Magnesium-containing silicon oxide negative electrode material for lithium ion batteries and preparation method thereof

A lithium-ion battery, magnesium silicon oxide technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of difficult process control, poor cycle performance, industrial application, and poor cycle performance of materials, so as to achieve convenient production process Control, easy industrial application, and the effect of improving efficiency for the first time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

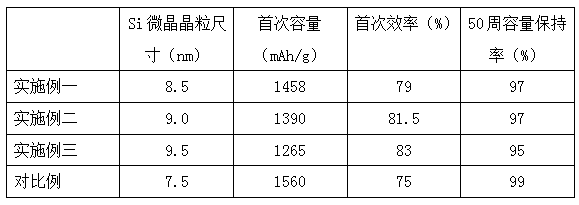

Embodiment 1

[0019] The method for preparing a magnesium-containing silicon oxide negative electrode material for a lithium ion battery according to Embodiment 1 is characterized in that: it comprises the following steps:

[0020] 1) Weigh silicon powder and magnesium powder in a mass ratio of 1:1.7, wherein the silicon powder has a purity of more than 99.9%, a particle size of D50≤8μm, and the magnesium powder has a purity of more than 99.9% and a maximum particle size of no more than 300μm.

[0021] 2), add the silicon powder and magnesium powder weighed in step 1) into the inert gas protection type mixer for mixing, add the mixed materials into the rotary heating furnace, and vacuum the rotary heating furnace to below 0.05Pa, and the temperature is 10℃ / The heating rate of min was heated to 550°C, kept for 3h, and then cooled to room temperature to obtain magnesium silicide;

[0022] 3) Weigh the silicon monoxide powder, its purity is not less than 99.9%, and the particle size D50 is le...

Embodiment 2

[0023] The preparation method of the magnesium-containing silicon oxide negative electrode material for lithium ion batteries of the second embodiment is characterized in that: it comprises the following steps:

[0024] 1) Weigh silicon powder and magnesium powder according to the mass ratio of 1:1.73, in which the purity of silicon powder is over 99.9%, the particle size D50 is less than or equal to 8 μm, the purity of magnesium powder is over 99.9%, and the maximum particle size is not more than 300 μm.

[0025] 2), add the silicon powder and magnesium powder weighed in step 1) into the inert gas protection type mixer for mixing, add the mixed materials into the rotary heating furnace, and vacuum the rotary heating furnace to below 0.05Pa, and the temperature is 10℃ / The heating rate of min was heated to 600°C, kept for 4h, and then cooled to room temperature to obtain magnesium silicide;

[0026] 3) Weigh silicon monoxide powder, its purity is not less than 99.9%, particle ...

Embodiment 3

[0027] The preparation method of the magnesium-containing silicon oxide negative electrode material for lithium ion batteries of the third embodiment is characterized in that: it comprises the following steps:

[0028] 1) Weigh silicon powder and magnesium powder according to the mass ratio of 1:1.75, in which the purity of silicon powder is more than 99.9%, the particle size D50 is less than or equal to 8μm, the purity of magnesium powder is more than 99.9%, and the maximum particle size is not more than 300μm.

[0029] 2), add the silicon powder and magnesium powder weighed in step 1) into the inert gas protection type mixer for mixing, add the mixed materials into the rotary heating furnace, and vacuum the rotary heating furnace to below 0.05Pa, and the temperature is 10℃ / The heating rate of min is heated up to 650 ° C, kept for 3-5 h, and then cooled to room temperature to obtain magnesium silicide;

[0030] 3) Weigh silicon monoxide powder, its purity is not less than 99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com