Nanoscale/micron size particle mixing type lead-free solder paste with size effect and manufacturing method thereof

A lead-free solder, size effect technology, applied in welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve the problems of organic residue precipitation, low metal content, and difficulty in forming complete and full solder joints. Achieve the effect of simple and feasible process, increase specific gravity, and avoid premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

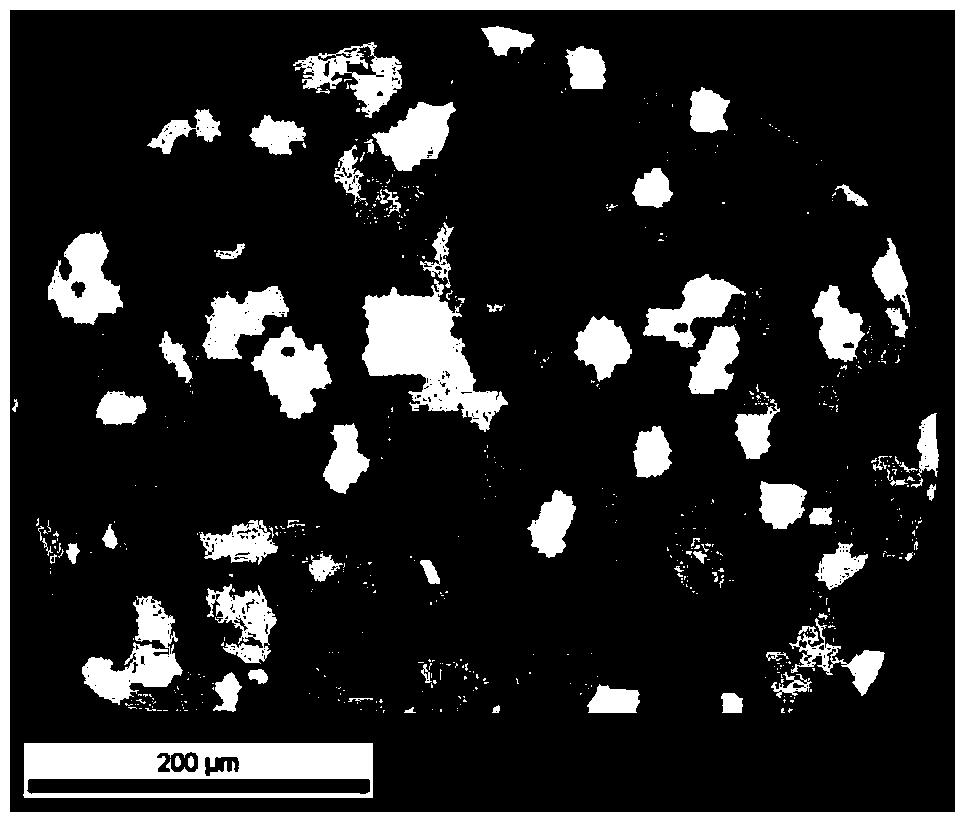

Embodiment 1

[0038] The nano / micron particle mixed type lead-free solder paste of the present embodiment is composed of Sn-3.0Ag-0.5Cu nano-solder powder (particle diameter is 5-15nm), Sn-3.0Ag-0.5Cu lead-free solder powder (particle diameter 25-45μm), composed of rosin flux, with a total mass of 5g, and its components are calculated by mass fraction as:

[0039] Nano lead-free solder Sn-3.0Ag-0.5Cu 30%

[0040] Micron lead-free solder Sn-3.0Ag-0.5Cu 60%

[0041] Rosin type solder paste 10%

[0042] Among them, the micron lead-free solder Sn-3.0Ag-0.5Cu used has a melting temperature range of 217-221°C, and the experimental steps are as follows:

[0043] First, separate the nano-lead-free solder stored in ethylene glycol liquid, and select stearic acid as the separation solution; slowly add the nano-lead-free solder to the solder paste / agent, and mechanically stir at a speed of 30r / min 30min, then introduce ultrasonic oscillation, continue stirring for 30min, then stop ultrasonic oscill...

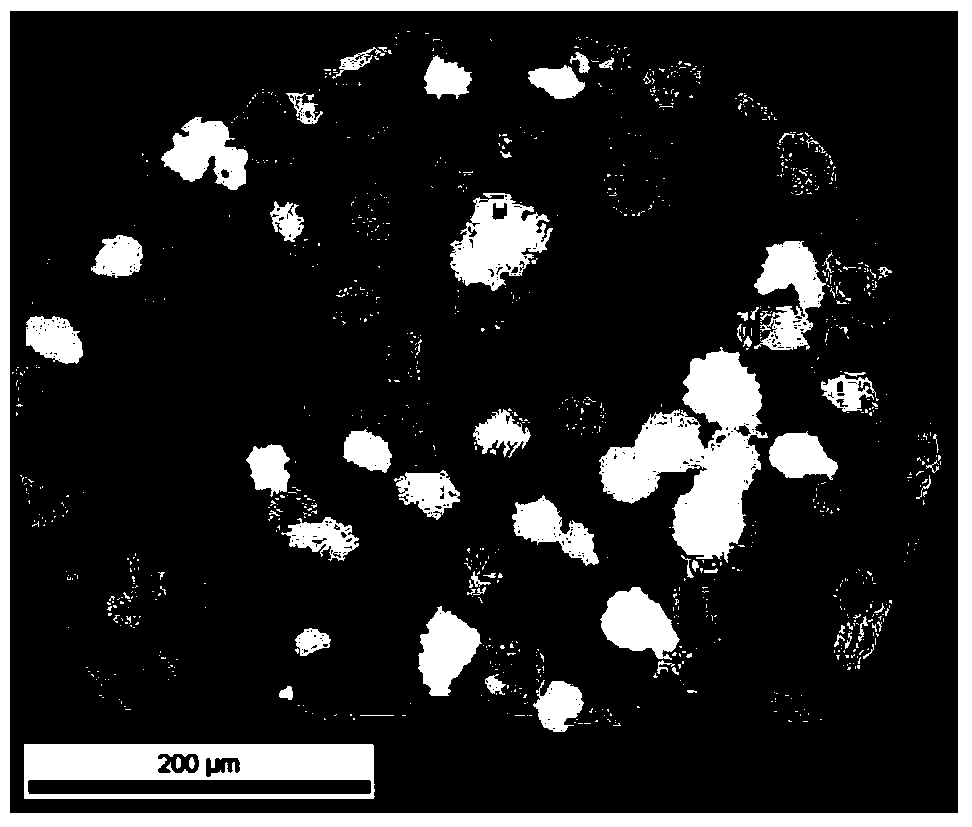

Embodiment 2

[0046] The nano / micron particle mixed type lead-free solder paste of the present embodiment is composed of Sn nano-solder powder (particle diameter is 5-15nm), Sn-1.0Ag-0.5Cu-0.01Ni micron lead-free solder powder (particle diameter is 25nm) -38μm), composed of rosin flux, with a total mass of 5g, and its components are calculated by mass fraction as:

[0047] Nano lead-free solder Sn 35%

[0048] Micron lead-free solder Sn-1.0Ag-0.5Cu-0.01Ni 55%

[0049] Rosin type solder paste 10%

[0050] Among them, the micron lead-free solder Sn-1.0Ag-0.5Cu-0.01Ni used in this example has a melting temperature range of 217-225°C, and the experimental steps are:

[0051] First, separate the nano-lead-free solder stored in ethylene glycol liquid, and choose stearic acid as the separation solution; slowly add the nano-lead-free solder to the rosin-type solder paste, and mechanically stir at a speed of 30r / min 30min, then introduce ultrasonic oscillation, continue stirring for 30min, then s...

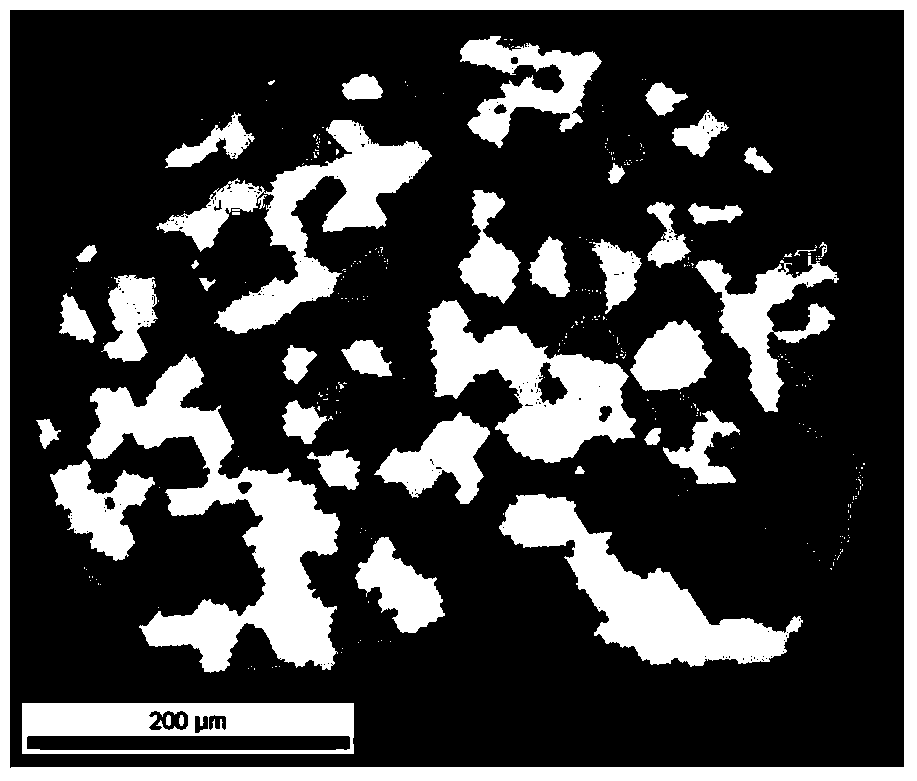

Embodiment 3

[0054] The nano / micron particle mixed type lead-free solder paste of the present embodiment is composed of Sn nano-solder powder (particle size is 5-15nm), Sn-3.5Cu lead-free solder powder (particle size is 25-45 μm), rosin Flux composition, the total mass is 5g, and its components are calculated by mass fraction as:

[0055] Nano lead-free solder Sn 45%

[0056] Micron lead-free solder Sn-3.5Cu 45%

[0057] Rosin type solder paste 10%

[0058] Among them, the micron lead-free solder Sn-3.5Ag used in this example has a melting temperature of 221°C, and the experimental steps are as follows:

[0059] First, separate the nano-lead-free solder stored in ethylene glycol liquid, and select stearic acid as the separation solution; slowly add the nano-lead-free solder to the solder paste / agent, and mechanically stir at a speed of 30r / min 30min, then introduce ultrasonic oscillation, continue stirring for 30min, then stop ultrasonic oscillation, slowly add micron-sized solder / paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com