Patents

Literature

38results about How to "Increase the degree of infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic bonding agent, ceramic bonding agent abrasive disk and preparation method of ceramic bonding agent abrasive disk

ActiveCN106737255AImprove liquidityHigh tensile strengthAbrasion apparatusGrinding devicesBoron nitrideGraphite

The invention discloses a ceramic bonding agent, a ceramic bonding agent abrasive disk and a preparation method of the ceramic bonding agent abrasive disk. The ceramic bonding agent comprises, by weight, 20-60 parts of SiO2, 10-30 parts of B2O3, 5-20 parts of Al2O3, 3-6 parts of Li2O, 6-15 parts of Bi2O3, 5-20 parts of P2O5, 0.2-1.5 parts of TiO2 and 0.5-2 parts of Sb2O5. A grinding layer of the ceramic bonding agent abrasive disk is composed of, by volume percentage, 5-50% of cubic boron nitride (CBN) or diamond, 5-40% of white corundum, 5-30% of the ceramic bonding agent and 3-5% of whiskers. The boron, aluminum and phosphorus silicate ceramic bonding agent disclosed by the invention has the good liquidity and tensile strength, can well infiltrate and control a grinding material, and has a good cutting capacity; the whiskers are added into the ceramic bonding agent, the strength of the ceramic bonding agent is increased, the grinding durability is improved, the hardness of the bonding agent is reduced, self-sharpening performance of a grinding tool is improved, and accordingly the durability of a grinding wheel is improved and the service life of the grinding wheel is prolonged. Efficient grinding on various steel materials is achieved through the synergistic effect of the CBN, the white corundum, the silicon carbide, wollastonite and the graphite, and high durability is achieved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

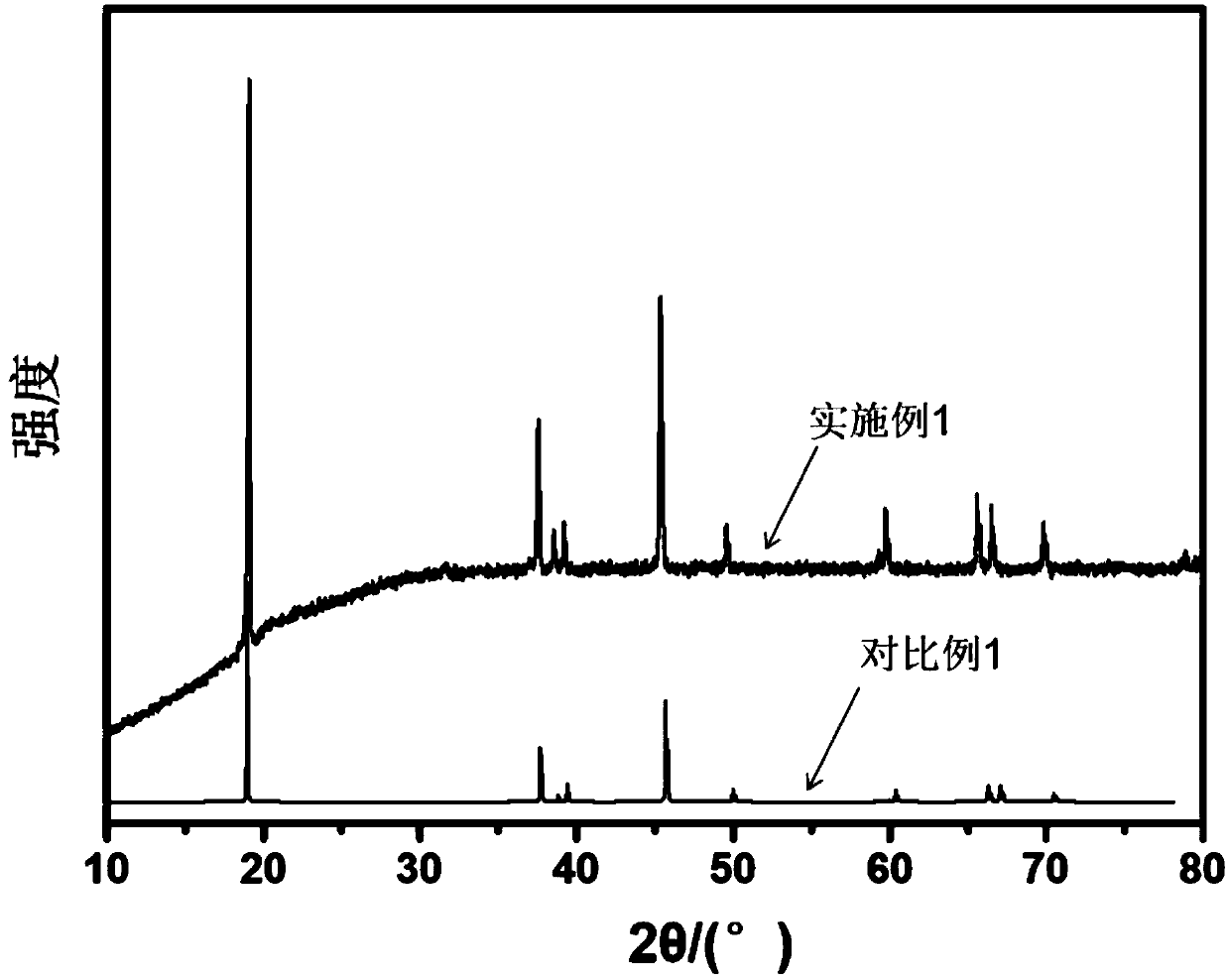

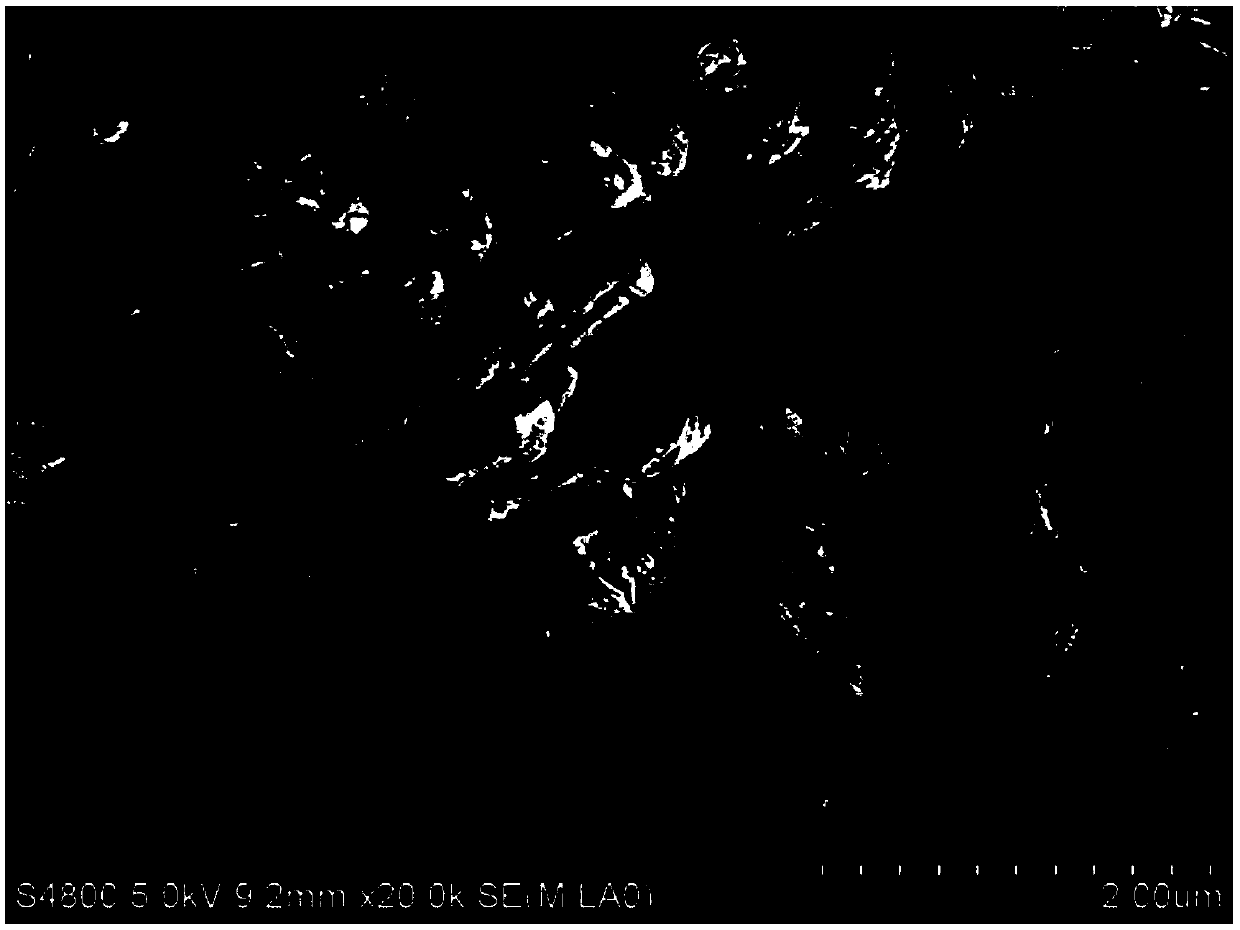

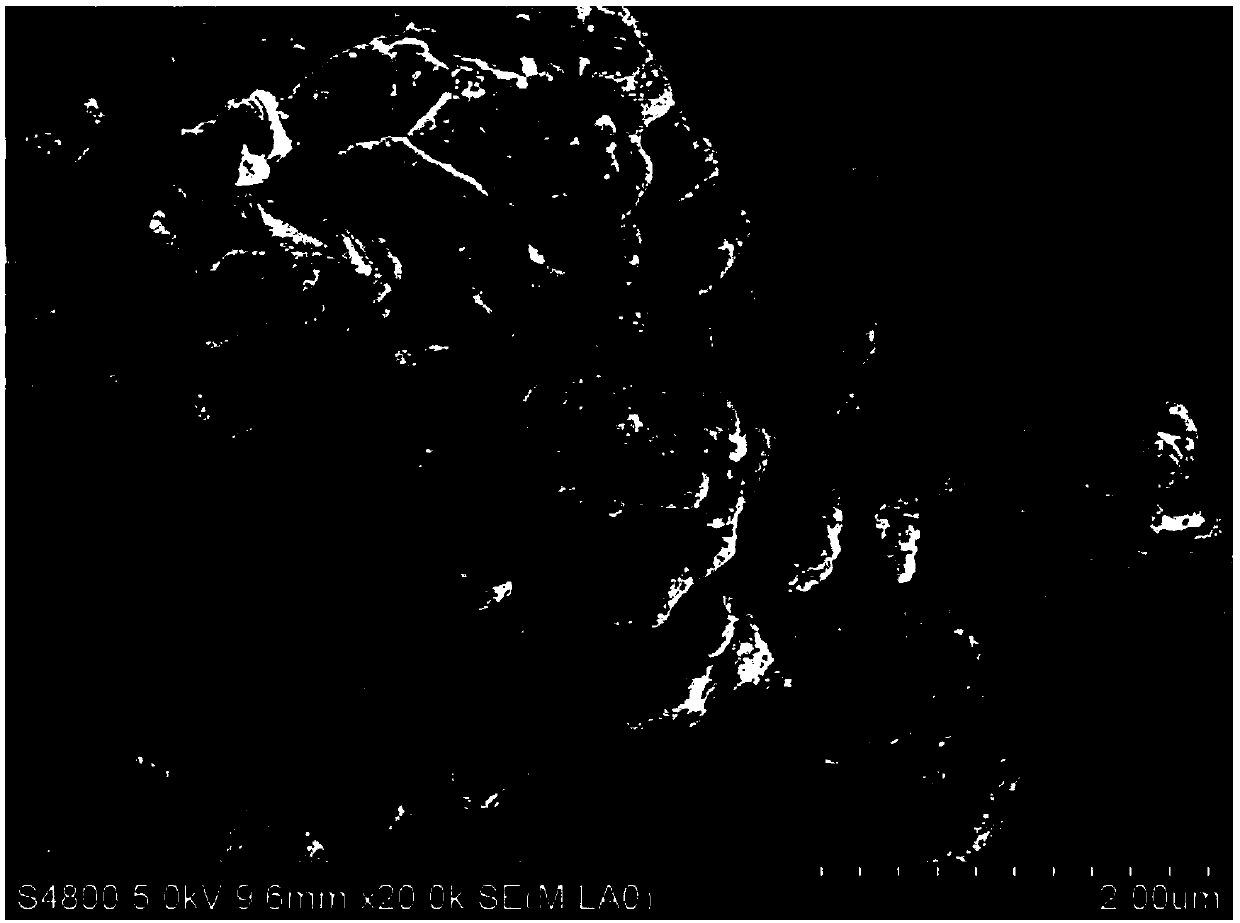

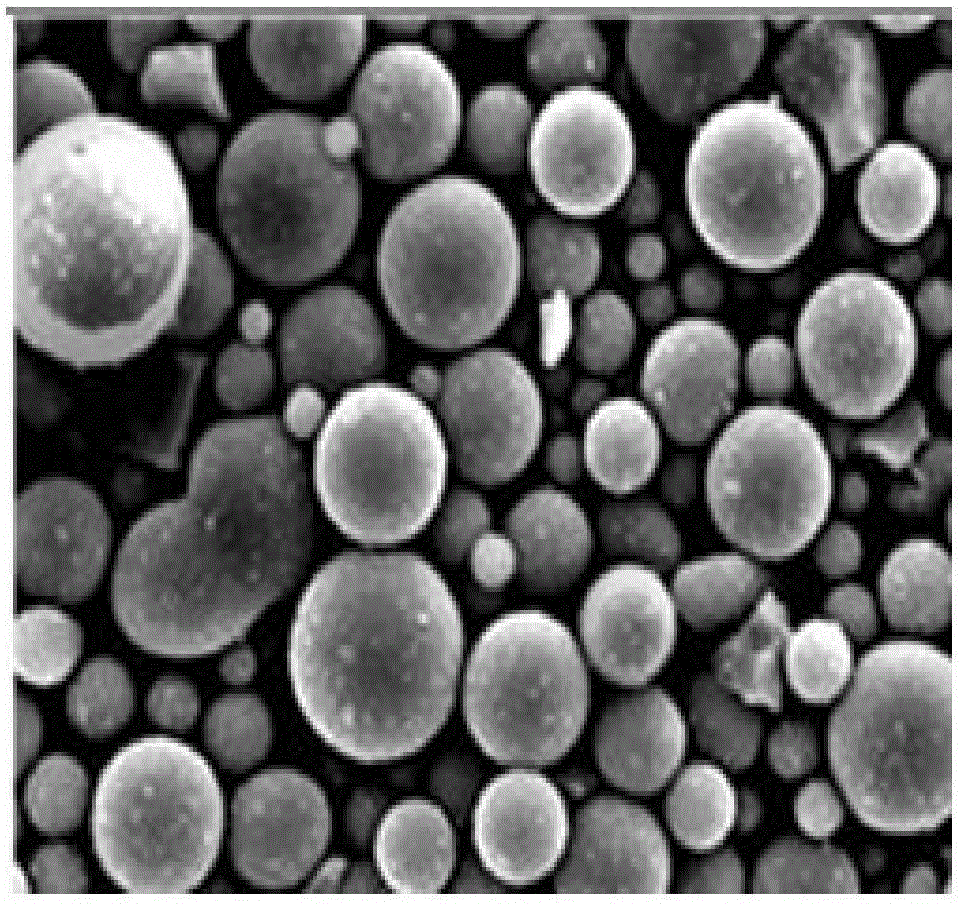

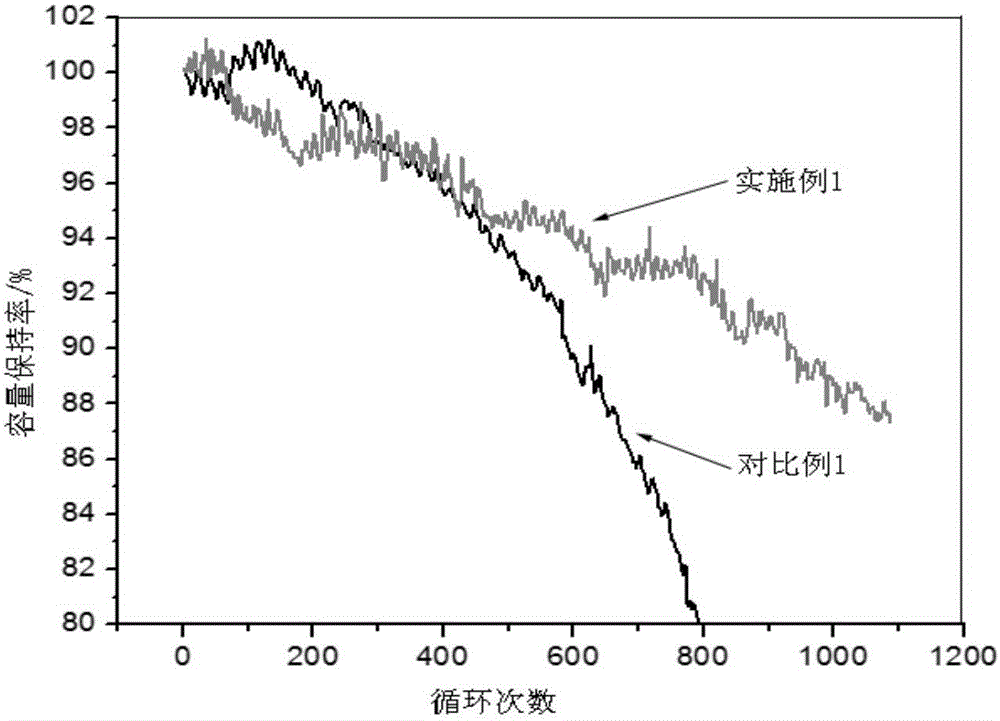

Preparation method of trimetallic MOF-derived ternary cathode material

InactiveCN109585835AImprove electrochemical performanceIncrease the degree of infiltrationSecondary cellsPositive electrodesManganeseCobalt

The invention discloses a preparation method of a trimetallic MOF-derived ternary cathode material. The trimetallic MOF-derived ternary cathode material comprises the following steps of: the step 1: employing a nickel-cobalt-manganese trimetallic organic framework material formed by solvothermal reaction as a reaction precursor; and the step 2: performing preparation by employing the reaction precursor and a lithium source by employing a high-temperature solid phase method to obtain a trimetallic MOF-derived ternary cathode material, wherein the trimetallic MOF-derived ternary cathode materialis Liz(NixCoyMn1-x-y)O2 with a surface coated with carbon, 0<=x<=1, 0<=y<=1, 0<=1-x-y<=1 and 1.08<=z<=1.3. The preparation method of the trimetallic MOF-derived ternary cathode material changes the coating means of complexity and difficult control in morphology, employs a simple and practicable mode to introduce an MOF carbon skeleton for coating without influence of the structure phase of the ternary material so as to greatly improve the circulation stability, the rate capability and the safety of the material and have potential application prospects.

Owner:SHANGHAI AEROSPACE POWER TECH

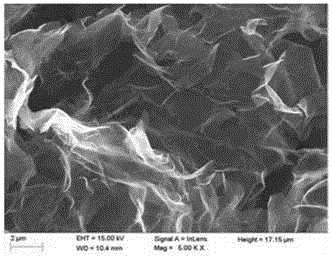

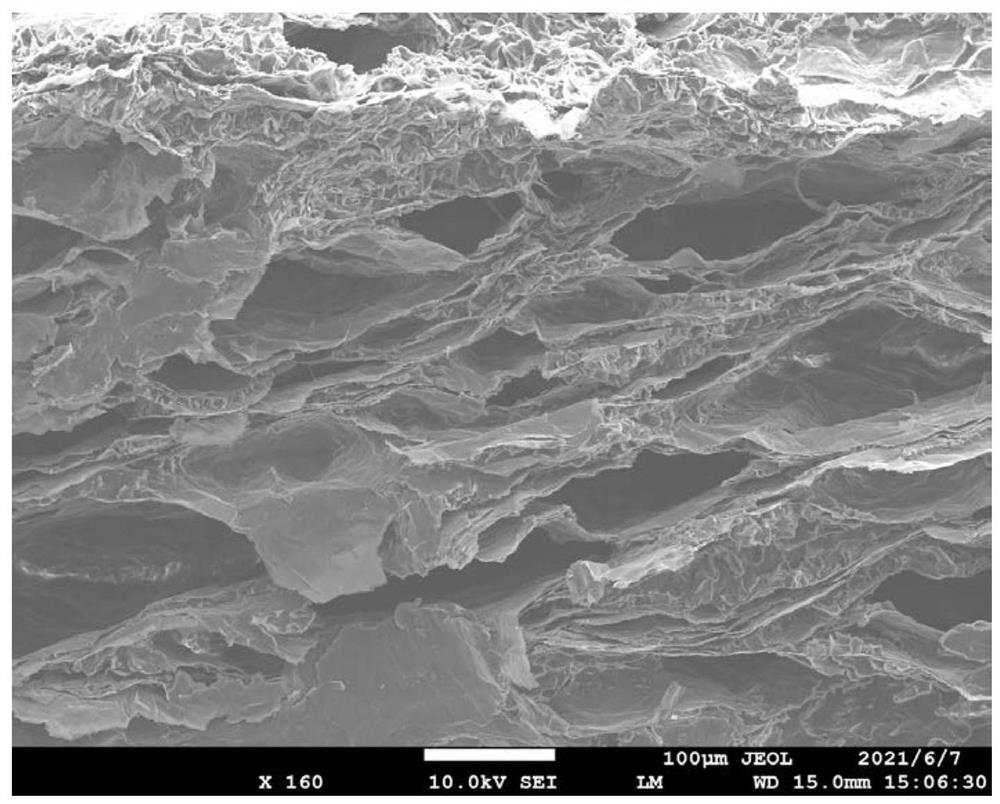

High thermal conductivity graphene composite interface material and preparing method thereof

InactiveCN106554626AImprove thermal conductivityGood compressibilityElectrical resistance and conductanceNetwork structure

The invention provides a high thermal conductivity graphene composite interface material. The high thermal conductivity graphene composite interface material comprises organosilicon polymer, heat conduction powder, graphene powder and an assisting agent. The heat conduction powder comprises spherical heat conduction powder and polyhedron heat conduction powder. The invention meanwhile provides a preparing method for the polyhedron high thermal conductivity graphene composite interface material. The above raw materials are mixed and calendered, and the high thermal conductivity graphene composite interface material is prepared. Through utilization of the polyhedron heat conduction powder and adding of graphene, the contact faces of the raw materials are increased, an effective heat conduction network structure is formed, accordingly, heat conduction channels are increased, the heat dissipation efficiency is improved, and accordingly the material heat conduction performance is improved. The thermal conductivity of the prepared high thermal conductivity graphene composite interface material reaches 7.5 W / m.K-9.5 W / m.K, meanwhile, through control over the adding amount of the graphene, the prepared high thermal conductivity graphene composite interface material has a certain insulating property, and the volume resistance is 1,010 omega.cm-1,013 omega.cm.

Owner:ZTE CORP +1

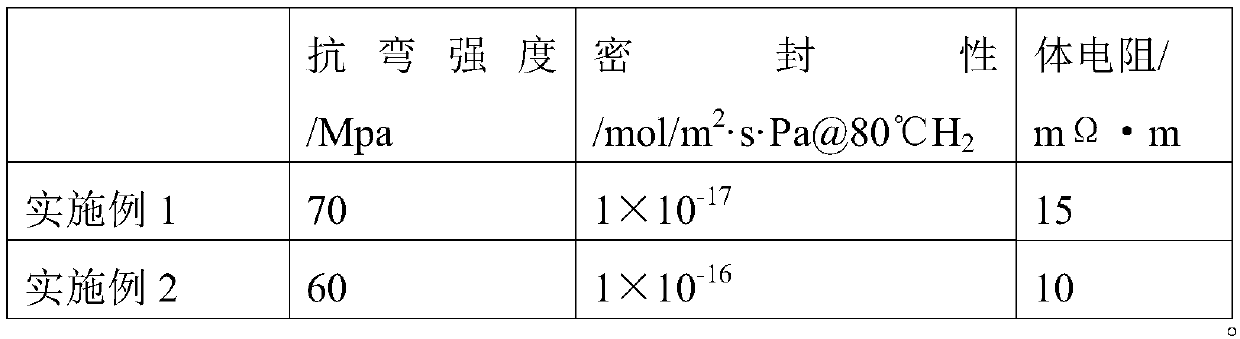

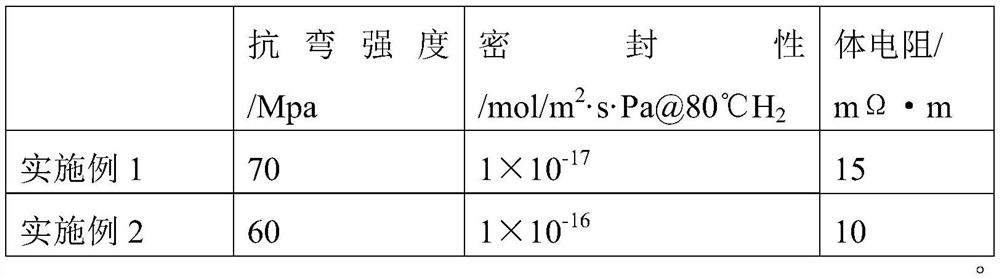

Fuel cell pole plate forming method based on expanded graphite

The invention relates to a fuel cell pole plate forming method based on expanded graphite. The fuel cell pole plate forming method comprises the following steps of (1) powder vacuum impregnation, wherein putting raw material powder of a fuel cell graphite plate into a reaction kettle, vacuumizing and maintaining for 10-30 minutes, and injecting the liquid resin under the condition that the vacuumcondition is not released, so that the raw material powder can be completely immersed; fully mixing and releasing the vacuum to obtain a wet material for later use; (1) preparing a plate, wherein preparing the wet material into an expanded graphite plate through an extrusion method; (3) cutting and forming; and (4) curing. Compared with the prior art, the substrate prepared by the fuel cell pole plate forming method has the advantages of being conductive, high in strength, good in sealing performance and the like.

Owner:SHANGHAI SHENLI TECH CO LTD

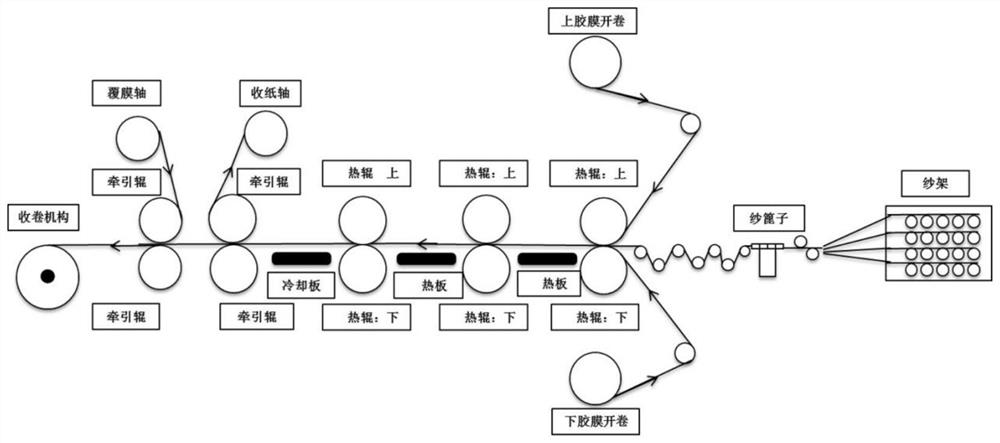

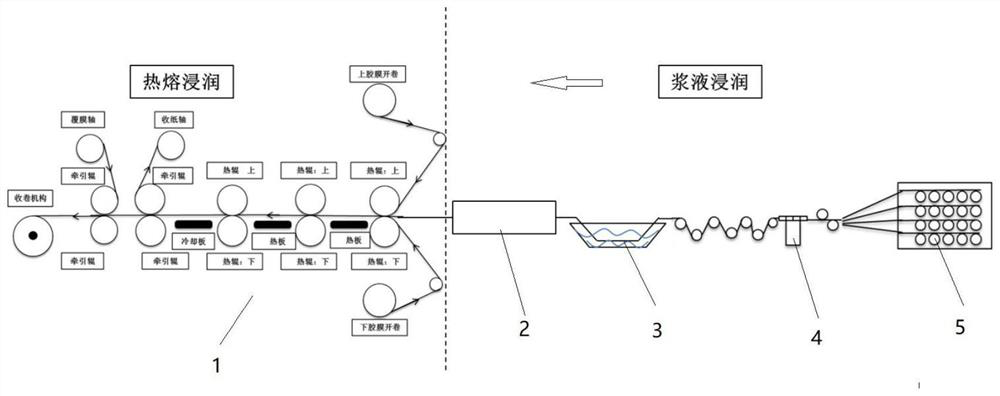

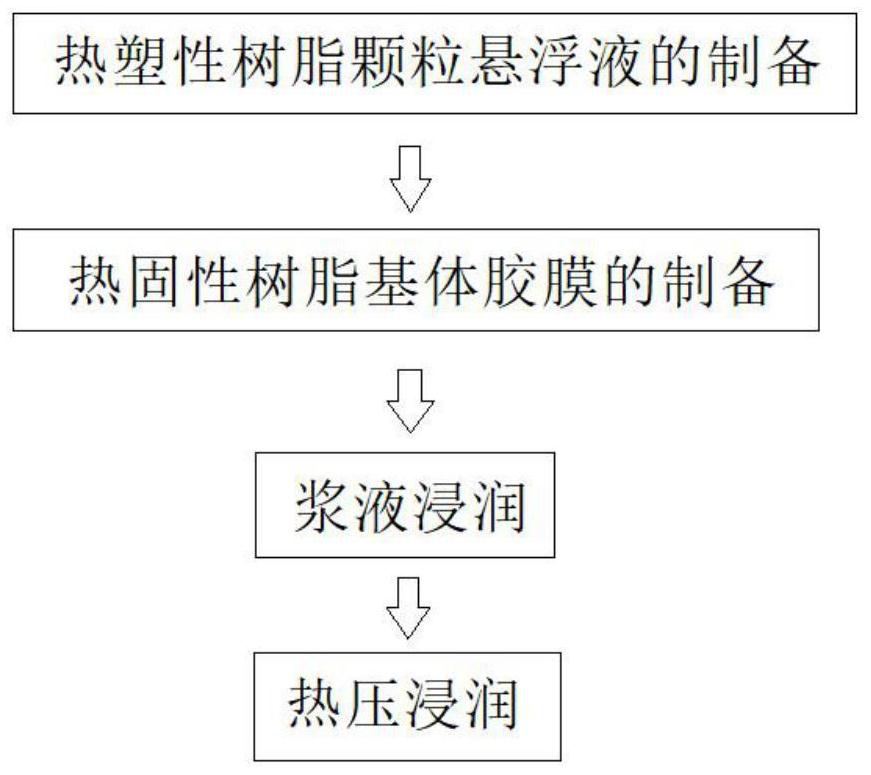

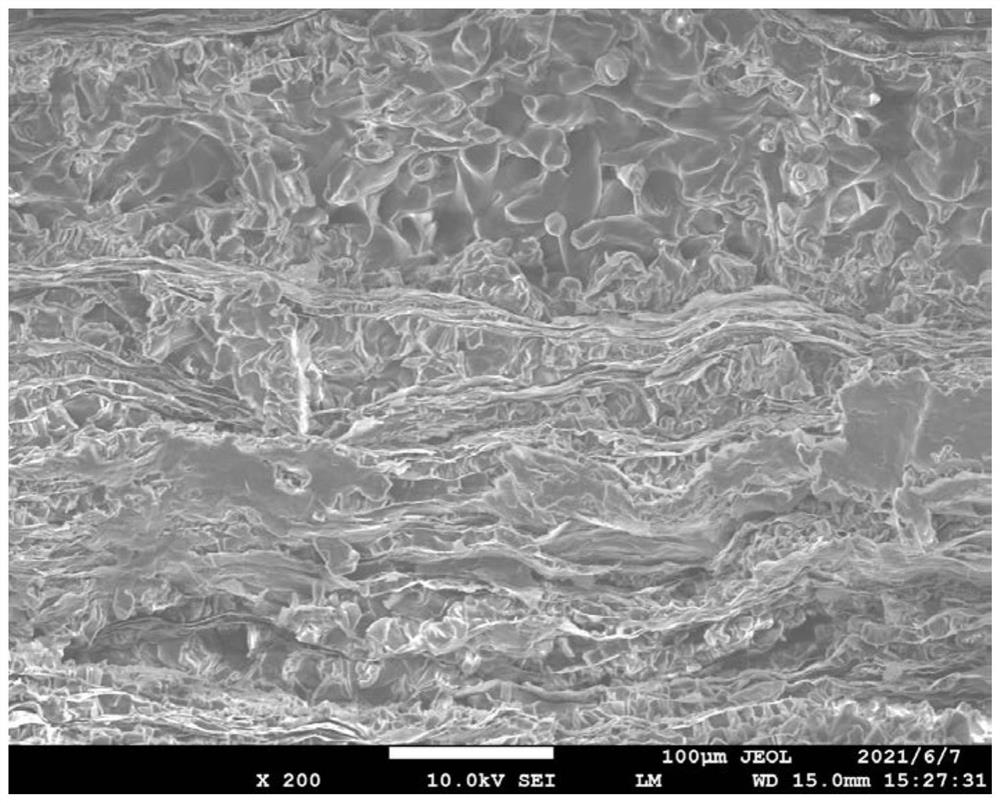

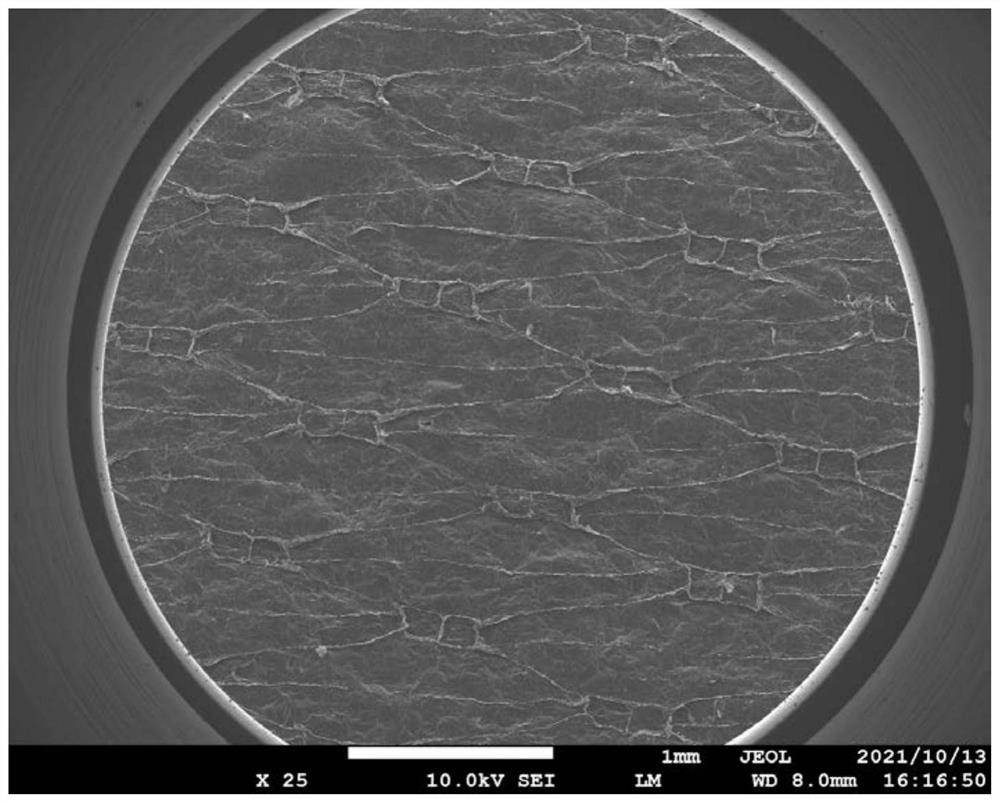

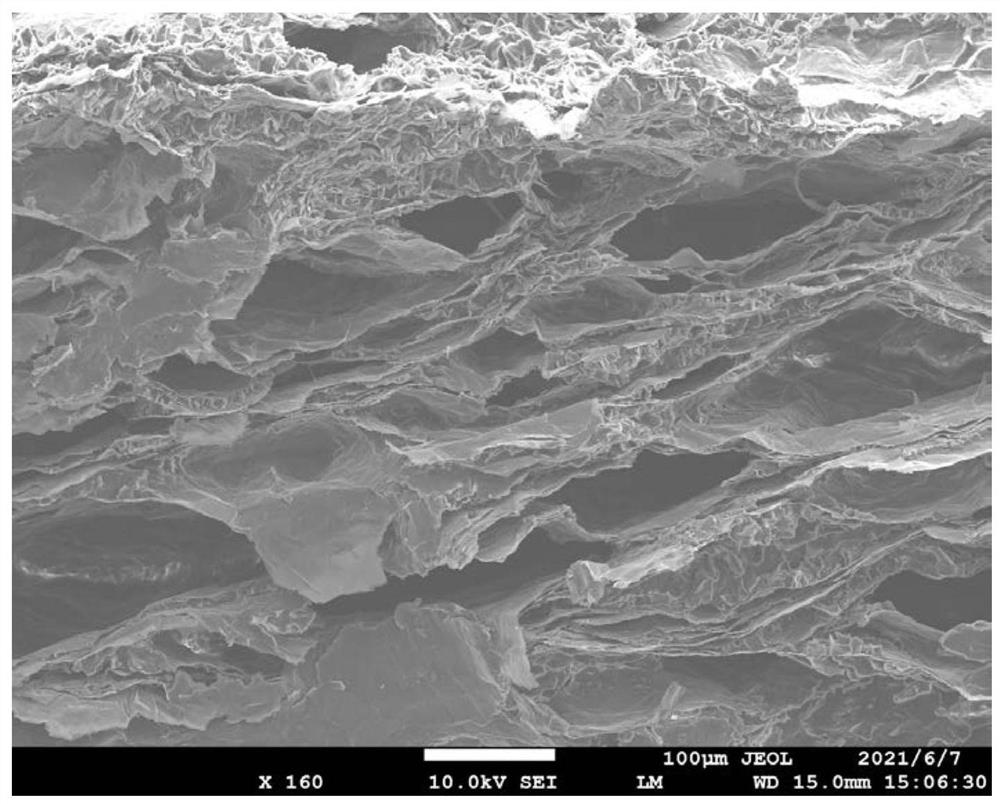

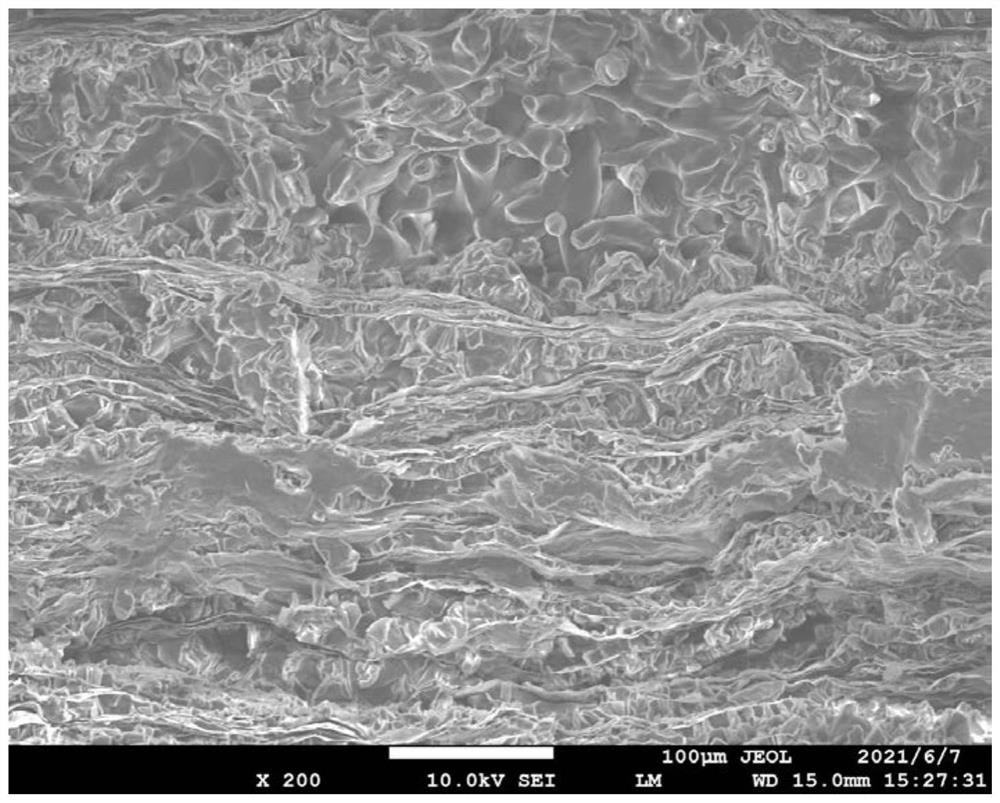

Preparation method and system of high-toughness thermosetting resin-based prepreg

The invention relates to the technical field of materials, in particular to a preparation method and system of a high-toughness thermosetting resin-based prepreg. According to the preparation method and system, thermoplastic resin particles and a resin matrix are prepared separately, and a reinforcing material is infiltrated separately; the method comprises the following steps: independently dispersing thermoplastic resin particles for toughening in a poor solvent, infiltrating a reinforcing material in the form of a thermoplastic resin particle suspension, drying the solvent to obtain a reinforcing material with uniformly distributed thermoplastic resin particles, and infiltrating the reinforcing material with other resin matrixes by a hot melting method to obtain the thermoplastic resin composite material. The thermoplastic resin particles of the high-toughness thermosetting resin-based prepreg are uniformly distributed, and the resin matrix of the high-toughness thermosetting resin-based prepreg is fully infiltrated; the prepreg preparation method provided by the invention can improve the infiltration degree of the resin on the reinforcing material and the consistency of the internal quality of the prepreg, and solves the preparation problem of the high-toughness resin-based composite material.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

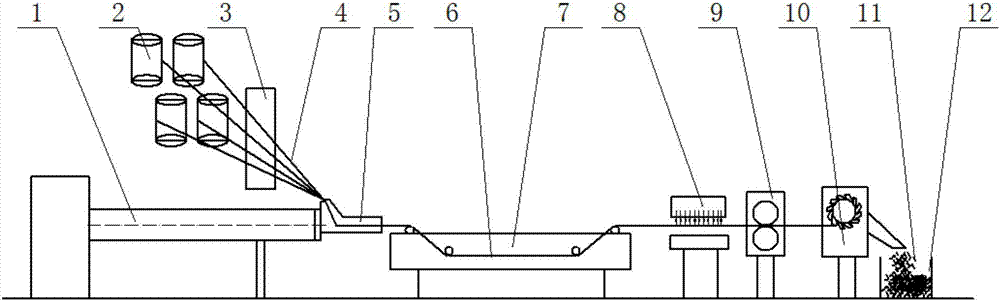

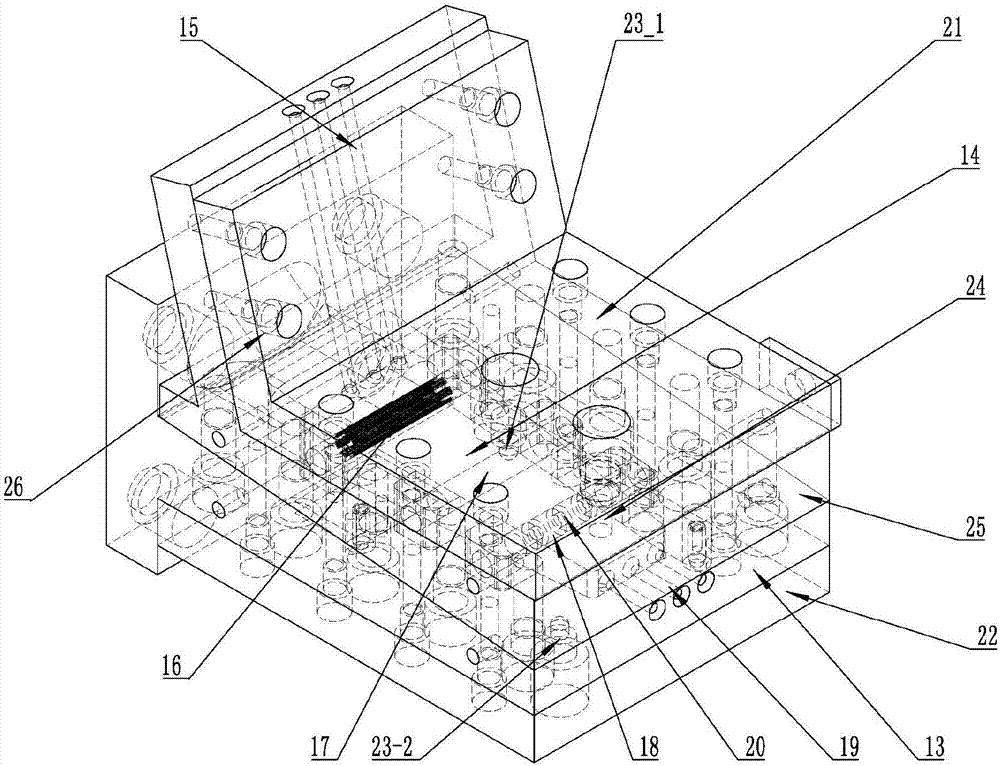

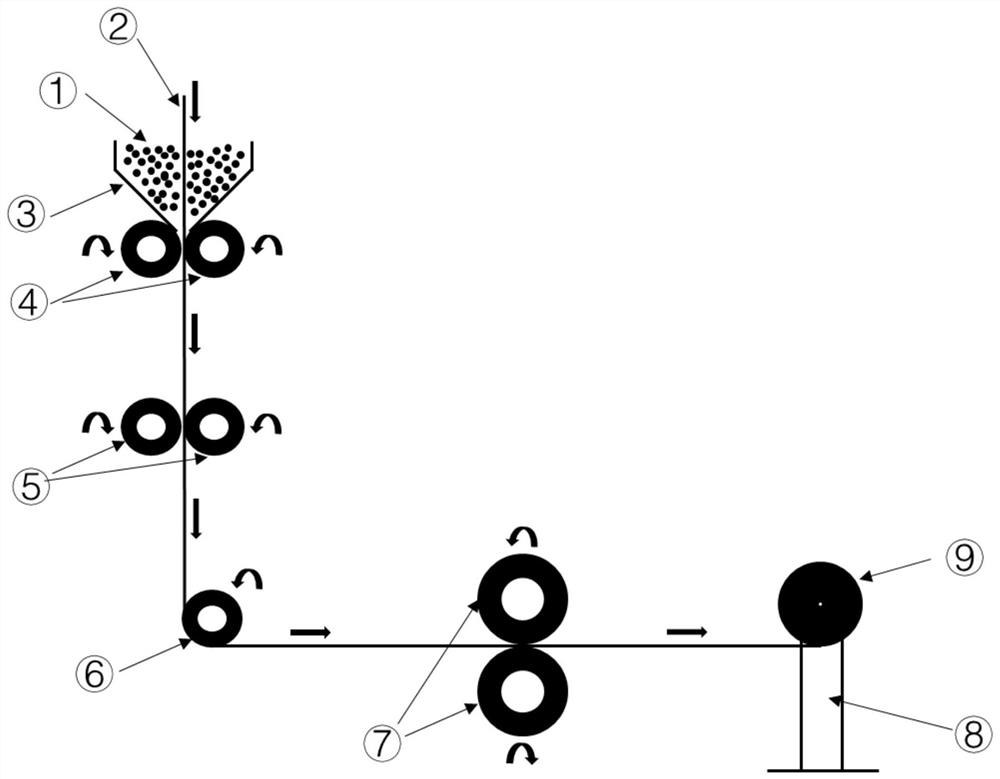

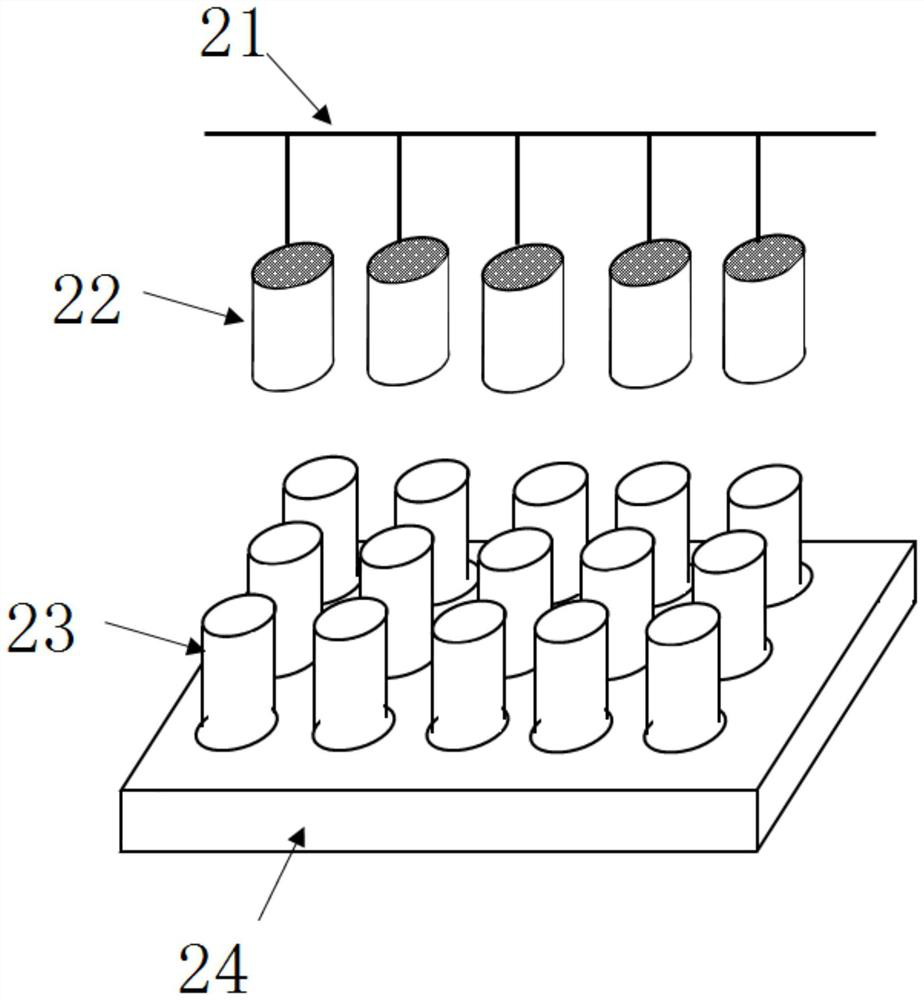

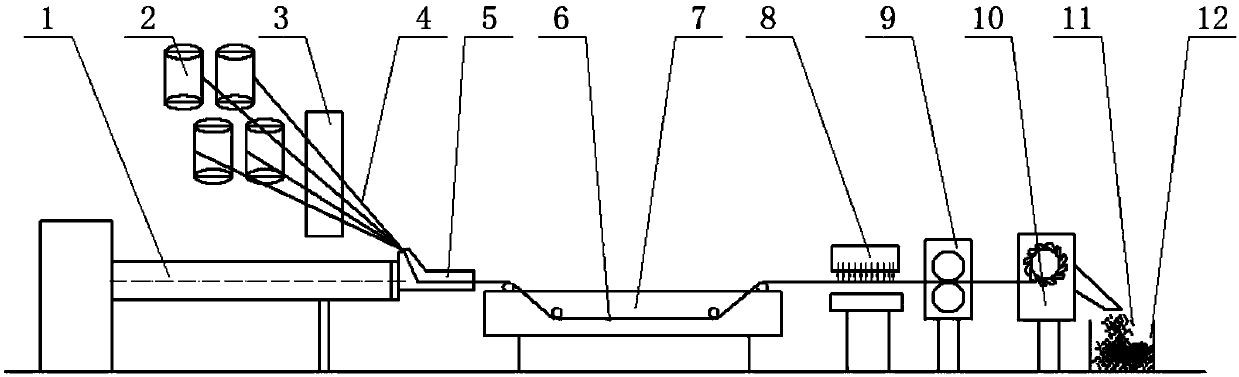

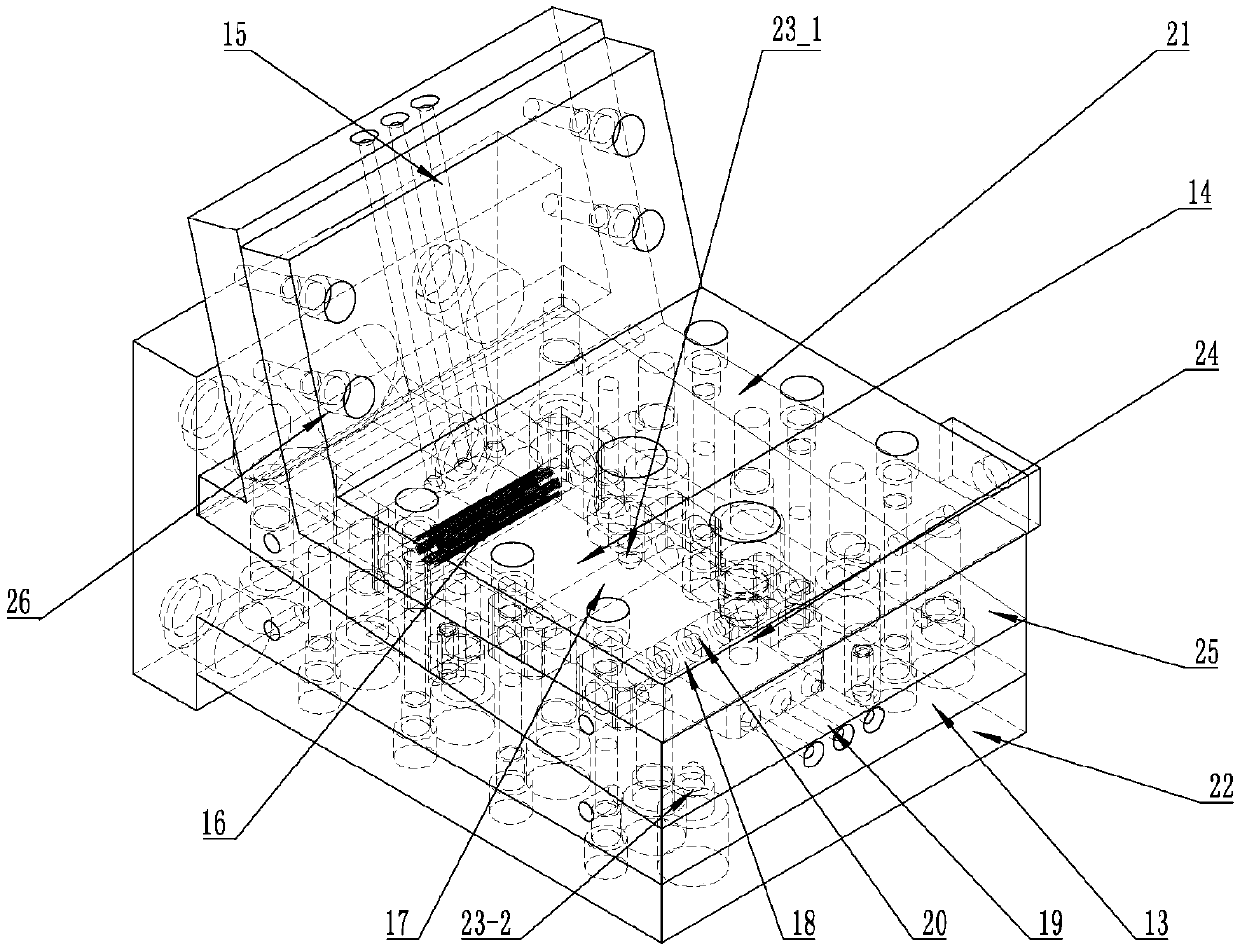

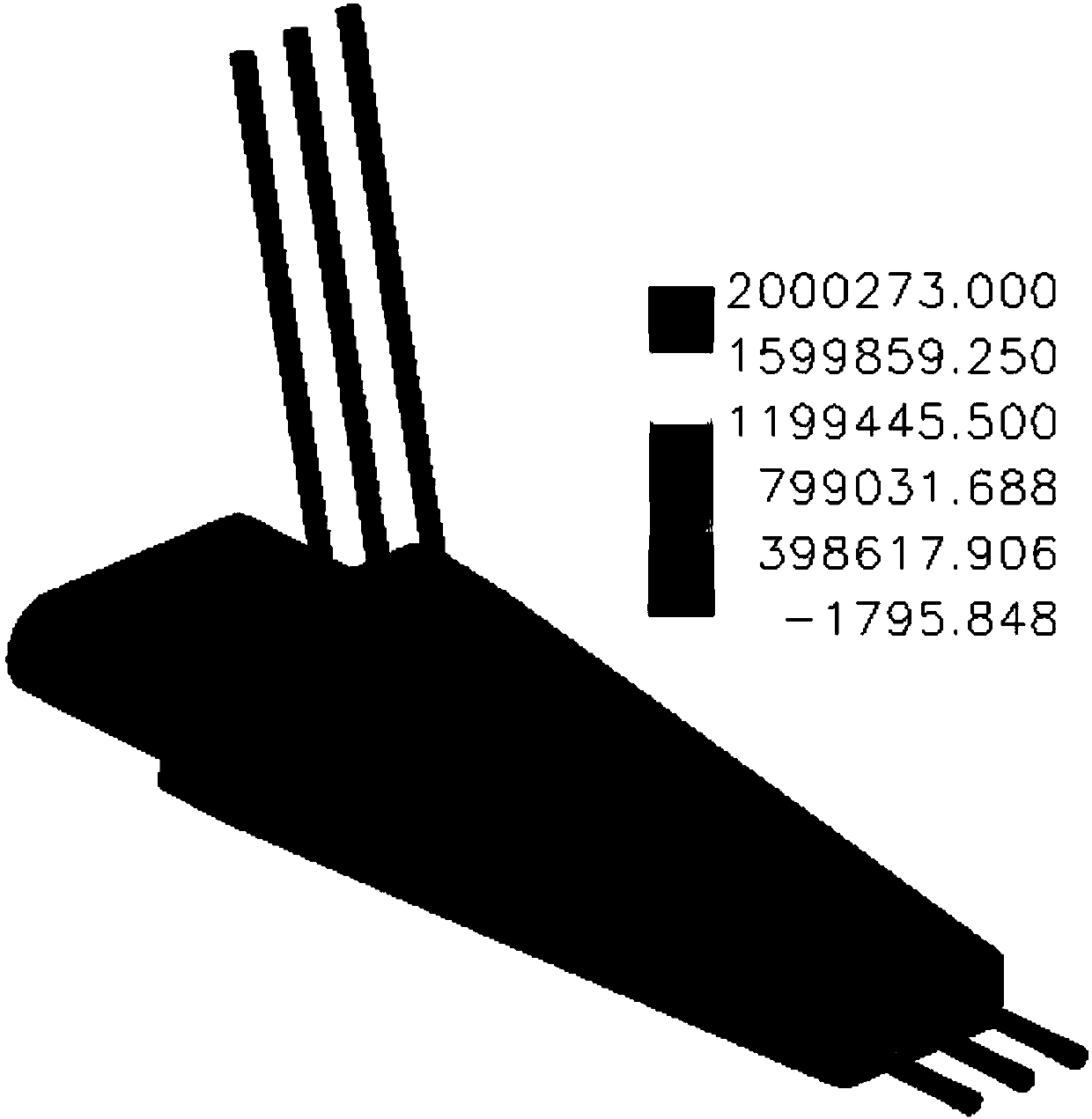

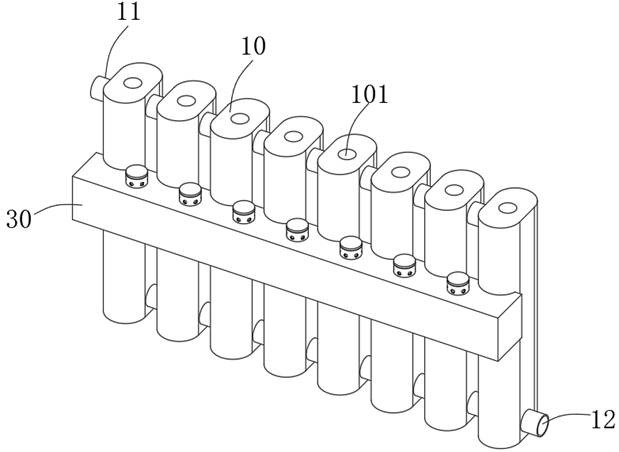

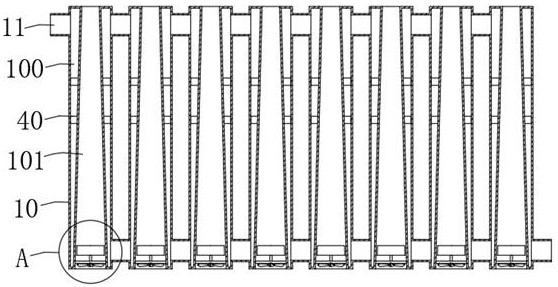

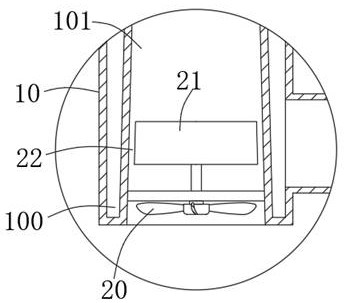

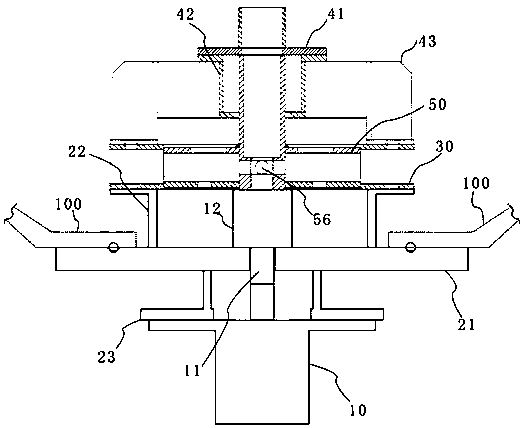

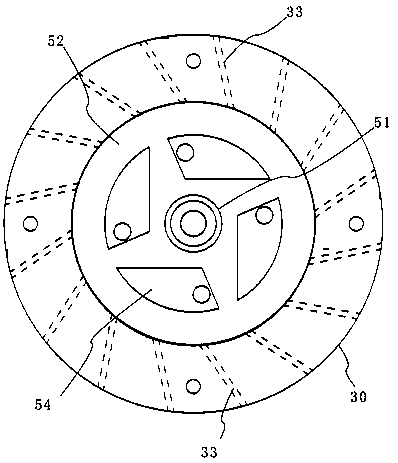

Pelletizing production line for long-fiber composite material

The invention discloses a pelletizing production line for a long-fiber composite material and belongs to the field of polymer modification equipment. The pelletizing production line comprises an extruder, a long fiber storage unit, a long fiber pretreatment unit, a long fiber wetting extrusion die, a cooling system, an air drying system, a traction system, a pelletizing system and a collecting system. The long fiber wetting extrusion die comprises a molten pool bottom plate, a molten pool upper plate, a guide pillar, an upper heater and a lower heater. A long fiber guide-in hole, a thermocouple installation hole and a melt pressure sensor installation hole are formed in the molten pool upper plate; and an extrusion die hole, a polymer melt feeding port and a thermocouple installation hole are formed in the molten pool bottom plate. A length calculation method for the long fiber guide-in hole and the extrusion die hole of the long-fiber wetting extrusion die is given out. By means of the pelletizing production line for the long-fiber composite material, the staying time of polymer melt in the extrusion die can be effectively shortened, the combining compactness and the wetting degree of long fibers and the polymer melt are improved, and in addition, the phenomena that the polymer melt overflows from the long fiber guide-in hole, and the polymer melt is extruded out of the edge of the die hole, and a polymer is scraped can be avoided.

Owner:BEIJING UNIV OF CHEM TECH

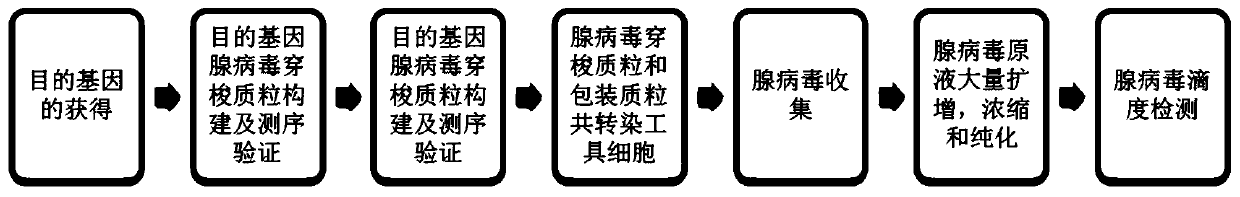

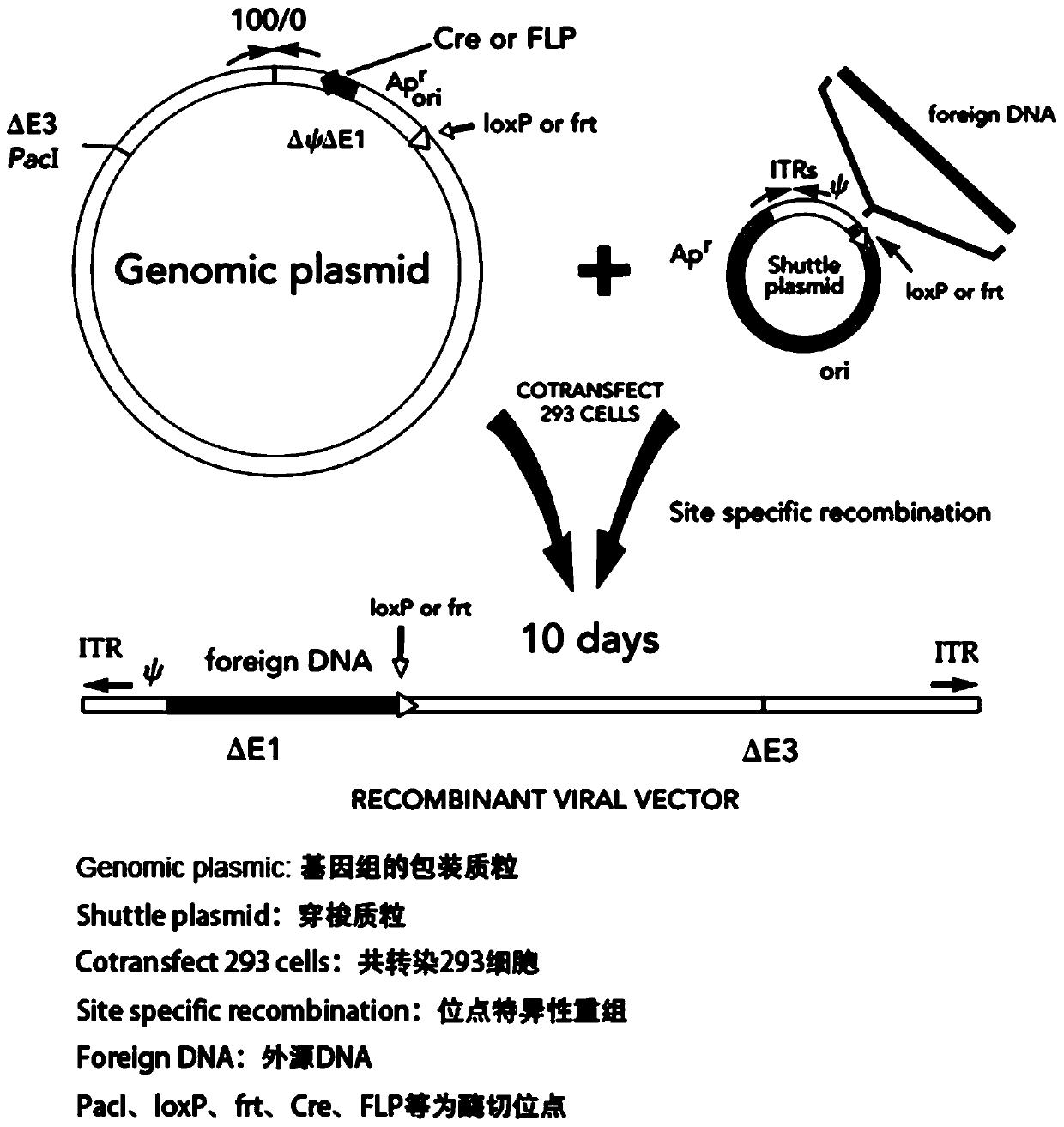

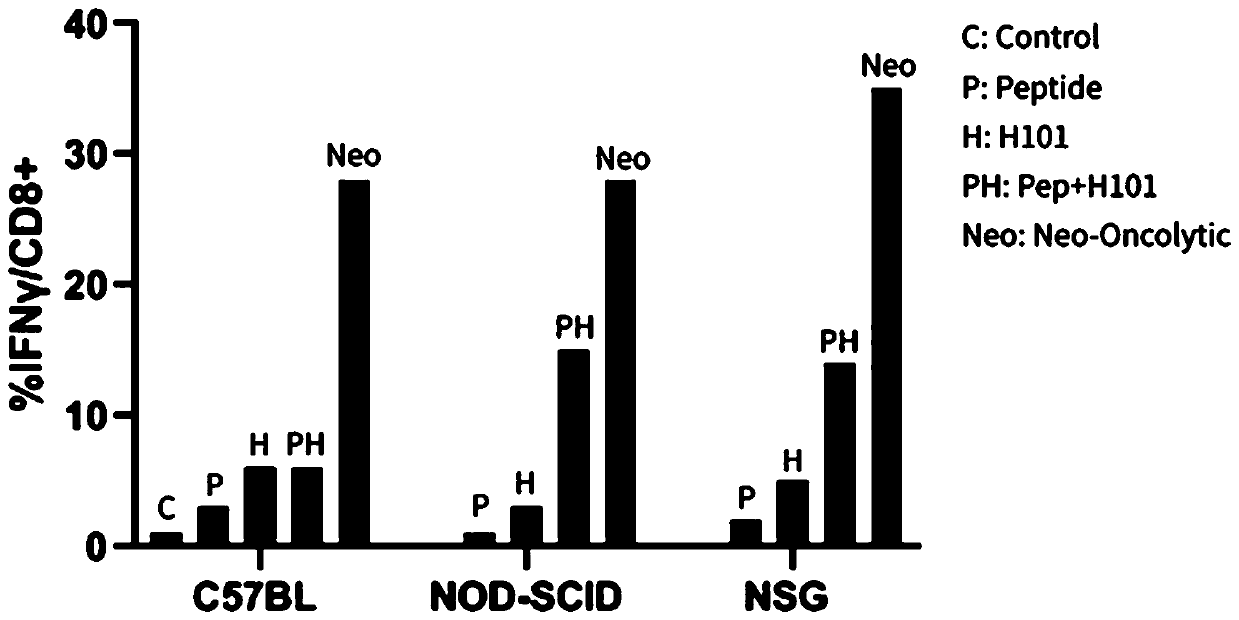

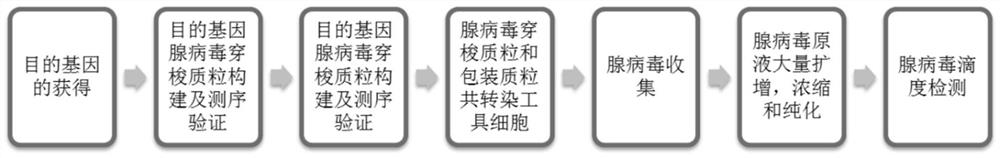

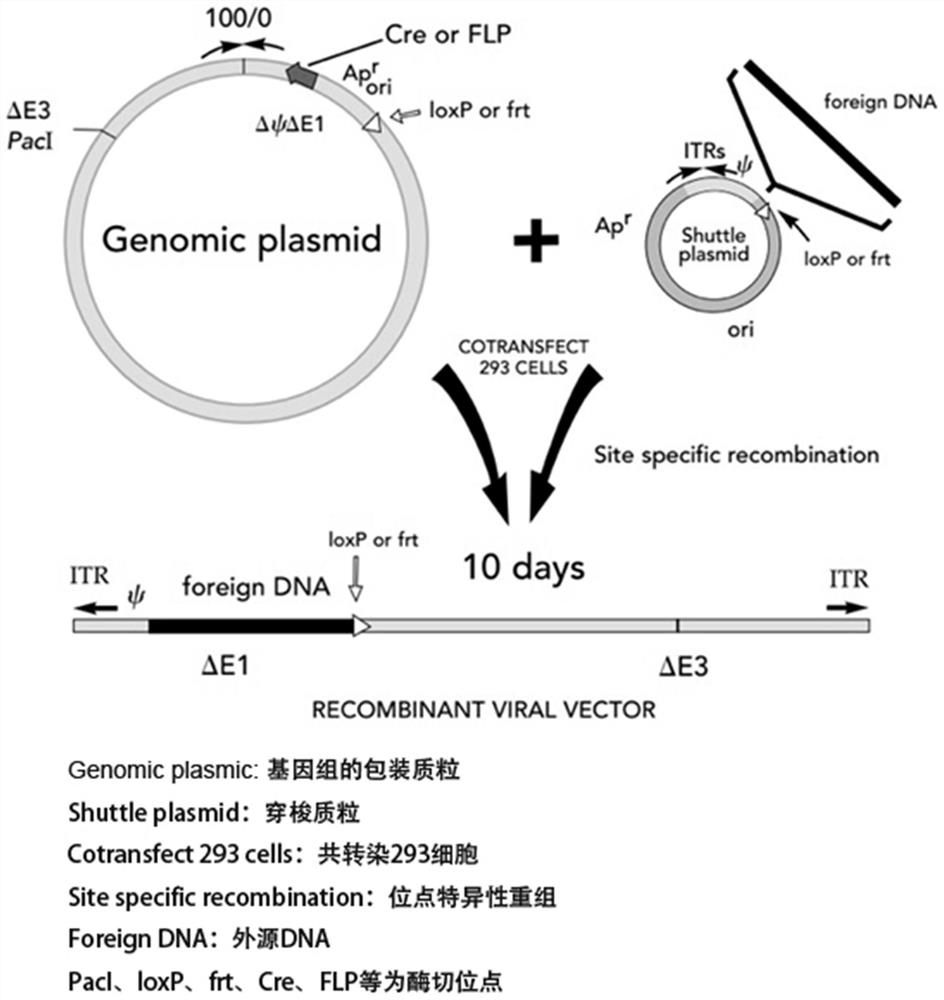

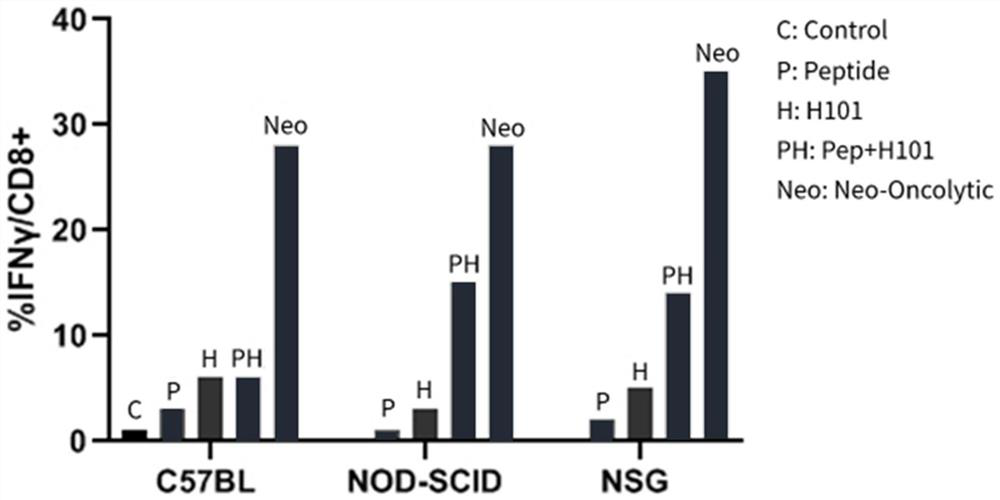

Oncolytic virus and neoantigen combined tumor vaccine and preparation method thereof

ActiveCN110433286AEnhance anti-cancer efficacyStimulate immune responseViral/bacteriophage medical ingredientsCancer antigen ingredientsAntigenOncolytic adenovirus

The invention discloses an oncolytic virus and neoantigen combined tumor vaccine and a preparation method thereof. The combined vaccine can be implemented through the following two ways: in the firstway, an immune response reaction generated from an oncolytic virus reagent is used for improving the efficiency for phagocytizing a polypeptide reagent by an antigen presenting cell, increasing the number of T cells which can specifically identify a neoantigen and improving the tumor invasion performance of the T cells so as to enhance the anti-cancer curative effect; and in the second way, a genecoding a tumor neoantigen is inserted into an oncolytic virus vector to massively express the tumor neoantigen, and is combined with the tumor killing performance of the oncolytic virus to further enhance the immune response reaction of a tumor focus local part and improve the invasion degree of the killing type T cell in a tumor tissue, so that the local part can generate an immune response reaction, and generation of an effector cell is stimulated to achieve an anti-cancer effect. Experiment comparison discovers that the first combined vaccine and the second combined vaccine have an excellent tumor inhibition effect, and the second combined vaccine has a remarkable tumor inhibition effect.

Owner:HANGZHOU NEOANTIGEN THERAPEUTICS CO LTD

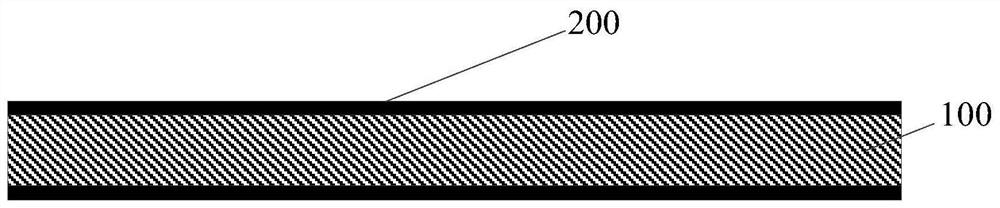

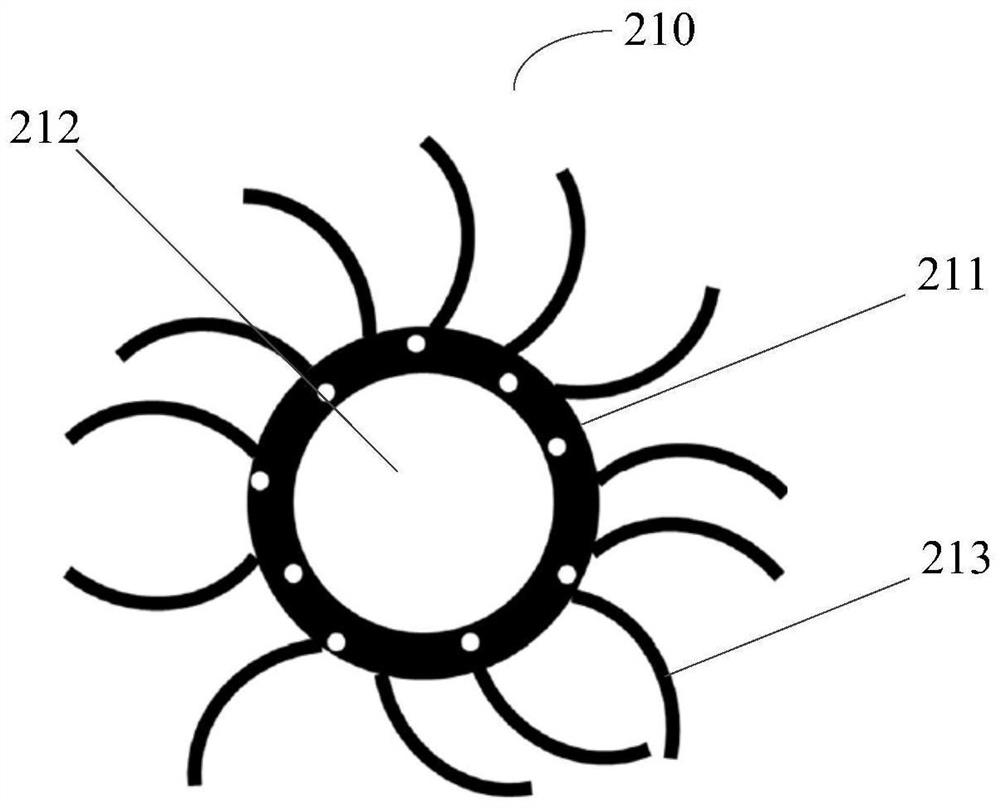

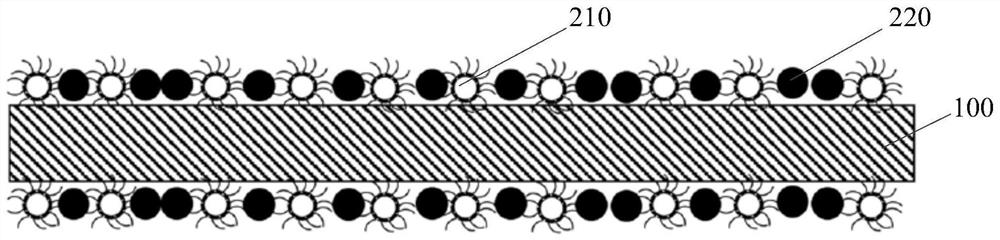

Battery separator, battery and preparation method of battery separator

PendingCN111613760AExcellent long cycle performanceIncrease fluid retentionSecondary cellsCell component detailsElectrolytic agentPhysical chemistry

The invention provides a battery separator, a battery and a preparation method of the battery separator. The battery separator comprises a substrate and a coating, wherein the substrate comprises a first surface and a second surface which are arranged back to back; and the coating is coated on at least one of the first surface and the second surface, the coating comprises first particles, the first particles comprise a silicon dioxide layer, the outer surface of the silicon dioxide layer is covered with a first polymer, and an accommodating chamber is formed in the silicon dioxide layer. The accommodating chamber is formed in first particles contained in the coating of the separator, so that a storage space can be provided for an electrolyte, the electrolyte retention amount of the batteryseparator is increased, and the infiltration degree of the battery separator is further improved. Besides, the first polymer grafted on the silicon dioxide layer can increase the adhesion force of the separator to a pole piece, so that a good interface is maintained, and the long cycle performance of the battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

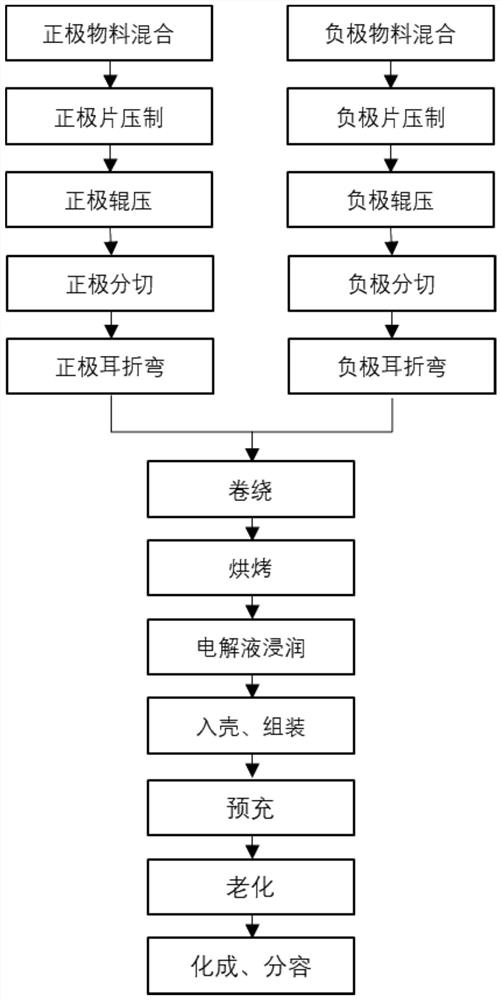

Manufacturing process of cylindrical lithium ion battery

PendingCN112652824APrevent floatingEvenly distributedFinal product manufactureSecondary cellsElectrolytic agentPhysical chemistry

The invention provides a manufacturing process of a cylindrical lithium ion battery, which belongs to the field of lithium ion batteries and comprises the following steps: S1, simultaneously manufacturing a positive plate and a negative plate, and preparing for winding; s2, winding: winding the positive plate and the negative plate which are manufactured in the step S1 and a diaphragm, arranging the diaphragm between the positive plate and the negative plate, and forming a roll core after winding; s3, baking to reduce the moisture value of the surface of the roll core; s4, electrolyte infiltration: immersing the roll core wound in the S2 into the electrolyte in a liquid injection chamber, changing the environment in the liquid injection chamber into a vacuum state, and taking out the roll core after liquid injection is completed; S5, assembling in a shell, clamping a battery shell, and carrying out roll core in-shell treatment on the roll core subjected to infiltration and liquid injection; and S6, pre-charging, aging, forming and grading capacity. According to the present invention, the coating process and the rolling process are combined together, the production process is substantially simplified, and the immersion type electrolyte injection process is adopted so as to effectively improve the infiltration degree of the electrolyte and improve the battery performance.

Owner:TIANJIN ENERGIES

Method for prolonging service life of cylindrical lithium-ion battery

InactiveCN105762417AExtend your lifeIncrease the degree of infiltrationFinal product manufactureElectrolyte accumulators manufactureCharge and dischargeEngineering

The invention relates to the technical field of cylindrical batteries and particularly discloses a method for prolonging the service life of a cylindrical lithium-ion battery. The method comprises the step of carrying out circulating charging and discharging on the cylindrical lithium-ion battery with qualified capacity grading by adopting 0-0.5C current at least. The method for prolonging the service life of the cylindrical lithium-ion battery, provided by the embodiment of the invention, is used for carrying out finite circulating charging and discharging on the cylindrical lithium-ion battery with the qualified capacity grading by small current, and active substances of the cylindrical lithium-ion battery are sufficiently activated, so that the infiltration degree of electrolyte on a pole piece is improved, the electrolyte is relatively uniformly distributed in a roll core, and furthermore, the effect of prolonging the cycle life of the battery is realized.

Owner:DONGGUAN CHUANGMING BATTERY TECH

Method for preparing electrode of lithium-ion battery

ActiveCN109599533AIncrease energy densityImprove conductivityMaterial nanotechnologyCell electrodesFiltrationMaterials science

The invention relates to a method for preparing an electrode of a lithium-ion battery, belonging to the technical field of lithium batteries. The method for preparing the electrode of the lithium-ionbattery disclosed by the invention includes the following steps: preparing a graphene oxide suspension, and storing the suspension in a dark environment for later use; preparing a nano-silicon particle suspension; adding the graphene oxide suspension to the nano-silicon particle suspension, performing ultrasonic stirring for 0.5-1.5h, and then performing suction filtration to form a layer of nano-silicon-graphene oxide paper on a filter membrane; and transferring the nano-silicon-graphene oxide paper from the filter membrane, performing air drying, heating to 670-730DEG C in a protective atmosphere, and performing heat preservation for 0.5-1.5h to obtain a nano-silicon-graphene paper composite electrode. The silicon-graphene composite electrode of the invention can be used as the negativeelectrode of the lithium-ion battery to effectively improve the specific capacity, energy density, cycle performance and other performance of the battery.

Owner:TAIZHOU UNIV

Glue brushing process for camera accessory

InactiveCN109672813AIncrease roughnessIncrease the degree of infiltrationTelevision system detailsColor television detailsPolymer scienceSurface cleaning

The invention discloses a glue brushing process for a camera accessory, which comprises surface cleaning, surface roughening, surface degreasing, surface oxidation flame processing, surface glue brushing, isolation processing and baking. By improving roughness of a surface of an adhesion material, an infiltration degree of glue solution for the surface of the adhesion material is improved, and a density of contact points between the glue solution and the adhesion material is increased, so that adhesion strength is improved; by carrying out surface degreasing on the adhesion material, a glue failure phenomenon caused by stains on the surface of the adhesion material is avoided; by carrying out oxidation flame processing on the surface of the adhesion material, a layer of isolation membraneis formed on the surface subjected to oxidation flame processing so as to prevent a case that a molecule material inside the adhesion material is migrated to the surface to cause a adhesion failure; and by reasonable squeezing time and isolation processing, damage to adhesion, which is caused by a case that substances such as oxygen and the like in the environment permeate into a glue layer to enable the glue layer to be deformed and reduce adhesion strength between glue and the adhesion material, is prevented.

Owner:东莞市章盈五金塑胶制品有限公司

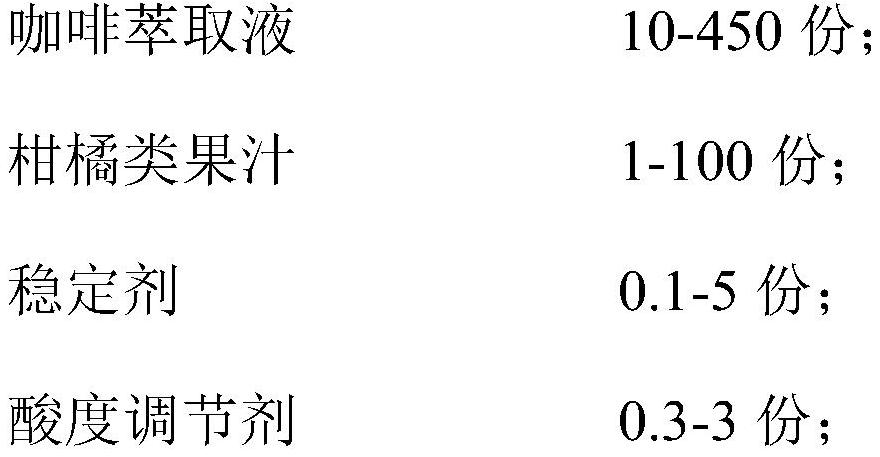

Coffee beverage and preparation method thereof

PendingCN112806459AEnhanced Flavor ReleaseOutstanding aromaCoffee extractionClimate change adaptationCoffeaFruit drinks

The invention discloses a coffee beverage and a preparation method thereof, and belongs to the technical field of food processing. The coffee beverage comprises the following raw material components in parts by weight: 10-450 parts of coffee extract liquor, 1-100 parts of citrus fruit juice, 0.1-5 parts of a stabilizer and 0.3-3 parts of an acidity regulator, wherein the citrus fruit juice comprises perfume lemon juice and grapefruit juice. The citrus fruit juice comprises the perfume lemon juice and the grapefruit juice and the coffee extract liquor are selected to cooperate for use in a specific proportion, so that the coffee flavor release is improved, the excellent fragrance of coffee is enhanced, meanwhile, the fragrance of the coffee is blended with the flavor of the juice, other flavor substances in the coffee cannot be covered, and moreover, the coffee beverage with sweet and fragrant taste, strong fragrance and excellent flavor and texture can be obtained without additional flavor blending treatment, and is deeply loved by people.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

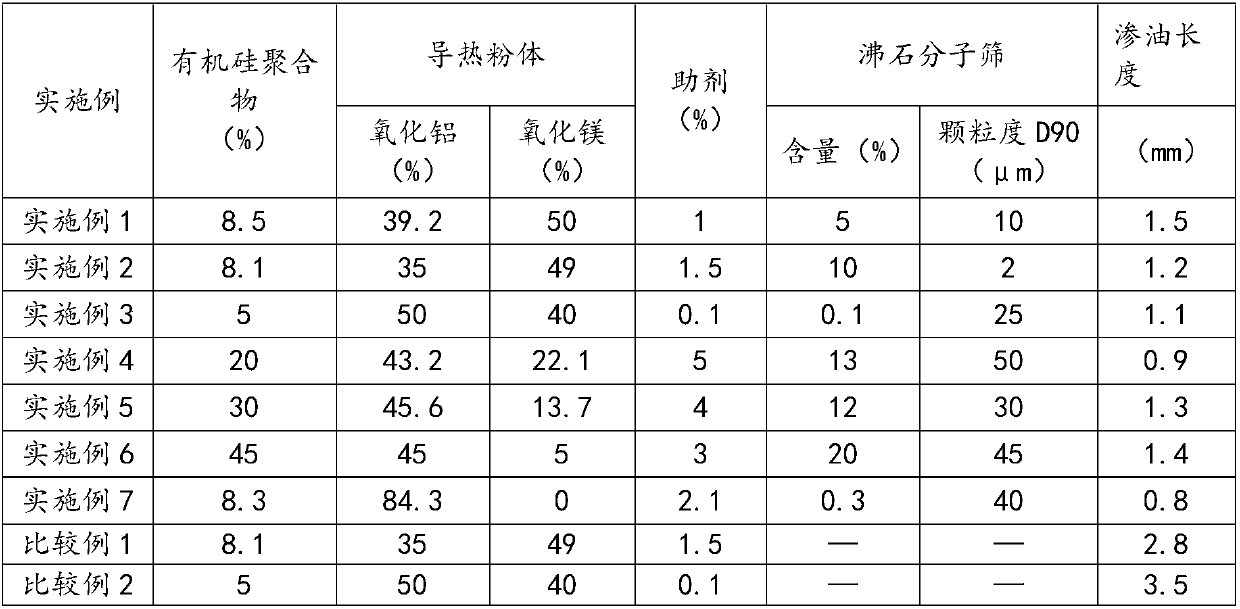

Single-component high thermal conductivity composite interfacial material with function of solving oil permeation by means of molecular sieve, and preparation method of composite interfacial material

InactiveCN107828388ASolve pollutionExtended service lifeHeat-exchange elementsMolecular sievePermeation

The invention discloses a single-component high thermal conductivity composite interfacial material with a function of solving oil permeation by means of a molecular sieve, and a preparation method ofthe composite interfacial material. The high thermal conductivity composite interfacial material is prepared from the following components by weight percent: 5-45% of an organosilicon polymer, 50-90%of heat conduction powder and 0.1-5% of additives, wherein the heat conduction powder is prepared from metallic oxide, and the metallic oxide is aluminum oxide with a particle size of 1-60mu m; during preparation, the zeolite molecular sieve is mixed with the organosilicon polymer in advance. By utilizing the moisture and water absorption performance of the added zeolite molecular sieve, the single-component high thermal conductivity composite interfacial material solves the problem of oil permeation.

Owner:苏州创励新材料科技有限公司

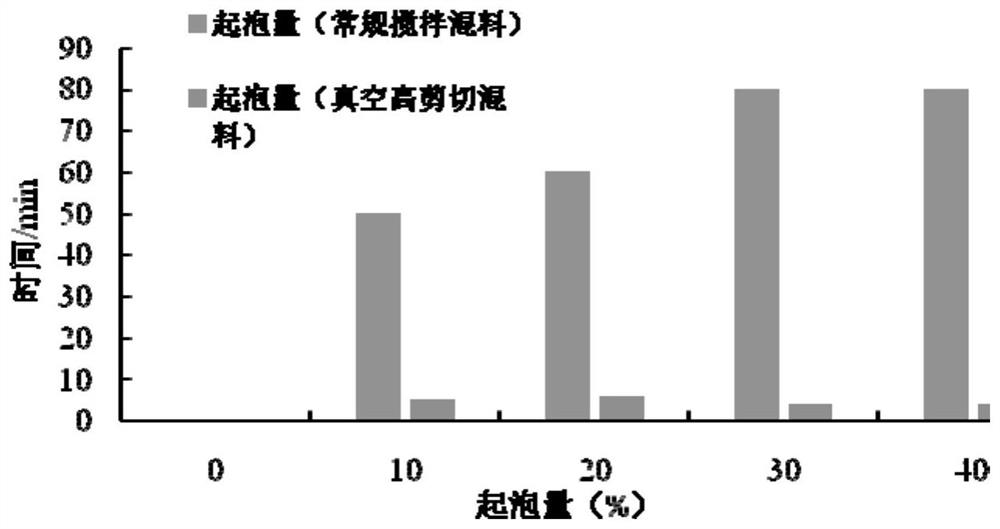

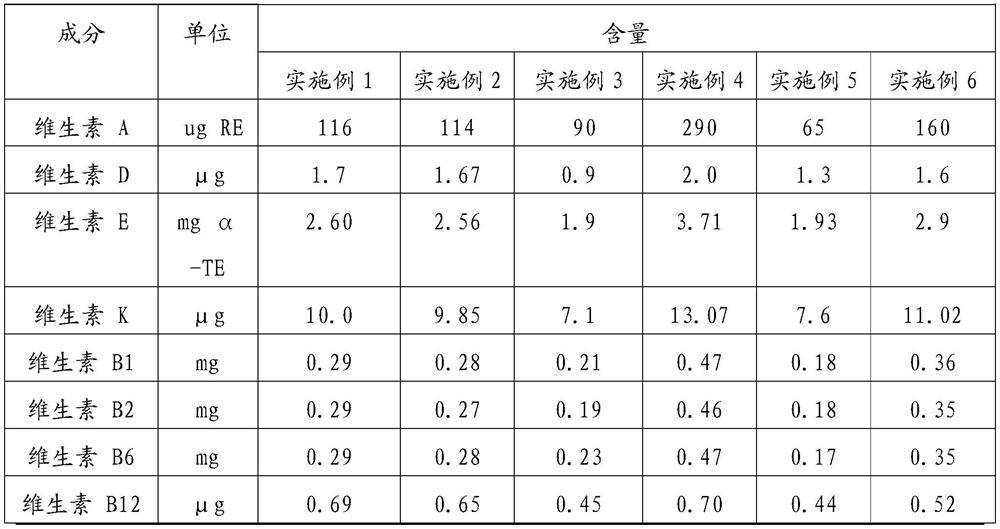

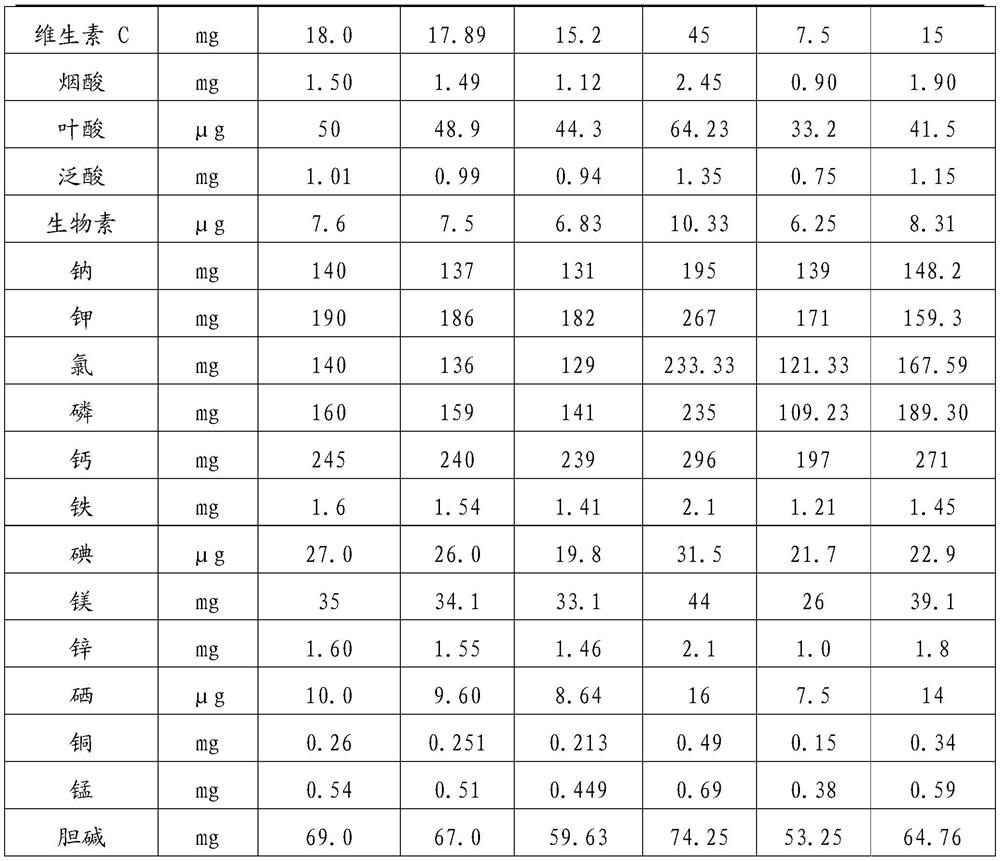

Formula food for special medical purposes based on novel mixing mode and preparation method thereof

PendingCN112425773APrevent oxidationIncrease the degree of infiltrationVitamin food ingredientsInorganic compound food ingredientsMultivitaminProcess engineering

The invention belongs to the field of formula foods for special medical purposes, and particularly relates to a formula food for special medical purposes based on a novel mixing mode and a preparationmethod thereof. The formula food for the special medical purposes based on the novel mixing mode comprises the following components in parts by mass: 60-100 parts of proteins, 25-56 parts of fat, 145-256 parts of carbohydrates, 0.5-1.5 parts of compound vitamins, 8-19 parts of compound mineral substances, 0.05-20 parts of an essence and 600-750 parts of water. A specific and efficient mixing method is designed according to the characteristics of high protein content, high solid content and easiness in foaming and caking in the material mixing process of the product, and air brought by powderand air generated in the material stirring process can be removed in a vacuum environment, so that the foaming amount is greatly reduced.

Owner:中恩(天津)医药科技有限公司

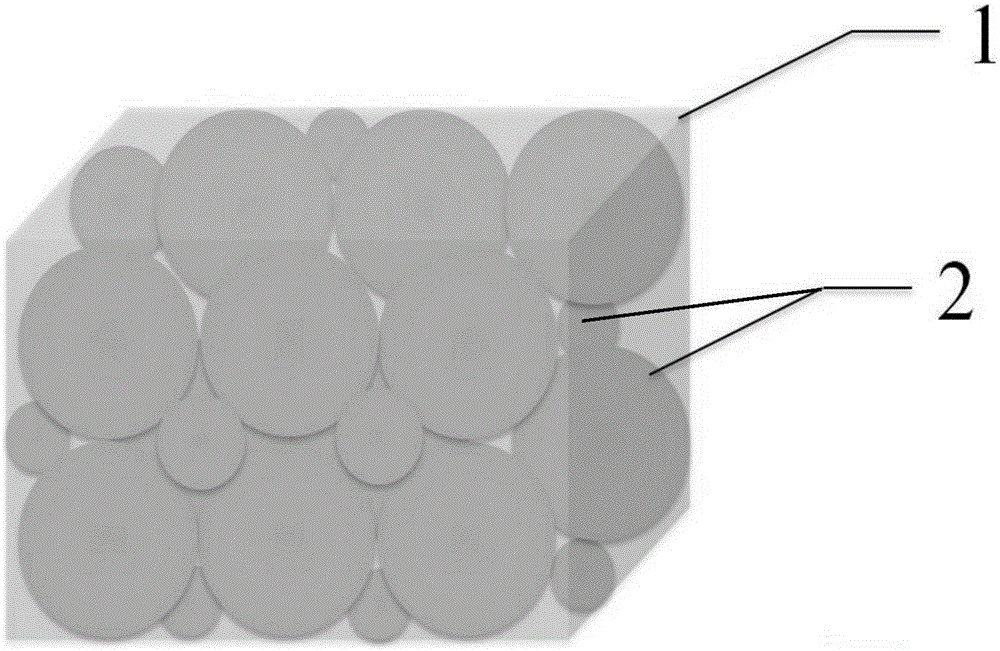

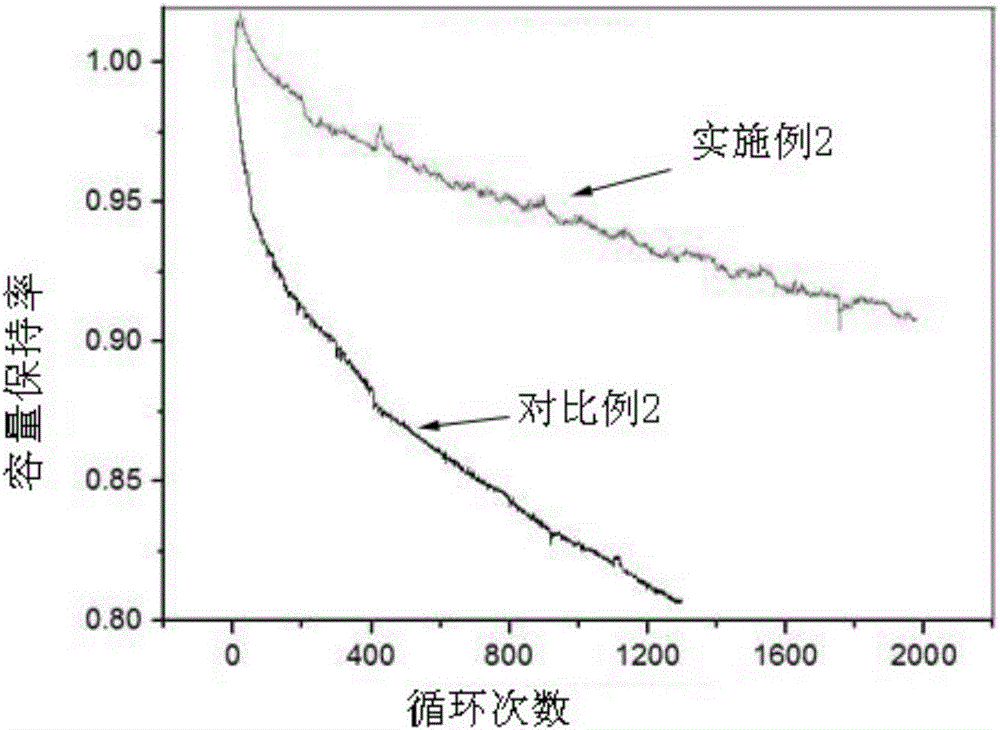

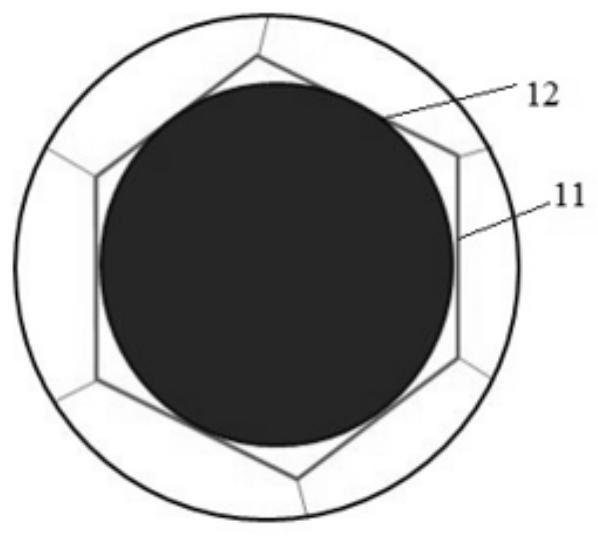

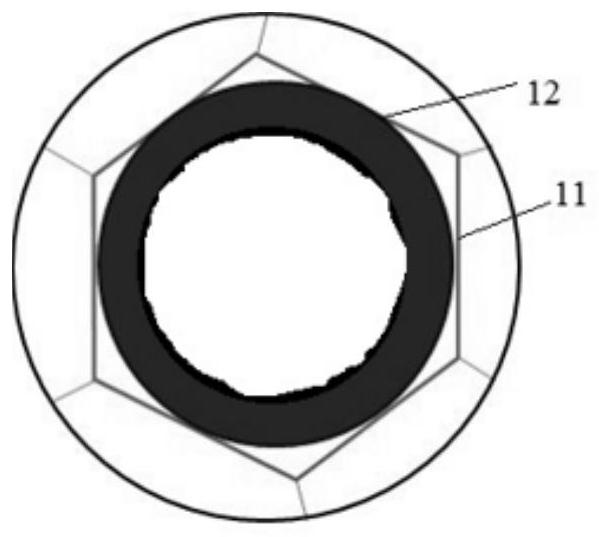

Positive electrode material, preparation method thereof and lithium ion battery

ActiveCN113611856ALarge specific surface areaImprove cycle stabilityPositive electrodesSecondary cell gas removalLithium-ion batteryBattery cell

The invention relates to the field of positive electrode materials, and provides a positive electrode material and a preparation method thereof, and a lithium ion battery. The positive electrode material comprises an active substance, wherein the chemical general formula of the active substance is LiaNixCoyMzO2, a is greater than or equal to 0.95 and less than or equal to 1.05, x is greater than or equal to 0.8 and less than 1, y + z is greater than 0 and less than or equal to 0.2, and M is selected from at least one of Mn, Al, Cu, Zn and Cr; and a coating layer formed on at least part of the surface of the active substance, wherein the coating layer comprises a covalent-organic framework material and a metal-organic framework material grown on the surface of the covalent-organic framework material. According to the positive electrode material, the preparation method thereof and the lithium ion battery, the structural stability of the material can be improved, and the cycling stability of the lithium ion battery can be improved.

Owner:贝特瑞(江苏)新材料科技有限公司

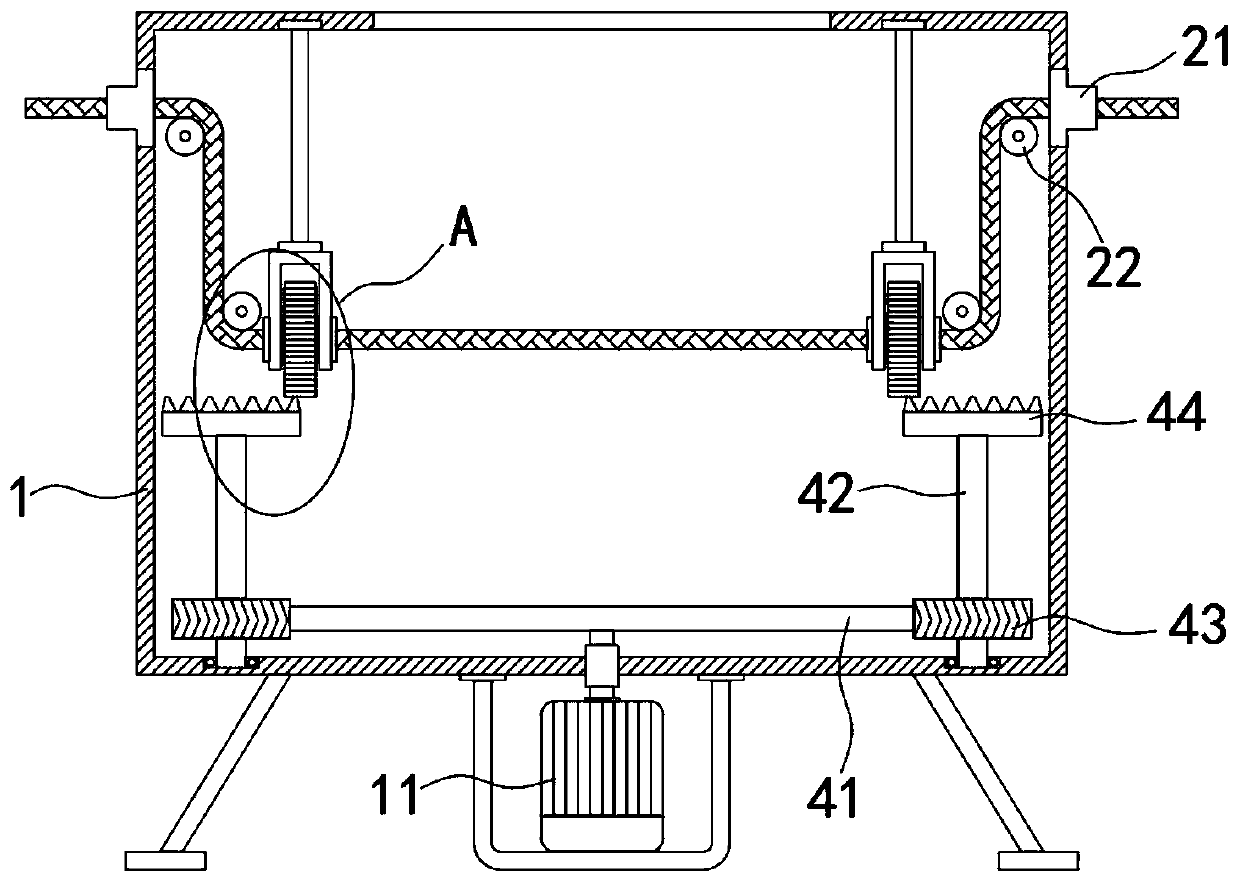

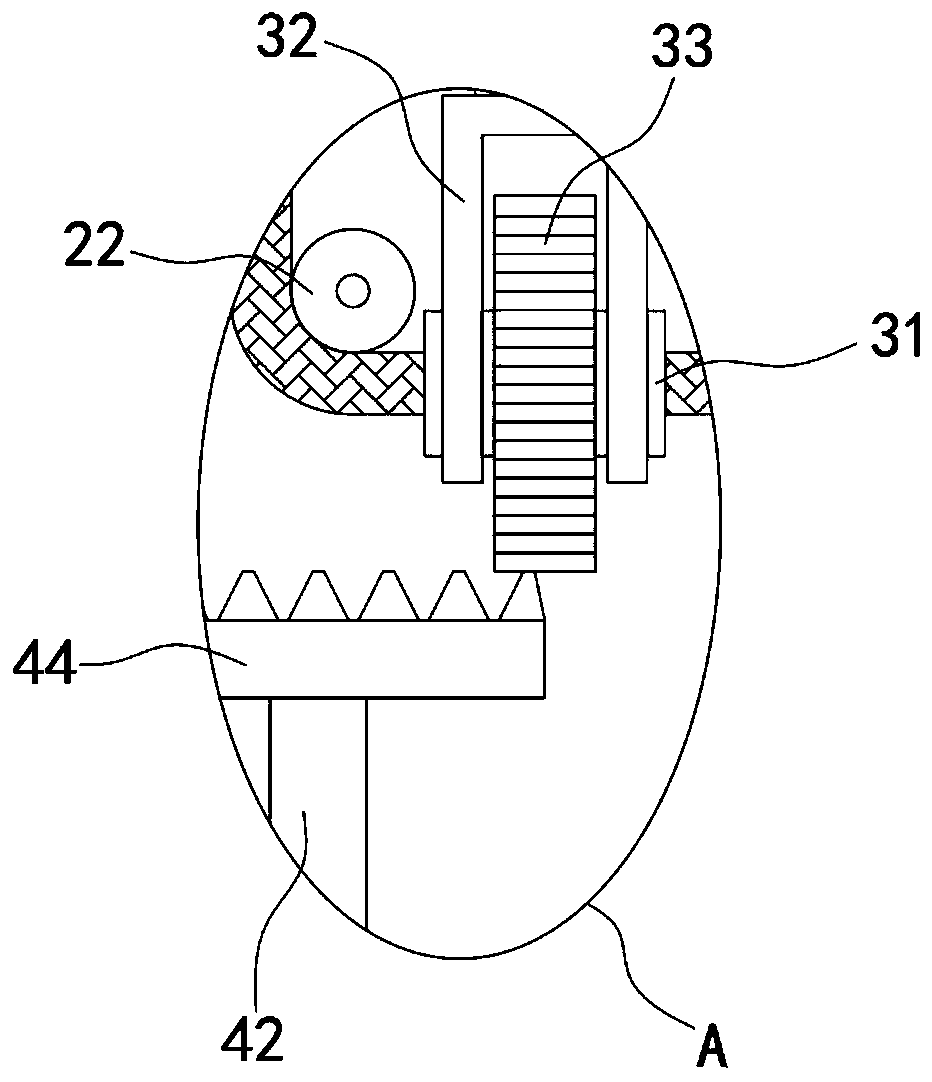

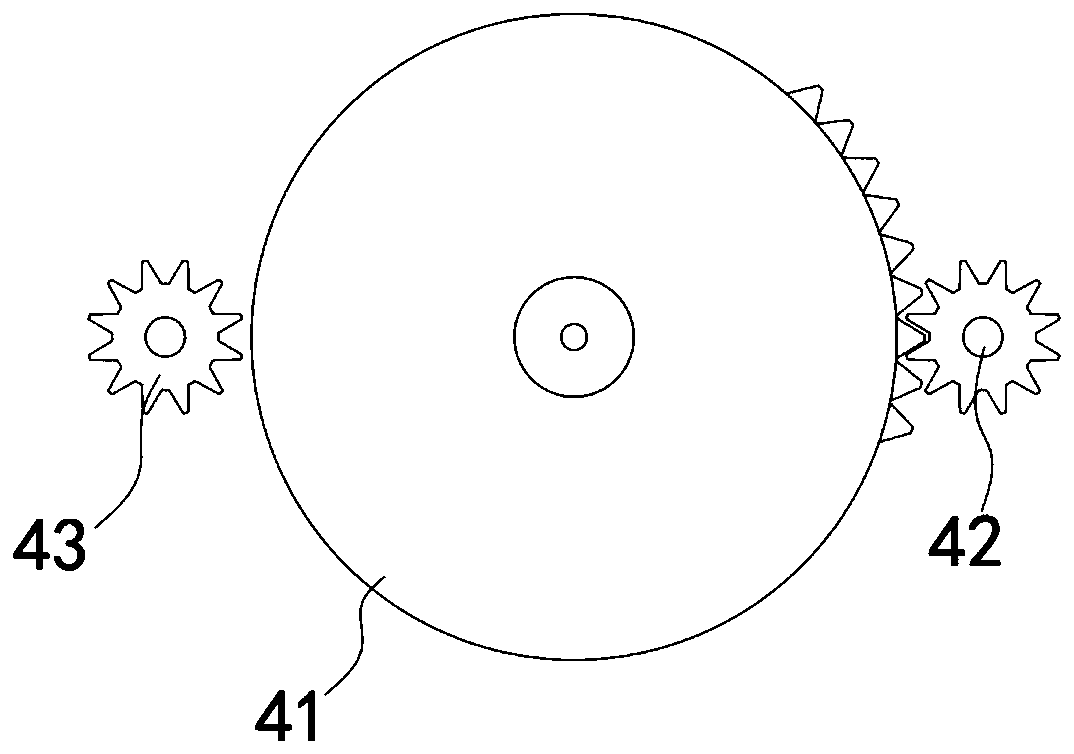

Catch-up type textile wire oil immersion equipment

InactiveCN111235787AAvoid wear and tearReduce frictionLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsTextile technologyWire rod

The invention belongs to the technical field of textiles, and particularly relates to catch-up type textile wire oil immersion equipment, which comprises a box body, wherein an oil liquid is filled inthe box body; a positioning mechanism and a torsion mechanism are both arranged on the front side and the rear side of the box body; a driving motor is fixedly arranged at the bottom of the box body;the driving motor drives the torsion mechanism through a transmission mechanism; the positioning mechanism comprises a routing pipe and a plurality of positioning rollers, wherein the routing pipe isfixedly arranged on the side wall of the box body in a penetrating manner, and the two ends of each positioning roller are respectively rotationally connected to the side walls on the two sides of the box body; and the torsion mechanism comprises a torsion tube and a fixing frame, wherein a plurality of radial limiting protrusions are formed inwards on the inner side wall of the torsion tube, andthe torsion tube is rotationally connected in the fixing frame. According to the catch-up type textile wire oil immersion equipment, through the arrangement of the torsion mechanisms, the two torsionmechanisms twist a linen thread to the opposite direction in sequence, the interior of the linen thread can be in full contact with the oil liquid, the infiltration speed is greatly accelerated, theredundant oil liquid can be extruded, the wetting degree of the oil liquid can be improved, and the whole infiltration effect of the linen thread can also be improved.

Owner:王珂欣

Tumor vaccine combined with oncolytic virus and neoantigen and preparation method thereof

ActiveCN110433286BEnhance anti-cancer efficacyStimulate immune responseViral/bacteriophage medical ingredientsCancer antigen ingredientsAntigenOncology

Owner:HANGZHOU NEOANTIGEN THERAPEUTICS CO LTD

Fuel cell plate forming method based on expanded graphite

The present invention relates to the forming method of the fuel cell pole plate based on expanded graphite, comprising the following steps: (1) powder vacuum impregnation: put the raw material powder of the fuel cell graphite plate into the reactor, vacuumize and maintain it for 10-30 minutes. Inject liquid resin under vacuum conditions so that the raw material powder can be completely submerged; release the vacuum after fully mixing to obtain "wet material" for later use; (2) plate making: the wet material is made into expanded graphite plate by extrusion; (3 ) cutting and forming; (4) curing. Compared with the prior art, the substrate prepared by the method of the invention has the advantages of good electrical conductivity, strength and sealing performance.

Owner:SHANGHAI SHENLI TECH CO LTD

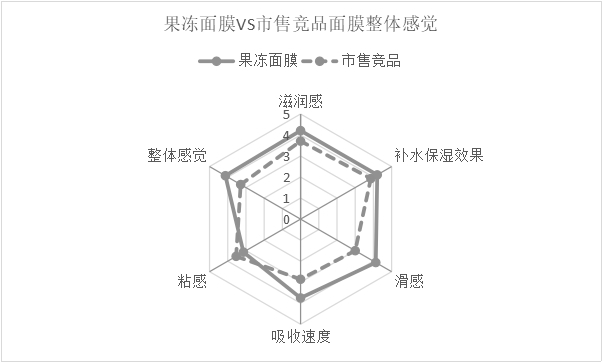

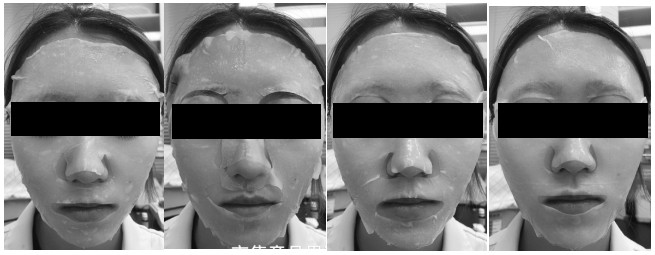

Jelly mask and preparation process thereof

PendingCN114642613AGood skin feelIncrease the degree of infiltrationCosmetic preparationsToilet preparationsBiotechnologyTremella

The invention discloses a jelly mask. The mask comprises a phase A, a phase B and a phase C, based on the total weight of the mask, the phase A is prepared from a humectant, a chelating agent, a thickening agent and a tremella and dendrobium extract, the phase B is prepared from 20% NaCI and / or 0.5 mol / L GaCI2, and the phase C is prepared from a preservative; the tremella and dendrobium extract is obtained by adding water to soak, washing and extracting. In the extraction step, the extraction pressure is 40 to 130 KPa; the extraction temperature is 105 to 125 DEG C; the extraction time is 1-4 hours. Experiments prove that the jelly mask improves the infiltration degree of the mask liquid to the mask cloth on the premise of ensuring the efficacy and stability, further improves the skin fitting degree and comfort of the mask cloth, integrally improves the skin feeling of the jelly mask, makes up for the defects of existing market products, and has a wide application prospect.

Owner:BEIJING ACAD OF TCM BEAUTY SUPPLEMENTS

A pelletizing production line for long-fiber composite materials

The invention discloses a pelletizing production line for a long-fiber composite material and belongs to the field of polymer modification equipment. The pelletizing production line comprises an extruder, a long fiber storage unit, a long fiber pretreatment unit, a long fiber wetting extrusion die, a cooling system, an air drying system, a traction system, a pelletizing system and a collecting system. The long fiber wetting extrusion die comprises a molten pool bottom plate, a molten pool upper plate, a guide pillar, an upper heater and a lower heater. A long fiber guide-in hole, a thermocouple installation hole and a melt pressure sensor installation hole are formed in the molten pool upper plate; and an extrusion die hole, a polymer melt feeding port and a thermocouple installation hole are formed in the molten pool bottom plate. A length calculation method for the long fiber guide-in hole and the extrusion die hole of the long-fiber wetting extrusion die is given out. By means of the pelletizing production line for the long-fiber composite material, the staying time of polymer melt in the extrusion die can be effectively shortened, the combining compactness and the wetting degree of long fibers and the polymer melt are improved, and in addition, the phenomena that the polymer melt overflows from the long fiber guide-in hole, and the polymer melt is extruded out of the edge of the die hole, and a polymer is scraped can be avoided.

Owner:BEIJING UNIV OF CHEM TECH

Steel plate type radiator

ActiveCN113701539AImprove cooling efficiencyIncrease riseHeat storage plantsHeat transfer modificationEngineeringHeating effect

The invention relates to the technical field of radiators, in particular to a steel plate type radiator which comprises at least two radiating plates, containing cavities are formed in the radiating plates, every two adjacent radiating plates are connected through a connecting pipe, the containing cavities in every two adjacent radiating plates communicate through the connecting pipe, and the steel plate type radiator further comprises a water inlet pipe and a water outlet pipe. The water inlet pipe communicates with any containing cavity, the water outlet pipe communicates with any containing cavity, a convection channel in a vertical state is arranged on the heat dissipation plate, the convection channel has a chimney effect, a fan is rotationally connected to the position, located at the bottom, in the convection channel, and a rotating disc is rotationally arranged in the convection channel and located above the fan. And a gap is reserved between the outer wall of a turntable and the inner wall of the convection channel, so that rapid rising and spreading of heated air in the convection channel are accelerated, the indoor temperature is rapidly increased, the heat dissipation efficiency of the heat dissipation plate is improved, and the heating effect is enhanced.

Owner:JINYUN SHENGDA IND CO LTD

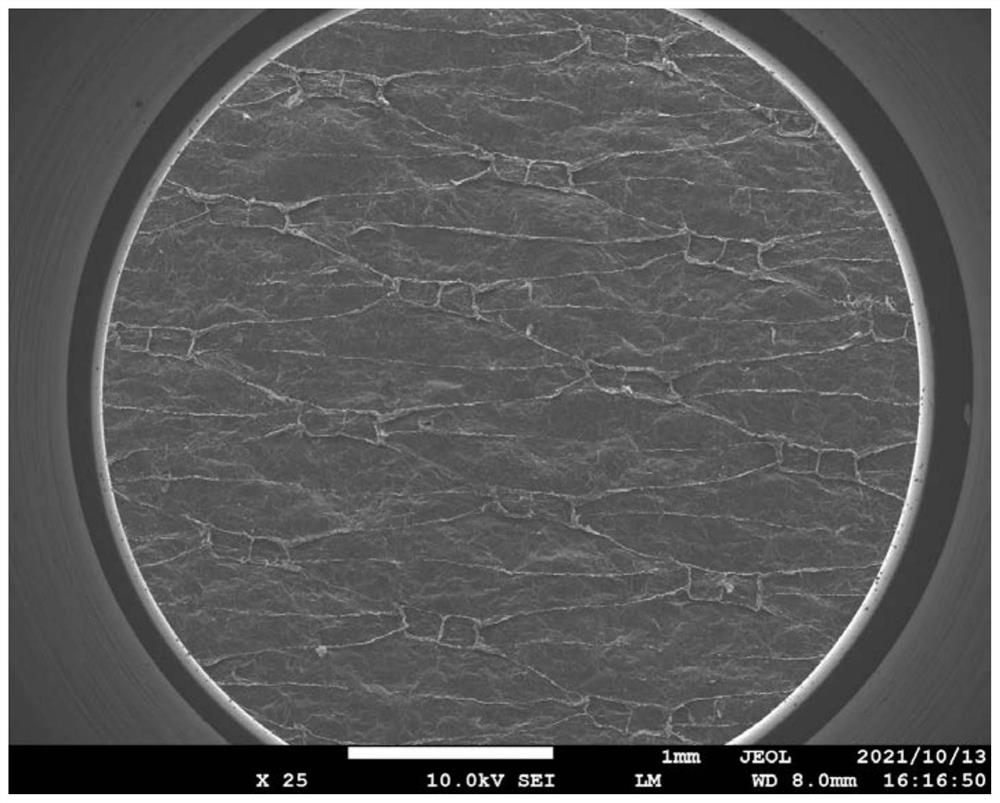

Graphene-based high-thermal-conductivity phase change material as well as preparation method and production device thereof

ActiveCN113897184AAvoid nudityHigh thermal conductivityChemical industryHeat-exchange elementsGraphiteGraphene

The invention relates to the technical field of phase change materials, in particular to a graphene-based high-thermal-conductivity phase change material and a preparation method and production device thereof. The preparation method comprises the following steps of: 1, putting graphene foam in a vacuum environment, and exhausting internal air; (2) heating and melting a phase change material at a temperature higher than the phase change temperature of the phase change material to obtain a liquid phase change material; and (3) injecting the liquid phase change material into the graphene foam, and after the graphene foam is filled with the liquid phase change material, cooling to solidify the liquid phase change material, thereby obtaining the graphene-based high-thermal-conductivity phase change material. The liquid phase change material fills the graphene foam in an injection manner, so that the situation that the exposed phase change material is molten into liquid and flows to a using device in the using process due to the fact that the phase change material is exposed on the surface of the foam is avoided, and after the surface of the graphene base is exposed, the heat-conducting property of the graphene-based phase change material and the stability of the product quality are improved.

Owner:GUANGDONG MORION NANOTECHNOLOGY CO LTD

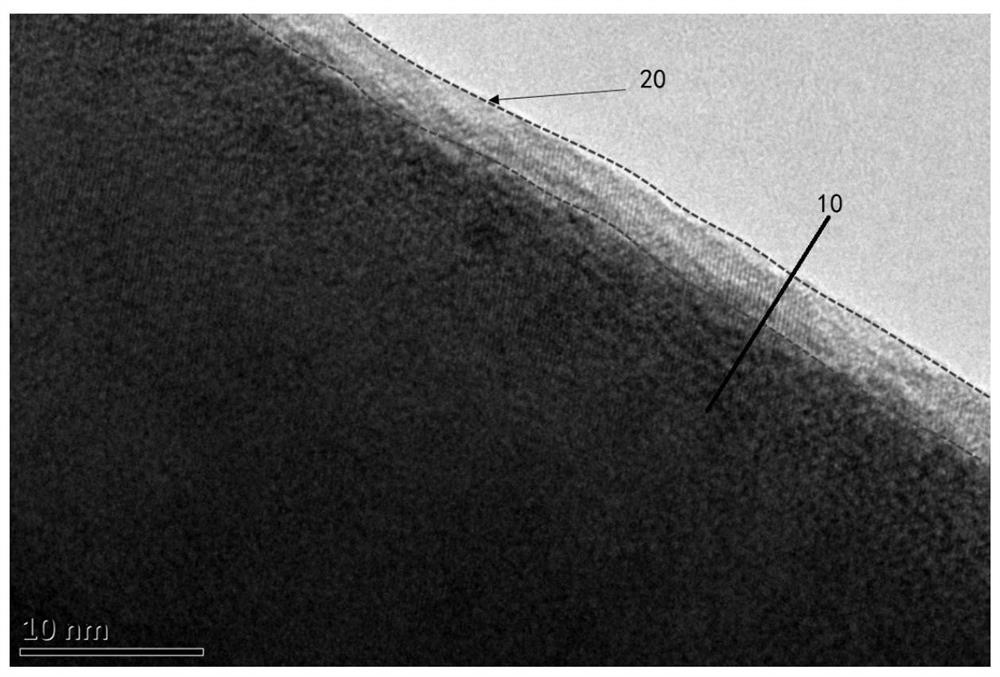

A kind of modified nickel-cobalt-manganese-aluminate lithium anode material and preparation method thereof

ActiveCN109256543BImprove securityInhibited DiffusionCell electrodesSecondary cellsAluminateManganese

Owner:PHENIX NEW ENERGY HUIZHOU CO LTD

Preparation method of vinegar

The invention discloses a preparation method of vinegar, and belongs to the technical field of vinegar. The preparation method of the vinegar comprises the following steps of raw material preparation,mixing, wetting, secondary cooking, alcohol fermentation, acetic acid fermentation, vinegar sprinkle and aging. The preparation method of the vinegar has the advantages that the preparation time is short, the cost is effectively reduced, the process is safe and controllable, the health and safety are guaranteed, the prepared vinegar has a dark brown and slightly bright visual effect, has a rich fragrance, is mild in the sour taste, has no odor, has no suspended matter, is clear, and has a strong visual effect.

Owner:福建益众新能源科技有限公司

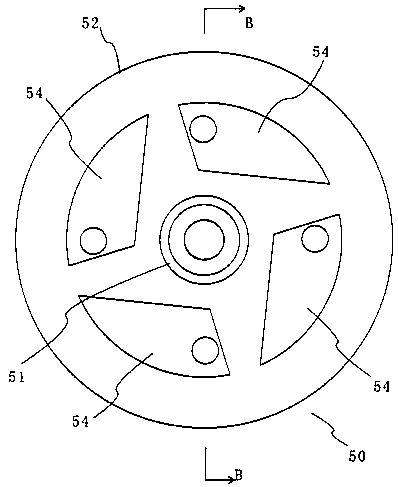

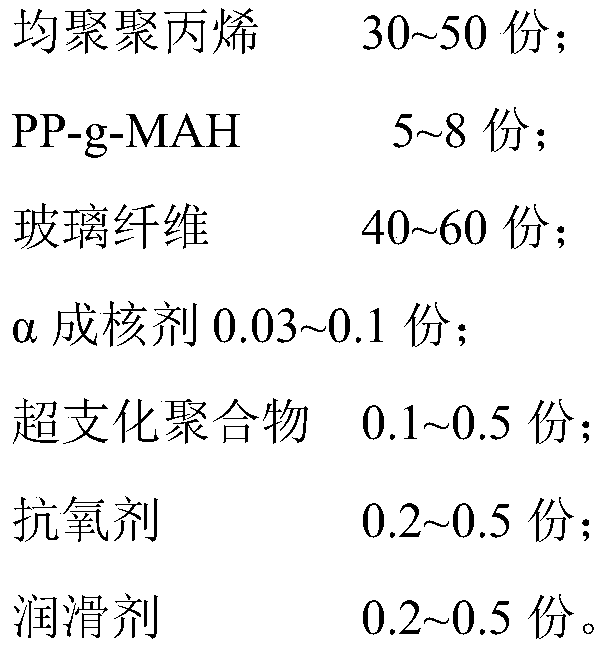

A high fluidity, bending, halogen-free, expansion flame retardant glass fiber reinforced polypropylene composite material for coil skeleton and its preparation method

The invention discloses a high-flow bending-resistant halogen-free expanded flame-retardant glass fiber reinforced polypropylene composite material for coil skeletons and a preparation method thereof.The polypropylene composite consists of 40%-60% by mass of a flame-retardant masterbatch and balanced glass fiber masterbatch. The invention also discloses a preparation method of the polypropylene composite material. According to the polypropylene composite material and the preparation method thereof, a hyperbranched polymer is added, so that the fluidity of the polypropylene composite materialis obviously improved, the spiral line flow length is improved, the molding time is shortened, and the processing efficiency is improved; in addition, the bending property and processing efficiency ofthe composite material are significantly improved through the addition of an alpha nucleating agent with isotropic shrinkage characteristics; the flame-retardant effect of the composite material reaches V0 at a thickness of 0.8 mm by introducing active nanometer zinc oxide and adopting double-stage side feeding; and finally, high-flow POE-g-MAH and high-flow high-rigidity copolymerized polypropylene play a synergistic effect on the bending resistance of the coil skeletons.

Owner:GUANGDONG JUSHI CHEM CO LTD

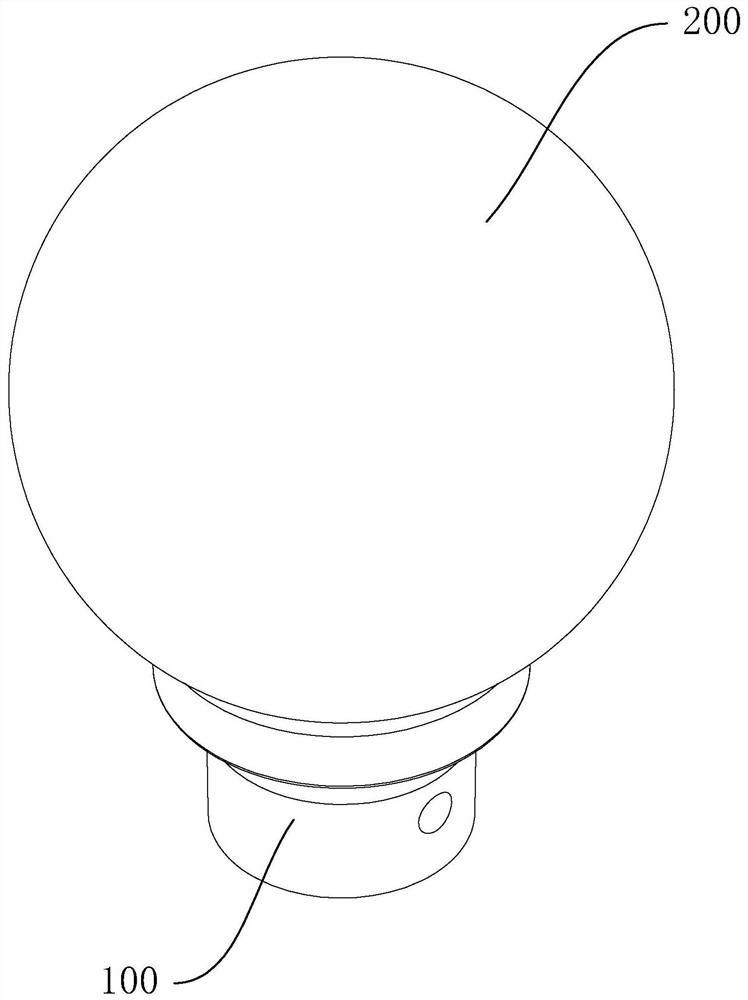

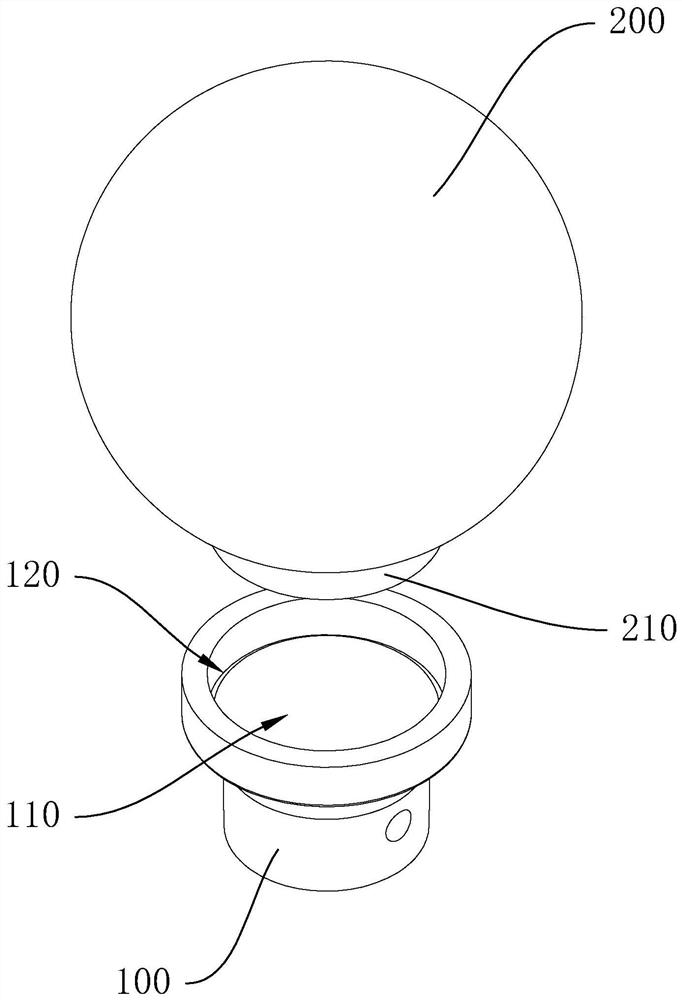

Crystal handle manufacturing process and crystal handle

InactiveCN113775249AIncreased durabilityImprove surface roughnessWing handlesWing knobsAdhesive cementSurface roughness

The invention discloses a crystal handle manufacturing process and a crystal handle. The crystal handle comprises a connecting base and a crystal body, wherein the connecting base is provided with a bonding groove, the crystal body is provided with a boss, scratches are formed on the inner wall face of the bonding groove, the boss is inserted into the bonding groove, and an adhesive layer is arranged between the boss and the bonding groove. The inner wall surface of the bonding groove is connected with the outer surface of the boss through a bonding layer; the crystal handle manufacturing process comprises the following steps of forming the scratches, wherein the scratches are formed on the inner wall face of the bonding groove; and bonding connection, wherein the inner wall face of the bonding groove and / or the outer surface of the boss are / is coated with an adhesive, and the boss is inserted into the bonding groove so that the inner wall face of the bonding groove and the outer surface of the boss can be bonded through the adhesive. By making the scratches on the inner wall face of the bonding groove, the surface roughness of the inner wall face of the bonding groove can be improved, the contact point density of the adhesive and a connecting base is improved, and therefore, the bonding strength between the connecting base and the crystal body can be improved.

Owner:胡淳龙

A kind of graphene-based high thermal conductivity phase change material and preparation method and production device thereof

ActiveCN113897184BAvoid nudityImprove thermal conductivityChemical industryHeat-exchange elementsLiquid statePhysical chemistry

Owner:GUANGDONG MORION NANOTECHNOLOGY CO LTD

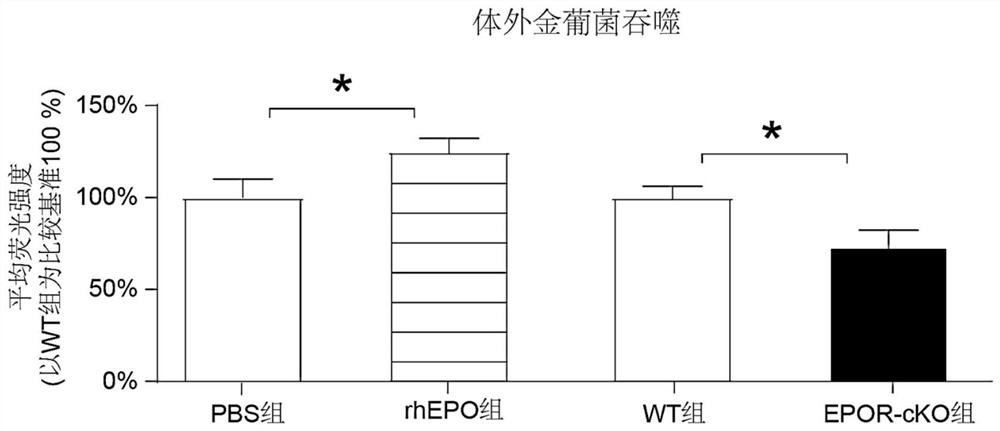

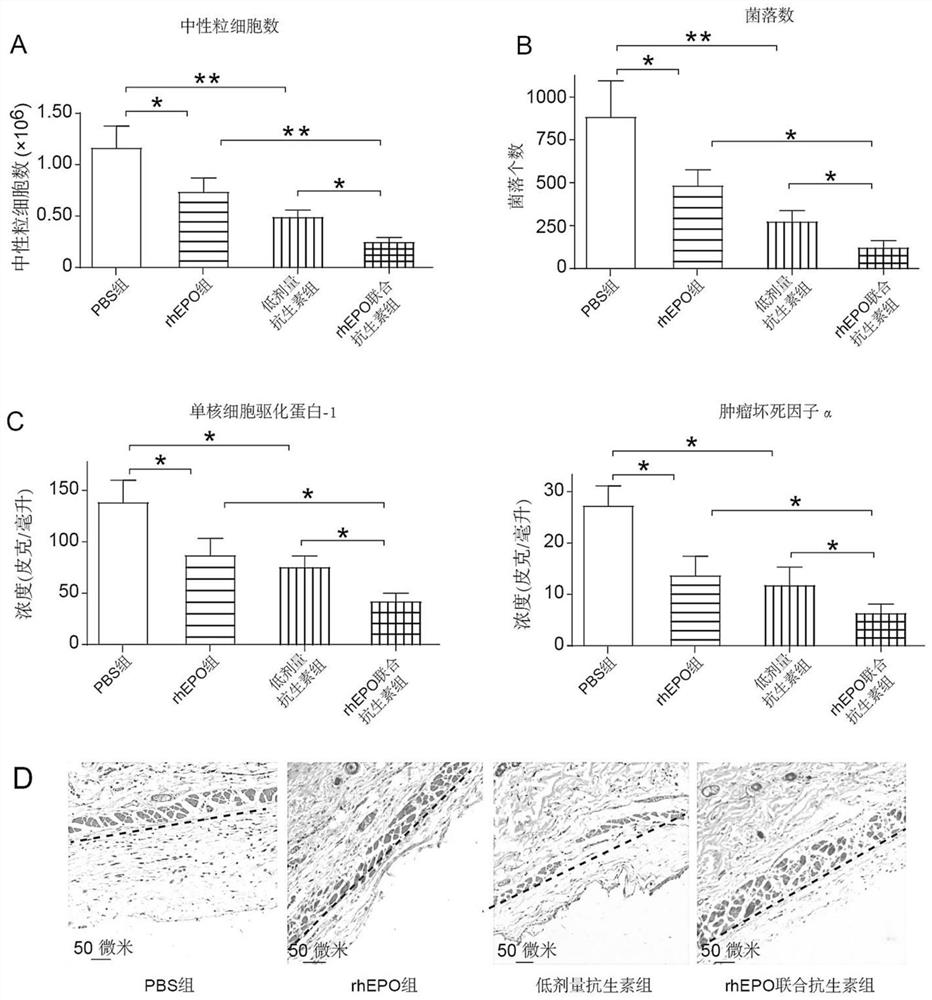

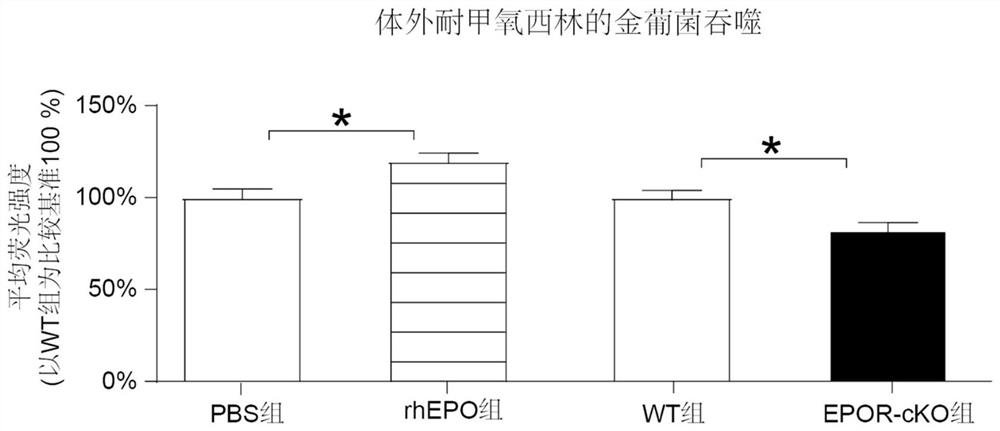

Application of epo in anti-Staphylococcus aureus infection drugs

ActiveCN111150837BPromote phagocytosisReduce the total number of coloniesAntibacterial agentsPeptide/protein ingredientsStaphyloccocus aureusPharmaceutical Substances

The invention belongs to the technical field of biomedicine, in particular to the application of EPO and its analogs in the preparation of medicines for treating Staphylococcus aureus infection and a method for promoting macrophage phagocytosis of Staphylococcus aureus in vitro. By adding EPO and its analogs to macrophages, promoting macrophage phagocytosis of Staphylococcus aureus can effectively combat Staphylococcus aureus infection. The present invention provides a new application of EPO and its analogs, and reveals that activation of EPOR in macrophages can promote the phagocytosis of Staphylococcus aureus by macrophages, especially the phagocytosis of methicillin-resistant Staphylococcus aureus.

Owner:ARMY MEDICAL UNIV

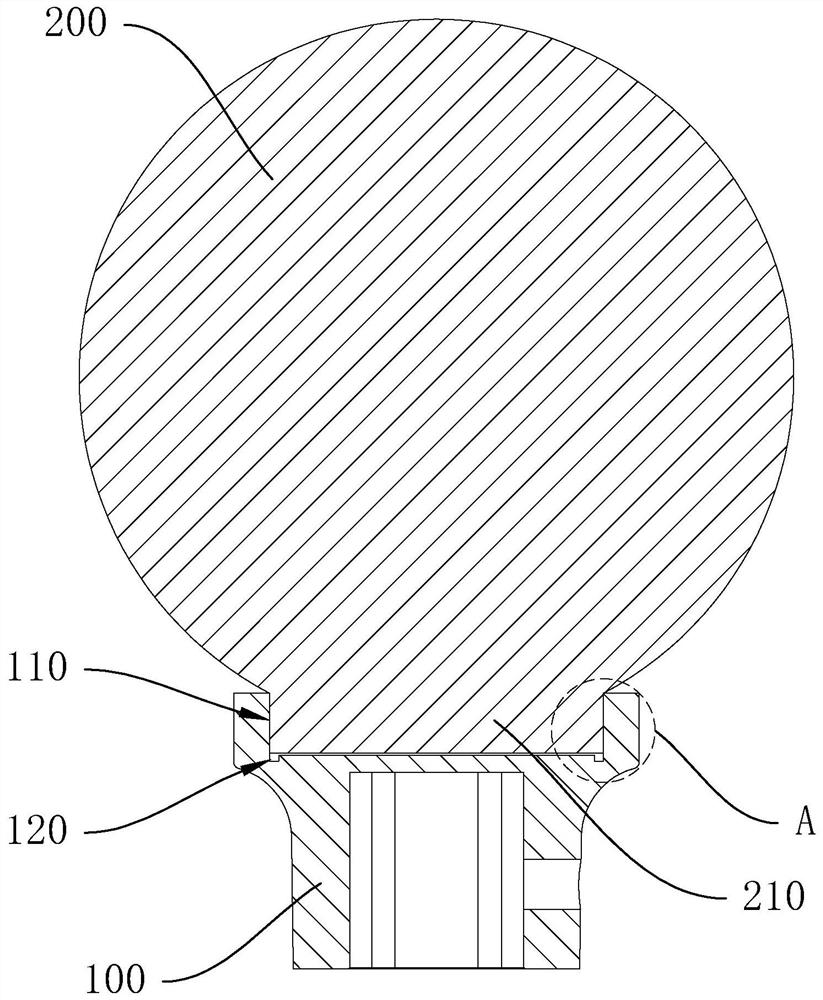

Racket surface structure of pike racket and preparation method thereof

InactiveCN112473103AWell mixedIncrease the degree of infiltrationCarbon fibresBraidEpoxyPotassium persulfate

According to the racket surface structure of a pike racket and a preparation method thereof, sizing treatment is conducted on carbon fibers through acetone, then oxidation treatment is conducted on the carbon fibers through a silver nitrate solution and a potassium peroxodisulfate solution, more oxygen-containing functional groups are formed on the surfaces of the carbon fibers, and therefore theinfiltration degree of the carbon fibers is enhanced; the melamine is grafted to the oxidized carbon fiber, so that the binding force between the carbon fiber and the epoxy resin is enhanced, the crack forming work, the expansion work and the impact work of the carbon fiber are further obviously increased, and corrosion resistance of the carbon fiber is improved; carbon fibers can be broken only by needing higher impact energy, and the mechanical properties of the carbon fibers are effectively improved, so impact resistance of the prepared racket surface structure of the pike racket is obviously improved, and the service life of the racket surface structure is obviously prolonged.

Owner:界首市扬泰体育用品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com