Patents

Literature

113results about How to "Eliminate sources of pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

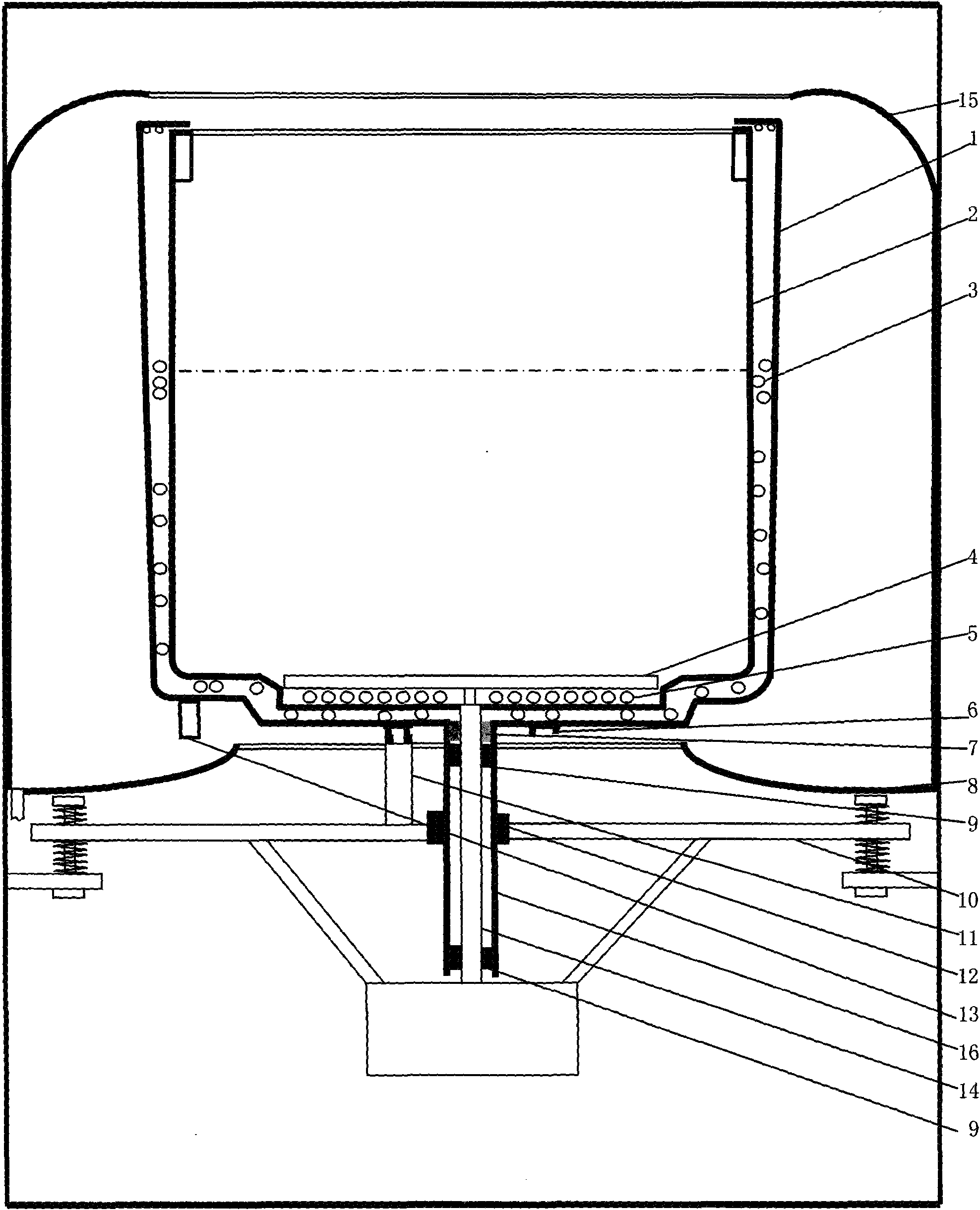

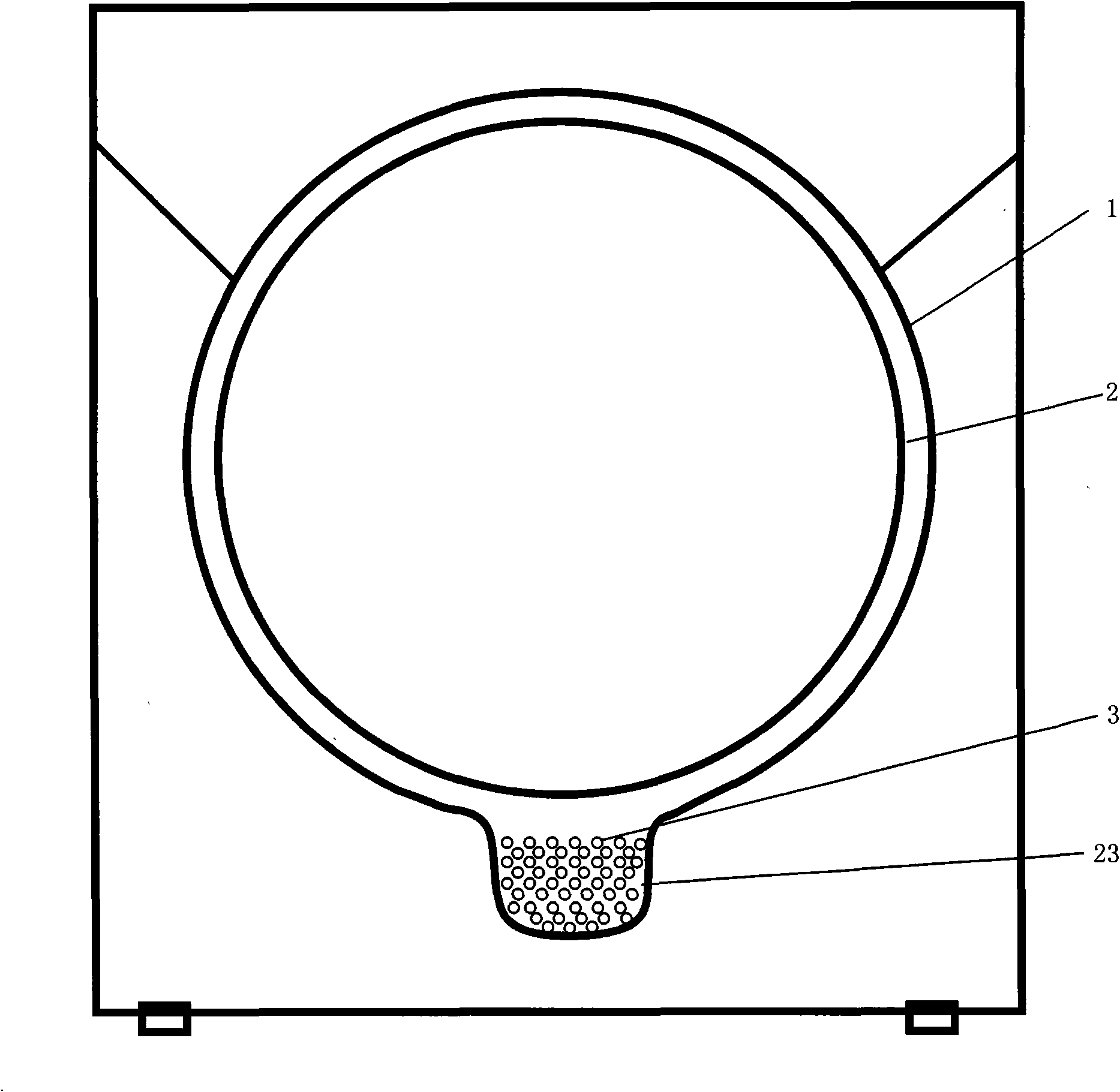

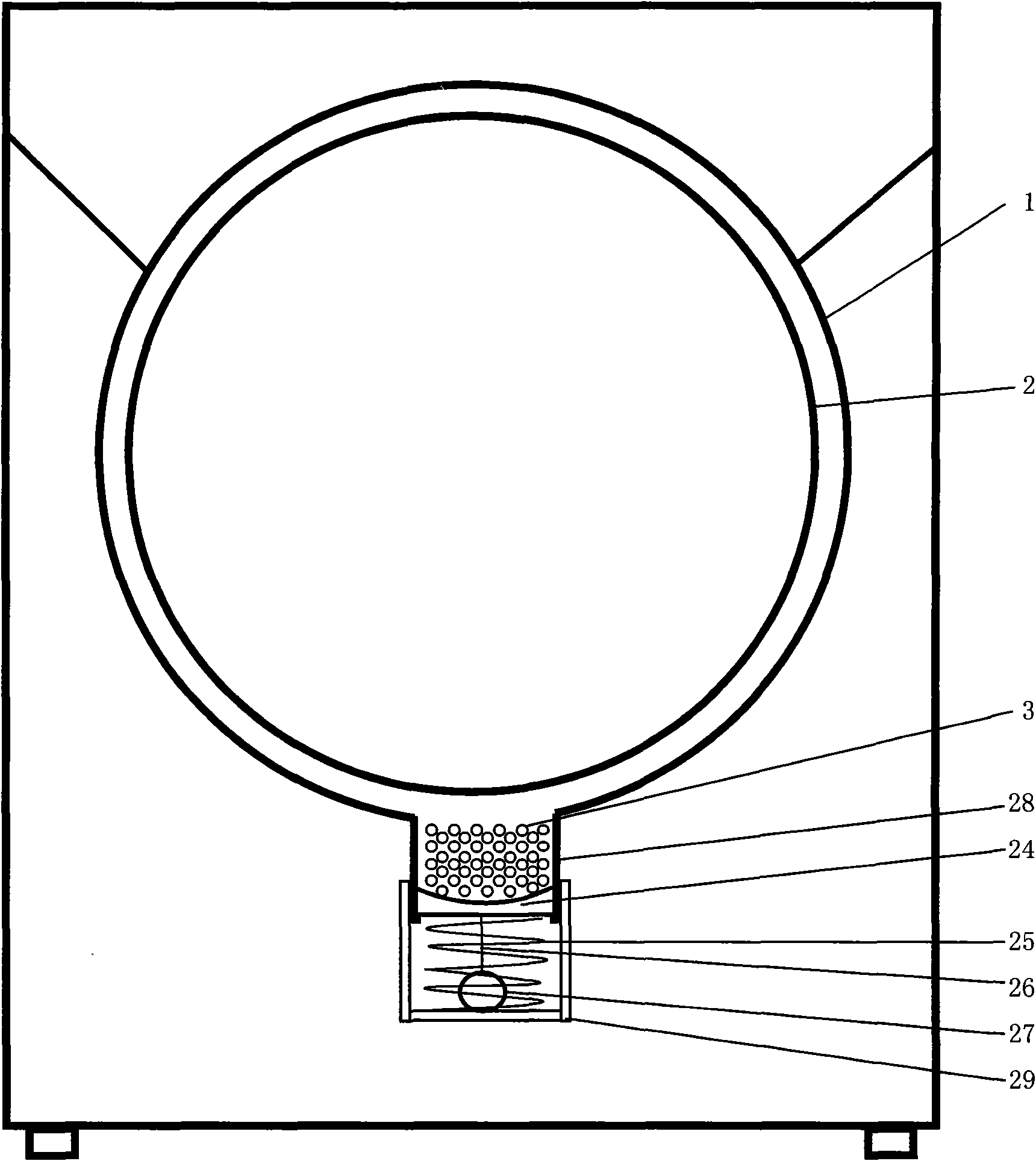

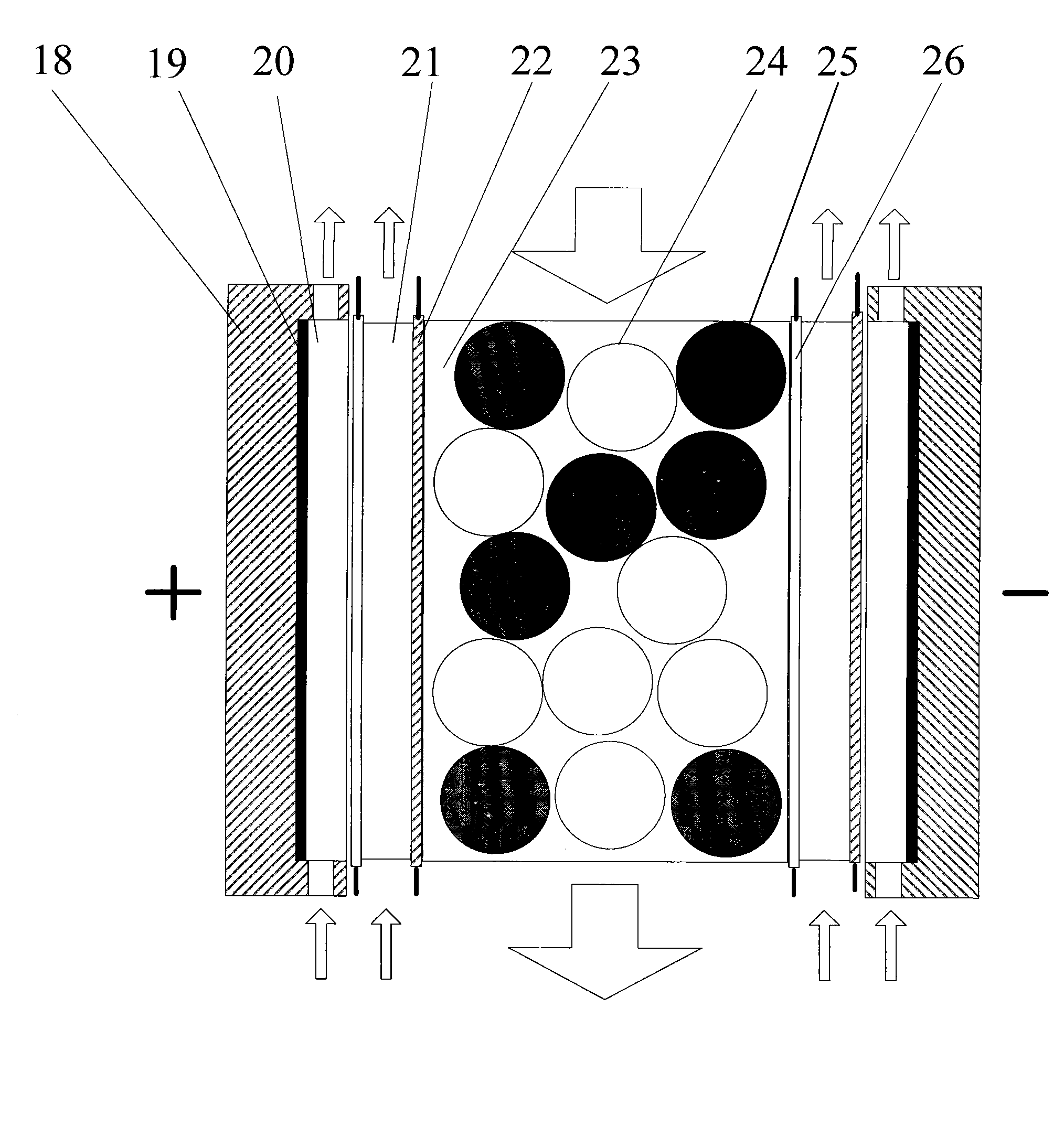

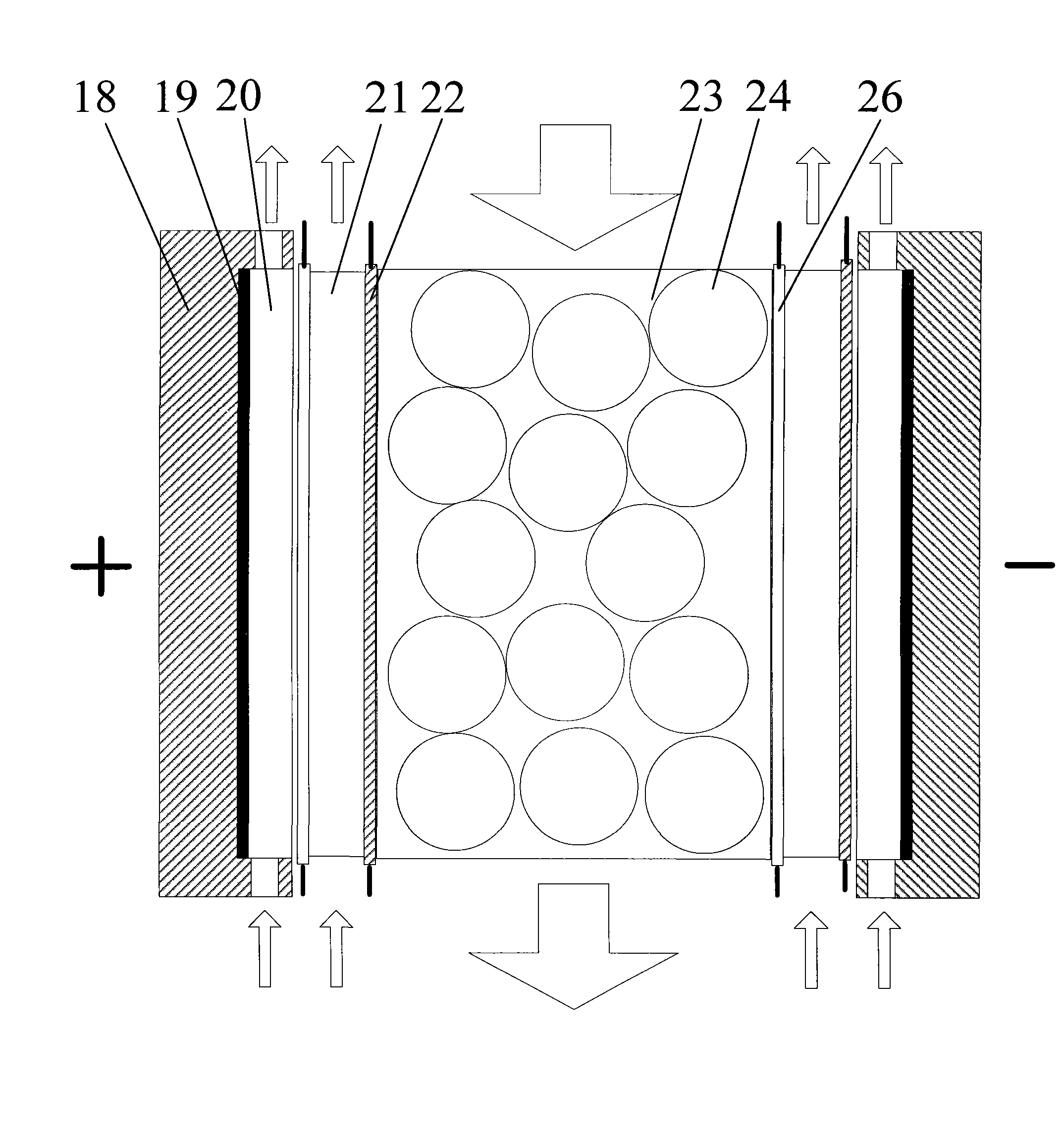

Self-cleaning device of full-automatic washing machine

InactiveCN101643994AEliminate sources of pollutionClean and comprehensiveOther washing machinesControl devices for washing apparatusPistonImpeller

The invention provides a self-cleaning device of a full-automatic washing machine, which is used for solving the problem of secondary contamination on clothes caused by clustered dirt in the interlayer between the water storage tank and the dehydration tank, and in the interlayer between the dehydration tank bottom and the impeller bottom of the washing machine. The interlayer between the water storage tank and the dehydration tank is provided with a plurality of clean balls 3, and a plurality of clean balls 5 are arranged between the dehydration tank bottom and the impeller bottom. When the washing machine washes or rinses, the clean balls perform friction with the water storage tank wall, the dehydration tank wall, the impeller bottom and the dehydration tank bottom to clean the dirt inthe positions, and simultaneously the clean balls are self cleaned through mutual collision and friction. By adopting the way in which the water storage tank rotates along with the dehydration tank when dehydrating and the storage tank wall or bottom is provided with a groove or a piston cylinder (to lead the clean balls to drop into the groove or the piston cylinder when dehydrating), the clean balls do not generate friction with the dehydration tank, thus prolonging the service life of the clean balls and saving energy; and the adoption of the way in which the water storage tank rotates along with the dehydration tank when dehydrating can decrease the width of the interlayer between the water storage tank and the dehydration tank to save water.

Owner:任文涛

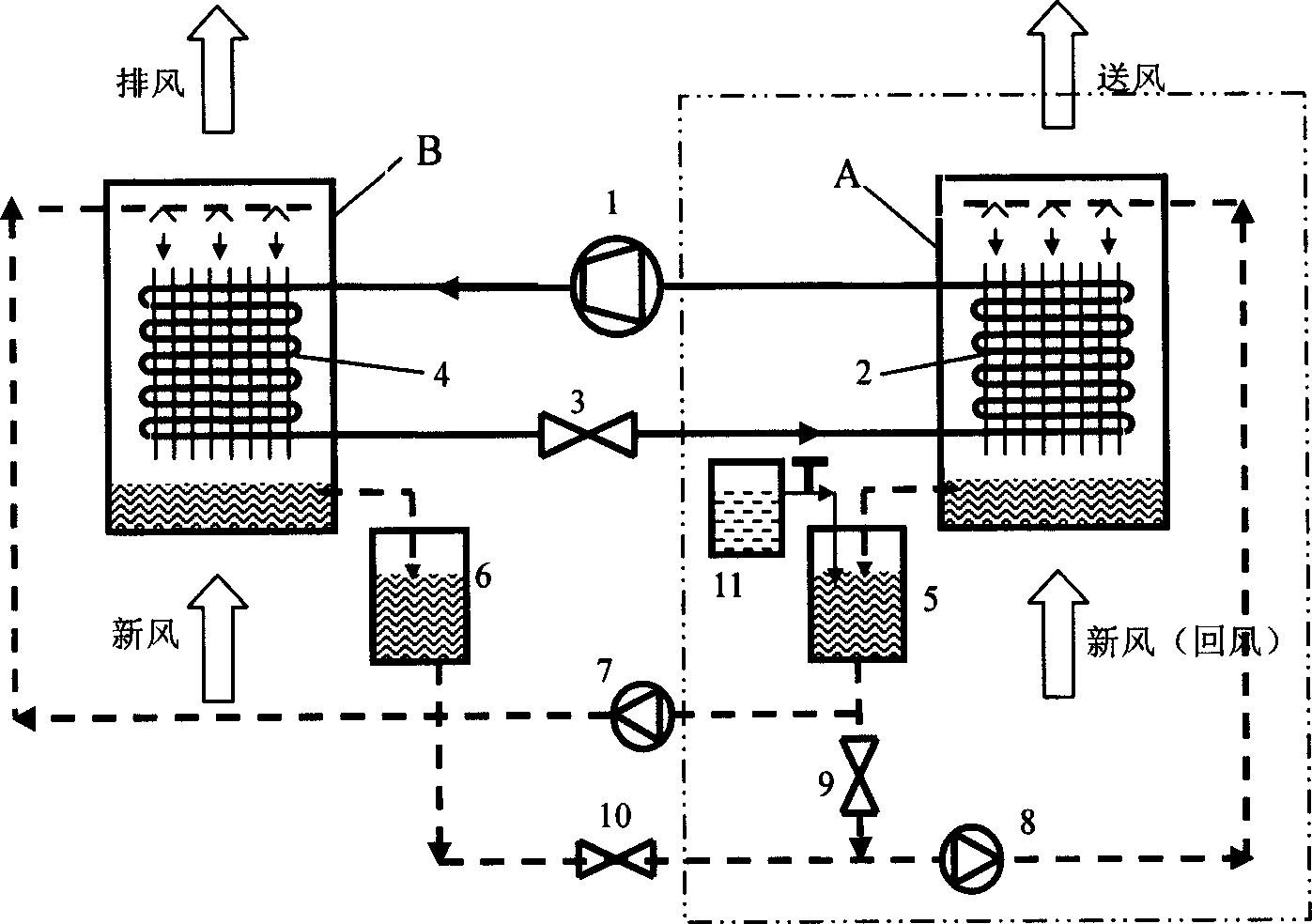

Temp and moisture independent control type air-conditioning system using solution as auxiliary working substance

InactiveCN1862121AAchieve bactericidal effectAchieve purification effectBoiler absorbersAir conditioning systemsEngineeringControl valves

The inventive air-conditioning system comprises refrigeration and solution cycle systems. The refrigeration cycle system has a compressor, an evaporator, an expansion valve and a condenser. The solution cycle system has a dehumidifier, a regenerating unit, a solution reservoir, a solution pump, a mixed solution valve and a control valve. Because of adding a solution cycle system, the invention can realize the accuracy independent control of temperature and humidity.

Owner:TSINGHUA UNIV +1

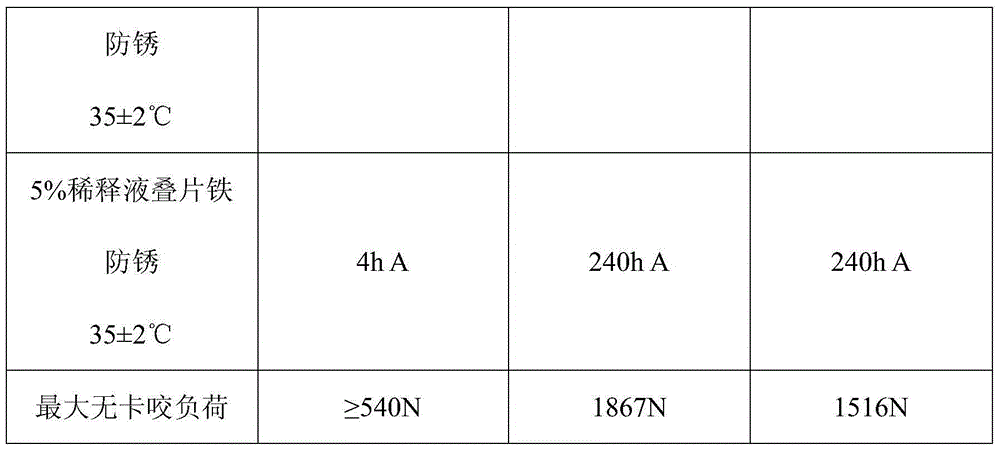

Graphene-modified chromium-free Dacromet coating material

ActiveCN103740152AHigh hardnessImprove corrosion resistanceAnti-corrosive paintsChromium freeFilm-forming agent

The present invention discloses a graphene-modified chromium-free Dacromet coating material, which comprises, by weight, 10-20% of zinc powder, 2-10% of aluminum powder, 2-20% of a film forming agent, 40-60.8% of a solvent, 0.1-5% of an auxiliary agent, 0.001-20% of graphene, and 0.1-5% of a filler. According to the present invention, compared with the traditional Dacromet coating, the graphene-modified chromium-free Dacromet coating material of the present invention provides substantially-increased hardness and substantially-increased adhesion, wherein the hardness of the coating of the present invention can be 7H so as to make the coating have good wear performance; the energy consumption is reduced, the conductivity of the coating is increased, and the corrosion resistance of the chromium-free Dacromet coating material is further increased; and the used raw materials do not contain substances harmful for environment and human body so as to fundamentally eliminate the pollution source.

Owner:NINGBO MORSH TECH

Electrolytic manganese slag comprehensive utilization technique

InactiveCN101306425AAvoid pollutionEliminate sources of pollutionSolid waste managementSolid waste disposalBuilding productElectrolysis

The invention relates to an electrolytic manganese slag processing method, in particular to an electrolytic manganese slag comprehensive utilization process. The method recovers the recyclable materials in electrolytic manganese slag through repeated water washing and filtering. The method can solve the air pollution source, particularly eliminate the water pollution source, and protect people health from being damaged. The method can extract higher-value chemical products through the scientific flow, and make the residuary filter residue into building products, thereby effectively utilizing the resource. Zero discharge is realized during the overall process of the technical proposal of the method, and because no additional chemical substances are added, additional environmental pollution can not be caused.

Owner:卿富安

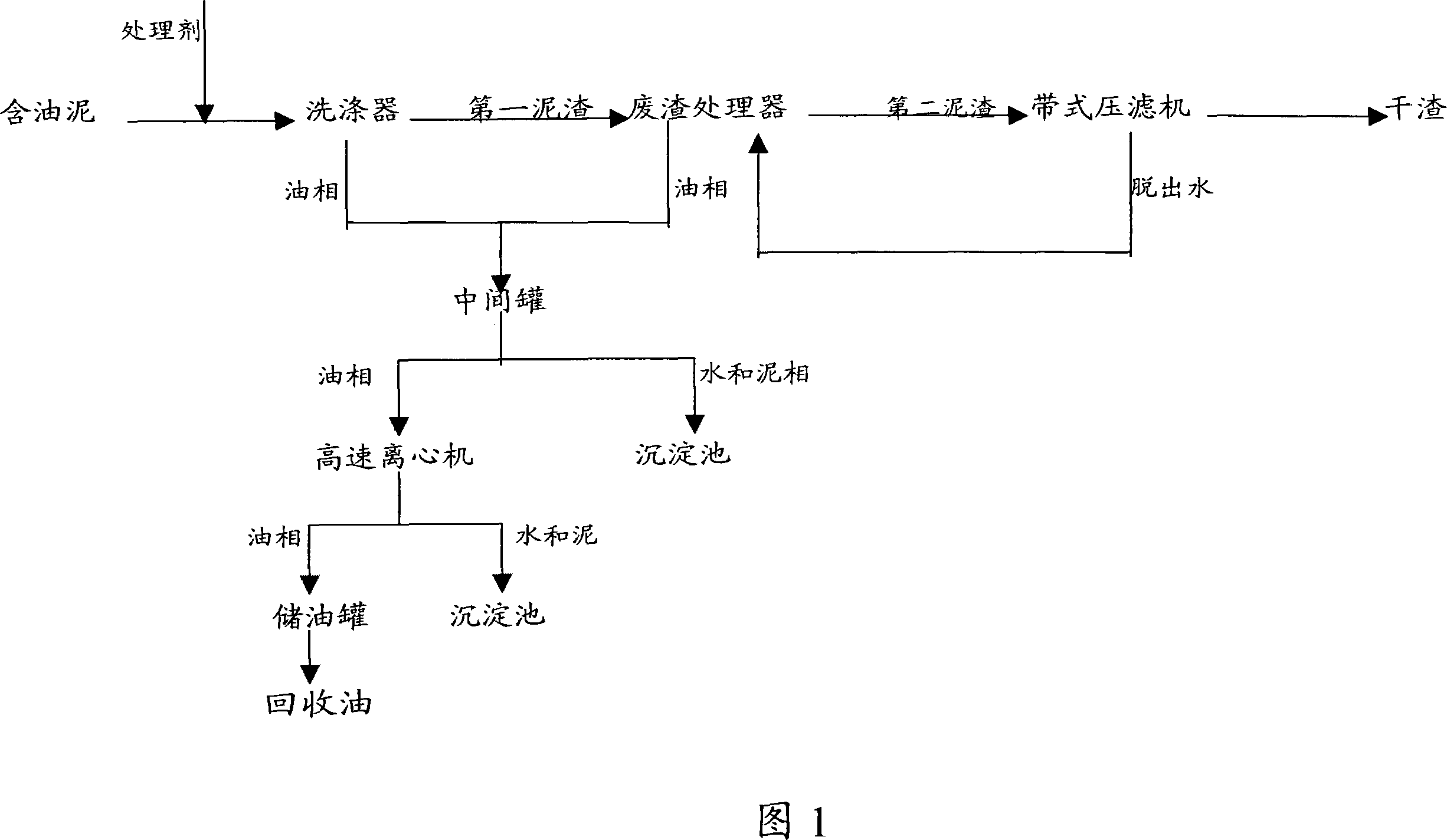

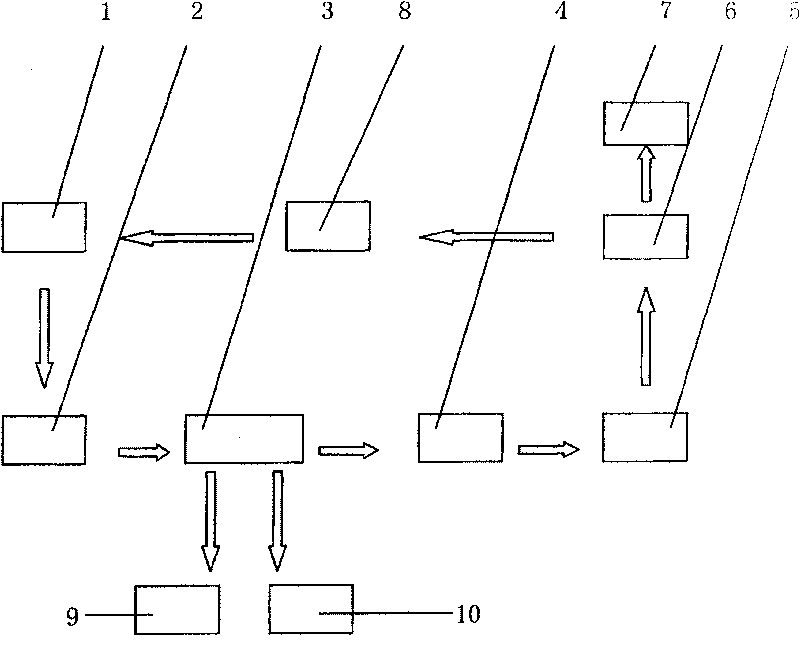

Method and system for processing oil-containing sludge

ActiveCN101250420AReduce pollution intensityEliminate sources of pollutionSludge treatmentSolid separationScrubberResidual oil

The invention relates to a method for processing oil-bearing mud, which comprises the following steps: firstly, mixing and stirring oil-bearing mud and right amount of water in a washer under the condition of heating, stewing, separating out oil phase and a first sludge layer, secondly, stirring in a middle tank, heating oil phase from the washer, stewing, and then discharging water and sludge on the lower portion, keeping oil phase on the upper portion, thirdly, finely separating oil phase which is kept in the middle tank in a centrifugal machine through a centrifugal effect, discharging oil phase which is separated into an oil storage tank, fourthly, stewing oil products which is from the centrifugal machine after dewatering and desliming in the oil storage tank, and getting recovery oil, fifthly, cavitating first mud residue from the washer in a mud residue processor, stripping residual oil in the first mud residue, and discharging oil phase on the upper portion of the mud residue processor into the middle tank. The invention also relates to a system which utilizes the method to process oil-bearing mud. Oil-bearing rate of oil-bearing mud which is processed by the method and the system of the invention is below 4%.

Owner:里群 +1

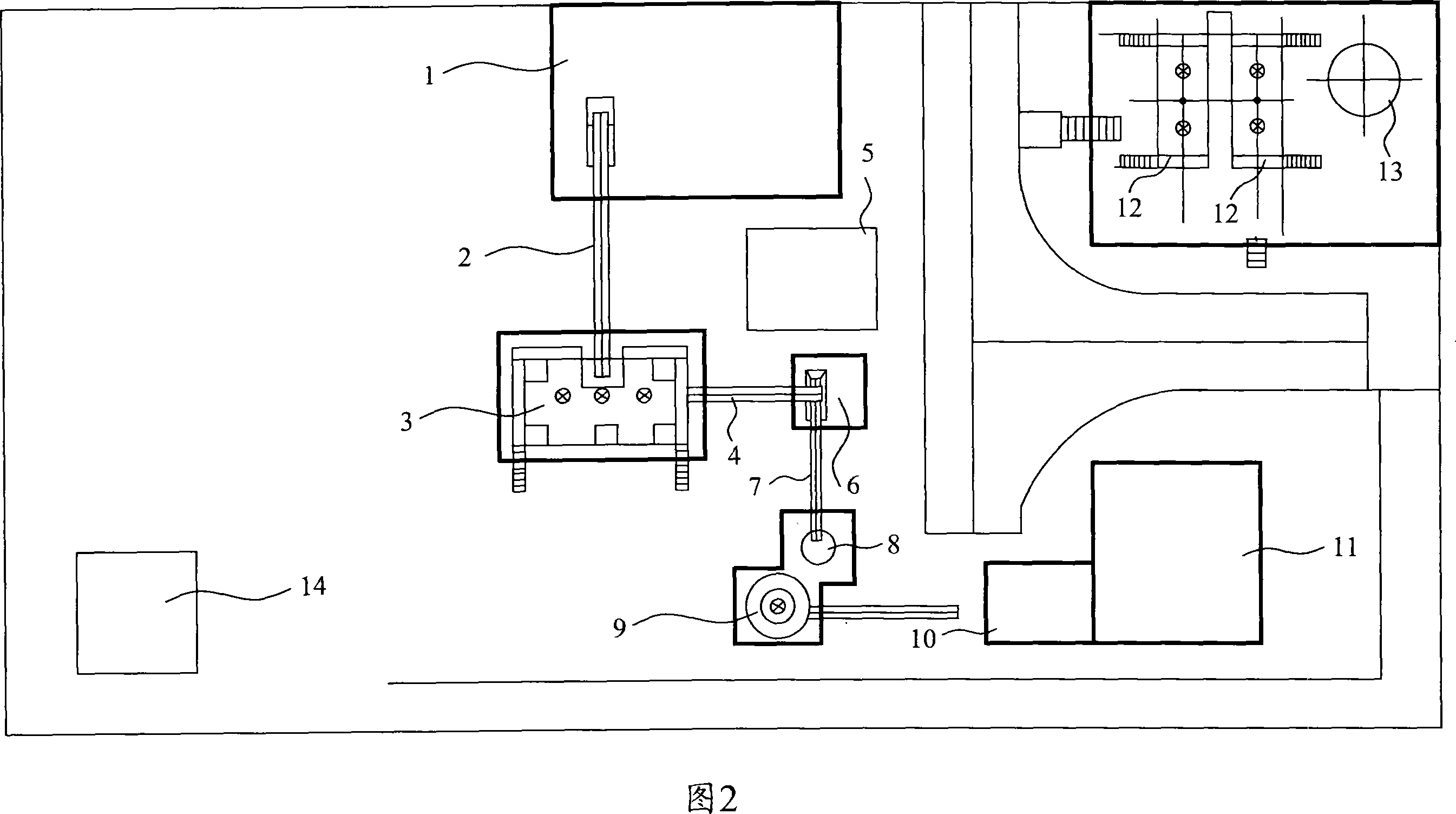

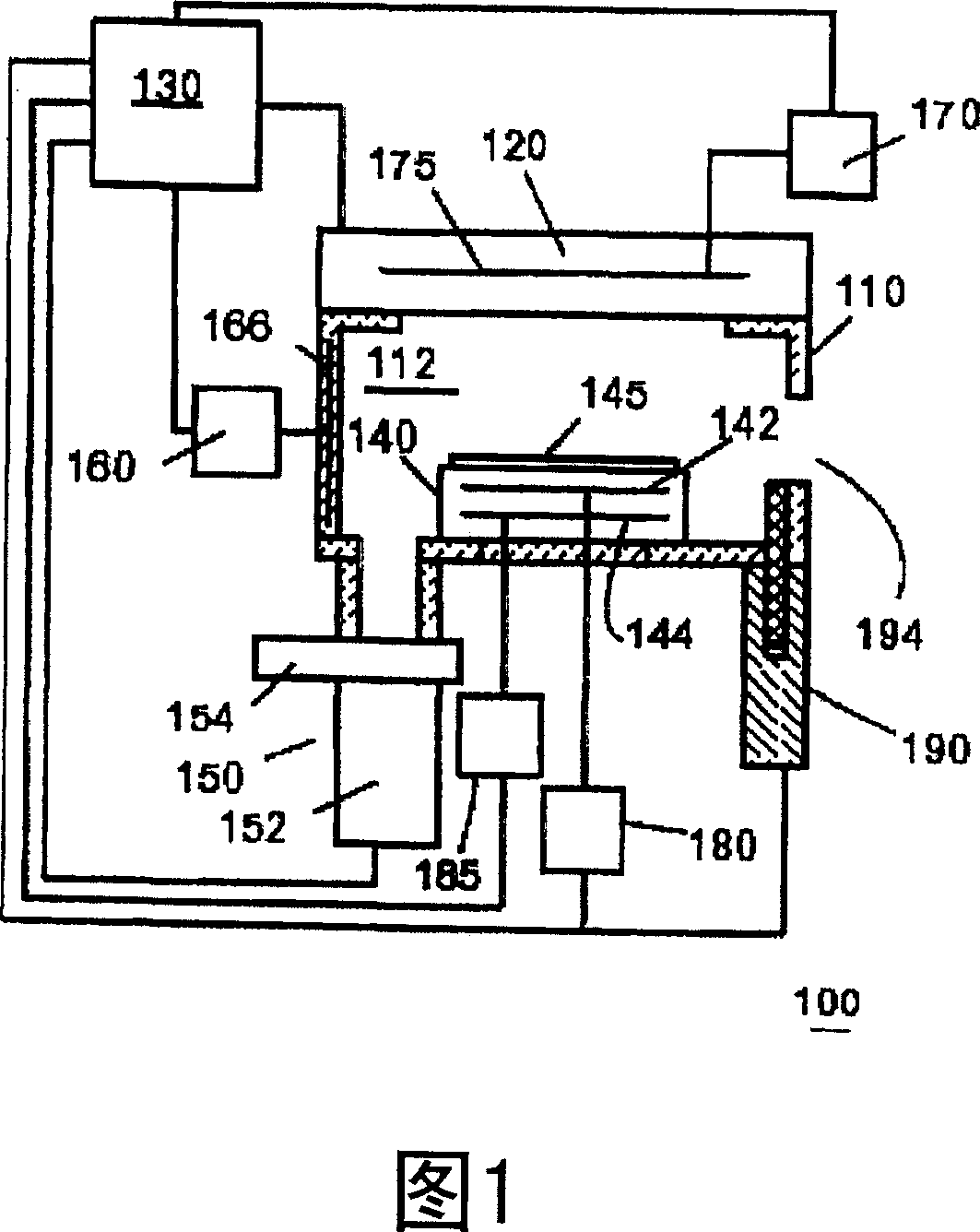

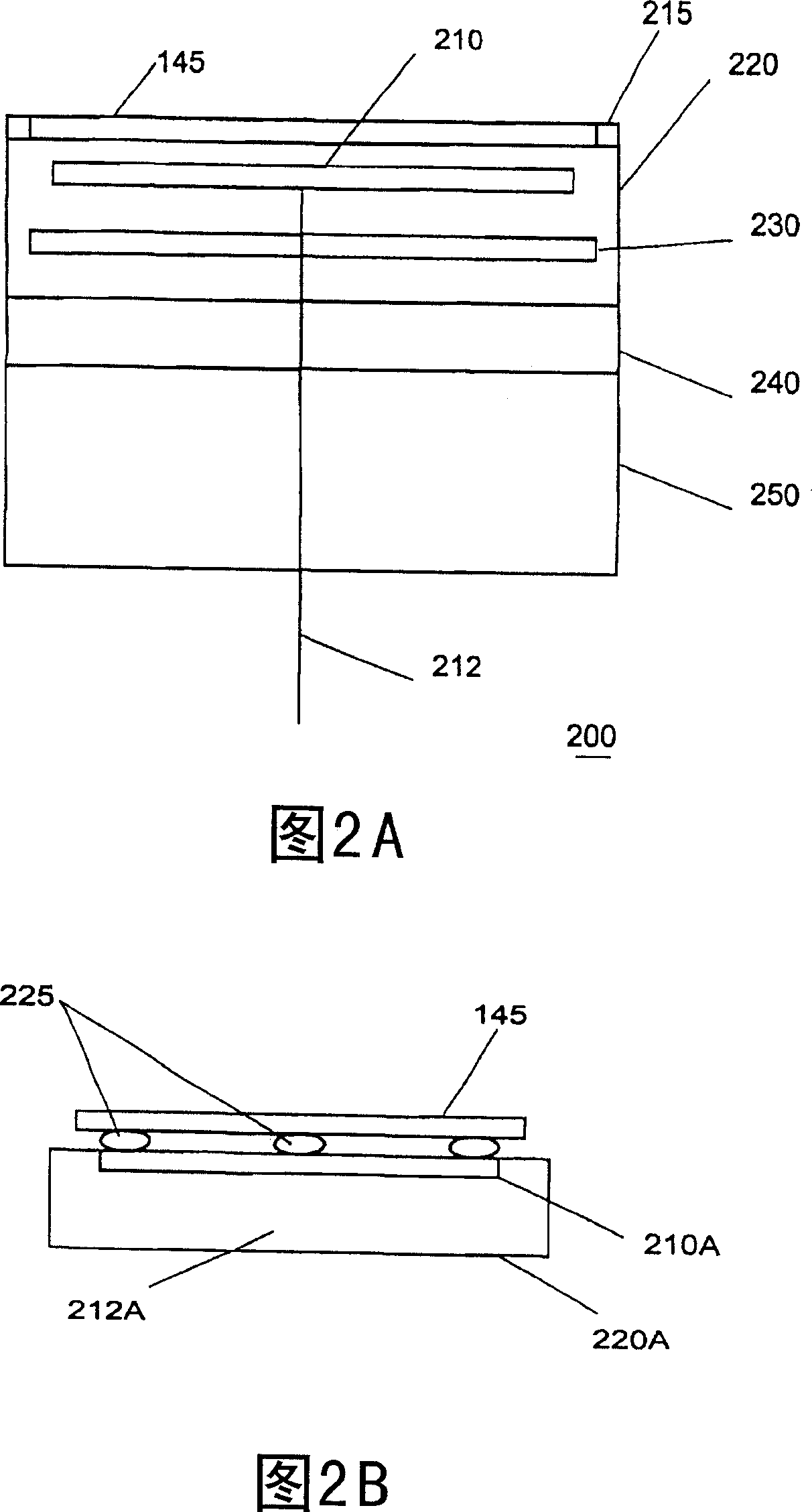

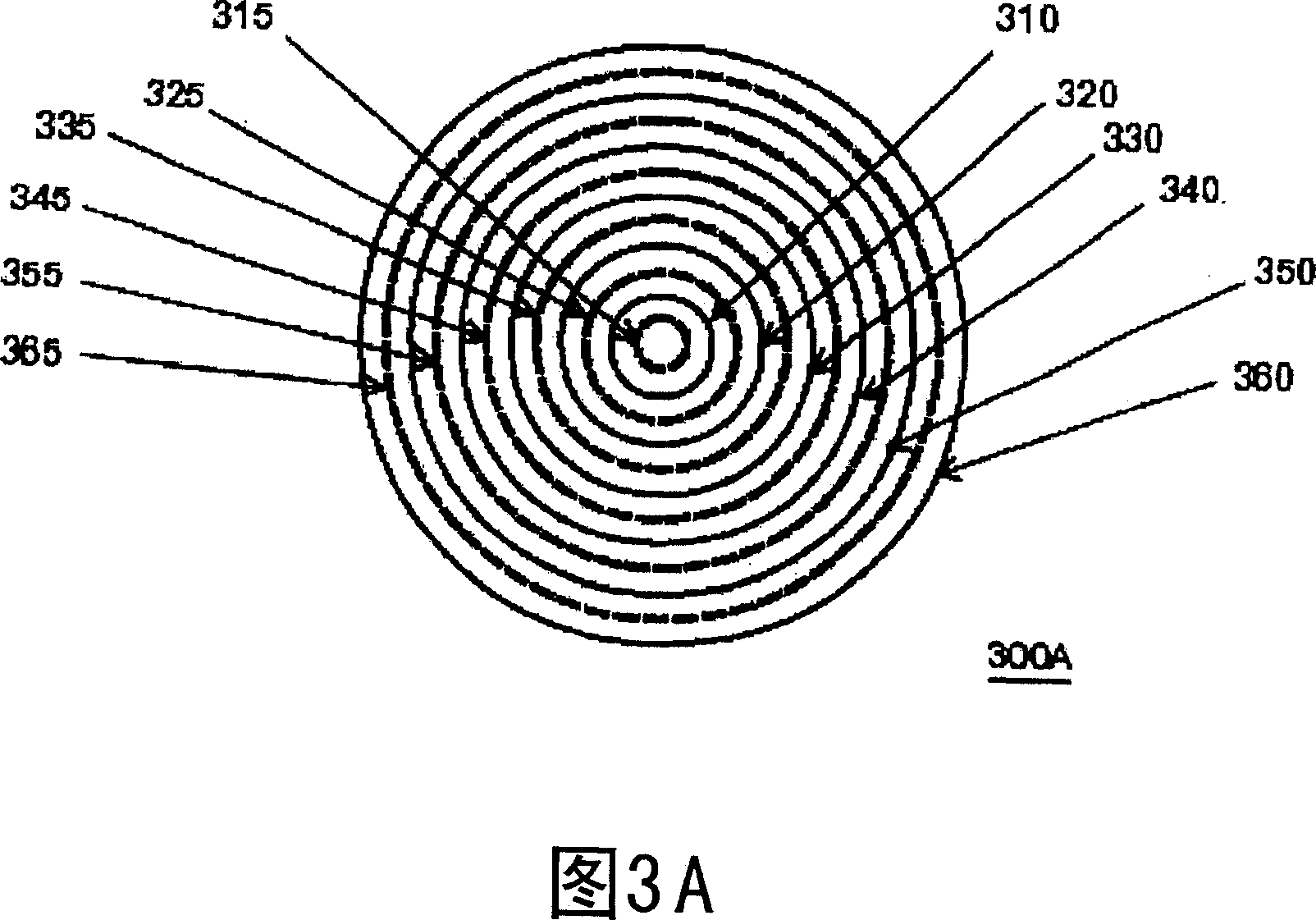

Wafer heater assembly

InactiveCN101023197AEliminate sources of pollutionEasy to controlElectric discharge tubesSemiconductor/solid-state device manufacturingHandling systemContamination

A wafer heating assembly is described having a unique heater element for use in a single wafer processing systems. The heating unit includes a carbon wire element encased in a quartz sheath. The heating unit is as contamination-free as the quartz, which permits direct contact to the wafer. The mechanical flexibility of the carbon 'wire' or 'braided' structure permits a coil configuration, which permits independent heater zone control across the wafer. The multiple independent heater zones across the wafer can permit temperature gradients to adjust film growth / deposition uniformity and rapid thermal adjustments with film uniformity superior to conventional single wafer systems and with minimum to no wafer warping. The low thermal mass permits a fast thermal response that enables a pulsed or digital thermal process that results in layer-by-layer film formation for improved thin film control.

Owner:TOKYO ELECTRON LTD

Preparation method of modified fungus bran adsorbent for discoloring dye waste water

InactiveCN101733075AEliminate sources of pollutionAbundant sources of raw materialsOther chemical processesWater/sewage treatment by sorptionChemistryAbsorption effect

The invention relates to a preparation method of a modified fungus bran adsorbent for discoloring dye waste water, belonging to the technical field of environmental protection. The preparation method comprises the following concrete steps: alkalizing and swelling the edible fungus bran which is dried and crushed in an excess NaOH solution at 50-120 DEG C for 1-12 hours, carrying out cationic modification on the swollen edible fungus bran, washing the swollen edible fungus bran with water, and drying the swollen edible fungus bran to obtain the modified fungus bran adsorbent for discoloring dye waste water. In the invention, the processed edible fungus bran is used as a raw material for preparing the adsorbent, wherein celluloses and thalli contained in the fungus bran are mainly used. By using the fungus bran for preparing the adsorbent, agricultural wastes are reasonably used, and pollution sources are eliminated. The invention has the advantages of simple process, low cost, economy,practicability and the like. After cationic modification, active groups in the fungus bran are increased, and the adsorbent has high stability, good absorption effect and wide application range, is renewable and can be widely used for treating dye waste water.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

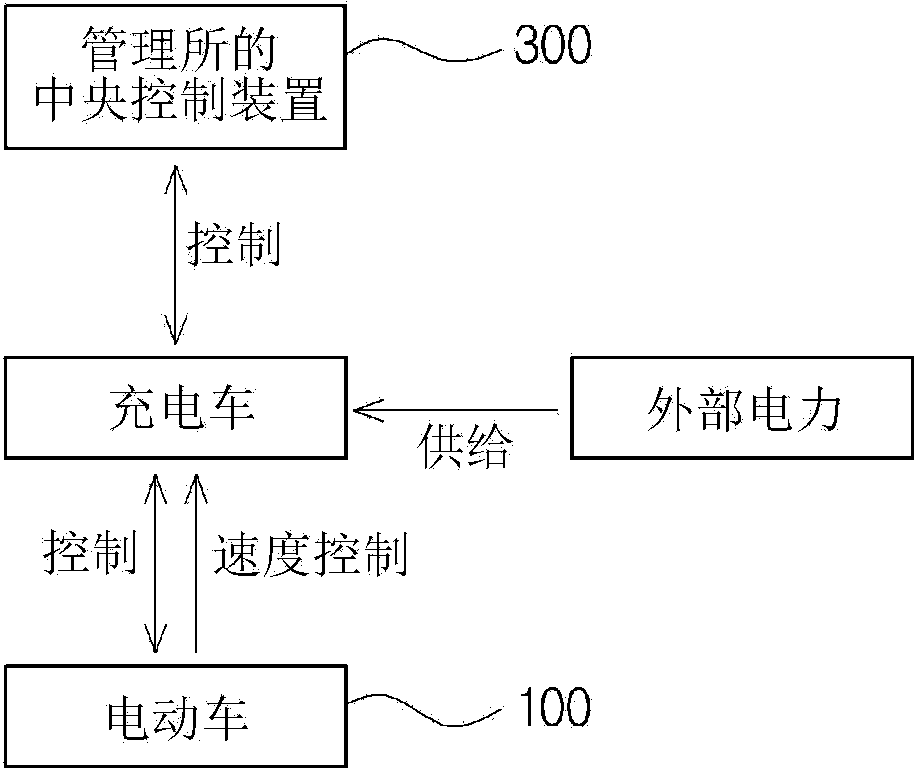

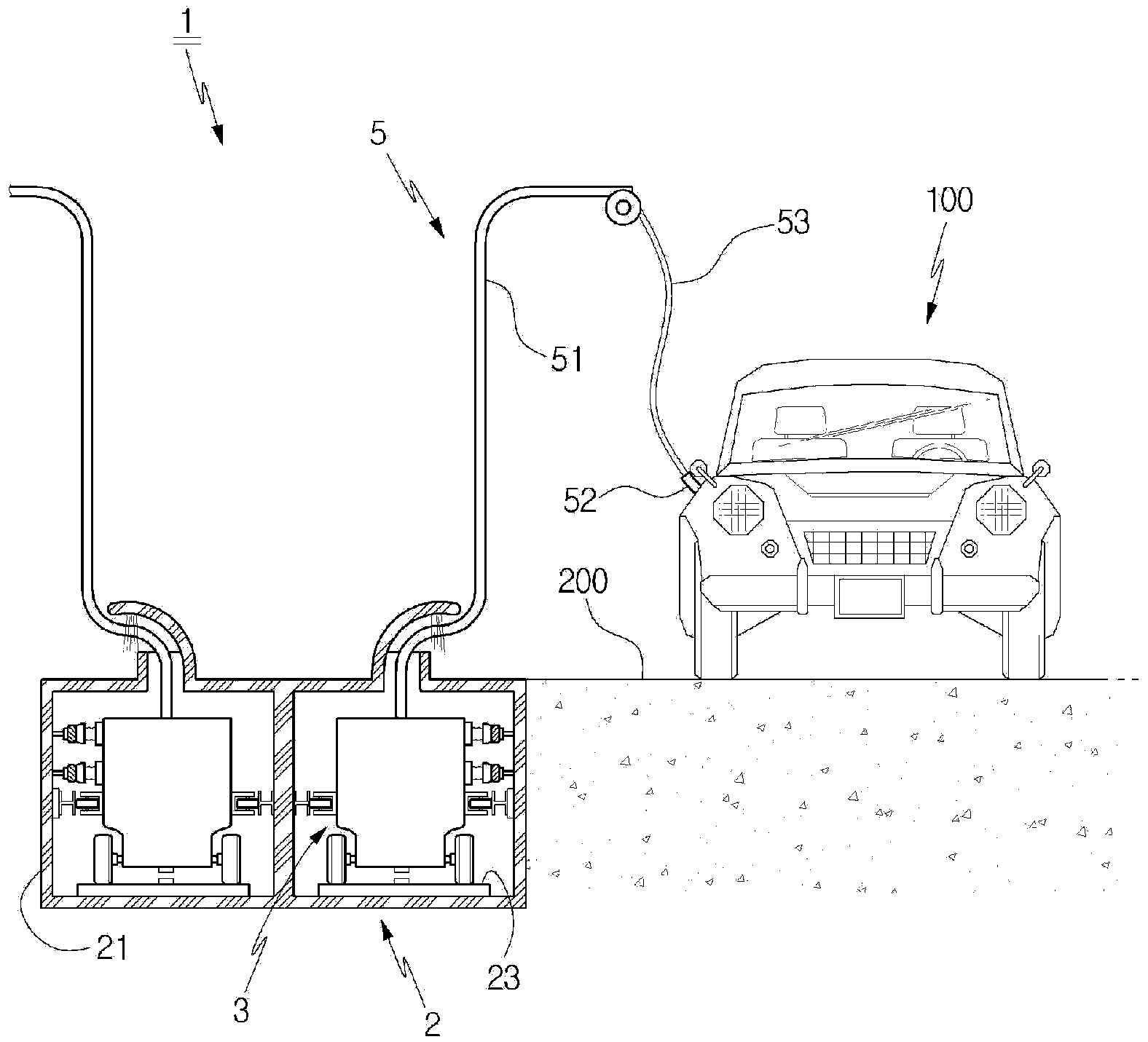

Charging device for electric car

InactiveCN103619642AHigh penetration rateEliminate sources of pollutionBatteries circuit arrangementsCharging stationsElectric carsElectric vehicle

The present invention relates to a charging device for an electric car, wherein: a recharging road for electric cars, on which a charging electric car having an electrically controlled speed can run at high speeds, is provided on an upper end of a support standing erect on the ground, underground or semi-underground along the edge of a road or a median strip; a power line for supplying power to the moving charging electric car is installed on the recharging road for electric cars; a charging power line assembly which is electrically connected with the moving electric vehicle is fixedly installed in the charging electric car; the electric car for charging, which moves along the recharging road for electric cars, and the power line are electrically connected in a contact or noncontact manner which is a widely known technique; and the charging power line assembly includes a traveler that is fixed to the charging electric car, a flexible means that is installed on an end of the traveler, and a charging electric wire that is wound on the flexible means and has a plug at the rear end thereof.

Owner:李镇局

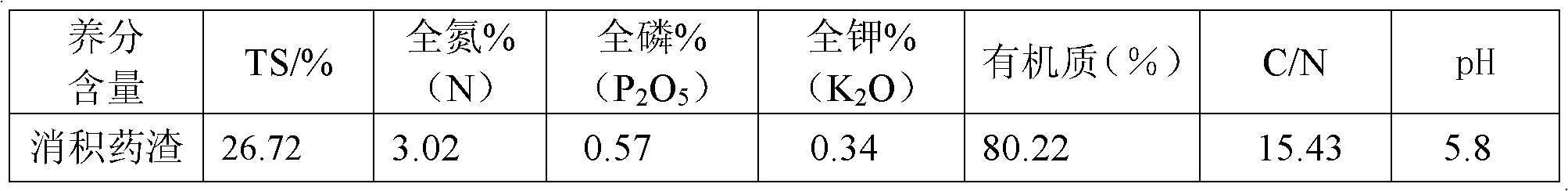

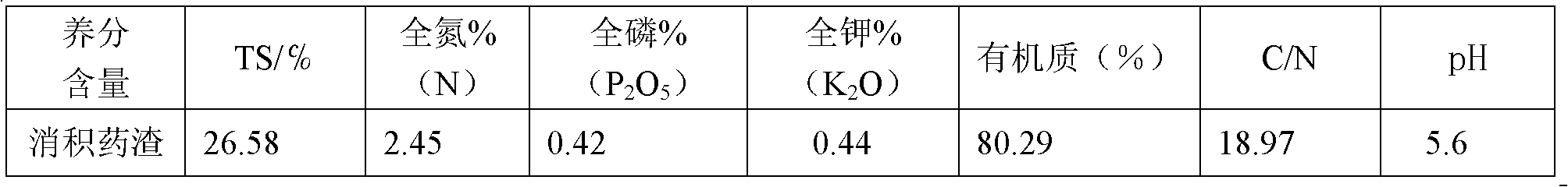

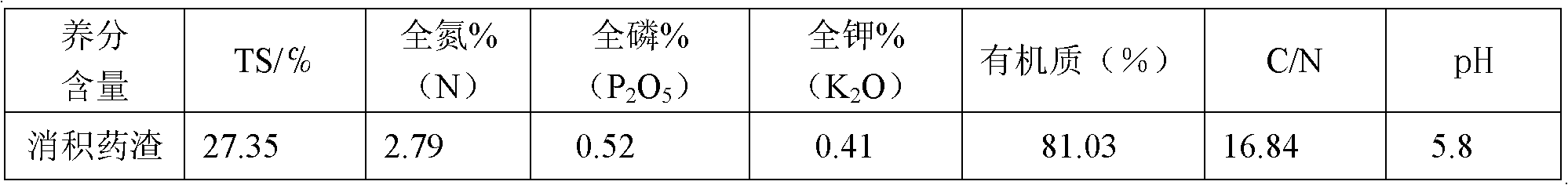

Method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials

ActiveCN102382859AEasy to operateSuitable for useWaste based fuelFermentationProduction effectMedicine

The invention relates to a method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials. Medicine dregs produced in a pharmaceutical factory of traditional Chinese medicine are used as fermentation raw materials, are united with waste water of the pharmaceutical factory for anaerobic fermentation, and are properly proportioned with biogas slurry and water for composting pretreatment, a proper amount of NaOH is added after the mixture enters a pool, the TS (total solid) concentration of the fermentation raw materials is 7-9%, 10-15% of biogas slurry is added as an inoculum so as to realize quick start, and the biogas production efficiency is high. Partial biogas slurry flows back after normal operation so as to ensure the concentration of microorganisms in an anaerobic tank. The traditional Chinese medicine dregs are taken as main raw materials for fermentation to produce the biogas, cow dung and other fermentation raw materials do not need to be added, the operation is simple, the gas production effect is good, the utilization ratio of the raw materials is high, the problem of environment pollution caused by the medicinedregs and the waste water can be solved, and simultaneously biogas energy sources can be recycled.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

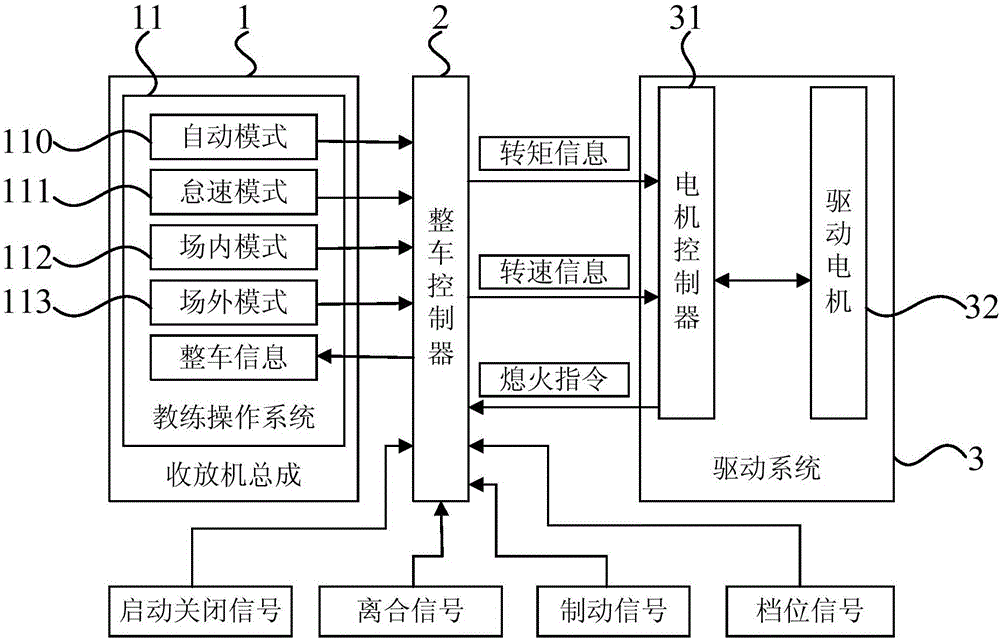

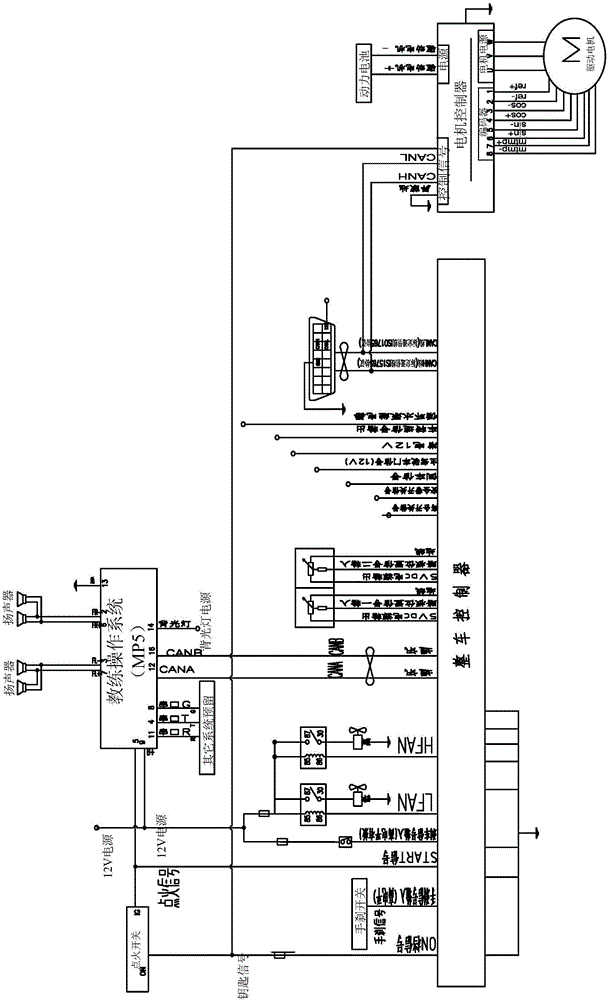

BEV (battery electric vehicle) based instructor control system

InactiveCN106828196AEliminate sources of pollutionImprove pass rateSpeed controllerOperating modesHuman–machine interfaceOperational costs

The invention discloses a BEV (battery electric vehicle) based instructor control system. The BEV based instructor control system comprises a radio assembly for sending a system instruction, a whole vehicle controller for receiving the instruction sent by the radio assembly and analyzing the instruction as well as a driving system for receiving and executing the instruction analyzed by the whole vehicle controller, wherein the whole vehicle controller and the driving system are further used for realizing flameout and idling functions of the vehicle; an instructor operating system is arranged on the radio assembly and has multiple modes, the modes are set and selected through a human-machine interface, and whole vehicle information is displayed simultaneously; the instructor operating system and the driving system are both in communication connection with the whole vehicle controller through CAN buses. With adoption of the structure, the BEV based instructor control system has the advantages that one of air pollution sources is effectively eliminated, the passing rate of teaching examination is increased, and the operation cost of a driving school is reduced.

Owner:BAODING ZHONGXING TIANYE NEW ENERGY AUTOMOBILE TECH CO LTD

Acidic soil adjusting fertilizer

InactiveCN104774090AImprove conveniencePromote growthFertilizer mixturesEcological environmentPhosphoric acid

The invention provides an acidic soil adjusting fertilizer. The acidic soil adjusting fertilizer is prepared from the following components by weight: 45 to 55 parts of plant ash, 10 to 25 parts of calcium powder, 8 to 12 parts of humic acid, 8 to 12 parts of modified plant straw, 4 to 6 parts of organic soil, 4 to 6 parts of bamboo charcoal, 2 to 4 parts of sawdust, 1 to 3 parts of olive residue, 2 to 4 parts of sea mud, 2 to 4 parts of calcium superphosphate, 1 to 3 parts of borax, 0.4 to 0.6 part of alpha-isolupanine, 1 to 3 parts of urea, 0.4 to 1 part of compound sodium nitrophenolate, 1 to 2 parts of tea residue, 1 to 2 parts of potassium fulvate, 0.4 to 1 part of shell powder, 1 to 2 parts of meerschaum powder, 1 to 2 parts of potassium chloride, 1 to 3 parts of modified corn starch, 0.4 to 1 part of pinecone, 1 to 2 parts of chelated magnesium, 1 to 2 parts of garlic extract and 1 to 2 parts of chinaberry extract. The acidic soil adjusting fertilizer can retain fertilizer and water and realize sustained release and controlled release, is slightly alkaline, has high biotic potassium content, is a superexcellent acidic soil amendment since common soil is slightly acidic and lacks potassium, eliminates a pollution source of a biomass power plant and better protects the ecological environment.

Owner:安徽金农生态农业科技发展有限公司

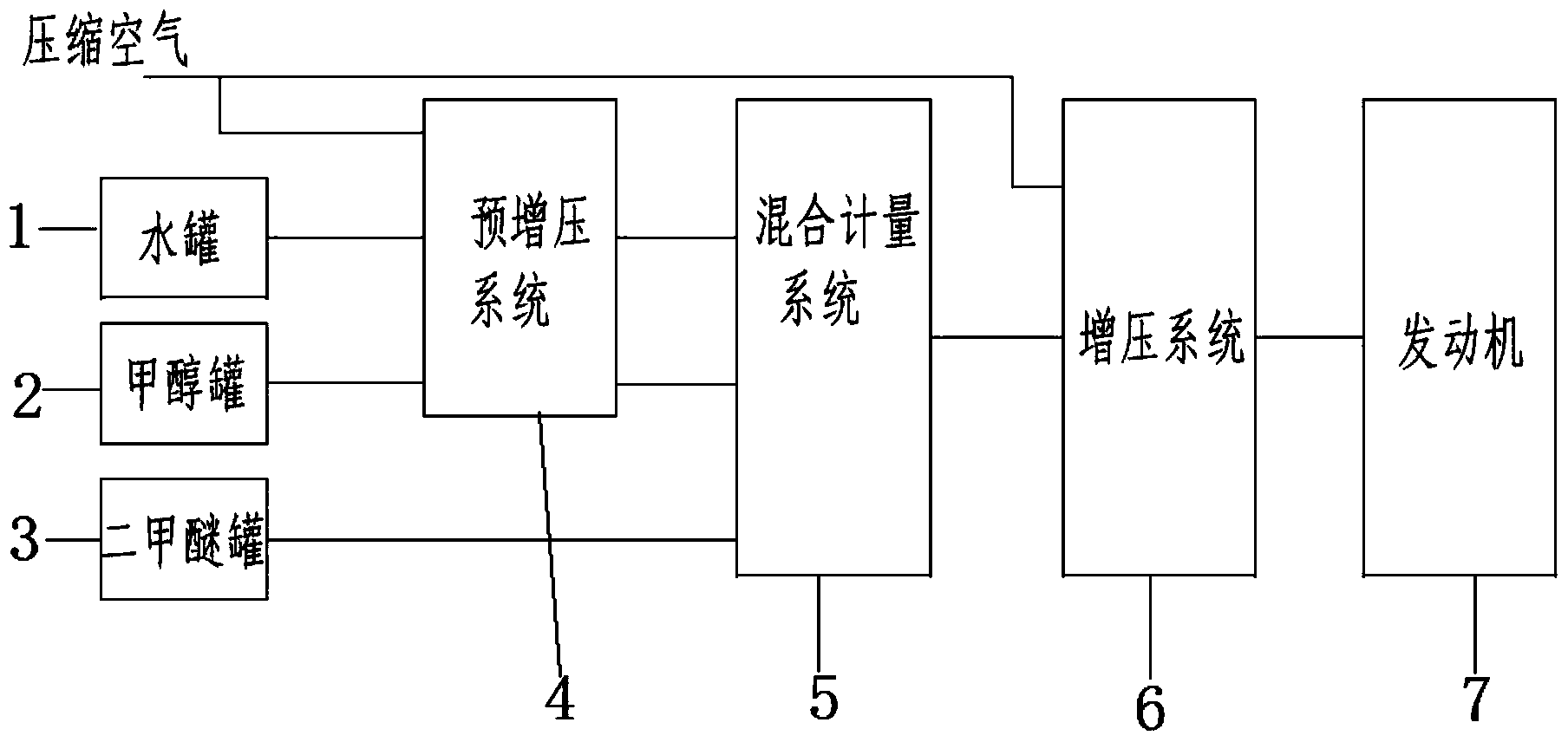

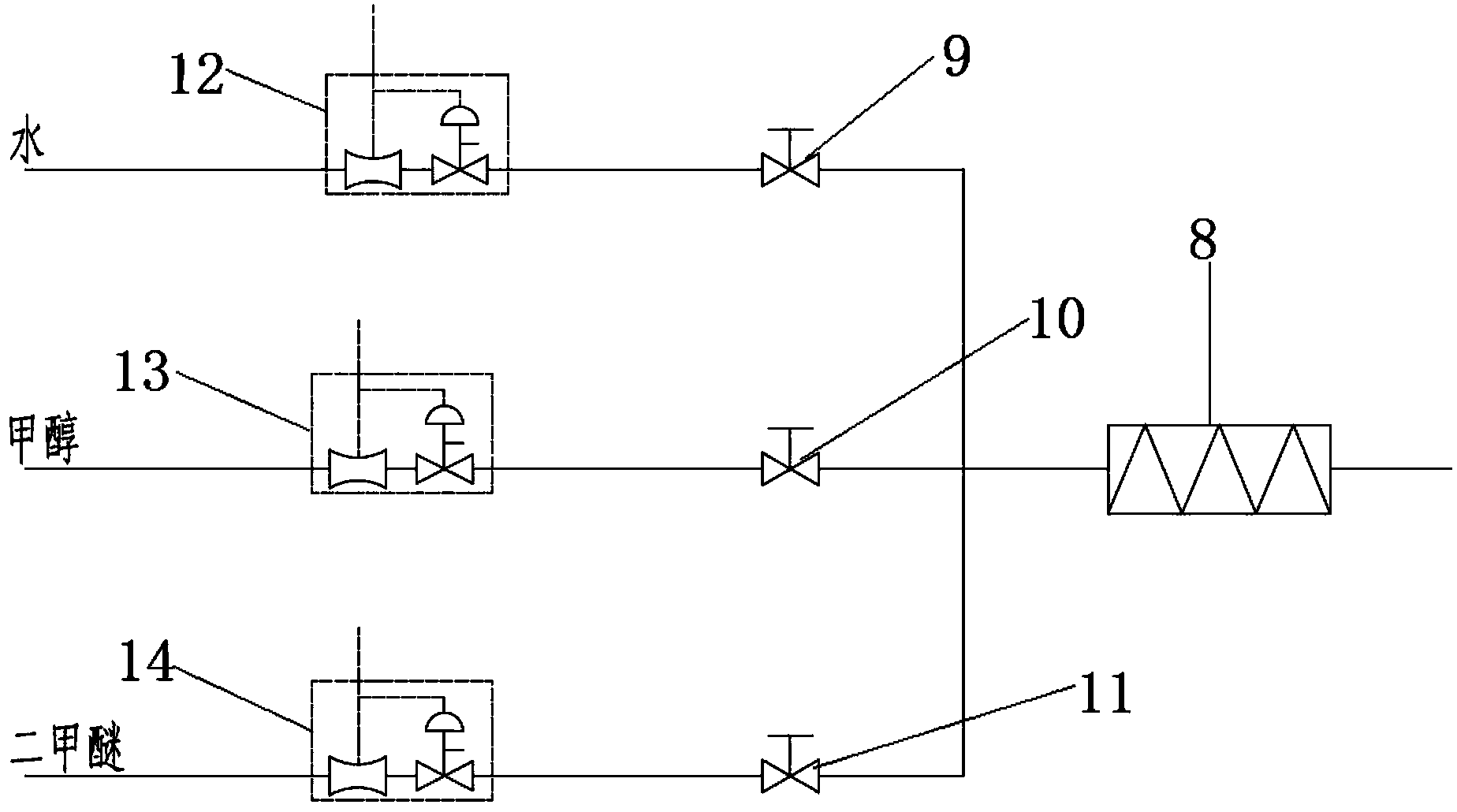

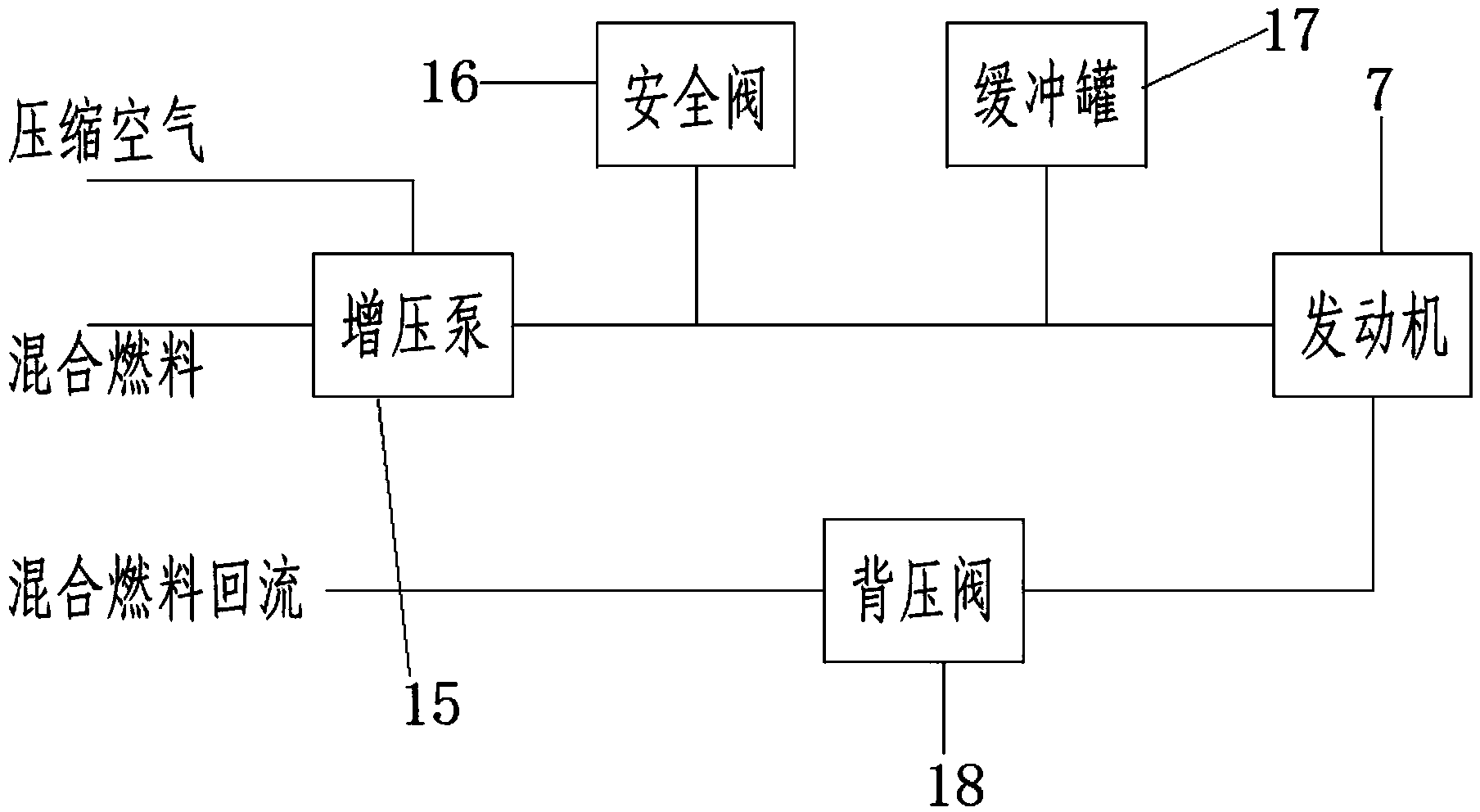

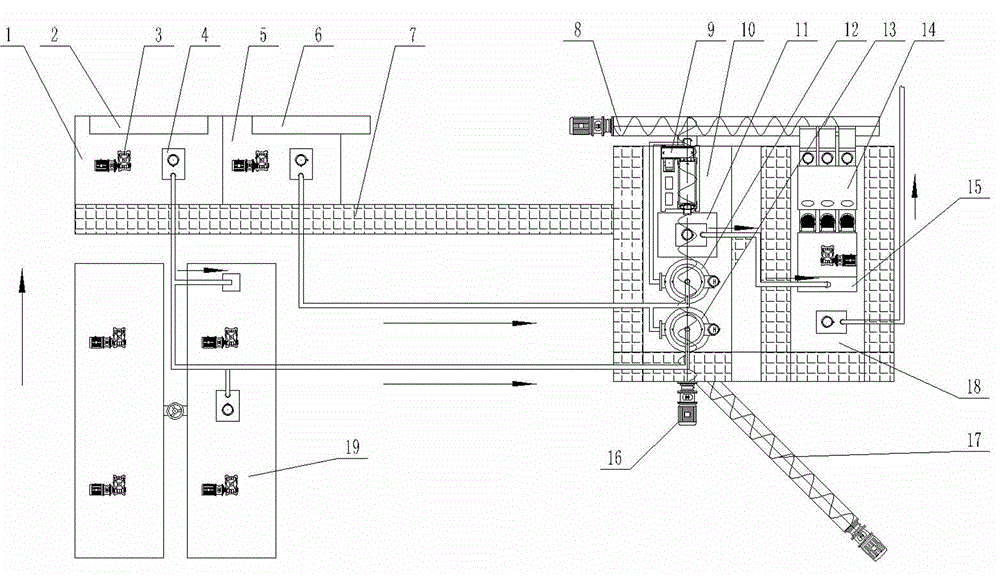

Methanol-based fuel high-pressure supplying device

ActiveCN104265450AAchieve hybridImprove availabilityInternal combustion piston enginesNon-fuel substance addition to fuelProcess engineeringInternal combustion engine

The invention discloses a methanol-based fuel high-pressure supplying device. The device comprises a methanol tank, a water tank and a dimethyl ether tank which respectively contain methanol, water and dimethyl ether; both the methanol tank and the water tank are connected with pre-pressurizing systems; the dimethyl ether tank is connected with a mixed measuring system; the pre-pressurizing systems and the mixed measuring system are connected, wherein the mixed measuring system is sequentially connected with a pressurizing system and an engine; in addition, the pressurizing system and the pre-pressurizing systems are all connected with air compressing devices. The methanol-based fuel high-pressure supplying device has the beneficial effects that methanol, dimethyl ether and water are mixed based on different ratios; in addition, the online control is realized; the demand on material supply at different pressures can be realized under a high pressure of 100 MPa; meanwhile, the flow rate can be adjusted within a certain range, and the utilization rate of the methanol-based fuel can be raised; the supplying system has a wide range of output pressure and can directly enter an internal combustion engine and other energy consumption devices without pressure reduction, and thus the energy consumption can be reduced; the self-cooling is realized, the operation can be individually performed, the pollution resource is avoided, and the long-time, safe, stable and reliable operation is reached.

Owner:北京海德利森科技有限公司

Formaldehyde-free wood adhesive film

The invention provides a formaldehyde-free wood adhesive film which comprises the following components in parts by weight: 100 parts of base material, 10-100 parts of filler, 5-15 parts of tackifier, 0.1-5 parts of crosslinking agent, 2-4 parts of stabilizer, 3-10 parts of maleic anhydride, 0-10 parts of cinnamic acid, 3-15 parts of atactic polypropylene or polyethylene wax, 0-3 parts of coupling agent, 1-5 parts of zinc oxide and 0.5-2.0 parts of stearic acid. The base material is a mixture of at least two of chloride high polymer, chlorosulfonate high polymer, ethylene-vinyl acetate copolymer, ethylene-ethyl acrylate copolymer and polyolefin; and the filler is at least one of shell powder, bark powder, wood meal, flour, short fiber, argil and graphite powder. The wood adhesive film is free of formaldehyde and organic volatile matters, can not influence and jeopardize the environment and human health, has the advantages of excellent environmental protection property and long shelf life, and is convenient for use, transportation and storage.

Owner:杨学荣

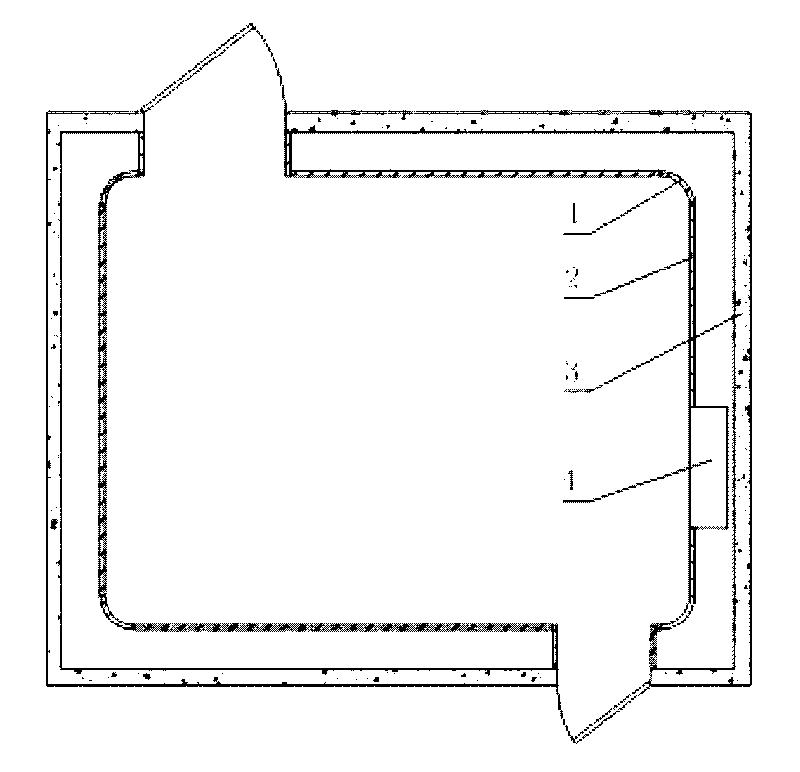

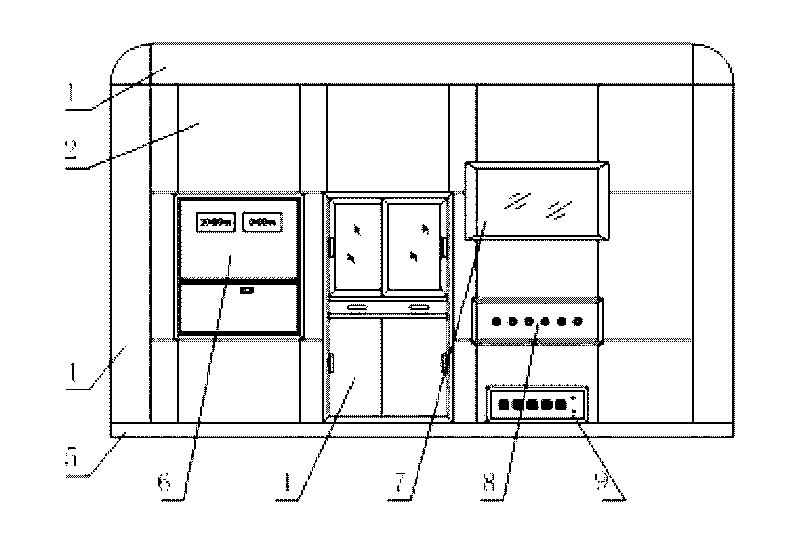

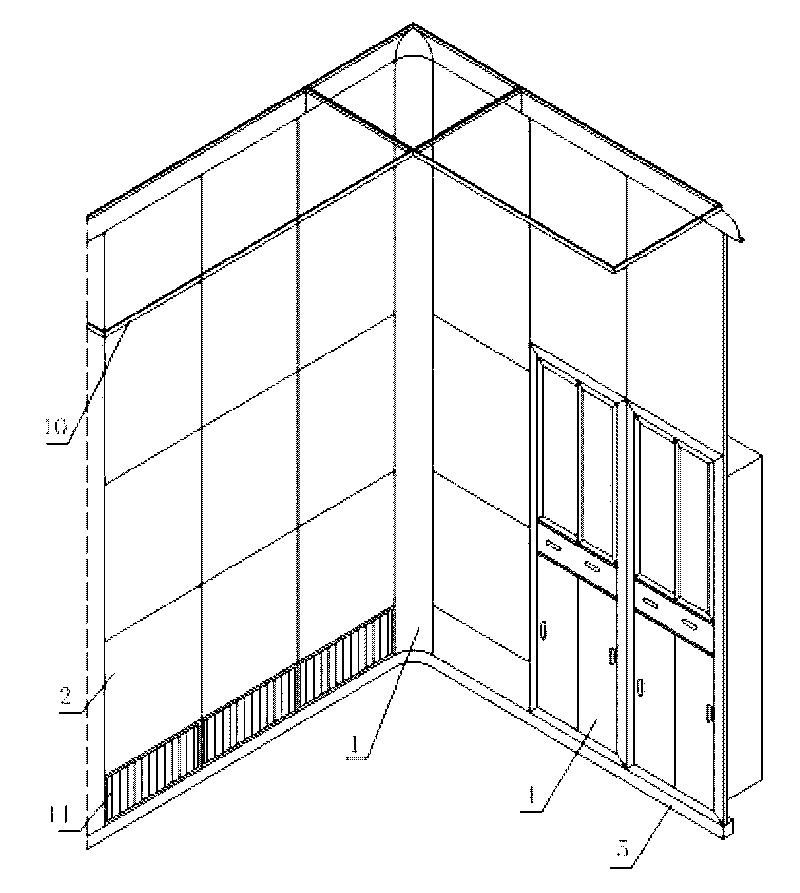

Clean operating room and construction method thereof

InactiveCN101736922AEasy to assemble and disassembleEasy to disassembleCovering/liningsHospitalsRear quarterKeel

The invention relates to a clean operating room and a construction method thereof. The clean operating room comprises floor layers, wall layers, and ceiling layers, wherein the floor layers are arranged on the civil construction ground surface; the wall layers are arranged in the civil construction wall surface; the ceiling layers are arranged below a civil construction ceiling; the wall layers are formed by combining keel ground corners fixed around the ground surface, and a plurality of modularized wall plates and corner plates fixed above the keel ground corners; the wall plates comprise flat panels and lateral plates which are bended towards the inner sides of the flat panels to form right angles and are fixedly connected with the peripheries of the flat panels; and the corner plates comprise arc panels and the lateral plates which are bended towards the inner sides of the arc panels to form right angles and are fixedly connected with the peripheries of the arc panels. The clean operating room has the advantage that the wall plates are convenient to disassemble and assemble.

Owner:西安市四腾工程有限公司

Organic carbon base fertilizer and production technology thereof

InactiveCN104892133AIncrease surface areaMaintain ecological balanceFertilizer mixturesPesticide residueAnimal feces

The invention discloses an organic carbon base fertilizer and production technology thereof. The carbon base fertilizer comprises the following raw materials, by weight: 30-35% of straw carbon powder, 8-12% of bamboo carbon powder, 10-15% of human excrement, 10-15% of pig dung, 5-10% of cow dung, 10-15% of chicken dung, 5-10% of sheep dung, and 2-5% of an organic matter extracting solution. According to the invention, no pollution is caused during a production process of the organic carbon base fertilizer; pollution sources of forestry and agricultural residues, and livestock dung are solved and are changed into treasures; cultivated land pollution can be effectively reduced; harmful bacteria of a cultivated land are killed; harms of heavy metal and pesticide residues for years are solved; and the surface area of soil is increased and is not hardened. The soil has extremely significant water-logging resistance, and ecological balance of the soil is restored.

Owner:朱建收

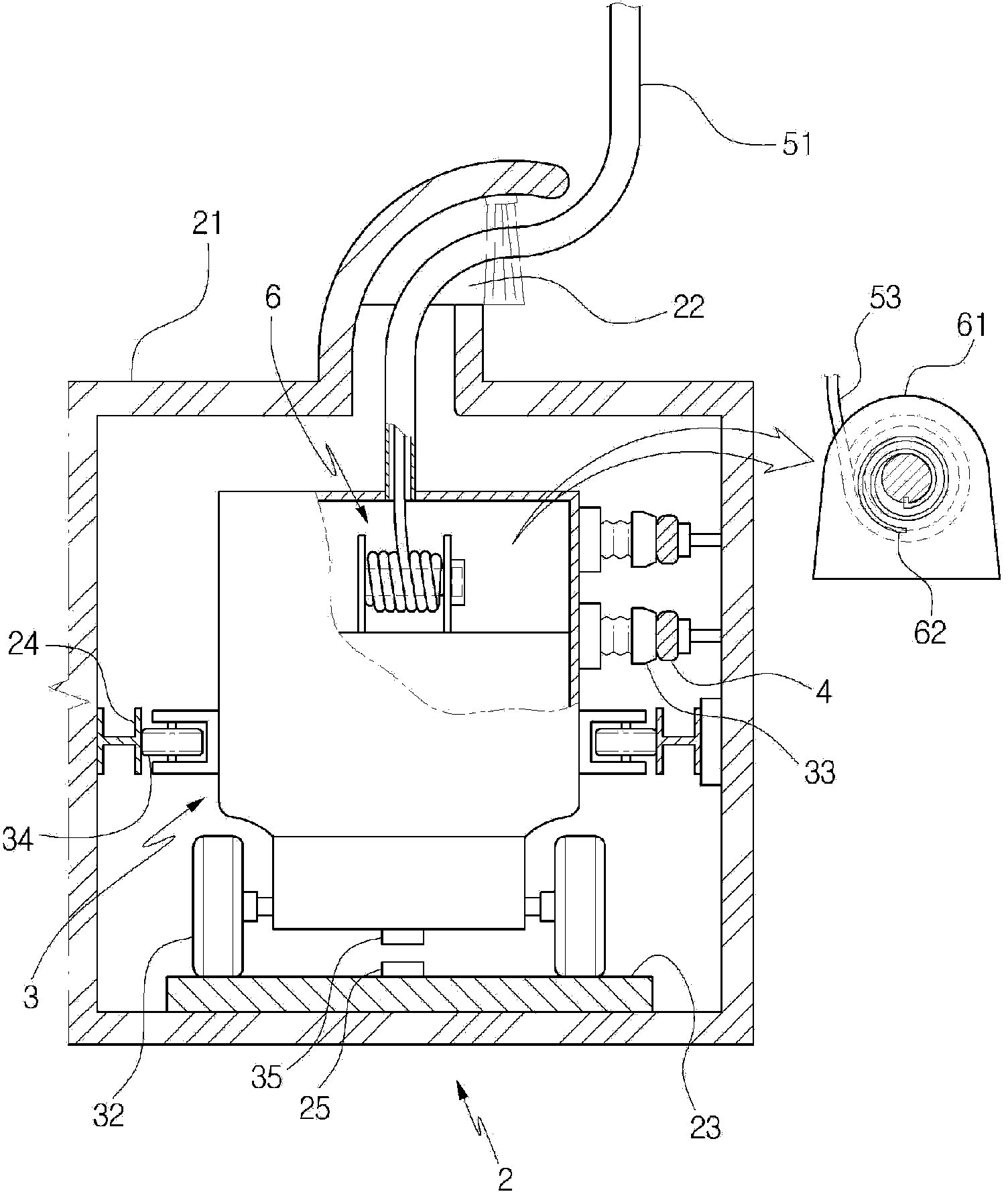

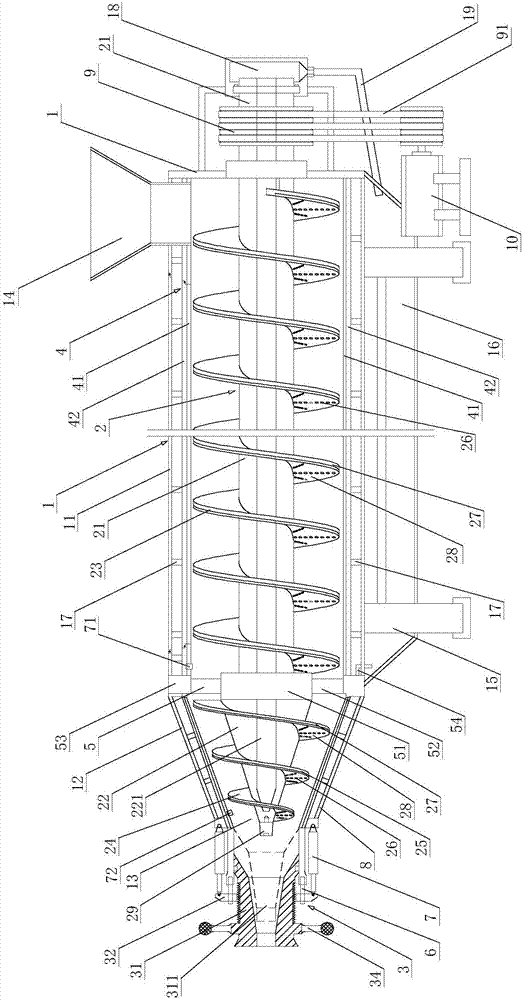

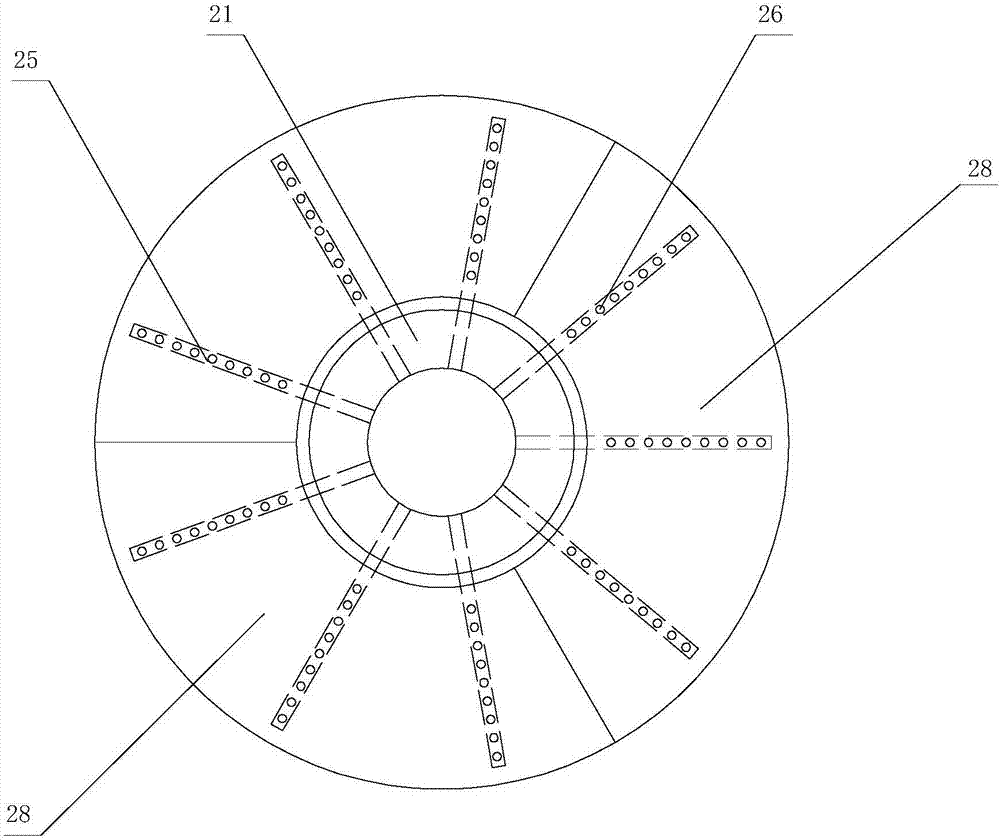

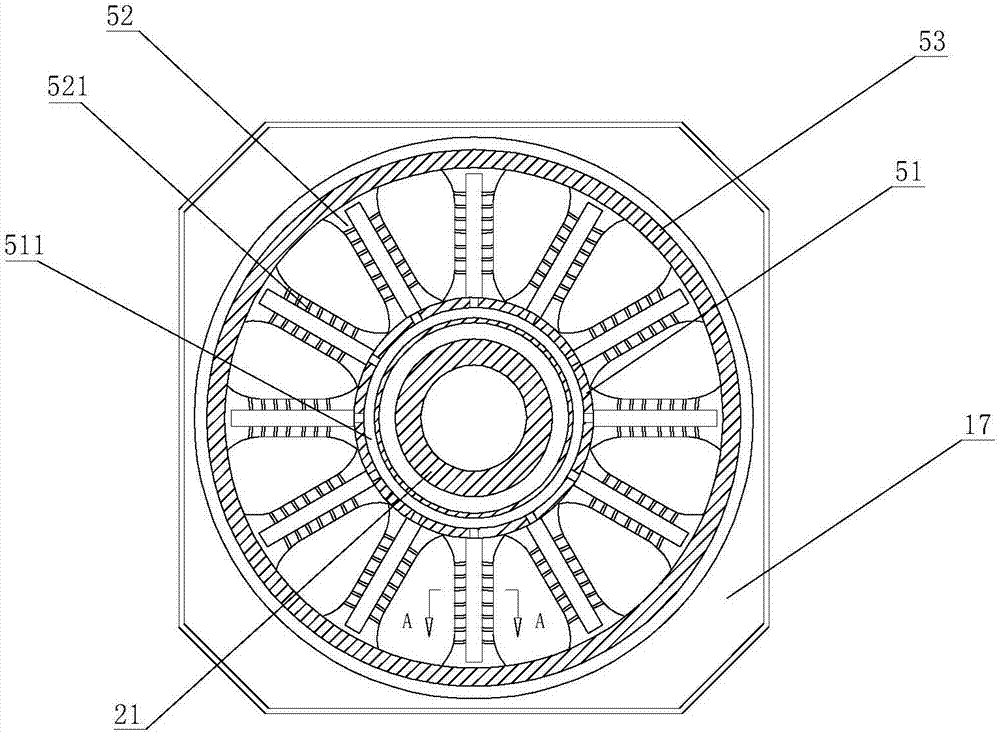

Novel horizontal screw-extrusion solid-liquid separation machine

The invention discloses a novel horizontal screw-extrusion solid-liquid separation machine. The novel horizontal screw-extrusion solid-liquid separation machine comprises a housing, a spoke support, a feeding dehydration mechanism and a pressure adjustment mechanism, wherein the housing comprises a main shell body and a conical shell body; the main shell body and the conical shell body are arranged at a front side and a rear side of the spoke support separately; a circular-barrel screen group is arranged in the main shell body; and a conical-barrel screen group matched with the conical shell body is arranged in the conical shell body. The feeding dehydration mechanism is arranged in the circular-barrel screen group, and comprises a hollow shaft and a front screw sheet; and the front screw sheet is arranged at an outer side of the hollow shaft. A conical press head is arranged at a rear end of the hollow shaft; and a rear screw sheet is arranged at an outer side of the conical press head. The pressure adjustment mechanism is arranged at a discharge port, and comprises a slide sleeve, a nut seat and a pressure adjustment cylinder group. According to the novel horizontal screw-extrusion solid-liquid separation machine disclosed by the invention, many dehydration structures are designed, classified dehydration is carried out on materials through the two screw sheets, and high dehydration capacity is achieved; a pressure on the materials can be adjusted in real time; and the novel horizontal screw-extrusion solid-liquid separation machine is small in size, high in efficiency, capable of avoiding material blockage, and high in automation degree.

Owner:苗增茂

Method for harmless treatment of drilling well waste mud

ActiveCN102381778AHigh strengthImprove efficiencyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationWell drillingColloid

The invention relates to a method for harmless treatment of drilling well waste mud. The method comprises the following steps of: firstly adding 150-250 mg / l of colloid destabilizing agent to the waste mud; fully stirring for 1-2 h; then adding 90-300 mg / l of ion settling agent to the waste mud; stirring for 1-3 h and adding 1-3 mg / l of adsorption flocculant; stirring for 1-3 h and standing for 1-2 d; then adding a solidifying agent accounting for 10-40% of total weight of the waste mud to the drilling well waste mud, wherein the solidifying agent is prepared by grinding, stirring and mixing 50-70% of coagulator, 10-25% of adsorbent and 15-35% of calcium oxide; standing for 10-20 d after the solidifying agent is added; and solidifying the drilling well waste mud to form a condensate. The method can solidify the drilling well waste mud with high water content, high organic matter and many harmful substances and has the characteristics of low treatment cost, convenience for use, long stabilization period, no secondary pollution or no damage to soil and meets the environmental protection requirement and the like.

Owner:BEIJING ENRUIDA TECH

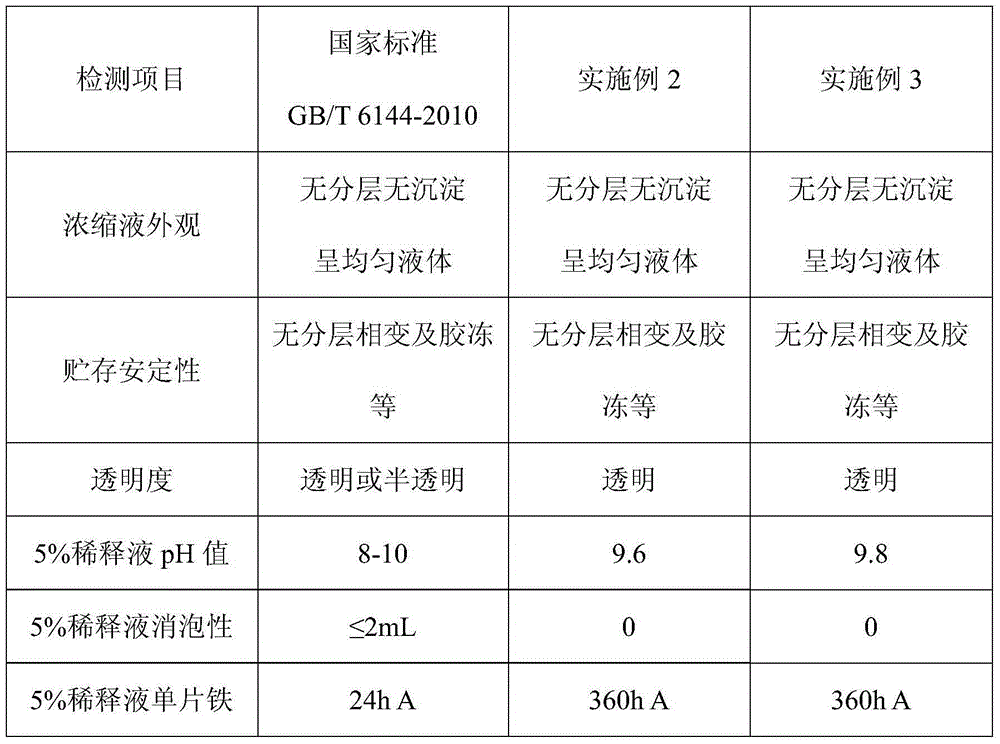

Honing solution and preparation method thereof

InactiveCN104911015AHas a cleaning effectImprove the lubrication effectLubricant compositionWater basedRust converter

The invention provides a honing solution and a preparation method thereof. The honing solution is prepared from the following components in percentage by mass: 10%-25% of extreme pressure additive, 10%-25% of penetrating agent, 5%-10% of anti-rusting agent, 0.5%-3% of bactericide, 0.1%-0.5% of softener, 0.1%-0.2% of defoamer and the balance of water. The metal processing solution is good in lubrication effect, excellent in anti-corrosion performance, and good in cooling property and cleaning property; various defects of products in the prior art can be solved; as the raw materials of the honing solution completely include no oily component, the pollution source is eliminated from the source; the honing solution is a real water-based product; the industrial production cost is greatly reduced; and besides, the honing solution is green and environment-friendly, friendly to the human body and the environment, and applicable to honing processing completely instead of oil based products.

Owner:SHAANXI YUHANG CHEM ENG

Electrolytic manganese slag comprehensive utilization technique

InactiveCN101306425BAvoid pollutionEliminate sources of pollutionSolid waste managementSolid waste disposalBuilding productElectrolysis

The invention relates to an electrolytic manganese slag processing method, in particular to an electrolytic manganese slag comprehensive utilization process. The method recovers the recyclable materials in electrolytic manganese slag through repeated water washing and filtering. The method can solve the air pollution source, particularly eliminate the water pollution source, and protect people health from being damaged. The method can extract higher-value chemical products through the scientific flow, and make the residuary filter residue into building products, thereby effectively utilizing the resource. Zero discharge is realized during the overall process of the technical proposal of the method, and because no additional chemical substances are added, additional environmental pollutioncan not be caused.

Owner:卿富安

Tech. process for reducing mineralization of extracting oil sewage

InactiveCN1693239AEmission reductionHigh water yieldWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentWater productionSewage

A process for demineralizing the sewage in oil field, which contains oil, polymers and high-mineralized water, includes such steps as coagulating, deposition, air floating, filtering, chemical cleaning in a circulating membrane unit for further treating, demineralizing in a nano-modified ion exchange unit, desalting, and using the treated water to prepare polymer for reusing it.

Owner:HARBIN INST OF TECH +1

Electro-deionization method and electro-deionization device for recycling ammonia nitrogen waste water

ActiveCN101648738ASimple processReduce processing costsDispersed particle separationAmmonium salt preparationAmmoniacal nitrogenEnvironmental engineering

The invention discloses an electro-deionization method and an electro-deionization method for recycling ammonia nitrogen waste water, wherein the electro-deionization method comprises the following steps: a plurality of modules which are connected in series or in parallel are selected to form a set of electro-deionization device according to the water quantity of waste water to be processed and the mass concentration of ammonium salt of the waste water, wherein inlet water of the device is ammonia nitrogen waste water that is preprocessed and accordant with requirements, producing water is process pure water, does not contain nitrogen-containing compounds and can be recycled; in addition, ammonium salt thickening solution is obtained by a thick water circulated thickening method, and the mass concentration of the ammonium salt reaches an expected requirement of 1-25 percent; and the thickening solution is evaporated, concentrated and crystallized to obtain the solid ammonia nitrogen product. The invention not only can reach the zero emission requirement of the system, but also simultaneously recycle the ammonium salt thickening solution and the process pure water. The invention hasadvanced process, low cost, low energy consumption and simple operation.

Owner:王方

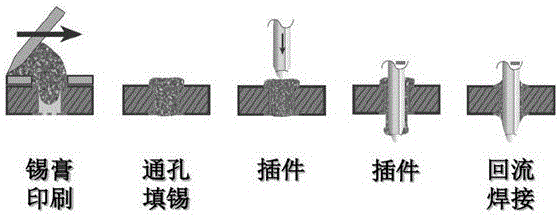

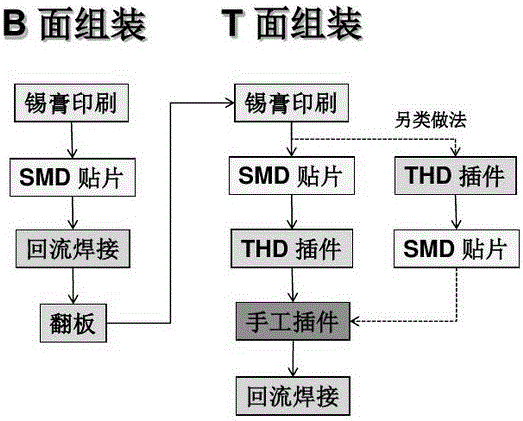

Manufacturing method for improving PCBA production efficiency

InactiveCN106852020AIncrease productivityShort manufacturing cyclePrinted circuit assemblingManufacturing technologyTemperature resistance

The invention discloses a manufacturing method for improving PCBA production efficiency, and belongs to the technical field of computer processing and manufacturing. The manufacturing method for improving PCBA production efficiency of the present invention includes the following steps: S1: making a printed steel plate with special openings to ensure that the solder paste at the position of the DIP material meets the welding requirements; S2: the components used in the production meet high temperature resistance and are suitable for SMT placement machines SMD packaging requirements for medium and high-speed machines and general-purpose machines; S3: DIP components are installed on the corresponding SMT machines through loading trolleys and feeders; S4: Automatic insertion machines are used for components that cannot meet the requirements of the SMT machines Or manually insert into the corresponding part position; S5: After reflow soldering, check the welding effect of the part. The manufacturing method for improving the PCBA production efficiency of the invention can greatly reduce the PCBA production cost, improve the product production quality, shorten the production cycle, and has good popularization and application value.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Clean production process for high purity gossypol

InactiveCN105693488AIncrease added valueEliminate sources of pollutionFatty oils/acids recovery from wasteFatty substance recoverySeparation technologySimulated moving bed

The invention belongs to the technical field of processing oil crops. Specifically relates to a clean production process of high-purity gossypol. It provides a simple, cheap and efficient clean production process for obtaining high-purity free gossypol, and can realize large-scale industrial preparation of free gossypol. Compared with the existing process, this process does not use acetic acid to convert gossypol to gossypol acetate, and then converts gossypol acetate to gossypol, and uses simulated moving bed chromatography continuous separation technology to directly obtain a purity of 98% Ur degree of high -purity glycol, from the source of the source, except for cotton oil soap -to -foot processing acidized oil, preparing wastewater, waste residue and acetic acid waste solvents accompanied by glycol, realizing the green cleaning of cotton oil soap foot processing, eliminating it, eliminating it It has greatly improved the quality and yield of gossypol and the co-produced cotton oil fatty acid, greatly increased the added value of cotton oil soapstock, and has broad application prospects in the field of cottonseed processing. .

Owner:JIANGNAN UNIV

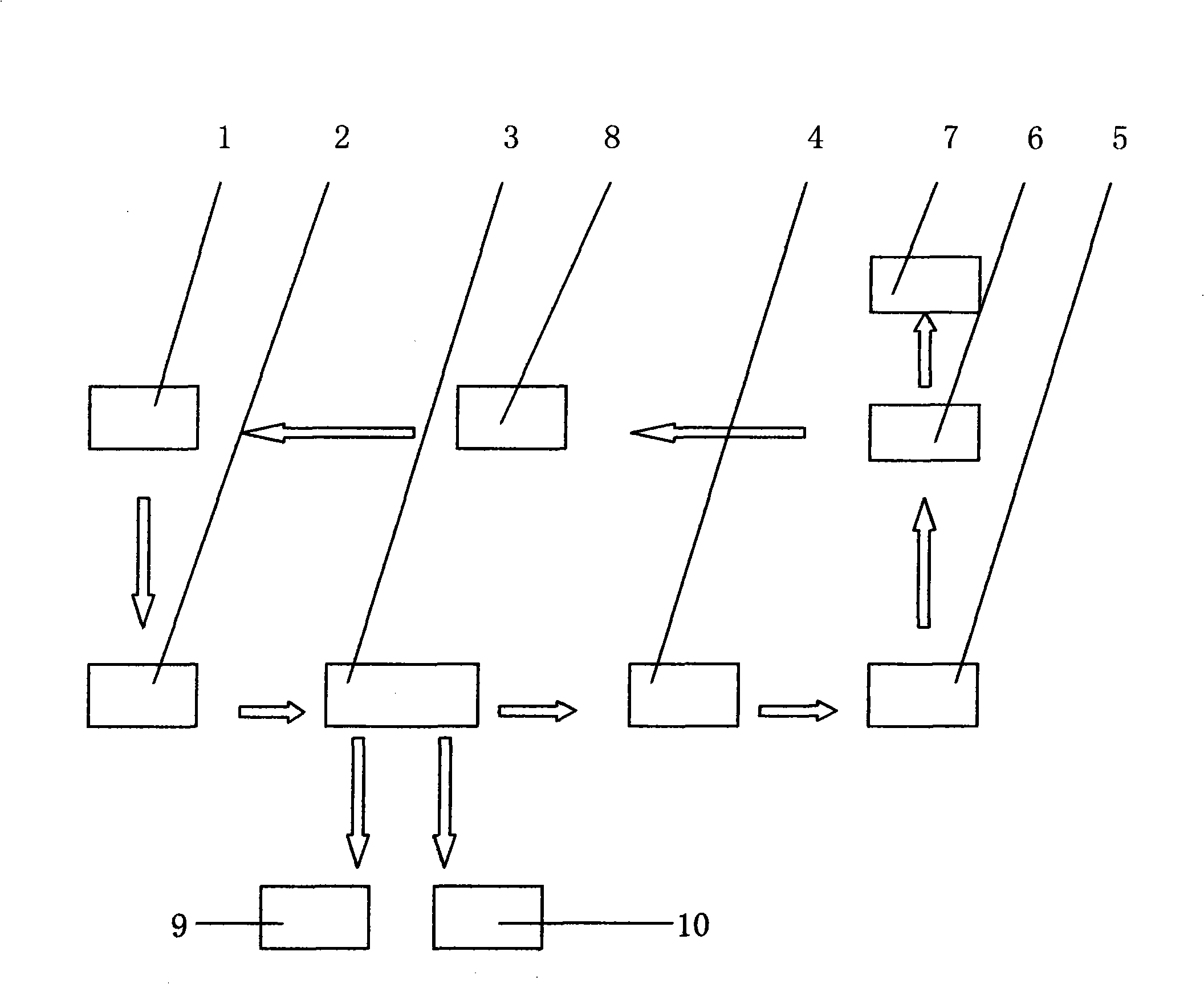

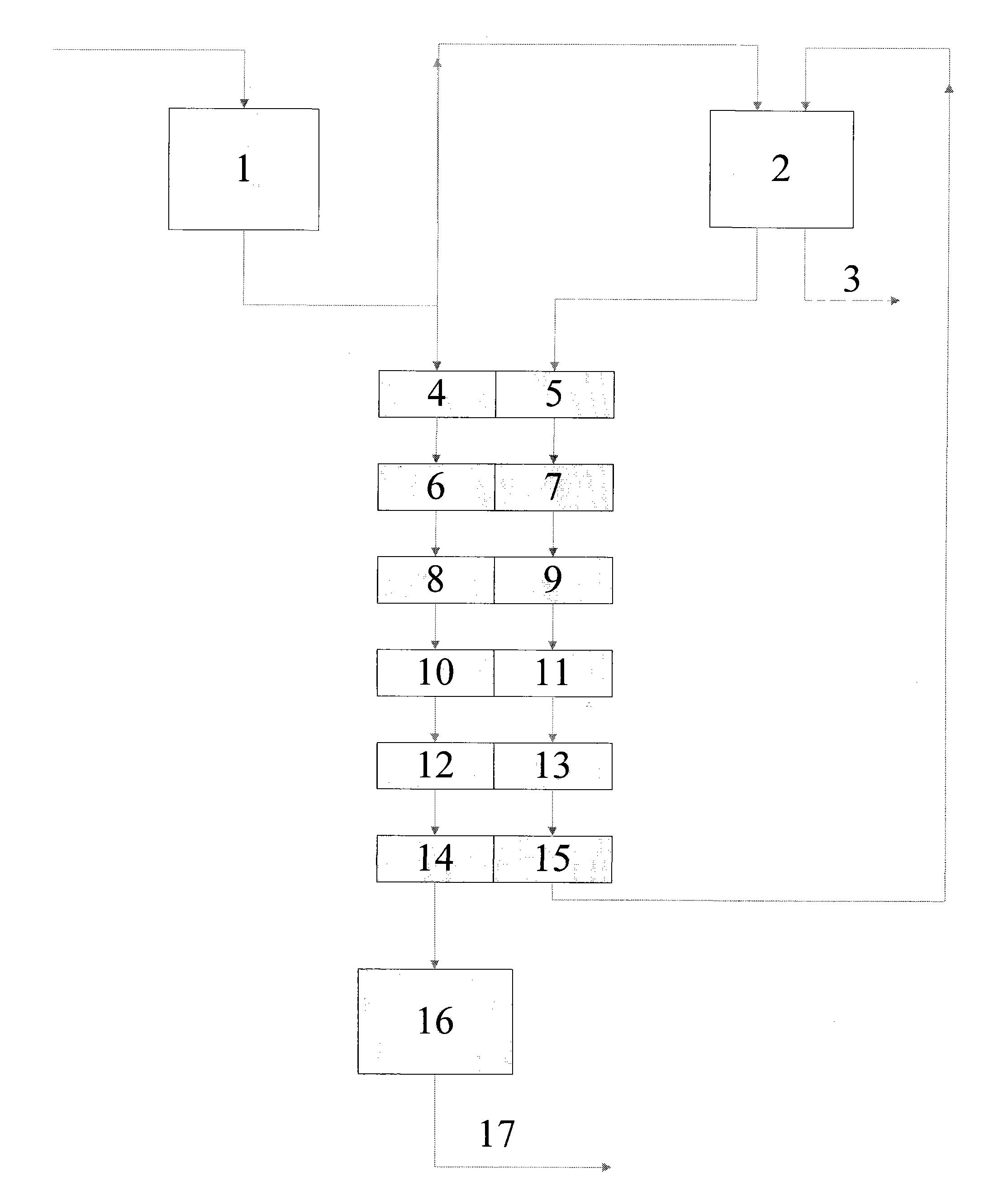

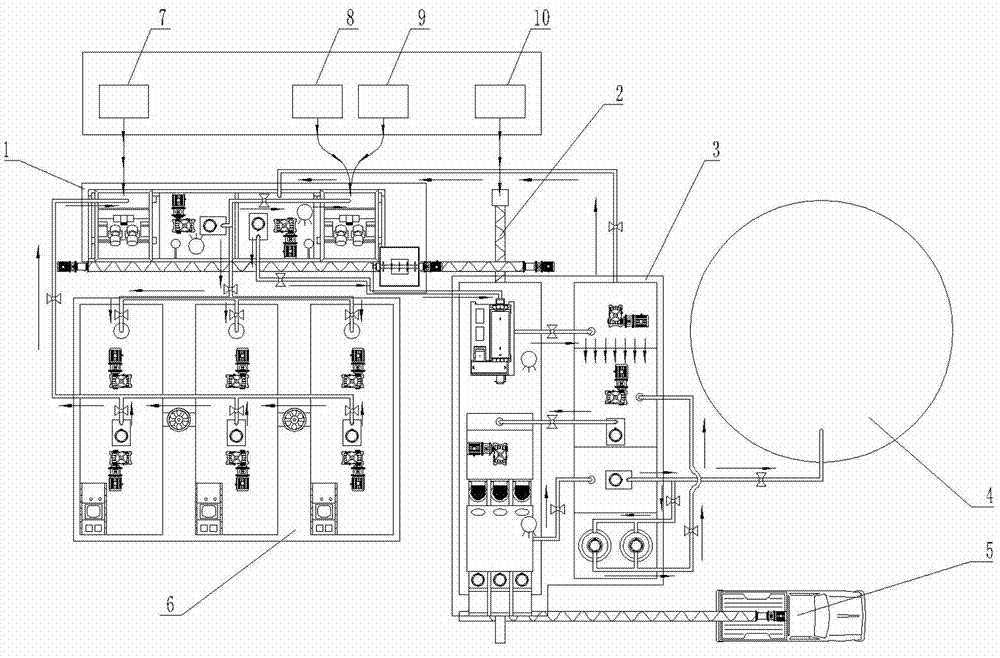

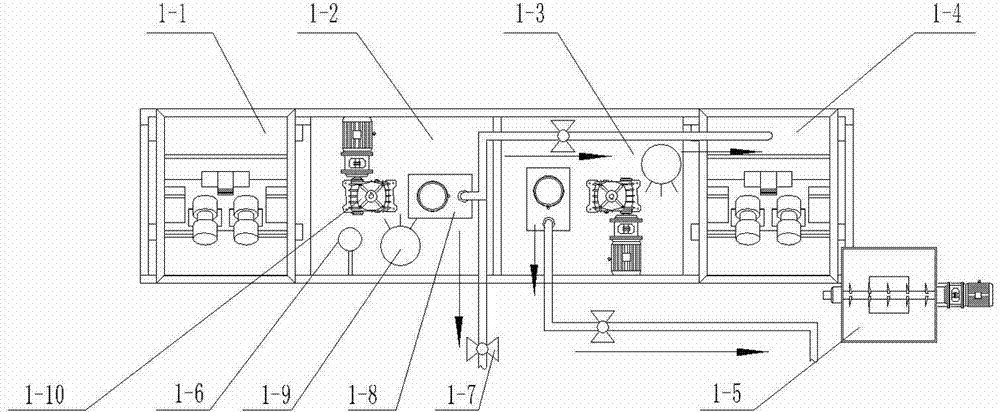

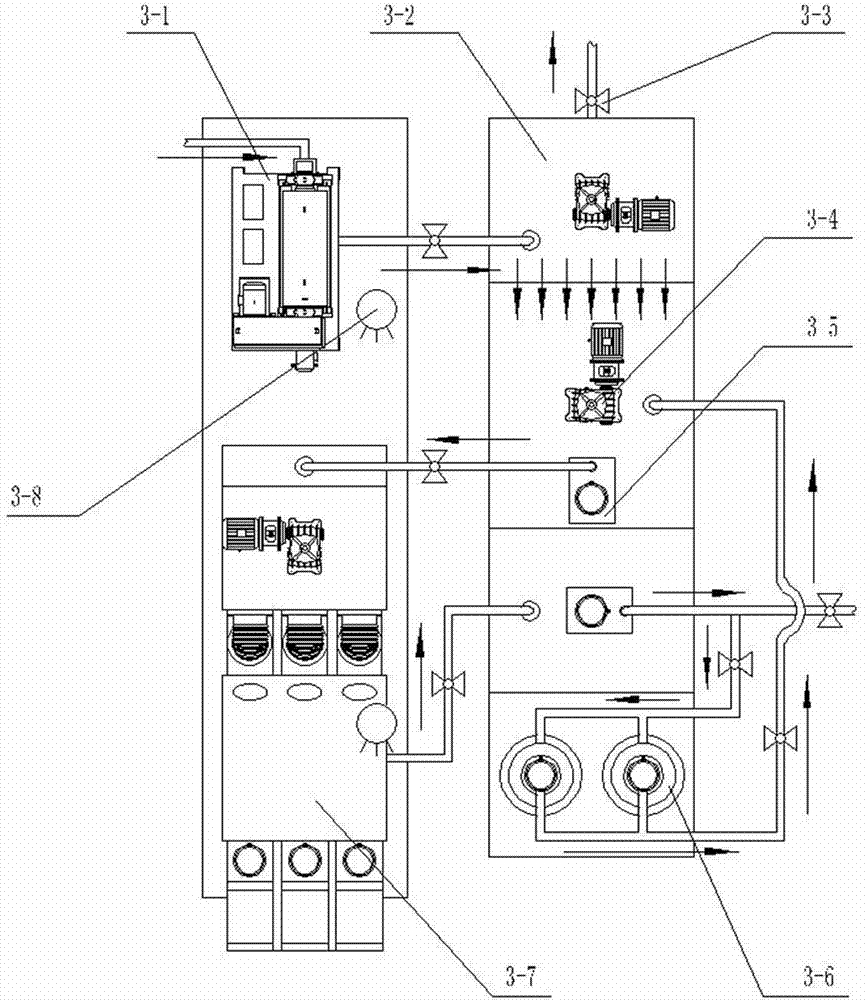

Drilling waste slurry integrated treatment system

ActiveCN104712273AImprove reuse rateScientifically Effective Classification and Divide and ConquerFlushingWell drillingSlurry

The invention discloses a drilling waste slurry integrated treatment system. The drilling waste slurry integrated treatment system comprises an automatic classification and collection module, a multi-grade solid-liquid separation combined module and a solid-phase conveying system, wherein the automatic classification and collection module comprises a plurality of rock debris slurry removing machine and slurry storage tank combinations which are connected in series; the multi-grade solid-liquid separation combined module comprises a sand scrap removing machine, a multifunctional adjusting tank and a water treatment regeneration device; the multifunctional adjusting tank comprises a medicine adding treatment region and a clean water temporary storage region; and the solid-phase conveying system is connected with a curing agent adding device. The high-grade waste slurry treatment combined system integrates a plurality of functions of collecting slurry, storing, carrying out solid-liquid separation, purifying the slurry, carrying out solid-phase conveying and field curing, recycling a liquid phase and the like; the waste slurry can be scientifically and effectively classified and treated by classes in a drilling process; and a drilling and curing innovative pattern is realized, and the national blank in the aspect is filled. By virtue of the drilling waste slurry integrated treatment system, the use amount of curing medicaments can be greatly reduced, and the recycling rate of a treated liquid phase also can be greatly improved.

Owner:天正浚源环保科技有限公司 +2

Integrated waste drilling mud treatment system capable of treating while drilling

ActiveCN104695881AScientifically Effective Classification and Divide and ConquerAchieve reductionFlushingFluid phaseWell drilling

The invention discloses an integrated waste drilling mud treatment system capable of treating while drilling. The integrated waste drilling mud treatment system capable of treating while drilling comprises two collecting tank bins, a multi-stage solid-liquid separation module, a deep treating module and a conveying system. The multi-stage solid-liquid separation module comprises a centrifugal machine, a liquid transfer bin, a coarse-mesh dryer and a fine-mesh dryer, wherein the mesh number of the fine-mesh dryer is larger than that of the coarse -mesh dryer, and a liquid outlet of the centrifugal machine is connected with the liquid transfer bin. The deep treating module comprises a water treating regenerator and a liquid recovery tank, and a liquid outlet of the water treating regenerator is connected with the liquid recovery tank. A feeding port of the coarse-mesh dryer is connected with the first collecting tank bin, and a feeding port of the fine-mesh dryer is connected with a liquid outlet of the coarse-mesh dryer and the second collecting tank bin. The integrated waste drilling mud treatment system capable of treating while drilling has the advantages that on one hand, use of solidifying chemical agents can be reduced greatly, so that harmful solid discharge is reduced fundamentally; on the other hand, liquid recovery ratio after treatment is increased greatly, so that waste drilling mud is reduced fundamentally.

Owner:天正浚源环保科技有限公司 +2

Method for preparing protein feed by utilizing waste liquid fermentation in production of ginkgo leaf extracts

InactiveCN104472856AEliminate sources of environmental pollutionGood economic and social benefitsAnimal feeding stuffLeavening agentFermentation starter

The invention discloses a method for preparing protein feed by utilizing waste liquid fermentation in production of ginkgo leaf extracts. The method is characterized by comprising the steps: adsorbing ginkgetin through macroreticular resins in the production of ginkgo leaf extracts; condensing effluent waste liquid which is obtained by the adsorption until the water content reaches 60-62 percent; adding concentrates including 2.5-3.5 percent of brown sugars, 1.5-2.5 percent of malt extracts and 0.25-0.5 percent of yeast extracts; performing hot-pressing sterilization; cooling the temperature to be below 40 DEG C; adding 8-12 percent of composite microbiological bacteria leavening agents at the temperature of 30-34 DEG C under the condition of the ventilation quantity of 0.8 m<3> / min to perform solid state fermentation for 60-72 hours; drying in vacuum at the temperature of 50-65 DEG C under the condition that the vacuum degree is -0.07--0.1MPa until the water content is 4-6 percent so as to obtain a fermentation protein feed product. According to the method, a new method, a new technology and a new technical route are provided for development and utilization of waste liquid caused by processing the ginkgo leaf extracts, and the feasibility is provided for effective utilization of wastes; moreover, the fermentation protein feed product is easy and simple in processing, high in utilization rate, low in cost and high in economic benefit, and has a great popularization and application value.

Owner:JIANGSU QIANYAOTANG GUOYI RES INST CO LTD

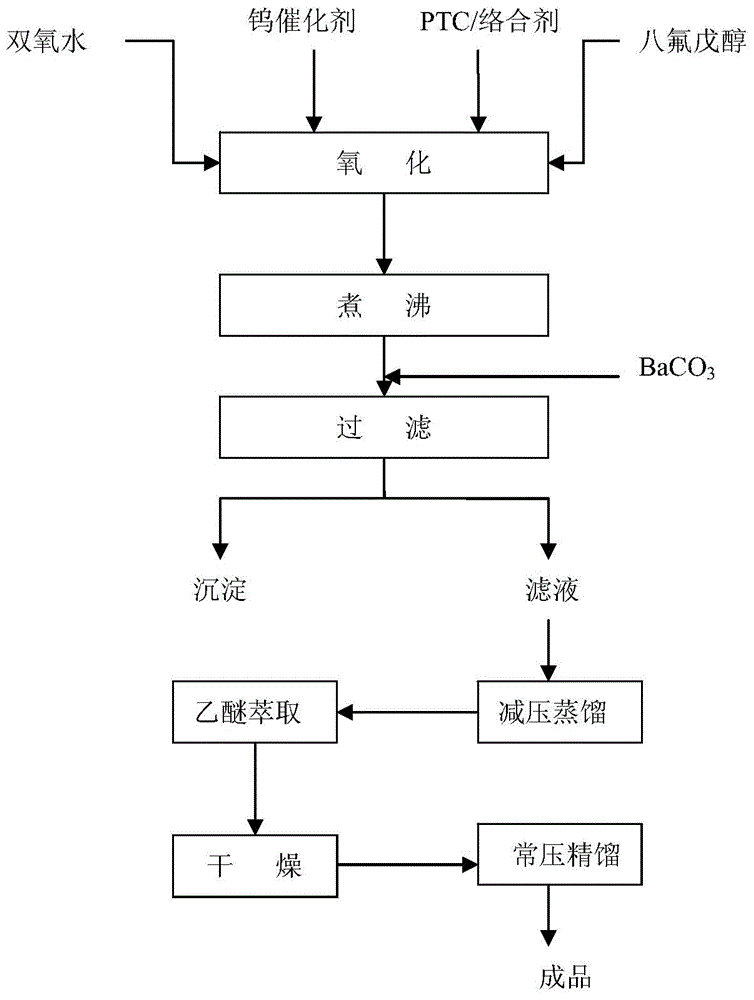

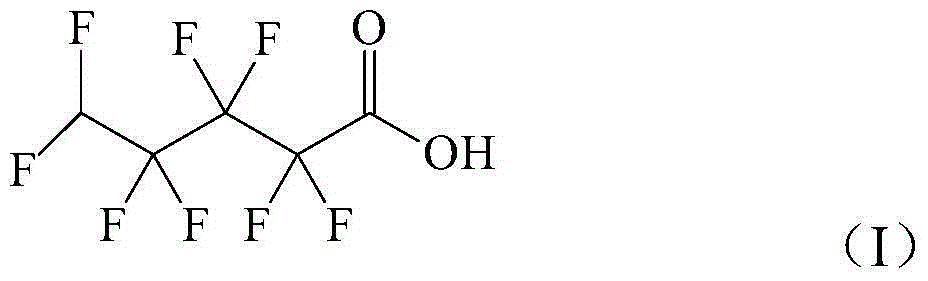

Method for preparing octafluorovaleric acid under catalytic oxidation action of oxydol

ActiveCN104355987AEliminate sources of pollutionImprove oxidation capacityOrganic compound preparationCarboxylic compound separation/purificationSodium tungstate dihydrateCatalytic oxidation

The invention belongs to the field of organic chemistry, and relates to a method for preparing octafluorovaleric acid under the catalytic oxidation action of oxydol. The method comprises the following steps: 1) mixing oxydol, a phase-transfer catalyst or complexing agent and sodium tungstate in a mole ratio of 100:(0.7-1.2):(0.7-1.2), and heating the mixture to 85-90 DEG C; 2) adding octafluoropentanol into the mixture obtained in the step 1); and 3) adding BaCO3 powder to precipitate the sodium tungstate in the reaction mixture, stirring for 0.5-1.5 hours, cooling to 40-60 DEG C, and filtering to remove the precipitate. The invention provides an environment-friendly economically-feasible method for preparing octafluorovaleric acid; and by using the oxydol as the oxidizer, the reaction product is single, and the only expected reaction byproduct is water, thereby basically eliminating the pollution source of the oxidation process.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

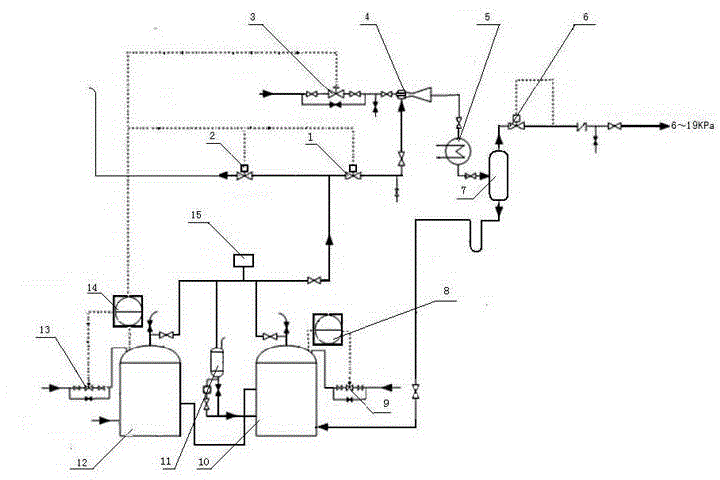

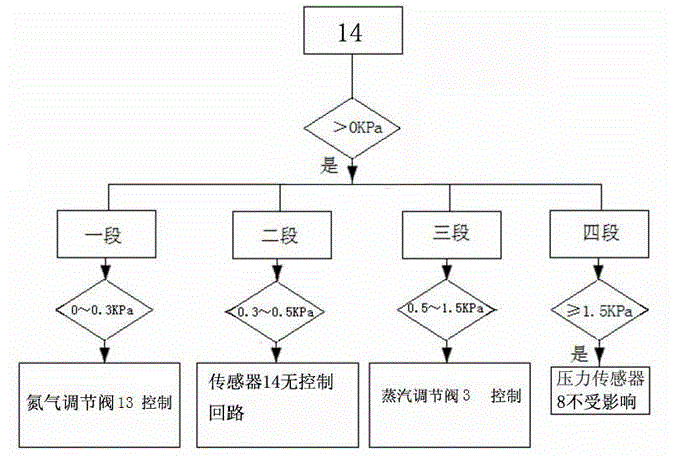

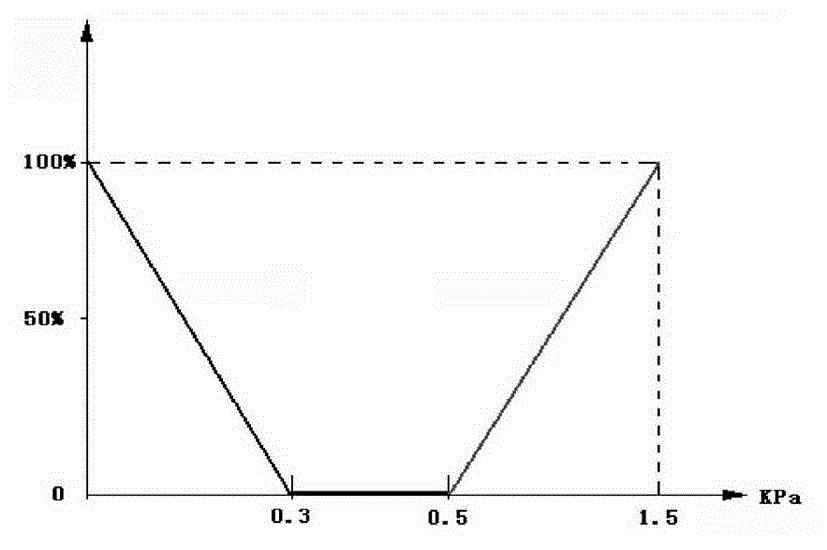

Sealed recovery and operation pressure stabilizing control method for tank top tail gas of refinery enterprise atmospheric storage tank

ActiveCN105668064AGuaranteed uptimeSolve the difficult problem of airtight recyclingLarge containersNitrogenSewage

The invention relates to a sealed recovery and operation pressure stabilizing control method for tank top tail gas of a refinery enterprise atmospheric storage tank. The sealed recovery and operation pressure stabilizing control method for the tank top tail gas of the refinery enterprise atmospheric storage tank is suitable for production requirements of a refinery enterprise and comprises the steps that the tank top tail gas in a steam jet compressor is subjected to gas-steam on-line supercharging and then conveyed to a cooler to be cooled to 45 DEG C; after the tank top tail gas is subjected to gas-liquid separation, non-condensable gas enters a refinery low-pressure gas flare system, and condensate liquid reflows to a sewage storage tank through self pressure. Normal operation of the sealed recovery and operation pressure stabilizing control method is controlled in a segmented mode, when the tank top pressure is 0-0.3 kPa, a nitrogen adjusting valve is opened, and a steam adjusting valve is closed; when the tank top pressure is 0.3-0.5 kPa, the nitrogen adjusting valve is closed, and the steam adjusting valve is closed; when the tank top pressure is 0.5-1.5 kPa, the nitrogen adjusting valve is closed, and the steam adjusting valve is opened; and when the tank top pressure is greater than or equal to 1.5 kPa, a control brake valve is opened. According to the sealed recovery and operation pressure stabilizing control method for the tank top tail gas of the refinery enterprise atmospheric storage tank, the tank top tail gas of the atmospheric storage tank is led into the refinery low-pressure gas flare system after being supercharged, the zero emission purpose is achieved, and the problem that the atmospheric storage tank is low in operation pressure is solved.

Owner:CHINA PETROLEUM & CHEM CORP

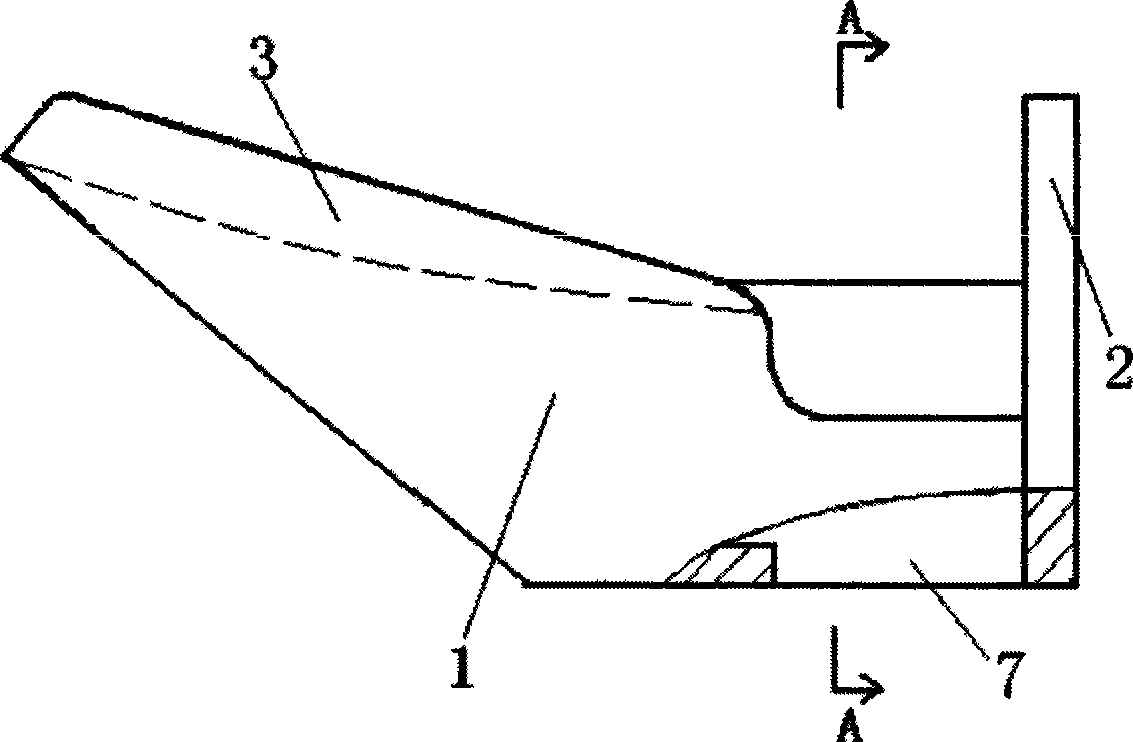

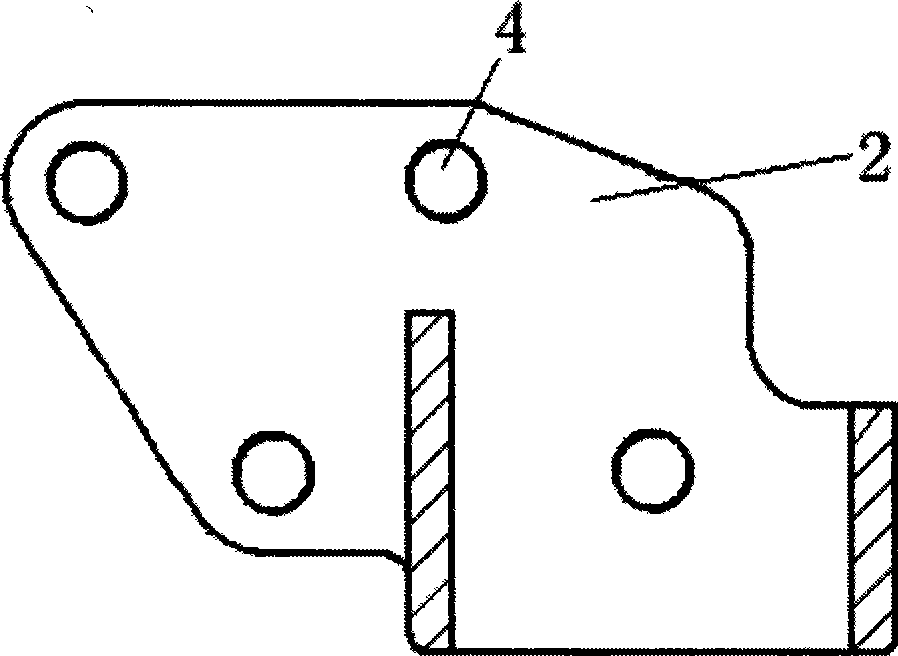

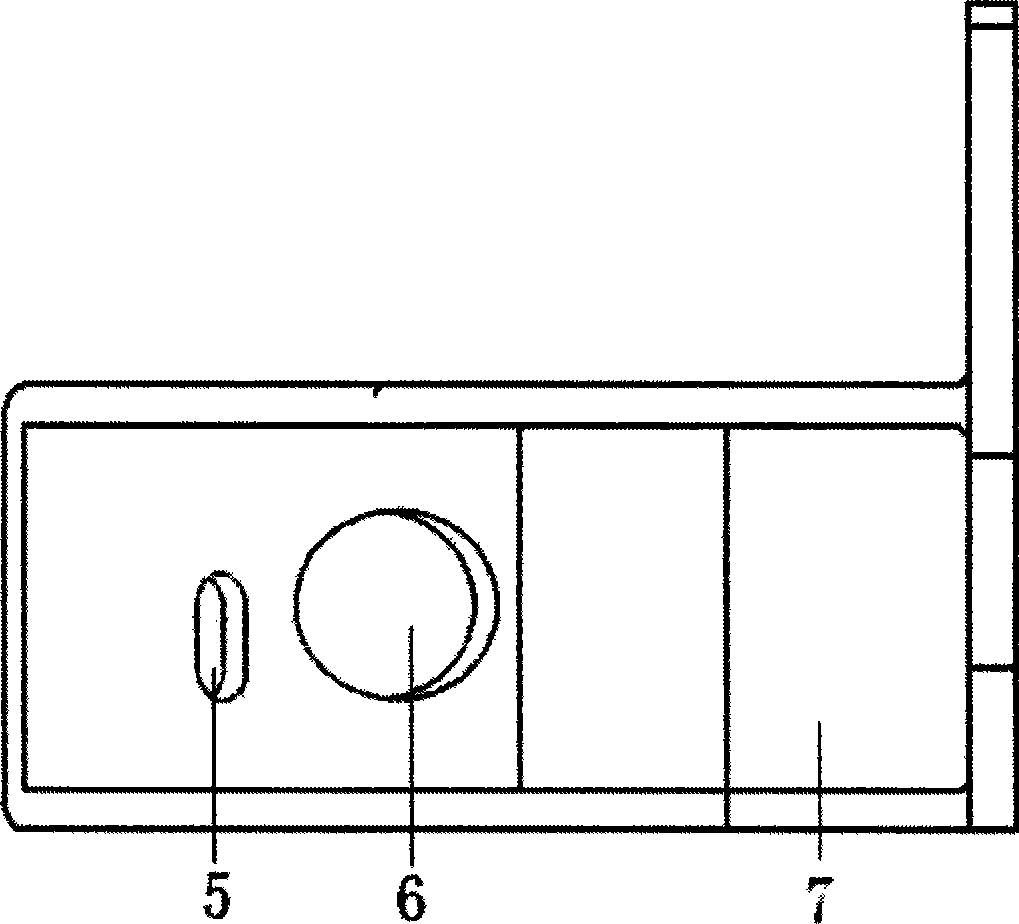

Support frame for connection of diesel engine and vehicle large frame and technique for processing the same

InactiveCN101503055AReduce labor intensityNo pollution in the processOther manufacturing equipments/toolsJet propulsion mountingPunchingDieseling

The invention relates to a support frame and the processing technique thereof, belonging to the technical field of the support frame. The support frame is characterized by comprising a steel plate (1) and a steel plate (2); the steel plate (1) and the steel plate (2) are integrally welded and fixed; the steel plate (1) is provided with a through hole (5) and a through hole (6) formed by punching; the steel plate (2) is distributed with drilling holes (4); the upper part of the steel plate (1) is fixed with a protrudent reinforcing rib (3). The processing technique comprises the steps of: trimming the steel plate (1) by a pressing machine; bending and swaging the trimmed steel plate (1) by the pressing machine; punching the bended steel plate (1) by the pressing machine to form through holes (5), (6); trimming and shaping the steel plate (2) by the pressing machine; and integrally welding the two shaped steel plates (1), (2). The invention utilizes steel plate punching and welding; the whole production process fully avoids the pollution source; the products have good quality, high strength, low cost; and the low labor intensity of the operators is reduced.

Owner:孙学祖

Method for preparing light catalyst for pesticide

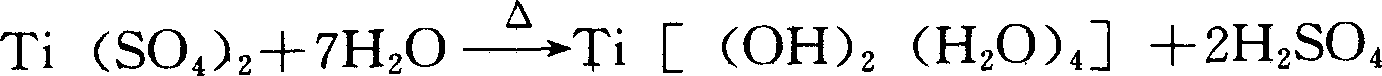

InactiveCN1616149ALow costEliminate sources of pollutionWater/sewage treatment by irradiationCatalyst activation/preparationAqueous solutionAdsorption effect

The present invention relates to chemical process, and is especially the preparation process of light catalyst for pesticide. The present invention features that TiO2 surface is modified with water solution of sodium dedecyl benzene sulfonate. In 200 ml of 1.0 % concentration water solution of sodium dedecyl benzene sulfonate, 2 g of TiO2 / Ag is added and stirred at 50 deg.c for 6 hr, and through subsequent filtering, washing, and drying at 100 deg.c, the pesticide sample has relatively high adsorption effect of 200 mg / g in water solution. The light catalyst for pesticide has the advantages of low cost, easy preparation, no secondary pollution and other advantages, and may be used in solving water pollution effectively.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com