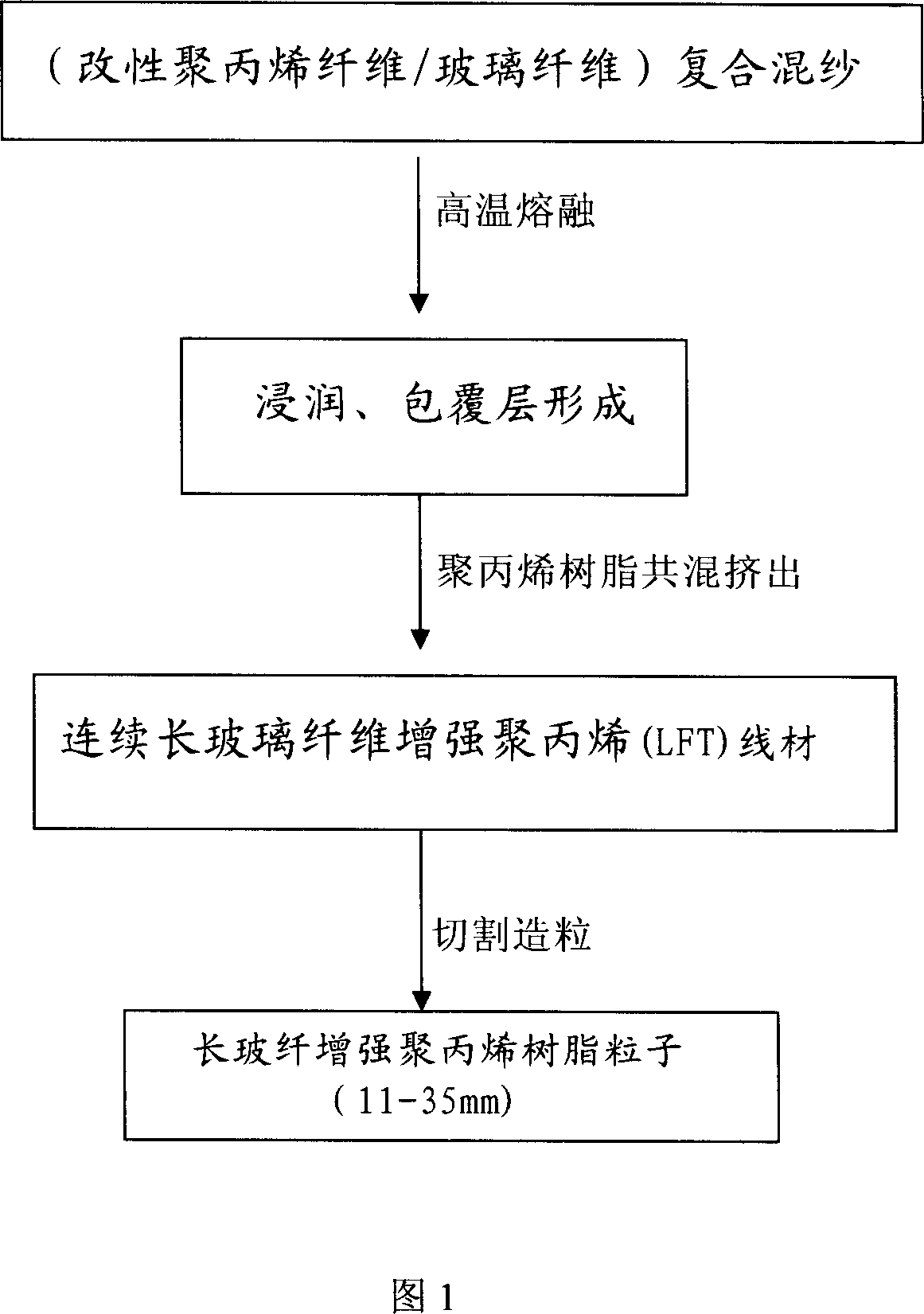

Continuous long glass fiber reinforced profax resin granular material preparation method

A polypropylene resin and long glass fiber technology is applied in the field of preparation of continuous long glass fiber reinforced polypropylene resin pellets. Improved UV resistance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 720kg of maleic anhydride grafted polypropylene (graft rate 0.8%) and polypropylene blending (weight ratio is 3: 97) resin fiber / glass fiber composite mixed yarn (each glass fiber diameter is 15um, each bundle of glass Fiber containing 2400, glass fiber content 75wt%), after high temperature 235 ~ 257 ℃ melting, with 98kg polypropylene resin, 2kg compatibilizer PP-g-MHA, 20g antioxidant 1010, 20g antioxidant 168, 10g anti-ultraviolet Blending agent 473 with each other evenly, and then put it into the 65-type single-screw extruder. The four control temperature zones of the extruder are: 185°C, 205°C, 215°C, 245°C from the hopper; the extrusion mold temperature: 240~255℃; compound blending yarn melting box temperature: 220~250℃; rotating speed 75 rpm; traction speed 35 m / min. Extruded to form continuous long fiber reinforced thermoplastic polypropylene (glass fiber content 35wt%) shaped wire. After cooling, cut and granulate, the length of LGFPP pellets is 11-13mm.

Embodiment 2

[0023] 690kg of acrylic grafted polypropylene (grafting rate 1.21%) and polypropylene blending (weight ratio is 4: 96) resin fiber / glass fiber (each glass fiber diameter is 12um, each bundle of glass fiber contains 6000) Composite mixed yarn (glass fiber content 60wt%), after melting at a high temperature of 235-257 ° C, with 94kg polypropylene resin, 2kg compatibilizer PP-g-MHA, 20g antioxidant 1010, 20g antioxidant 168, 10g anti-ultraviolet agent 473 mixed with each other evenly, put into 65-type single-screw extruder, the four control temperature zones of the extruder from the hopper are: 195°C, 210°C, 220°C, 245°C; extrusion mold temperature: 245~ 265°C; composite mixed yarn melting box temperature: 255~260°C; speed 80 rpm; traction speed 25 m / min. Extruded to form continuous long fiber reinforced thermoplastic polypropylene (glass fiber content 35wt%) shaped wire. After cooling, cut and granulate, the length of LGFPP pellets is 11-15mm.

Embodiment 3

[0025] 715kg of glycidyl methacrylate grafted polypropylene (graft ratio 1.1) blended with polypropylene (weight ratio is 5:95) resin fiber / glass fiber (each glass fiber diameter is 16um, each bundle of glass fiber Containing 2400 pieces) composite mixed yarn (glass fiber content 75wt%), melted at a high temperature of 238-265°C, mixed with 106kg polypropylene resin, 2kg compatibilizer PP-g-MHA, 20g antioxidant 1076, 20g antioxidant 1098, 10g of anti-ultraviolet agent 473 is mixed with each other evenly, put into the 65-type single-screw extruder, and the four control temperature zones of the extruder are: 190°C, 215°C, 220°C, 245°C from the hopper; Temperature: 260-270°C; compound blending yarn melting box temperature: 250-260°C; speed 70 rpm; traction speed 30 m / min. Extruded to form continuous long fiber reinforced thermoplastic polypropylene (glass fiber content 35wt%) shaped wire. After cooling, cut and granulate, the length of LGFPP pellets is 11-14mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com