Patents

Literature

704 results about "Micron size" patented technology

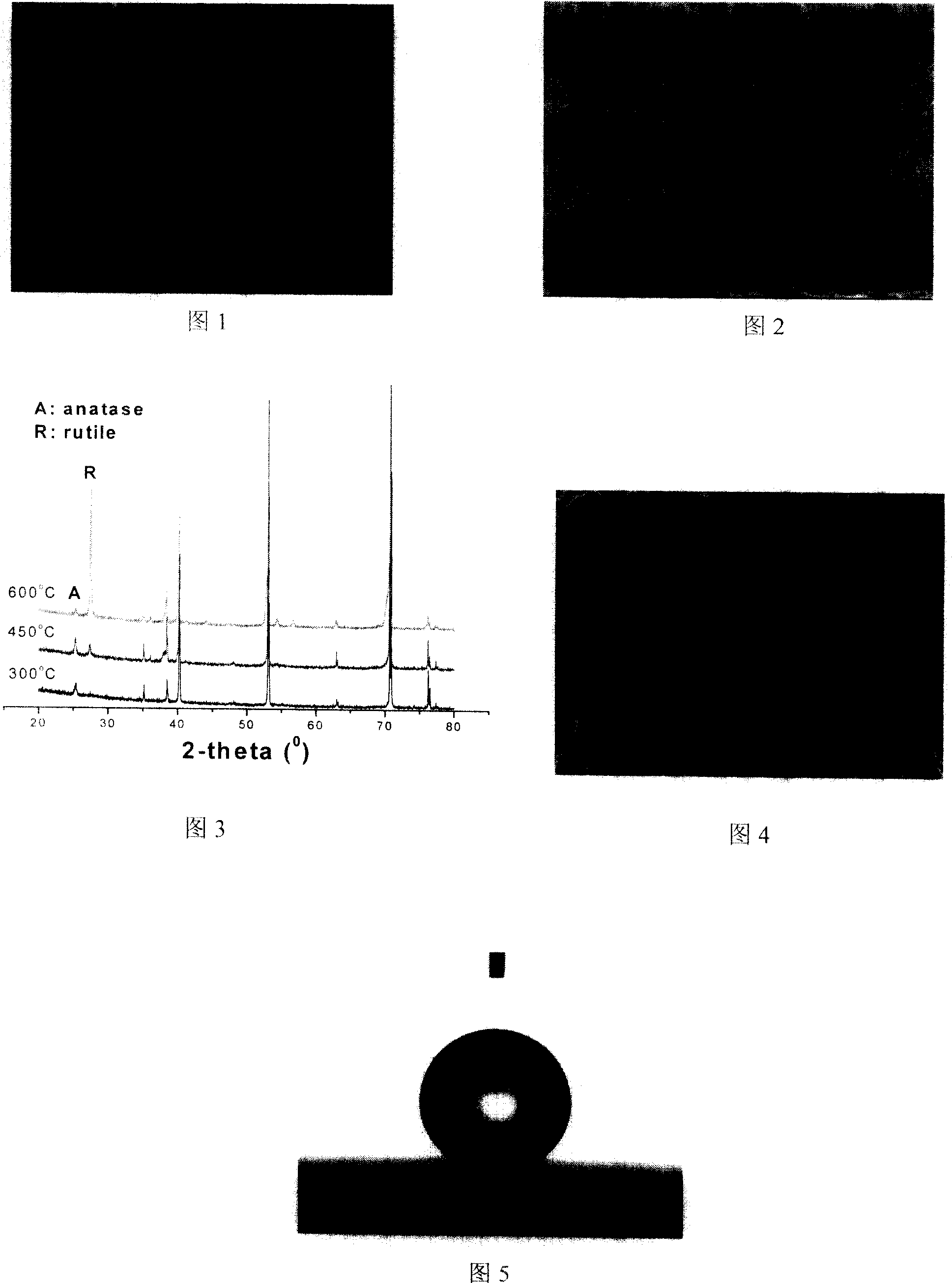

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A "micron" is an abbreviated term for "micrometer", or a millionth of a meter (1/1,000,000 meters). This is about .00004 inches. For Size comparison, a human red blood cell is about 5 microns across. A human hair is about 75 microns across (depending on the person).

Lithium iron phosphate cathode materials with enhanced energy density and power performance

InactiveUS20090155689A1Powerful performanceHigh discharge ratePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberPhosphate

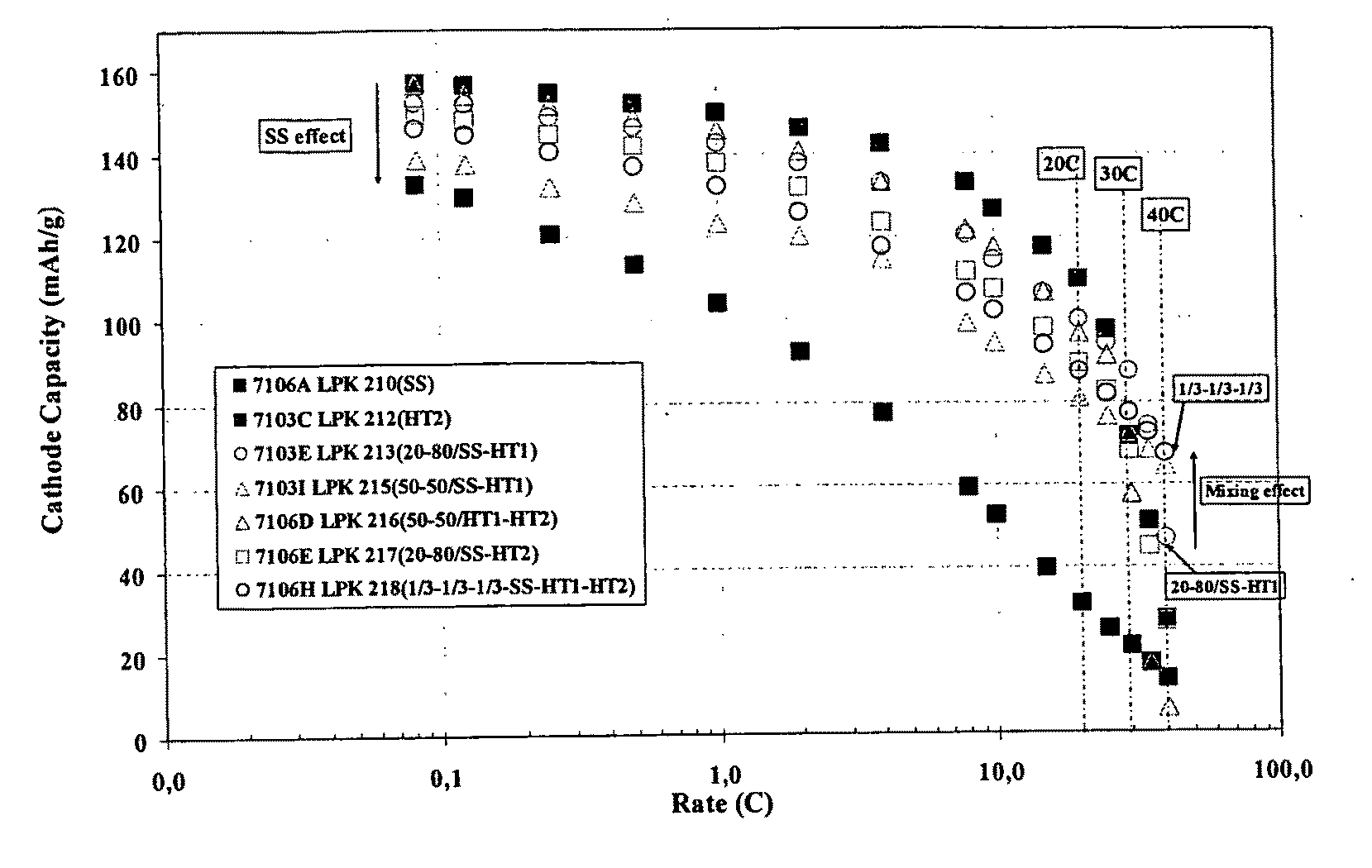

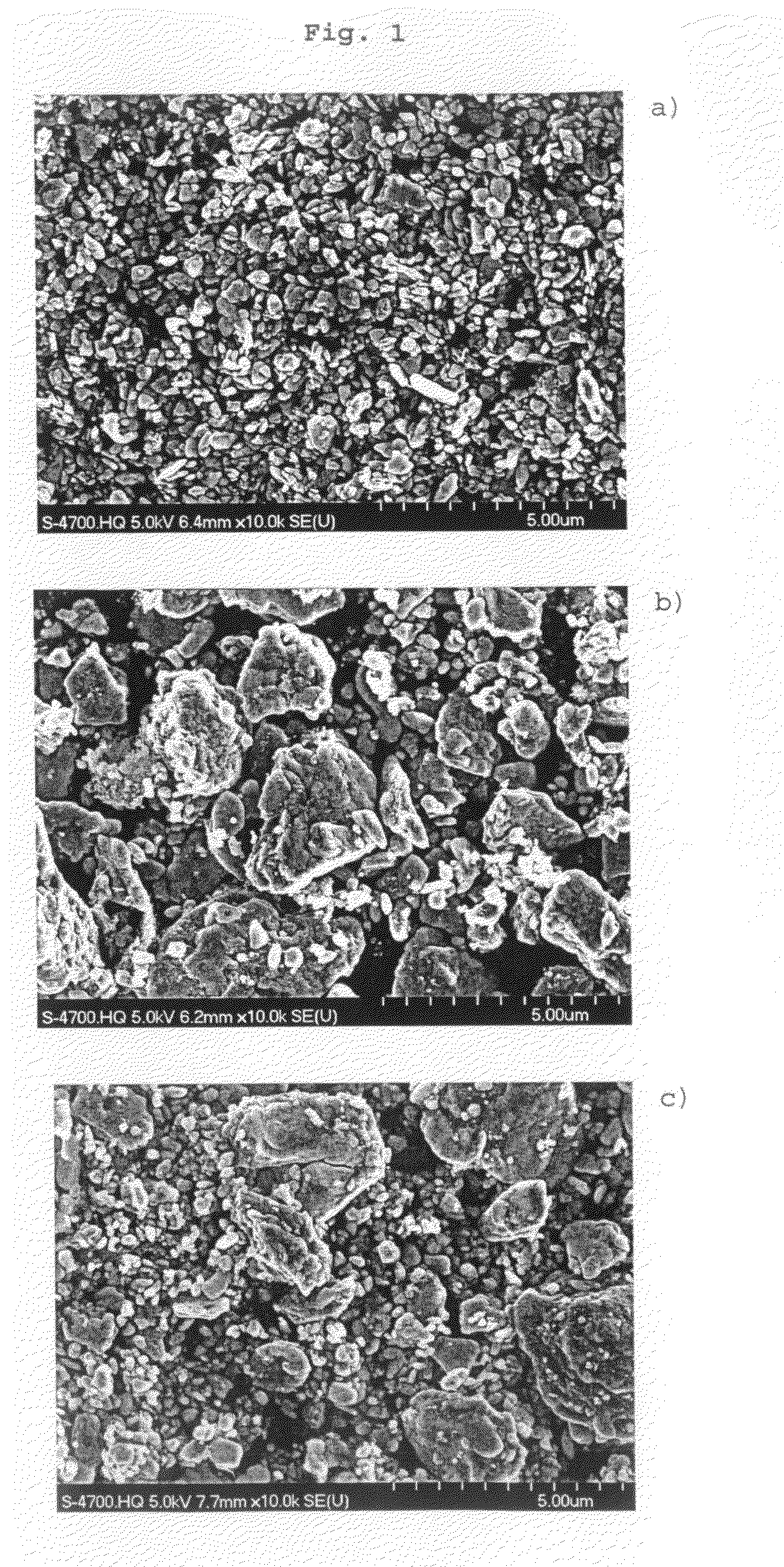

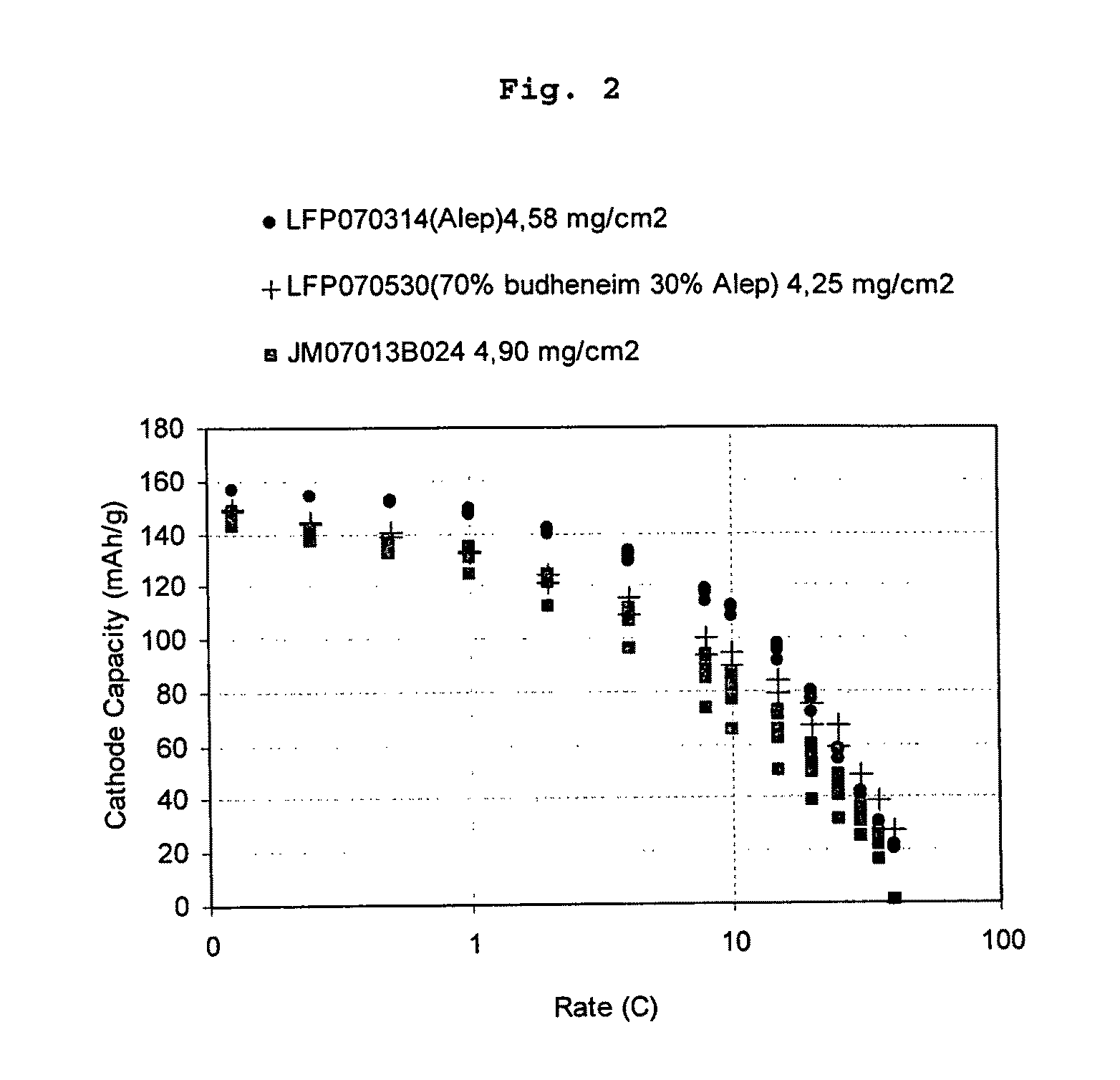

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:PHOSTECH LITHIUM

Small spherical particles of low molecular weight organic molecules and methods of preparation and use thereof

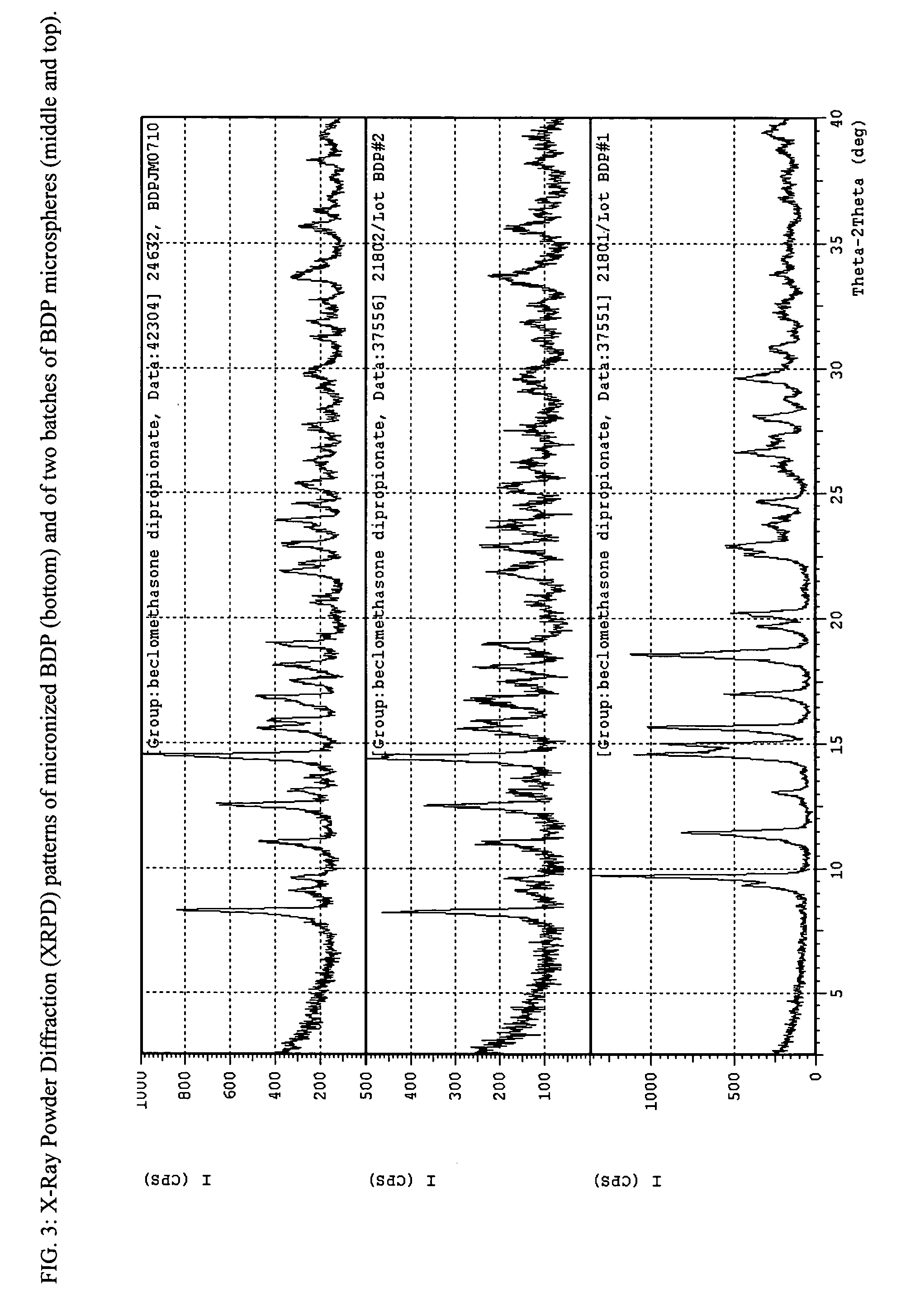

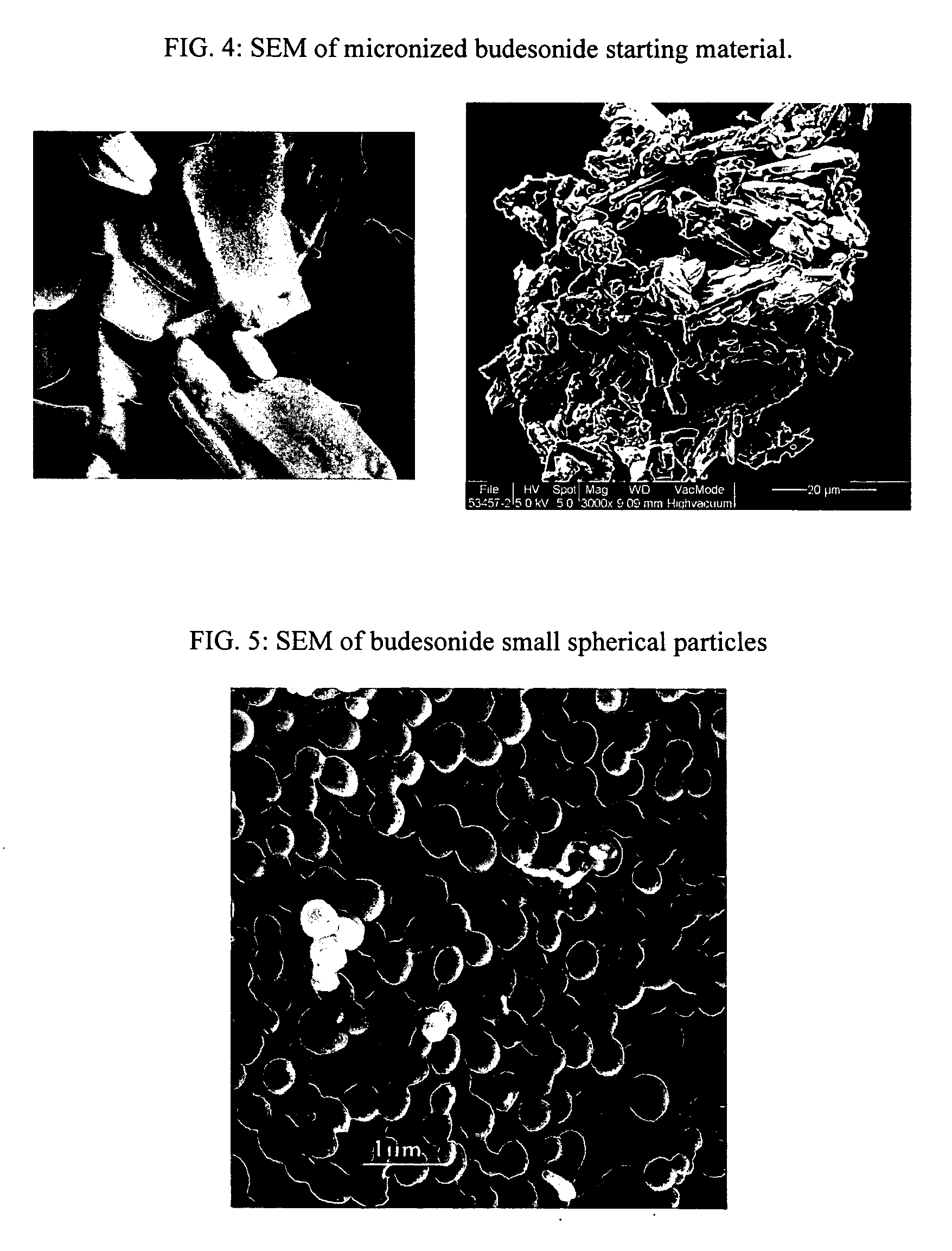

InactiveUS20050048127A1Uniform sizeHigh ratio of surface areaPowder deliveryChemical physicsNanosized particle

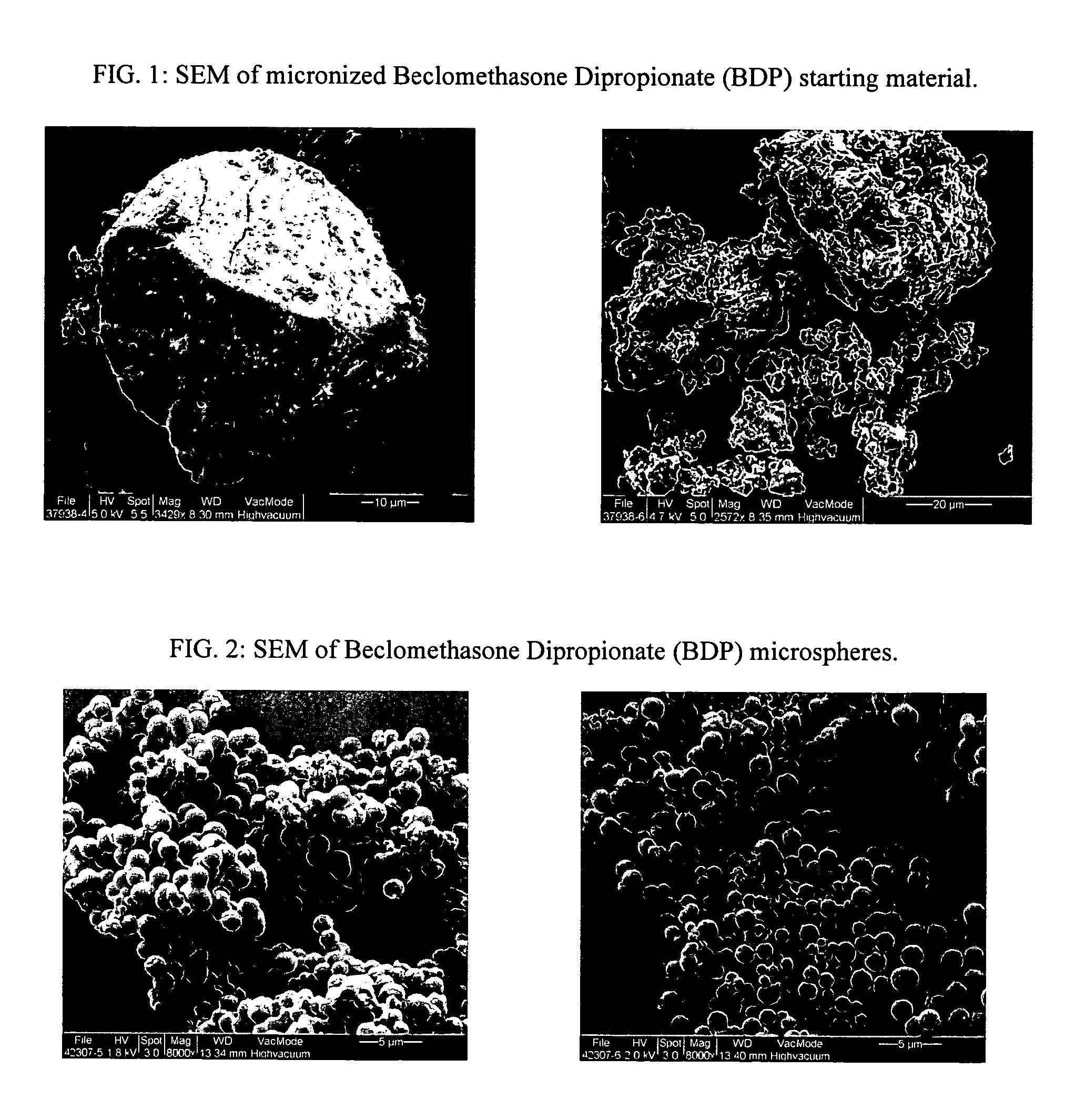

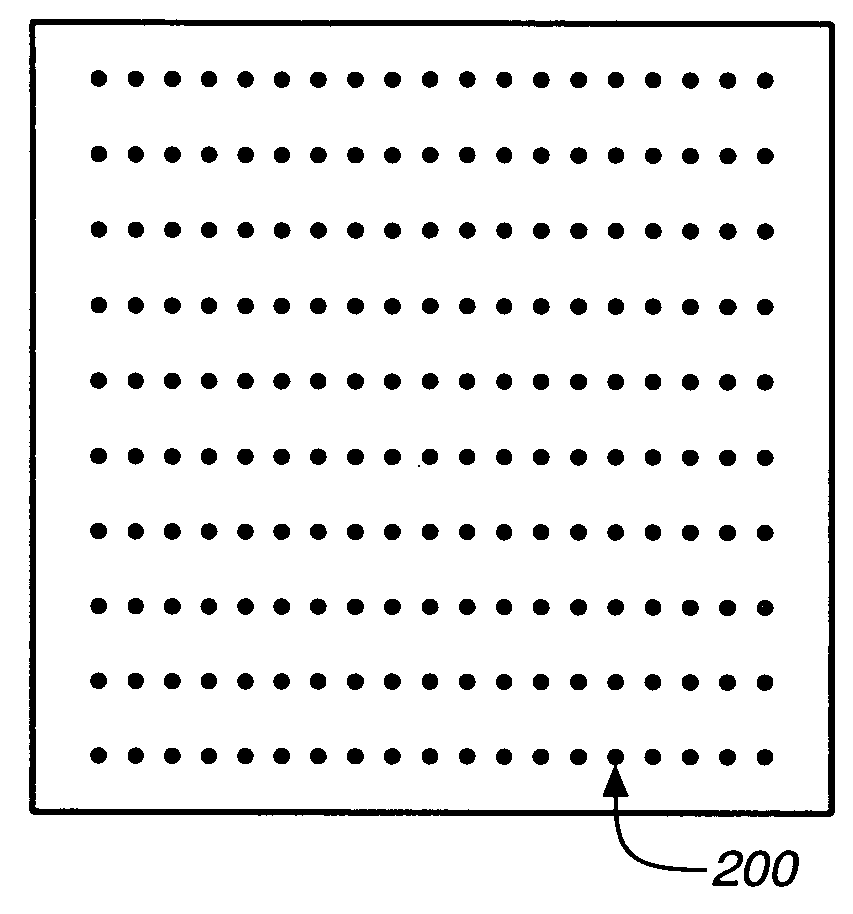

The invention provides homogeneous small spherical particles of low molecular weight organic molecules, said small spherical particles having a uniform shape, a narrow size distribution and average diameter of 0.01-200 μm. The invention further provides methods of preparation and methods of use of the small spherical particles. These small spherical particles are suitable for applications that require delivery of micron-size or nanosized particles with uniform size and good aerodynamic or flow characteristics. Pulmonary, intravenous, and other means of administration are among the delivery routes that may benefit from these small spherical particles.

Owner:BAXTER INT INC +1

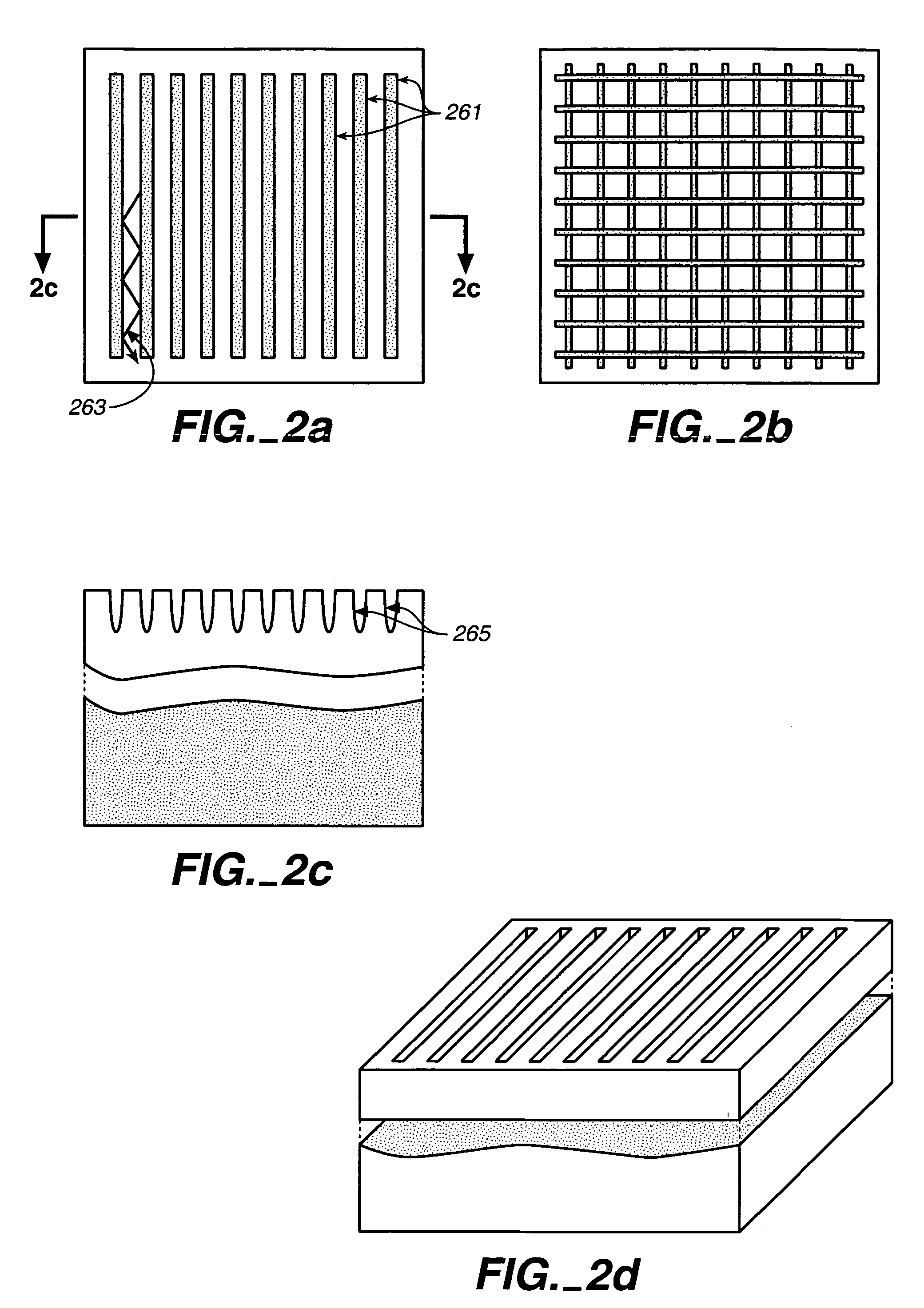

High-efficiency light extraction structures and methods for solid-state lighting

InactiveUS20060237735A1Improve performanceImprove lighting effectsSolid-state devicesSemiconductor devicesPhotonicsLight emitting device

A soft solder flowing into the recesses of a semiconductor thin film LED provides: (a) increased bonding strength and better mechanical durability, (b) improved heat dissipation, (c) enhanced light extraction when the LED film is bonded to a new carrier. Annealing localized islands of absorbing metal creates an ohmic contact. Those isolated islands are inter-connected by a layer of a highly reflective metal. This design enables a significant absorption reduction within the LED device and leads to a significant improvement of light extraction. Additionally, the light extraction efficiency of an isotropic light emitting device is improved via surface shaping of the device by a 2D-array of micro-lenses and photonic band gap structure. For manufacturability purpose the making of micron-size lenses of the surface of the chip may preferably be performed as a final step, preferably with optical lithography.

Owner:DICON FIBEROPTICS

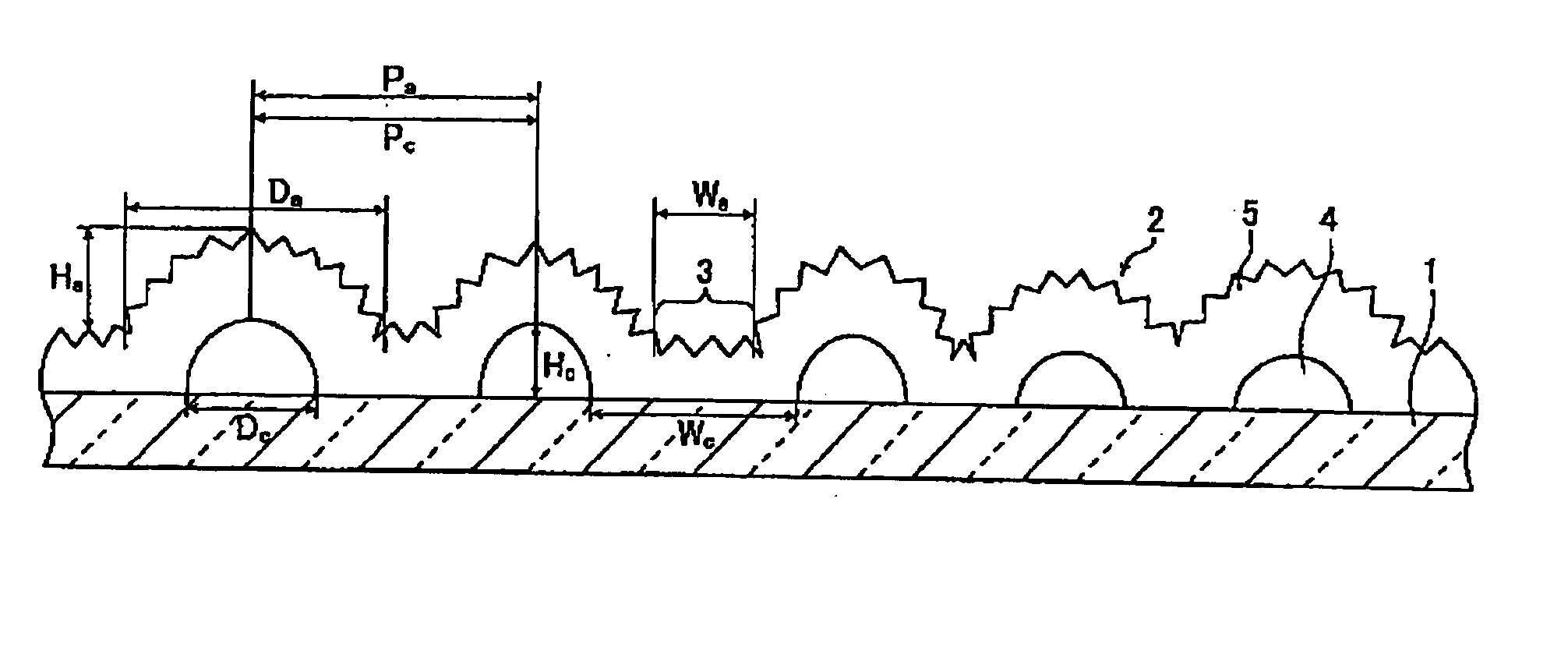

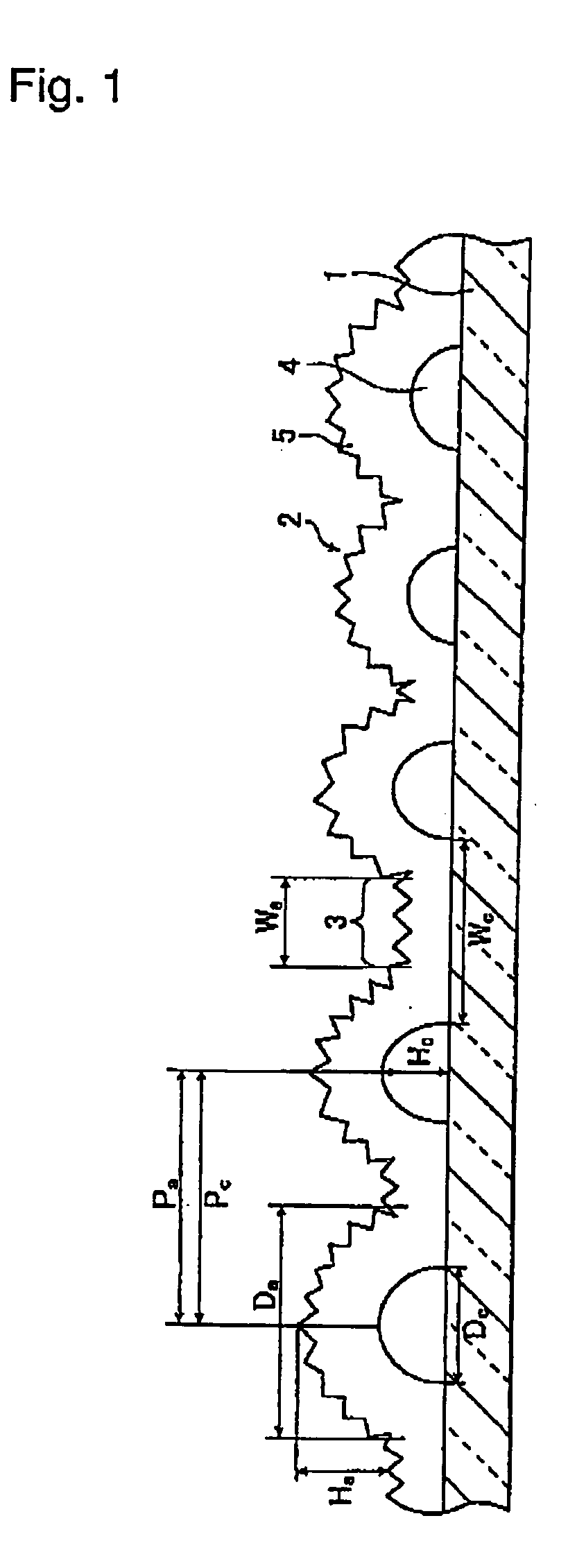

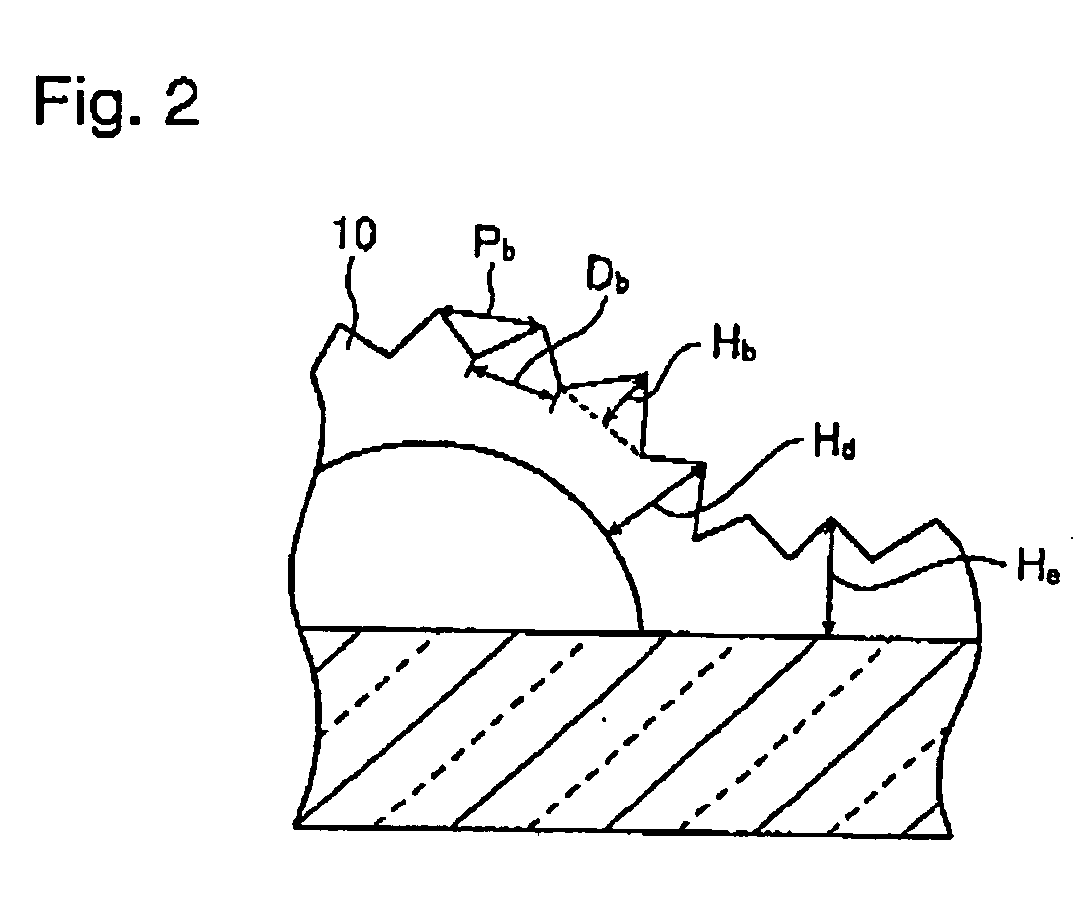

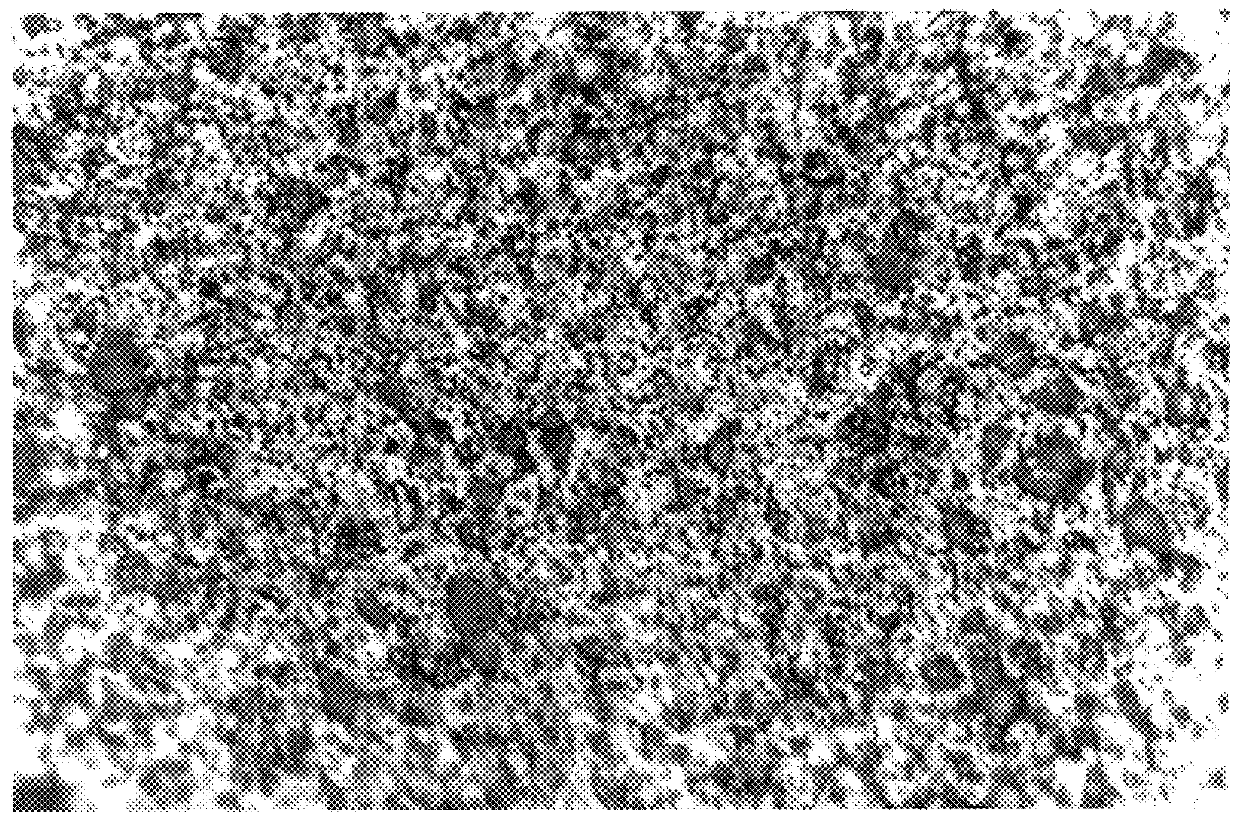

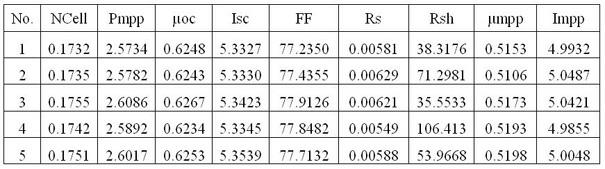

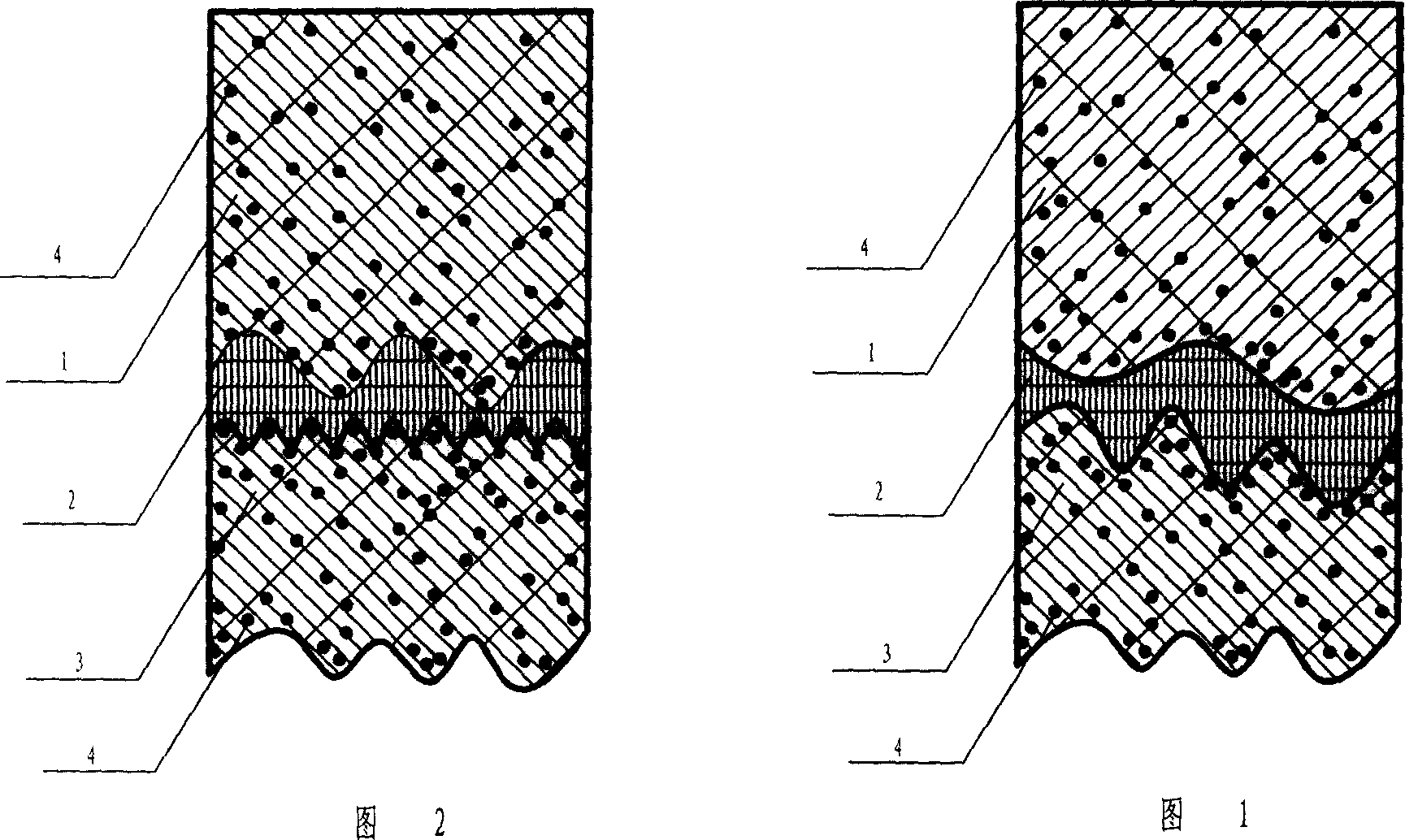

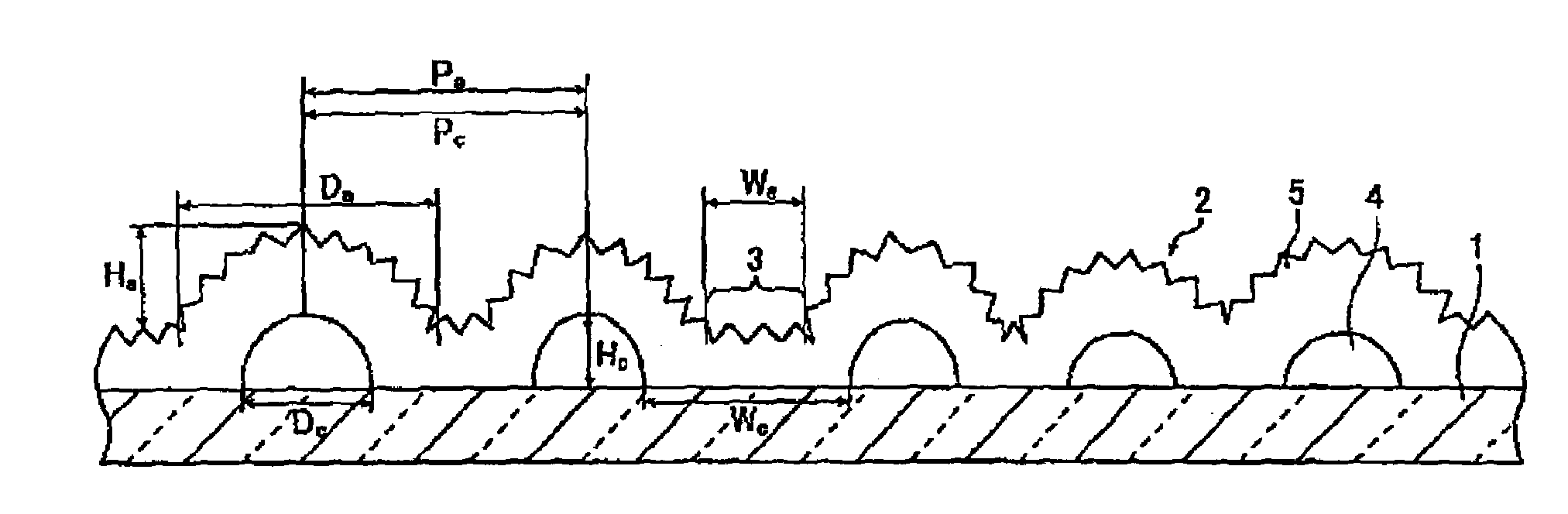

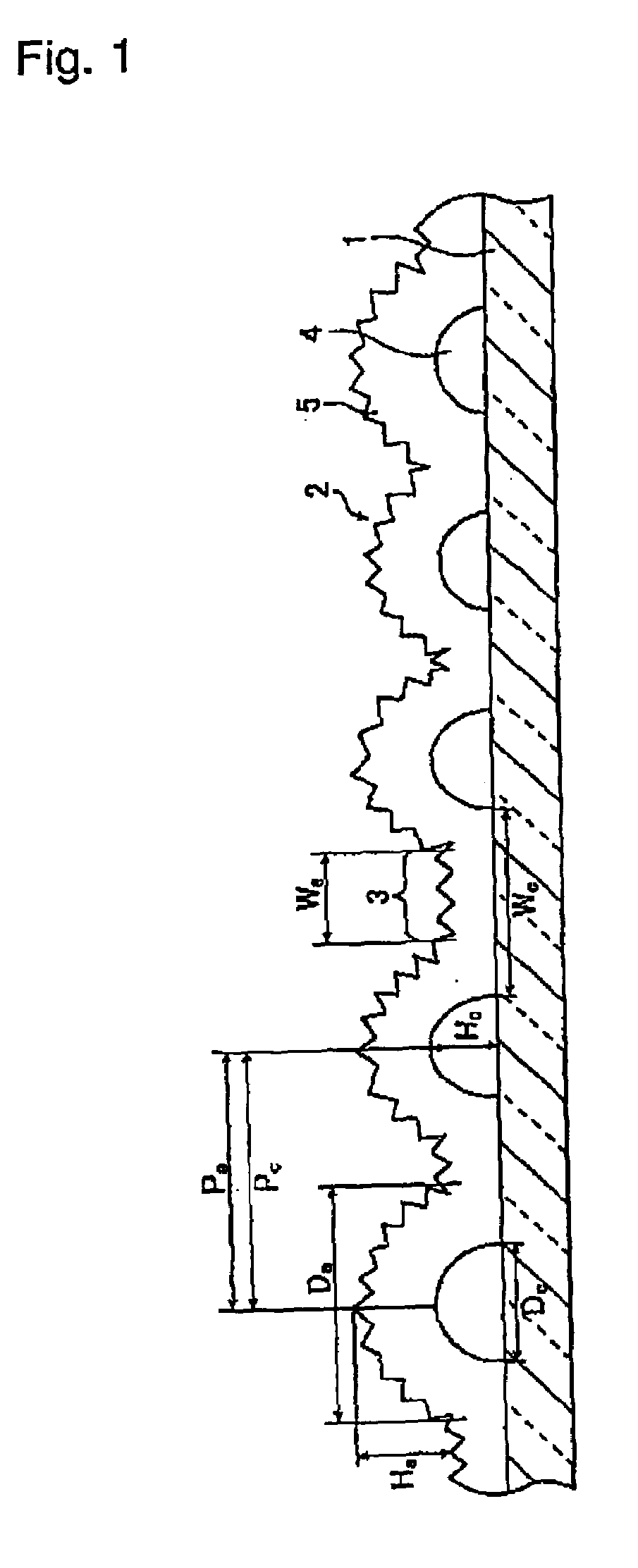

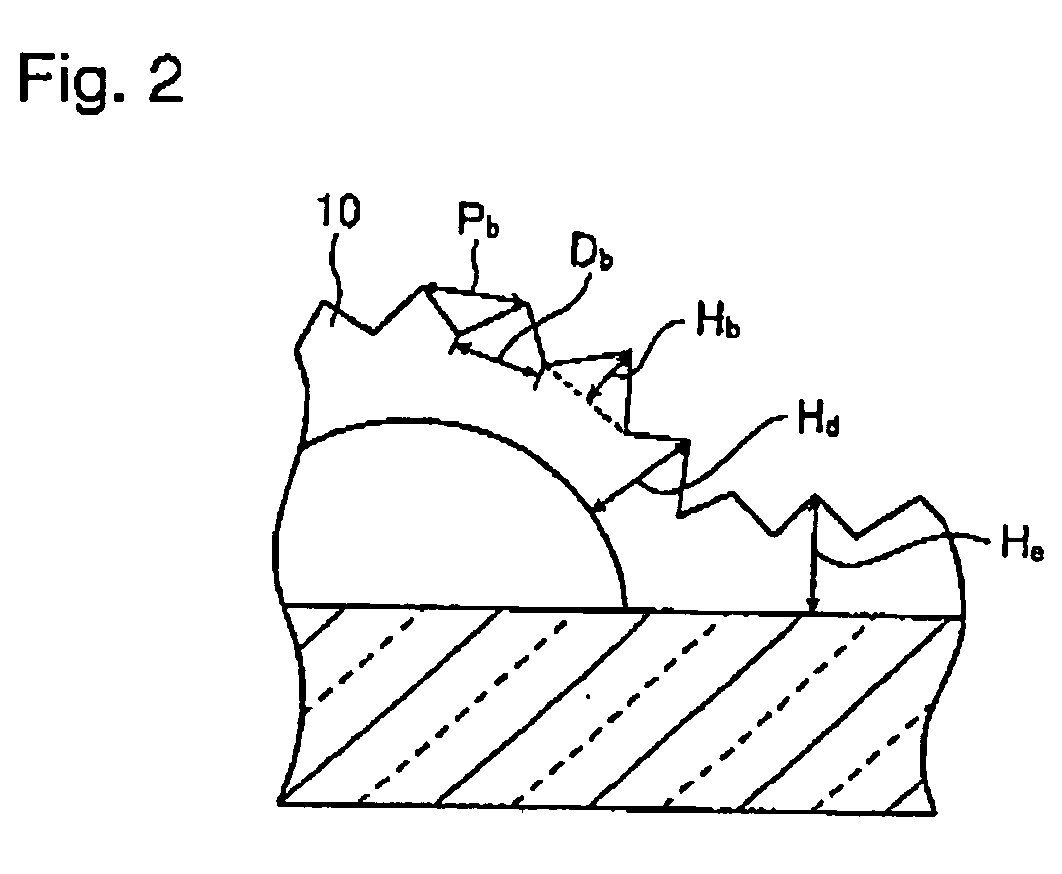

Substrate with transparent conductive oxide film, process for its production and photoelectric conversion element

InactiveUS20050000564A1Conductive materialSolid-state devicesElectrical resistance and conductancePhotoelectric conversion

A substrate with a transparent conductive oxide film (especially a substrate with a transparent conductive oxide film useful as a substrate for a thin-film silicon-based solar cell) being excellent in mass production efficiency and being characterized by having a low resistance, a high transparency and a good light scattering performance over a full wavelength region (300 nm to 3 μm) of solar ray, a process for its production, and a photoelectric conversion element (especially, solar cell) employing the substrate, are presented. A substrate with a transparent conductive oxide film, comprising a substrate and a transparent conductive oxide layer formed on the substrate and constituted by a plurality of ridges is and a plurality of flat portions, wherein the surfaces of the ridges and the flat portions, have many continuous micron-size protrusions.

Owner:ASAHI GLASS CO LTD

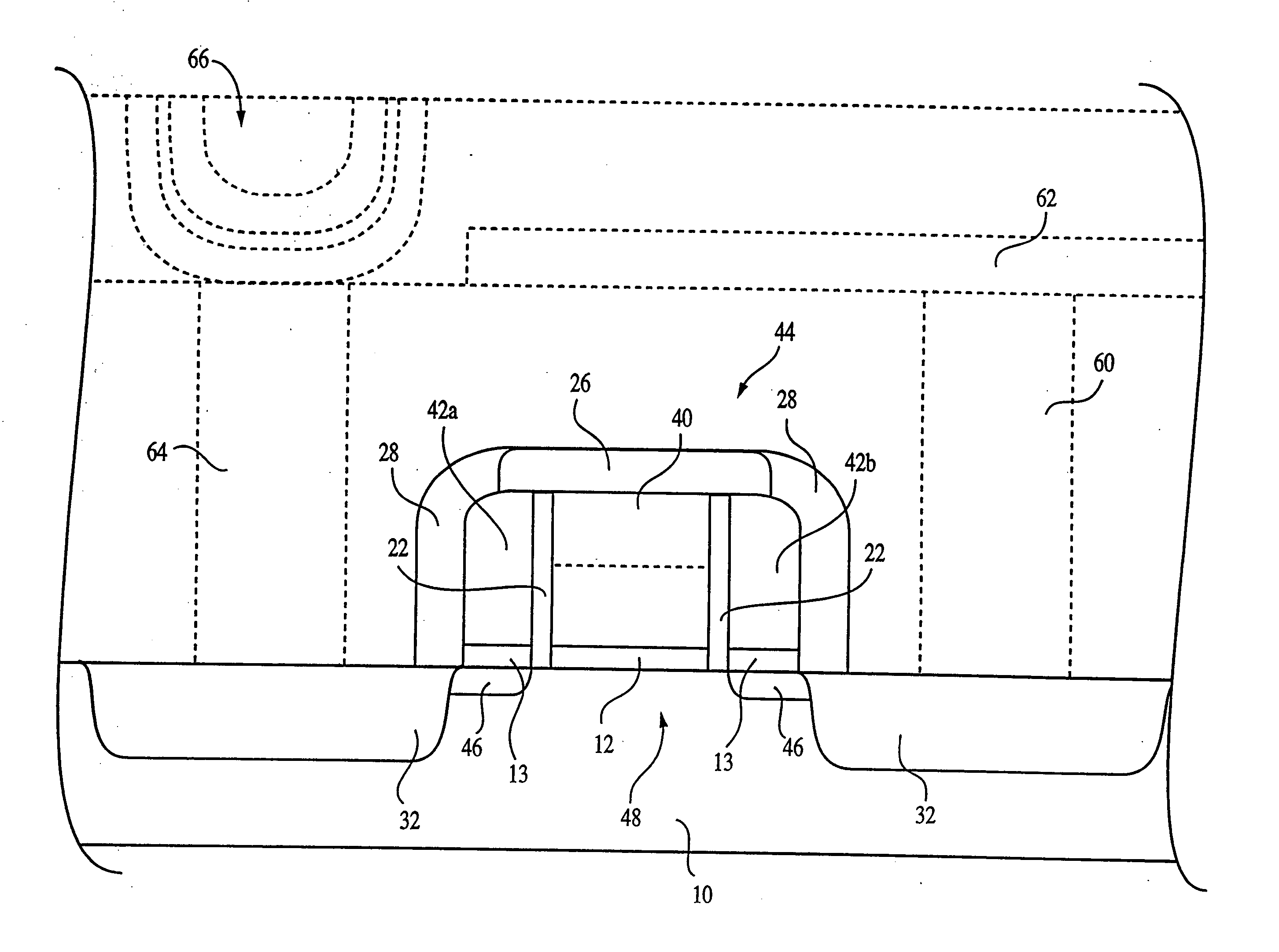

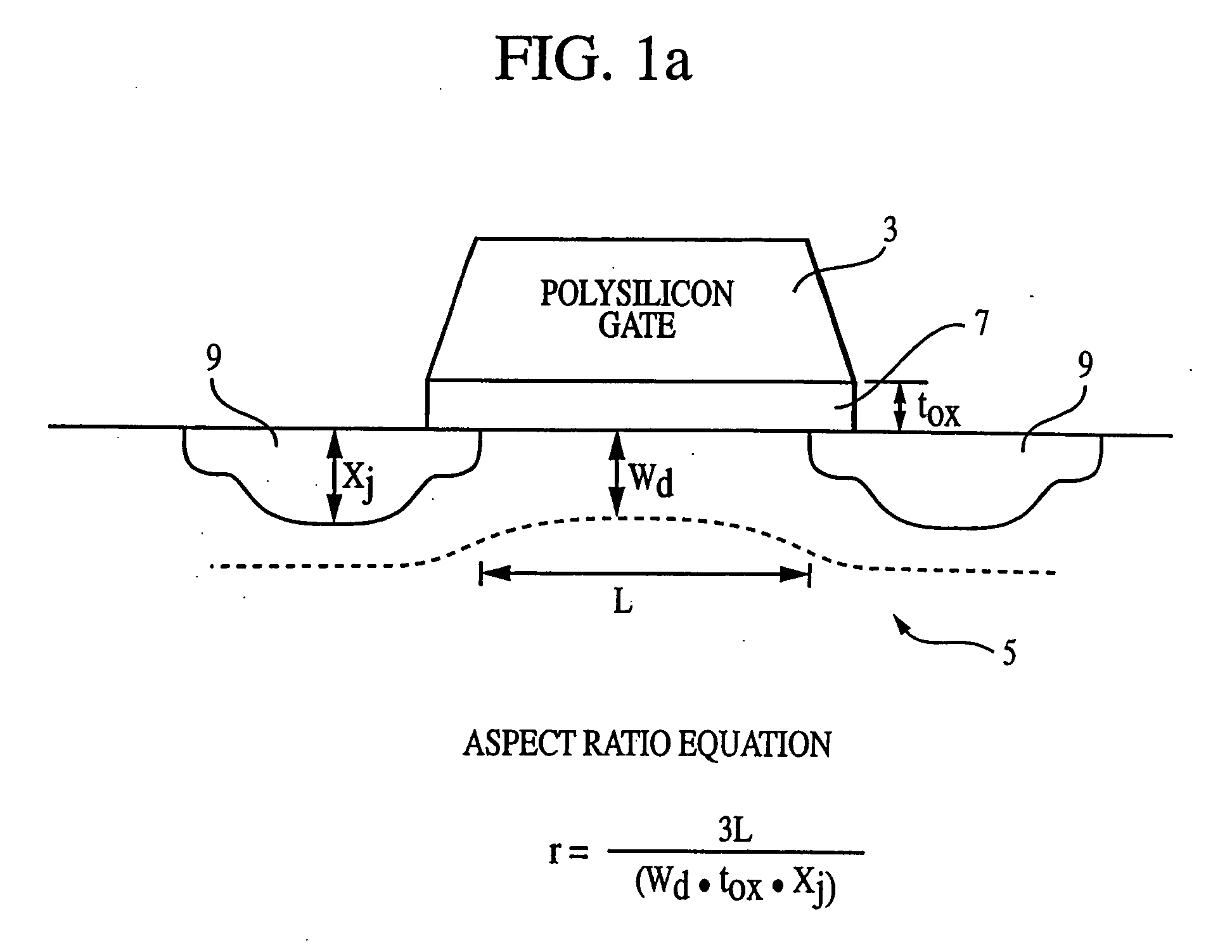

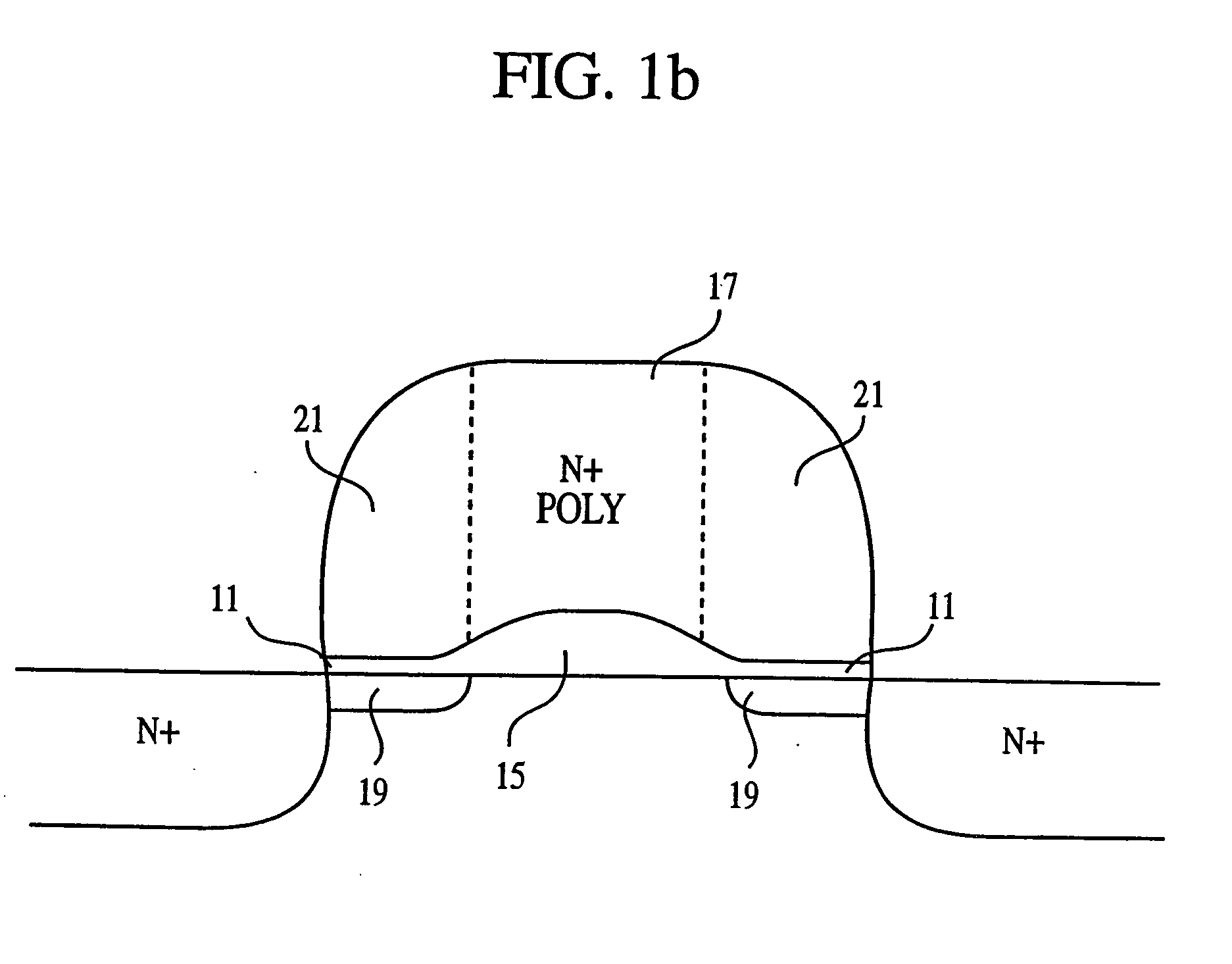

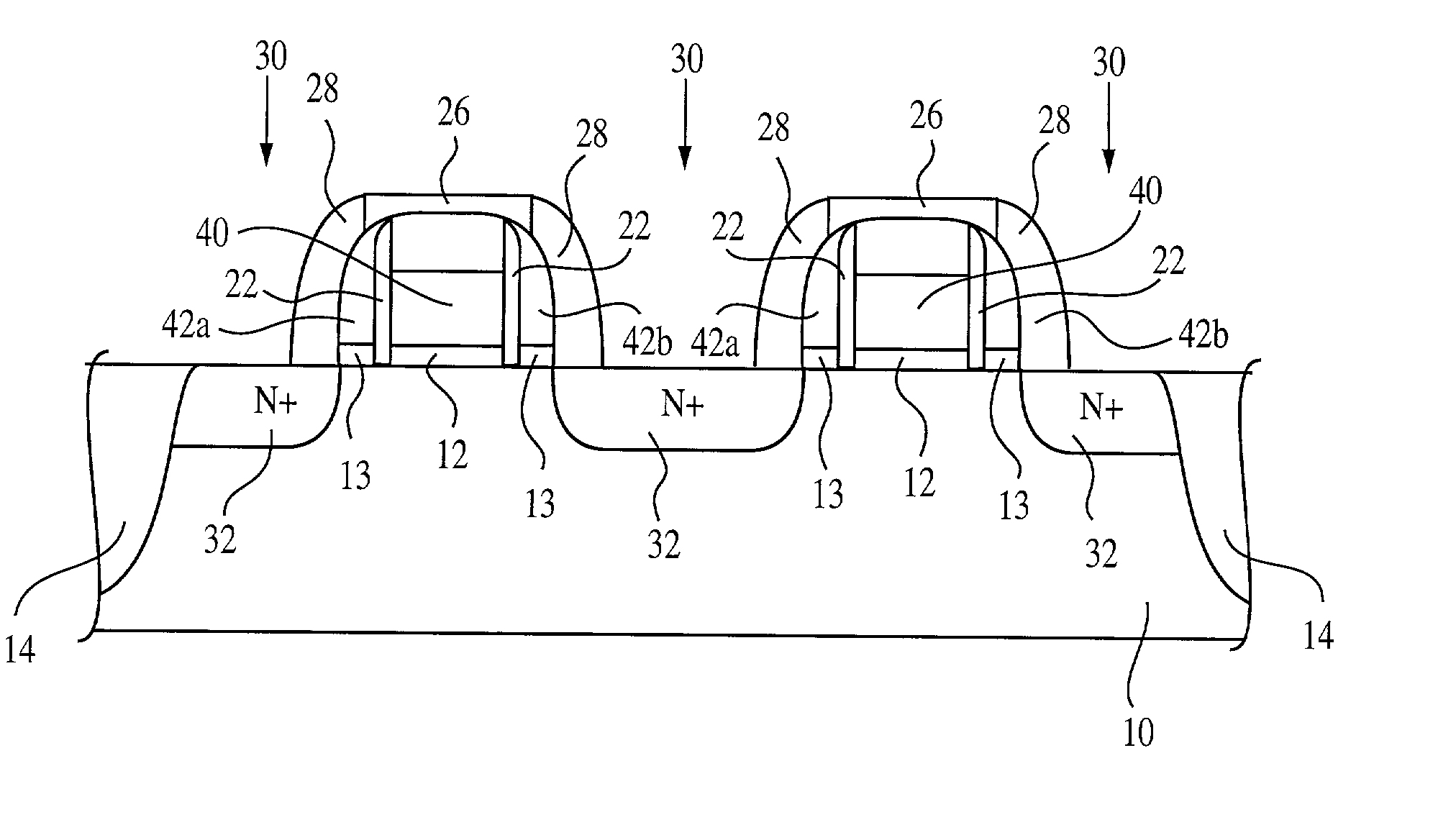

Technique to mitigate short channel effects with vertical gate transistor with different gate materials

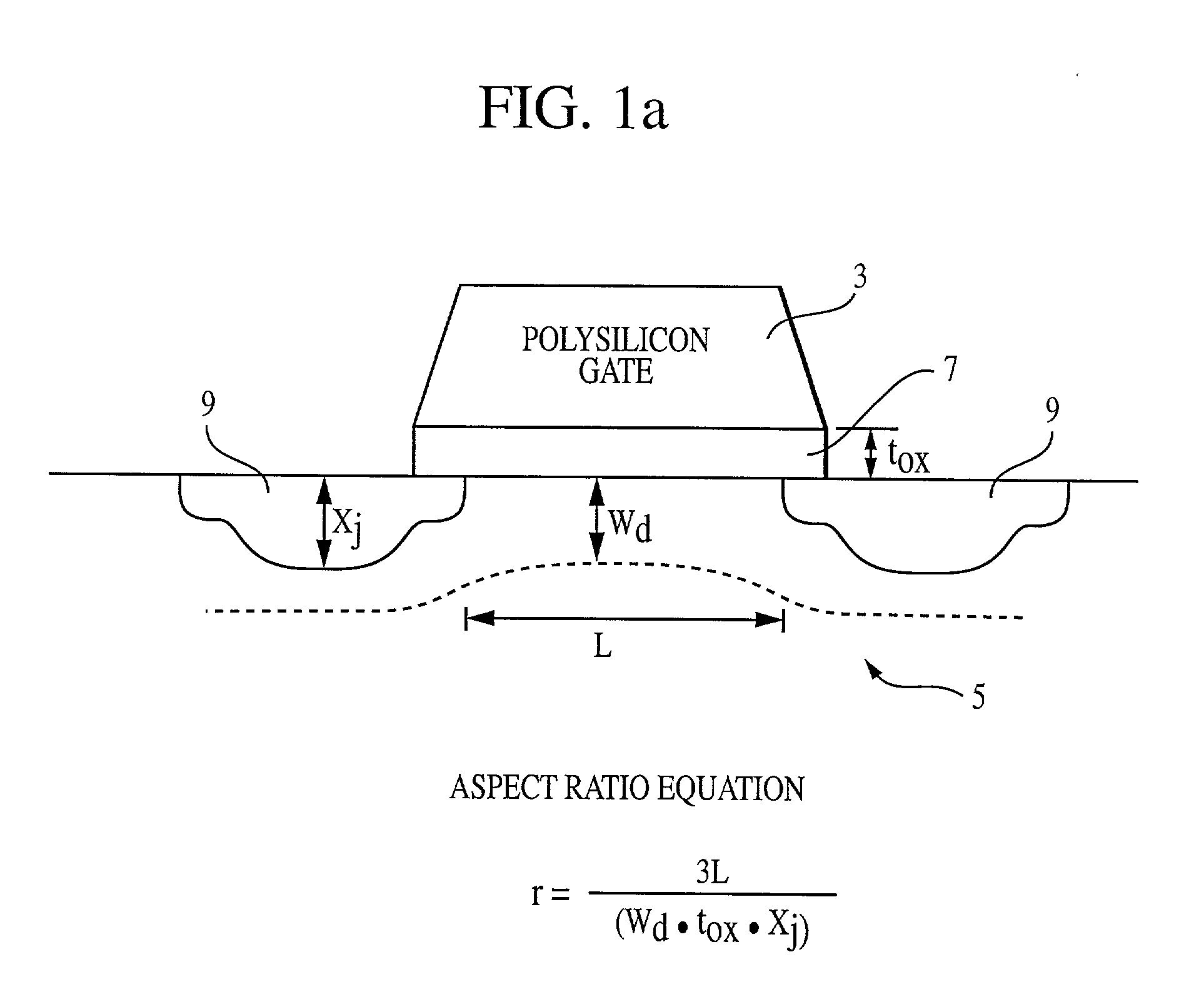

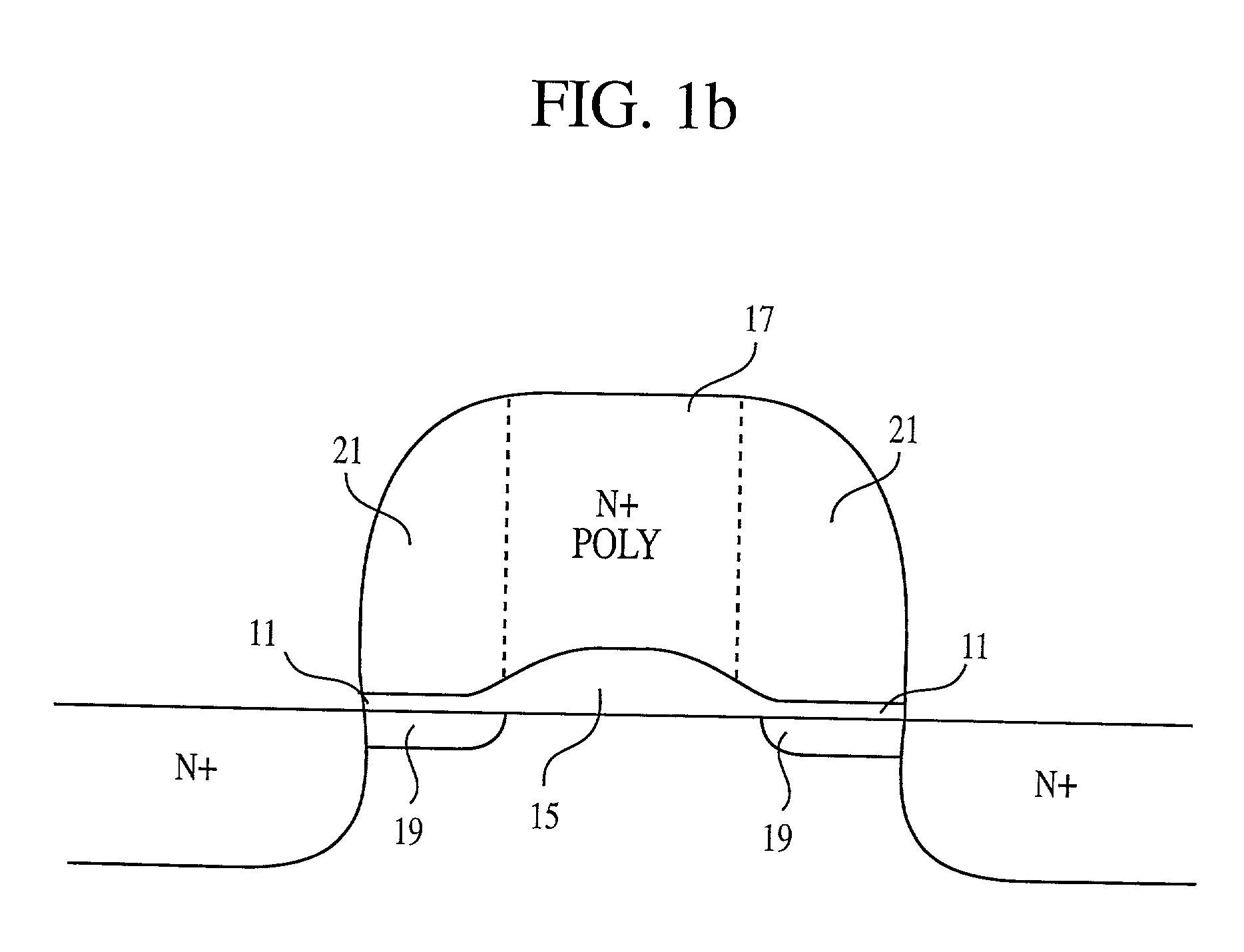

InactiveUS20050145959A1Reduce negative impactImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricEngineering

A process of forming a transistor with three vertical gate electrodes including a high-k gate dielectric and the resulting transistor. By forming such a transistor it is possible to maintain an acceptable aspect ratio as MOSFET structures are scaled down to sub-micron sizes. The transistor gate electrodes can be formed of different materials so that the workfunctions of the three electrodes can be tailored. The three electrodes are positioned over a single channel and operate as a single gate having outer and inner gate regions.

Owner:MICRON TECH INC

Technique to mitigate short channel effects with vertical gate transistor with different gate materials

InactiveUS20020130378A1Improve performanceSuppression of short channel effectsSolid-state devicesSemiconductor/solid-state device manufacturingReverse short-channel effectScale down

This invention relates to a process of forming a transistor with three vertical gate electrodes and the resulting transistor. By forming such a transistor it is possible to maintain an acceptable aspect ratio as MOSFET structures are scaled down to sub-micron sizes. The transistor gate electrodes can be formed of different materials so that the workfunctions of the three electrodes can be tailored. The three electrodes are positioned over a single channel and operate as a single gate having outer and inner gate regions.

Owner:MICRON TECH INC

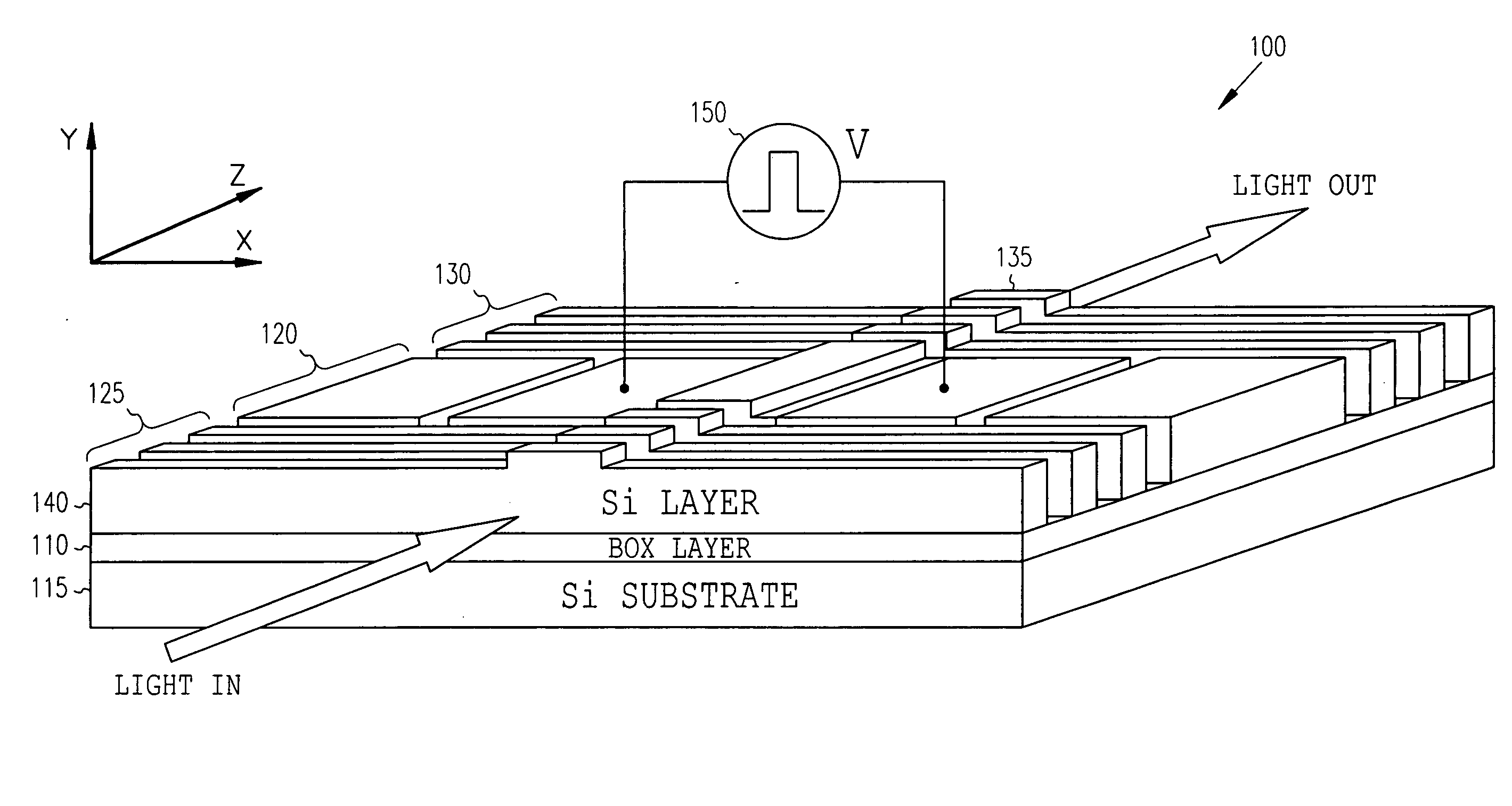

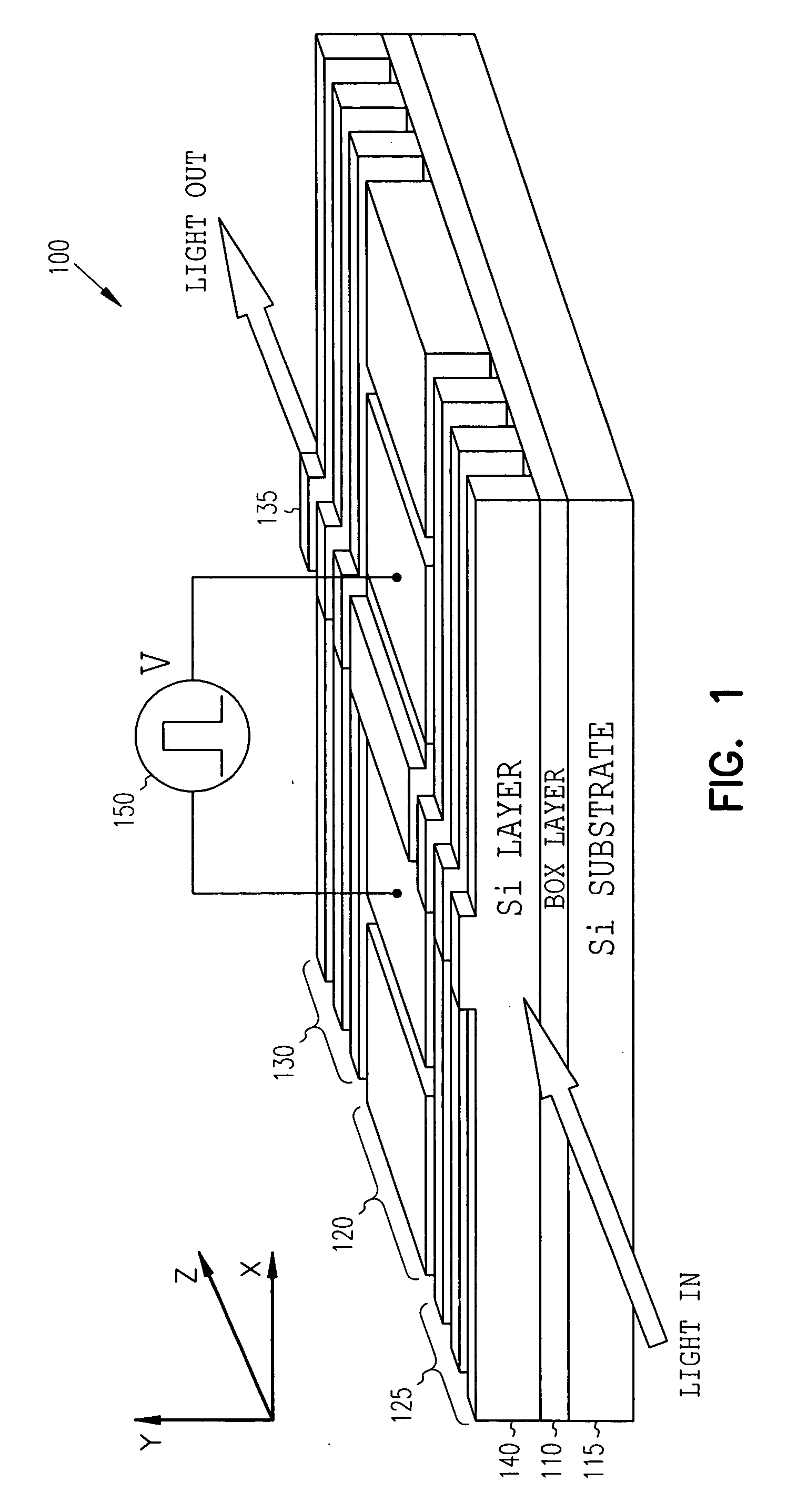

Electro-optic modulator on rib waveguide

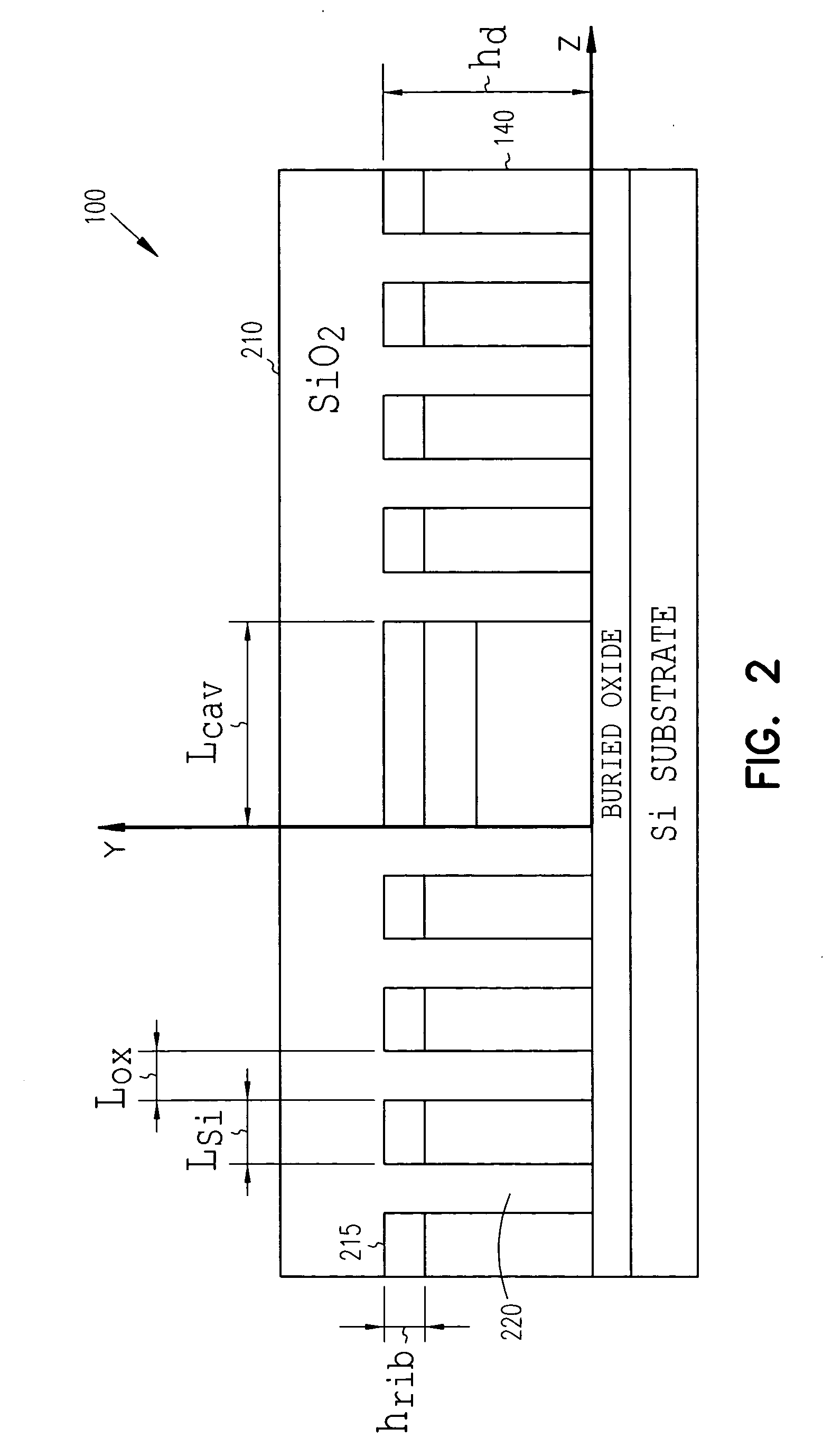

InactiveUS20050089257A1Refractive index variesOptical waveguide light guideNon-linear opticsCharge carrierRefractive index

An electro-optic modulator is formed on a silicon-on-insulator (SOI) rib waveguide. An optical field in the modulator is confined by using an electrically modulated microcavity. The microcavity has reflectors on each side. In one embodiment, a planar Fabry-Perot microcavity is used with deep Si / SiO2 Bragg reflectors. Carriers may be laterally confined in the microcavity region by employing deep etched lateral trenches. The refractive index of the microcavity is varied by using the free-carrier dispersion effect produced by a p-i-n diode formed about the microcavity. In one embodiment, the modulator confines both optical field and charge carriers in a micron-size region.

Owner:CORNELL RES FOUNDATION INC

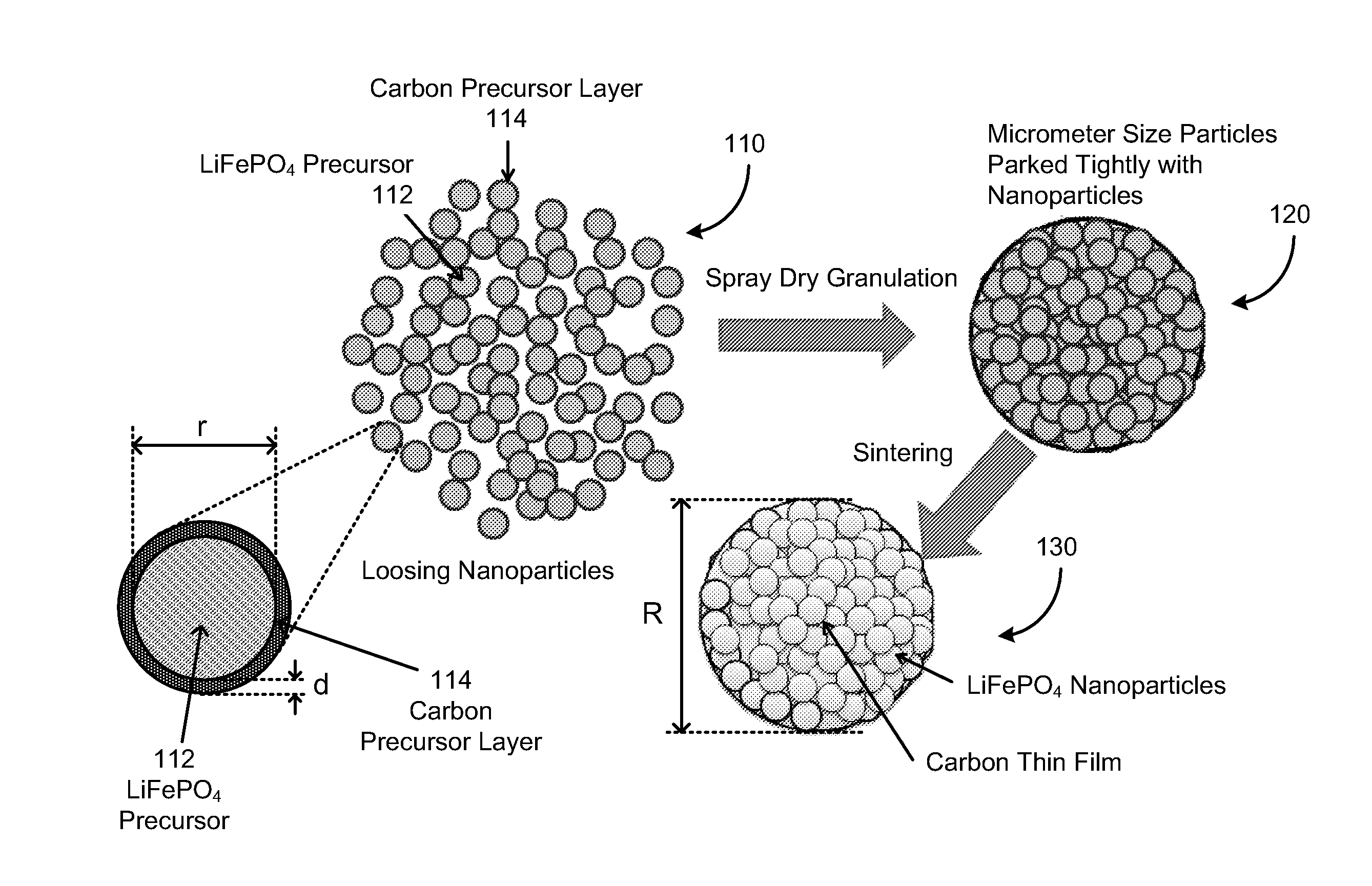

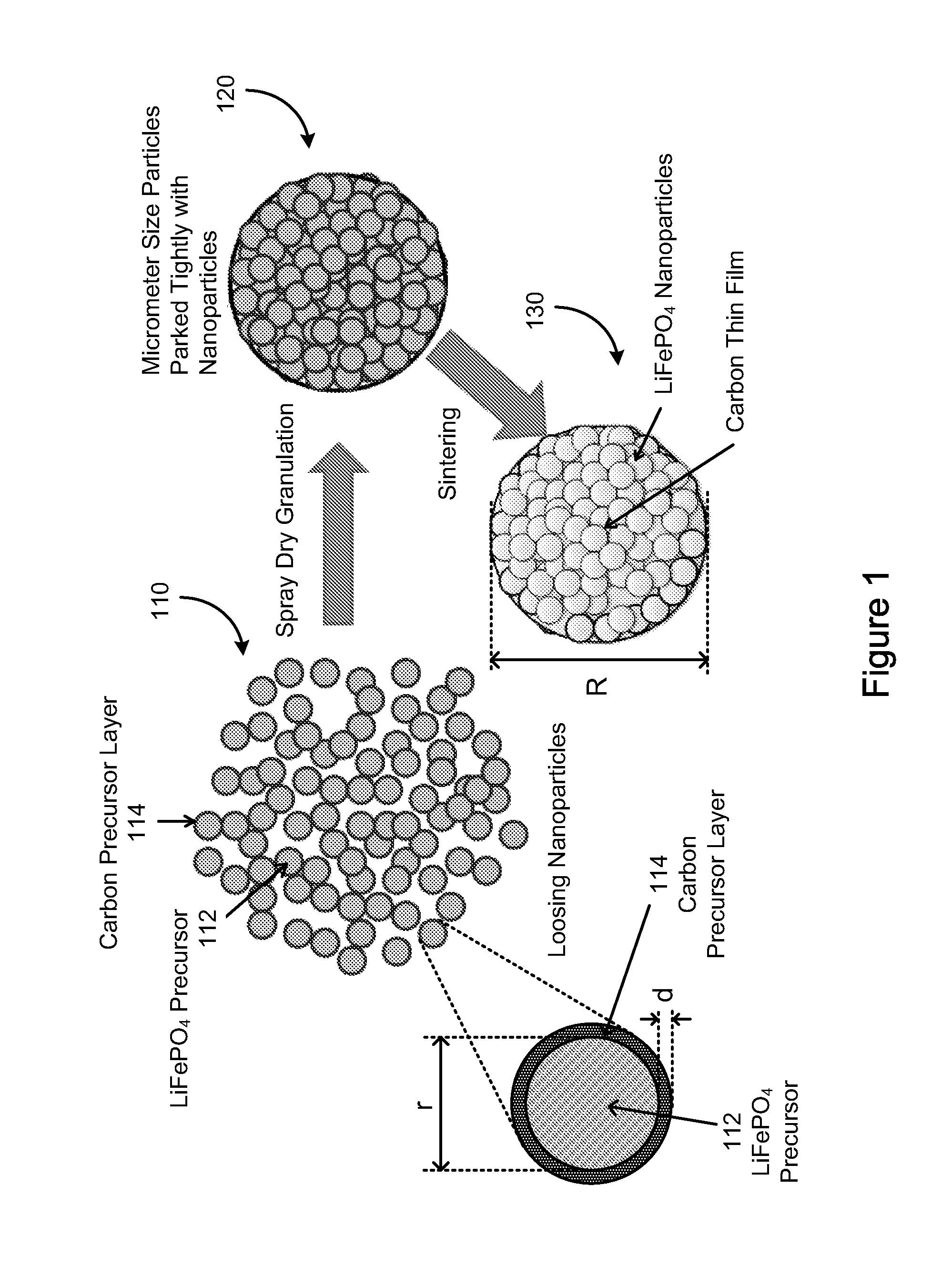

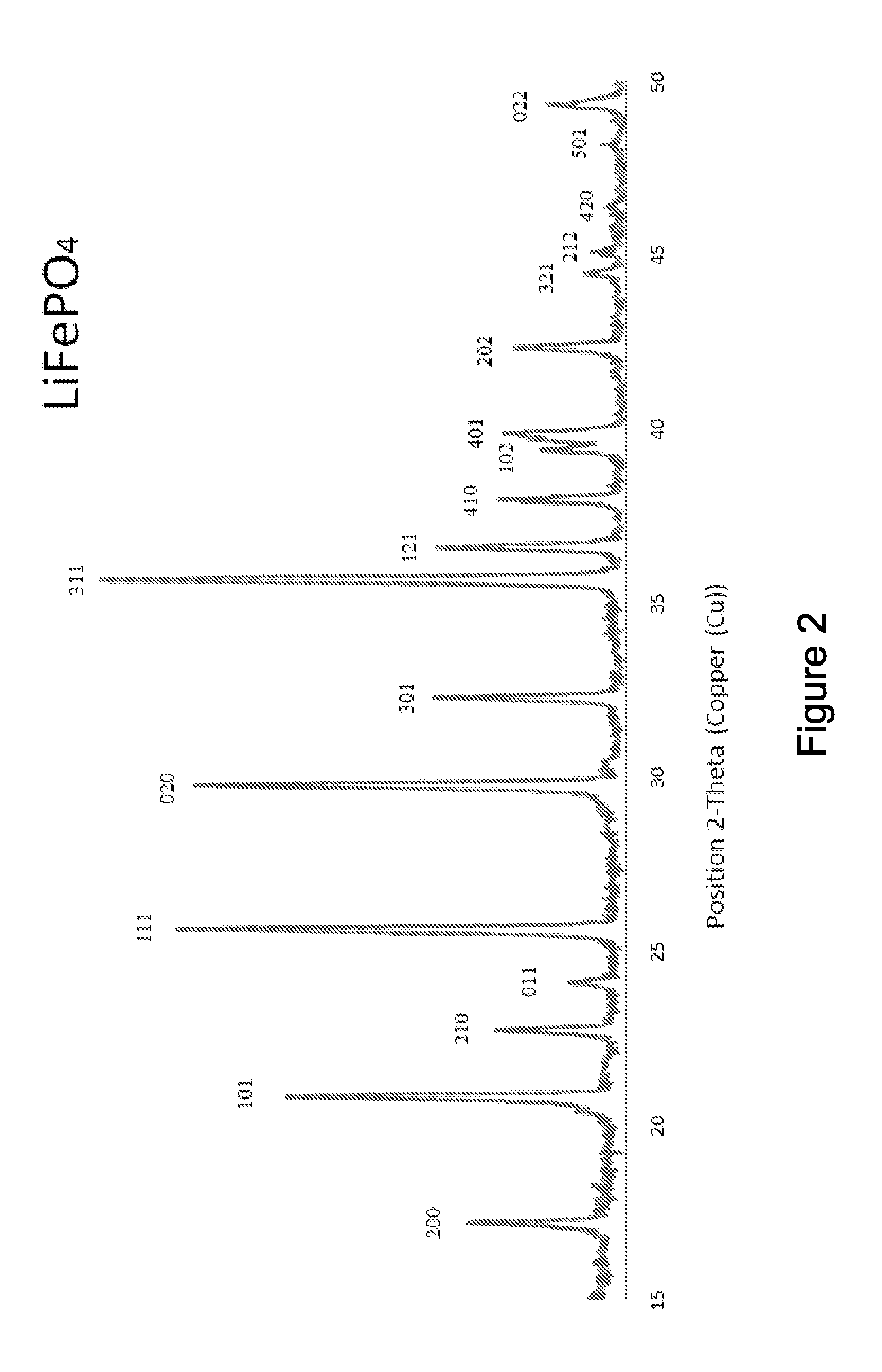

Electrode active composite materials and methods of making thereof

ActiveUS20100279117A1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesNanoparticleLithium metal

In one aspect of the invention, a method of synthesizing a lithium metal phosphate composite usable for a lithium secondary battery includes the steps of forming a nanometer-size precursor comprising lithium source and metal phosphate nanoparticles having each nanoparticle at least partially coated a layer of carbon precursor, spray drying the nanometer-size precursor at a first desired temperature to form micron-size particles packed with the lithium metal phosphate precursor nanoparticles, and sintering the micron-size particles at a second desired temperature under an inert and / or reduction atmosphere to form a micron-size lithium metal phosphate composite.

Owner:MEECOTECH

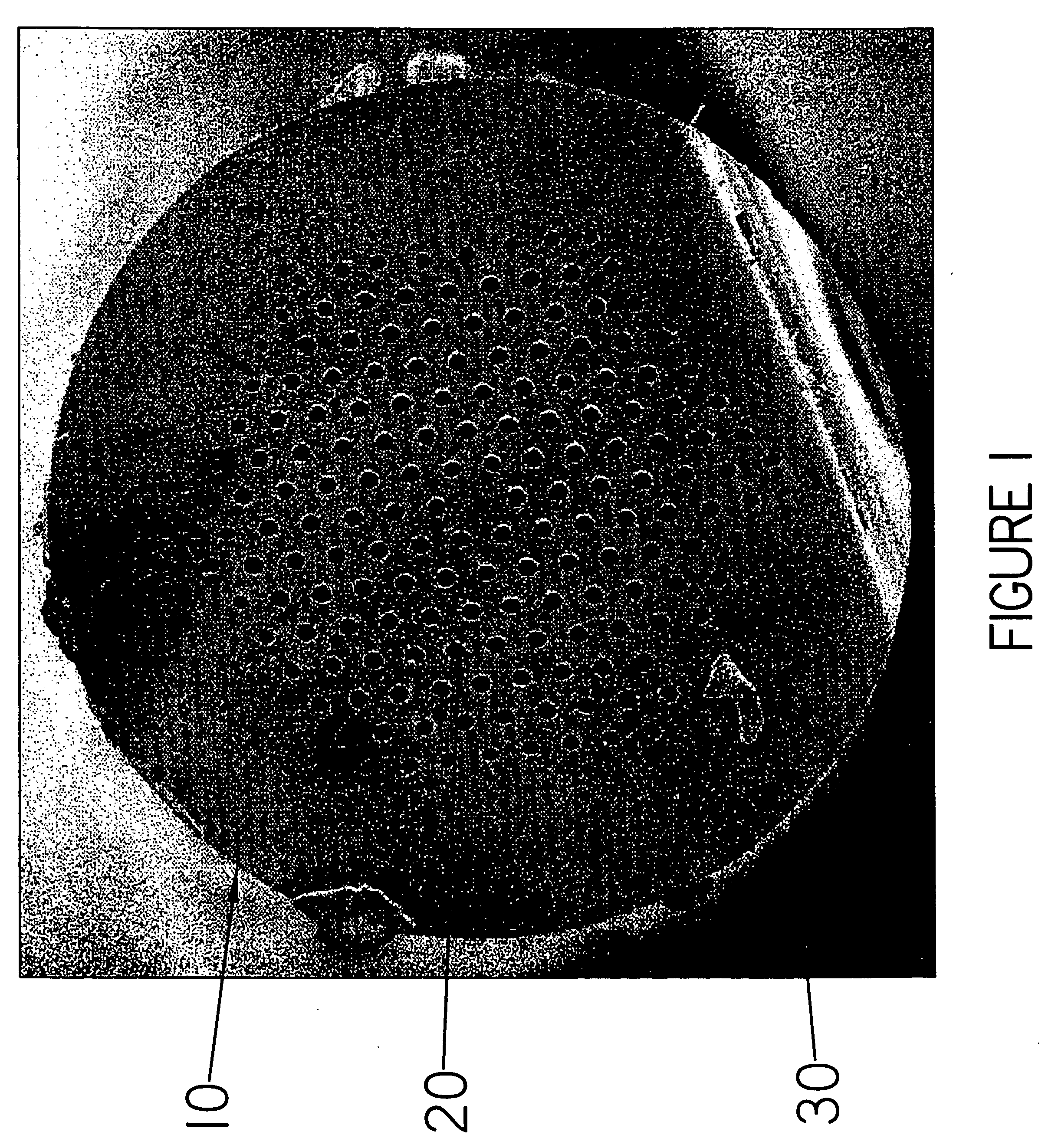

Composite porous membrane and process for producing the same

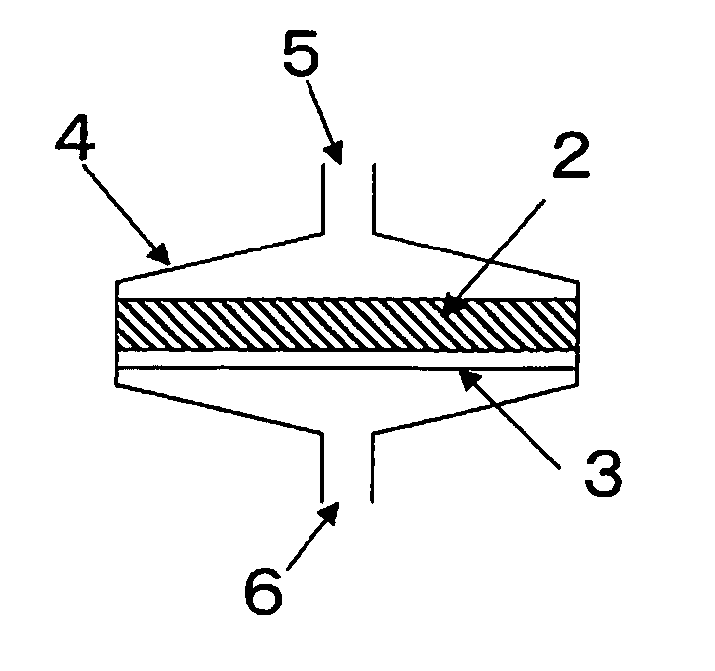

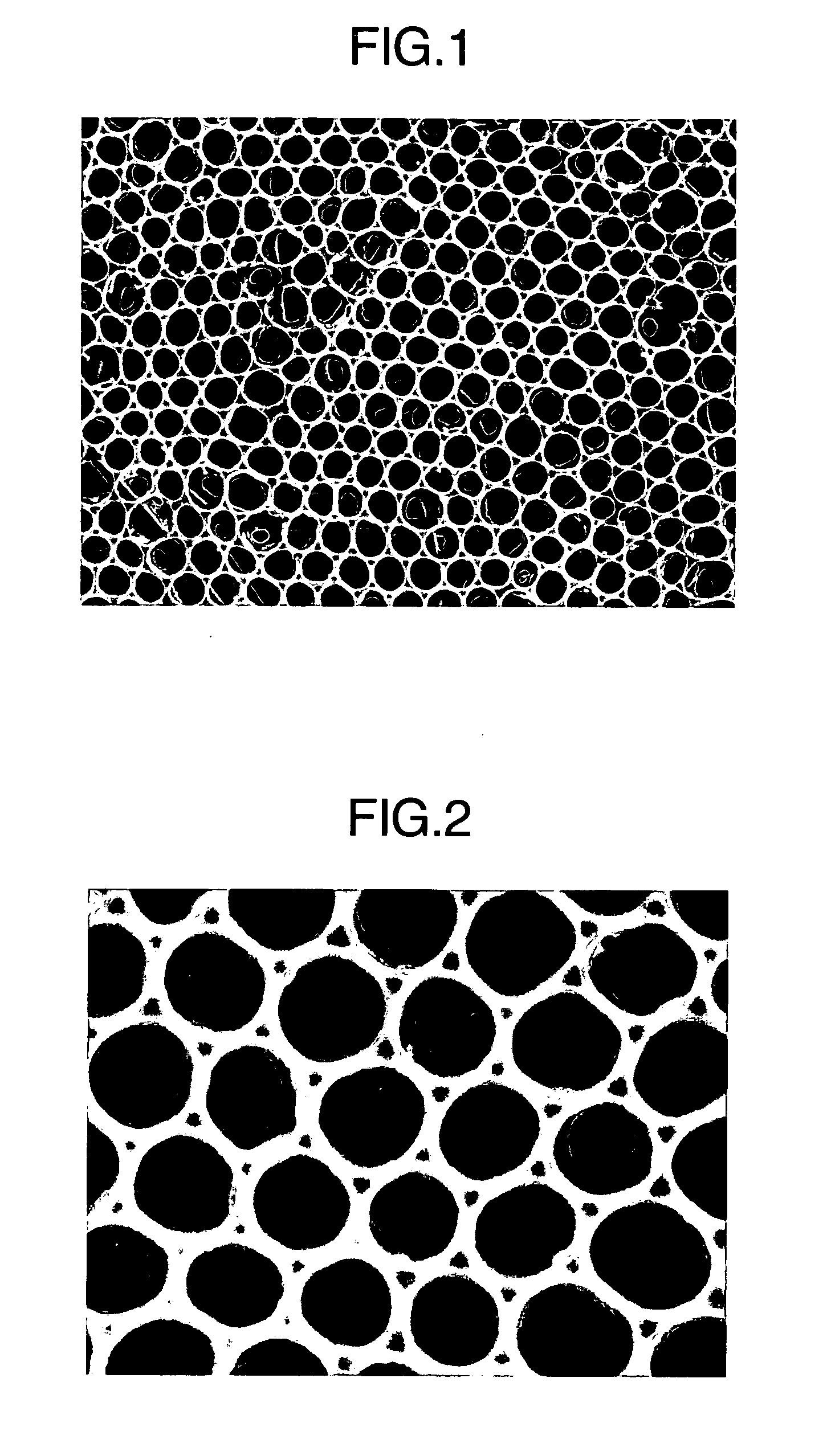

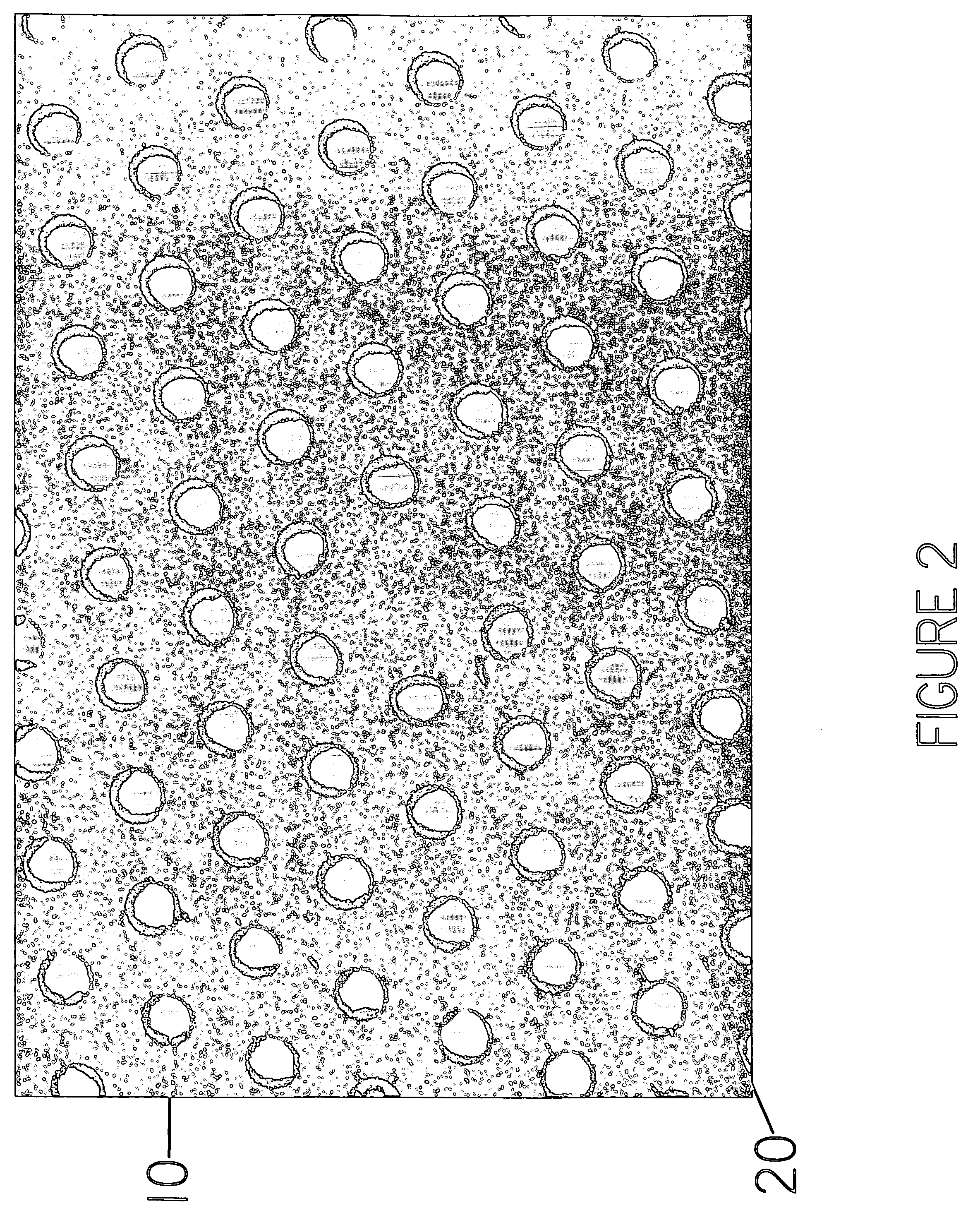

InactiveUS20070029256A1Good size uniformityLow filtration resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsWhite blood cellMicron size

[Problems]To provide a membrane material that realizes effective and efficient separation of a target substance of micron size, being easy to handle and that can be worked into various forms; a blood filtration membrane and a leukocyte removing filter unit that realizes a substantial reduction of filter material volume while retaining high capability of removing leukocytes, thereby reducing the loss of hemocyte suspension; and a cell culturing diaphragm suitable for co-culturing and a relevant method of cell culturing. [Means for Solving Problems]There is provided a composite porous membrane comprising a porous membrane comprised of an organic polymeric compound, and a supporting porous membrane adjacent to the porous membrane, characterized in that the organic polymeric compound constituting the porous membrane penetrates in at least part of a surface adjacent to porous membrane of the supporting porous membrane, the porous membrane having specified opening ratio, average pore diameter, standard deviation of pore diameter, ratio of through pore, average membrane thickness, standard deviation of membrane thickness and internal structure, and that the supporting porous membrane has communicating pores of 0.5D μm or greater average pore diameter. Further, there are provided a blood filtration membrane comprising the composite porous membrane; a leukocyte removing filter unit comprising the composite porous membrane as a second filter; and, utilizing the composite porous membrane, a cell culturing diaphragm and method of cell culturing.

Owner:ASAHI KASEI MEDICAL CO LTD

Titanium alloy based dispersion-strengthened composites

Titanium based metal matrix composites reinforced with ceramic particulate are well known, based on a blend of titanium alloy powders with ceramic powders, e.g., aluminum oxide powders, utilizing a low energy ball milling process, followed by cold compacting and sintering to produce an appropriate composite. This prior art process is disadvantaged from the point of view that there are virtually no particles in the blend below the micrometer size range, which lack has a deleterious effect on the subsequent processing of the composite. This problem has been overcome by utilizing dry high energy intensive milling in the process, which has the effect of providing the necessary number of small particles below the micrometer size range as well as enhancing the reactivity of different particles with one another. In order to produce a titanium base alloy alumina metal matrix composite, titanium dioxide powder is blended with aluminum powder and subjected to dry high energy intensive milling until the separate particle phases achieve a size of 500 nanometers maximum. The intermediate powder product is then heated to form the titanium alloy / amumina metal matrix composite in which the ceramic particles have an average diameter of no more than 3 mu, and the oxide consists of more than 10% and less than 60% by volume fraction of the total composite. The composites have extensive application to tough and strong engineering alloys.

Owner:TITANOX DEV

Nanometer and micron water-soluble microgel reservoir oil material and preparation method thereof

ActiveCN1927895AMeet the needs of profile control and water pluggingImprove liquidityFluid removalCross-linkPolymer science

The present invention relates to nanometer and micron polymer material, and is especially one kind of nanometer and micron water soluble microgel oil-displacing material with wide size range and its reverse emulsion polymerizing preparation process. In the reverse emulsion polymerization process, water soluble monomer and cross-linking agent react to form pre-crosslinked spheroid water soluble microgel polymer with certain elasticity. As one kind of oil-displacing material, the nanometer and micron water soluble microgel material is opaque reverse emulsion, and has excellent flowability and stability, viscosity at 25 deg.c lower than 400 mPa.s, no obvious delamination. When the material and water soluble surfactant are injected simultaneously into water, the material will disperse fast and swelled to form microgel grains of 100 nm to 20 micron size.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Silver paste for positive electrode of crystalline silicon solar cell and preparation method thereof

InactiveCN102157219AReduce contact resistanceImprove rheologyNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetallurgy

The invention discloses high-conductivity silver paste for a positive electrode of a crystalline silicon solar cell. The silver paste comprises the following components in percentage by weight: 75-90% of Ag powder, 2-10% of glass powder and 5-20% of organic carrier, wherein the glass powder comprises the following components in percentage by weight: 30-75% of PbO, 7-30% of SiO2, 2-30% of Bi2O3, 1-5% of Al2O3, 1-5% of V2O5, 1-10% of ZnO, 1-5% of Ag2O and 1-8% of MgO. The silver paste has the following beneficial effects: the micron-sized silver powder is adopted to prepare the silver paste, the prepared silver paste has good rheological behavior and thixotropy, a single wafer consumes less silver paste, and the compactness of the positive grid line is improved, thus improving the conductivity; and the glass powder with low-melting erosion property is adopted and can effectively and moderately erode the antireflective film, thus reducing the contact resistance of the crystalline silicon solar cell and improving the conversion efficiency.

Owner:XIAN INTAIN NEW ENERGY MATERIALS SCI & TECH +1

Integral engineering rack of interface osteochondro tissue with bionic function

InactiveCN101020083AIncrease connection areaImprove connection strengthJoint implantsSubchondral boneBiocompatibility Testing

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Substrate with transparent conductive oxide film, process for its production and photoelectric conversion element

InactiveUS7179527B2Conductive materialSolid-state devicesElectrical resistance and conductancePhotoelectric conversion

A substrate with a transparent conductive oxide film (especially a substrate with a transparent conductive oxide film useful as a substrate for a thin-film silicon-based solar cell) being excellent in mass production efficiency and being characterized by having a low resistance, a high transparency and a good light scattering performance over a full wavelength region (300 nm to 3 μm) of solar ray, a process for its production, and a photoelectric conversion element (especially, solar cell) employing the substrate, are presented. A substrate with a transparent conductive oxide film, comprising a substrate and a transparent conductive oxide layer formed on the substrate and constituted by a plurality of ridges is and a plurality of flat portions, wherein the surfaces of the ridges and the flat portions, have many continuous micron-size protrusions.

Owner:AGC INC

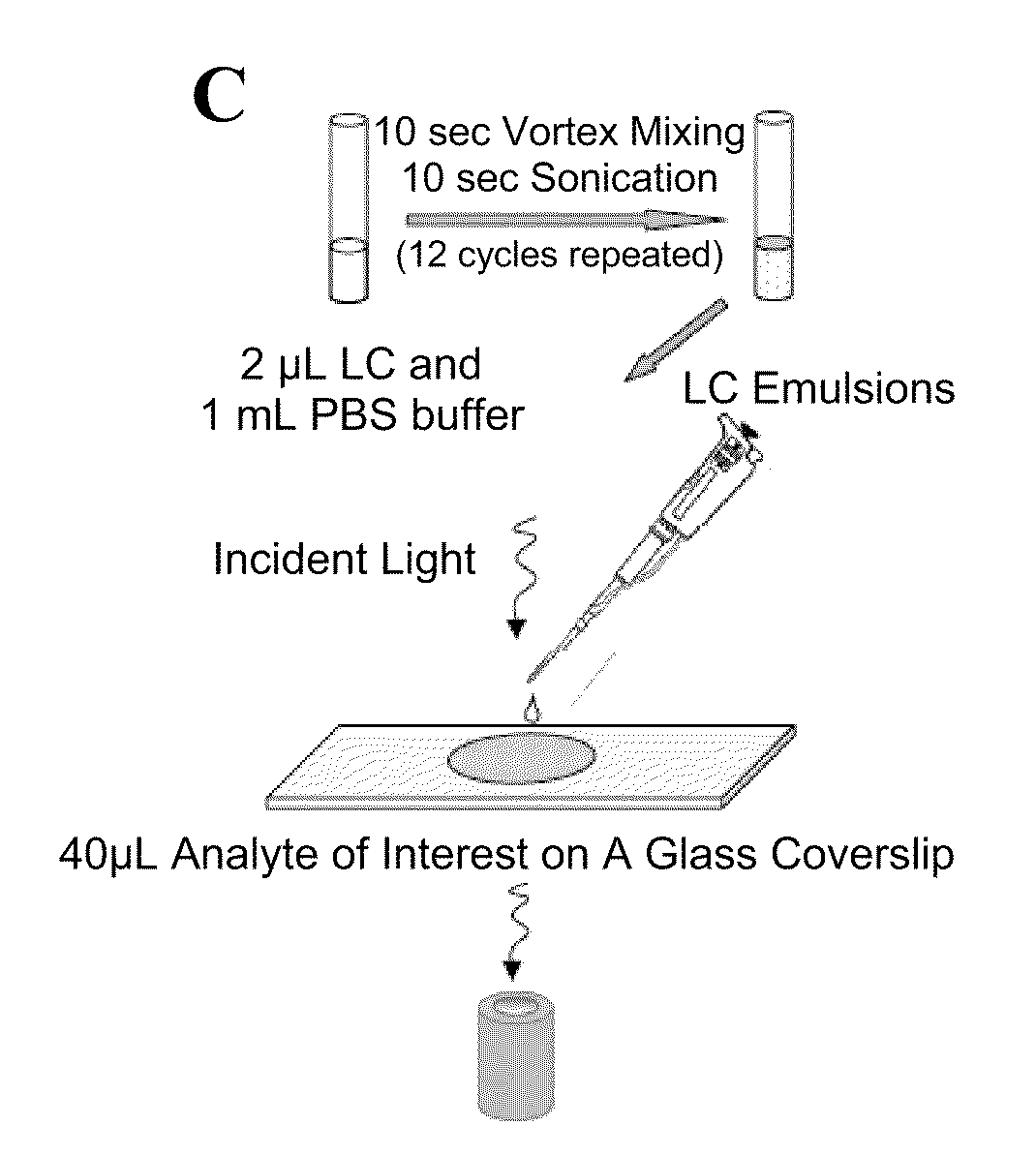

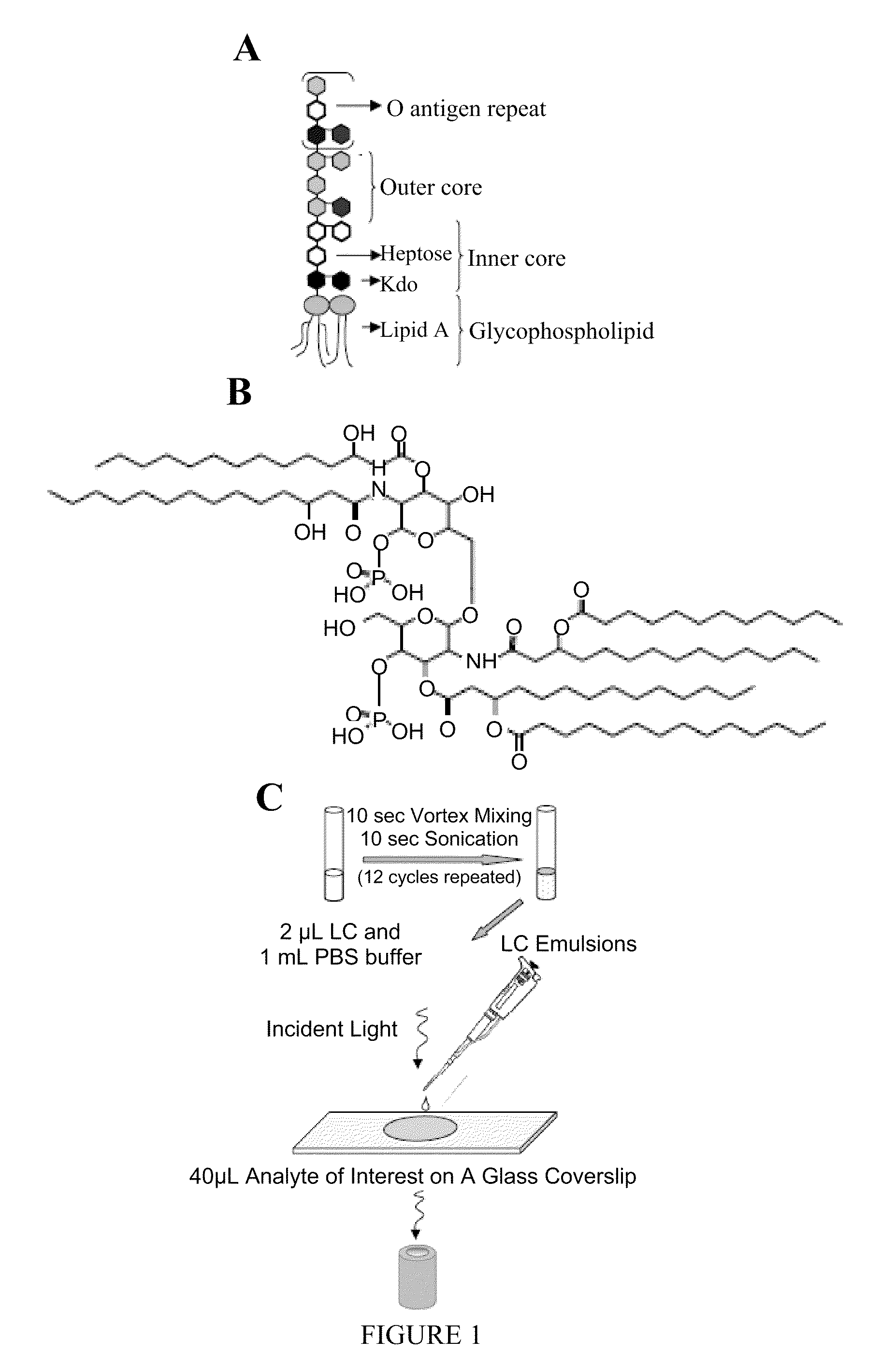

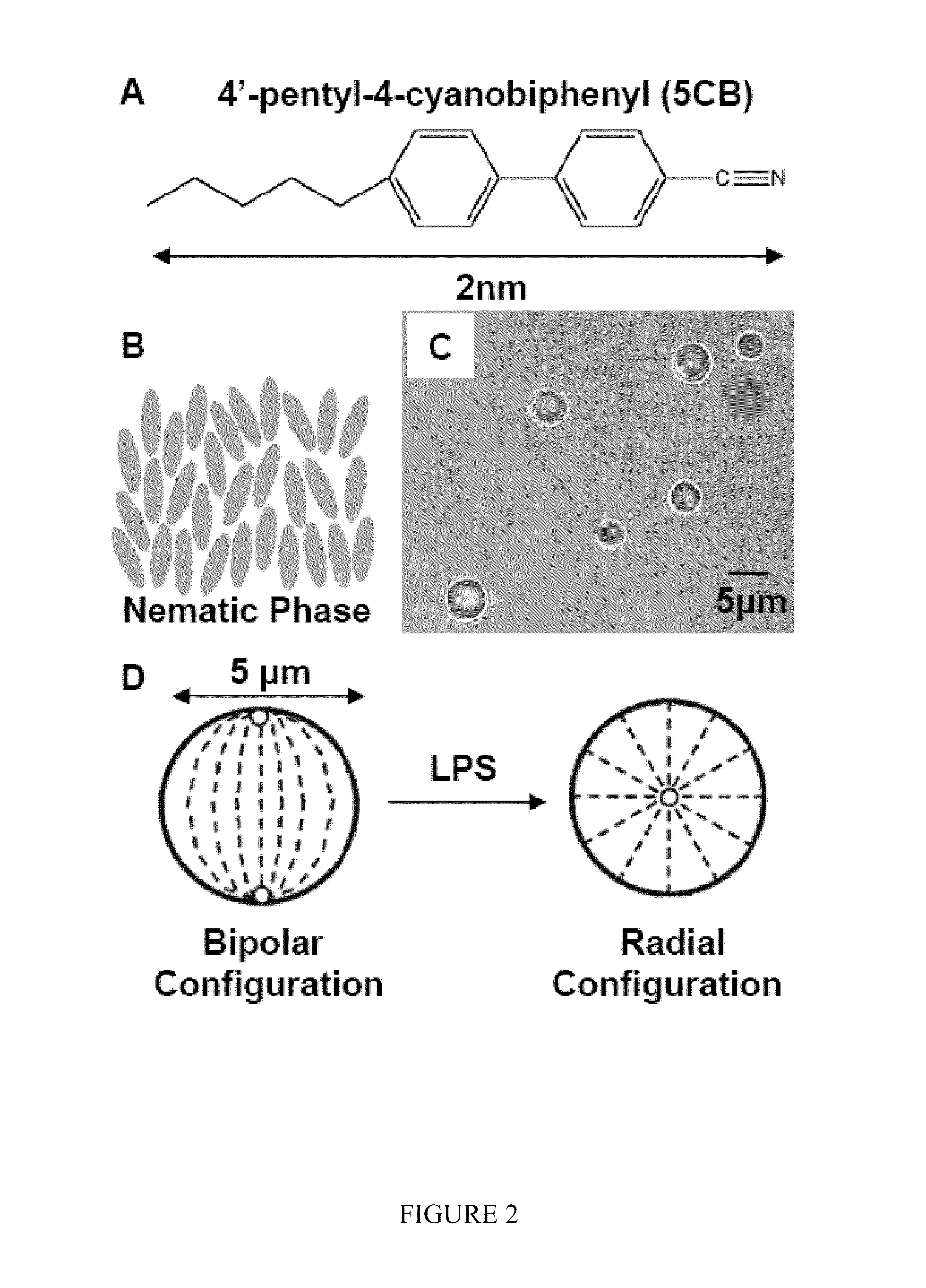

Analyte detection using liquid crystals

ActiveUS20110007261A1Easy to fixMaterial analysis by observing effect on chemical indicatorPolarisation-affecting propertiesAnalyteTest sample

Devices and methods for using changes in the defects in micrometer sized dispersed liquid crystal domains to detect or quantify analytes in a test sample, including endotoxin lipopolysaccharide (LPS), are disclosed. The dispersed liquid crystal microdomains are exposed to the test sample, and any changes in the number of defects in the liquid crystal microdomains are detected by detecting changes in the anchoring configuration of the microdomains. Such changes in anchoring configuration indicate the presence of analyte in the test sample.

Owner:WISCONSIN ALUMNI RES FOUND

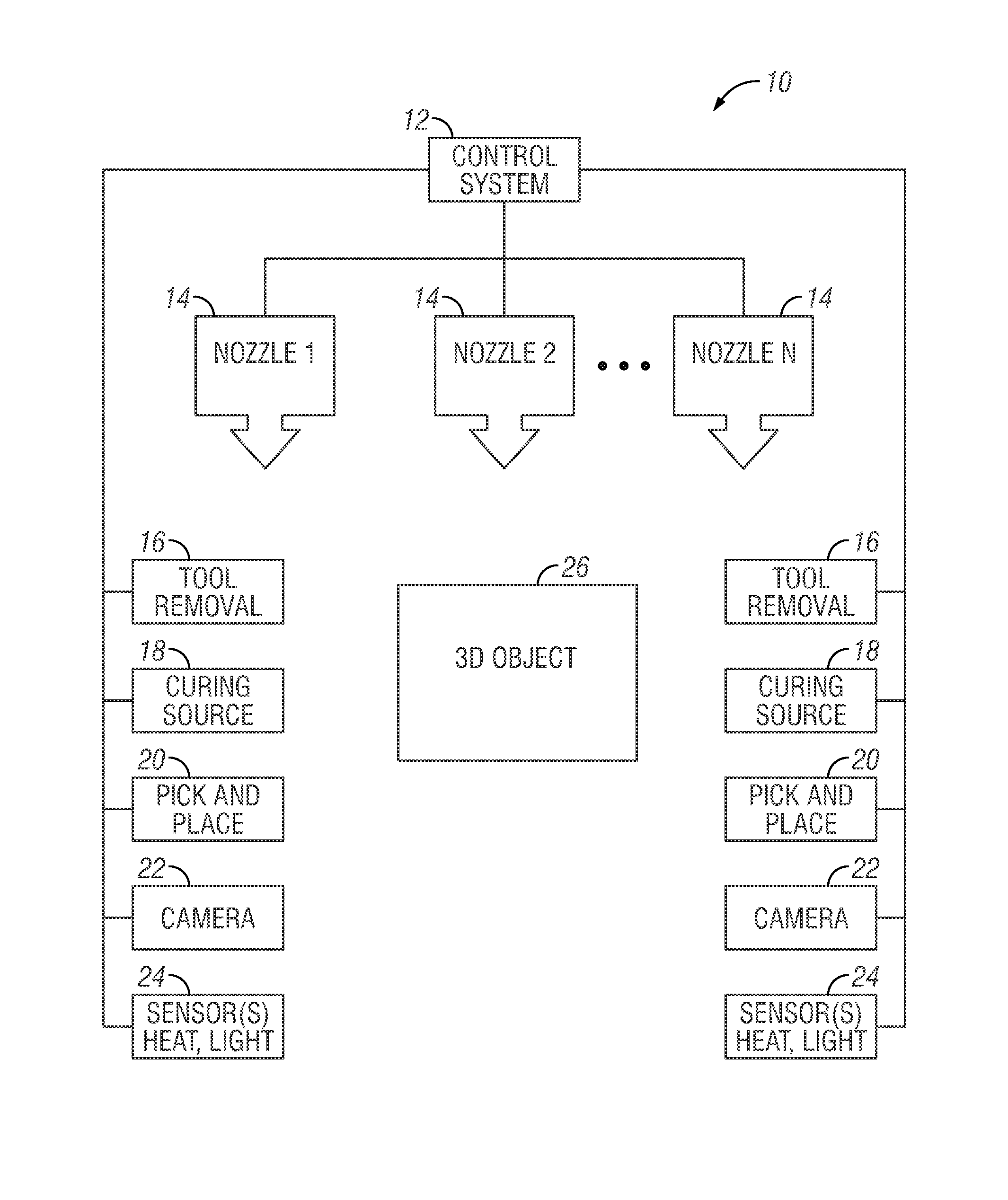

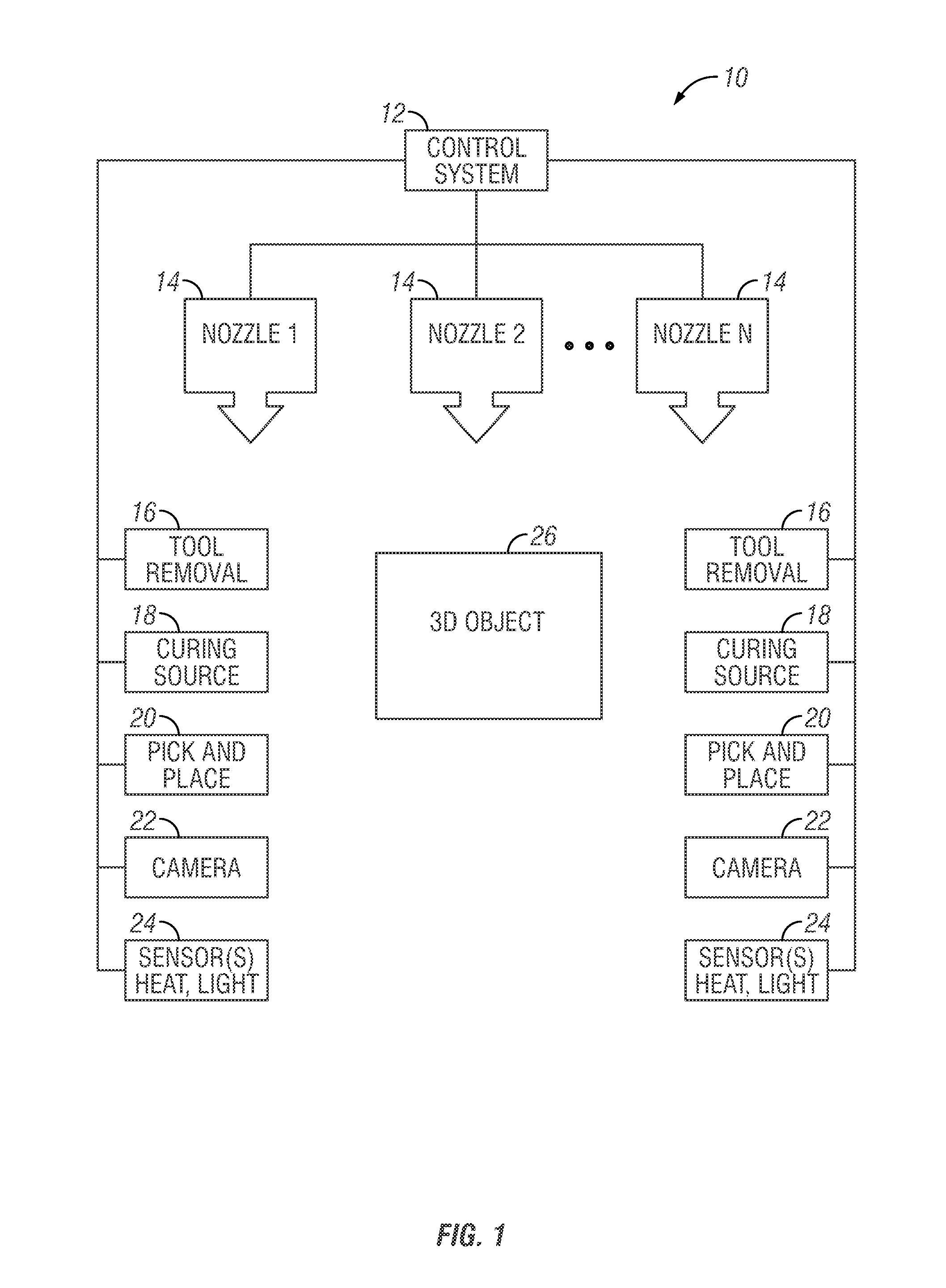

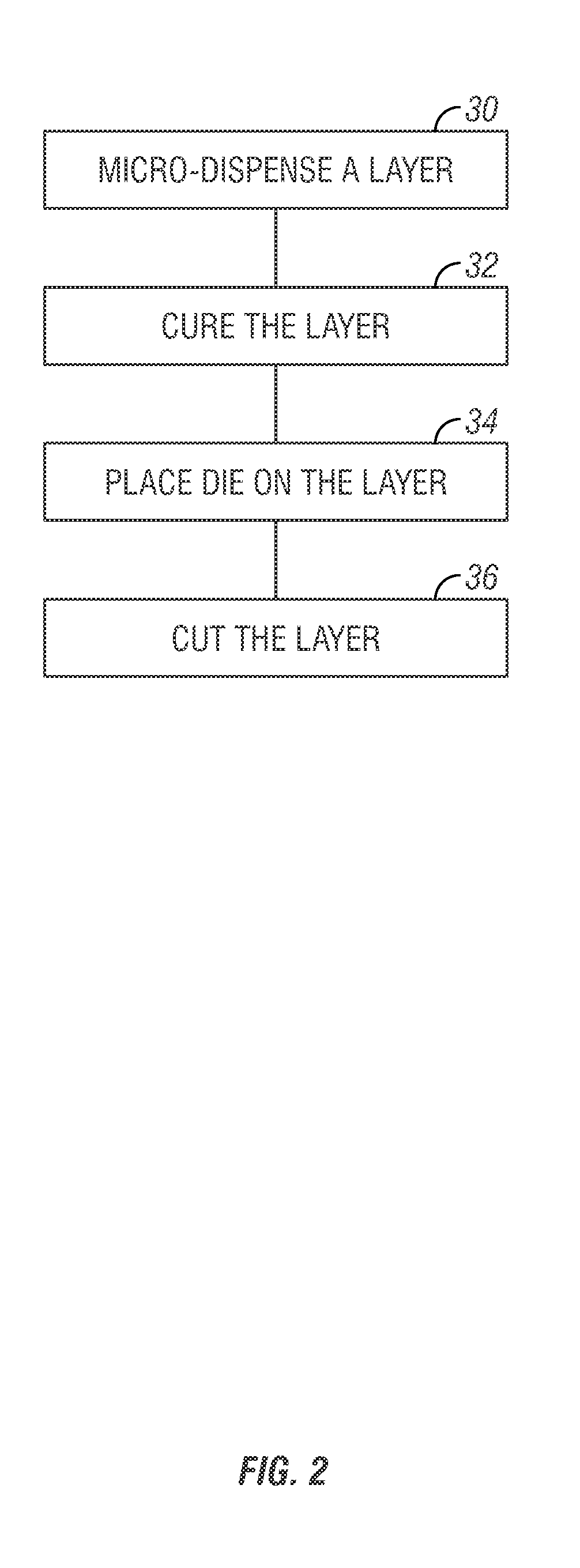

Micro-dispensing multi-layered 3D objects with curing steps

ActiveUS20130193619A1Good conditionHigher viscous materialConfectioneryWood working apparatusNanometreMultiple layer

A method of building a three dimensional (3D) structure includes micro-dispensing a layer comprising a material using a syringe-based micro-dispensing tool, curing the layer, and repeating the steps of micro-dispensing and curing a plurality of times in order to build the three-dimensional structure. The material may be loaded with nano to micron sized particles, tubes, or strings.

Owner:SCIPERIO

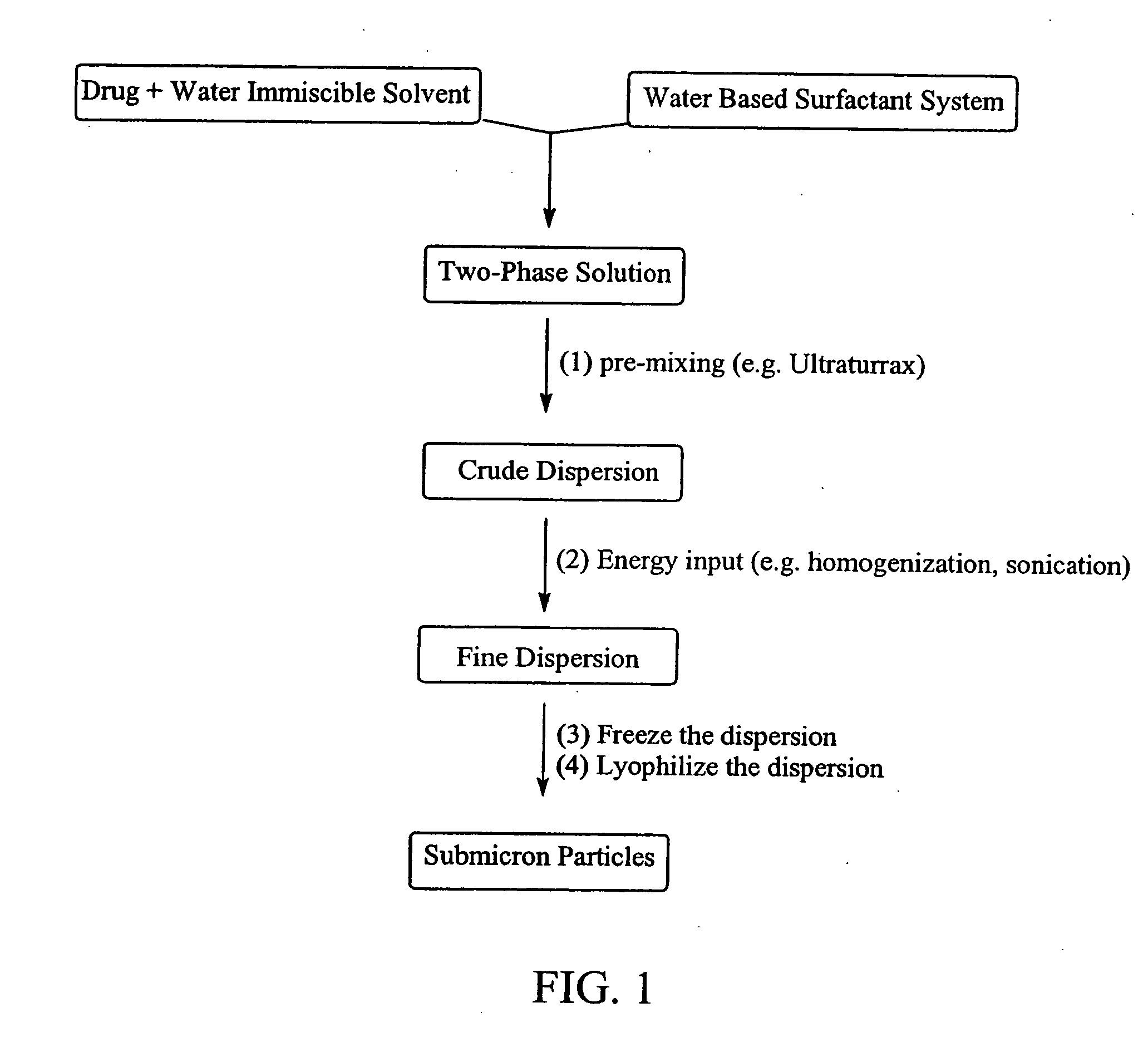

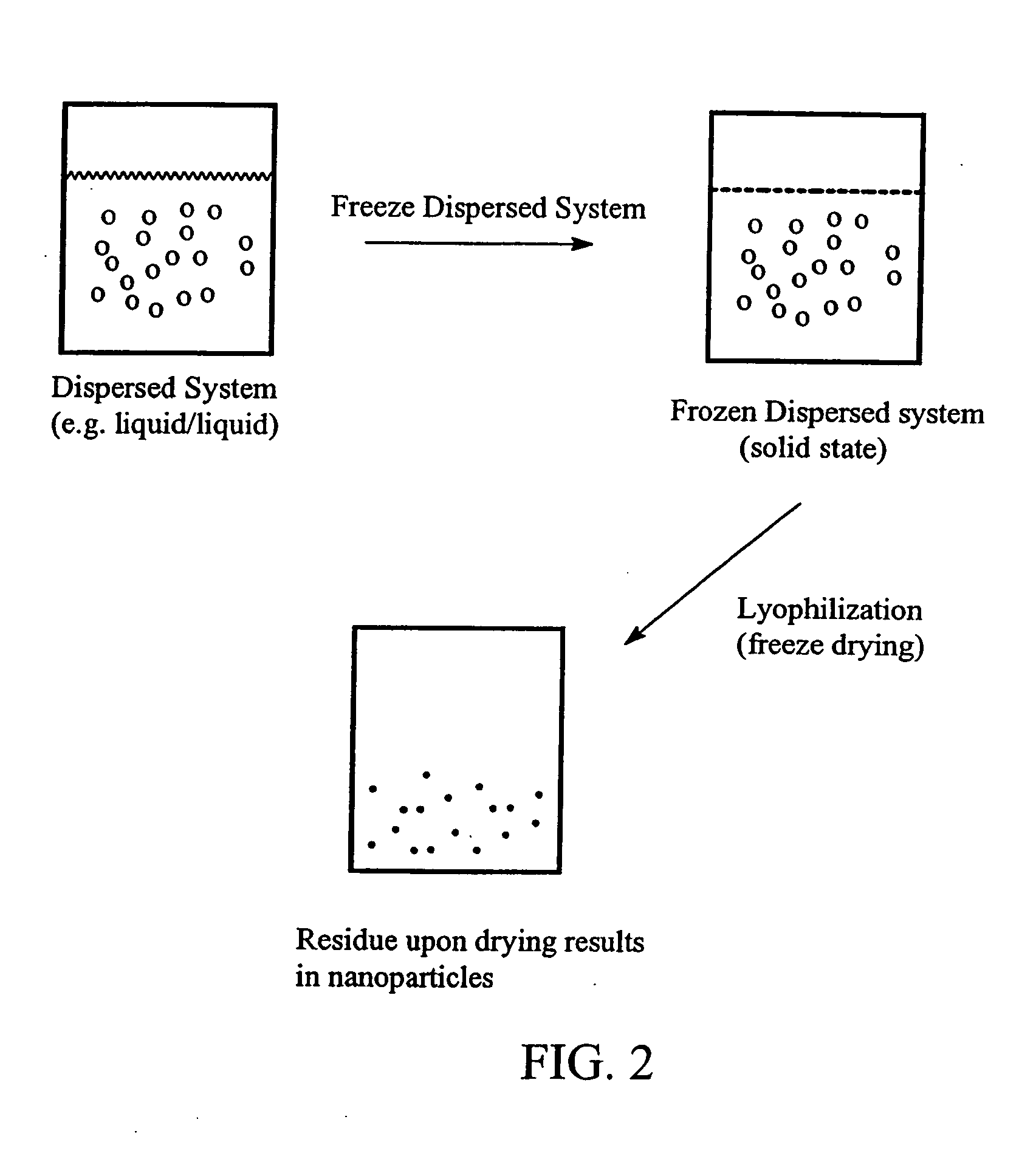

Preparation of submicron sized nanoparticles via dispersion lyophilization

InactiveUS20050013868A1Powder deliveryOrganic active ingredientsSimple Organic CompoundsNanoparticle

The present invention relates to a process for preparing submicron sized nanoparticles of a poorly water soluble compound by lyophilizing a dispersion or microdispersion of a multiphase system having an organic phase and an aqueous phase, the organic phase having the poorly water soluble organic compound therein. The method is preferably used to prepare nanoparticles of a poorly water soluble, pharmaceutically active compound suitable for in vivo delivery, particularly by parenteral routes.

Owner:BAXTER INT INC

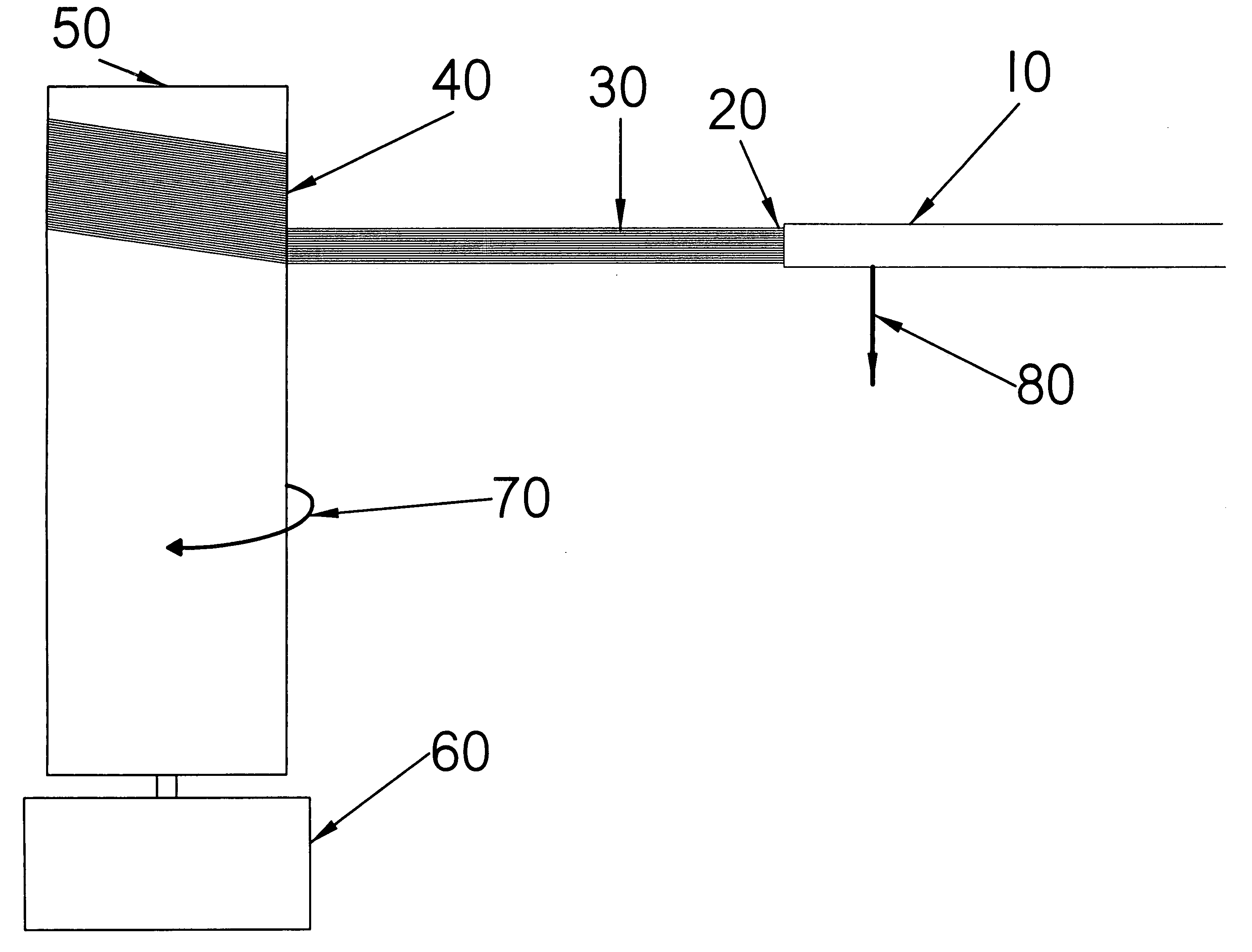

Method of synthesis and delivery of complex pharmaceuticals, chemical substances and polymers through the process of electrospraying, electrospinning or extrusion utilizing holey fibers

A method of synthesizing complex, multi-part pharmaceuticals, chemical substances and engineered polymers through the process of electrospraying, electrospinning or extrusion utilizing tiny glass fiber known as “Holey” Fibers. The “holey” fibers have a unique property associated with them as they contain various combinations of micron sized holes running the length of the glass fiber. The holes can be made homogenous, i.e. all the same diameter, or of varying dimensions in concentric rings, enabling several chemicals to be combined together at synthesis. The advantage of using a glass holey fiber is that it is made from a chemically inert glass, that will not affect to chemicals involved with the exception of certain fluorine substances.

Owner:DZIEKAN MICHAEL E +2

Negative poisson's ratio material and its preparing method and use

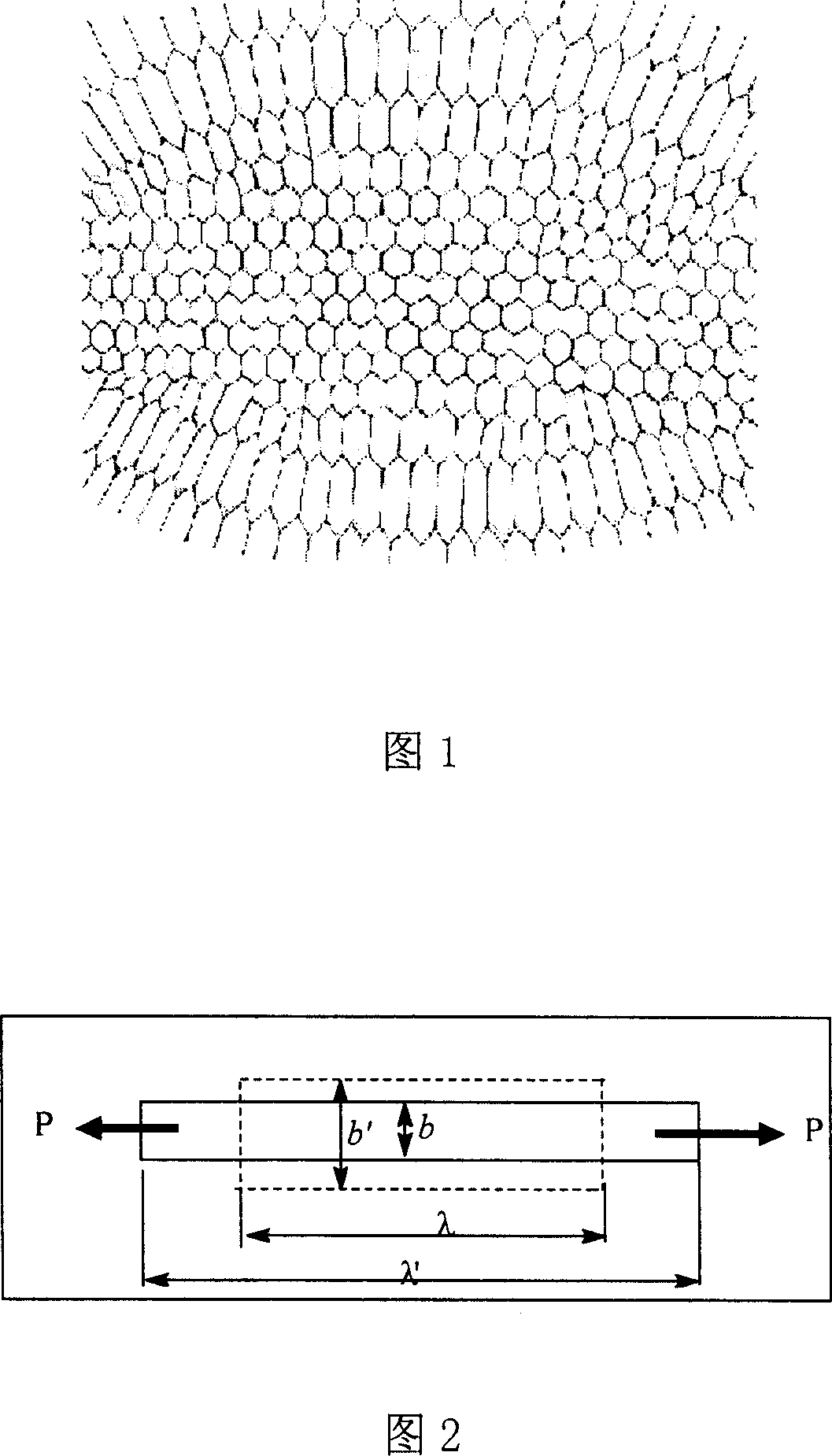

InactiveCN1986621AImprove stress resistanceImprove impact absorption performanceSynthetic resin layered productsHoneycomb likeHoneycomb structure

The present invention relates to composite polymer material, and is especially stretching material with negative Poisson's ratio and its preparation process and use. The foamed material obtained through secondary foaming process or screw extrusion foaming process has microscopic double fan-shaped composite structure with middle layer of regular honeycomb structure, outer layer of ordered gradually lengthened arrangement and micropores of 80-150 micron size. The foamed material has the mechanical performance of perpendicularly expanding while being stretched and perpendicularly contracting while being extruded. By means of special preparation process, the foamed material may have raised compression resistance, shock absorption, rebound elasticity and other mechanical performance. The unique mechanical performance makes the material possess application in composite board, waste water treatment, deep water job and other fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

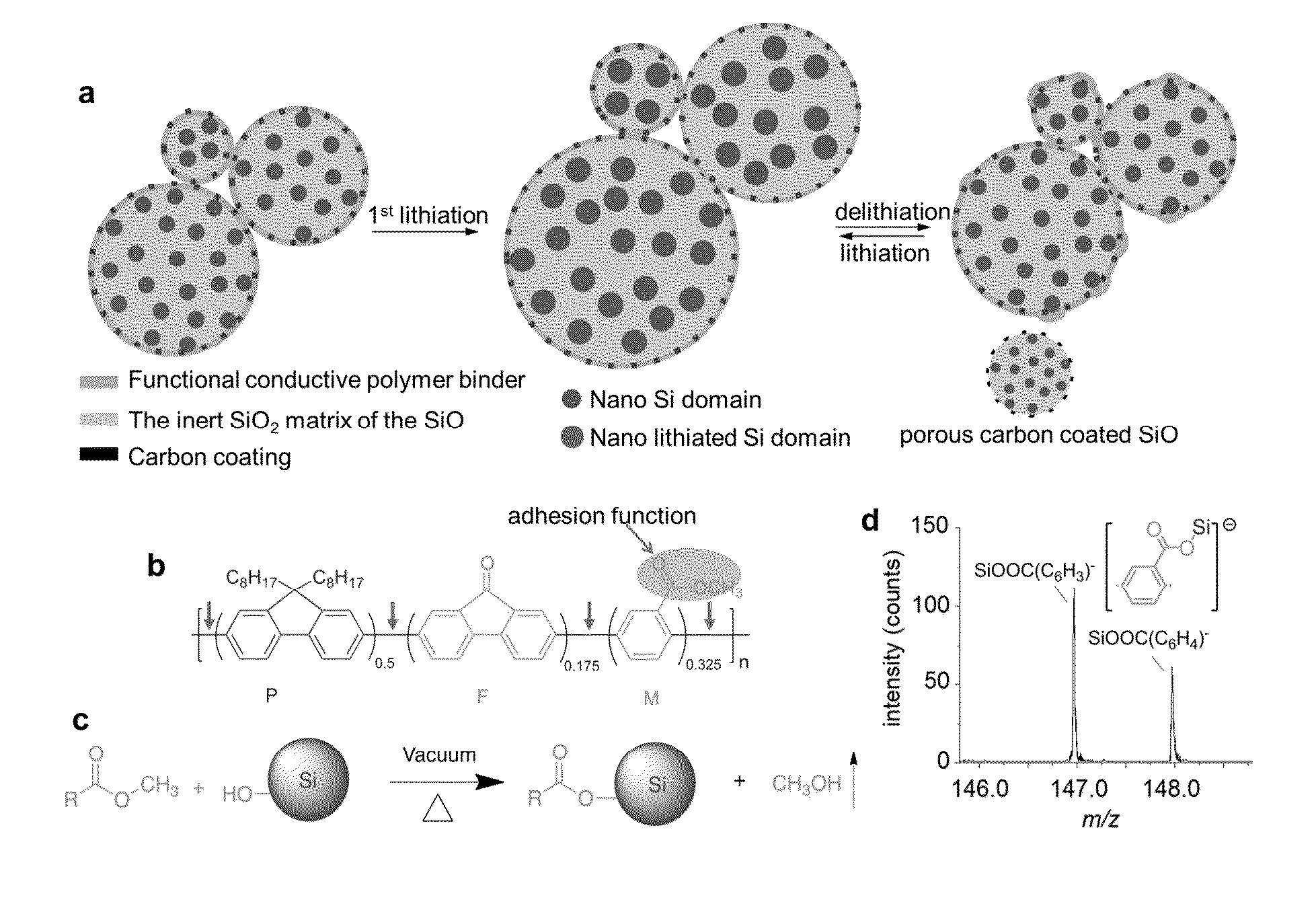

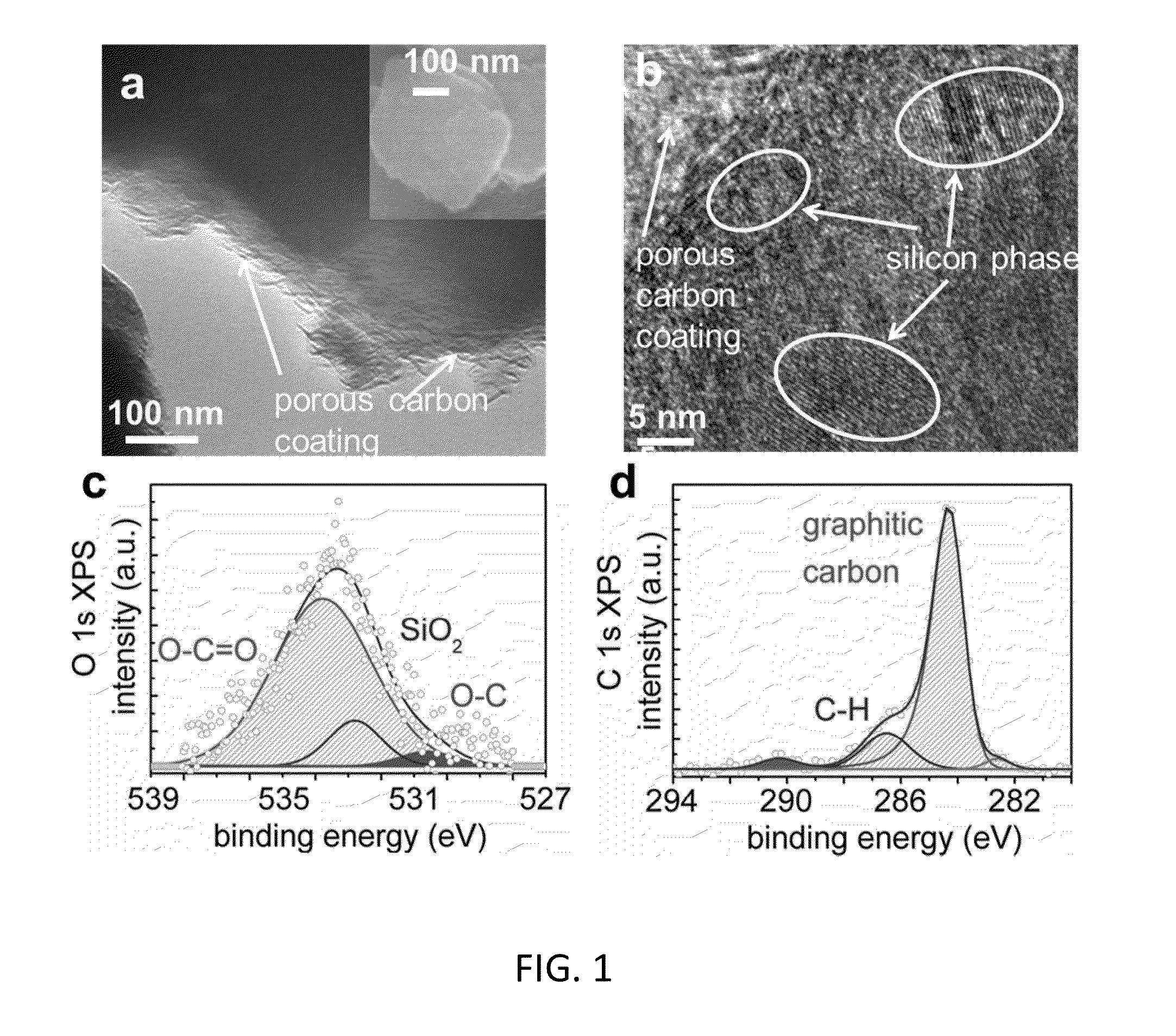

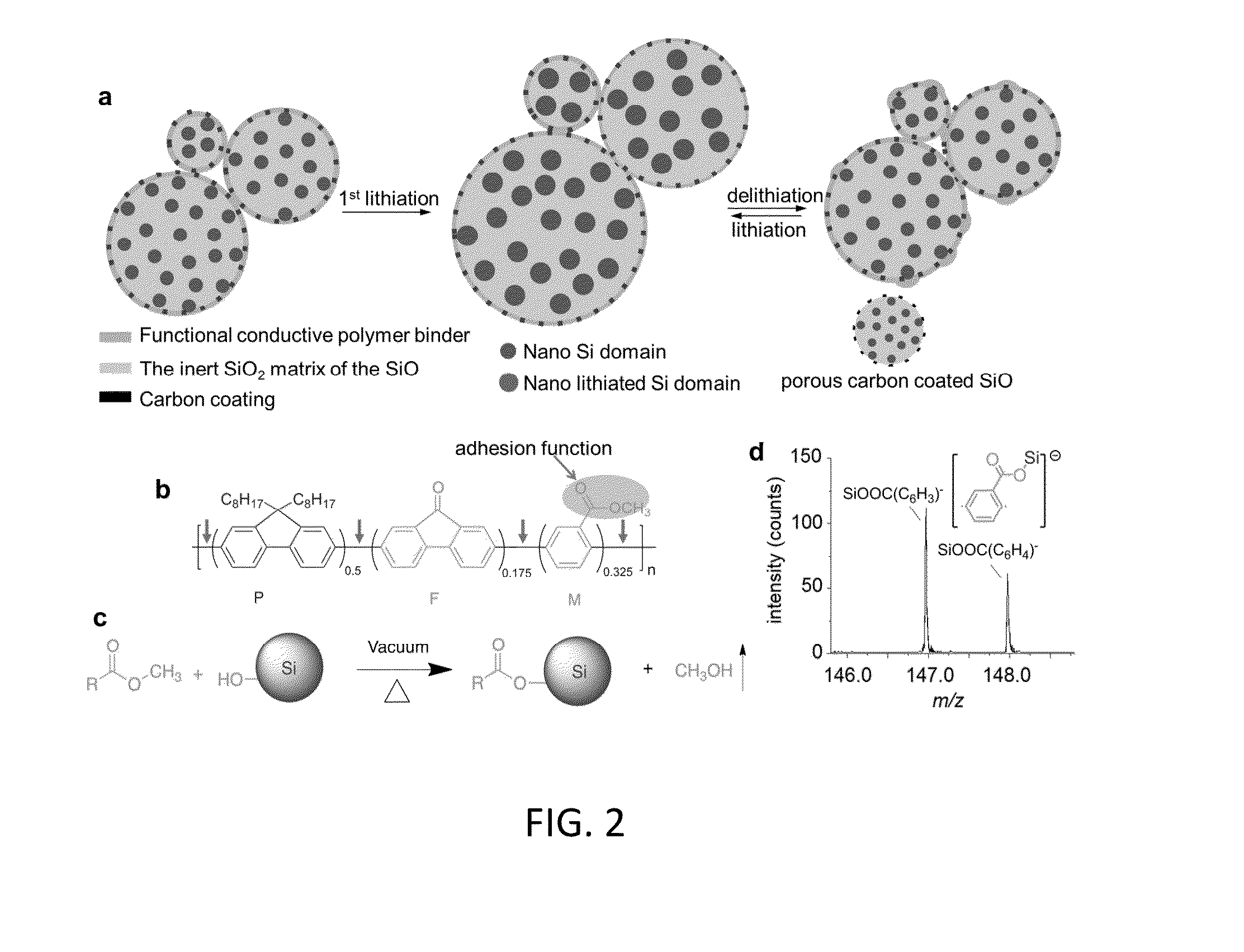

Silicon Oxide (SiO) Anode Enabled by a Conductive Polymer Binder and Performance Enhancement by Stabilized Lithium Metal Power (SLMP)

InactiveUS20150364755A1Electrode carriers/collectorsConductive materialPerformance enhancementSilicon monoxide

Silicon alloys have the highest specific capacity when used as anode material for lithium-ion batteries, however, the drastic volume change inherent in their use causes formidable challenges toward achieving stable cycling performance. Large quantities of binders and conductive additives are typically necessary to maintain good cell performance. In one embodiment of the invention, only 2% (by weight) functional conductive polymer binder without any conductive additives was successfully used with a micron-size silicon monoxide (SiO) anode material, demonstrating stable and high gravimetric capacity (>1000 mAh / g) for ˜500 cycles and more than 90% capacity retention. Prelithiation of this anode using stabilized lithium metal powder (SLMP®) improves the first cycle Coulombic efficiency of a SiO / NMC full cell from ˜48% to ˜90%. This combination enables good capacity retention of more than 80% after 100 cycles at C / 3 in a lithium-ion full cell.

Owner:RGT UNIV OF CALIFORNIA

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

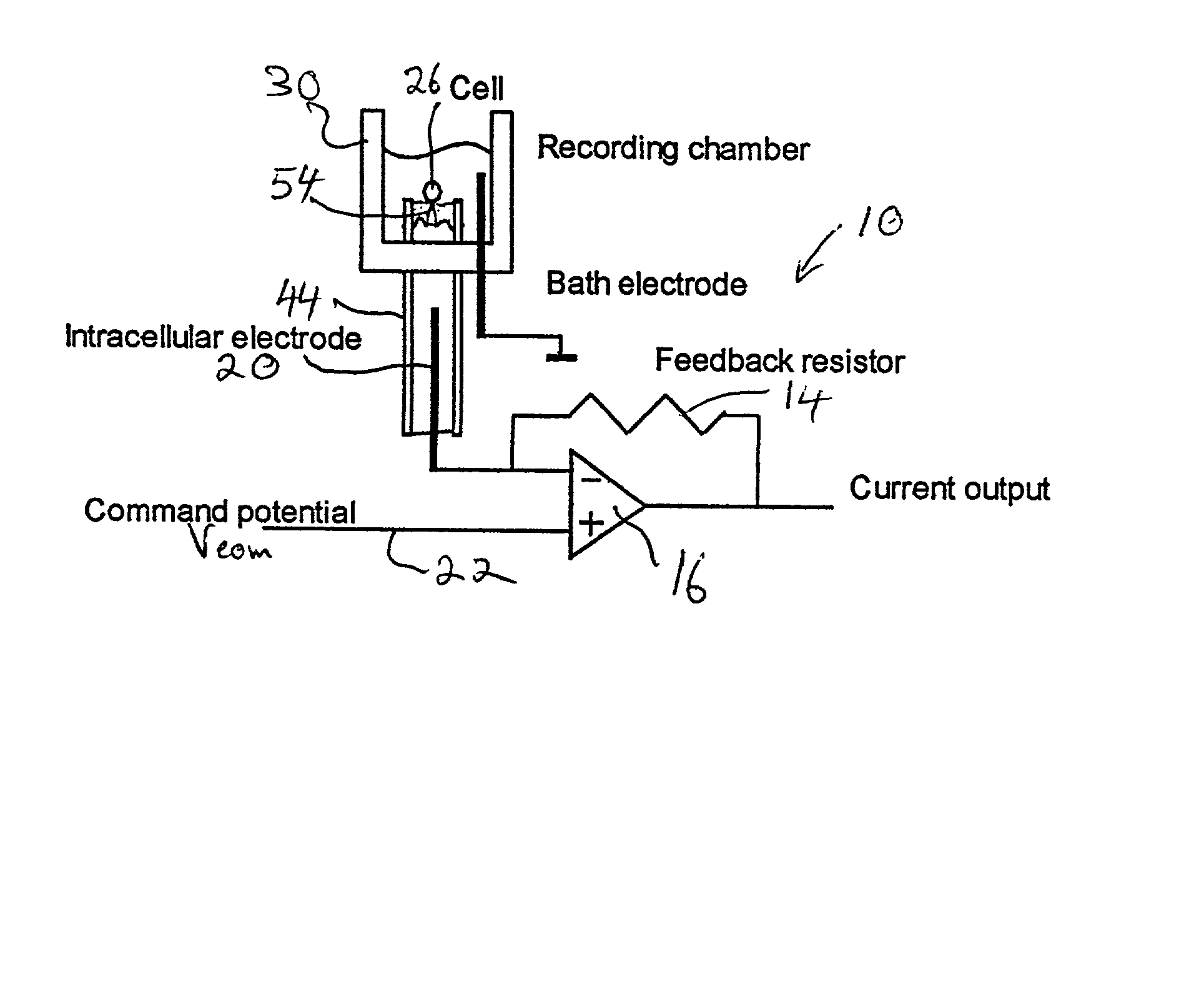

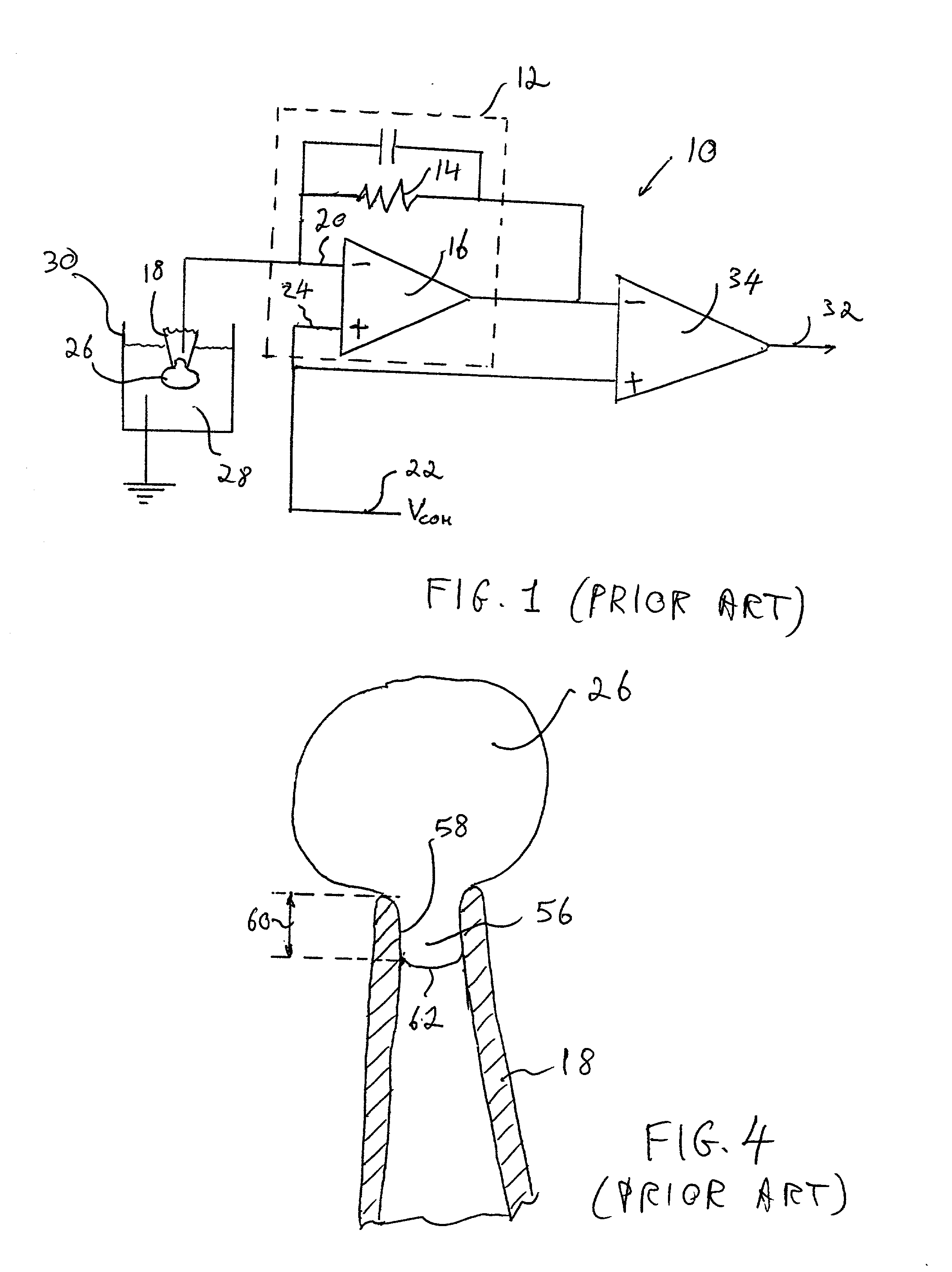

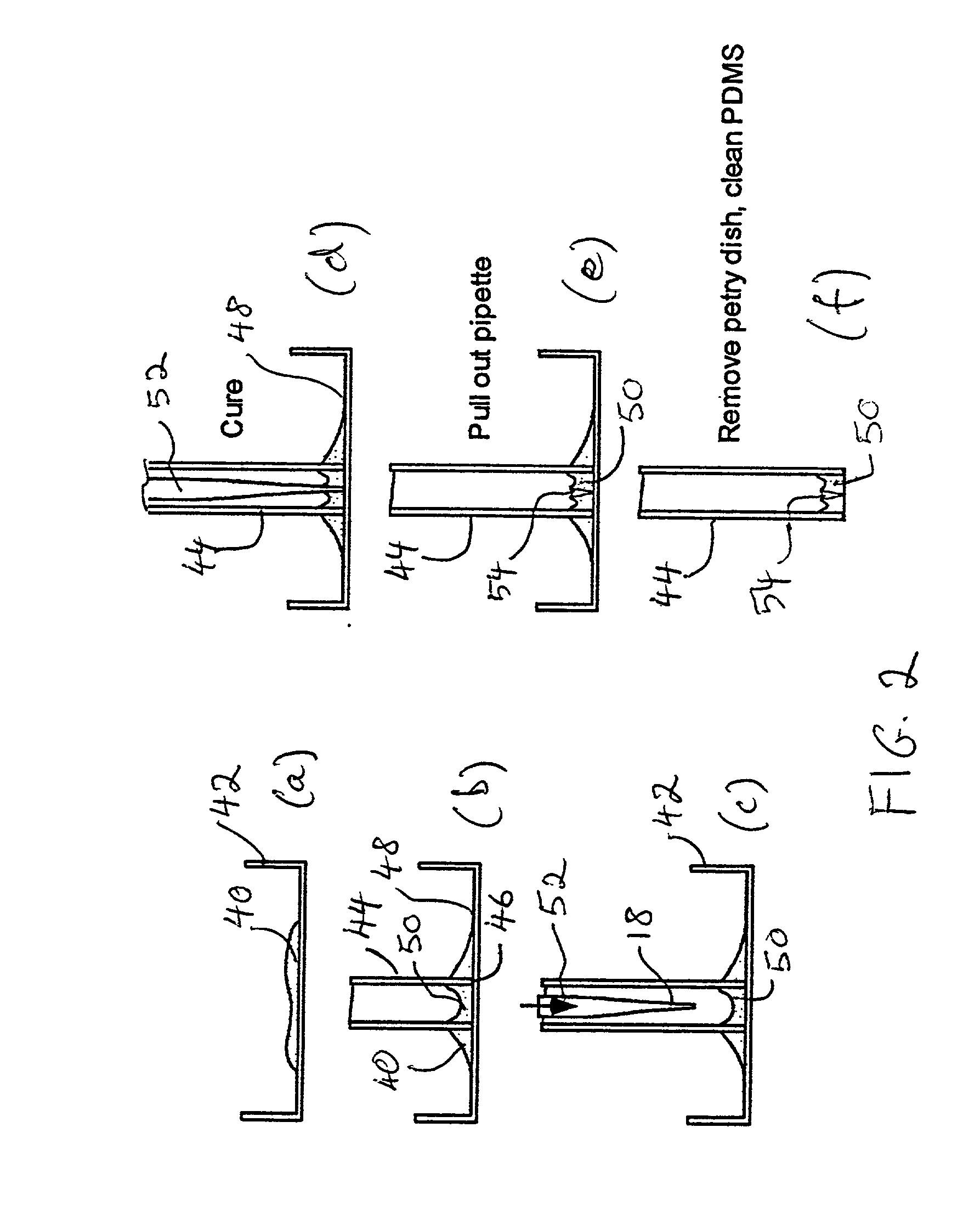

Polymeric electrode for electrophysiological testing

InactiveUS20020195337A1Reduce manual operationsSuitable for useImmobilised enzymesBioreactor/fermenter combinationsBiological membraneBiomedical engineering

A polymeric material such as PDMS is molded into an electrode structure containing a micron-size aperture for receiving and forming a giga-ohm seal with a biological membrane One end of a tube is filled with uncured polymeric material and pressed against a support surface to prevent drainage. A conventional micropipette having a size suitable for sliding through the tube is introduced, tip first, into the tube and is allowed to fall through the polymeric material and rest against the support surface. The assembly is heated to cure the polymer and the micropipette is removed from the tube, thereby leaving a polymeric plug at the end of the tube with an aperture suitable in shape and size for patch-clamp giga-ohm seal electrode applications. A multi-well tray with a polymeric electrode plug in each well is constructed using the same approach.

Owner:MOLECULAR DEVICES

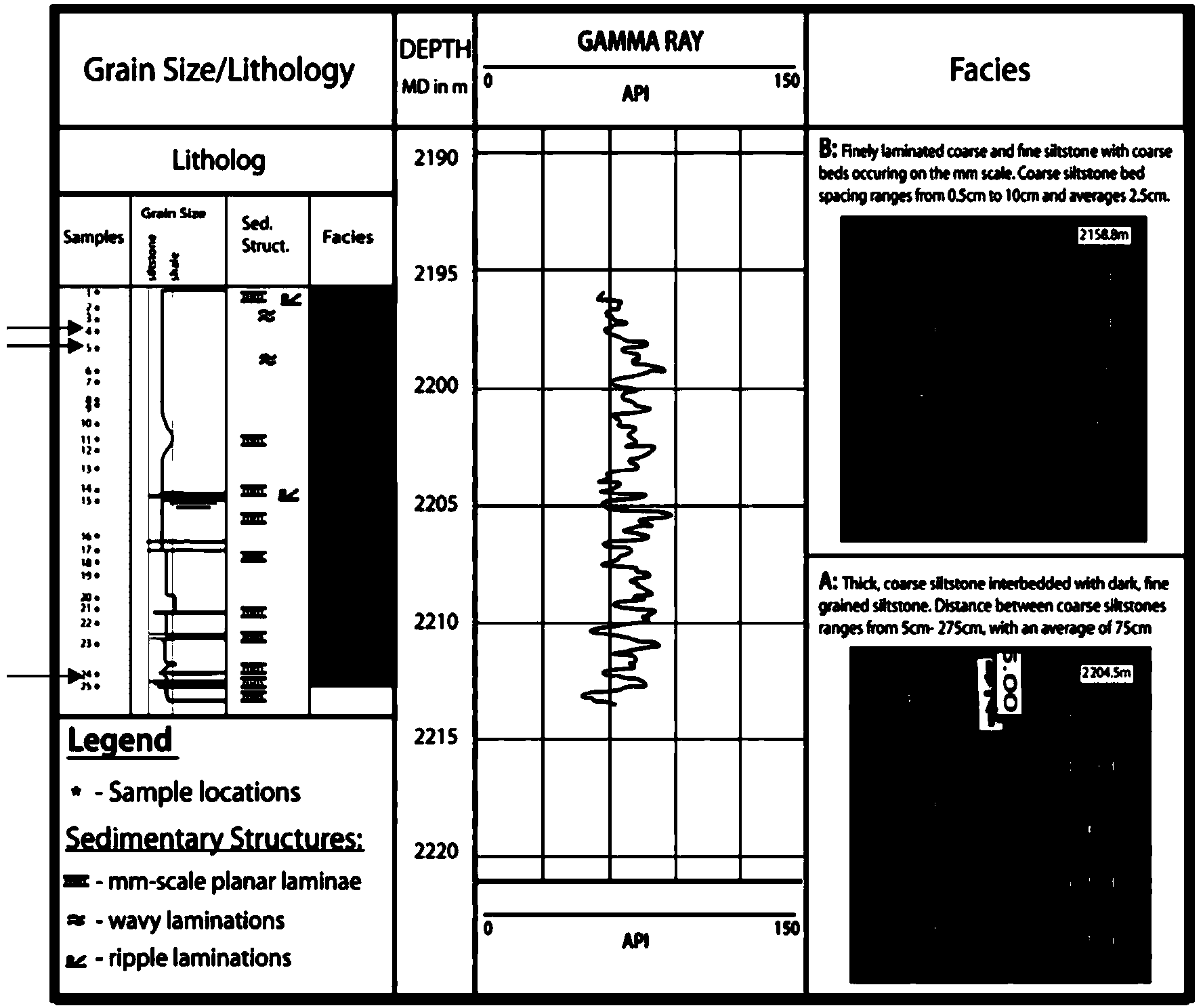

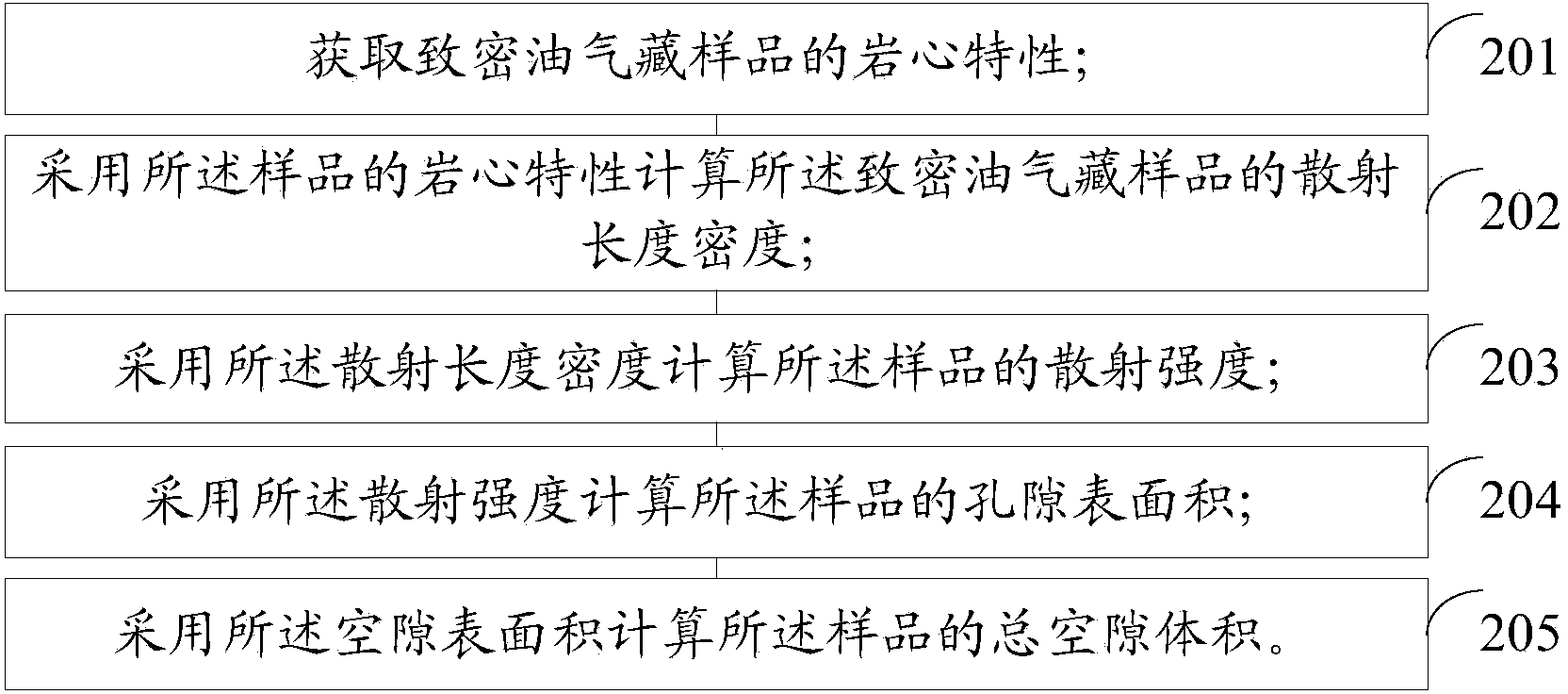

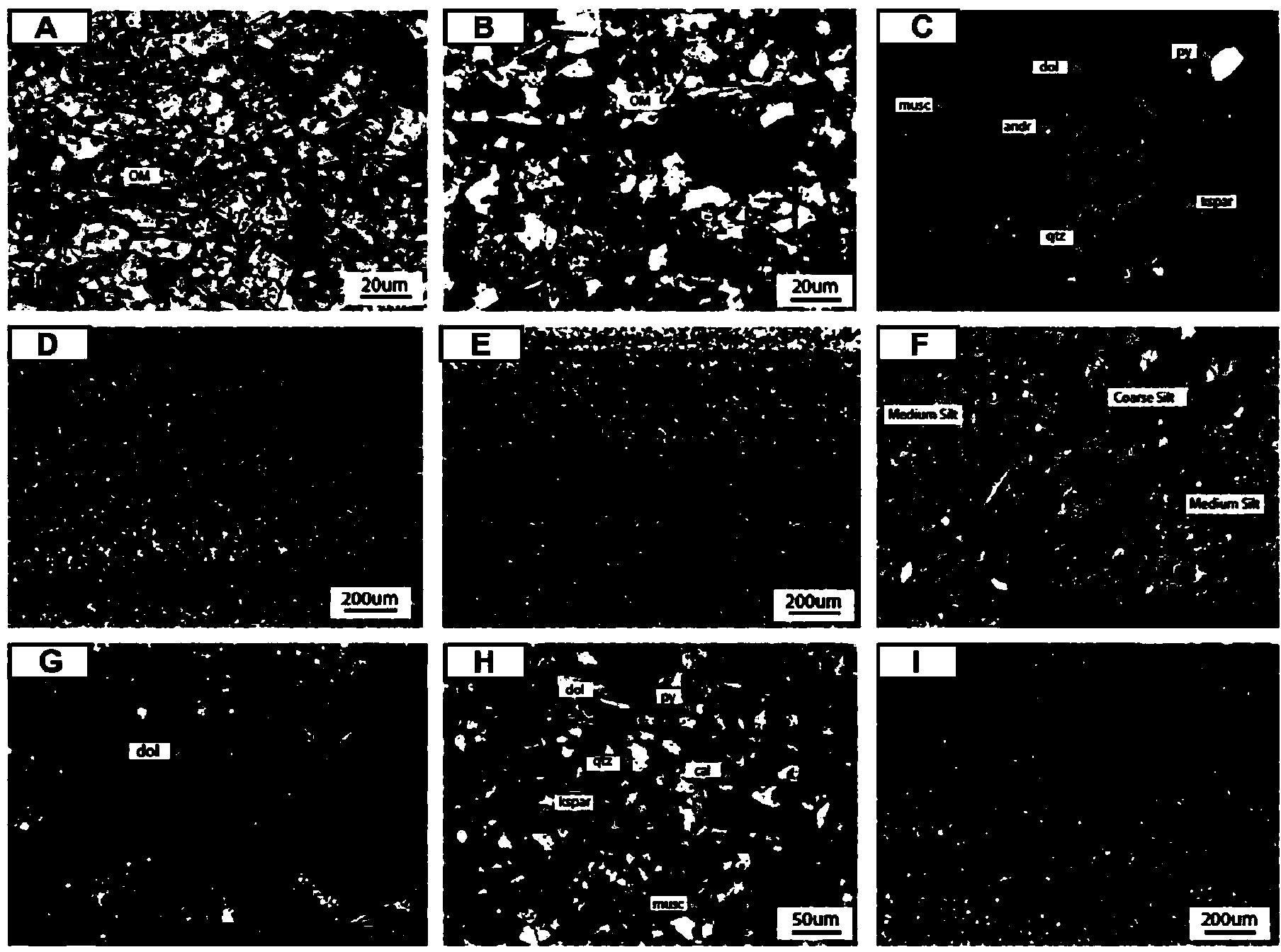

Measuring method and system for reservoir pore structure of compact oil and gas reservoir

InactiveCN103528933ALess microporous contentImprove measurement accuracyPermeability/surface area analysisUltimate tensile strengthScattering length

Owner:PEKING UNIV

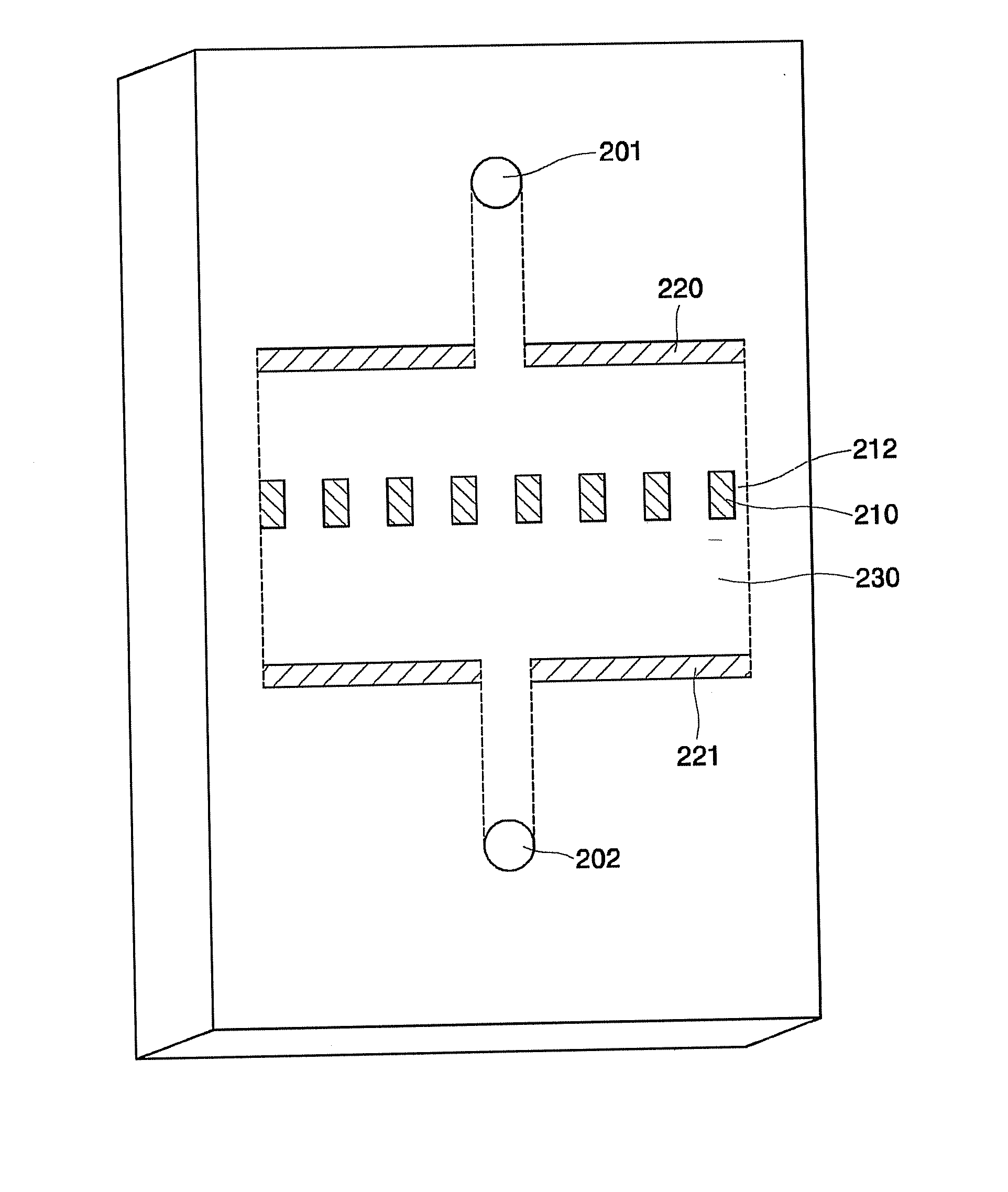

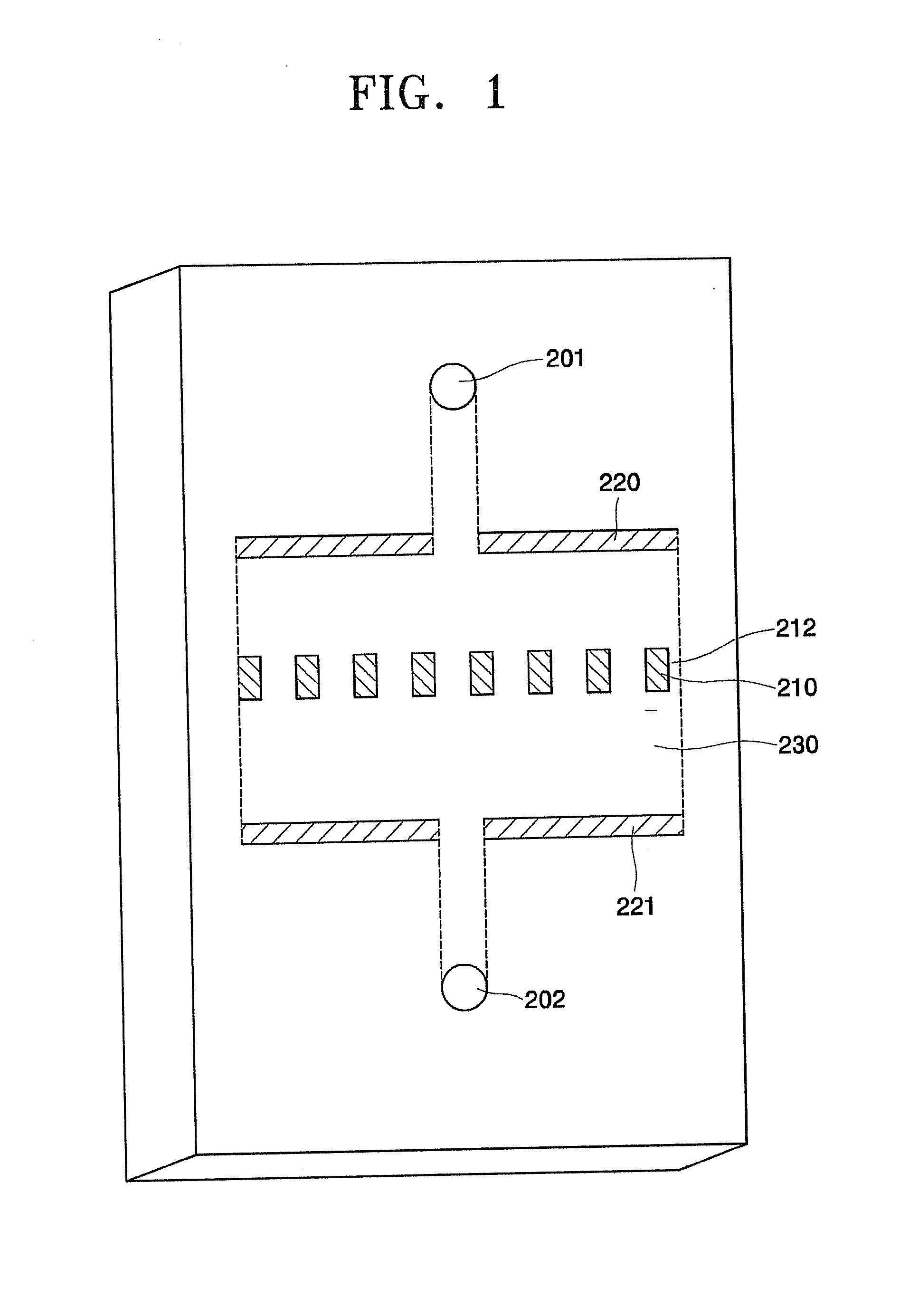

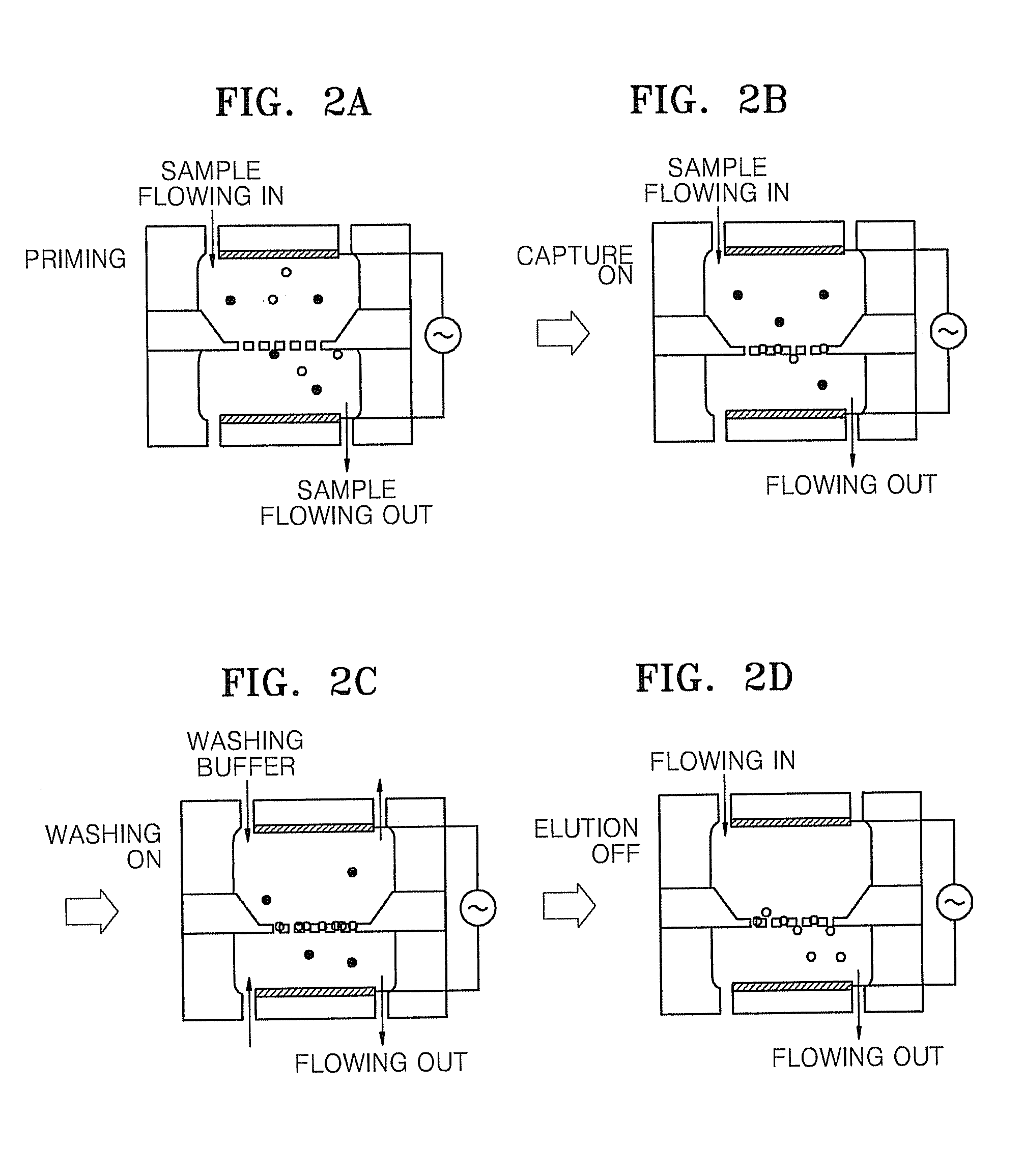

Apparatus for and method of separating polarizable analyte using dielectrophoresis

ActiveUS20070284254A1Increase generationAvoid small quantitiesDielectrophoresisElectrostatic separatorsAnalyteDielectrophoresis

An apparatus separating a polarizable analyte using dielectrophoresis includes a vessel including a membrane having a plurality of nano- to micro-sized pores, the membrane disposed inside the vessel, electrodes generating spatially non-uniform electric fields in the nano- to micro-sized pores of the membrane when an AC voltage is applied to the electrodes, and a power source applying the AC voltage to the electrodes, wherein a sectional area of the pores varies along a depth of the pores. A method of separating a polarizable material uses the apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

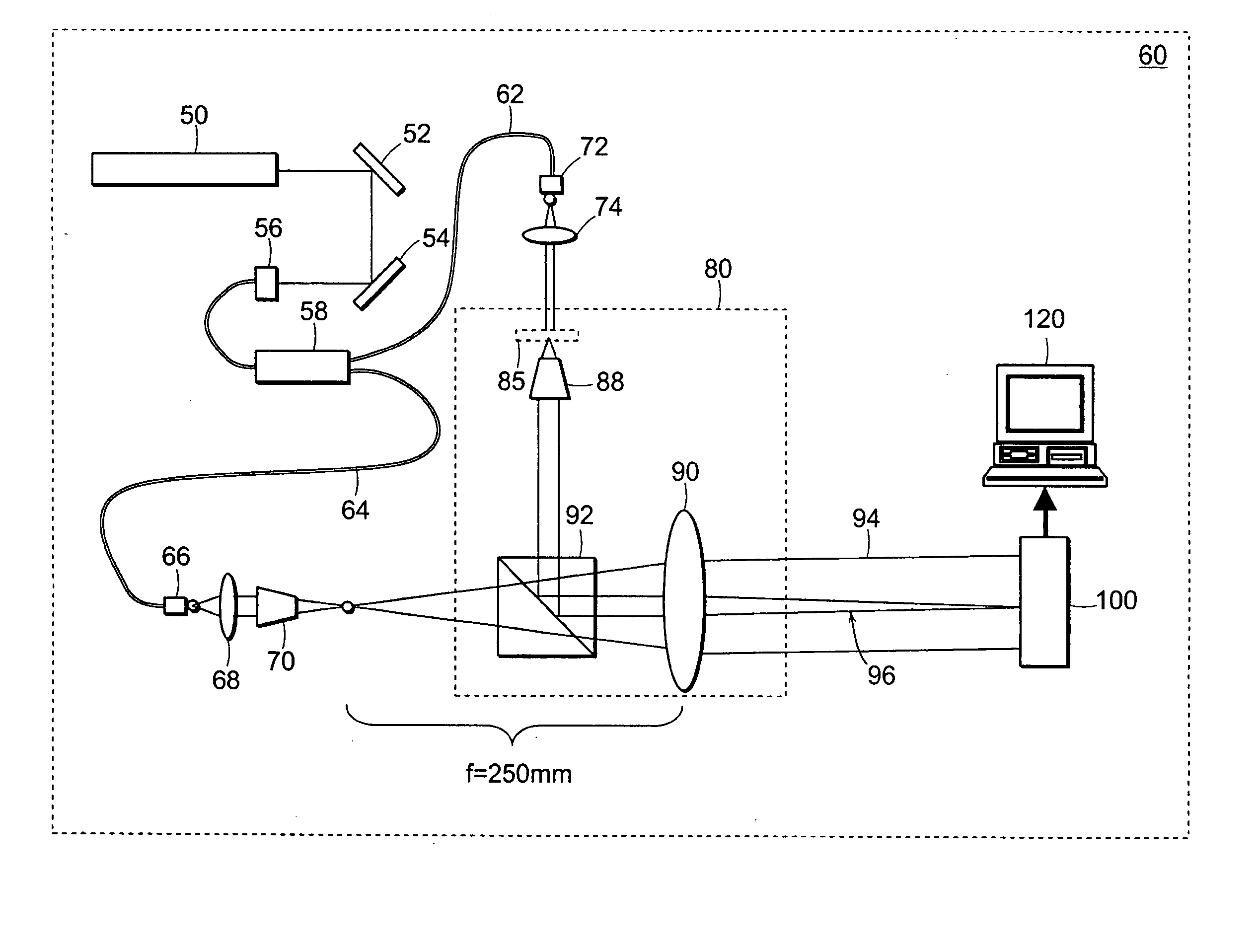

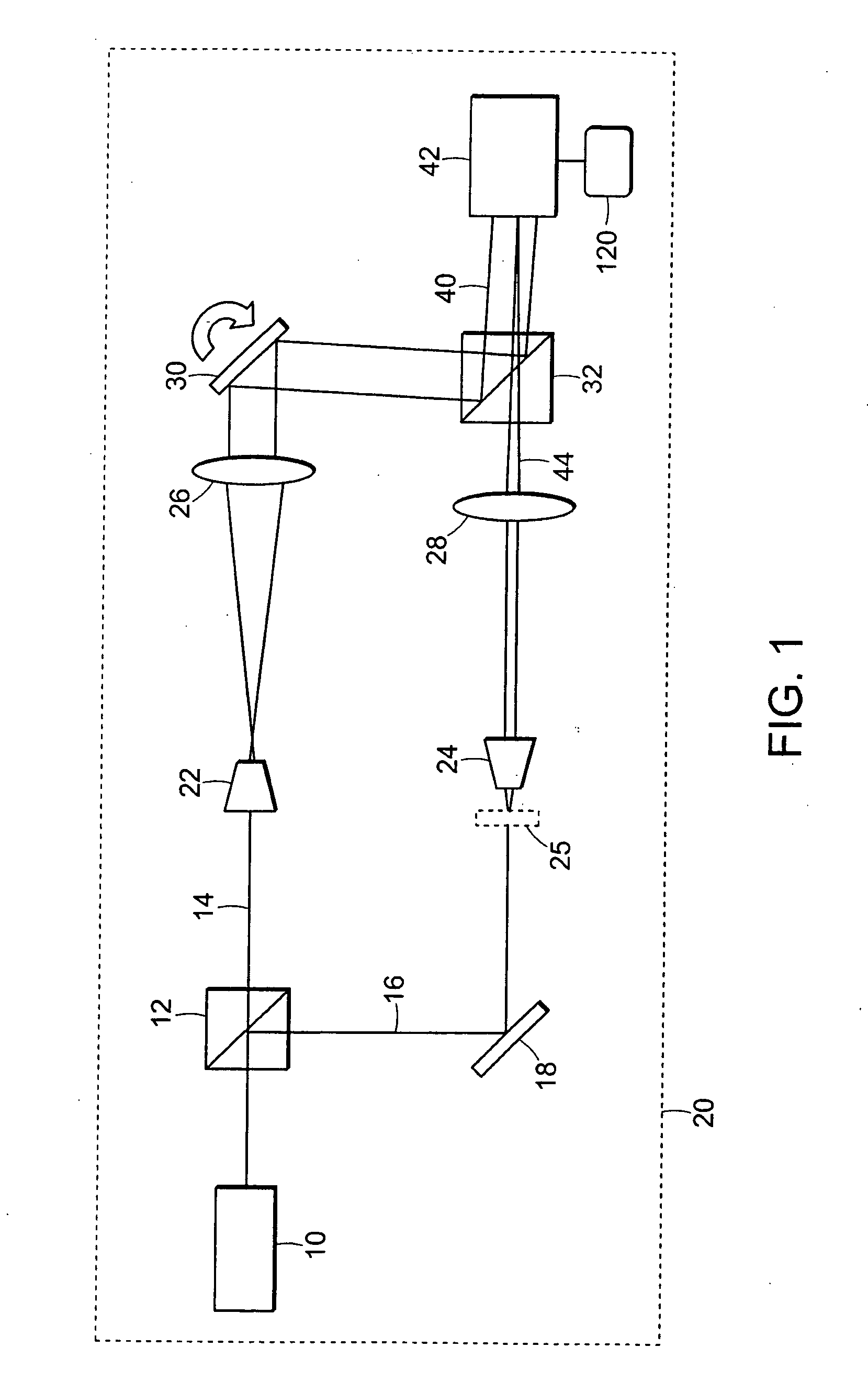

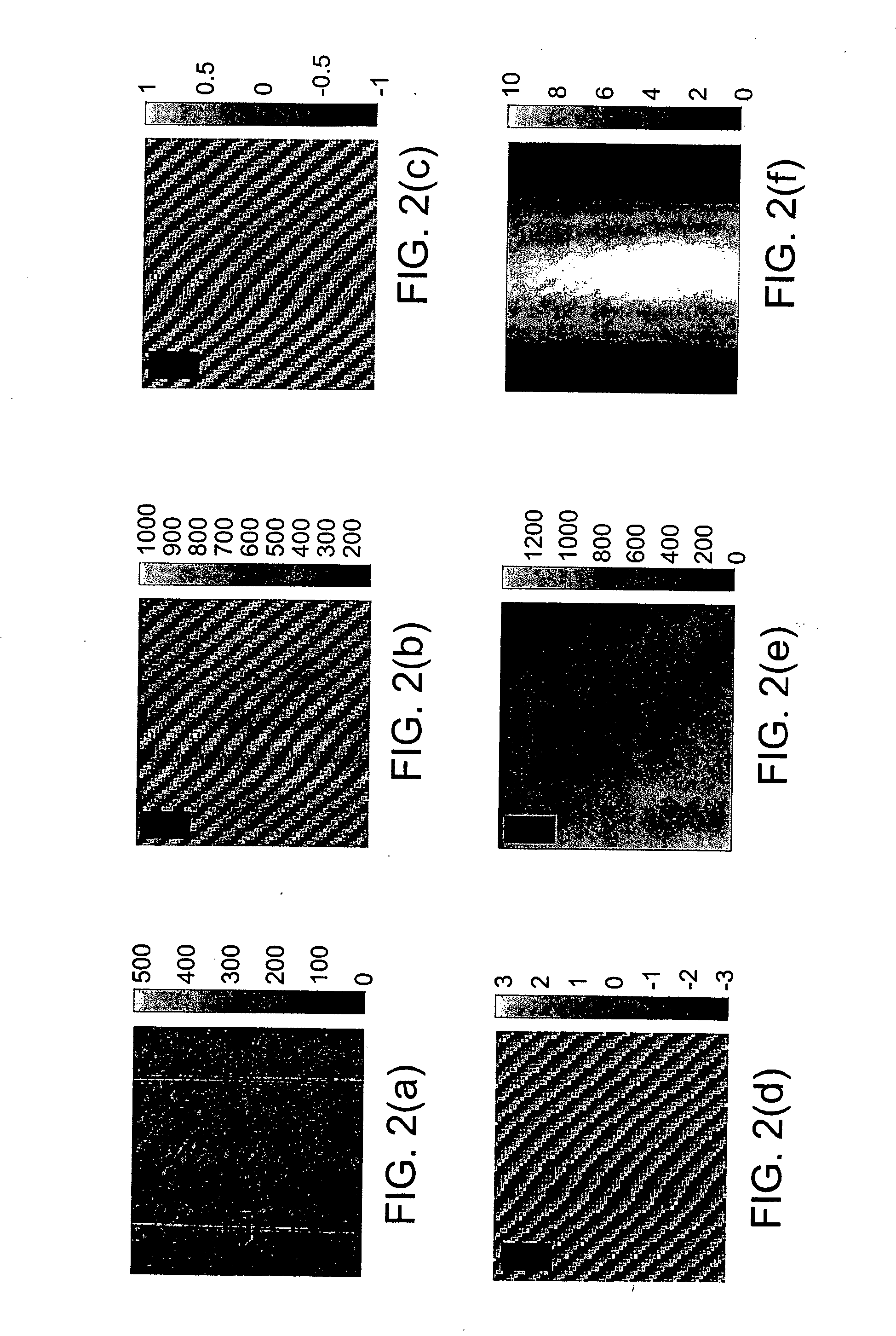

System and method for Hilbert phase imaging

ActiveUS20060291712A1Enable quantificationSolid-state devicesMaterial analysis by optical meansBiological cellImage resolution

Hilbert phase microscopy (HPM) as an optical technique for measuring high transverse resolution quantitative phase images associated with optically transparent objects. Due to its single-shot nature, HPM is suitable for investigating rapid phenomena that take place in transparent structures such as biological cells. A preferred embodiment is used for measuring biological systems including measurements on red blood cells, while its ability to quantify dynamic processes on the millisecond scale, for example, can be illustrated with measurements on evaporating micron-size water droplets.

Owner:MASSACHUSETTS INST OF TECH +1

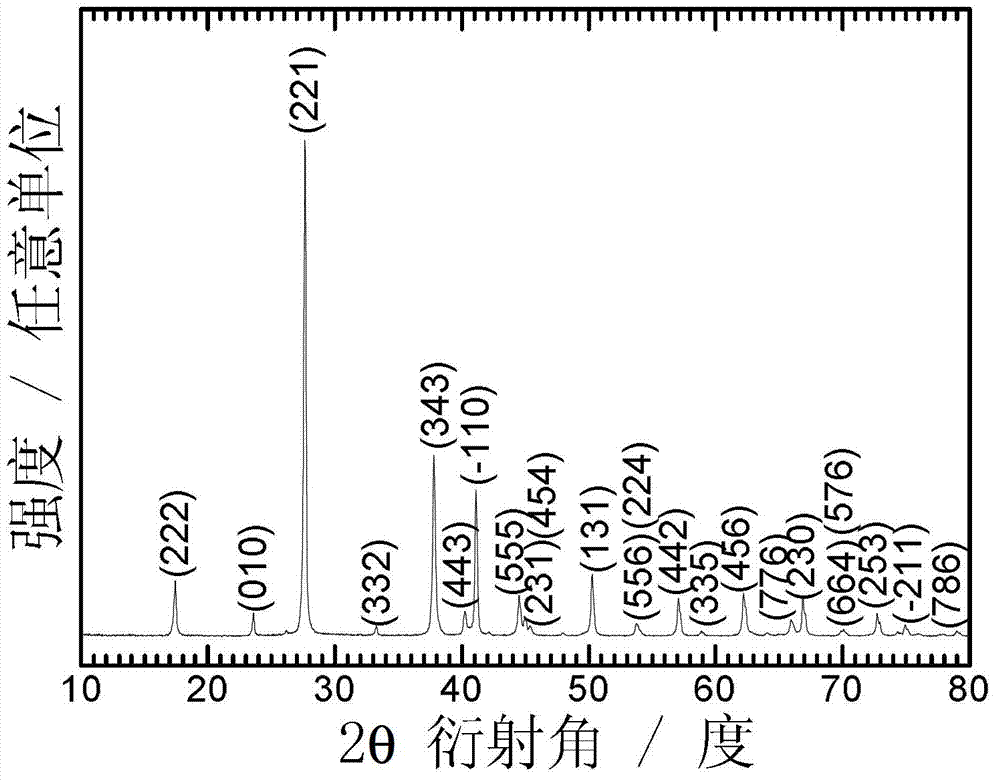

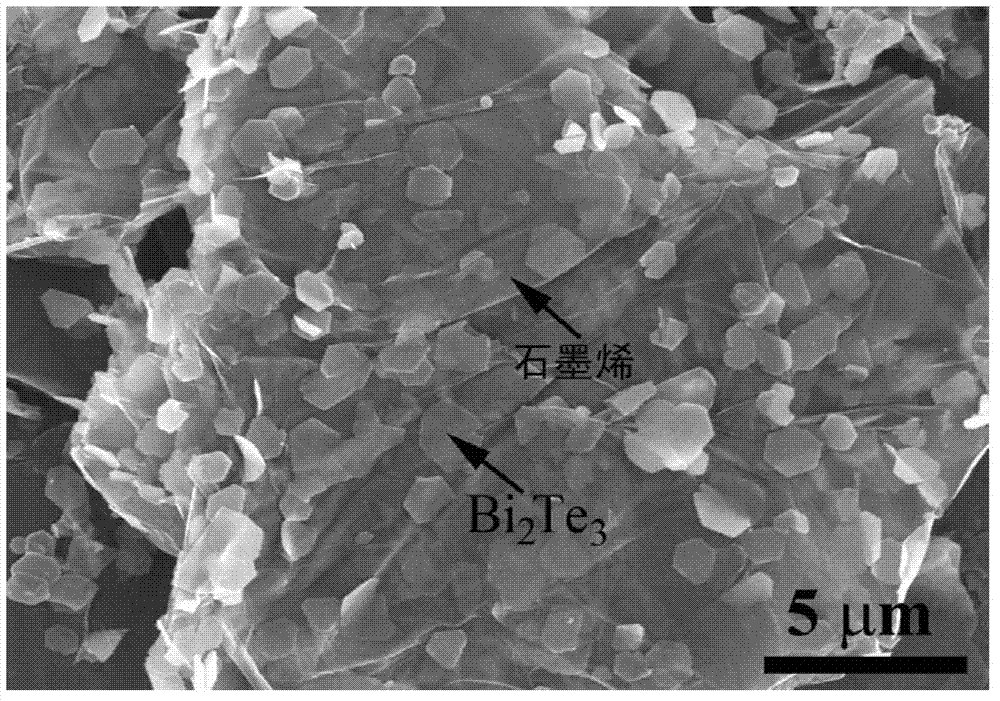

Bi2Te3 thin-piece/graphene composite material, preparation method and applications thereof

InactiveCN102760827AImprove thermoelectric performanceAvoid reunionGrapheneThermoelectric device junction materialsSolventCvd graphene

The invention discloses a Bi2Te3 thin-piece / graphene composite material. The Bi2Te3 thin-piece / graphene composite material consists of a micron-sized Bi2Te3 thin sheet and graphene. Due to the actions of dispersion, bearing and isolation of the graphene, the sintering of the micron-sized Bi2Te3 thin sheet in the heat-treatment process can be effectively prevented for maintaining effective scattering of the crystal boundary to phonons, and the great significance for improving the thermoelectric properties of the Bi2Te3 material is embodied. The composite material can be used as a thermoelectric material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal method or a one-step solvothermal method, and has the advantages of simple process, low cost, short period and low energy consumption and the like.

Owner:ZHEJIANG UNIV

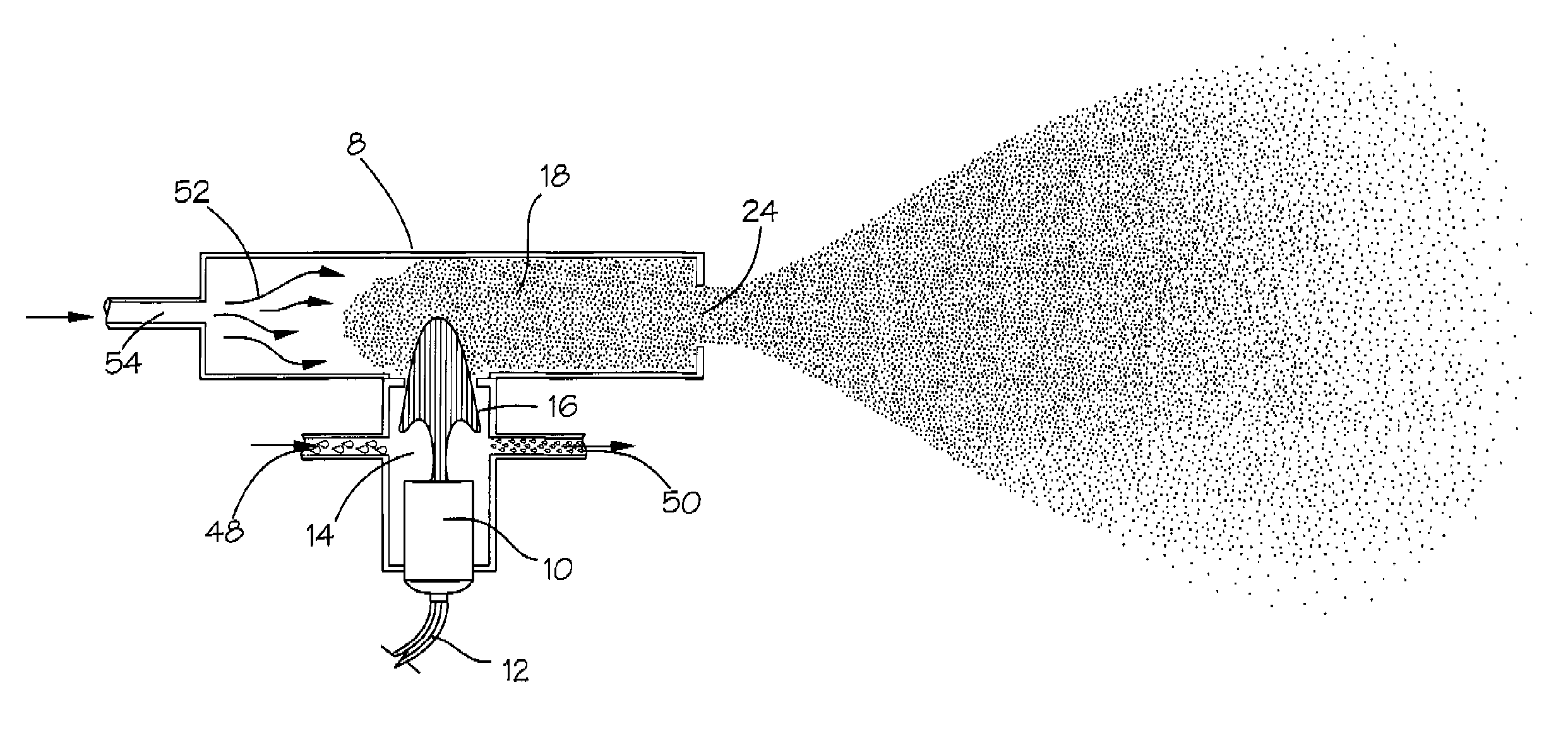

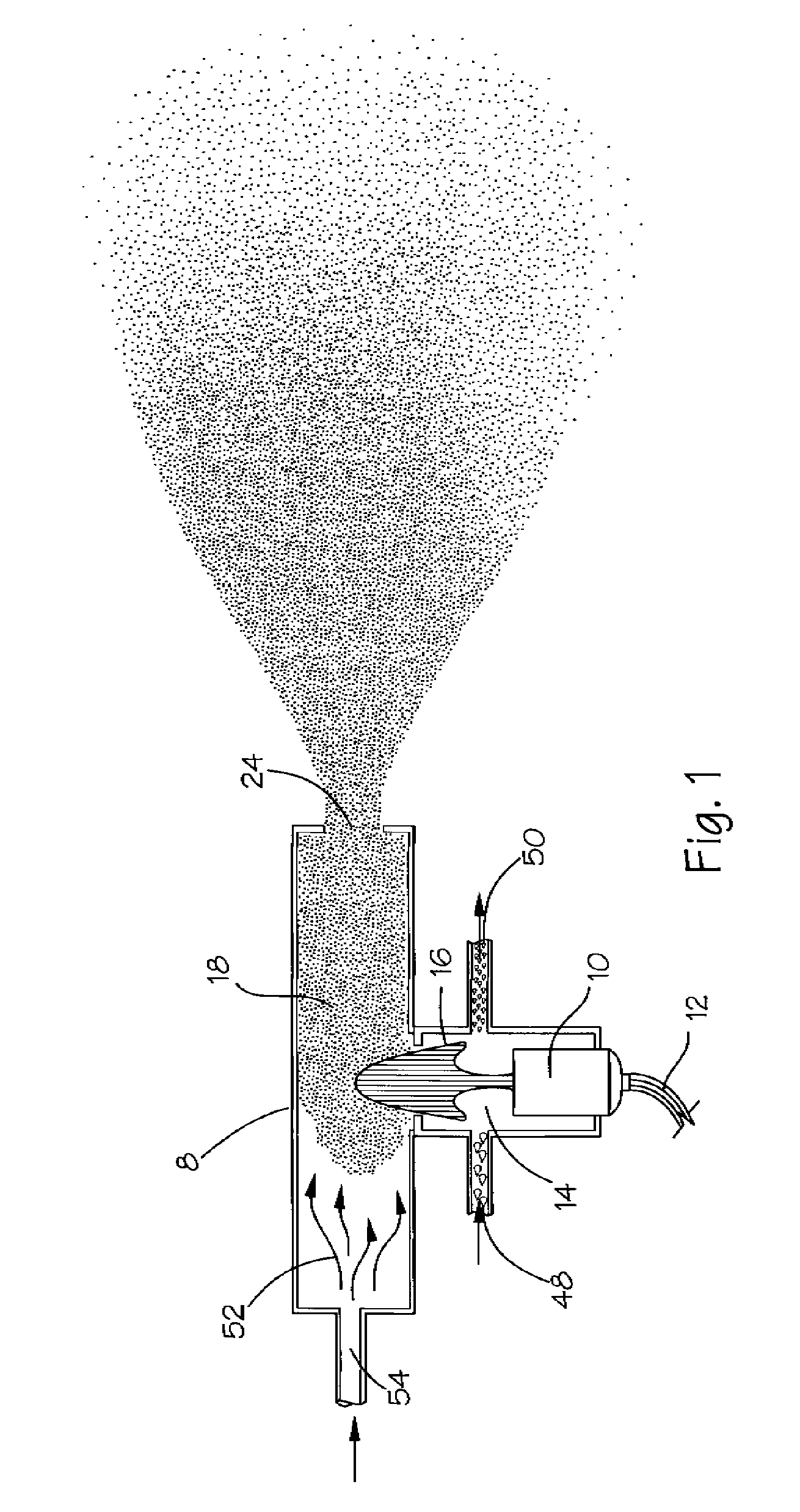

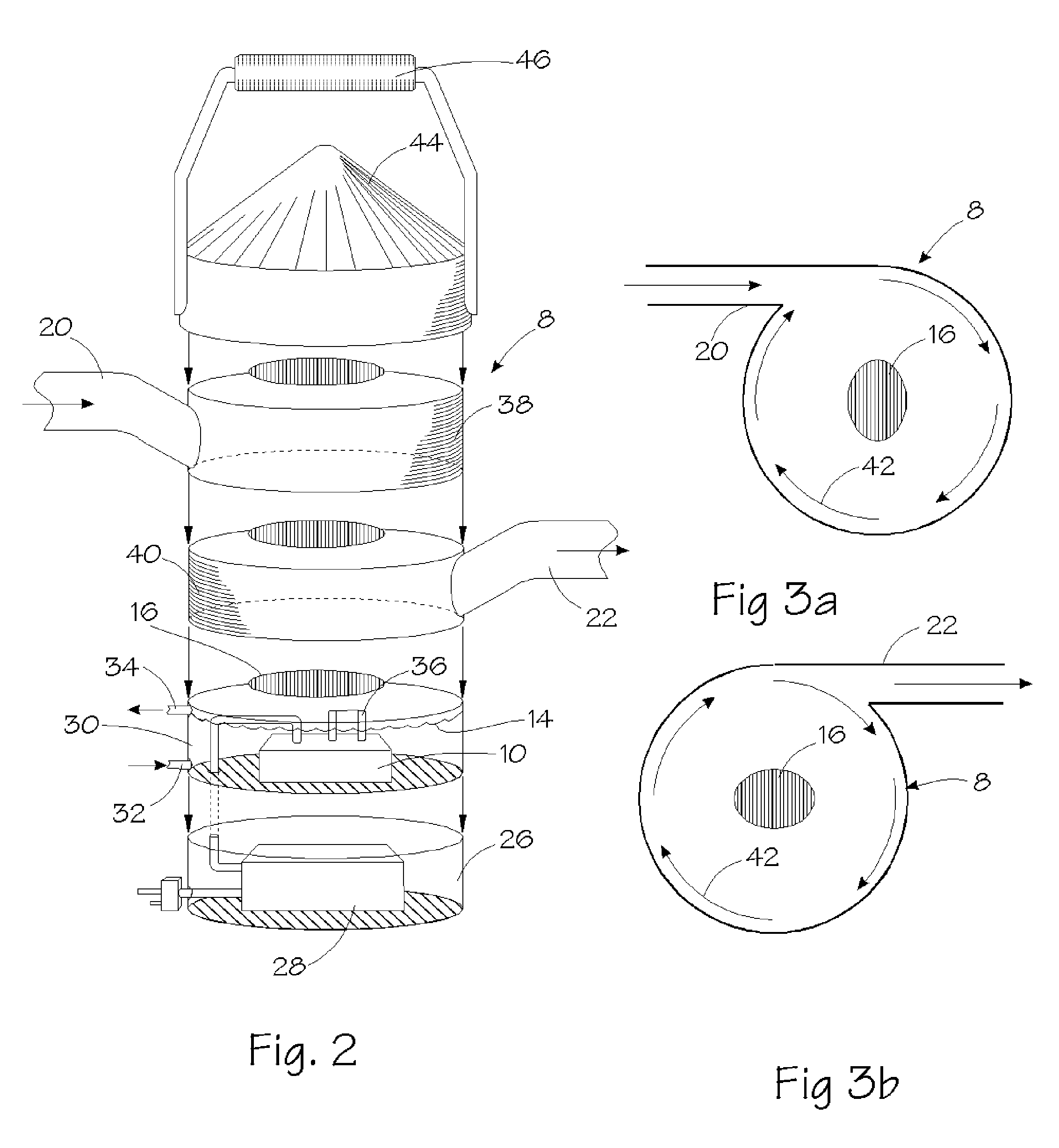

Fire Suppression Using Water Mist with Ultrafine Size Droplets

InactiveUS20060196681A1Enhance safety and economics of fire protectionImprove efficiencyMovable spraying apparatusSpray nozzlesAmbient pressureEngineering

Owner:NANOMIST SYST

Construction method of titanium surface micrometre-grade pattern based on ultra-hydrophilic/ultra-hydrophobic characteristic

InactiveCN101016642APracticalImprove controllabilitySurface reaction electrolytic coatingElectrochemical anodizationUltraviolet lights

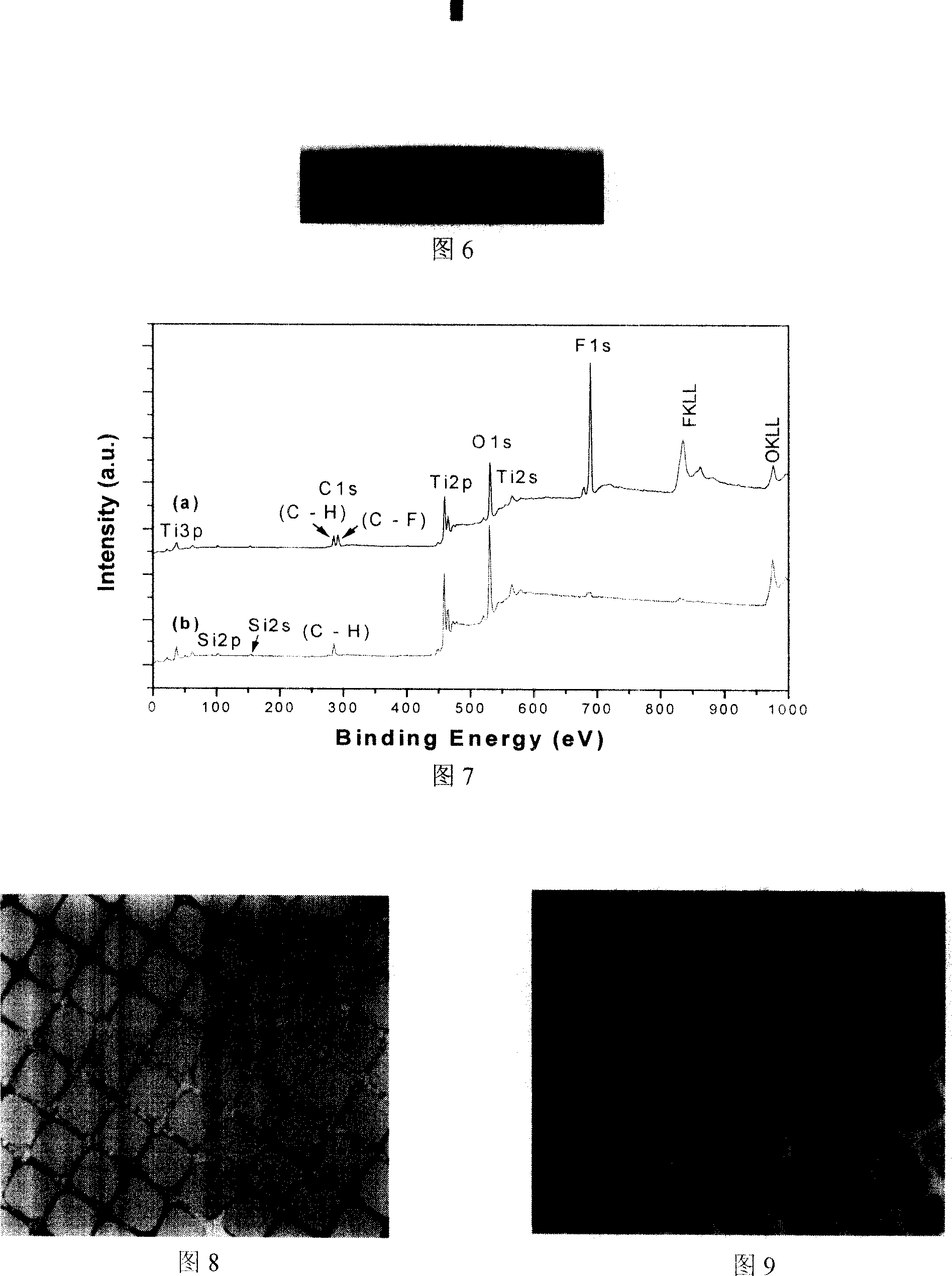

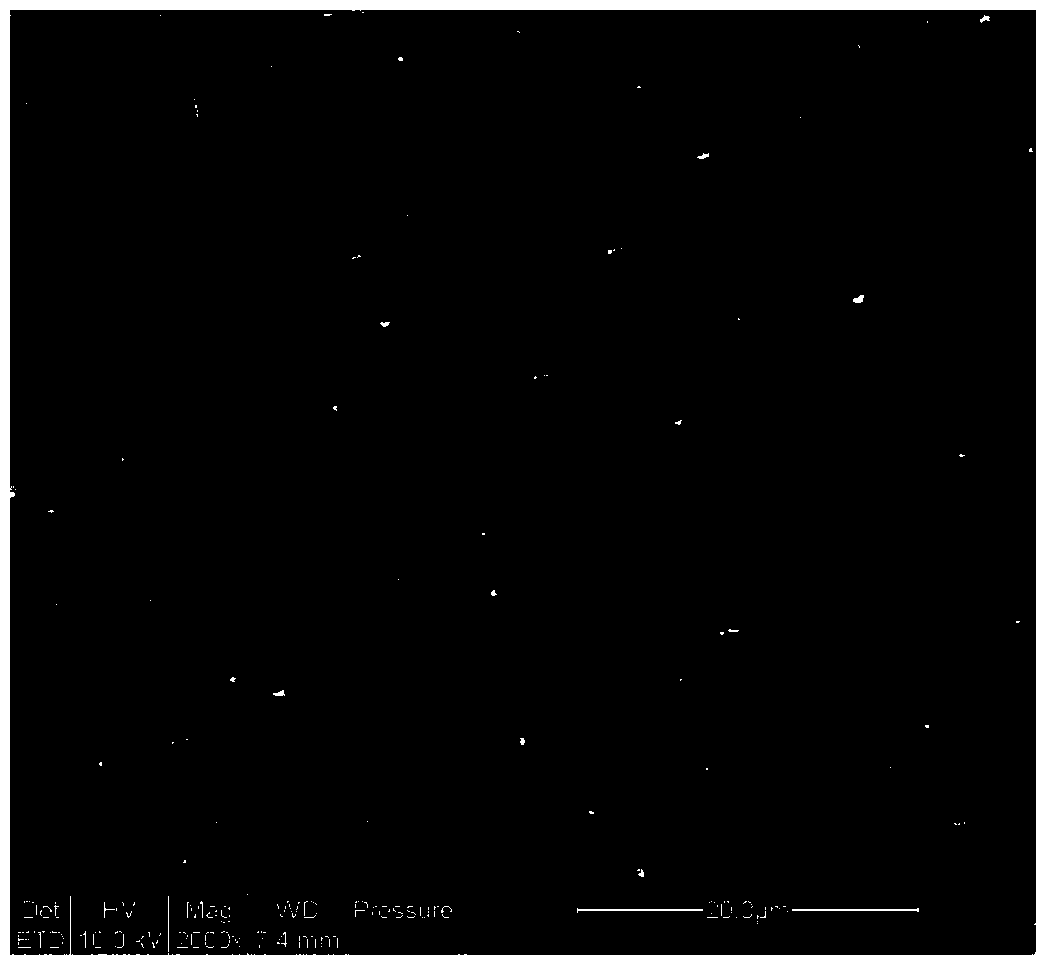

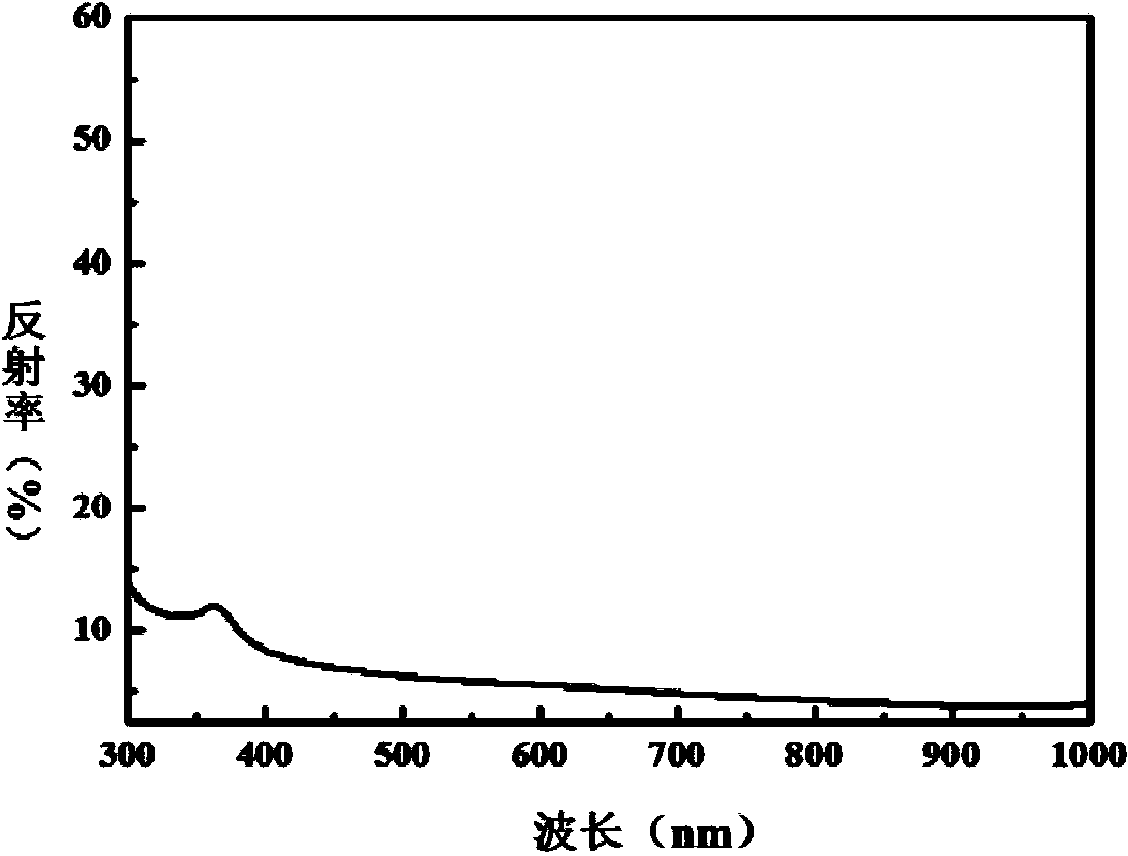

The invention discloses a construction method of titanium surface micron-size picture based on super hydrophilic / super hydrophobic peculiarity, which comprises the following steps: pre-processing the surface of base material; allocating electrolytic solution; controlling voltage and temperature; proceeding electro chemical anodic oxidation; getting titanium oxide nanometer structure array film layer; proceeding heat treatment; getting example; soaking in fluorine silicane methanol solution at 10-240 min; getting out; drying at 120-160 deg.c; getting super hydrophobic TiO2 nanometer structure array film layer; covering photomask; irradiating with ultraviolet light; getting the final picture.

Owner:XIAMEN UNIV

Acidic texturing solution for etching solar cell silicon wafer, texturing method, solar cell silicon wafer and manufacturing method of solar cell silicon wafer

ActiveCN104195645AReduce reflectionIncrease the optical pathAfter-treatment detailsFinal product manufactureInverted pyramidFluoride

The invention discloses an acidic texturing solution for etching a solar cell silicon wafer, a texturing method, a solar cell silicon wafer and a manufacturing method of the solar cell silicon wafer. The acidic texturing solution comprises a copper ion source for providing 0.1-25mmol / L copper ions, a fluoride ion source for providing 0.5-10mol / L fluoride ions, and a 0.1-1.0mol / L oxidant for oxidizing copper into the copper ions. The surface of the silicon wafer is preferably textured by virtue of the acidic texturing solution and thus an independent, complete and compactly arranged micron-size inverted pyramid-shaped structure is formed on the surface of the silicon wafer at a relatively low temperature and a relatively short time. By adopting the inverted pyramid-shaped structure, the reflectivity of an incident light on the textured surface is reduced to 5%-15% such that the efficiency of the solar cell is improved. The inverted pyramid-shaped structure disclosed by the invention is not limited to the preparation of an HIT and a conventional diffusion cell and can be also applied in other solar cells and optoelectronic devices using a silicon substrate.

Owner:深圳市石金科技股份有限公司

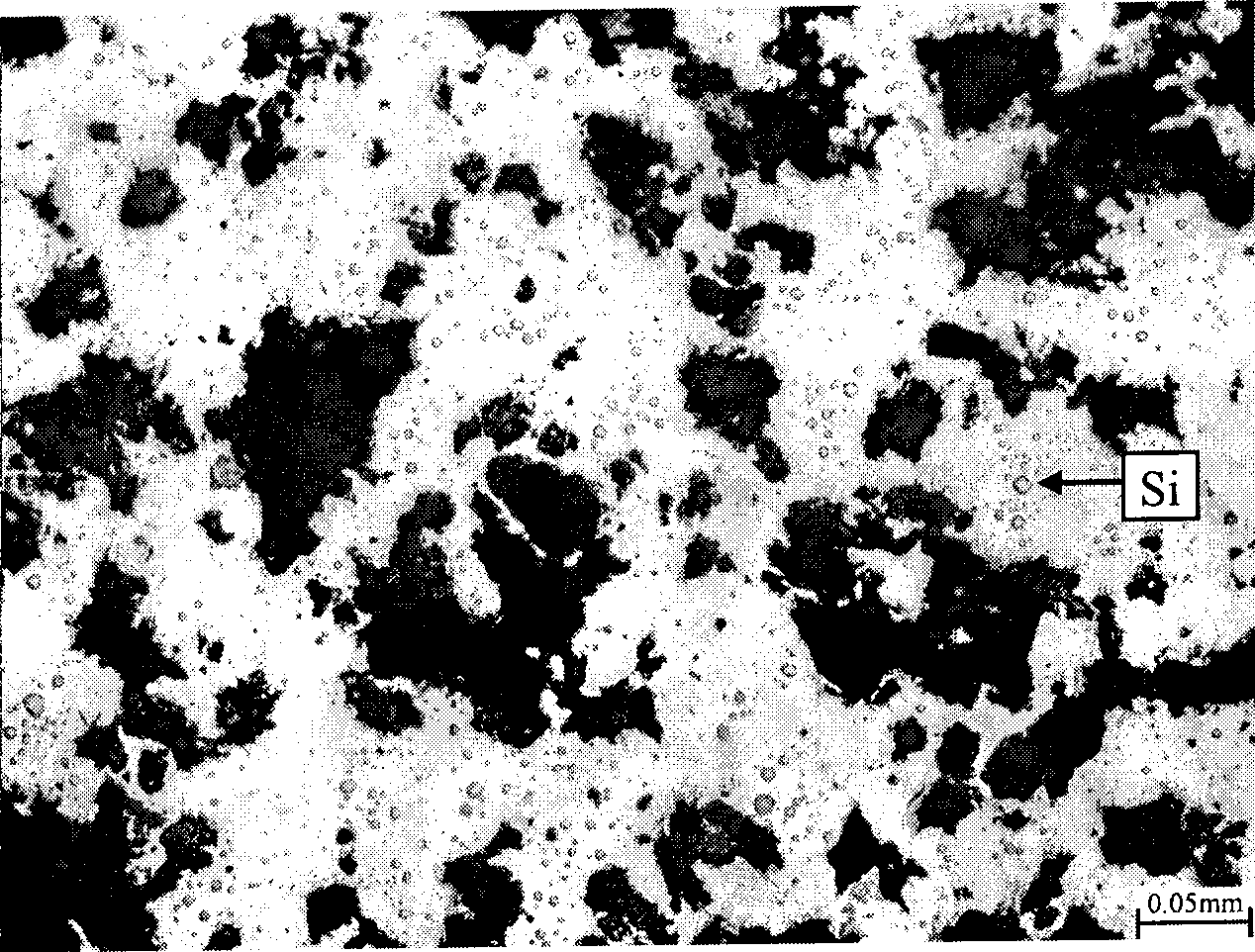

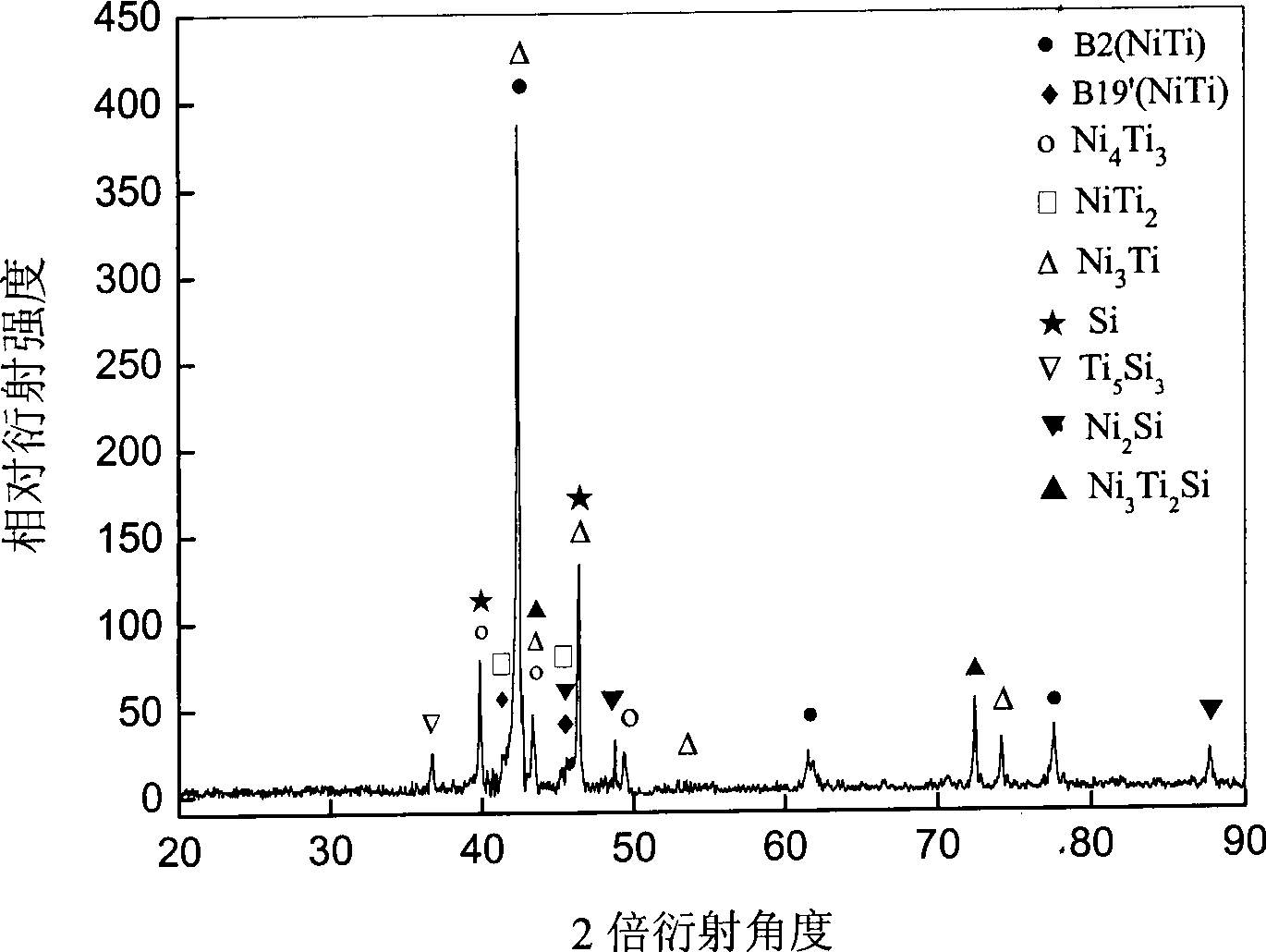

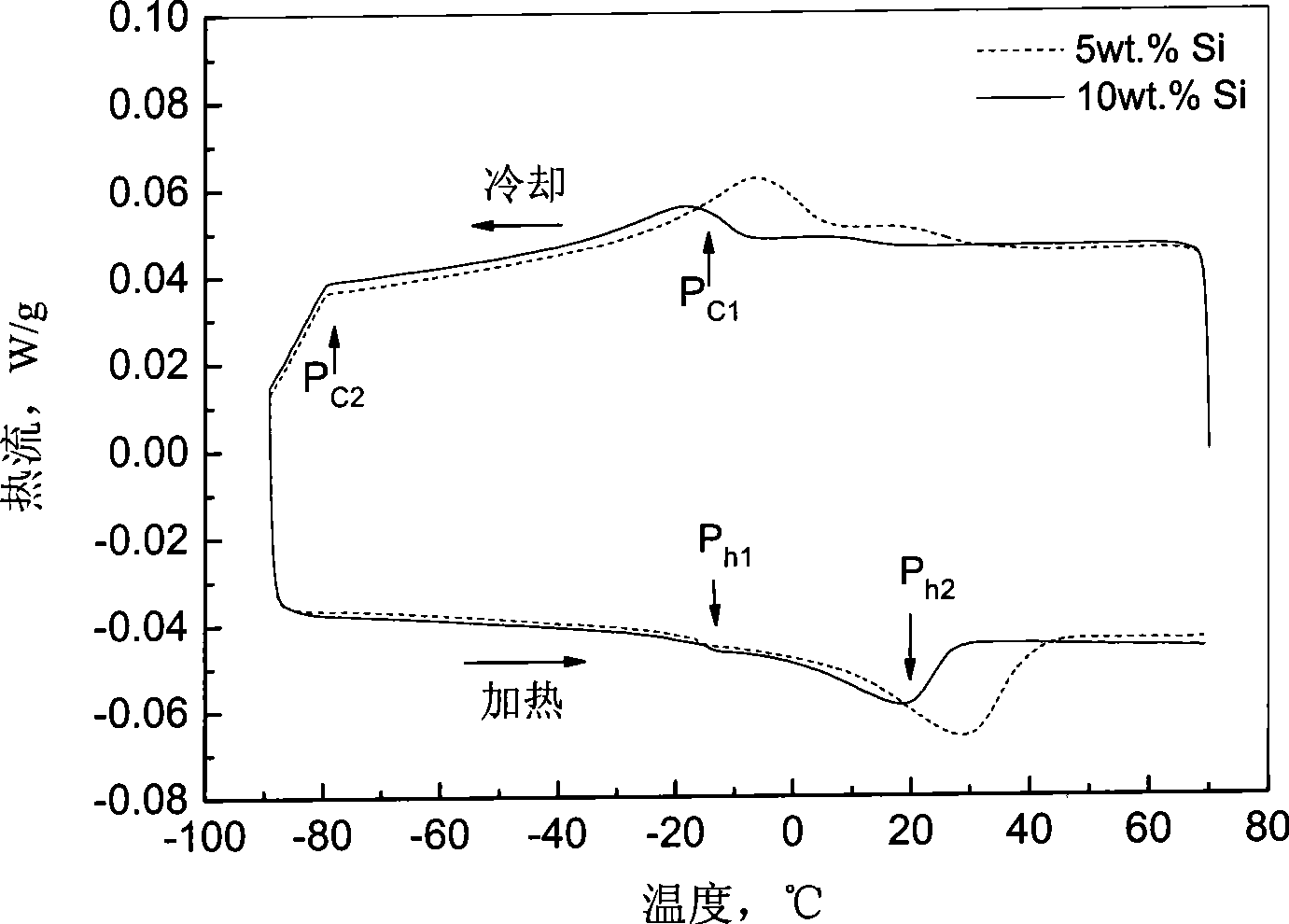

Preparation of particle reinforced damping porous nickel-titanium memory alloy based composite material

InactiveCN101440439AImprove mechanical propertiesImprove damping performanceTitanium alloyMechanical property

The invention discloses a method for preparing a granular reinforced damping porous nickel-titanium memorial alloy based composite material. The method comprises: after evenly mixing silicon granules or aluminum oxide granules of nickel-titanium metal powder and a controlled material according to a certain proportion by adopting a step powder-sintering method, pressing the granules into a raw blank, and then integrally sintering the pressed granules once by adopting a step heating mode to prepare the composite material, wherein the silicon granules or the aluminum oxide granules account for 5 to 15 percent of weight of the raw blank. Through introducing the porous granular controlled material with low density and micron size into the nickel-titanium memorial alloy, the method quantitatively controls damping and mechanical properties of the nickel-titanium alloy, and finally obtains the novel high-damping porous nickel-titanium alloy based composite material. The composite porous nickel-titanium memorial alloy still has shape memory effect and hyperelastic deformation capability, and has better strength and damping capability compared with the common porous nickel-titanium alloy; and the method has the advantages of good adaptability, simple preparation process and low cost, and can be used for manufacturing composite damping materials, damping structures and devices.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com