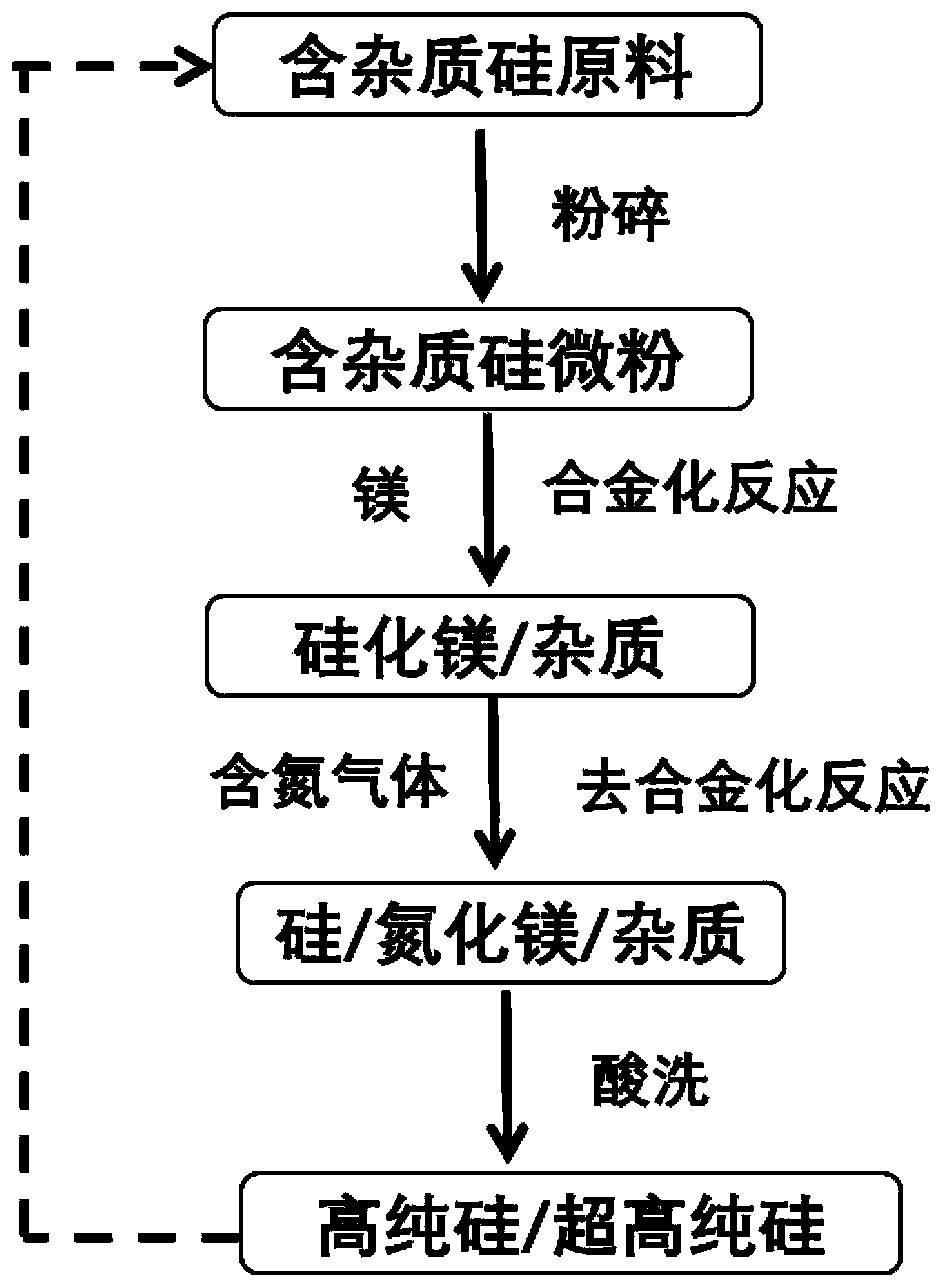

Method for purifying silicon through phase separation and dealloying

ActiveCN109941998AAchieve the first separationAchieve separationSilicon compoundsReaction temperatureMetal impurities

The invention belongs to the technical field of purification of silicon, and particularly relates to a method for purifying silicon through a phase separation and dealloying reaction method. Firstly,a silicon raw material containing metal or non-metal impurities is mixed with magnesium powder, and then a sufficient reaction is carried out under the inert atmosphere, so that silicon atoms in the silicon raw material react with magnesium to be converted into magnesium silicide, and the impurities in the silicon raw material are separated from silicon to obtain a first product; then the first product is subjected to a nitridation reaction under the nitrogenous atmosphere, the magnesium silicide in the first product is converted into liquid-phase magnesium nitride at the reaction temperature,silicon separates crystals from the liquid-phase magnesium nitride, three-dimensional porous silicon and magnesium nitride distributed in pore passages of the three-dimensional porous silicon are formed, and a second product is obtained; in the process of separating out the crystals by the silicon, the impurities are further separated and dissolved in the liquid-phase magnesium nitride; finally,the second product is treated through acid pickling, wherein the magnesium nitride and the impurities are dissolved and converted into a solution, and a solid product is high-purity porous silicon.

Owner:WUHAN UNIV OF SCI & TECH

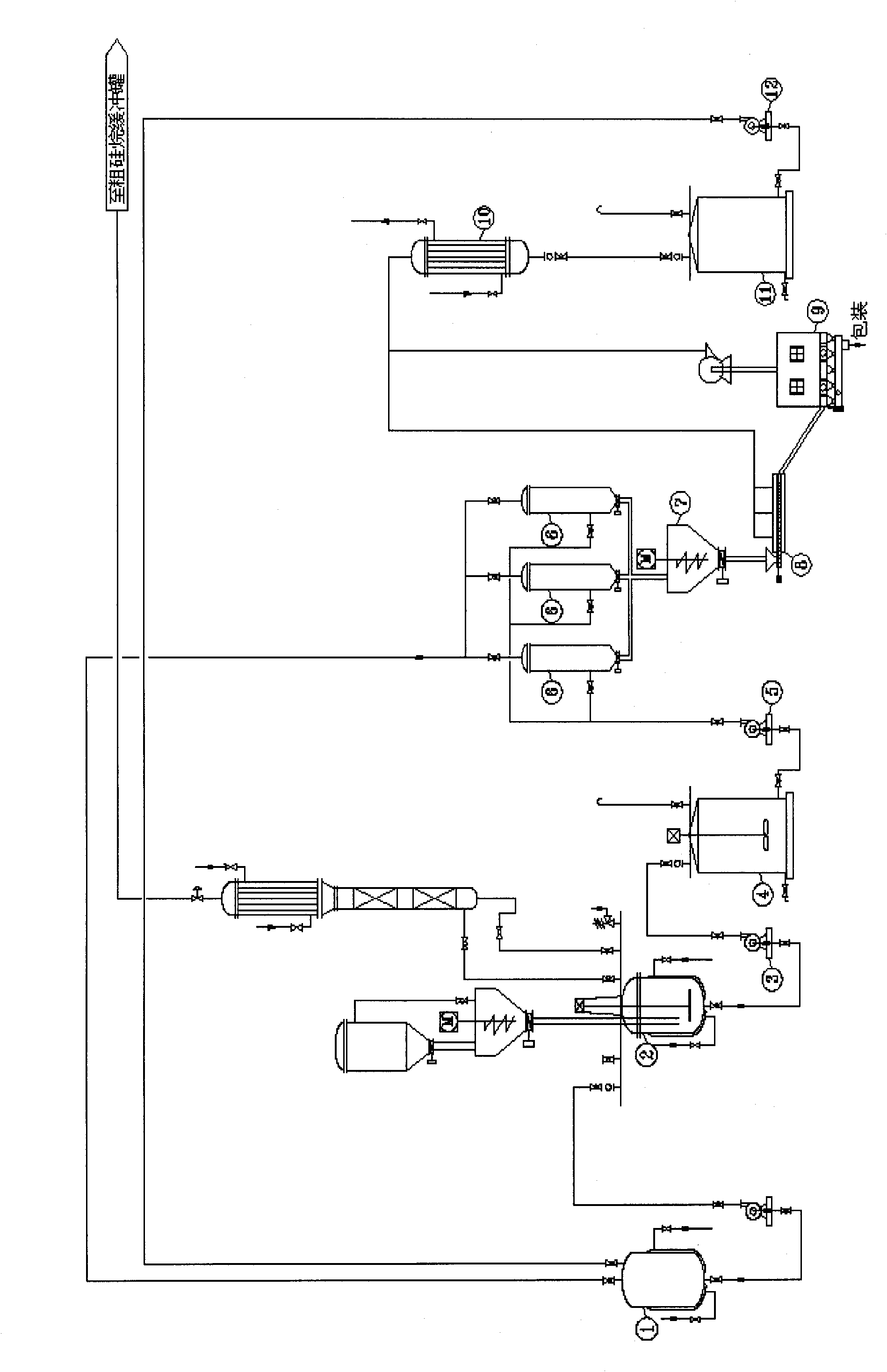

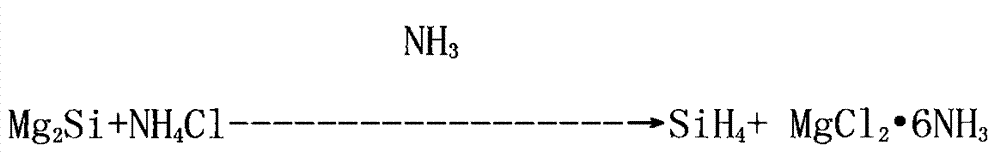

Process technology of method for preparing silane by using magnesium silicide

InactiveCN102205968AIdeal production technologyReasonable methodSilicon hydridesMolecular sieveSilanes

The invention discloses a process technology of a method for preparing silane by using magnesium silicide. In the method process for preparing the silane, a raw material preparation system, a silane gas preparation system and a molecular sieve adsorption purification silane liquefaction and vaporization system are mainly provided. The technology has a reasonable process, makes manufacture simple and is an ideal technology for silane preparation.

Owner:TIANJIN TAIHENG GASES

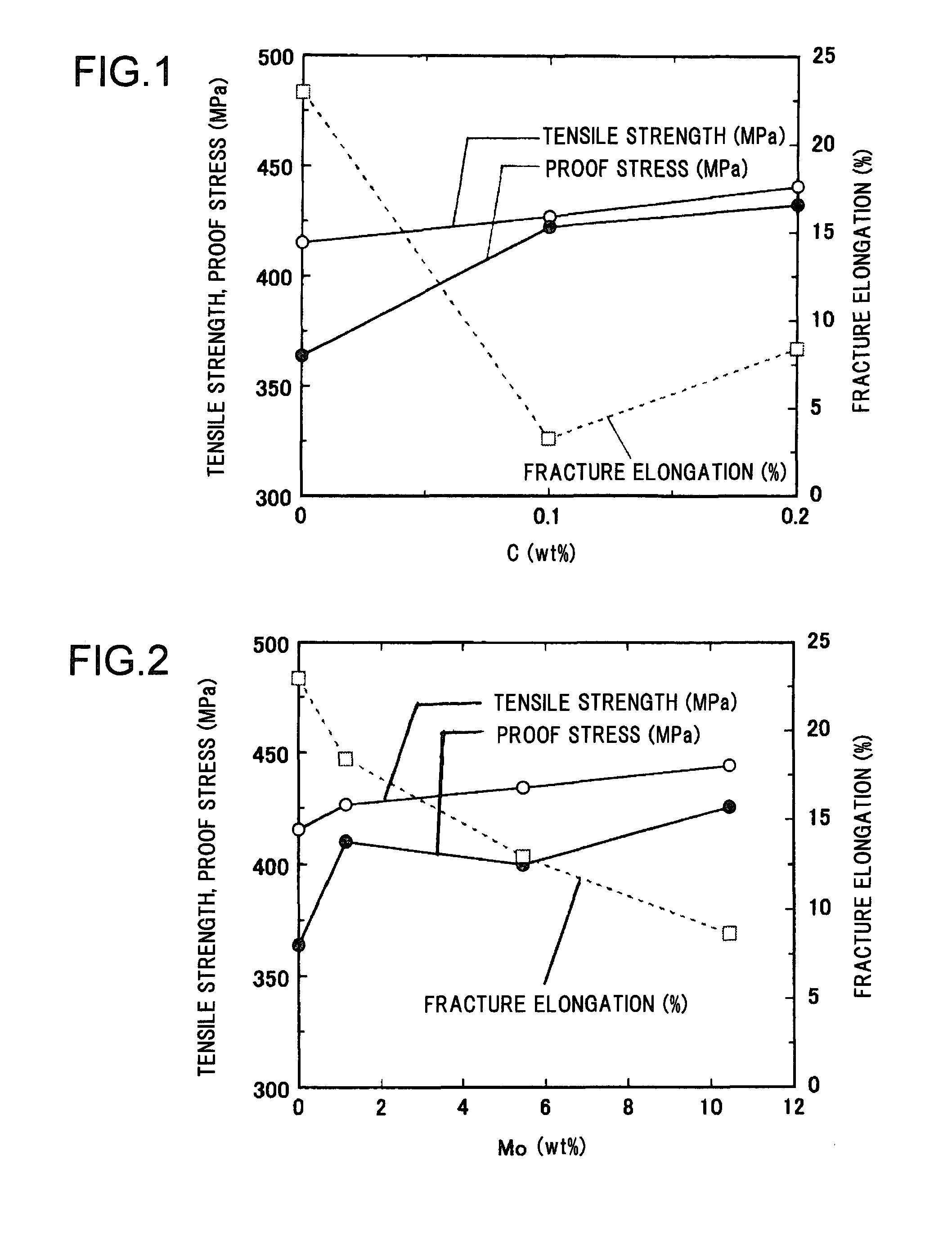

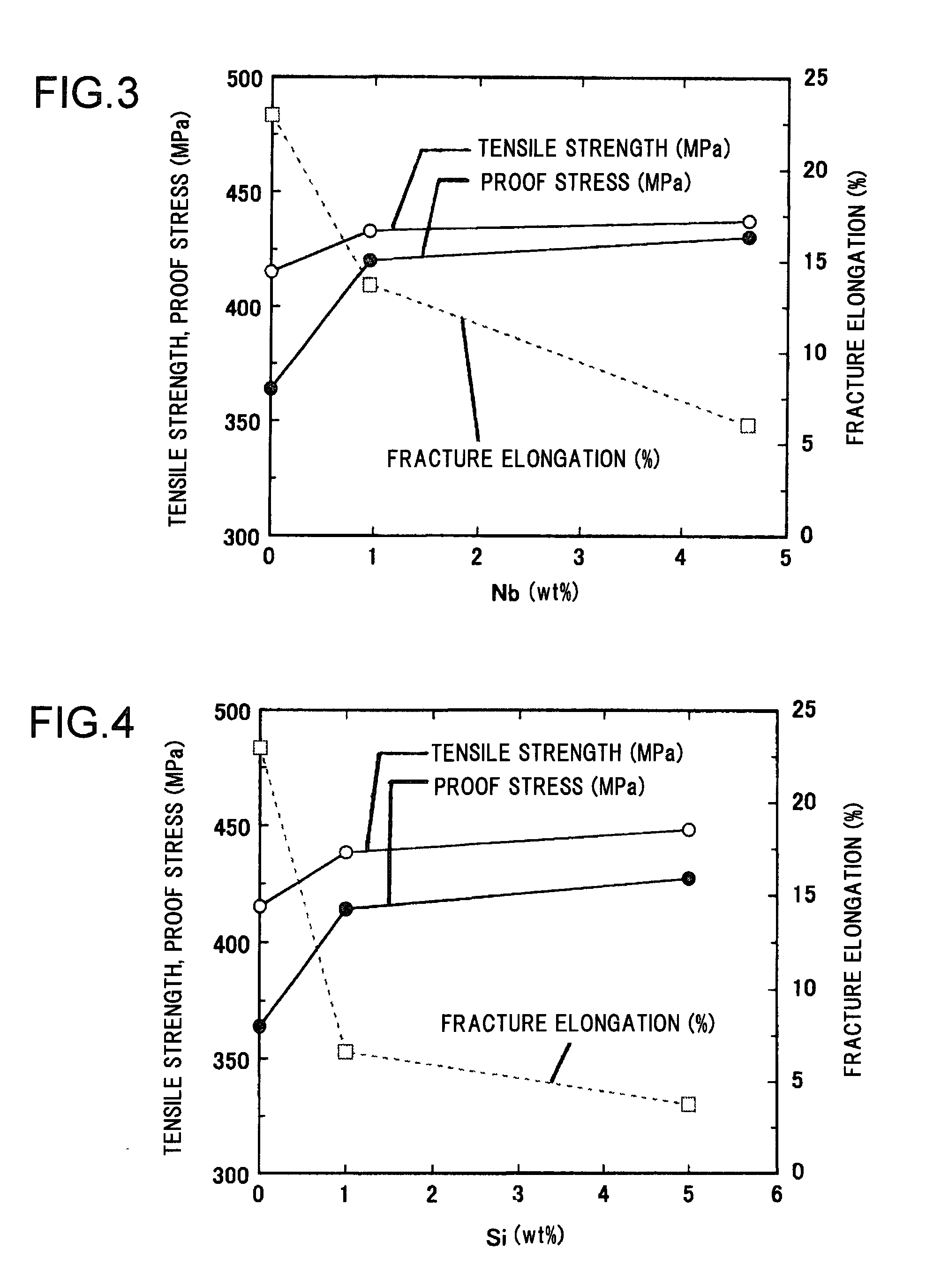

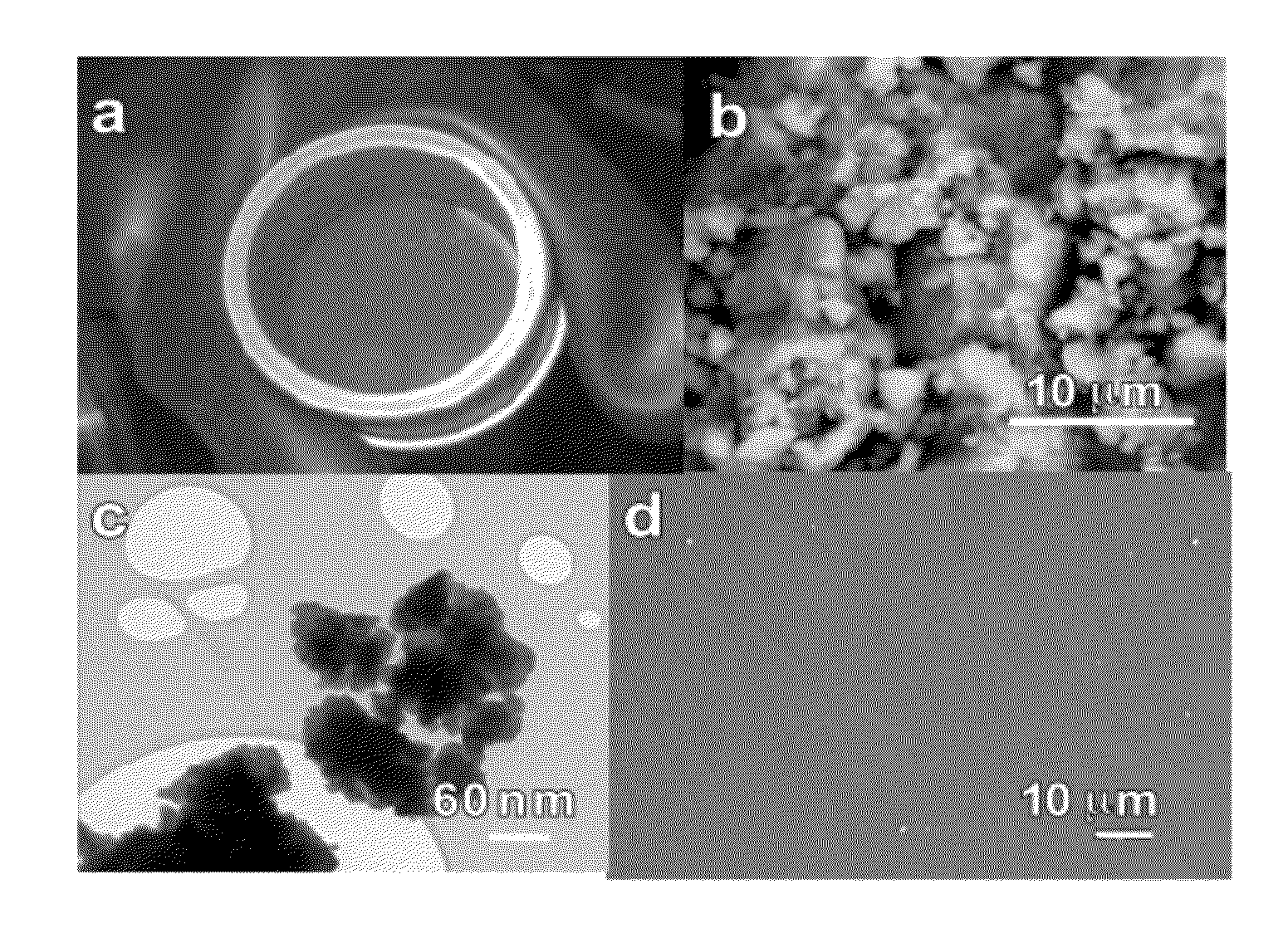

High-strength non-combustible magnesium alloy

InactiveUS20090269237A1High tensile strengthHigh proof stressProcess efficiency improvementNiobiumHigh intensity

The high-strength non-combustible magnesium alloy is obtained by adding at least one supplementary additive selected from among carbon (C), molybdenum (Mo), niobium (Nb), silicon (Si), tungsten (W), alumina (Al2O3), magnesium silicide (Mg2Si) and silicon carbide (SiC) to small chip-like blocks of a non-combustible magnesium alloy resulting from adding 0.5 to 5.0% by mass of calcium to a magnesium alloy to produce a crushed product, and subjecting the same to forming, sintering and plastic working. The high-strength non-combustible magnesium alloy exhibits excellent joining ability, and can therefore enhance weldability when used in a filler metal.

Owner:NAT INST OF ADVANCED IND SCI & TECH

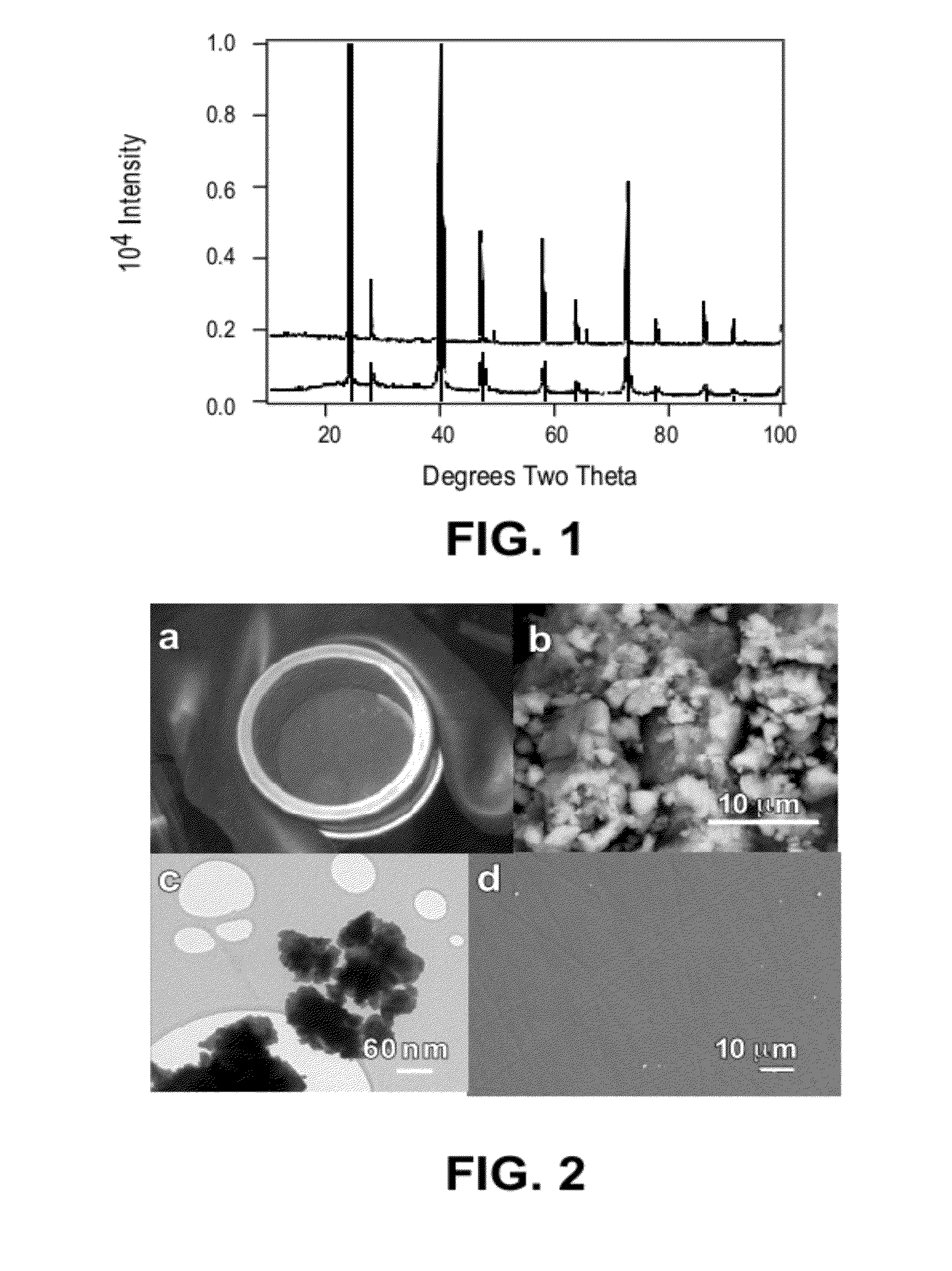

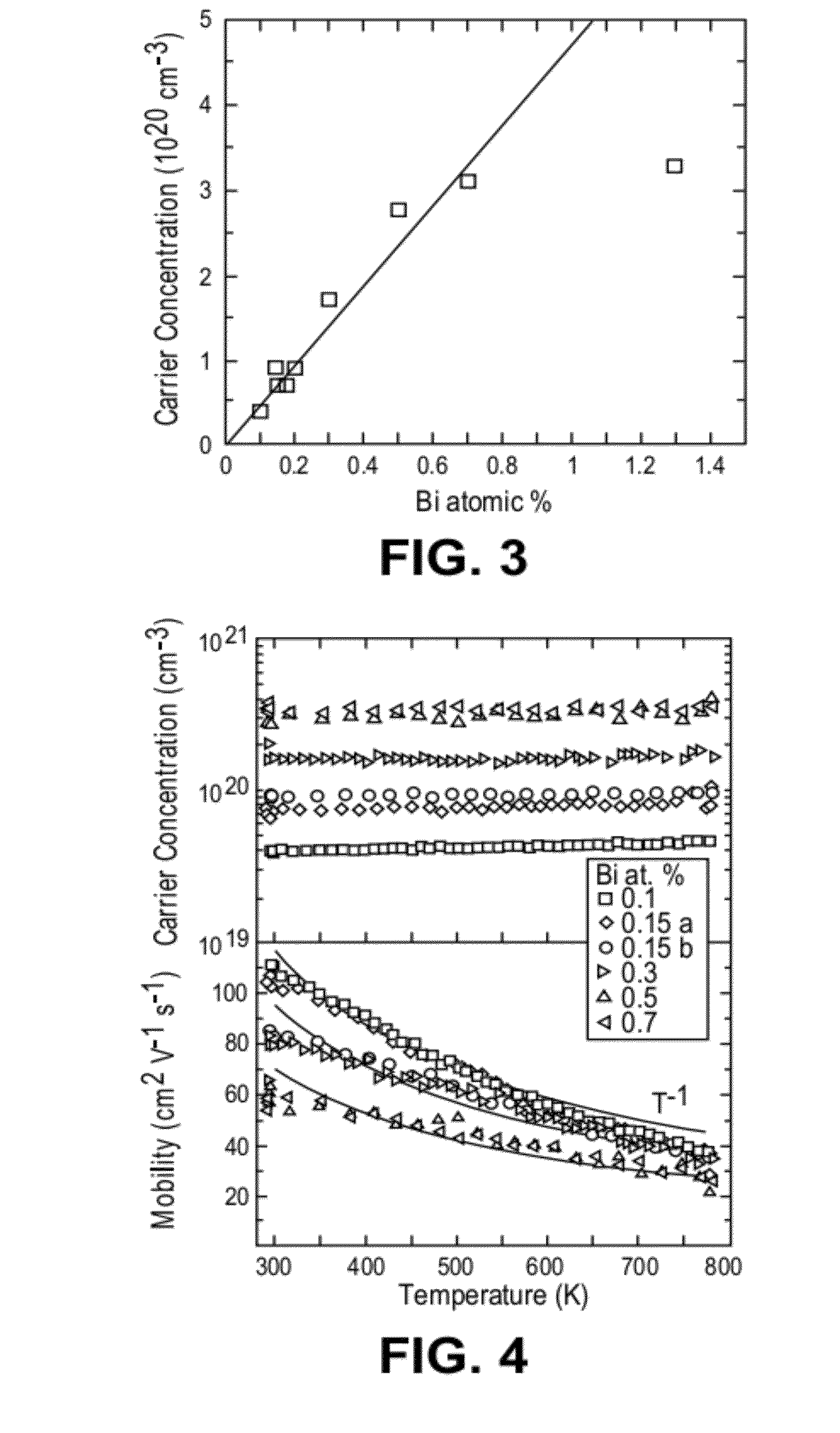

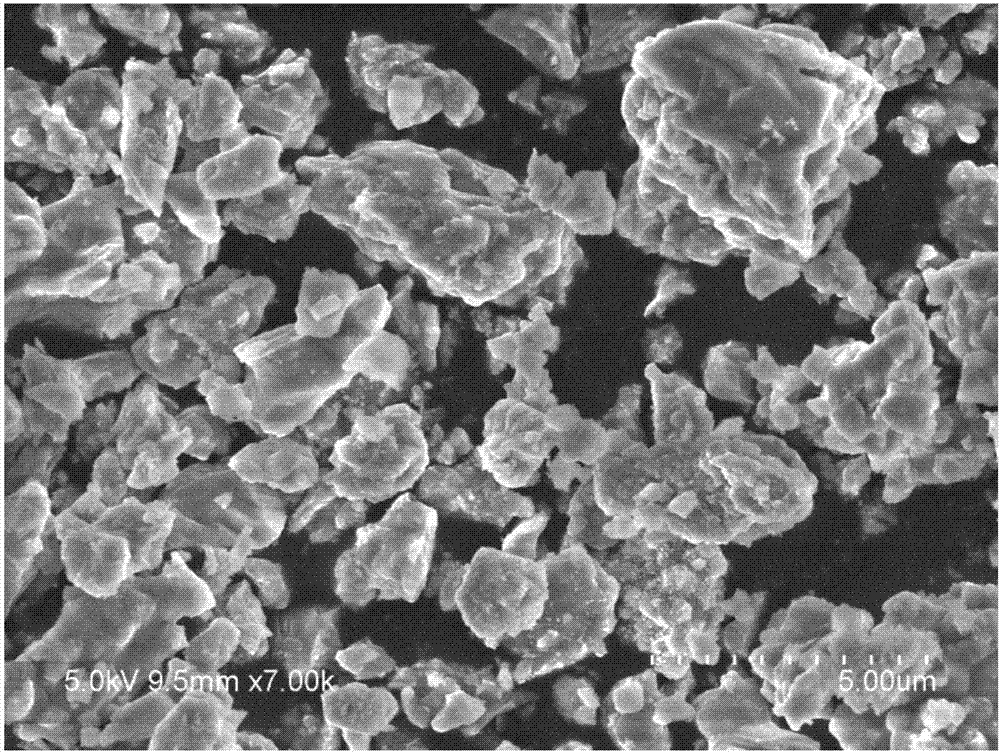

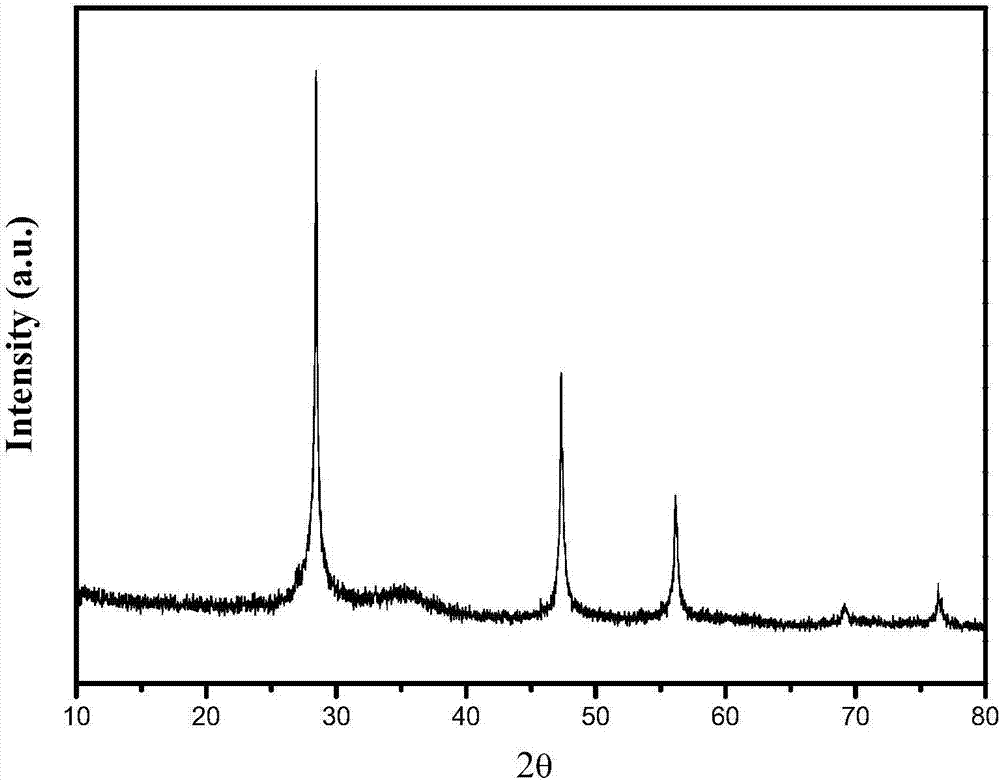

Mechanochemical synthesis and thermoelectric properties of magnesium silicide and related alloys

Owner:CALIFORNIA INST OF TECH +1

Porous silicon nano-material and preparation method and use thereof

ActiveCN107539990AEasy to scale up and synthesizeEasy to operateCell electrodesSecondary cellsCarbon coatingHigh energy

The invention discloses a preparation method of a porous silicon nano-material. The preparation method comprises that chlorosilane and magnesium silicide undergo a reaction in an anhydrous organic solvent under action of an activator at the room temperature to 200 DEG C to produce the porous silicon nano-material having mesopores and a large specific surface area. Compared with the traditional synthesis method, the preparation method is easy to operate, has mild reaction conditions, has a high yield, easily realizes large-scale synthesis and has a low cost. After carbon coating treatment, theporous silicon nano-material can be used as a negative electrode material of a lithium-ion battery and has high energy density and excellent cycling performances.

Owner:NANJING UNIV

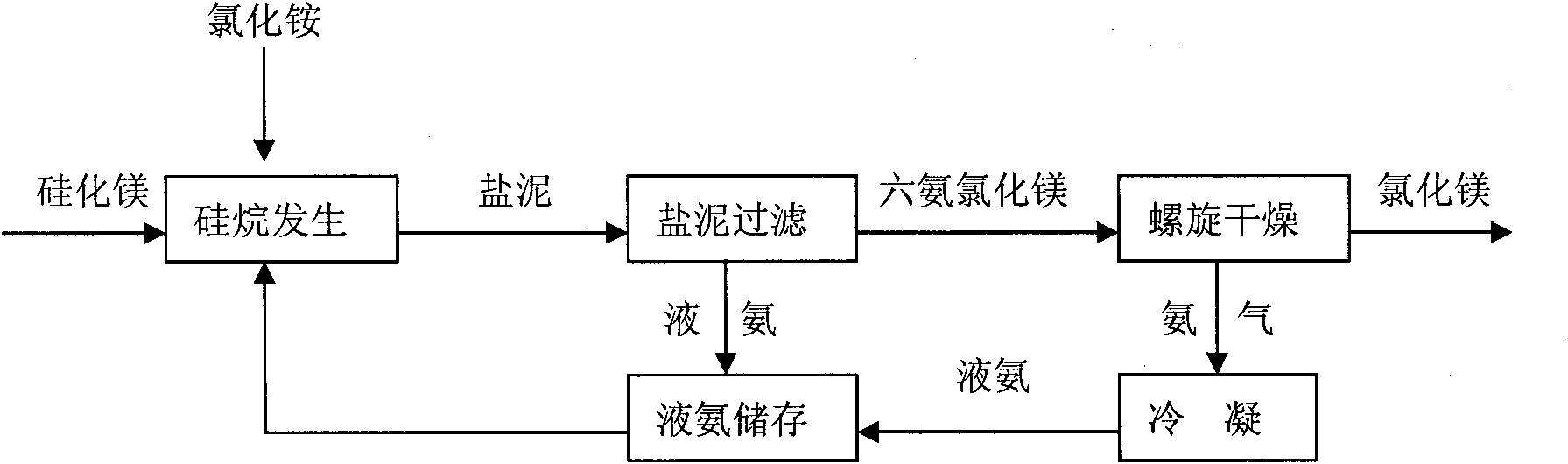

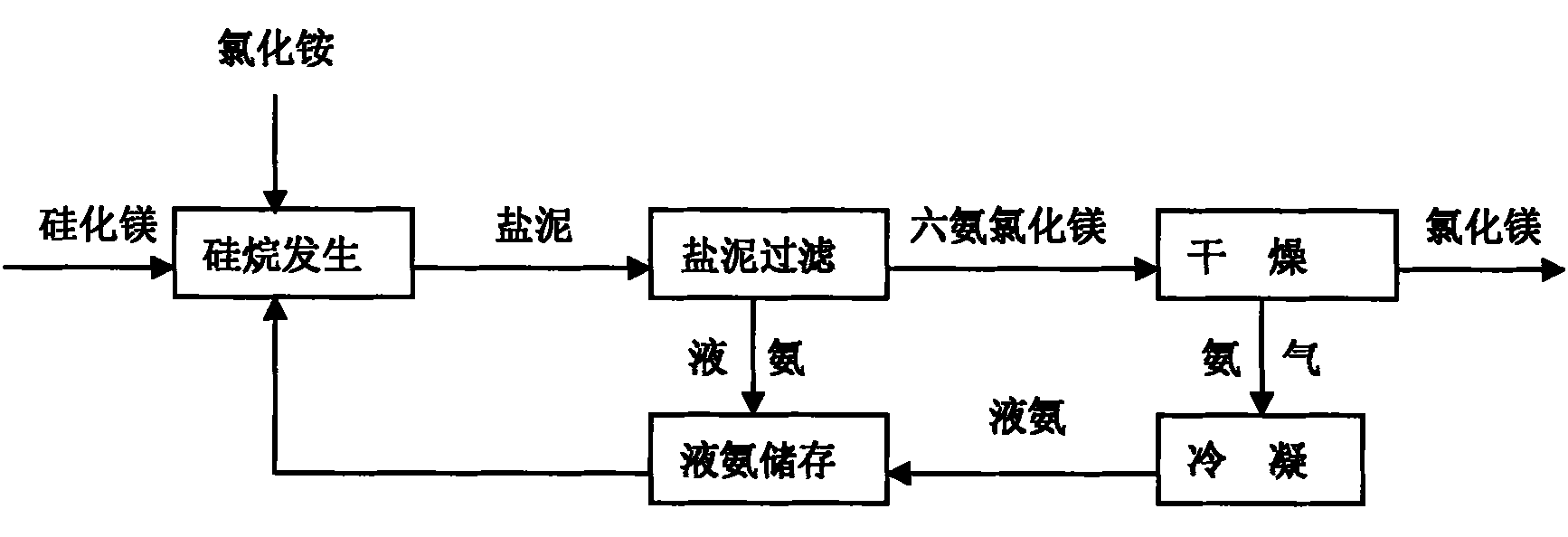

Method and device for separating magnesium chloride hexammoniate during silane production by the magnesium silicide method

ActiveCN101817541AEfficient recyclingImprove drying efficiencyMagnesium chloridesAmmonia preparation/separationComing outSilanes

The invention discloses a method for separating and recycling magnesium chloride hexammoniate and liquid ammonia during silane production by a magnesium silicide method, which comprises the following process steps of: inputting the magnesium chloride hexammoniate and liquid ammonia salt slurry produced during silane production by the magnesium silicide method into a filter; inputting the liquid ammonia coming out of the top of the filter into a liquid ammonia storage tank for recycle; conveying the salt slurry coming out of the lower part of the filter into a dryer through a salt slurry feeder; conveying the ammonia gas coming out of the upper part of the dryer into a condenser to liquefy the ammonia gas in the condenser in which the temperature is lower than 33.5 DEG C below zero; and inputting the ammonia gas into the liquid ammonia storage tank for recycle. The invention further discloses a device implementing the method. With the device and method, the invention realizes large-scale industrial production, and magnesium chloride hexammoniate and liquid ammonia are separated and recycled through a continuous liquid-solid filter with fast separation, high efficiency and little liquid in solid. In addition, the filtered wet magnesium chloride hexammoniate is continuously dried at high temperature with high drying efficiency, and the complex ammonia is effectively recycled.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Method for producing silane gas

The invention discloses a production method for silane gas, relating to a production method for gas. The invention solves the problems that the existing method for producing silane gas has low product purity and low yield, and the method can not meet the need of commercial process. The method comprises the following steps: 1. silica fume, magnesium powder and ammonium chloride are weighed and taken out; 2. magnesium silicide is obtained after the silica fume is mixed and reacted with the magnesium powder; and 3. the weighed and taken out ammonium chloride and the magnesium silicide are mixed and reacted in a reactor which takes liquid ammonia as the media, and then silane gas is obtained after the obtained reactant undertakes molecular sieve adsorption and deep cooling purification. The obtained silane gas has the purity of 99.99 percent and the yield of over 95 percent, and the method also meets the need of commercial process.

Owner:王少志

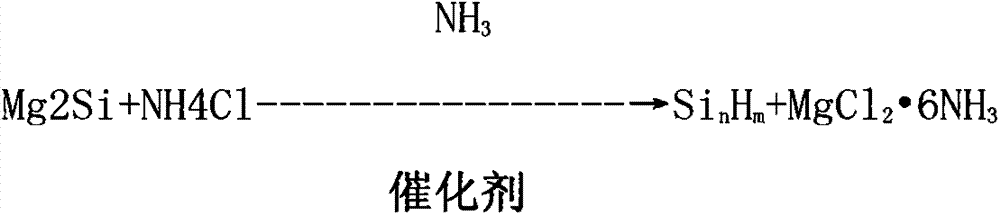

Manufacturing method for silane type product

The invention provides a manufacturing method for a silane type product. The manufacturing method for the silane type product comprises the following steps: A, preparing magnesium silicide from silica powder and magnesium powder in the presence of a catalyst; B, enabling the magnesium silicide and ammonia chloride to react to generate silane type gas and hexammoniated magnesium chloride in the presence of liquid ammonia and the catalyst; C, performing a separation reaction on the hexammoniated magnesium chloride to obtain magnesium chloride and liquid ammonia; D, performing electrolysis on the magnesium chloride to obtain magnesium powder and chlorine gas; E, performing a reaction on the chlorine gas obtained in the step D and the liquid ammonia obtained in the step C to generate ammonia chloride, and applying the obtained ammonia chloride to the step B. The manufacturing method for the silane type product is completely completed under a chloride-free and halogen-free environment; the risk of chloride and halogen in the subsequent use can be fully eliminated; furthermore, all side-products and intermediate products can be recovered and reutilized, so that the top requirement of environment protection is achieved.

Owner:上海万寅安全环保科技有限公司 +2

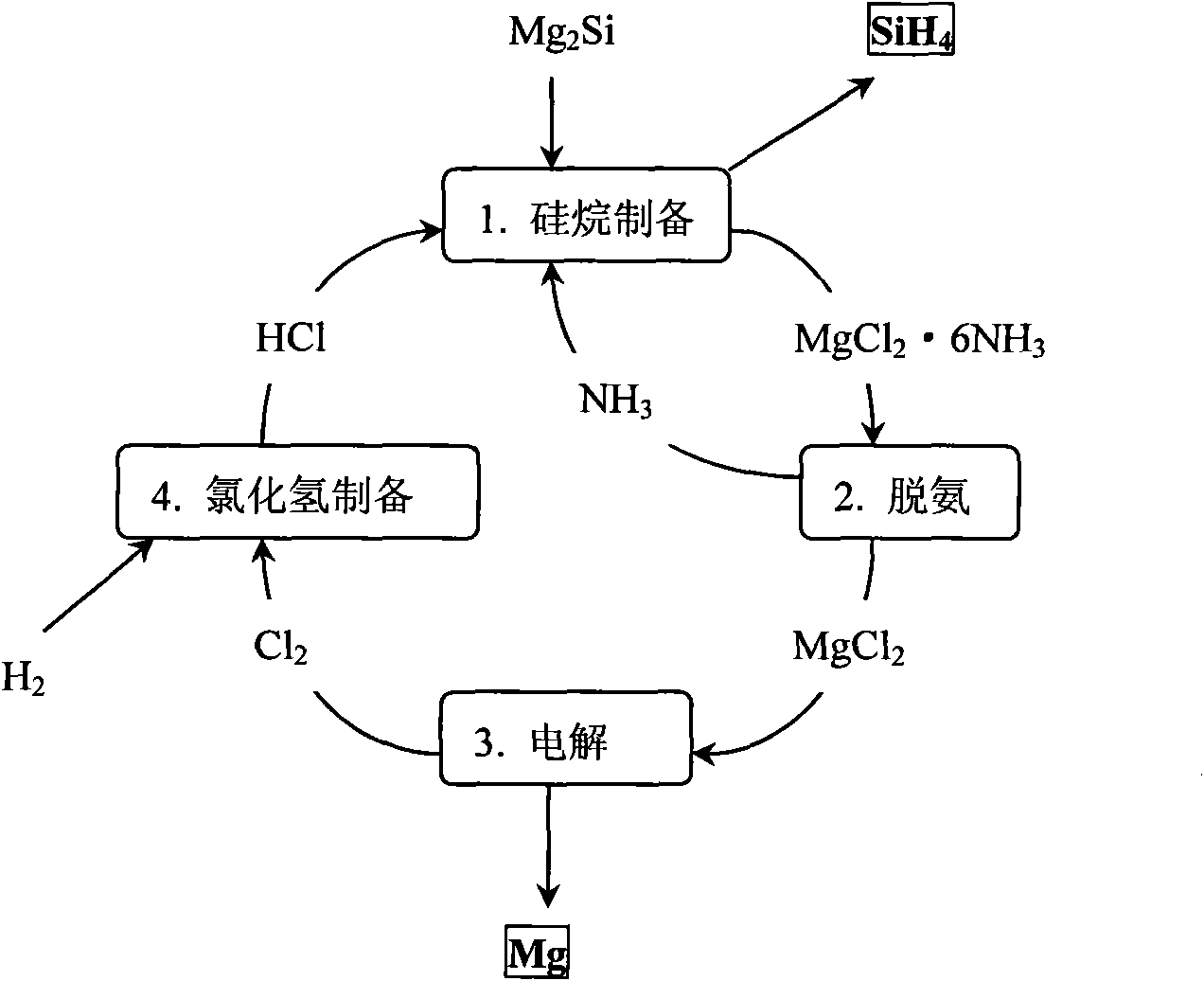

Application of byproducts in preparation of silane through magnesium silicide process

InactiveCN102030332ALow costCreate pollutionChlorine/hydrogen-chlorideSilicon hydridesHydrogenElectrolysis

The invention provides an application of byproducts in the preparation of silane through magnesium silicide process, i.e. the process for joint production of the silane and metal magnesium is further provided by using the byproducts in the preparation of the metal magnesium through the electrolysis process and the preparation of the magnesium through the electrolysis process in the magnesium silicide process in a circulating manner. In the application of the byproducts in the preparation of the silane through the magnesium silicide process, the byproduct which is magnesium chloride in the preparation of the silane through the magnesium silicide process is used in the electrolysis process for preparing the metal magnesium. The byproduct which is chlorine gas and got during the process of preparing the metal magnesium through the electrolysis process is further burned with hydrogen, then anhydrous hydrogen chloride is got, and the anhydrous hydrogen chloride further becomes raw material for preparing the silane through the magnesium silicide process. The byproducts in the two processes of preparing the silane through the magnesium silicide process and preparing the magnesium through the electrolysis process in the joint production are the raw materials for each other, thereby reducing the cost and simultaneously reducing the pollution.

Owner:鲍坚仁 +2

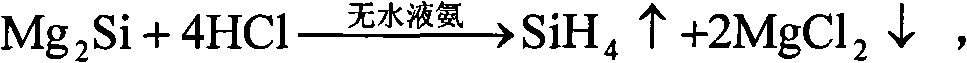

Preparation method of porous Si/SiC/C material and negative electrode material

ActiveCN111477849AReduce usageSolve the problem of garbage disposalSecondary cellsNegative electrodesElectrical batteryMagnesium silicide

The invention relates to a preparation method of a porous Si / SiC / C material and a negative electrode material. The preparation method comprises the steps of S1 grinding and mixing waste silicon powderand magnesium powder according to a mass ratio, placing the mixture and absolute ethyl alcohol in a planetary ball mill for physical ball milling, and drying to obtain silicon-magnesium alloy powder;S2 under the protection of inert gas, carrying out heating reaction on the silicon-magnesium alloy powder, carrying out furnace cooling and grinding to acquire magnesium silicide powder; and S3 carrying out heating reaction on the magnesium silicide powder in a CO2 atmosphere, and carrying out furnace cooling, grinding and acid pickling to obtain the porous Si / SiC / C material. The porous Si / SiC / Cmaterial is used as a lithium ion battery negative electrode material. The porous structure on the SiC / C protective layer is utilized to alleviate the volume expansion effect of the internally coatedsilicon, and the SiC / C layer can coat the silicon more completely, thereby effectively enhancing the rate capability and cycle performance of the silicon-carbon negative electrode material.

Owner:XIAMEN UNIV OF TECH

Magnesiothermic methods of producing high-purity silicon

Magnesiothermic methods of producing solid silicon are provided. In a first embodiment, solid silica and magnesium gas are reacted at a temperature from 400° C. to 1000° C. to produce solid silicon and solid magnesium oxide, the silicon having a purity from 98.0 to 99.9999%. The silicon is separated from the magnesium oxide using an electrostatic technology. In a second embodiment, the solid silicon is reacted with magnesium gas to produce solid magnesium silicide. The magnesium silicide is contacted with hydrogen chloride gas or hydrochloric acid to produce silane gas. The silane gas is thermally decomposed to produce solid silicon and hydrogen gas, the silicon having a purity of at least 99.9999%. The solid silicon and hydrogen gas are separated into two processing streams. The hydrogen gas is recycled for reaction with chlorine gas to produce hydrogen chloride gas.

Owner:ORION LAB

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

ActiveCN102237519BAvoid pollutionHigh specific capacityCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com