Patents

Literature

2173 results about "Reflow soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux) is used to temporarily attach one or thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven or under an infrared lamp or by soldering individual joints [unconventionally] with a desoldering hot air pencil.

Pre-solder structure on semiconductor package substrate and method for fabricating the same

InactiveUS20050167830A1Pad pitchFabrication cost is increasedPrinted circuit assemblingSemiconductor/solid-state device detailsResistSemiconductor package

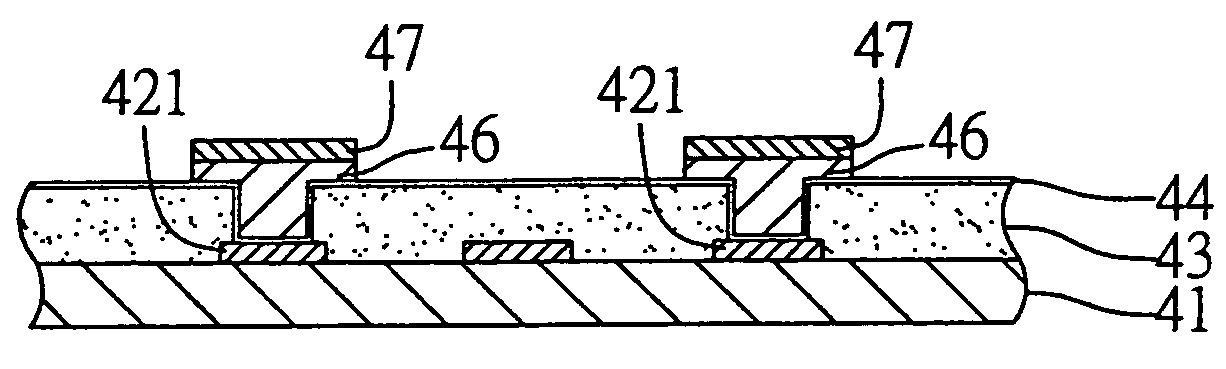

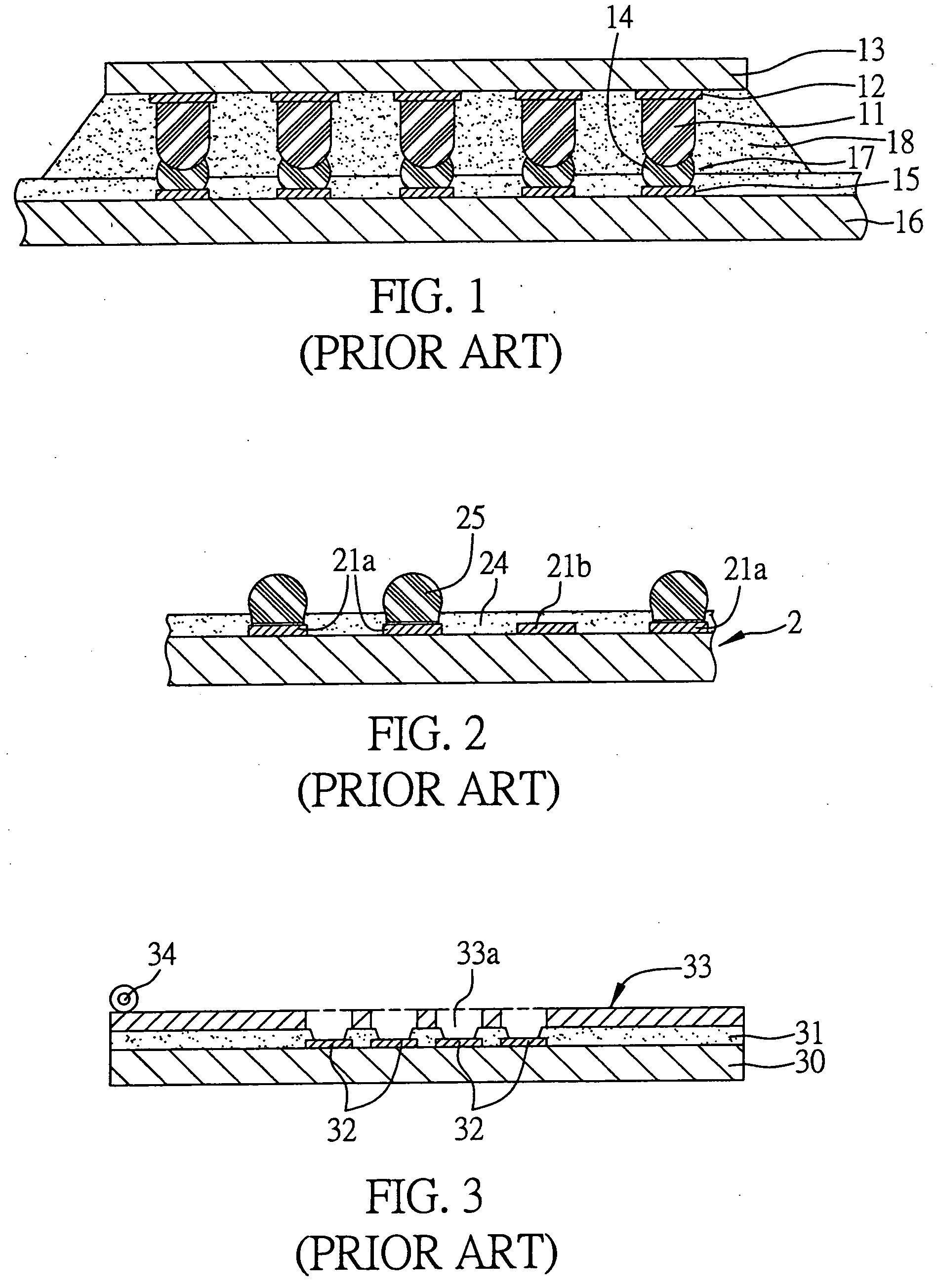

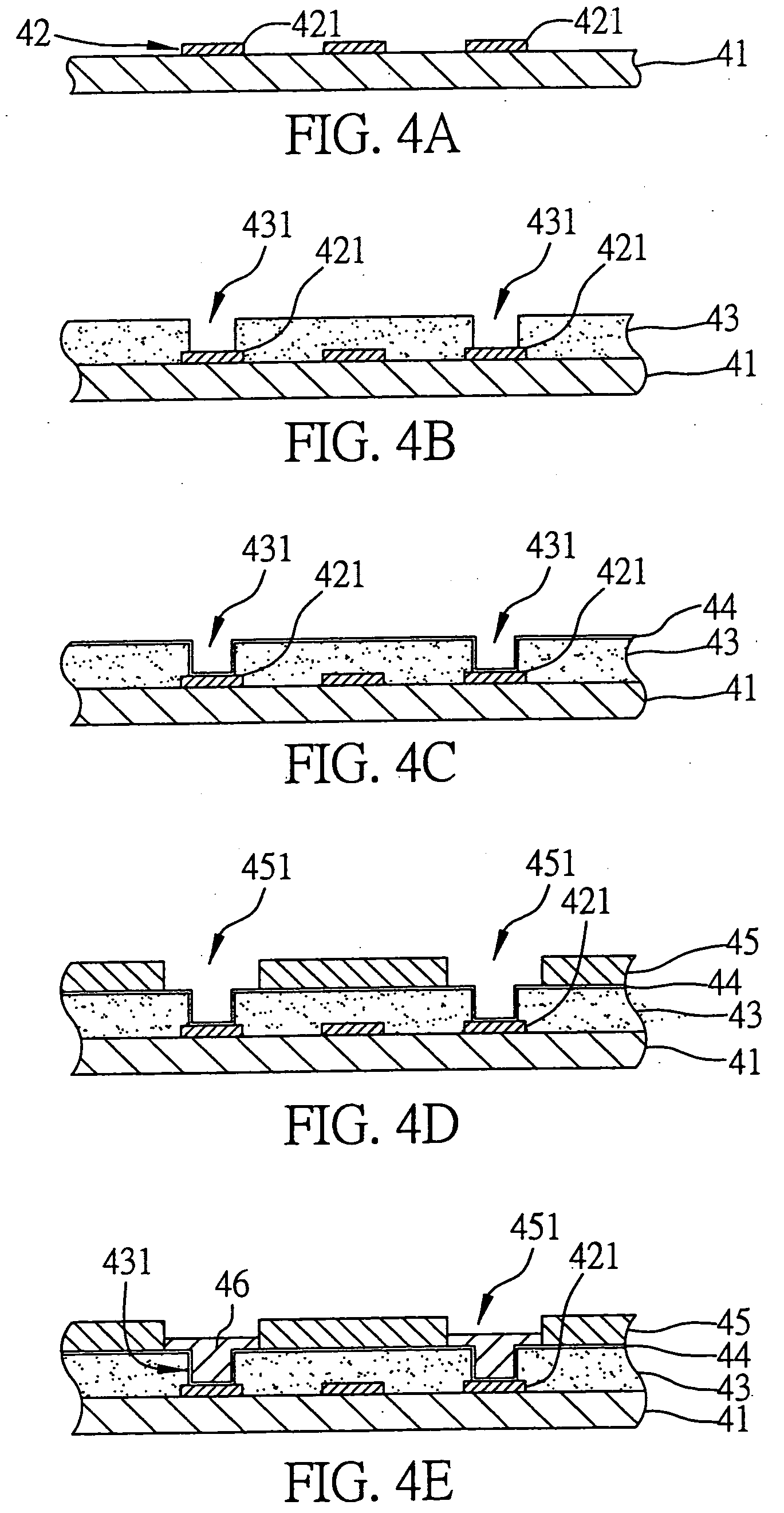

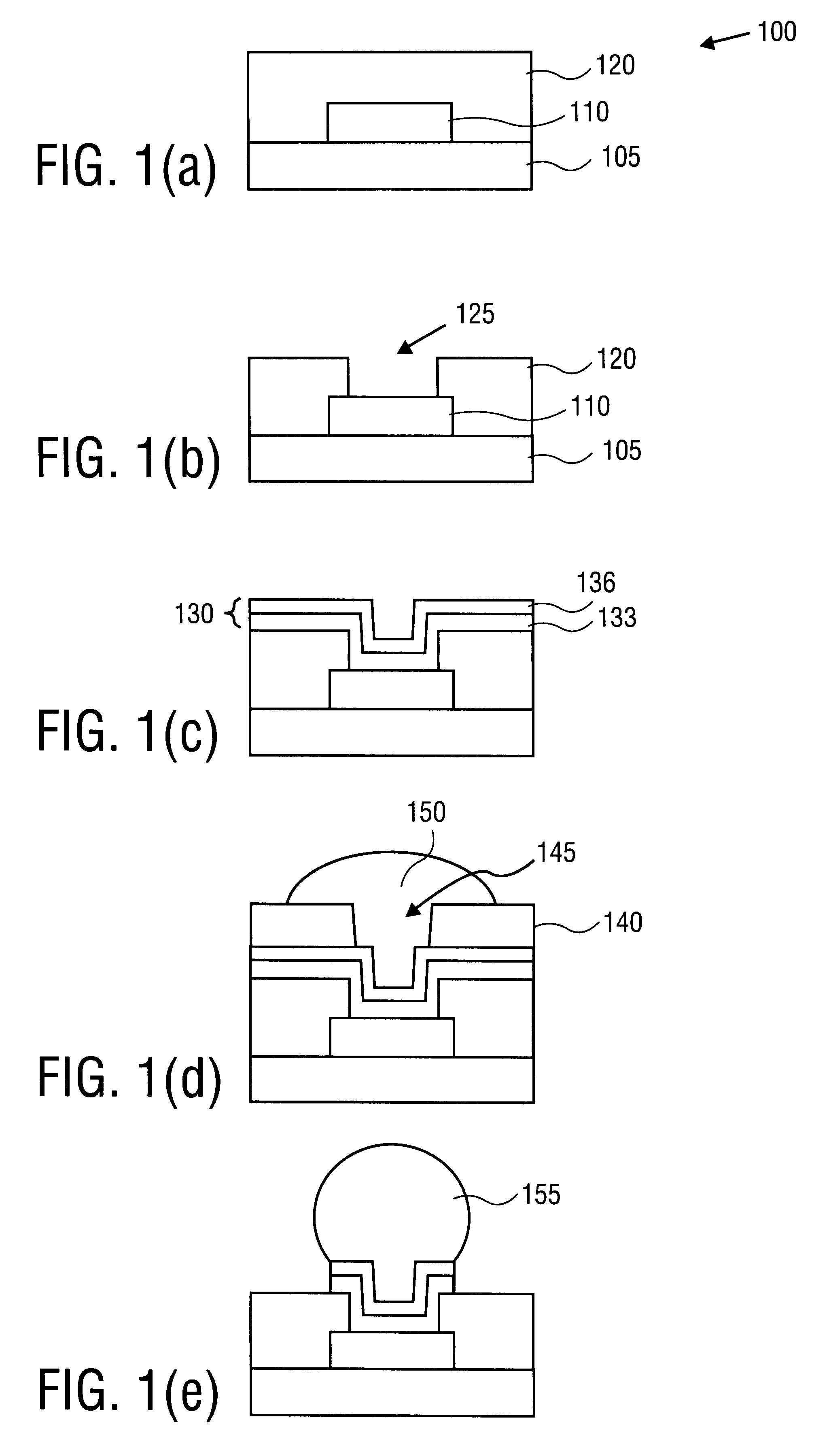

A pre-solder structure on a semiconductor package substrate and a method for fabricating the same are proposed. A plurality of conductive pads are formed on the substrate, and a protective layer having a plurality of openings for exposing the conductive pads is formed over the substrate. A conductive seed layer is deposited over the protective layer and openings. A patterned resist layer is formed on the seed layer and has openings corresponding in position to the conductive pads. A plurality of conductive pillars and a solder material are deposited in sequence in each of the openings. The resist layer and the seed layer not covered by the conductive pillars and the solder material are removed. The solder material is subject to a reflow-soldering process to form pre-solder bumps covering the conductive pillars.

Owner:PHOENIX PRECISION TECH CORP

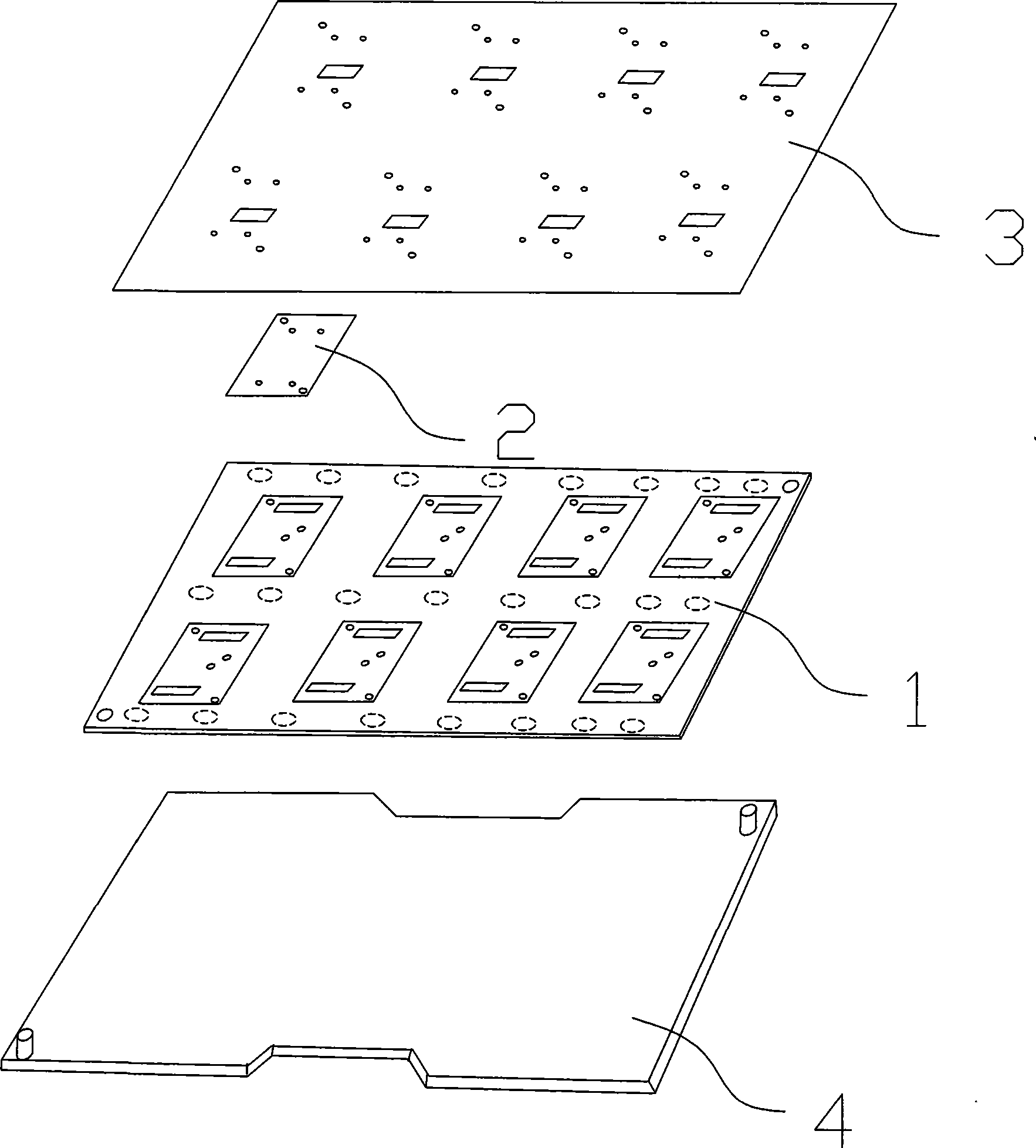

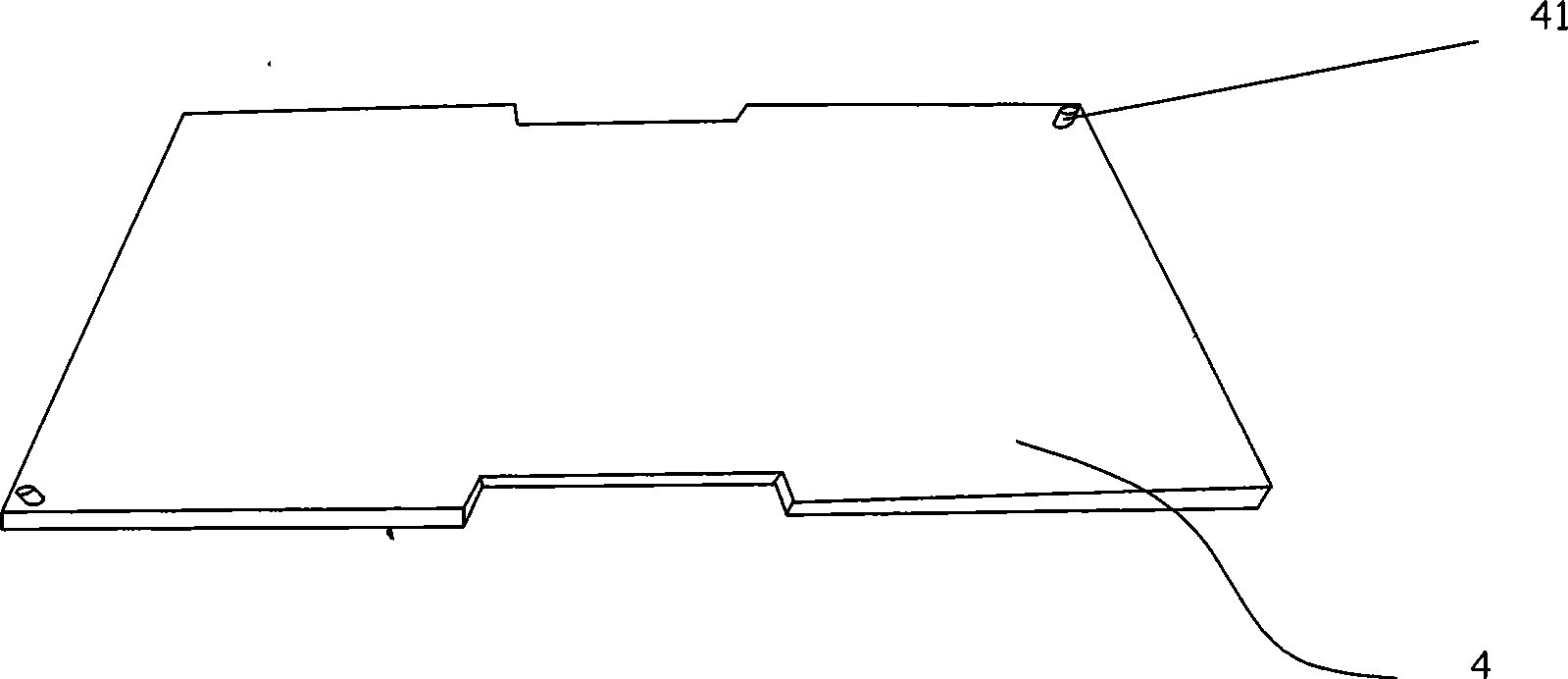

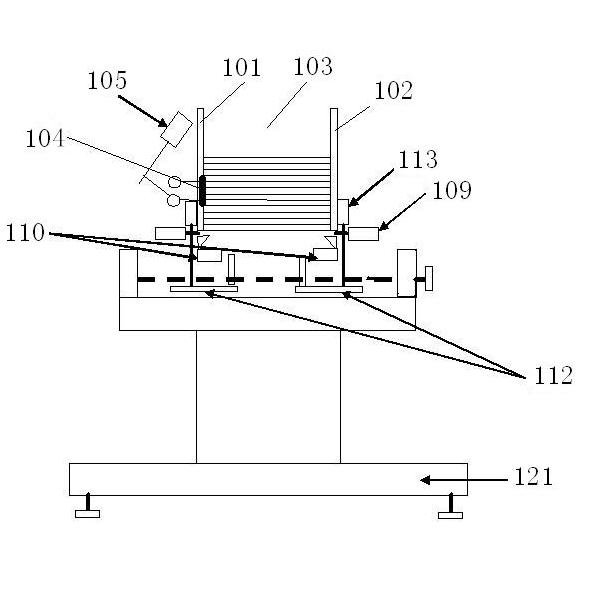

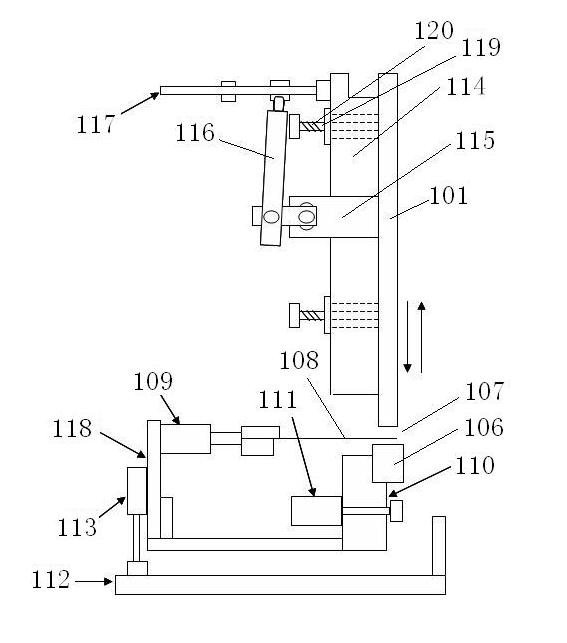

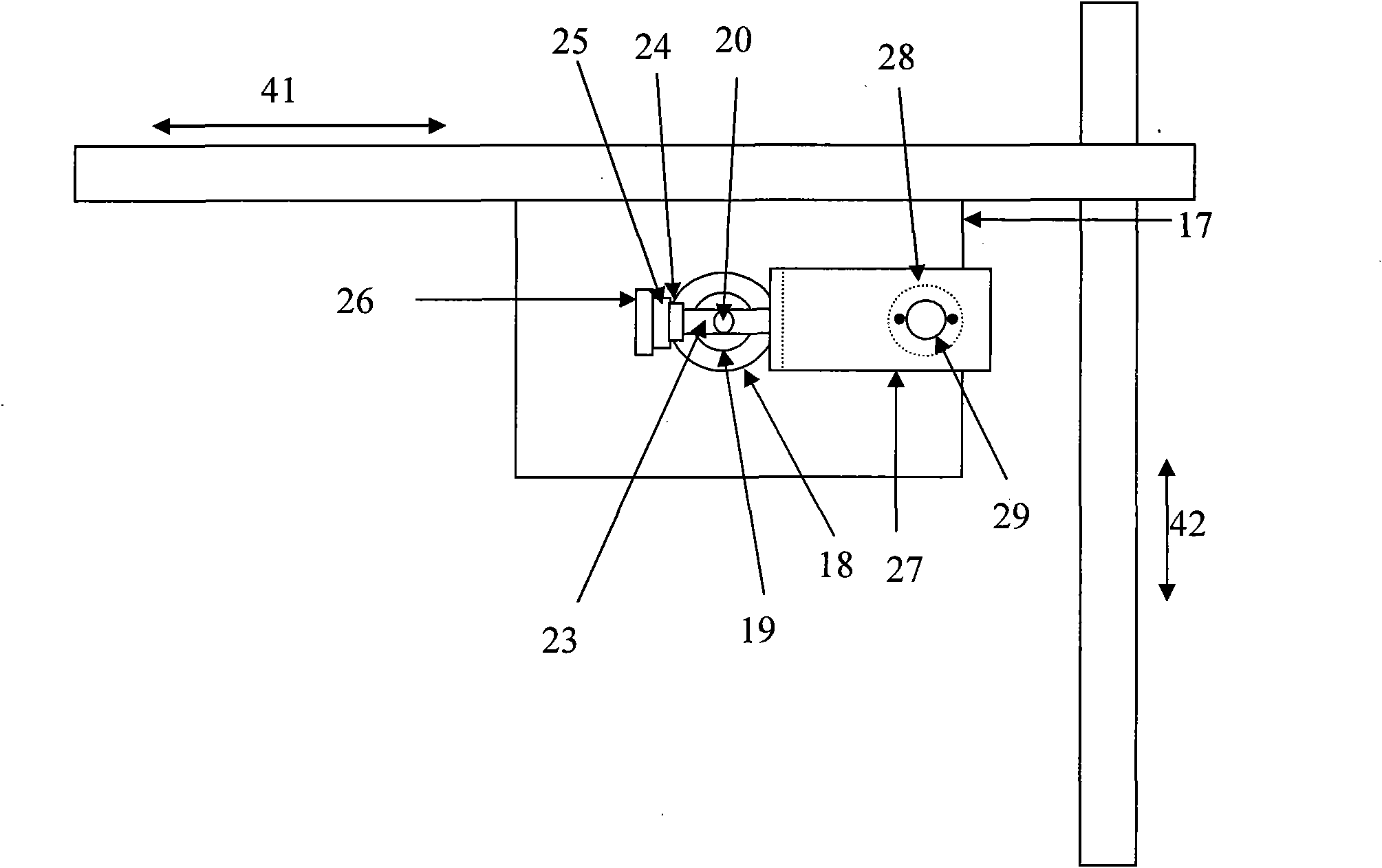

Surface mounting process for flexible circuit board and used magnetic tool and steel mesh

ActiveCN101384136AExtended service lifeLow costPrinted circuit assemblingManufacturing technologyFlexible circuits

The invention relates to the manufacturing technology of printed wiring board, in particular to a flexible printed circuit (FPC) surface mount technology (SMT) as well as a magnetic tool and a steel mesh which are used for the FPCSMT. The magnetic tool comprises a buckle cover board and a magnetic carrying tray, wherein the magnetic carrying tray is a magnetic baseplate, the buckle cover board is a metal sheet which can be attracted by the magnetic baseplate, and the buckle cover board is provided with a slotted hole used for the solder paste printing and the surface mounting of a FPC. The invention is characterized in that the buckle cover board is a steel sheet which can be attracted by the magnetic baseplate, the step layer which is the same as the buckle cover board in shape is etched on the magnetic carrying tray, the depth of the step layer is the same as the thickness of the steel sheet; before the circuit board printing, the magnetic carrying tray is fixed on a positioning base, and then the FPC and the buckle cover board are arranged on the magnetic carrying tray; after the accurate positioning, the FPC and the magnetic tool are taken down the positioning base to conduct the solder paste printing process, the surface mounting process and the reflow soldering process.

Owner:东莞市贞观盛智控科技有限公司

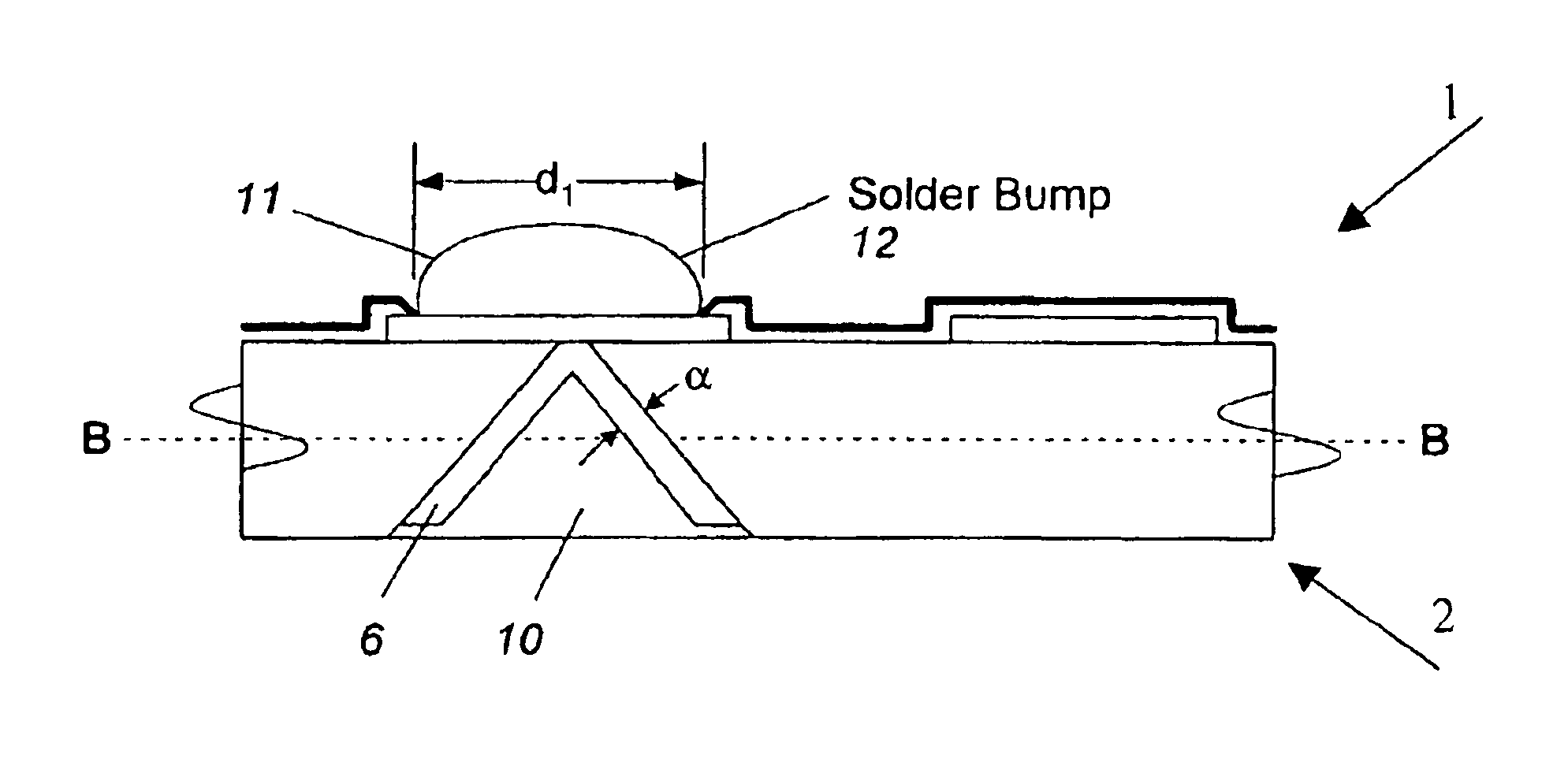

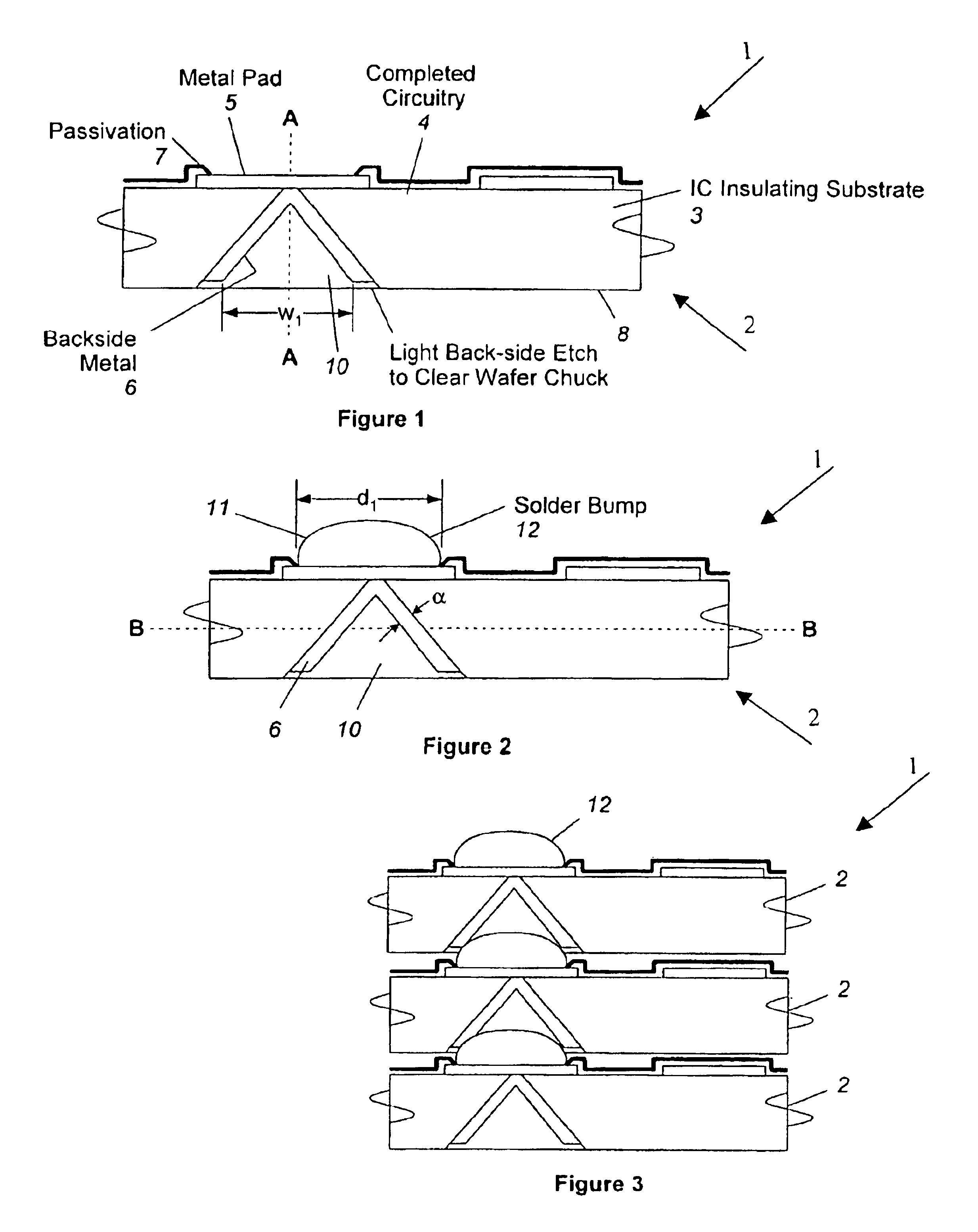

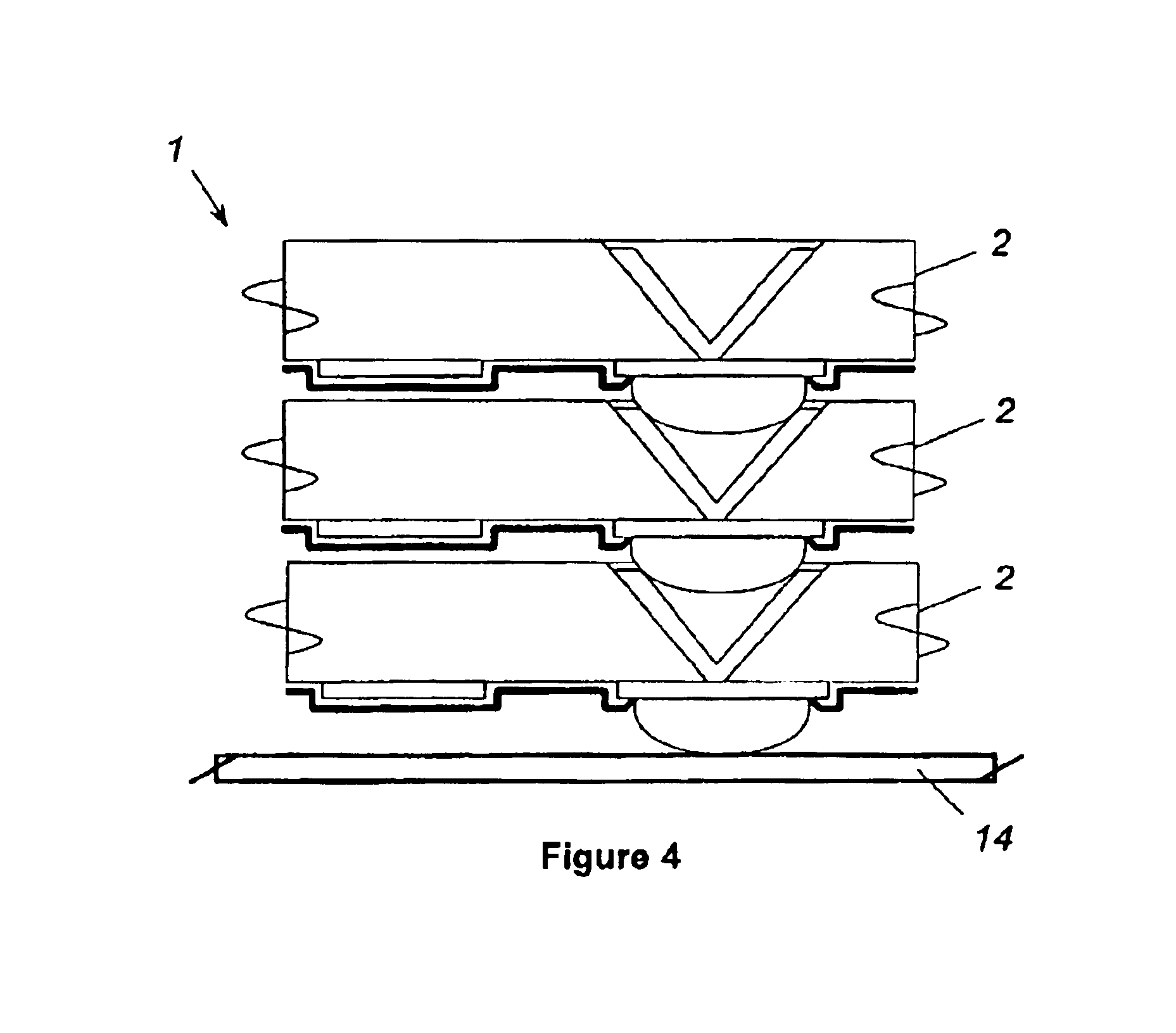

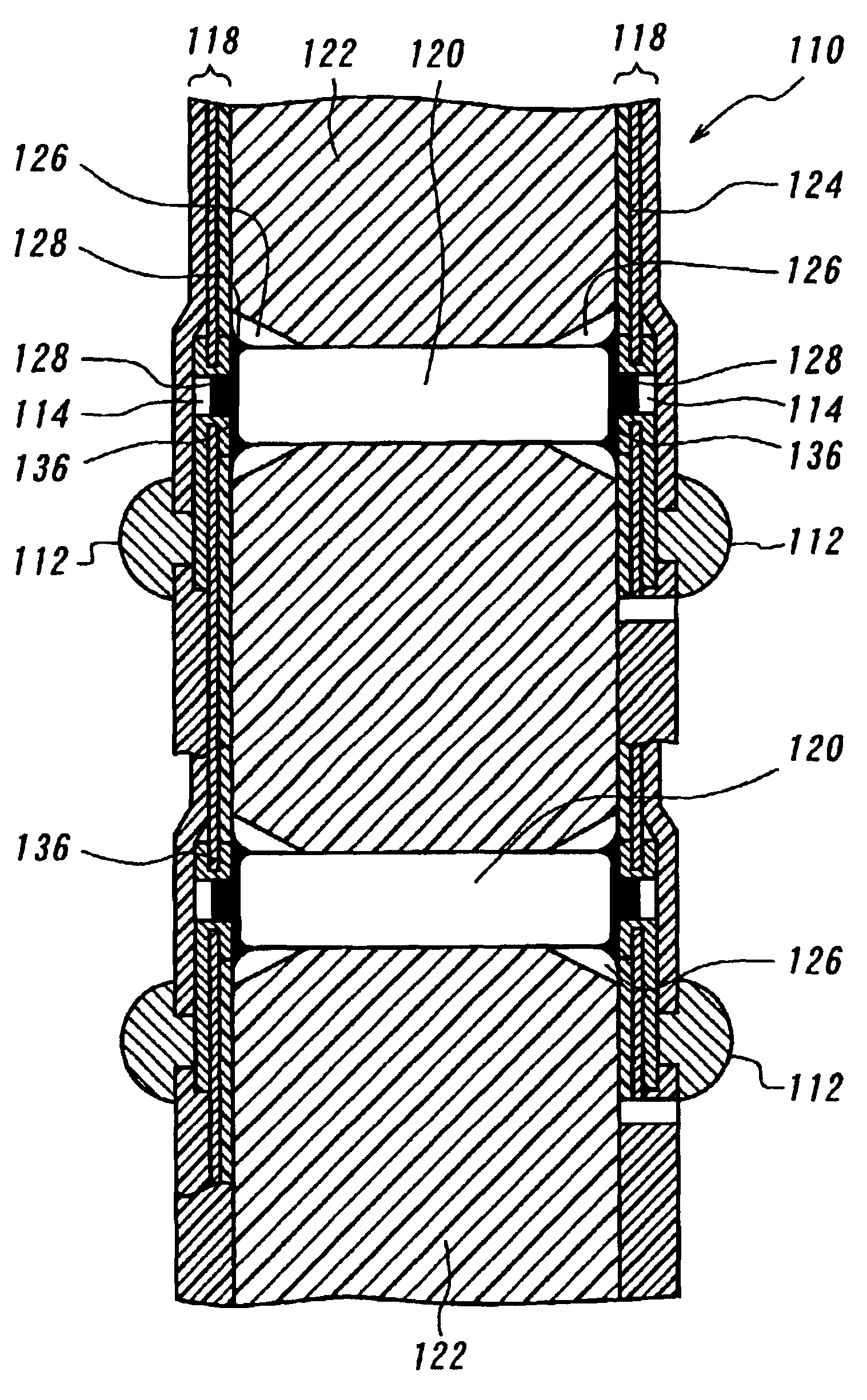

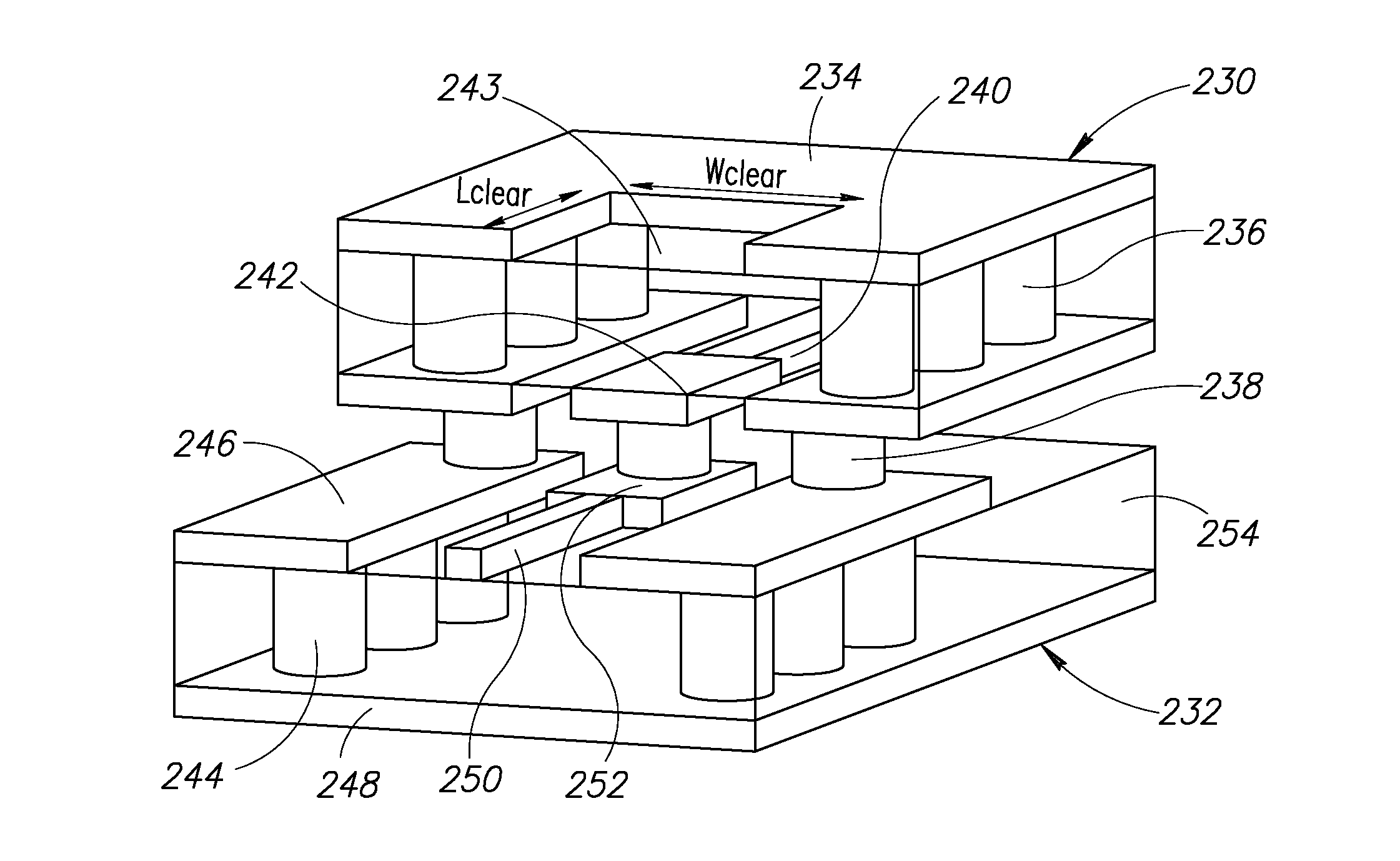

High performance vias for vertical IC packaging

InactiveUS6936913B2Low costSemiconductor/solid-state device detailsSolid-state devicesMicroelectromechanical systemsEngineering

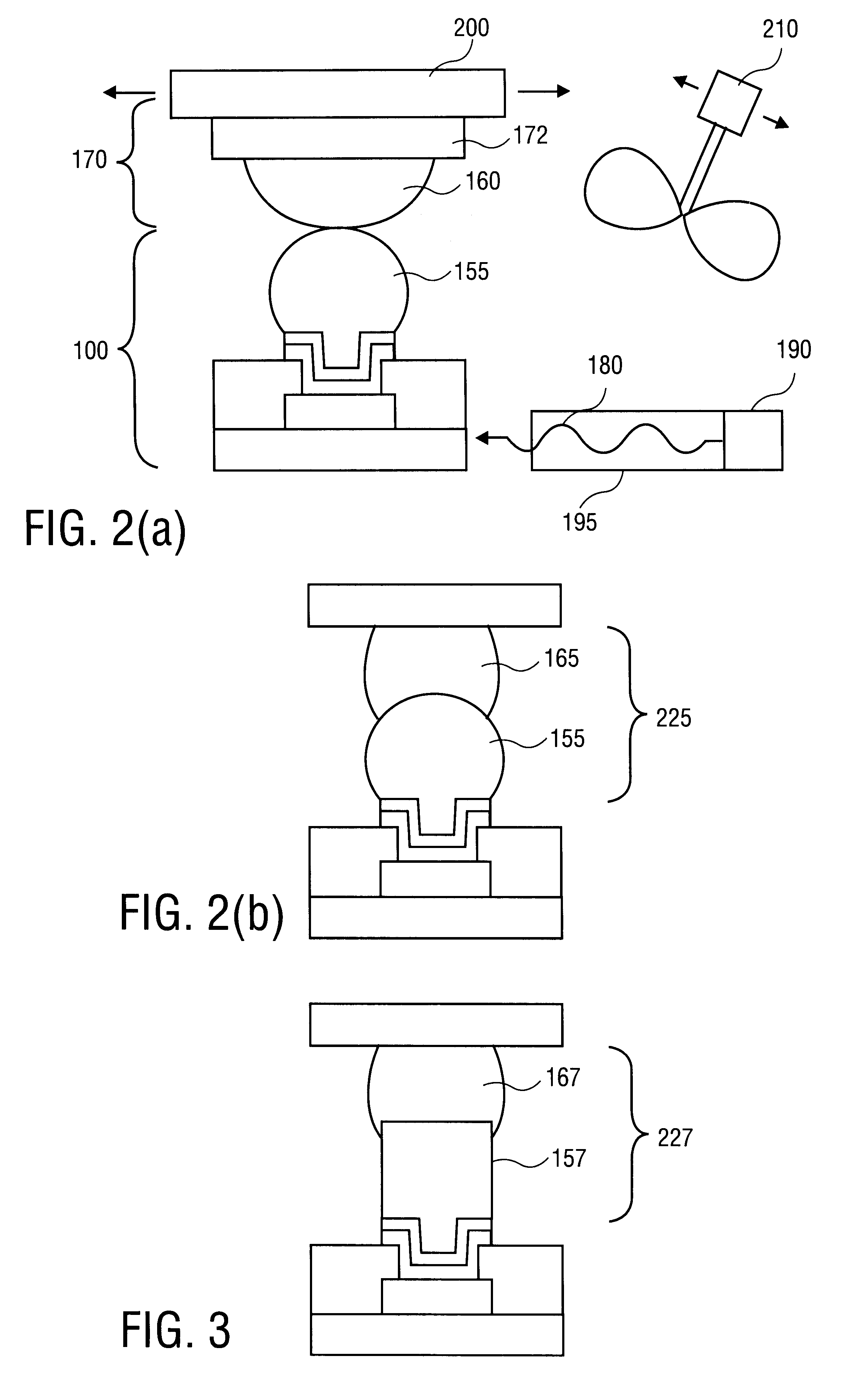

A semiconductor device, a microelectromechanical system package and a method of making the same utilize high performance vias for vertical IC packaging. A semiconductor die of the device / package has a substrate with integrated circuitry formed on a front side of the substrate. A metal bonding pad overlies the substrate on the front side of the substrate and is electrically connected to the integrated circuitry. A solder bump is located on the metal bonding pad. An electrically conductive via extends through the substrate from the metal bonding pad to a back side of the substrate where the via forms a side wall of a via hole. A plurality of the substrates are stacked on one another with the outer end of the solder bump of one substrate fitting within the via hole of an adjacent substrate. During reflow soldering, surface tension forces of the molten solder bump self-align the substrates.

Owner:NORTHROP GRUMMAN SYST CORP

Method of fabricating a circuit arrangement with thermal vias

InactiveUS6190941B1Prevent penetrationThe method is simple and reliablePrinted circuit assemblingFinal product manufactureScreen printingEngineering

An electronic component is mounted on a substrate such as a circuit board by means of a soldering process such as reflow soldering. The circuit board has a thermal via hole therethrough to provide a heat dissipation path from the top surface to the bottom surface of the circuit board, for dissipating heat from the electronic component. To prevent molten solder from penetrating through the via hole during the soldering process, the via hole is sealed prior to the soldering process. The via hole is sealed from the bottom surface of the substrate by carrying out a screen printing process including at least two printing passes to print a sealing material into the open hole of the thermal via.

Owner:DAIMLER AG

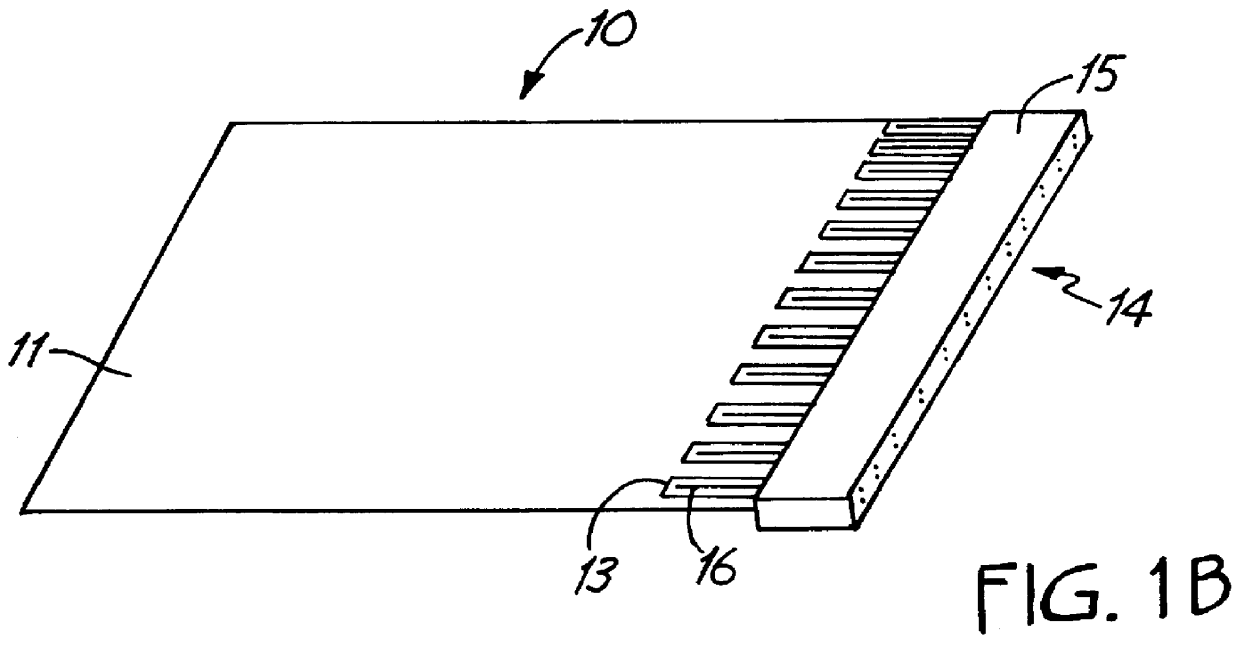

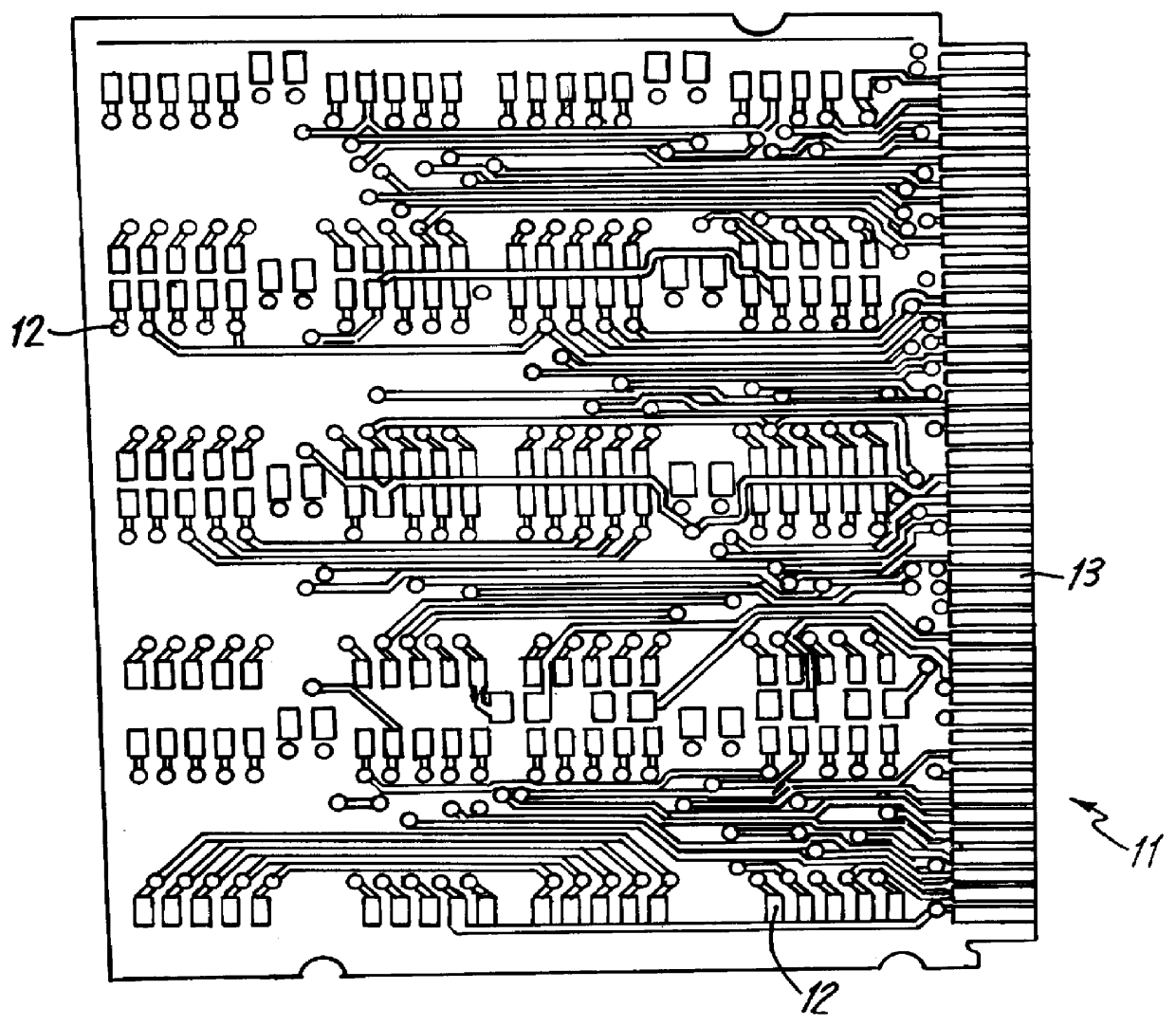

Reflow soldering method

InactiveUS6010061APrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

With the present invention, a reflow soldering method is provided for soldering a nonvertically approaching lead, which is part of a nonvertically approaching device (e.g, an edge connector), to a corresponding soldering surface (e.g., a pad on a circuit card) that includes solder. The soldering surface and solder are heated in an oven to melt the solder. While the solder is liquids, the nonvertically approaching lead is mated with the soldering surface as it is inserted into the solder. The soldering surface, solder, and nonvertically approaching lead are then cooled, and the solder solidifies to conductively mount the nonvertically approaching lead to the soldering surface.

Owner:PLEXUS PROPERTY HLDG +2

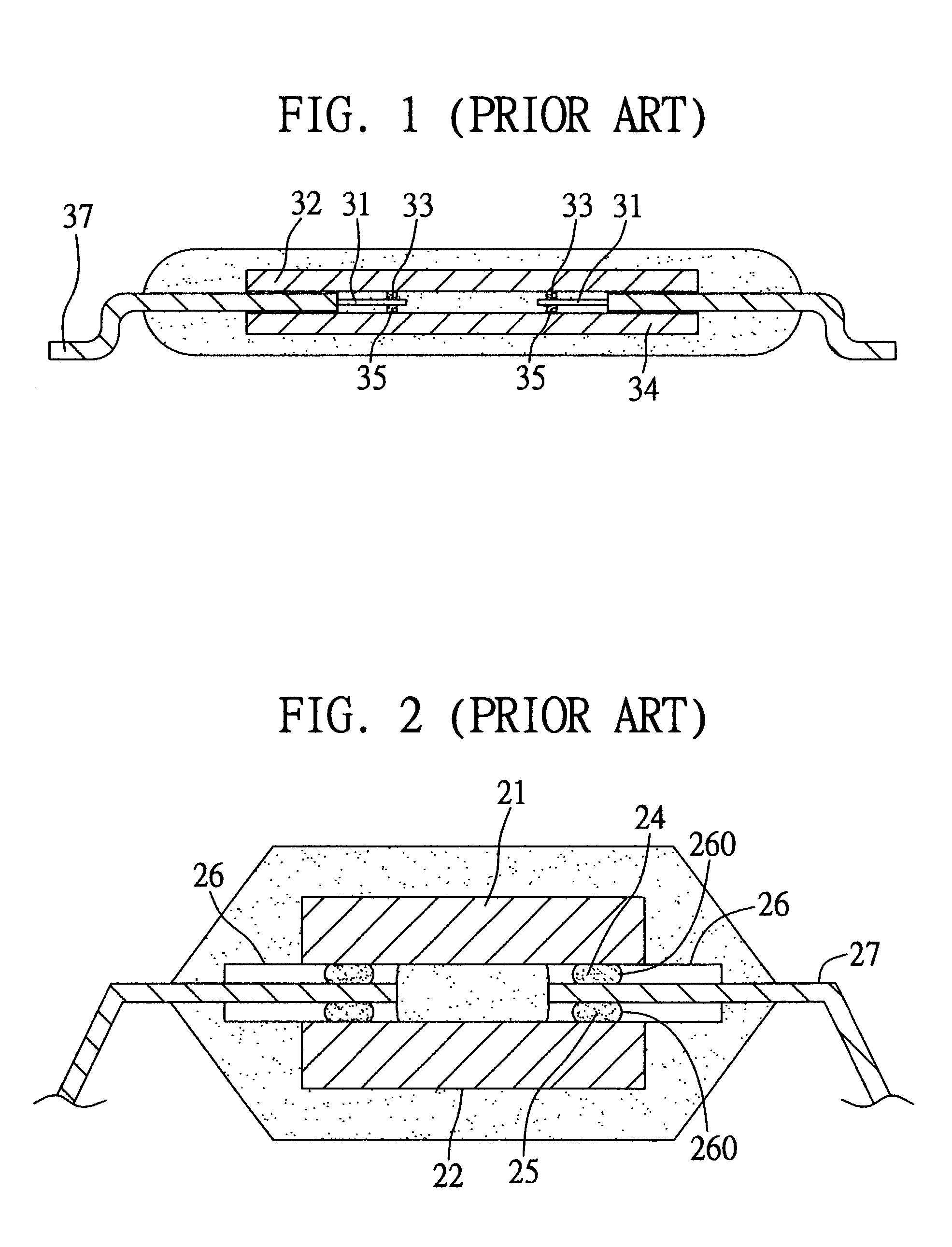

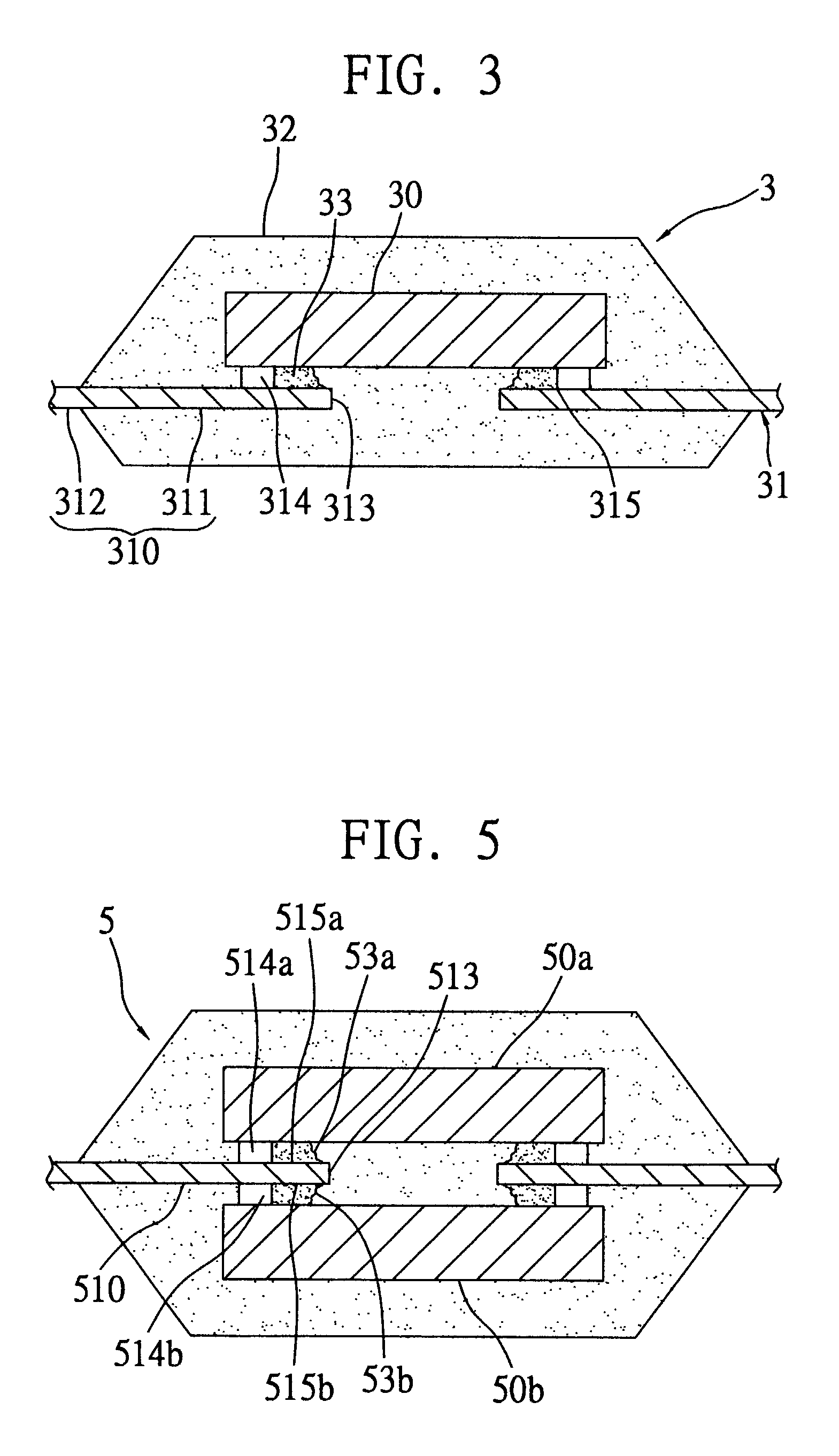

Flip-chip semiconductor package with lead frame as chip carrier and fabrication method thereof

InactiveUS7274088B2Quality assuranceIncrease contentSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionSemiconductor package

Owner:SILICONWARE PRECISION IND CO LTD

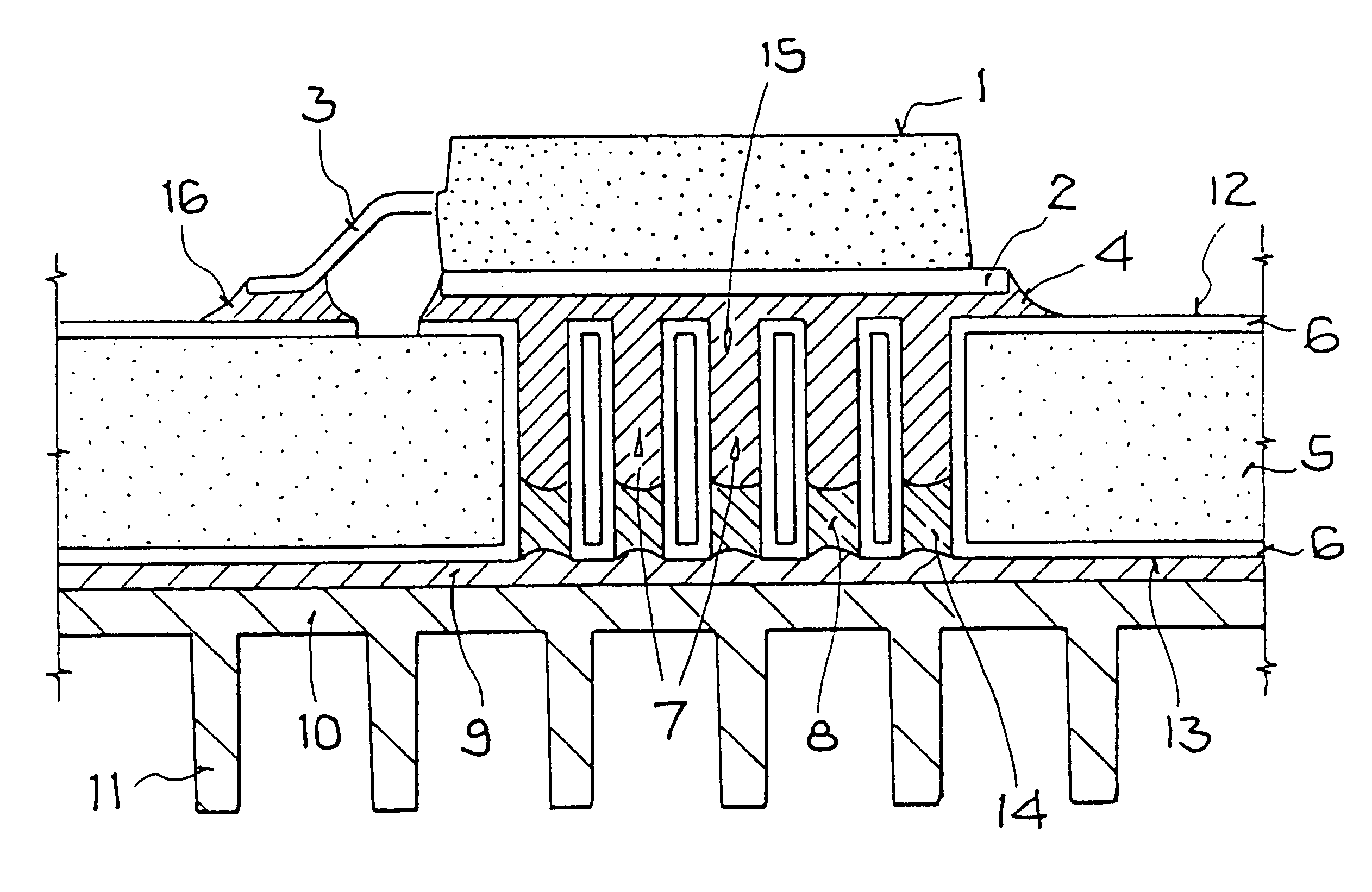

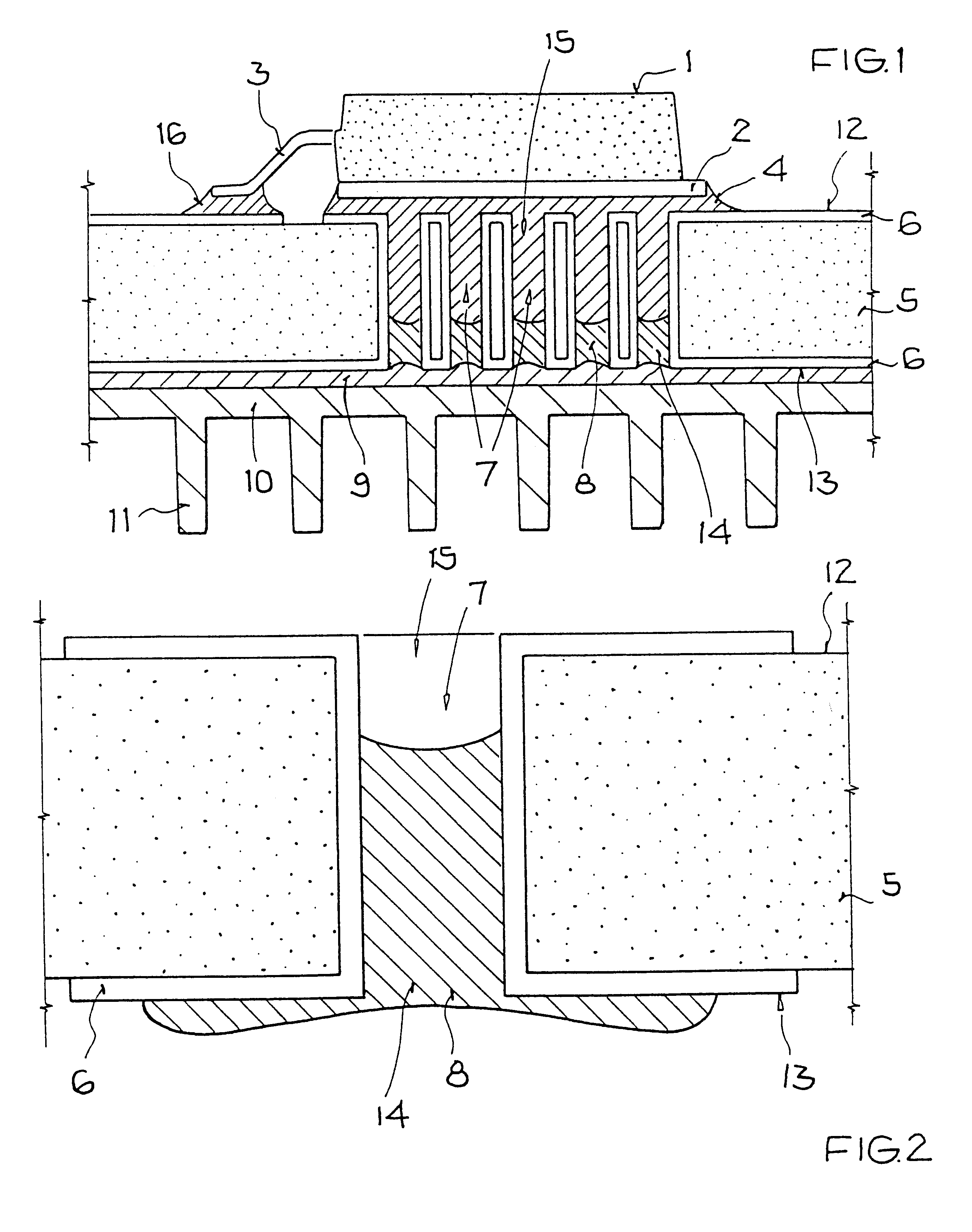

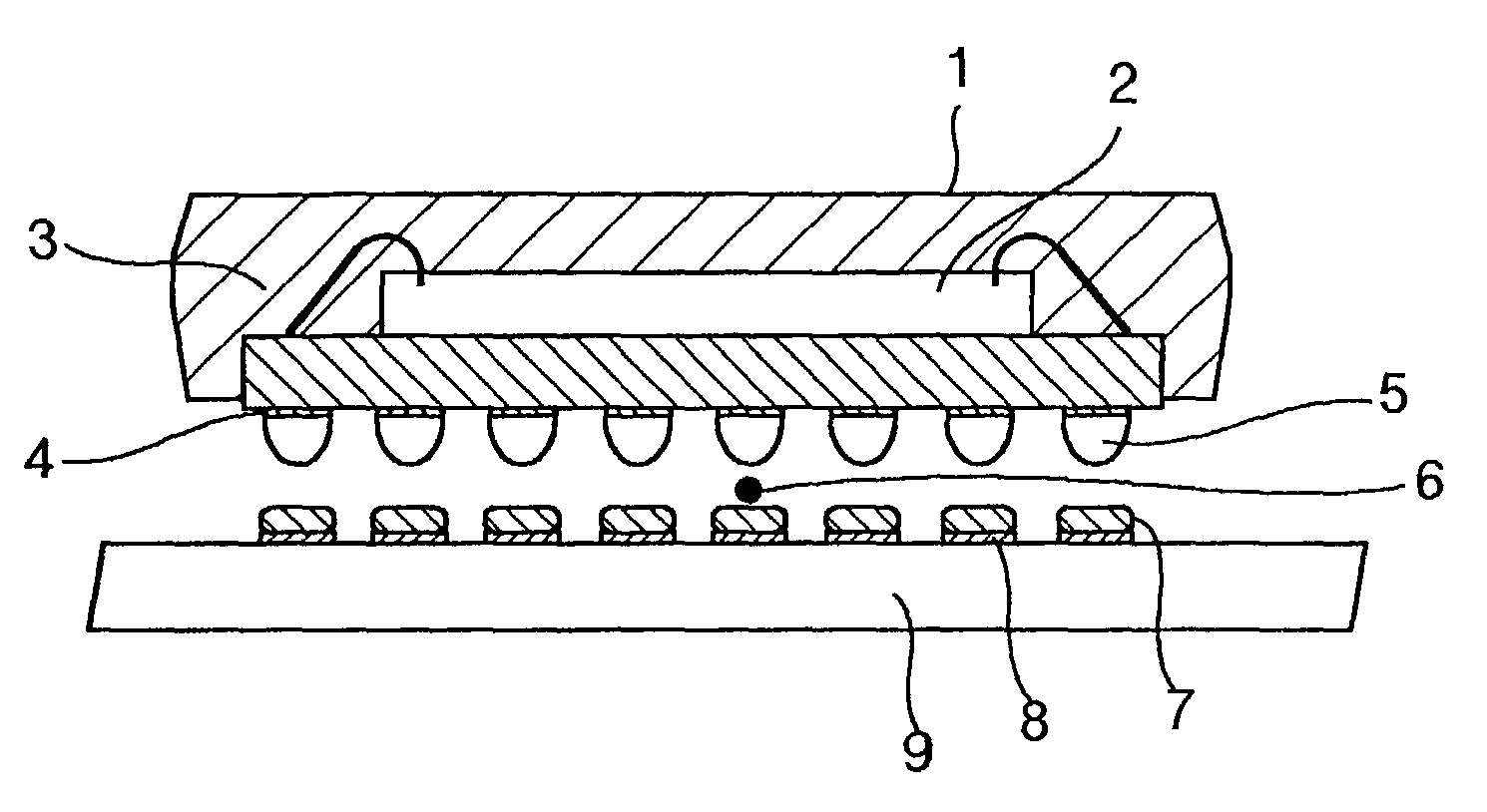

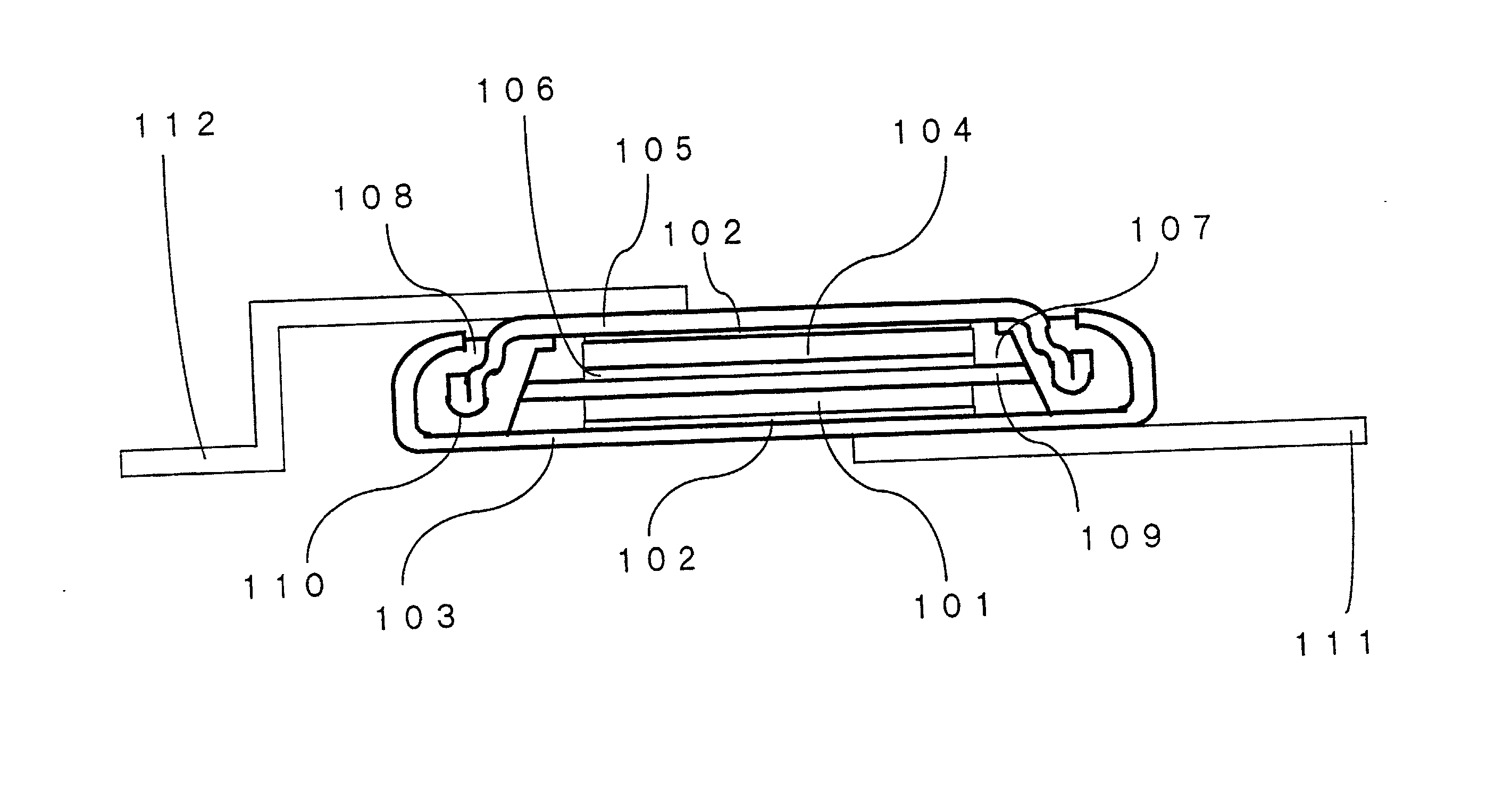

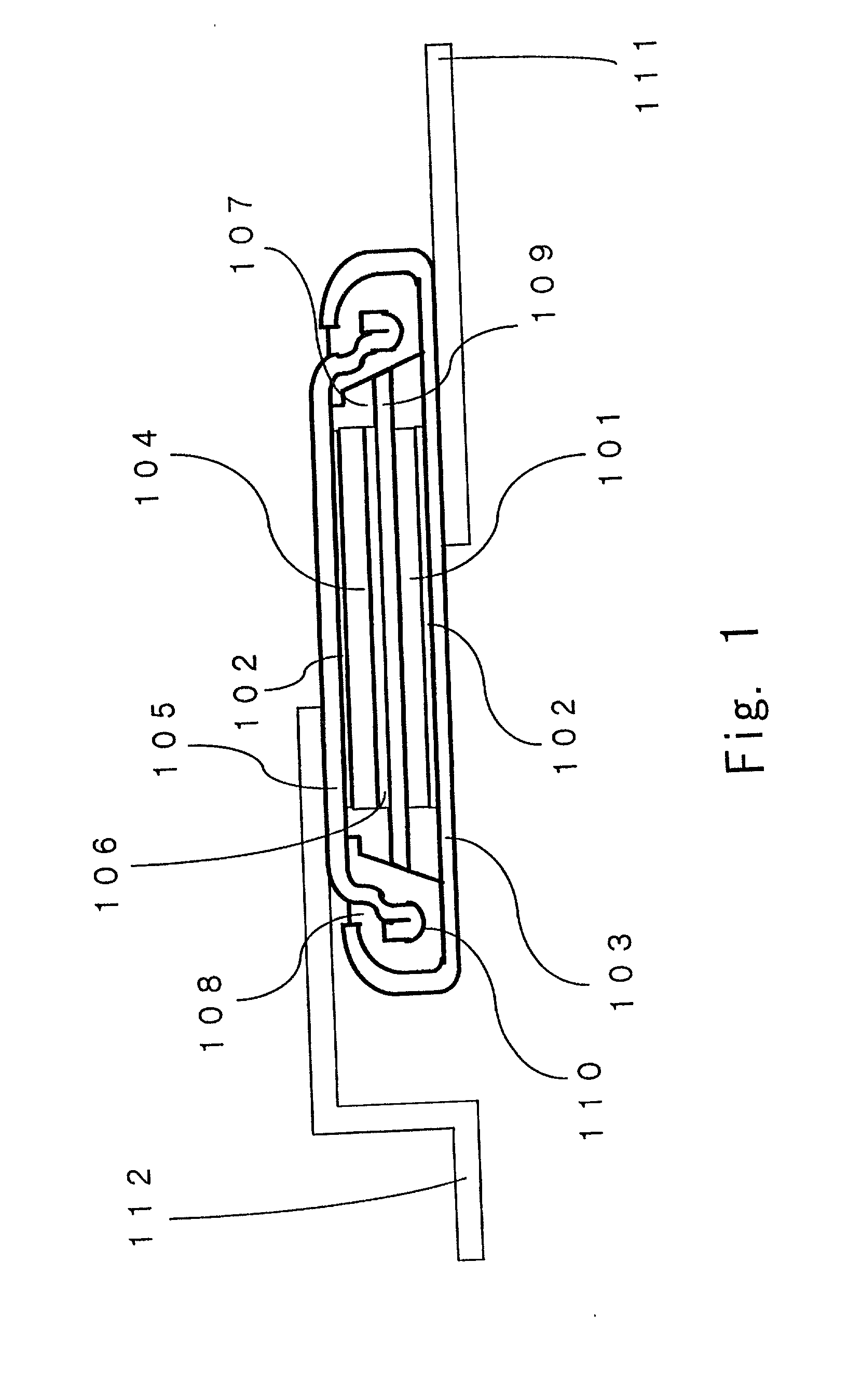

Electrical connector

InactiveUS6857880B2Easy to manufactureEliminate disadvantagesPrinted circuit assemblingElectrically conductive connectionsElastomerElectrical conductor

An electrical connector includes an elastomer layer or board and a plurality of fine lead wires embedded in the elastomer layer and extending rectilinearly therein at right angles to both the surfaces of the elastomer layer. Recesses are formed in the elastomer layer around peripheries of openings of through-holes in which the fine lead wires are embedded. The electrical connector further includes two flexible printed circuit boards on both the sides, each including electric contacts to be connected to mating contacts, connection portions each formed with a through-hole passing therethrough, and conductors each electrically connecting the connection portion to the electric contact. When the flexible printed circuit boards and the fine lead wires are electrically connected by vapor reflow soldering, the flexible printed circuit boards and the elastomer layer having the fine lead wires embedded therein are clamped by restraining jigs to prevent from the flexible printed circuit boards from moving away from the elastomer layer. With this arrangement, reliable connection between the fine lead wires and the flexible printed circuit boards can be achieved without need to control the length of the fine lead wires without any risk of the flexible boards being deflected or warped during soldering even if circumferences of portions to be electrically connected are covered by the insulator.

Owner:THE FUJIKURA CABLE WORKS LTD

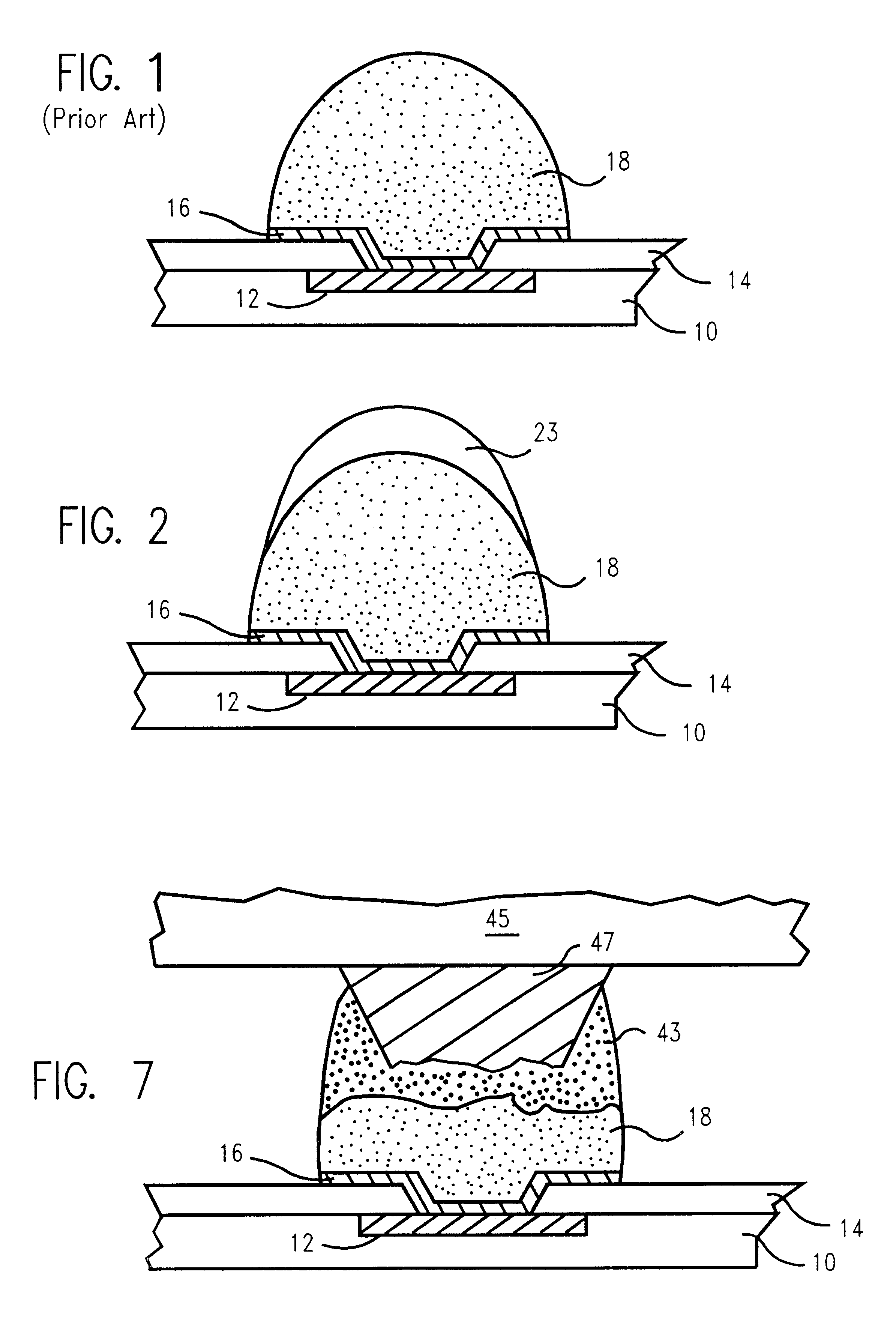

Method for forming reflowed solder ball with low melting point metal cap

InactiveUS6344234B1Reduce the hole diameterMinimal diameterFinal product manufactureSemiconductor/solid-state device detailsTinningIndium

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:ULTRATECH INT INC

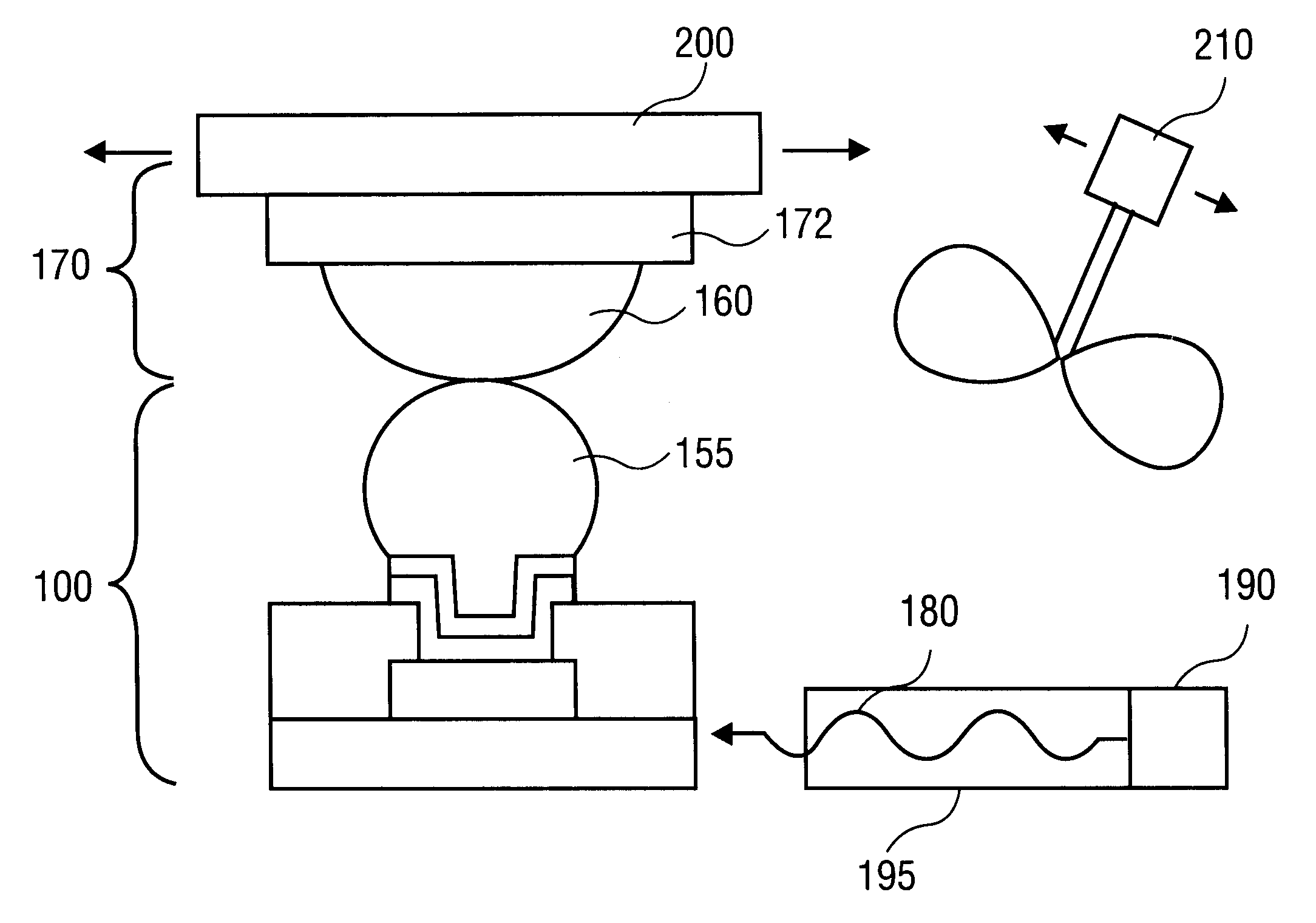

Solder reflow with microwave energy

The present invention includes a mechanical joint between a die and a substrate that is reflowed by microwave energy and a method of forming such a mechanical joint by printing a solder over a substrate, placing the solder in contact with a bump over a die, reflowing the solder with microwave energy, and forming a mechanical joint from the solder and the bump.

Owner:INTEL CORP

Solder alloy

Owner:爱尔发加热有限公司

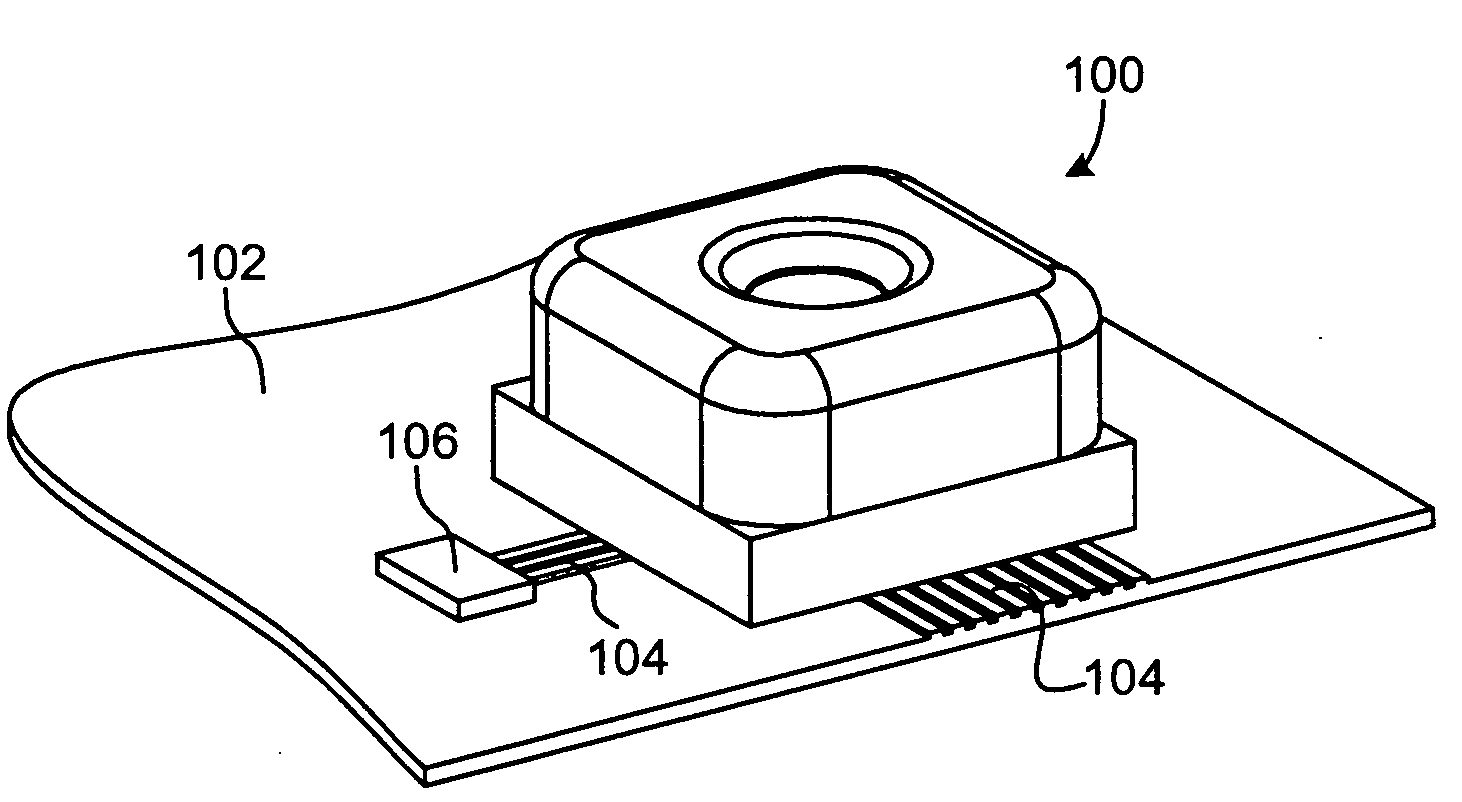

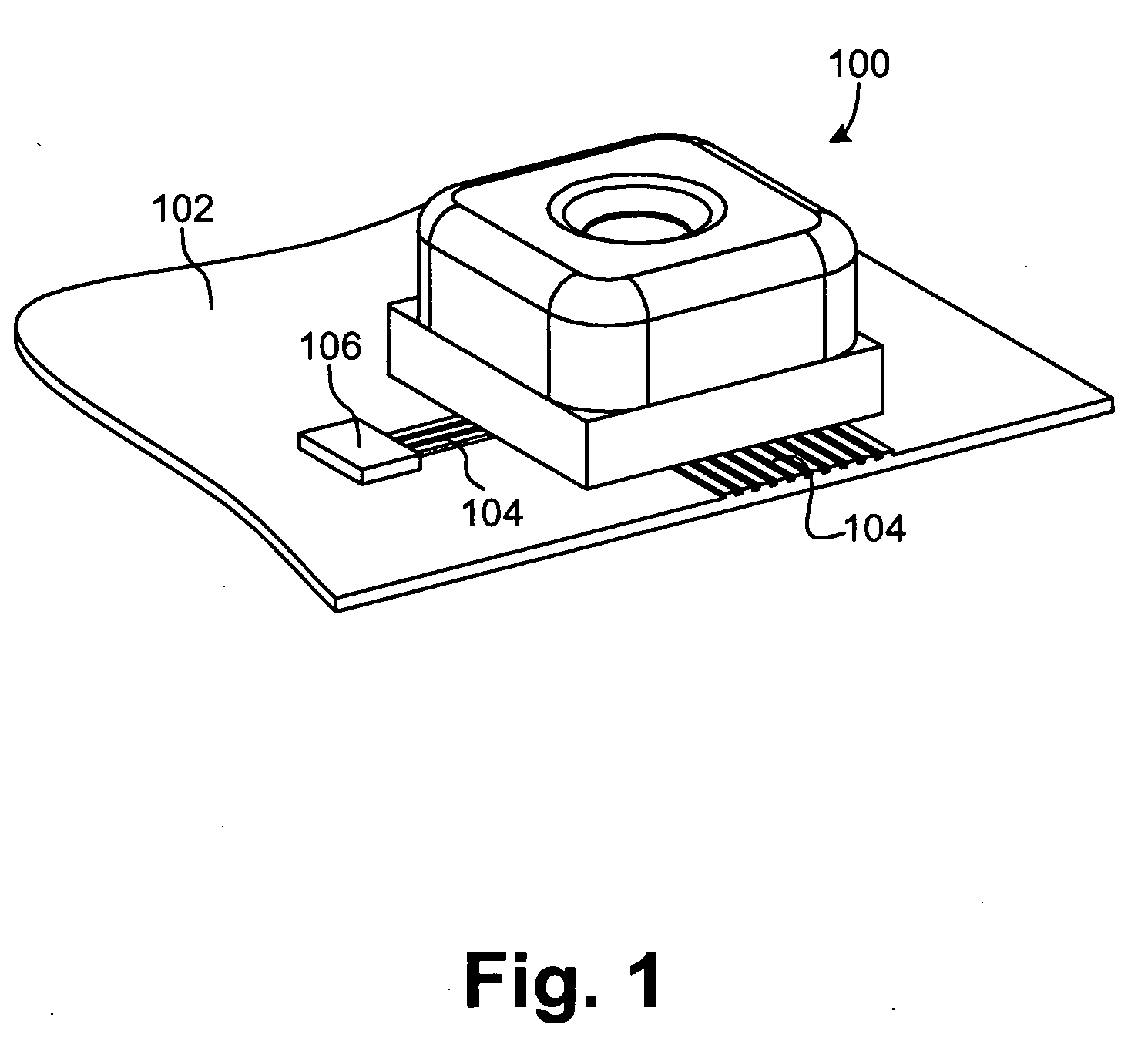

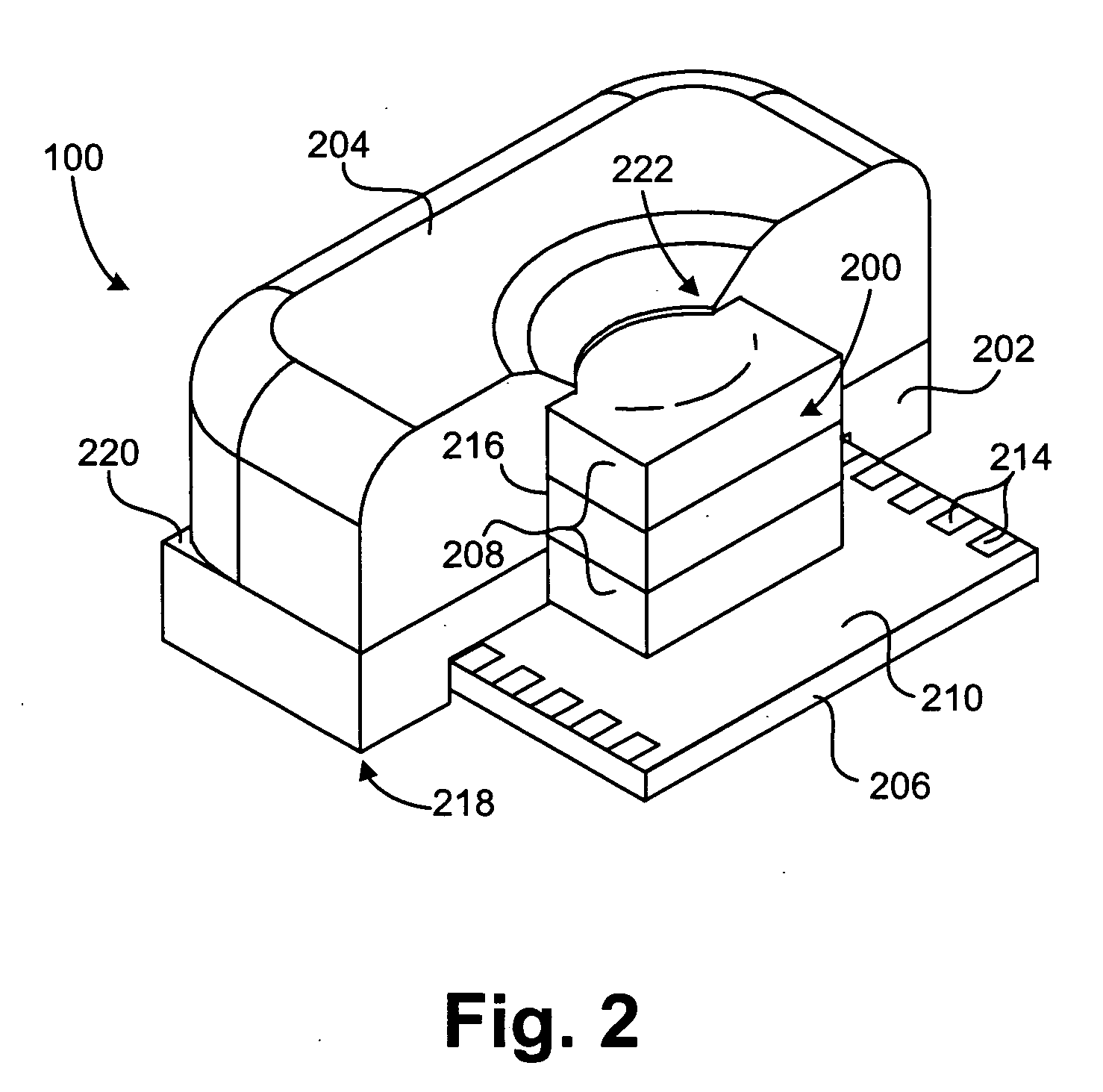

Wafer level camera module with molded housing and method of manufacturing

ActiveUS20110037886A1Easy to installOvercome problemsTelevision system detailsSolid-state devicesTransfer moldingSolder ball

A disclosed method of manufacturing a camera module includes providing an optical assembly, providing an integrated circuit image capture device (ICD), fixing the optical assembly directly to the ICD, then forming a housing directly over the optical assembly. The method further includes forming the housing over the ICD and the optical assembly via transfer molding. The method further includes forming solder balls on the rear surface of the ICD so as to enable the camera module to be reflow soldered to a host device. In an alternative embodiment of the present invention, the method includes providing a second ICD, providing a second optical assembly, providing a housing substrate, fixing the first optical assembly over the first ICD, fixing the second optical assembly over the second ICD, and forming the housing substrate over both the first and second optical assemblies. The alternative method further includes separating the housing substrate in to a first portion formed over the first optical assembly and second portion formed over the second optical assembly, providing a second housing substrate, and forming the second housing substrate over the first and second portions.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

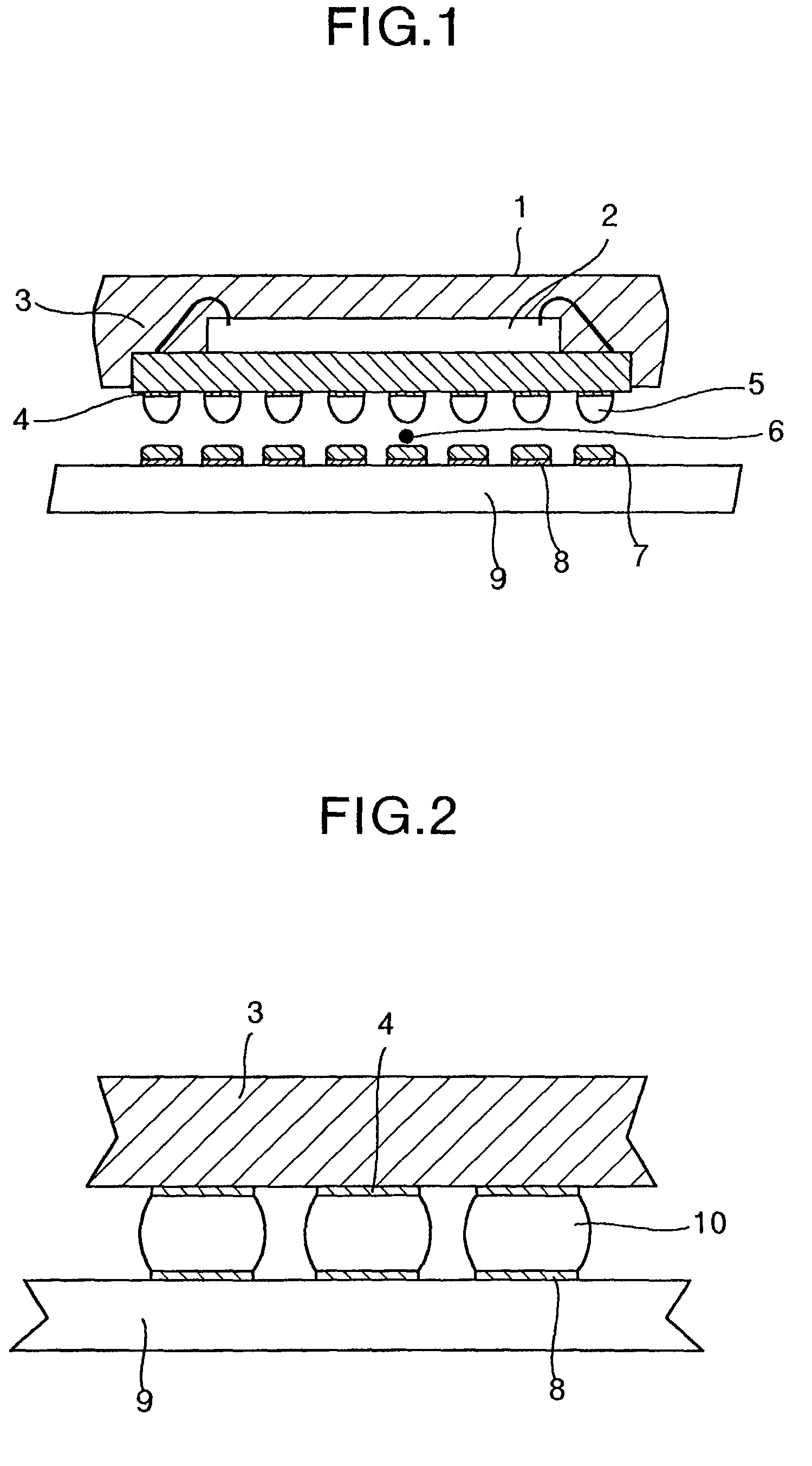

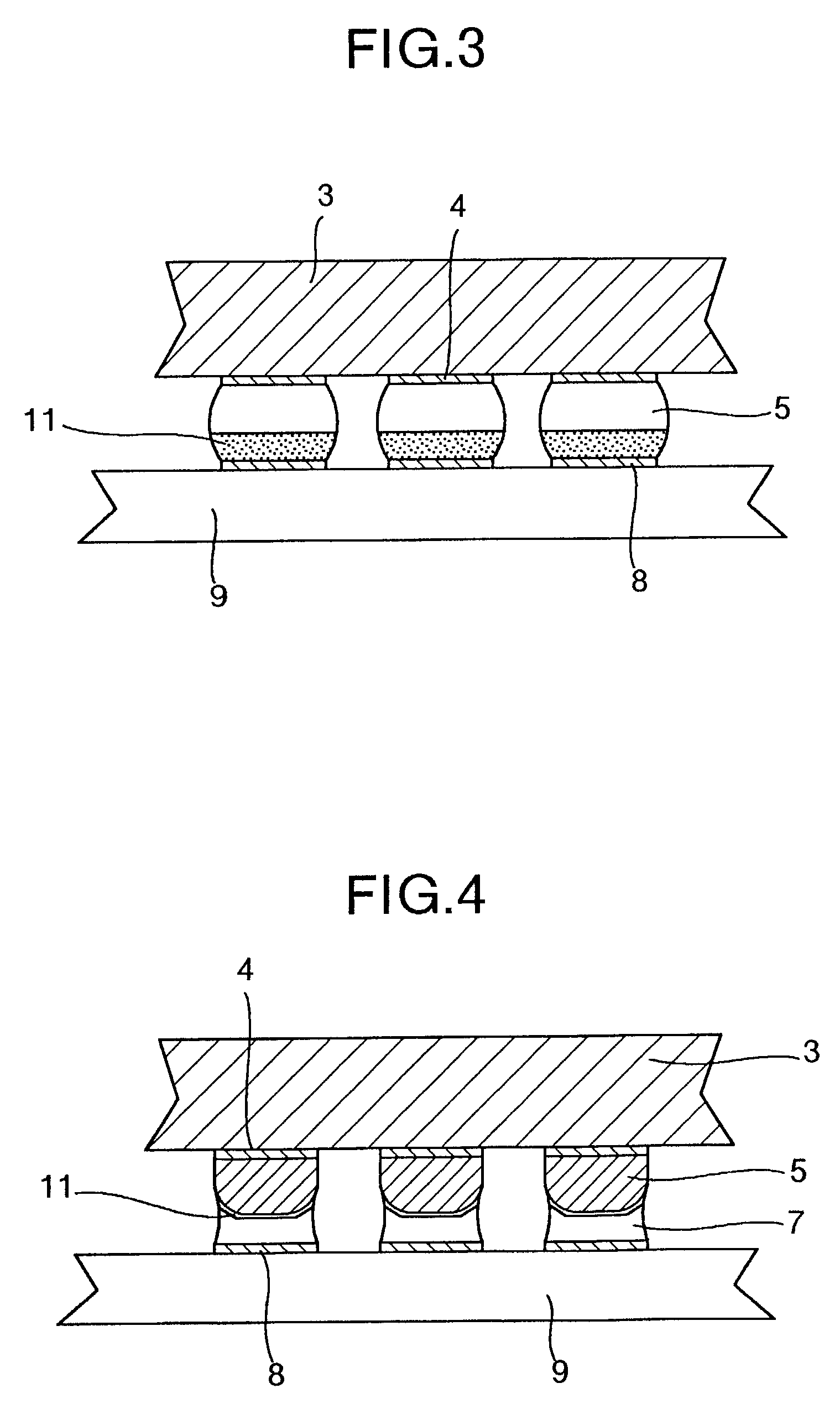

Semiconductor device having solder bumps reliably reflow solderable

InactiveUS7145236B2Improve reliabilityPromote meltingPrinted circuit assemblingFinal product manufactureMetallurgySolder paste

A semiconductor module solder bonding of high reliability in which the heat resisting properties of the circuit substrate and electronic parts are taken into consideration. In order to achieve this, there are provided semiconductor devices each having solder bumps as external pads, and a circuit substrate bonded to the external pads of each of the semiconductor devices through a solder paste, each of the solder bumps being made of a first lead-free solder, the solder paste being made of a second lead-free solder having a melting point lower than that of the first lead-free solder.

Owner:RENESAS ELECTRONICS CORP

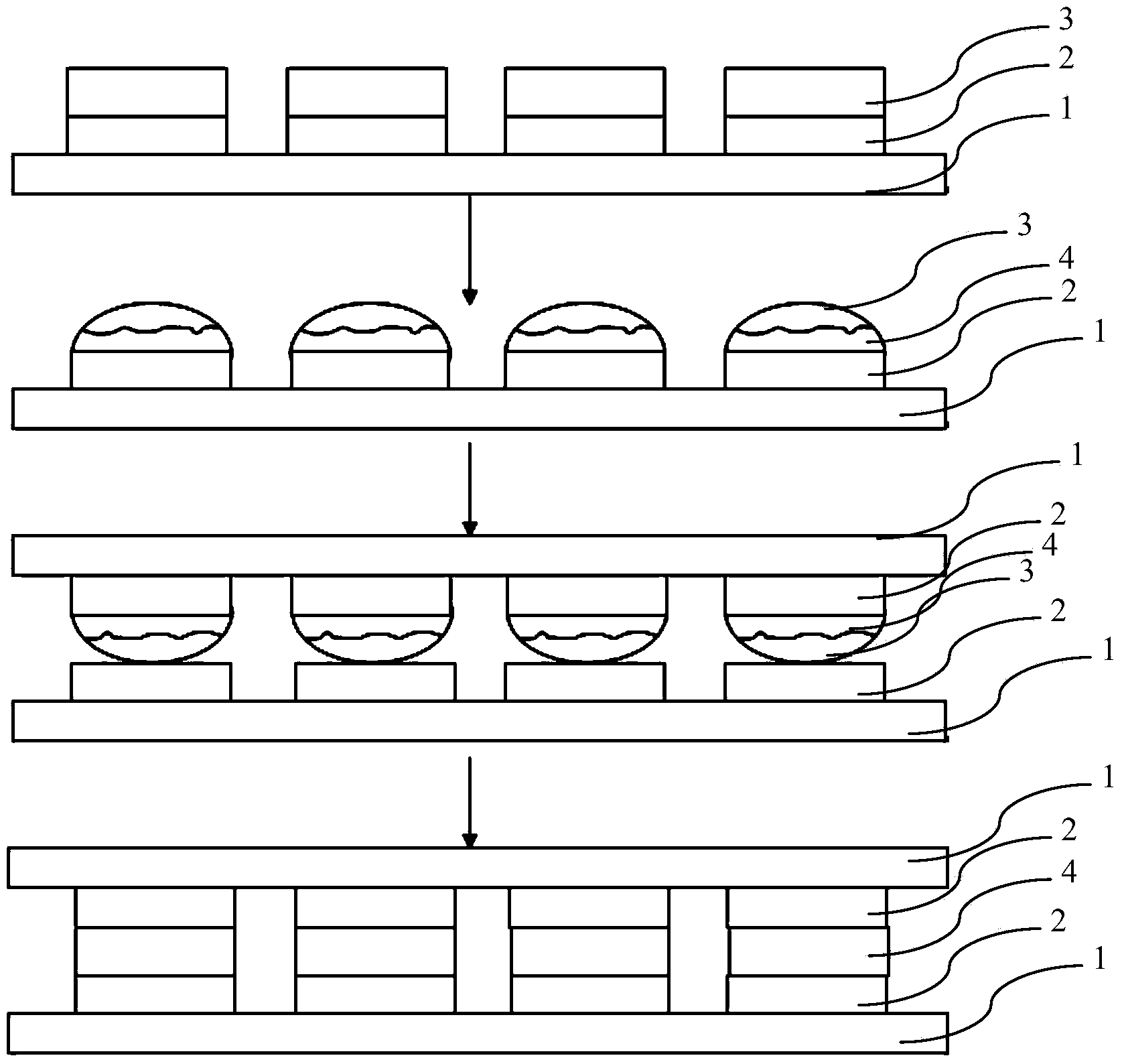

Method for preparing and applying single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure

ActiveCN103658899AAvoid premature failureUniform orientation distributionSolid-state devicesSemiconductor/solid-state device manufacturingProcess conditionsIntermetallic

The invention provides a method for preparing and applying a single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure. The method for preparing the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure comprises the first step of arraying a Cu welding disc on a wafer through the electroplating technology, the second step of manufacturing bosses by preparing brazing filler metal prepared on the Cu welding disc, the third step of carrying out hot-wind remelting on the manufactured bosses for 30s-120s, the fourth step of carrying out solid-phase aging processes on chips obtained in the third step, the fifth step of placing the welding point bosses prepared in the fourth step into hydrochloric acid, oscillating the welding point bosses through ultrasound, washing and drying the welding point bosses to obtain a preferred orientation Cu6Sn5 welding disc, the sixth step of reversely buckling the welding point bosses prepared in the fifth step into a corresponding circuit board Cu metal layer, and obtaining the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure through the reflow welding technology. Uniform and stable welding point structure can be obtained when the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure is applied to large two-level packaging at the appropriate conditions.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +3

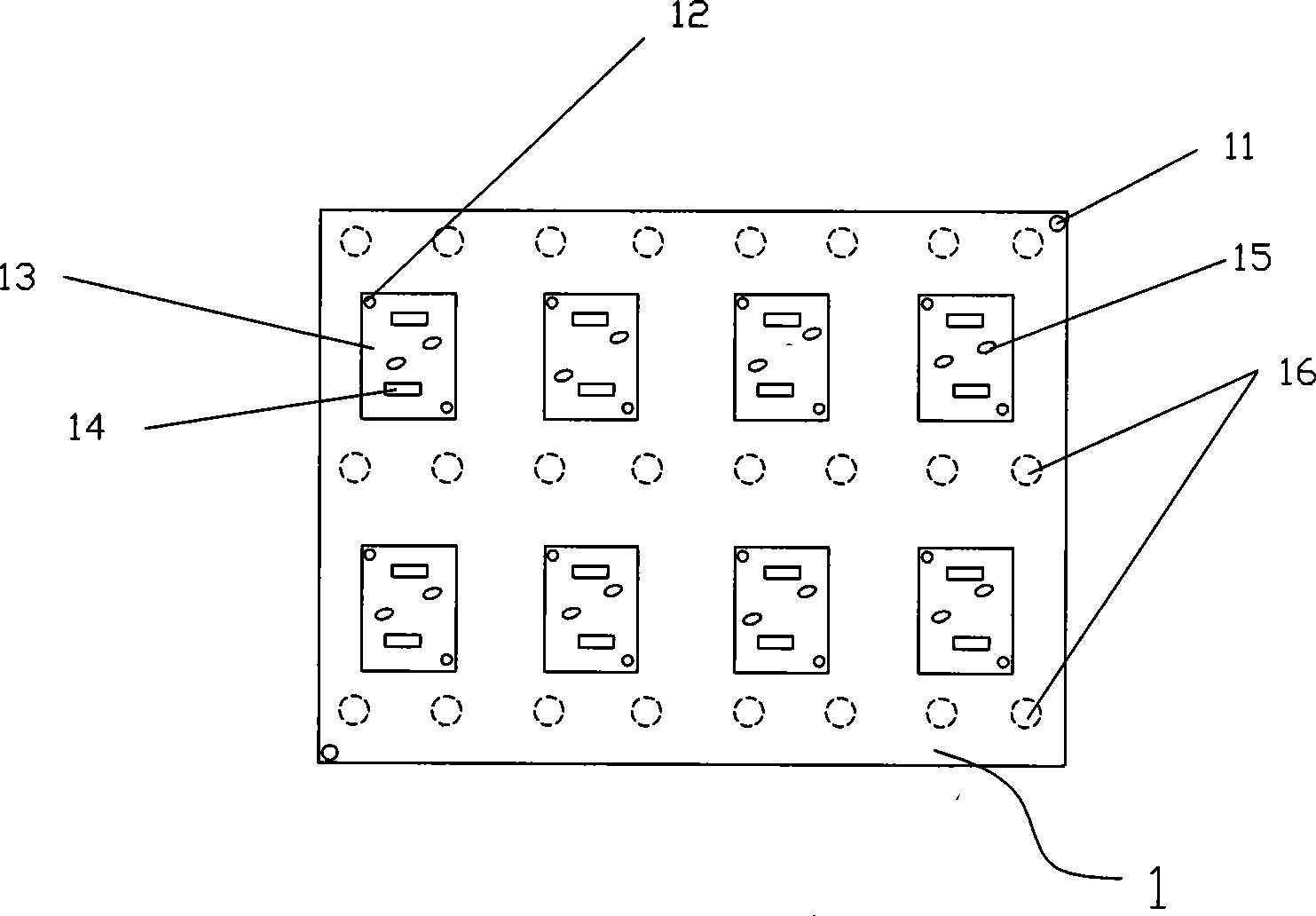

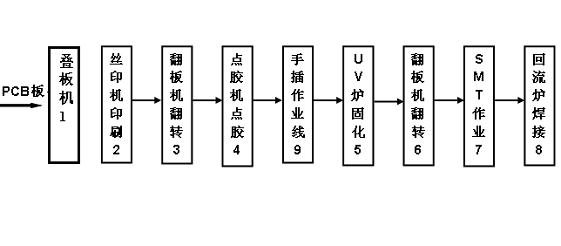

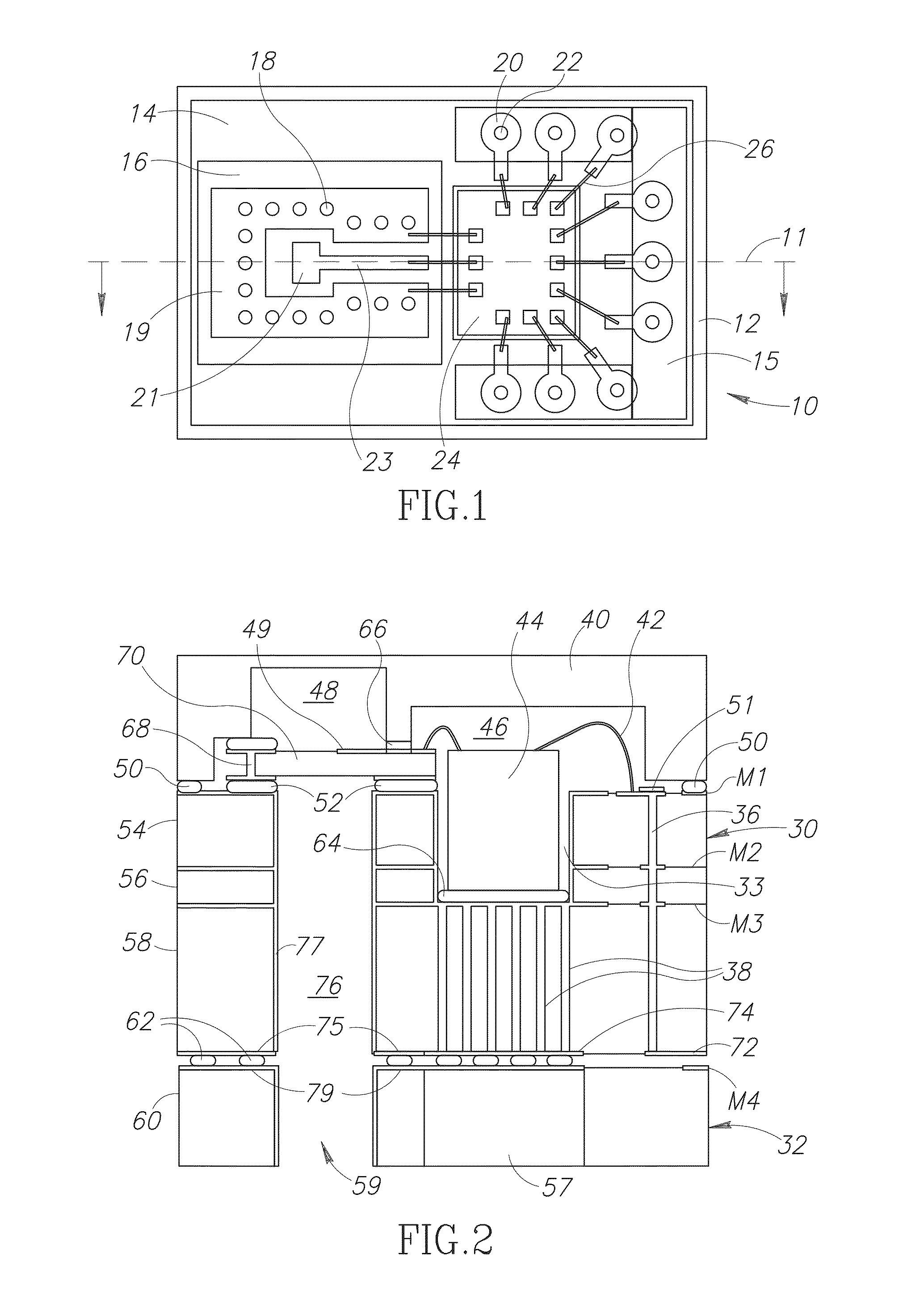

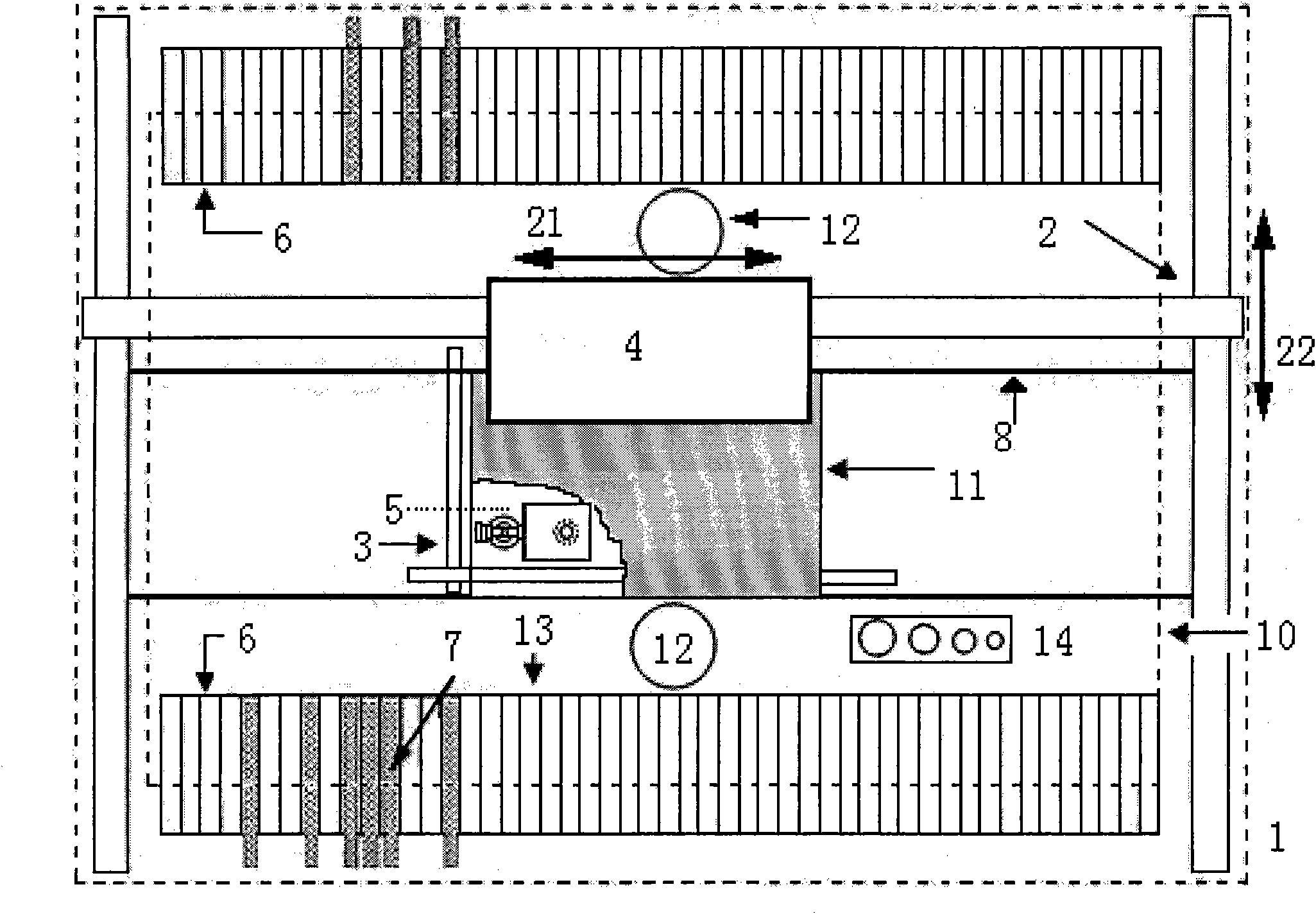

PCB (Printed Circuit Board) production line combining manual in process processing and paster processing

ActiveCN101977484AShorten production timeReduce turnoverPrinted circuit assemblingElectrical componentsProduction lineUV curing

The invention discloses a PCB (Printed Circuit Board) production line combining a manual in process processing and paster processing, which is characterized by comprising a board feeding machine (1), a screen printing machine (2), as well as a first board overturning machine (3), an adhesive dispenser (4), a UV curing oven (5), a second board overturning machine (6), SMT (Surface Mounting Technology) equipment (7) and a reflow soldering heating curing oven (8). The first board overturning machine (3) is responsible for overturning a PCB subjected to low-temperature solder past printing of the screen printing machine (2) and then dispensing an adhesive, and after adhesive dispensing, a UV adhesive with a large long-pin device is cured under UV irradiation; after the PCB is overturned by the second board overturning machine, the step of paster production begins; and finally, PCB heating curing is finished in the reflow soldering heating curing oven (8). The invention combines SMT operation and manual in process operation together to realize a double-faced reflow soldering technology, solves the defects of traditional wave-soldering technology, and saves energy since reflow soldering is performed only twice and elements are heated twice.

Owner:NANJING PANDA ELECTRONICS MFG

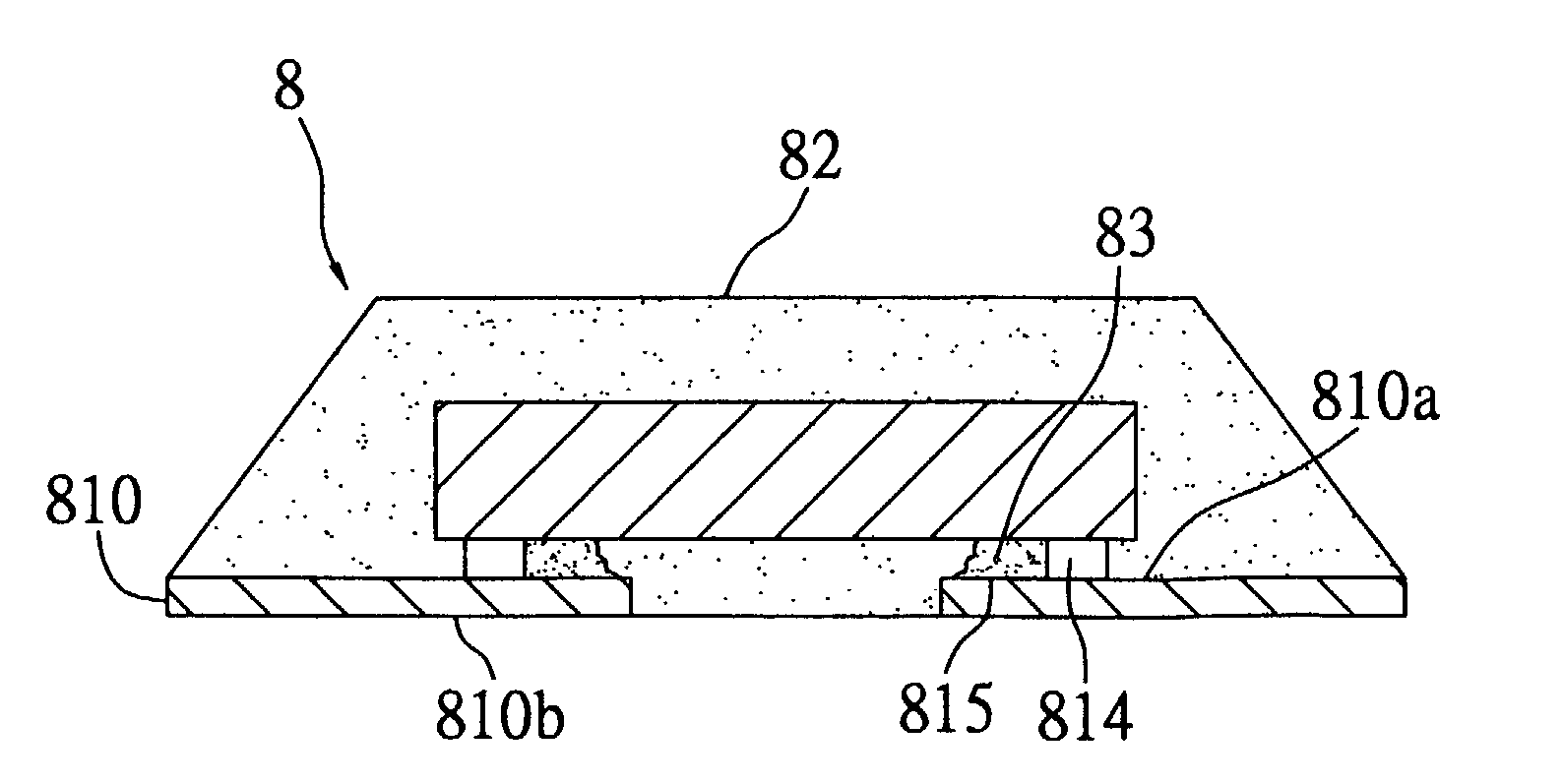

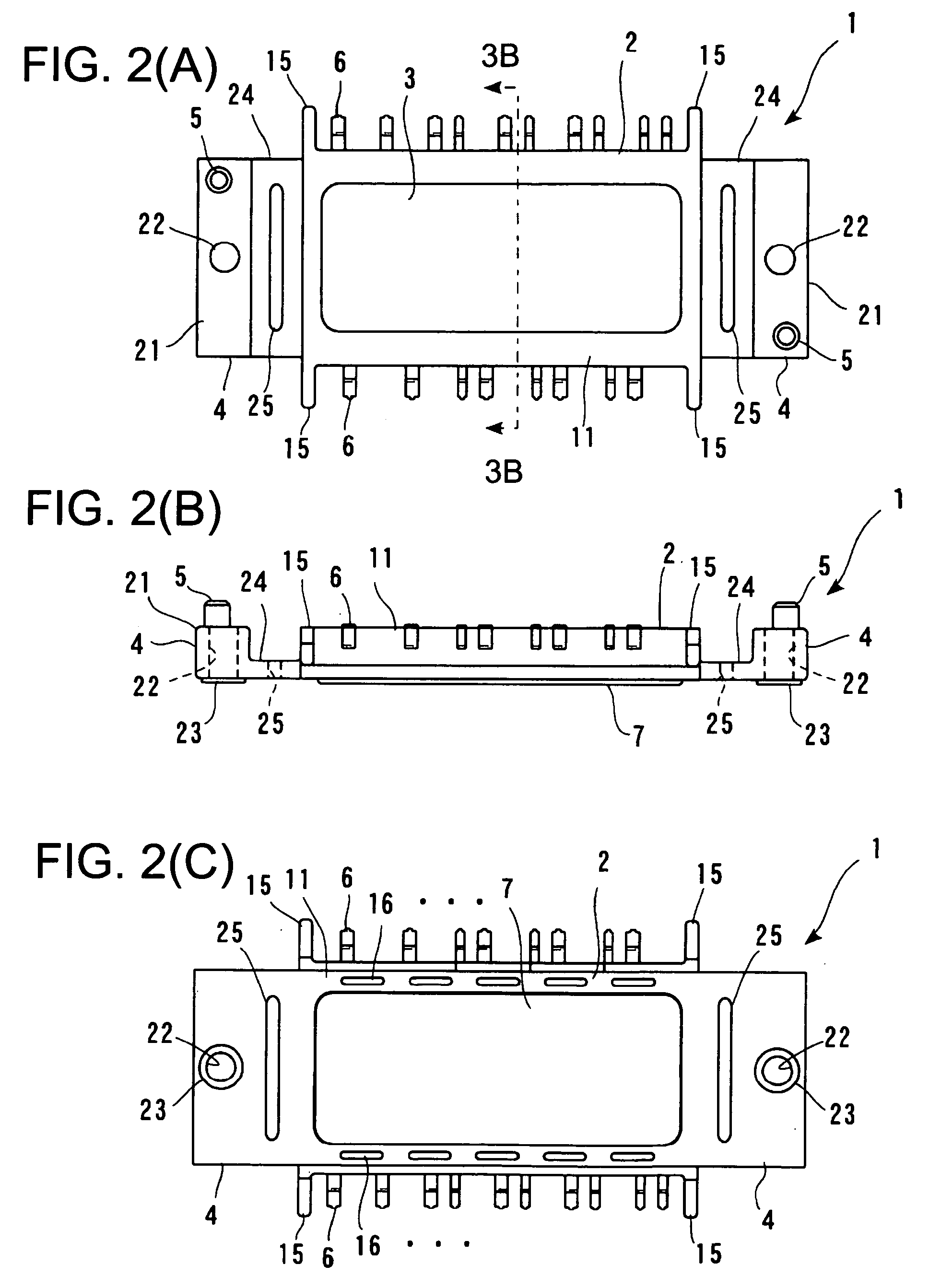

Power semiconductor module and method of manufacturing the same

ActiveUS20060060982A1Strengthens the adhesion of the thermosetting resinSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSingle step

A power semiconductor module and a method of manufacture thereof includes lead a frame carrying lead having inner and outer lead portions. The outer lead portions, which are connected by soldering to semiconductor chips simultaneously, eliminate the need for using bonding wires. Since no bonding wire is used for connecting the leads and the semiconductor chips, a sufficient current capacity is obtained. The bonding between an insulating circuit board and the semiconductor chips and the bonding between the semiconductor chips and the leads can be made simultaneously in a single step of reflow-soldering. As a result, the mounting time can be shortened and the power semiconductor module can be manufactured more efficiently.

Owner:FUJI ELECTRIC CO LTD

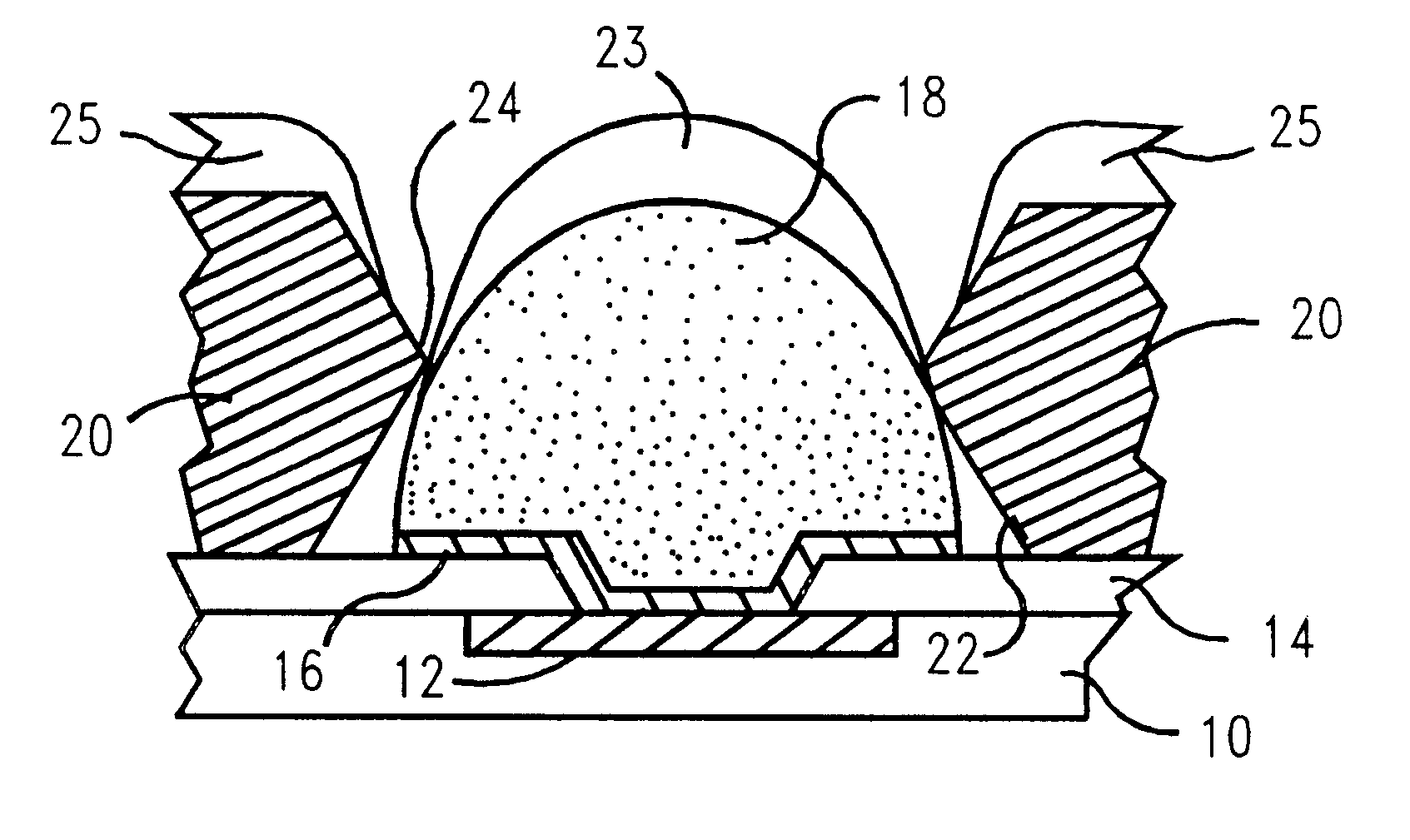

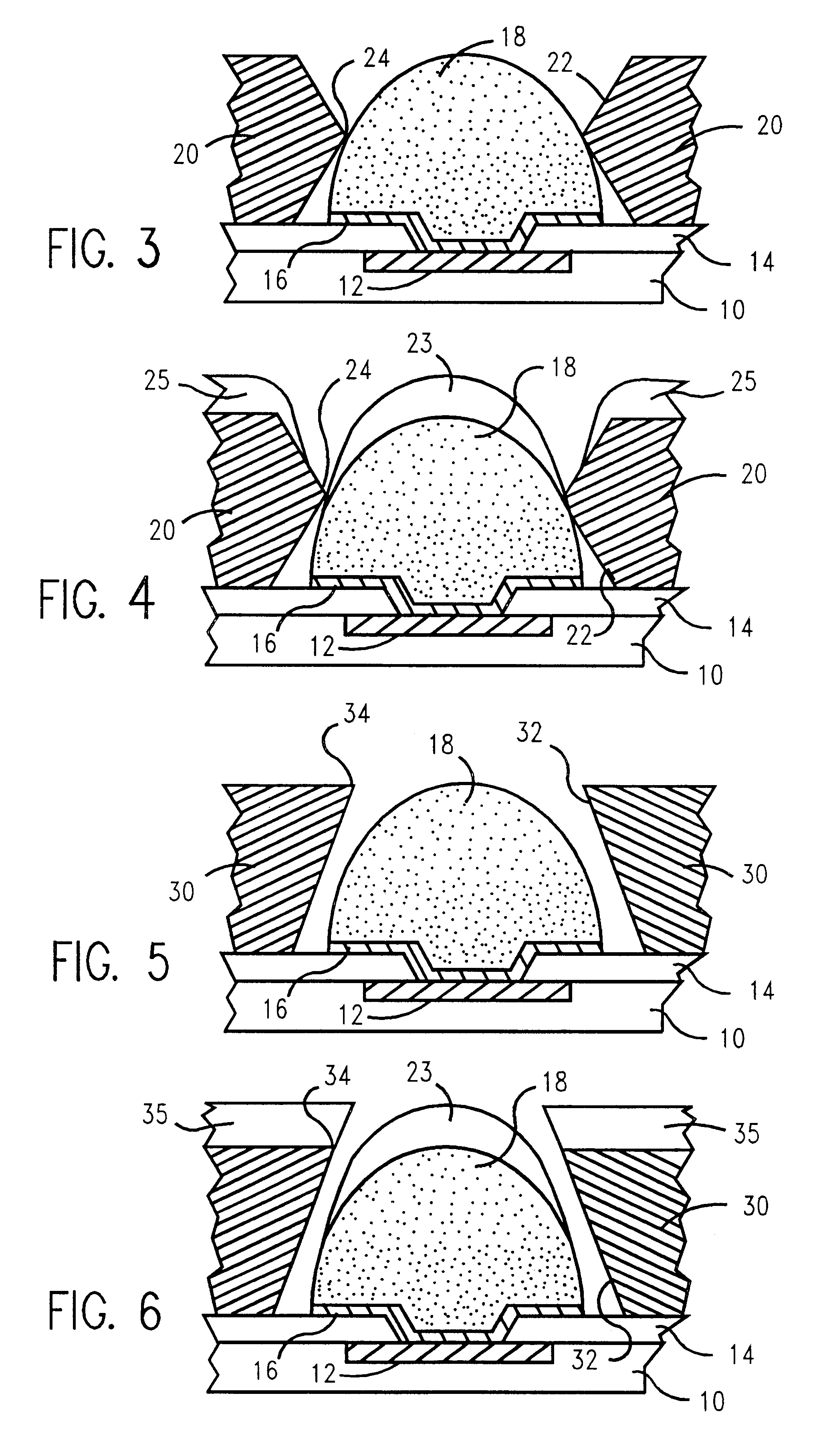

Overmolded electronic module with an integrated electromagnetic shield using SMT shield wall components

InactiveUS20080112151A1Easy to manufactureMinimal spaceMagnetic/electric field screeningFinal product manufactureSurface mountingElectromagnetic shielding

An electronic module with an integrated electromagnetic shield using surface mount shield wall components has been disclosed. Each surface mount shield wall component provides side shielding of circuitry within the overmolded electronic module and provides an exposed conductive shield wall section to which a top conductive shield can be applied. By including the shield structure as part of the overmolded electronic module, the need for a separate shield and separate process steps for installing the separate shield can be eliminated. Each surface mount shield wall component comprises a non-conductive portion that provides stability during a reflow soldering process, but at least a sacrificial portion of the non-conductive portion can be removed to reduce the amount of area occupied by the overmoldable shield structure.

Owner:SKYWORKS SOLUTIONS INC

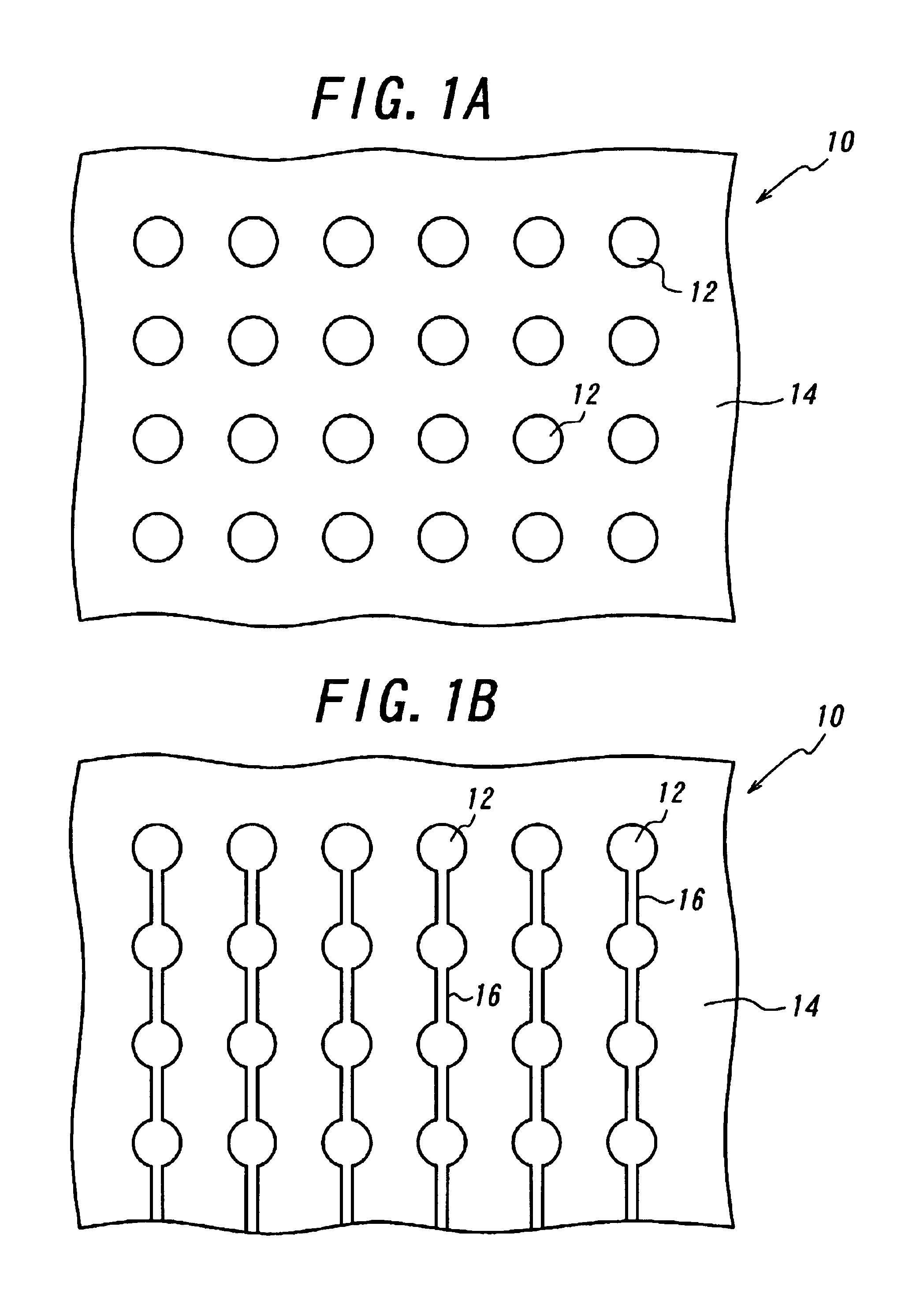

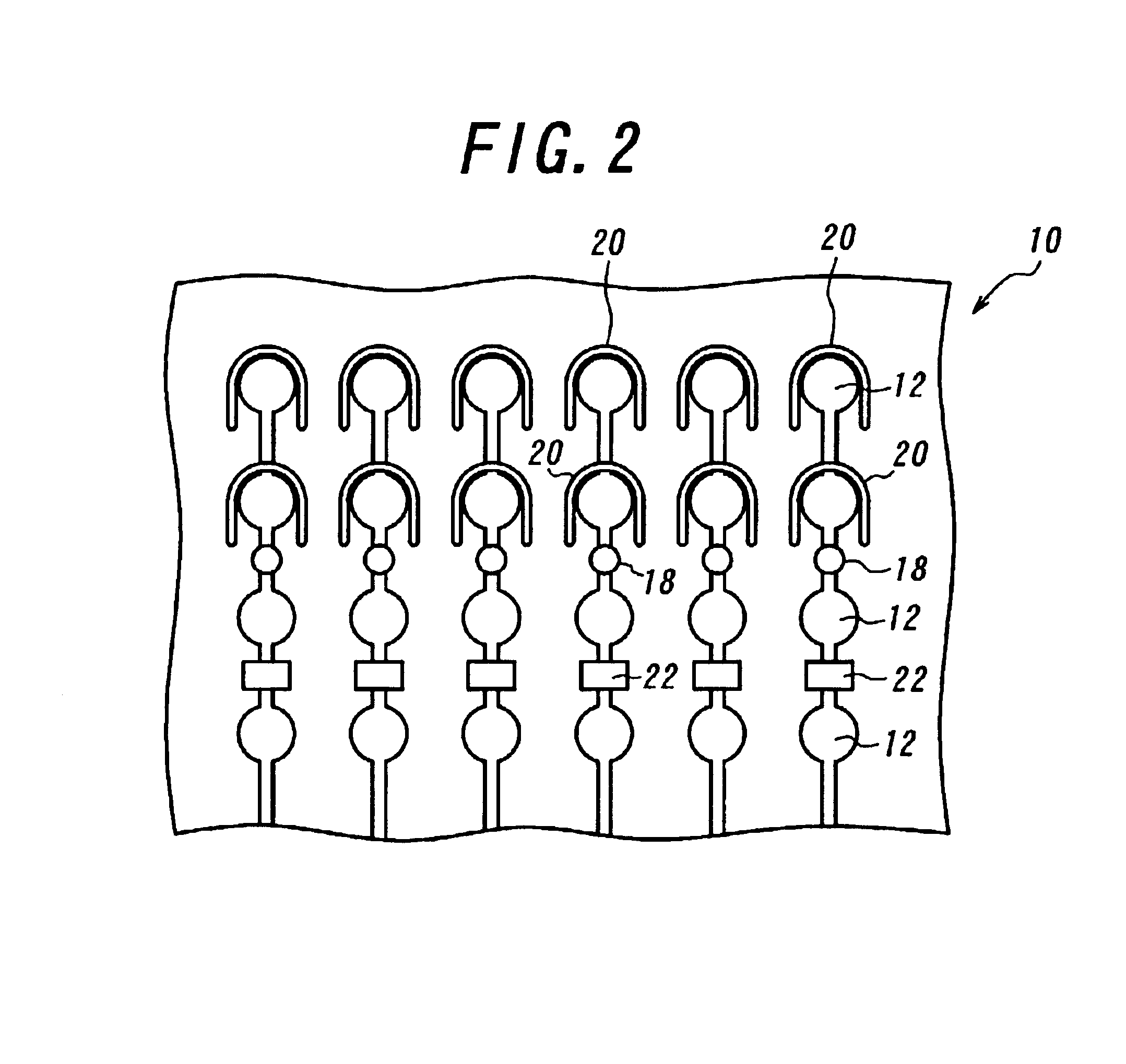

Anti-tombstoning lead free alloys for surface mount reflow soldering

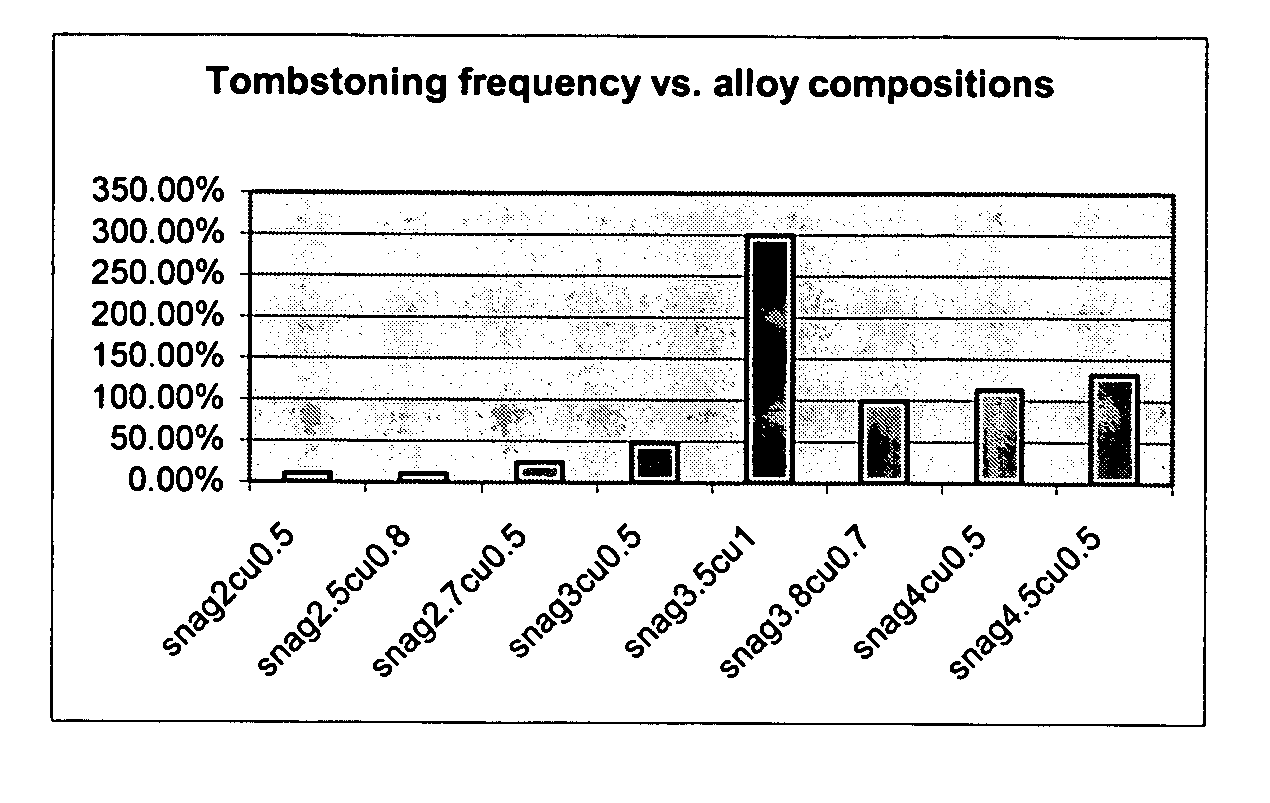

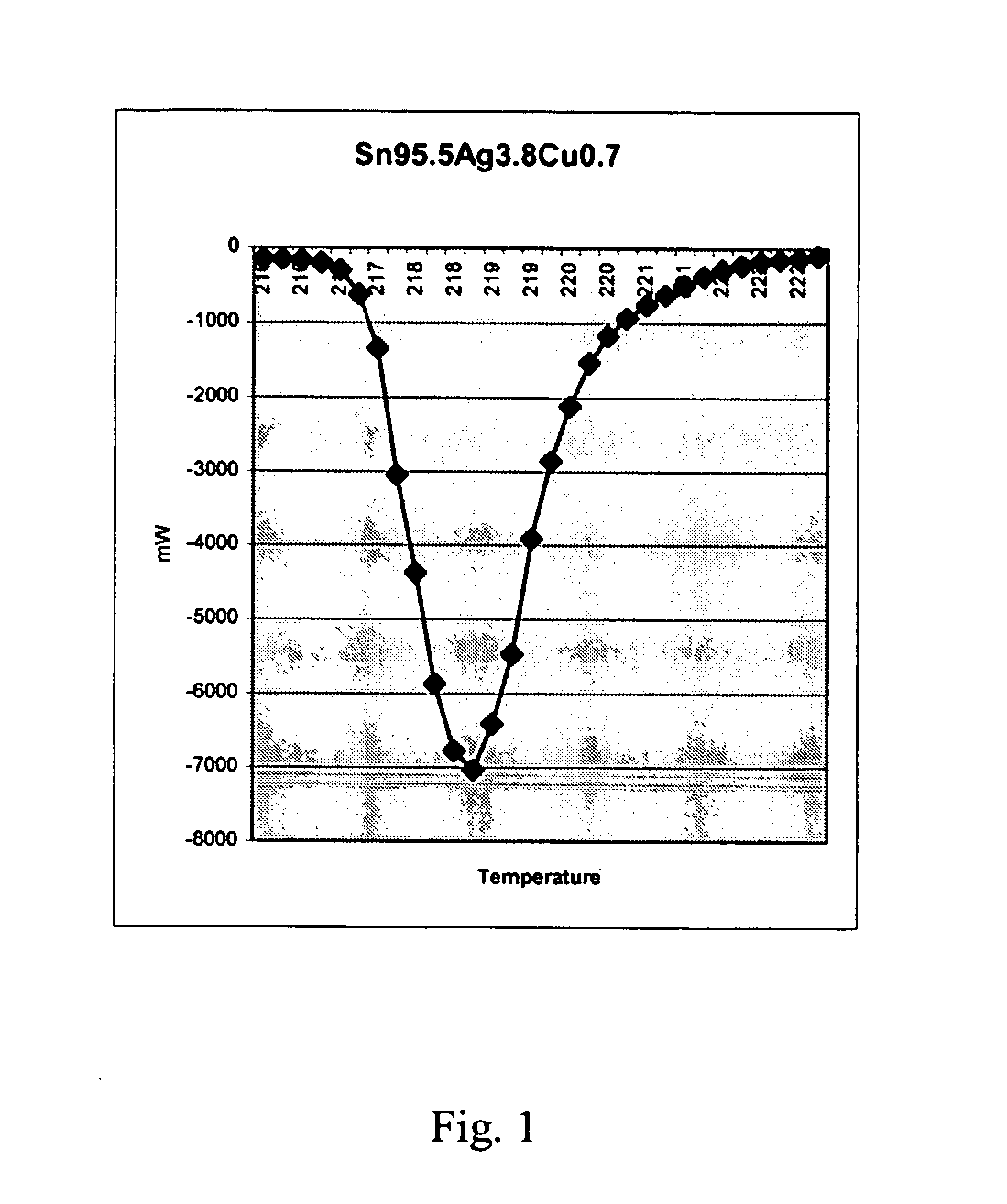

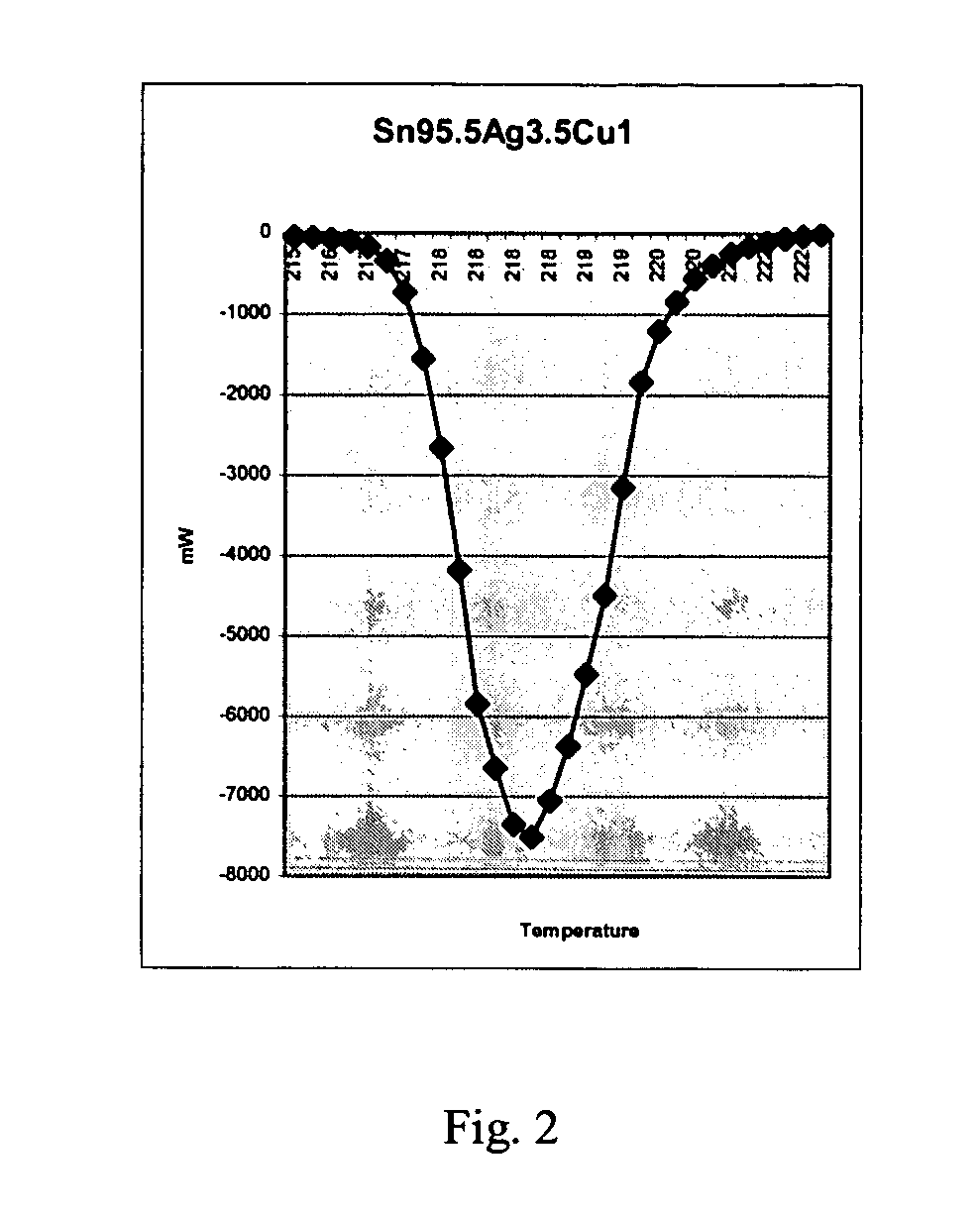

InactiveUS20050100474A1Reducing tombstoning effectPrinted circuit assemblingFinal product manufactureSurface mountingCopper

A lead-free solder alloy composition comprising tin, silver and copper, and a process for reflow soldering for minimizing tombstoning frequency are disclosed. In one particular exemplary embodiment, the lead-free Sn—Ag—Cu solder alloys for minimizing the tombstoning effect of the present disclosure display high mass fraction during melting and prolonged melting as shown by a widened DSC peaks, that allows for a balanced surface tension on both ends of the chip component to develop. In accordance with further aspects of this exemplary embodiment, the alloys display a mass fraction of solid during melting greater than 20% and a DSC peak width greater than 8° C. using a 5° C. / min scan rate. In accordance with further aspects of this exemplary embodiment, the alloy comprises on a weight basis Ag 1-4.5%, Cu 0.3-1% balanced with Sn.

Owner:INDIUM CORPORATION

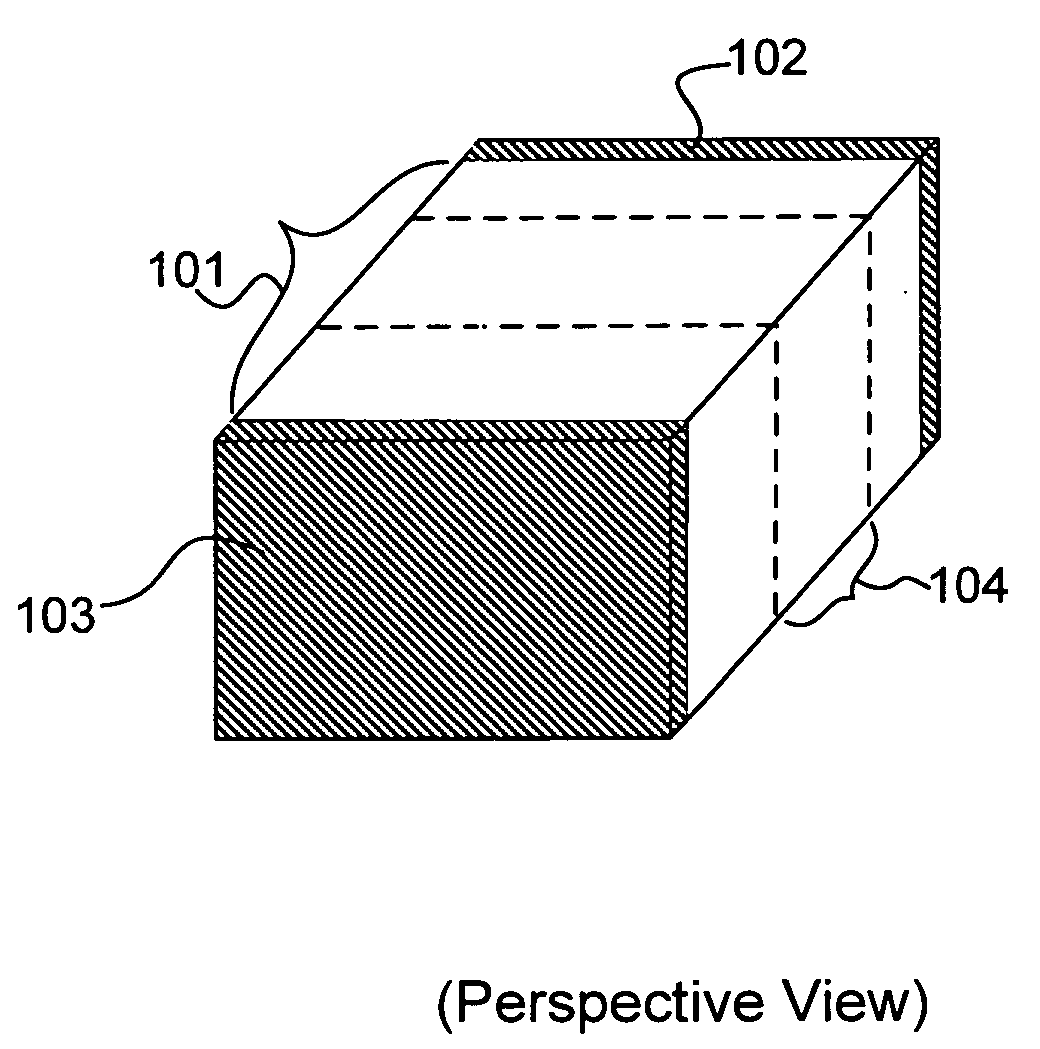

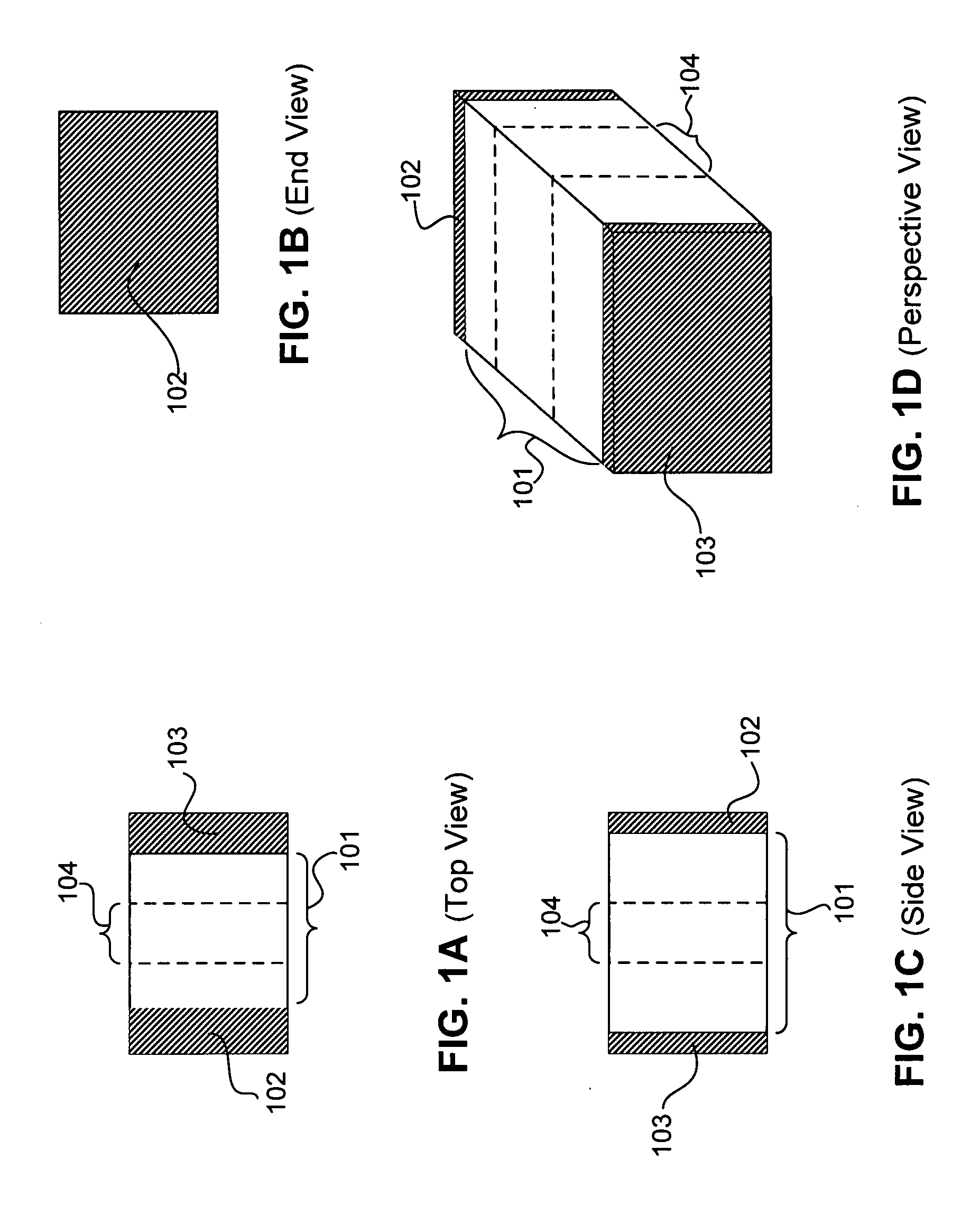

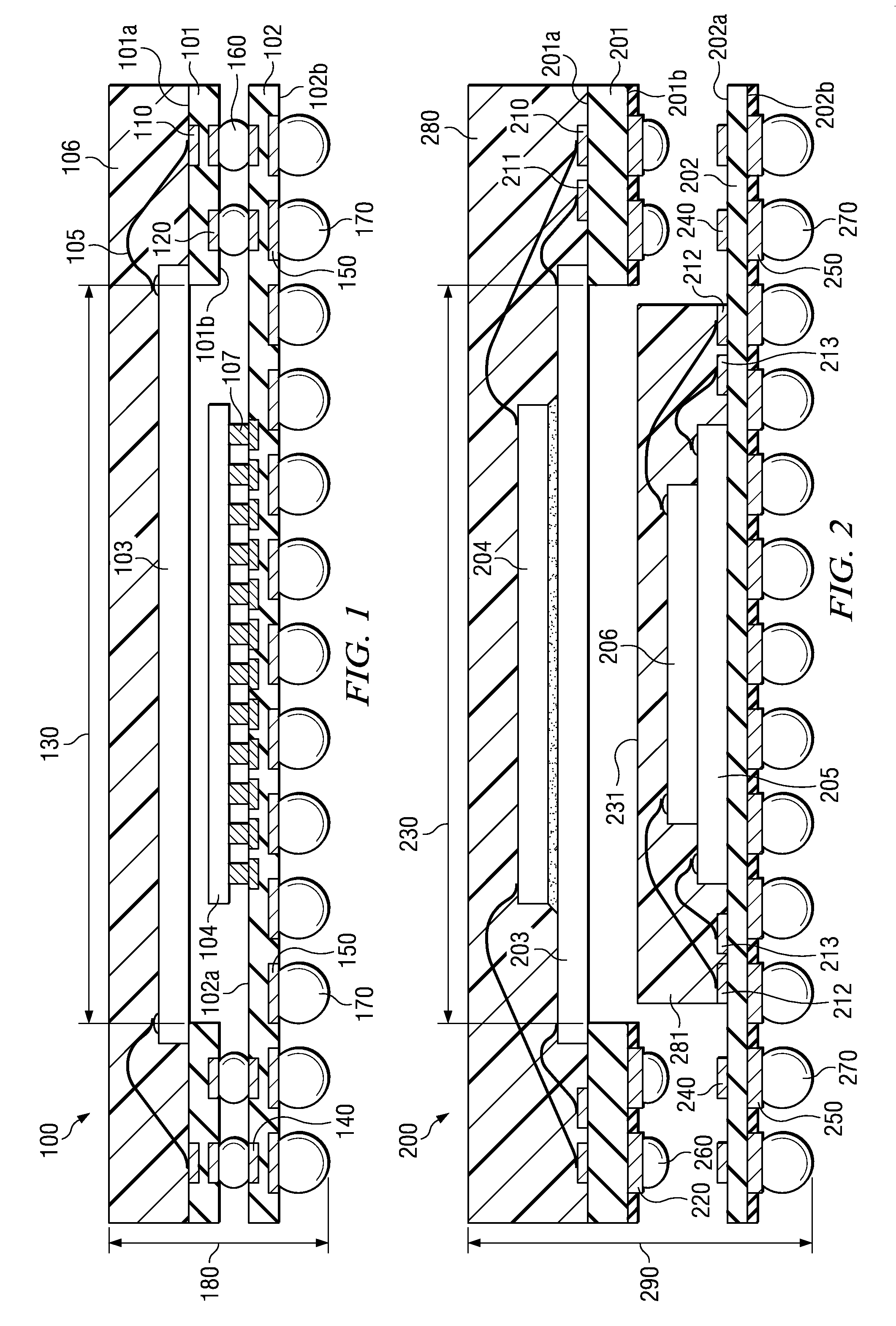

Low profile semiconductor package-on-package

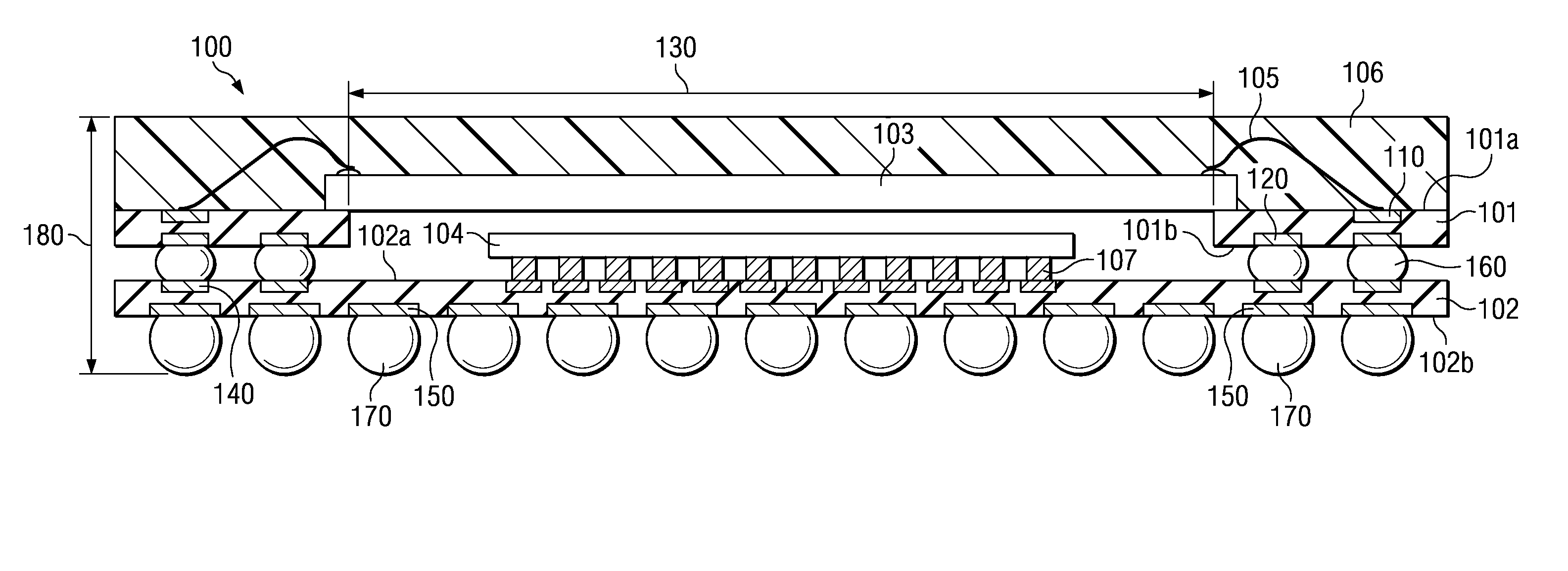

InactiveUS20070216008A1Shorten the time to marketImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor system (100) with two substrates has a first substrate (101) with a first and a second surface, electrical contact pads (110, 120) on the first and the second surface, and a central opening (130). The second substrate (102) has a third and a fourth surface, and electrical contact pads (140, 150) on the third and the fourth surface. Metal reflow bodies (160) connect the pads (120, 140) on the second and the third surface. A first semiconductor chip (103), or chip stack, is on the first surface over the opening (130), and a second semiconductor chip (104), or chip stack, is on the third surface inside the opening.

Owner:TEXAS INSTR INC

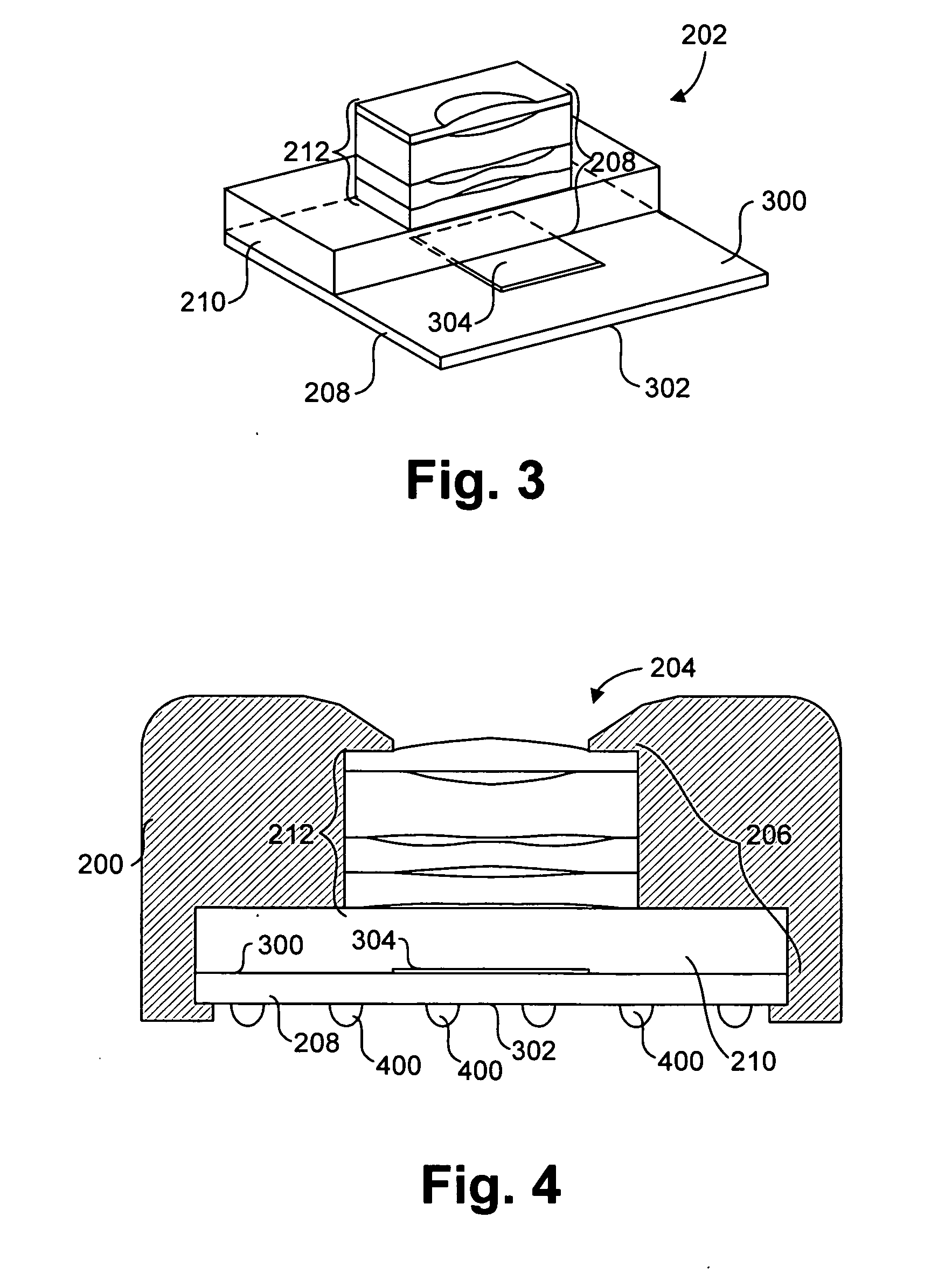

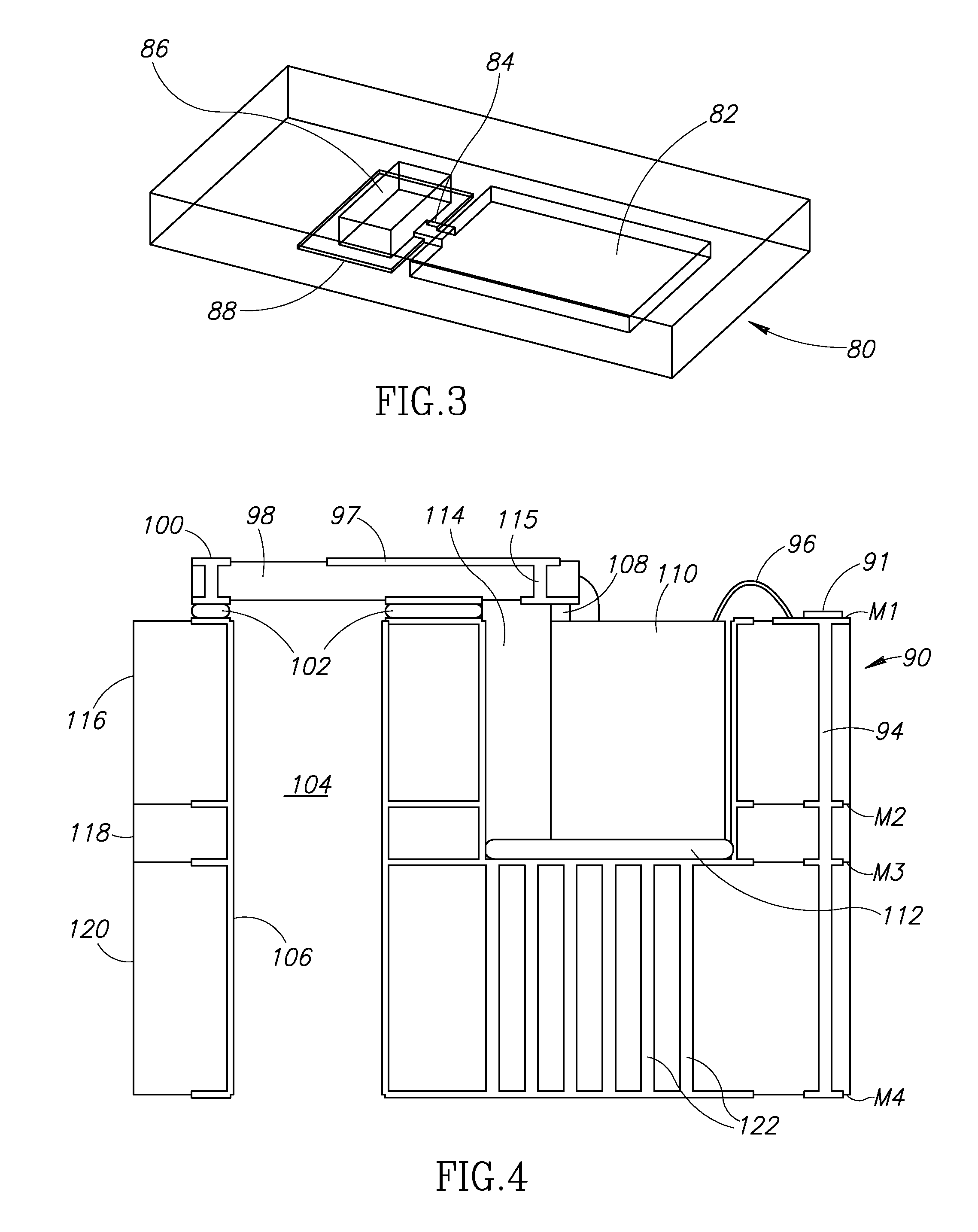

Small form factor modules using wafer level optics with bottom cavity and flip-chip assembly

ActiveUS20100053423A1Good adhesionAssembly toleranceTelevision system detailsPrinted circuit assemblingSmall form factorCamera module

A disclosed method of manufacturing a camera module includes providing a stack of optical elements, providing an integrated circuit image capture device (ICD) having a top surface with an array of sensors, rigidly attaching the stack of optical elements to top surface of the image capture device, providing a substrate having an opening therethrough and a recess around said opening, and attaching the image capture device to the substrate such that edges of the image capture device are disposed in the recess and the stack of optical elements extends through the opening. The method further includes providing a second substrate (e.g., host PCB) and mounting the substrate on the second substrate to attach the camera module to the host device. Optionally, the substrate is mounted to the second substrate via a reflow solder process.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

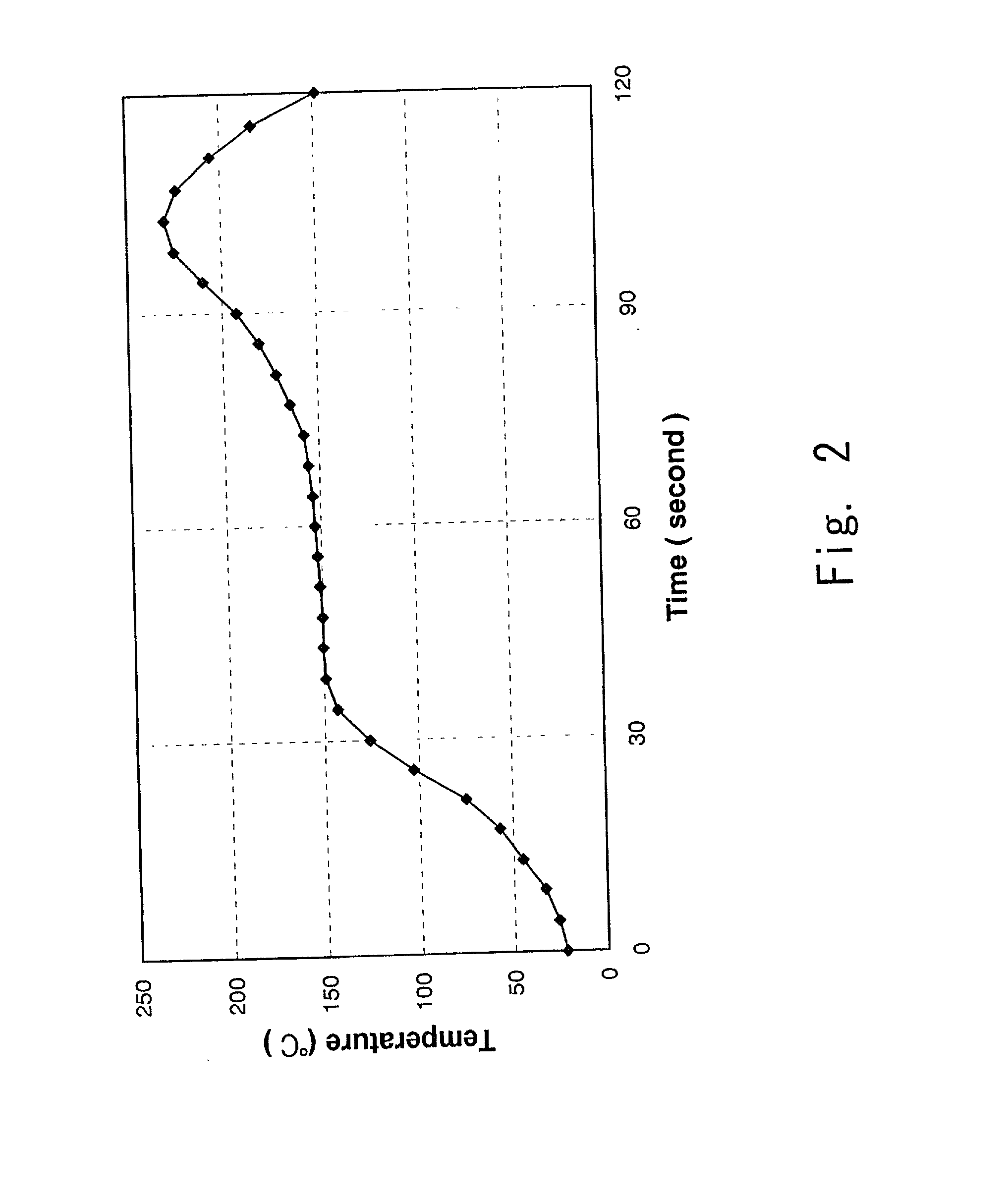

Non-aqueous electrolyte secondary

A non-aqueous electrolyte secondary battery capable of being assembled by reflow soldering is provided. The assembled non-aqueous electrolyte secondary battery is heat-treated following the temperature-time profile close to that for the reflow soldering, and then provided with the terminals by welding.

Owner:WATANABE SHUNJI +3

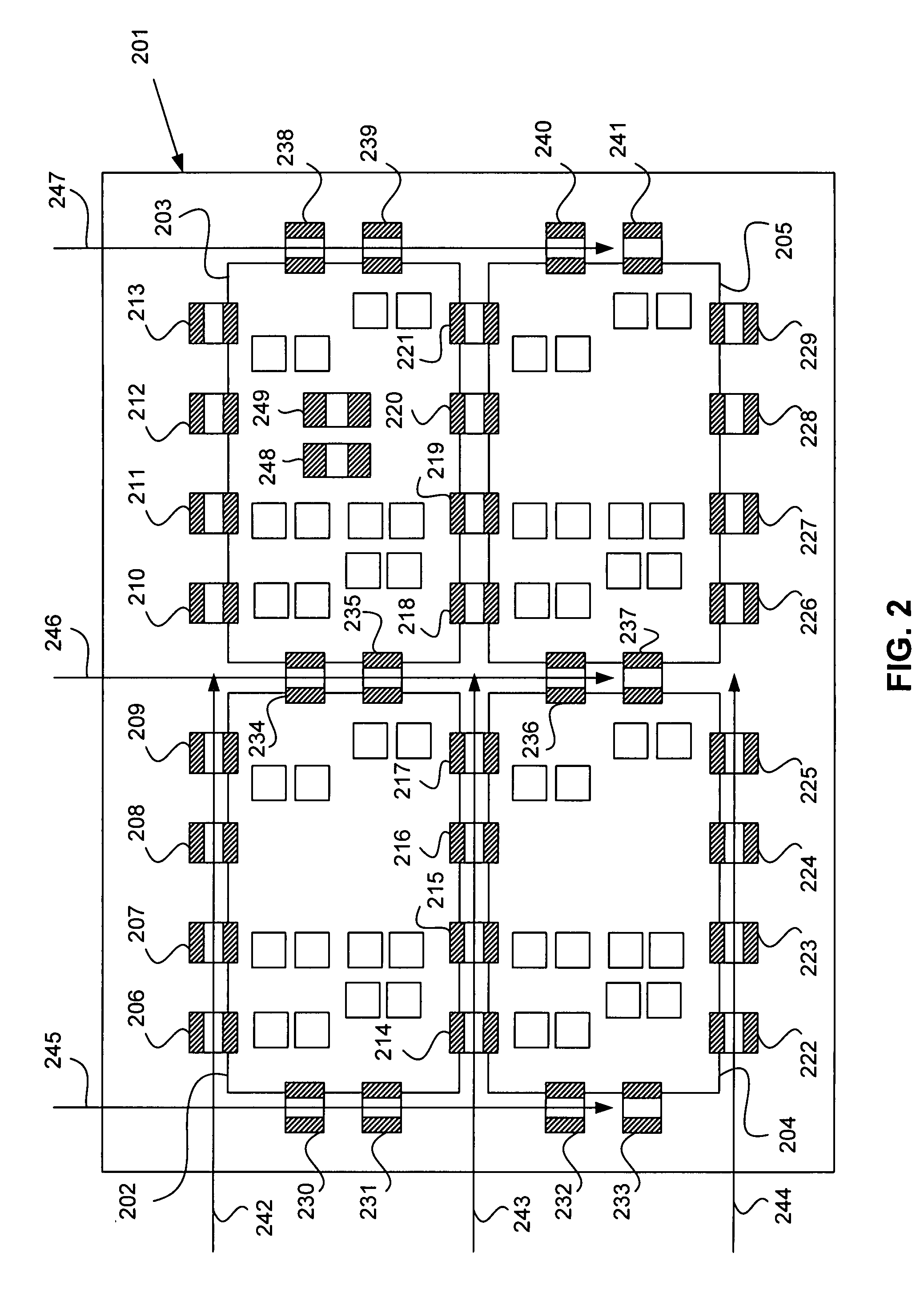

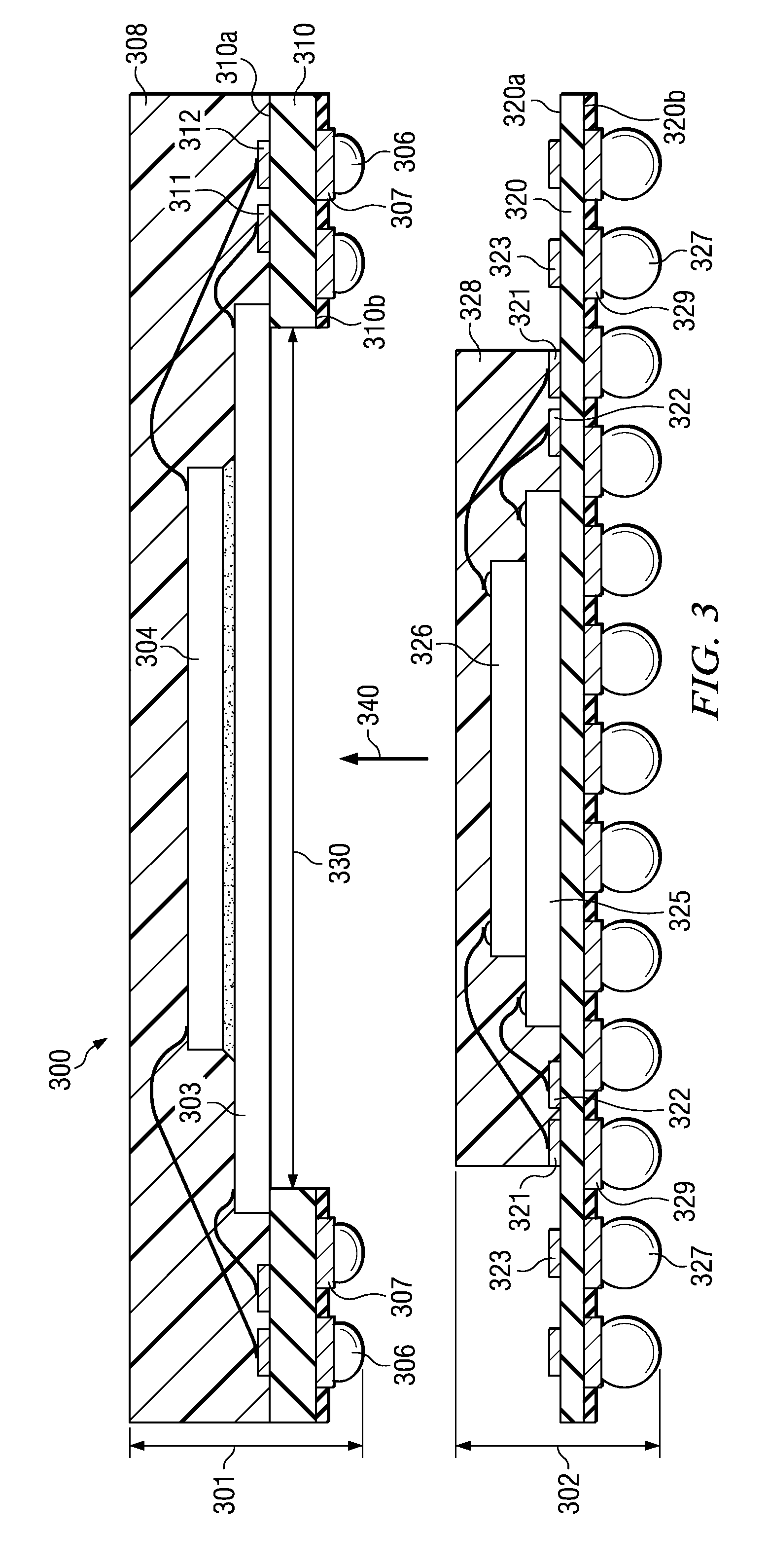

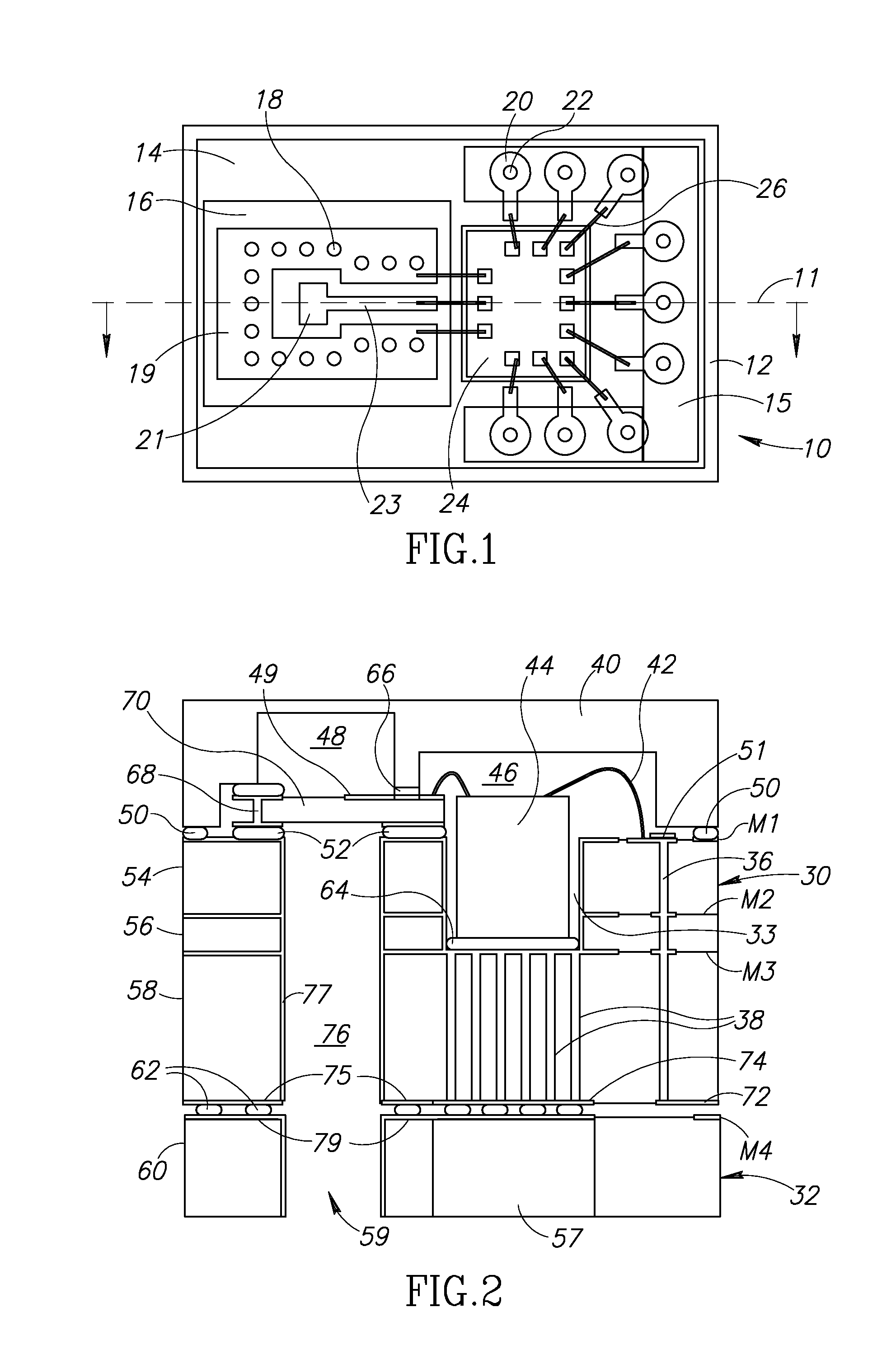

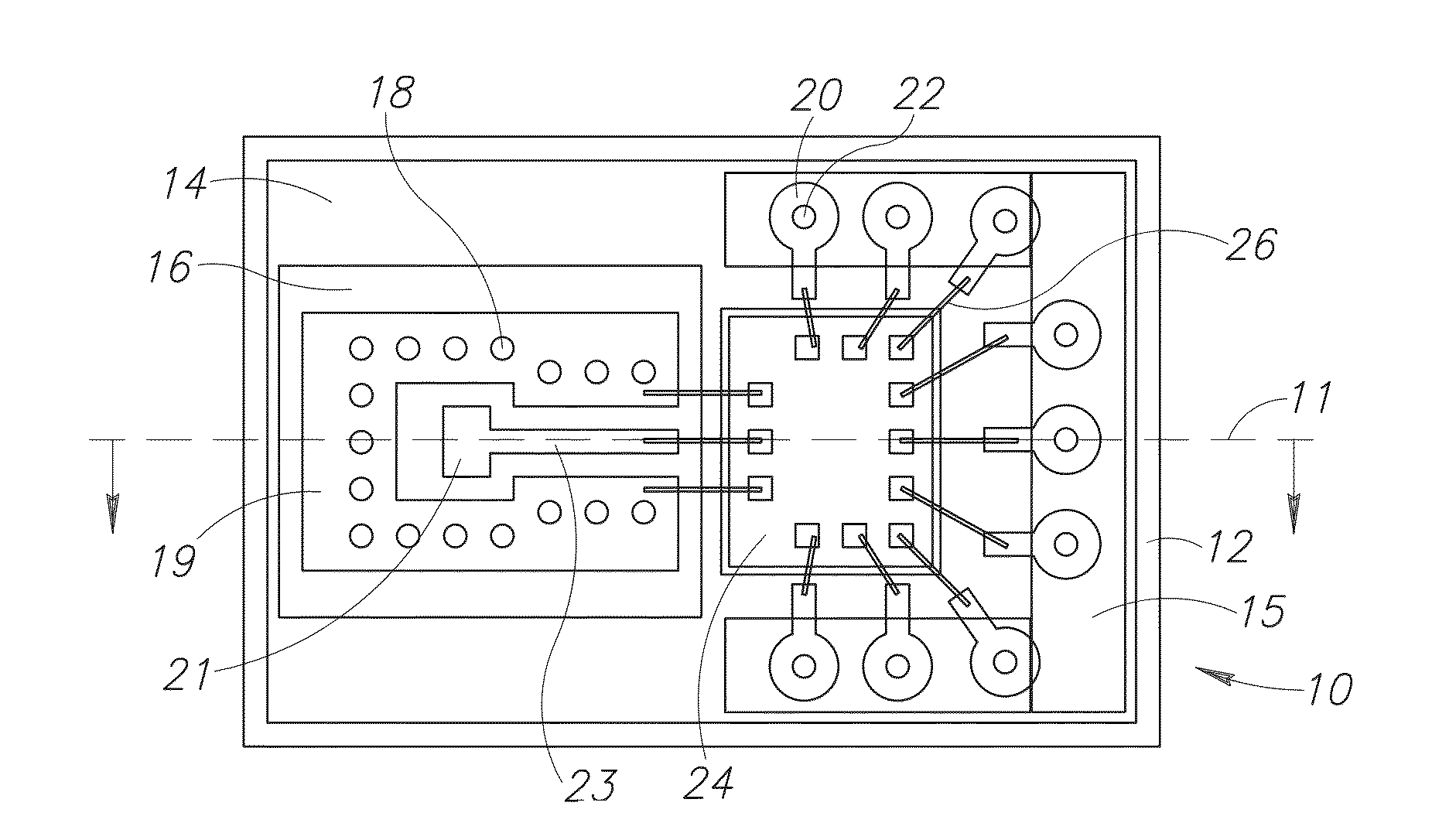

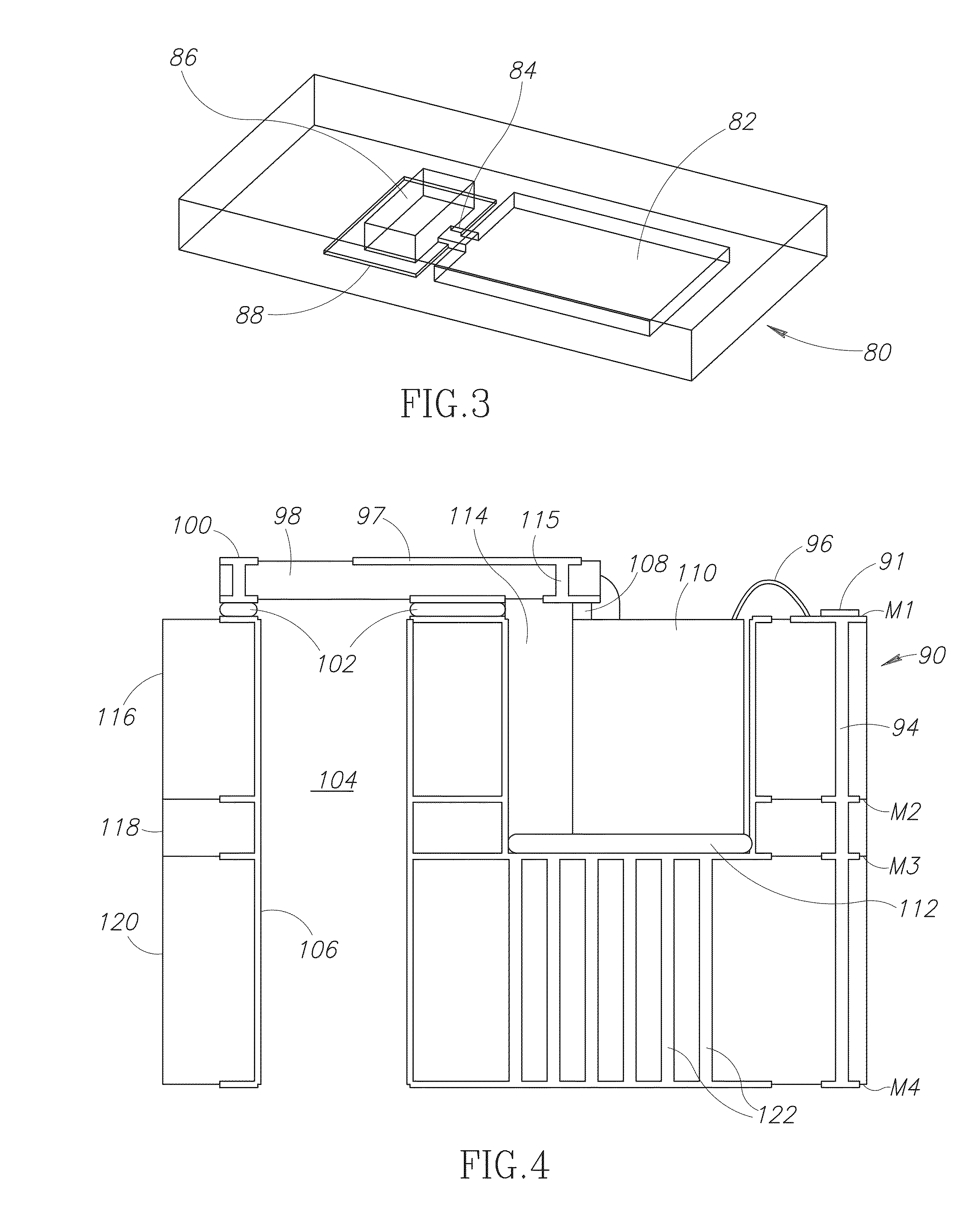

High frequency transition matching in an electronic package for millimeter wave semiconductor dies

ActiveUS20130256849A1Improving Impedance MatchingEasy transferSemiconductor/solid-state device detailsSolid-state devicesRadiation lossSemiconductor chip

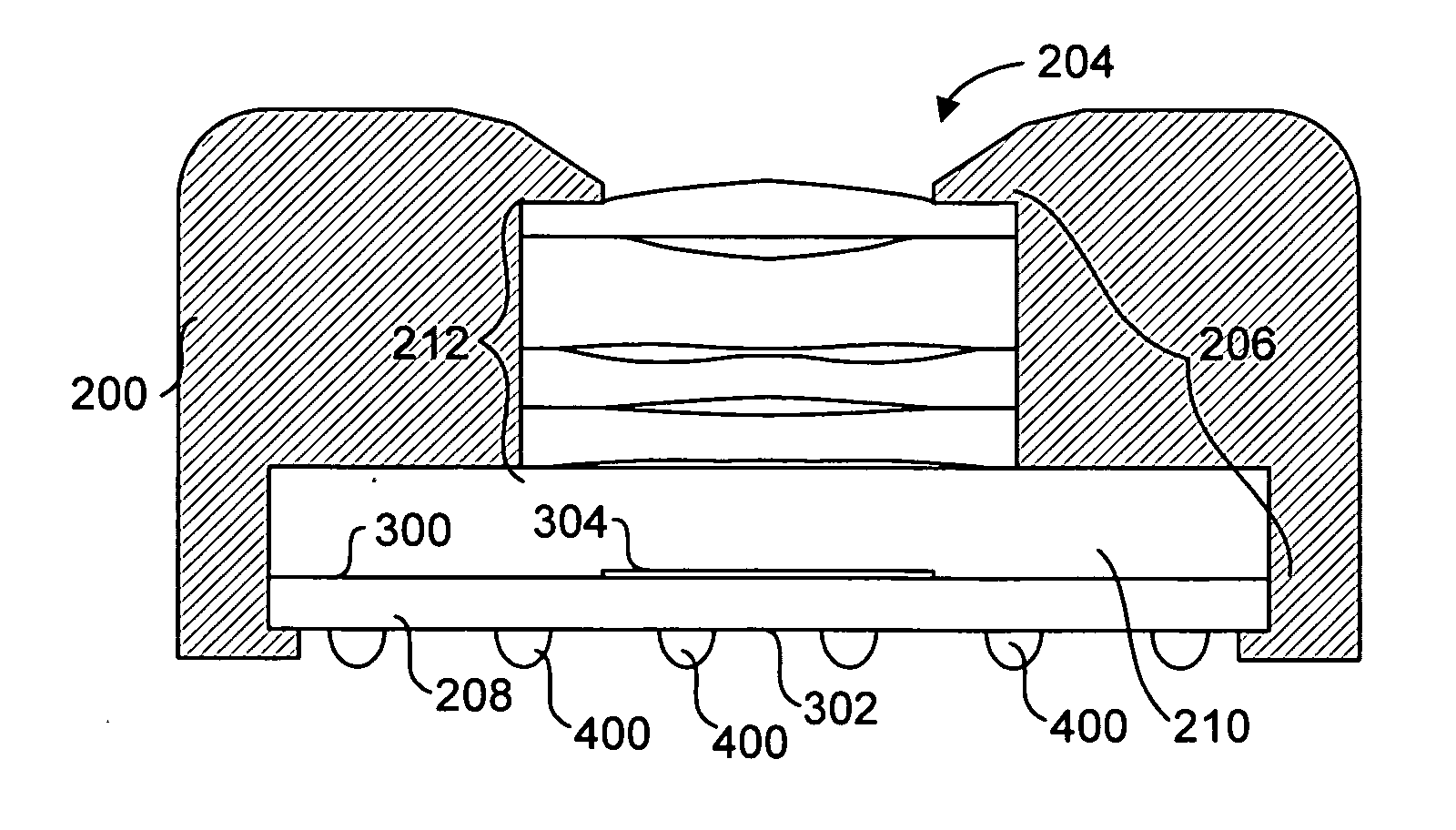

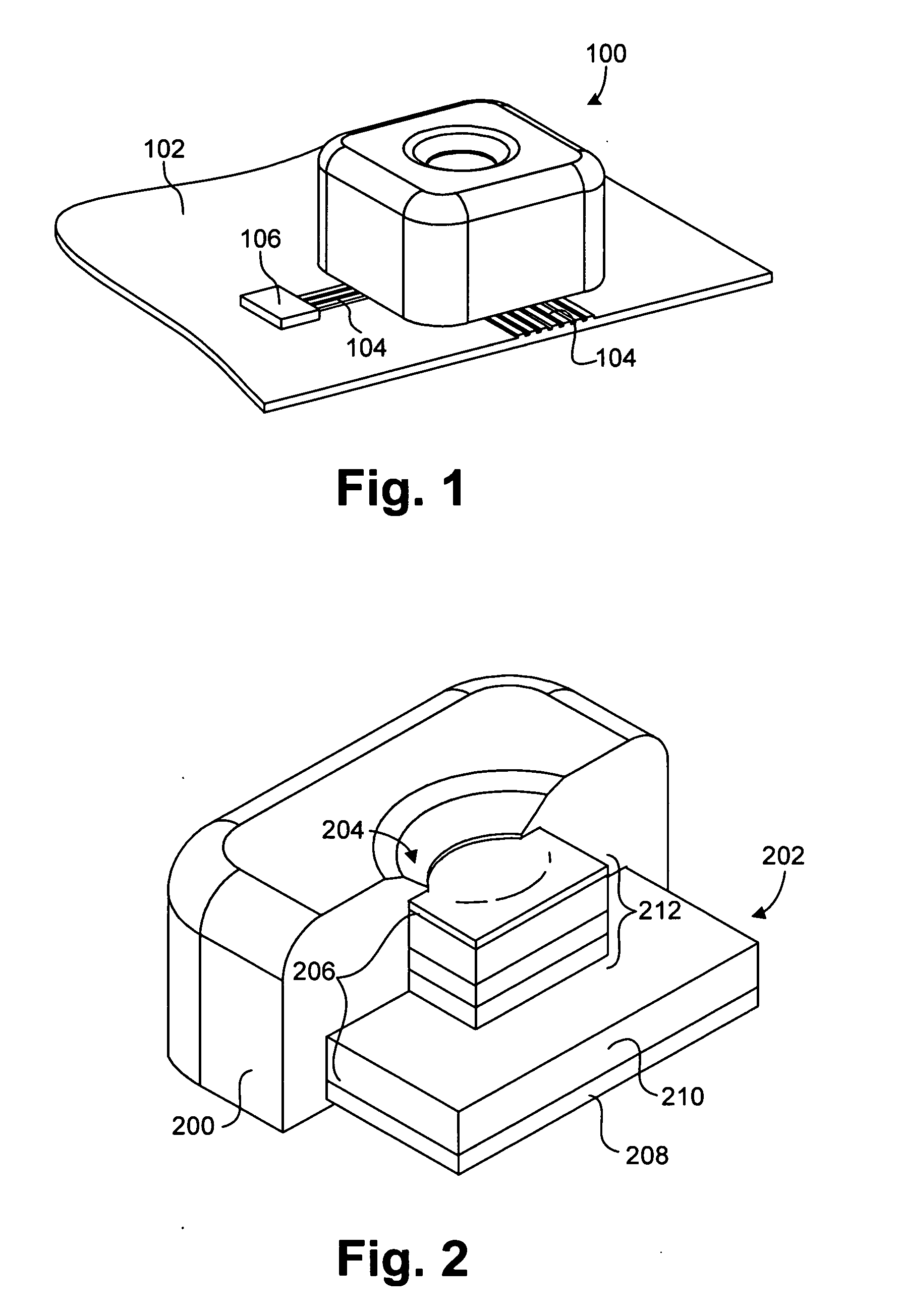

A mmWave electronics package constructed from common Printed Circuit Board (PCB) technology and a metal cover. Assembly of the package uses standard pick and place technology and heat is dissipated directly to a pad on the package. Input / output of mmWave signal(s) is achieved through a rectangular waveguide. Mounting of the electronic package to an electrical printed circuit board (PCB) is performed using conventional reflow soldering processes and includes a waveguide I / O connected to an mmWave antenna. The electronic package provides for transmission of low frequency, dc and ground signals from the semiconductor chip inside the package to the PCB it is mounted on. An impedance matching scheme matches the chip to high frequency board transition by altering the ground plane within the chip. A ground plane on the high frequency board encircles the high frequency signal bump to confine the electromagnetic fields to the bump region reducing radiation loss.

Owner:AY DEE KAY LLC DBA INDIE SEMICON

Electronic package for millimeter wave semiconductor dies

ActiveUS20130256850A1Effective coolingLow costSemiconductor/solid-state device detailsSolid-state devicesRadiation lossSemiconductor chip

A mmWave electronics package constructed from common Printed Circuit Board (PCB) technology and a metal cover. Assembly of the package uses standard pick and place technology and heat is dissipated directly to a pad on the package. Input / output of mmWave signal(s) is achieved through a rectangular waveguide. Mounting of the electronic package to an electrical printed circuit board (PCB) is performed using conventional reflow soldering processes and includes a waveguide I / O connected to an mmWave antenna. The electronic package provides for transmission of low frequency, dc and ground signals from the semiconductor chip inside the package to the PCB it is mounted on. An impedance matching scheme matches the chip to high frequency board transition by altering the ground plane within the chip. A ground plane on the high frequency board encircles the high frequency signal bump to confine the electromagnetic fields to the bump region reducing radiation loss.

Owner:AY DEE KAY LLC DBA INDIE SEMICON

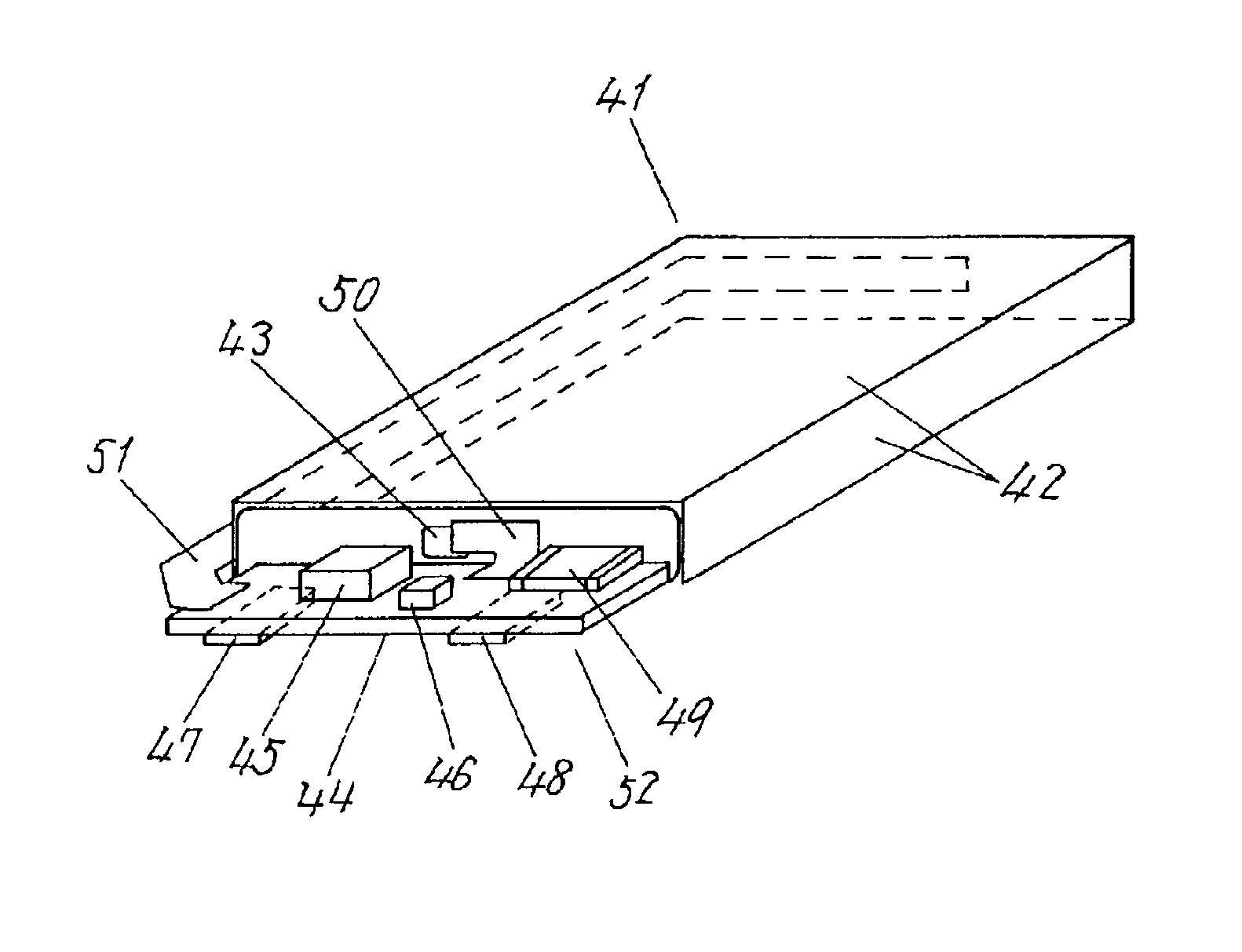

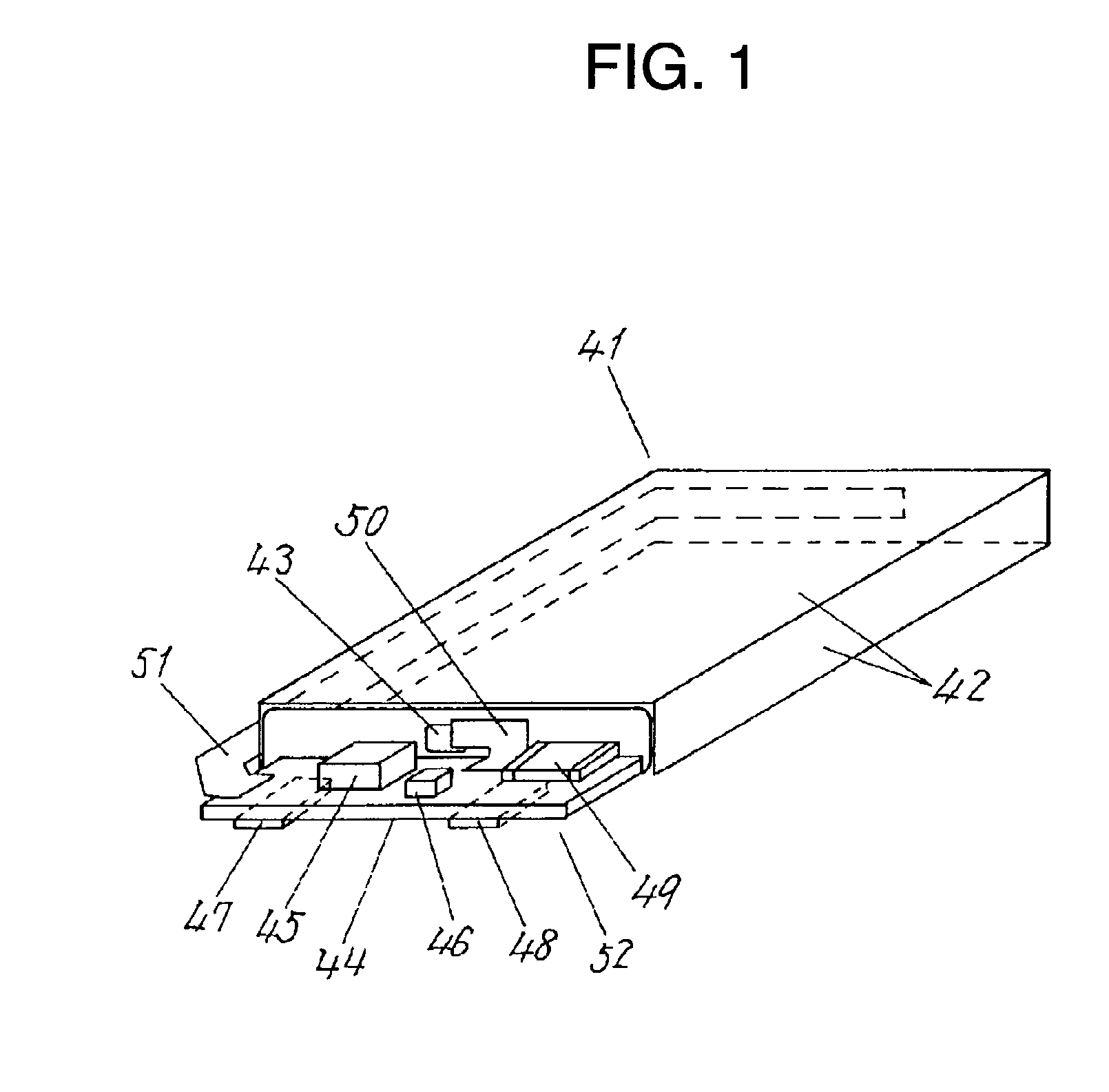

Battery pack and method of producing the same

InactiveUS6994926B2Improve performanceExtended operating timePrimary cell to battery groupingPrimary cell maintainance/servicingElectrical resistance and conductanceSurface mounting

The protection circuit unit 52 is an integrated body comprising a surface-mount type PTC thermistor 49 mounted by a soldering on a printed circuit board 44 through reflow soldering or the like soldering method together with a protection IC 45 and a FET unit 46. The surface-mount type PTC thermistor 49, as compared with a PTC thermistor with leads, can be mounted readily on the printed circuit board 44, without requiring bending and welding work of a lead to be connected to a negative terminal of prismatic battery cell 41, for forming a circuit. As a result, change in a resistance due to a bending stress, a thermal stress, etc. can be eliminated. Furthermore, a degree of thermal coupling with the battery cell 41 can be adjusted by changing a location of the thermistor 49. Thus, varieties of control functions can be implemented.

Owner:PANASONIC CORP

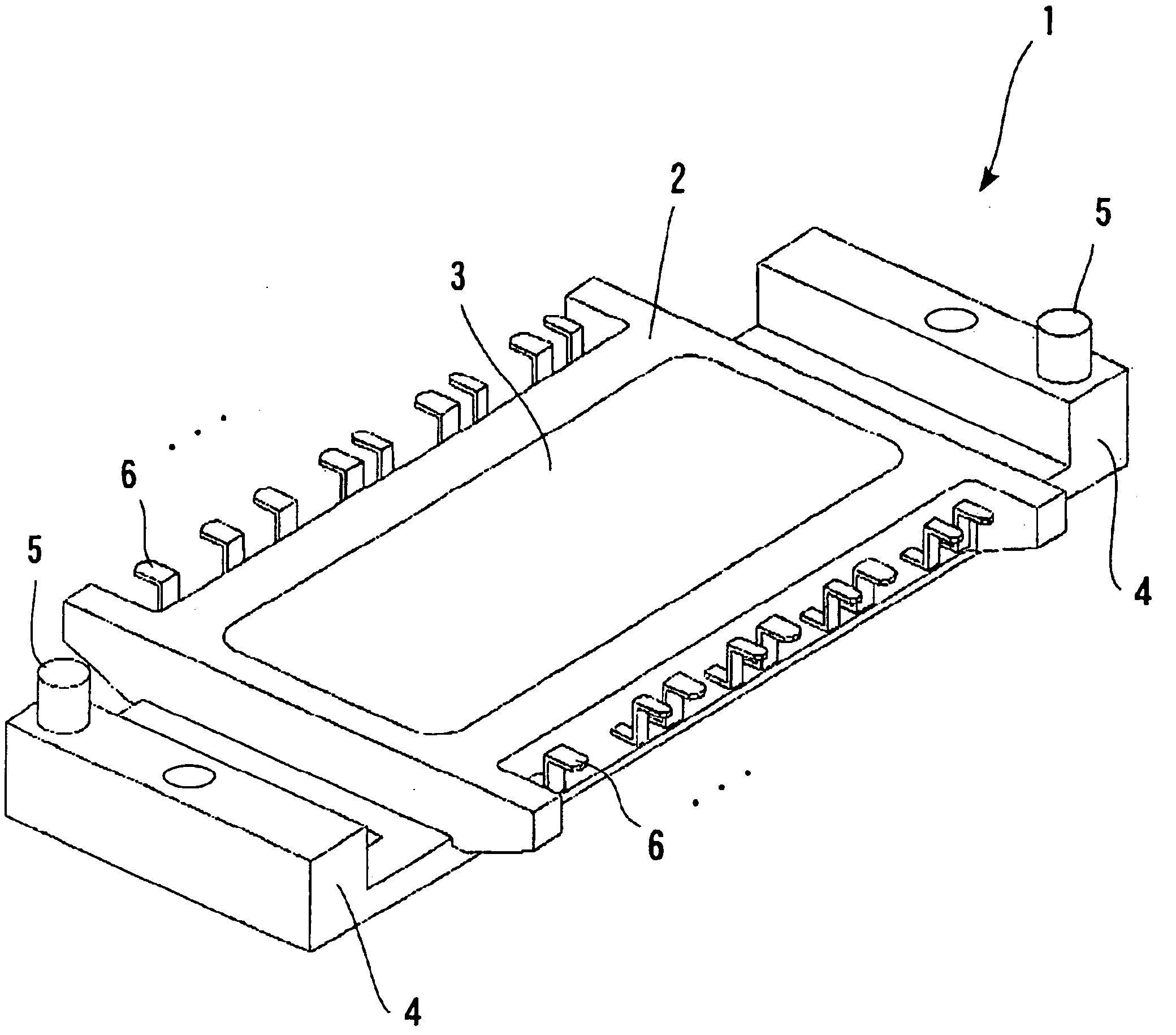

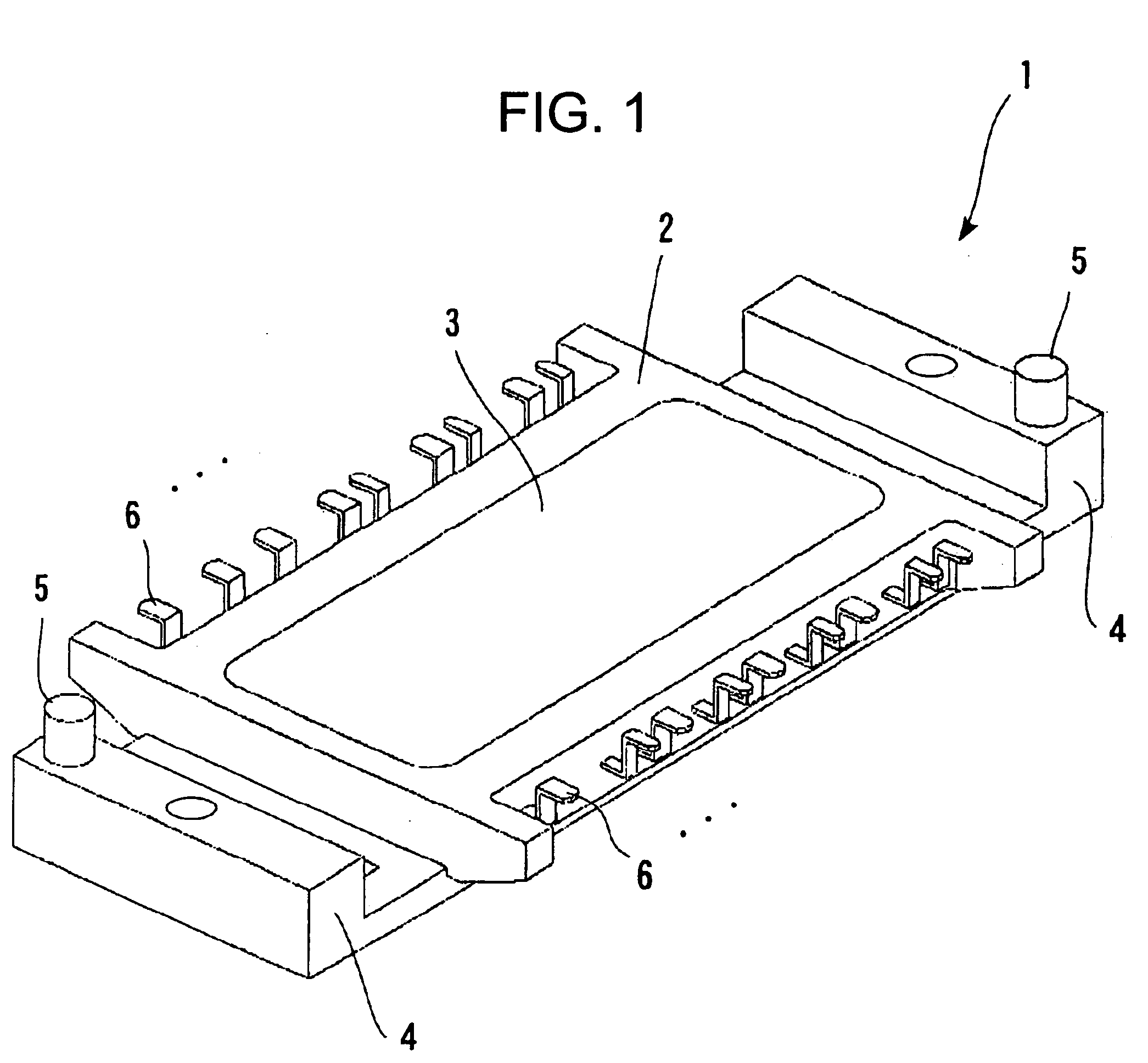

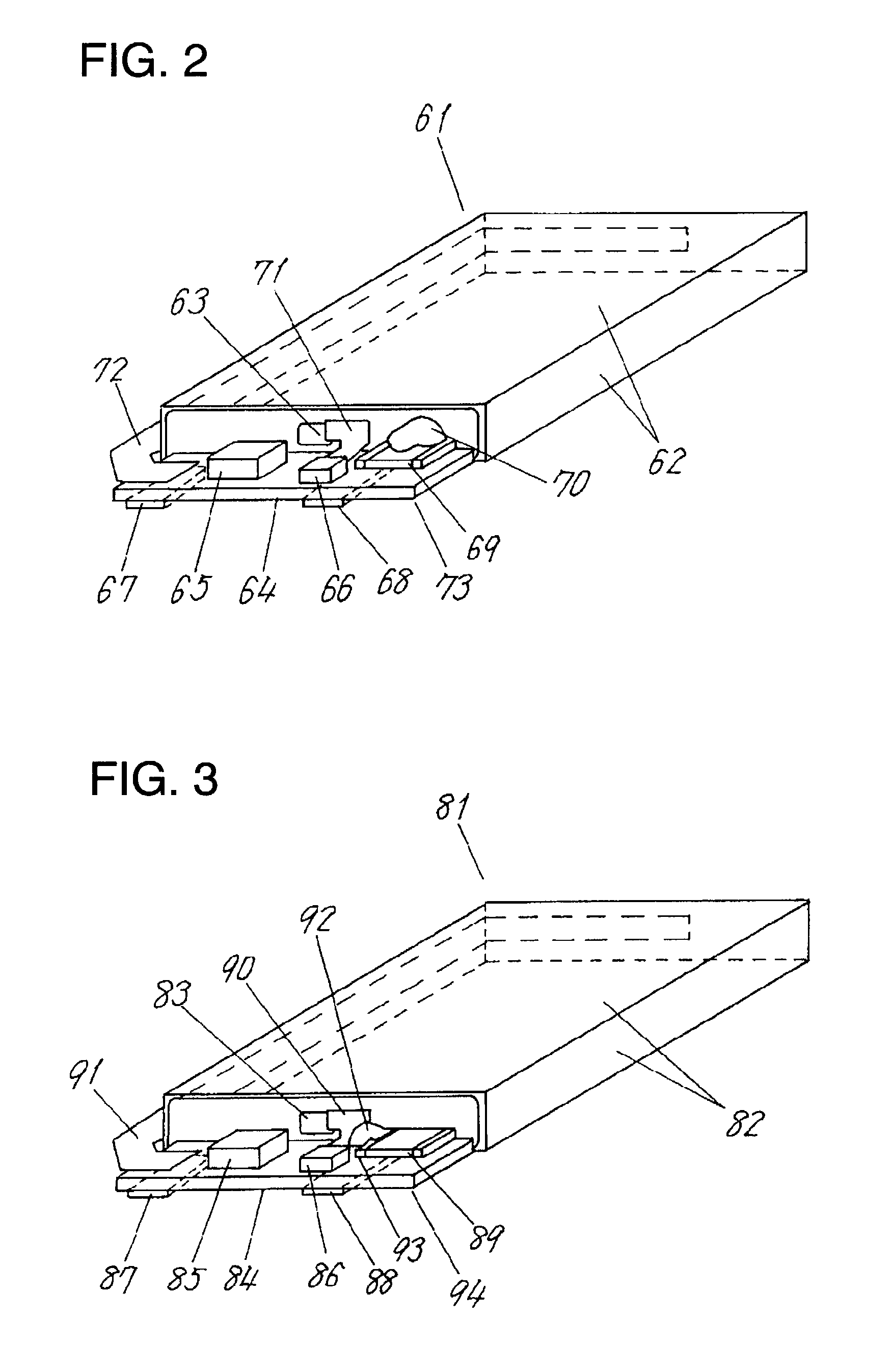

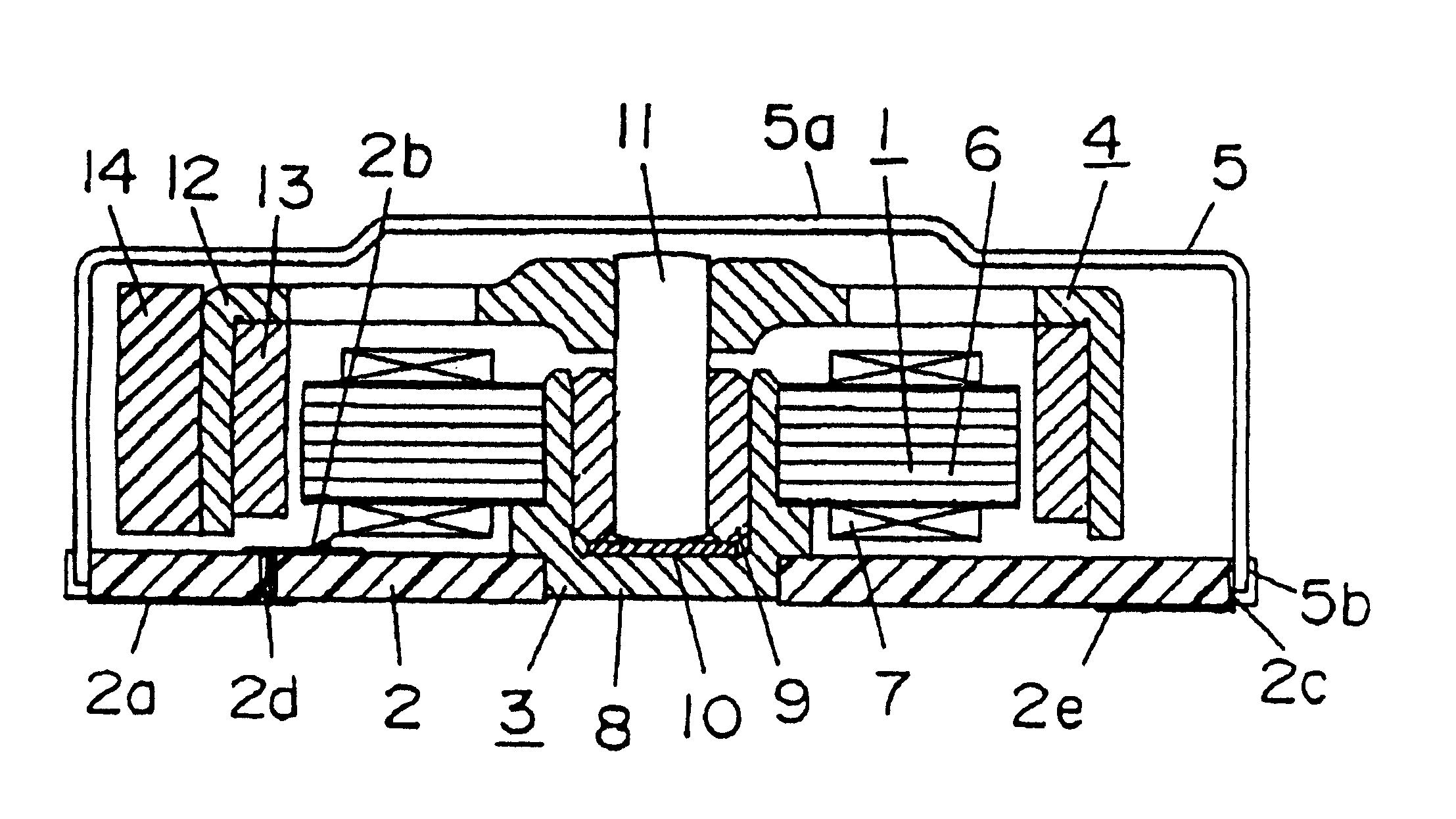

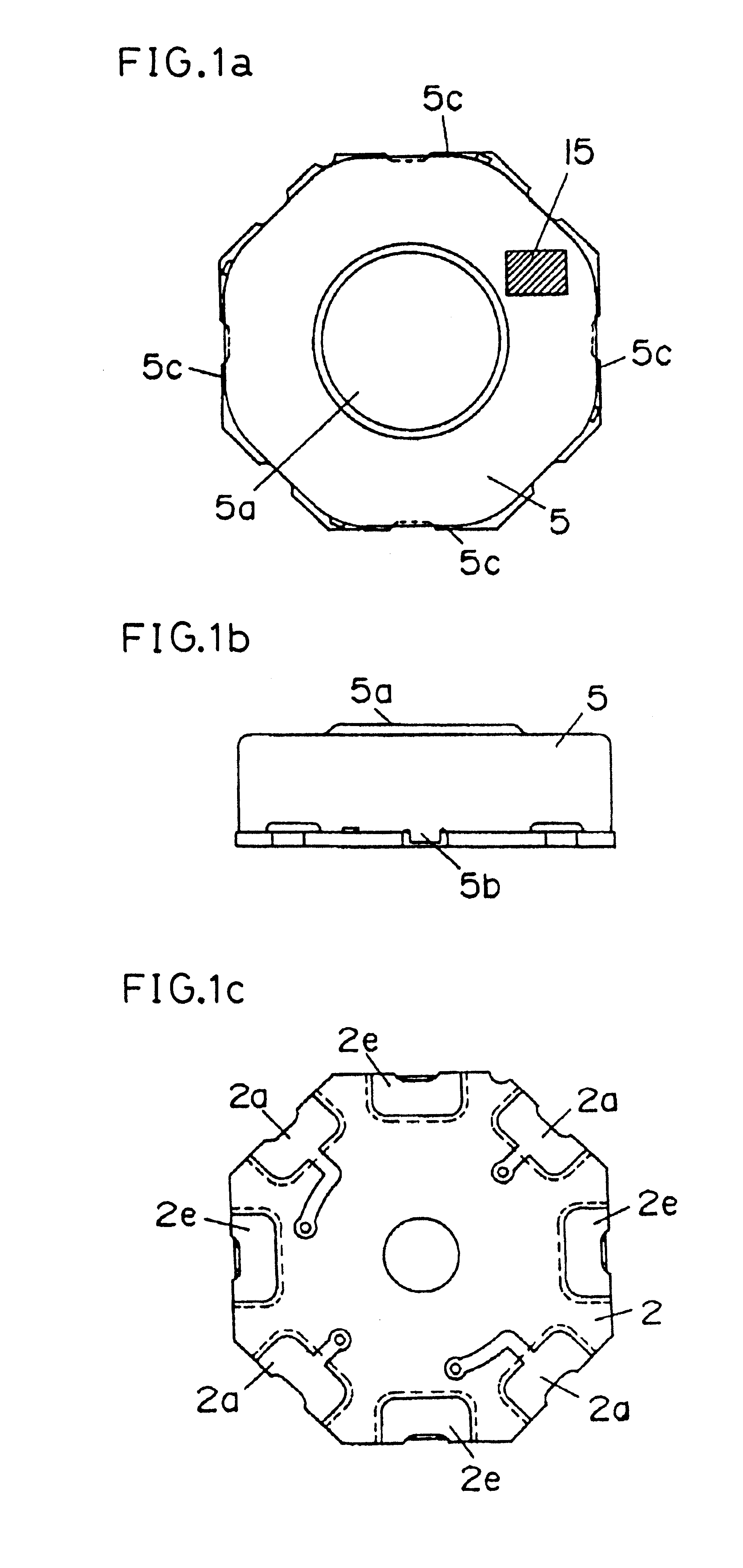

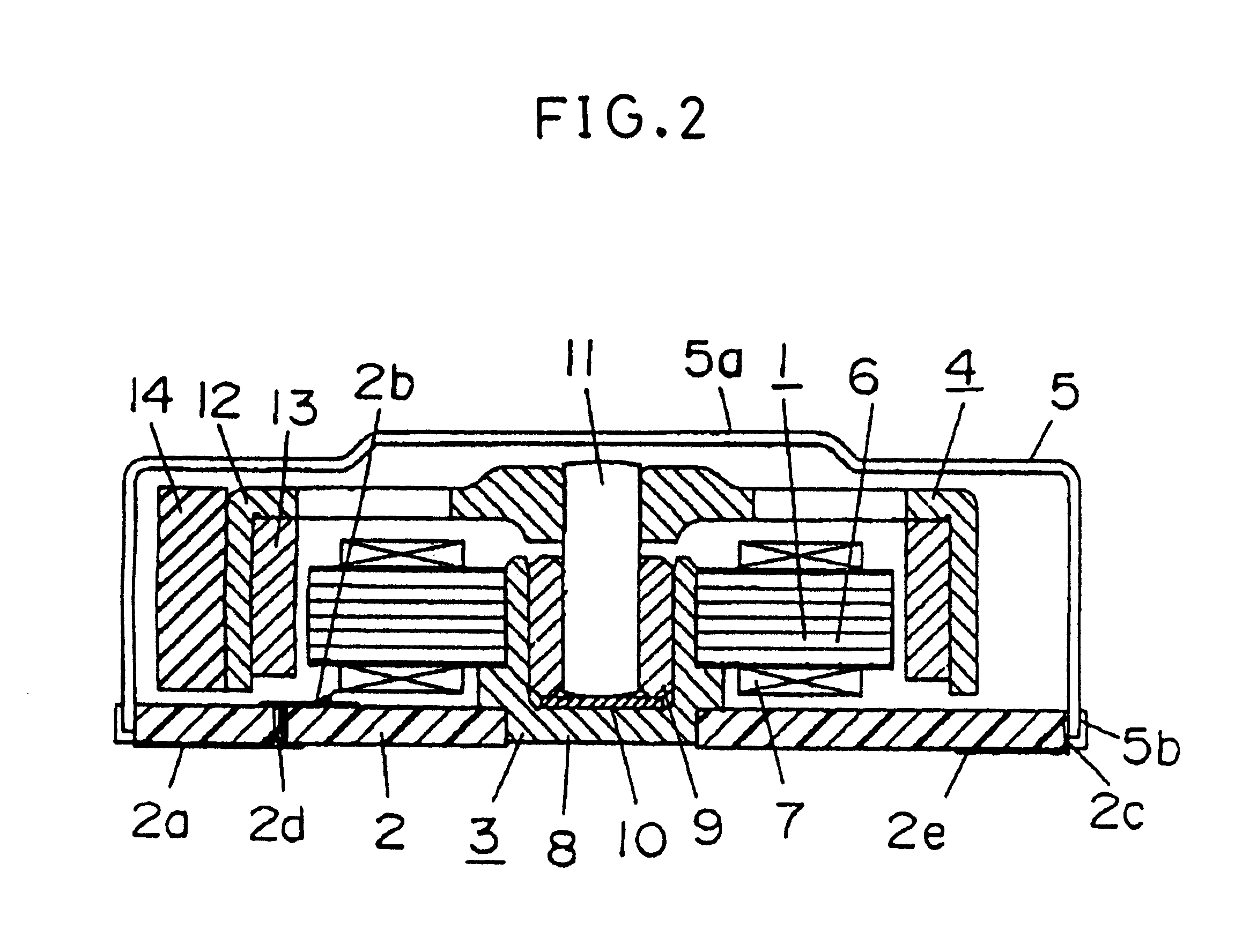

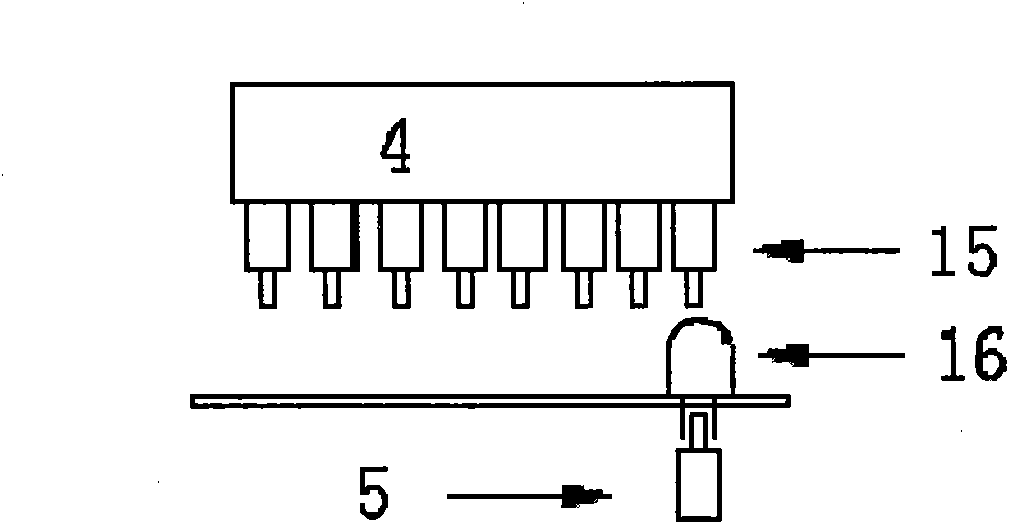

Brushless motor and its assembly method

InactiveUS6365995B1Highly integratedHigh densityFrequency-division multiplex detailsTime-division multiplexBrushless motorsHigh productivity

Brushless motors for portable information equipment that can be simultaneously reflow-soldered to a substrate and efficiently and densely mounted thereon in such a way that the coupled portion between the motor and the substrate has a high impact resistance, thereby providing small and reliable portable information equipment having a high productivity. The brushless motor including a housing having a bottom surface, a side surface, and a top surface, the bottom surface being located adjacent and opposite to a substrate of equipment; a plurality of lands (2a, 2e) on the bottom surface that can be mechanically or electrically joined with the substrate of the equipment; a stator (1), a bearing device (3), and a rotor (4) inside said housing, the stator (1) having a stator core (6) and a coil (7) wound around the stator core (6), the rotor (4) having a magnet (13) and being supported by the bearing device (3) so as to rotatably surround the periphery of the stator (1), the rotor (4) further including a circular weight (14).

Owner:PANASONIC CORP

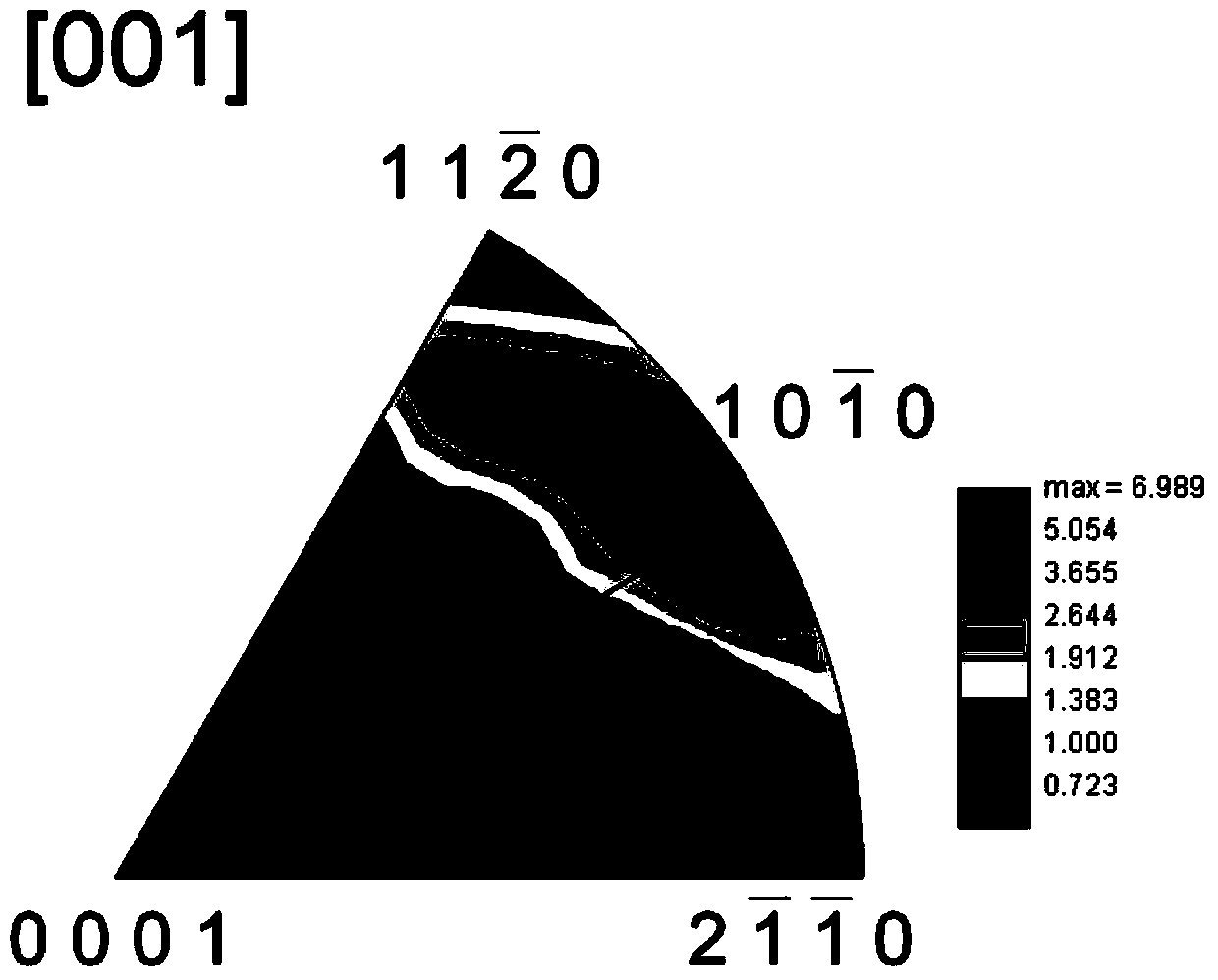

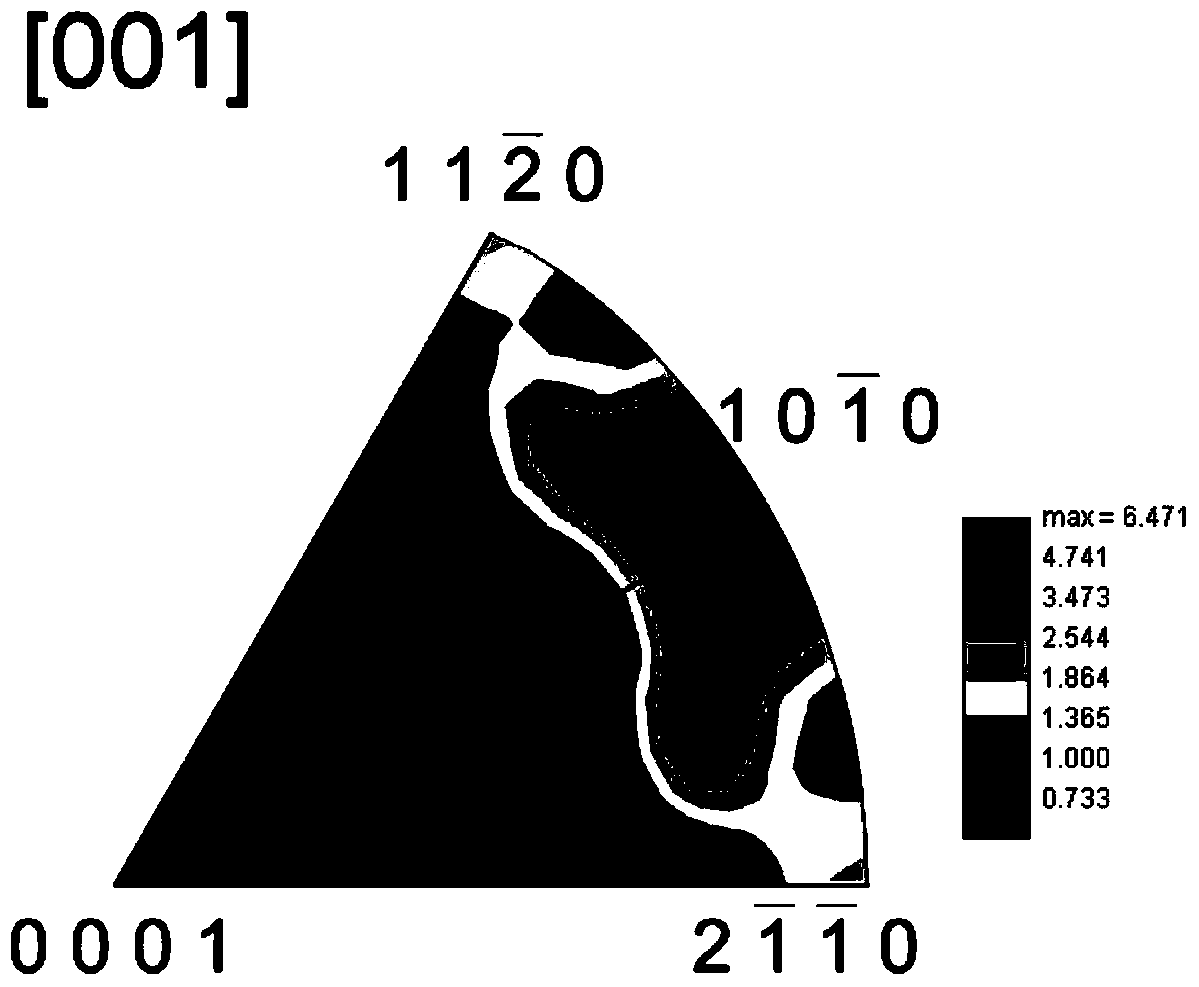

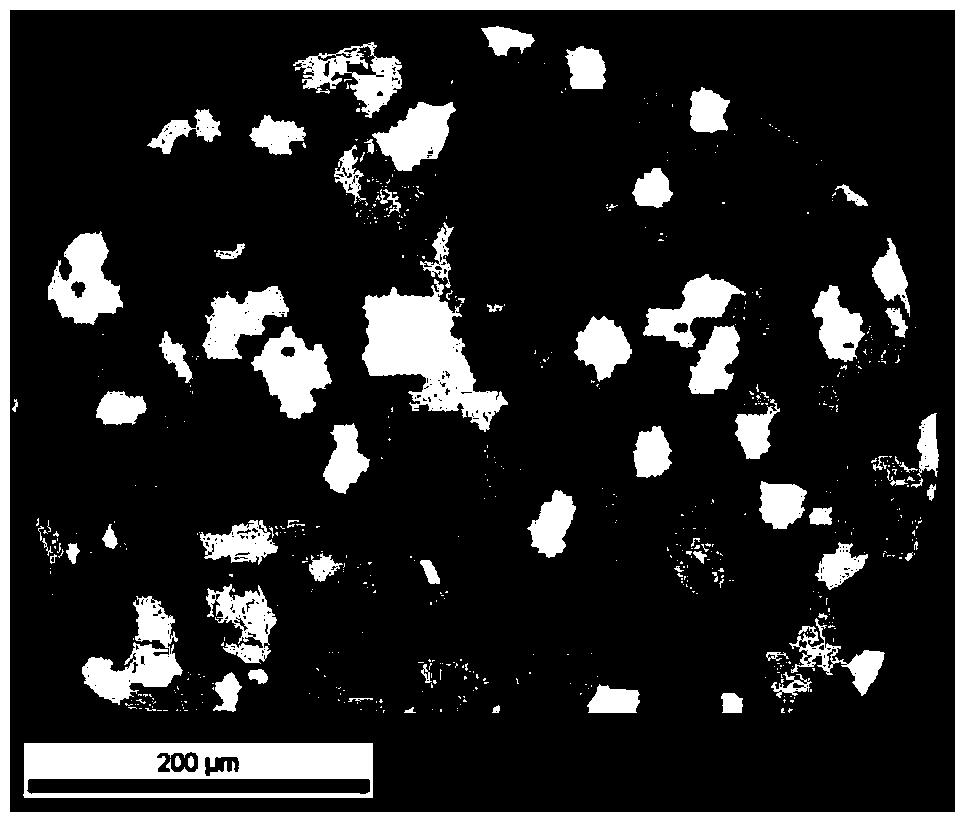

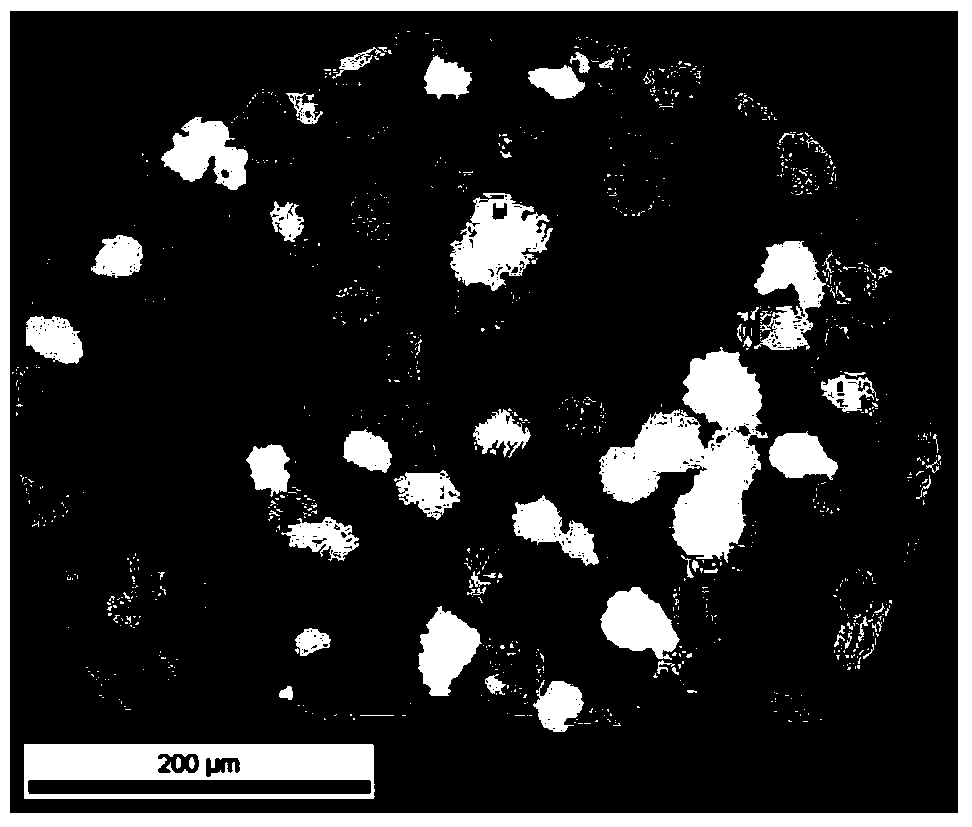

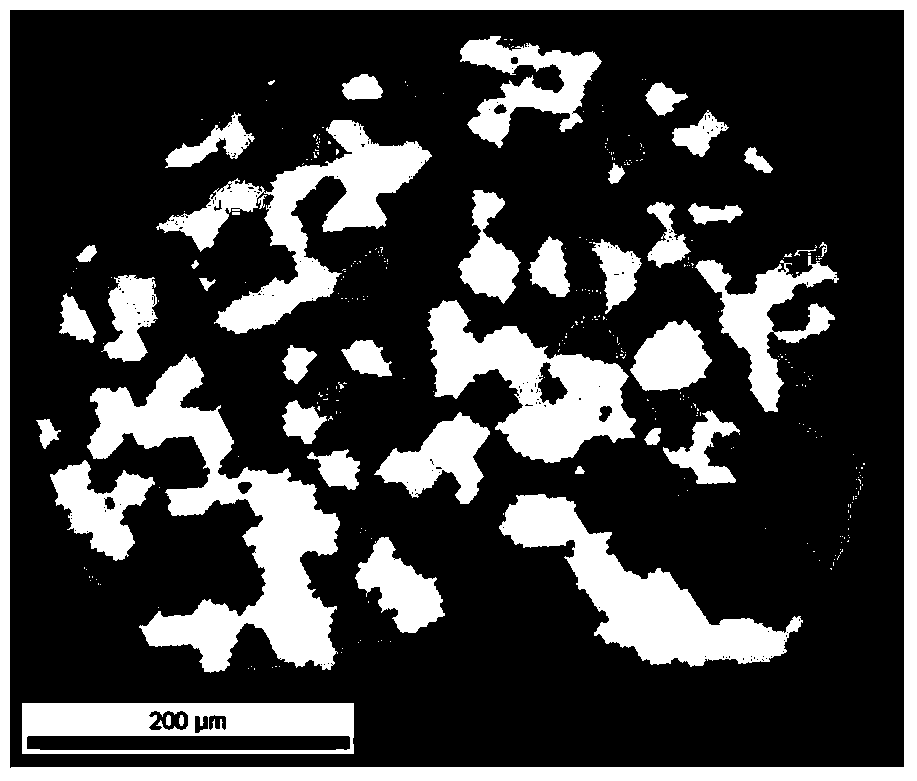

Nanoscale/micron size particle mixing type lead-free solder paste with size effect and manufacturing method thereof

ActiveCN103639614ARetain low melting point propertiesIncrease the proportionTransportation and packagingWelding/cutting media/materialsHybrid typeSolder paste

The invention provides nanoscale / micron size particle mixing type lead-free solder paste with a size effect and a manufacturing method thereof. The method comprises the following steps that nanoscale solder is slowly added into solder flux or a solder agent, after mechanical mixing, ultrasonic oscillation is lead in, mixing is continued, then the ultrasonic oscillation is stopped, micron size solder / flux is slowly added, and the mixed type solder paste which is uniformly mixed is obtained through continuously mixing. The manufacturing method has the advantages that process of the method is simple and feasible, the large size micron size solder is added in the nanoscale solder paste, the proportion of metal components in the solder paste is improved, and the low-melting-point property of nanometer brazing filler metal is maintained; mellow and full solder dots are formed at the low reflow soldering temperature; the obtained solder dots are polycrystal solder dots, and the grain sizes in the solder dots can be changed by adjusting the size distribution of micron size nanoscale solder, so that advance failure of the solder dots is avoided.

Owner:马鑫 +4

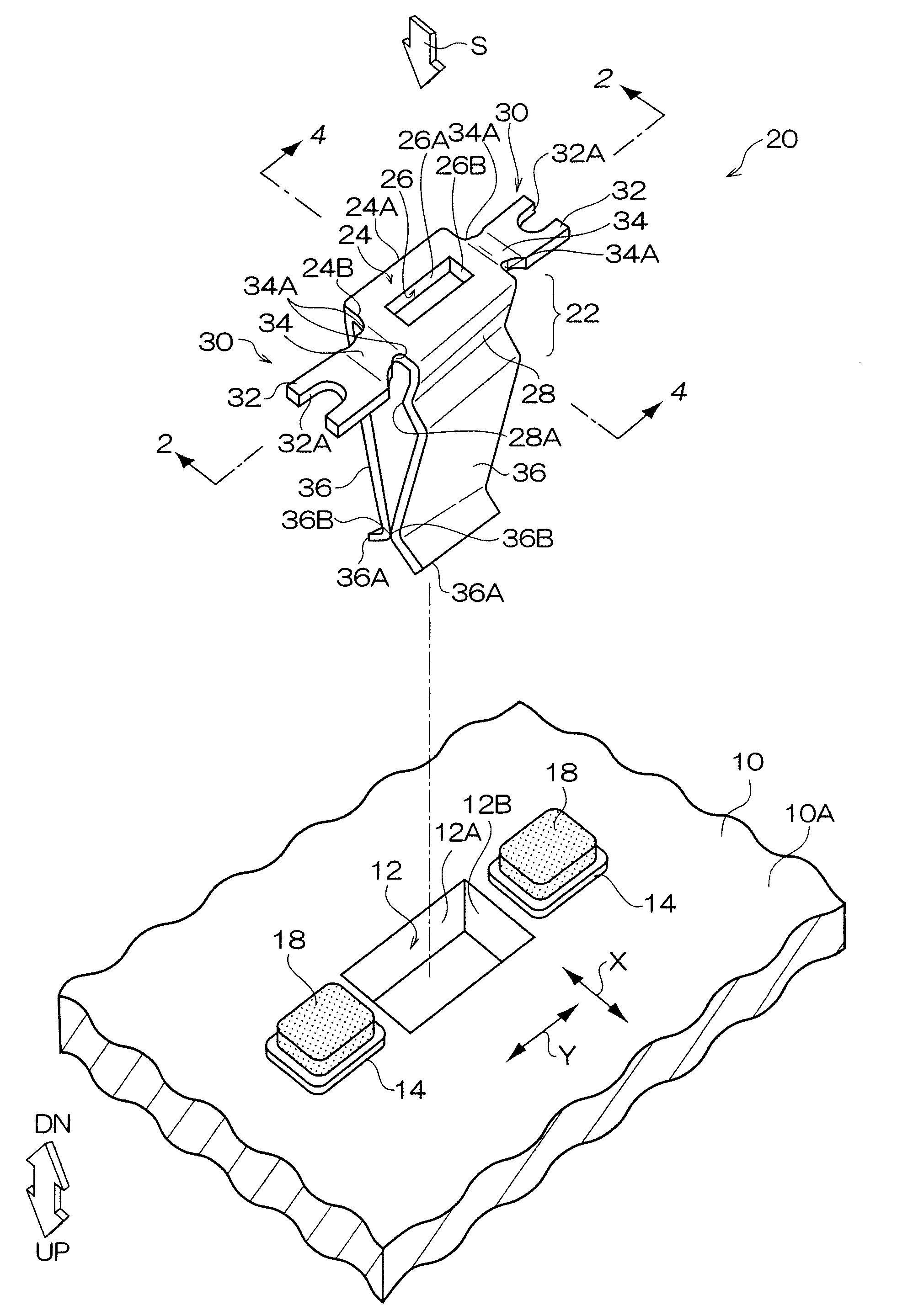

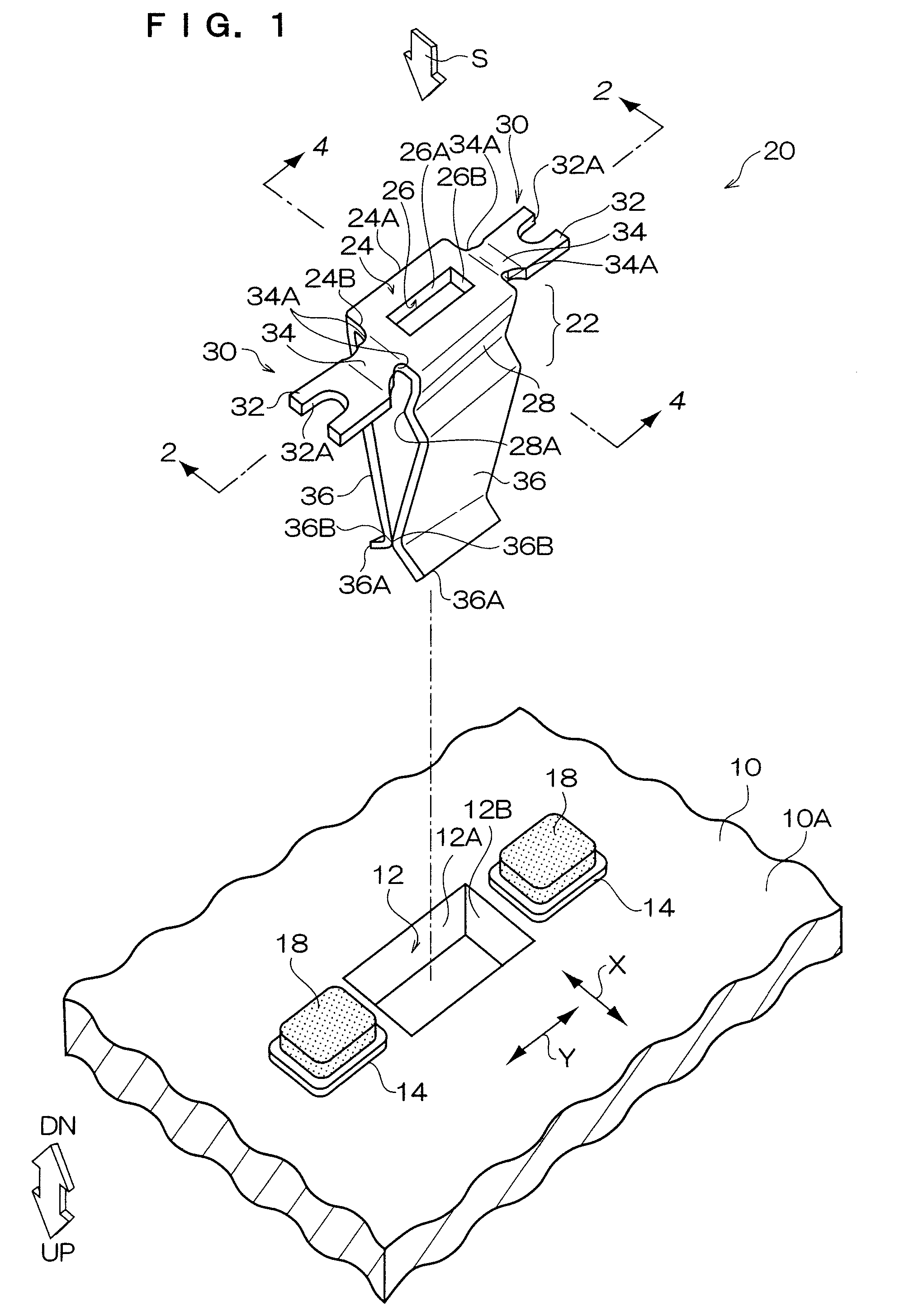

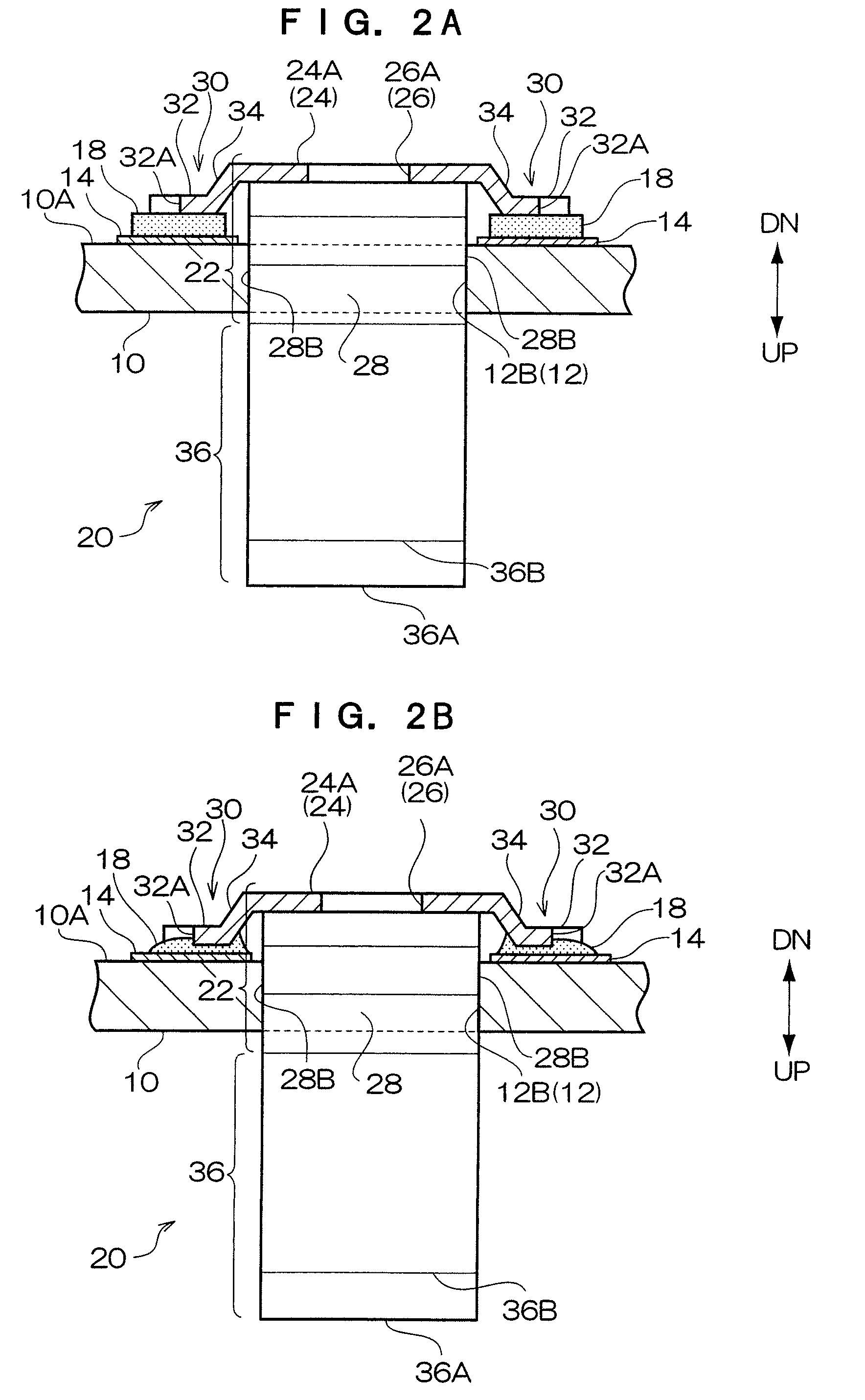

Female connector, female connector mounting structure, and method of mounting female connector to substrate

InactiveUS7357651B2Good effectCoupling device detailsSoldered/welded conductive connectionsMechanical engineeringReflow soldering

A single pole female connector has: a mounting base portion in which is formed a terminal insertion hole into which a male terminal can be inserted; an extending portion extending outwardly from the mounting base portion; and a terminal contacting portion which extends from a peripheral edge of the mounting base portion in a direction substantially orthogonal to a plate portion, and which is formed so as to be able to nip the male terminal. The extending portion is electrically connected by being reflow soldered to a land at a reverse surface of the substrate. It is difficult for cream solder to enter into a male terminal insertion path at an inner side of the female connector.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO +1

Full-automatic LED (Light Emitting Diode) and components mounting and inserting all-in-one machine and running method thereof

InactiveCN102065674AAchieve high efficiencyAchieve energy savingElectrical componentsSemiconductor devicesScreen printingControl system

The invention discloses a full-automatic LED (Light Emitting Diode) and components mounting and inserting all-in-one machine and a running method thereof. A foot striking mechanism moving platform, a foot striking mechanism and an LED suction nozzle are additionally arranged on the basis of the original mounter, the functions of a control system are updated, and two processes of mounting and inserting the components are combined, therefore, the full full-automatic LED and components mounting and inserting all-in-one machine is formed. The running method comprises the following steps of: determining the mounting and inserting position and the rotation angle of a mounting and inserting head according to the suction position deviation and the suction angle deviation of the components by the control system; and striking foot by the foot striking mechanism when inserting the LED by a mounting and inserting head mechanism so as to make a tube foot of the LED, which is exposed from the lowerpart of a PCB (Printed Circuit Board), bent and then fixed on the PCB to finish the assembly of the LED components. In the invention, the mounting process and the inserting process are integrated on one machine, and the traditional processes of silk-screen printing, mounting, reflow soldering, detecting to insert, wave-soldering and detecting are simplified; therefore, the invention has the advantages of high efficiency and energy conservation.

Owner:SOUTH CHINA UNIV OF TECH

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

Low silver hypoeutectic Sn-Cu-Ag lead-free solder for electronic micro connection

InactiveCN101214591ALow costImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaDip solderingWave crest

The invention provides a low-Ag hypo eutectic Sn-Cu-Ag lead-free solder the components of which are 0.5 to 0.65wt percent of Cu, 0.1 to 0.45wt percent of Ag, 0.001 to 0.1wt percent of Ni, 0.001 to 0.3wt percent of Sb, 0.001 to 0.2wt percent of Bi and / or In, 0 to 0.01wt percent of P, 0 to 0.03wt percent of Ge and the rest is Sn. The solder is further characterized in that (1) the content of Ag in the solder of Cu plus Ag is less than 1wt percent is not more than 0.45wt percent; (2) the gross of the microelements like Ni, Sb, Bi, In, P, and Ge, etc., that are added is not more than 0.5wt percent. The solder has the advantages of low cost and excellent oxidation, wettability and overflow resistances, can remarkably reduce the waste of the solder, improve the forming of the welding point, remarkably reduce the connecting defects of braze welding. The solder can replace a Sn-Cu-Ag hypo eutectic material and is suitable for the wave crest welding, dip soldering as well as manual welding and reflow soldering for electric products.

Owner:重庆工学院

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20070203308A1Improve heat resistanceImprove practicalityPrinted circuit aspectsThin material handlingPolymer scienceMetal foil

A resin composition excellent in heat resistance after moisture absorption, lead-free solder reflow properties, dimensional stability and electrical characteristics for high-multilayer and high-frequency-capable printed wiring boards, which composition comprises a bisphenol A type epoxy resin (a) having at least two epoxy groups per molecule and a secondary hydroxyl group amount of 0.4 meq / g or less, a novolak type epoxy resin (b) at least two epoxy groups per molecule, a cyanate ester resin (c) having at least two cyanate groups per molecule and spherical silica having an average particle diameter of 4 μm or less, wherein the equivalent ratio of cyanate groups / epoxy groups in the resin composition is in the range of 0.7 to 1.45, and a prepreg and a metal-foil-clad laminate each of which comprises the resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com