Patents

Literature

141 results about "Long-fiber-reinforced thermoplastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long-fiber-reinforced thermoplastic (LFRTs) is a type of easily mouldable thermoplastic used to create a variety of components used primarily in the automotive industry. LFRTs are one of the fastest growing categories in thermoplastic technologies. Leading this expansion is one of the oldest forms, glass mat thermoplastic (GMT) and two of the segment’s newest: precompounded (pelletized) LFRTs (long-fiber-reinforced thermoplastics), also known as LFTs, and inline compounded (ILC) or direct LFTs (D-LFTs).

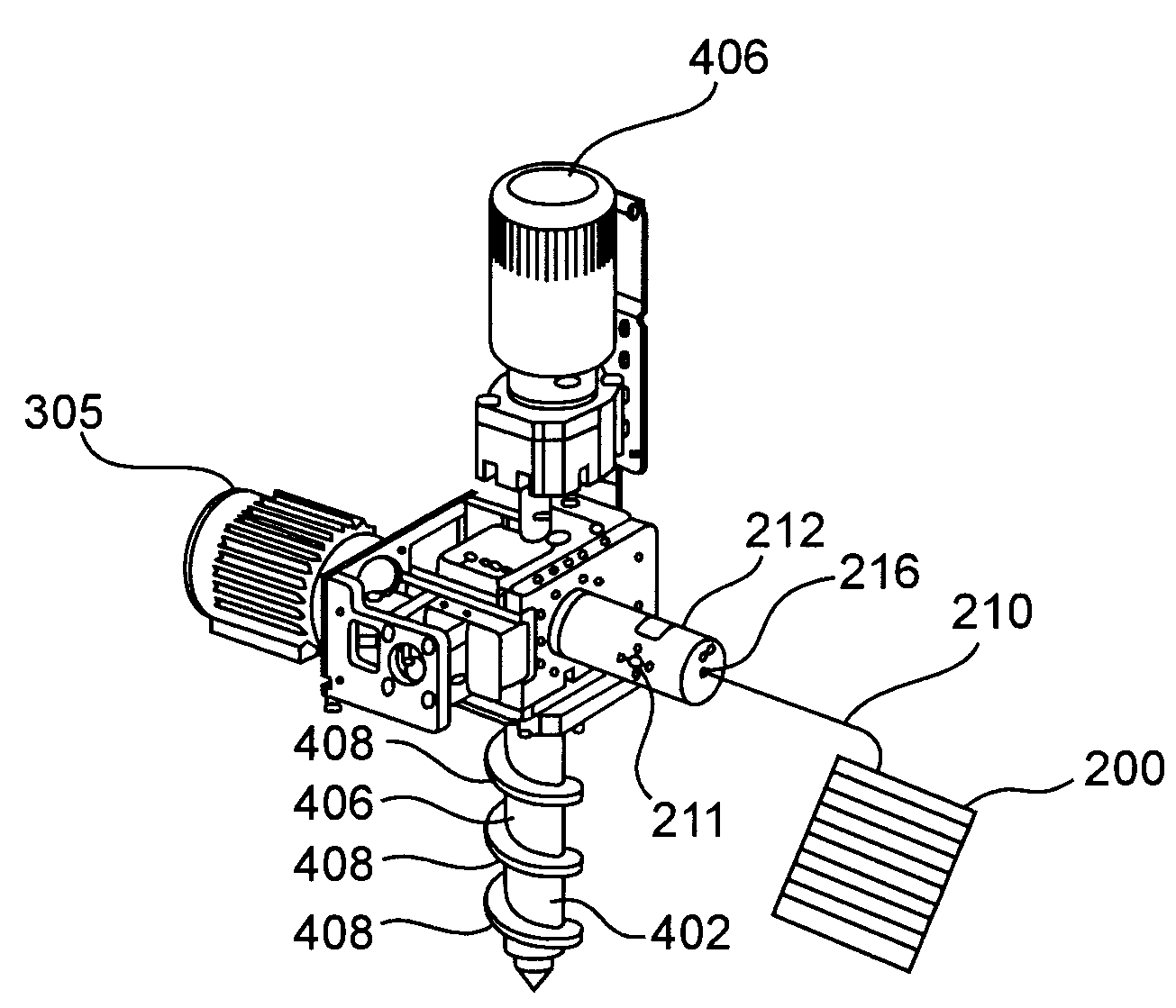

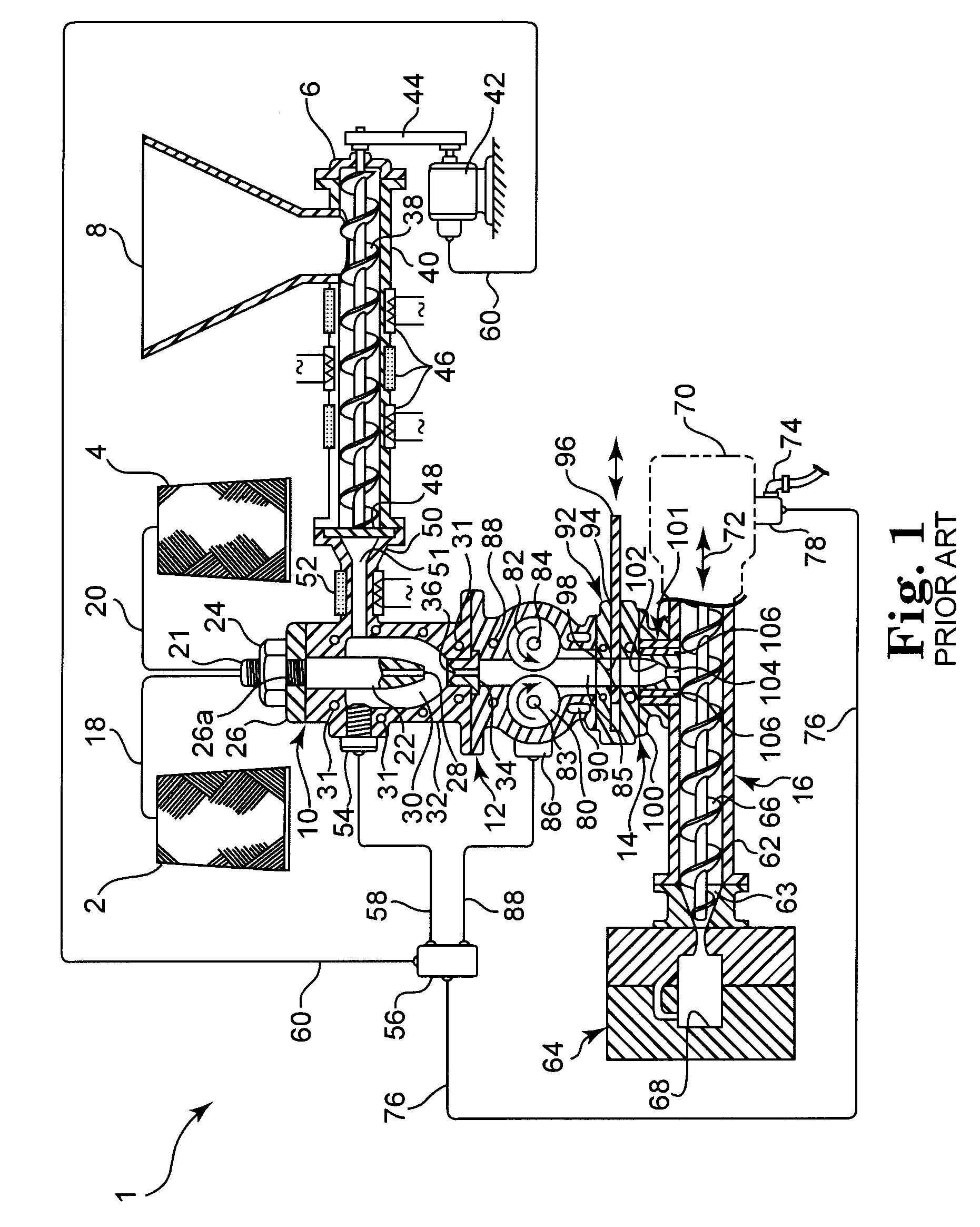

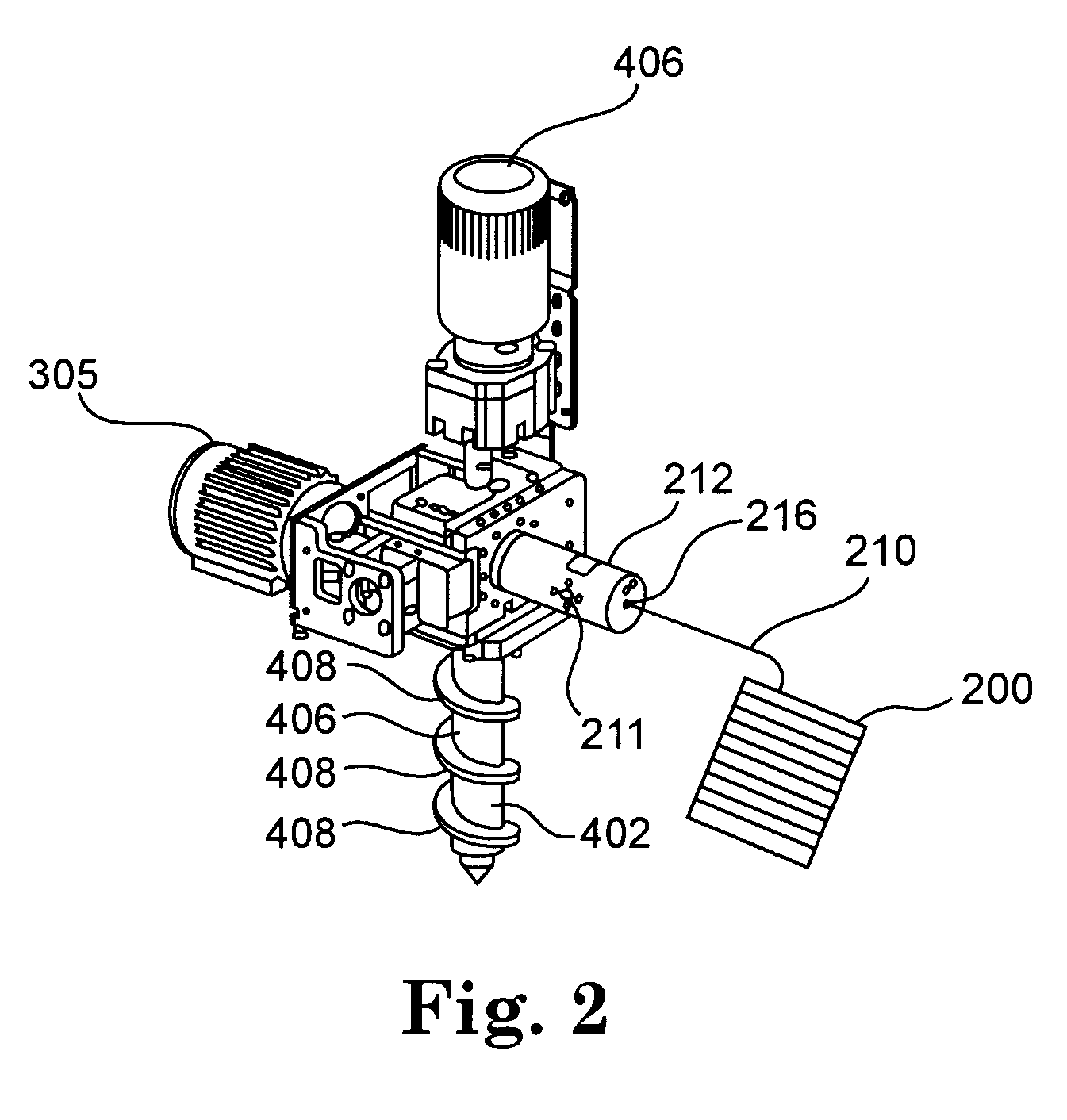

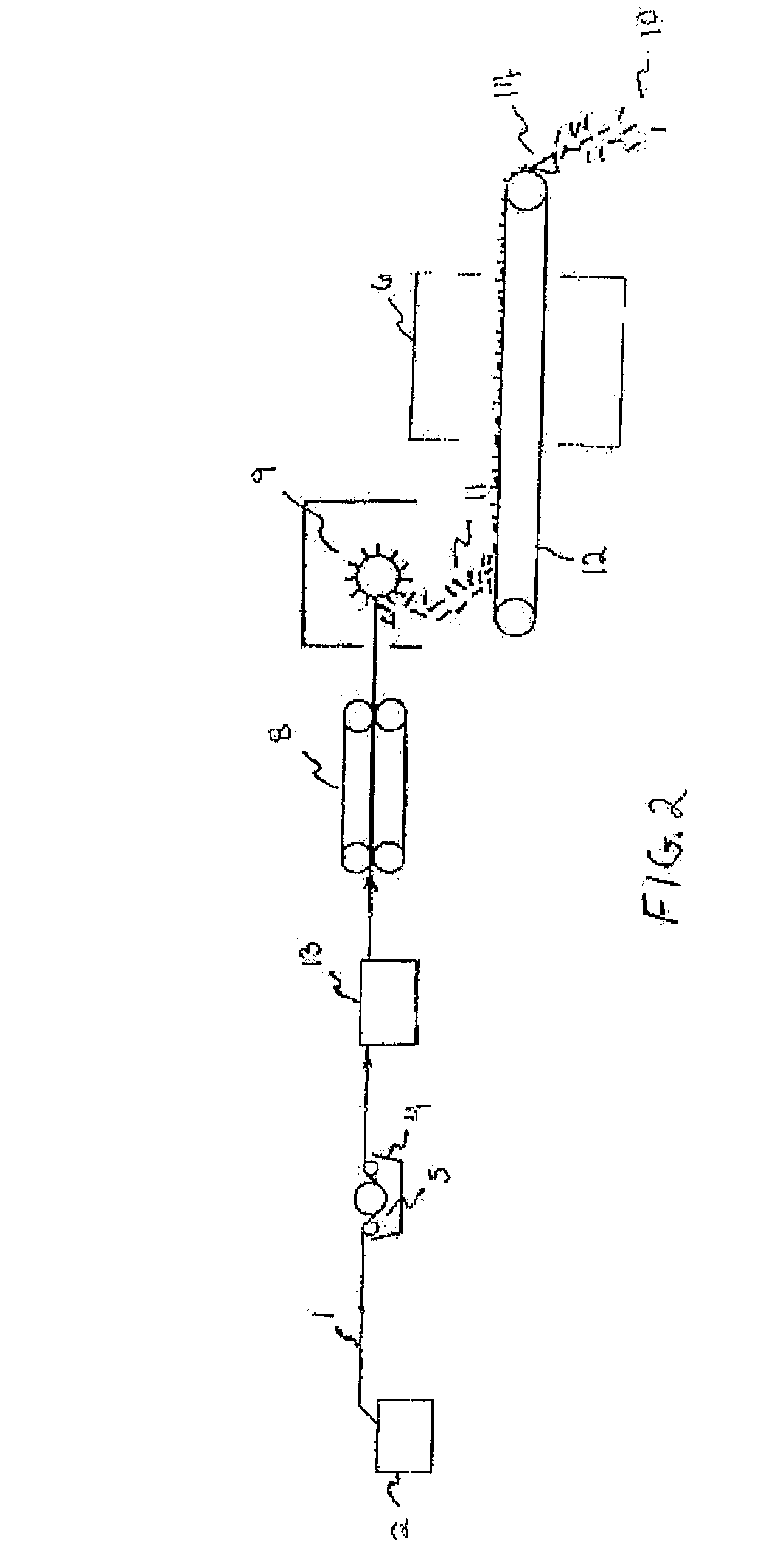

Reinforced thermoplastic resin and device and method for producing very long fiber reinforced thermoplastic resins

Improved reinforced thermoplastic resin, and devices and methods for producing the improved reinforced thermoplastic resin. The invention comprises complete fiber strand dispersion and wet out without breaking fiber filaments after cutting the fiber to a designated length. Certain embodiments of the present invention may comprise a zero-shear down screw which rotates very slowly. Thus, the resin and glass fiber bundles are slowly kneaded and the individual filaments unbundled from the fiber bundles resulting in complete wet-out of each filament without creating a pressure flow path for the substrate material and the entrained glass fibers and unbundled filaments. Optimized geometrically-controlled openings may be provided at the end of the down screw, providing further breakage-free kneading of the individual filaments. Certain embodiments may comprise an extended length cutting chamber which allow cutting very long individual fiber lengths. Temperature reduction mechanisms may be provided which provide a thermal block between the down screw assembly and the main frame assembly.

Owner:PLASTICOMP

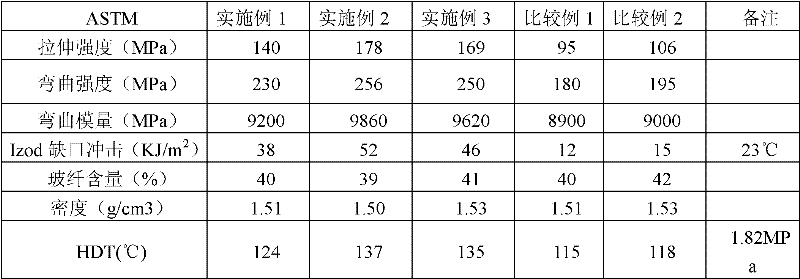

Continuous long fiber reinforced thermoplastic polyurethane material and preparation method thereof

The invention belongs to the technical field of high polymer materials and discloses a continuous long fiber reinforced thermoplastic polyurethane material and a preparation method thereof. The continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention comprises the following components in parts by weight: 200-800 parts of thermoplastic polyurethane, 800-200 parts of continuous long fiber reinforcing agent, 10-30 parts of compatilizer, 10-20 parts of antioxidant, 2-6 parts of lubricating agent and 5-10 parts of crosslinking agent. Compared with the prior art, the continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention is simple in structure, reasonable in design and strong in practicability; and a long glass fiber reinforced thermoplastic polyurethane material is adopted, thereby greatly improving the rigidity and strength of the material and obviously improving the anti-impact property and heat-resistant property of the material.

Owner:HEFEI GENIUS NEW MATERIALS

Molding material and resin-adhered reinforcing fiber bundle

ActiveUS20120015186A1Improve mechanical propertiesExcellently light in weightMixingYarnFiber bundleLong-fiber-reinforced thermoplastic

A molding material comprising the following components (A) to (D) at the following ratios, in which the component (D) is bonded to a composite comprising the components (A) to (C) and the order in the weight average molecular weight is component (D)>component (B)>component (C); (A) 1 to 75 wt % of a reinforcing fiber bundle; (B) 0.01 to 10 wt % of a first propylene-based resin; (C) 0.01 to 10 wt % of a second propylene-based resin having carboxylate groups bound to the polymer chains thereof; and (D) 5 to 98.98 wt % of a third propylene-based resin. A molding material of this invention provides a long fiber-reinforced thermoplastic resin molding material containing a propylene-based resin as the matrix resin, which allows the reinforcing fibers to be well dispersed into the molded article produced at the time of injection molding and allows the molded article produced to have excellent mechanical properties.

Owner:TORAY IND INC

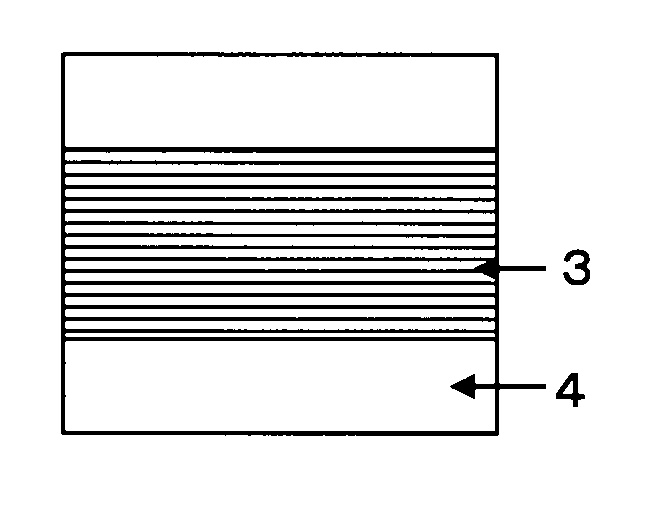

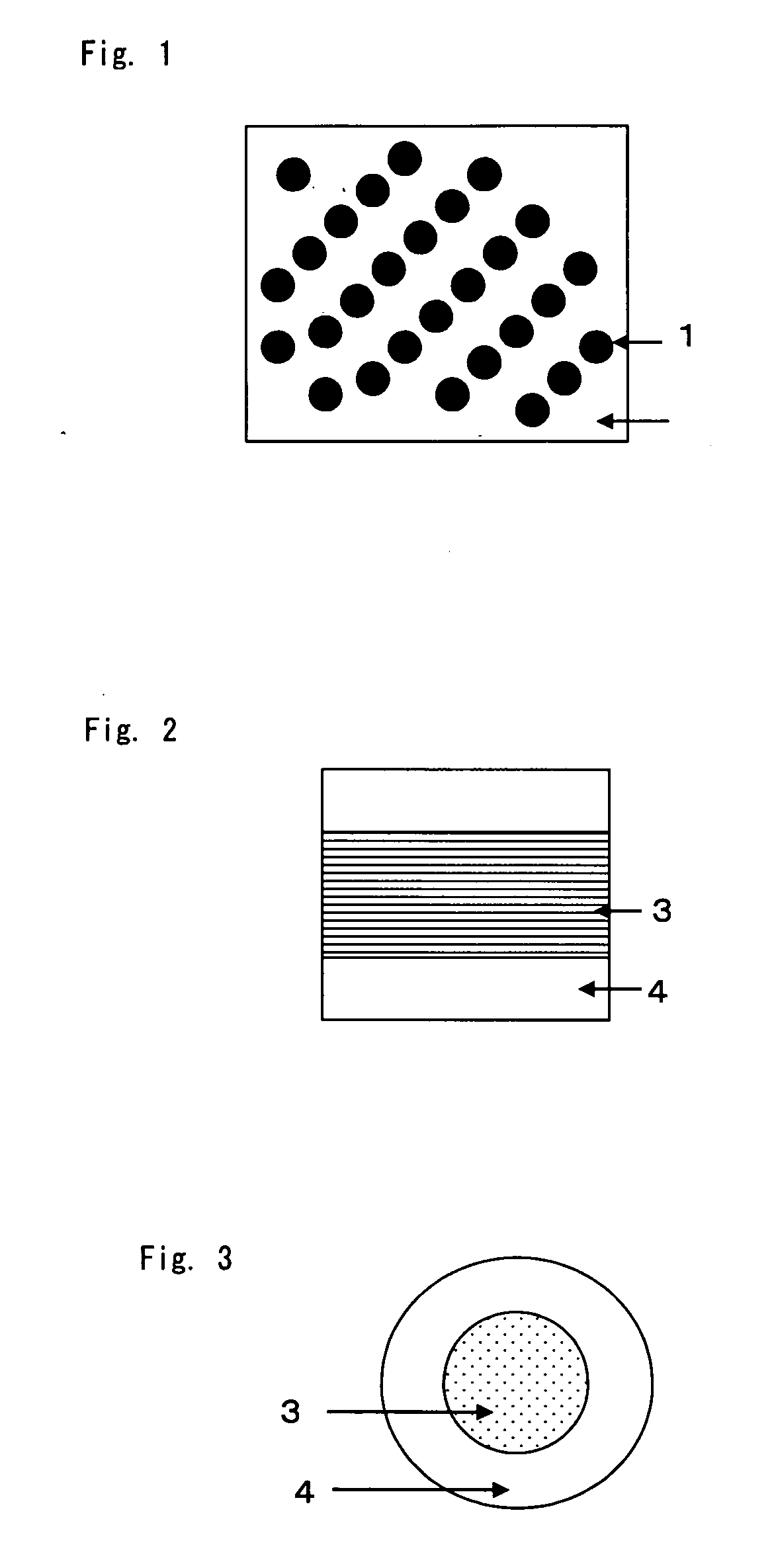

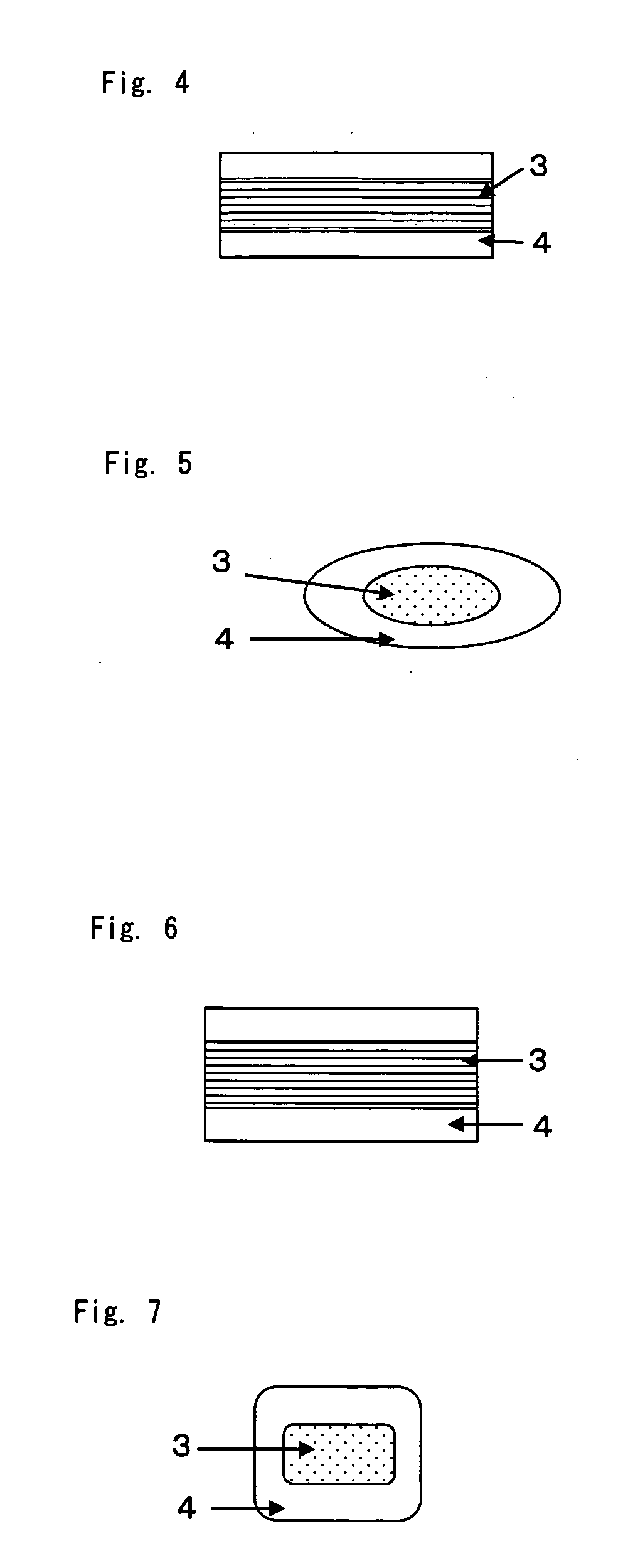

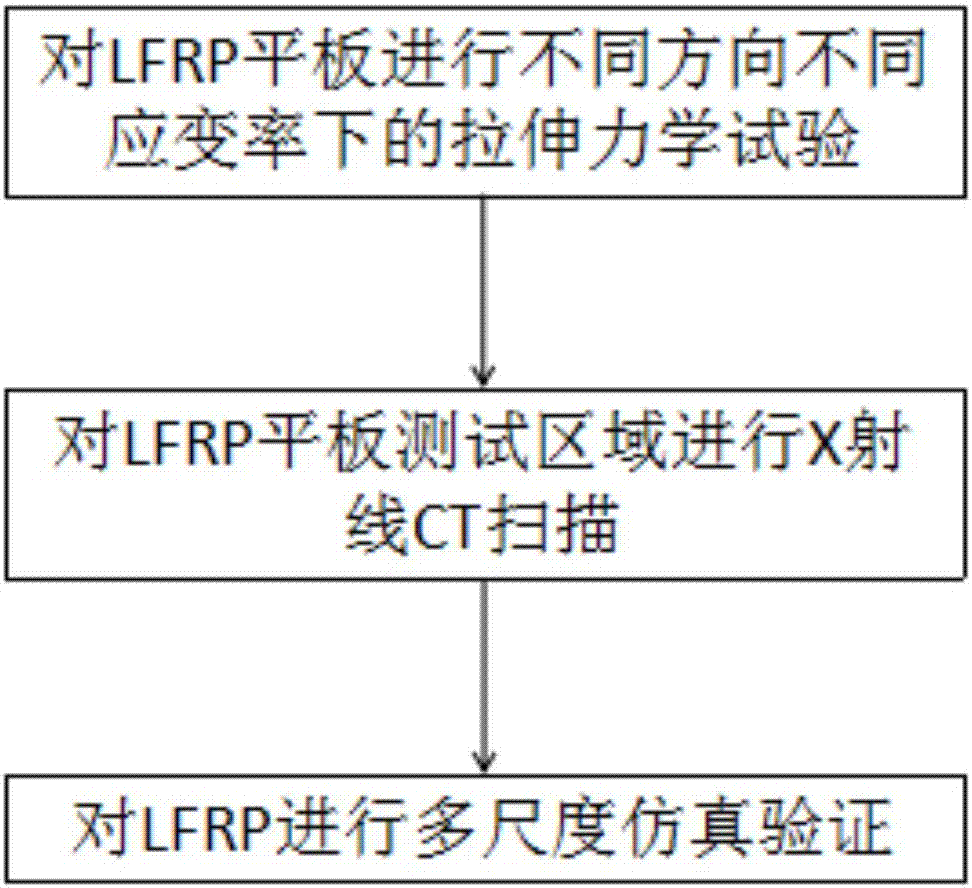

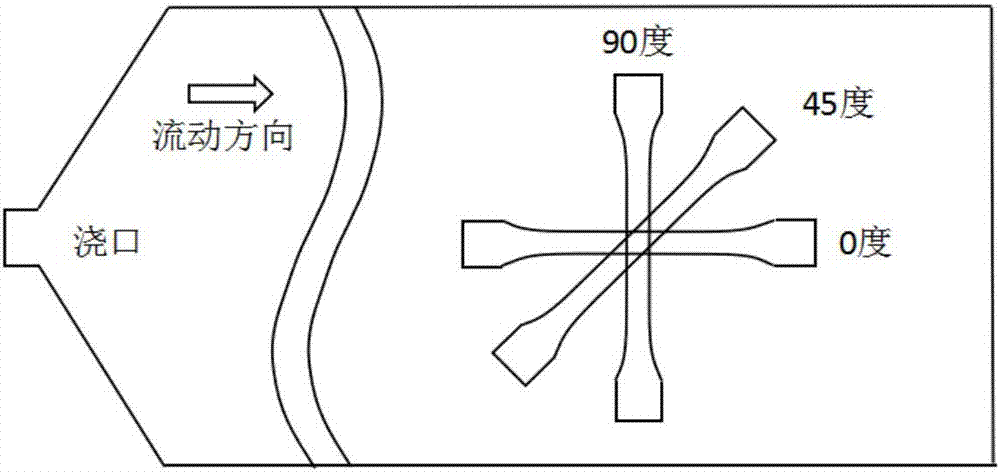

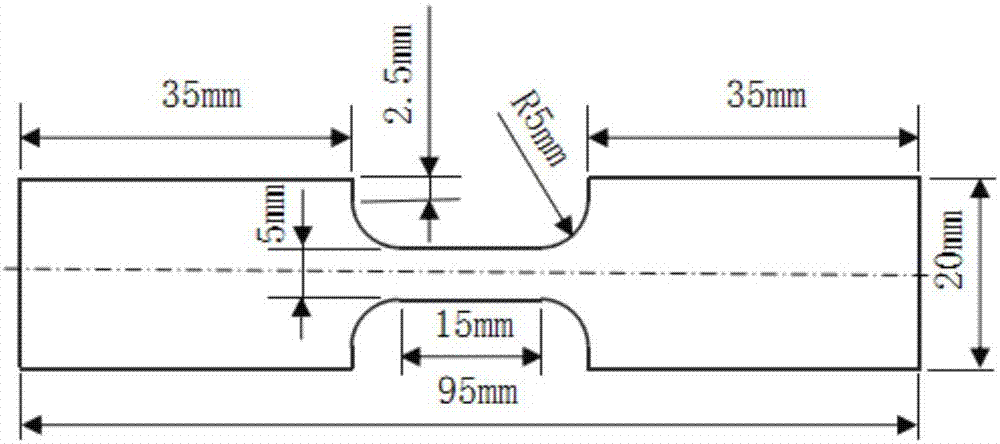

Long fiber reinforced thermoplastic composite material multi-scale simulation method

InactiveCN107356478ALow imaging resolutionRequires minimizationMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationElement modelX-ray

The invention discloses a long fiber reinforced thermoplastic composite material multi-scale simulation method to solve the problem of difficult accurate simulation of long fiber reinforced thermoplastic composite material in simulation because of strain rate effect and anisotropic mechanical properties. The method includes the steps of: 1. conducting tensile test on an LFRP plate under different directions and different strain rates; 2. performing x-ray CT scanning on an LFRP plate test area; and 3) carrying out multi-scale simulation verification on the LFRP plate: 1) viscoelastic-viscoplastic material model and failure; and 2) simulation verification: using ABAQUS software and Digimat software coupling to establish a simulation finite element model, conducting simulating calculation of tensile test under three strain rates, wherein 0.001s<-1> and 1s<-1> adopt implicit algorithm, and 100s<-1> adopts display algorithm; fixing one end of the finite element sample model, and applying load to the other end along the length direction, and comparing all the mechanical characteristic curves obtained by simulating calculation with test data.

Owner:JILIN UNIV

Continuous fiber reinforced thermoplastic prepreg tape braided fabric and continuous fiber reinforced thermoplastic prepreg tape plate preparation method

InactiveCN102615839AImprove performanceHigh impact strengthEngineeringLong-fiber-reinforced thermoplastic

The invention relates to a prepreg tape braided fabric plate preparation method, in particular to a continuous fiber reinforced thermoplastic prepreg tape braided fabric and a continuous fiber reinforced thermoplastic prepreg tape plate preparation method. The preparation method comprises the steps: the continuous fiber reinforced thermoplastic prepreg tape with an excellent soaking effect is prepared in a melting soaking manner, a powder soaking manner or other manners at first, so that the defect of difficult soaking can be effectively overcome; then braided fabric is obtained through different braiding manners as required; and finally the plate with excellent performance is prepared through different moulding manners. Meanwhile, the braided fabric can be directly used for reinforcing short or long fiber reinforced thermoplastic composite materials, and can greatly improve the material performance, particularly impact strength.

Owner:EAST CHINA UNIV OF SCI & TECH

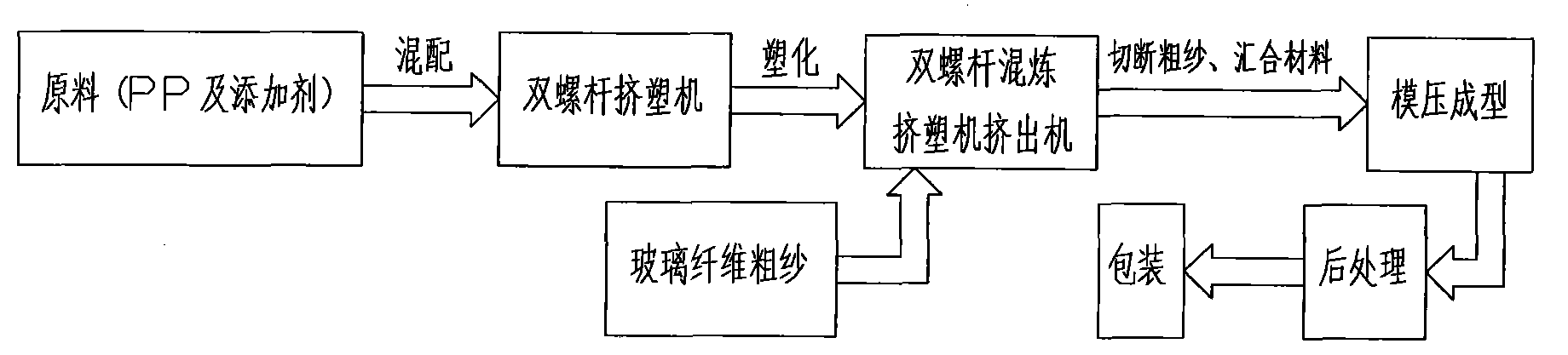

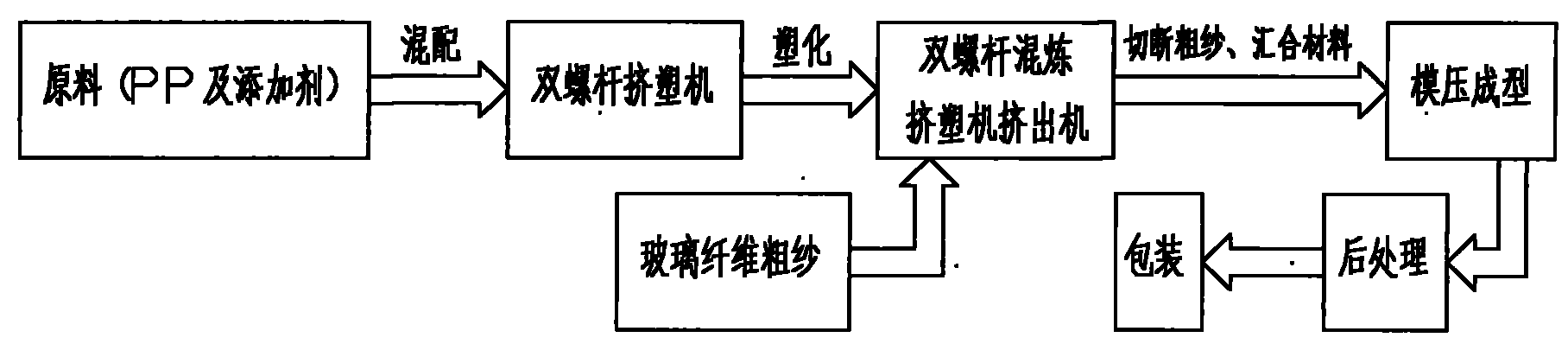

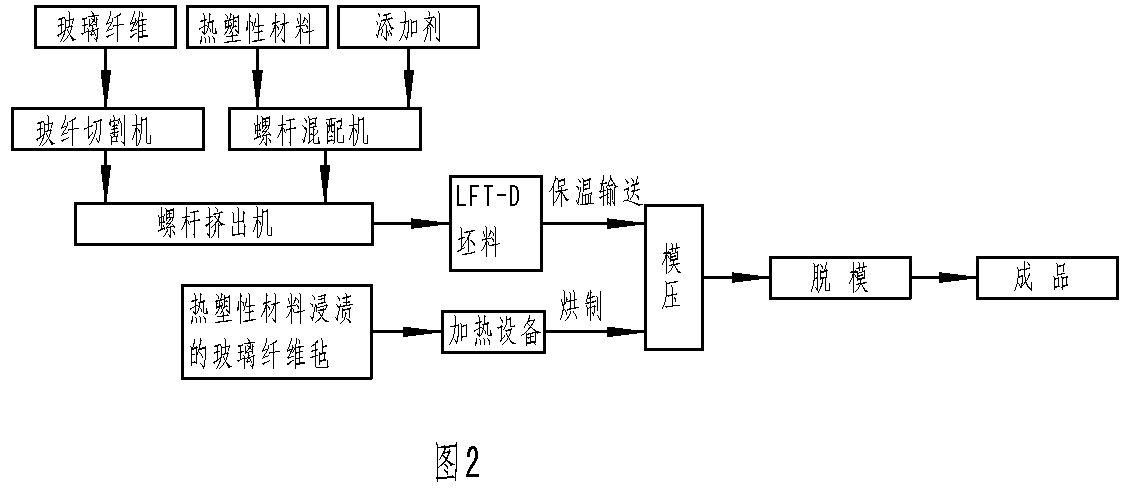

Automobile bottom deflector made of LFT-D (Fiber Reinforce Thermoplastic-Direct) material and manufacture method thereof

InactiveCN101935420AFlexible choiceImprove impact resistanceComponent optimizationVehicle body streamliningGlass fiberWork in process

The invention relates to an automobile bottom deflector made of an LFT-D (Fiber Reinforce Thermoplastic-Direct) material and a manufacture method thereof. The automobile bottom deflector made of the LFT-D material is directly produced by a raw material jointly comprising glass fibers, PP (Polypropylene) and necessary additives, wherein the formula of the LFT-D raw material can be correspondingly adjusted according to the requirements of products; the average length of the glass fibers in the automobile bottom deflector made of the LFT-D material reaches 25mm; and the density thereof is 2 / 3 of the density of an SMC (Sheet Molding Compound) material. The LFT-D production process has the advantage of flexible material selection and can be used for adjusting different additives, fiber contents and the fiber length on line so as to meet the requirement of a final product; an LFT-D material product has good mechanical properties and heat resistant properties such as shock resistance, creep resistance, and the like and has light weight; the LFT-D material can be used for producing products with more complicated structures; and semi-finished products in the LFT-D on-line production process are removed, thus the process has the advantages of low raw material and production cost, product recycling and short production period.

Owner:上海耀华大中新材料有限公司

Preparation method of aramid fiber modified long glass fiber reinforced thermoplastic

The invention relates to a formula, in which a thermoplastic material is produced from aramid fibers, long glass fibers and thermoplastic resin, and a manufacturing method of the thermoplastic, and belongs to the technical field of modified plastic and composite materials. On the basis of a long glass fiber reinforced thermoplastic granule process (LFT-G), by means of high strength, high toughness and high flexibility of the aramid fibers, the aramid fibers are uniformly dispersed and vertically and horizontally located in a three-dimensional rigid framework of the long glass fiber reinforced thermoplastic, thus improving the toughness and anti-impact strength of the composite material. By means of original LFT-G producing device, the method employs simple equipment and has short production route, is low in power consumption of the required equipment, has convenient operations and outstanding product performances. The product satisfies requirement of low-carbon environment protection and energy saving and emission reduction, and has good application prospect in the fields of automobiles, household appliances, aerospace, building materials, equipment manufacturing, etc.

Owner:SHANDONG DAWN POLYMER CO LTD

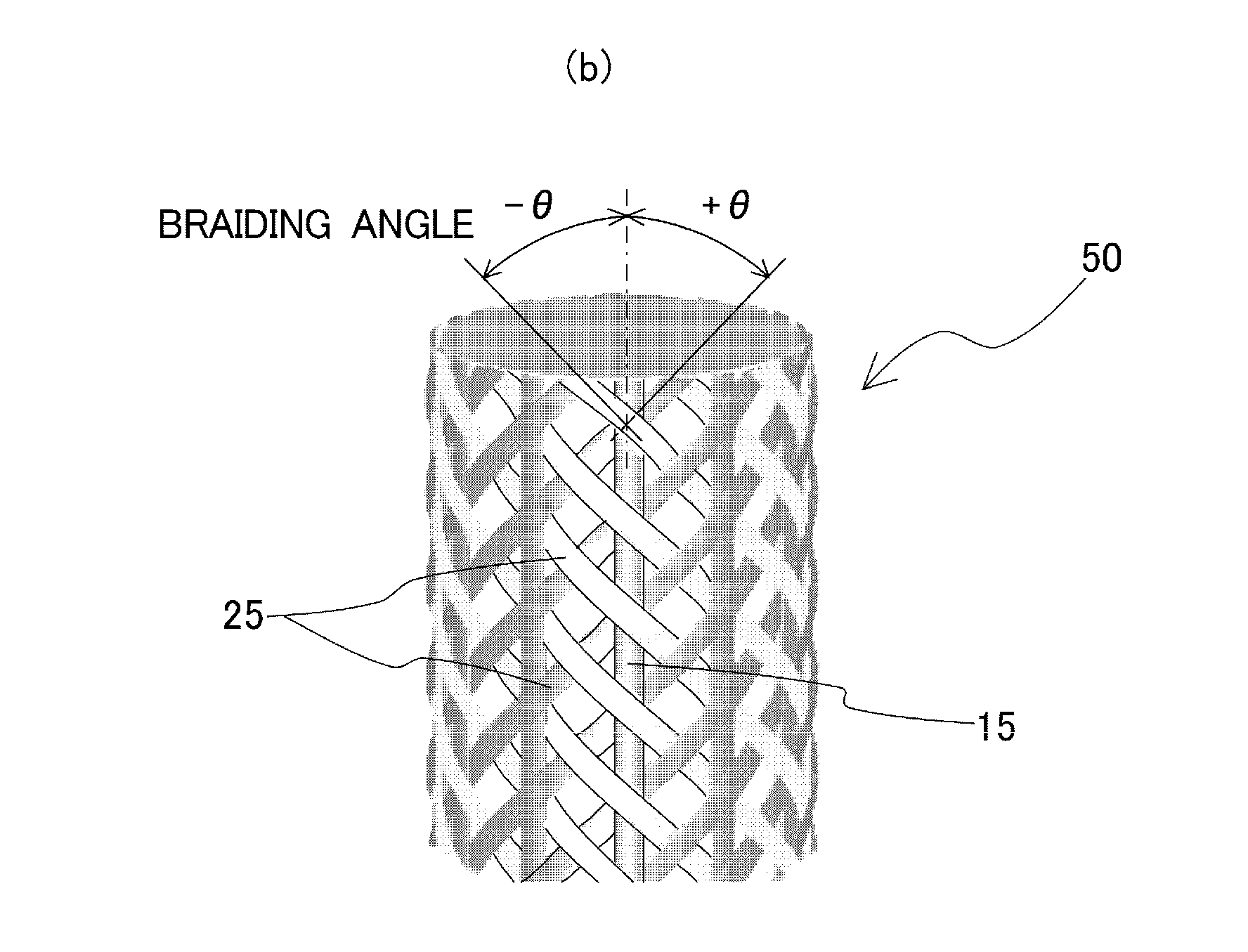

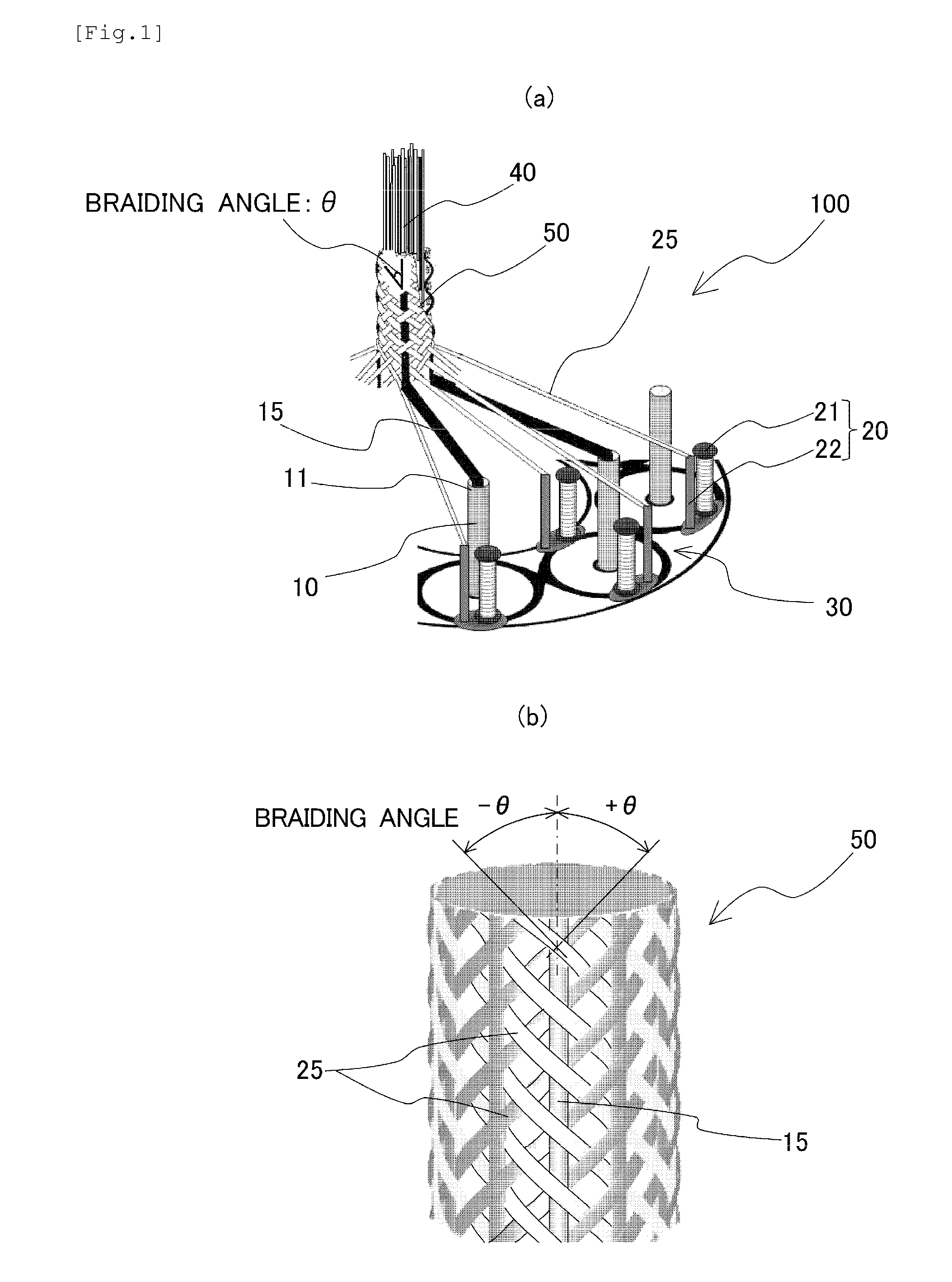

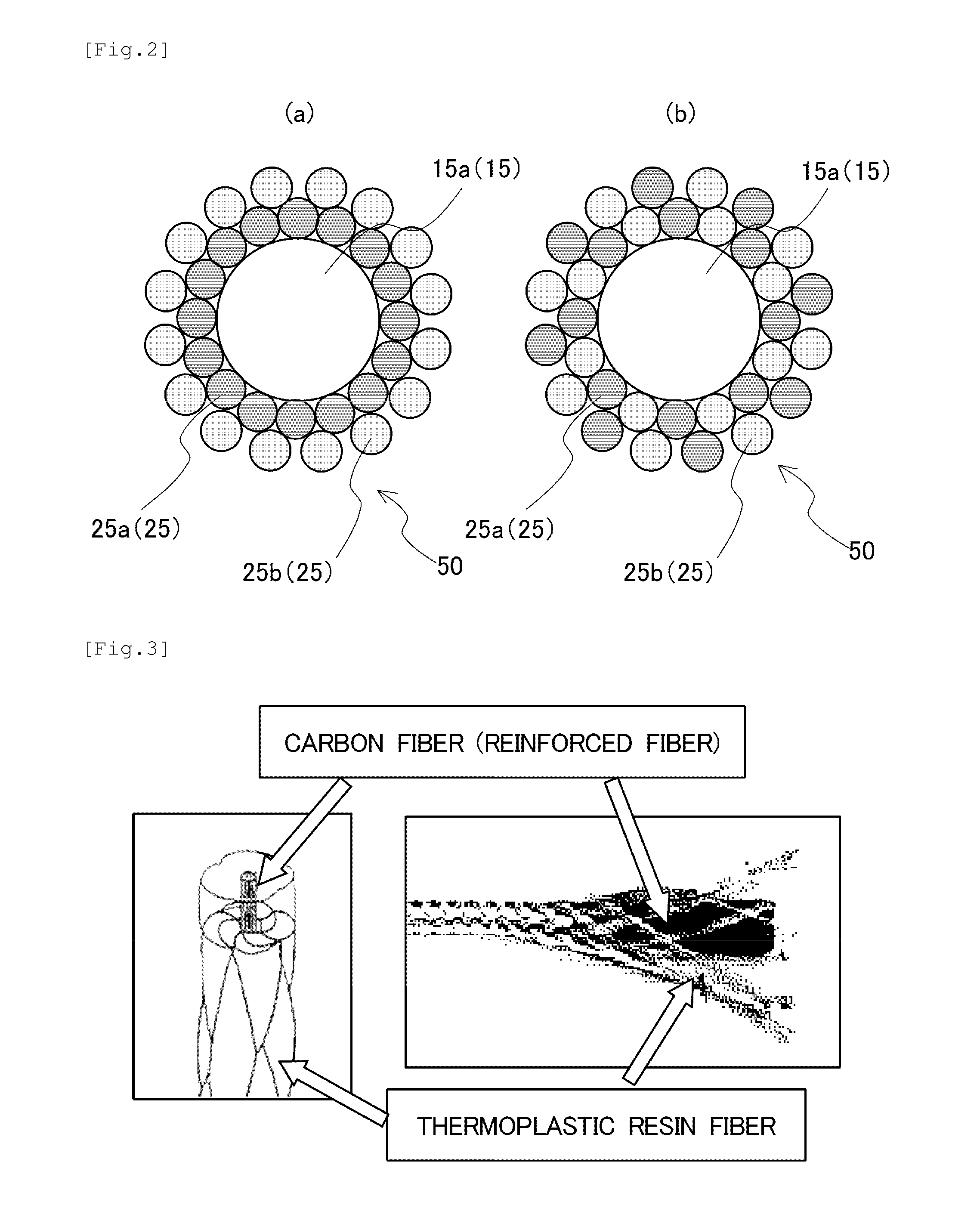

Reinforced fiber/resin fiber composite, and method for manufacturing same

InactiveUS20140230634A1Easy to carryImprove featuresOrnamental textile articlesBraidLong-fiber-reinforced thermoplasticFibre reinforcement

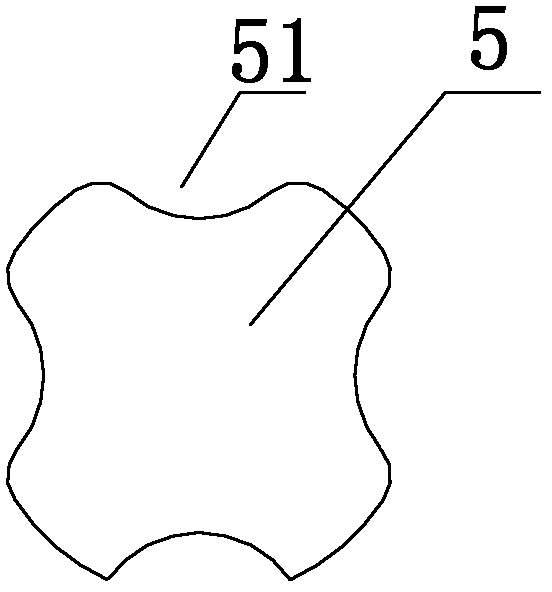

A reinforced fiber / resin fiber composite is provided in which the ratio and arrangement of a long fiber and a thermoplastic resin fiber included in an intermediate material are accurately controlled to simultaneously provide good impregnation characteristics of the long fiber and good interfacial characteristics between the long fiber and the thermoplastic resin. A reinforced fiber / resin fiber composite (50) is provided which is an intermediate material for a long-fiber reinforced thermoplastic resin structure. The reinforced fiber (15) is a long fiber extending in a longitudinal direction. The resin fiber (25) includes at least two thermoplastic resin fibers. The at least two thermoplastic resin fibers are arranged around the reinforced fiber (15) to surround the reinforced fiber (15).

Owner:NAT UNIV KYOTO INST OF TECH

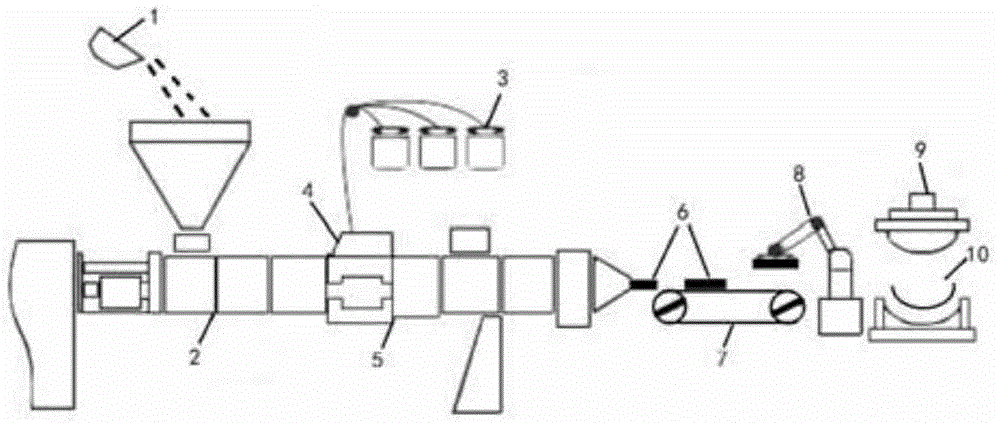

Method for preparing bicycle frame from long-fiber reinforced thermoplastic composite material through on-line direct molding

The invention relates to a method for preparing a bicycle frame from a long-fiber reinforced thermoplastic composite material through on-line direct molding. The method comprises the following steps of: plasticizing thermoplastic resin and an additive in a cylinder of a double-screw extruder by controlling processing temperature, drawing continuous fiber out from a creel, adjusting tension and leading into the cylinder of the double-screw extruder, uniformly mixing fiber into thermoplastic resin melt through cutting of a screw, and directly feeding thermoplastic resin melt mixed with the continuous fiber into a bicycle frame compacting tool set or pushing into a bicycle frame injection model and molding. Compared with the prior art, the method has the advantages that: mould pressing or injection molding can be directly performed, welding is not required, products prepared from the long-fiber reinforced thermoplastic composite material through on-line direct molding have the characteristics of high intensity, light weight, high impact resistance, low cost and the like.

Owner:HEFEI GENIUS NEW MATERIALS

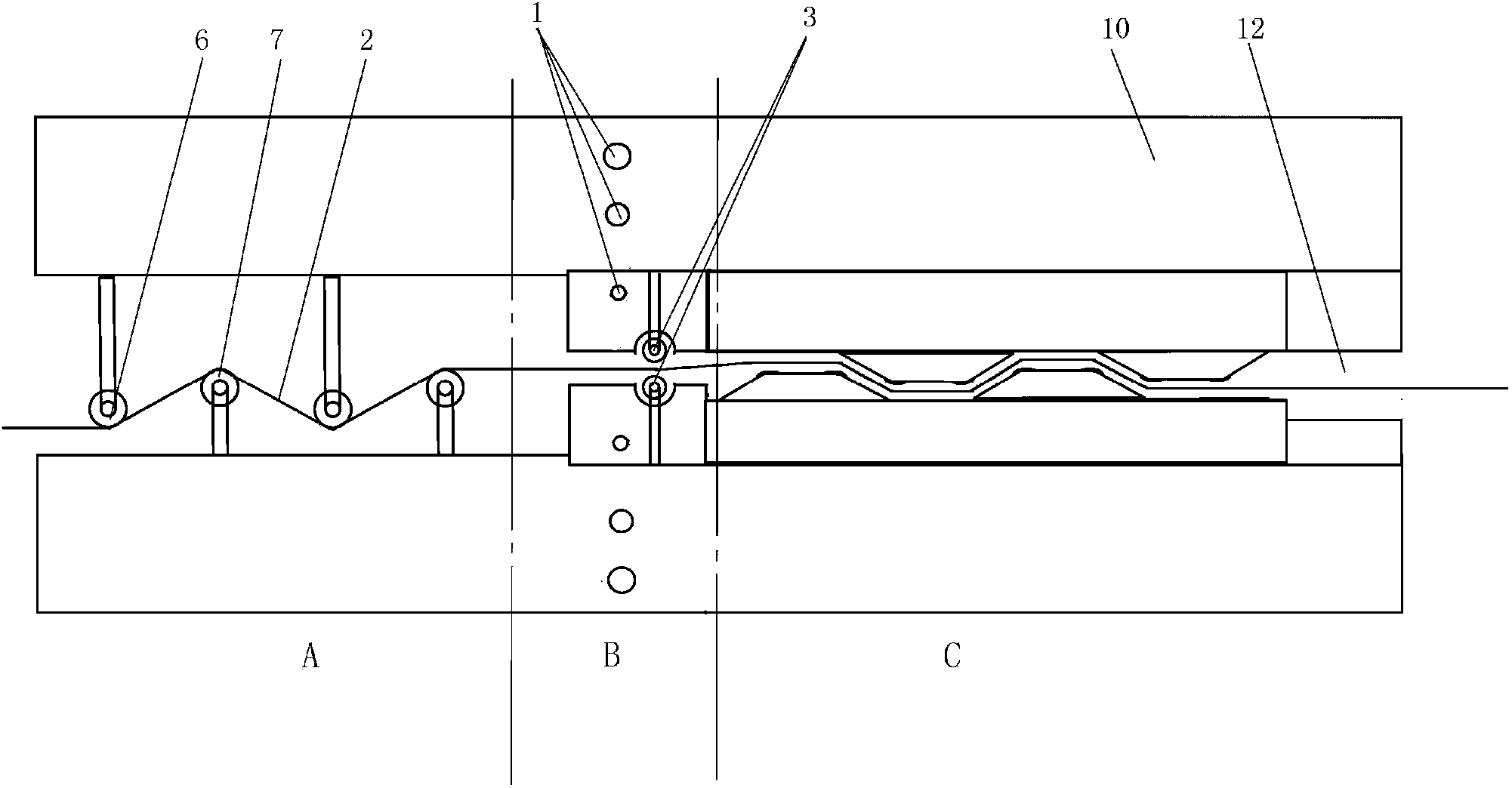

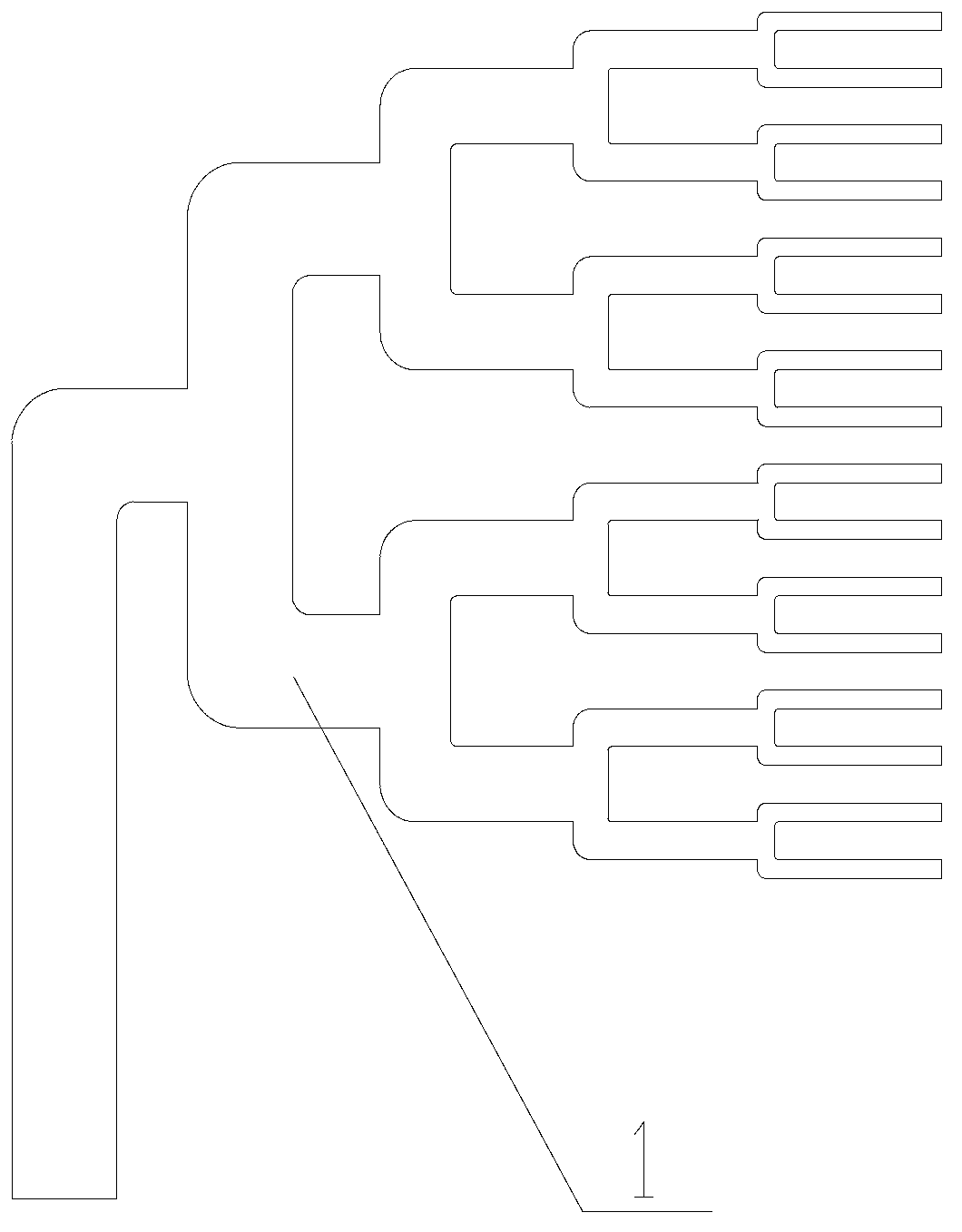

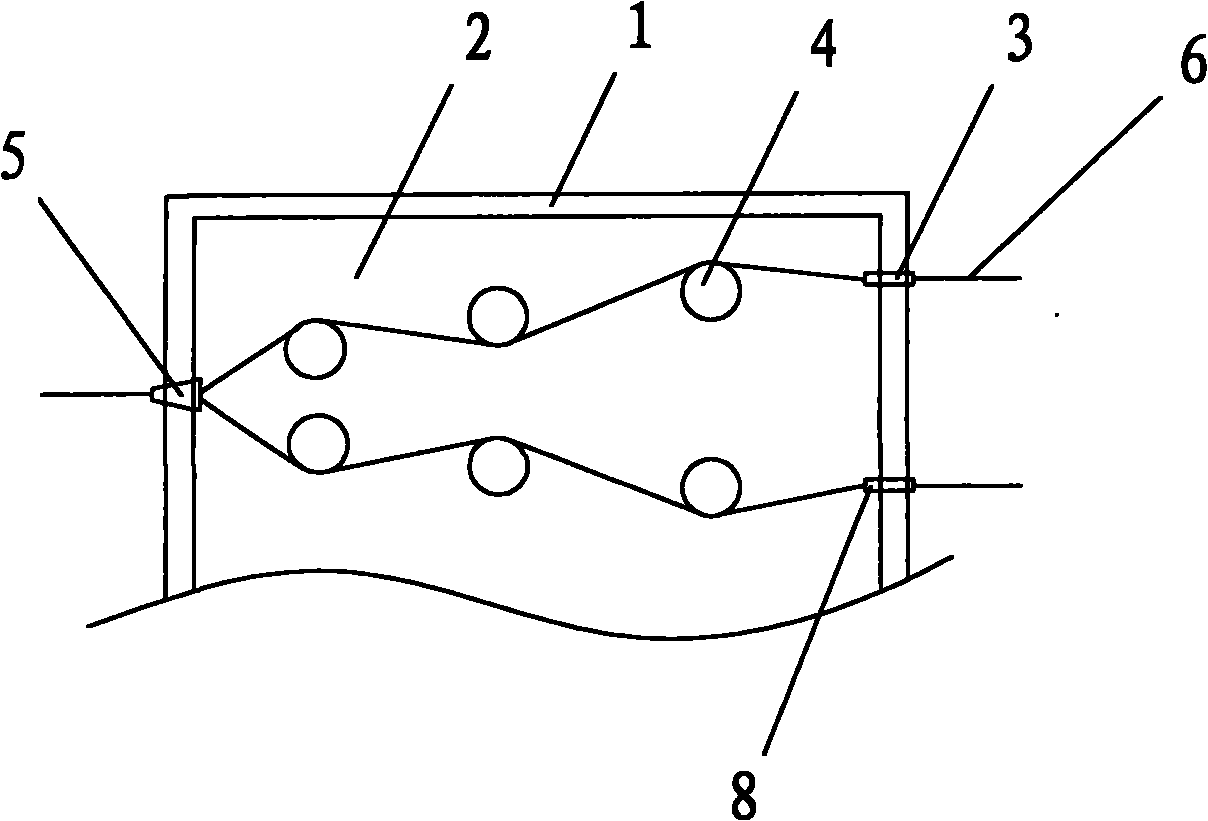

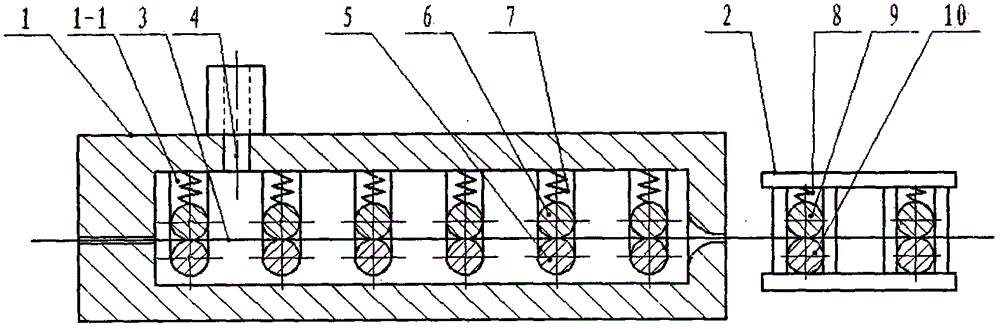

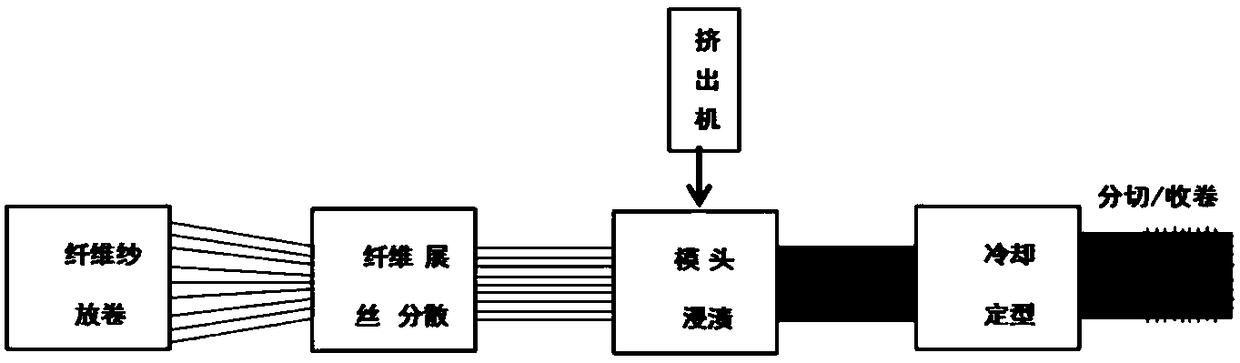

Equipment and method for impregnating continuous long fiber reinforced thermoplastics

The invention discloses equipment and a method for impregnating, and particularly relates to equipment and a method for impregnating continuous long fiber reinforced thermoplastics. The invention provides the equipment and the method for impregnating the continuous long fiber reinforced thermoplastics of which the fiber bundles are not interfered with one another, which comprise an equipment outer body, wherein a melt inlet is arranged at the upstream end of the equipment outer body, an extruding outlet is arranged at the downstream end of the equipment outer body, impregnating runners are arranged in the equipment outer body, the two ends of the impregnating runners are respectively communicated with the melt inlet and the extruding outlet, at least two impregnating runners are arranged in parallel, and long fiber feed ports which have the same number as that of the impregnating runners are arranged on the side wall of the equipment outer body and are respectively communicated with each impregnating runner. Because each impregnating runner is separately arranged, fibers can be separately impregnated and fed, and are not interfered with one another, so the production can be ensured to be stable.

Owner:SICHUAN UNIV

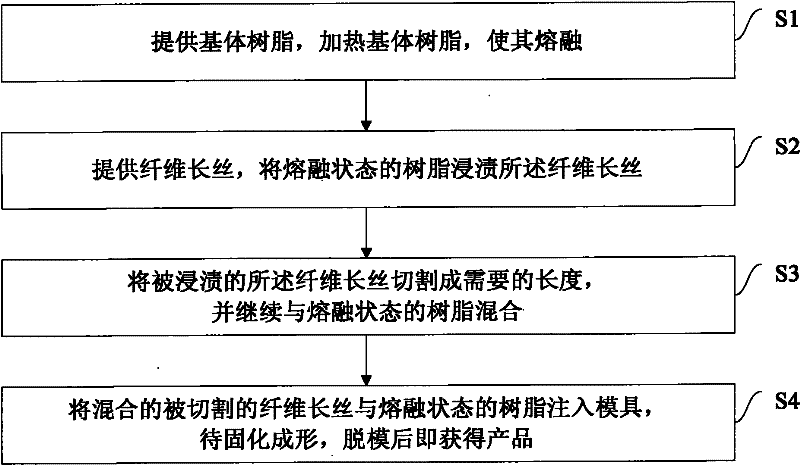

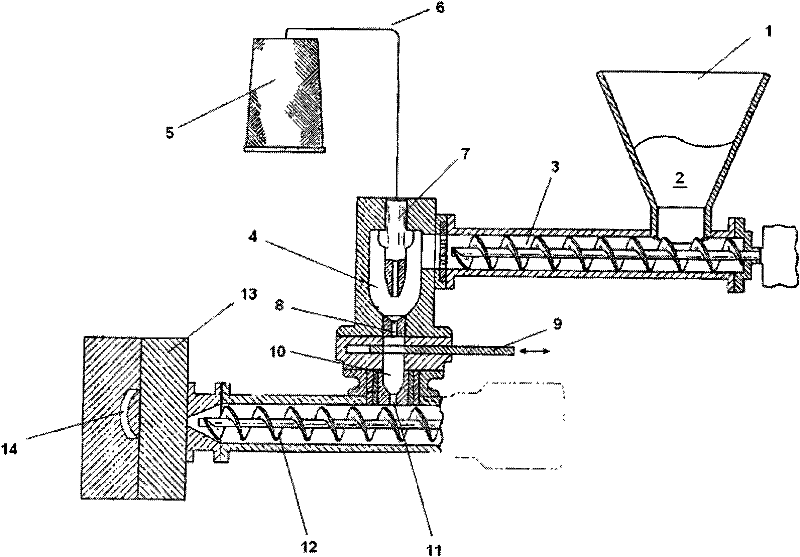

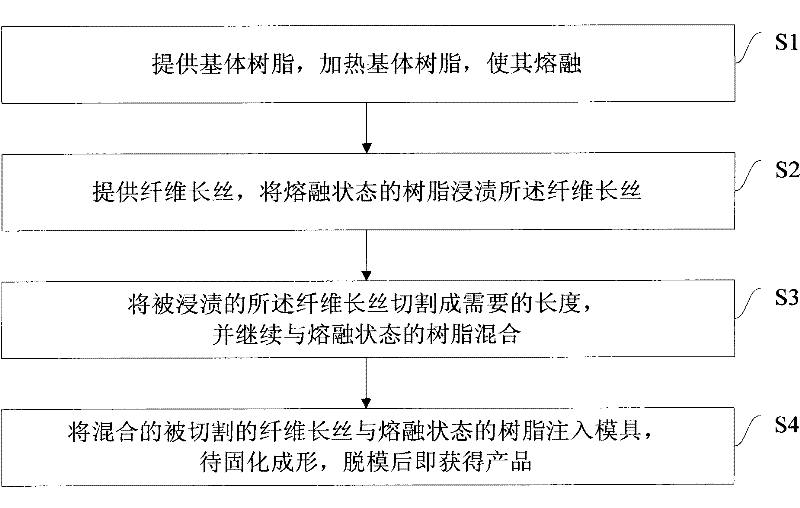

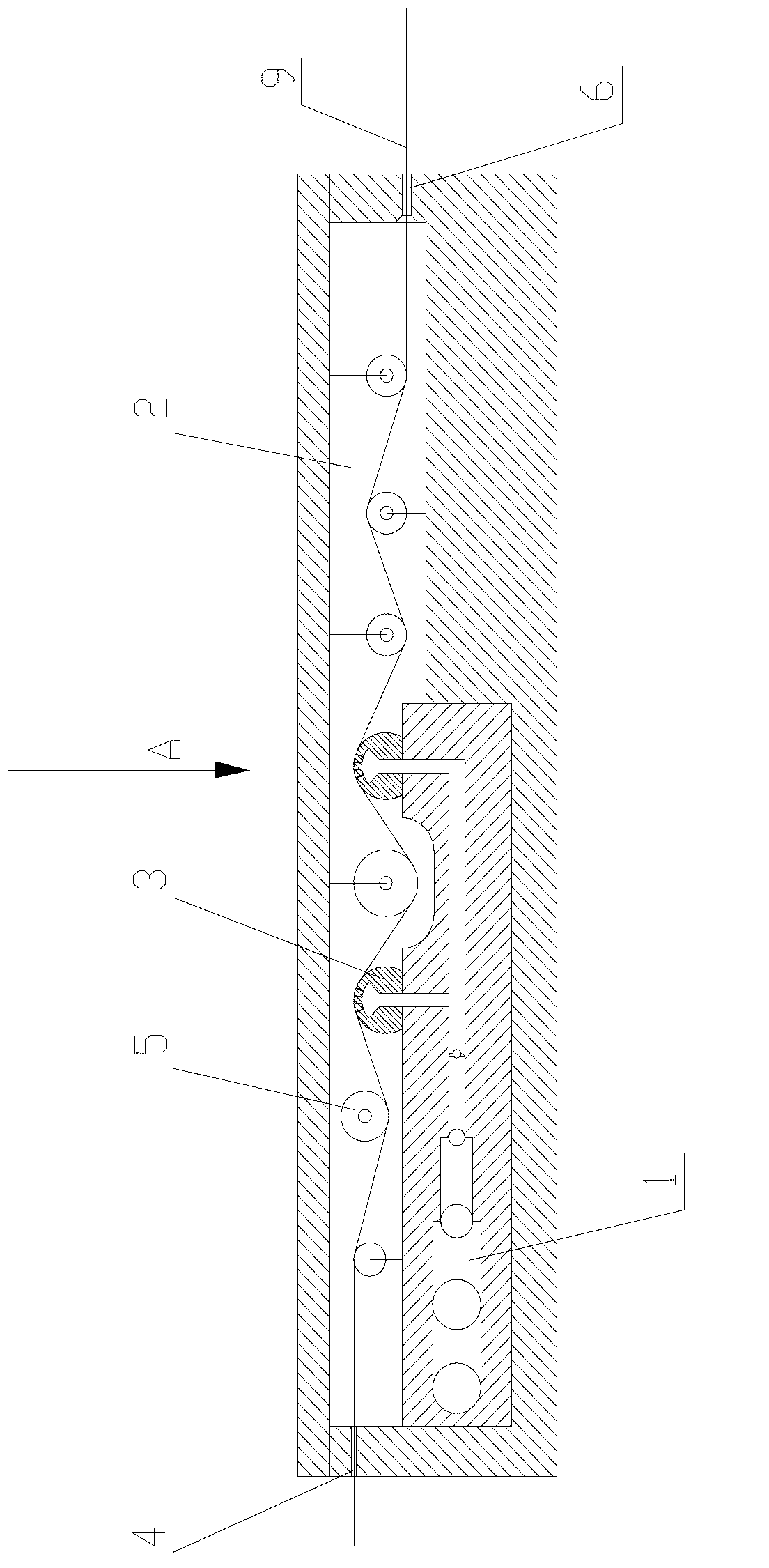

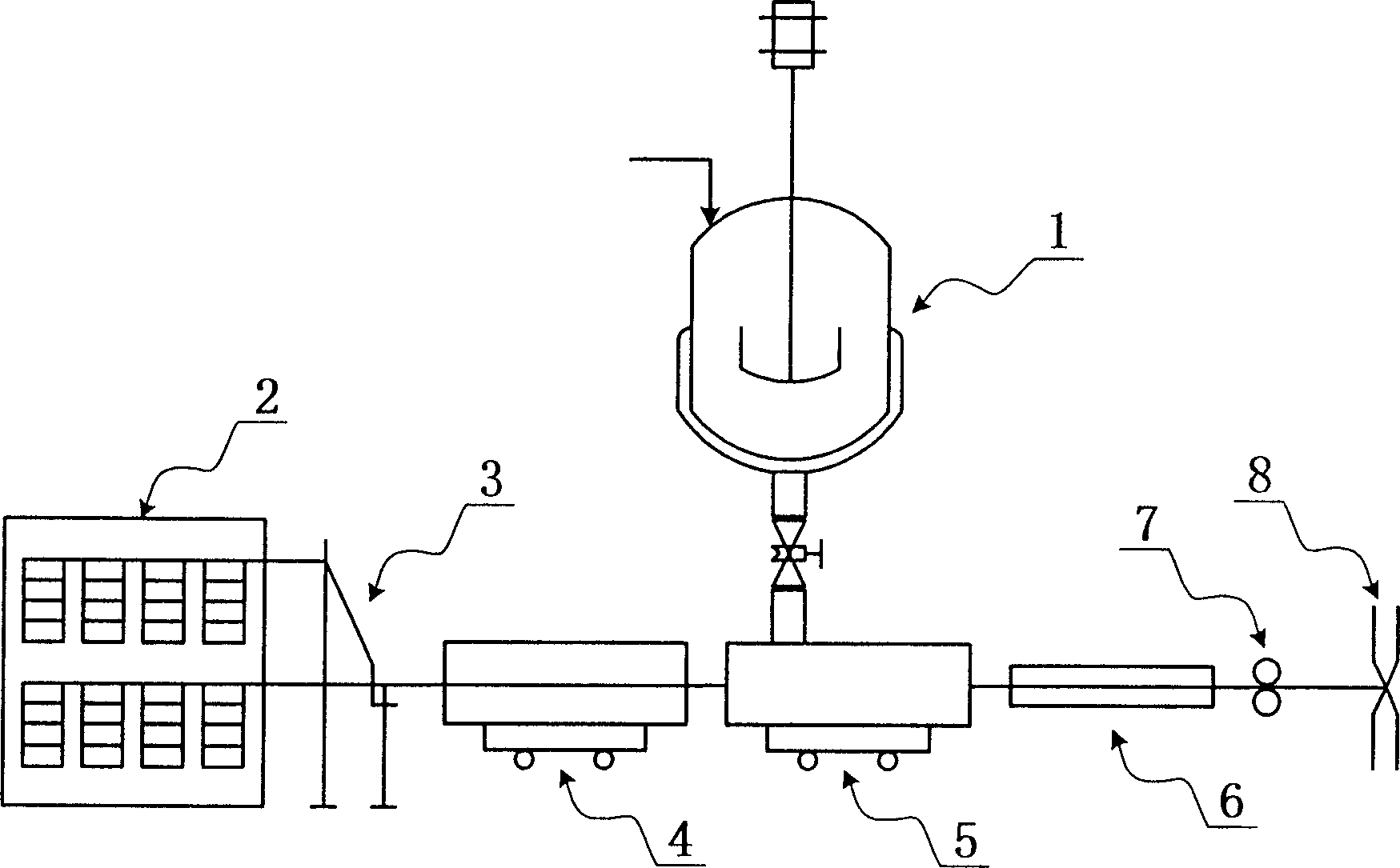

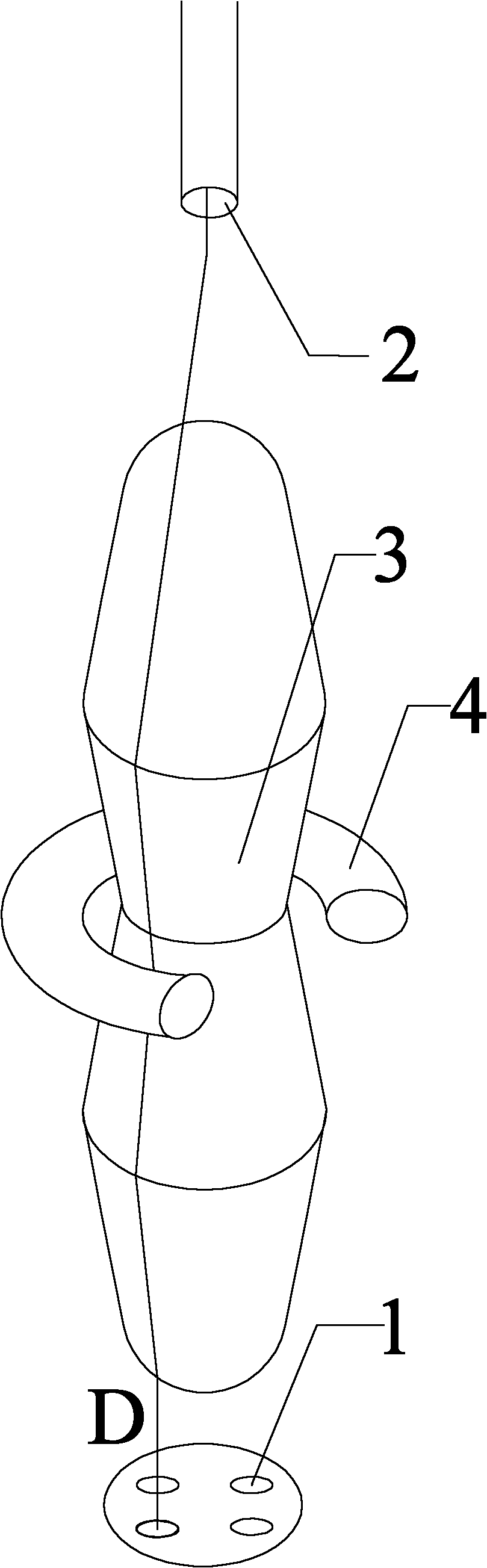

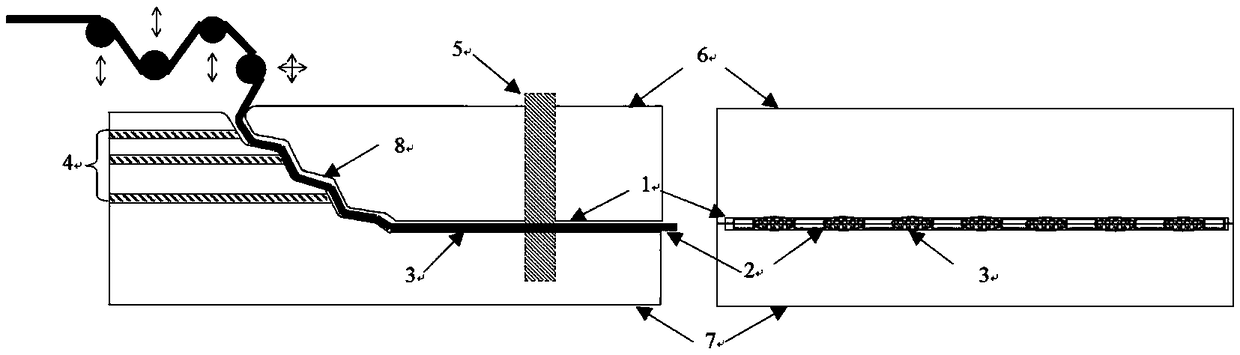

Method and device for preparing long fiber reinforced thermoplastic resin composite material

The invention discloses a method for preparing a long fiber reinforced thermoplastic resin composite material, which comprises: providing a matrix resin, heating the matrix resin to melt it; providing fiber filaments, impregnating the fiber filaments with the molten resin; The impregnated fiber filaments are cut into required lengths, and continue to be mixed with molten resin; the mixed cut fiber filaments and molten resin are injected into a mold, and the product is obtained after being solidified and molded . The invention also discloses a device for preparing long fiber reinforced thermoplastic resin composite material. The use of the invention reduces the breakage of the fiber during the granulation process and increases the limit length of the glass fiber in the product.

Owner:SHANGHAI CEDAR COMPOSITES TECHNOLOGY CO LTD

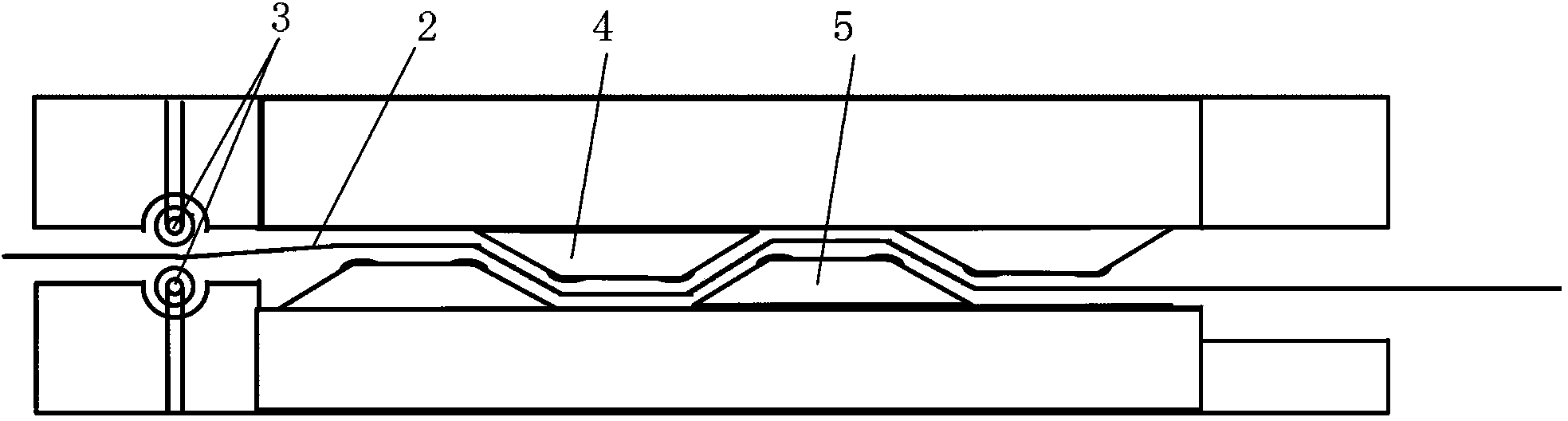

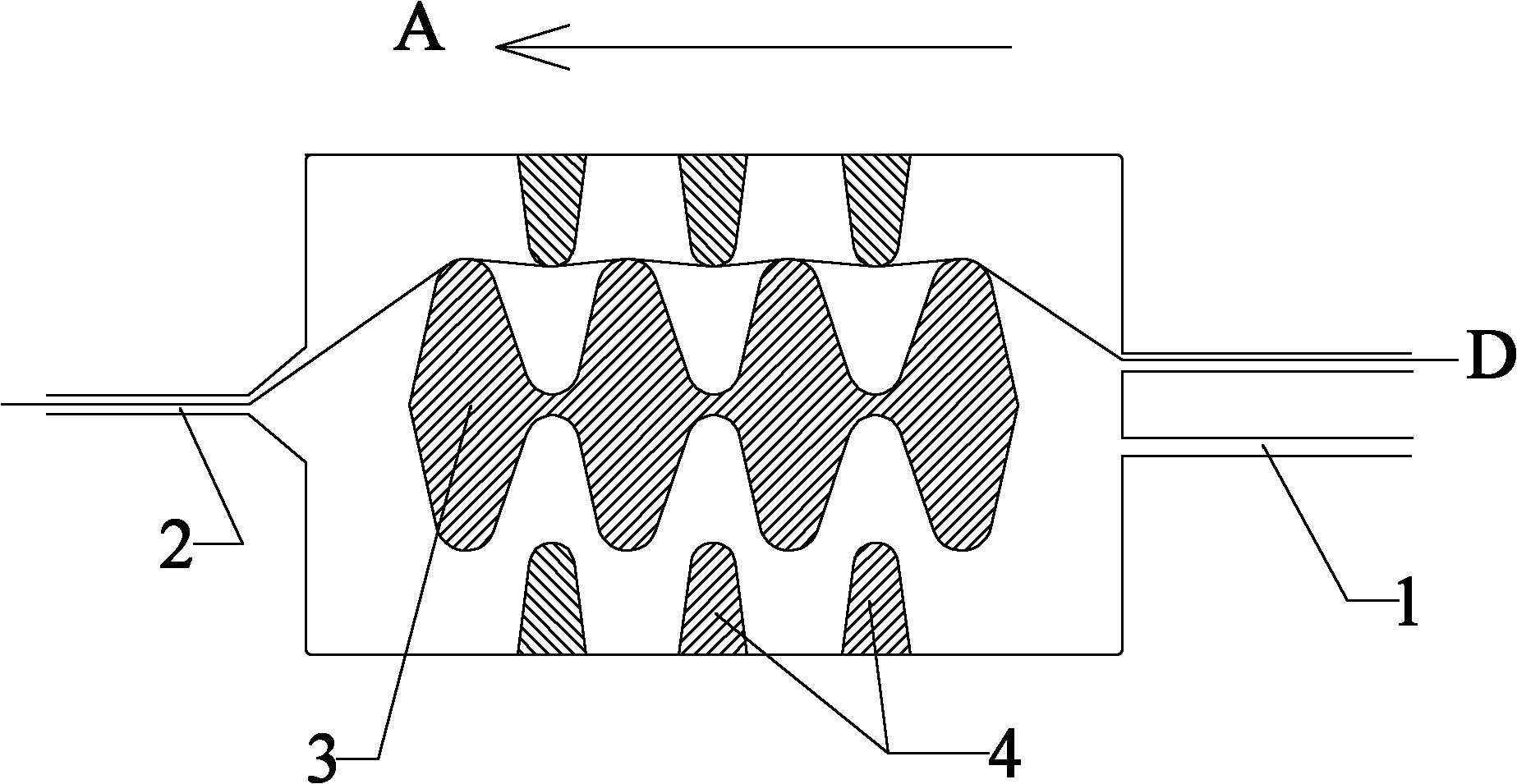

Double-faced melt impregnation method and device for continuous long fiber reinforced thermoplastic resin

The invention discloses a double-faced melt impregnation method and device for continuous long fiber reinforced thermoplastic resin. The method comprises the steps of firstly carrying out pre-dispersion and preheating on continuous long fibers, then carrying out comprehensive packaging and infiltration by virtue of a double-faced distribution runner, carrying out fiber re-dispersion processing, and sending the treated fibers out of a fiber channel. The device is characterized in that a fiber pre-dispersion region, a resin-infiltration fiber region and a fiber re-dispersion region are arranged in the fiber channel in a melt impregnation machine head, wherein the double-faced distribution runner is arranged in the resin-infiltration fiber region and comprises an upper-layer distribution runner and a lower-layer distribution runner which are structurally symmetrical; a pre-dispersion device is arranged in the fiber pre-dispersion region, and a re-dispersion device is arranged in the fiber re-dispersion region. According to the double-faced melt impregnation method and device, an impregnation effect of resin melt to continuous long fiber bundles is balanced, purposes of complete cladding, permeation and infiltration are achieved, a phenomenon that the single sides of the fibers are not tightly clad is avoided, the long-time continuous stable production is realized, and the yield and the quality of a product are substantially improved.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

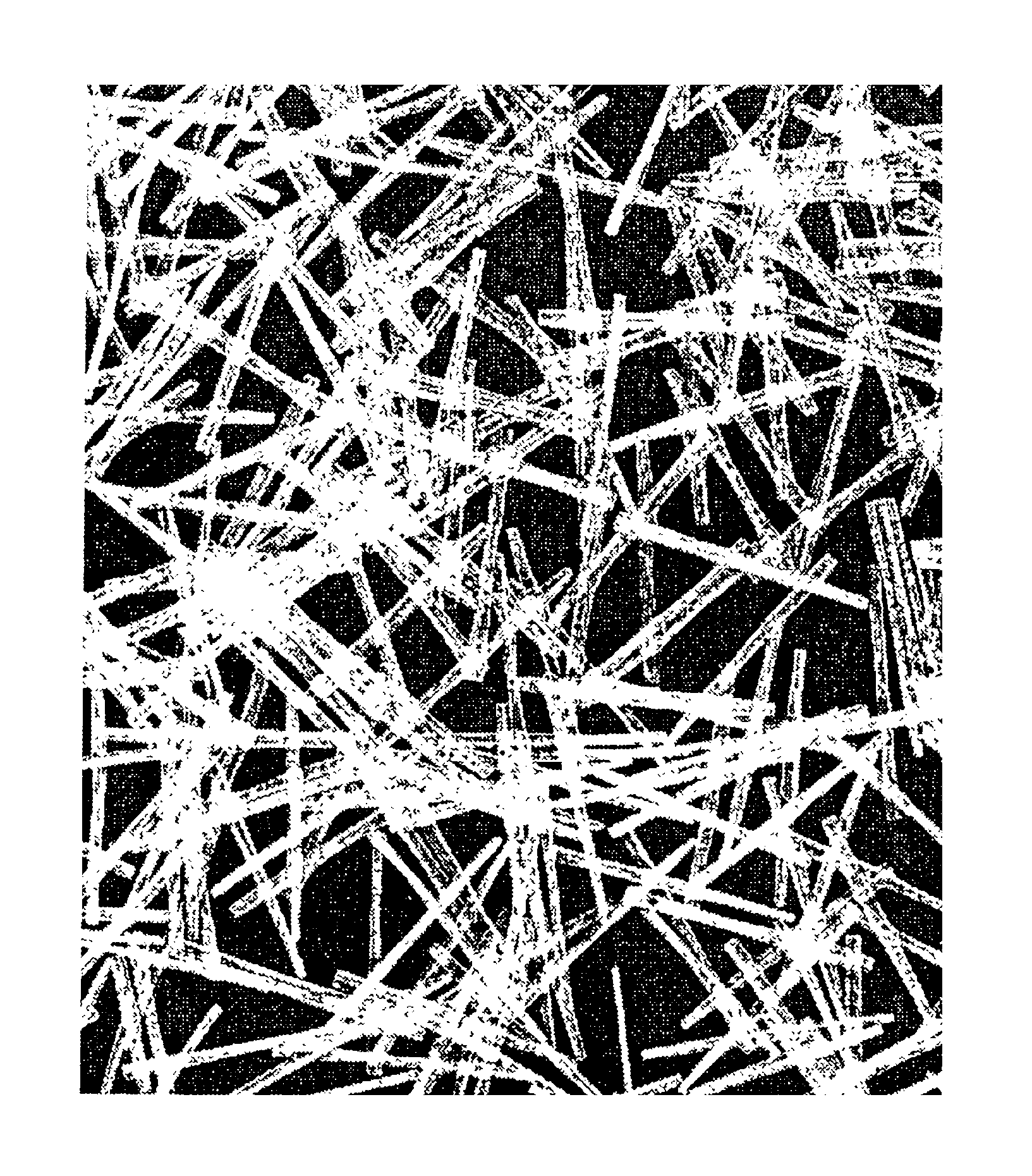

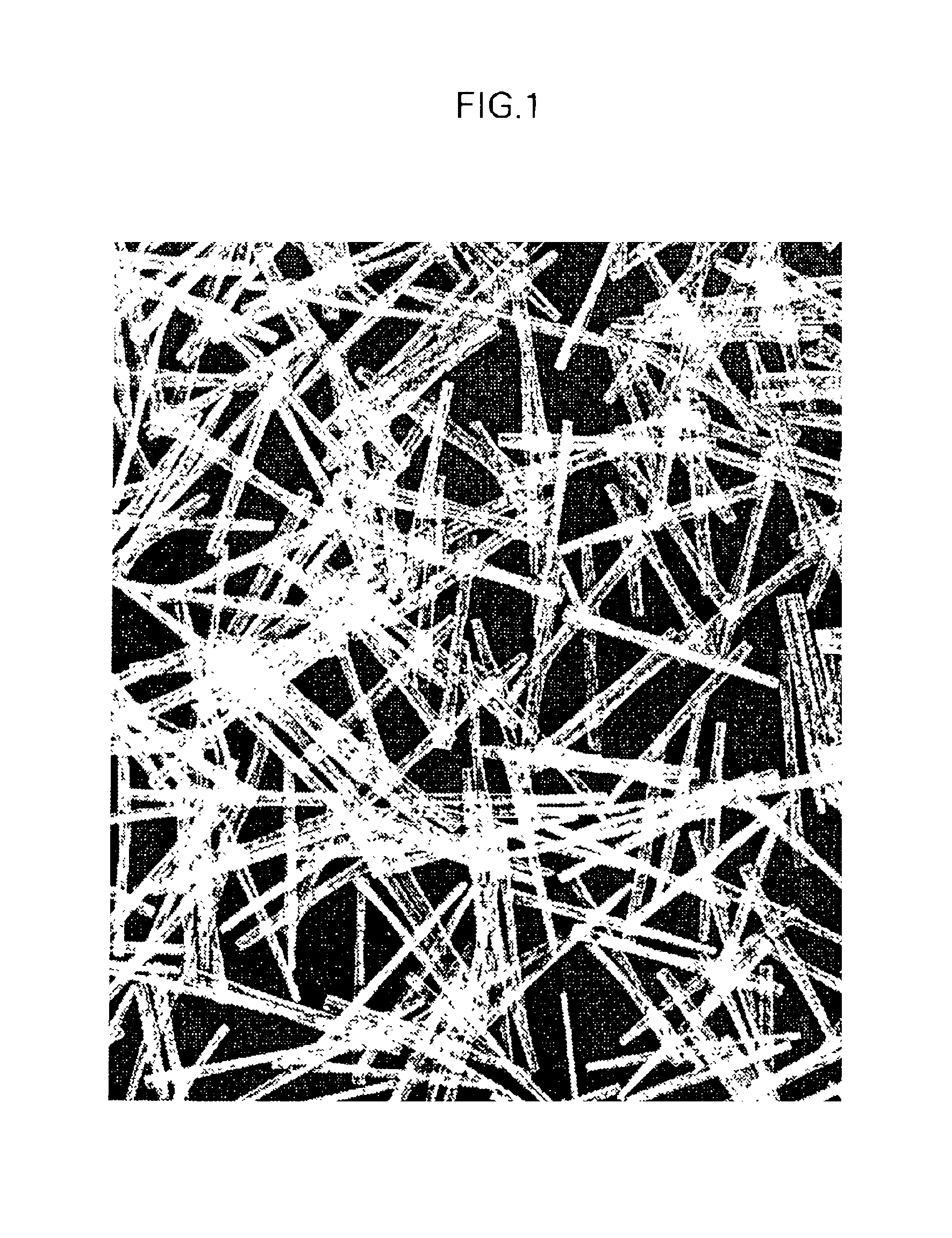

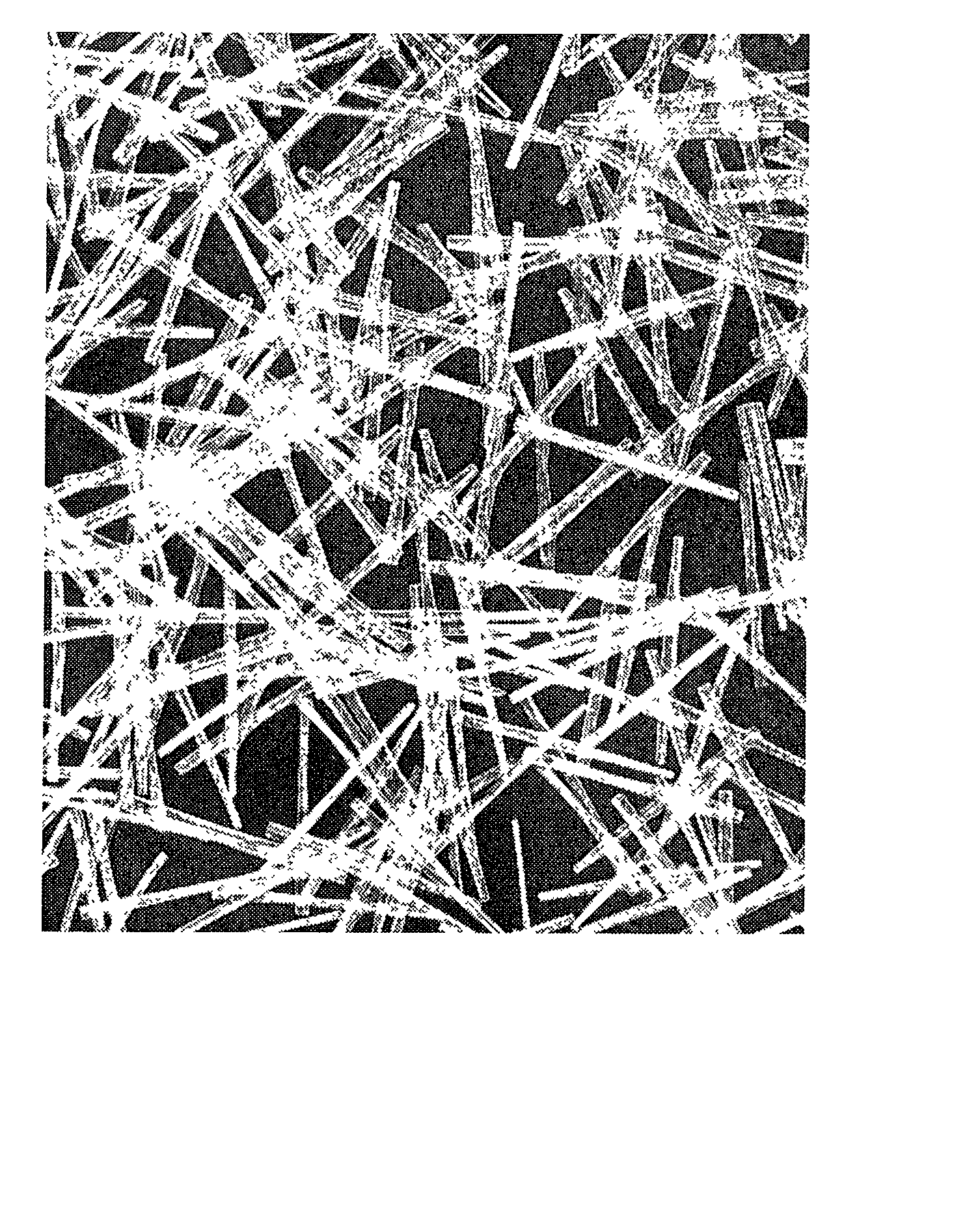

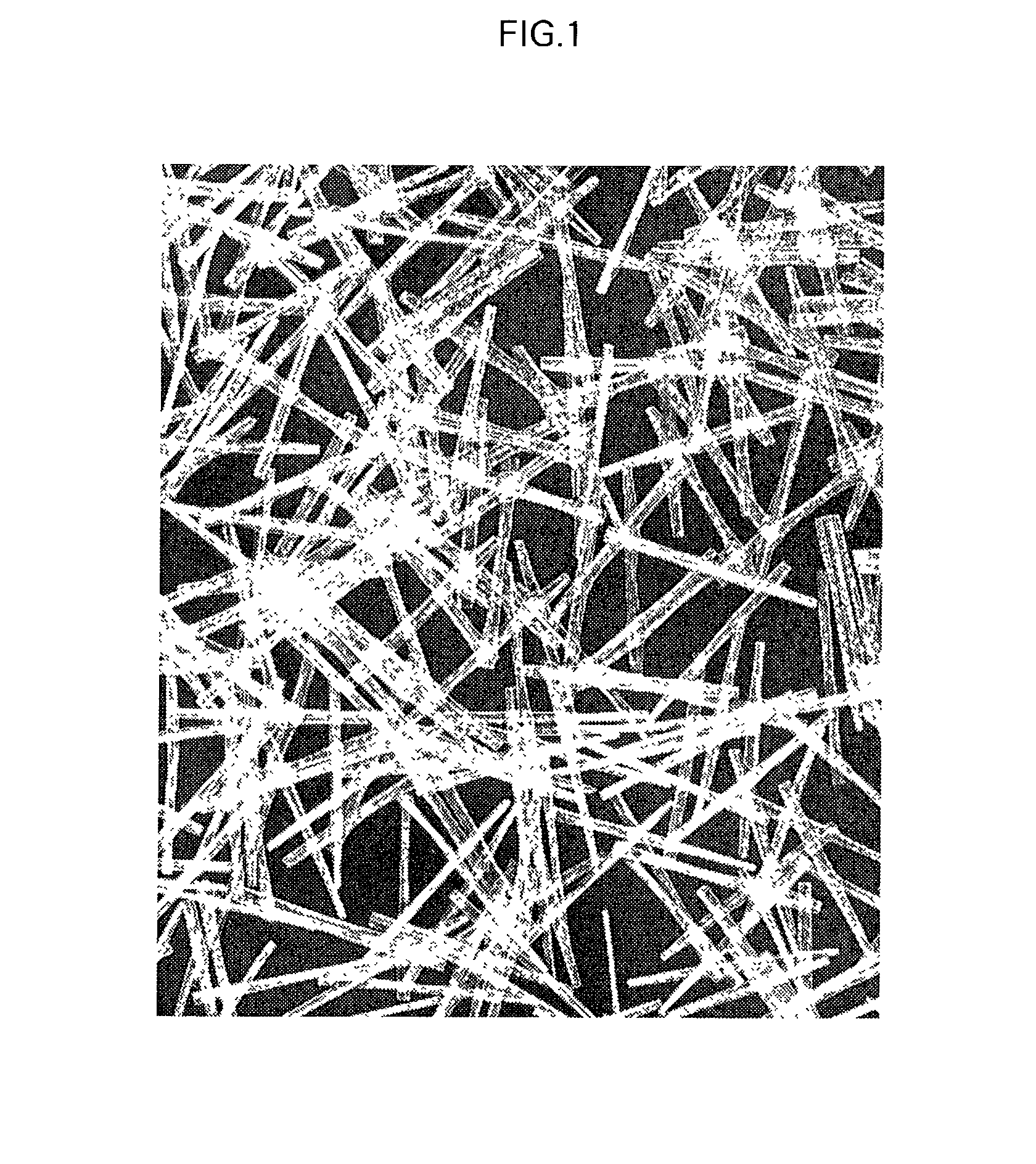

Long-fiber-reinforced thermoplastice resin sheets, production process thereof, and composite structures reinforced by the sheets

InactiveUS6841230B2Increased durabilityImprove rigiditySuperstructure subunitsTraffic signalsHot meltEngineering

A long-fiber-reinforced thermoplastic resin sheet comprises short strands, each of which has a width of from 0.2 to 5 mm and a length of from 10 to 150 mm and is made of a unidirectionally long-fiber-reinforced thermoplastic resin. The short strands are oriented at random and are fixed together at intersections thereof. The long-fiber-reinforced thermoplastic resin sheet has a basis weight of from 30 to 500 g / m2 and is provided with openings therein. The long-fiber-reinforced thermoplastic resin sheet can be produced by evenly spreading and piling up short strands of substantially circular or elliptical sections, and subjecting the short strands to pressureless hot-melt adhesion or to hot-melt compression bonding under pressure such that the sheet has a basis weight of from 30 to 500 g / m2 and is provided with openings therein. The short strands of the substantially circular or elliptical sections have an average diameter of from 0.1 to 1.5 mm and an average length of from 10 to 150 mm, and are made of a unidirectionally long-fiber-reinforced thermoplastic resin.

Owner:TS TECH CO LTD

Long Fiber-Reinforced Thermoplastic Concentrate and Method for Its Preparation

InactiveUS20090202829A1High molecular weightLiquid surface applicatorsLayered productsLong-fiber-reinforced thermoplasticPolymer chemistry

Disclosed is a process to make a long fiber-reinforced thermoplastic concentrate wherein a continuous fiber strand is coated with an aqueous melt-kneaded thermoplastic dispersion, dried, and chopped.

Owner:FOX RICHARD T +4

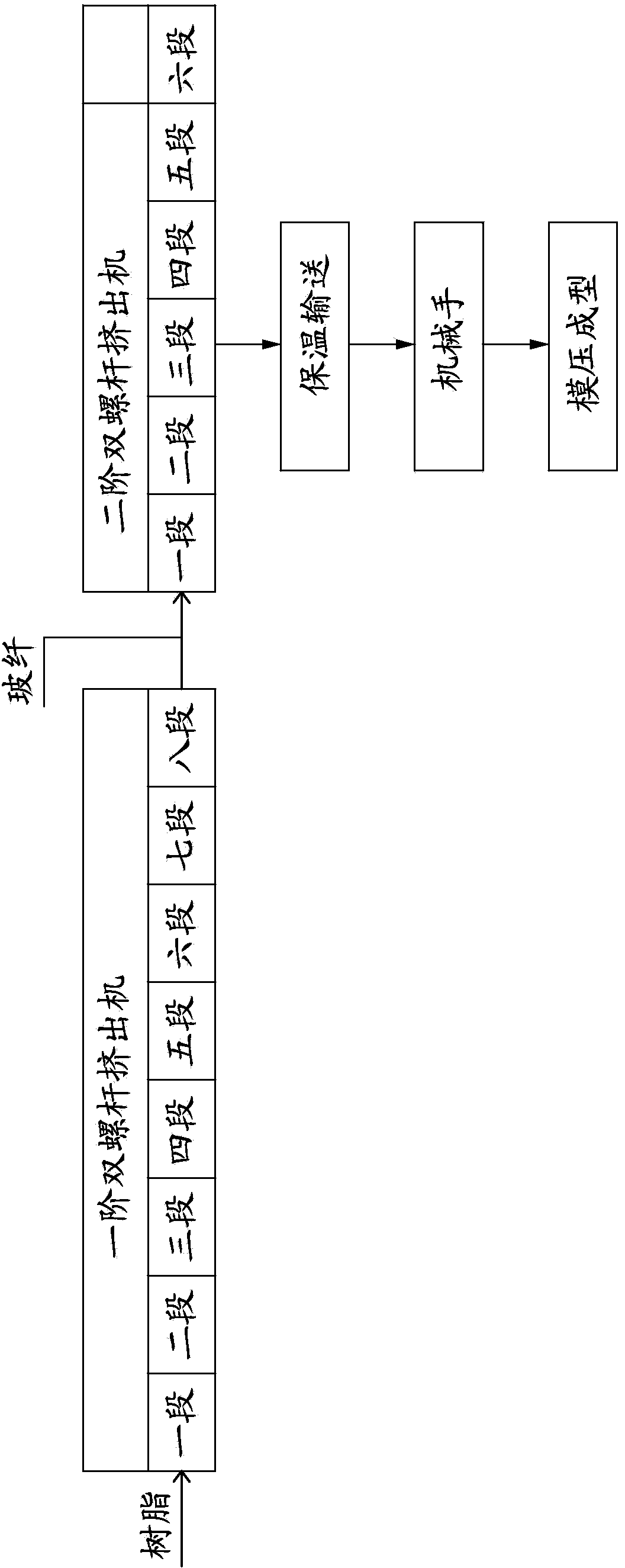

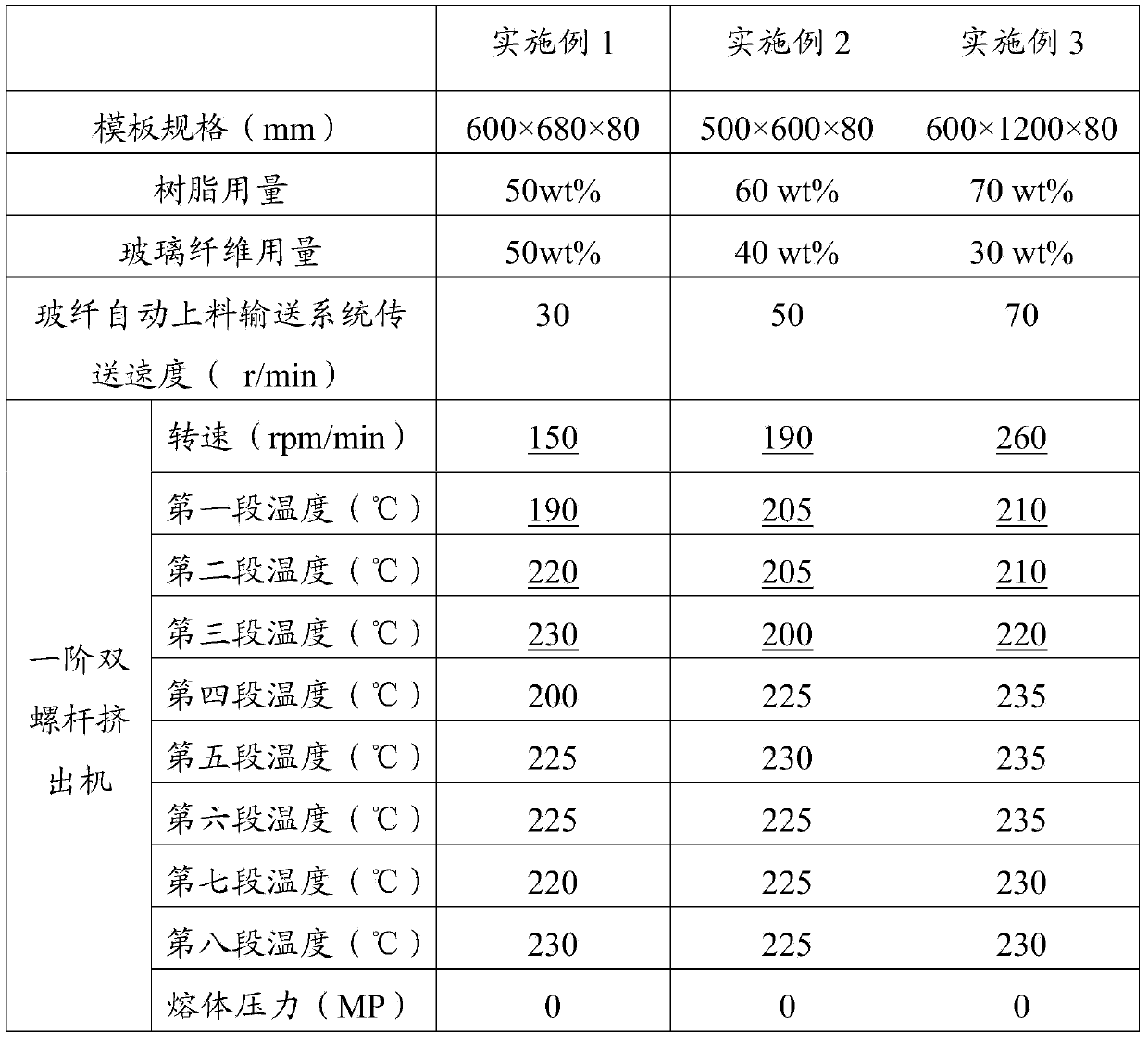

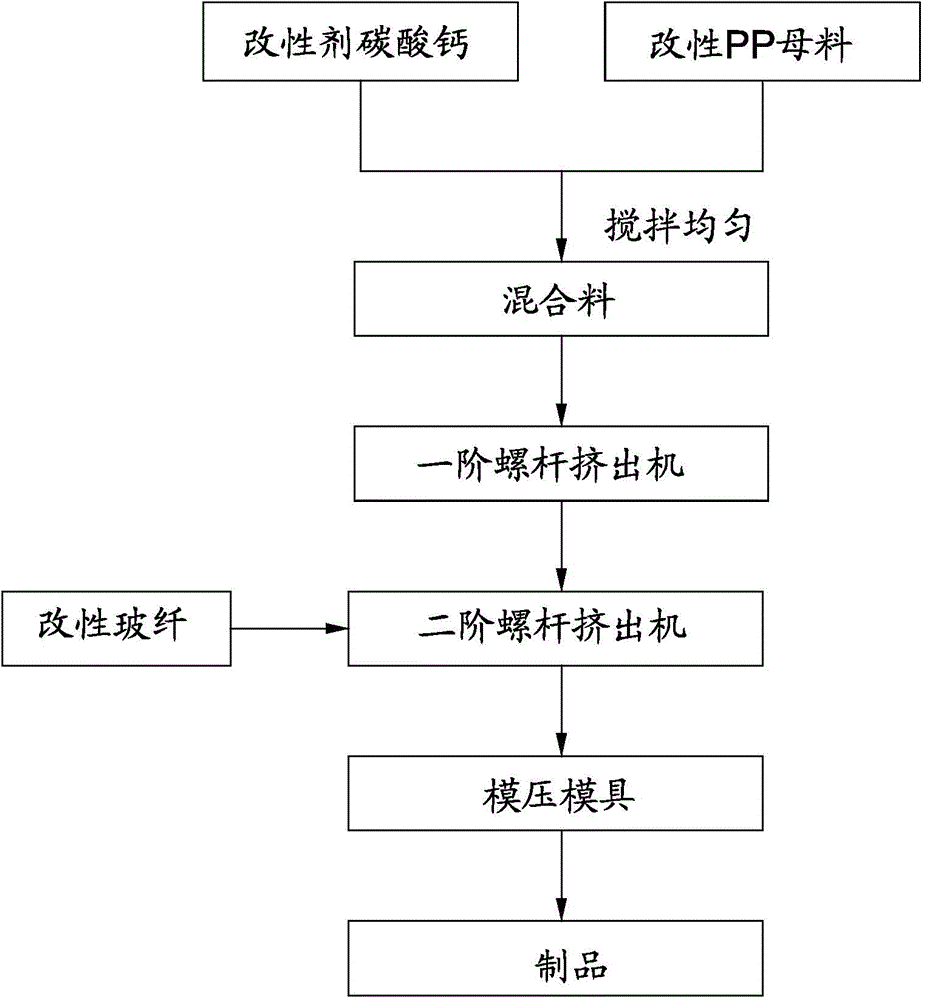

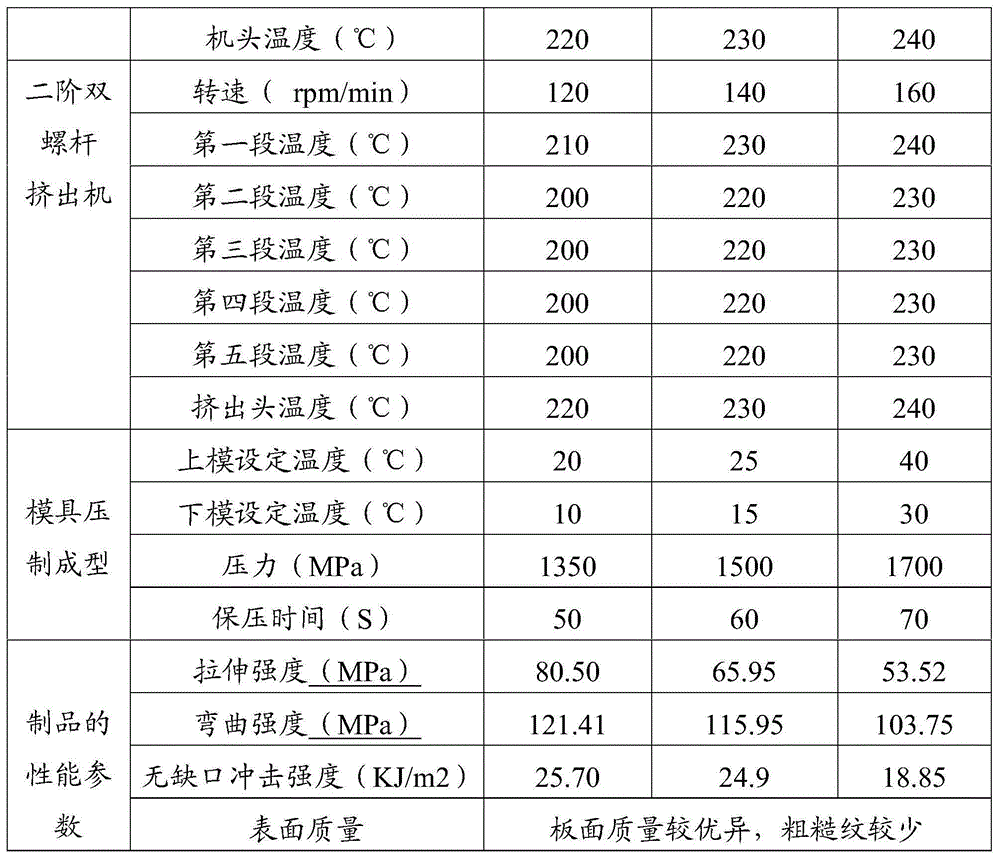

LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of composite building template

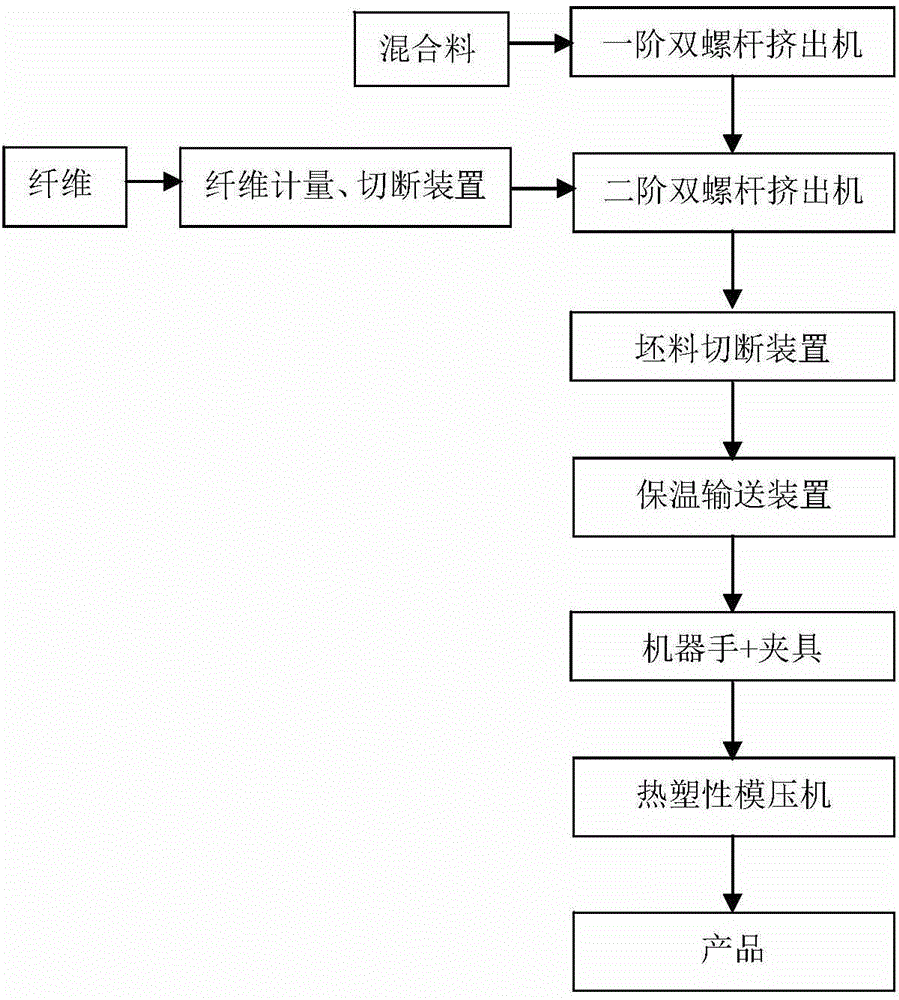

The invention provides an LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of a composite building template. The forming process comprises the following steps of (10) performing quantitative measurement on resin from a vacuum feeding system to a vector type weighing system according to the weight of the template; then feeding the resin to a first-stage twin-screw extruder to be heated and fused; feeding into a second-stage twin-screw extruder in a feed opening of the second-stage twin-screw extruder together with glass fibers, so as to be mixed and plasticized, wherein the glass fibers are cut according to the set length of 24 to 25mm by a glass fiber measuring and cutting device and then are added into the fused resin; performing the secondary length change under the shearing action of the fused resin; and (20) uniformly plasticizing by the second-stage twin-screw extruder, cutting raw materials by a second-stage screw die cutter according to the weight of the template, then insulating and conveying to a material taking and displacement position and putting the raw materials into a press mold by a manipulator for pressing and forming. By using the forming process, the glass fibers in a product are long, and the performance of a product is effectively improved.

Owner:福建易安特新型建材有限公司

Continuous melting dipping machine head and method for forming long fiber reinforced thermoplastic resin

InactiveCN102848489ABalanced impregnation effectImprove impregnation uniformityCoatingsGlass fiberFiber bundle

The invention discloses a continuous melting dipping machine head and a method for forming a long fiber reinforced thermoplastic resin. According to the melting dipping machine head, a melt distributing flow channel and a dipping flow channel are arranged in the machine head; each material outlet of the melt distributing flow channel is connected with the dipping flow channel through a discharging roller; an inlet channel and an outlet channel are arranged at two ends of the dipping flow channel; at least one group of tension rollers are arranged between the inlet channel and the discharging roller; and at least one group of the tension rollers are arranged between the outlet channel and the discharging roller. The method comprises the following steps of: feeding continuous long fiber bundles into the dipping flow channel through the inlet channel, and drawing out of the continuous long fiber bundles from the outlet channel after the continuous long fiber bundles penetrate through the discharging roller, in a process, thermoplastic melt penetrates through a discharging roller permeating glass fiber through the melt distributing flow channel and is fed into the dipping flow channel; and further dipping the continuous long fiber bundles. According to the melting dipping machine head provided by the invention, the melt distributing flow channel is arranged and is connected with the dipping flow channel through the discharging roller, thus, melt contacted with each long fiber bundle can be consistent in pressure and flow rate, and balance of a dipping effect of each continuous long fiber can be ensured.

Owner:KINGFA SCI & TECH CO LTD +1

Device and method for production of long-fiber-reinforced thermoplastic resin

InactiveCN101786330ASmall linear densityEasy to disperse and disintegrateFiber bundleLong-fiber-reinforced thermoplastic

Owner:合肥圆融供应链管理有限公司

Application of fiber reinforced thermoplastic composite material in molding and preparing automobile parts

ActiveCN106627789AStrong structural designMeet the technical requirements of lean productionSuperstructure subunitsVehiclesLong-fiber-reinforced thermoplasticThermoplastic composites

The invention relates to an application of a fiber reinforced thermoplastic composite material in molding and preparing automobile parts. The fiber reinforced thermoplastic composite material comprises a long fiber reinforced thermoplastic composite material and a continuous fiber reinforced thermoplastic composite material. An automobile part particularly prefers an automobile fender assembly; the automobile fender assembly comprises a fender supporting rod, a supporting rod base, a fender suspension frame and a taillight supporter; and the reinforcement body of the continuous fiber reinforced thermoplastic composite material is a three-dimensional fabric structure and / or a one-way tape structure. The application of the fiber reinforced thermoplastic composite material in molding and preparing the automobile parts is advantaged in that the material structure can be easily designed, the process is efficient, simple and convenient, the product performance is excellent and the application is easy to be industrially implemented.

Owner:株洲时代工程塑料科技有限责任公司

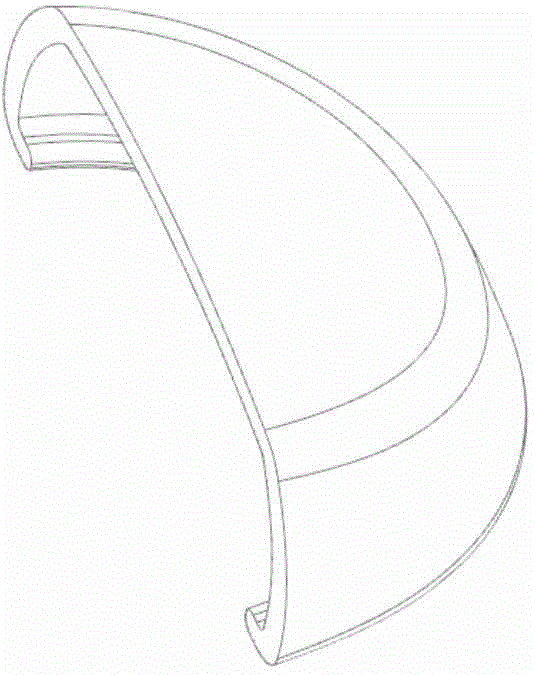

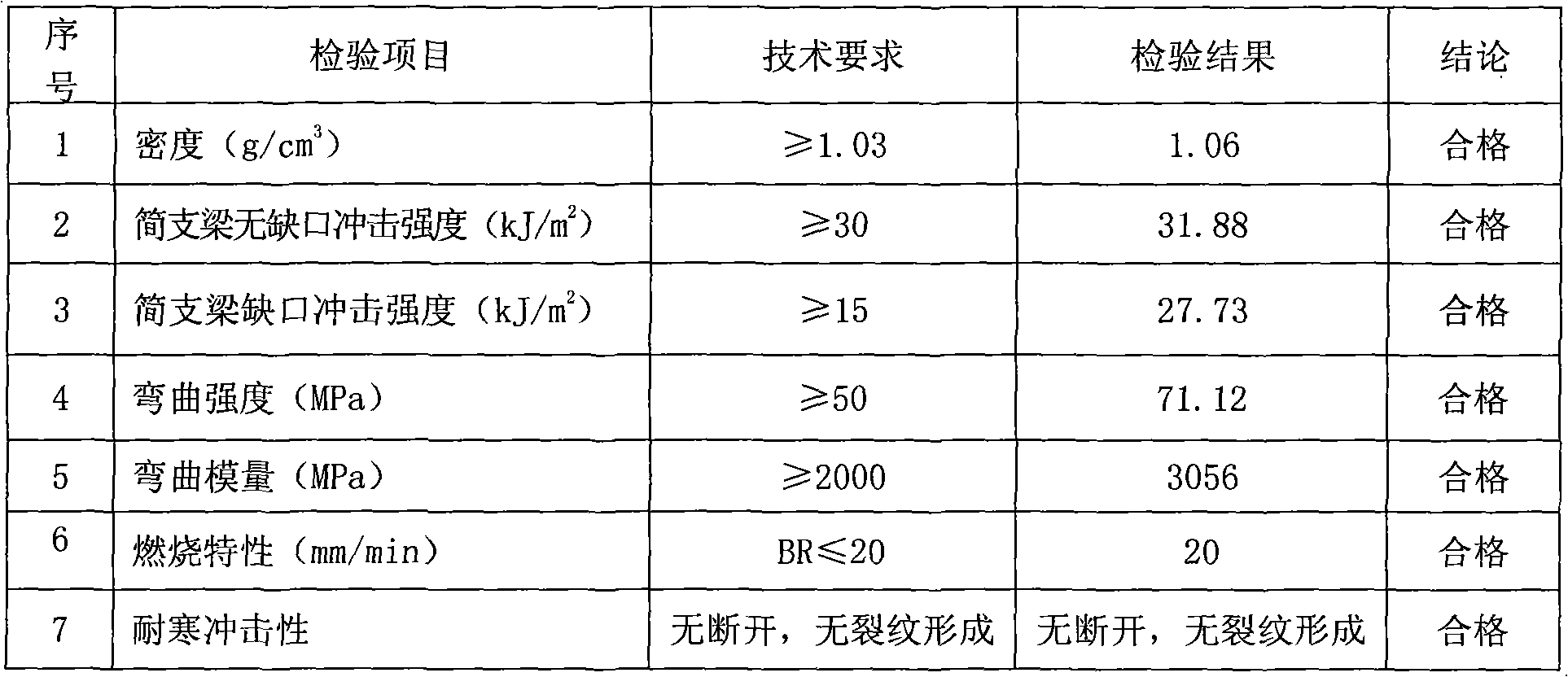

A safety shoe protective toecap made of a long fiber reinforced thermoplastic resin composite material and a preparing method thereof

The invention belongs to the technical field of polymer composite materials, and relates to a safety shoe protective toecap made of a long fiber reinforced thermoplastic resin composite material and a preparing method thereof. The protective toecap is prepared from following components by weight: 100 parts of thermostatic resin, 150-300 parts of continuous fiber, 0.1-0.5 part of an antioxidant, 0.2-1.0 part of a coupling agent and 0.2-1.0 part of a lubricant. The protective toecap is prepared by adopting an LFT-D mould pressing one-step production process, can meet requirements of the European standard EN345. Compared with LFT-G and short fiber reinforced thermoplastic resin composite materials, the method reduces the cost, reduces costs of production, transportation and storage of semi-finished products, ensures good impact performance of the protective toecap, and overcomes the disadvantages of steel toecaps, namely poor insulation properties, high specific gravity, low elastic deformation, poor comfortable sensation, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Plastic pipe enhanced by continuous fiber winding

The invention relates to a plastic tube which uses long fiber (glass fiber, carbon fiber, and metallic fiber) to strengthen the thermal plastic (polythene, polypropylene, and rigid polyvinyl chloride) to coil and shape a plastic tube whose diameter is 4m, while the pressure can reach 1.2MPa, and the thickness is lower than general tubes, with high strength (stress strength can reach 20-30MPa), lower cost and light weight. The invention can be used to pressure transmit the tap water. The method for coating long fiber with adhesive is similar to the one for extruding wire, that coating the adhesive on the fiber to be coiled on the plastic tube with bottom layer, or online extruding coating to be coiled on one heated cylinder stainless steel core, to attain said continuous long fiber strengthen thermal plastic.

Owner:BEIJING UNIV OF CHEM TECH

Long-fiber reinforced thermoplastic composite material of longitude and latitude glass fiber surface, and molding method and application thereof

The invention relates to a long-fiber reinforced thermoplastic composite material of a longitude and latitude glass fiber surface, and a molding method and application thereof. The composite material comprises a base body and a surface layer, wherein the base body is a long-fiber reinforced thermoplastic composite material; the surface layer is a glass fiber mat surface layer which is dipped by the thermoplastic material; and the surface layer is heated into a molten state, and pressed together with the base material in the molten state to be cross-linked into a whole. The molding method comprises the preparation processes of putting the surface layer into a mold cavity of mold pressing equipment after heating the surface into the molten state, simultaneously evenly mixing the thermoplastic composite material of the base body with the glass fiber and then transporting to the mold cavity of the mold pressing equipment; and putting above the glass fiber mat in the molten state, mold-pressing and molding. The arts and crafts material can be applied to manufacturing of a building template. The arrangement order of long fibers of an LFT-D (long fiber reinforced thermoplastic in direct pressing) process for reinforcing the thermoplastic composite material is improved by providing the longitude and latitude glass fiber mat on the surface and fusing with an LFT-D base body to form a whole; and the mechanical property of the pressed and molded product is greatly improved after the long-fiber reinforced thermoplastic composite material is applied to preparation of the building template.

Owner:FUJIAN HAIYUAN NEW MATERIAL TECH

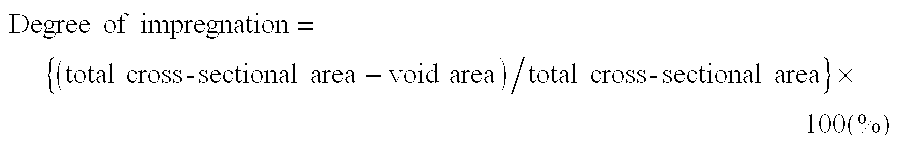

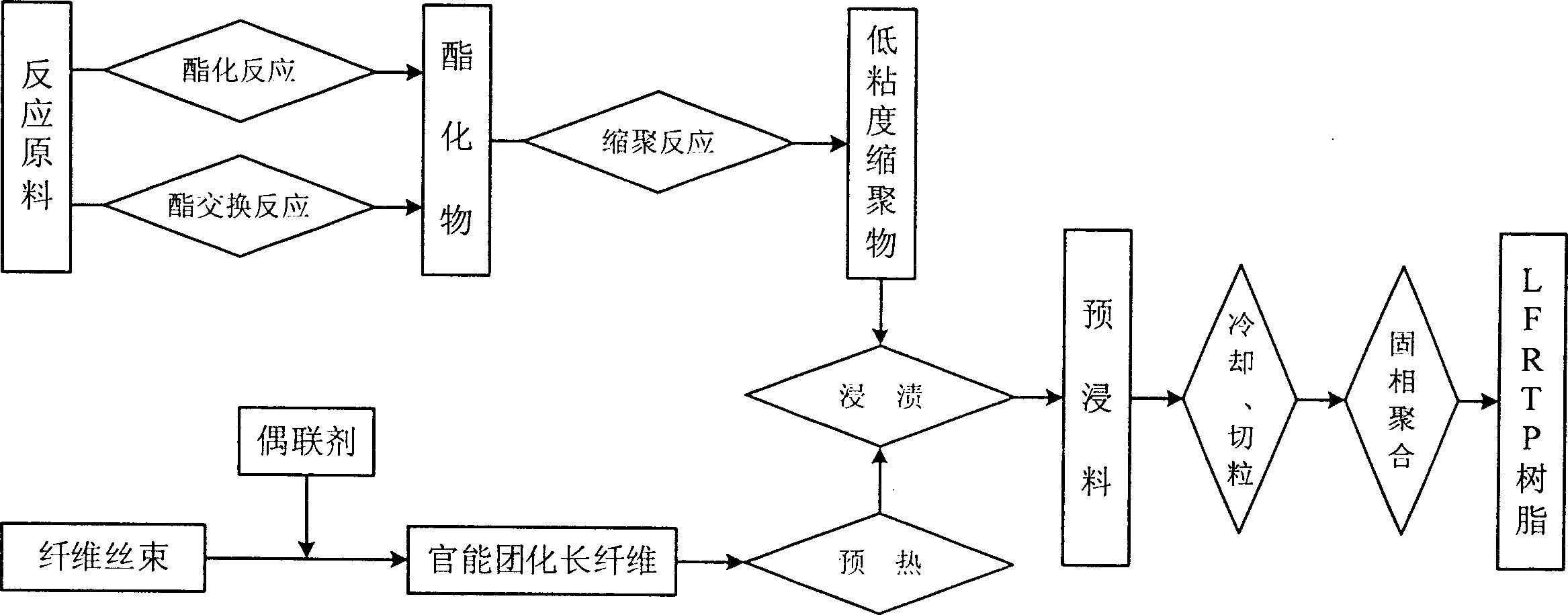

Method for preparing polycondensation reaction type reinforced thermoplastic resin in long fibres

ActiveCN1872913ASolve key technical difficultiesIncrease the degree of infiltrationFiber bundleLong-fiber-reinforced thermoplastic

This invention relates to a method for manufacturing long-fiber-reinforced thermoplastic resin by condensation polymerization. The method comprises: (1) performing esterification or interesterification on the raw material to form esterified material; (2) performing melt-condensation polymerization to obtain low-viscosity condensation polymer, and introducing the molten condensation polymer into a dip tank; (3) preheating fiber bundles, and passing through the inside of the dip tank so that the molten condensation polymer adhere to the surface of the fibers to form predipped material; (4) cooling and cutting to obtain low-viscosity chips; (5) performing solid phase condensation polymerization to obtain the final product. The method can integrate esterification (interesterification), condensation polymerization, dipping and solid phase condensation polymerization, thus can utilize present equipment to manufacture long-fiber-reinforced thermoplastic resin, such as PET, PTT, PBT and PEN.

Owner:SINOPEC YIZHENG CHEM FIBER

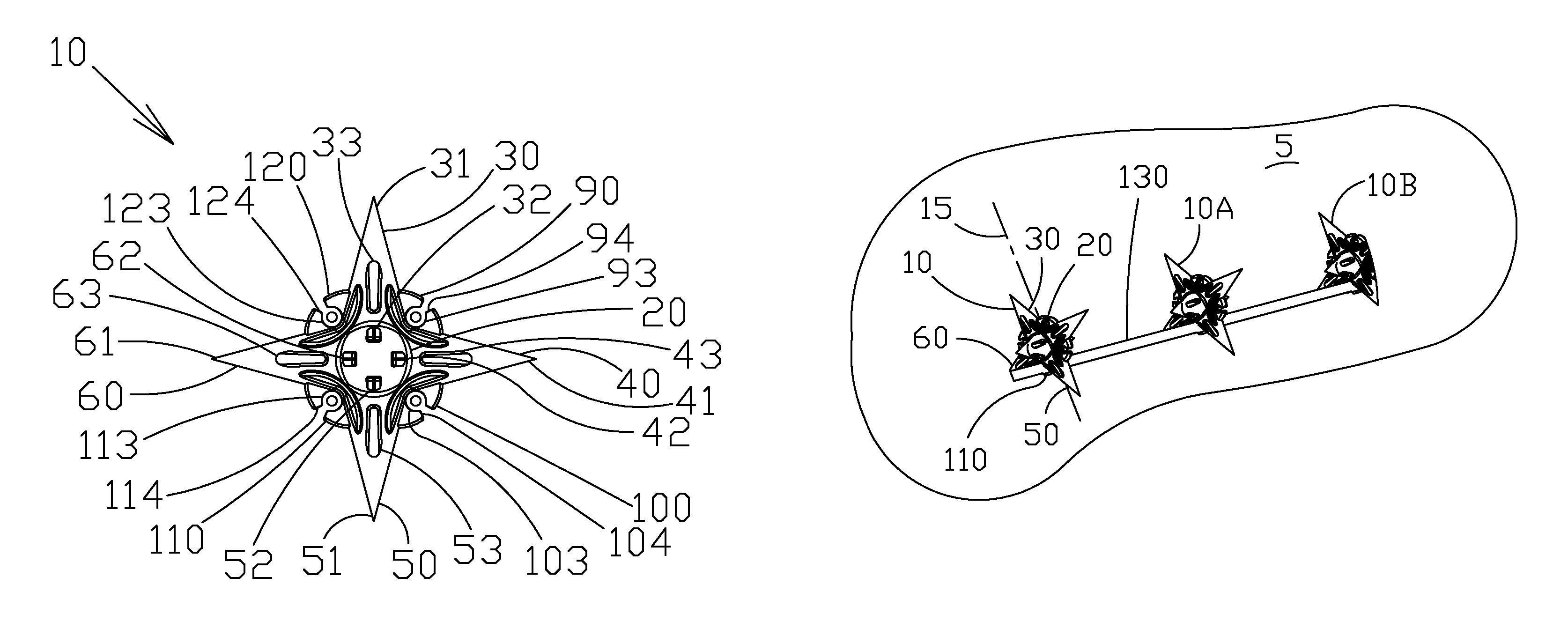

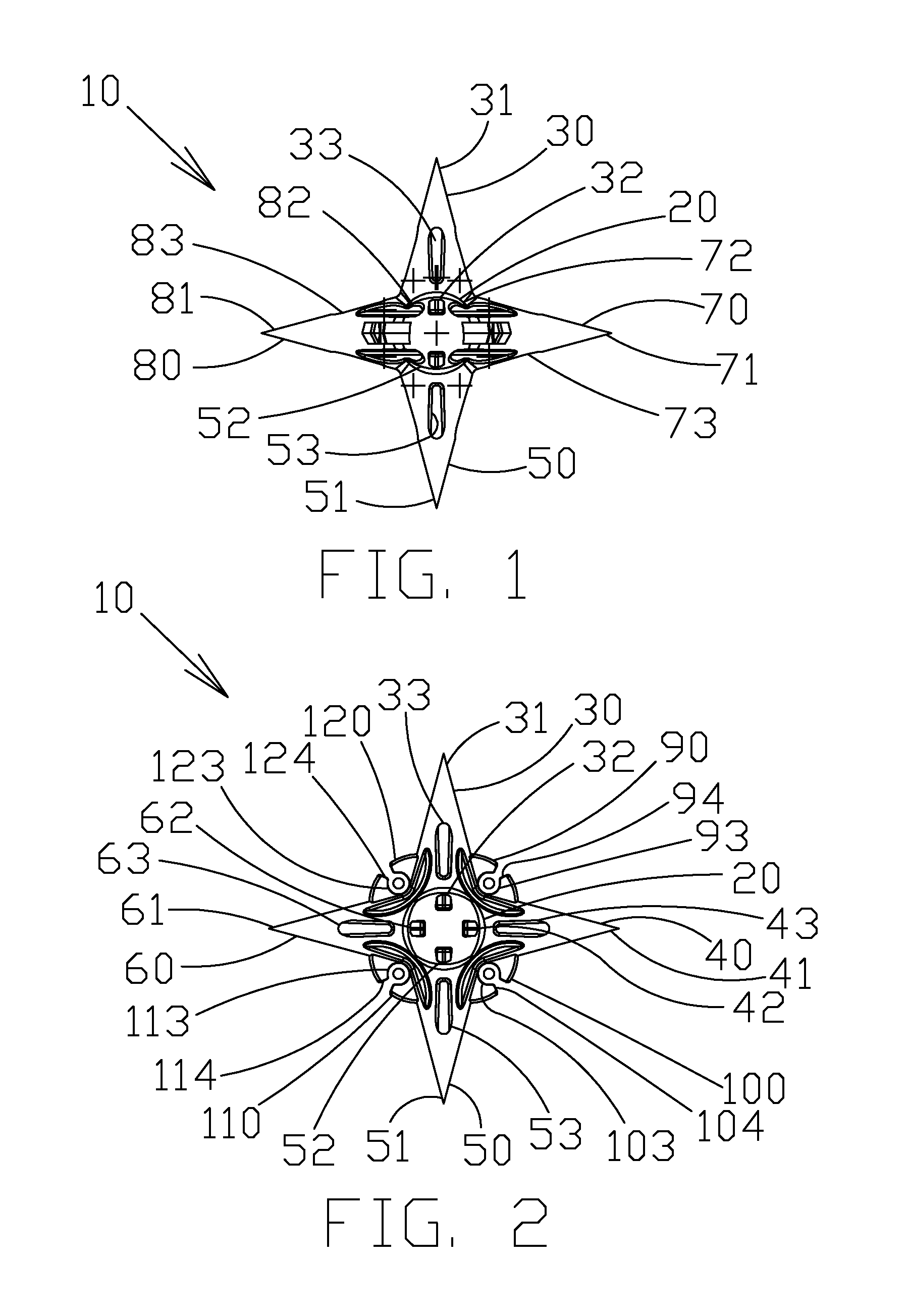

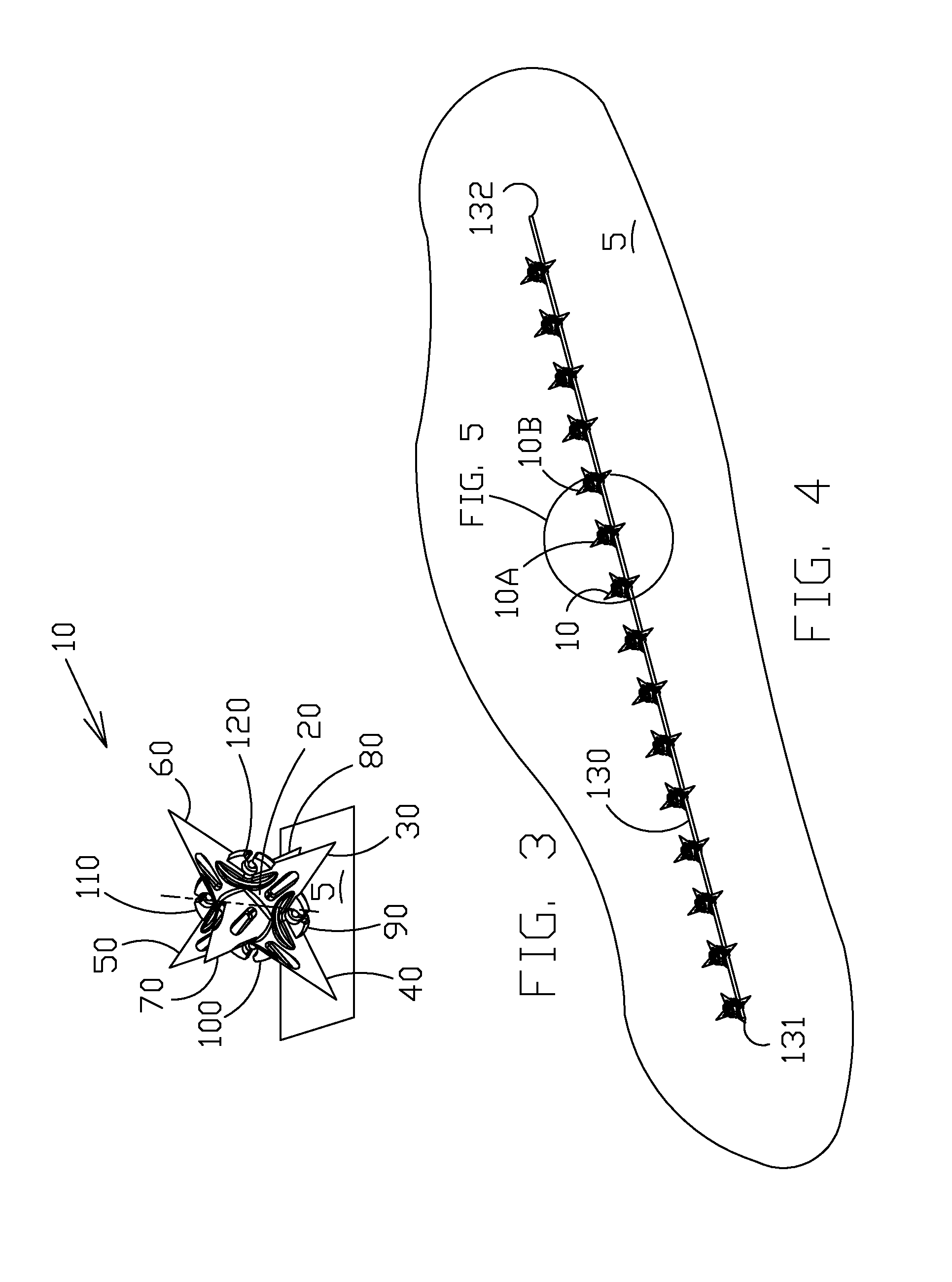

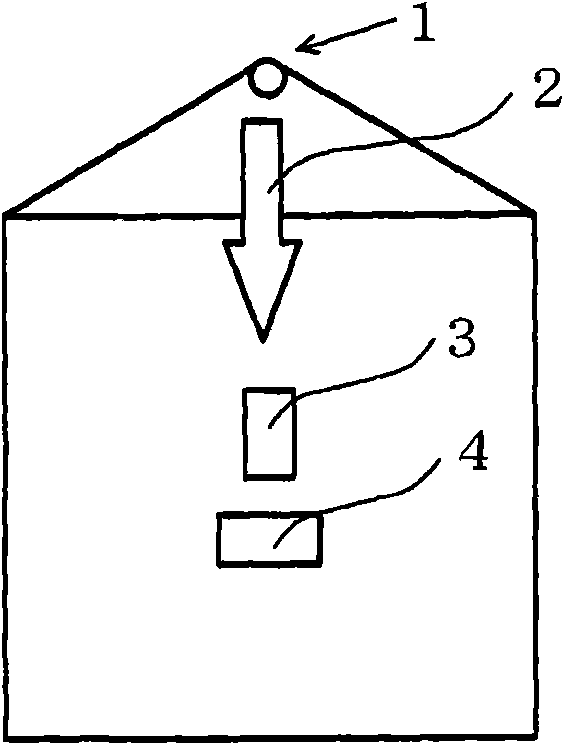

Road spikes with improved characteristics and methods of deployment

The present invention relates to road spikes that can made of long fiber reinforced thermoplastics that, when deployed, are geometrically positioned to puncture or disable a tire. The spikes can be formed of a long fiber reinforced thermoplastic containing 10-70% long fibers by weight. Spikes of this material can be made as direct and / or alternative replacements for existing metal spikes or as unique integrated devices. One integrated component is a device having several piercing elements that are deployed in a vertically divergent manner spaced about a vertical axis wherein at least one piercing element is directed towards the direction of the oncoming vehicle. In one embodiment deployable from a string, this is accomplished through the use of spikes with six piercing elements that are self-leveling and self-centering. In another embodiment, several clusters can be fixed to a tube that is foldable and extendable.

Owner:PLASTICOMP

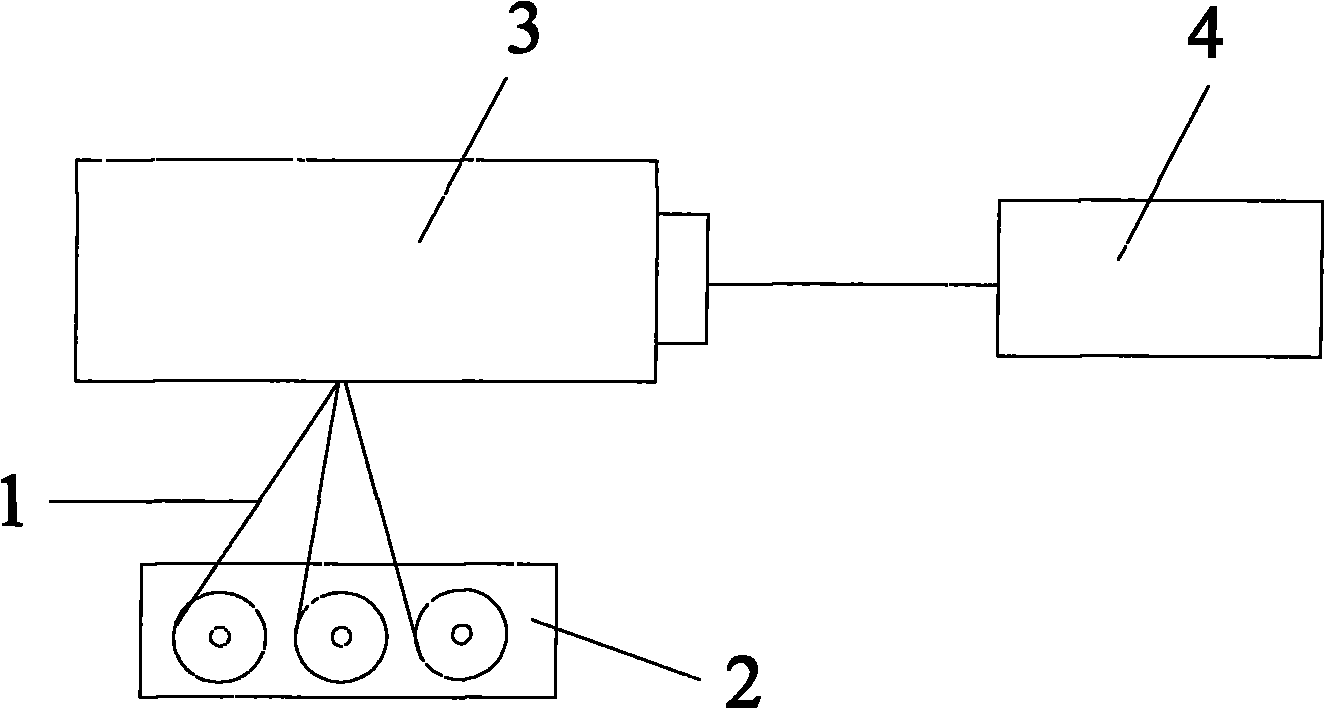

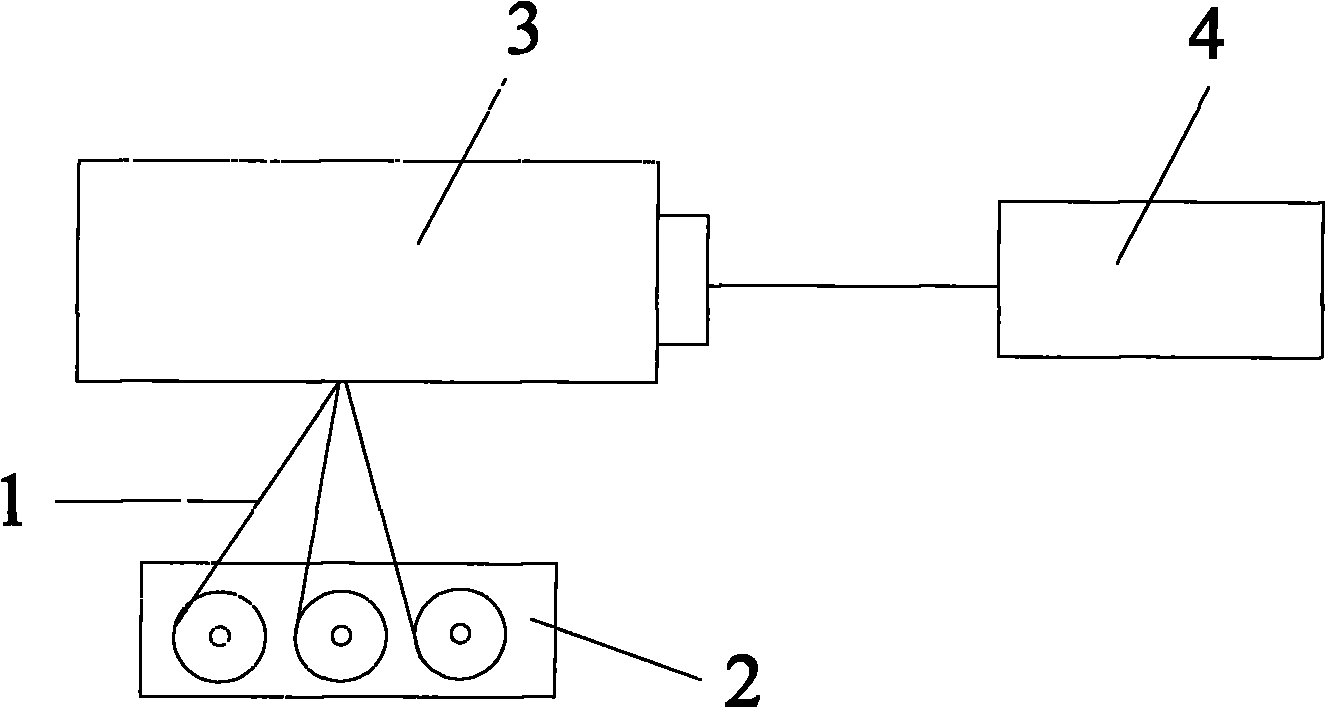

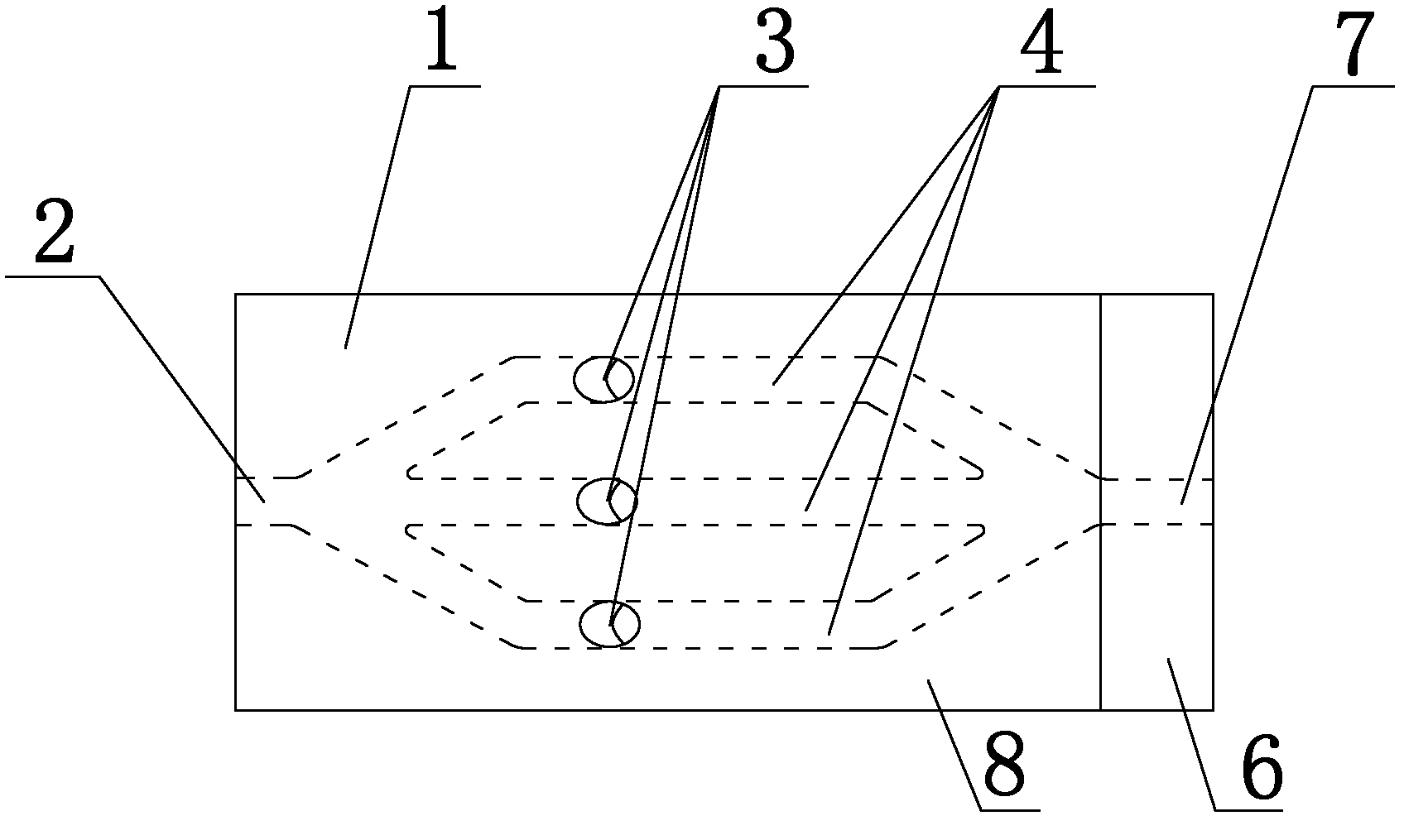

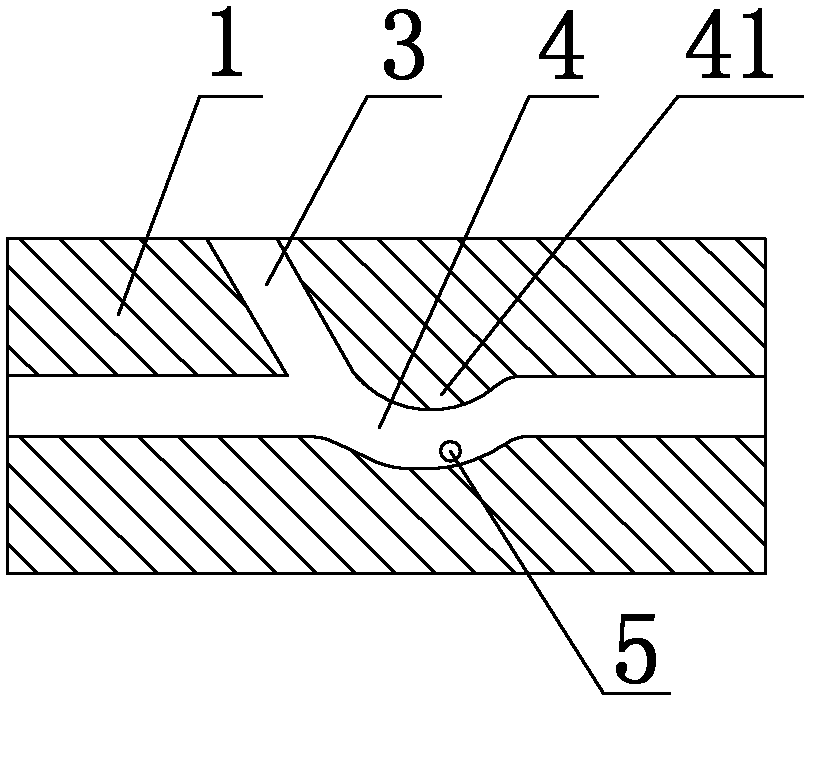

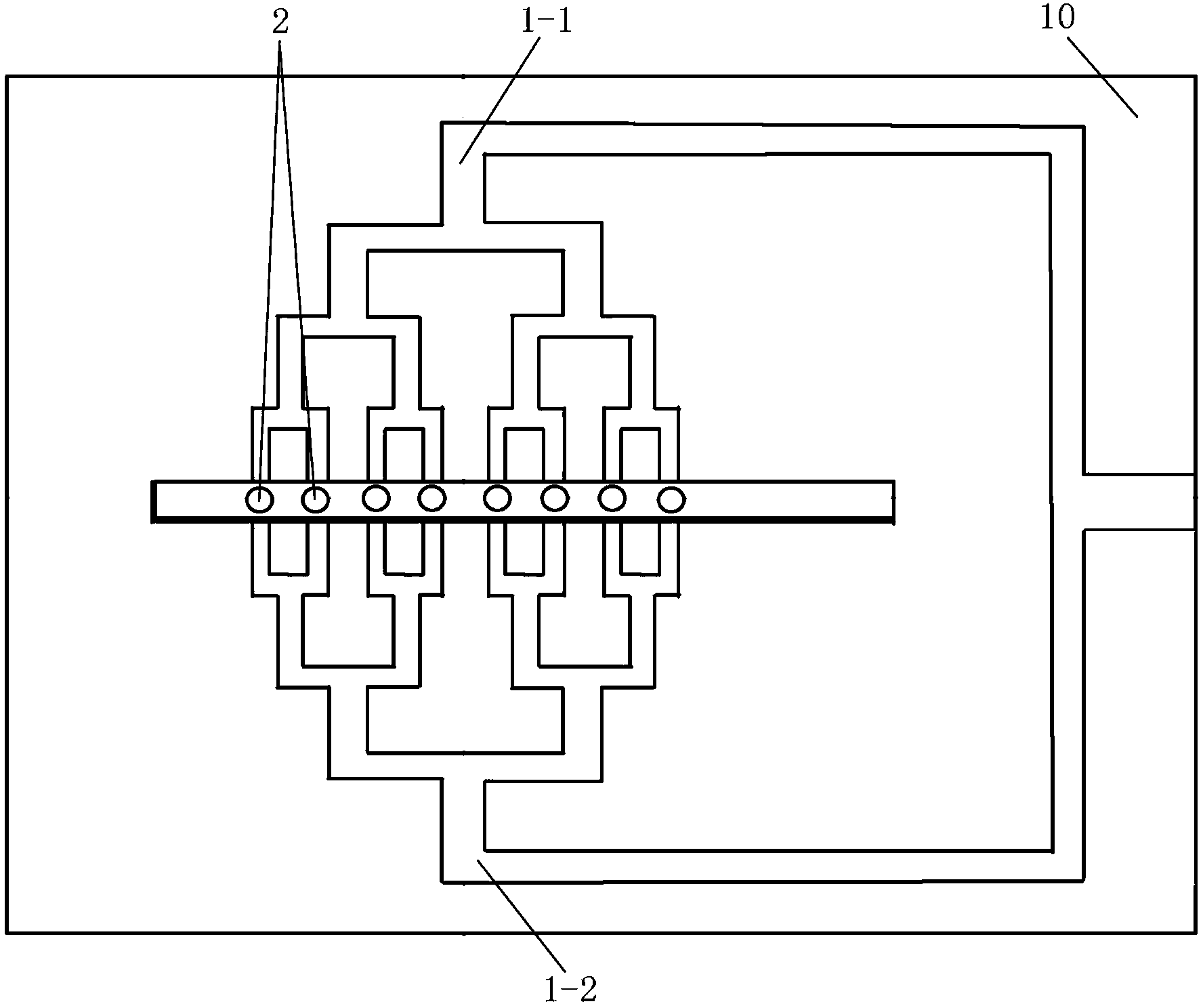

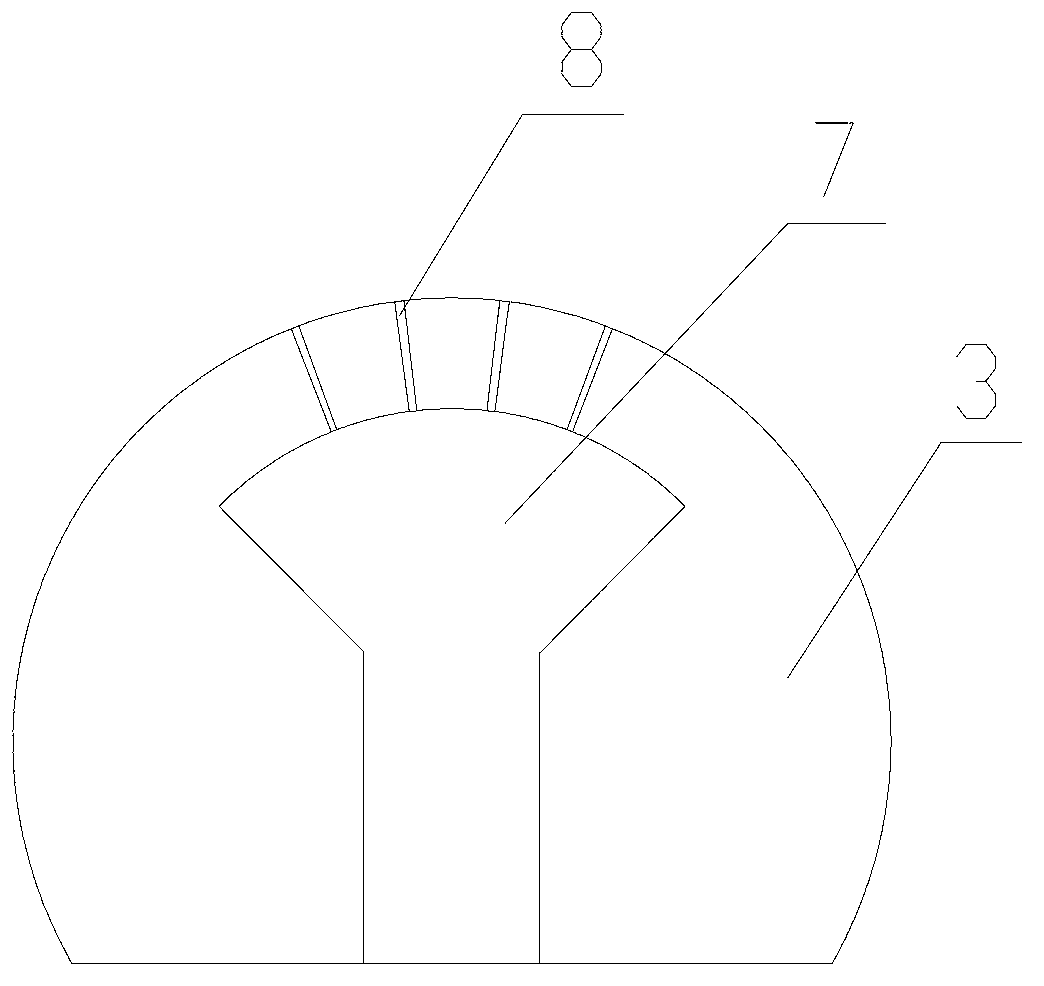

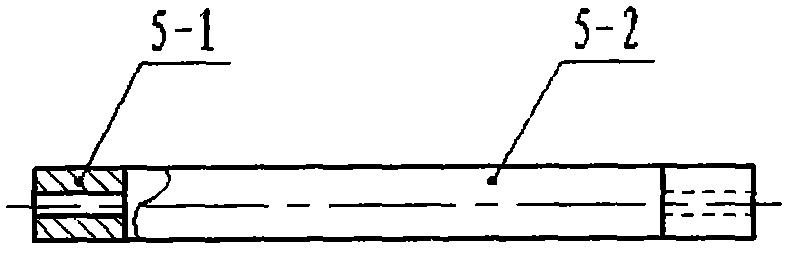

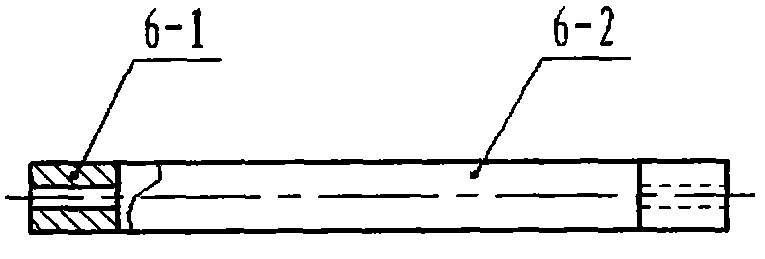

Production equipment and method for long fiber reinforced thermoplastic

ActiveCN102601887AReduce wearImprove dispersion efficiencyCoatingsPolymer scienceLong-fiber-reinforced thermoplastic

The invention discloses a dispersed structure during production of long fiber reinforced thermoplastic when grey yarns are impregnated, an impregnating mould head that uses the dispersed structure and a production method that uses the impregnating mould head. The dispersed structure provided by the invention is provided with a rotary dispersing core that is capable of dispersing the grey yarns effectively, has small abrasion and is not easy to break the mould head. The impregnating mould head that comprises a plurality of impregnating units and uses the structure is convenient to disassemble and has good universality and high efficiency. Compared with prior production method, the production method for long fiber reinforced thermoplastic that uses the impregnating mould head uses multiple strands and units to impregnate so that reinforced fiber is distributed uniformly in the bar (cross section) and ensures that fiber is not exposed so as to improve the production efficiency and quality. Meanwhile, as monofilament is not easy to break the mould head, the continuous production capacity of the production equipment is high.

Owner:JURONG BASTEP COMPOSITE MATERIALS

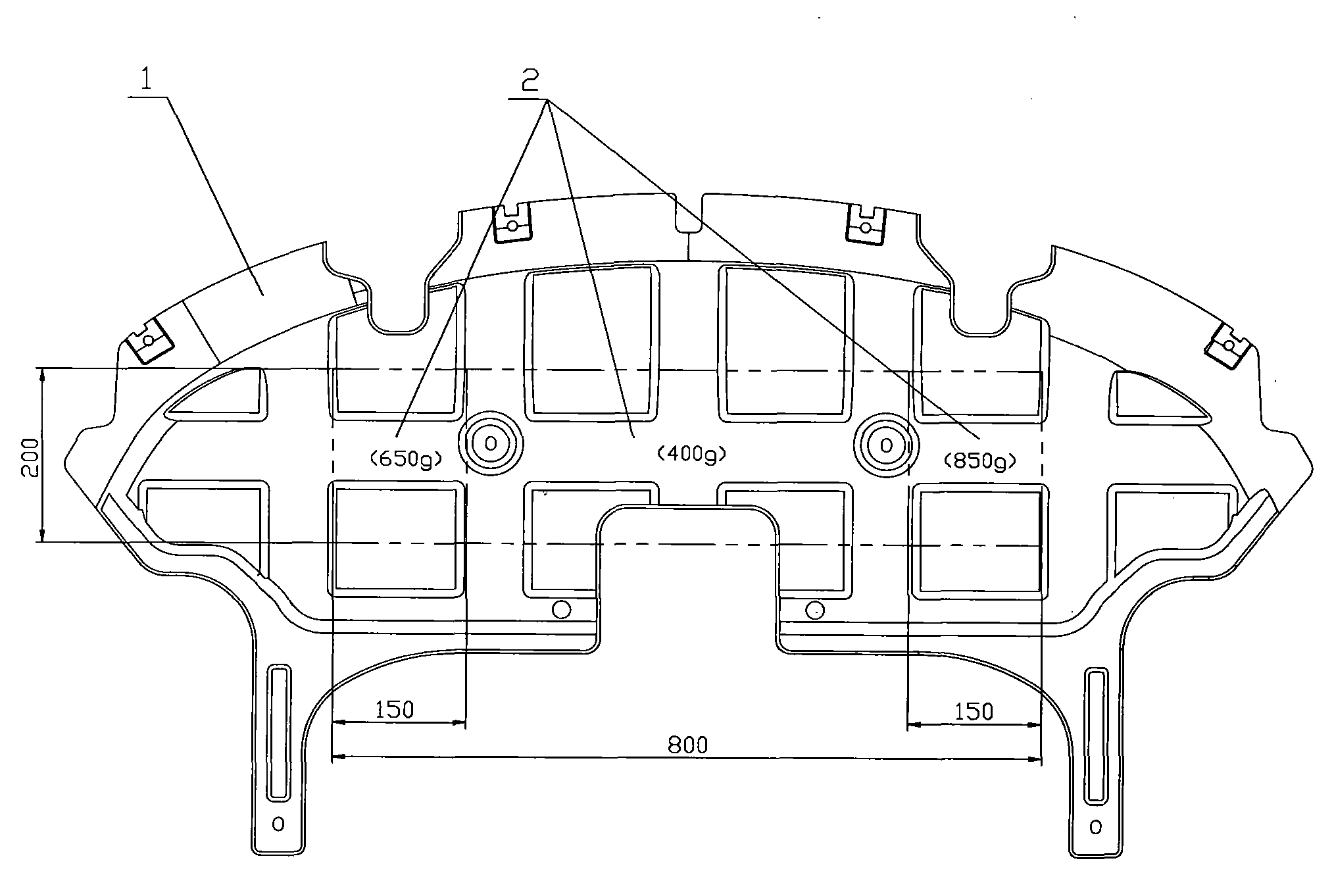

Long glass fiber reinforced polypropylene resin engine skid plate of passenger vehicle

InactiveCN101987603AStrong impact resistanceImprove corrosion resistanceDeflectorsGlass fiberRoom temperature

The invention relates to a long glass fiber reinforced polypropylene resin engine skid plate of a passenger vehicle, which is characterized in that the engine skid plate is prepared by using the long glass fiber reinforced polypropylene resins as a raw material through the steps of fusing the long fiber reinforced thermoplastics (LFT) into sheets; putting the obtained sheets into a mould for 40sec at the normal temperature according to a preset method; and carrying out mold stripping, wherein the pressure of the mould is 22MPa, and the pressure keeping time of the mould is 18sec. Because the whole forming process of the engine skid plate is implemented only through a single heating course, the energy consumption is low; meanwhile, the intermediate links such as storing, transporting and preheating prepreg materials are reduced, therefore, the energy consumption and manual work are saved, and the production cost is low.

Owner:FAW GROUP

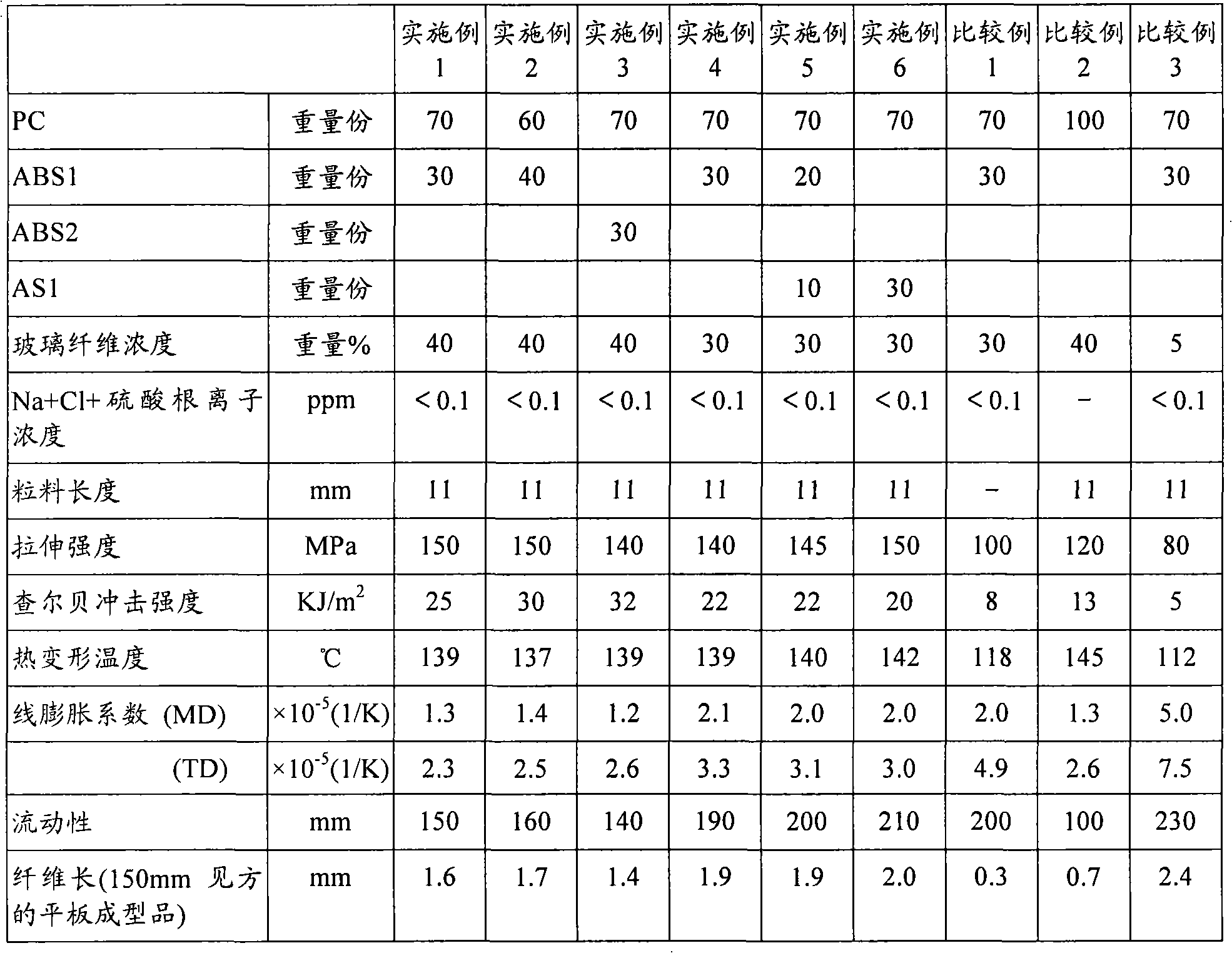

Filament-reinforced thermoplastic resin composition

Disclosed is a polycarbonate resin composition which is small in anisotropy of linear expansion coefficient, while being excellent in dimensional stability, fluidity and heat resistance. Specifically disclosed is a long fiber-reinforced thermoplastic resin composition obtained by blending 11-200 parts by weight of a reinforcing fiber per 100 parts by weight of a composition composed of a polycarbonate resin (PC) and a styrene resin (SR).

Owner:DAICEL POLYMER LTD

Long-fiber-reinforced thermoplastice resin sheets, production process thereof, and composite structures reinforced by the sheets

InactiveUS20030104191A1Maintain good propertiesGood in handling property and processabilitySuperstructure subunitsTraffic signalsEngineeringHot melt

A long-fiber-reinforced thermoplastic resin sheet comprises short strands, each of which has a width of from 0.2 to 5 mm and a length of from 10 to 150 mm and is made of a unidirectionally long-fiber-reinforced thermoplastic resin. The short strands are oriented at random and are fixed together at intersections thereof. The long-fiber-reinforced thermoplastic resin sheet has a basis weight of from 30 to 500 g / m2 and is provided with openings therein. The long-fiber-reinforced thermoplastic resin sheet can be produced by evenly spreading and piling up short strands of substantially circular or elliptical sections, and subjecting the short strands to pressureless hot-melt adhesion or to hot-melt compression bonding under pressure such that the sheet has a basis weight of from 30 to 500 g / m2 and is provided with openings therein. The short strands of the substantially circular or elliptical sections have an average diameter of from 0.1 to 1.5 mm and an average length of from 10 to 150 mm, and are made of a unidirectionally long-fiber-reinforced thermoplastic resin.

Owner:TS TECH CO LTD

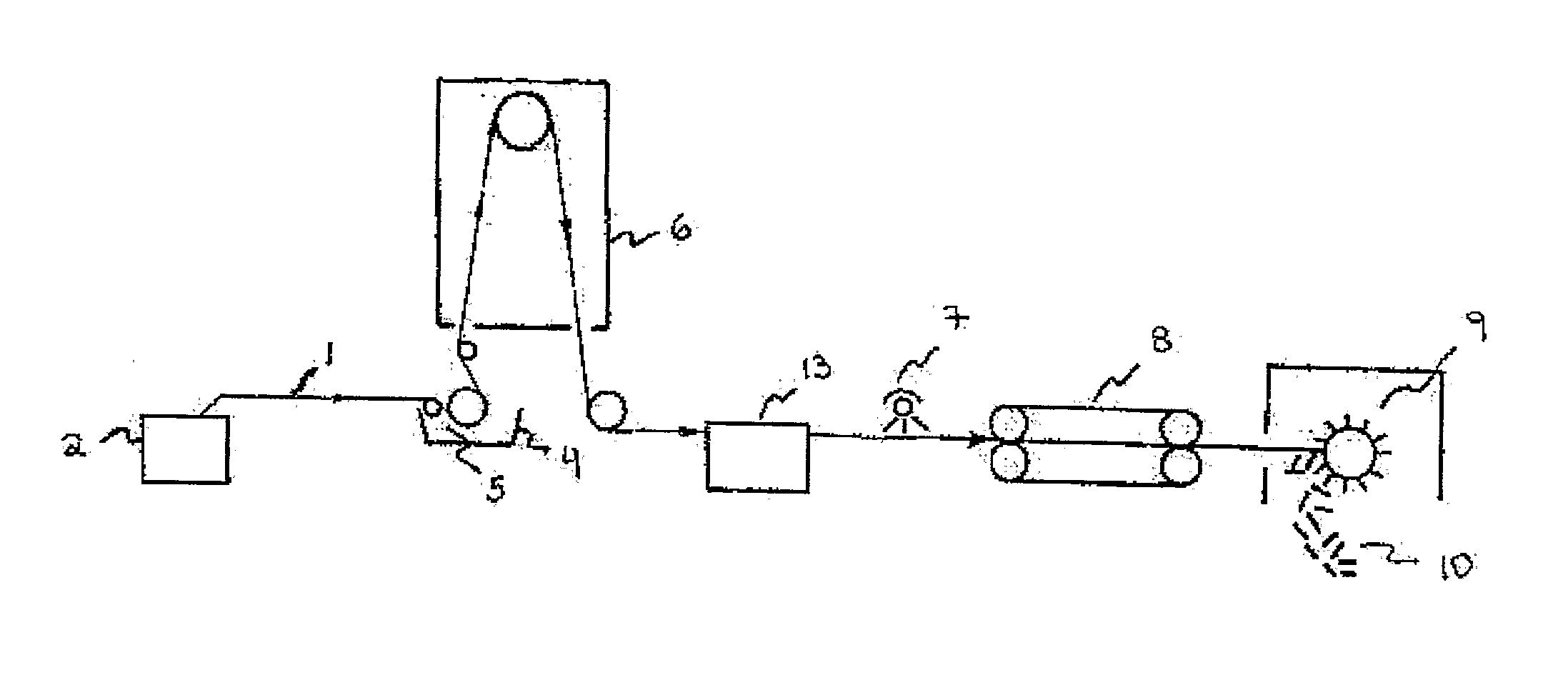

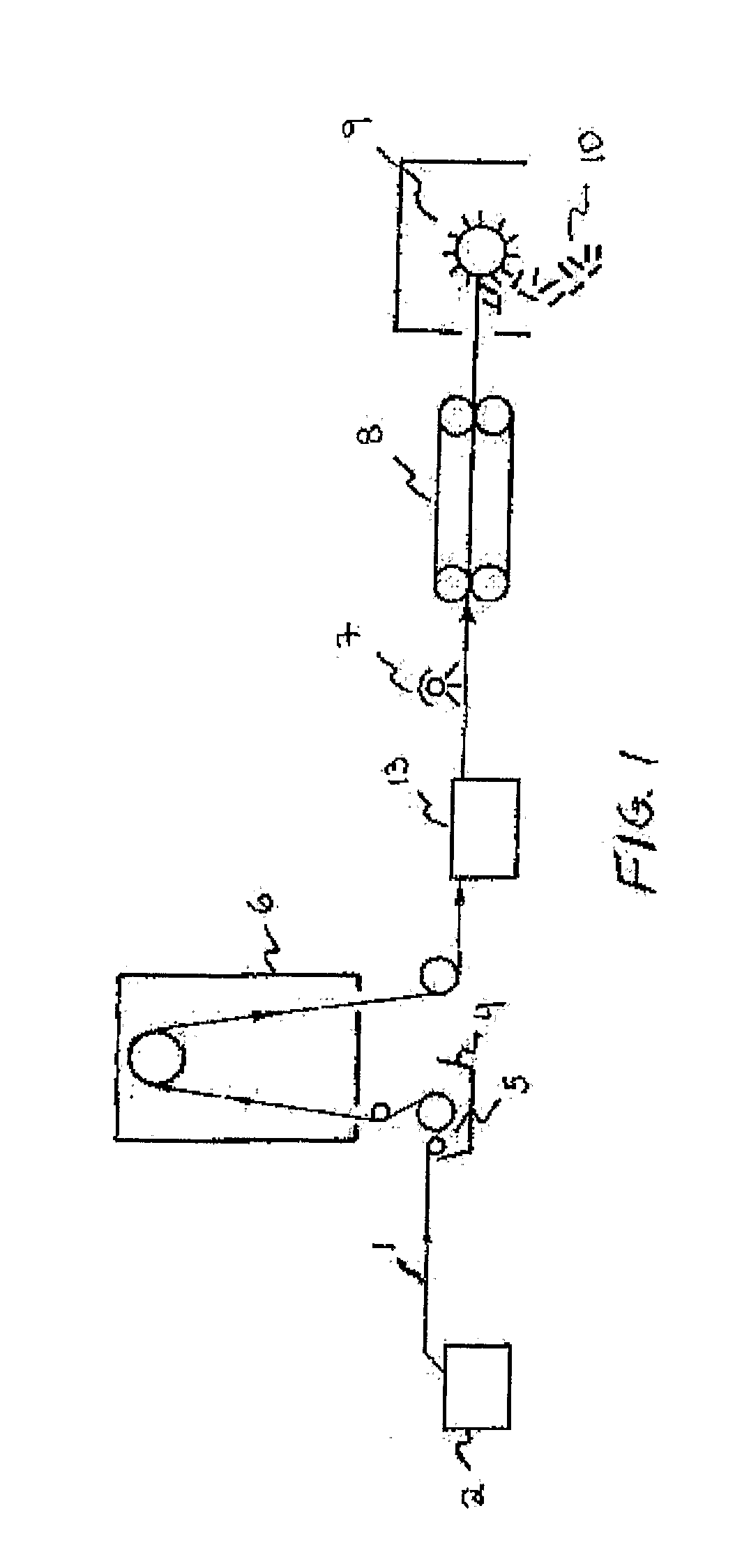

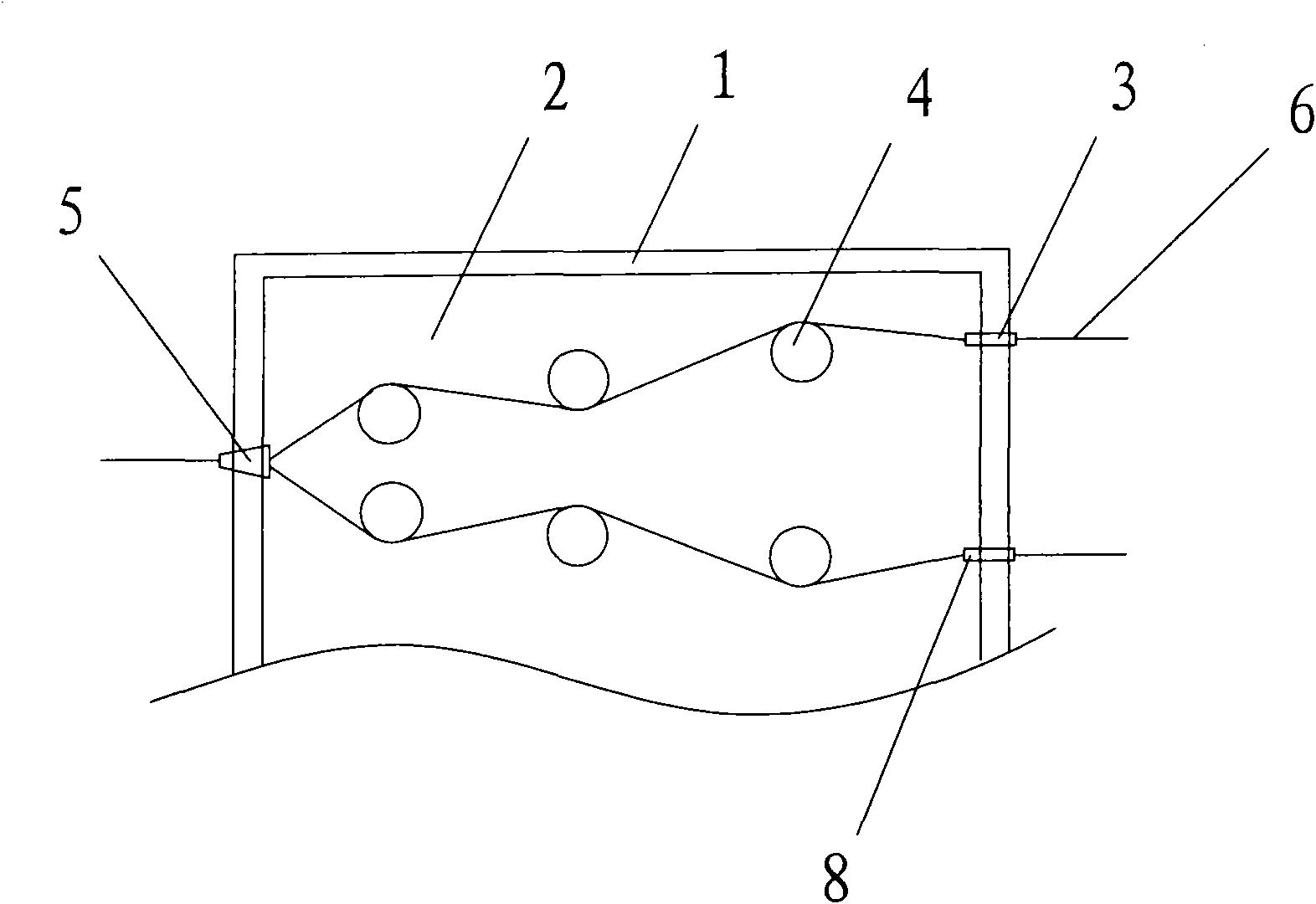

Plant fiber impregnation device and method

ActiveCN104827686AGuaranteed fluffyPromote infiltrationPlant fibreLong-fiber-reinforced thermoplastic

The invention relates to a plant fiber impregnation device and method applicable to natural plant fiber impregnation molten resin. The plant fiber impregnation device comprises a melting and impregnation die (1) and a cooling and rolling device (2), wherein the melting and impregnation die (1) comprises a die cavity, a feed inlet (4) and 4-8 and impregnation roller pairs located in the die cavity, each impregnation roller pair comprises an upper impregnation roller (6), a lower impregnation roller (5) and an impregnation roller spring (7), and the impregnation roller spring (7) applies certain elastic pressure to the upper impregnation roller (6) to allow certain pressure to exist between the upper impregnation roller (6) and the lower impregnation roller (5); the cooling and rolling device (2) comprises 2-4 compression roller pairs, each compression roller pair comprises an upper compression roller (9), a lower compression roller (10) and a compression roller spring (8), and the compression roller spring (8) applies certain elastic pressure to the upper compression roller (9) to allow certain pressure to exist between the upper compression roller (9) and the lower compression roller (10). The plant fiber impregnation device has the advantages that natural plant fibers are carded into strips and pass the plant fiber impregnation device, and natural long fiber reinforced thermoplastic polymer pre-impregnated materials.

Owner:BEIJING UNIV OF CHEM TECH

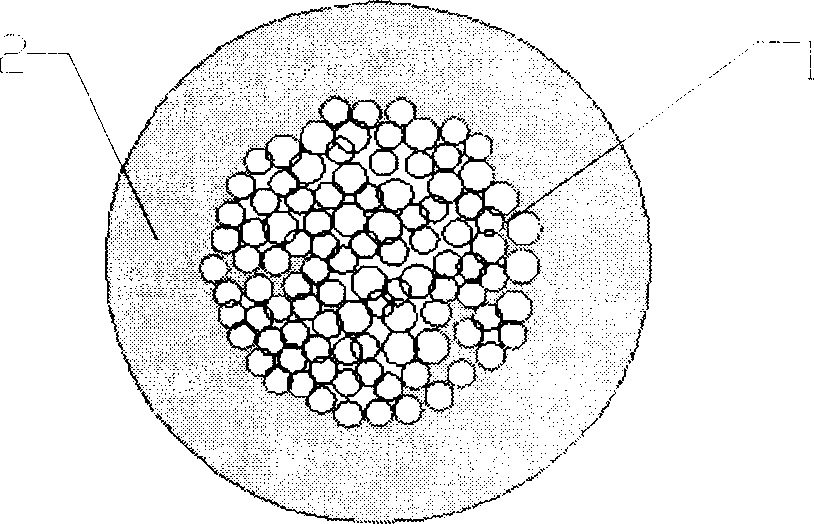

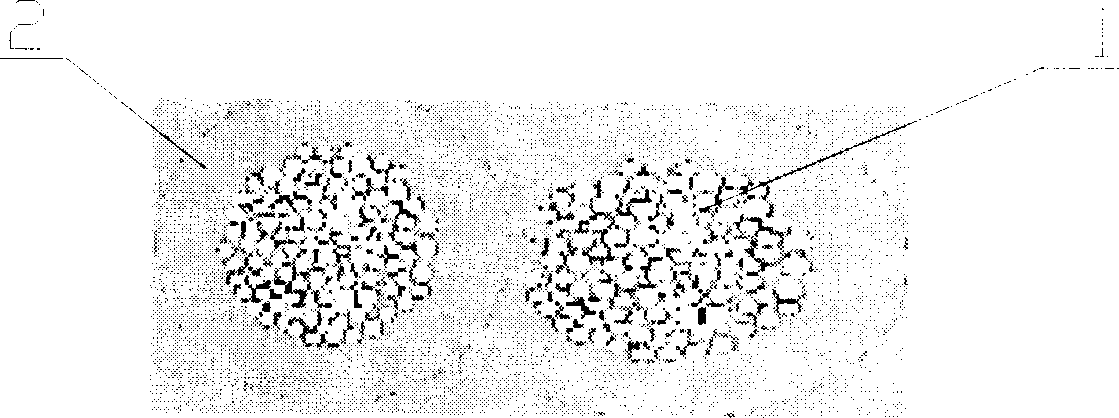

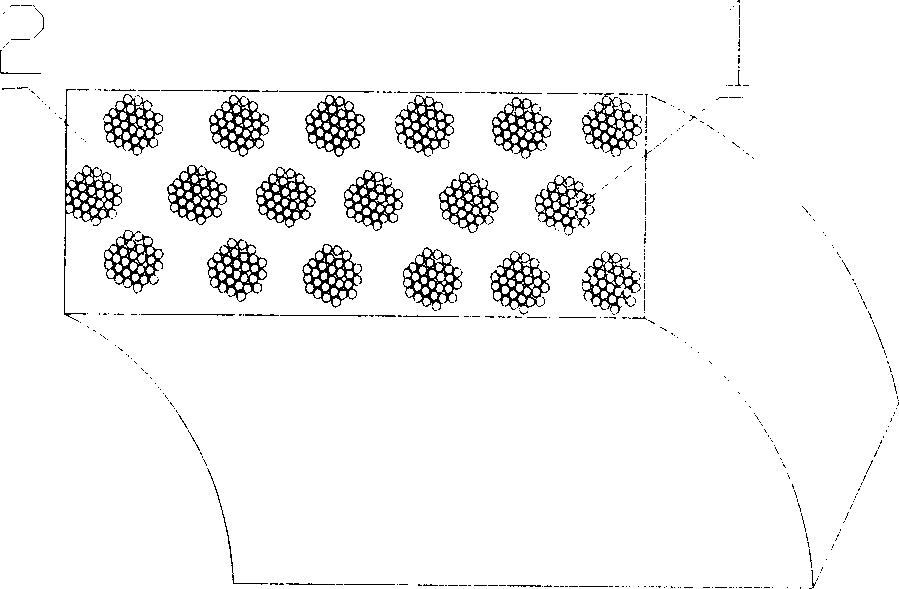

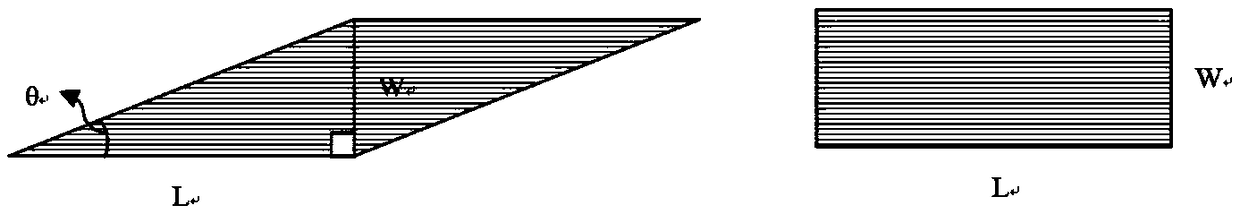

Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

The invention provides a discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and a preparation method thereof. The mold pressing precast body comprises slices formed by slitting / cutting of continuous fiber reinforced thermoplastic composite material preimpregnated sheets / preimpregnated yarns, wherein the length L range of the slices is 5-200 mm, the width W range of the slices is 2-30 mm, and the weight percentage content of fibers in the slices is 20-90 wt%; and high-strength isotropous complicated parts with high size stability can be prepared through secondary mold pressing of the precast body, so that the defects of easy warpup, fiber length loss, weaker part performances, anisotropic mechanical performances of continuous fiber reinforced composite materials and difficult machining of different-thickness complicated parts after mold pressing injection molding of short-fiber and long-fiber particles are made up.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

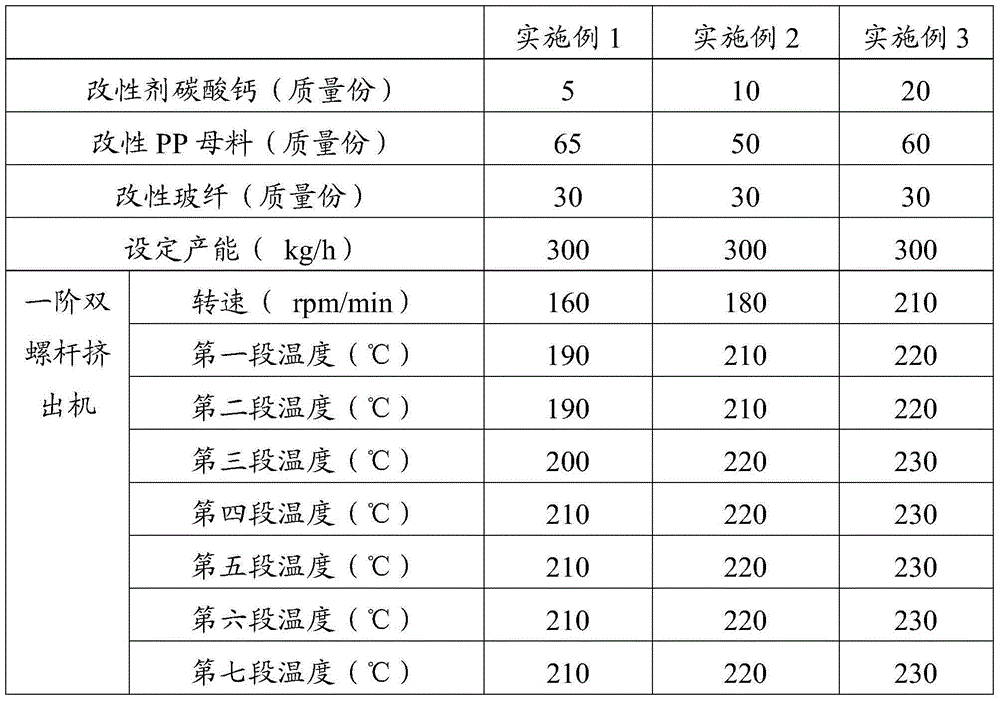

LFT-D (Long-Fiber Reinforce Thermoplastic Direct) forming method of building template filled with calcium carbonate

ActiveCN104059293AImprove thermal stabilityImprove toughnessGlass fiberLong-fiber-reinforced thermoplastic

The invention provides an LFT-D (Long-Fiber Reinforce Thermoplastic Direct) forming method of a building template. The LFT-D forming method comprises the following steps of: uniformly stirring 5-20 parts by weight of modifying agent calcium carbonate and 50-65 parts by weight of modified PP (Propene Polymer) master batch to obtain a uniformly mixed mixture; fusing and plasticizing the mixture through a first-order screw extruder; feeding 30 parts by weight of modified glass fibers and the mixture which is fused and plasticized through the first-order screw extruder into a second-order screw extruder together, and extruding after fusing and mixing; clamping the mixture extruded through the second-order screw extruder into a mould-pressing mould by a mechanical arm, and assembling the mould-pressing mould and maintaining pressure to obtain a product. The LFT-D forming method provided by the invention takes superfine heavy calcium carbonate as an inorganic filler, can be used for constructing the inorganic filler / glass fiber / PP composite material system and solves the problems on the aspects of fiber exposure and the like of a glass fiber / PP composite material system.

Owner:福建易安特新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com