Catch-up type textile wire oil immersion equipment

A technology of oil immersion and equipment, which is applied in the direction of textile material equipment configuration, textile material treatment, textile material drum treatment, etc. It can solve the problems of poor oil immersion effect of the twine oil immersion device, improve the wetting effect, and improve the wetting effect. degree, effect of promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

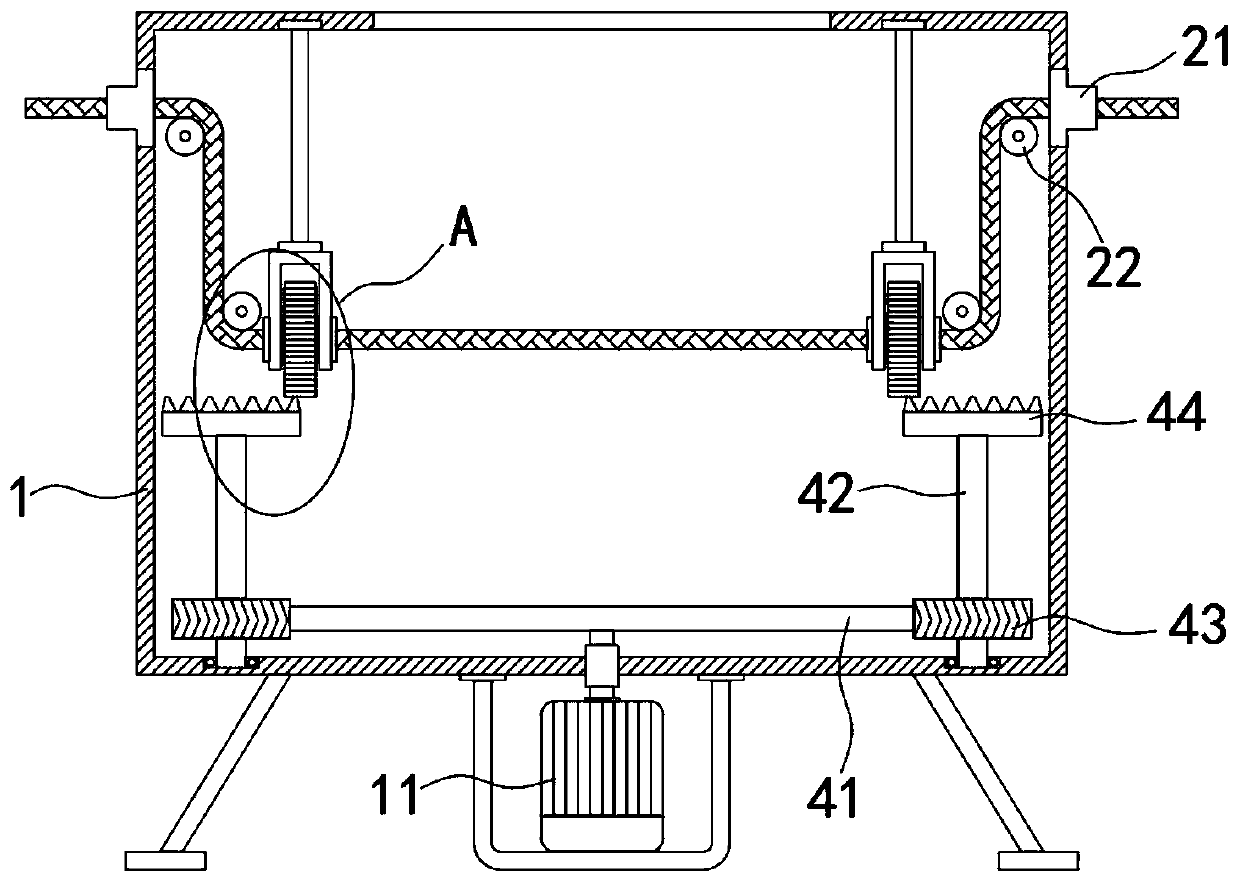

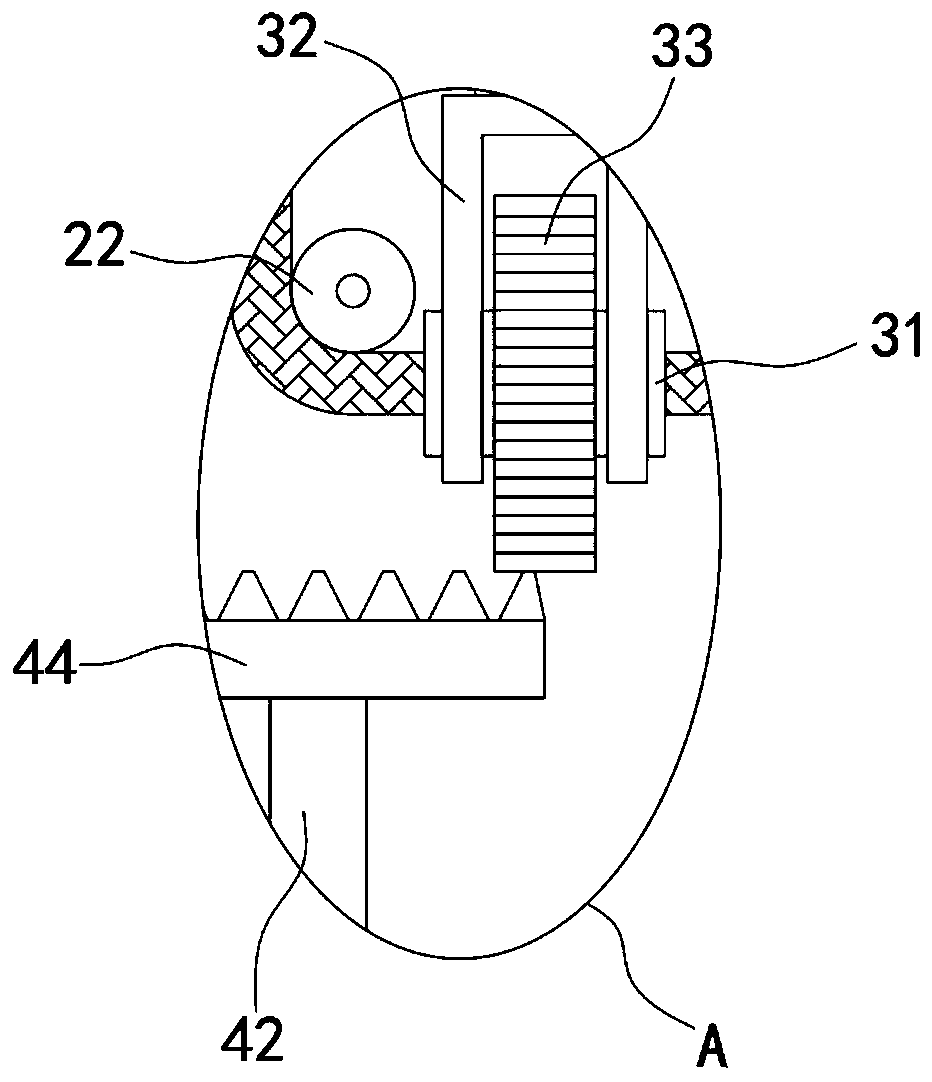

[0038] Such as Figure 1-4 As shown, a chasing type textile wire oil immersion equipment includes a box body 1 filled with oil, the front and rear sides of the box body 1 are equipped with positioning mechanisms and twisting mechanisms, and the bottom of the box body 1 is fixed and installed There is a driving motor 11, and the driving motor 11 drives the torsion mechanism through a transmission mechanism.

[0039] The positioning mechanism includes: a wiring pipe 21, which is fixedly arranged on the side wall of the box body 1; a plurality of positioning rollers 22, and the two ends of the positioning rollers 22 are respectively connected to the side walls on both sides of the box body 1 in rotation, It is used to limit the twine so that at least a part of the twine is located in the middle and lower part of the box body 1, so that the twine can be fully immersed in oil. By setting the positioning roller 22 and the wire pipe 21, the twine can be limited so that the twine move...

Embodiment 2

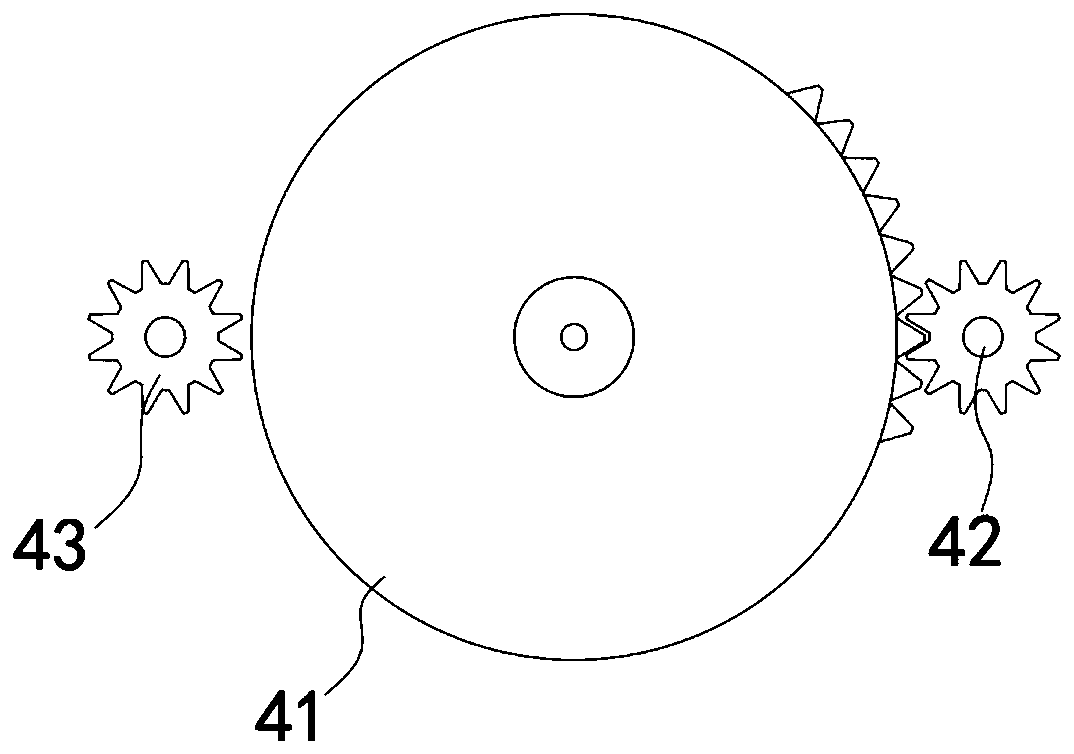

[0048] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the intermittent driving member 41 includes a ring gear 411, the inside of the ring gear 411 is provided with all teeth, and the outside is provided with some teeth, and the middle part of the ring gear 411 is provided with There is a central gear 412, and the central gear 412 is coaxially fixedly connected with the extension shaft. A plurality of driven gears 413 are meshed between the central gear 412 and the ring gear 411. It should be noted that the internal teeth of the ring gear 411 and the central gear 412 And the driven gear 413 is a humanoid gear, which can play the role of limit support for the ring gear 411, and prevent the ring gear 411 from falling under the action of its own gravity. The driven gear 413 is fixedly connected with the stirring shaft 414, and the stirring shaft 414 The lower end is rotatably connected with the inner bottom surface of the box body 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com