Silver paste for positive electrode of crystalline silicon solar cell and preparation method thereof

A technology of solar cells and front electrodes, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as affecting the conductivity of grid lines and loose sintered film structure of nano-silver powder, etc. To achieve the effect of improving conductivity, rheology and thixotropy, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

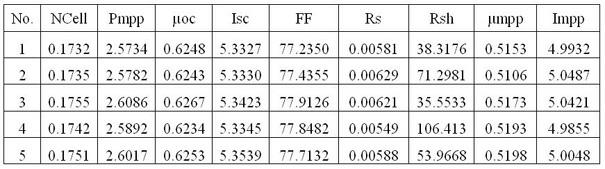

Examples

Embodiment 1

[0025] A crystalline silicon solar photovoltaic cell front electrode silver paste, the composition and weight percentage are: 80% of Ag powder, 3.5% of glass powder, and 16.5% of organic vehicle.

[0026] The tap density of the above silver powder is 3.6g / cm 3 , the average particle size is 2.0 μm, and the particle size range of Ag powder is D50 1.3, D90 2.3 μm;

[0027] The composition and weight percentage of glass frit are 50% PbO, 30% SiO 2 , 10% Bi 2 o 3 , 1% Al 2 o 3 , 2.5% of V 2 o 5 , 5% ZnO, 1% silver oxide, 0.5% magnesium oxide. The softening point of the glass powder is 450°C, the average particle size of the powder is 1.5 μm, and the D90 is not more than 10 μm;

[0028] The binder in the organic vehicle is ethyl cellulose (5%); the organic solvent is selected from terpineol (40%), tributyl citrate (10%), butyl carbitol acetate (20%), Dibutyl phthalate (15%); additives selected from modified polyamide waxes (5%), modified hydrogenated castor oil (3%), dieth...

Embodiment 2

[0037]A silver paste for the front electrode of a crystalline silicon solar photovoltaic cell comprises the following composition and weight percent: 85% of Ag powder, 5.5% of glass powder, and 9.5% of organic vehicle.

[0038] The tap density of the above silver powder is 4.0g / cm 3 , the average particle size is 2.0 μm, and the particle size range of Ag powder is D50 1.3, D90 2.3 μm;

[0039] The composition and weight percentage of glass frit are 59% PbO, 19% SiO 2 , 5% Bi 2 o 3 , 3% Al 2 o 3 , 5% of V 2 o 5 , 3% ZnO, 3% silver oxide, 3% magnesium oxide; the softening point of the glass powder is 450°C, the average particle size of the powder is 1.5 μm, and the D90 is not more than 10 μm;

[0040] The binder in the organic vehicle is ethyl cellulose (5%), epoxy resin (2.5%); the organic solvent is selected from terpineol (60%), butyl carbitol acetate (10%), phthalate Dibutyl diformate (15%); additives selected from modified polyamide wax (3.5%), modified hydrogenated...

Embodiment 3

[0043] A silver paste for the front electrode of a crystalline silicon solar photovoltaic cell, the composition and weight percent of which are: 87% of Ag powder, 3.5% of glass powder, and 9.5% of organic vehicle.

[0044] The tap density of the above silver powder is 4.3g / cm 3 , the average particle size is 2.0 μm, and the particle size range of Ag powder is D50 1.3, D90 2.3 μm;

[0045] The composition and weight percentage of glass frit is 45% PbO, 20% SiO 2 , 5% Bi 2 o 3 , 3% Al 2 o 3 , 5% of V 2 o 5 , 7% ZnO, 5% silver oxide, 3.5% magnesium oxide, 2% TiO 2 , 1% CaO, 1% Na 2 O, 2.5% P 2 o 5 ; The softening point of the glass powder is 440°C, the average particle size of the powder is 1.5 μm, and the D90 is not more than 10 μm;

[0046] The binder in the organic vehicle is ethyl cellulose (5%); the organic solvent is selected from terpineol (40%), tributyl citrate (10%), triethanolamine (20%), lecithin (15%) ); additives are selected from modified polyamide wax ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com