Patents

Literature

928 results about "Thixotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thixotropy is a time-dependent shear thinning property. Certain gels or fluids that are thick or viscous under static conditions will flow (become thin, less viscous) over time when shaken, agitated, sheared or otherwise stressed (time dependent viscosity). They then take a fixed time to return to a more viscous state. Some non-Newtonian pseudoplastic fluids show a time-dependent change in viscosity; the longer the fluid undergoes shear stress, the lower its viscosity. A thixotropic fluid is a fluid which takes a finite time to attain equilibrium viscosity when introduced to a steep change in shear rate. Some thixotropic fluids return to a gel state almost instantly, such as ketchup, and are called pseudoplastic fluids. Others such as yogurt take much longer and can become nearly solid. Many gels and colloids are thixotropic materials, exhibiting a stable form at rest but becoming fluid when agitated. Thixotropy arises because particles or structured solutes require time to organize. An excellent overview of thixotropy has been provided by Mewis and Wagner.

Method and reagent for producing narrow, homogenous reagent stripes

ActiveUS20050008537A1Analysis using chemical indicatorsAnalysis by subjecting material to chemical reactionReagent stripTest strips

The present invention concerns a reagent coating mass which can be used in slot-die-coating of flat support materials in the manufacturing processes of test strips. Advantageously, the reagent mass of the invention exhibits certain superior rheological properties such as viscosity, surface tension and thixotropy. The reagent mass is preferably used to coat thin, narrow and homogeneous stripes of reagent material onto flat web material.

Owner:ROCHE OPERATIONS +1

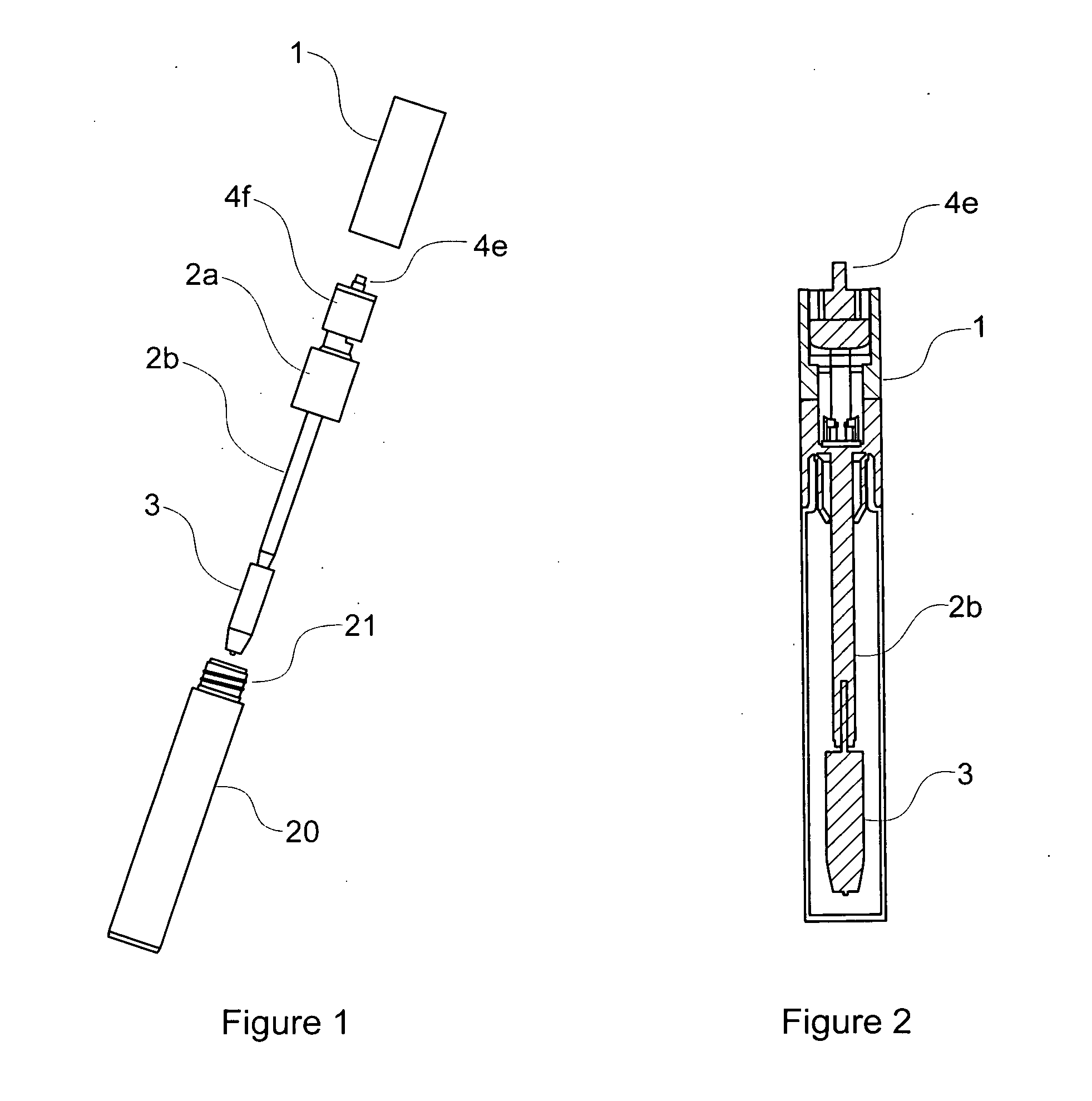

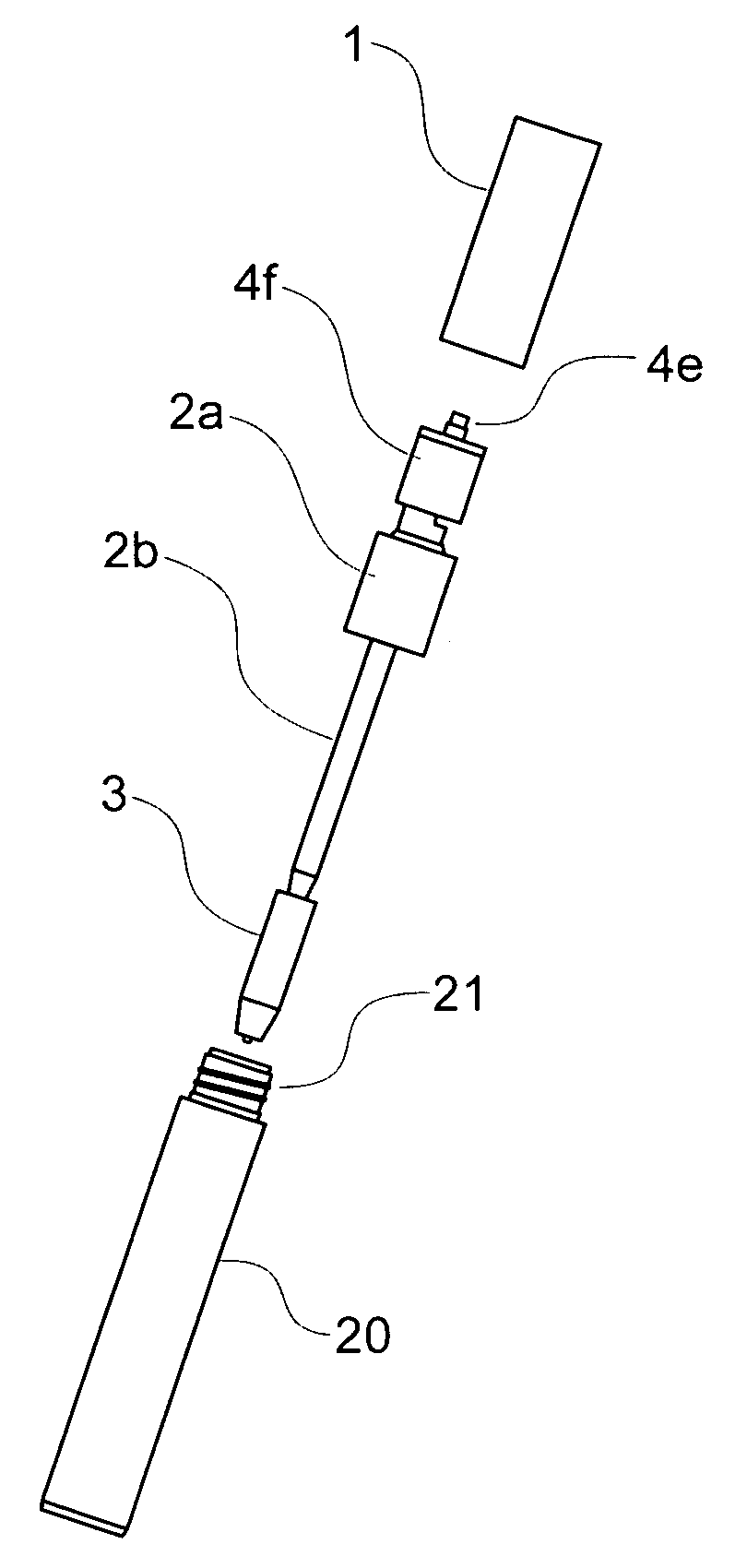

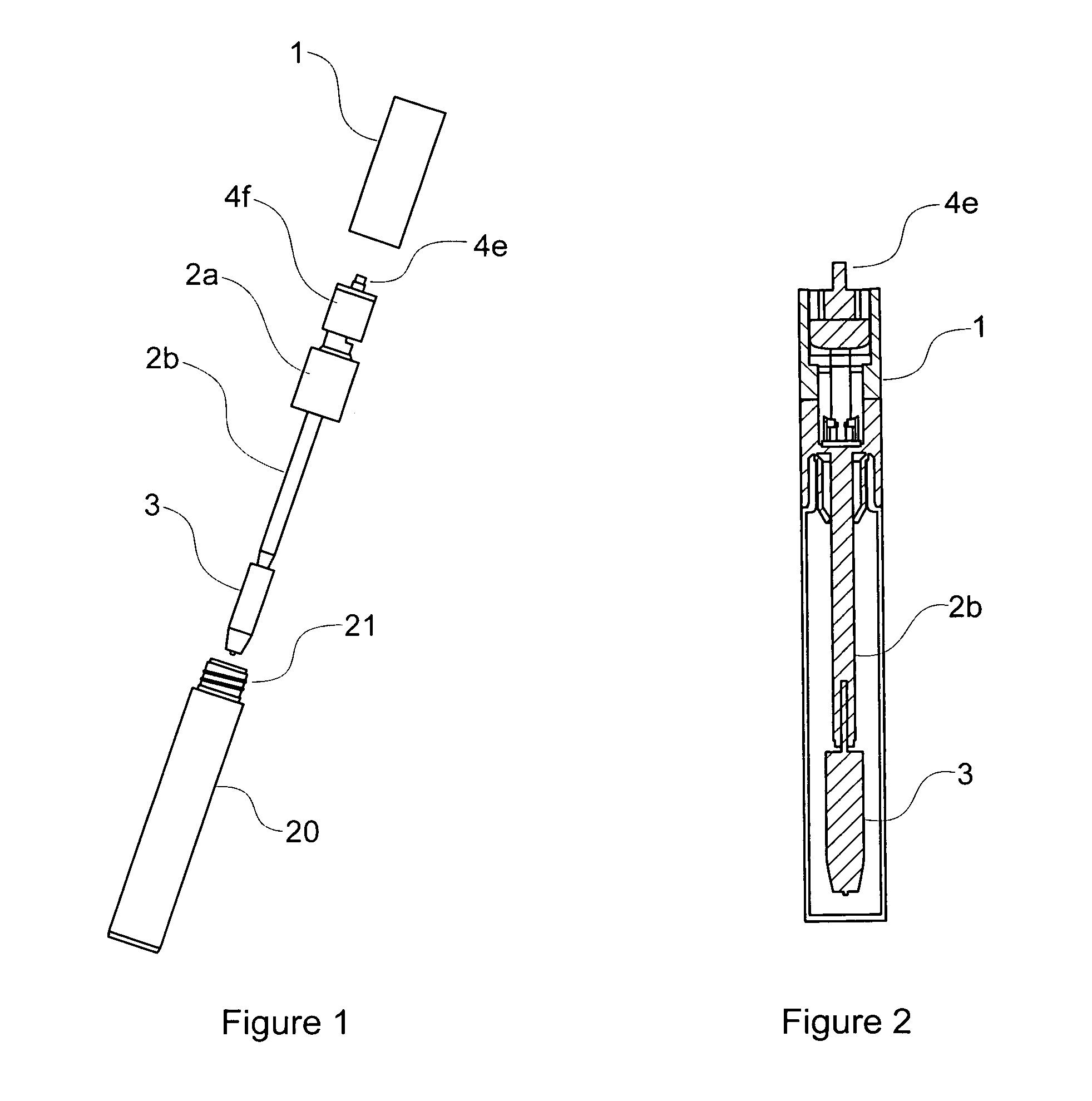

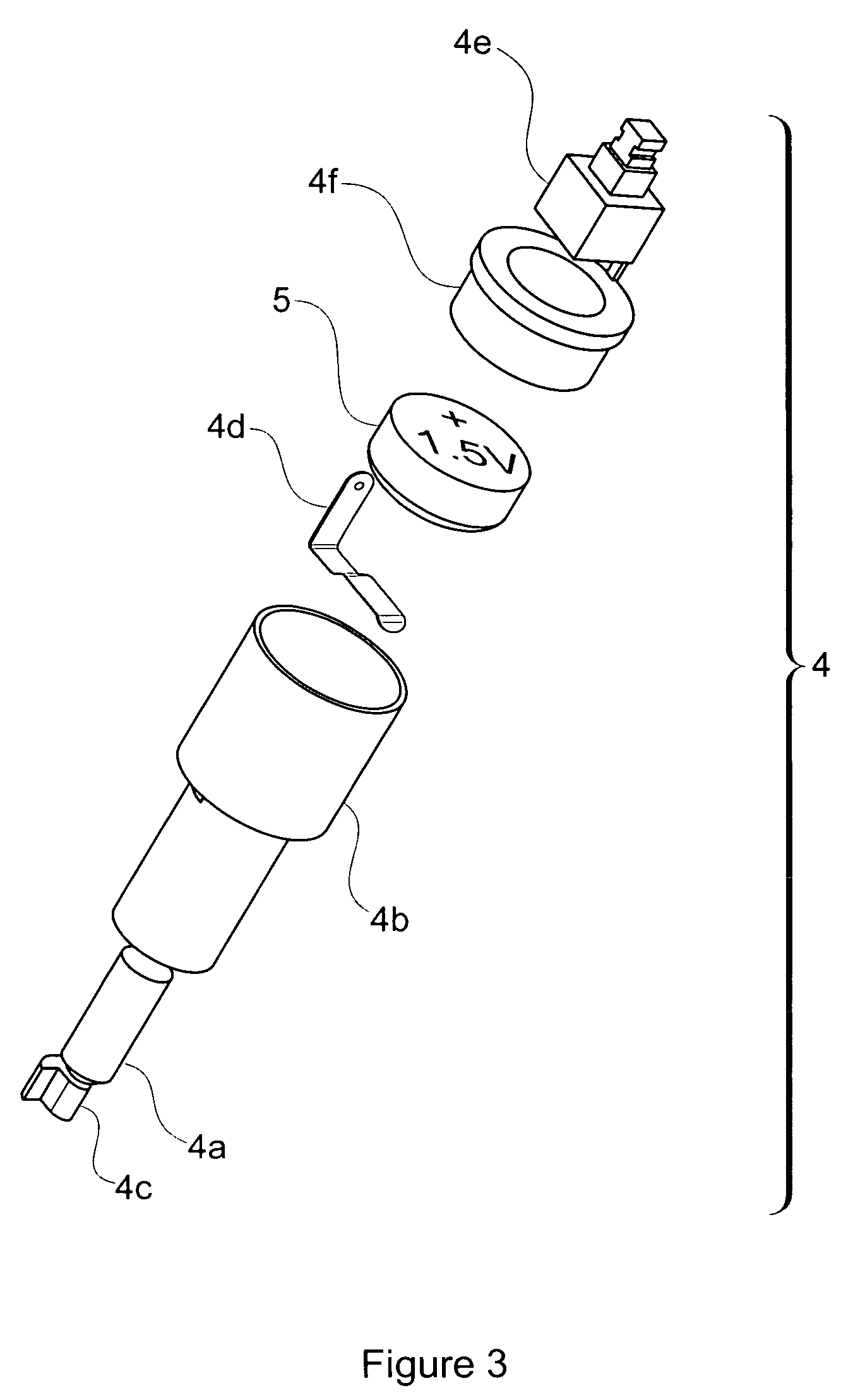

Vibrating mascara applicator, suitable compositions and method of use

ActiveUS20060032512A1Improved mascara applicatorChange performanceCarpet cleanersBrush bodiesControl mannerEngineering

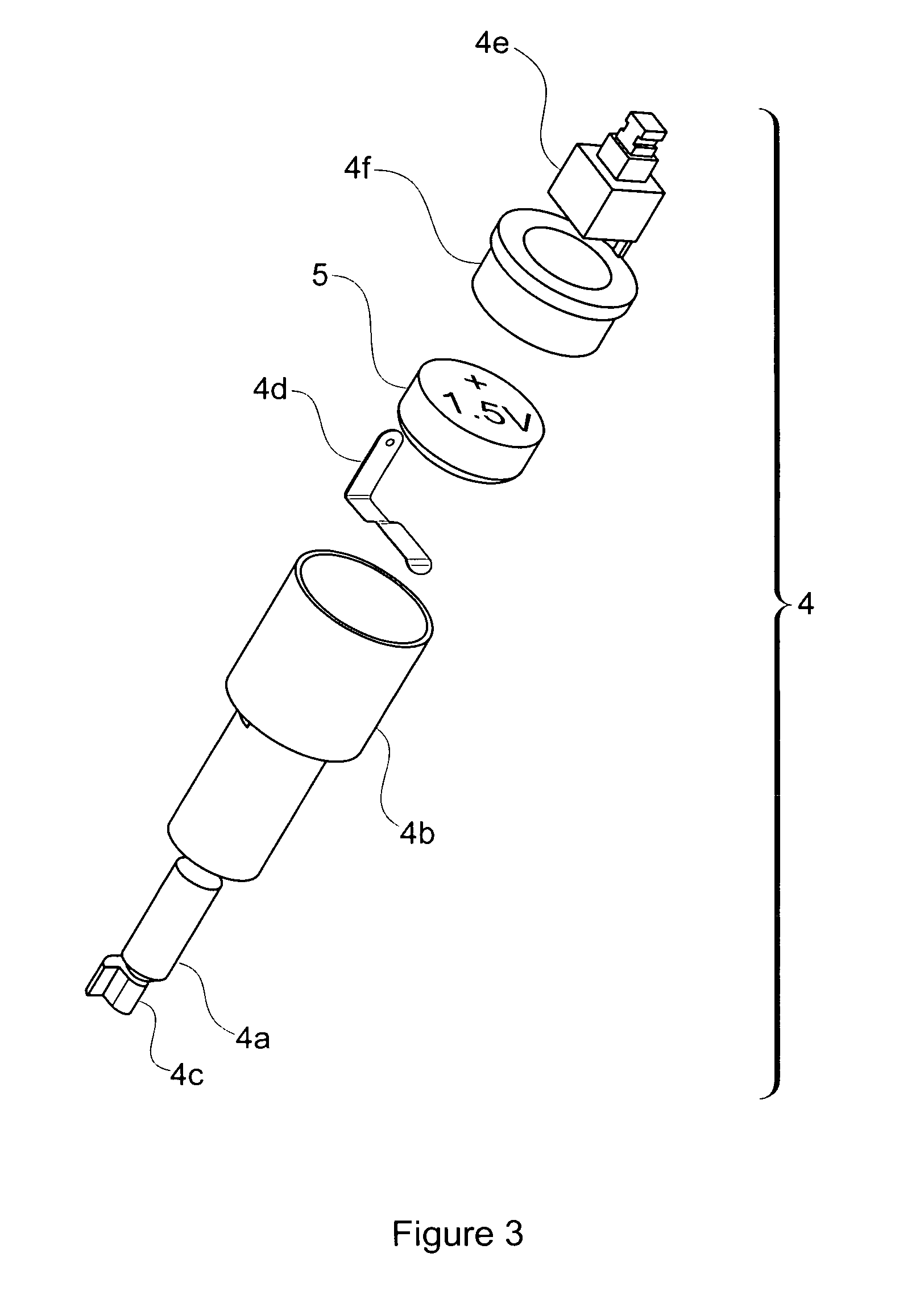

The present invention is mascara applicator with vibrating applicator head. The head is caused to vibrate in a controlled manner through electromechanical urging. The frequency, amplitude and geometry of the vibrating head are sufficient to significantly alter the rheological properties of thixotropic and anti-thixotropic mascara compositions, including an effect that persists after the vibration has stopped. The present invention allows the mascara to be manipulated for improved results, greater flexibility in formulation, benefits in manufacture, as well as other benefits.

Owner:ELC MANAGEMENT LLC

Method For Monitoring Thixotropy In Concrete Mixing Drum

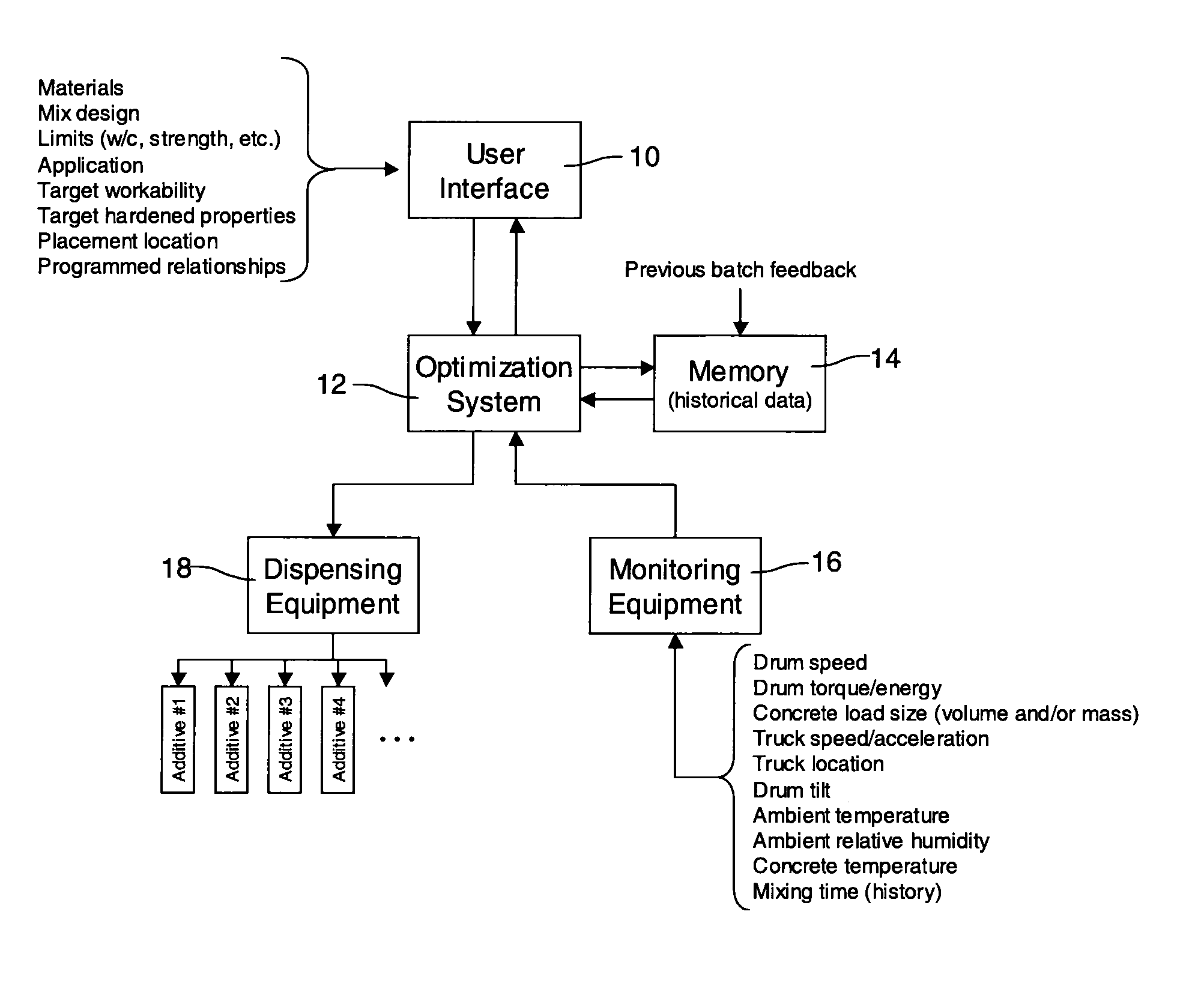

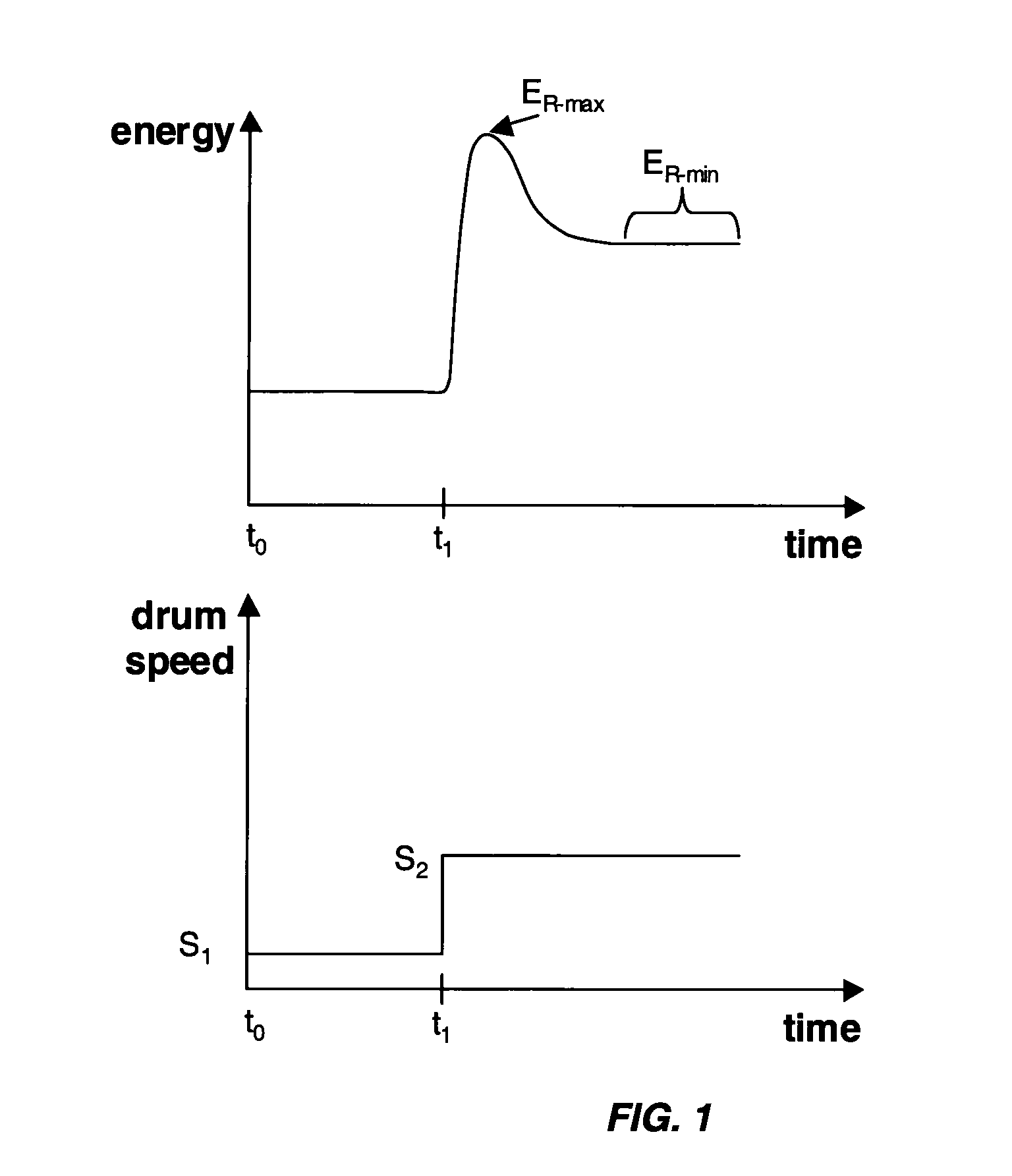

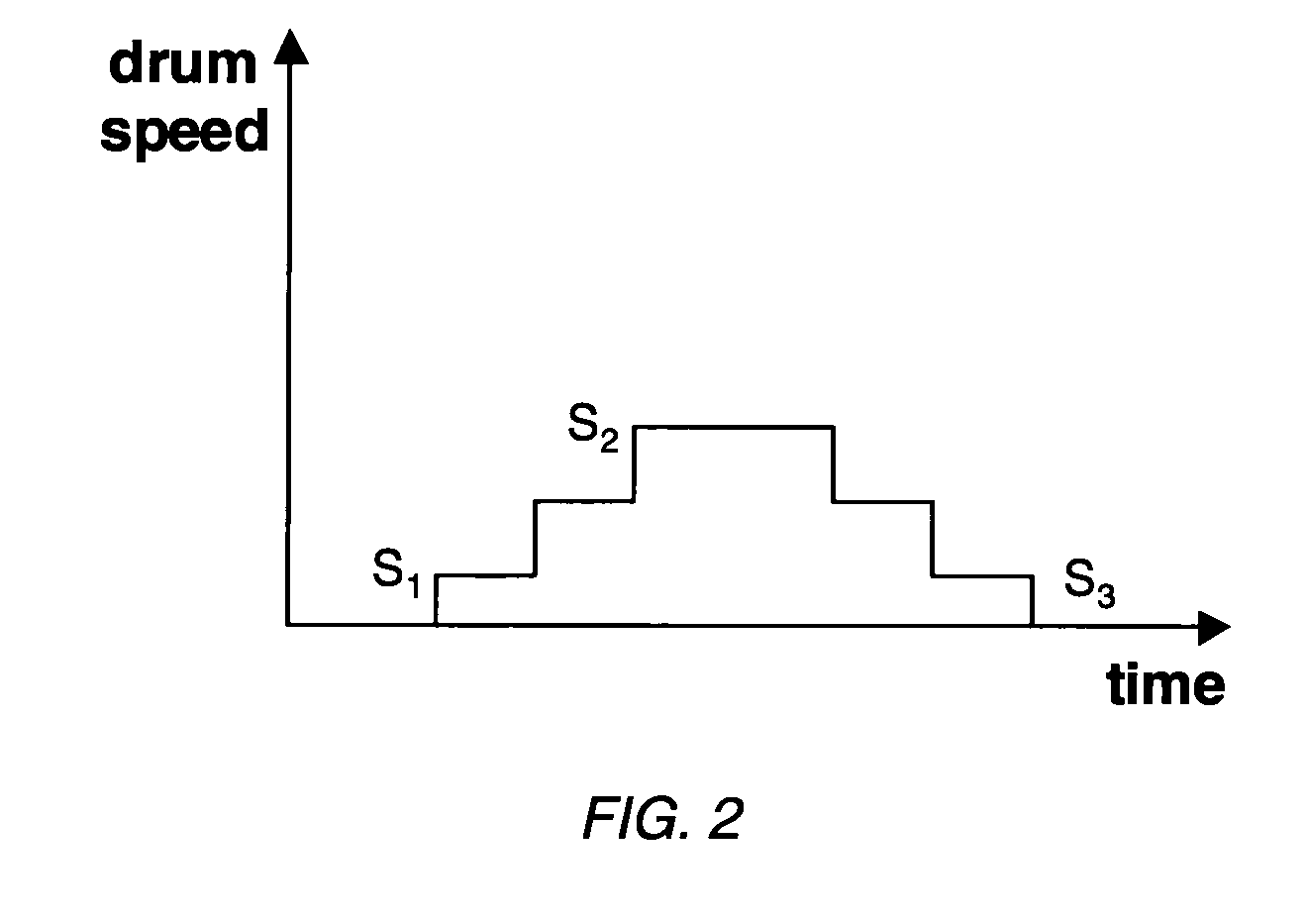

The invention provides ‘thixotropy’ monitoring, by measuring the reversible, time-dependent reduction in viscosity occurring when concrete is subjected to mixing, and employs a mixing drum and conventional slump monitoring equipment as used on ready-mix trucks. In one embodiment, the drum is rotated until concrete is completely mixed; the speed is altered, such as by increasing it to a predetermined level; and the energy required to rotate the drum (ER) is monitored; the maximum (ER-MAX) and minimum (ER-MIN) values are recorded in computer memory; and these values are compared to pre-determined (target) values. Rheology factors (including viscosity, yield stress, and / or thixotropy) can be adjusted accordingly by adding liquid component(s) into the mix. This method, suitable for delivery of highly fluid concrete speed such as SCC, can involve transit and placement rheology targets during monitoring.

Owner:GCP APPL TECH INC

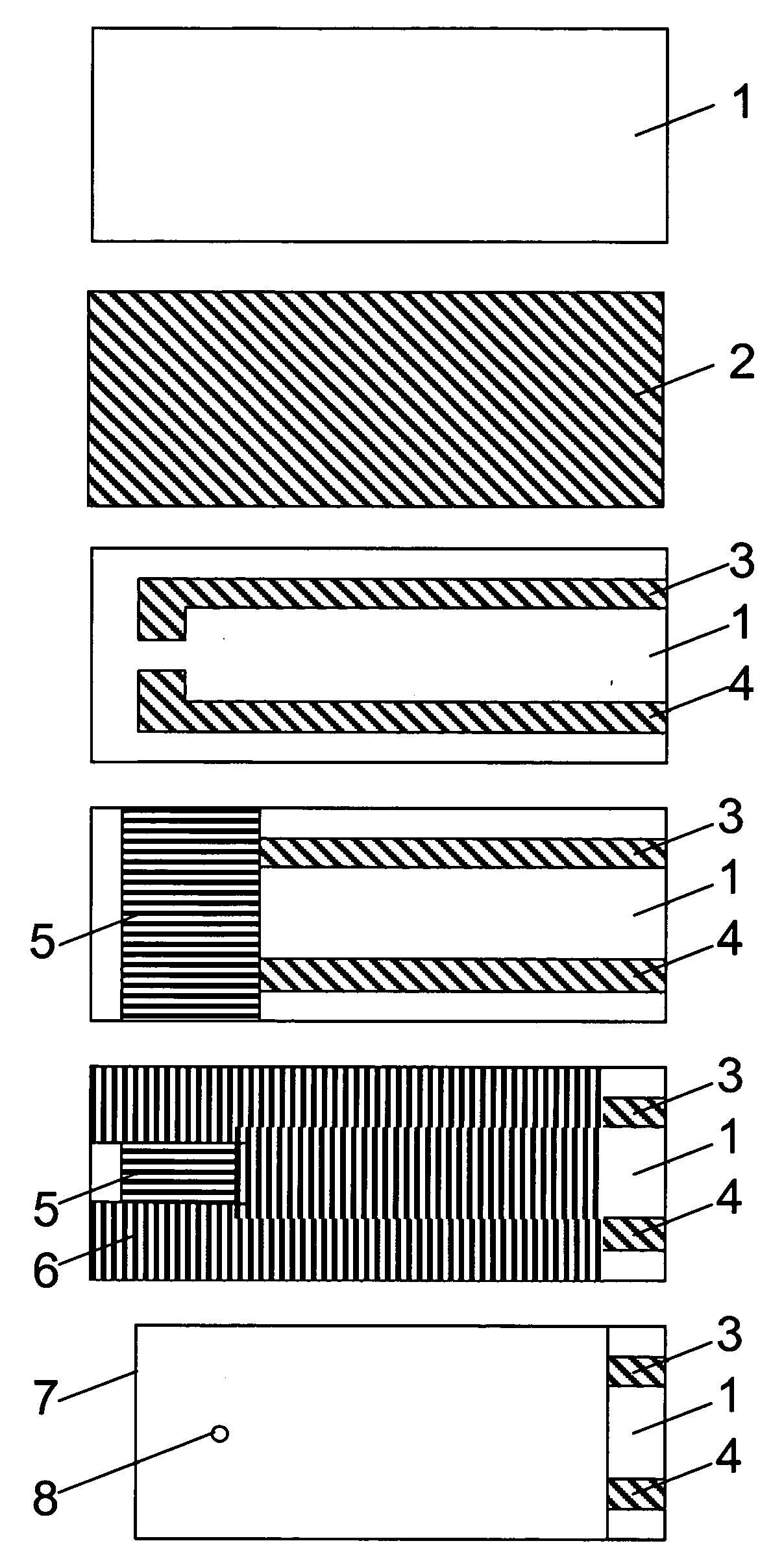

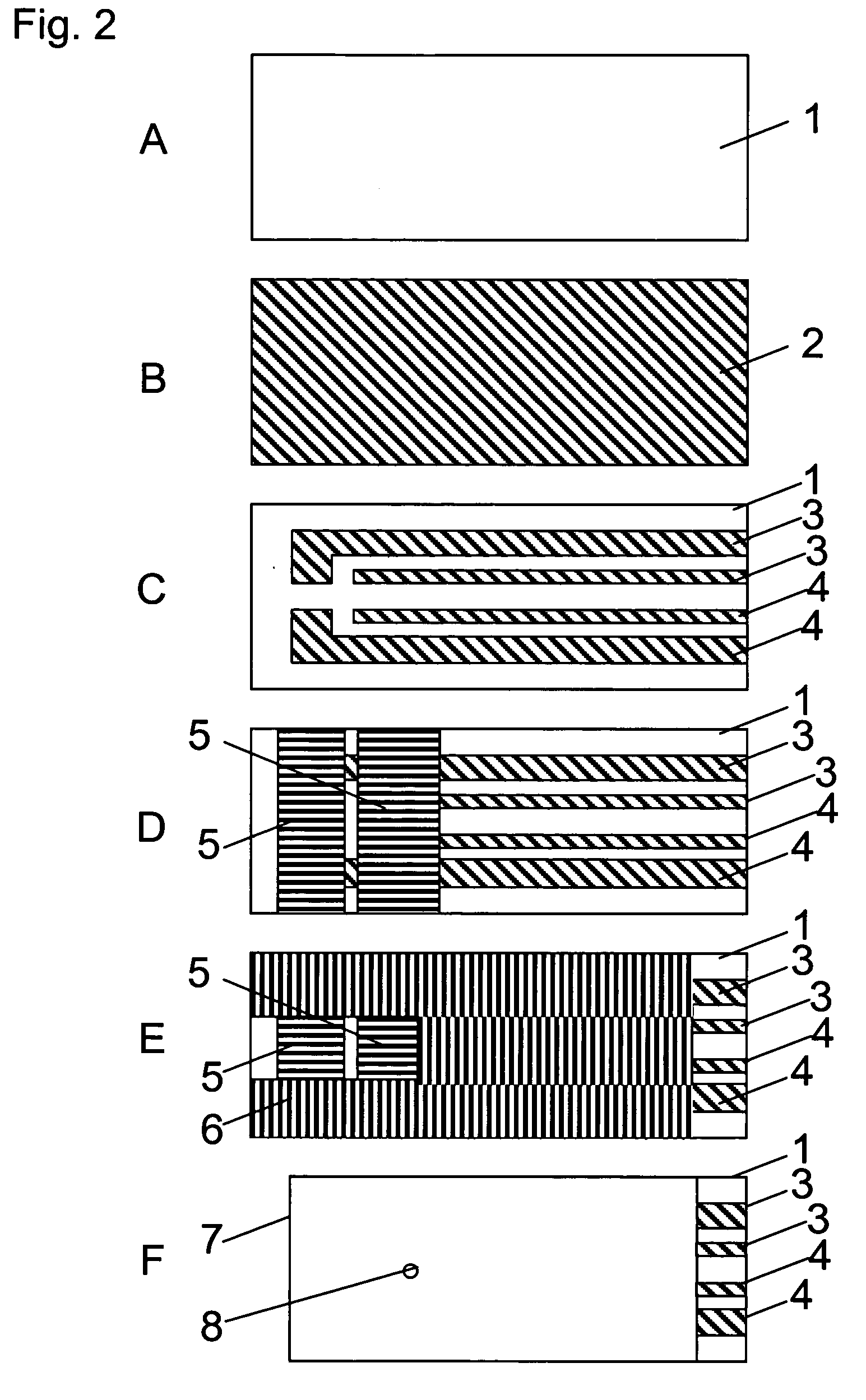

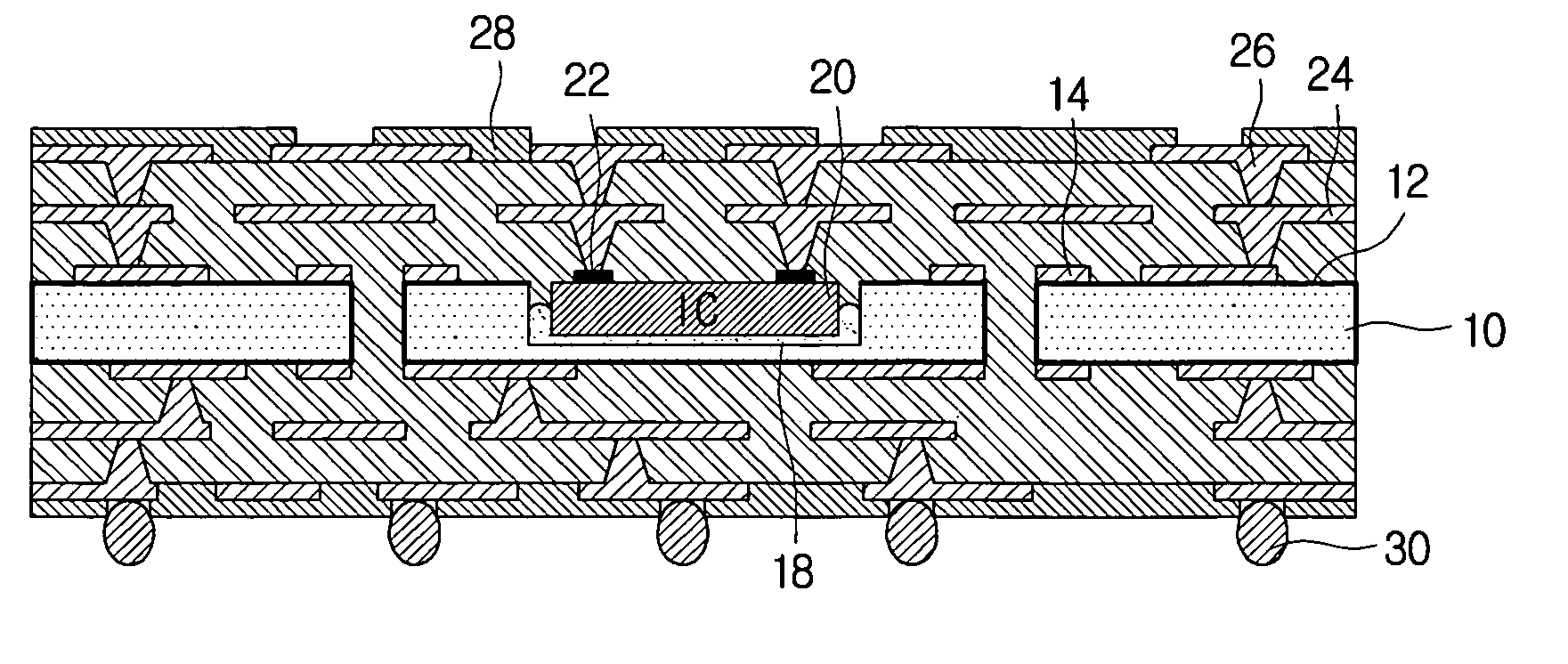

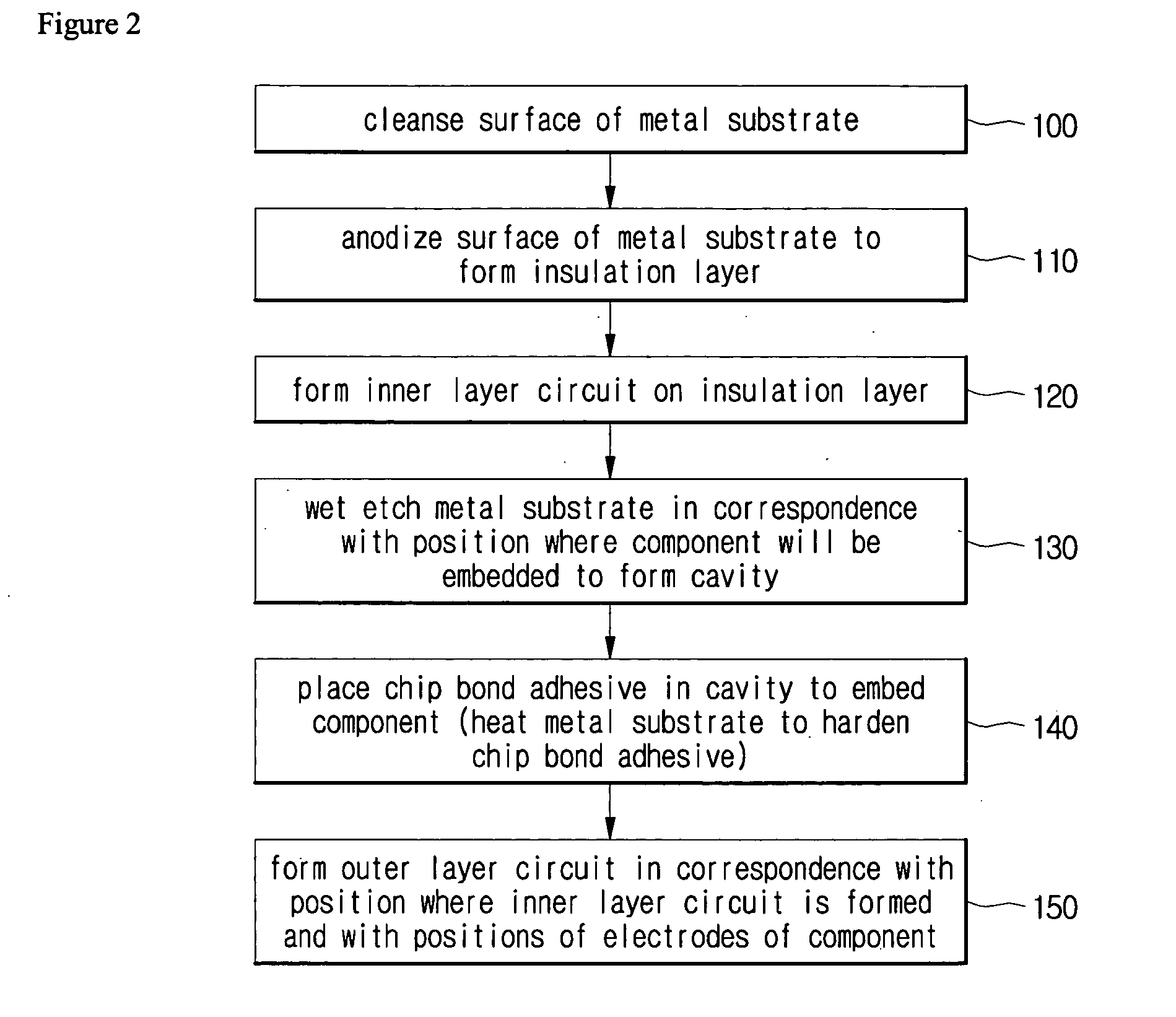

Printed circuit board and manufacturing method thereof

InactiveUS20070074900A1Increase stiffnessImprove heat-releasing propertyPrinted circuit assemblingPrinted electric component incorporationManufacturing cost reductionEtching

A printed circuit board and manufacturing method thereof are disclosed. By use of a method of manufacturing a printed circuit board, which uses a metal substrate as a core member and has an electronic component embedded in the metal substrate, mainly comprising: (a) anodizing at least one surface of the metal substrate to form at least one insulation layer, (b) forming an inner layer circuit on the at least one insulation layer, (d) placing chip bond adhesive in correspondence with a position where the electronic component is to be embedded and mounting the electronic component, and (e) forming an outer layer circuit in correspondence with a position where the inner layer circuit is formed and with positions of the electrodes of the electronic component, and which may further comprise an operation (c) of etching the metal substrate to form a cavity in correspondence with a position where the electronic component is to be embedded between the operations (b) and (d), a metal substrate, such as that of aluminum, etc., is rendered electrically insulating by applying an anodizing process and is used as a core member in a printed circuit board, so that bending stiffness and heat-releasing property are improved; wet etching can be applied, so that manufacturing costs are reduced; and a chip bond adhesive, die attach film, or nonconductive paste, etc., that is high in thixotropy is used in embedding the electronic component, so that the degree of precision may be increased for the position and height of the electronic component when embedding the electronic component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Nano porous concrete taking thixotropic colloid as template agent and preparation method

InactiveCN105294141AHas a three-dimensional network microporous structureNo pollution in the processCeramicwareBrickThixotropy

The invention relates to porous concrete and a preparation method thereof, in particular to novel nano porous concrete which is prepared by taking thixotropic colloid as a template agent to form a uniform-water-phase three-dimensional network nano porous structure and adding cementing materials, fine aggregate, coarse aggregate, an admixture and an additive. The nano porous concrete has the characteristics of being light, high in strength and low in heat conductivity, can be prefabricated into bricks, building blocks, plates, and assembly type stairs, wallboards, balcony slabs and roof panel parts in a factory, can be also cast on a construction site, and further can be prepared into mortar, thereby having remarkable practical significance on promotion of development of housing industrialization and green building concrete material in our country.

Owner:浙江圣润纳米科技有限公司

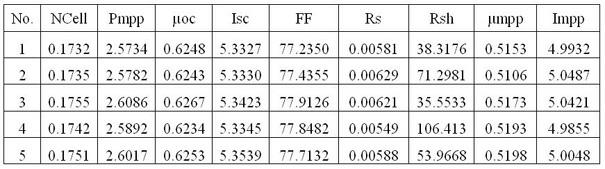

Silver paste for positive electrode of crystalline silicon solar cell and preparation method thereof

InactiveCN102157219AReduce contact resistanceImprove rheologyNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetallurgy

The invention discloses high-conductivity silver paste for a positive electrode of a crystalline silicon solar cell. The silver paste comprises the following components in percentage by weight: 75-90% of Ag powder, 2-10% of glass powder and 5-20% of organic carrier, wherein the glass powder comprises the following components in percentage by weight: 30-75% of PbO, 7-30% of SiO2, 2-30% of Bi2O3, 1-5% of Al2O3, 1-5% of V2O5, 1-10% of ZnO, 1-5% of Ag2O and 1-8% of MgO. The silver paste has the following beneficial effects: the micron-sized silver powder is adopted to prepare the silver paste, the prepared silver paste has good rheological behavior and thixotropy, a single wafer consumes less silver paste, and the compactness of the positive grid line is improved, thus improving the conductivity; and the glass powder with low-melting erosion property is adopted and can effectively and moderately erode the antireflective film, thus reducing the contact resistance of the crystalline silicon solar cell and improving the conversion efficiency.

Owner:XIAN INTAIN NEW ENERGY MATERIALS SCI & TECH +1

Sand-in-water colorful imitation stone paint

InactiveCN104312351AHigh transparencyHigh viscosityAntifouling/underwater paintsPaints with biocidesElastomerCrack resistance

The invention discloses sand-in-water colorful imitation stone paint. The invention provides sand-in-water colorful imitation stone paint which has a thick coating, high bonding strength, good water resistance, ageing resistance and good storage stability and is a technical progress in the paint industry. The paint is prepared by preparing a crosslinking agent, a dispersing agent, cellulose, a defoaming agent, bactericide, a pH (potential of hydrogen) regulator, a thickening agent, an antifreezing agent, a film formation assistant, a setting agent, titanium dioxide, colored sand and emulsion into a protection glue solution, base paint and a continuous phase and mixing the protection glue solution, the base paint and the continuous phase uniformly. In the paint, the crosslinking agent is an elastomer and nano gel with high grade of transparency, high viscosity and high thixotropy; after the colored sand is added to the paint, colored particle hardness of the paint is adjustable; the paint is suitable for various colors and patterns; and the paint has the advantages of good storage stability, no color bleeding, high possibility of granulation, good water resistance, lasting weatherability, crack resistance high stone imitation degree, simple construction, low cost and workhour saving.

Owner:广西启利新材料科技股份有限公司

Production process of paste attapulgite clay

The invention provides a process of preparing paste formed attapulgite clay. The key points of the technical proposal include: the process of preparing paste formed attapulgite clay comprises the steps of pulping, sodium treatment, acidizing treatment, water washing and impurity screening out, and the mud obtained is subjected to precipitation to obtain the paste formed attapulgite clay. The attapulgite ore mud is subjected to the steps of sodium treatment, acidizing treatment, water washing and impurity screening out, and become natural gel with good thixotropy and stickiness, and the pH value is neutral. The attapulgite clay obtained by the preparation process of the invention has viscosity, expansion capacity, colloid value, whiteness degree, specific surface area, adsorbability and dirt removing power greatly improved, and the invention is suitably applied to the production of the paste formed attapulgite clay.

Owner:许盛英

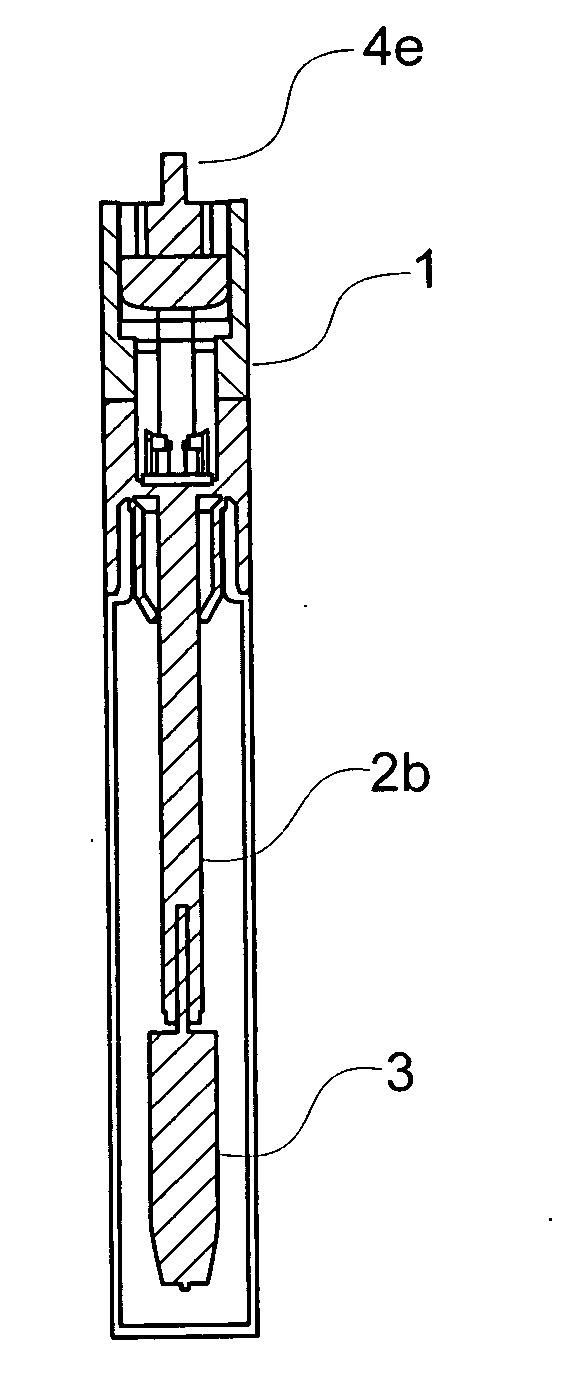

Vibrating mascara applicator, suitable compositions and method of use

ActiveUS7465114B2Improved mascara applicatorChange performanceCarpet cleanersBrush bodiesControl mannerEngineering

A mascara applicator with vibrating applicator head. The head is caused to vibrate in a controlled manner through electro-mechanical urging. The frequency, amplitude and geometry of the vibrating head are sufficient to significantly alter the rheological properties of thixotropic and anti-thixotropic mascara compositions, including an effect that persists after the vibration has stopped. The device allows the mascara to be manipulated for improved results, greater flexibility in formulation, benefits in manufacture, as well as other benefits.

Owner:ELC MANAGEMENT LLC

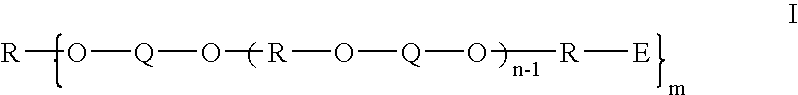

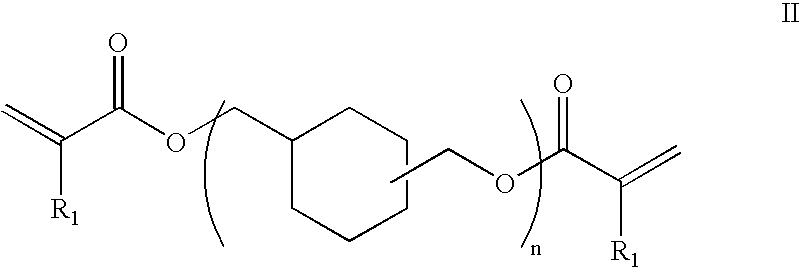

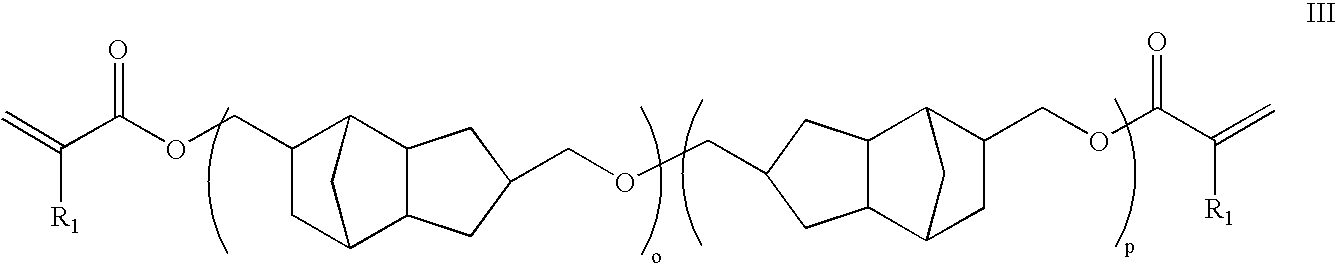

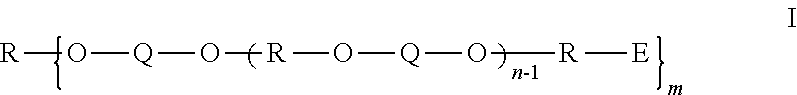

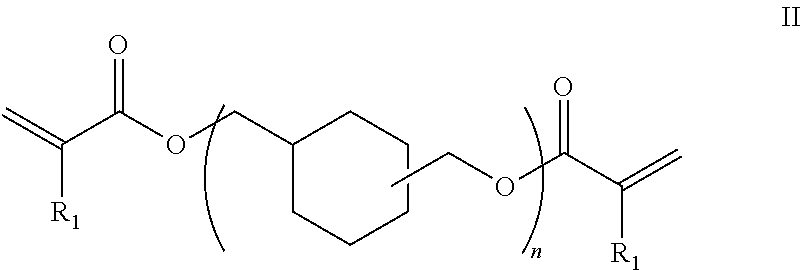

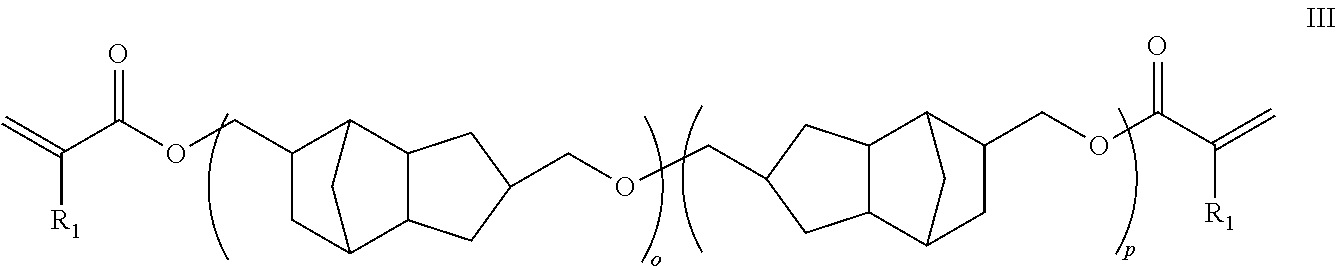

Thermosetting polyether oligomers, compostions and methods for use thereof

InactiveUS20090061244A1Low viscosityImprove conductivityOrganic chemistryOrganic compound preparationOligomerAdhesive

The invention is based on the discovery that certain polyether oligomers bearing curable moieties are useful as adhesives for the microelectonic packaging industry. Specifically, certain thermoset adhesive compositions containing polyether oligomers of the invention have good adhesion with lower viscosity, lower resistivity, higher conductivity and higher thixotropy when compared to acrylate- and maleimide-based thermoset adhesives.

Owner:DESIGNER MOLECULES

Environmentally-friendly barium-free thixotropic antirust oil

The invention discloses an environmentally-friendly barium-free thixotropic antirust oil, which is characterized by comprising the following components in percentage by weight: antirusting agent 4.0-25.0, thixotropic agent 0.1-5.0, antioxidant 0.1-3.0 and base oil 72.0-94.0. The preparation method of the environmentally-friendly barium-free thixotropic antirust oil comprises: firstly, adding the base oil into a reaction kettle, stirring the base oil, heating the base oil to 110 to 120 DEG C, adding the antirusting agent, stirring the mixture for continuous dehydration for 1 hour, and cooling the mixture to 50 to 60 DEG C; and secondly, adding the antioxidant, stirring the mixture for 3 hours at a constant temperature of 50 to 60 DEG C, adding the thixotropic agent, stirring the mixture for1 hour at 50 to 60 DEG C, cooling the resulting product to 40 DEG C, filtering the resulting product and discharging the resulting product. For obtaining antirust oil films that are insusceptible toflow and free from heavy metal barium, the antirust oil selects a proper barium-free corrosion inhibiter to ensure excellent antirust performance besides the thixotropic agent added for quickly forming stable oil films of antirust oil.

Owner:沈阳防锈包装材料有限责任公司

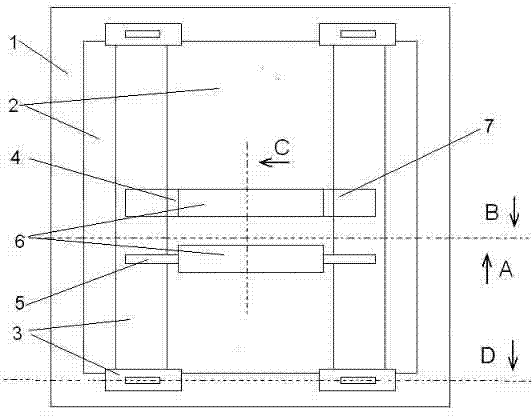

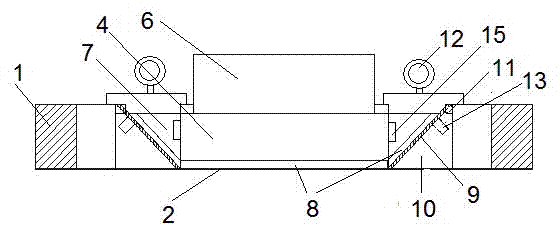

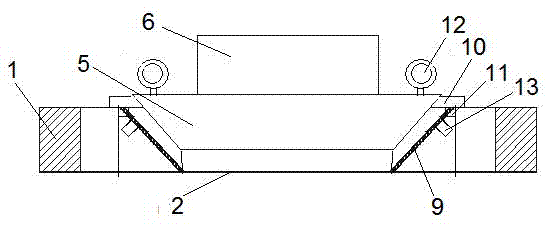

Screen printing device for solar batteries

InactiveCN102336051ASimple structural designLittle impact on deformabilityFinal product manufactureScreen printersScreen printingSlurry

The invention discloses a screen printing device for solar batteries. The screen printing device comprises a printing scraper, an auxiliary scraper, a feed back knife and a printing screen. The device is characterized in that two baffle structures are mounted on the printing screen, at two sides close to the ends of the printing scraper, wherein each baffle structure is mainly composed of a baffle surface, a baffle frame and an installation rack; the bottom of the baffle surface is in split type contact with a screen surface, or adhered to the screen surface through a flexible material; edges of the feed back knife, the printing scraper and the auxiliary scraper are in seamless contact with the baffle surface; a printing head drives the scrapers and the feed back knife to contact the baffle surface in a sliding manner, so that the paste moves in a range defined by the baffle surfaces at the two sides, the scraper and the feed back knife, and slurry is prevented from flowing to the two sides; and the device can ensure uniform fluidity, viscosity and thixotropy of the slurry and avoid the local drying and waste of the slurry, thereby improving electrode printing efficiency and printing quality.

Owner:NANCHANG UNIV

Acidified zeolite

The invention discloses an acidified zeolite. The technical scheme is as follows: the acidified zeolite is composed of zeolite, attapulgite clay, magnesia, hydrochloric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The acidified zeolite materials are input into a mill and milled, and the milled powder is the acidified zeolite. The production method of acidified red mud adopts acidification before composite proportioning, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate; and the acidified zeolite can effectively remove ammonia, iron, fluorine, phosphides and micro pollutants in domestic sewage, and can be used for removing or recovering heavy metal ions and treating radioactive waste. The acidified rear has the characteristics of favorable thixotropy, favorable heat stability, favorable plasticity and favorable binding property, and is suitable for producing drying agents, adsorptive separation agents, molecular sieves, catalysts, defluorination soil improvers, deodorizers and firefighting products.

Owner:江苏世澳非金属应用科技有限公司

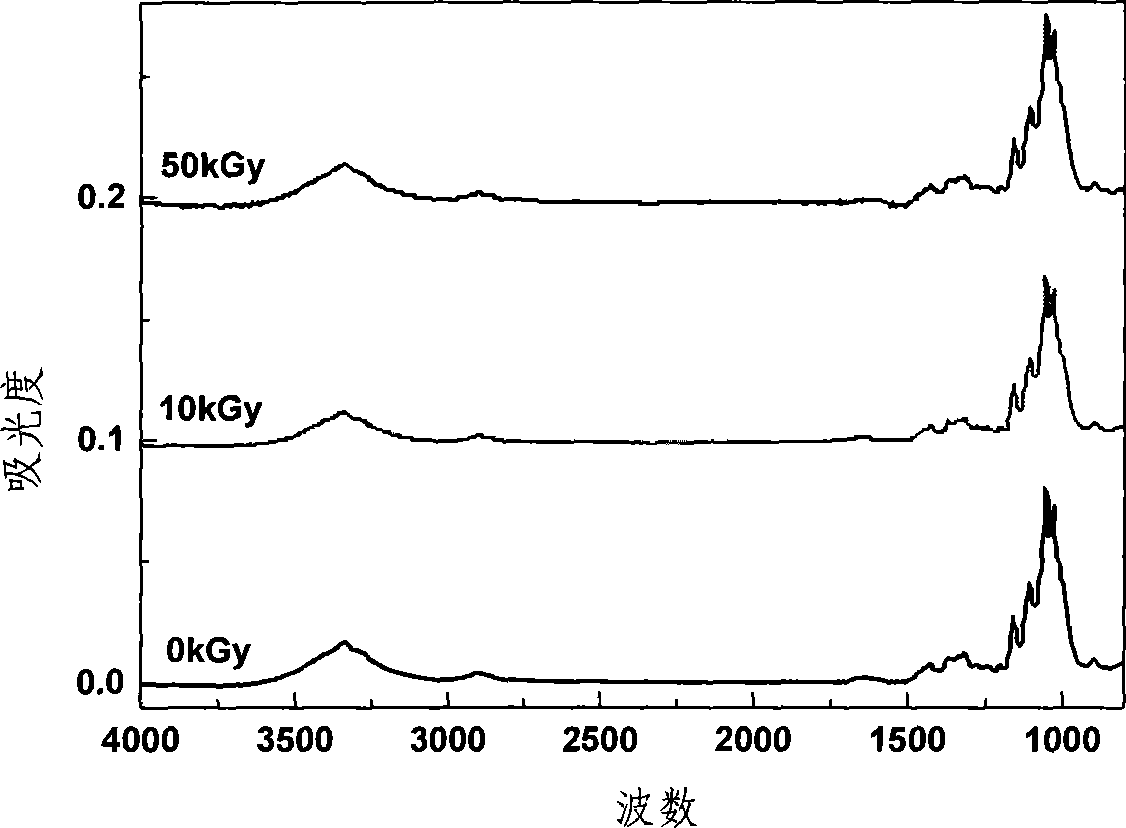

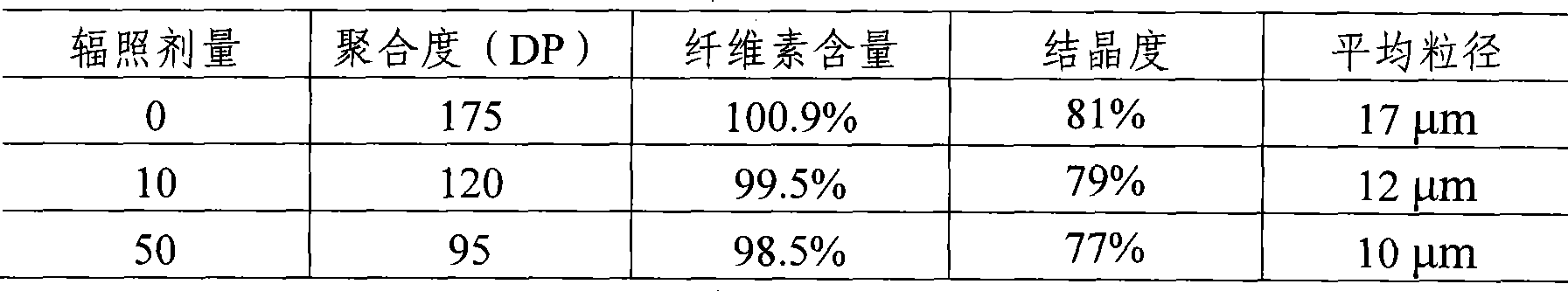

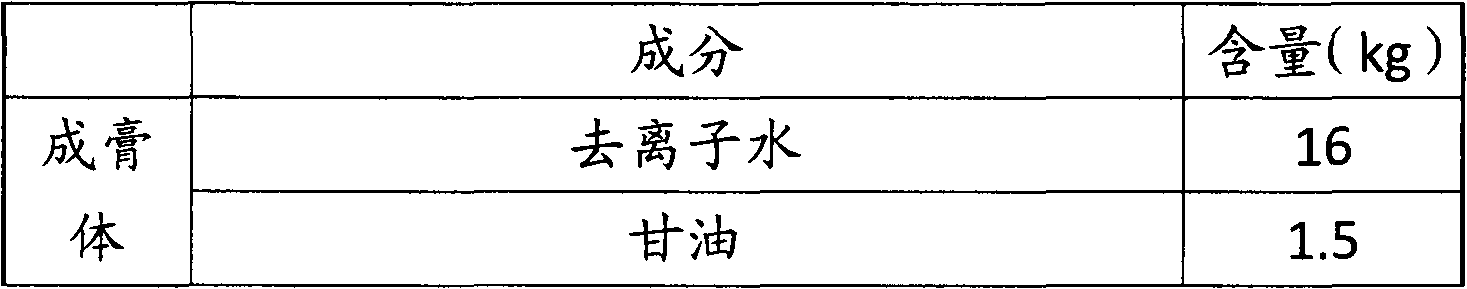

Ultra-fine microcrystalline cellulose and preparation thereof

InactiveCN101481424AGood dispersionImprove stabilityCosmetic preparationsToilet preparationsFood additiveEmulsion

The invention relates to superfine microcrystalline cellulose with particle size less than 10mum. The superfine microcrystalline cellulose with the particle size less than 10mum is obtained by degradation and superfine treatment of microcrystalline cellulose. The superfine microcrystalline cellulose can be widely applied to preparation of food additives, pharmaceutic adjuvants, emulsion stabilizers of cosmetics and thickening stabilizers of coating, and has high dispersibility and storage stability in water, better forming property, adhesiveness, water swellable property, thickening property, thixotropy and the like.

Owner:PEKING UNIV +1

Practical method for preparing high thixotropy surface treating nano calcium carbonate

InactiveCN101475759AImprove thixotropyParticle size controllablePigment treatment with non-polymer organic compoundsPolyurethane adhesiveCarbonization

The invention discloses a practical method for preparing high-thixotropy surface treatment nano calcium carbonate, which comprises the following steps: firstly, calcining and digesting preferable limestone, and then controlling carbonization of the limestone in a special reactor to obtain nano calcium carbonate primary slurry; secondly, carrying out surface treatment on the nano calcium carbonate according to practical and special control technology; and finally dehydrating, drying, crushing and grading the coated slurry. The shape of the obtained calcium carbonate is cubic, the particle diameter is 50 to 100 nanometers, and the specific surface area is 20 to 40 m / g. The obtained powder has good dispersion effect and thixotropy, is suitable for occasions needing high thixotropy, such as high-performance silicone adhesive, epoxy adhesive, polysulfide adhesive, polyurethane adhesive, automotive primary coat, floor coating and the like, and has wide market prospect. The method has simple raw materials and process requirement, stabalizes the production and reduces the cost.

Owner:山东海泽纳米材料有限公司

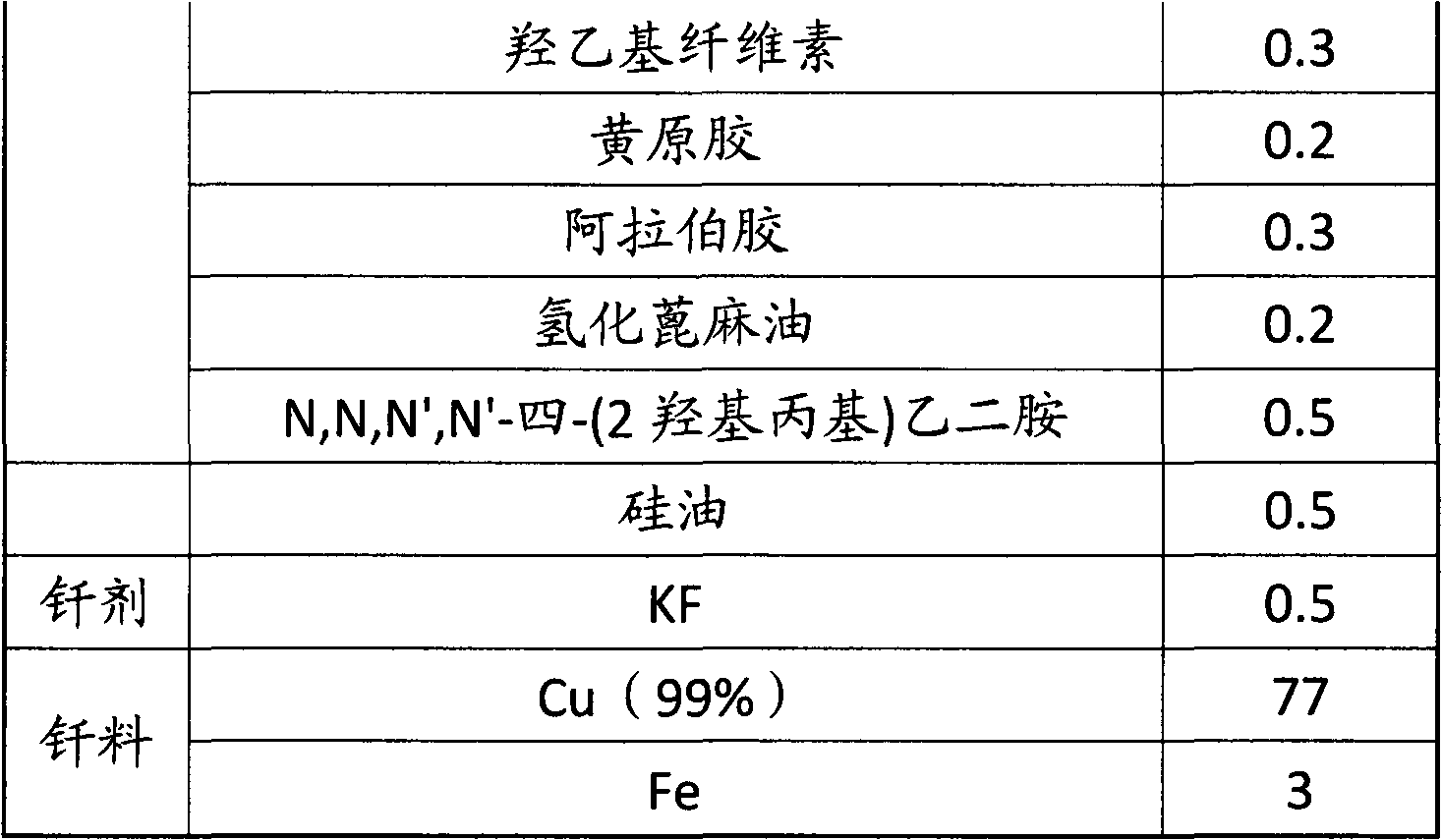

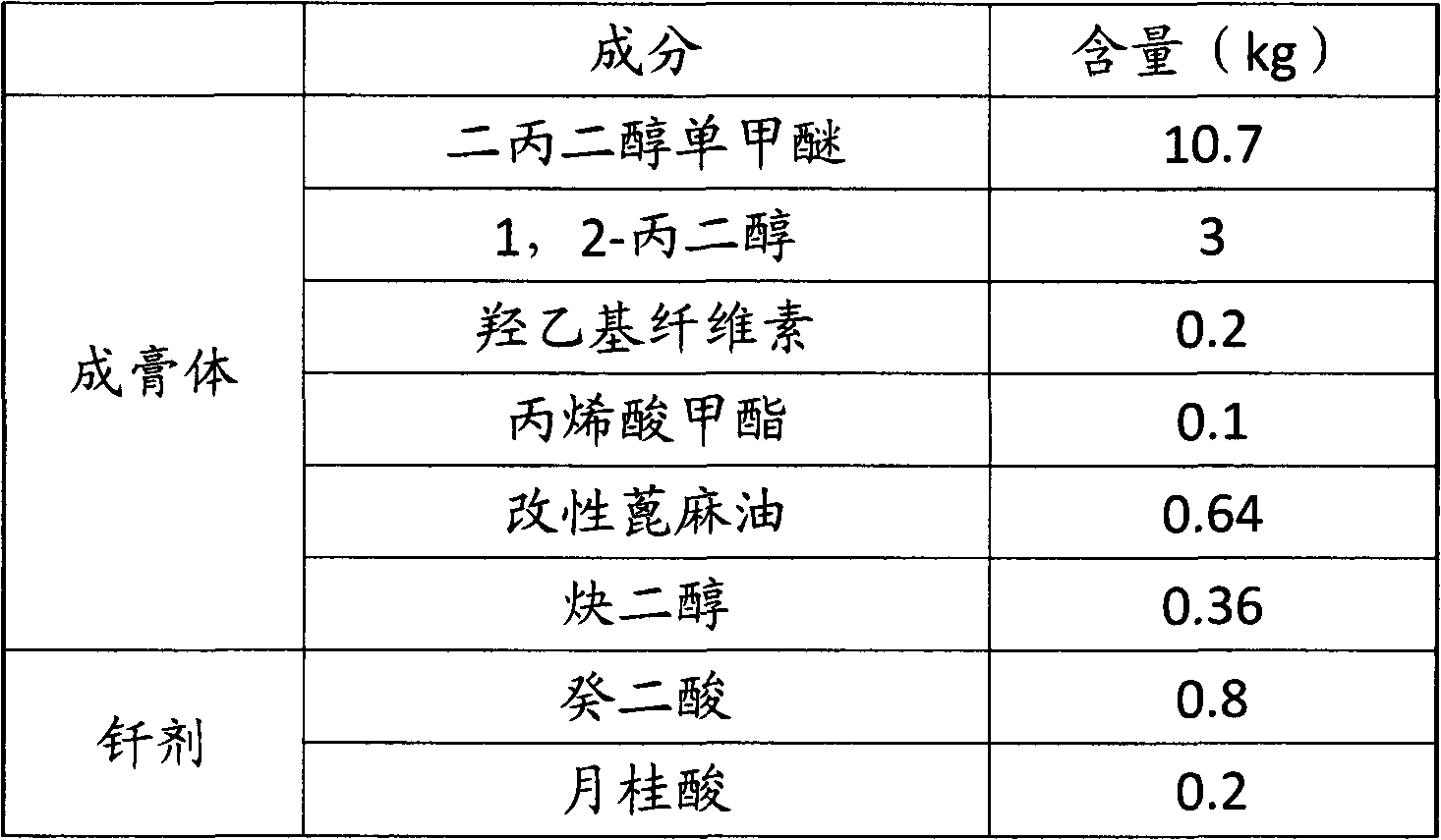

Copper welding paste for braze welding and preparation method thereof

ActiveCN103659053ALess corrosiveAvoid cleaningWelding/cutting media/materialsSoldering mediaPipe fittingSuccinic acid

The invention discloses copper welding paste for braze welding, a preparation method of the copper welding paste for braze welding and the application of the copper welding paste for braze welding. The copper welding paste for braze welding comprises 67wt%-92wt% of brazing filler metal, 8wt%-33wt% of pasty fluid and brazing flux of which the mass is 0-5% that of the brazing filler metal, wherein the brazing filler metal comprises Cu and / or one or more types of Cu alloy, the brazing flux comprises any one or more than two components of CaF2, KF, NaF, BaF2, sebacic acid, succinic acid, lauric acid and boric acid, and the pasty fluid comprises a solvent, a thickening agent, a rheological agent, an antifoaming agent and an activating agent. When the copper welding paste prepared through the method is applied before braze welding, the copper welding paste has good thixotropy, collapse resistance and fluidity; after braze welding, a part has high joint strength, a weld joint is plump and free of residues, and the part does not need cleaning; the copper welding paste can be widely applied to welding automobile pipe fittings, copper-based heat dissipation assemblies and stainless steel parts.

Owner:SUZHOU CUBRAZING MATERIALS CO LTD

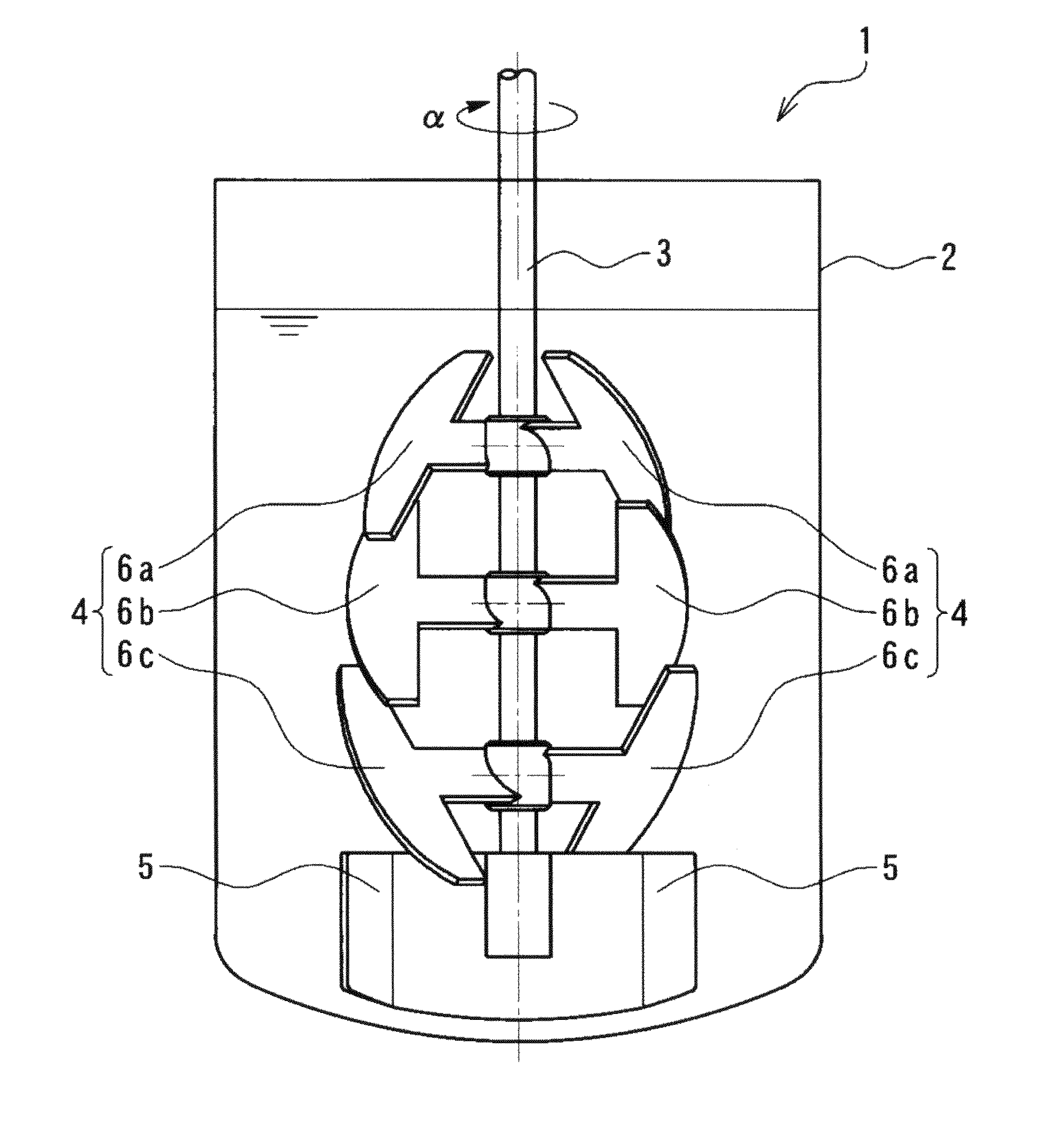

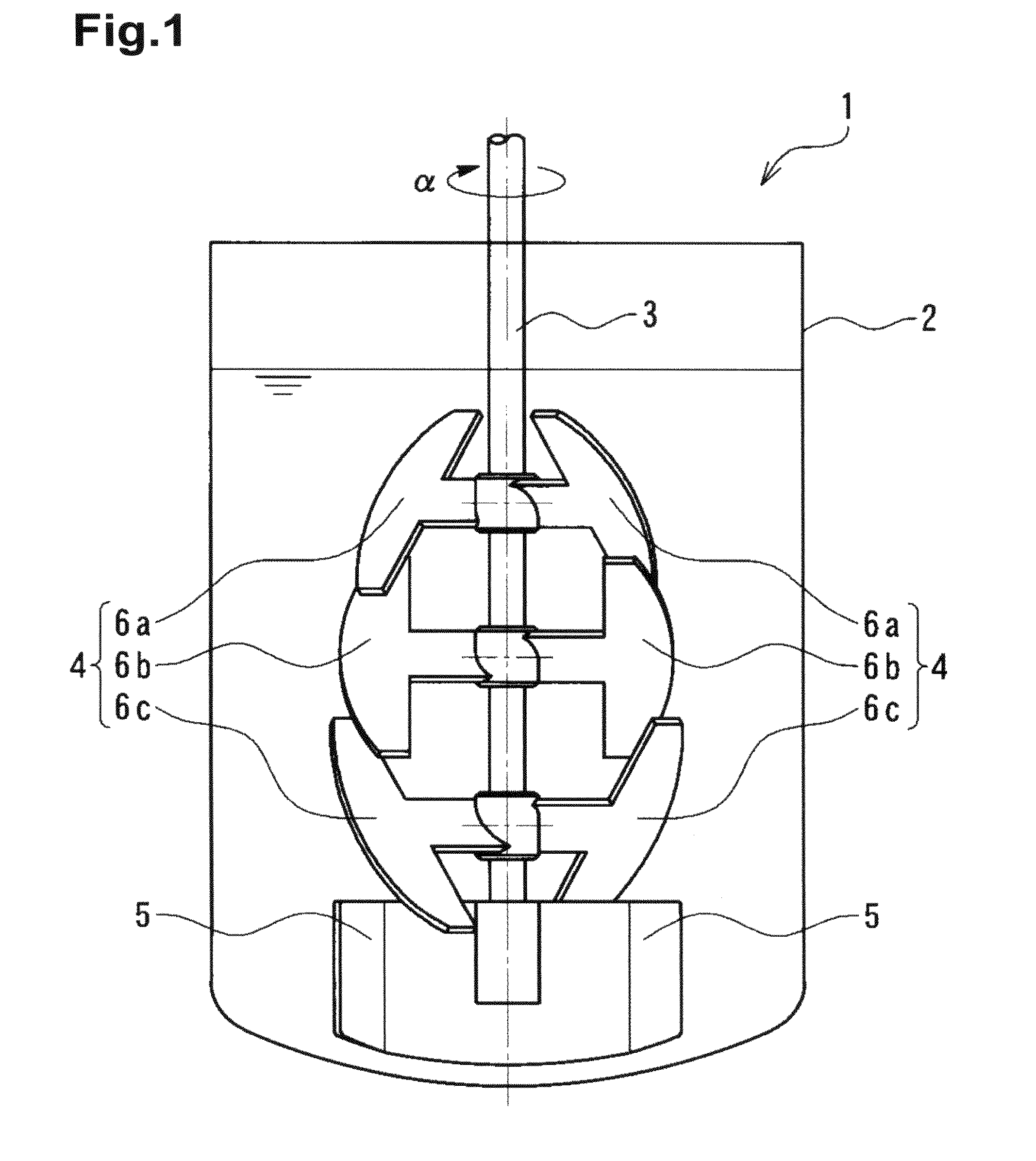

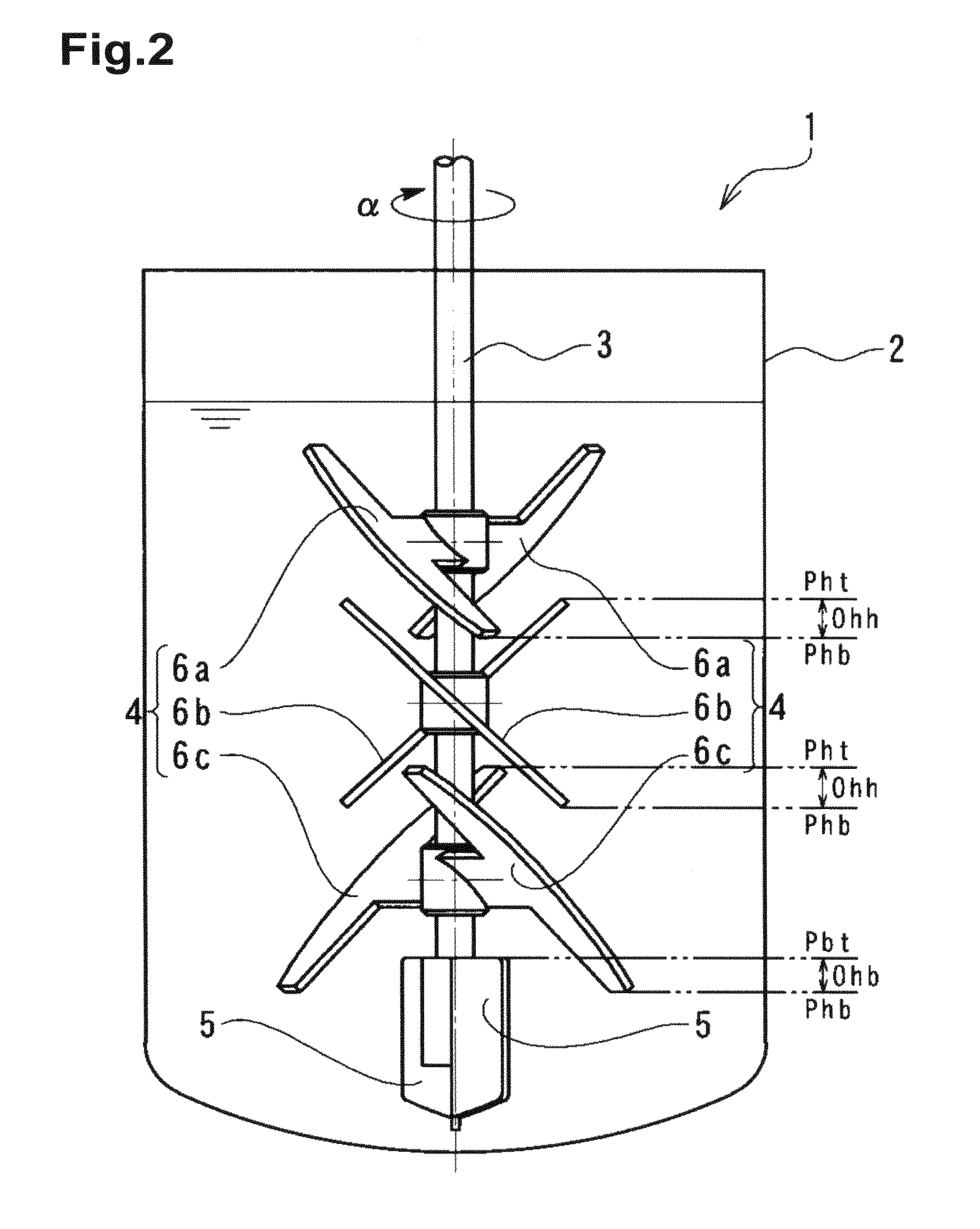

Agitation apparatus and agitation method

ActiveUS20110261643A1Rapid and efficientReduce riskFlow mixersRotary stirring mixersEngineeringThixotropy

An agitation apparatus and an agitation method that ensure rapid and homogeneous agitation / mixing of fluids with a wide spectrum of viscosities from low to high levels and fluids with high thixotropy throughout an agitation vessel are provided. In an agitation apparatus, a lowest upper agitation blade is arranged to be vertically adjacent to a lower blade. As viewed from above, a line on a plane connecting a lower end portion of the lowest upper agitation blade to the center of an agitation shaft is arranged by a predetermined angle with respect to the center line of the lower blade in a blade radial direction. As viewed from the side, a horizontal cross section including the lower end portion of the lowest upper agitation blade is located below a horizontal cross section including an upper end portion of the lower blade.

Owner:DAINIPPON INK & CHEM INC

Fluoropolymer composition

InactiveUS20070117929A1Increase melt viscosityImprove the extrusion effectTetrafluoroethyleneMolten state

A melt-mixed composition of non-melt flowable polytetrafluoroethylene (PTFE) and melt-fabricable perfluoropolymer is provided that exhibits thixotropy at increasing shear rate in the molten state and high elongation at break even at PTFE concentrations well above 4 wt %, based on the combined weight of the PTFE and the perfluoropolymer, e.g. at least 200% up to at least 30 wt % PTFE, the composition also exhibiting the structure of a dispersion of submicrometer-size particles of the PTFE in a continuous phase of the melt-fabricable perfluoropolymer.

Owner:EI DU PONT DE NEMOURS & CO

Heat conductive phase-change material and production method thereof

The invention relates to a heat conductive phase-change material which consists of the following components in percentage by weight: 75-90% of heat conductive filler, 2-8% of low-melting-point solid resin, 5-15% of liquid resin, 0.01-1% of an antioxidant and 0.02-2% of a coupling agent, and the phase-change material is prepared through a production method of mixing raw materials, mixing the heat conductive filler, pressing and forming, and cooling. The heat conductive phase-change material, which is prepared by mixing the heat conductive filler, the low-melting-point solid resin, the liquid resin, the antioxidant and the coupling agent, disclosed by the invention has the advantages that the phase-change material is in a shape of flaky solid at room temperature, so that the material is convenient in using and operation and can be directly attached on the surface of a heat-radiating component; when the component runs to the working temperature of the heat conductive phase-change material, phase change occurs and the material becomes soft, so as to wet the surface of the component to a great extent, and contact thermal resistance is reduced to the lowest so as to guarantee a heat conductive interstitial property better than that of heat conductive grease or a graphite flake; in addition, with excellent thixotropy, the material, when being used in a vertical direction, is protected away from circumstance of overflow or flowing.

Owner:PINGHU ALLIED IND

Method for preparing silicone sealant

ActiveCN103642452AIncrease the amount addedImprove stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention discloses a method for preparing silicone sealant. The method comprises the following steps: adding alpha,omega-dyhydroxy polydimethylsiloxane, filler and dimethyl silicon oil into a vacuum kneading machine, vacuuming, heating and mixing for 2-5 hours; stopping heating, introducing nitrogen to change the vacuum state, adding a silane coupling agent, mixing for 0.5-1 hour at the vacuum degree of -0.06 to -0.1Mpa, introducing nitrogen to change the vacuum state; sealing and cooling to room temperature, subsequently transferring into a stirring machine, adding a cross-linking agent, a thickening agent and a catalyst, vacuuming, and uniformly stirring and mixing so as to obtain the silicone sealant. According to a product of the silicone sealant, the addition amount of the filler is increased, the product stability and the surface smoothness are improved, the thixotropy and the deep curing are also improved, the curing homogeneity is good, the tensile strength, the elasticity and the cohesiveness are greatly improved, expensive white carbon black can be replaced, the filling amount is large, the curing time is short, the construction efficiency is improved, the process is simple and feasible, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

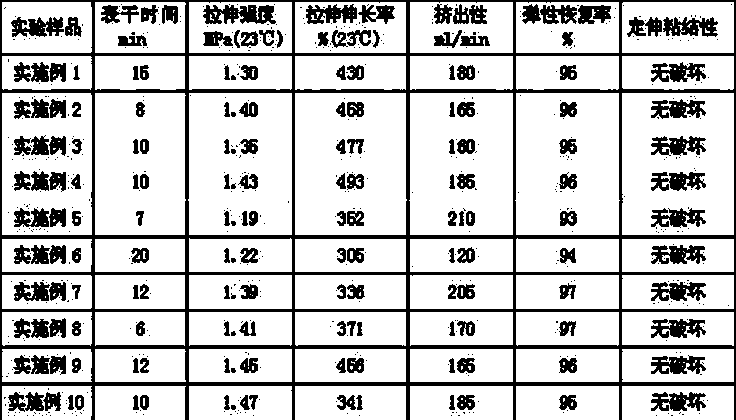

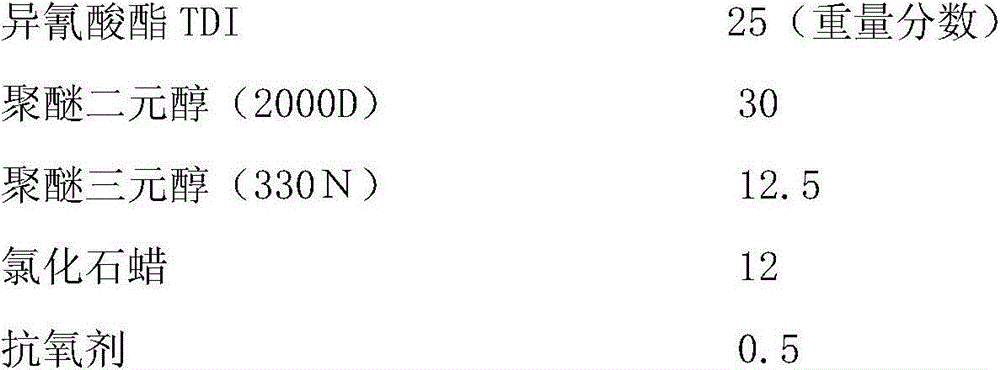

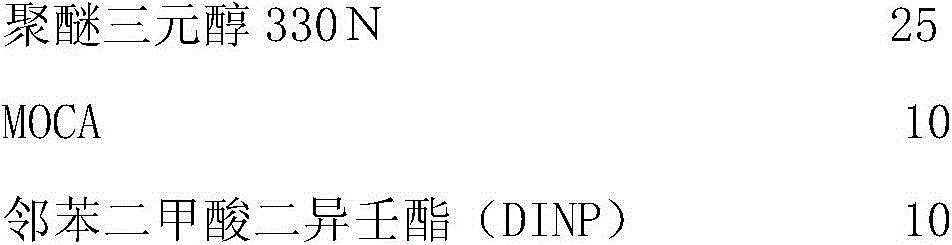

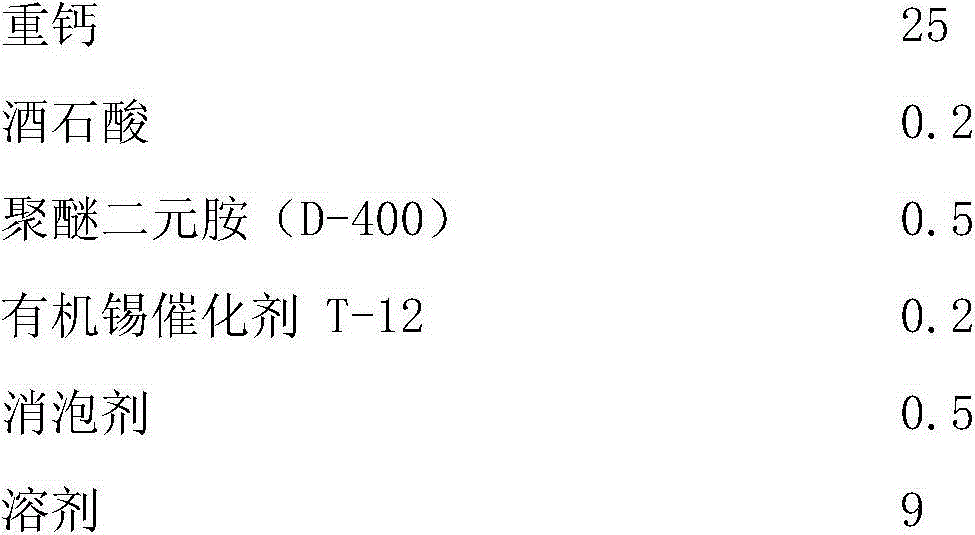

Double-component chemical-reaction thixotropic polyurethane waterproof paint and preparation method thereof

ActiveCN104559734AOvercome the shortcomings of good leveling, poor thixotropy, and flow in facade constructionGood thixotropyPolyurea/polyurethane coatingsChemical reactionSolvent

The invention discloses a double-component chemical-reaction thixotropic polyurethane waterproof paint which is composed of a component A and a component B. The component A comprises the following ingredients in parts by weight: 20-40 parts of isocyanate, 20-50 parts of polyether glycol, 5-15 parts of plasticizer and 0-1 part of high-performance assistant. The component B comprises the following ingredients in parts by weight: 20-40 parts of polyether glycol, 5-30 parts of chain extender, 5-20 parts of plasticizer, 0.1-1 part of polymerization inhibitor, 0.1-1 part of amine reactant, 0.2-1 part of catalyst, 20-40 parts of pigment and filler, 5-20 parts of solvent and 0.1-1 part of high-performance assistant. Since the component B contains the special-type amine reactant capable of reacting with isocyanate, the polyurea compound can be quickly generated after the two components are mixed under the action of the specific polymerization inhibitor; and the compound can form abundant hydrogen bonds with the polyurethane prepolymer, so that the double-component chemical-reaction thixotropic polyurethane waterproof paint has favorable thixotropy and constructability.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

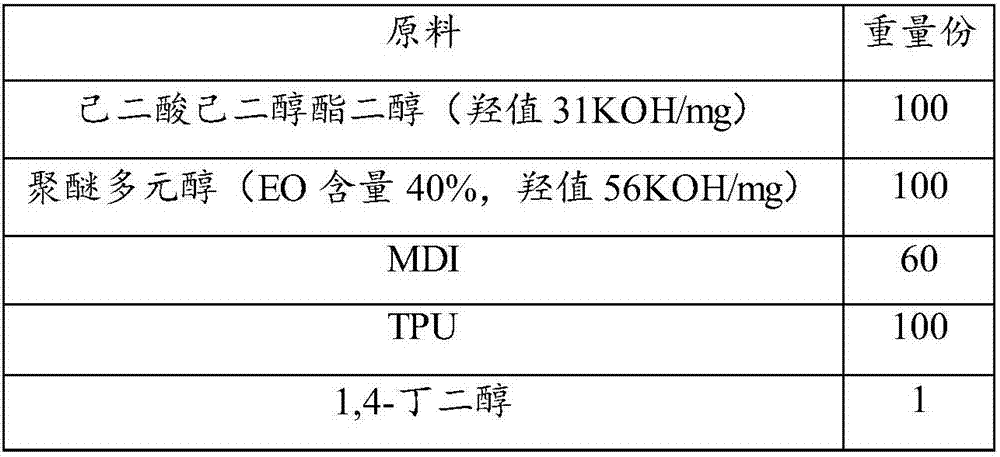

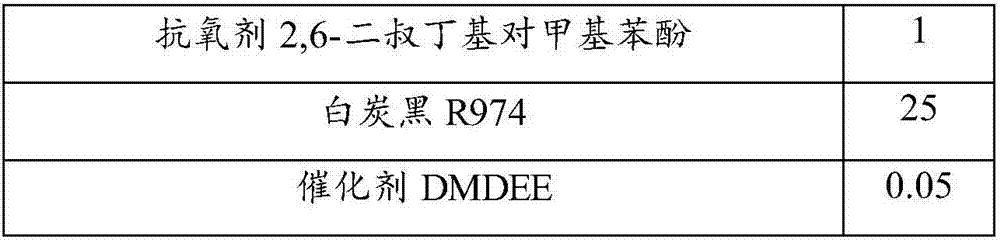

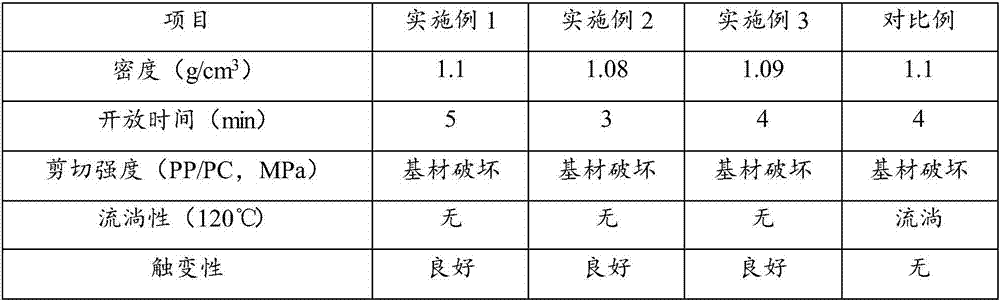

Reaction type polyurethane hot melt adhesive as well as preparation method and application thereof

ActiveCN107987779AGood water permeabilityGood high temperature non-dripping propertiesPolyureas/polyurethane adhesivesPolyesterEthylene oxide

The invention provides a reaction type polyurethane hot melt adhesive as well as a preparation method and application thereof. The reaction type polyurethane hot melt adhesive is prepared from the following raw materials with the components in parts by weight: 100-120 parts of polyester polyol, 1-150 parts of polyether polyol, 50-100 parts of isocyanate, 50-350 parts of a modifier, 1-5 parts of achain extender, 1-5 parts of an antioxidant and 0.01-0.1 part of a catalyst, wherein the mass percentage of ethylene oxide in the polyether polyol is 40-50%; the hydroxyl value is 21-112KOH / mg; the modifier consists of a tackifying resin and a filler in a mass ratio of 1-6 to 1. Due to the addition of the polyether polyol with ethylene oxide of a specific mass content, and under coactions of the modifier of components of specific contents, the water permeability of a hot melt adhesive before curing is improved, and the obtained product is good in high-temperature flow-free property, relativelyrapid deep curing property and excellent thixotropy, and can be used as a hot melt adhesive for vehicle lamps.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Method for preparing polycarboxylic compound ceramic water reducing agent

The invention discloses a method for preparing a polycarboxylic compound ceramic water reducing agent. The method comprises the following steps of: mixing maleic anhydride, an initiator and water; raising a temperature; adding mixed solution of acrylic acid and an inorganic chain transfer agent; performing a reaction at a constant temperature; adding an inorganic salt quencher to obtain a polycarboxylic water reducing agent main body, namely an acrylic acid-maleic anhydride copolymer; cooling to the temperature of between 40 and 50 DEG C; adjusting the pH value of a reaction system to be between 7 and 8 by using 25 to 35 mass percent NaOH solution to obtain a polycarboxylate copolymer; compounding the polycarboxylate copolymer with an inorganic salt; and dissolving the compound in the water so as to prepare the polycarboxylic compound ceramic water reducing agent. The method has the characteristics of mild reaction conditions without nitrogen for protection, simple synthesis process, low requirement on equipment, low energy consumption, and low production cost. After the compound water reducing agent is added into ceramic slurry, the water content of the slurry is below 38 percent; the thixotropy is good; and combination properties of a ceramic product can be improved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

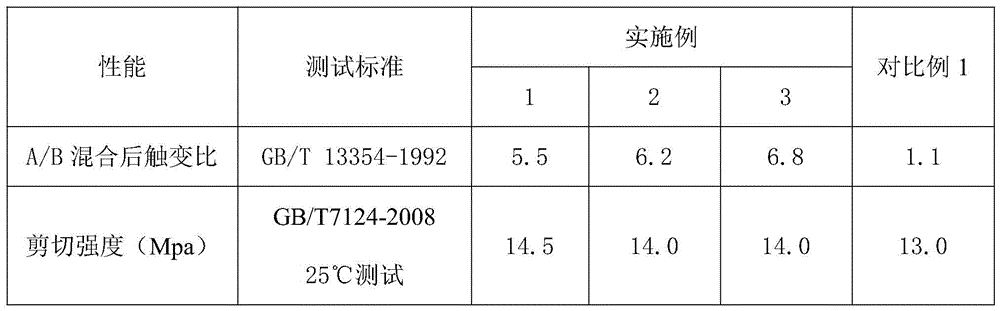

Dual-component high-thixotropy polyurethane adhesive

ActiveCN105602514AImprove thixotropyHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRefrigerator carPolyurethane adhesive

The invention discloses a dual-component high-thixotropy polyurethane adhesive. The dual-component high-thixotropy polyurethane adhesive is prepared from a component A and a component B. The component A is prepared from castor oil, polyether polyol, a chain extension agent, surfactant, gas-phase silica, filler and a drying agent according to the weight ratio, and the component B is prepared from isocyanate. The dual-component high-thixotropy polyurethane adhesive is high in strength, raw materials are easy to obtain, good thixotropy is achieved, the effect of applying adhesives in the fade or the vertical face is achieved, and the dual-component high-thixotropy polyurethane adhesive is particularly suitable for plate alignment adhesives, rod alignment adhesives and adhesion of two contact faces and is applied to compartment structural element adhesion in compartments of refrigerator cars and trucks.

Owner:上海都昱新材料科技有限公司

Pyrophillite lost foam casting coating and preparation method thereof

InactiveCN101444827AGood suspensionImprove thixotropyFoundry mouldsFoundry coresSoluble glassOctanol

The invention discloses a pyrophillite lost foam casting coating and a preparation method thereof. The coating comprises the following components by the mass percentage: 90% to 95.8% of pyrophillite refractory powder, 0.2% to 0.7% of sodium carboxymethyl cellulose, 1.9% to 4.4% of swell soil, 1.9% to 5.3% of soluble glass, 0.1% to 0.18% of polyethylene alkyl polyol ether, and 0.05% to 0.1% of N-octanol, and the mass percentage of the components is 100% in total, wherein, pyrophillite refractory powder is pyrophillite or mixture of pyrophillite and other refractory materials. The invention has the advantages that the pyrophillite lost foam casting coating has favorable suspension property and thixotropy, as well as excellent ventilation property and relatively high surface strength; and the preparation technology is simple, the operation is convenient, the raw material is abundant and the production cost is low. The invention is mainly used for producing refractory material on the surface of foam plastic mould of lost foam pieces.

Owner:HAIAN HENGYE SILK

Material for imparing thixotropy and pasty resin composition

InactiveUS20050004266A1High viscositySatisfactory degreeCalcium/strontium/barium carbonatesPigmenting treatmentNuclear chemistrySaturated fatty acid

Surface-treated calcium carbonate characterized by giving, upon analysis by the method of mercury penetration, a void diameter distribution curve which has a peak for the most probable void diameter at smaller than 0.03 μm and has a most probable void volume of 0.05 to 0.5 cm3 / g; and a pasty resin composition containing the surface-treated calcium carbonate. The calcium carbonate preferably comprises one obtained by surface-treating calcium carbonate having a BET specific surface area of 10 to 100 m2 / g with an unsaturated fatty acid (A) and a saturated fatty acid (B).

Owner:SHIRAISHI KOGYO KAISHA LTD

Method for preparing full-mold casting coating

ActiveCN102500745AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresHigh surfaceTemperature resistance

The invention discloses a method for preparing a full-mold casting coating. The full-mold casting coating prepared by the method is high in anti-burn-on capacity and capable of improving rigidity and high-temperature resistance of molds, while cost is reduced to the utmost extent. A high-current rheological fluid is formed by optimizing blending of aggregates and various additives, and has betterwettability and brushing property to foamed plastic molds. According to practices, the coating thickness of the coating can be at least 1.7mm after the coating is brushed by twice and is capable of meeting requirements for anti-burn-on capacity and transporting of large-size castings. The full-mold casting coating has excellent suspended property, thixotropy, breathabililty and higher surface strength, the method for preparing the full-mold casting coating is simple, convenient in operation and low in cost, and raw materials for preparing the full-mold casting coating are rich. In addition, surfaces of the full-mold castings produced by the full-mold casting coating are smooth and bright and free of defects of wrinkles, carbon black and the like, and coating layers on the surfaces are easy to be stripped and convenient to be cleaned.

Owner:南通市通州区俊朗建筑工程有限公司

Environmental-protection low halogen-content surface mounting adhesive capable of quick solidification under low temperature

InactiveCN101760161AShelf life stabilityFast curing at low temperatureEpoxy resin adhesivesHalogenAdhesive

The invention discloses an environmental-protection low halogen-content (the total halogen content is smaller than 450ppm) surface mounting adhesive capable of quick solidification under low temperature. The adhesive is composed of high-purity liquid epoxy resin, modified epoxy resin, high-purity active diluent, a halogen-free latent firming agent, an accelerating agent, a thixotropic agent, an ion absorbing agent, high-purity inorganic padding and pigment. The weight percent of the above components is as follows: the high-purity liquid epoxy resin: 20 to 80%; the modified epoxy resin 0 to 10%; the high-purity active diluent: 1 to 10%; the halogen-free latent firming agent: 1 to 8%; the accelerating agent: 2 to 20%; the thixotropic agent 3 to 10%; the ion absorbing agent: 0 to 1%; the high-purity inorganic padding: 0 to 30%; and pigment: 0 to 3%. Compared a the present product, the halogen content of the adhesive is low, the total halogen content is smaller than 450ppm, the thixotropy is good, and the electric performance is excellent. The adhesive can be quickly solidified in 40 to 50 seconds under the temperature of 100 DEG C. With high adhesion power and good heat / impact resisting performance, the adhesive can be widely used in the technical field of surface mounting with strict requirement for environmental protection.

Owner:SHENZHEN DOVER TECH

Thermosetting polyether oligomers, compositions and methods for use thereof

InactiveUS7928153B2Low viscosityImprove conductivityOrganic chemistryOrganic compound preparationAdhesiveHigh conductivity

Owner:DESIGNER MOLECULES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com